Patents

Literature

124 results about "Diaspore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diaspore /ˈdaɪəspɔːr/, also known as diasporite, empholite, kayserite, or tanatarite, is an aluminium oxide hydroxide mineral, α-AlO(OH), crystallizing in the orthorhombic system and isomorphous with goethite. It occurs sometimes as flattened crystals, but usually as lamellar or scaly masses, the flattened surface being a direction of perfect cleavage on which the lustre is markedly pearly in character. It is colorless or greyish-white, yellowish, sometimes violet in color, and varies from translucent to transparent. It may be readily distinguished from other colorless transparent minerals with a perfect cleavage and pearly luster—like mica, talc, brucite, and gypsum— by its greater hardness of 6.5 - 7. The specific gravity is 3.4. When heated before the blowpipe it decrepitates violently, breaking up into white pearly scales.

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

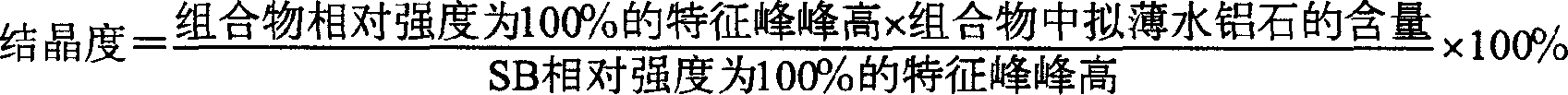

Quasi-thin empholite composition containing organic reaming agent

ActiveCN1611300AReduce crystallinityLarge hole volumeCatalyst activation/preparationRefining to eliminate hetero atomsDiasporeResidual oil

The present invention relates to a pseudothin diaspore composition containing organic pore-expanding agent. Said composition contains 92-99.5 wt% of pseudothin diaspore and 0.5-8 wt% of organic pore-expanding agent, in which the crystallinity of pseudothin diaspore is 10-70%. In the pseudothin diaspore composition provided by said invention the organic pore-expanding agent content is low, after high-temperature calcination the alumina with large pore capacity and large pore diameter can be obtained. Said alumina can be used as carrier material for preparing hydrodemetalization catalyst for heavy oil, residual oil and short residuum specially.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst

ActiveCN1978593AImprove hydrothermal activity stabilityGood macromolecular cracking performanceCatalytic crackingRare-earth elementDiaspore

The invention discloses a cracking catalyst. The character is in that the catalyst has one kind of mesoporous material which is the (0-0.3)Na2O .(40-85)Al2O3 .(10-55)SiO2 .(1-20)MxOy, the metal M is one element in IB, IIB,IVB,VB,VIB,VIIB,VIIIB or lanthanide series rare earth; The x is the highest valence of O, y is the highest valence of M. The structure of the mesoporous material is same as the thin diaspore structure and the specific area is 200-400 square m / g, the hole volume is 0.5-2.0ml / g and the average size is 8-20nm, the most probable size is 5-15nm. The catalyst can be used in the catalytic cracking reaction directly, so it can improve the raw oil and the heavy oil percent conversion but decrease the sulfur content of FCC gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

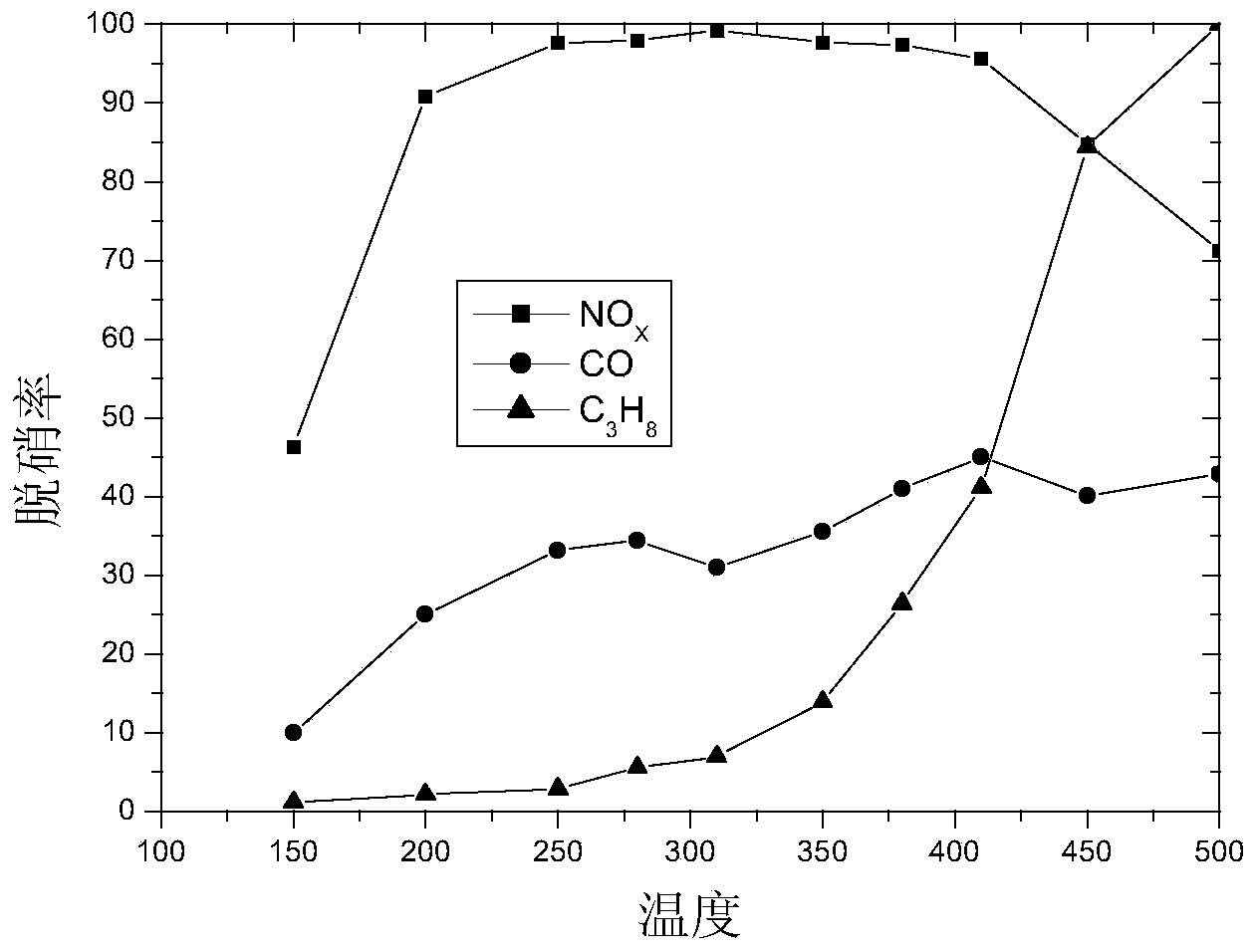

Three-way NOx, CO and HC removing catalyst used in marine engine, and preparation method thereof

ActiveCN103433028AImprove denitrification activityComponents are non-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCobalt

The invention relates to a three-way NOx, CO and HC removing catalyst used in a marine engine, and a preparation method thereof. The catalyst takes cerium-tin-tungsten composite oxide as an active component, takes one or more oxides of cobalt, ferrum, nickel, copper, lanthanum, molybdenum, manganese, zirconium, silver and yttrium as a promoter, and takes AlSiTi composite oxide as a carrier. A saturated active component solution, a saturated cobalt promoter ionic solution, strong acid alumina gel, diaspore, clayey, titanium dioxide and an organic forming agent are stirred uniformly, mixed, aged and extruded for formation, and the integral type catalyst is obtained through drying and roasting. According to the invention, the catalyst has high NOx removing efficiency, the active temperature window is wide, and the CO and HC removing efficiency is high in a low-temperature collaborated catalyzing manner. According to the catalyst, as the components of the catalyst are nontoxic and environmental-friendly, the catalyst has the advantages that the mechanical strength is high, the vibration resistance as well as the heat resistance is excellent, the preparation technology is simple, and the cost is low. The three-way NOx, CO and HC removing catalyst is applicable to treatment of NOx, CO and HC in tail gas of a marine diesel engine, and is also applicable to treatment to tail gas of other moving sources diesel engines such as automobiles.

Owner:南京环福新材料科技有限公司

Diesel oil hydrotreating catalyst and method for preparing the same

ActiveCN1803996AIncrease cetane numberImprove desulfurizationHydrocarbon oils treatmentMolecular sieveDiaspore

The disclosed catalyst special to low-grade diesel fuel hydrotreatment comprises: given the catalyst, 1-70wt% SiO2-Al2O3 with quasi-thin diaspore structure, 1-60wt% Y-form molecular sieve, and 5-80wt% Al2O3; wherein, given the oxide, 1-15wt% VIII metal constituent, and 10-40wt% VIB metal constituent. The product is prepared by mixing, forming, baking and then adding at least one of former metal constituent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrated alumina with structure of similar to thin diaspore of containing additive

ActiveCN1915486AHigh conversion capacity of heavy oilHigh yieldCatalyst activation/preparationAlkaline earth metalHydrated alumina

A hydrated alumina containing additive (0.5-40 Wt %) and with alpha-AlO (OH) structure for preparing the catalyst used for catalytic cracking reaction. Said additive is chosen from RE metal, La-family metal, Si, Ga, B and P. Its preparing process includes such steps as mixing alpha-AlO (OH) with H2O and acid while stirring, ageing, and mixing with additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

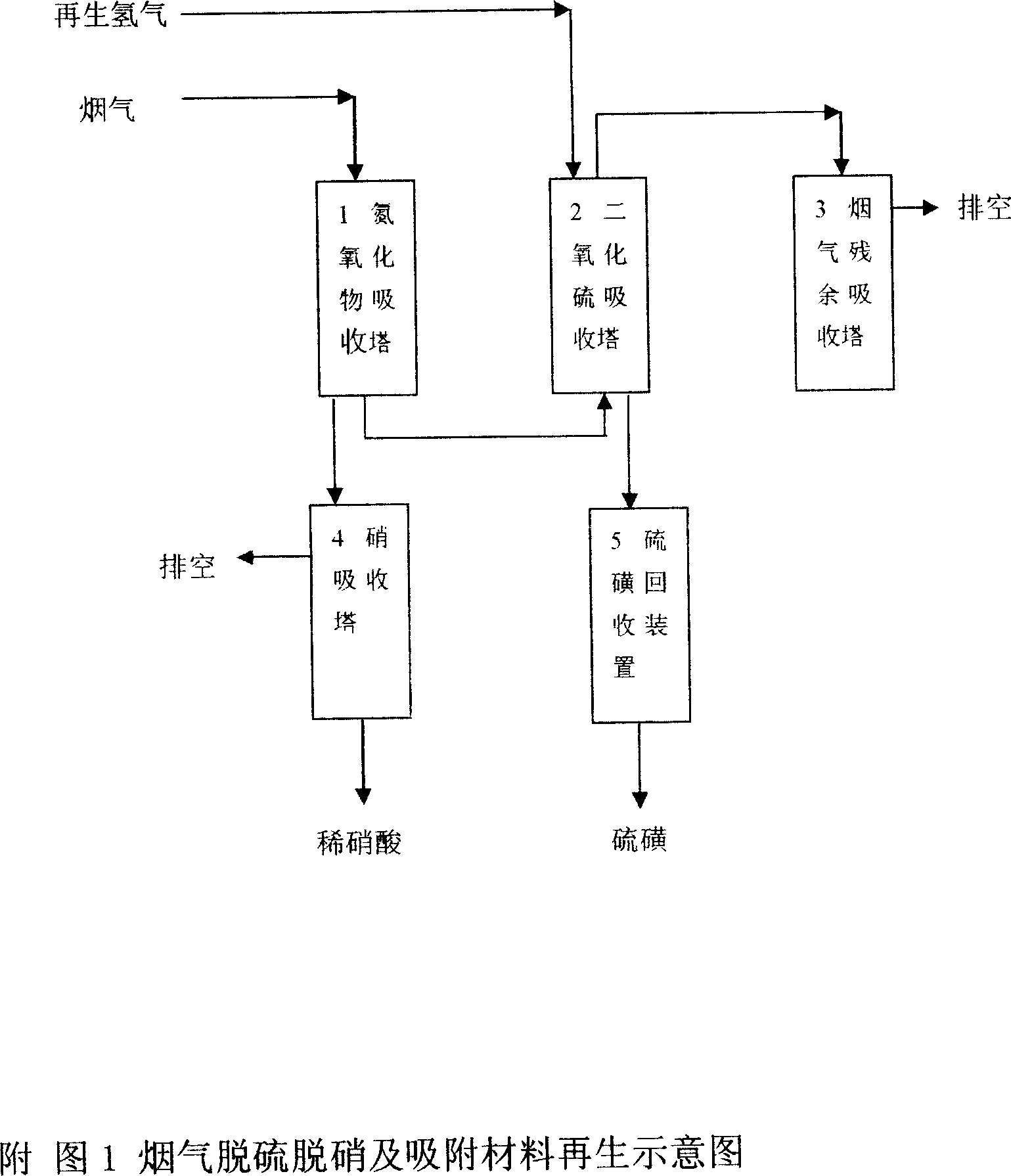

Preparation process of flue gas desulfurization and denitration material

InactiveCN1919447ALarge adsorption capacityImprove efficiencyOther chemical processesAluminium silicatesDiasporeSilica gel

The invention discloses a preparing method of smoke desulfurizing and denitration material in the environmental protective material technological domain, which comprises the following steps: adopting parallel current method to co-sediment composite liquid with bivalent metal Cu, Mg and Zn and multipartial metal Al, Fe and Co with sodium hydroxide and sodium carbonate solution to form waterlike talc material, pulping, blending caoline, silica gel, satin diaspore and alhydrogel, adding sesban powder and or methyl cellulose, preparing the moulding carrier, sintering to obtain the smoke desulfurizing denitration material, regenerating adsorbing liquid through denitrating to prepare diluted nitric acid, reducing sulfur dioxide after saturated adsorption through hydrogen to prepare sulphur.

