Patents

Literature

8954 results about "Working fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

For fluid power, a working fluid is a gas or liquid that primarily transfers force, motion, or mechanical energy. In hydraulics, water or hydraulic fluid transfers force between hydraulic components such as hydraulic pumps, hydraulic cylinders, and hydraulic motors that are assembled into hydraulic machinery, hydraulic drive systems, etc. In pneumatics, air or another gas transfers force between pneumatic components such as compressors, vacuum pumps, pneumatic cylinders, and pneumatic motors. In pneumatic systems, the working gas also stores energy because it is compressible. (Gases also heat up as they are compressed and cool as they expand; this incidental heat pump is rarely exploited.) (Some gases also condense into liquids as they are compressed and boil as they expand.)

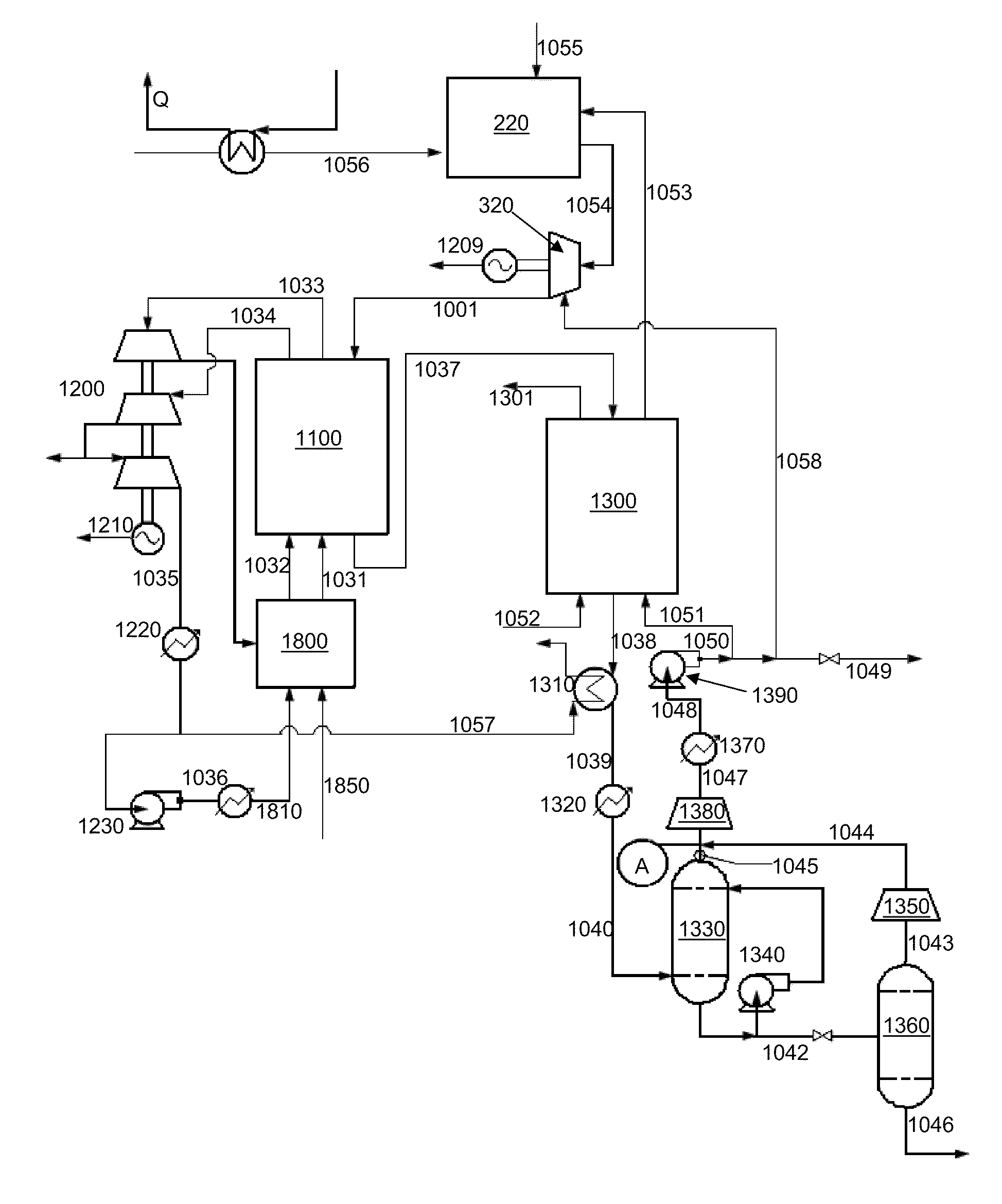

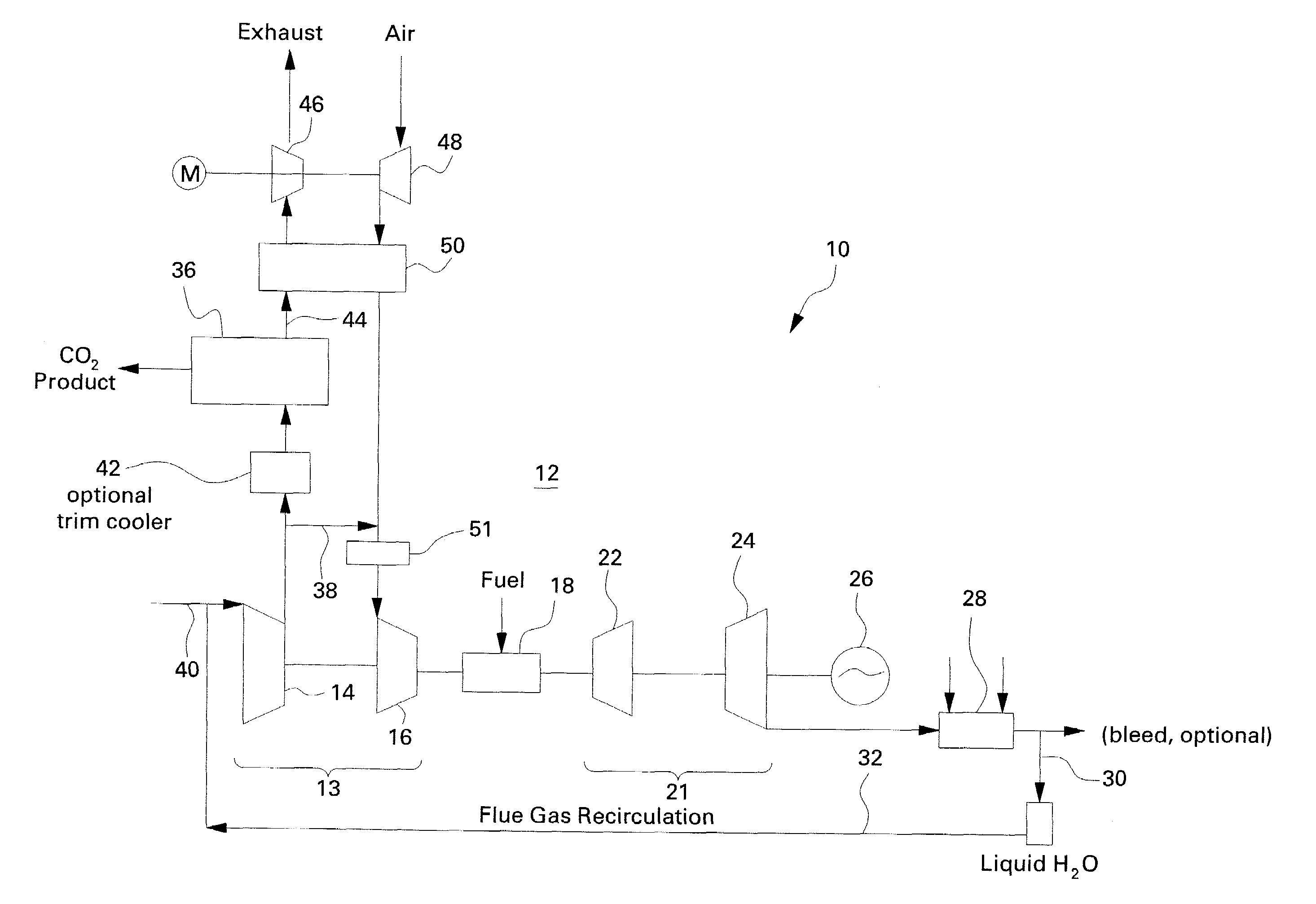

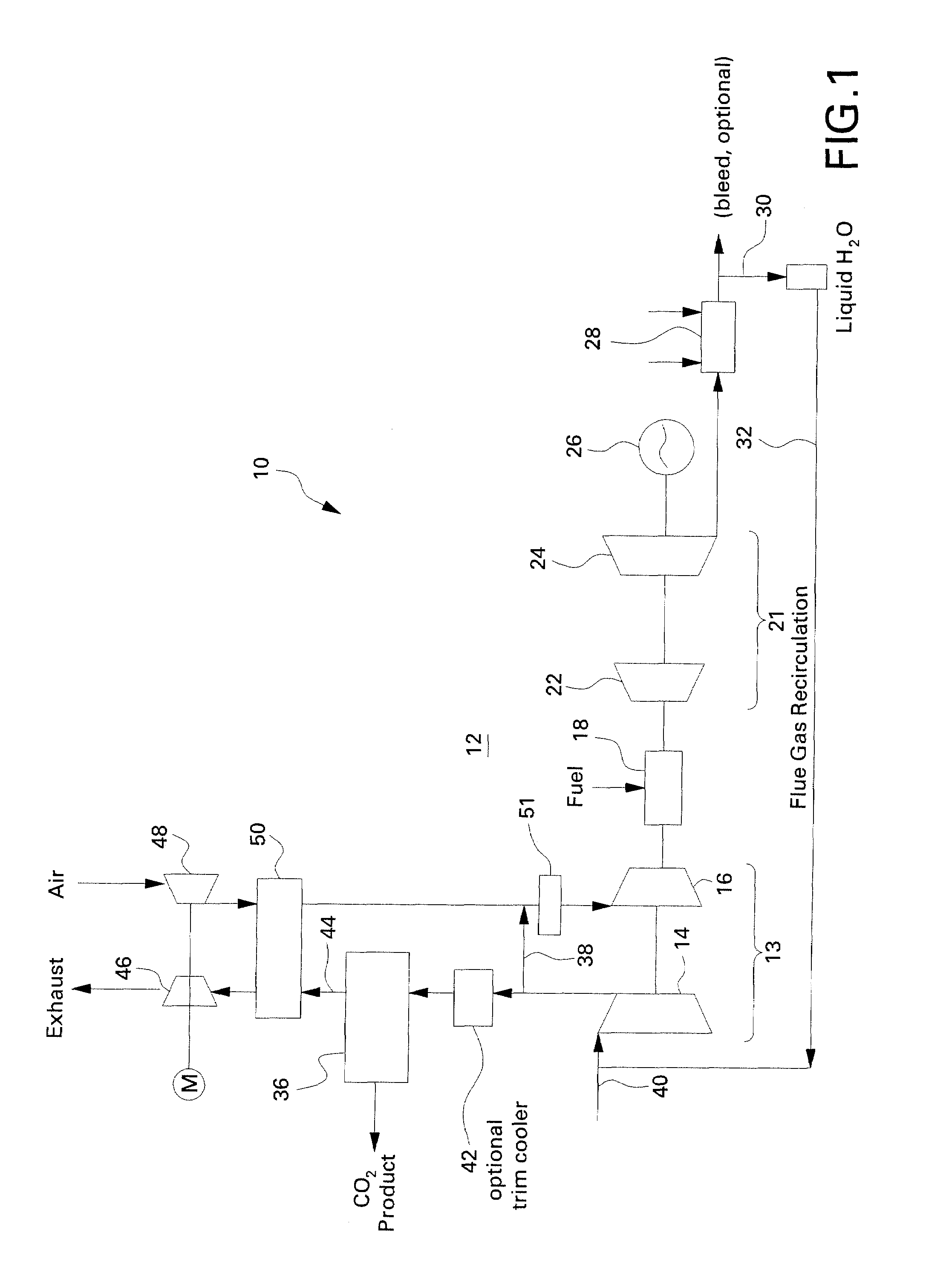

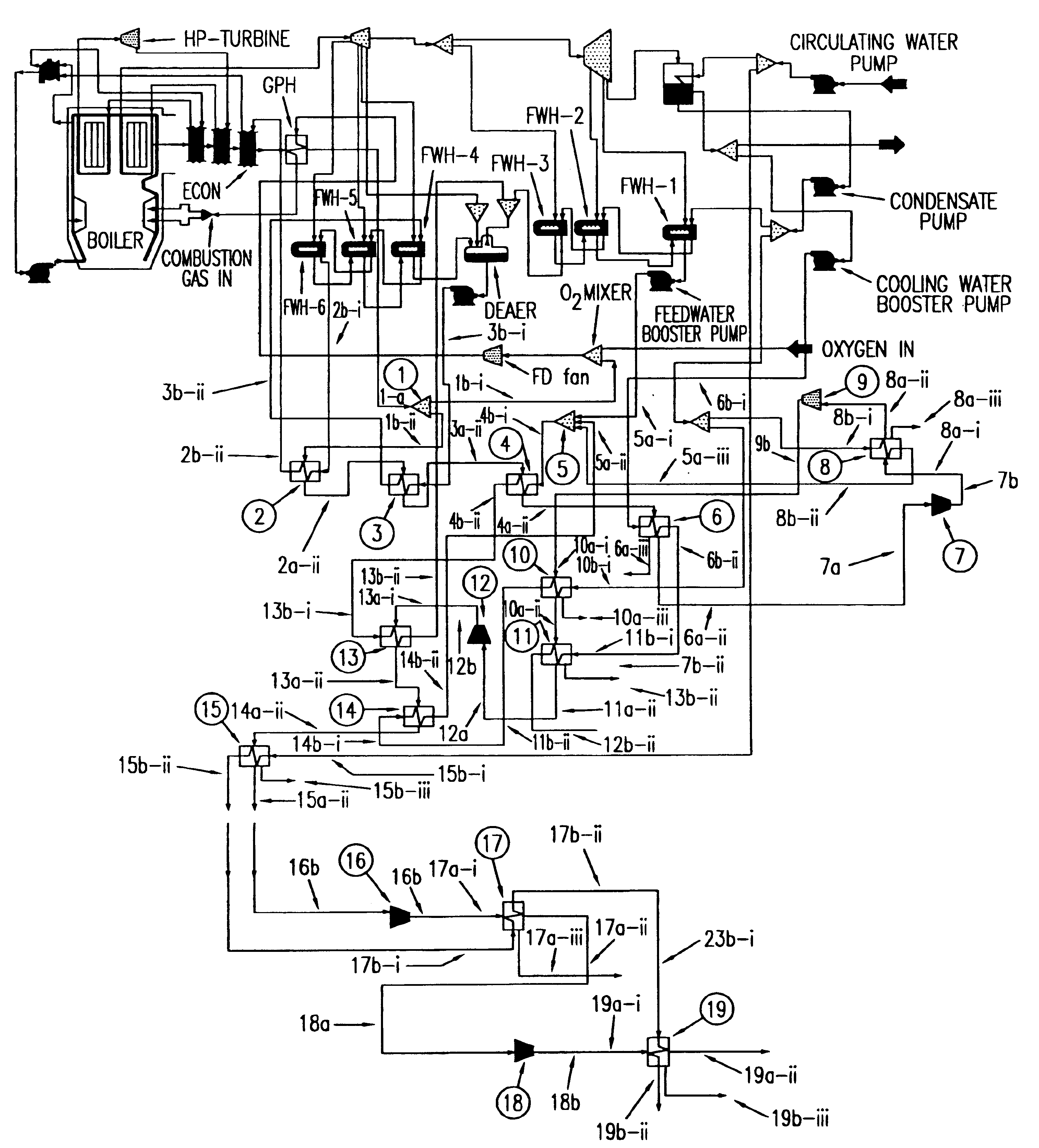

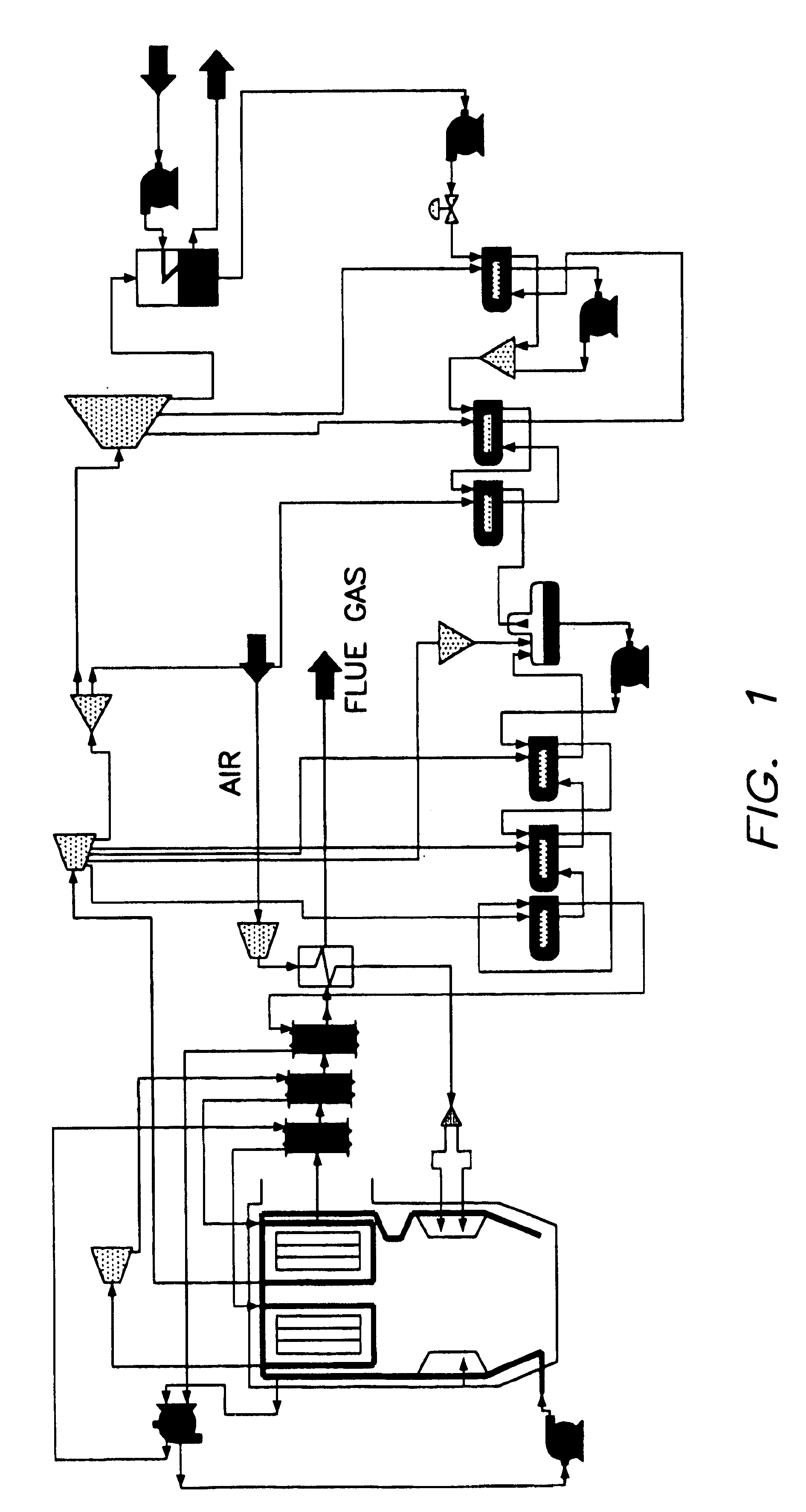

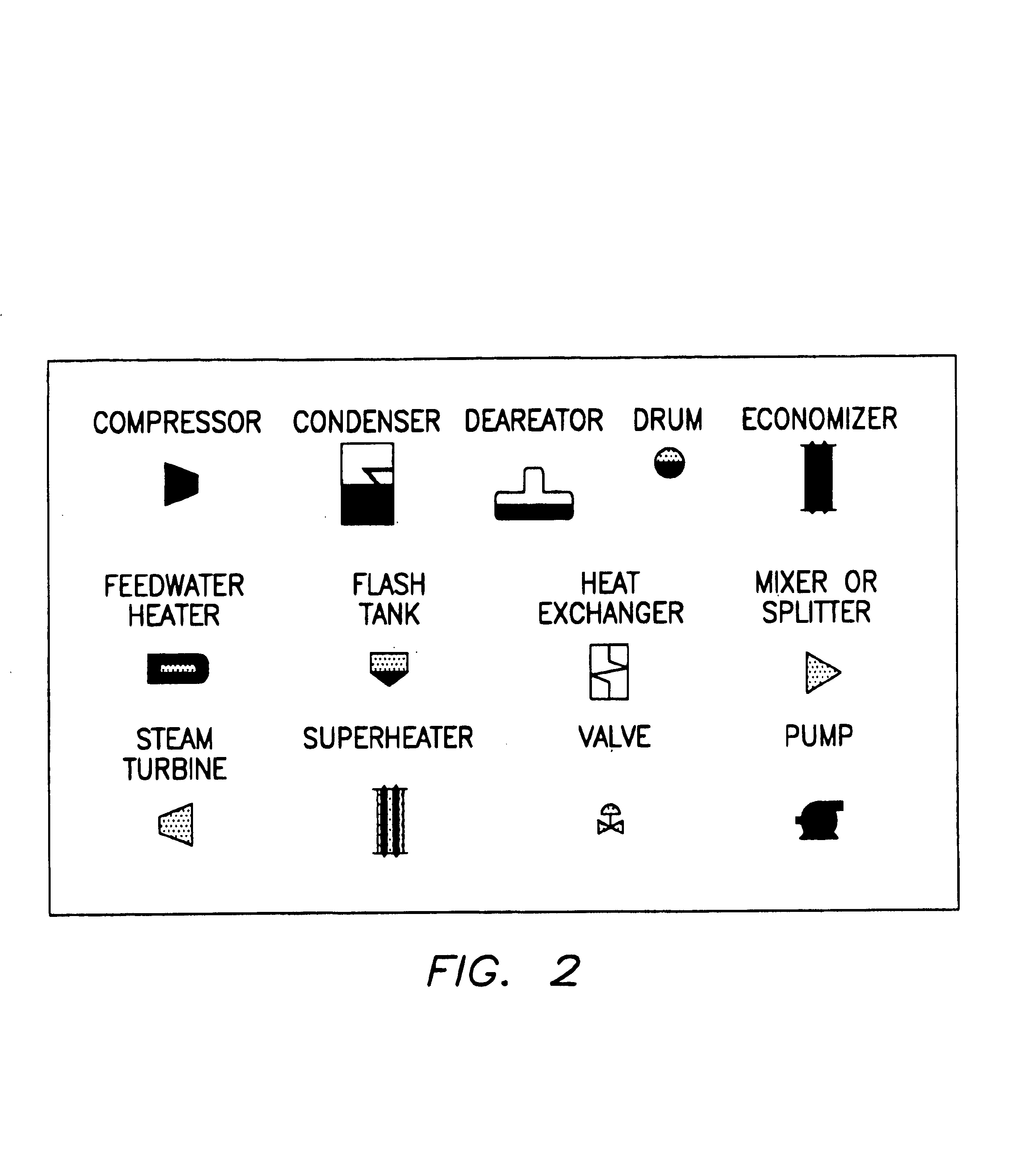

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

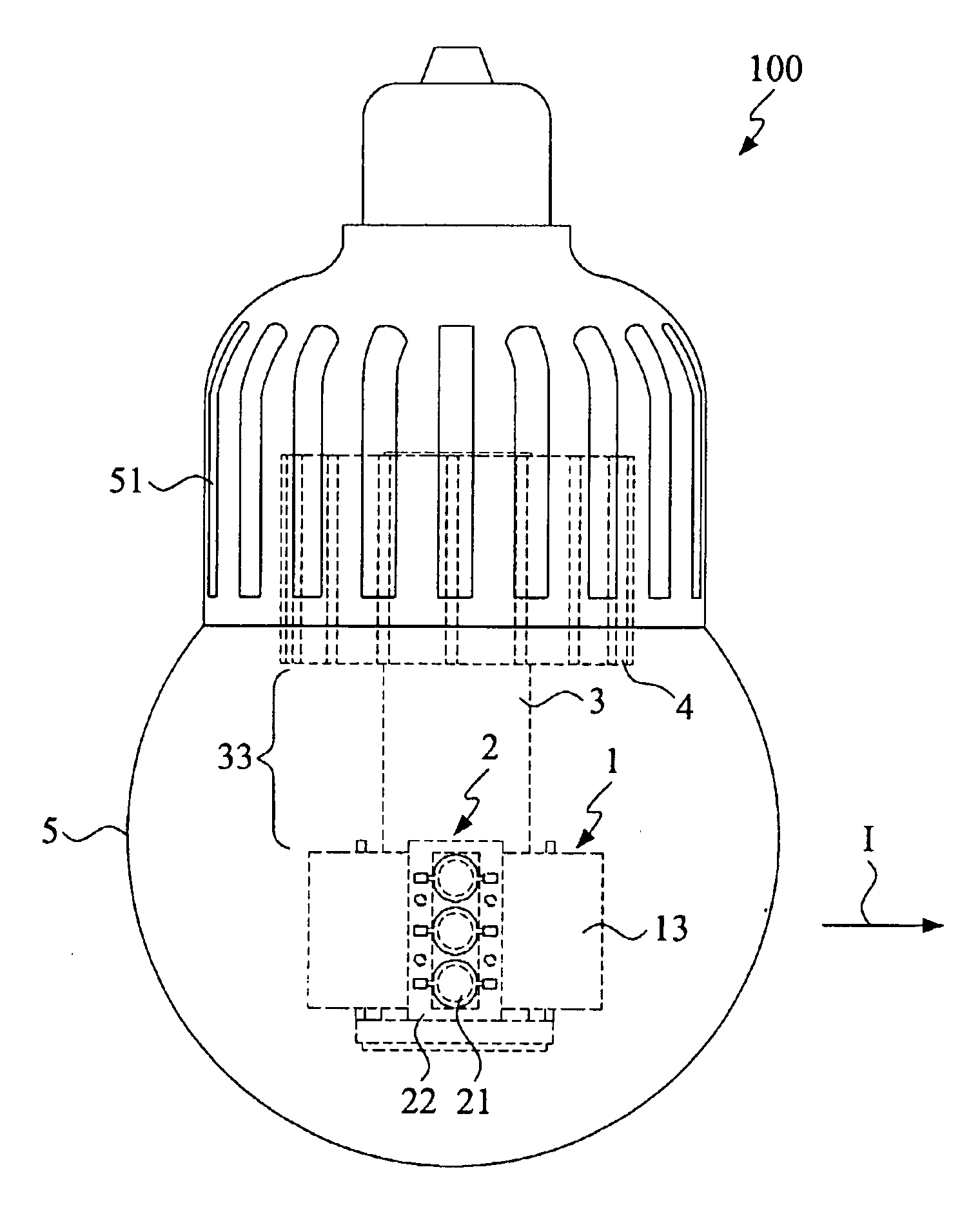

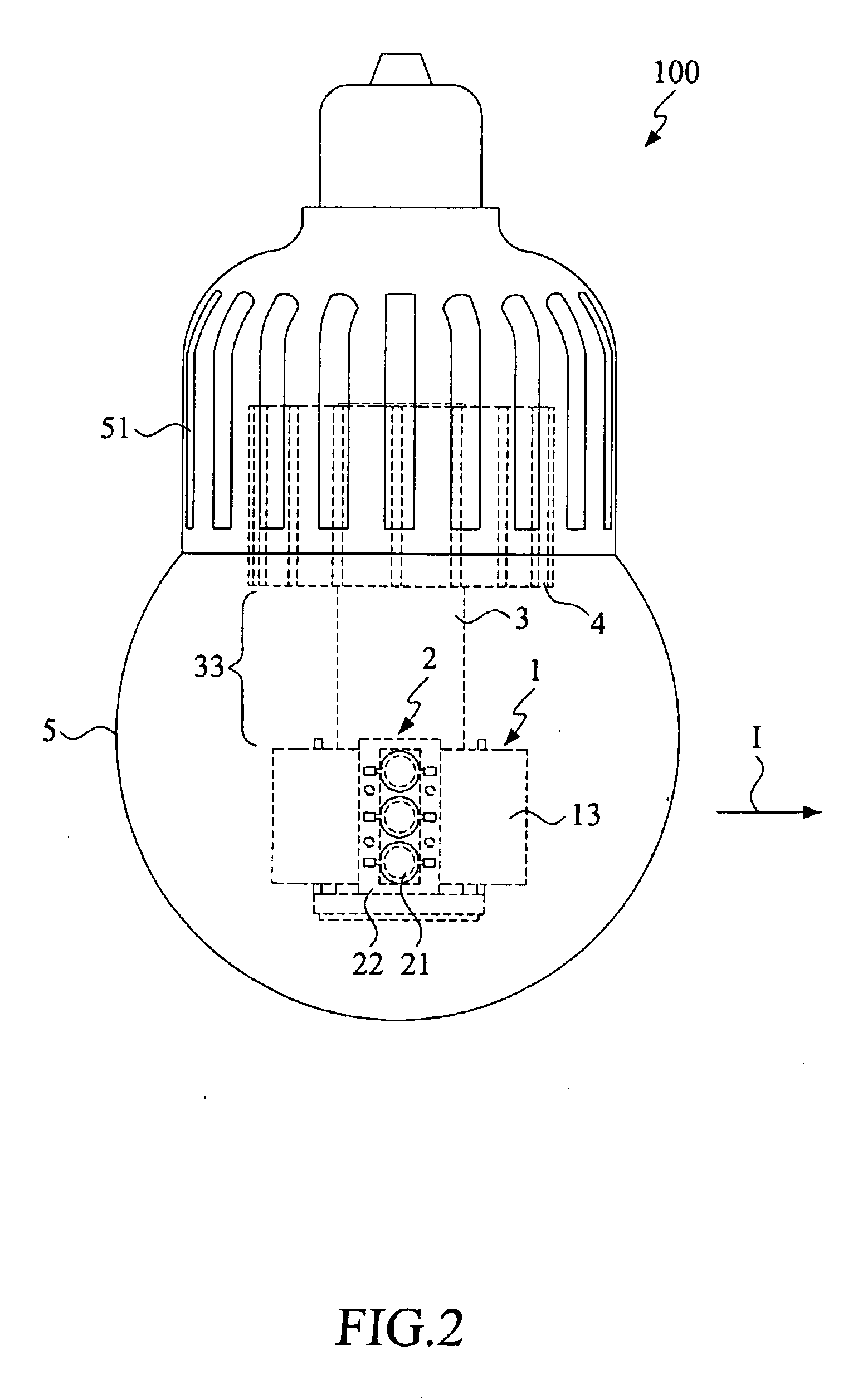

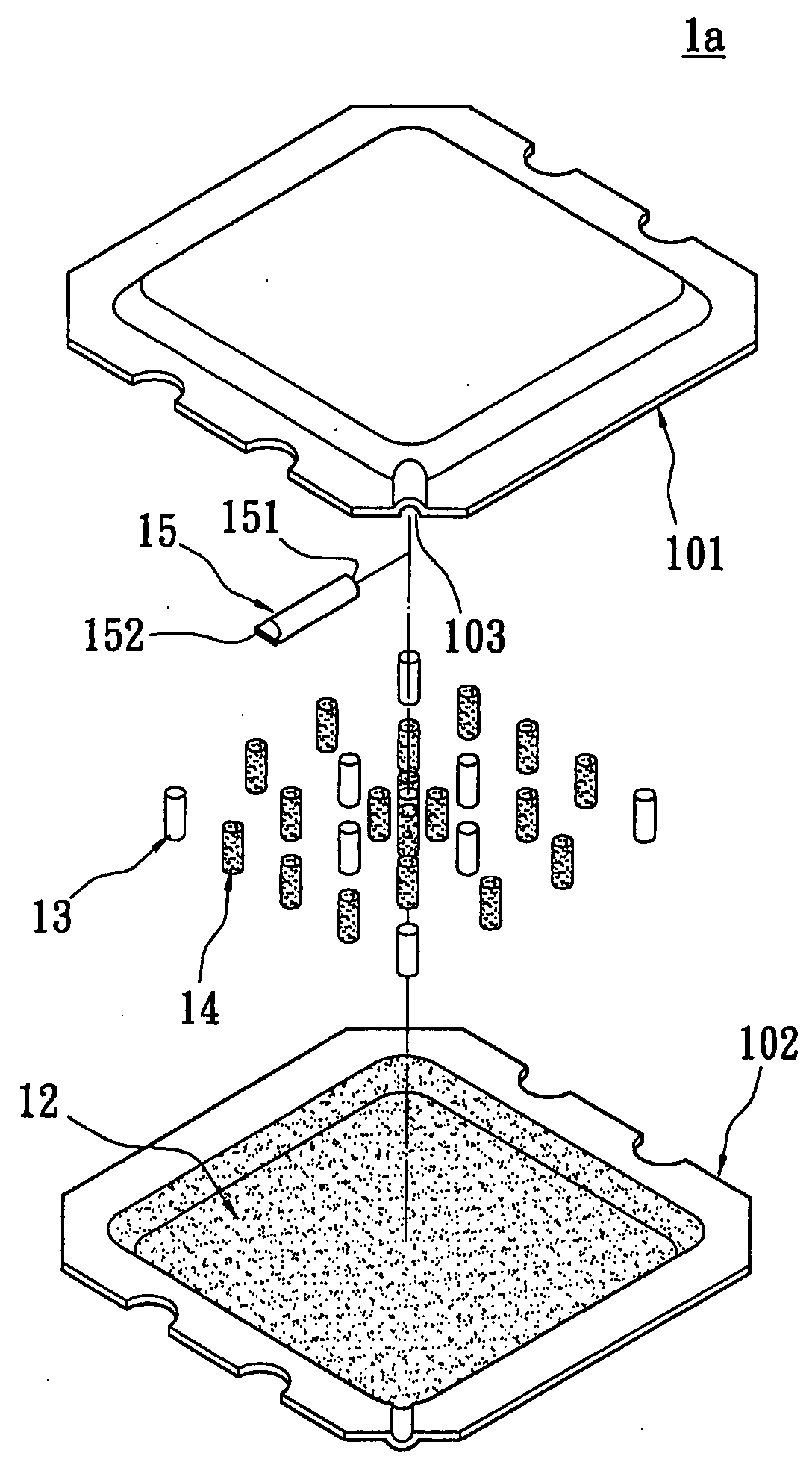

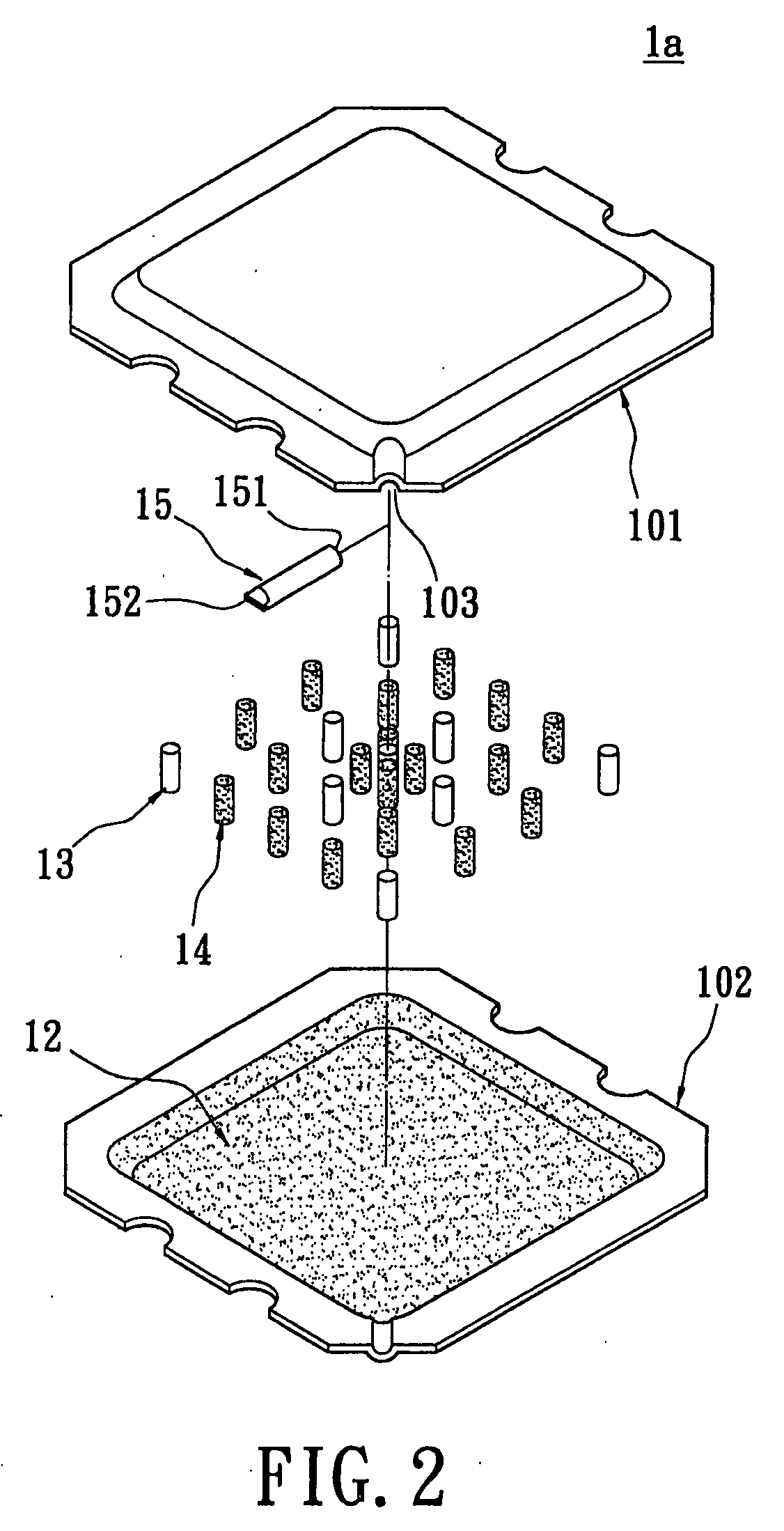

High power LED lighting assembly incorporated with a heat dissipation module with heat pipe

InactiveUS20080253125A1Reduce power consumptionIncrease powerPoint-like light sourceLighting heating/cooling arrangementsThermal energyWorking fluid

A high power light emitting diode (LED) lighting assembly incorporated with heat dissipation module is provided. The LED lighting assembly includes a heat exchange base, at least one LED array, at least one heat pipe and a heat dissipation module. The heat exchange base includes at least one LED configuration plan for mounting of the LED array and at least a hollow part for insertion of the heat pipe. The LED array is arranged at a predetermined projecting angle at the LED configuration plane. The heat pipe includes a heated section, a cooling section and a conducting section, and contains a working fluid therein. The heat exchange base is mounted to the heated section and the heat dissipation module is mounted to the cooling section. The thermal energy generated by the LEDs is conducted from the heat exchange base to the heated section of the heat pipe, whereby allowing the working fluid in the heat pipe to be heated and vaporized, and flows, from the conducting section to the cooling section for dissipation at the heat dissipation module.

