Patents

Literature

41 results about "Fracture geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method Of Manufacture And The Use Of A Functional Proppant For Determination Of Subterranean Fracture Geometries

ActiveUS20090288820A1Accurate imagingPromote recoveryMaterial nanotechnologyElectric/magnetic detection for well-loggingElectricityGeophone

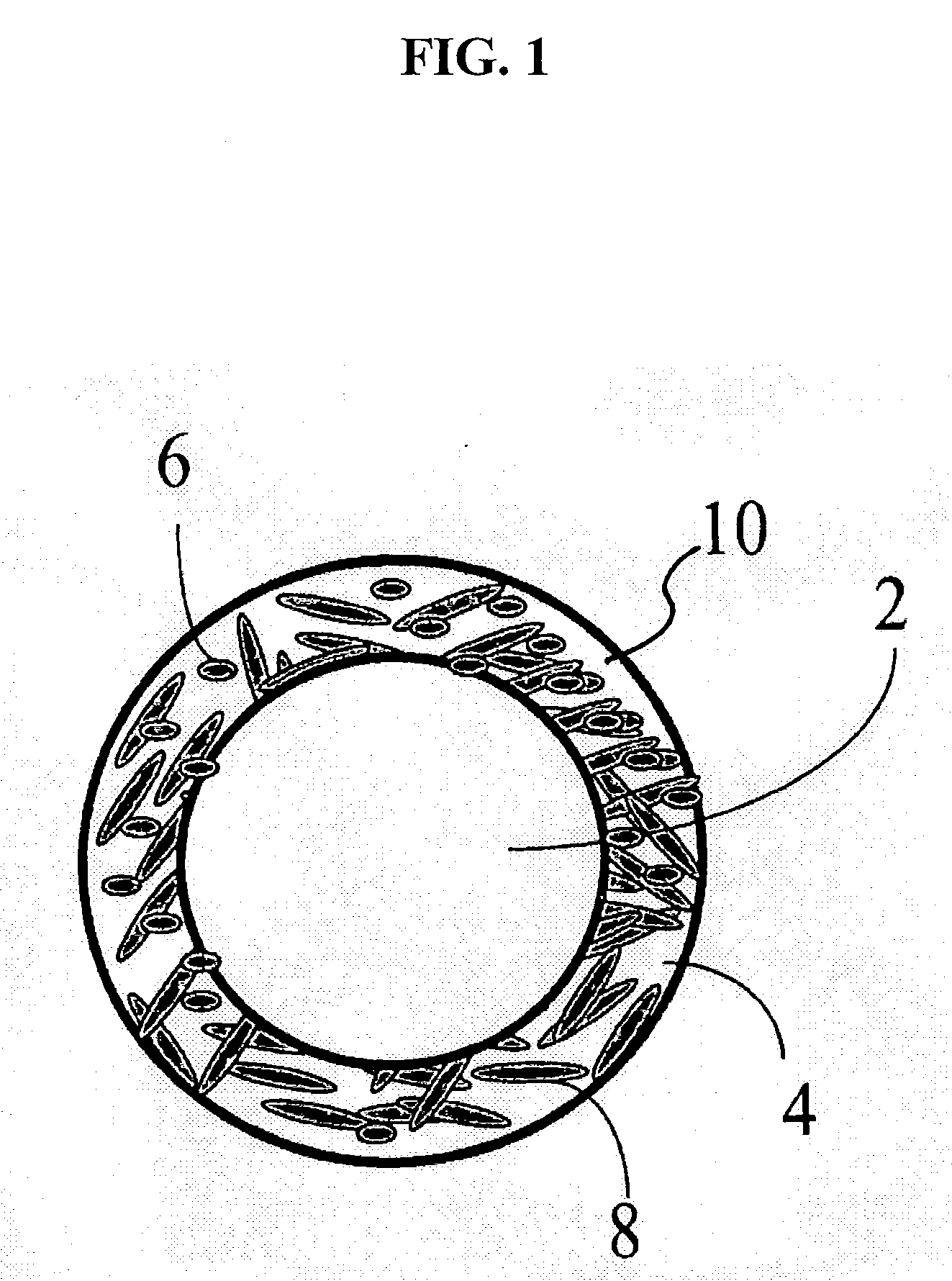

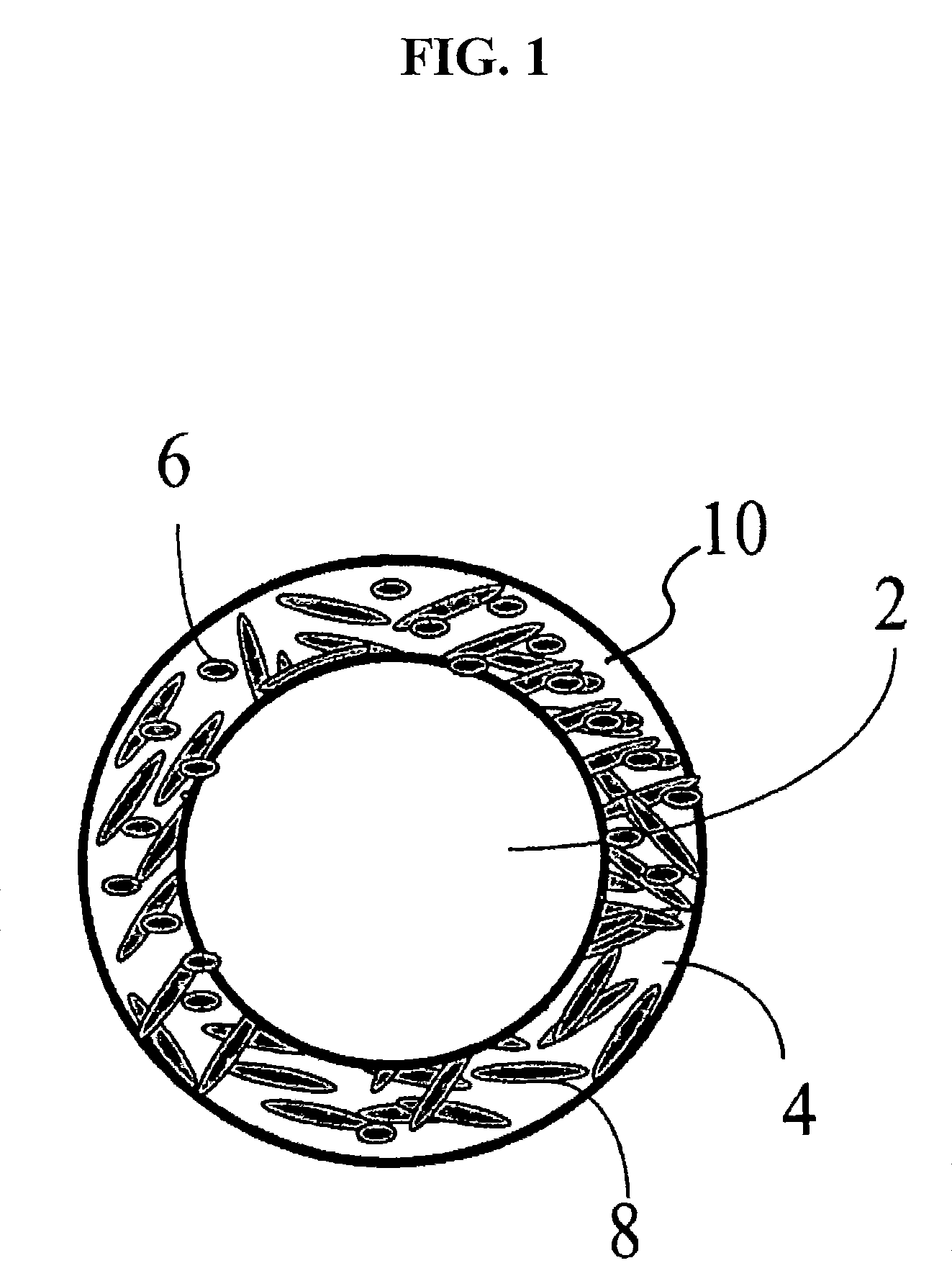

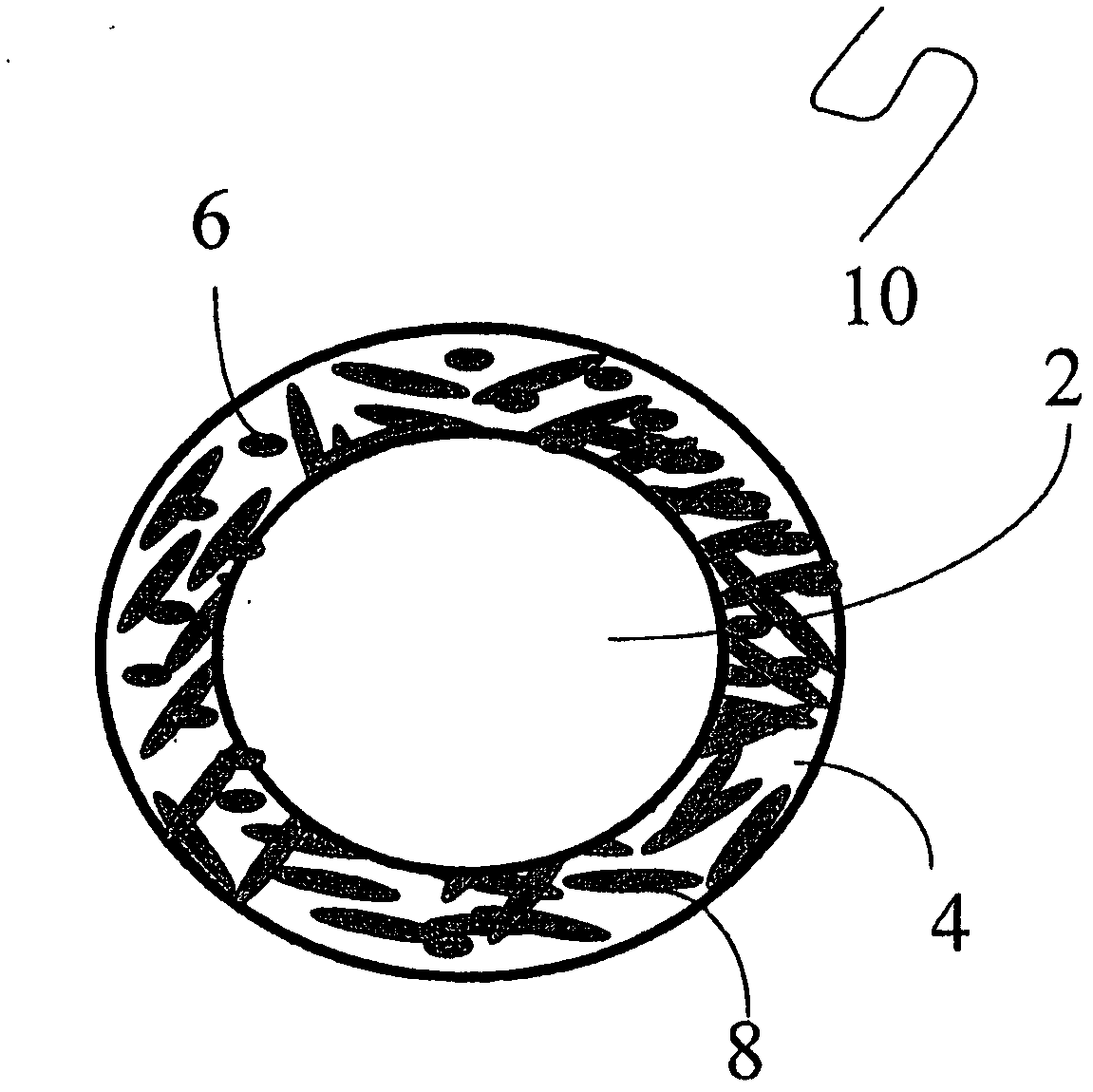

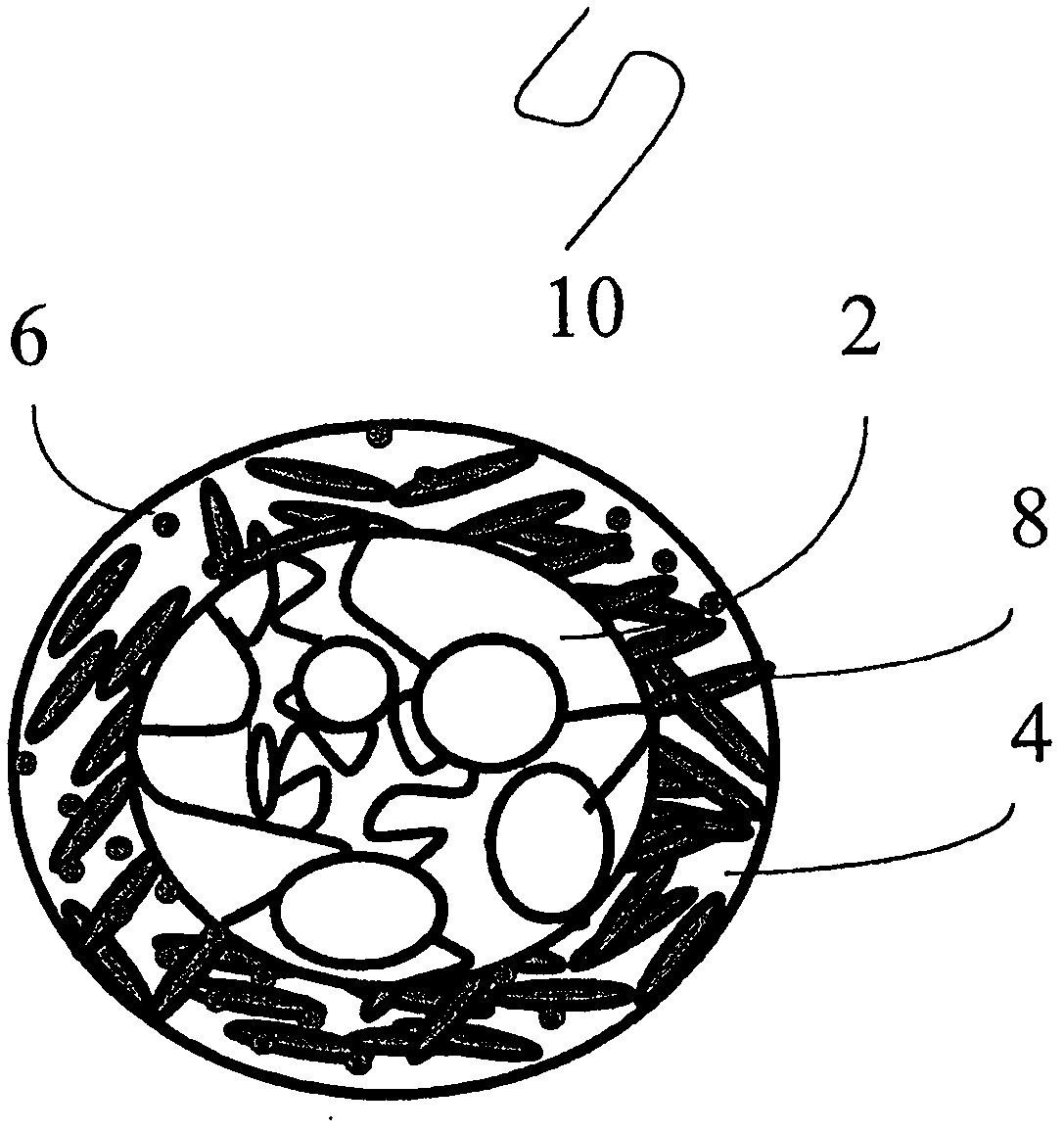

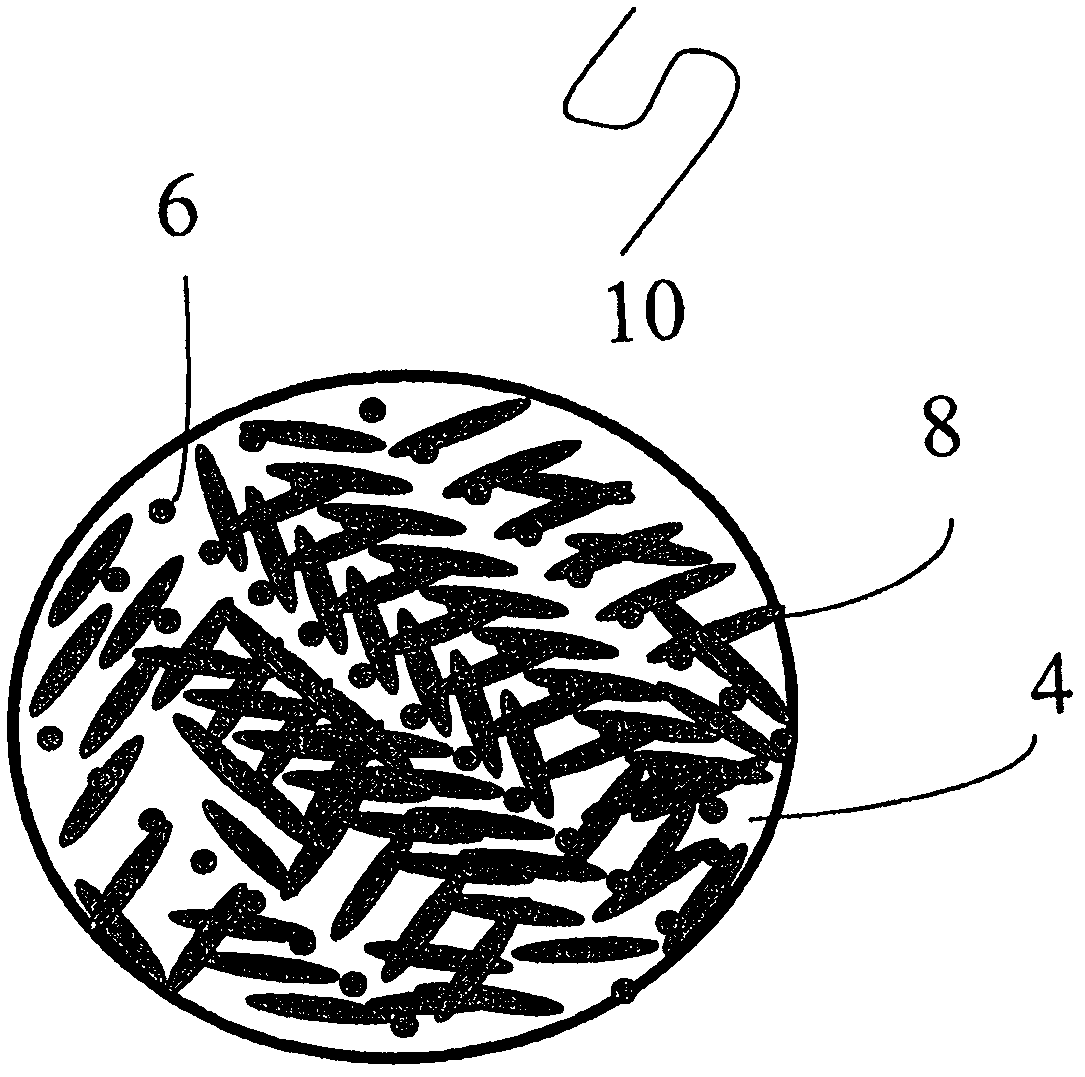

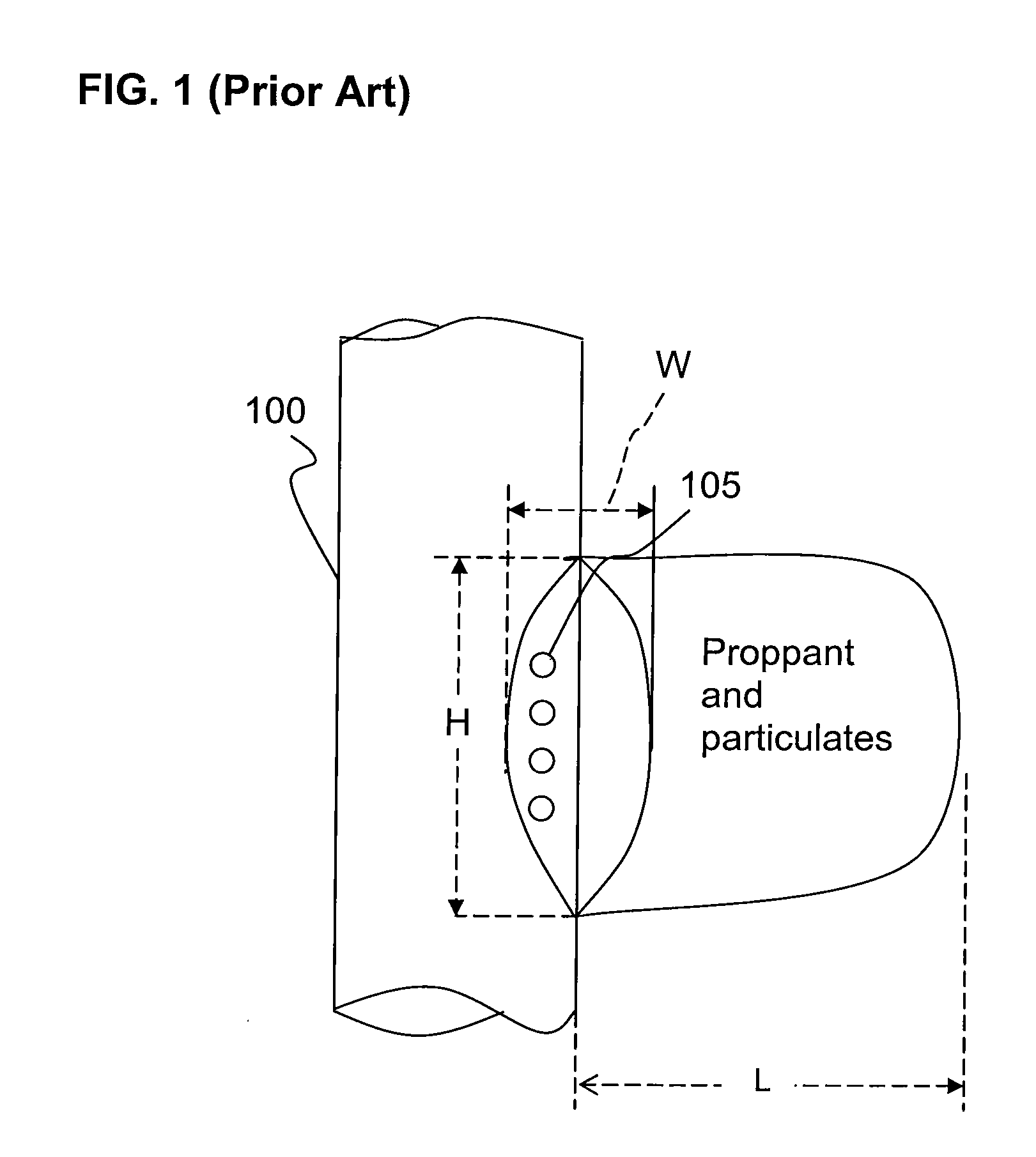

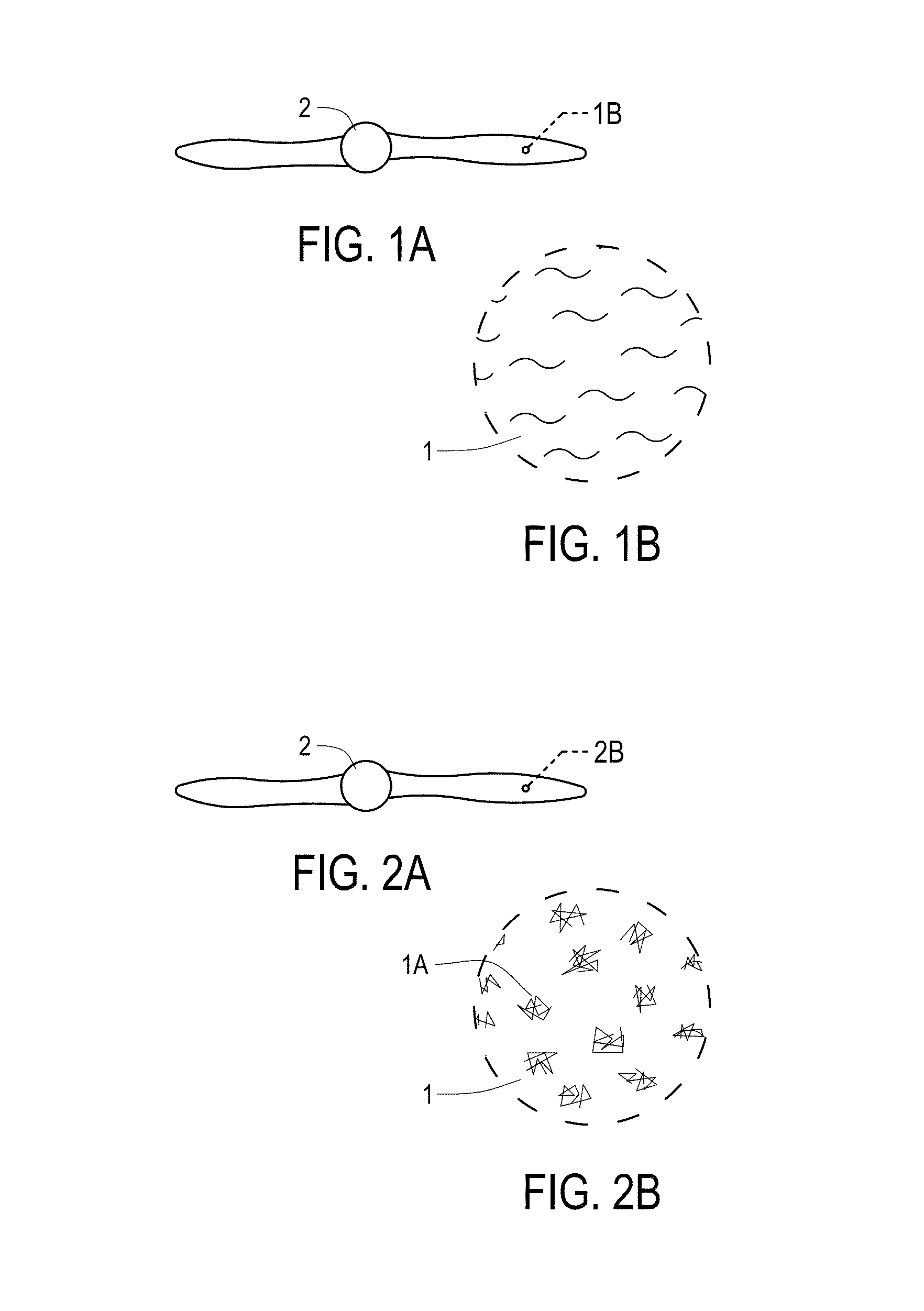

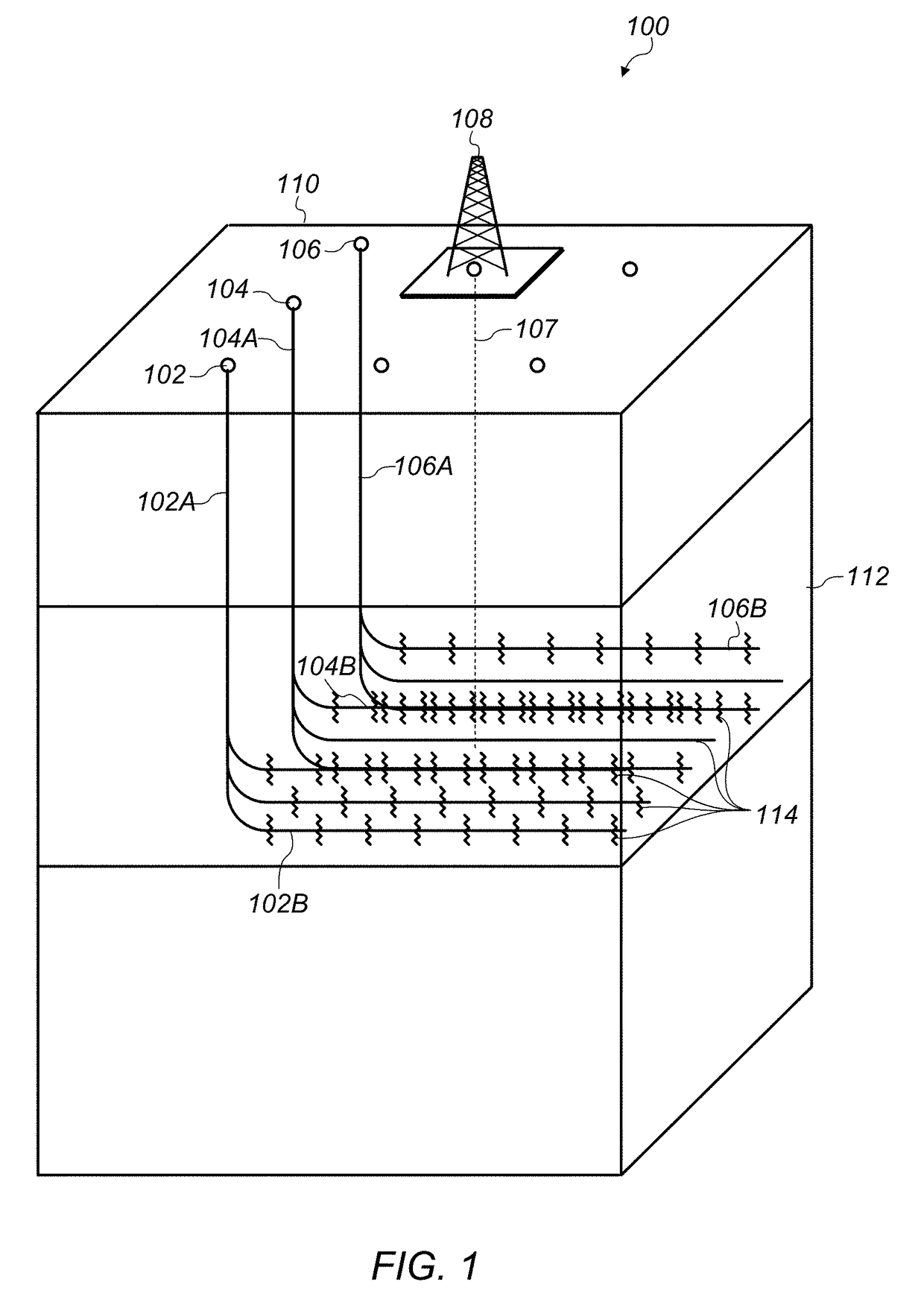

Proppants having added functional properties are provided, as are methods that use the proppants to track and trace the characteristics of a fracture in a geologic formation. Information obtained by the methods can be used to design a fracturing job, to increase conductivity in the fracture, and to enhance oil and gas recovery from the geologic formation. The functionalized proppants can be detected by a variety of methods utilizing, for example, an airborne magnetometer survey, ground penetrating radar, a high resolution accelerometer, a geophone, nuclear magnetic resonance, ultra-sound, impedance measurements, piezoelectric activity, radioactivity, and the like. Methods of mapping a subterranean formation are also provided and use the functionalized proppants to detect characteristics of the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Means and method for assessing the geometry of a subterranean fracture during or after a hydraulic fracturing treatment

A method is given of fracturing a subterranean formation including the step of a) pumping at least one device actively transmitting data that provide information on the device position, and further comprising the step of assessing the fracture geometry based on the positions of said at least one device, or b) pumping metallic elements, preferably as proppant agents, and further locating the position of said metallic elements with a tool selected from the group consisting of magnetometers, resistivity tools, electromagnetic devices and ultra-long arrays of electrodes, and further comprising the step of assessing the fracture geometry based on the positions of said metallic elements. The method allows monitoring of the fracture geometry and proppant placement.

Owner:SCHLUMBERGER TECH CORP

Method of manufacture and the use of a functional proppant for determination of subterranean fracture geometries

ActiveUS8168570B2Accurate imagingPromote recoveryElectric/magnetic detection for well-loggingMaterial nanotechnologyGeophoneElectricity

Proppants having added functional properties are provided, as are methods that use the proppants to track and trace the characteristics of a fracture in a geologic formation. Information obtained by the methods can be used to design a fracturing job, to increase conductivity in the fracture, and to enhance oil and gas recovery from the geologic formation. The functionalized proppants can be detected by a variety of methods utilizing, for example, an airborne magnetometer survey, ground penetrating radar, a high resolution accelerometer, a geophone, nuclear magnetic resonance, ultra-sound, impedance measurements, piezoelectric activity, radioactivity, and the like. Methods of mapping a subterranean formation are also provided and use the functionalized proppants to detect characteristics of the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and compositions for fracturing subterranean formations

Owner:BAKER HUGHES INC

Evaluation of fracture geometries in rock formations

InactiveUS20050017723A1Minimize the differenceError minimizationElectric/magnetic detection for well-loggingSurveyFracturing fluidElectric field

A method of evaluating the geometry of a hydraulic fracture in a rock formation comprises the steps of: obtaining measured values of electric and / or magnetic fields induced by the forward or back propagation of a fracturing fluid between the fracture and the rock formation; and determining the geometry of the fracture from the measured values.

