Patents

Literature

5435 results about "Spark plug" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air mixture by an electric spark, while containing combustion pressure within the engine. A spark plug has a metal threaded shell, electrically isolated from a central electrode by a porcelain insulator. The central electrode, which may contain a resistor, is connected by a heavily insulated wire to the output terminal of an ignition coil or magneto. The spark plug's metal shell is screwed into the engine's cylinder head and thus electrically grounded. The central electrode protrudes through the porcelain insulator into the combustion chamber, forming one or more spark gaps between the inner end of the central electrode and usually one or more protuberances or structures attached to the inner end of the threaded shell and designated the side, earth, or ground electrode(s).

Spark plug heating for a spark ignited engine

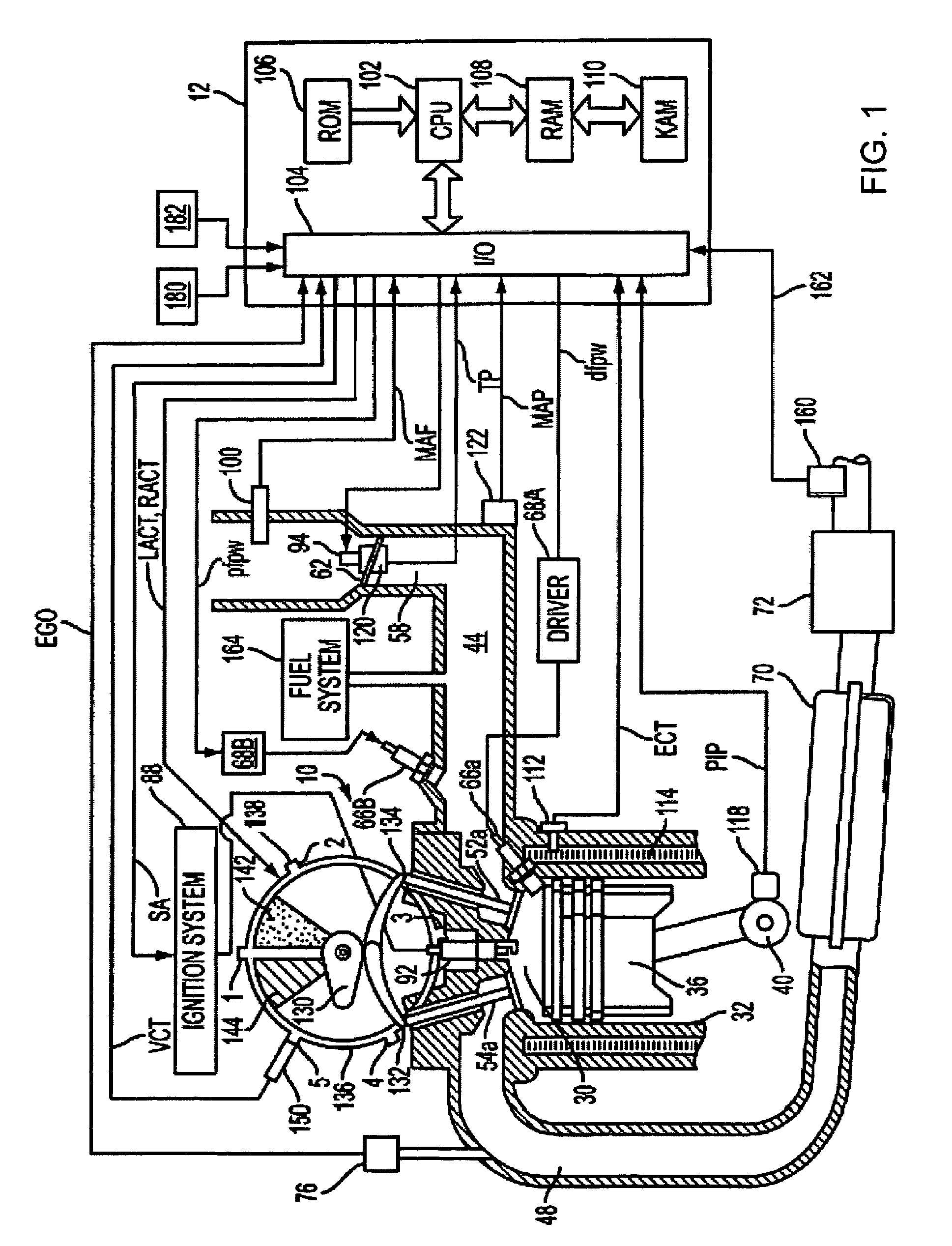

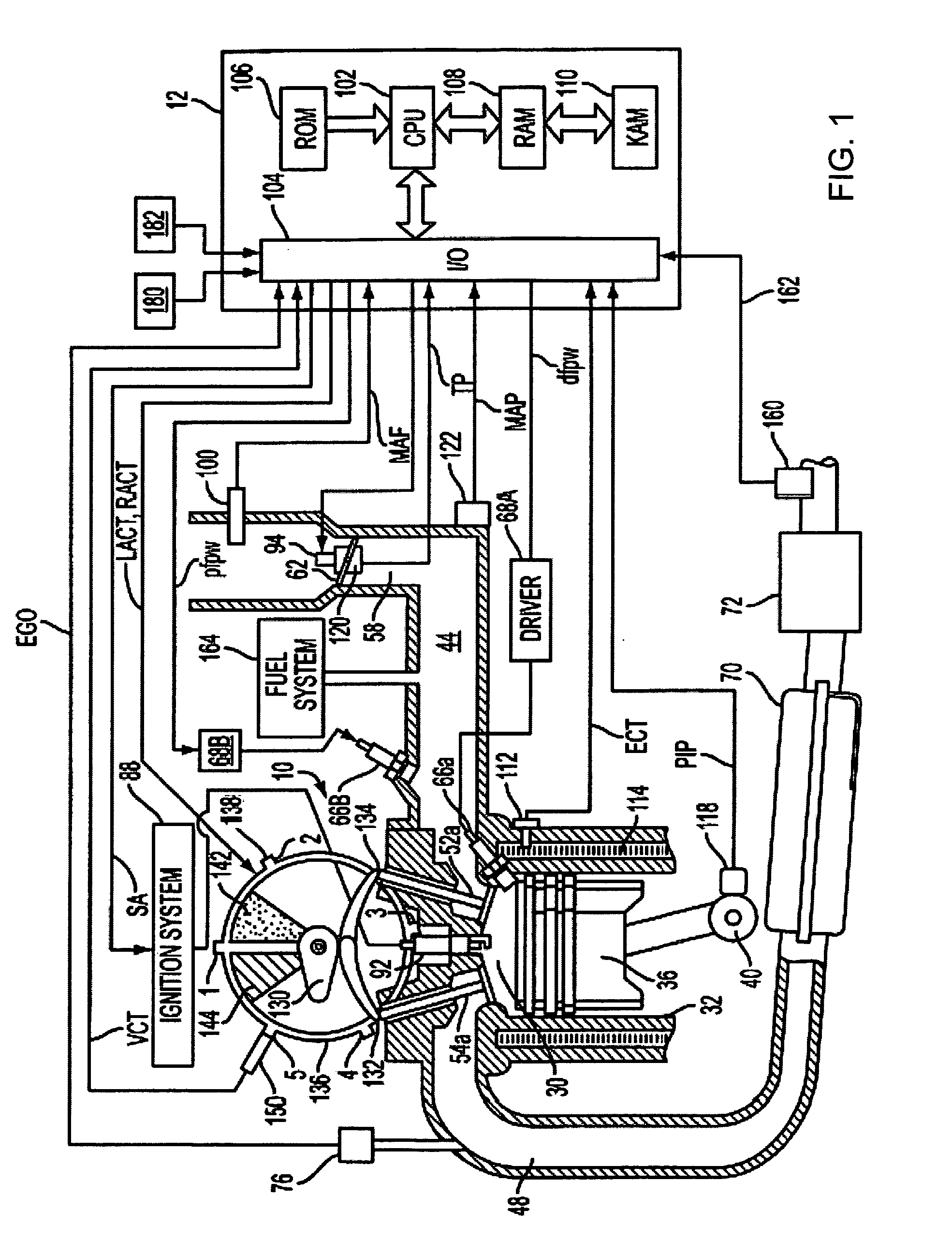

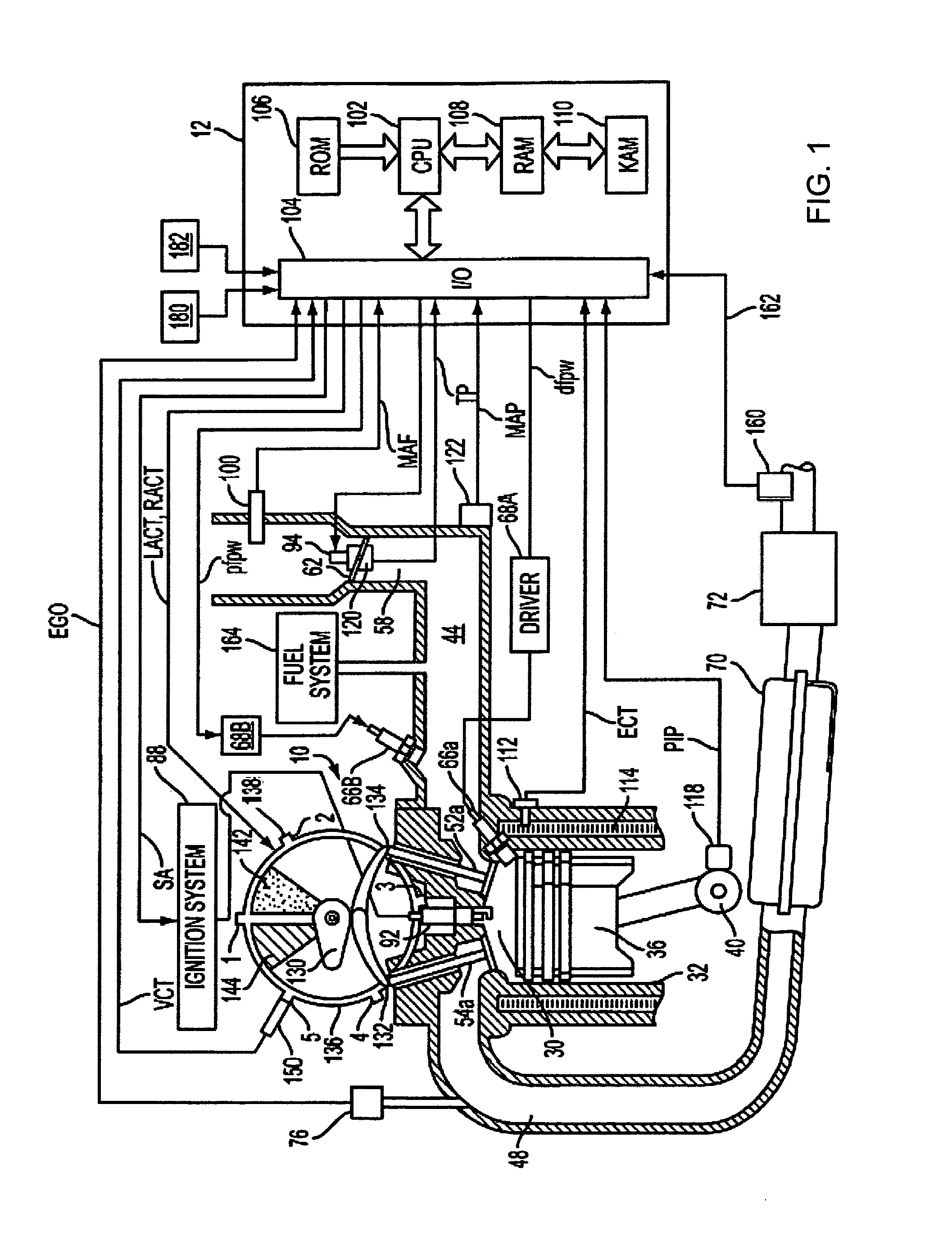

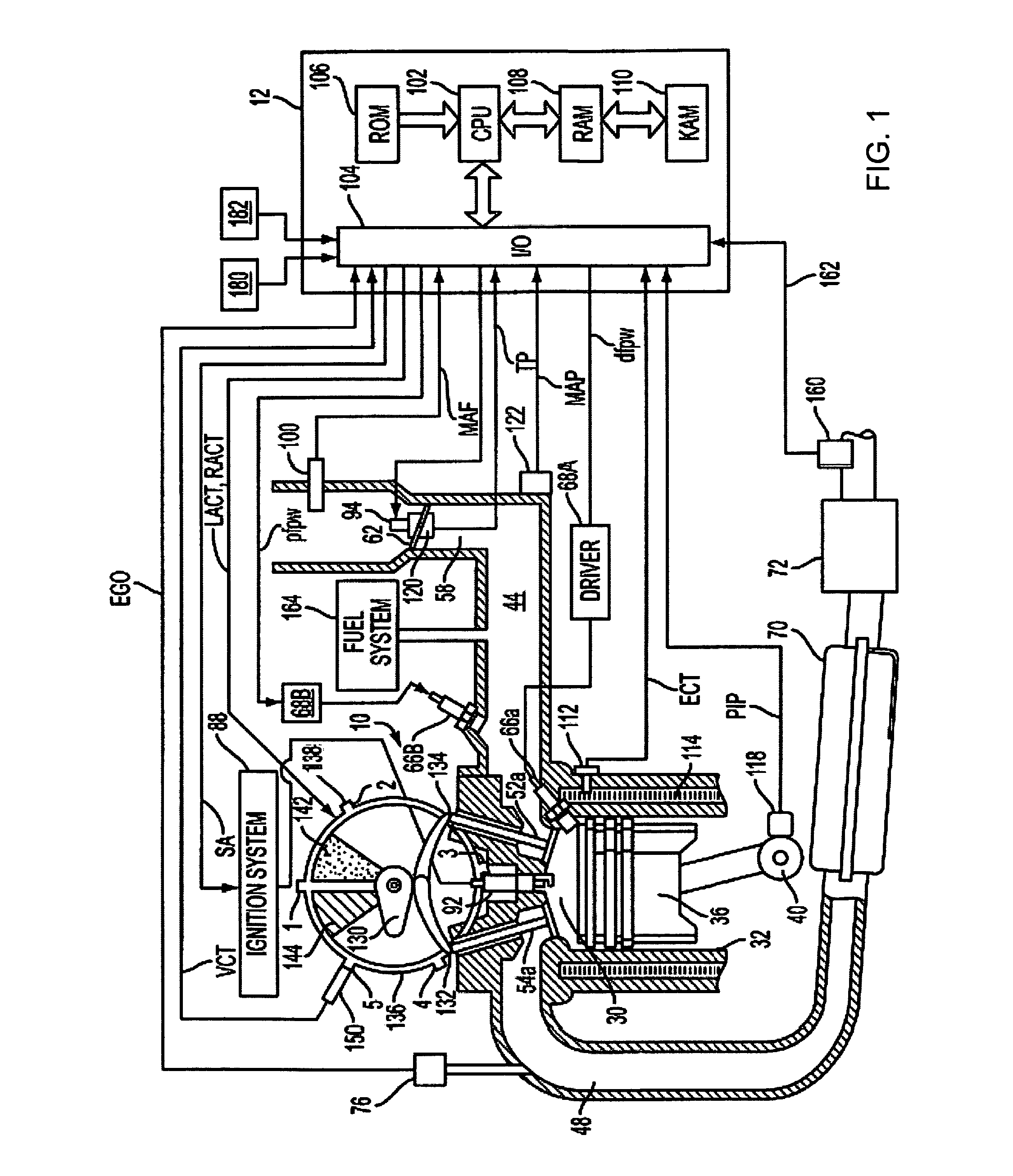

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, a spark plug heating system configured to supply heat to the spark plug, and a control system configured to vary an amount of heat supplied to the spark plug by the spark plug heating system responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

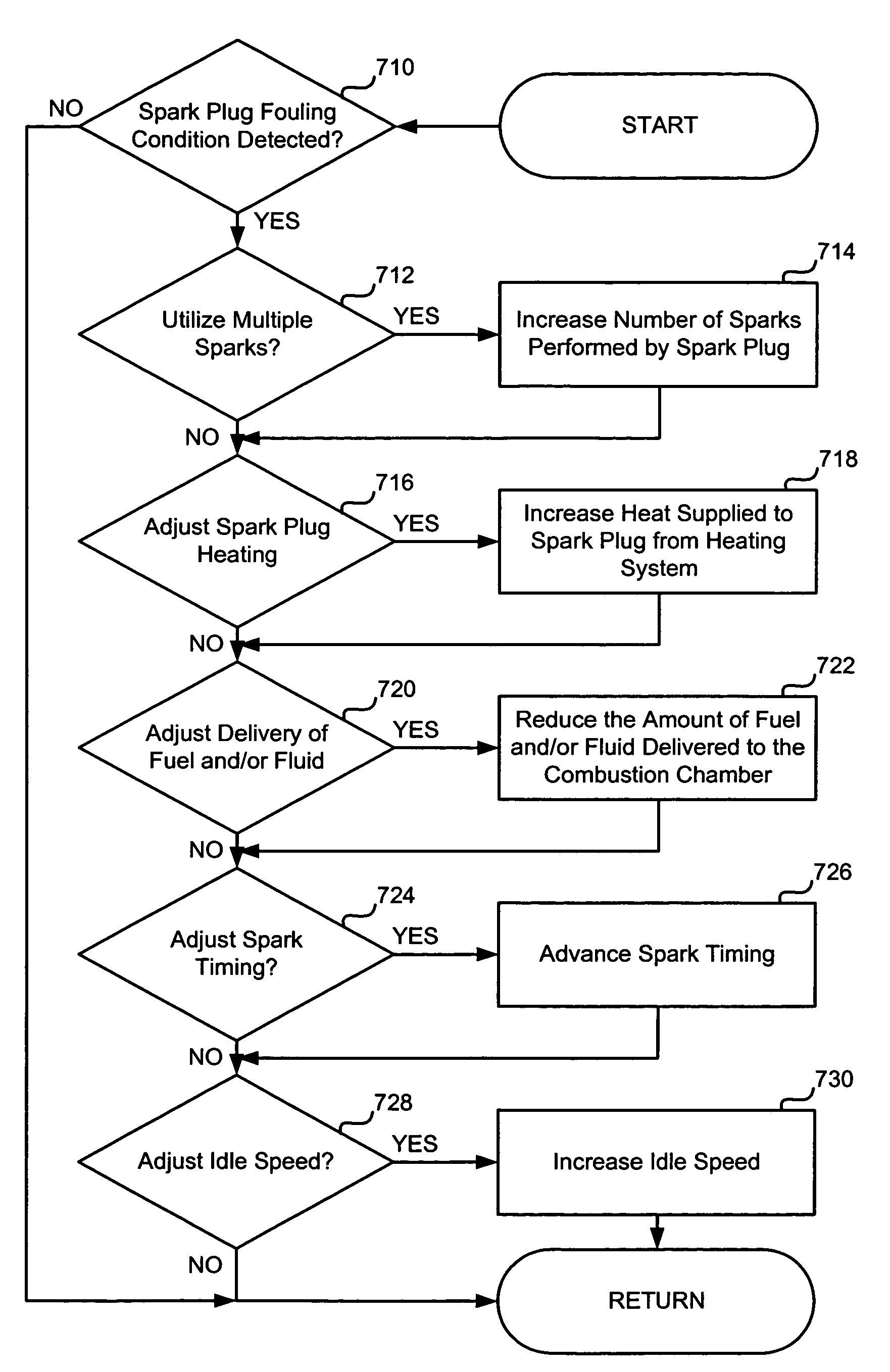

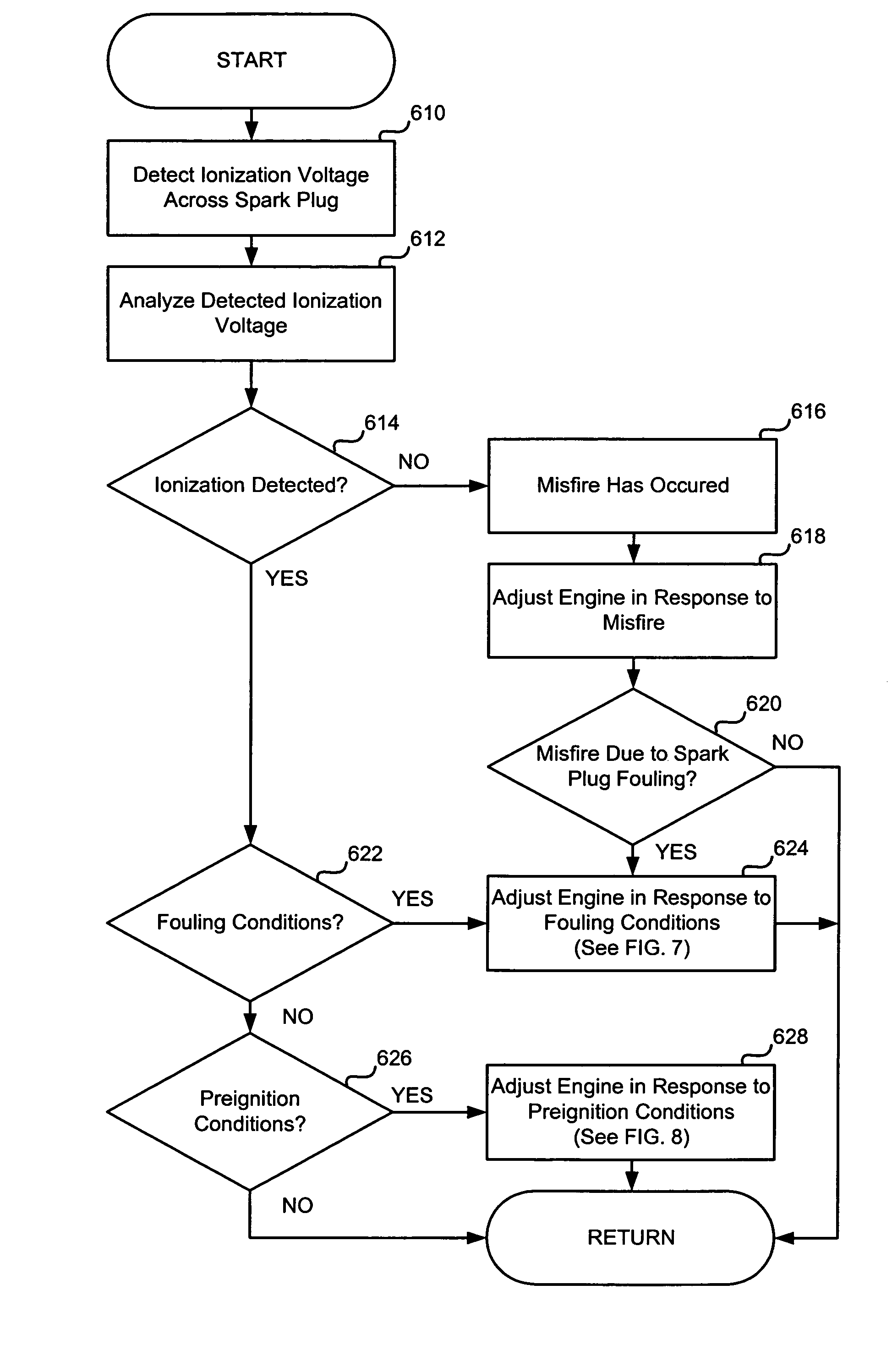

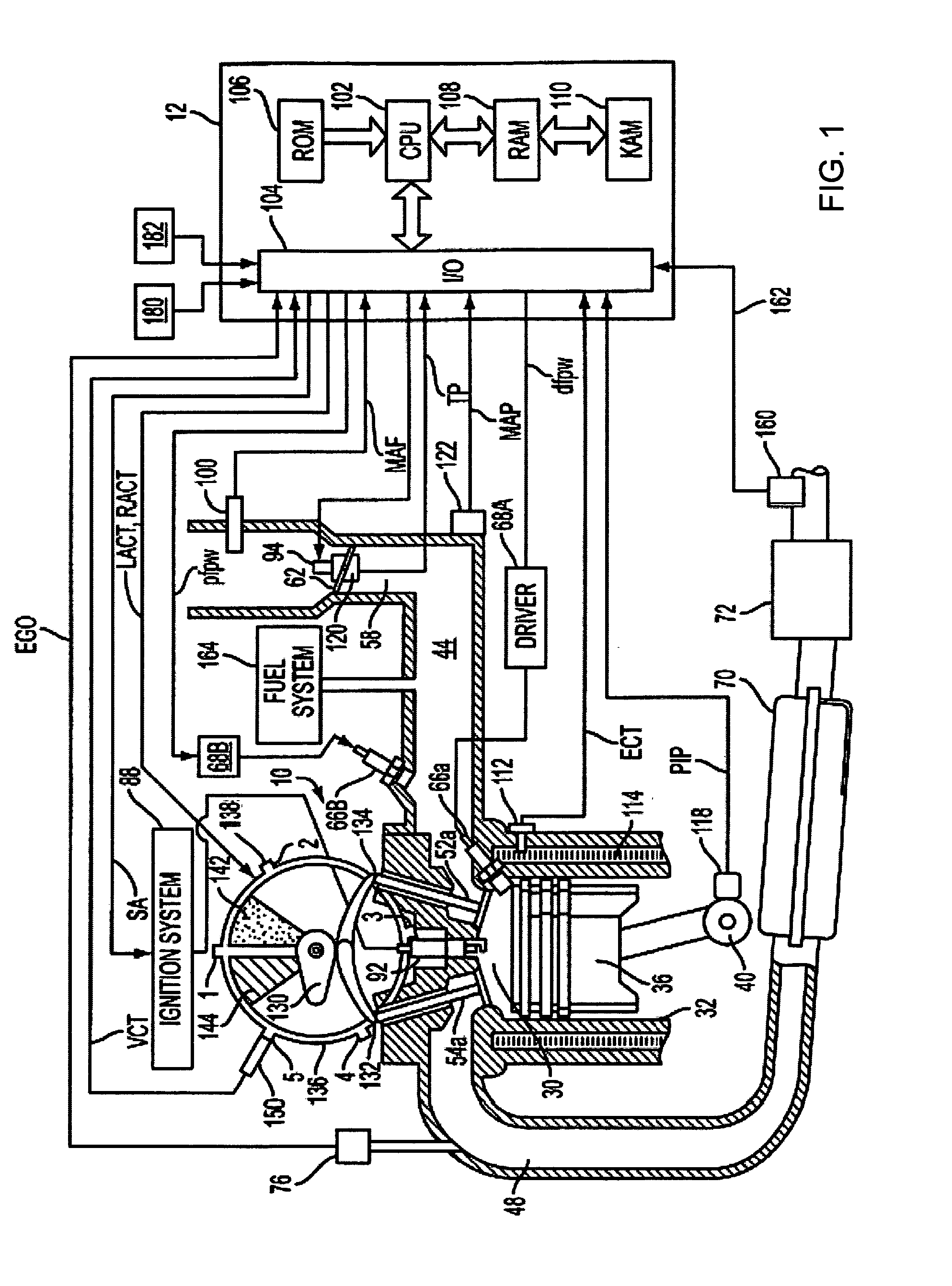

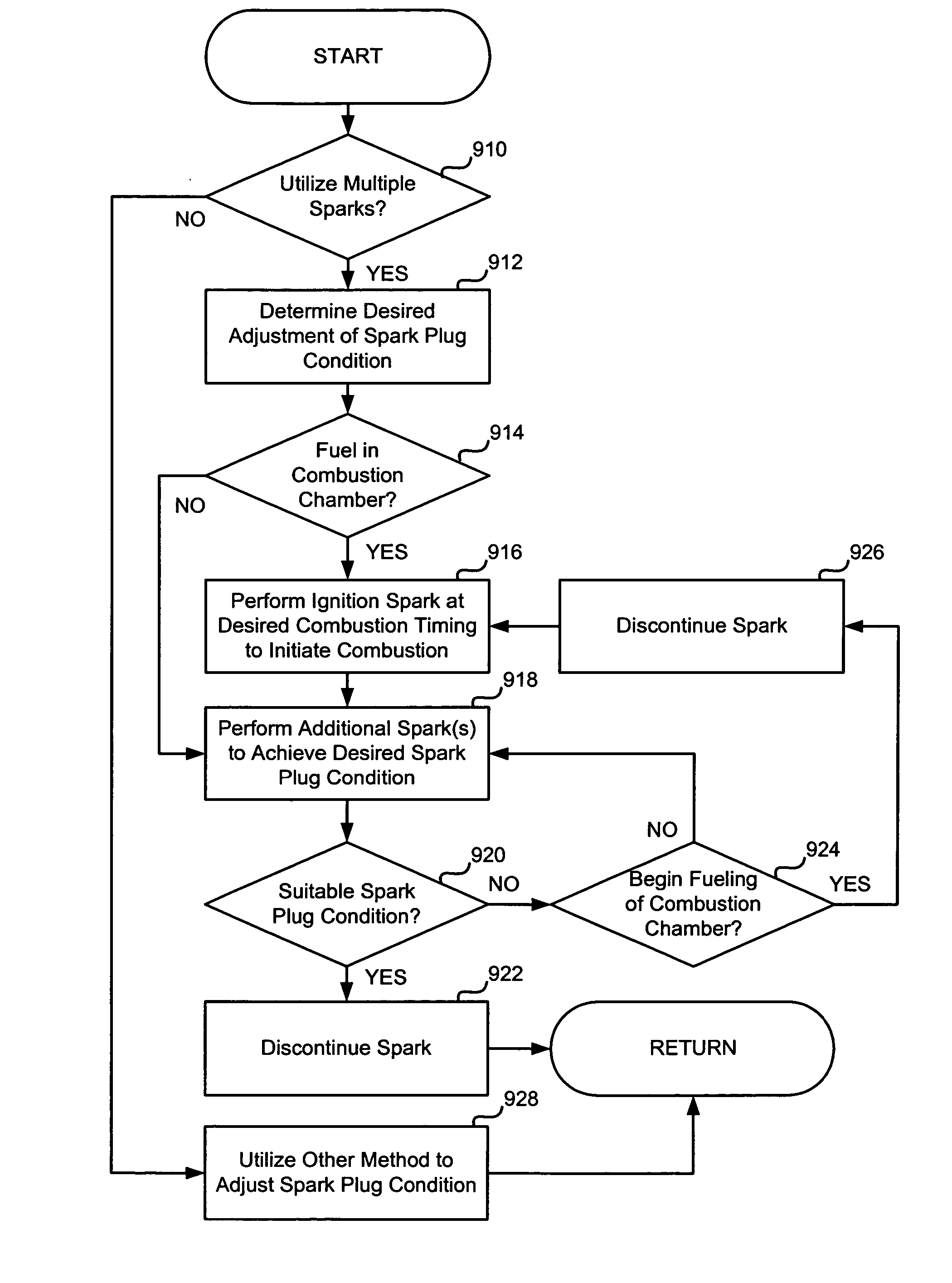

Spark control for improved engine operation

InactiveUS20070215130A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberControl system

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a substance to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, and a control system configured to vary a number of sparks performed by the spark plug in relation to a combustion event of the combustion chamber responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

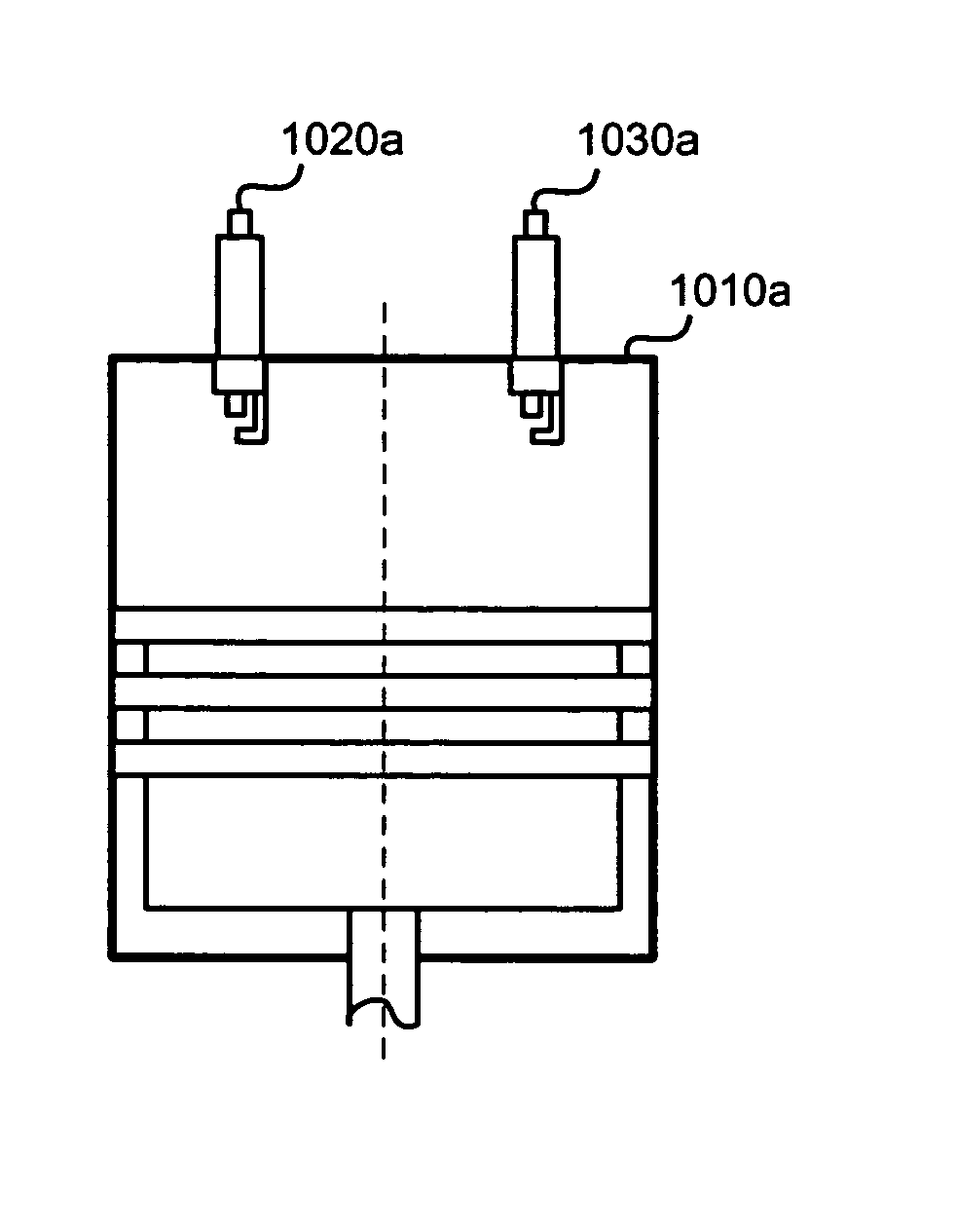

Spark plug

InactiveUS6495948B1Improve fuel efficiencyIncrease combustion pressureSparking plugsFuel injection apparatusInternal combustion engineSpark plug

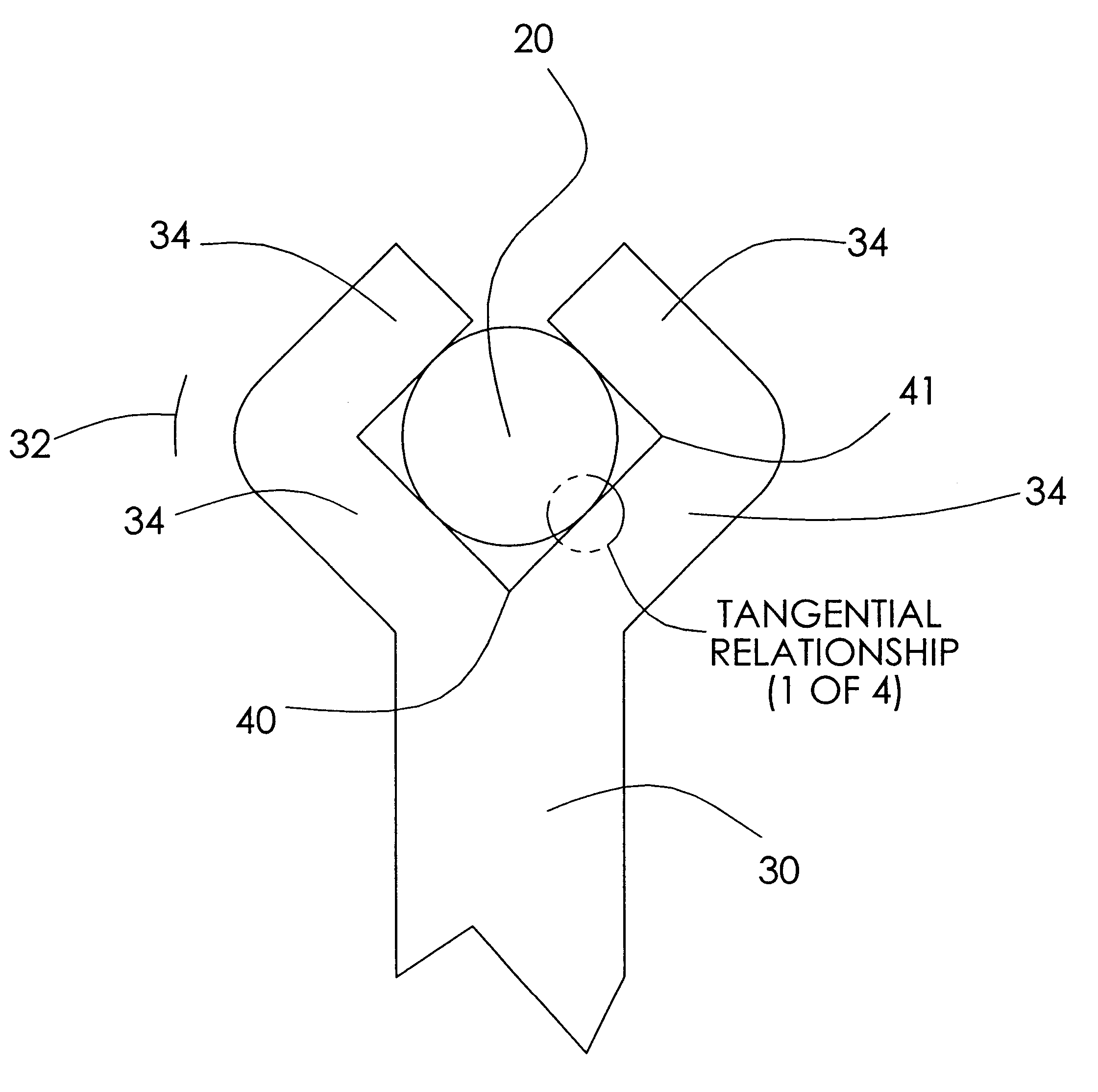

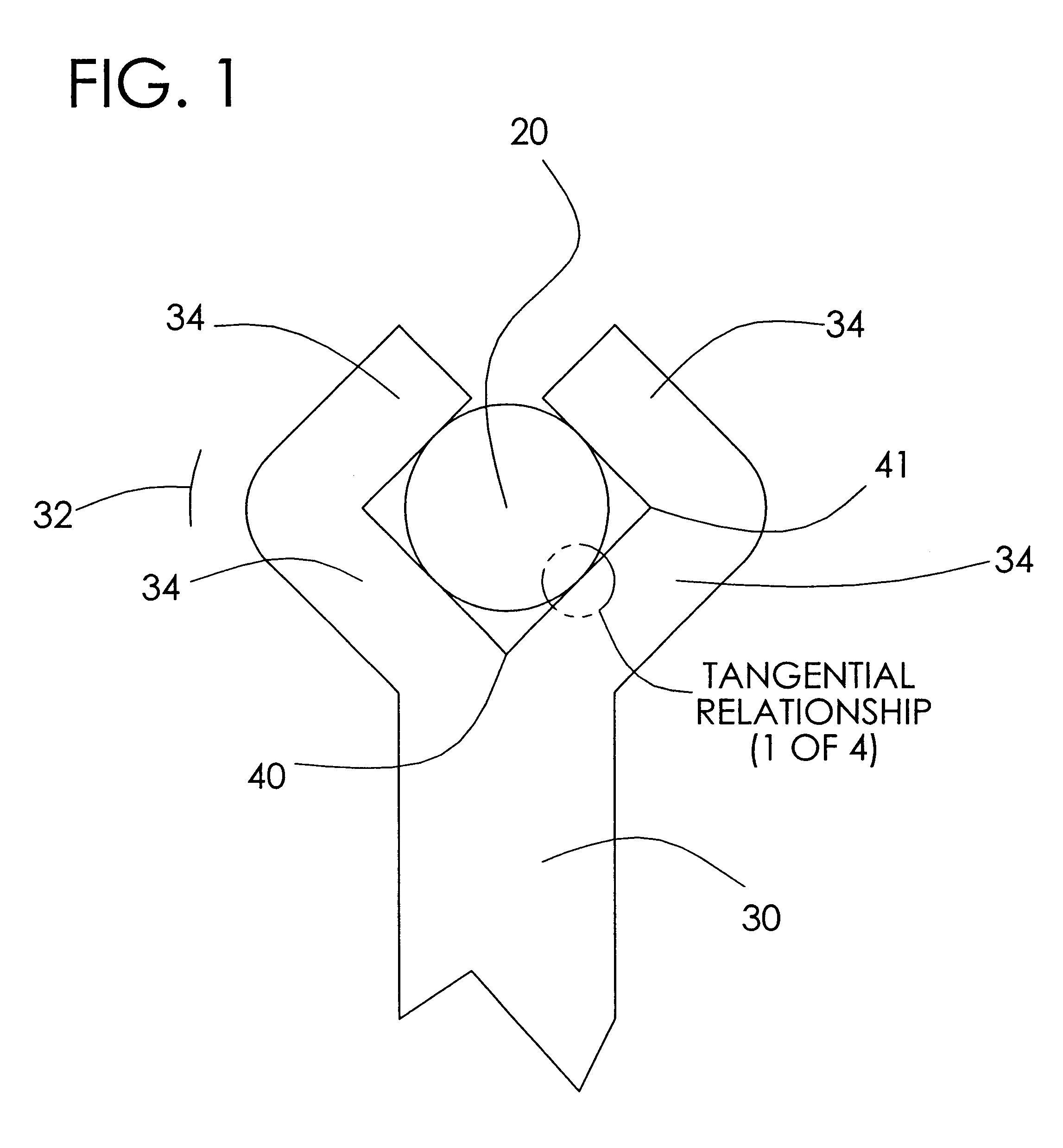

The present invention relates to improved spark plugs for igniting a fuel charge in an internal combustion engine, and is particularly concerned with an improved spark plug construction which improves combustion pressure and fuel mileage and diminishes exhaust pollution. The spark plug includes a center electrode and a ground electrode. In one embodiment, the ground electrode has an elongate edge that extends past the major dimension of the center electrode. The elongate edge can either be positioned substantially tangentially to or within a "zone" outside of the center electrode's periphery. Preferably, the edge of the center electrode and the lower interior edge of the ground electrode will be presented towards one another such that the edges are or are among the closest portions within the sparking region.