Owner:TAMKANG UNIVERSITY

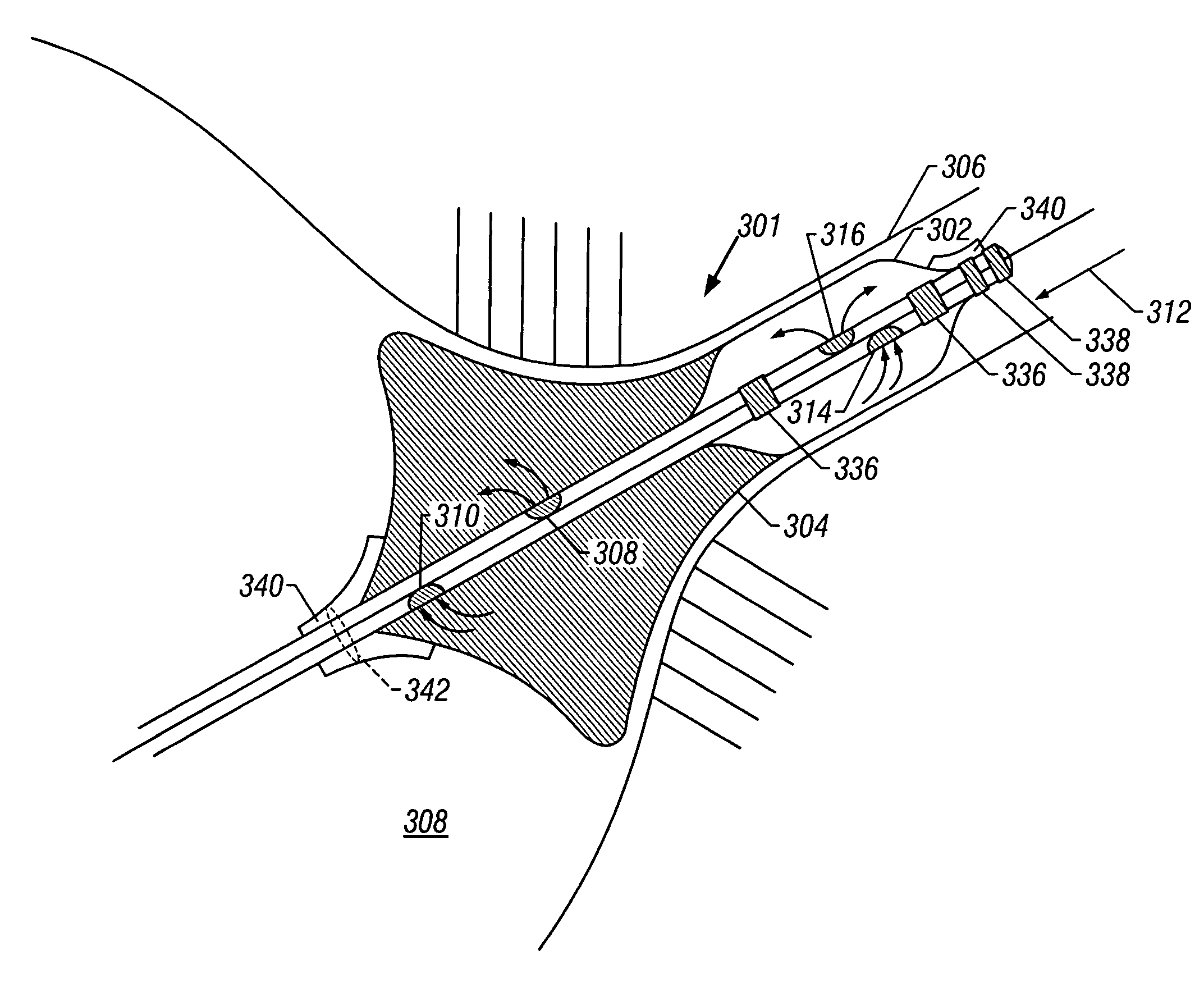

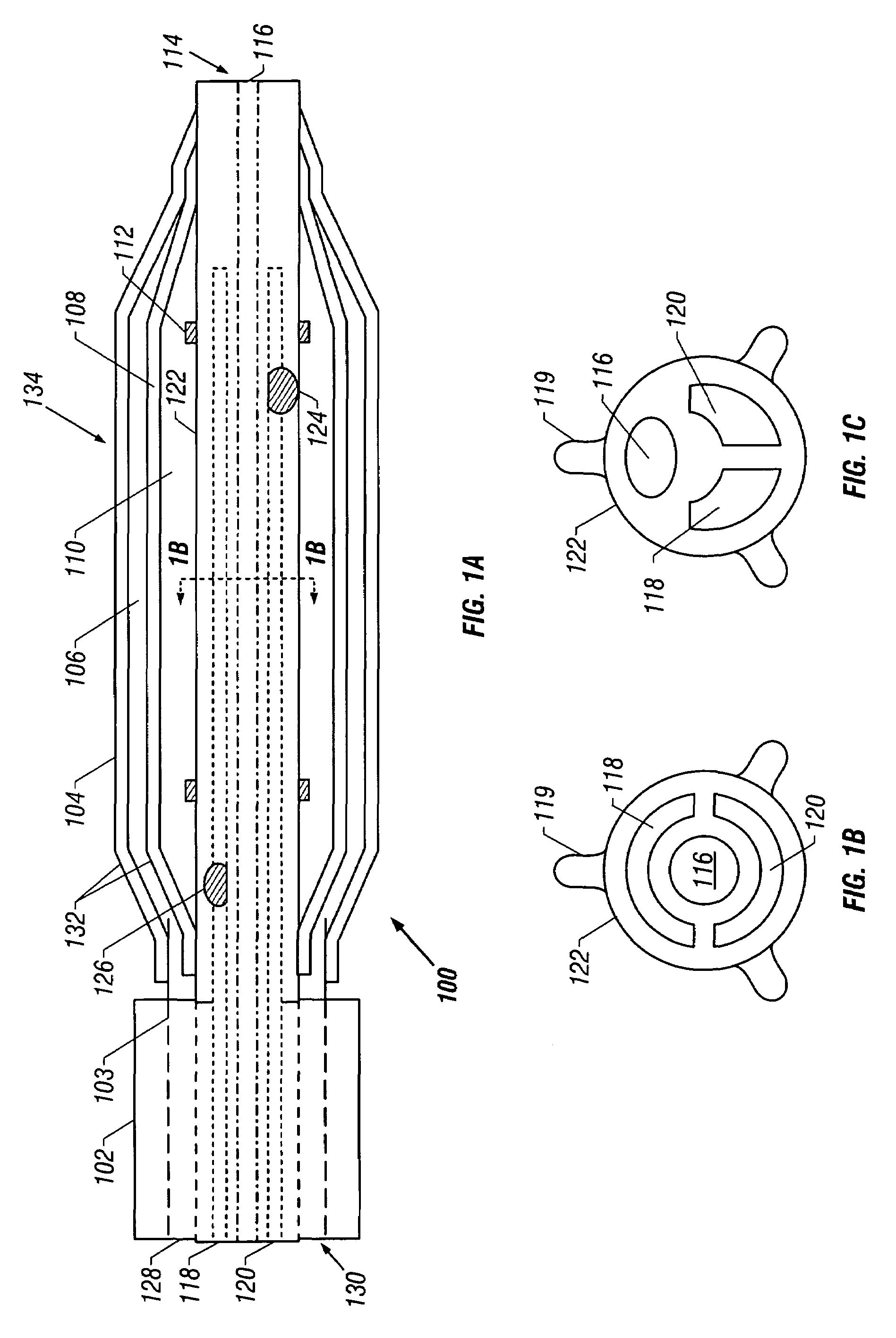

Articulation device for selective organ cooling apparatus

Owner:INNERCOOL THERAPIES INC

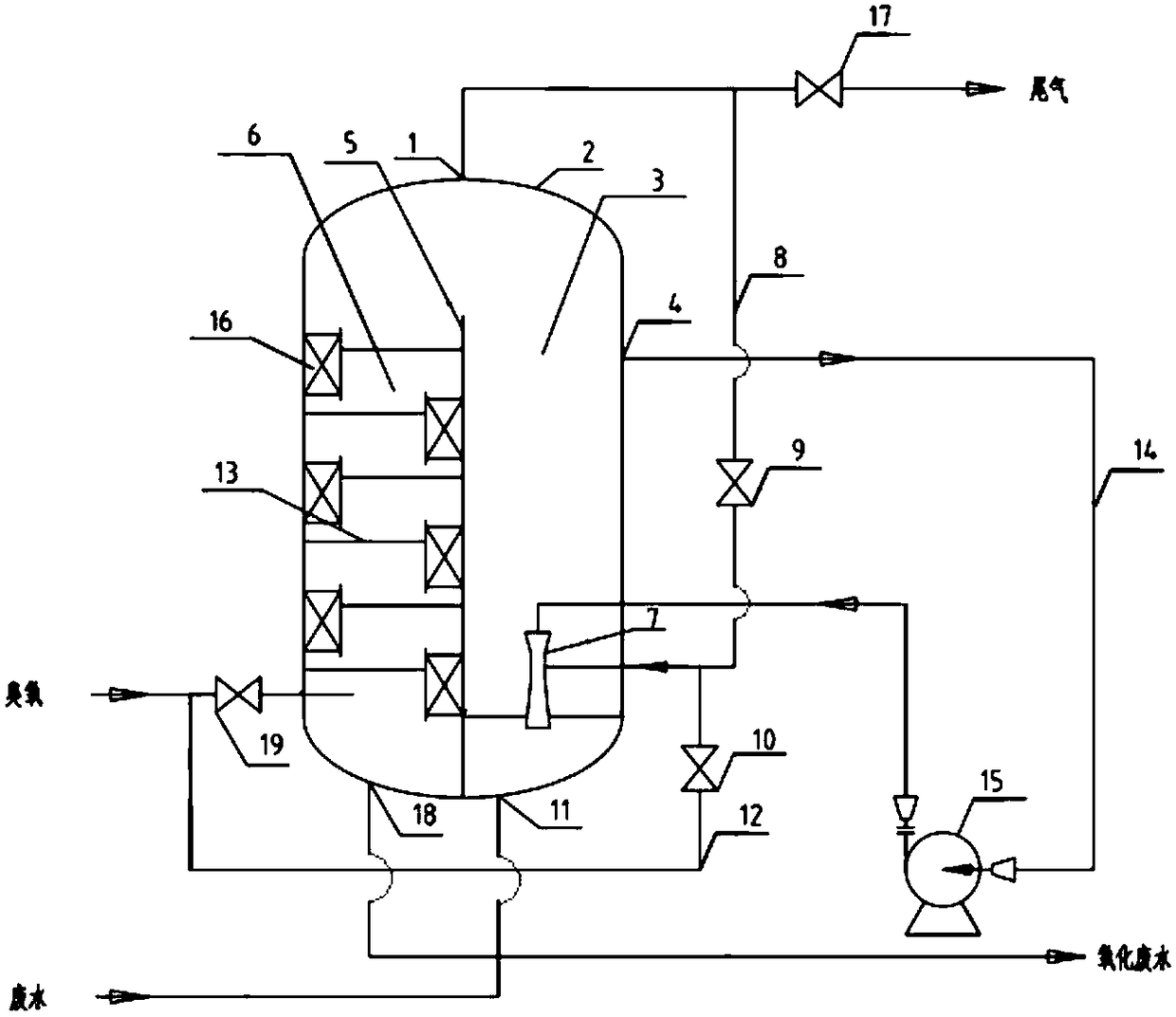

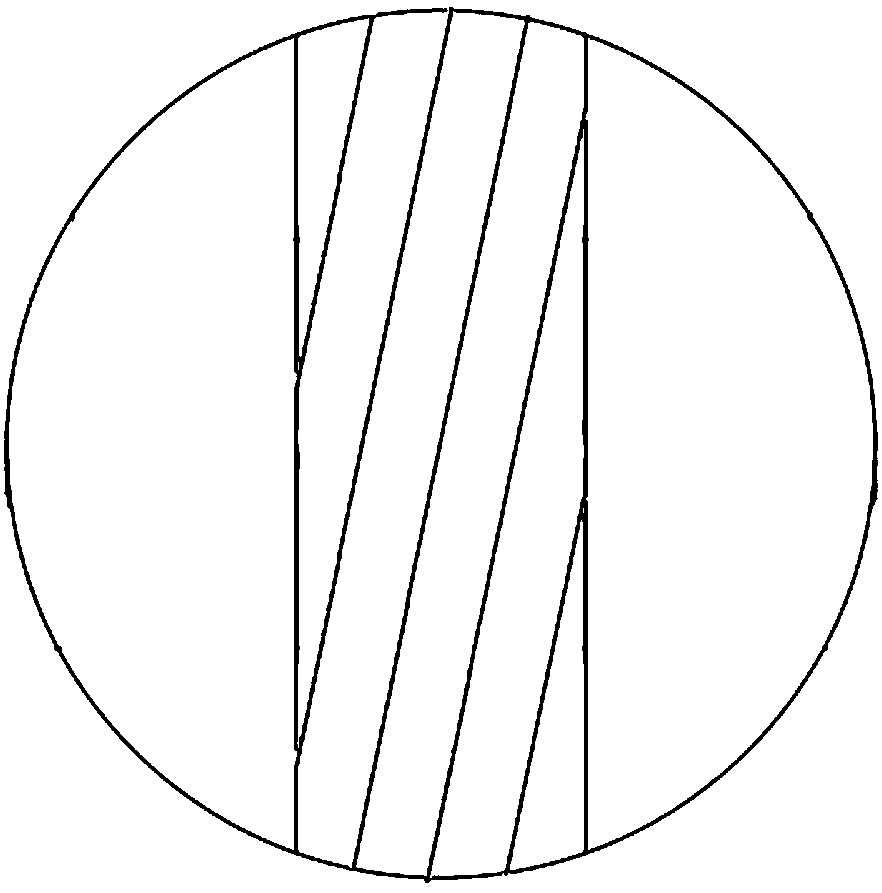

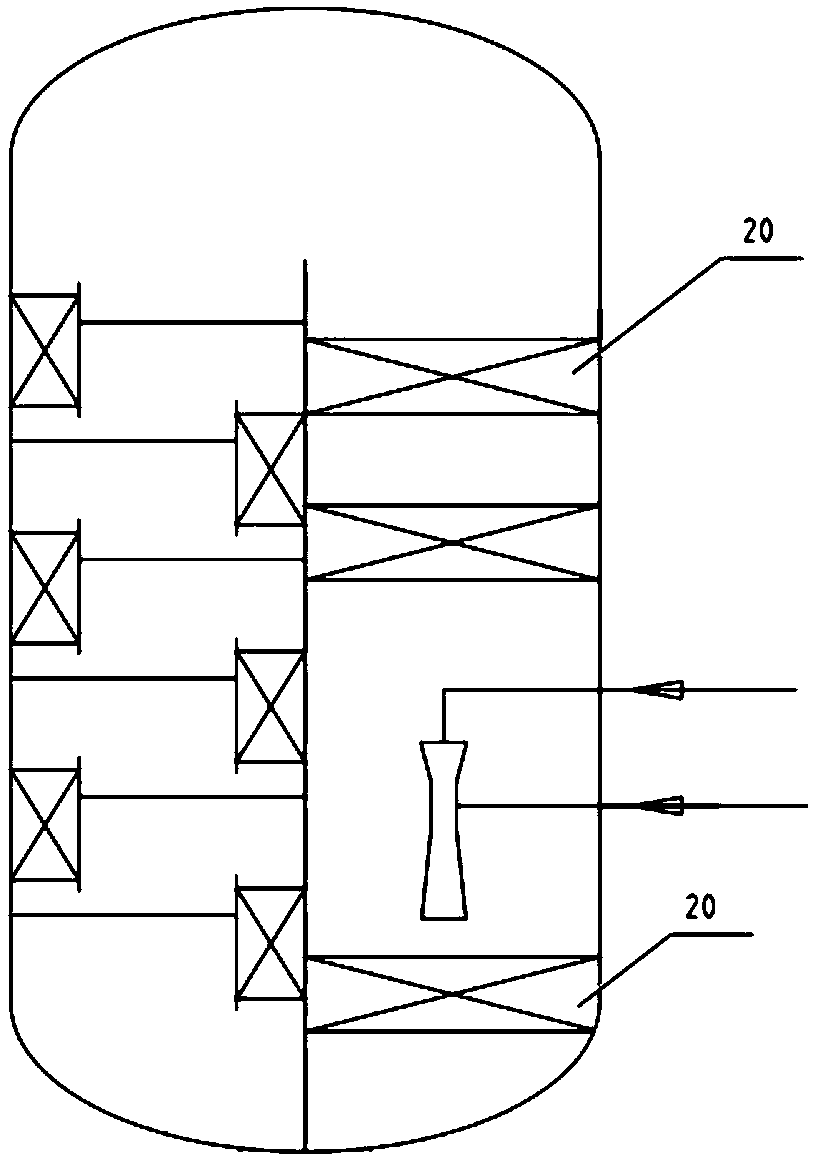

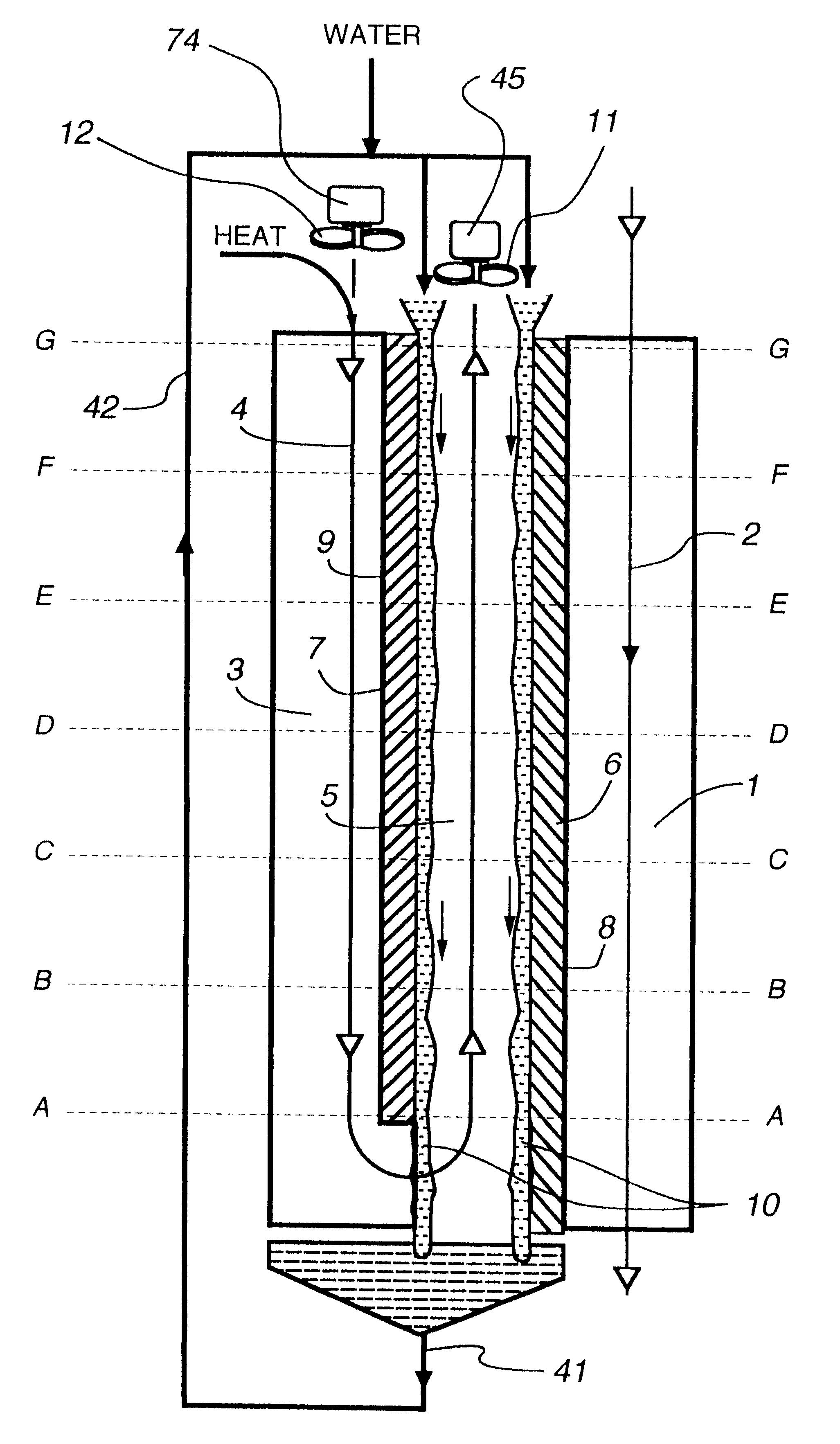

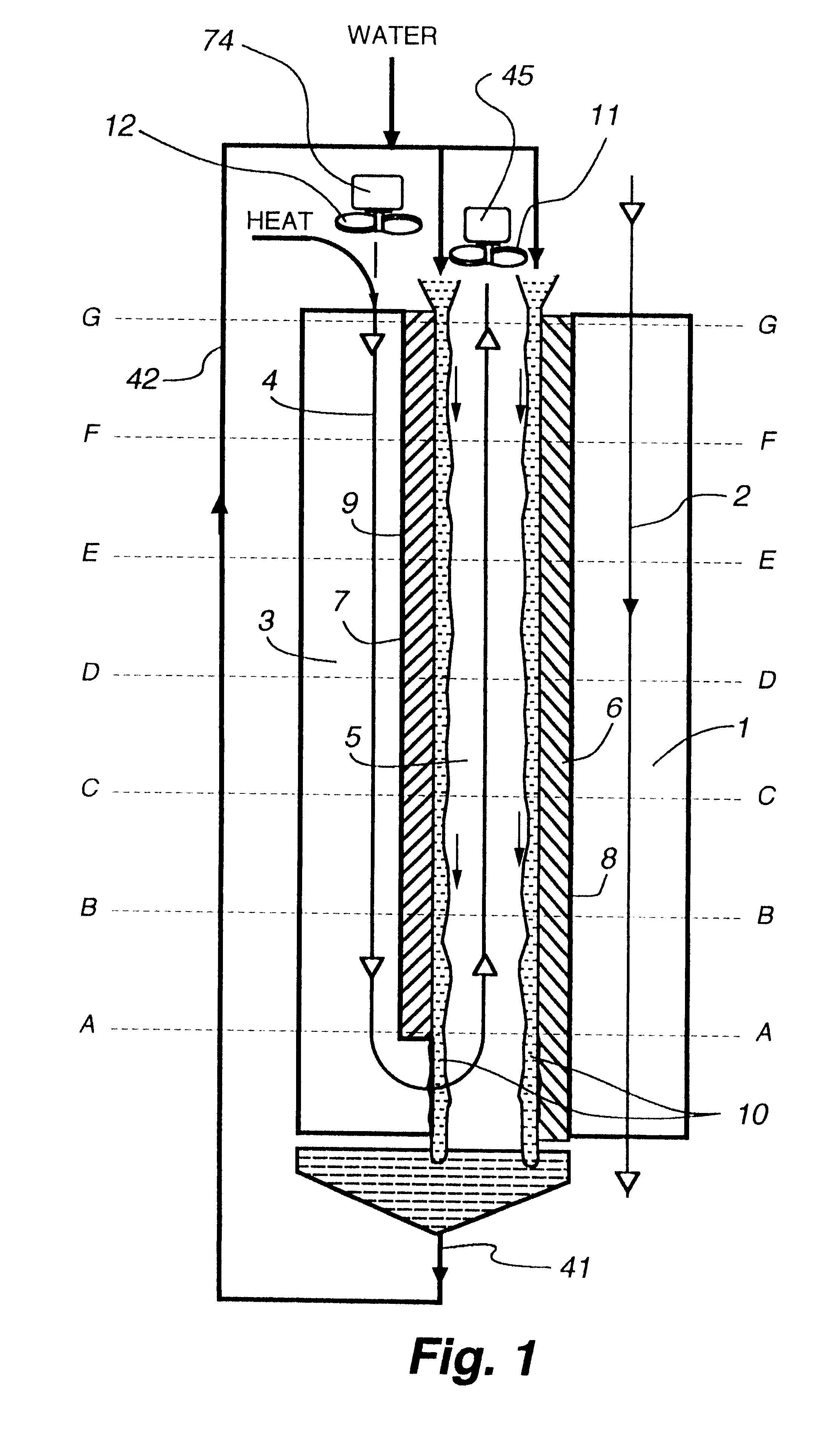

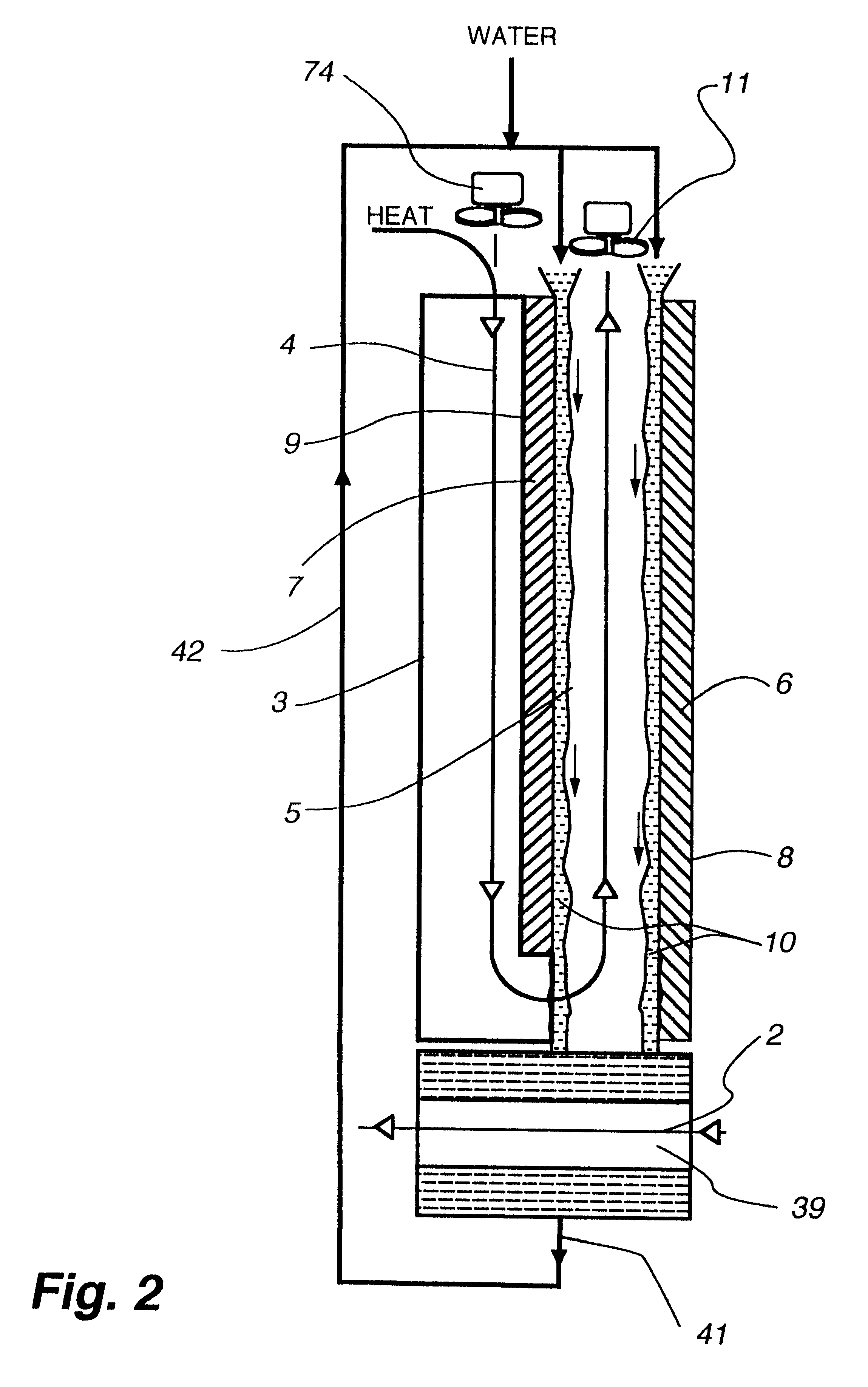

Reactor for catalytically oxidizing wastewater through ozone and application method thereof

PendingCN109437390AEnhanced mass transferReduce backmixingWater/sewage treatment by oxidationWorking fluidChemical oxygen demand

The invention discloses a reactor for catalytically oxidizing wastewater through ozone and an application method thereof. The reactor comprises a reaction chamber, a water inlet, a water outlet, a gasoutlet and a circulating water outlet, wherein a separation plate in the reaction chamber is used for separating the lower part of the reaction chamber into a jet flow reaction chamber and a tower type reaction chamber; the jet flow reaction chamber is internally provided with a first catalysis bed layer and an ejector; the circulating water outlet is connected with a working fluid inlet of the ejector; the gas outlet is connected with a sucked liquid inlet of the ejector through a gas circulating pipe; the water inlet is arranged at the bottom of the jet flow reaction chamber; the tower typereaction chamber is internally provided with a tower plate and a second catalysis bed layer; the water outlet is arranged at the bottom of the tower type reaction chamber; a gas inlet is communicatedwith the lower side of the tower plate and the gas circulating pipe; the gas circulating pipe is connected with a tail gas outlet. The reactor has the advantages of high mass transfer efficiency, rapid reaction speed, high ozone utilization rate, high COD (Chemical Oxygen Demand) removal rate and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

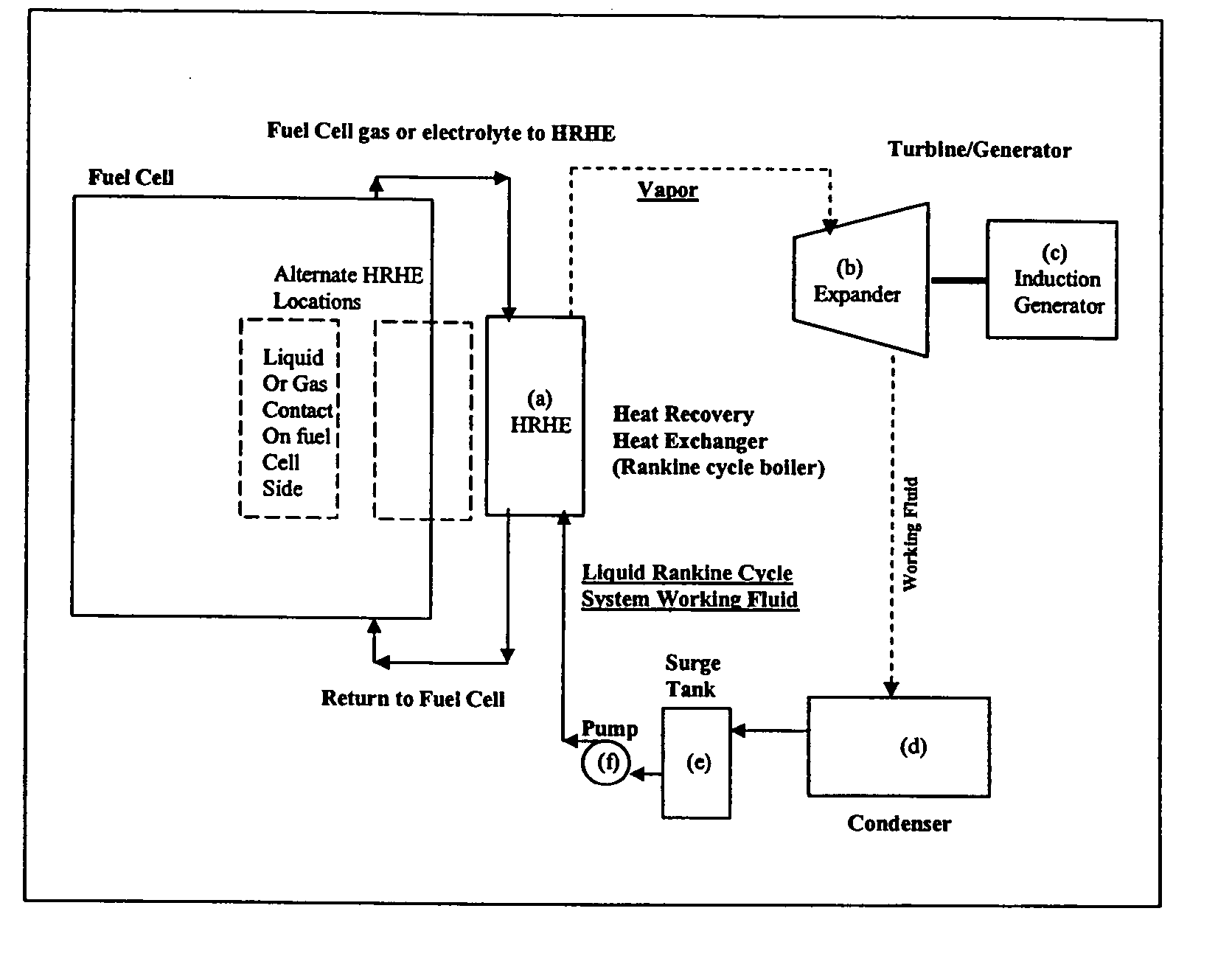

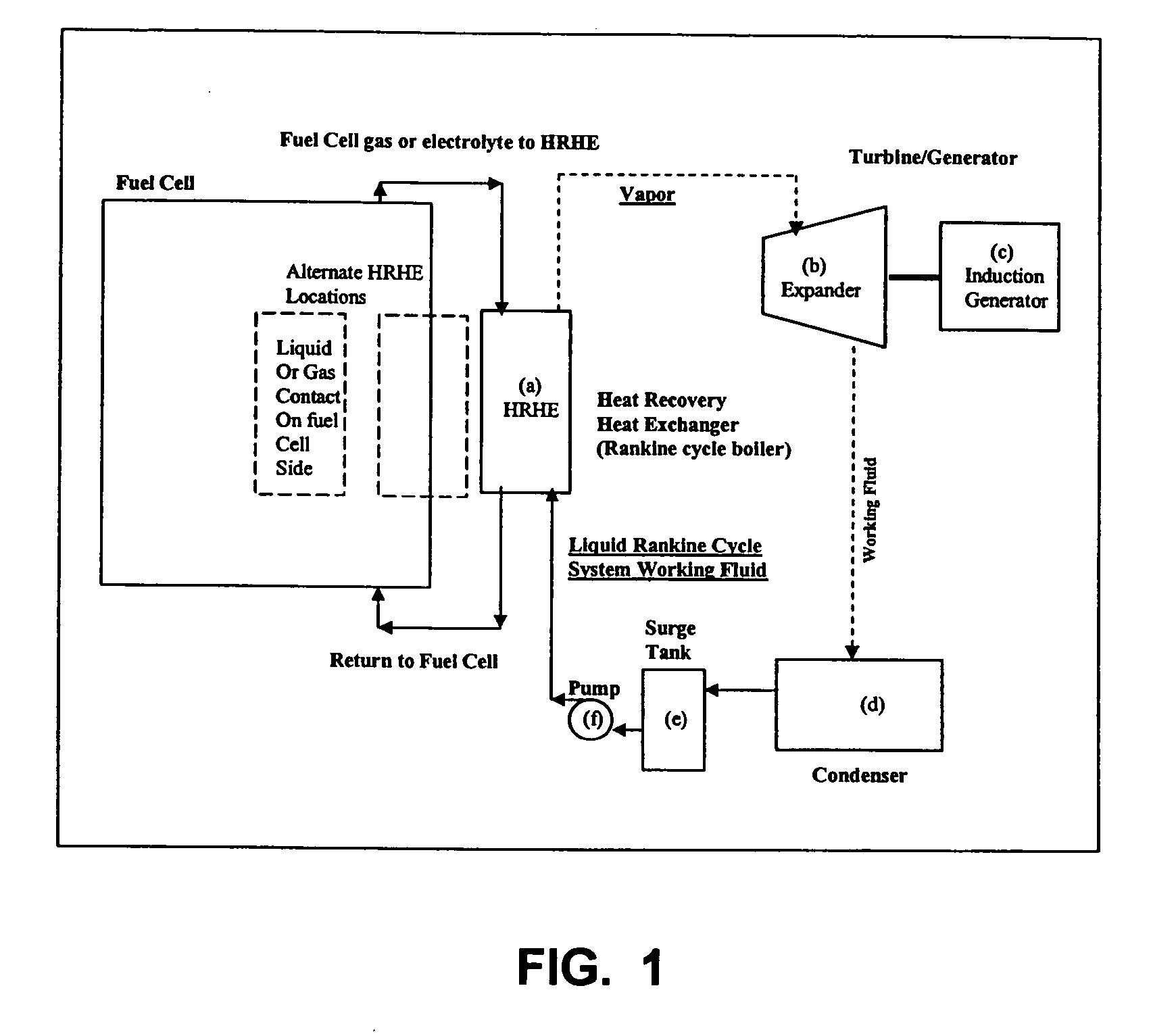

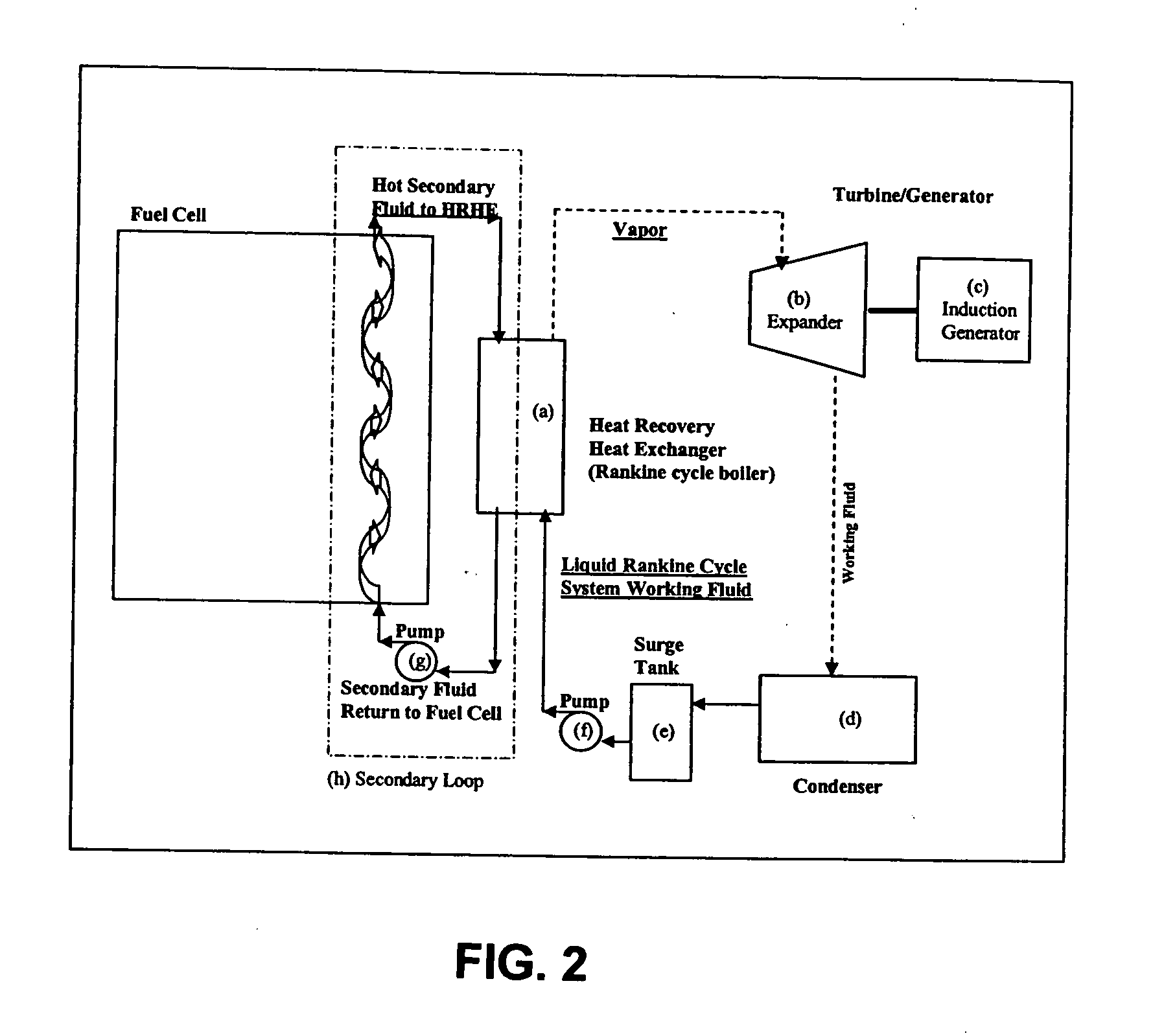

Working fluids for thermal energy conversion of waste heat from fuel cells using rankine cycle systems

A process for recovering waste heat which comprises: (a) passing a liquid phase working fluid through a heat exchanger in communication with a process which produces the waste heat; (b) removing a vapor phase working fluid from the heat exchanger; (c) passing the vapor phase working fluid to an expander, wherein the waste heat is converted into mechanical energy; and (d) passing the vapor phase working fluid from the expander to a condenser, wherein the vapor phase working fluid is condensed to the liquid phase working fluid. The preferred working fluid is an organic Rankine cycle system working fluid comprising compounds having the following general structure: where x, y, z, and m are each selected from the group consisting of: fluorine, hydrogen, Rf, and R, wherein R and Rf are each an alkyl, aryl, or alkylaryl of 1 to 6 carbon atoms, and wherein Rf is partially or fully fluorinated.

