Patents

Literature

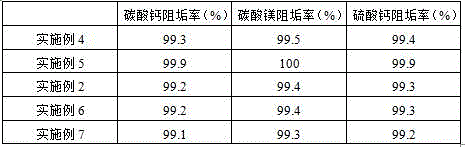

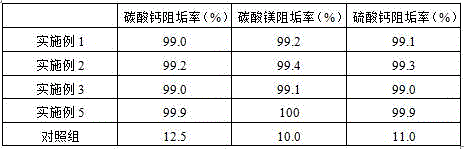

54results about How to "High anti-scaling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

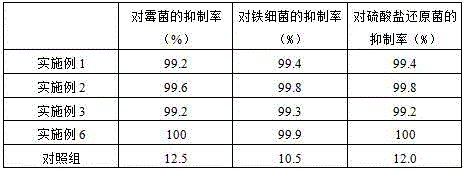

Non-phosphorus corrosion and scale inhibitor

InactiveCN108002558AGood chemical stabilityImprove thermal stabilitySpecific water treatment objectivesScale removal and water softeningEutrophicationZinc sulphate heptahydrate

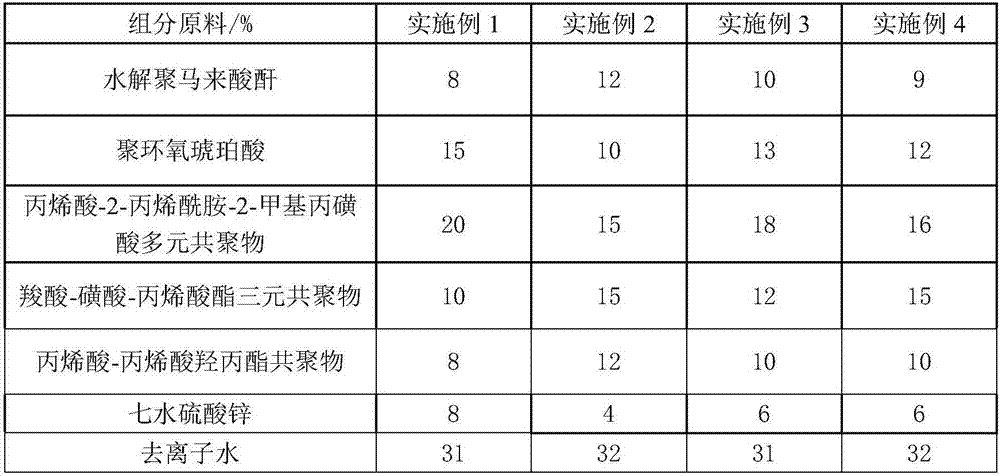

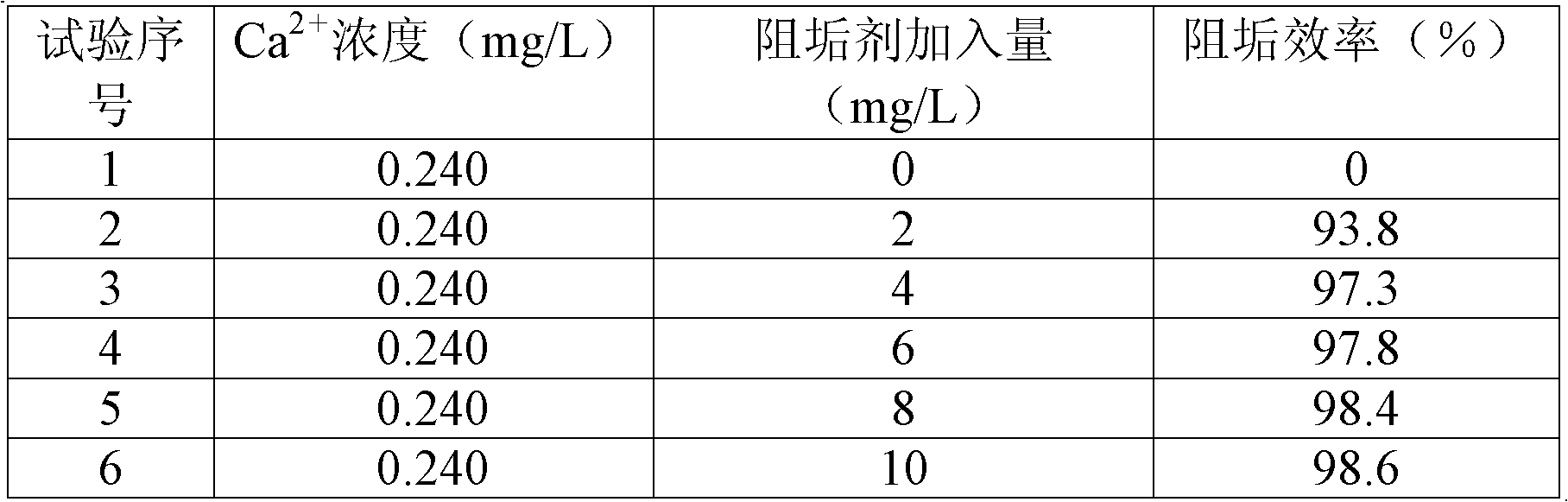

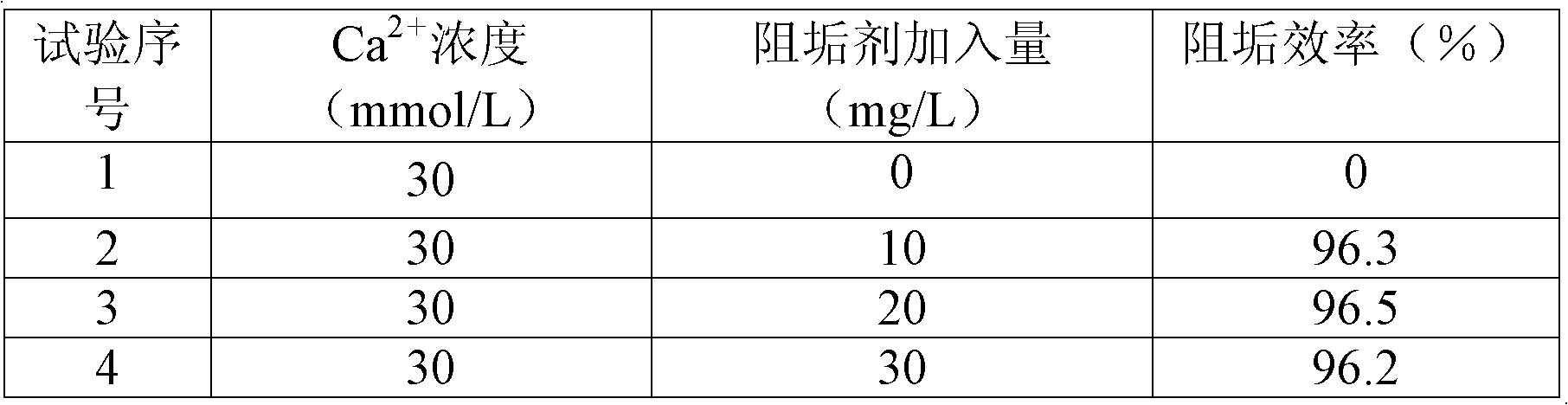

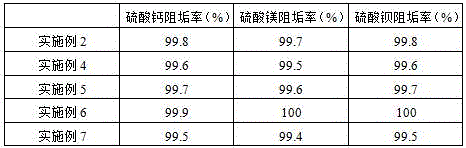

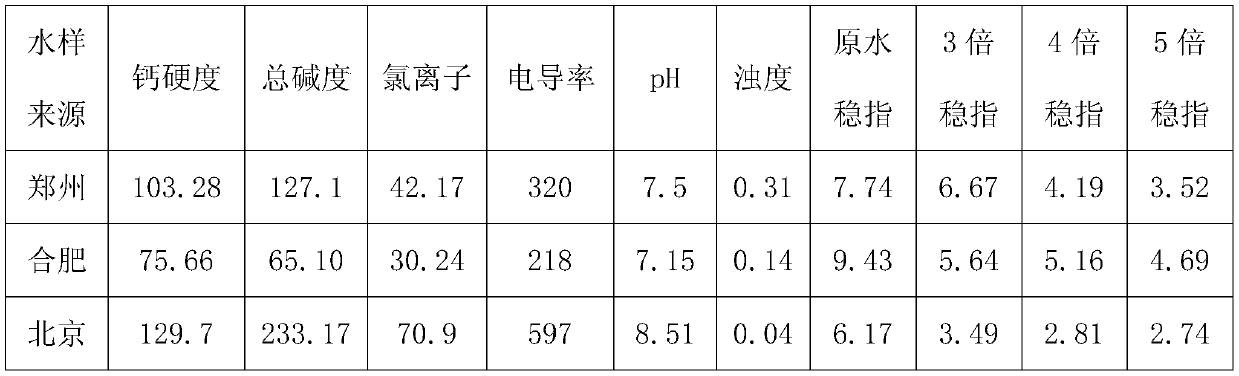

The invention discloses a non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following components in percentage by weight: 8 to 12 percent of hydrolytic polymaleic anhydride, 10 to 15 percent of polyepoxysuccinic acid, 15 to 20 percent of acrylic acid-2-acrylamido-2-methylpropanesulfonic acid multipolymer, 10 to 15 percent of carboxylic acid-sulfonic acid-acrylate terpolymer, 8 to 12 percent of acrylic acid-hydroxypropyl acrylate copolymer, 4 to 8 percent of zinc sulphate heptahydrate and the balance of deionized water. The invention further discloses a preparation method of the corrosion and scale inhibitor. The preparation method comprises the following steps: weighing the components according to the formula; adding the components into a stirrer in sequence; stirring at normal temperature and under normal pressure to obtain the corrosion and scale inhibitor. The corrosion and scale inhibitor disclosed by the invention has the advantages of freeness from phosphorus, adoption of safe and environment-friendly components, simple production process, high scale-inhibiting efficiency, high corrosion-inhibiting performance, prevention of eutrophication of a water body caused by discharge of phosphorus, and very high compatibility; the adhesion of microorganisms to equipment can be reduced effectively, and the corrosionand and scale inhibiting performance can be enhanced greatly.

