Patents

Literature

31893 results about "Aluminium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium oxide (IUPAC name) or aluminum oxide (American English) is a chemical compound of aluminium and oxygen with the chemical formula Al₂O₃. It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium(III) oxide. It is commonly called alumina and may also be called aloxide, aloxite, or alundum depending on particular forms or applications. It occurs naturally in its crystalline polymorphic phase α-Al₂O₃ as the mineral corundum, varieties of which form the precious gemstones ruby and sapphire. Al₂O₃ is significant in its use to produce aluminium metal, as an abrasive owing to its hardness, and as a refractory material owing to its high melting point.

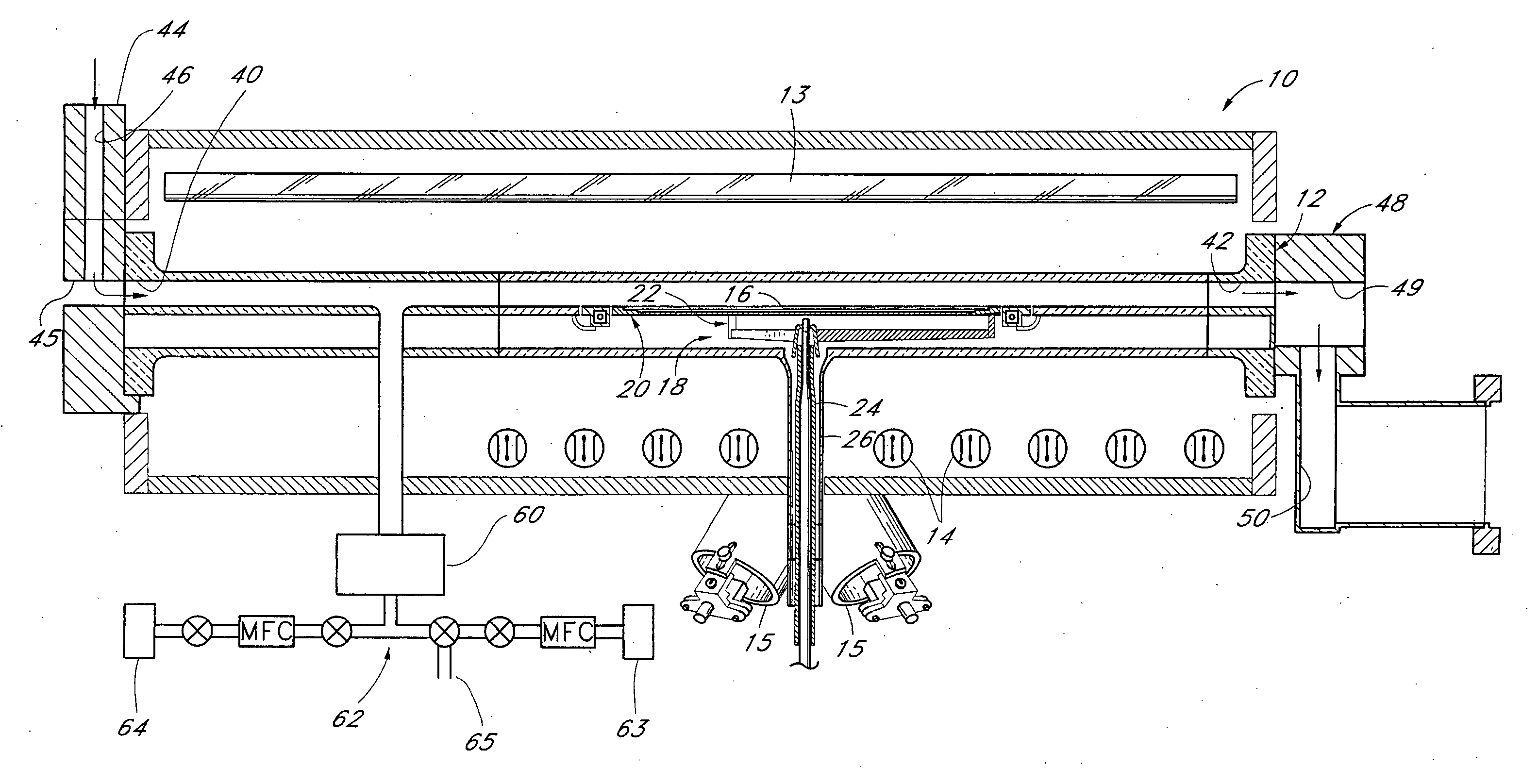

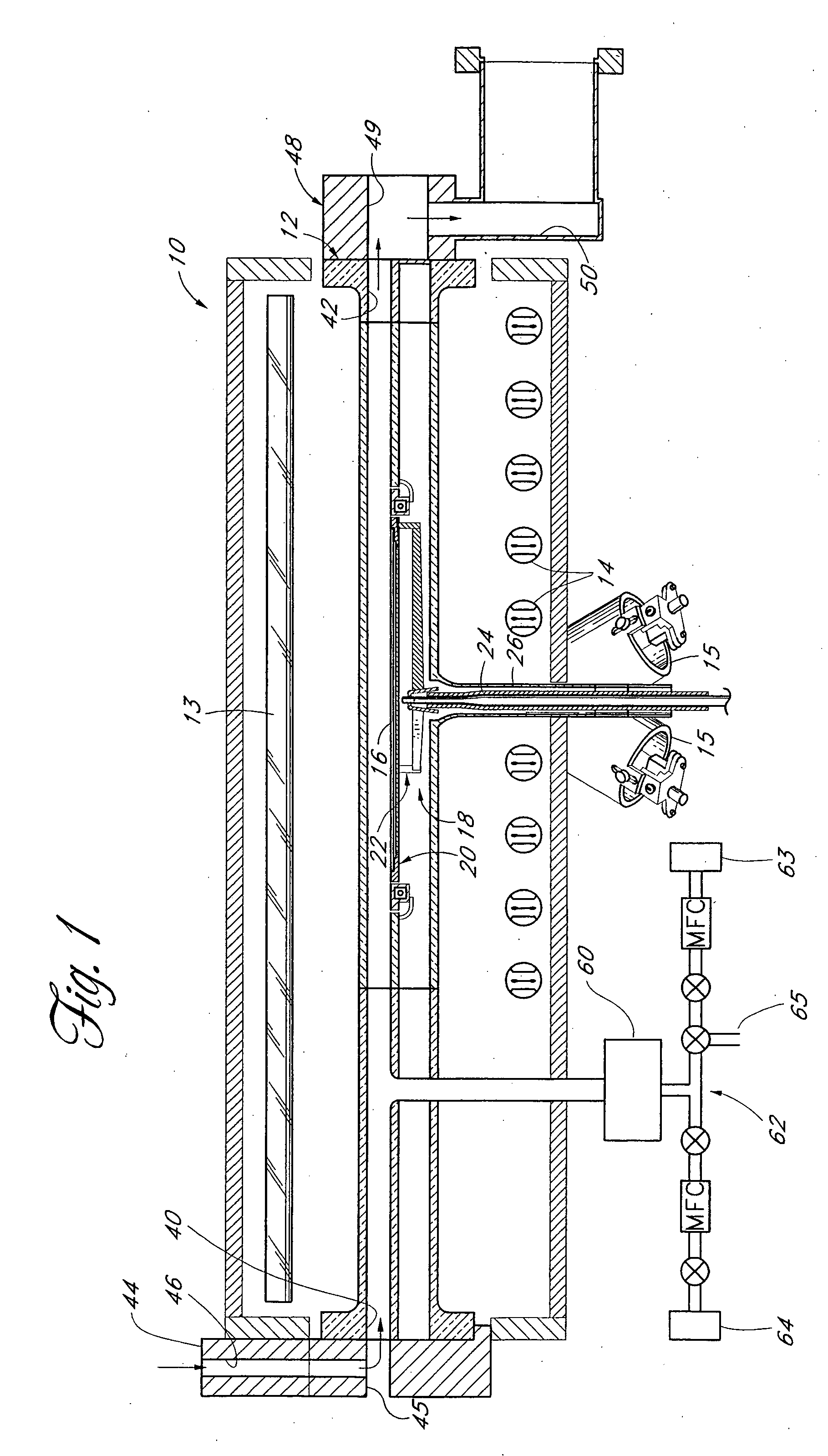

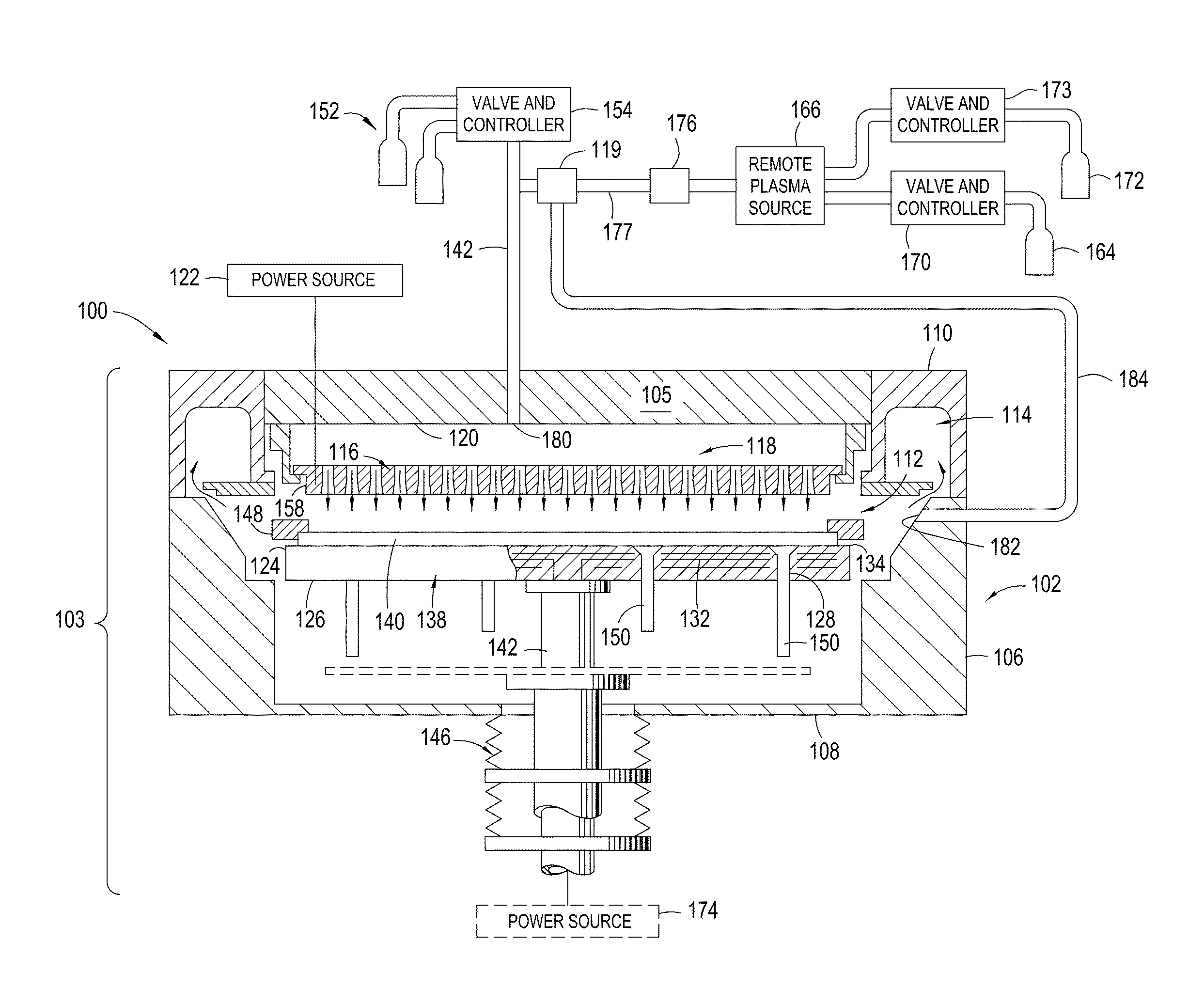

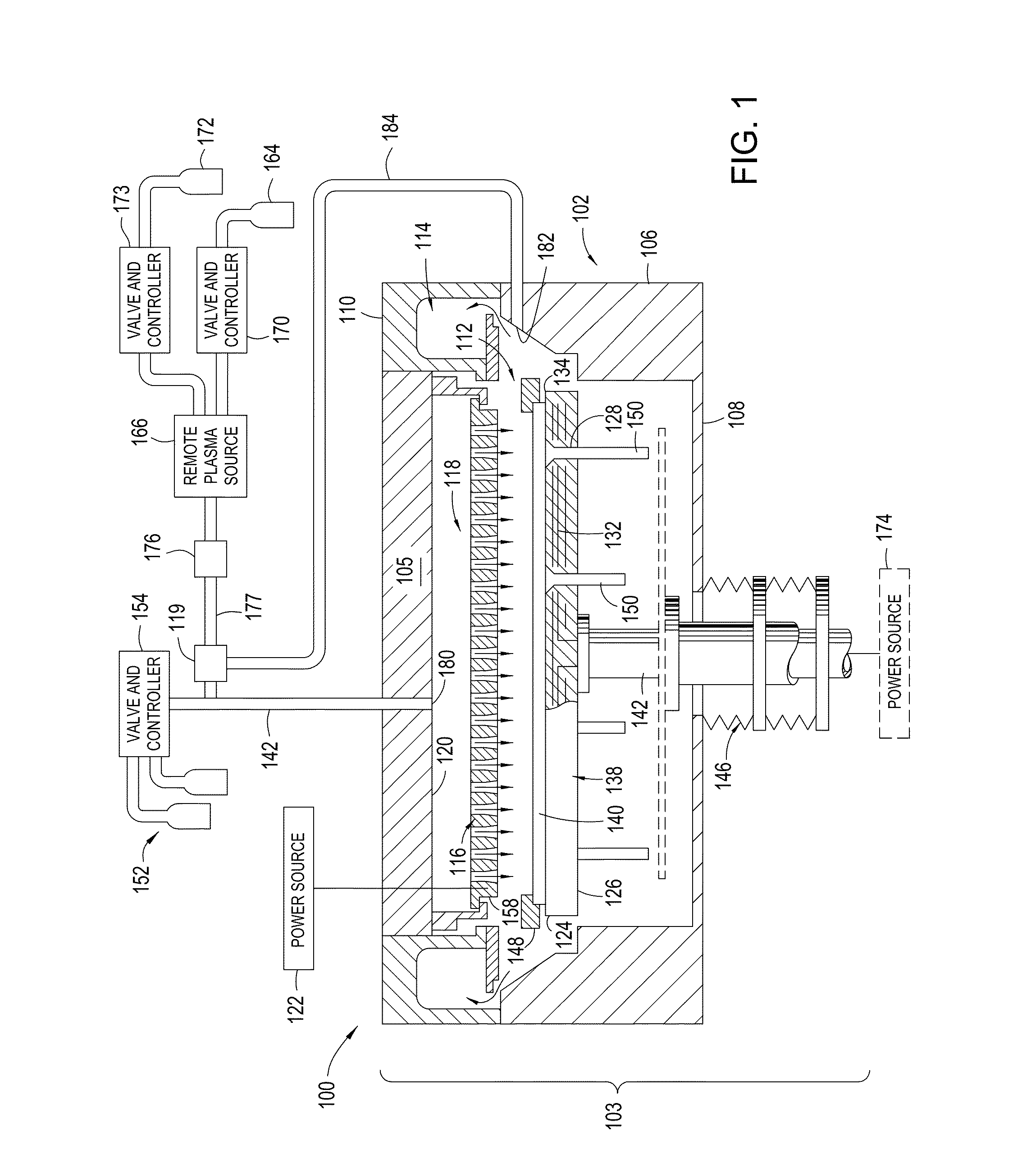

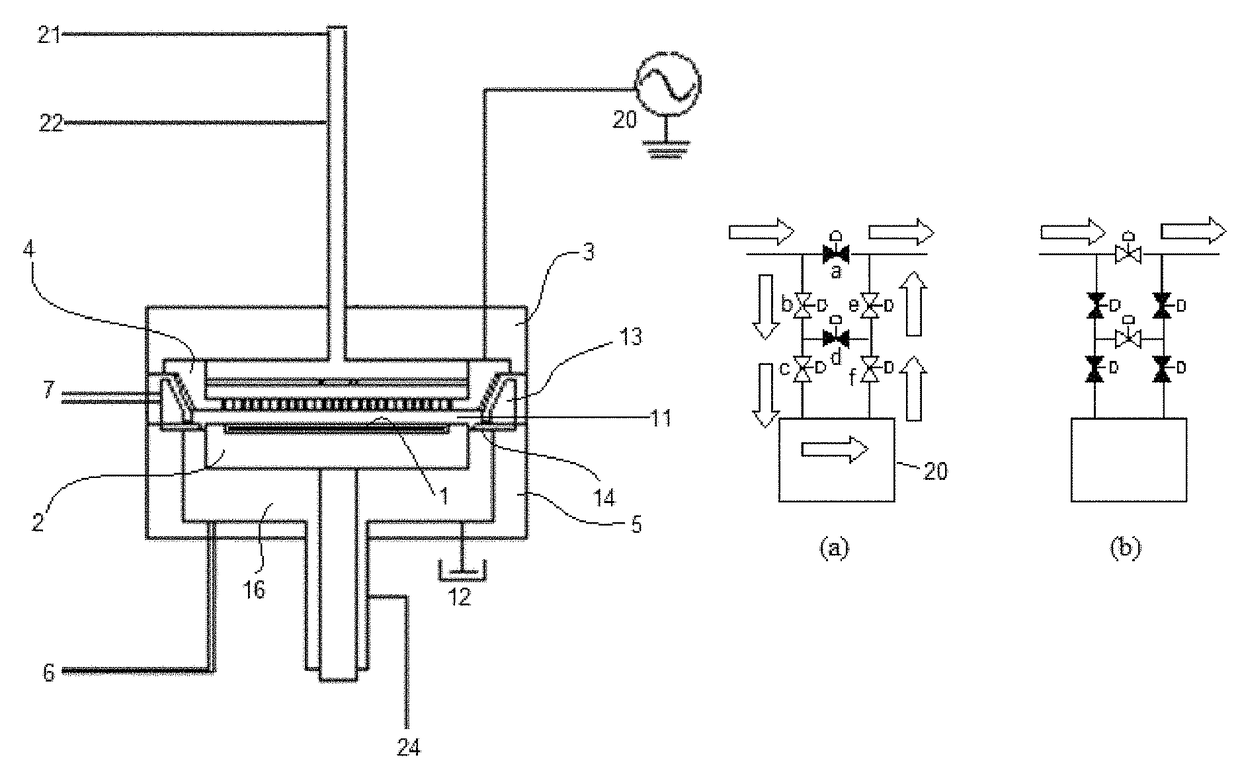

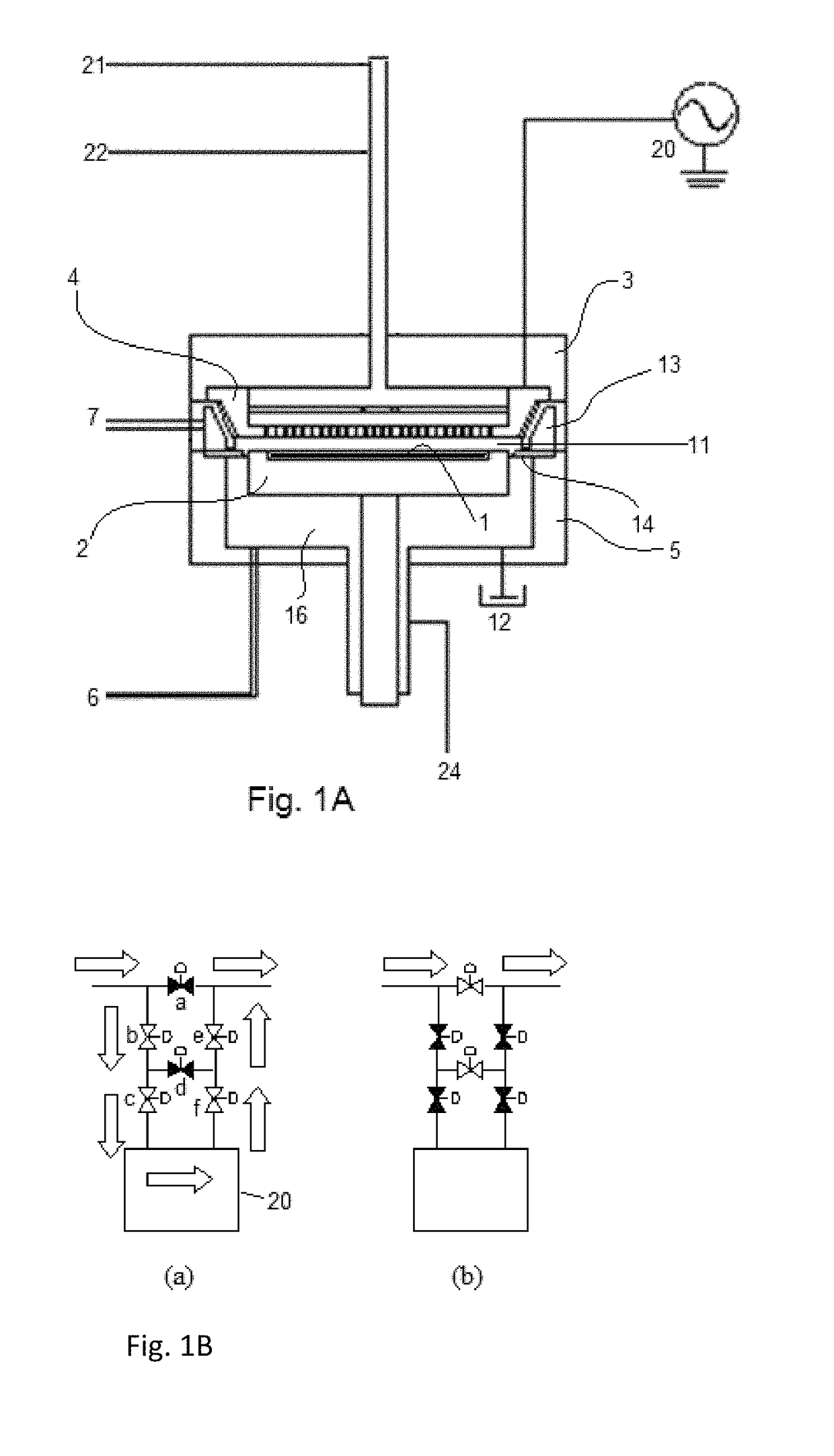

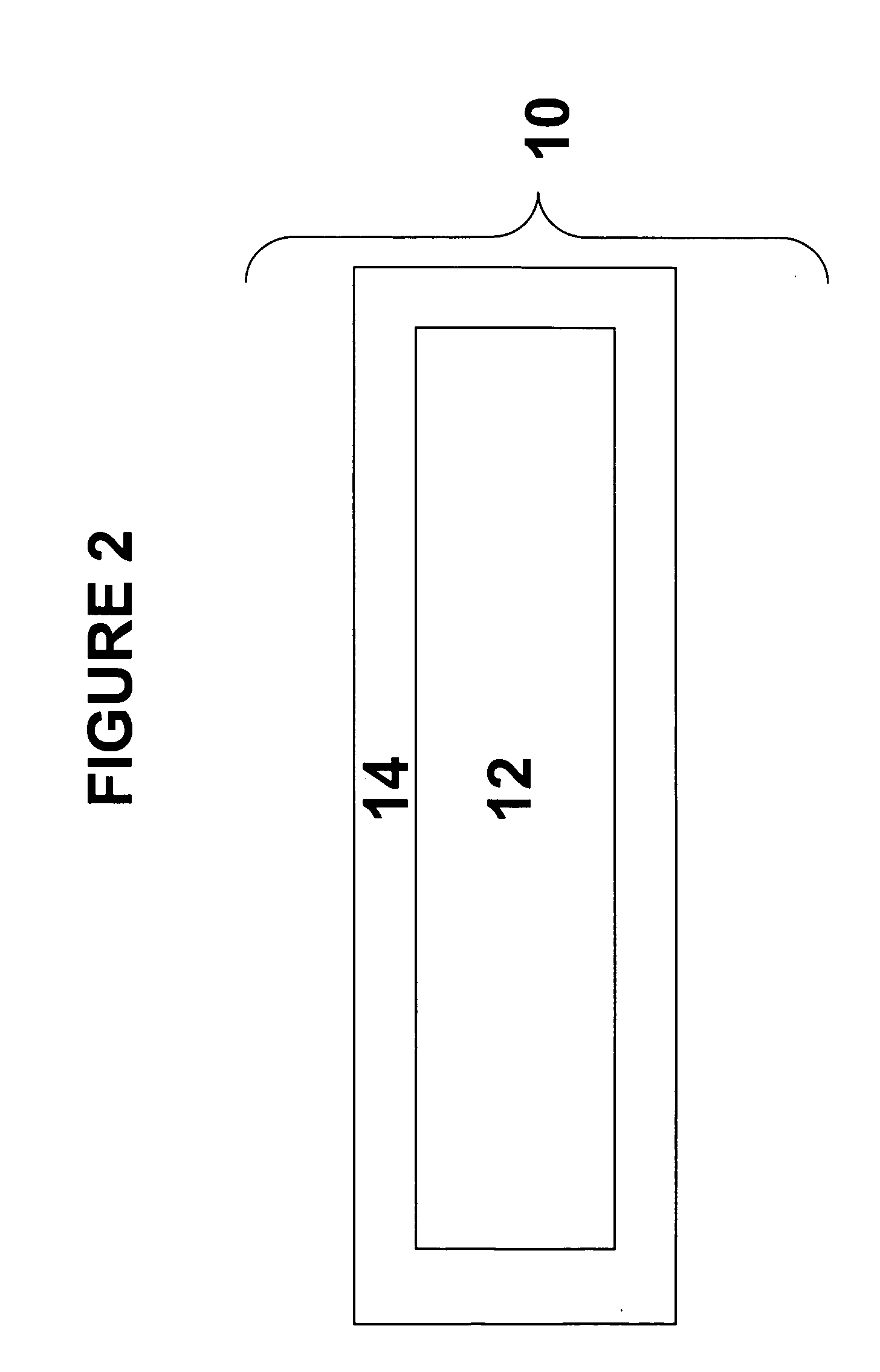

Methods, systems, and apparatus for atomic-layer deposition of aluminum oxides in integrated circuits

InactiveUS20030207032A1Small volumeConsumes less gasPretreated surfacesChemical vapor deposition coatingProduct gasIntegrated circuit layout