Owner:SCHLUMBERGER TECH CORP

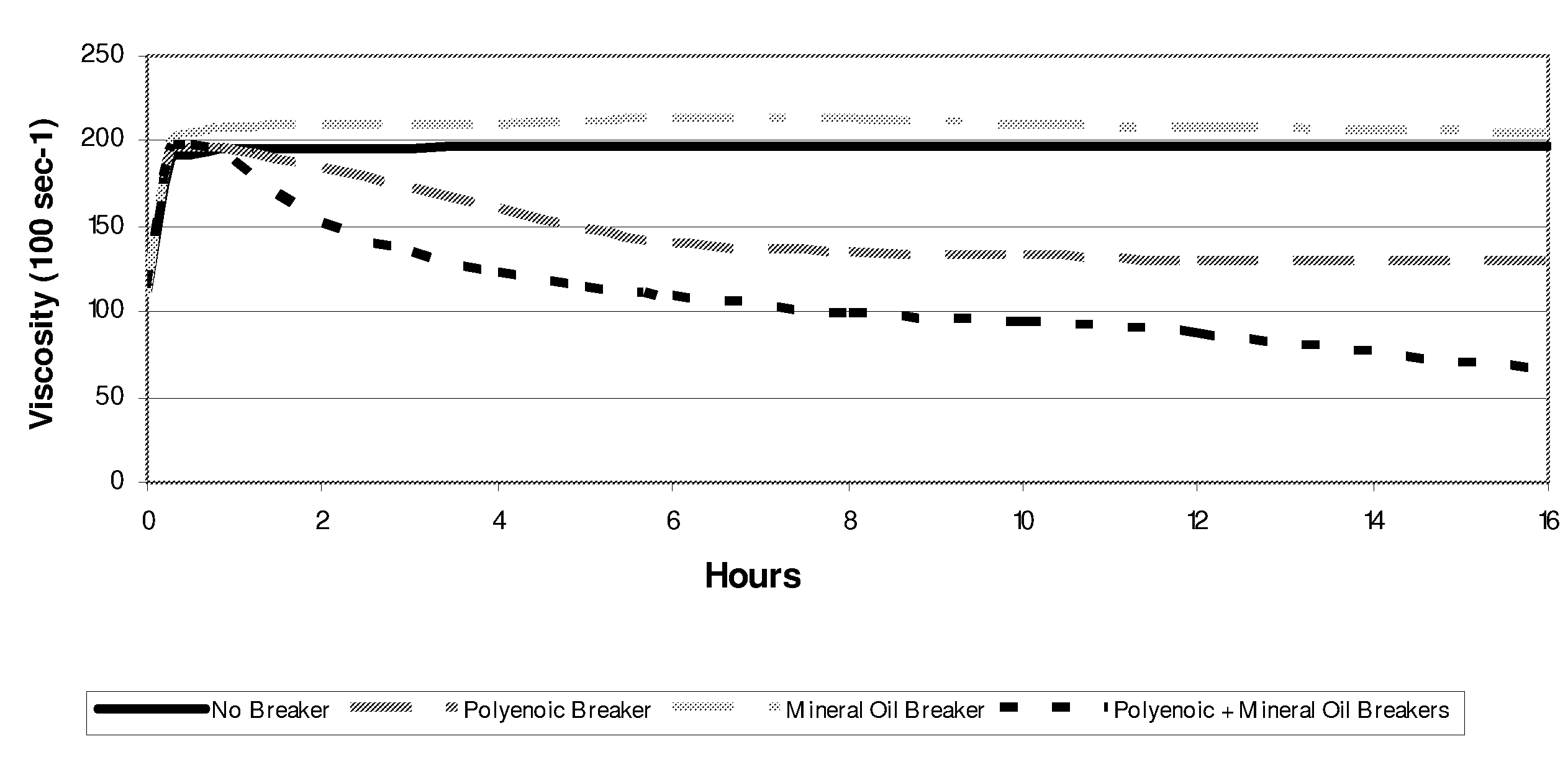

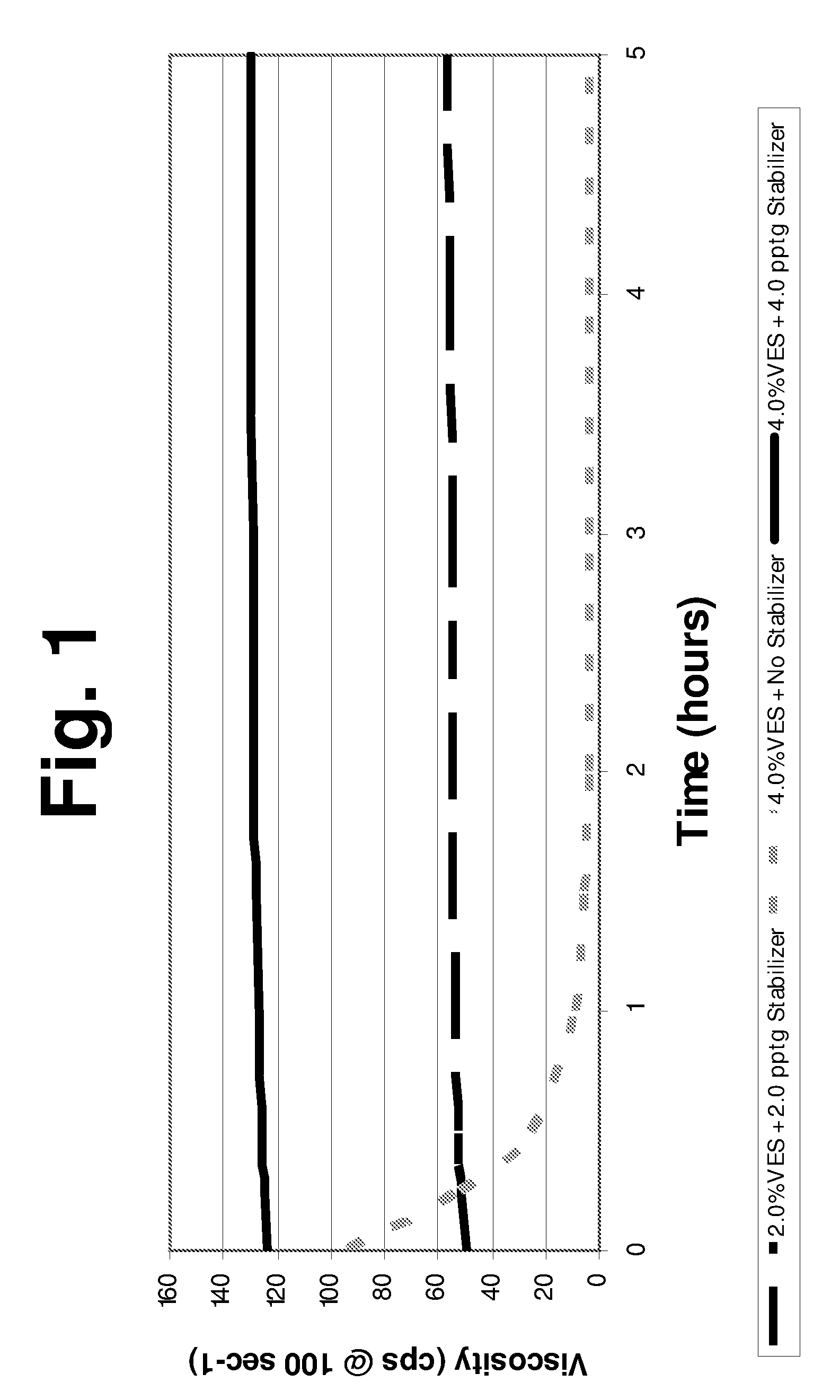

Methods and Compositions for Fracturing Subterranean Formations

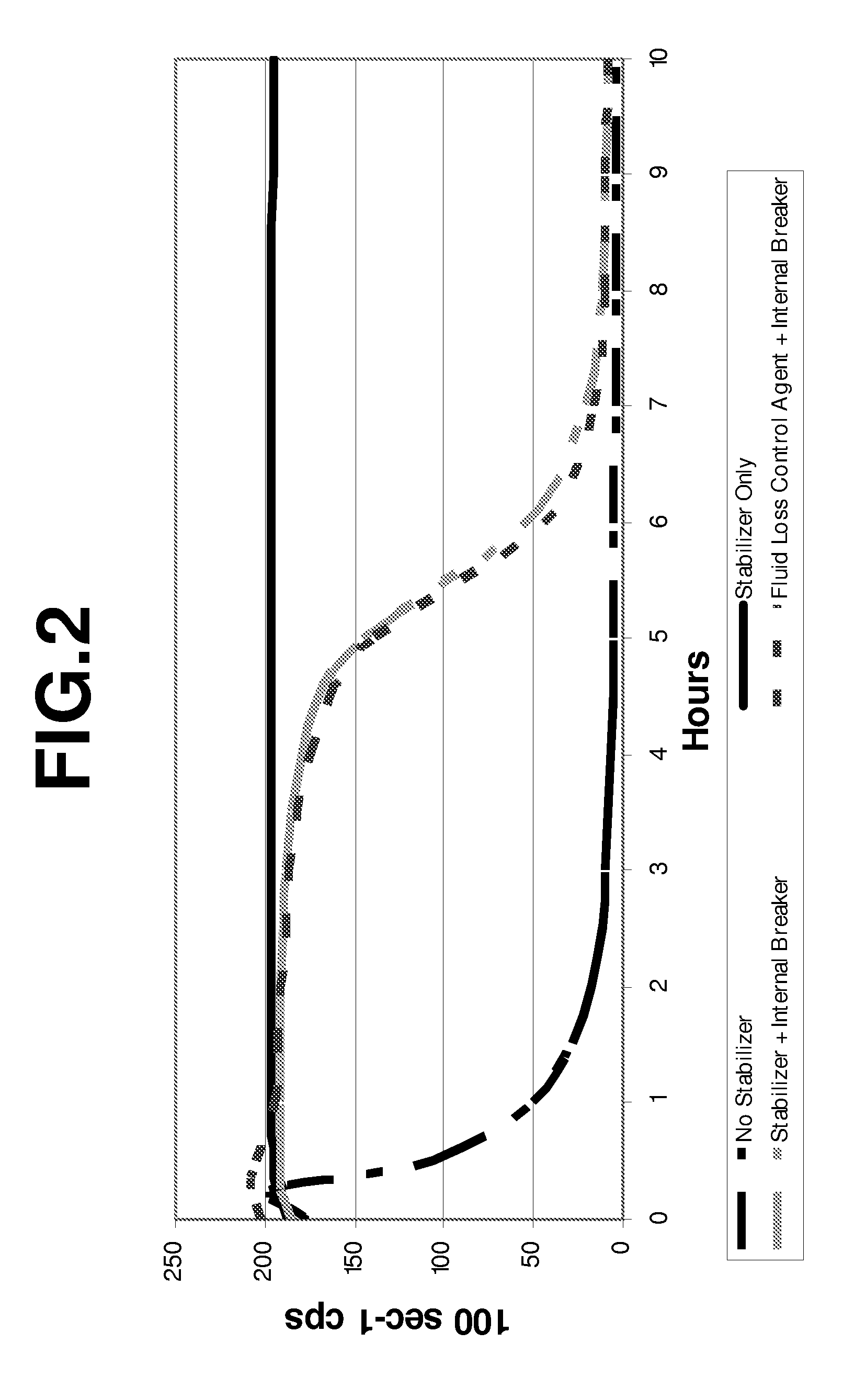

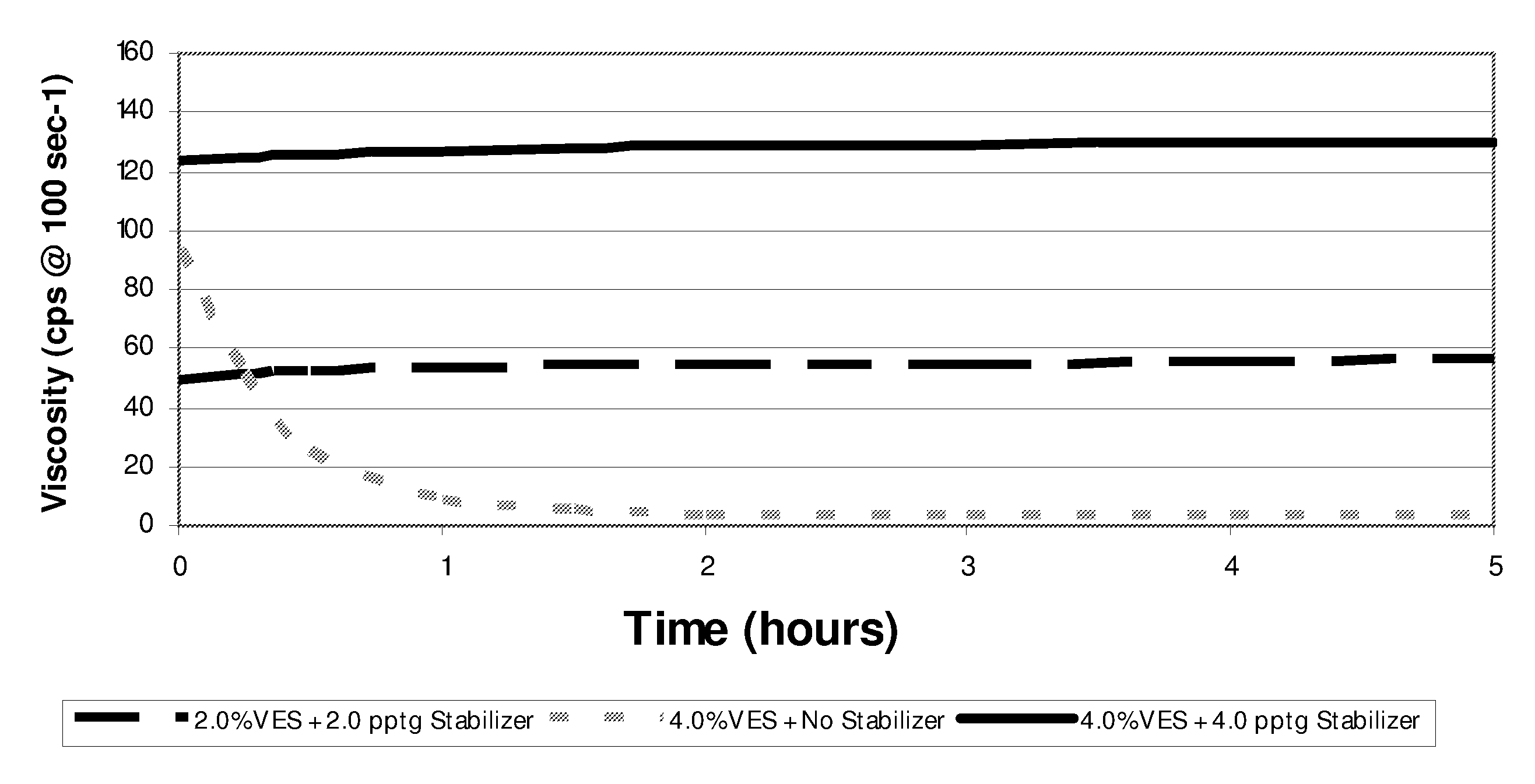

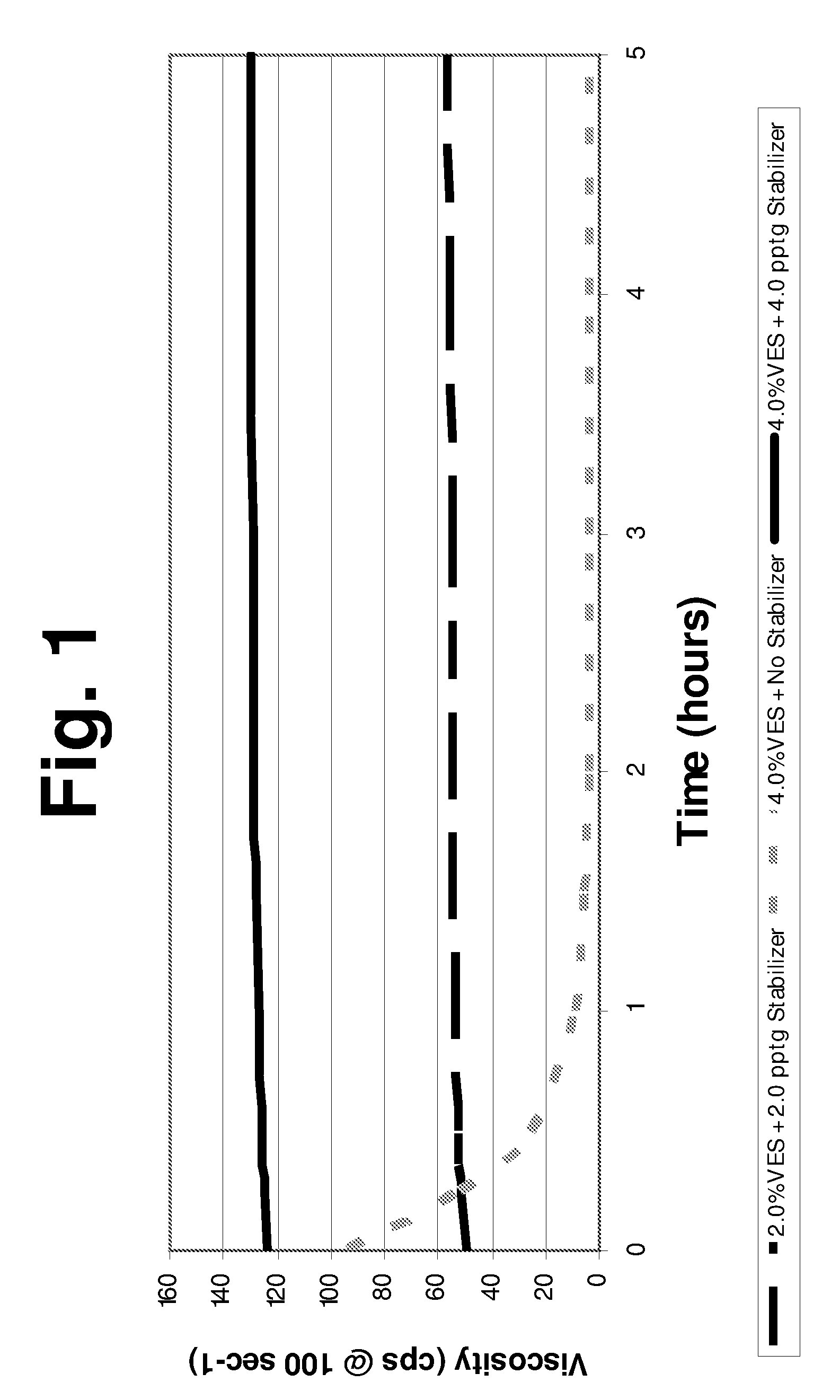

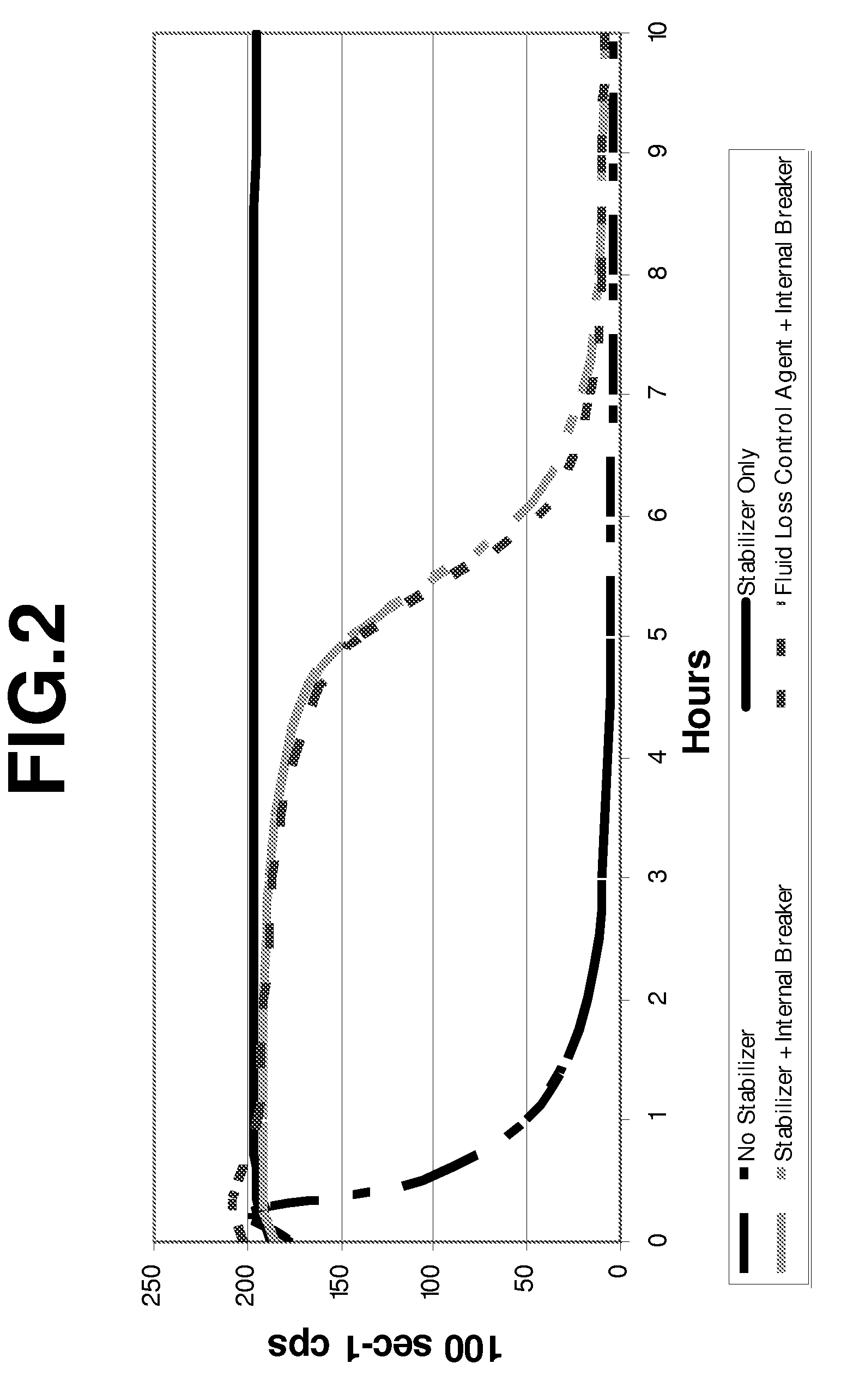

ActiveUS20080202744A1High viscosityLow viscosityFluid removalFlushingProduction rateFracturing fluid

Viscoelastic surfactant (VES) gelled aqueous fluids containing water, a VES, an internal breaker, a VES stabilizer, a fluid loss control agent and a viscosity enhancer are useful as treating fluids and particularly as fracturing fluids for subterranean formations. These VES-based fluids have faster and more complete clean-up than polymer-based fracturing fluids. The use of an internal breaker permits ready removal of the unique VES micelle based pseudo-filter cake with several advantages including reducing the typical VES loading and total fluid volume since more VES fluid stays within the fracture, generating a more optimum fracture geometry for enhanced reservoir productivity, and treating reservoirs with permeability above the present VES limit of approximately 400 md to at least 2000 md.

Owner:BAKER HUGHES INC

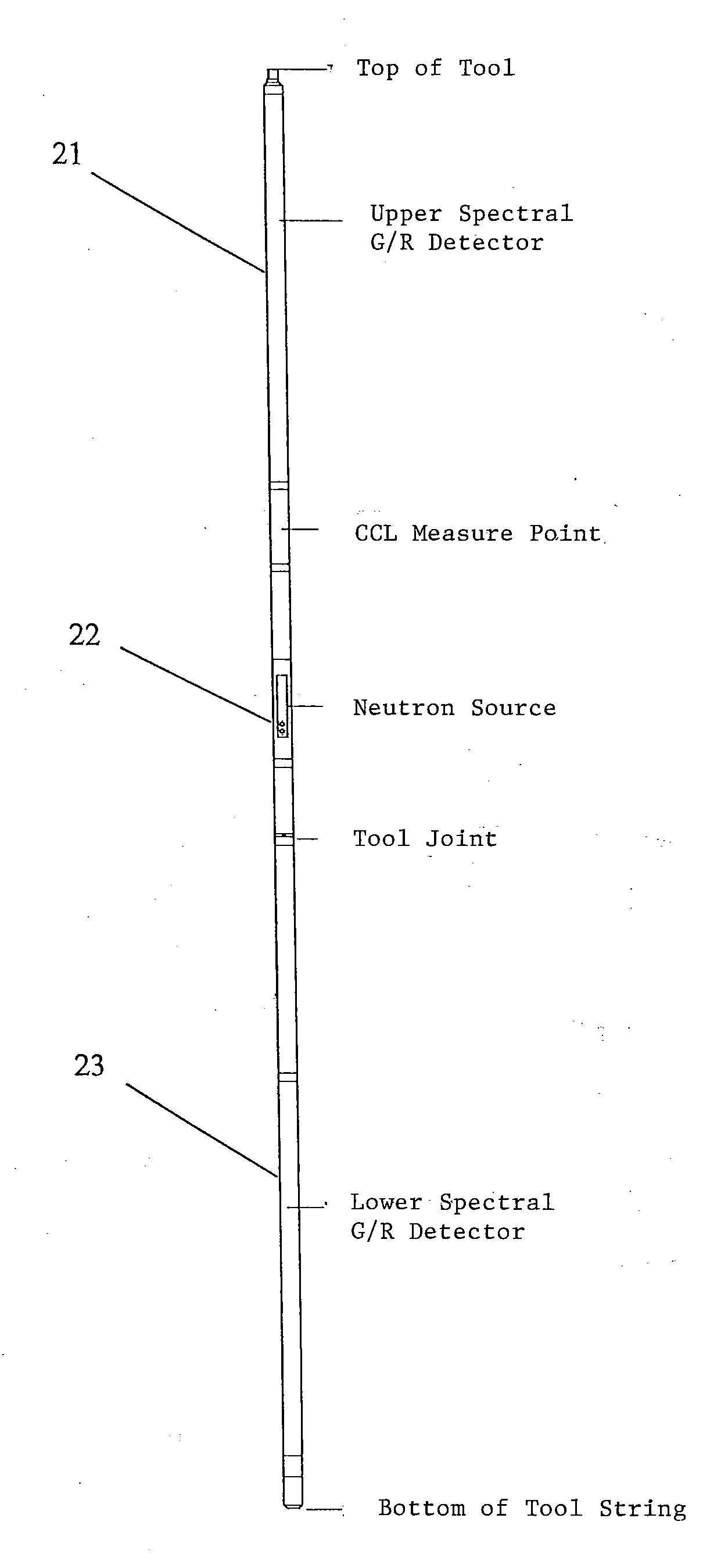

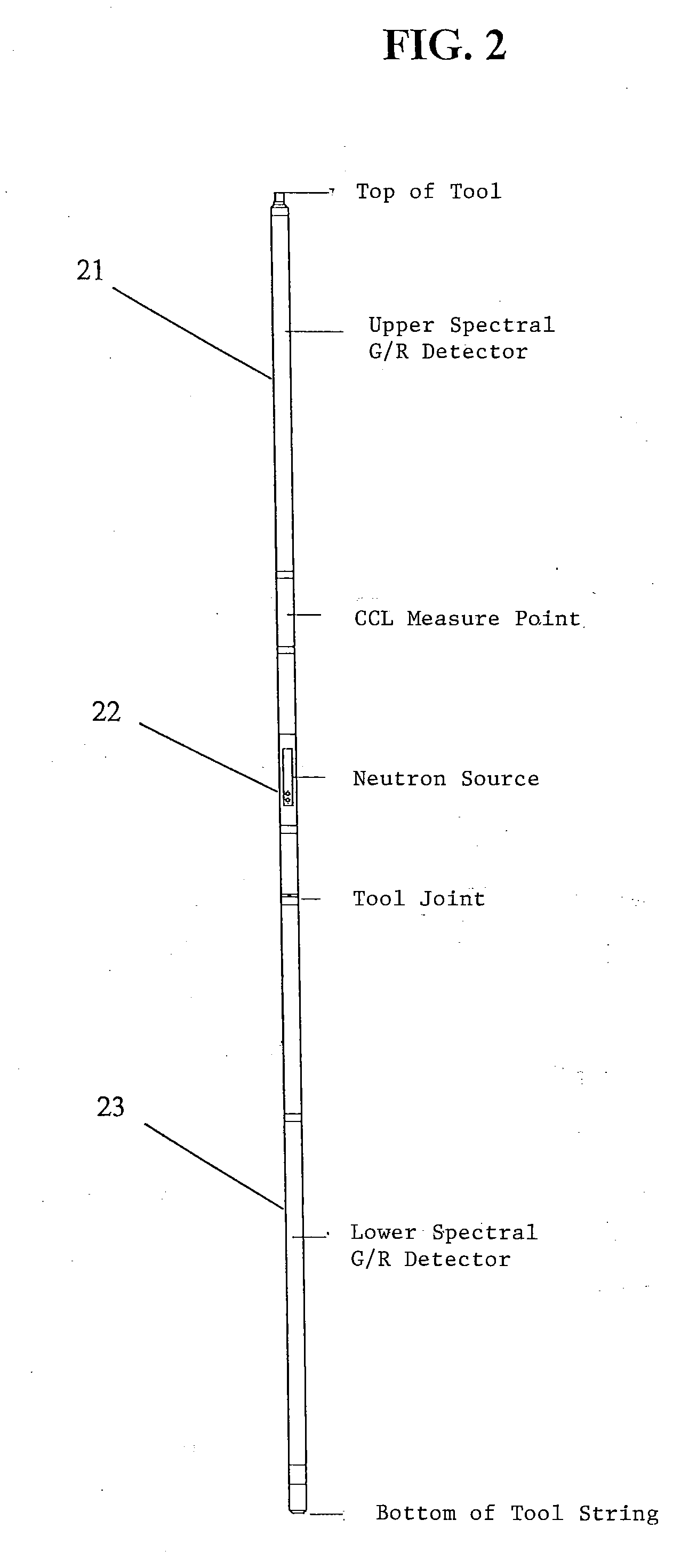

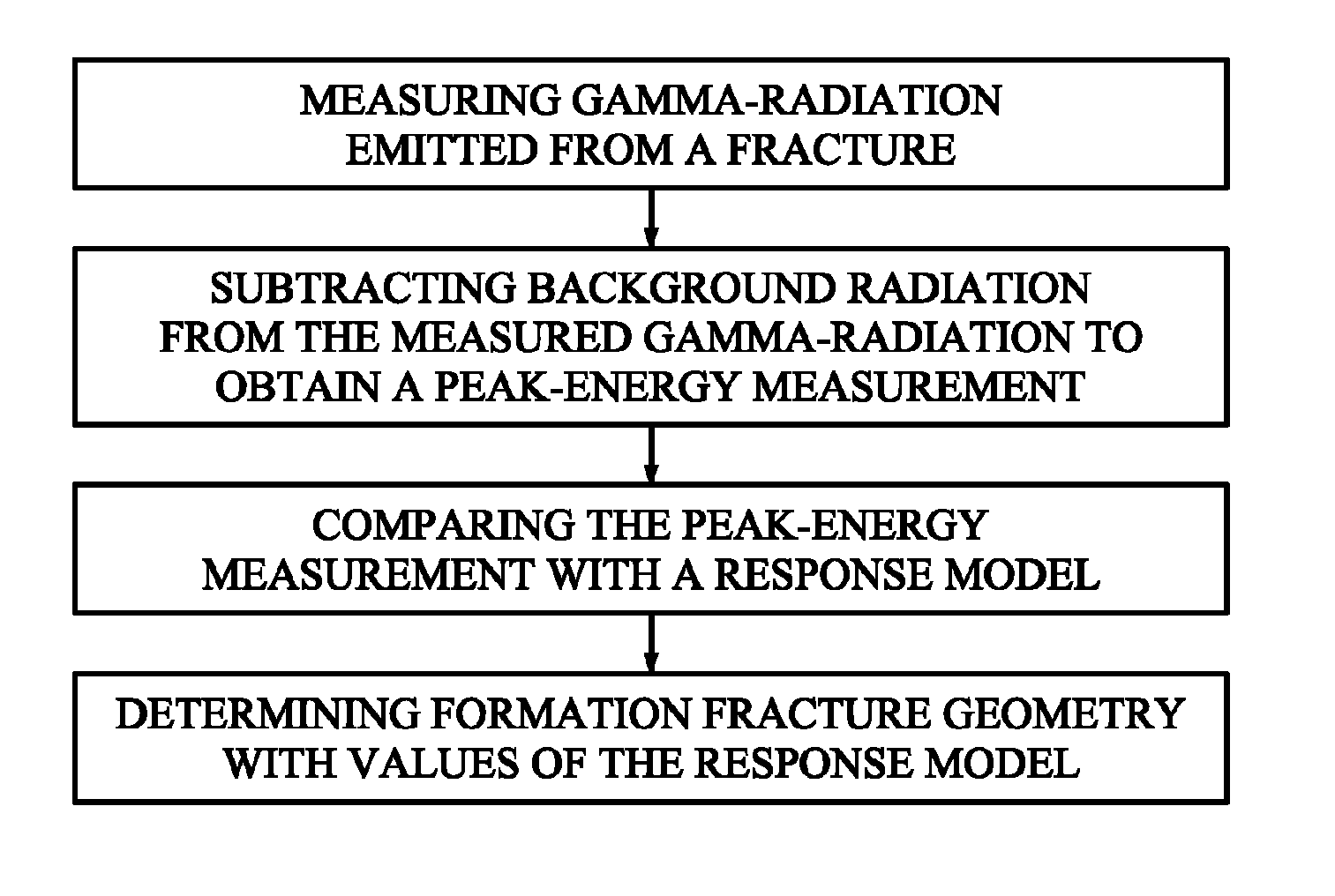

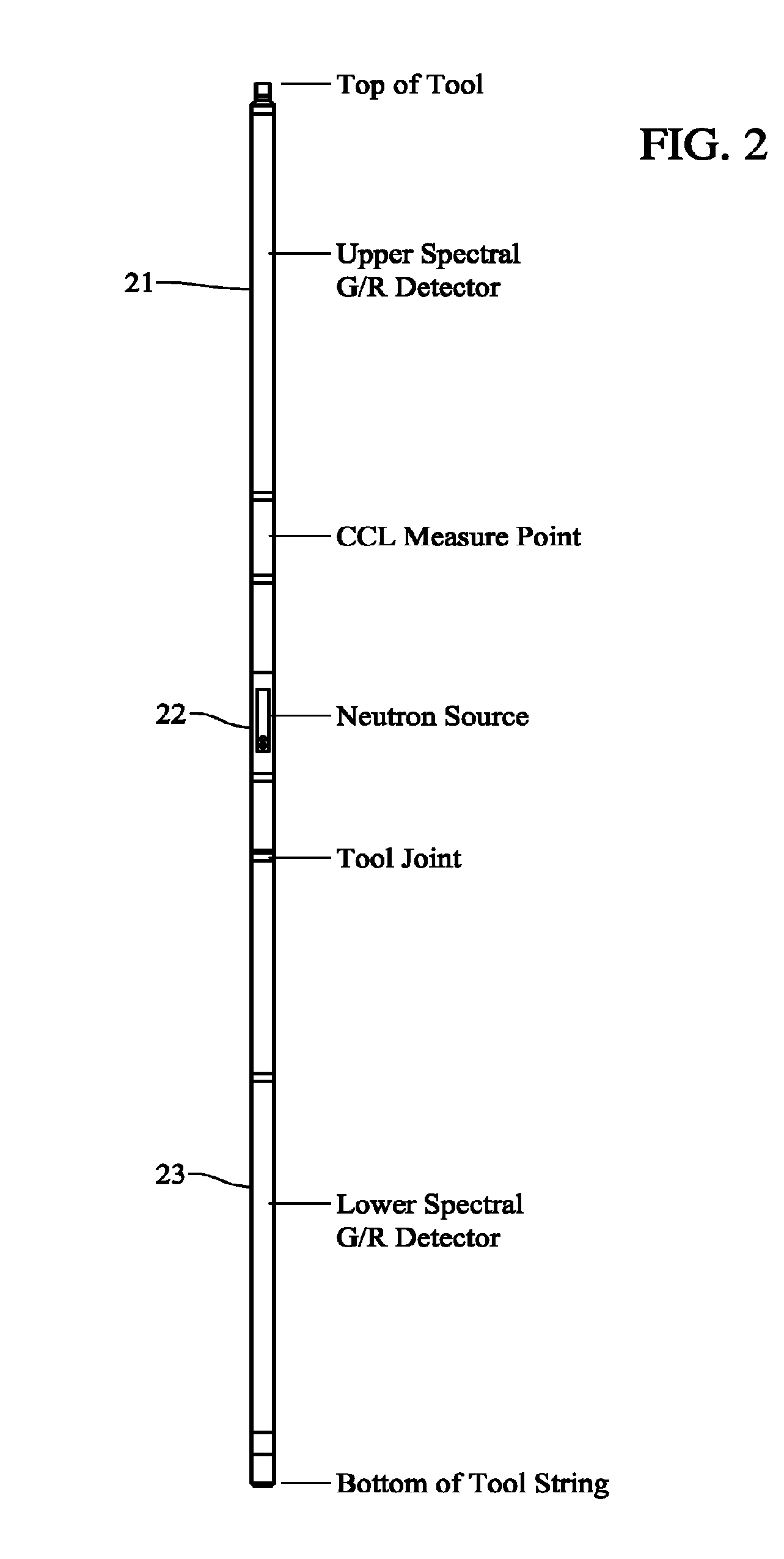

Method and tool for determination of fracture geometry in subterranean formations based on in-situ neutron activation analysis

A method for determining fracture geometry of a subterranean formation from radiation emitted from a fracture in the formation, including measuring gamma-radiation emitted from the fracture; subtracting background radiation from the measured gamma-radiation to obtain a peak-energy measurement; comparing the peak-energy measurement with a gamma-ray transport / spectrometer response model; and determining formation fracture geometry of the fracture in accordance with values associated with the response model.

