Patents

Literature

326 results about "Rock pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rock Pressure. the pressure on the liquid (petroleum, water) and gas that saturate the pore space or cracks of reservoirs in oil and gas fields. Rock pressure is an important parameter characterizing the energy of oil-, gas-, and water-bearing beds.

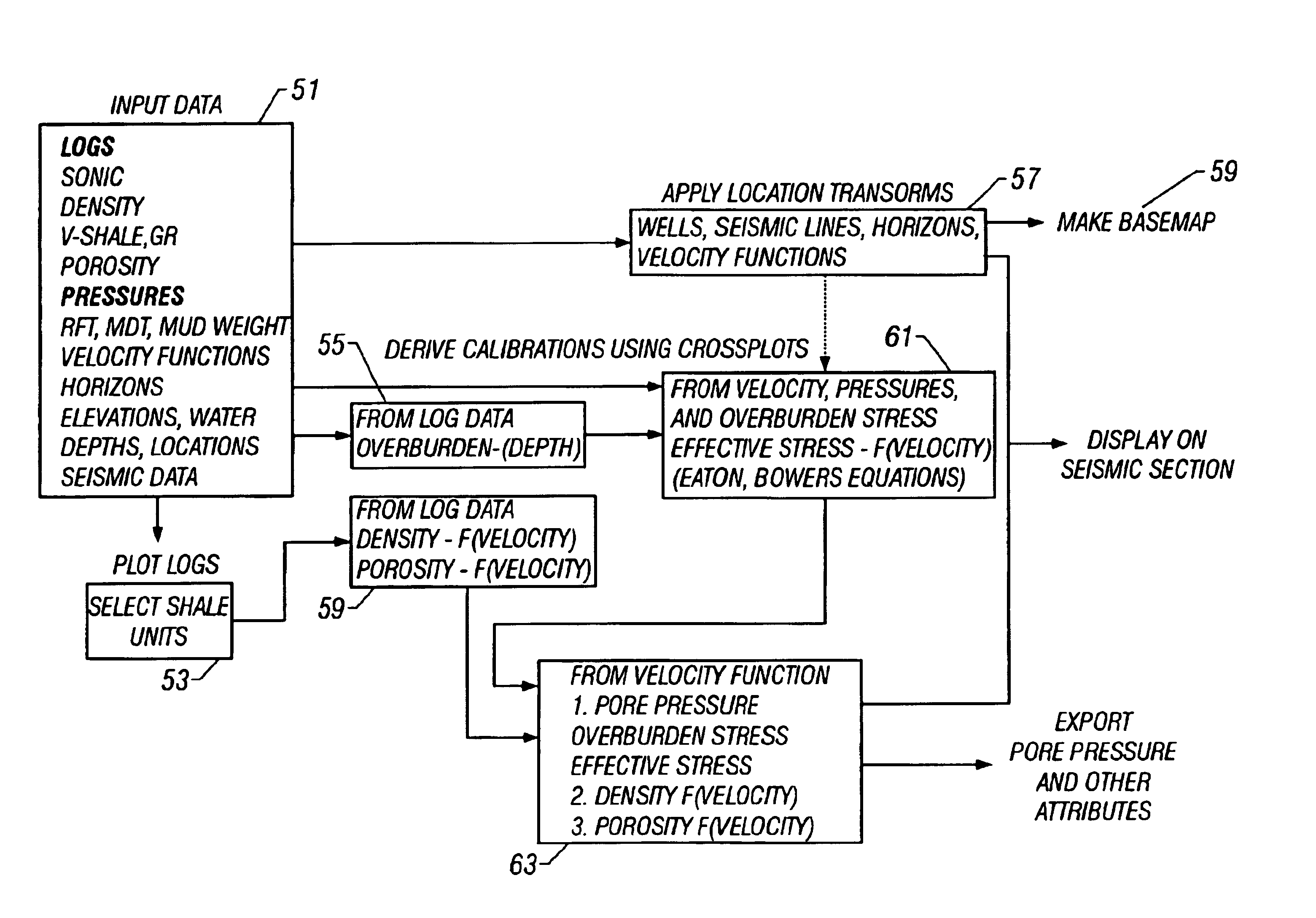

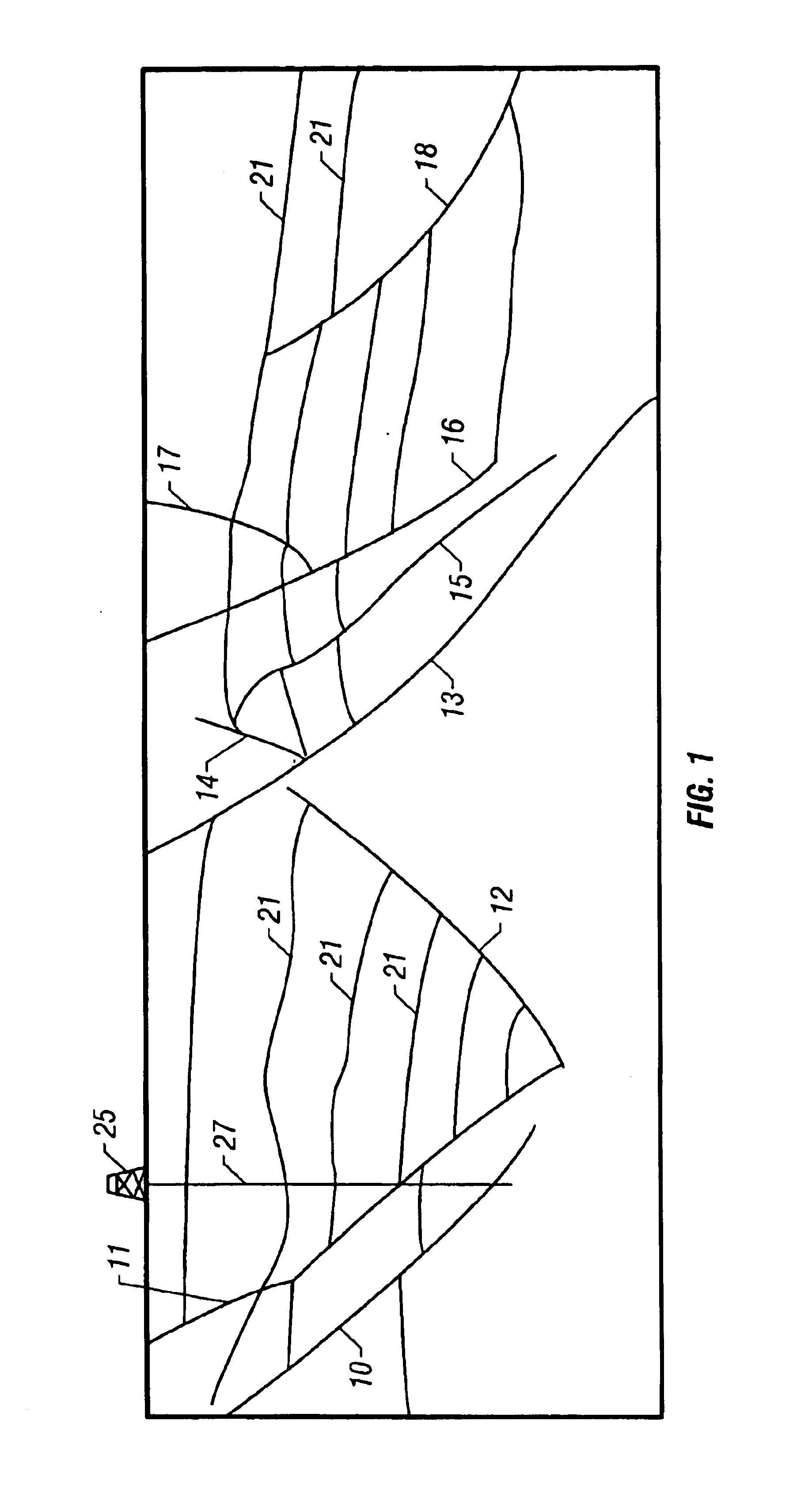

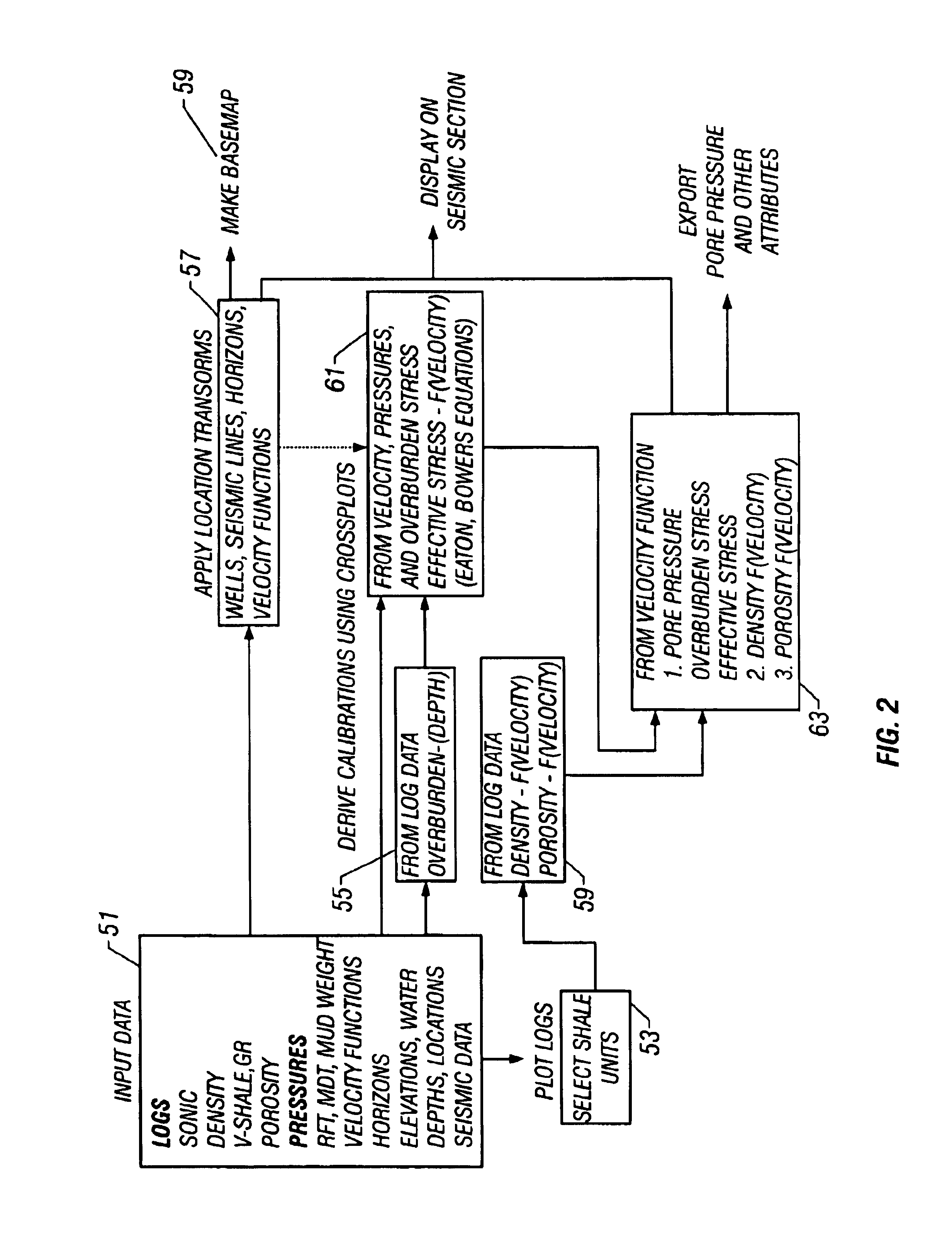

Method and process for prediction of subsurface fluid and rock pressures in the earth

A method of determination of fluid pressures in a subsurface region of the earth uses seismic velocities and calibrations relating the seismic velocities to the effective stress on the subsurface sediments. The seismic velocities may be keyed to defined seismic horizons and may be obtained from many methods, including velocity spectra, post-stack inversion, pre-stack inversion, VSP or tomography. Overburden stresses may be obtained from density logs, relations between density and velocity, or from inversion of potential fields data. The seismic data may be P-P, P-S, or S-S data. The calibrations may be predetermined or may be derived from well information including well logs and well pressure measurements. The calibrations may also include the effect of unloading. The determined pressures may be used in the analysis of fluid flow in reservoirs, basin and prospect modeling and in fault integrity analysis.

Owner:CONOCOPHILLIPS CO

Method for controlling large deformation by releasing pressure of high-stress roadway surrounding rocks

ActiveCN104763432AEffective control of deformationControl deformationMining devicesTunnelsDeformation monitoringHigh stress

Owner:徐州天骋智能科技有限公司

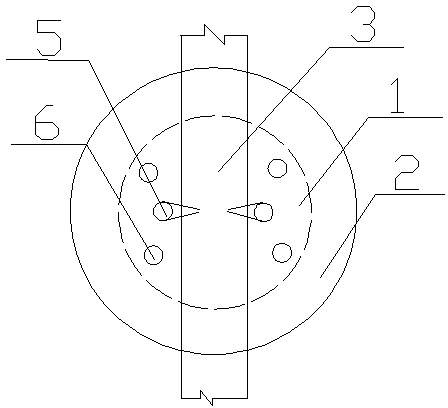

Method and device for synchronously measuring rock sound wave and acoustic emission

ActiveCN103954690ASimple methodSimple and fast operationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesData acquisitionTest fixture

The invention discloses a method and a device for synchronously measuring rock sound wave and acoustic emission. The method comprises the following steps: A, putting sealing pressing ends for transmitting and receiving a sound wave signal at two ends of a rock sample, and keeping a longitudinal wave probe and a transverse wave probe inside the sealing pressing ends identical in the vertical direction; B, arranging and fixing an acoustic emission receiving probe outside the rock test sample; C, starting a sound wave and acoustic emission testing system, and starting a rock pressure machine for a loading experiment till the rock sample is damaged; D, performing aftertreatment on acquired data to obtain the number and the position and the ultrasonic speed change information of acoustic emission events of the rock; and E, respectively connecting a sound wave testing device and an acoustic emission testing device with experiment pressure machine base adapters, and connecting with a data acquisition and processing system through corresponding adapters. The method is feasible and simple and convenient to operate, synchronous acquisition of sound wave and acoustic emission information in rock mechanics tests is achieved, and positioning of a rock acoustic emission position is achieved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

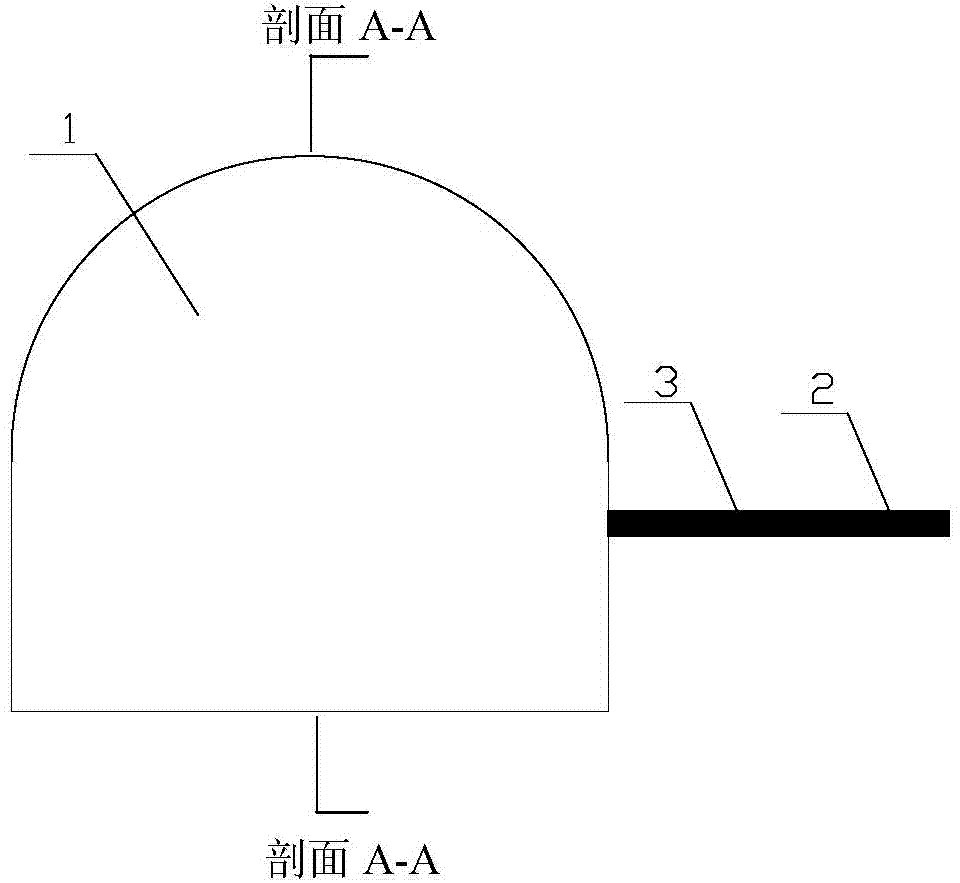

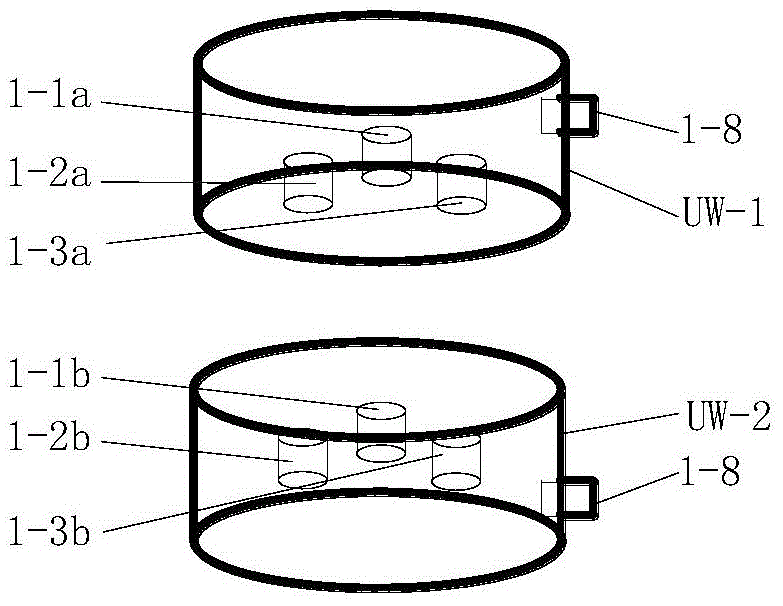

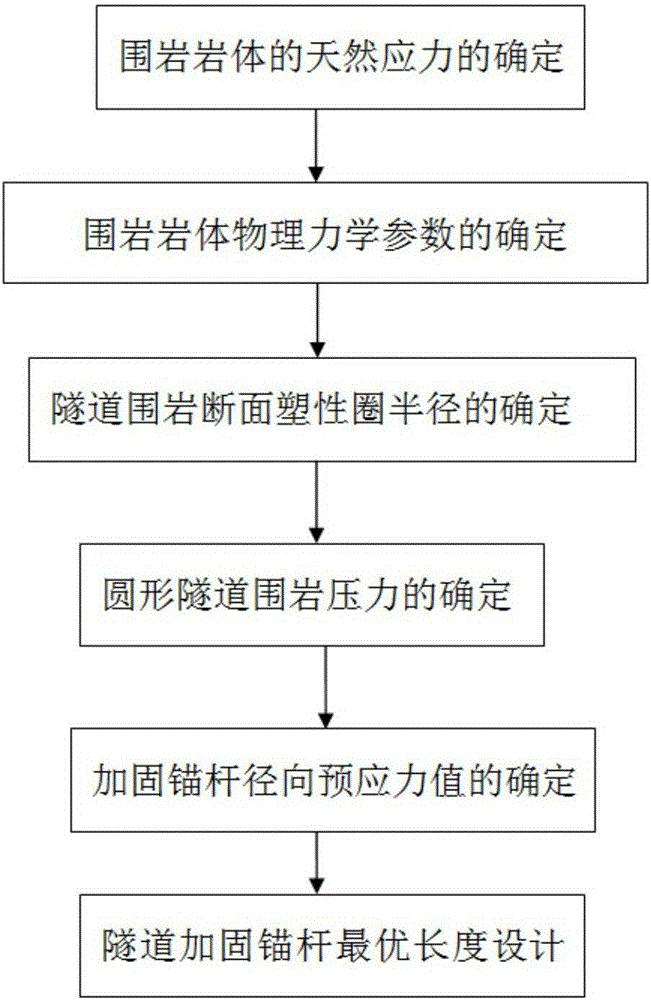

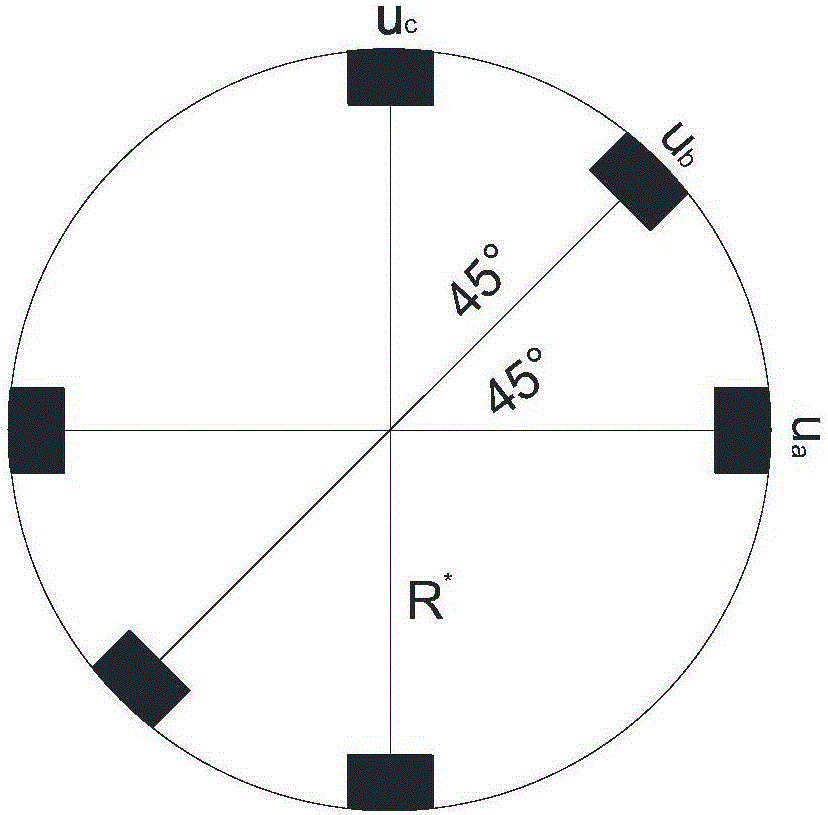

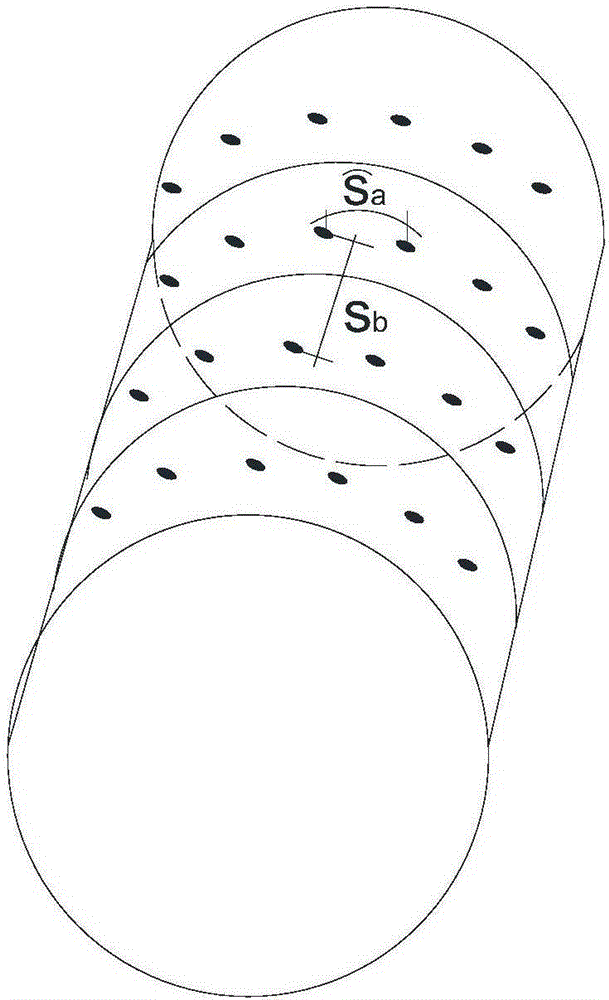

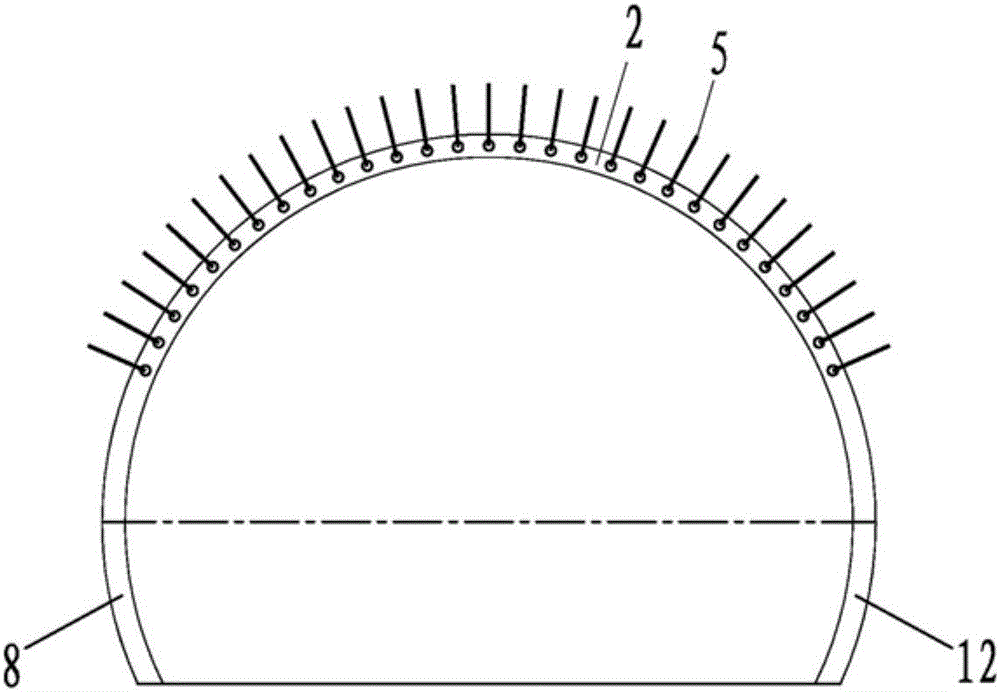

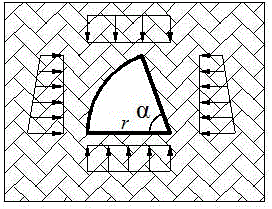

Determination method of tunnel surrounding rock prestressing force reinforcing anchor rod length and radial prestressing force values

