Patents

Literature

39 results about "Dynamite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamite is an explosive made of nitroglycerin, sorbents (such as powdered shells or clay) and stabilizers. It was invented by the Swedish chemist and engineer Alfred Nobel in Geesthacht and patented in 1867. It rapidly gained wide-scale use as a more powerful alternative to black powder.

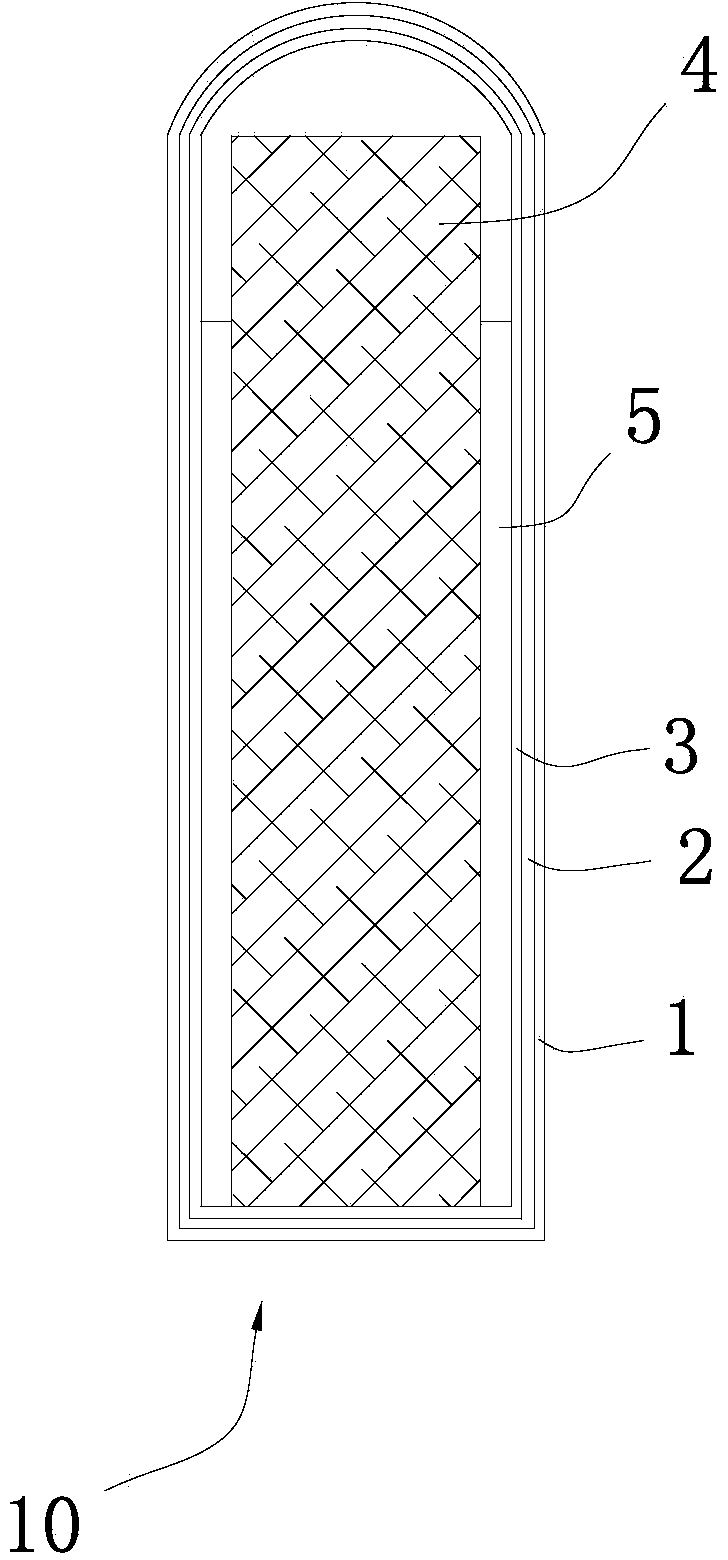

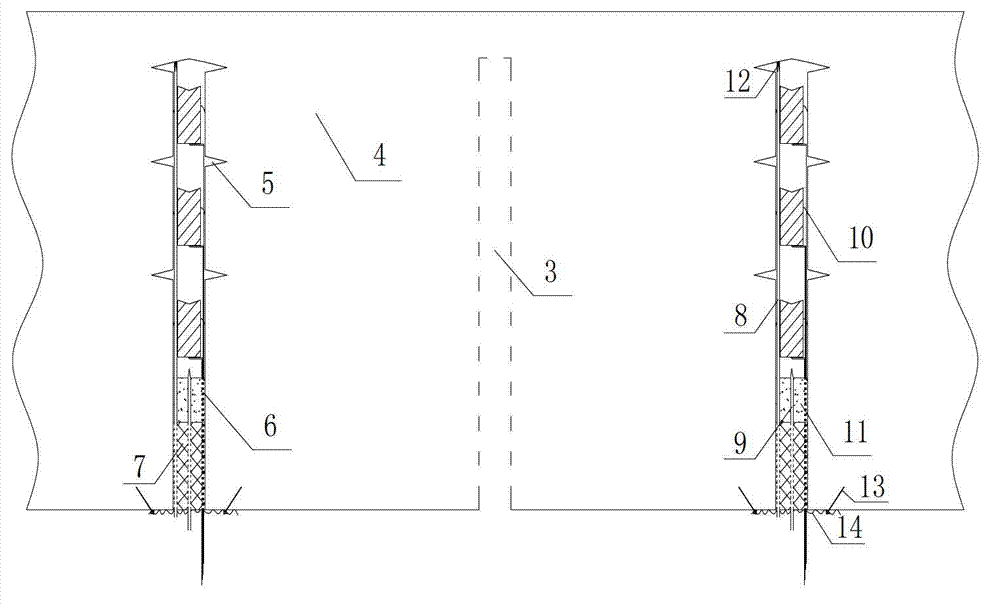

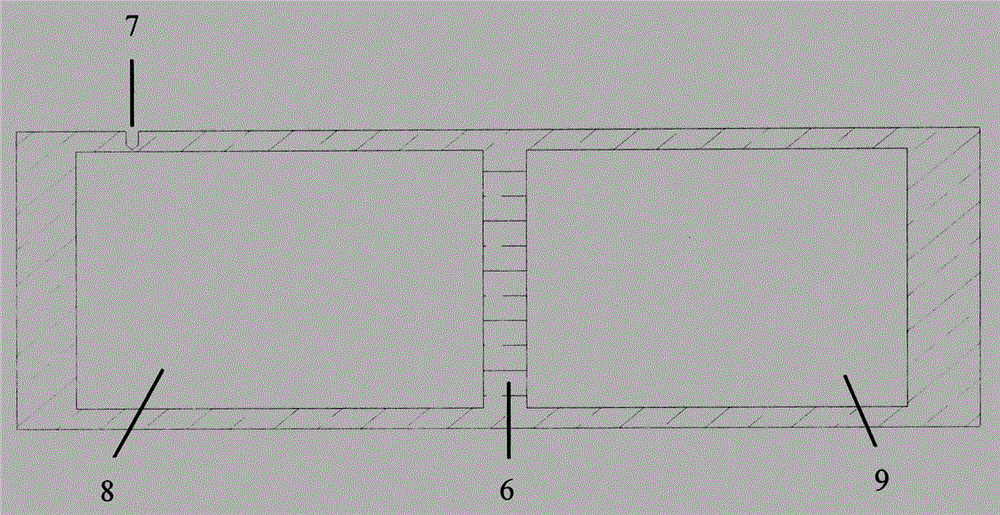

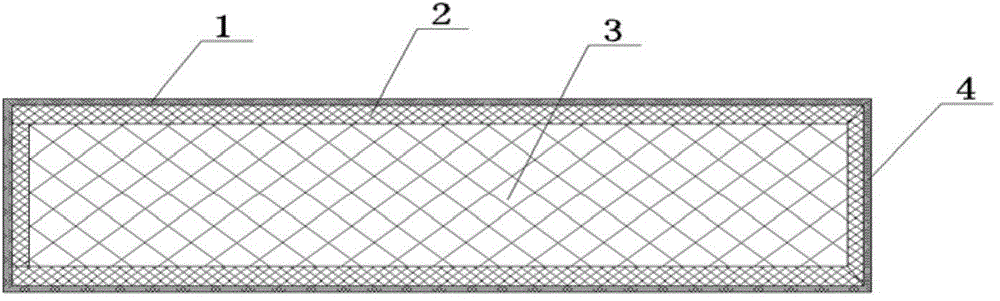

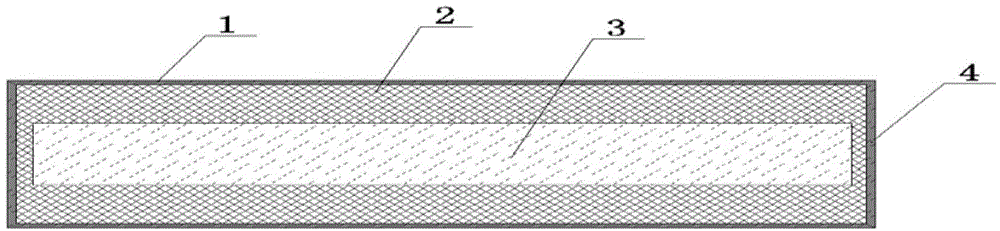

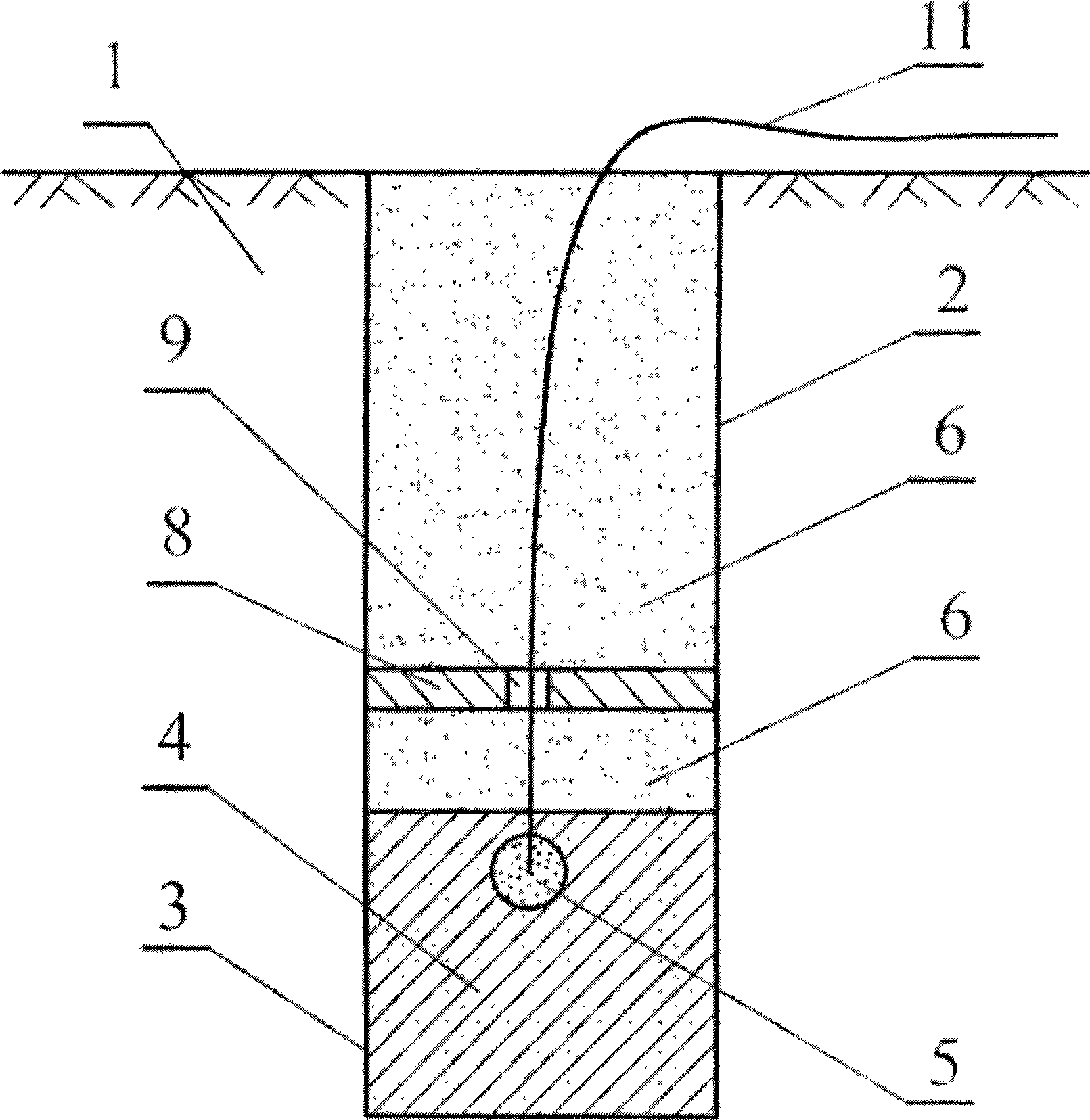

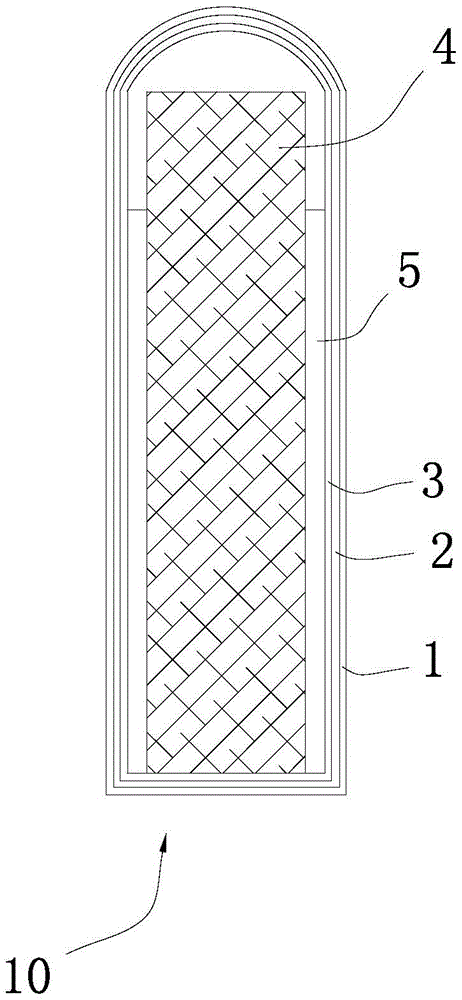

Temperature-resistance thermal insulation protecting bush

ActiveCN104006709ALow thermal conductivitySafe blasting operationsThermal insulationBlastingInsulation layerDynamite

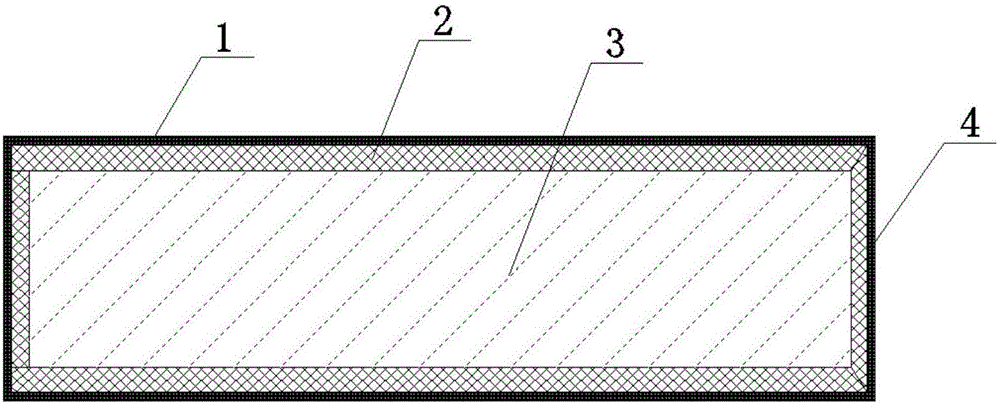

The invention discloses a temperature-resistance thermal insulation protecting bush which is used for charge blasting in a high-temperature blast hole and comprises a cylinder body with a cavity. The cylinder body is formed by stacking a fireproof layer, an insulation layer and a waterproof layer from exterior to interior in a composite mode, the cavity of the cylinder body is filled with a stick dynamite in a non-coupling mode, the gap between the inner wall of the cylinder and the stick dynamite is filled with high heat capacity liquid, the cylinder body is formed by stacking the fireproof layer, the insulation layer and the waterproof layer in the composite mode, each layer is made of heat insulation flame retardant materials, the heat conductivity coefficient is small, in the process that external heat energy is transmitted to the interior of the cylinder body, and the heat is gradually and greatly attenuated. Meanwhile, the high heat capacity liquid serving as energy consumed liquid is contained, the high specific heat capacity characteristics of the liquid are utilized for achieving energy conversion, a large amount of heat is absorbed, it is ensured that the temperature of the stick dynamite in the cylinder body is within the suitable range, under the heat insulation action of the cylinder and the heat absorption action of the high thermal capacity liquid, even though the temperature of the blast hole is high, blasting work can be safely performed, the bush is not limited by construction conditions, and operation is convenient and rapid.

Owner:HONGDA MINING IND

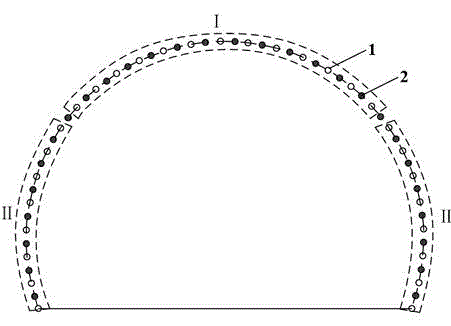

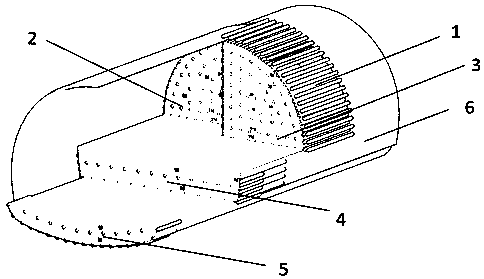

Permafrost region road tunnel peripheral hole blasting construction method

InactiveCN103983147APrevent thermal melt landslidesBlock free radical reactionBlastingDetonatorDynamite

The invention relates to the field of tunnel construction, in particular to a permafrost region road tunnel peripheral hole blasting construction method. The method comprises the following steps of step 1, according to the grade of a tunnel peripheral rock, determining a digging way and the single-circulation advanced depth; step 2, according to the position of the designed digging outline of a tunnel, drilling holes in the periphery at set intervals; step 3, after drilling the holes, cleaning the holes; step 4, filling dynamite into each blast hole, and connecting a percussion cap and a detonating cord; step 5, filling NaCl solution into each blast hole and each shock-absorbing hole, wherein each hole opening is blocked by stemming; step 6, using a blasting way to arrange a blasting network by using area-by-area blasting, blasting the peripheral holes in hole wall position areas, and then blasting the peripheral holes in the arch top. When the tunnel peripheral holes are designed, an un-coupled dynamite filling structure is adopted, and a section-to-section blasting way, a millisecond blasting way and a shock-absorbing design are adopted, so that the blasting heat is reduced, the blasting temperature of the peripheral rock is reduced, the stability of the permafrost is guaranteed, the construction cost is reduced, and construction is simply, conveniently and quickly performed.

Owner:TONGJI UNIV

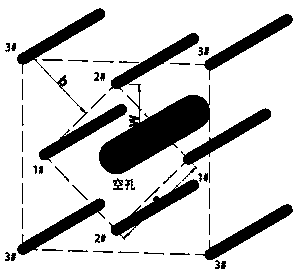

Hard roof directional pressurized explosion control method

InactiveCN103206903AImprove the utilization rate of explosion energyGood effect of dust suppressionBlastingDrill holeCoal

Disclosed is a hard roof directional pressurized explosion control method. Special drilling arrangement, loading structures and hole sealing manners are selected according to self-conditions of a roof, pressurized explosion transferring media is used to fully expel air in cracks, the characteristics of low compressing performance and high dynamite utilization rate of the pressurized explosion transferring media is utilized to perform directional or non-directional control explosion to slotted drilling holes or complete drilling holes, and expansion and pulse of the pressurized explosion transferring media are utilized for secondary loosening and weakening of surround rock of the drilling holes to accelerate development and penetrating of the roof cracks and strengthen presplitting weakening of the hard roof. The method mainly includes parallelly drilling holes and alternately loading dynamites at intervals; cutting grooves of the drilling holes; and explosion safety protection. The method is convenient to implement, simple to operate, low in cost and wide in application range, and can be popularized in loosening and weakening of common roofs or top coal and coal layers.