Owner:HEXION INC

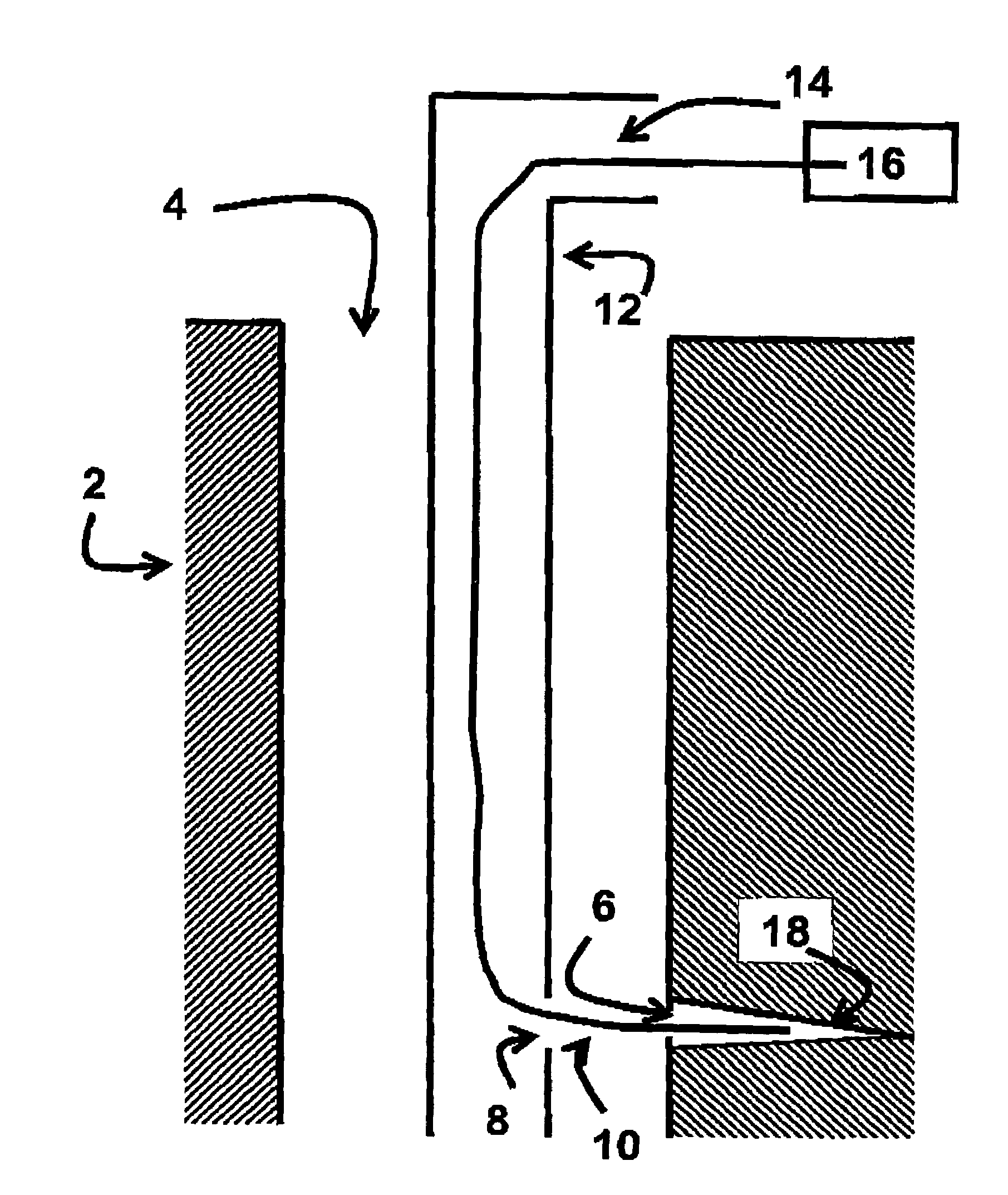

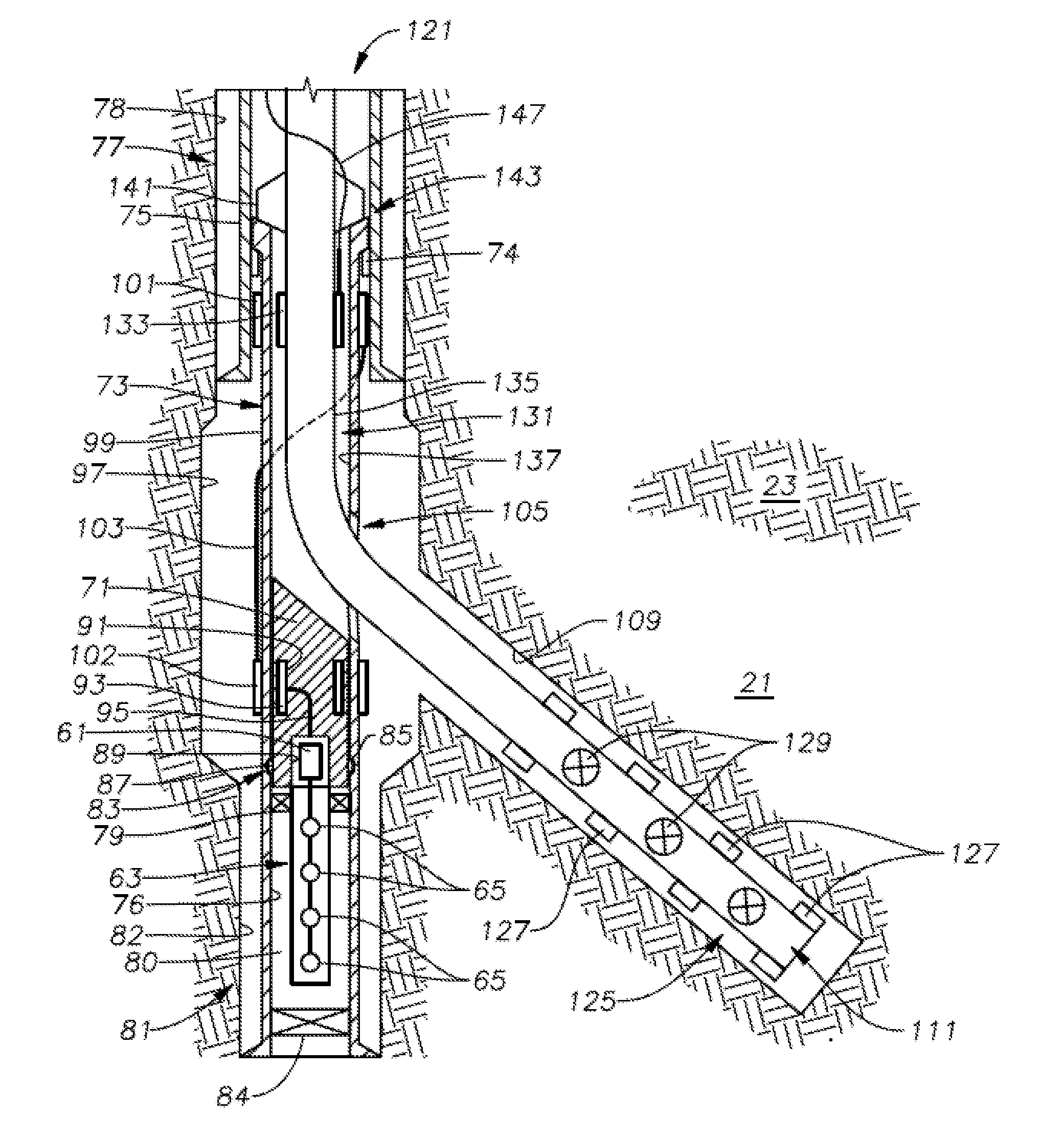

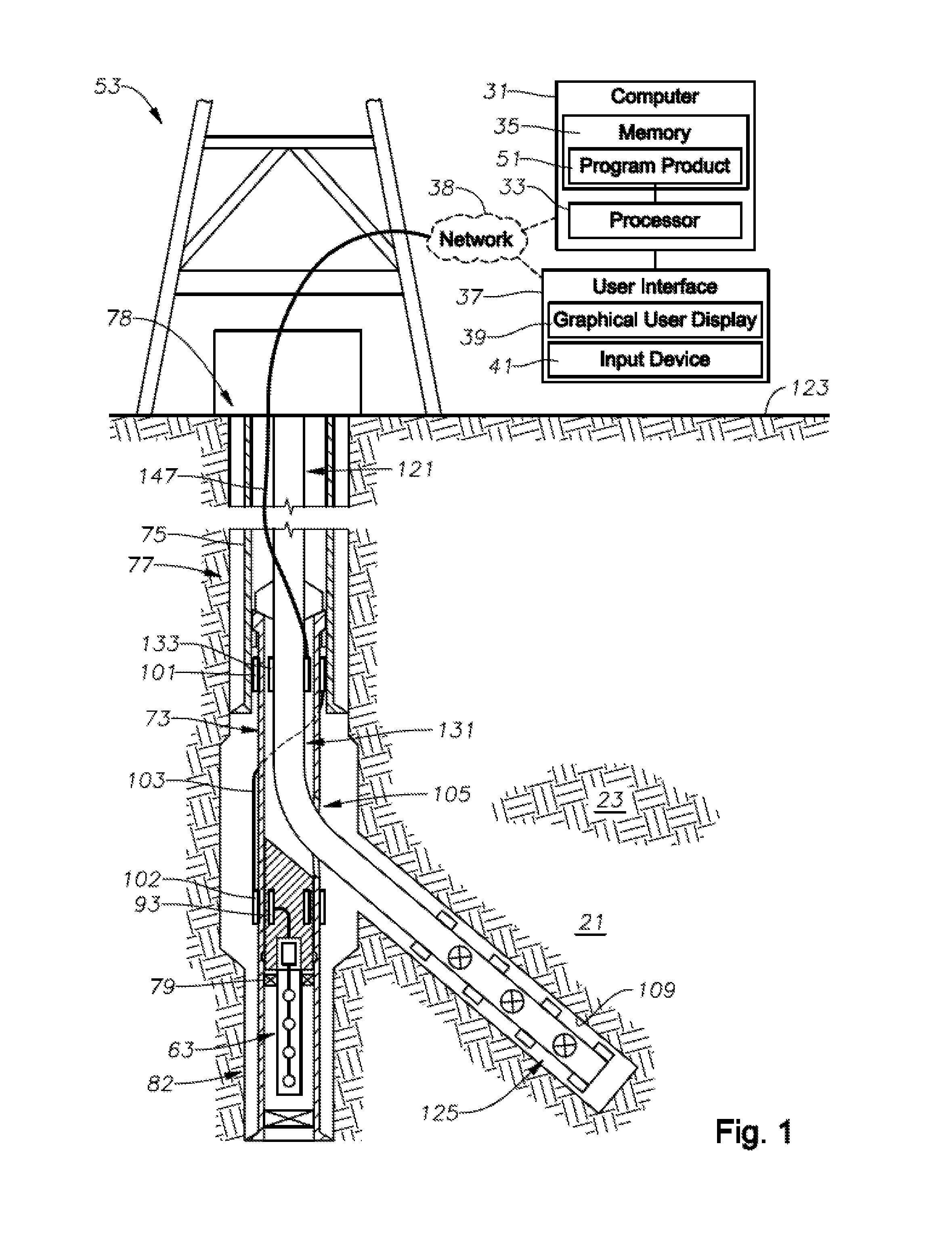

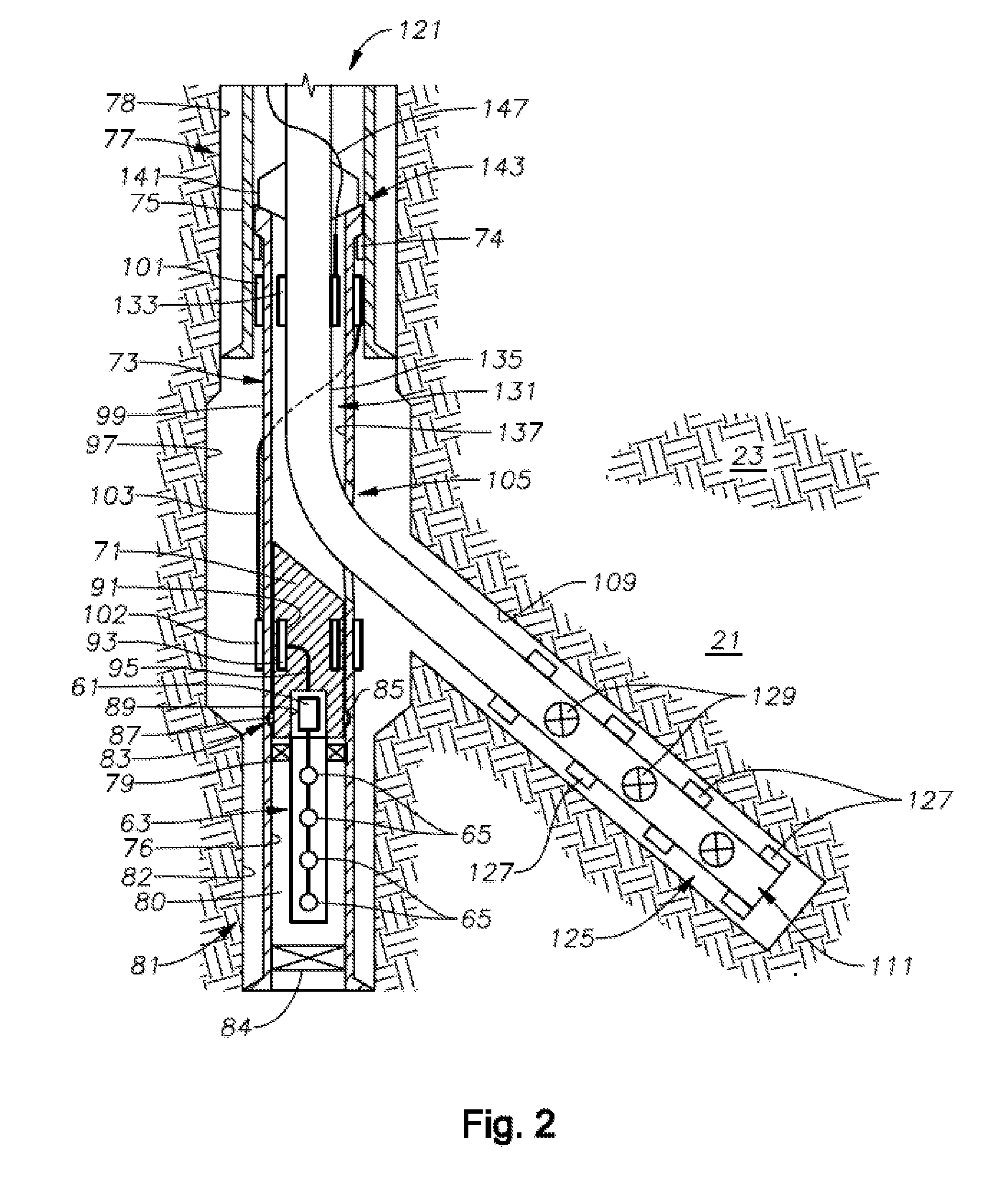

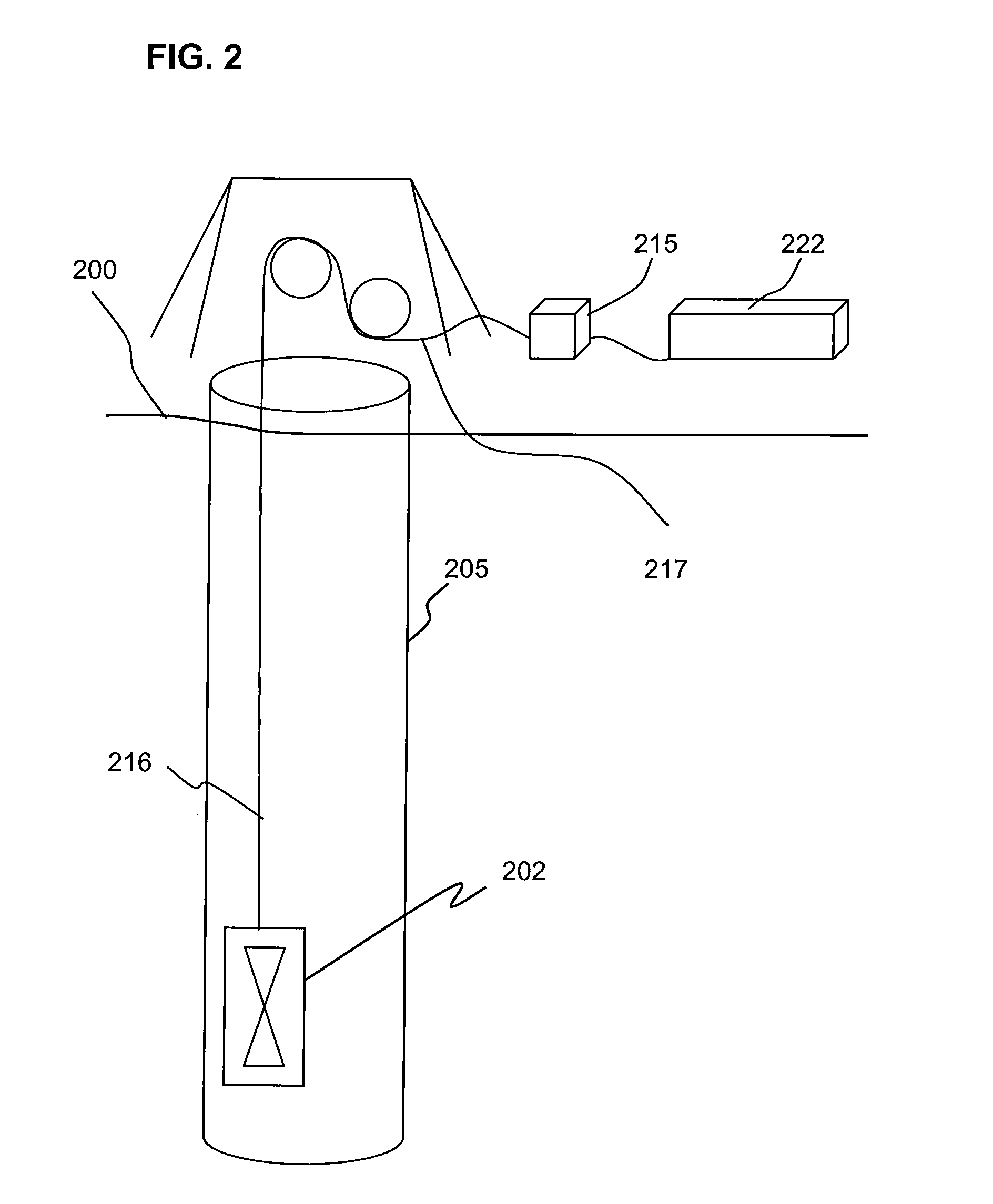

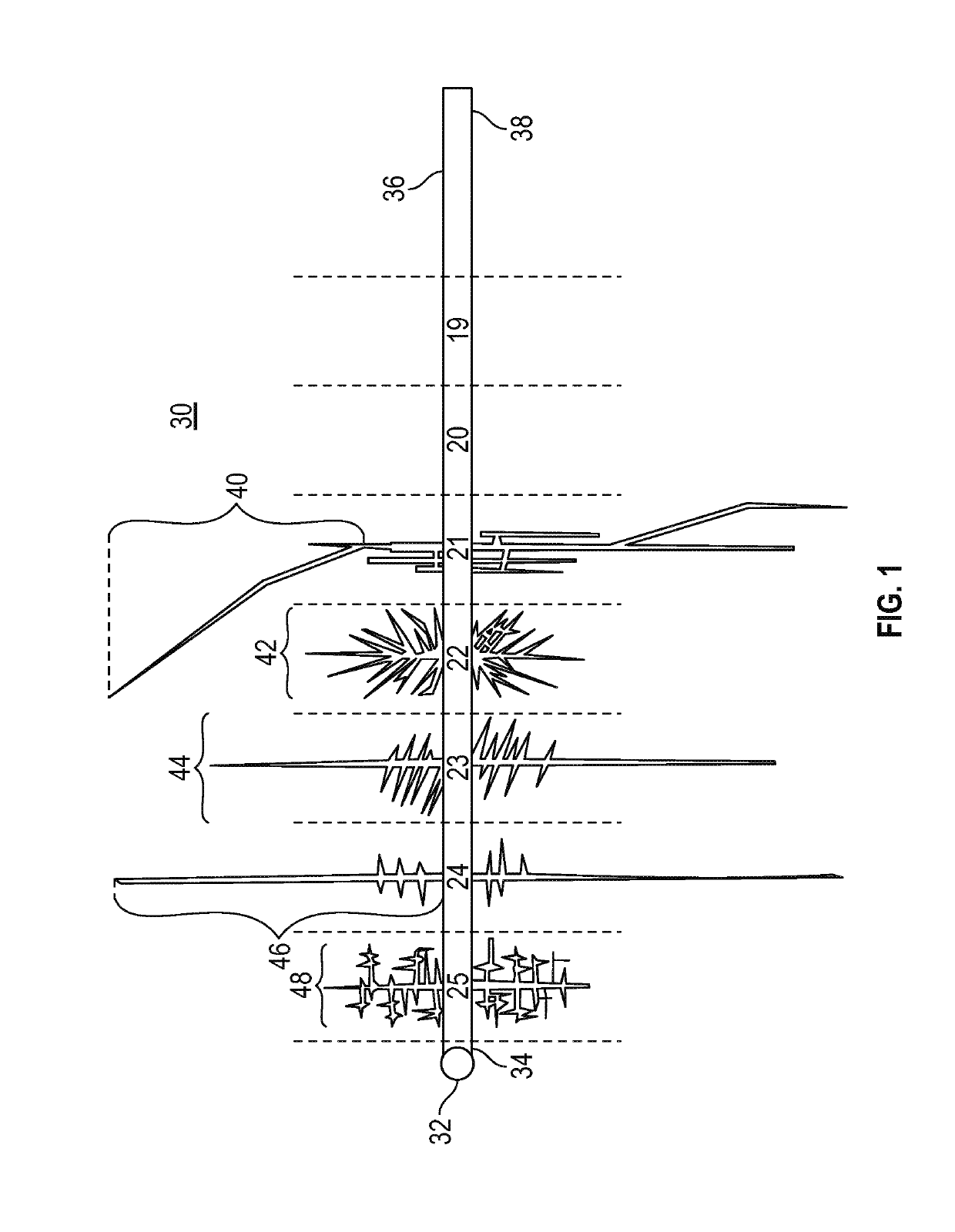

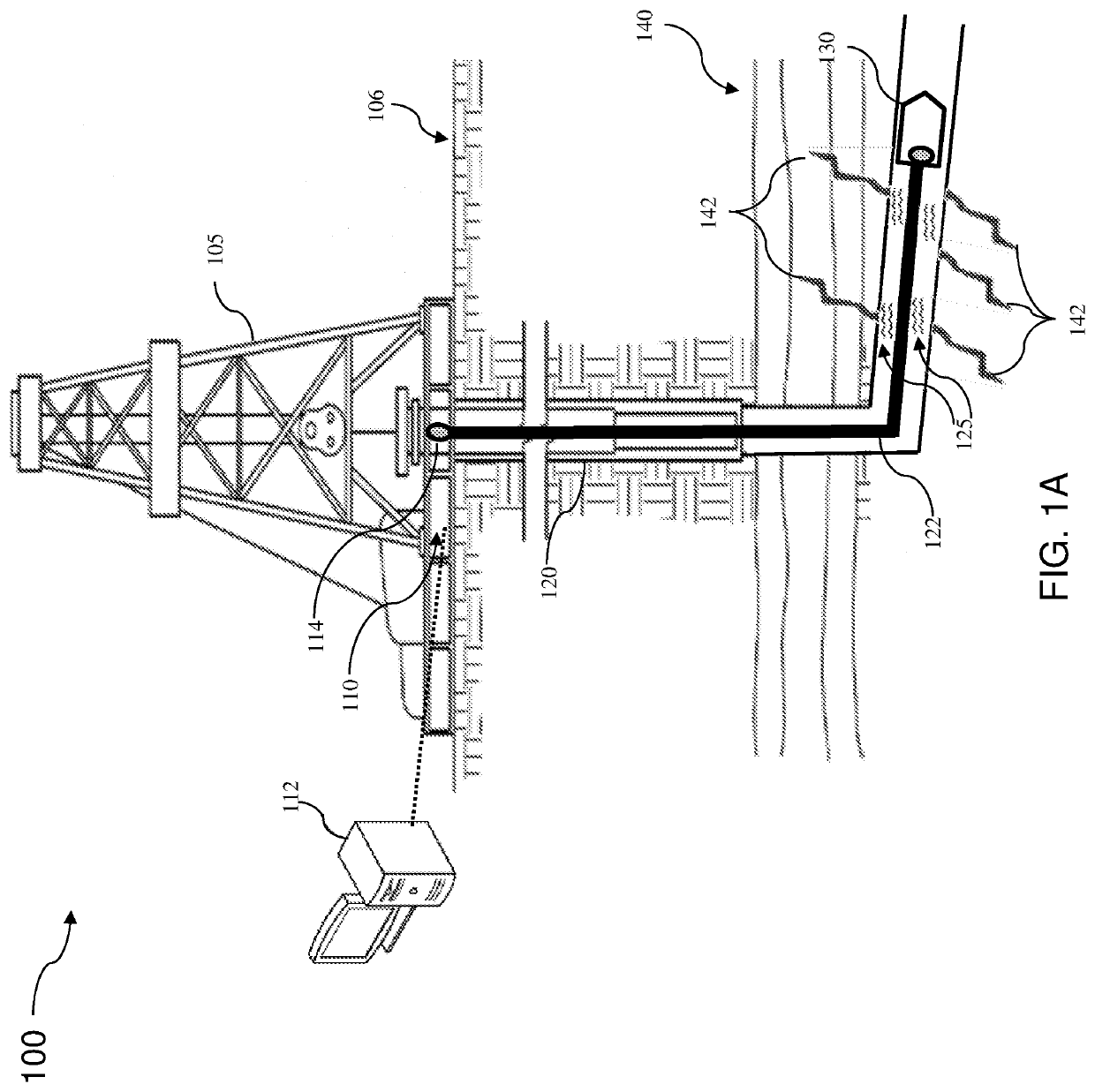

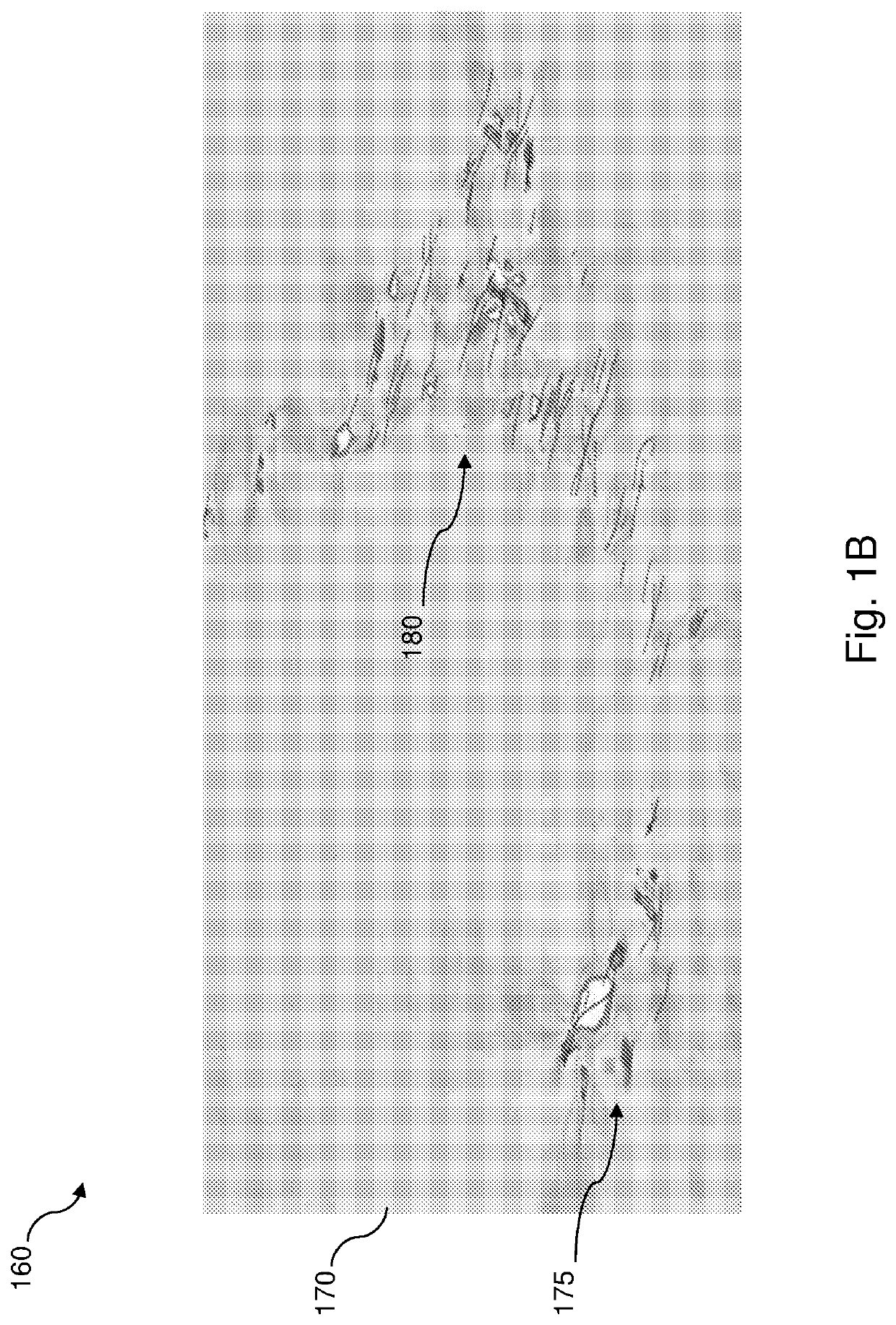

Method For Real-Time Monitoring and Transmitting Hydraulic Fracture Seismic Events to Surface Using the Pilot Hole of the Treatment Well as the Monitoring Well