Owner:HONEYWELL INT INC

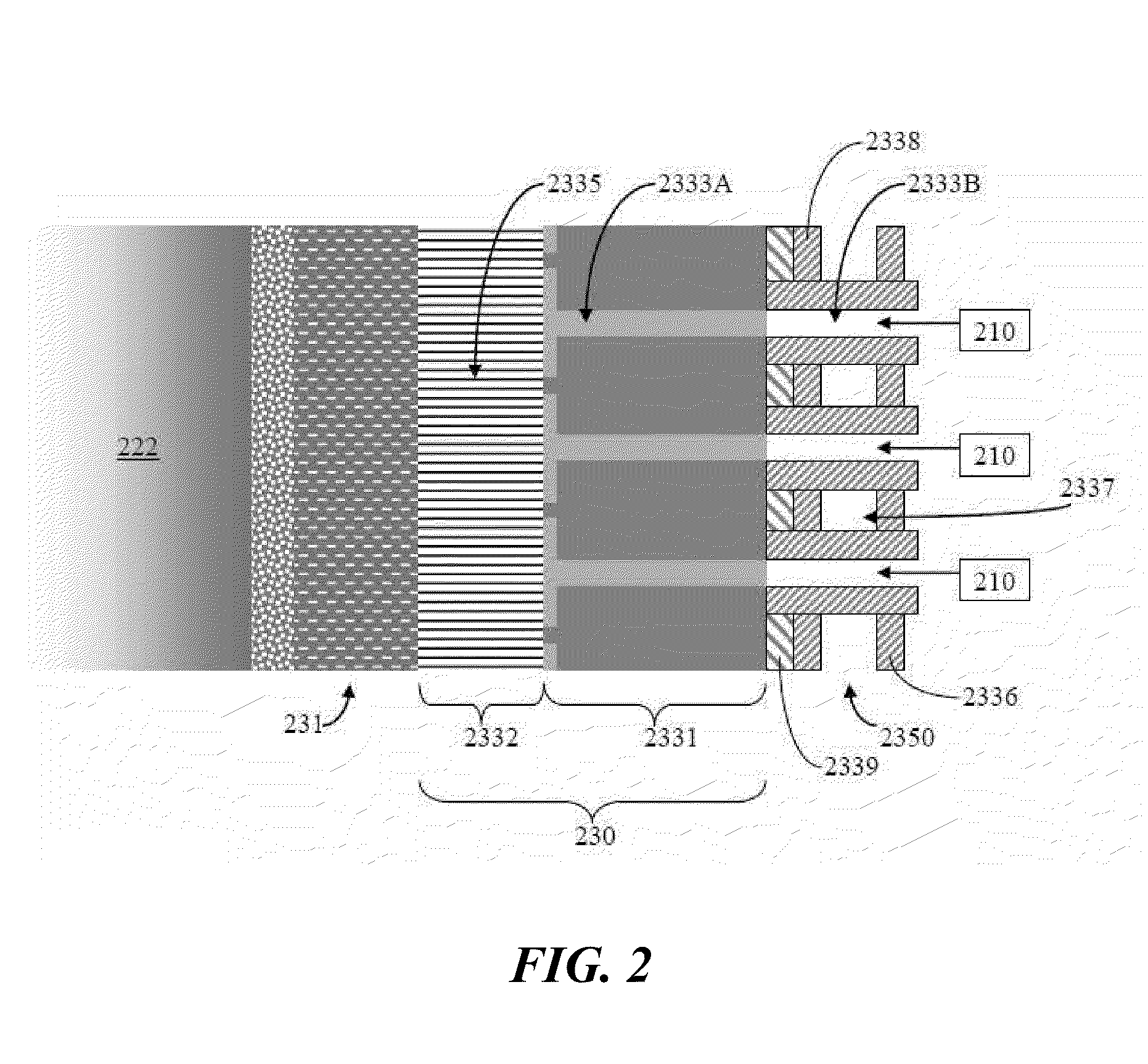

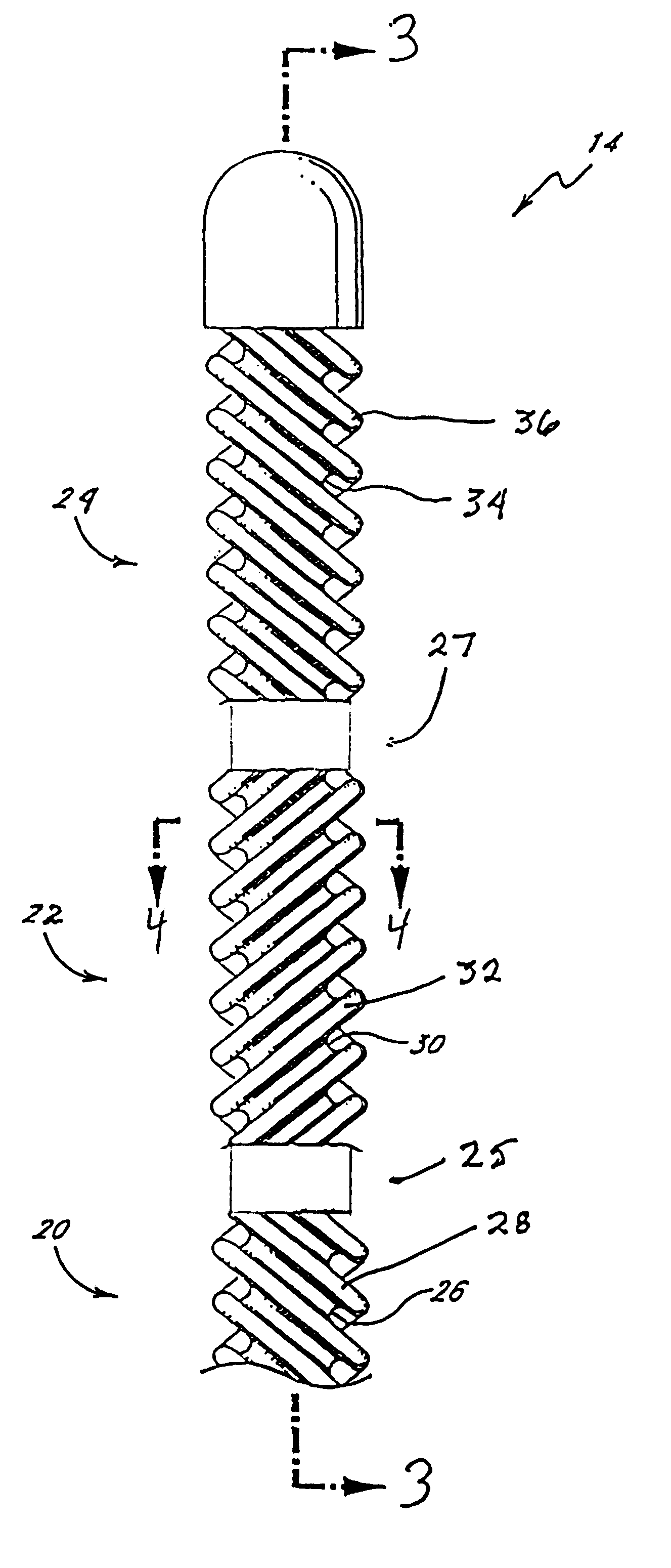

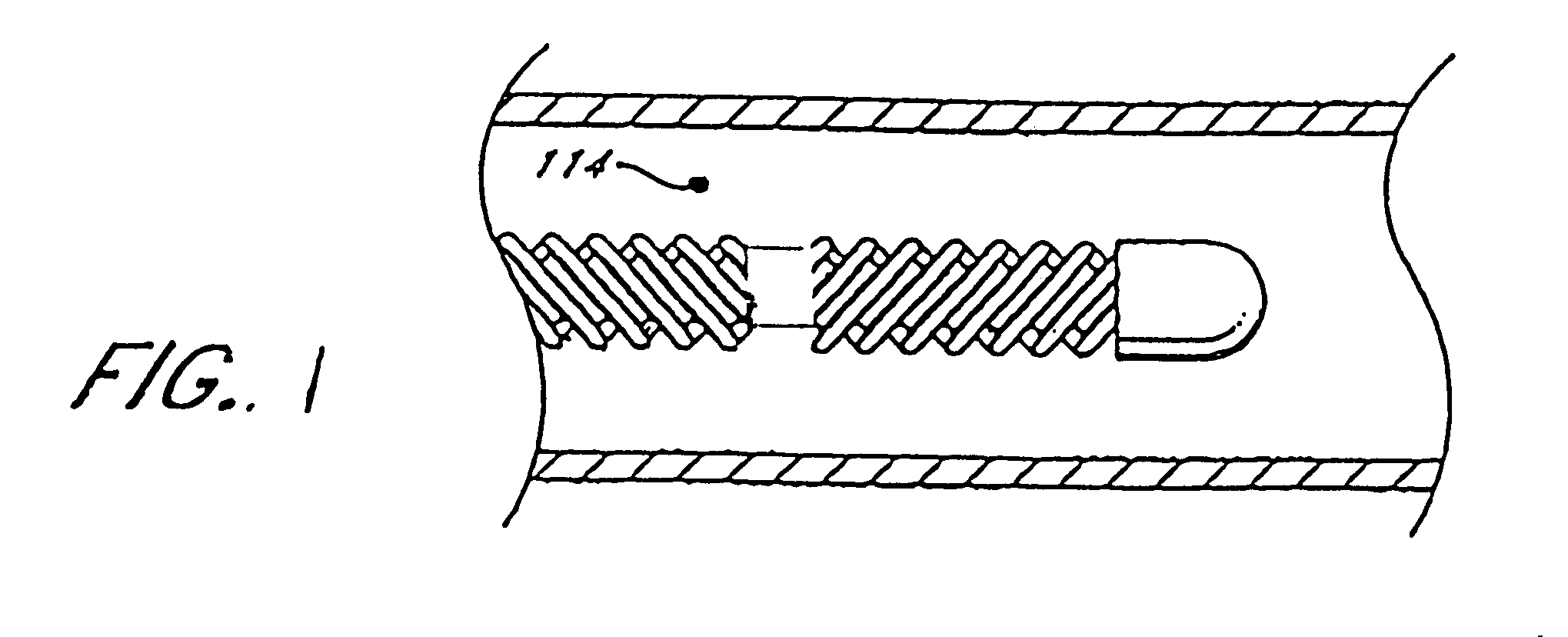

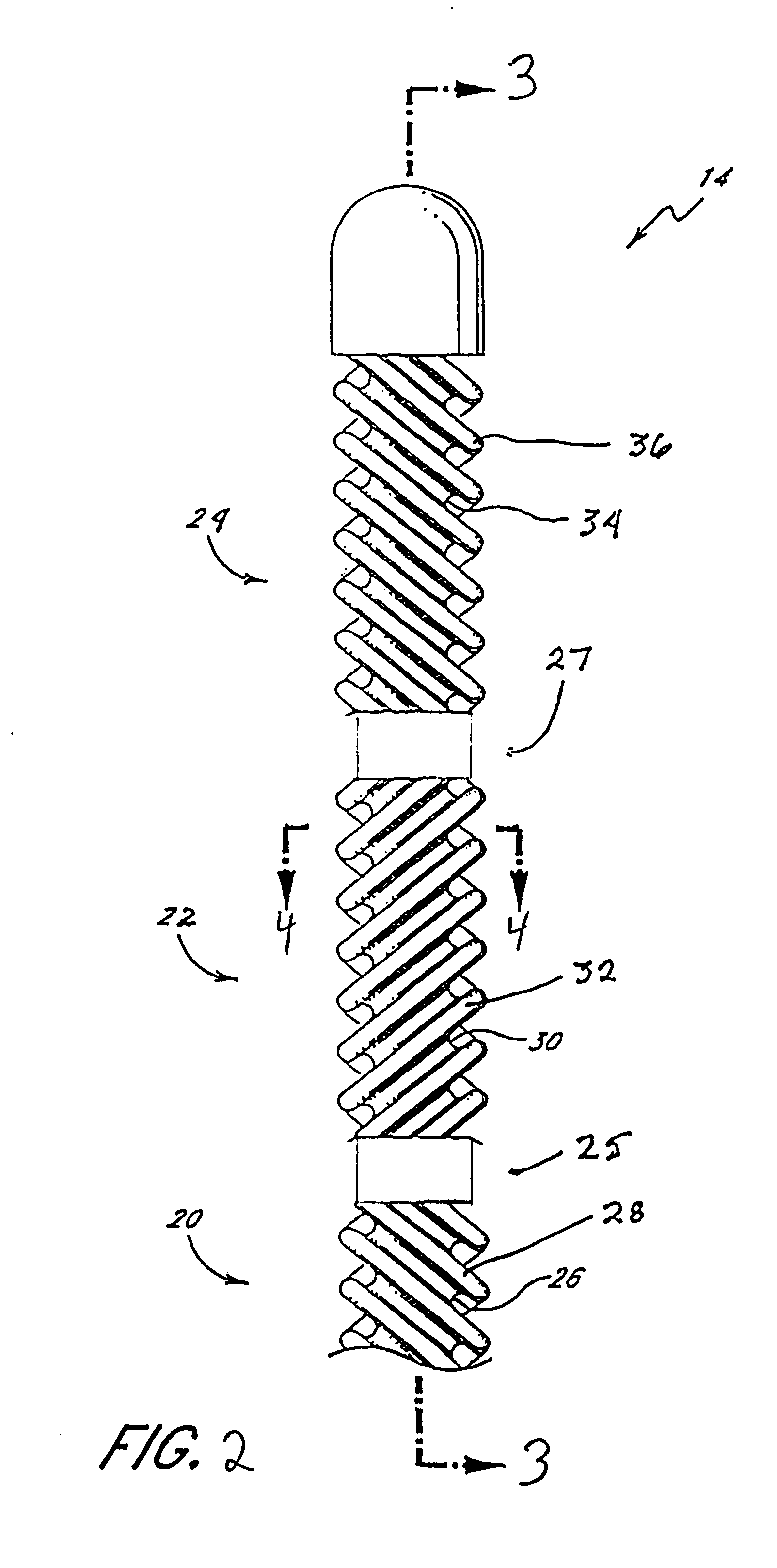

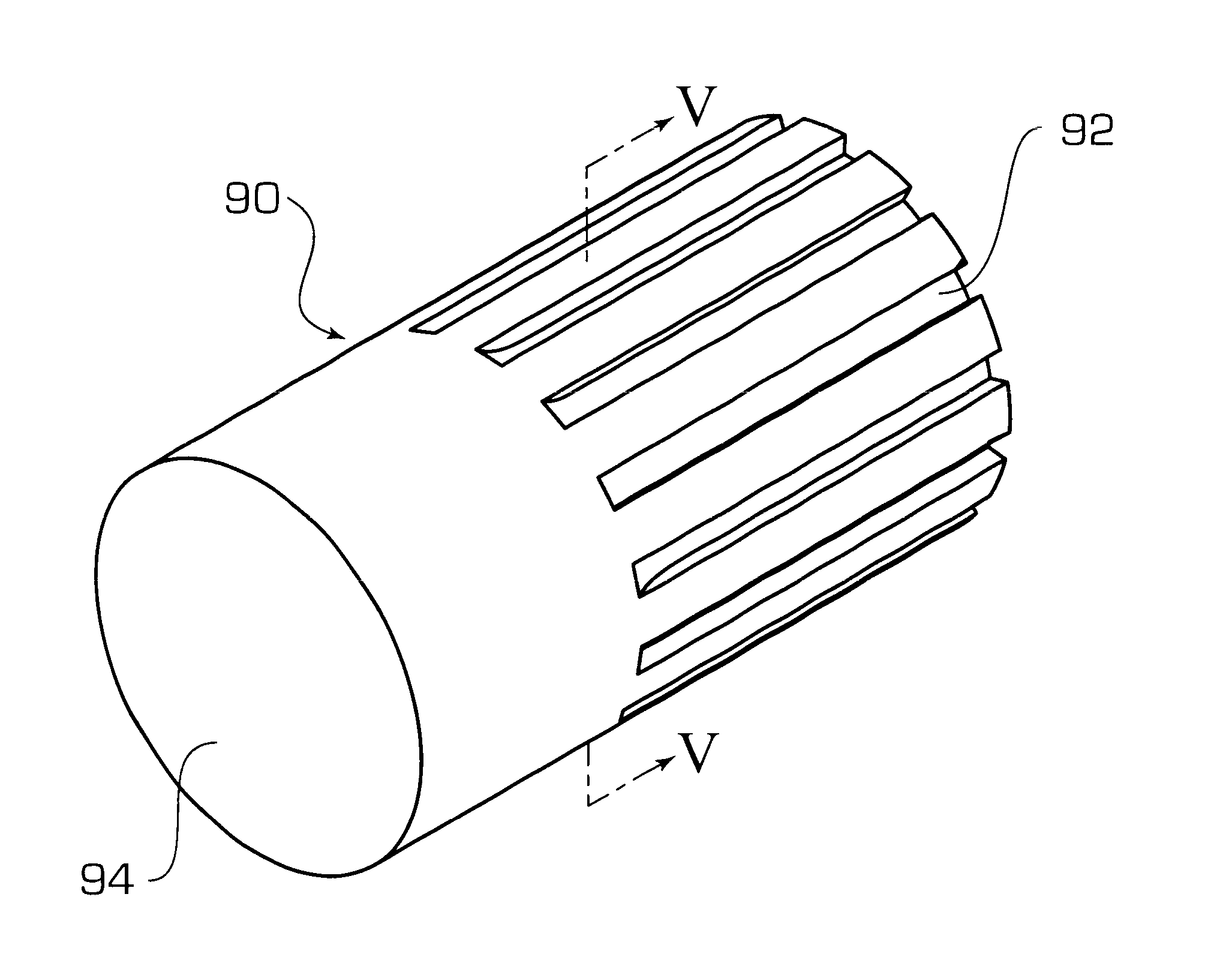

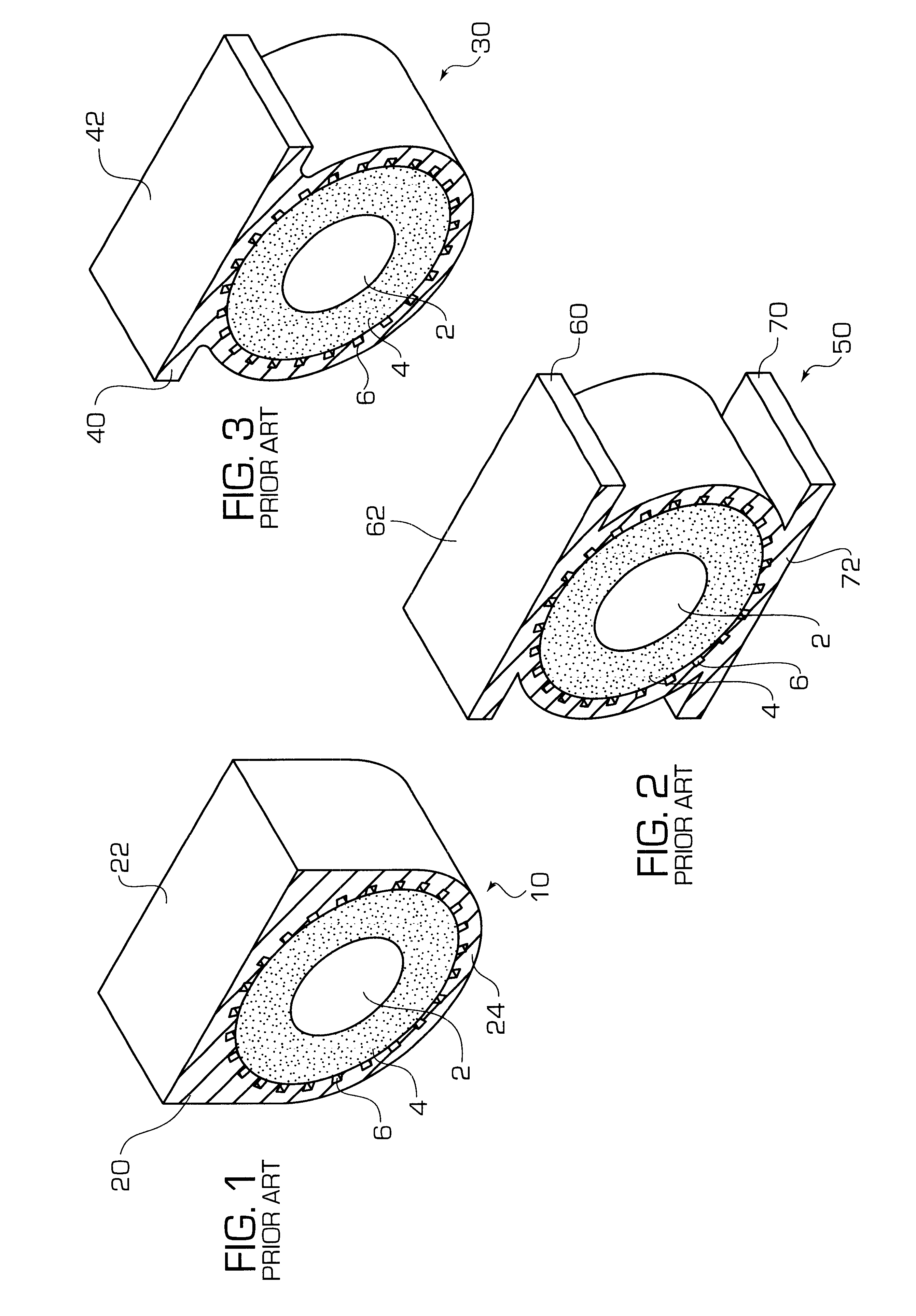

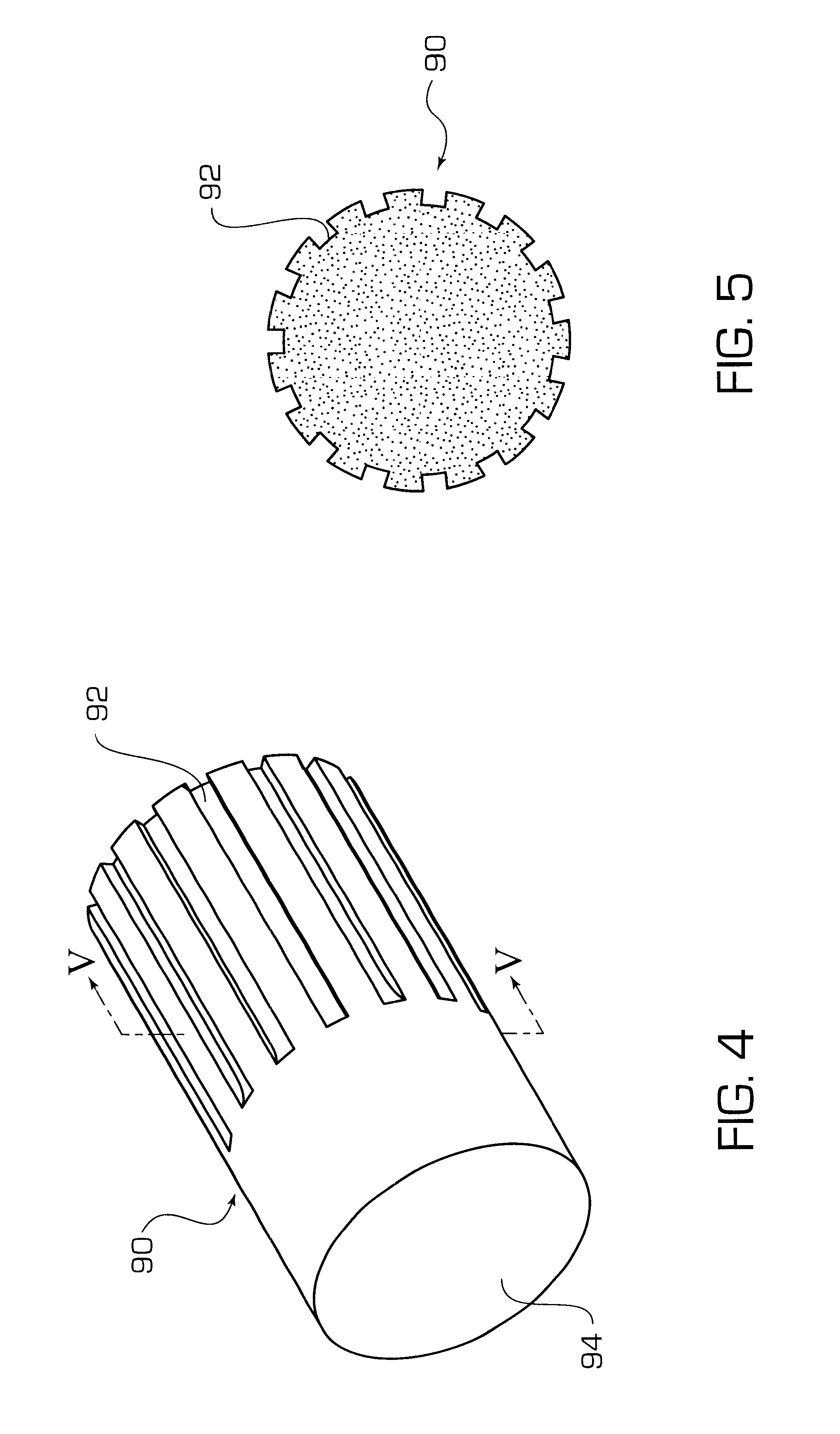

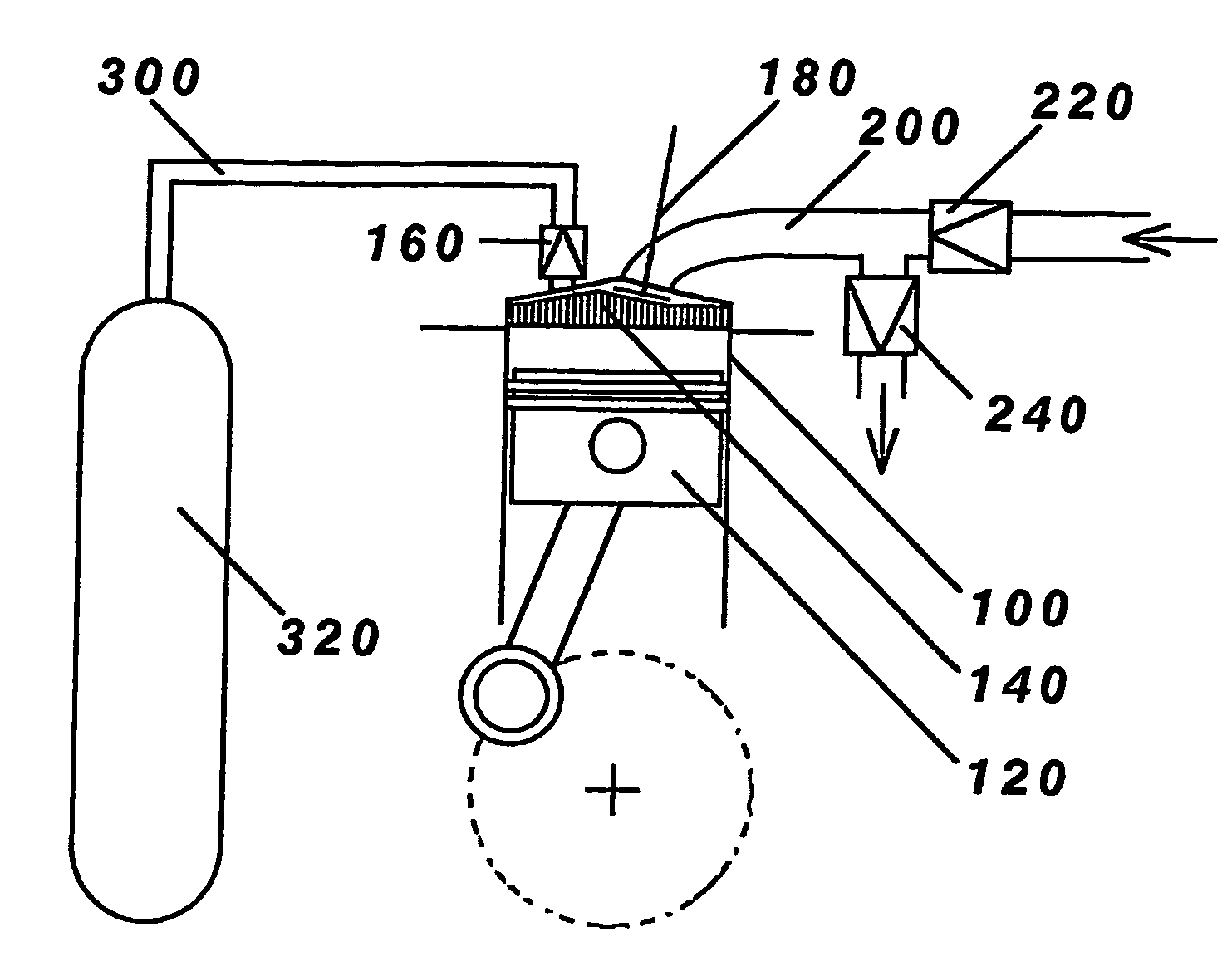

Loop heat pipe incorporating an evaporator having a wick that is liquid superheat tolerant and is resistant to back-conduction

InactiveUS6382309B1Semiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A capillary wick for use in capillary evaporators has properties that prevent nucleation inside the body of the wick, resulting in suppression of back-conduction of heat from vapor channels to the liquid reservoir. Use of a central liquid flow channel in the wick is eliminated, and pore size in the wick is chosen to maximize available pressure for fluid pumping, while preventing nucleation in the wick body. The wick is embodied with different geometries, including cylindrical and flat. A flat capillary evaporator has substantially planar heat input surfaces for convenient mating to planar heat sources. The flat capillary evaporator is capable of being used with working fluids having high vapor pressures (i.e., greater that 10 psia). To contain the pressure of the vaporized working fluid, the opposed planar plates of the evaporator are brazed or sintered to opposing sides of a metal wick. Additionally, a terrestrial loop heat pipe and a loop heat pipe having overall flat geometry are disclosed.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

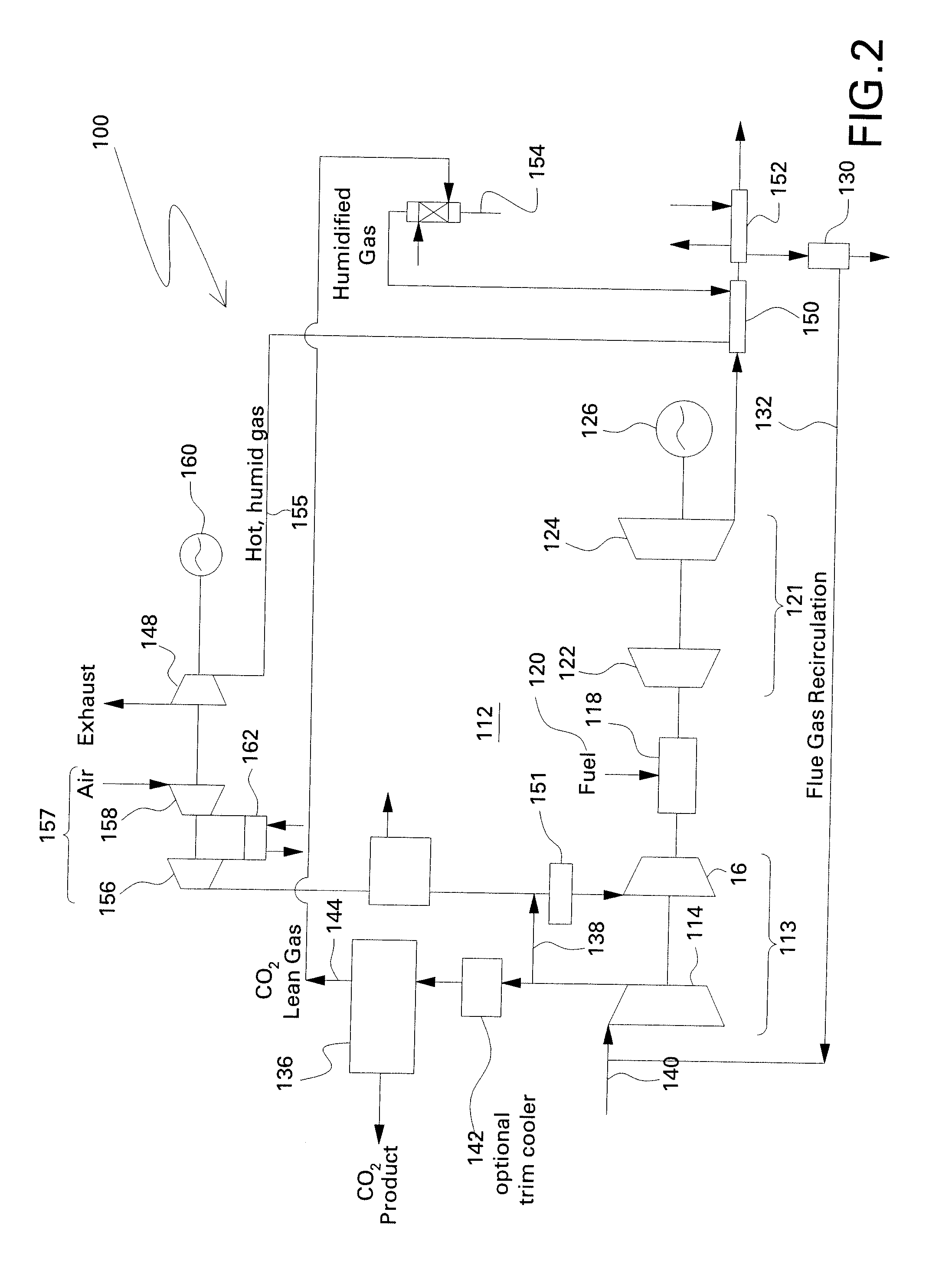

Power plants that utilize gas turbines for power generation and processes for lowering co2 emissions

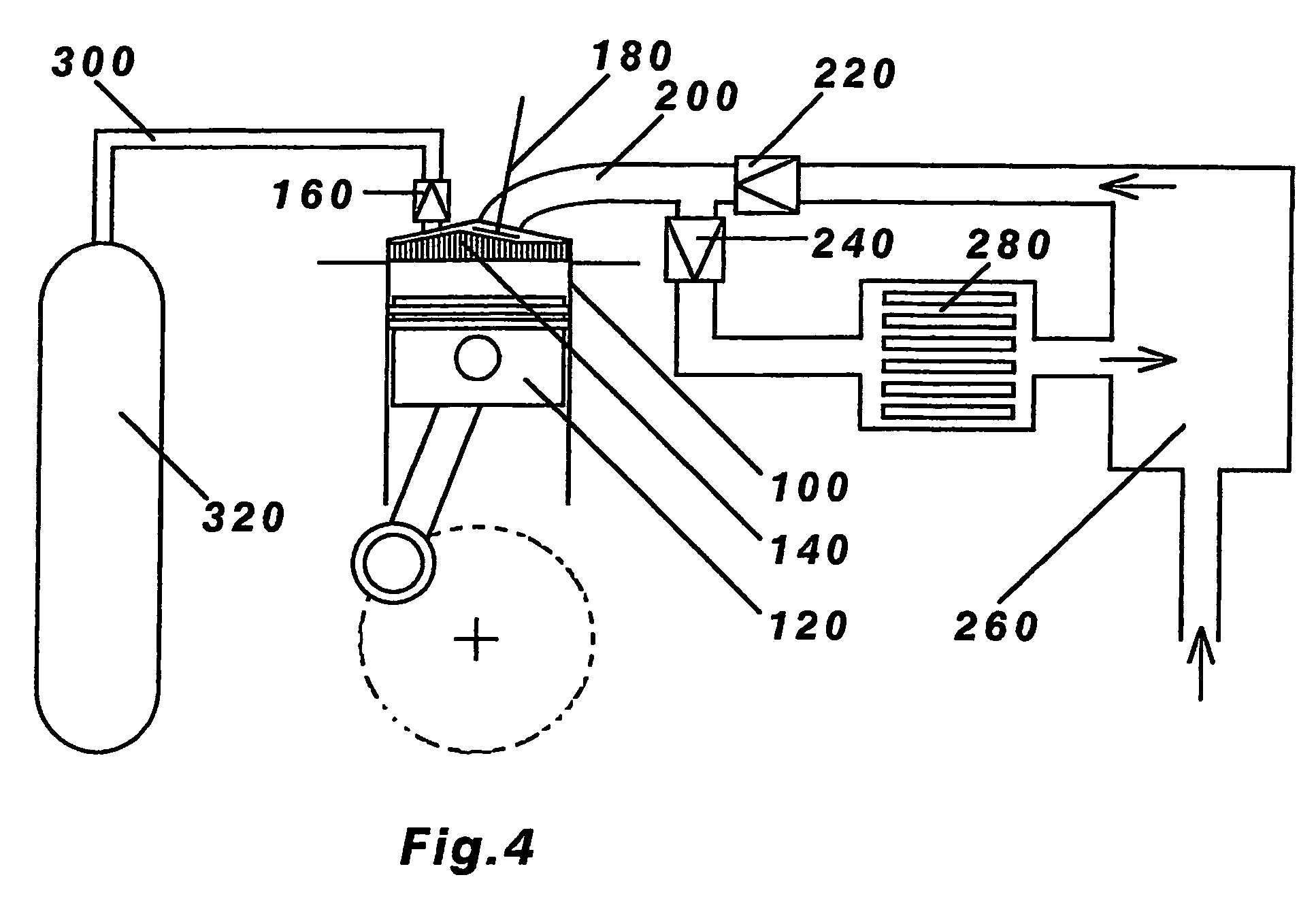

ActiveUS20080104958A1Reduce carbon dioxide emissionsEmission reductionGas treatmentInternal combustion piston enginesPower stationWorking fluid

Power plants and process for lowering CO2 emissions generally includes extracting a portion of the recirculated CO2-rich flue gas mid-way through the compression pathway of a gas turbine and removing the CO2 in a separation unit. The remaining portion of the CO2 rich flue gas (i.e., the portion of the recirculated flue gas that was not fed to the separation unit) is mixed with fresh air coming from an additional compressor-expander and then fed back to the compression pathway. As a result, flue gas recirculation increases the CO2 concentration within the working fluid, leading to an additional increase in CO2 partial pressure. As the concentration and partial pressure of CO2 is increased, a lower energy penalty is observed to remove the CO2. Moreover, a reduced volume is fed to the CO2 separation unit during operation. Consequently, the size of the separation equipment can be reduced as well as the energy required for the separation process.