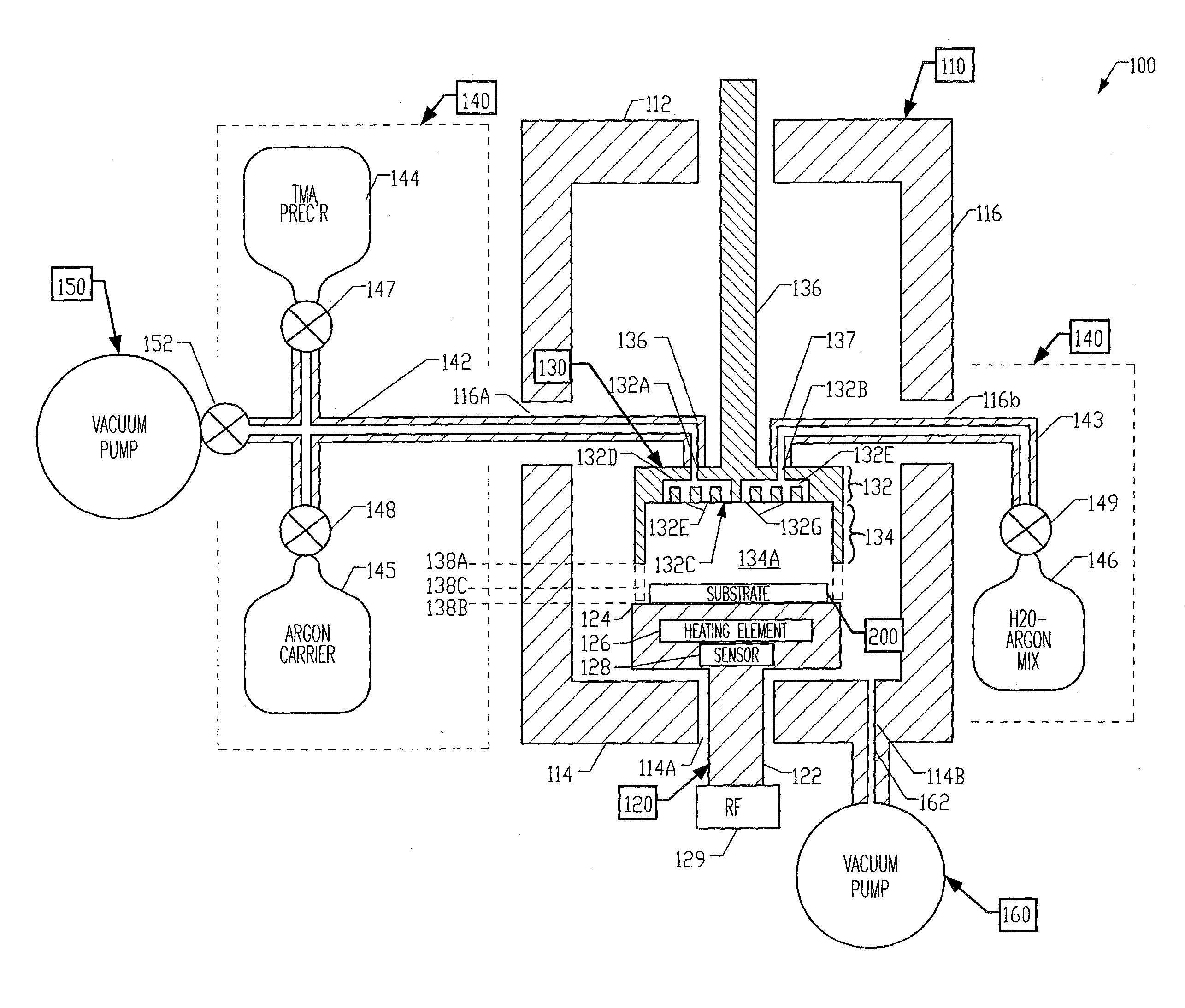

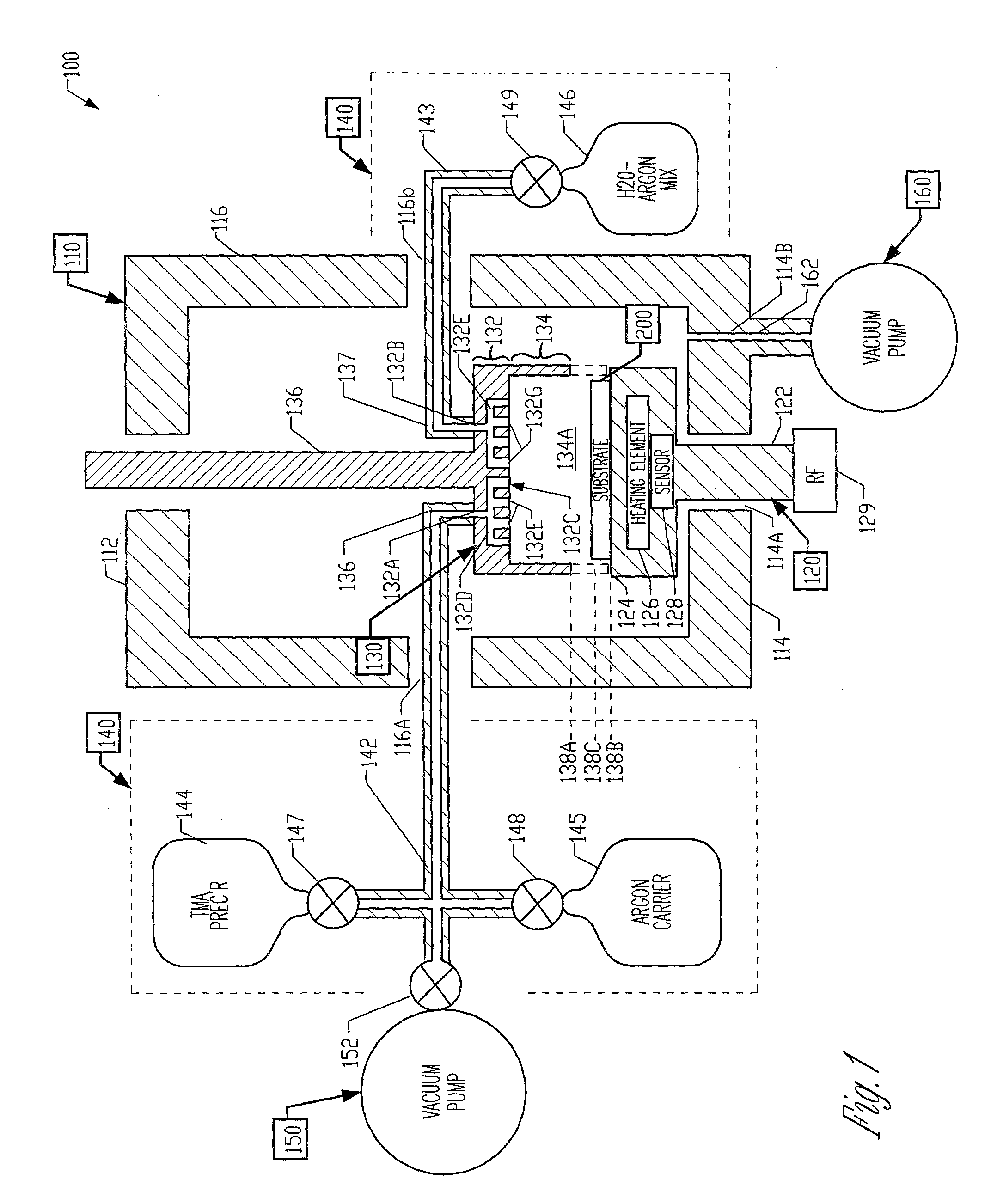

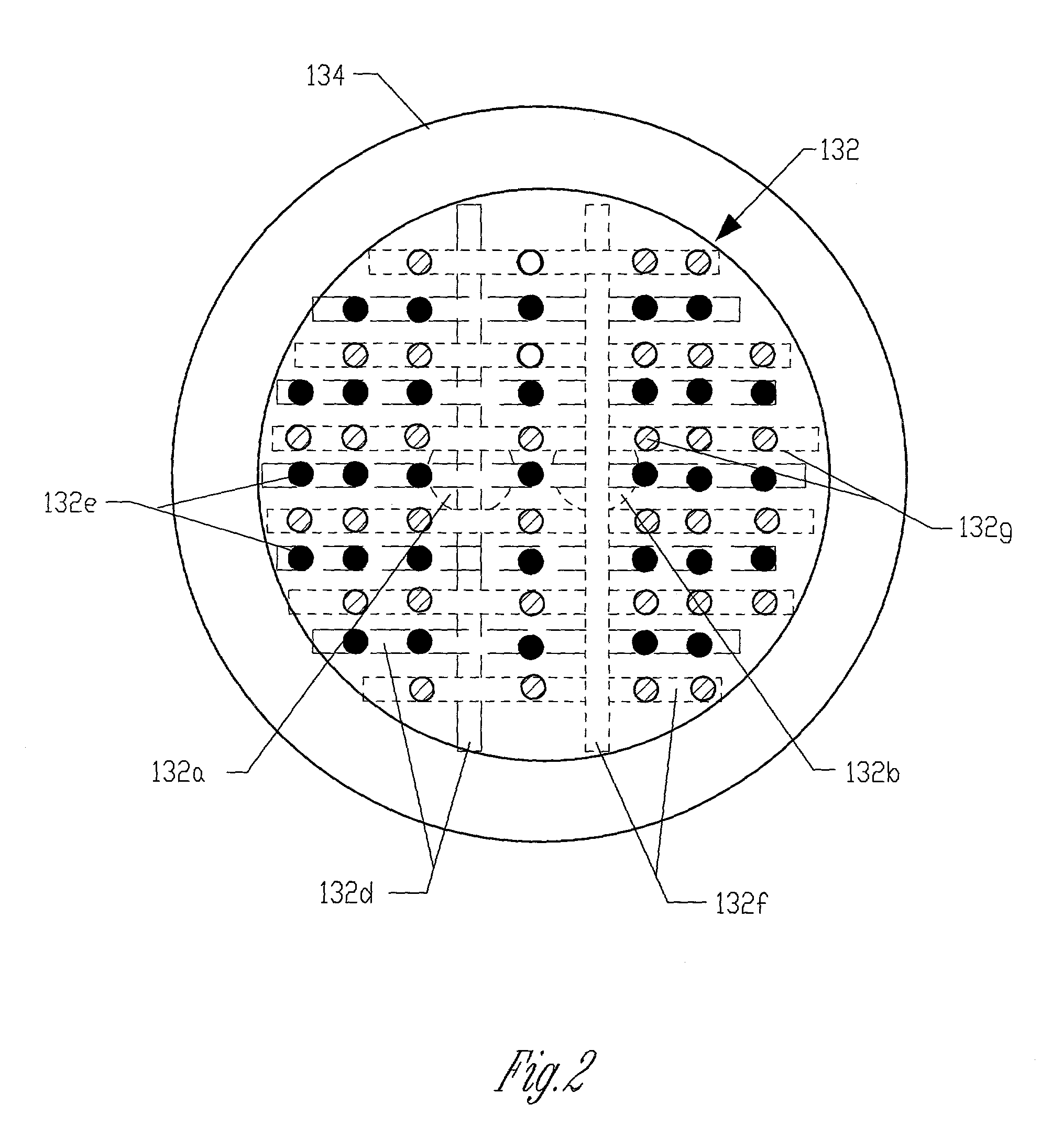

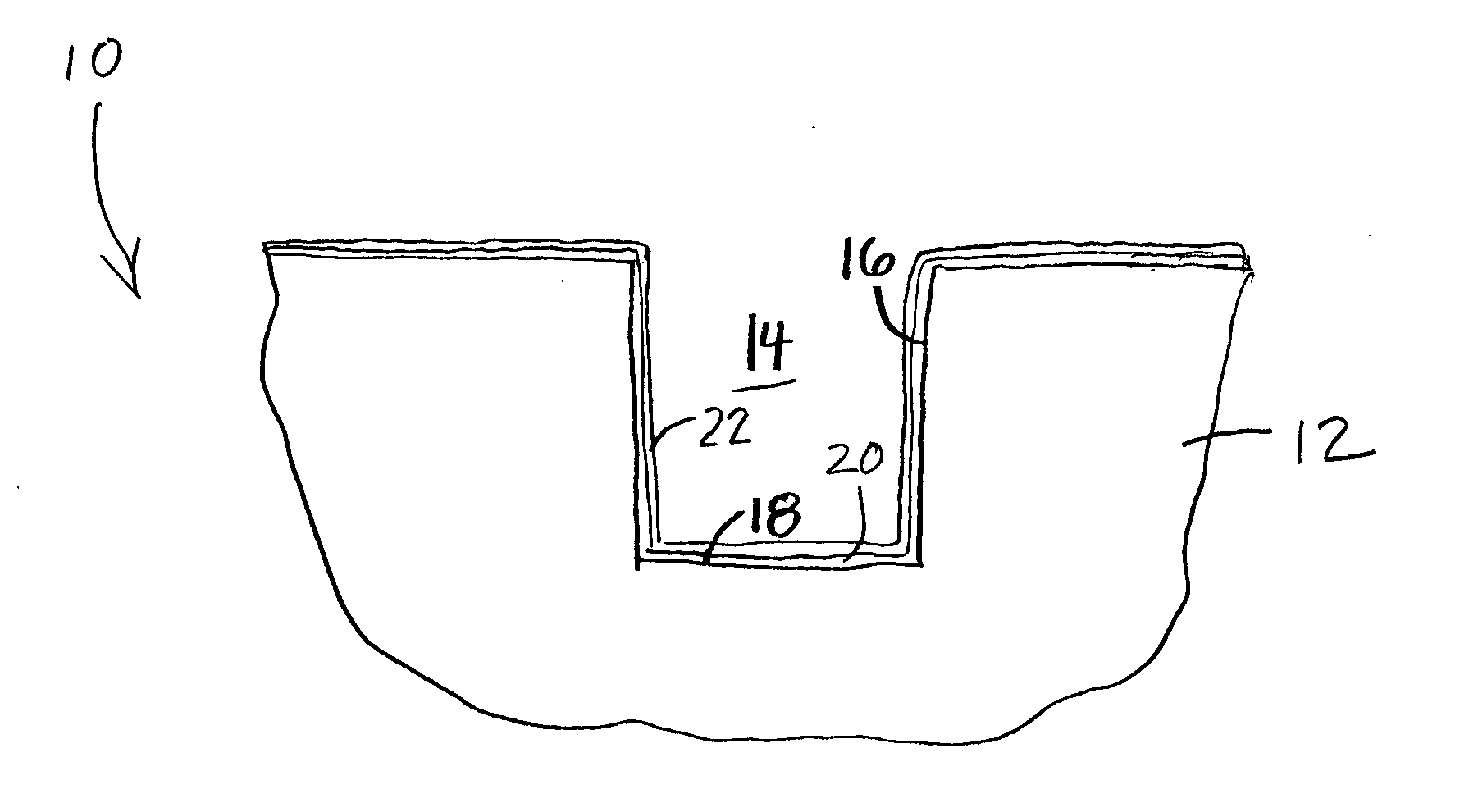

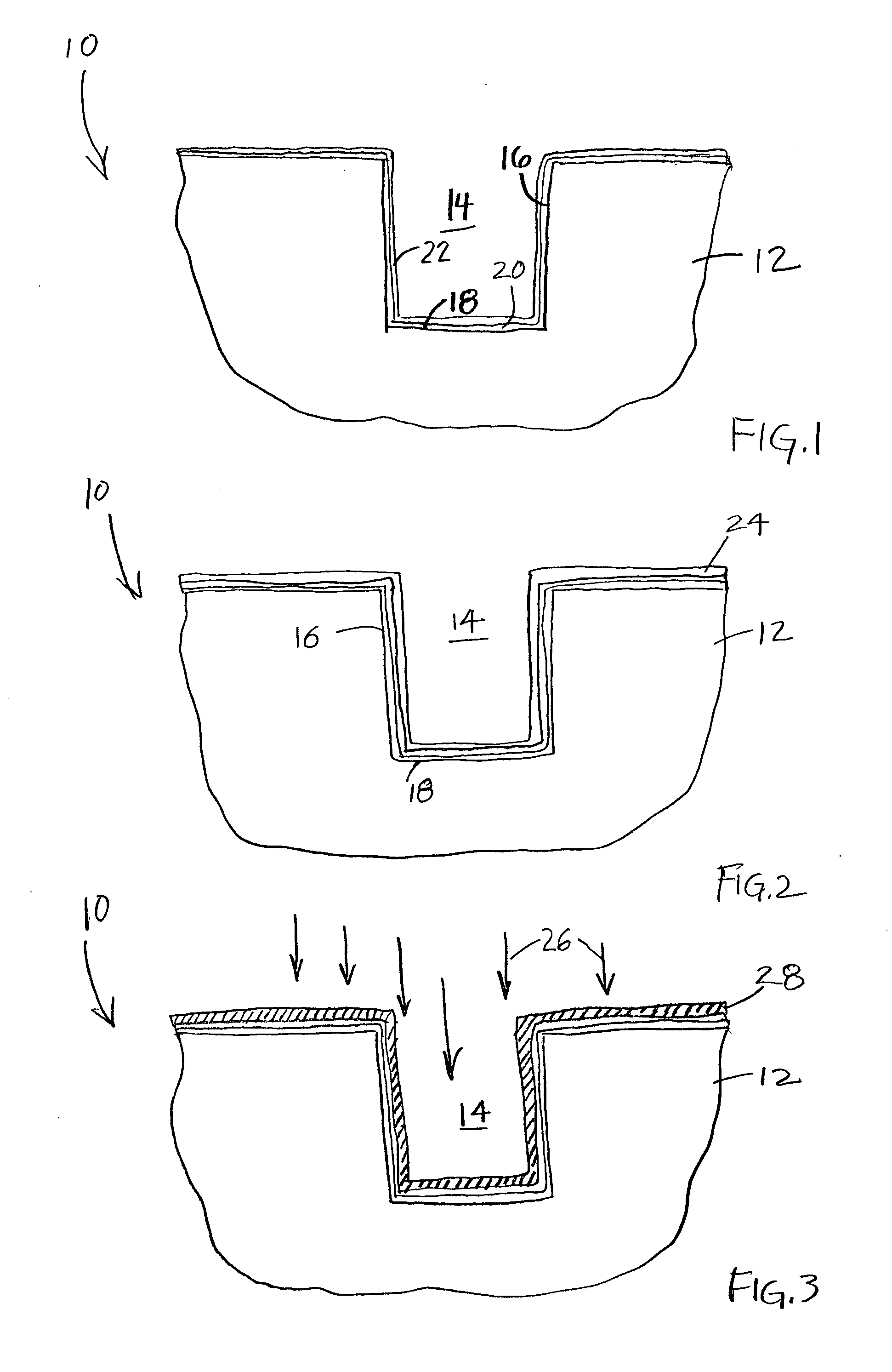

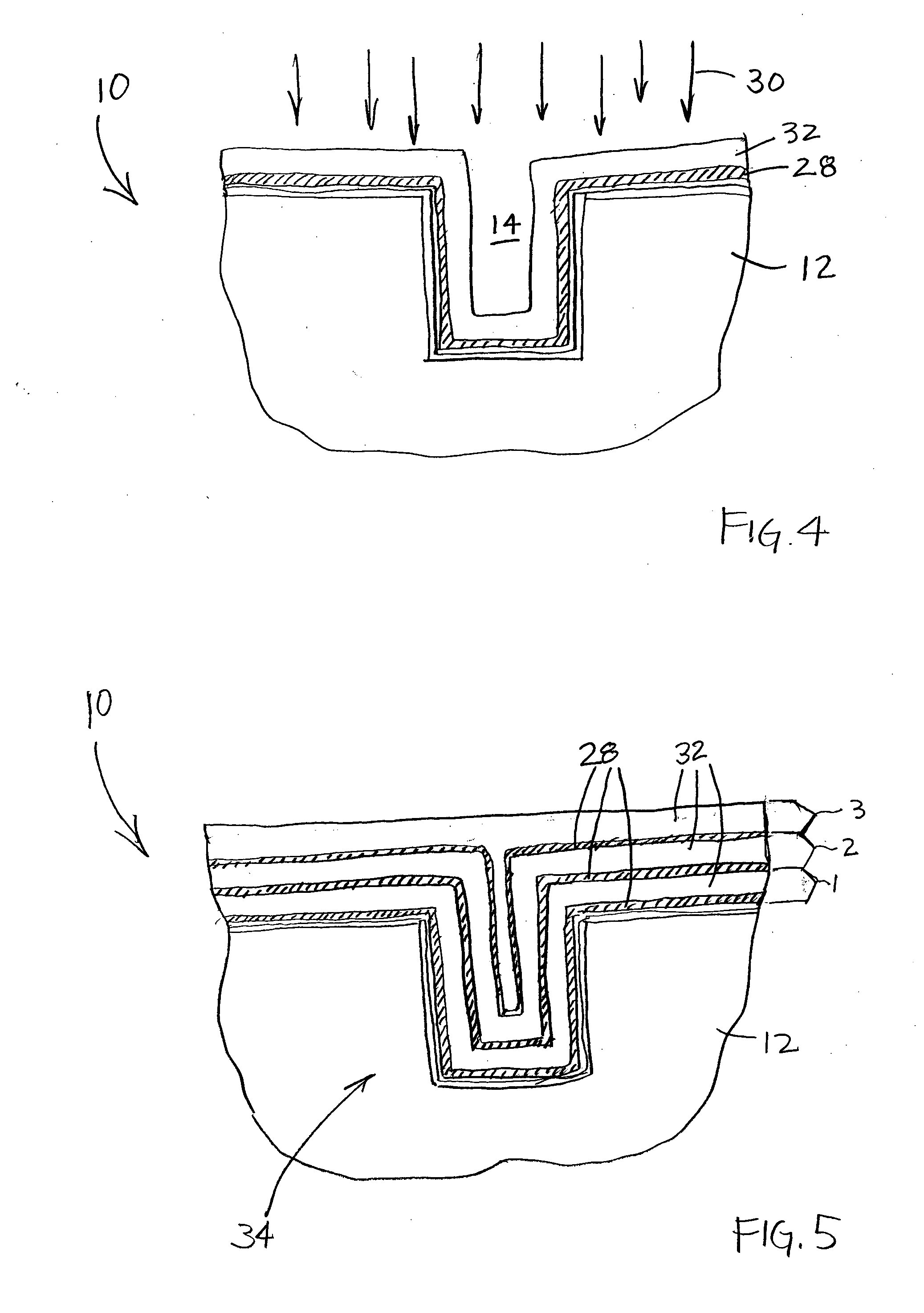

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common layer-formation technique, known as chemical-vapor deposition (CVD), produces uneven layers and covers vertical surfaces poorly. An emergent technique, atomic-layer deposition, overcomes these shortcomings, but has others, such as slow deposition rates and longer than desirable cycle times, particularly as applied to deposition of aluminum oxide. Accordingly, the inventors devised unique atomic-layer deposition systems, methods, and apparatus suitable for aluminum-oxide deposition. One exemplary system includes an outer chamber, a substrate holder, and a gas-distribution fixture that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which ultimately requires less time to fill and purge and thus promises to reduce cycle times for deposition of materials, such as aluminum oxide.

Owner:MICRON TECH INC

Gas distribution plate fabricated from a solid yttrium oxide-comprising substrate

InactiveUS20050056218A1Extended service lifePromote resultsAfter-treatment apparatusElectric discharge tubesVolumetric Mass DensityYttrium

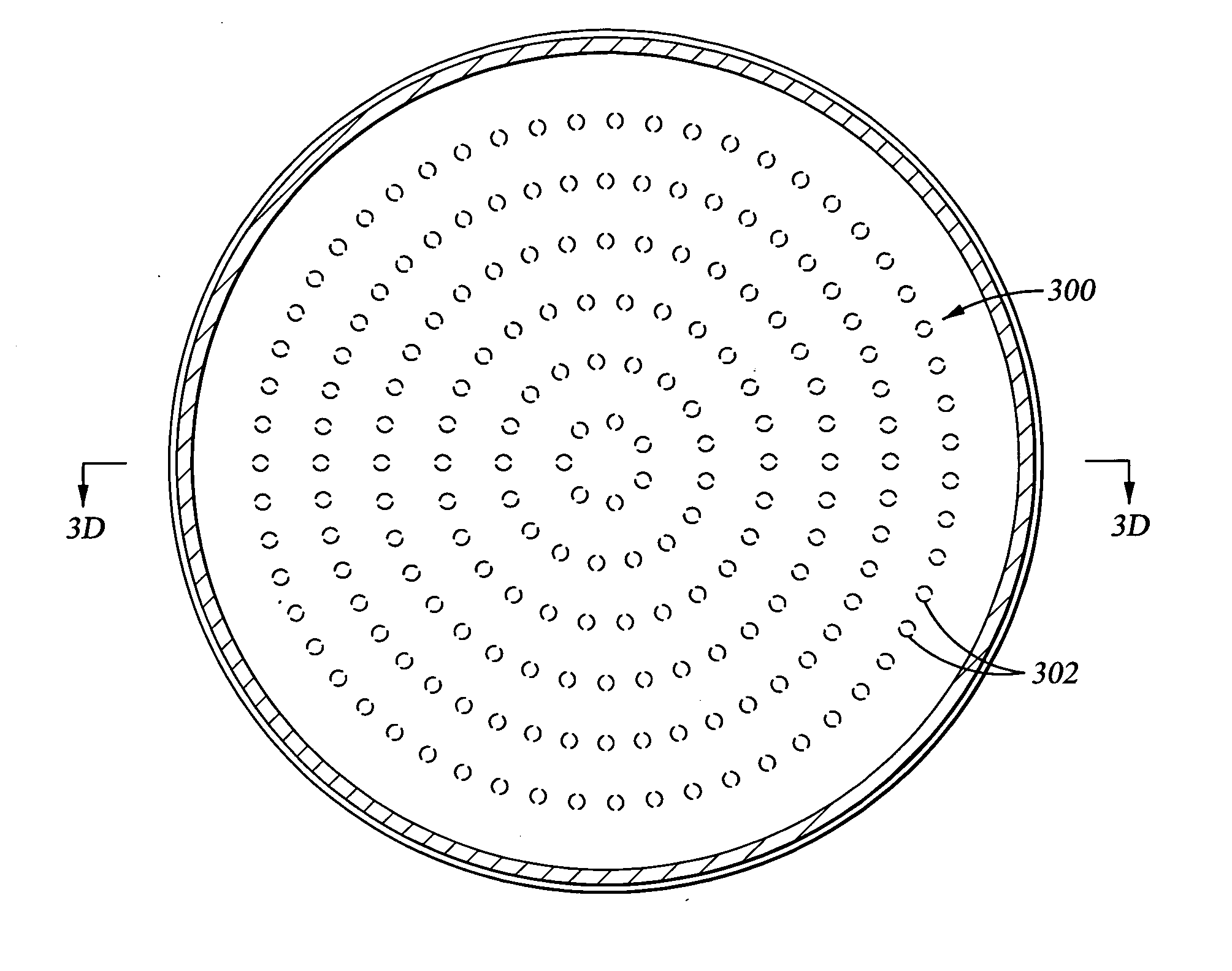

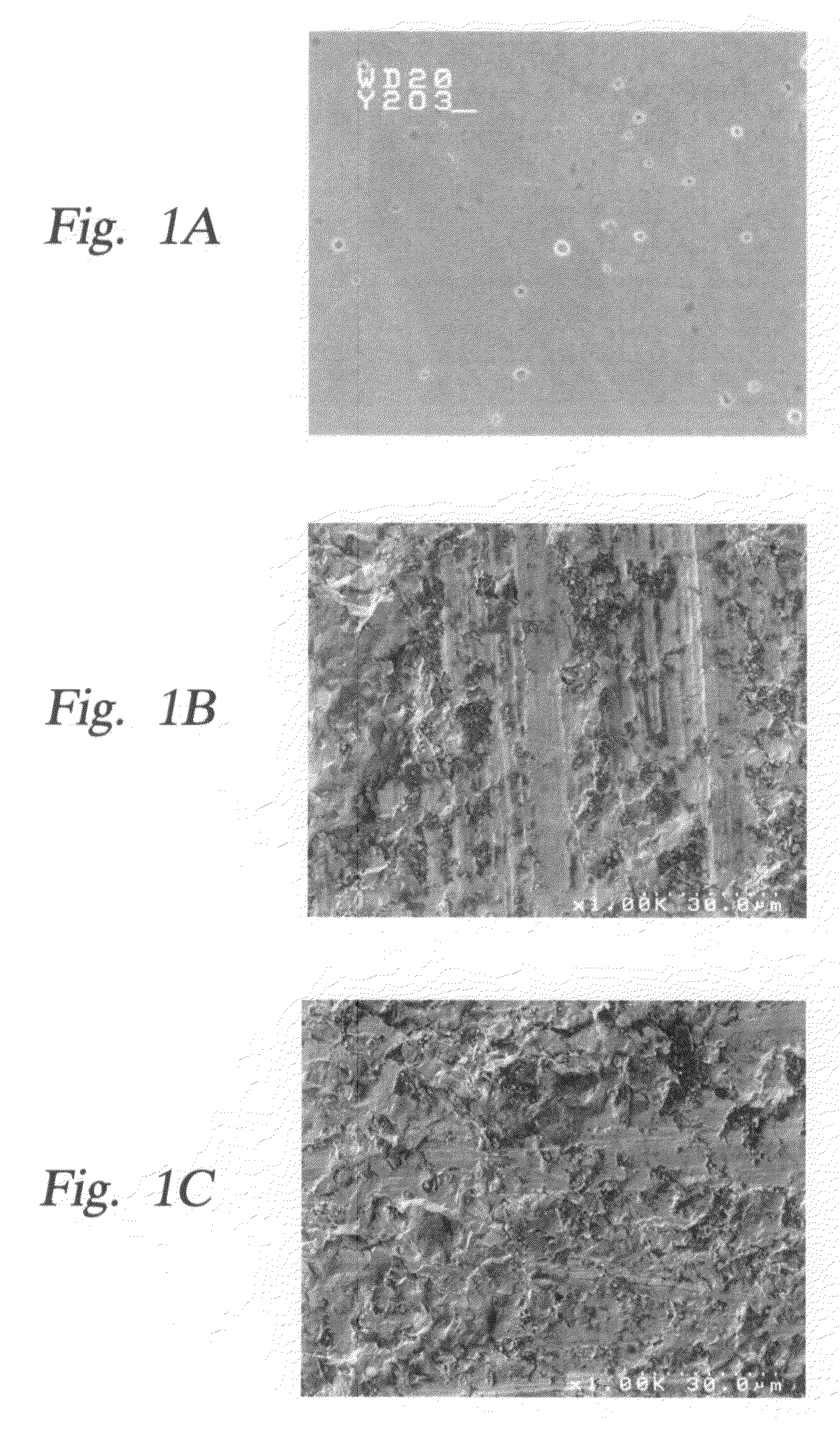

Disclosed herein is a gas distribution plate for use in a gas distribution assembly for a processing chamber, where the gas distribution plate is fabricated from a solid yttrium oxide-comprising substrate, which may also include aluminum oxide. The gas distribution plate includes a plurality of through-holes, which are typically crescent-shaped. Through-holes which have been formed in the solid yttrium oxide-comprising substrate by ultrasonic drilling perform particularly well. The solid yttrium oxide-comprising substrate-typically comprises at least 99.9% yttrium oxide, and has a density of at least 4.92 g / cm3, a water absorbency of about 0.02% or less, and an average grain size within the range of about 10 μm to about 25 μm. Also disclosed herein are methods for fabricating and cleaning the yttrium oxide-comprising gas distribution plate.