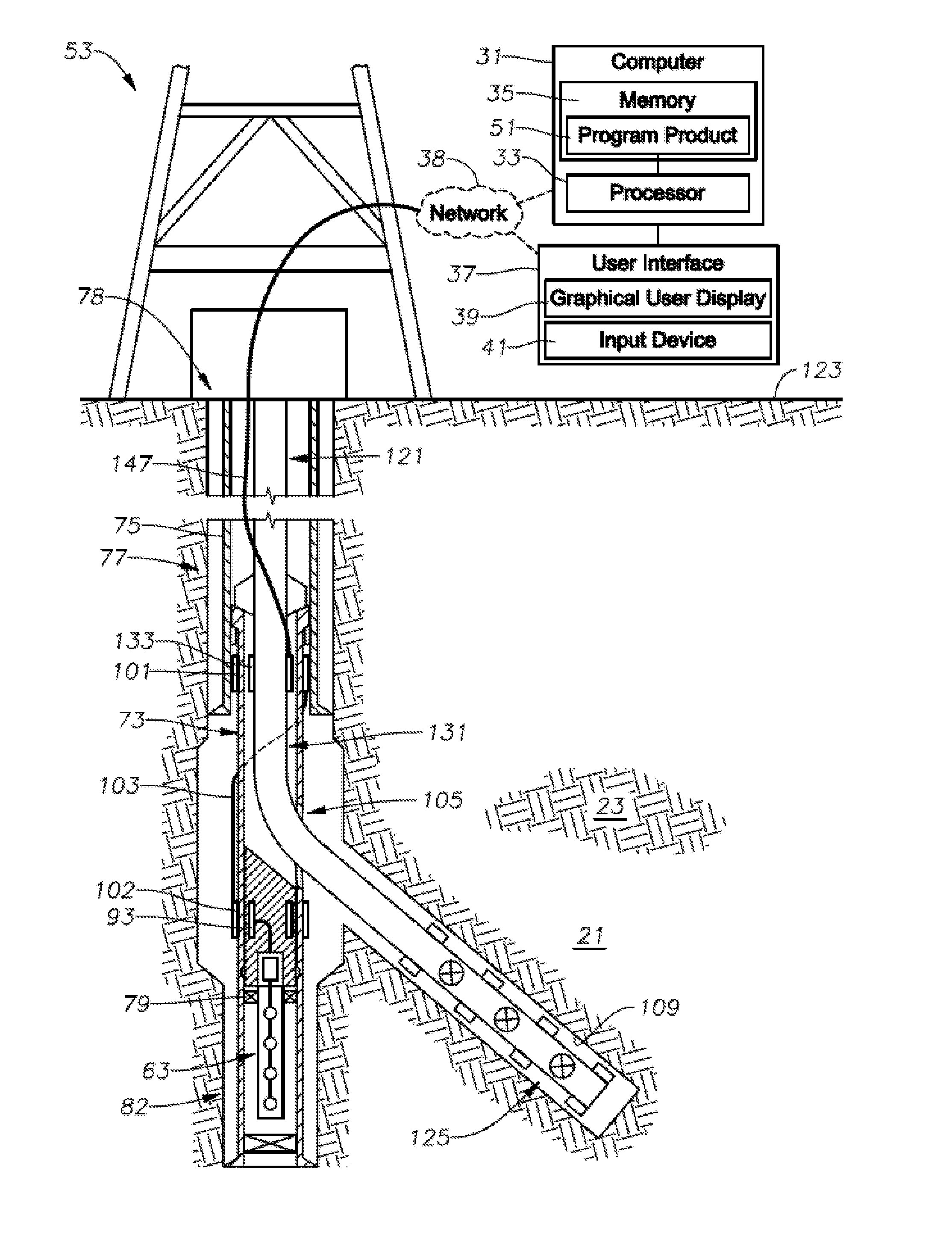

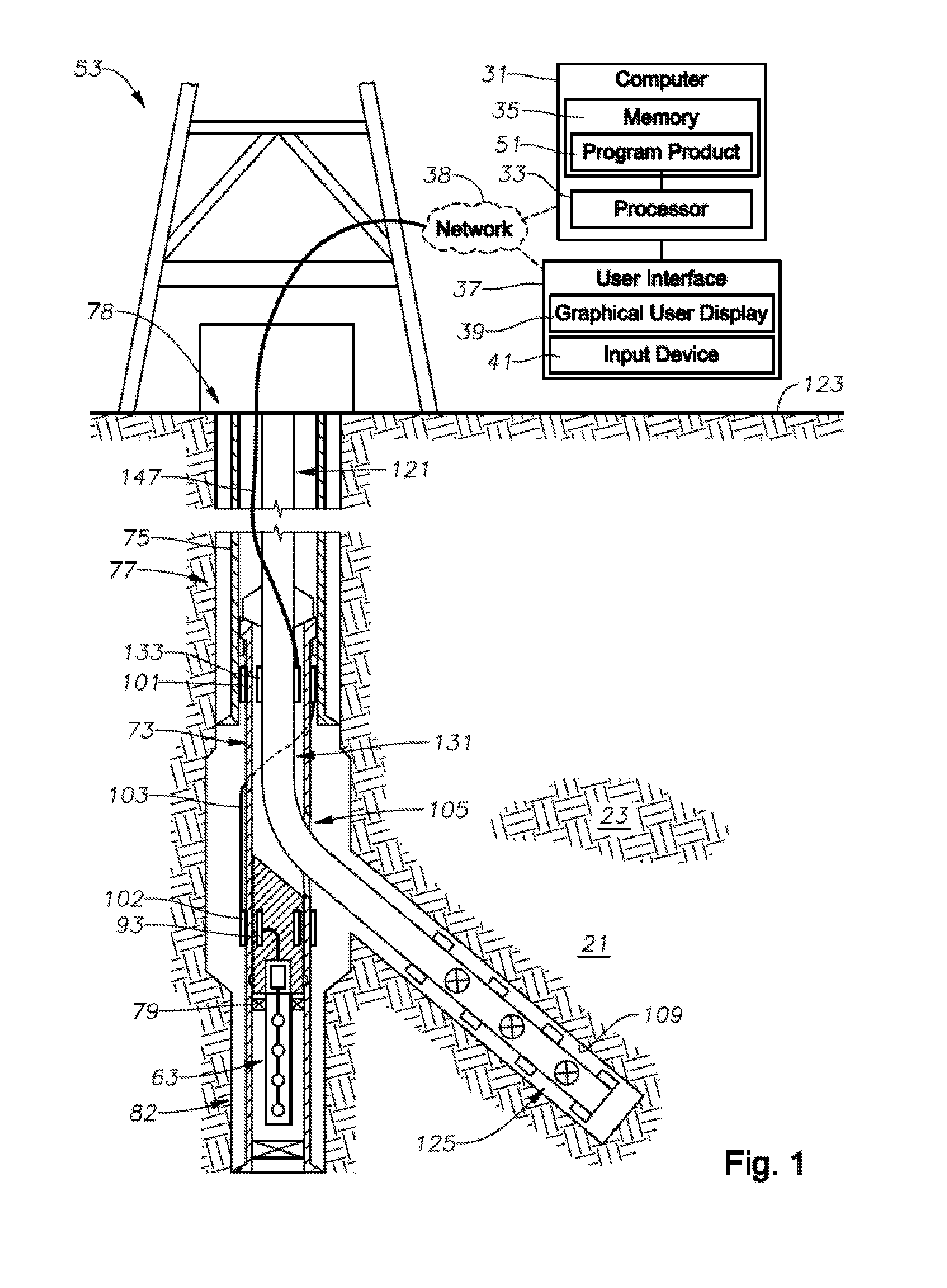

Methods for determining hydraulic fracture geometry and / or areal extent of an area of interest in a reservoir, are provided. An exemplary method includes isolating downhole acoustic receiver equipment in a lower portion of a first wellbore from fracturing operations located in a second wellbore connected to the first wellbore. Communications between surface equipment in the downhole acoustic receiver equipment is provided through a communications conduit bypass that permits well operations in the second wellbore without interfering with communications between the surface equipment and the downhole acoustic receiver equipment.

Owner:SAUDI ARABIAN OIL CO

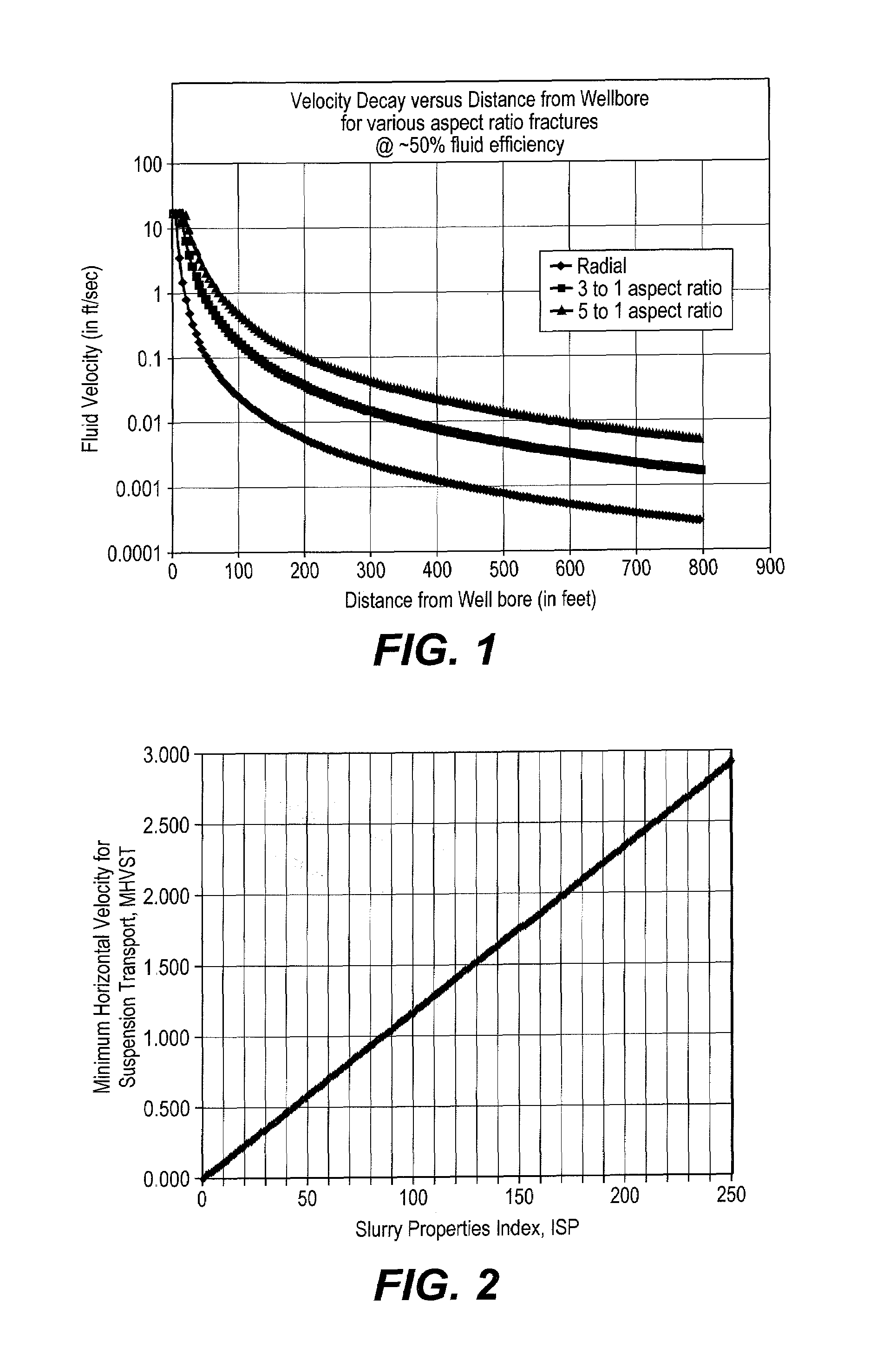

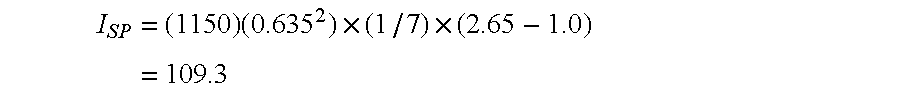

Method of fracturing a subterranean formation at optimized and pre-determined conditions

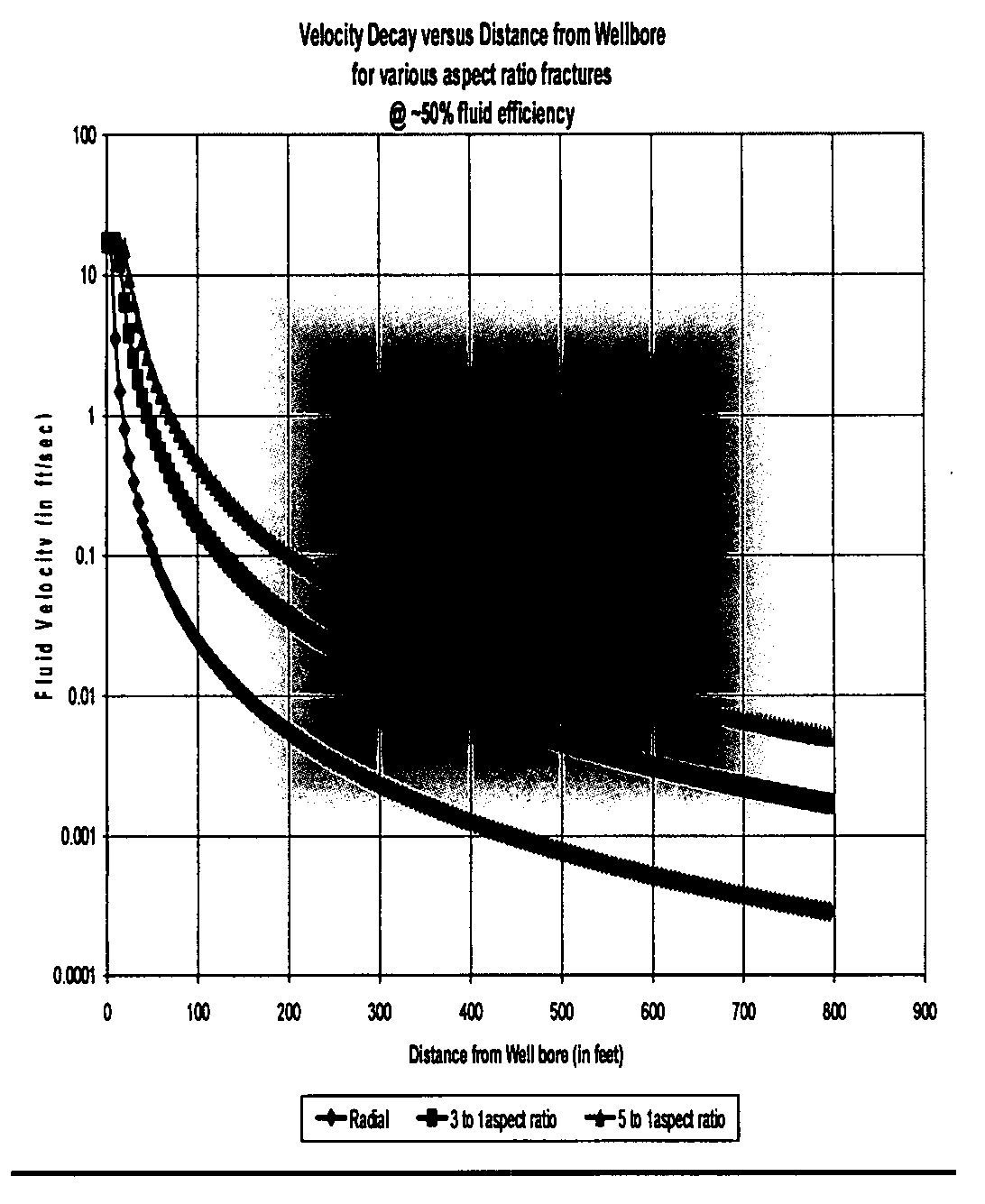

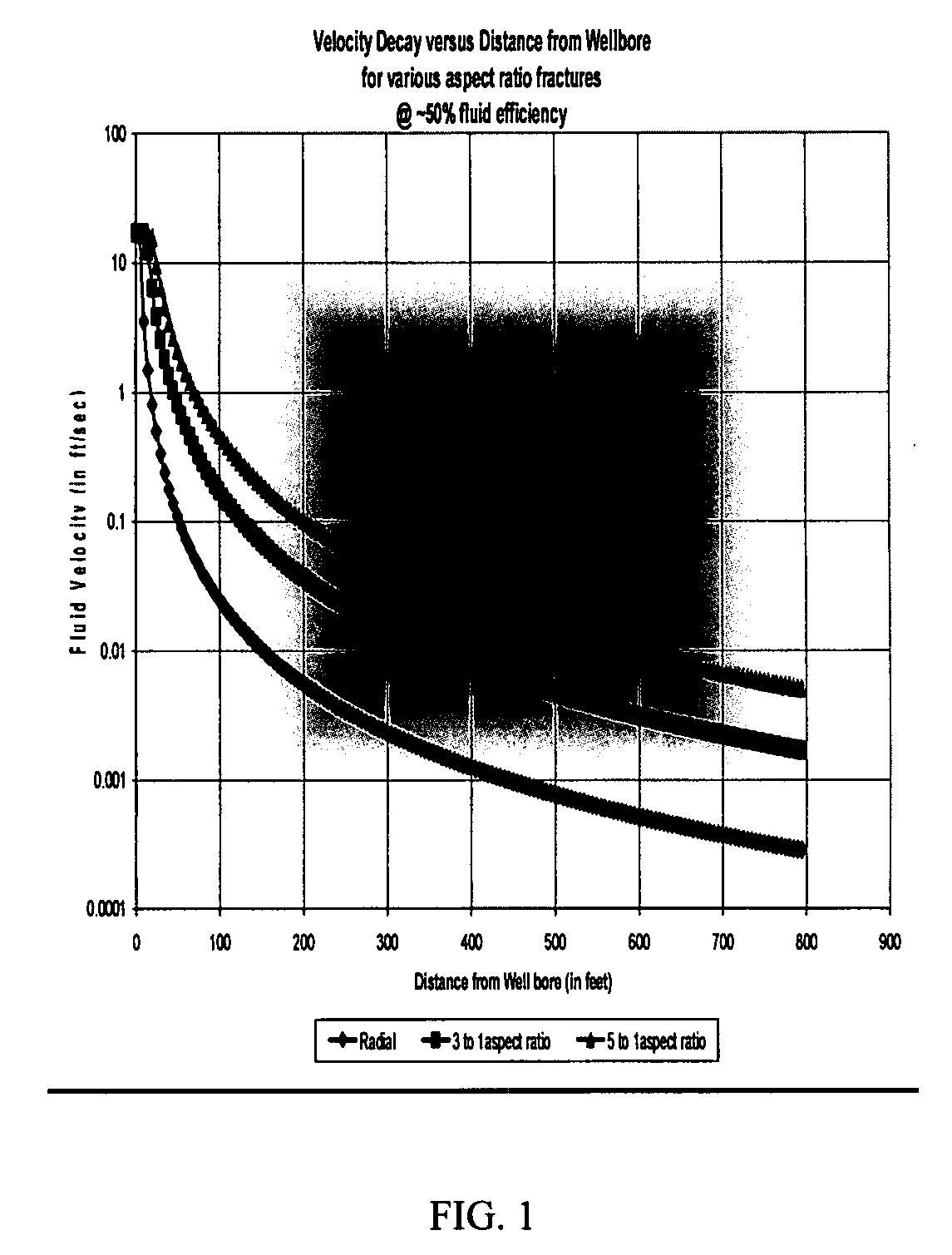

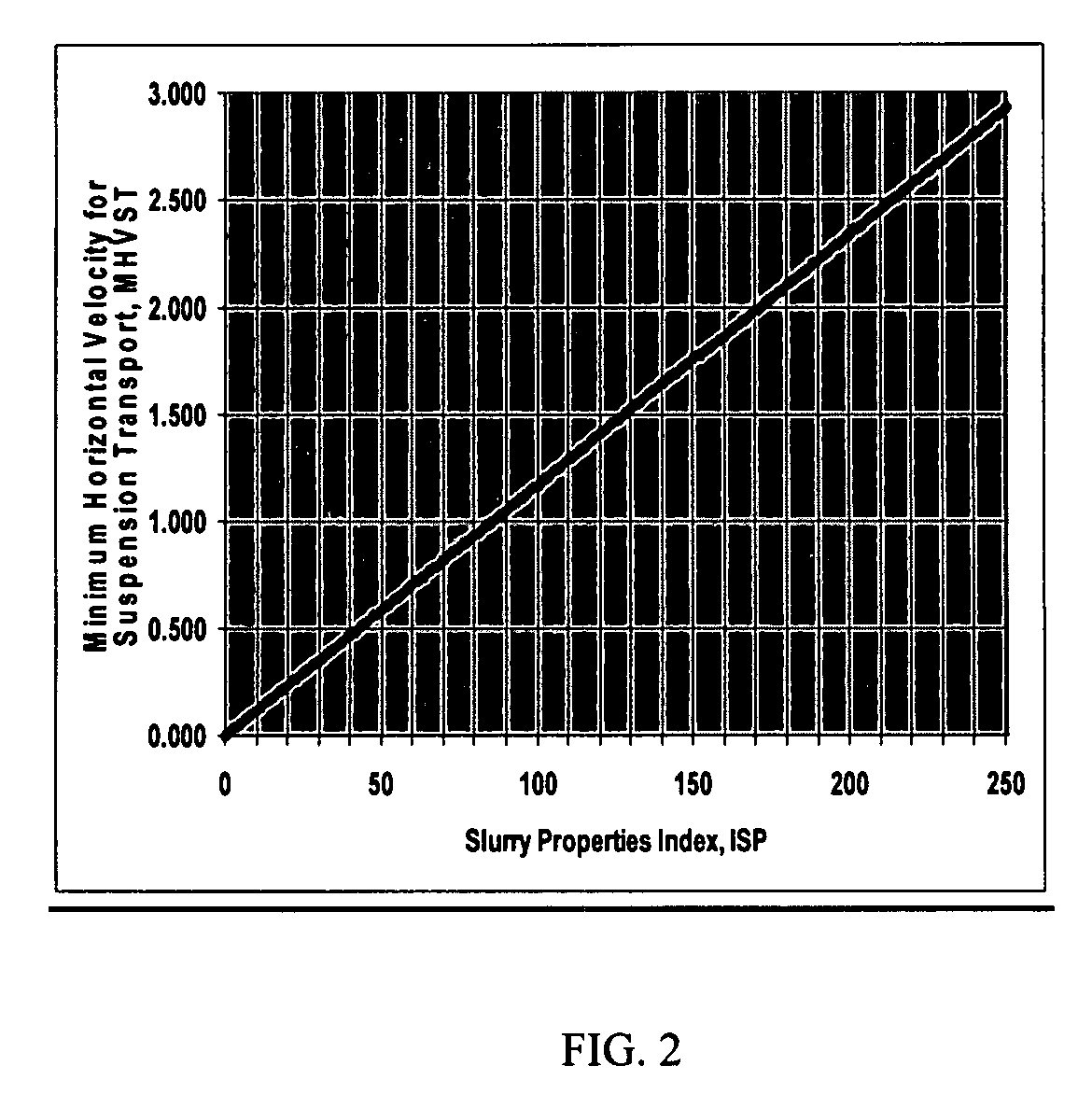

Prior to a hydraulic fracturing treatment, the estimated fracture length may be estimated with knowledge of certain physical properties of the proppant and transport fluid such as fluid viscosity, proppant size and specific gravity of the transport slurry as well as fracture geometry and the treatment injection rate. The estimated fracture length may be determined by the equation:(DPST)B=qi×(1 / A)×CTRANS×(d2prop)×(1 / μfluid)×(ΔSGPS) (I)wherein:DPST is thus the estimated propped fracture length;B is the exponent from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;qi is the injection rate per foot of injection height, bpm / ft.; andA is the multiplier from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;CTRANS, the transport coefficient, is the slope of the linear regression of the ISP vs. MHVST.dprop is the median proppant diameter, in mm.;μfluid is the apparent viscosity of the transport fluid, in cP; andΔ SGPS is SGprop−SGfluid, SGprop being the specific gravity of the proppant andSGfluid being the specific gravity of the transport fluid.The minimum horizontal flow velocity, MHVST, for transport of the transport slurry based upon the terminal settling velocity of the proppant, Vt, may be determined in accordance with Equation (II):MHVST, =Vt×10 (II)Via rearrangements of the same derived equations, a model for optimizing the transport fluid, proppant, and / or treating parameters necessary to achieve a desired propped fracture length may further be determined.

Owner:BAKER HUGHES INC

Method for real-time monitoring and transmitting hydraulic fracture seismic events to surface using the pilot hole of the treatment well as the monitoring well

Methods for determining hydraulic fracture geometry and / or areal extent of an area of interest in a reservoir, are provided. An exemplary method includes isolating downhole acoustic receiver equipment in a lower portion of a first wellbore from fracturing operations located in a second wellbore connected to the first wellbore. Communications between surface equipment in the downhole acoustic receiver equipment is provided through a communications conduit bypass that permits well operations in the second wellbore without interfering with communications between the surface equipment and the downhole acoustic receiver equipment.

Owner:SAUDI ARABIAN OIL CO

Means and method for assessing the geometry of a subterranean fracture during or after a hydraulic fracturing treatment

A method is given of fracturing a subterranean formation including the step of a) pumping at least one device actively transmitting data that provide information on the device position, and further comprising the step of assessing the fracture geometry based on the positions of said at least one device, or b) pumping metallic elements, preferably as proppant agents, and further locating the position of said metallic elements with a tool selected from the group consisting of magnetometers, resistivity tools, electromagnetic devices and ultra-long arrays of electrodes, and further comprising the step of assessing the fracture geometry based on the positions of said metallic elements. The method allows monitoring of the fracture geometry and proppant placement.

Owner:SCHLUMBERGER TECH CORP

Method and tool for determination of fracture geometry in subterranean formations based on in-situ neutron activation analysis

A method for determining fracture geometry of a subterranean formation from radiation emitted from a fracture in the formation, including measuring gamma-radiation emitted from the fracture; subtracting background radiation from the measured gamma-radiation to obtain a peak-energy measurement; comparing the peak-energy measurement with a gamma-ray transport / spectrometer response model; and determining formation fracture geometry of the fracture in accordance with values associated with the response model.

Owner:HEXION INC

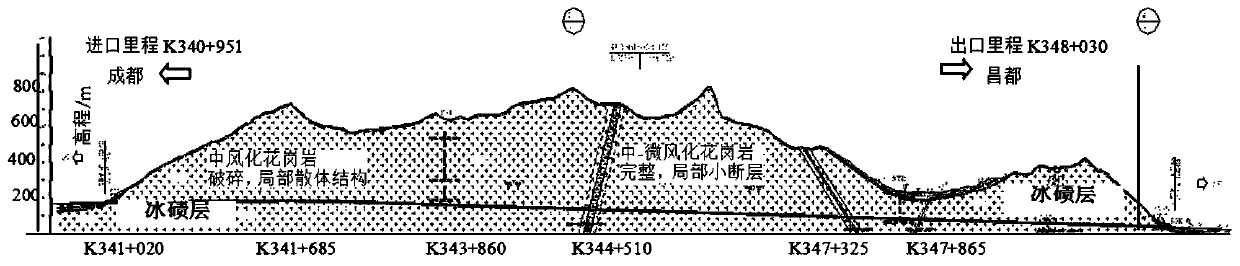

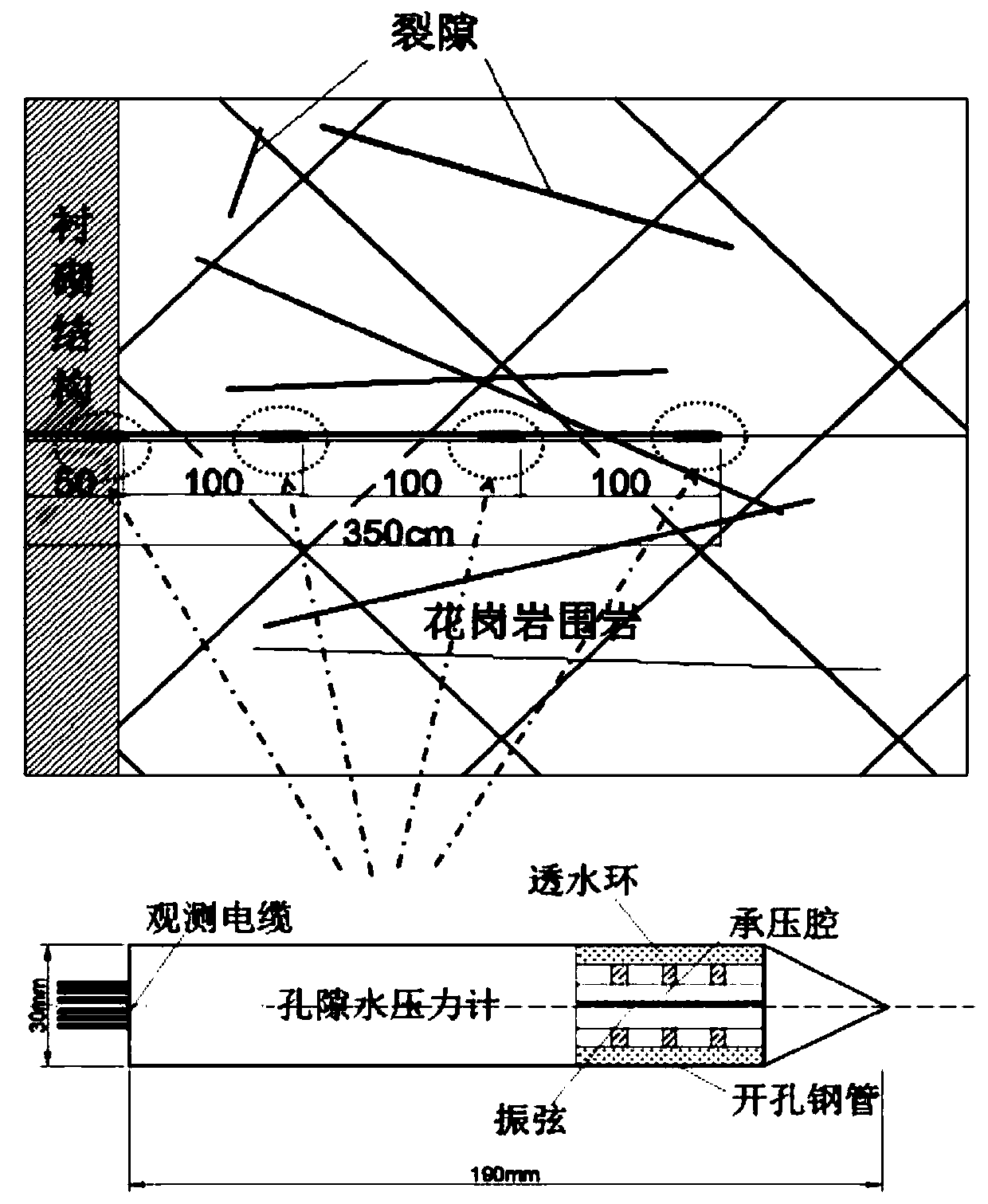

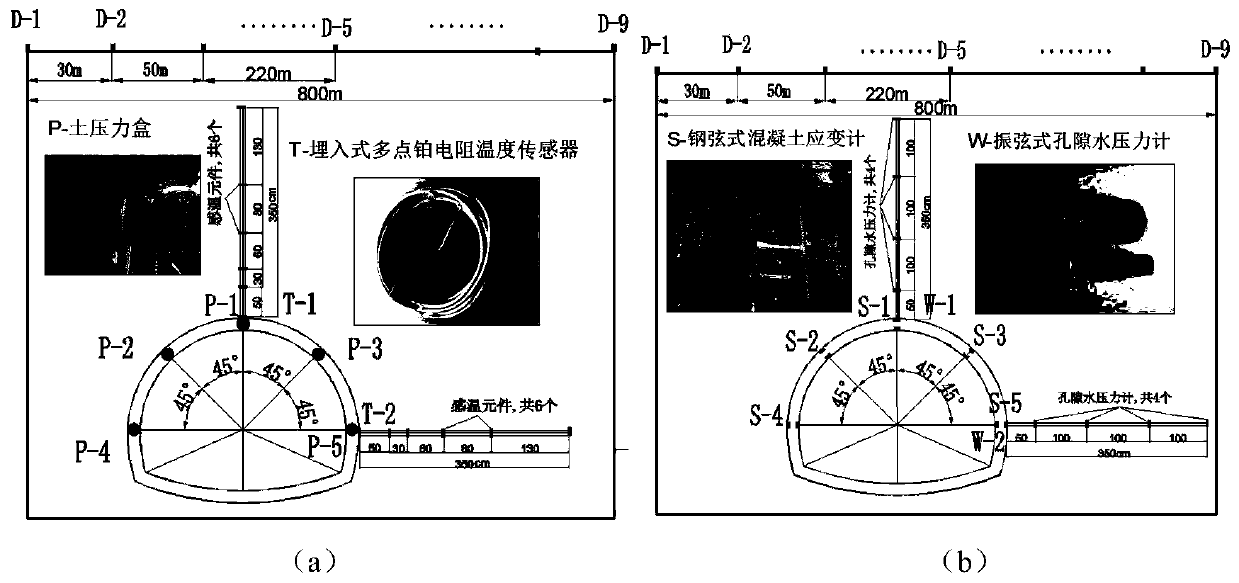

Frost heave force model of rock tunnel based on rock-water-ice force in-situ test

InactiveCN110596177AAvoid structureAvoid discussionEarth material testingMaterial thermal analysisFreeze thawingPore water pressure

The present invention discloses a frost heave force model of a rock tunnel based on a rock-water-ice force in-situ test. A pore water pressure gauge, an earth pressure box, and a multi-point platinumresistance temperature sensor are used in a combination manner to perform a frost heave force in-situ test on fractured rocks, the temporal and spatial evolution laws of the fissure water pressure, the ice pressure, and the surrounding rock pressure before and after freezing of the fractured rocks are obtained, and theoretical model calculation results, in-situ test results, and existing researchresults are compared and analyzed. According to the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention, in-situ testing on siteis used, the test method is innovated outside the previous test system mainly containing the freeze-thaw cycle mechanics test of fractured rock masses, the lack of measurement methods is compensated,the frost heave force in natural water-containing cracks is obtained, and starting from macro and engineering applications, the discussion of the meso-structure and fracture geometry of fractured rocks is avoided; the general area of low-temperature water-ice phase transition and the direction of water migration are considered; and the frost heave force model of the rock tunnel based on the rock-water-ice force in-situ test provided by the present invention will provide a reference for similar projects of the currently developed Sichuan-Tibet Highway.