Owner:新疆水处理工程技术研究中心有限公司

Scale inhibitor specially used for seawater circulating cooling water

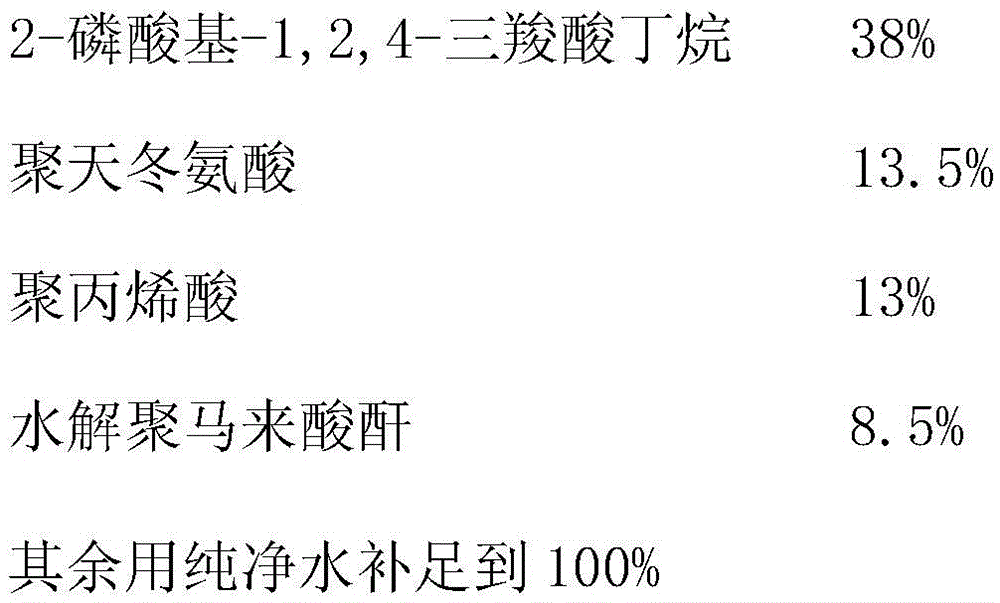

InactiveCN101962234AMeet environmental protection requirementsEfficient scale inhibitionScale removal and water softeningPolyaspartic acidWater quality

At present, most scale inhibitor of fresh water contains phosphorus so as to be not environment-friendly, and when the existing non-phosphorus scale inhibitor of the fresh water is applied to seawater, the scale inhibition efficiency is low since the water quality of the seawater is more different from that of the fresh water. The invention discloses a scale inhibitor specially used for a seawater circulating cooling water system, which is characterized by comprising the components by weight percent: 20-40% of polyacrylic acid (PAA), 20-35% of acrylate copolymer, 10-30% of hydrolytic polymaleic anhydride, 10-20% of polyaspartic acid and 5-15% of surface active agent. The invention uses monomers to form non-phosphorus component which is the non-phosphorus scale inhibitor and is in accordance with the environmental protection requirements; and the invention has the characteristic of high efficiency in scale inhibition, and leads the fresh water to be replaced by the seawater which is taken as industrial circulating cooling water and is popularized and applied.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Composite antisludging agent of reverse osmosis/nanofiltration system

ActiveCN103007768AImprove work efficiencyExtended cleaning cycleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisColloidal silicaUltrafiltration

The invention provides a composite antisludging agent of a reverse osmosis / nanofiltration system. The composite antisludging agent comprises the following components in percentage by weight: 2%-10% of cyclodextrin solution, namely a component I, 80%-90% of at least one or a mixture of amino trimethylene phosphonic acid (ATMP), a copolymer of maleic anhydride-acrylic acid (MA-AA), 2-phosphonic acid butane-1, 2,4-tricarboxylic acid (PBTCA), and hydroxyl ethylidene diphosphonic acid (HEDP), namely a component II, and 1%-10% of 2,2-dibromo-2-cyano-acetamid (DBNPA), namely a component III. The composite antisludging agent is prepared by mixing the component II and the component III, and then fusing the obtained mixture with the component I. When being applied to the reverse osmosis / nanofiltration / ultrafiltration system, the composite antisludging agent can be used for effectively relieving the pollution to the reverse osmosis / nanofiltration / ultrafiltration system caused by polcard, calcium sulphate salt, barium sulfate, strontium sulfate, calcium fluoride, colloidal iron and colloidal silica, relieving biological contamination simultaneously, improving the working efficiency of the system, prolonging the cleaning period and the service life of the reverse osmosis / nanofiltration / ultrafiltration system, and reducing the cost of reverse osmosis.

Owner:辽宁莱特莱德环境工程有限公司

Non-phosphorus type environment-friendly slow-release scaling inhibitor

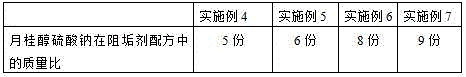

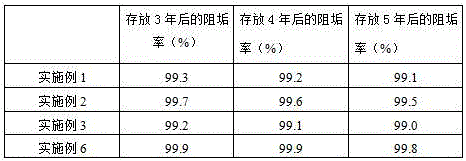

InactiveCN105776589ASimple production processHigh anti-scaling efficiencySpecific water treatment objectivesScale removal and water softeningAraboascorbic AcidFatty alcohol

The invention discloses a non-phosphorus type environment-friendly slow-release scaling inhibitor which is prepared from the following components: tannin, polyacrylic acid, ammonium salt, D-erythorbic acid, silicate, a non-phosphorus polymeric corrosion inhibitor, a maleic acid-crylic acid copolymer, fatty alcohol-polyoxyethylene ether, zinc salt, a dispersing agent and deionized water. The non-phosphorus efficient slow-release scaling inhibitor with safe and environment-friendly components is provided, due to the reasonable design, all the substances in the formula can be prepared into the environment-friendly corrosion inhibitor with a good corrosion inhibition effect and high storage stability.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing phosphine poly-maleic anhydride water scale inhibitor

InactiveCN102304196AIncrease diversityImprove chelation abilityScale removal and water softeningRefluxReaction temperature

The invention discloses a method for preparing a phosphine poly-maleic anhydride water scale inhibitor. The method comprises the following steps of: (1) adding maleic anhydride, hypophosphite compound and a catalyst into a reaction vessel which is provided with a thermometer, a stirrer and a reflux condenser, wherein the dosage of the catalyst accounts for 0.004 to 0.02 percent of the total mass of materials; adding water, dissolving the maleic anhydride and the hypophosphite compound in water under a gradually heating condition, starting the stirrer to uniformly mix; (2) adding oxidant and water into a dripping tank, and uniformly mixing, wherein the mass ratio of the maleic anhydride to the hypophosphite compound to the oxidant is 0.5-1.8:0.2-0.6:0.5-1.5; and (3) slowly dripping the oxidant solution in the dripping tank into the reactor, controlling the reaction temperature to be between 60 and 120 DEG C and the reaction time to be between 0.5 and 10h, and cooling and packaging after the reaction is completed.

Owner:CHENGDU YULONG CHEM

Method for synthesizing polyepoxysuecinic acid salt

InactiveCN101538362AReduce hydrolysis rateIncrease polymerization rateScale removal and water softeningCalcium hydroxideFiltration

The invention discloses a method for synthesizing a polyepoxysuecinic acid salt, which is characterized by comprising the following steps of: dissolving maleic anhydride in deionized water; adding a solution of sodium hydroxide at 30 to 60 DEG C with stirring; adding sodium tungstate and hydrogen peroxide when the temperature is controlled to be between 60 to 100 DEG C; adjusting the pH value to 5 to 7 for reaction for 2 to 100 hours; cooling the reaction solution to below 20 DEG C; adding a precipitator, mixing and stirring the precipitator and the solution; performing suction filtration, adding water into filtrate obtained after suction filtration; keeping the pH value between 6 and 7; heating the filtrate added with water to 70 to 100 DEG C to obtain an epoxysuecinic acid salt; preparing a 0.2 to 4.0 mol / L aqueous solution of the epoxysuecinic acid salt; adding calcium hydroxide and a polymerization promoter into the aqueous solution for performing polymerization reaction till liquid turns yellowish and pasty; and cooling the yellowish and pasty liquid to room temperature to obtain the polyepoxysuccinic acid salt. The method has the advantages of good product quality, low raw material cost and product scale inhibition performance advantageous over that of the prior art.

Owner:北京合创同盛科技有限公司

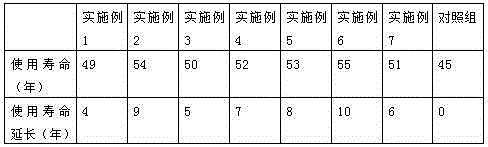

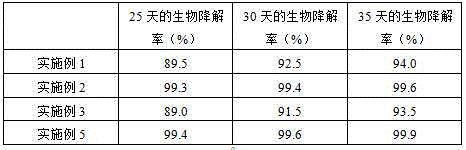

Environment-friendly slow-release polymer scale inhibitor and preparation method thereof

ActiveCN107304078ABiodegradableWon't happenWaste water treatment from quariesWater treatment compoundsOil fieldRelease time

The invention discloses an environment-friendly slow-release polymer scale inhibitor, which is good in scale inhibition and slow release effects. The dosage of the scale inhibitor which needs to be added within a maintenance cycle can be estimated in advance according to the actual production condition of an oil well; the scale inhibitor is put into a sieve tube at the lower end of an oil-well pump of the oil well in regular repair and maintenance processes of an oil-well pipeline and a gathering pipeline; scale inhibition components are slowly dissolved and released to achieve the long-term scale inhibition effect through one-off addition when a produced liquid flows through the sieve tube, so that the long-term effective concentration can be maintained, the scale inhibiting ratio within the effective service cycle (about 90-120d) is greater than 85%, the effective release time can reach 90d or over, the protection period on the pipeline is long, and the production and maintenance cost of an oil field can be effectively reduced. The environment-friendly slow-release polymer scale inhibitor is nontoxic, harmless and degradable, and does not harm the formation and surrounding environment, and is environmentally friendly and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Corrosion mitigation and scale inhibition method for aluminum heat exchanger

InactiveCN104528966AComponent safety and environmental protectionSimple production processTreatment using complexing/solubilising chemicalsHexamethylenetetramineEngineering

The invention discloses a corrosion mitigation and scale inhibition method for an aluminum heat exchanger, belonging to the field of water treatment. A corrosion mitigation and scale inhibition agent used in the invention comprises polyaspartic acid, sodium silicate, phthalic diglycol diacrylate, poly(diallyldimethylammonium chloride), hexamethylenetetramine, bis(hydroxymethyl)-imidazolidinyl urea, methylisothiazolinone, trehalose, trihydroxymethyl aminomethane and water. The corrosion mitigation and scale inhibition agent prepared through an appropriate technical process has the advantages of storage stability, safe and environment-friendly components, no environmental pollution and the like, has excellent corrosion mitigation effect on an aluminum heat exchanger, is simple in preparation method, reasonable in design and easy to prepare, and has favorable application prospects.

Owner:赵哲 +2

Preparation method of modified polyaspartic acid scale inhibitor

InactiveCN104556431AApplicable to industrializationEasy to operateSpecific water treatment objectivesWater contaminantsPolyaspartic acidL-Aspartate

The invention provides a preparation method of a modified polyaspartic acid scale inhibitor and belongs to the technical field of water treatment of macromolecule materials. The preparation method of the modified polyaspartic acid scale inhibitor comprises the following two steps: firstly carrying out pyrocondensation polymerization reaction to obtain polysuccinimide in presence of a catalyst while L-aspartic acid is taken as a raw material; and secondly carrying out copolymerization on tripolycyanamide and polysuccinimide for 1-2 hours, and then washing and hydrolyzing, so that the modified polyaspartic acid scale inhibitor is obtained. The preparation method of the modified polyaspartic acid scale inhibitor can be used for obviously improving scale inhibition efficiency of polyaspartic acid and has the advantages of simple technique, easy operation, low environmental pollution, low production cost and the like.