Owner:GENERAL ELECTRIC CO +1

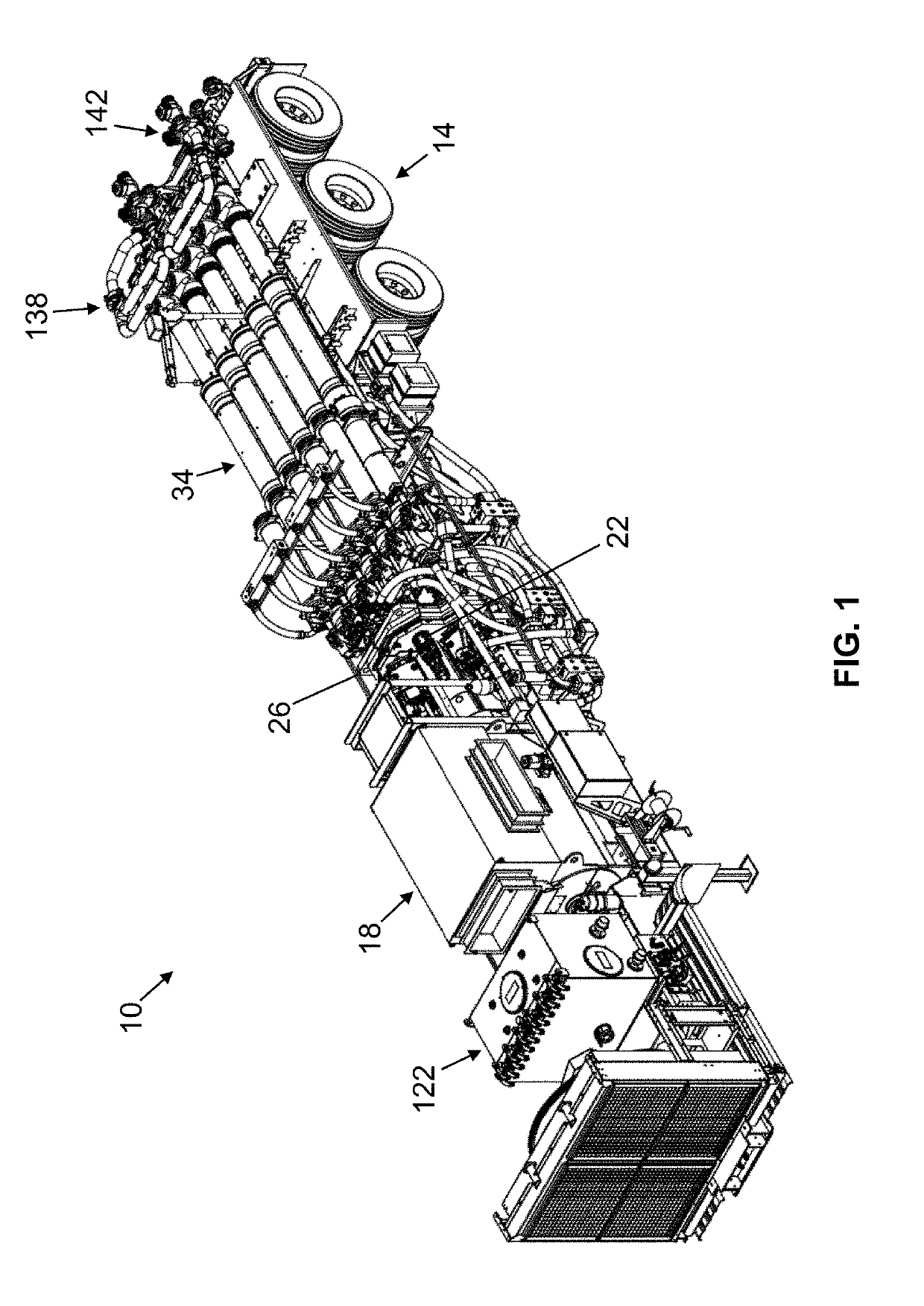

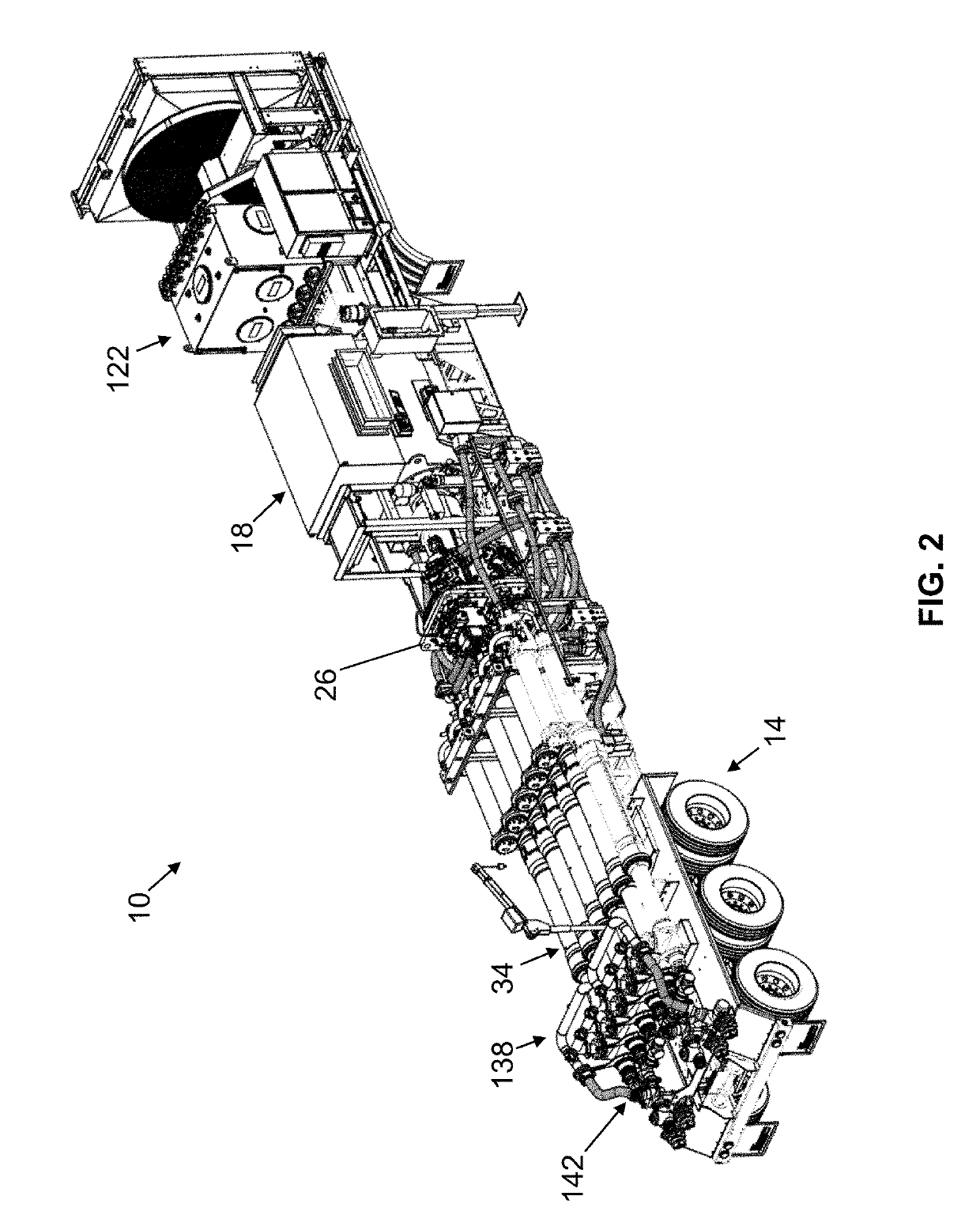

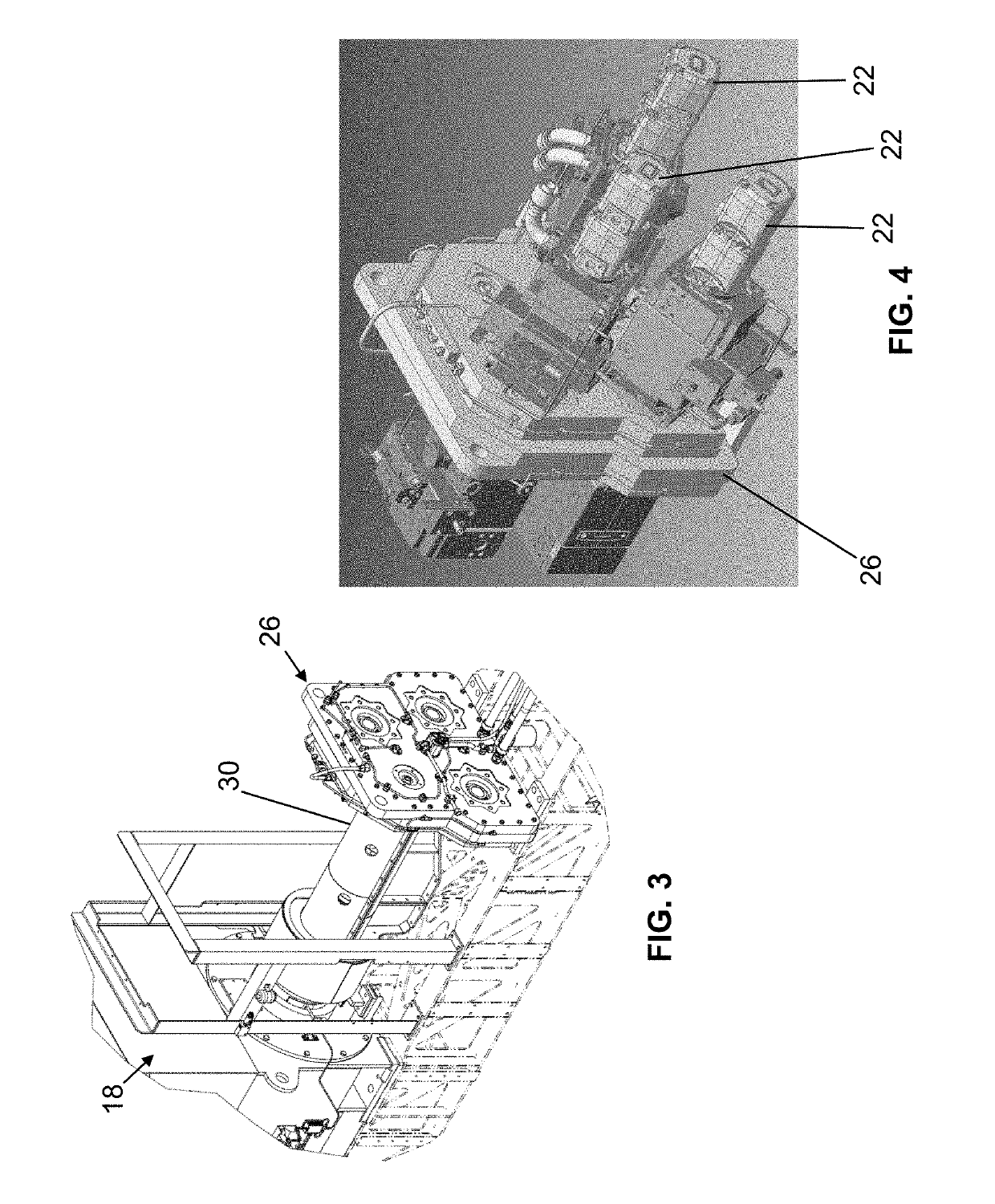

Well Service Pump System

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates a diesel engine, a hydraulic drive gear box, open loop hydraulic Pumps, hydraulic ram cylinders, controls for the hydraulic system hydraulic cylinders, working fluid end cylinders and a coupling to connect the hydraulic cylinders and the working fluid ends. The engine powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of a working fluid end cylinder. There is no crankshaft or automatic transmission required. The linear design allows for a longer plunger stroke length while still allowing highway transport on a truck or skid.

Owner:AMERIFORGE GRP

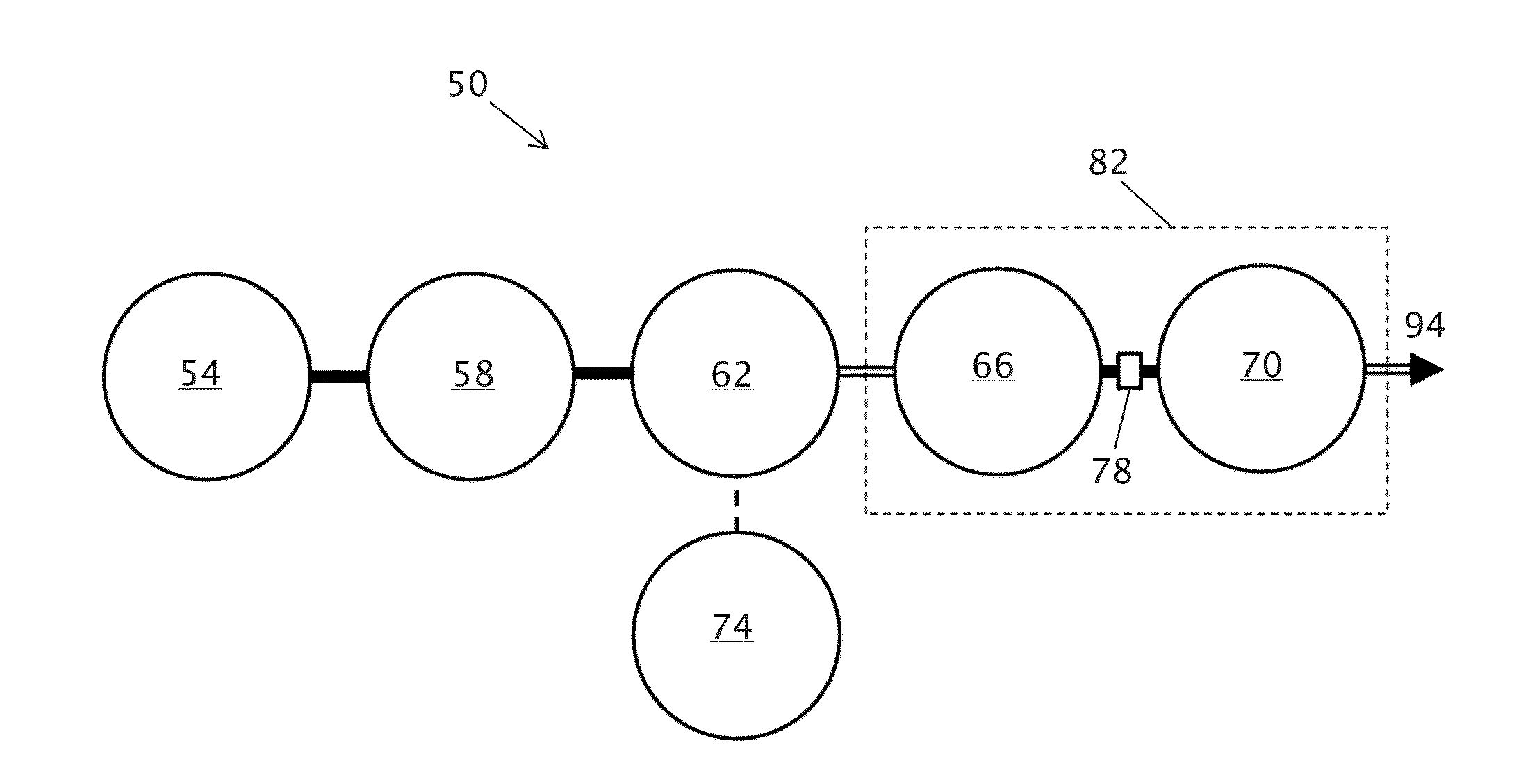

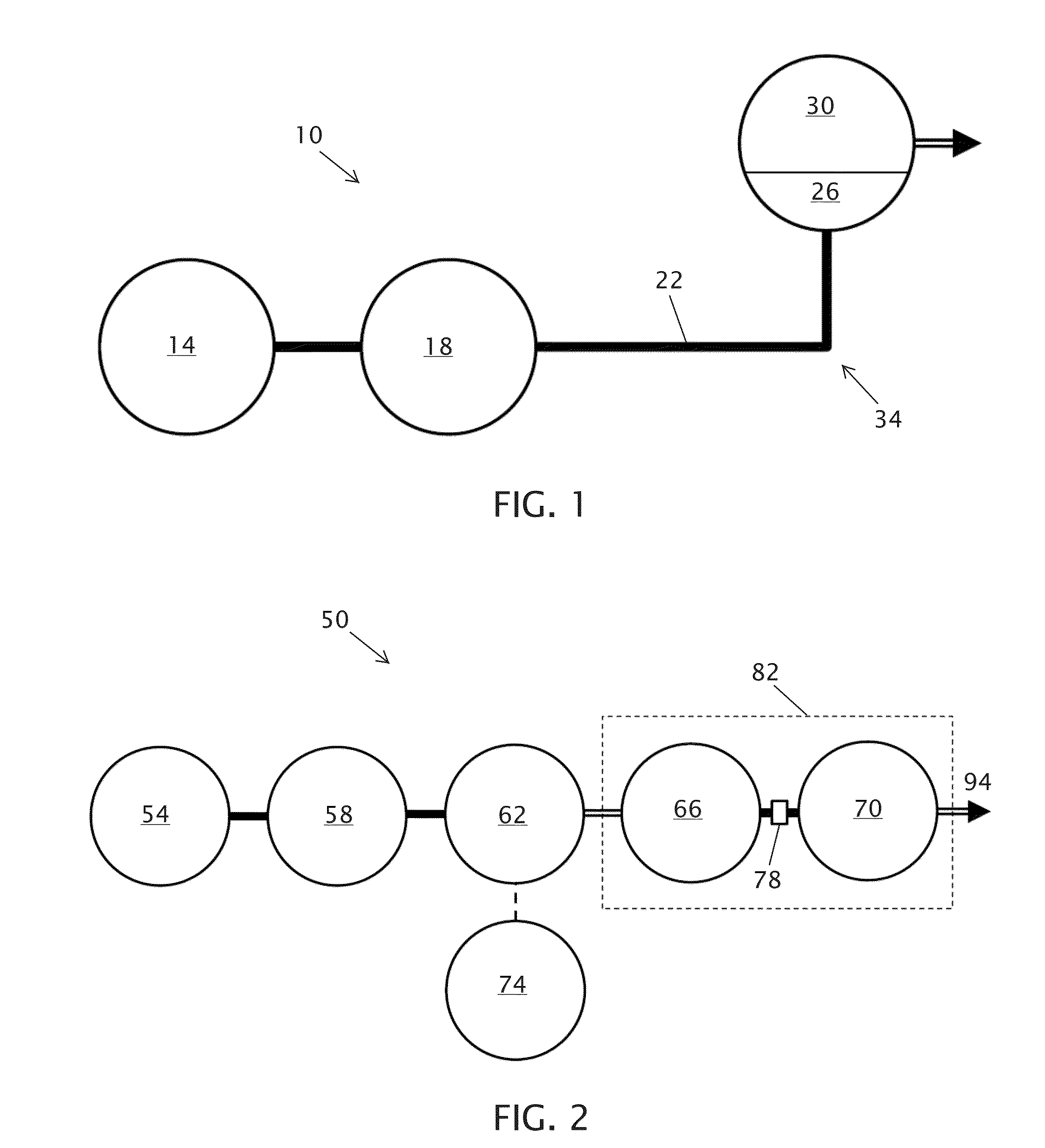

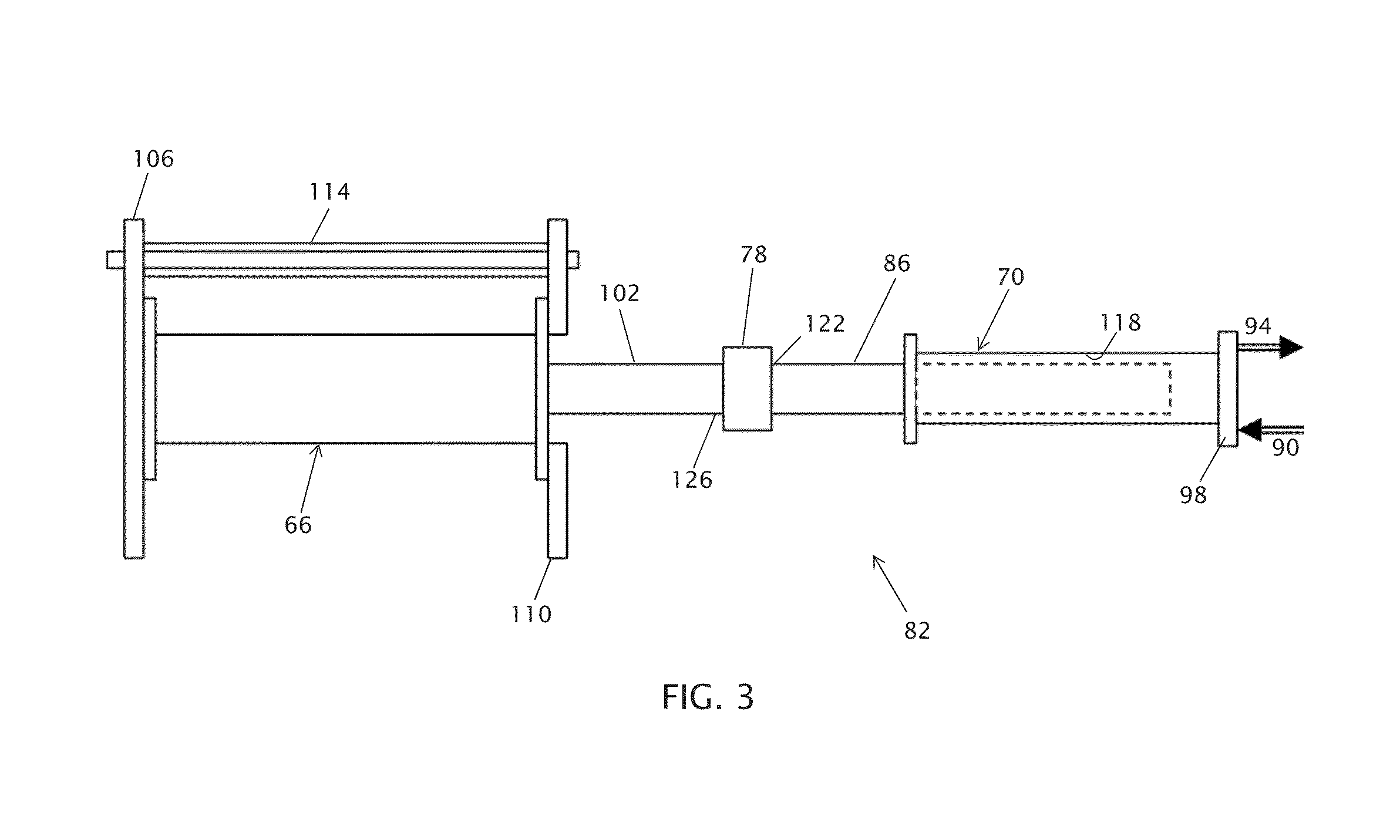

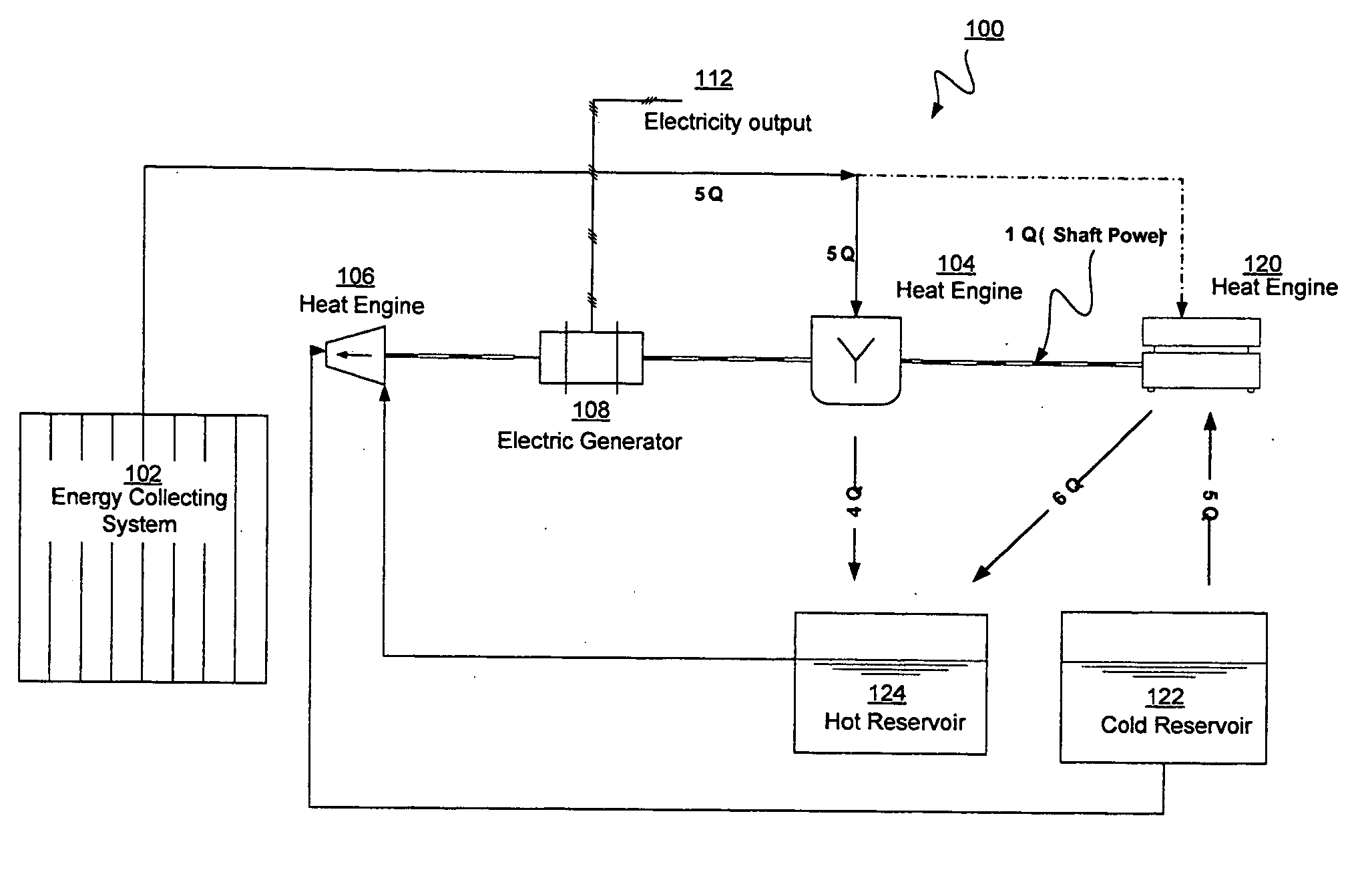

Efficient low temperature thermal energy storage

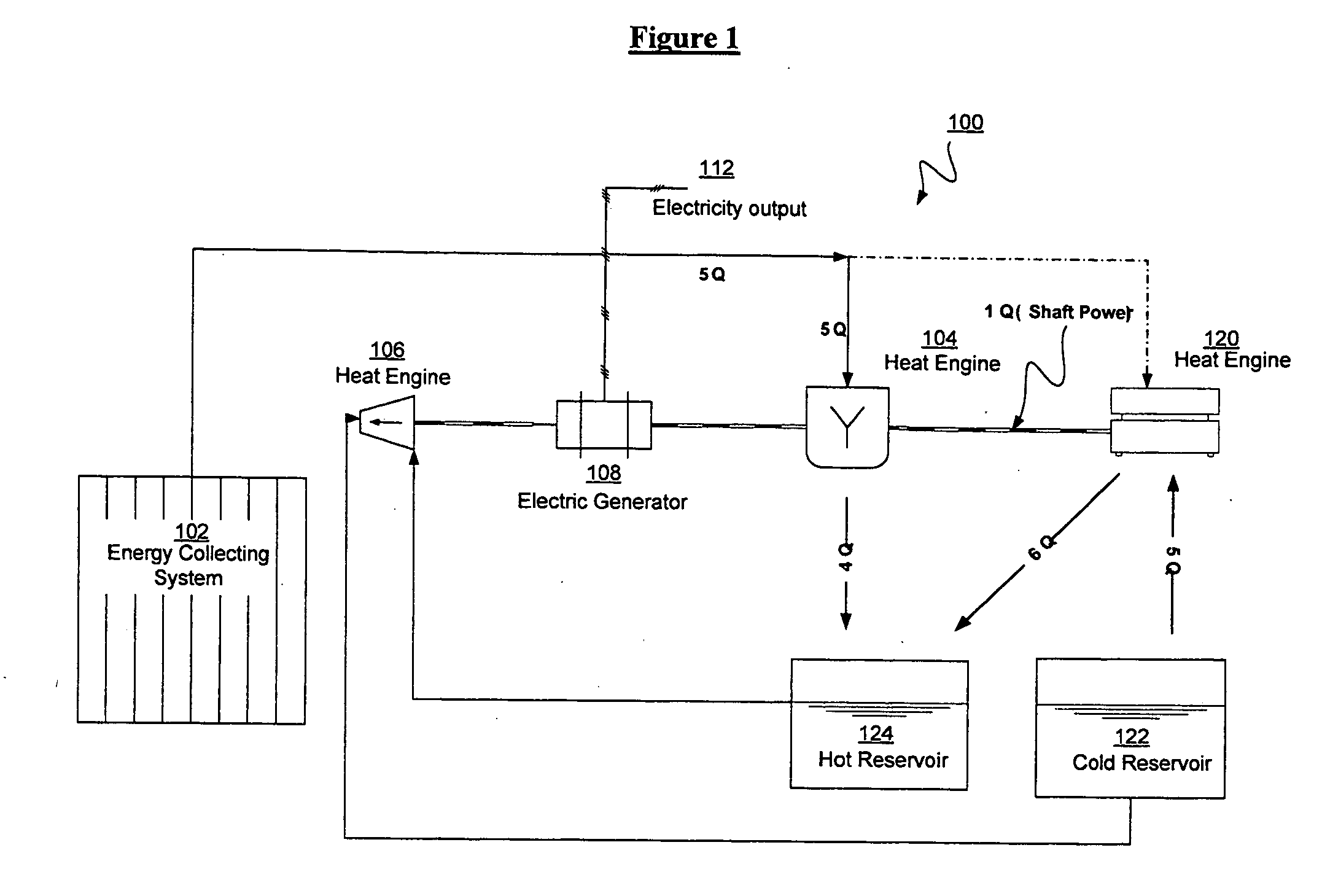

InactiveUS20090179429A1Improve heating efficiencyInternal combustion piston enginesFrom solar energyThermal energyWorking fluid

Thermal energy derived from a low temperature heat source is stored in one reservoir above ambient temperature and in another reservoir below ambient temperature for use in driving an organic Rankine cycle engine to produce electricity. The organic Rankine cycle engine may utilize an organic working fluid that boils below or near ambient temperature. Solar energy may be used to power a heat pump or chiller that provides the hot and cold storage fluids stored in hot and cold reservoirs for use in the organic Rankine cycle engine.

Owner:AREVA SOLAR

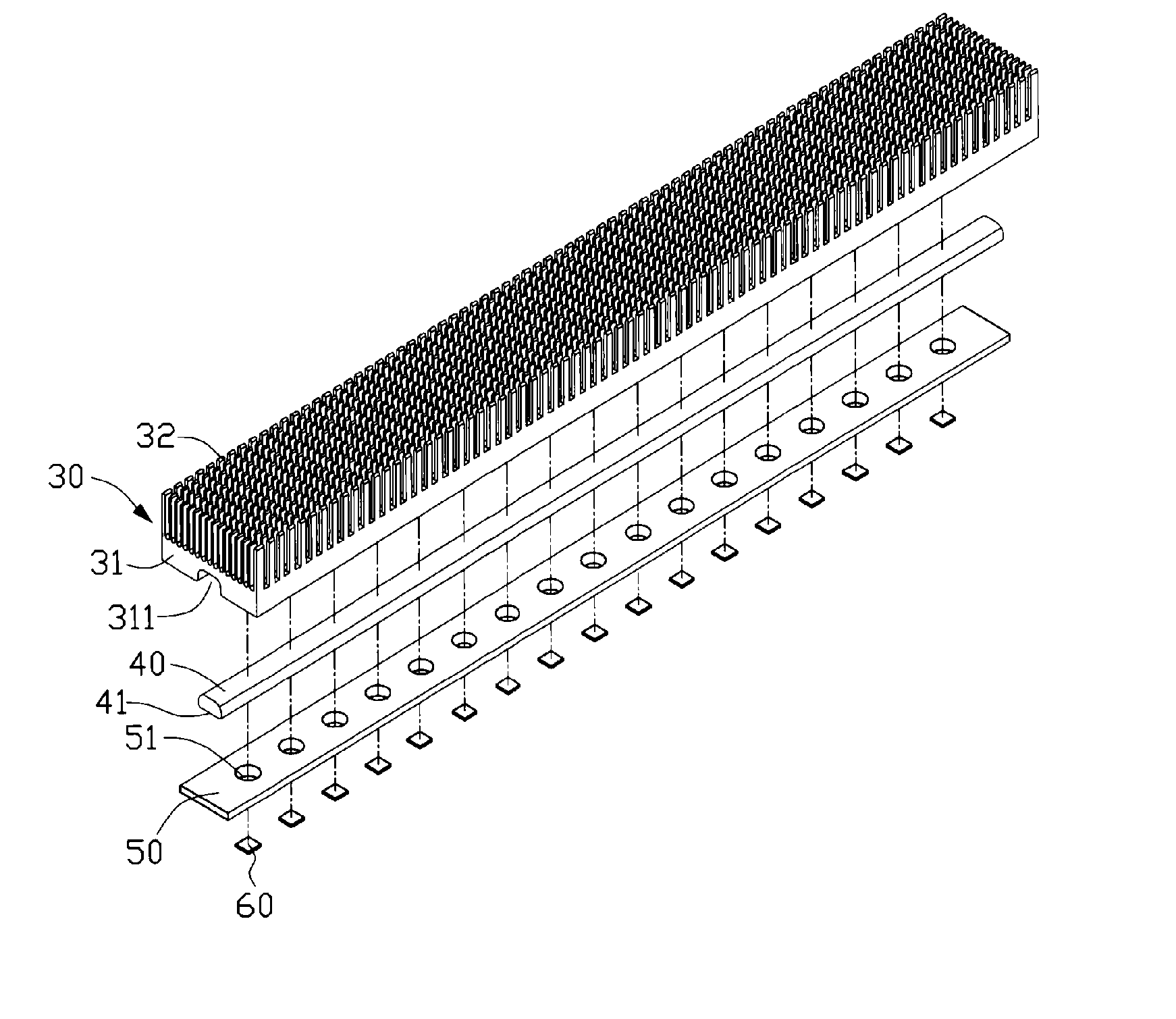

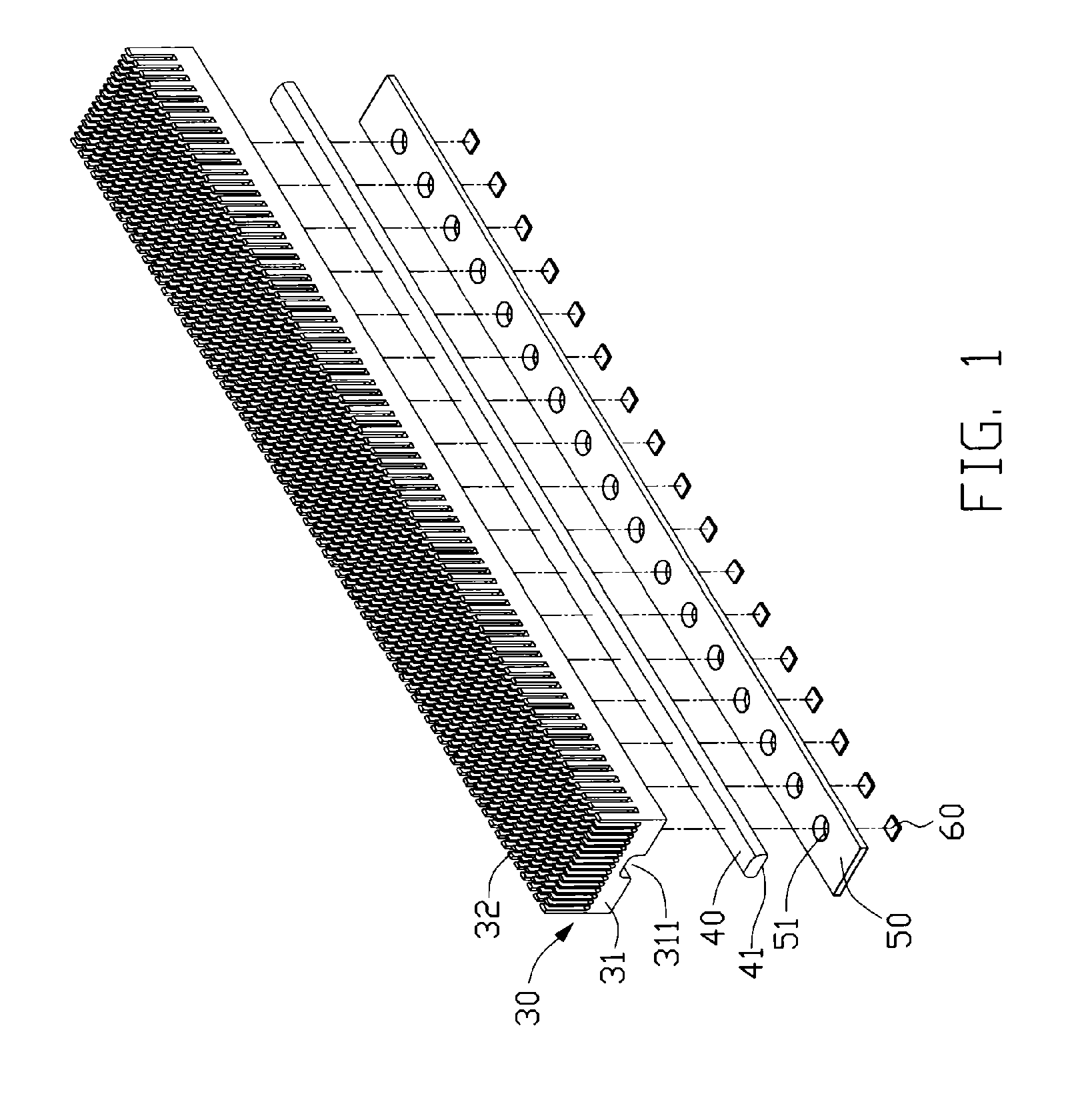

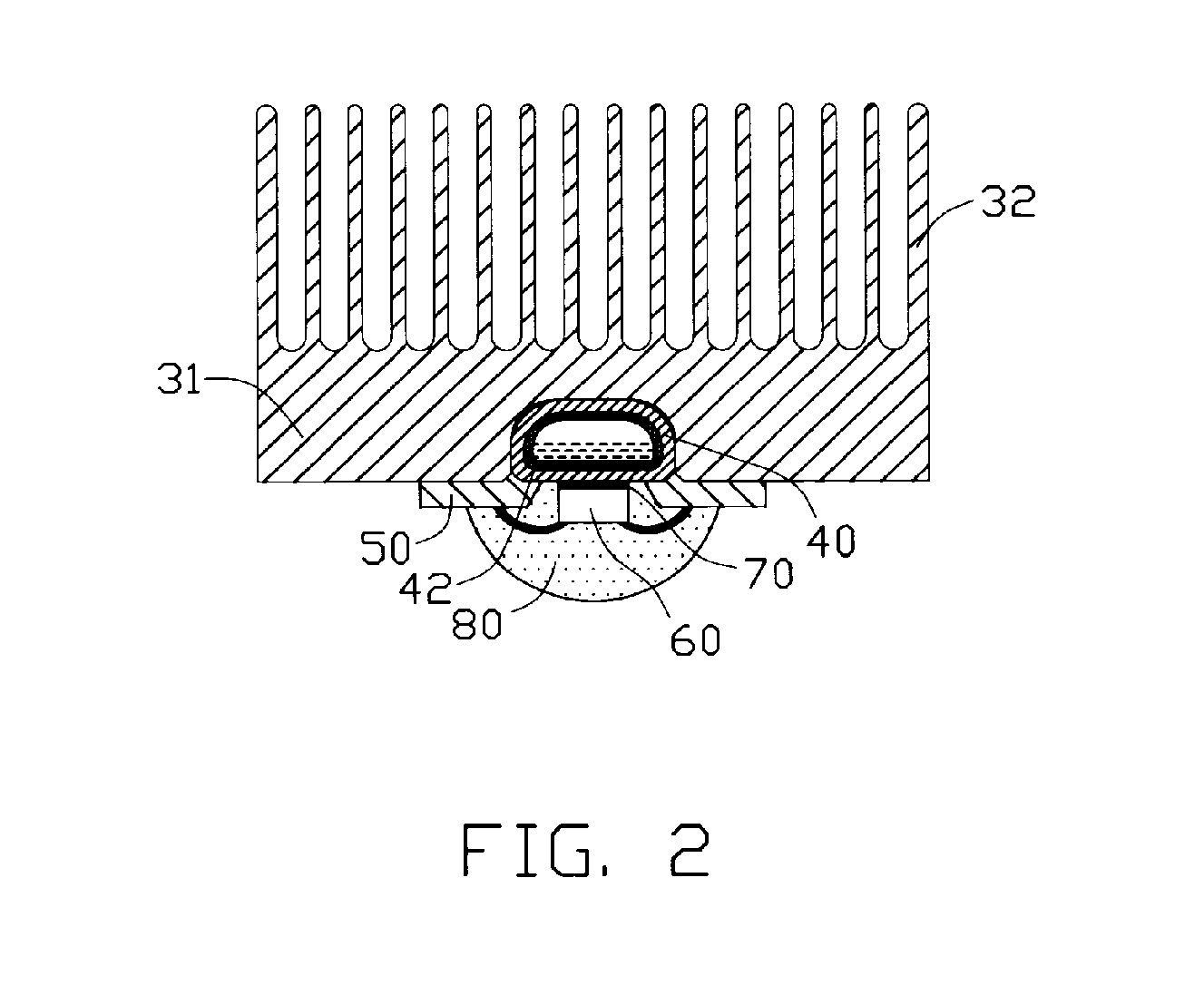

Light-emitting diode assembly and method of fabrication

A light-emitting diode (LED) assembly and a method for fabrication thereof are disclosed. The LED assembly includes a heat-absorbing member in which a working fluid is provided, an LED die (60) directly attached to the heat-absorbing member, and a heat-dissipating member thermally attached to the heat-absorbing member. The heat-absorbing member absorbs heat via the working fluid from the LED die and transfers the heat to the heat-dissipating member for dissipation. The method involves directly attaching the LED die to the heat-absorbing member.

Owner:HON HAI PRECISION IND CO LTD

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

Vapor chamber structure with improved wick and method for manufacturing the same

InactiveUS20090025910A1Improve thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat transfer efficiency

A vapor chamber structure includes a casing, a working fluid, and an improved wick layer. The casing has an airtight vacuum chamber. The working fluid is filled into the airtight vacuum chamber. The wick layer is formed on a surface of the airtight vacuum chamber. Therefore, the present invention can increase the backflow velocity of the working fluid and improve the boiling of the working fluid due to the match of the improved wick structure. Because the backflow velocity and boiling of the working fluid is increased, the heat-transmitting efficiency is increased.

Owner:THERMAL TECH

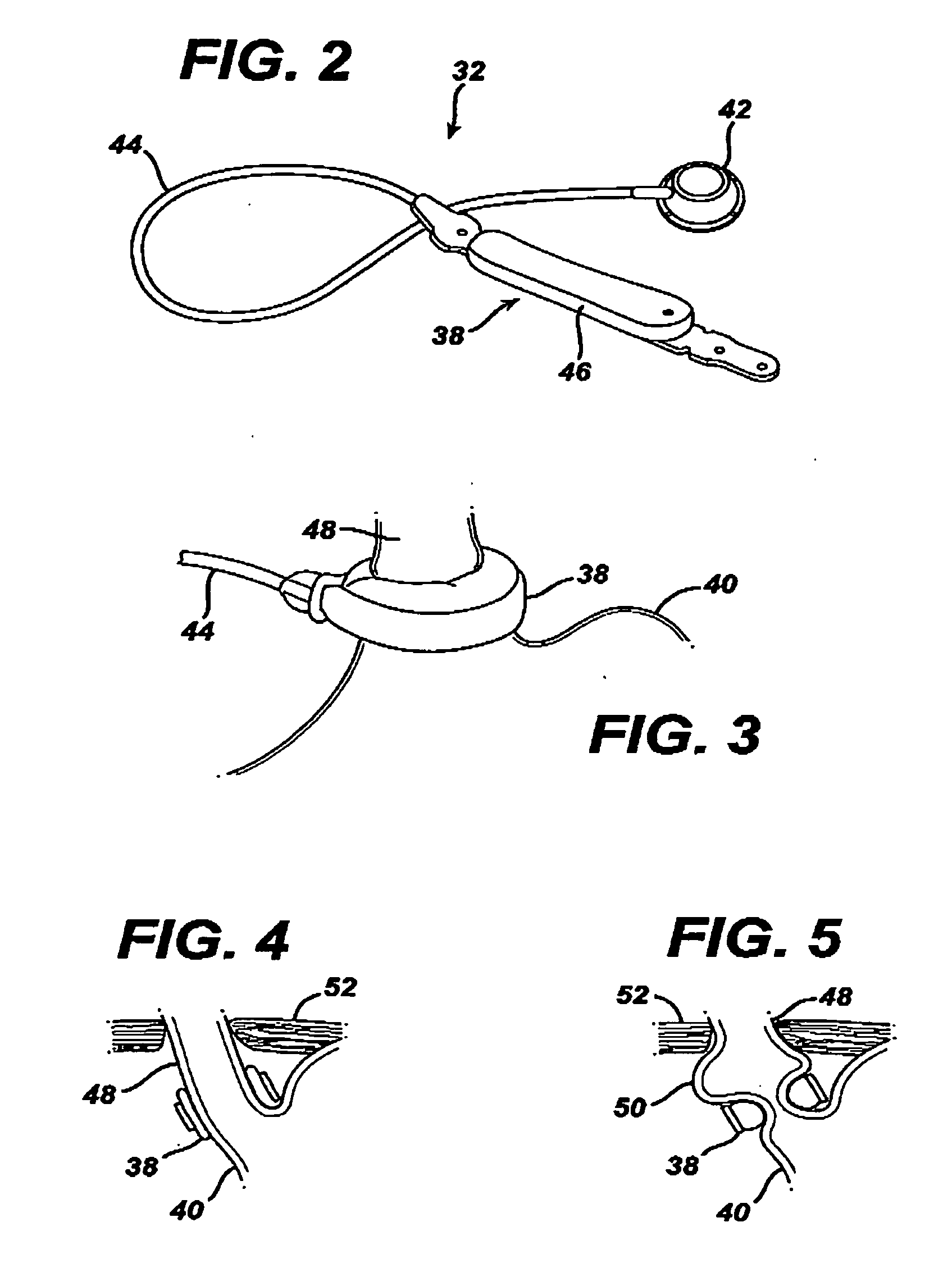

Method and device for performing cooling- or cryo-therapies for, e.g., angioplasty with reduced restenosis or pulmonary vein cell necrosis to inhibit atrial fibrillation employing microporous balloon

InactiveUS7449018B2Inhibit and reduce rateMinimize and inhibit biochemical eventCatheterDiagnostic recording/measuringAtrial cavityWorking fluid

An enhanced method and device are provided to inhibit or reduce restenosis following angioplasty or stent placement. A porous balloon-tipped catheter is disposed in the area treated or opened through balloon angioplasty immediately following angioplasty. The balloon, which can have a dual balloon structure, may be delivered through a guiding catheter and over a guidewire already in place. A fluid such as a perfluorocarbon flows into the balloon to freeze the tissue adjacent the balloon, this cooling being associated with reduction of restenosis. A similar catheter may be used to reduce atrial fibrillation by inserting and inflating the porous balloon such that an exterior surface of the balloon, as well as a portion of the cold working fluid, from the microporosity contacts at least a partial circumference of the portion of the pulmonary vein adjacent the left atrium.

