Patents

Literature

498results about "Steam regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

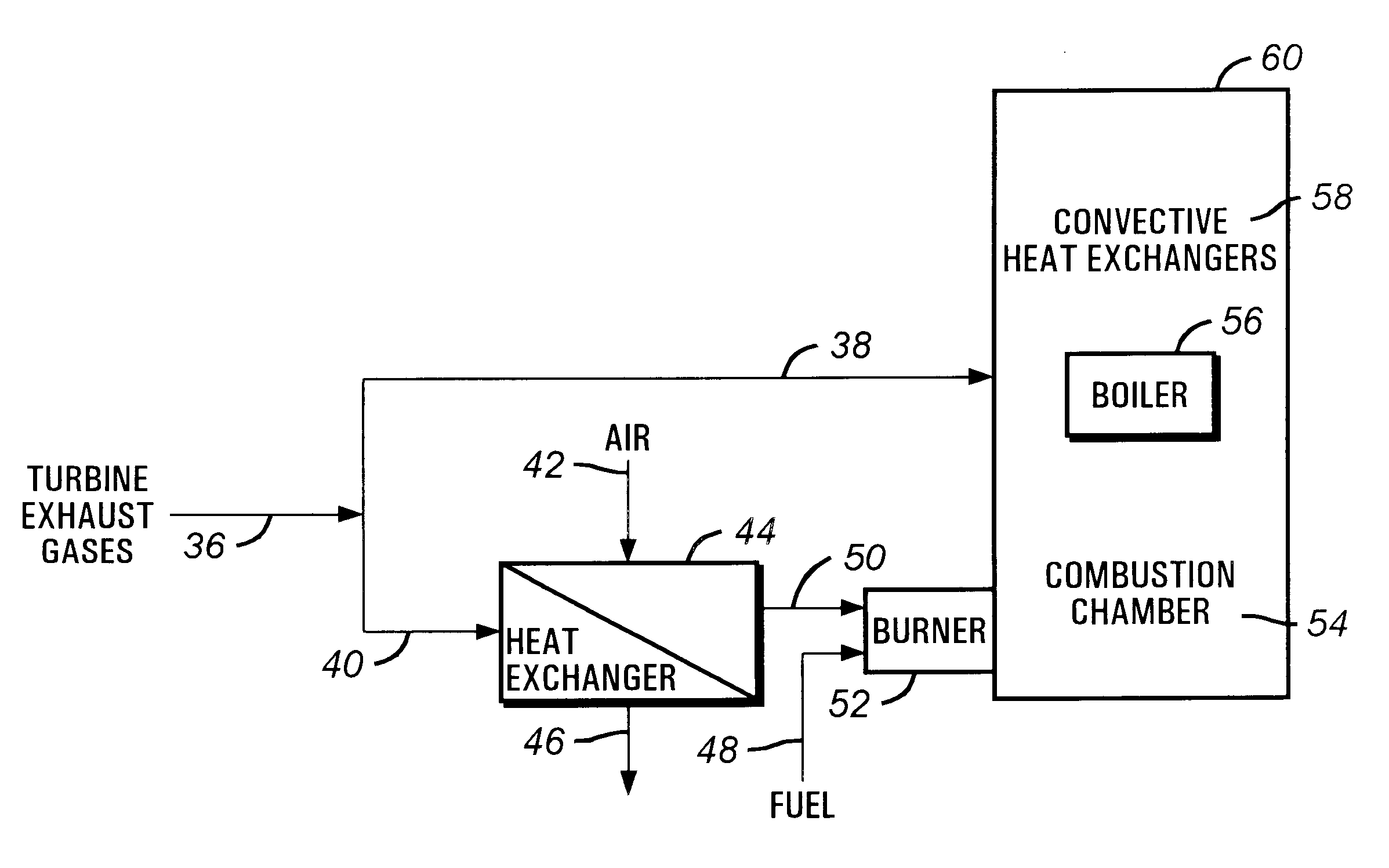

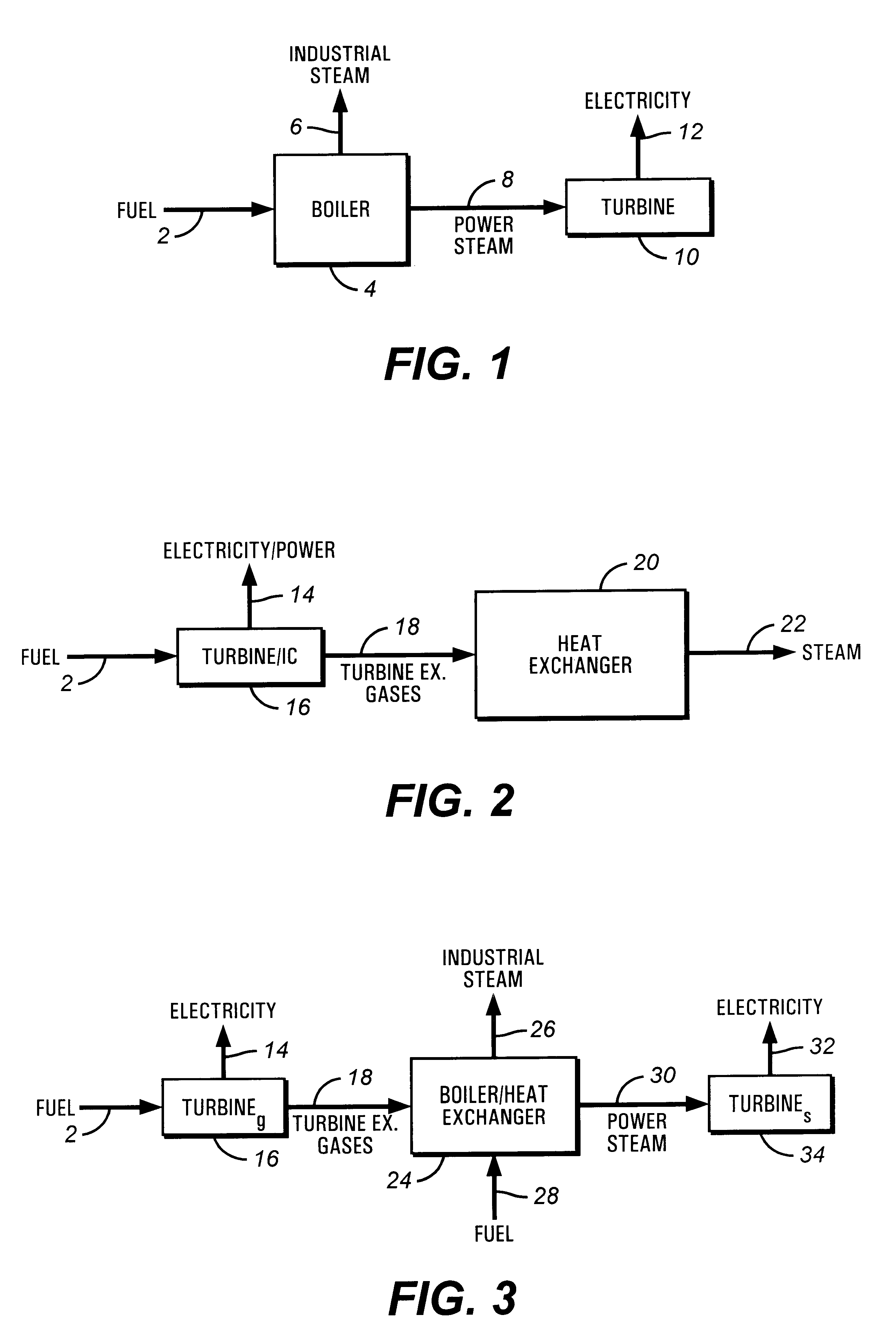

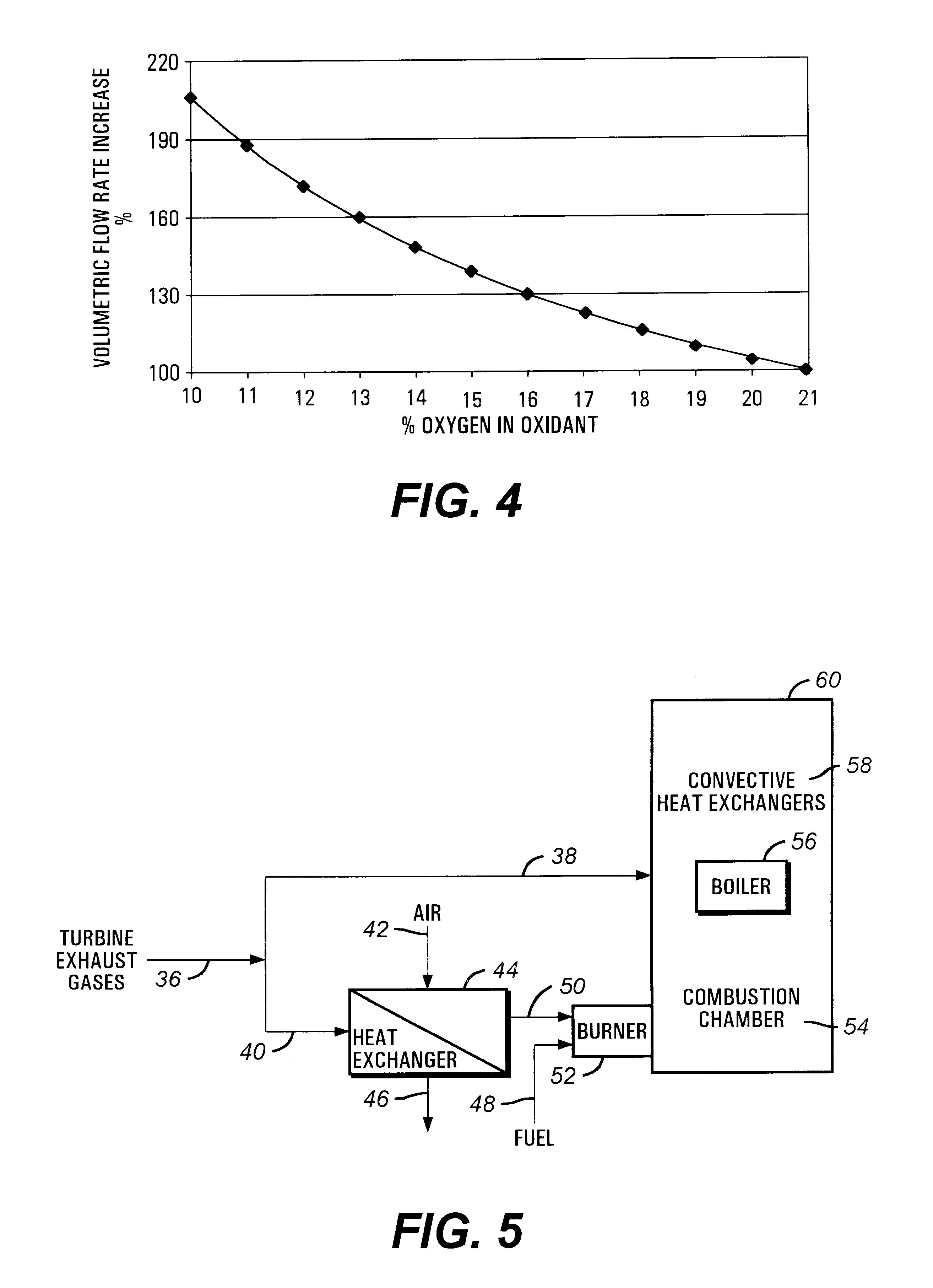

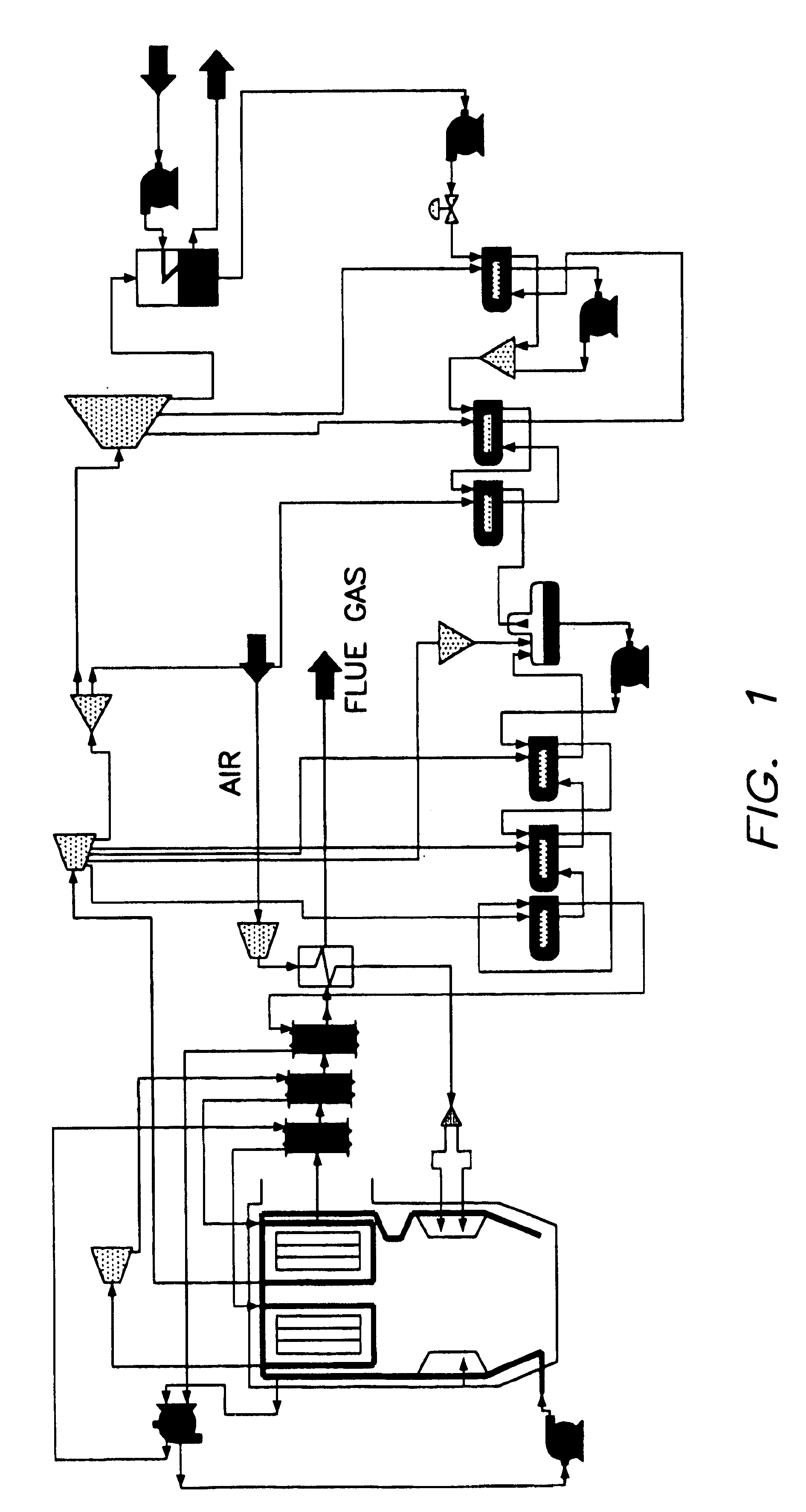

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

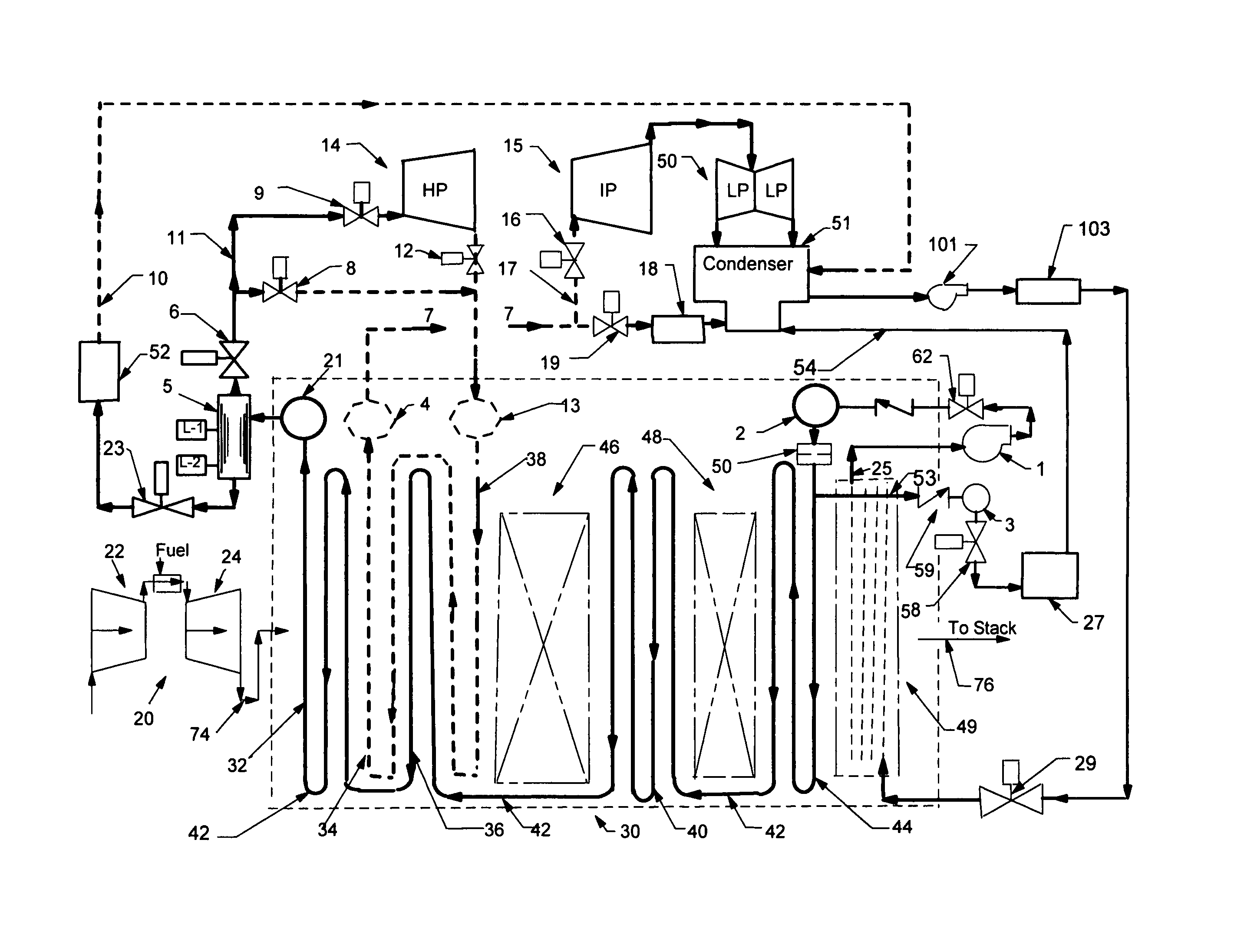

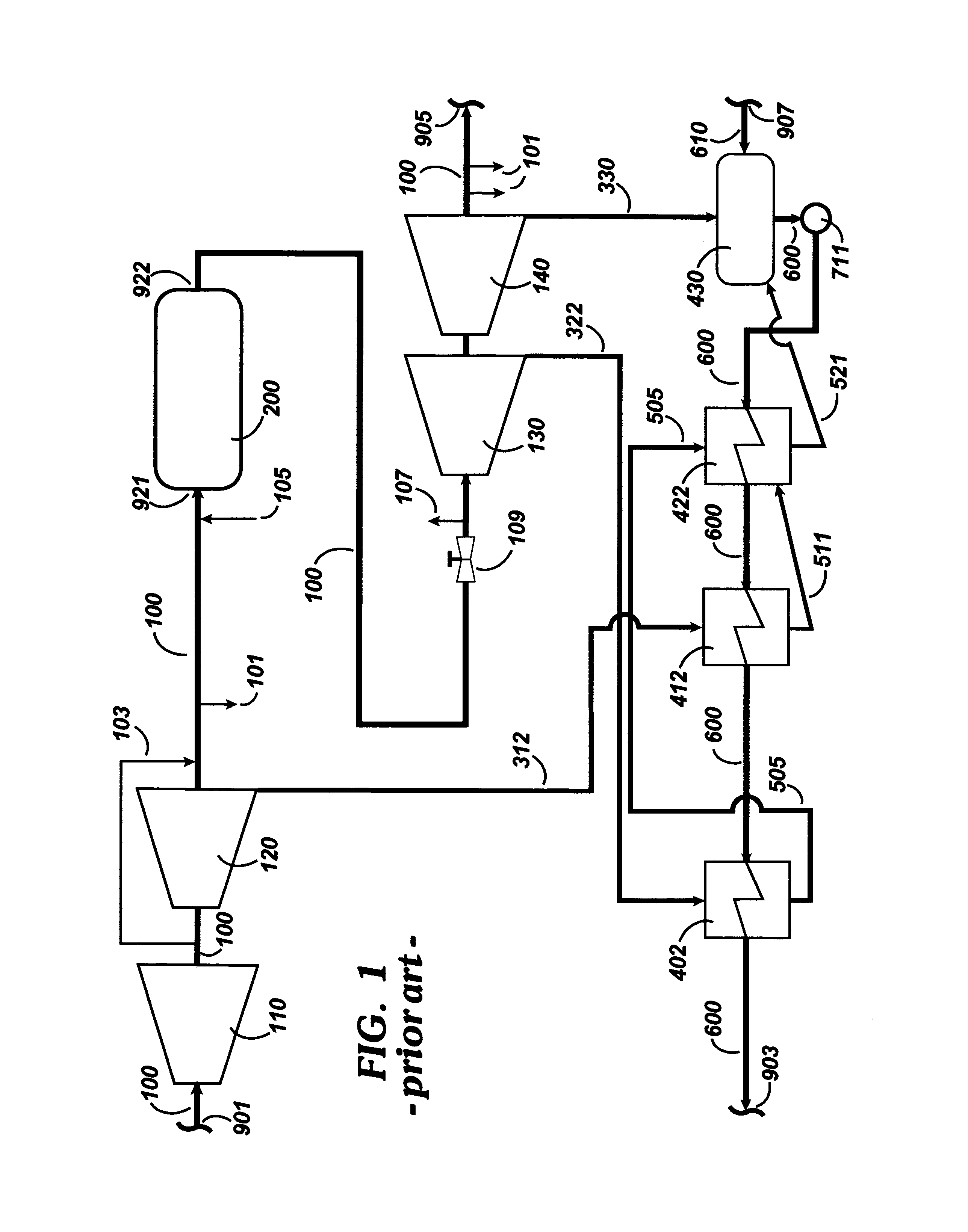

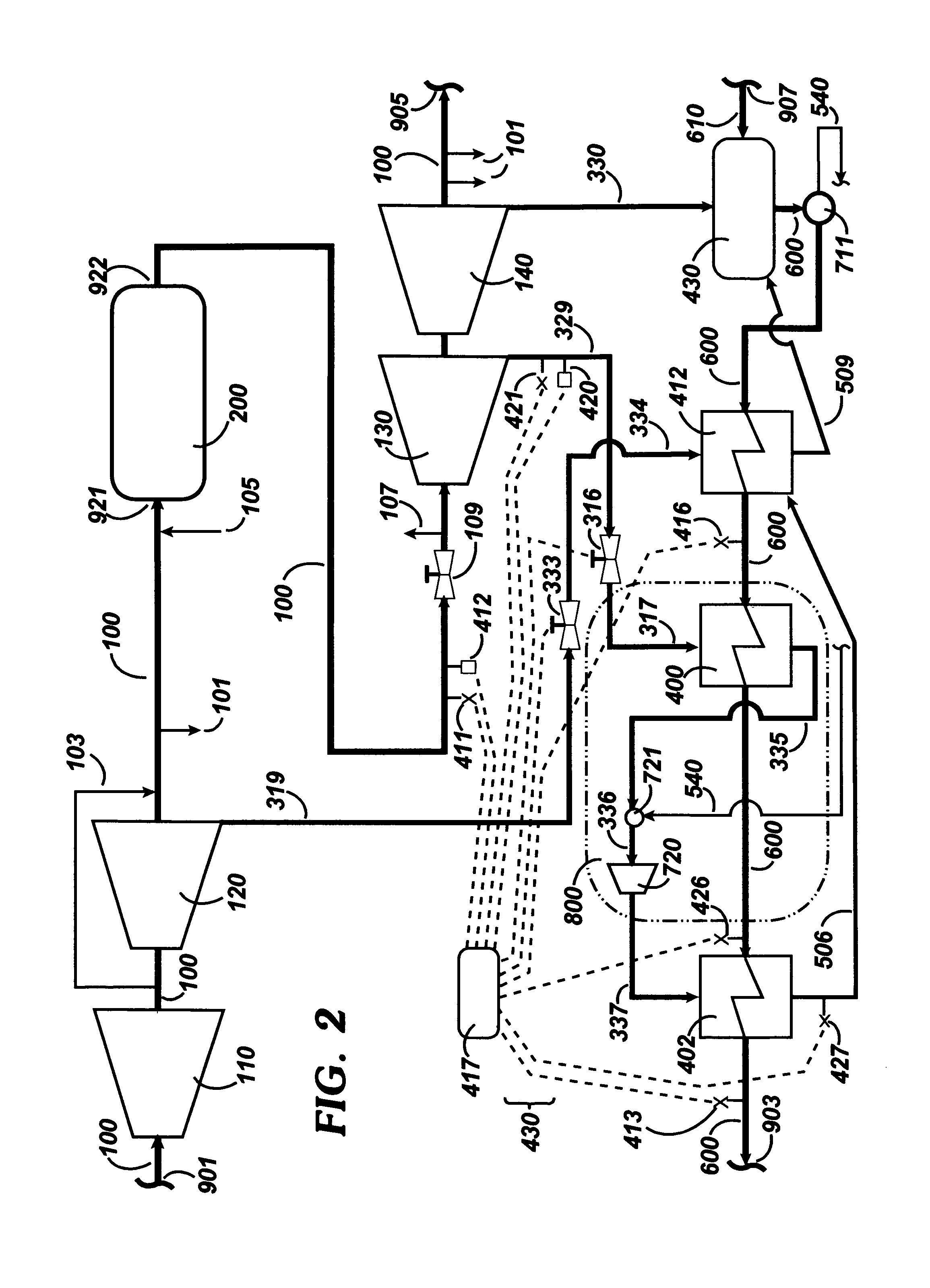

