Patents

Literature

697 results about "Marine engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inboard motor is a marine propulsion system for boats. As opposed to an outboard motor where an engine is mounted outside the hull of the craft, an inboard motor is an engine enclosed within the hull of the boat, usually connected to a propulsion screw by a driveshaft.

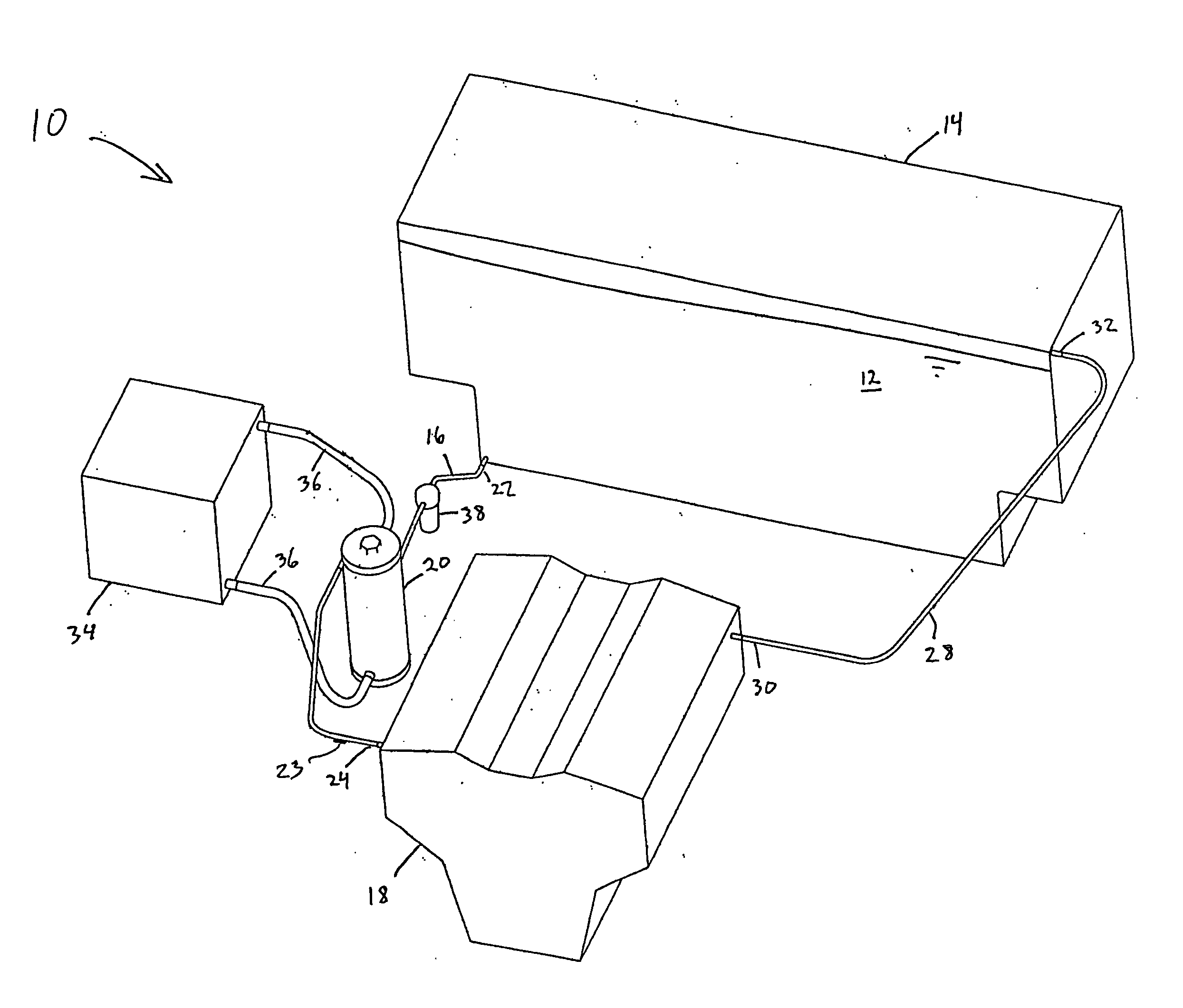

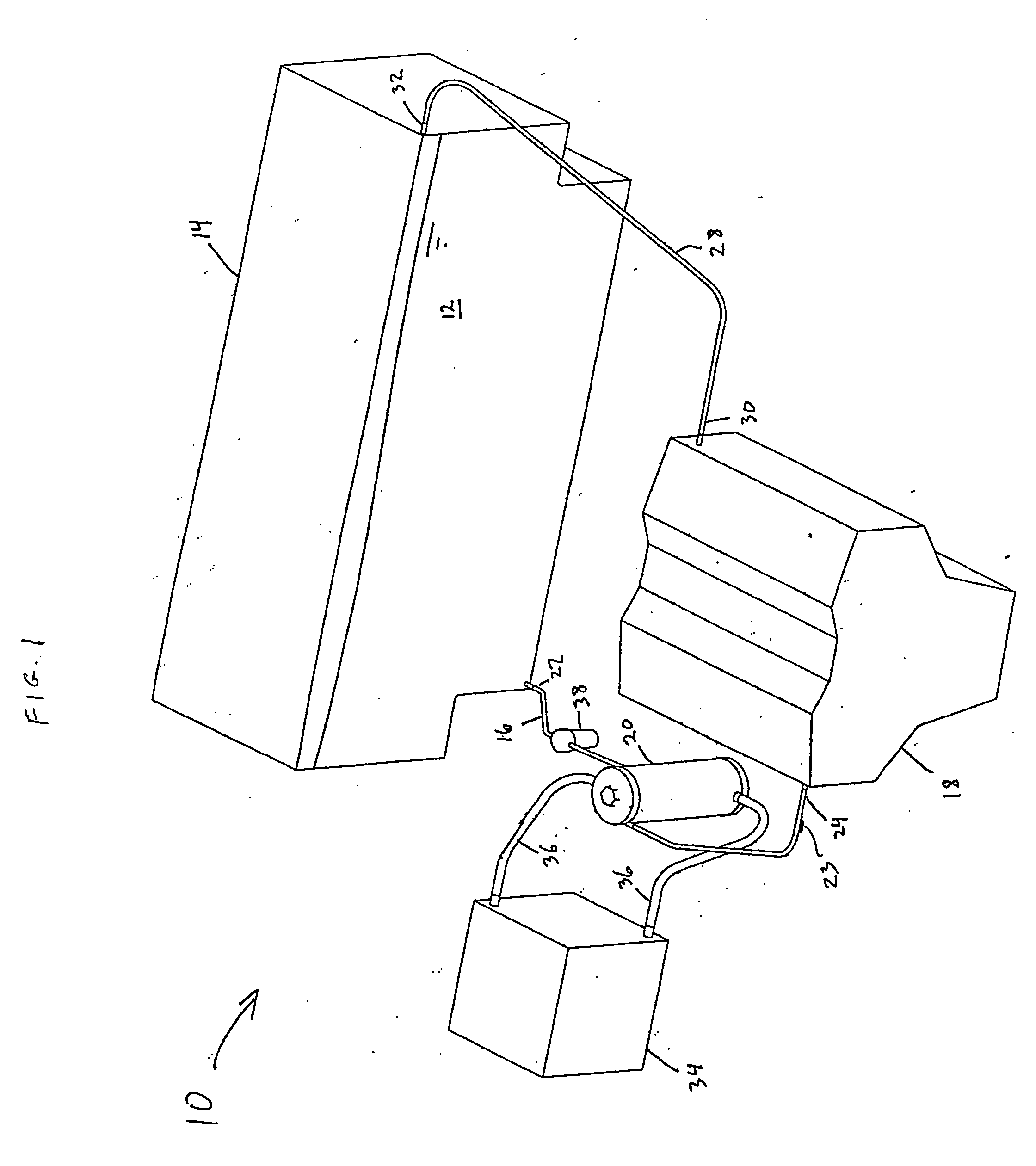

Marine engine fuel cooling system

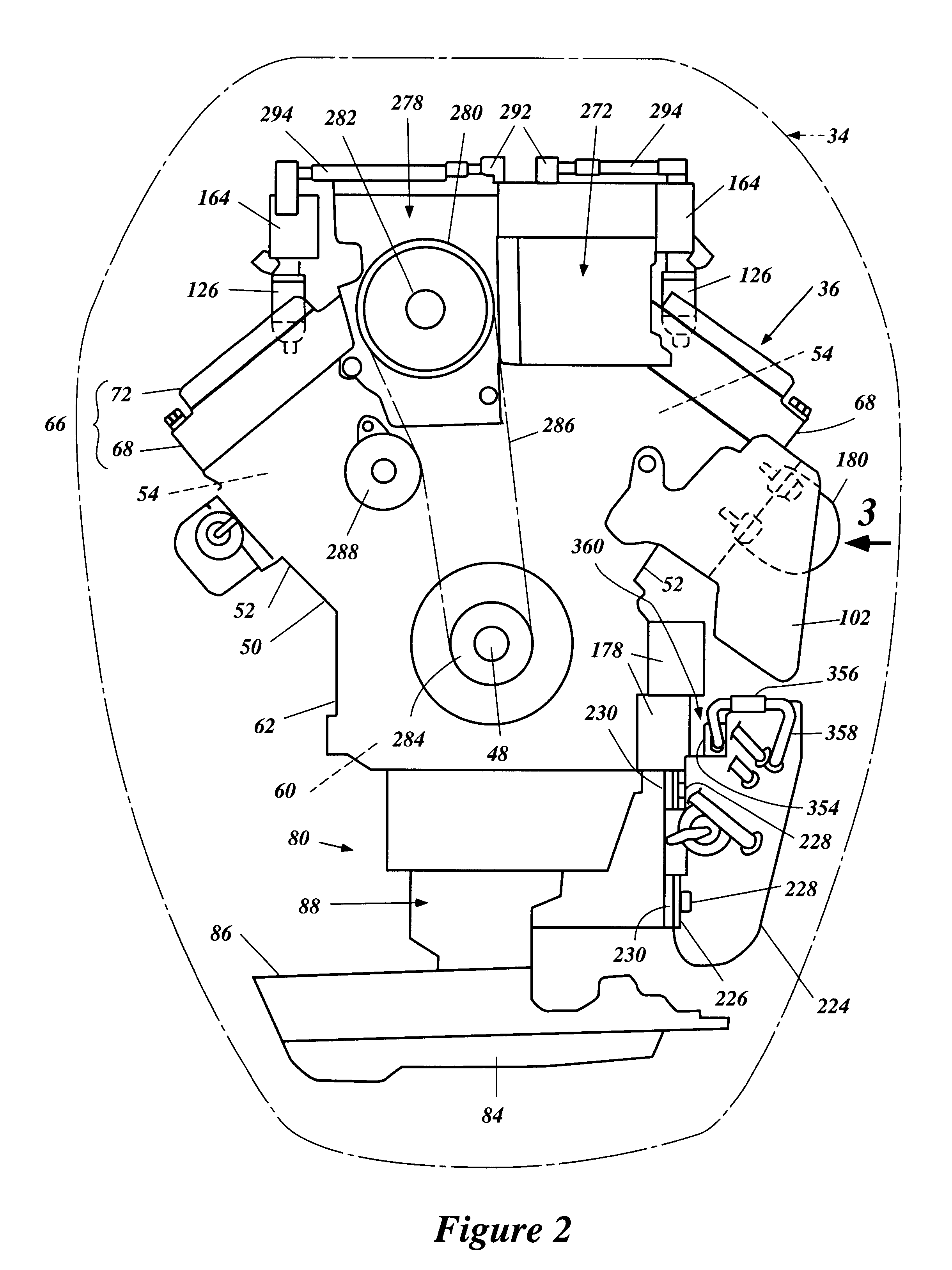

InactiveUS20060124113A1Internal combustion piston enginesThermal treatment of fuelNuclear engineeringFuel tank

A fuel cooling system for a marine inboard engine, including a fuel tank, a fuel supply conduit, and a heat exchanger. The fuel supply conduit includes first and second ends, and extends between the fuel tank and a fuel injection system for the engine. The heat exchanger is disposed intermediate the first and second ends of the fuel supply conduit, and includes a fuel passage in fluid communication with the fuel supply conduit, and a coolant passage in fluid communication with a coolant side of a closed-loop auxiliary cooling system.

Owner:ROBERTS FOREST G SR

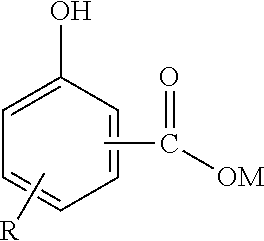

Marine engine lubrication

InactiveUS20120028522A1Easy to handlePropulsion power plantsOutboard propulsion unitsEngineeringFuel oil

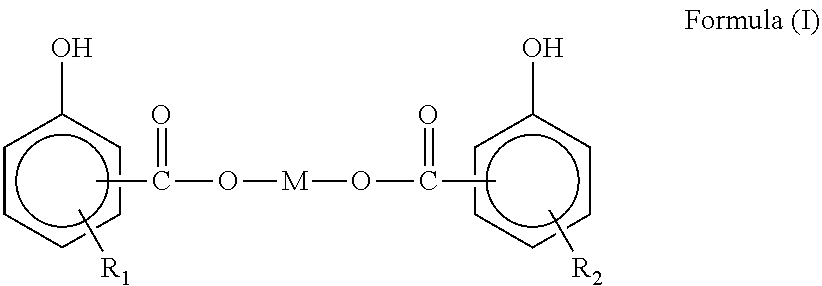

Trunk piston marine engine lubrication, when the engine is fueled by heavy fuel oil, is effected by a composition comprising a major amount of an oil of lubricating viscosity containing at least 50 mass % of a basestock containing greater than or equal to 90% saturates and less than or equal to 0.03% sulphur or a mixture thereof, and respective minor amounts of an over-based metal hydrocarbyl-substituted hydroxybenzoate detergent other than such a detergent having a basicity index of less than two and a degree of carbonation of 80% or greater and at least 1 mass % of a hydrocarbyl-substituted carboxylic acid, anhydride, ester or amide thereof. Asphaltene precipitation in the lubricant, caused by the presence of contaminant heavy fuel oil, is prevented or inhibited.

Owner:INFINEUM INT LTD

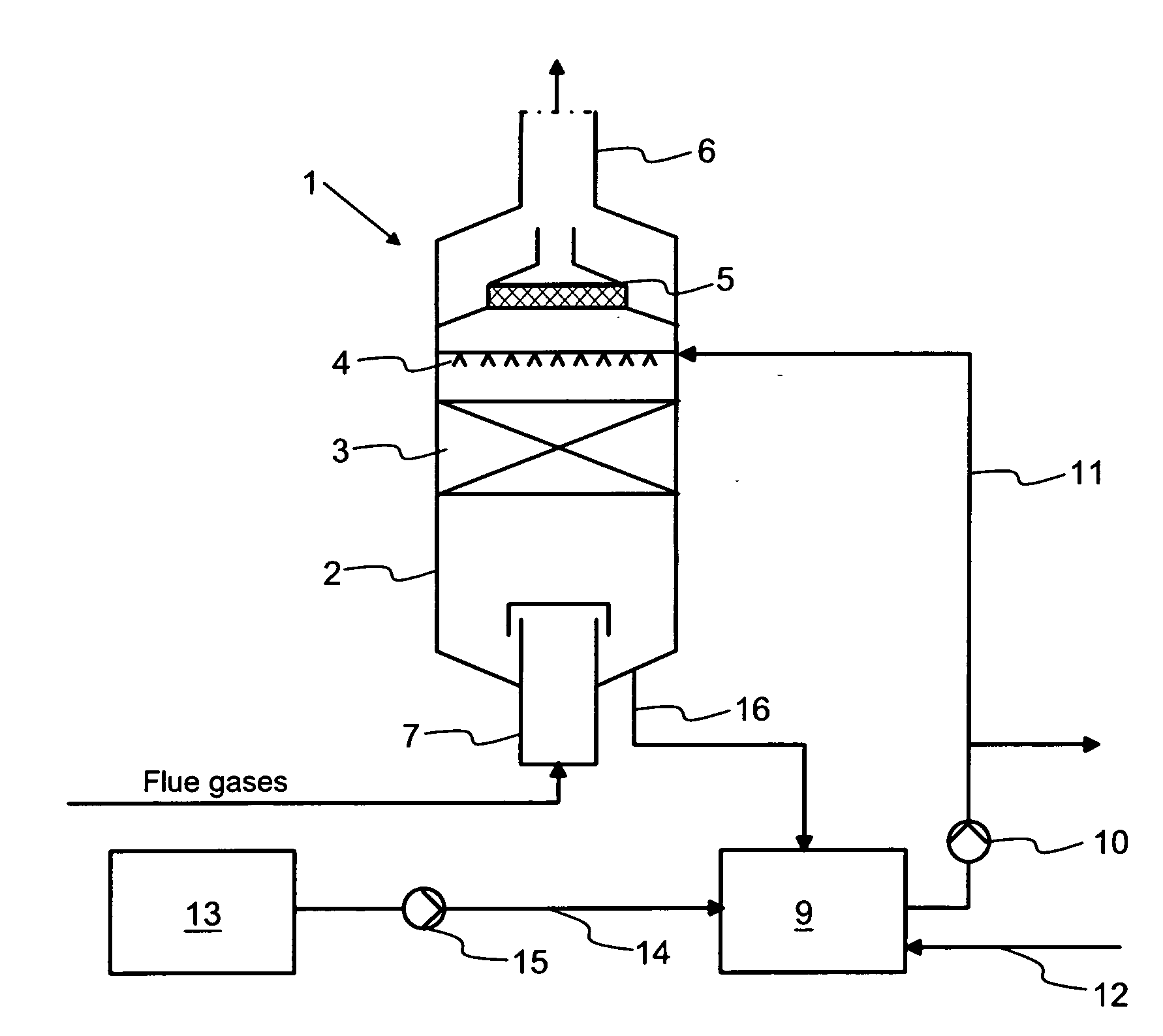

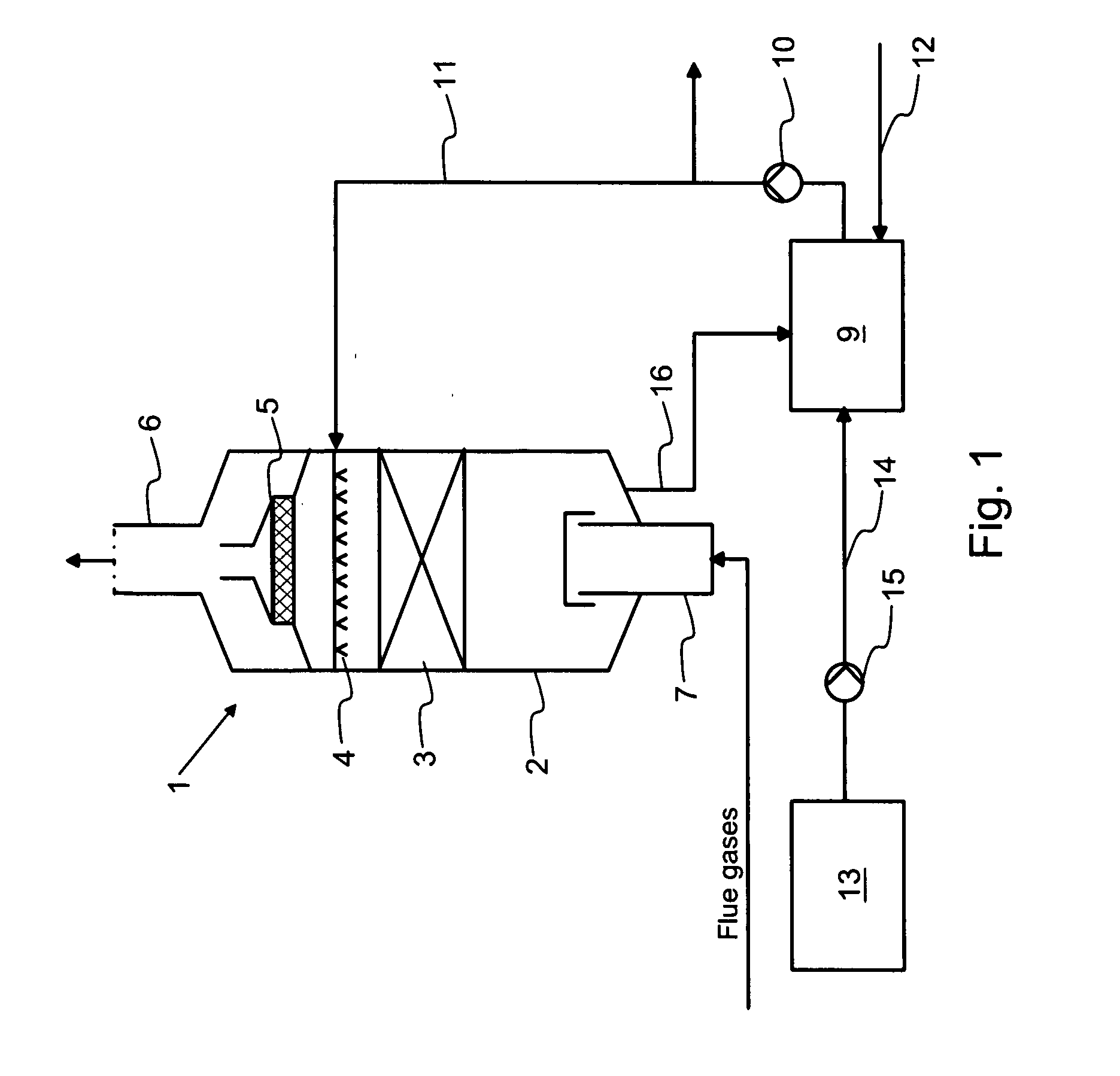

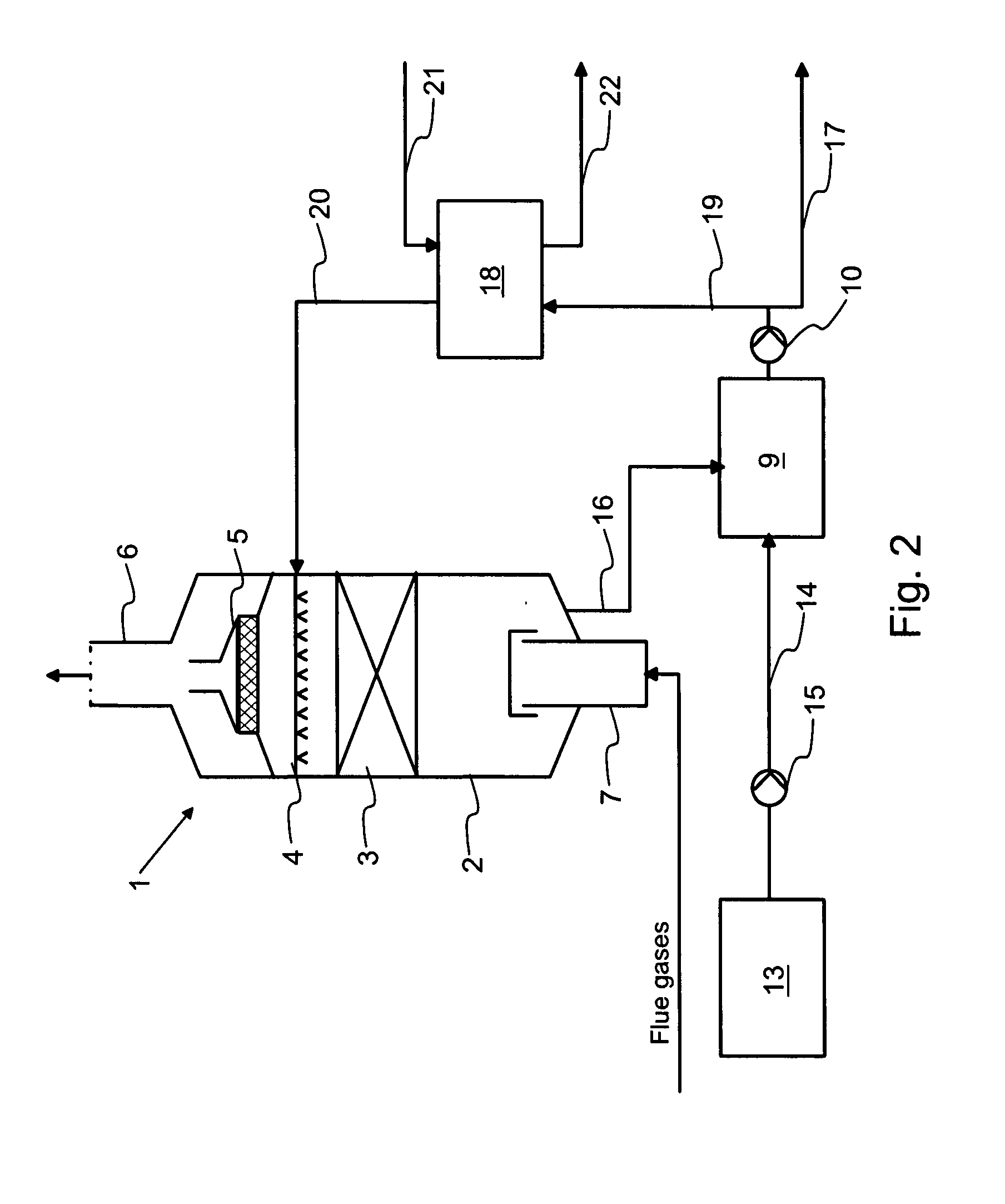

Method and an equipment for reducing the sulphur dioxide emissions of a marine engine

ActiveUS20080044335A1Reduce usageEmission reductionCombination devicesInternal combustion piston enginesSulfurFlue gas

A method and an equipment for reducing sulphur dioxide emissions of a marine engine, wherein flue gases are scrubbed with a scrubbing solution in a scrubber. Fresh water with added sulphur removal reagent is used as the scrubbing solution.

Owner:METSO POWER OY

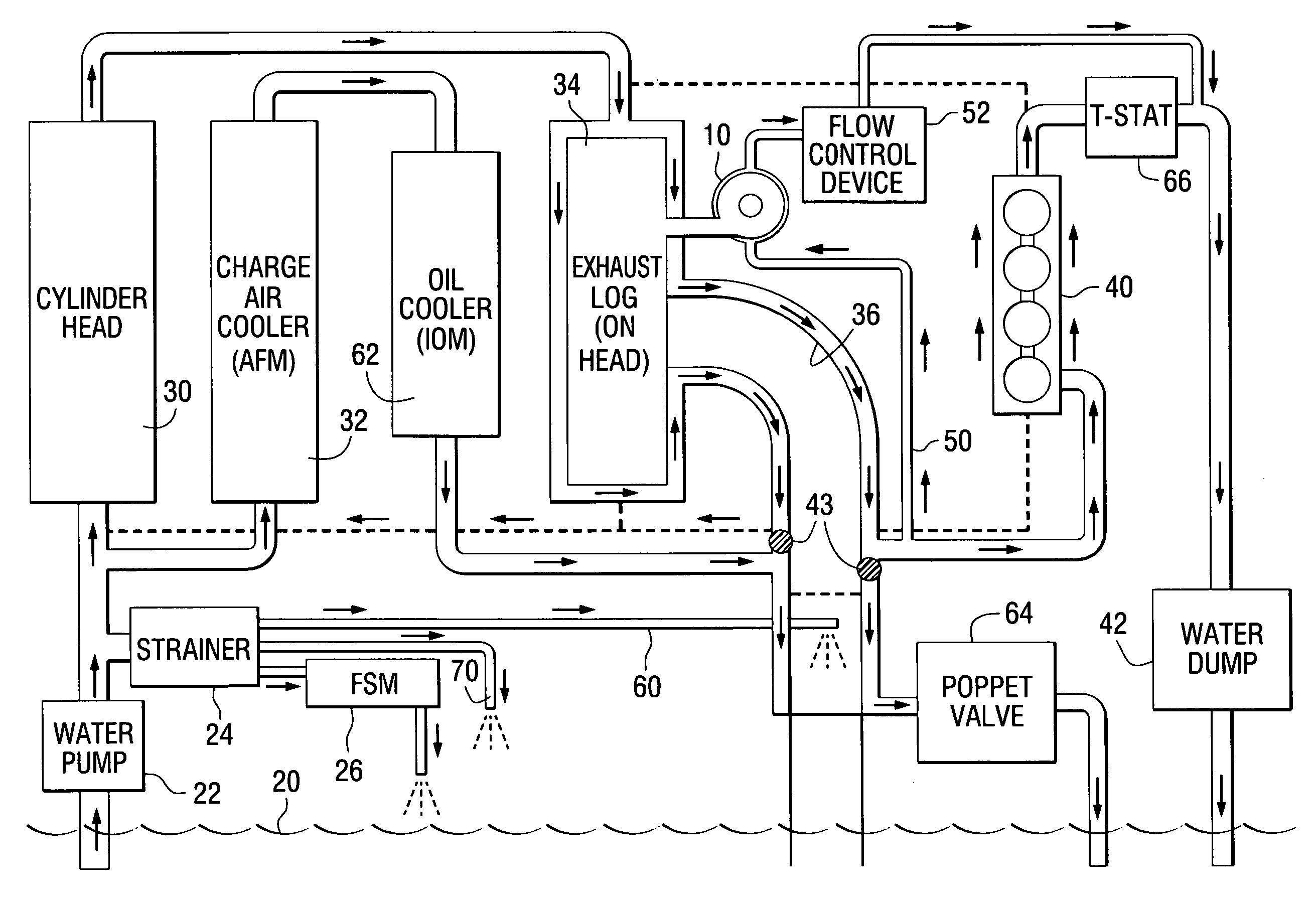

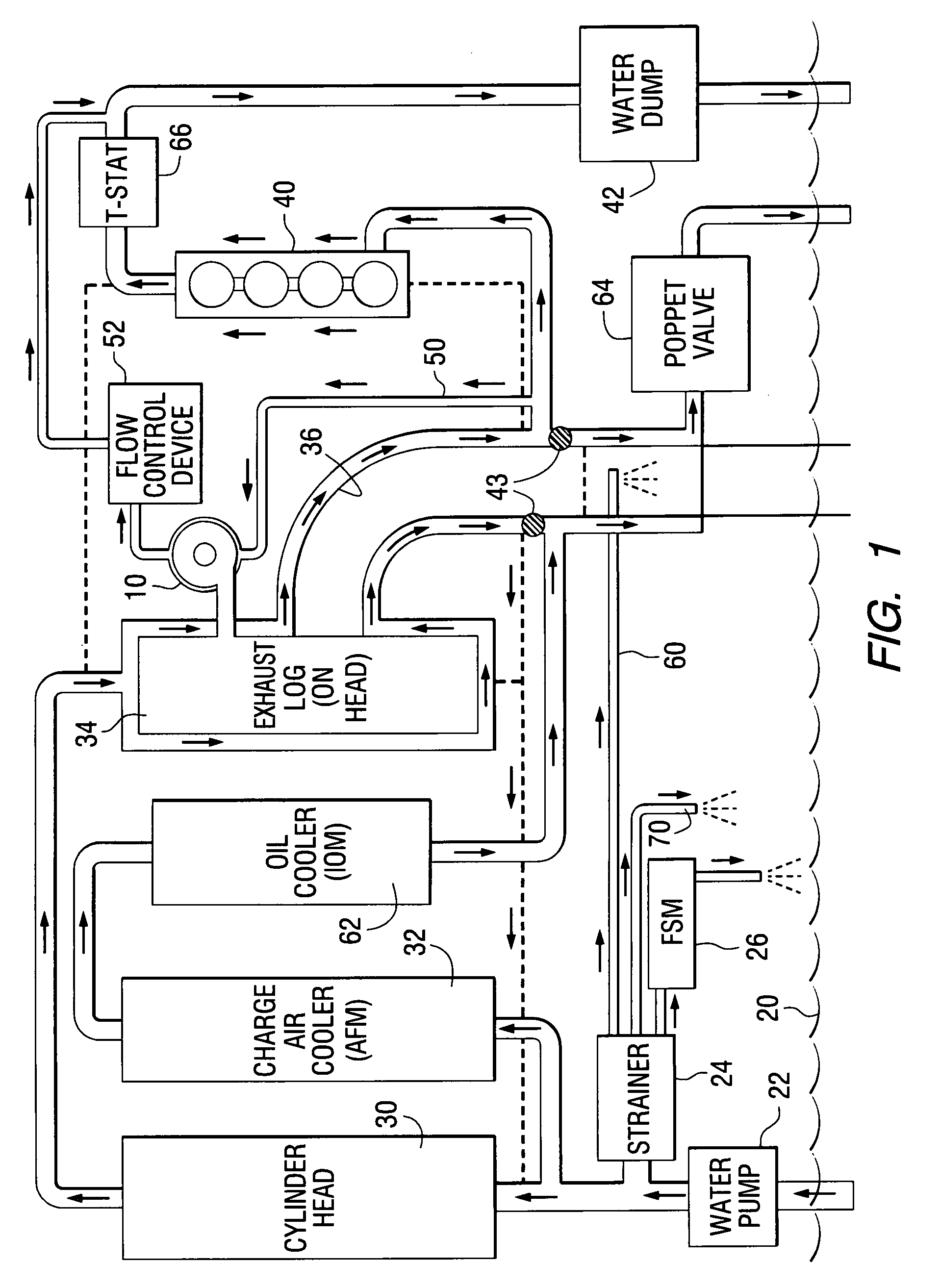

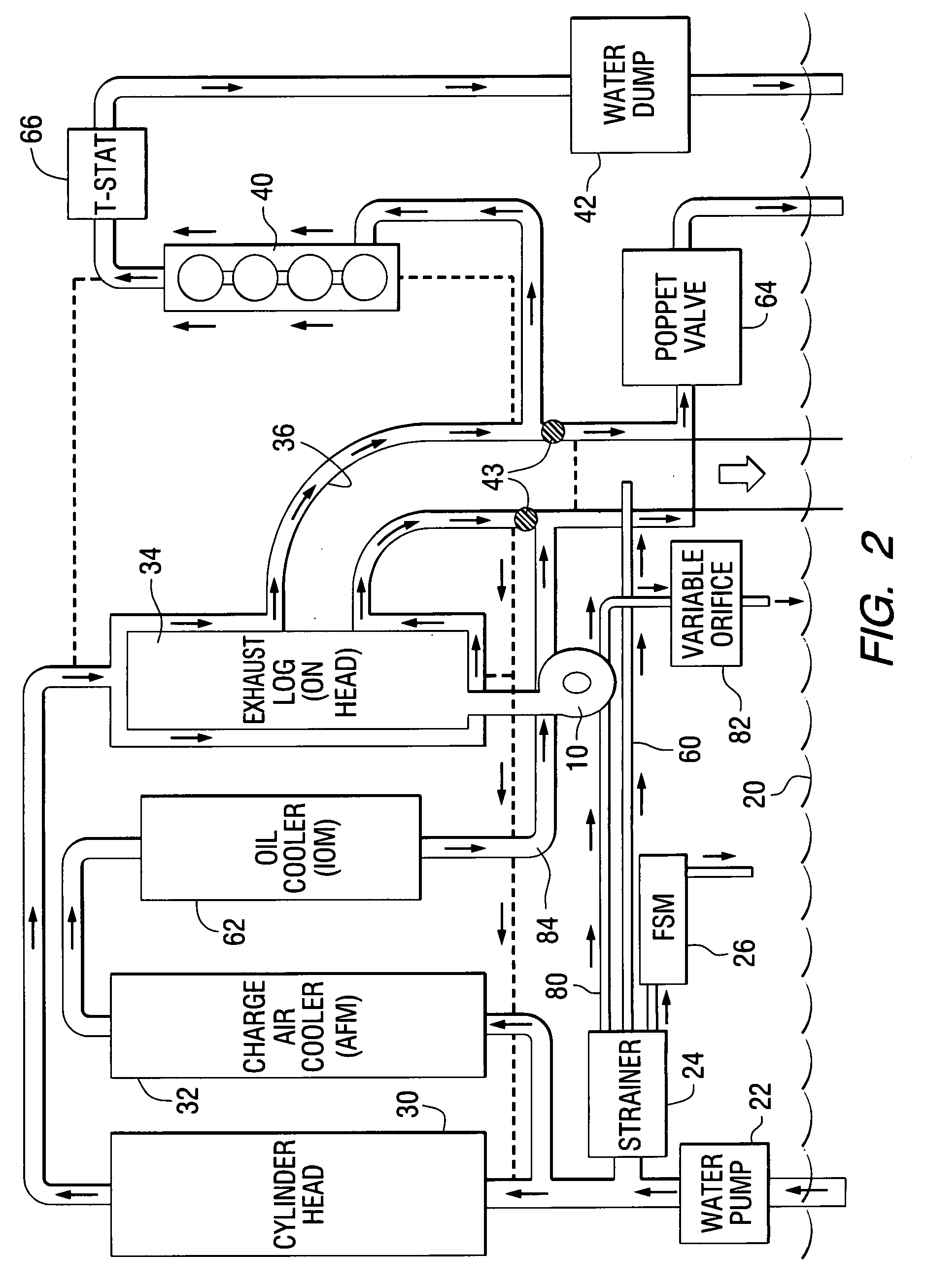

Cooling system for a turbocharged marine propulsion device

A cooling system for a marine engine having a turbocharger provides for the flow of coolant through heat emitting objects prior to flowing through a coolant jacket of the turbocharger itself. This avoids the potentially disadvantageous circumstance of directing cold water directly from a body of water through the cooling jacket of the turbocharger. Both open loop and closed loop versions of the invention are illustrated and described.