Owner:程池

Application of scale inhibitor containing itaconic acid in hidden salt elimination tube

InactiveCN106115949ANo cloggingExtended service lifeScale removal and water softeningSulfite saltSodium salt

The invention relates to a scale inhibitor containing itaconic acid. The scale inhibitor comprises the following components in parts by weight: 32-36 parts of sodium ethylenediamine tetramethylene phosphonate, 21-25 parts of tetrasodium aminotrimethylene phosphonate , 11-15 parts of sodium polyacrylate, 10-14 parts of tartaric acid, 10-14 parts of itaconic acid, 6-10 parts of methylisothiazolinone, 6-10 parts of 2,2-dibromo-3-nitrilopropionamide 10 parts, 5-9 parts of tolyltriazole, 5-9 parts of sodium sulfite, 1-9 parts of sodium lauryl sulfate, 2-6 parts of methyl amyl alcohol, 1-5 parts of licorice extract, moon peach leaf 1-5 parts of extract, 52-56 parts of water, the antiscalant of the present invention is stable in nature, has a long storage period, and has good scale inhibition effect on the precipitation of inorganic salts in the salt-discharging dark pipe, and has no effect on the salt-discharging dark pipe. Corrosion and scale inhibition efficiency is high, the dosage is small, when it is discharged to the external environment, it will not cause environmental pollution, and there is no need for subsequent treatment costs.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

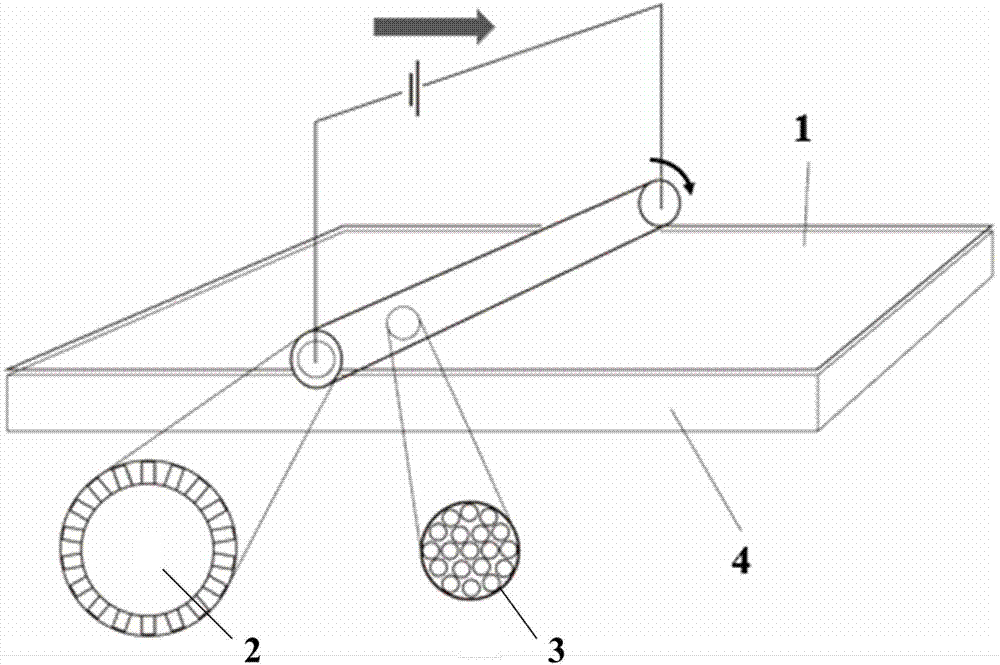

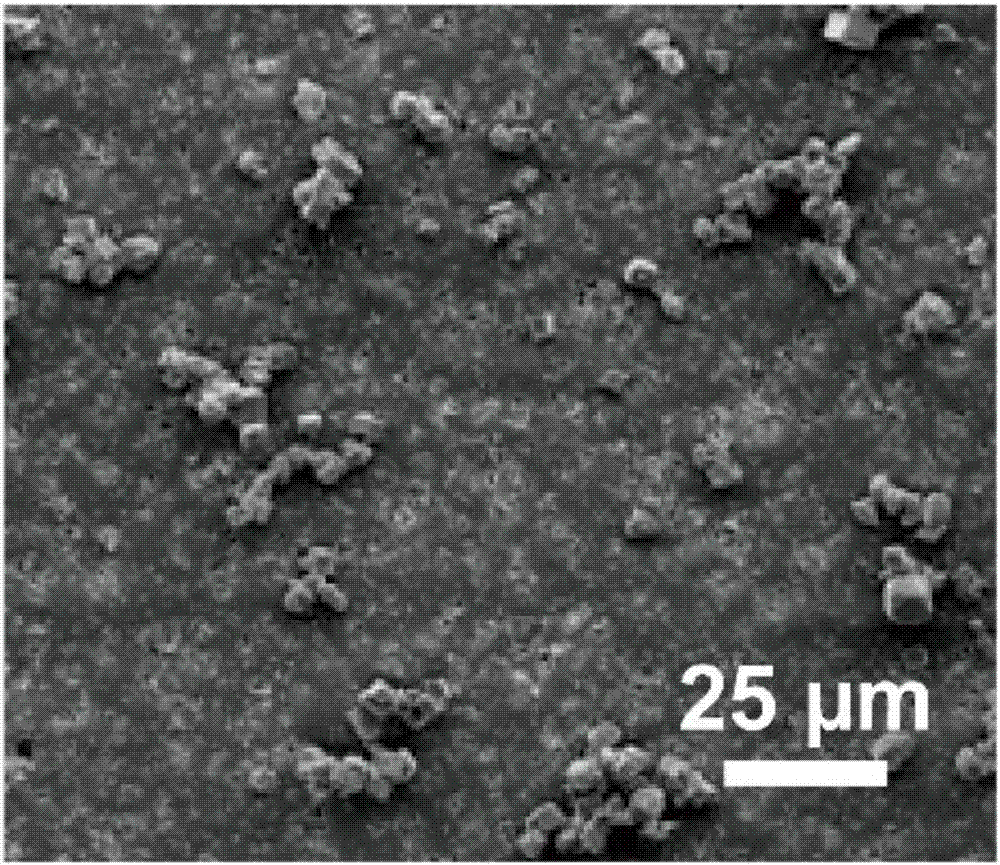

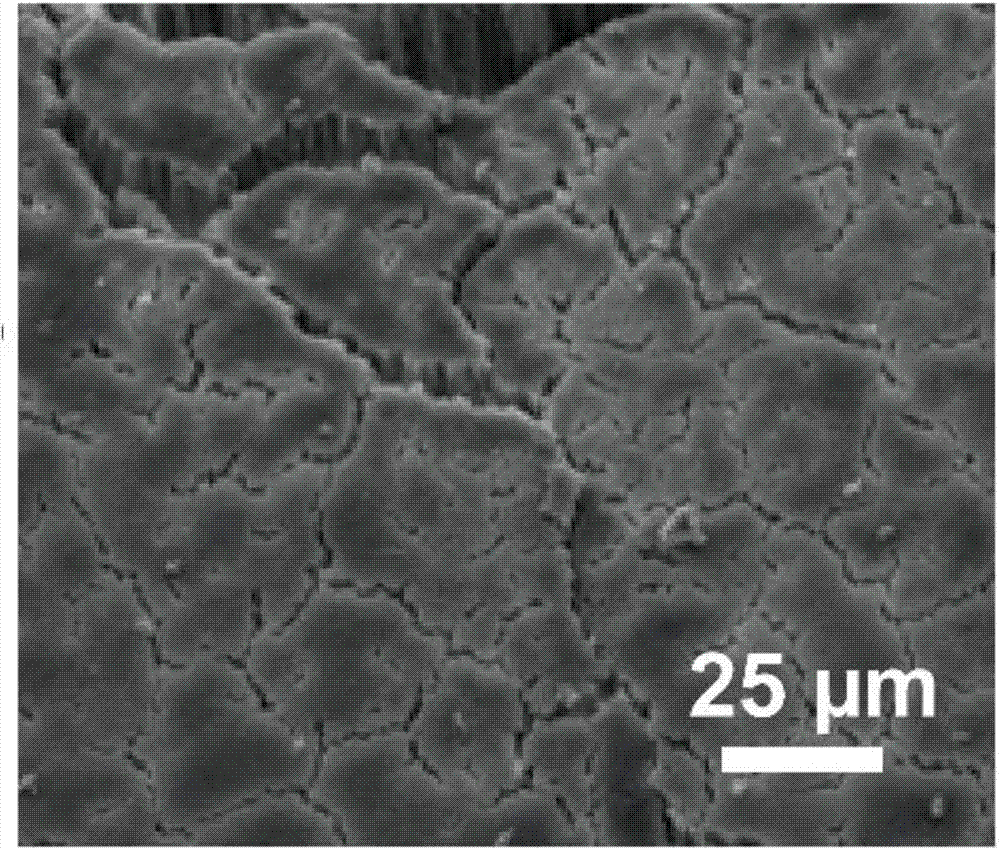

Composite coating with cilium structure and preparation method and application thereof

ActiveCN107141946AImprove performanceReduce performanceSurface reaction electrolytic coatingCoated surfaceMineral particles

The invention discloses a composite coating with a cilium structure and a preparation method and an application thereof. The composite coating with the cilium structure comprises a bottom coating and a surface coating. The surface coating is applied to the bottom coating. The bottom coating and the surface coating are fixed by means of cross linking. The surface coating has the nano cilium structure. The preparation method comprises the following steps of: firstly, coating the surface of a substrate with the bottom coating; and then continuously rolling and embossing the surface coating on the coating through an aluminum oxide porous rod and curing and applying the surface coating to the bottom coating to obtain a water-scale-preventing coating product. According to the composite coating with the cilium structure, hydrophilcity of a hydrogel and the nano cilium structure generate a synergistic effect, so that the nucleating probability of mineral particles in water on the surface of the coating can be reduced, and adhesion to generated mineral microcrystals is effectively reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for synthesizing polyepoxysuecinic acid salt

InactiveCN101538362BHigh degree of polymerizationGood for anti-scaling performanceScale removal and water softeningCalcium hydroxideFiltration

The invention discloses a method for synthesizing a polyepoxysuecinic acid salt, which is characterized by comprising the following steps of: dissolving maleic anhydride in deionized water; adding a solution of sodium hydroxide at 30 to 60 DEG C with stirring; adding sodium tungstate and hydrogen peroxide when the temperature is controlled to be between 60 to 100 DEG C; adjusting the pH value to 5 to 7 for reaction for 2 to 100 hours; cooling the reaction solution to below 20 DEG C; adding a precipitator, mixing and stirring the precipitator and the solution; performing suction filtration, adding water into filtrate obtained after suction filtration; keeping the pH value between 6 and 7; heating the filtrate added with water to 70 to 100 DEG C to obtain an epoxysuecinic acid salt; preparing a 0.2 to 4.0 mol / L aqueous solution of the epoxysuecinic acid salt; adding calcium hydroxide and a polymerization promoter into the aqueous solution for performing polymerization reaction till liquid turns yellowish and pasty; and cooling the yellowish and pasty liquid to room temperature to obtain the polyepoxysuccinic acid salt. The method has the advantages of good product quality, low raw material cost and product scale inhibition performance advantageous over that of the prior art.