Owner:CHINA UNIV OF MINING & TECH

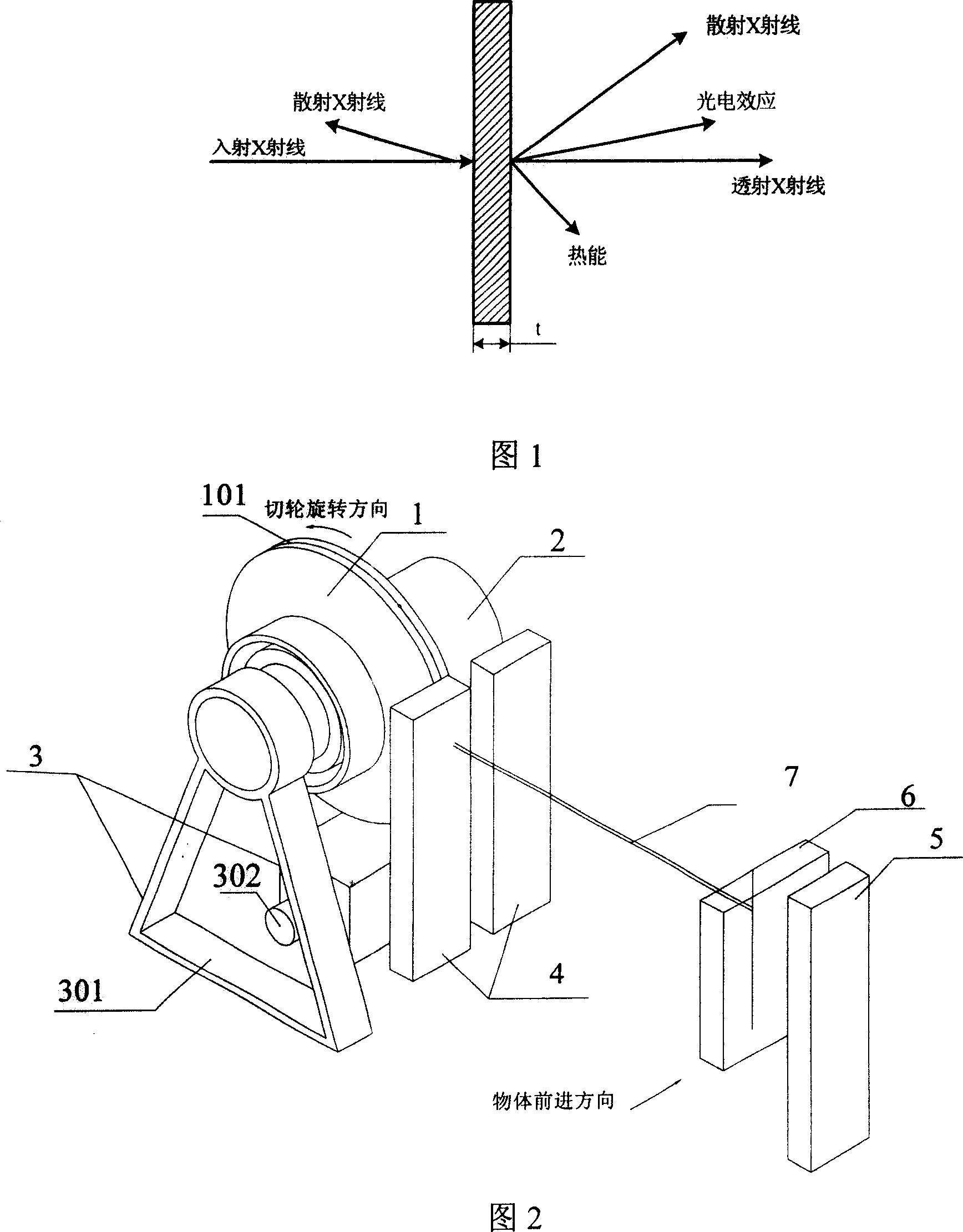

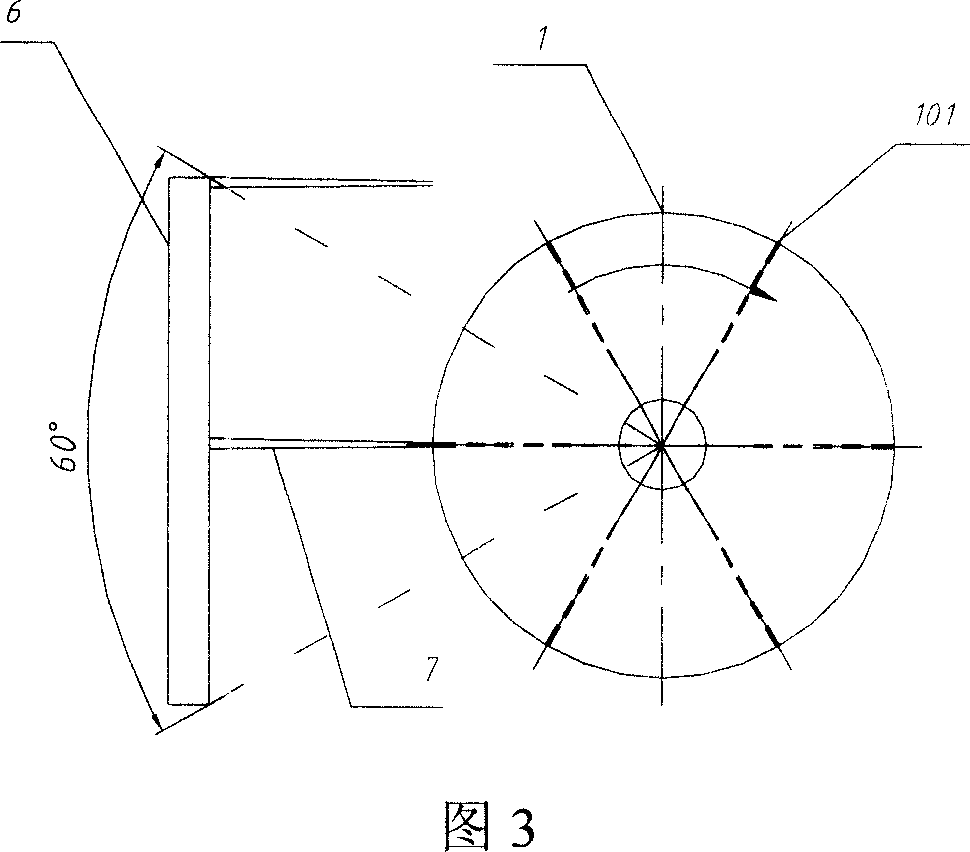

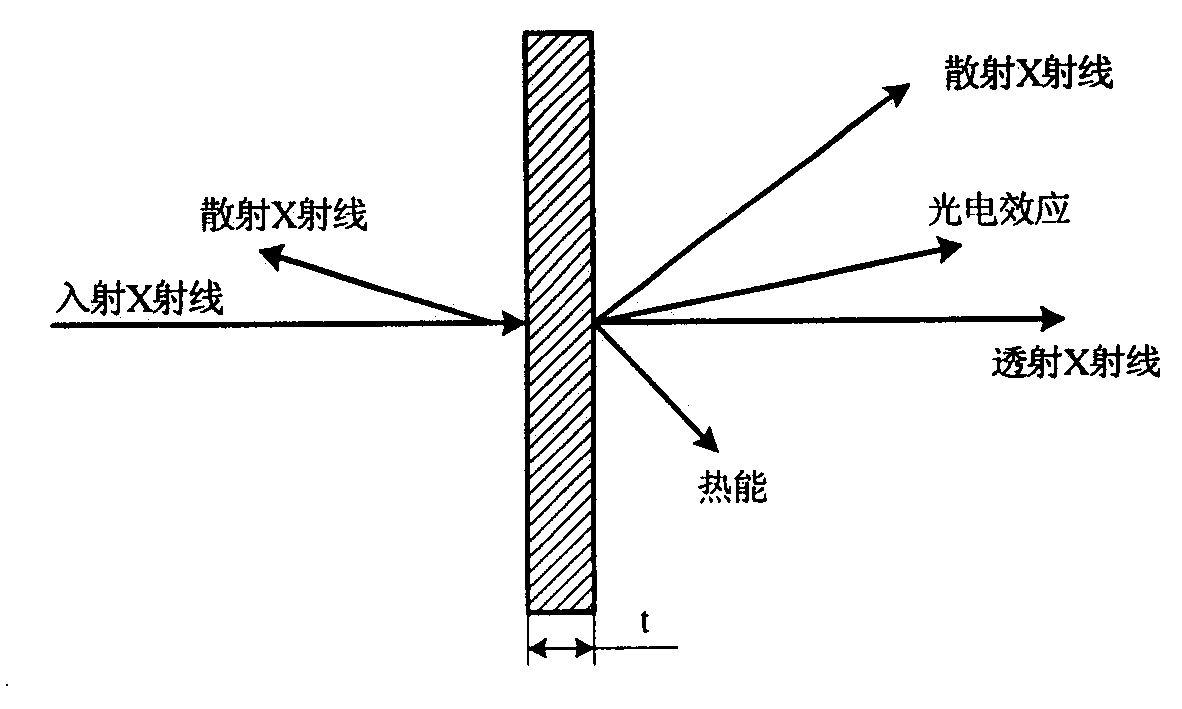

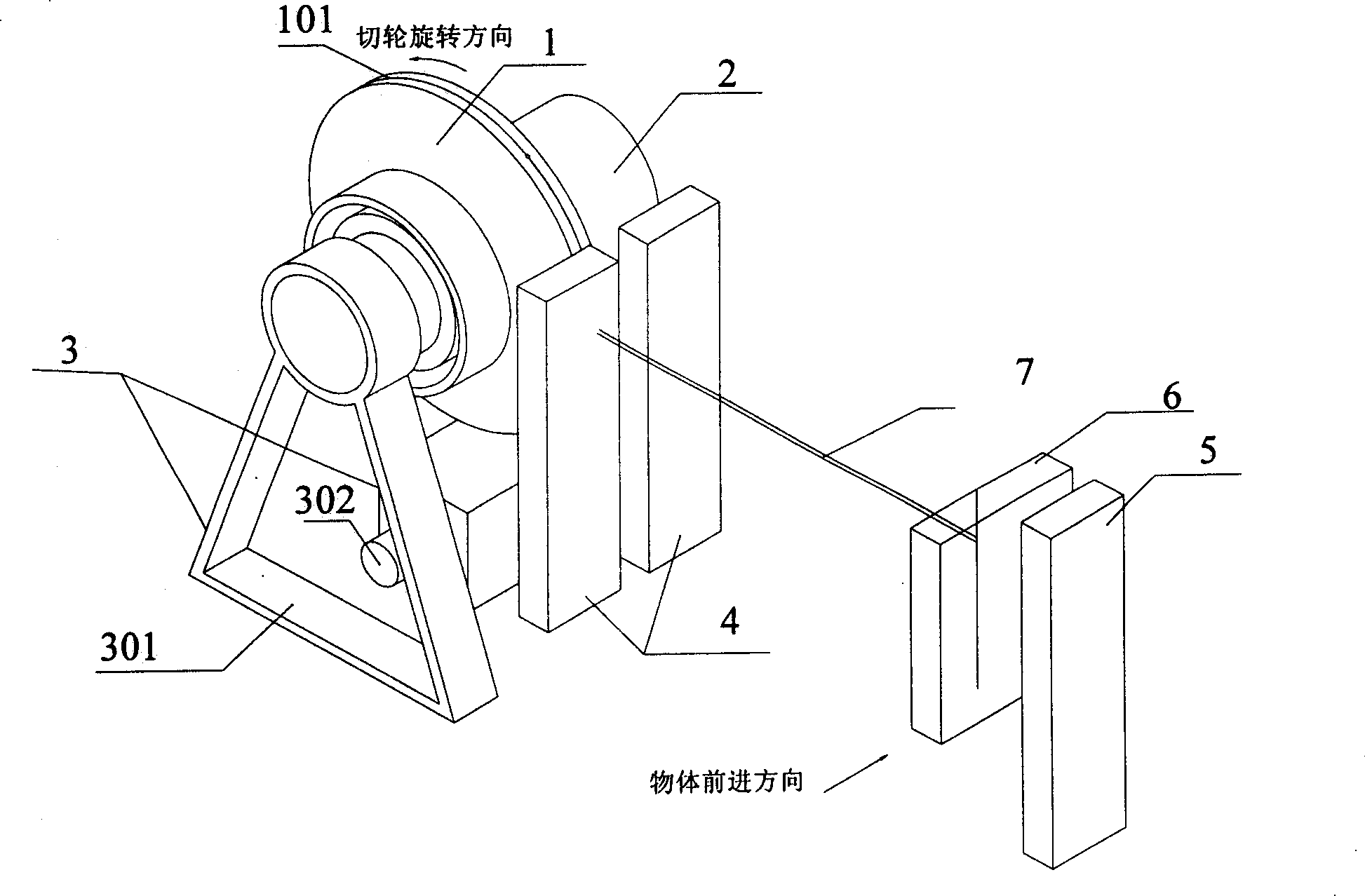

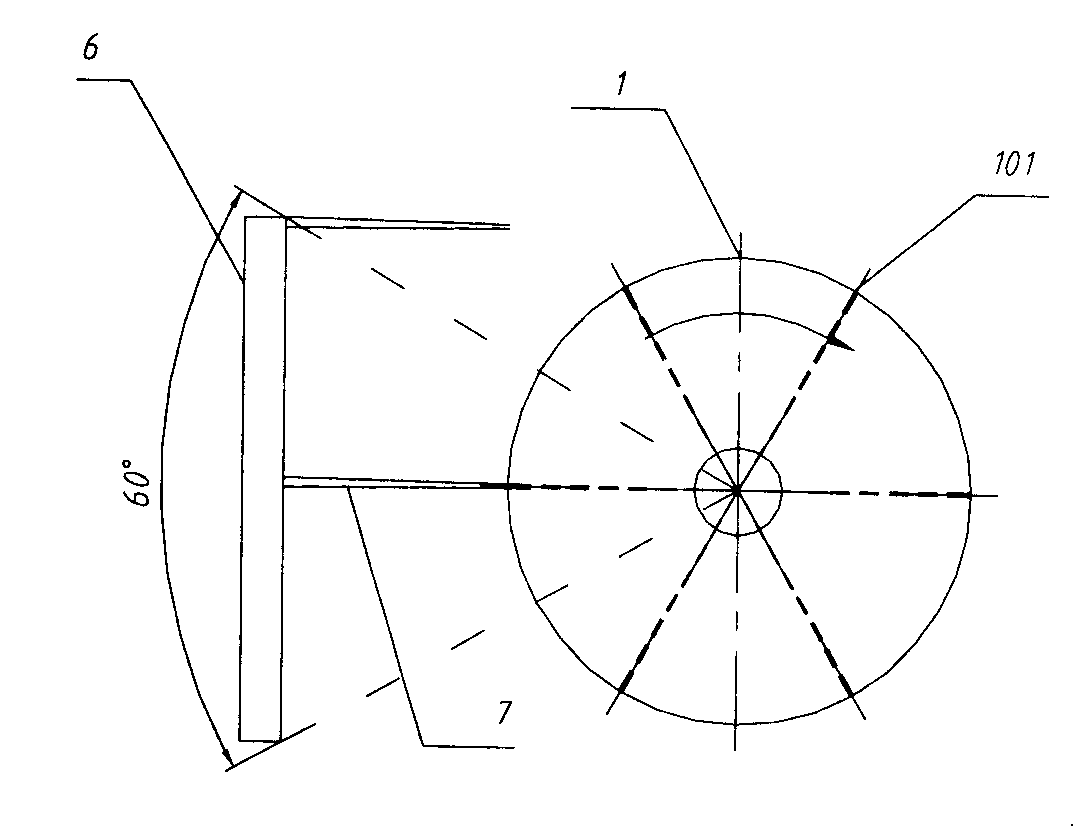

Device for testing explosive with backscatter technology

ActiveCN101113960AHigh-resolutionIncreased riskMaterial analysis by transmitting radiationDetonatorDynamite

The invention relates to a device of detecting dynamite by backscatter technique, which is characterized in that the device includes a cutting wheel collimating element, an X-actinogen which is arranged in the axial direction of cutting wheel collimating element, a driving element which is arranged below the cutting wheel collimating element, a backscatter detector with circuitry conjunction and a transmission detector. By adopting the new means for forming flying dots, the invention improves the resolution of backscatter image and the ability of assessment dynamite and detonator.

Owner:SHANGHAI EASTIMAGE EQUIP

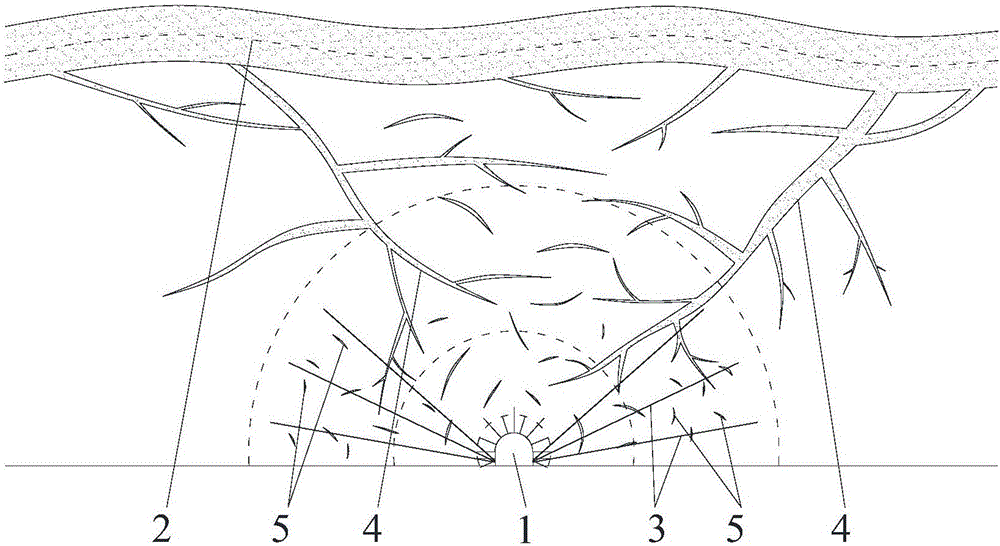

Wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method

ActiveCN106761852AIncrease pressure relief spaceIncreased blast energy rangeUnderground chambersTunnel liningWide areaDynamite

The invention discloses a wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method. According to the wide-area underwater coal rock pressure-bearing micro-blasting grouting and water blocking method, a plurality of groups of drill holes are formed in coal rocks, and the deep-hole pressure-bearing micro-blasting technology is applied, so that on the one hand, the pressure relief and crack increasing space inside the coal rocks can be effective enlarged, and on the other hand, the efficient and uniform transmission characteristics of solid-liquid coupling explosion propagation mediums on the loaded circumference inside the holes can be given full play of, the violent dynamic loading effects of dynamite explosion can be reduced, the pressure relief and crack increasing range of the coal rock can be enlarged, large-space and all-around penetration of main and auxiliary water conduction fractures inside coal can be fully achieved, and a large-range fracture borehole structure can be formed; subsequent high-pressure grouting and blocking operations can facilitate comprehensive blocking of the main and auxiliary water conduction fractures inside the coal rocks to form a wide-area grouting curtain and to block surrounding rock water conduction fracture channels at a large area, so that significant water blocking effects can be achieved, and static rock breaking crack increasing under the dynamic loading effects of in-hole dynamite explosion and comprehensive blocking of surrounding rock wide-area water conduction fractures can be achieved.