The invention discloses a determination method of tunnel surrounding rock prestressing force reinforcing anchor rod length and radial prestressing force values. According to the surrounding rock elastic-plastic theory and the plastic zone distribution regulation, and, on the basis that a tunnel plastic ring radius R and a surrounding rock pressure force are comprehensively determined, the minimum length value and a radial minimum prestressing force value of a tunnel surrounding rock reinforcing anchor rod are determined. The determination method advantageous in that, according to the surrounding rock elastic-plastic theory and the plastic zone distribution regulation, and, on the basis that the tunnel plastic ring radius R and the surrounding rock pressure force are comprehensively determined, the minimum length value and the radial minimum prestressing force value of the tunnel surrounding rock reinforcing anchor rod are determined, the calculation process is relative clear and concise, and a measured result is high in accuracy and accurate, has a small error compared with the actual and can guide the practice well.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

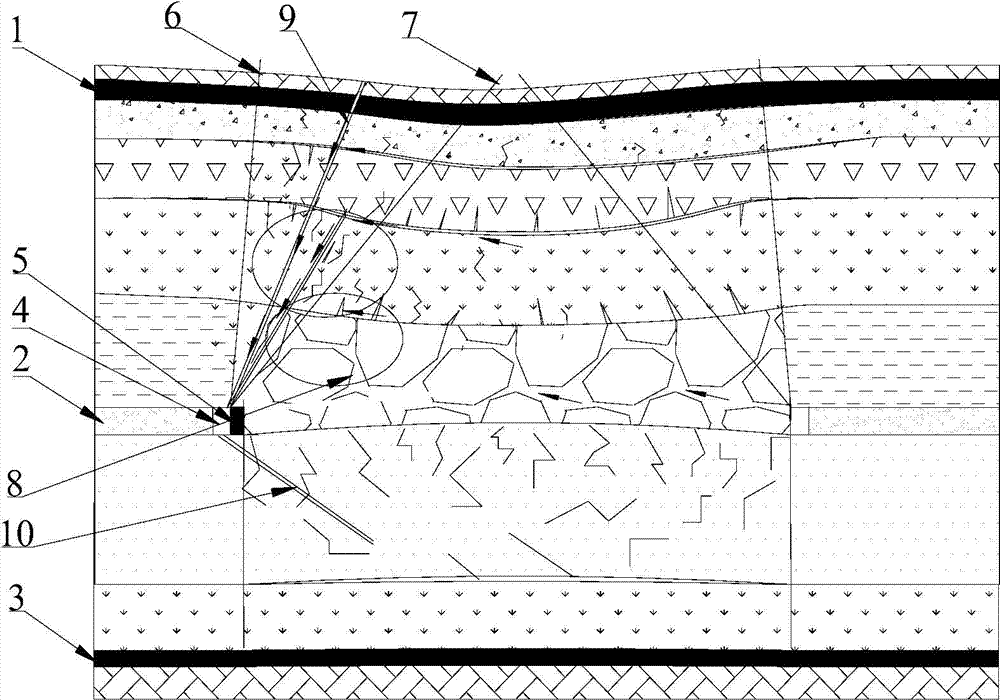

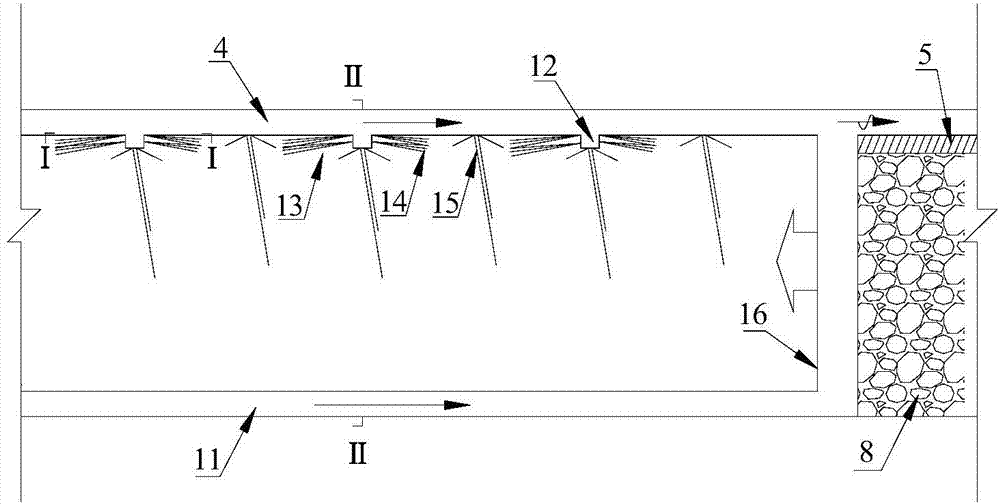

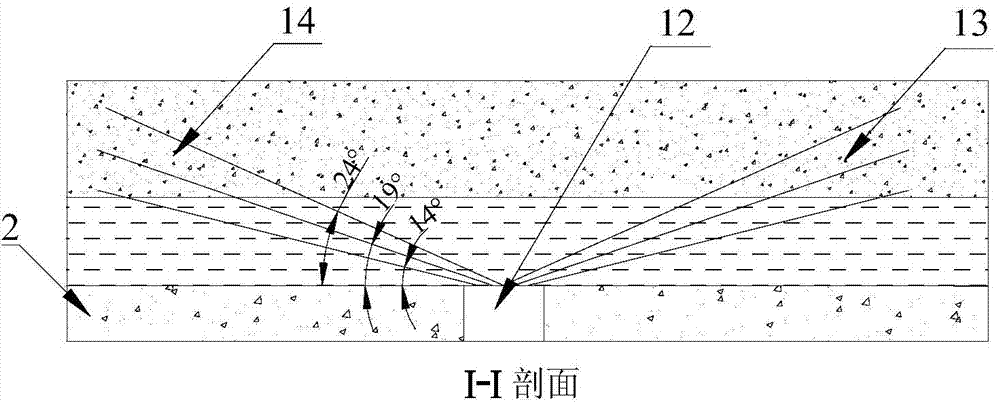

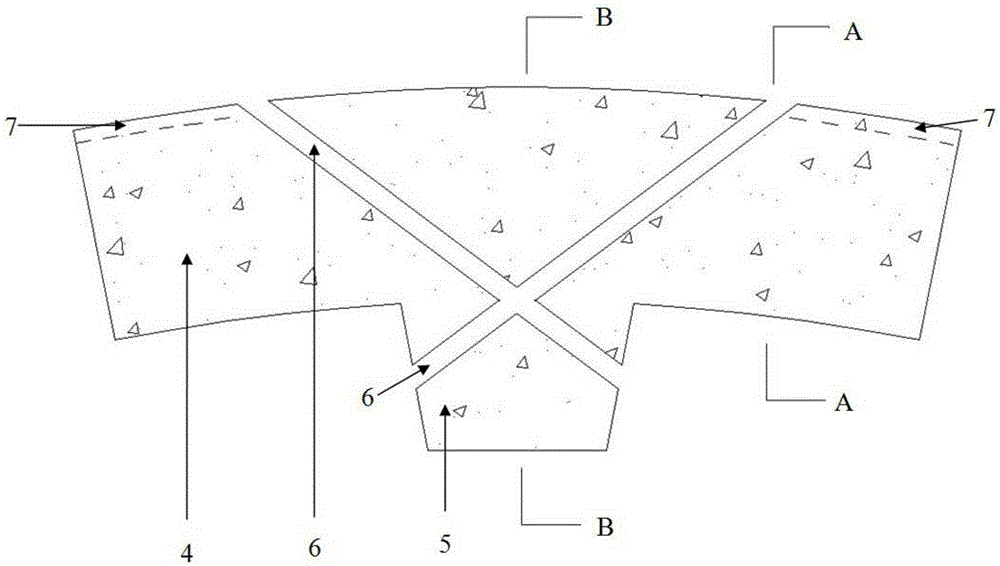

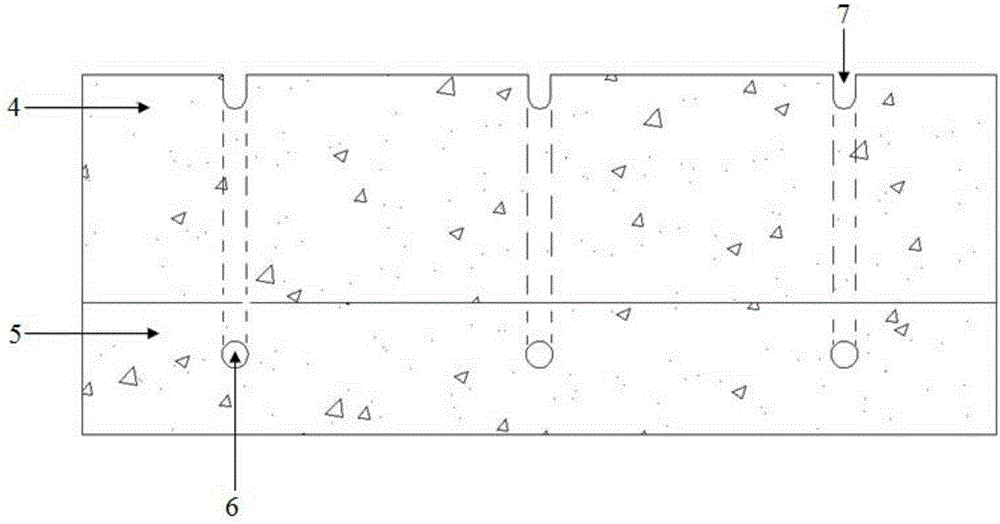

Coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of working face of first mining total rock pressure relief

InactiveCN104712358ALayer selection is flexibleSolve the outstanding problem of safe miningFluid removalGas removalLithologyPlate pressure

The invention discloses a coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of a working face of first mining total rock pressure relief. When a first mining pressure relief coal seam can not be selected, the coal and rock seams are moved and broken through the working face of first mining total rock pressure relief, an upper covered coal seam with high gas and a lower covered coal seam which high gas are subjected to pressure relief and swollen, fractures of a surrounding rock mass are developed, the gas permeability is increased, the gas is subjected to desorption and transportation, and finally a top plate pressure relief annular fracture area and a bottom plate pressure relief annular fracture area are generated. To create a favorable stress environment of retained roadway surrounding rock, retained roadway mining empty side cantilever crest truncation is conducted to first advance mining drill site toward and backward the working face in a bi-directional mode, according to the top plate lithologic characters, the first advance is subjected to top plate deep hole pre-splitting and cover caving so that it is guaranteed that the top plate is sufficiently collapsed to fill a worked out section. By means of the method, the prominent problems of exhausting and mining of coal seam group pressure relief gas and safe mining when the first mining pressure relief coal seam of the coal seam group with high gas content is difficult to select are solved.

Owner:CHINA UNIV OF MINING & TECH

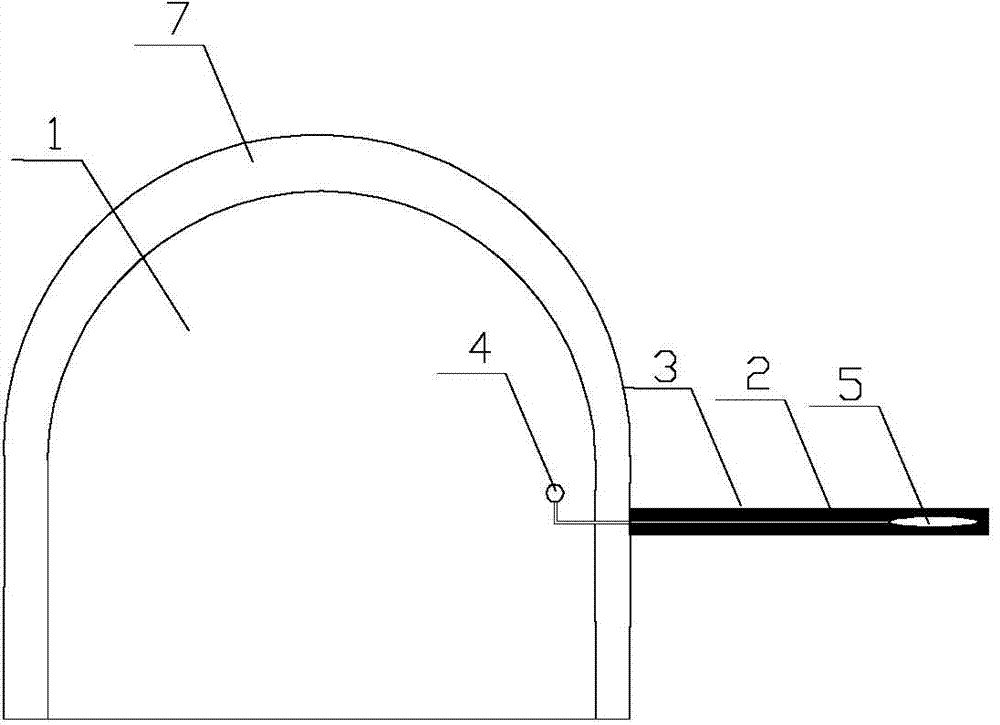

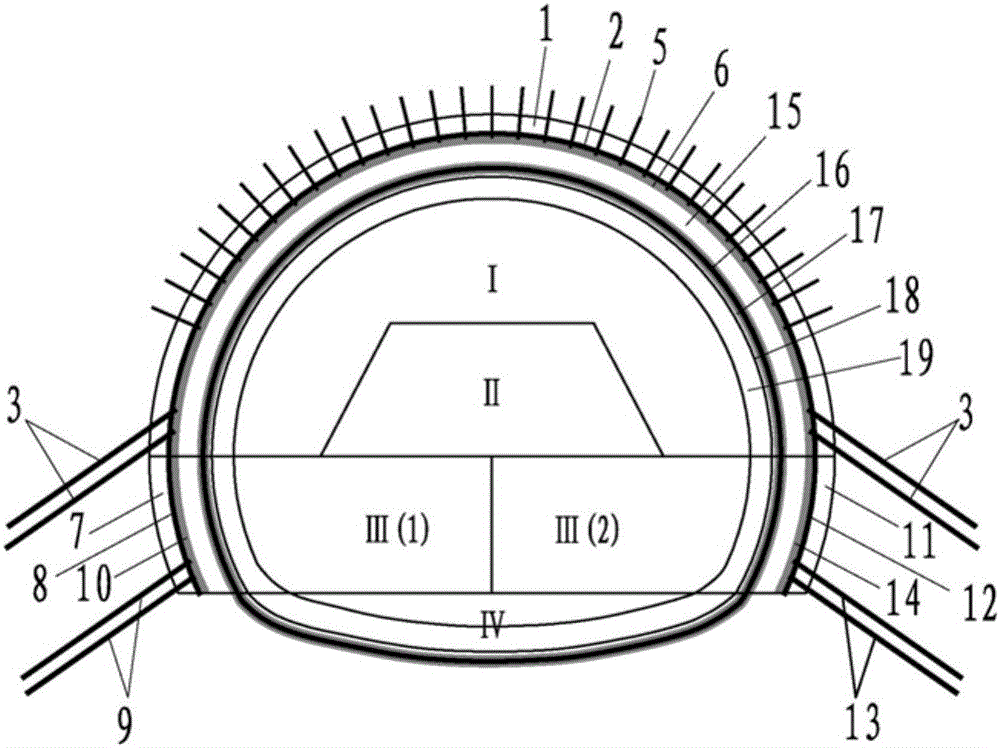

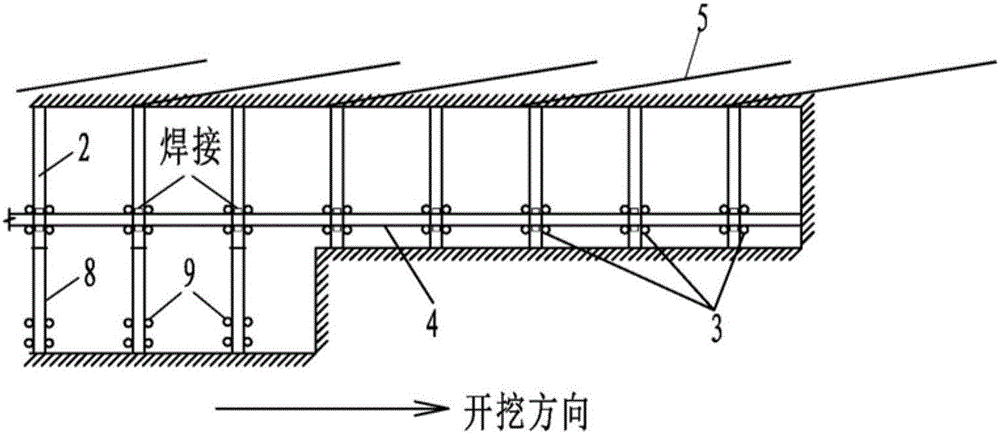

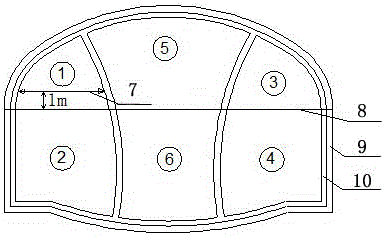

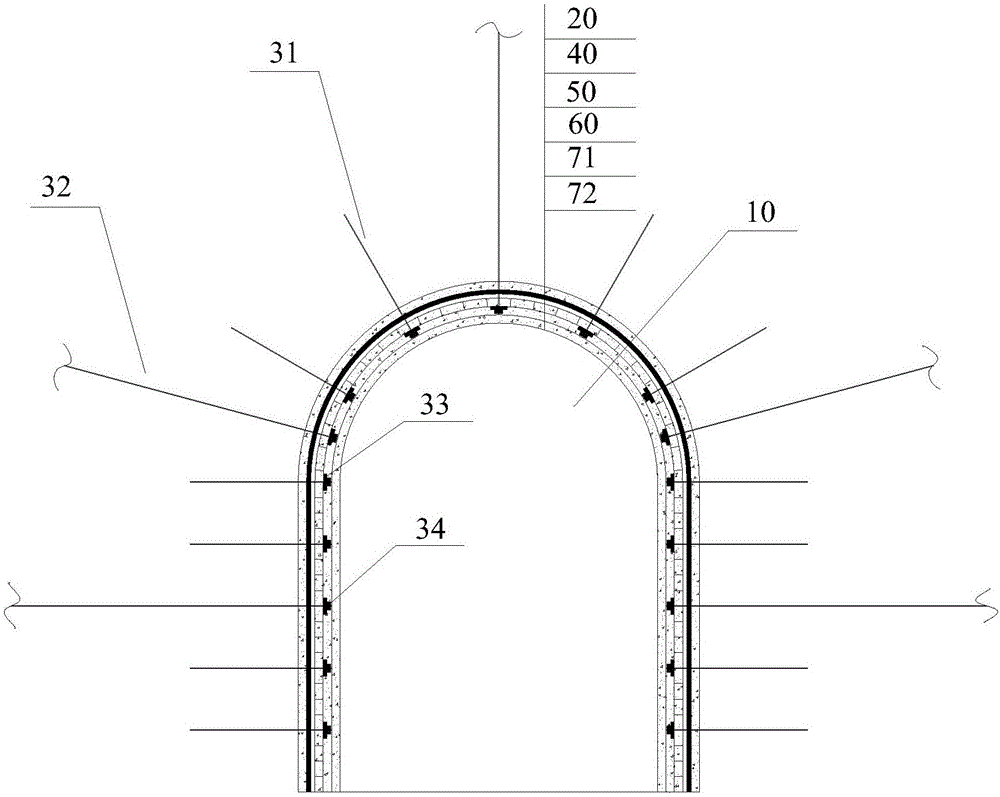

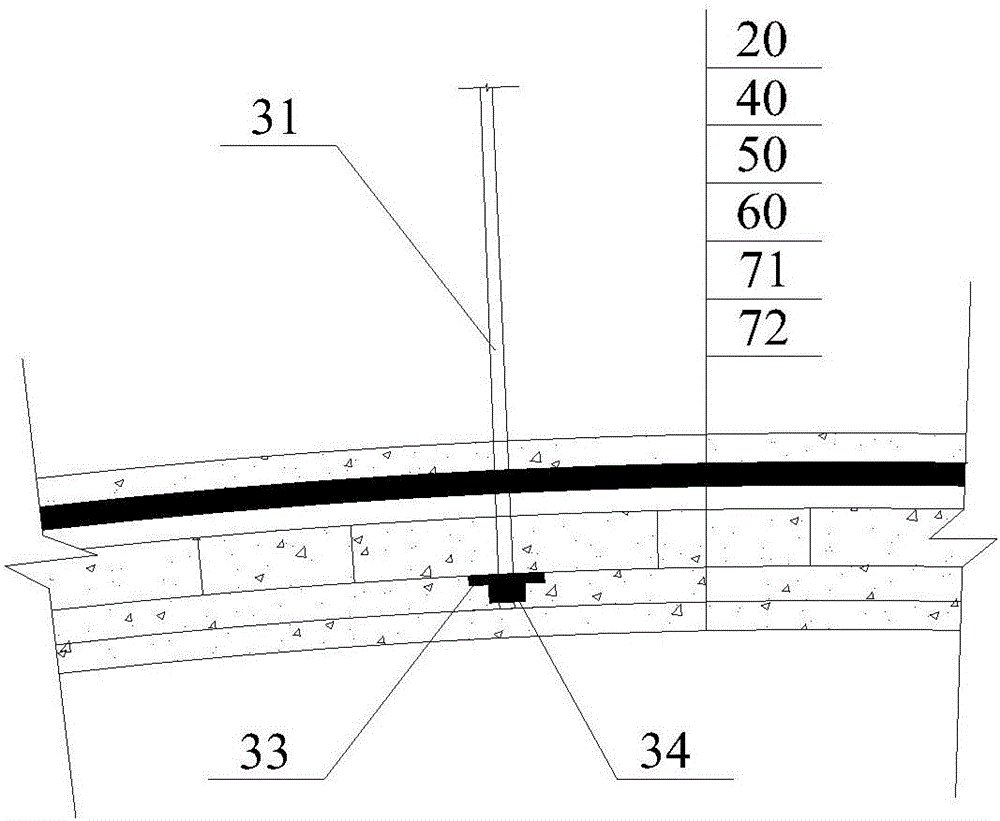

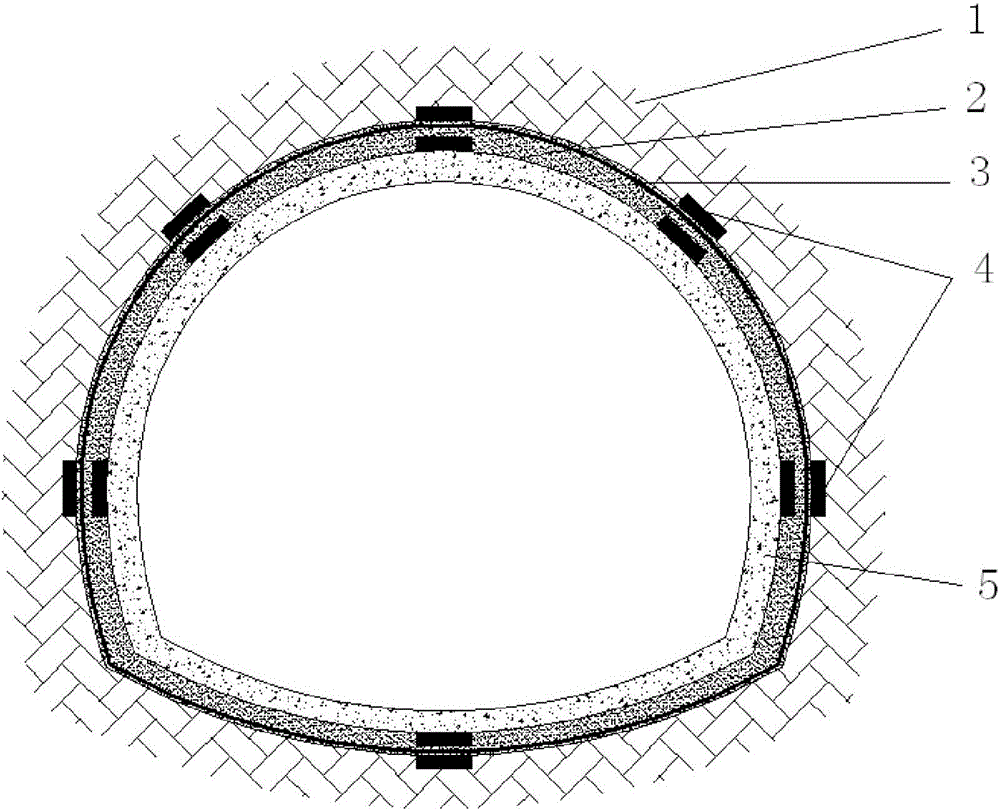

Soft rock large-deformation tunnel support structure system and construction method thereof

ActiveCN106761810APrevent intrusionReduce surrounding rock pressureUnderground chambersTunnel liningShotcreteStructure of the Earth

The invention relates to the field of tunnel engineering, in particular to a soft rock large-deformation tunnel support structure system and a construction method thereof. According to the soft rock large-deformation tunnel support structure system and the construction method thereof, double layers of elastic foam boards are arranged between surrounding rock and primary supports, thus enough surrounding rock deformation space is reserved so as to adapt to the requirement of soft rock tunnel large deformation, the problem of limit intrusion caused by too large surrounding rock deformation can be avoided, and surrounding rock pressure acting on a support structure can also be reduced effectively. The primary supports are reinforced, sprayed concrete spalling chipping, steel frame warp dislocation breakage, secondary lining cracking and other phenomena caused by too large stress on the support structure can be avoided by adopting the double-layer primary supports, and finally safety and reliability of the soft rock large-deformation tunnel support structure are ensured. Aiming at the characteristics that a soft rock large-deformation tunnel system is not obvious in anchor rod effect and waste time and labor, application of a system anchor rod in a soft rock large-deformation tunnel is canceled, the measures of reinforcement of a locking anchor pipe and steel frame longitudinal connection are provided, corresponding reasonable support parameters are given, and thus tunnel subsidence can be controlled better.