Owner:PYROTEK E3 LLC

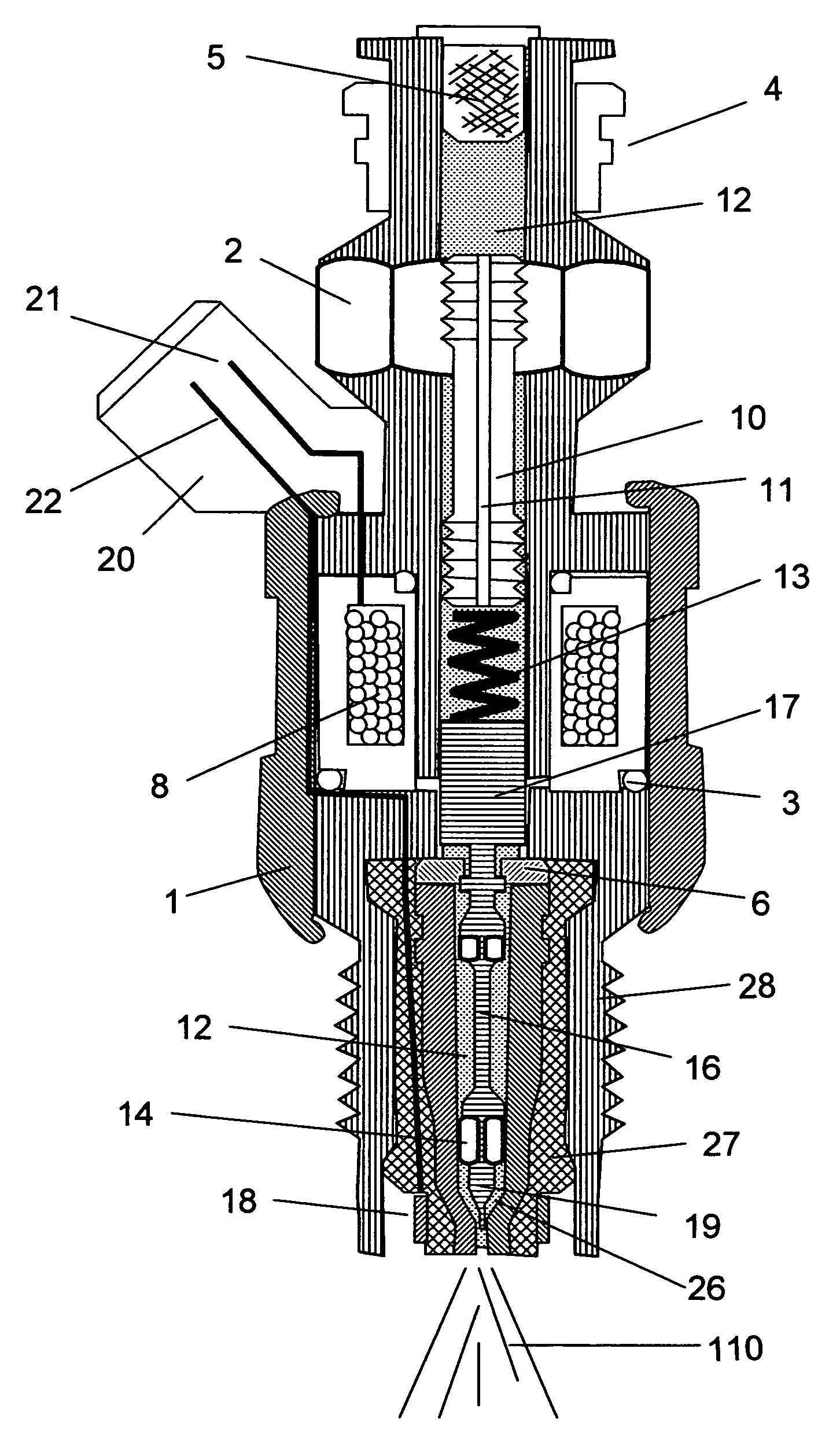

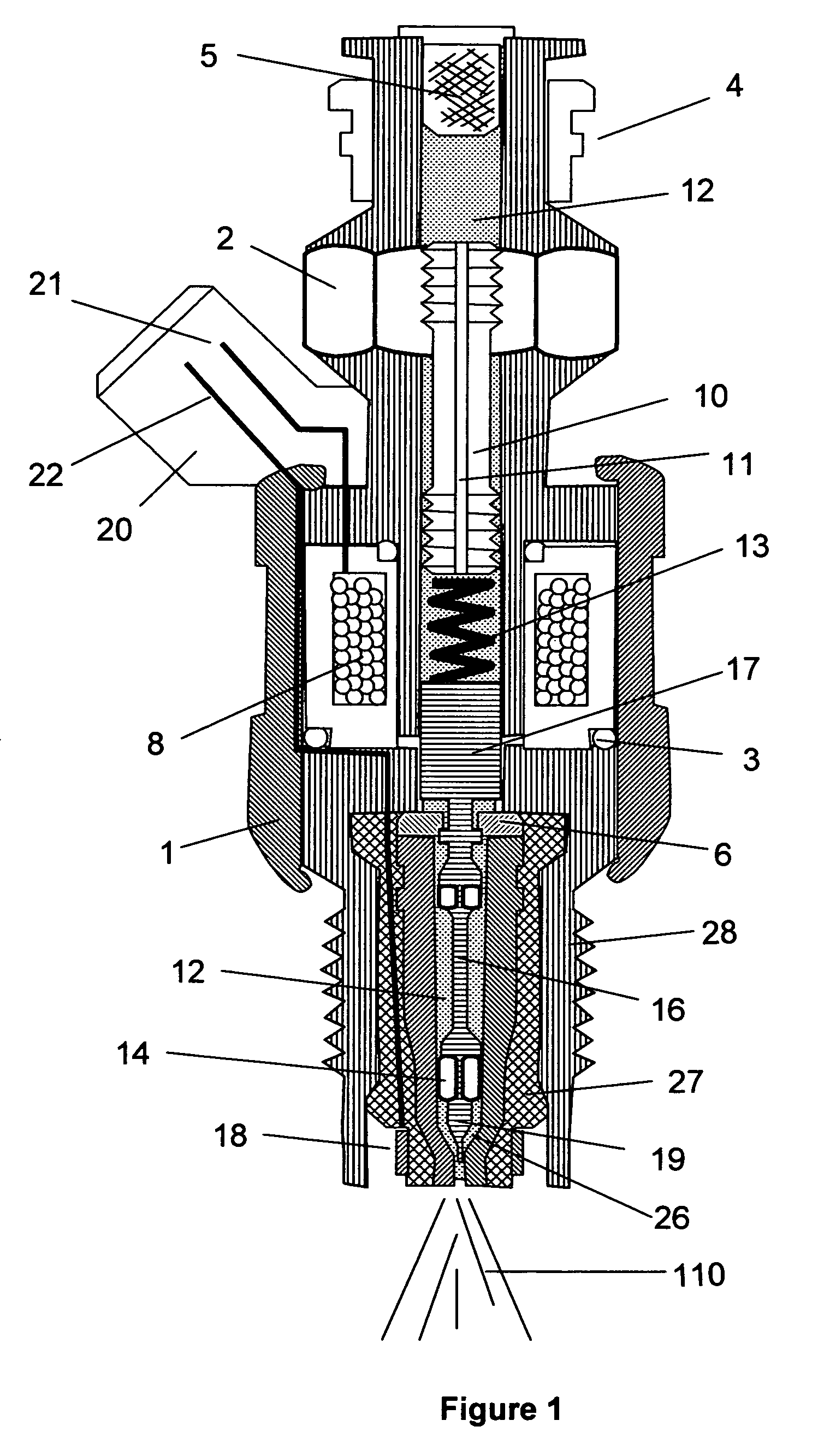

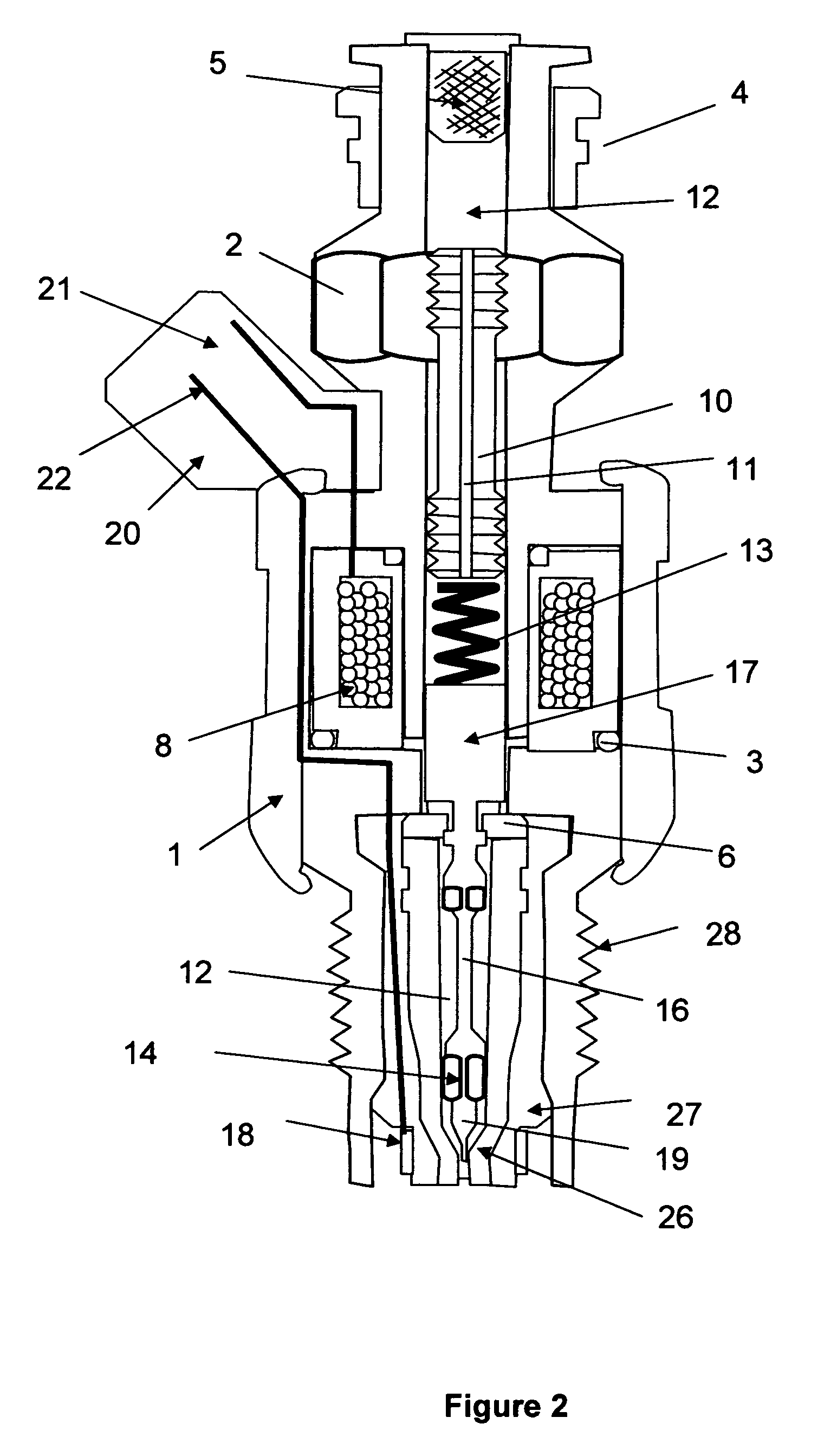

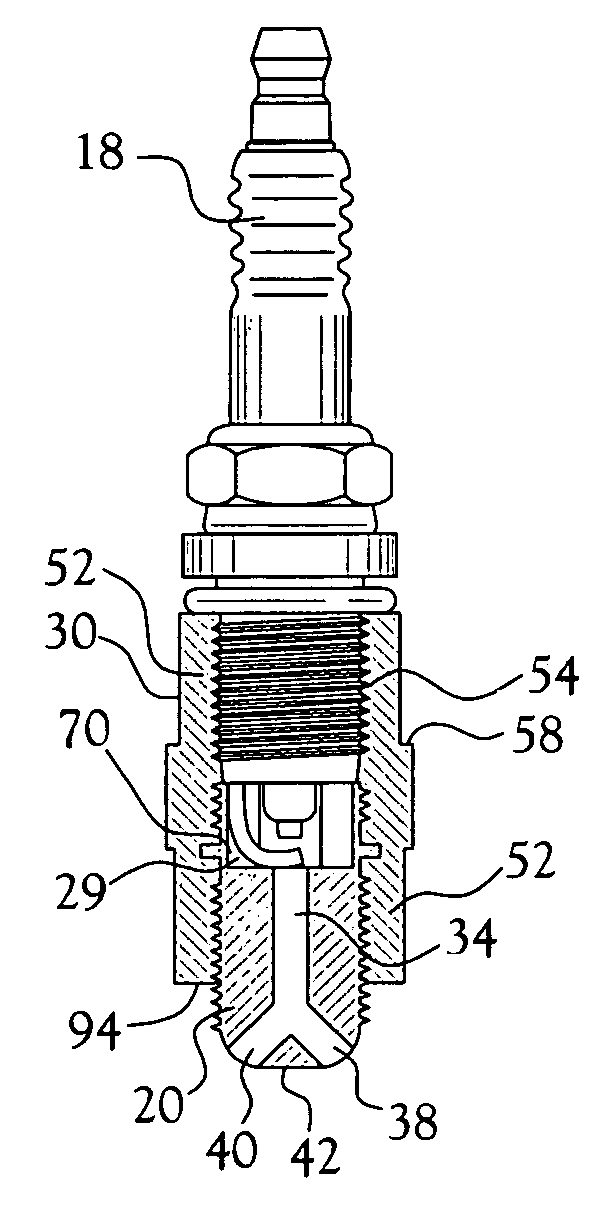

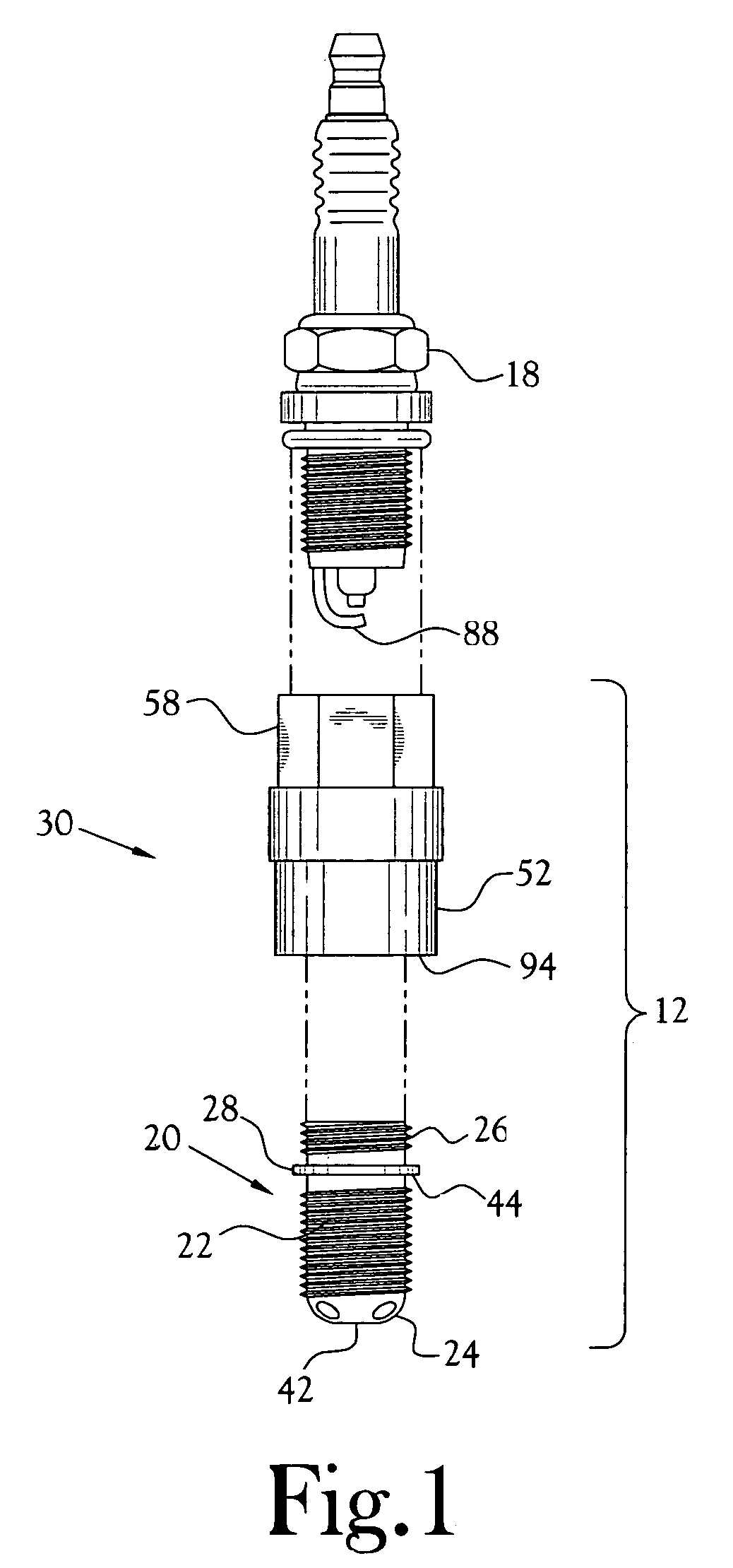

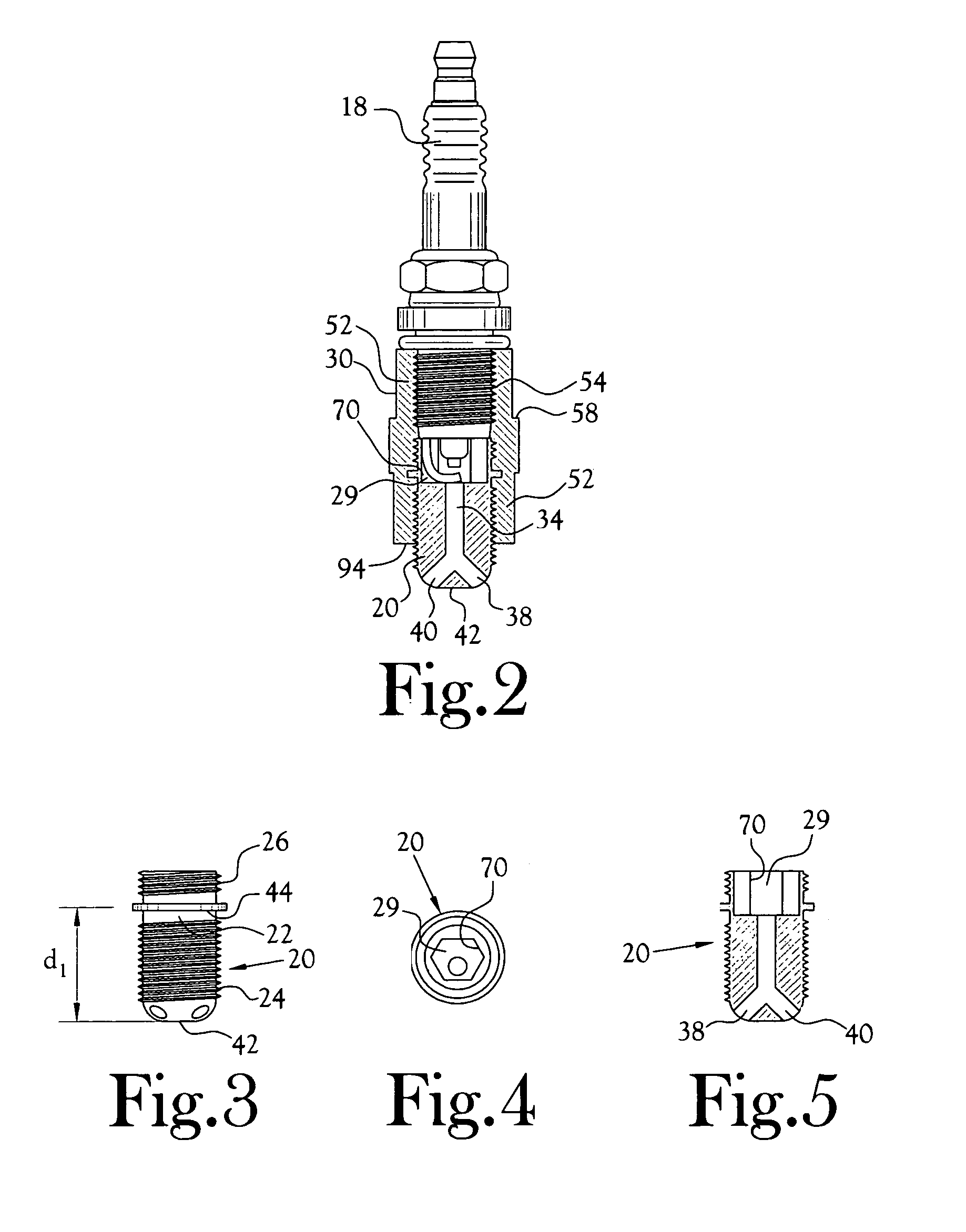

Fuel injector spark plug

InactiveUS6955154B1Eliminates excess fuel useRemove heatSparking plugsFuel injection apparatusCombustionEngineering

A spark plug and fuel injector combination. The spark plug has a central channel that funnels fuel into the lower portion of the spark plug, where it is superheated. A solenoid system causes a needle valve to rise up to allow a measured quantity of fuel to be injected into a cylinder through a nozzle, where it vaporizes upon exiting the spark plug. A spring releases the needle valve to close the nozzle. The spark plug also has an ignition ring on the base. The ignition ring produces an encompassing spark, which produces complete combustion of the vaporized fuel. This produces more power and better fuel economy.

Owner:DOUGLAS DENIS

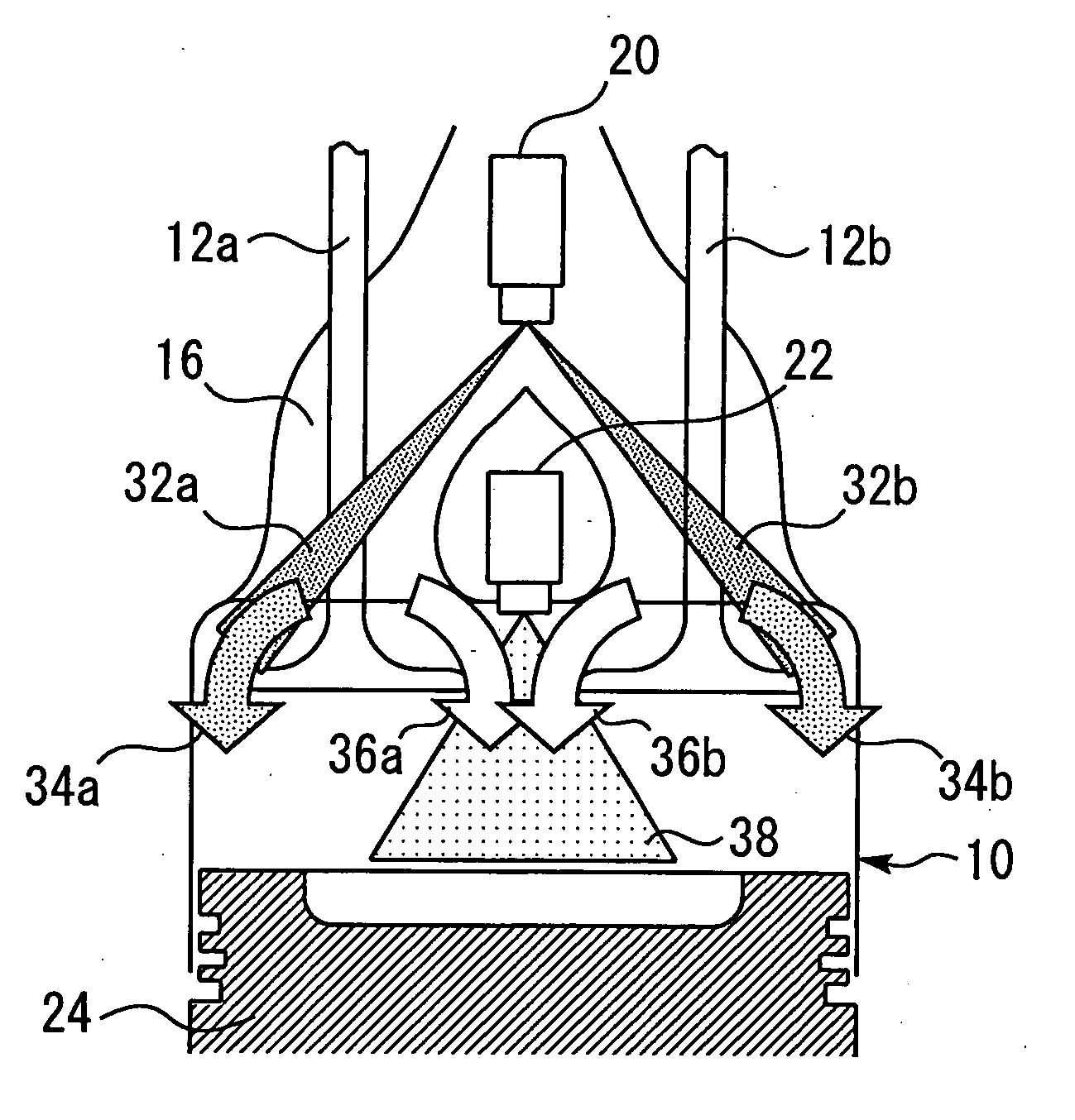

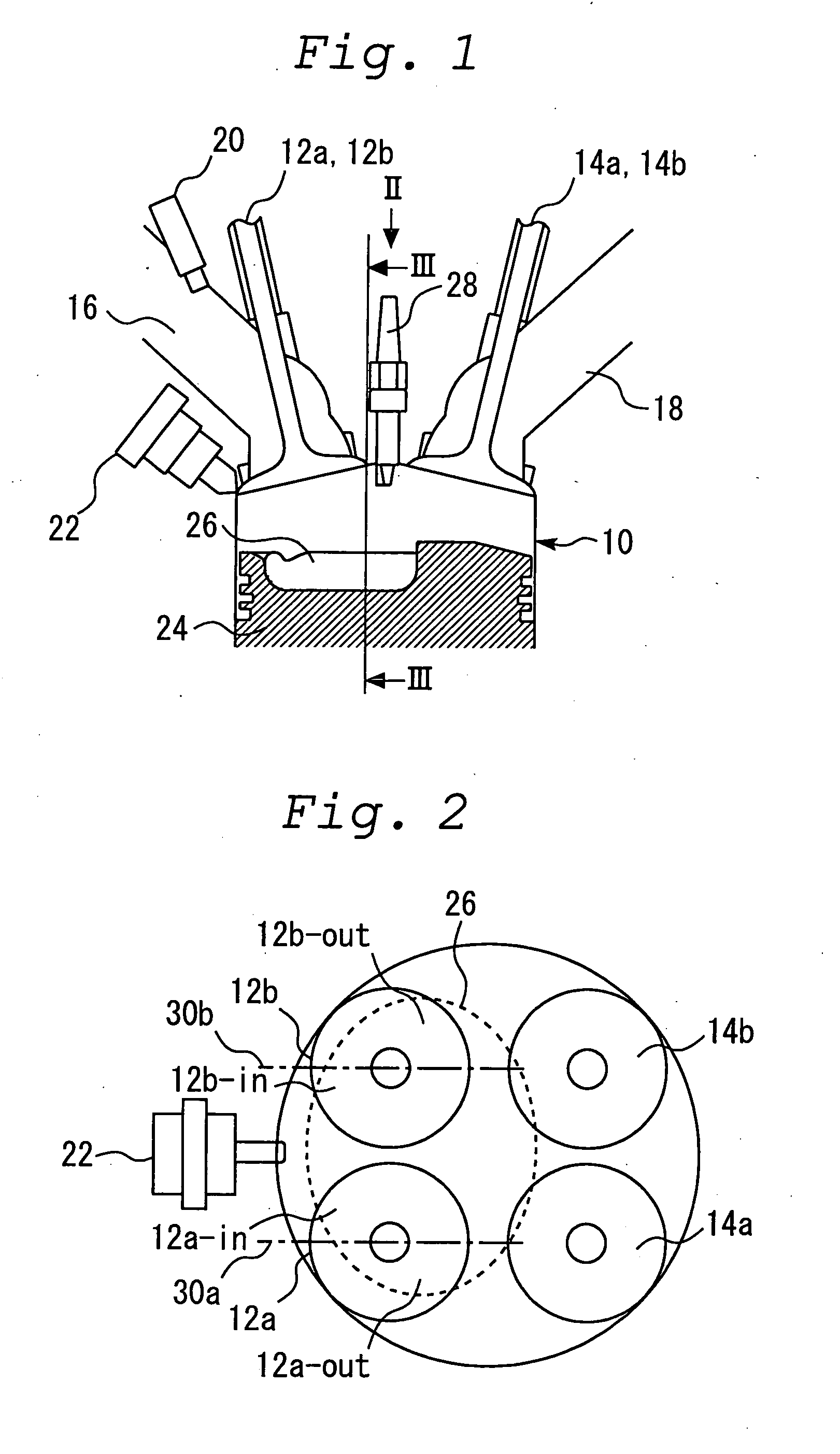

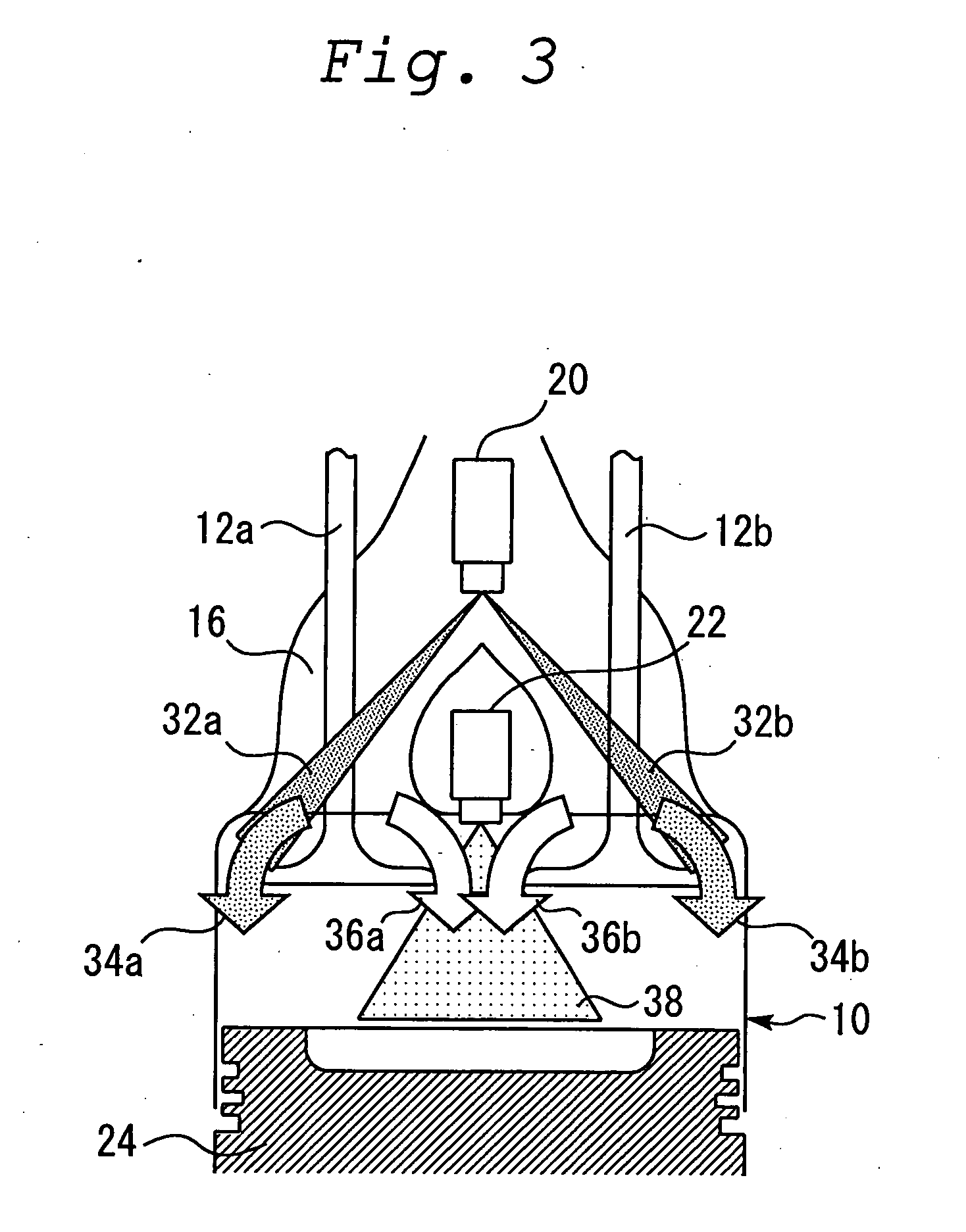

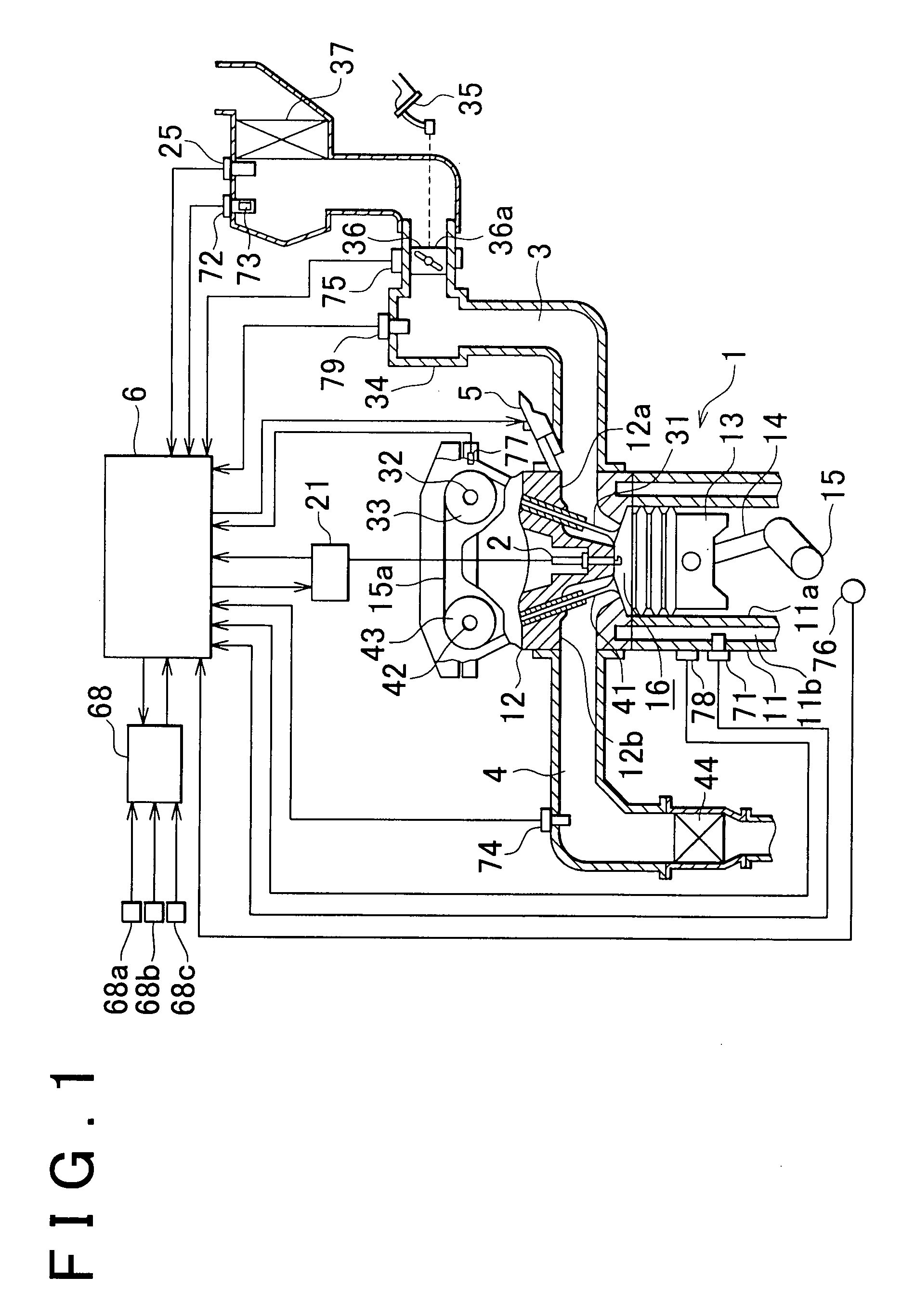

Spark ignition internal combustion engine

Each cylinder is provided with an ignition plug, two intake valves, an intra-cylinder fuel injector, and a port fuel injector. When homogeneous combustion is demanded, the intra-cylinder fuel injector and port fuel injector inject fuel on the same engine cycle. The port fuel injector is installed so that the amount of fuel directed toward outer regions of the intake valves is larger than that of fuel directed toward inner regions of the intake valves, thereby causing only fresh air to flow to regions near the inner regions of the intake valves.