Owner:ZOLL CIRCULATION

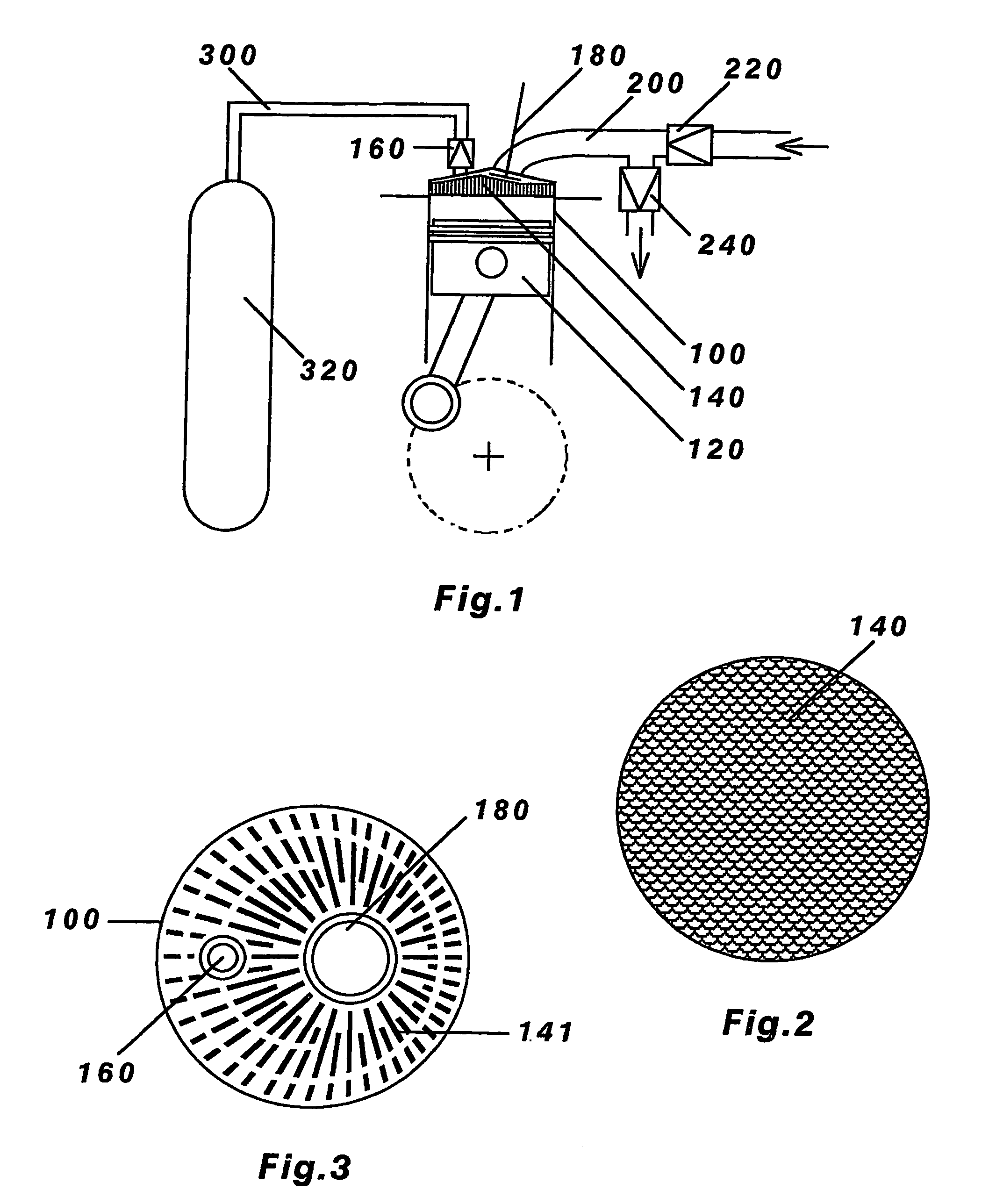

Isothermal reciprocating machines

InactiveUS20060248886A1High materialIncrease heating capacityPositive displacement pump componentsMulti-stage pumpsWorking fluidGas compressor

A reciprocating gas compressor is described operating according to an extended cycle of 4,6 or more strokes, wherein the first two strokes are sequential induction and compression strokes using a low pressure gas as working fluid and compressing it to a high pressure gas, and the remaining strokes are pairs of sequential filling and emptying strokes using more of the low pressure gas as heat transfer fluid for transferring heat from inside the gas compressor to outside the gas compressor. The gas compressor also contains an in-cylinder heat regenerator for absorbing heat from the compressed gas and releasing heat to the heat transfer fluid thus achieving near-isothermal compression. Using parallel principles, a reciprocating gas expander is also described for achieving near-isothermal expansion. Also described are reciprocating machines using the near-isothermal gas compressor and near-isothermal gas expander in combination according to the Ericsson heat engine cycle, the Stirling heat engine cycle and the Stirling refrigeration cycle.

Owner:MA THOMAS TSOI HEI

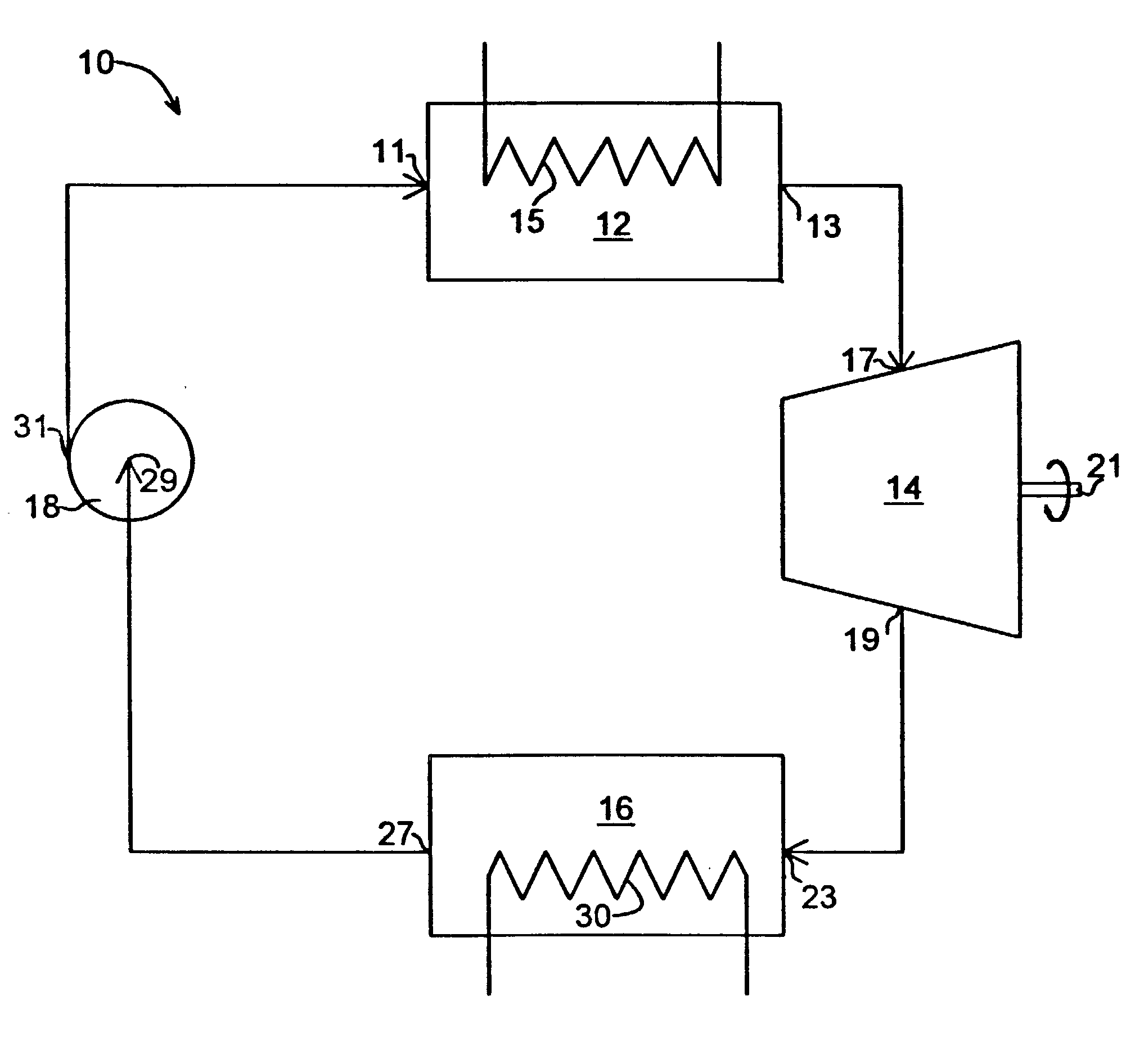

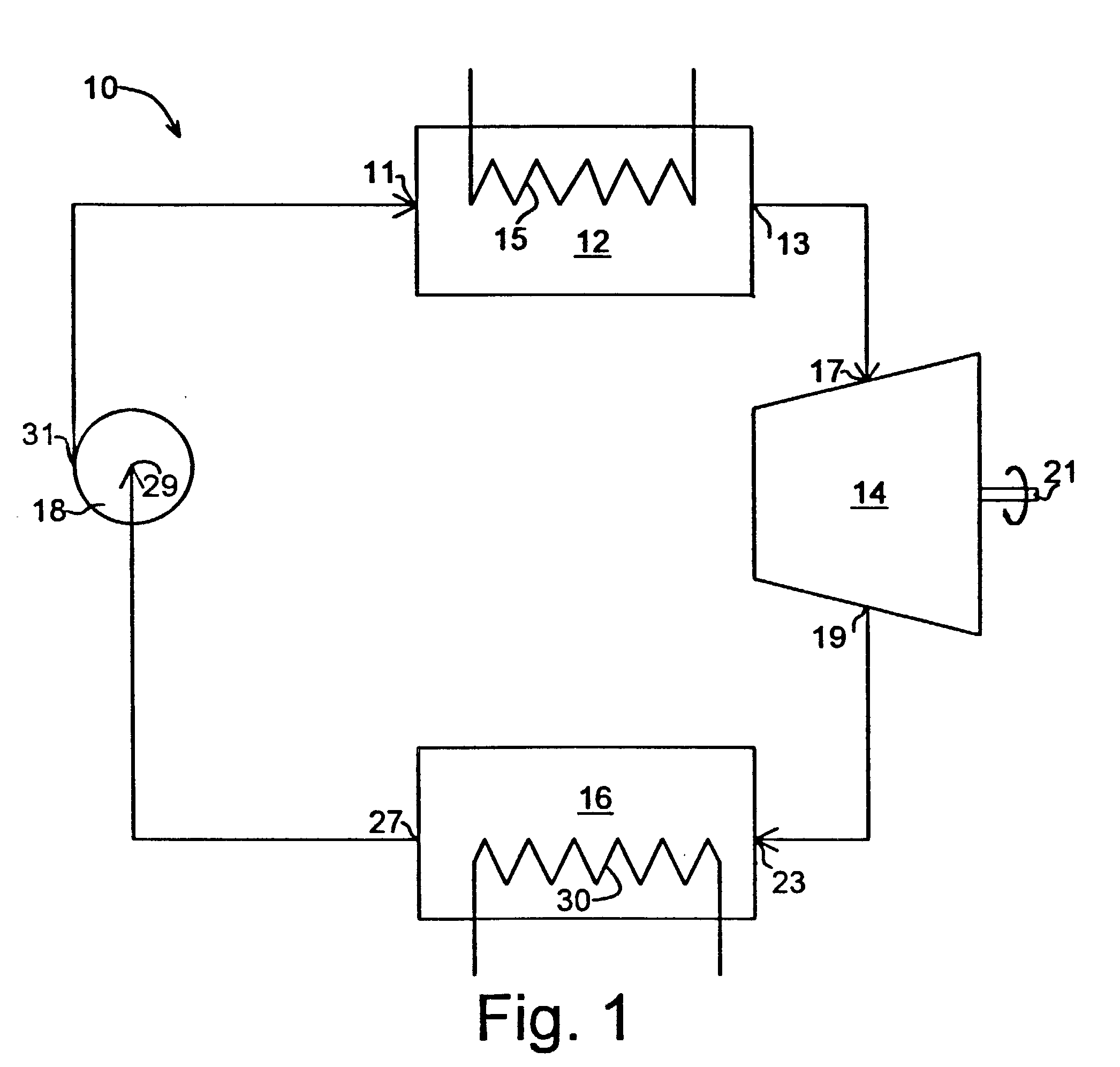

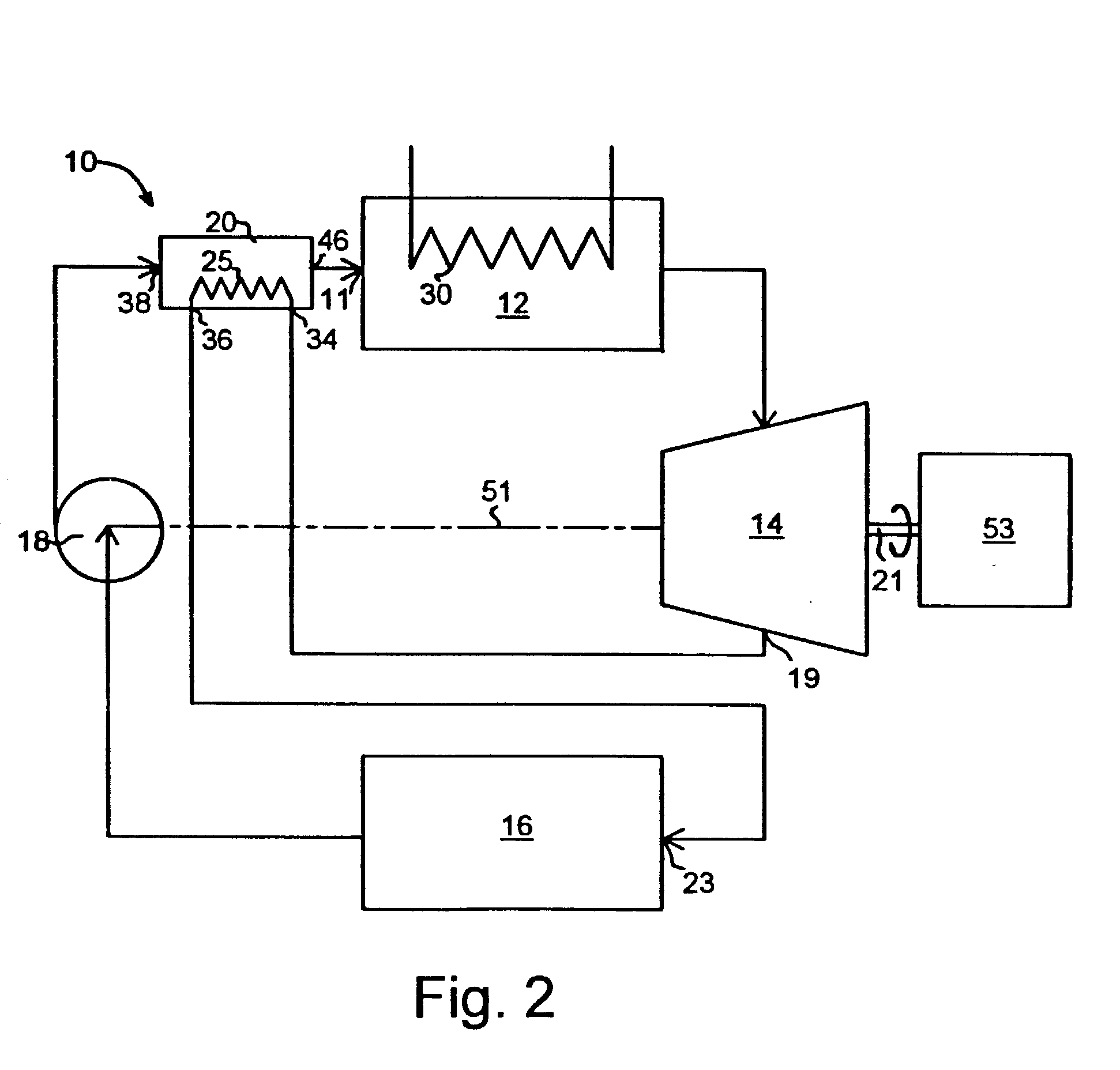

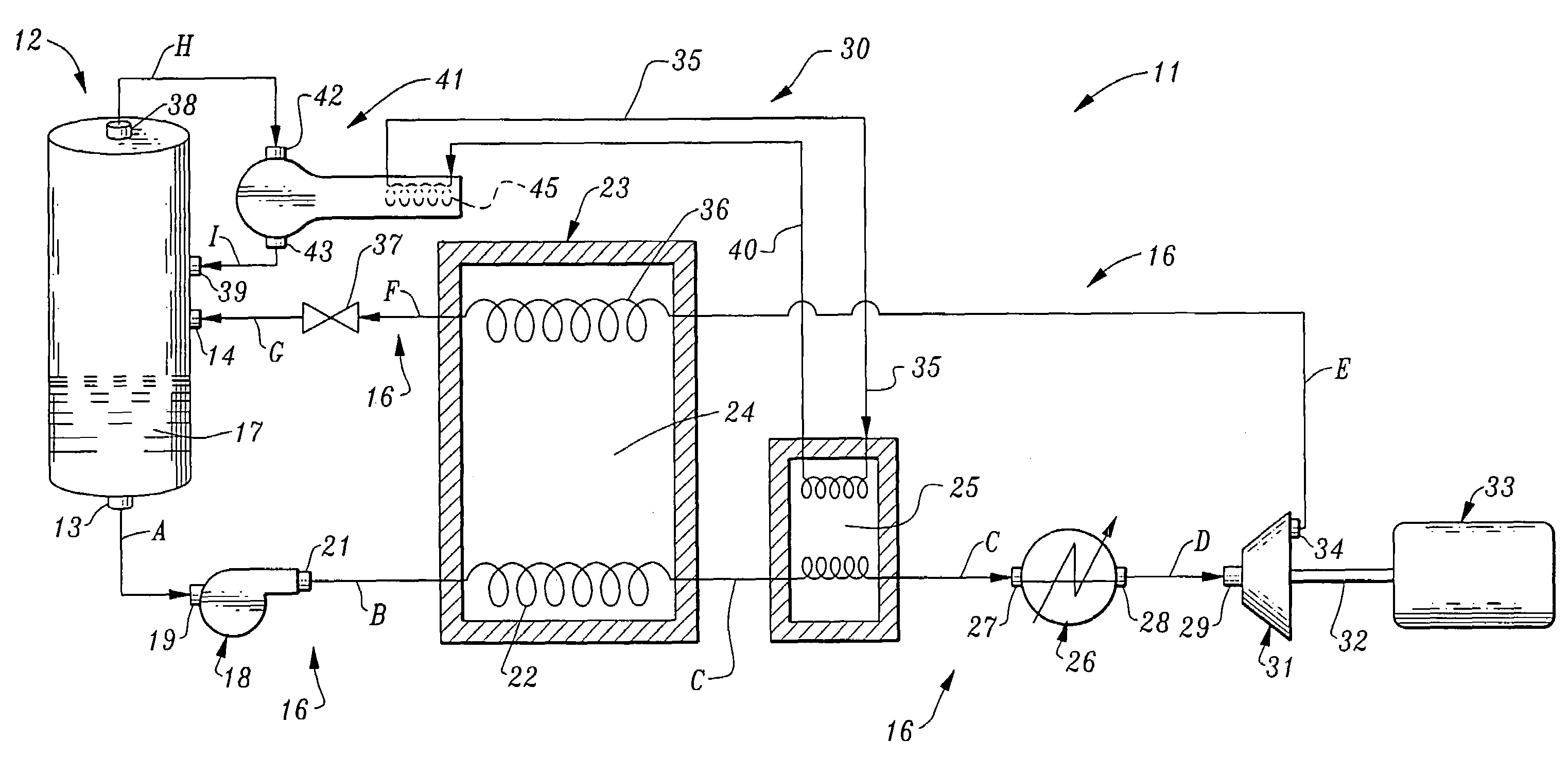

Heat engine

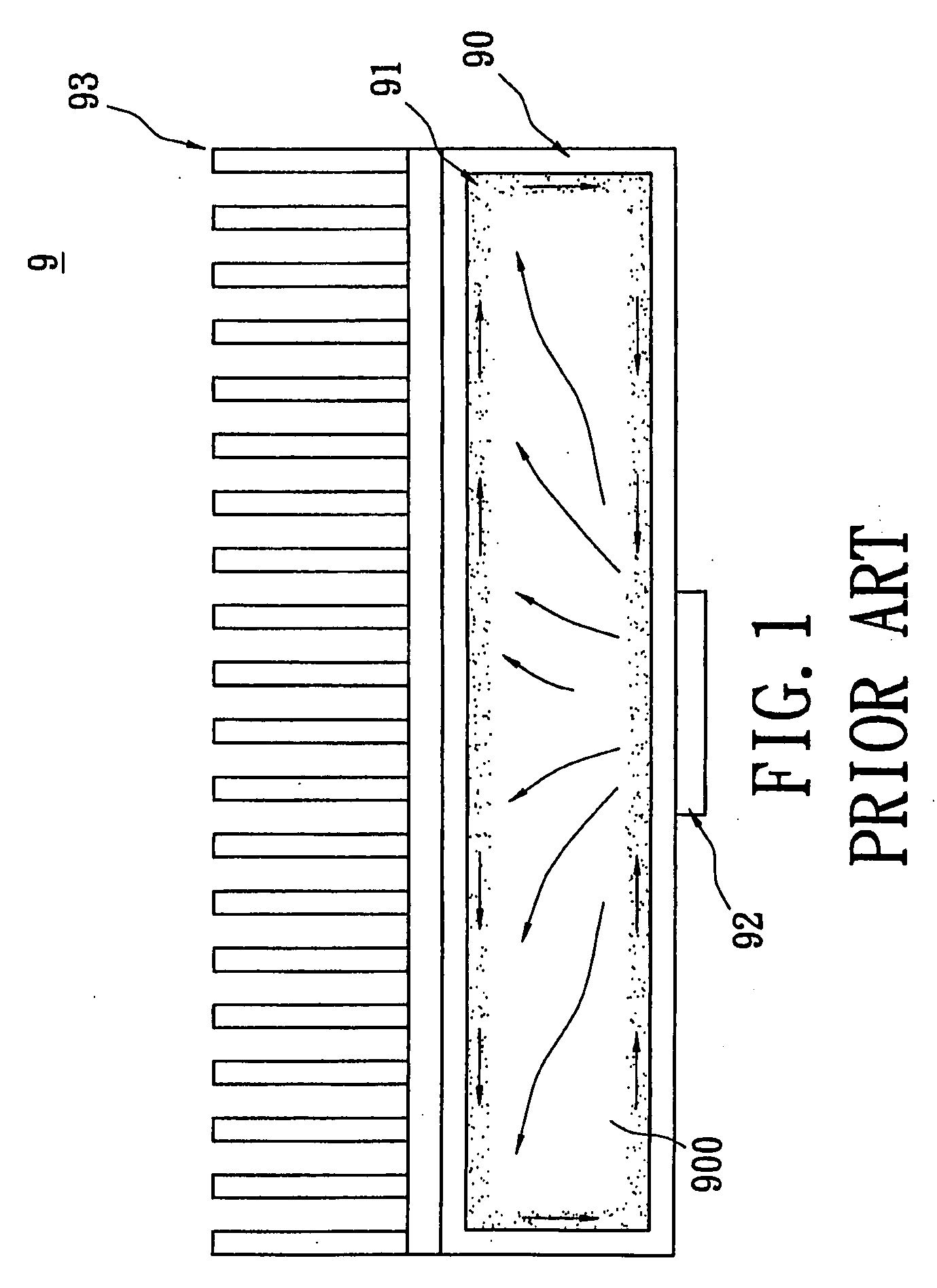

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

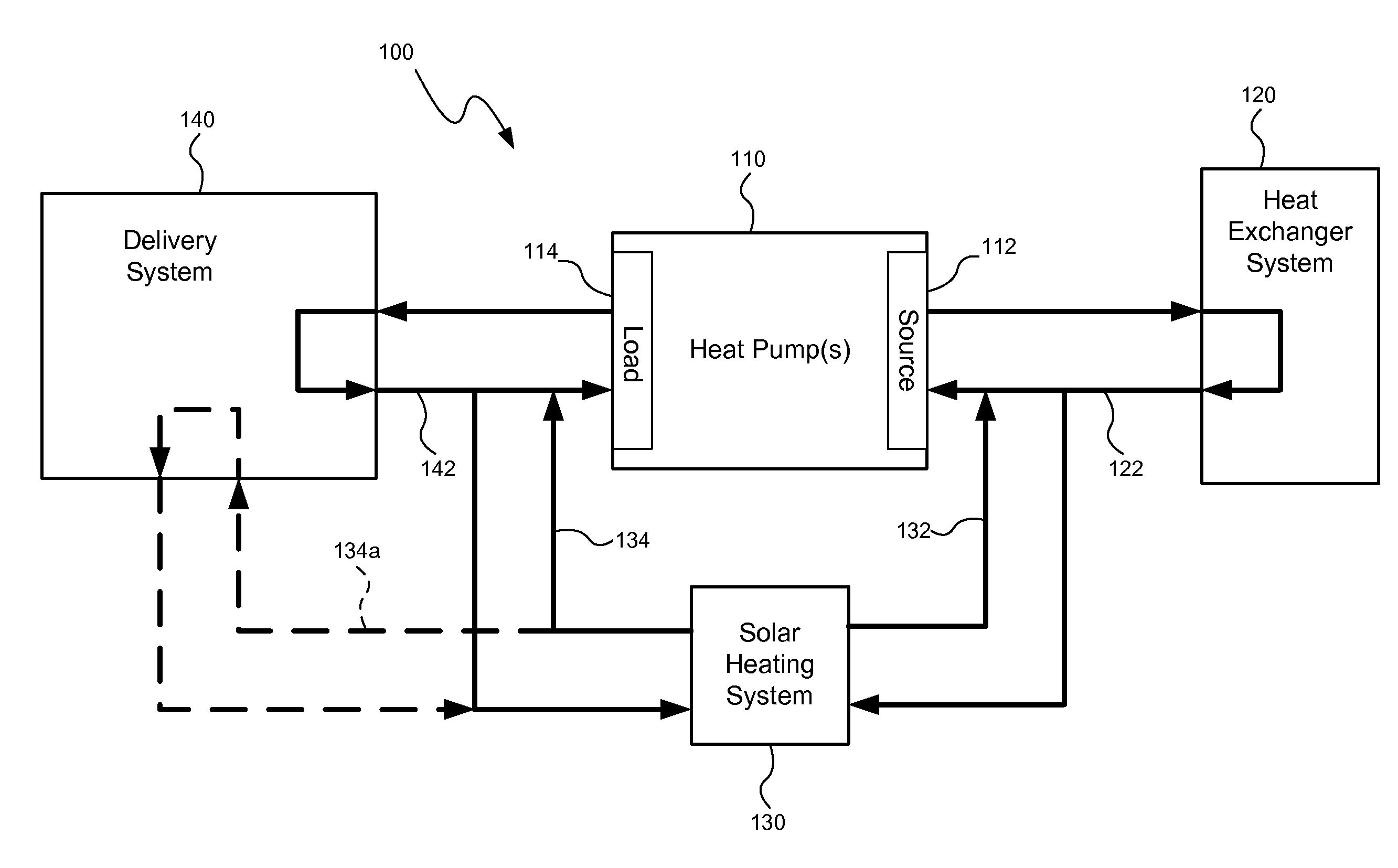

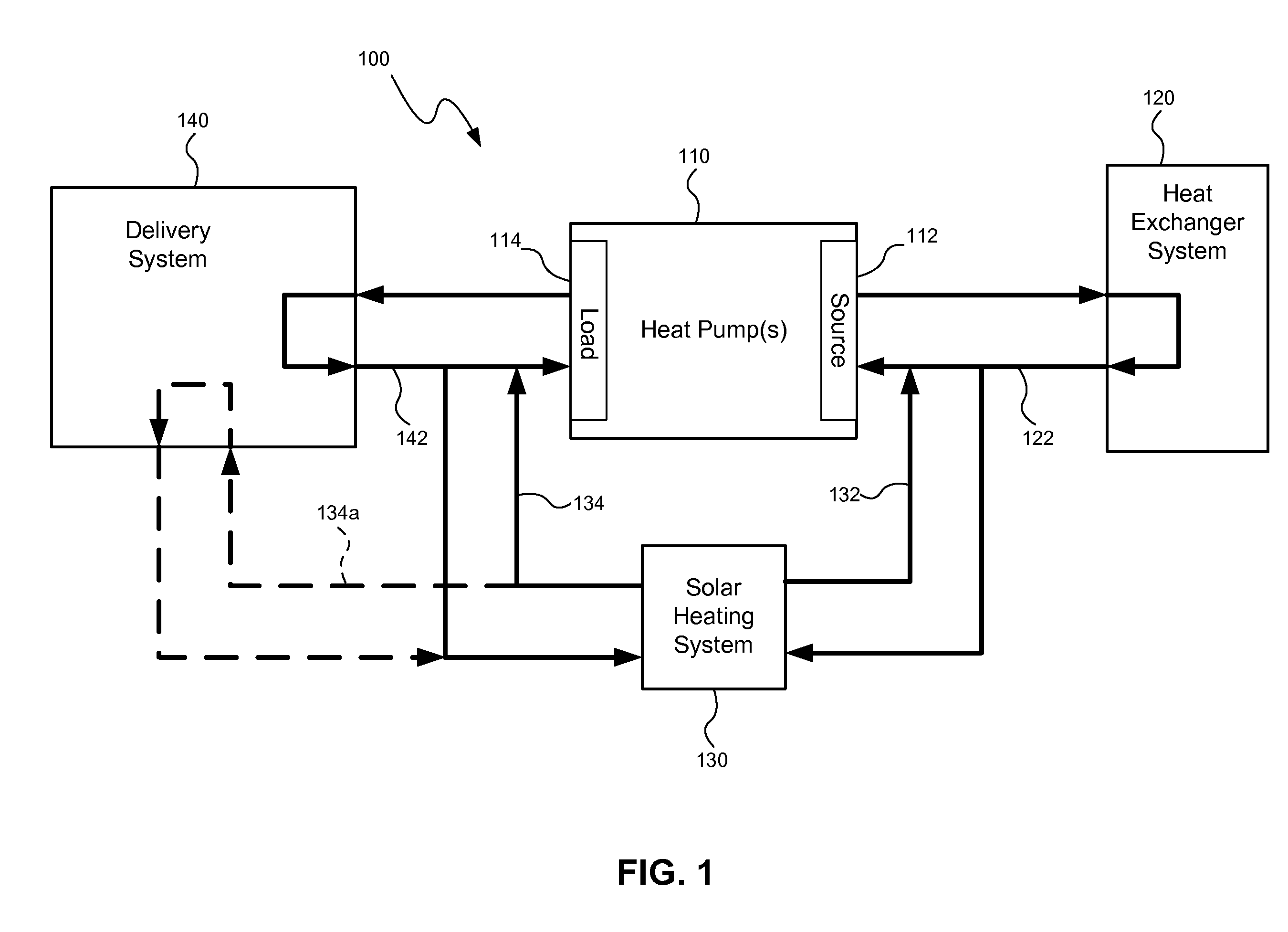

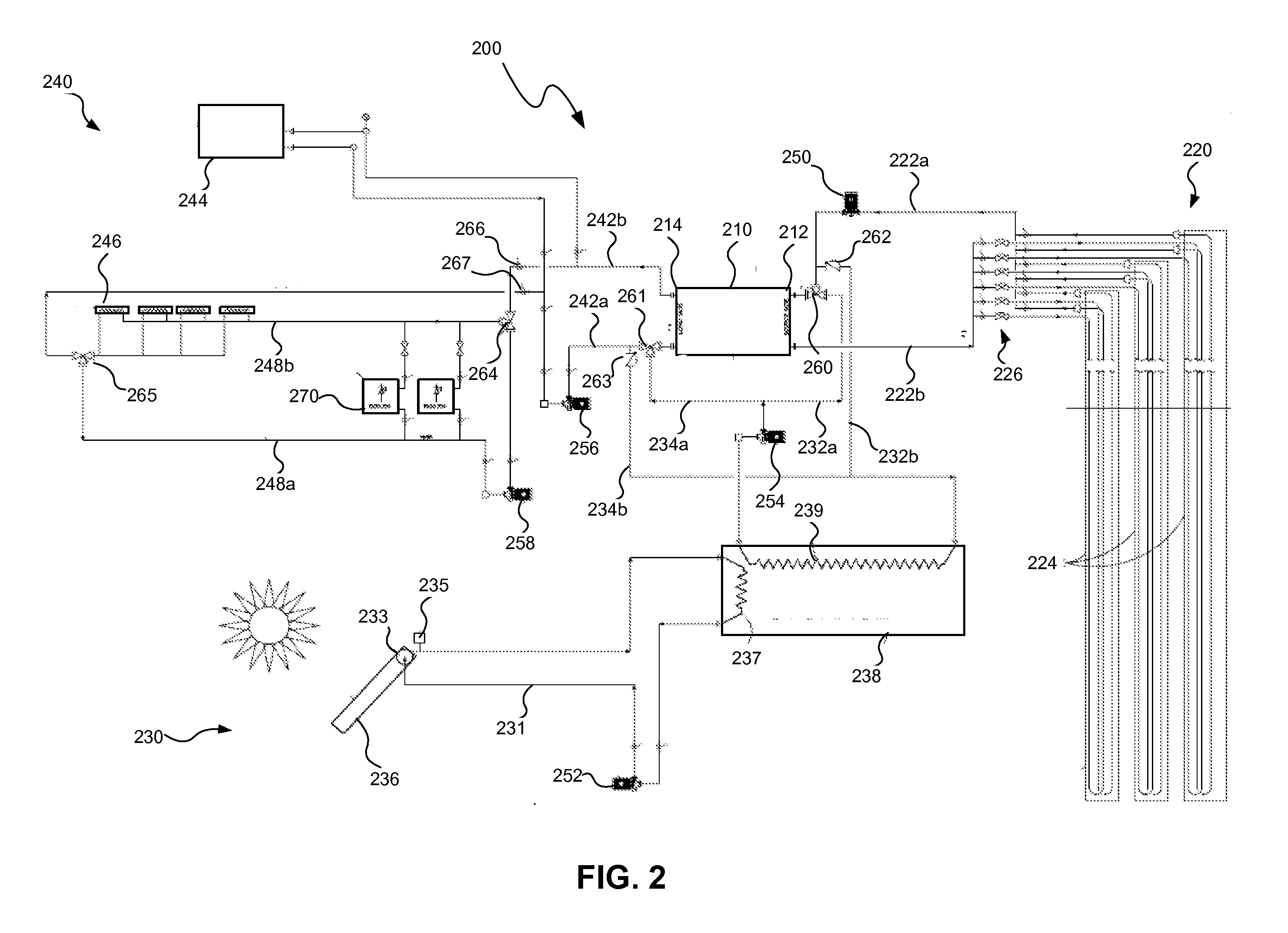

Hybrid heating and/or cooling system

A hybrid heating and / or cooling system may combine different energy sources (e.g., solar and geothermal) into a single system. The hybrid heating and / or cooling system may include one or more heat pumps, a heat exchanger system, a solar and / or waste energy system, and a delivery system for delivering heat (and / or cool air) to a space such as a building. These systems may be interconnected and controlled using various conduits, pumps, valves and controls. The solar energy system may provide heat (e.g., low grade heat) to the working fluid at the input to the source side of the heat pump and / or may provide heat (e.g., high grade heat) to the delivery system for direct solar and / or waste energy heating.