Owner:SOUTHWEST JIAOTONG UNIV

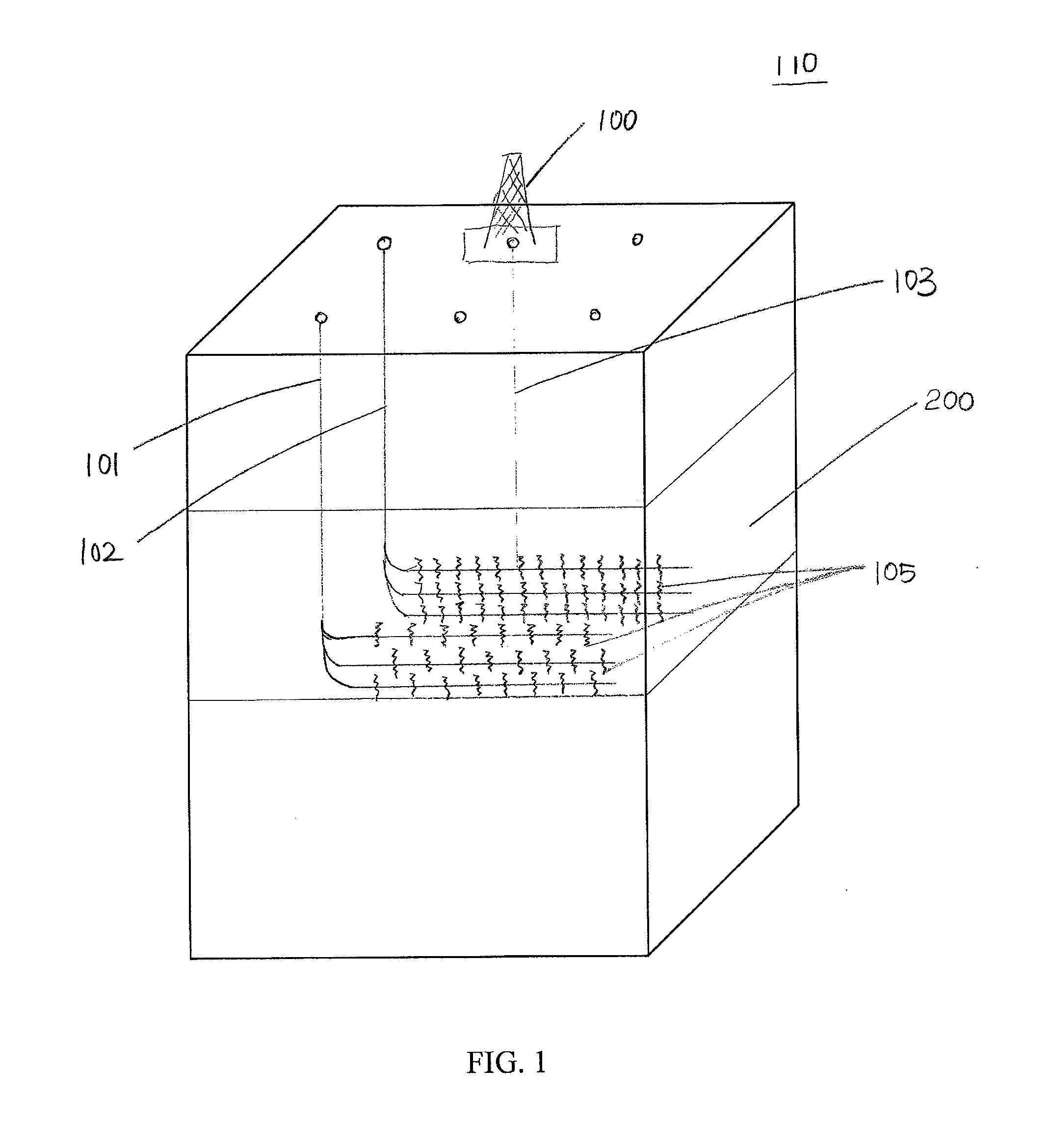

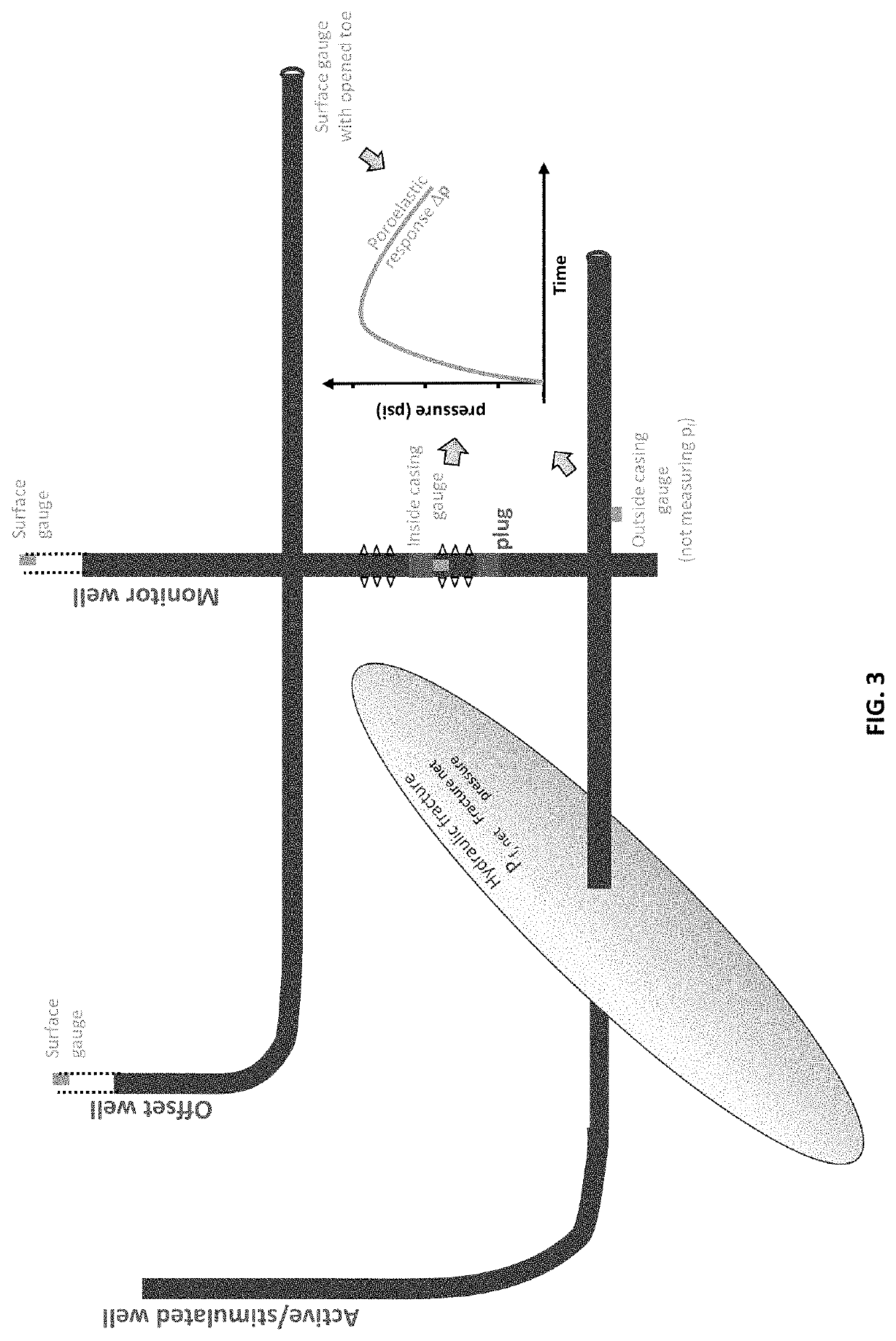

Method of acquiring information of hydraulic fracture geometry for evaluating and optimizing well spacing for multi-well pad

ActiveUS20160237799A1Low costImprove certaintySurveyFluid removalMechanical engineeringFracture geometry

Owner:STATOIL GULF SERVICES

System for real-time monitoring and transmitting hydraulic fracture seismic events to surface using the pilot hole of the treatment well as the monitoring well

Owner:SAUDI ARABIAN OIL CO

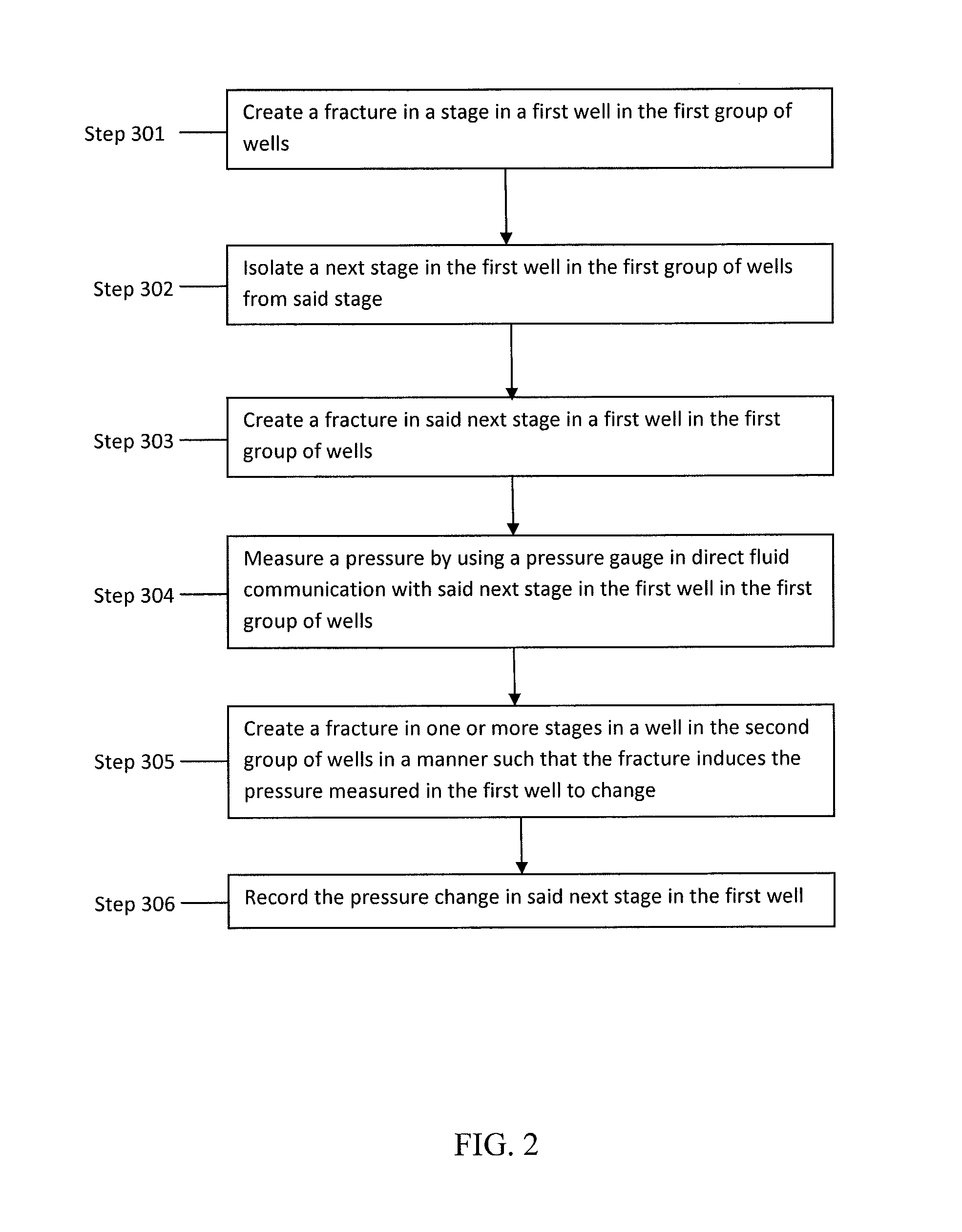

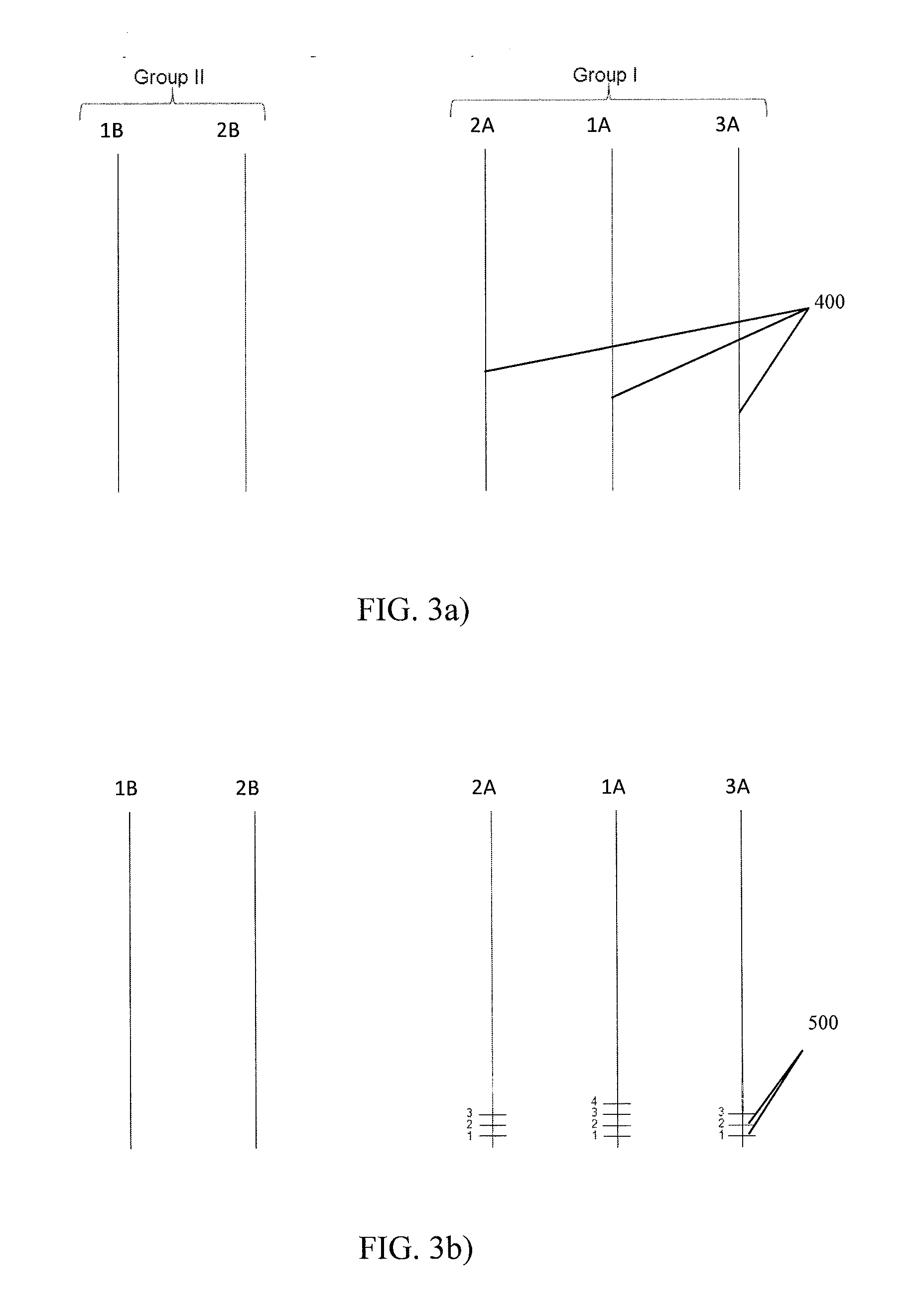

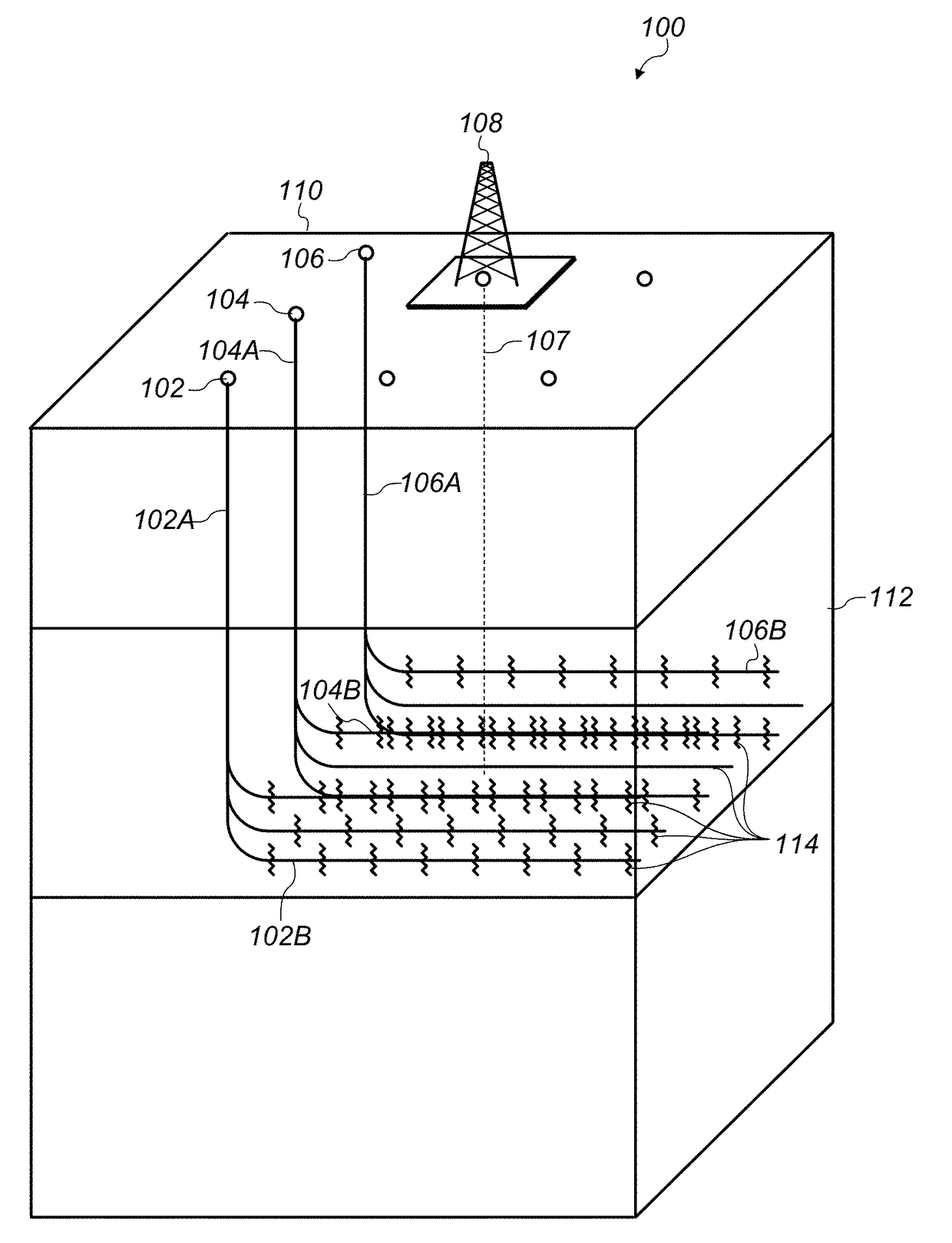

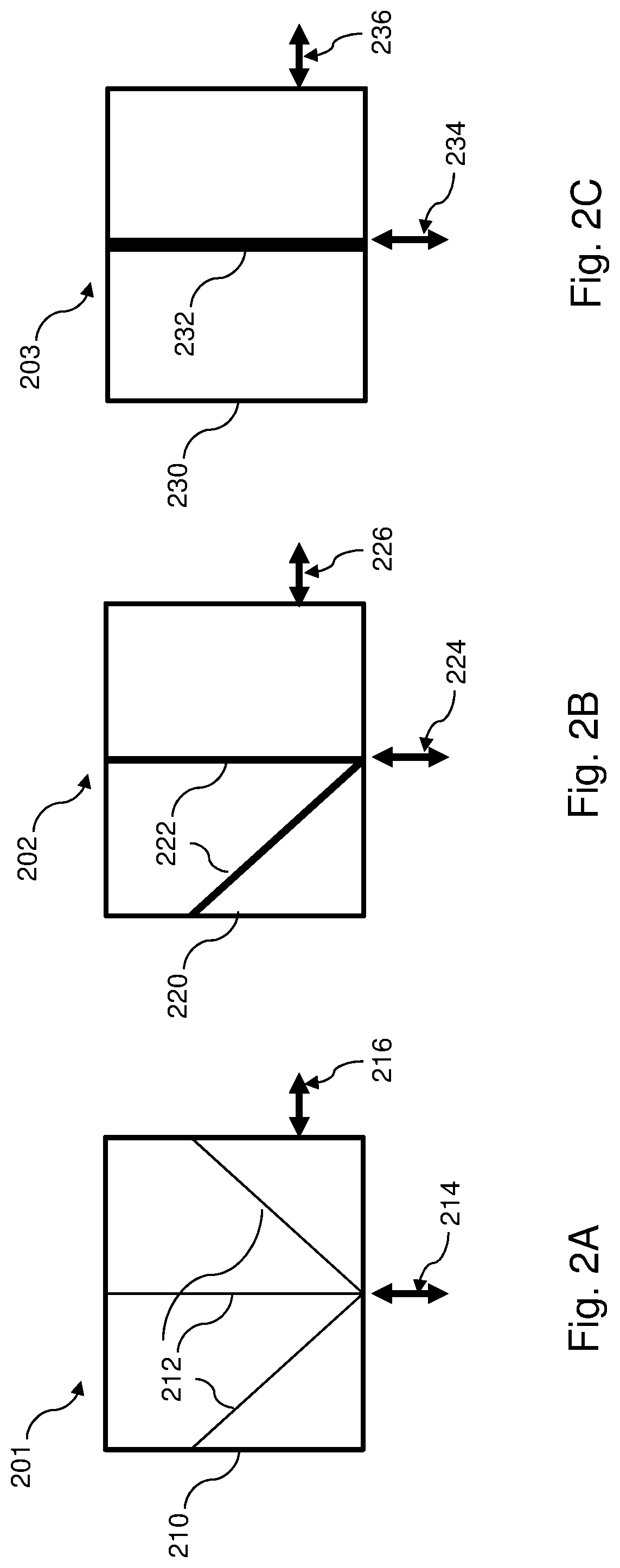

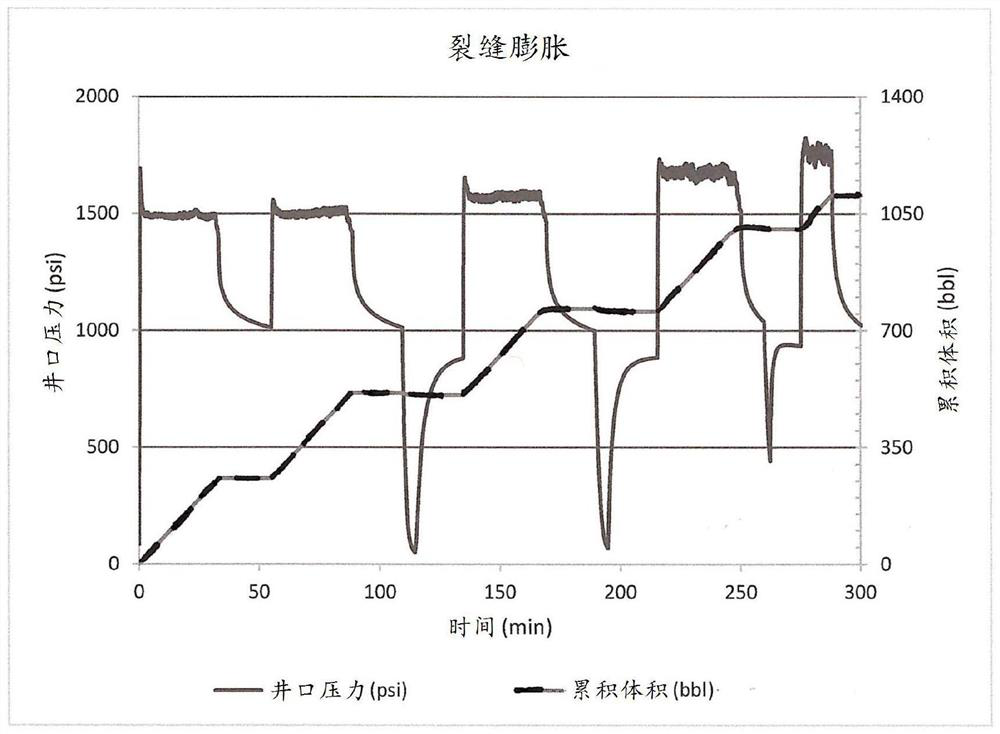

Mapping of fracture geometries in a multi-well stimulation process

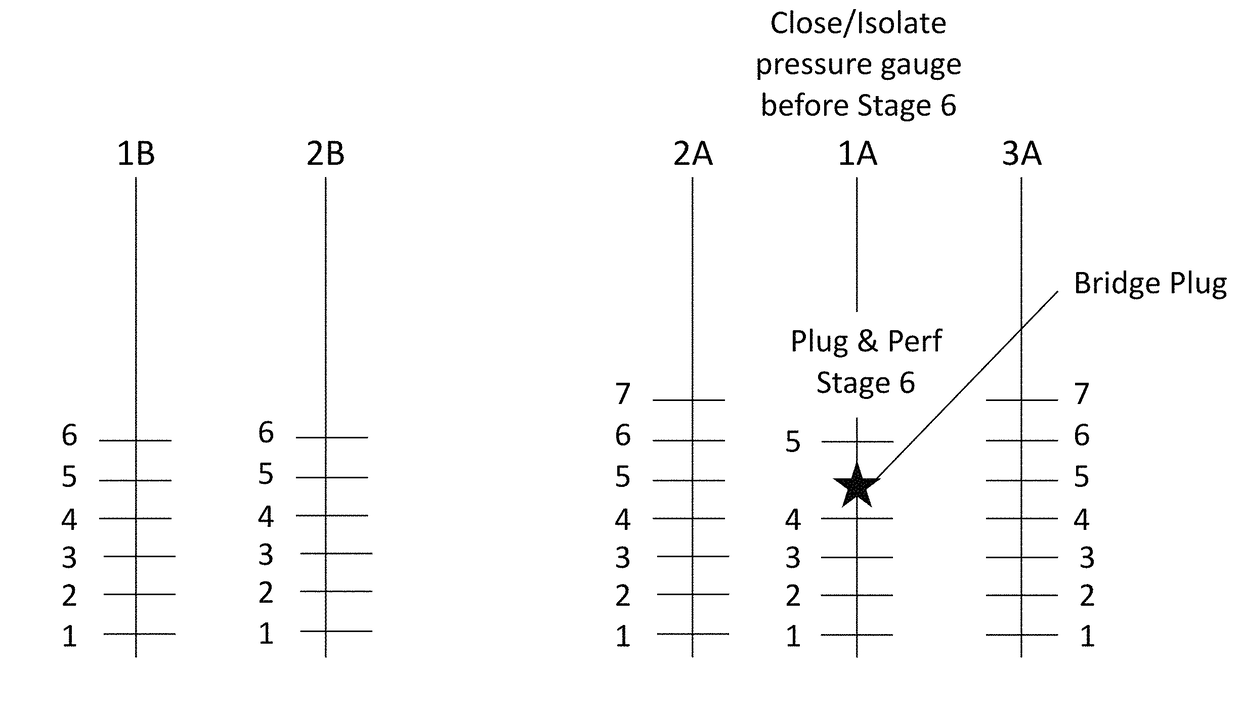

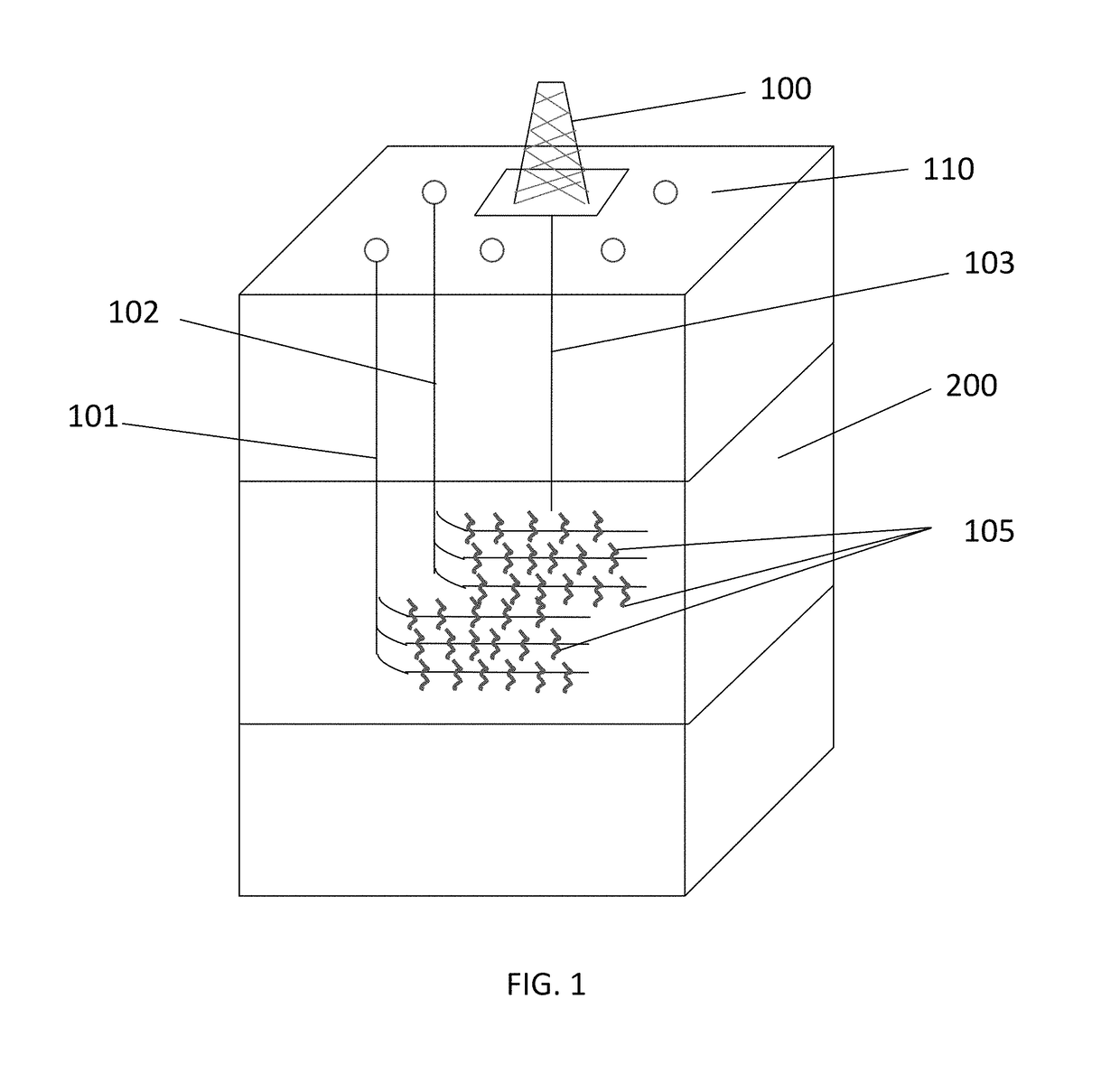

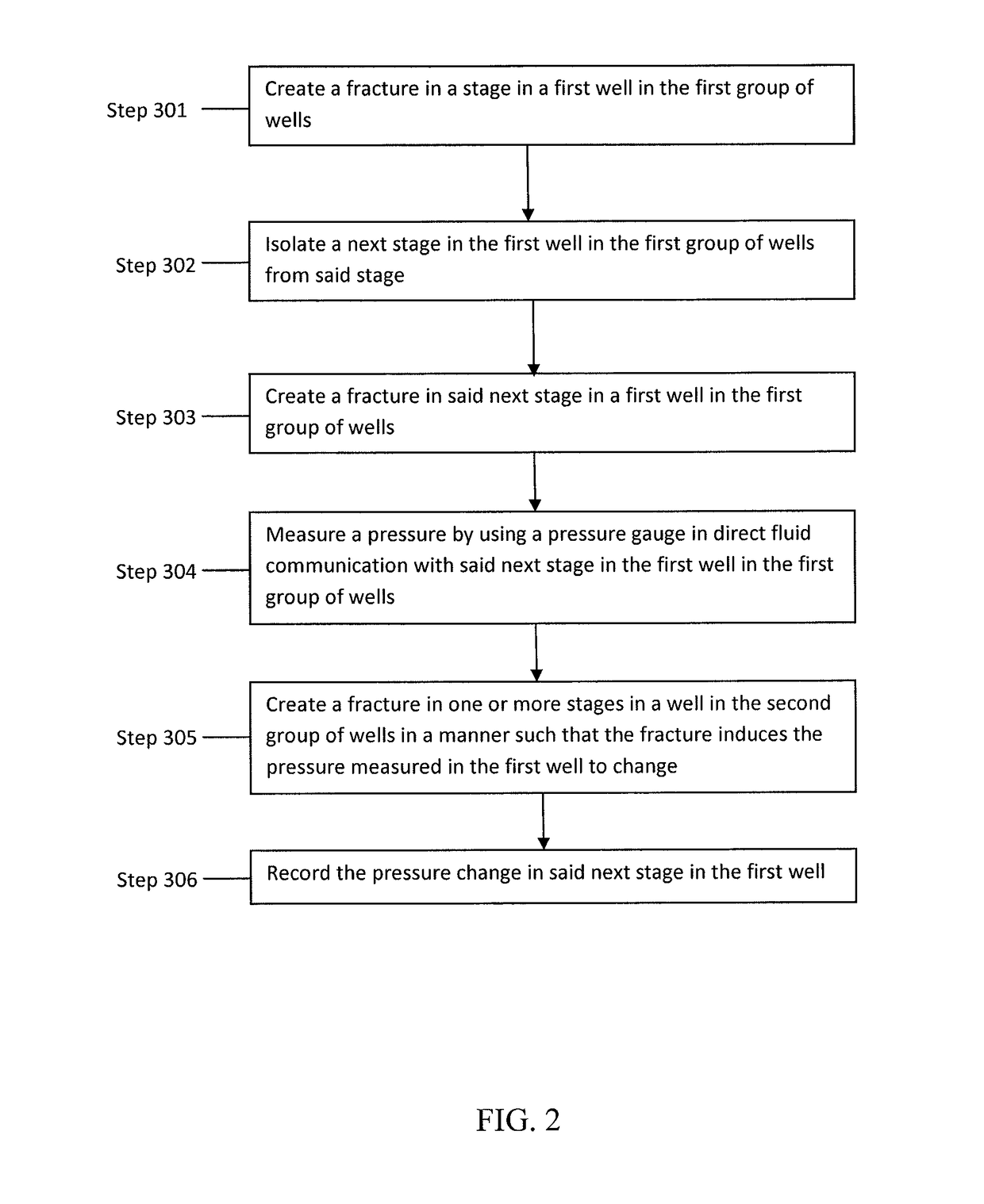

Systems and methods for assessing geometric fractures parameters in a subsurface formation are disclosed. A first pressure signal and a second pressure signal in a first (observation) wellbore in the subsurface formation may be assessed using a pressure sensor in direct fluid communication with a fluid in the first wellbore. The fluid in the first wellbore may be in direct fluid communication with at least a first fracture in the subsurface formation. The first pressure signal may include a pressure change that is induced by a second fracture being formed from a second (stimulation) wellbore in the subsurface formation. The second pressure signal may include a pressure change that is induced by a third fracture being formed from the second wellbore. One or more geometric parameters of the second and third fractures may be assessed using the first pressure signal and the second pressure signal.