Owner:CHINA UNIV OF MINING & TECH

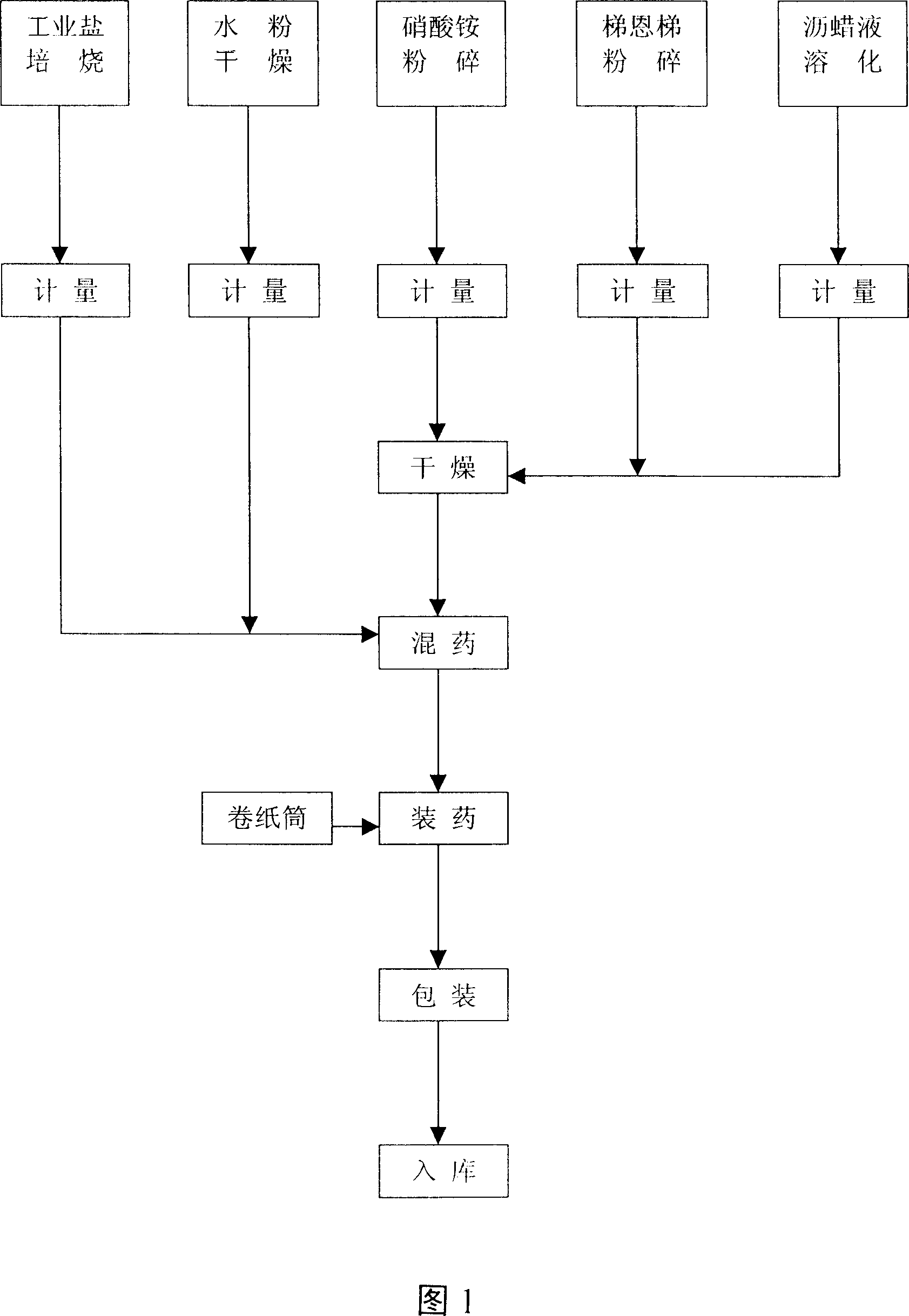

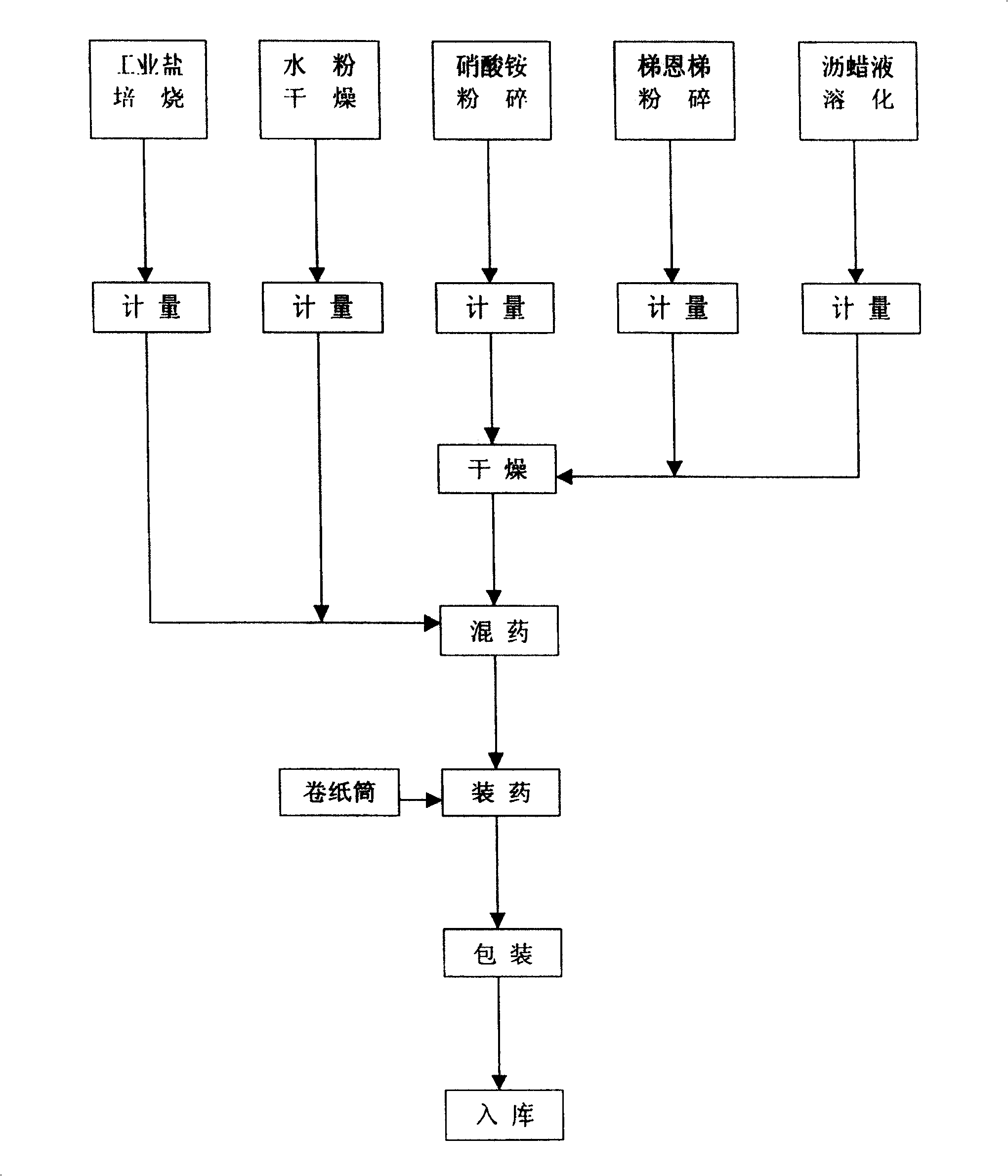

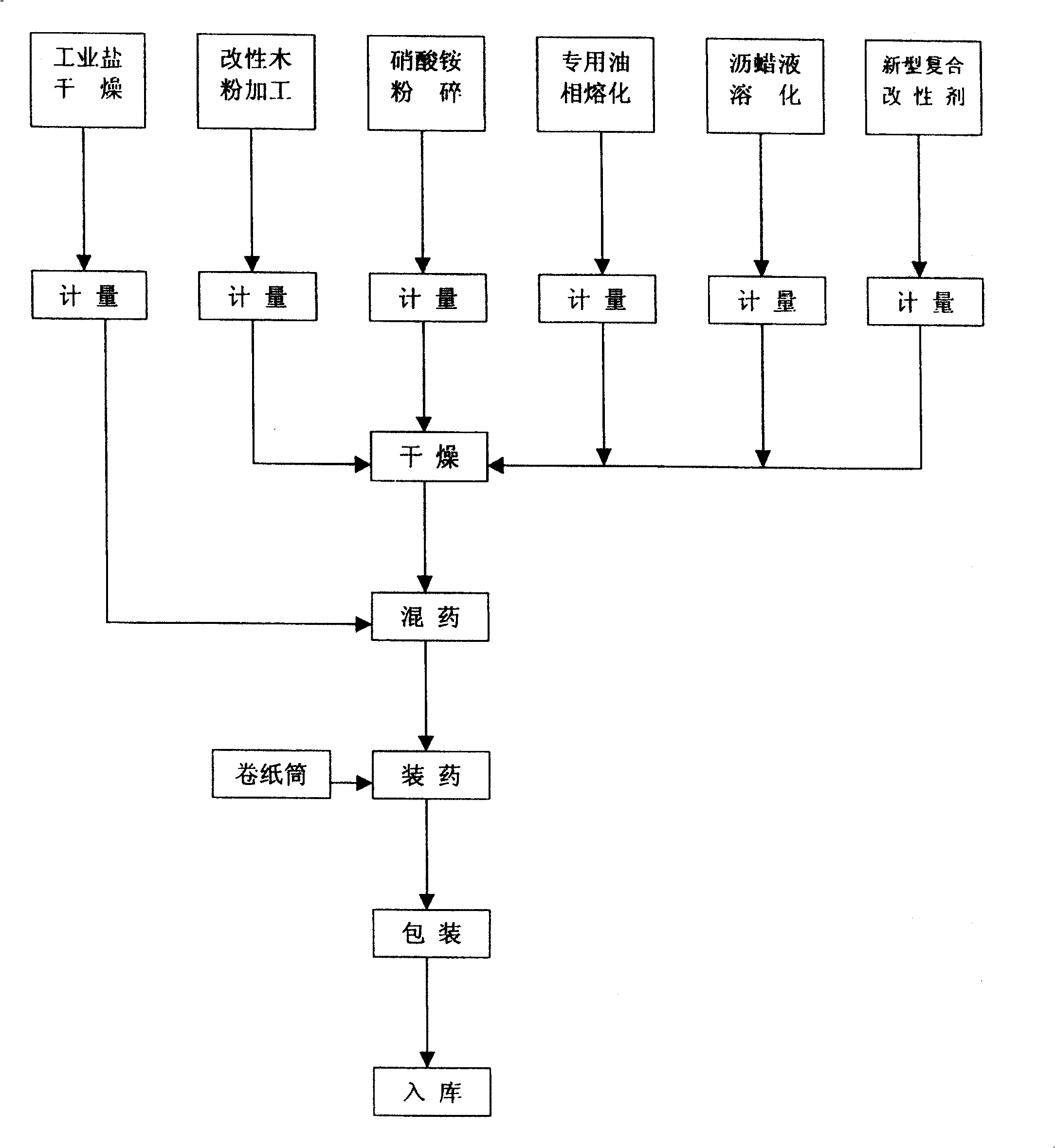

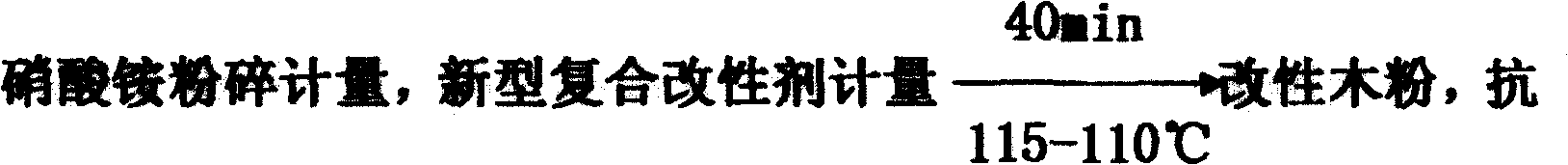

Powdery modified ammonium nitrate fuel oil for coal mine

InactiveCN1966475ALess one-time investmentImprove the intrinsic safety of productionExplosive working-up apparatusProduction lineDynamite

The invention disclosed a kind of powdered reshaped ammonio oil dynamite which is allowed to be used in coal mines. The dynamite is mainly constituted by 68.6-80 part (by weight) of ammonium nitrate, 4-6 parts (by weight) of reshaped wood powder, 1.6-3 parts of compound oil phase, 14-21 parts of industrial salt, 0.3-0.5 part of modifier and 0-1.0 part of water repellent agent. The invention can use the present producing devices to produce the dynamite in one stage or two stages which decreases the one time cost of the producing line substantially. The TNT element is totally omitted in the invention through the regulated formula and producing technologies as well as the new materials. The quality of the product has achieved or surpassed the technological standard of dynamites which is allowed to be used for coal mines in GB12437-2000. It has solved all the problems in many factories that produce the coal mine dynamites by edge-runner; besides, it is in line with the policies and requests in civilian exploding industry.

Owner:盛世平

Application of molybdenum trioxide on dynamite preparation, high-power mixed dynamite and preparation method thereof

InactiveCN101519334AEnsure safetyHigh densityNitroglycerine explosive compositionsSingle substance explosivesDynamiteMaximum density

The invention discloses the application of molybdenum trioxide on dynamite preparation, which is as follows: high-power mixed dynamite is prepared from 25 to 35 mass percent of aluminum powder, 50 to 55 mass percent of molybdenum trioxide powder, 10 to 15 mass percent of simple-ingredient dynamite and 2 to 5 mass percent of insensitive agent. The invention also discloses a preparation method of the high-power mixed dynamite. The maximum density, the highest explosion heat and the highest explosion speed of the high-power mixed dynamite prepared by the invention are respectively 1.5g / cm<3>, 4.7 MJ / kg, and 9400 m / s. After explosion, the pollution of the dynamite on the environment is greatly reduced, the dynamite preparation safety is greatly improved, and the prepared dynamite has excellent stability.

Owner:HENAN UNIV OF SCI & TECH

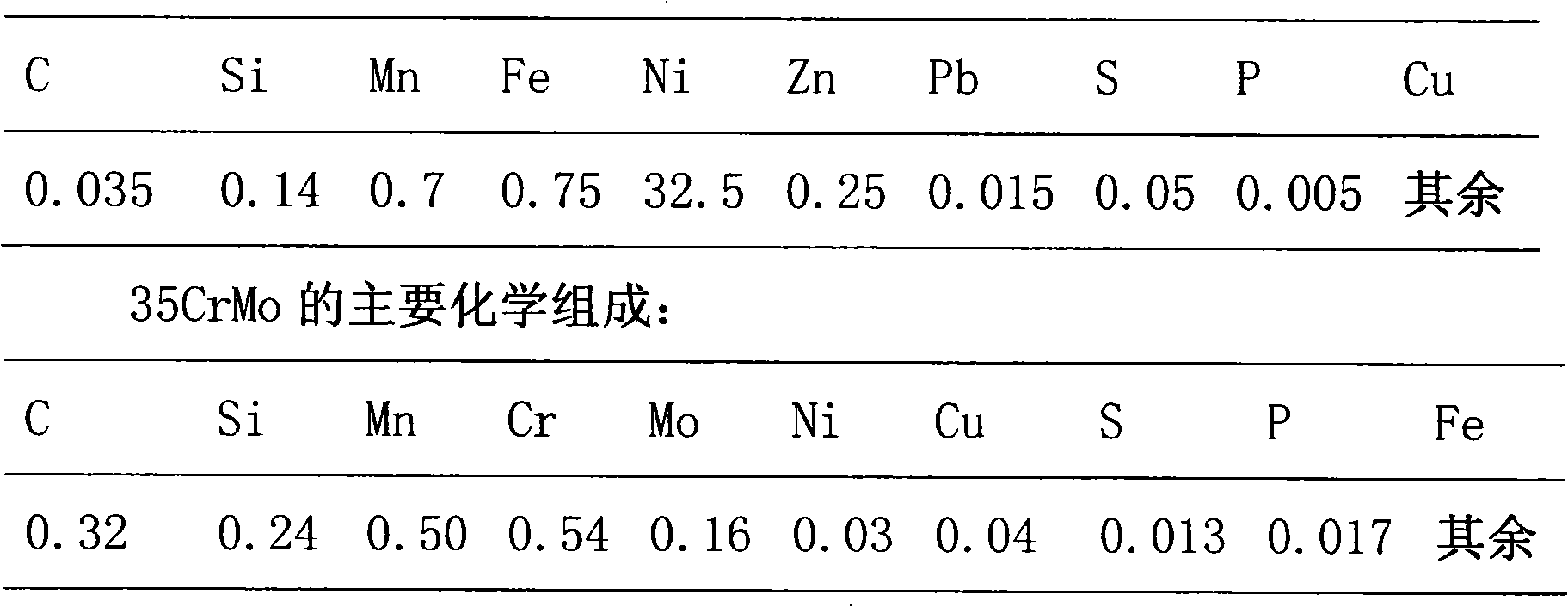

Big thickness BFe30-1-1/35CrMo explosive welding high intensity high corrosion resistance composite board

The invention provides a heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate. Firstly, the explosion speed of dynamite is controlled within about 800-1000m / s by the optimal design of dynamite formula. Secondly, by a principle of selecting the lower limit of the charging main parameter, the charging auxiliary parameters such as clearance and charging size of basic composite plate are reasonably designed, sand soil foundation added by water is selected and configured and the water content and density thereof are controlled, thus ensuring the once recombination rate of the heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate to achieve 100 percent and the adhesion strength thereof to achieve or even exceed the national standard, and avoiding the crack generation of the heavy section composite plate and high-strength basic plate during the explosion welding process. Finally, the subsequent crack of the composite pate is ensured not to be generated in the subsequent processing by the formulation of heat disposal parameters. The composite plate has ultra-high anticorrosion performance and extremely high high-temperature strength and anti-impact toughness.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