Owner:THE H L TURNER GROUP

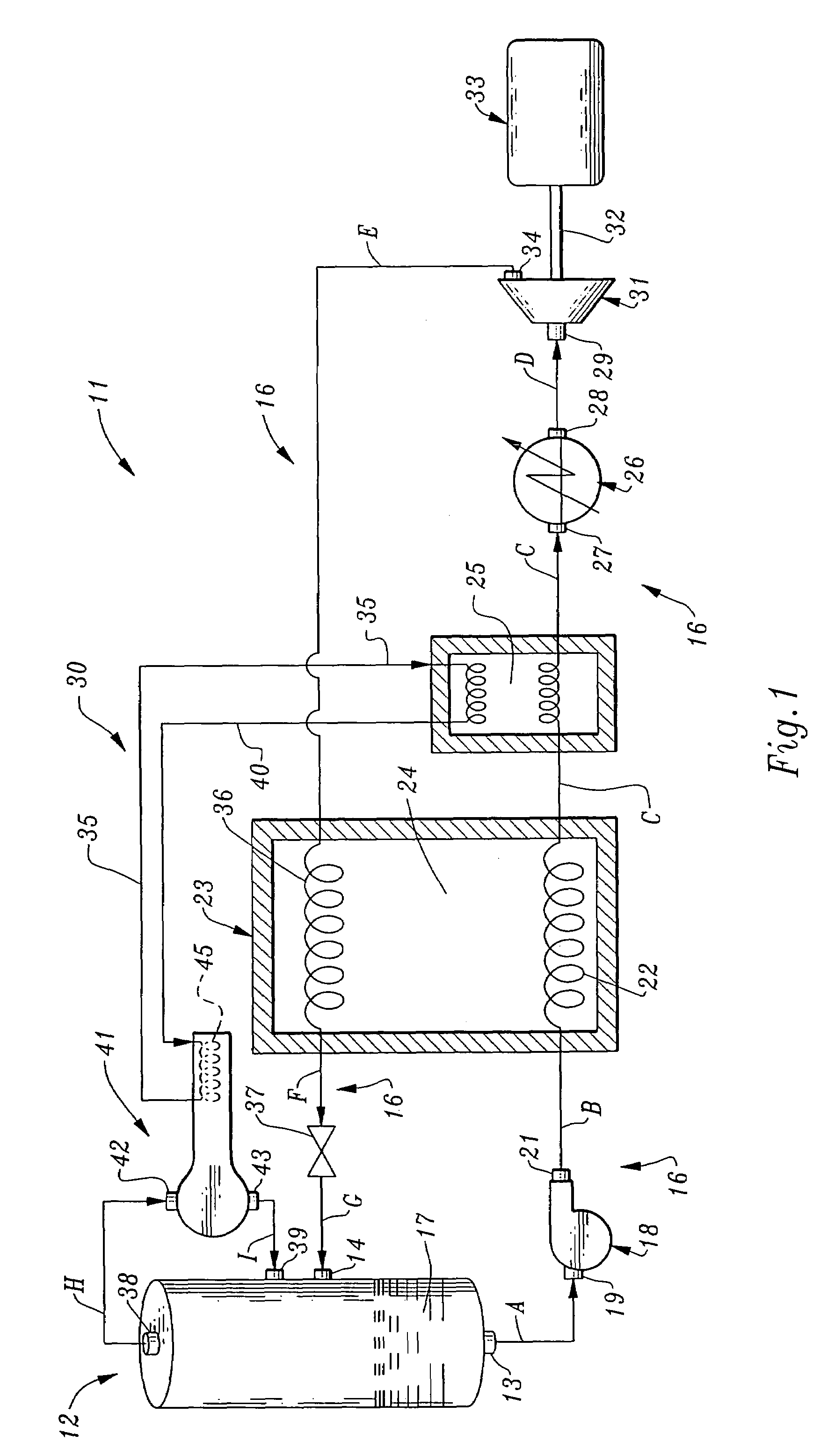

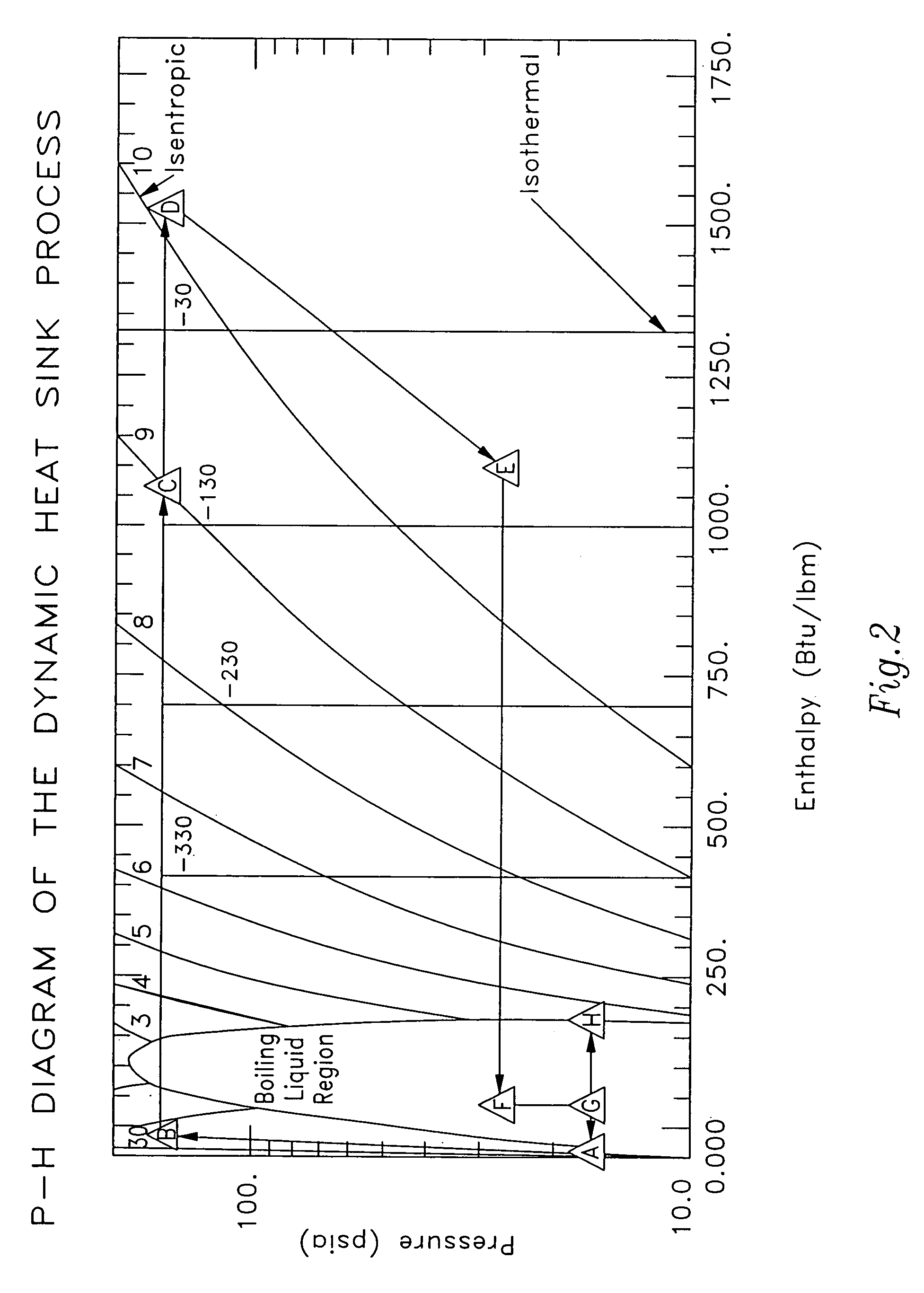

Dynamic heat sink engine

InactiveUS7047744B1Decrease in overall heat dutyImprove the coefficient of performanceFrom solar energySteam accumulatorsLiquid lineWorking fluid

A dynamic heat sink engine including a storage vessel having a working fluid outlet and a working fluid inlet. The lower portion of the storage vessel contains a cryogenic working fluid, such as liquid hydrogen, at a temperature at near its boiling point. The engine further includes a working fluid circuit extending between the working fluid outlet and the working fluid inlet of the storage vessel. The working fluid circuit includes the serial connection of the following components from the working fluid outlet to the working fluid inlet: a fluid pump; a vaporizer having a liquid line passing therethrough; a heater; an expansion engine having a rotary output shaft; an electrical generator connected to the rotary output shaft of the expansion engine; a vapor line passing through the vaporizer, the vaporizer including a heat exchanger providing thermal communication between the liquid line and the vapor line.

Owner:ROBERTSON STUART J +1

Compositions comprising e-1,2-difluoroethylene and uses thereof

InactiveUS20110253927A1Lower global warming potentialHeat recovery systemsOther chemical processesWorking fluidPower cycle

The present invention relates to compositions for use in refrigeration, air-conditioning, and heat pump systems wherein the composition comprises E-1,2-difluoroethylene. The compositions of the present invention are useful in processes for producing cooling or heat, as heat transfer fluids, foam blowing agents, aerosol propellants, and power cycle working fluids.

Owner:THE CHEMOURS CO FC LLC

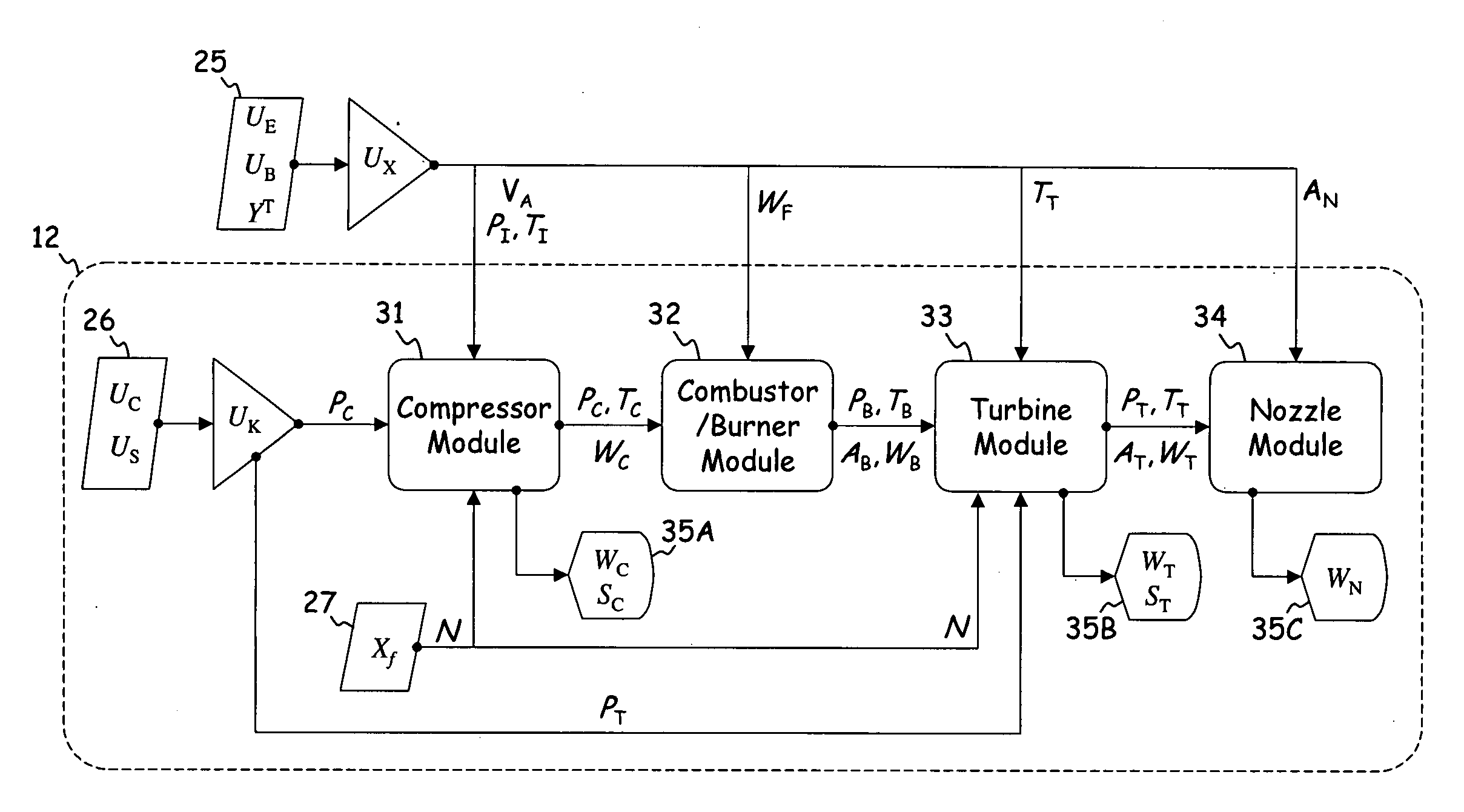

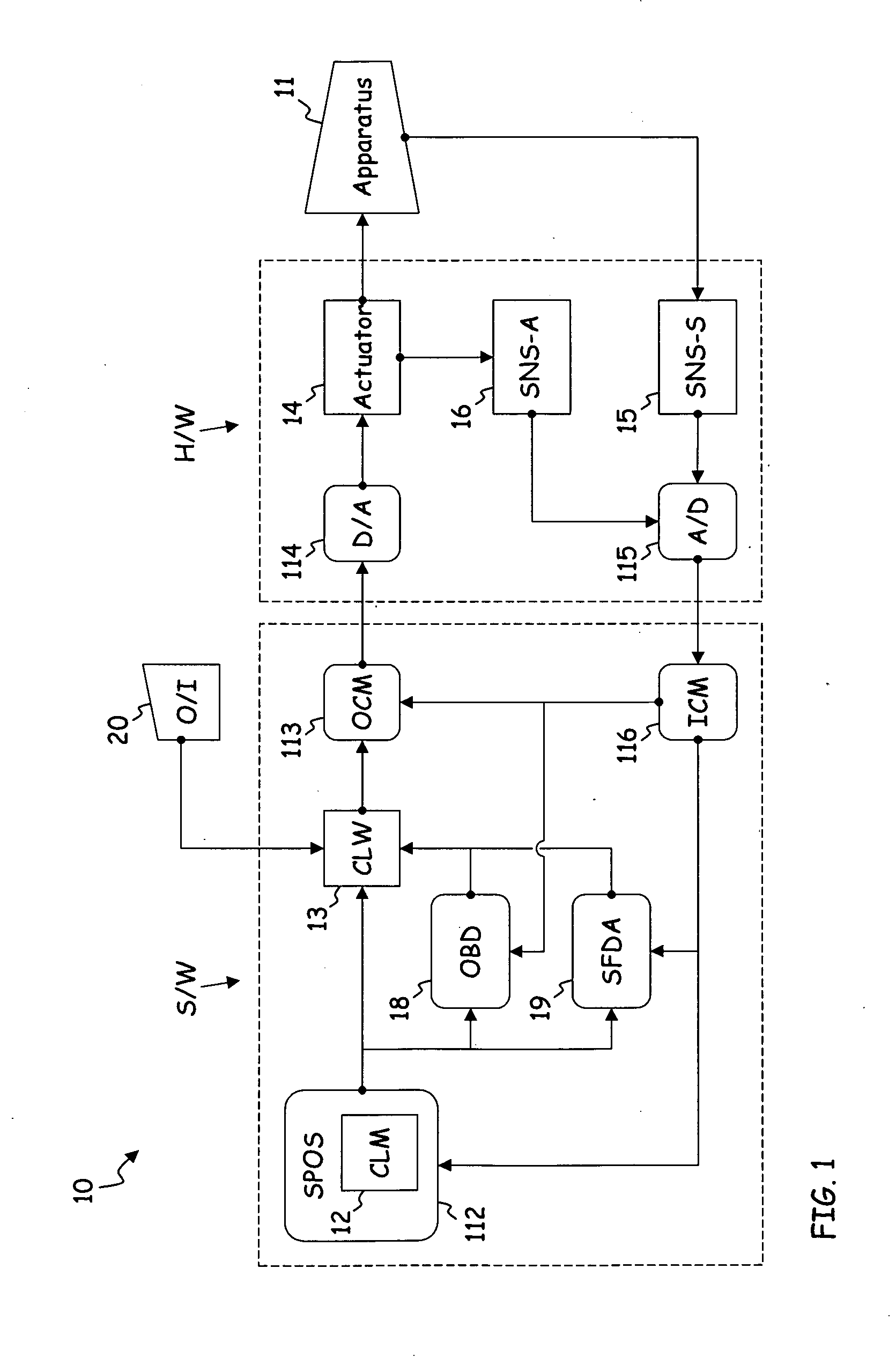

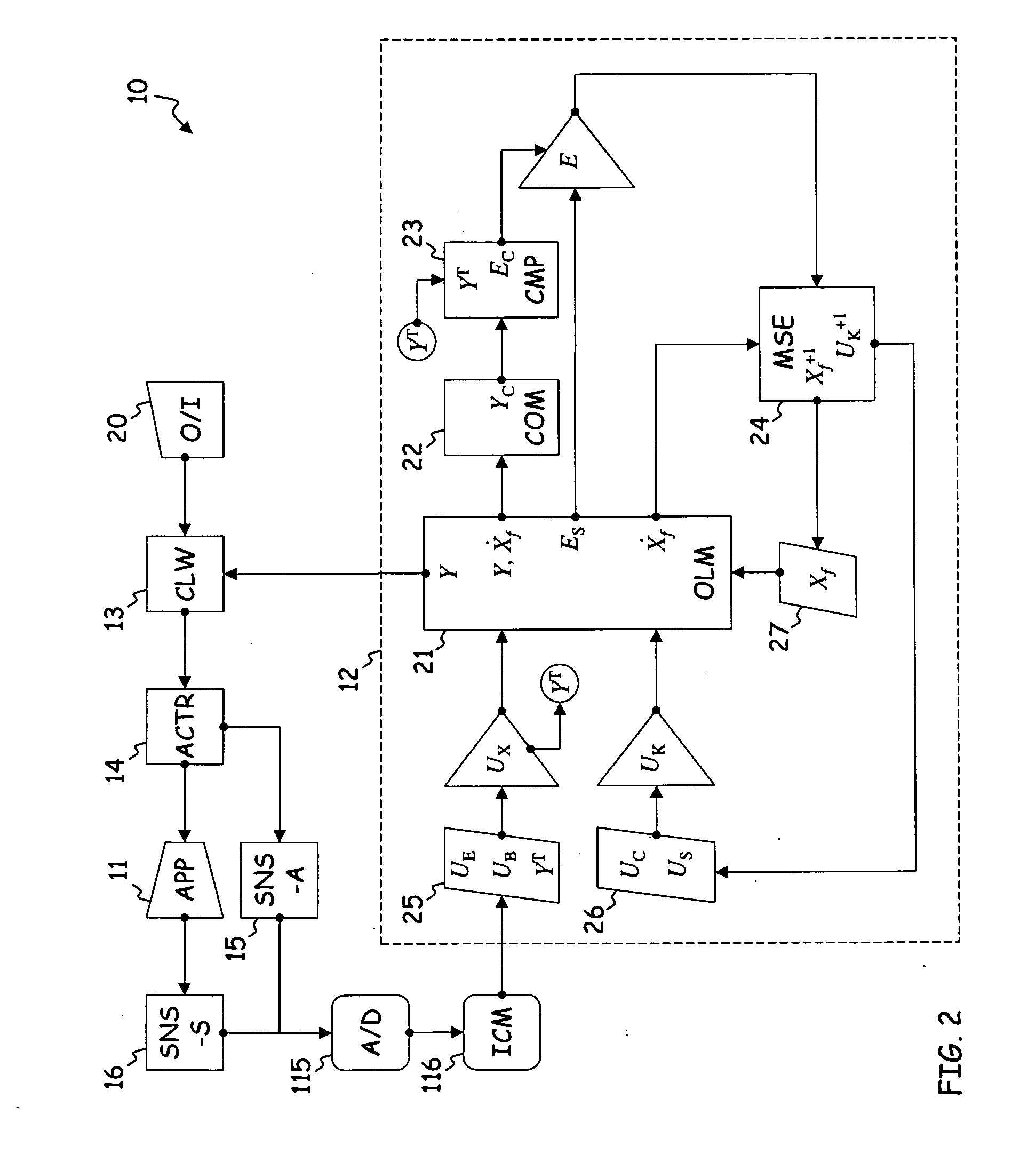

System and method for design and control of engineering systems utilizing component-level dynamic mathematical model

ActiveUS20110077783A1Error minimizationSimulator controlFlow control using electric meansWorking fluidMathematical model

A control system comprises a controller for positioning an actuator in a working fluid flow and a model processor for directing the controller as a function of a model feedback. The model processor comprises an output module, a comparator and an estimator. The output module generates the model feedback as a function of a constraint, a model state and a model input describing fluid parameters measured along the working fluid flow. The comparator generates an error by comparing the model feedback to the model input. The estimator generates the constraint and the model state, such that the error is minimized.

Owner:RTX CORP

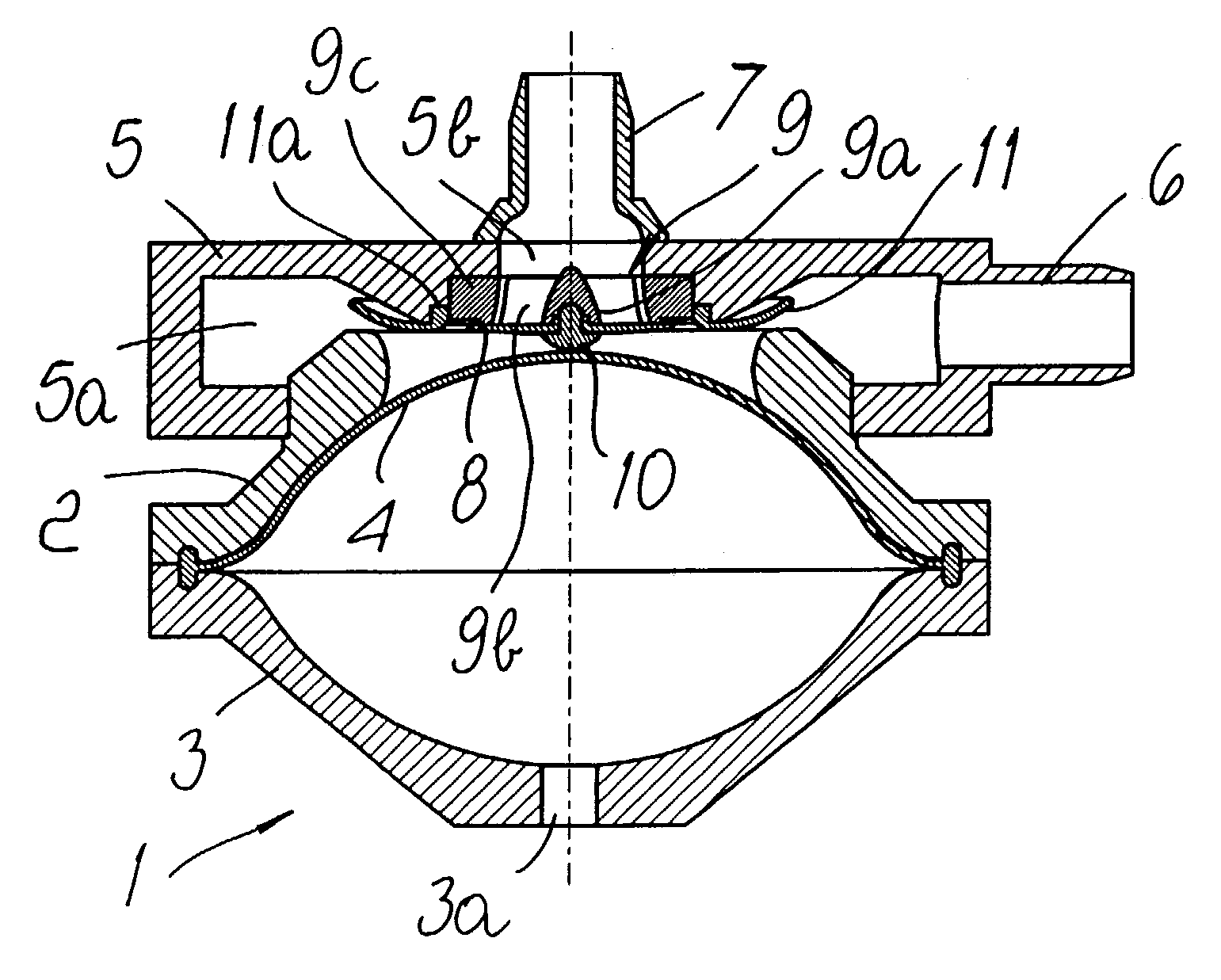

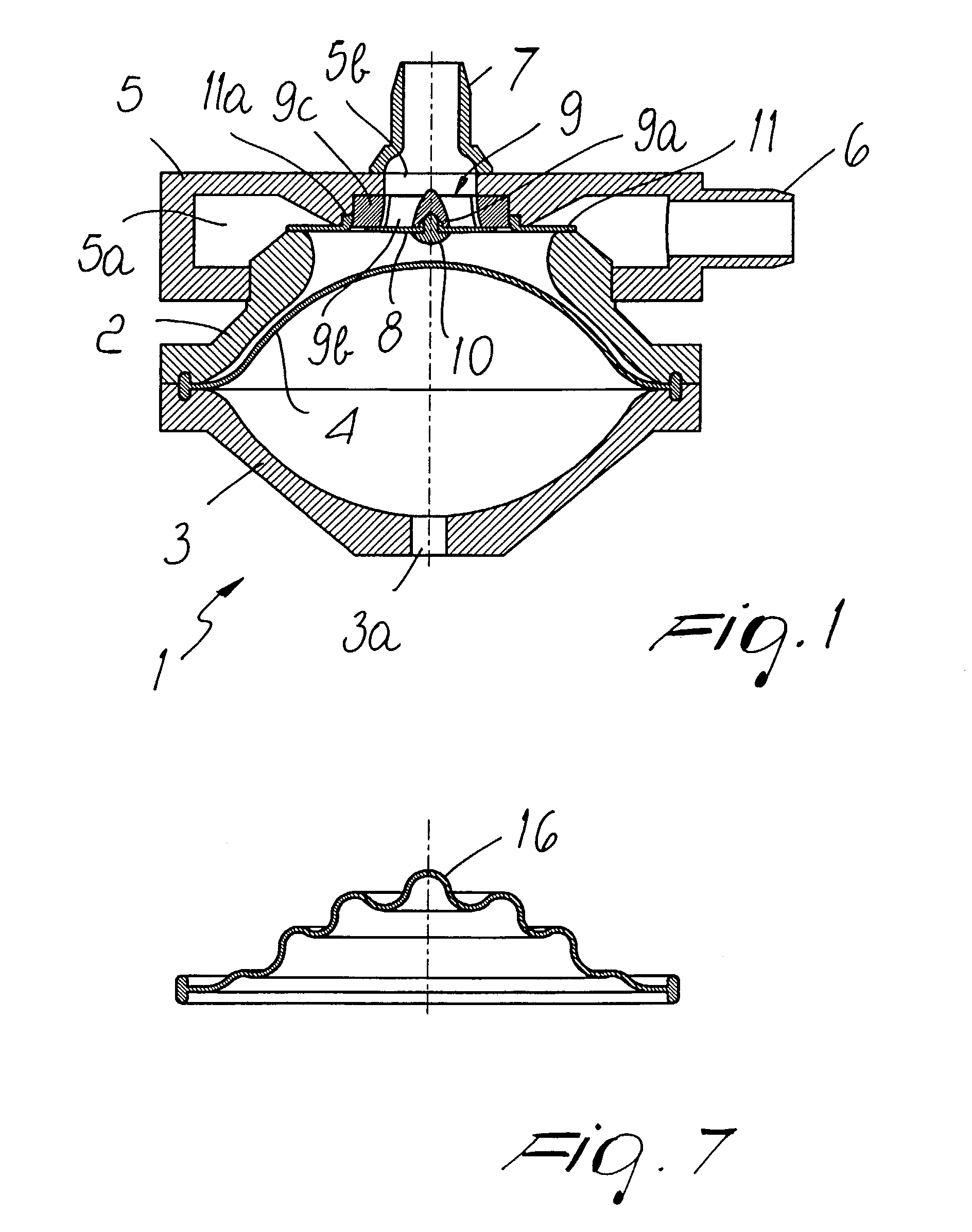

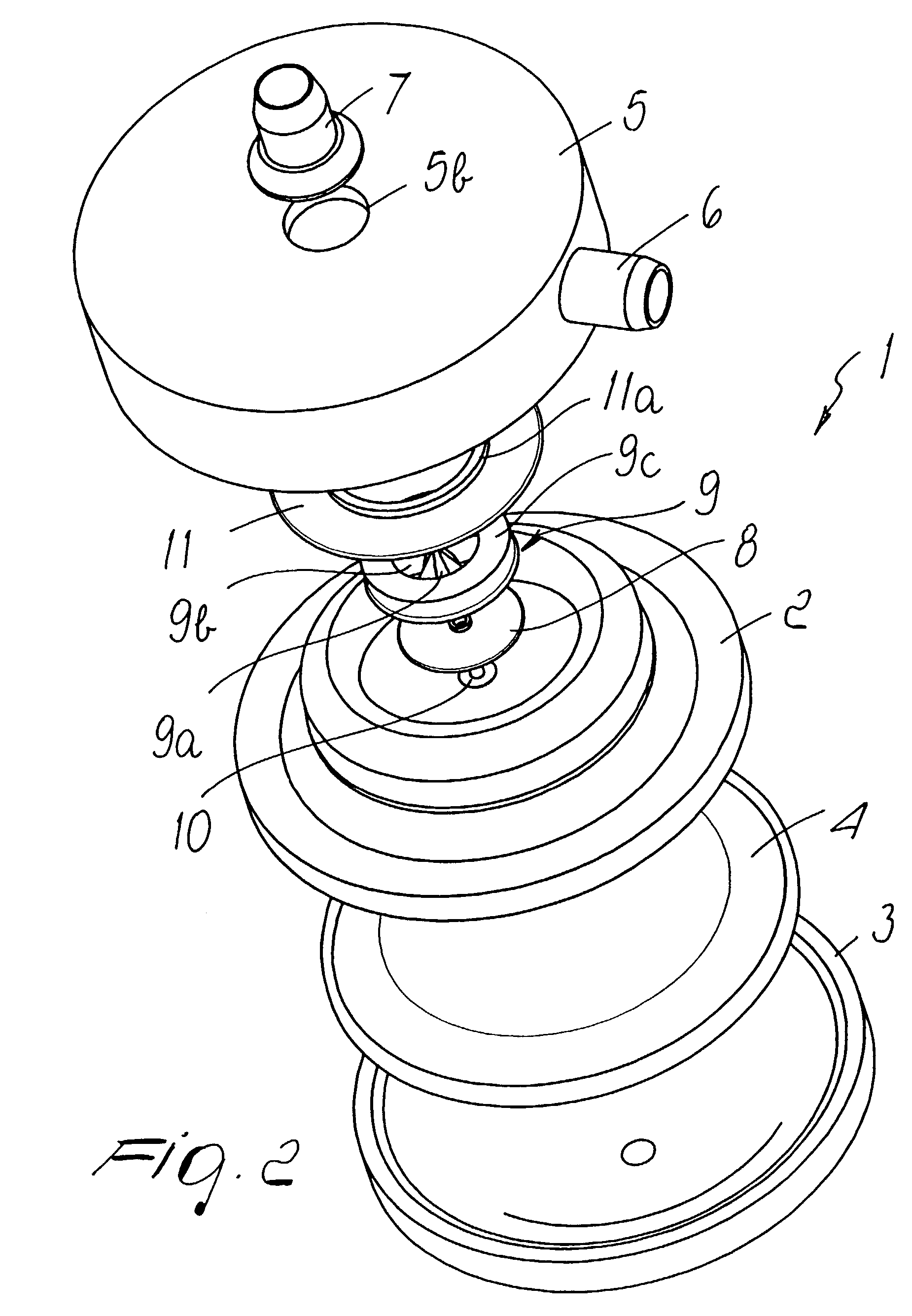

Blood pumping unit, with a coplanar disk inlet valve and an annular outlet valve

InactiveUS7029245B2Maximum of constructive simplicityLow costFlexible member pumpsDialysis systemsWorking fluidInlet valve

A unit for pumping fluid, particularly blood, is provided with an enclosure that has two half-shells and an elastic membrane fixed perimetrically to the enclosure in order to divide its space into two parts. One of the half-shells is provided with valves that are located at the opening of two connecting ducts for the intake and delivery of the fluid, and the other half-shell is connected to a line of working fluid that is alternately pressurized and depressurized. The first valve is a disk-shaped sheet made of elastic material. The first valve is in a central position with a support that is fixed to the opening of the first duct for connection to the outside and is suitable to rest at its peripheral region on the support. A second valve is a sheet of elastic material located at the peripheral region of the disk at the opening of the second duct for connection to the outside which lies at the peripheral region of the opening of the first duct.

Owner:SORIN GRP ITAL SRL

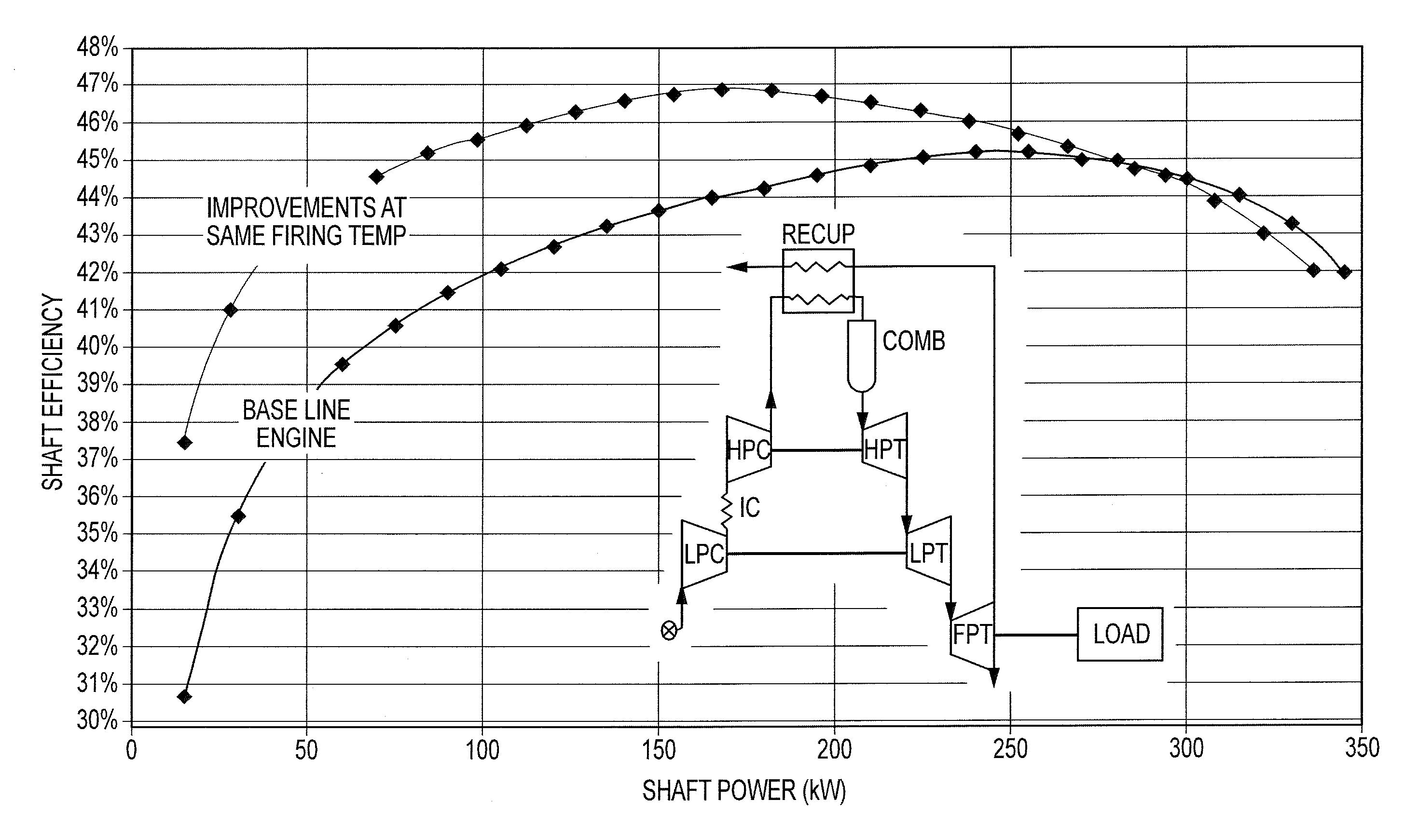

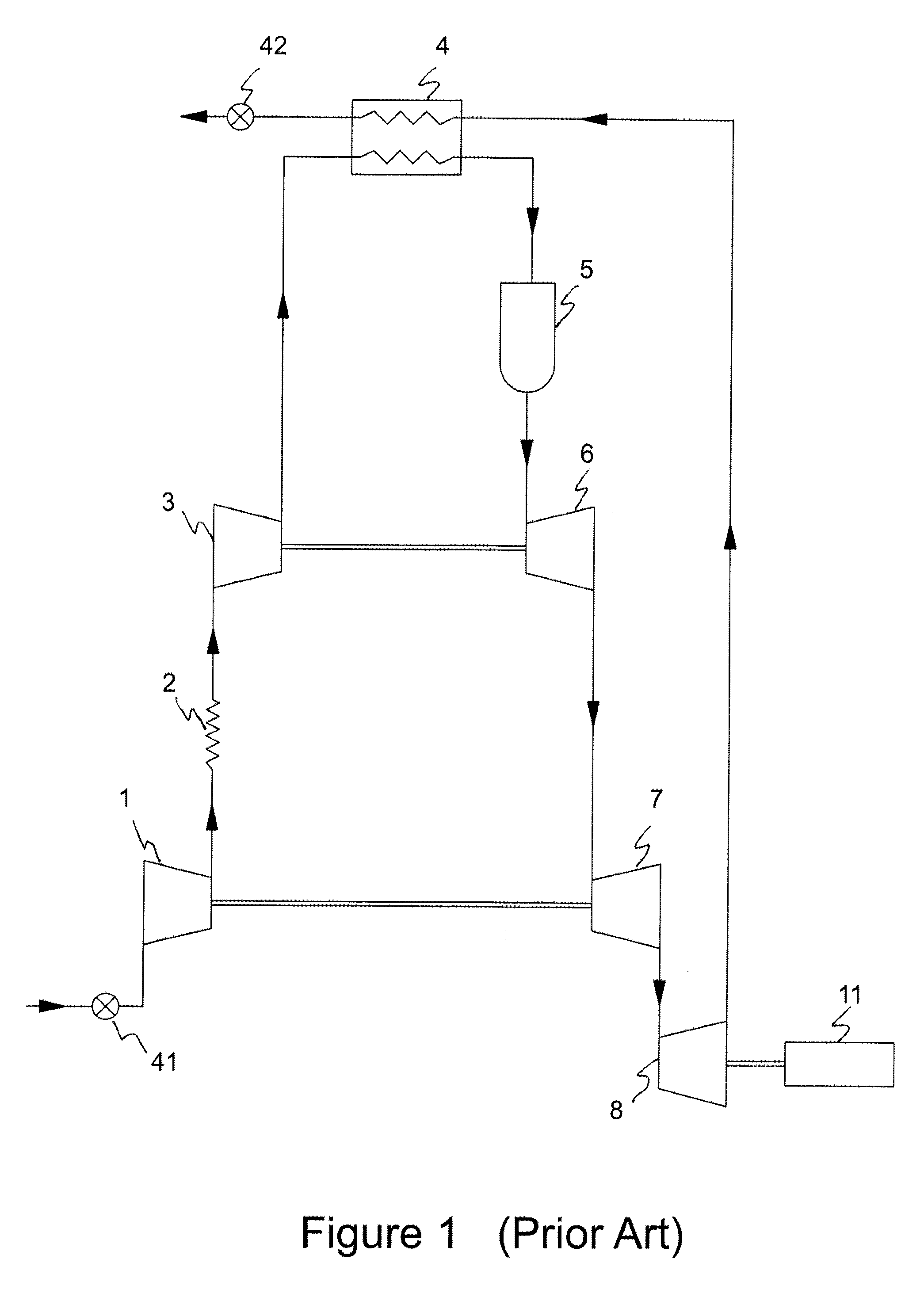

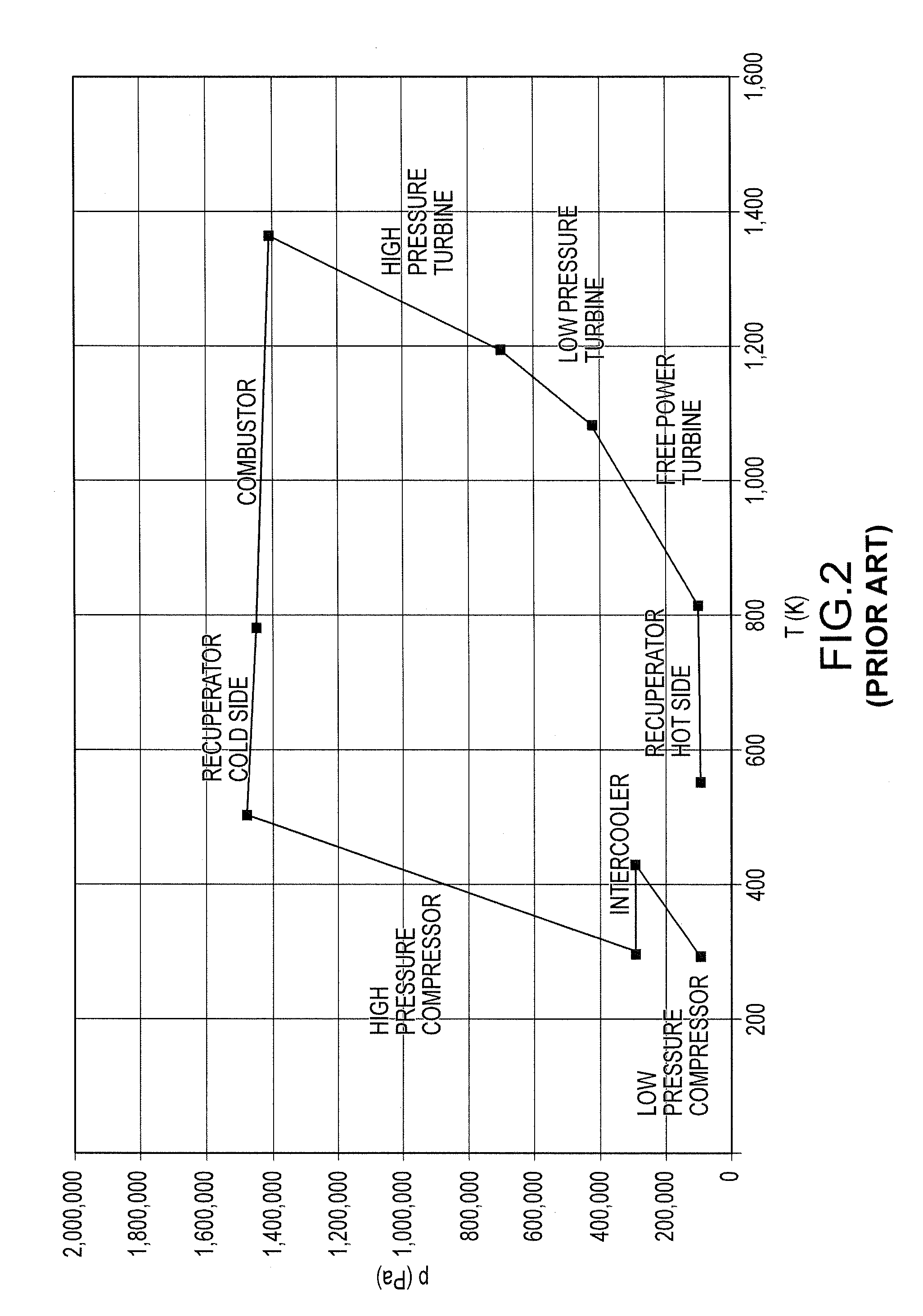

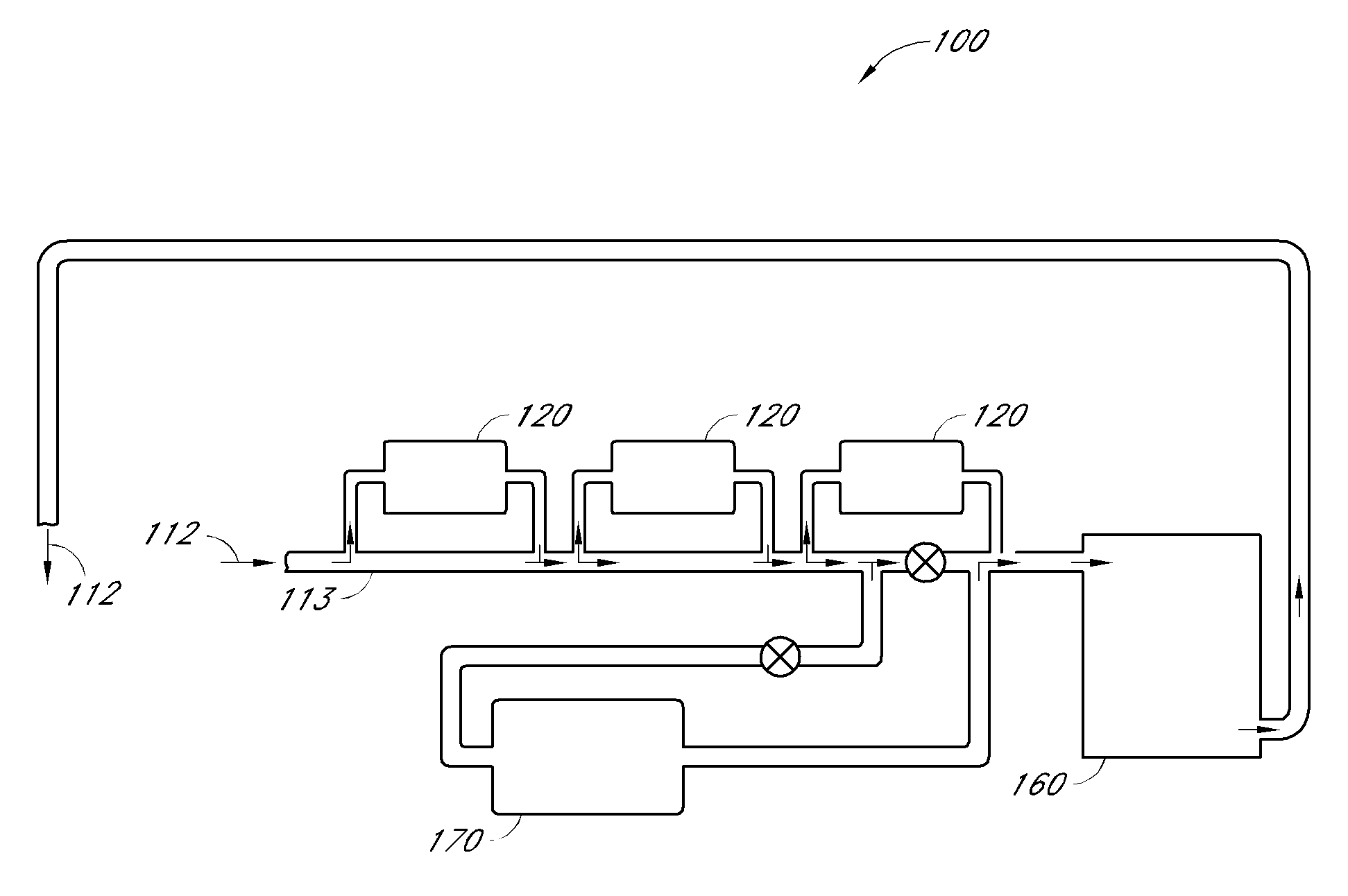

High efficiency compact gas turbine engine

InactiveUS20120324903A1Improve engine efficiencyThe process is compact and efficientGas turbine plantsEfficient propulsion technologiesWorking fluidCombustor

This disclosure relates to a highly efficient gas turbine engine architecture utilizing multiple stages of intercooling and reheat, ceramic technology, turbocharger technology and high pressure combustion. The approach includes utilizing a conventional dry low NOx combustor for the main combustor and thermal reactors for the reheat apparatuses. In a first configuration, there are three separate turbo-compressor spools and a free power turbine spool. In a second configuration, there are three separate turbo-compressor spools but no free power spool. In a third configuration, all the compressors and turbines are on a single shaft. Each of these configurations can include two stages of intercooling, two stages of reheat and a recuperator to preheat the working fluid before it enters the main combustor.

