Composite coating with cilium structure and preparation method and application thereof

A technology of composite coating and cilia, which is applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of environmental pollution, scale crystal adhesion on the surface, etc., and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

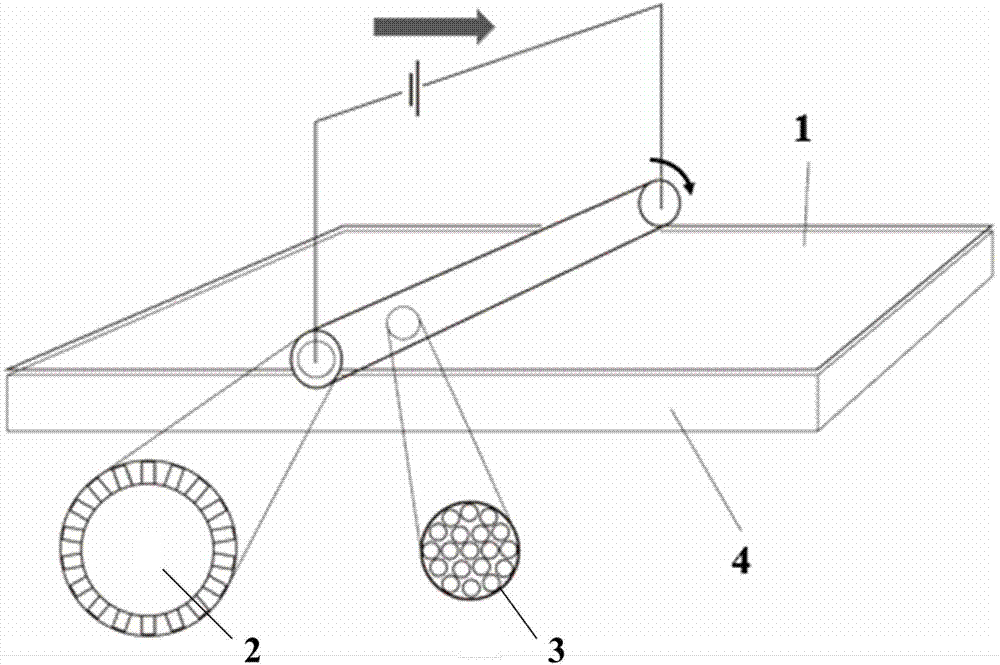

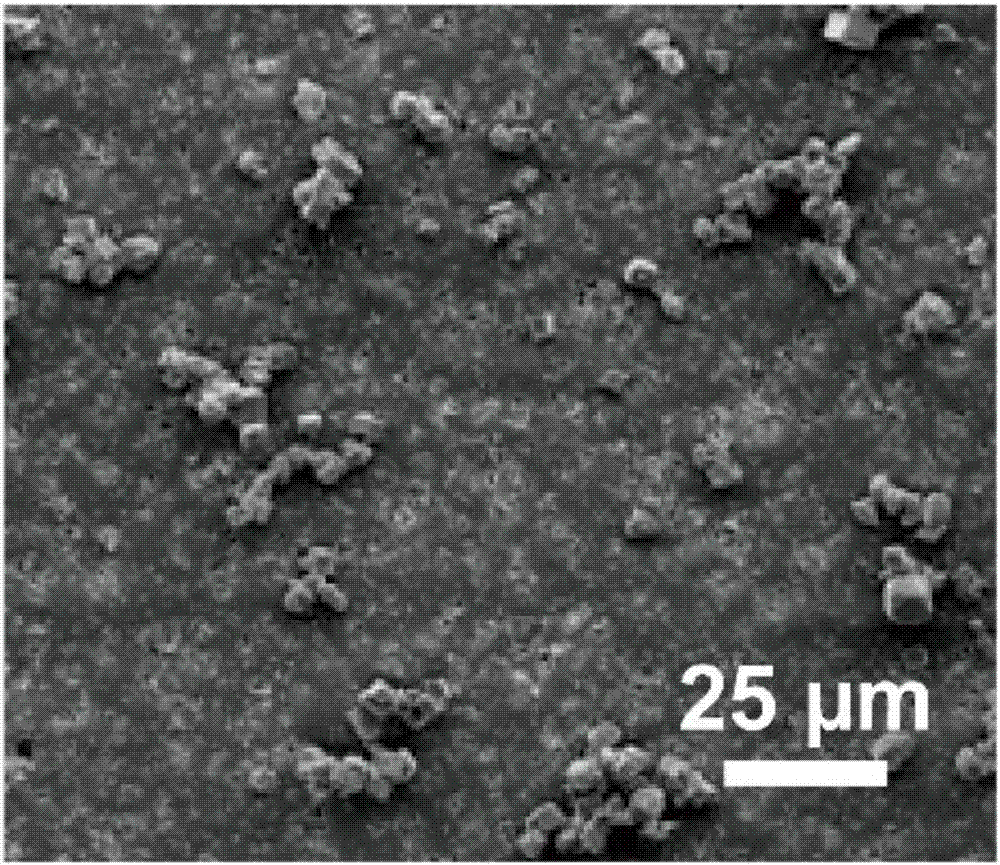

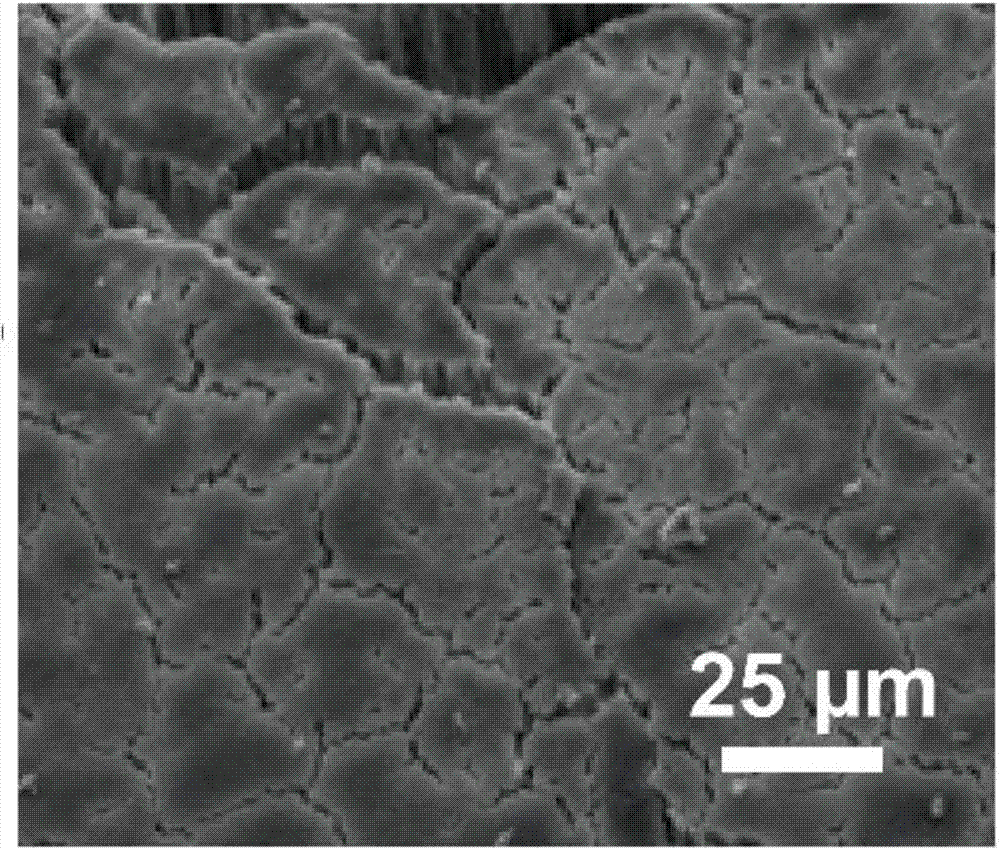

[0079] A porous alumina rod such as figure 1 The enlargement of the cross-section 2 of the alumina rod and the small hole on the outer surface of the alumina rod in image 3 As shown, its surface has honeycomb pores, and the preparation method is as follows:

[0080] 1) Connect the aluminum rod to the positive pole of the power supply as the anode, and connect the graphite to the negative pole of the power supply as the cathode. Immerse in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 at 0°C, turn on the power, set the voltage to 15V, and electropolish for 20 minutes;

[0081] 2) Immerse the electropolished anode and cathode in step 1) in an oxalic acid solution with a concentration of 0.1mol / L at 0°C, turn on the power, set the voltage to 40V, and oxidize for 6h;

[0082] 3) Dip the oxidized aluminum rod in step 2) into a phosphoric acid solution with a mass concentration of 4 wt% at 30°C, and expand the holes for 10 minutes. After washing with...

Embodiment 2

[0085] A porous aluminum oxide rod, the preparation method is as follows:

[0086] 1) Connect the aluminum rod to the positive pole of the power supply as the anode, and connect the graphite to the negative pole of the power supply as the cathode. Immerse in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 at 0°C, turn on the power, set the voltage to 15V, and electropolish for 20 minutes;