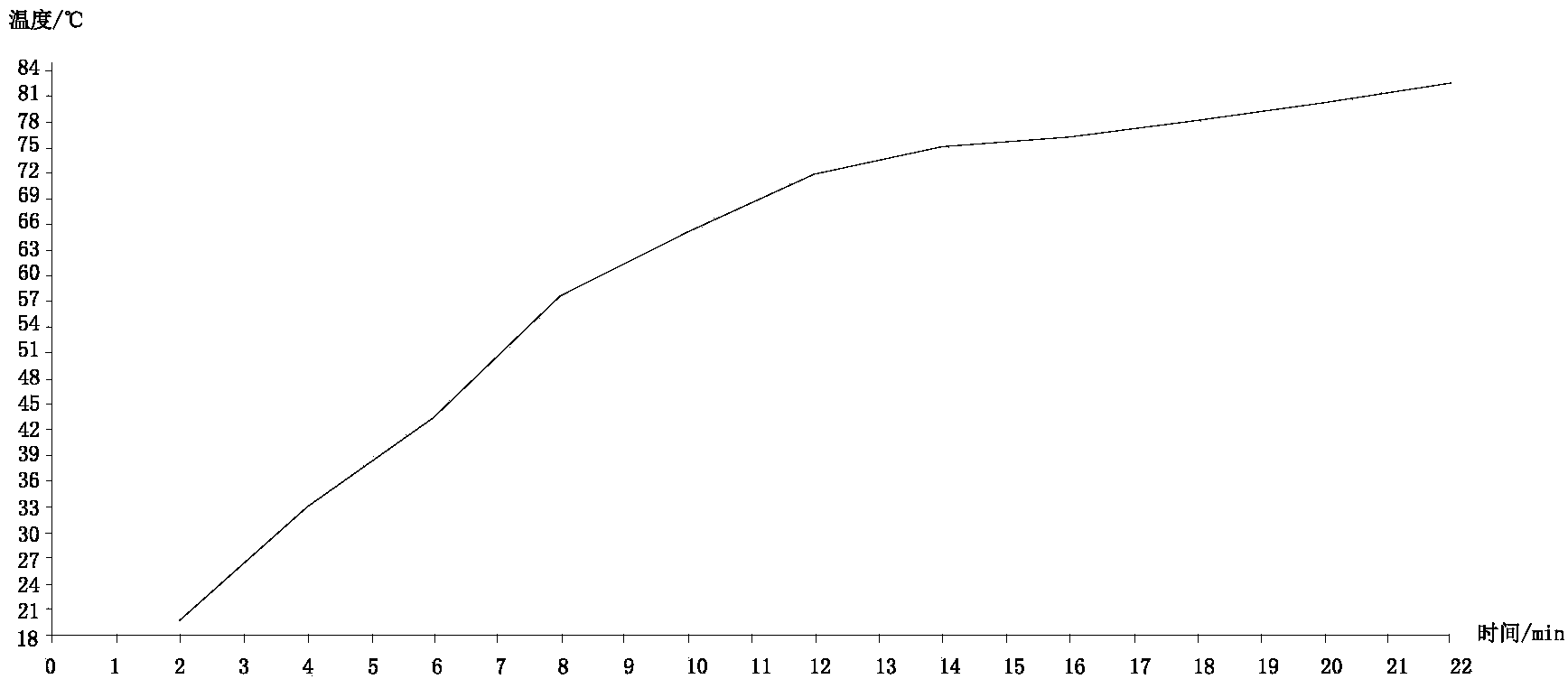

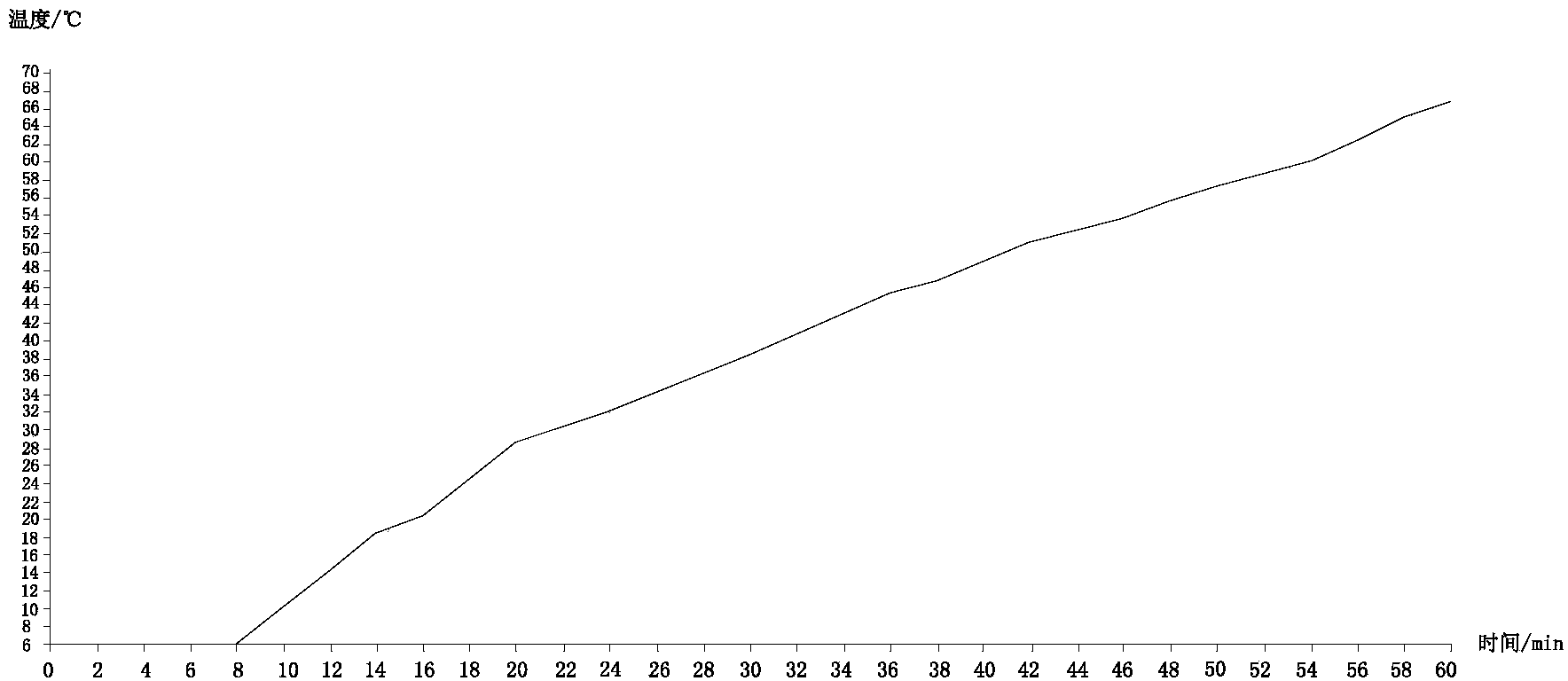

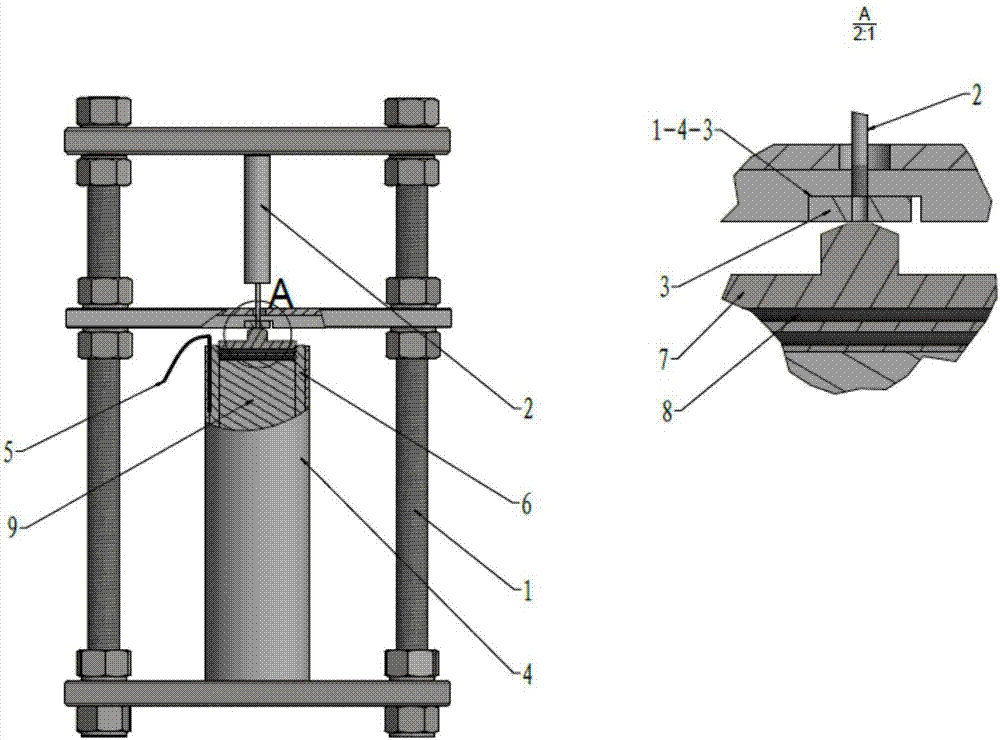

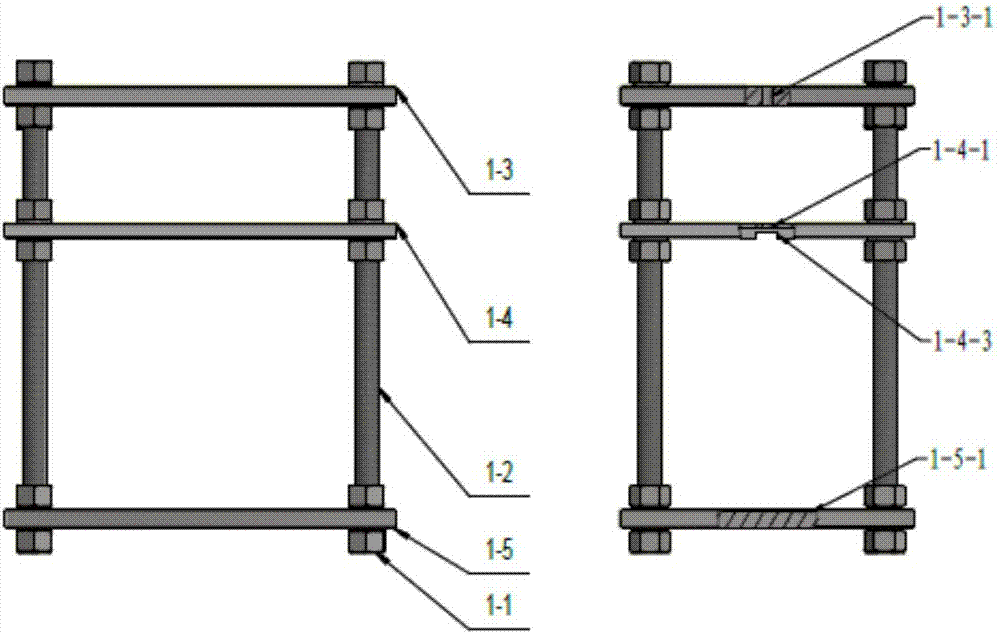

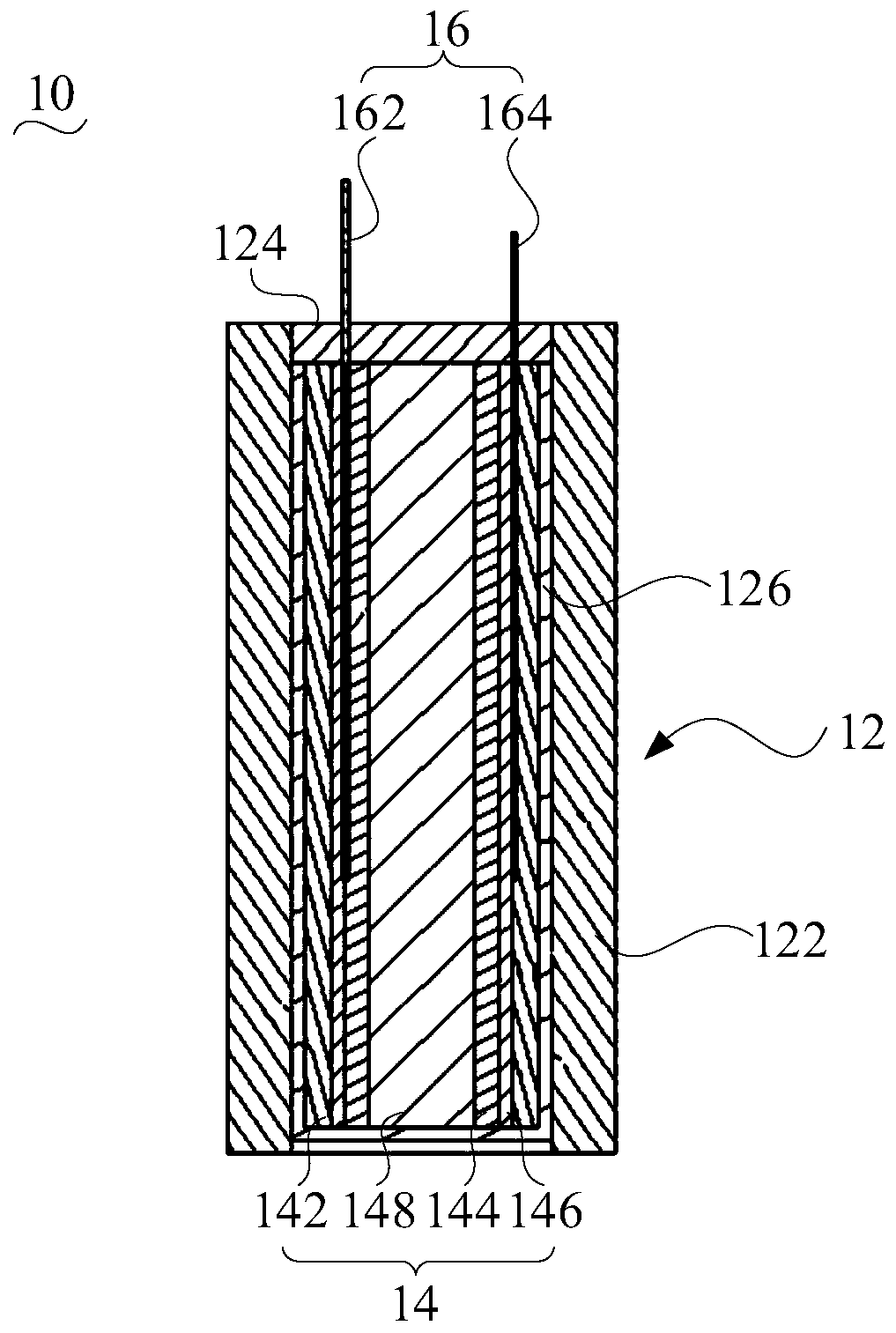

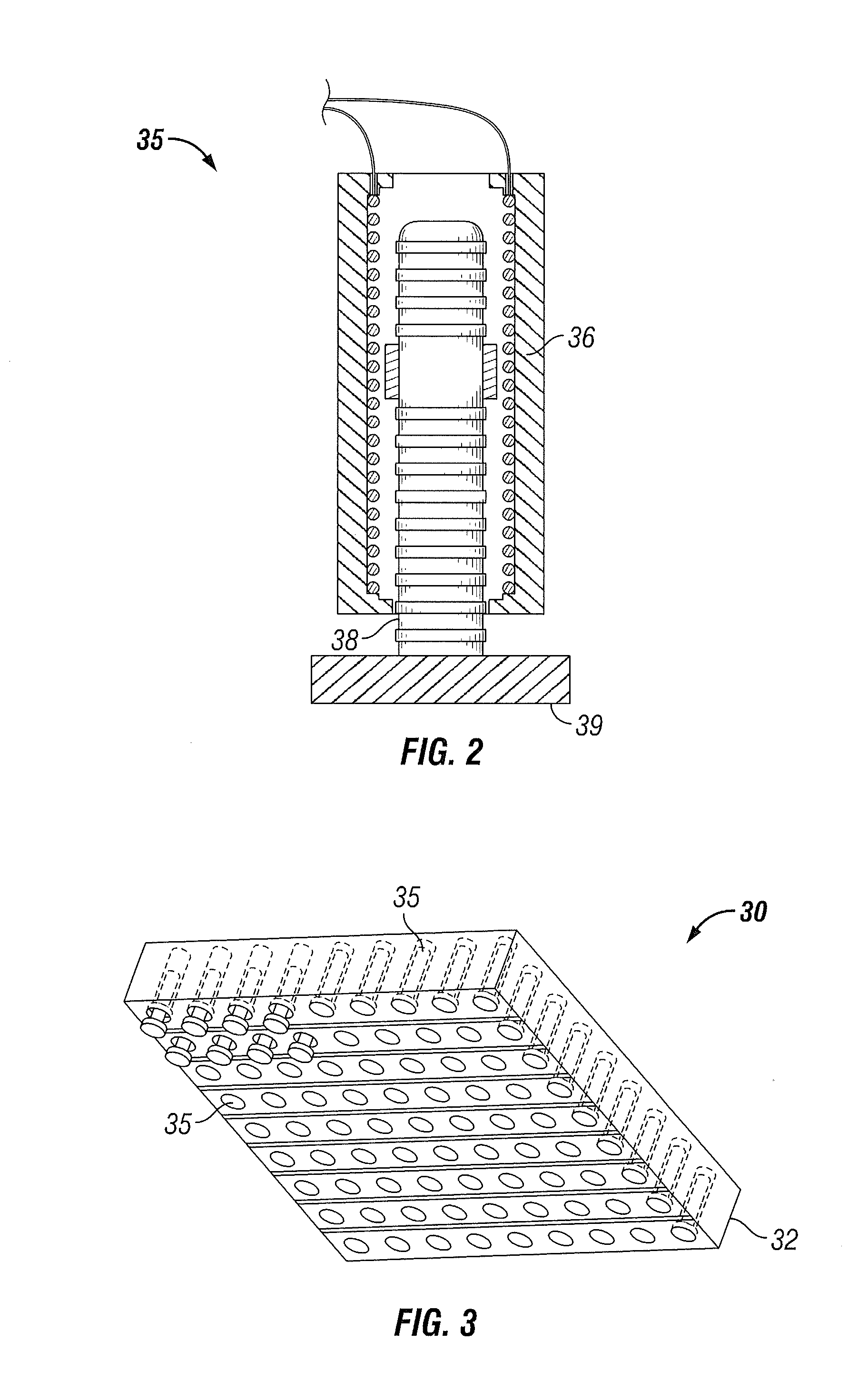

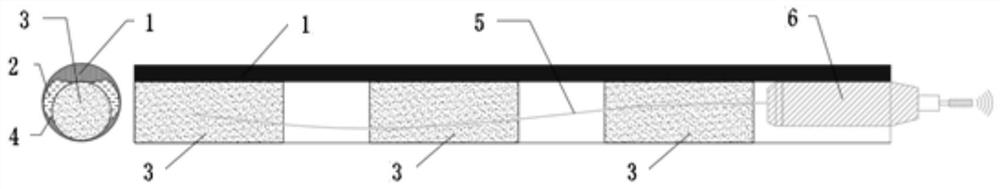

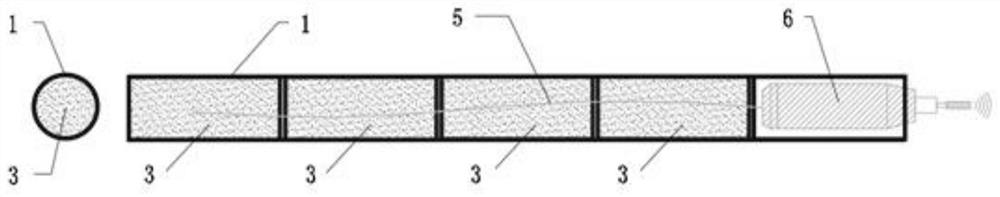

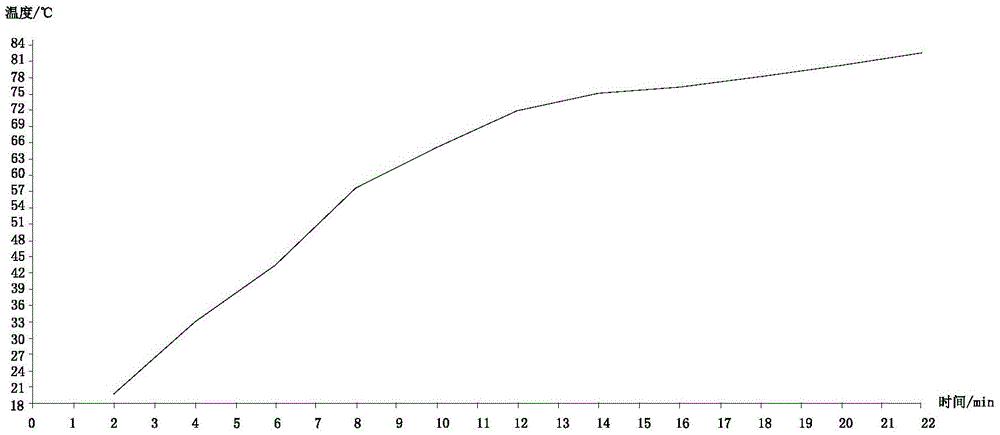

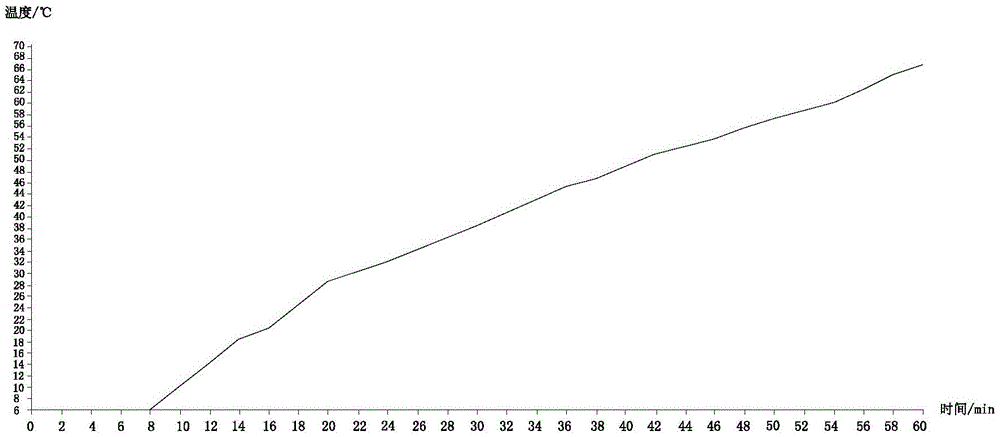

High-energy dynamite charging thermal expansivity measuring device and method

ActiveCN107389725AAccurate acquisitionEfficient acquisitionMaterial thermal coefficient of expansionAll solid stateDynamite

The invention discloses a high-energy dynamite charging thermal expansivity measuring device and method. The problem that an existing test device fails to measure solid state dynamite charging thermal expansion characteristic parameters is solved. According to the basic principle of the device and method, a heating jacket is used for heating dynamite charging to a certain temperature, a thermocouple is used for measuring a dynamite temperature in real time, spring steel with a known deformation coefficient is used for measuring pressure generated when the dynamite charging is heated and expanded, meanwhile, deformation of the spring steel is used for pushing a displacement sensor located above to obtain displacement data, and thus, a three-dimensional relational graph of the temperature, the expansibility and the expansion size of the dynamite charging is established. The device and method provided by the invention have the advantages of high universality, high accuracy and low cost, the requirements for measuring expansion parameters of liquid explosives, slurry explosives and all-solid-state explosives can be met simultaneously, and a more comprehensive data support is provided for middle-large sized ammunition charging designs.

Owner:XIAN MODERN CHEM RES INST

Device for testing explosive with backscatter technology

The invention relates to a device of detecting dynamite by backscatter technique, which is characterized in that the device includes a cutting wheel collimating element, an X-actinogen which is arranged in the axial direction of cutting wheel collimating element, a driving element which is arranged below the cutting wheel collimating element, a backscatter detector with circuitry conjunction and a transmission detector. By adopting the new means for forming flying dots, the invention improves the resolution of backscatter image and the ability of assessment dynamite and detonator.

Owner:SHANGHAI EASTIMAGE EQUIP

Ammonia dynamite for explosive compound welding of titanium plate and steel plate

InactiveCN101560130AHigh detonation velocityLow costExplosivesNon-electric welding apparatusTO-18Microcrystalline wax

The invention provides ammonia dynamite for the explosive compound welding of a titanium plate and a steel plate, which is stable in explosion velocity and good in welding effect. The invention adopts a technical proposal that the ammonia dynamite for the explosive compound welding of the titanium plate and the steel plate comprises the following components by weight percentage: 68 to 74 percent of ammonium nitrate, 8 to 13 percent of wood meal, 14 to 18 percent of sodium chloride and 0.5 to 1.0 percent of modifier, wherein the modifier comprises the following components by weight percentage: 40 to 50 percent of octadecylamine, 15 to 25 percent of wax, 25 to 35 percent of microcrystalline wax and 3.5 to 6.5 percent of sodium lauryl sulfate. The method for preparing the ammonia dynamite for the explosive compound welding of the titanium plate and the steel plate comprises the following steps: mixing the ammonium nitrate and the modifier to puff the ammonium nitrate; adding the wood meal and the sodium chloride; and grinding and mixing the materials to obtain the ammonia dynamite for the explosive compound welding of the titanium plate and the steel plate.

Owner:HUBEI TIANSHEN INDAL

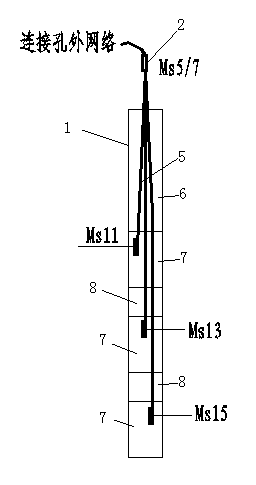

Deep-hole bench slight vibrating exploding method

ActiveCN103307939AReduce vibration speedImprove the efficiency of blasting excavationBlastingDetonatorDynamite

The invention provides a deep-hole bench slight vibrating exploding method which comprises the following steps: decking and blocking in the deep hole exploring hole at intervals and blocking the opening of the hole, leading the sections with explosives to the opening of the hole through different differential millisecond detonators, forming a single hole single fire dynamite network through the different differential millisecond detonators outside the hole, each delay detector outside the hole is connected with a delay detector inside the hole educed to the opening of the hole, and is connected with a detonate electrical detonator and a exploder, so as to achieve the purpose of realizing single hole multi fire dynamite on the premise of single hole single fire dynamite. The method provided by the invention is suitable for deep-hole bench slight vibrating exploding close to residential area with special requirements (particle vibration velocity less than 0.2 cm / s), minimizes the single fire dynamite explosive volume, and realizes slight vibrating exploding. The method provided by the invention is reasonable in design and strong in practicality, improves the efficiency, and accelerates the construction progress.