Owner:ICR TURBINE ENGINE CORP

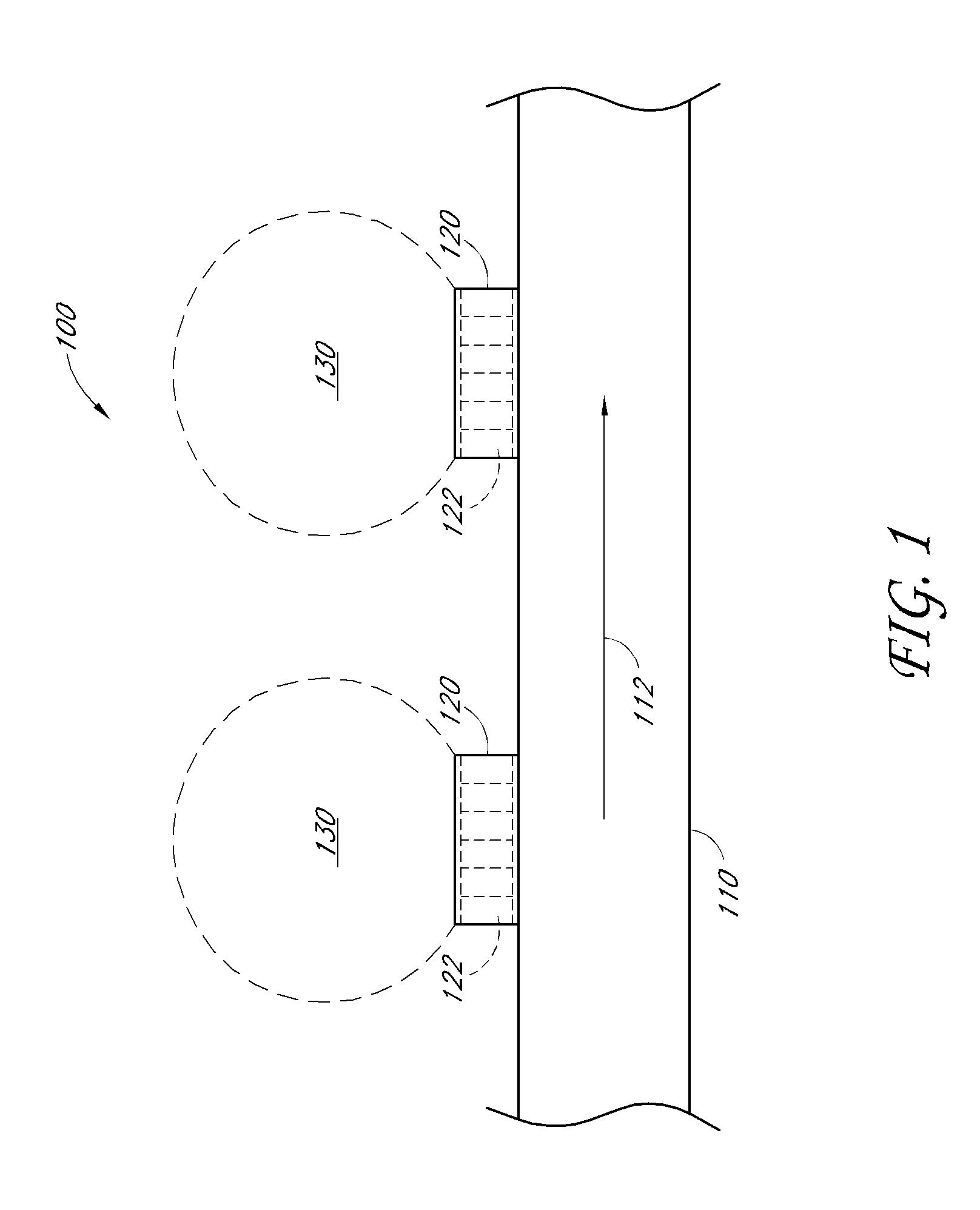

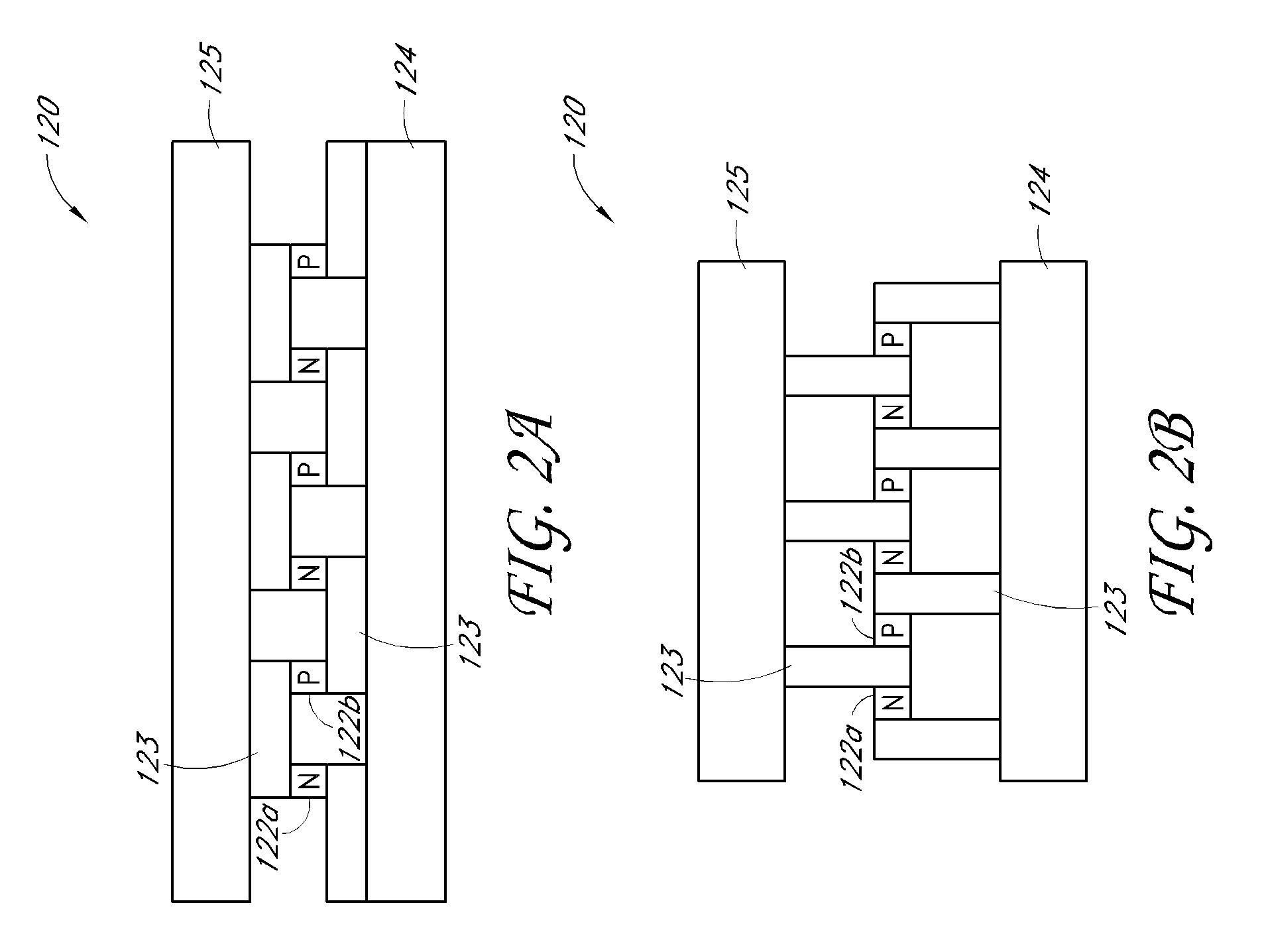

System and method for distributed thermoelectric heating and cooling

ActiveUS20090000310A1Vehicle seatsVehicle heating/cooling devicesThermoelectric coolingWorking fluid

A thermoelectric system and method provides distributed localized heating, cooling, or both heating and cooling. The thermoelectric system includes a plurality of thermoelectric assemblies. Each thermoelectric assembly comprises a plurality of thermoelectric elements, and each thermoelectric assembly is in thermal communication with a first working fluid and in thermal communication with a region corresponding to the thermoelectric assembly. Each thermoelectric assembly is selectively operable either to heat the region corresponding to the thermoelectric assembly by transferring heat from the first working fluid to the region corresponding to the thermoelectric assembly or to cool the region corresponding to the thermoelectric assembly by transferring heat from the region corresponding to the thermoelectric assembly to the first working fluid. Each thermoelectric assembly is operable independently from operation of other thermoelectric assemblies of the plurality of thermoelectric assemblies.

Owner:GENTHERM INC

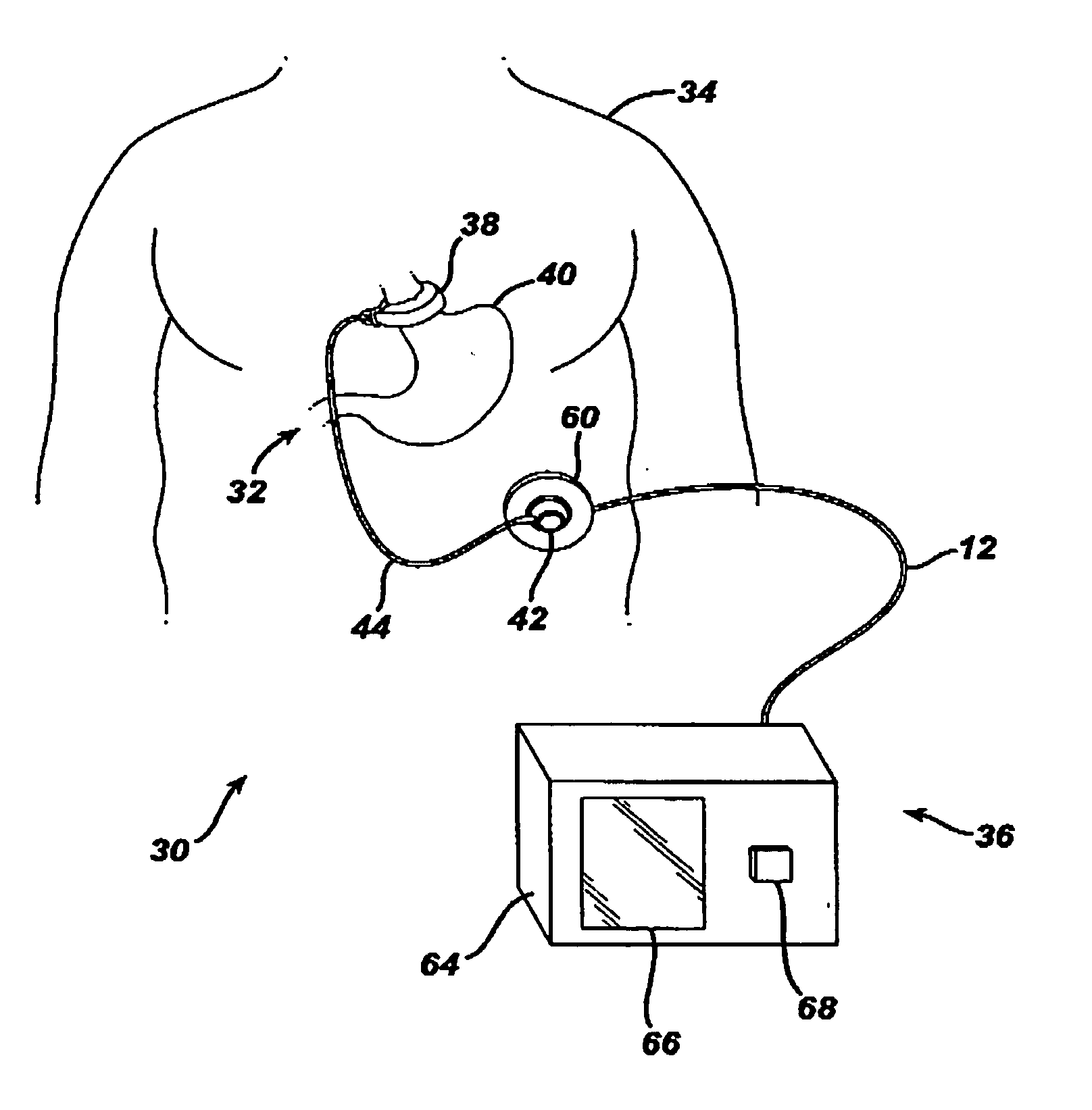

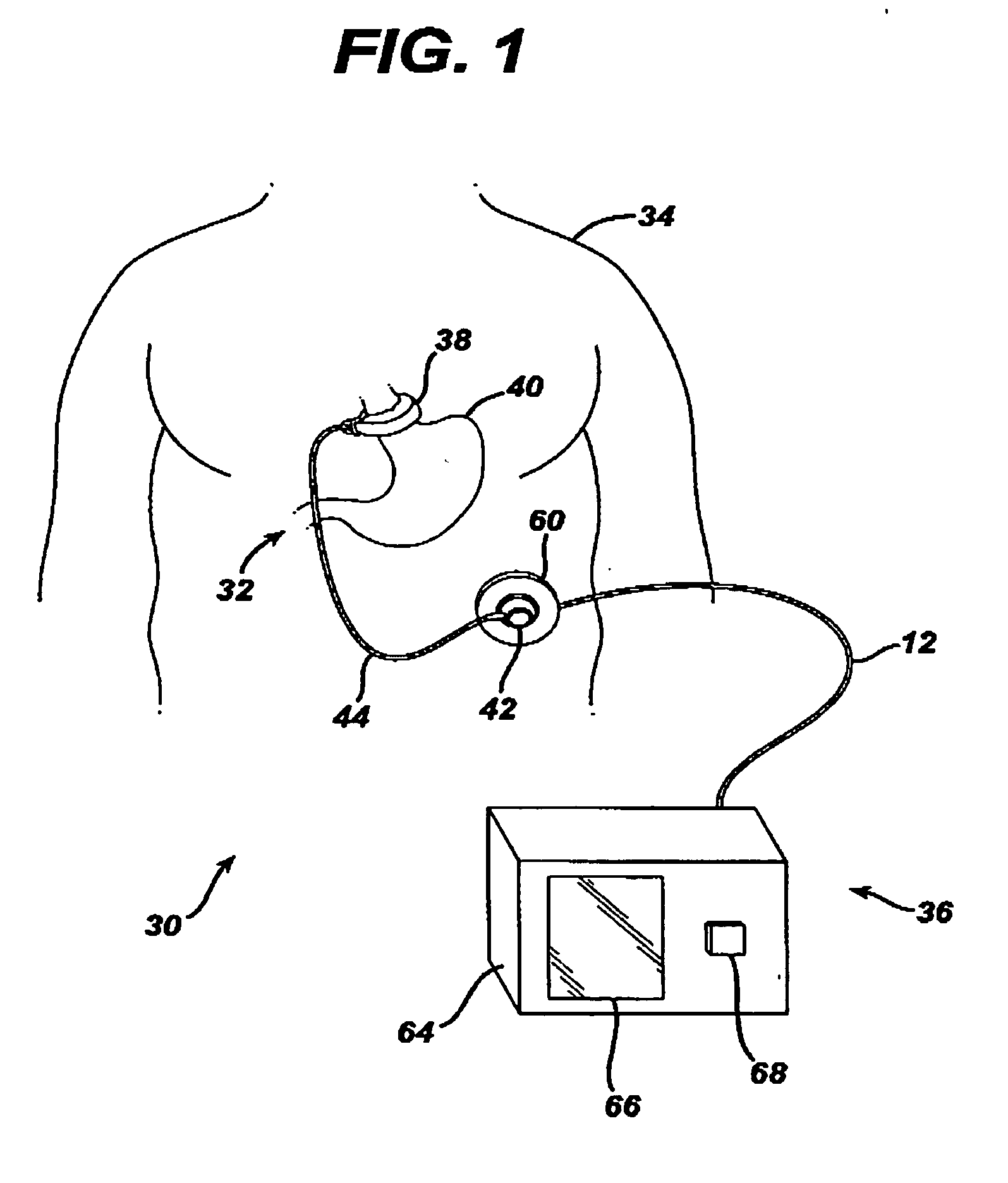

Non-invasive measurement of fluid pressure in an adjustable gastric band

A food intake restriction device for forming a restriction in a patient's gastro-intestinal tract and non-invasively communicating pressure data regarding the restriction to an external monitor. The device includes a food intake restriction device implanted substantially about a patient's gastro-intestinal tract to form a restricted opening in the tract. A port is connected to the restriction device. The port contains a working fluid for affecting the size of the restricted opening. A pressure sensing system communicates with the working fluid to measure the pressure of the working fluid. A transmitter communicates the measured fluid pressure to the external monitor.

Owner:ETHICON ENDO SURGERY INC

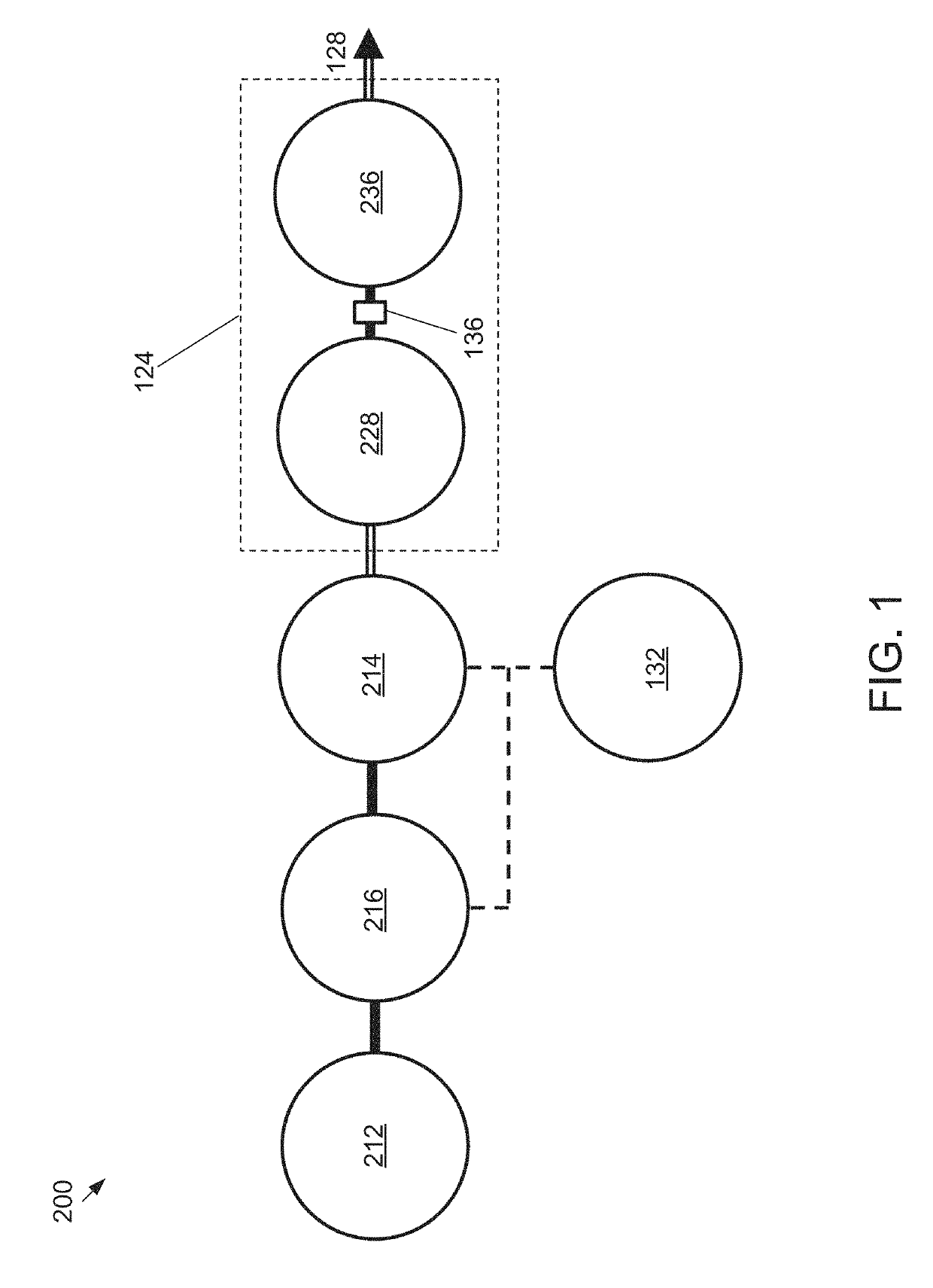

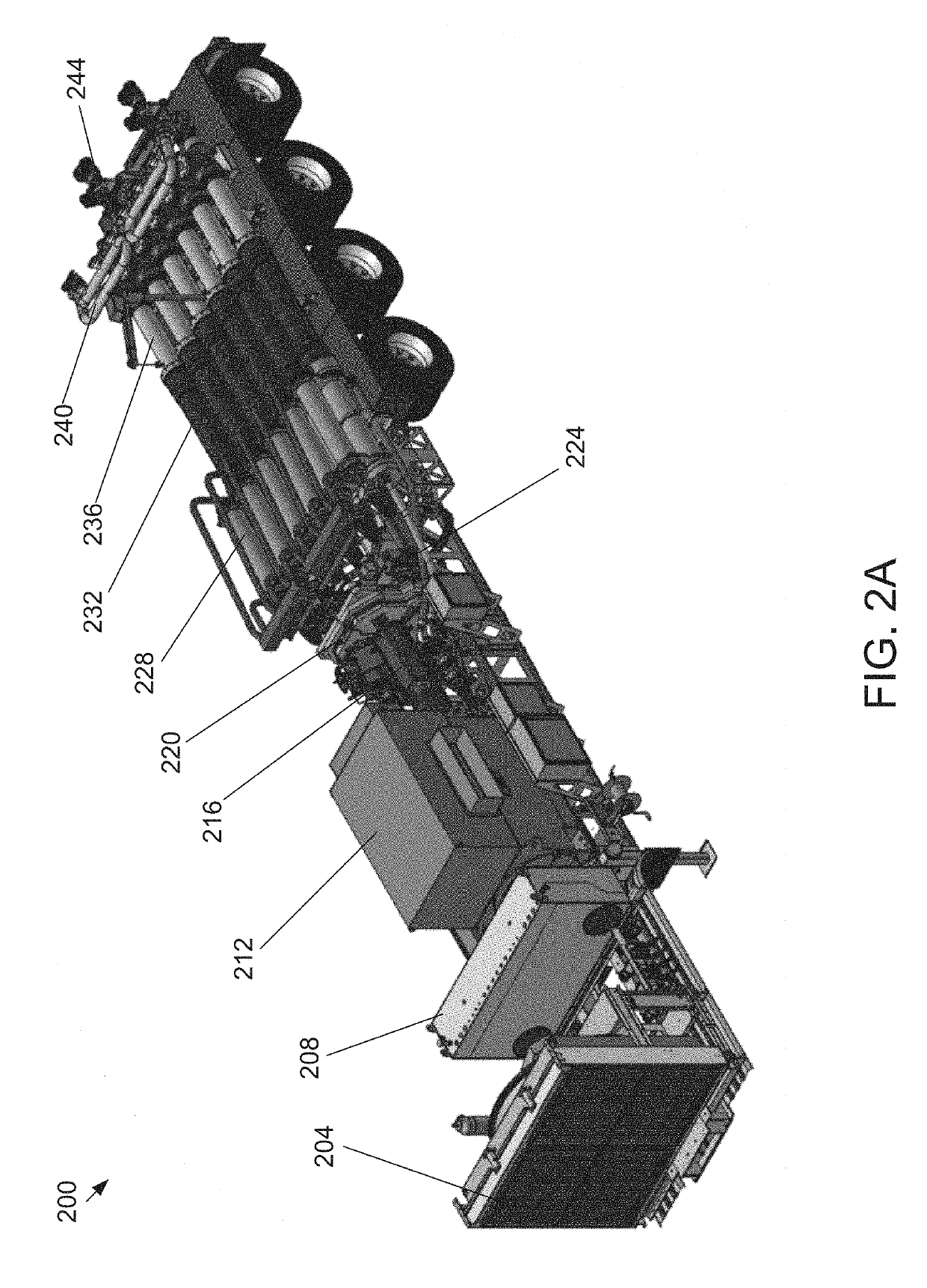

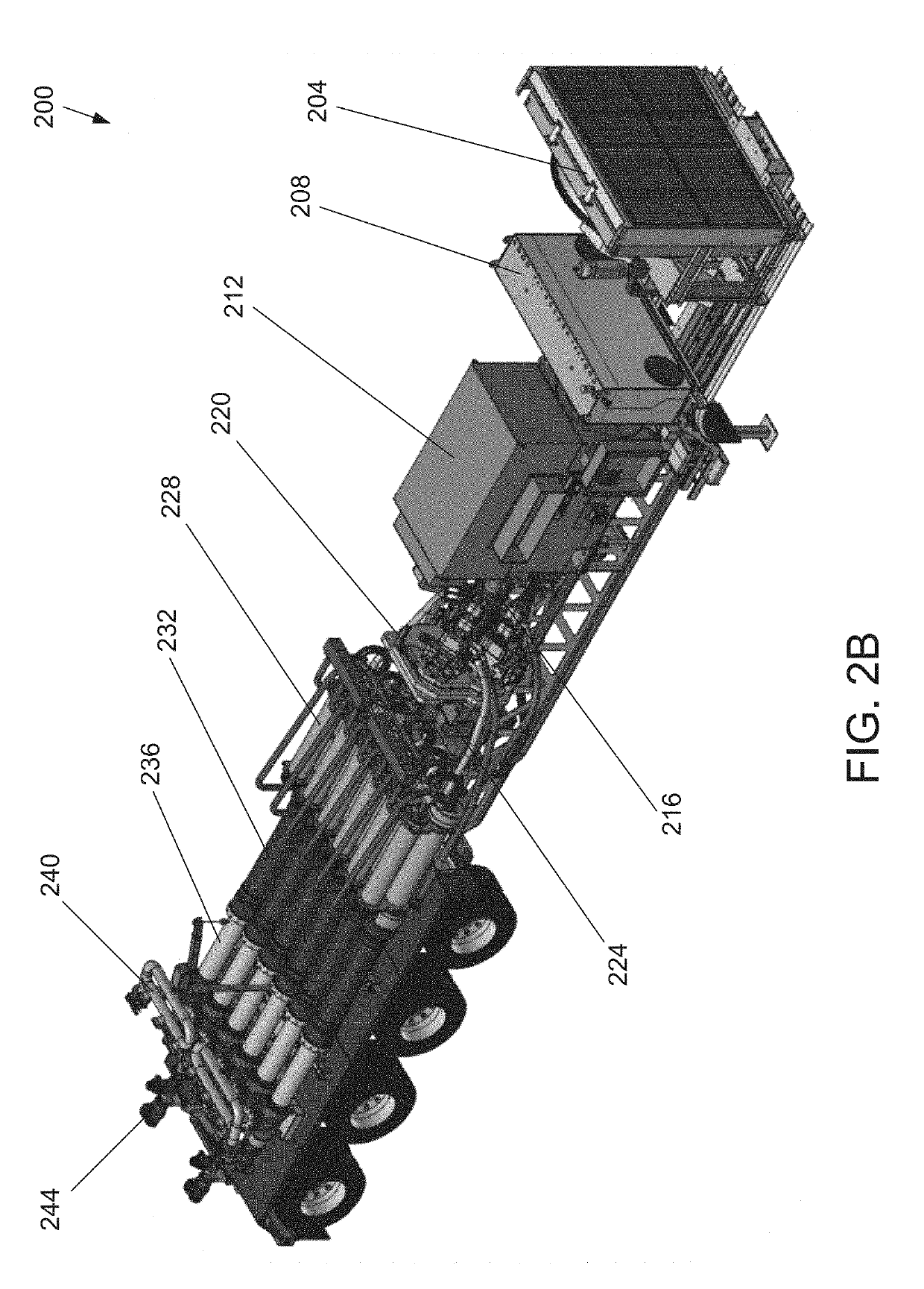

Well service pump systems and related methods

A well service pump system supplies high pressure working fluid to a well. The pump system includes a closed-loop hydraulic circuit for actuating a plurality of working pump assemblies. The pump system is powered by a motor, which transfers mechanical energy to a plurality of pumps, which, in turn, provide hydraulic fluid to operate hydraulic ram cylinders, and thereby operate the working pump assemblies. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of the working fluid end cylinder to operate the working pump assembly.

Owner:AMERIFORGE GRP

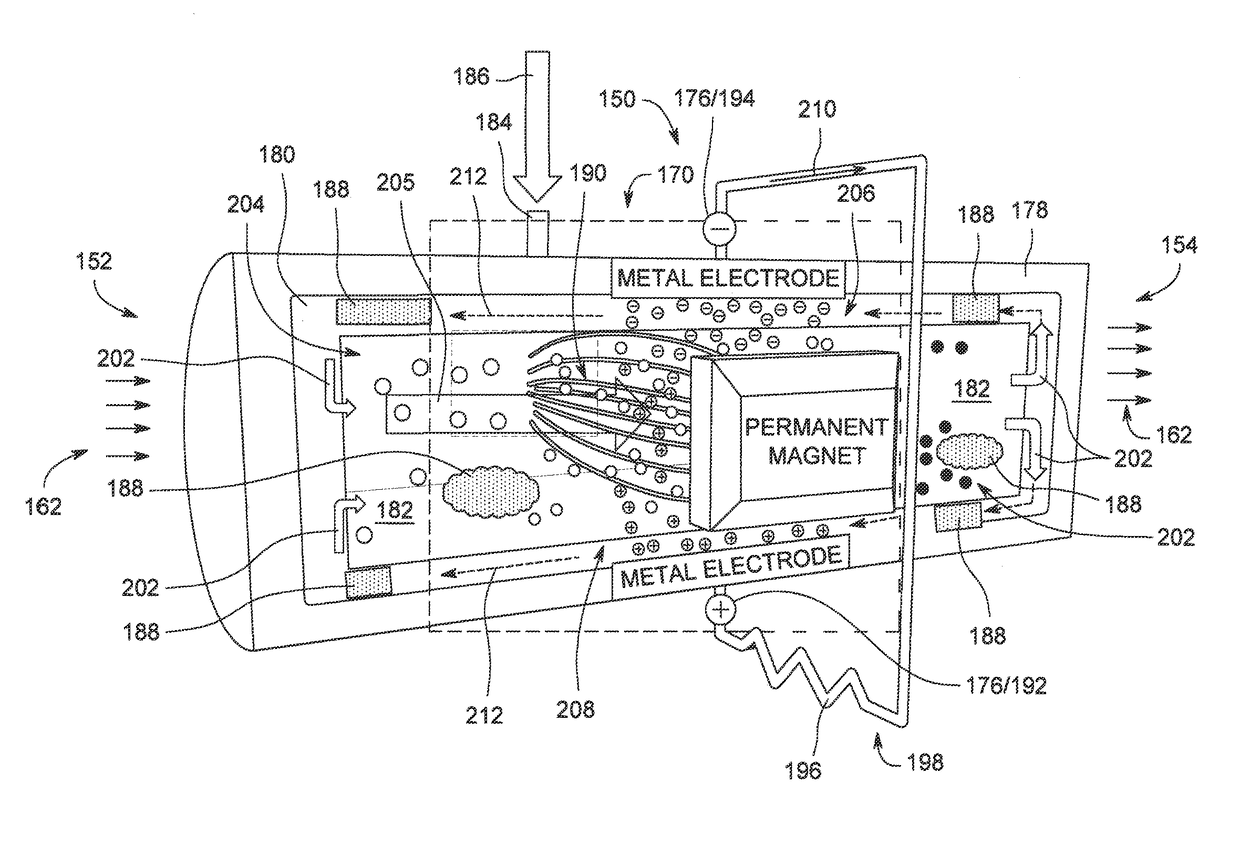

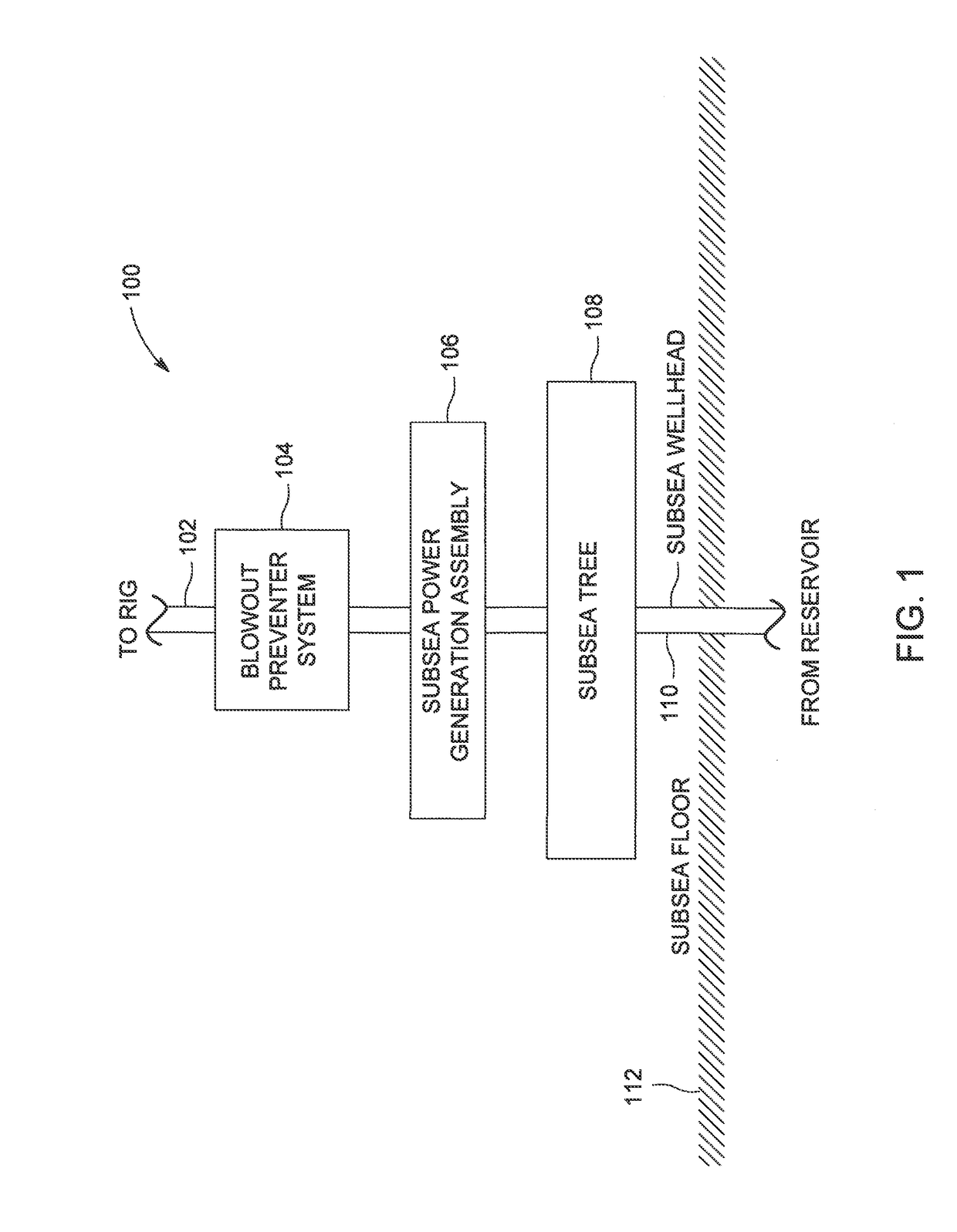

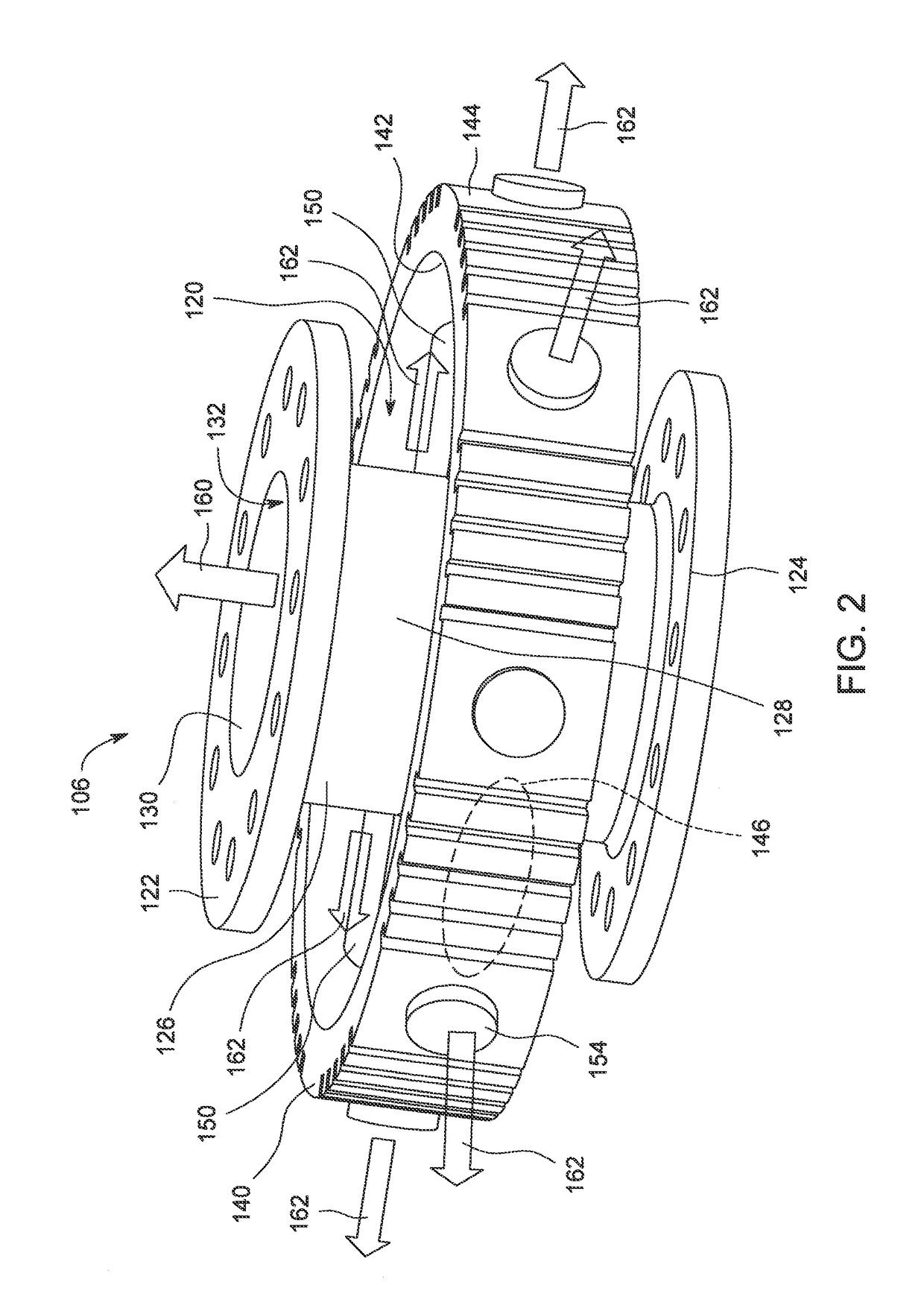

Submersible power generators and method of operating thereof

A submersible liquid-vapor generator (LVG) includes an evaporator portion in heat transfer communication with a heat energy source. The LVG also includes a magnetic field apparatus coupled in flow communication with the evaporator portion. The LVG further includes a condenser portion coupled in flow communication with the magnetic field apparatus. The LVG also includes a hybrid working fluid including nanoparticles. The evaporator portion, the magnetic field portion, and the condenser portion at least partially define a hybrid working vapor flow path. The LVG further includes an electrically non-conductive wick structure coupled in flow communication with the evaporator portion and the condenser portion. The wick structure at least partially defines a hybrid working liquid flow path extending between the condenser portion and the evaporator portion.