Owner:BRUNSWICK CORPORATION

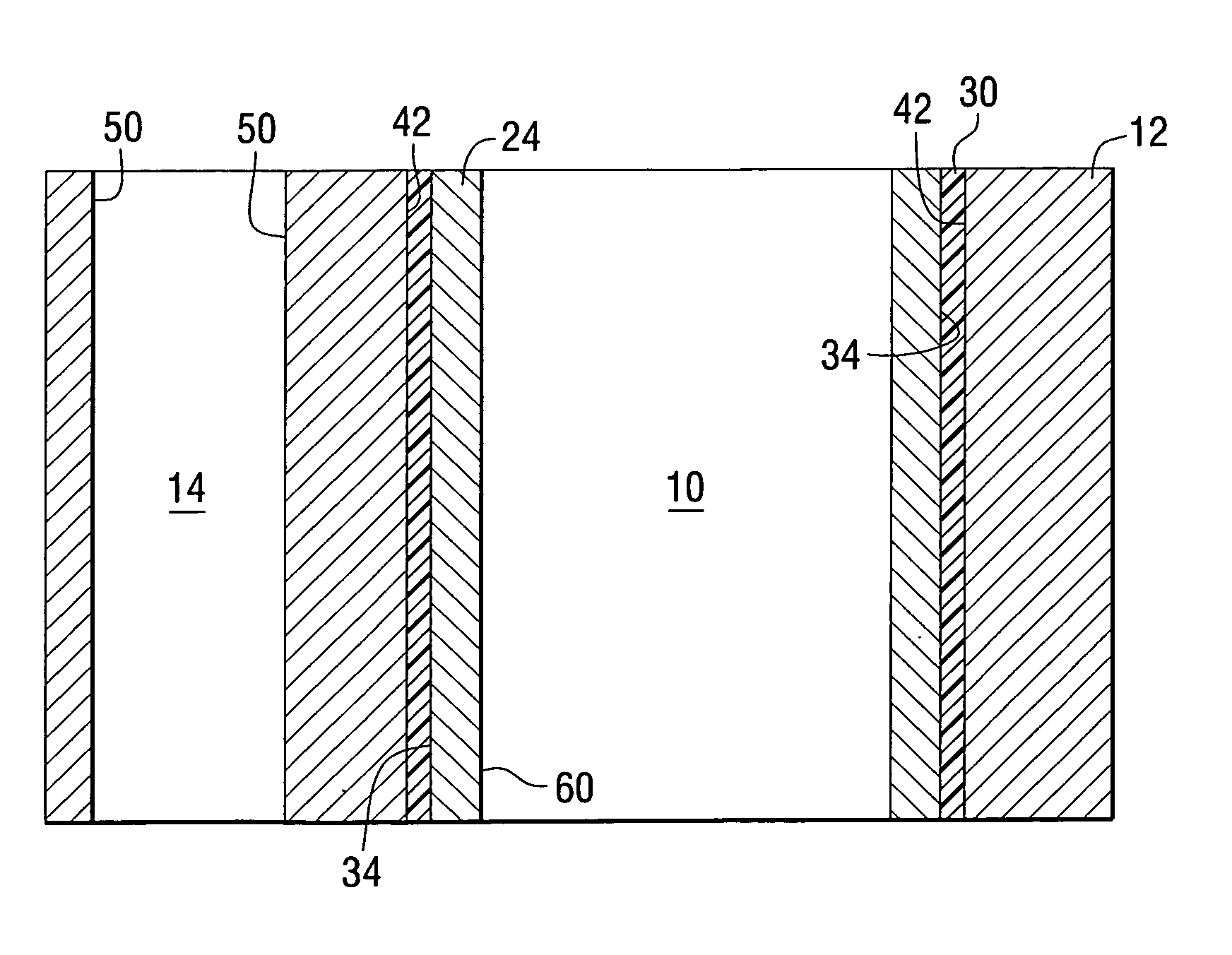

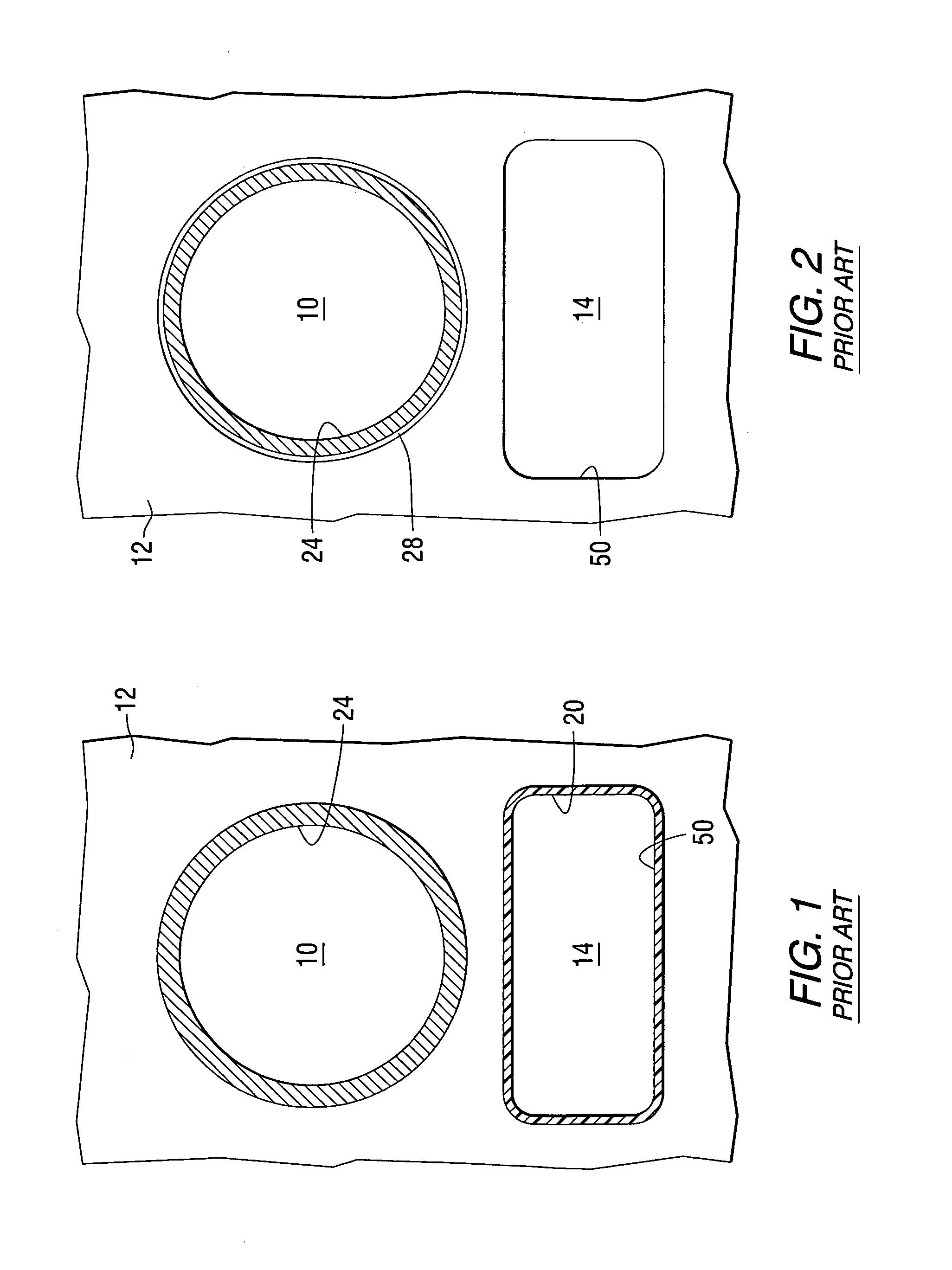

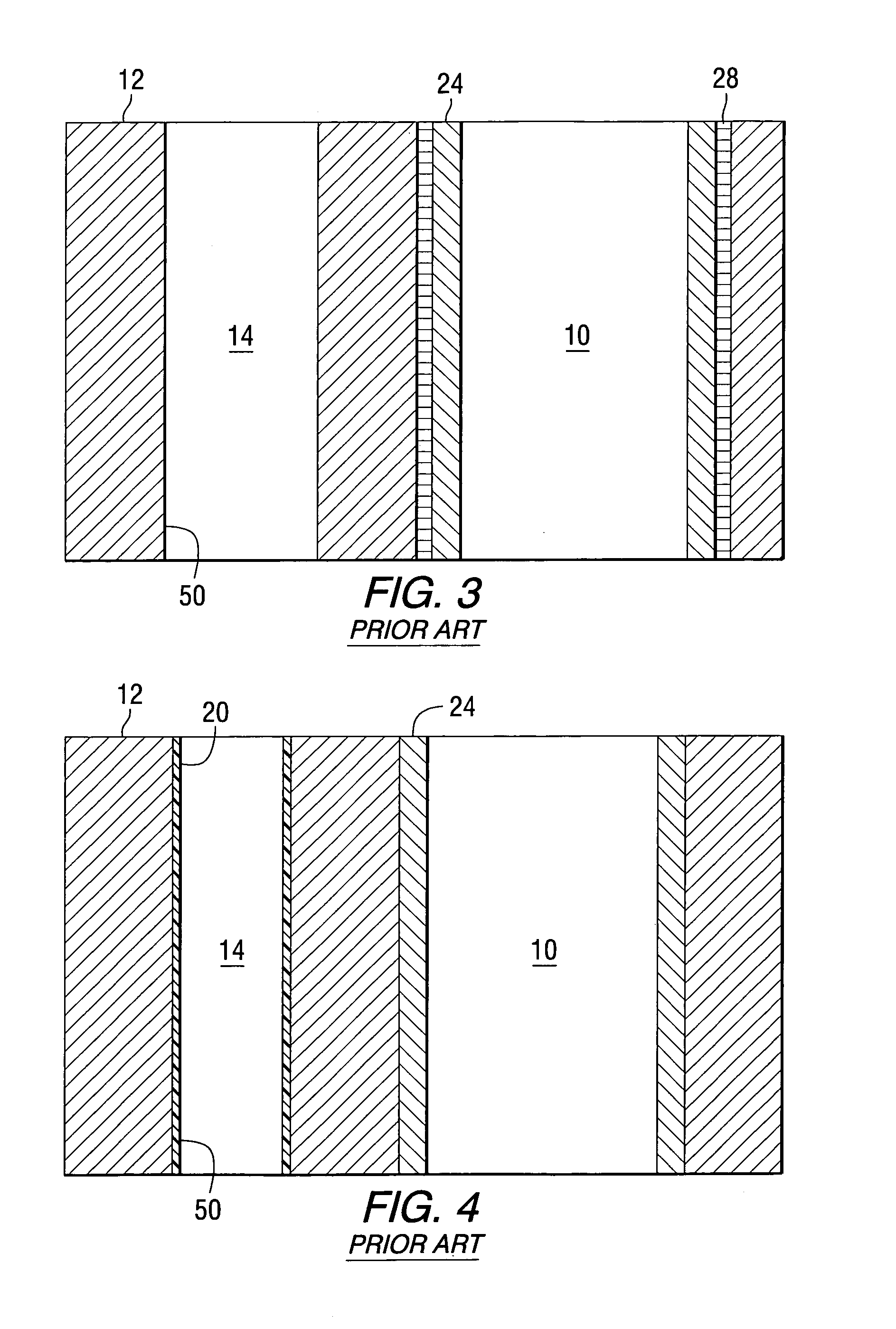

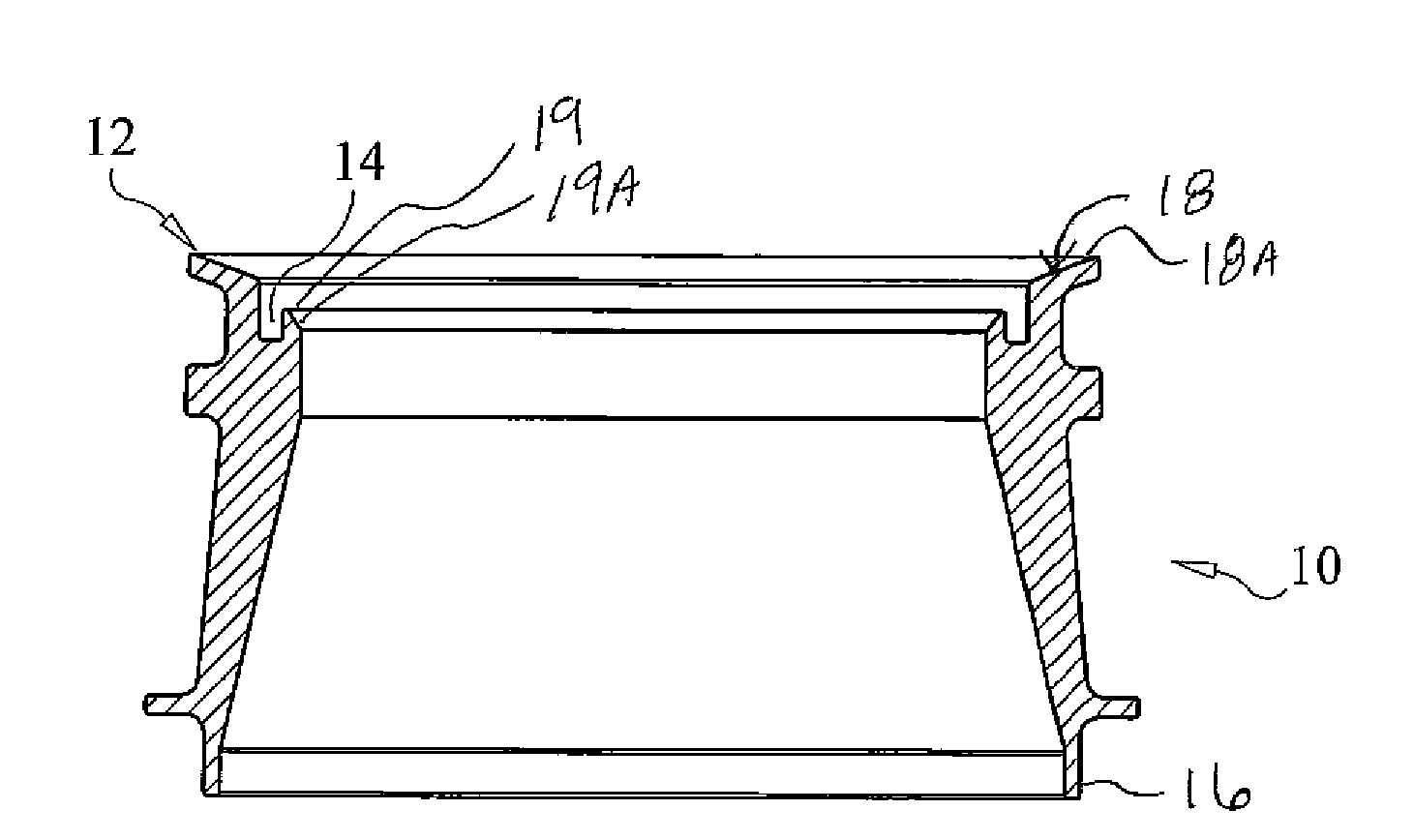

Insulated cylinder liner for a marine engine

InactiveUS7191770B1High glass transition temperatureCylinder headsCylindersPolyethylene terephthalateEngineering

An engine is made by providing a layer of material between the outer surface of a cylinder liner and the inner surface of the cylinder opening within an engine block. The material can be a polymer or a ceramic. Polyether ether ketone or polyethylene terephthalate can be a polymer used for these purposes. Zirconia or yttria can be ceramic used for these purposes. An electro-deposited paint can serve as the layer of thermally insulative material.

Owner:BRUNSWICK CORPORATION

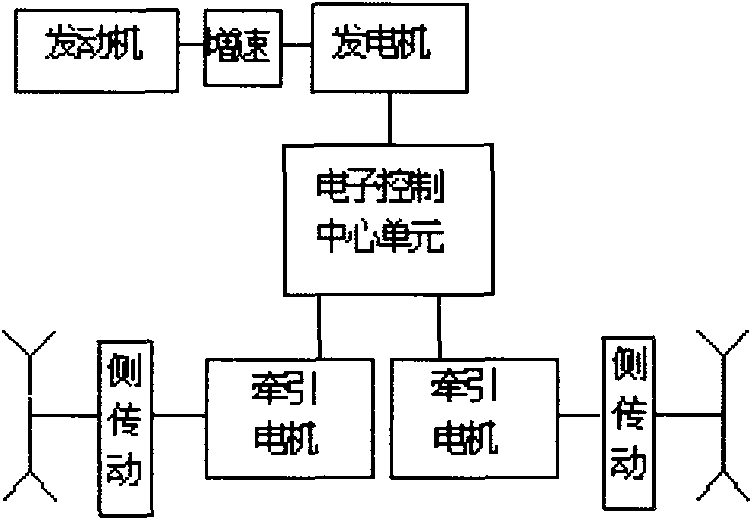

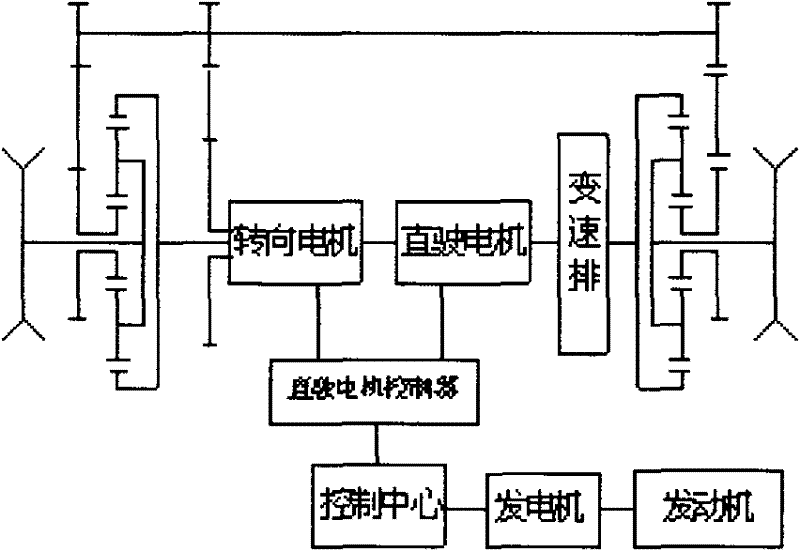

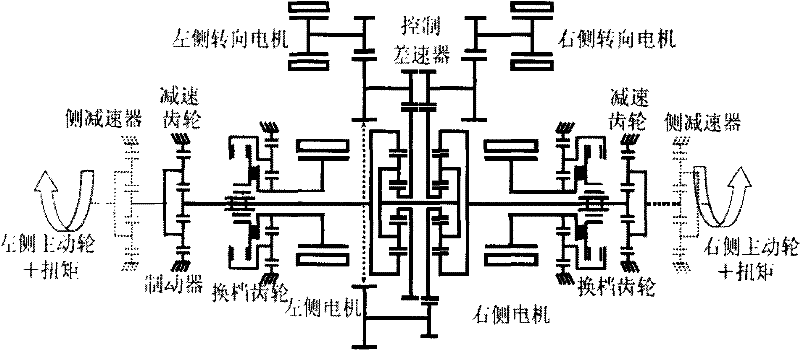

Electromechanical compound transmission device of tracked vehicle

ActiveCN102229319AReduced drive power requirementsReduce development difficultyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectricityPower coupling

The invention relates to an electromechanical compound transmission device of a tracked vehicle and belongs to the field of arrangement or installation of automobile transmission devices. The transmission device is composed of two motors, a planetary gear shift mechanism and a power coupling mechanism; when the tracked vehicle runs straight, the transmission device provided by the invention controls the two motors to be at the same speed; and when the tracked vehicle changes the direction, one part of overturning circulation power at the inner side is recycled as electric power and transmitted to the motor at the outer side by taking the motor at the inner side as a power generator, one part of the overturning circulation power is output to an outside tracked belt through a power coupling mechanism in a mechanical mode, and the power driving requirement of the motor at the outer side is reduced. Through the transmission device provided by the invention, the high requirements for the motors by a double-side motor individual driving type are reduced, the system power waste for the horizontal-axis zero speed difference electromechanical compound driving type is avoided, the overturning system with double-flow transmission for the traditional tracked belt is saved, thus the system efficiency is utilized fully, the device has the advantages of flexible arrangement, small general size and the like, and the device is extremely suitable for high-power tracked vehicles.

Owner:CHINA NORTH VEHICLE RES INST

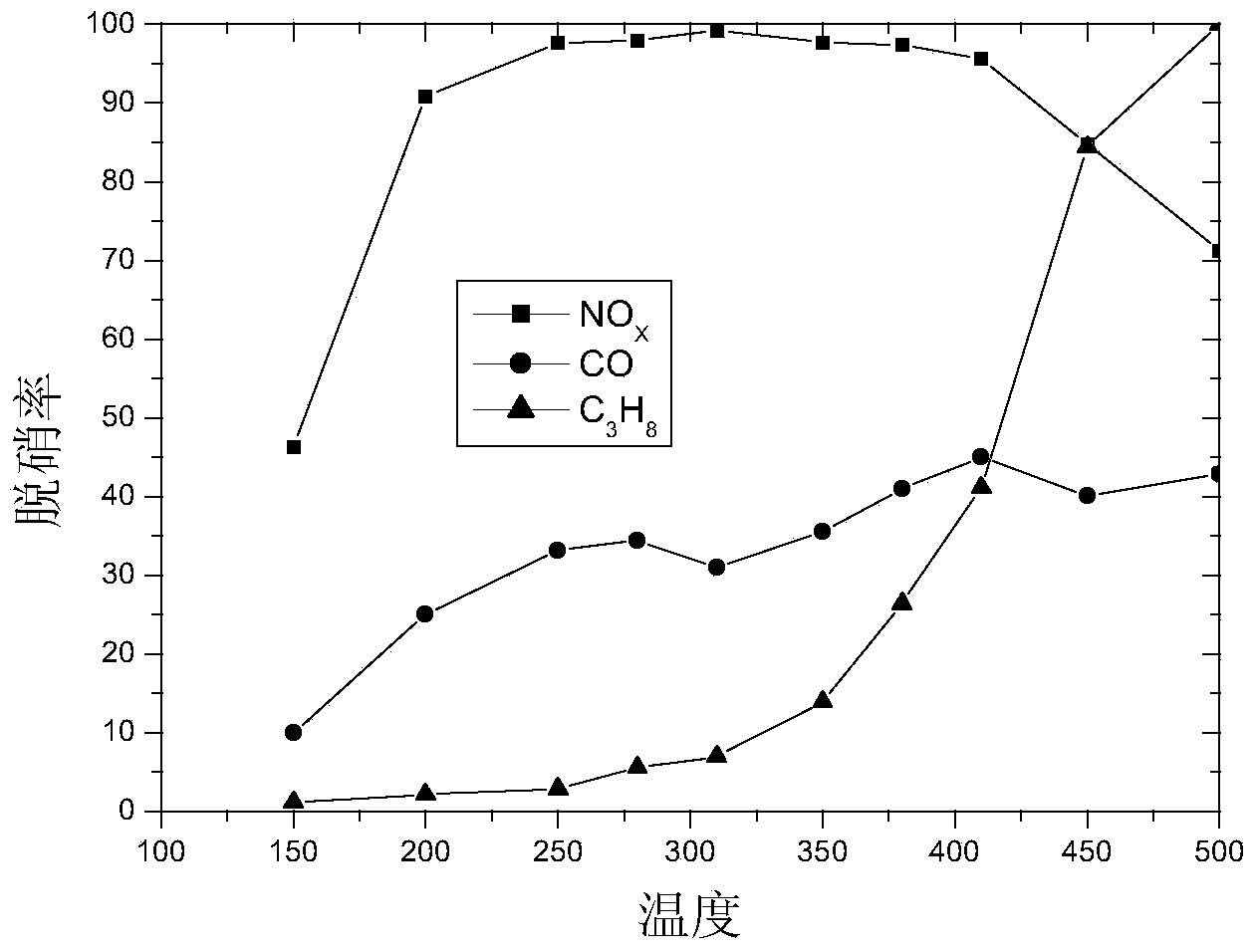

Three-way NOx, CO and HC removing catalyst used in marine engine, and preparation method thereof

ActiveCN103433028AImprove denitrification activityComponents are non-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCobalt

The invention relates to a three-way NOx, CO and HC removing catalyst used in a marine engine, and a preparation method thereof. The catalyst takes cerium-tin-tungsten composite oxide as an active component, takes one or more oxides of cobalt, ferrum, nickel, copper, lanthanum, molybdenum, manganese, zirconium, silver and yttrium as a promoter, and takes AlSiTi composite oxide as a carrier. A saturated active component solution, a saturated cobalt promoter ionic solution, strong acid alumina gel, diaspore, clayey, titanium dioxide and an organic forming agent are stirred uniformly, mixed, aged and extruded for formation, and the integral type catalyst is obtained through drying and roasting. According to the invention, the catalyst has high NOx removing efficiency, the active temperature window is wide, and the CO and HC removing efficiency is high in a low-temperature collaborated catalyzing manner. According to the catalyst, as the components of the catalyst are nontoxic and environmental-friendly, the catalyst has the advantages that the mechanical strength is high, the vibration resistance as well as the heat resistance is excellent, the preparation technology is simple, and the cost is low. The three-way NOx, CO and HC removing catalyst is applicable to treatment of NOx, CO and HC in tail gas of a marine diesel engine, and is also applicable to treatment to tail gas of other moving sources diesel engines such as automobiles.