Owner:CHANGAN UNIV

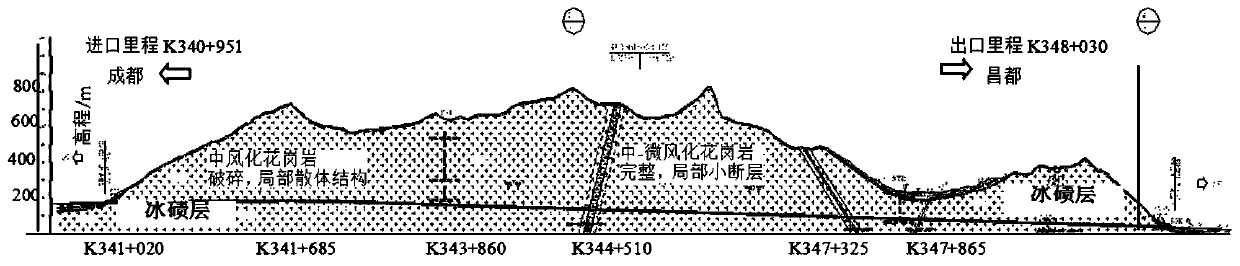

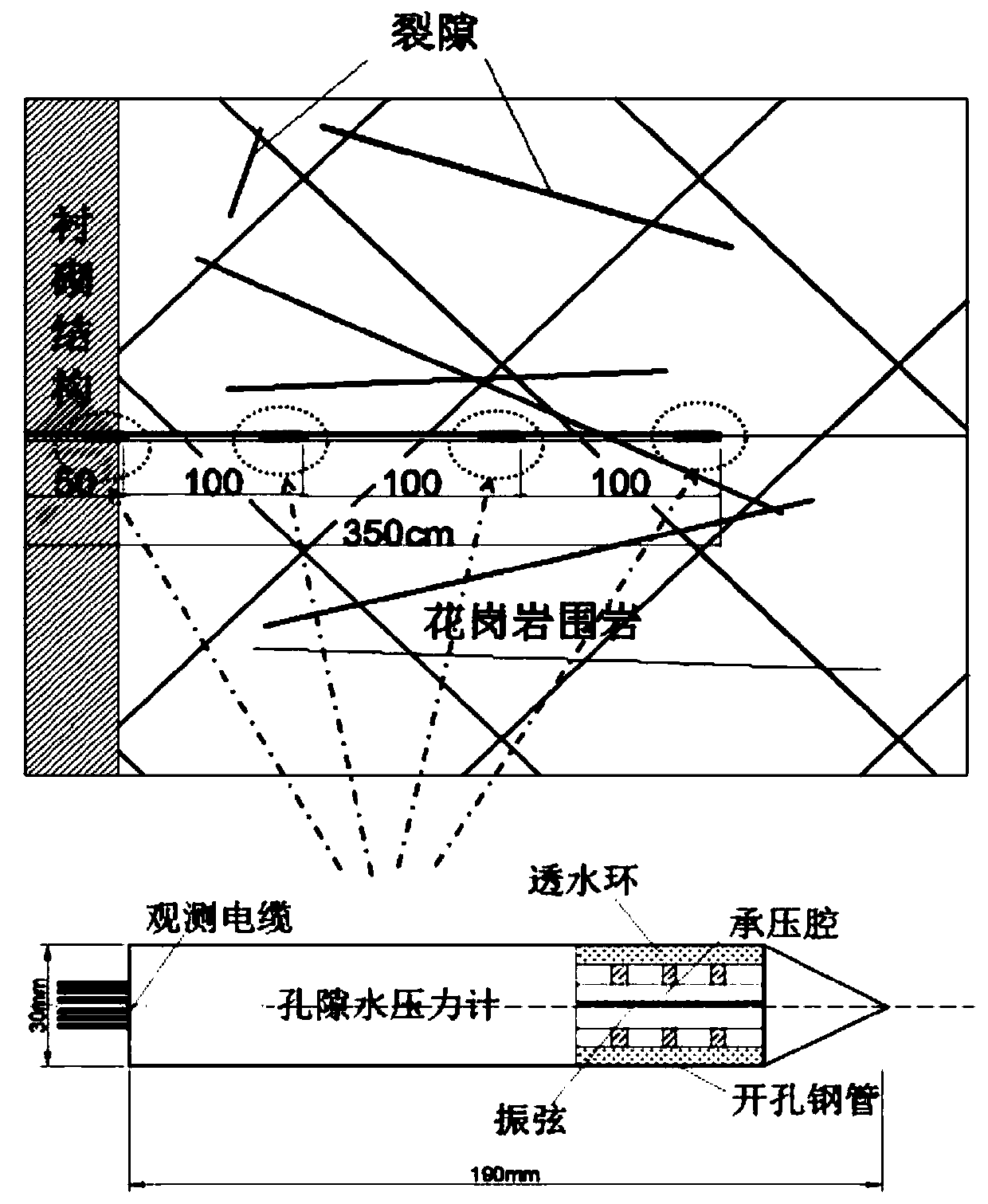

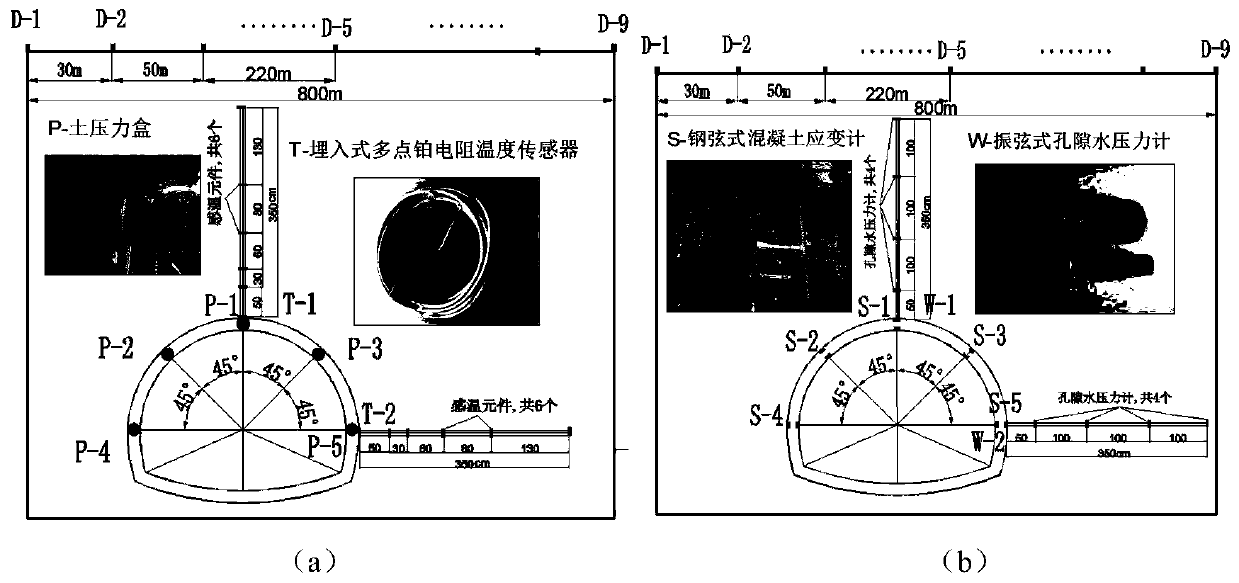

Frost heave force model of rock tunnel based on rock-water-ice force in-situ test

InactiveCN110596177AAvoid structureAvoid discussionEarth material testingMaterial thermal analysisFreeze thawingPore water pressure

The present invention discloses a frost heave force model of a rock tunnel based on a rock-water-ice force in-situ test. A pore water pressure gauge, an earth pressure box, and a multi-point platinumresistance temperature sensor are used in a combination manner to perform a frost heave force in-situ test on fractured rocks, the temporal and spatial evolution laws of the fissure water pressure, the ice pressure, and the surrounding rock pressure before and after freezing of the fractured rocks are obtained, and theoretical model calculation results, in-situ test results, and existing researchresults are compared and analyzed. According to the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention, in-situ testing on siteis used, the test method is innovated outside the previous test system mainly containing the freeze-thaw cycle mechanics test of fractured rock masses, the lack of measurement methods is compensated,the frost heave force in natural water-containing cracks is obtained, and starting from macro and engineering applications, the discussion of the meso-structure and fracture geometry of fractured rocks is avoided; the general area of low-temperature water-ice phase transition and the direction of water migration are considered; and the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention will provide a reference for similar projects of the currently developed Sichuan-Tibet Highway.

Owner:SOUTHWEST JIAOTONG UNIV

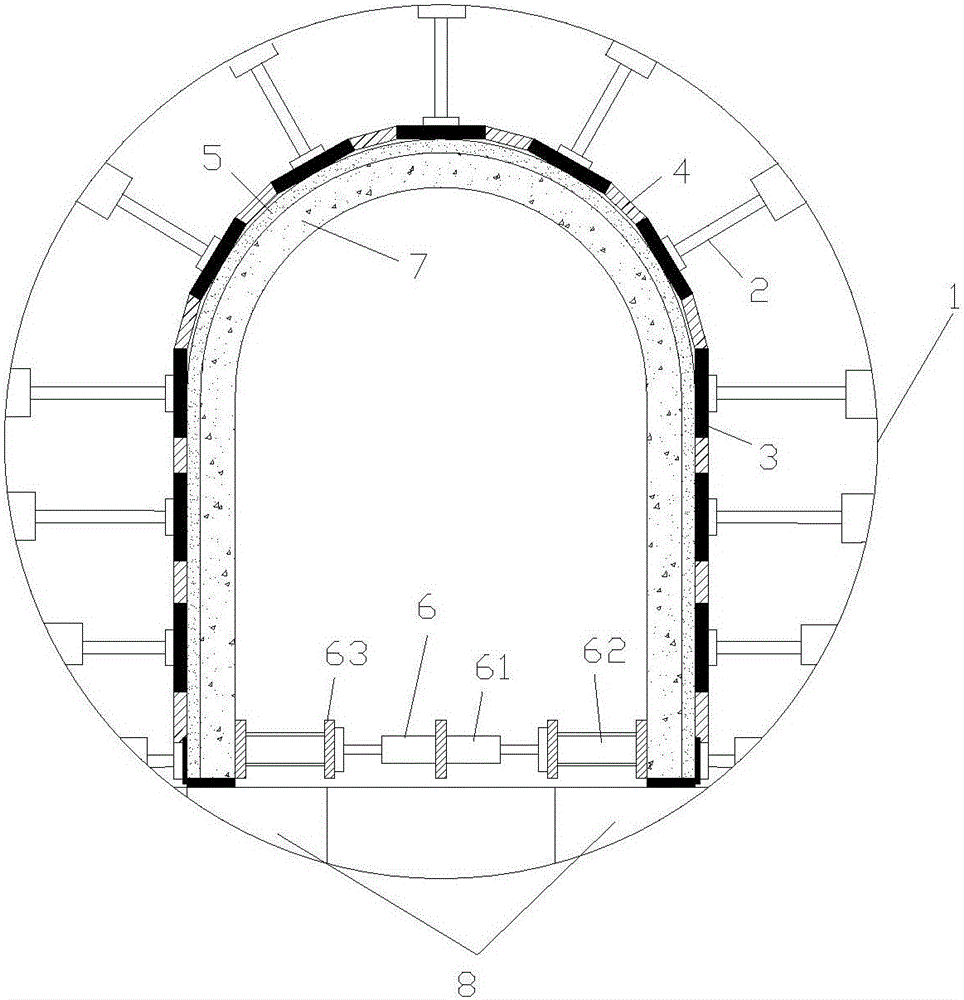

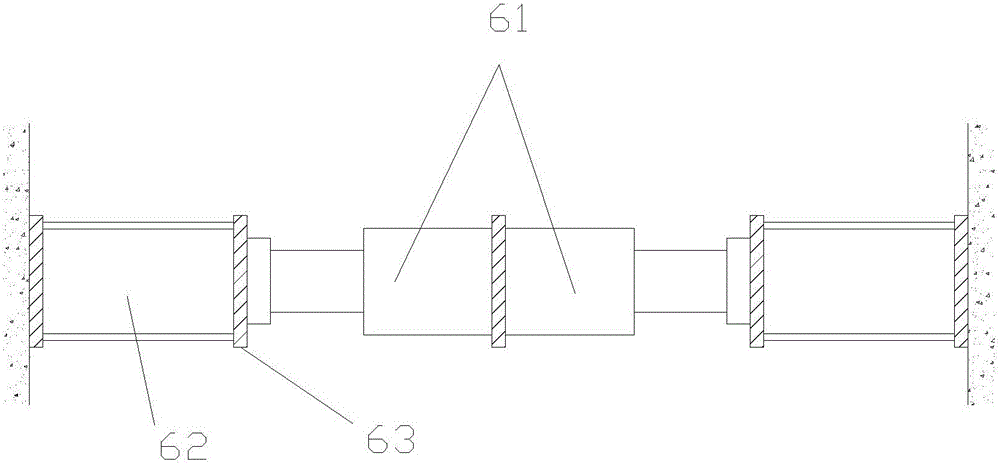

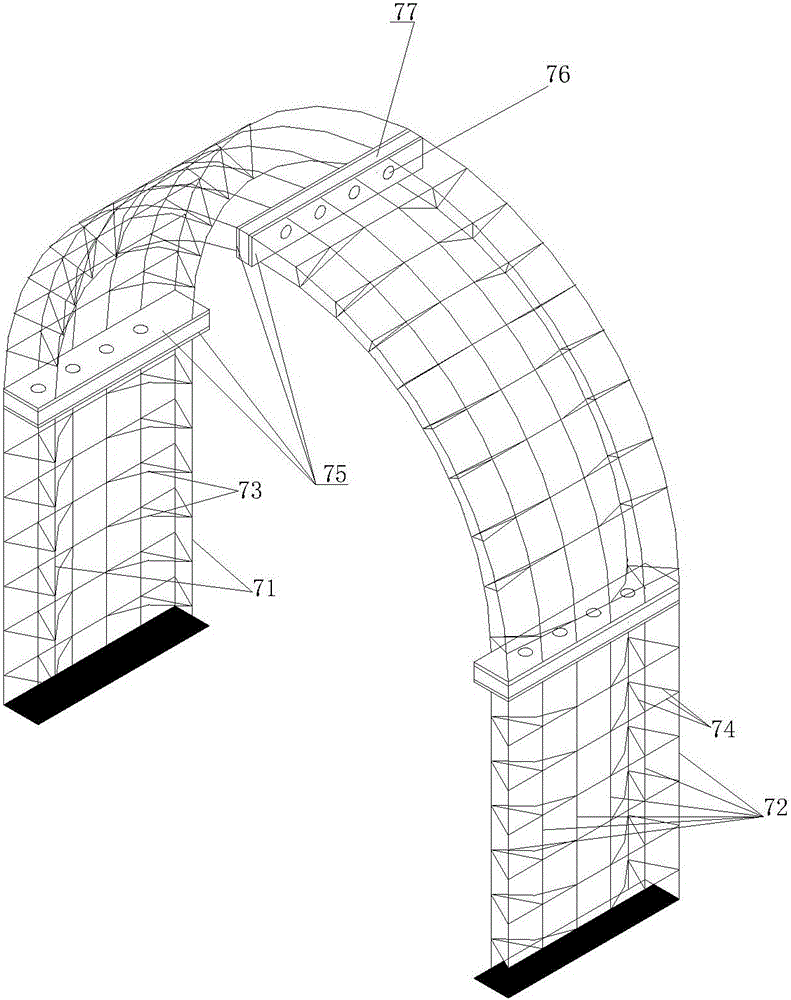

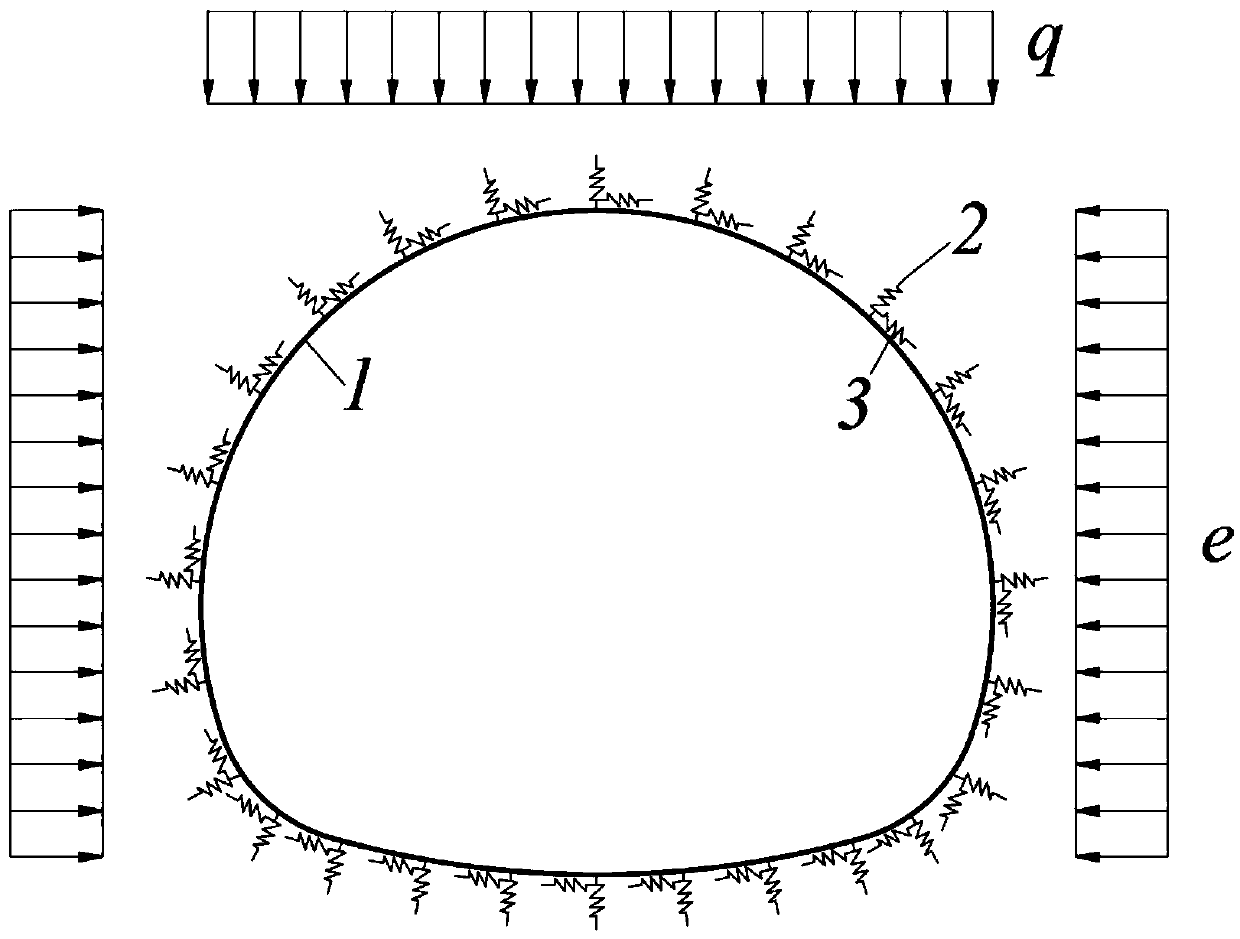

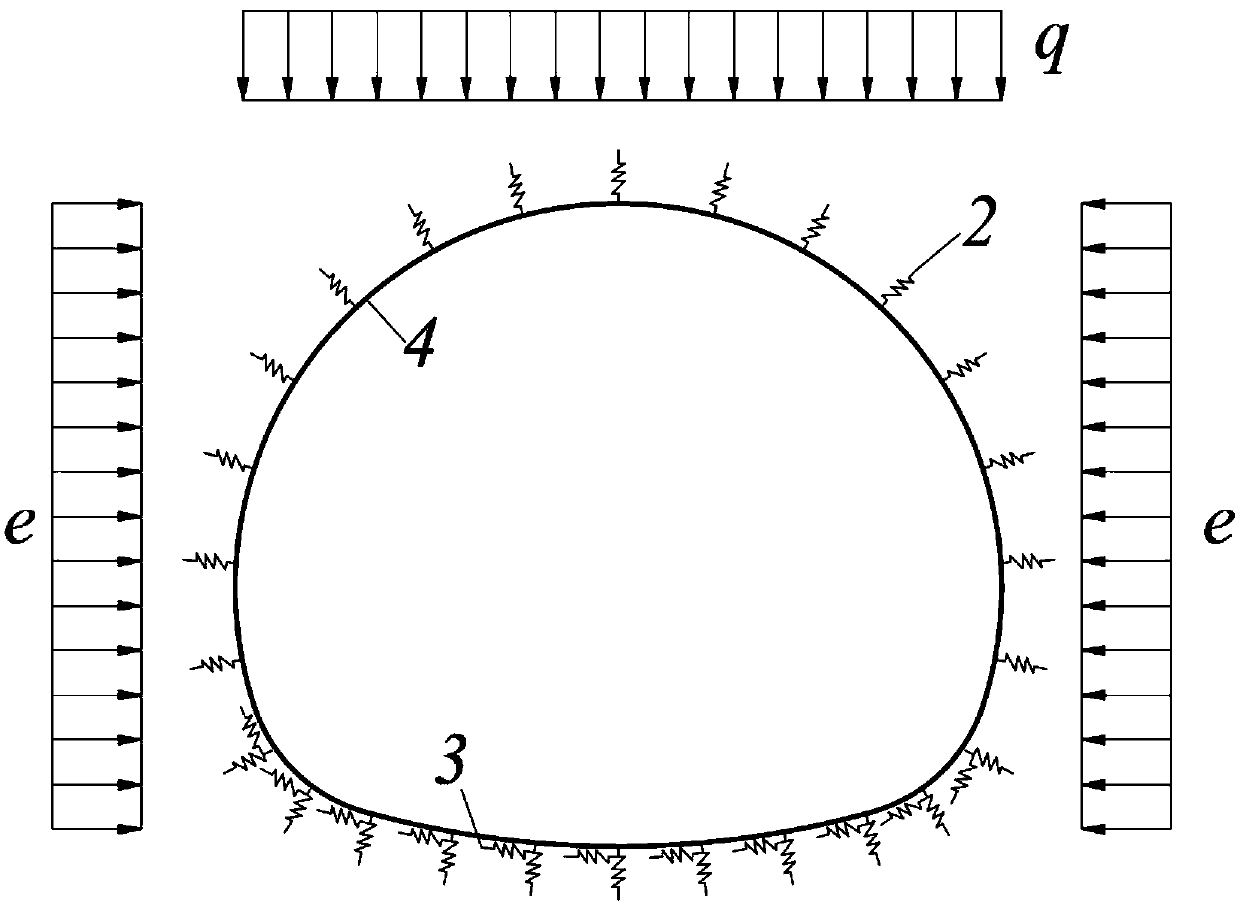

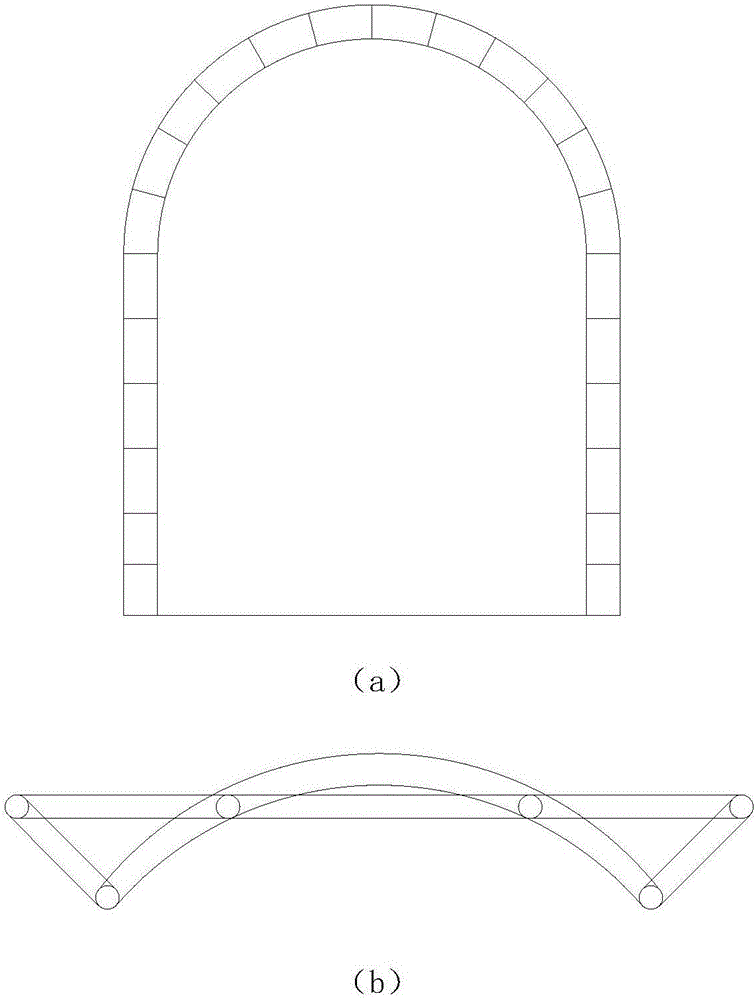

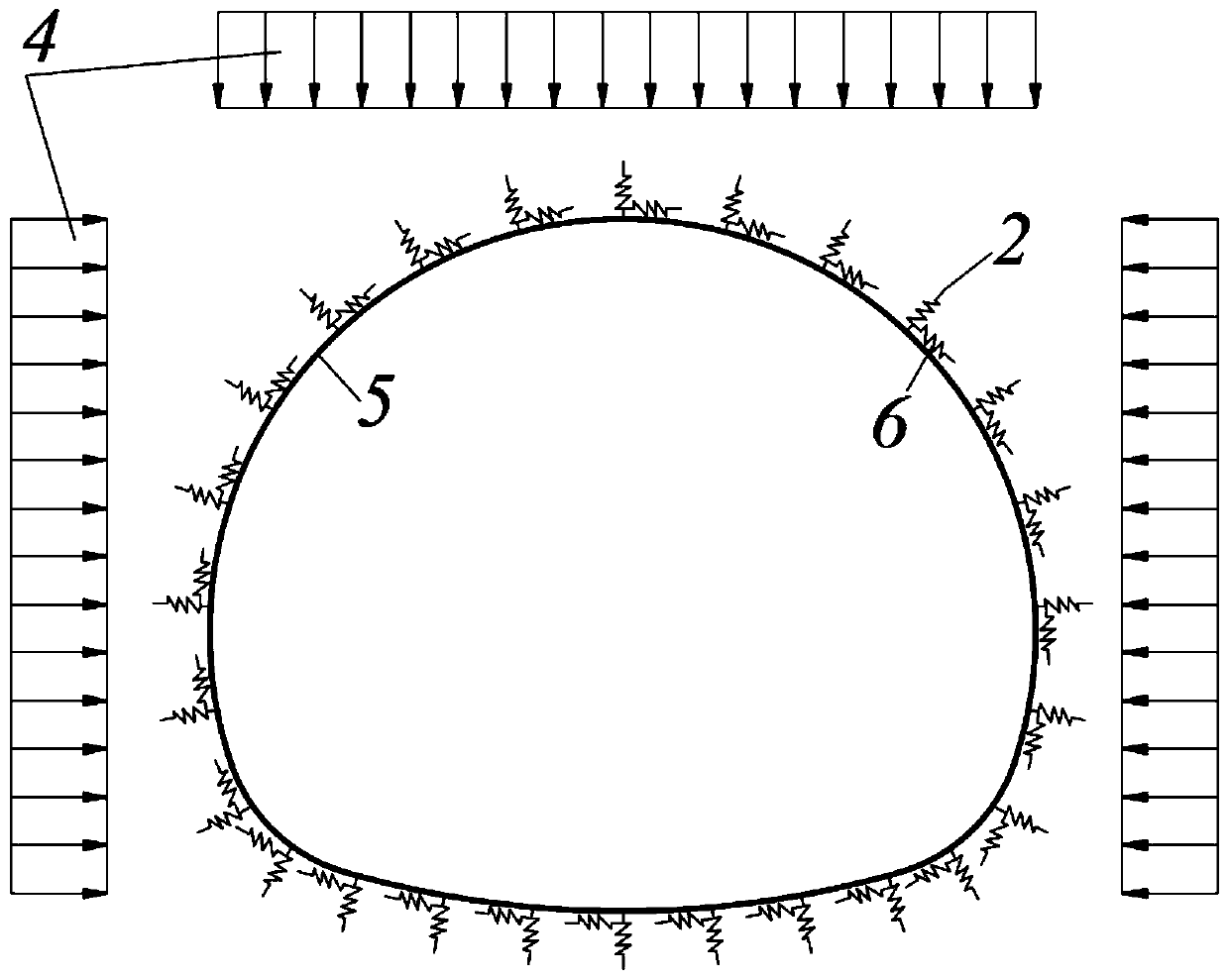

Tunnel lining supporting structure indoor model test method

InactiveCN105806714AAvoid stress concentrationMaterial strength using tensile/compressive forcesEngineeringModel test