Owner:APPLIED MATERIALS INC

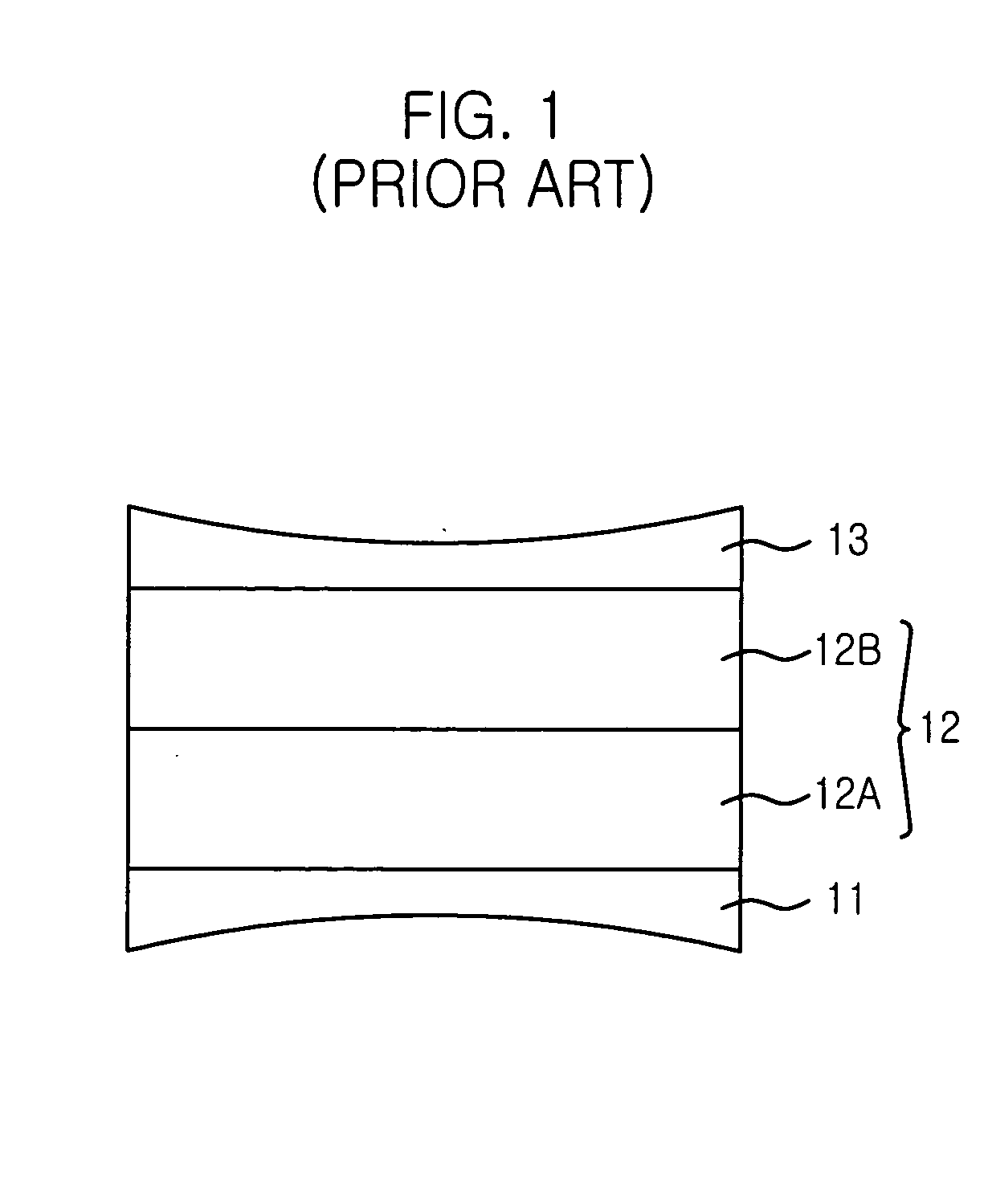

Thin films

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

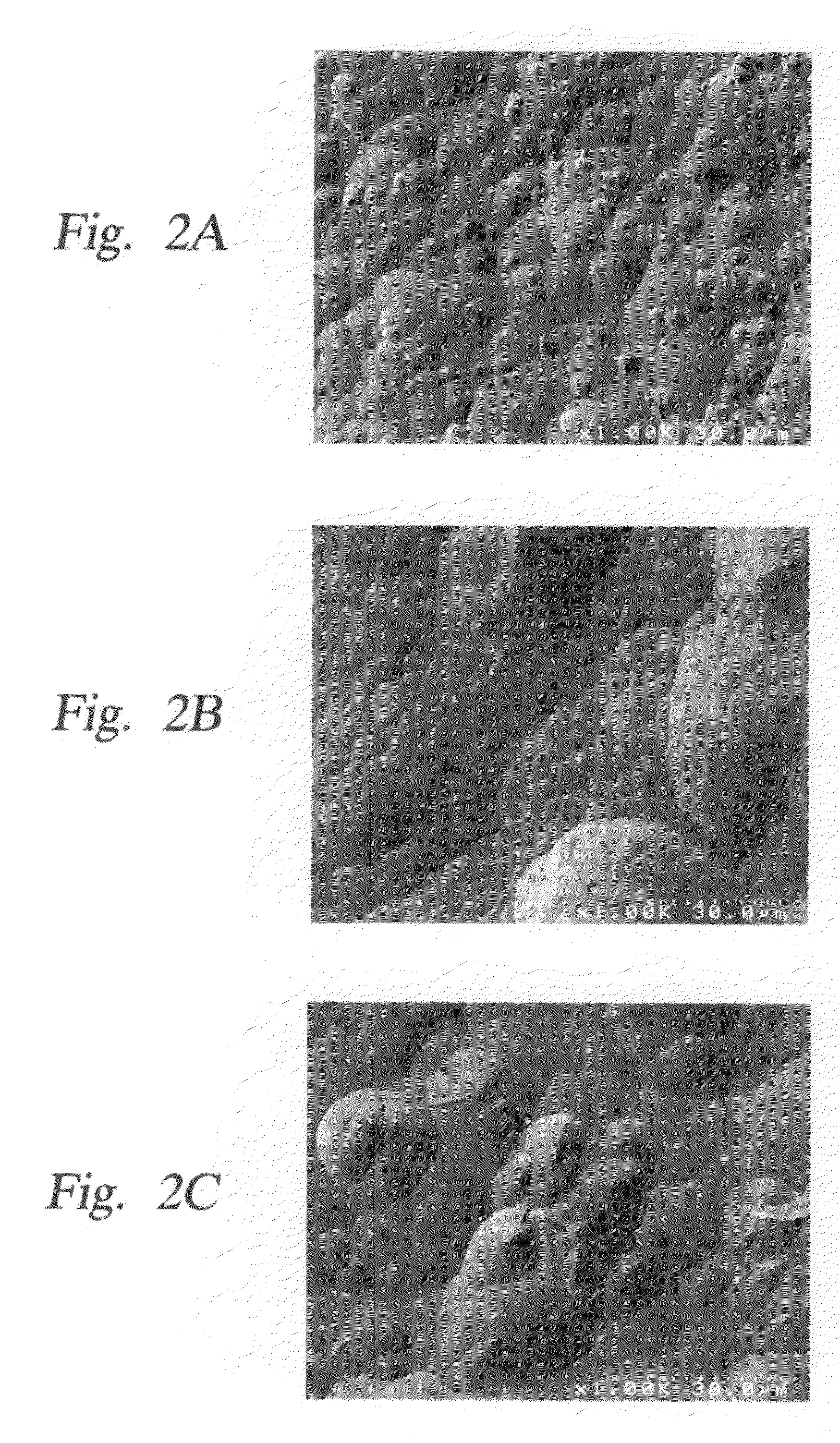

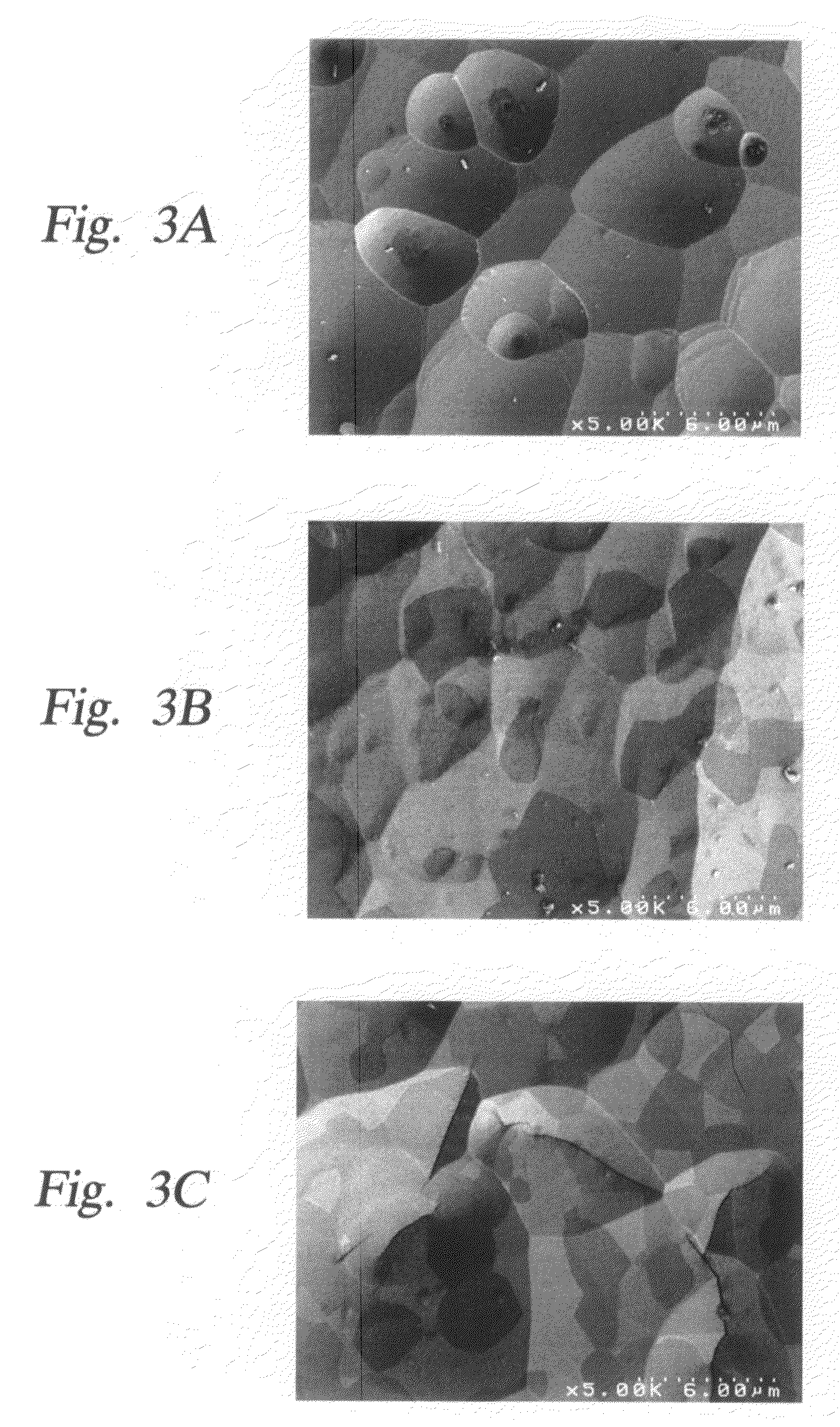

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

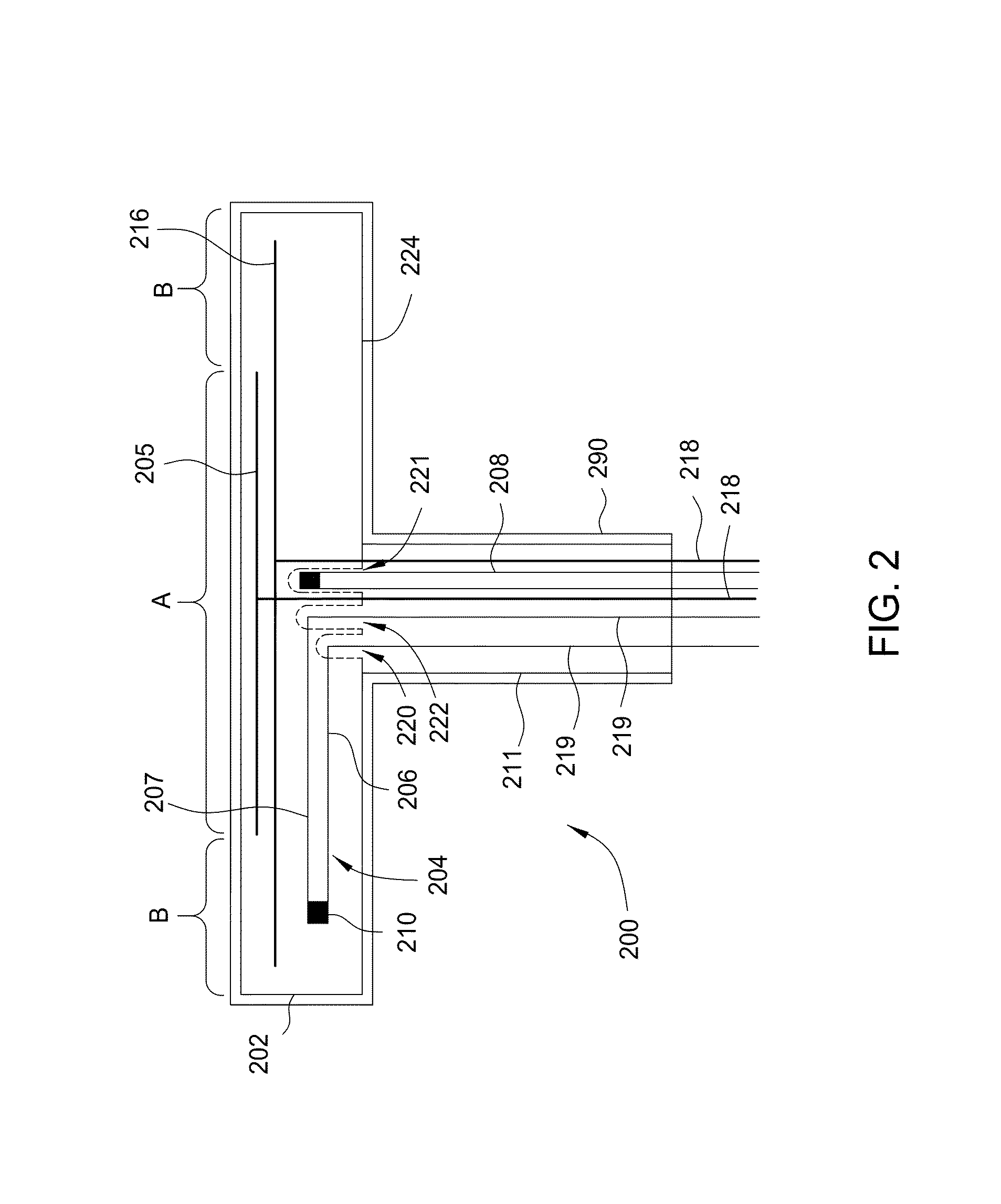

Method of increasing deposition rate of silicon dioxide on a catalyst

ActiveUS20060046518A1Good step coverageIncrease production outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

Hafnium oxide and aluminium oxide alloyed dielectric layer and method for fabricating the same

InactiveUS20050110069A1Preventing break down voltageReduce voltageTransistorSolid-state devicesAtomic layer depositionDielectric layer

The present invention relates to a dielectric layer alloyed with hafnium oxide and aluminum oxide and a method for fabricating the same. At this time, the dielectric layer is deposited by an atomic layer deposition technique. The method for fabricating the hafnium oxide and aluminum oxide alloyed dielectric layer includes the steps of: depositing a single atomic layer of hafnium oxide by repeatedly performing a first cycle of an atomic layer deposition technique; depositing a single atomic layer of aluminum oxide by repeatedly performing a second cycle of the atomic layer deposition technique; and depositing a dielectric layer alloyed with the single atomic layer of hafnium oxide and the single atomic layer of aluminum oxide by repeatedly performing a third cycle including the admixed first and second cycles.

Owner:SK HYNIX INC

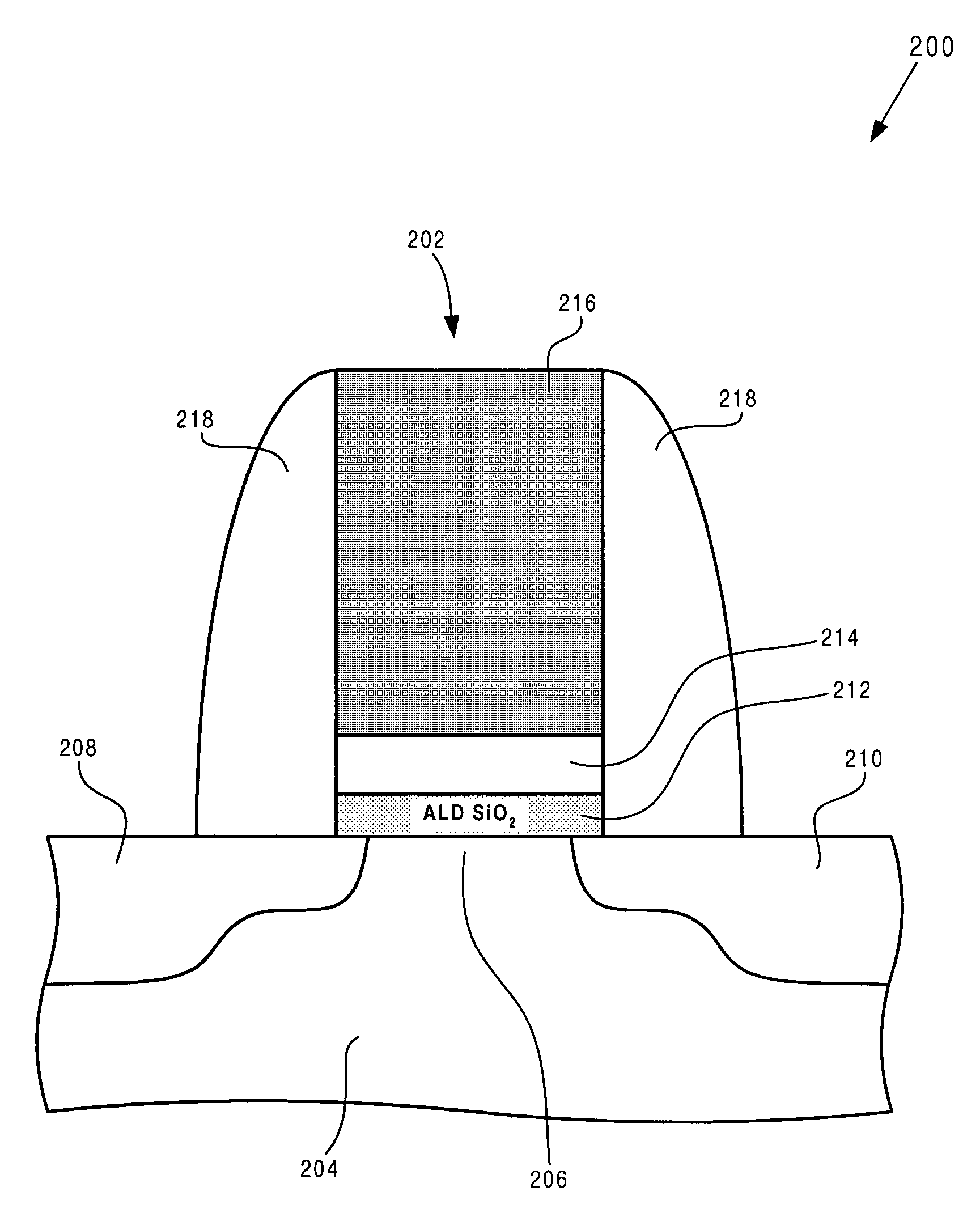

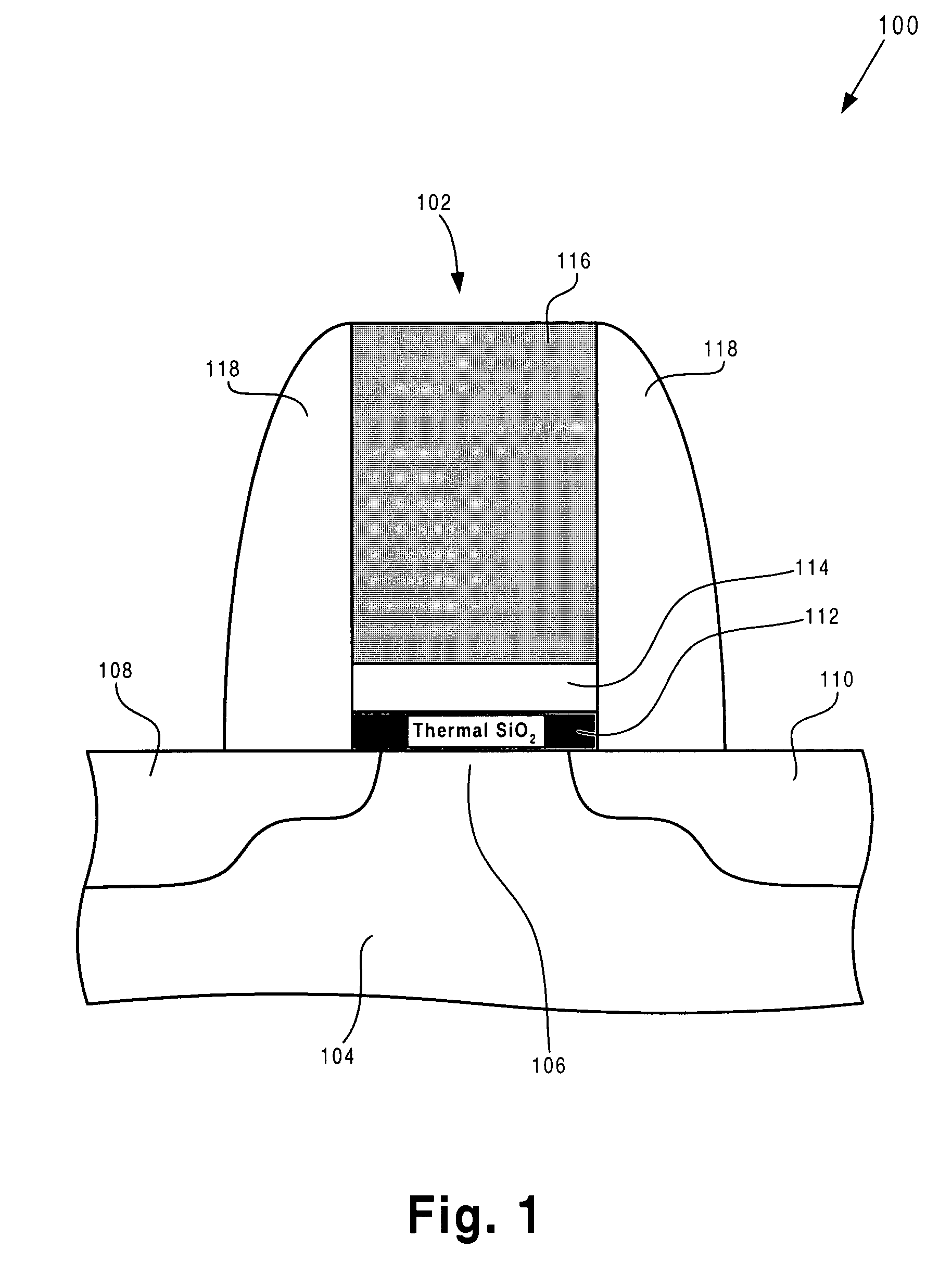

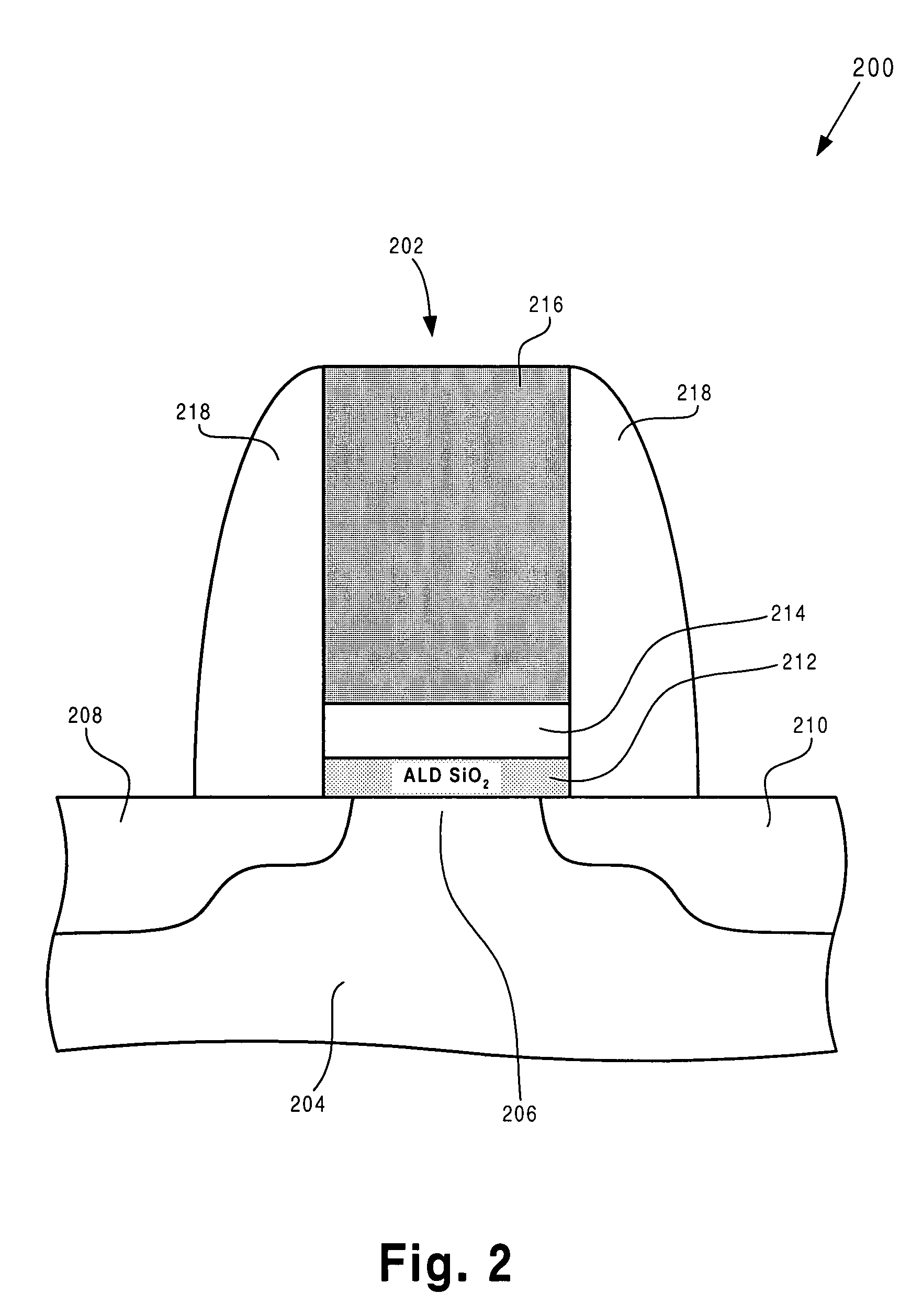

Method for forming a thin, high quality buffer layer in a field effect transistor and related structure

ActiveUS7071051B1Readily apparentSemiconductor/solid-state device manufacturingSemiconductor devicesOrganic field-effect transistorOptoelectronics

According to one exemplary embodiment, a method for forming a field-effect transistor on a substrate comprises a step of forming a buffer layer on the substrate, where the buffer layer comprises ALD silicon dioxide. The buffer layer can be formed by utilizing a silicon tetrachloride precursor in an atomic layer deposition process, for example. The buffer layer comprises substantially no pin-hole defects and may have a thickness, for example, that is less than approximately 5.0 Angstroms. The method further comprises forming a high-k dielectric layer over the buffer layer. The high-k dielectric layer may be, for example, hafnium oxide, zirconium oxide, or aluminum oxide. According to this exemplary embodiment, the method further comprises forming a gate electrode layer over the high-k dielectric layer. The gate electrode layer may be polycrystalline silicon, for example.