Owner:南京环福新材料科技有限公司

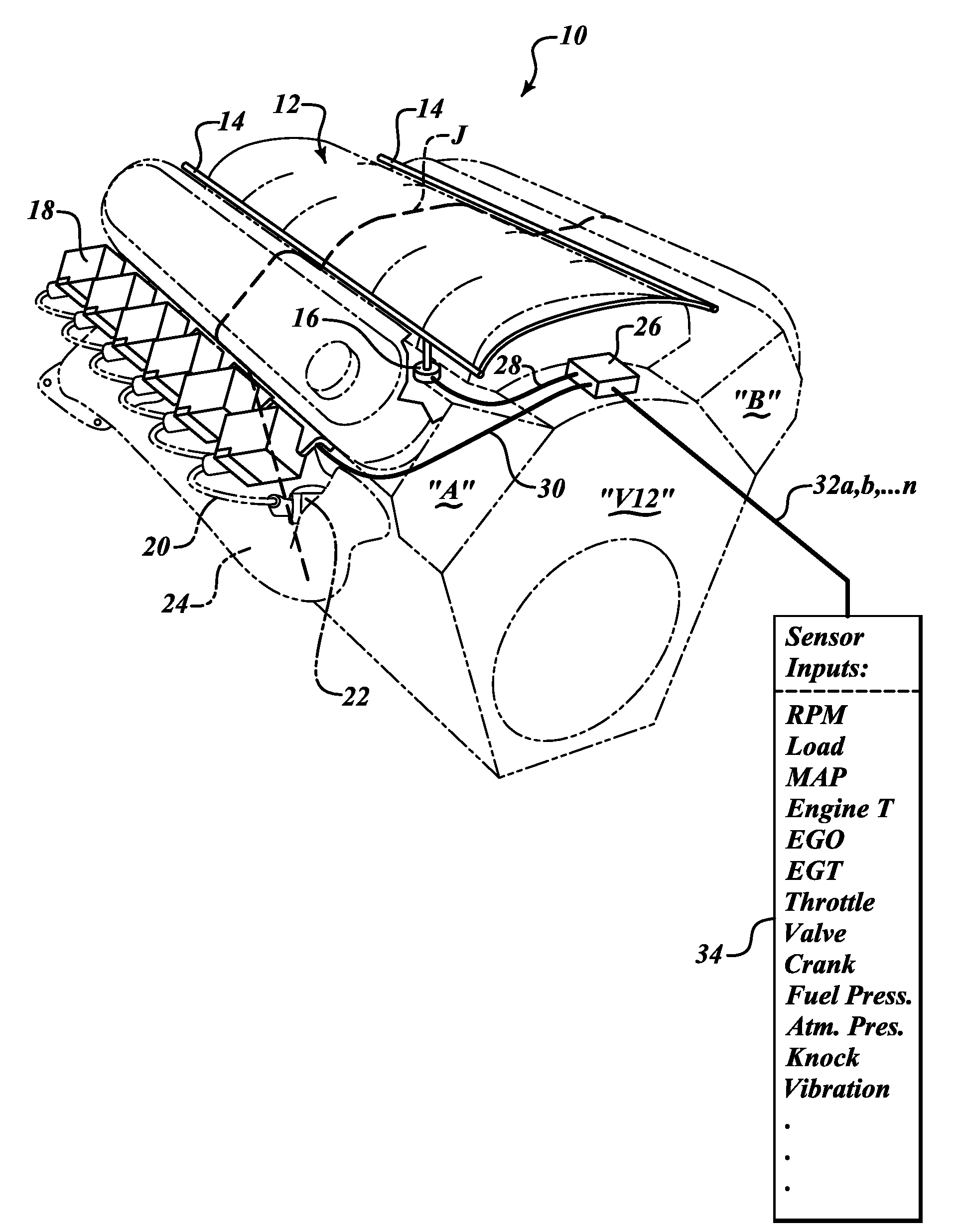

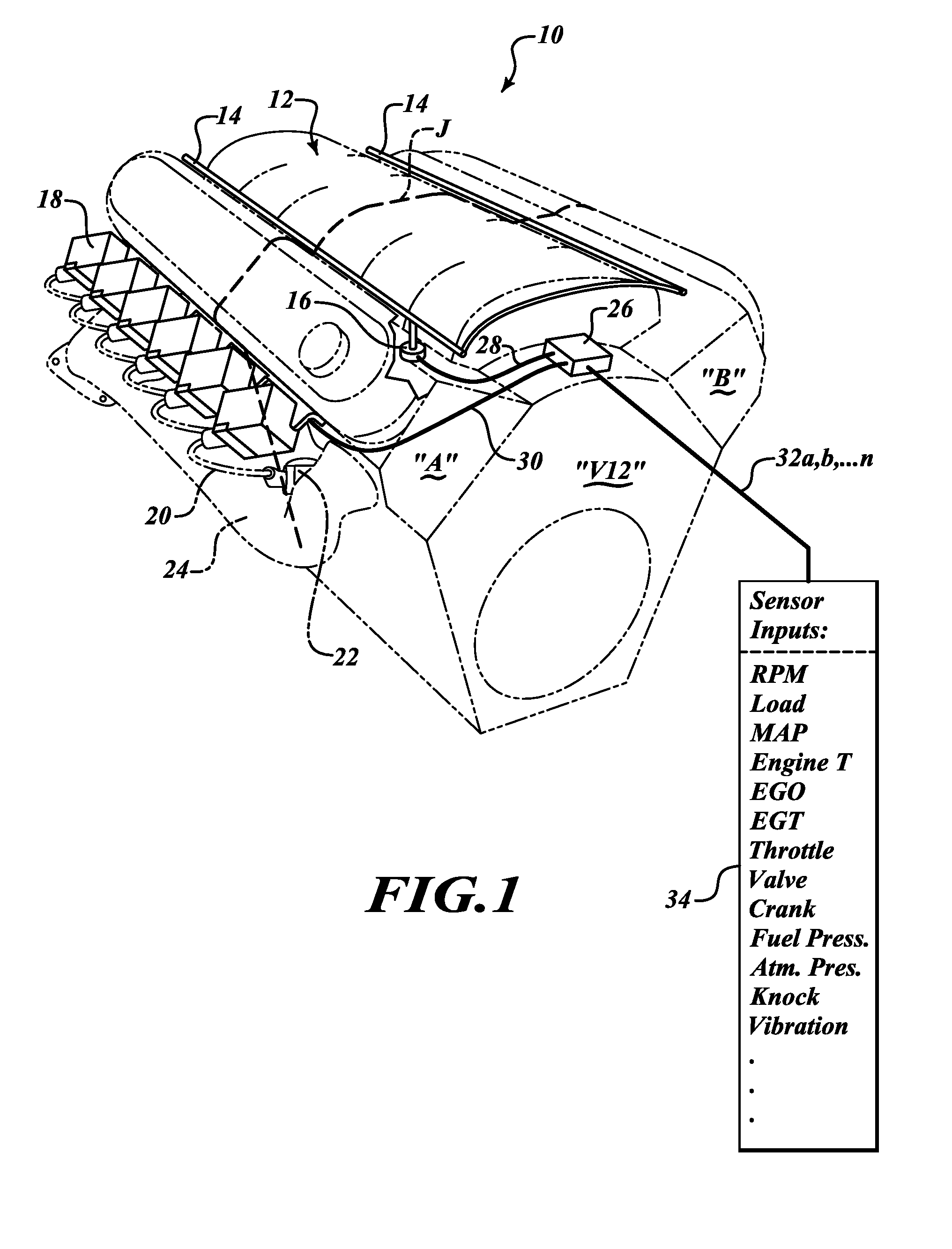

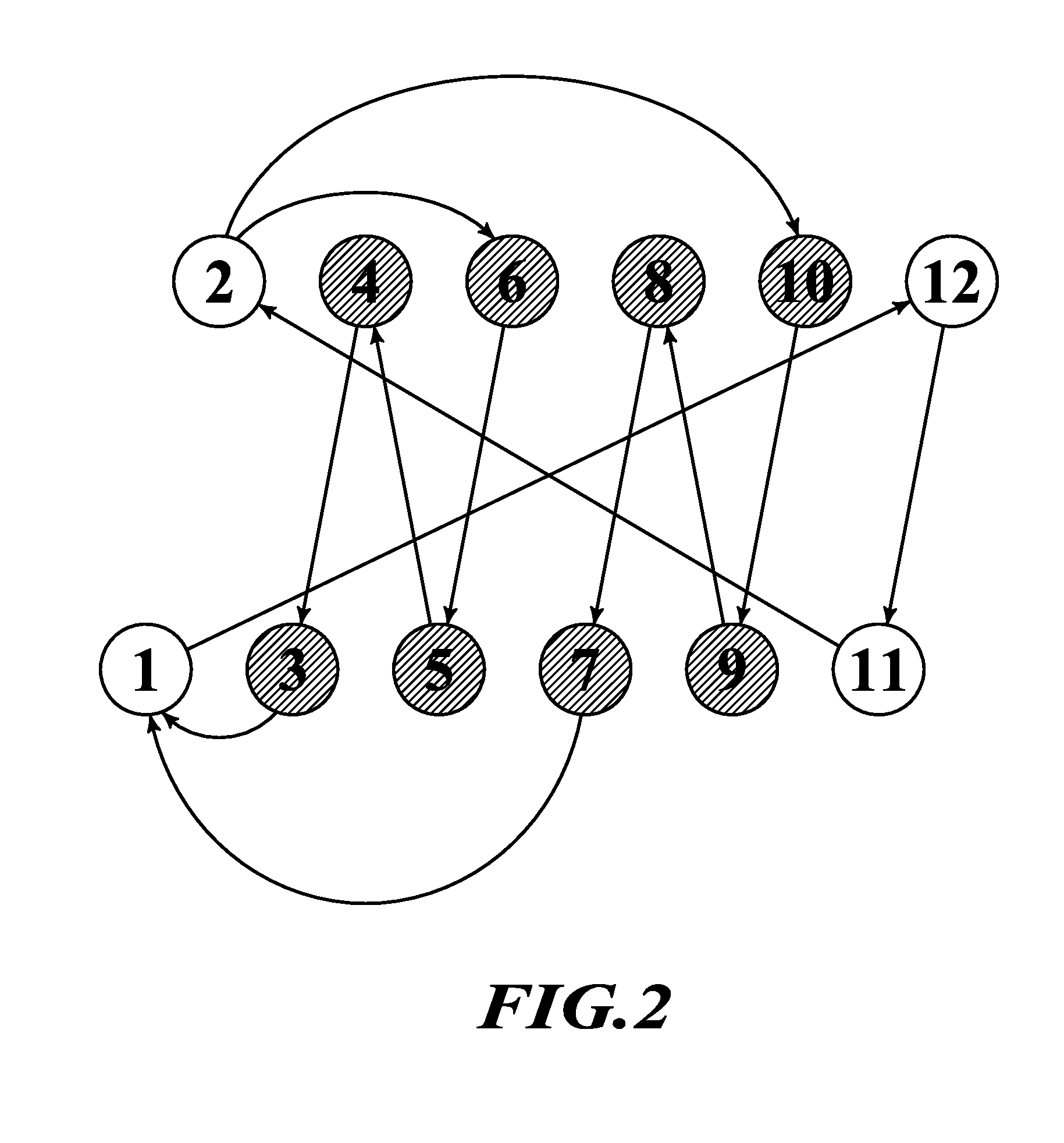

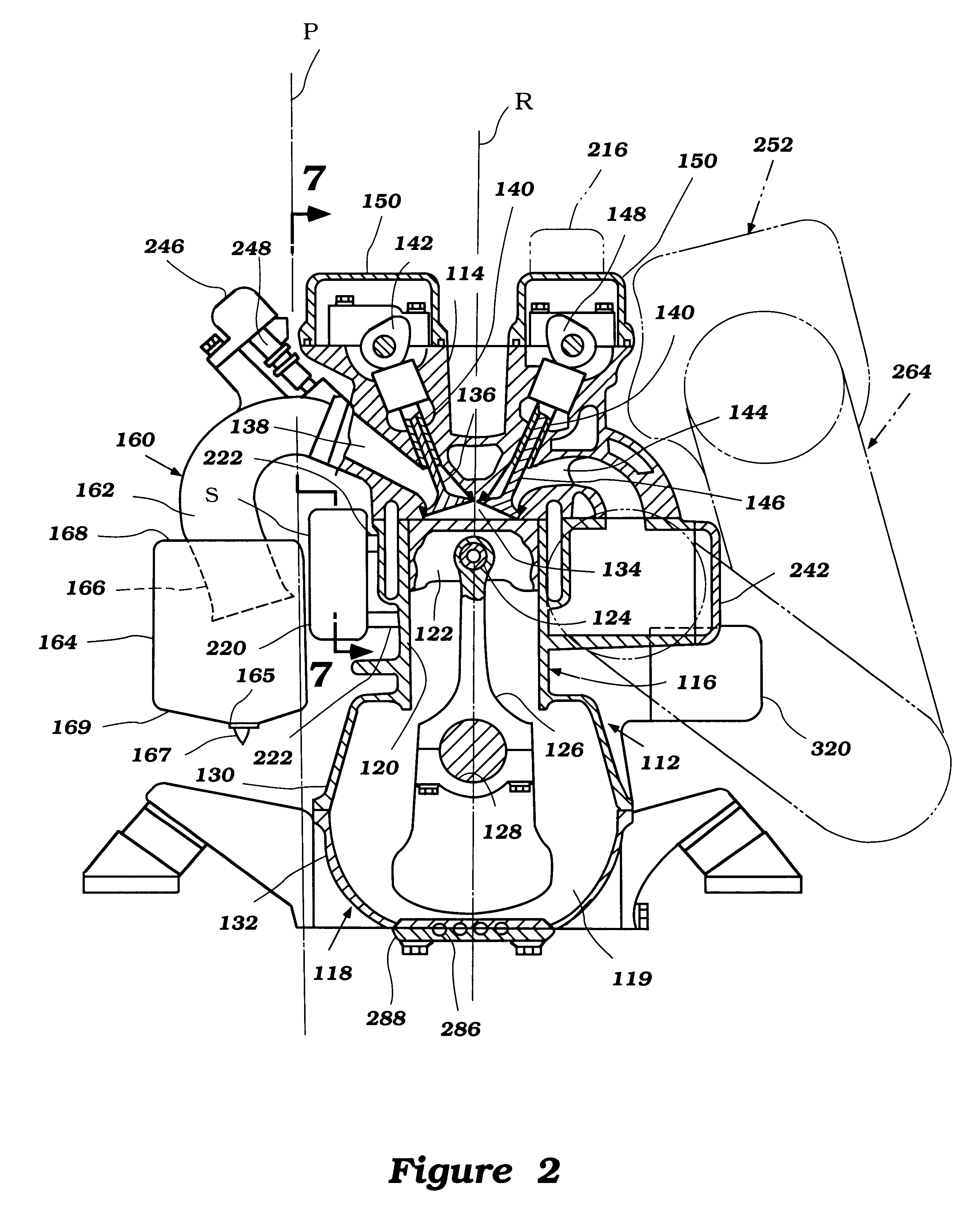

Even fire 90a°v12 IC engines, fueling and firing sequence controllers, and methods of operation by ps/p technology and ifr compensation by fuel feed control

InactiveUS20090099755A1Sure easyEmission reductionElectrical controlElectric ignition installationAirplaneAutomotive engine

90° V12 reciprocating, EFI / DIS fueled / fired, IC engines having a PCM controller operating the engine in an Even Fire ignition mode, in a novel fueling and firing sequence called Progressive Single / Pair (PS / P) firing, wherein the cylinders of each of a set of four pairs of internal cylinders are simultaneously fueled and fired in parallel to produce a pump-gas fueled power curve greatly improved over V6 and V8 engines. The inherent imbalance-induced transitory vibration in IFR RPM is compensated-for by fuel feed control, namely, leaning one cylinder of each pair-fired cylinder pair. The inventive 90° V12 retro-fits into the engine compartment of conventional vehicles and can use any liquid or gaseous fuel. The inventive 90° V12 has use in the exemplary fields of: automotive engines; heavy military and industrial equipment and vehicle engines; marine engines; aircraft engines; and stationary power sources; in both 2-cycle and 4-cycle modes, and in normally aspirated, super-charged and turbo-charged configurations.

Owner:HARBERT RICHARD H

Exhaust system for watercraft

An improved exhaust system for a marine engine utilizes a catalyst positioned within the exhaust system to maximize engine performance while minimizing the deterioration of catalyst. The exhaust system includes an exhaust manifold, an expansion chamber, a water trap and an exhaust pipe connecting the expansion chamber to the water trap. The exhaust pipe includes a catalyst chamber that houses the catalyst in such a way as to minimize the collection of water in the catalyst chamber as well as to inhibit a back flow of water to the catalyst chamber. The expansion chamber and the exhaust pipe are preferably fixed to the body of the engine to reduce vibration generated by the passage of the exhaust gases through the exhaust system.

Owner:YAMAHA MOTOR CO LTD

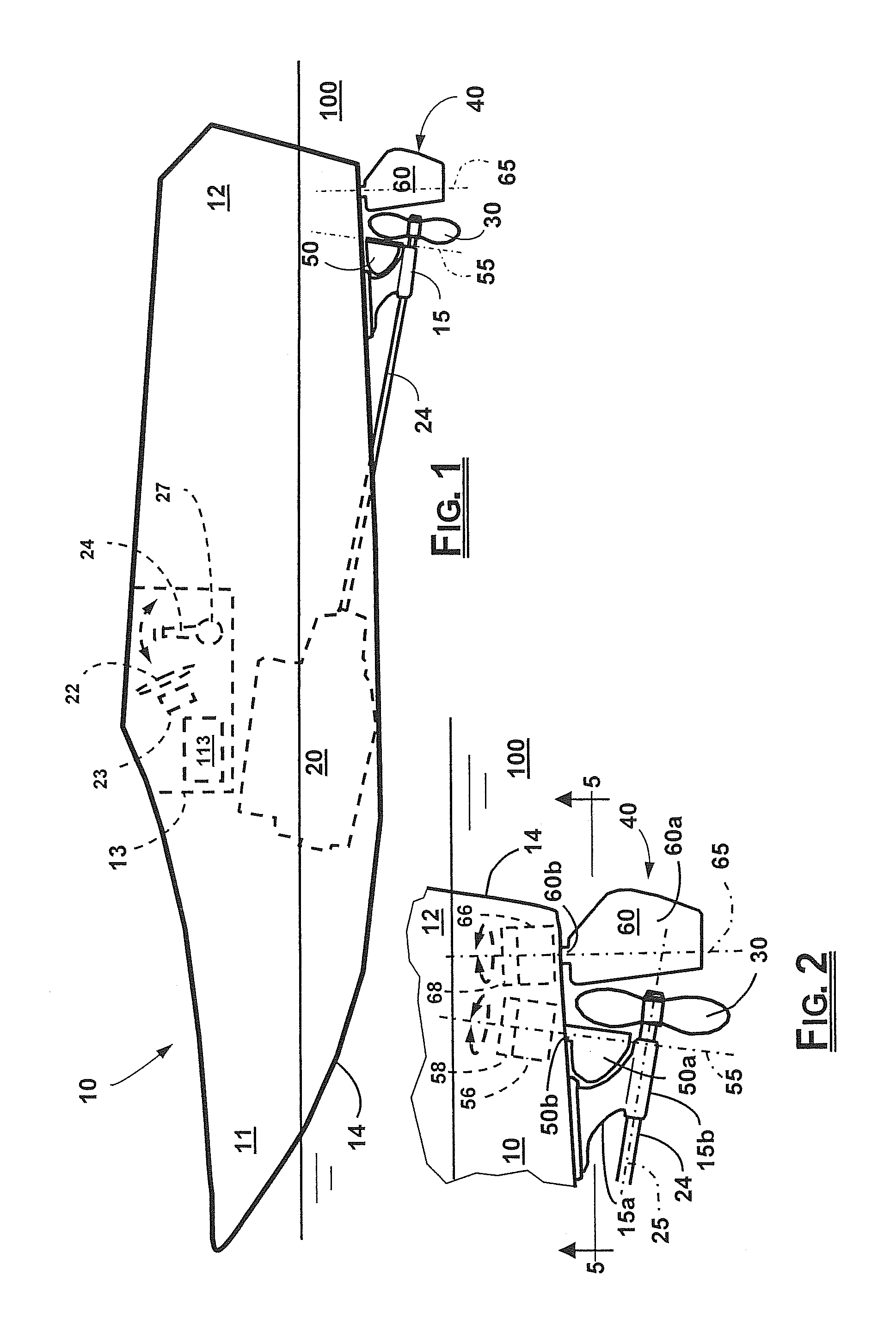

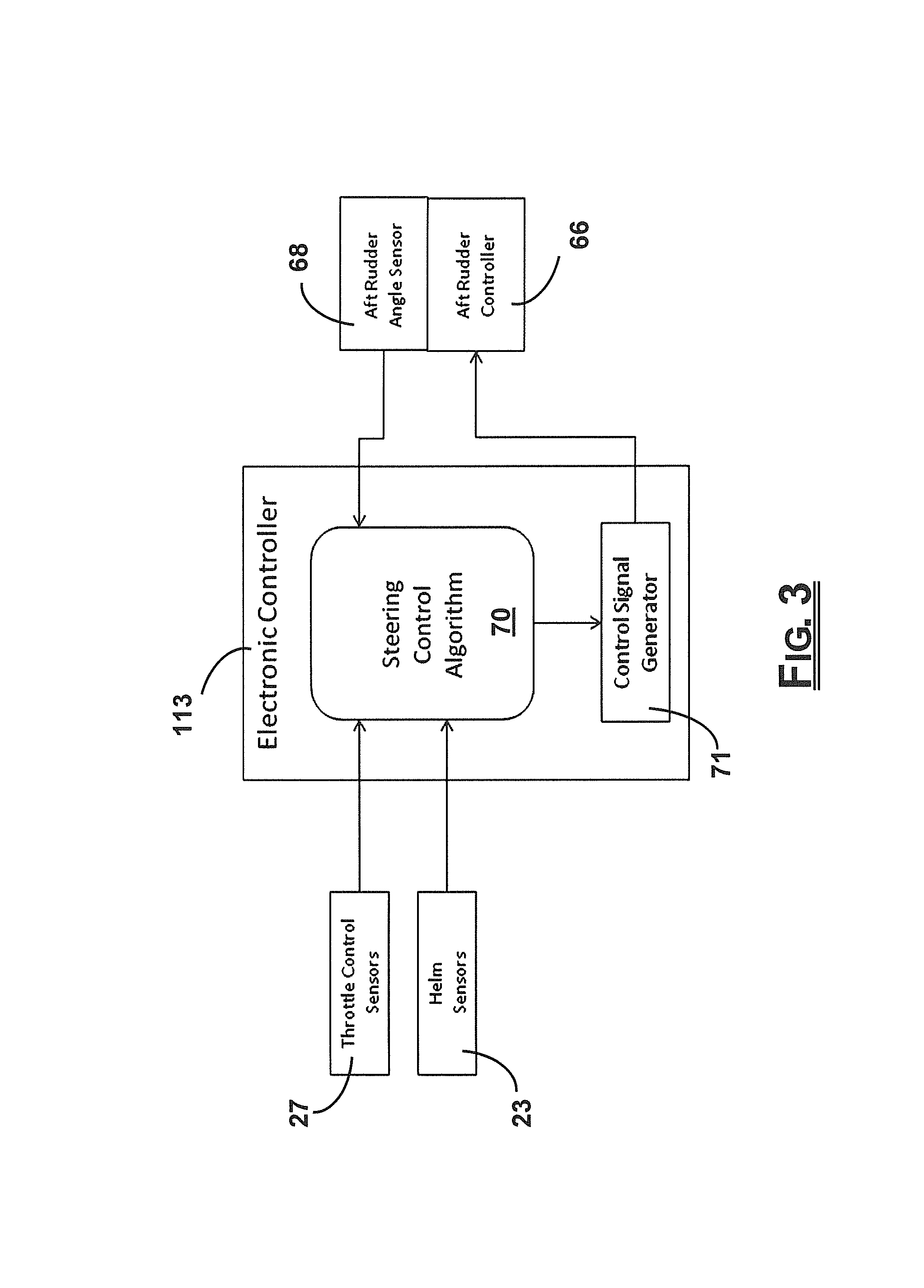

Dual rudder watercraft steering control system for enhanced maneuverability

ActiveUS8943988B1Easy steeringImprove the forceSpeed controllerSteering ruddersThrottle controlElectronic controller

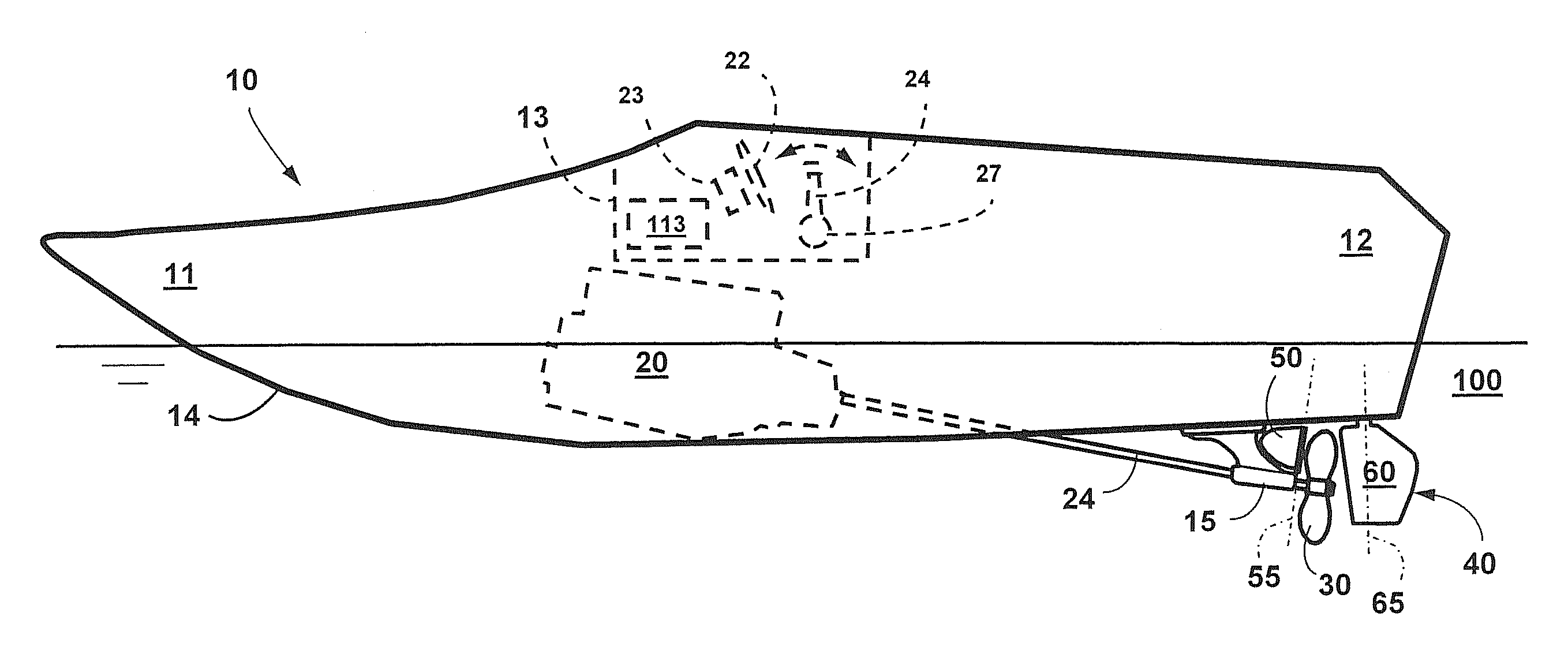

A steering control system for ski boat with an inboard motor and a single, non-steerable propeller. The control system augments the traditional aft rudder with a forward rudder (located immediately in front of the propeller), and controls one or both rudders to improve steering when backing and in low forward speed conditions. The control system may control only the forward rudder, while the pre-existing controls operate the aft rudder, or optionally controls both rudders. The rudder angle control algorithm calculates proportional rudder angles based on helm and throttle settings, or optimal rudder angles based on more sensed conditions including the operator's helm and throttle controls, the ski boat's direction and speed, propeller RPM and thrust direction, and each rudder's angle. An electronic controller sends control signals to the rudders to achieve the optimal rudder angles.

Owner:ENOVATION CONTROLS

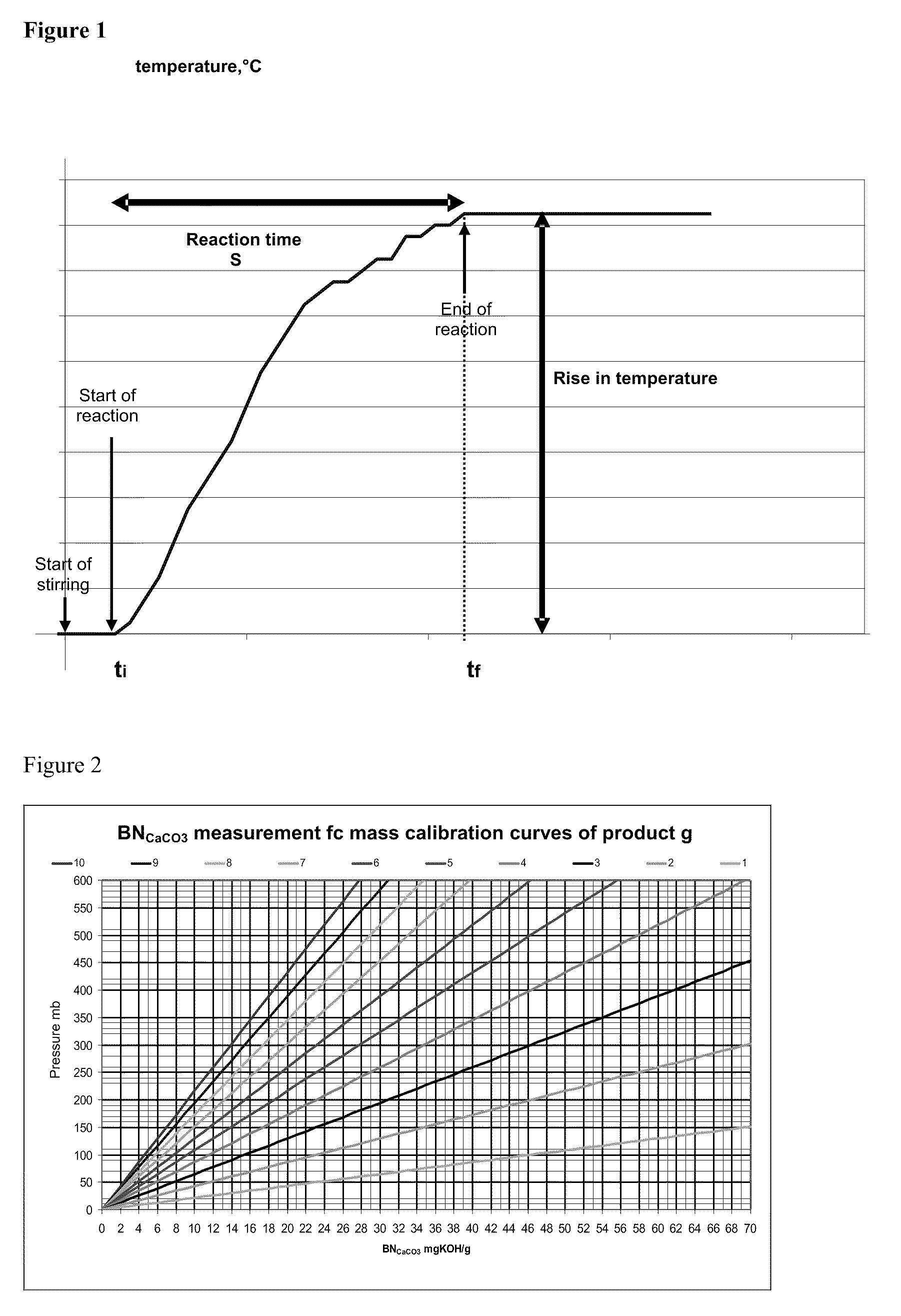

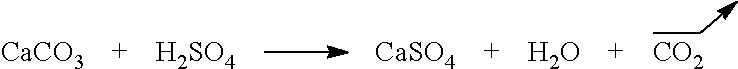

Cylinder lubricant for a two-stroke marine engine

The present invention relates to a cylinder lubricant having a BN determined according to standard ASTM D-2896 greater than or equal to 15, preferably greater than 20, preferably greater than 30, advantageously greater than 40 milligrams of potash per gram of lubricant, comprising:one or more lubricating base oils for marine engines,at least one detergent based on alkali or alkaline-earth metals, overbased with metallic carbonate salts, optionally in combination with one or more neutral detergents,one or more fatty amines and / or derivatives of oil-soluble fatty amines having a BN determined according to standard ASTM D-2896 comprised between 150 and 600 milligrams of potash per gram, preferably comprised between 200 and 500 milligrams of potash per gram.This lubricant has sufficient neutralization power vis-à-vis the sulphuric acid formed during the combustion of high-sulphur fuel oils, whilst limiting the formation of deposits during the use of low-sulphur fuel oils.

Owner:TOTAL RAFFINAGE MARKETING

Small temperature-rise low-entropy mixing combustion engine

InactiveCN102086823AImprove efficiencyPromote environmental protectionInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberEngine efficiency

The invention discloses a small temperature-rise low-entropy mixing combustion engine which comprises a combustion chamber, an expanding agent source and a fuel source, wherein the combustion chamber is arranged as a piston engine combustion chamber and a marine engine combustion chamber; the fuel source is communicated with the combustion chamber through a fuel lead-in control mechanism; the expanding agent source is communicated with the combustion chamber through an expanding agent lead-in control mechanism; and more than 5% of the heat generated by the combustion of the fuel in the fuel source entering the combustion chamber is absorbed by the expanding agent in the expanding agent source in the combustion chamber by virtue of the control of a combustion control device for the fuel lead-in control mechanism and the expanding agent lead-in control mechanism. The small temperature-rise low-entropy mixing combustion engine disclosed by the invention has the advantages of high efficiency and good environmental friendliness.

Owner:靳北彪

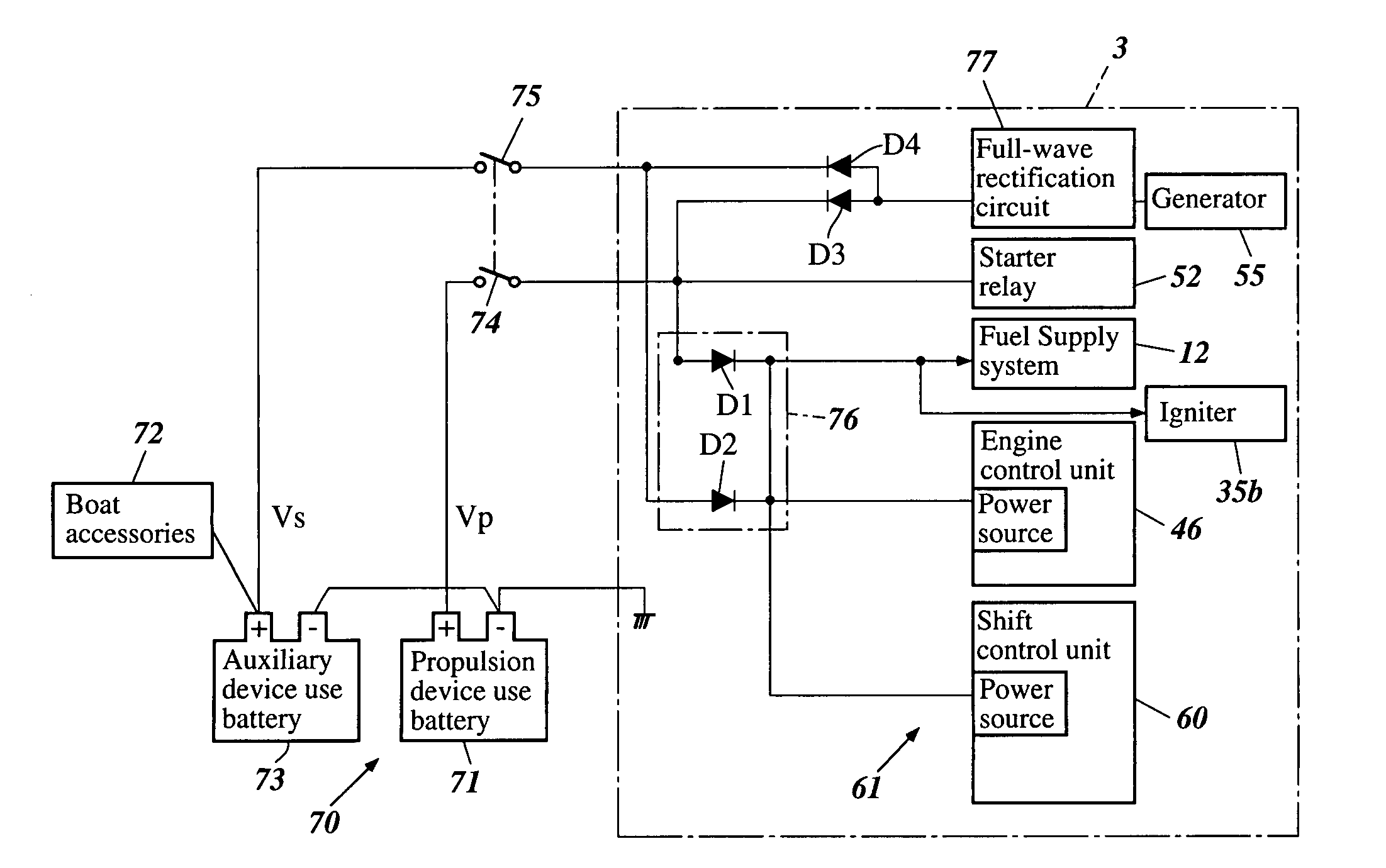

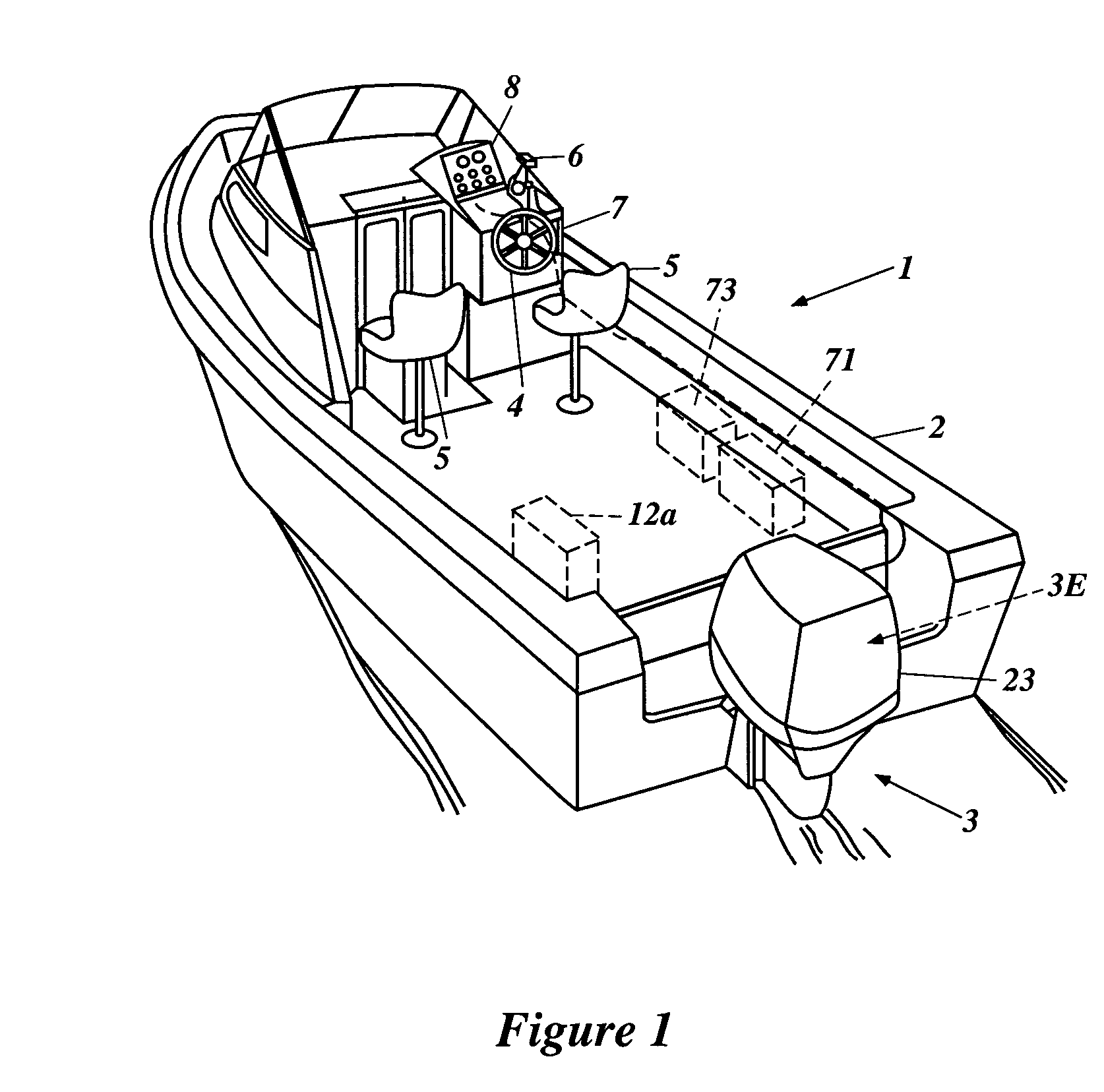

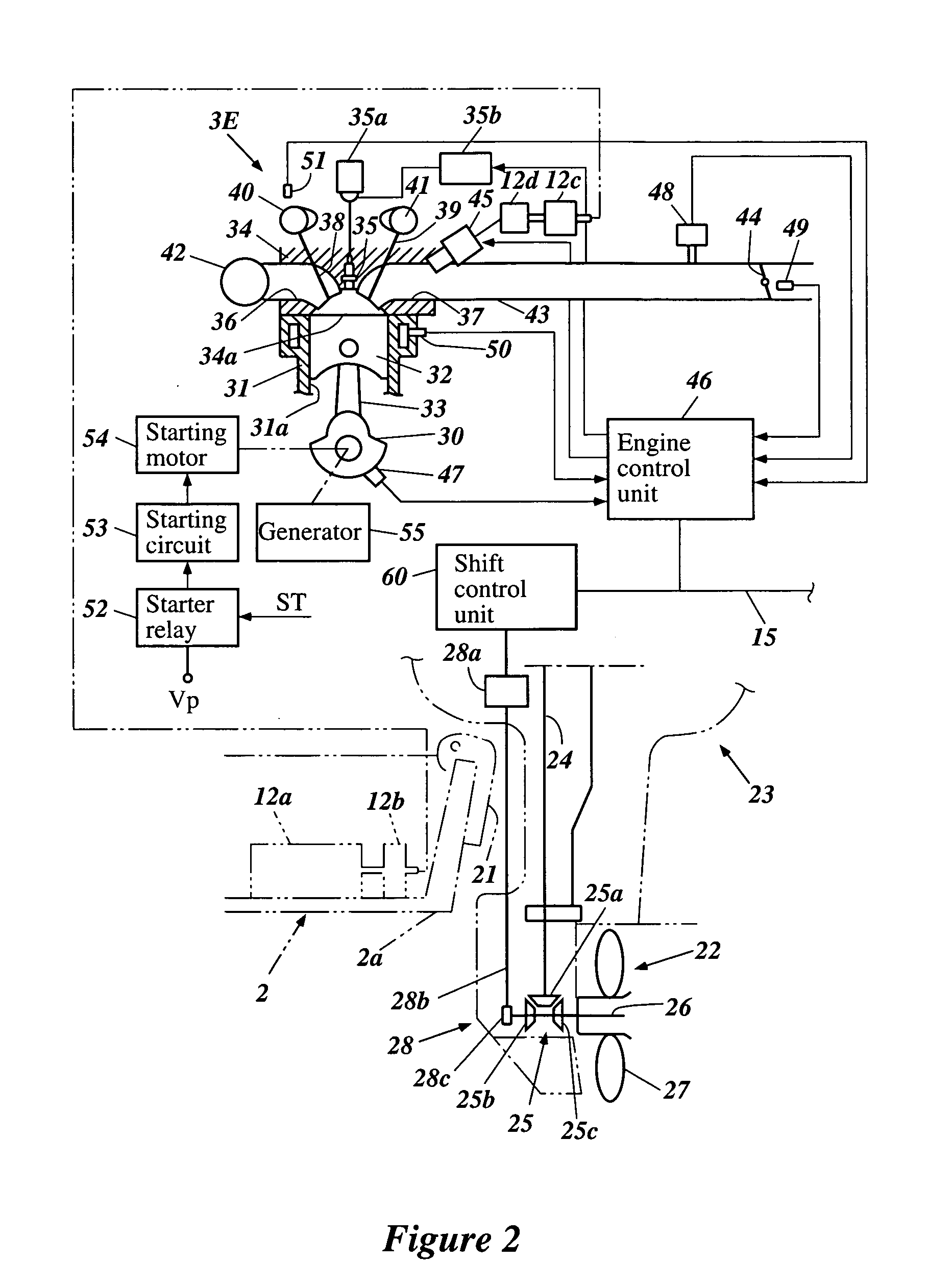

Power source device for boat

InactiveUS20050287880A1Batteries circuit arrangementsPropulsion based emission reductionElectrical batteryVoltage drop

To maintain stabilized operation of a boat engine, a propulsion device may be provided with two separate batteries for different uses in case one of the batteries suffers a voltage drop. A power source device is provided with a propulsion battery for supplying power to engine-related components of an outboard motor and an auxiliary battery for supplying power to boat accessories. An anomaly time power supply circuit is connected to the power supply route of the propulsion battery and the power supply route of the auxiliary battery. Electric power from the auxiliary battery is supplied to the engine-related components when the charged voltage of the propulsion battery lowers below the charged voltage of the auxiliary battery, so that power to the engine-related components is supplemented in order to maintain stabilized operation of the engine.