An indoor model test method for a tunnel lining support structure, which consists of three parts: a jack, a retractable lateral support and a tunnel lining support structure. The jack is arranged around the lining support structure to simulate the effect of surrounding rock pressure on the lining , the retractable lateral support connects the two feet of the lining support structure, which is used to simulate the two-way yielding support effect of the surrounding rock of the tunnel floor on the lining footing structure. The type, materials and geometric dimensions of the tunnel lining support structure are based on The actual engineering prototype is scaled down to a certain scale. The invention is used in the indoor model test research of geotechnical engineering, and well simulates the mechanical action of the tunnel or mine roadway surrounding rock pressure on the lining support structure. The test operation is effective and reliable, and it is used to test the mechanical properties, deformation and failure characteristics of the lining structure. And further applied to engineering practice, providing reliable data and reference.

Owner:ANHUI UNIV OF SCI & TECH

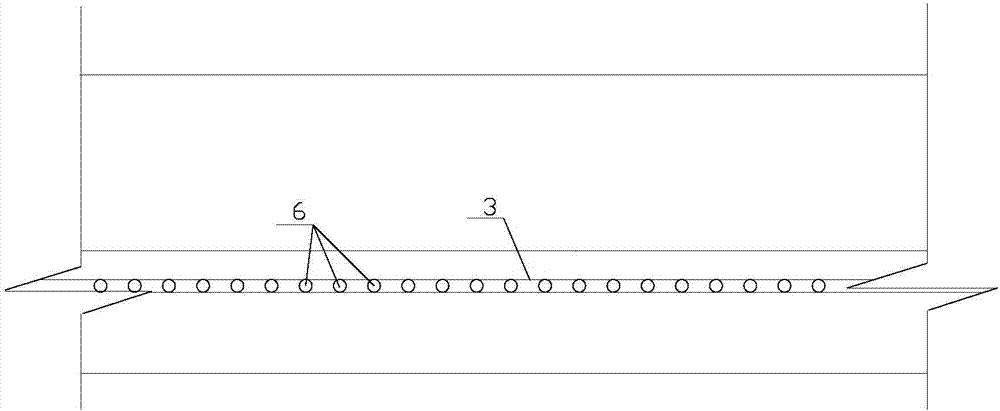

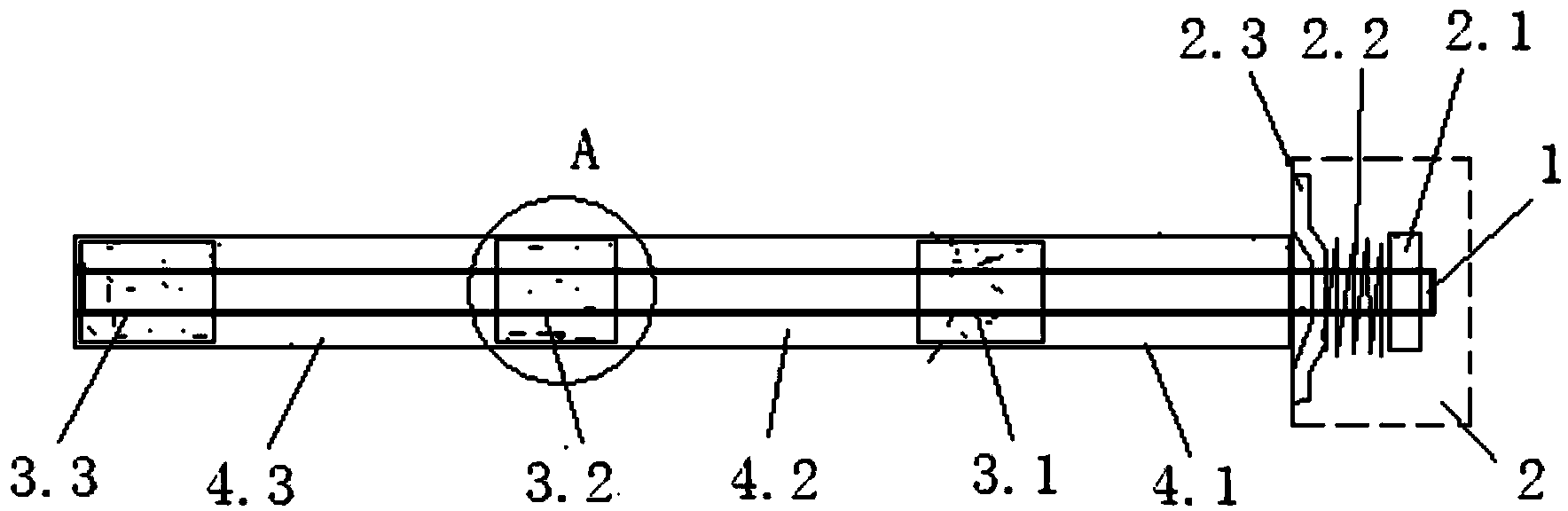

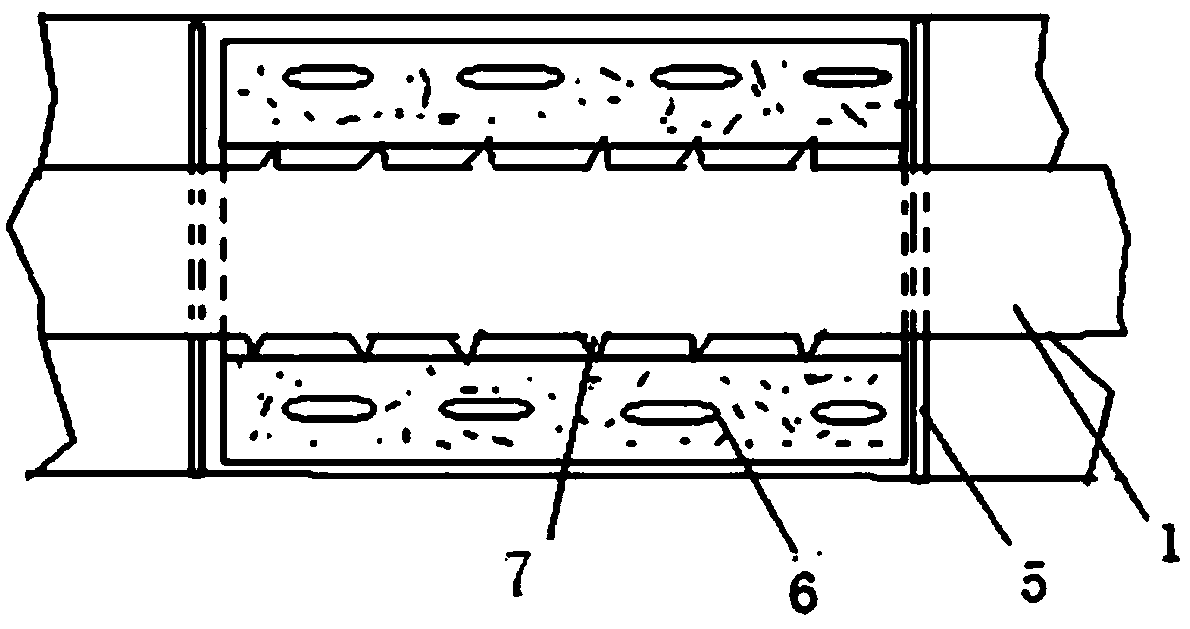

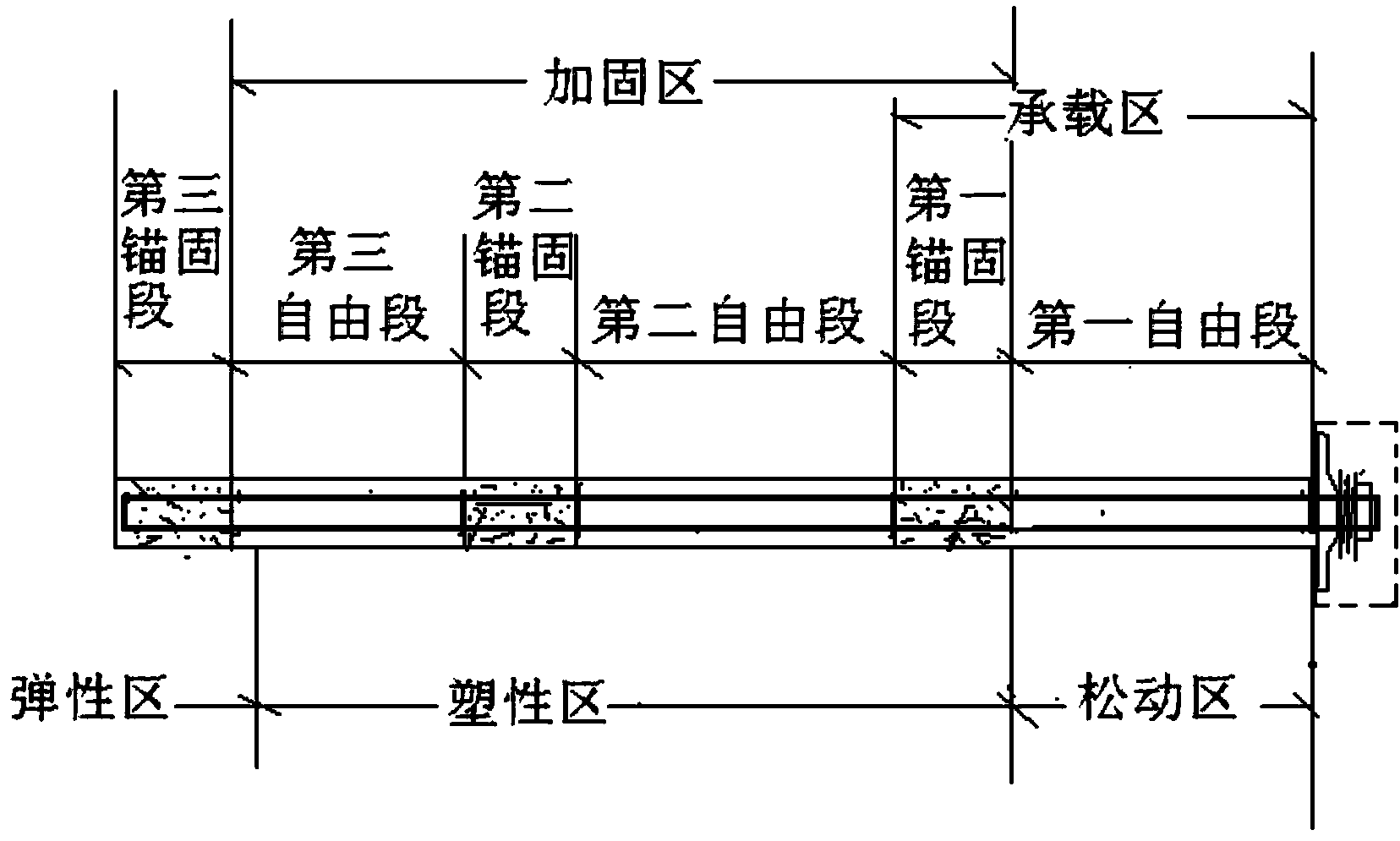

Multistage anchoring type resin anchor rod and anchoring method thereof

InactiveCN103758551AEliminate transfer stacking effectsAvoid failureAnchoring boltsStress concentrationAnnular cutter

The invention discloses a multistage anchoring type resin anchor rod and an anchoring method of the multistage anchoring type resin anchor rod. The multistage anchoring type resin anchor rod comprises an anchor rod body and an orifice pretensioner. Point anchoring sections are arranged on the anchor rod at intervals. Other sections are free sections. According to the point anchoring sections, tooth-shaped annular cutters are machined at the positions, provided with the point anchoring sections, of the anchor rod body. The tooth-shaped annular cutters are sleeved with two-component anchoring resin cartridges. The two ends of each two-component anchoring resin cartridge are sleeved with isolation gaskets. Accordingly, the anchor rod body is sequentially divided into the first free section, the first point anchoring section, the second free section, the second point anchoring section, the third free section and the third point anchoring section from an orifice, and it is required that the first free section is located in a surrounding rock loose area, the third point anchoring section is located in a surrounding rock elastic area, and other sections are located in a surrounding rod plastic area. The number of the point anchoring sections, the number of the free sections and the lengths of all the sections can be adjusted according to the surrounding rock pressure distribution characteristics, loads are dispersed, ultra-strong stress concentration is prevented from happening to the ends of the anchor rod, and the anchor rod body is prevented from breaking or being pulled out.

Owner:SHANDONG UNIV OF SCI & TECH

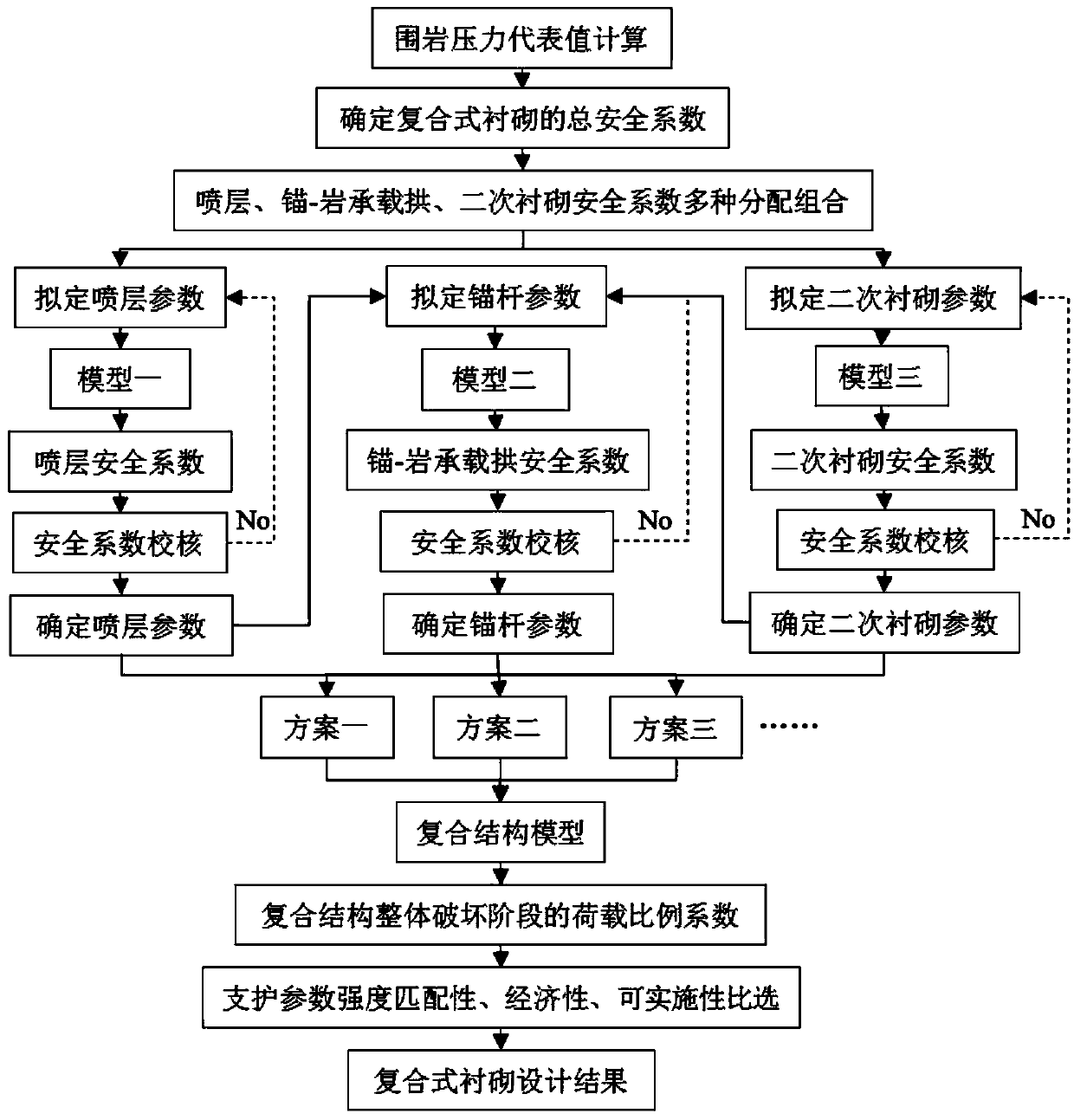

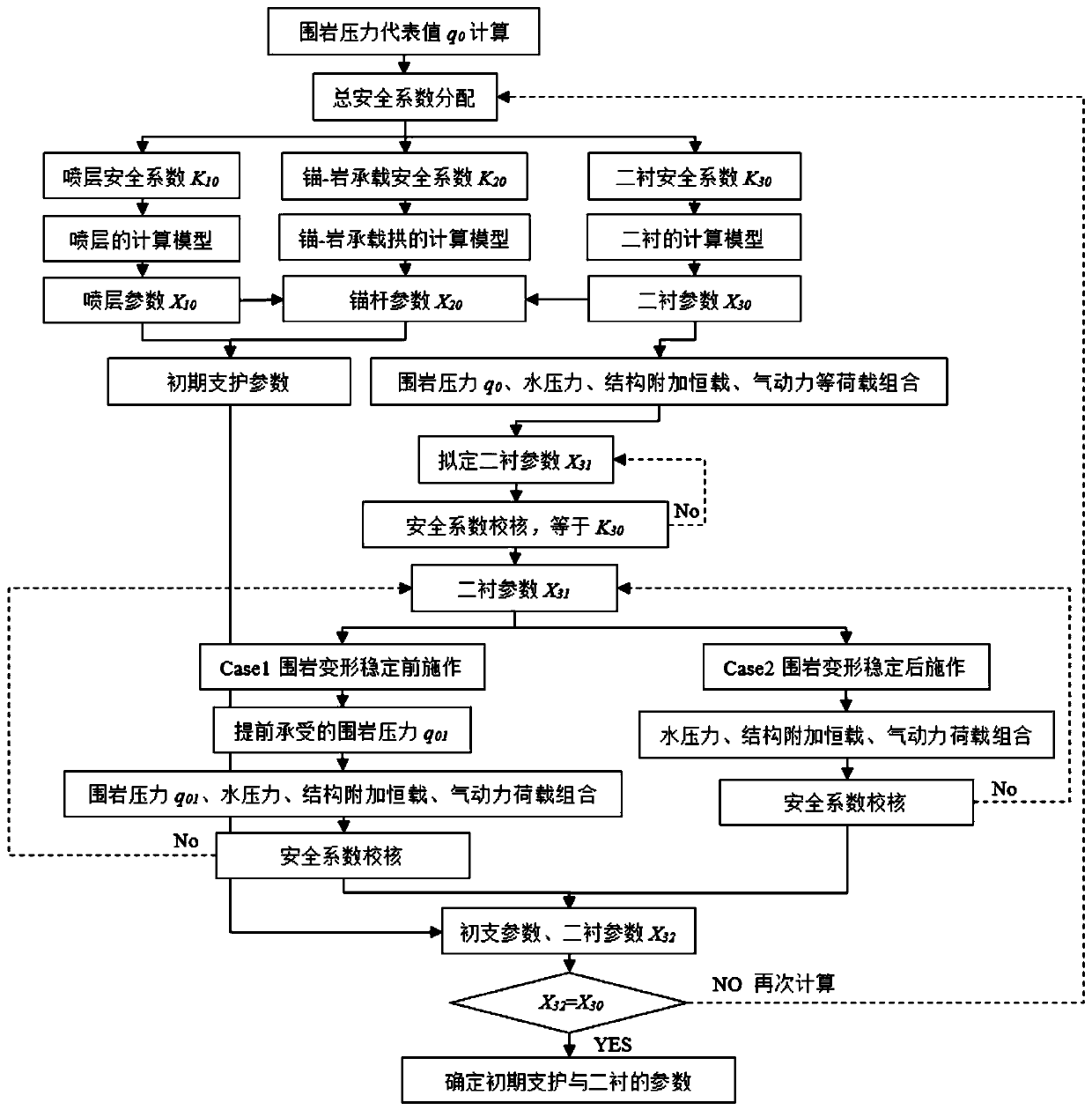

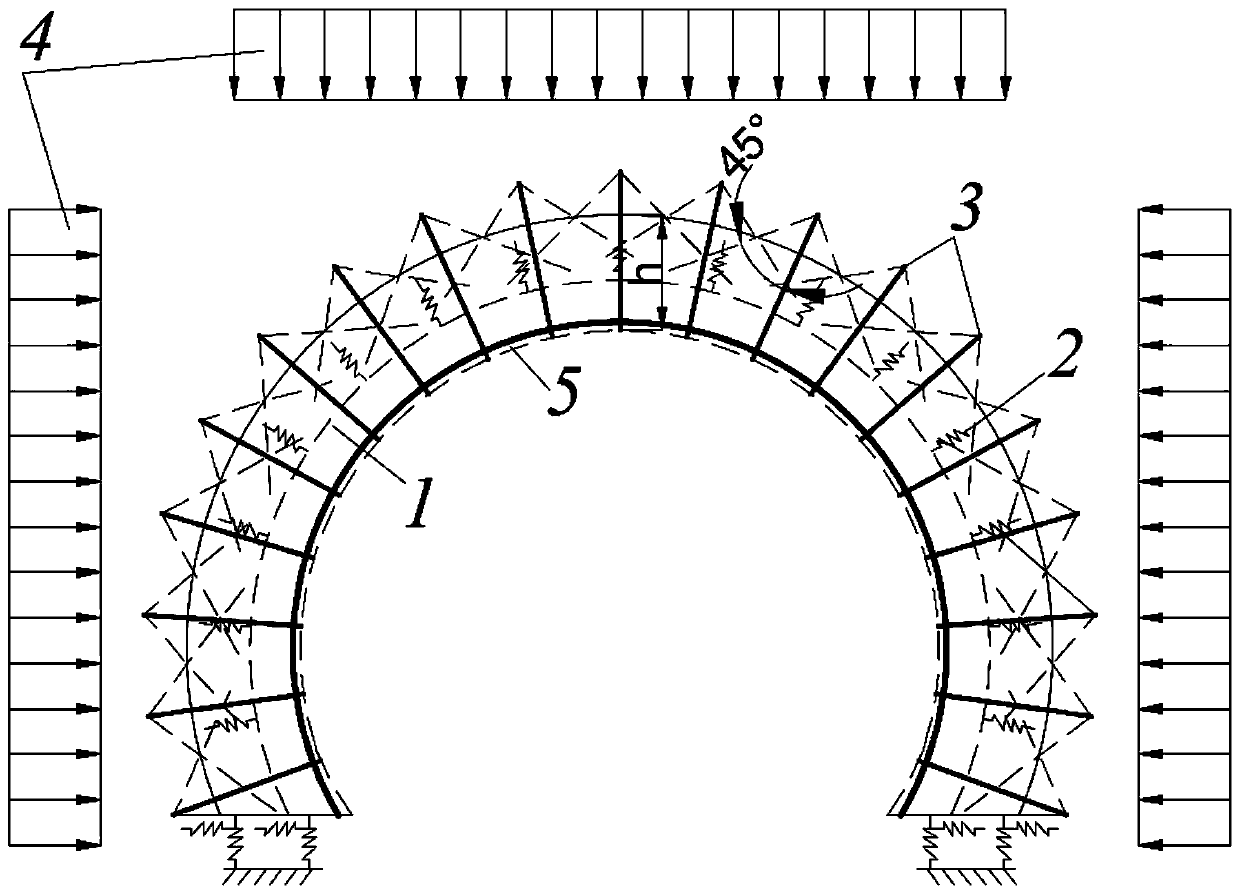

Method for designing tunnel composite lining based on total safety factor process