Owner:TIANJIN CHEM RES & DESIGN INST

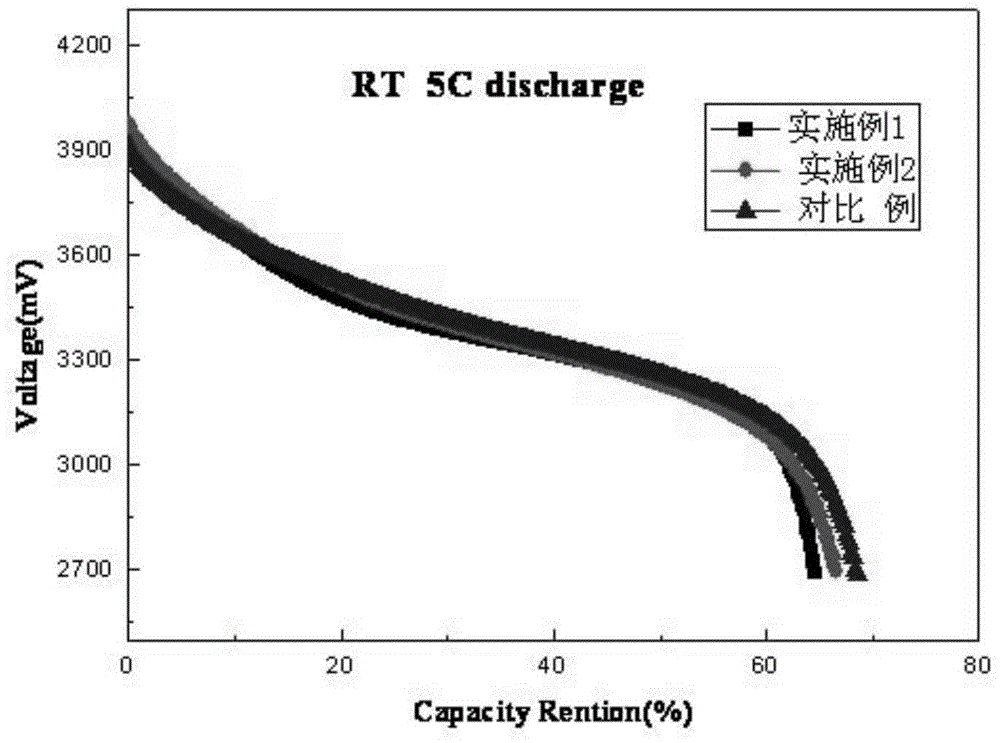

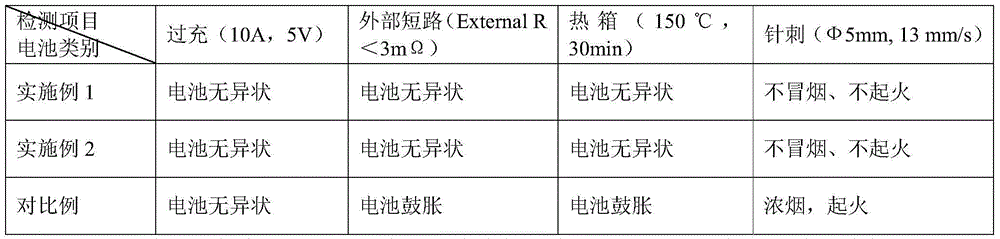

Positive electrode of safe lithium-ion power battery and lithium-ion battery comprising positive electrode

ActiveCN105470515ASmall granularityNarrow particle size distributionSecondary cellsElectrode collector coatingPyrrolidinonesDiaspore

The invention relates to the field of lithium-ion batteries, and discloses a positive electrode of a safe lithium-ion power battery and the lithium-ion battery comprising the positive electrode. The positive electrode of the battery comprises a positive current collector, a positive active material and ceramic slurry, wherein the ceramic slurry coats the surface of the positive active material and is an oil system or a water system; the oil ceramic slurry comprises the following components in percentage by weight: 35wt%-45wt% of inorganic ceramic particles, 6wt%-10wt% of polyvinylidene fluoride, 1wt%-3wt% of polyvinylpyrrolidone and 45wt%-55wt% of 1-methyl-2-pyrrolidinone; and the water ceramic slurry comprises the following components in percentage by weight: 35wt%-40wt% of inorganic ceramic particles, 6wt%-10wt% of butadiene styrene rubber, 1wt%-3wt% of carboxymethylcellulose, 1wt%-3wt% of polyvinylpyrrolidone and 45wt%-55wt% of deionized water; and the inorganic ceramic particles comprise one or more of boehmite and diaspore. The ceramic slurry coats the surface of the positive active material, so that the safety performance of the battery is improved; meanwhile, the influence on the electrochemical properties of the battery is extremely small; and the stability is good.