Owner:YAMAHA MARINE KK

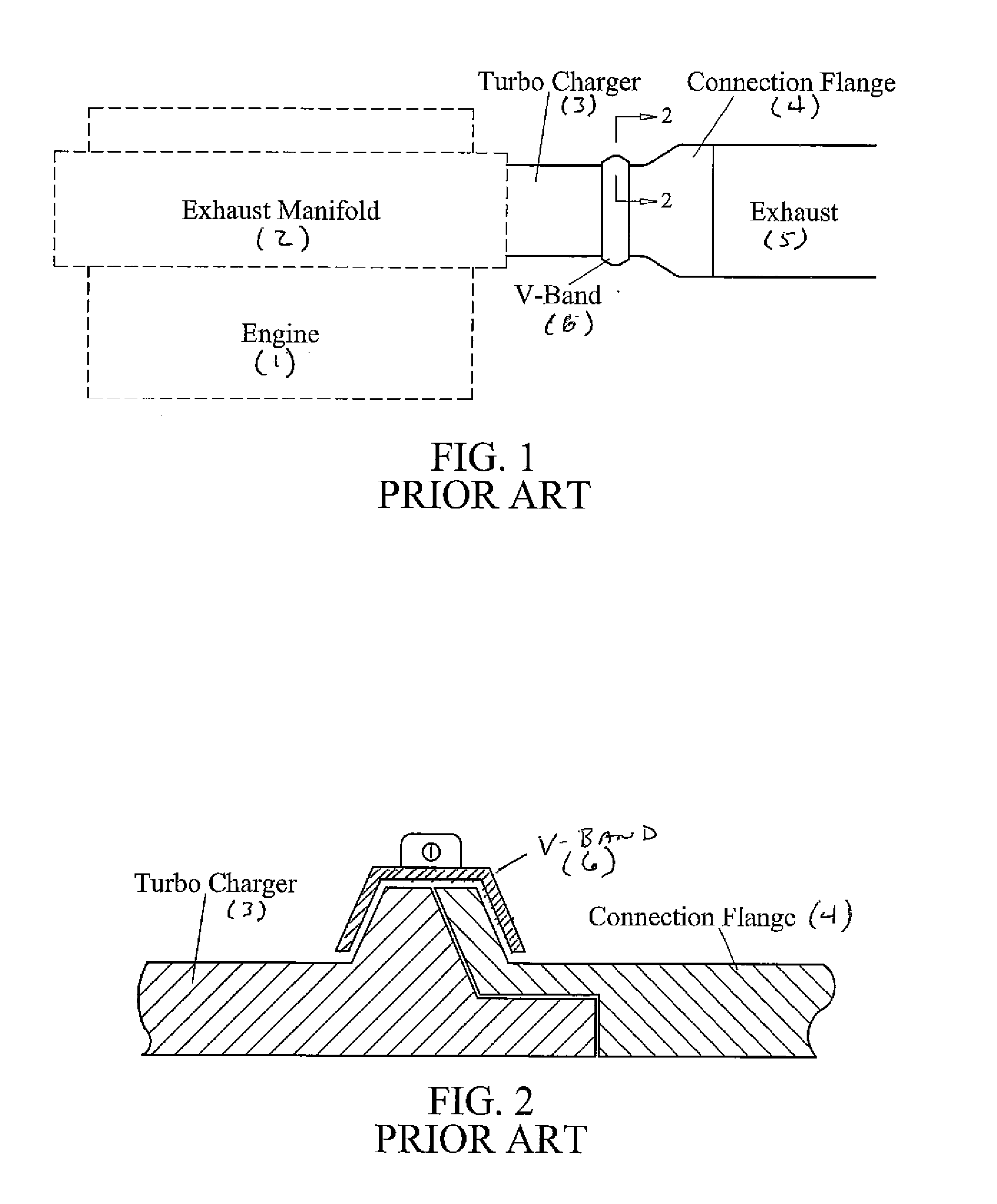

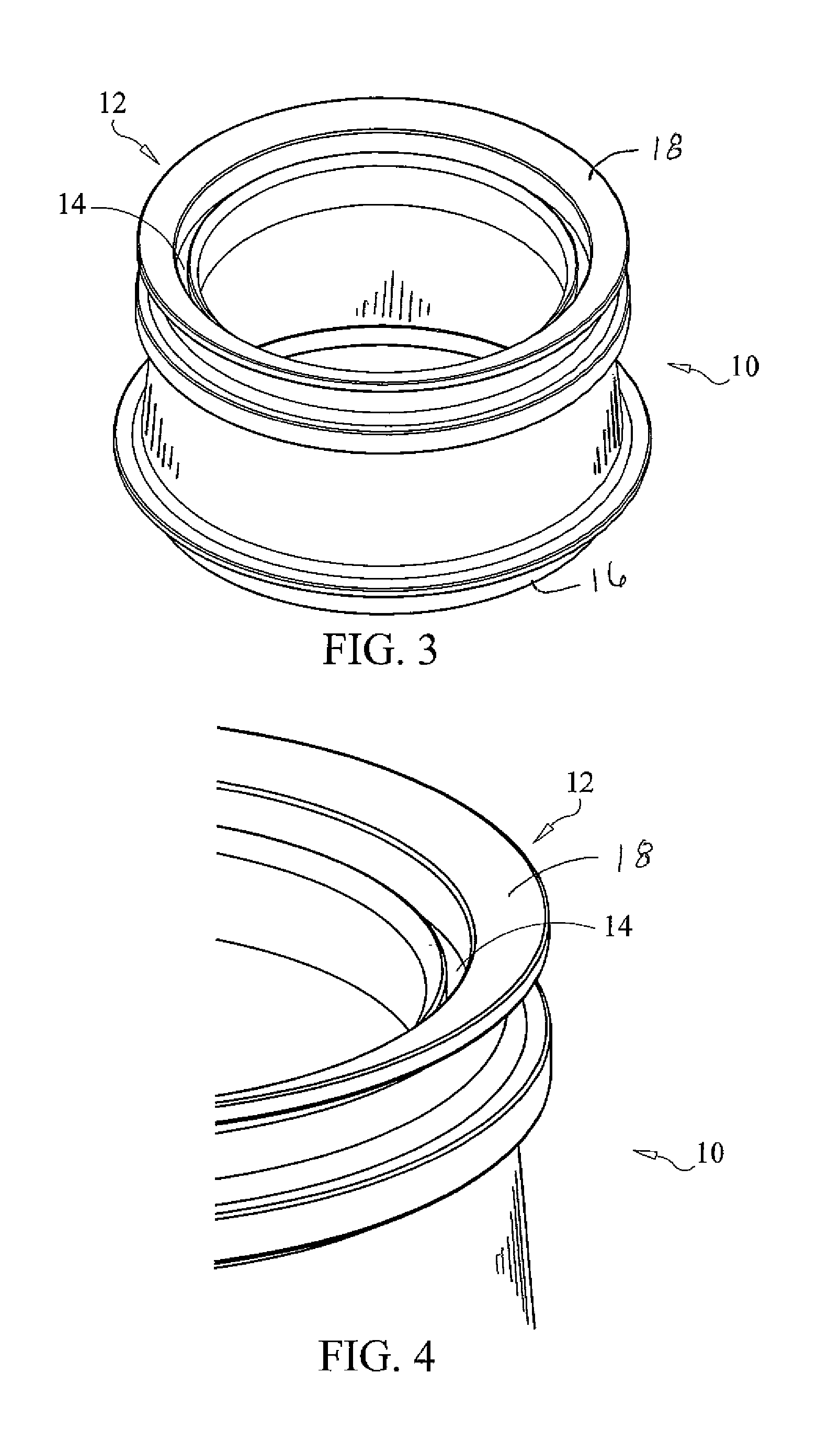

Gasketed connection of marine engine exhaust outlet to exhaust conduit

A connecting flange comprises a generally open ended cylindrical body having an inlet adapted for receiving a gasket for providing a sealing connection with a turbocharger housing, and an outlet for connection to marine exhaust conduit. The connector inlet terminates in an end having a radially flared angularly disposed end wall adapted for mating abutting engagement with a correspondingly angled turbocharger housing end wall. The connector inlet end further includes circumferential axially recessed groove that receives spiral wound gasket in a configuration wherein the gasket forms redundant seals at a plurality of locations. The connector inlet structure cooperates with the turbo charger outlet structure to completely enclose the gasket thereby protecting the gasket from hot corrosive exhaust gases. A V-Band clamp is disposed in covering relation with the connector end wall and abutting turbocharger housing component to secure the connector to the turbocharger.

Owner:WOODS WOODROW

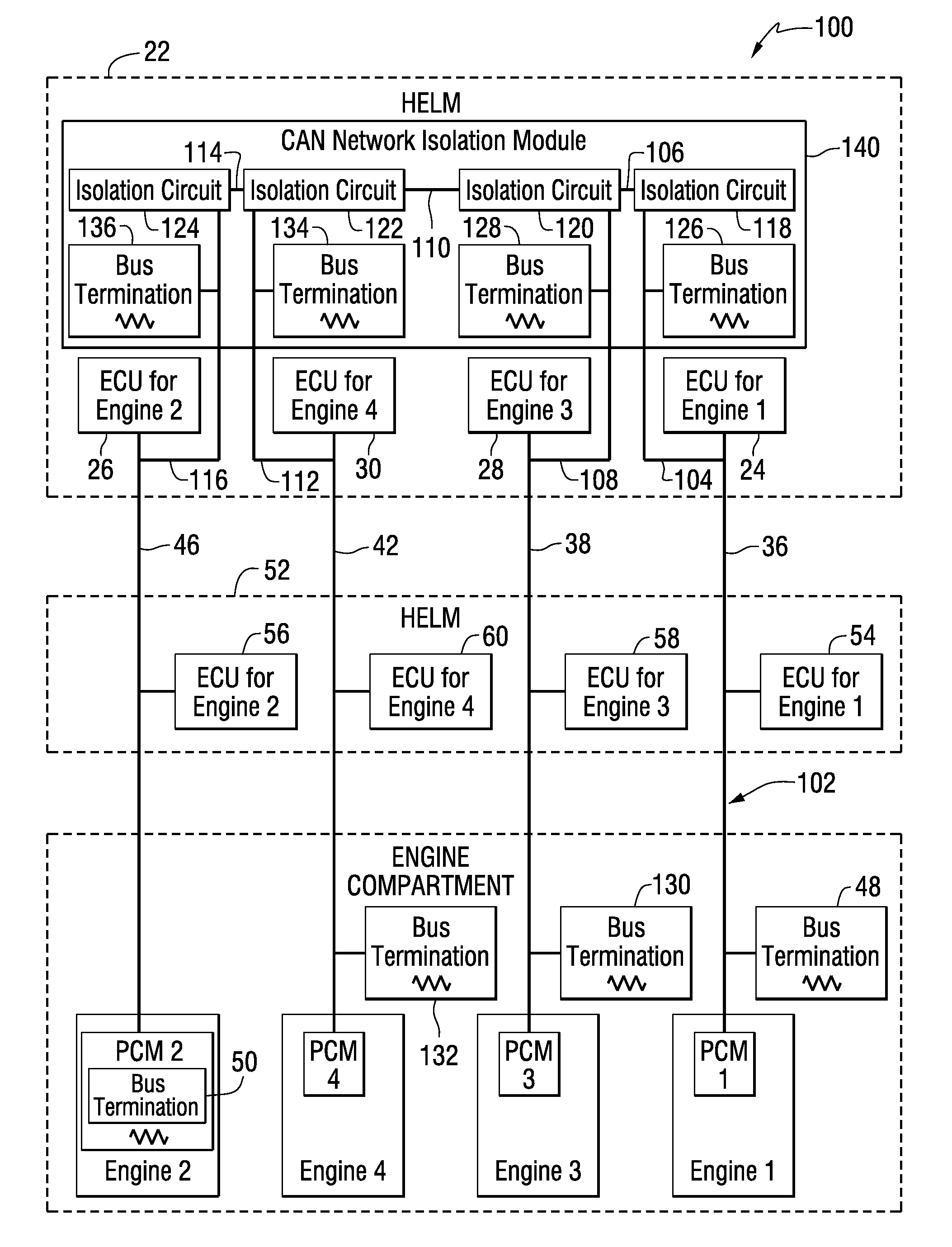

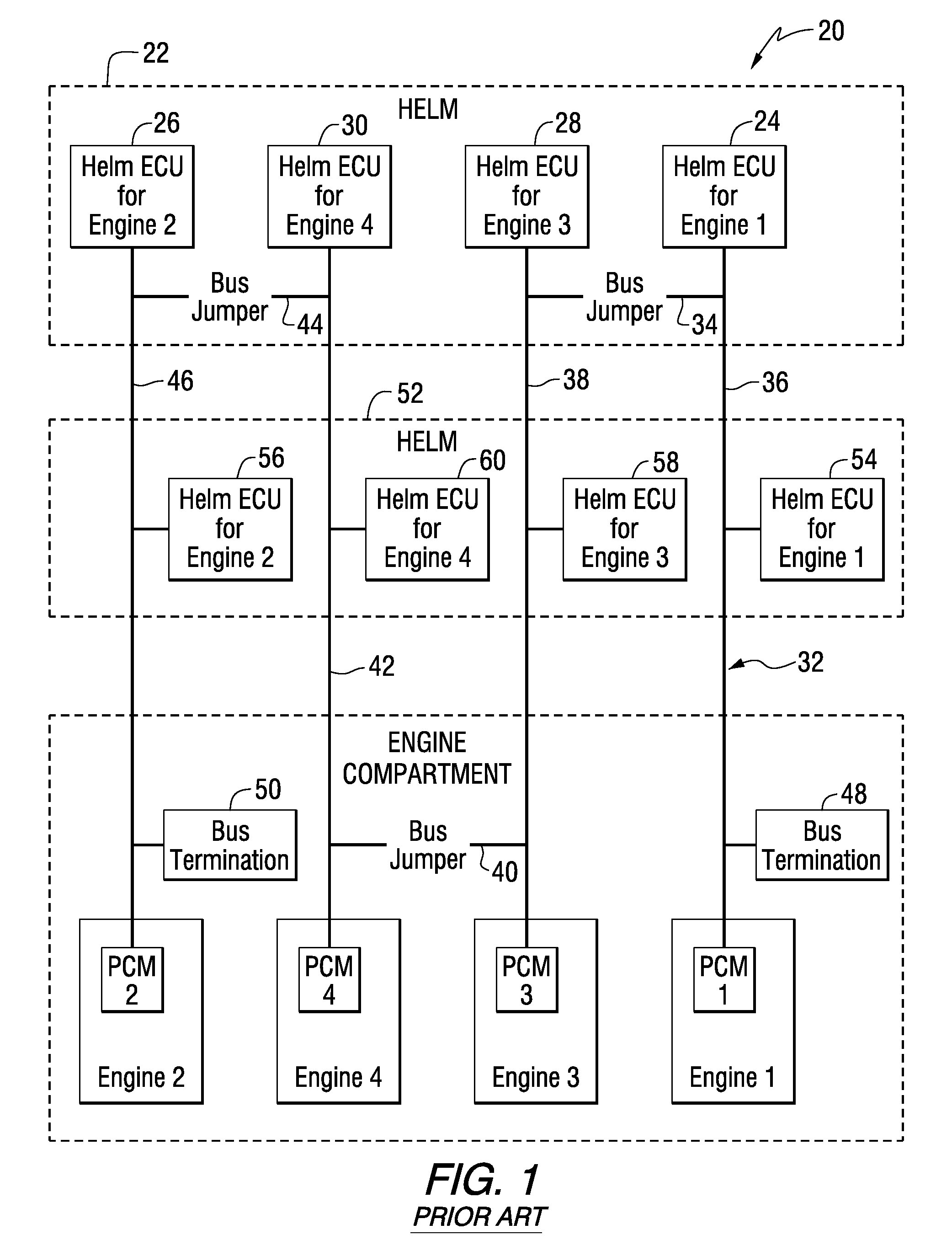

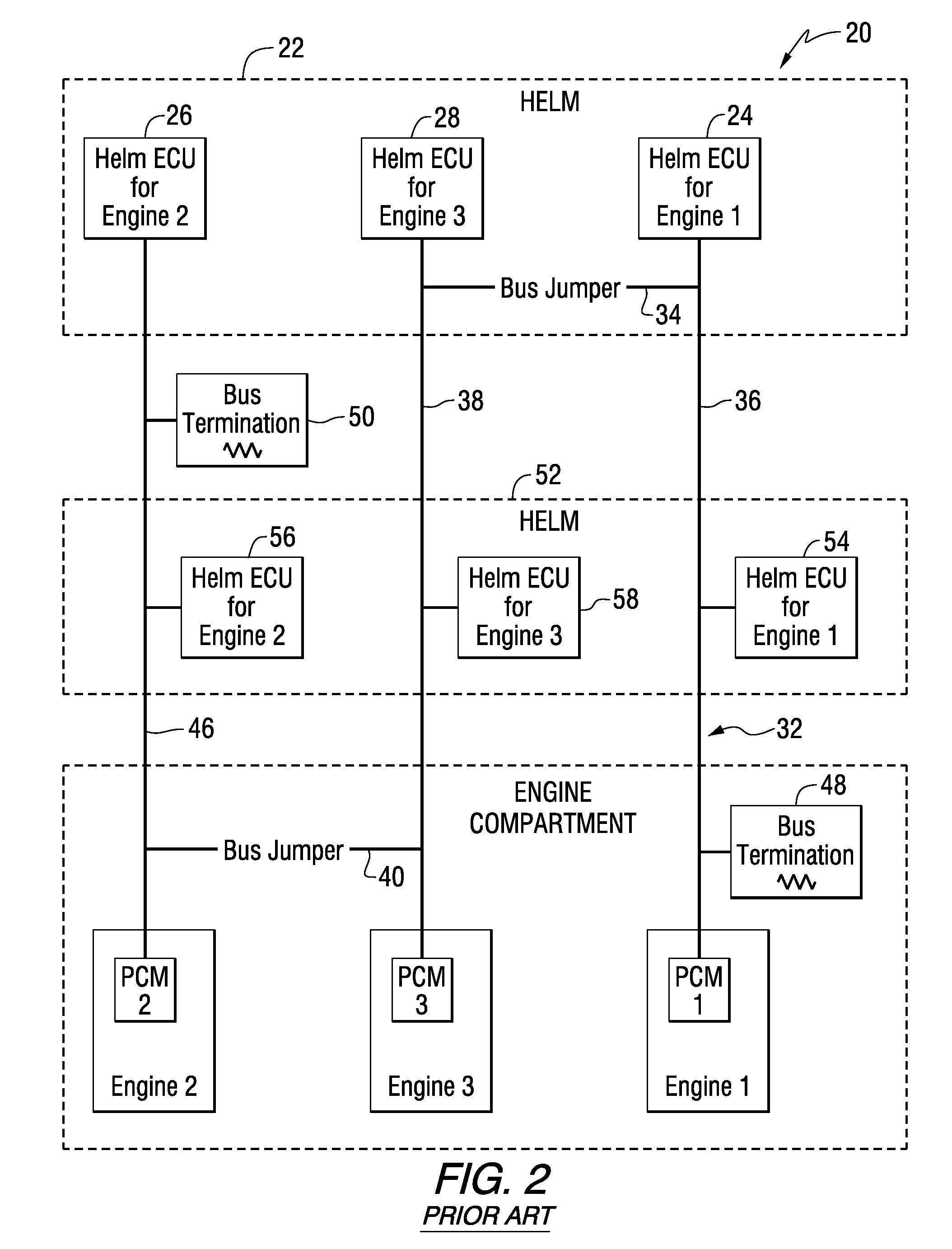

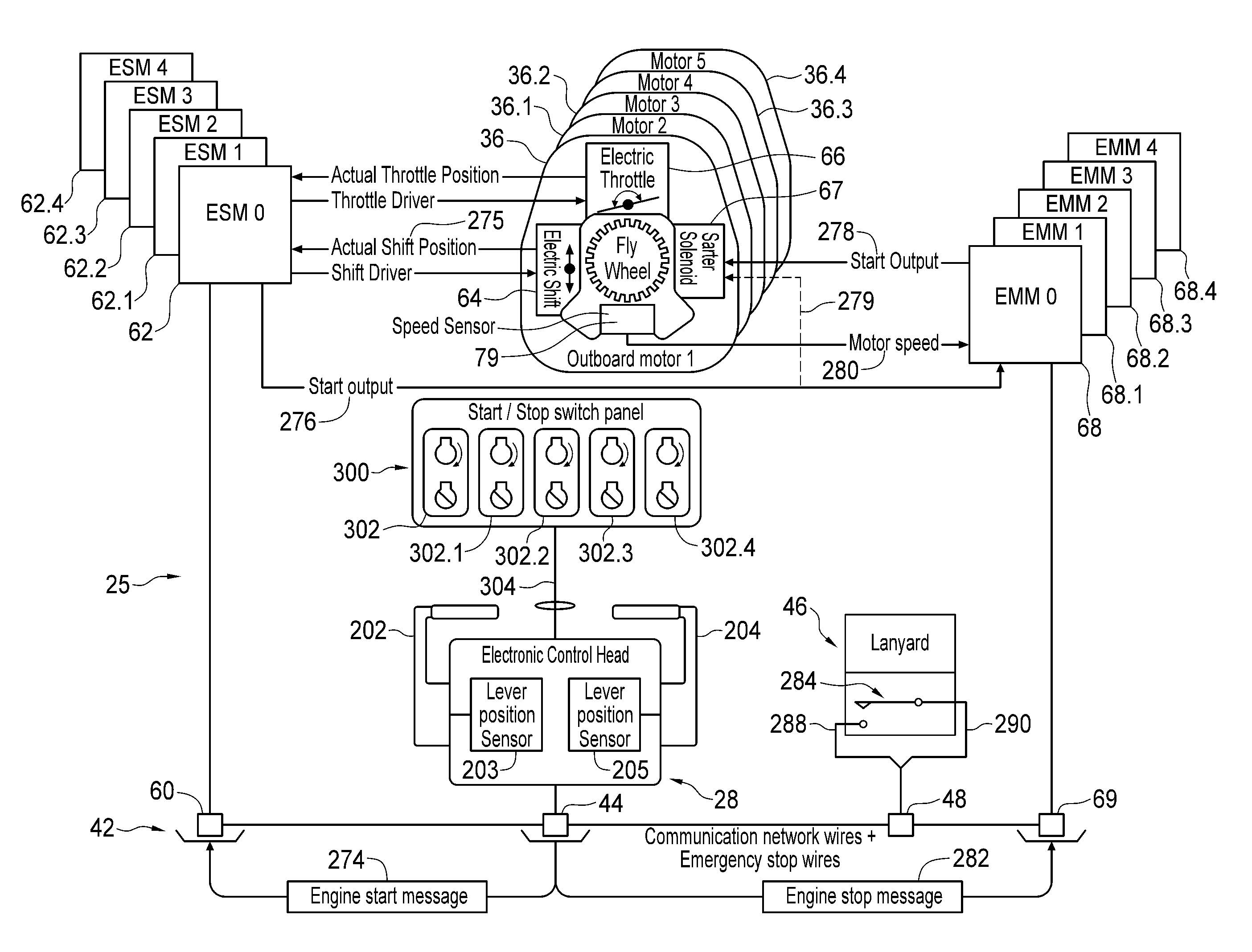

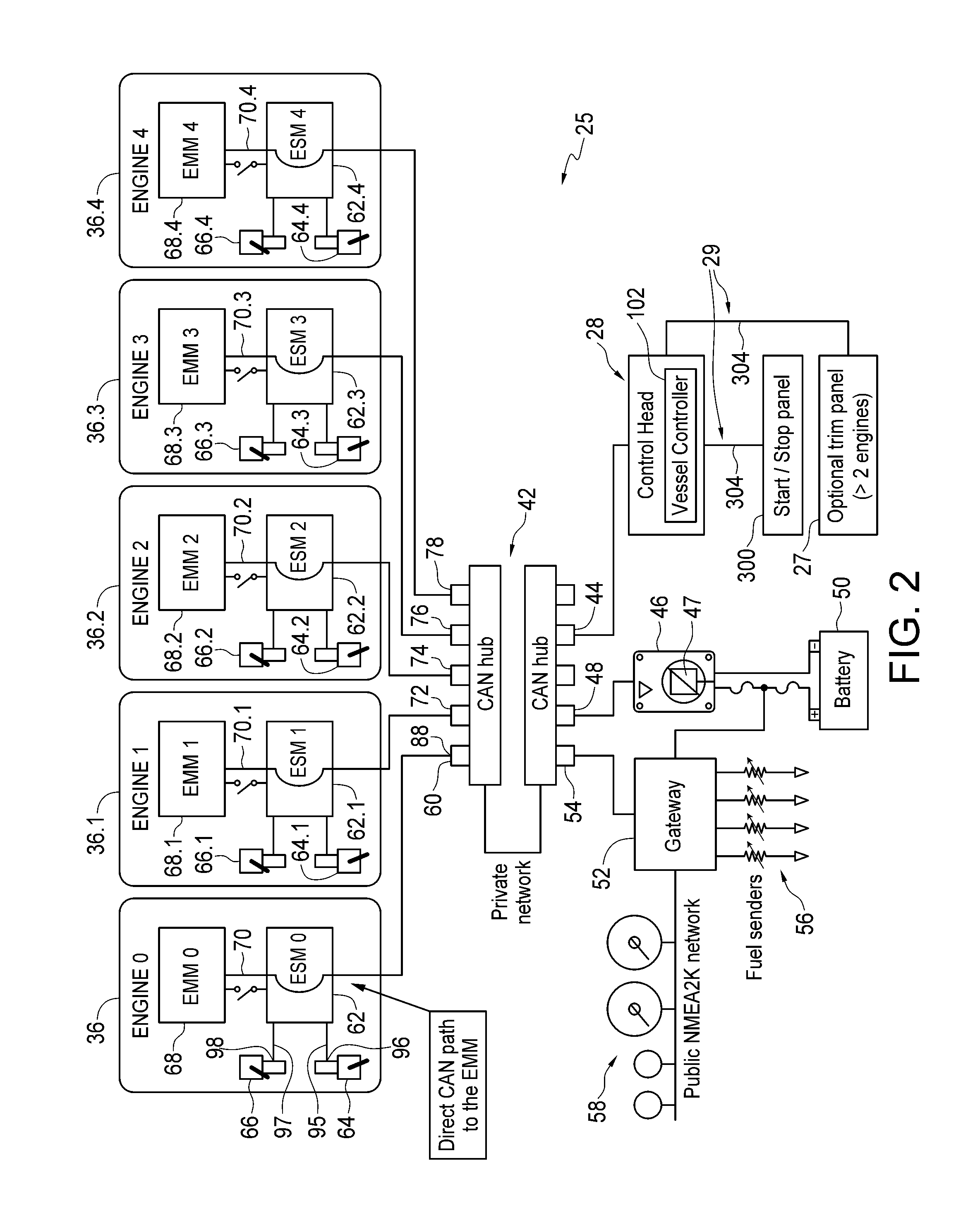

Marine propulsion drive-by-wire control system with shared isolated bus

A marine propulsion drive-by-wire control system controls multiple marine engines, each one or more PCMs, propulsion control modules for controlling engine functions which may include steering or vessel vectoring. A helm has multiple ECUs, electronic control units, for controlling the multiple marine engines. A CAN, controller area network, bus connects the ECUs and PCMs with multiple PCM and ECU buses. The ECU buses are connected through respective isolation circuits isolating the respective ECU bus from spurious signals in another ECU bus.

Owner:BRUNSWICK CORPORATION

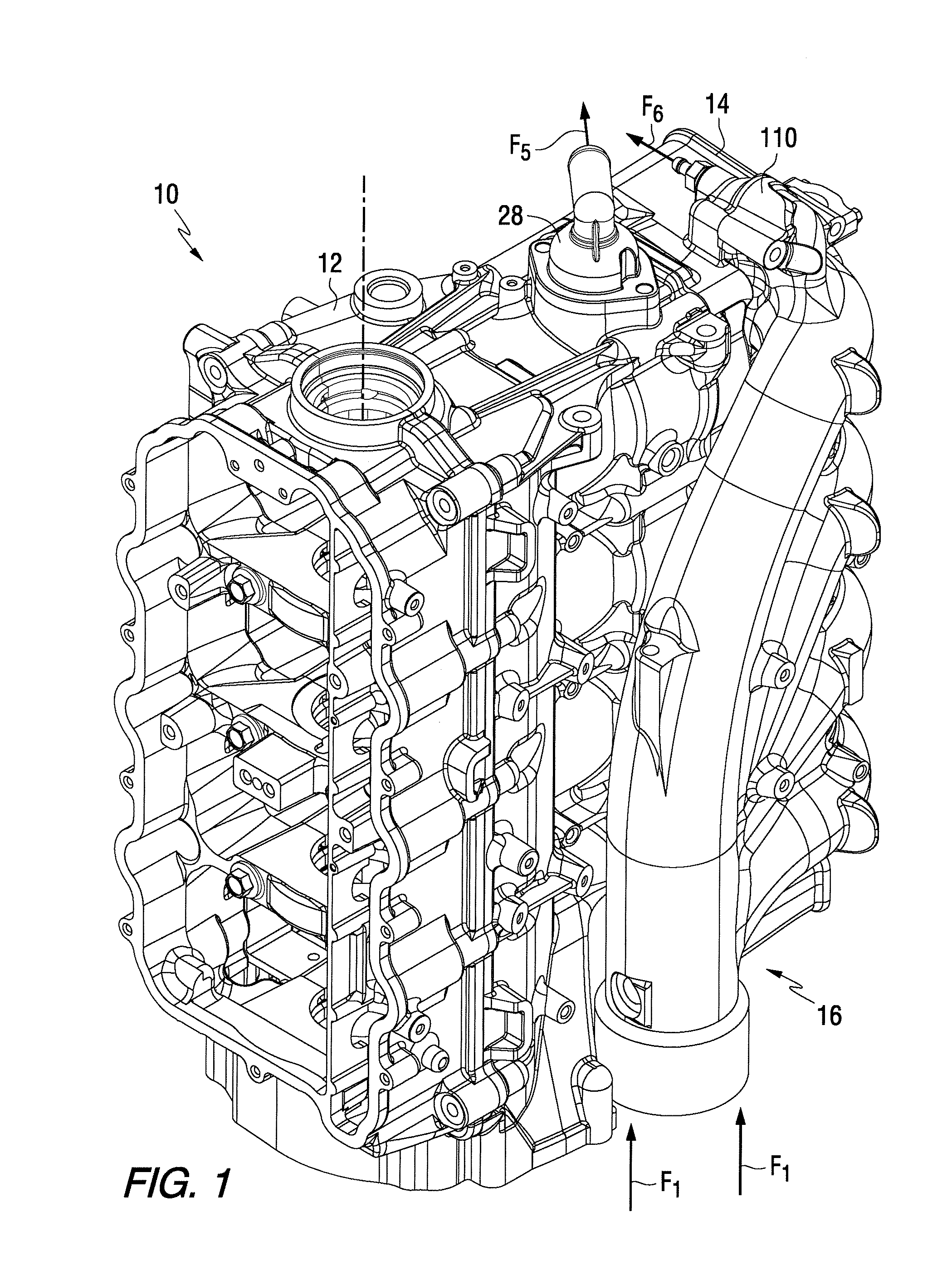

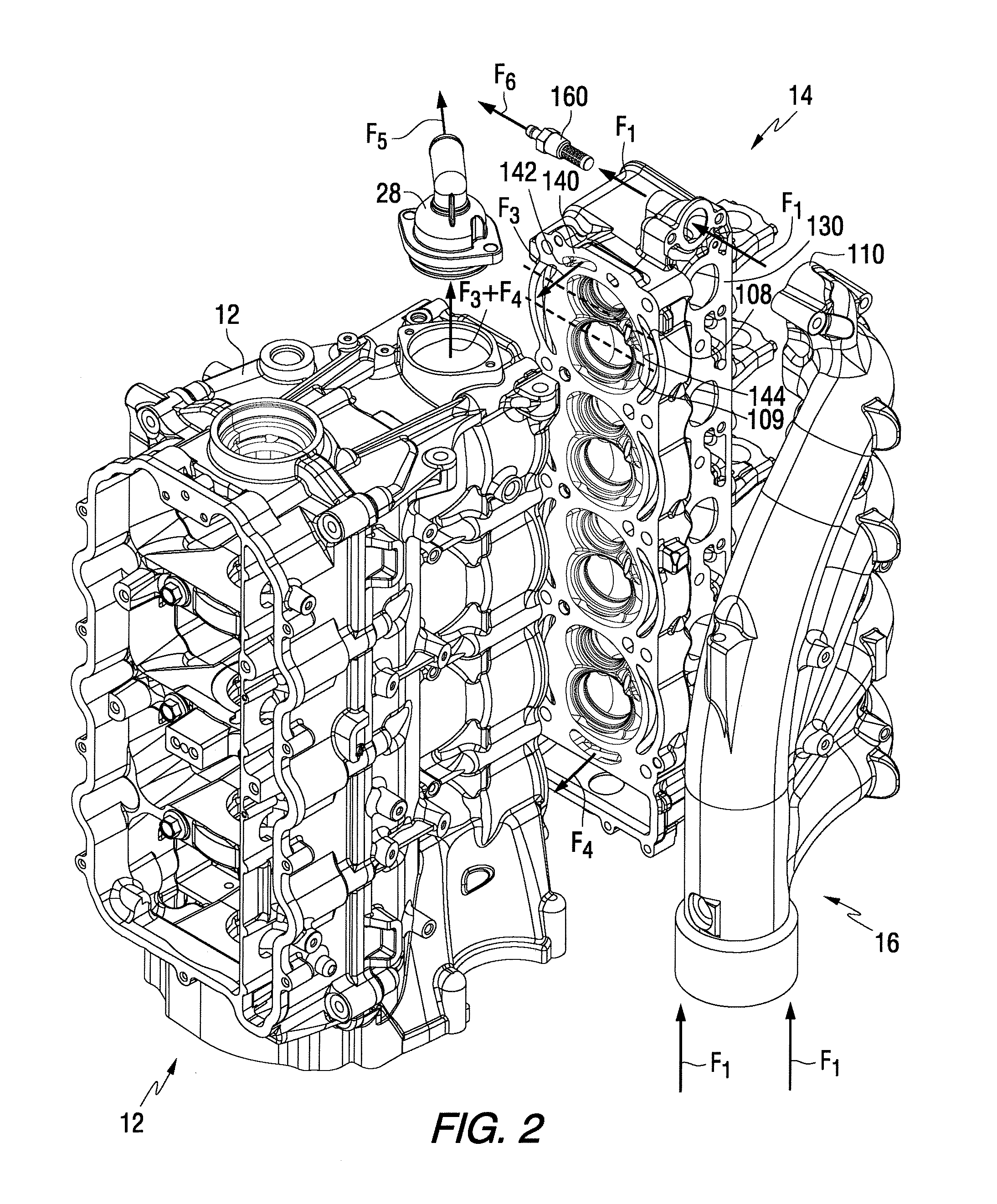

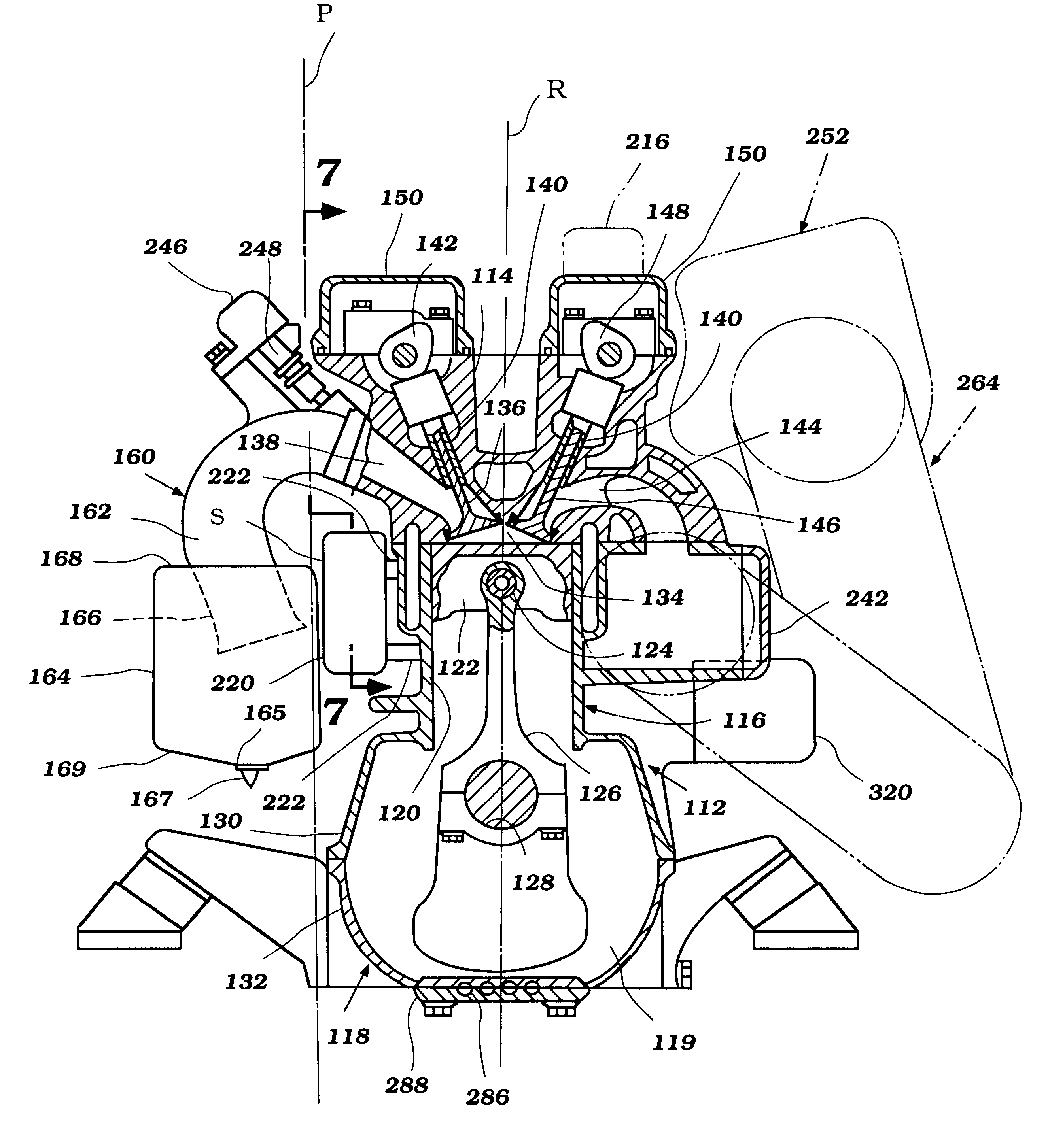

Method for cooling a four stroke marine engine with multiple path coolant flow through its cylinder head