ActiveCN109667598AAvoid blindnessAvoid randomnessUnderground chambersTunnel liningEngineeringUltimate tensile strength

The invention relates to a method for designing a tunnel composite lining based on a total safety factor process. The method comprises the following steps: confirming a surrounding rock pressure representative value of the composite lining; confirming a total safety factor of the composite lining according to the support type; primarily distributing the confirmed total safety factor of the composite lining, thereby acquiring respective safety factors of spraying layer, anchor rod-surrounding rock bearing arch and secondary lining; confirming parameters of spraying layer, anchor rod-surroundingrock bearing arch and secondary lining according to a distribution result of each safety factor and a corresponding load structure model; acquiring a load proportional coefficient of composite structure in general damage stage by adopting a composite structure model according to the parameters of spraying layer, anchor rod-surrounding rock bearing arch and secondary lining; acquiring strength matching degree of support components by comparing the relationship between the load proportional coefficient and the sum of the safety factors of spraying layer and secondary lining; comprehensively analyzing and selecting an optimal supporting scheme according to multiple sets of supporting parameters confirmed on the basis of multiple sets of distribution results of total safety factor and throughcomparison and selection of strength matching degree, economic efficiency and practicability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

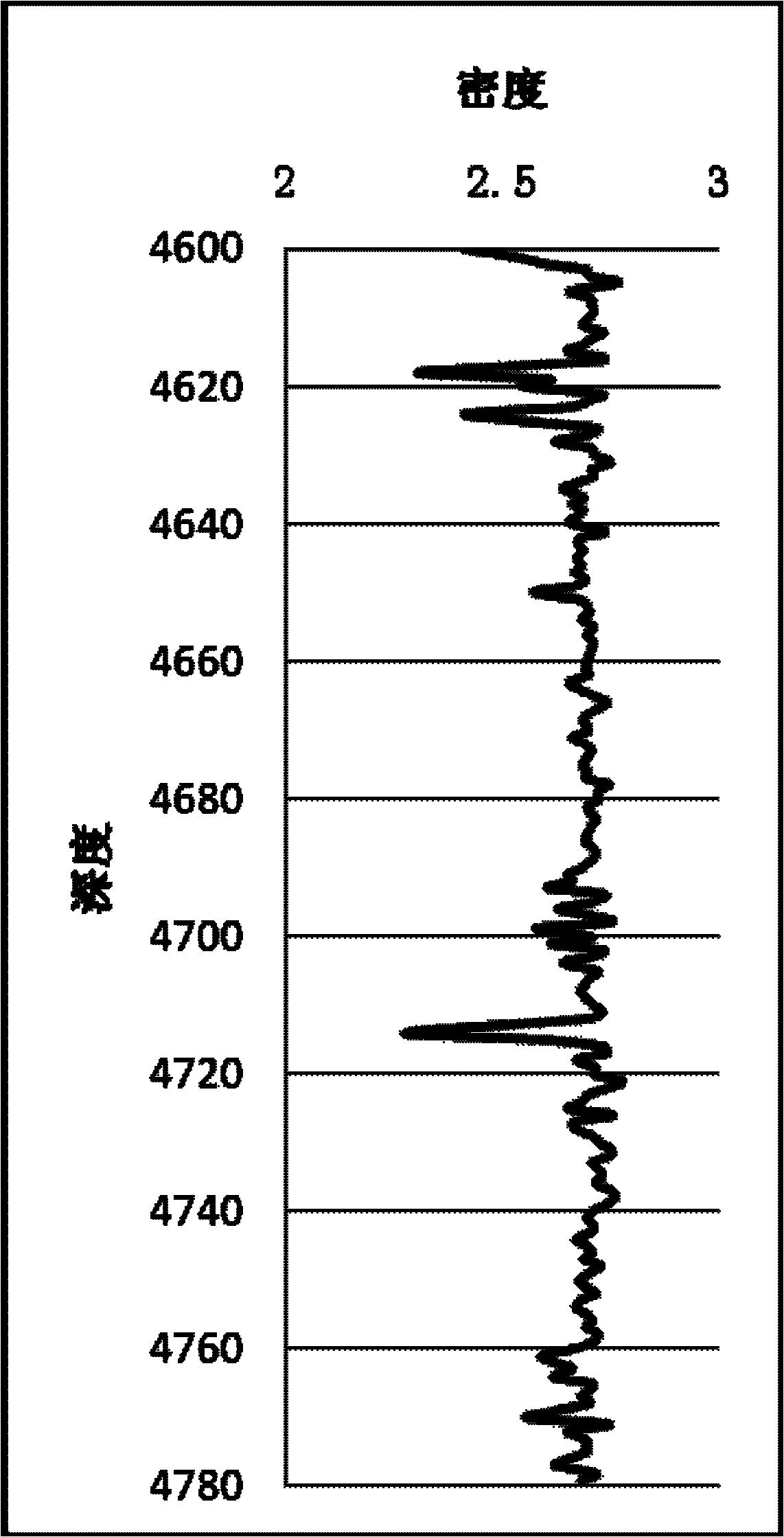

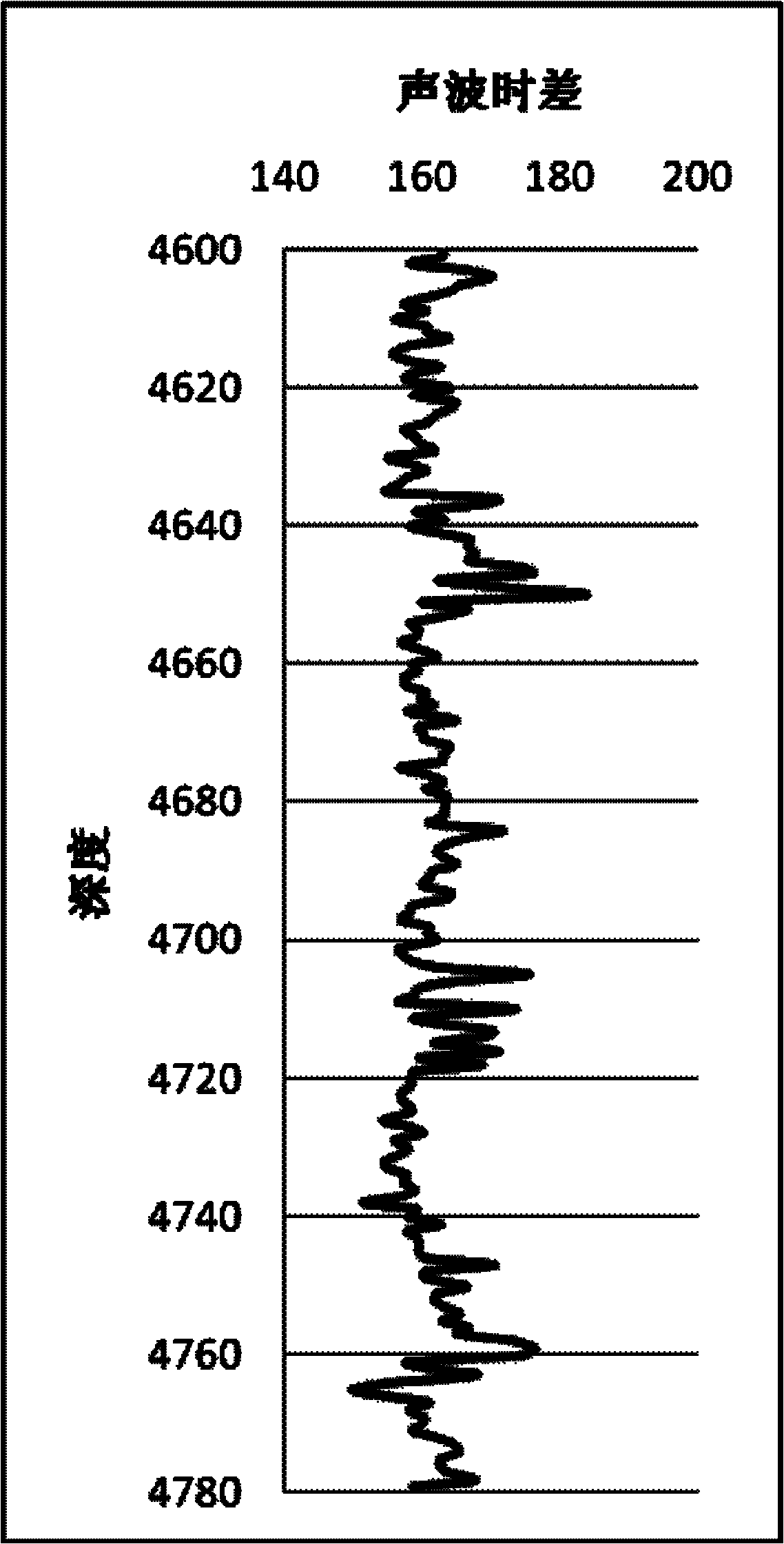

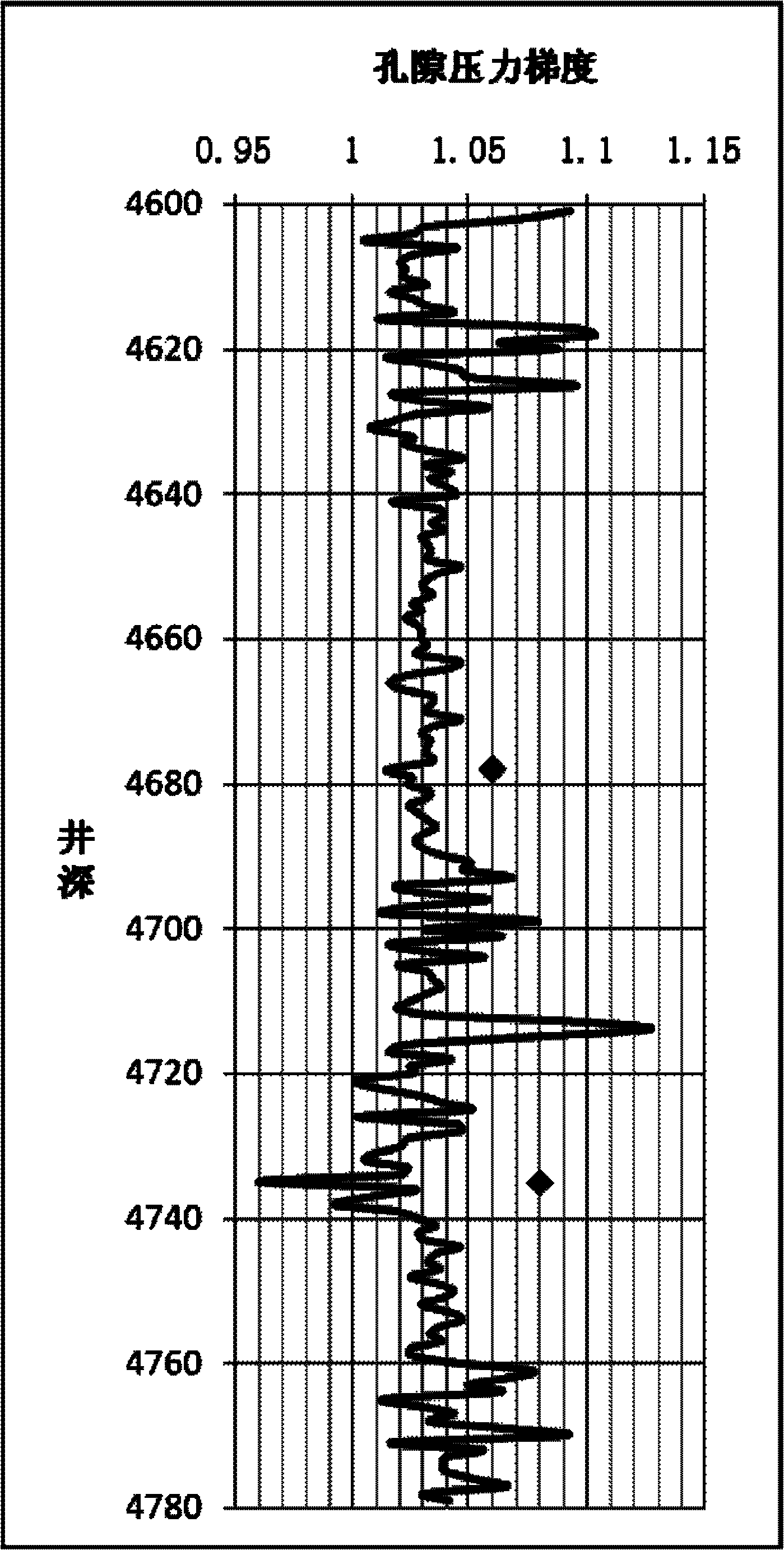

Method for detecting limestone formation pore pressure

The invention discloses a method for detecting limestone formation pore pressure, which is applied in the technical field of oil field drilling, and comprises the following steps of sampling rock mechanics parameter data of sampled well rocks with a same geologic structure, establishing an effective stress model, requesting feature data of overlying rock pressure and depth, establishing an overlying rock pressure model, establishing a detection model of the limestone formation pore pressure and detecting the limestone formation pore pressure. The method has the benefits of having a higher fitting degree and better trend compliance, and basically solving the difficulty that a traditional method is not applicable to the detection on the limestone formation pore pressure compared with formation pore pressure data actually measured in field.

Owner:PETROCHINA CO LTD

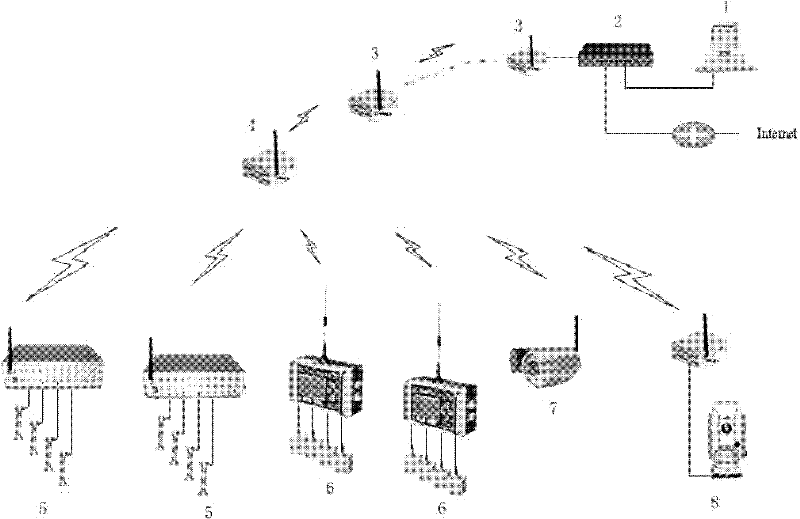

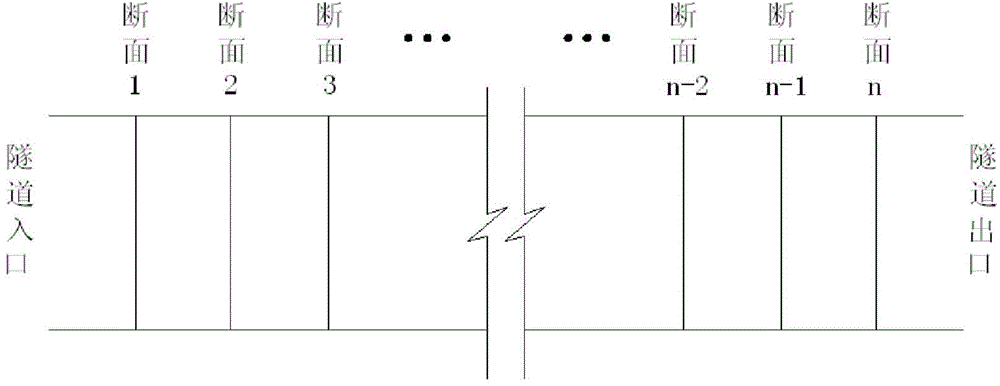

Summarized information monitoring system of tunnel

ActiveCN102608963AQuick collectionAccurate collectionProgramme total factory controlEngineeringBlasting vibration

The invention relates to a summarized information monitoring system of a tunnel. The summarized information monitoring system mainly comprises an automatic frequency monitor, an automatic blast vibration monitor, an automatic video acquiring monitor, an automatic three-dimensional section monitor, a wireless route repeater, a wireless high-speed repeater station, a network exchanger and a monitoring host. The monitoring host is connected with the network exchanger, the wireless high-speed repeater station and the wireless route repeater sequentially; the wireless route repeater is connected with the automatic frequency monitor, the automatic blast vibration monitor, the automatic video acquiring monitor and the automatic three-dimensional section monitor respectively; the automatic frequency monitor is connected with a vibration-wire sensor; and the automatic blast vibration monitor is connected with a three-direction or one-direction speedometer. The summarized information monitoring system disclosed by the invention can implement monitoring, pre-alarming and forecasting on surrounding rock pressure, rock mass vibration and clearance variation.

Owner:北京市政路桥锐诚科技有限公司

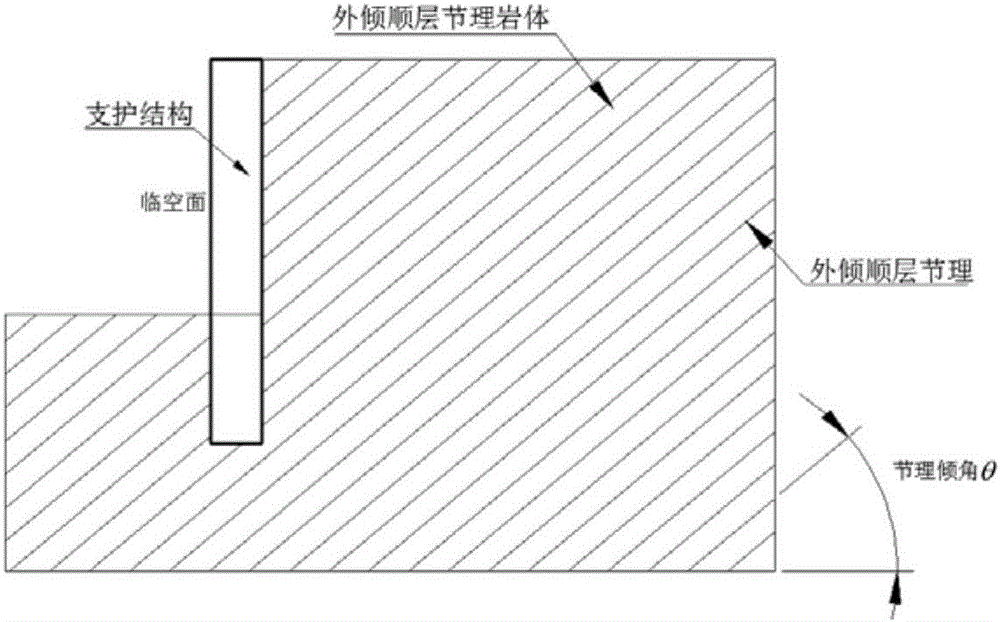

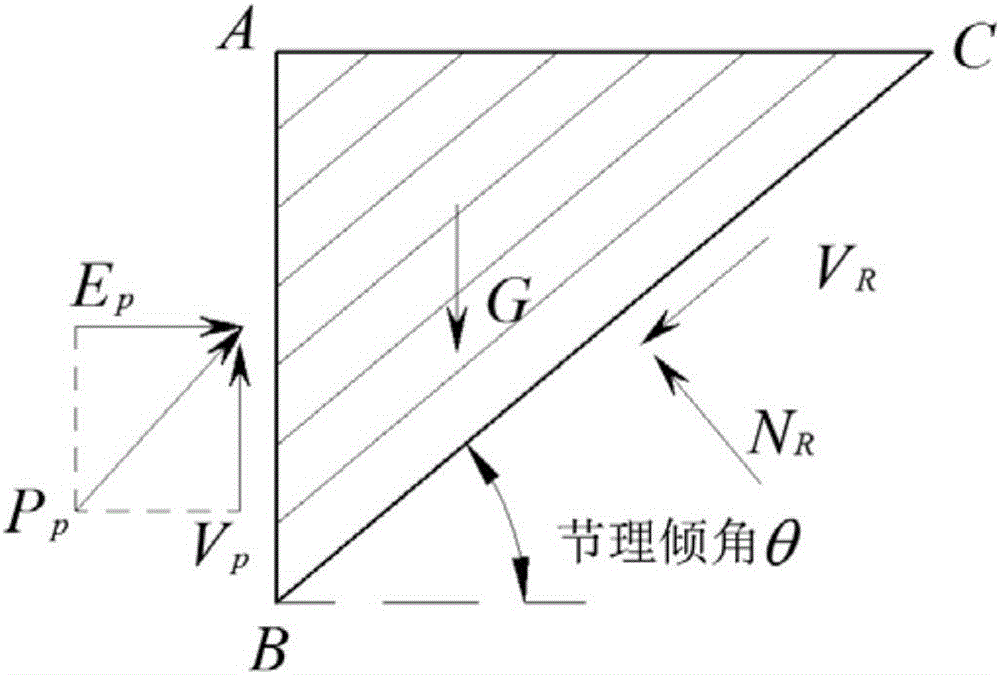

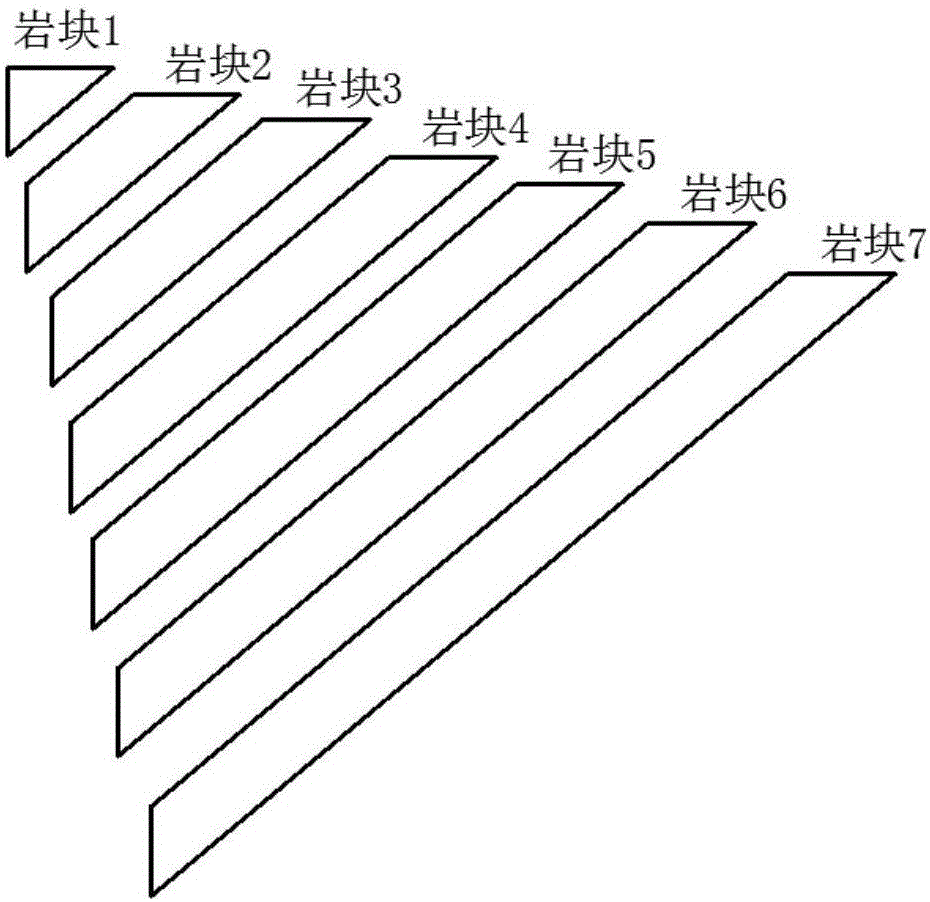

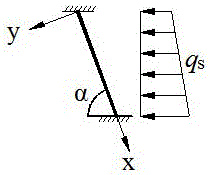

Method for calculating pressure of passive lateral rocks for jointed rocks on outwardly-inclined bedding slope

ActiveCN106547942AReliable data referenceAccurate Data ReferenceDesign optimisation/simulationSpecial data processing applicationsSoil mechanicsEngineering

The invention relates to a method for calculating pressure of passive lateral rocks for jointed rocks on an outwardly-inclined bedding slope, pertaining to the technical field of rock pressure analyses in rock and soil mechanics. The method comprises following steps: dispersing bedding joint rocks based on joint surfaces into rigid rocks in a definite number by taking jointed rocks on the outwardly-inclined bedding slope as an object of study; taking pressure of passive lateral rocks as an objective function and shearing force and normal force of joint surfaces as unknown quantities based on a Pan Jiazheng maximum principle to create an equilibrium equation satisfying damaged rocks, yield conditions of joint surfaces, and yield conditions of contact surfaces for rocks and supporting structures; and solving them to obtain the maximum limit value for passive lateral rocks for jointed rocks the an outwardly-inclined bedding slope. The method for calculating pressure of passive lateral rocks for jointed rocks on the outwardly-inclined bedding slope has following beneficial effects: the method is accurate in concept, high in calculation precision, and easy and convenient in engineering application and can be applied to design of structures for retaining walls on jointed rock slopes, slide-resistant piles and pile-anchor supports.