Owner:GLOBALFOUNDRIES US INC

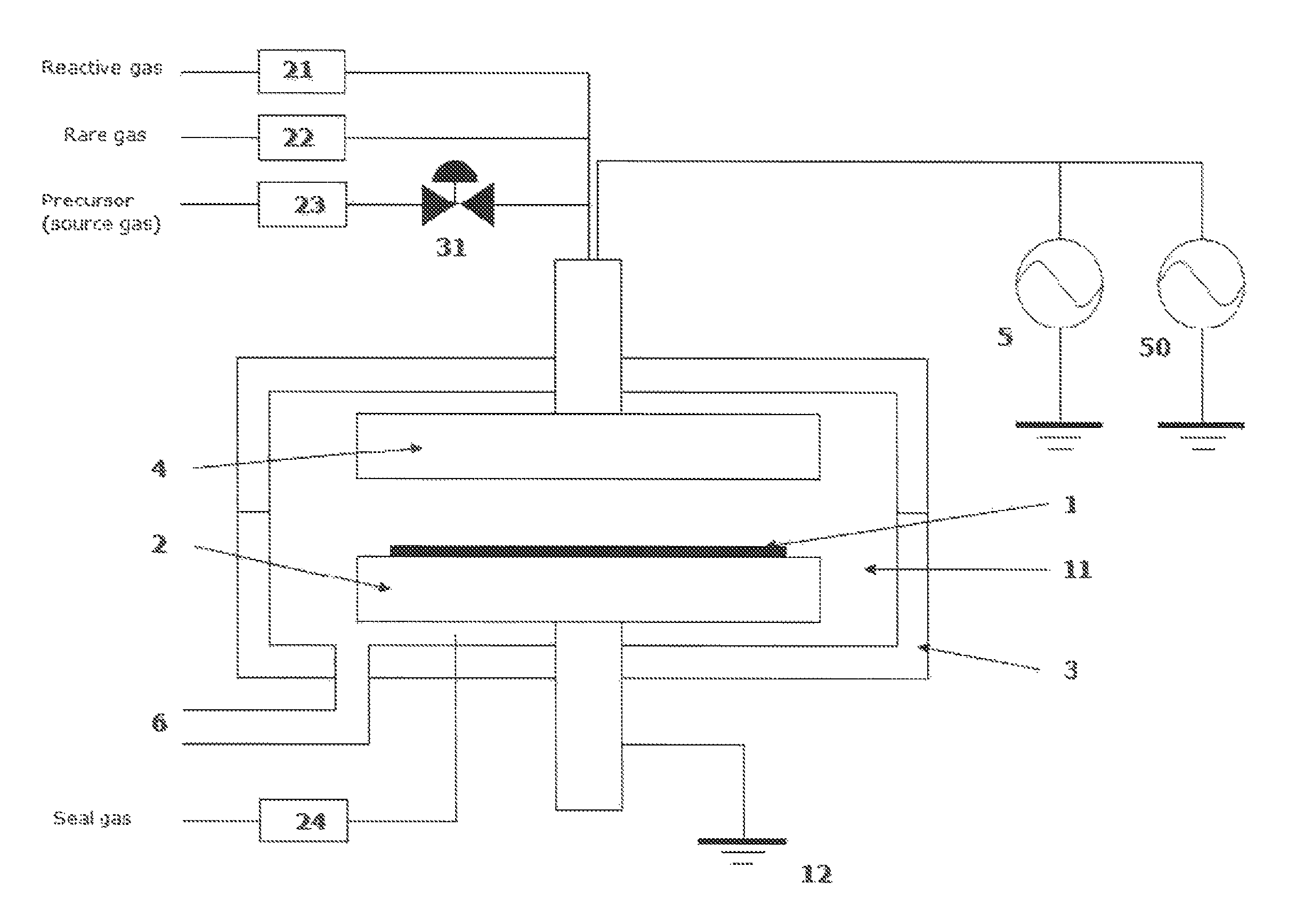

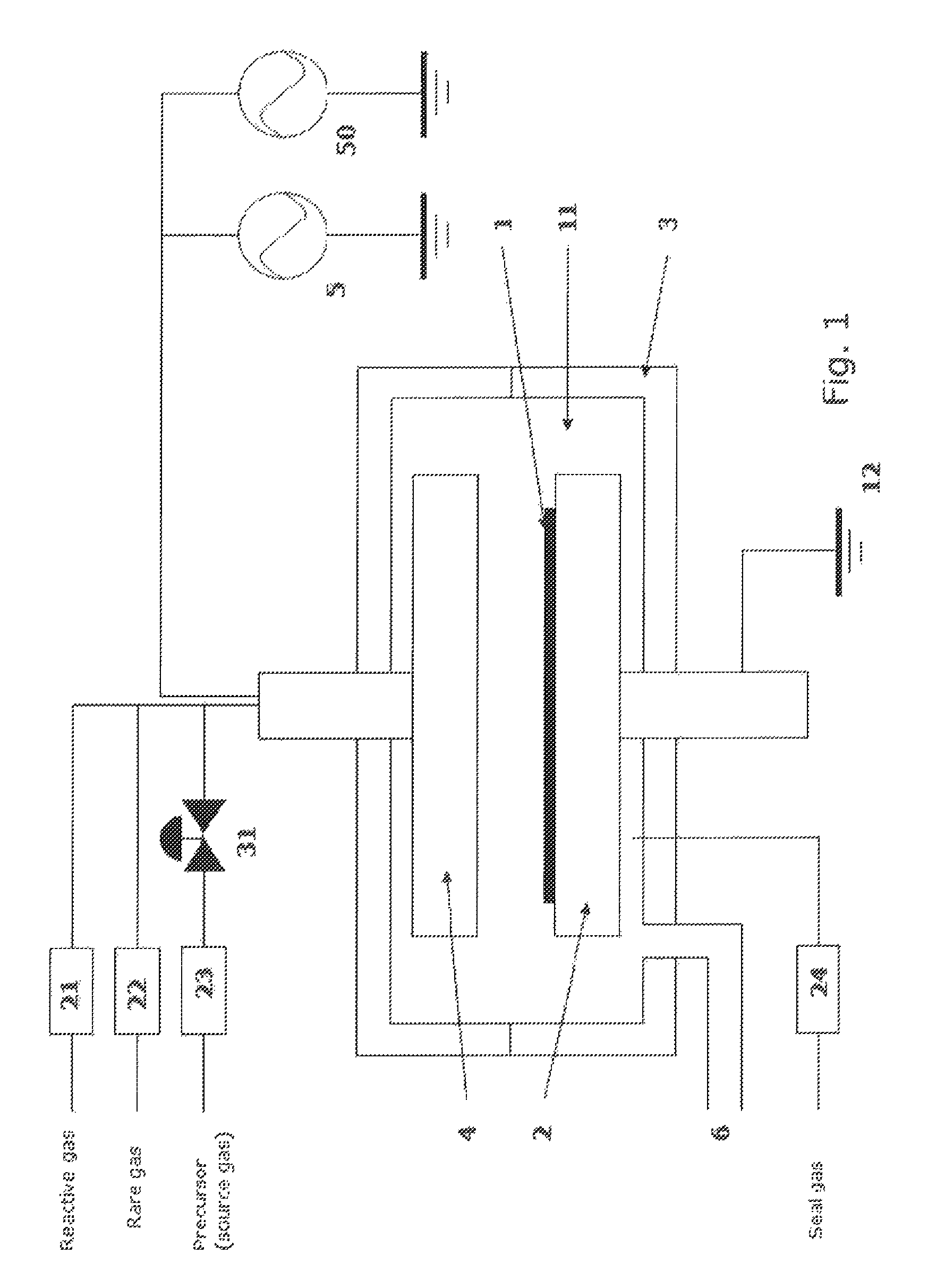

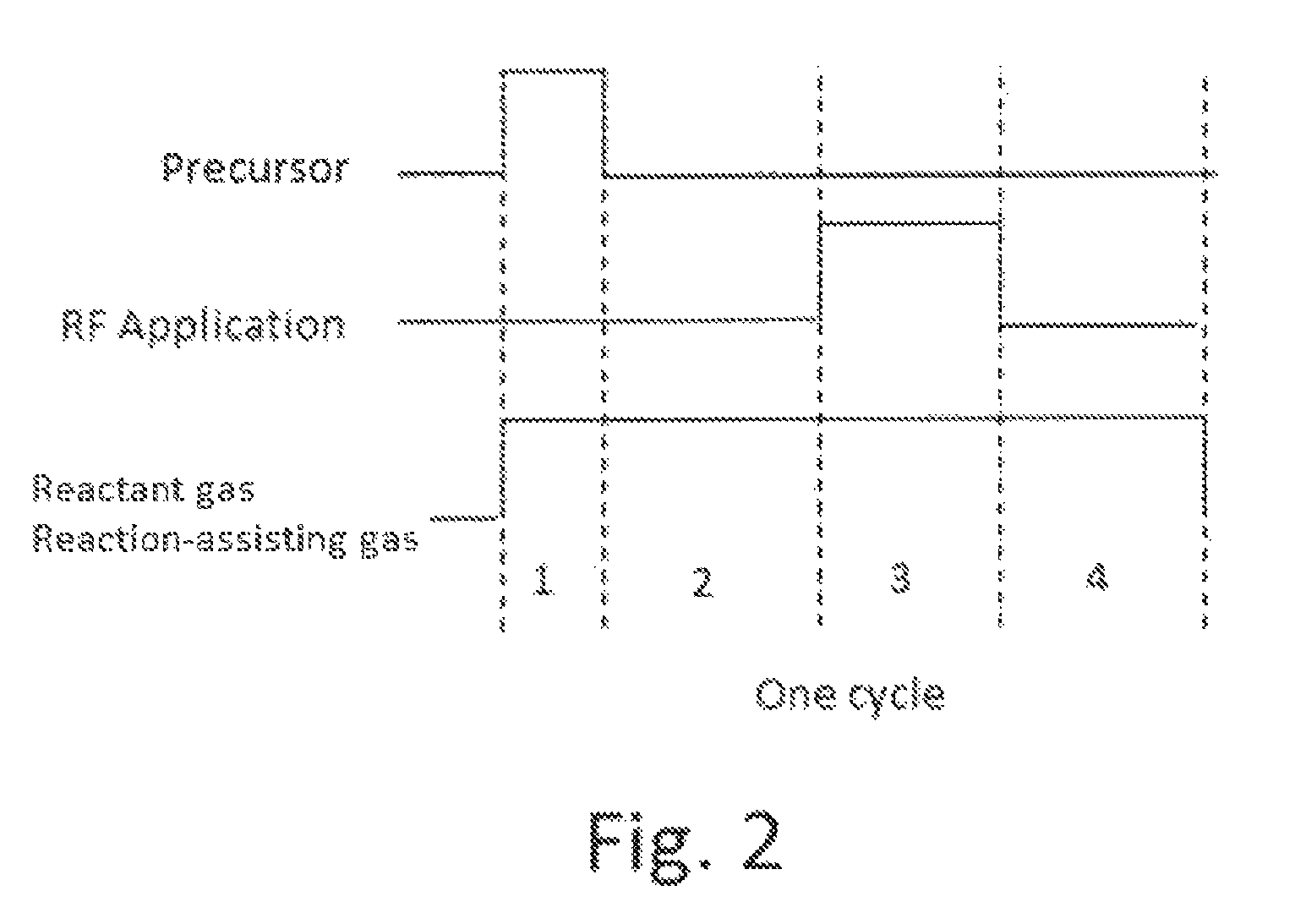

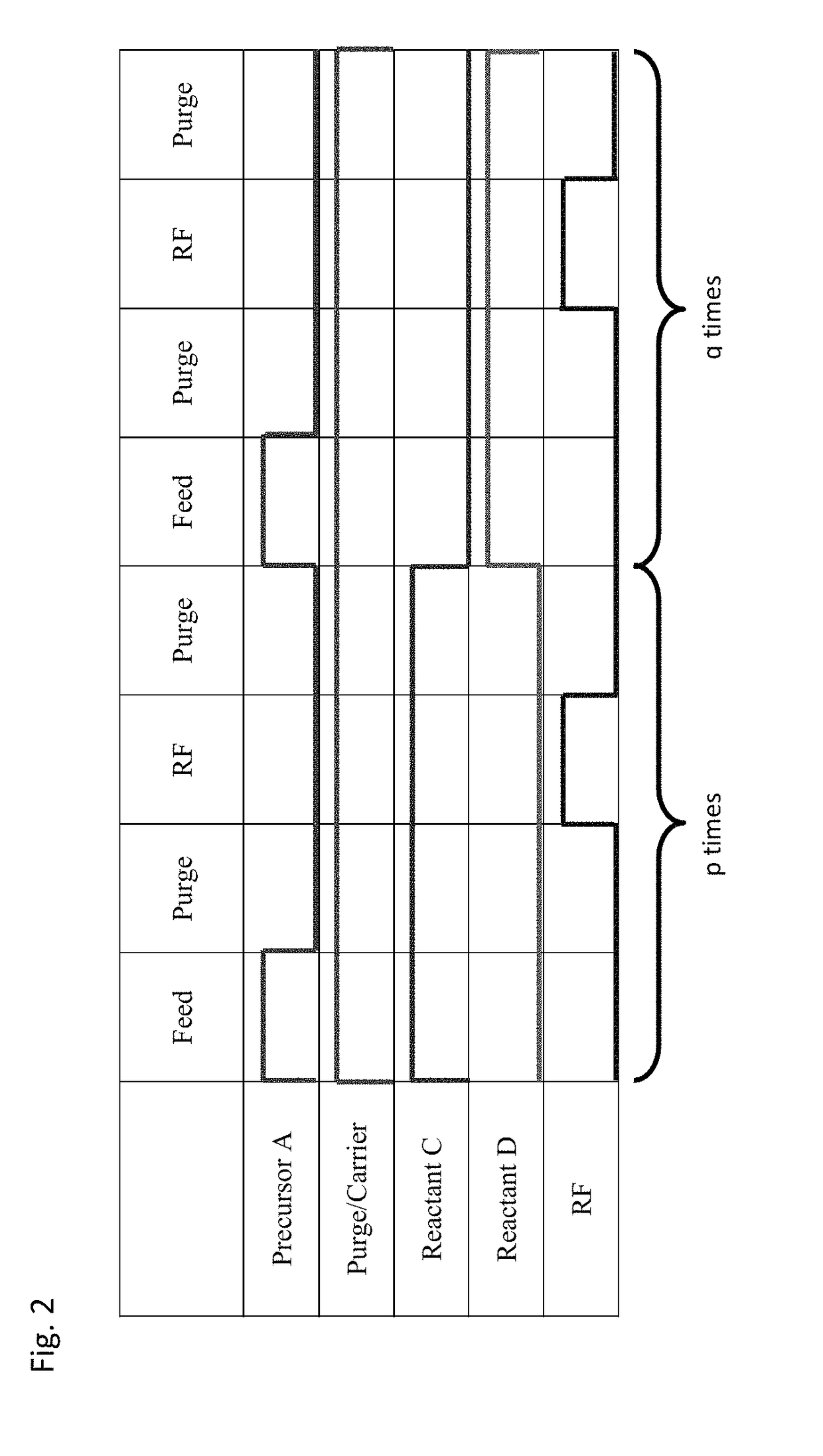

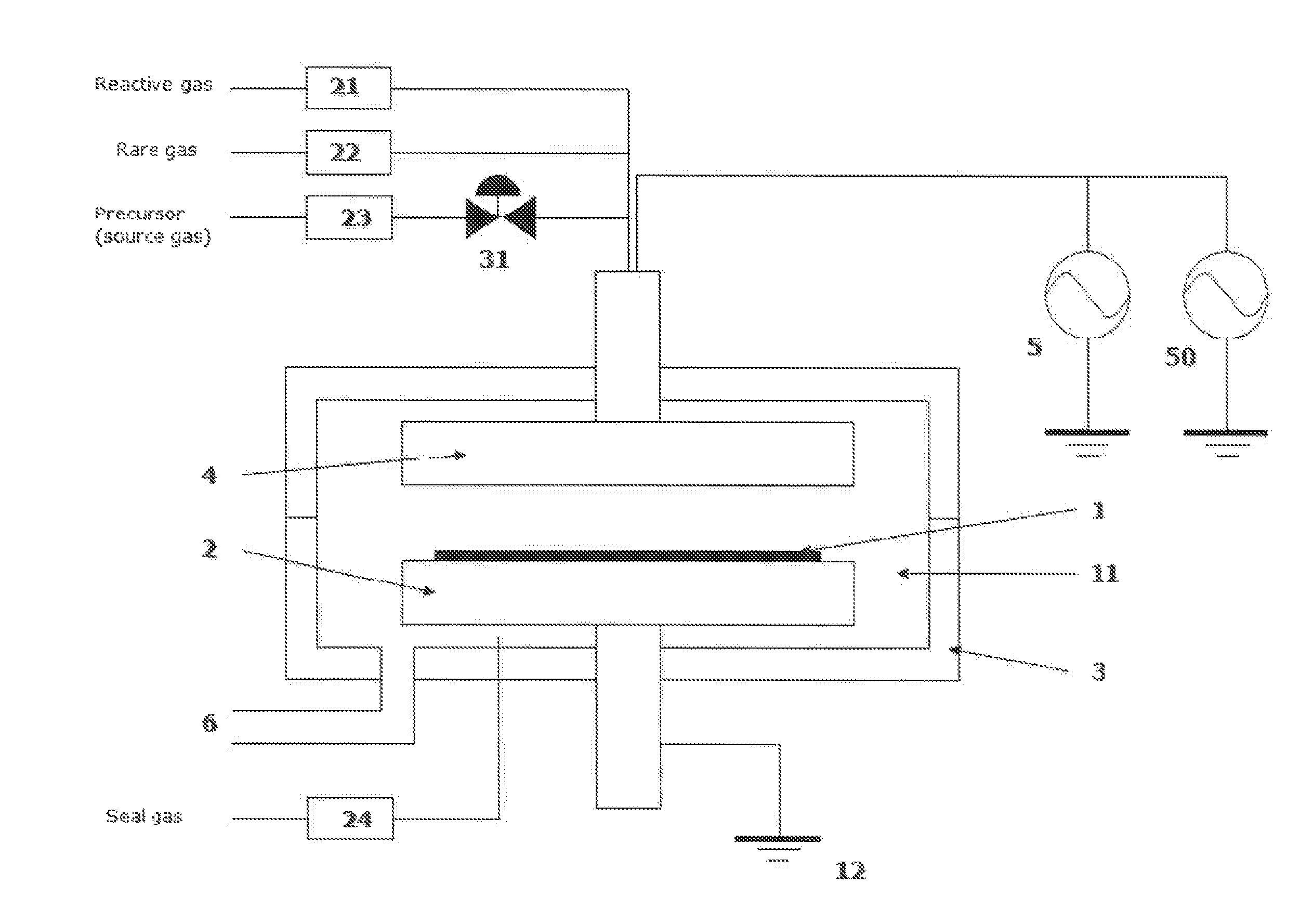

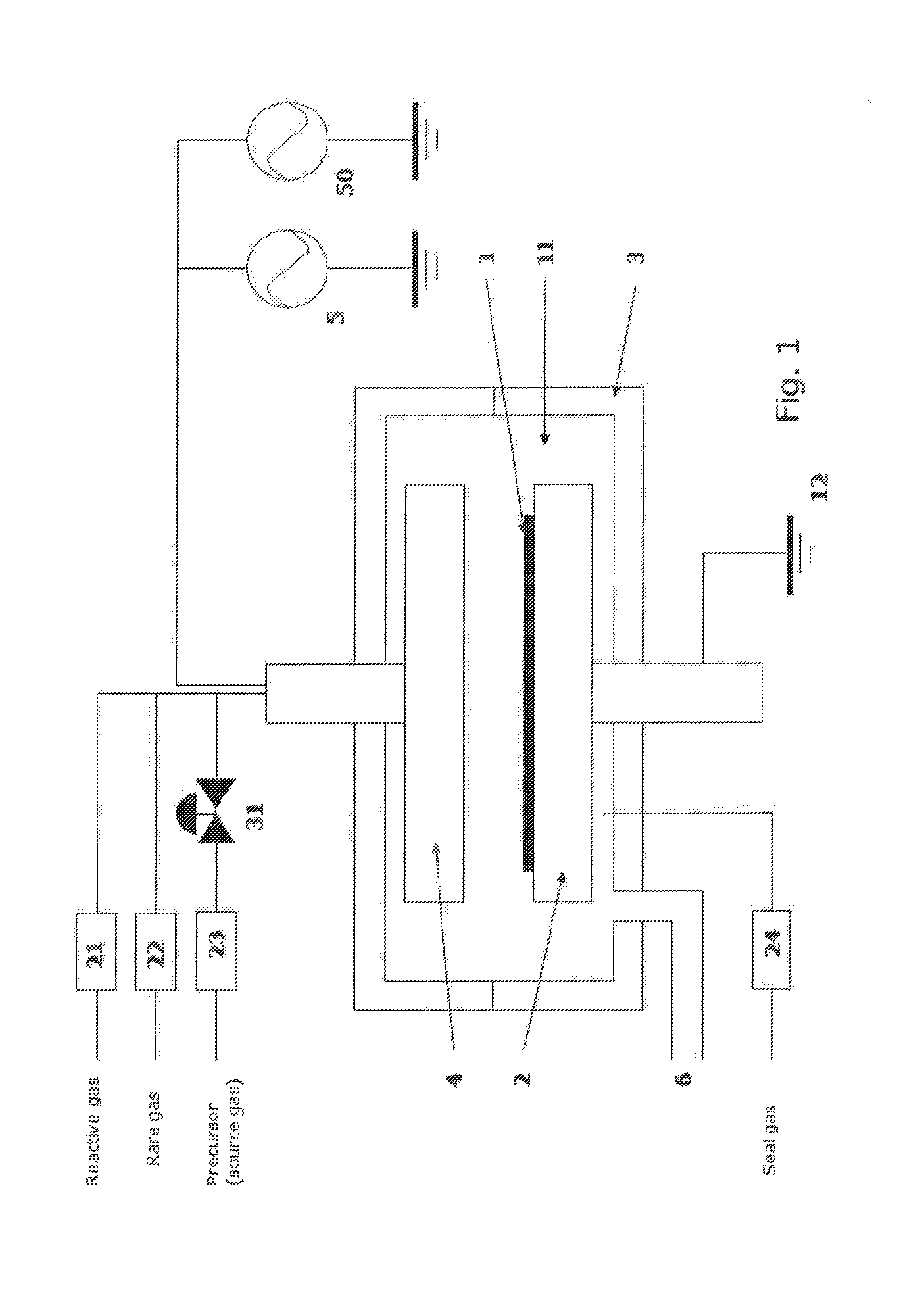

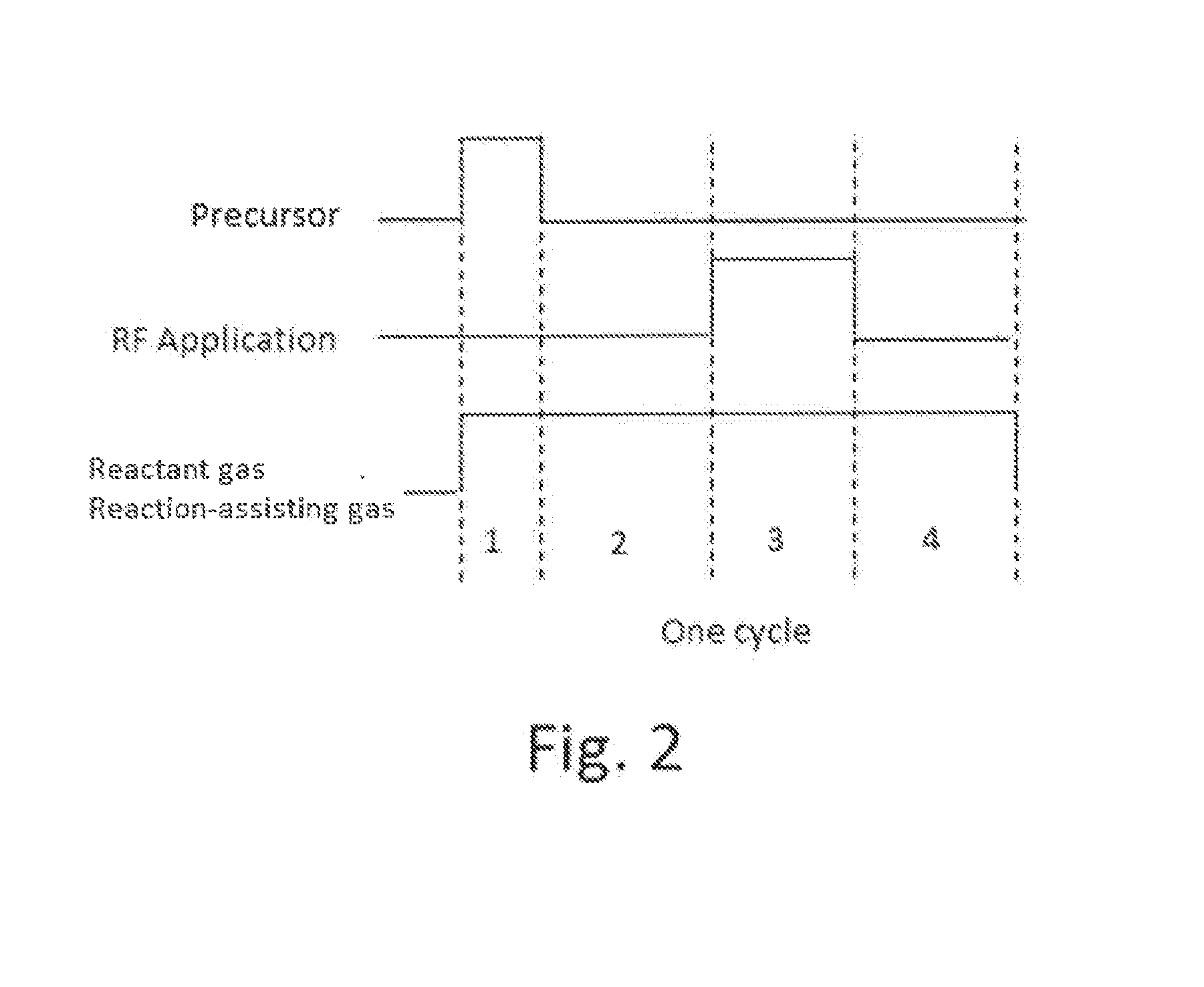

Method for forming aluminum oxide film using Al compound containing alkyl group and alkoxy or alkylamine group

ActiveUS8784950B2Safety with regard to handling and storage of the precursor can be ensuredDamage is causedChemical vapor deposition coatingPlasma techniqueProduct gasPhotochemistry

A method for forming a conformal film of aluminum oxide on a substrate having a patterned underlying layer by PEALD includes: adsorbing an Al precursor containing an Al—C bond and an Al—O—C or Al—N—C bond; providing an oxidizing gas and an inert gas; applying RF power to the reactant gas and the reaction-assisting gas to react the adsorbed precursor with the reactant gas on the surface, thereby forming a conformal film of aluminum oxide on the patterned underlying layer of the substrate, wherein the substrate is kept at a temperature of about 200° C. or lower.

Owner:ASM IP HLDG BV

Method for forming aluminum nitride-based film by PEALD

ActiveUS9711345B2Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

Owner:ASM IP HLDG BV

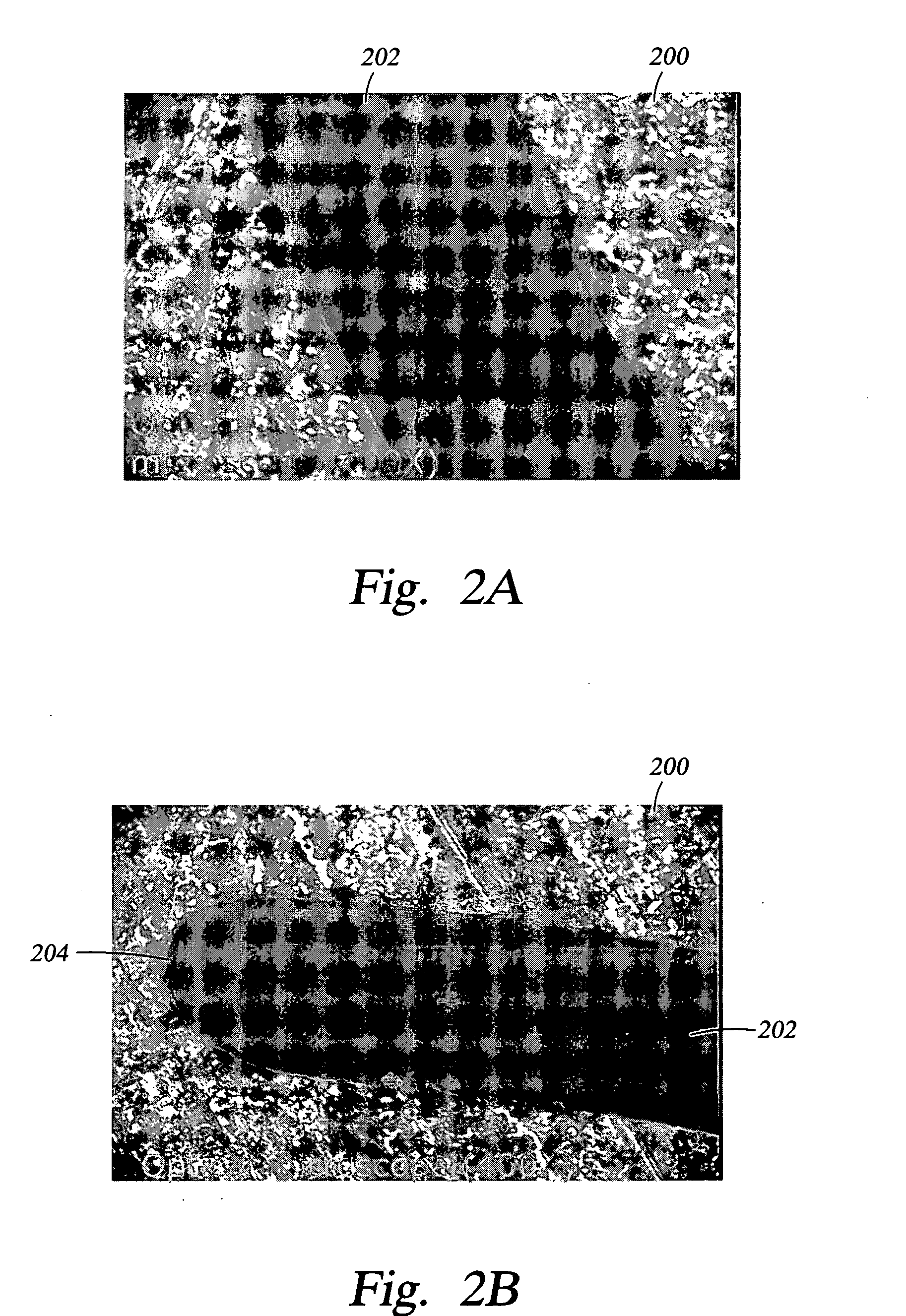

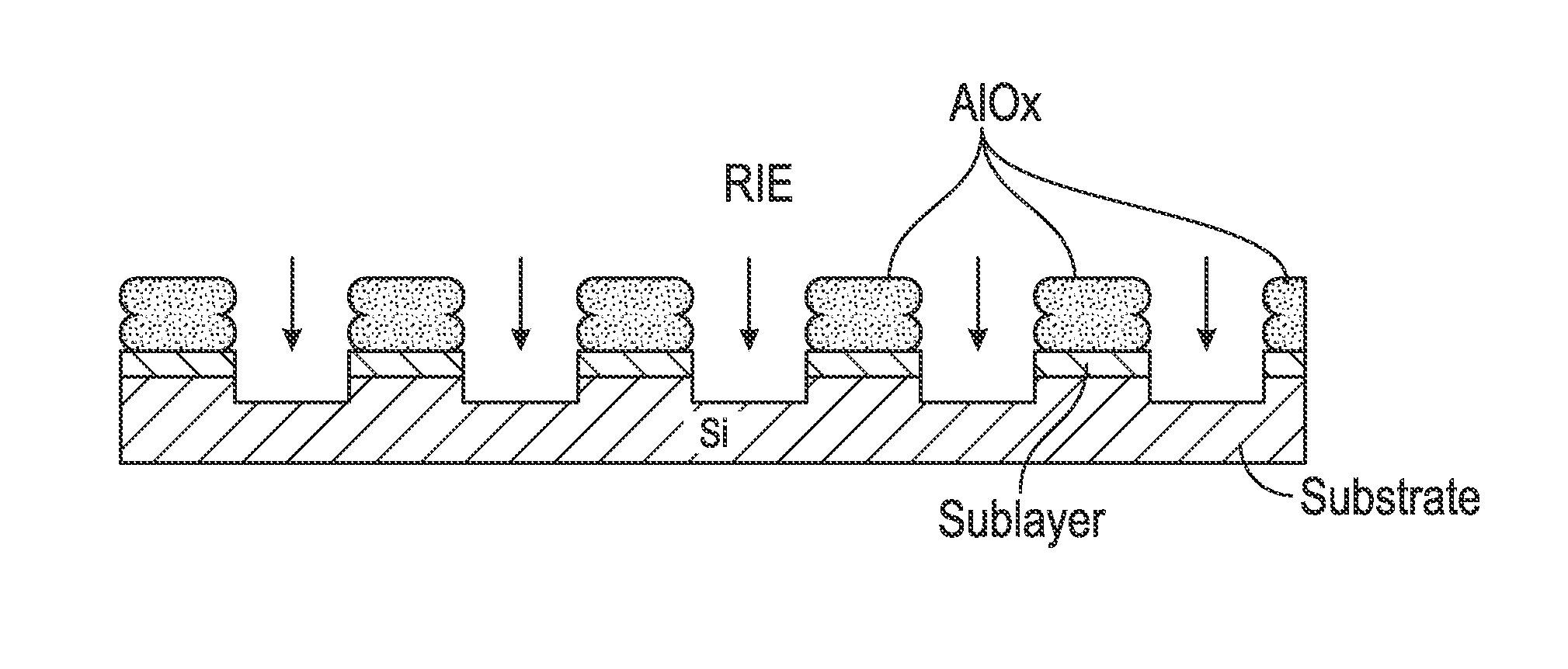

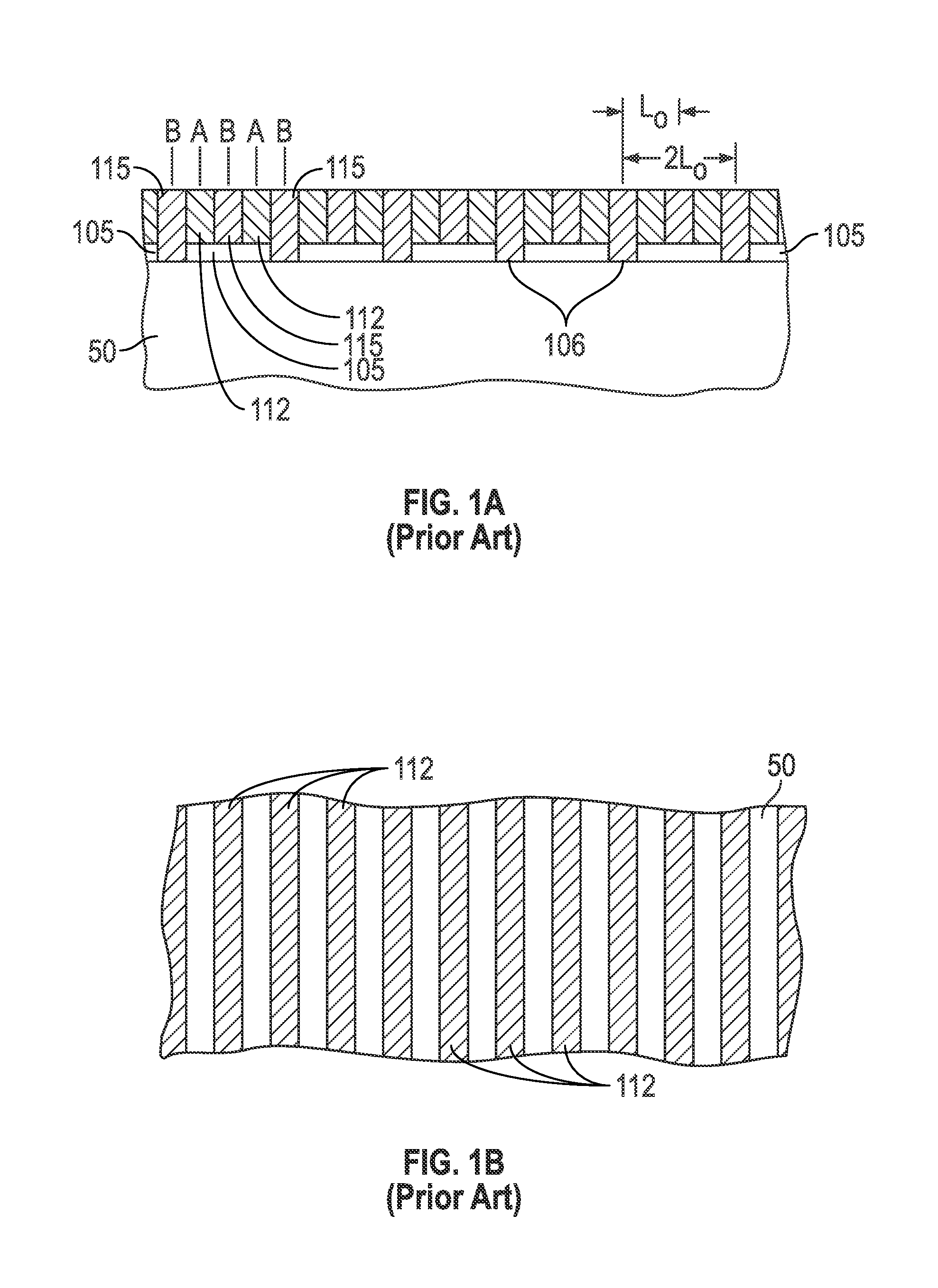

Method for making a chemical contrast pattern using block copolymers and sequential infiltration synthesis

ActiveUS20140346142A1Decorative surface effectsPhotomechanical apparatusInorganic materialsAtomic layer deposition

A method for making a chemical contrast pattern uses directed self-assembly of block copolymers (BCPs) and sequential infiltration synthesis (SIS) of an inorganic material. For an example with poly(styrene-block-methyl methacrylate) (PS-b-PMMA) as the BCP and alumina as the inorganic material, the PS and PMMA self-assemble on a suitable substrate. The PMMA is removed and the PS is oxidized. A surface modification polymer (SMP) is deposited on the oxidized PS and the exposed substrate and the SMP not bound to the substrate is removed. The structure is placed in an atomic layer deposition chamber. Alumina precursors reactive with the oxidized PS are introduced and infuse by SIS into the oxidized PS, thereby forming on the substrate a chemical contrast pattern of SMP and alumina. The resulting chemical contrast pattern can be used for lithographic masks, for example to etch the underlying substrate to make an imprint template.

Owner:WESTERN DIGITAL TECH INC

Method for forming aluminum nitride-based film by peald

ActiveUS20170062209A1Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

A method for forming an aluminum nitride-based film on a substrate by plasma-enhanced atomic layer deposition (PEALD) includes: (a) forming at least one aluminum nitride (AlN) monolayer and (b) forming at least one aluminum oxide (AlO) monolayer, wherein steps (a) and (b) are alternately conducted continuously to form a laminate. Steps (a) and (b) are discontinued before a total thickness of the laminate exceeds 10 nm, preferably 5 nm.

Owner:ASM IP HLDG BV

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

Method for Forming Aluminum Oxide Film Using Al Compound Containing Alkyl Group and Alkoxy or Alkylamine Group

ActiveUS20140017414A1Increase deposition rateDamage is causedChemical vapor deposition coatingPlasma techniquePhotochemistryConformal film

A method for forming a conformal film of aluminum oxide on a substrate having a patterned underlying layer by PEALD includes: adsorbing an Al precursor containing an Al—C bond and an Al—O—C or Al—N—C bond; providing an oxidizing gas and an inert gas; applying RF power to the reactant gas and the reaction-assisting gas to react the adsorbed precursor with the reactant gas on the surface, thereby forming a conformal film of aluminum oxide on the patterned underlying layer of the substrate, wherein the substrate is kept at a temperature of about 200° C. or lower.

Owner:ASM IP HLDG BV

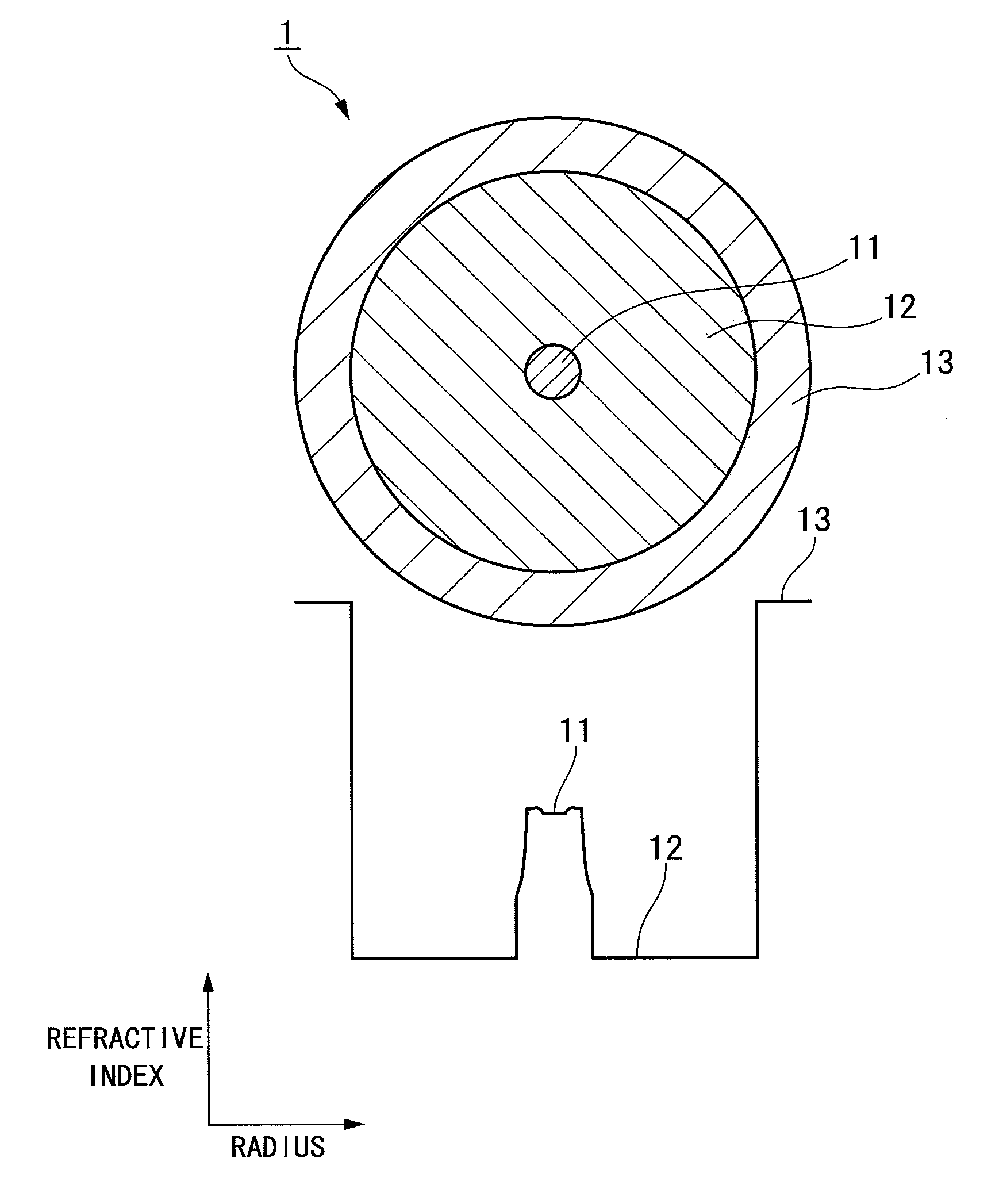

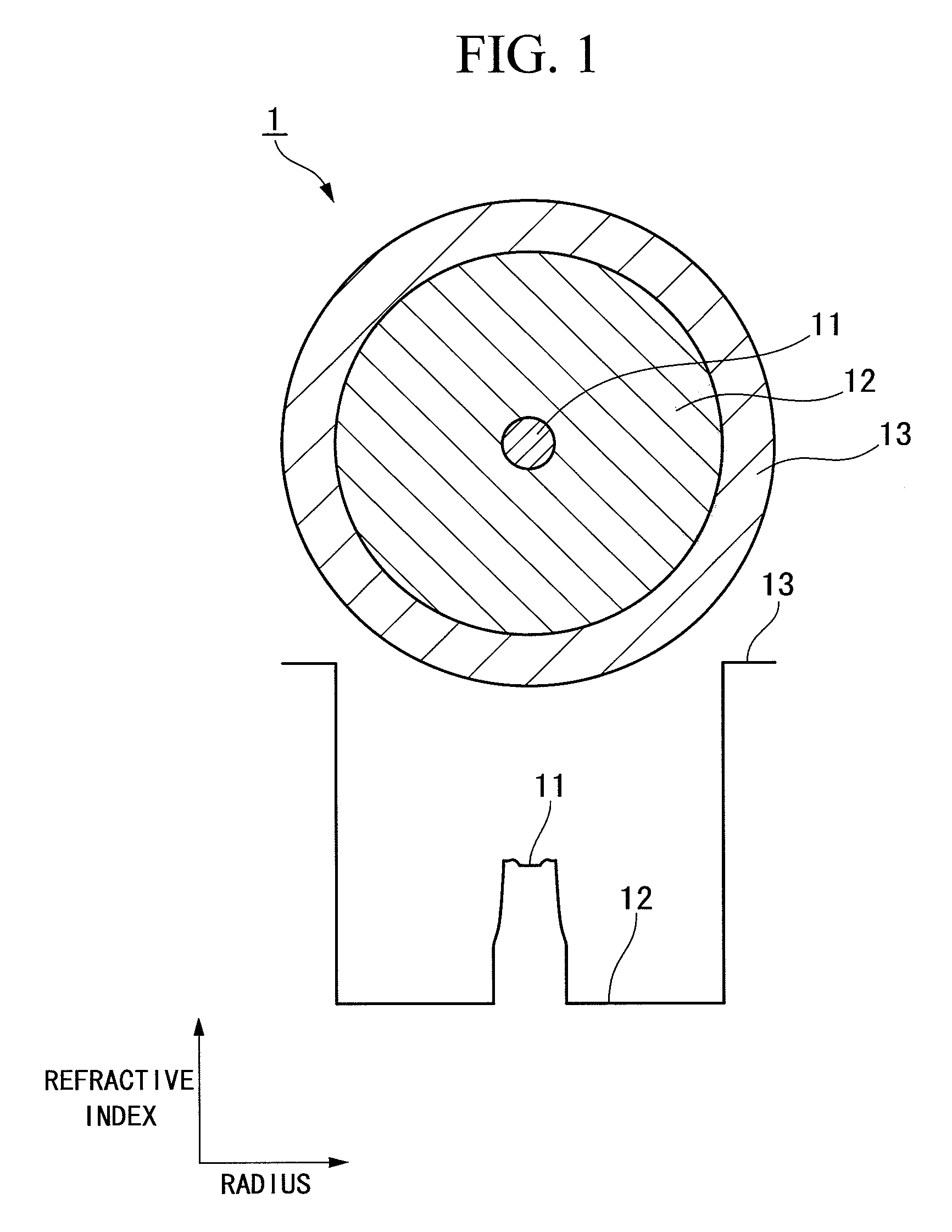

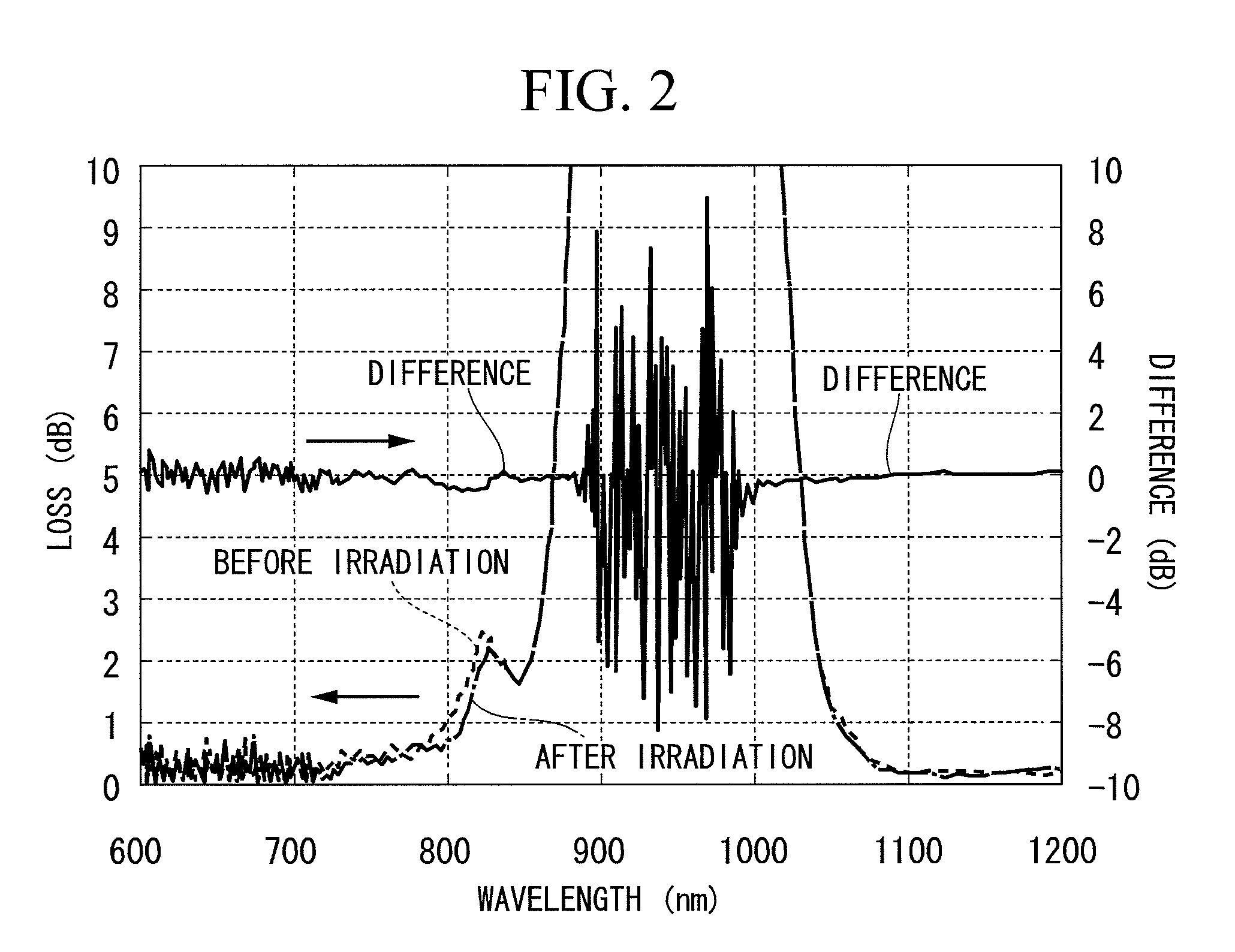

Ytterbium-doped optical fiber, fiber laser, and fiber amplifier

ActiveUS8363313B2Avoid small quantitiesSuperior optical amplificationLaser using scattering effectsOptical fibre with polarisationYTTERBIUM OXIDEDiphosphorus

An ytterbium-doped optical fiber of the present invention includes: a core which contains ytterbium, aluminum, and phosphorus and does not contain germanium; and a cladding which surrounds this core. The ytterbium concentration in the core in terms of ytterbium oxide is 0.09 to 0.68 mole percent. The molar ratio between the phosphorus concentration in the core in terms of diphosphorus pentoxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 30. The molar ratio between the aluminum concentration in the core in terms of aluminum oxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 32. The molar ratio between the above aluminum concentration in terms of aluminum oxide and the above phosphorus concentration in terms of diphosphorus pentoxide is 1 to 2.5.