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

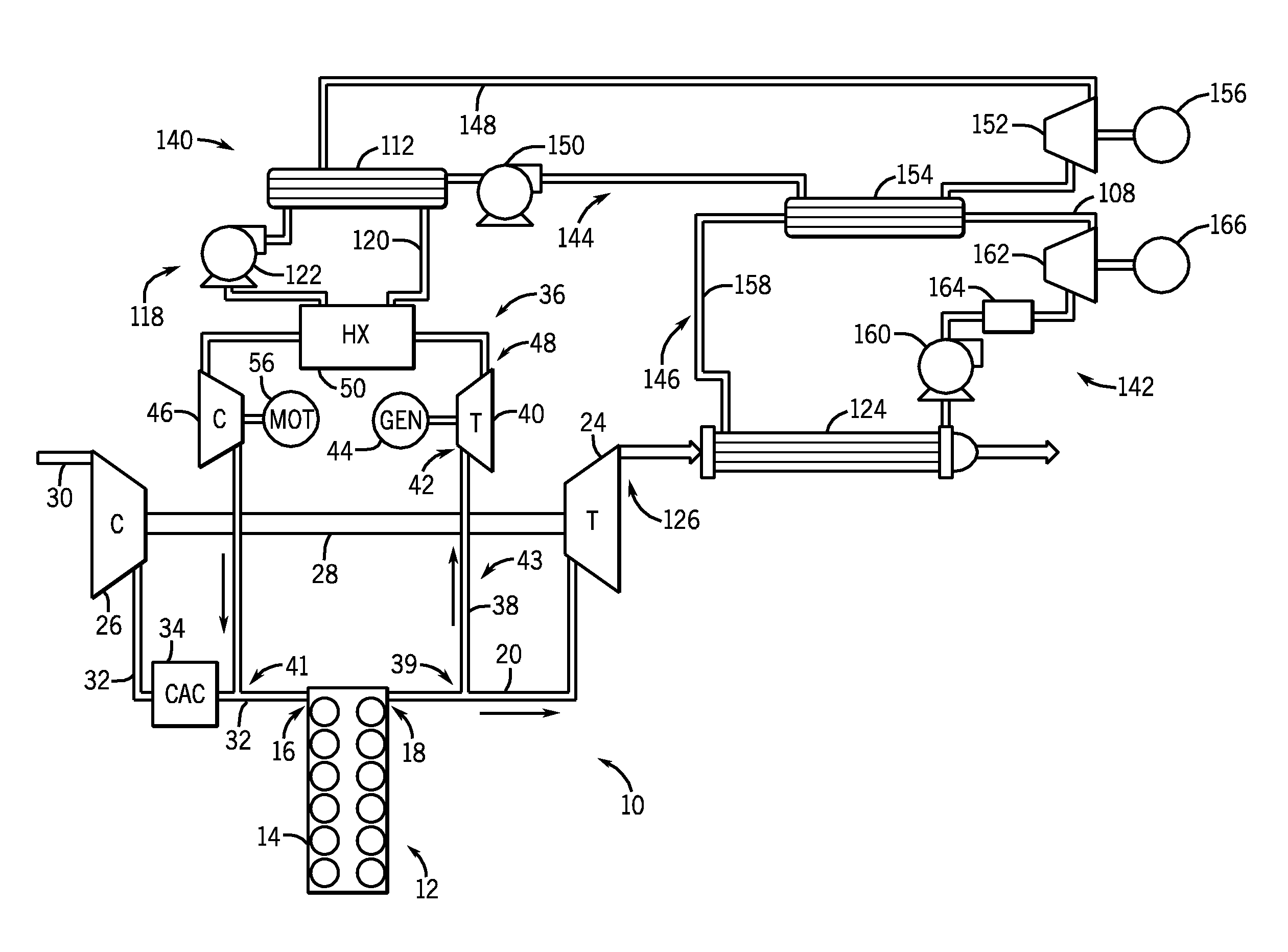

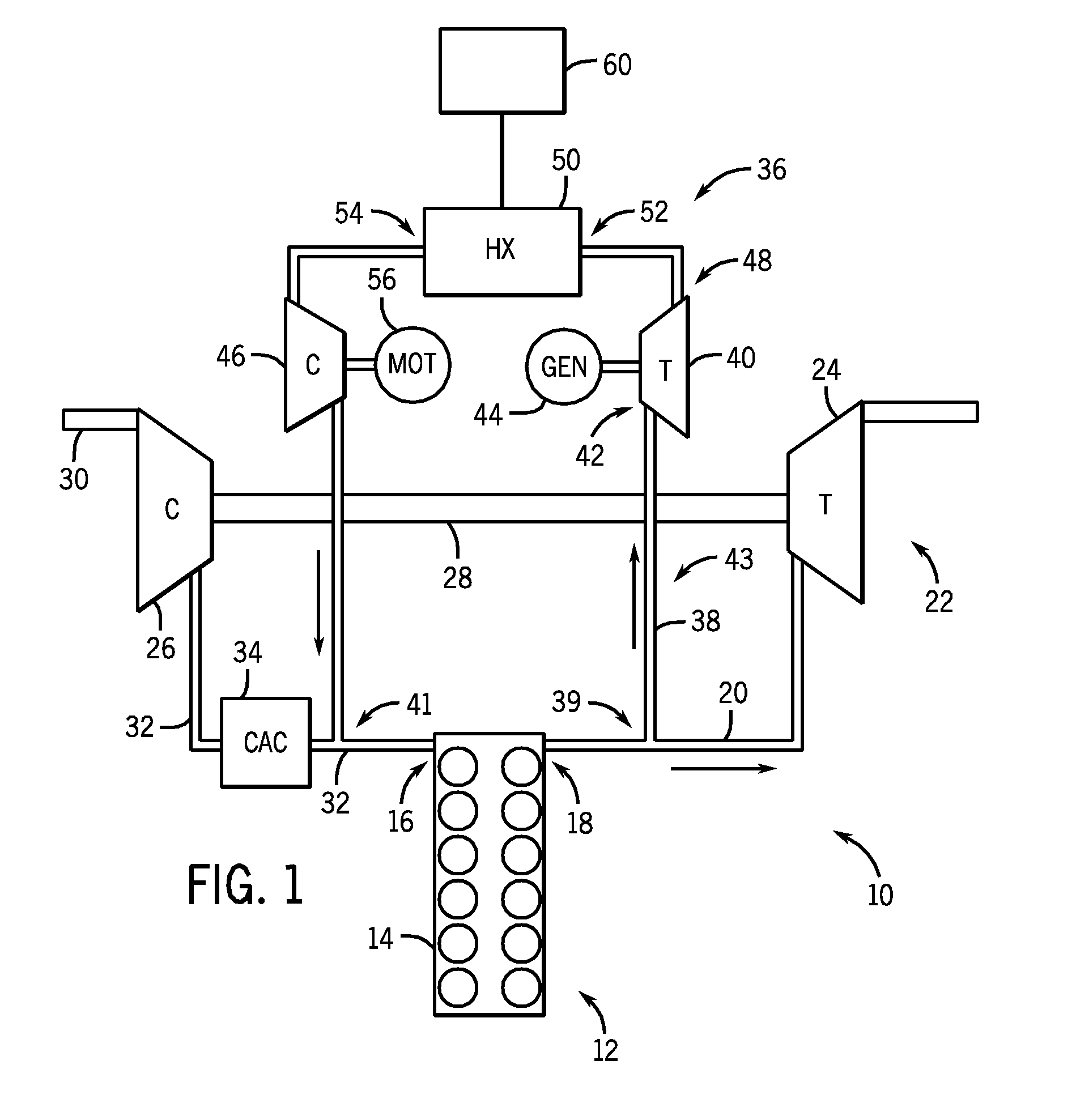

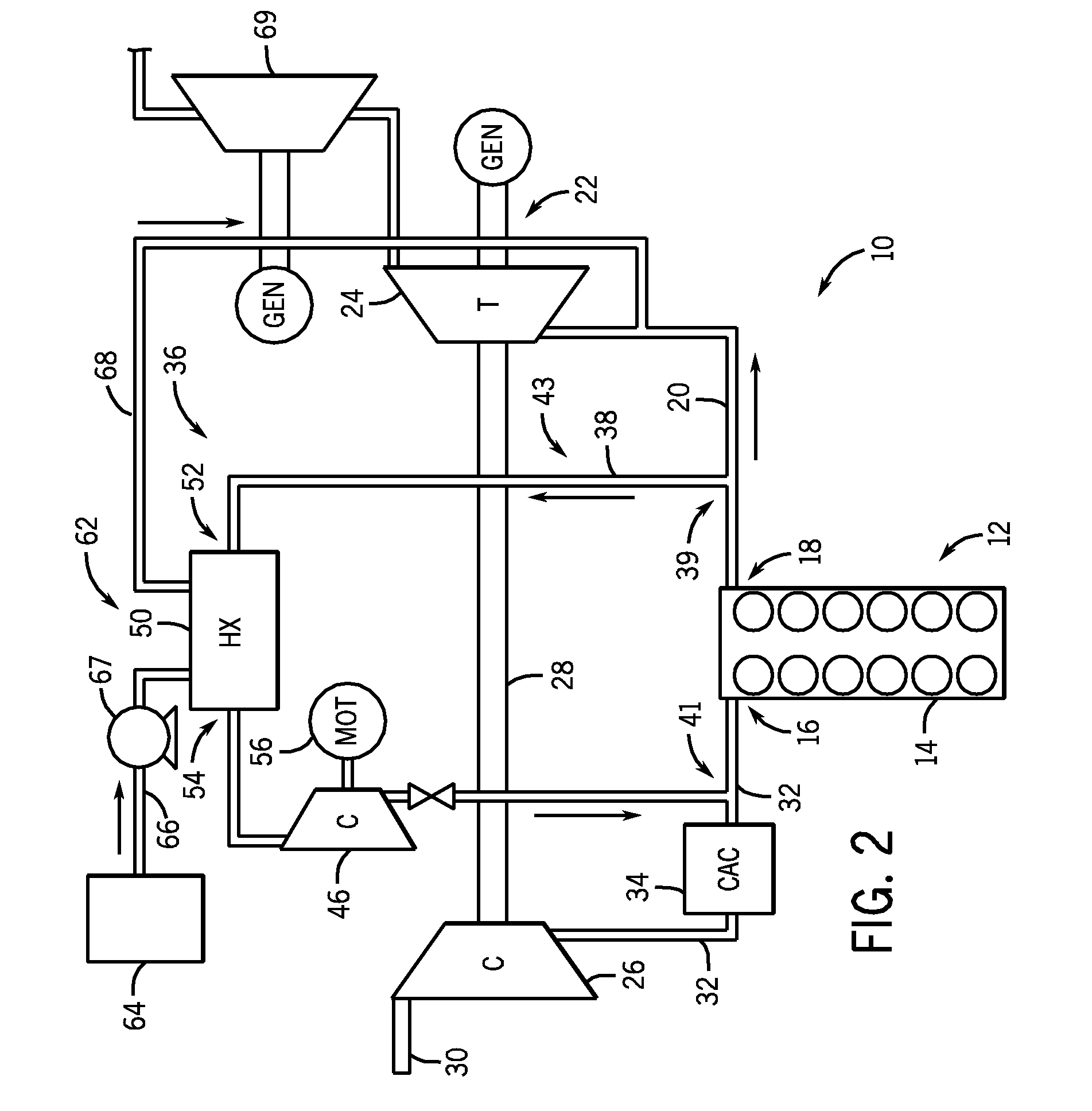

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

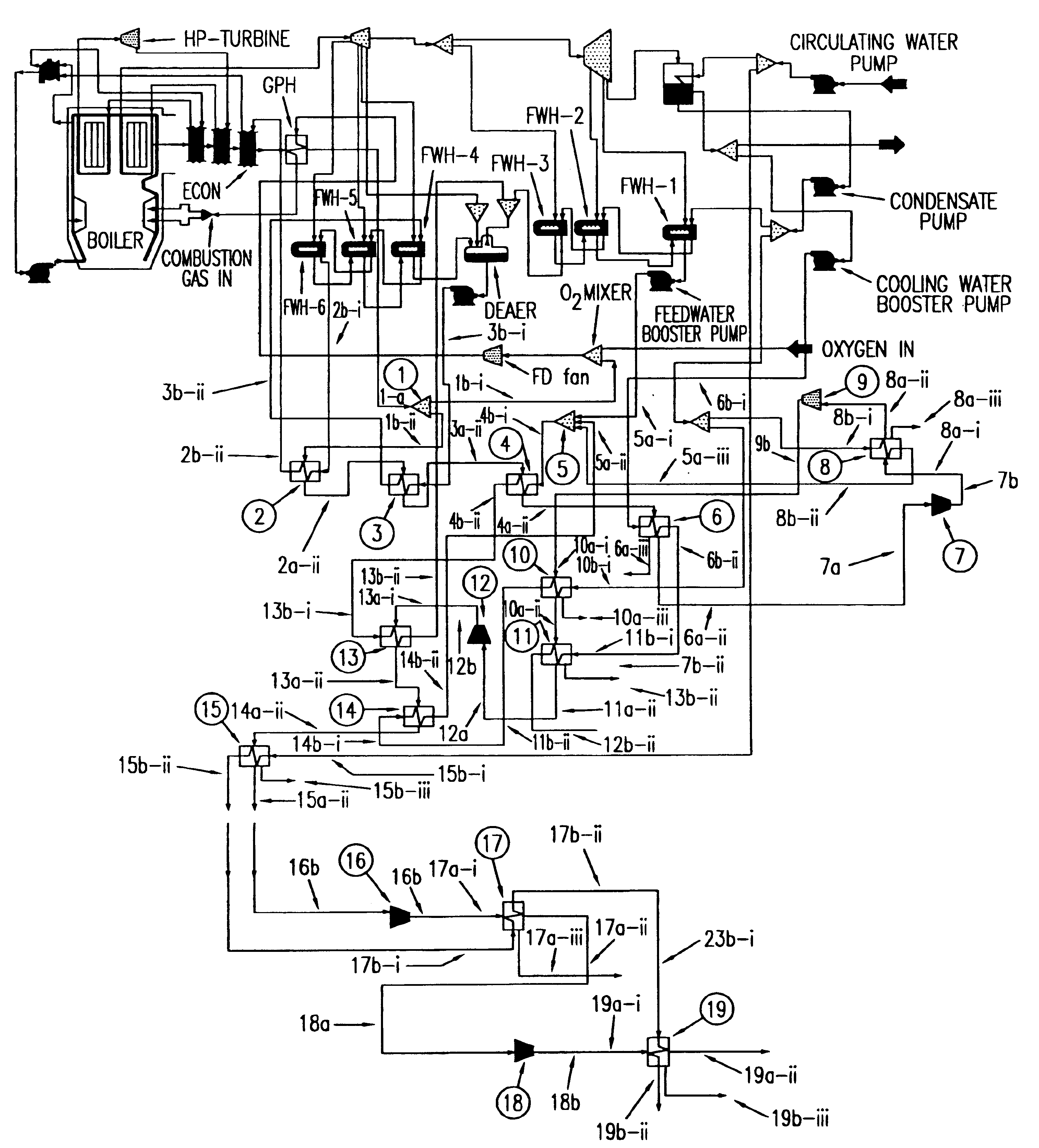

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

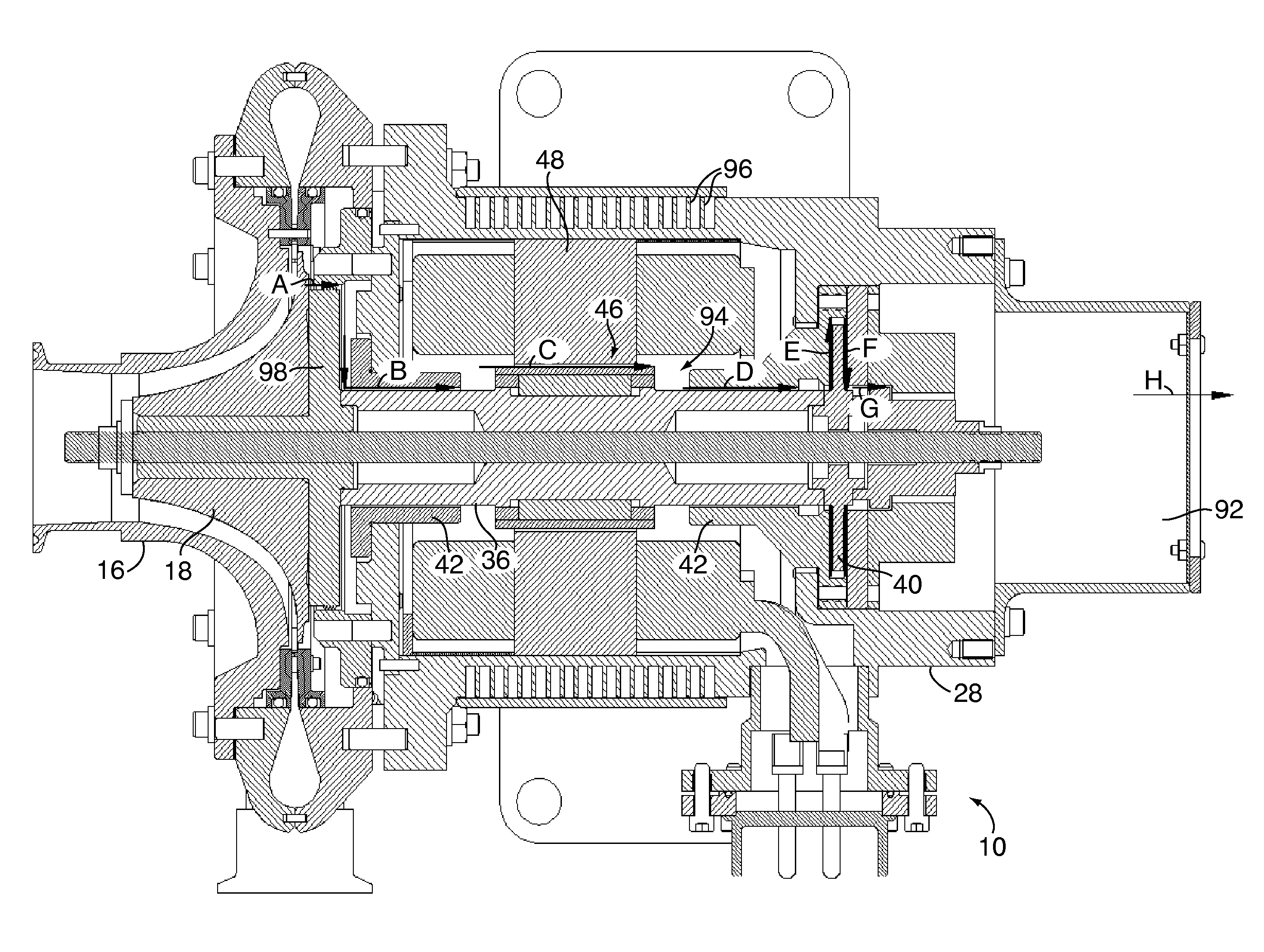

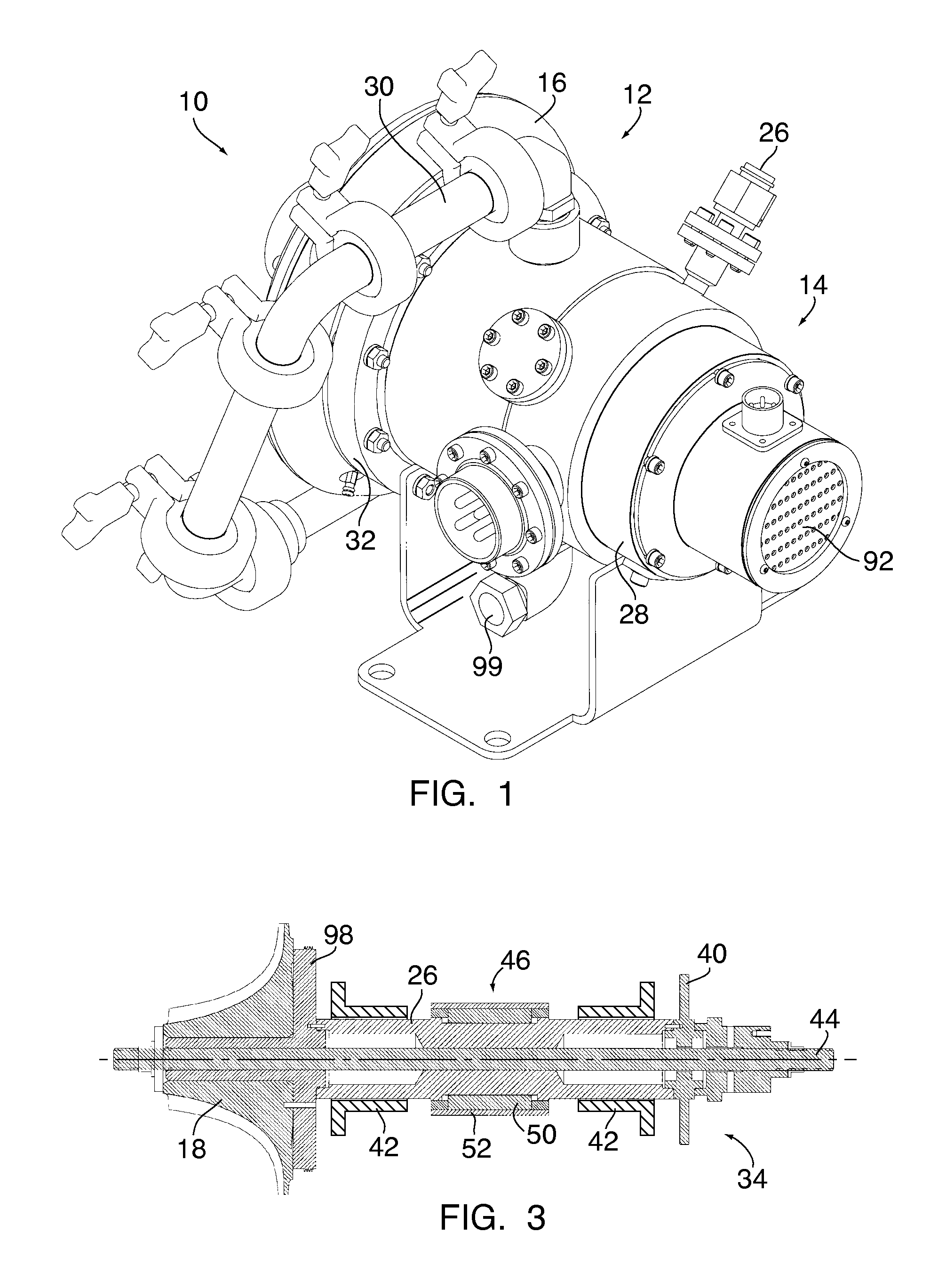

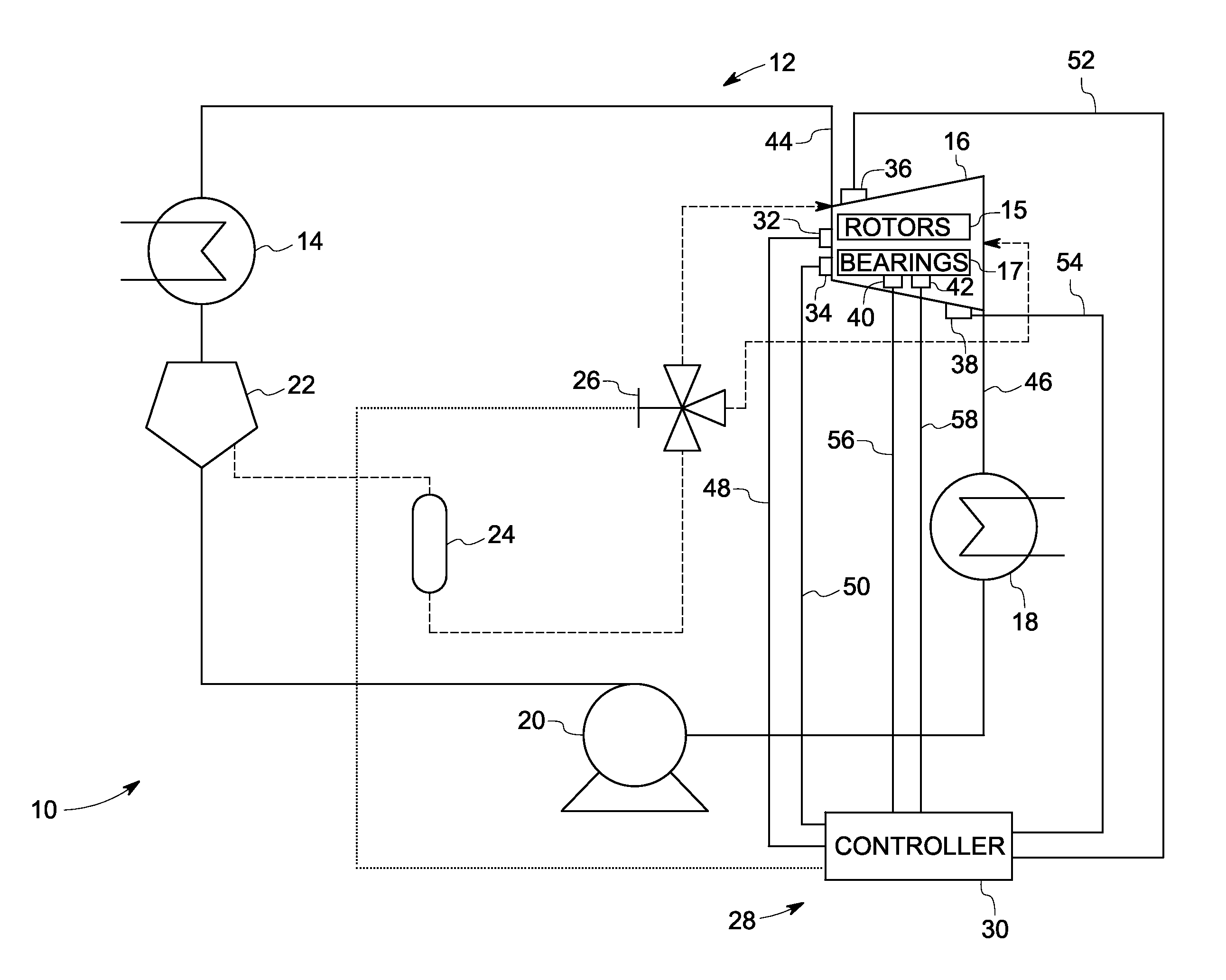