Owner:KUNMING UNIV OF SCI & TECH

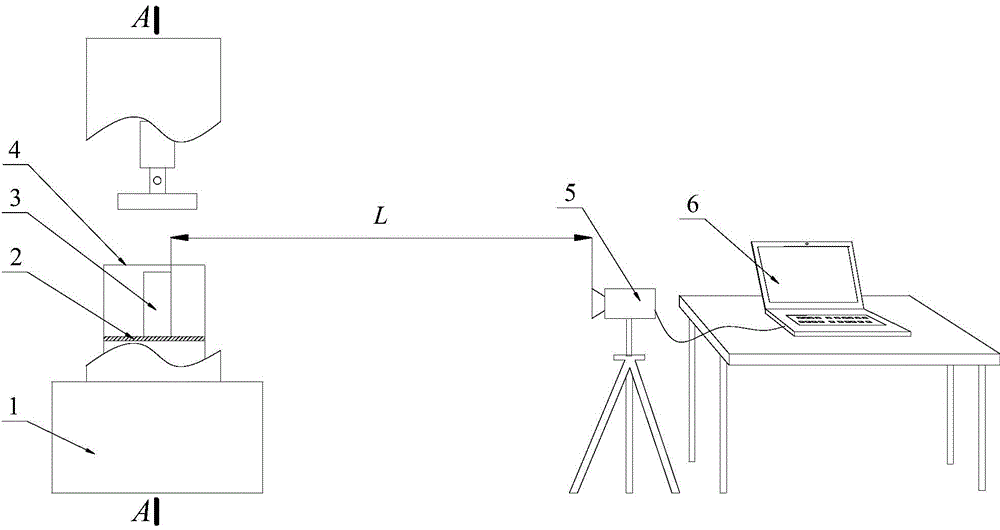

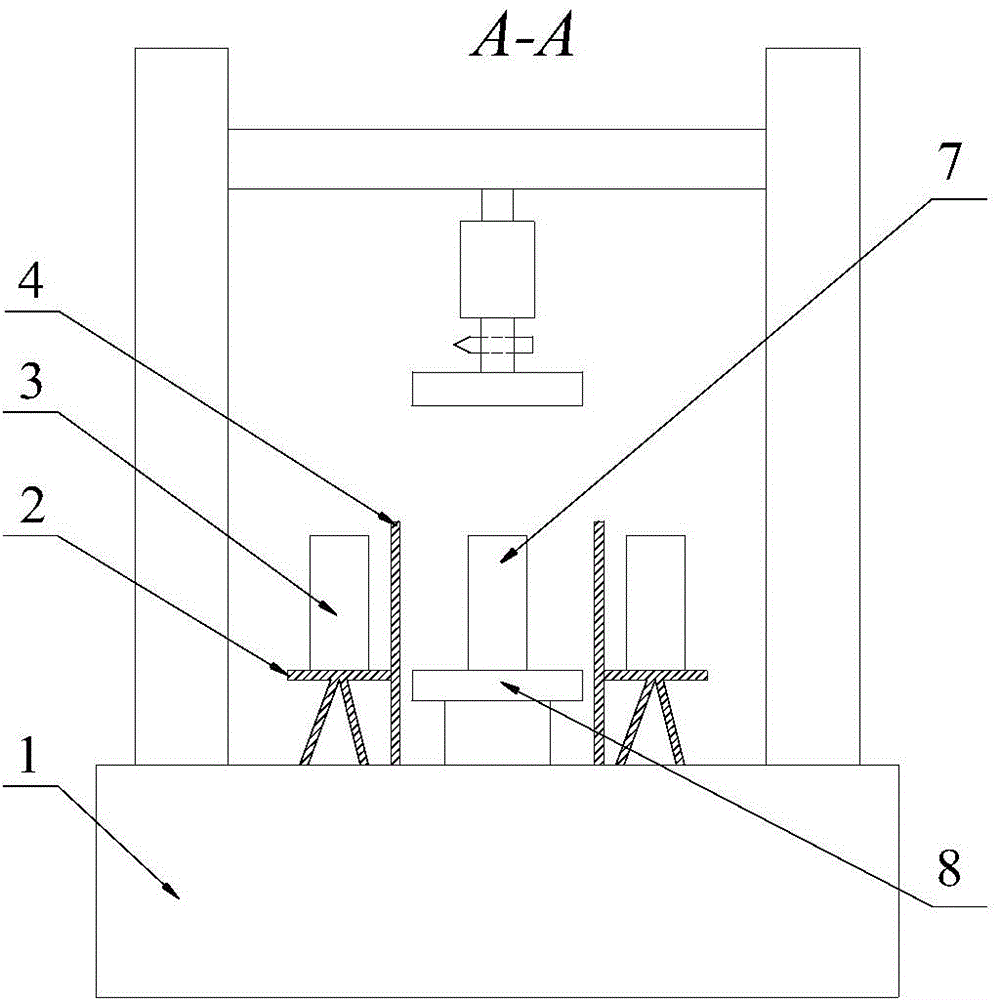

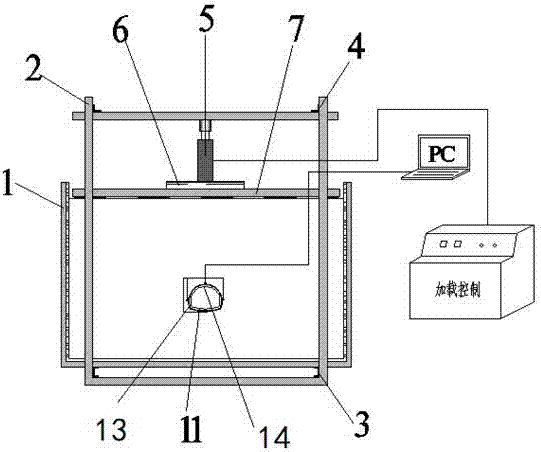

Coal rock fracture development infrared radiation monitoring test method

ActiveCN103983514AReduce mistakesReduce the impact of errorsMaterial strength using tensile/compressive forcesWorkbenchCoal

The invention discloses a coal rock fracture development infrared radiation monitoring test method which is suitable for a coal rock fracture development infrared radiation monitoring test for researching a coal rock deformation condition of a mine. Supports for arranging coal rock test blocks are respectively arranged on two sides of a workbench of a rock press; three prepared coal rock test blocks are respectively arranged on the workbench and the supports; the rock press applies pressure on the loaded coal rock test blocks according to set pressure and set speed; a computer is used for processing infrared radiation mean temperature data of the loaded coal rock test blocks and a reference coal rock test block so as to obtain real infrared radiation data required by coal rock fracture development. The shortcoming of high environment and background factor influence on the conventional coal rock test block loading destroy infrared radiation monitoring test is overcome; an error caused by test conditions and the environment is reduced, the accuracy, the scientificity and the effectiveness of a test result are greatly improved, and instruction significance for the coal rock test block infrared radiation monitoring test is realized.

Owner:CHINA UNIV OF MINING & TECH

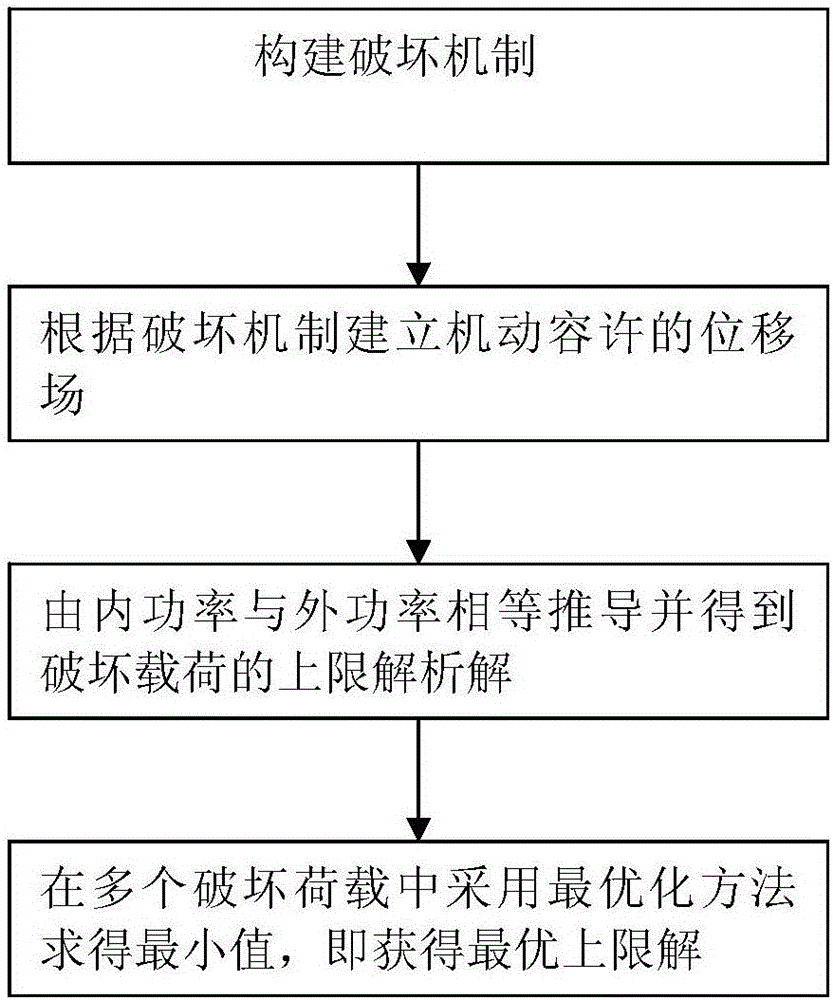

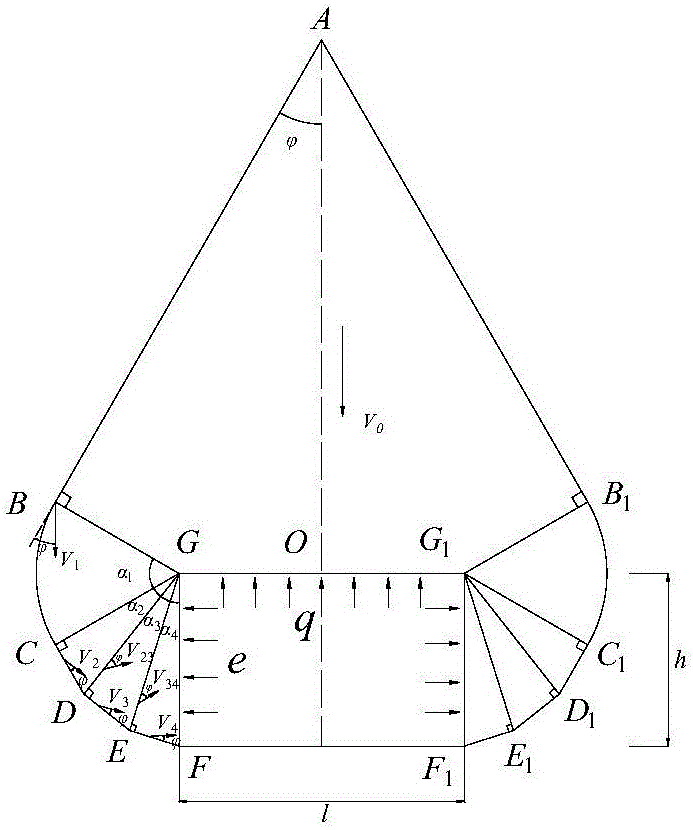

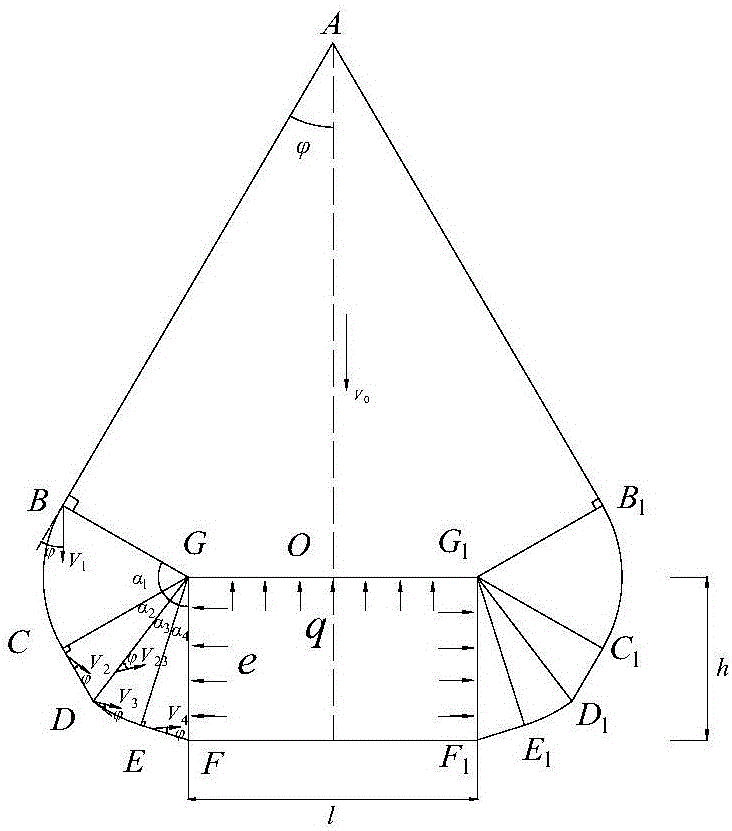

Deep chamber surrounding rock pressure calculating method

InactiveCN106682330AHigh precisionDesign optimisation/simulationSpecial data processing applicationsFracture loadEngineering structures

The invention discloses a deep chamber surrounding rock pressure calculating method. The method comprises the following steps that a kinetically admissible velocity field is built according to the failure mechanism; upper limit analytical solutions of fracture loads are derived and obtained on the basis that internal power is equal to external power; a minimum value is obtained in the plurality of fracture loads, that is the optimal upper limit solution is obtained. The failure mechanism comprising a wedge-shaped collapsing body sliding down, a rotational arc body with the vertex angle as the center of a circle and n translational triangular bodies is provided, then the upper limit analytical solutions of fracture loads are derived and obtained on the basis that the internal power is equal to the external power, the minimum value is obtained in the plurality of fracture loads by means of the optimization method, and the optimal upper limit solution is obtained. The upper limit solution is a strict upper limit value of the surrounding rock pressure, and a theory reference can be provided for supporting designs of the engineering structure.

Owner:HUNAN UNIV OF SCI & TECH

Method for calculating surrounding rock pressure of shallow tunnel

InactiveCN106644206AEasy and accurate calculationForce measurementDeformation monitoringBack calculation

The invention relates to the technical field of tunnel engineering. A method for calculating the surrounding rock pressure of a shallow tunnel comprises the following steps: selecting a convergence deformation monitoring point of the surrounding rock; constructing a structural mechanics model at the monitoring point; deriving a calculation relation between the convergence deformation and the surrounding rock pressure; substituting engineering actual data and convergence monitoring data into the calculation relation to calculate the displacement on the left and right sides of the monitoring point and the convergence deformation of the monitoring points; and calculating the surrounding rock friction angle and the surrounding rock pressure. The method analyzes a relationship between the convergence deformation and the surrounding rock pressure of the sidewall surrounding rock in the construction of a double side wall tunneling method, establishes the structural mechanics model, and obtains the surrounding rock pressure from the field monitoring data by means of back calculation. Compared with a calculation method that depends on empirical parameters, the method of the invnetion is more accurate and more represents the actual surrounding rock pressure of the tunnel, and the convergence deformation data of the tunnel is easier to obtain and the calculation is convenient and accurate.

Owner:SOUTHWEST PETROLEUM UNIV

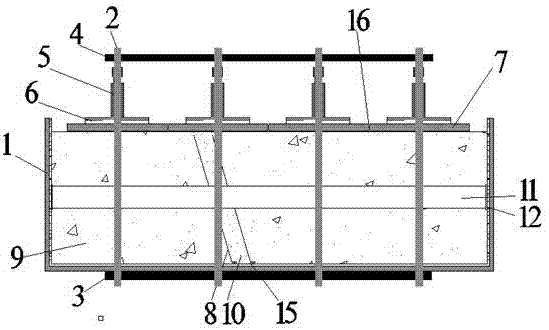

Fault-passing tunnel excavation simulating experimental device

The invention provides a fault-passing tunnel excavation simulating experimental device. Short steel plates hinged in pairs are used for simulating nonuniform surrounding rock pressure caused by bulk density difference or elevation difference of a surrounding rock. The hinged short steel plates can transfer a shearing force but not transfer a bending moment, so that the possibility of producing shearing damage due to sudden pressure change is avoided while the nonuniform surrounding rock pressure is simulated; through a gauze, the thickness and the dip angle of a fault can be flexibly controlled, so that an actual fault model is accorded better, and especially in a loose and soft fault, the simulating effect is more obvious; horseshoe-shaped soft rubber pads at the two ends of a tunnel lining model not only can prevent a surrounding rock material from entering the tunnel, but also can prevent occurrence of a phenomenon that the tunnel lining model is damaged or tempered glass is cracked due to concentrated stress caused by direct contact between a tunnel structure and the tempered glass on the front and back sides under the action of a pressure. The fault-passing tunnel excavation simulating experimental device can research quantitative influence of the geological fault on the tunnel by controlling a single variable.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Supporting structure for composite anchor mesh steel bar support of deep well high-stress soft rock roadway and construction method thereof

InactiveCN106761811AImprove stabilityAvoid loose damageUnderground chambersTunnel liningSupporting systemShotcrete

The invention provides a supporting structure for a composite anchor mesh steel bar support of a deep well high-stress soft rock roadway and a construction method thereof. Firstly, anchor rods and anchor ropes are stroke into the interior of surrounding rock, and the set length is exposed; then, steel bar meshes and polyester fiber meshes are laid and hung through the outward-exposing portion of the anchor rods and the anchor ropes, the steel bar meshes are closely attached to the surrounding rock to be laid, and the polyester fiber meshes are closely attached to the steel bar meshes to be laid; a steel bar mesh shell support is erected; the anchor rods and the anchor ropes pass through the steel bar meshes, the polyester fiber meshes and the steel bar mesh shell support in sequence and are fixed on the steel bar mesh shell support through trays and nuts; a first concrete shotcrete layer is poured to close the whole supporting structure, and initial supporting is finished; and finally, a second concrete shotcrete layer is poured, and second supporting is finished. Through initial supporting, the whole structure and the surrounding rock deforms jointly, the yielding effect is given play, and surrounding rock pressure is released, and then second supporting is conducted. Meanwhile, the flexibility and pressure releasing effects of the polyester fiber meshes are utilized, so that the surrounding rock pressure is evenly distributed in the whole supporting system.

Owner:ANHUI UNIV OF SCI & TECH

Fire-drive oil-production ignition method for metamorphic rock burial hill high-cogulation oil pool

Present invention relates to a metamorphic rock burial hill high pour-point oil reservoir fire flood ignition method. The difference of combustion of oil in-situ with other oil recovery method is utilizing high solidification points oil composition as fuel continuously generating, to drive in-place oil out of ground, current fire flood ignition method technology mainly used for symmetrical sand body and thin interbed, but it is difficult to be used for metamorphic rock burial hill high solidification points oil reservoir duo to low permeability of strata and porosity. Therefore said invention fills high-temperature air in well after to proceed manual pressing crack to ground, heating up high solidification points oil in rock pressure crack to above 400 degree centigrade, to make crude oil fluidal disposition, extracting crude oil from horizontal well, when oil layer burning, exhausting out burning layer air through gas recovery, to make whole oil layer being stable combustion state for raising recovery ratio. Said invention is simple and convenience for construction, can be widely used for metamorphic rock burial hill viscous crude, high solidification points oil exploitation.

Owner:尤尼斯油气技术(中国)有限公司

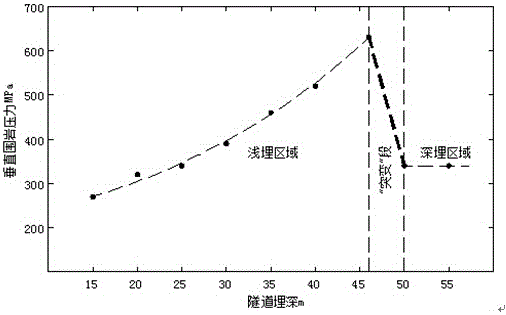

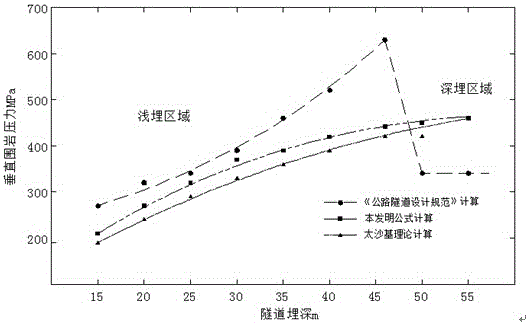

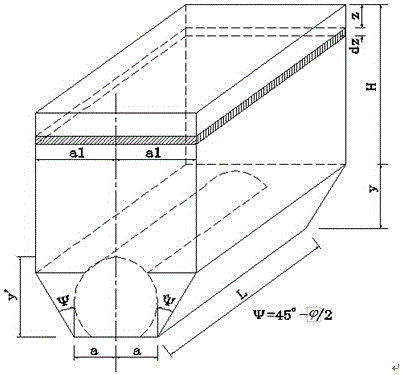

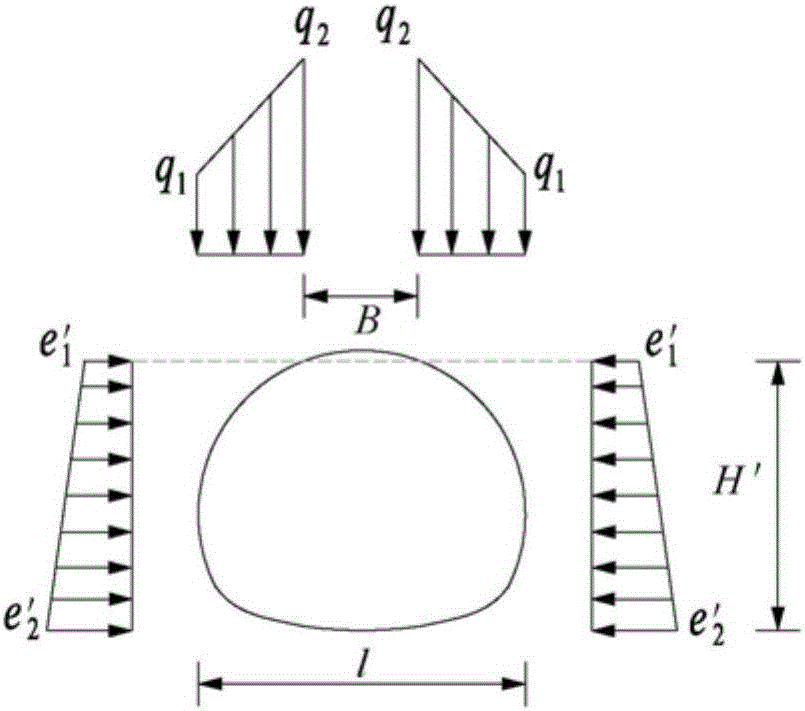

Universal design calculation method for deep/shallow-buried vertical surrounding rock pressure of tunnel and underground space

ActiveCN106383945AGeometric CADSpecial data processing applicationsClassical mechanicsStructural engineering

The invention discloses a universal design calculation method for deep / shallow-buried vertical surrounding rock pressure of a tunnel and an underground space. The method comprises the following steps of: 1, determining shapes and sizes of the tunnels and underground spaces: buried depth (H), unlined tunnel semi-width (alpha), stratum sliding surface semi-width (alpha1), tunnel height (y) and tunnel length (L); 2, determining physical parameters according to geological conditions and surrounding rock levels of the tunnel and the underground space: surrounding rock cohesive force (c), internal friction angle (phi), unit weight (gamma), Poisson ratio (mu) and initial side pressure coefficient (xi); 3, calculating and designing the following contents according to above known physical parameters: 3.1 average vertical ground pressure <delta>flat of the tops of deep / shallow caverns; 3.2 deep / shallow buried boundary depth Hmax, wherein the tunnel is a shallow-buried tunnel when the buried depth is less than Hmax, and the tunnel is a deep-buried tunnel when the buried depth is greater than or equal to Hmax; and 3.3 vertical ground pressure of the shallow-buried cavern. According to the method, no load mutation phenomenon is generated at the deep / shallow-buried boundaries, and through plenty of actual measurements and verifications, the condition is identical to the practical condition.

Owner:中国市政工程西北设计研究院有限公司

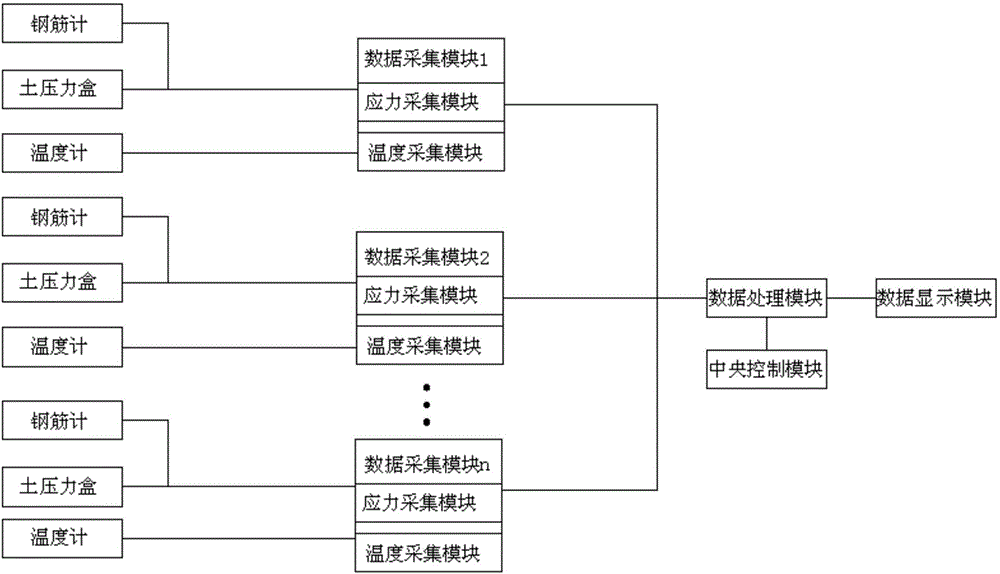

Surrounding rock pressure-frost heaving force monitoring system for tunnel in cold region and mounting method thereof

InactiveCN104481592AImprove practicalityThe test data is complete and reliableMining devicesData displayReal-time data

The invention belongs to the technical field of monitoring of tunnels, and specifically relates to a surrounding rock pressure-frost heaving force monitoring system for a tunnel in a cold region and a mounting structure of the monitoring system. The system comprises a plurality of sensor modules which are arranged on a testing section to measure real-time data, a plurality of data acquiring modules which are arranged on each testing section to acquire the data of the sensor modules, data processing module for collecting and processing the data acquired by the data acquiring modules, a central control module for controlling the working states of the data acquiring modules and the data processing modules, and a data display module for displaying the data acquired by the data acquiring modules; the data acquiring modules are respectively connected with the sensor modules and the data processing module; the data processing module is respectively connected with the central control module and the data display module. The monitoring system has the advantages that the gradations are distinct, all testing sections are connected in parallel for working, and the damage of some testing section does not influence the work on other testing sections, so that the practicability is high; in addition, the testing data are complete and reliable, the data processing is simple and clear, the data continuity is high, and therefore, the analysis can be conveniently carried out.