Owner:北京合创同盛科技有限公司

Scale inhibitor for circulating water of boilers

InactiveCN108862643AStrong alkali resistanceGood synergyScale removal and water softeningCalcium biphosphatePolyaspartic acid

The invention provides a scale inhibitor for circulating water of boilers. The scale inhibitor is prepared from the following raw materials in parts by weight: 20-25 parts of polyepoxysuccinic acid, 12-16 parts of modified polyaspartic acid, 6-10 parts of starch, 10-15 parts of zinc salt, 4-8 parts of mercaptobenzothiazole, 1-3 parts of surfactants and 25-30 parts of water; the modified polyaspartic acid is prepared from lignosulfonic acid and oxalic acid through modification. By the scale inhibitor, environmental problems caused by phosphorus-containing mendicants in existing phosphorus-containing circulating cooling water are solved, and the good scale inhibition effect on calcium carbonate and calcium phosphate is achieved.

Owner:芜湖市颂晖商贸有限公司

Scale inhibitor for industrial circulating cooling water

InactiveCN108706748AStrong alkali resistanceIt has dual functions of anti-scaling and slow-releaseSpecific water treatment objectivesScale removal and water softeningCalcium biphosphatePolyaspartic acid

The invention provides a scale inhibitor for industrial circulating cooling water. The scale inhibitor is prepared from the following raw materials in parts by weight: 20 to 25 parts of polyepoxysuccinic acid, 12 to 16 parts of modified polyaspartic acid, 6 to 10 parts of acrylic-2-acryloylamino-2-methylpropionic acid copolymer, 10 to 15 parts of sodium gluconate, 3 to 6 parts of benzotriazole, 1to 3 parts of surfactant and 25 to 30 parts of water, wherein the modified polyaspartic acid is mainly prepared from lignosulfonic acid and oxalic acid by modification. The scale inhibitor solves theenvironmental problems caused by phosphorus-containing agents in existing phosphorus-containing circulating cooling water, and has very high scale inhibition performance for calcium carbonate and calcium phosphate.

Owner:芜湖市颂晖商贸有限公司

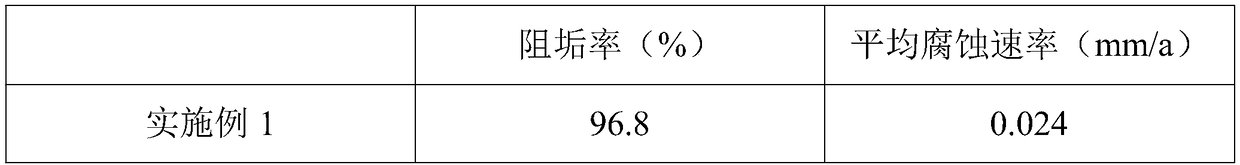

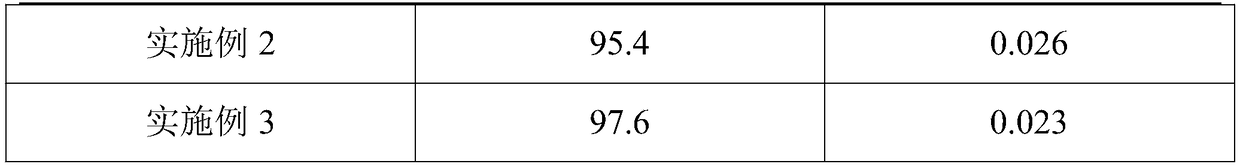

Phosphorus-free scale and corrosion inhibitor and preparation method thereof

InactiveCN110526424AReduce contentReduce depositionScale removal and water softeningNon-contaminated water treatmentBenzoic acidPolyaspartic acid

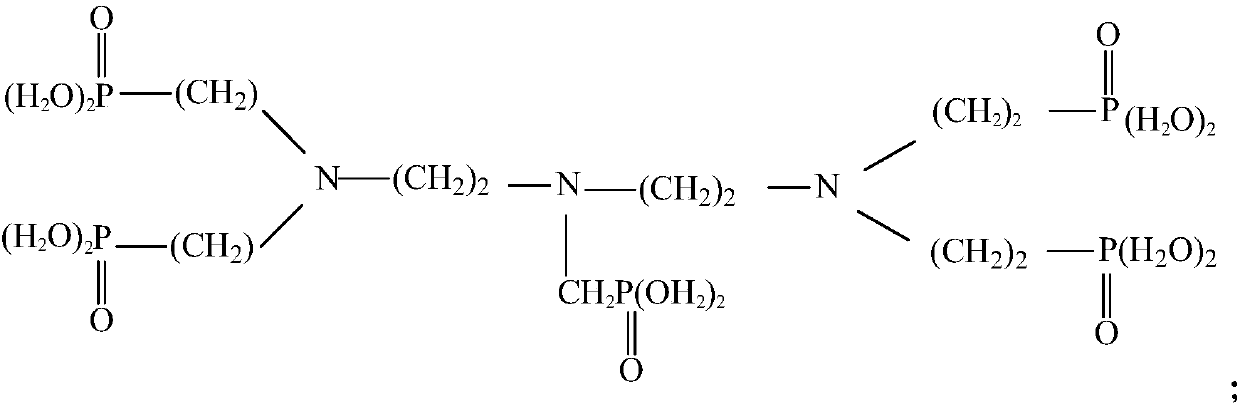

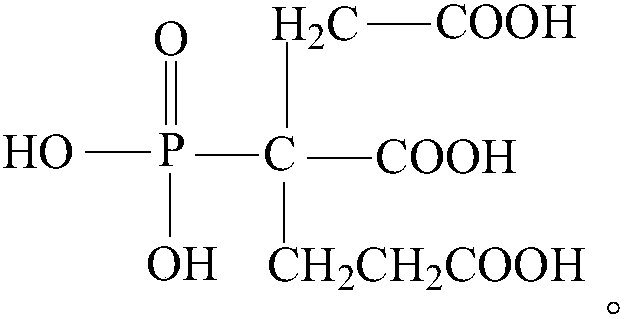

The invention provides a phosphorus-free scale and corrosion inhibitor. The phosphorus-free scale and corrosion inhibitor is characterized by being prepared from the following components in percentages by mass: 10-12% of gluconic acid and / or a salt thereof, 5-8% of benzoic acid and / or a salt thereof, 8-10% of 2-acrylamido-2-methylpropanesulfonic acid, 5-8% of polyaspartic acid and / or a salt thereof, 5-8% of polyepoxysuccinic acid and analogues thereof, 1-3% of ethylenediaminetetraacetic acid and / or a salt thereof and the balance of water. A scale and corrosion inhibitor phosphorus-free water treatment formula is adopted, and the effect is excellent.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

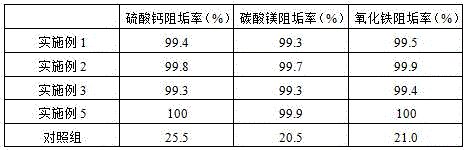

Scale inhibitor and application thereof

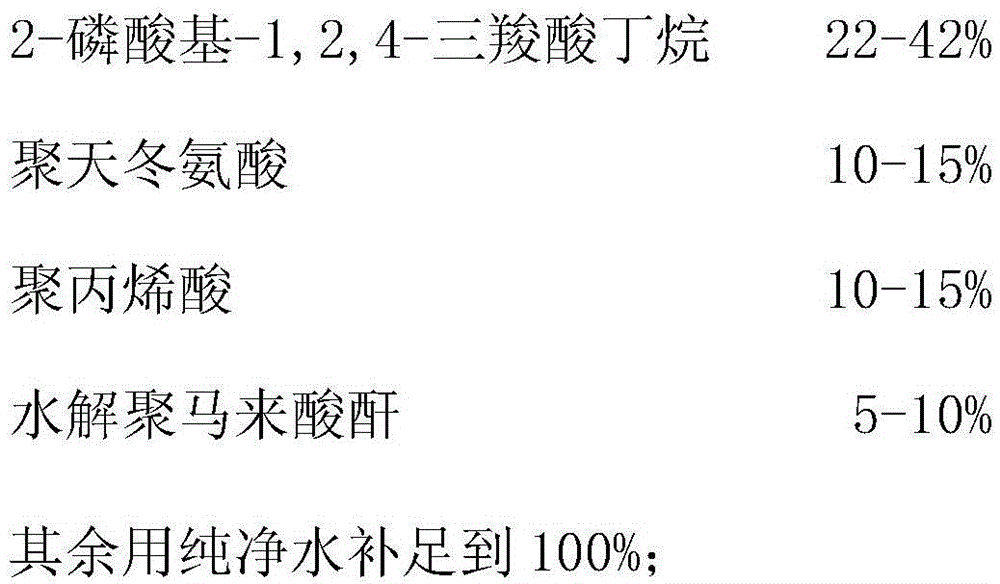

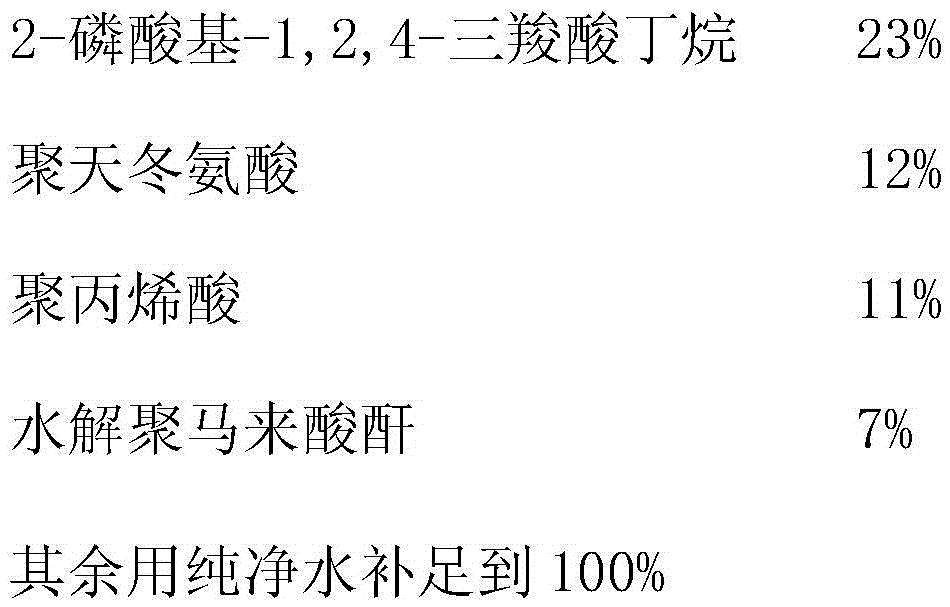

PendingCN107640833AHigh anti-scaling efficiencyReduce corrosionScale removal and water softeningPolyaspartic acidStereochemistry

The invention discloses a scale inhibitor and application thereof. The scale inhibitor is prepared from the following components: polyepoxysuccinic acid (A), diethylenetriaminepenta acid (B), 2-phosphonobutane-1,2,4-tricarboxylic acid (C) and polyaspartic acid (D). The scale inhibitor disclosed by the invention has high scale inhibition efficiency; moreover, compared with a general scale inhibitor, the scale inhibitor provided by the invention still has a very high scale inhibition rate when the pH value is within the range of 9 to 11.