Owner:REVEAL ENERGY SERVICES INC

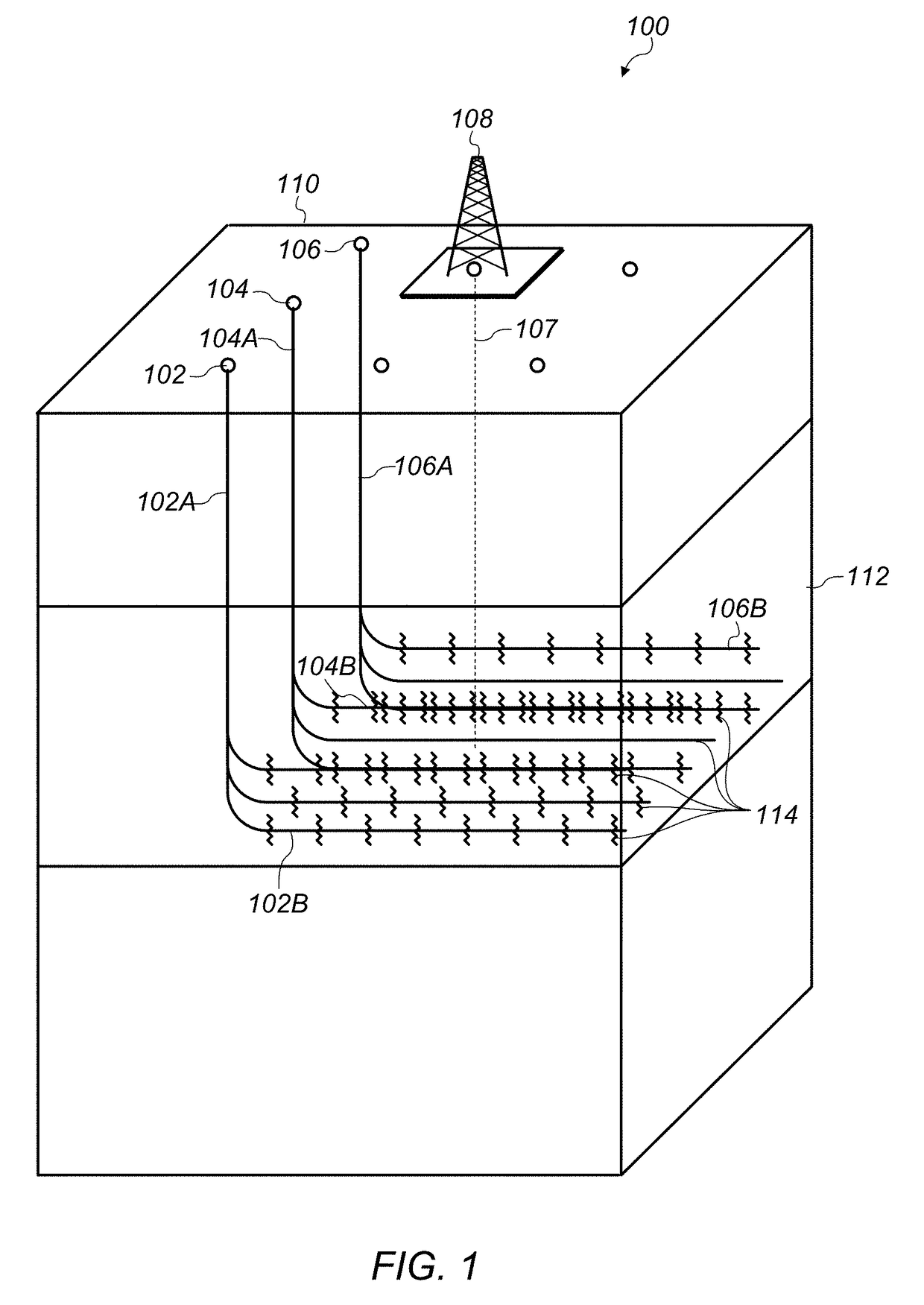

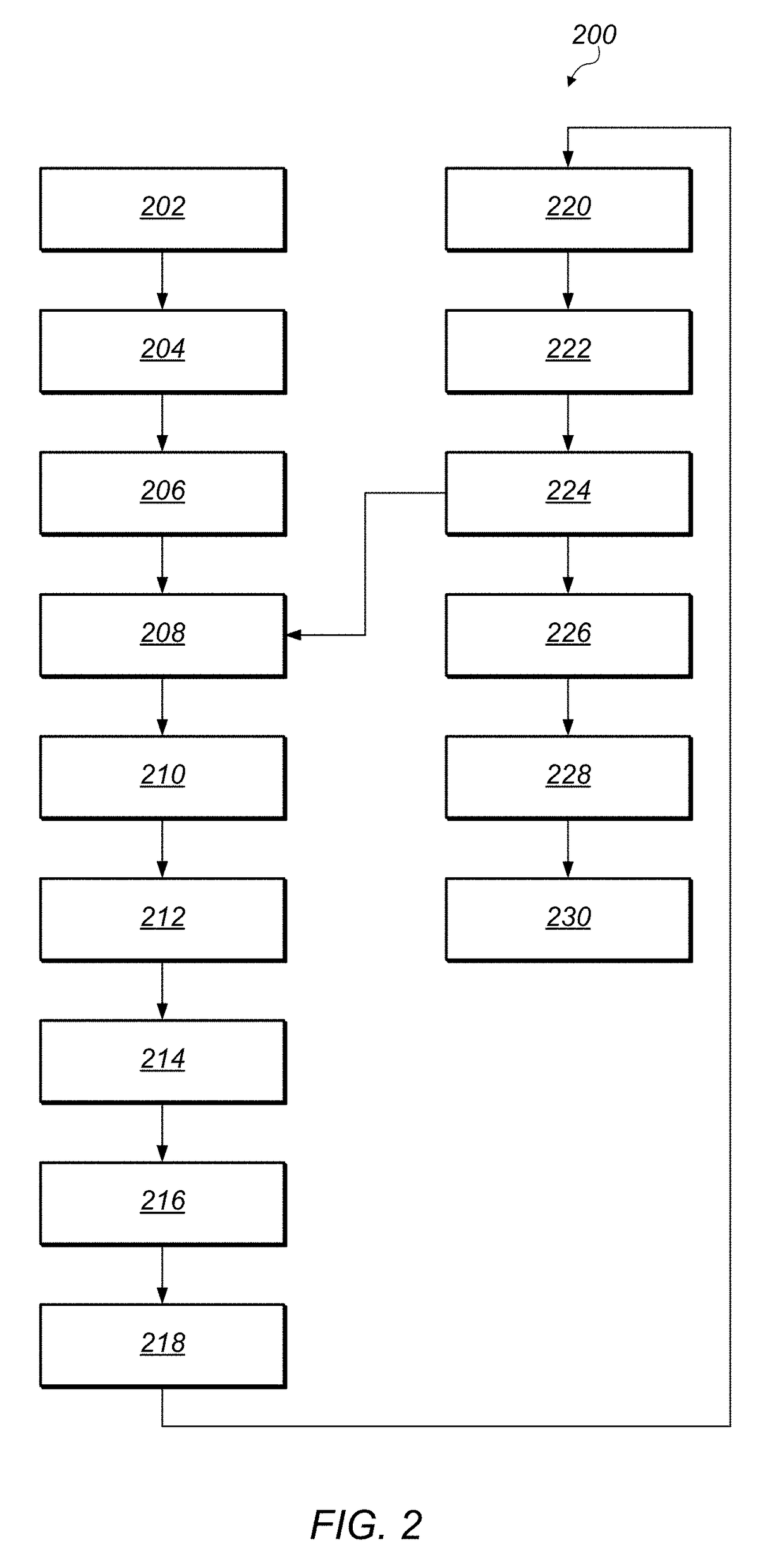

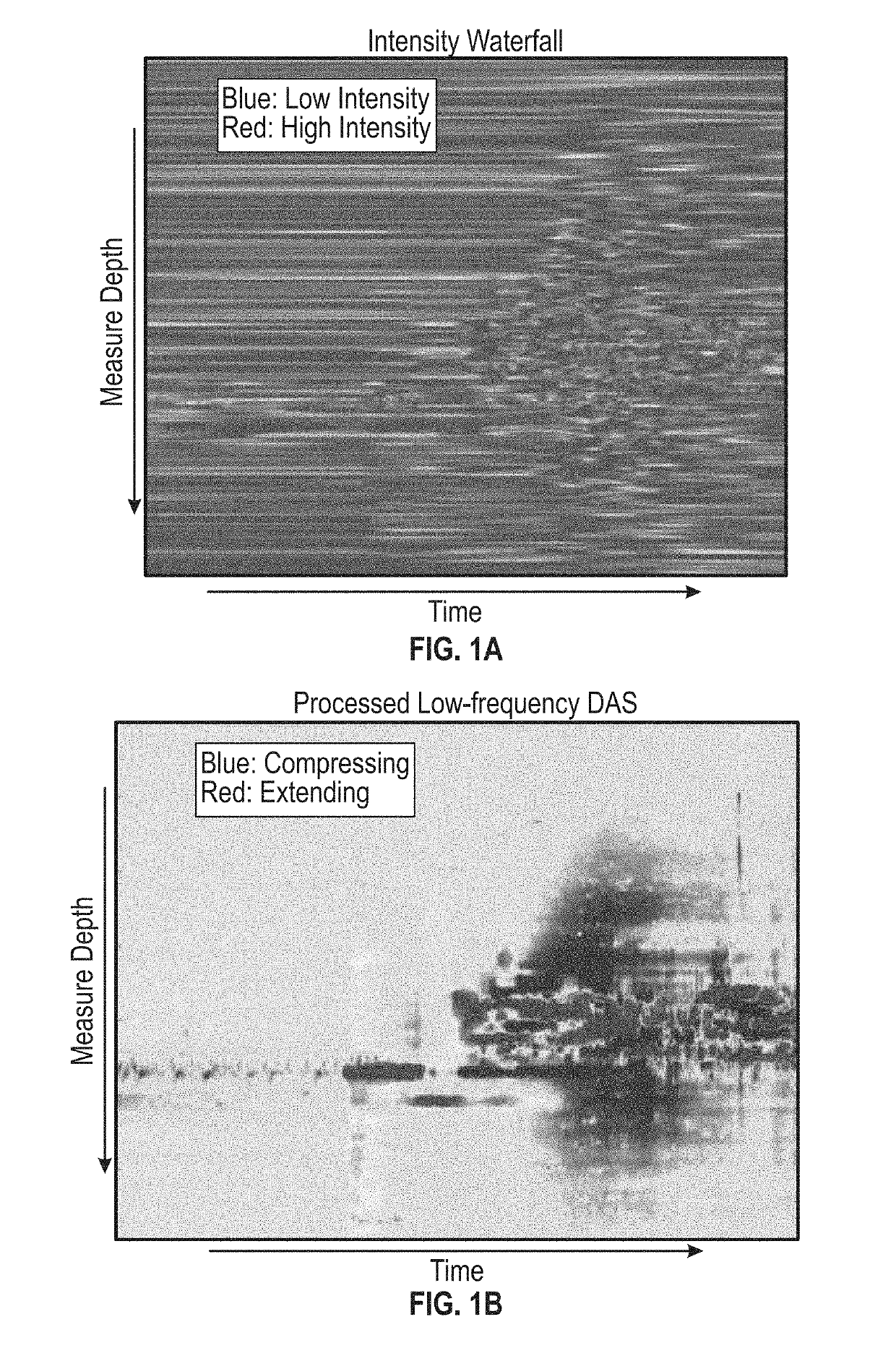

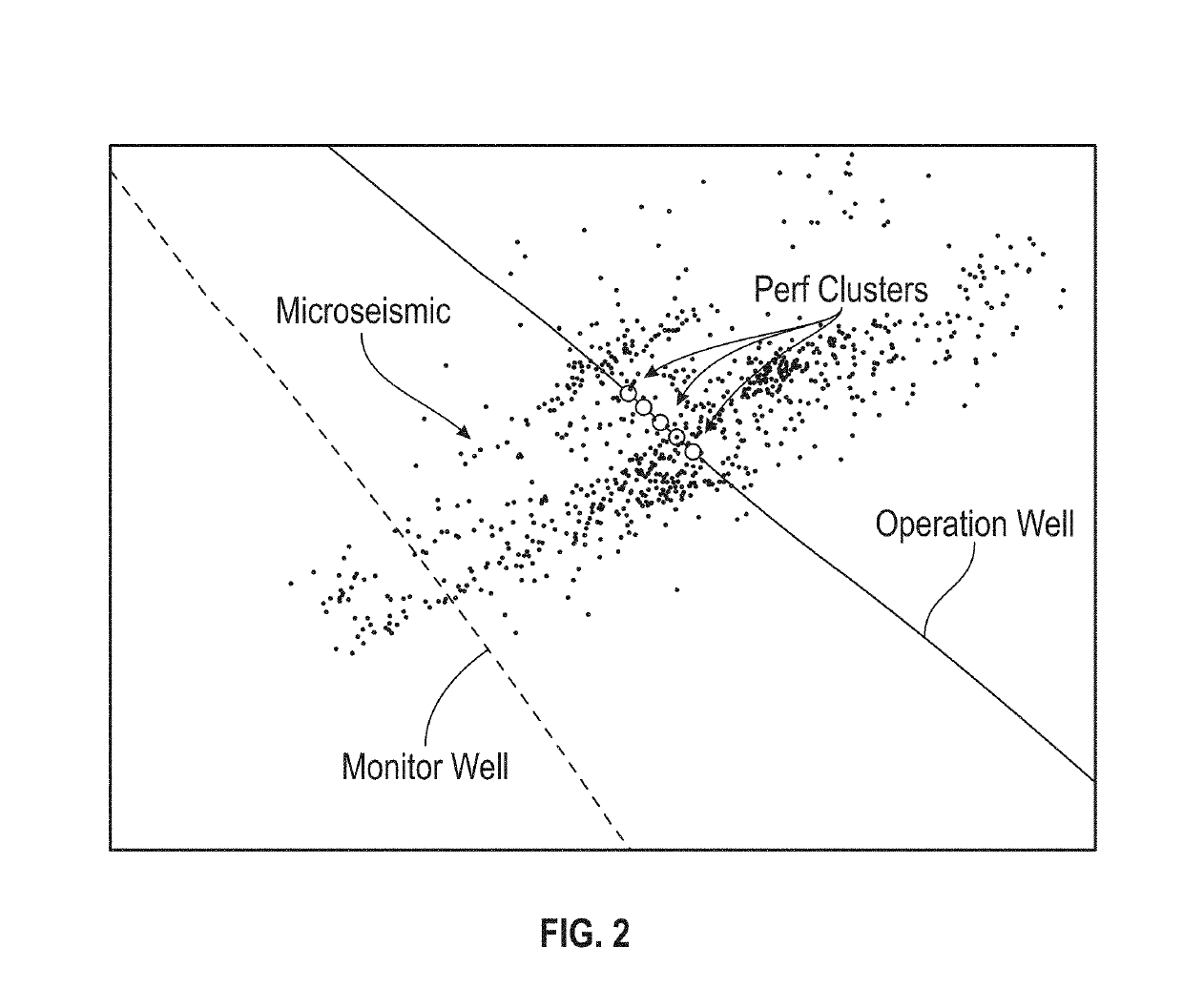

Low frequency distributed acoustic sensing hydraulic fracture geometry

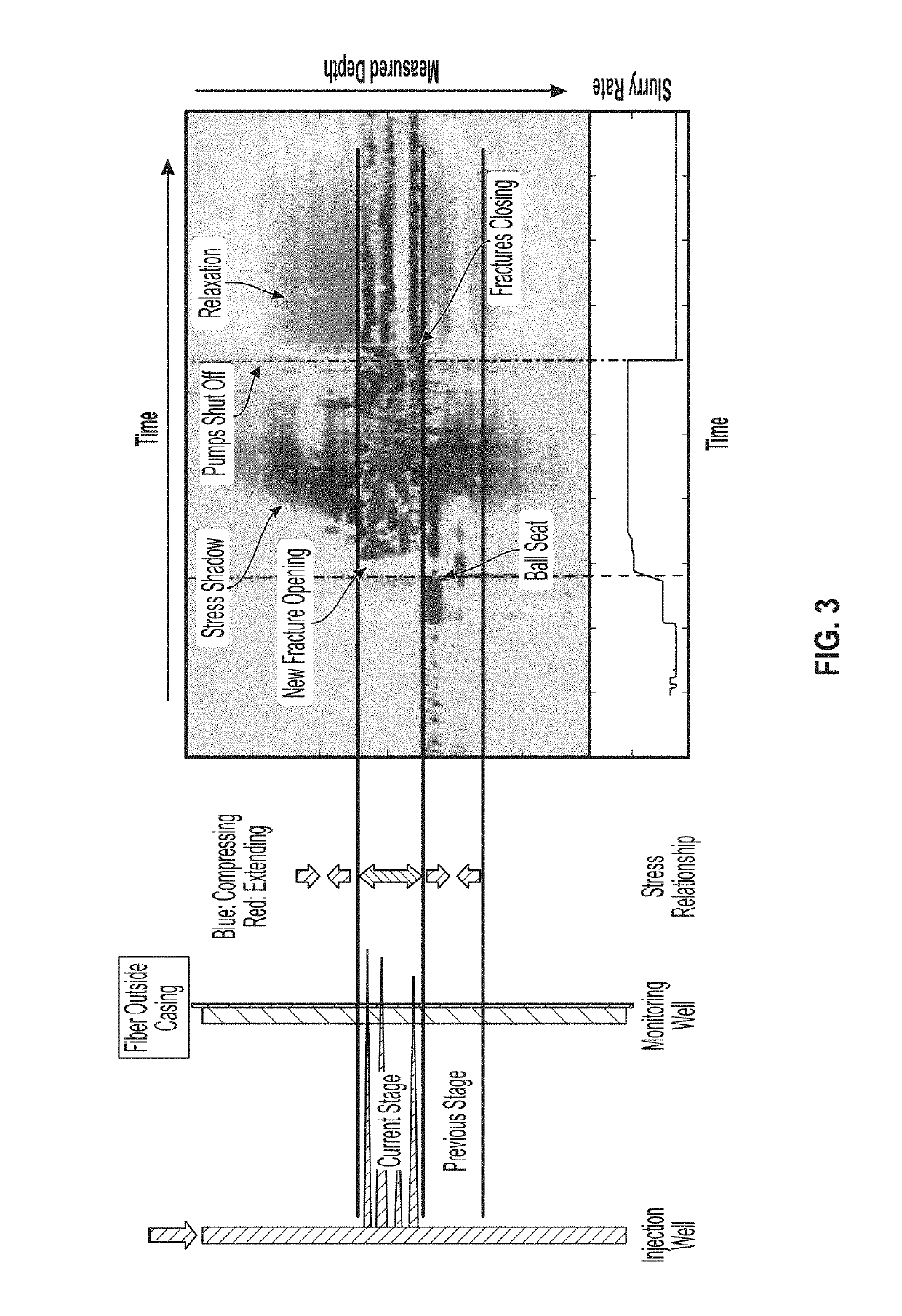

Monitoring and diagnosing completion during hydraulic fracturing operations provides insights into the fracture geometry, inter-well frac hits and connectivity. Conventional monitoring methods (microseismic, borehole gauges, tracers, etc.) can provide a range of information about the stimulated rock volume but may often be limited in detail or clouded by uncertainty. Utilization of DAS as a fracture monitoring tool is growing, however most of the applications have been limited to acoustic frequency bands of the DAS recorded signal. In this paper, we demonstrate some examples of using the low-frequency band of Distributed Acoustic Sensing (DAS) signal to constrain hydraulic fracture geometry. DAS data were acquired in both offset horizontal and vertical monitor wells. In horizontal wells, DAS data records formation strain perturbation due to fracture propagation. Events like fracture opening and closing, stress shadow creation and relaxation, ball seat and plug isolation can be clearly identified. In vertical wells, DAS response agrees well with co-located pressure and temperature gauges, and illuminates the vertical extent of hydraulic fractures. DAS data in the low-frequency band is a powerful attribute to monitor small strain and temperature perturbation in or near the monitor wells. With different fibered monitor well design, the far-field fracture length, height, width, and density can be accurately measured using cross-well DAS observations.

Owner:CONOCOPHILLIPS CO

Method of acquiring information of hydraulic fracture geometry for evaluating and optimizing well spacing for multi-well pad

Owner:STATOIL GULF SERVICES

Methods and compositions for determination of fracture geometry in subterranean formations

Articles and methods utilizing radiation susceptible materials are provided herein. In one aspect, a proppant, a treatment fluid, or both, may comprise a radiation susceptible material. In another aspect, a method is provided comprising disposing in a formation fracture, a proppant and / or a treatment fluid that comprises a radiation susceptible material, irradiating the radiation susceptible material with neutrons, measuring gamma-radiation emitted from the radiation susceptible material in a single pass, and determining formation fracture height from the measured gamma-radiation. The single-pass may be a continuous process or a periodic process.

Owner:MOMENTIVE SPECIALTY CHEM RES BELGIUM

Method for real-time monitoring and transmitting hydraulic fracture seismic events to surface using the pilot hole of the treatment well as the monitoring well