Owner:CHANGAN UNIV

A tunnel composite lining design method comprising secondary lining under the action of multiple loads

ActiveCN109885911ARealize Quantitative DesignGuaranteed reliabilitySpecial data processing applicationsShotcreteConstant load

The invention relates to a tunnel composite lining design method comprising secondary lining under the action of multiple loads. The secondary lining not only bears the surrounding rock pressure, butalso bears the water pressure, structure additional constant loads and other loads; and through the safety coefficient distribution, the safety coefficients of the anchor rod-surrounding rock bearingarch, the sprayed concrete layer and the secondary lining are obtained, and the corresponding initial design parameters are obtained through respective calculation models and surrounding rock pressure. The parameters of the secondary lining are planned again, so that the safety coefficient of the secondary lining under load combination of surrounding rock pressure, water pressure, structure additional constant load and the like is not lower than that of the distributed secondary lining. By checking whether the secondary lining parameters can meet the requirements of the standard for the safety coefficient of the single structure or not according to the secondary lining construction opportunity, and obtaining the secondary lining parameters meeting the requirements, and comparing with theinitial design parameters of the secondary lining, and checking and adjusting the safety coefficient distribution values of the anchor rod surrounding rock bearing arch and the spraying layer, the parameters of the anchor rod and the spraying layer are determined, and the quantitative design of the composite lining is realized.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

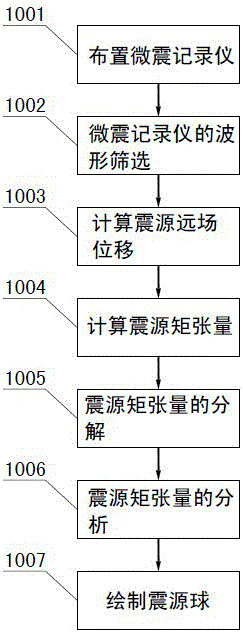

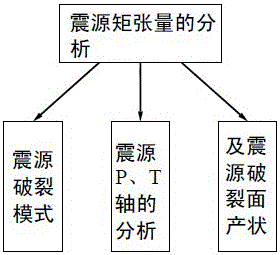

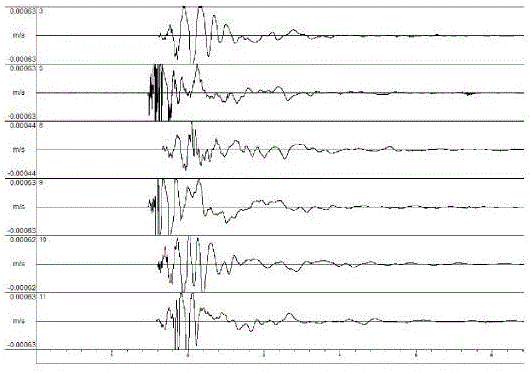

Micro-seismic identification method based on coal petrography impact instability mode

ActiveCN106154307AHigh precisionImprove applicabilityEarthquake measurementSeismic signal processingMicrotremorDecomposition

The invention, which belongs to the technical field of the micro-seismic characteristic analysis of the impact rock pressure, provides a micro-seismic identification method based on a coal petrography impact instability mode. The method comprises: step 1001, a plurality of microseismographs are arranged at different positions at a same stope to carry out micro-seismic monitoring and each microseismograph forms a micro-seismic signal record; step 1002, a plurality of micro-seismic waveforms are screened among the micro-seismic records monitored by the microseismographs; step 1003, on the basis of a focus far-field displacement calculation step, a focus far-field displacement value of each micro-seismic waveform is calculated; step 1004, calculation is carried out to obtain a focus moment tensor; step 1005, the focus moment tensor obtained by calculation at the step 1004 is decomposed; and step 1006, the focus moment tensor after decomposition at the step 1005 is analyzed to obtain a focus fracture mode, focus P and T axes, and focus fracture plane occurrence.

Owner:CHINA UNIV OF MINING & TECH

High-intensity large-shrinkage sealed cambered-plate support structural element

InactiveCN104763442ASolve stressSolve the large amount of deformationUnderground chambersTunnel liningReinforced concreteHigh intensity

The invention discloses a high-intensity large-shrinkage sealed cambered-plate support structural element. The structural element comprises a circular structure defined by four to eight reinforcement concrete cambered plates. A yielding wood block is arranged between the adjacent reinforcement concrete cambered plates. Corresponding pin holes and connection steel pins are formed at the end of the adjacent reinforcement concrete cambered plates. The connection steel pins are inserted in the pin holes to connect the two adjacent sections of cambered plates in series, and pressure relief windows are formed in bottom cambered plates. The structural element has the advantages of being large in shrinkage, reliable in structural stability, fast in construction speed and capable of solving the technical problems of large deep-well soft-rock roadway surrounding rock pressure, large deformation and poor stability effectively.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

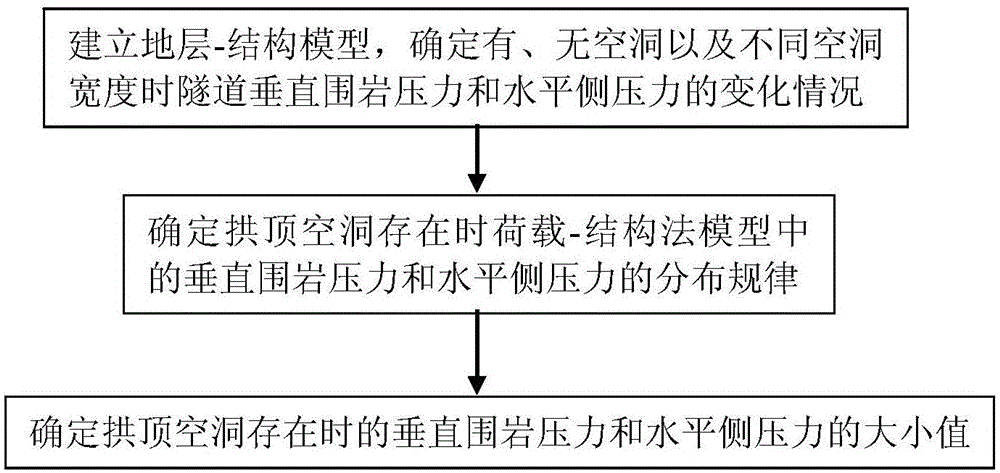

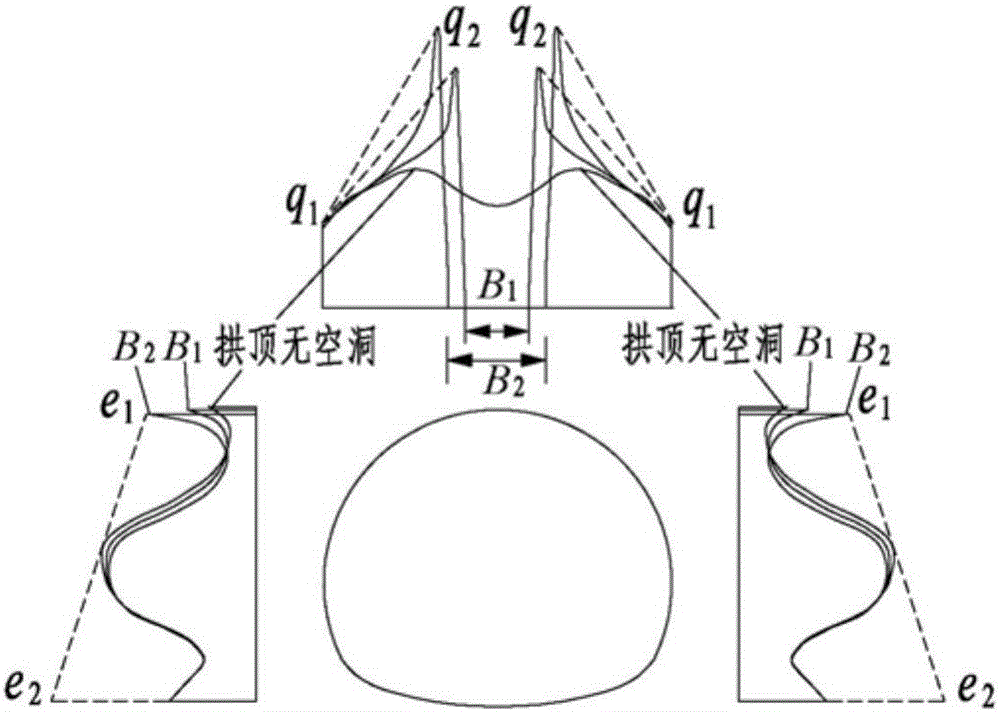

Method for determining surrounding rock pressure of tunnel having cavity behind lining

ActiveCN106570276AAssess securityDesign optimisation/simulationSpecial data processing applicationsStructure of the EarthClerestory

The invention relates to the field of tunnel engineering, and in particular relates to a method for determining the surrounding rock pressure of a tunnel having a cavity behind a lining. By means of the method, disappearance of the surrounding rock pressure of an area, where a cavity is, is considered; furthermore, on the basis of revealing the distribution rule and size of the surrounding rock pressure when the cavity exists, the change feature of the surrounding rock pressure when the cavity exists is considered; and thus, the security of a lining structure when the cavity exists can be evaluated more comprehensively. The method disclosed by the invention comprises the following steps of: (1), respectively establishing tunnel stratum-structure models when a cavity exists or does not exist on the arch of the lining, and then, obtaining the change conditions of the vertical surrounding rock pressure and the horizontal lateral pressure of the tunnel through finite element calculation and analysis when the cavity exists or does not exist and when cavity widths are different; (2), determining the distribution rules of the vertical surrounding rock pressure and the horizontal lateral pressure in a load-structure method model when the cavity exists on the arch exists; and (3), determining the values of the vertical surrounding rock pressure and the horizontal lateral pressure when the cavity exists on the arch exists.

Owner:CHANGAN UNIV

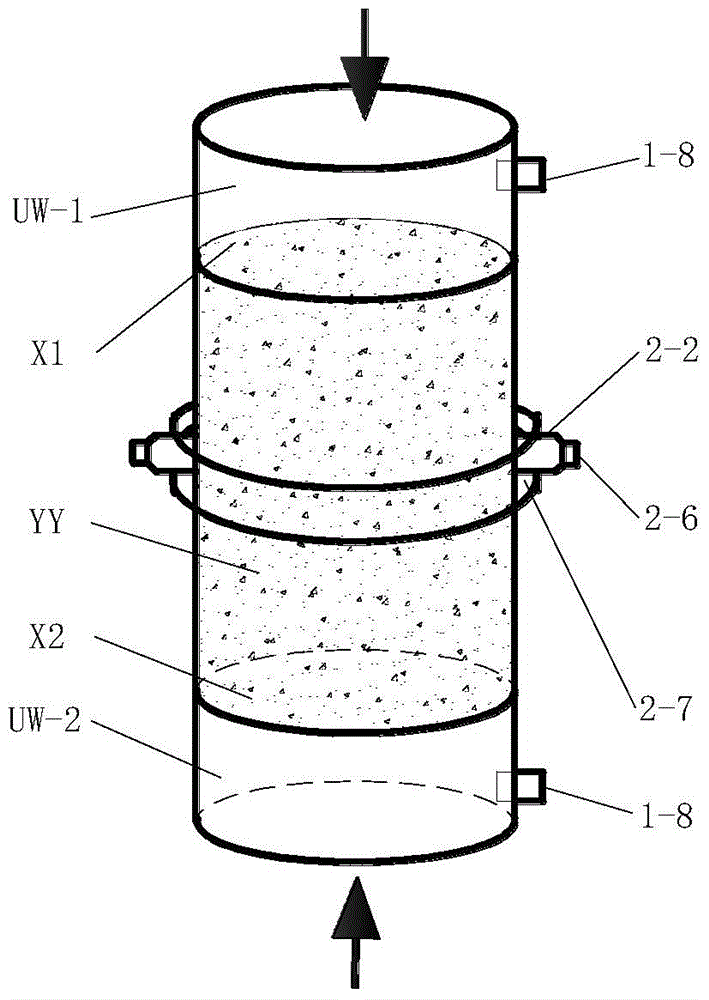

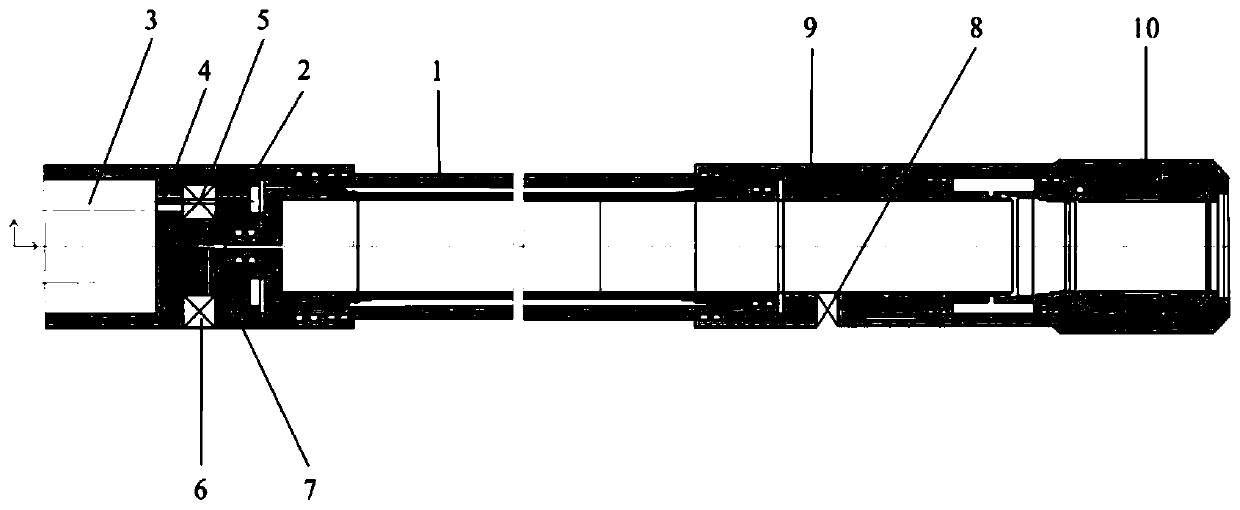

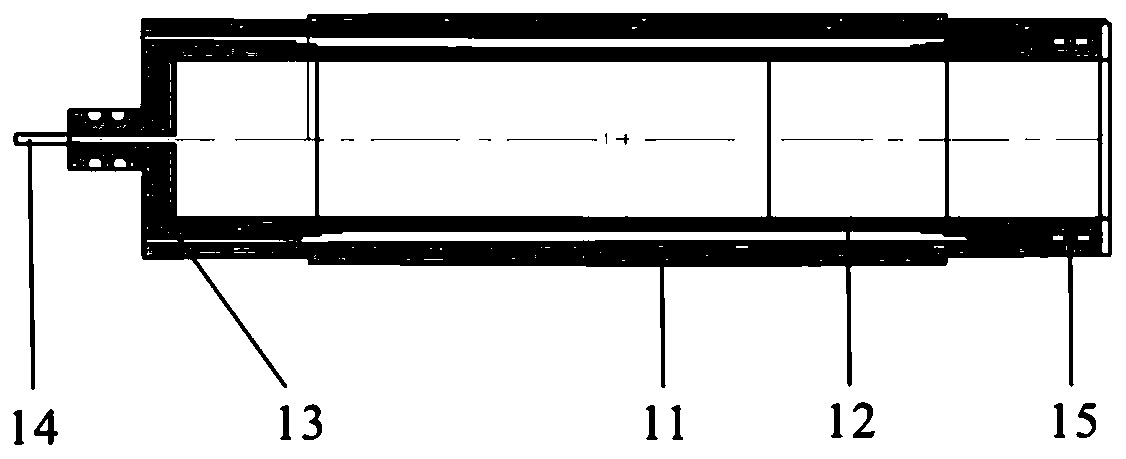

Coal rock pressure-maintaining coring inner barrel

ActiveCN111335837AAccurate measurementImplement Penetration TestingCore removalThermodynamicsRock core

The invention discloses a coal rock pressure-maintaining coring inner barrel. An inner rubber sleeve is inserted into an outer tube of a rock core holding barrel, a confining pressure cavity is formedbetween the inner rubber sleeve and the inner wall of the outer tube of the holding barrel, sealing plugs and sealing rings are arranged at the two ends of the inner rubber sleeve, the sealing plug and the sealing ring at the upper end are used in cooperation to seal an upper end opening of the confining pressure cavity, the sealing plug and the sealing ring at the lower end are used in cooperation to seal a lower end opening of the confining pressure cavity, one end of an upper end connecting piece is connected with the upper end of the rock core holding barrel in a sealed mode, the other end of the upper end connecting piece is connected with a pressure supply bin, the pressure supply bin is communicated with the confining pressure cavity through a pressure supply pipeline, and a pressure supply valve is arranged on the pressure supply pipeline and used for controlling supply of fluid of reference pressure; and one end of a lower end connecting piece is hermetically connected with the lower end of the hollow rock core holding barrel, the other end of the lower end connecting piece is connected with a ball valve, an outlet pipeline is arranged at the upper end of the rock core holding barrel, and the outlet pipeline at the upper end is provided with an upper end outlet valve. By means of the coal rock pressure-maintaining coring inner barrel, accurate measurement of the gas content can be guaranteed, and the coal rock stratum condition permeability can be tested without taking out a rock core.

Owner:PETROCHINA CO LTD

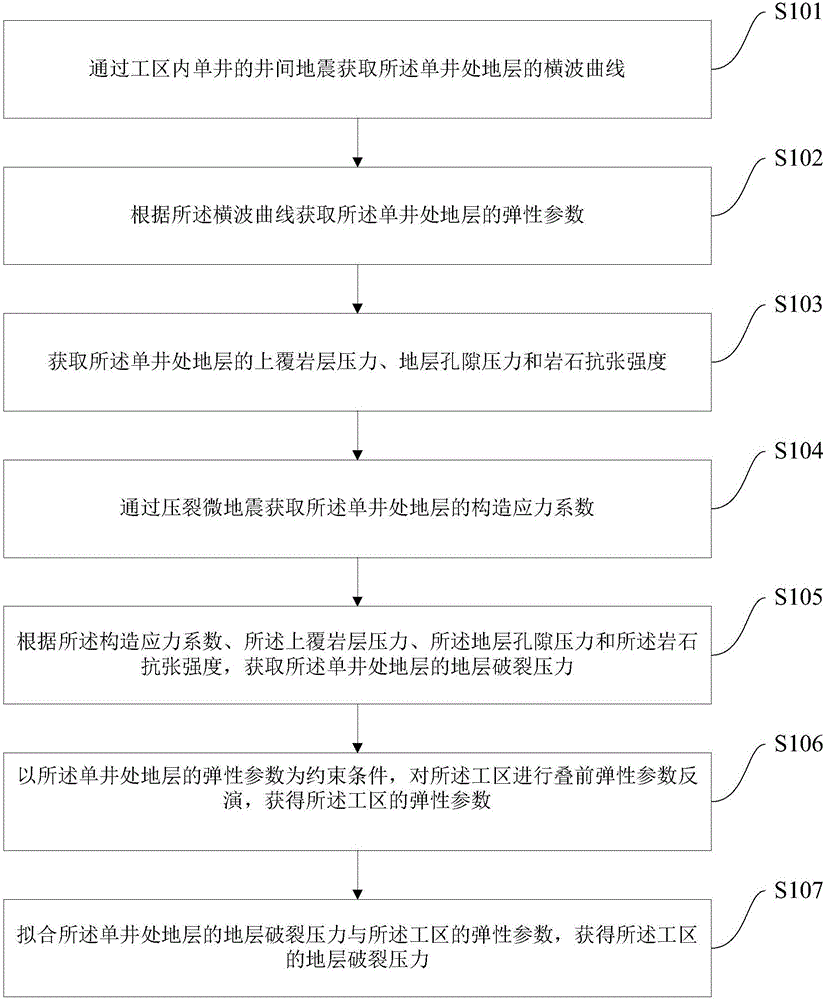

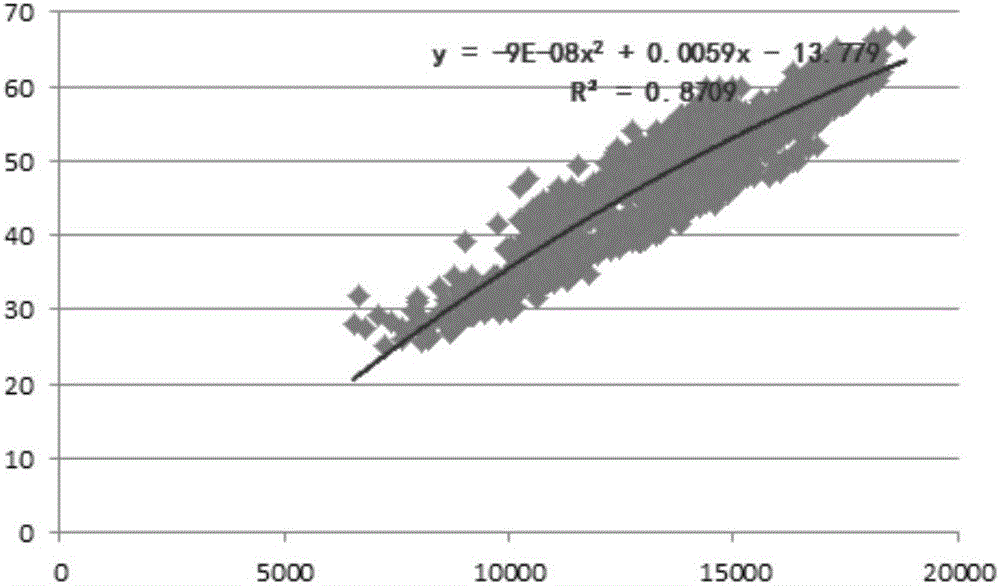

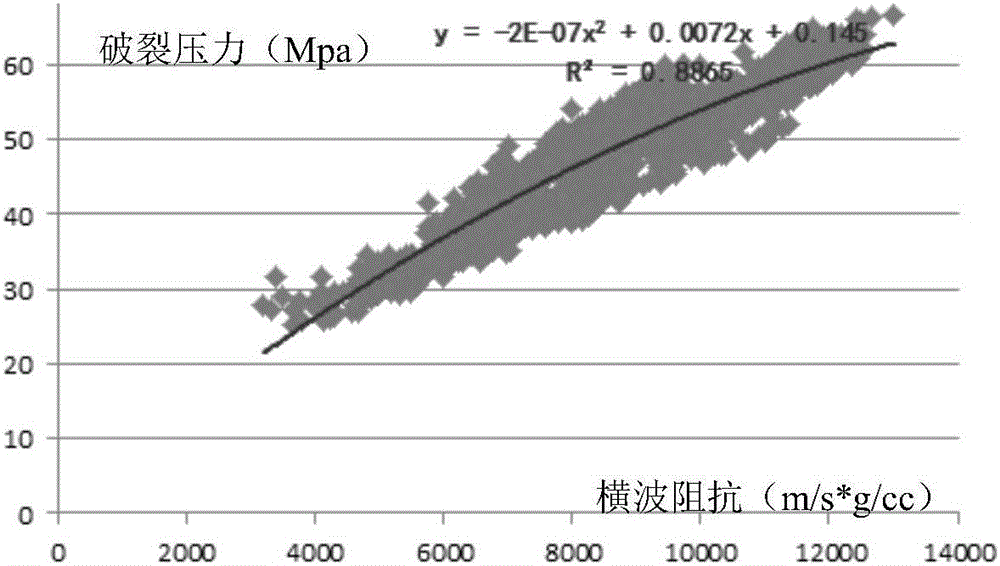

Stratum rupture pressure prediction method

InactiveCN106324680AHigh precisionSeismic signal processingSeismology for water-loggingTectonic stressGeomorphology

The invention provides a stratum rupture pressure prediction method. The stratum rupture pressure prediction method comprises steps of obtaining a transverse wave curve of a stratum at a single well through earthquake between single wells in a work area; obtaining an elastic parameter of the single well according to the transverse wave curve; obtaining overlaying rock pressure, the stratum formation pore pressure and rock tension resistance strength of the stratum at the single well; obtaining a tectonic stress coefficient of the single well through a fracture micro-earthquake; obtaining the stratum rupture pressure of the stratum at the single well according to the tectonic stress coefficient, the overlaying rock stratum pressure, the stratum pore pressure and the rock tension resistance strength; performing pre-stack elastic parameter inversion on the work area to obtain the elastic parameter of the work area by using the elastic parameter of the stratum of the single well as a constraint condition; and fitting the stratum rupture pressure of the stratum at the single well and the elastic parameter of the work area to obtain the stratum rupture pressure of the work area. The stratum rupture pressure prediction method can improve the prediction accuracy of the stratum rupture pressure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