Owner:FUJIKURA LTD

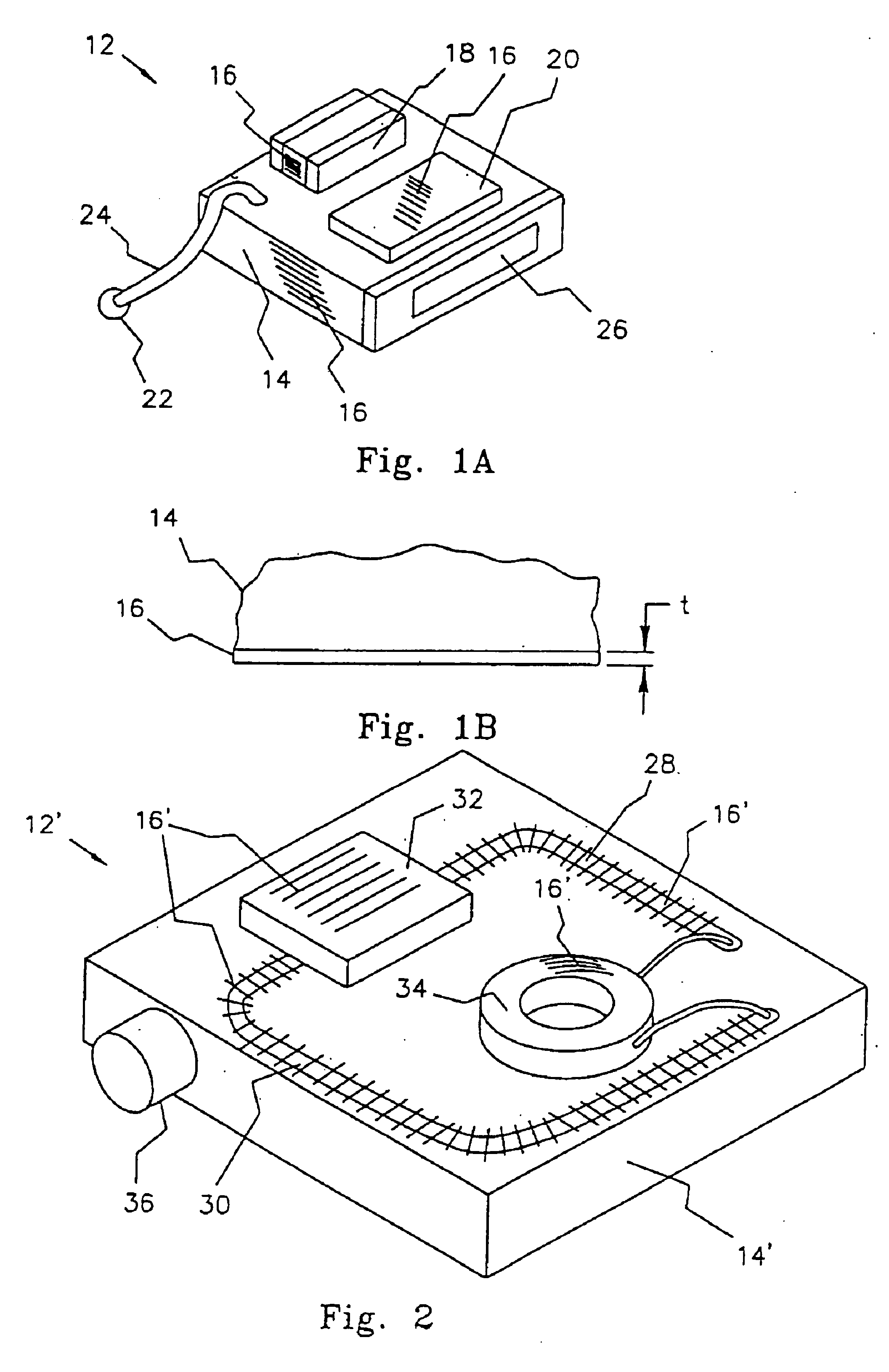

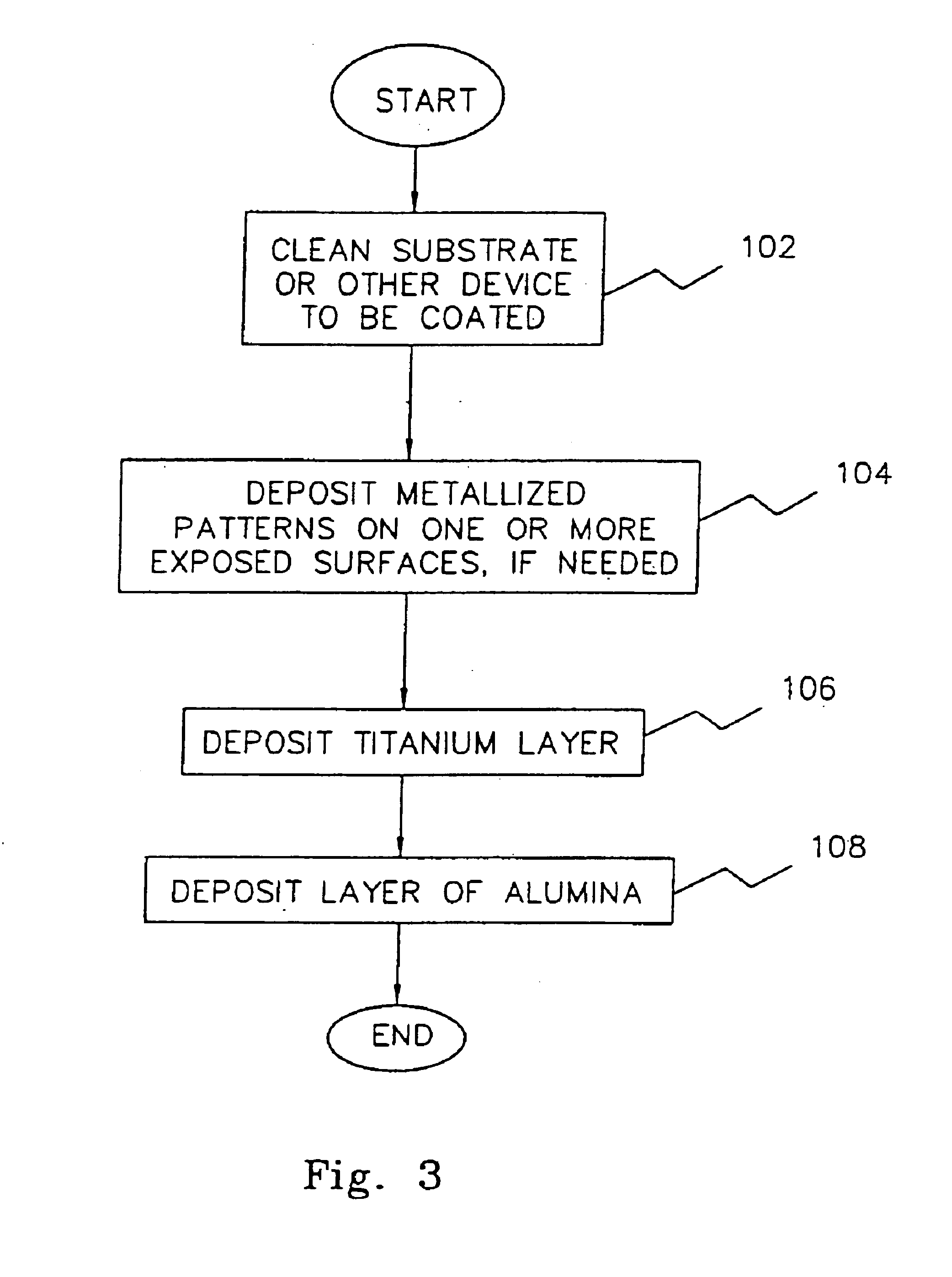

Alumina insulation for coating implantable components and other microminiature devices

InactiveUS6844023B2Efficient use ofImprove insulation performanceElectrotherapyVacuum evaporation coatingBiocompatible coatingThin layer

A protective, biocompatible coating or encapsulation material protects and insulates a component or device intended to be implanted in living tissue. The coating or encapsulation material comprises a thin layer or layers of alumina, zirconia or other ceramic, less than 25 microns thick, e.g., 5-10 microns thick. The alumina layer(s) may be applied at relatively low temperature. Once applied, the layer provides excellent hermeticity, and prevents electrical leakage. Even though very thin, the alumina layer retains excellent insulating characteristics. In one embodiment, an alumina layer less than about 6 microns thick provides an insulative coating that exhibits less than 10 pA of leakage current over an area 75 mils by 25 mils area while soaking in a saline solution at temperatures up to 80° C. over a three month period.