A cooling system for a marine engine is provided with various cooling channels which allow the advantageous removal of heat at different rates from different portions of the engine. A split flow of water is conducted through the cylinder head, in opposite directions, to individually cool the exhaust port and intake ports at different rates. This increases the velocity of coolant flow in the downward direction through the cylinder head to avoid the accumulation of air bubbles and the formation of air pockets that could otherwise cause hot spots within the cylinder head. A parallel coolant path is provided so that a certain quantity of water can bypass the engine block and avoid overcooling the cylinder walls.

Owner:BRUNSWICK CORPORATION

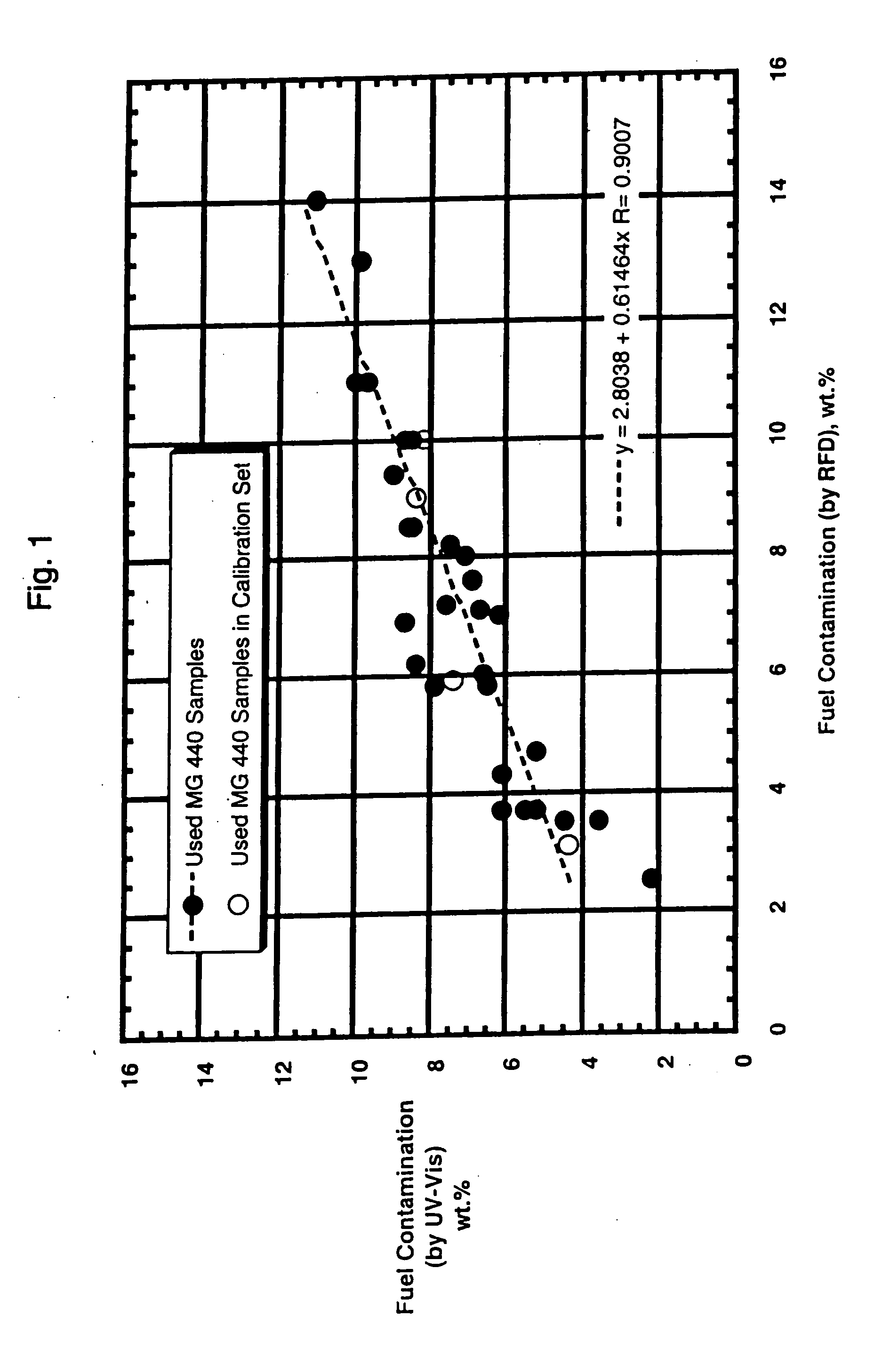

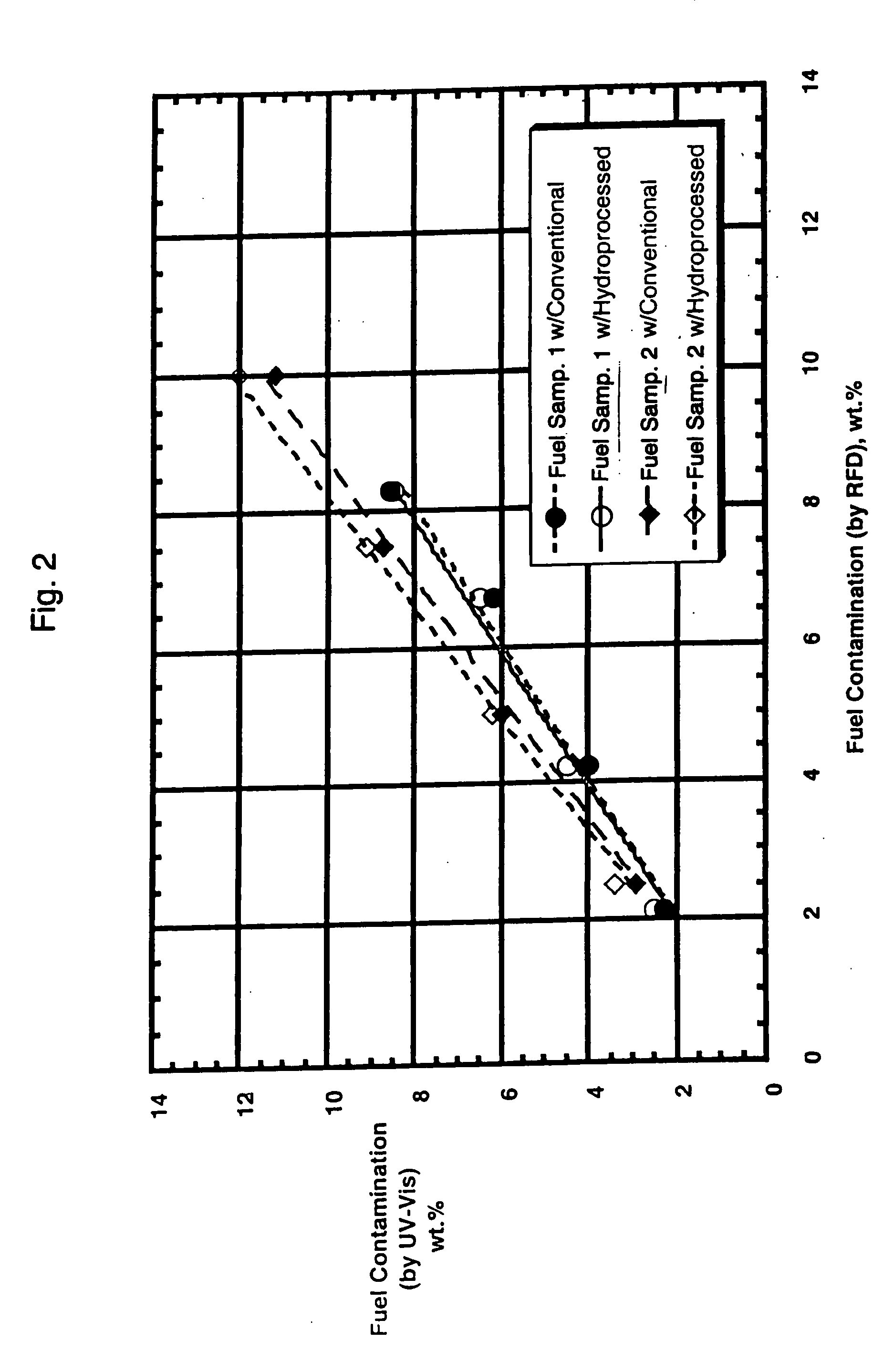

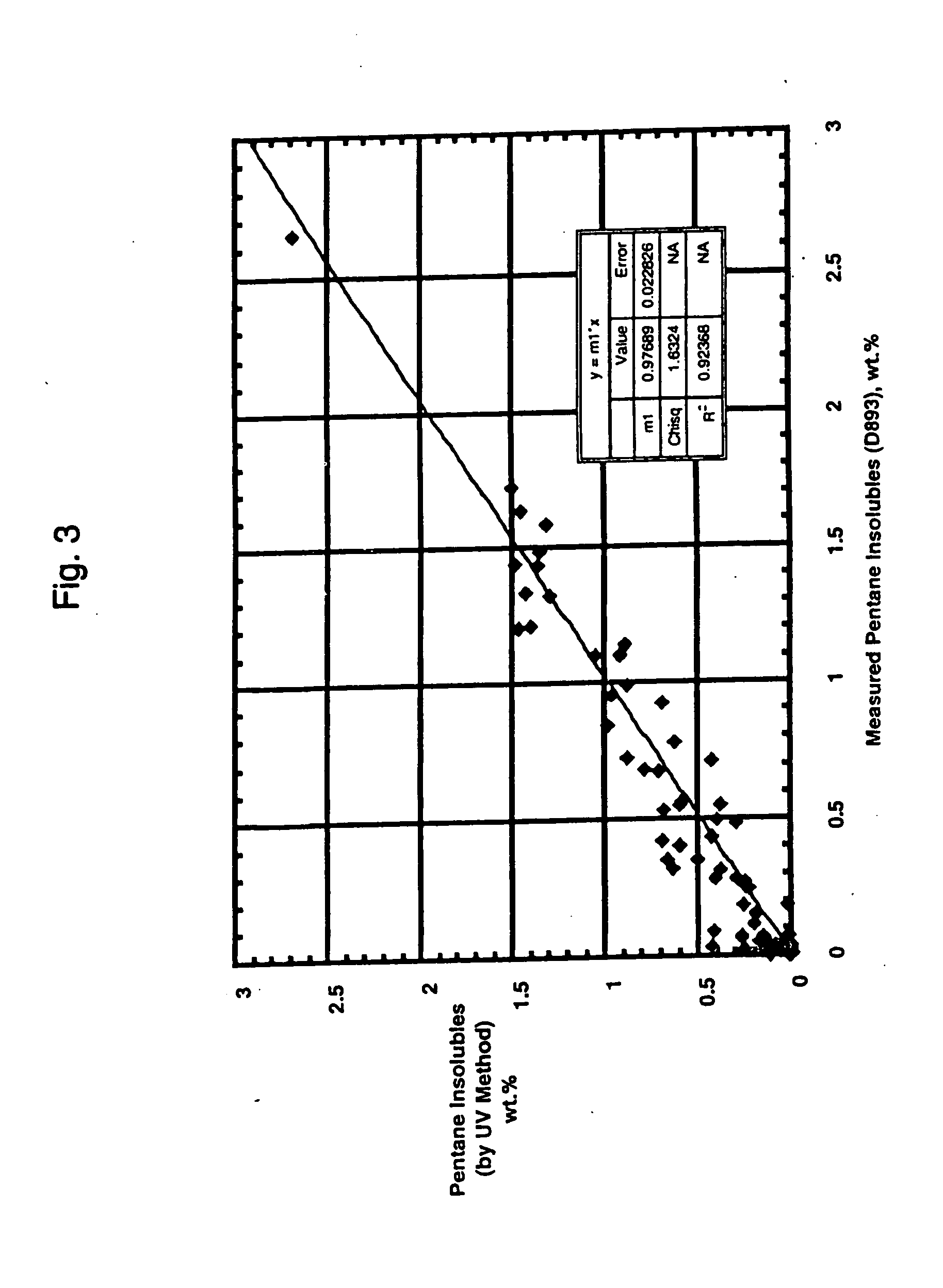

Method for determining asphaltenes contamination in used marine engine lubricants using UV-visible spectroscopy and chemometrics

InactiveUS20070231912A1Difficult to estimateMaterial analysis by observing effect on chemical indicatorOptically investigating flaws/contaminationReference sampleSpectroscopy

A method for determining contamination in marine diesel lubricating oils. The method has been found to have particular utility in estimating asphaltenes contamination in marine diesel lubricating oils. The method includes the steps of: (a) obtaining spectral raw data over a frequency range substantially equivalent to that of ultraviolet-visible light for reference lubricating oil samples with known properties and concentrations of asphaltenes; (b) performing chemometric techniques to the spectral raw data obtained in step (a) to develop a calibration model and calibrate the spectral data with actual values for parameters reflecting the level of asphaltenes contamination of the reference samples, the actual values determined by means of conventional analytical methods; (c) obtaining spectra of samples of marine diesel lubricating oil of unknown concentration of asphaltenes over a frequency range substantially equivalent to that of ultraviolet-visible light; and (d) processing the obtained spectral raw data of step (c) and applying the developed calibration model to the processed data in order to determine the parameters reflecting the level of asphaltenes present in the marine diesel lubricating oil.

Owner:EXXON RES & ENG CO

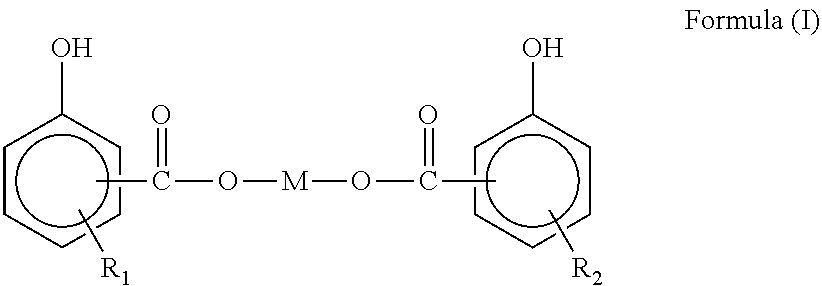

System oil formulation for marine two-stroke engines

ActiveUS20110077182A1Improve protectionEasy to controlOrganic compound preparationLiquid carbonaceous fuelsMechanical componentsCarboxylic salt

In one aspect of the present invention, a marine system oil composition is provided for lubrication of mechanical components in marine engines, for example, two-stroke, cross-head marine diesel engines and methods / additives for using the marine system oil composition in the same. In one aspect of the present invention, a marine system oil composition is provided that has salt of a carboxylate-containing detergent comprising at least one alkyl-substituted hydroxyaromatic carboxylic acid, wherein at least 50 mole % of, the alkyl groups are C20 or greater.

Owner:CHEVRON ORONITE TECH BV

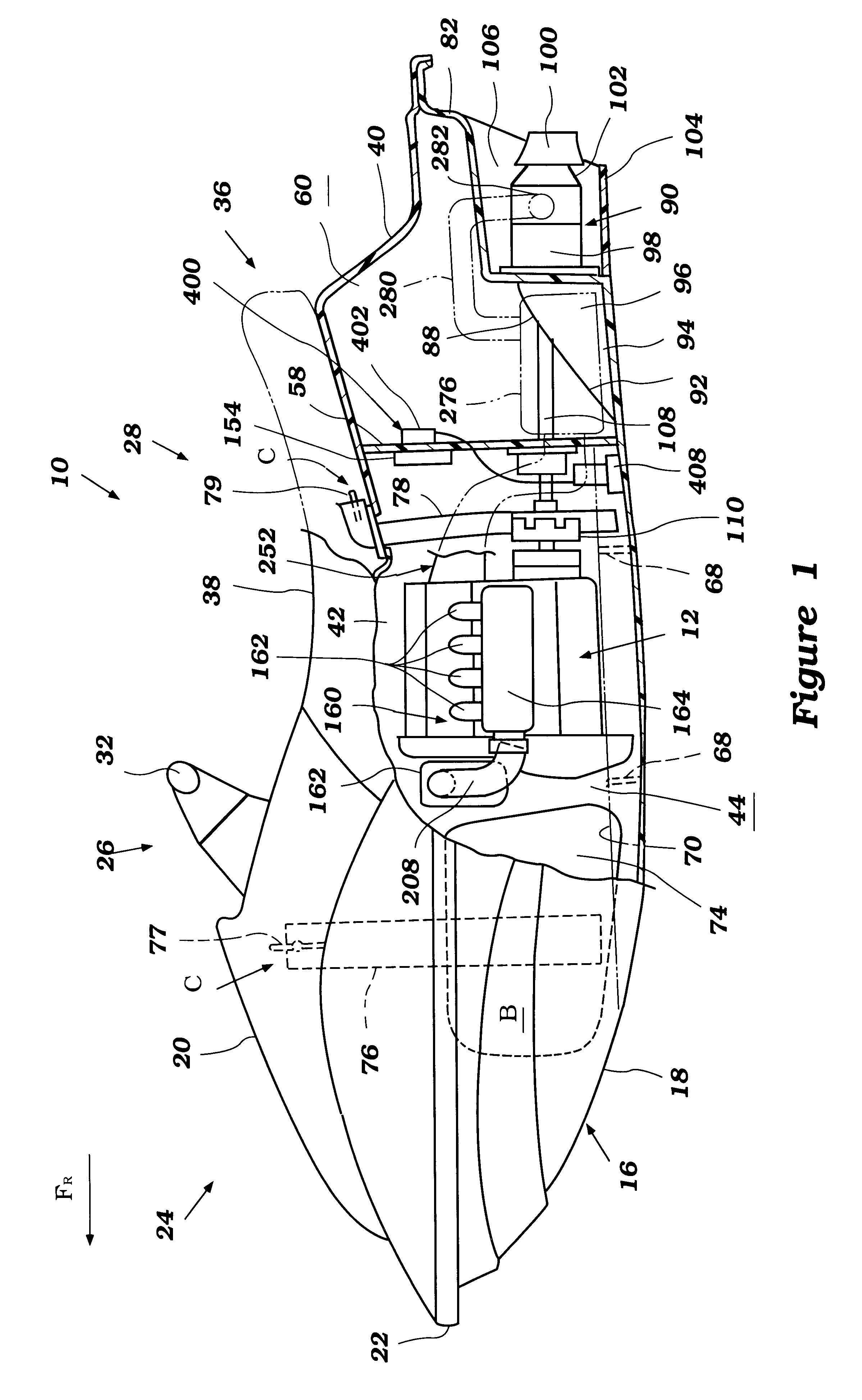

Torsional damper for watercraft propulsion system

A vibrational damper reduces torsional vibration within a crankshaft of a marine engine. The vibrational damper is located on an end of the crankshaft opposite of the flywheel and includes an inertia ring that adds additional mass to this opposite end. In addition, the vibrational damper includes an elastic member that suspends the inertia ring about the crankshaft. The elastic member effectively dampens torsional vibrations. The torsional damper desirably is cooled by an air flow so as to maintain it's dampening efficiency. A ventilation duct, which is positioned directly above the vibrational damper, supplies the cooling air. Cooling is enhanced by locating a bilge system inlet below and slightly behind the vibrational damper. An air flow stream occurs between the duct and the bilge inlet and across the torsional damper to cool the torsional damper.

Owner:YAMAHA MOTOR CO LTD

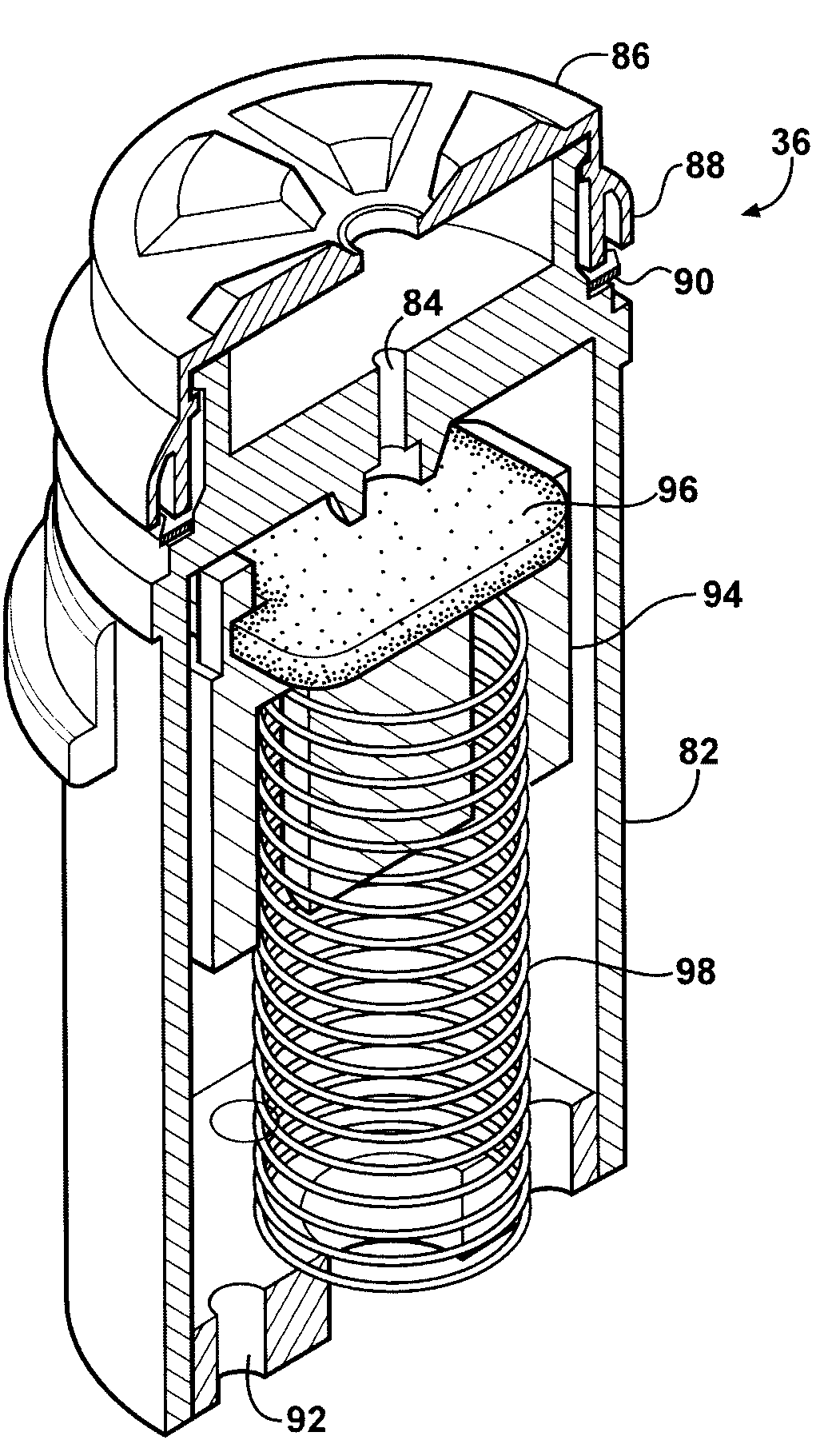

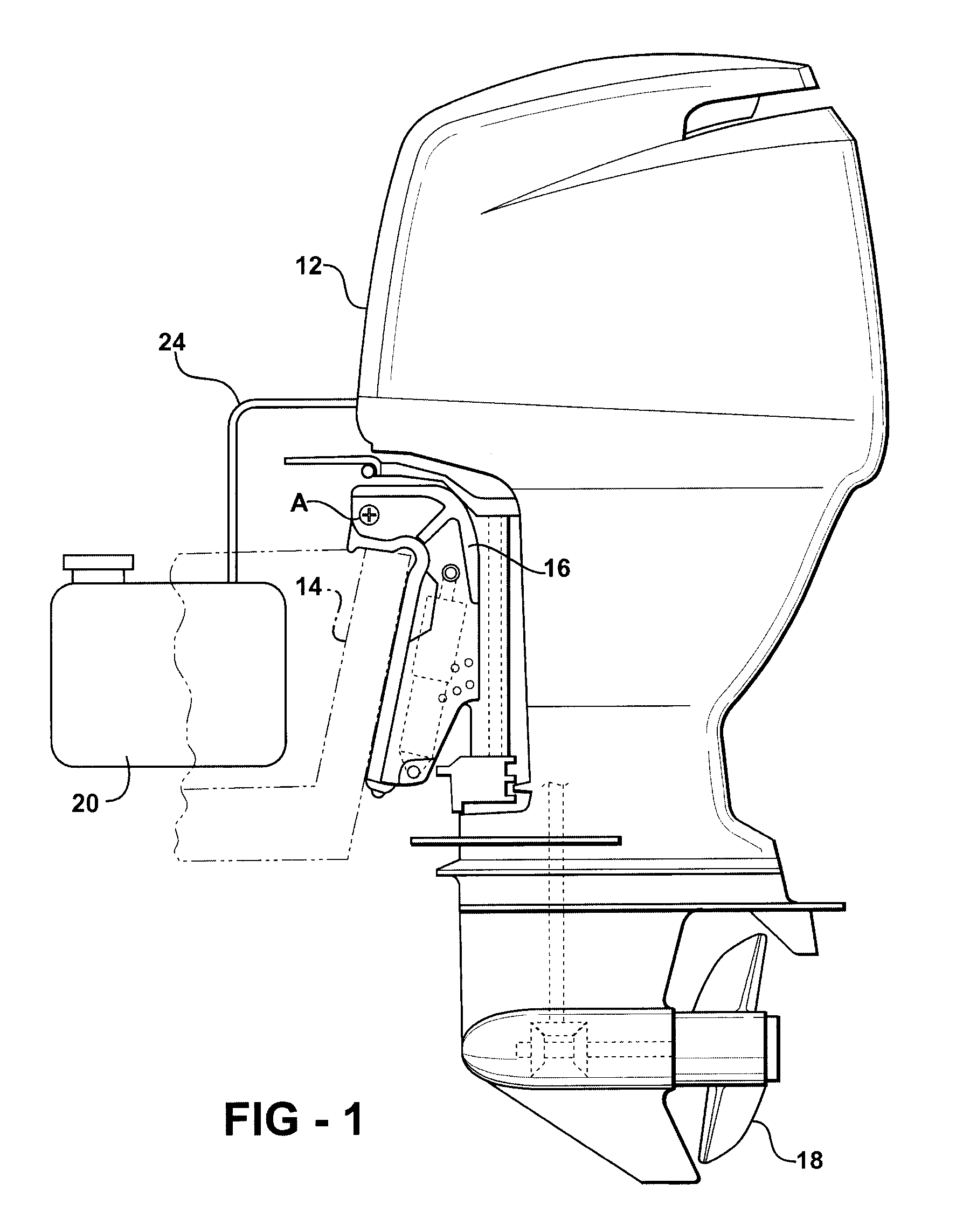

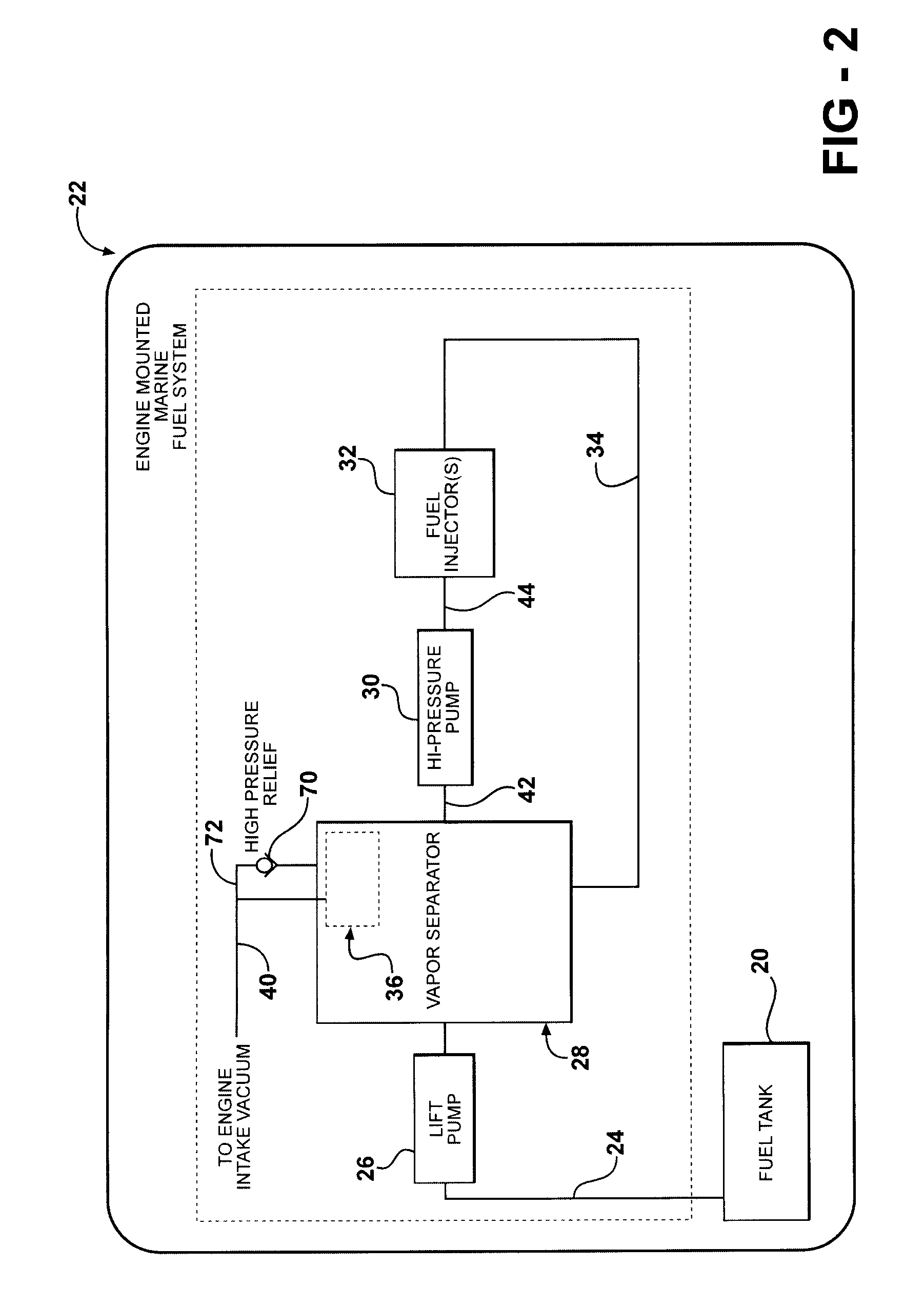

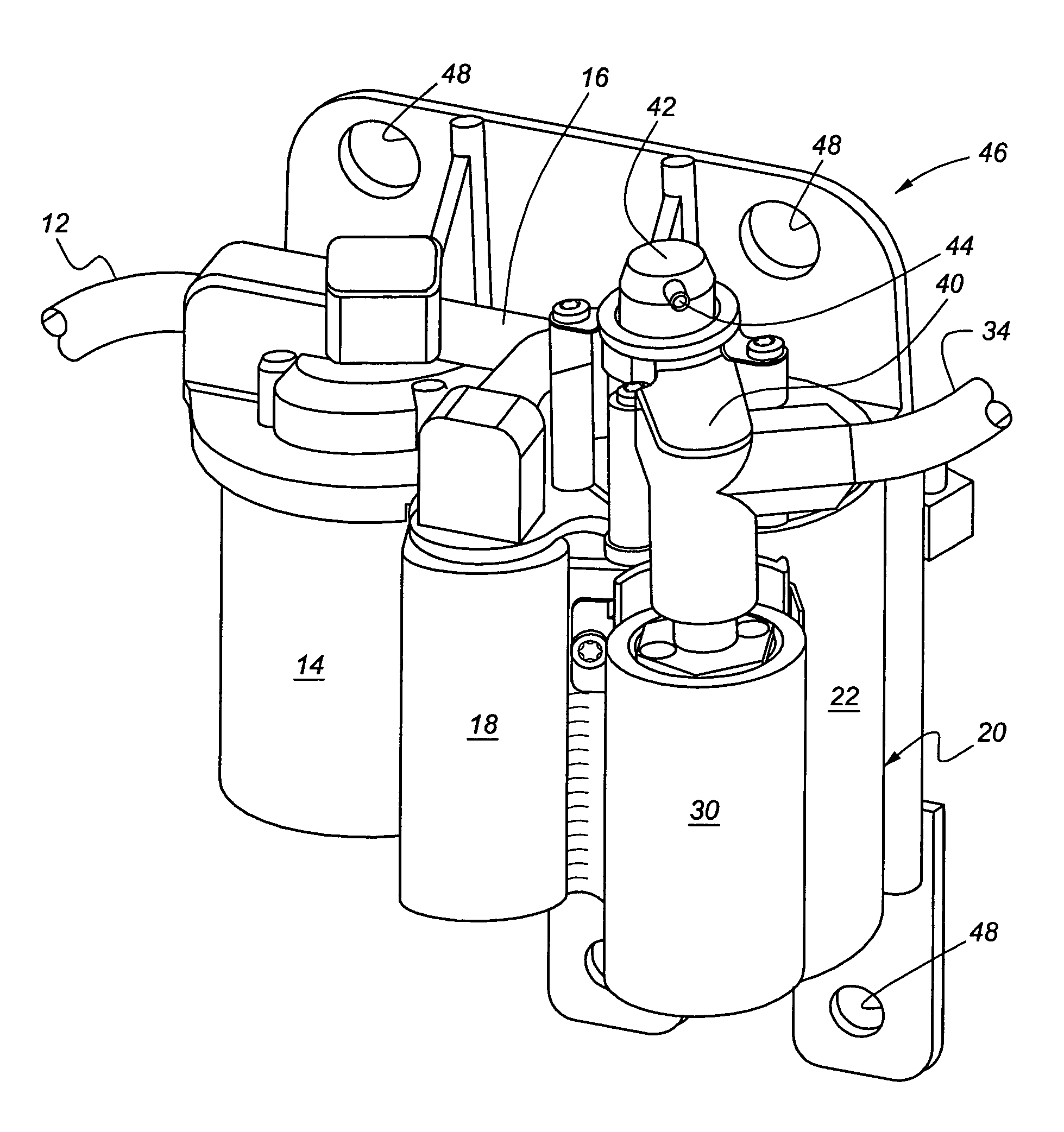

Marine fuel vapor separator with vent control device

ActiveUS7503314B2Prevent leakageNon-fuel substance addition to fuelMachines/enginesLiquid fuelControl of respiration

