Methods and materials for manipulating hydraulic fracture geometry

A technology of hydraulic fractures and geometric shapes, which is applied in the fields of hydropower generation, chemical instruments and methods, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

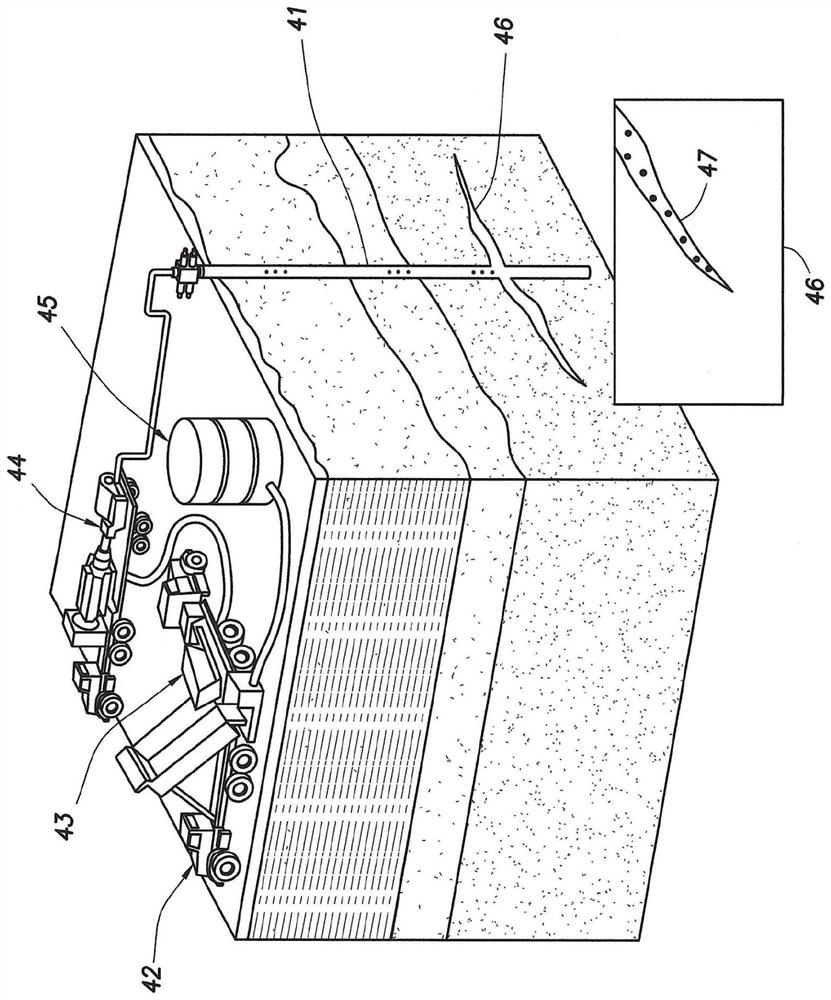

[0031] In a demonstration of one embodiment of the method of the present invention, first, a horizontal fracture was formed at a depth of 1210 feet using 50 bbl of water thickened with guar gum. Fractures were monitored during shut-in for 24 hours and then decompressed. The fracture was then swelled with 100 bbl of water containing a mixture of pre-swollen 1-2 mm and sub-millimeter preformed polyacrylamide PPG particles. Bentonite clay and mineral fibers were added to the PPG blend. An increase in injection pressure was observed during injection, rather than a decrease as expected for short horizontal hydraulic fractures. Fractures were observed during shut-in, and then a series of similar injections of 250 bbl each were performed for a total of up to 1000 bbl. After each stage, the pressure was monitored and then flowback was tested through a fixed choke. At each stage, the injection and shut-in pressures increase, while the flowback volume increases roughly proportional t...

example 2-

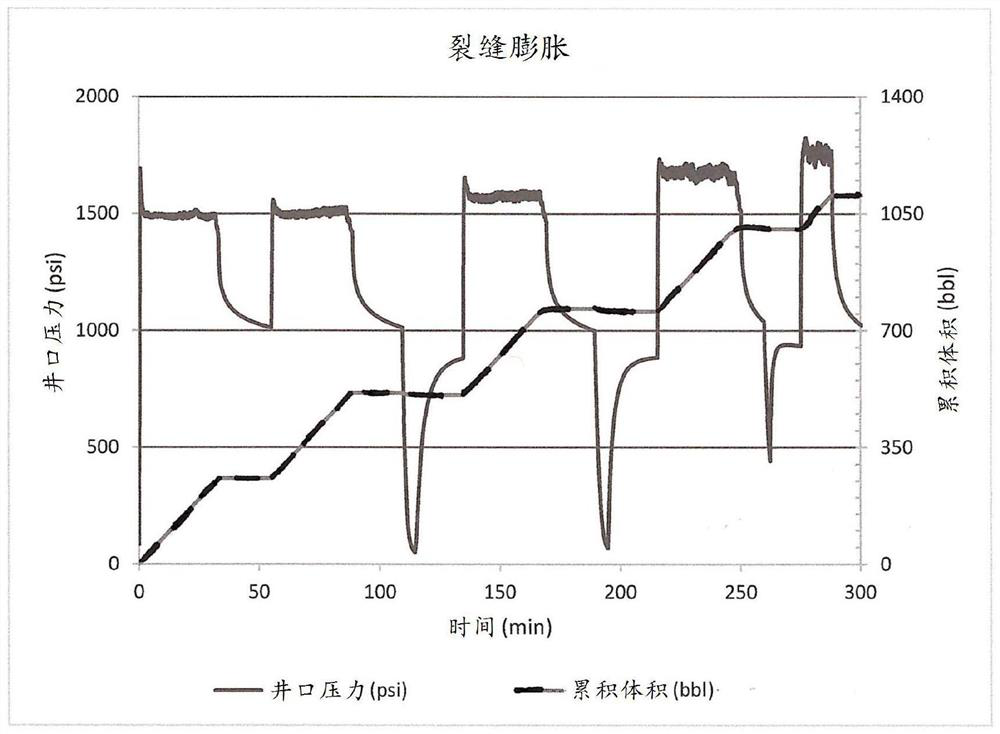

[0032] Example 2 - Engineered Tip-Screen Out

[0033] Horizontal fractures formed at 1210 feet were evaluated for potential engineered end screenouts in preformed fractures using a mixture of lost circulation material and conformance control material. Such materials are used in oil fields to seal off thiefzones encountered during drilling or water flood operations and contain particles and fibers ranging in size from microns to centimeters. Typical materials include bentonite clay, crushed walnut shells, mineral fibers, and expanded PPG, among others. The candidate mixture was supplied while expanding the horizontal fracture in stages to 1000 bbl of fluid. figure 2 The pressure response shown shows that the horizontal fractures expand in width at a nominally constant length. A freely expanding horizontal fracture usually exhibits a monotonically decreasing net pressure as the fracture extends, asymptotically approaching the overburden pressure. Instead, the system shows in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com