Owner:SINOHYDRO BUREAU 14 CO LTD +1

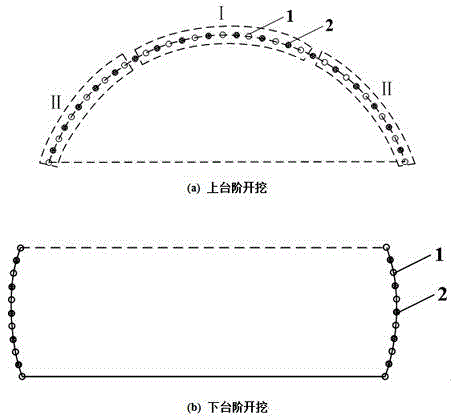

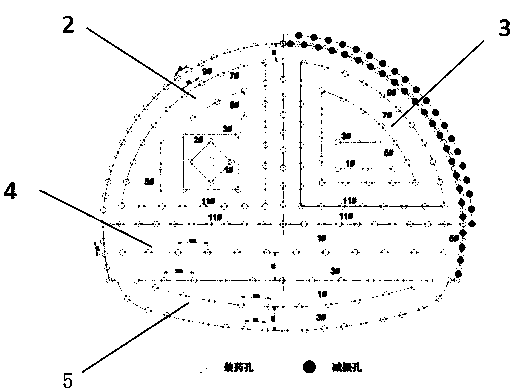

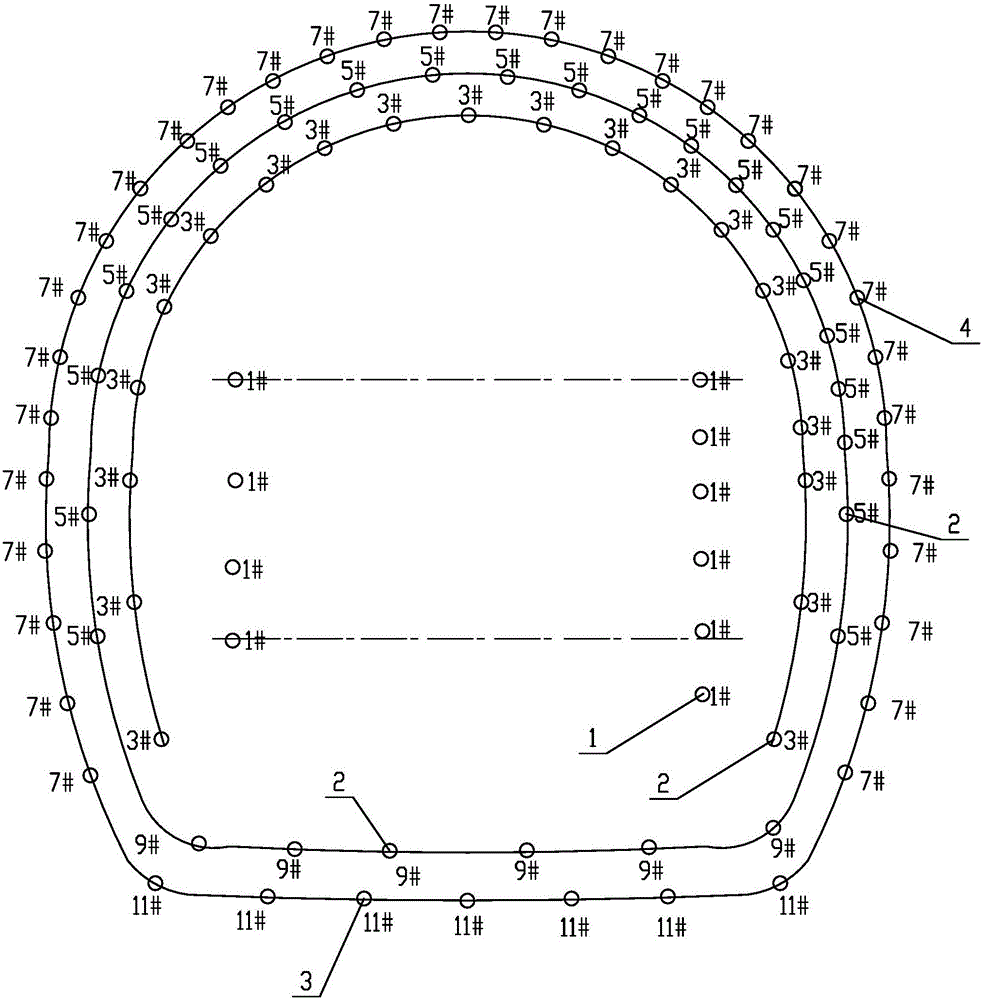

Method for controlling blasting vibration in adjacent existing tunnel excavation

The invention discloses a method for controlling blasting vibration in adjacent existing tunnel excavation. The method comprises the following steps of setting out for hole layout, shock-absorbing hole layout, positioning and drilling, hole clearing, charging, connecting with a detonating network, excavation and supporting, unexplored dynamite disposing, monitoring and measurement and the like. Through the adoption of a reasonable grooving process, a hole layout mode, a charging structure, a detonation method and a vibration damping method, the disturbance to the existing tunnel during the excavation process can be reduced as far as possible, the excavation footage can be effectively increased, the amount of explosives can be effectively reduced, and the cost is reduced when the construction period is shortened, thereby shortening the impact period of blasting disturbance. The method has great guiding significance and promotion value for newly building tunnels near the adjacent existing tunnels, and has broad application prospects.

Owner:浙江省建投交通基础建设集团有限公司 +1

Firecracker and firecracker structure

The invention relates to a firecracker which comprises a shell, a dynamite-free fuel unit and a connector unit. The connector unit is used for applying voltage to the dynamite-free fuel unit. The dynamite-free fuel unit can generate expansion gas after the preset voltage is applied to the dynamite-free fuel unit, so that expanding pressure triggering explosion is formed. According to the firecracker, the preset voltage needs to be applied to the firecracker, then explosion happens, in comparison with a firecracker with dynamite in the prior art, on one hand, storing and transporting are facilitated, the firecracker is not influenced easily by outside environment, and the potential safety hazard is small; on the other hand, the fuel unit is a dynamite-free unit, after explosion, emission ofa large quantity of gas such as sulfur dioxide and sulfur monoxide is avoided, and environmental pollution is avoided. Explosion only occurs after the voltage needs to applied to each firecracker, the chain reaction does not occur easily, energy generated by explosion is controllable relatively, and the potential safety hazard can be further reduced. The invention further provides a firecracker structure.

Owner:HUNAN BEYOND FIRE TECH CO LTD

Water pressure composite quick blocking method applied in drilling and blasting

The invention discloses a water pressure composite quick blocking method applied in drilling and blasting. The quick blocking comprises a water bag, a dynamite roll, a water bag and a high-molecular resin sealing bag. the water bag of the first segment is placed at the bottom of a hole opening; the dynamite roll of the second segment is closely connected with the water bag in series; the water bag of the third segment is placed behind the dynamite roll of the second segment; the high-molecular resin material of the fourth segment is placed in a drilling after kneading, squeezing and foaming; the high-molecular resin material flows out as liquid and penetrates into the space among the dynamite, the water bags and socks; quick solidification is performed and blast holes are blocked. the viscosity of the high-molecular resin material with rocks is larger than that of traditional stemming. the impact wave produced by the explosion of the dynamite is directly applied on rocks through the water bag installed at the bottom of the blast hole and therefore the explosive energy consumption is reduced and blast hole utilization is increased. The water bags in the blast hole generates water atomization effect during explosion which can reduce air impact wave, absorb explosive dust and dilute poisonous gases.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

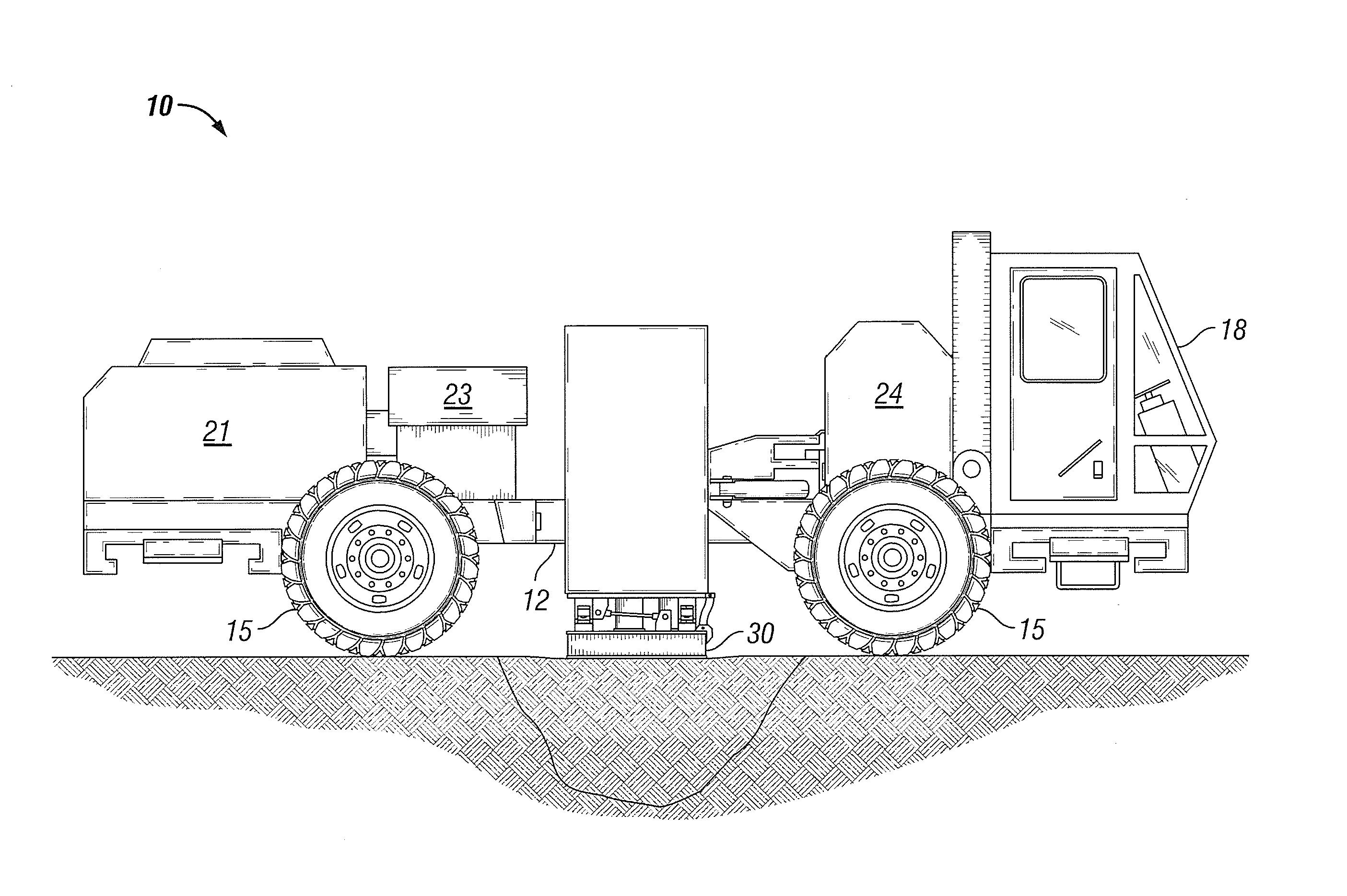

Quasi-impulsive displacement source

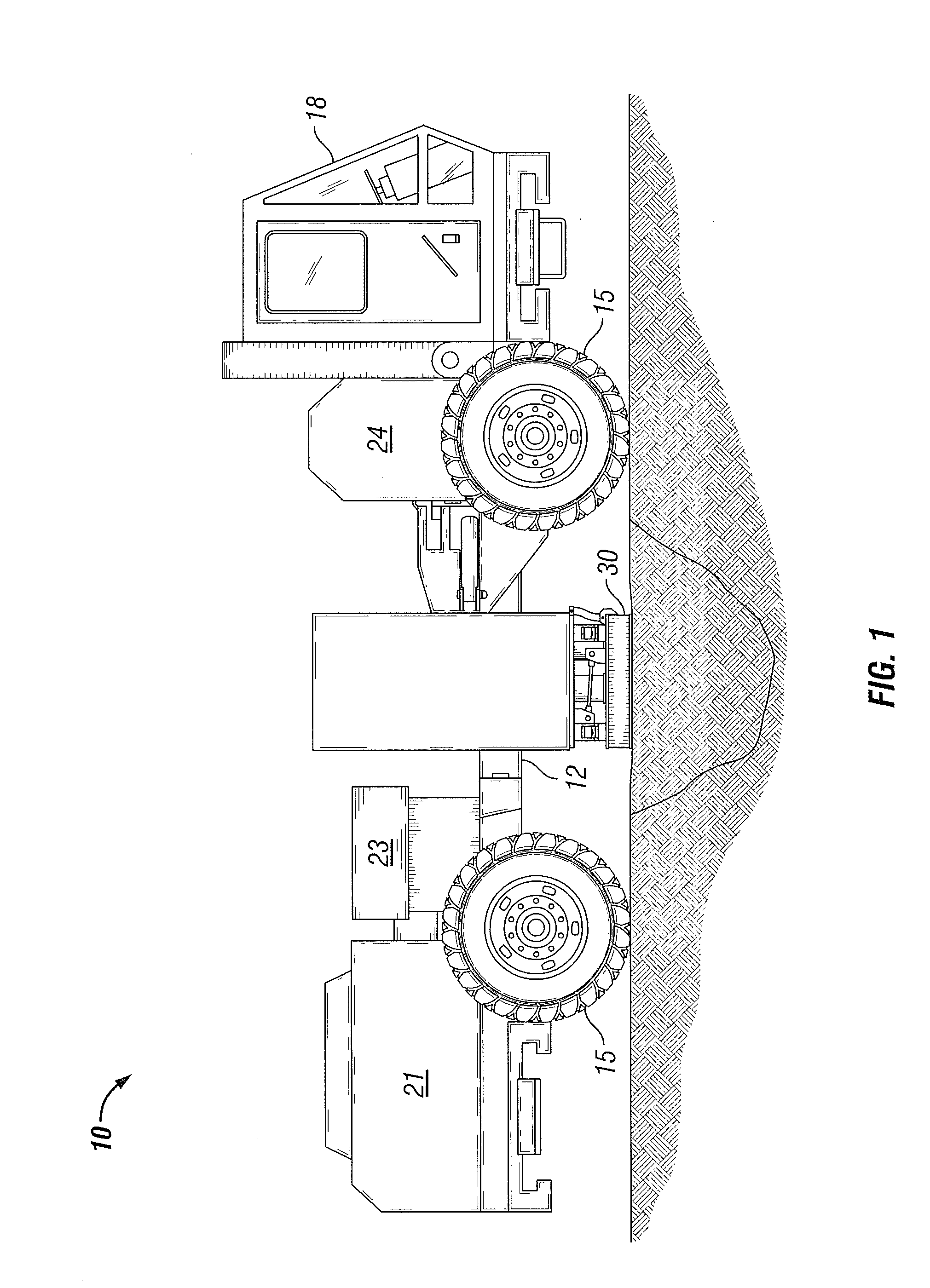

The invention is an electric seismic vibrator source of the type used in seismic prospecting for hydrocarbons that creates a quasi-impulsive burst of seismic energy onto the ground and into the earth. The source uses an engine and generator combination to create electric power for all systems on the source such as driving a frame of linear electric motors that direct a rod or piston to contact the ground. All of the linear electric motors are driven against the ground in a high power pulse that delivers a band-limited spectrum of seismic energy over a very brief period of time that would like a “pop” and be measured in milliseconds. A quasi-impulsive seismic pulse would create a wave field that resembles the seismic data acquired using dynamite or other explosive seismic systems without the ultrahigh frequencies of a true explosive pulse. The quick burst or several quick bursts may further speed up the survey by minimizing the time that a vibe spends on a source point.