Owner:MEDTRONIC MIMIMED INC

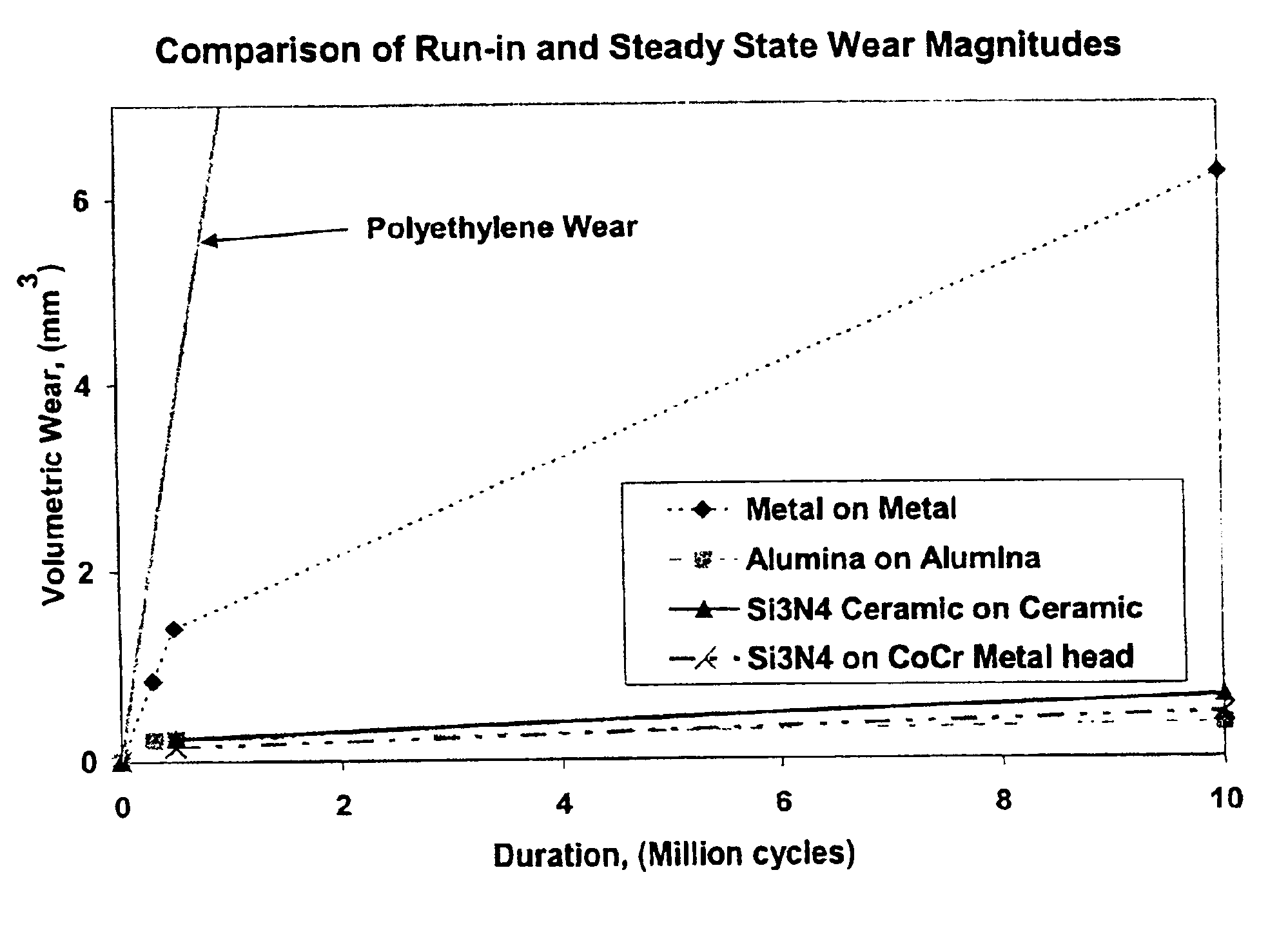

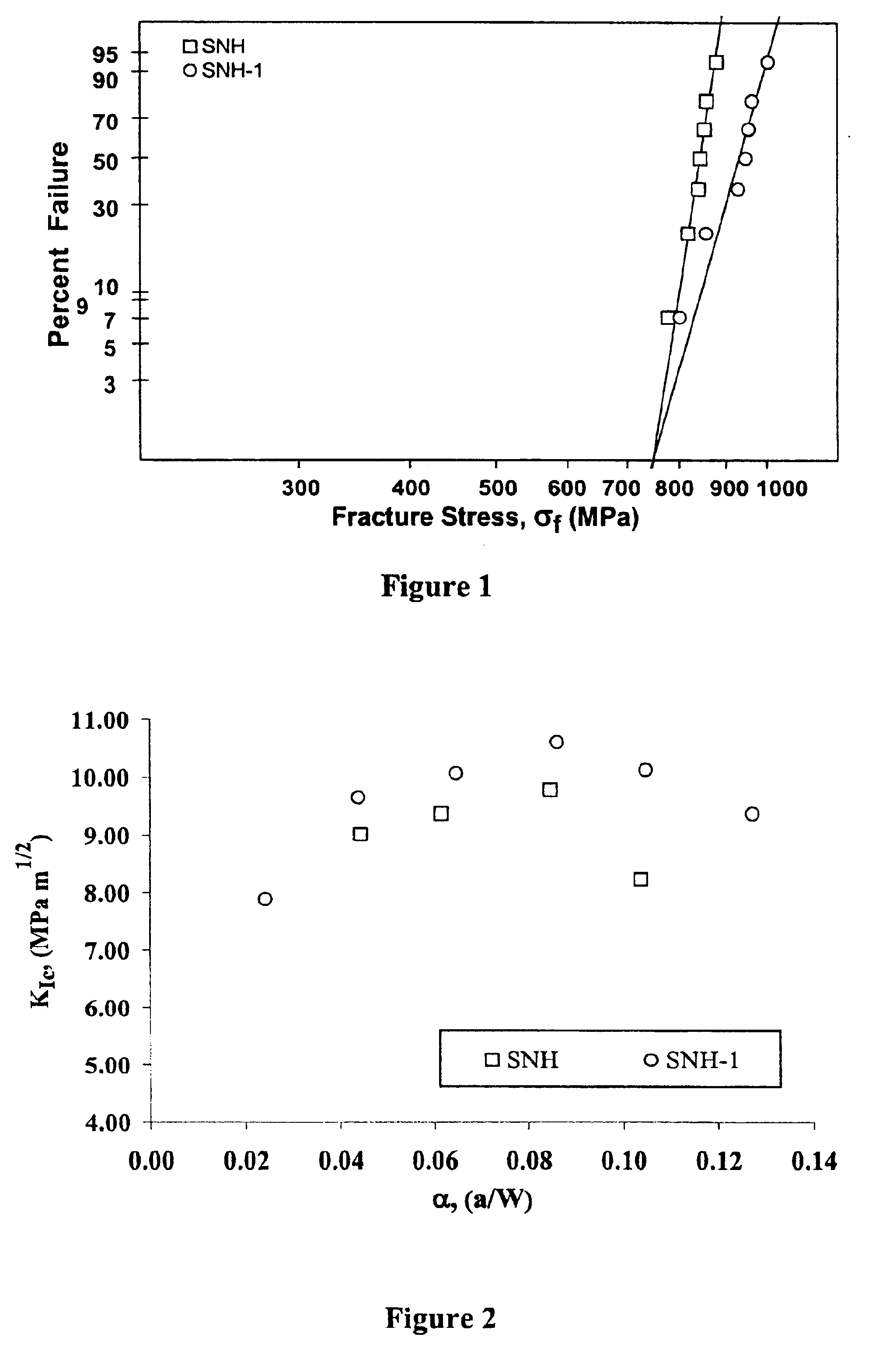

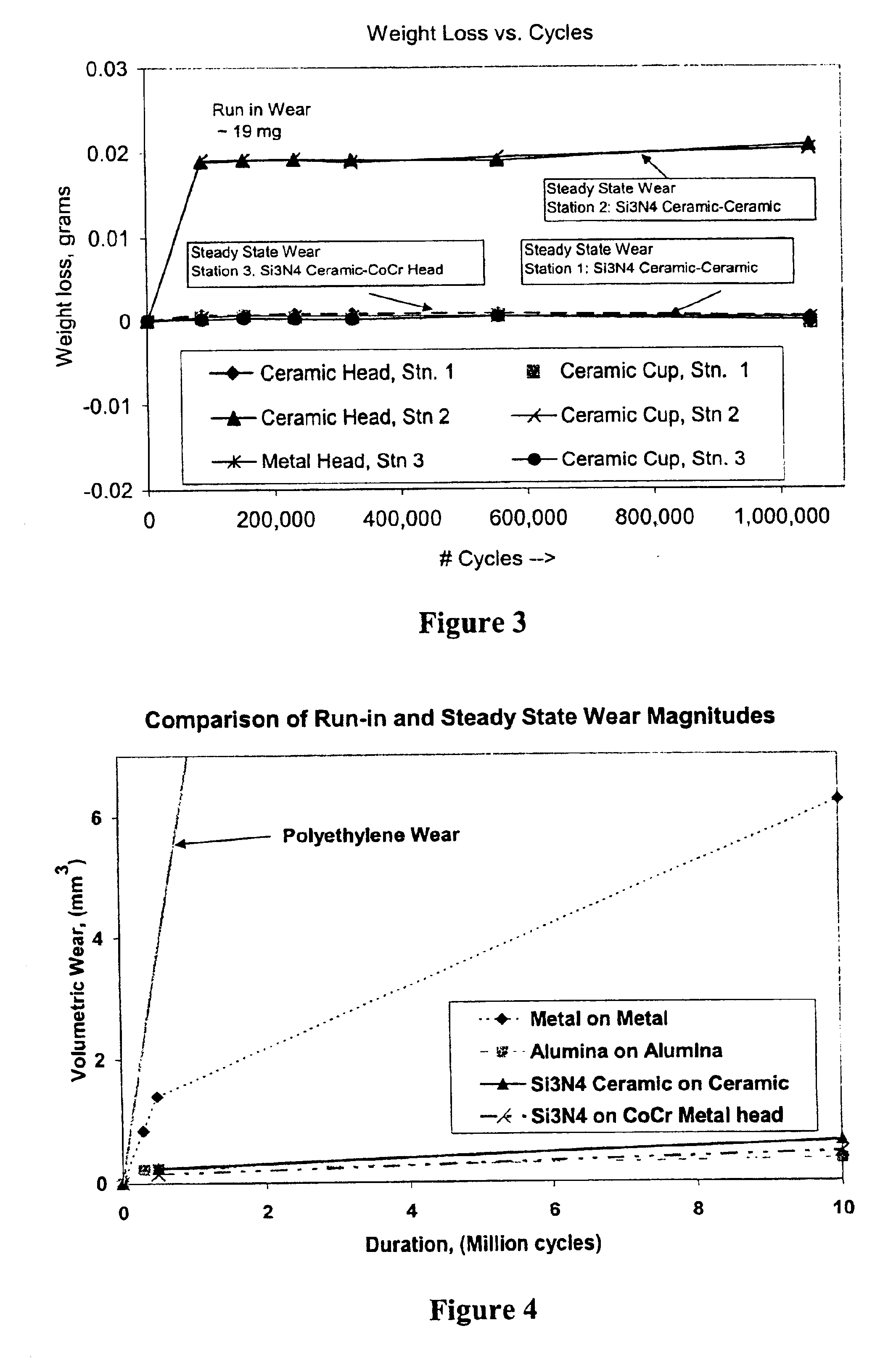

Metal-ceramic composite articulation

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

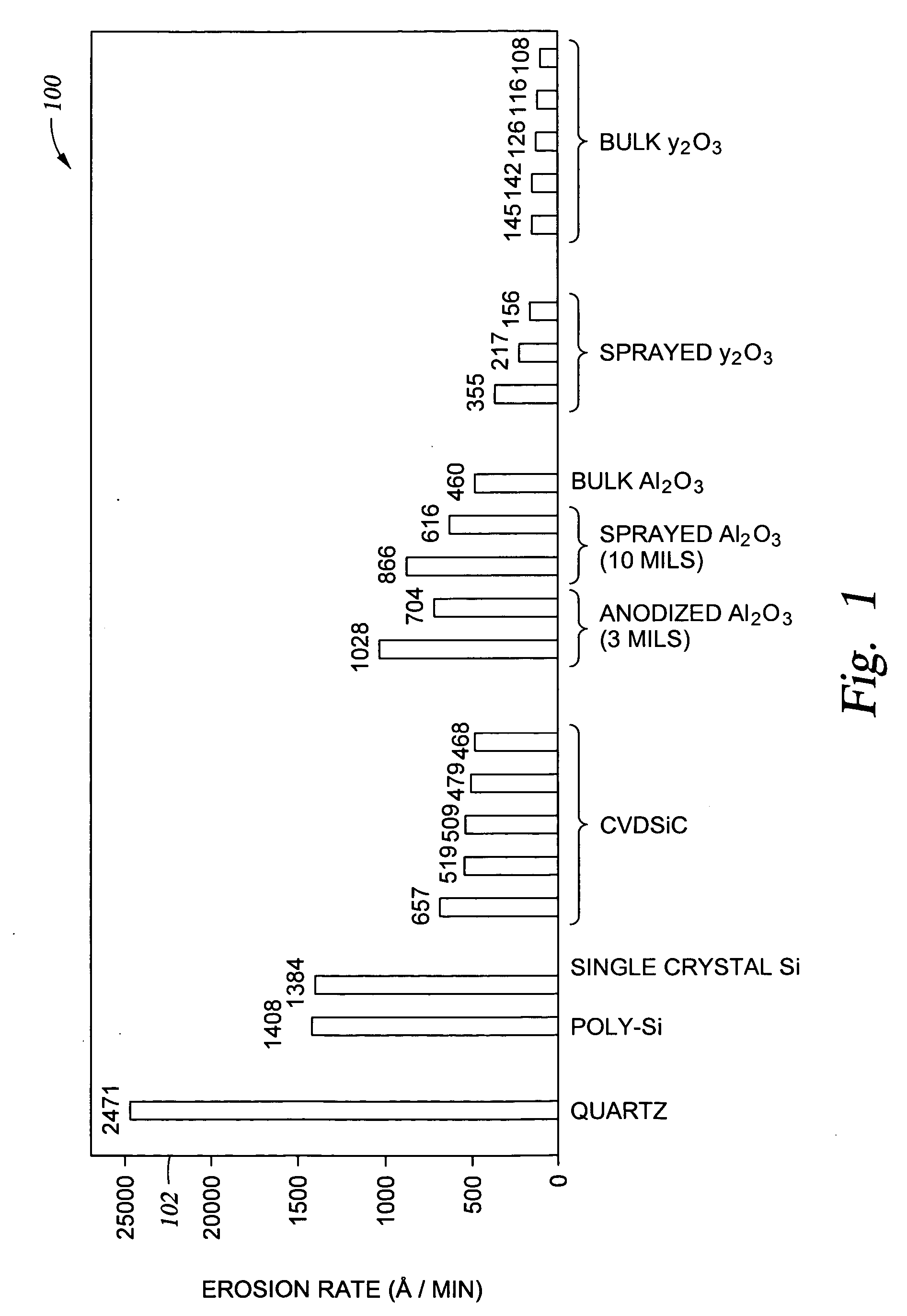

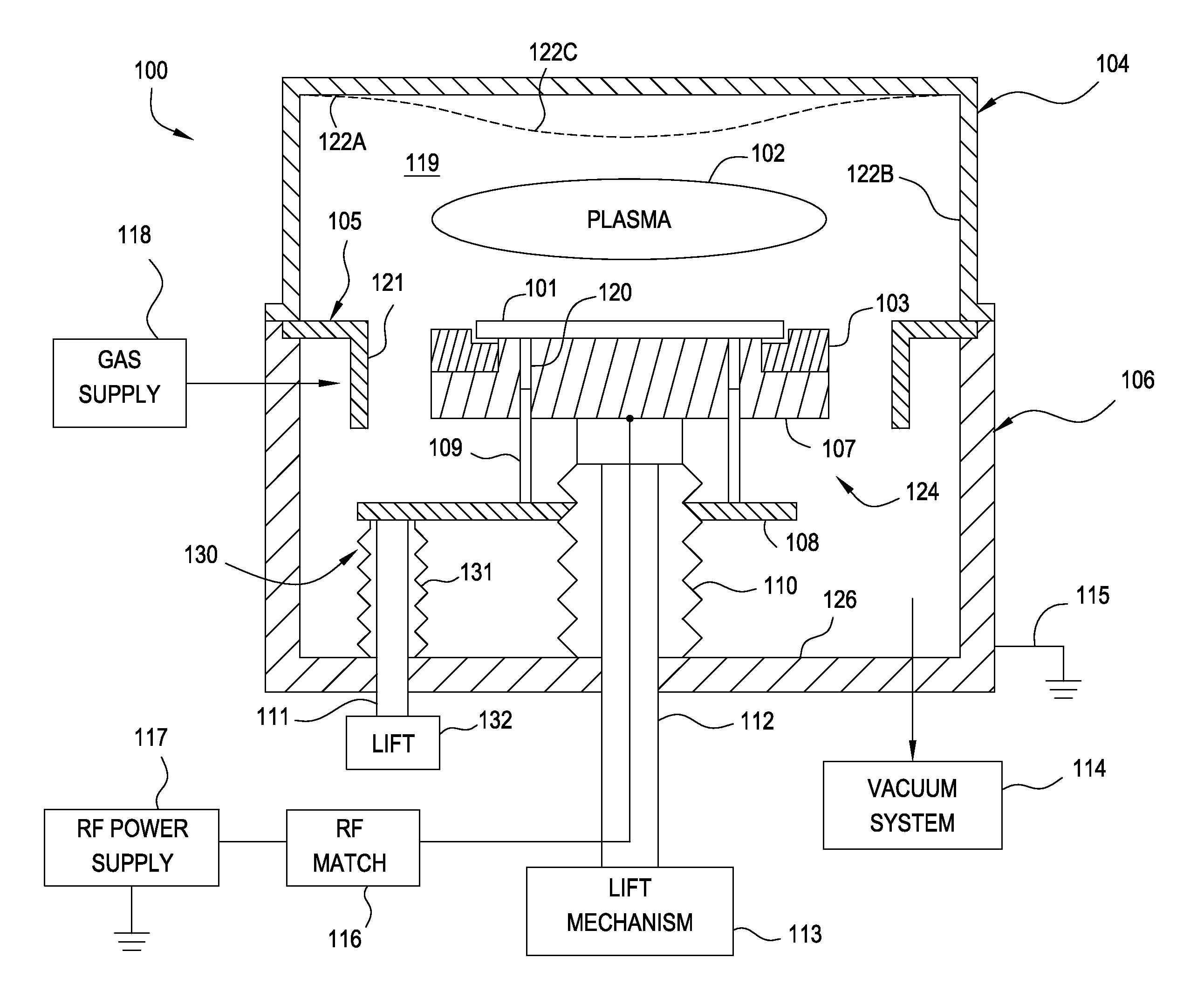

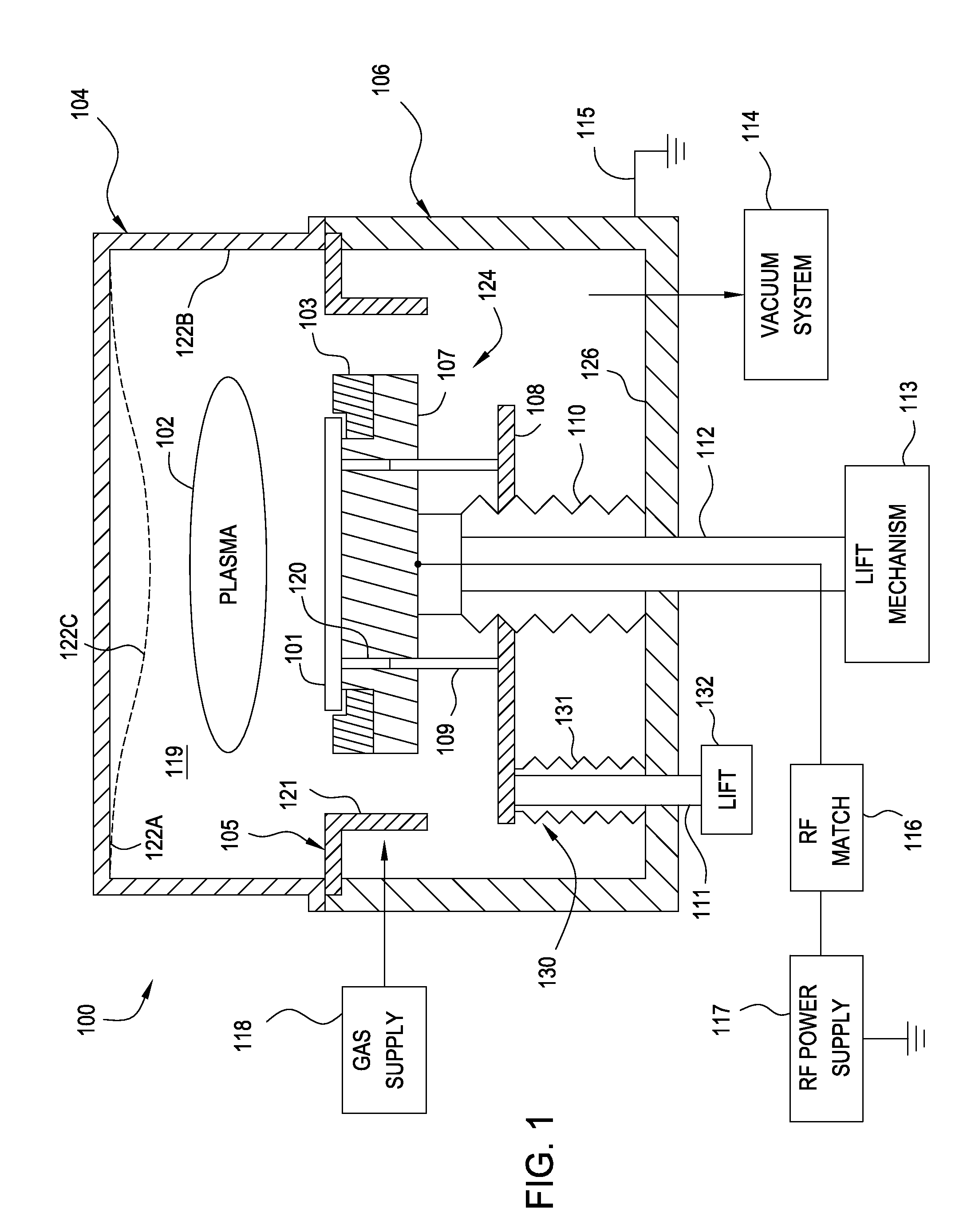

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

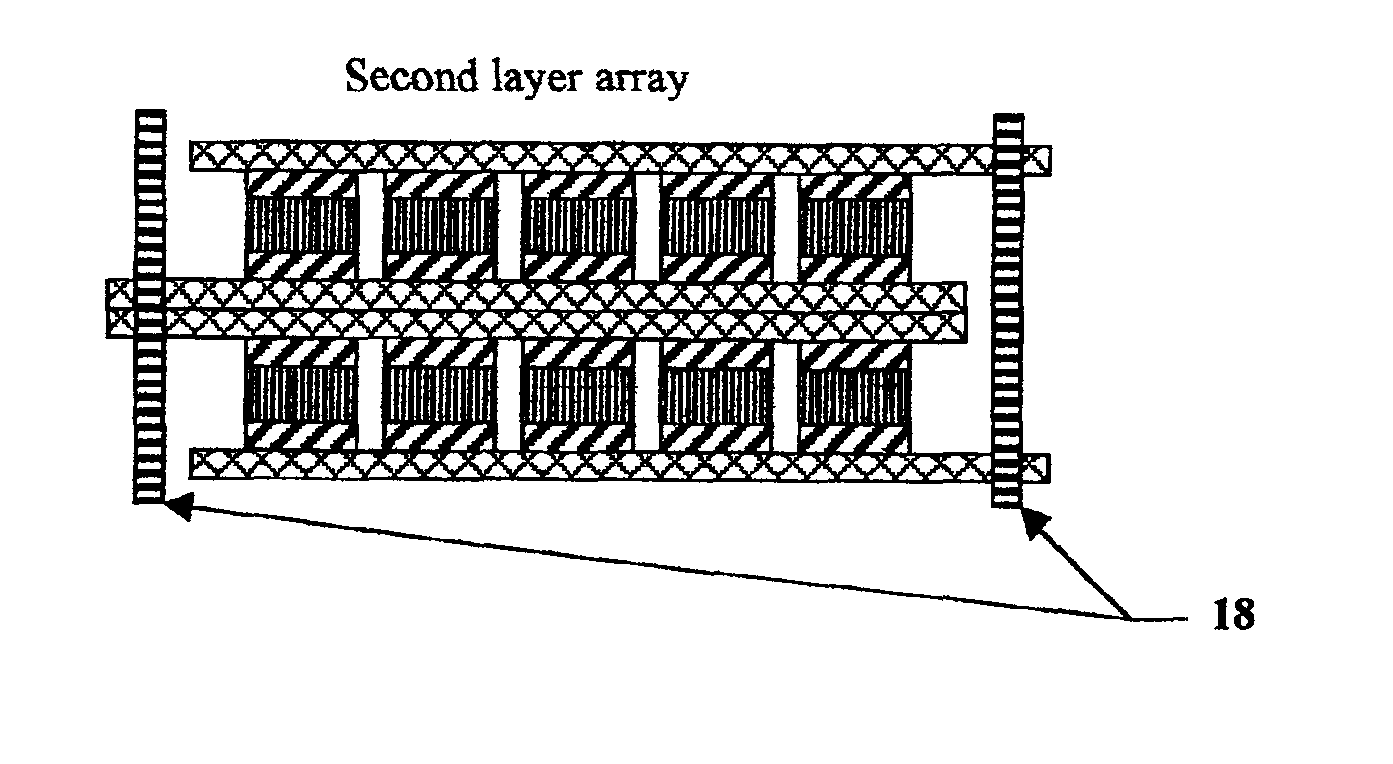

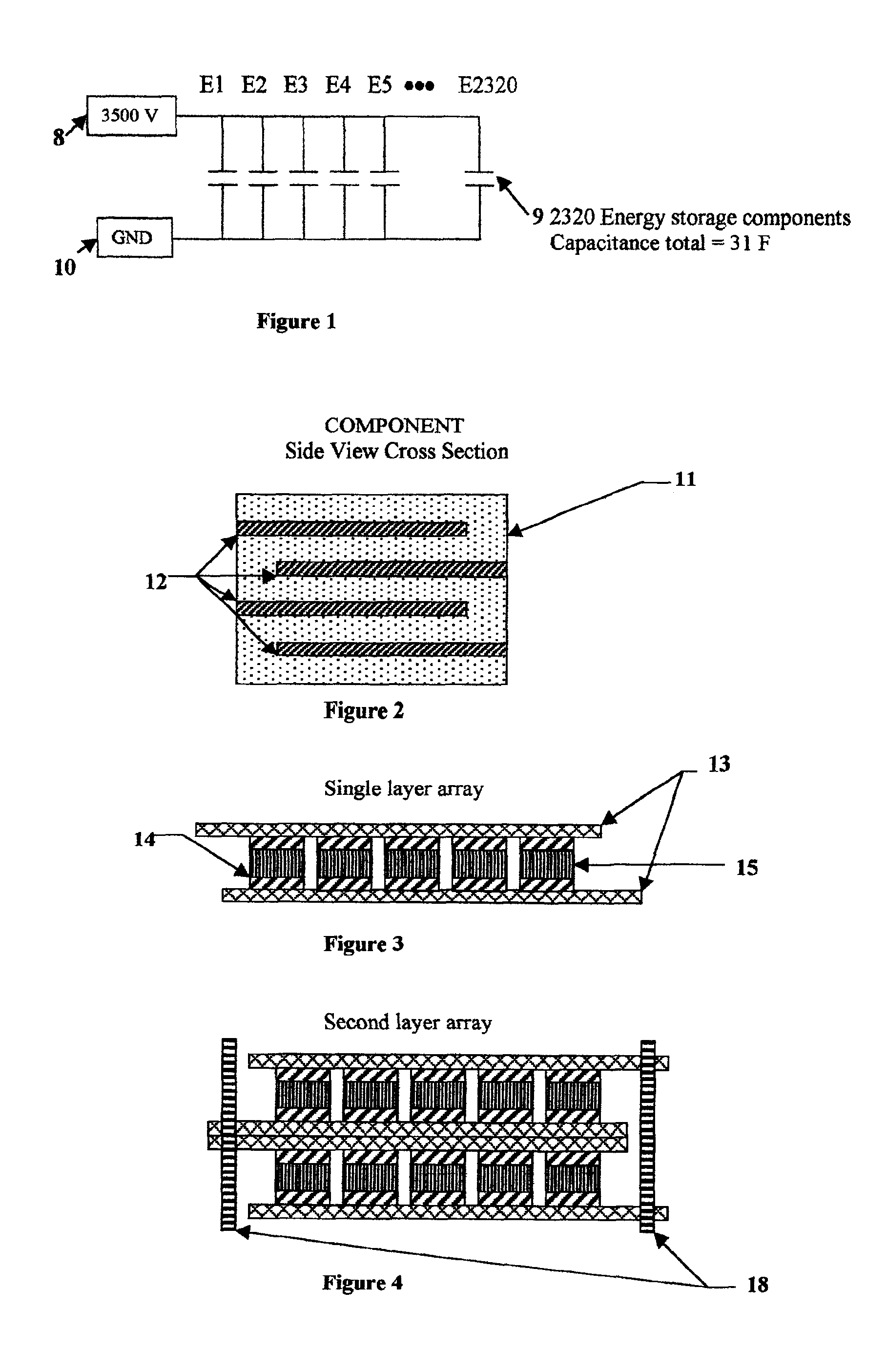

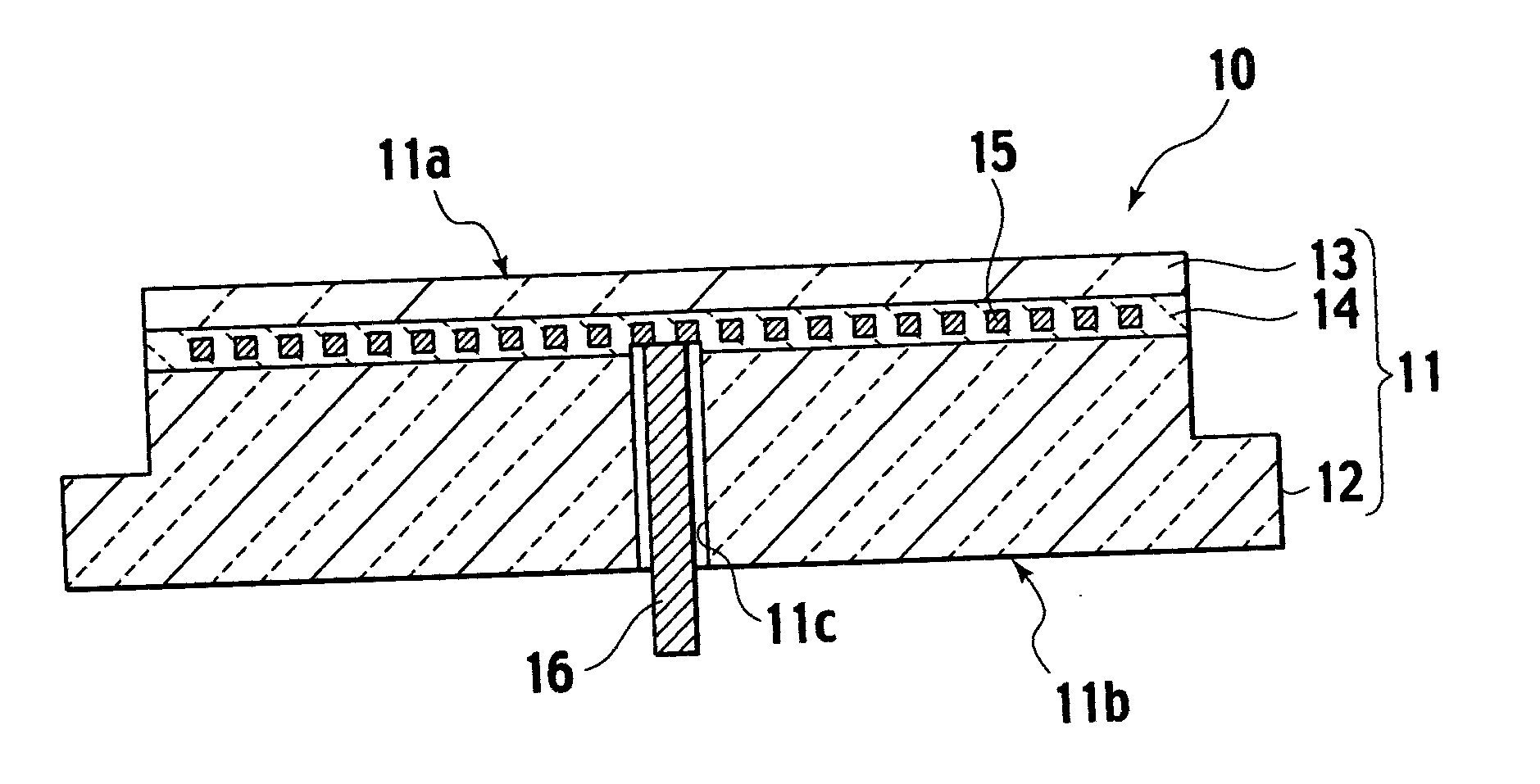

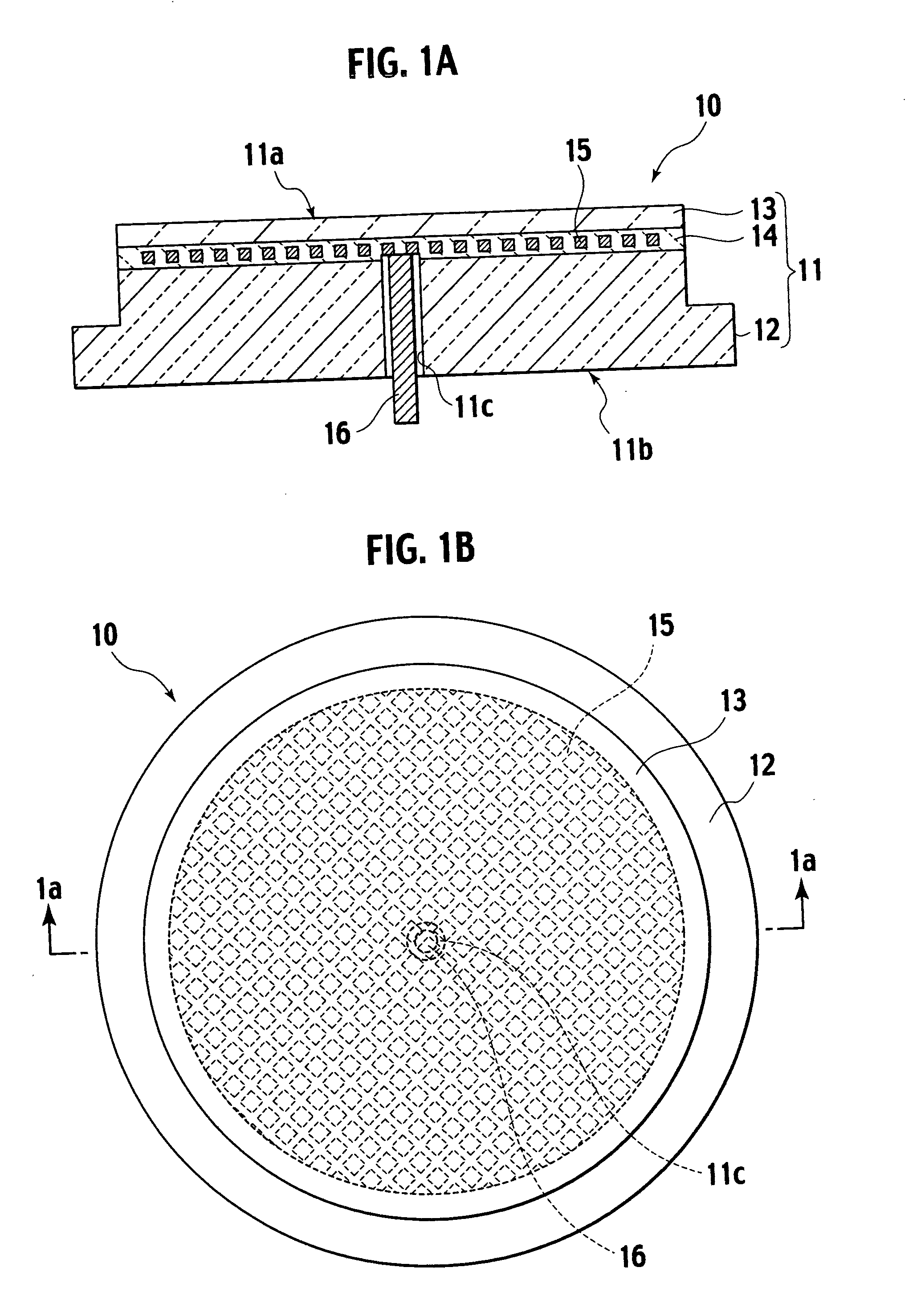

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS7033406B2Reduce sinteringLowering hot-isostatic-pressing temperatureElectrical storage systemFixed capacitor electrodesBarium titanatePermittivity

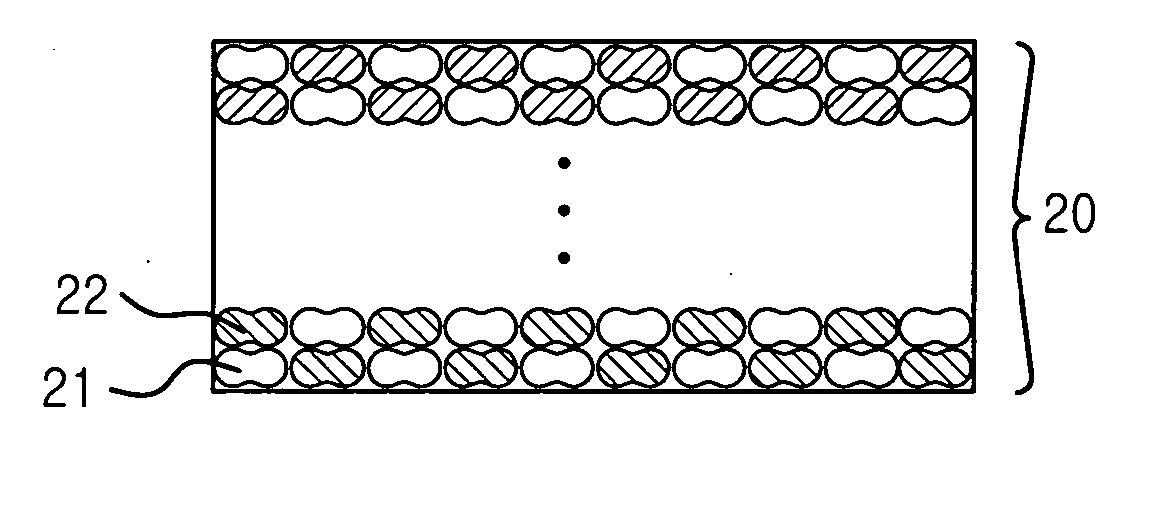

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

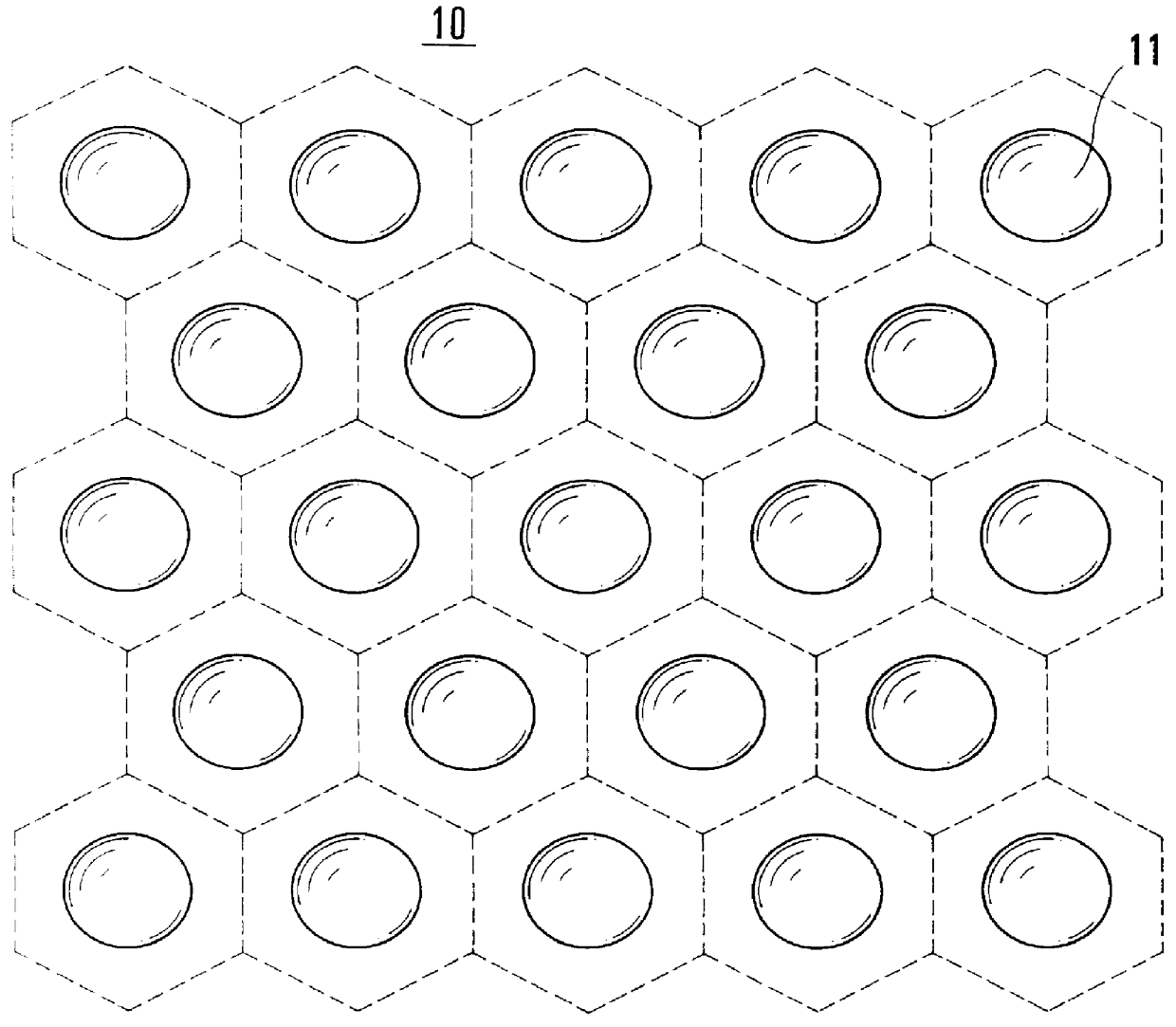

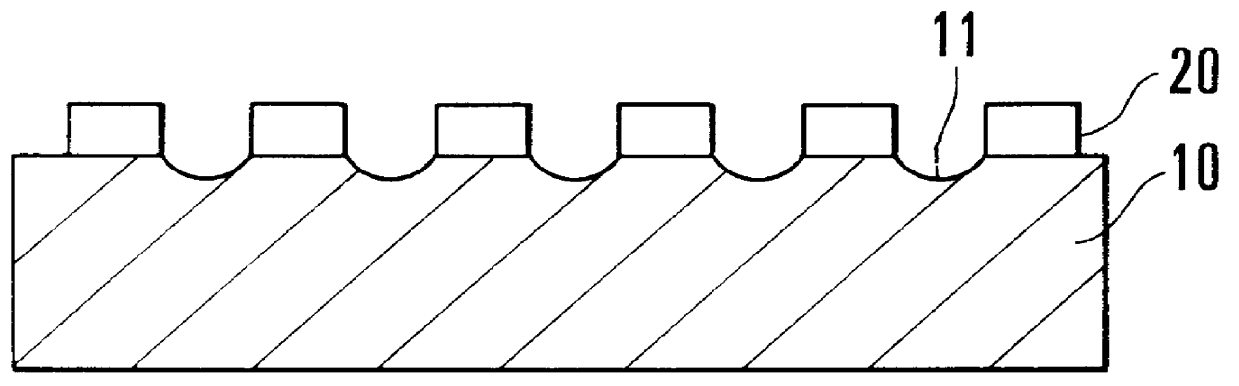

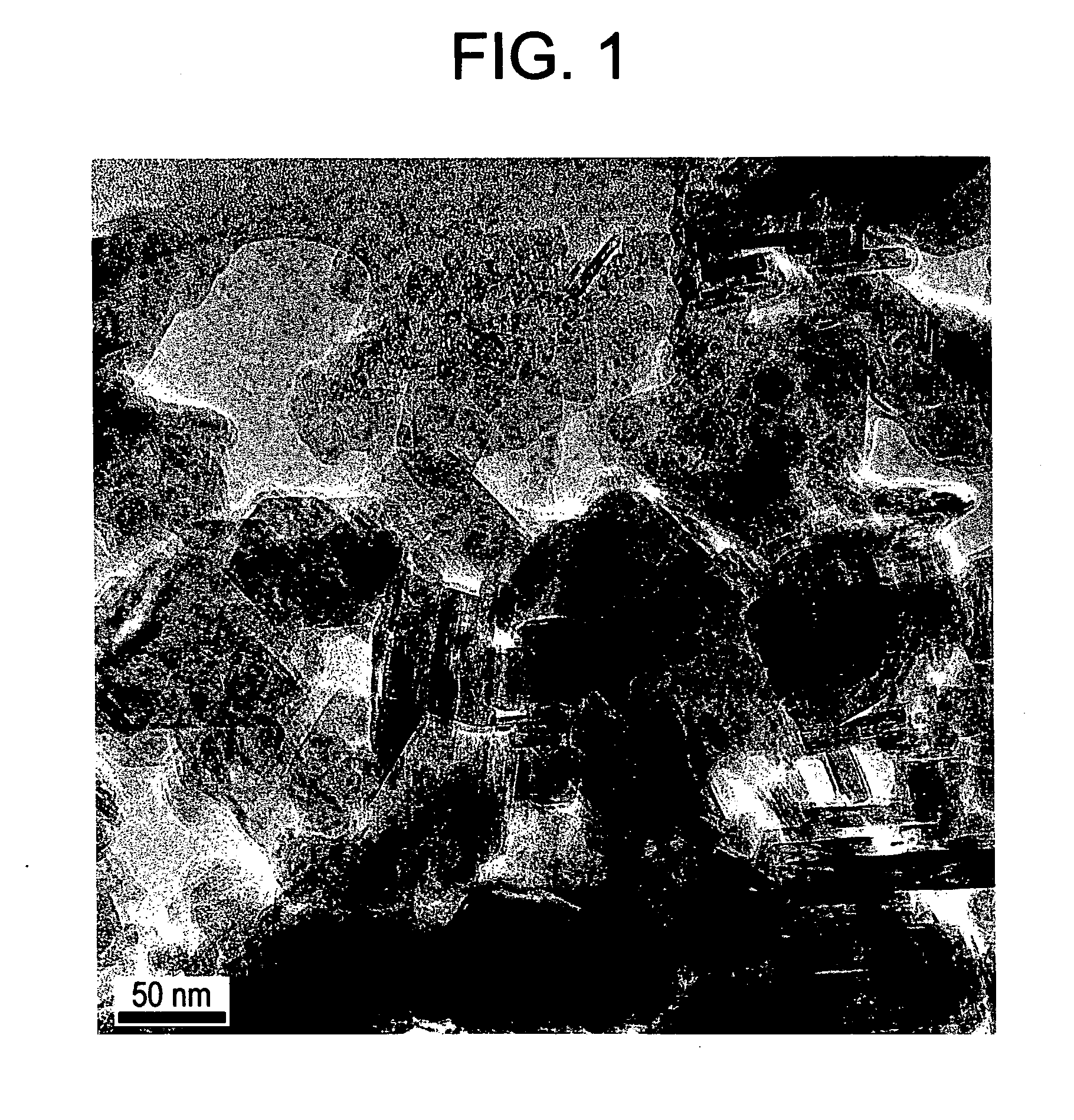

Method of manufacturing porous anodized alumina film

PCT No. PCT / JP97 / 02965 Sec. 371 Date Nov. 2, 1998 Sec. 102(e) Date Nov. 2, 1998 PCT Filed Aug. 26, 1997 PCT Pub. No. WO98 / 09005 PCT Pub. Date Mar. 5, 1998A plurality of recesses having the same interval and array as those of pores of an alumina film, which are to be formed in anodizing, are formed on a smooth surface of an aluminum plate in advance, and then, the aluminum plate is anodized. With this process, the roundness of the pores of the porous anodized alumina film and the uniformity of pore size are improved, and the pores are regularly arrayed at a predetermined interval. The recesses are formed by pressing a substrate having a plurality of projections on its surface against the aluminum plate surface to be anodized.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