Owner:CECEP L&T ENVIRONMENTAL TECH

Reverse osmosis scale inhibitor and preparation method thereof

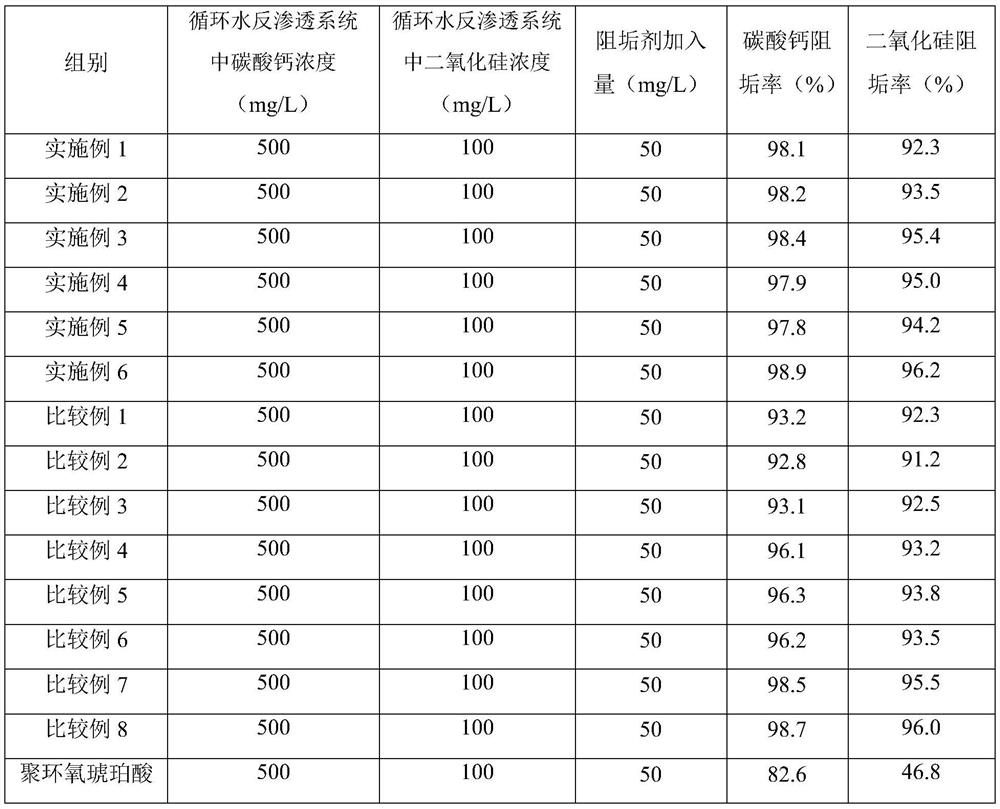

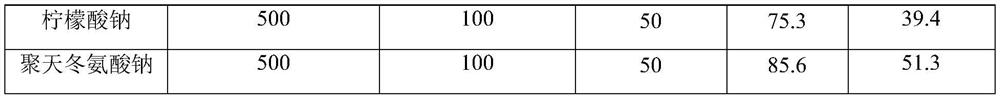

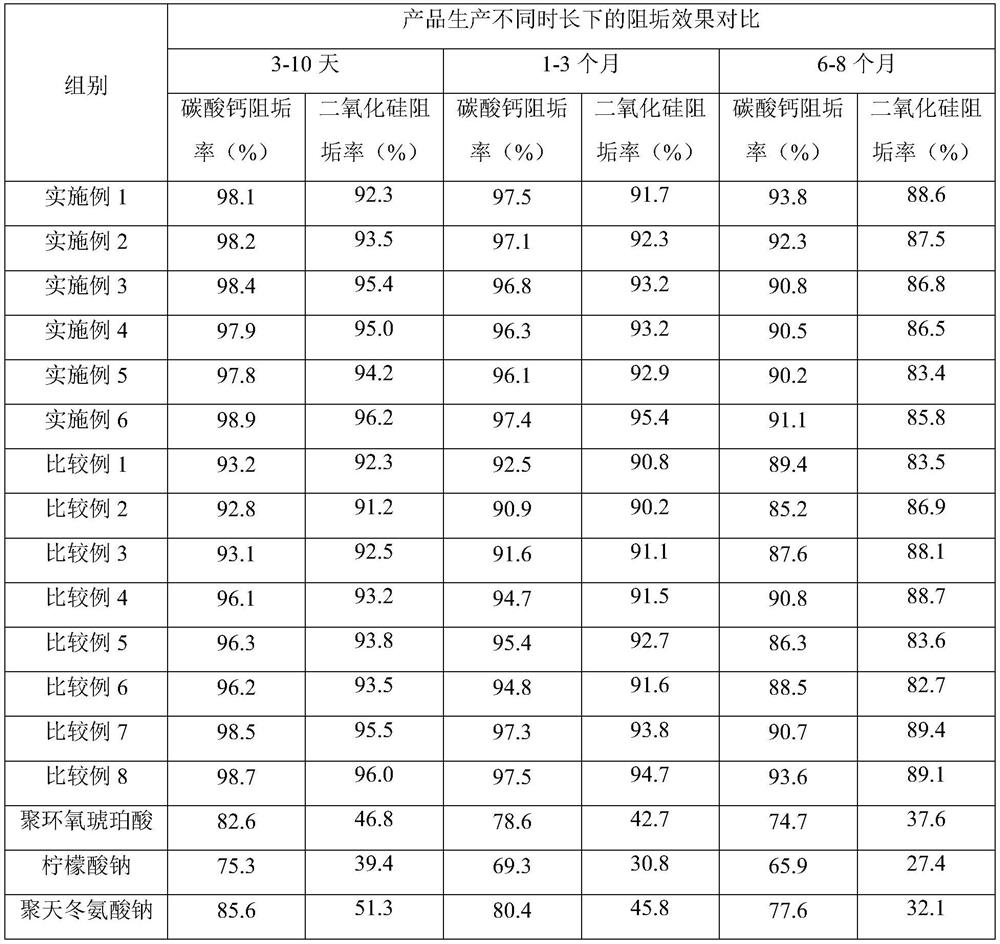

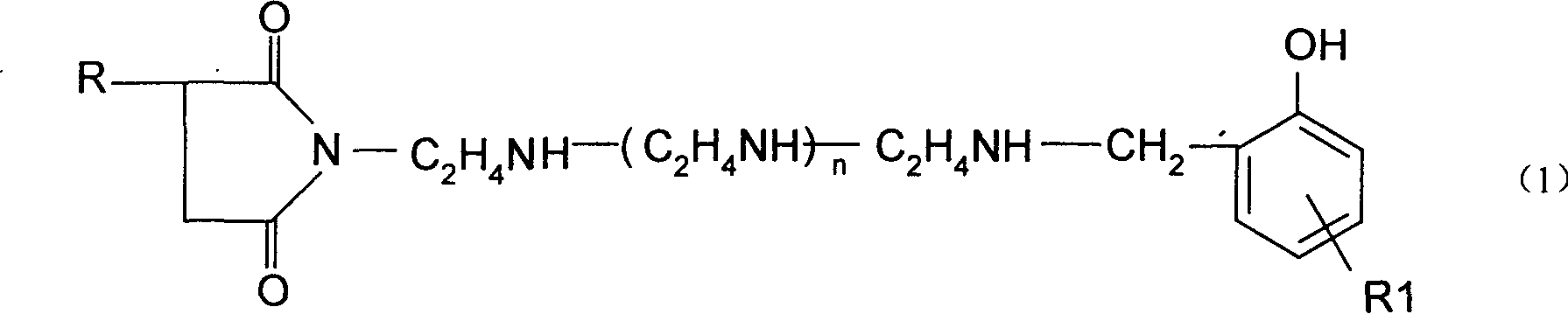

PendingCN113522025AHigh anti-scaling efficiencyReduce dosageScale removal and water softeningReverse osmosisMeth-Reverse osmosis

The invention provides a reverse osmosis scale inhibitor and a preparation method thereof, and the reverse osmosis scale inhibitor is mainly prepared from the following raw materials in parts by mass: 10 to 15 parts of sodium citrate, 15 to 25 parts of hydrolytic polymaleic anhydride, 20 to 25 parts of polyepoxysuccinate, 10 to 15 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 1 to 5 parts of polylactic acid and 15 to 44 parts of deionized water. The reverse osmosis scale inhibitor disclosed by the invention has good scale inhibition performance on silicon scale and calcium scale, is high in scale inhibition performance, environment-friendly, stable in property and long in storage period, and can ensure long-period stable operation of a system.

Owner:新疆水处理工程技术研究中心有限公司

Scale inhibitor of refining equipment

InactiveCN1283754CHigh anti-scaling efficiencyReduce coking and foulingThermal non-catalytic crackingProcess equipmentDistillation

Owner:张喜文

Metal oil dirt cleaning agent and preparation method thereof

The invention discloses a metal oil dirt cleaning agent and a preparation method thereof and belongs to the field of cleaning agents. Based on styrene, butyl acrylate and crylic acid as main monomers,emulsion is modified, and good film forming performance, aging resistance, water resistance and salt mist resistance are achieved. The emulsion serves as the main component, an auxiliary agent for preventing corrosion of the metal surface is formed through compounding, film forming performance is good, a protective film can be formed on the metal surface after cleaning, a metal substrate can be well isolated from the outside environment, thus corrosion to the metal substrate is delayed effectively, and the metal surface is protected. The problems that at present, certain phosphorus-containingauxiliary agents and APEO surfactants are often added into metal oil dirt cleaning agents and cause large harm to the environment, the existing cleaning agents only have a cleaning function generallyand do not have a rustproof function, rustproof treatment is needed immediately after cleaning, time and labor are wasted, and cost is high are solved.