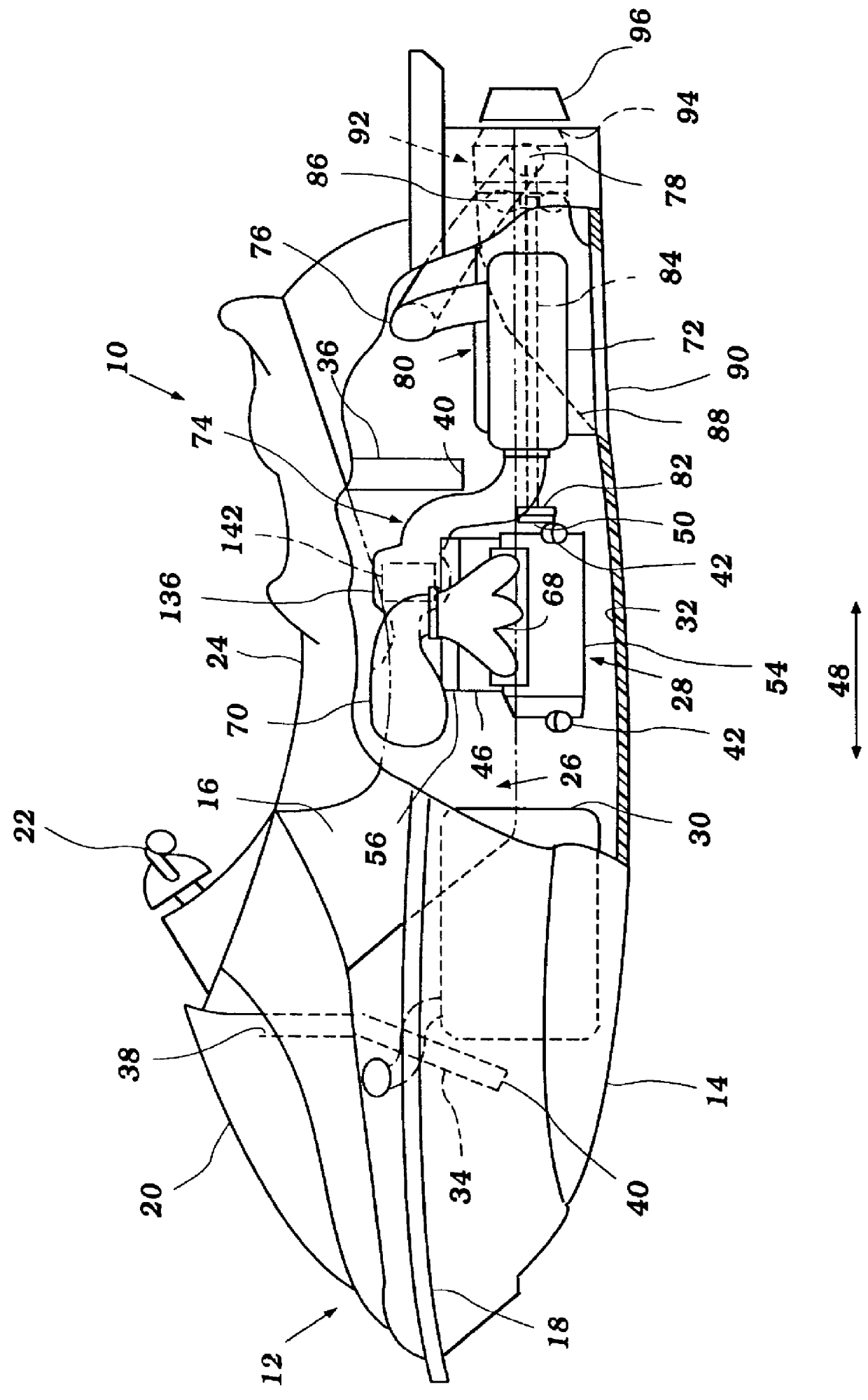

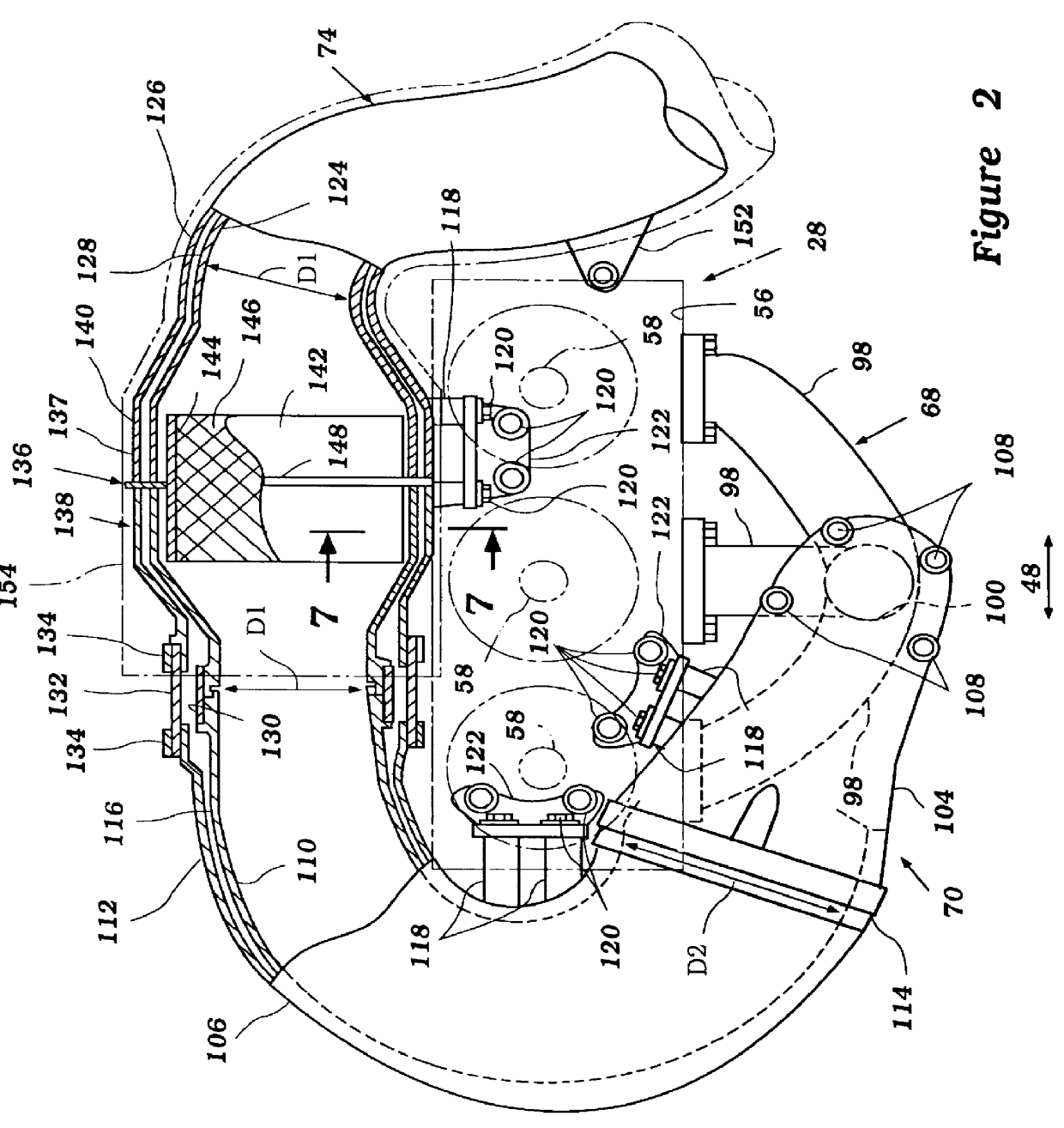

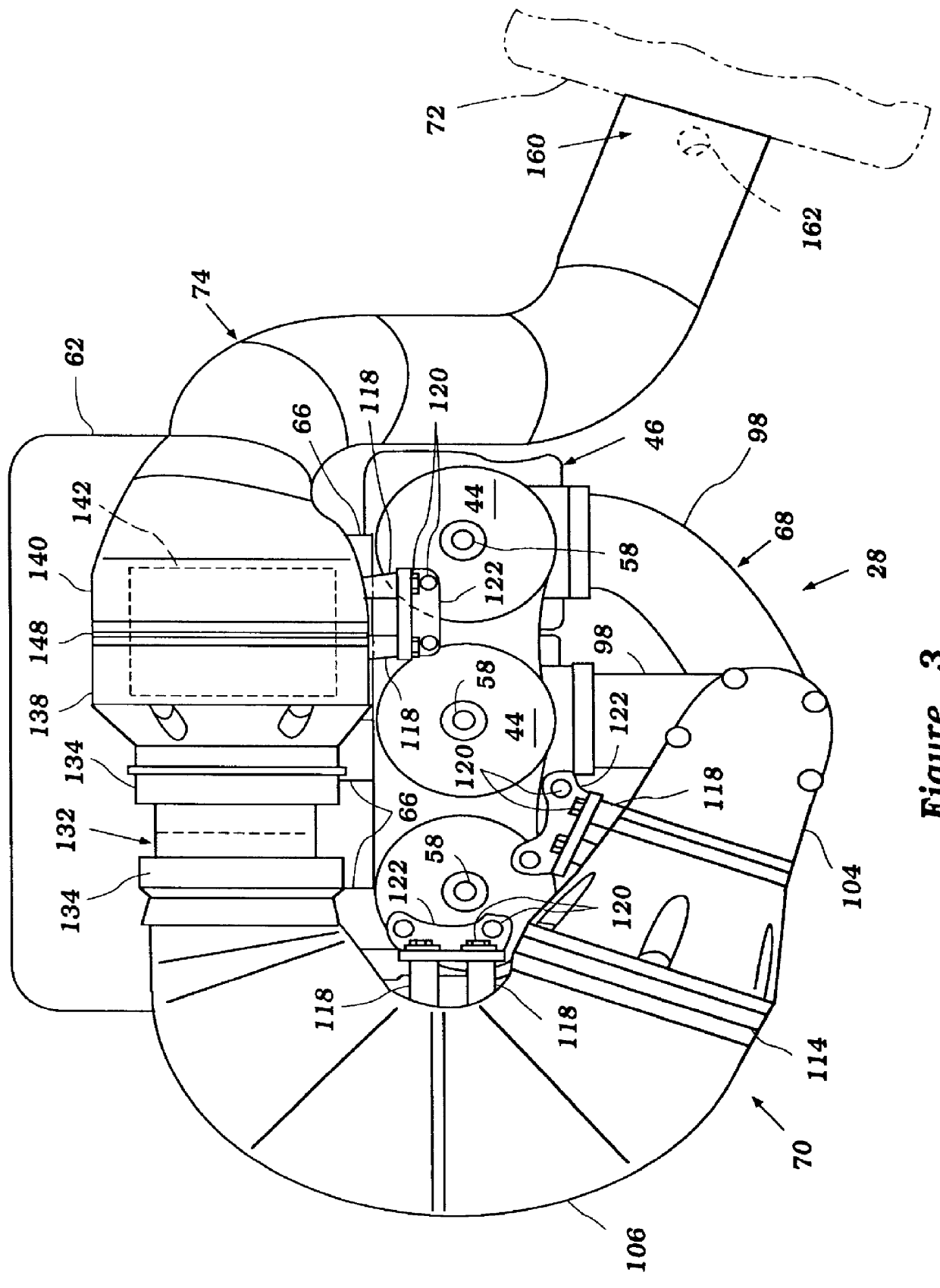

A fuel supply system for an outboard marine engine includes a vapor separator (28) having a uni-directional vapor vent device (36) for preventing fuel leakage when the engine (12) is tipped on its side. The vapor separator (28) includes an enclosed interior chamber (50) which is filled with liquid fuel by a suction pump. A separate, high pressure pump transfers the liquid fuel from the interior chamber (50) to a fuel injection system (32) of the engine (12). The vapor vent device (36) includes a generally tubular casing having an enclosed top end permeated by an escape passage (84), and a float (94) slidably disposed within the casing (82) for movement toward and away from sealing engagement with the escape passage (84). A spring (98) urges the float (94) toward a sealed condition against the escape passage (84), but is too weak to overcome the weight of the float (94) unless the engine (12) is tipped more than about 25 degrees from vertical, or unless the level of fuel in the interior chamber (50) lifts the float (94).

Owner:CARTER FUEL SYST

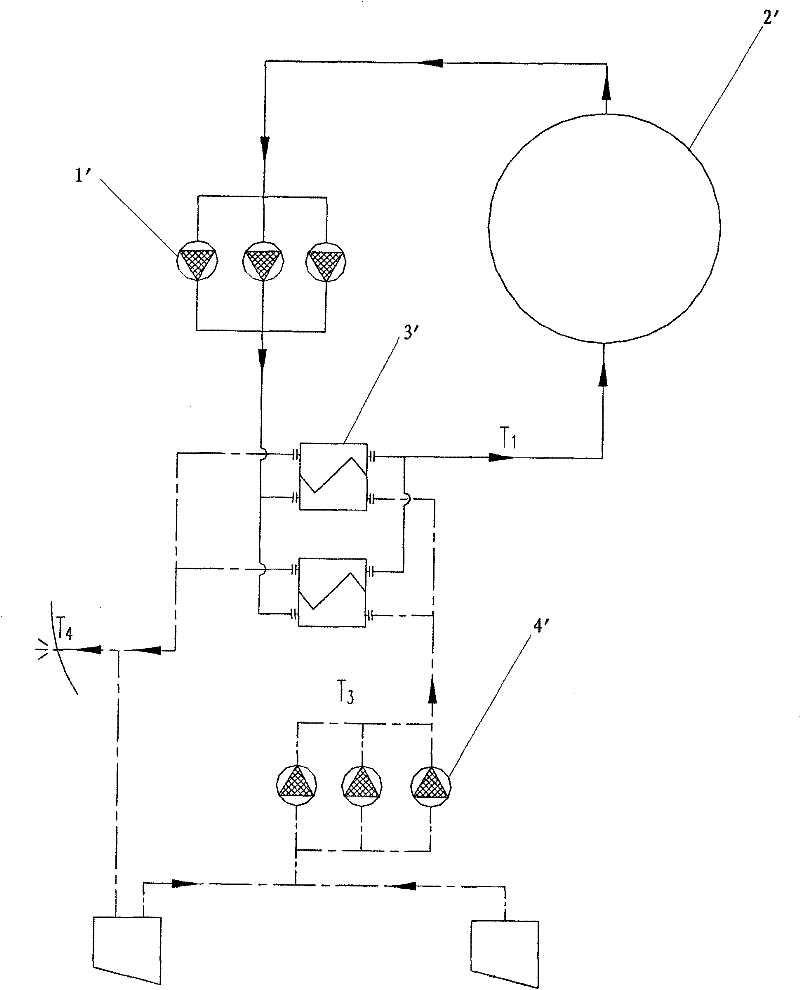

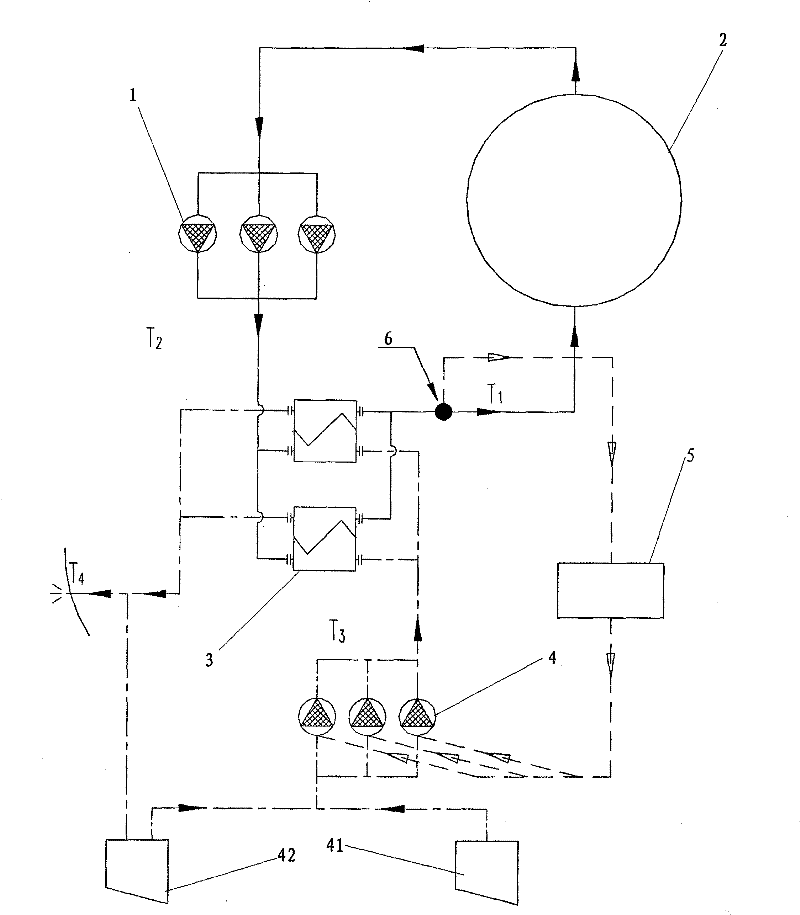

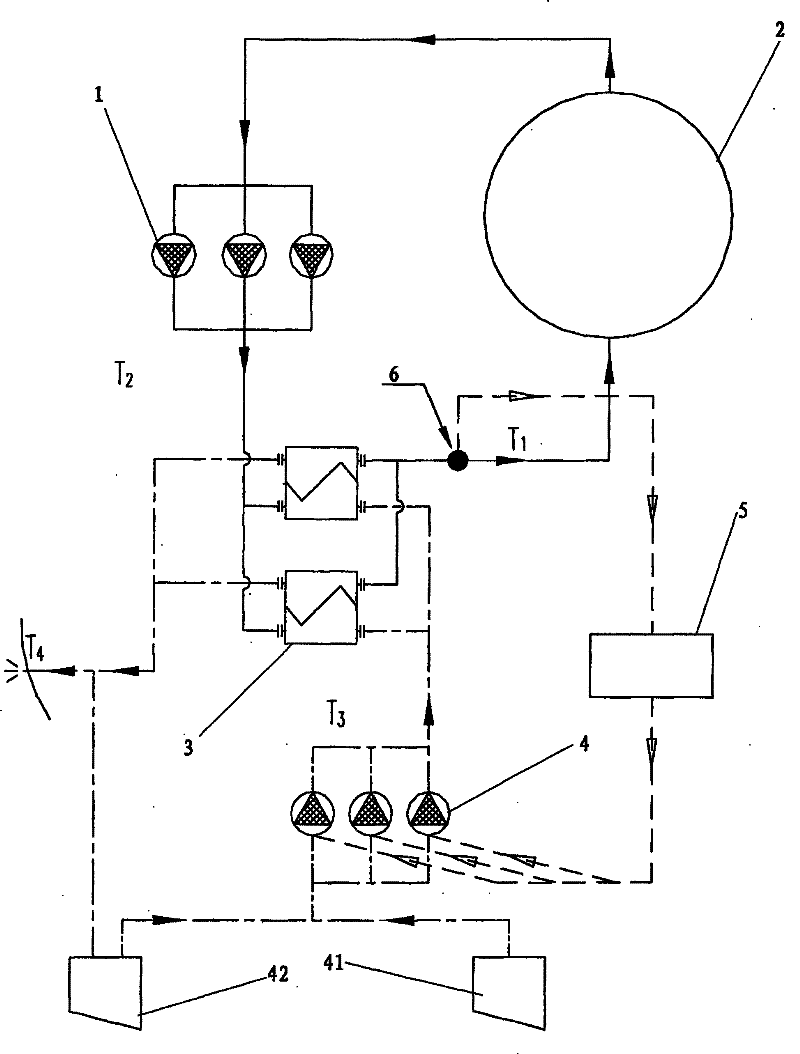

Automatic temperature-control variable flow type central cooling system for ship

InactiveCN102180256AReduce operating costsReduce energy consumptionAuxillariesVessel ventillation/heating/coolingTemperature controlAutomatic control

The invention relates to an automatic temperature-control variable flow type central cooling system for a ship, comprising a fresh water cooling pipeline and a seawater cooling pipeline, wherein the fresh water cooling pipeline comprises a low-temperature fresh water cooling pump, a device needing to be cooled and a central cooler which constitute a closed circulation pipeline; the seawater cooling pipeline comprises an open circulation pipeline consisting of a seawater cooling pump and a central cooler; and circulating fresh water flowing through the central cooler is cooled by sea water. The central cooling system is characterized in that the seawater cooling pump is connected with an automatic control unit which can control the seawater flow according to the cooling quantity of the device needing to be cooled. Through the automatic temperature-control variable flow type central cooling system for the ship, under the working condition of non-full load operation of a marine engine system of the ship, the underdeck system energy consumption and the exhaust gas discharge are effectively decreased, the operating cost of the ship is reduced and the concept of environmental friendliness is realized in the meantime.