Owner:CONOCOPHILLIPS CO

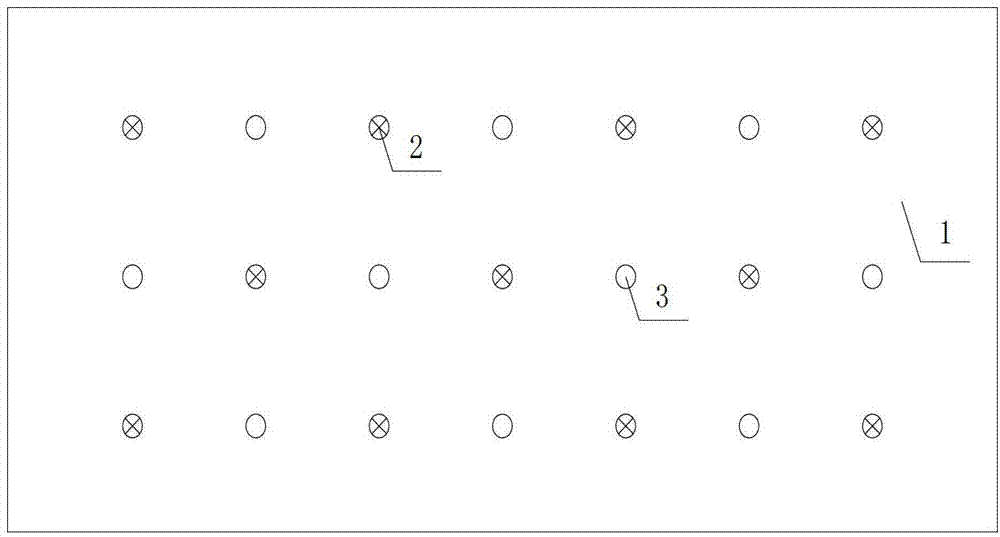

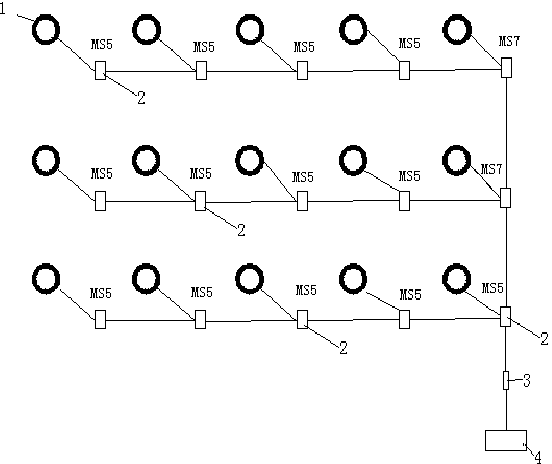

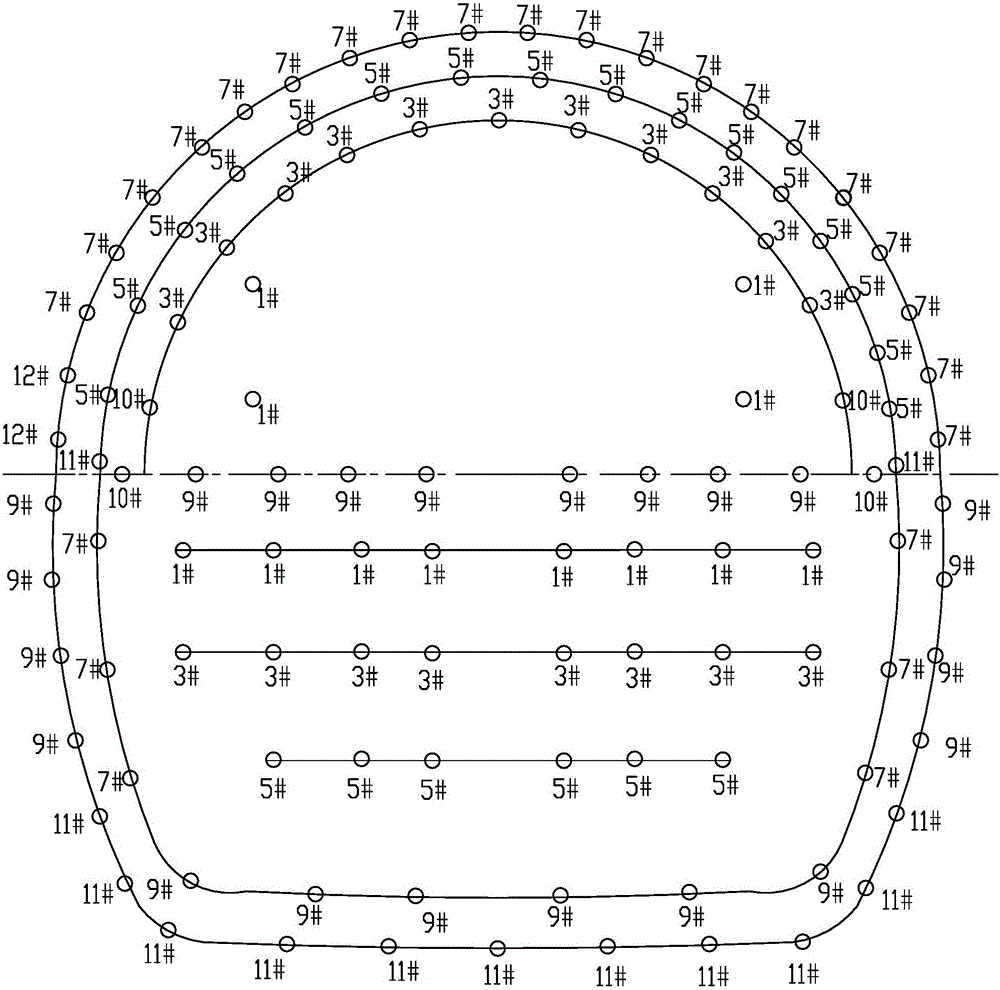

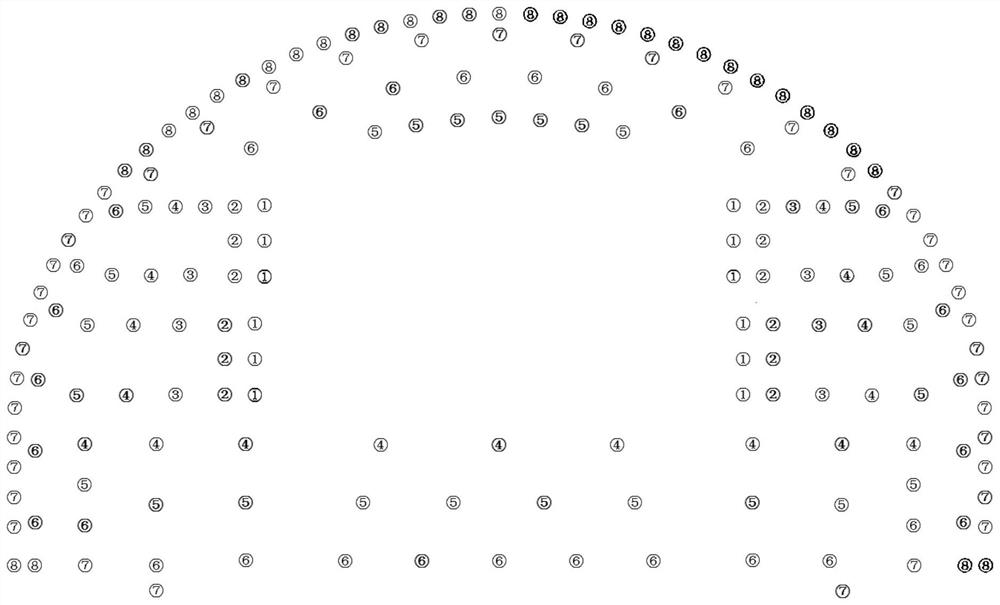

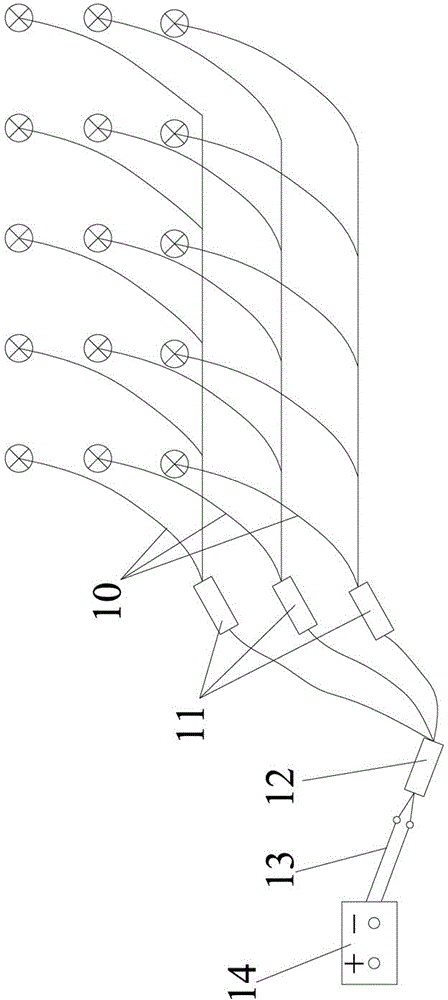

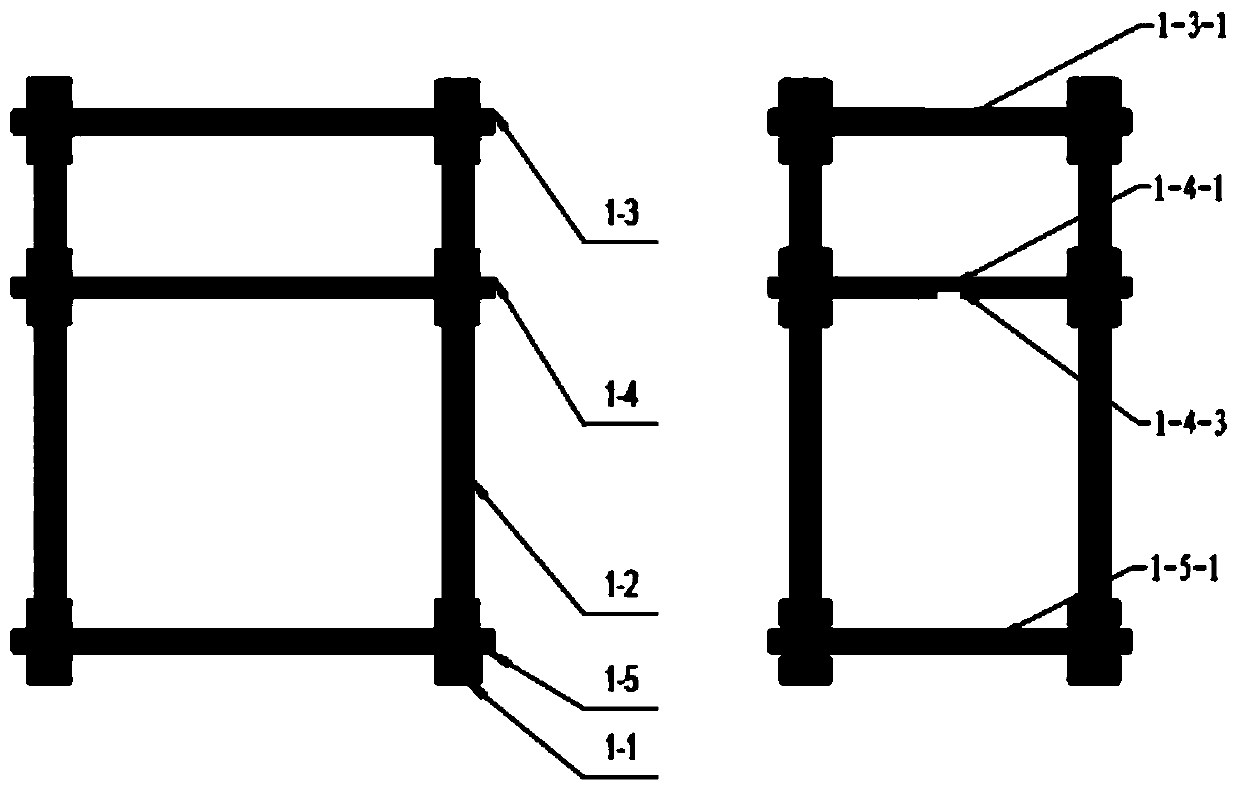

Blasting network structure used for slight dynamite

InactiveCN105823388AMeet construction requirementsNo damage to surrounding facilitiesBlastingRailway tunnelDynamite

The invention discloses a blasting network structure for microseismic blasting suitable for urban subway blasting engineering, which includes blastholes distributed on the blasting network, and the blastholes include peripheral holes, cutting holes, driving holes and floor holes. Cutting holes are arranged in the center of the blasting network structure, the peripheral holes, floor holes and driving holes are distributed in the periphery of the cutting holes in sequence, the driving holes are evenly distributed, and the hole spacing of the cutting holes is 1.5 times the hole pitch of the peripheral eye. This application aims at the characteristics of the complexity of urban subway construction compared with general railway tunnel construction. The design of the blasting network structure fully meets the requirements of urban subway construction, and will not damage surrounding facilities, which is safe and reliable.

Owner:中铁二十二局集团第一工程有限公司 +1

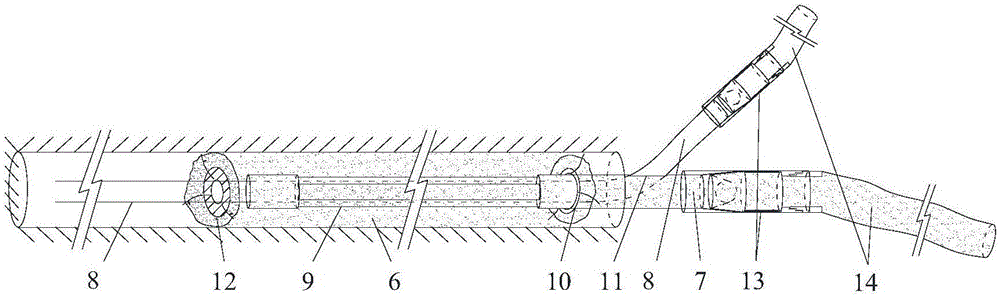

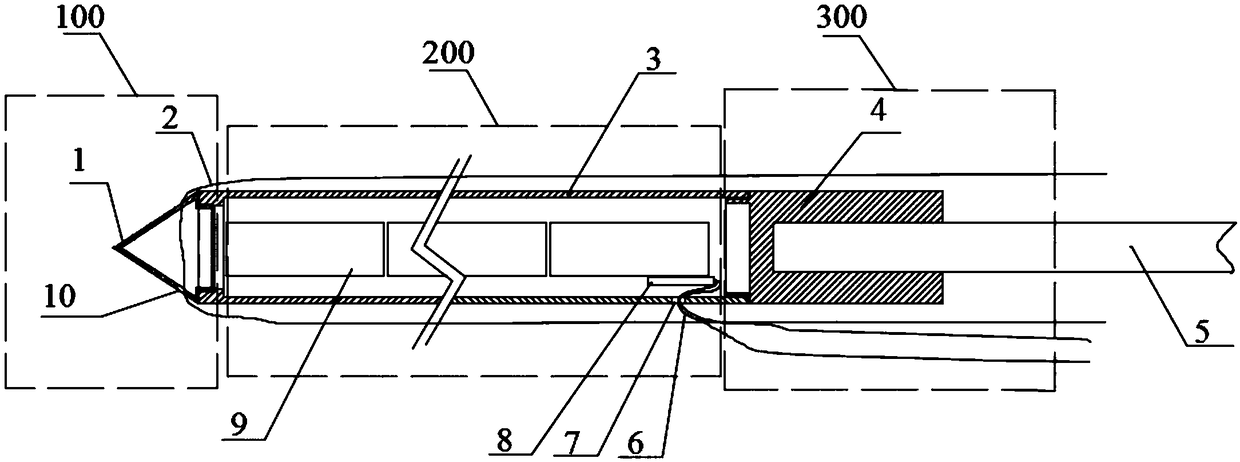

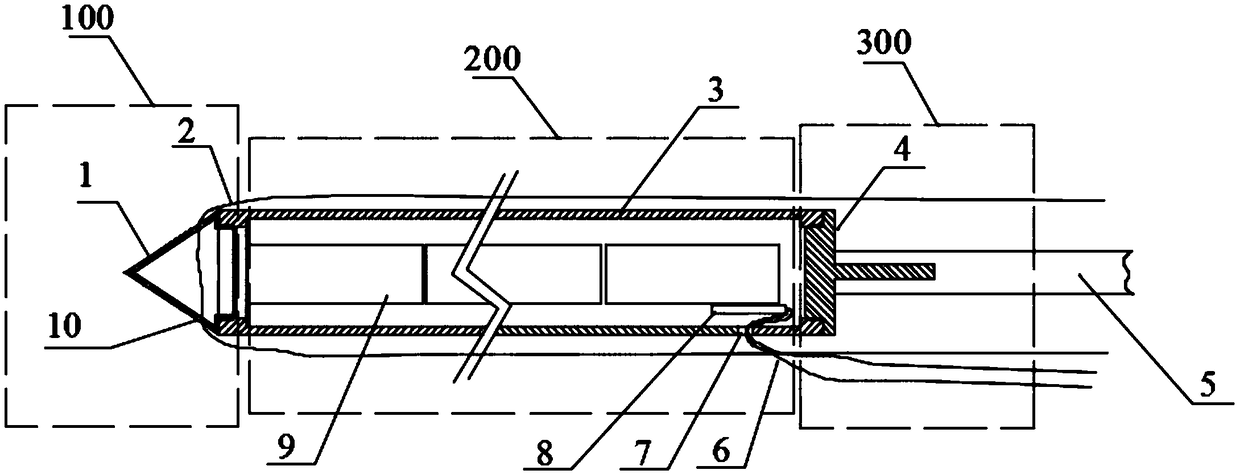

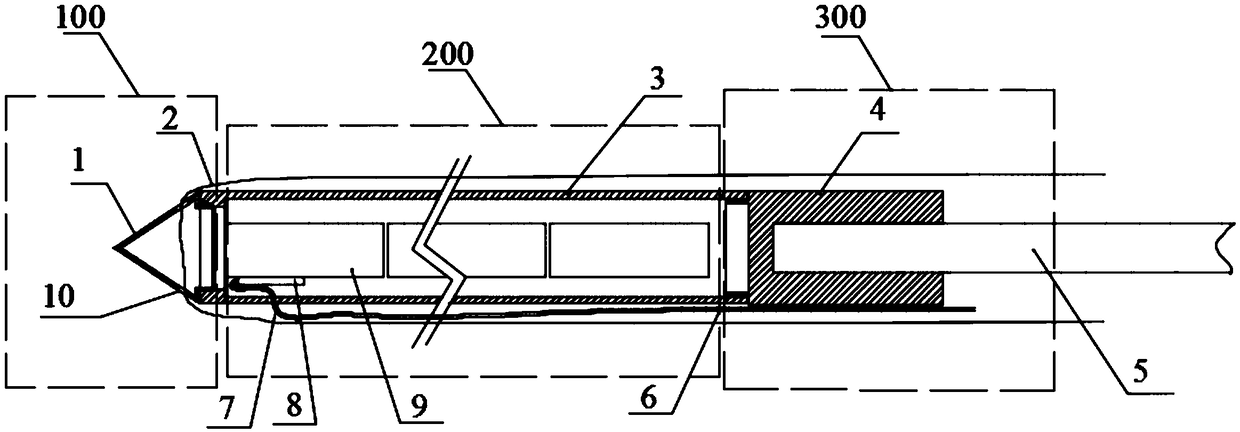

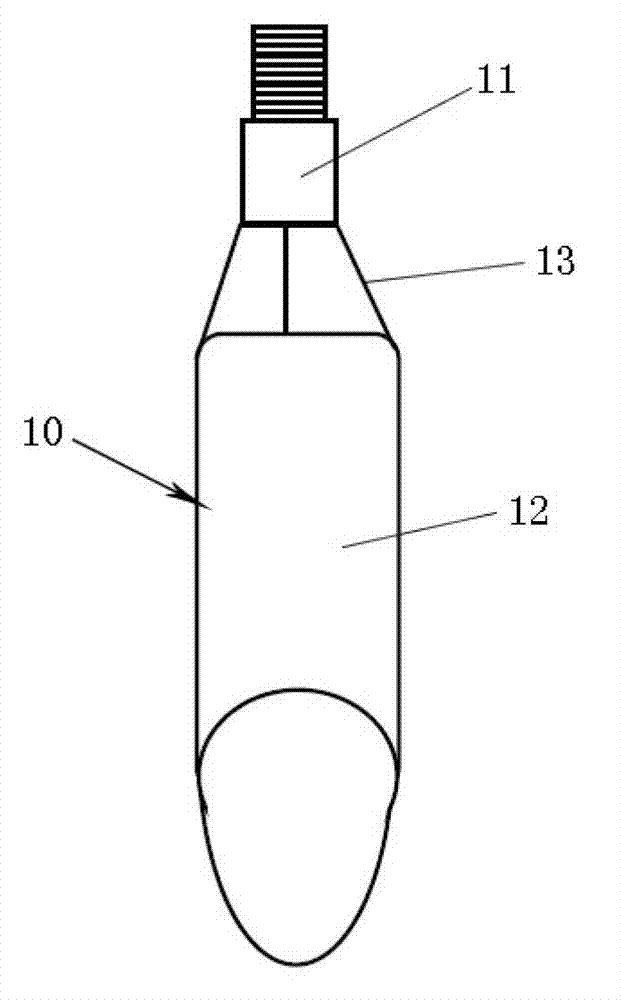

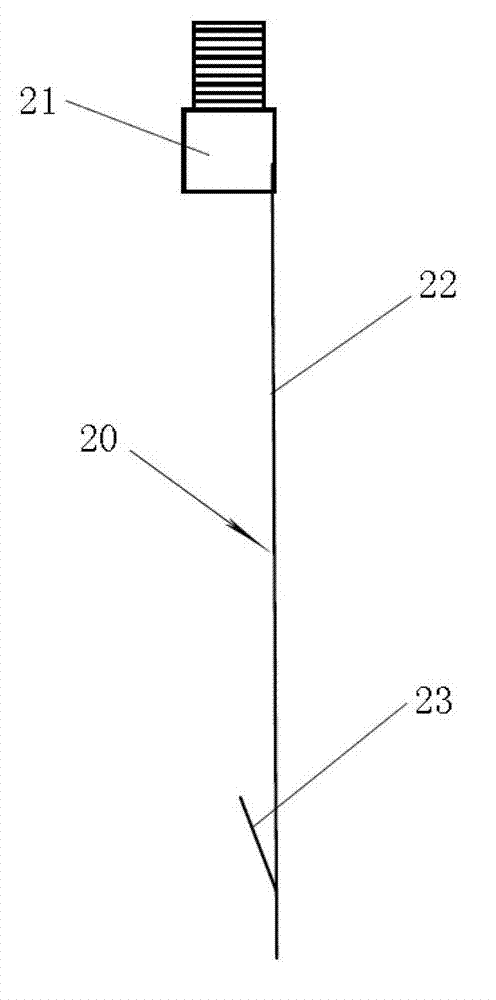

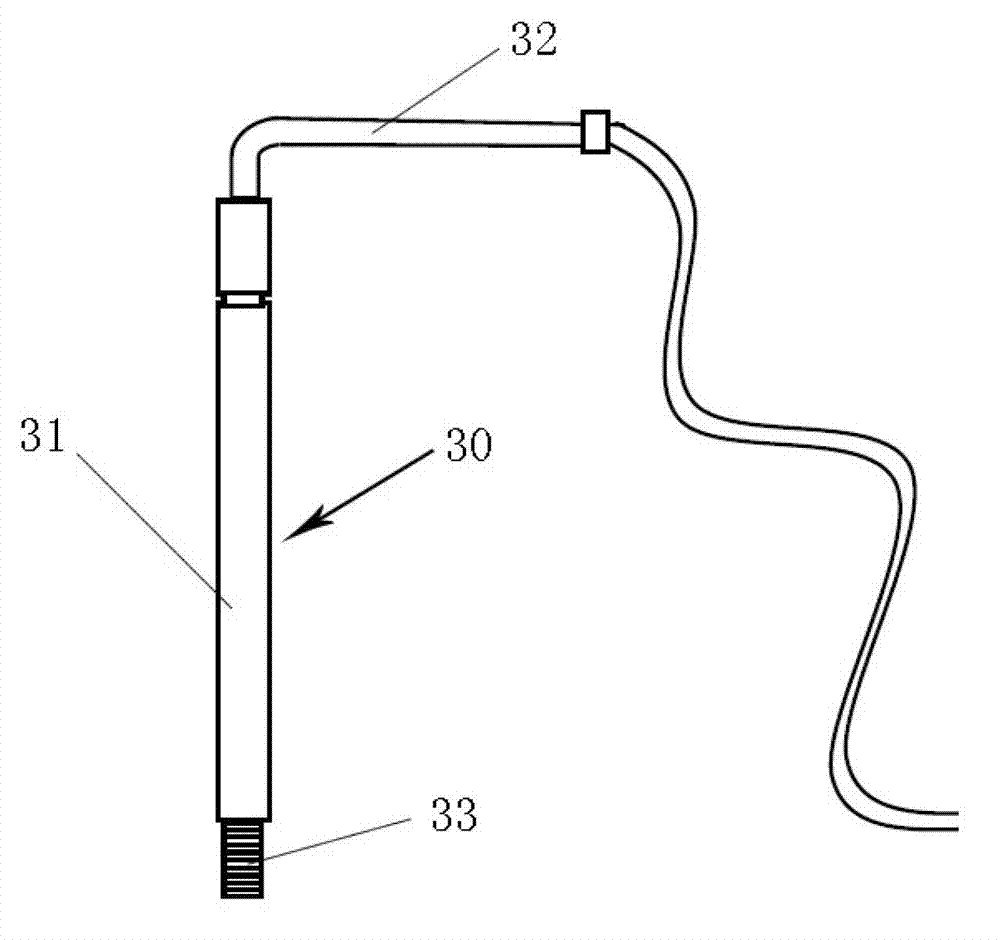

Deep hole blasting explosive cartridge

The invention discloses a deep hole blasting explosive cartridge. The deep hole blasting explosive cartridge comprises a front guide device, a powder charging device and a powder feeding device. The front guide device is a hollow taper end cap, the side wall of the taper end cap is symmetrically provided with two through holes, an oil wire rope penetrates through the through holes, and half of theoil wire rope is larger than the hole depth of a drill hole. The powder charging device comprises a hollow cylindrical powder charging cylinder, the taper end cap is connected to one end of the powder charging cylinder, the powder charging cylinder is provided with a laryard hole, the powder charging cylinder is internally provided with a plurality of stick dynamites and a detonating detonator, and a laryard of the detonator penetrates through the laryard hole and extends to the outer end of the drill hole. The powder feeding device comprises a tail end cap connected to the other end of the powder charging cylinder, and the other end of the tail end cap is provided with a groove or a protrusion matched with a powder feeding rod. According to the deep hole blasting explosive cartridge, powder charging is convenient and stable, powder can be precisely fed to a preset position, the success rate of explosion of loosening explosive powder is increased, the loosening blasting cost is reduced, and the deep hole blasting explosive cartridge is conveniently taken out when misfire detonation of the explosive powder occurs.