Owner:TOYOTA JIDOSHA KK

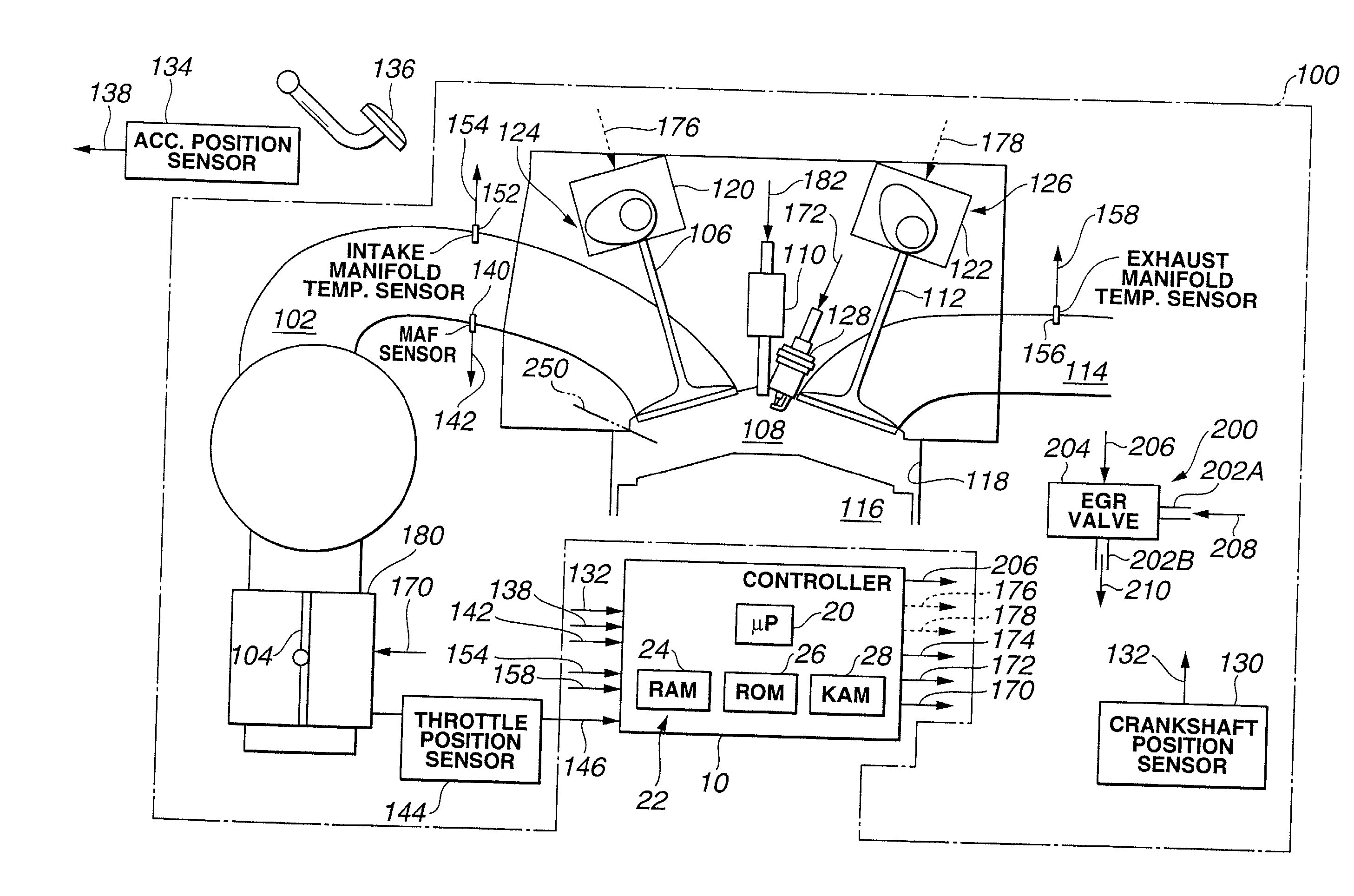

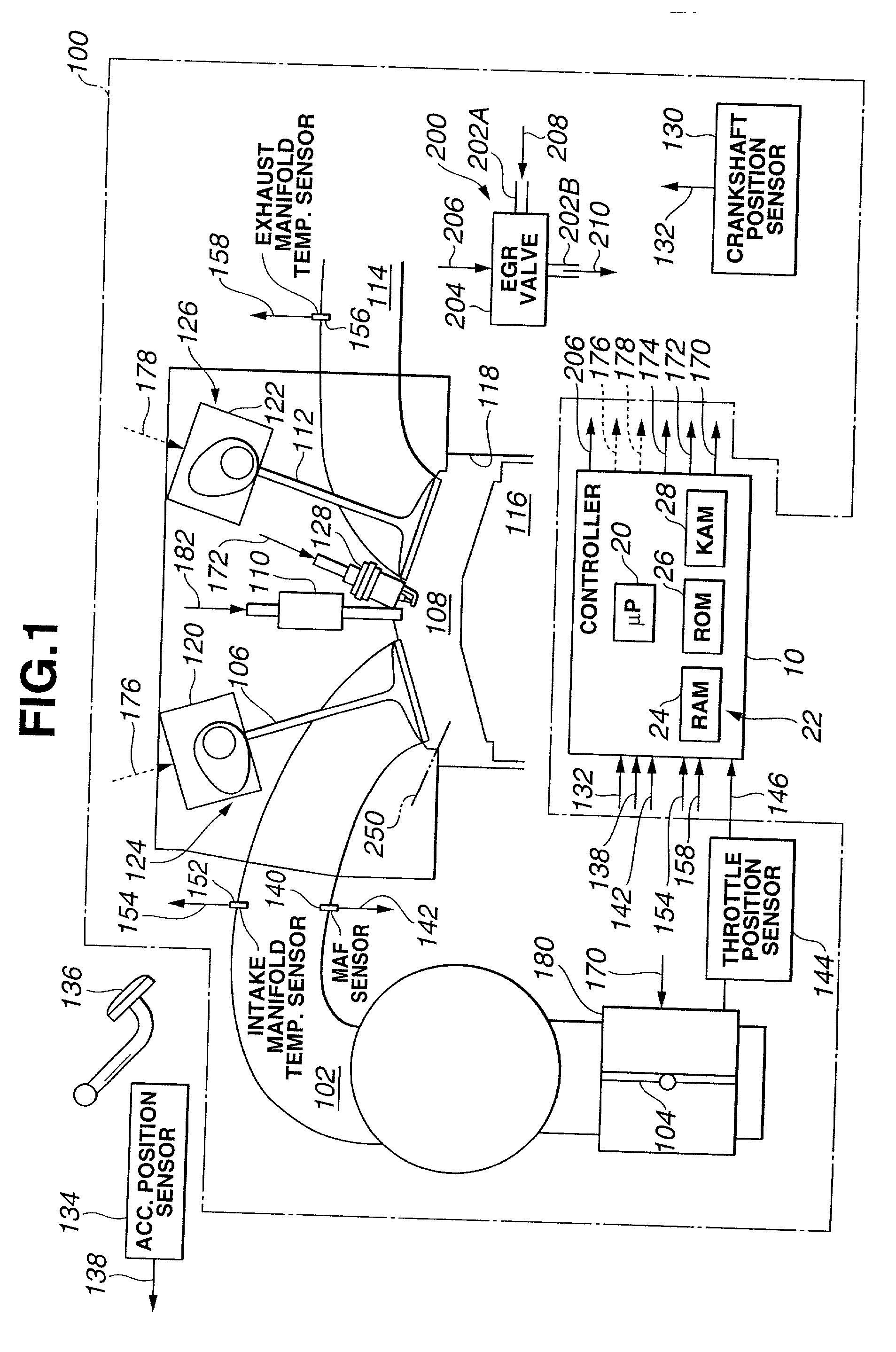

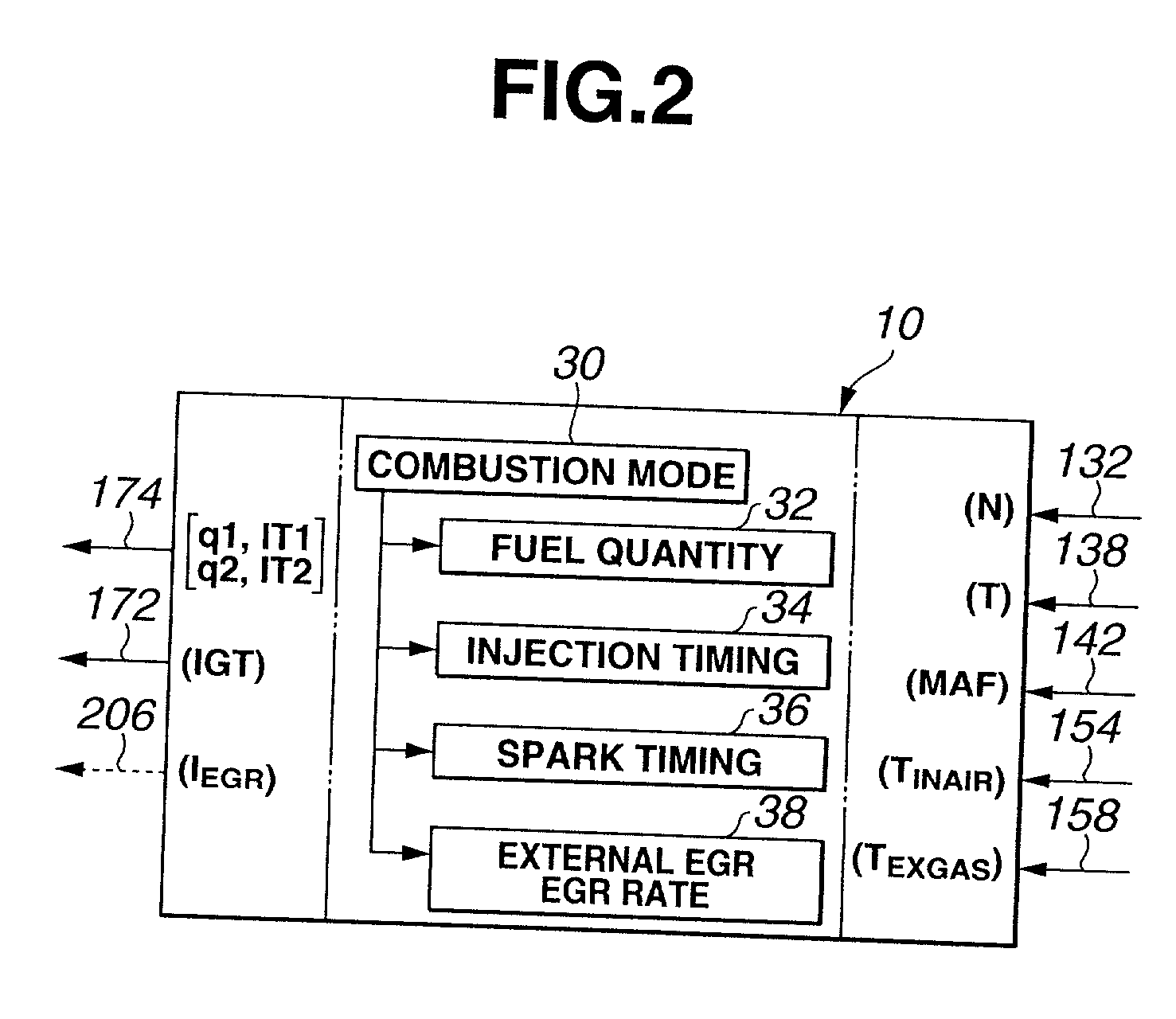

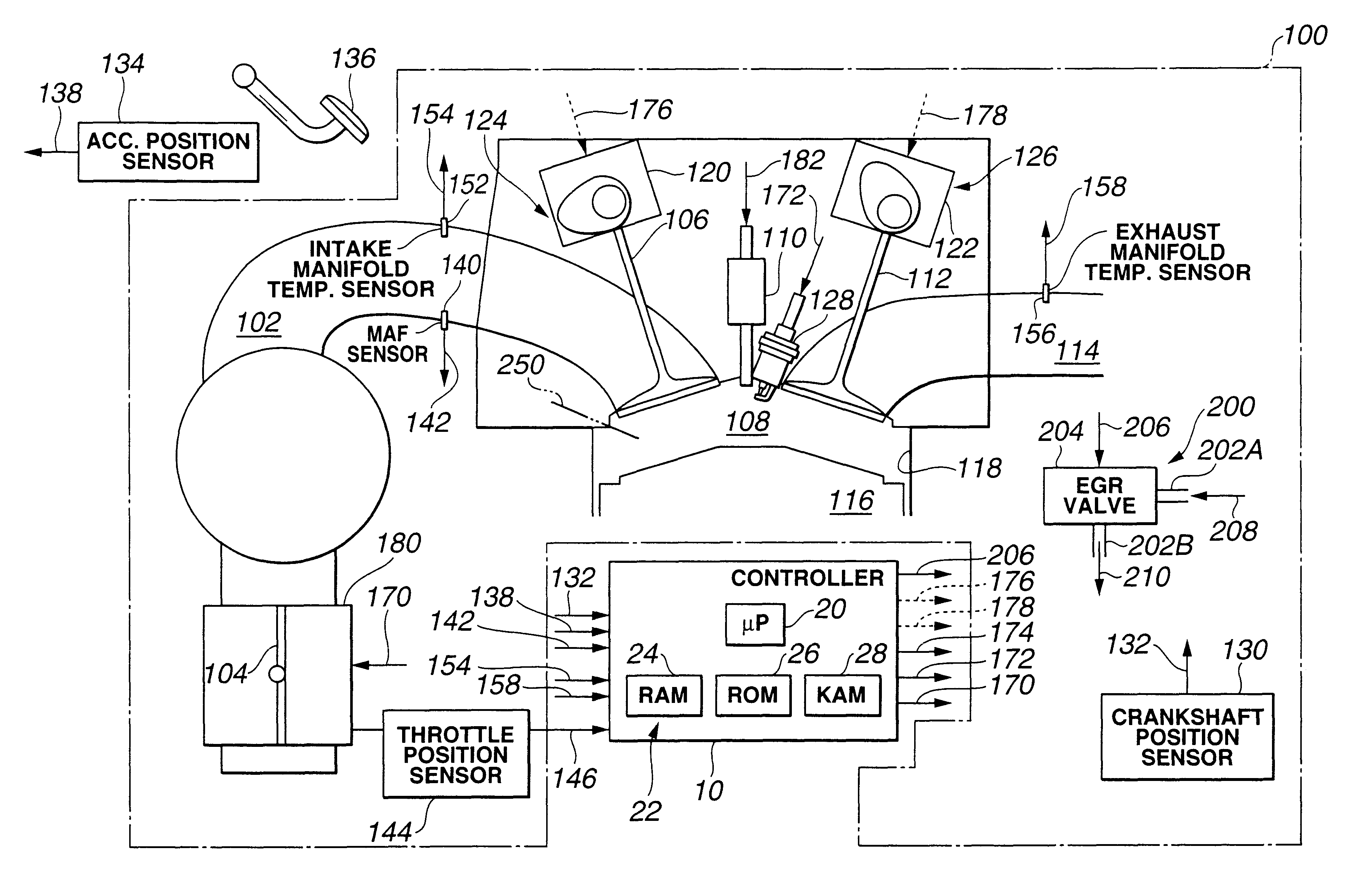

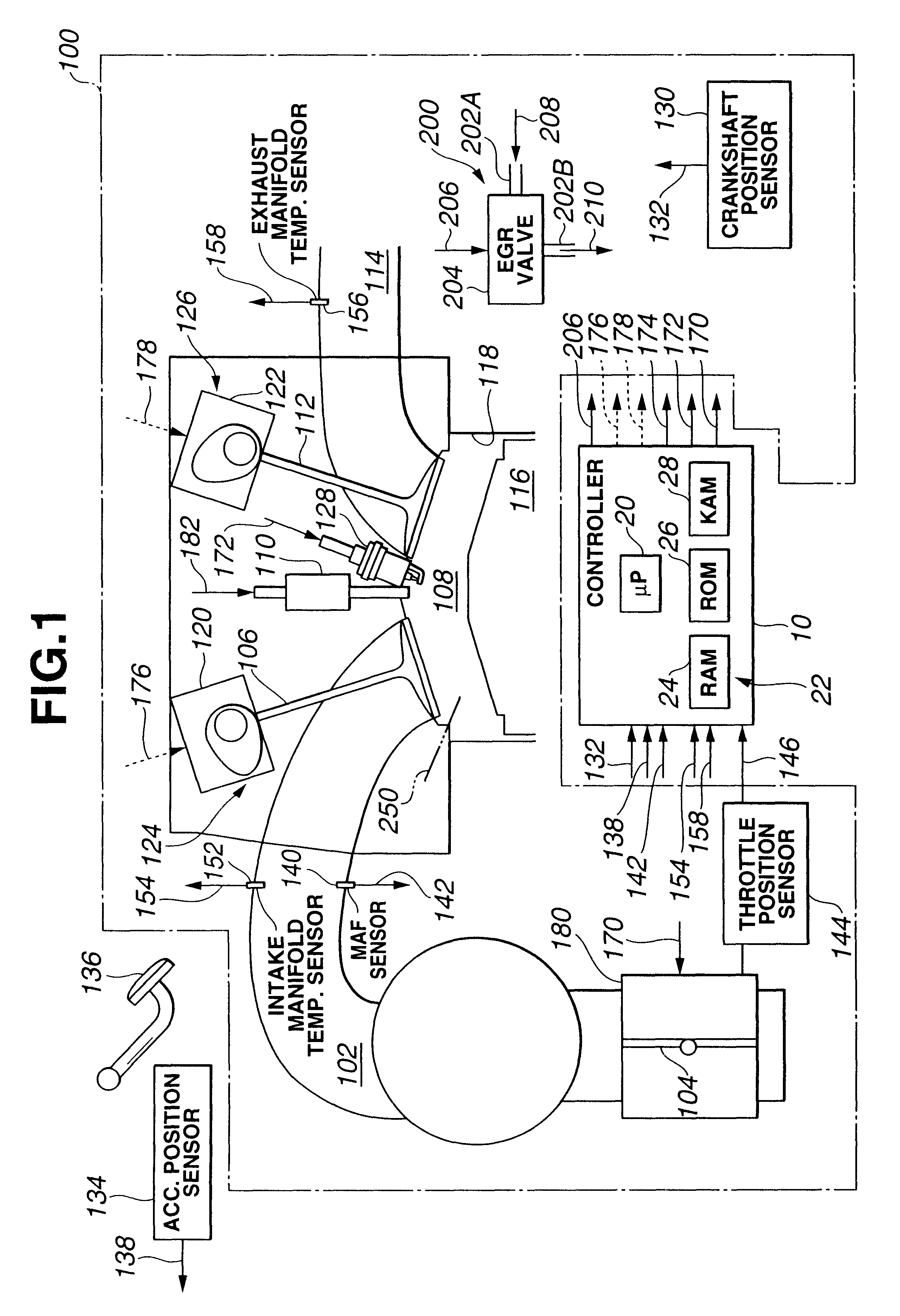

System and method for enhanced combustion control in an internal combustion engine

InactiveUS20020059914A1Electrical controlInternal combustion piston enginesExternal combustion engineStaged combustion

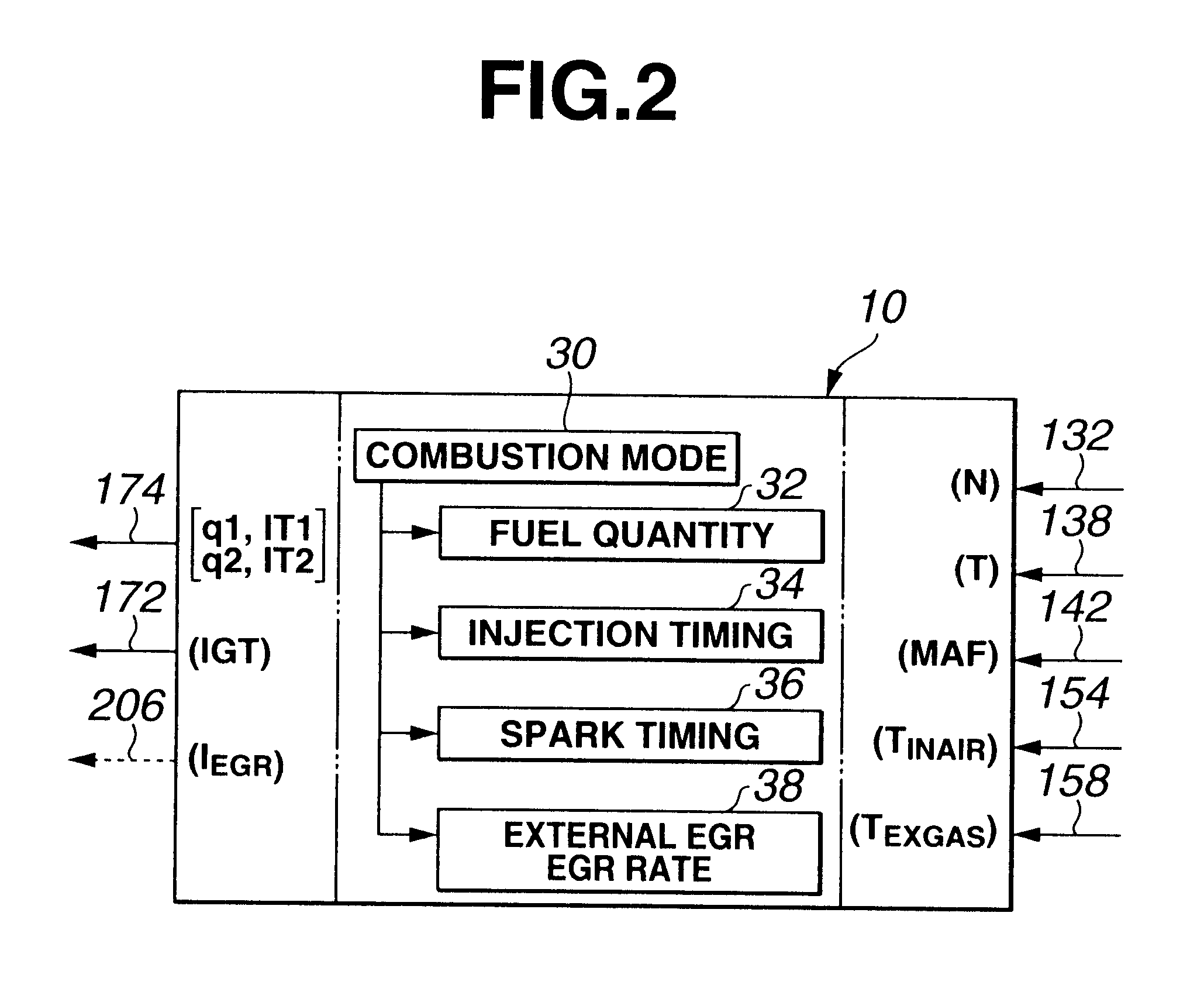

A system and method for enhanced combustion control in an internal combustion engine is disclosed. A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. An engine controller is programmed to perform control over initiation timing of the second stage combustion in response to at least one of the engine speed and load. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

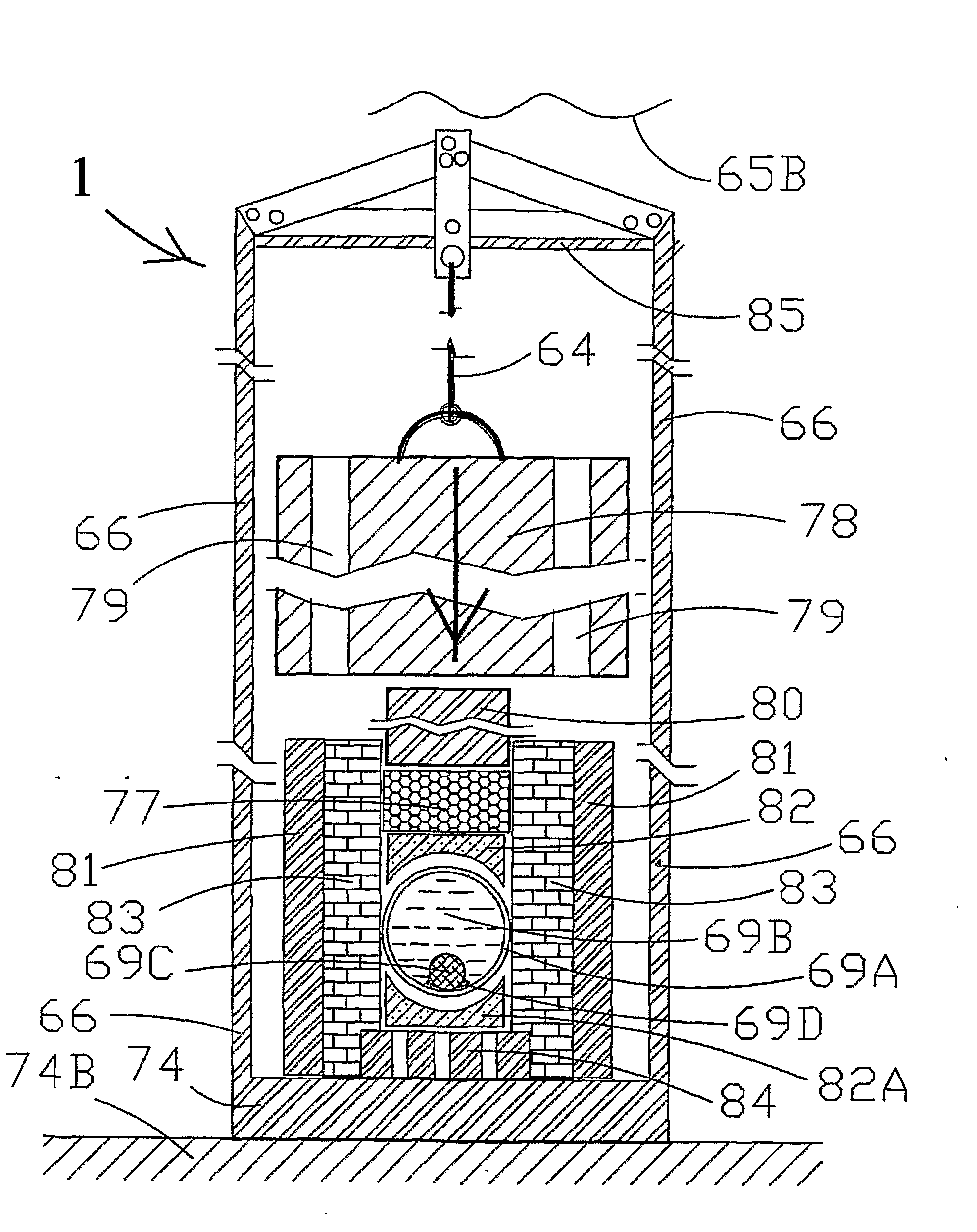

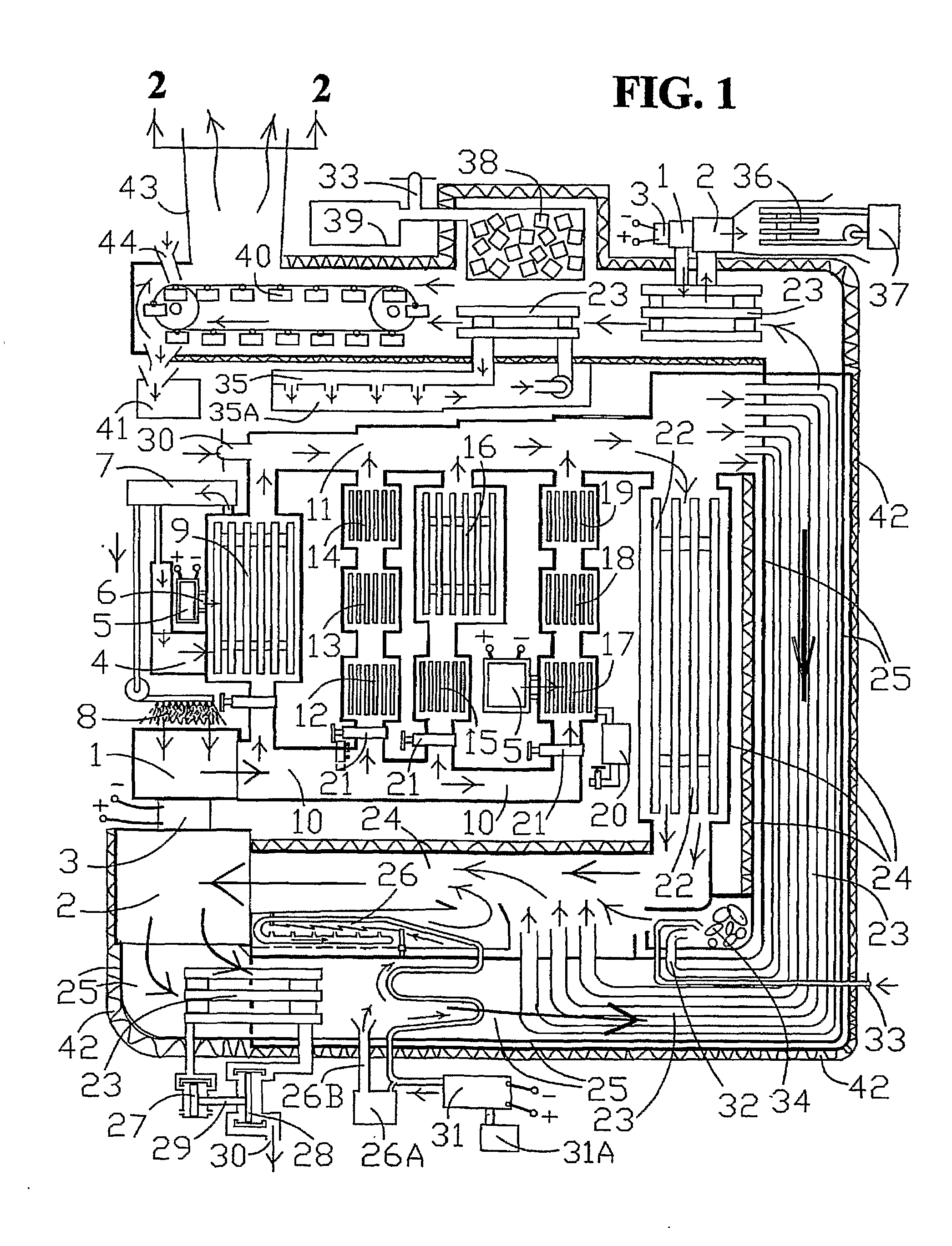

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

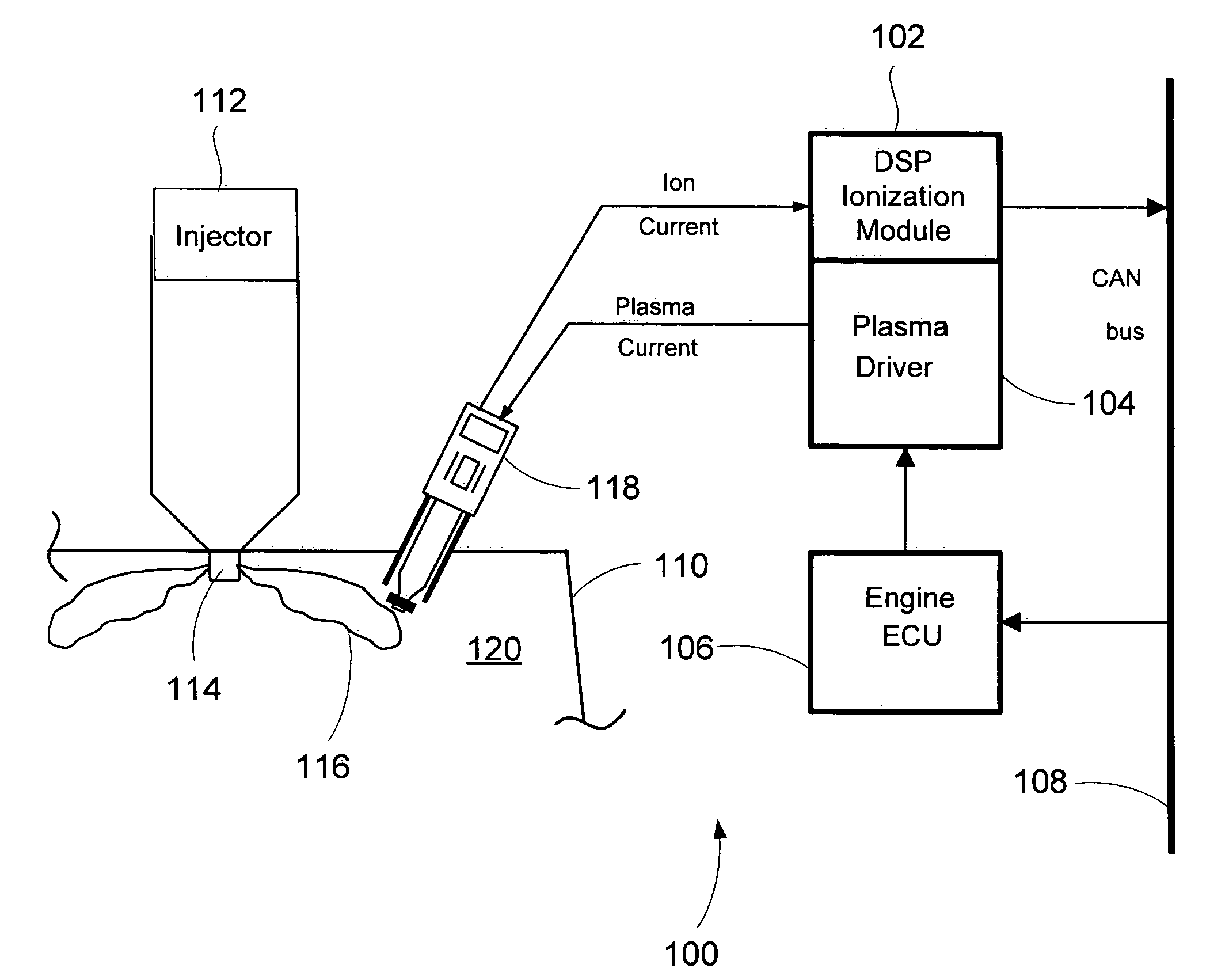

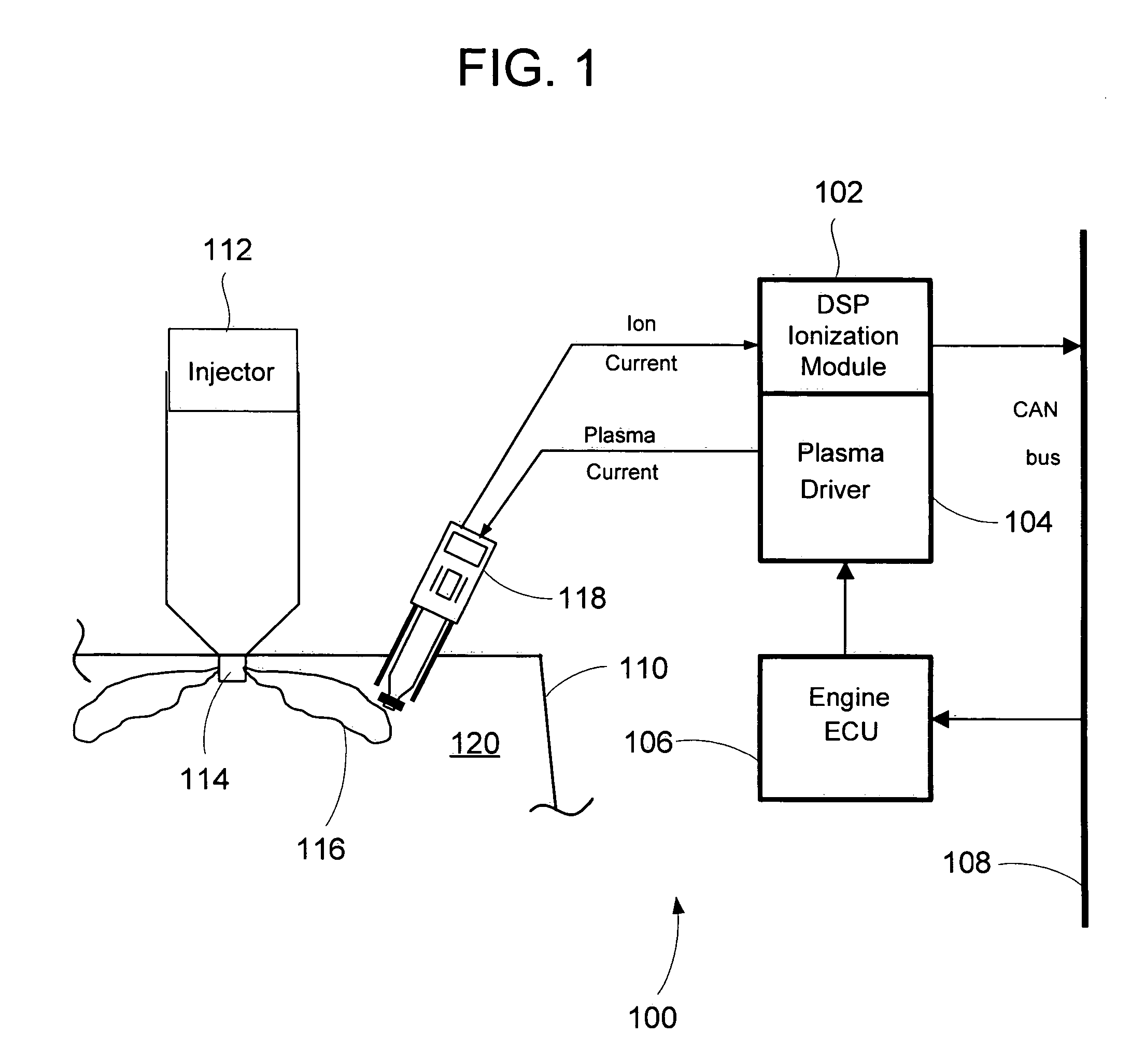

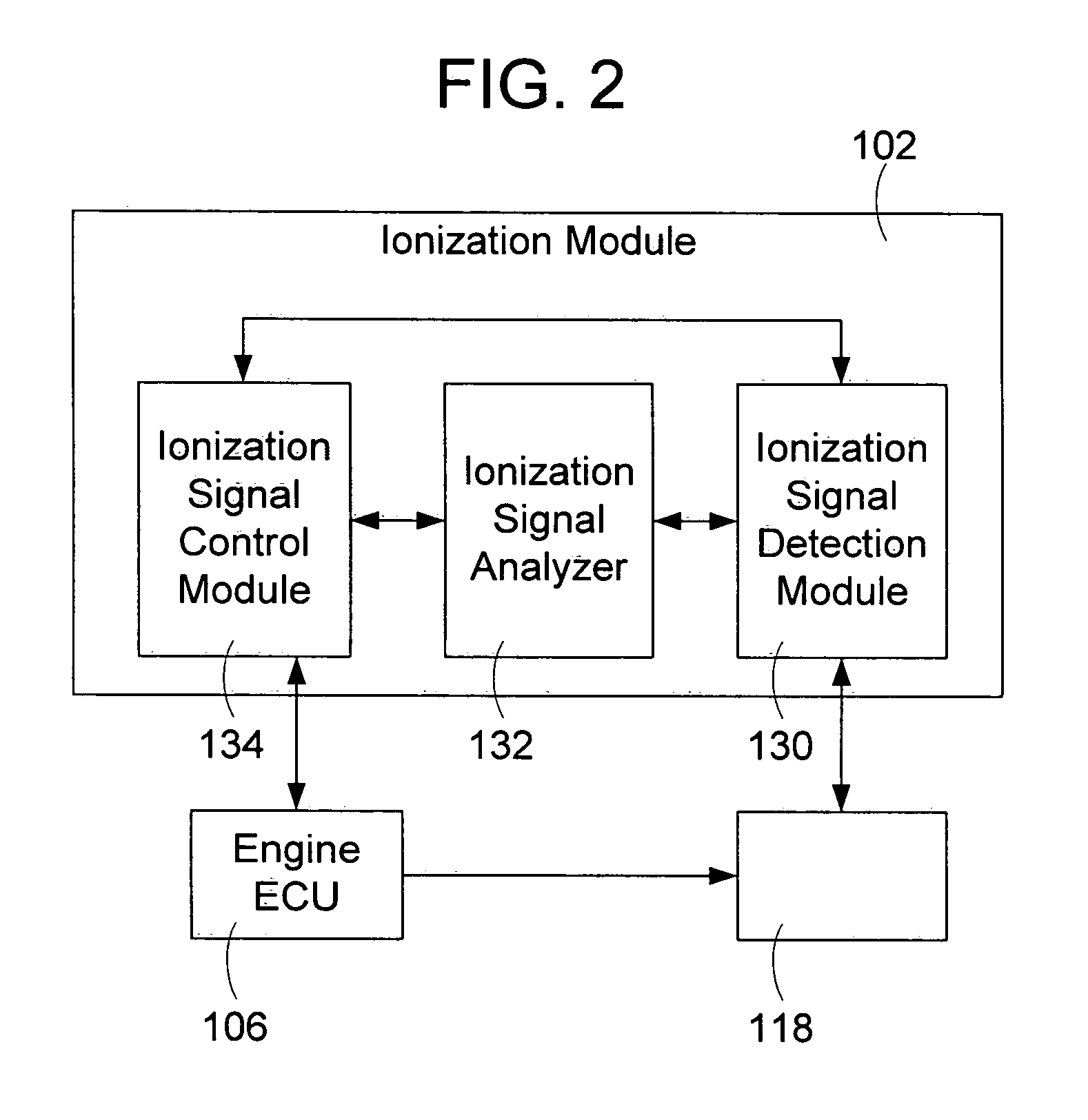

Method and apparatus for detecting ionization signal in diesel and dual mode engines with plasma discharge system