Owner:BESTWAY MARINE & ENERGY TECH CO LTD

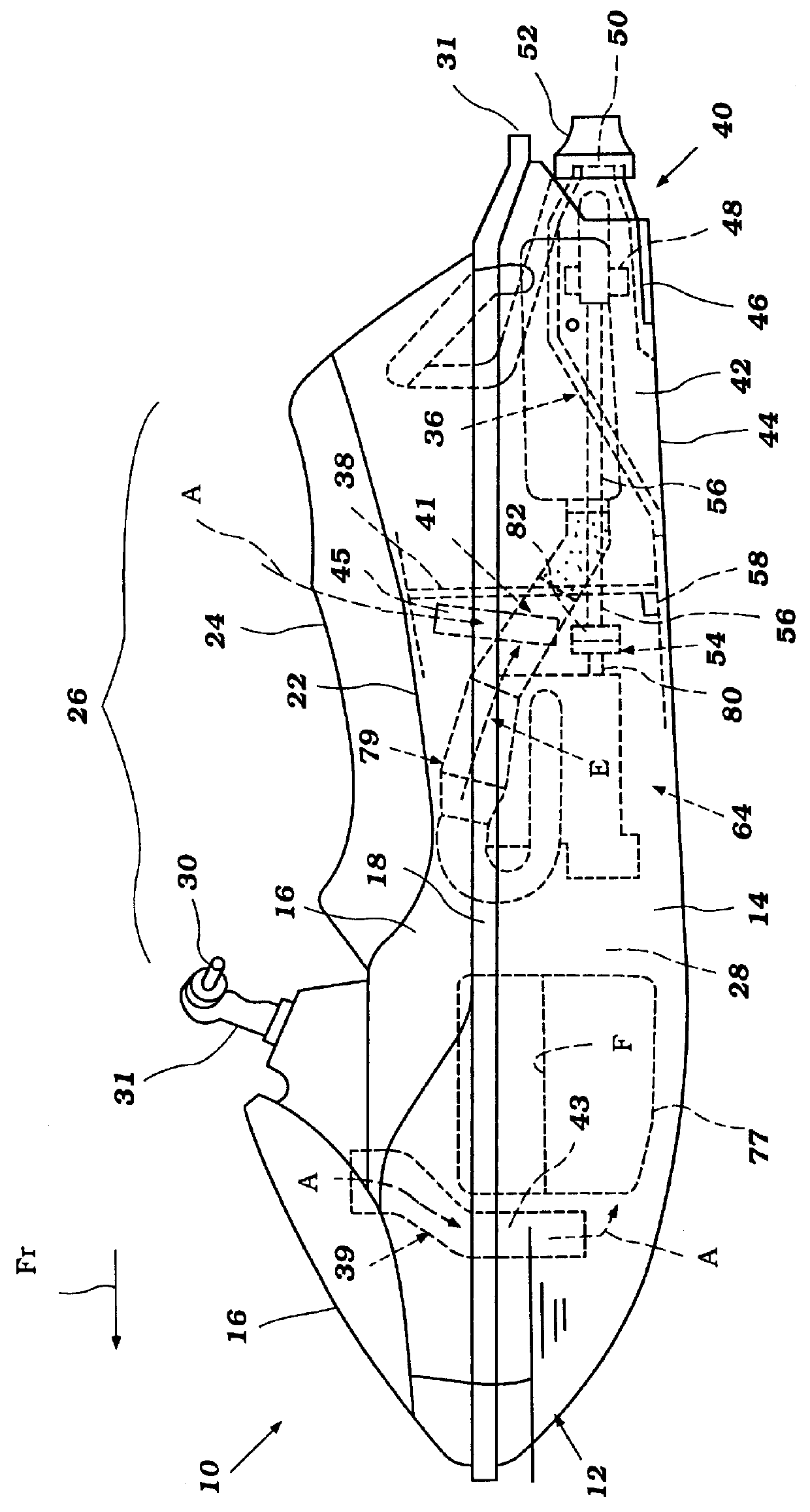

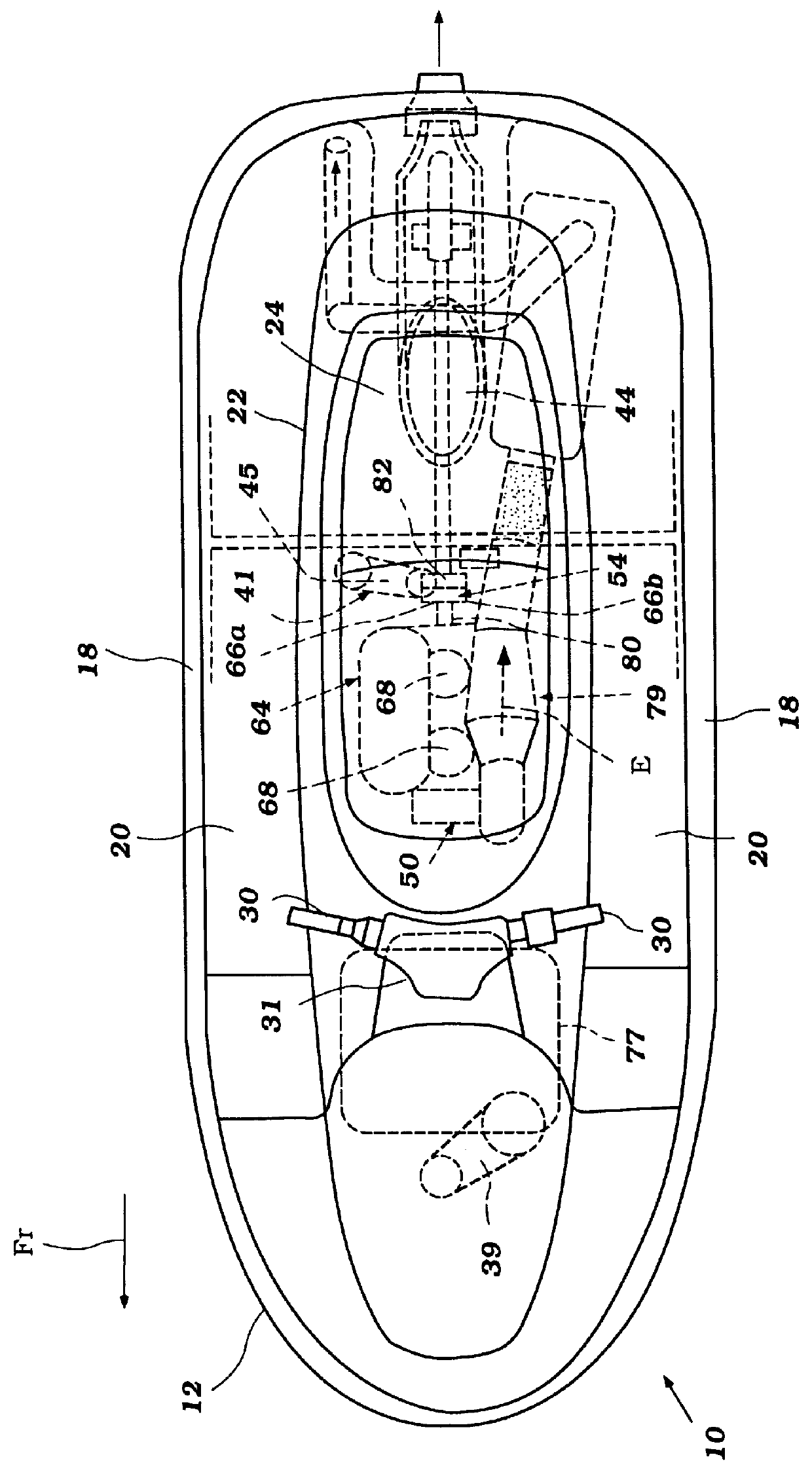

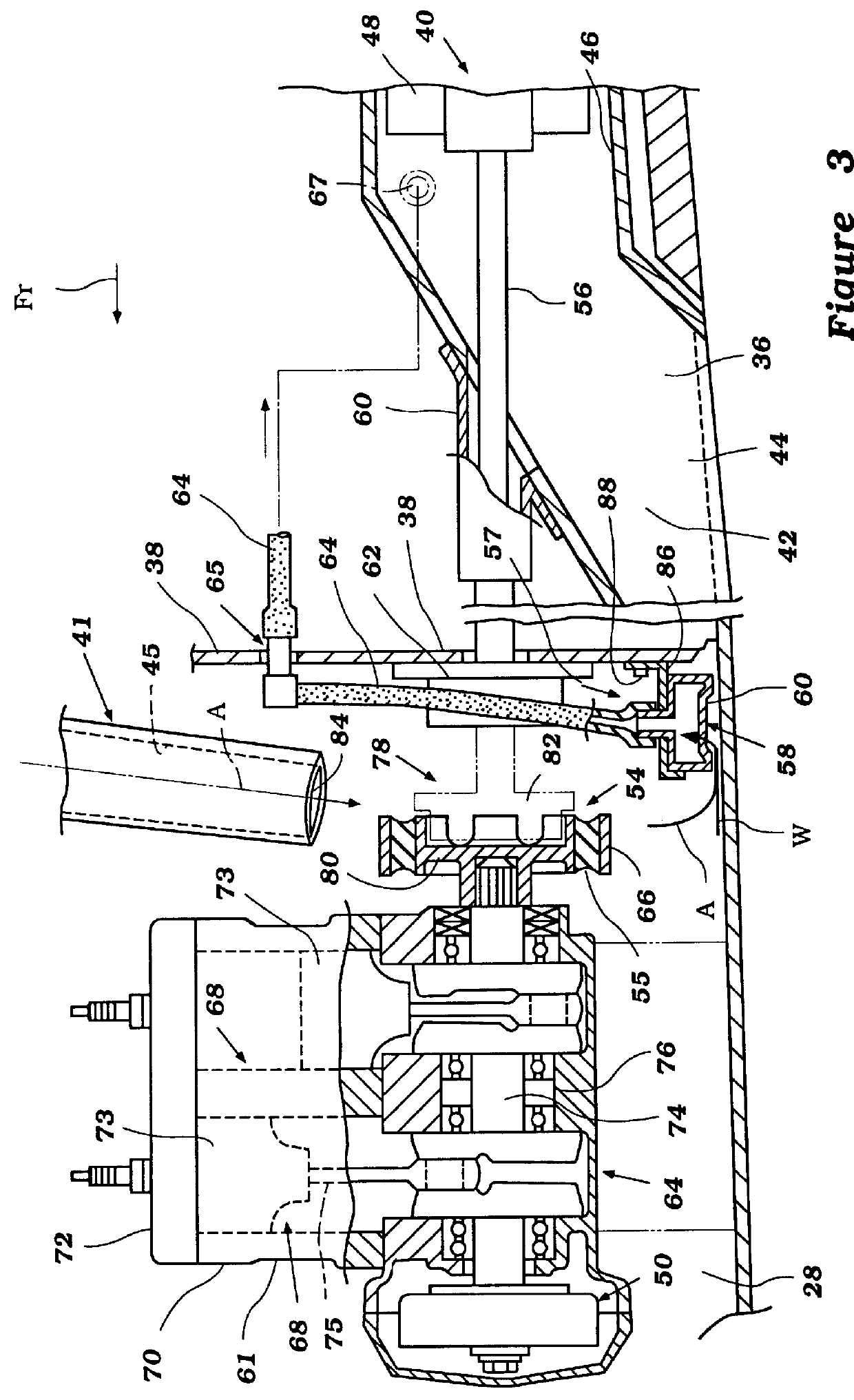

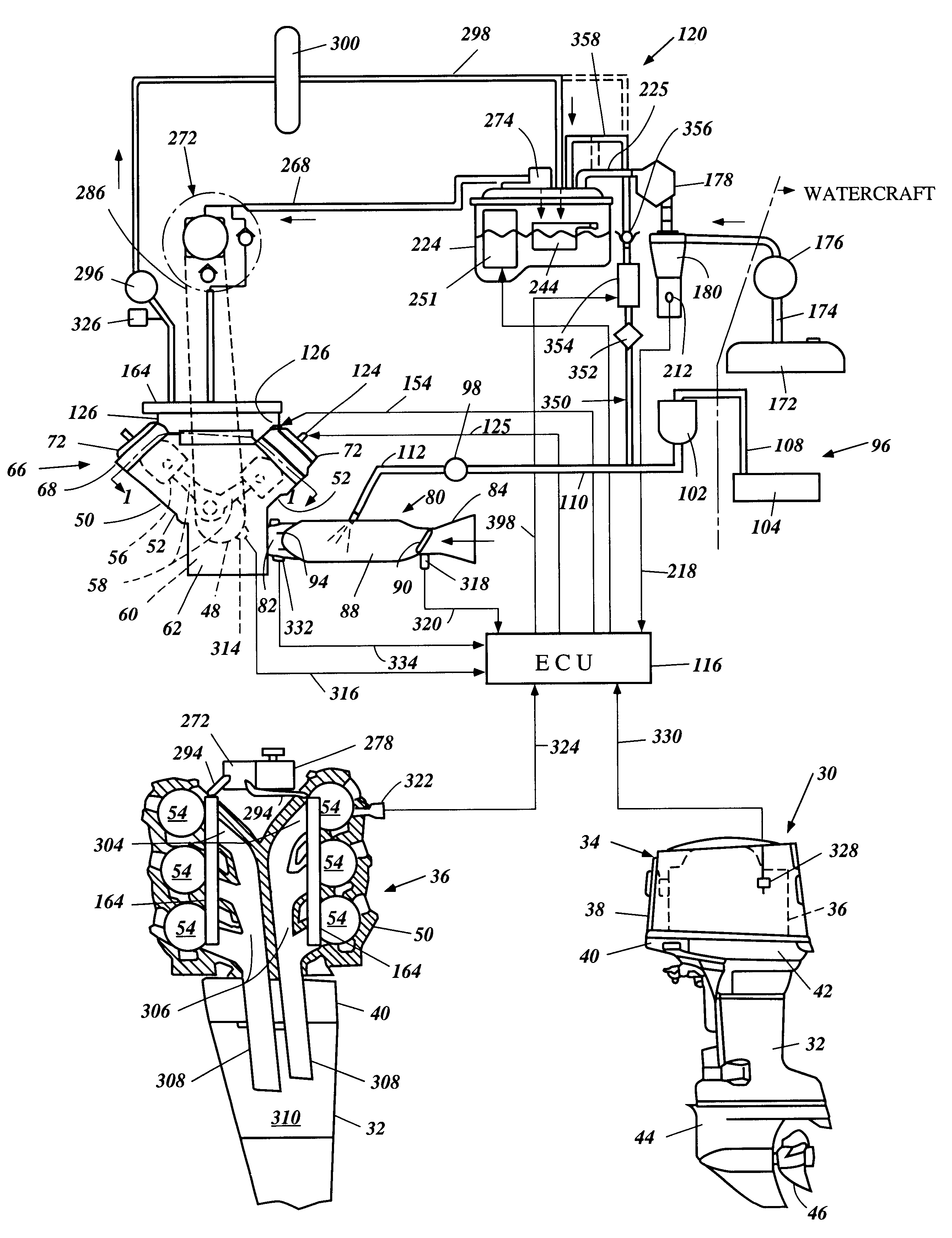

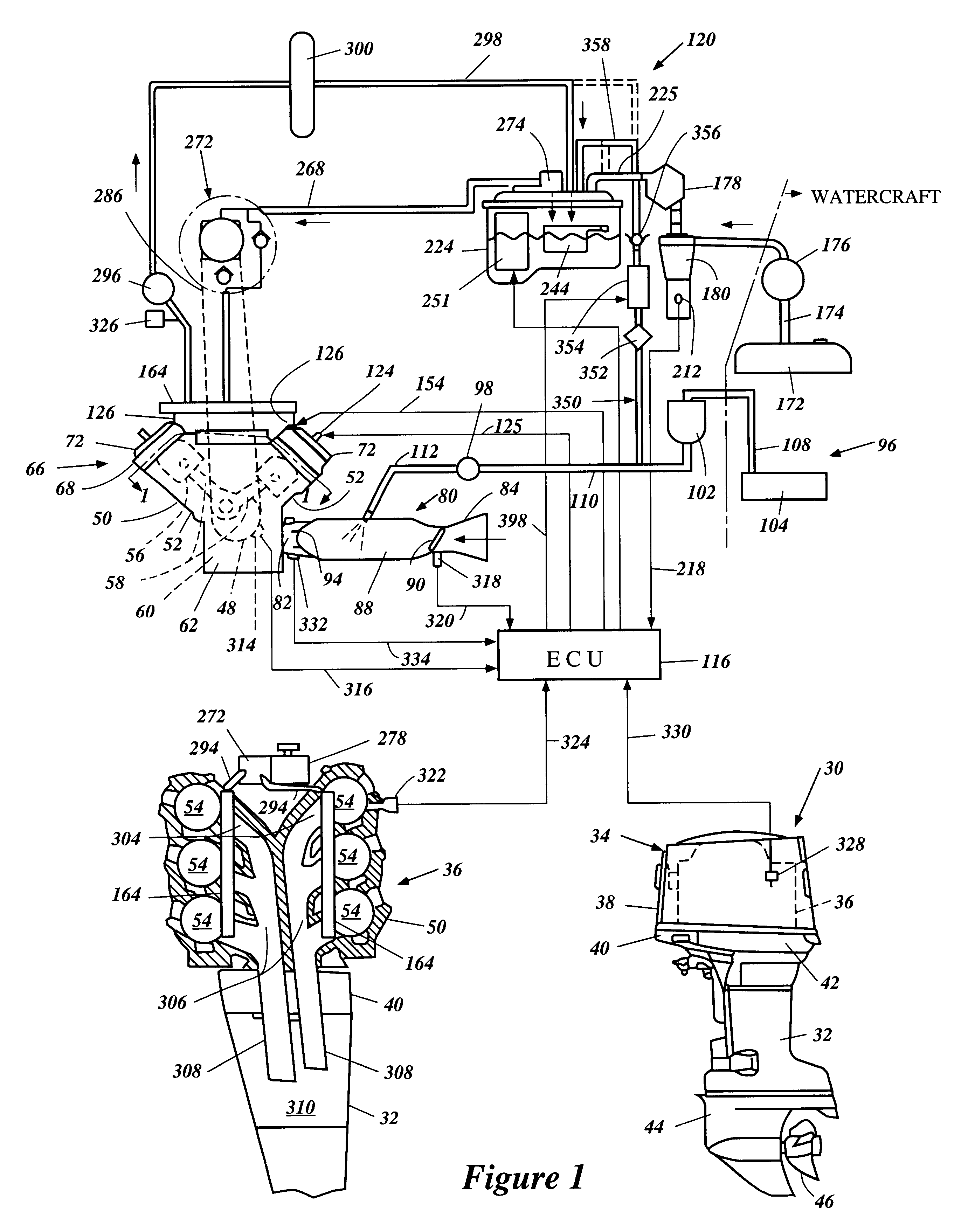

Vapor system arrangement for marine engine

A personal watercraft features a hull defining an engine compartment. An engine is mounted within the engine compartment. The engine comprises a cylinder head, a cylinder body and a crankcase. An induction system supplies air to the engine for combustion. The induction system comprising an intake box, an intake silencer, and a set of intake pipes that extend from the intake box to the engine. The intake pipes extend upward and inward toward the engine. A protective chamber is formed by an inside surface of the intake box, an outside surface of the engine and a lower surface of the pipes. A vapor separator is disposed within this protective chamber. The protective chamber can be augmented by an overhanging portion of the cylinder head, a protrusion from the cylinder body or other extensions from the intake box.

Owner:YAMAHA MOTOR CO LTD

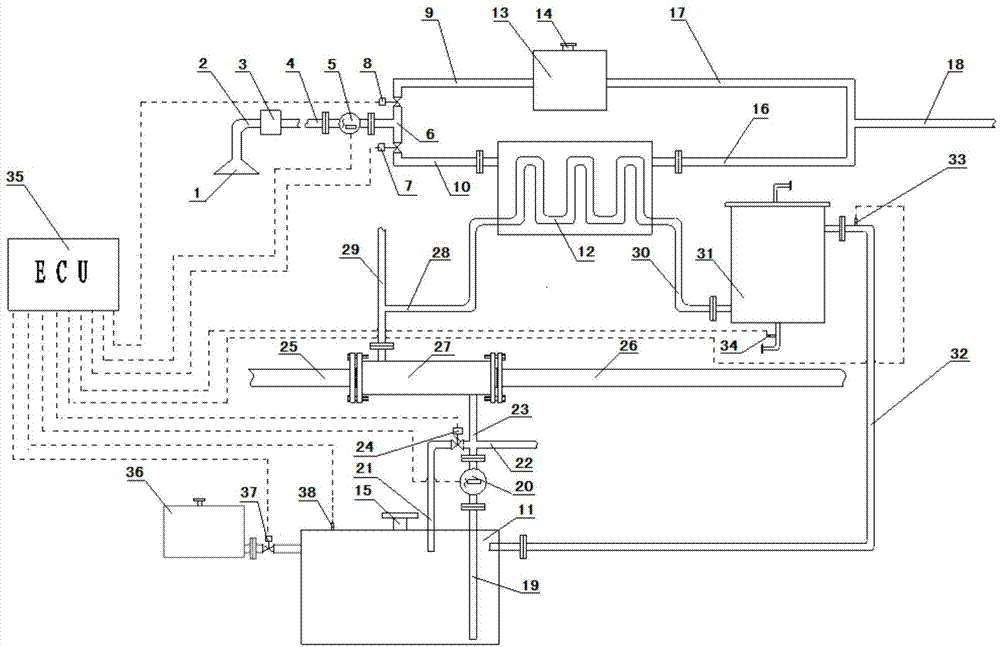

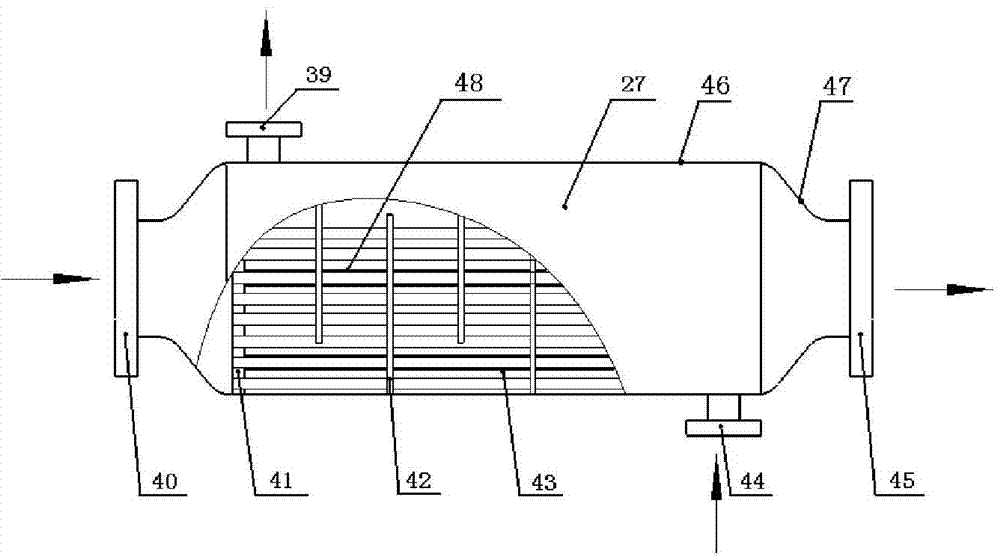

Ship gas/dual fuel engine LNG gasifying system based on exhaust energy recycling and control method thereof

ActiveCN103899440AImprove gasification effectImprove utilization efficiencyInternal combustion piston enginesFuel supply apparatusExpansion tankPlate heat exchanger

The invention aims at providing a ship gas / dual fuel engine LNG gasifying system based on exhaust energy recycling and a control method thereof. The ship gas / dual fuel engine LNG gasifying system comprises a heat transfer medium box, an exhaust heat exchanger, a heat dissipating device, an engine expansion water tank, an LNG gasifier and a liquid collecting plate. A heat transfer medium in the heat transfer medium box enters the exhaust heat exchanger through a first adjustable flow pump, enters the LNG gasifier after flowing through the heat dissipating device and then flows back to the heat transfer medium box, an external water source enters the engine expansion water tank and the heat dissipating device respectively through the liquid collecting plate and a three-way valve and then is drained, the external water source entering the heat dissipating device and the heat transfer medium are not mixed, and in other words, the external water source and the heat transfer medium flow in corresponding pipelines. The ship gas / dual fuel engine LNG gasifying system is high in heat dissipating capability and good in LNG gasifying effect, the engine exhaust emission heat can be recycled fully, the fuel utilization efficiency of an engine is improved, and the working environment of cabin marine engine operators can be obviously improved.

Owner:HARBIN ENG UNIV

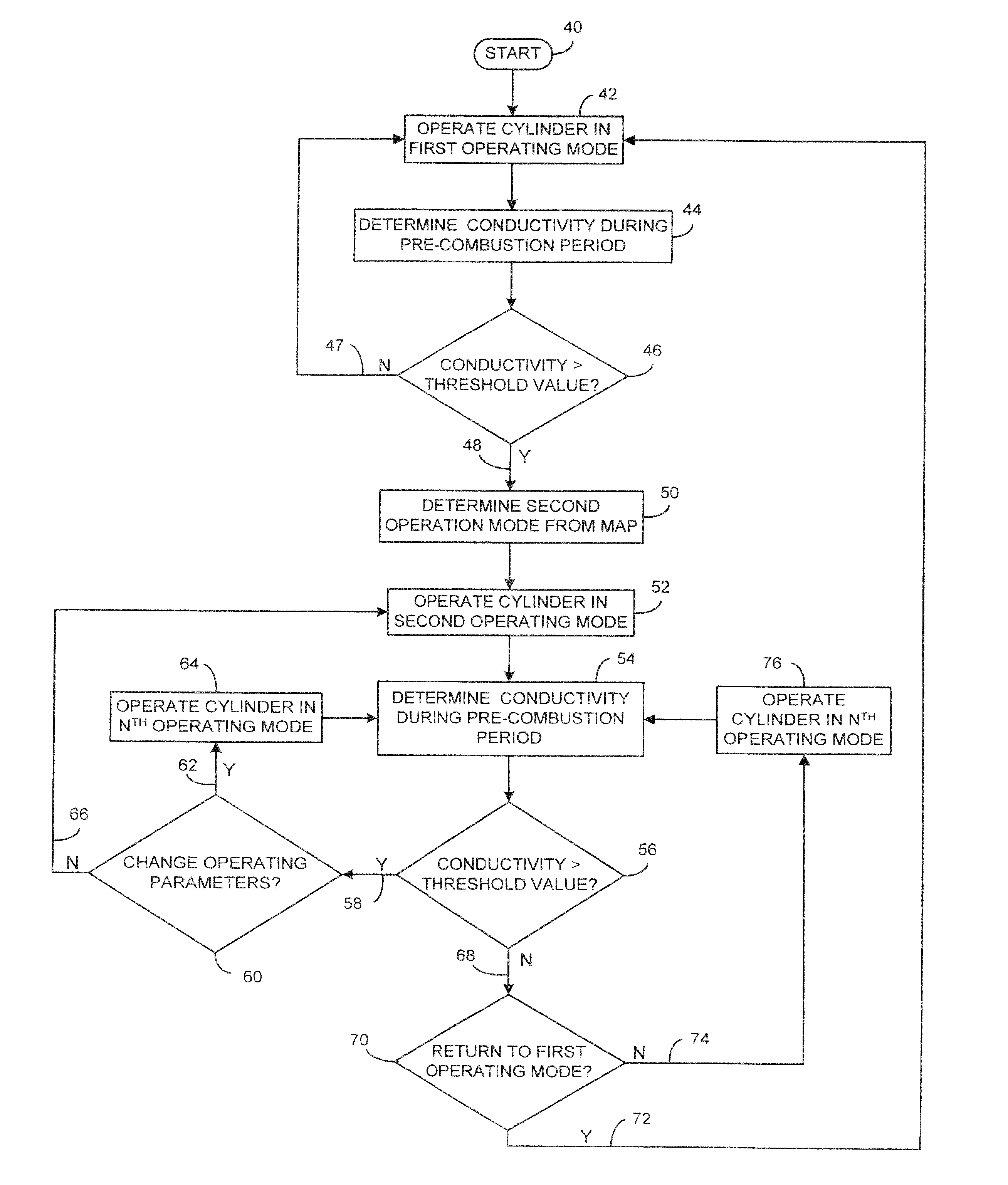

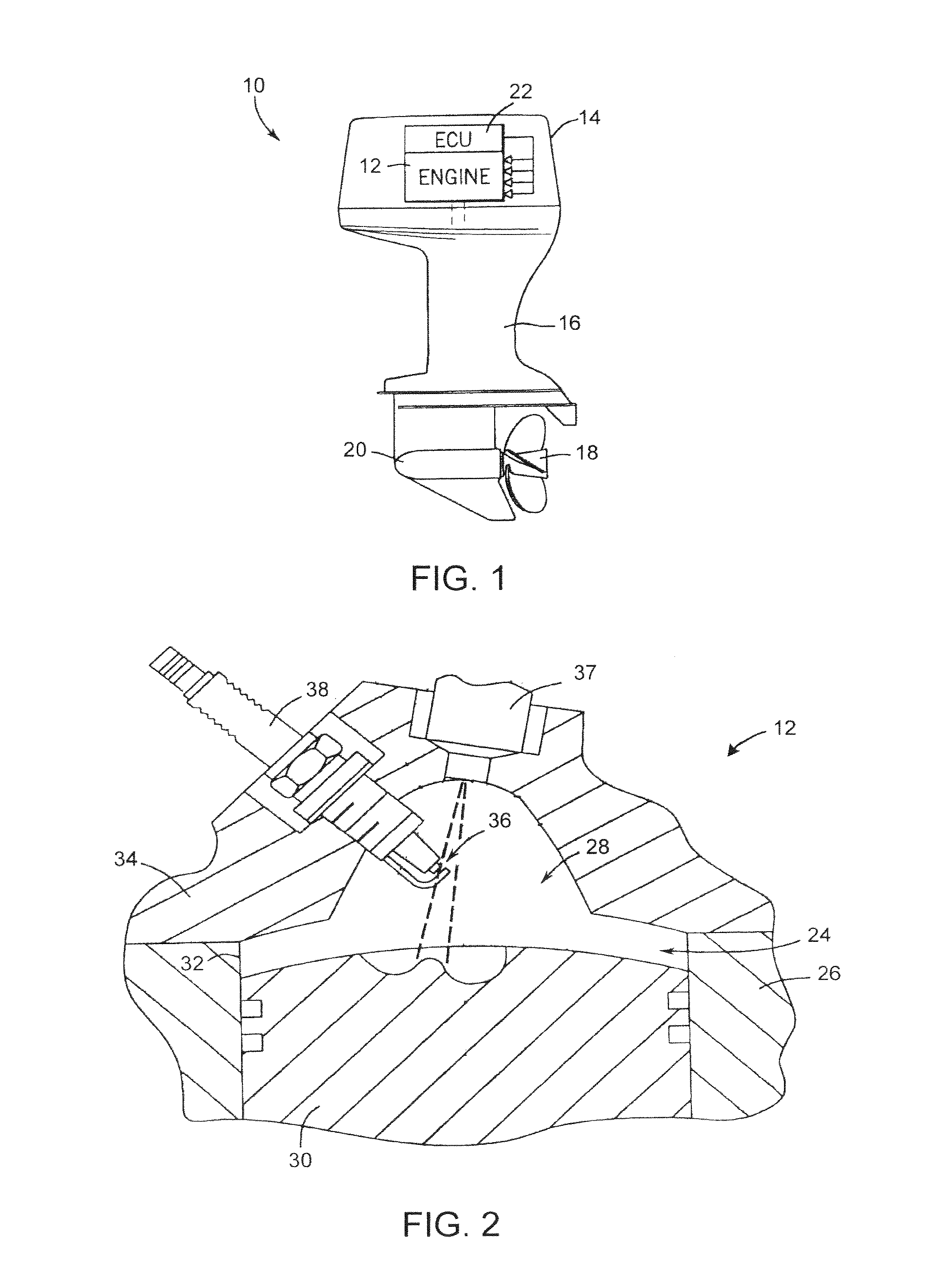

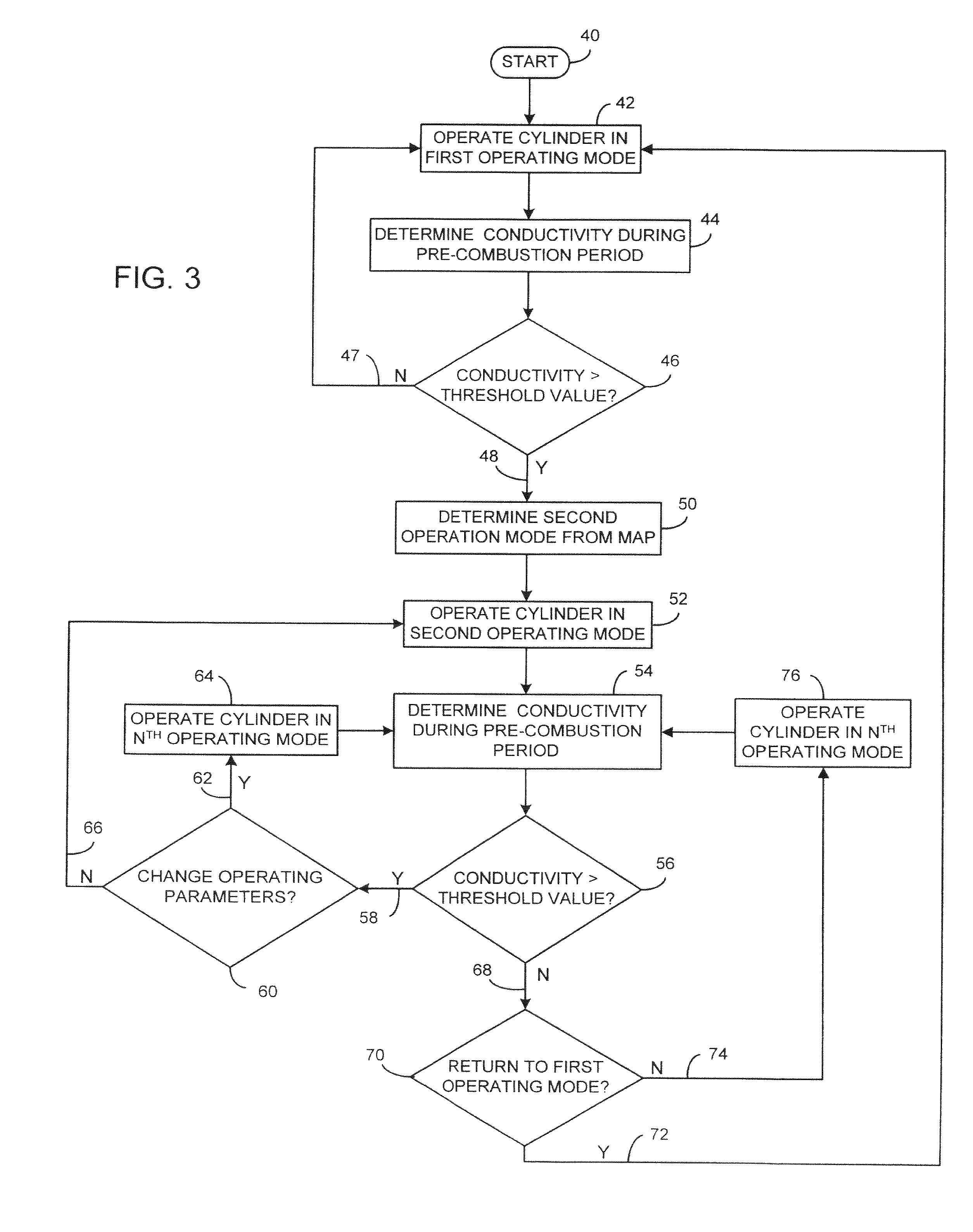

System and method to detect and correct spark plug fouling in a marine engine

ActiveUS20050022776A1Reduce ionizationElectrical controlCombustion enginesCombustion chamberOperation mode

A system and method for operating a combustion engine including a combustion chamber operable in at least a first operating mode and second operating mode. An engine control unit (ECU) performs conductivity sensing within the combustion chamber and interprets the results. Specifically, the ECU determines the current between a pair of spark plug electrodes placed within a combustion chamber of a combustion engine prior to, or after, combustion. The ECU determines whether the current between the pair of electrodes is indicative of spark plug fouling. If spark plug fouling is determined, the ECU can modify the mode of operation to correct the spark plug fouling and clean the deposits on the spark plug while the engine is in operation and without operation intervention.

Owner:BRP US

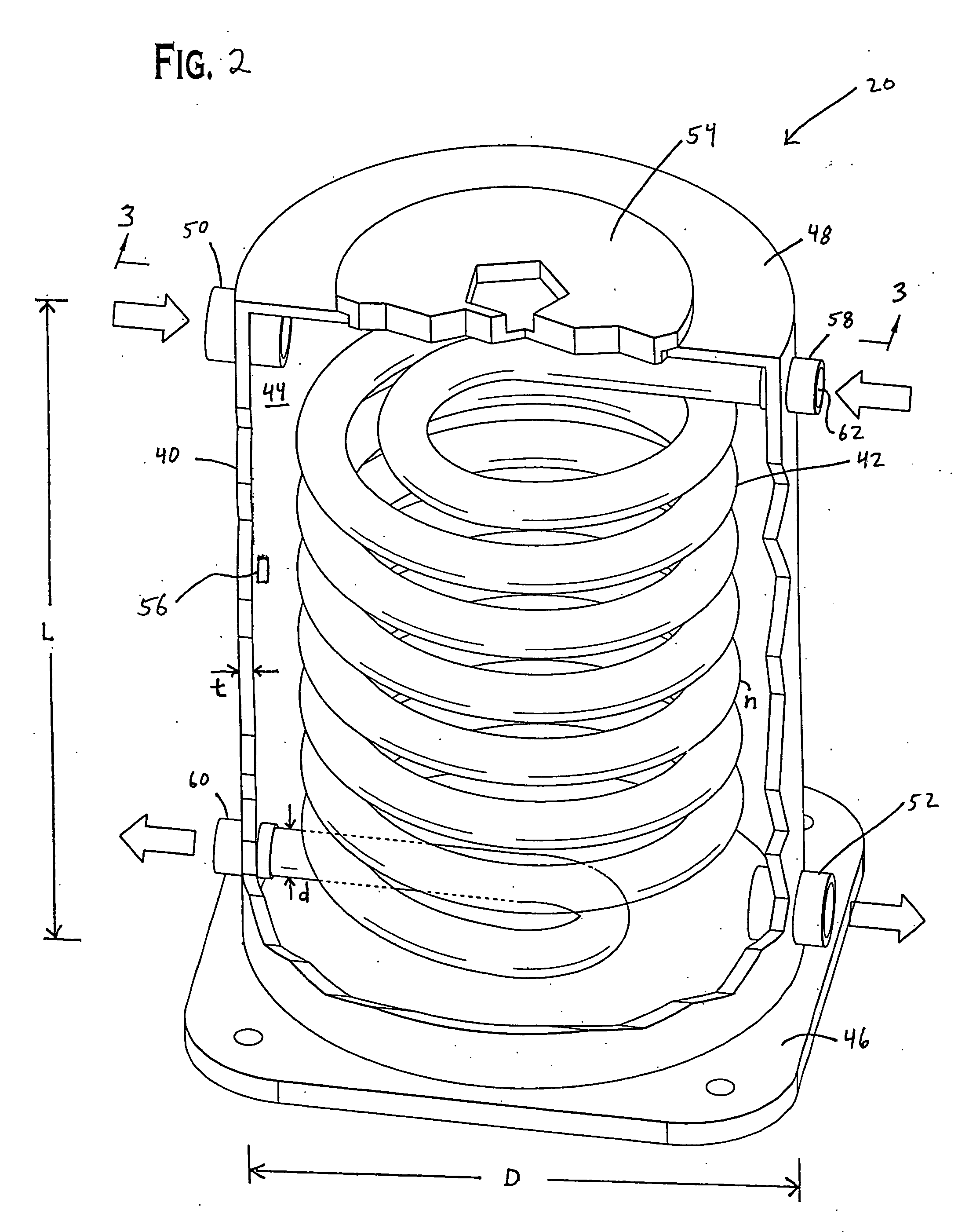

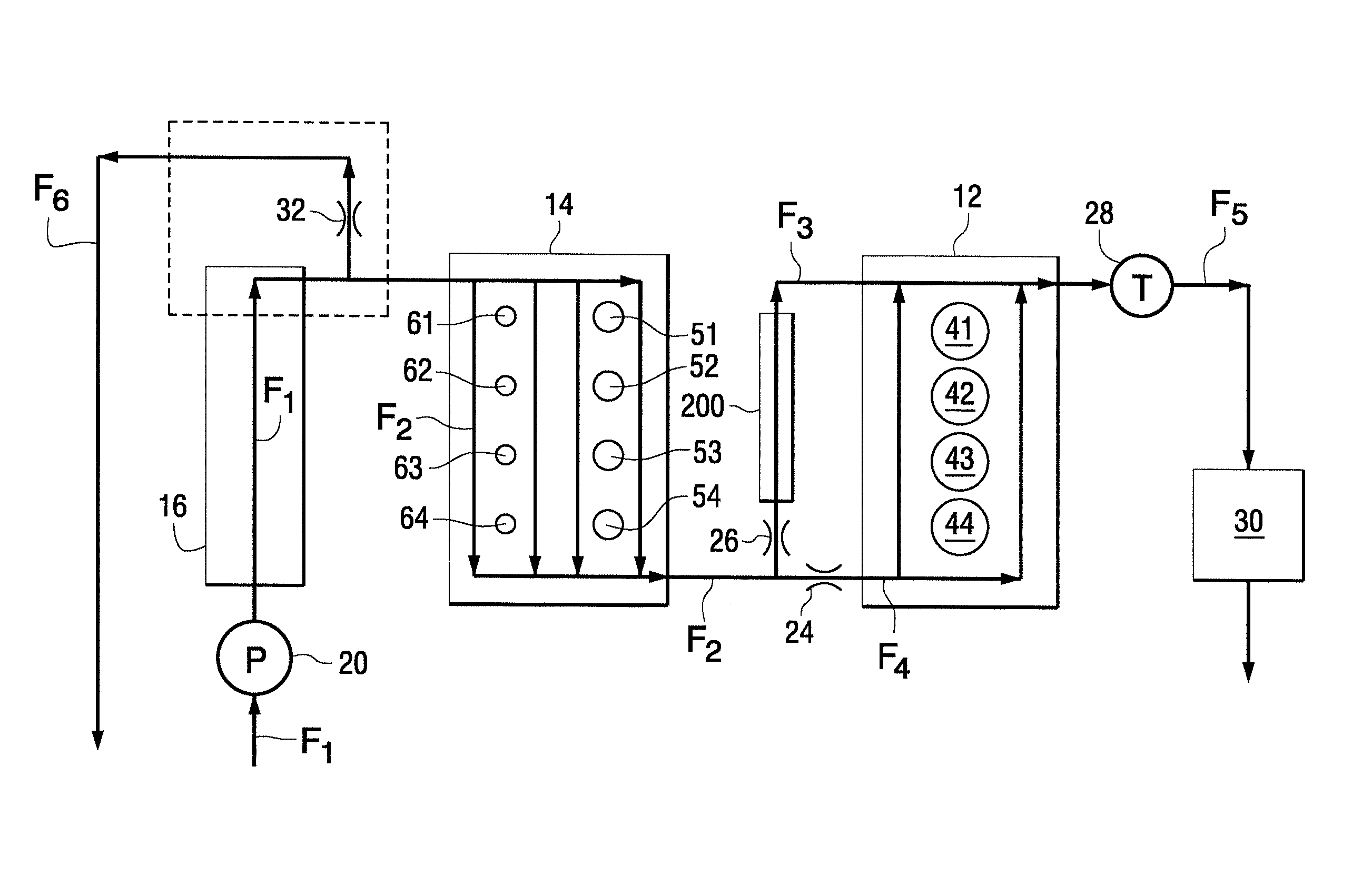

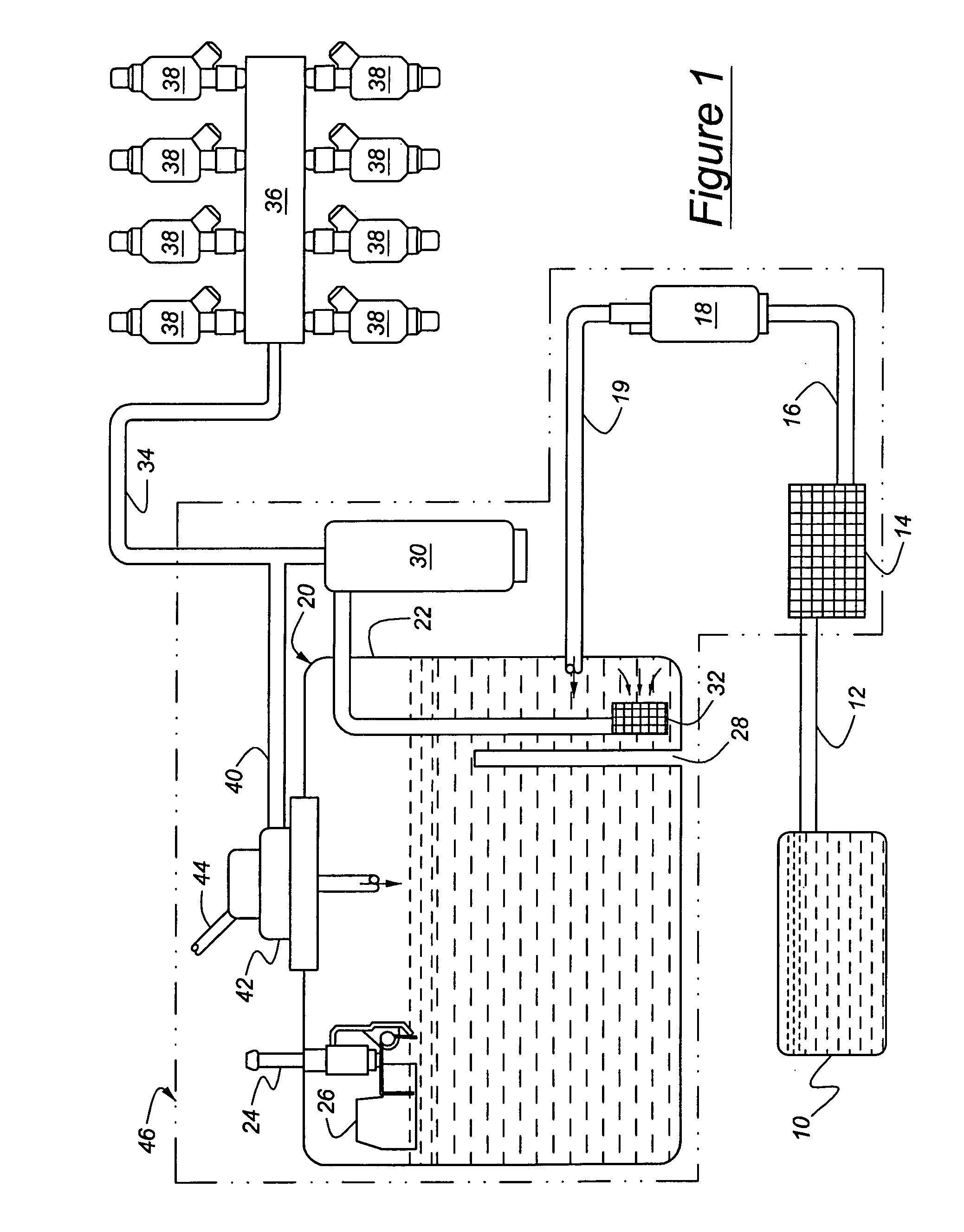

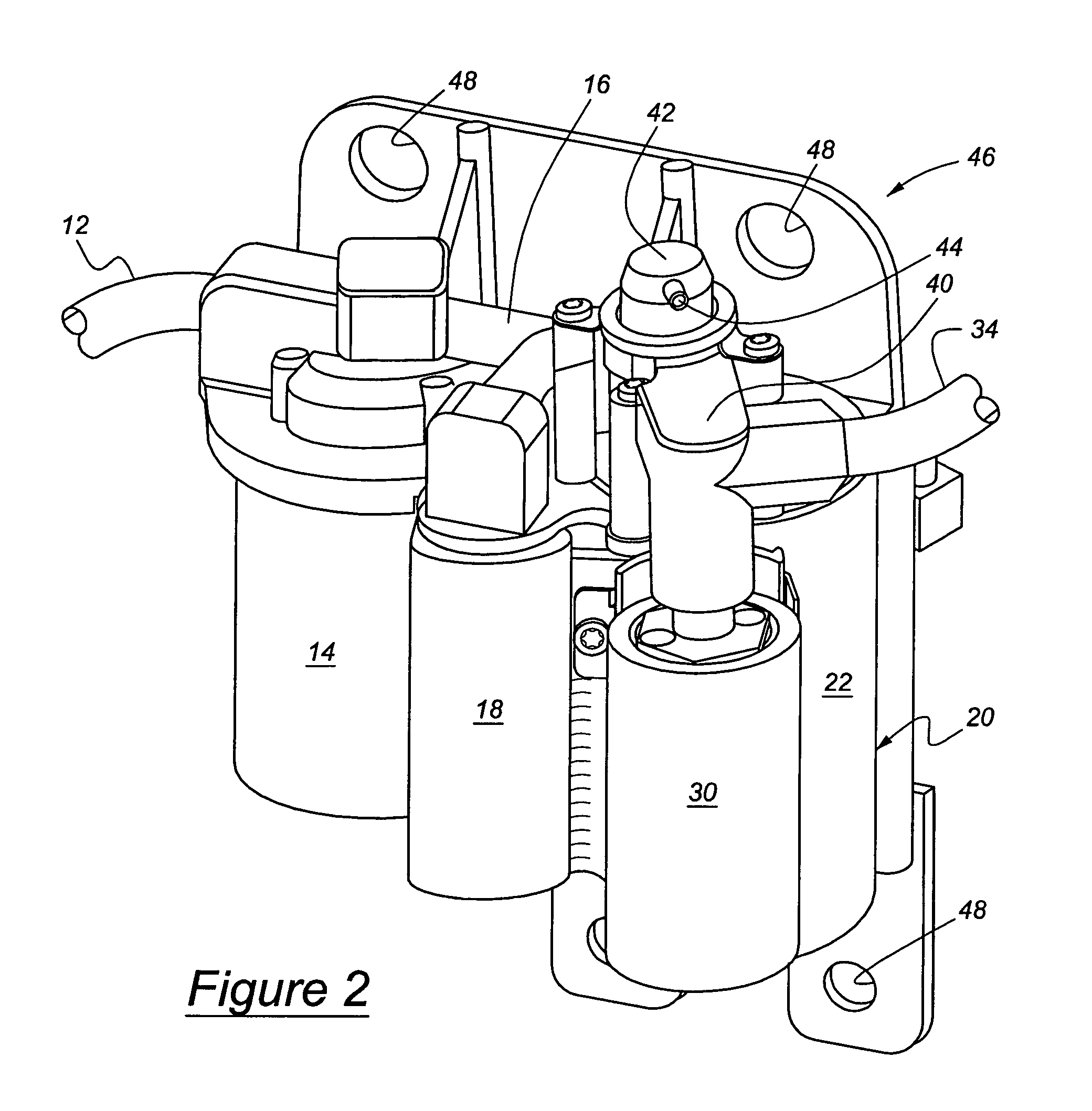

Marine vapor separator with bypass line

ActiveUS7168414B2Eliminates added design and fabrication costReduce riskNon-fuel substance addition to fuelFuel injection apparatusLine tubingWater filter