Owner:CHINA UNIV OF MINING & TECH

Composite dynamite for stainless compound steel plate and its preparation method

InactiveCN1994982AIncreased Explosive Bonding RateLow detonation velocityExplosivesNon-electric welding apparatusPearliteAmmonium nitrate

The invention discloses a composite explosive and making method of stainless steel composite steel board, which comprises the following parts: 95% ammonium nitrate, 4-6% composite oil and 3-10% water-increasing pearlite. The making method of composite explosive comprises the following steps: I, bulking 95% ammonium nitrate; II. adding ammonium nitrate in the 4-6% composite oil; IV. adding 3-10% water-increasing pearlite in the ammonium nitrate; V. stirring evenly; VI. drying.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

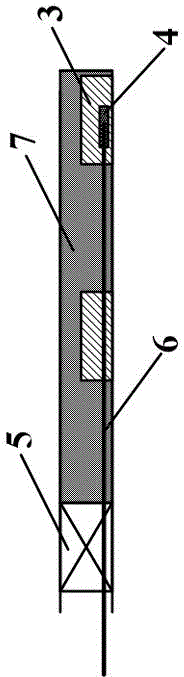

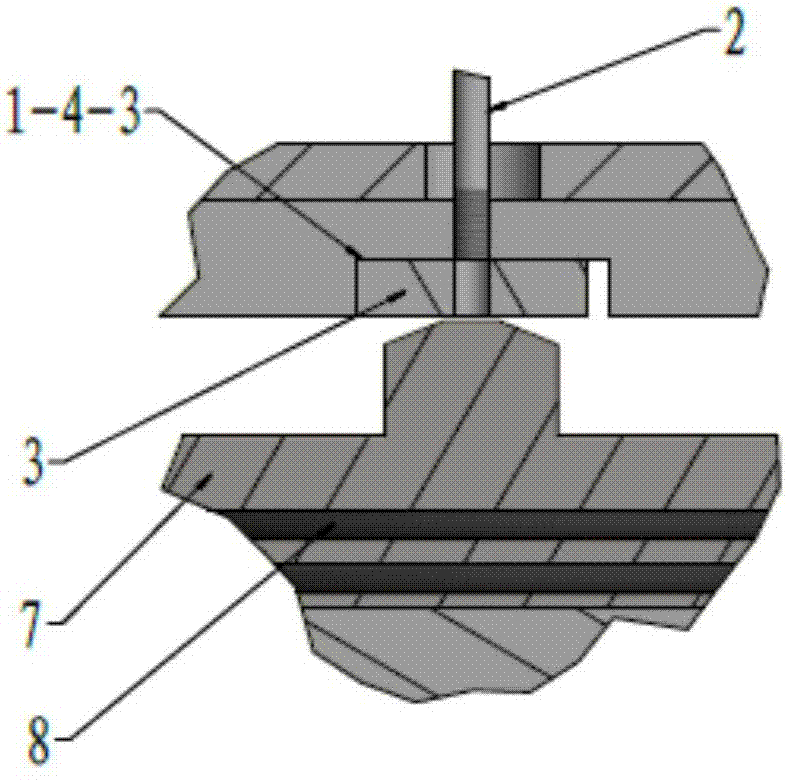

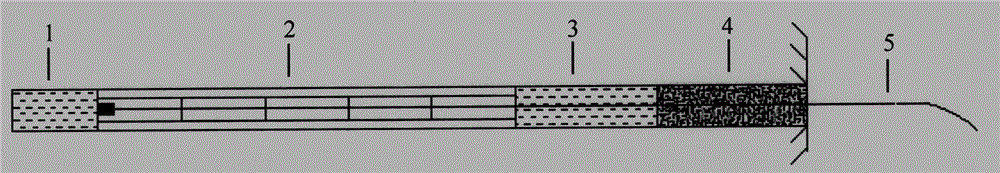

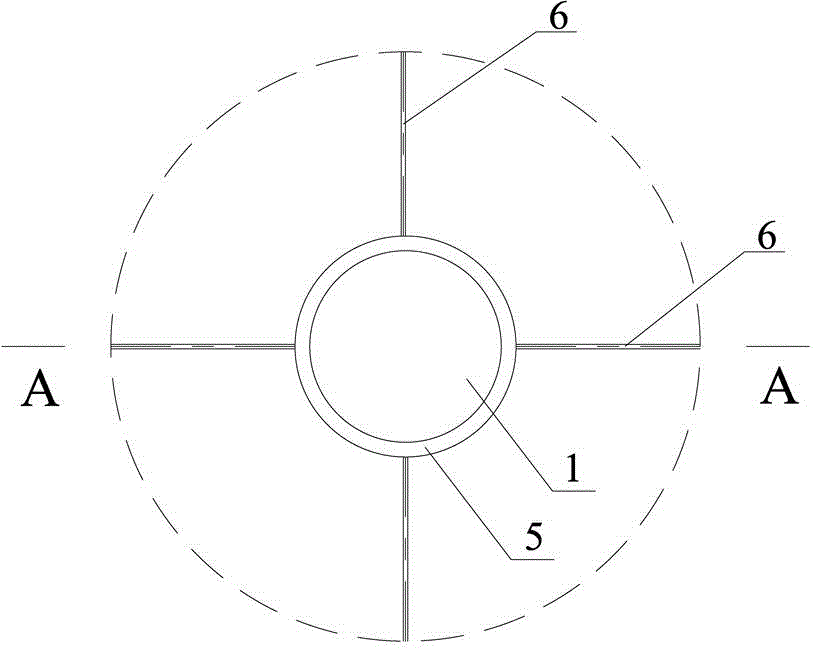

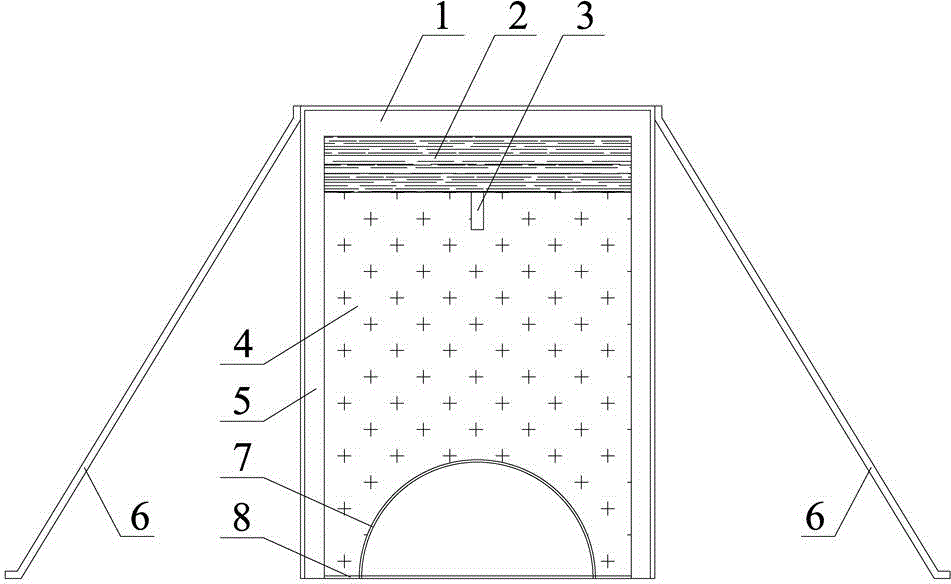

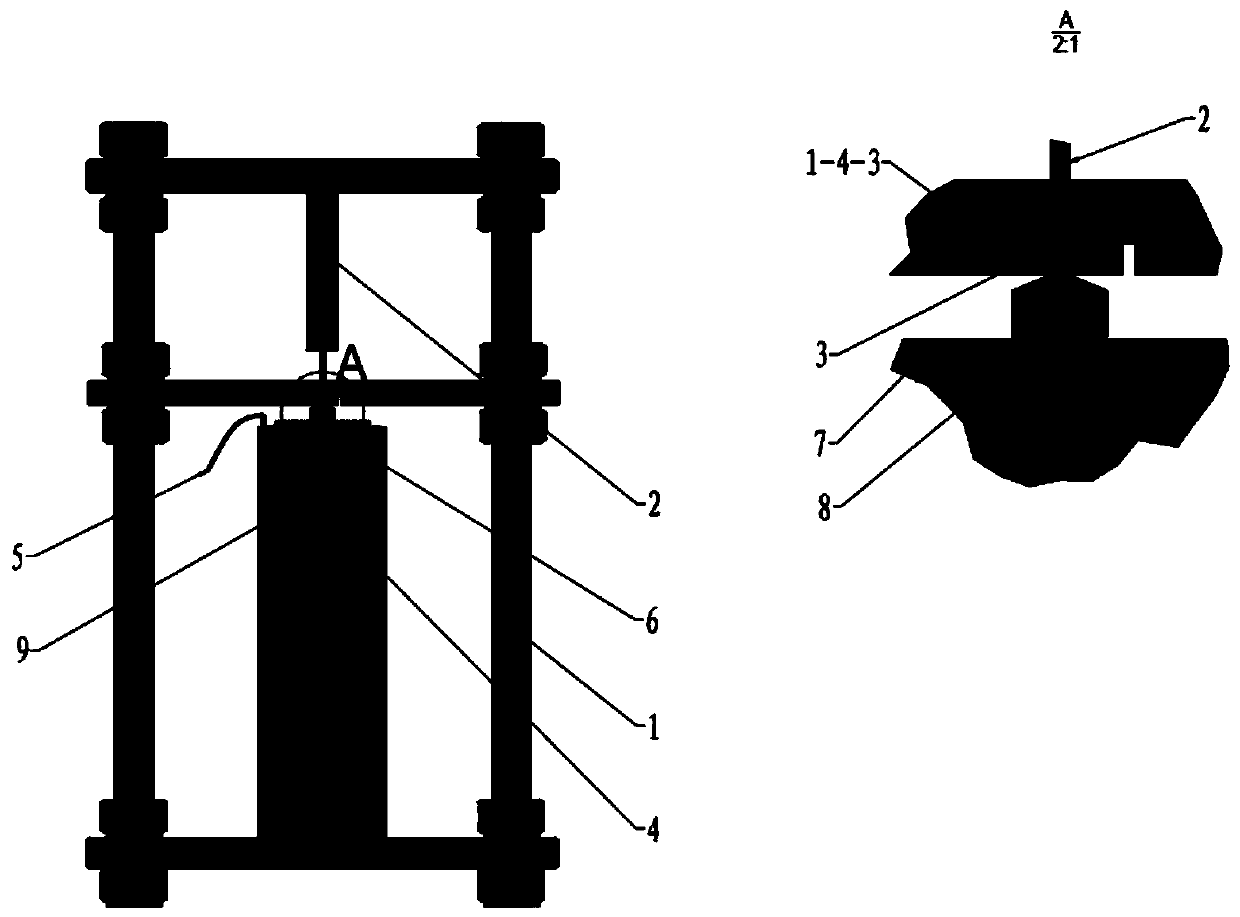

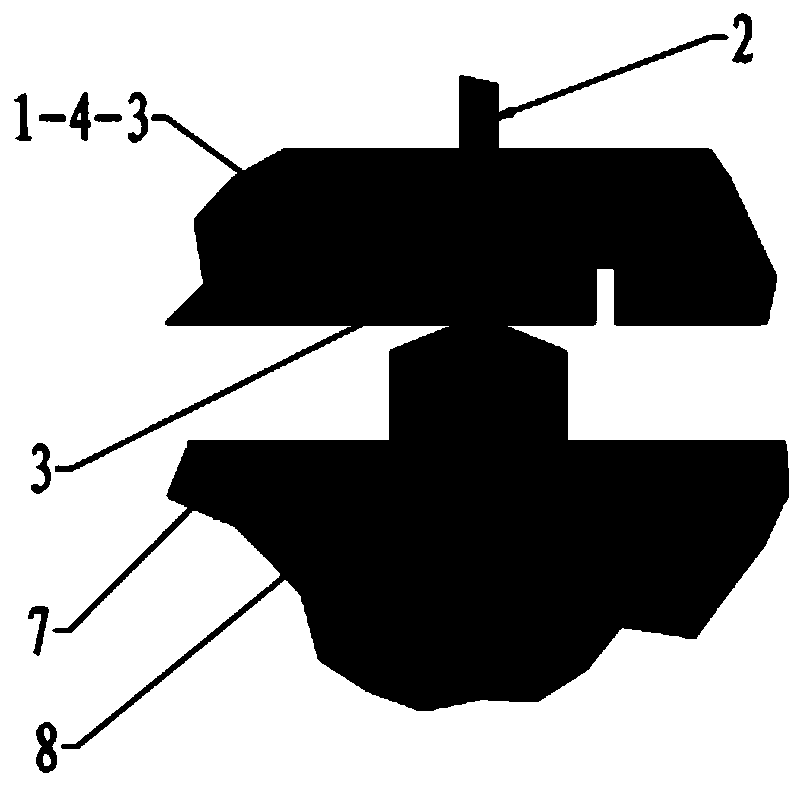

Testing device and method for gap distance of cylindrical dynamite under constraint conditions

PendingCN109668934AImprove accuracyMaterial exposibilityNuclear energy generationDynamiteEngineering

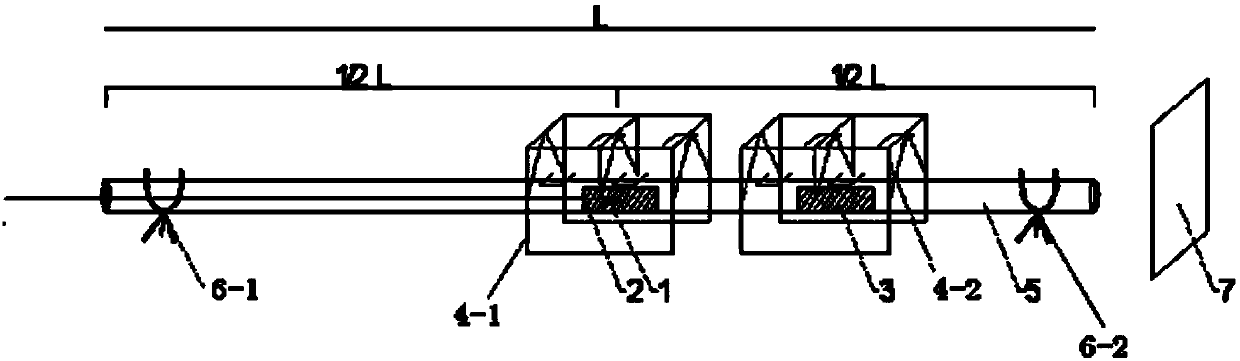

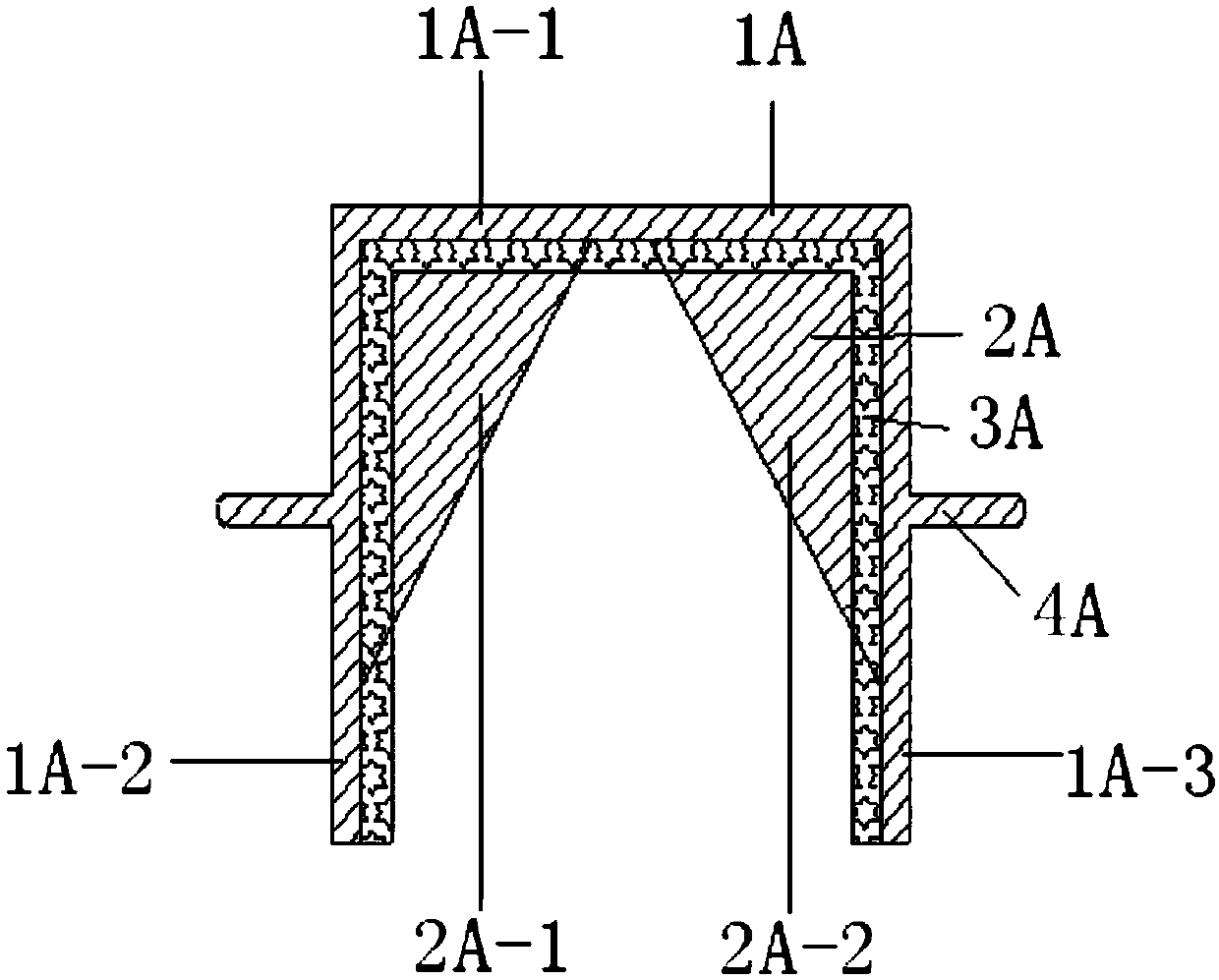

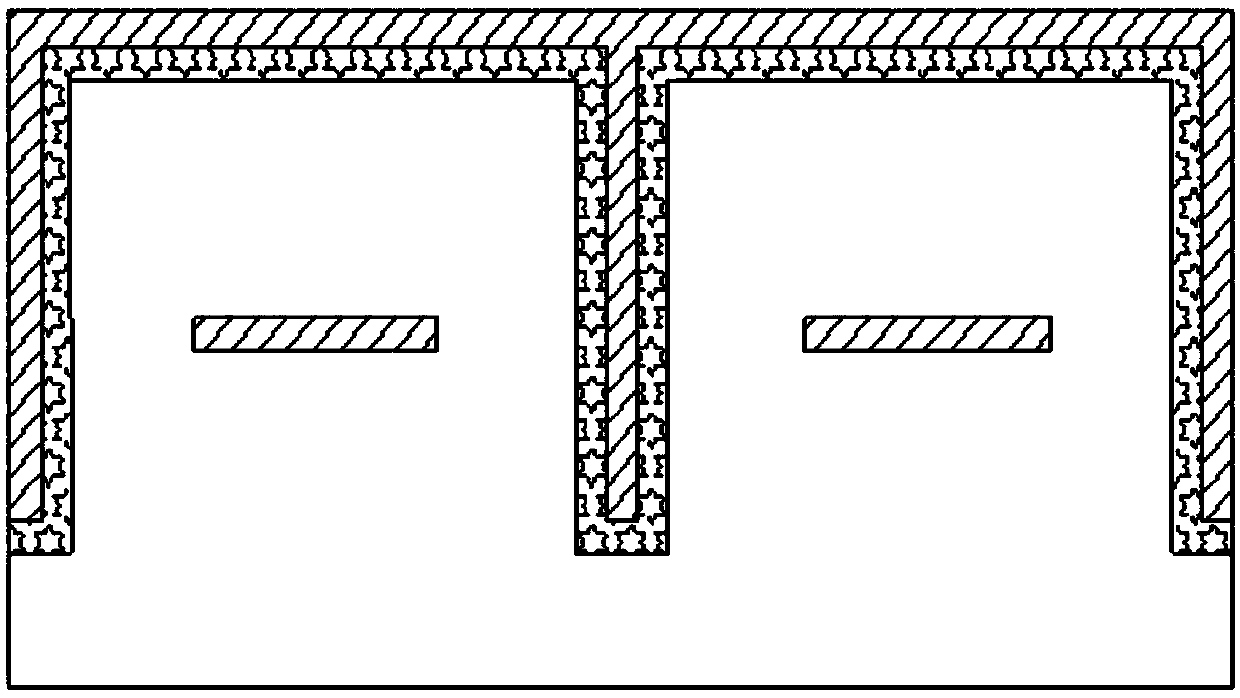

The invention provides a testing device and method for gap distance of cylindrical dynamite under constraint conditions. The testing device comprises a rigid constraint pipeline (5), a first rigid anti-splash protection cover (4-1), a second rigid anti-splash protection cover (4-2), a first rigid claw-shaped supporting frame (6-1), a second rigid claw-shaped supporting frame (6-2) and a rigid witness steel-plate (7), wherein a positive dynamite distributing bag (2) and a negative dynamite distributing bag (3) are respectively arranged inside the rigid constraint pipeline (5) at a certain space; the positive dynamite distributing bag (2) is positioned at the middle position inside the rigid constraint pipeline (5); and the negative dynamite distributing bag (3) is positioned on one side ofthe positive dynamite distributing bag (2). The testing device and method provided by the invention has the advantages that the testing method is a testing method which is convenient to implement andcan effectively simulate the gap distance of the cylindrical dynamite under blasthole constraint conditions, thus determining the gap distance of the cylindrical dynamite under the blasthole constraint conditions and improving the accuracy of gap distance tests.