Owner:WOODWARD GOVERNOR CO

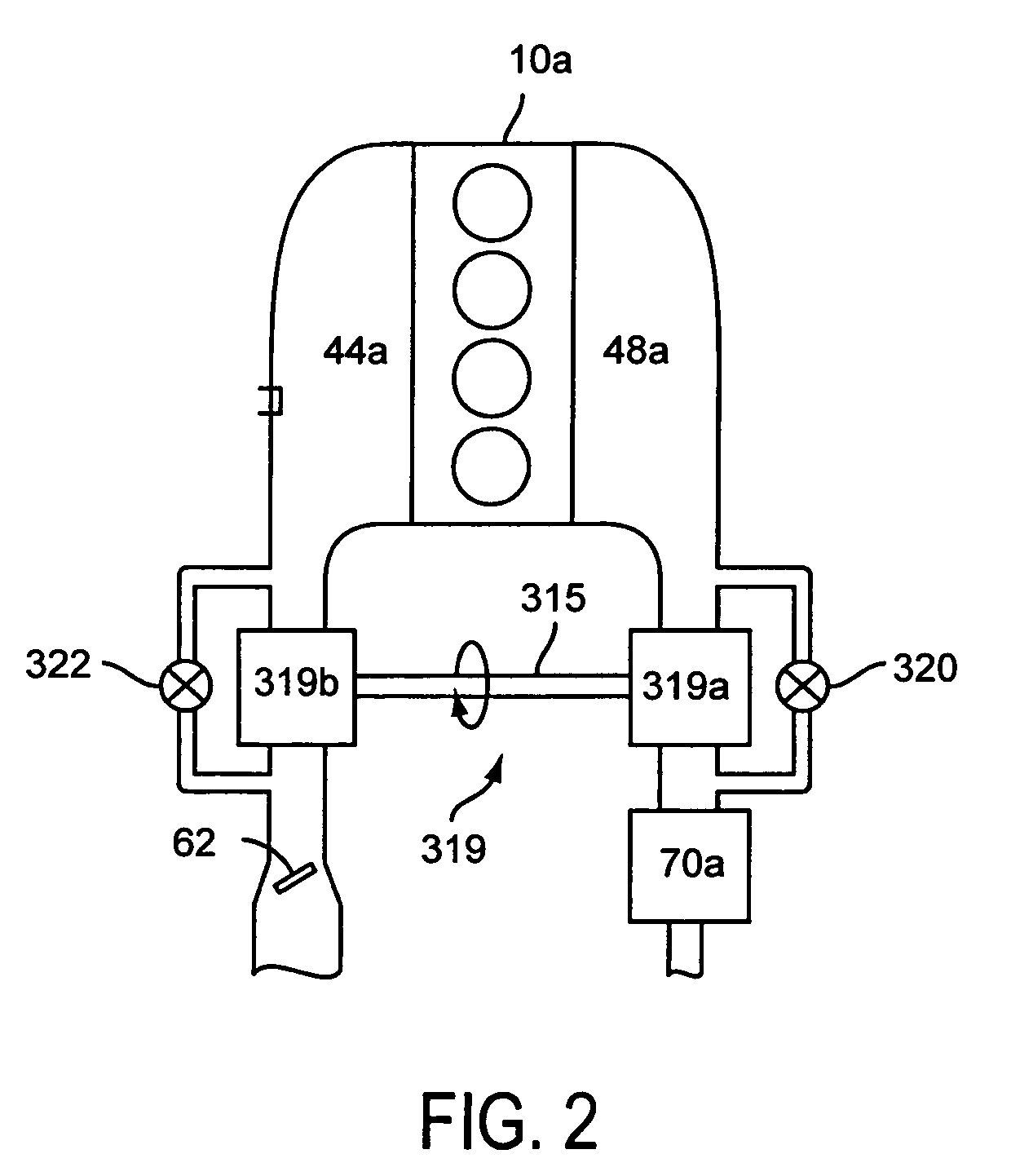

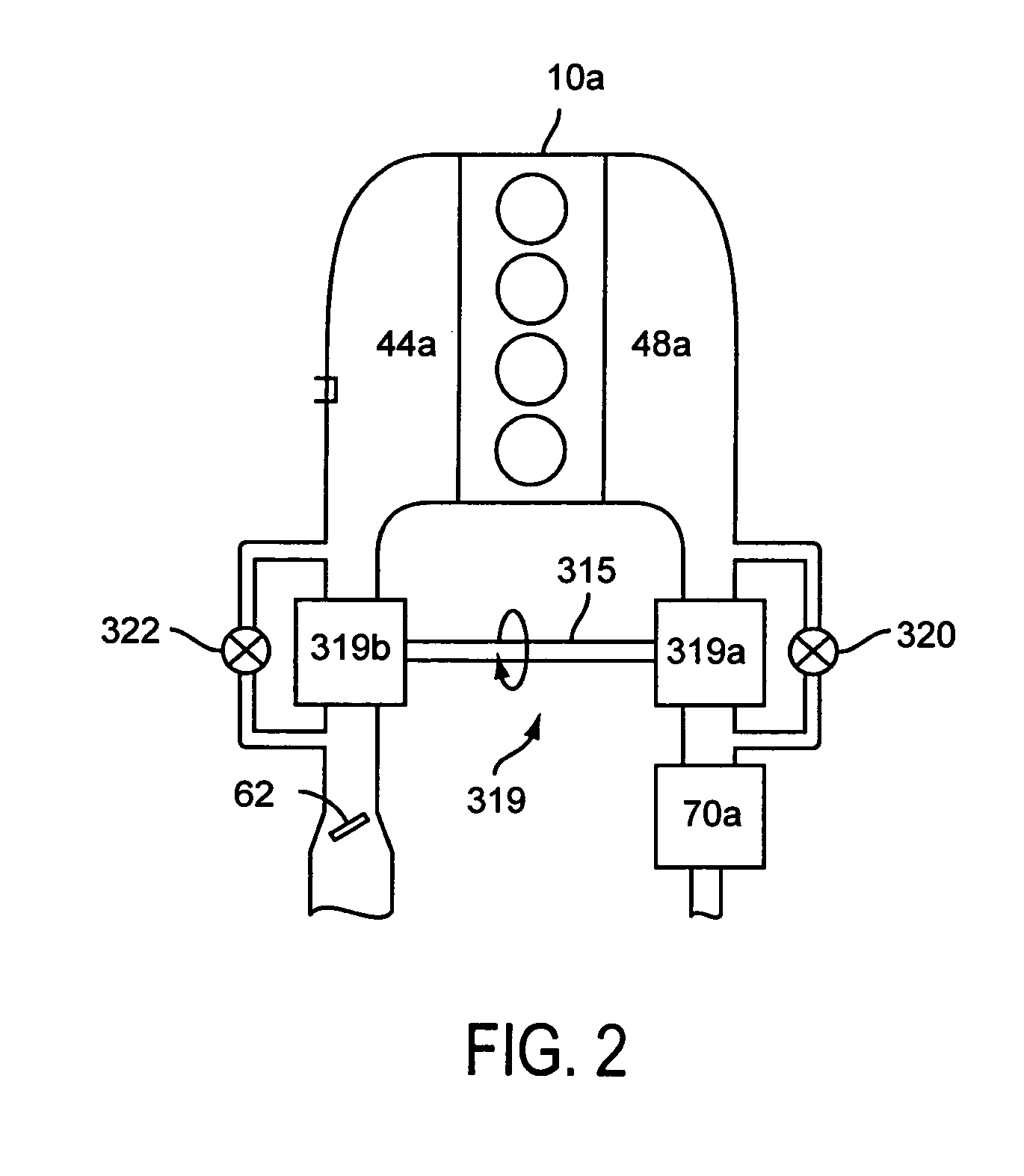

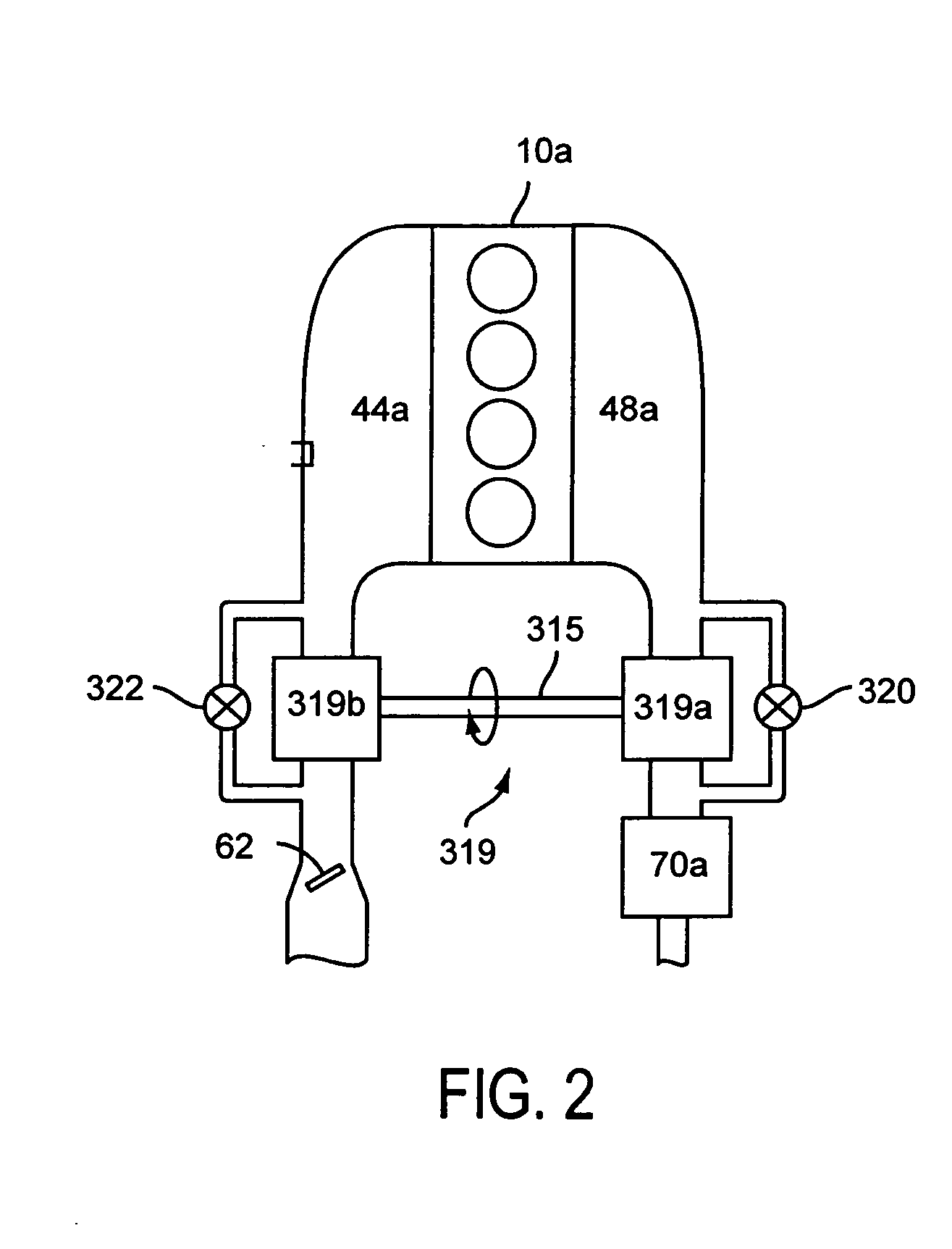

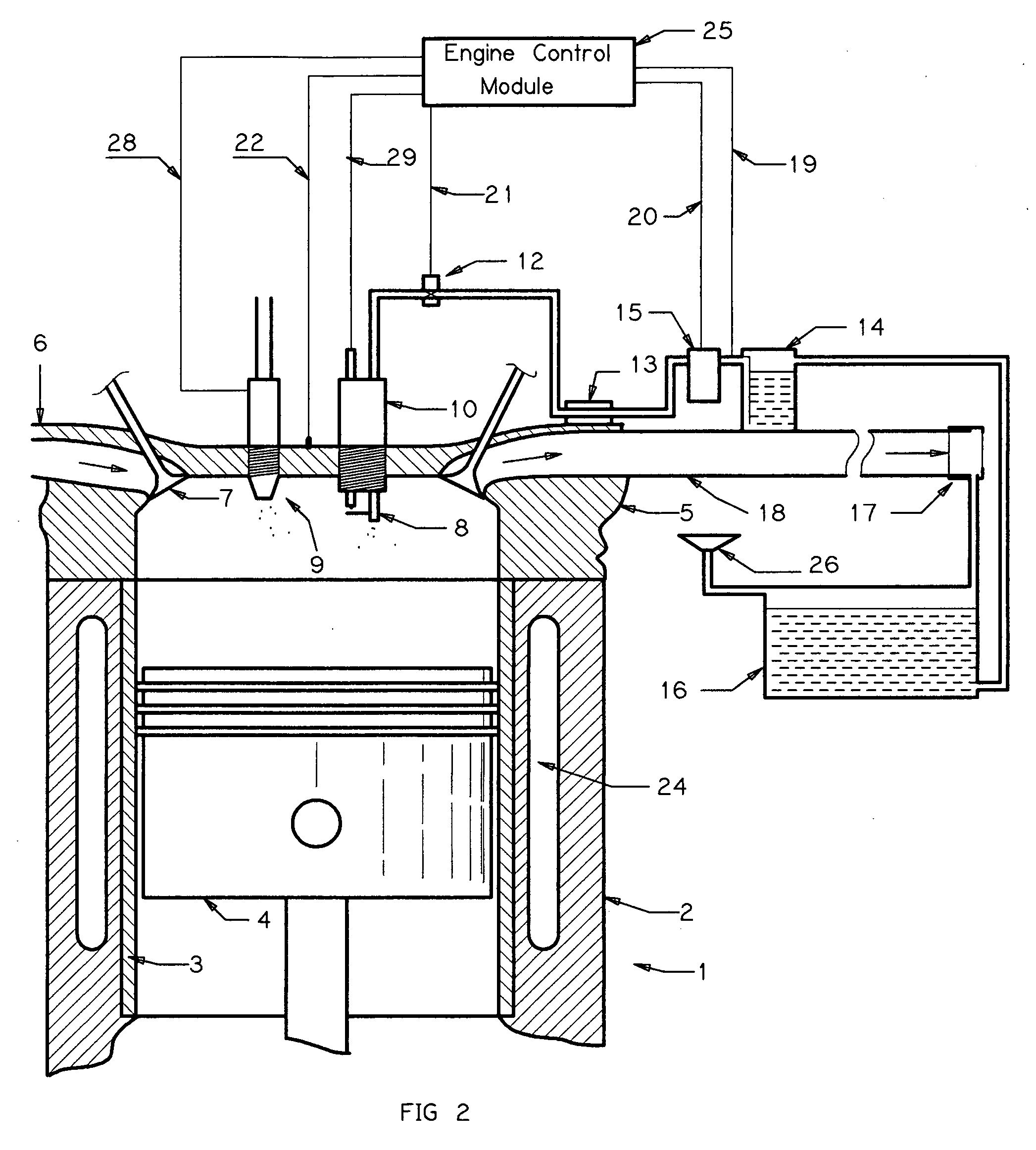

First and second spark plugs for improved combustion control

InactiveUS20070215102A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberHydrocotyle bowlesioides

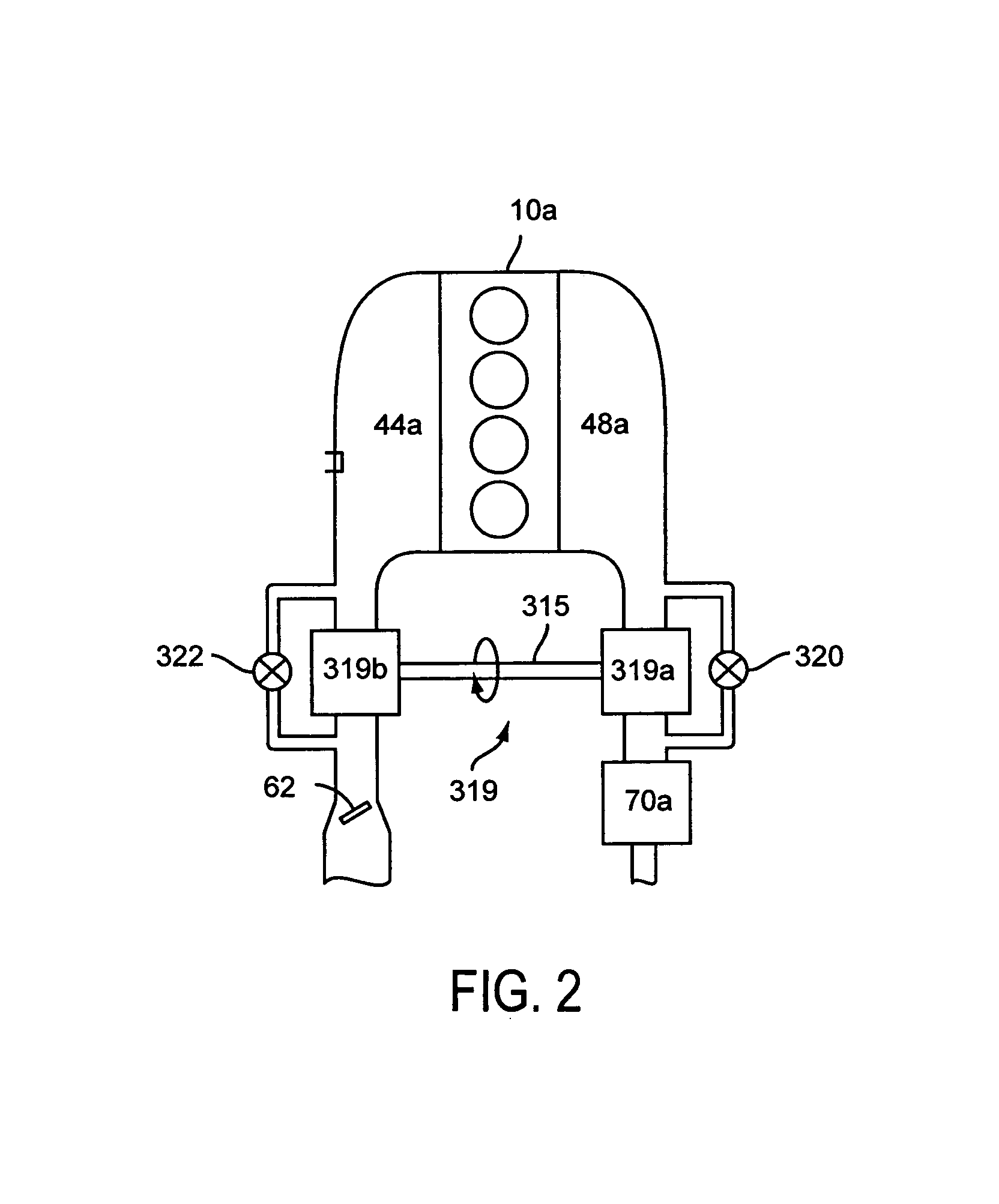

An engine system, comprising of a combustion chamber; a first spark plug configured to perform a spark within the combustion chamber, said first plug configured to have a first heat range; a second spark plug configured to produce a spark within the combustion chamber, said second plug configured to have a second heat range different from said first heat range of said first plug; and a delivery system configured to deliver a hydrocarbon fuel and a fluid including an alcohol to the combustion chamber in varying resulting ratios.

Owner:FORD GLOBAL TECH LLC

First and second spark plugs for improved combustion control

InactiveUS20070215101A1Low costImprove charge cooling effectElectric ignition installationCombustion enginesCombustion chamberInternal combustion engine

A method of operating an internal combustion engine having at least one combustion chamber including a first spark plug and a second spark plug, wherein the first spark plug is configured to operate at a higher temperature than the second spark plug, the method comprising of varying at least a resulting ratio of an amount of a fuel and an amount of a fluid delivered to the combustion chamber responsive to a first condition, and selectively using at least one of the first spark plug and the second spark plug to ignite at least one of the fuel and the fluid delivered to the combustion chamber.