Owner:WANXIANG 123 CO LTD

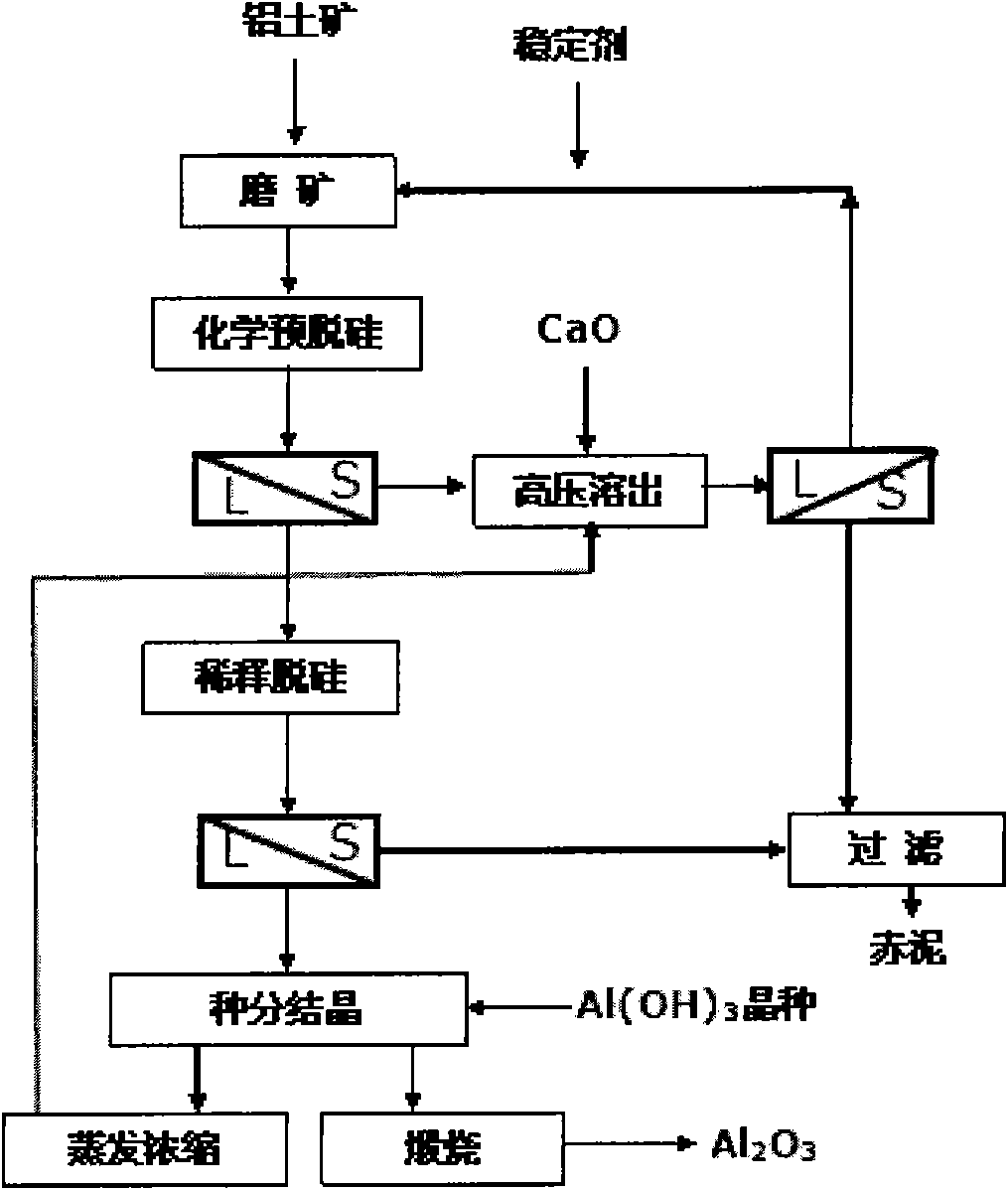

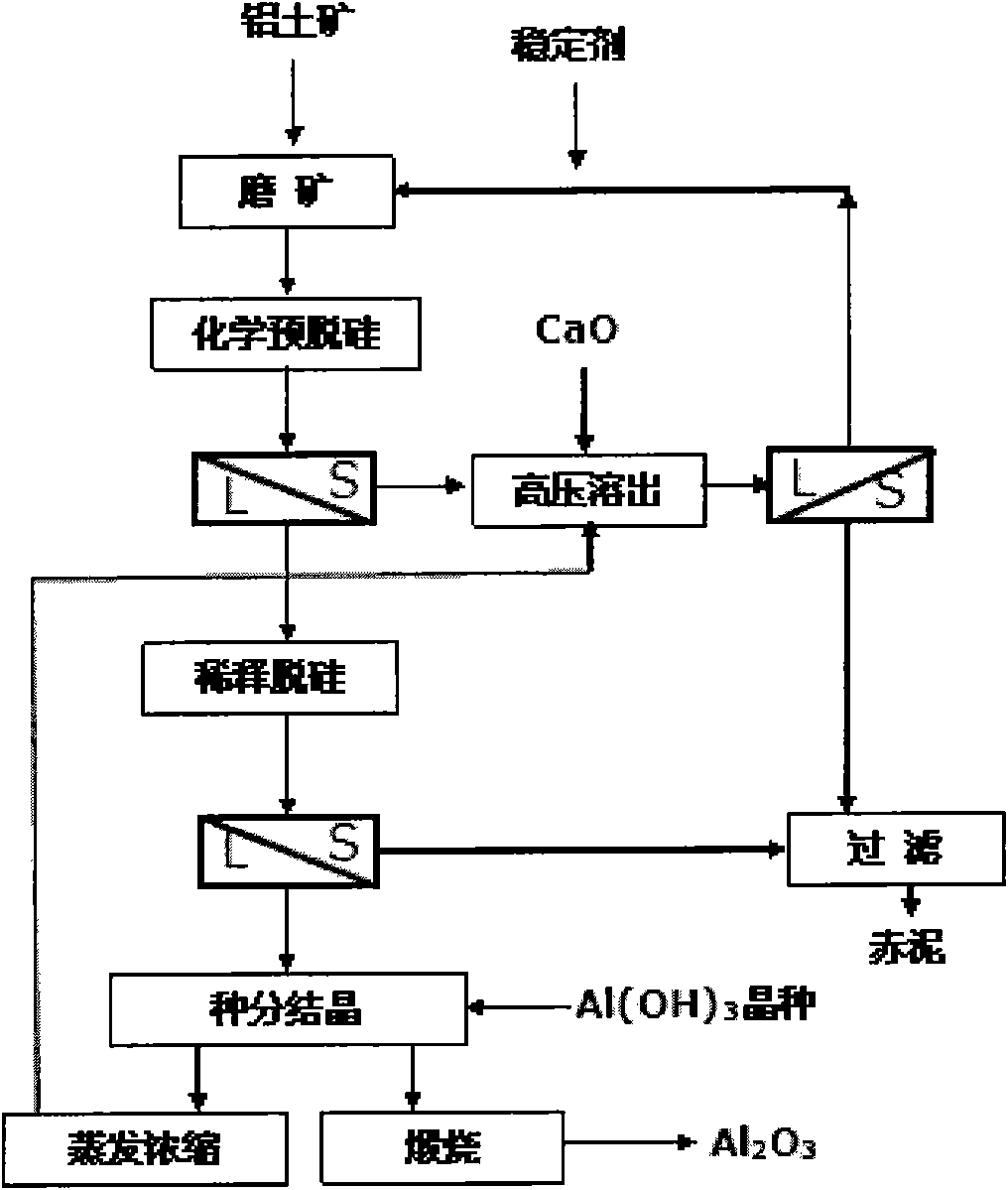

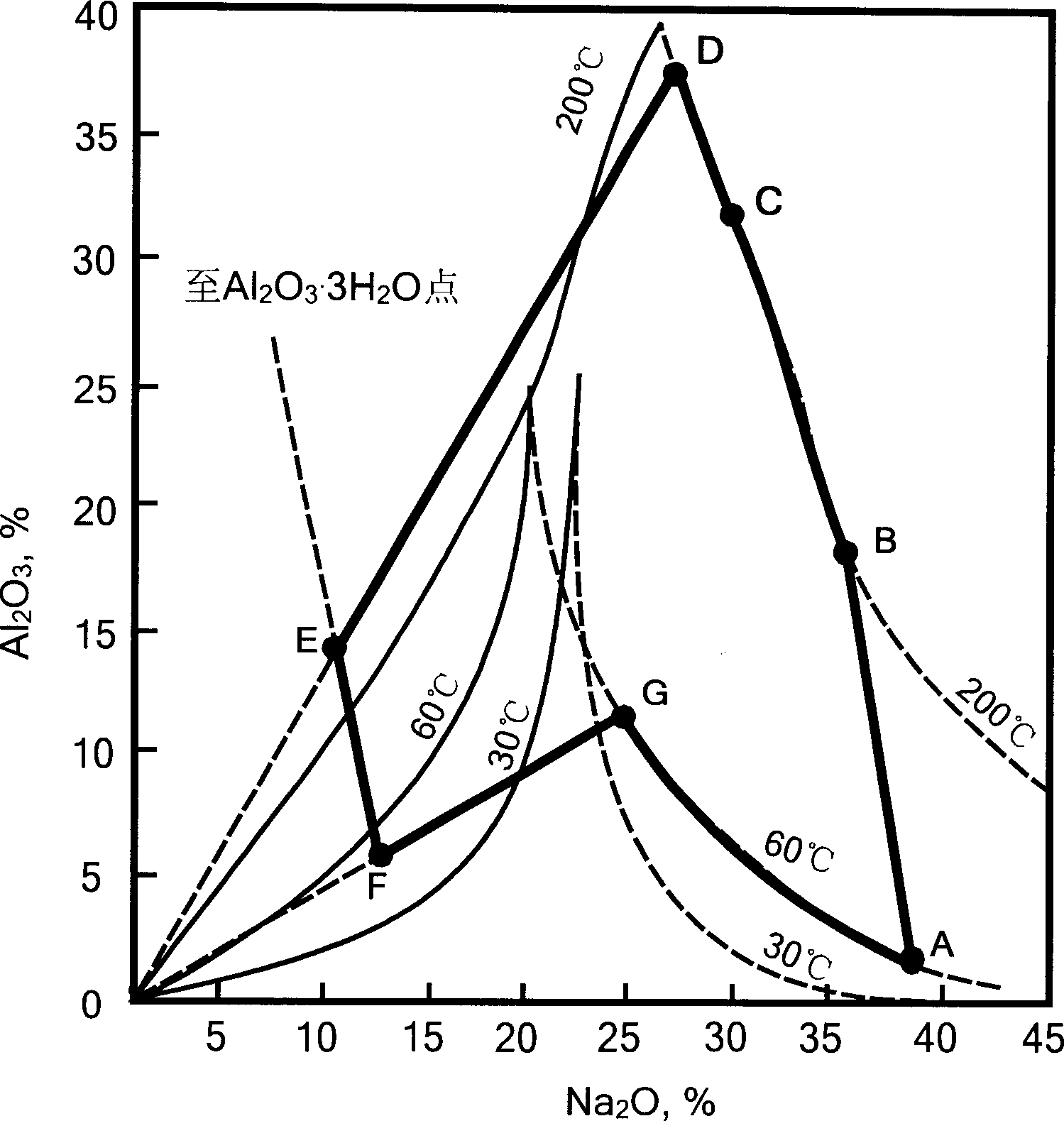

Method for modifying Bayer process, processing low-grade diaspore bauxite and producing alumina

The invention provides a method for modifying a Bayer process, processing low-grade diaspore bauxite and producing alumina. The method comprises steps that: (1) silicon is chemically pre-removed, wherein the low-grade bauxite is immersed into a sodium aluminate solution containing a stabilizing agent, such that a slurry containing dissolved silica is obtained; (2) obtained high-silicon sodium aluminate solution is processed through desilication, wherein desilication crystal seeds are added to the slurry processed through filtration, such that desilication is carried out; (3) the sodium aluminate solution is processed through seed precipitation, wherein aluminum hydroxide crystal seeds are added to the sodium aluminate solution processed through desilication, such that seed precipitation is carried out; (4) the obtained aluminum hydroxide product is baked, such that an alumina product is obtained; (5) a high-pressure dissolution process is carried out, wherein the obtained seed precipitation mother liquor is processed through evaporation and alkali supplementation, and is used in high-pressure dissolution of a concentrate obtained in the step (2); a stabilizing agent is added to the obtained sodium aluminate solution, the sodium aluminate solution is then used for processing the next batch of bauxite, and the steps (1) to (4) are repeated. The method provided by the invention is suitable to be used for processing low-grade diaspore bauxite. With the method, a silicon scaling problem in alumina industries can be effectively solved, energy consumption can be substantially improved, and the quality of the finished product alumina can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for mesoporous hollow alumina particle

ActiveCN101746793AAvoid multi-step synthetic processesSimple synthetic routeMicroballoon preparationMicrocapsule preparationDiasporeMaterials science

The invention provides a preparation method for a mesoporous hollow alumina particle in the technical field of a porous carrier. The mesoporous hollow alumina particle is sphere-like, the average particle diameter is from 0.1 to 5mm, the wall of the particle is made of mesoporous Gamma-alumina, the thickness of the particle is from 20 to 200mum, the pore volume of the wall of the particle is from 0.27 to 0.50cm3 / g, and the average aperture is from 3.24 to 5.09nm. The preparation method is characterized in that: a white transparent thin diaspore hollow sphere is obtained after polyose electrolyte solution is added to thin diaspore collosol, and the mesoporous hollow alumina particle is obtained after the ageing and calcining are carried out. With simple steps, the preparation method in the invention provides a simple, convenient and economical synthesizing way for the synthesis of the organic hollow sphere.

Owner:SHANGHAI JIAO TONG UNIV +1

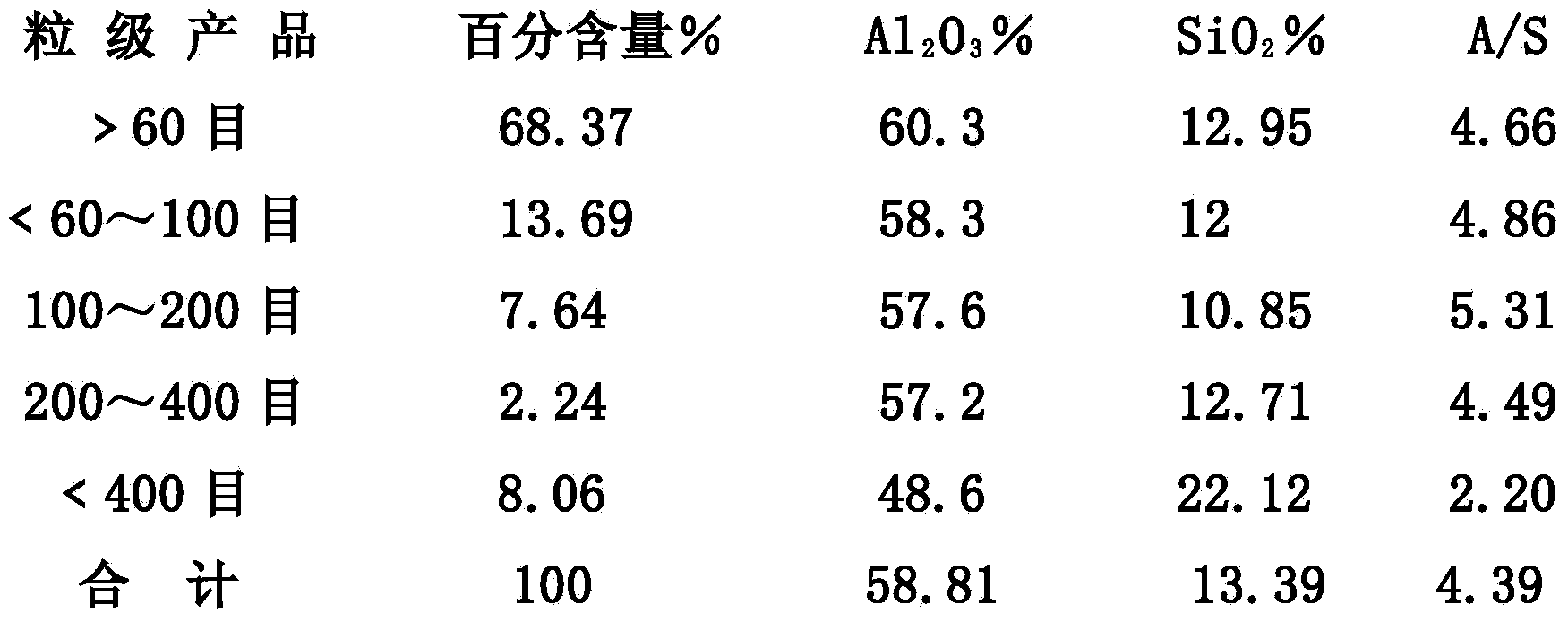

Floatation method of desulfurizing and desiliconizing diaspore type bauxite

ActiveCN1562494AIncrease profitImprove the difference in surface hydrophilic/hydrophobic propertiesFlotationDiasporeEngineering

A floatation technology for desulfurizing and desiliconizing the diasporite-type bauxite features that the reverse floatation to desulfurize and the forward floatation for desiliconizing are sequentially performed to increase the utilization rate of bauxite and the recovery rate of Al2O3.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