Owner:CHANGZHOU AMANTE CHEM CO LTD

Application of scale inhibitor with good antibacterial effect in salt discharge underground pipe

InactiveCN106242095AExtended service lifeNo cloggingBiocideScale removal and water softeningButylated hydroxytoluenePolyacrylamide

The invention relates to a scale inhibitor with good antibacterial effect, and the scale inhibitor comprises the following components by weight: 33-37 parts of ethylenediamine tetramethylene phosphonic acid, 18-22 parts of amino trimethylene phosphonic acid pentasodium, 9-13 parts of poly aspartic acid, 8-12 parts of citric acid, 10-14 parts of hydroxyethylidene-1,1-diphosphonic acid, 3-7 parts of sodium polyacrylate, 10-14 parts of dithiocyano-methane, 9-13 parts of dioctadecyl dimethyl ammonium chloride, 3-7 parts of butylated hydroxytoluene, 3-7 parts of dioctyl sodium sulfosuccinate, 3-7 parts of polyacrylamide, 1-5 parts of dandelion extract, 1-5 parts of lemon extract and 56-60 parts of water, the scale inhibitor has good inhibitory effect on bacteria breeding in a salt discharge underground pipe, has good scale inhibition effect on inorganic salt precipitation in the salt discharge underground pipe, is stable in property and long in storage period, and may not cause corrosion of the wall of the salt discharge underground pipe.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

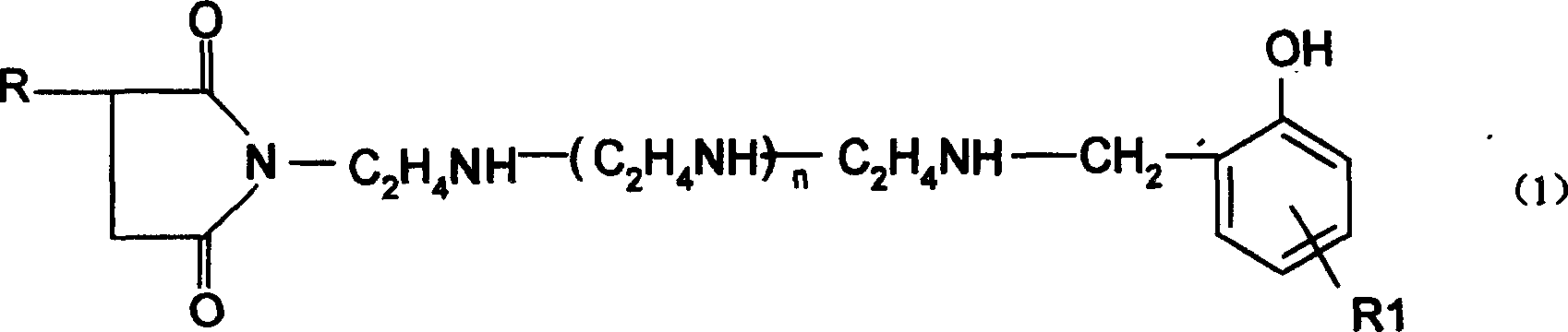

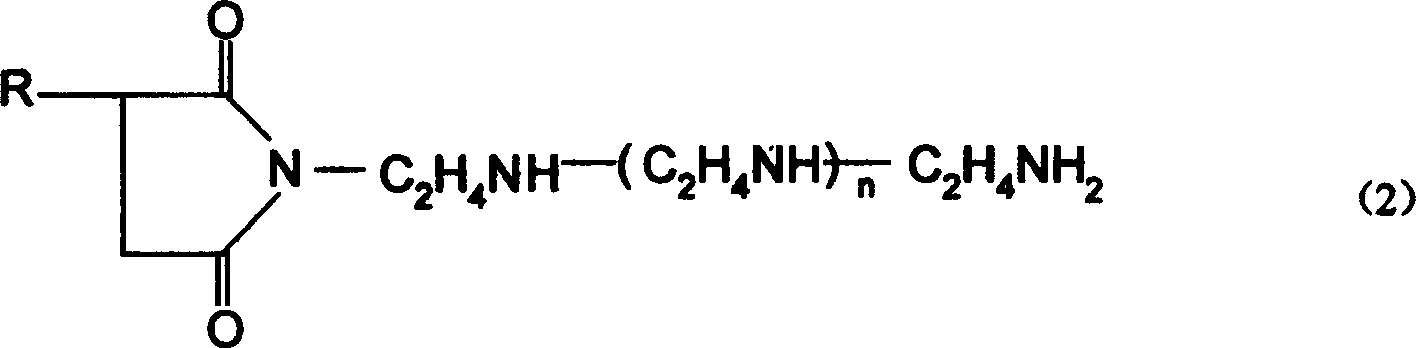

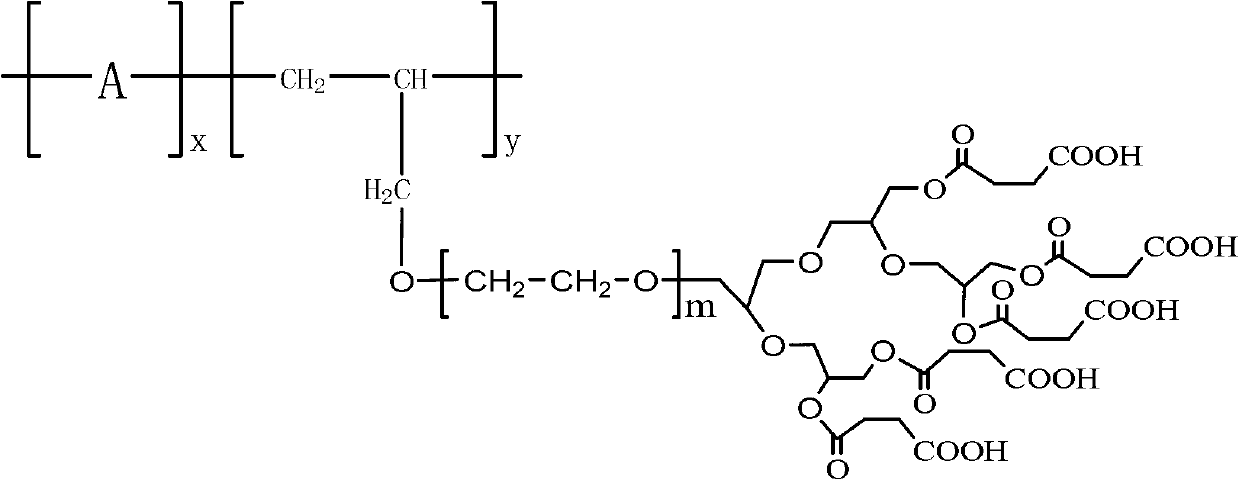

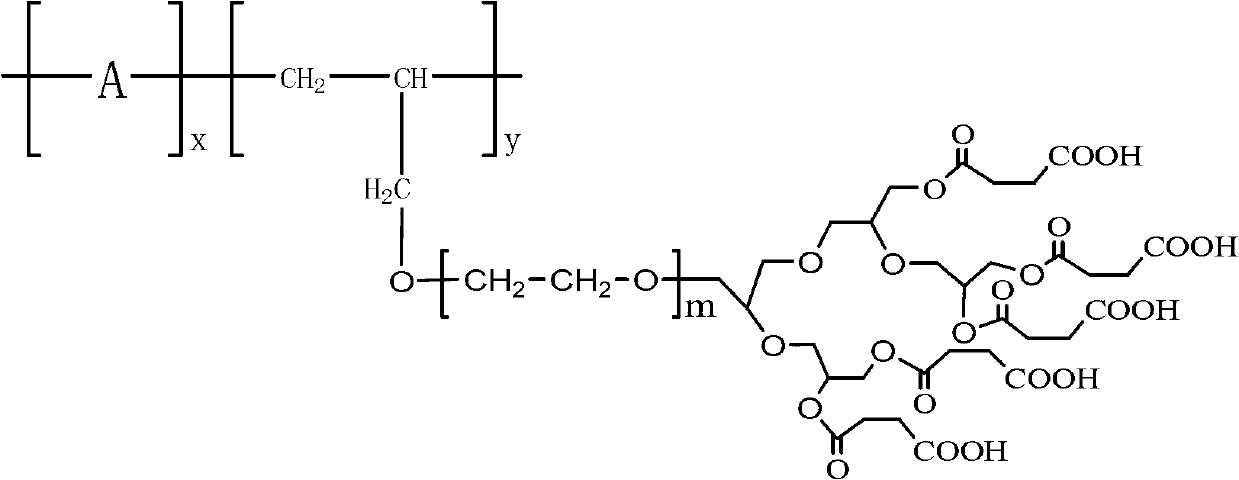

Environment-friendly branched polyether water treatment agent and preparation method thereof

InactiveCN102807285AImprove performancePromote degradationScale removal and water softeningWater qualityNitrogen

The invention provides an environment-friendly branched polyether water treatment agent (APEZ), and relates to a phosphorus-free and nitrogen-free and biodegradable environment-friendly branched polyether water treatment agent and a preparation method of the water treatment agent, belongs to the field of preparation and application of water treatment agents, and is applicable to a circulating cooling water system, in particular to high-calcium cooling water. The water treatment agent is prepared by subjecting polyether carboxylic acid reactive monomer and vinyl unsaturated double-bond containing monomer to free-radical copolymerization, and the water treatment agent has a structural formula shown in the description, wherein A is a repetition structure unit obtained by copolymerizing the vinyl unsaturated double-bond containing monomer, and the repetition structure unit has the polymerization degree x of 1 to 5000, and polymerization degree y of 1 to 5000, and the repetitive unit m is 1 to 100. A dirt dispersion agent is biodegradable, has excellent effect of inhibiting scales from Ca3 (PO4)2, CaCo3 and CaSO4, and high dispersion performance, and is an environment-friendly polyether water treatment agent.

Owner:SOUTHEAST UNIV

Application of antisludging agent containing citric acid in salt elimination closed conduit

InactiveCN106082460AStable in natureLong storage periodSpecific water treatment objectivesScale removal and water softeningTricarboxylic acidSodium sulfate

The invention relates to an antisludging agent containing citric acid. The antisludging agent is prepared from, by weight, 26-30 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, 15-19 parts of diethylenetriamine pentasodium bistriaminopenta, 7-11 parts of polyaspartic acid, 6-10 parts of citric acid, 4-8 parts of 1-bromo-3-chloro-5,5-dimethyl hydantoin, 4-8 parts of tertiary butyl hydroquinone, 3-7 parts of sodium glycocholate, 3-7 parts of lauryl sodium sulfate, 2-6 parts of tertiary butylhydroquinone, 0.5-0.9 part of a Kombuchka extracting solution, 0.4-0.8 part of a cactus extracting solution and 54-58 parts of deionized water. The antisludging agent is stable in character and long in storage life, has the good scale inhibition effect on inorganic salt sedimentations in a salt elimination closed conduit, and is free of corrosion of the salt elimination closed conduit.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