Owner:FORD GLOBAL TECH LLC

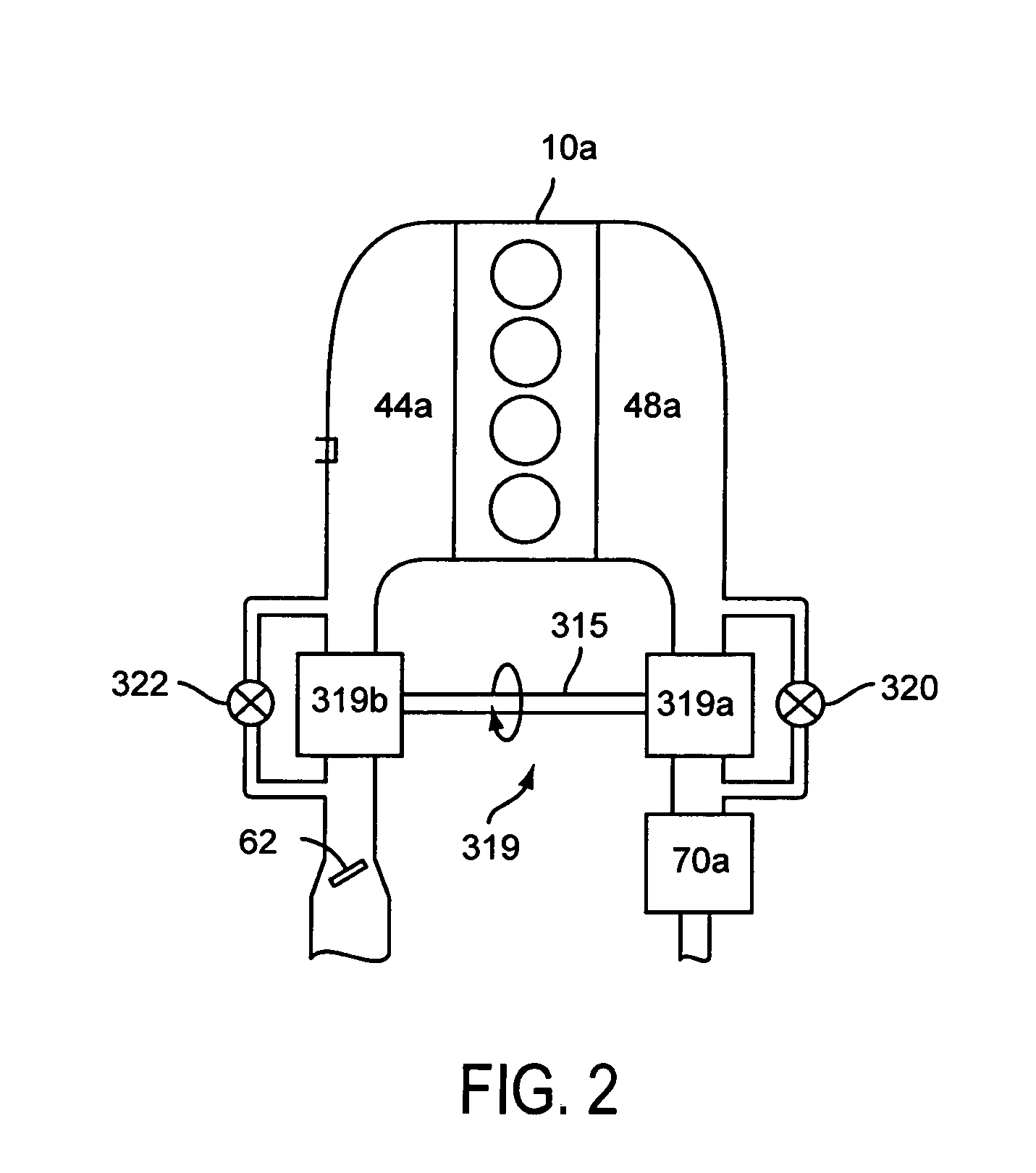

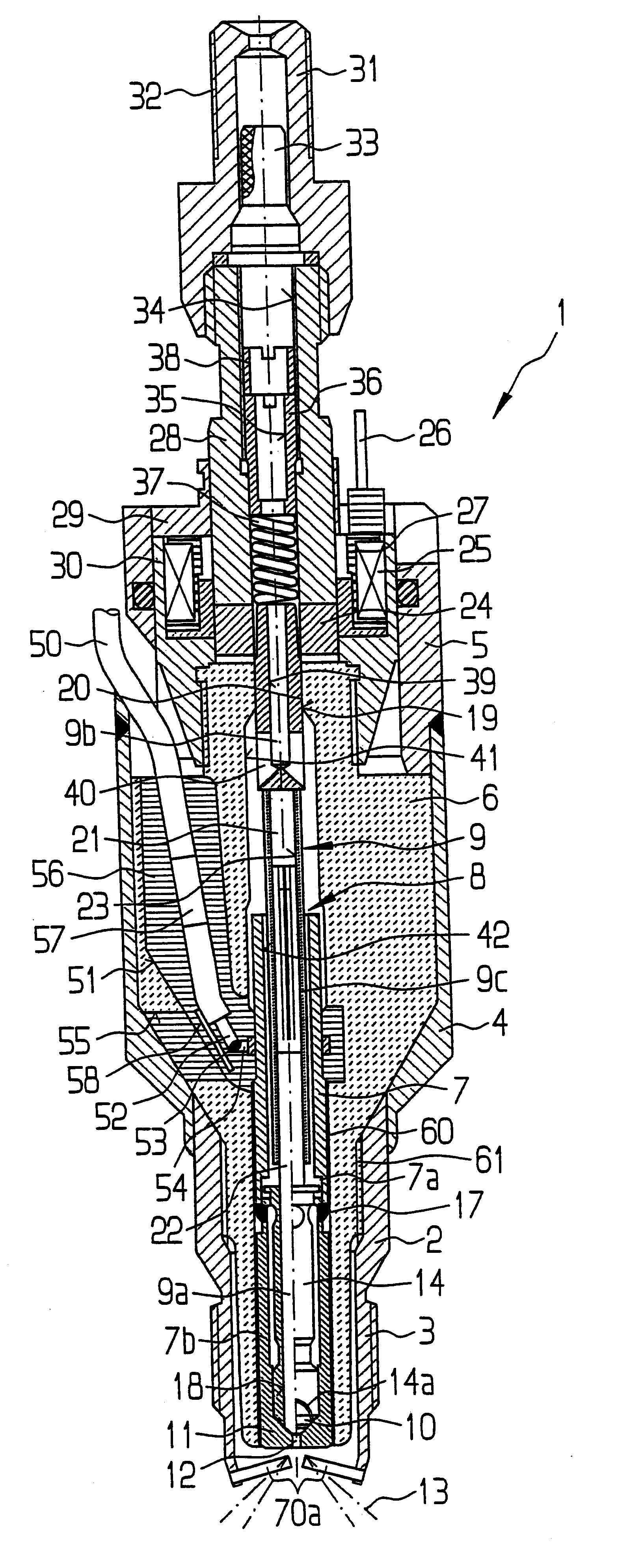

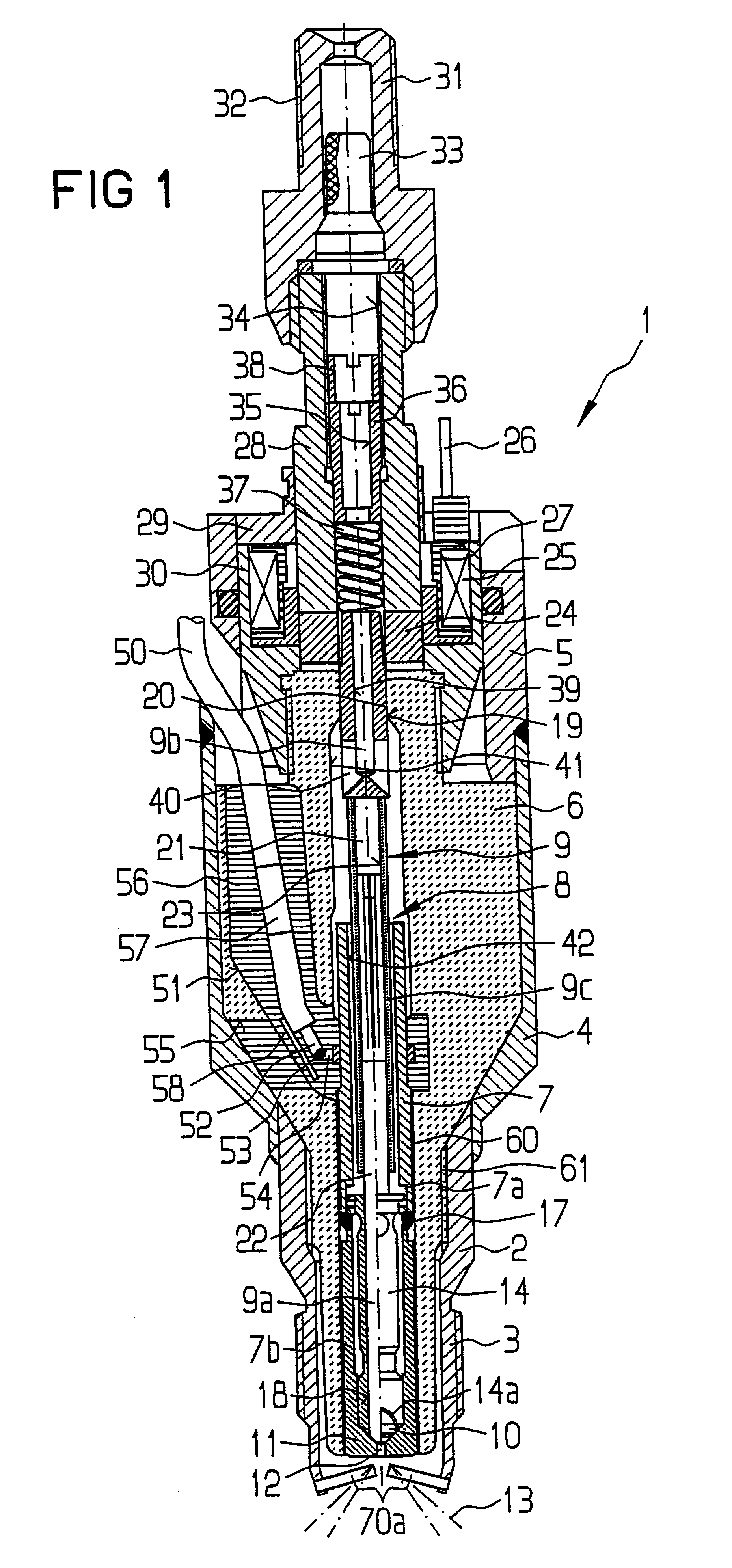

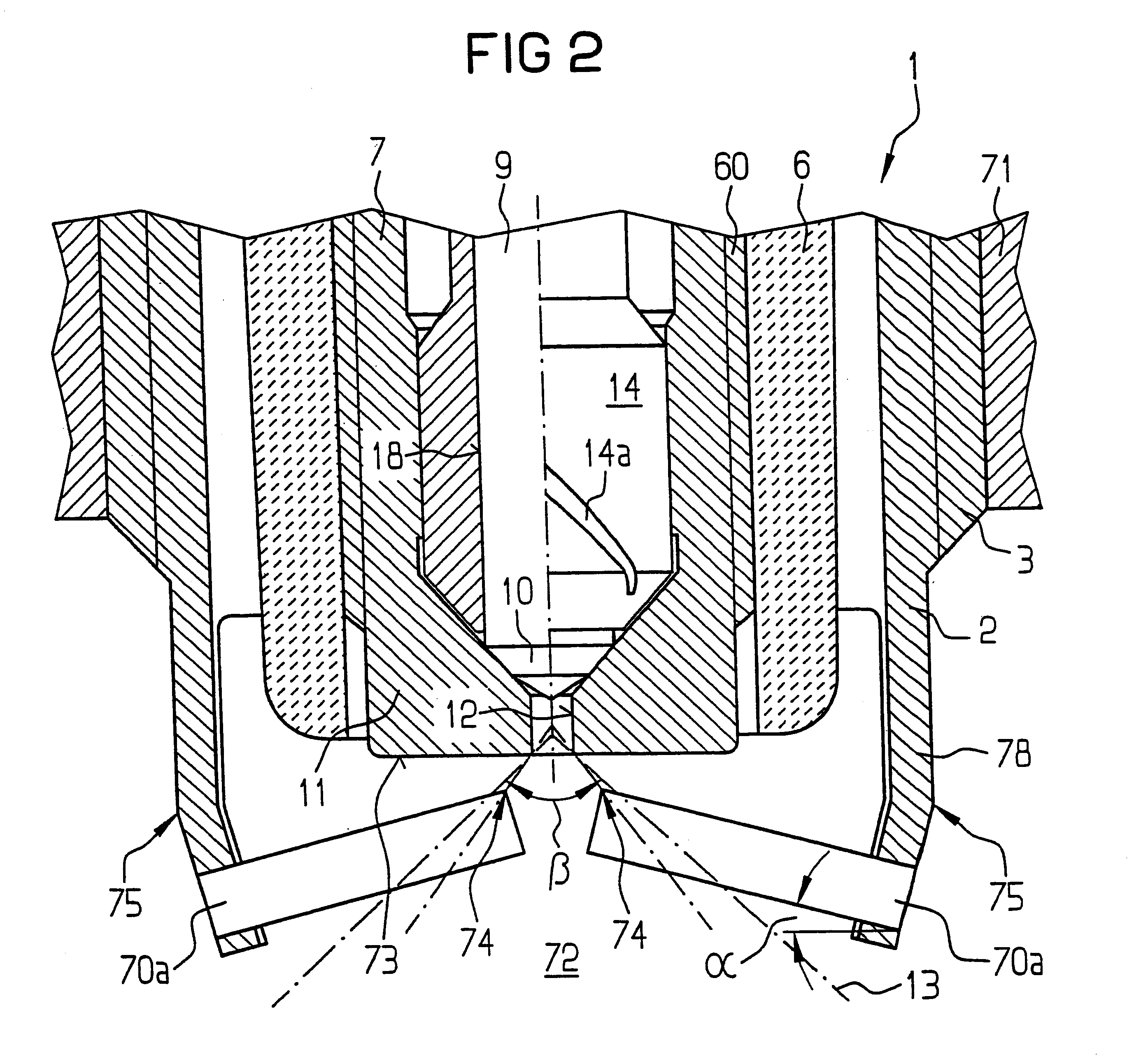

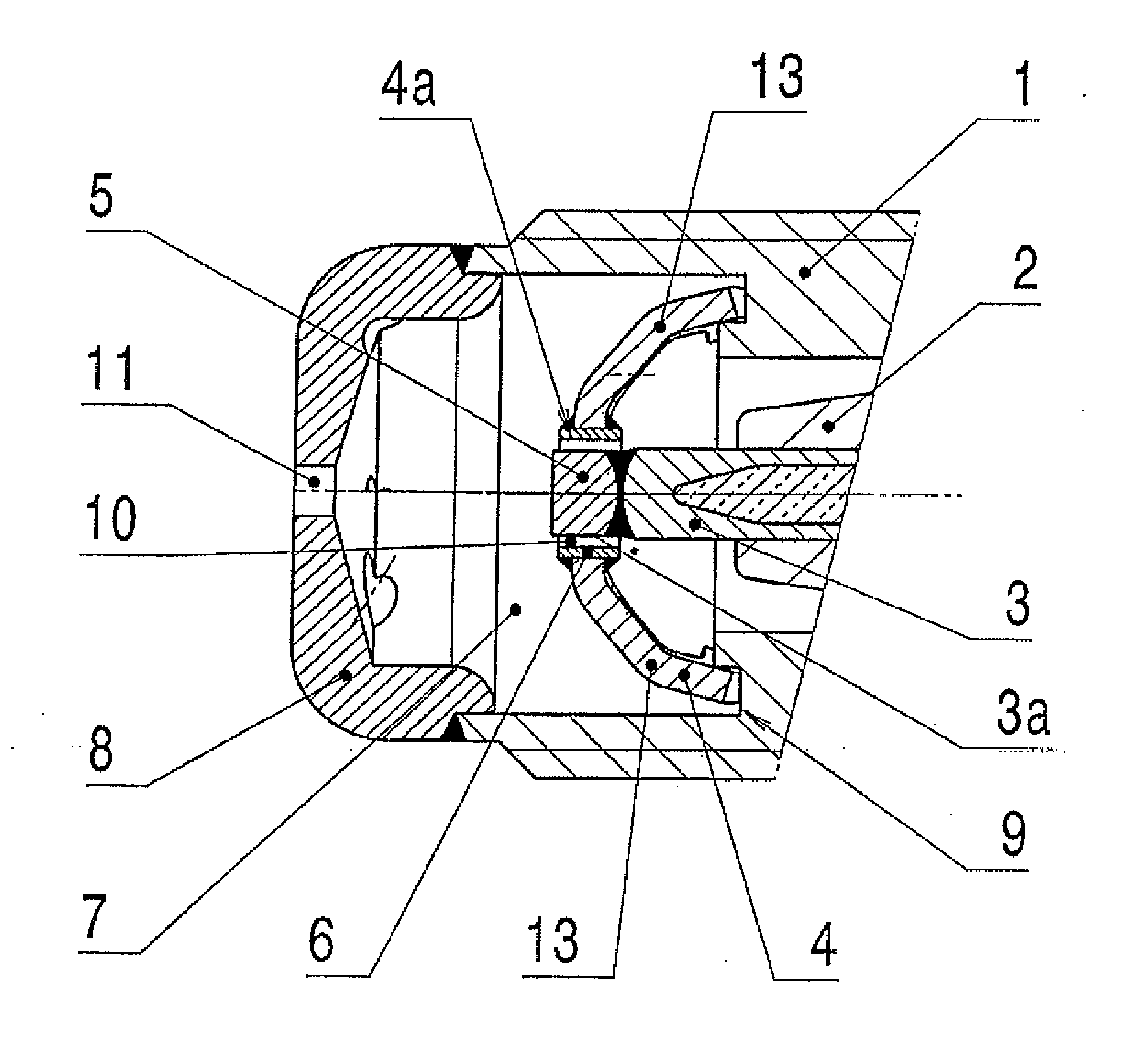

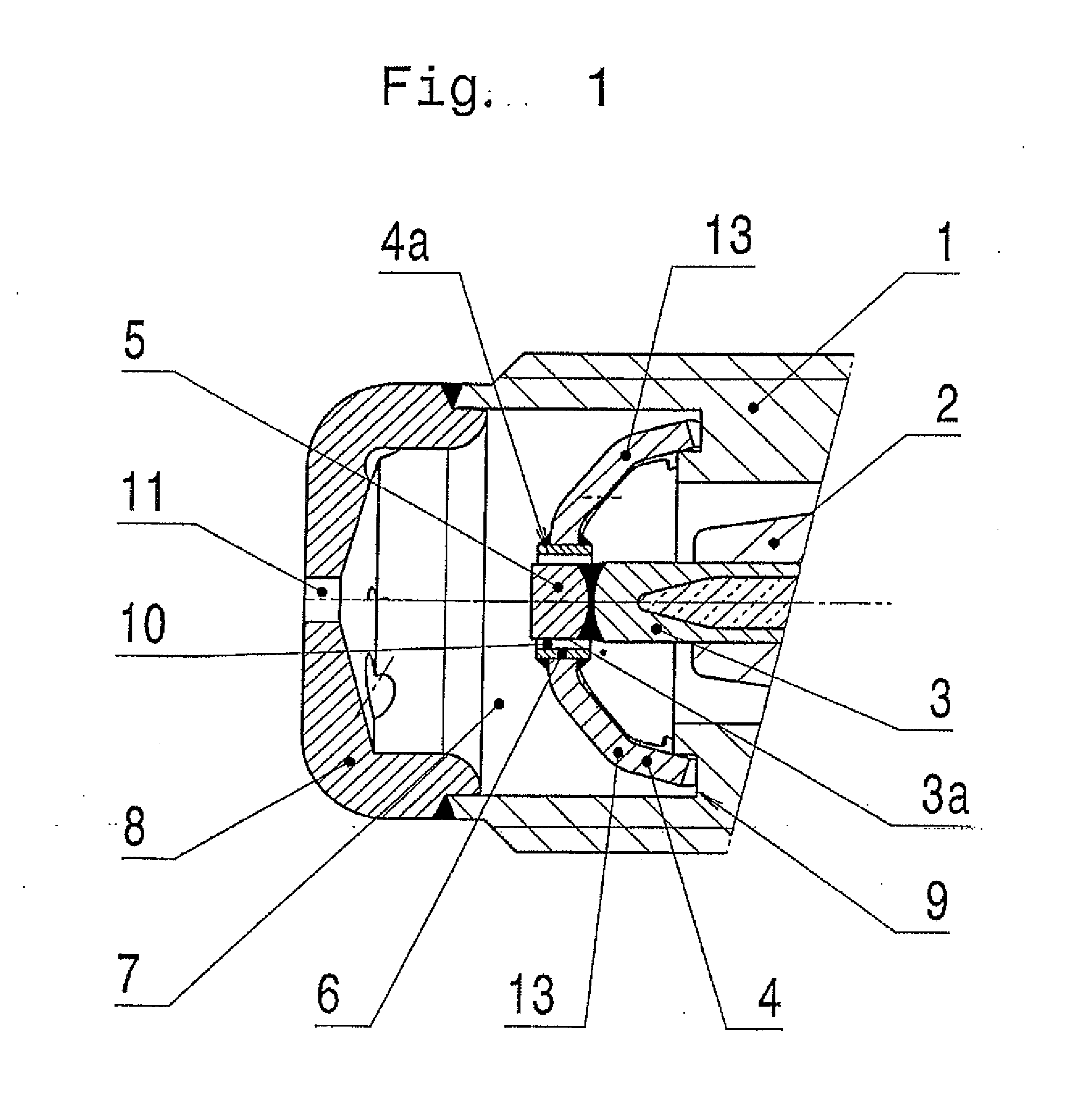

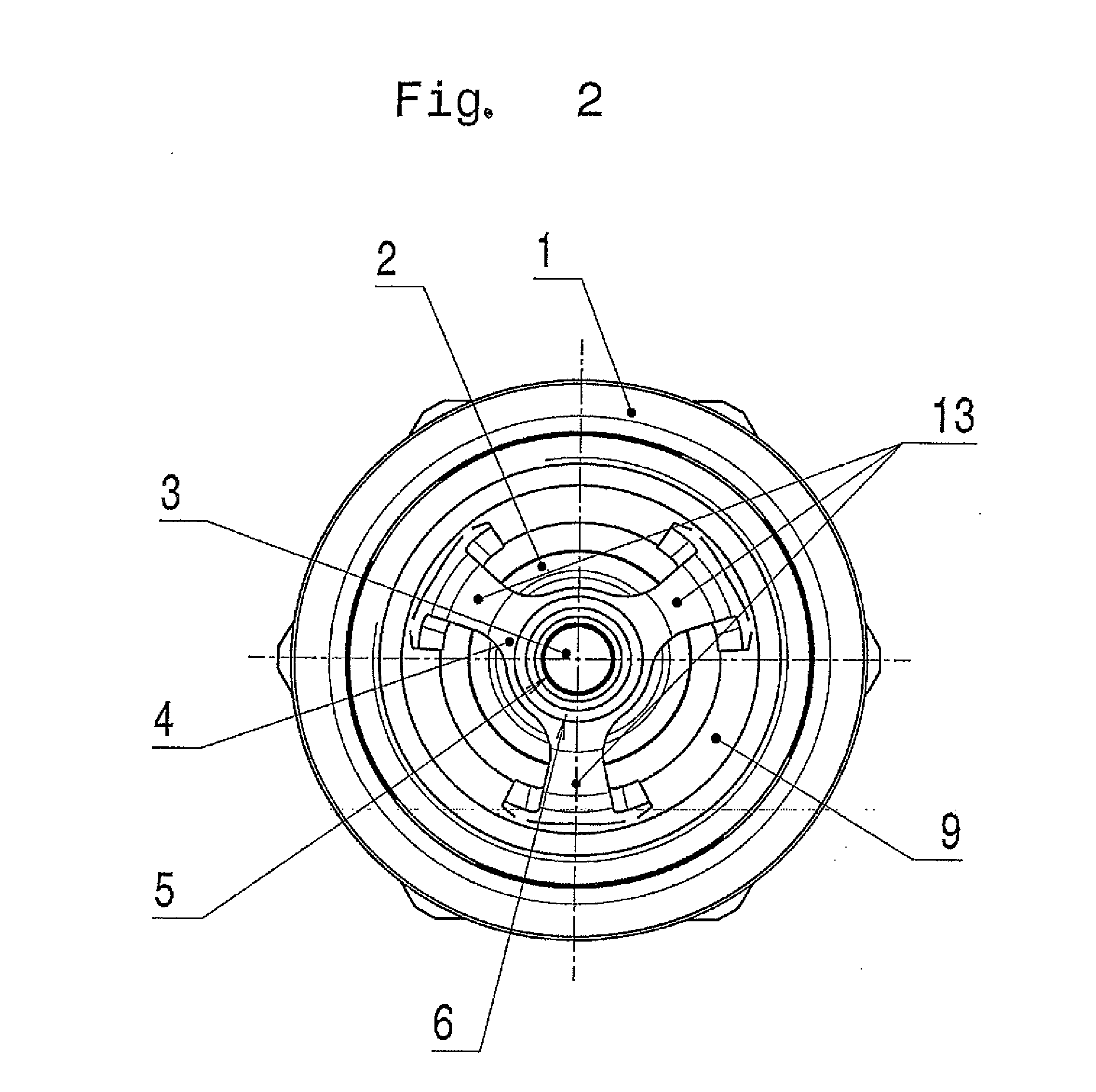

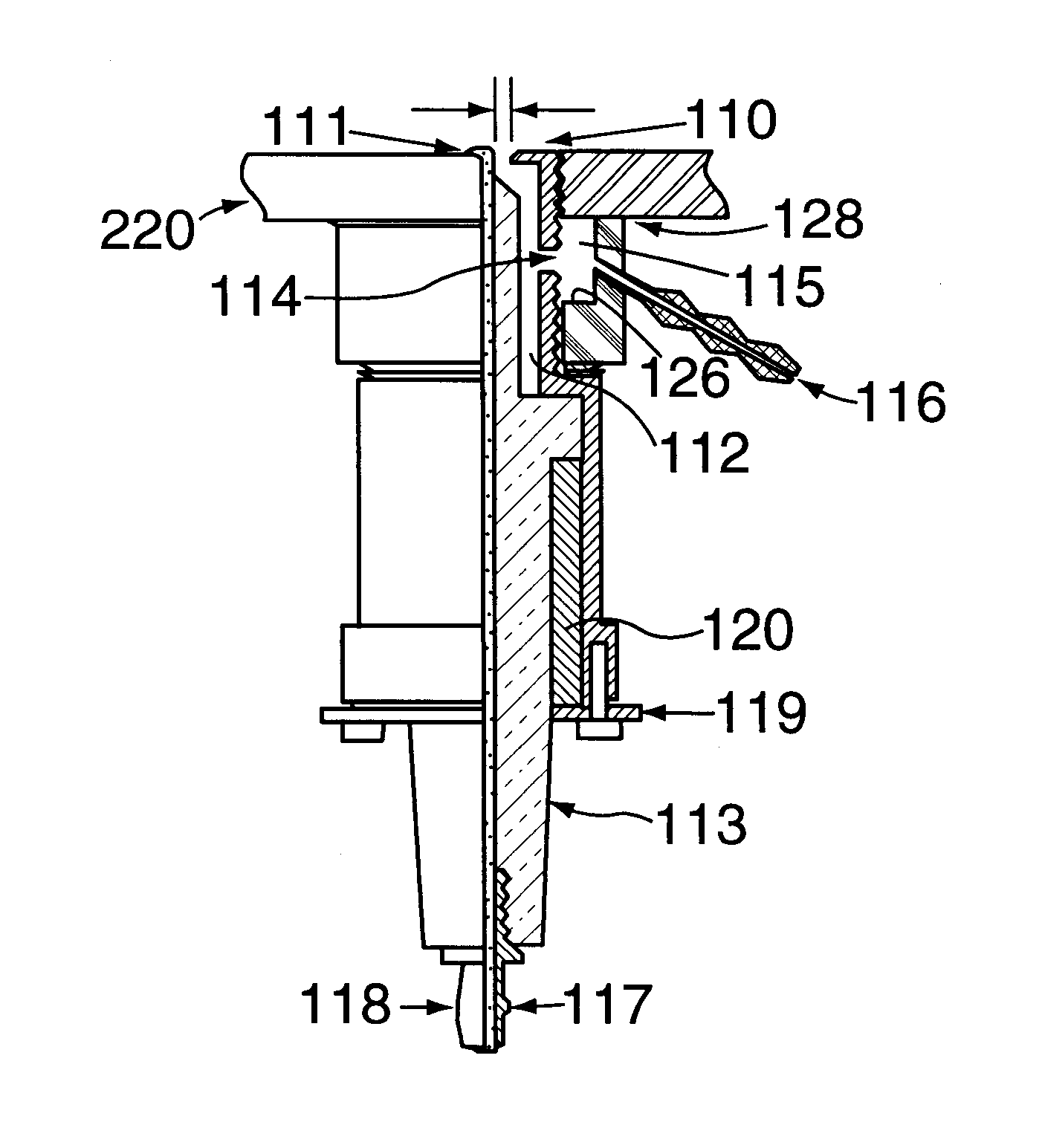

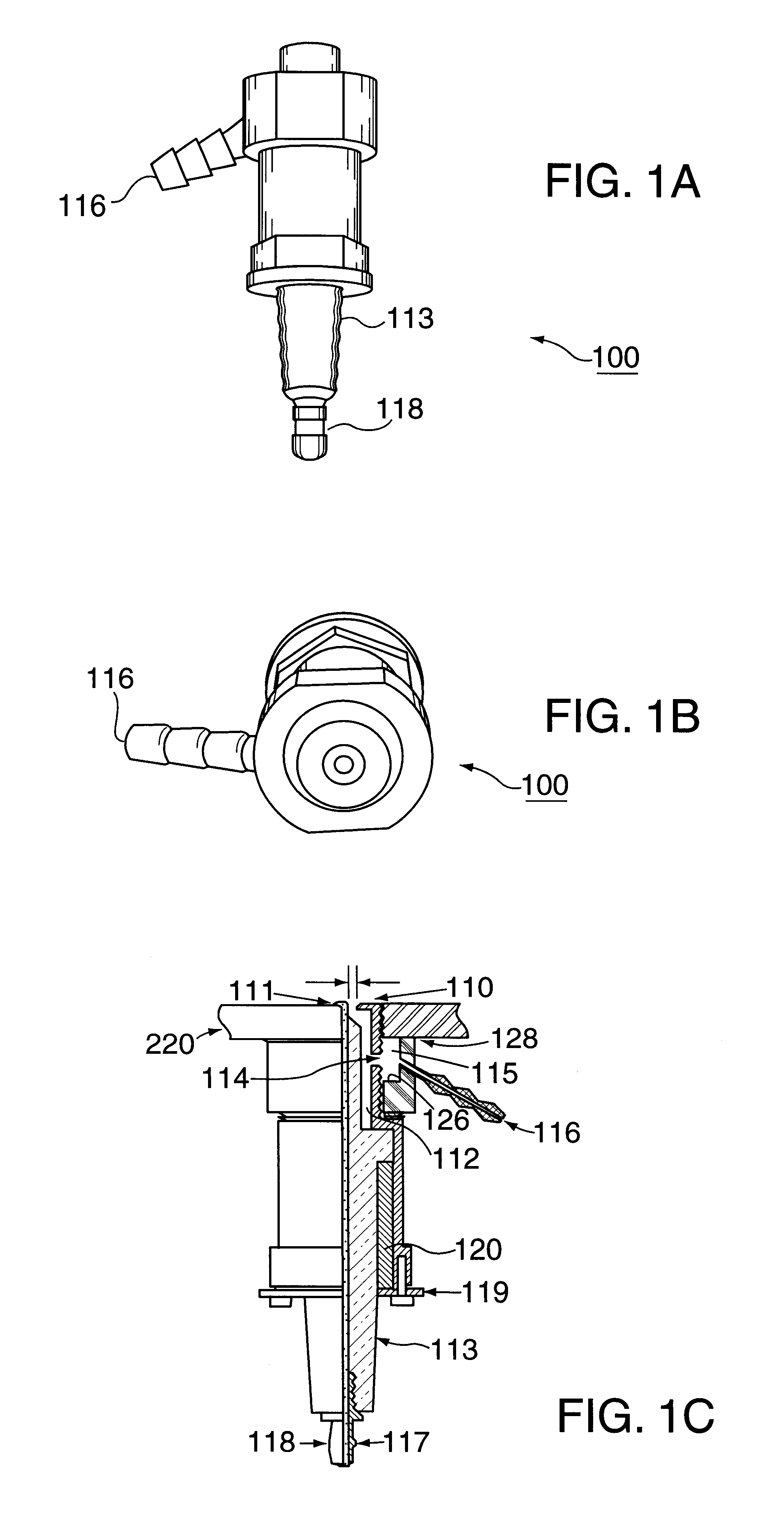

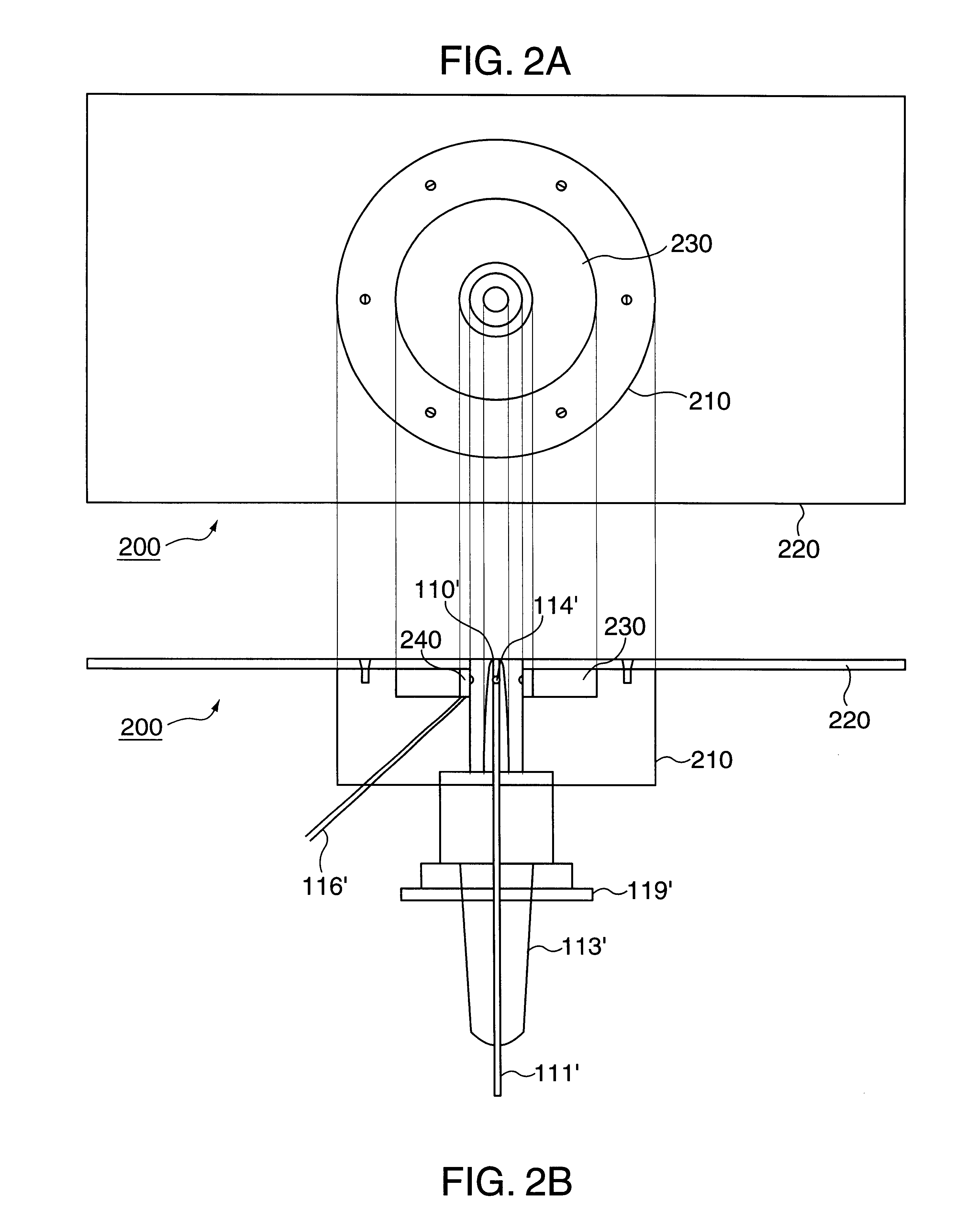

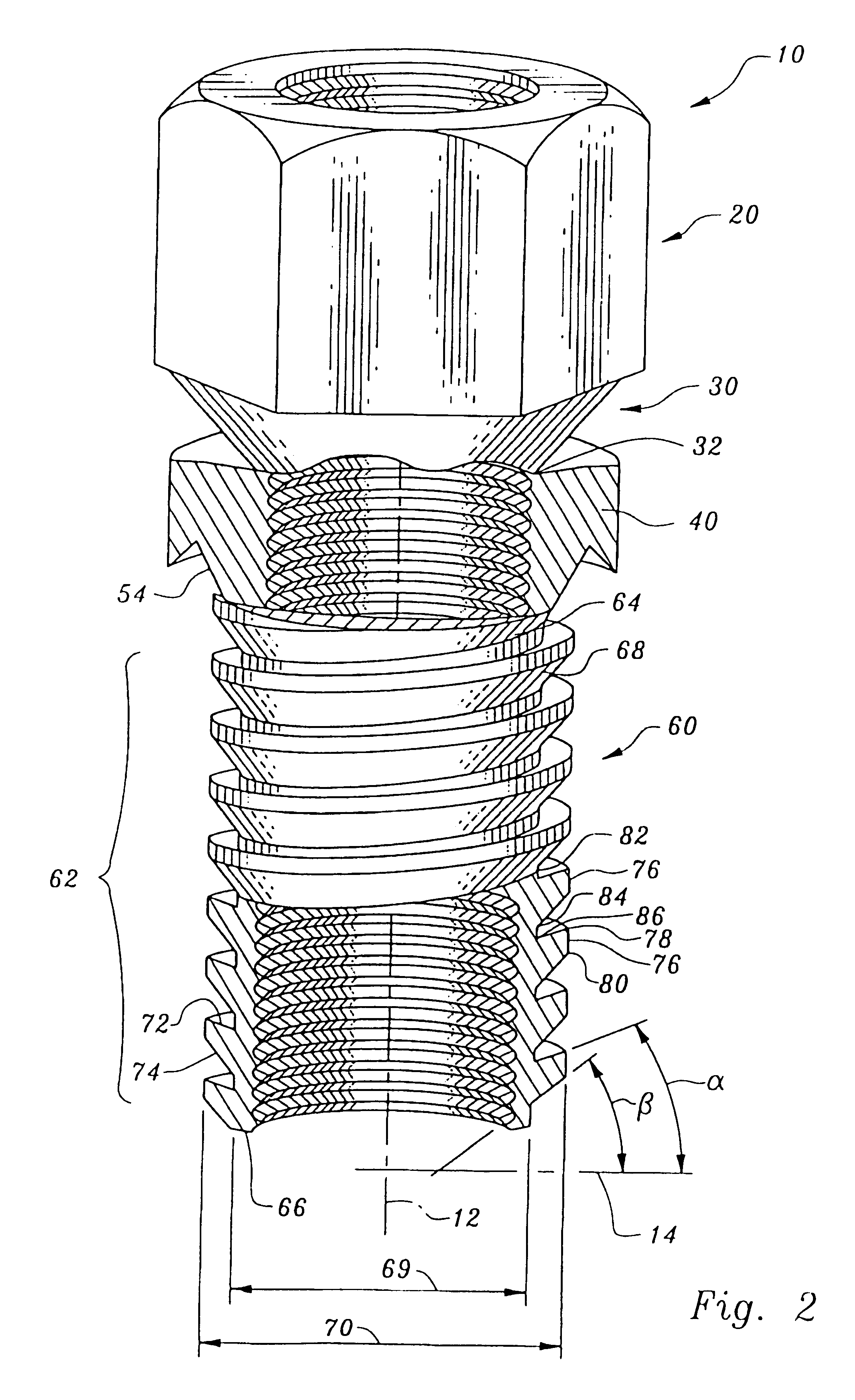

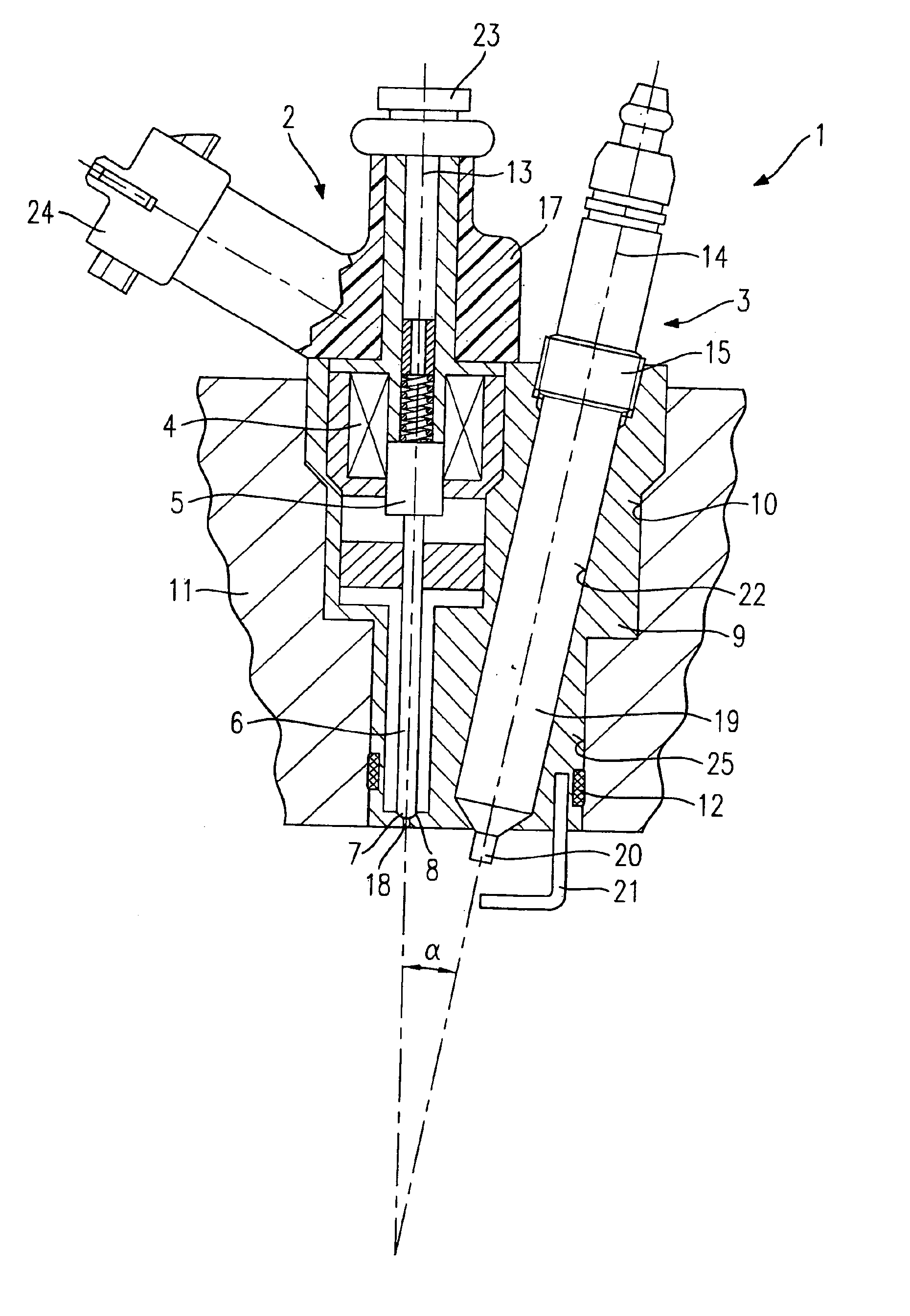

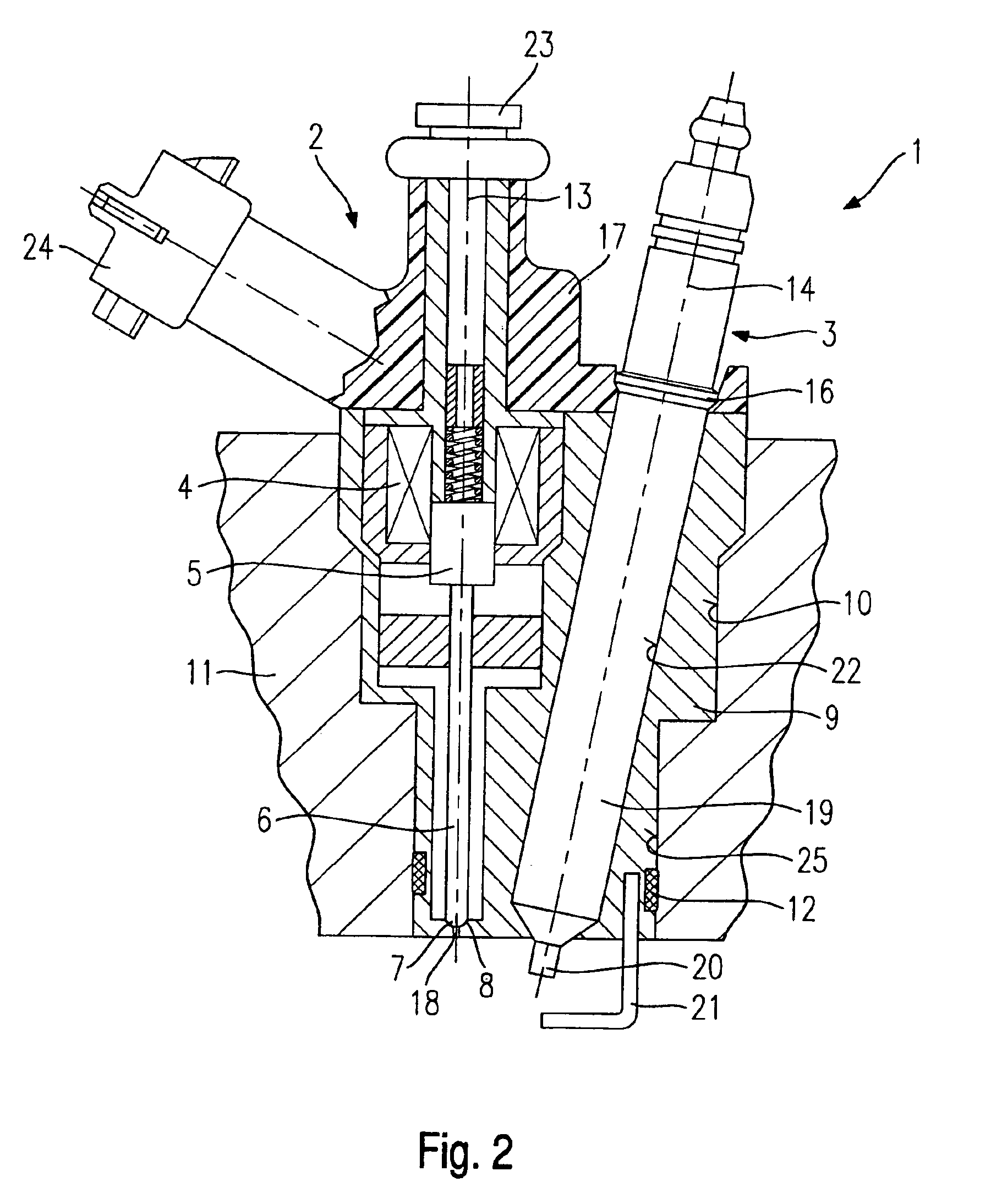

Fuel injection valve with integrated spark plug

A fuel injector having an integrated spark plug (1) for injecting fuel directly into a combustion chamber (72) of an internal combustion engine and for igniting the fuel that is injected into the combustion chamber (72) has a valve body (7), which, together with a valve-closure member (10), forms a sealing seat. Disposed contiguously to the sealing seat is a discharge orifice (12), which discharges at a valve-body (7) end face (73) facing the combustion chamber (72). Provision is also made for a housing body (2) that is insulated from the valve body (7), and for an ignition electrode (70a) that is connected to the housing body (2). In this context, a spark arc-over is produced between the valve body (7) and the ignition electrode (70a). The ignition electrode (70a) and the valve body (7) are formed in such a way that the spark arc-over takes place between the end face (73) of the valve body (7) facing the combustion chamber (72) and the ignition electrode (70a). In the vicinity of the discharge orifice (12), the ignition electrode (70a) has an edge (74) in order to reproducibly define the position of the spark arc-over at the end face (73) of the valve body (7) with respect to the position of the discharge orifice (12).

Owner:ROBERT BOSCH GMBH

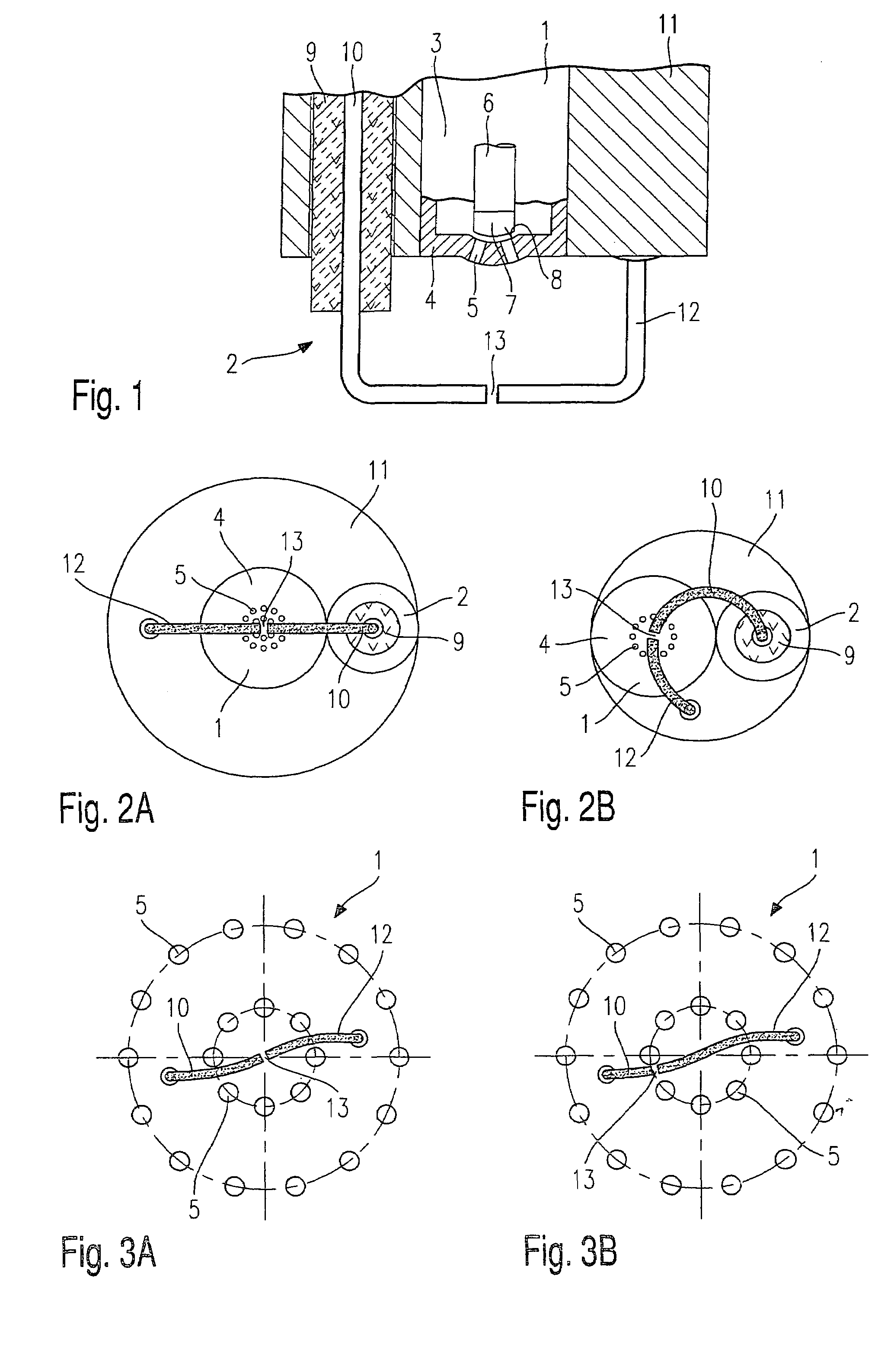

Combined fuel injection valve-ignition plug

InactiveUS7077100B2Sparking plugsFuel injection apparatusCombustion chamberInternal combustion engine

A fuel injector having an integrated spark plug is provided, the fuel injector providing direct injection of fuel into a combustion chamber of an internal combustion engine, and the spark plug for igniting the fuel injected into the combustion chamber. Also provided is a spark-plug insulator that insulates a first electrode and a second electrode which is set apart from the first electrode by a spark gap, the fuel injector and the spark-plug insulator of the spark plug being arranged in a shared housing. The spark gap has a width of 50 to 300 μm and is disposed in front of the fuel injector at a distance of 3 to 10 mm.

