Planarization composition

a technology of composition and planarization, applied in the field of new slurry, can solve the problems of increasing technical demand, scratching the metal surface of the wafer, and difficult to maintain uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

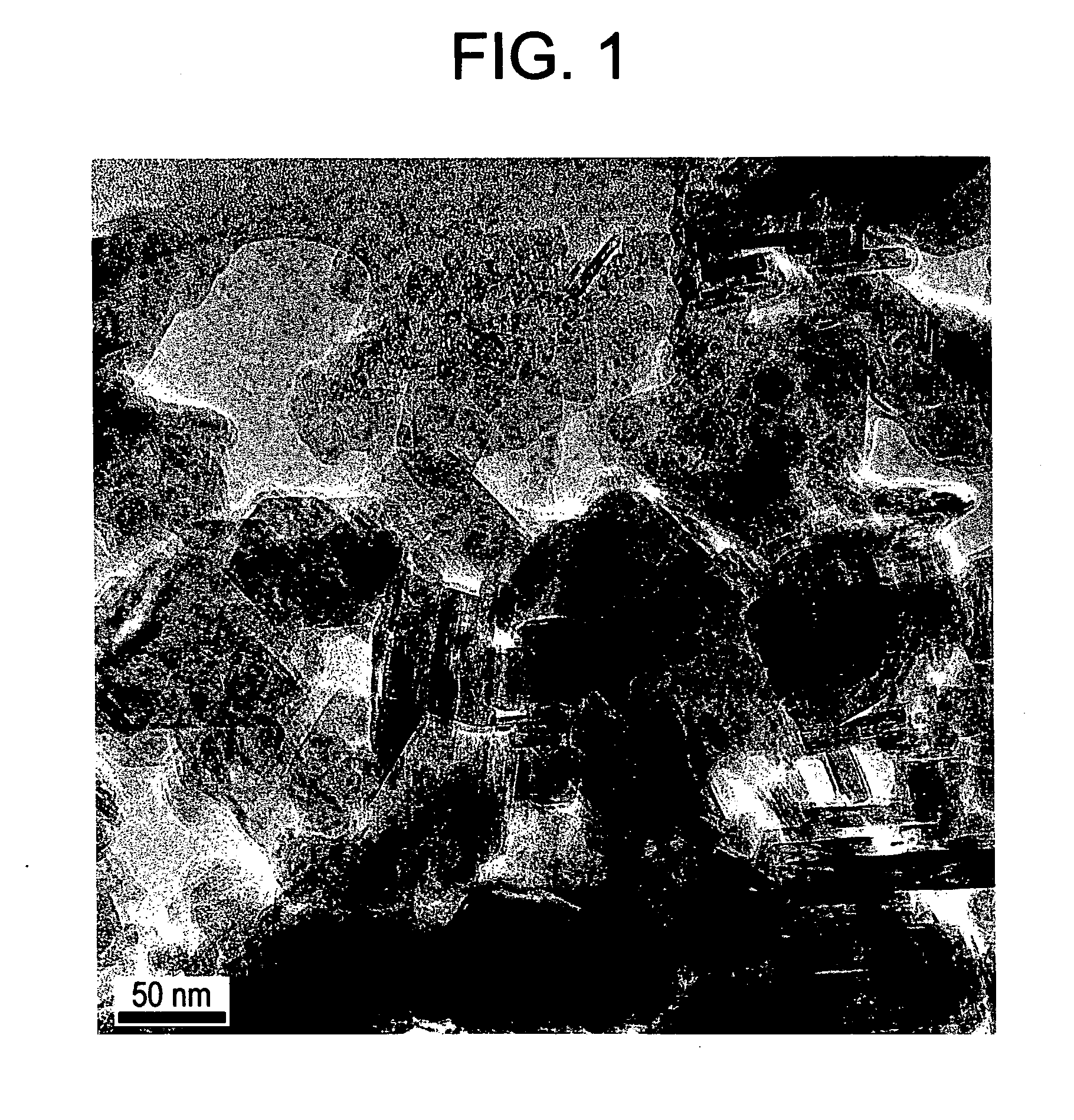

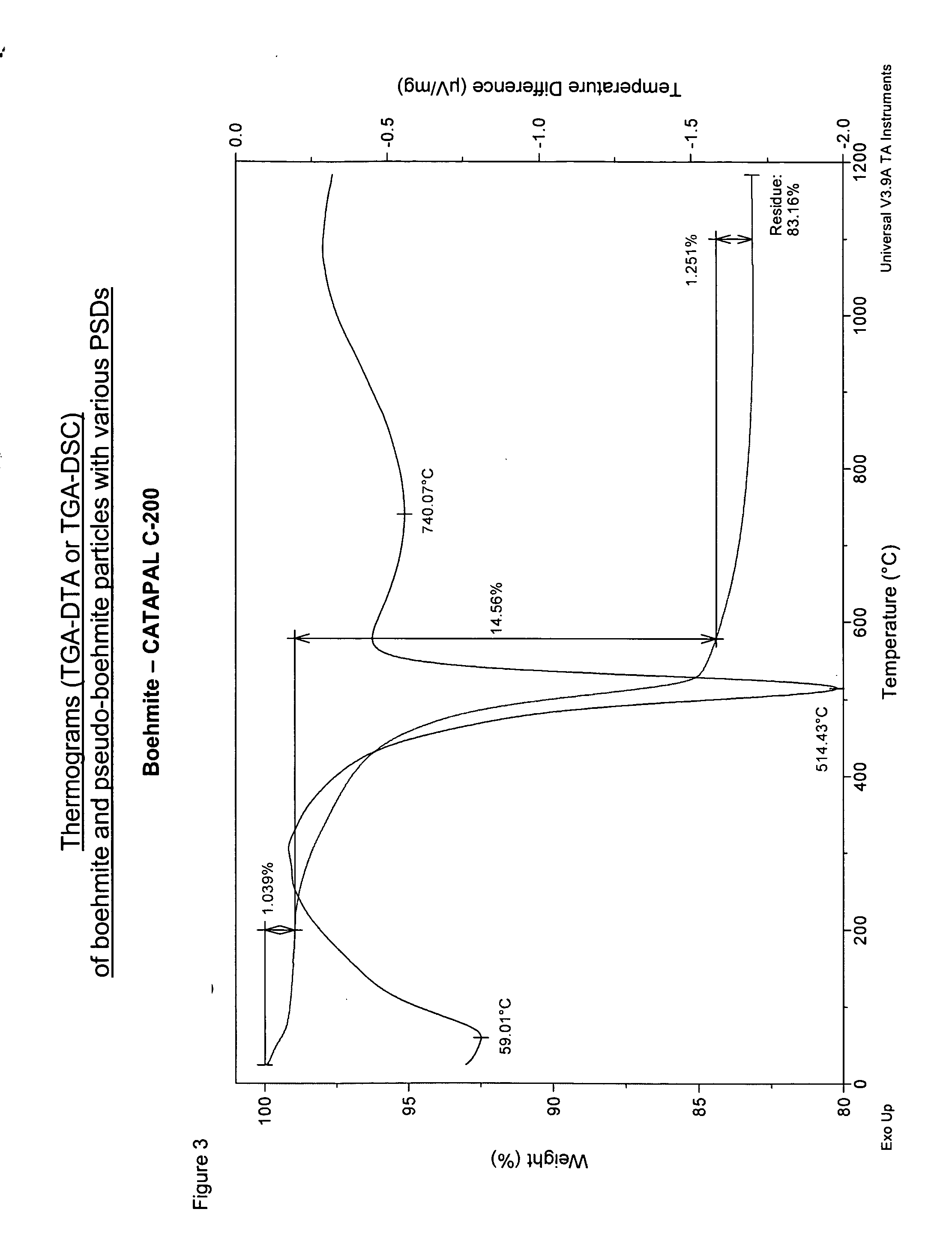

[0022] The present invention uses a component having the formula Al2O3.xH2O where x ranges from 1 to 3. When x is 1 in the preceding formula, the resulting product is known as diaspore and has a Mohs' hardness of about 6.5-7. When x ranges from greater than 1 to 2, i.e., 1.1, 1.2, 1.3, 1.4, 1.5, 1.6, 1.7, 1.8, 1.9, or 2, the resulting products are known as boehmite or pseudoboehmite and have a Mohs' hardness of about 2.5-3. When x is 3 in the preceding formula, the resulting products are known as gibbsite, doyleite, nordstrandite (all with Mohs' hardness of about 2.5-3), or bayerite, Preferably, the component is boehmite or pseudoboemite.

[0023] Examples of the phrase “at least one non-spherical component having the formula Al2O3.xH2O” as used herein includes but is not limited to the following mixtures of phases: Al2O3.1.2H2O and Al2O3.1.6H2O, Al2O3.1.2H2O and Al2O3.2H2O, and Al2O3.1.6H2O and Al2O3.2H2O, and Al2O3.1.5H2O and Al2O3.3H2O. One useful commercially available mixture is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com