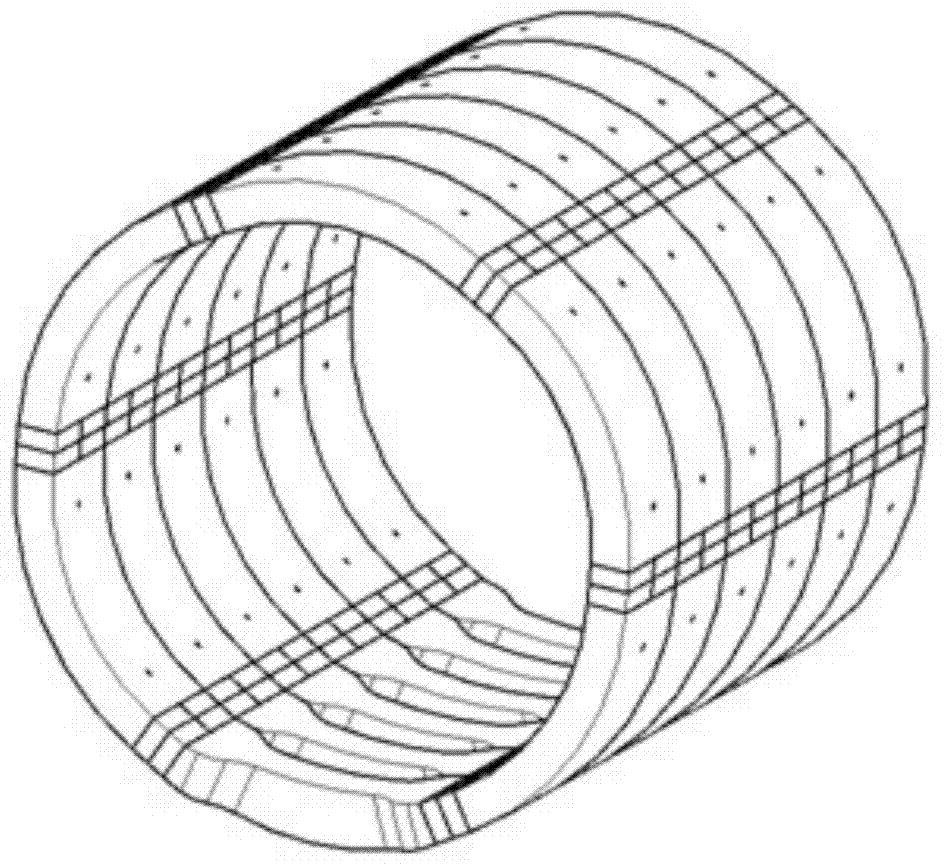

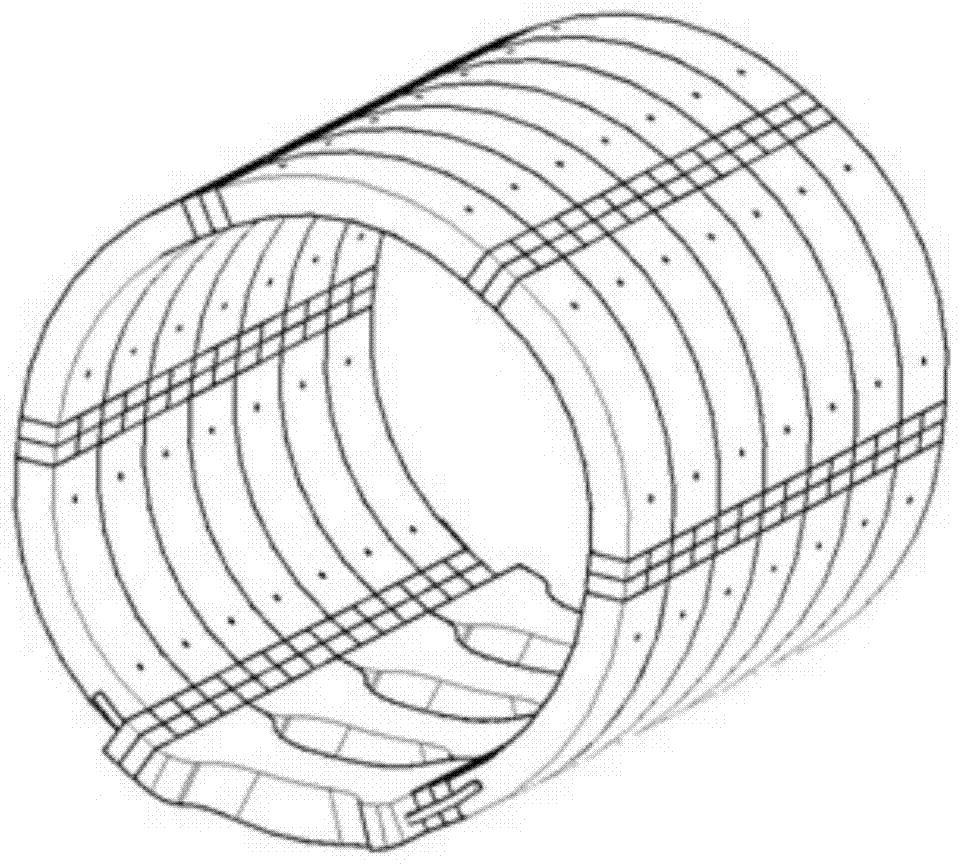

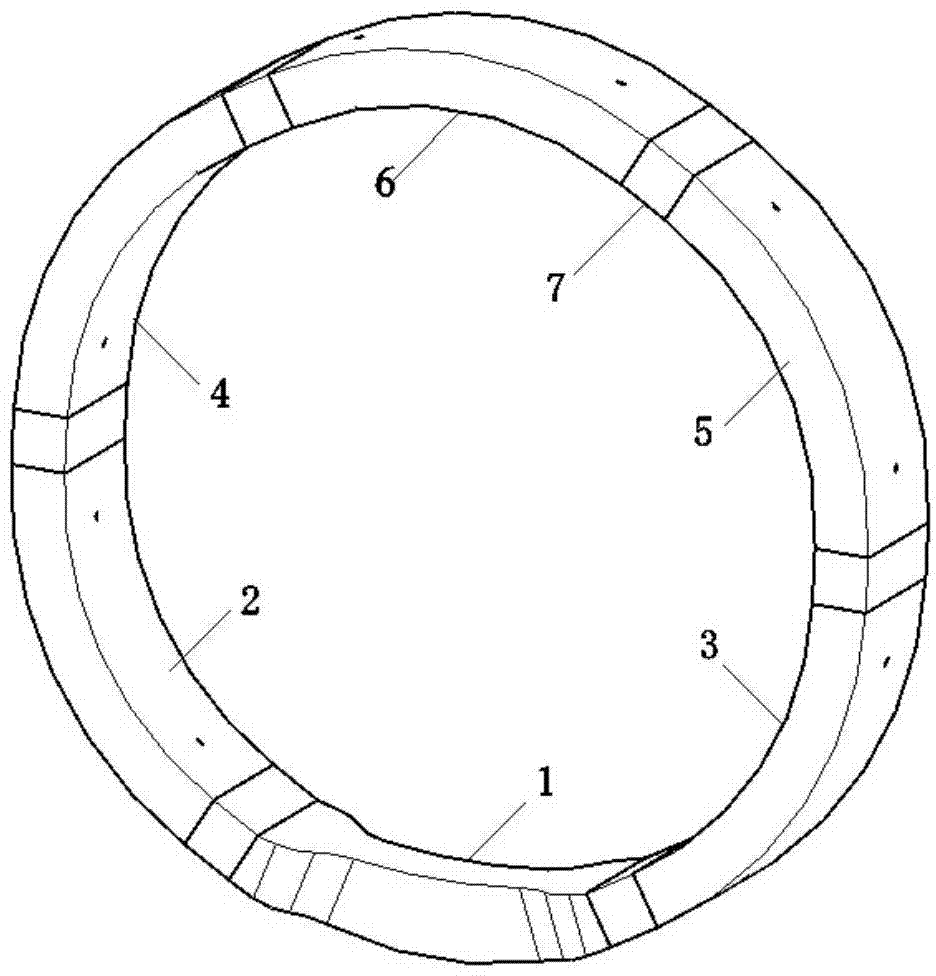

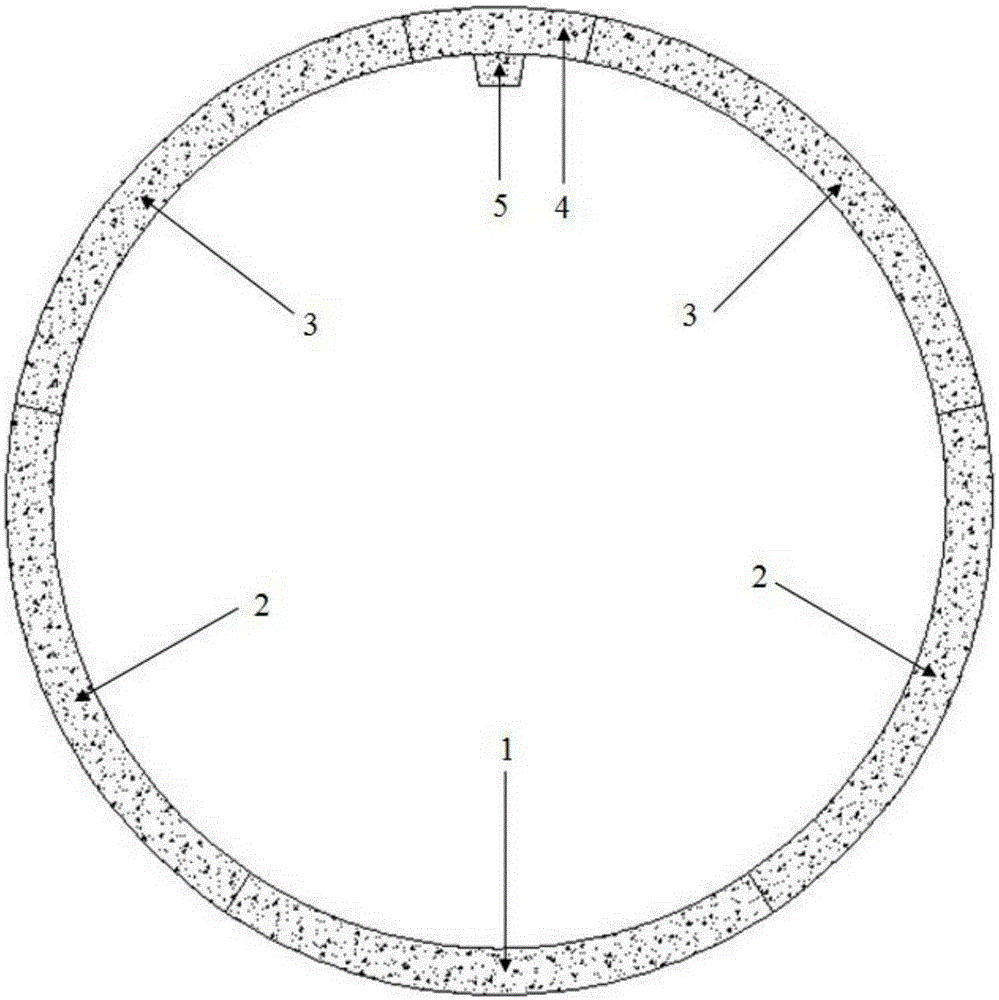

Circumferential prestress strengthening tunnel segment and manufacturing method

ActiveCN105178983AGuaranteed stressPrevent openingUnderground chambersTunnel liningPre stressEngineering

The invention relates to a circumferential prestress strengthening tunnel segment and a manufacturing method. A tunnel segment part mainly comprises an arch bottom block, wherein one adjacent block is arranged at each of two ends of the arch bottom block; a connection block clings to the end part of each adjacent block; a top sealing block is arranged between the two connection blocks; reserved grooves are formed in the outer side of the arch bottom block, the outer sides of the adjacent blocks, the outer sides of the connection blocks and the outer side of the top sealing block; reserved channels are formed in the inner part of the top sealing block; after steel strands pre-tighten the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block through the reserved grooves, the end parts of the steel strands penetrate through the top sealing block and protrude out of the sealing block; each steel strand protruding out of the top sealing block is fixed by a lockset, so that the prestress application is realized; the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block together form a closed cylindrical structure. Through the adoption of the tunnel segment provided by the invention, the integrality of the segment and the capability of resisting surrounding rock pressure can be effectively improved, and the manufacturing method is time-saving and material-saving.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

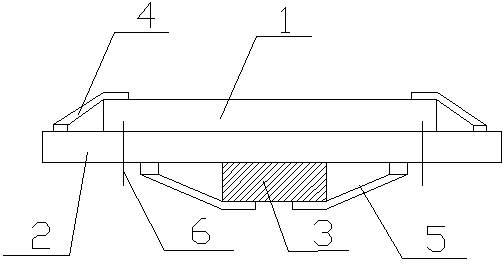

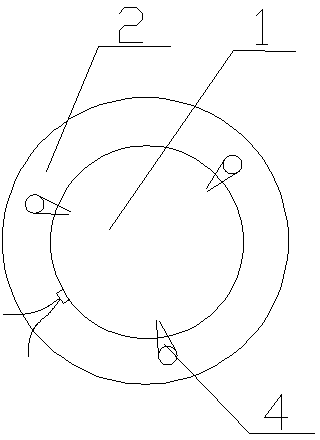

Rock tunnel surrounding rock pressure gauge fixing device

InactiveCN103822739AFlexible posture adjustmentImprove the fixing strengthUnderground chambersForce measurementGauge fixingStructural engineering

The invention discloses a rock tunnel surrounding rock pressure gauge fixing device. The rock tunnel surrounding rock pressure gauge fixing device comprises a base plate and a steel arch, wherein a pressure gauge is fixed to the base plate through fastening screws, the base plate is fixed to the steel arch through positioning screws, and a plurality of adjustment bolts used for adjusting the inclination angel of the pressure gauge are arranged between the base plate and the steel arch, so that the pressure gauge can be closely attached to a surrounding rock excavation face. The rock tunnel surrounding rock pressure gauge fixing device is simple in structure and convenient to operate, the angle of the pressure gauge and the angle of excavated surrounding rock can be adjusted effectively through the adjustment bolts, the spatial posture of the pressure gauge can be adjusted flexibly due to the fact that both the adopted fastening screws and the adopted positioning screws are elastic, and the fixing strength of the pressure gauge is improved effectively due to the fact that the base plate is fixed to the steel arch.

Owner:LUOYANG INST OF SCI & TECH

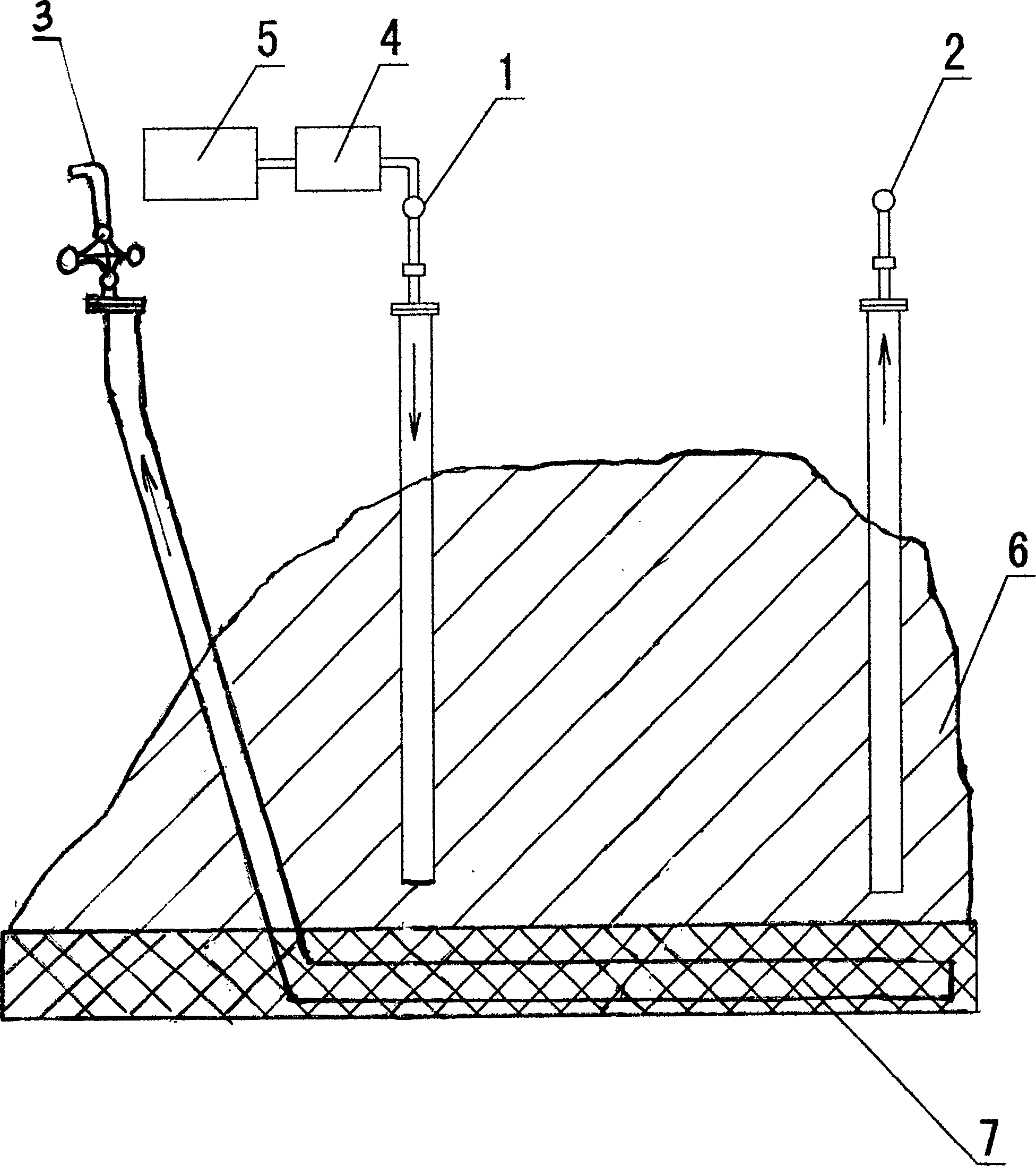

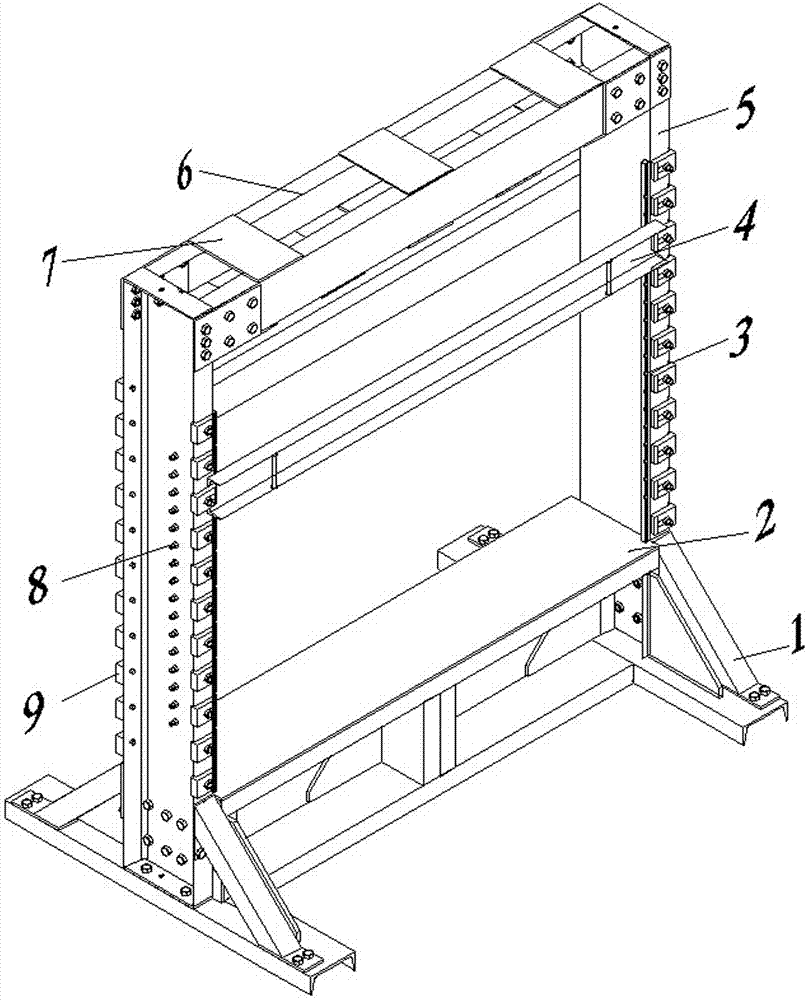

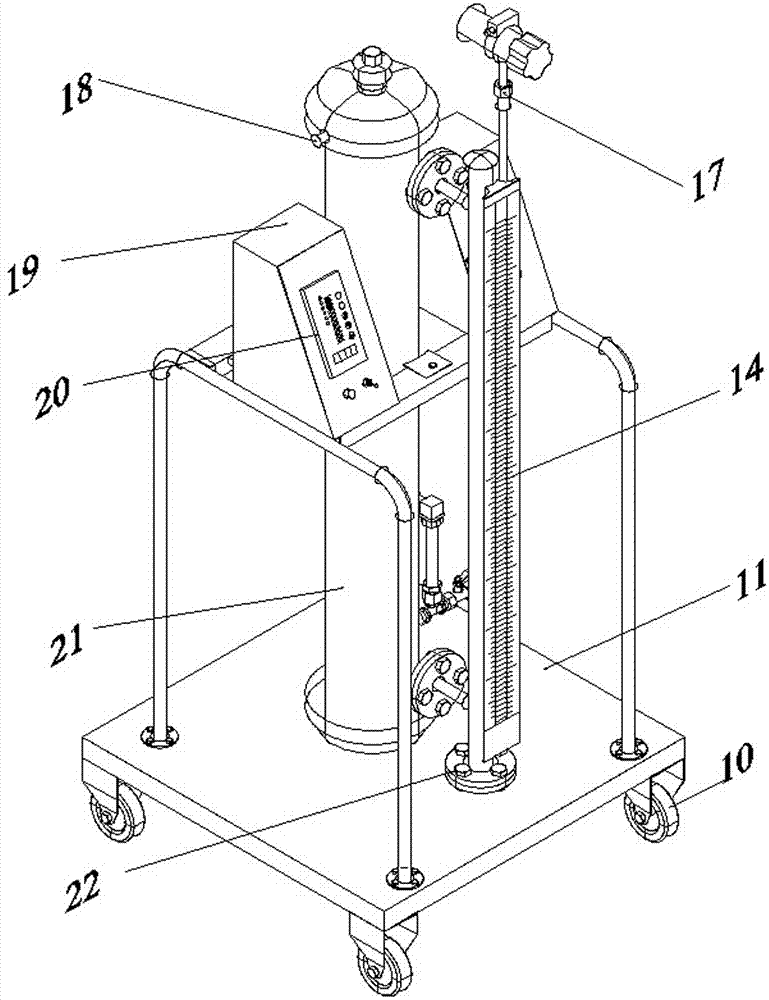

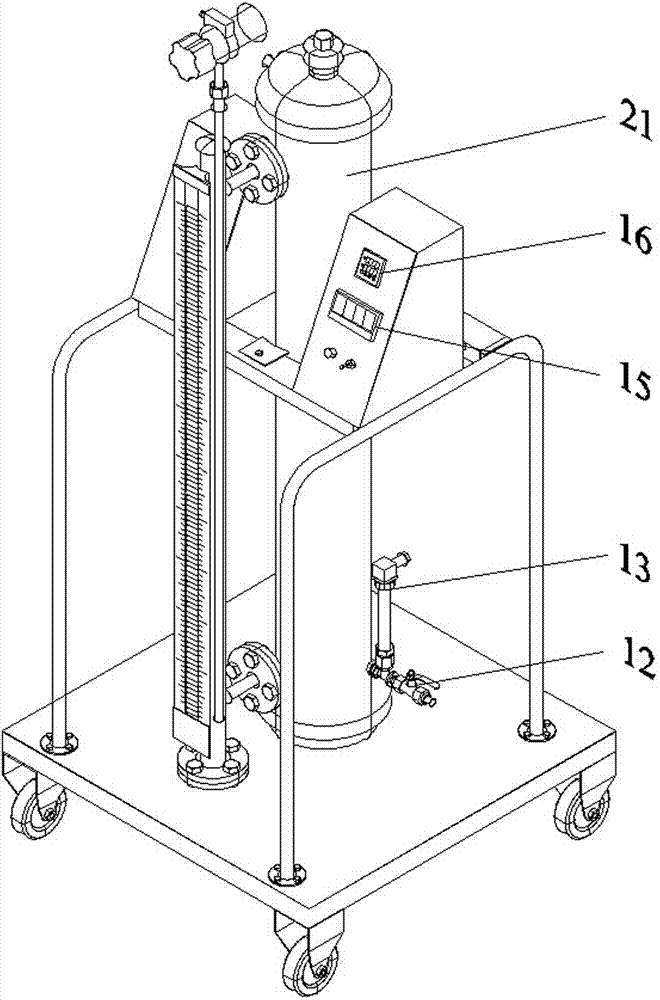

Experimental device for simulating overlaying strata migration and water and sand bursting of underground coal mining

ActiveCN104849428AImprove work efficiencyEasy maintenanceEarth material testingSoil scienceConfined water

The invention discloses an experimental device for simulating overlaying strata migration and water and sand bursting of underground coal mining, and belongs to the technical field of coal mining. By using the experimental device, a similar material simulation experiment of real-time monitoring of water pressure and water volume of an overlaying aquifer during coal mining below the aquifer. One end of a water injection high-pressure hose is connected with a water drain valve of a pressure water tank in a surface water pressure simulation experimental device, and the other end of the water injection high-pressure hose is connected with a water inlet joint on a rock pressure model frame; one end of a gas injection high-pressure hose is connected with a gas inlet joint of the pressure water tank in the surface water pressure simulation experimental device, and the other end of the gas injection high-pressure hose is connected with a gas outlet joint of a gas storage tank. The device can be widely applied to similar simulation experiments of overlaying strata migration and water and sand bursting of coal mining below an upper overlaying water body or on a pressure bearing water body.

Owner:NORTH CHINA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com