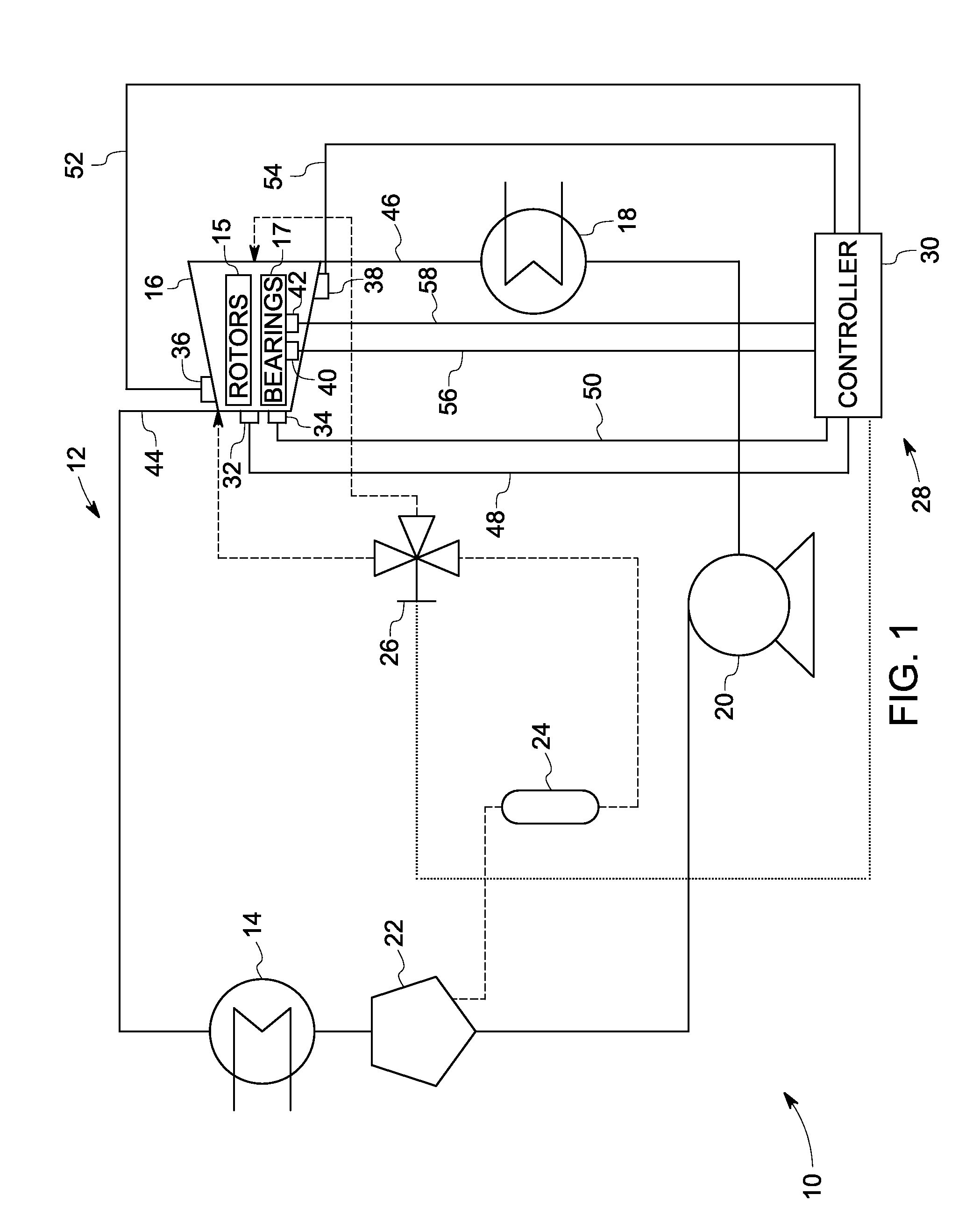

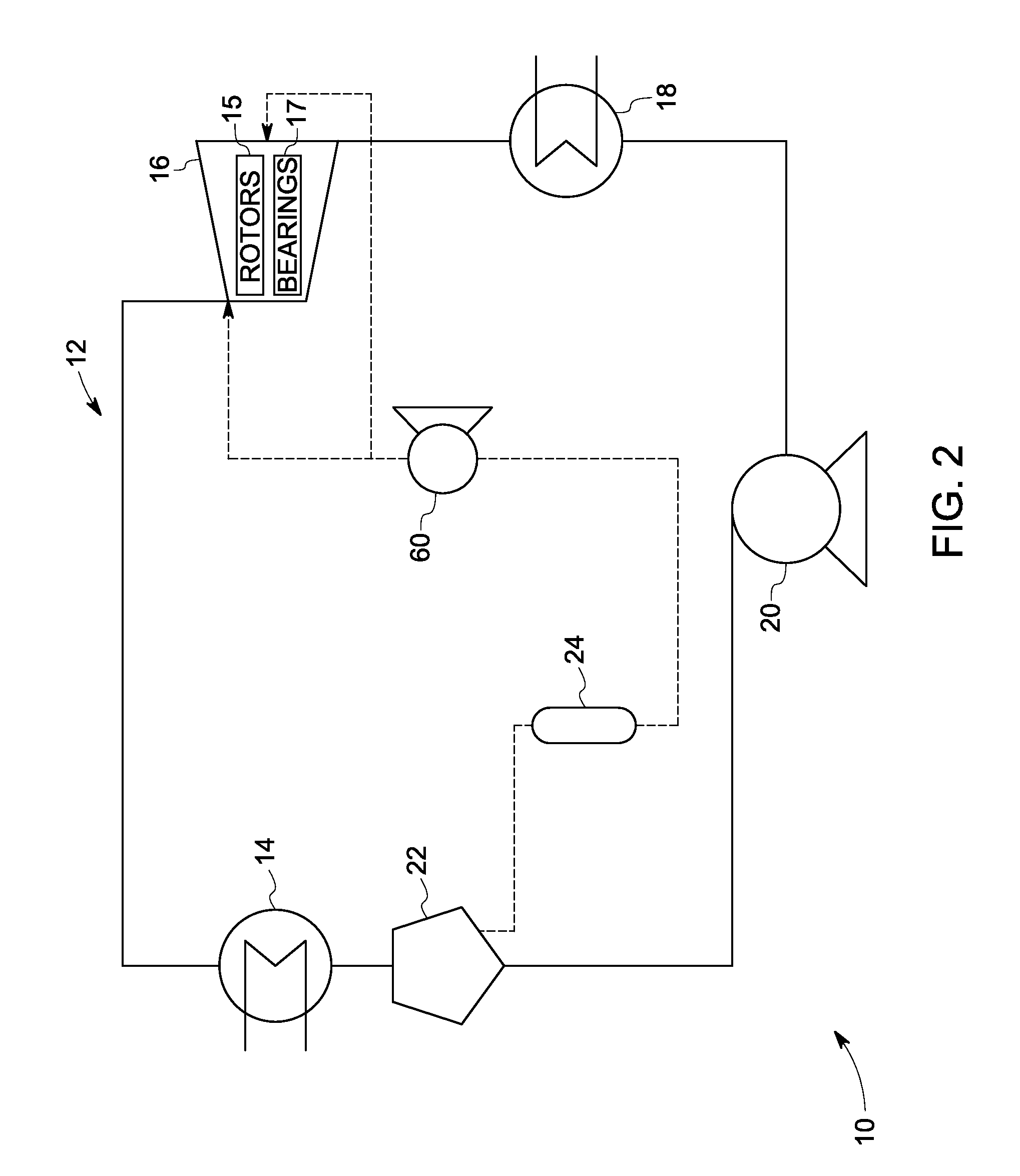

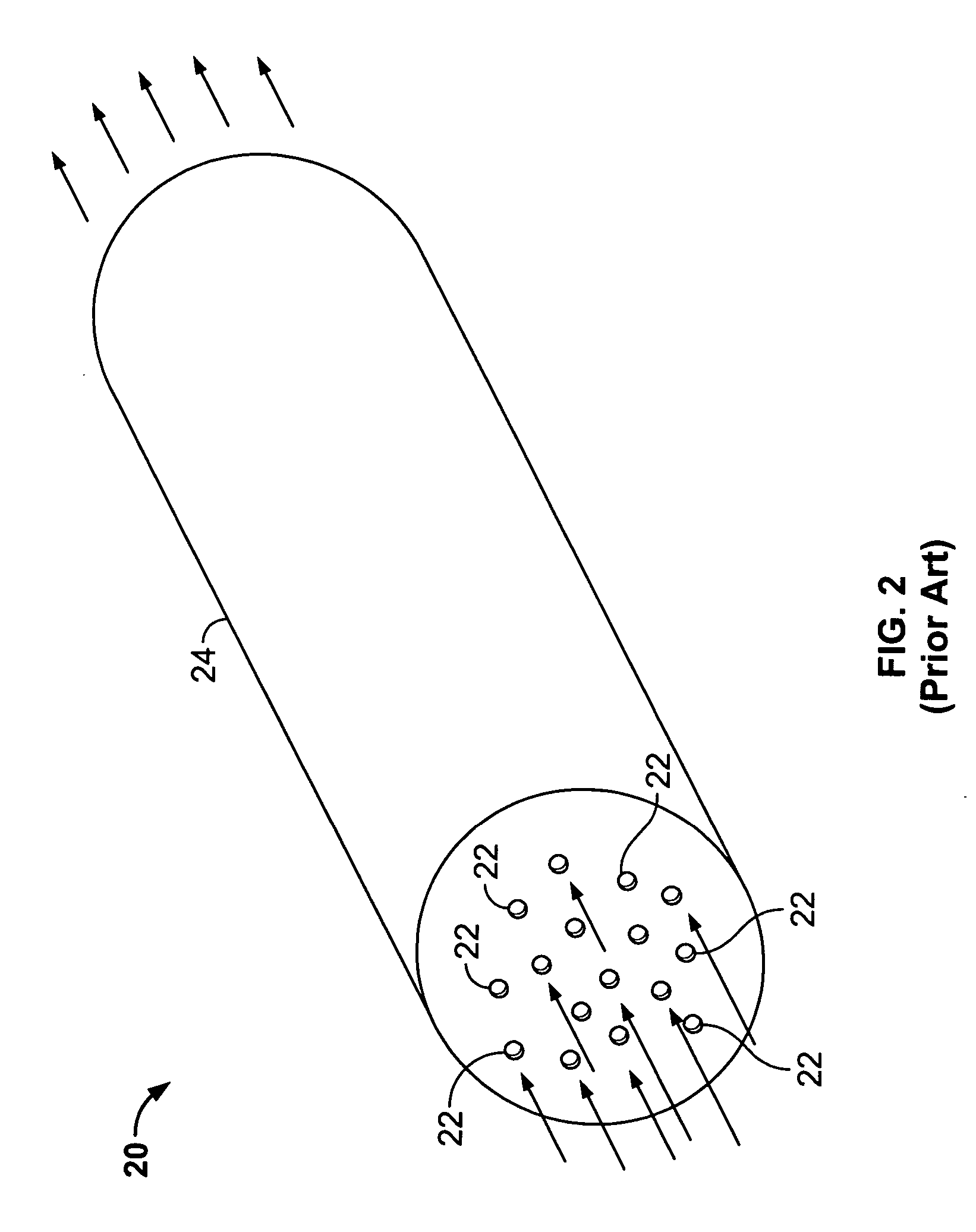

Turboalternator with hydrodynamic bearings

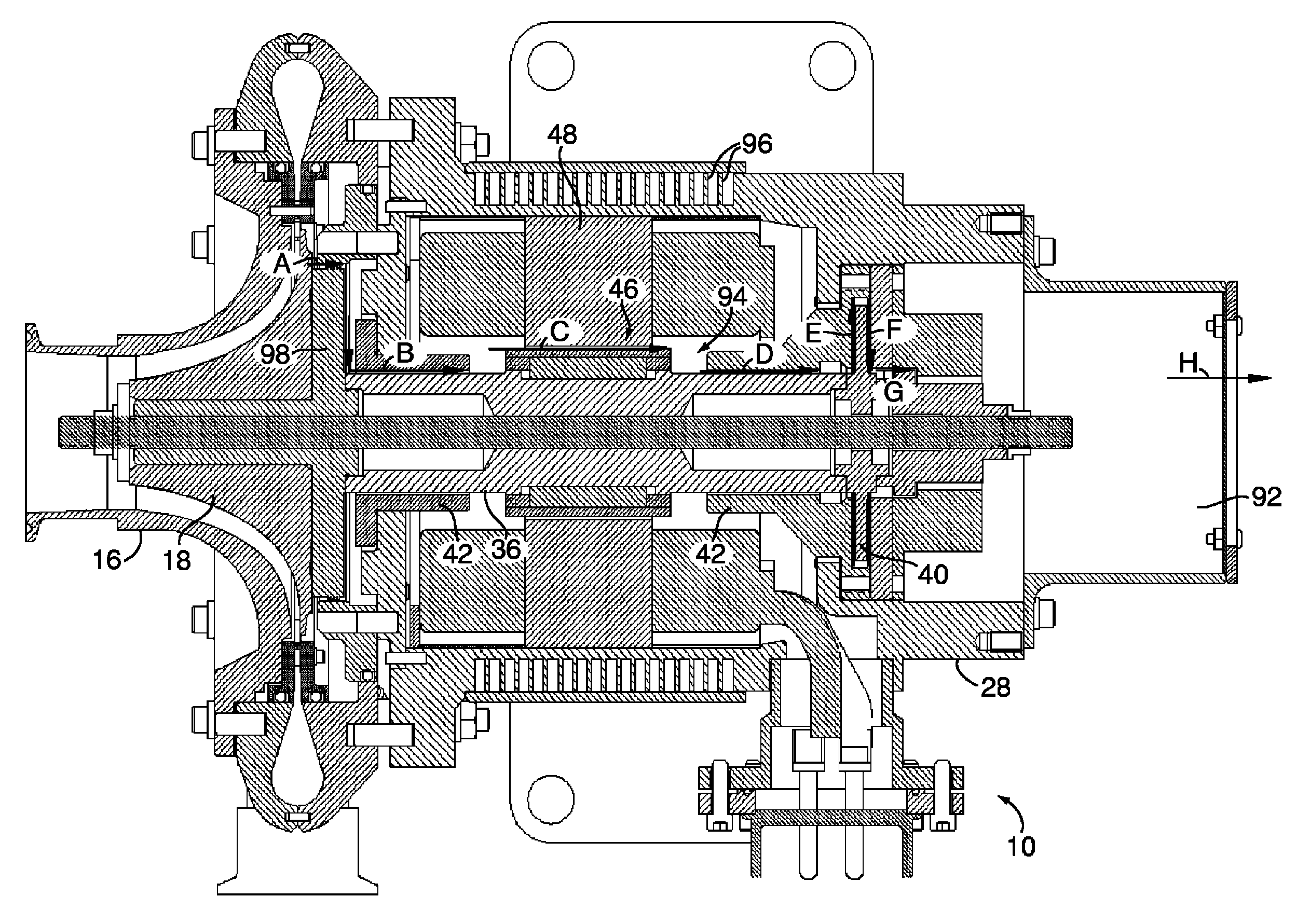

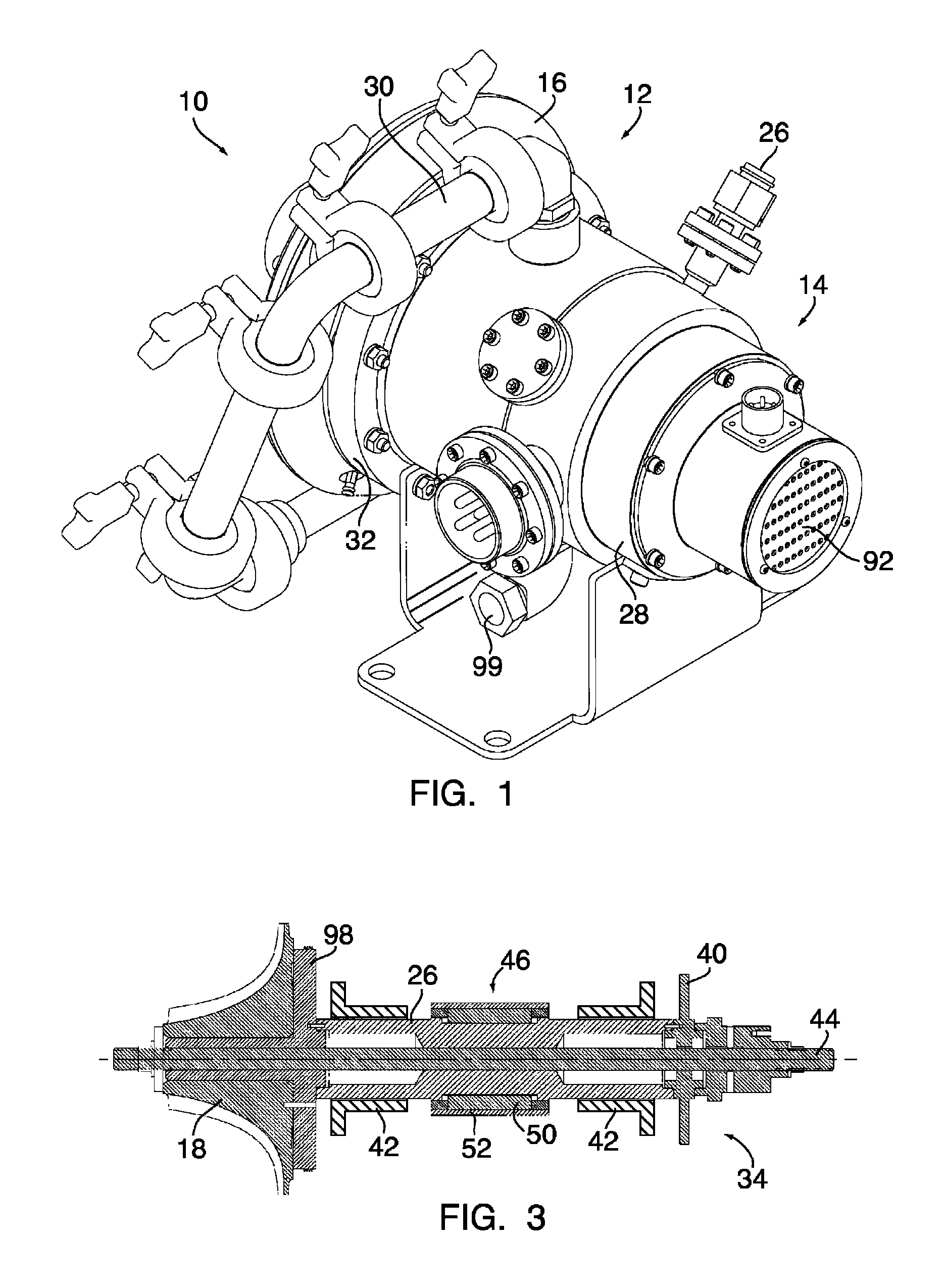

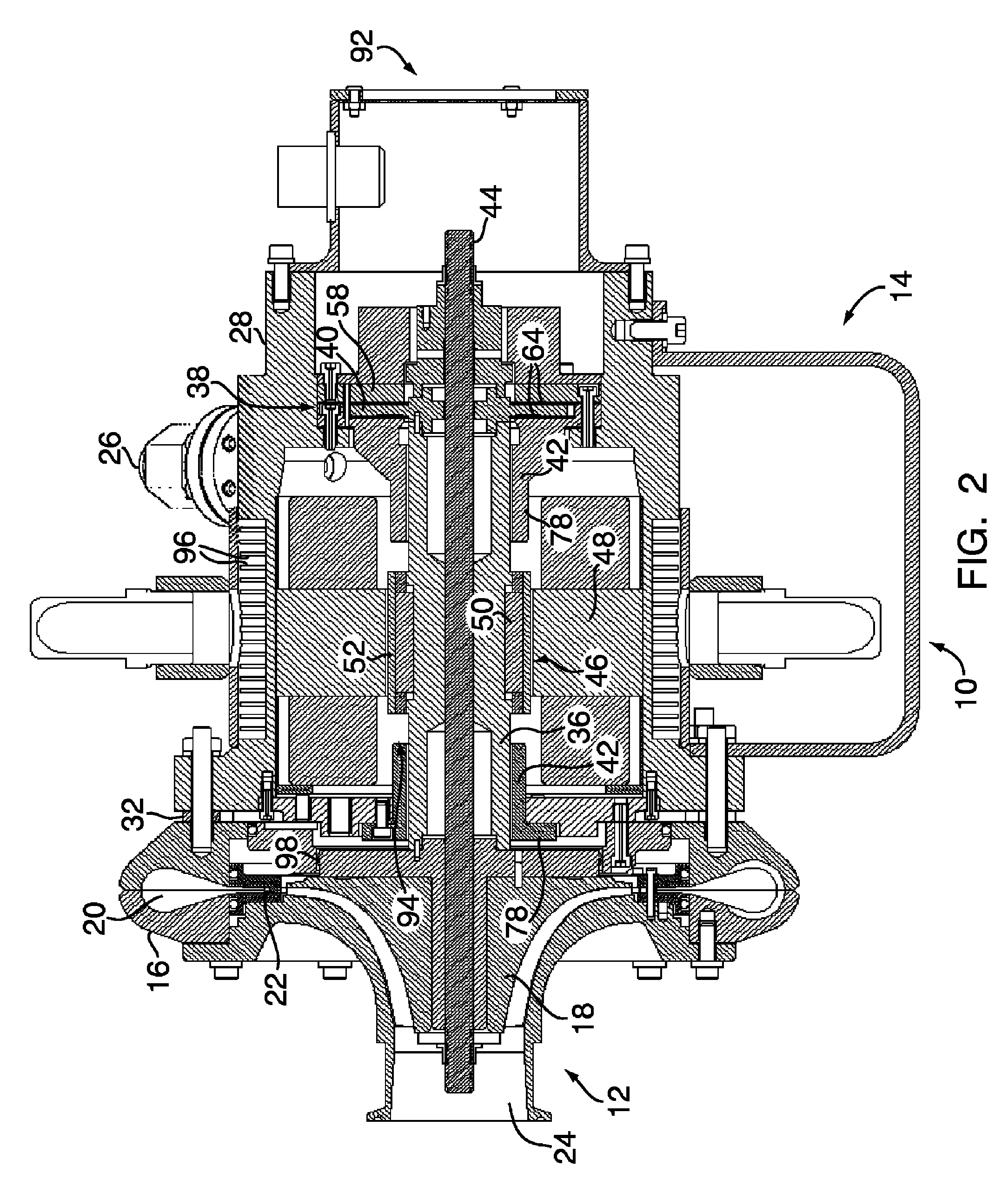

ActiveUS20080246281A1Recovery of wasted energyReduce pressureLiquid degasificationPump componentsStored energyAlternator

This invention provides a small, high efficiency, oil-free turbine-driven alternator (i.e. turboalternator) suitable for conversion of stored energy in a process gas to electrical power, facilitating recapture of energy during operation that would otherwise be wasted. The turboalternator includes a turbine and a generating device operatively connected together by a rotating shaft capable of rotating at high speeds. The rotating shaft is supported by foil gas bearings.