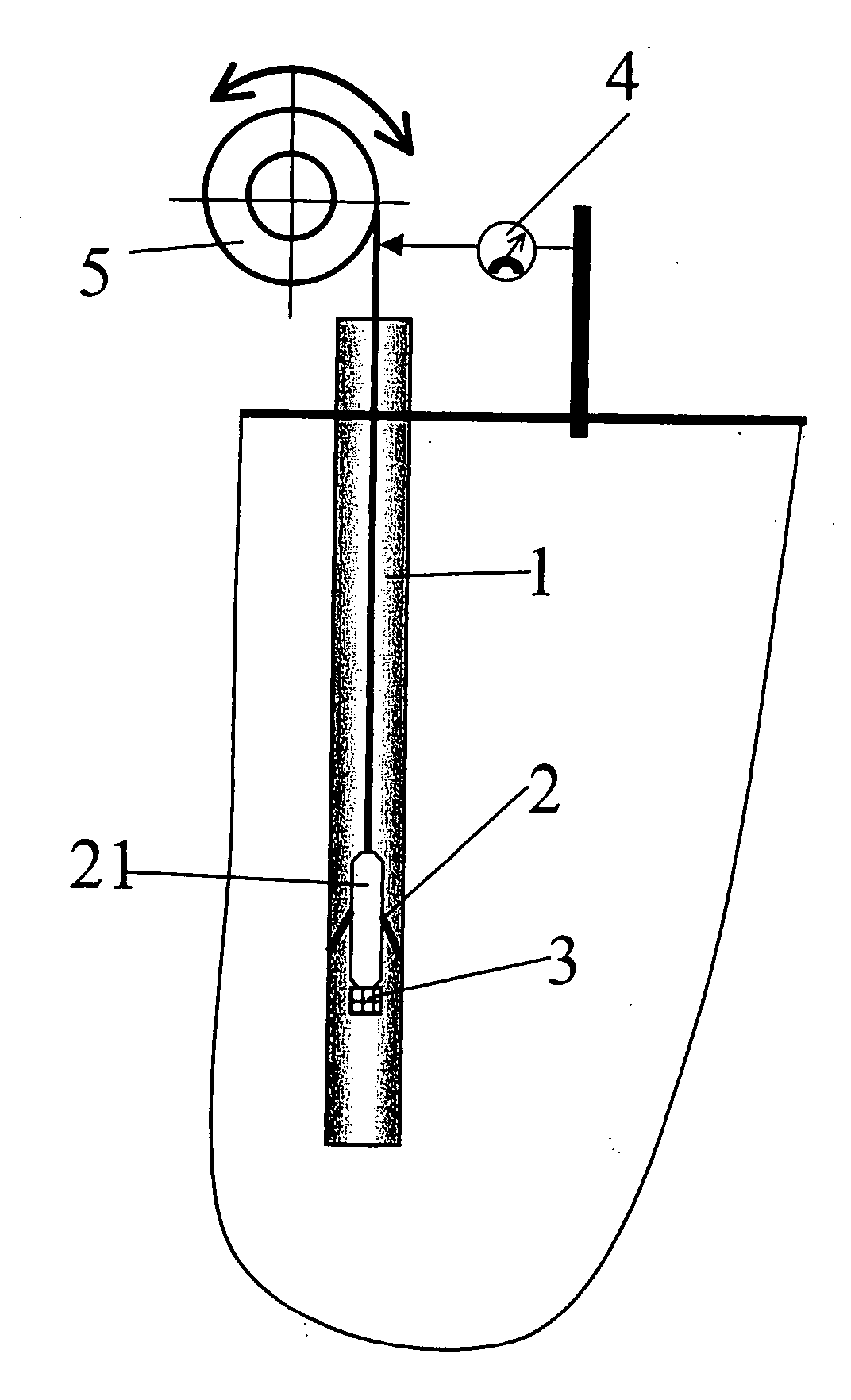

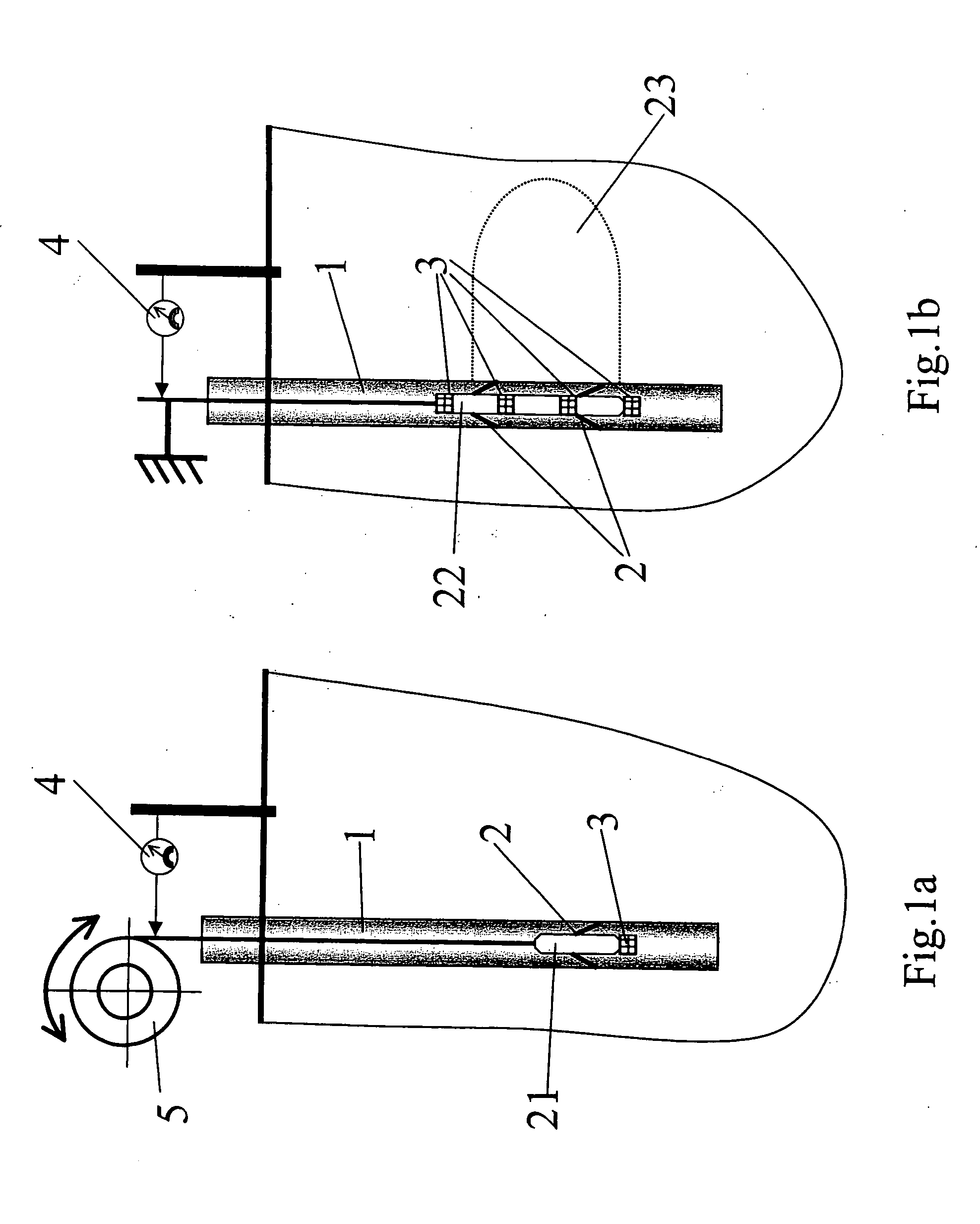

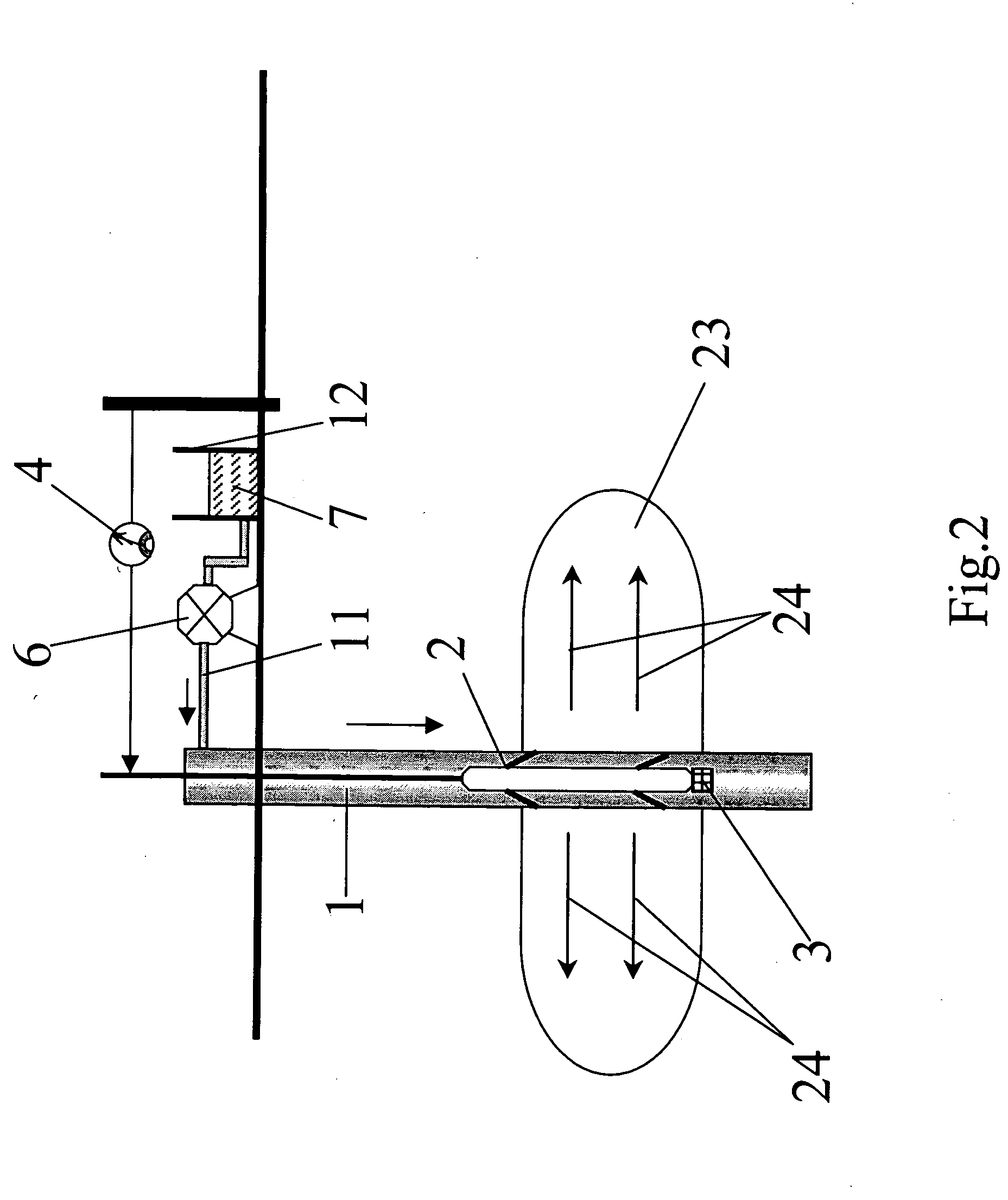

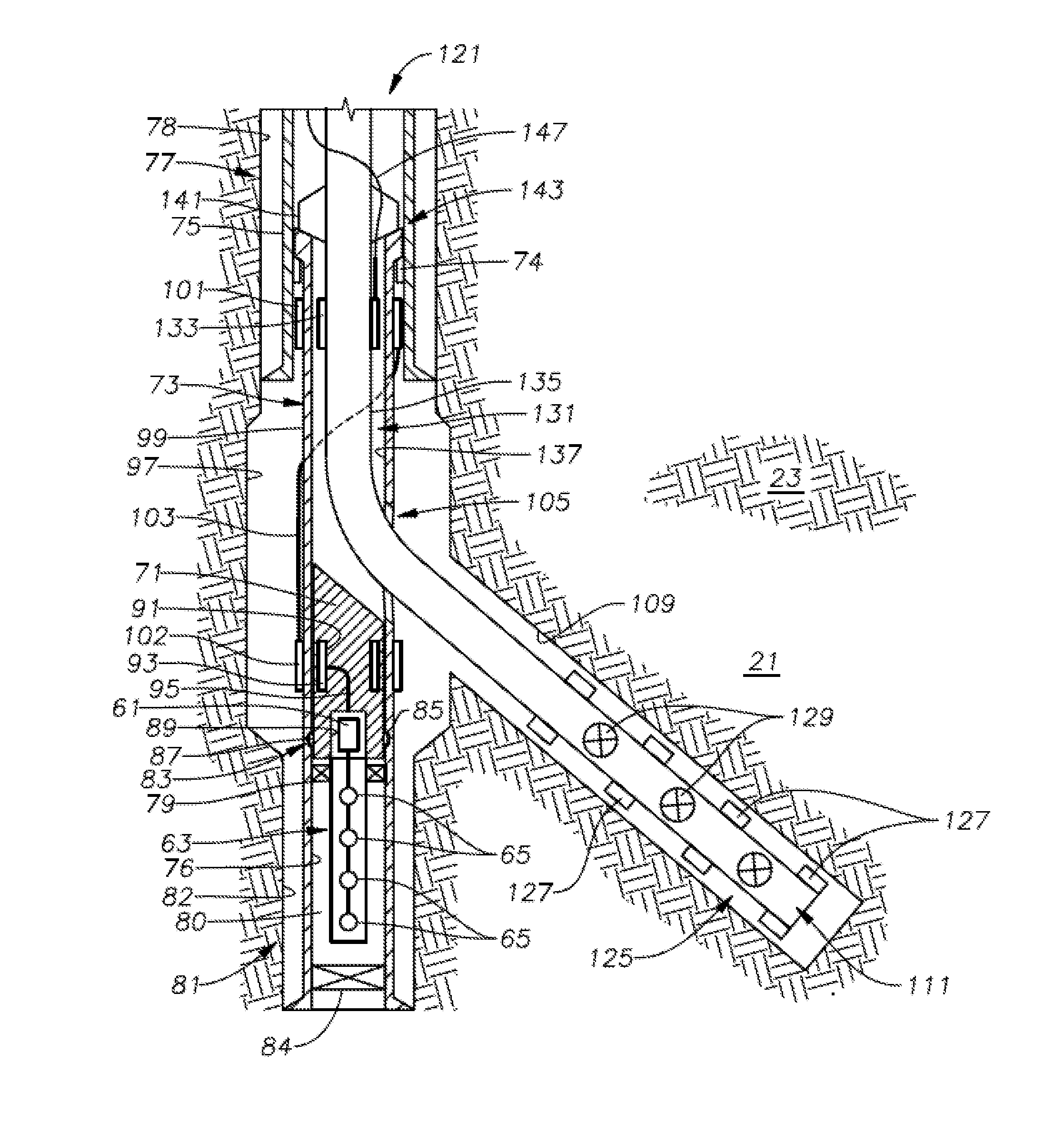

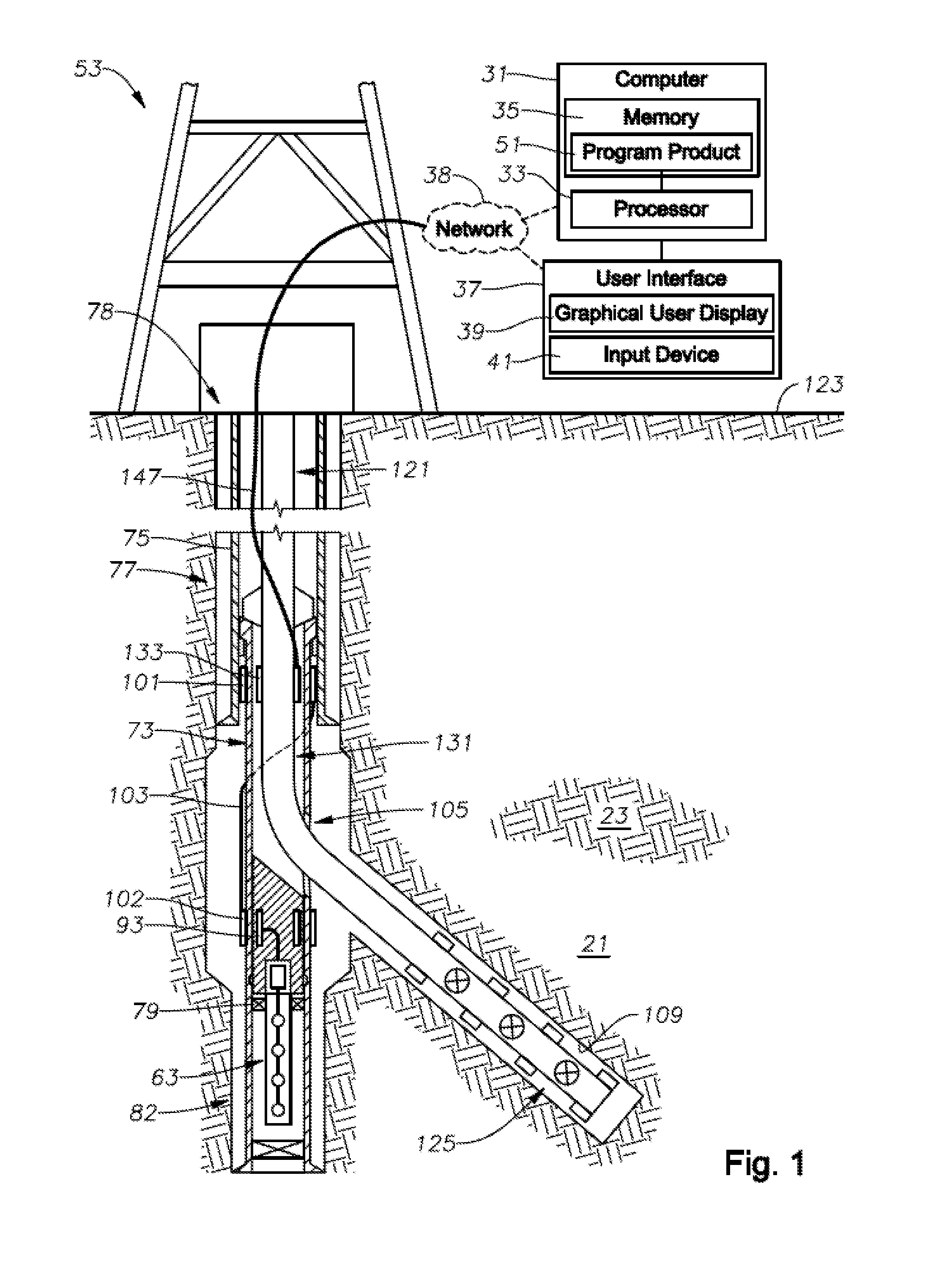

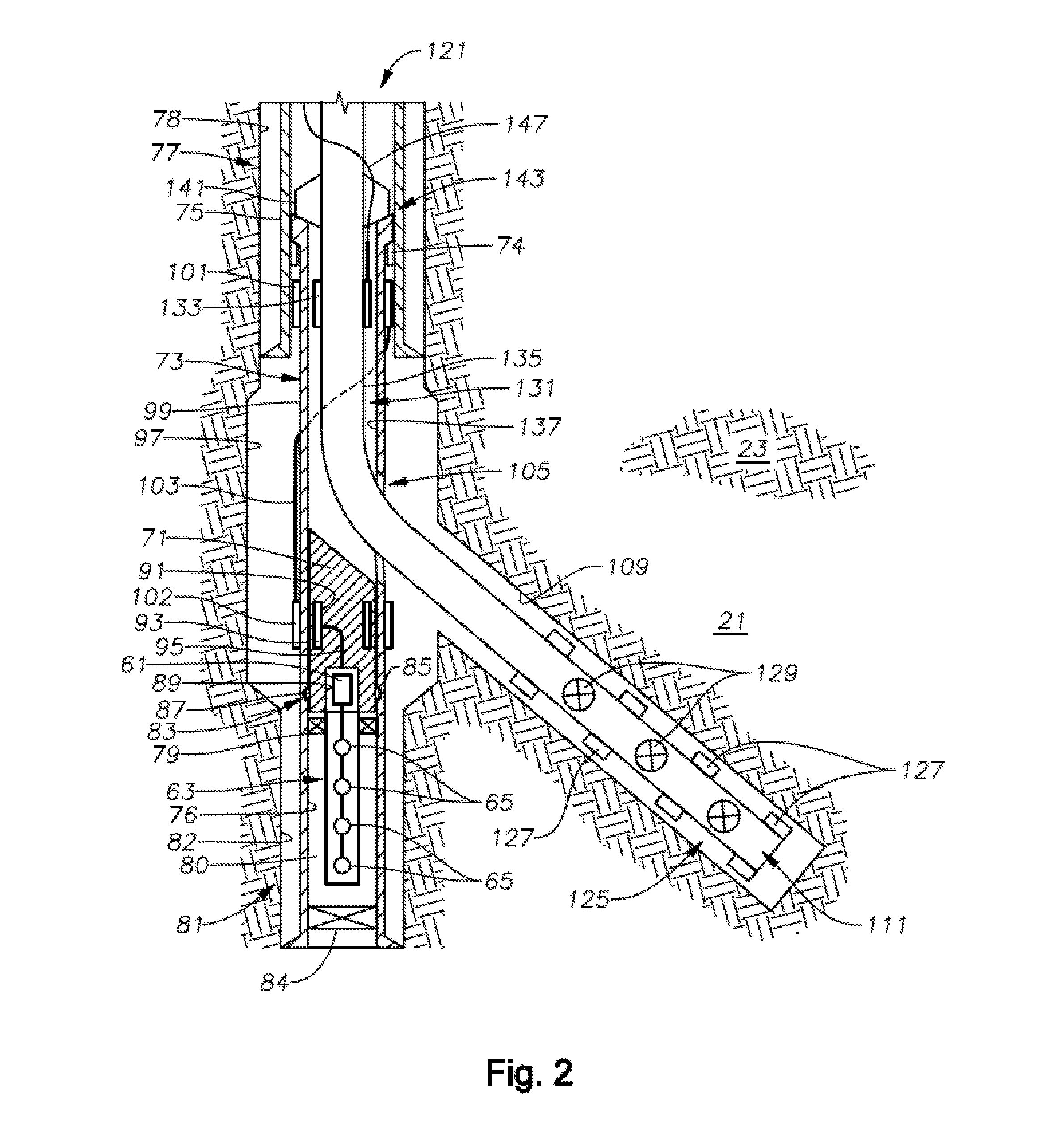

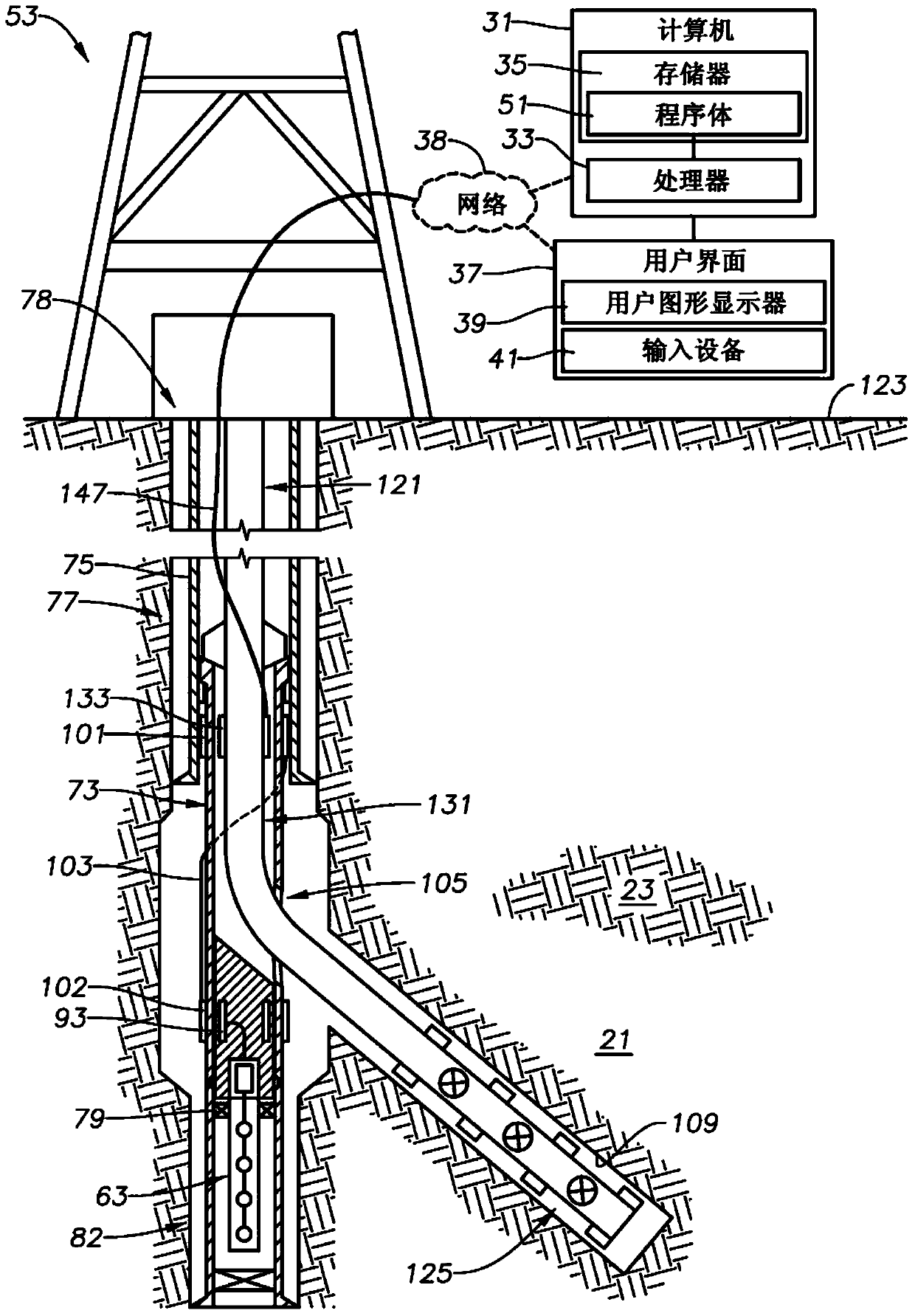

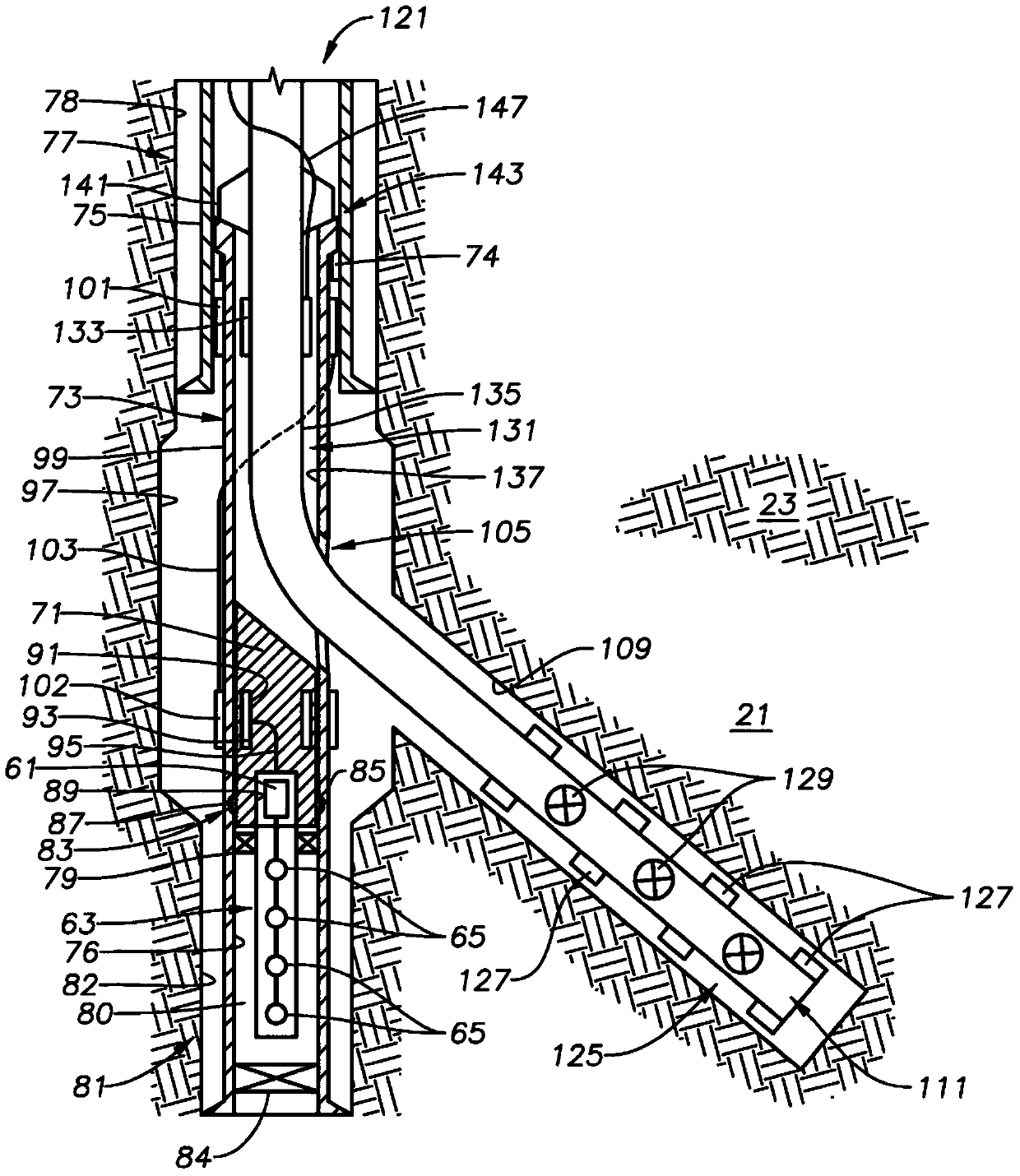

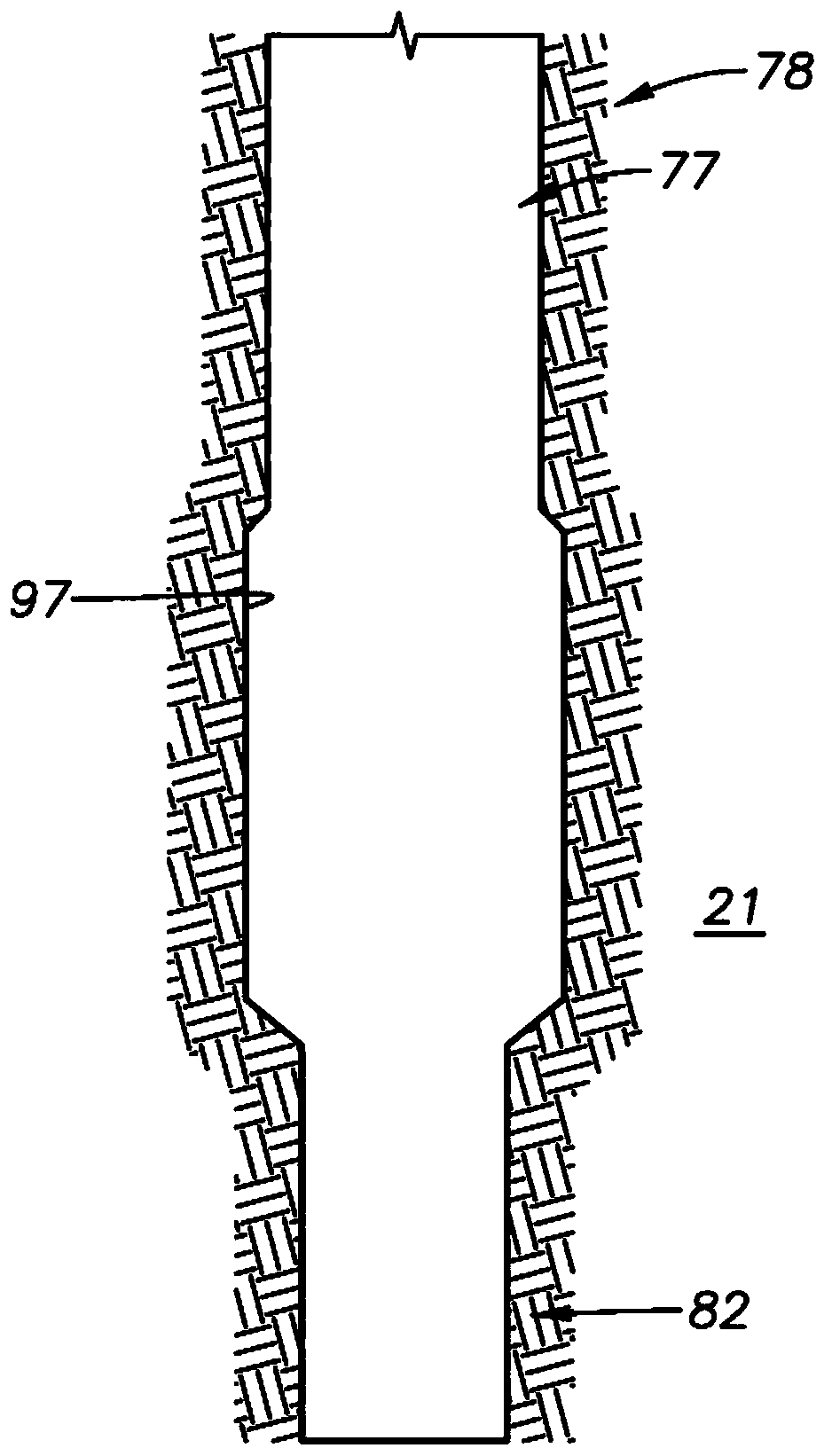

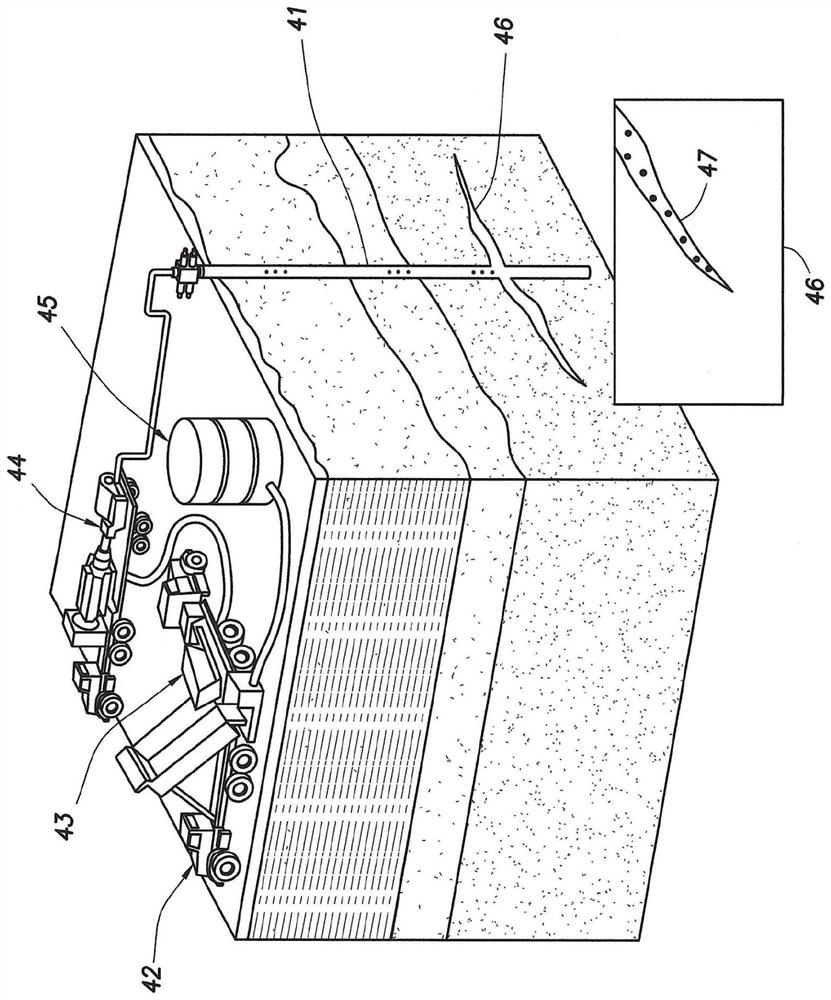

InactiveCN103857872ALow costReduce or remove restrictionsDrilling rodsConstructionsEngineeringAcoustics

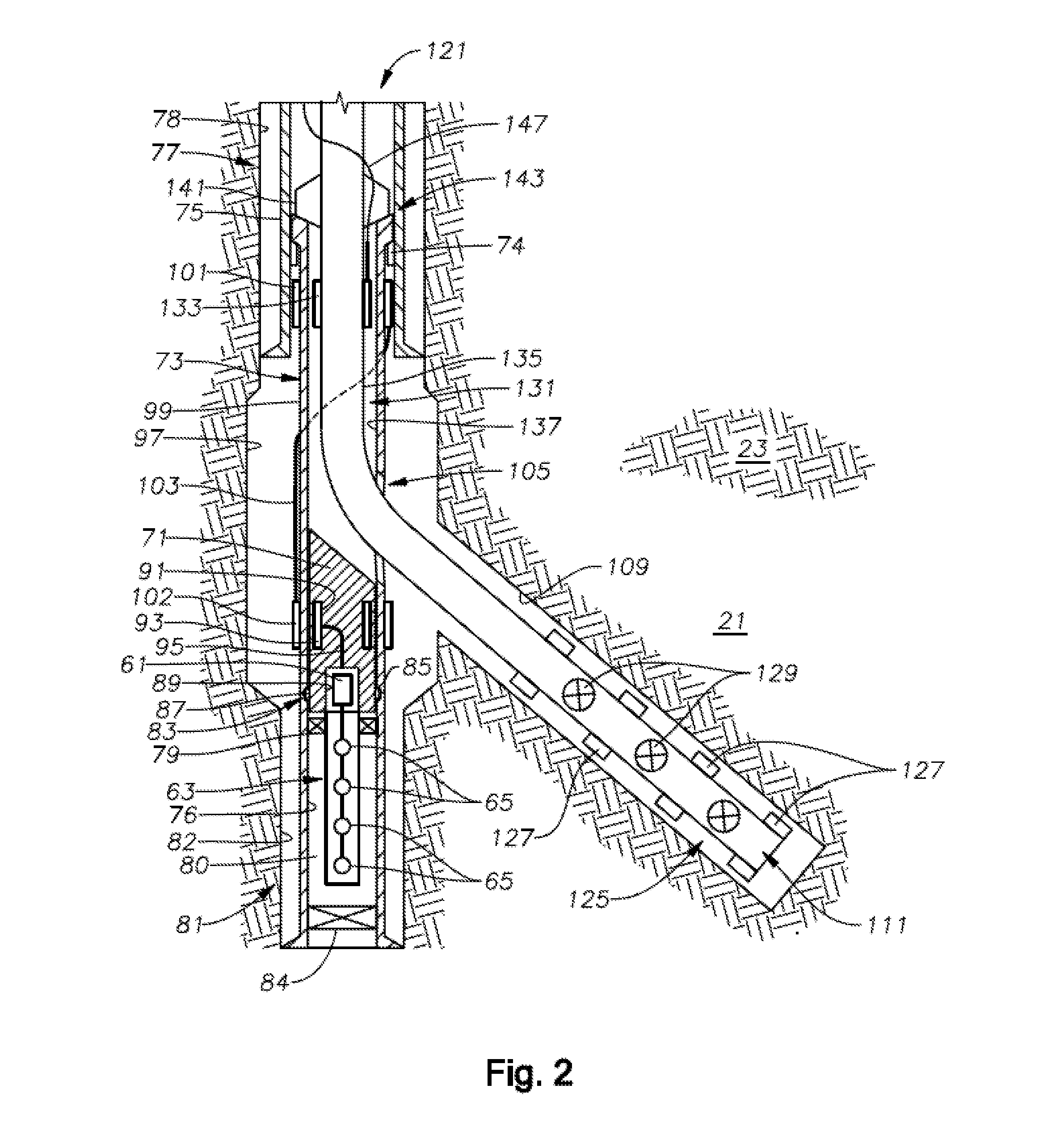

Methods for determining hydraulic fracture geometry and / or area! extent of an area of interest (21) in a reservoir (23), are provided. An exemplar}' method includes isolating downhole acoustic receiver equipment (63) in a lower portion of a first wellbore (78) from fracturing operations located in a second wellbore (109) connected to the first wellbore (78). Communications between surface equipment (31, 38) in the downhole acoustic receiver equipment (63) is provided through a communications conduit bypass (101, 133; 103; 102, 93) that permits well operations in the second wellbore (109) without interfering with communications between the surface equipment (31, 38) and the downhole acoustic receiver equipment (63).