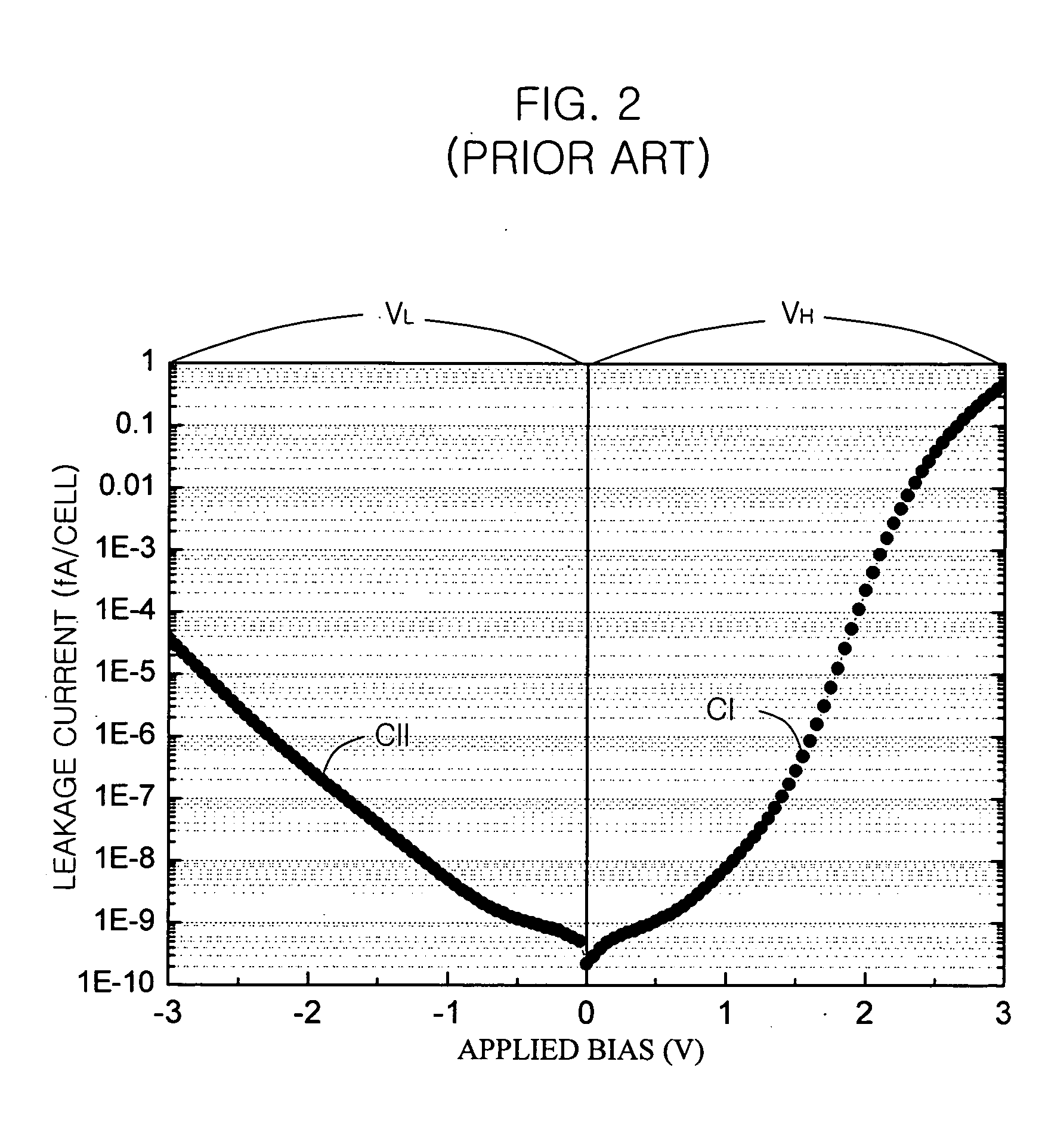

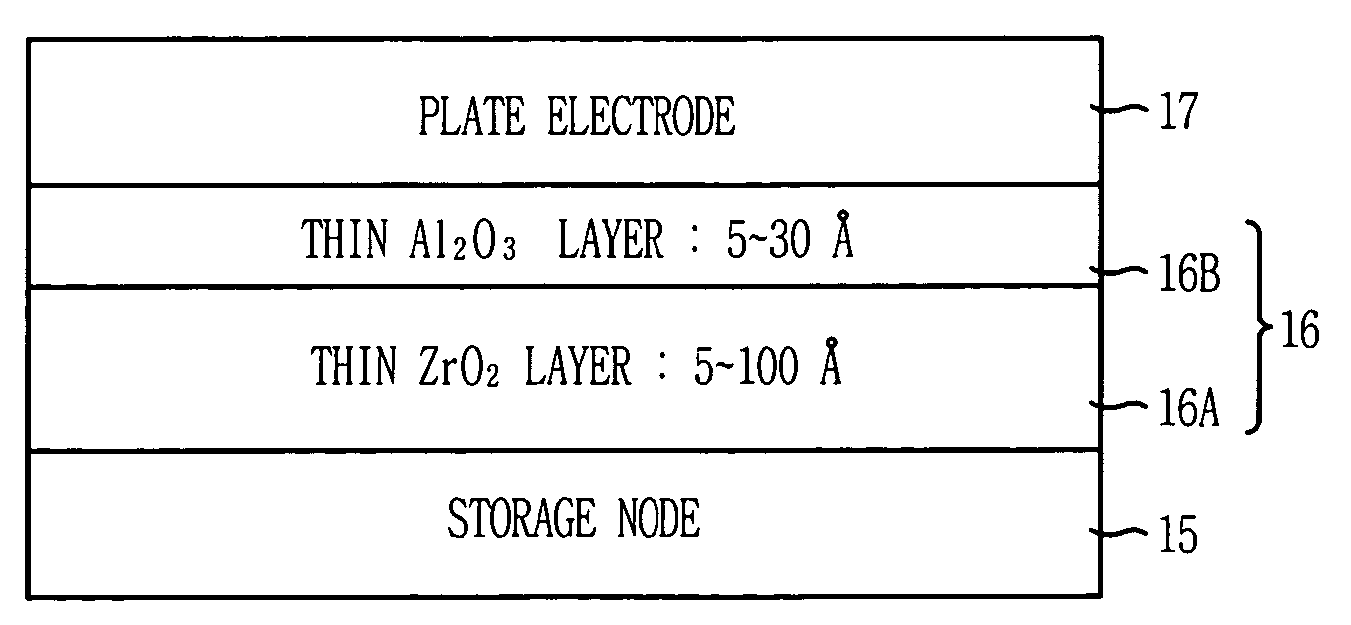

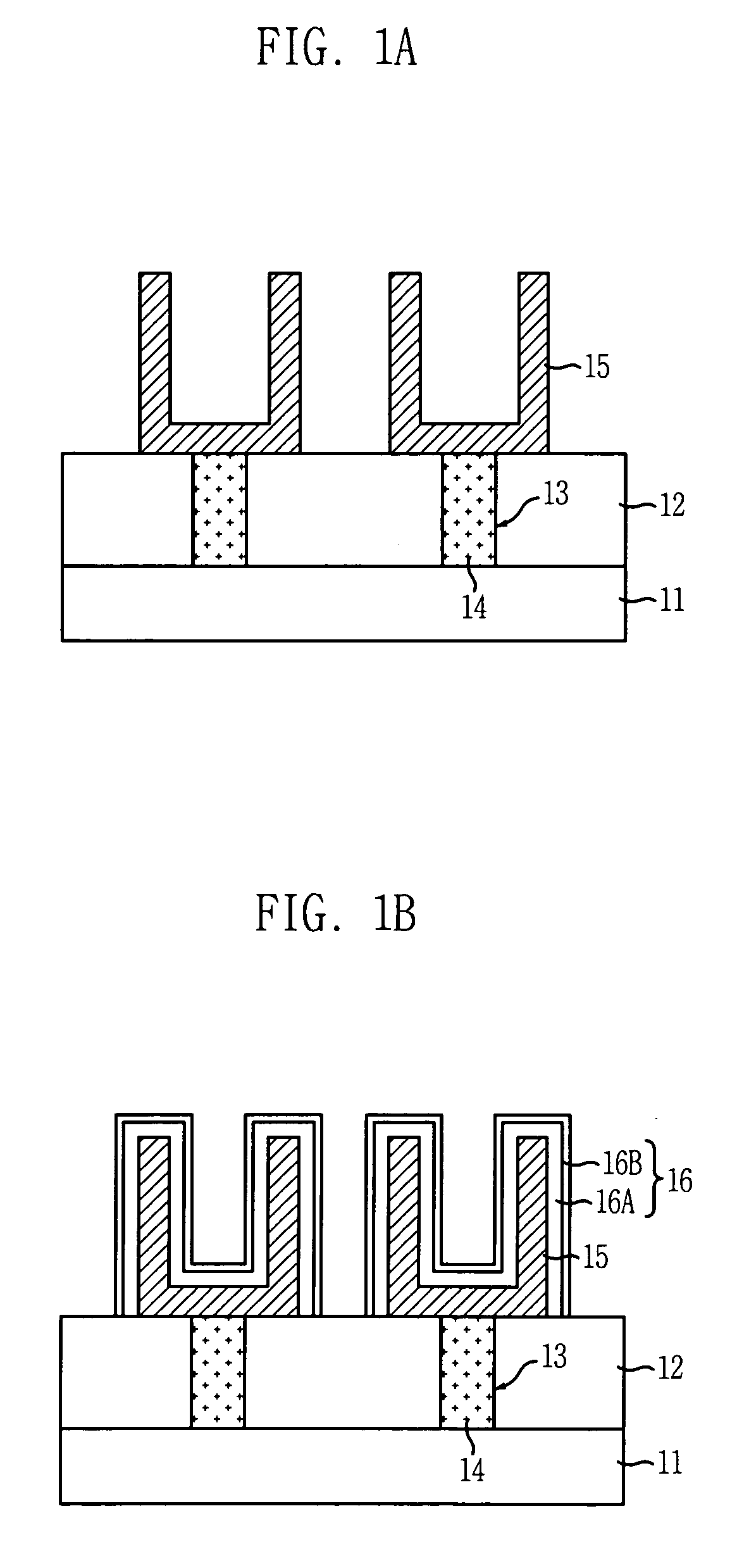

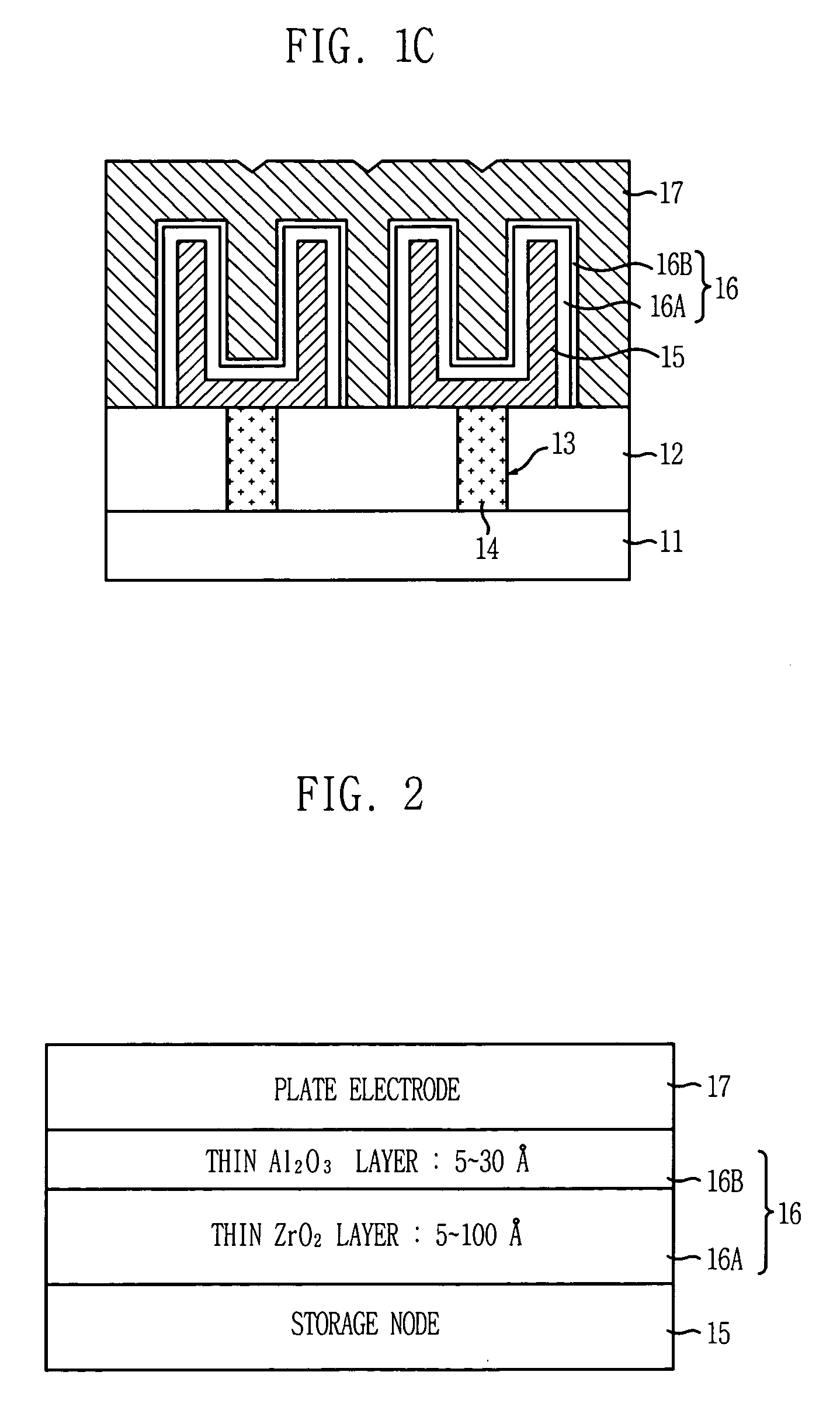

Capacitor with zirconium oxide and method for fabricating the same

ActiveUS20060097305A1Secure leakage current characteristicSecure capacitance levelTransistorSolid-state devicesOptoelectronicsDielectric structure

A capacitor with zirconium oxide and a method for fabricating the same are provided. The method includes: forming a storage node; forming a multi-layered dielectric structure on the storage node, the multi-layered dielectric structure including a zirconium oxide (ZrO2) layer and an aluminum oxide (Al2O3) layer; and forming a plate electrode on the multi-layered dielectric structure.

Owner:SK HYNIX INC

Method for preparing alumina supporter

InactiveCN1488441ANo pollution in the processNo special pollutionCatalyst carriersRefining to eliminate hetero atomsContaminationMetal

The invention discloses a manufacturing method for aluminium dioxide, blends two kinds of different thin water aluminium wafer powder evenly, and then carries on dissolving and forming, drying, baking and gets the aluminum oxide. The first kind of thin water aluminum mine has a hole capacity of 0.50ml / g~0.80ml / g, the proportion accounts for 5w%~50w% of Al2O3 . the hole capacity of the second aluminum mine is about 0.85ml / g ~1.50ml / g. There has no contamination by using the method; the diameter of the carrier is in the range of 6nm~35nm and 100nm~2000nm; the carrier can be used as carrier of protection agent in heavy oil producing, metal eliminating catalyst and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

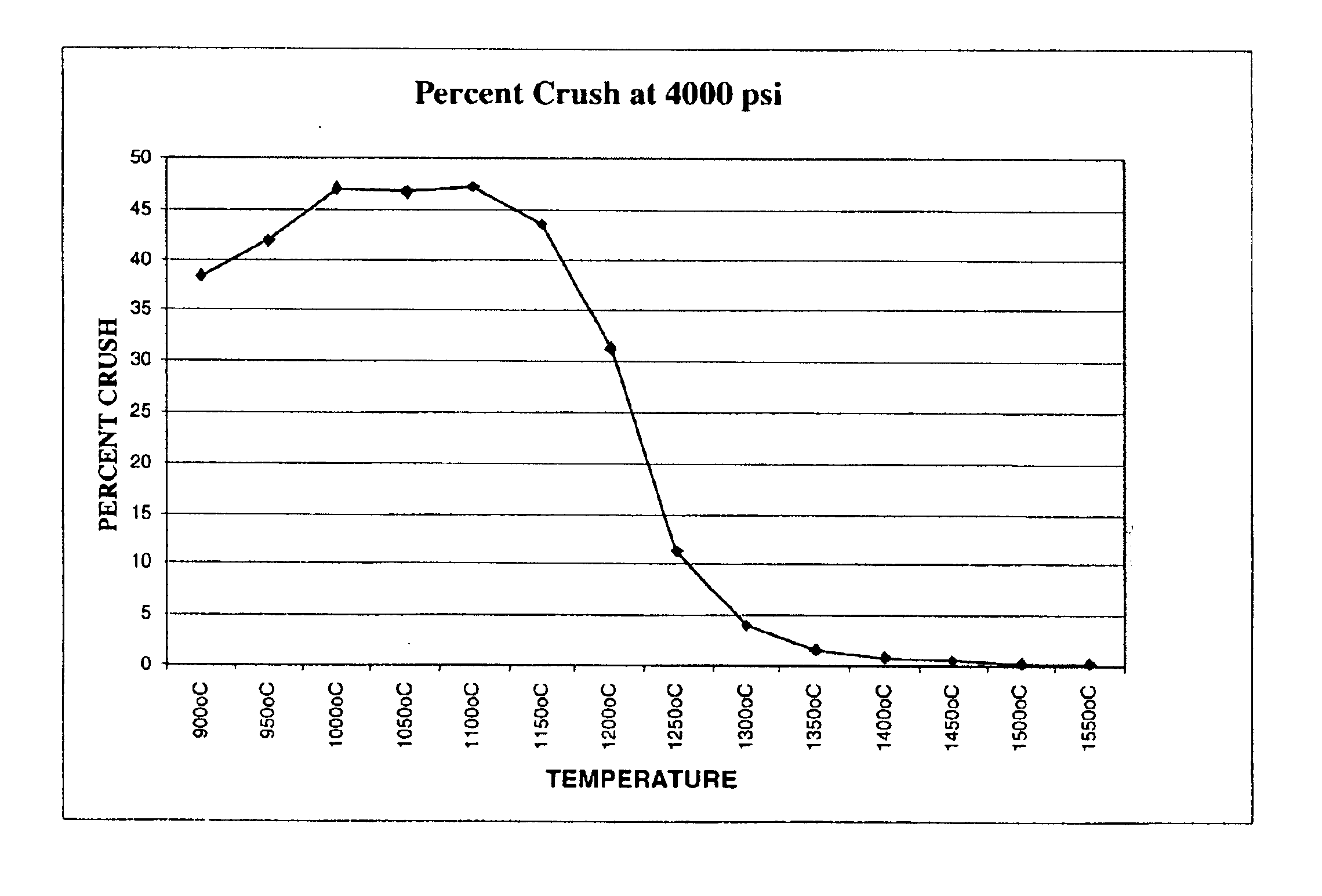

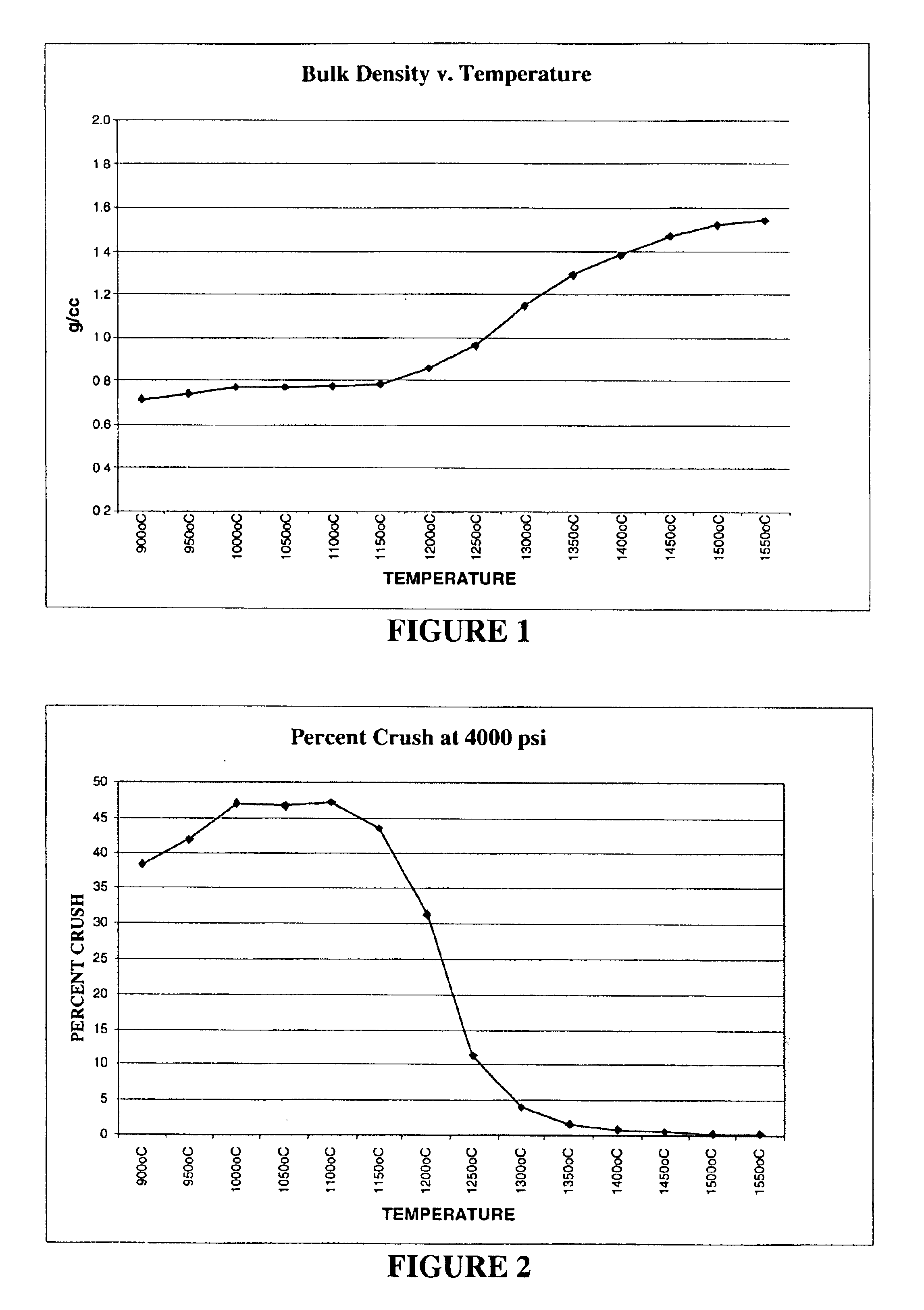

Low density proppant

Owner:CARBO CERAMICS

Ceramic member and manufacturing method for the same

ActiveUS20060073349A1Improve corrosion resistanceHigh mechanical strengthLiquid surface applicatorsSemiconductor/solid-state device manufacturingAluminium oxide

Owner:NGK INSULATORS LTD

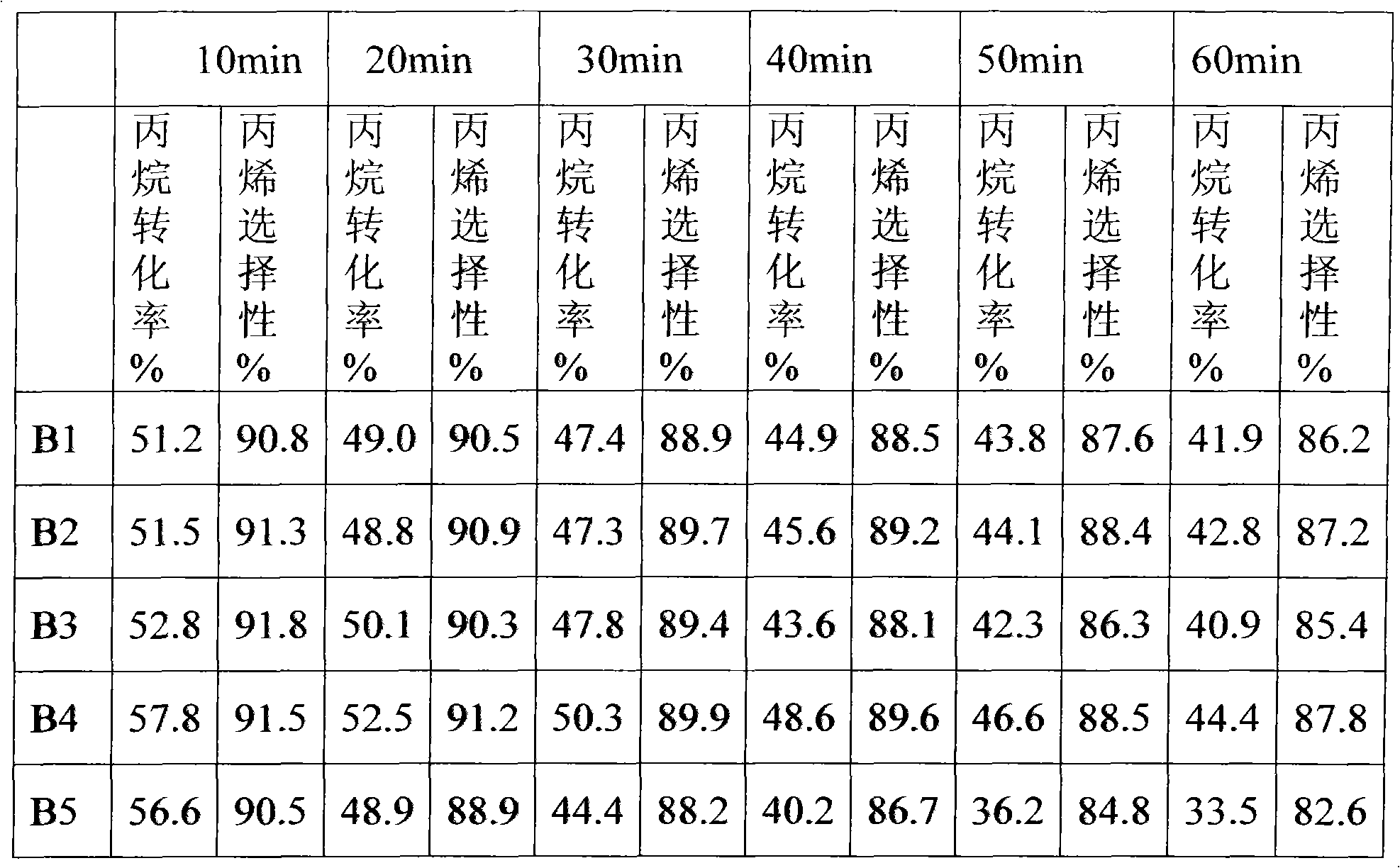

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922AEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

The invention discloses a low-carbon alkane dehydrogenation catalyst and a preparation method thereof. The catalyst is prepared from chromium serving as an active metal ingredient, alkali metal serving as an auxiliary catalytic ingredient and chromium-containing aluminum oxide serving as a carrier, wherein the weight content of the chromium oxide in the carrier is 2.0 to 15.0 percent. In the method, the active metal ingredient, namely chromium, is introduced into the aluminum oxide carrier by partially using a kneading method and partially using an immersion method; pseudo-boehmite mixed with chromium is processed by adopting a three-step roasting method and a hydrothermal method; and thus, the porous structure and the surface character of the carrier can be improved, the content and the distribution of the active metal chromium in the carrier and the mutual effect between the active metal and the aluminum oxide are further modulated, the activity and the stability of the catalyst are improved, the carbon depositing resistance of the catalyst is enhanced, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Planarization composition

The present invention provides CMP abrasive slurry that is substantially free of aluminum oxide and comprises liquid and solids wherein the solids comprises: (a) in an amount of at least about 90 weight percent based on the solids, at least one non-spherical component having formula Al2O3.xH2O where x ranges from 1 to 3; and (b) up to about one weight percent based on the solids portion of submicron alpha-alumina. The CMP abrasive slurry may be used to polish metallic or dielectric surfaces in computer wafers.