In a fuel supply system, liquid fuel is supplied to a marine engine from a fuel tank (10). The fuel first passes through a water filter (14), a lift pump (18) and is temporarily deposited in a vapor separator (20) where vapors given off from the fuel are collected and vented. A high pressure pump (30) withdraws liquid fuel from the vapor separator (200 and delivers it under pressure to an engine injector system (36) via a fuel delivery line (34). The fuel pressure between the high pressure pump (30) and the engine injector system (36) is monitored to determine whether the engine injector system (36) is being presented with more fuel than is required for efficient engine operation. If more fuel than needed is being supplied by the high pressure pump (30), the unneeded fuel is returned to the vapor separator (20) through a bypass line (40). A pressure regulator (42) along the bypass line (40) prevents the return of fuel to the vapor separator (20) when the pressure differential between the vapor separator (20) and the fuel being delivered to the engine injector system (36) reaches a predetermined value. The bypass line (40) comprises a short path from the fuel delivery line (34) and returns fuel back into the vapor separator (20) without traversing large spaces. The water filter (14), lift pump (18), vapor separator (20), high pressure pump (30), by-pass line (40) and pressure regulator (42) are contained as an integral unit (46).

Owner:CARTER FUEL SYST

Fuel injection system for marine engine

A fuel injection system for a marine engine includes an improved construction that, by the introduction of lubricant into the fuel, inhibits components of the system from rusting in the event that water, particularly salt water, is mixed with the fuel. The engine includes a lubricant delivery system to deliver lubricant to at least one portion of the engine that needs lubrication. A premix lubricant pump is provided for supplying lubricant with the fuel injection device from the lubricant delivery system so as to mix the part of the lubricant to the fuel. An ECU controls an amount of the part of the lubricant so as to be in a proper and extremely small range.

Owner:SANSHIN KOGYO CO LTD

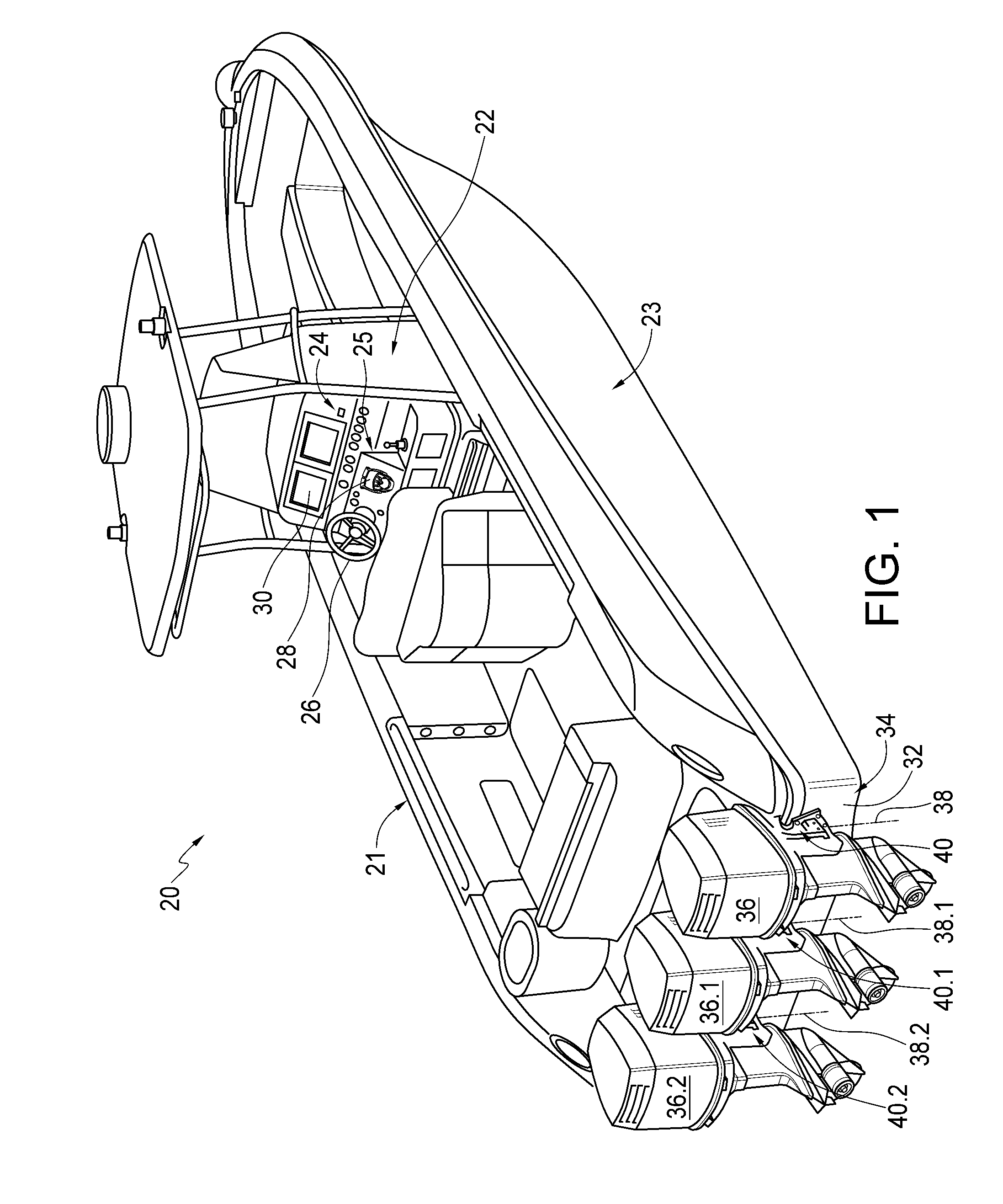

Control system and method for starting and stopping marine engines

The present invention relates to a start-protection system for an engine of a marine vessel. The engine has gears and a shift actuator for operatively shifting the gears. The system includes a first position sensor disposed to operatively sense whether the engine is in a forward, neutral or a reverse gear position. The first position sensor generates a signal representative of the gear position. The system includes a second position sensor adjacent to a shift control which controls shift functions of the engine. The second position sensor generates a signal representative of the position of the shift control. The system includes processing means. The processing means are configured to receive the signals of the position sensors, determine the gear position and the position of the shift control and enable the engine to start upon determining that both the shift control and the engine are in neutral positions.

Owner:MARINE CANADA ACQUISITIONS INC

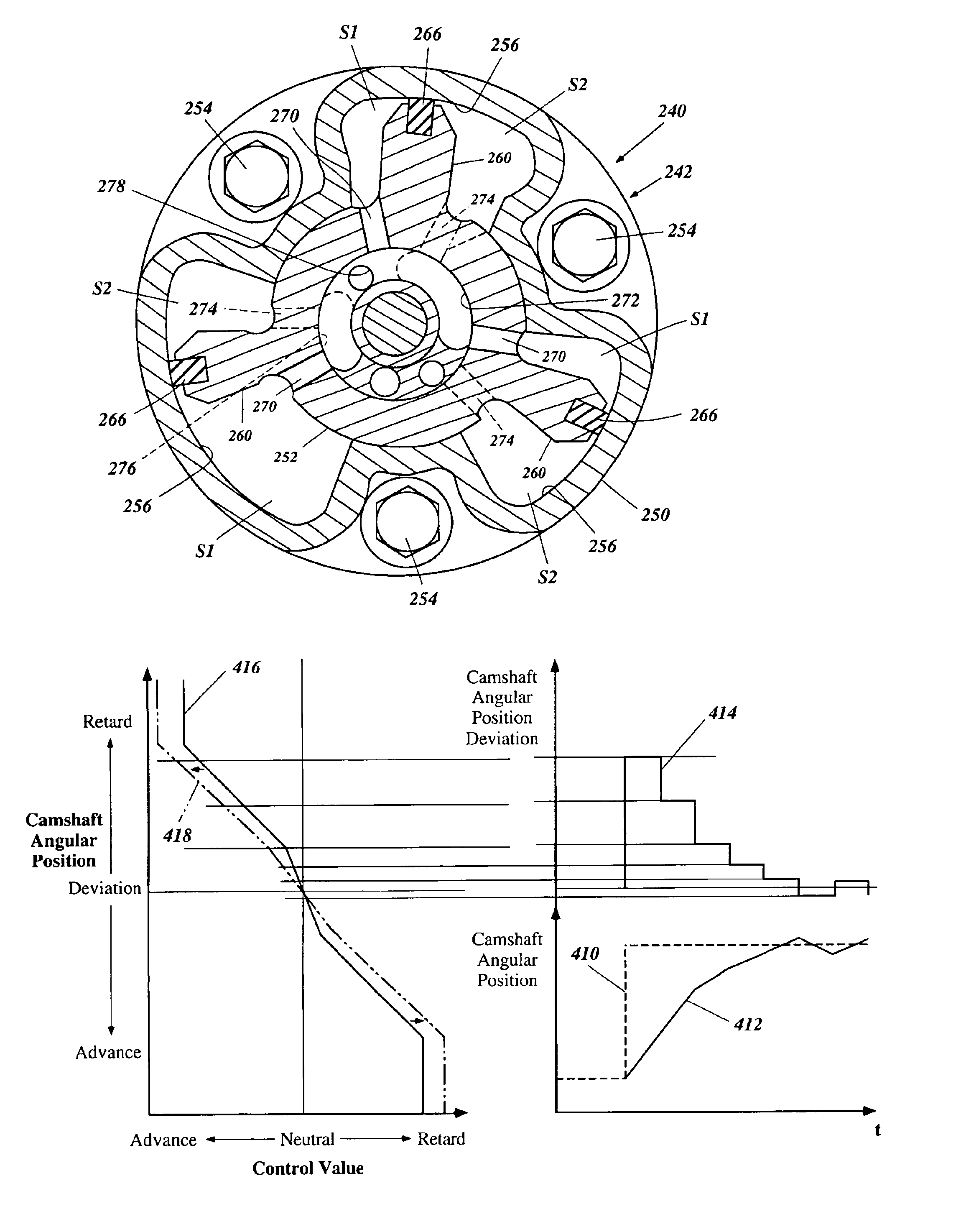

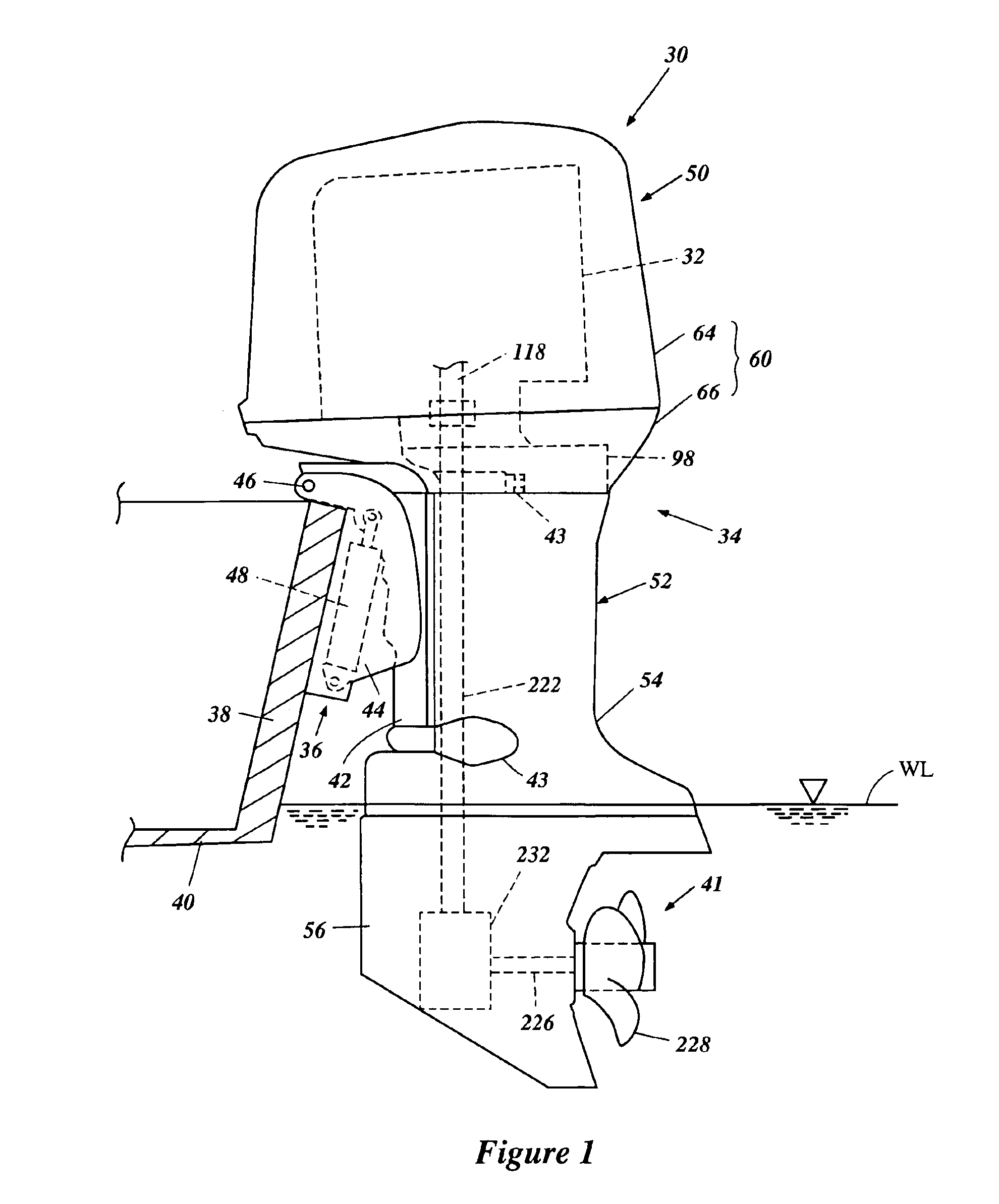

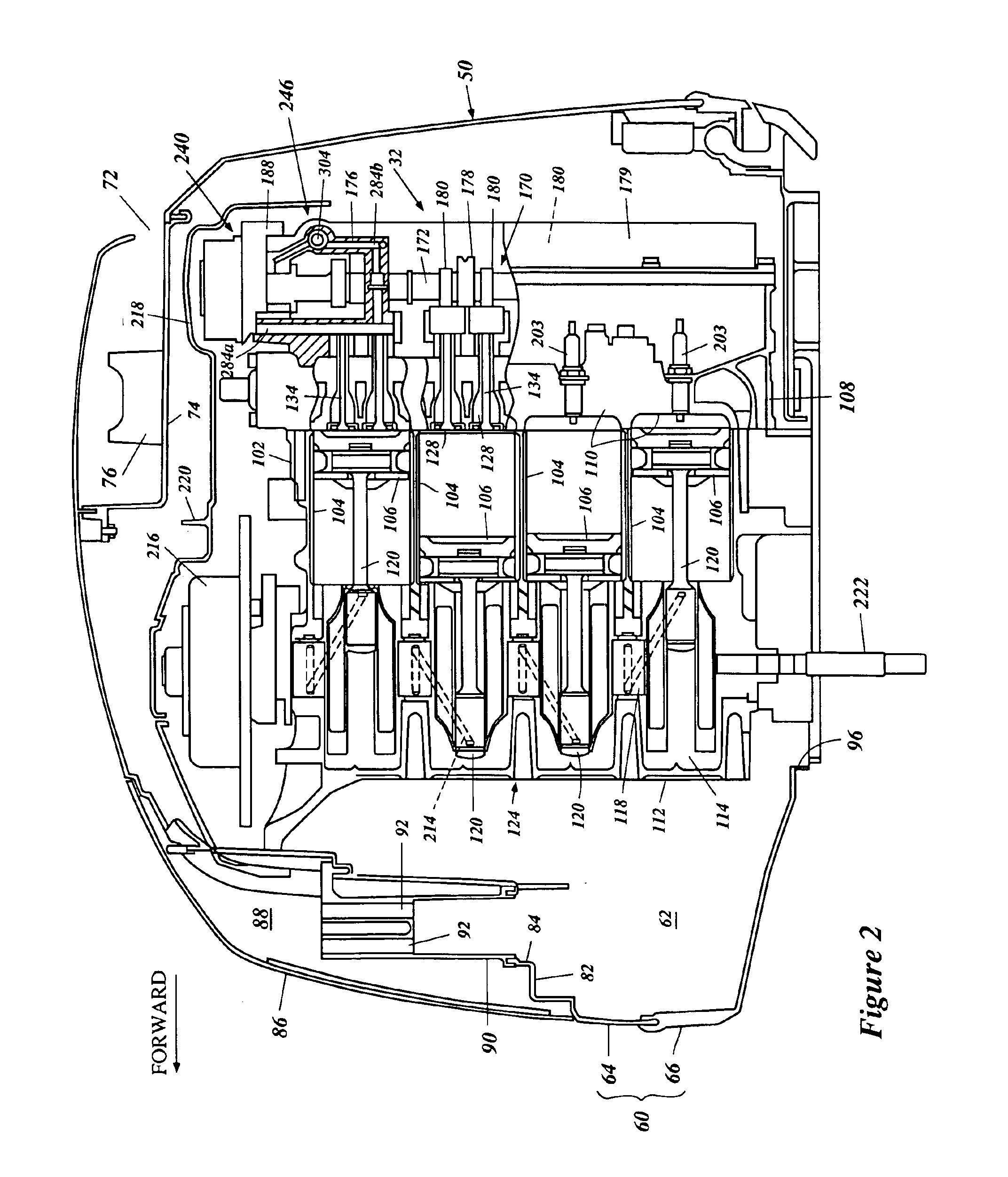

Valve timing control for marine engine

InactiveUS6957635B2Accurately follow commandLow viscosityCamsValve arrangementsExhaust valveCombustion chamber

An engine for a marine drive has a combustion chamber. An engine body of the engine defines intake and exhaust ports communicating with the combustion chamber. An air induction system communicates with the combustion chamber through intake ports. An exhaust system communicates with the combustion chamber through the exhaust ports. Intake valves move between an opening position and a closing position of the intake ports. Exhaust valves move between an opening position and a closing position of the exhaust ports. Camshafts actuate the intake and the exhaust valves. A hydraulic VVT mechanism changes an actuating timing of the camshaft at which the camshaft actuates the intake valves or the exhaust valves. An ECU controls the VVT mechanism based upon a control characteristic. A temperature sensor, such as an oil temperature sensor, a water temperature sensor and an engine body temperature sensor, senses a temperature of oil of the VVT or a temperature relating to the temperature of the oil and sends a temperature signal to the ECU. The ECU adjusts the control characteristic when the temperature is lower than a preset temperature.

Owner:YAMAHA MARINE KK

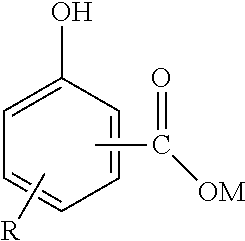

Marine engine lubrication

ActiveUS20120103303A1Not effectiveEasy to handleCombustion enginesEngine controllersEngineeringFuel oil

Trunk piston marine engine lubrication, when the engine is fueled by heavy fuel oil, is effected by a composition comprising a major amount of an oil of lubricating viscosity and a minor amount of one or more phenolic compounds comprising distilled cashew nut shell liquid or hydrogenated distilled cashew nut shell liquid. Asphaltene precipitation in the lubricant, caused by the presence of contaminant heavy fuel oil, is prevented or inhibited.

Owner:INFINEUM INT LTD

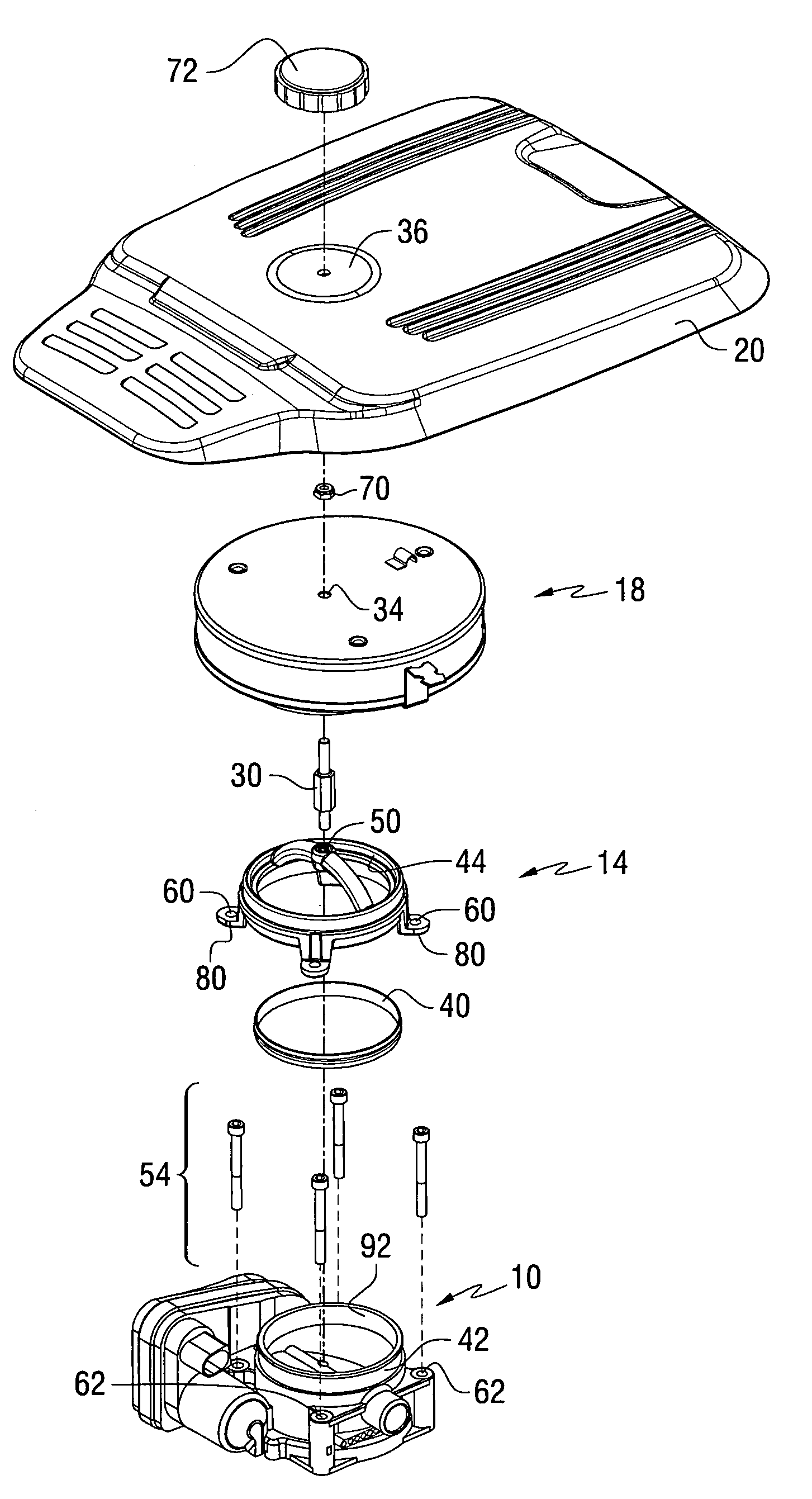

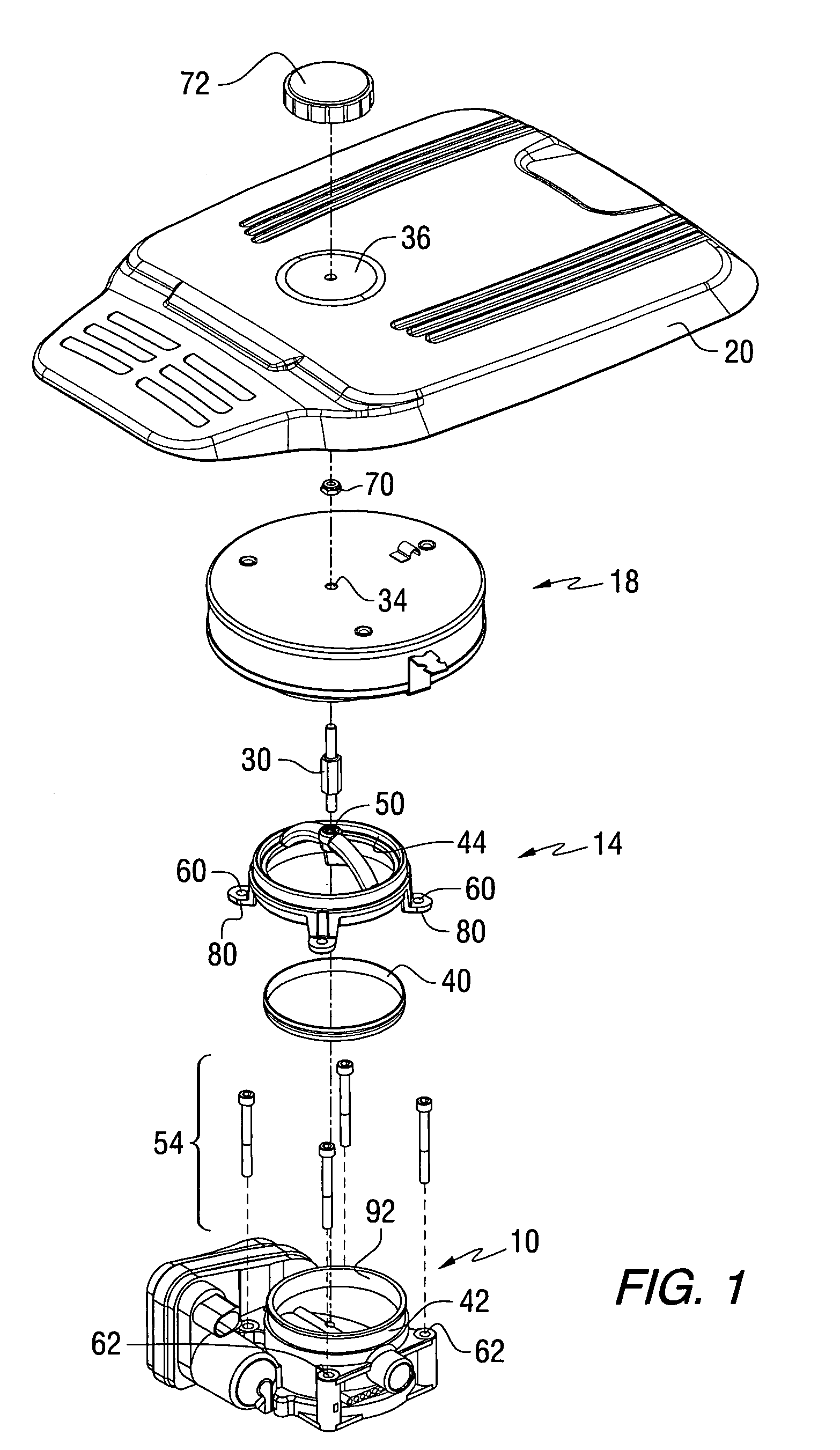

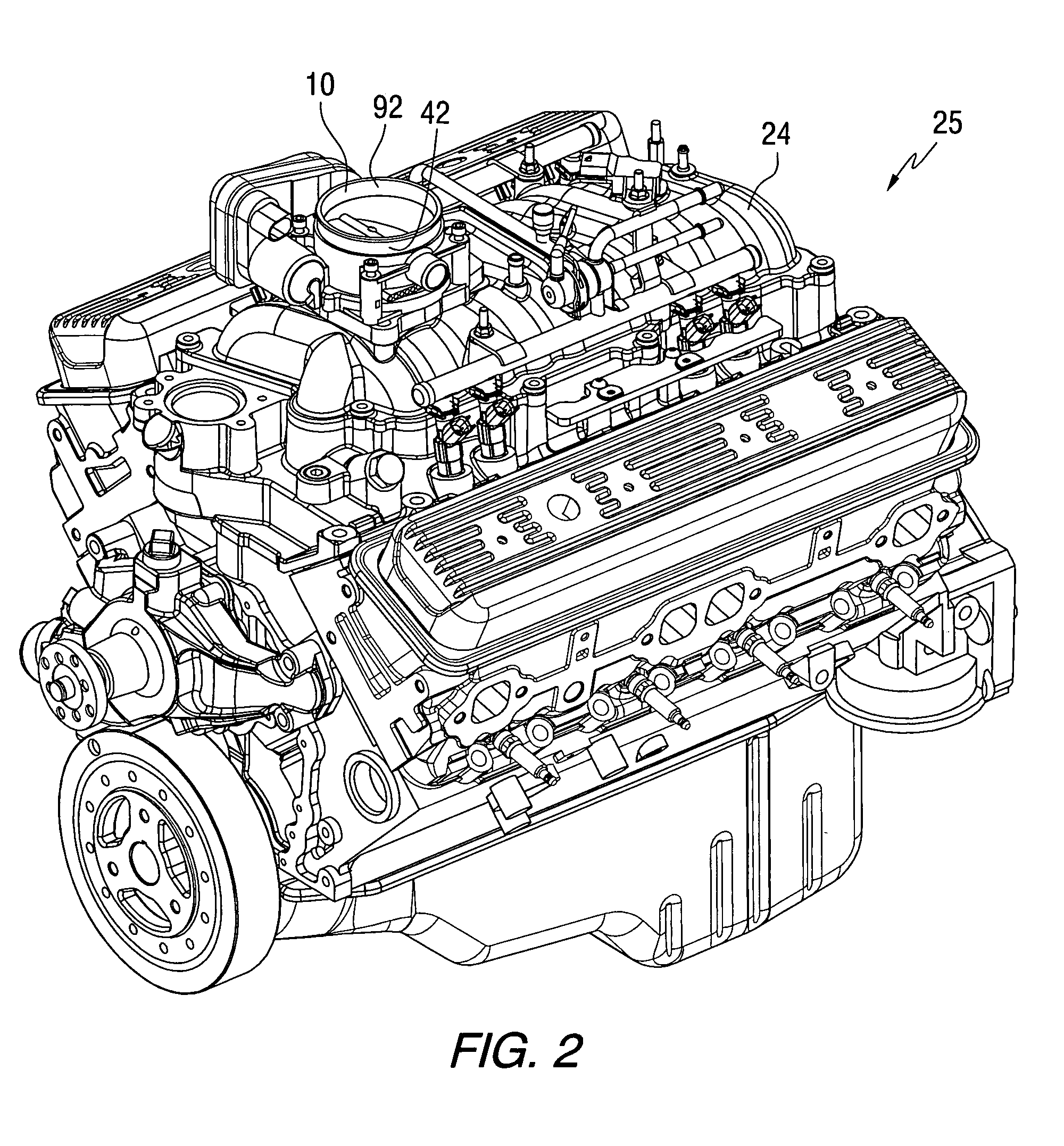

Component mounting system for a marine engine

InactiveUS7137378B1Retained in placeNoise may disadvantageouslyNon-fuel substance addition to fuelEngine controllersSupporting systemEngineering

An attachment and support system is provided for supporting a flame arrestor and cover at a preselected position relative to a throttle body which, in turn, is attached to an air intake manifold. A support member is attached, by four bolts, to the air intake manifold. The four bolts, or alternative attachment components, simultaneously attach the throttle body to the air intake manifold and the support member to the throttle body. Both the flame arrestor and cover are attached, by a stud, to the support member.

Owner:BRUNSWICK CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com