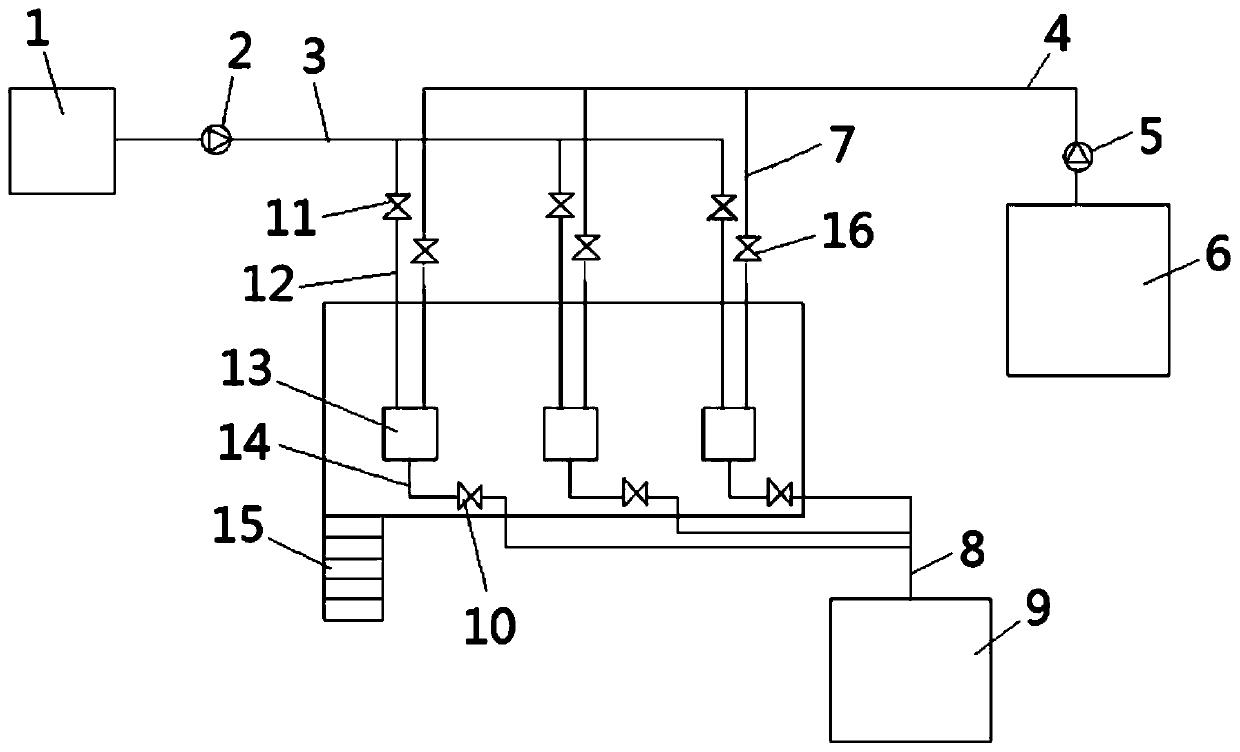

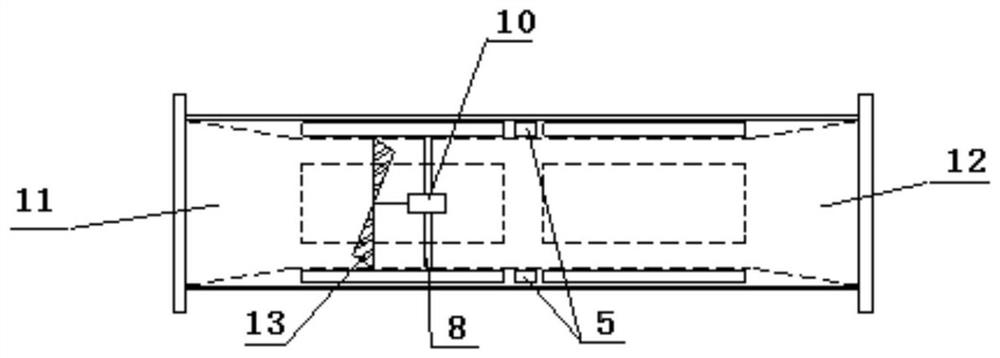

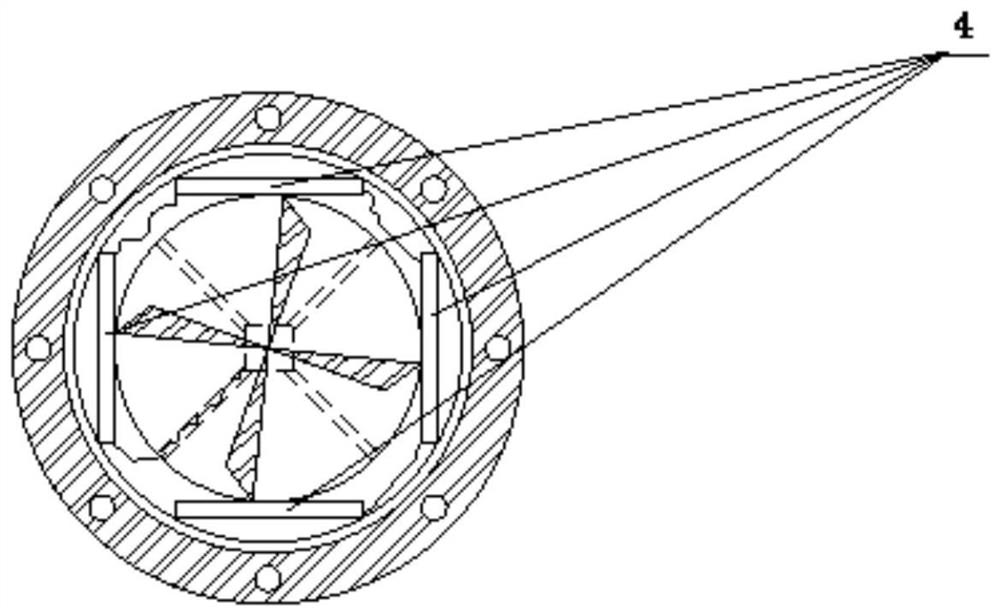

Fluorescence automatic detection non-phosphorus scale and corrosion inhibitor and processing equipment thereof

PendingCN109761379AReduce depositionGuaranteed service lifeScale removal and water softeningHigh concentrationAutomatic control

The invention relates to the field of water treatment, in particular to a fluorescence automatic detection non-phosphorus scale and corrosion inhibitor, which is prepared from the following raw materials in percentage by mass: 20 to 25 percent of sodium gluconate, 14 to 18 percent of sodium benzoate, 3 to 6 percent of 2-acrylamide-2-methylpro panesulfonic acid, 2 to 4 percent of benzotriazole, 15to 18 percent of polyaspartic acid, 0.1 percent of fluorescent agents and the balance water. The invention also discloses processing equipment of the fluorescence automatic detection non-phosphorus scale and corrosion inhibitor. The equipment comprises a water tank, a chemical adding tube, a chemical tube and a material tube. The efficient low-phosphorus or no-phosphorus water treatment formula isused; the conventional scale and corrosion inhibitor is replaced; the scale decomposition of the circulation water system can be reduced; the scale inhibition efficiency is improved; the corrosion isreduced; the heat exchange effect of the equipment is ensured; the service life of the equipment and a pipeline is prolonged; the biological degradation is easy; the environment is protected; the high-concentration times are realized; the water consumption is reduced; the fluorescence automatic detection non-phosphorus scale and corrosion inhibitor can be conveniently connected with element tracking equipment for intelligently and automatically detecting the water quality; the chemical addition is automatically controlled; the cost is reduced.

Owner:BEIJING JIEYUTONG ENVIRONMENTAL PROTECTION SCI & TECH

Antiscalant for reverse osmosis

ActiveCN104906961BBiodegradableGood retarding effectSemi-permeable membranesScale removal and water softeningHexamethylenetetramineReverse osmosis

The invention discloses a novel reverse-osmosis scale inhibitor which comprises the following raw materials in parts by weight: 2-8 parts of sodium citrate, 33-45 parts of hydrolytic polymaleic anhydride, 28-37 parts of polyepoxysuccinic acid salt, 9-15 parts of urotropine, 13-20 parts of polylactic acid, and 40-50 parts of water. A preparation method comprises the following steps: adding sodium citrate, hydrolytic polymaleic anhydride, polyepoxysuccinic acid salt, urotropine and half of water into a reaction kettle, heating to 40-50 DEG C, and stirring for uniformly dissolving; dissolving polylactic acid with the rest water to obtain a polylactic acid solution; heating the materials in the reaction kettle to 70-75 DEG C, dropwise adding the polylactic acid solution, and keeping the temperature for 3-4h after the dropwise adding is finished; and cooling to room temperature so as to obtain the novel reverse-osmosis scale inhibitor. The novel reverse-osmosis scale inhibitor disclosed by the invention has the scale inhibition rate being up to 95%, is small in adding amount, environmentally friendly, stable in property, and long in storage period, and can be used for solving the problems that existing reverse-osmosis inhibitors mainly are foreign products and are limited in treatment capacity, complex in synthesis, relatively high in production cost, and the like in the prior art.

Owner:浙江川宁环保科技有限公司

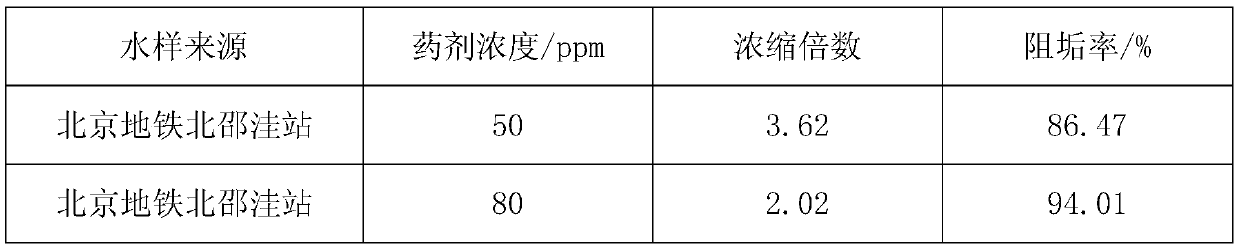

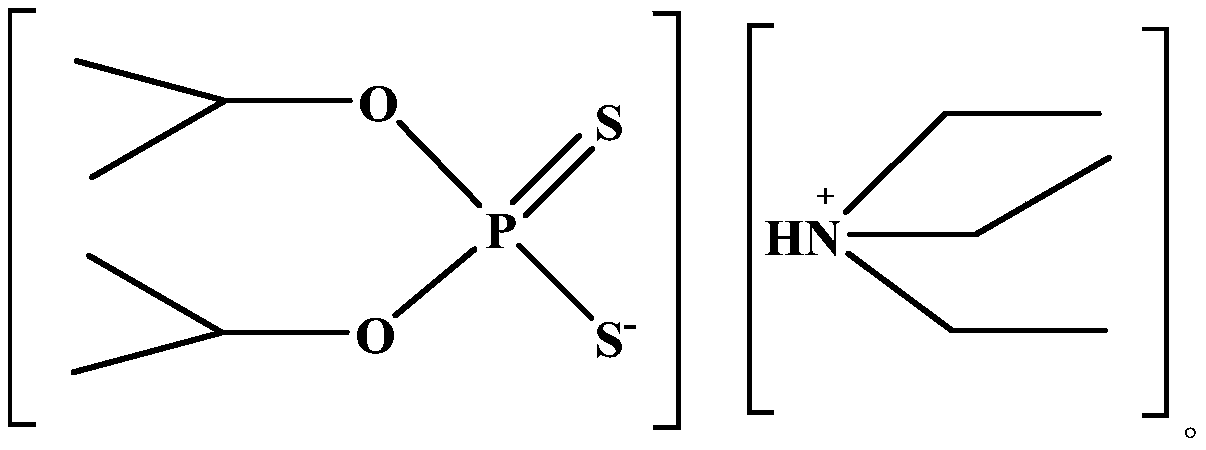

Novel scale inhibitor and application thereof

ActiveCN110127871AGood water solubilityImprove performanceSpecific water treatment objectivesScale removal and water softeningSocial benefitsSolubility

The invention discloses a novel scale inhibitor and application thereof, belongs to the field of water treatment, and aims to solve the problem that the existing scale inhibitor for industrial circulating water is generally a compound scale inhibitor formed by mixing a plurality of substances and is large in use amount. The novel scale inhibitor is a single-component scale inhibitor, and the molecular formula of the scale inhibitor is O,O'-diisopropyldithiophosphate triethylamine. The scale inhibitor has the advantages of being single in component, small in dosage, high in scale inhibition efficiency, stable in performance, good in water solubility and easy to use. The scale inhibitor can improve the recycling rate of circulating water and reduce the consumption of water resources. The novel scale inhibitor is suitable for scale inhibition of circulating water, is especially suitable for scale inhibition of circulating water in the fields of oil field sewage systems, small boilers, heating networks and the like, has wide application values and good application prospects, can bring remarkable economic benefits and social benefits, and is worthy of large-scale popularization and application.