Owner:R & D DYNAMICS

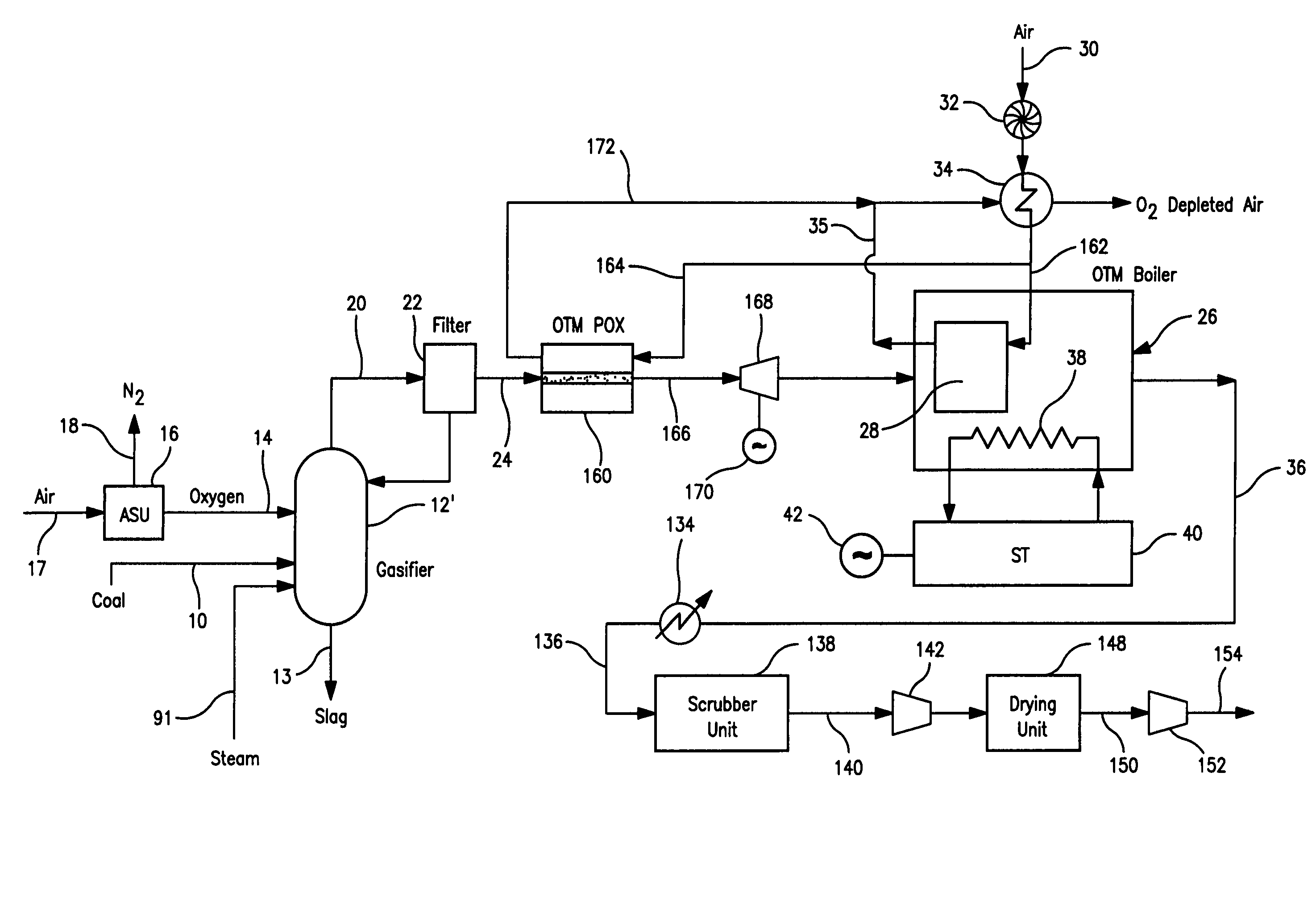

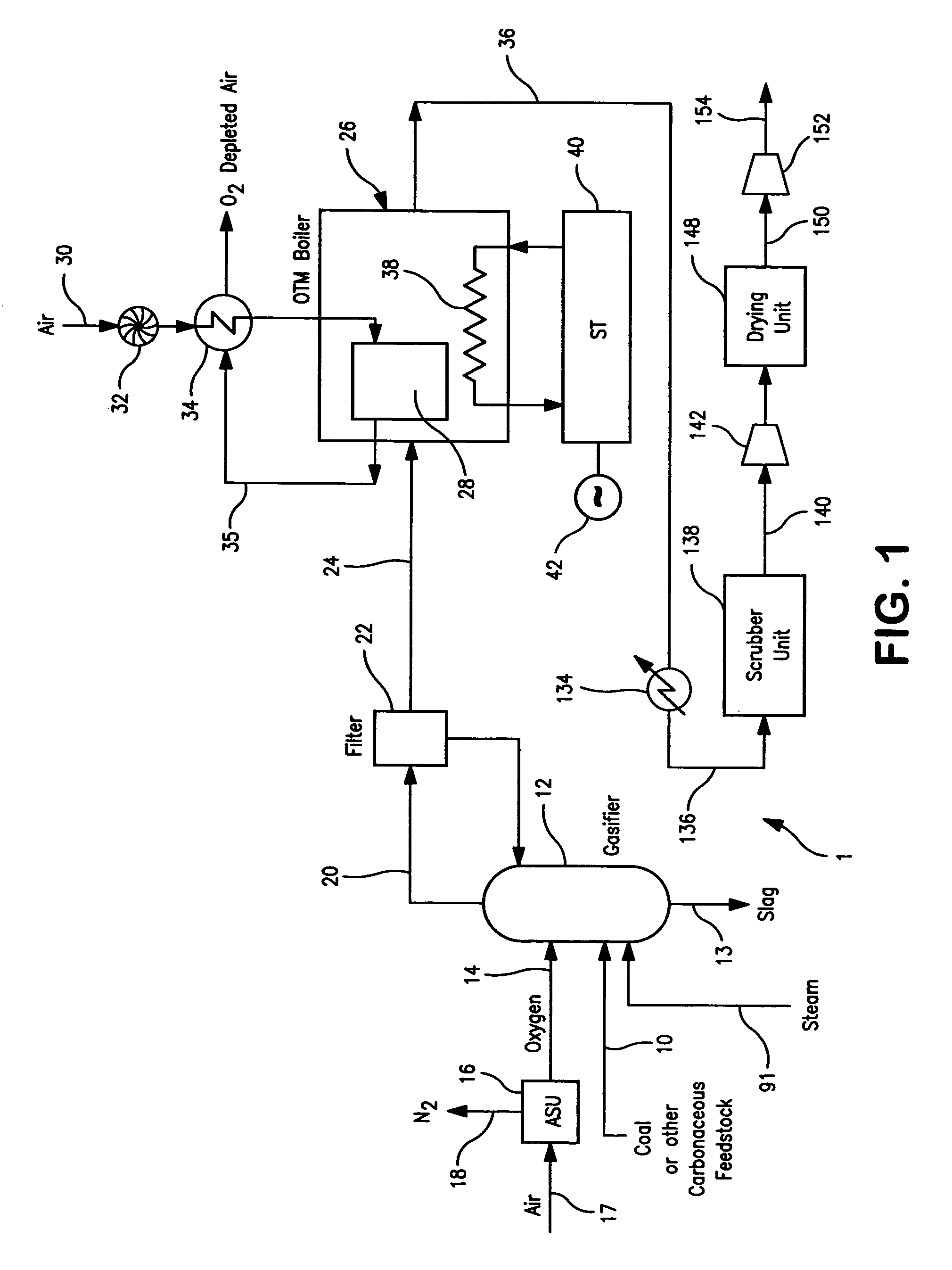

Electrical power generation method

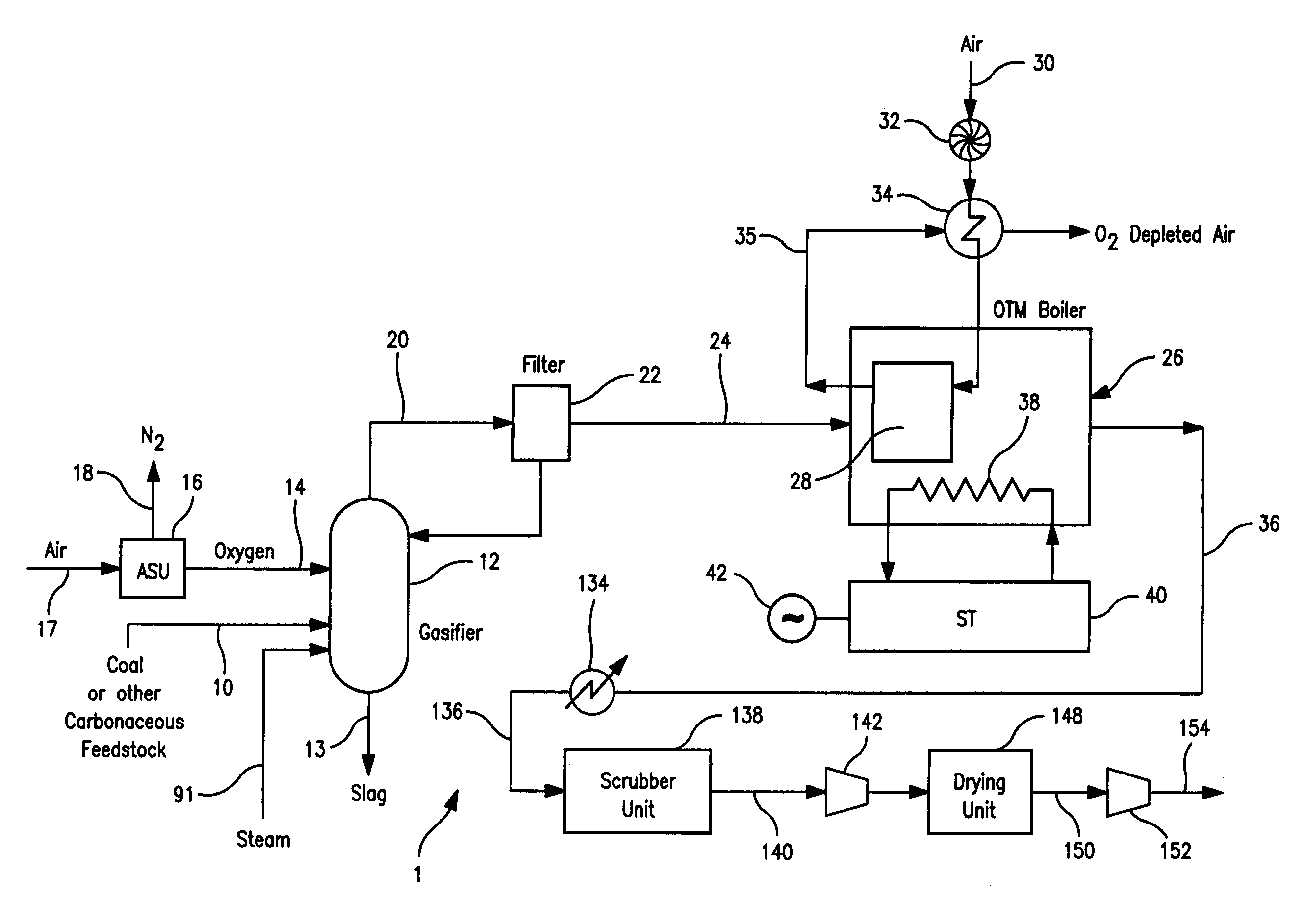

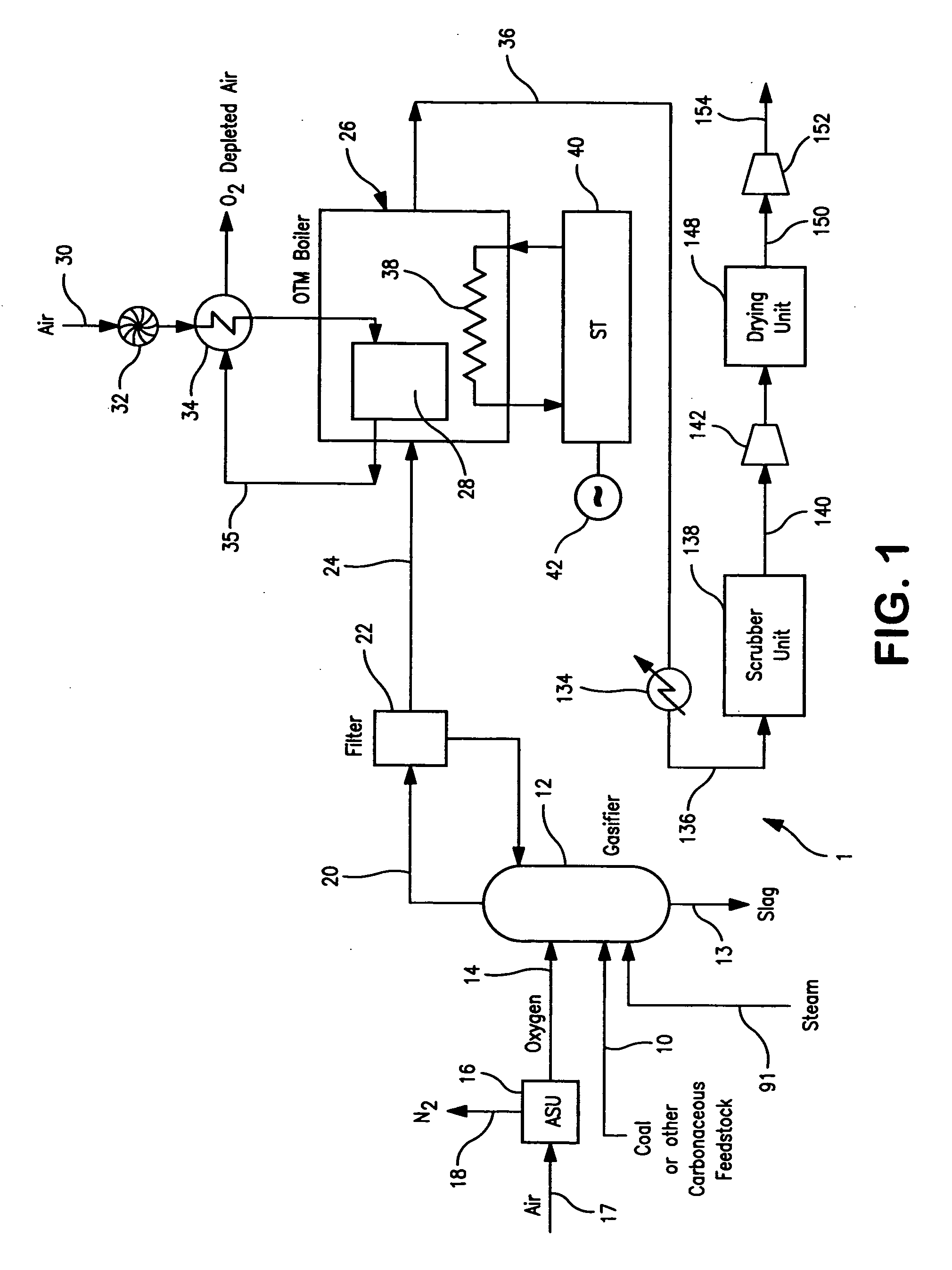

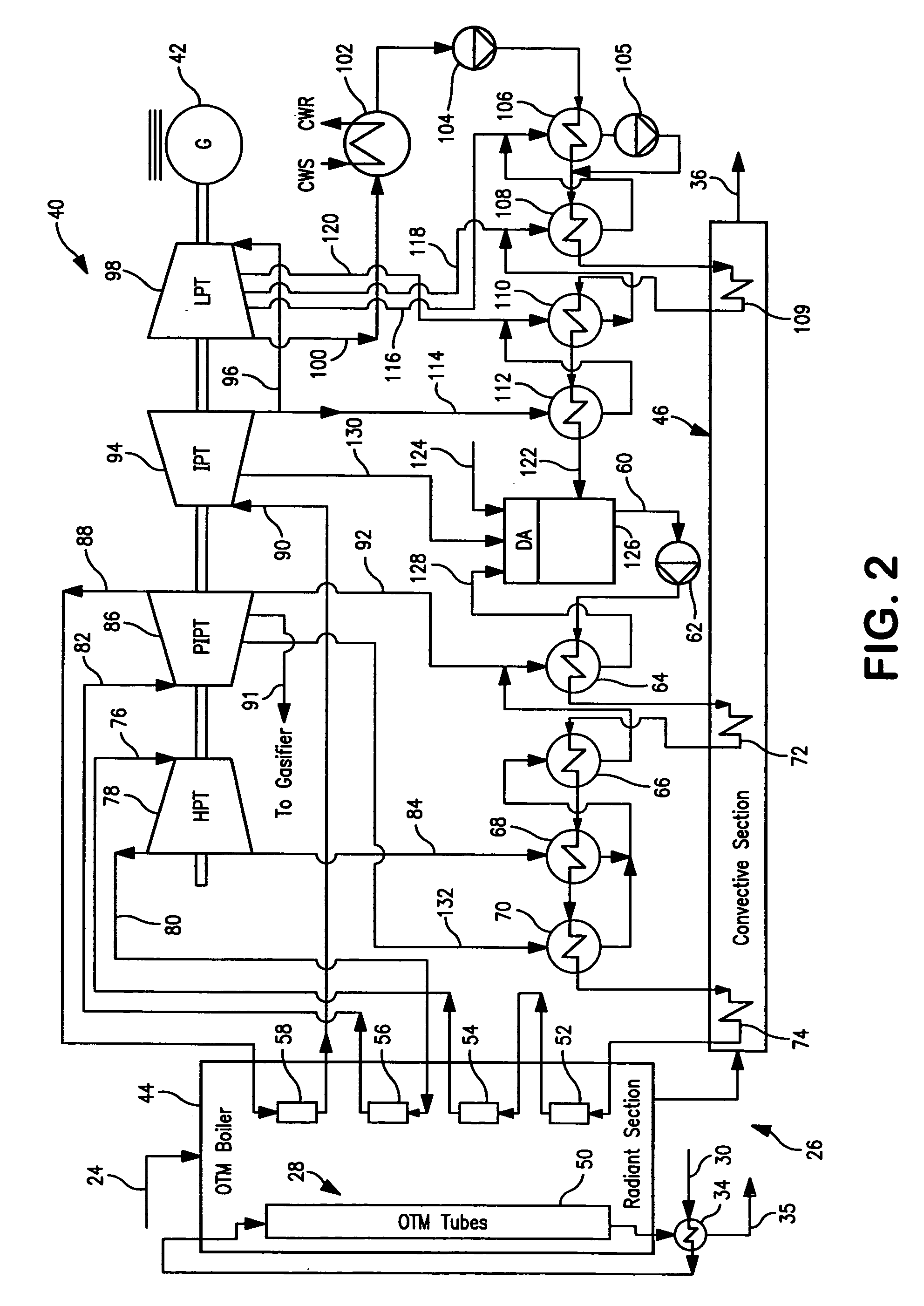

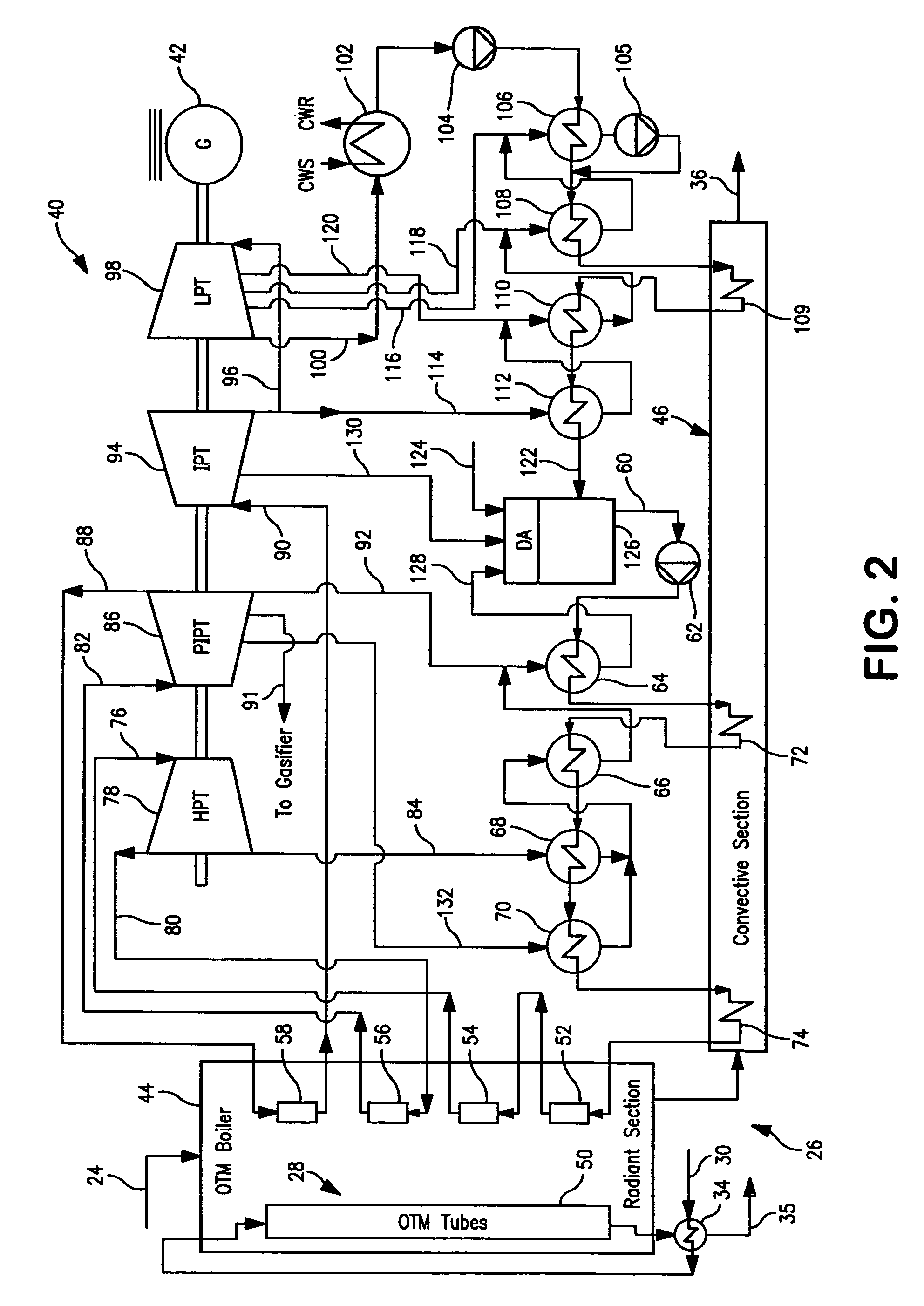

A method of generating electrical power in which a synthesis gas stream generated in a gasifier is combusted in an oxygen transport membrane system of a boiler. The combustion generates heat to raise steam to in turn generate electricity by a generator coupled to a steam turbine. The resultant flue gas can be purified to produce a carbon dioxide product.