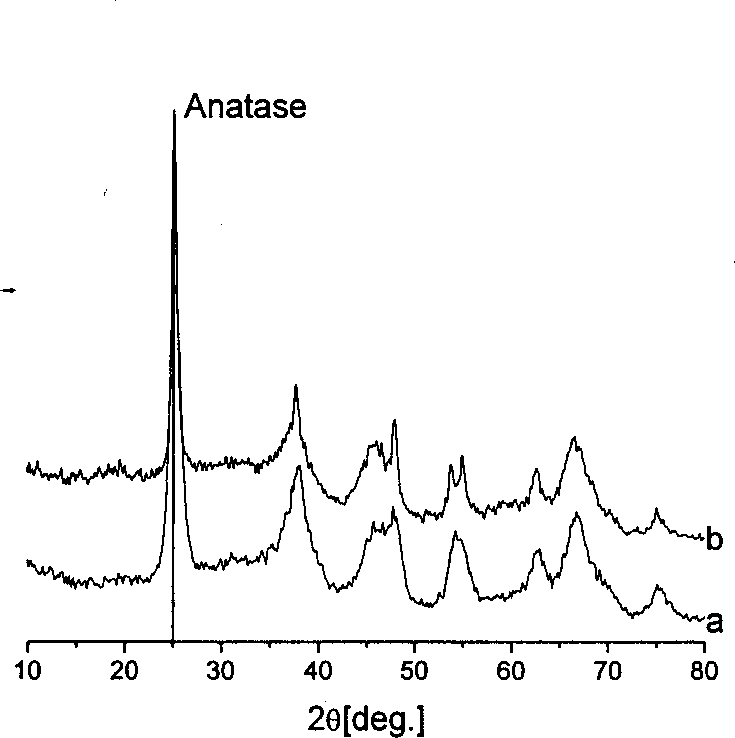

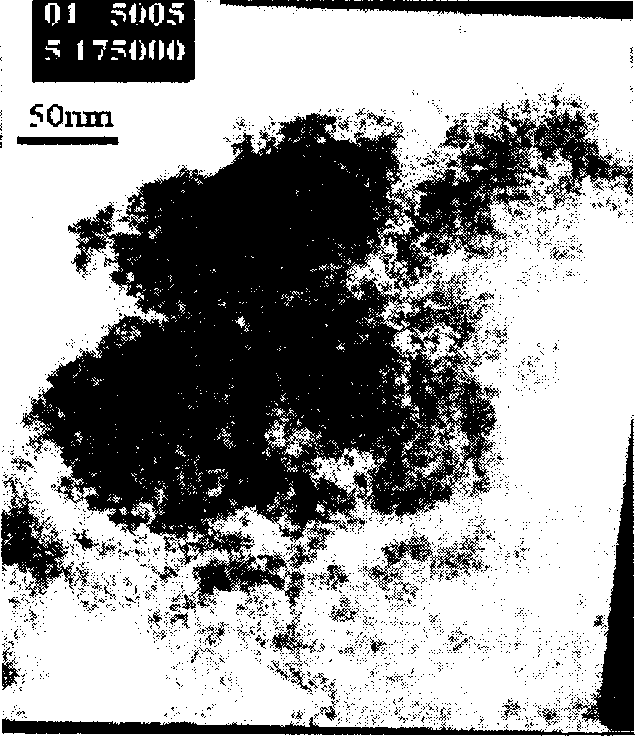

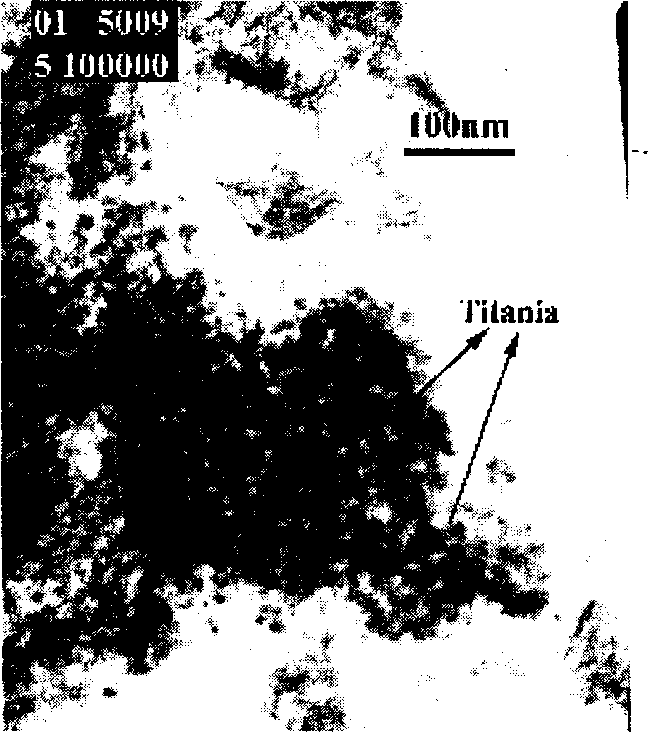

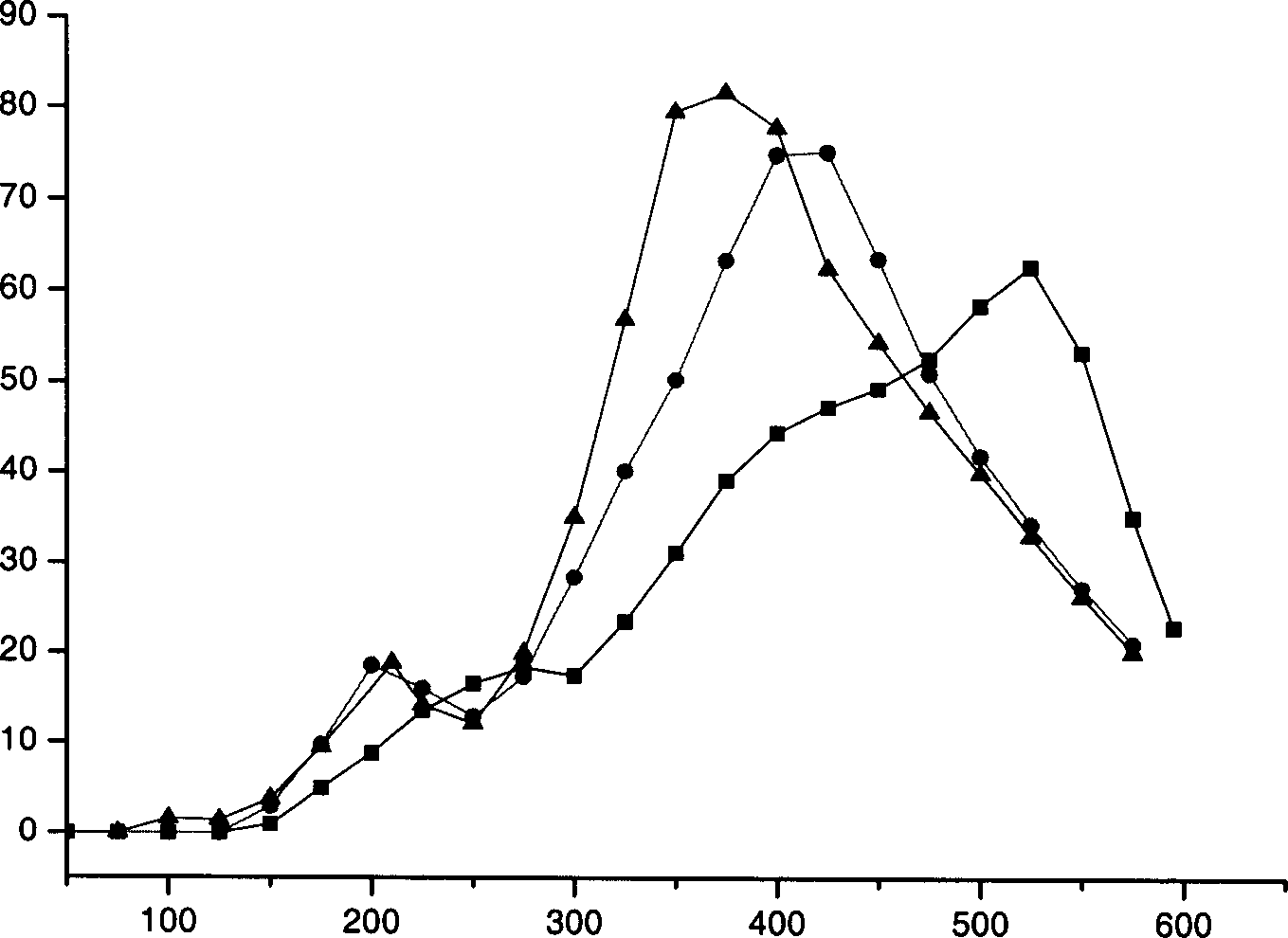

Composite loading nano-titania carrier and its prepn

A loading type of nanometer titania composite carrier is constituted by loading 5-20 nm TiO2 in 10-40 wt% onto gamma-Al2O3. Titania sol is first prepared through sol-gel process and then dropped into pseudo-then diaspore pulp of different solution; and the product is finally processed through drying, calcination successively at 200, 300, 400 and 500 deg.c for 2 hr each. The present invention loads nanometer Tio2 onto macroporous Al2O3 to form the composite nanometer carrier. This can utilize the superority of nanometer TiO2 while overcoming the demerits. By means of the micro design, surface acidity regulation of loaded TiO2 and loading active component, the hydrorefining activity of catalyst may be raised effectively.

Owner:NANKAI UNIV

Preparation process of selective reduction catalyst for lean-burn gasoline motor car exhausted gas nitrogen oxide

InactiveCN1762585AEmission controlHigh selectivityInternal combustion piston enginesDispersed particle separationDiasporeCordierite

The preparation method for catalyst to selective reduce nitrogen oxide in tail gas from gasoline vehicle comprises: with quasi-thin diaspore dry powder as material, nitric acid as peptizer and urea as dispersant, grinding to obtain aluminum solution; dipping the 200-800 pores / inch2 cordierite honeycomb ceramic carrier into said solution, taking out to dry and form Al2O3 coat; excessive immersing into silver nitrate solution, taking out to calcine and obtain the product. This catalyst has high catalytic conversion rate to NOx special at low temperature, solves the difficulty that it is hard to remove NOx on oxygen-enriched condition, and has well environmental benefit.

Owner:TSINGHUA UNIV

In-situ preparation method of sulfur transfer agent for FCC regenerated flue gas

InactiveCN1994535AImprove adsorption capacityEfficient desorption performanceCatalytic crackingDispersed particle separationMagnesium saltCerium

The invention relates to a method for preparing fluid catalyst crack (FCC) regenerate smoke sulfur transfer agent, wherein at room temperature, it mixes the mixture of magnesium salt, zinc salt, ferric salt, cerium salt, with the diaspore at same volume; immerges for 4-24h; drying at 80-120Deg. C, for 4-12h; brakes at 600-850Deg C for 4-12h, to obtain the solid sulfur transfer agent while the MgO content is 10-20%, the ZnO content is 1-5%, the Fe2O3 content is 1-5%, and the CeO2 content is 2-6%. The inventive product has high SOX adsorption effect and high mechanical strength.

Owner:EAST CHINA NORMAL UNIV

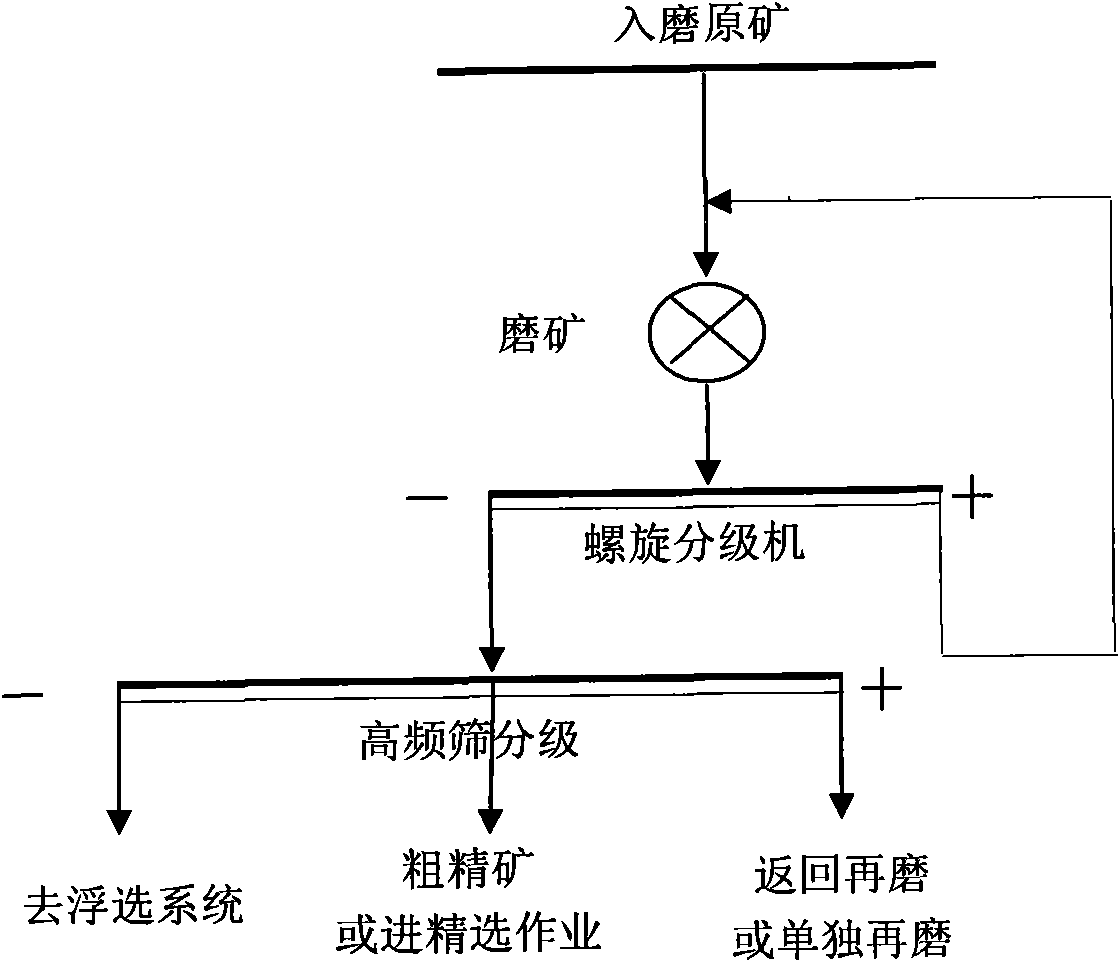

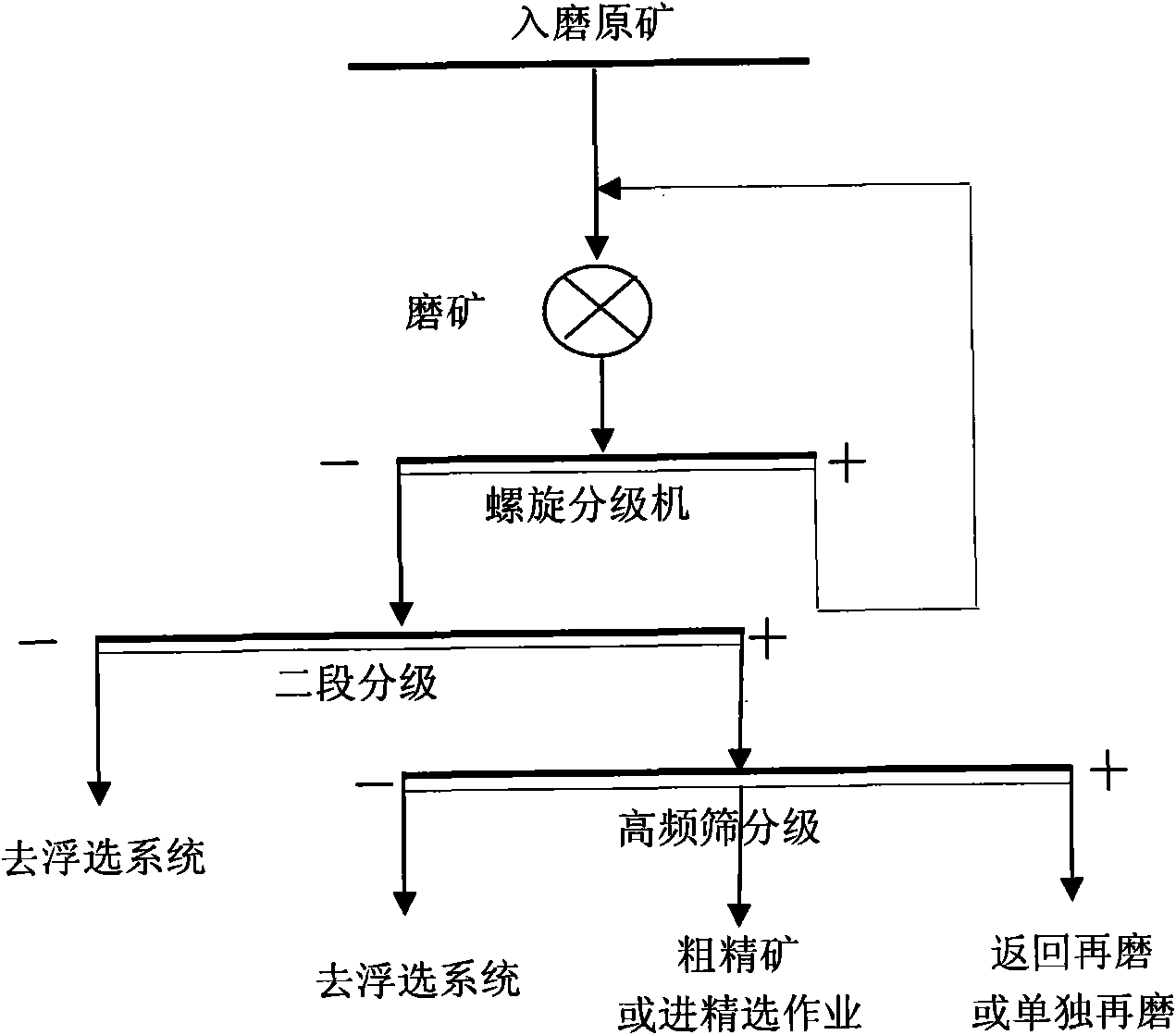

Method for mineral dressing and silicon removal of bauxite

InactiveCN101850297ASimple technical processGood technical and economic effectFlotationWet separationDiasporeLarge size