Owner:中交一公局第五工程有限公司 +1

Colloid heat insulation protection structure as well as preparation method and application thereof

ActiveCN104457467AImprove temperature resistanceStable performance of thermal insulation structureBlastingInsulation layerDynamite

The invention discloses a colloid heat insulation protection structure applied to blasting in a high-temperature fire area. A colloid heat insulation layer is adopted at the external part of each of stick dynamite and initiating equipment, and the colloid heat insulation layers are fitted with each other uniformly; the external part of each colloid heat insulation layer is supported by a coupling fixing material; the colloid heat insulation layers are made of a composite high polymer material which is high in specific heat capacity, heat insulation and fire resistance and can resist temperature of 450 to 600 DEG C, and are in a gelatinization state. Due to the high specific heat capacity, temperature resistance, heat insulation and flame resistance of the colloid structure, the high temperature resistance and heat insulation performance of the whole explosive charging structure are improved, so that the initiating equipment and the stick dynamite are within the range of safe temperature within the blasting operation time; the use requirement specified by the safety standard of coal mine is met, and a certain scale of explosive can be blasted within safe time to meet the requirement of the blasting construction in high-temperature fire area in a mining area. Furthermore, the colloid material is simple in preparing procedure, convenient to produce in an industrial scale, low in cost, and sufficient in raw materials, so that the colloid heat insulation structure is low in total cost, and has an excellent market application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Unexploded dynamite processing tool and unexploded dynamite processing method

Owner:CHINA PETROLEUM & CHEM CORP +1

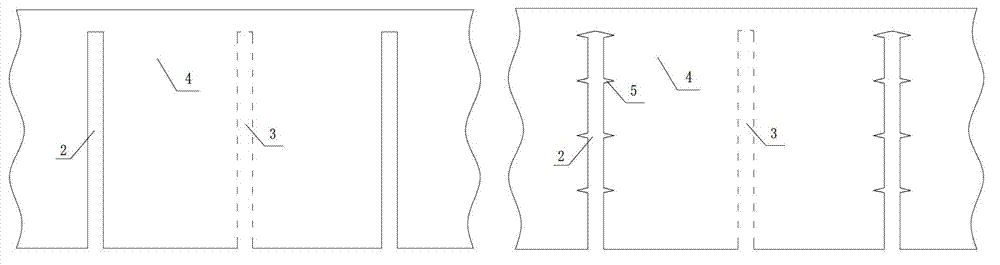

Drilling and blasting method tunnel assembly type blasting construction method

ActiveCN113432498ARealize intelligent blasting operationPrecise control of detonation timeMining devicesBlastingDetonationDynamite

The invention relates to a drilling and blasting method tunnel assembly type blasting construction method, and belongs to the field of tunnel drilling and blasting method construction. A single-hole dynamite container is prefabricated in advance according to the collected blast hole surrounding rock information, and the dynamite container is put quickly on site, so that charging convenience is realized. Slurry is packaged in charging pipes of the single-hole dynamite containers for peripheral holes, hydraulic fracturing blasting is achieved, and the blasting efficiency is improved. An unmanned mechanical arm is used for installing the single-hole dynamite containers, personnel participation is reduced, and the construction safety level is improved. The single-hole dynamite containers are provided with blasting control terminals, information interaction is carried out between remote blasting control equipment and the blasting control terminals, after all the single-hole dynamite containers are installed, position information is sent to locate the positions of blast holes, and the remote blasting control equipment carries out blast hole identification and detonation delay time design according to the position information of the blast holes and by means of a preset program, and intelligent blasting is achieved. The blasting control terminals are provided with clock units for overall timing, and when a communication signal is delayed, the blasting time is accurately controlled through the clock units.

Owner:CHONGQING VOCATIONAL INST OF ENG

Method for forming architectural materials by explosion

The invention discloses a method for forming a building material in a mode of dynamite explosive blast, which comprises the following steps: digging out a passage (2) and a bin (3) for placing dynamites and materials in a stratum (1), and pouring quantitative amount of a material (4) in the bin (3); placing an explosive cartridge (5) at a position which can contact the material (4); backfilling blockages (6) and fixing a mould (8) in the passage (2); and detonating the explosive cartridge (5) to obtain a material (7) generated under the action of explosive blast. The material (4) is either a hydrous fluid or gel state material or an unhydrous single substance particle or a mixture of a few types of substances. The method uses the stratum as a restraint body for restricting the range of the explosion reaction, thereby having greater flexibility and plastic deformation capacity, safe operation and low cost.

Owner:SHANDONG UNIV OF SCI & TECH

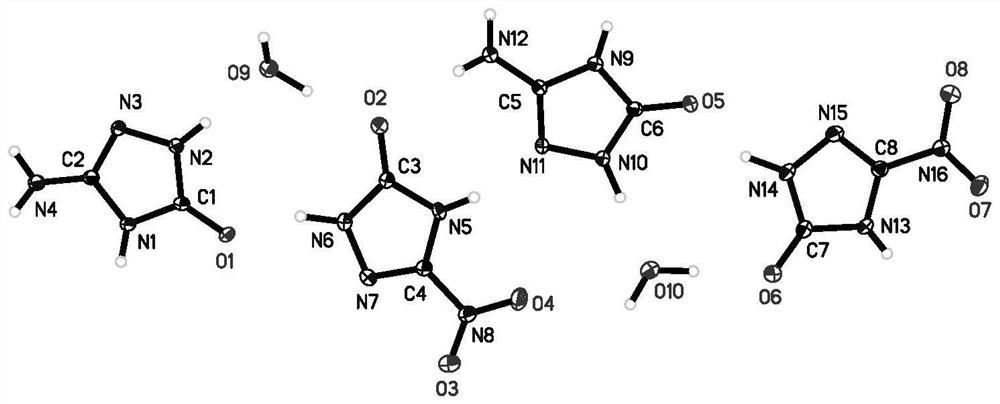

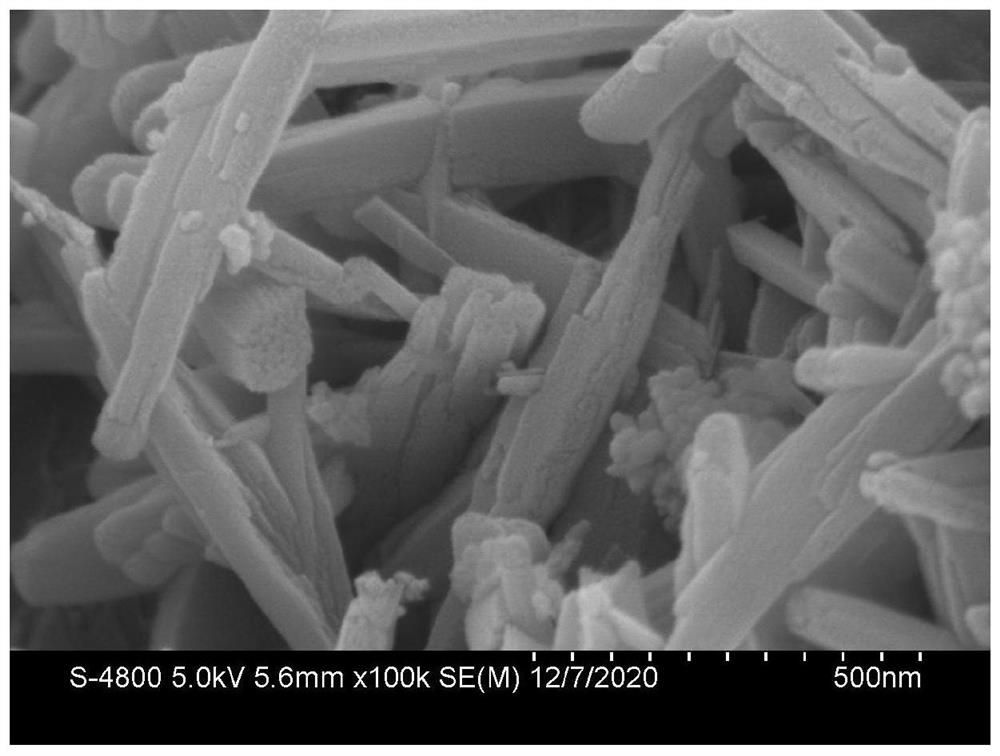

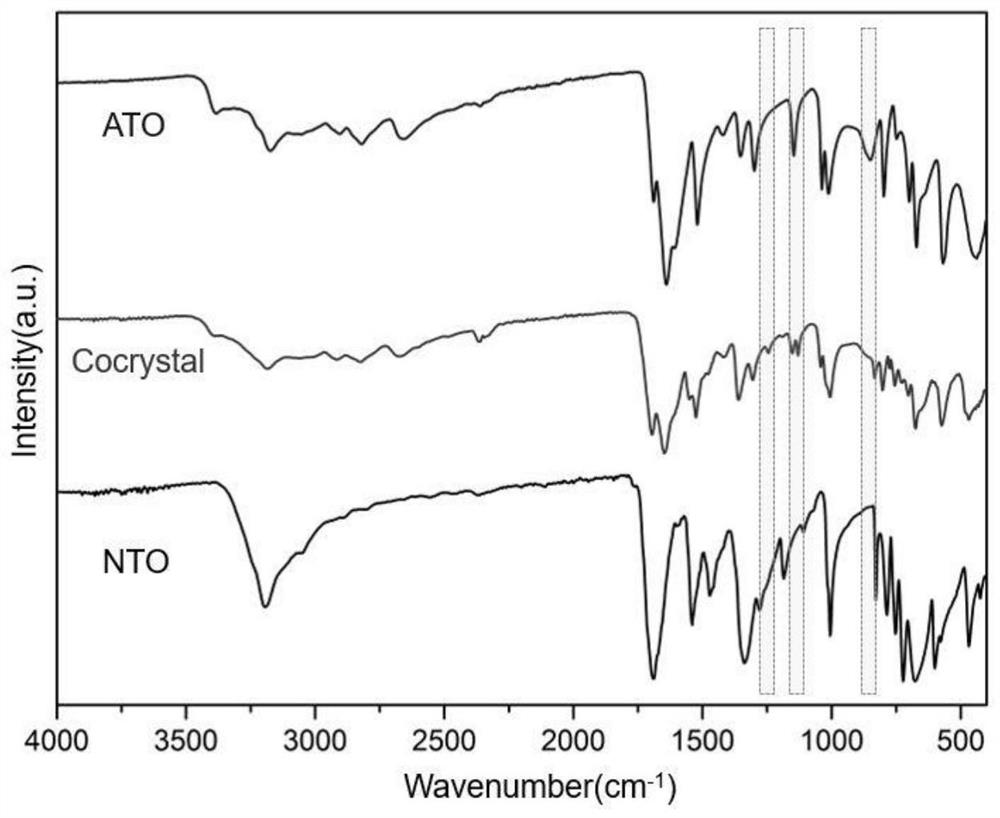

A kind of nto and ato eutectic explosive and preparation method thereof

ActiveCN113121294BIncrease acidityLow mechanical sensitivityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingDynamiteExplosive Agents

The invention relates to an NTO / ATO eutectic explosive and a preparation method thereof, belonging to the field of energetic materials. The present invention uses 3-nitro-1,2,4-triazole-5-ketone (NTO) and 5-amino-1,2,4-triazole-3-ketone (ATO) as raw materials, and adopts solvent evaporation method to prepare NTO / ATO eutectic explosives. The method comprises the following steps: at room temperature, NTO and ATO are dissolved in a solvent with a pH value of 2 to 3, after being fully mixed, they are left to stand in a constant temperature environment to slowly volatilize and crystallize, and the NTO / ATO eutectic is obtained by filtering and drying explosives. The NTO / ATO eutectic explosive prepared by the invention has a pKa of 8.72, and its acidity is much lower than that of NTO, which effectively improves the acidity problem of NTO. At the same time, NTO / ATO eutectic explosives have good safety. The preparation method of the invention is simple, the conditions are mild, and the production cost is low. As a high-energy and low-sensitivity explosive, the eutectic explosive has good application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Underwater energy-gathered blasting device and blasting method

Owner:POWERCHINA HUADONG ENG COPORATION LTD

A hydraulic composite rapid plugging method for drilling and blasting

The invention discloses a water pressure composite quick blocking method applied in drilling and blasting. The quick blocking comprises a water bag, a dynamite roll, a water bag and a high-molecular resin sealing bag. the water bag of the first segment is placed at the bottom of a hole opening; the dynamite roll of the second segment is closely connected with the water bag in series; the water bag of the third segment is placed behind the dynamite roll of the second segment; the high-molecular resin material of the fourth segment is placed in a drilling after kneading, squeezing and foaming; the high-molecular resin material flows out as liquid and penetrates into the space among the dynamite, the water bags and socks; quick solidification is performed and blast holes are blocked. the viscosity of the high-molecular resin material with rocks is larger than that of traditional stemming. the impact wave produced by the explosion of the dynamite is directly applied on rocks through the water bag installed at the bottom of the blast hole and therefore the explosive energy consumption is reduced and blast hole utilization is increased. The water bags in the blast hole generates water atomization effect during explosion which can reduce air impact wave, absorb explosive dust and dilute poisonous gases.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

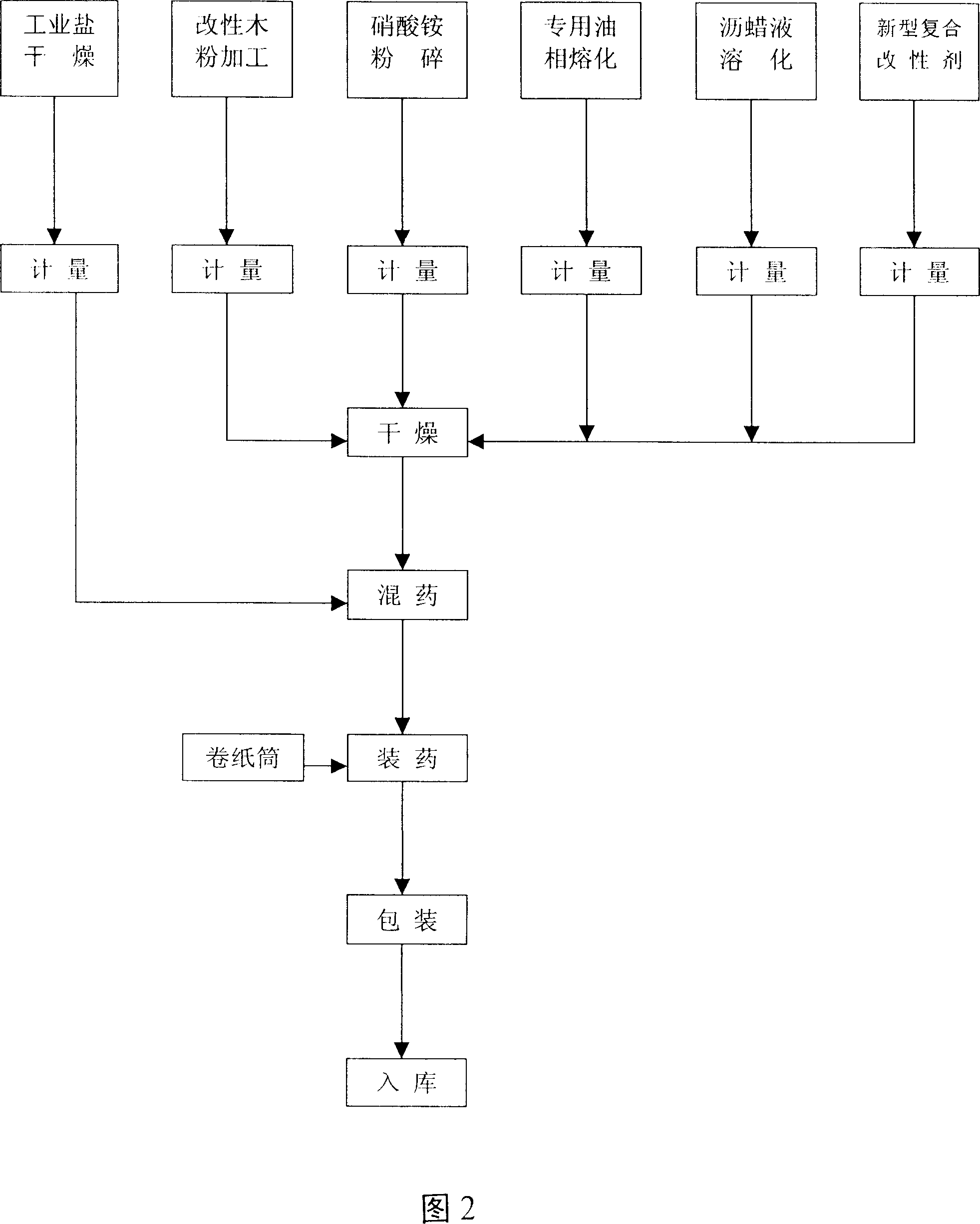

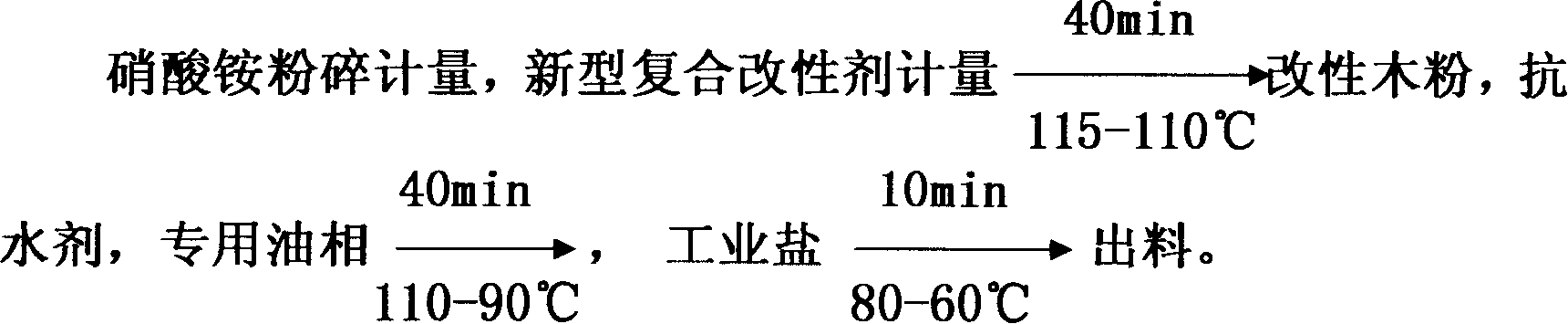

Powdery modified ammonium nitrate fuel oil for coal mine

InactiveCN100450980CLess one-time investmentImprove the intrinsic safety of productionExplosive working-up apparatusProduction lineDynamite

The invention disclosed a kind of powdered reshaped ammonio oil dynamite which is allowed to be used in coal mines. The dynamite is mainly constituted by 68.6-80 part (by weight) of ammonium nitrate, 4-6 parts (by weight) of reshaped wood powder, 1.6-3 parts of compound oil phase, 14-21 parts of industrial salt, 0.3-0.5 part of modifier and 0-1.0 part of water repellent agent. The invention can use the present producing devices to produce the dynamite in one stage or two stages which decreases the one time cost of the producing line substantially. The TNT element is totally omitted in the invention through the regulated formula and producing technologies as well as the new materials. The quality of the product has achieved or surpassed the technological standard of dynamites which is allowed to be used for coal mines in GB12437-2000. It has solved all the problems in many factories that produce the coal mine dynamites by edge-runner; besides, it is in line with the policies and requests in civilian exploding industry.

Owner:盛世平

Heat-resistant insulation sheath

ActiveCN104006709BLow thermal conductivitySafe blasting operationsThermal insulationBlastingDynamiteInsulation layer

The invention discloses a temperature-resistance thermal insulation protecting bush which is used for charge blasting in a high-temperature blast hole and comprises a cylinder body with a cavity. The cylinder body is formed by stacking a fireproof layer, an insulation layer and a waterproof layer from exterior to interior in a composite mode, the cavity of the cylinder body is filled with a stick dynamite in a non-coupling mode, the gap between the inner wall of the cylinder and the stick dynamite is filled with high heat capacity liquid, the cylinder body is formed by stacking the fireproof layer, the insulation layer and the waterproof layer in the composite mode, each layer is made of heat insulation flame retardant materials, the heat conductivity coefficient is small, in the process that external heat energy is transmitted to the interior of the cylinder body, and the heat is gradually and greatly attenuated. Meanwhile, the high heat capacity liquid serving as energy consumed liquid is contained, the high specific heat capacity characteristics of the liquid are utilized for achieving energy conversion, a large amount of heat is absorbed, it is ensured that the temperature of the stick dynamite in the cylinder body is within the suitable range, under the heat insulation action of the cylinder and the heat absorption action of the high thermal capacity liquid, even though the temperature of the blast hole is high, blasting work can be safely performed, the bush is not limited by construction conditions, and operation is convenient and rapid.

Owner:HONGDA MINING IND

Device and method for measuring thermal expansion coefficient of high-energy explosive charge

ActiveCN107389725BAccurate acquisitionEfficient acquisitionMaterial thermal coefficient of expansionAll solid stateDynamite

The invention discloses a high-energy dynamite charging thermal expansivity measuring device and method. The problem that an existing test device fails to measure solid state dynamite charging thermal expansion characteristic parameters is solved. According to the basic principle of the device and method, a heating jacket is used for heating dynamite charging to a certain temperature, a thermocouple is used for measuring a dynamite temperature in real time, spring steel with a known deformation coefficient is used for measuring pressure generated when the dynamite charging is heated and expanded, meanwhile, deformation of the spring steel is used for pushing a displacement sensor located above to obtain displacement data, and thus, a three-dimensional relational graph of the temperature, the expansibility and the expansion size of the dynamite charging is established. The device and method provided by the invention have the advantages of high universality, high accuracy and low cost, the requirements for measuring expansion parameters of liquid explosives, slurry explosives and all-solid-state explosives can be met simultaneously, and a more comprehensive data support is provided for middle-large sized ammunition charging designs.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com