Owner:SAUDI ARABIAN OIL CO

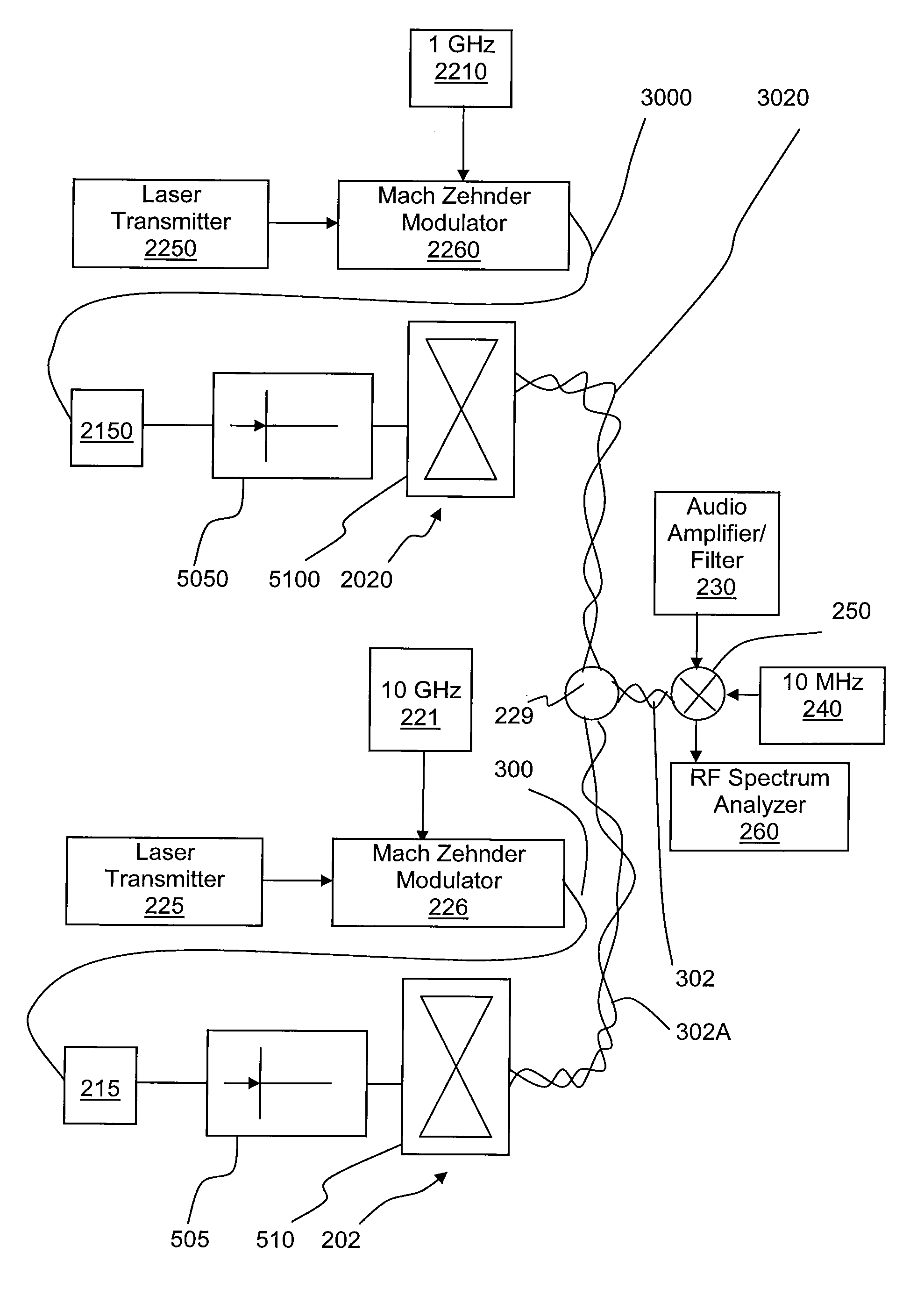

Wellbore casing mounted device for determination of fracture geometry and method for using same

A logging system and method for measuring propped fractures and down-hole subterranean formation conditions including: a radar source; an optical source; an optical modulator for modulating an optical signal from the optical source according to a signal from the radar source; a photodiode for converting the modulated optical signal output from the optical modulator to the source radar signal. A transmitter and receiver unit receives the source radar signal from the photodiode and transmits the source radar signal via at least one antenna attached to the casing and in communication with at least one photodiode into the formation and receives a reflected radar signal. A mixer mixes the reflected radar signal with the source radar signal to provide an output. This can describe fractures connected to the wellbore and differentiate between the dimensions of the two vertical wings of a propped fracture.

Owner:HEXION INC

Method of fracturing a subterranean formation at optimized and pre-determined conditions

Prior to a hydraulic fracturing treatment, the estimated fracture length may be estimated with knowledge of certain physical properties of the proppant and transport fluid such as fluid viscosity, proppant size and specific gravity of the transport slurry as well as fracture geometry and the treatment injection rate. The estimated fracture length may be determined by a specific equation.

Owner:BAKER HUGHES HLDG LLC

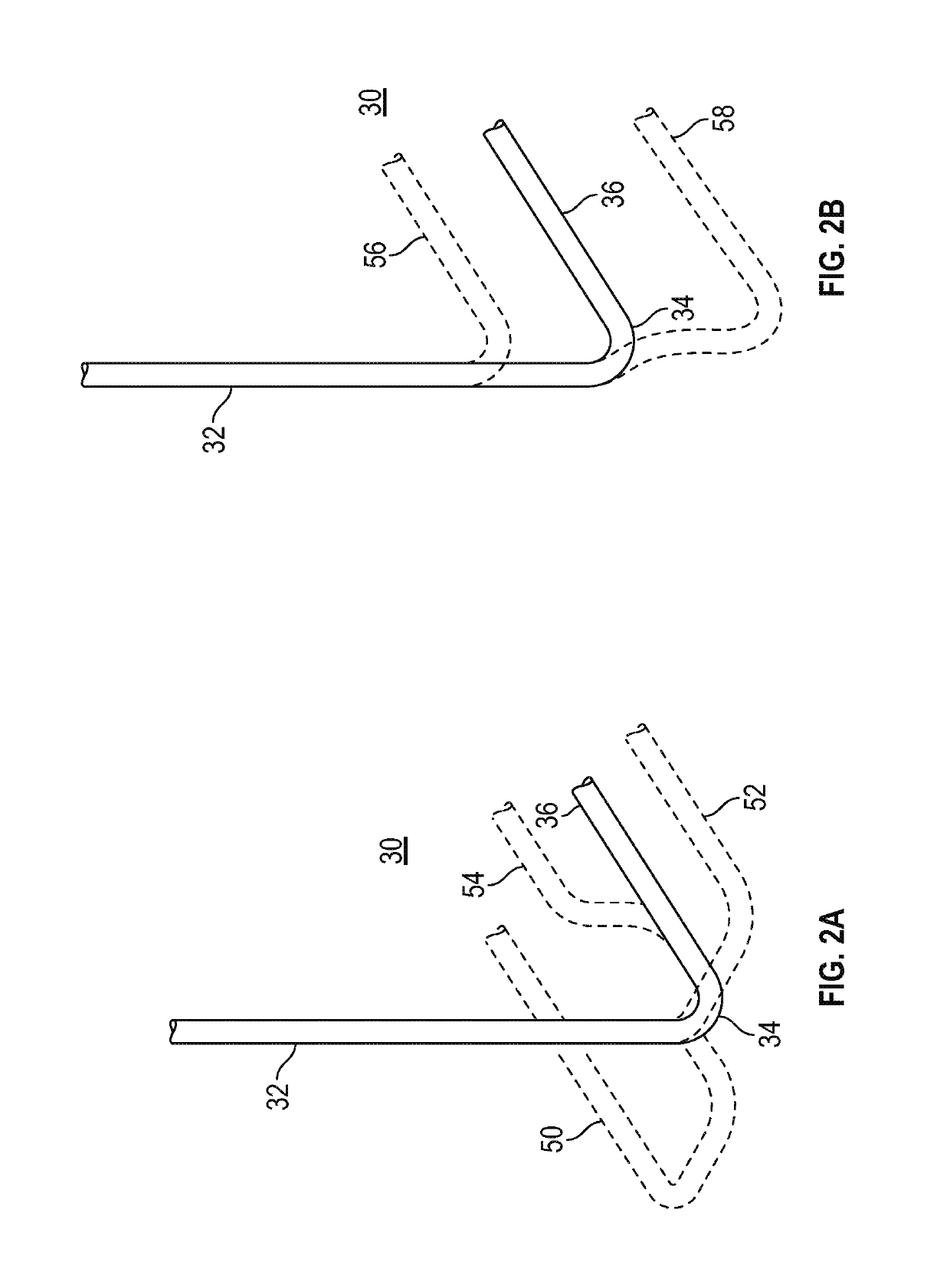

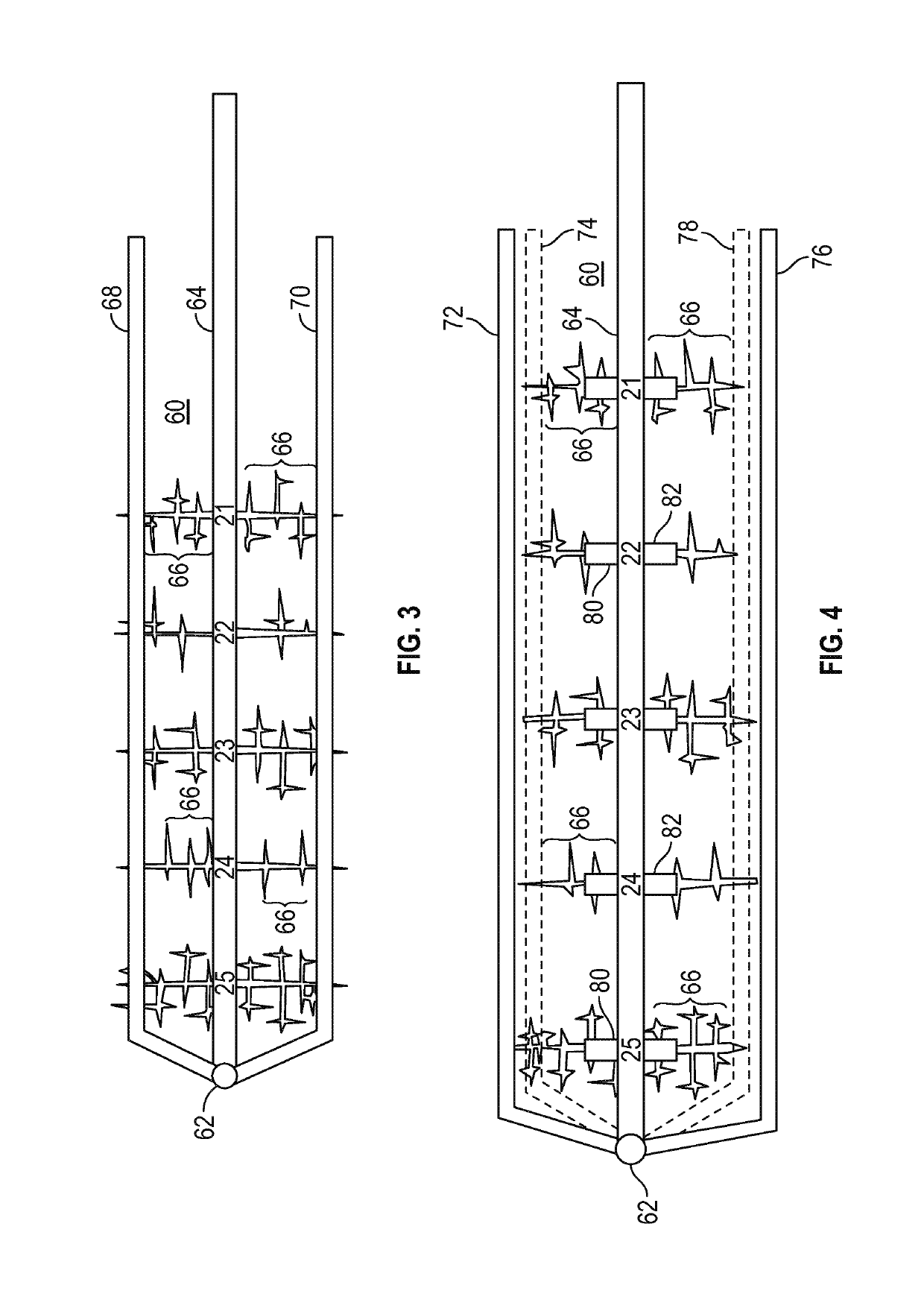

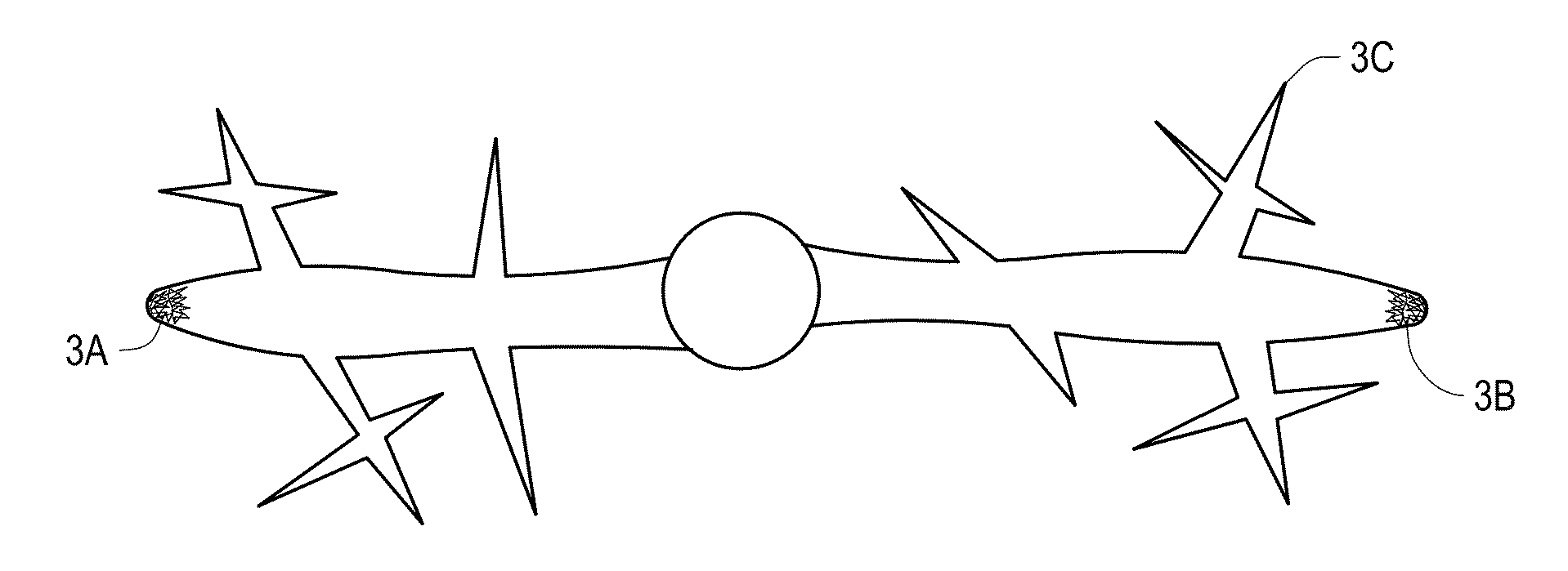

Diagnostic lateral wellbores and methods of use

Improving the knowledge about how hydraulic fracture networks are generated in subsurface shale volumes in unconventional wellbores may be accomplished with various configurations of at least one diagnostic lateral wellbore using at least one diagnostic device disposed in the diagnostic lateral wellbore. By extending diagnostic lateral wellbores from adjacent lateral wellbores and / or separately drilling diagnostic lateral wellbores, and analyzing signals received by diagnostic devices placed in the diagnostic lateral wellbores, knowledge about fracture networks, the parameters that control fracture geometry and reservoir production and how reservoirs react to refracturing techniques may be greatly improved. Additionally, such diagnostic lateral wellbores can provide quicker location of sweet-spot horizons in reservoirs.

Owner:BAKER HUGHES INC

Controlling fracture geometry with the use of shrinkable materials

A method for treating a subterranean formation utilizing a composition having a plurality of shrinkable materials. The method of treatment may include providing a hydraulic fracture into the subterranean formation, and injecting a slurry having a plurality of shrinkable materials into a far field. The shrinkable materials may shrink once a threshold is reached.

Owner:SCHLUMBERGER TECH CORP

Ubiquitous real-time fracture monitoring

Method for characterizing subterranean formation is described. One method involves simulating a poroelastic pressure response of known fracture geometry utilizing a geomechanical model to generate a simulated poroelastic pressure response. Compiling a database of simulated poroelastic pressure responses. Measuring a poroelastic pressure response of the subterranean formation during a hydraulic fracturing operation to generate a measured poroelastic pressure response. Identifying a closest simulated poroelastic pressure response in the library of simulated poroelastic pressure response. Estimating a geometrical parameter of a fracture or fractures in the subterranean formation based on the closest simulated poroelastic pressure response

Owner:CONOCOPHILLIPS CO

Simulating hydraulic fracturing geometry propagation using a differential stress and pattern-based model

The disclosure presents a technique to generate a fracture model using a differential stress map and model inputs. The technique simulates the fracture model using fracture fronts, initiated at perforations of a perforation stage of a hydraulic fracturing (HF) wellbore. Each fracture front is evaluated using a propagation step of a fracture model process. Using the relative differential stress states, a fracture pattern is composited to the fracture model. At each propagation step, the total energy available from the simulated fluid being pumped into the wellbore location is reduced by the amount necessary to generate the computed fractures. Once the remaining energy is reduced to a level where no further fractures can be created, or if a map boundary is encountered, the fracture model process terminates. The generated fracture model can be communicated to update HF job plans, wellbore placements, and other uses of the fracture model.

Owner:LANDMARK GRAPHICS

Mapping of fracture geometries in a multi-well stimulation process

Owner:REVEAL ENERGY SERVICES INC

Method of calibrating fracture geometry to microseismic events

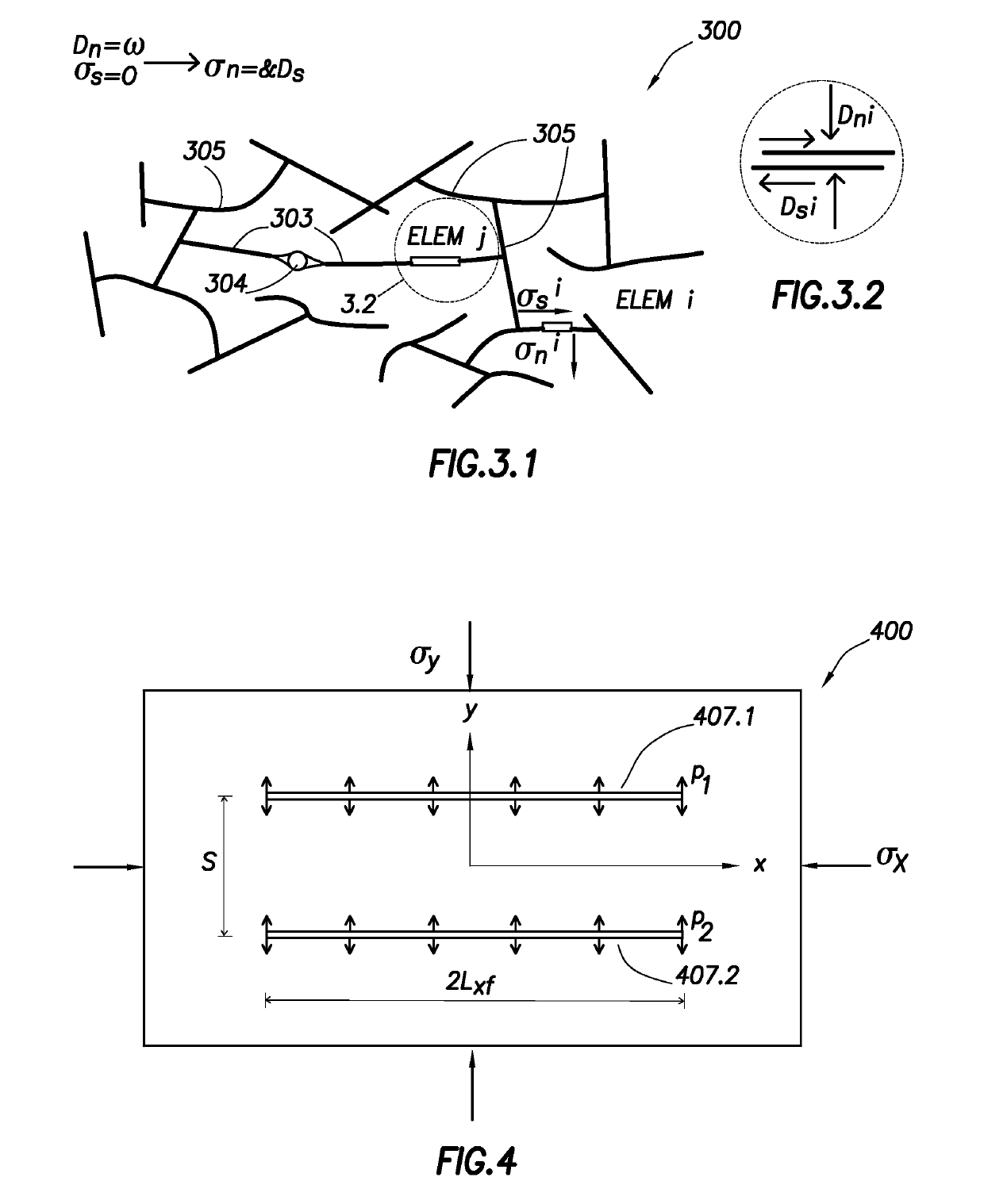

A method of performing a fracture operation is provided at a wellsite. The wellsite is positioned about a subterranean formation having a wellbore therethrough and a complex fracture network therein. The complex fracture network includes natural fractures, and the wellsite stimulated by injection of an injection fluid with proppant into the complex fracture network. The method involves generating wellsite data comprising measurements of microseismic events of the subterranean formation, modeling a hydraulic fracture network and a discrete fracture network of the complex fracture network based on the wellsite data, and performing a seismic moment operation. The method involves determining an actual seismic moment density based on the wellsite data and a predicted seismic moment density based on shear and tensile components of the simulated hydraulic fracture network, and calibrating the discrete fracture network based on a comparison of the predicted moment density and the actual moment density.

Owner:SCHLUMBERGER TECH CORP

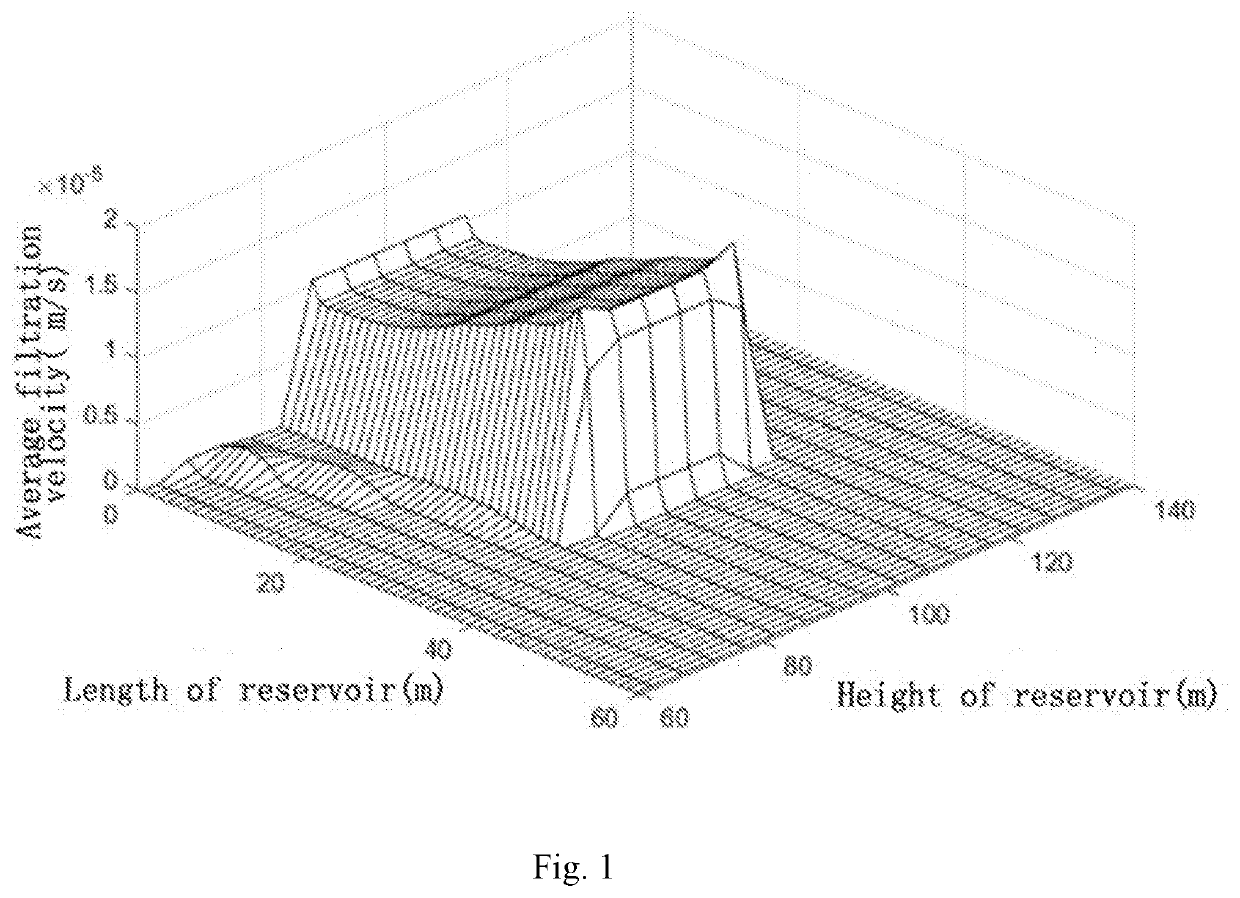

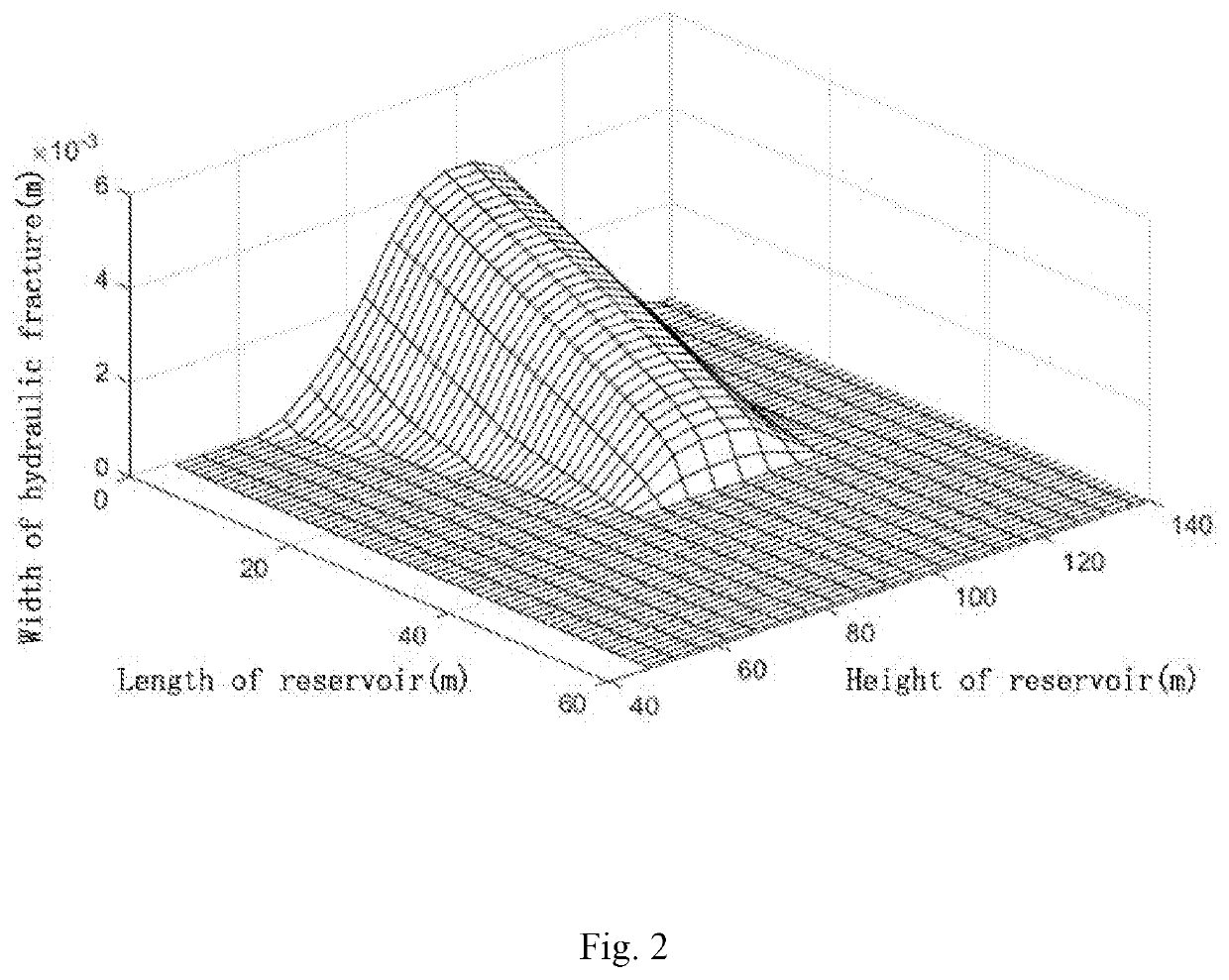

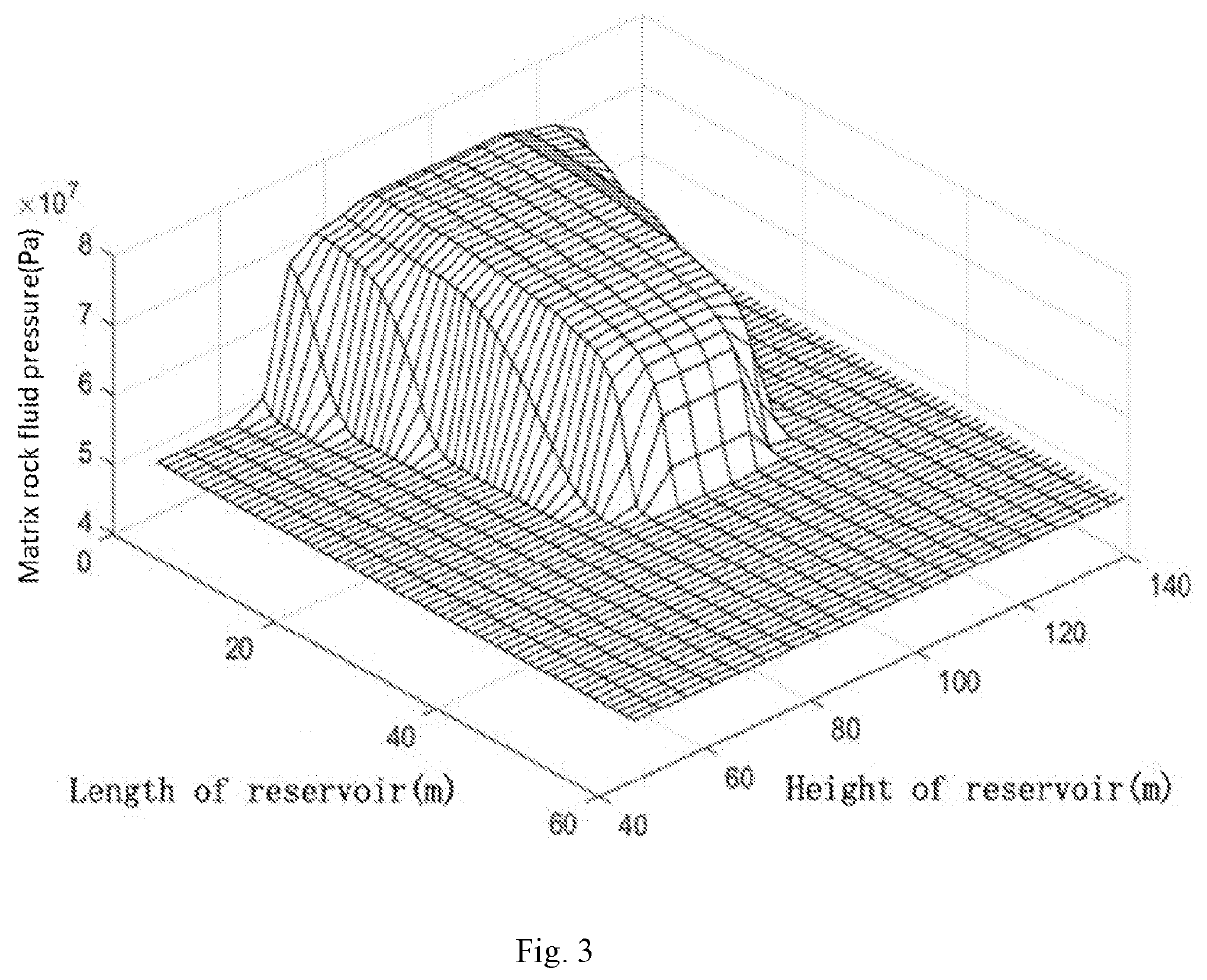

Method of calculating etching profile of acid-etched fracture system considering complex filtration media

ActiveUS20210048293A1Simulation is accurateImprove optimization accuracySurveyFluid removalAcid etchingAcid fracturing

The invention introduces a method of calculating etching profile of acid-etched fracture system considering complex filtration media, which mainly considers dynamic filtration caused by natural fractures and acid-etched wormholes in acid fracturing, calculates the above filtration process by a numerical method, and finally calculates acid etching profile of acid-etched fracture system based on acid concentration profile. Calculation equations include fluid pressure in natural fractures, filtration velocity in natural fractures, fracture geometry of hydraulic fractures, fluid pressure in matrix rock, acid concentration profile in natural fractures and hydraulic fractures, acid etching width in hydraulic fractures and natural fractures, and length of acid-etched wormhole, etc. The invention is reliable in principle and efficient in calculation, which is also beneficial to accurately calculating fracture etching profiles of acid fracturing in naturally-fractured reservoirs, improving the accuracy of optimizing acid fracturing treatment parameters, and providing guiding significance for acid fracturing optimization of naturally-fractured carbonate reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

Methods and materials for manipulating hydraulic fracture geometry

A method for manipulating hydraulic fracture geometry. In one embodiment, the method includes injecting fracturing fluid into a well to create one or more hydraulic fractures in a subterranean formation, and then substantially draining any fluid in the one or more hydraulic fractures. The method may also include injecting a hydrophilic polymer and one or more cross-linking agents into the well to subsequently form a low density hydrogel, which may then desand only each end of the one or more hydraulic fractures. A working fluid may then be injected into the well to increase the fracture width of the one or more hydraulic fractures without substantially increasing the fracture length. In alternative embodiments, a hydrophilic polymer may be fully cross-linked by the one or more cross-linking agents and injected as pre-crosslinked gel particles (PPGs), which may also de-sand only each end of the one or more hydraulic fractures.

Owner:QUIDNET ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com