The invention provides a method for mineral dressing and silicon removal of bauxite, and particularly relates to a method for mineral dressing and silicon removal of diaspore type bauxite. The method comprises an ore-grinding grading process and a flotation silicon removal process, and is characterized in that: the product of ore grinding is graded for two or three times, wherein a double-layer high-frequency vibrating screen is used at the last time of grading; and among three products obtained by grading of the double-layer high-frequency vibrating screen, large-size grains are reground and re-dressed, medium-size grains are used as rough concentrates or enter the flotation system for concentration, and small-size grains enter the flotation system for flotation silicon removal. The method has the advantages of effectively solving the technical problem that the grinding machine is high in energy consumption and low in treating capacity, the problem that the grain size of the flotation materials is small and other problems, better performing flotation silicon removal of bauxite, obtaining bauxite concentrates with qualified grade, along with good process technique and economic indexes.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

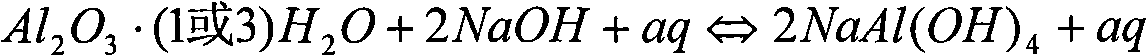

Method for extracting alumina from high silicon bauxite

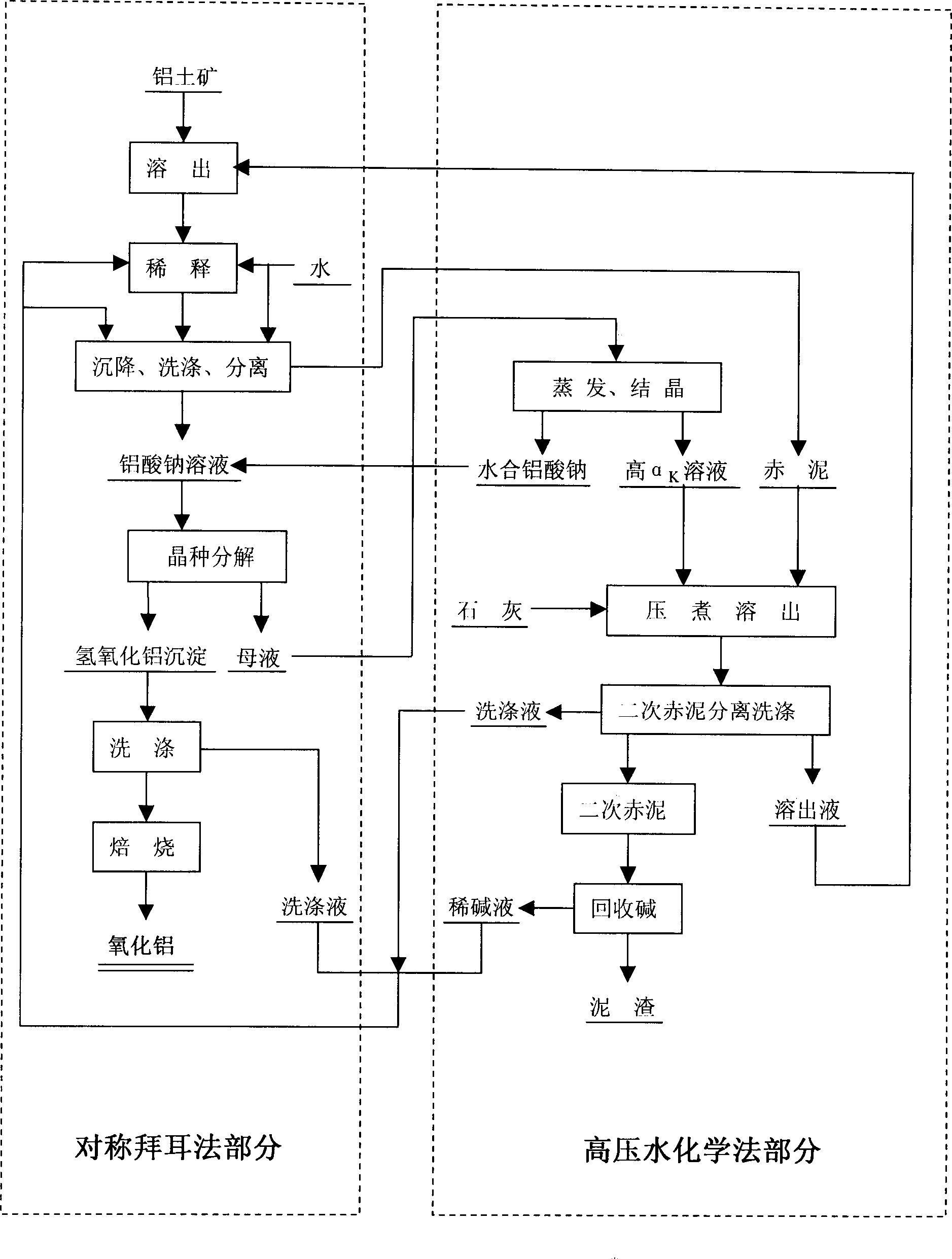

InactiveCN1807251AEfficient decompositionReduce energy consumptionAluminium compoundsHybrid typeRed mud

The invention relates to a technique to produce alumina with bauxite by alkaline method, which comprises: combining the symmetrical Bayer process at 100-250Deg and high-pressure hydrochemical method at 200-300Deg to treat directly high-silicon bauxite to extract alumina and treat red mud to recover Al2O3 combined by SiO2 and send obtained solution to the symmetrical Bayer process, respectively; hydrolyzing the generated calcium sodium silicate hydrate to recover the combined alkali; adding lime in any system by 1-3 times mole ratio as the SiO2. This invention can decompose the bauxite effectively with low alkali quantity and energy consumption, and fits to treat the diaspore, boehmite and aluminum trihydrate or the mixture.

Owner:CENT SOUTH UNIV

Micrometre grade thin diaspore preparation method

InactiveCN1733607AHigh activitySeed rate increaseAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateDiaspore

The invention relates to preparation method for micron thin diaspore, which comprises steps: at 0~9Deg, using 8~30% H2O2 solution of 3.0~7.0 times to deposite the sodium aluminate solution contained 50~250g / L-Al2O3 with causticization coefficient alphaK 1.30~3.50; aging there action slurry, filtering, clearing, dispersing withethanol, and baking to prepare the thin diaspore crystal seed; adding the crystal seed into oversaturated sodium aluminate solution contained 50~250g / L-Al2O3 with alphaK 1.30~3.50, and obtaining the objective product. This method has high seed-separation rate of 50% or more, and needs mild reaction condition.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