Owner:PRAXAIR TECH INC

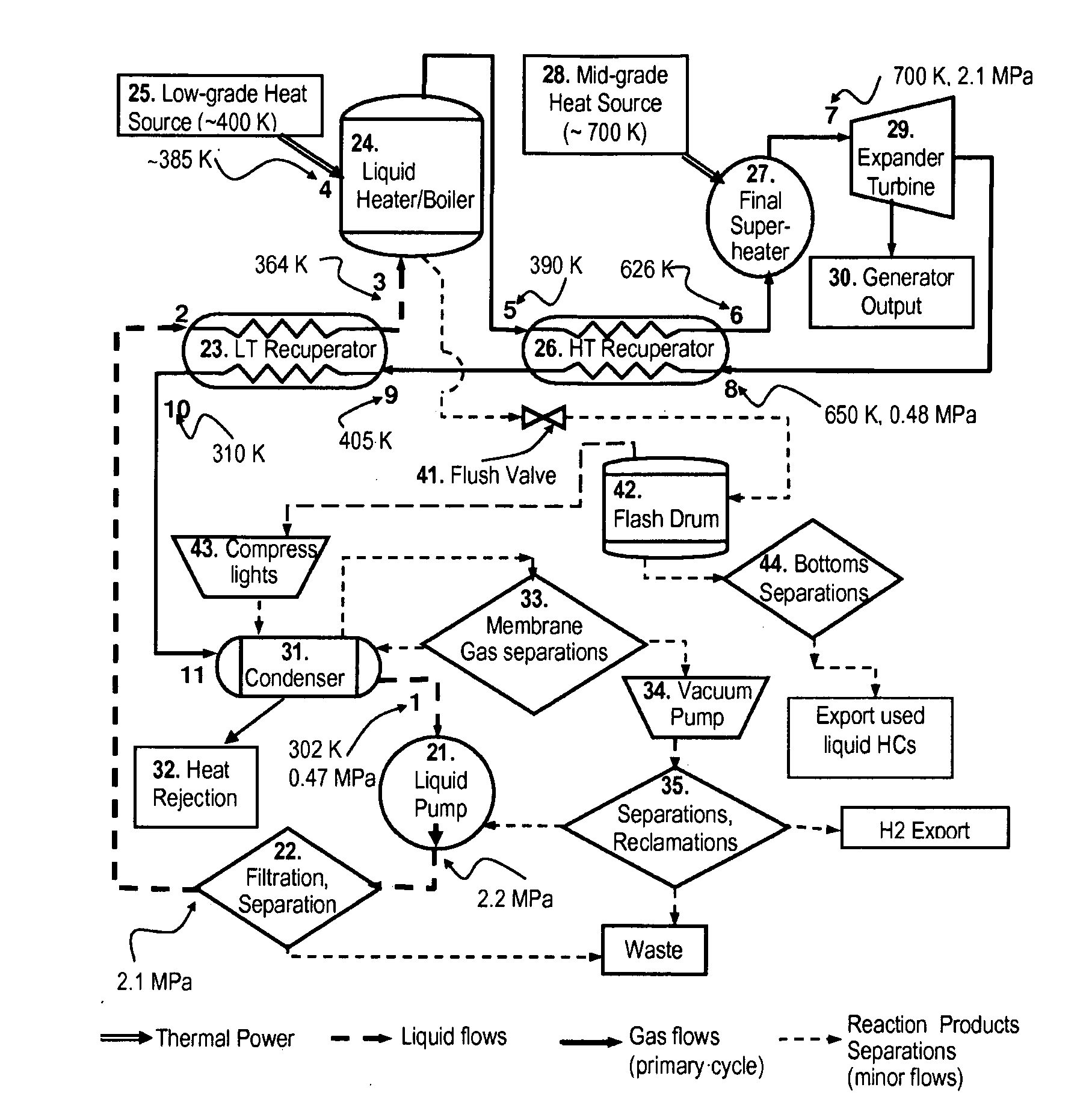

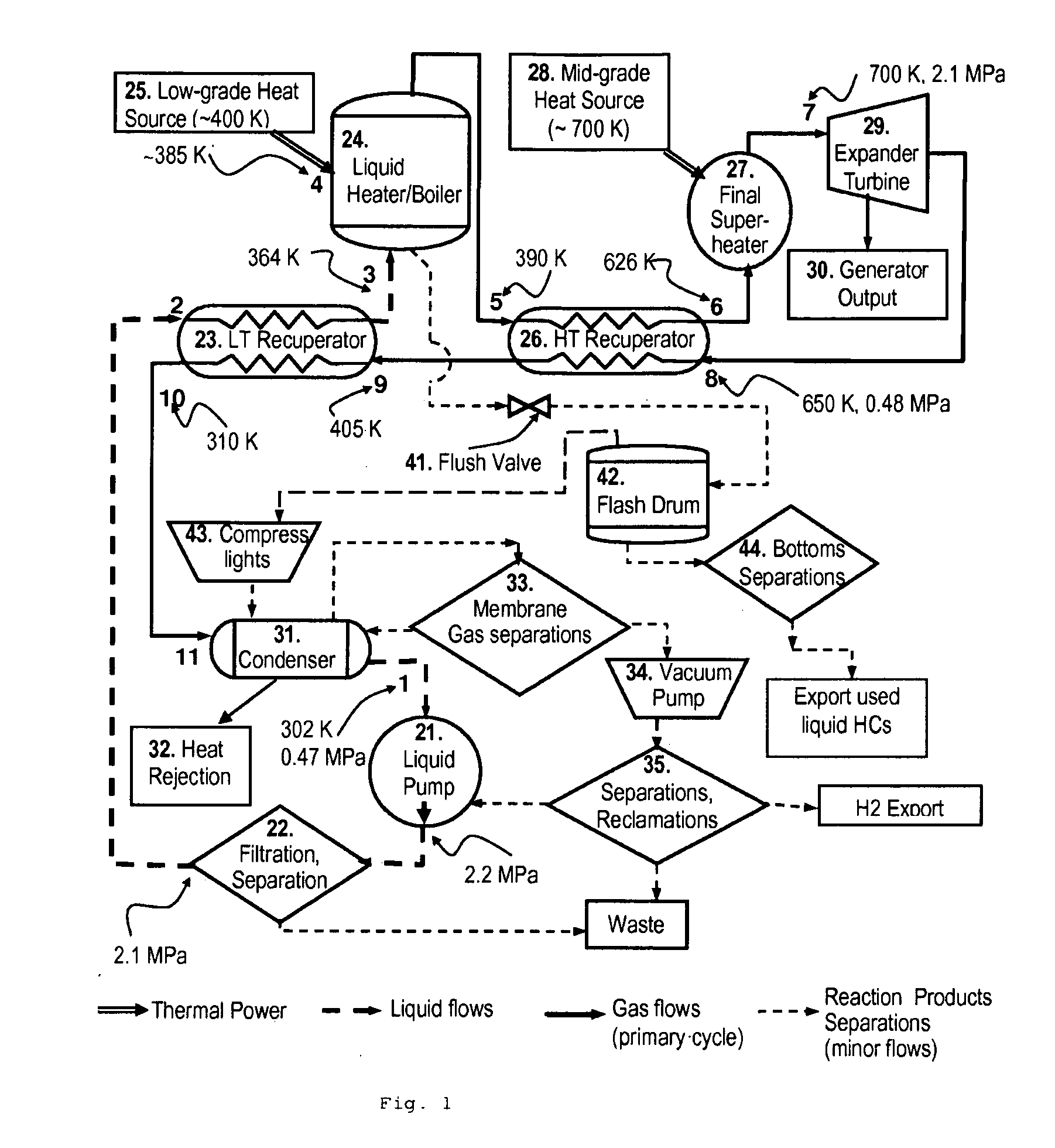

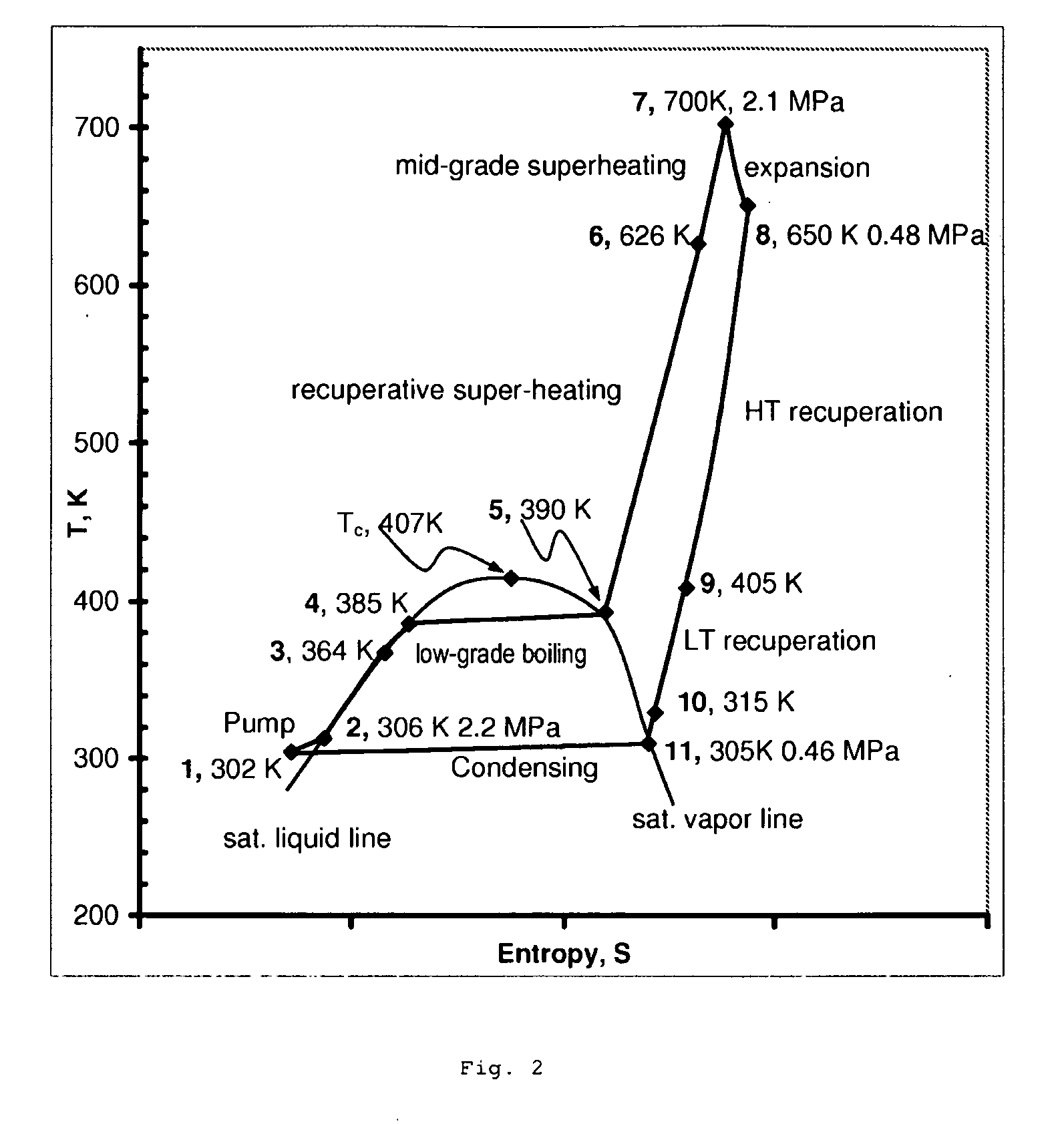

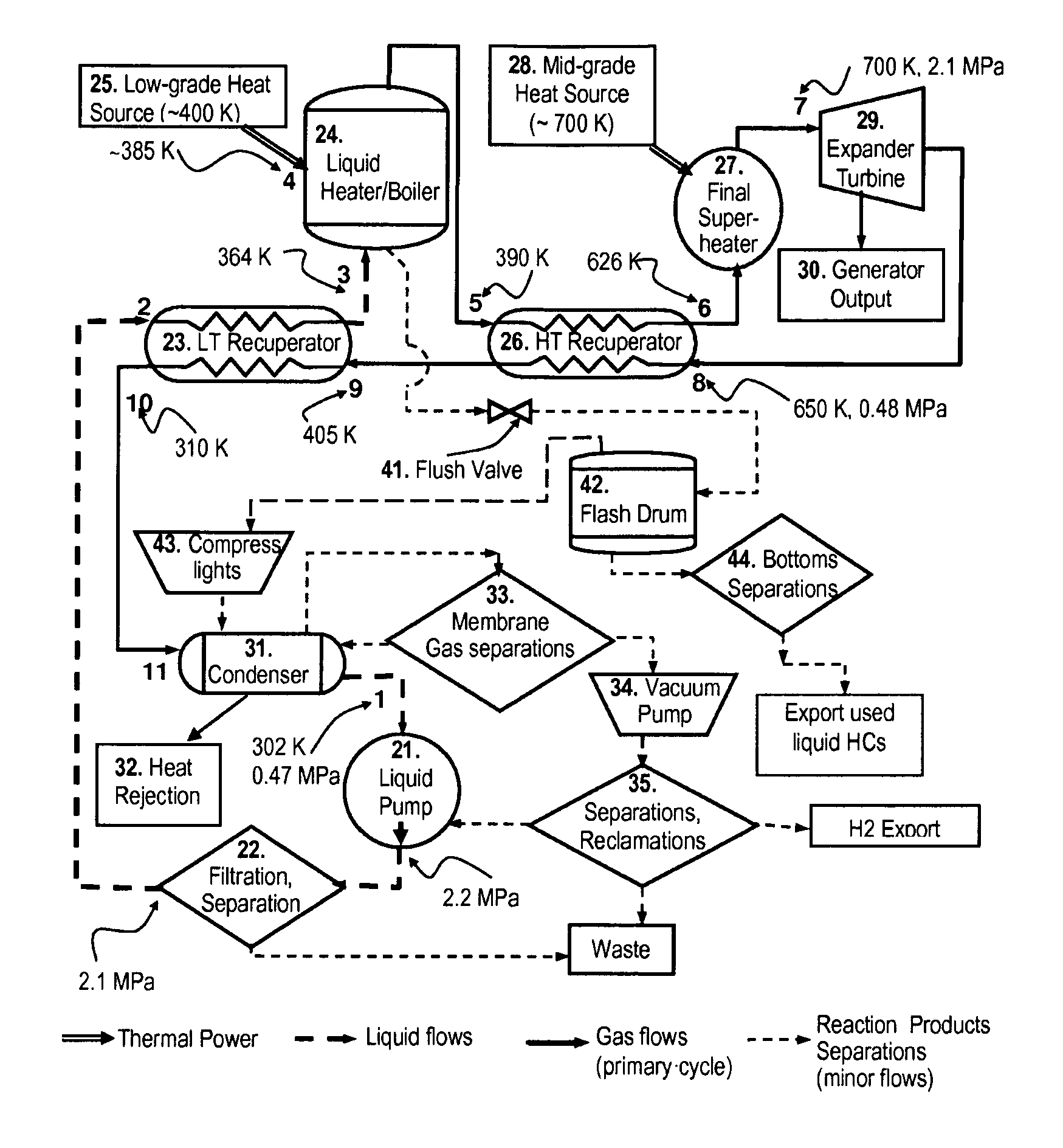

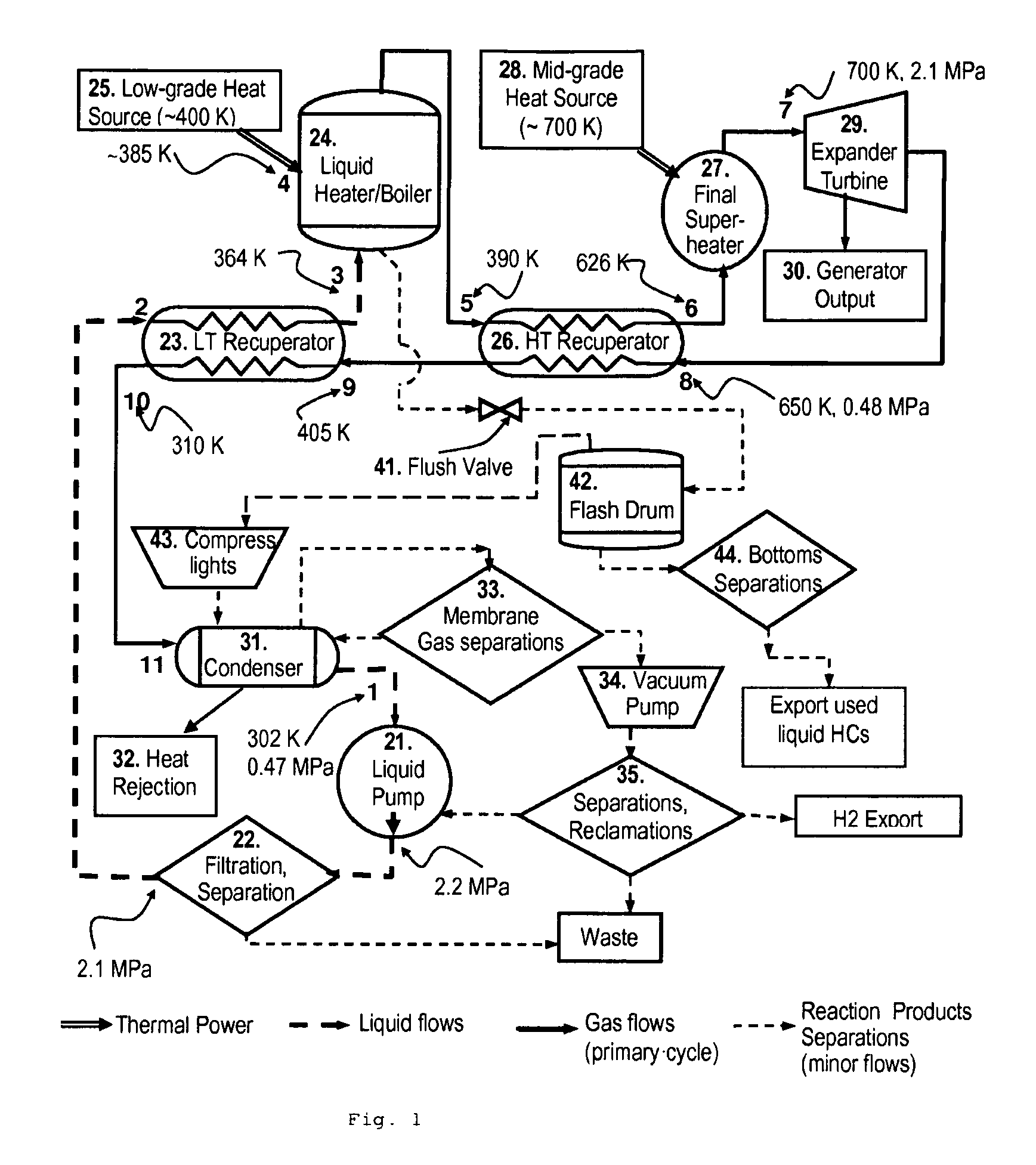

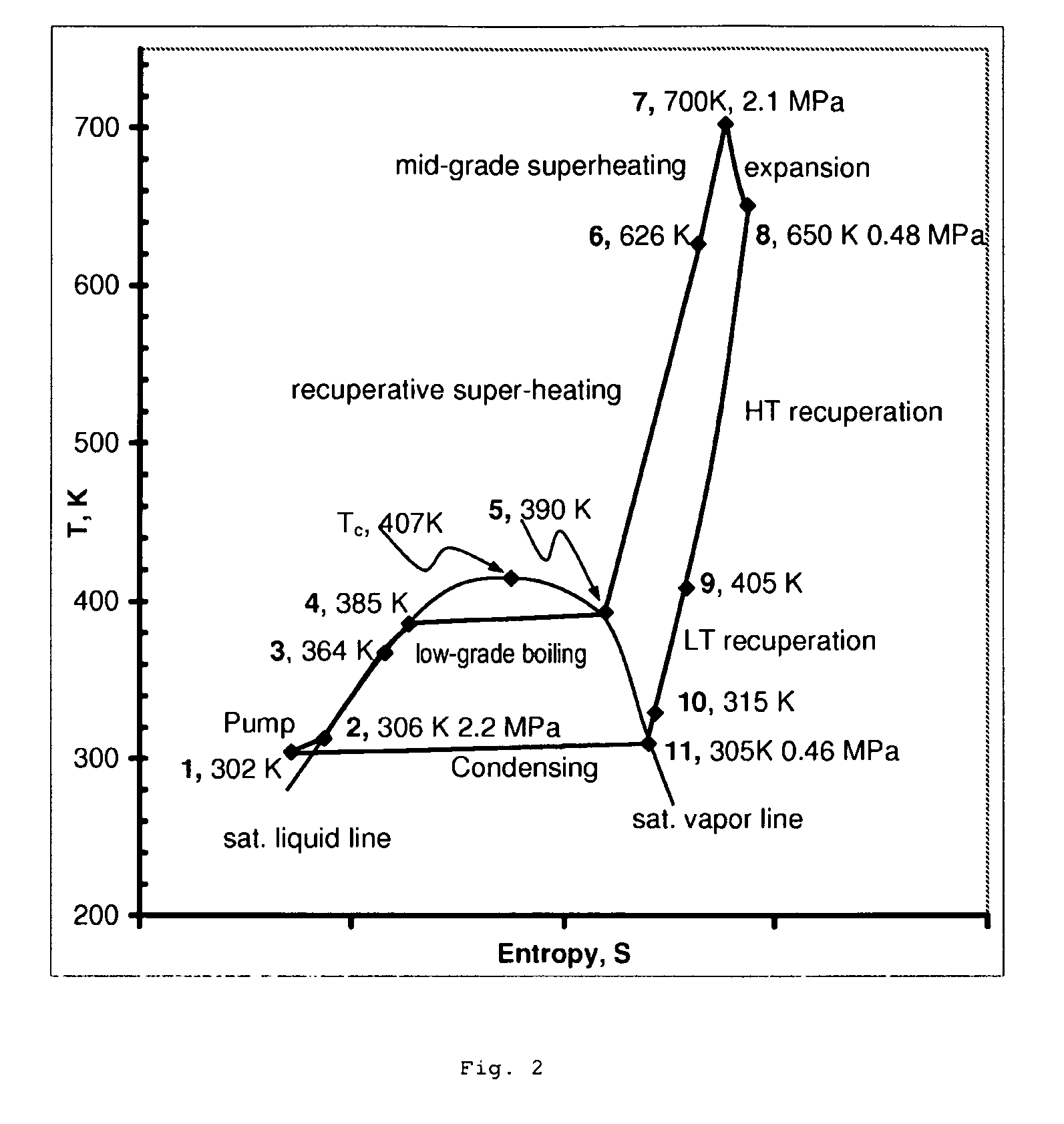

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

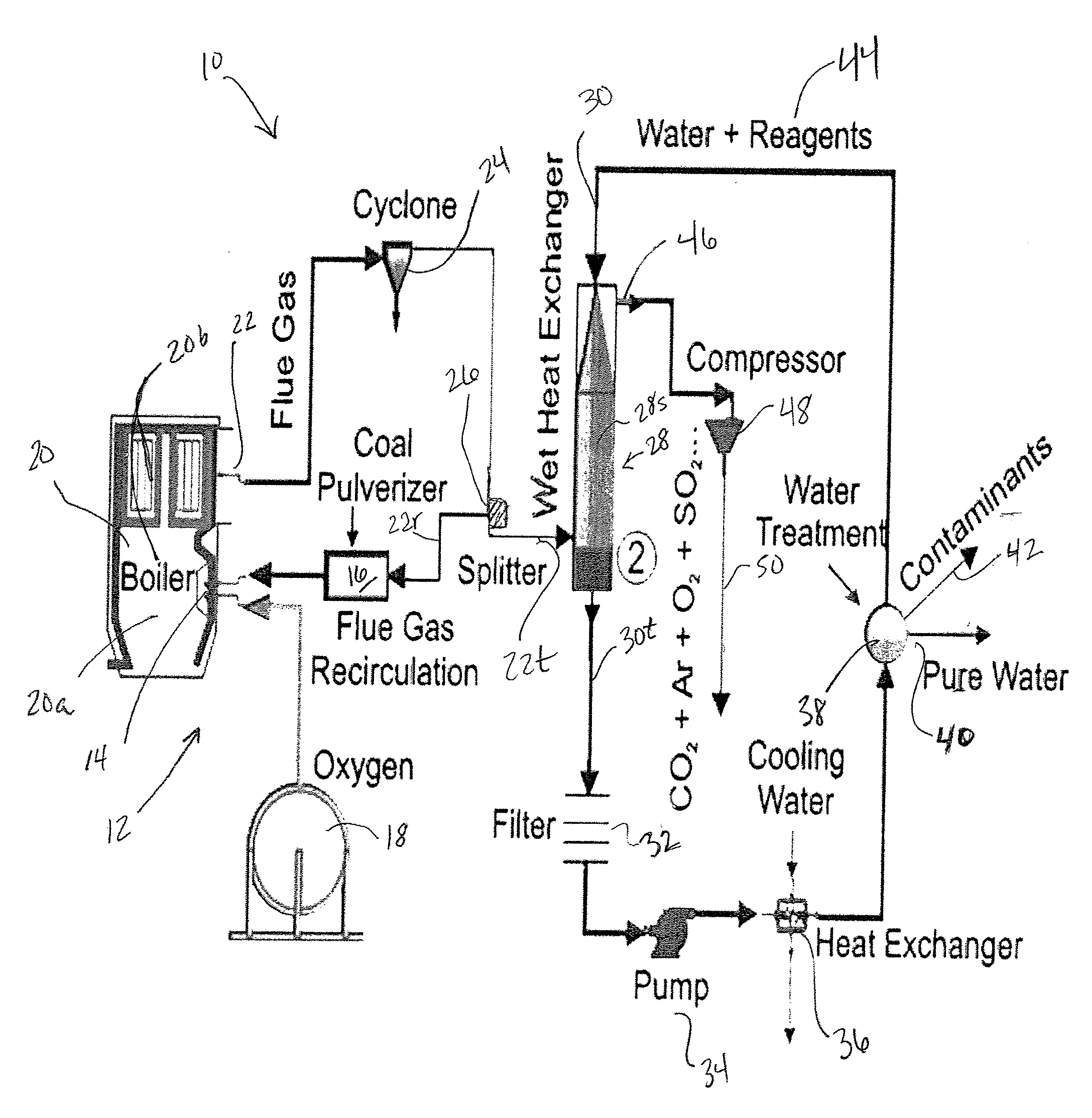

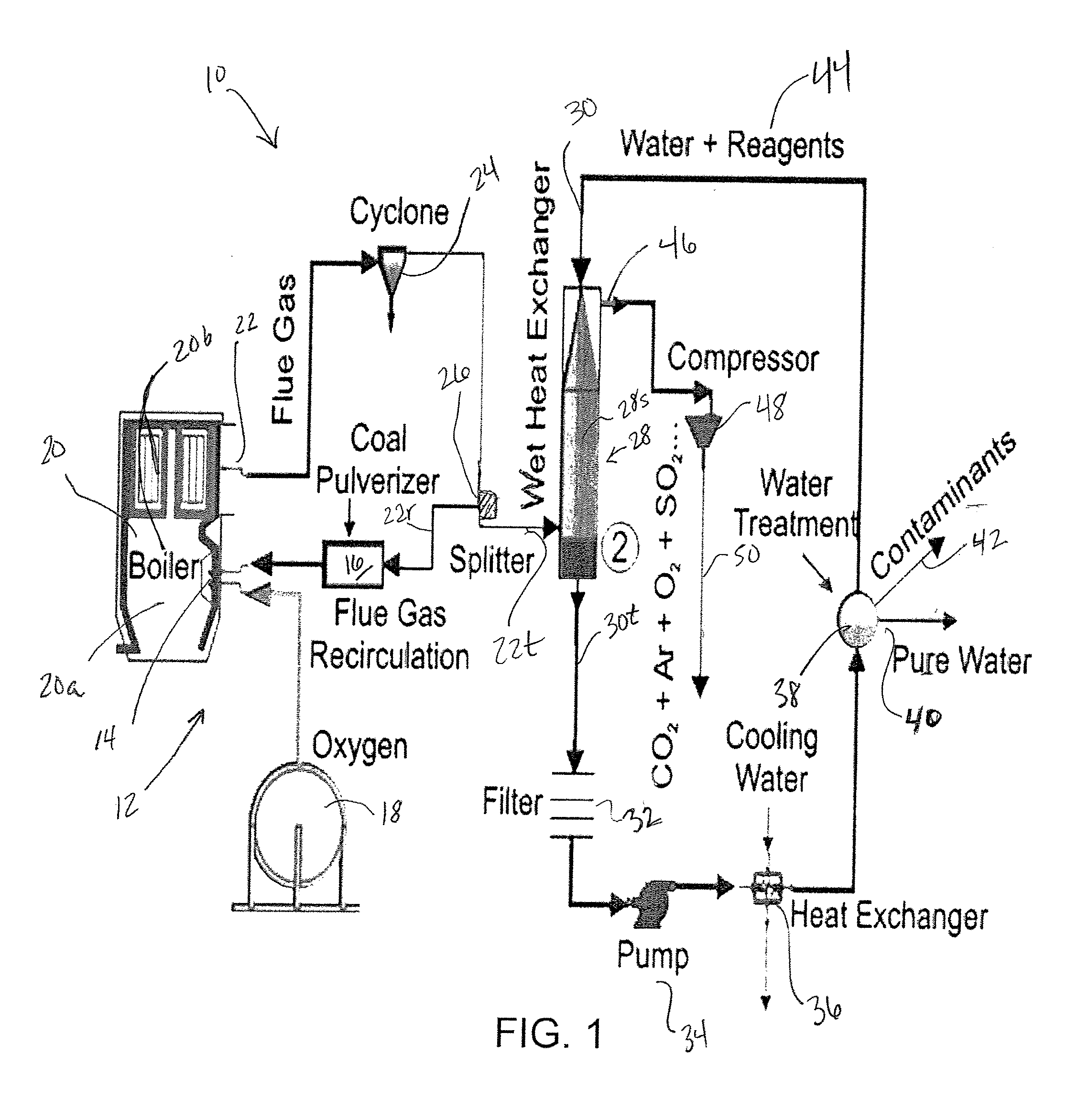