Owner:四川文理学院

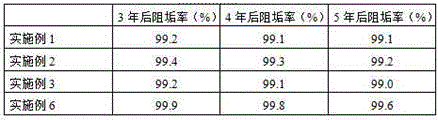

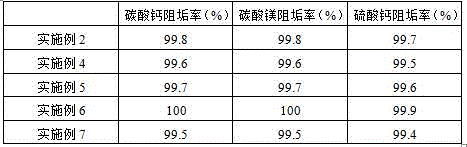

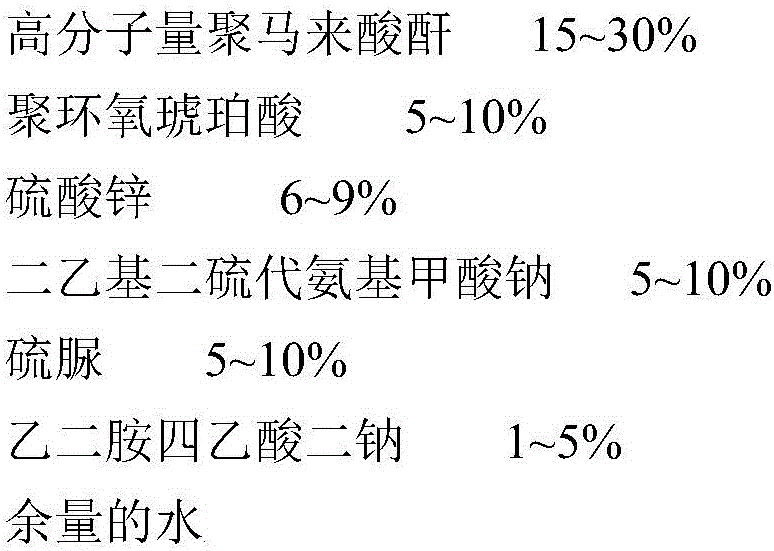

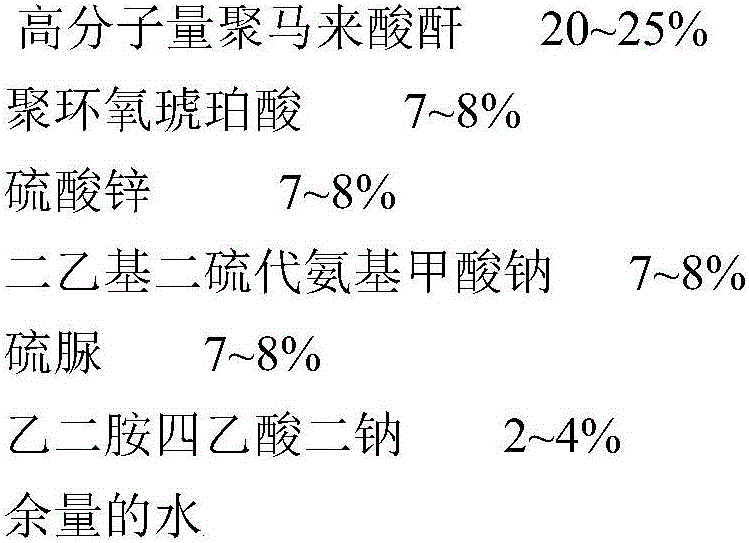

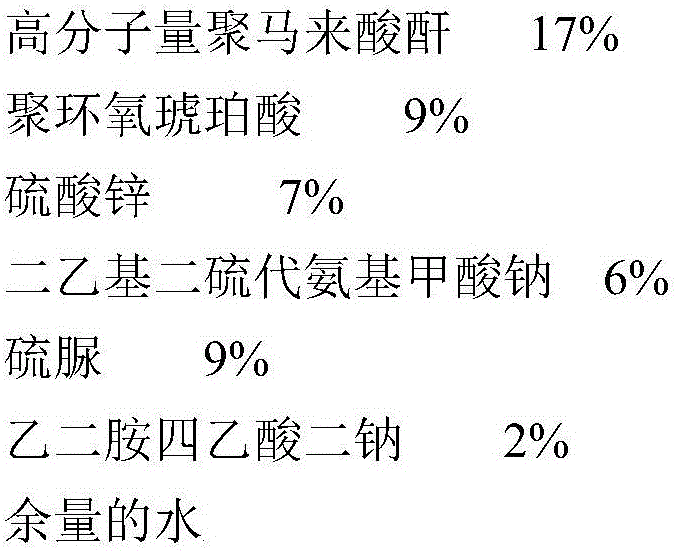

Scale and corrosion inhibitor for oil field system

ActiveCN104925966BGood compatibilityGood synergyWaste water treatment from quariesTreatment using complexing/solubilising chemicalsThioureaSodium carbamate

The invention provides a scale and corrosion inhibitor for oil field systems, which belongs to the technical field of water treatment, and its ingredients are composed of 15-30% of high molecular weight polymaleic anhydride, 5-10% of polyepoxy succinic acid, and zinc sulfate 6~9%, sodium diethyldithiocarbamate 5~10%, thiourea 5~10%, disodium edetate 1~5% and the rest water. The invention provides an efficient, phosphorus-free and environmentally friendly scale and corrosion inhibitor for oil field systems, especially suitable for oil field systems with high alkalinity, high salinity, high chloride radicals, and serious silicate scale. The components have good compatibility, synergy and complementarity, and the scale inhibition rate can be as high as 99.9%, and the corrosion inhibition rate can be as high as 98.5%.

Owner:安徽海瀚水处理科技有限公司

Scale removal and prevention agent for boiler and preparation method of scale removal and prevention agent

InactiveCN104445646AHigh anti-scaling efficiencyLong drug release cycleSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsSodium phosphatesAmmonium nitrate

The invention discloses a scale removal and prevention agent for a boiler and a preparation method of the scale removal and prevention agent. The scale removal and prevention agent is prepared from the following raw materials in parts by weight: 25-60 parts of citric acid, 15-35 parts of hydrochloric acid, 12-40 parts of sodium chloride, 12-35 parts of sodium hexametaphosphate, 8-25 parts of sodium pyrophosphate, 13-25 parts of acrylic acid, 8-22 parts of ammonium nitrate, 8-19 parts of sulfamic acid and 35-60 parts of de-ionized water. The scale removal and prevention agent can be used for different boilers, the scale prevention rate reaches more than 95%, and the energy consumption of the boiler is remarkably reduced.

Owner:苏州启德胜环保科技有限公司

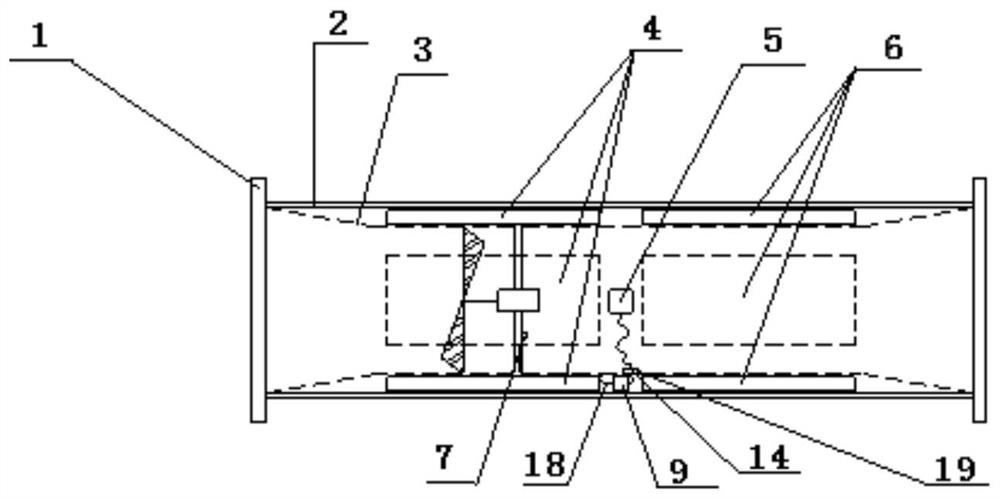

anti-scaling equipment

ActiveCN108275787BGuaranteed transmission efficiencySufficient powerScale removal and water softeningEngineeringIndustrial water

Owner:XI'AN POLYTECHNIC UNIVERSITY

A kind of membrane antiscalant and preparation method thereof

ActiveCN104258734BControl formationImprove stabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAlkalinityPolyaspartic acid

Owner:山东森盛隆环保科技有限公司

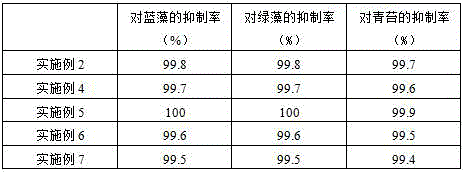

Application of antisludging agent for inhibiting algae breeding to salt removal closed conduit

InactiveCN106082461AEnhanced inhibitory effectExtended service lifeSpecific water treatment objectivesScale removal and water softeningAlkylphenolDioxyethylene Ether

The invention relates to an antisludging agent for inhibiting algae breeding. The antisludging agent is prepared from, by weight, 23-27 parts of diethylene triamine penta methylene phosphonic acid, 15-19 parts of hydroxyethanediphosphonic acid sodium salt, 10-14 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 10-14 parts of zinc sulfate, 3-7 parts of 1-bromo-3-chloro-5,5-dimethyl-2,4-imidazolidinedione, 3-7 parts of trichloroisocyanuric acid, 2-6 parts of butylated hydroxyanisole, 2-6 parts of alkylphenol ethoxylates, 2-6 parts of lauryl sodium sulfate, 1-5 parts of 2,6-bis-4-methylphenol, 0.5-0.9 part of bitter orange petal raw extraction solution, 0.5-0.9 part of bergamot extraction solution and 55-59 parts of deionized water. The antisludging agent has a good inhibition function on algae breeding in a salt removal closed conduit, has a good antisludging effect on precipitation of inorganic salt in the salt removal closed conduit, is biodegradable, and does not corrode the wall of the salt removal closed conduit.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com