Owner:ROBERT BOSCH GMBH

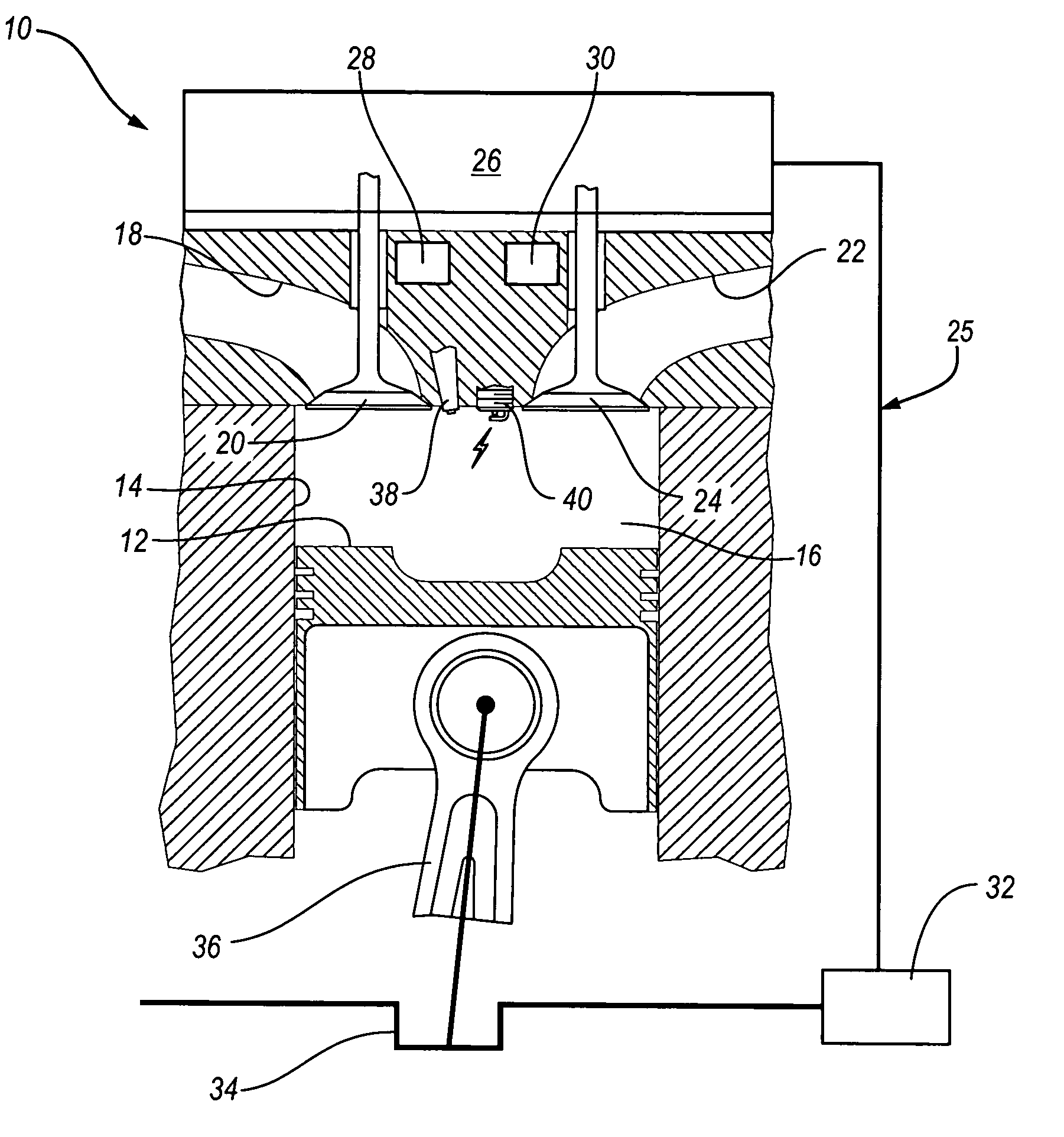

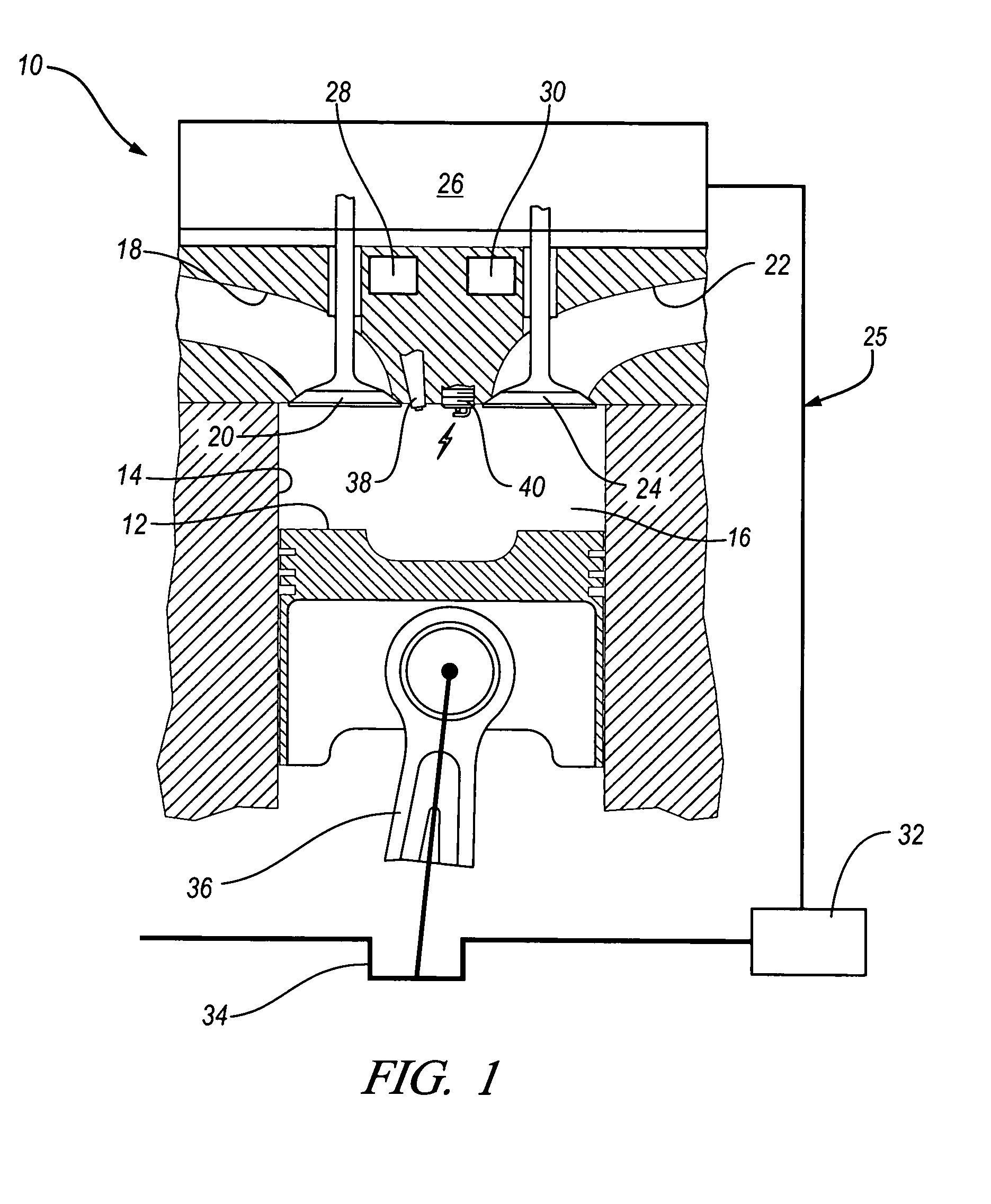

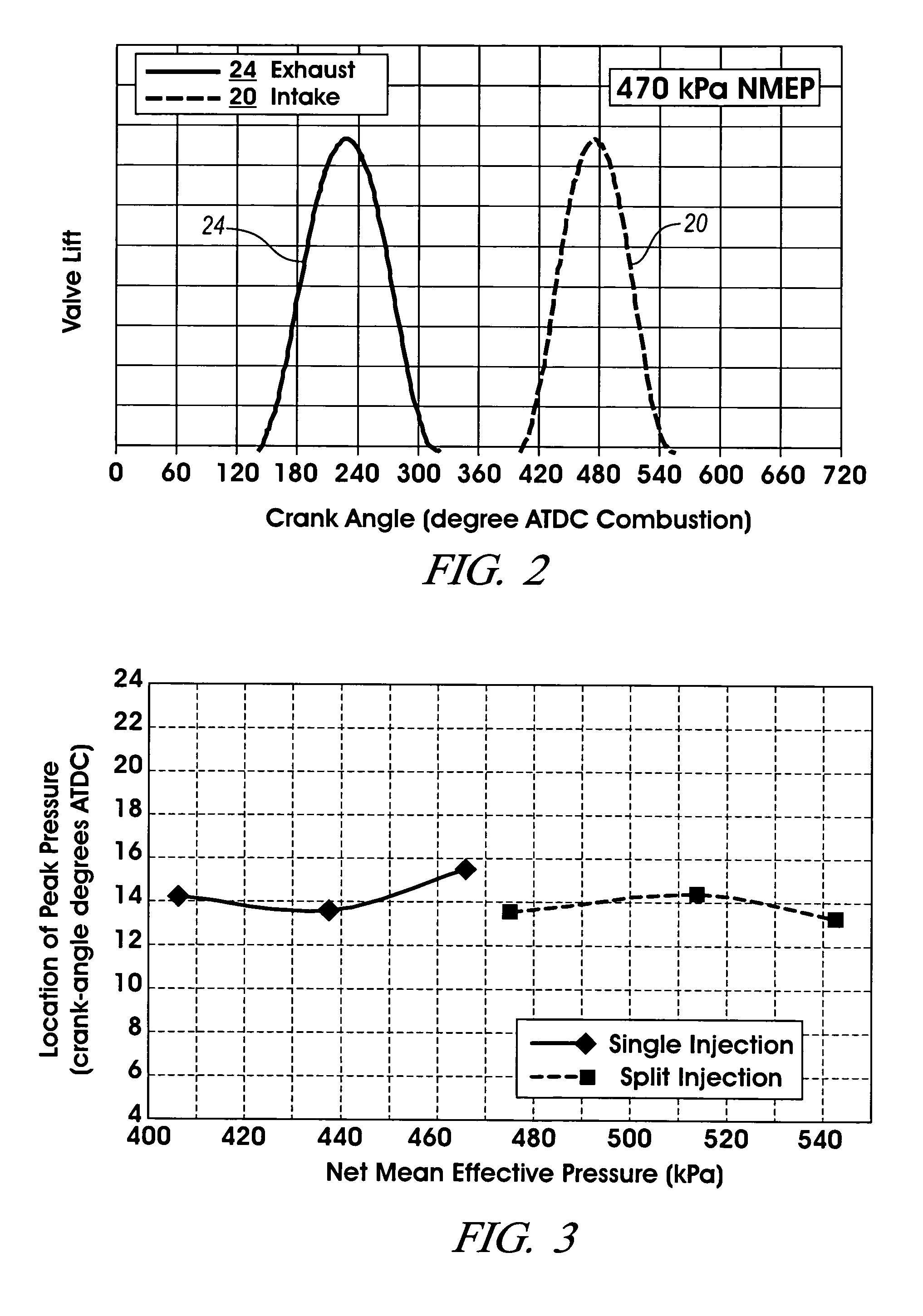

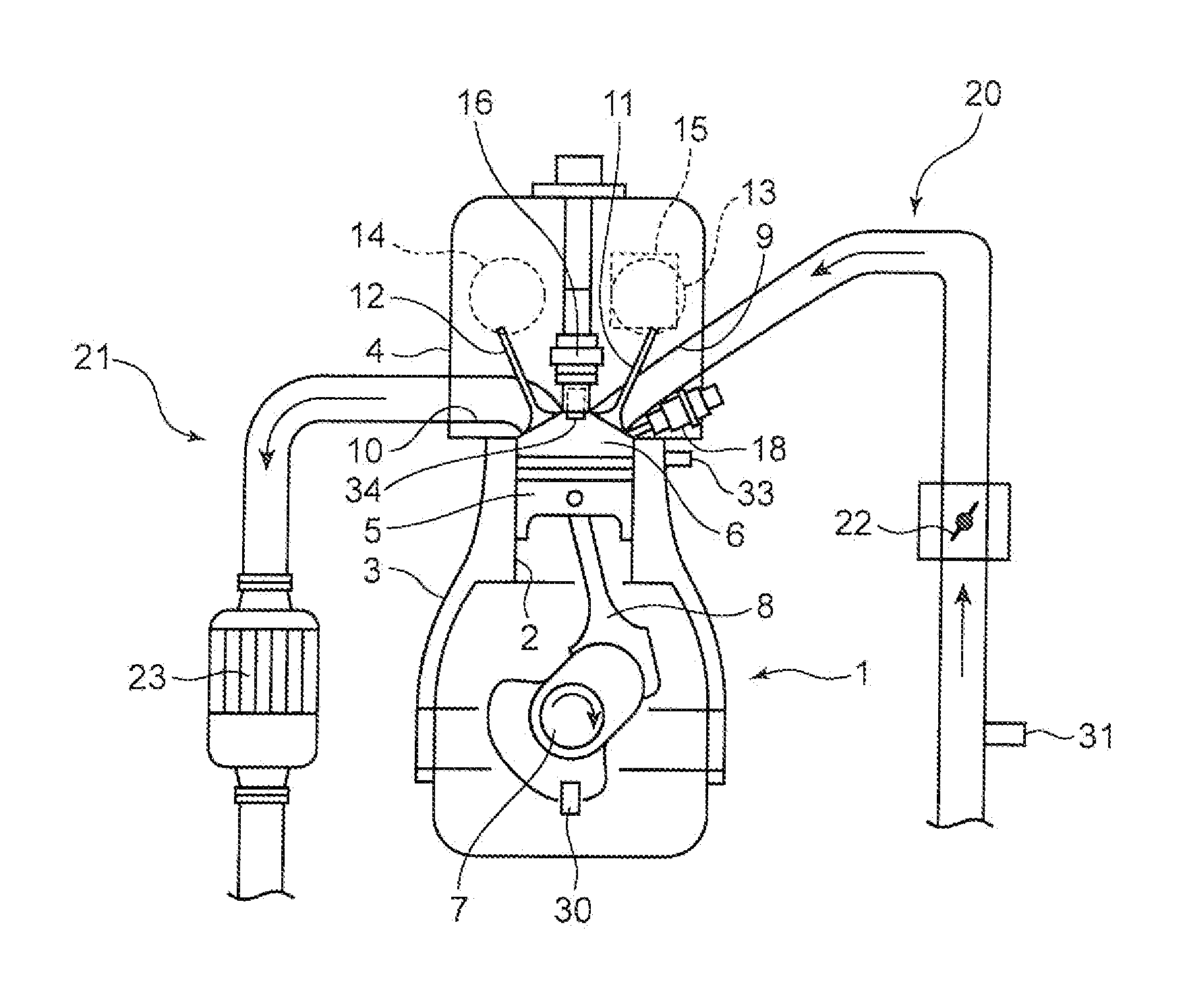

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

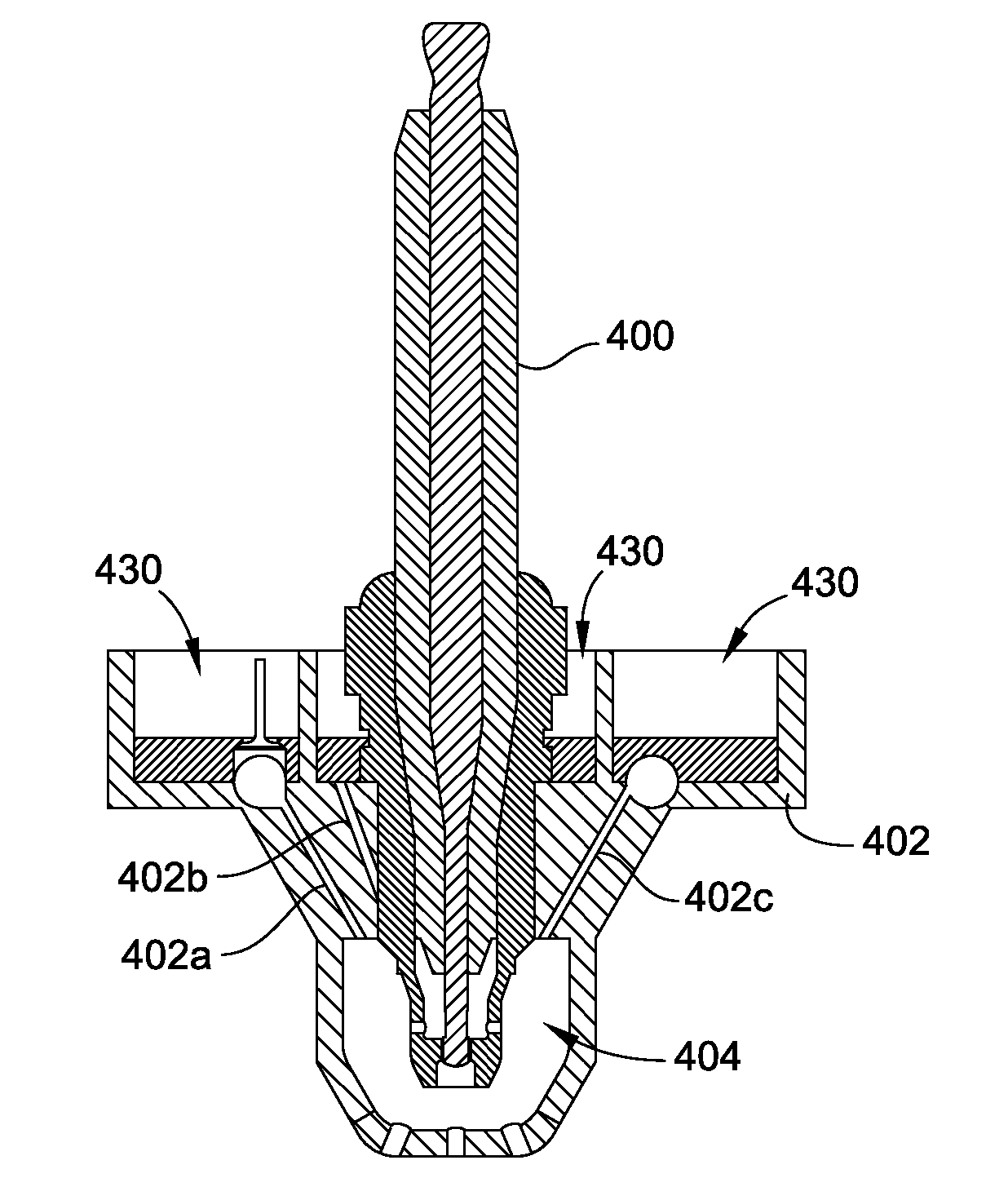

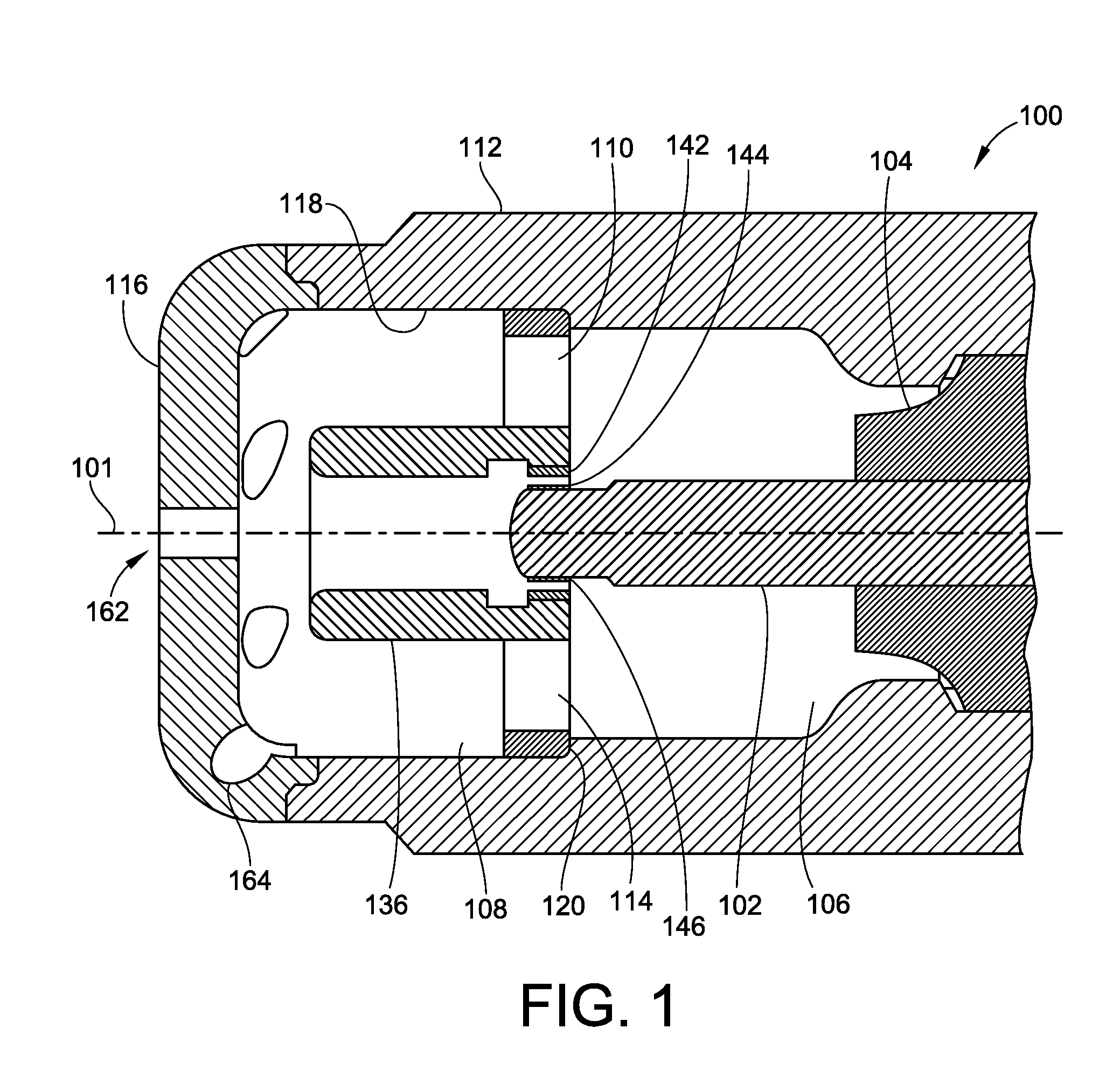

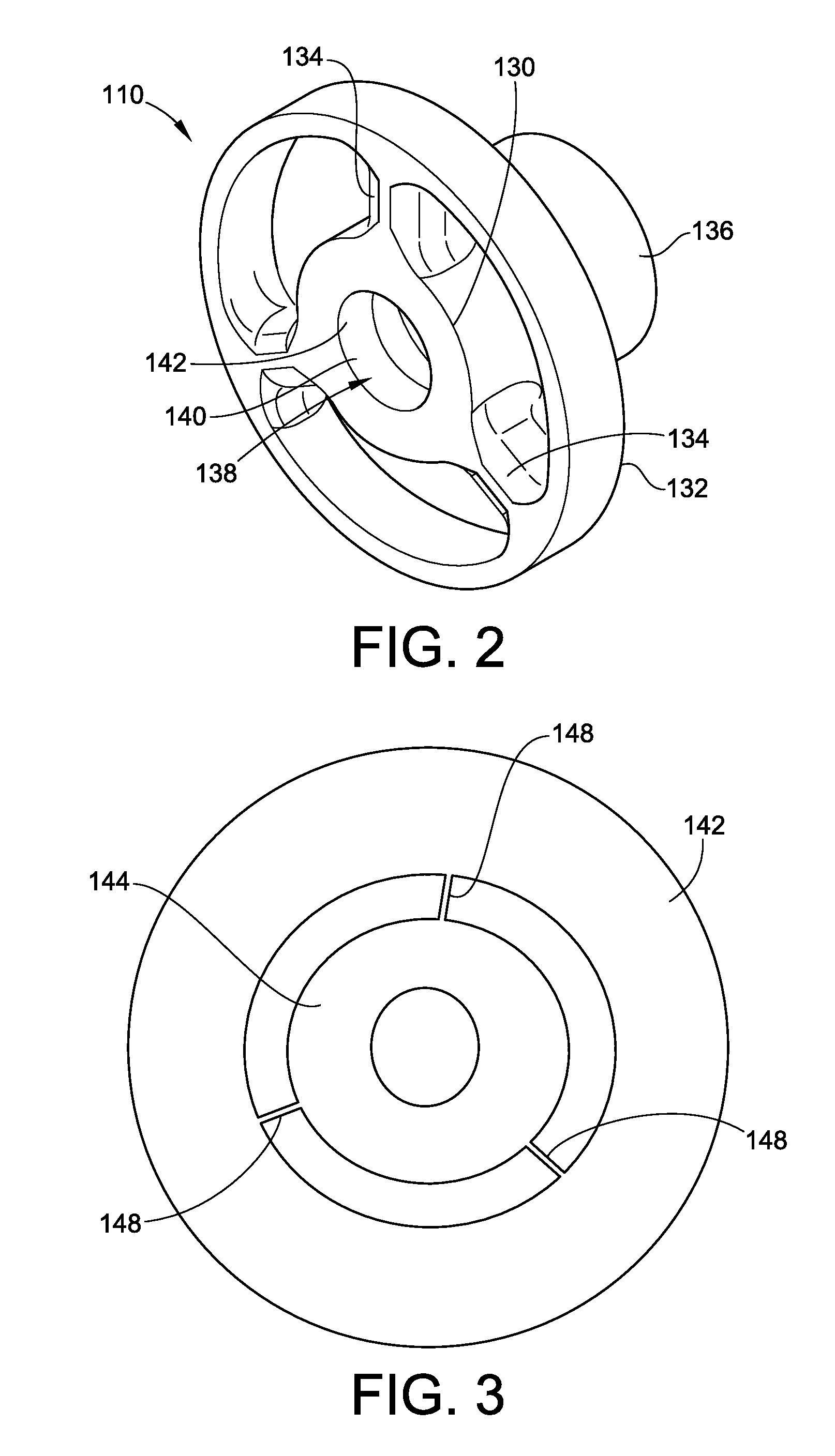

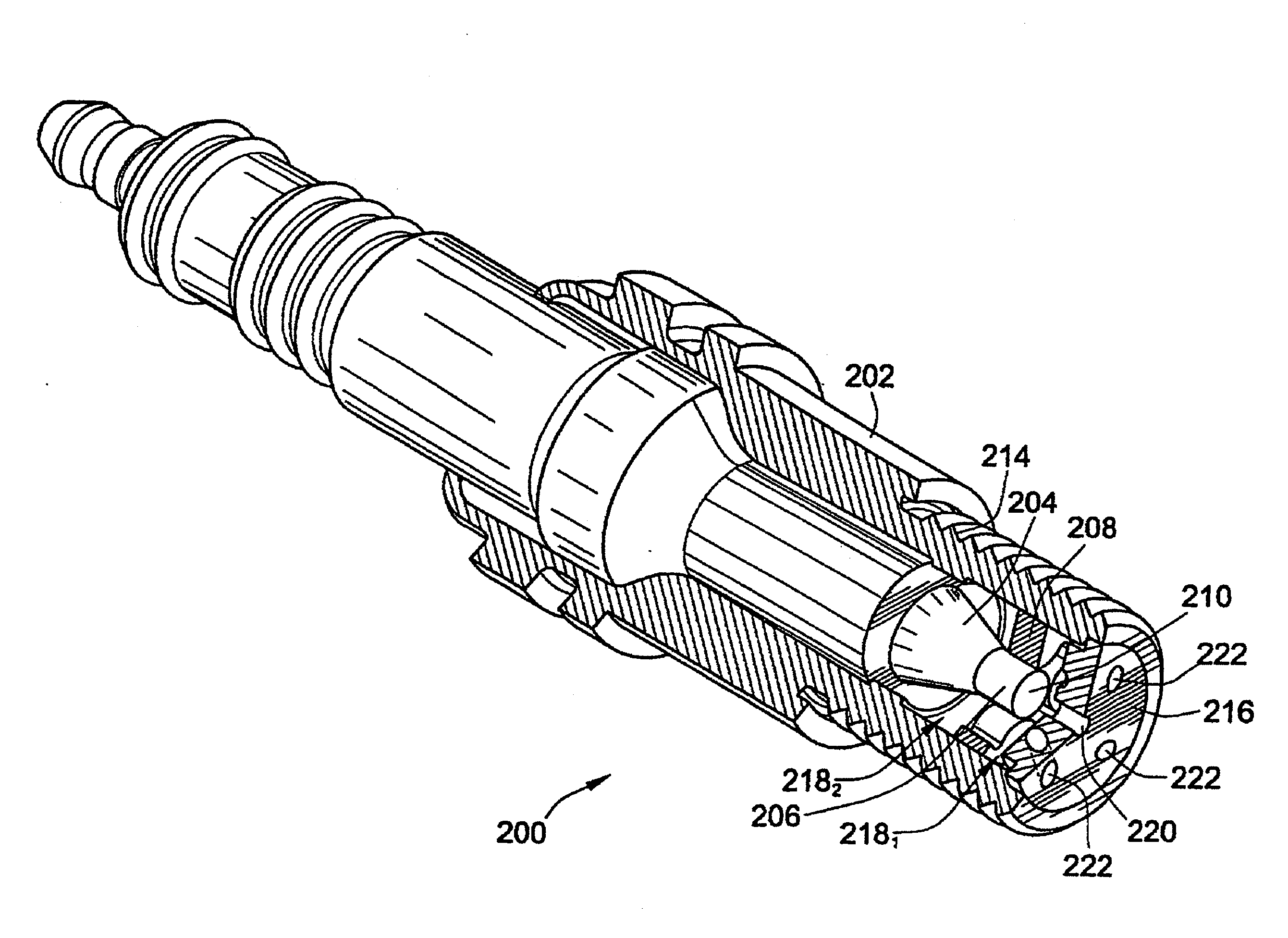

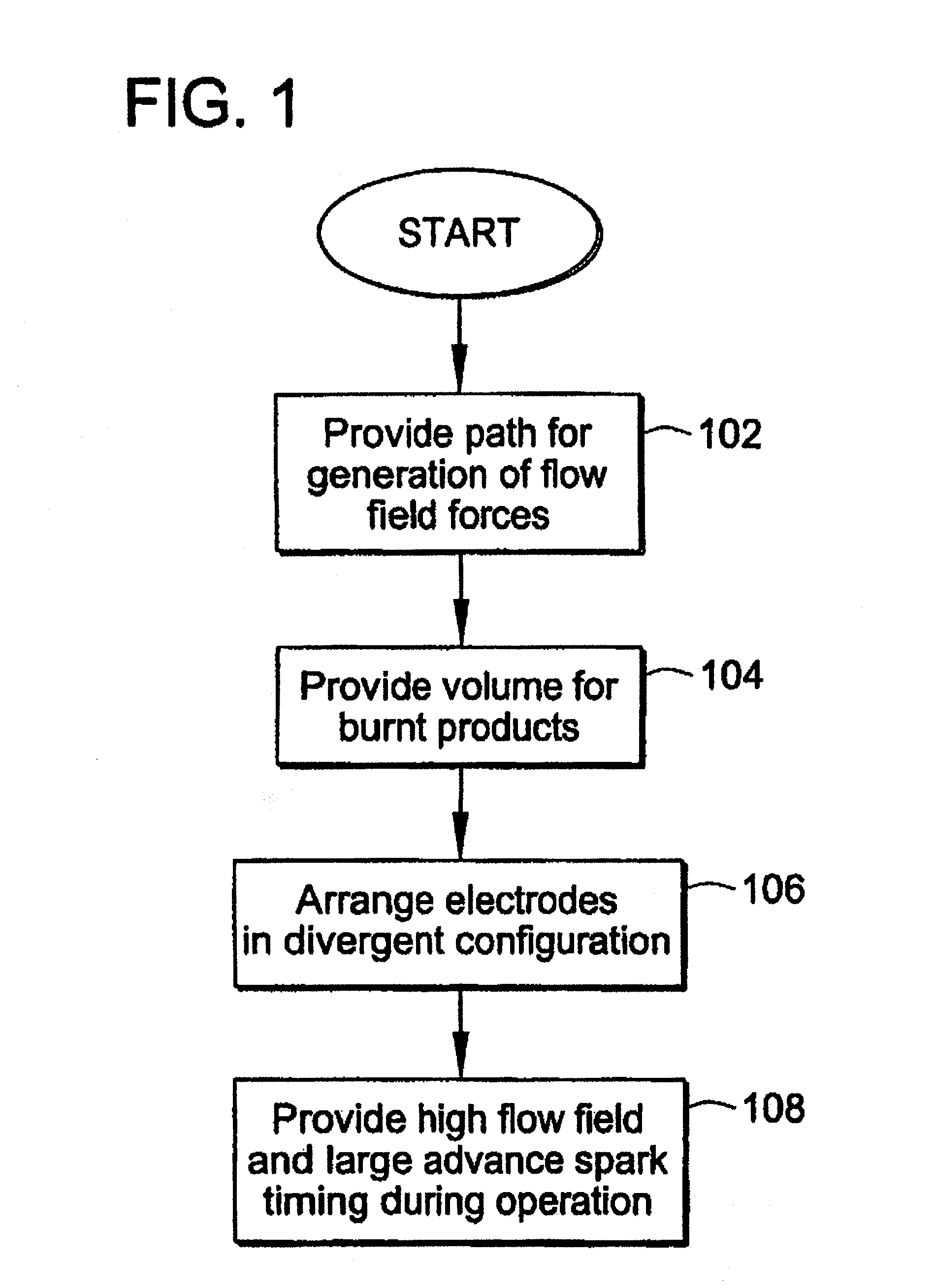

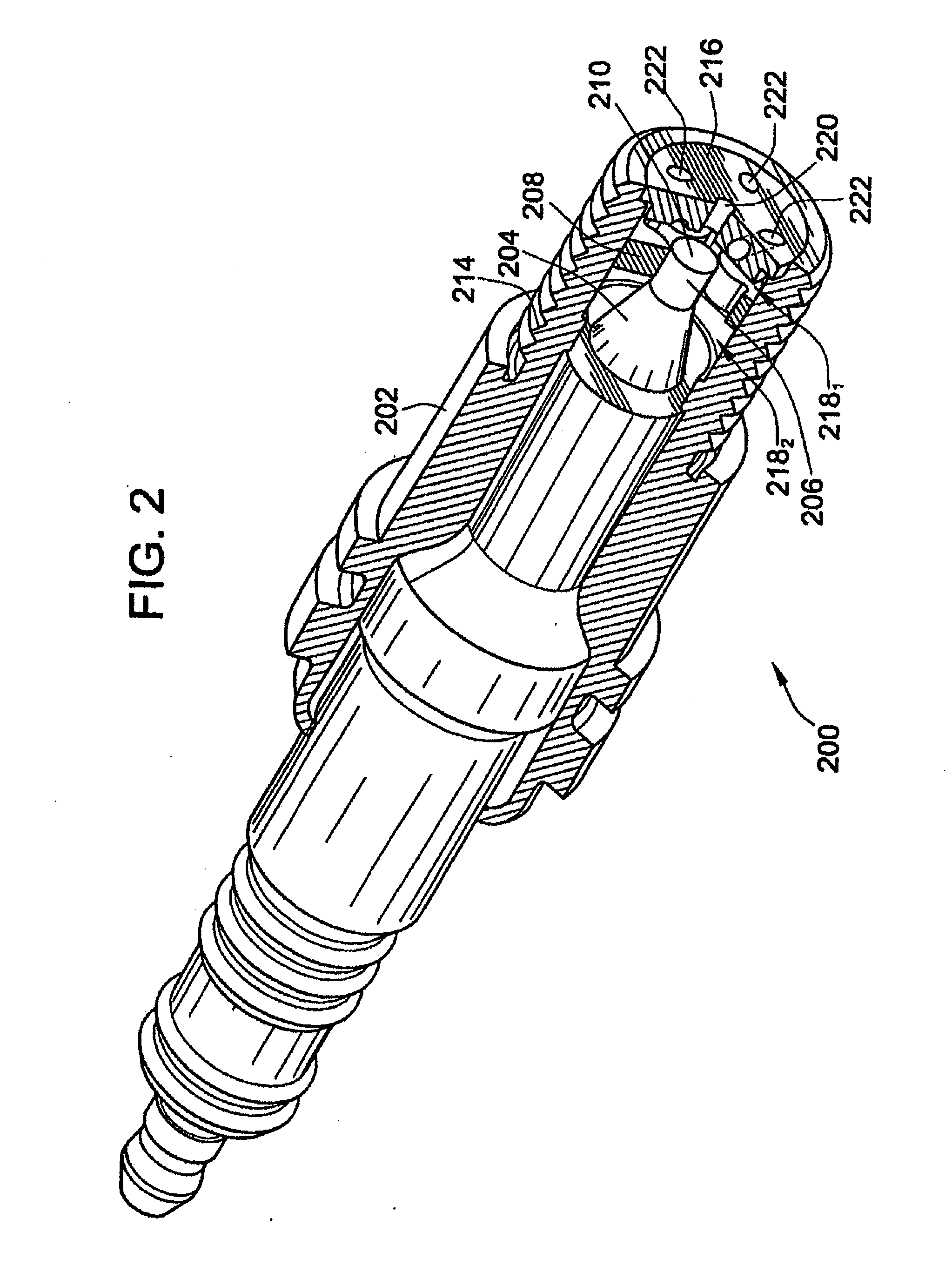

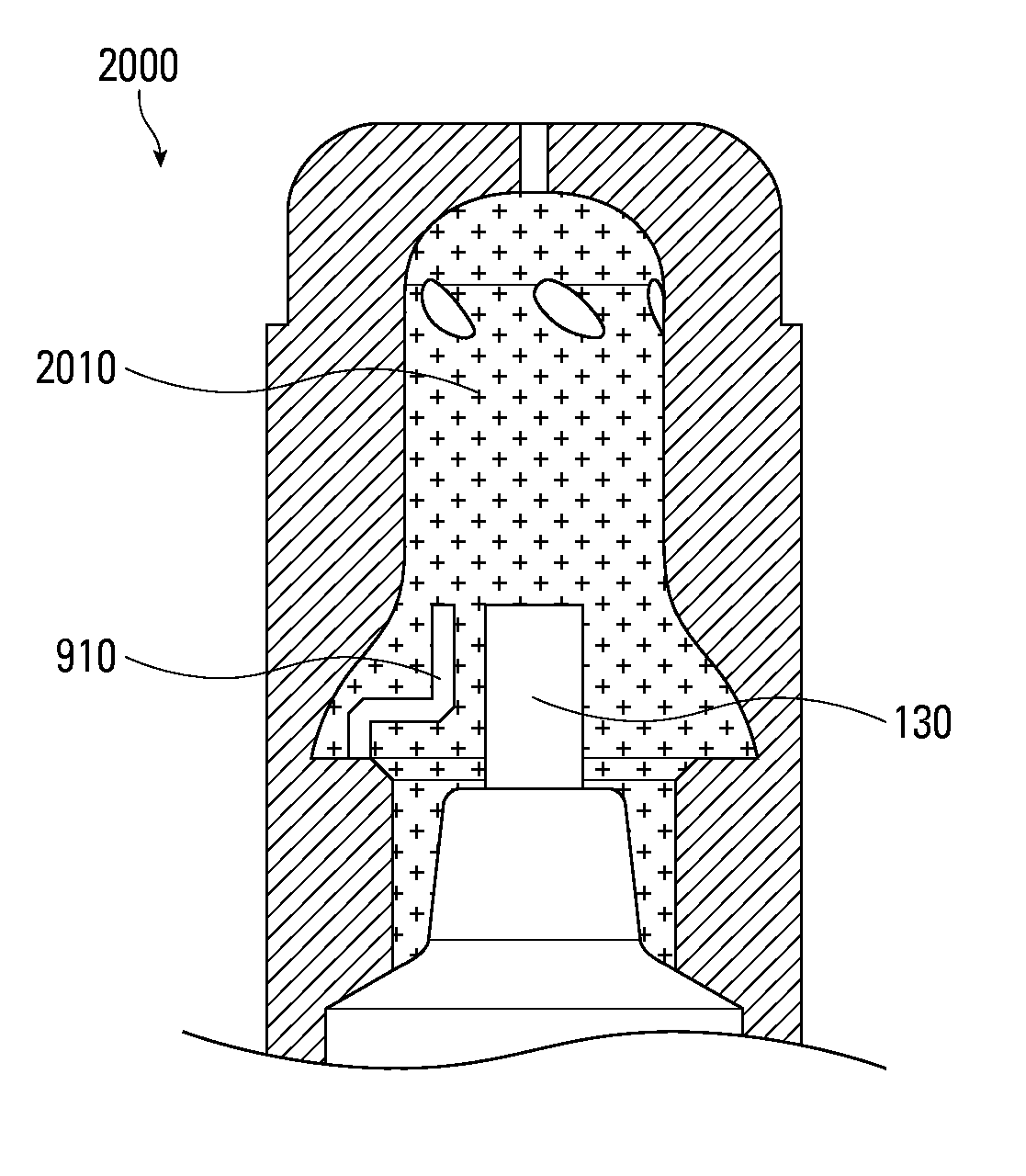

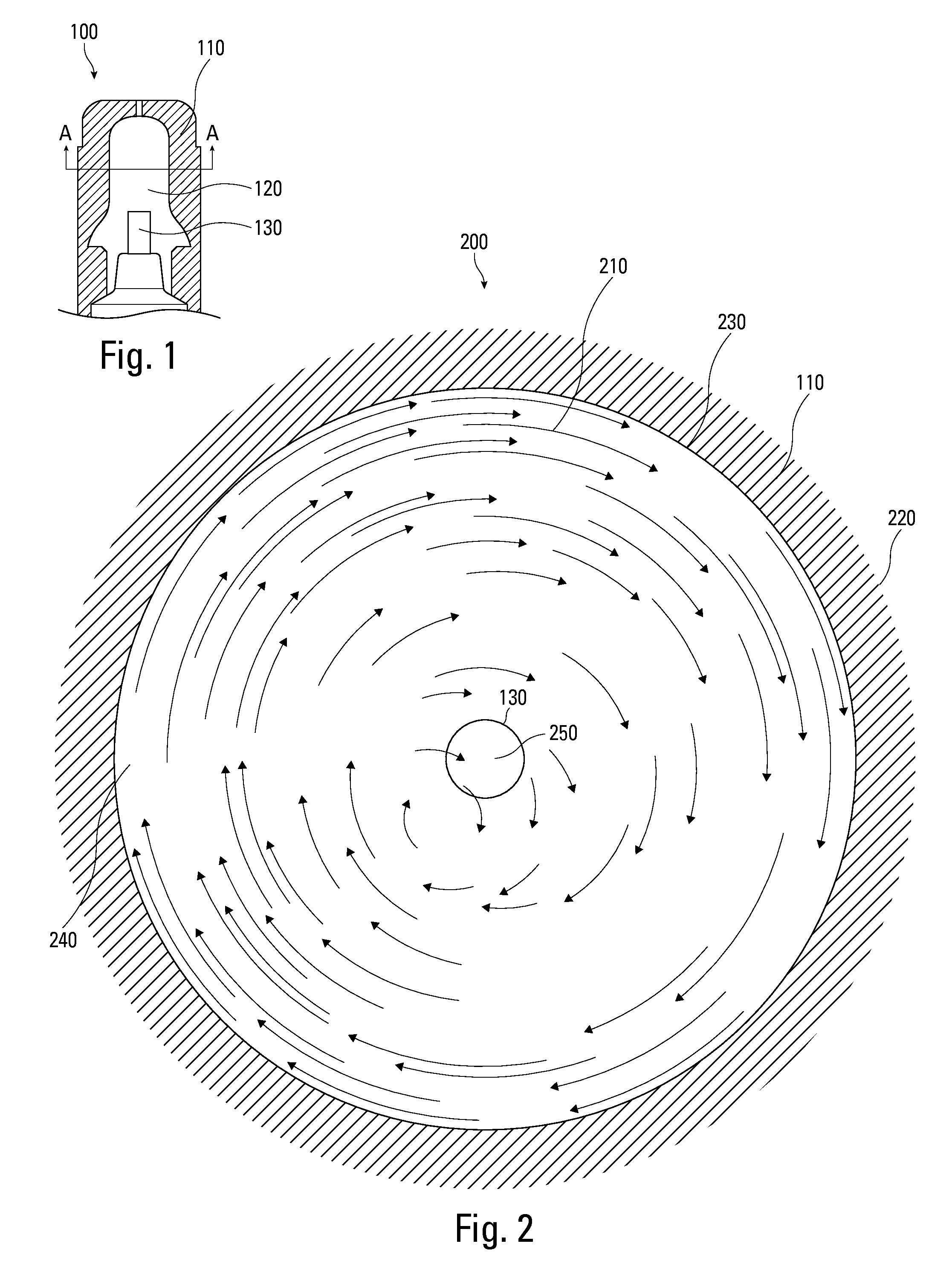

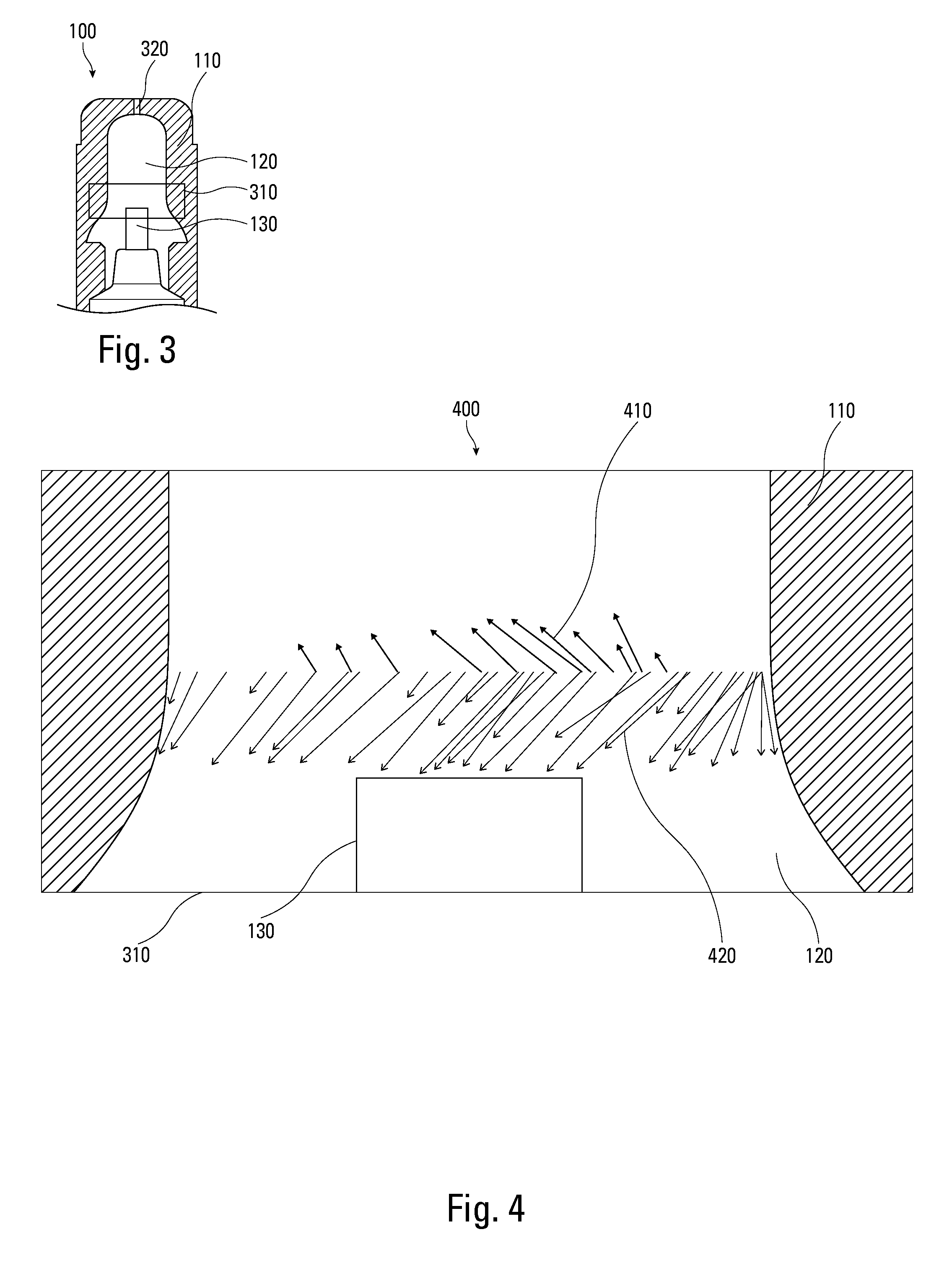

Controlled Spark Ignited Flame Kernel Flow in Fuel-Fed Prechambers

ActiveUS20120125287A1Improve flowHigh trafficSparking plugsInternal combustion piston enginesAlloyEngineering

A pre-chamber spark plug that includes a shell. Additionally, the pre-chamber spark plug includes an insulator disposed within the shell. In a particular embodiment, a center electrode has a first portion surrounded by the insulator, and a second portion that extends from the insulator into a pre-chamber. The pre-chamber defined by the shell. In a further embodiment, a ground electrode is attached to the insulator. In particular embodiments, the ground electrode is tubular in shape and includes an inner spark surface ring spaced in surrounding relation to the center electrode to create a spark gap, an outer ring attached to the shell, and a plurality of rounded spokes connecting the inner and outer rings. In a particular embodiment, the ground and center electrodes accommodate attachment of precious metal alloys to increase electrode surface life. In another embodiment the ground electrode and insulator is coaxial to the center electrode.

Owner:WOODWARD GOVERNOR CO

System and method for enhanced combustion control in an internal combustion engine

InactiveUS6609493B2Electrical controlInternal combustion piston enginesExternal combustion engineEngineering

A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

Spark Plug for a Gas-Operated Internal Combustion Engine

ActiveUS20110148274A1Extended service lifeIncrease volumeSparking plugsExternal combustion engineEngineering

The invention relates to a spark plug for a gas-fired internal combustion engine, and Includes a metallic body, with an insulator fastened in the body. A central electrode, leads through the insulator and includes a protruding end of a precious metal alloy. An annular ground electrode is fastened to the body and surrounds the end of the central electrode which, at the inside thereof facing the central electrode is provided with a precious metal or with a precious metal alloy. The mutually facing surfaces of the central electrode and ground electrode formed by the precious metal or the precious metal alloy are coaxially disposed cylinder surfaces. A cap is provided and attached to the body and which, after installation of the spark plug into a combustion chamber of the internal combustion engine, shields the central electrode and the ground electrode from the combustion chamber. Together with the body of the spark plug, the central electrode forms an ante-chamber, in which the central electrode and the ground electrode are disposed. The cap having at least one opening, which enables a gas exchange between the ante-chamber and the space outside of the ante-chamber. According to the invention, a deviation of the cylinder surfaces from the ideal cylinder geometry is less than +−20 μm, and a deviation of the positions of the axes of the cylinder surfaces from their ideal coaxial position is less than +−50 μm.

Owner:FEDERAL MOGUL IGNITION

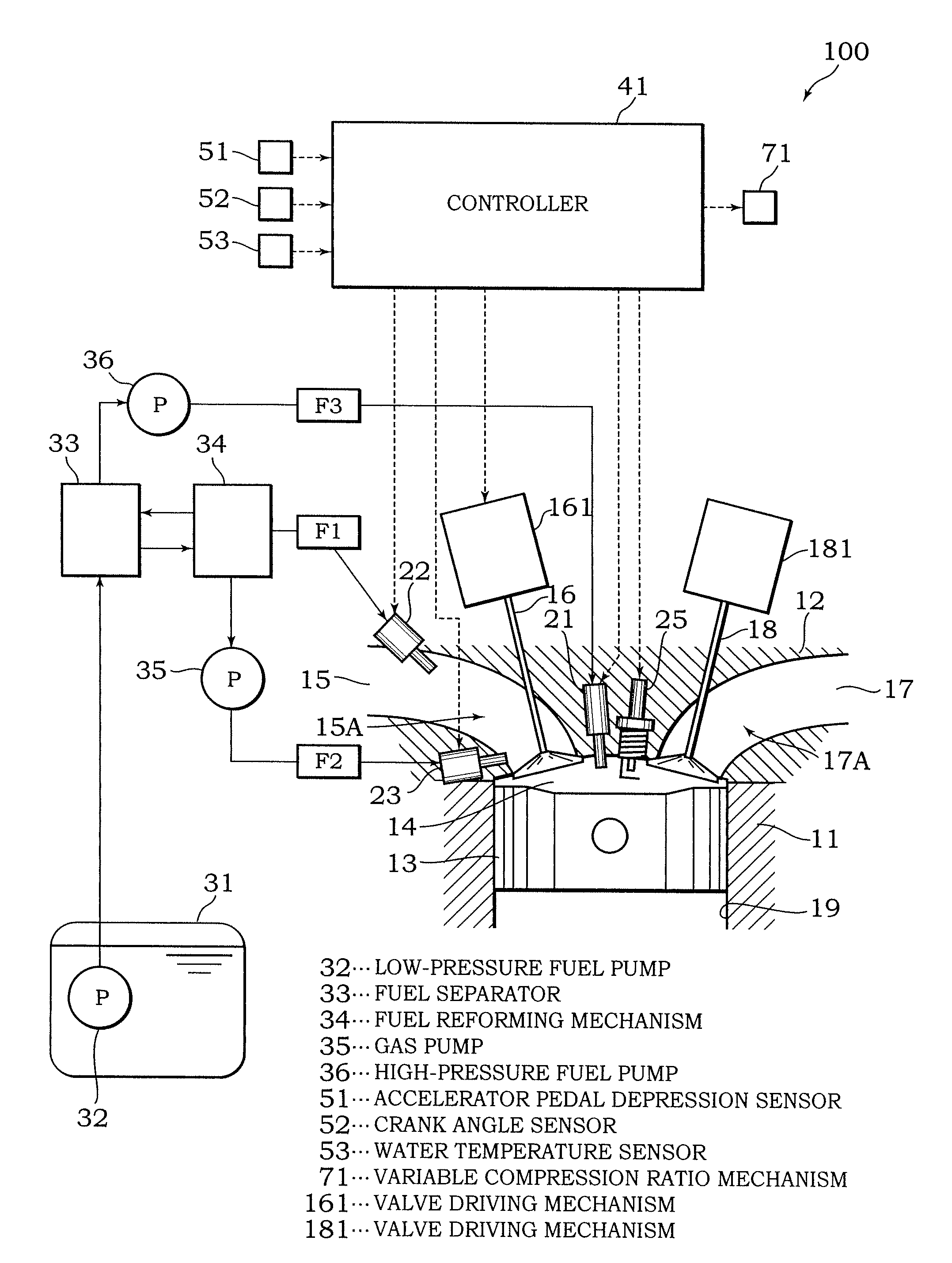

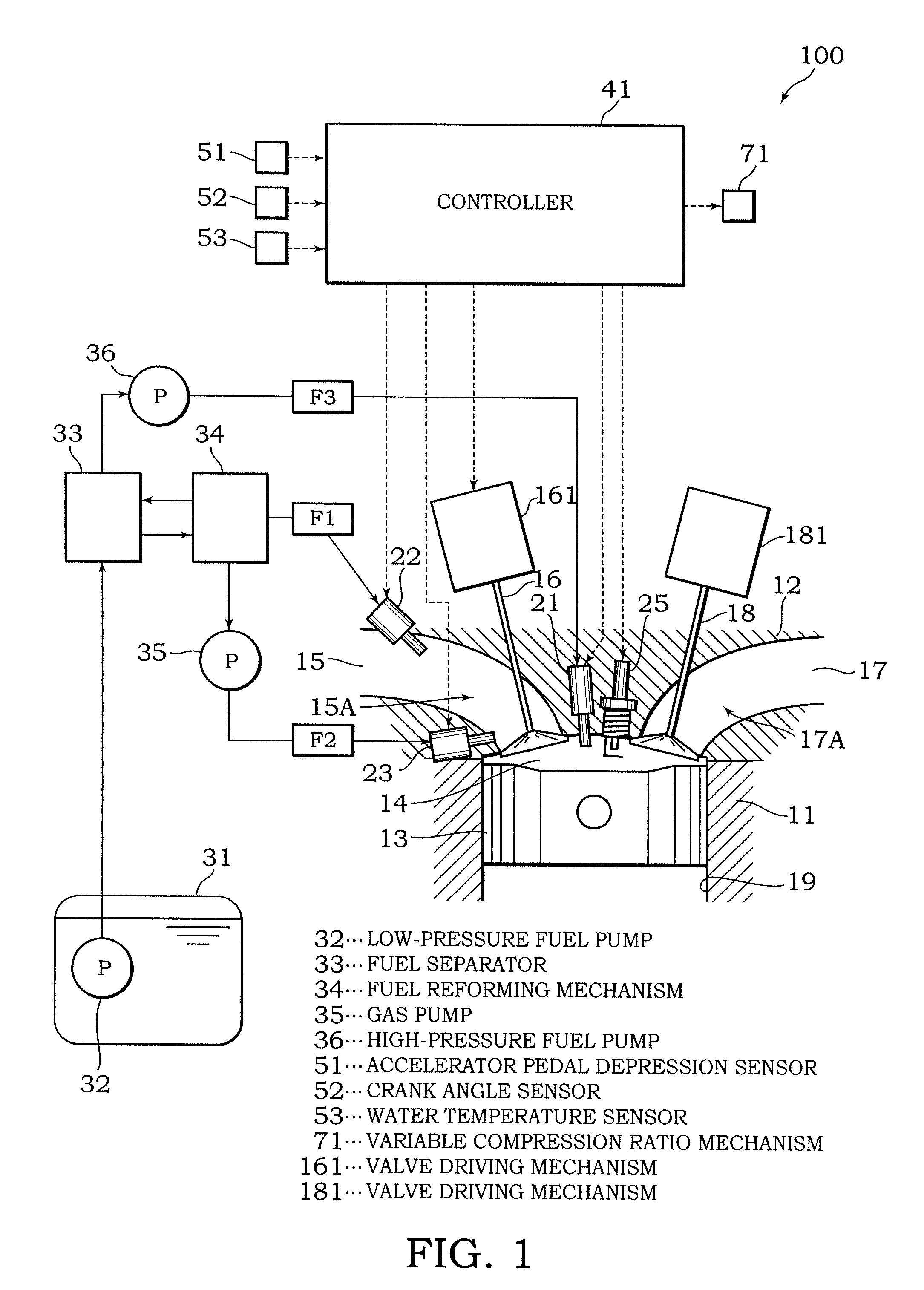

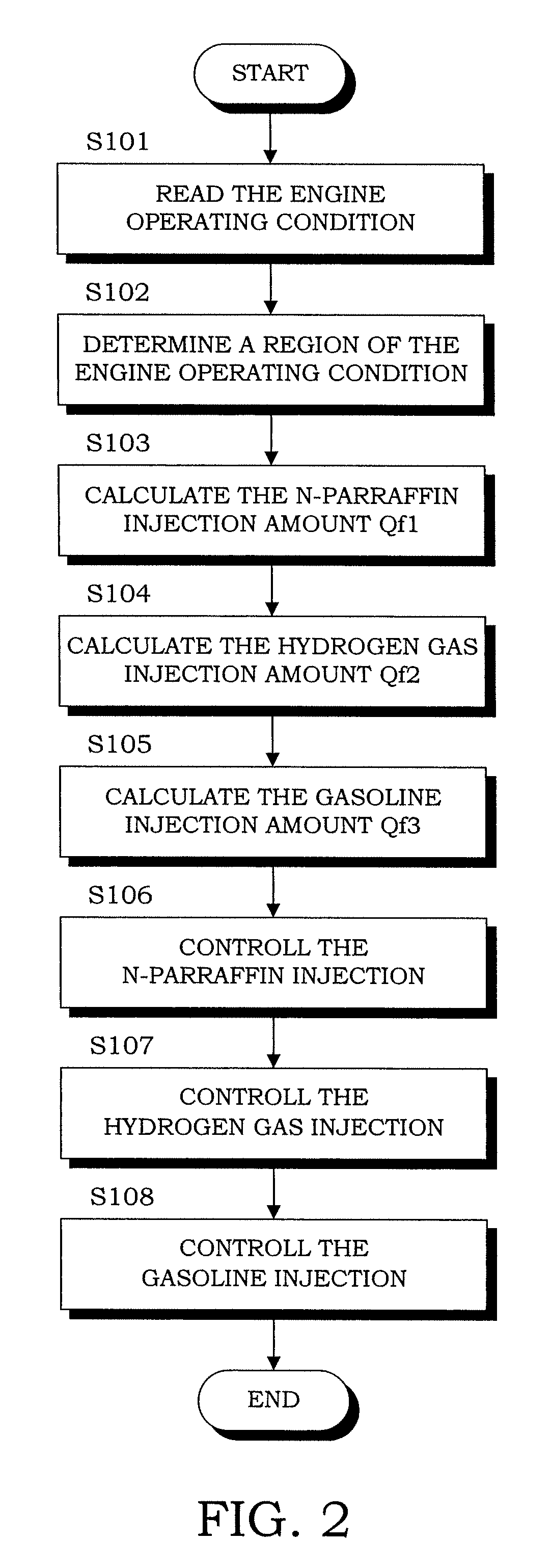

Internal combustion engine

InactiveUS20090043479A1High-temperature combustionIncrease temperatureElectrical controlInternal combustion piston enginesCombustion chamberFlame propagation

An internal combustion engine (100) comprises a fuel injection valve (21, 22) which supplies a first fuel having a higher self-ignitability than gasoline and a second fuel having a higher combustion speed than gasoline such that an air-fuel mixture containing the first fuel and the second fuel is formed in a combustion chamber (14), a spark plug (25) which ignites the air-fuel mixture, and a programmable controller (41) programmed to control supply proportions of the first fuel and the second fuel such that the ignited air-fuel mixture undergoes flame propagation combustion and then undergoes self-ignition combustion. Thus, a reduction in emissions can be achieved, and high thermal efficiency can be realized through the self-ignition combustion.