Owner:GENERAL ELECTRIC CO

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

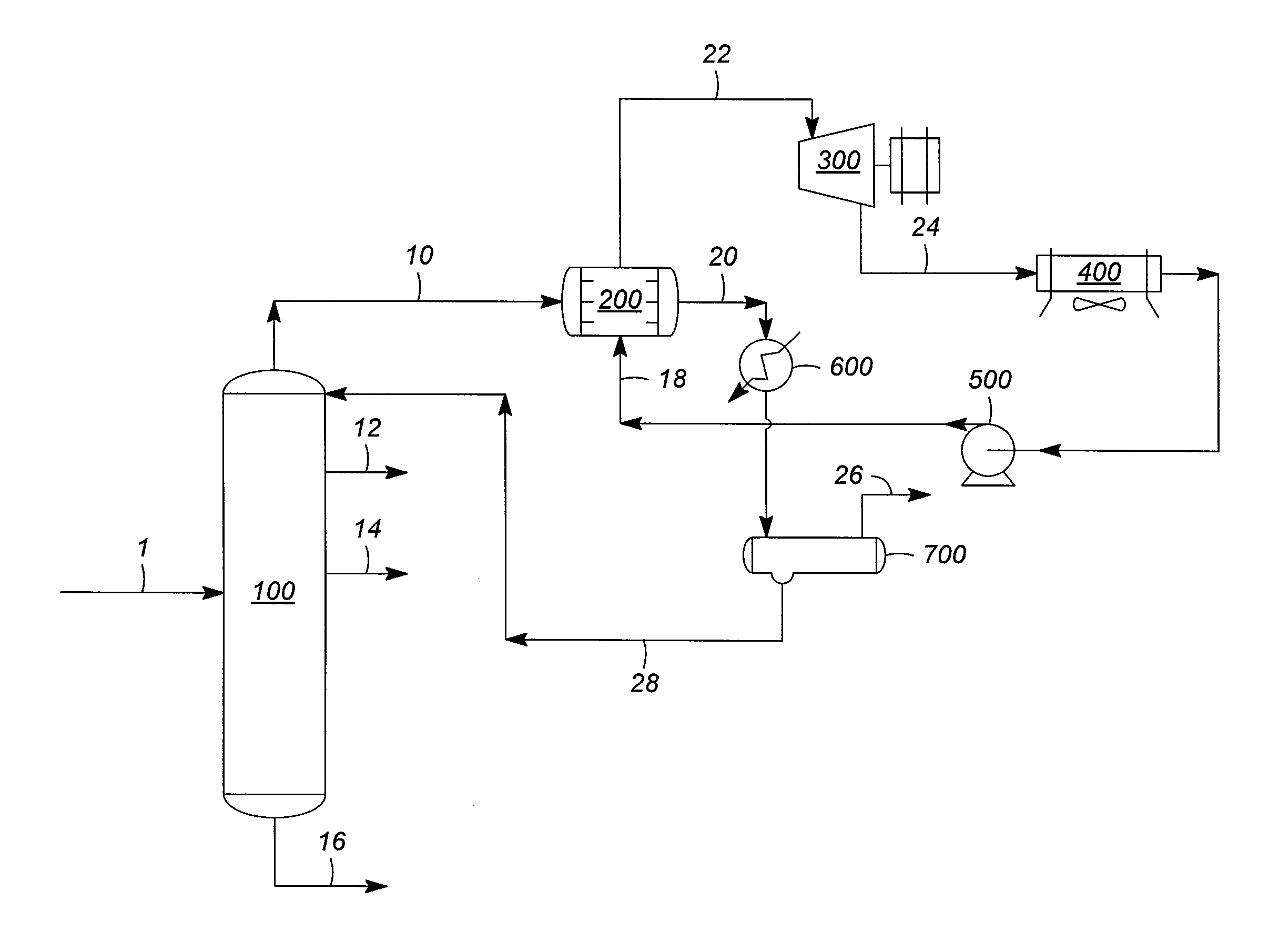

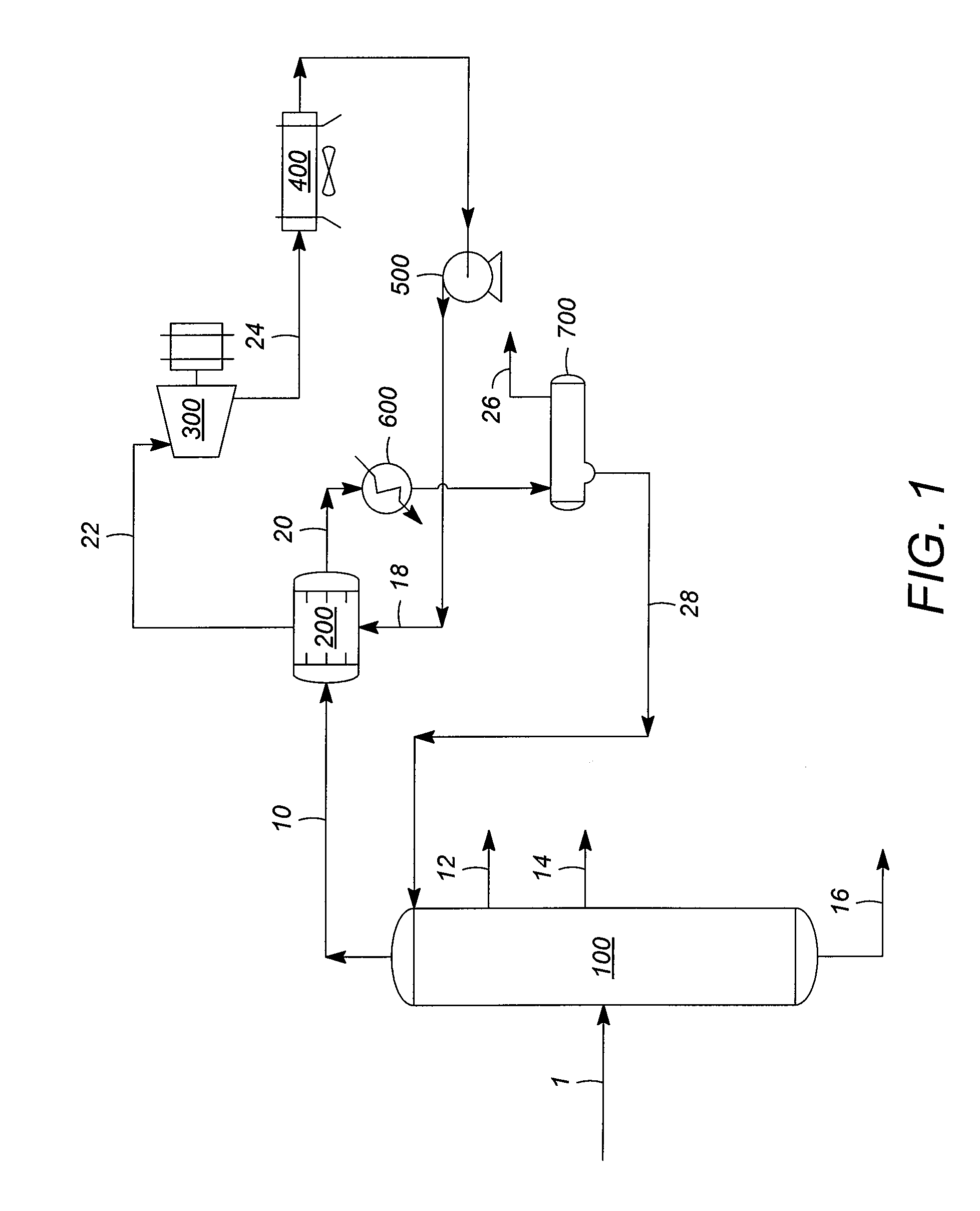

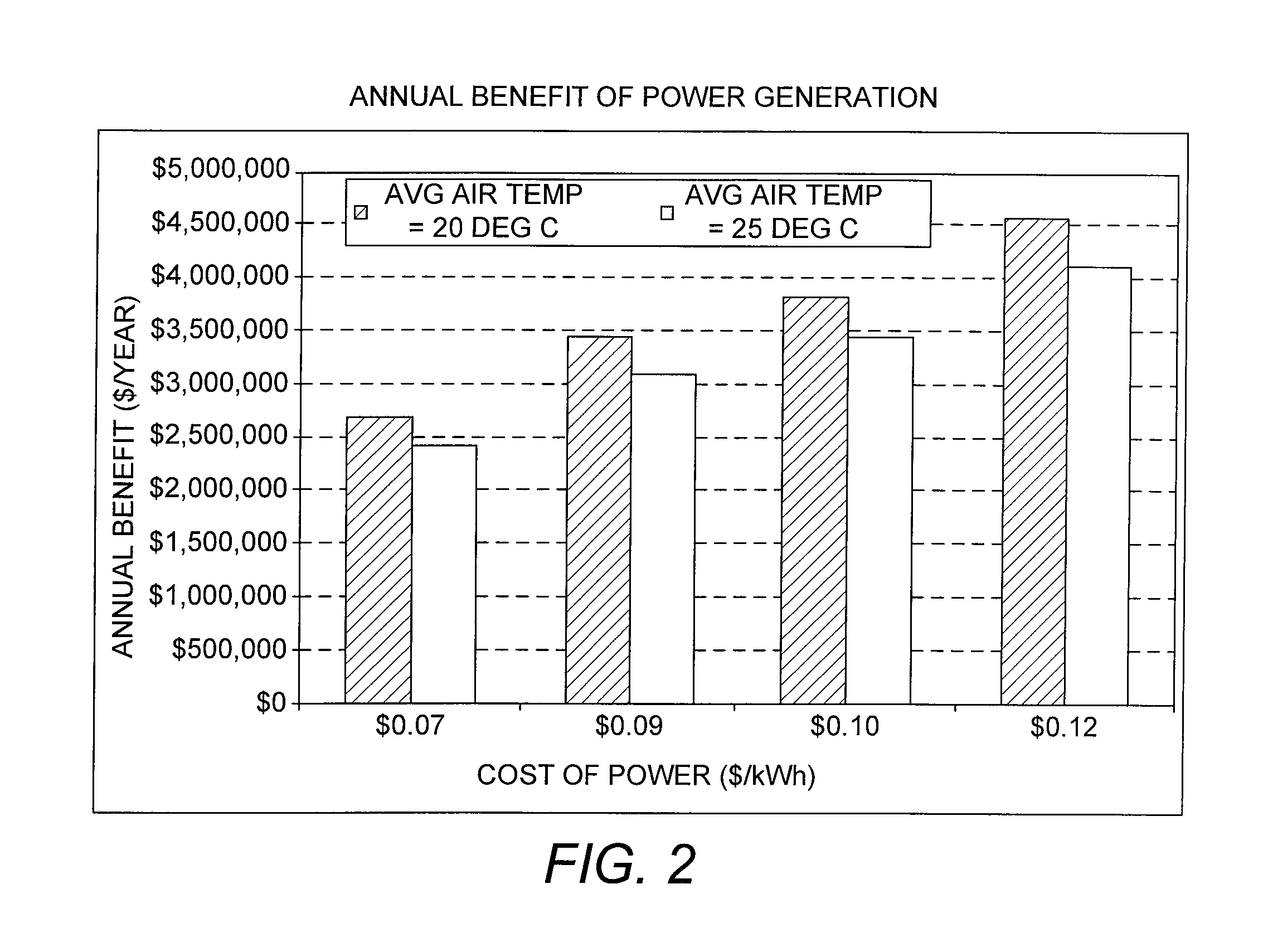

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

Well service pump power system and methods

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates an electric motor, a variable frequency drive (VFD), a pump drive, closed loop variable flow rate hydraulic pumps, hydraulic ram cylinders, working fluid end cylinders, and a coupling to connect the hydraulic ram cylinders and the working fluid end cylinders. The electric motor powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. The VFD is connected to a single one of the hydraulic pumps at a time and applies power to the connected pump, via the pump drive, to drive the connected pump from a cold start to an operating speed. The VFD is connected sequentially, one pump at a time, to each of the hydraulic pumps and disconnected from each pump once the pump reaches the operating speed. Once the pump reaches operating speed, the pump is connected to receive power directly to the electric motor.

Owner:AMERIFORGE GRP

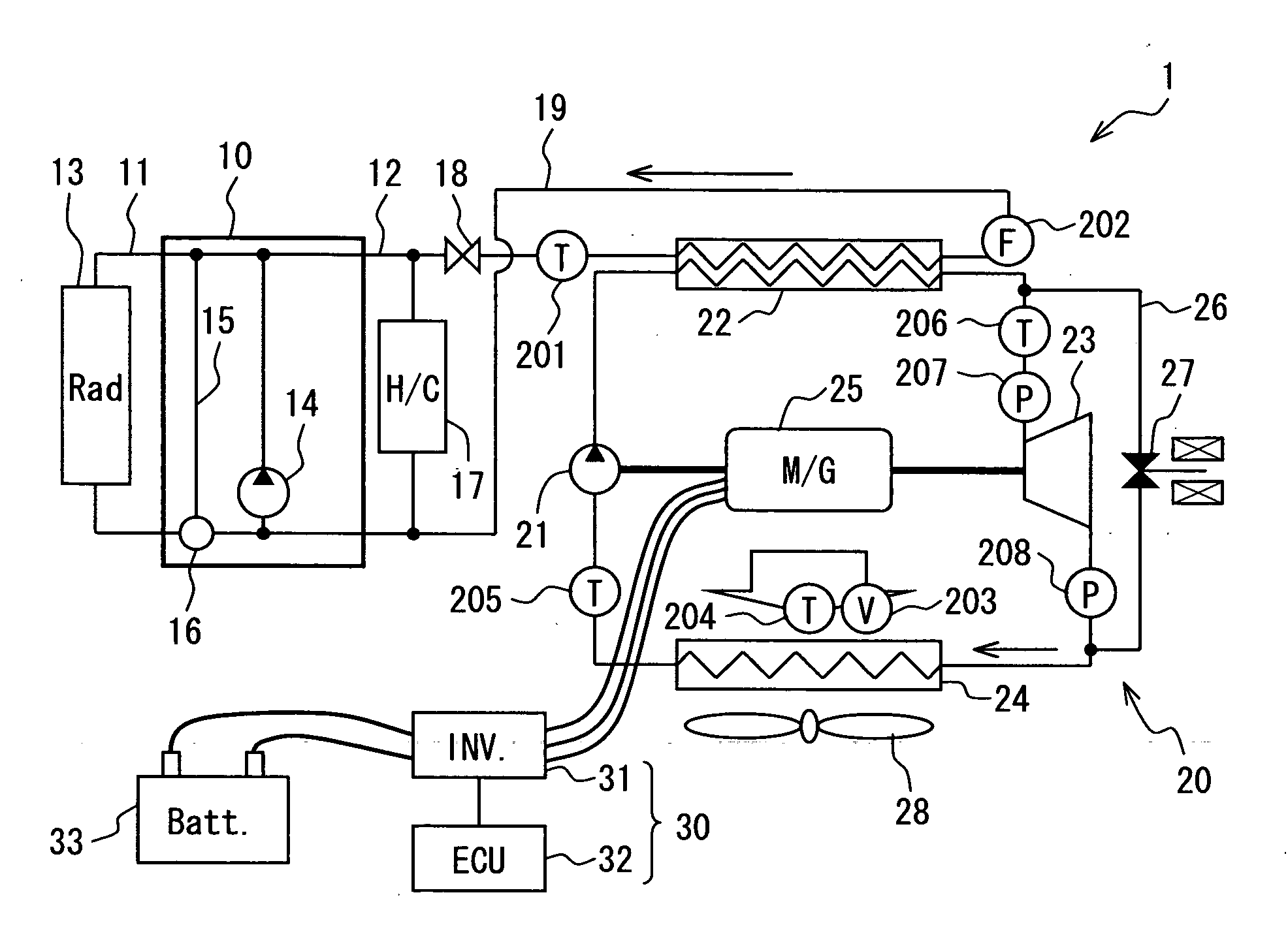

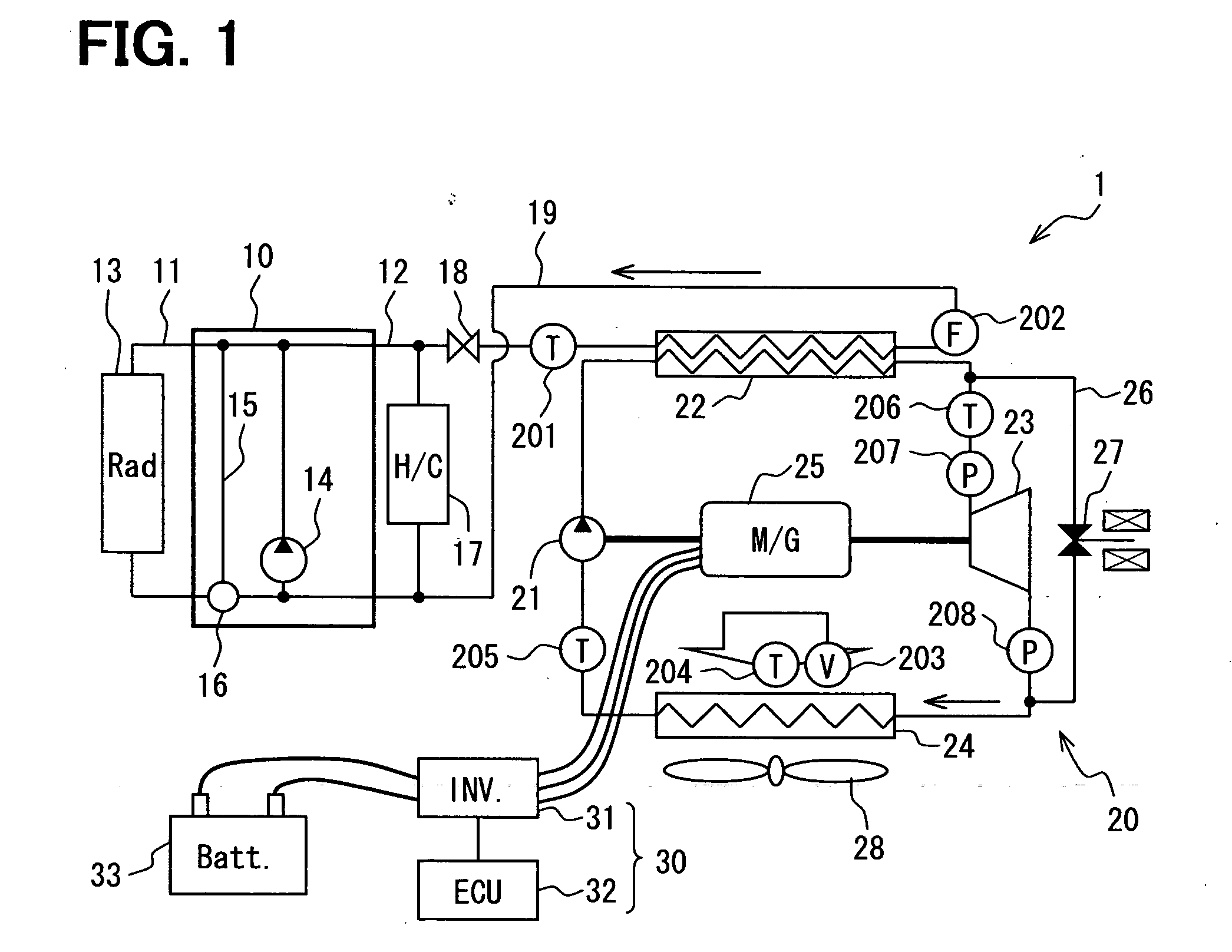

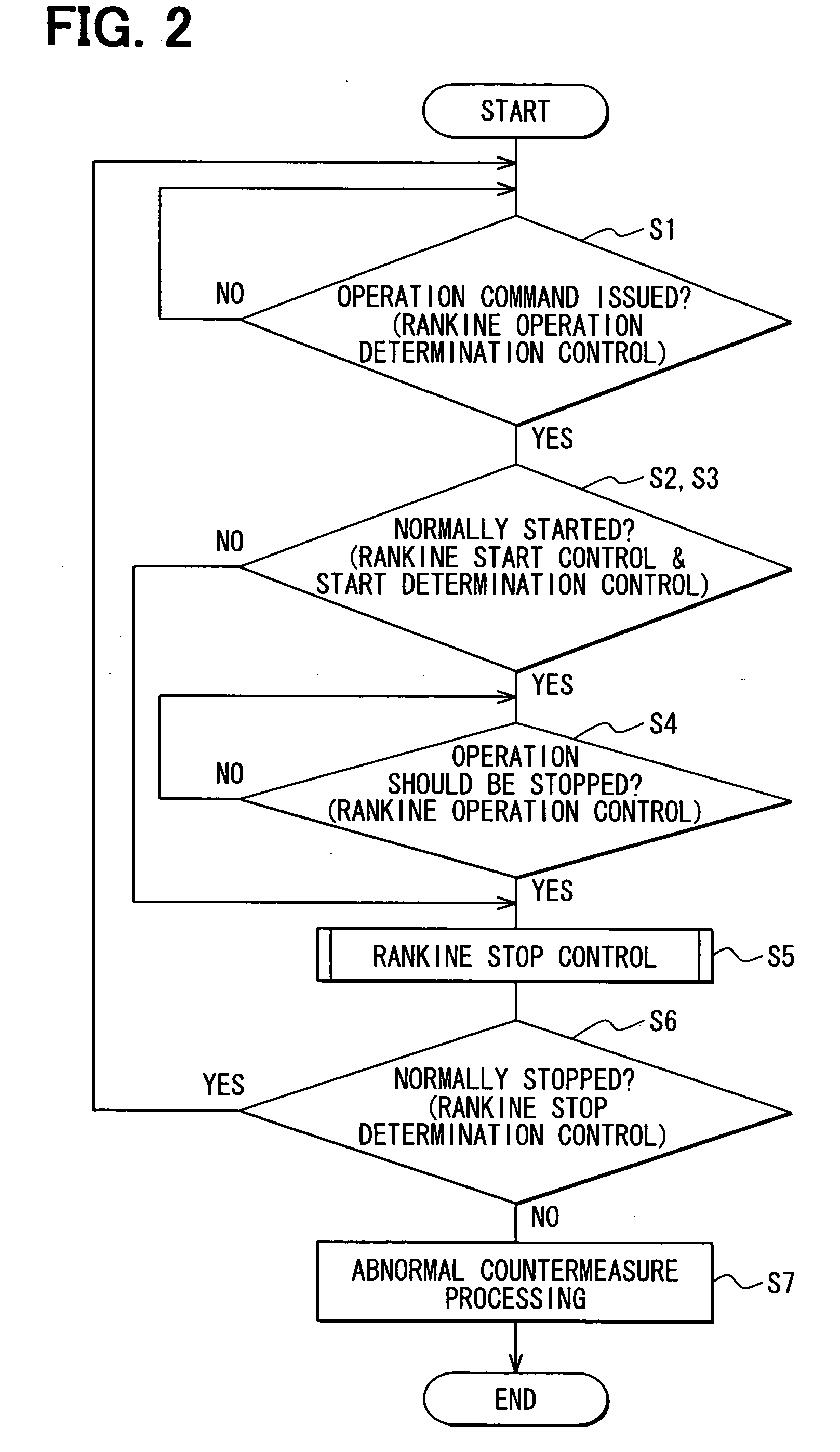

Waste heat recovery apparatus

InactiveUS20090071156A1High speedImprove discharge performanceInternal combustion piston enginesEngine componentsWorking fluidEngineering

A waste heat recovery apparatus including a Rankine cycle which includes a heater for heating an operation fluid by waste heat from a heat-generating device, an expansion unit for converting energy of expansion of the operation fluid flowing out from the heater into mechanical energy, and a condenser for condensing and liquefying the expanded operation fluid, a temperature detector for detecting the temperature of the operation fluid on the inlet side of the expansion unit, a pressure detector for detecting inlet-side pressure of the expansion unit, a pressure detector for detecting outlet-side pressure of the expansion unit, and a control unit. The control unit controls a command rotational speed of the expansion unit based on superheated degree information at the inlet of the expansion unit obtained from the operation fluid temperature and the inlet-side pressure, and pressure information in which the outlet-side pressure is considered.

Owner:DENSO CORP +1

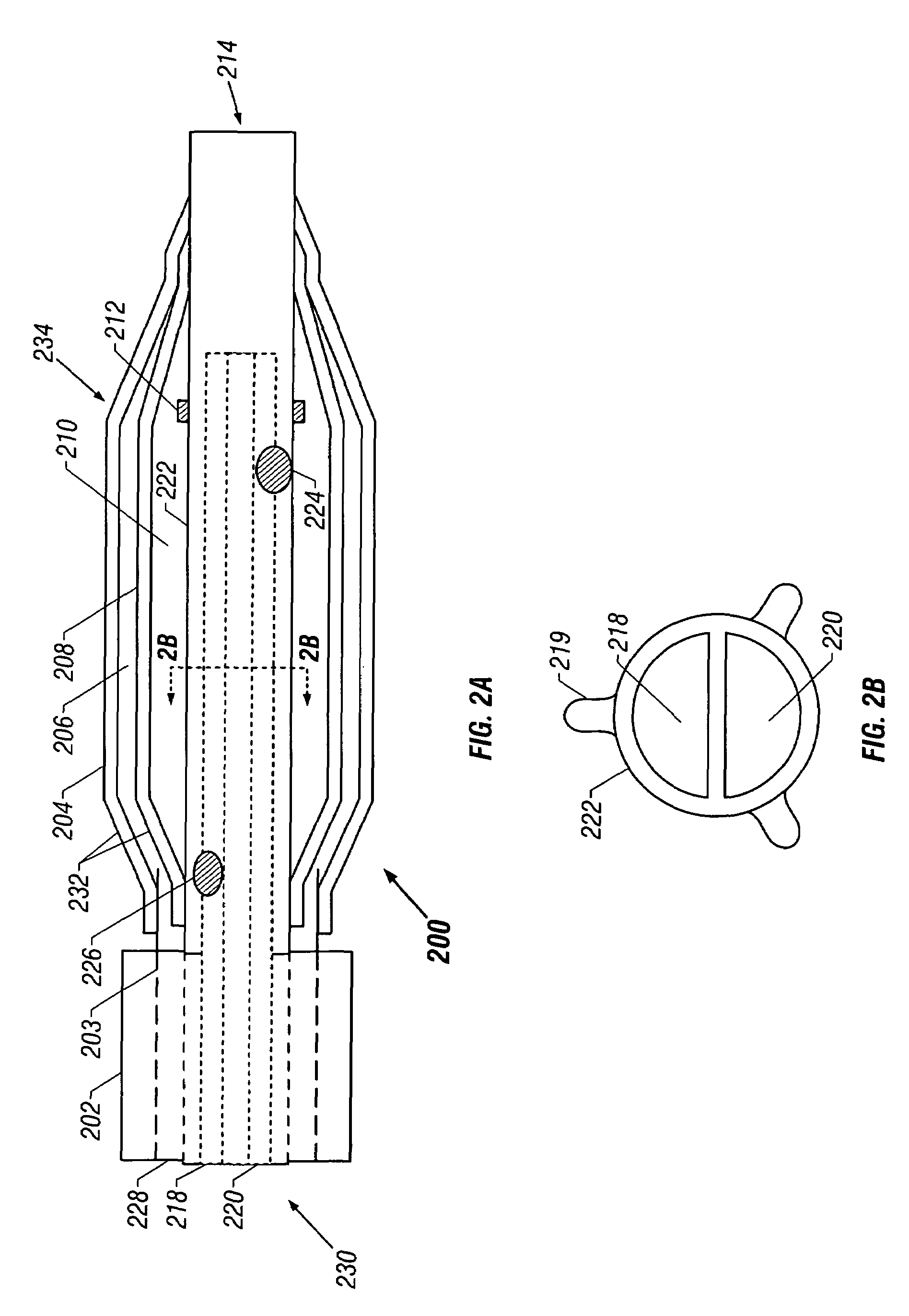

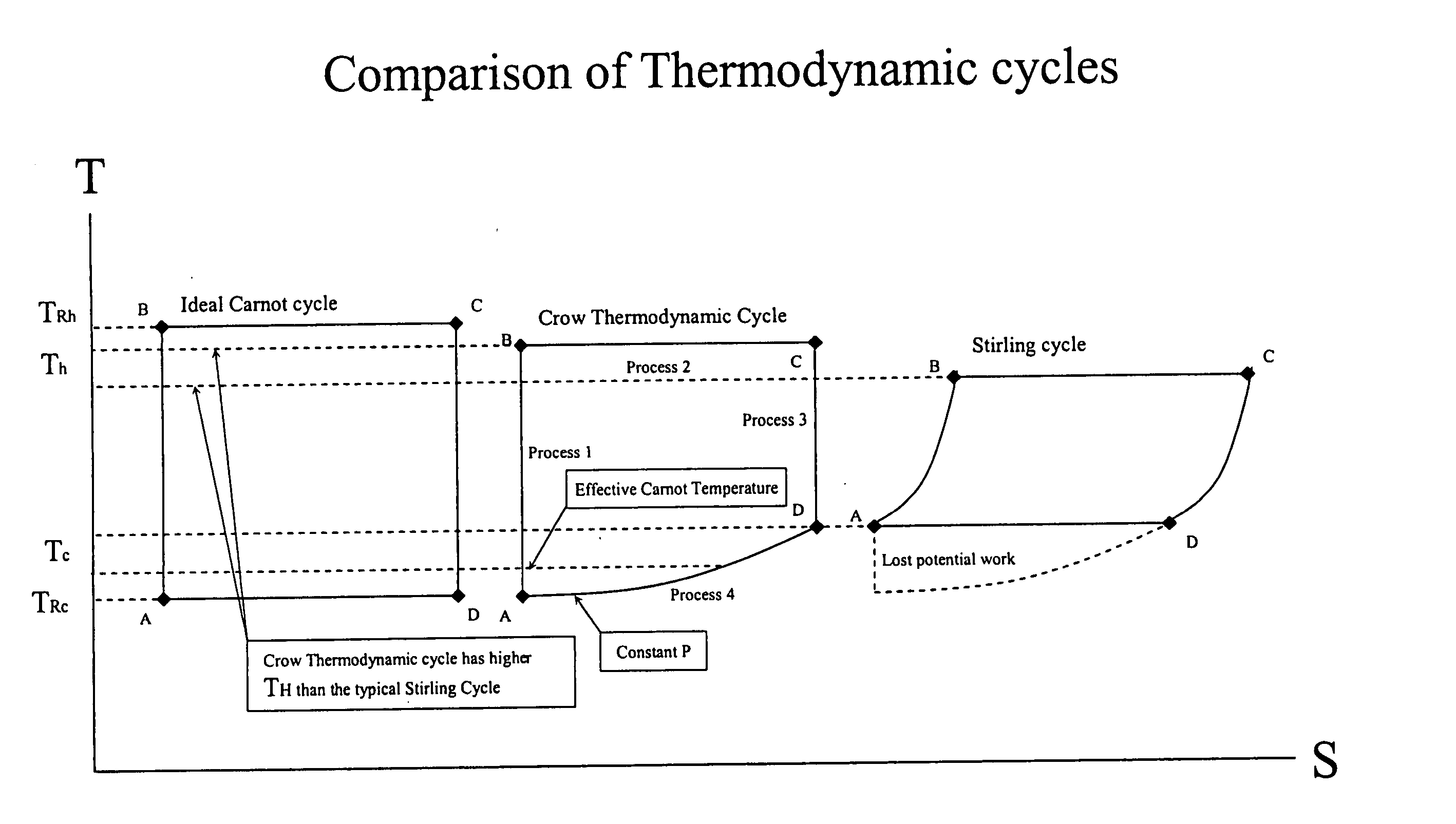

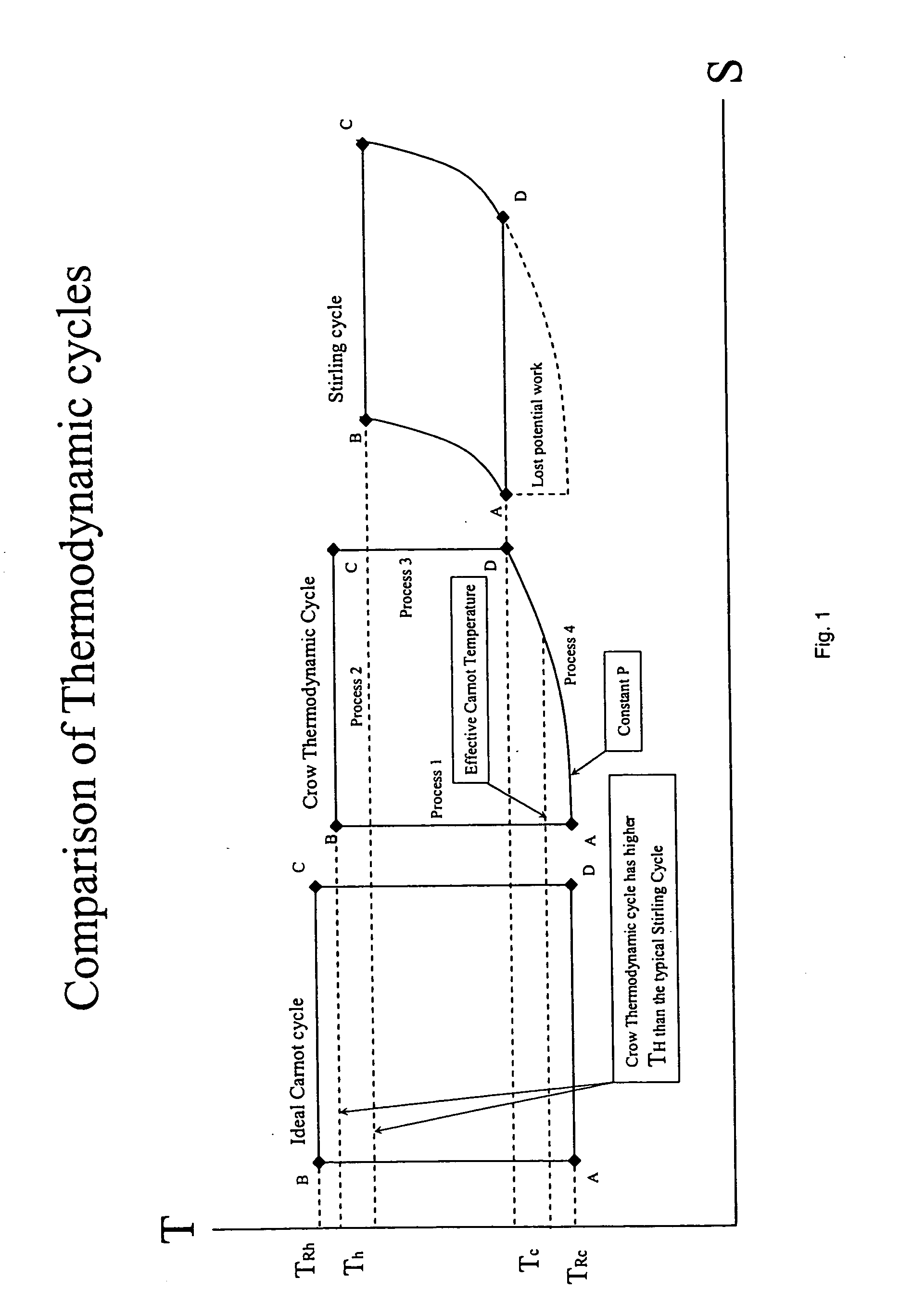

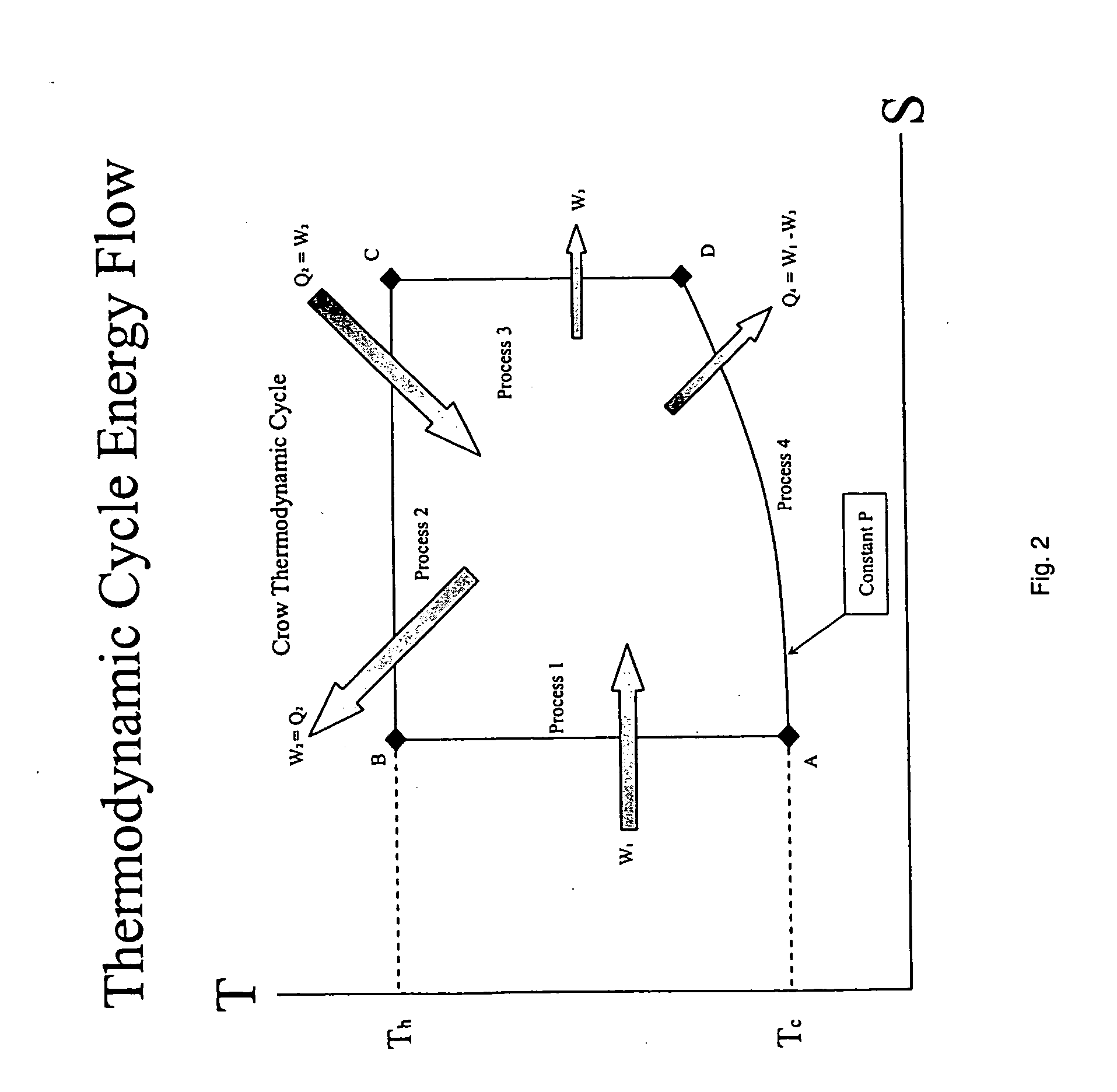

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS20060090467A1Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyWorking fluid

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com