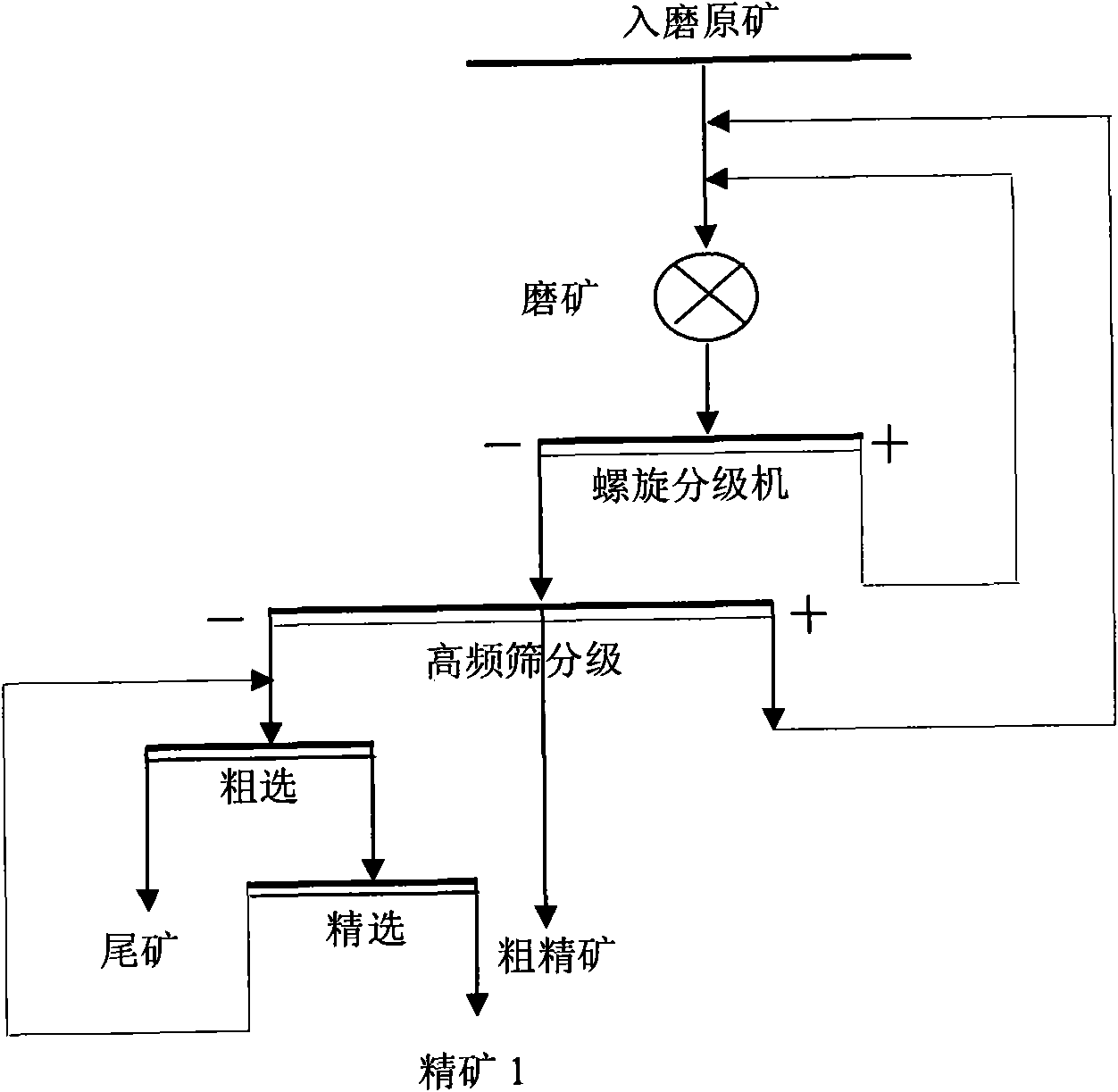

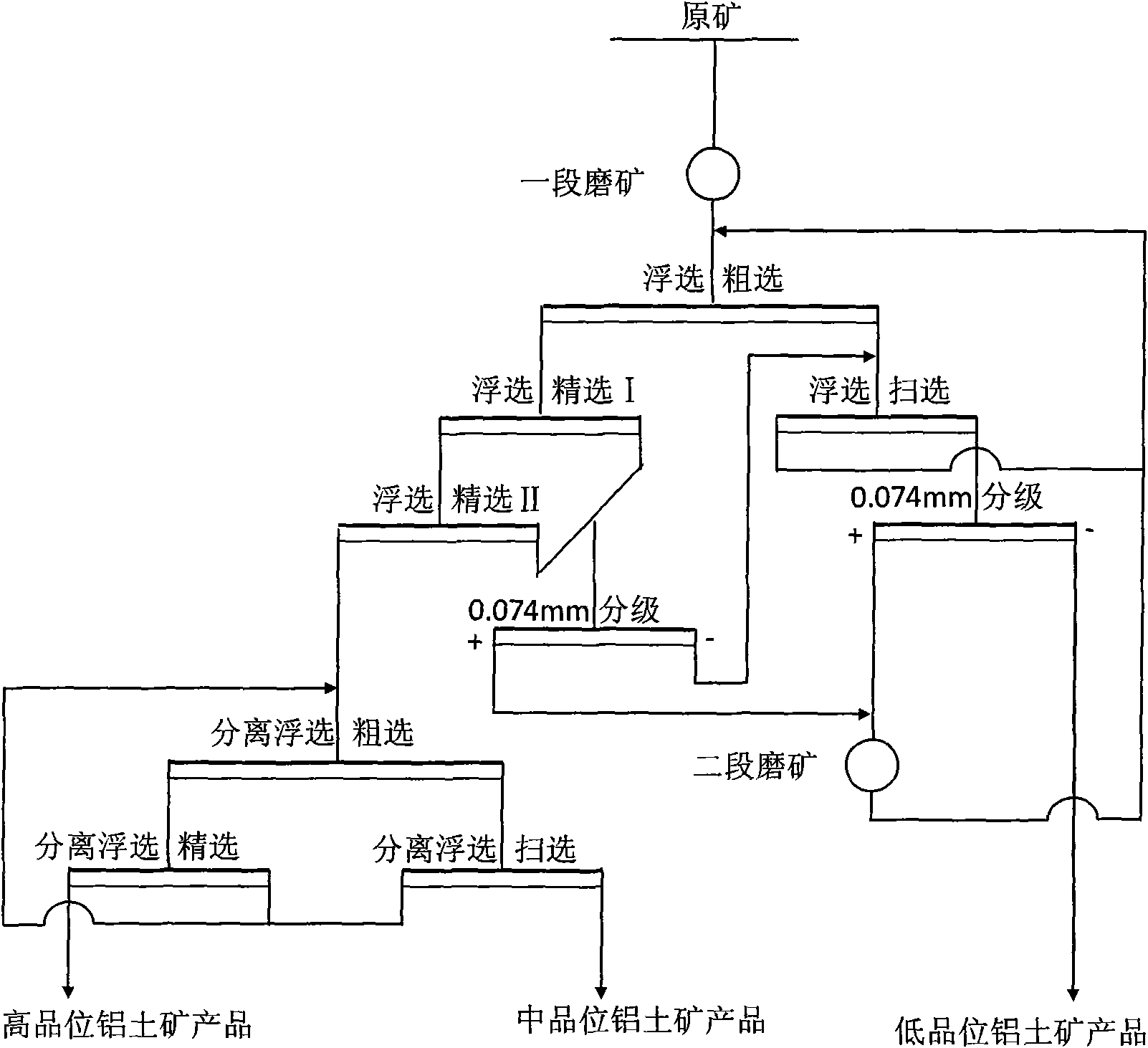

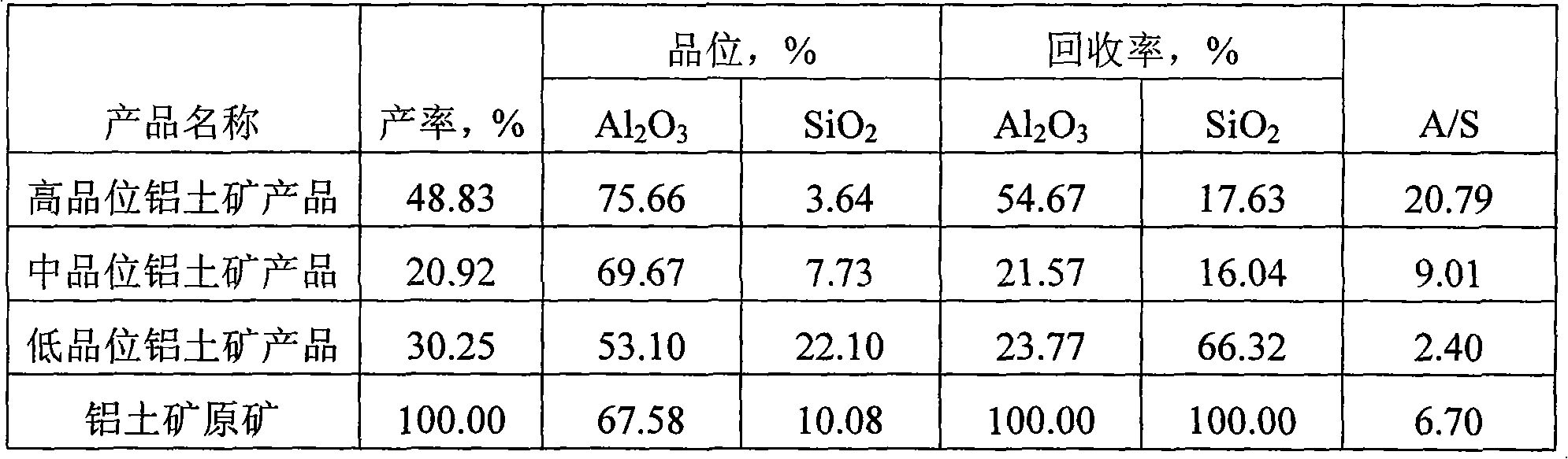

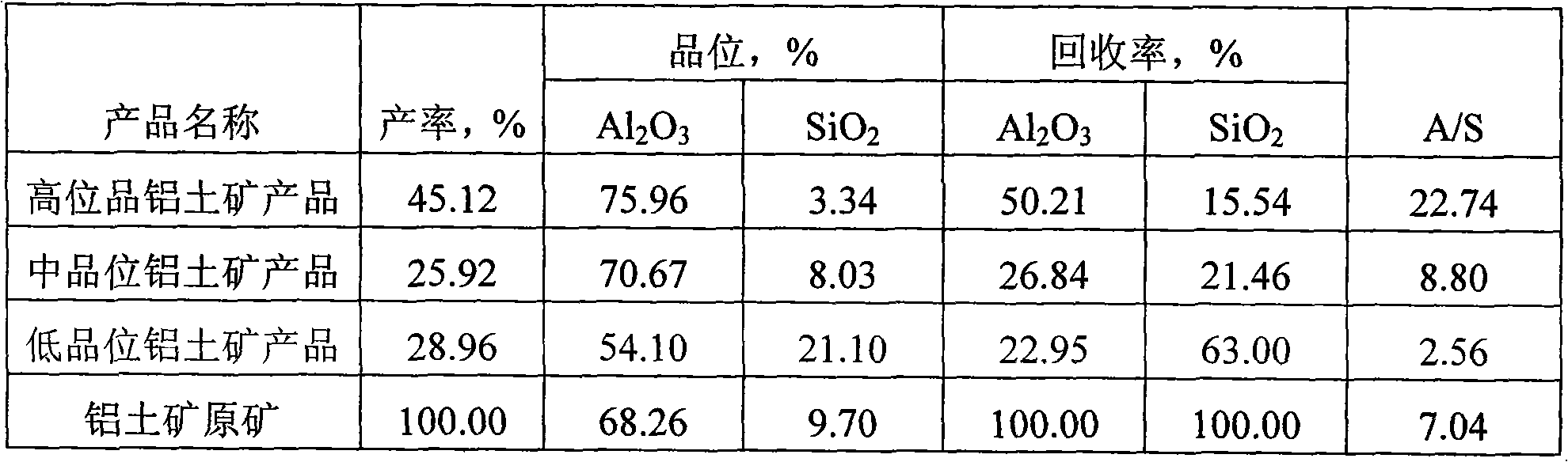

Beneficiating method of diaspore type bauxite

The invention relates to a beneficiating method of diaspore type bauxite, which is characterized by comprising the following steps: carrying out single-stage coarse grinding on raw bauxite, enabling ground bauxite products and a flotation reagent to act, and directly entering a rough concentration task; carrying out single scavenging on rough concentration base flow, grading scavenged base flow to obtain a low-grade bauxite product as a fine fraction product; carrying out twice blank selection on rough concentration foam, intensively grading the base flow, scavenging the fine fraction product, combining the scavenged foam and twice-grading coarse fraction regrinding products, and intensively carrying out floatation and rough concentration with the single-stage ground bauxite products; carrying out single rough concentration, single selection and single scavenging on the selected II foam, and then obtaining a high-grade bauxite product and a medium-grade bauxite product. The beneficiating method can obtain three kinds of products with different A / S, wherein a high aluminum product with the Al2O3 content being higher than 75 percent is used for calcining high aluminum clinkers, a medium aluminum product with the A / S being 8-12 is used for producing alumina by a Bayer process, and a low aluminum product with the A / S being about 2.55 is used for synthesizing mullite type refractory material, thereby realizing tailless production; the comprehensive utilization ratio of diaspore type bauxite approaches to 100 percent.

Owner:XIAOYI TIANZHANG ALUMINUM

Preparation method of porous activated aluminum oxide adsorbing material

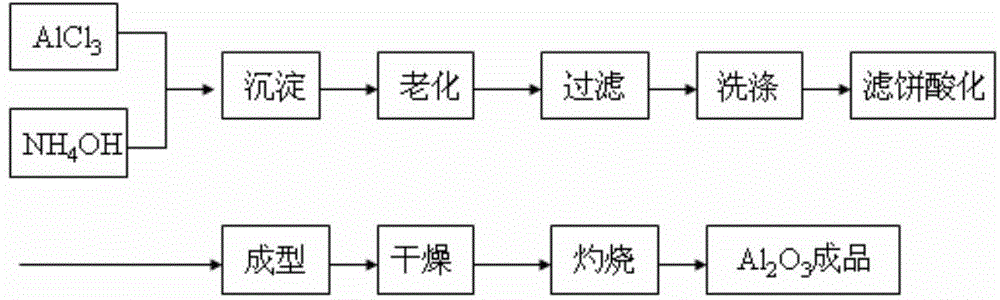

InactiveCN104445323AEliminate the effects ofSolve processing problemsOther chemical processesAlkali metal chloridesDiasporeTetrachloroaluminate

The invention relates to a preparation method of a porous activated aluminum oxide adsorbing material. The preparation method comprises the following steps: (1) dissolving and hydrolyzing solid sodium tetrachloroaluminate by using an ethanol water solution; (2) adding water into an obtained solution to generate aluminum trichloride hexahydrate; (3) adding ammonia water for reaction to generate hydrated alumina suspension liquid, and ageing to obtain alpha-diaspore; (4) peptizing by using acid to obtain sol, dropwise adding the sol into an oil-ammonia column by adopting a dripping method, allowing the sol to retract to form balls under the effect of a surface tensile force in oil, putting the balls into ammonia water, neutralizing and ageing to form hard gel ball-like substances, washing away oil ammonia by using water and drying; and (5) baking to obtain the porous activated aluminum oxide adsorbing material. The preparation method disclosed by the invention can be used for solving the problems of wastewater treatment, improving cyclic utilization of resources, realizing value maximization and increasing the additional value of byproducts; the porous activated aluminum oxide adsorbing material is good in thermal stability at high temperature, large in specific surface area, good in adsorption performance, simple in production process, convenient to operate, low in cost and basically free of environmental pollution from aspect of production technology.

Owner:武汉铂莱材料科技有限公司

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

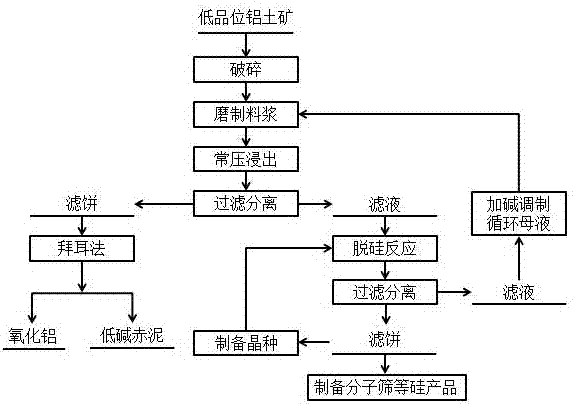

Method for producing aluminium oxide and by-product silicon by low-temperature alkali digestion of low-grade bauxite

InactiveCN107235501AAluminium silicatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagRed mud

The invention relates to a method for producing aluminium oxide and a by-product silicon by low-temperature alkali digestion of low-grade bauxite, and belongs to the technical field of aluminium oxide production. The method comprises the following steps: firstly, smashed low-grade diasporic bauxite and a circulating mother liquid are grinded to form a mineral slurry; secondly, a digestion reaction is performed enable kaolinite in the mineral to be dissolved, react and enter a solution, filtration residues are high-grade bauxite concentrate, and the high-grade bauxite concentrate is processed for produce aluminium oxide and low-alkali red mud by adopting a Bayer process; sodium aluminosilicate in a filtrate is subjected to desilication reaction, so that sodium-silicon residues, and a filtrate containing aluminium oxide, silicon oxide and sodium oxide are obtained; and finally, the filtrate is supplemented by sodium hydroxide, and the supplemented filtrate is used as the circulating mother liquid to return for preparation of the mineral slurry through grinding, and part of the sodium-silicon residues are used as a seed crystal to return to a desilication process, and the other part of the sodium-silicon residues are used to prepare silicon products such as molecular sieves. The method is a whole-procedure wet treatment process, aluminium and silicone are fully extracted from the bauxite for preparing the corresponding products, also alkali consumption in the red mud during the Bayer process is substantially reduced, the alkali content in the red mud is reduced, and recycle value of the red mud is improved.