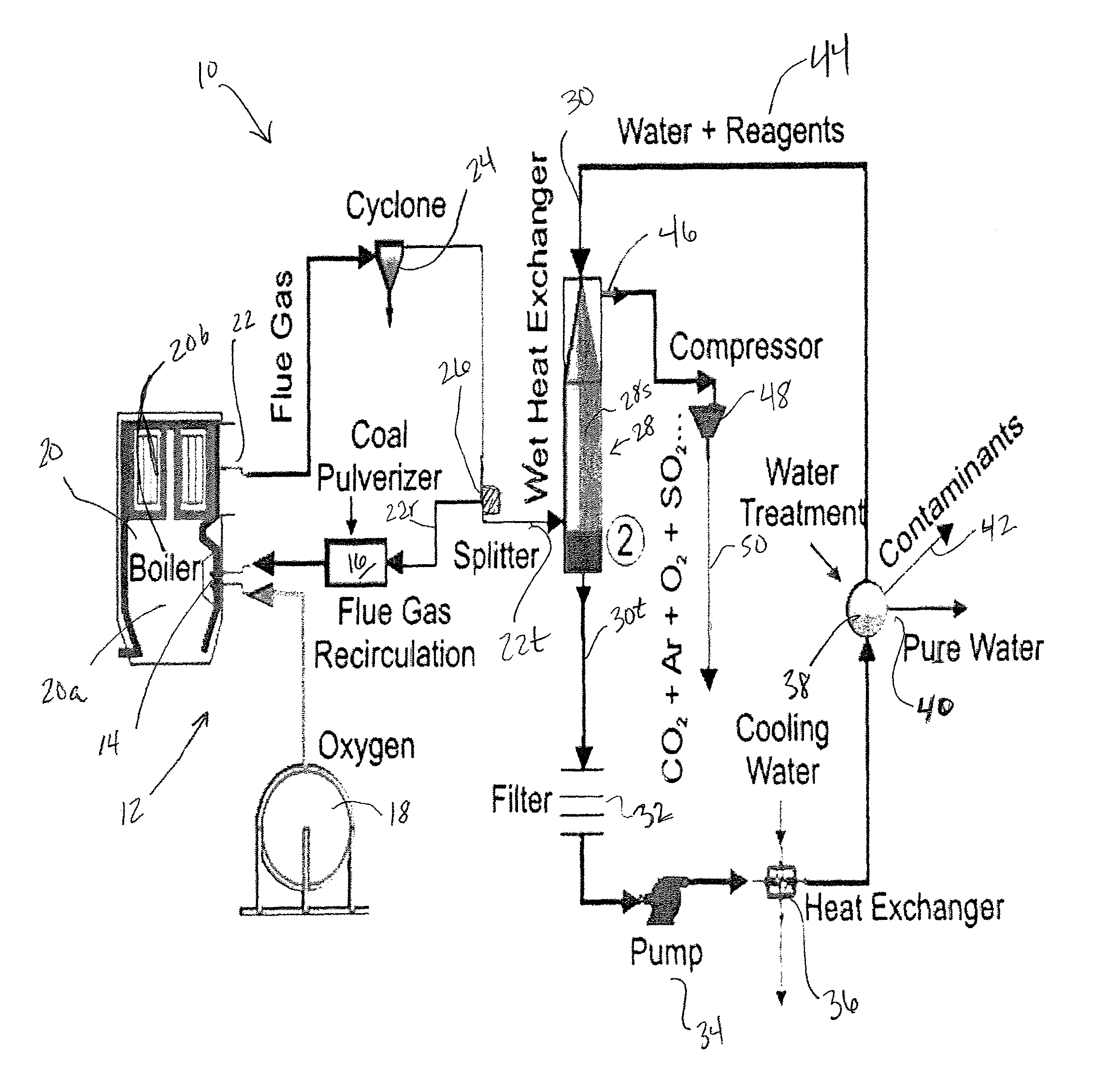

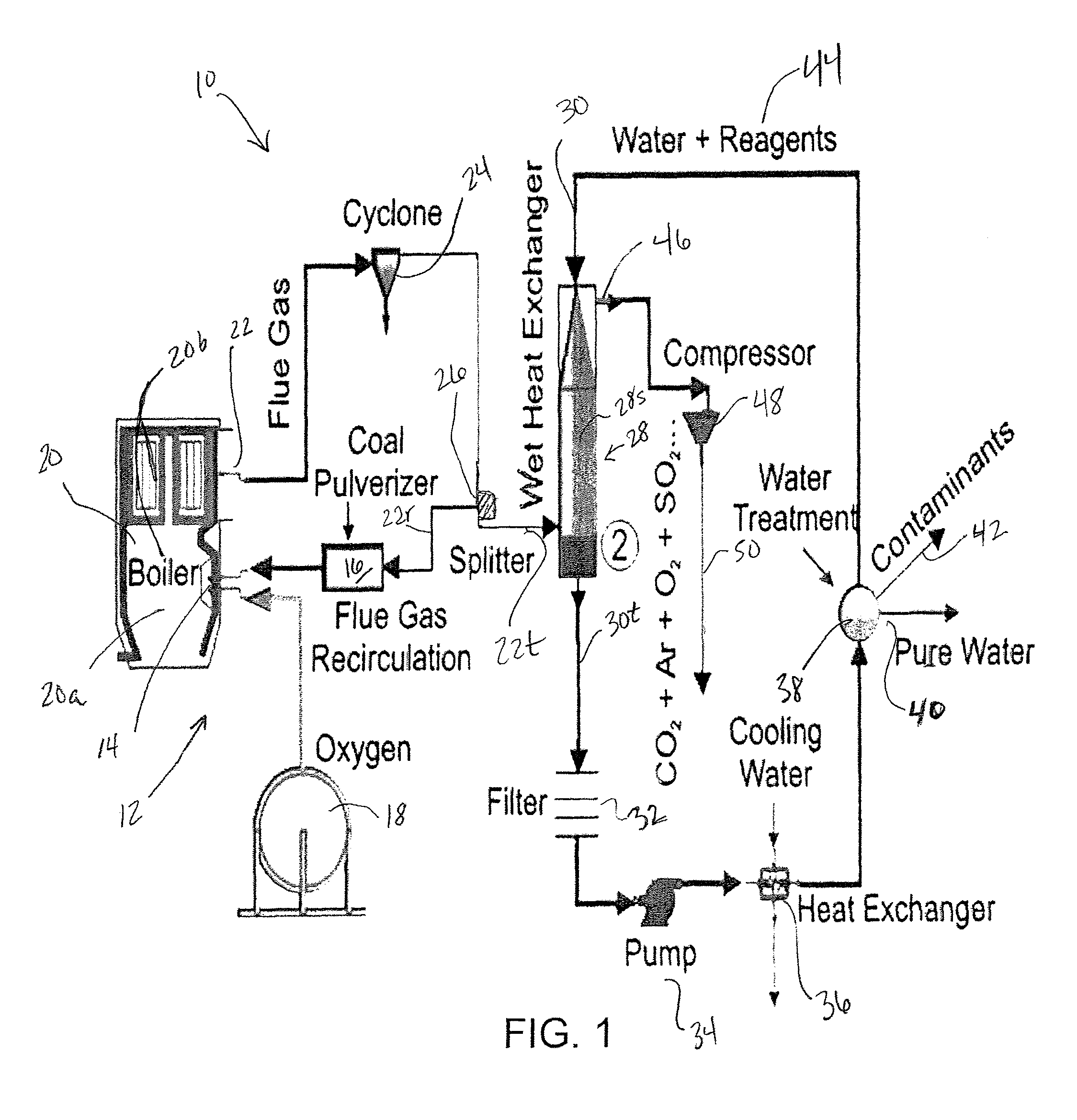

Integrated capture of fossil fuel gas pollutants including co2 with energy recovery

ActiveUS20080016868A1Increase costMaximum recoveryUsing liquid separation agentEmission preventionParticulatesEnergy recovery

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