Owner:NISSAN MOTOR CO LTD

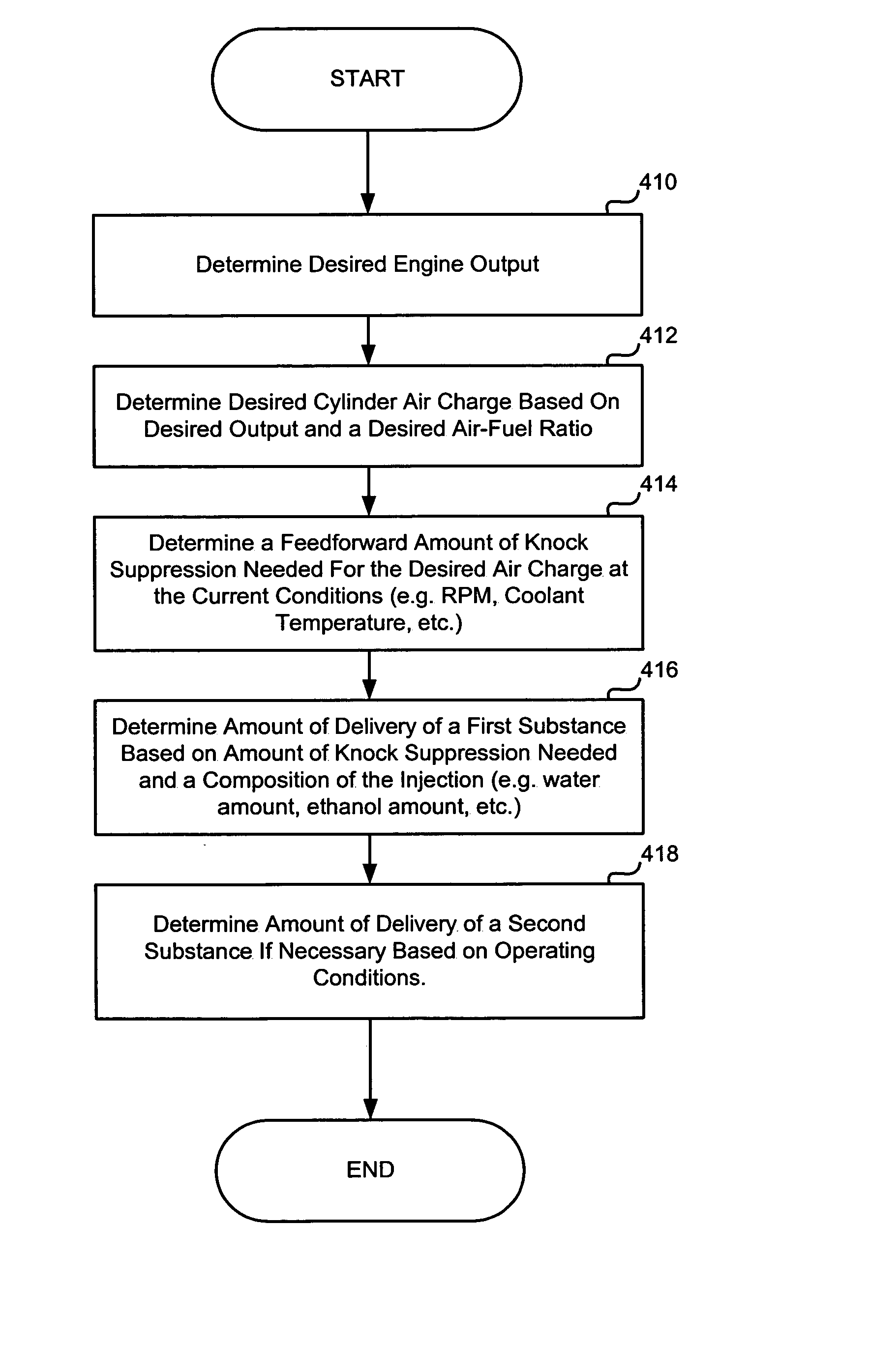

Combustion control system for an engine utilizing a first fuel and a second fuel

A system for an engine of a vehicle, comprising of a combustion chamber, a delivery system configured to deliver a fuel and a fluid to the combustion chamber, an ignition system including a spark plug configured to deliver a spark to the combustion chamber, and a control system configured to respond to a change in a condition of the ignition system by varying at least one of an amount of the fuel and an amount of the fluid delivered to the combustion chamber to vary a ratio of the fluid and the fuel.

Owner:FORD GLOBAL TECH LLC

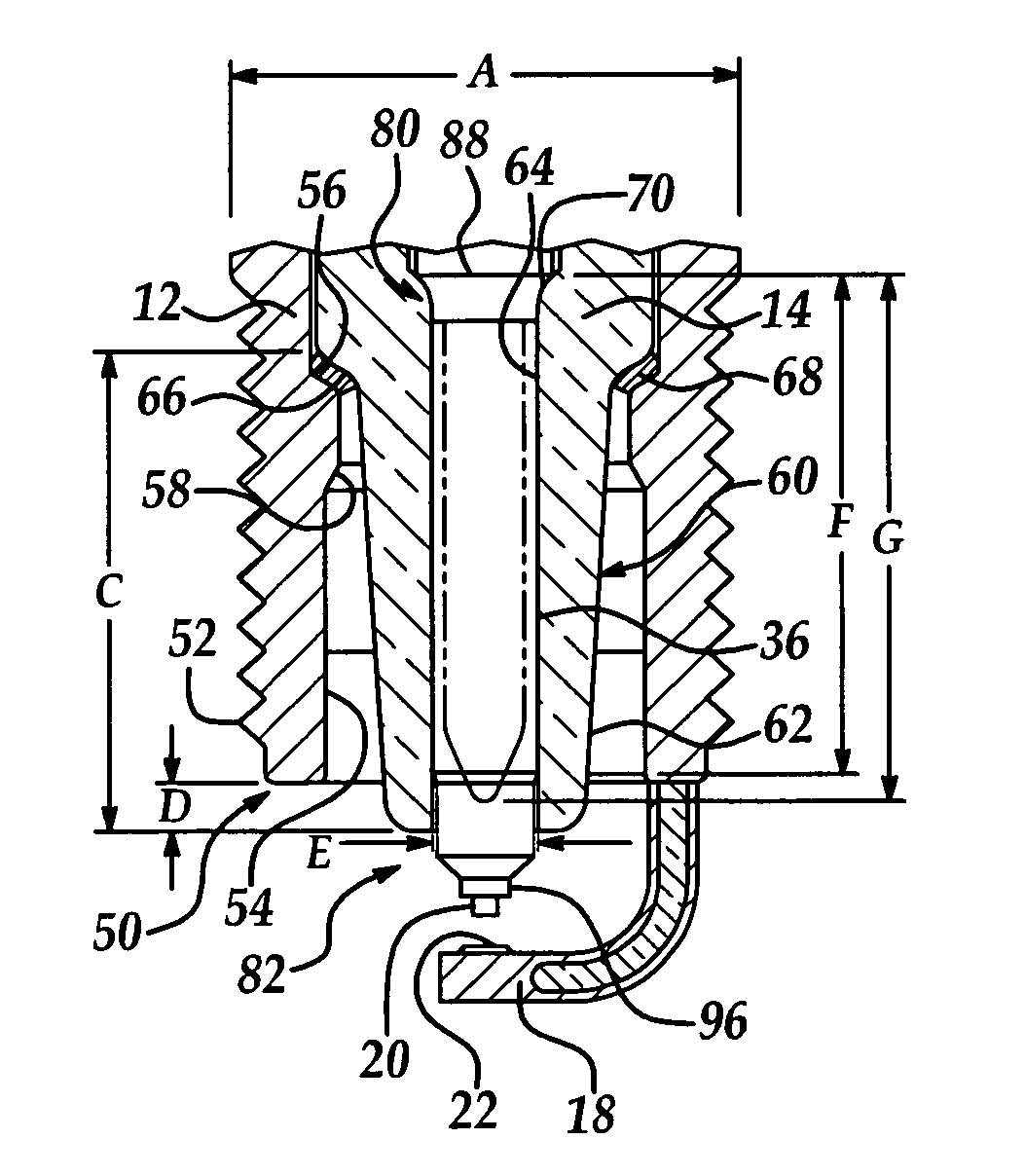

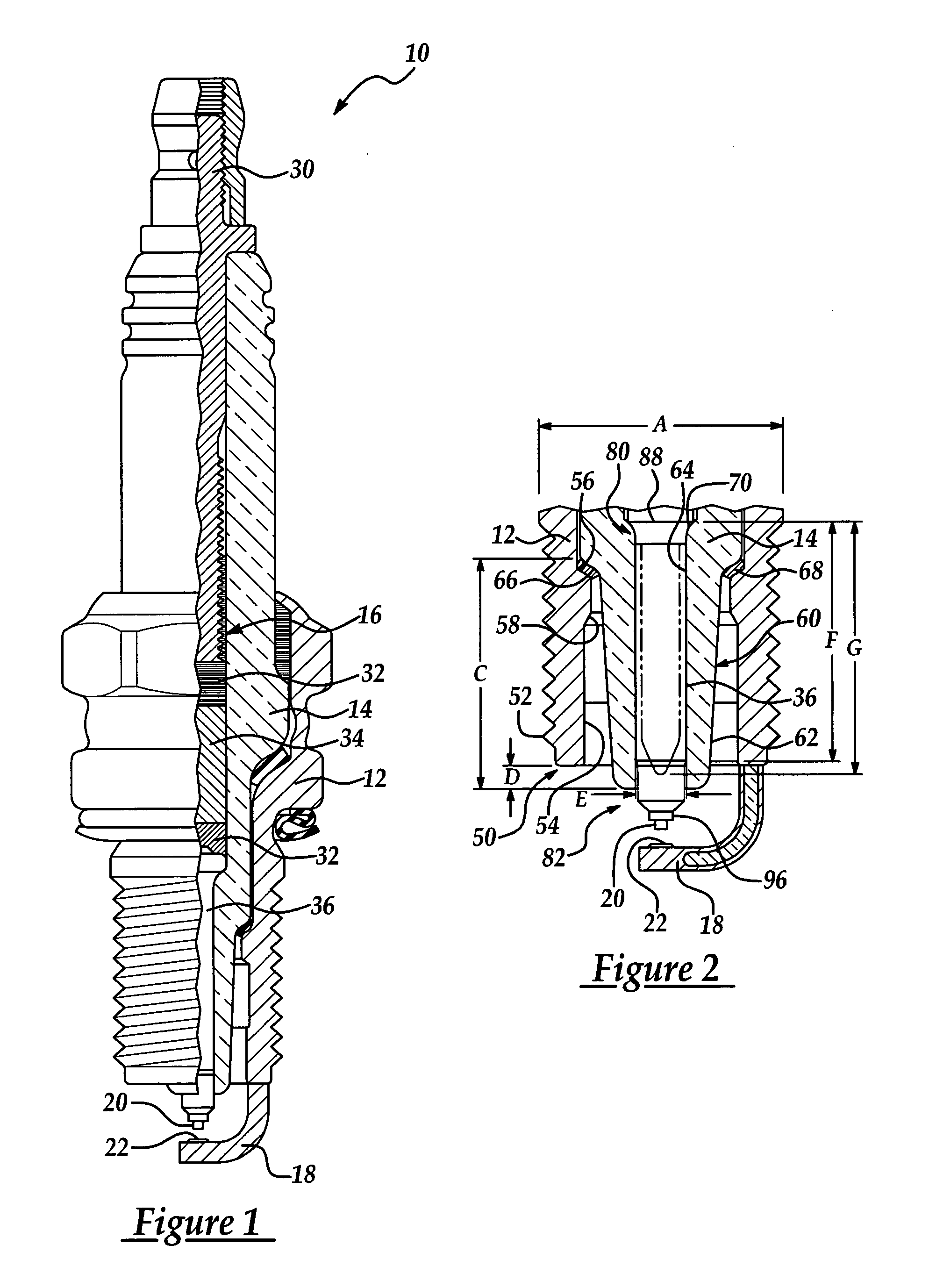

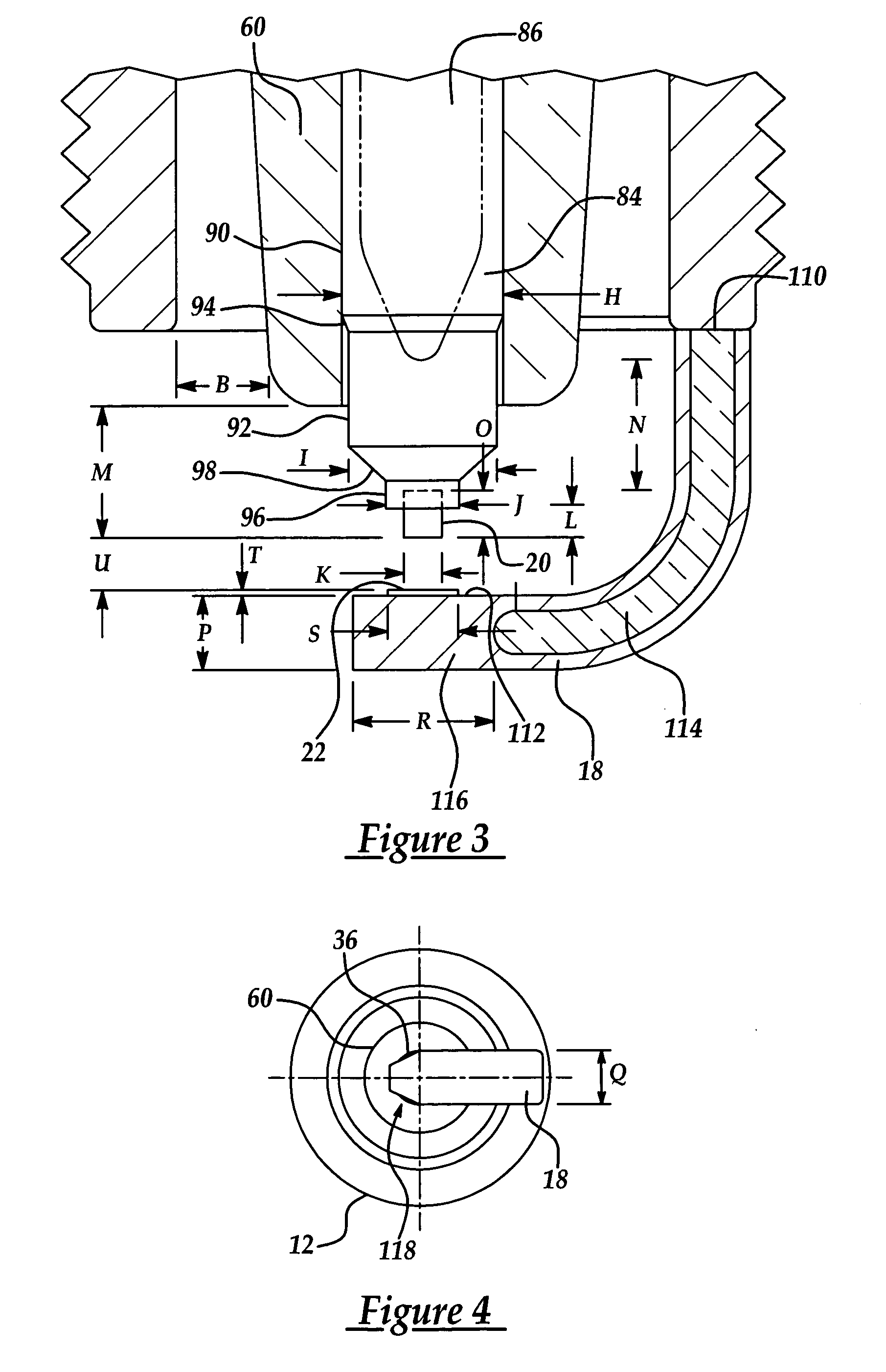

Spark plug configuration having a metal noble tip

A spark plug having a particular firing end configuration that satisfies numerous dimensional ranges for improved performance. The spark plug generally includes a shell, an insulator, and center and ground electrodes, with the electrodes each having a copper core for improved thermal conductivity and a noble metal insert for improved erosion and corrosion resistance. The noble metal insert for the center electrode is preferably in the form of a cylindrical Ir-based tip, which is received within a complimentary recess formed in the center electrode. The noble metal insert for the ground electrode is in the form of a flat Pt-based pad attached to a surface of the ground electrode. Various dimensional ranges are provided for the various components of the spark plug assembly, both individually and in combination with other dimensions.

Owner:FEDERAL MOGUL IGNITION UK

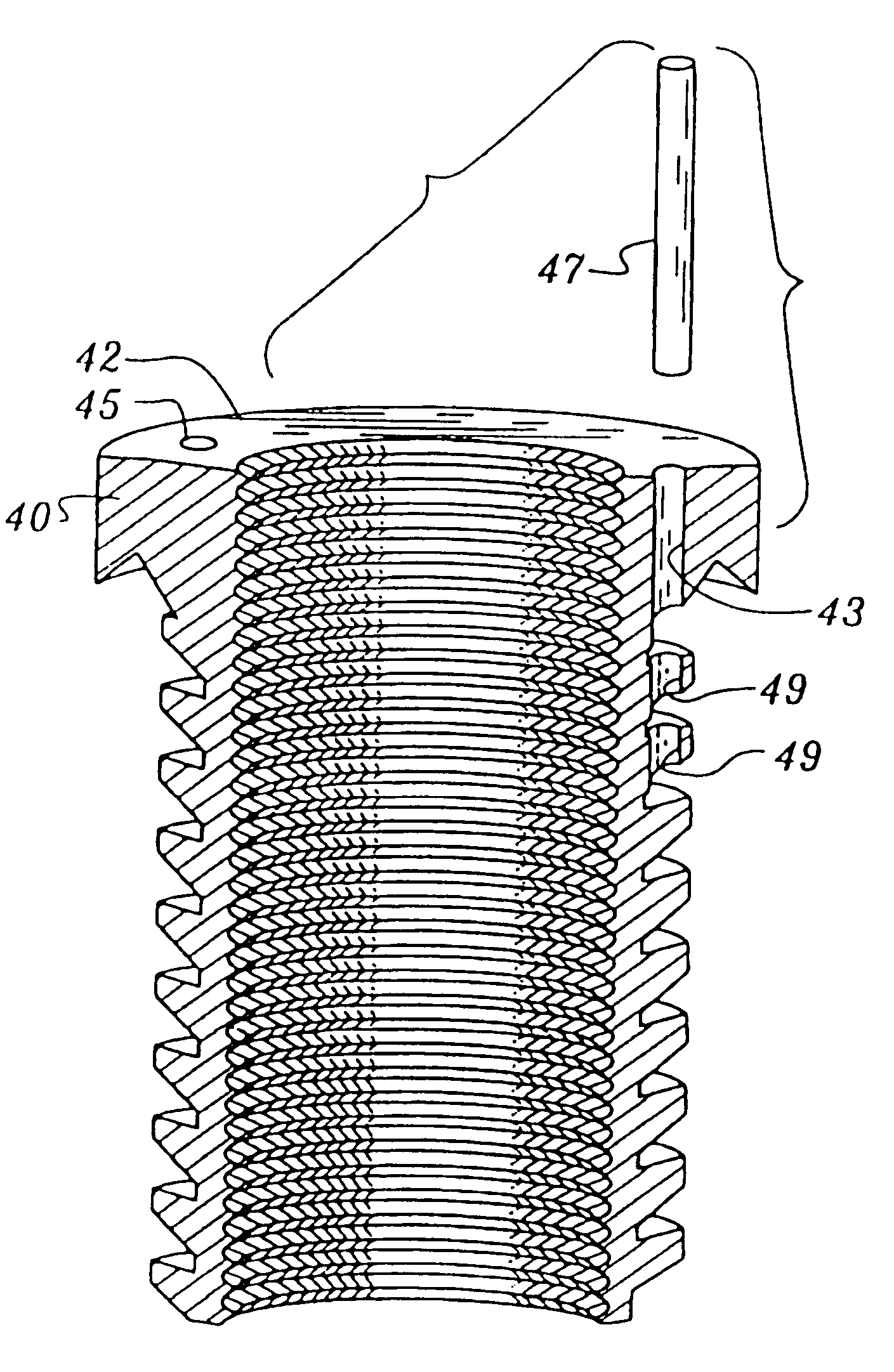

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

Spark ignition modifier module and method

InactiveUS7104246B1Easy to operateSparking plugsInternal combustion piston enginesCylinder blockSpark plug

A multi-part module including a flame cone and a connector adapted to be interposed between the normal spark plug port in an internal combustion engine block and a spark plug suitable for use with the engine in question. In the method, a quantity of fuel / air mixture is captured in a chamber which also houses the electrode of a spark plug. Upon generation of a spark from the spark plug, this quantity of fuel / air mixture ignites, generating a flame which propagates through one or more channels in a flame cone interposed between the spark plug and the cylinder of the engine and exits into the cylinder through multiple directionally oriented ports, whereupon the flame fronts rapidly ignite substantially all the fuel / air mixture held within the cylinder.

Owner:SMARTPLUG

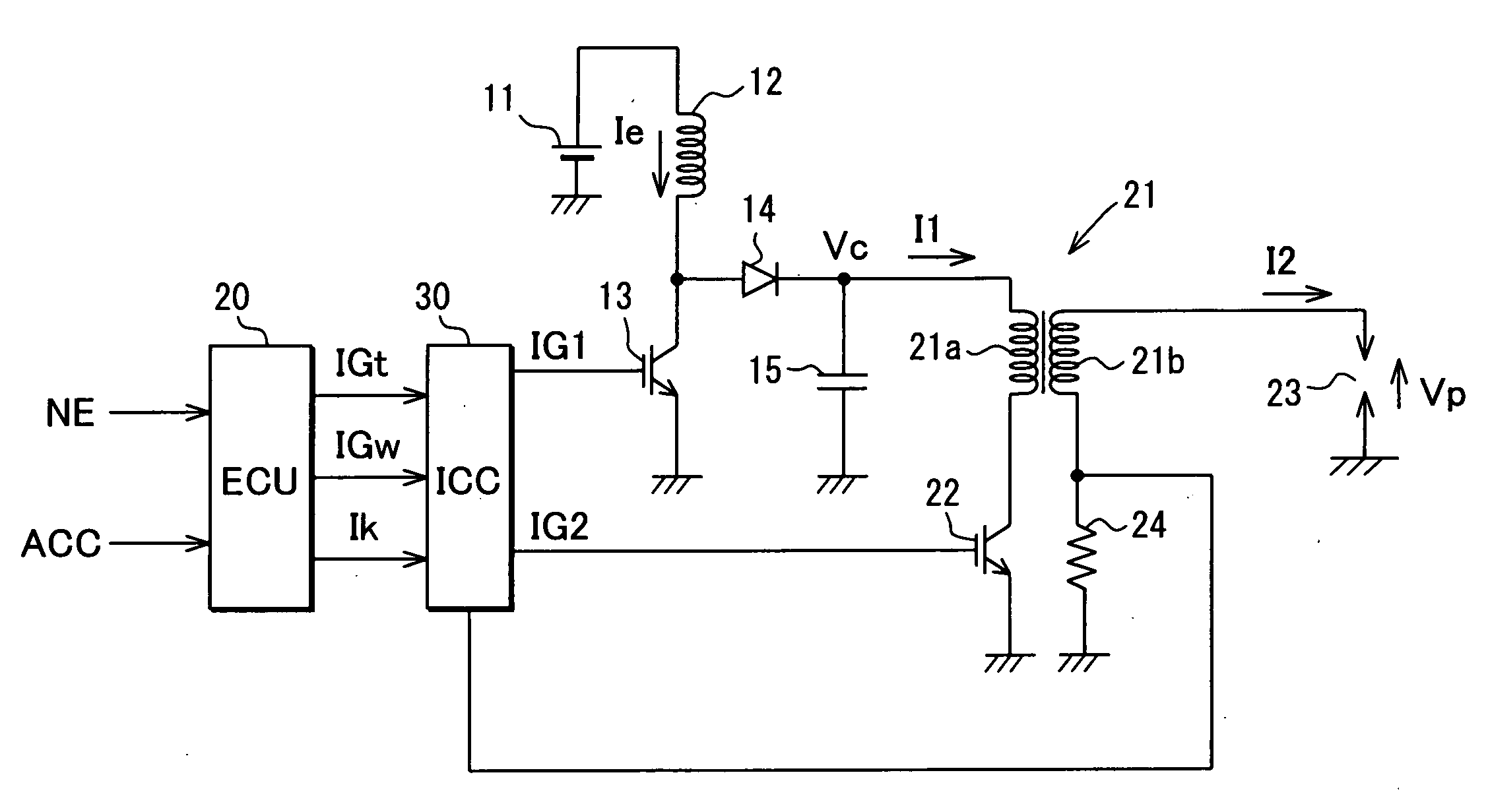

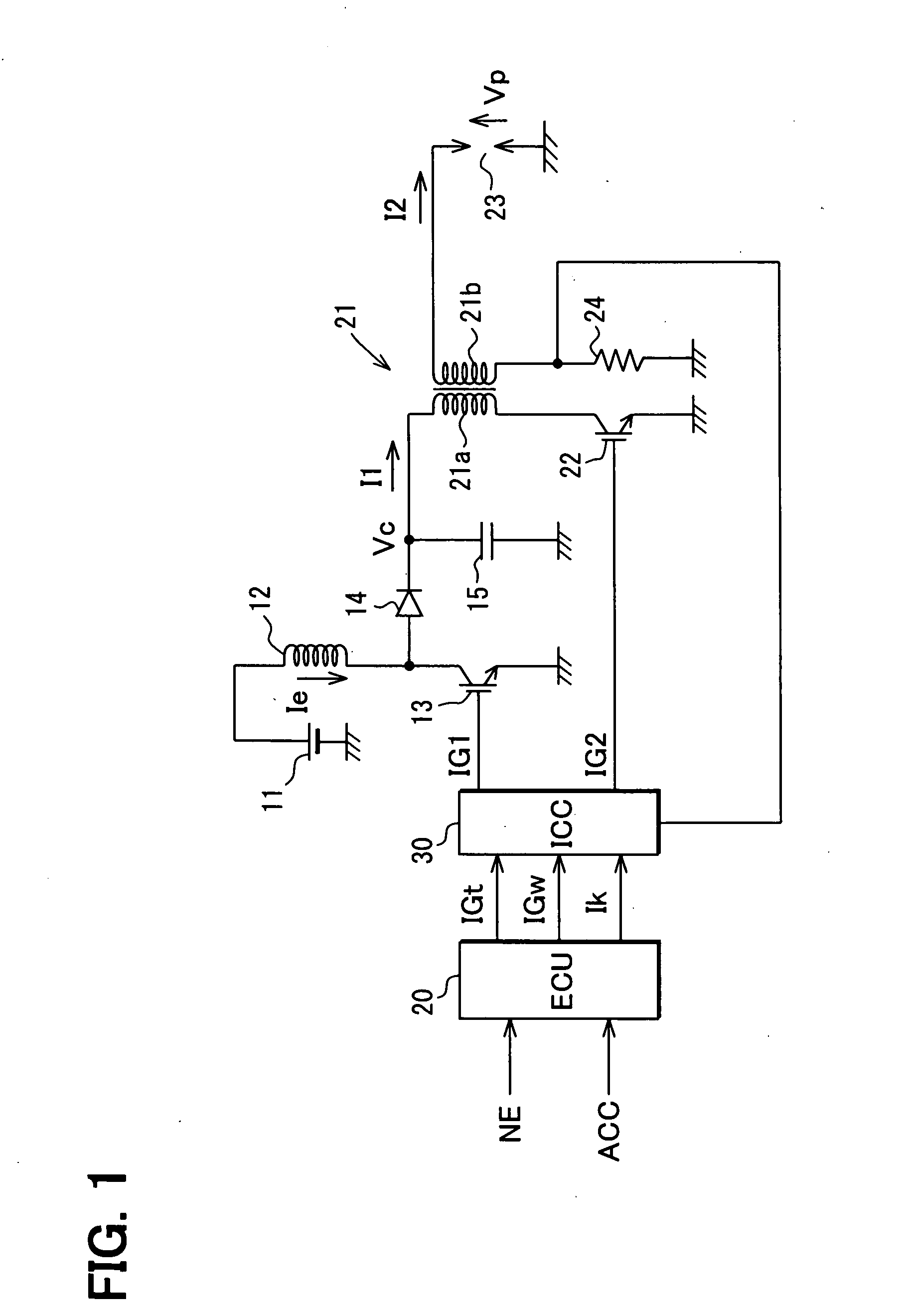

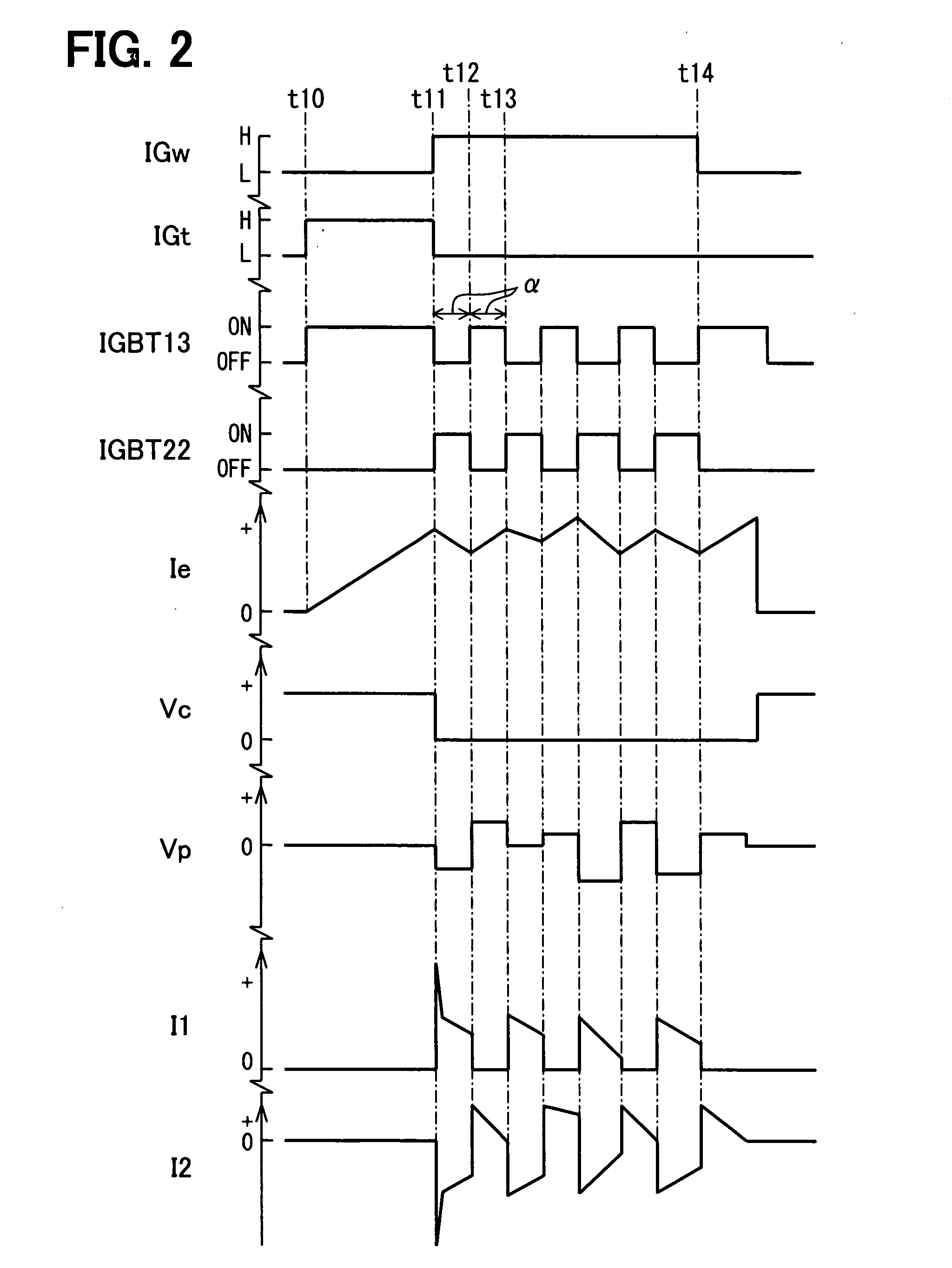

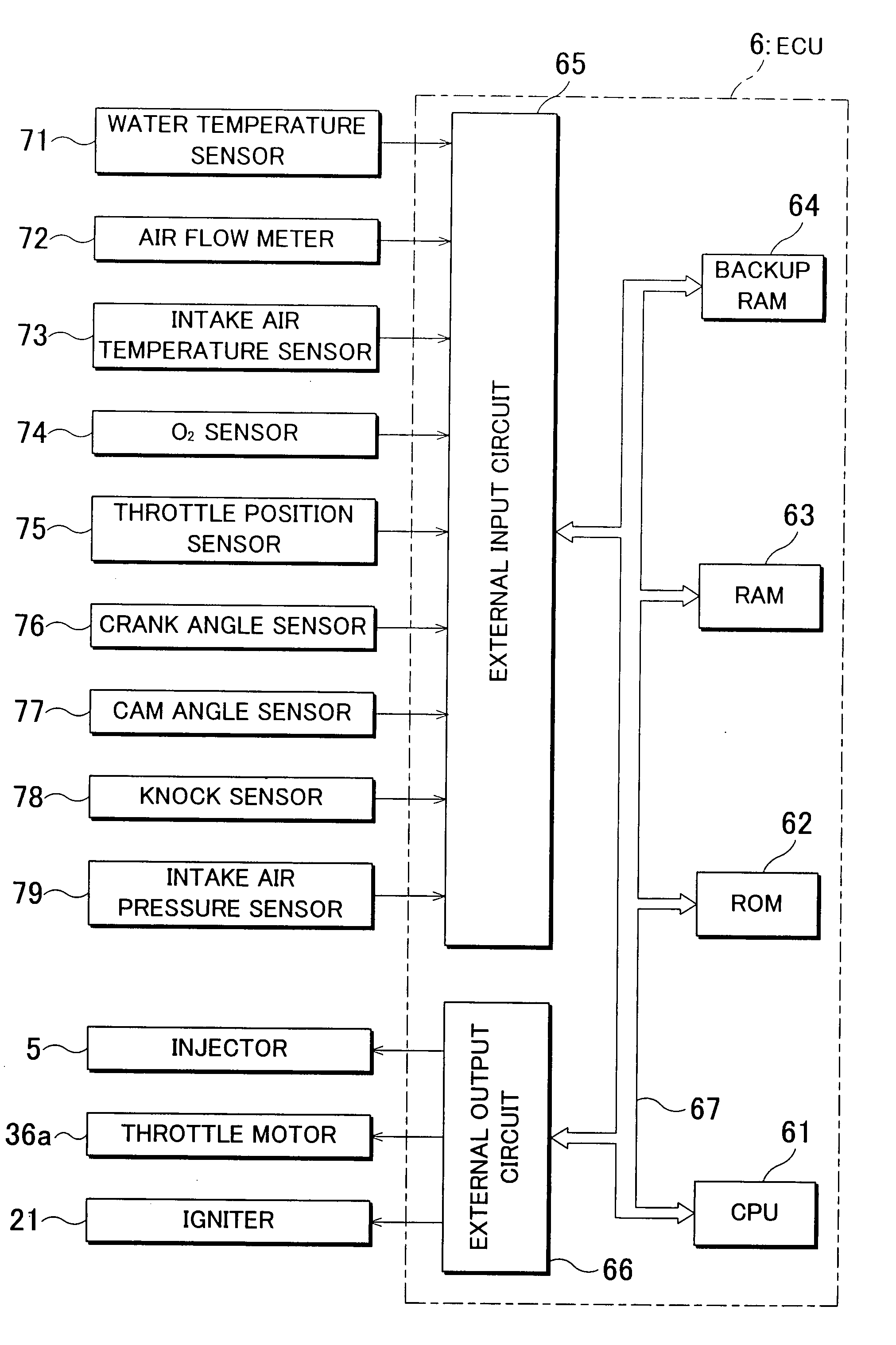

Multiple discharge ignition control apparatus and method for internal combustion engines

InactiveUS20070181110A1Strong enoughMachines/enginesAdvancing/retarding ignitionElectrical batteryEngineering

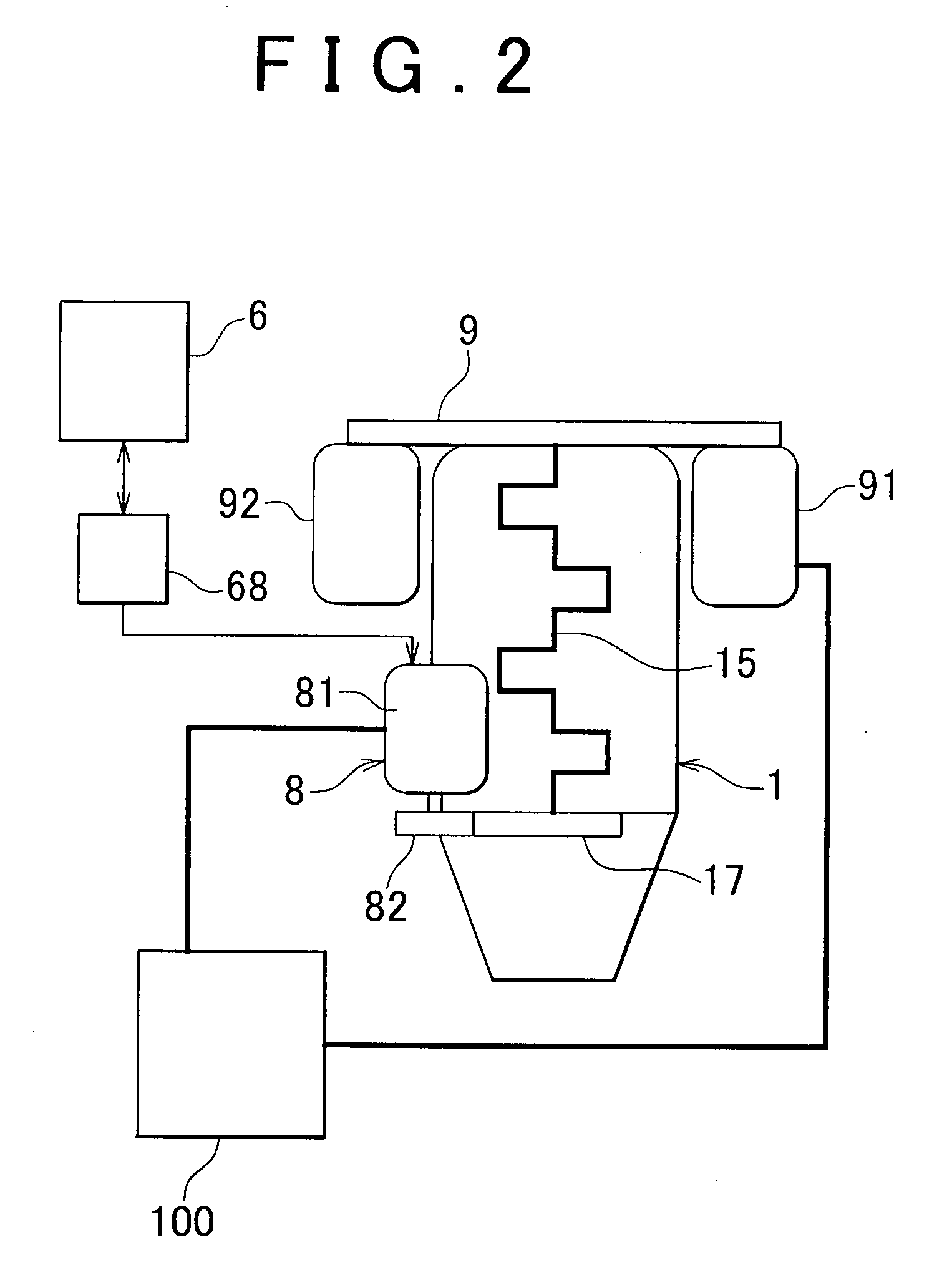

In a multiple discharge ignition control apparatus, a battery, an energy storage coil and a first IGBT are connected in series. Further, the energy storage coil, a diode, a primary coil and a second IGBT are connected in series. The energy storage coil is connected with a capacitor through the diode, and a secondary coil is connected with a spark plug and a resistor for current detection. An ignition control circuit switches the IGBTs between ON and OFF each time the secondary current detected by the resistor reaches a positive or negative discharge holding current in multiple discharge operation. A booster circuit is provided in addition to the energy storage coil and its output is feedback-controlled.

Owner:DENSO CORP

Automatic internal combustion engine stop device, internal combustion engine provided with the same and automatic internal combustion engine stop method

ActiveUS20070199533A1Short timeGrowth inhibitionPower operated startersElectrical controlStops deviceEngineering

In an automatic stop device that automatically stops the operation of an internal combustion engine after a predetermined automatic stop condition is satisfied, a load acting on the engine is removed when the automatic stop condition is satisfied. When the automatic stop condition is satisfied, the between the magnitude of the load on the internal combustion engine before and after of the automatic stop condition is satisfied is determined, and an ignition timing retard amount of an ignition plug is decided such that the retard amount is increased as the difference becomes greater. The ignition timing is retarded by the retard amount substantially at the same moment as the load removing operation before the automatic stop control is initiated.