Owner:NORTHEASTERN UNIV

Flotation gangue subsidence method of alumyte

The present invention relates to the deposition dewatering process of floated tail ore, and is especially the deposition dewatering process of floated tail ore of diaspore type alumyte. The present invention features that into the floated tail ore slurry, sulfuric acid or sulfate, aluminum sulfate, ferrous sulfate, zinc sulfate, copper sulfate, barium sulfate or alum in acidity after hydrolysis is first added to regulate pH value to 6.5-7.5; and polyacrylamide as organic flocculant in the amount of 0.001-0.01 % of the dry tail ore slurry weight is then added for flocculation and deposition. The present invention can raise the concentration of tail ore slurry from 6-11 % to over 25 %, reduce the overflow floated matter to below 1 g / L and make the overflow water capable of being reused.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

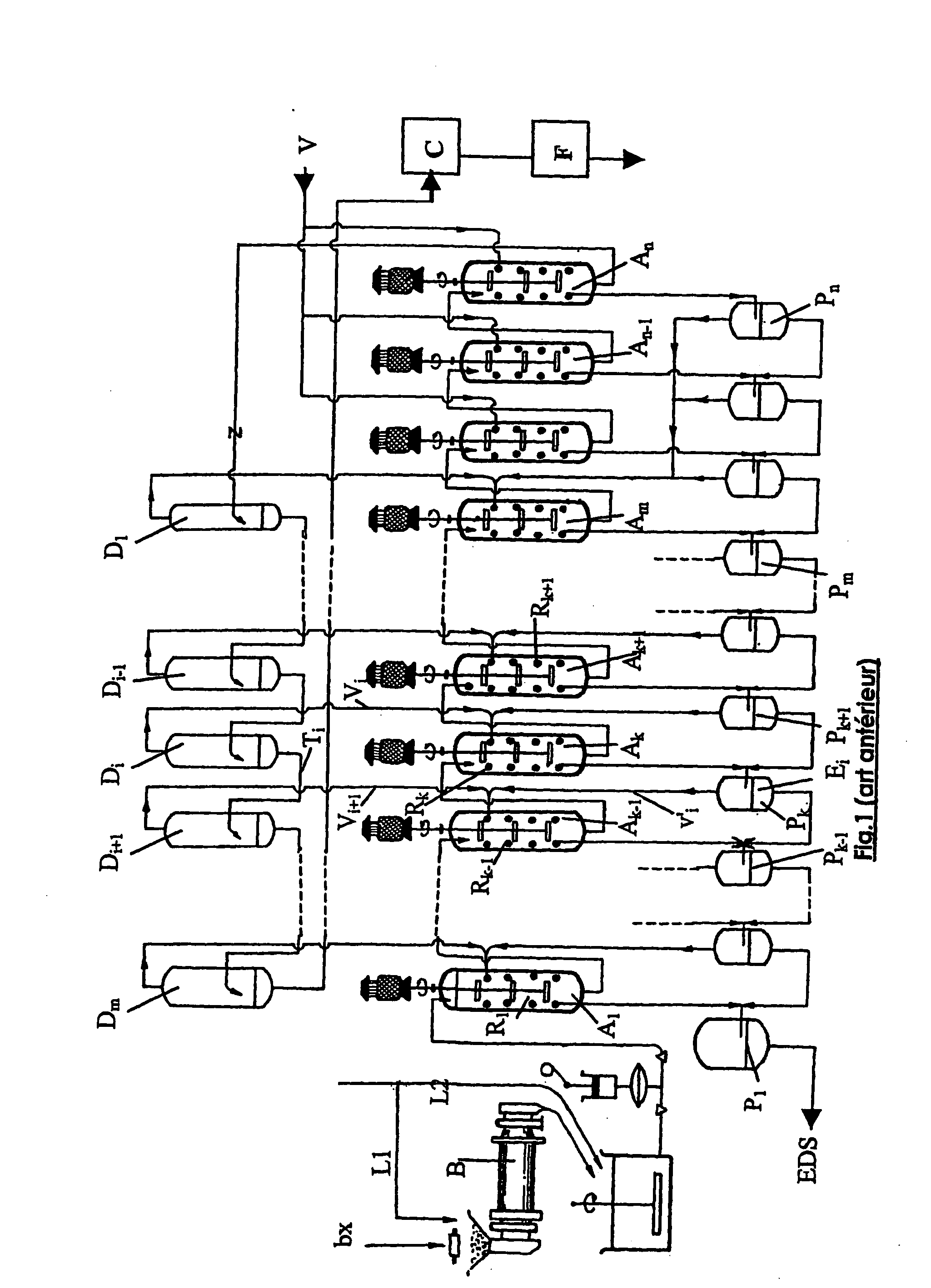

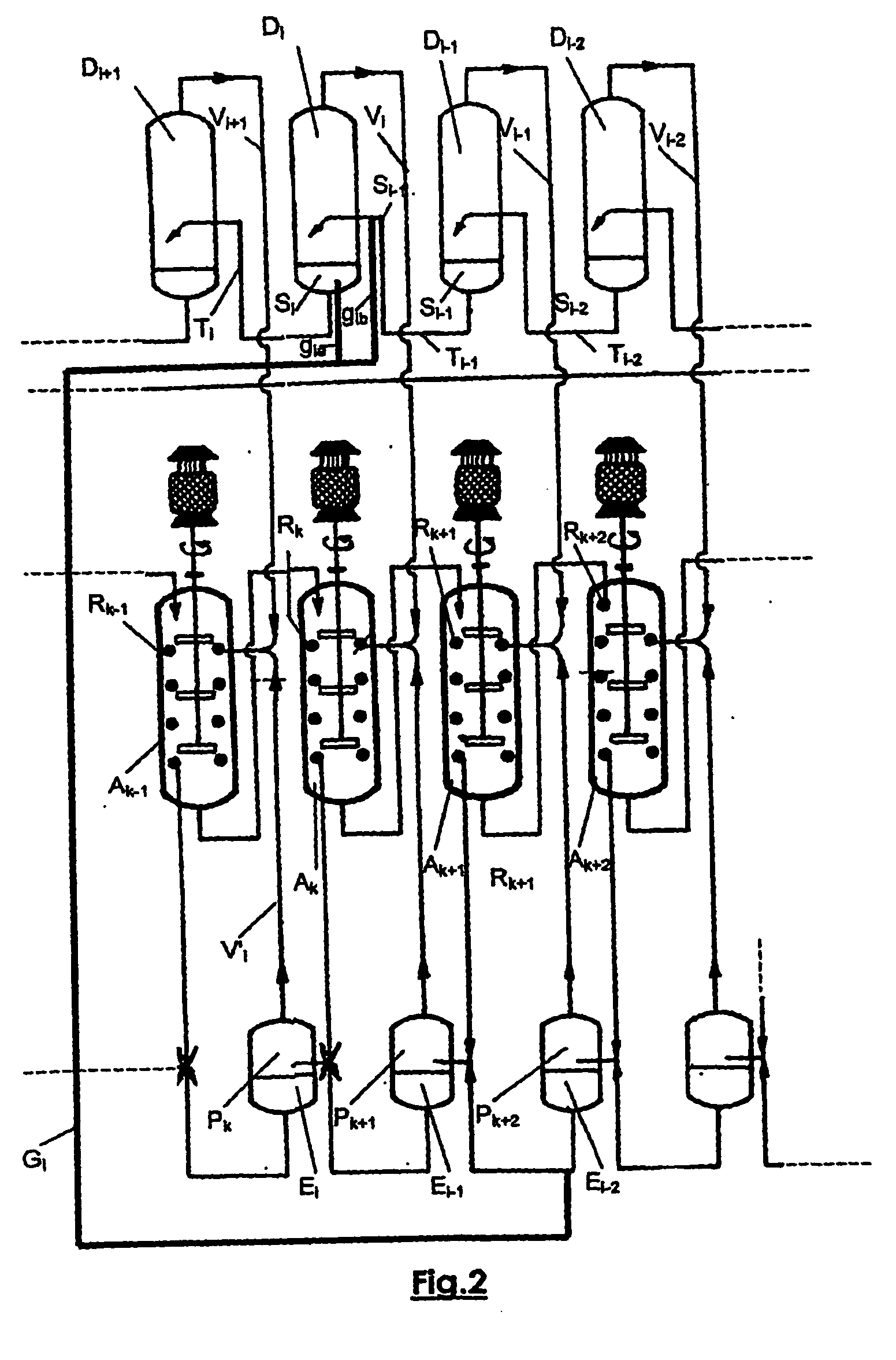

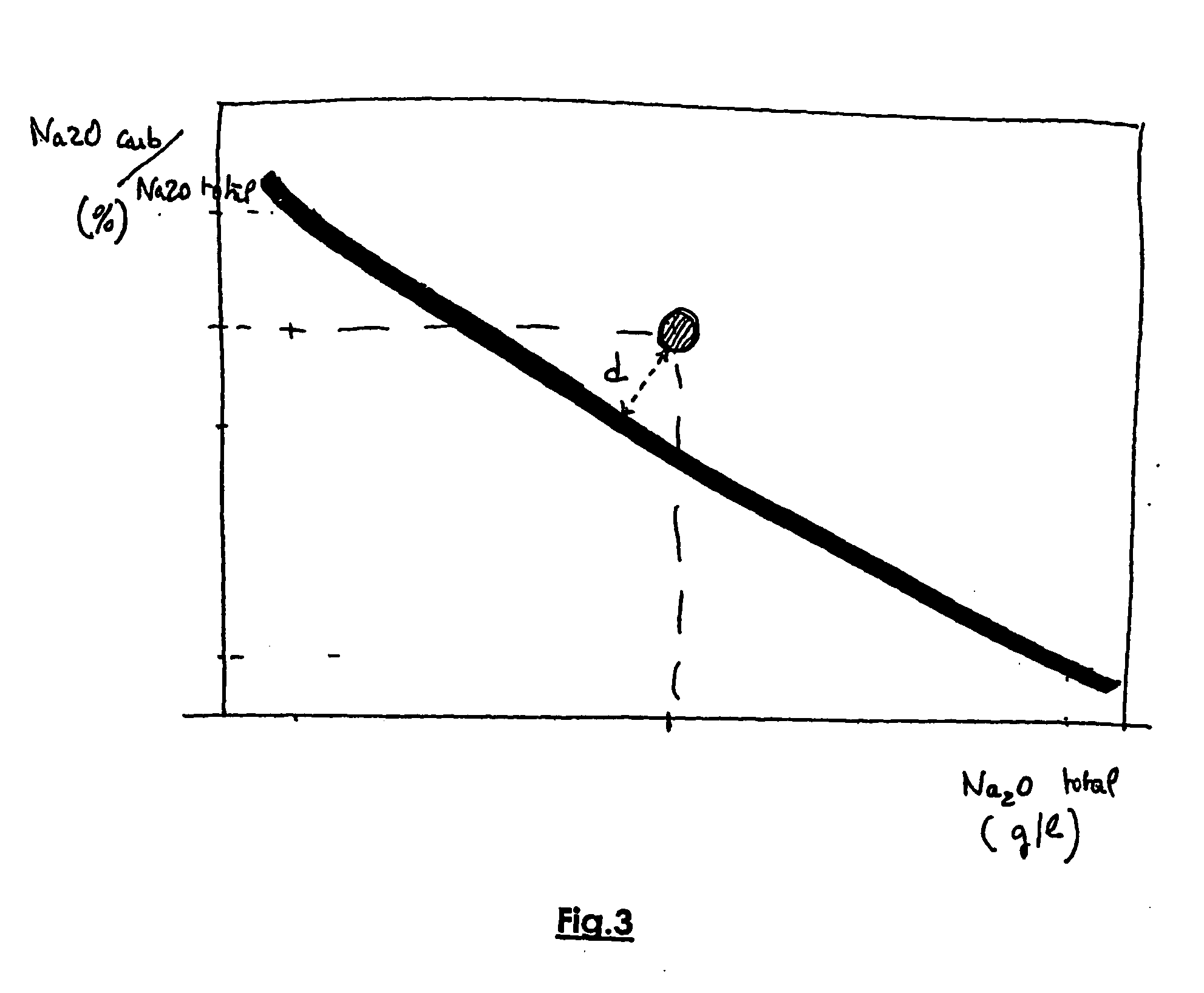

Solubilisation of carbonates by recycling condensates during digestion of monohydrate bauxites under pressure

InactiveUS20050123460A1Minimize energy consumptionReduce energy consumptionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesDiasporeDigestion

A method for the production of aluminum from bauxites containing aluminum monohydate of the diaspore or boehmite type which may contain more than 1.5% by weight of calcium carbonates. The ore is digested by the following steps: a1) a suspension, produced from the milled bauxite ore and the concentrated aluminate liquor is fed to a plant containing a series of n autoclaves and a series of m regulators supplying m tubular reheaters across m autoclaves with steam; a2) the suspension first travels across the series of autoclaves, and on exiting the last autoclave A, the digestion of the ore is practically complete and a3) the suspension then travels across the series of regulators, the condensation water from the steam V coming from the regulator D and feeding the reheater R is collected in a purge pot P. In at least one position in the series of regulators, the suspension is diluted on entering a regulator with the water coming from the condensation of the steam from one or several upstream regulators.

Owner:PECHINEY ALUMINUM

Mesoporous alumina preparation method based on cross-linking reaction

ActiveCN101817543AThe method is simpleEasy to controlNanostructure manufactureAluminium oxides/hydroxidesCross-linkDiaspore

The invention discloses a mesoporous alumina preparation method based on cross-linking reaction in the field of porous support technology. The preparation method comprises the steps of: weighting polyose electrolyte and dissolving in pure water to prepare a polyose electrolyte solution; adding an aluminum nitrate solution or mixed liquid of the aluminum nitrate solution and ammonia water and stirring uniformly to obtain compound sol; standing for 24h to obtain gel; aging for 24 hours and then carrying out constant-temperature drying treatment at 80 DEG C; crushing and then calcining for 8 hours at 650 DEG C to prepare white mesoporous alumina. The invention realizes the synthesis of the mesoporous alumina in a water phase system by taking cheap and environmental-protection saccharides which can be post-processed easily as a structural guide agent and using thin diaspore sol which is cheap and easily prepared as an aluminum precusor.