[0087] 2) Immerse the electropolished anode and cathode in step 1) in an oxalic acid solution with a concentration of 0.1mol / L at 0°C, turn on the power, set the voltage to 140V, and oxidize for 6 hours;

[0088] 3) Immerse the oxidized aluminum rod in step 2) in a phosphoric acid solution with a mass concentration of 4 wt% at 30°C, and expand the holes for 30 minutes. After washing with acetone and water, dry in a vacuum oven at 70°C for 6 hours to obtain a porous alumina rod.

[0089] The depth of the pores on the outer surface of the prepared alumina porous r...

Embodiment 3

[0091] A porous aluminum oxide rod, the preparation method is as follows:

[0092] 1) Connect the aluminum rod to the positive pole of the power supply as the anode, and connect the graphite to the negative pole of the power supply as the cathode. Immerse in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 at 0°C, turn on the power, set the voltage to 15V, and electropolish for 20 minutes;

[0093] 2) Immerse the electropolished anode and cathode in step 1) in an oxalic acid solution with a concentration of 0.2 mol / L at 0°C, turn on the power, set the voltage to 200V, and oxidize for 3 hours;

[0094] 3) Dip the oxidized aluminum rod in step 2) into a phosphoric acid solution with a mass concentration of 4 wt% at 30°C, and expand the holes for 10 minutes. After washing with acetone and water, dry in a vacuum oven at 70°C for 6 hours to obtain a porous alumina rod.

[0095] The depth of the pores on the outer surface of the prepared alumina porous ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com