Owner:TOYOTA JIDOSHA KK +1

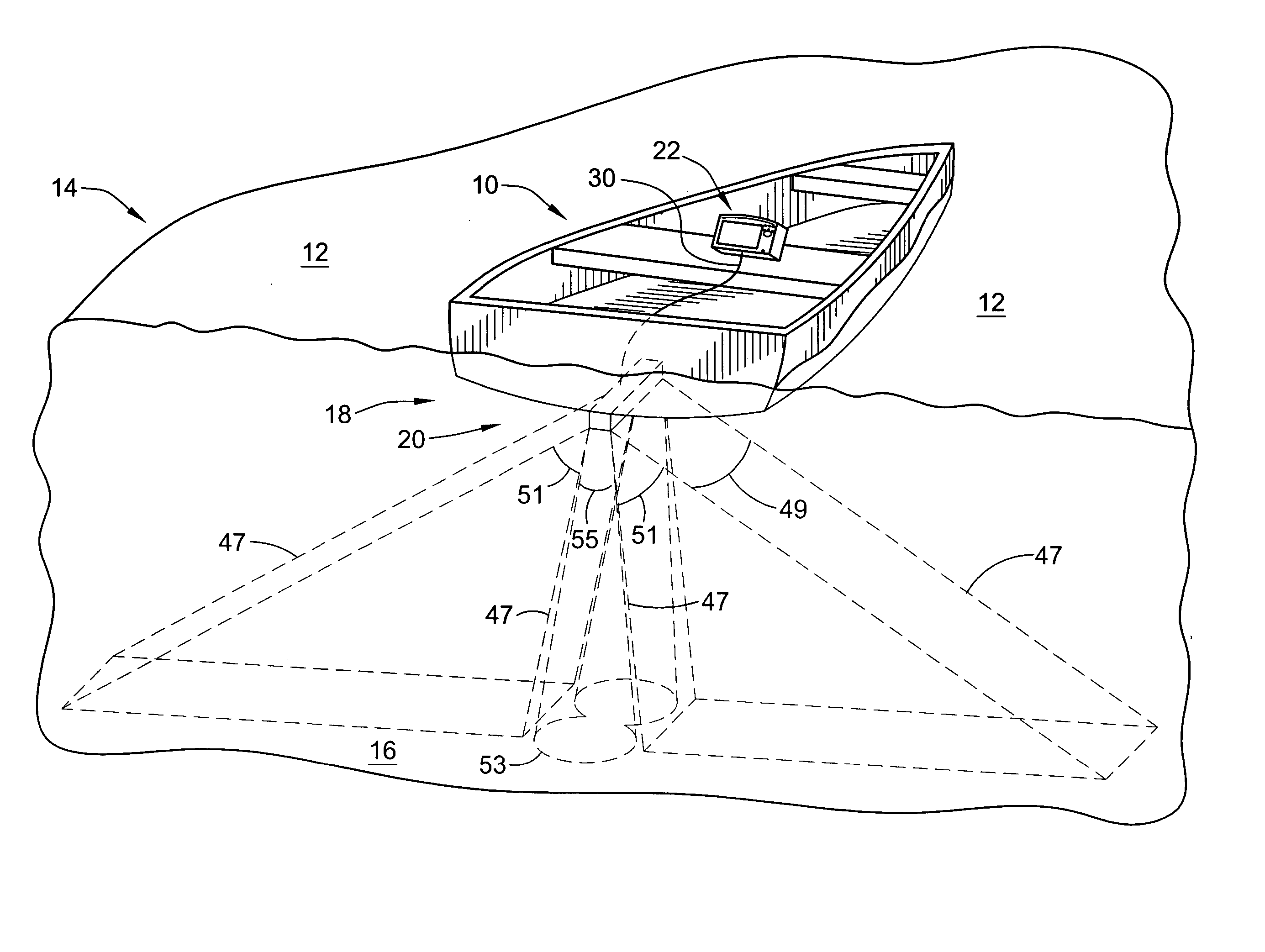

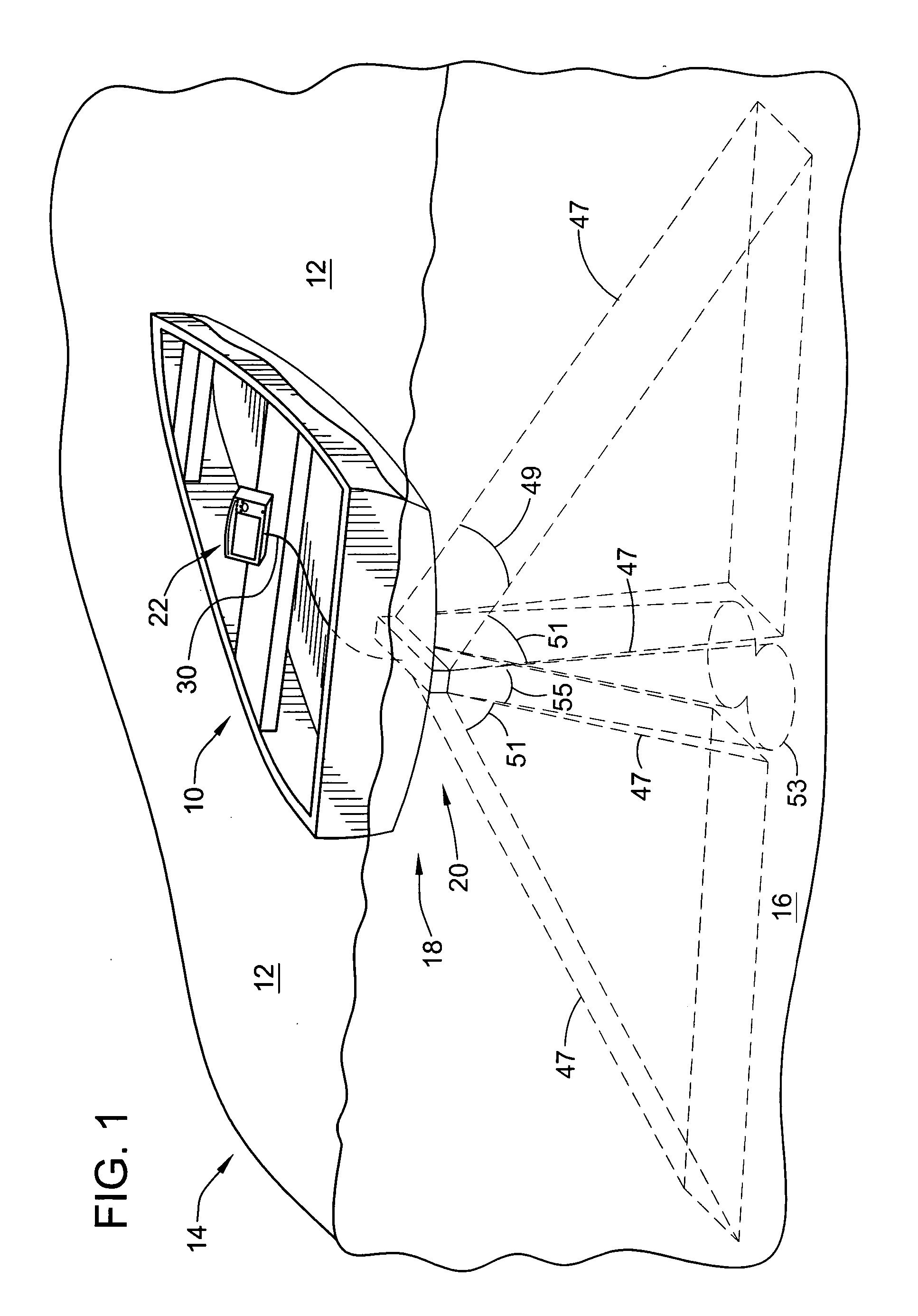

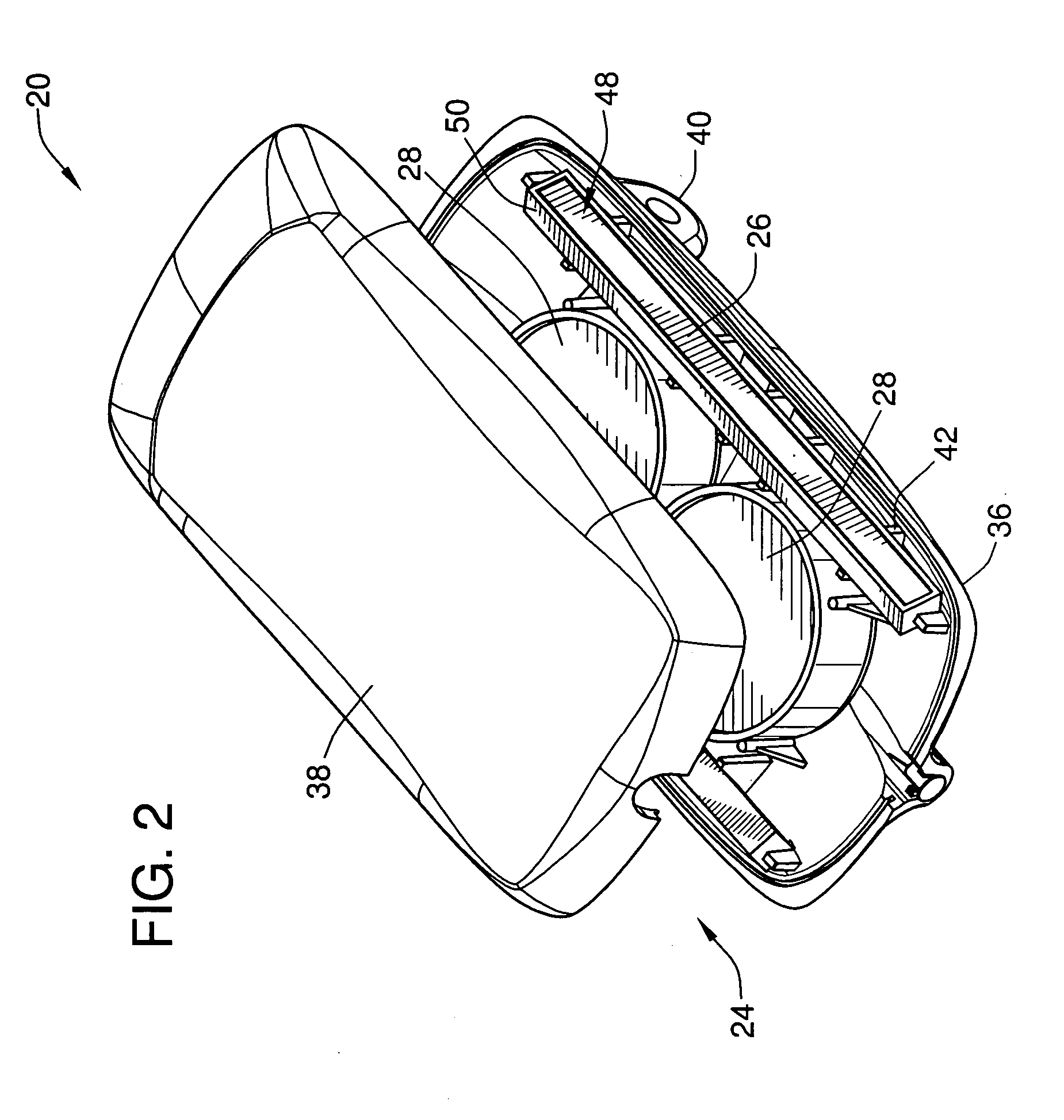

Sonar imaging system for mounting to watercraft

ActiveUS20060023570A1High speedLower the targetSatellite radio beaconingAcoustic wave reradiationSonar imagingTransducer

Owner:JOHNSON OUTDOORS

Methods and apparatus for generating a plasma torch

InactiveUS6329628B1SmallSmall sizeArc welding apparatusPlasma welding apparatusHigh densityVolumetric Mass Density

A modular system for constructing an atmospheric pressure plasma source. A plasma torch module may be constructed by reassembling the structural components of two (2) different models of spark plugs. Each module can produce a plasma torch having a radius of about 1 cm or more, a height of about 6 cm, and a peak density exceeding 1013 cm-3. A set of modules, each connected in series, may be used with a ballasting capacitor such that an array can be operated while sharing a common power supply to produce a plasma having a relatively large volume and a relatively high density. A system having a number of plasma torch modules may be used in applications for absorbing radiation, reducing air drag and igniting fuel.

Owner:POLYTECHNIC INST OF NEW YORK

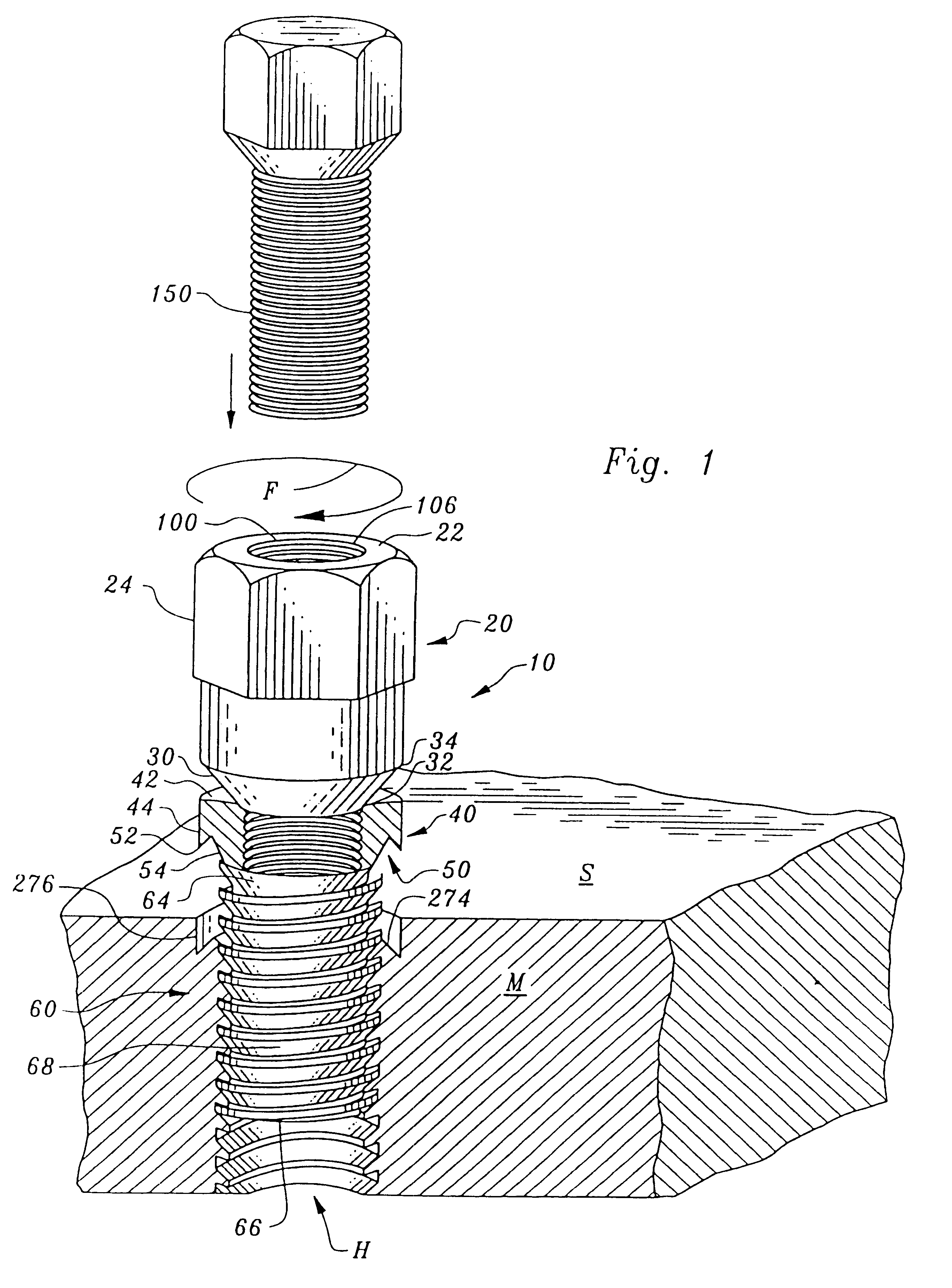

Insert retention mechanism

An insert for use in allowing spark plugs, fasteners, couplings for hydraulic fittings and pipe threads of a given dimension to be used in a material.

Owner:LOCK N STITCH INC

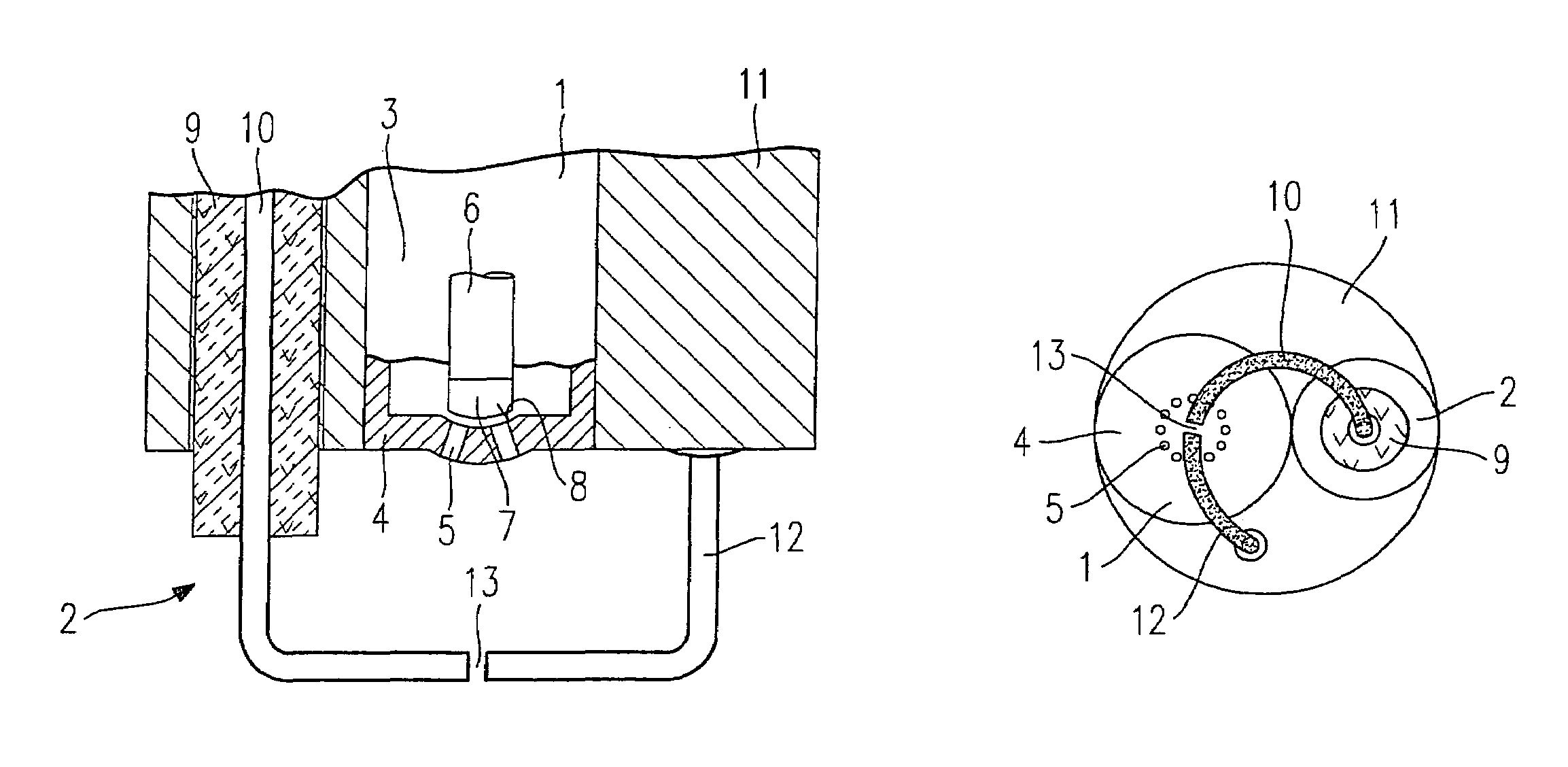

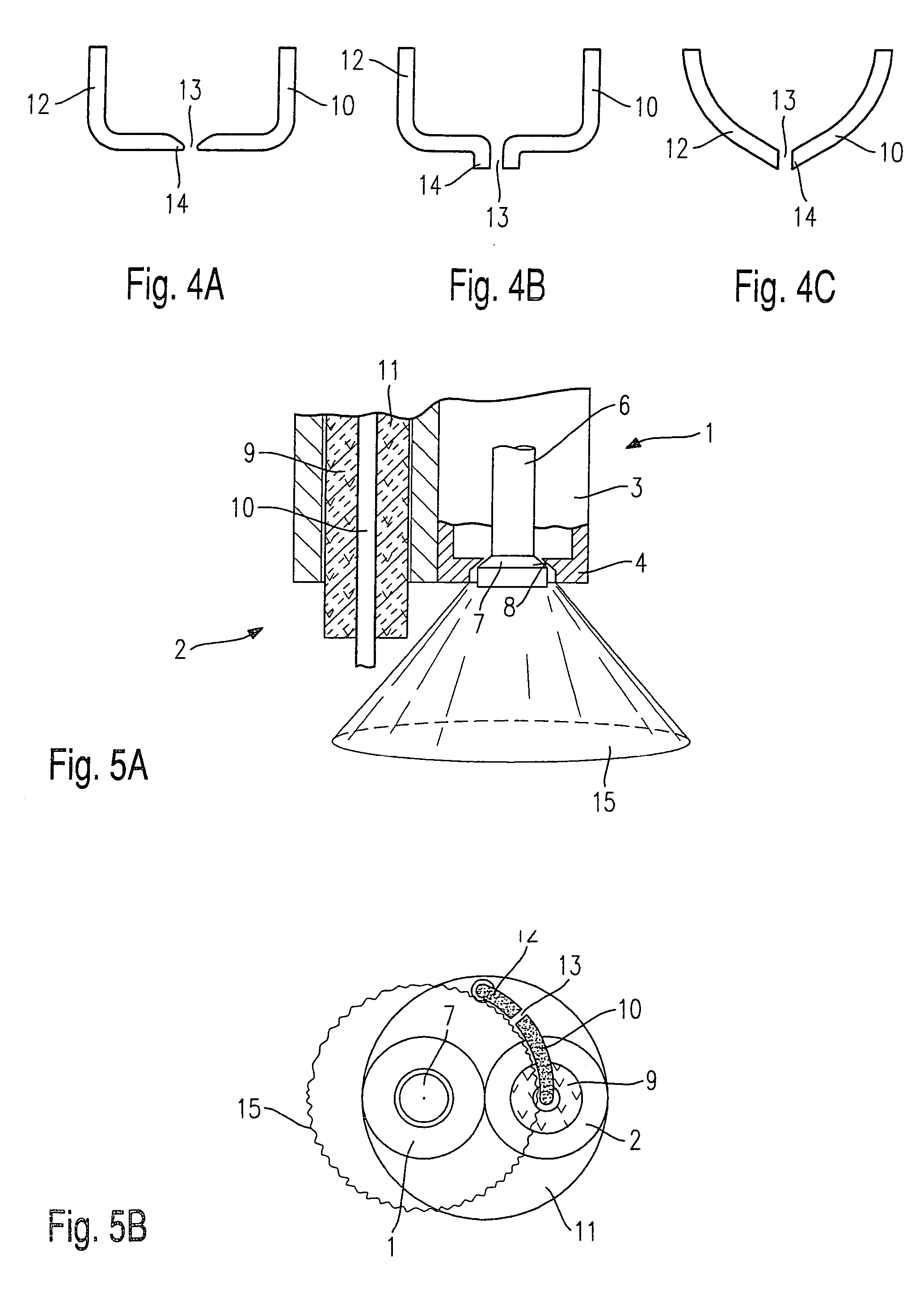

Combined fuel injection valve/ignition plug

InactiveUS6871630B2Easy to installSpace minimizationSparking plugsCombustion enginesExternal combustion engineInternal combustion engine

A fuel injector-spark plug combination comprises a fuel injector for the direct injection of fuel into a combustion chamber of an internal combustion engine and a spark plug with a spark-plug insulator, a first electrode and a second electrode for igniting the fuel injected into the combustion chamber. The fuel injector includes an actuator cooperating with an actuation device, which is in force-locking, operative connection to a valve needle, the valve needle, or a valve-closure member connected thereto, cooperating with a valve-seat surface to form a sealing seat. The valve needle of the fuel injector and the spark-plug insulator of the spark plug are positioned in a shared housing at a biaxial offset.

Owner:ROBERT BOSCH GMBH

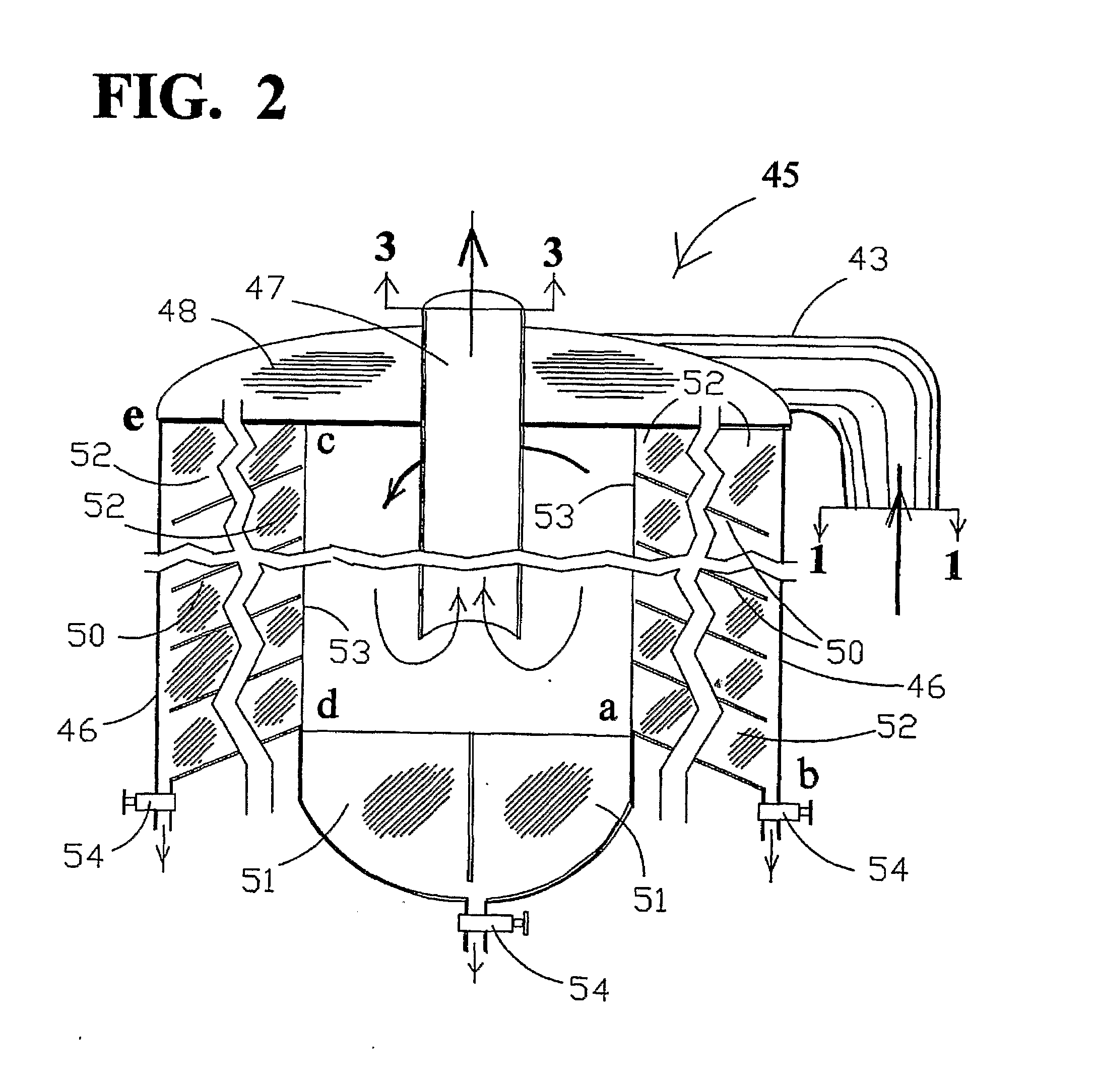

Method and apparatus for achieving high power flame jets while reducing quenching and autoignition in prechamber spark plugs for gas engines

ActiveUS20130055986A1Increase ignition delayPrevent spontaneous combustionSparking plugsInternal combustion piston enginesEngineeringQuenching

A prechamber spark plug may have a prechamber having a pre-determined aspect ratio and hole pattern to achieve particular combustion performance characteristics. The aspect ratio and hole pattern may induce a rotational flow of fuel-air in-filling streams inside the prechamber volume. The rotational flow of the fuel-air mixture may include both radial flow and axial flow characteristics based on the aspect ratio and hole pattern. Axial flow characteristics can include a first axial direction proximate the periphery of the rotational flow and a counter second axial direction approaching the center of the rotational flow. The radial and axial flow characteristics may further include radial air-fuel ratio stratification and / or axial air-fuel ratio stratification. The rotational flow, the radial flow and the axial flow may be adjusted by alteration of the aspect ratio and hole pattern to achieve particular combustion performance characteristics in relation to a wide variety of spark gap geometries.

Owner:PROMETHEUS APPLIED TECH

Steam Combustion Engine

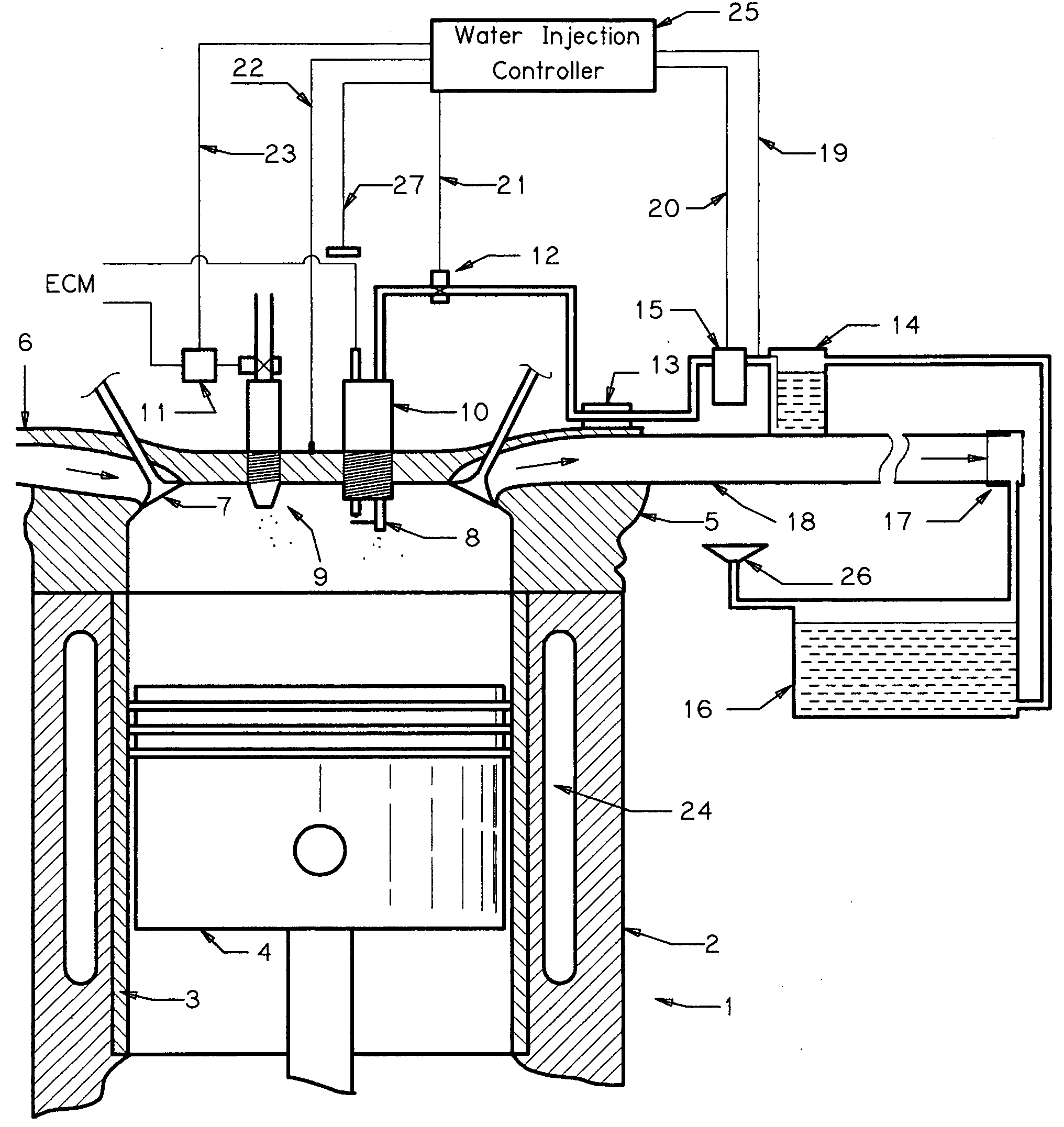

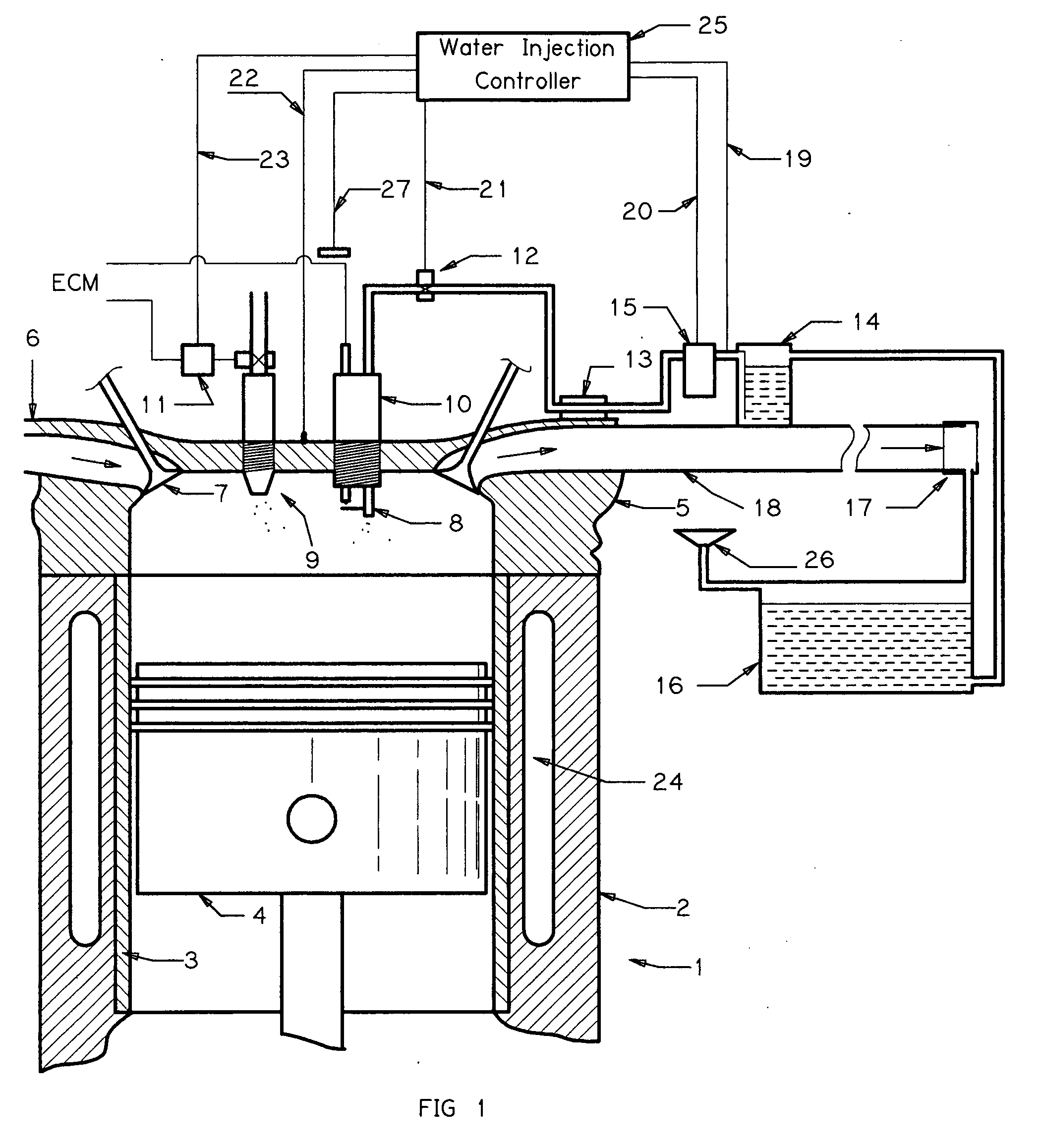

InactiveUS20100077986A1Improve fuel efficiencyFuel injection amount is reducedNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberOtto cycle

A steam combustion engine is improved from a conventional internal combustion engine by replacing spark plugs with water injection spark plugs, which inject small amount of boiling water into combustion chamber at the beginning of the fuel burning cycle if the engine temperature reaches preset limit. A steam combustion engine controller monitors the temperature of the engine, intercepts and alters fuel injection signal, turns on and off water injection solenoid at the right timing with the right amount. The apparatus can convert conventional vehicle into a steam combustion engine vehicle, reducing fuel consumption and emission by taking advantage of the waste heat and turning water into steam to generate extra useful work. This steam combustion engine can reach 40% efficiency instead of 20% in existing internal combustion engine. This apparatus can be used in any Otto cycle combustion engines found in electric generators, lawn mower, etc besides in most vehicles.

Owner:CHEN JACK YAJIE

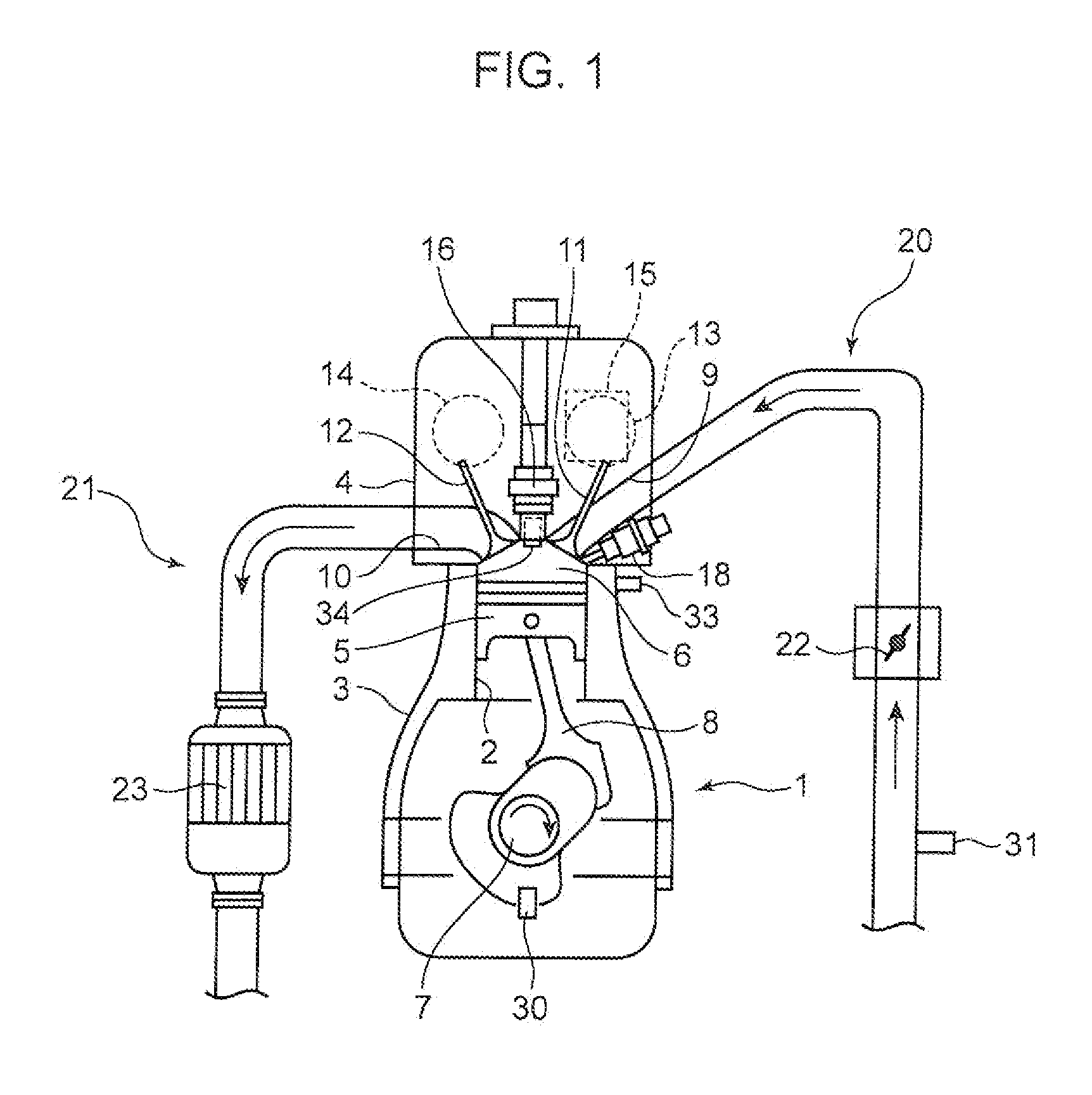

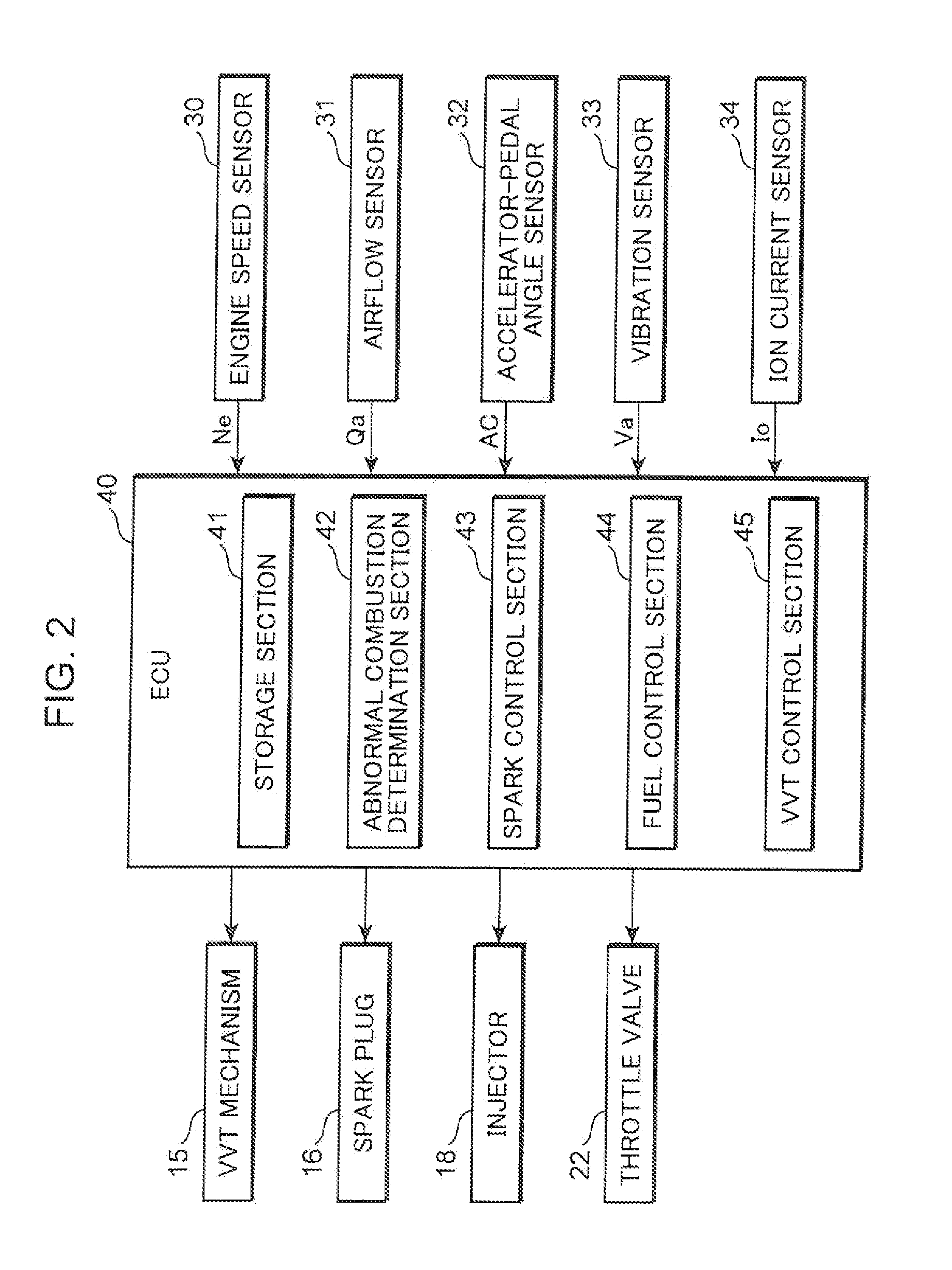

Abnormal combustion detection method for spark-ignition engine, and spark-ignition engine

ActiveUS20110246049A1Enough can be detectedInternal-combustion engine testingAnalogue computers for vehiclesTop dead centerEngineering

When a maximum value of vibration intensity (maximum vibration intensity) (Vmax) acquired from a vibration sensor (33) in a low engine speed / high engine load (operating region (R)) is equal to or greater than a given threshold value (X), a spark timing of a spark plug (16) is shifted from a point set in a normal state on a retard side with respect to a compression top dead center, farther toward the retard side. Then, when a maximum vibration intensity (Vmax2) acquired after the spark timing retard is greater than a maximum vibration intensity (Vmax1) acquired before the spark timing retard, it is determined that preignition occurs. This technique makes it possible to reliably detect preignition using the vibration sensor, while distinguishing the preignition from knocking. An in-cylinder pressure sensor for detecting an in-cylinder pressure of an engine may be used to determine the presence or absence of the preignition, in the same manner.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com