Owner:SHANGHAI JIAO TONG UNIV +1

Lightweight iolite-mullite composite ceramic material and preparation method thereof

The invention provides a lightweight iolite-mullite composite ceramic material and a preparation method thereof. According to a technical scheme in the invention, the preparation method comprises the following steps: with 20 to 70 wt% of diaspore, 10 to 30 wt% of amorphous silica, 5 to 30 wt% of talcum powder and 10 to 40 wt% of clay as raw materials, adding 3 to 10 wt% of water and carrying out stirring, molding, drying and maintenance at a temperature of 1250 to 1350 DEG C for 2 to 6 h so as to prepare a porous iolite-mullite composite material; and then with composite material particles respectively with a particle size of 2 to 1 mm and a particle size of 1 to 0.088 mm as aggregate and powder with a particle size of less than 0.088 mm as a matrix, adding dextrin water and successively carrying out uniform mixing, molding, drying and maintenance at a temperature of 1250 to 1350 DEG C for 2 to 6 h so as to prepare the lightweight iolite-mullite composite ceramic material. The preparation method has the characteristics of low cost, environment friendliness, energy conservation, environment friendliness and controllable chemical composition; and the prepared lightweight iolite-mullite composite ceramic material has small volume density, uniform phase component and pore size distribution, excellent mechanical properties at normal temperature, good high temperature performance and high thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

Cracking catalyst

ActiveCN1978593BImprove hydrothermal activity stabilityGood macromolecular cracking performanceCatalytic crackingRare-earth elementDiaspore

The invention discloses a cracking catalyst. The character is in that the catalyst has one kind of mesoporous material which is the (0-0.3)Na2O .(40-85)Al2O3 .(10-55)SiO2 .(1-20)MxOy, the metal M is one element in IB, IIB,IVB,VB,VIB,VIIB,VIIIB or lanthanide series rare earth; The x is the highest valence of O, y is the highest valence of M. The structure of the mesoporous material is same as the thin diaspore structure and the specific area is 200-400 square m / g, the hole volume is 0.5-2.0ml / g and the average size is 8-20nm, the most probable size is 5-15nm. The catalyst can be used in the catalytic cracking reaction directly, so it can improve the raw oil and the heavy oil percent conversion but decrease the sulfur content of FCC gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing unformed aluminium hydroxide

InactiveCN1843924AAvoid or suppress generationReduce volumeProductsReagentsHigh concentrationAluminium hydroxide

The invention discloses a method for preparing non-shaped aluminum hydroxide, relating to an aluminum hydroxide, especially relating to a method for preparing aluminum hydroxide with high acid dissolubility and low density. The method comprises following steps: preparing strong sodium metaaluminate with gibbsite and sodium-hydroxide to control solution caustic ratio; diluting with deioned water and adding hole enlarging agent; adding deioned water into autoclave firstly, got solution of raw material and carbon dioxide flows into autoclave to control glue forming temperature; regulating feeding flow rate and filtering, washing and drying slurry and getting said product. The invention employs continous feeding and carbon dioxide of high concentration for glue forming to fasten neutralizing reaction and shorten glue forming time, and thus prevents diaspore generation, saves cooling device, increases device usage or reduces autoclave volumn. The product can dissolve into hydrogene nitrate of 20% completely and the bulk density is less than or equal to 0.4 g / ml.

Owner:XIAMEN UNIV

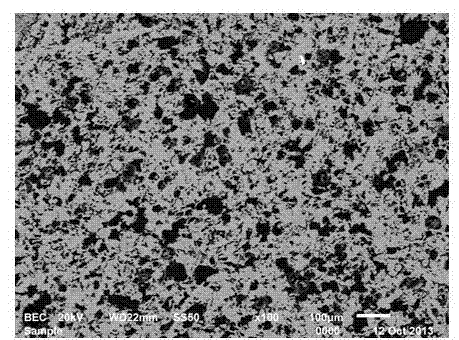

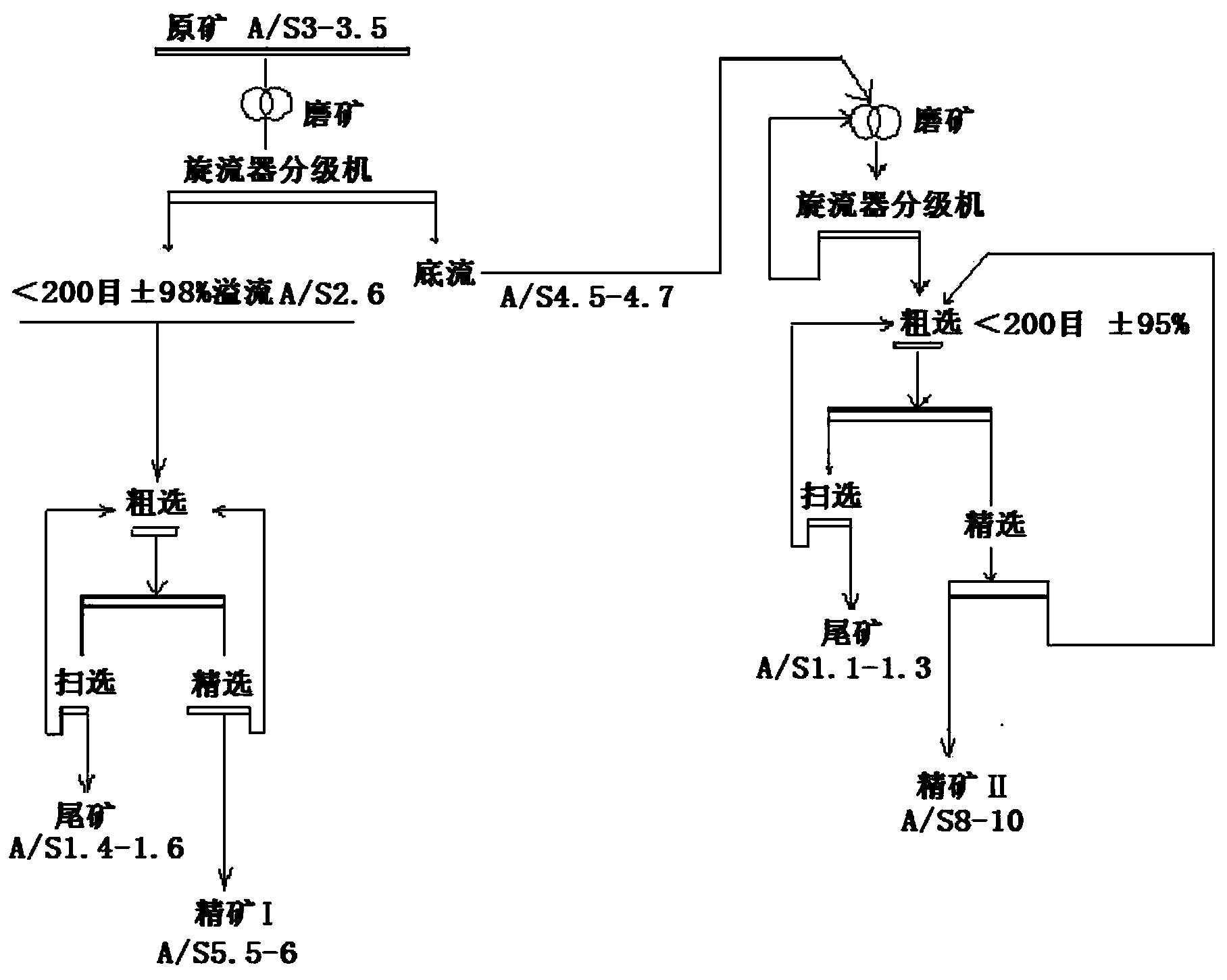

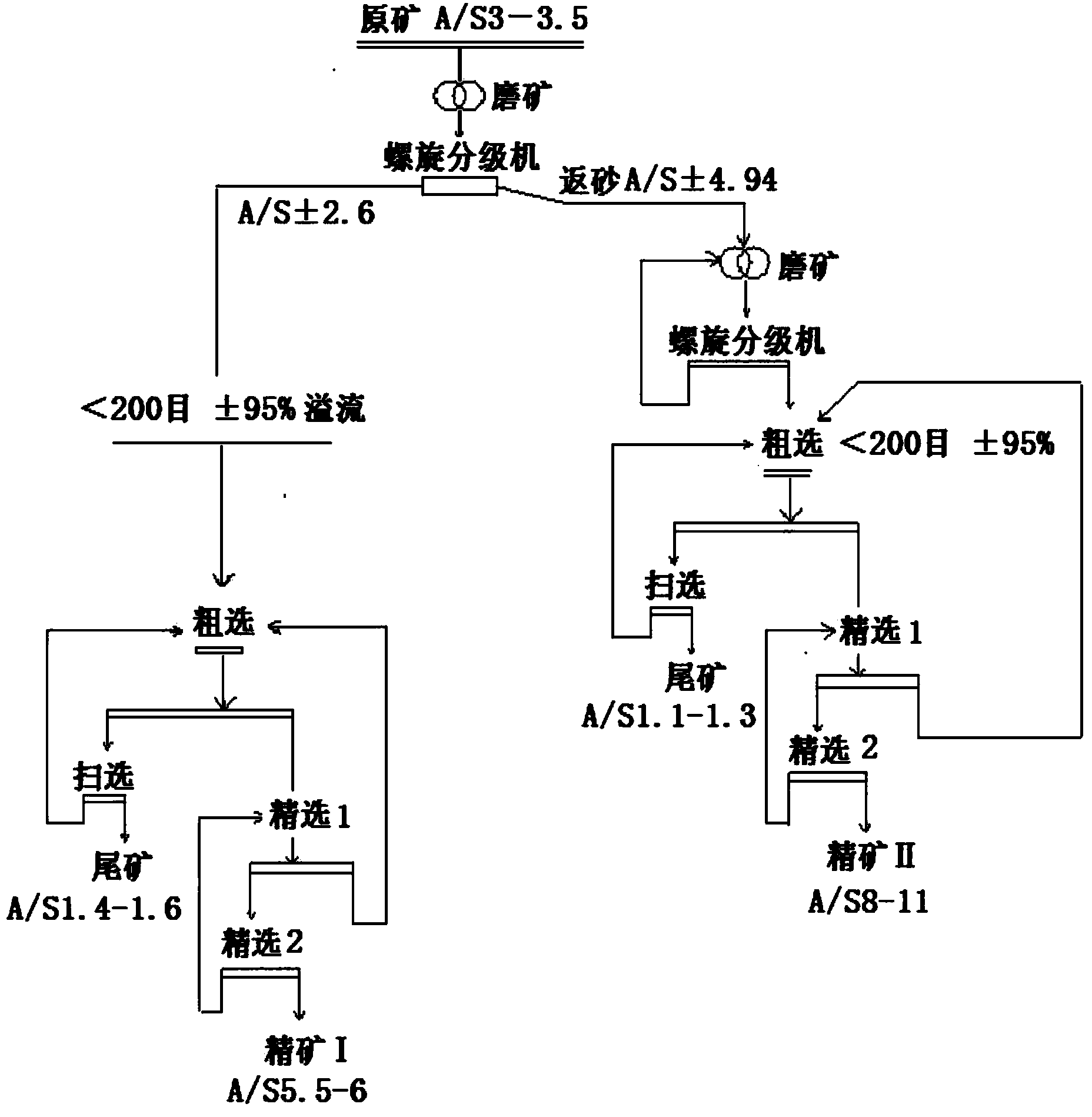

Low-quality raw bauxite ore open-grinding and dressing technology

InactiveCN103521363AHigh recovery rateLow costVortex flow apparatusMohs scale of mineral hardnessKaolinite

The invention provides a low-quality raw bauxite ore open-grinding and dressing technology. The technology comprises the following steps of roughing, scavenging and selecting so as to obtain concentrate with A / S of 5.6-6; feeding the bottom flow or return sand discharged by a classifying machine into another grinding machine for grinding and then classifying by another classifying machine, wherein the A / S of the bottom flow or return sand achieves the middle-quality bauxite standard, and the ore granularity is less than 60 meshes; roughing, scavenging and selecting overflow in which the ore with granularity less than 200 meshes accounts for + / -95% so as to obtain concentrate with A / S of 8-11. By fully utilizing the difference in Mohs hardness of diaspore and kaolinite, the technology improves A / S of bauxite concentrate to 8 above, can improve the production of alumina, and is high in Al2O3 recovery rate, energy-saving, low in cost and low in alkaline consumption; for ore dressing enterprises, the technology can increase the yield, save energy and reduce the cost, has favorable quality and price, and generates great benefit; the technology can also be used for producing in high-aluminum clay ore dressing enterprises; the technology can be used for dressing middle-grade bauxite, and the A / S of the concentrate can be stabilized at 11-12.

Owner:李耀吾

Stripping process for high iron diaspore bauxite

The invention provides a method for dissolving out ferric diaspore type bauxite and relates to the method for dissolving out the bauxite in an alumina producing process. The method is characterized in that in the process, preprocessing alkali solution and lime CaO are used for preprocessing the ferric diaspore type bauxite; then solid-liquid separation is carried out, the separated solid is dissolved out under dissolving-out condition by normal Bayer process; the used preprocessing alkali solution is added with the lime to remove alumina in the solution, so as to realize the regeneration of the preprocessing alkali solution. In the method of the invention, only the lime is used as an additive, therefore the method has simple procedures and the ratio of aluminum and silicon (A / S) and the ratio of natrium and silicon (N / S) in the dissolved-out red mud are obviously reduced, which is applicable to processing the diaspore type bauxite with high content of ferric oxide (the content of the Fe2O3 is more than or equal to 8 percent).

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com