Owner:BASF AG +1

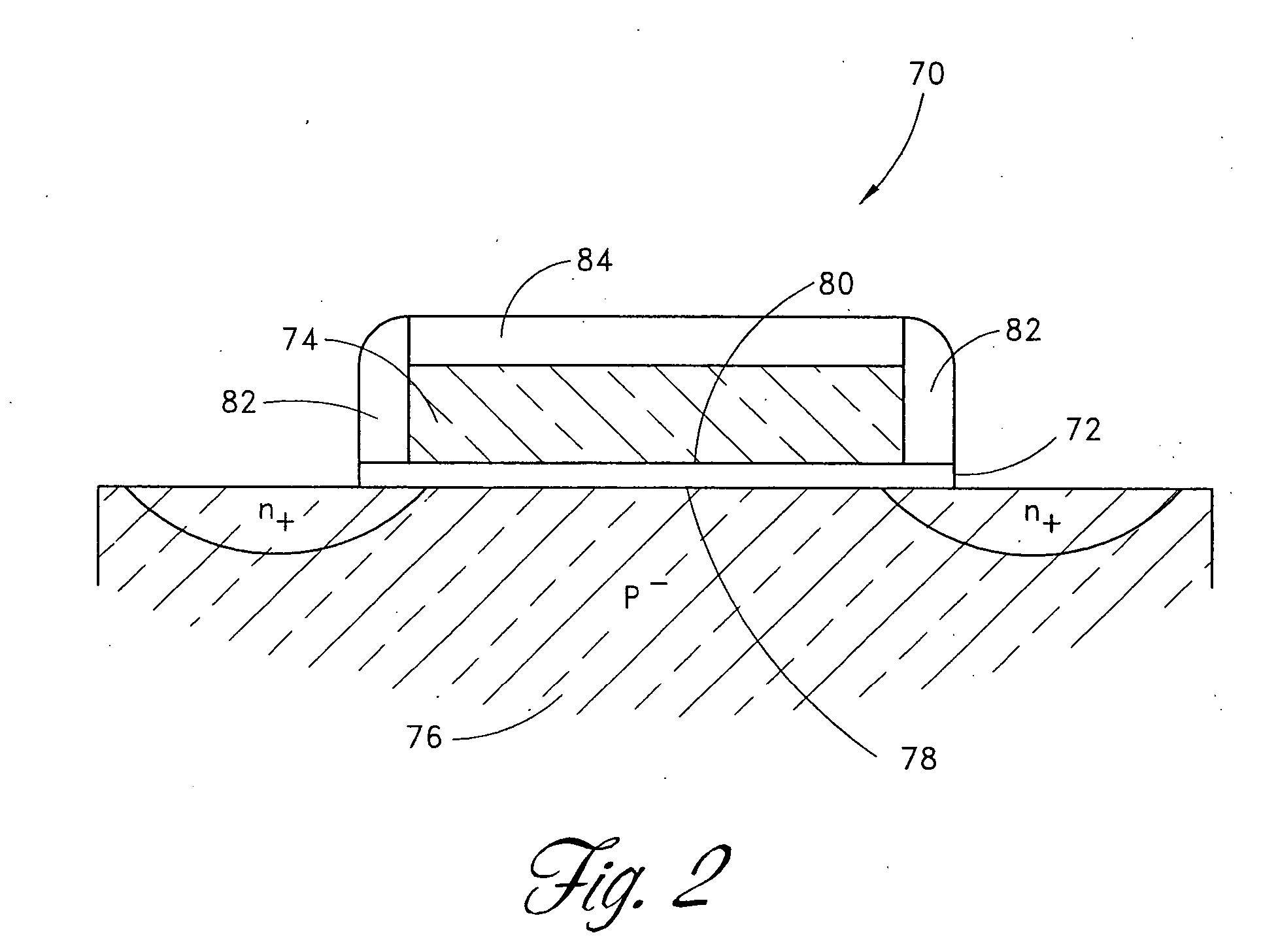

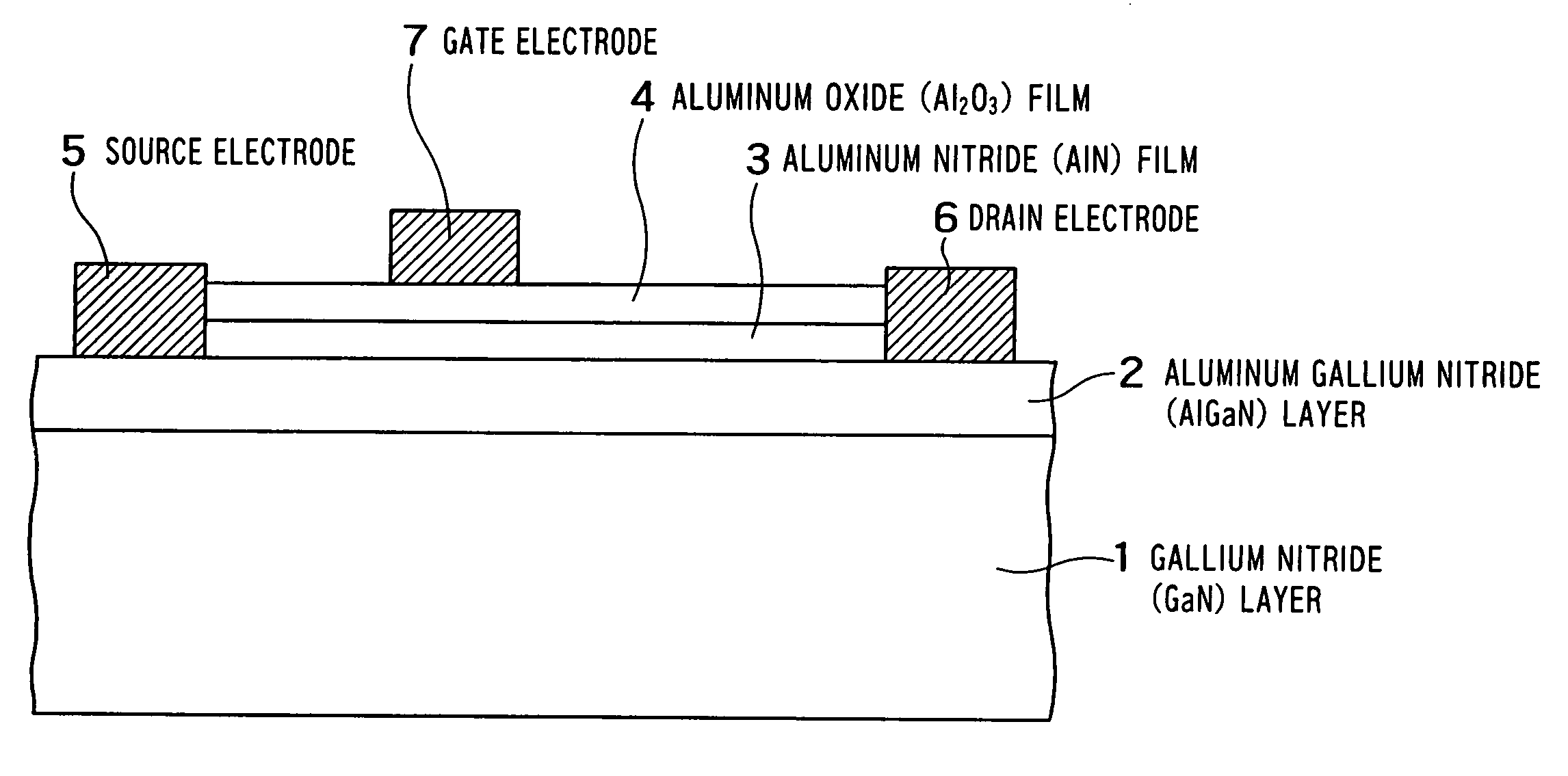

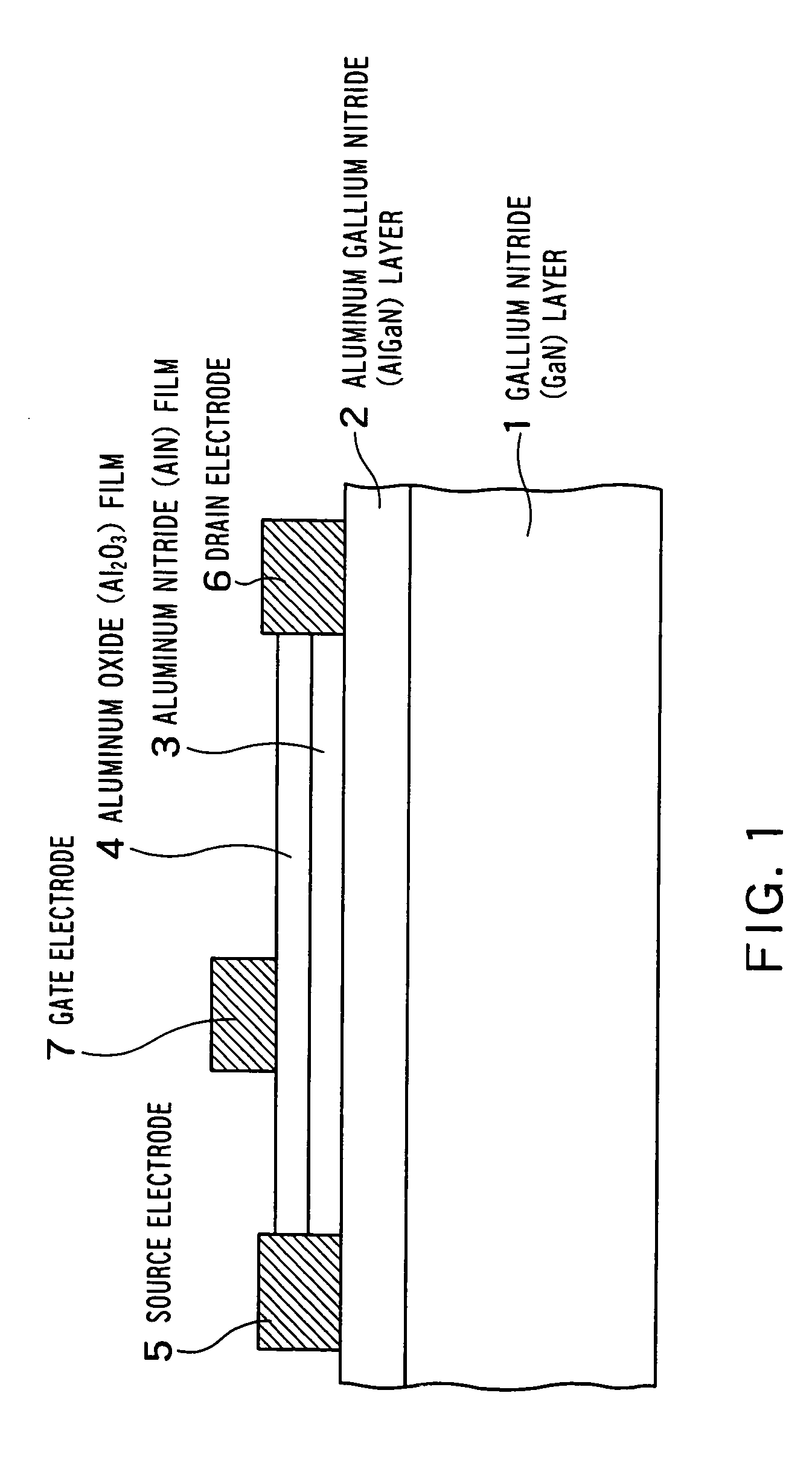

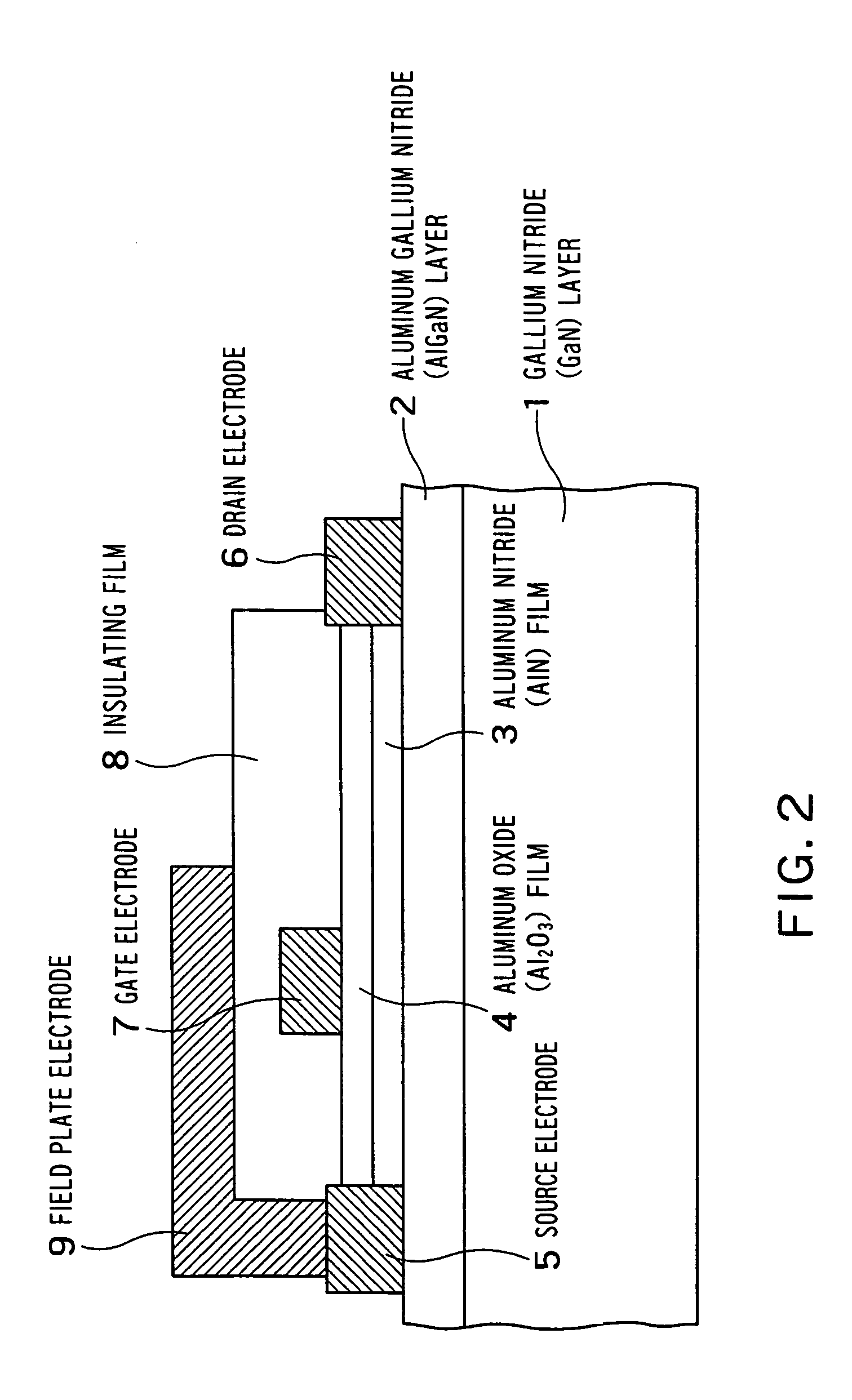

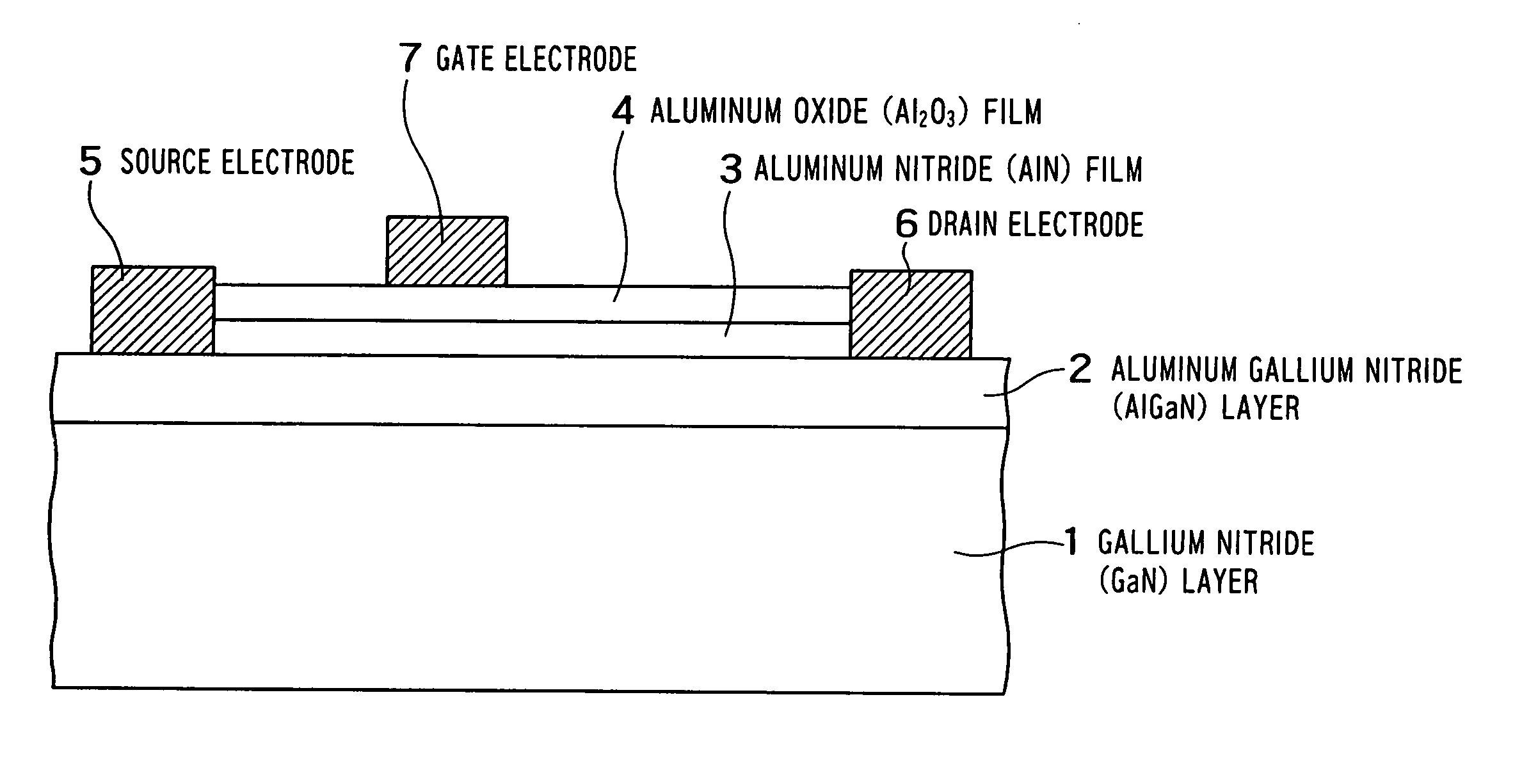

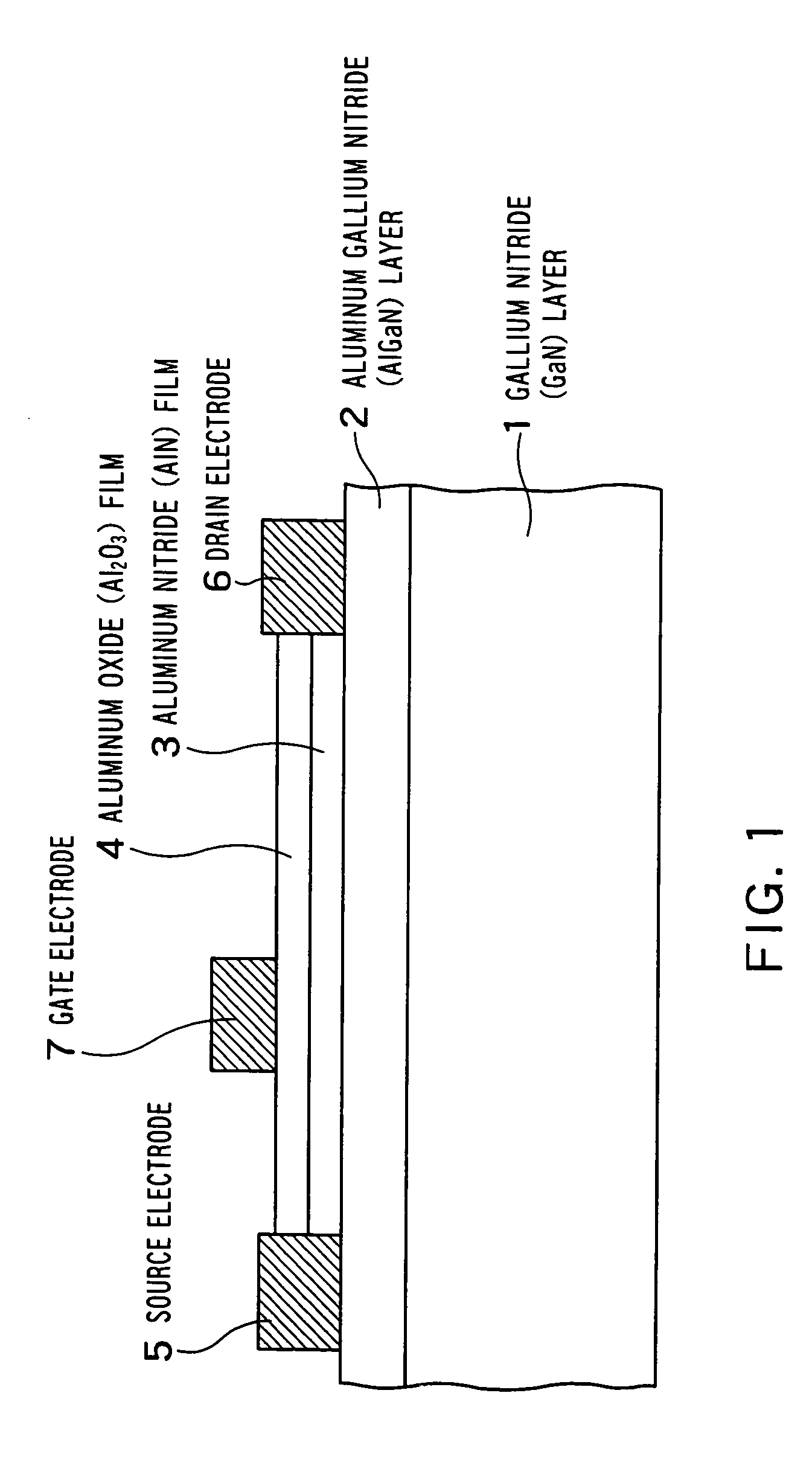

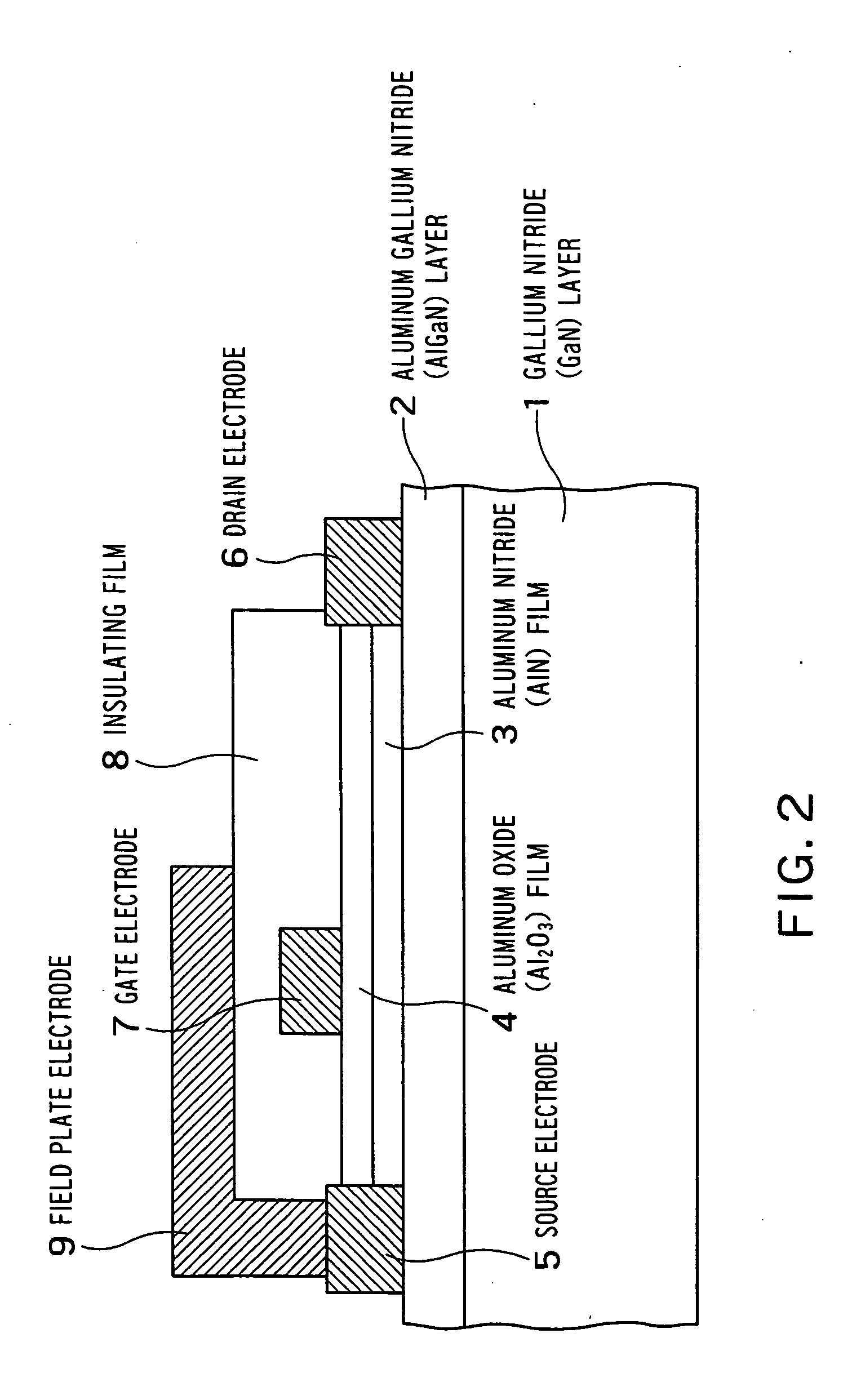

Nitride semiconductor device such as transverse power FET for high frequency signal amplification or power control

InactiveUS7304331B2Semiconductor/solid-state device manufacturingSemiconductor devicesNon dopedSignal amplification

A nitride semiconductor device according to one embodiment of the present invention includes: a non-doped first aluminum gallium nitride (AlxGa1-xN (0≦x≦1)) layer which is formed as a channel layer; a non-doped or n type second aluminum gallium nitride (AlyGa1-yN (0≦y≦1, x <y)) layer which is formed on the first aluminum gallium nitride layer as a barrier layer; an aluminum nitride (AlN) film which is formed on the second aluminum gallium nitride layer as a gate insulating film lower layer; an aluminum oxide (AL2O3) film which is formed on the aluminum nitride film as a gate insulating film upper layer; a source electrode and a drain electrode which are formed as first and second main electrodes to be electrically connected to the second aluminum gallium nitride layer, respectively; and a gate electrode which is formed on the aluminum oxide film as a control electrode.

Owner:KK TOSHIBA

Nitride semiconductor device

InactiveUS20060011915A1Semiconductor/solid-state device manufacturingSemiconductor devicesNon dopedNitride semiconductors

A nitride semiconductor device according to one embodiment of the present invention comprises: a non-doped first aluminum gallium nitride (AlxGa1-xN (0≦x≦1)) layer which is formed as a channel layer; a non-doped or n type second aluminum gallium nitride (AlyGa1-yN (0≦x≦1,x<y)) layer which is formed on the first aluminum gallium nitride layer as a barrier layer; an aluminum nitride (AlN) film which is formed on the second aluminum gallium nitride layer as a gate insulating film lower layer; an aluminum oxide (Al2O3) film which is formed on the aluminum nitride film as a gate insulating film upper layer; a source electrode and a drain electrode which are formed as first and second main electrodes to be electrically connected to the second aluminum gallium nitride layer, respectively; and a gate electrode which is formed on the aluminum oxide film as a control electrode.

Owner:KK TOSHIBA

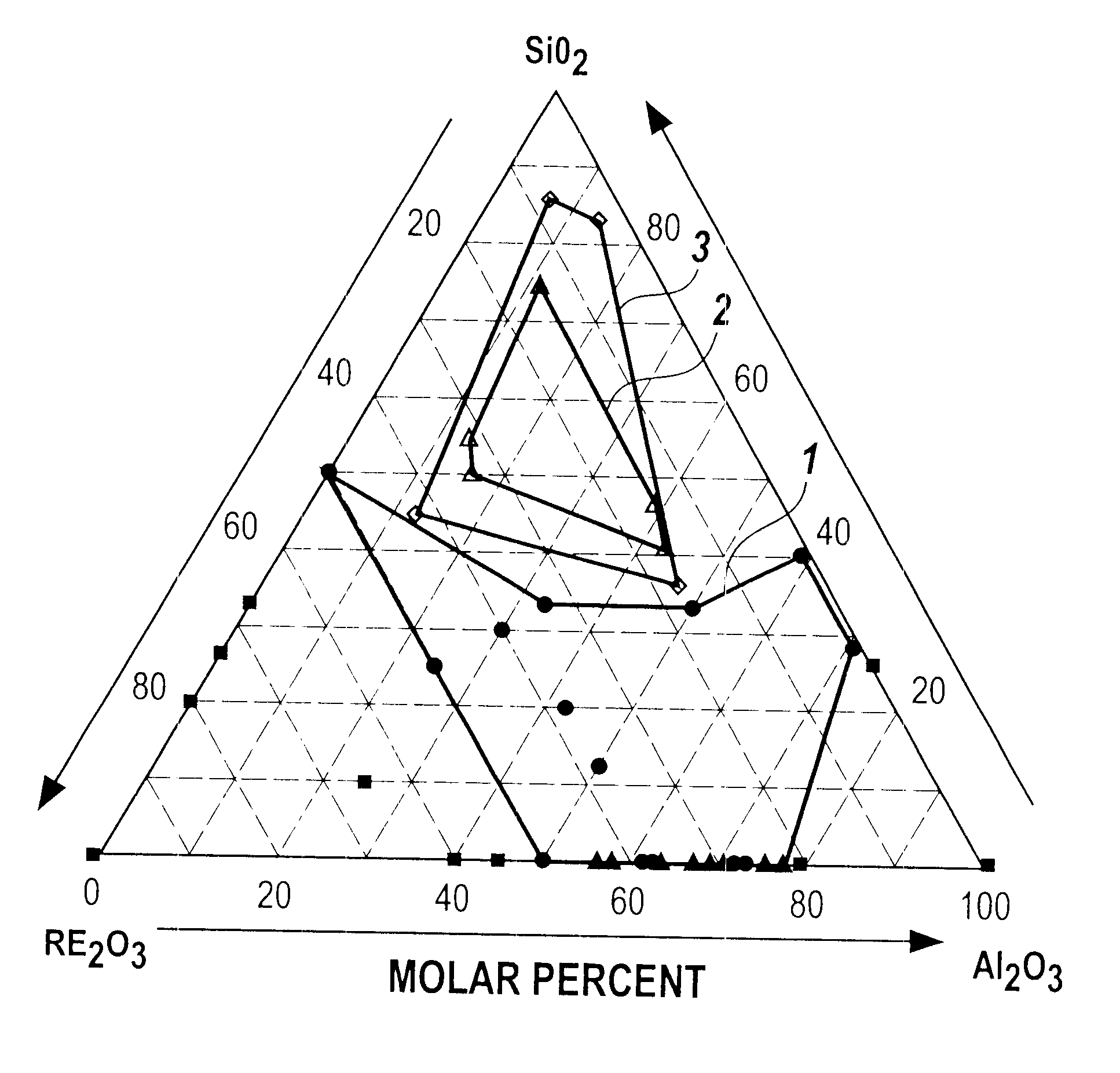

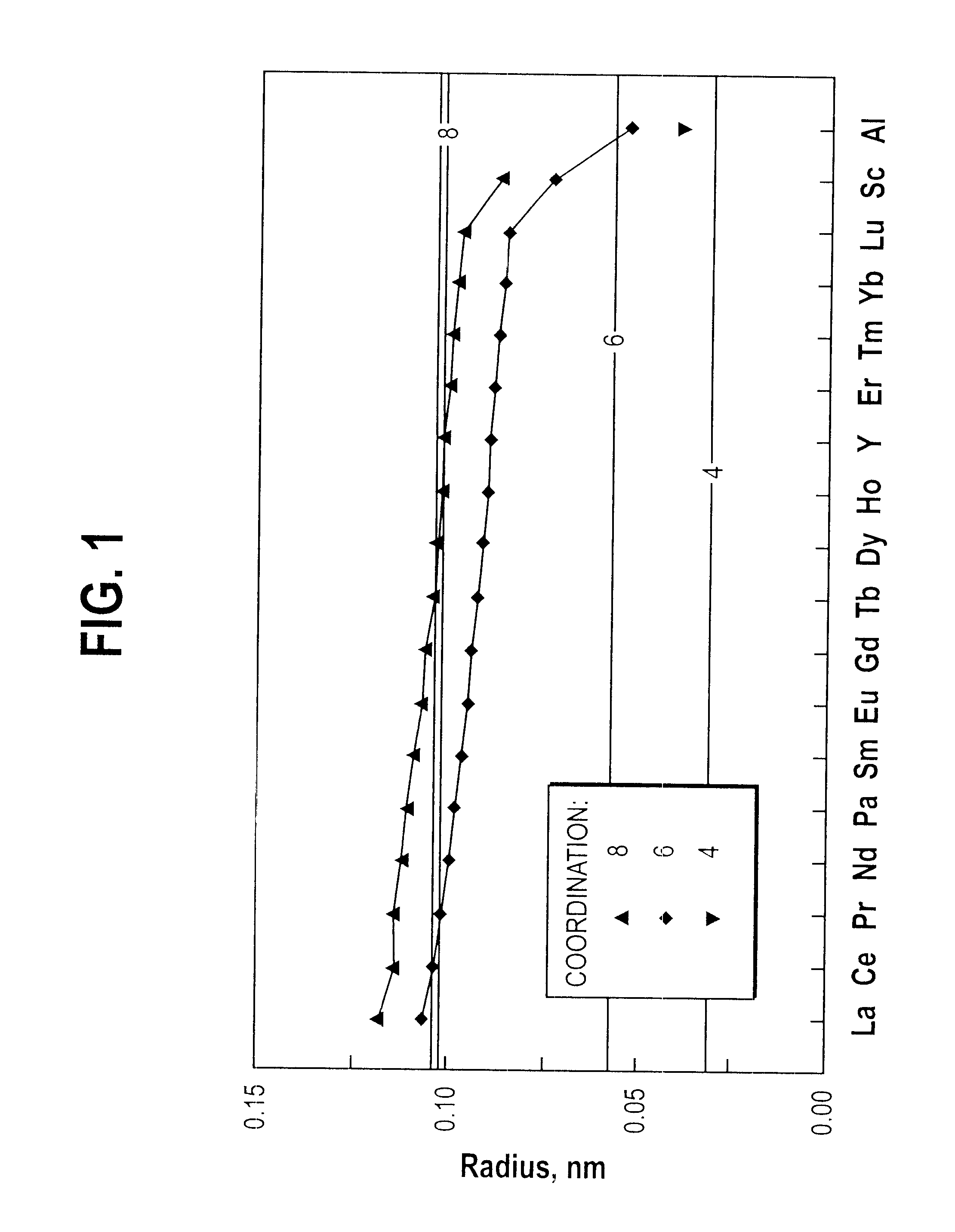

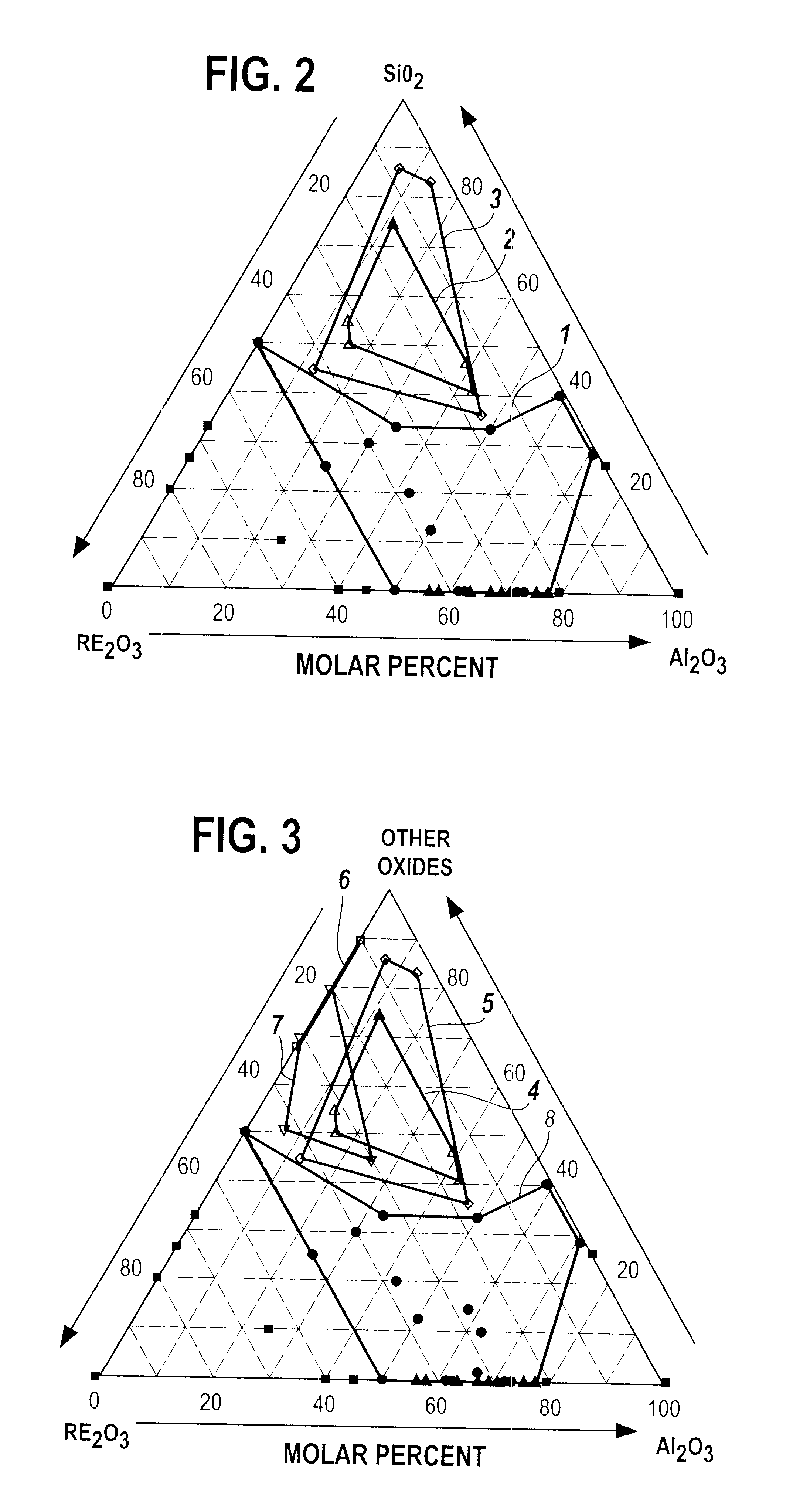

Single phase rare earth oxide-aluminum oxide glasses

A bulk single phase glass comprising 23 molar % to 50 molar % rare earth oxides, RE203, and 50 molar % to 77 molar % aluminum oxide, A12O3 is provided. The glass contains at least 50 molar % of Al2O3+RE2O3 and smaller amounts of oxide glass forming agents and other oxides than are found in prior art glasses. The addition of small amounts of lanthanum oxide, La2O3, prevents phase separation. The single phase glass is useful for optical applications such as lasers and optical amplifiers.

Owner:CONTAINERLESS RES

Cracking catalyst for petroleum hydrocarbon, and preparation method

A cracking catalyst for petroleum hydrocarbon is proportionally prepared from clay, aluminum oxide prepared from alpha-AlO(OH), Y-type molecular sieve containing RE and P and silicon oxide. Its advantages are strong power to convert heavy oil and high output rate of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

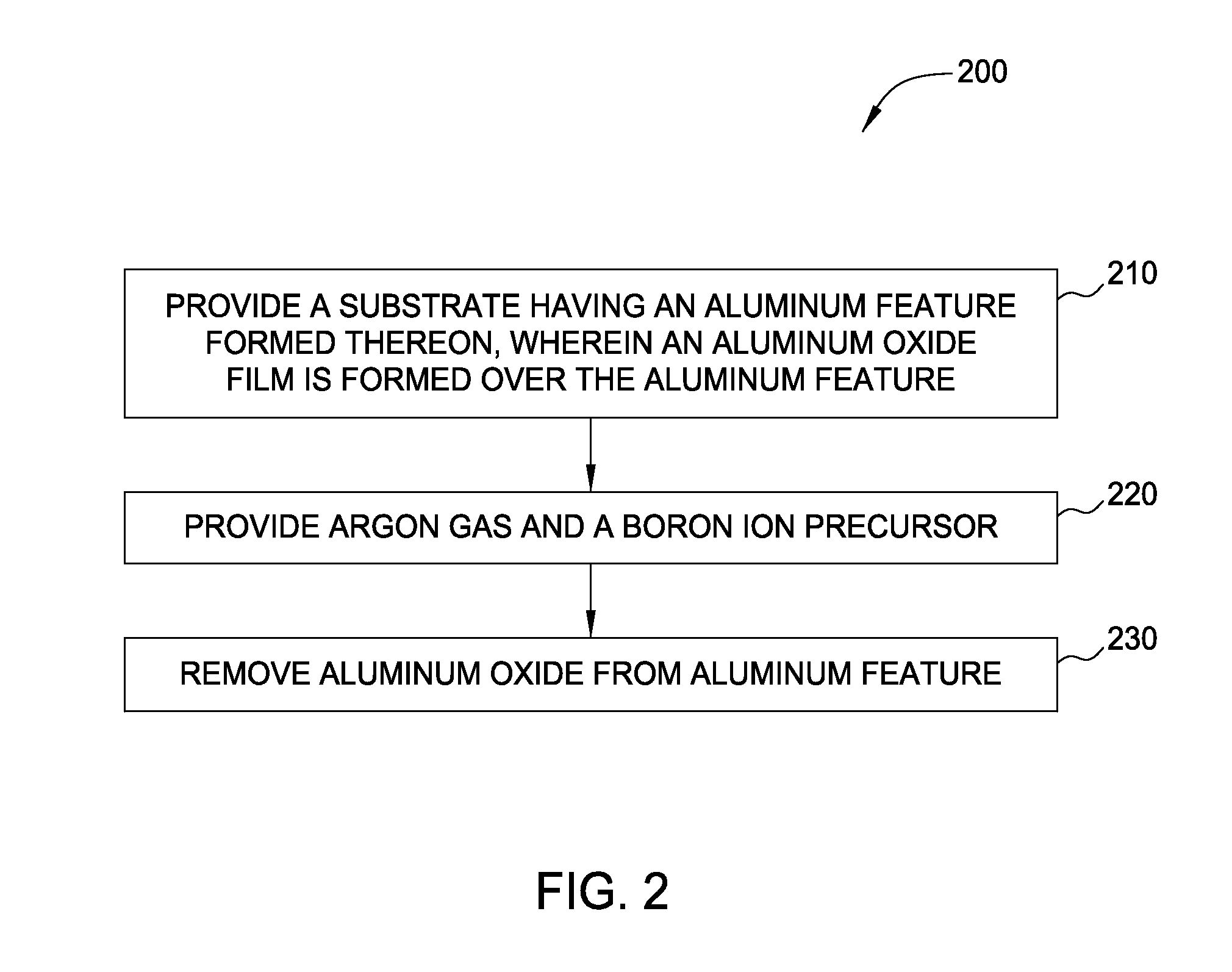

Boron ionization for aluminum oxide etch enhancement

Embodiments described herein generally provide a method for performing a semiconductor precleaning process. More specifically, embodiments provided herein relate to boron ionization for aluminum oxide etch enhancement. A process for removing native oxide from aluminum may utilize ionized boron alone or in combination with a halogen plasma. The ionized boron may provide improved aluminum oxide etching properties while being highly selective for native oxides more generally.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com