Integrated capture of fossil fuel gas pollutants including CO2 with energy recovery

ActiveUS8038773B2Maximum recoveryUsing liquid separation agentEmission preventionParticulatesAtmospheric air

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

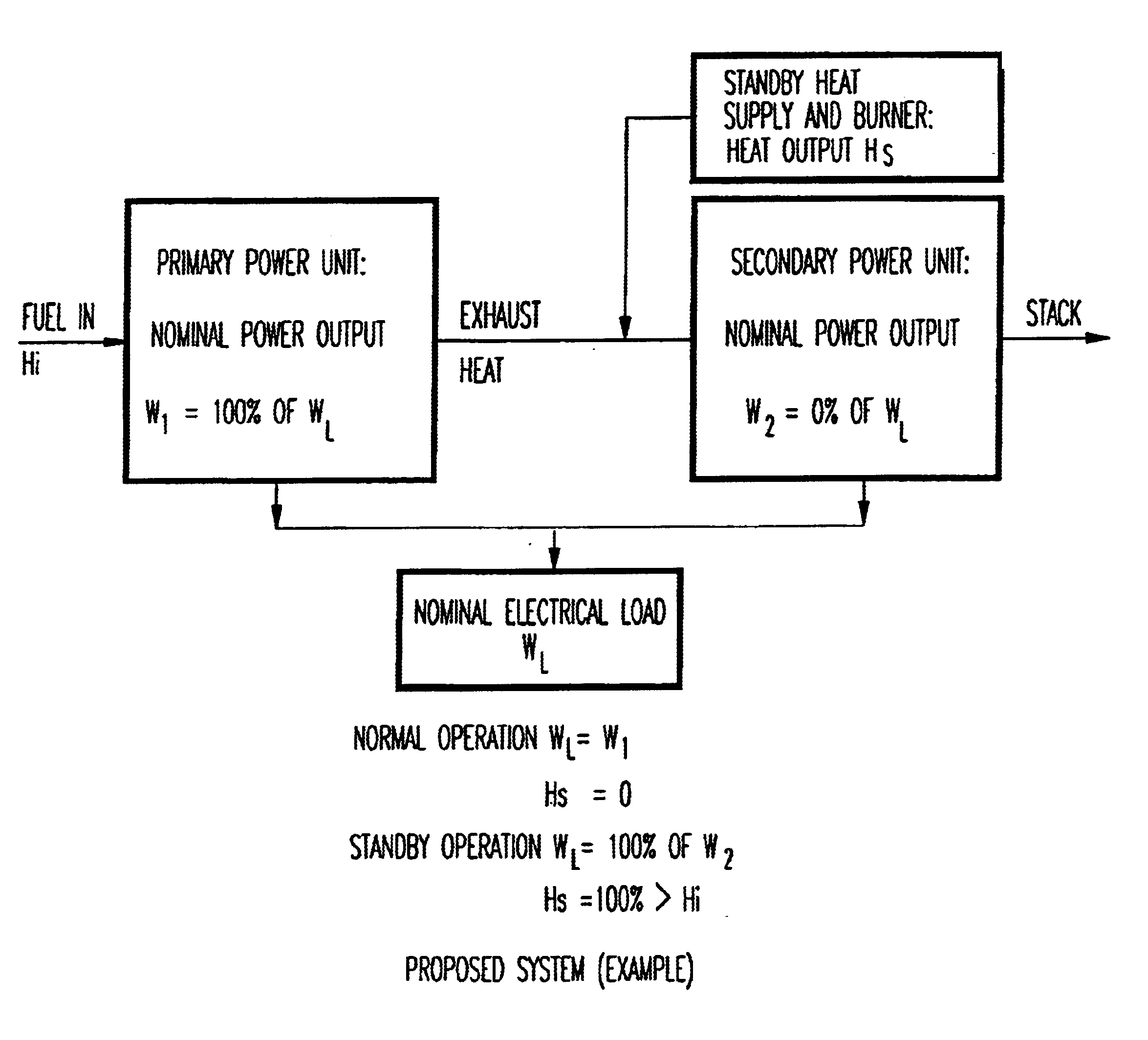

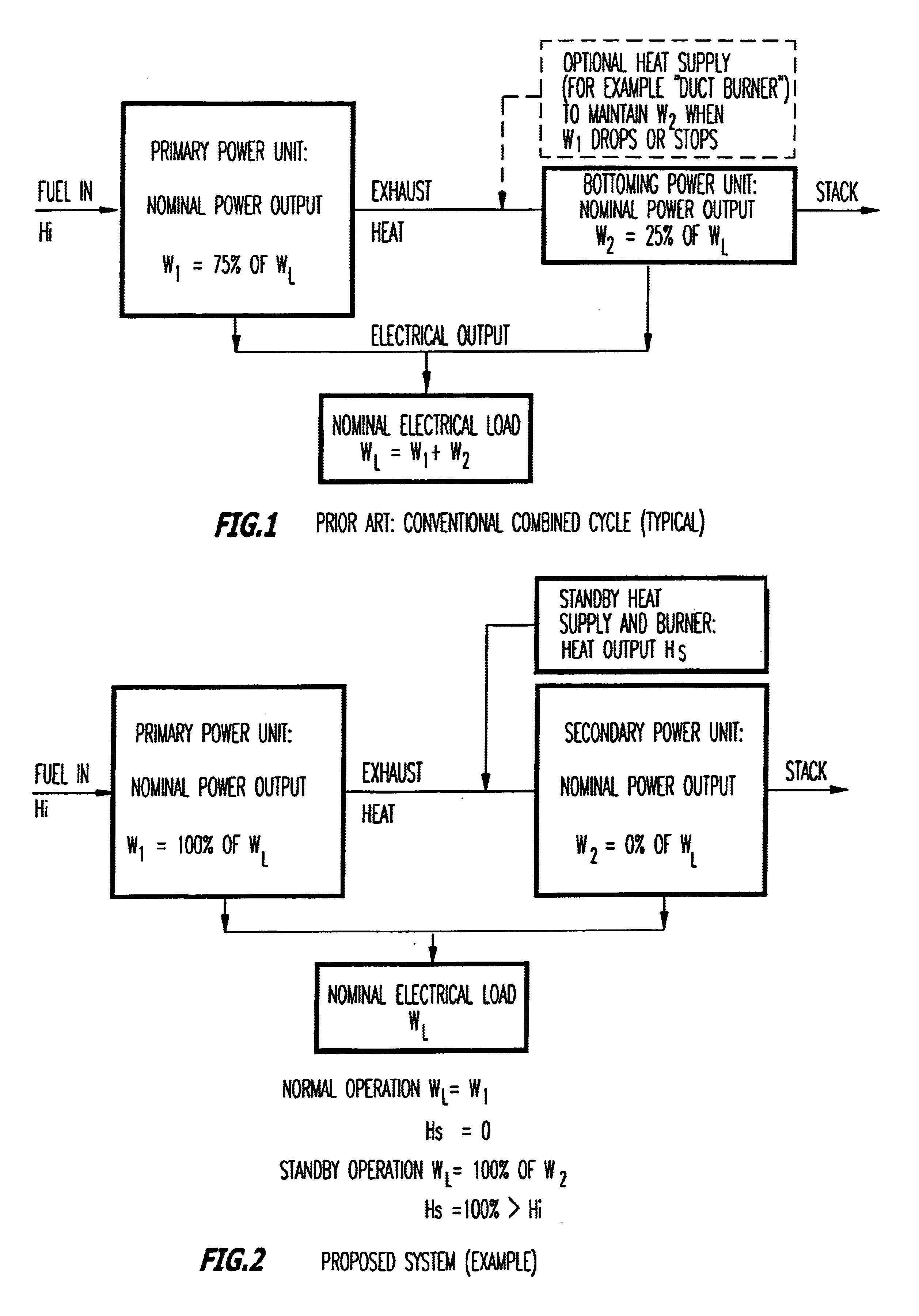

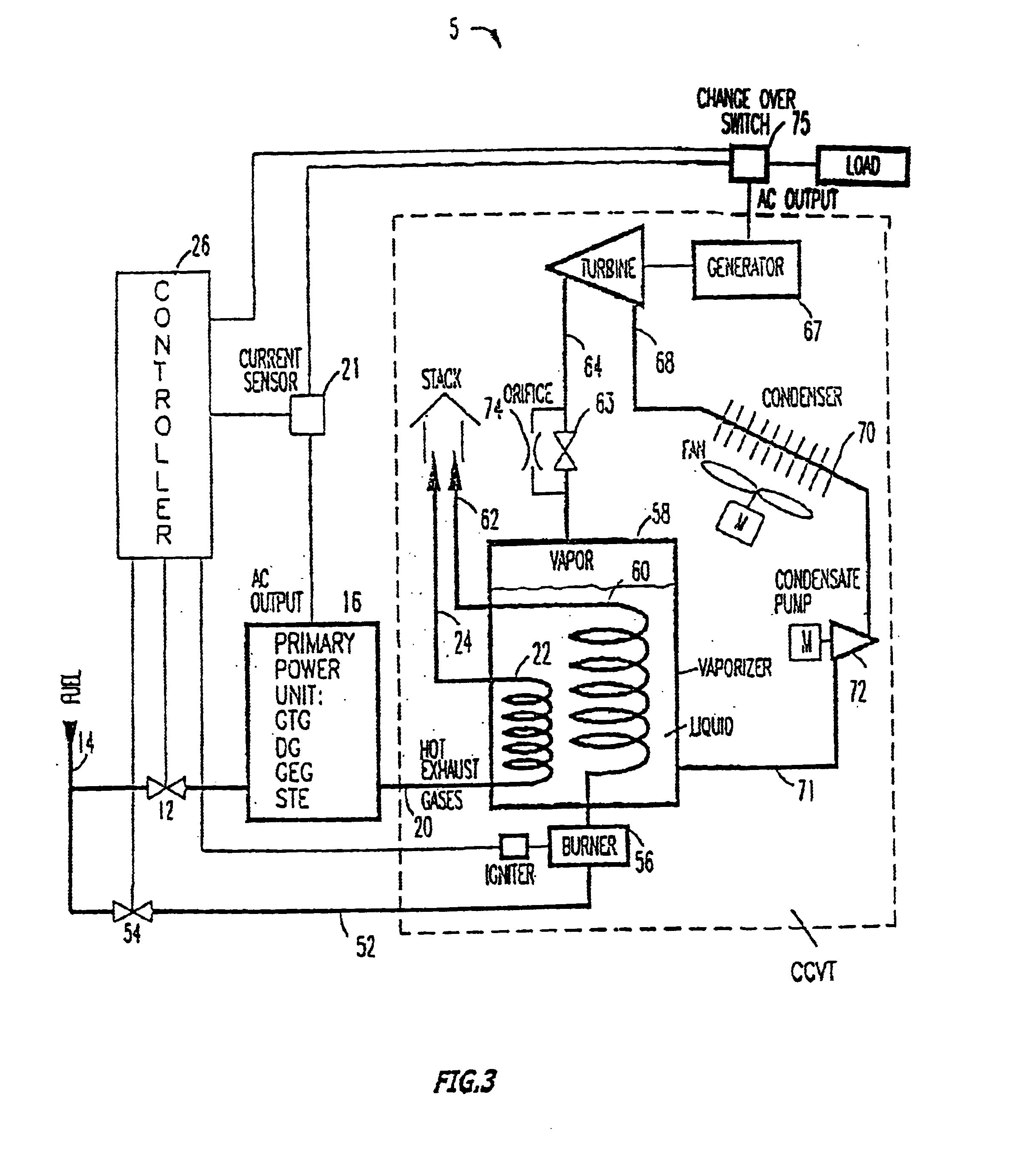

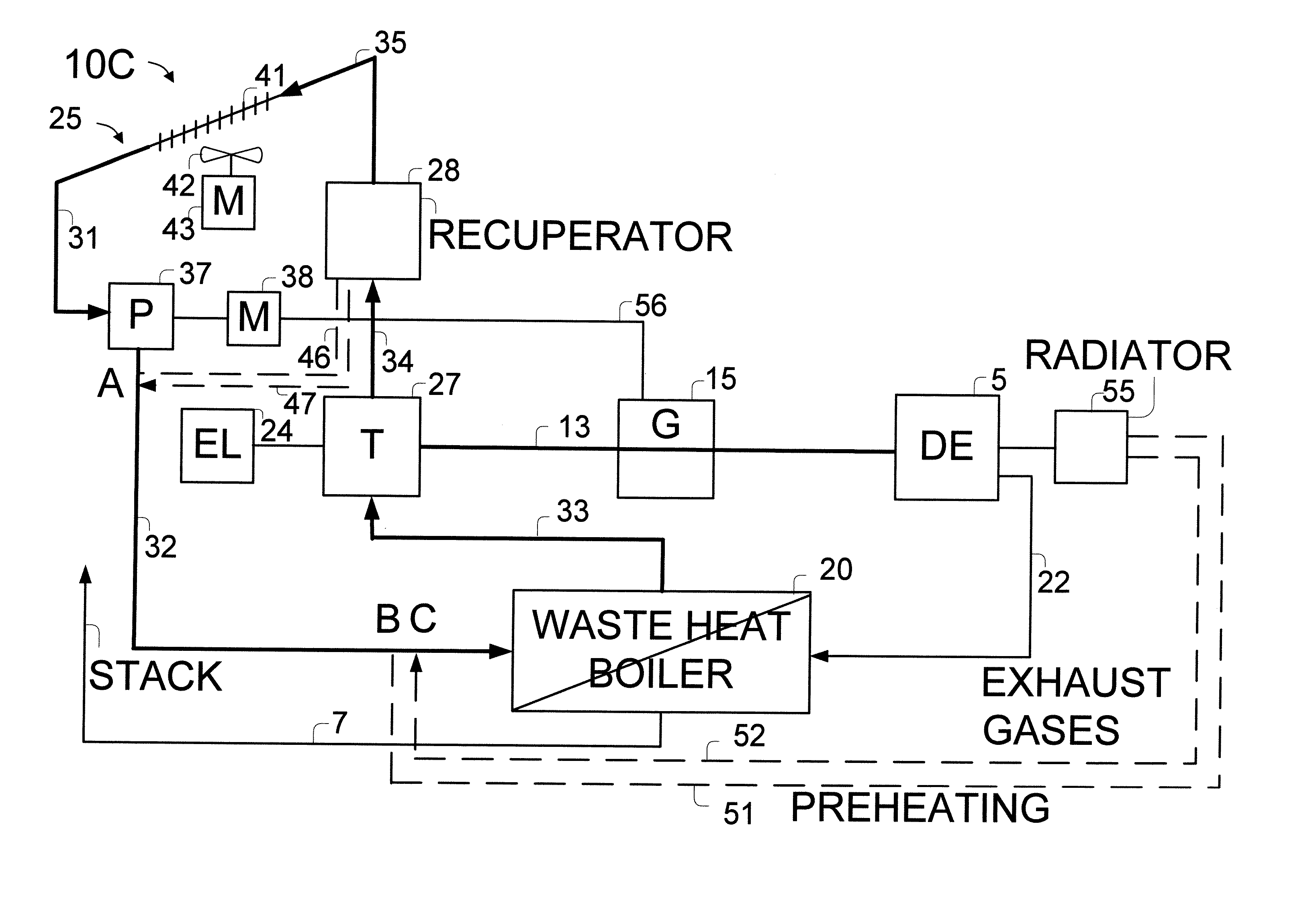

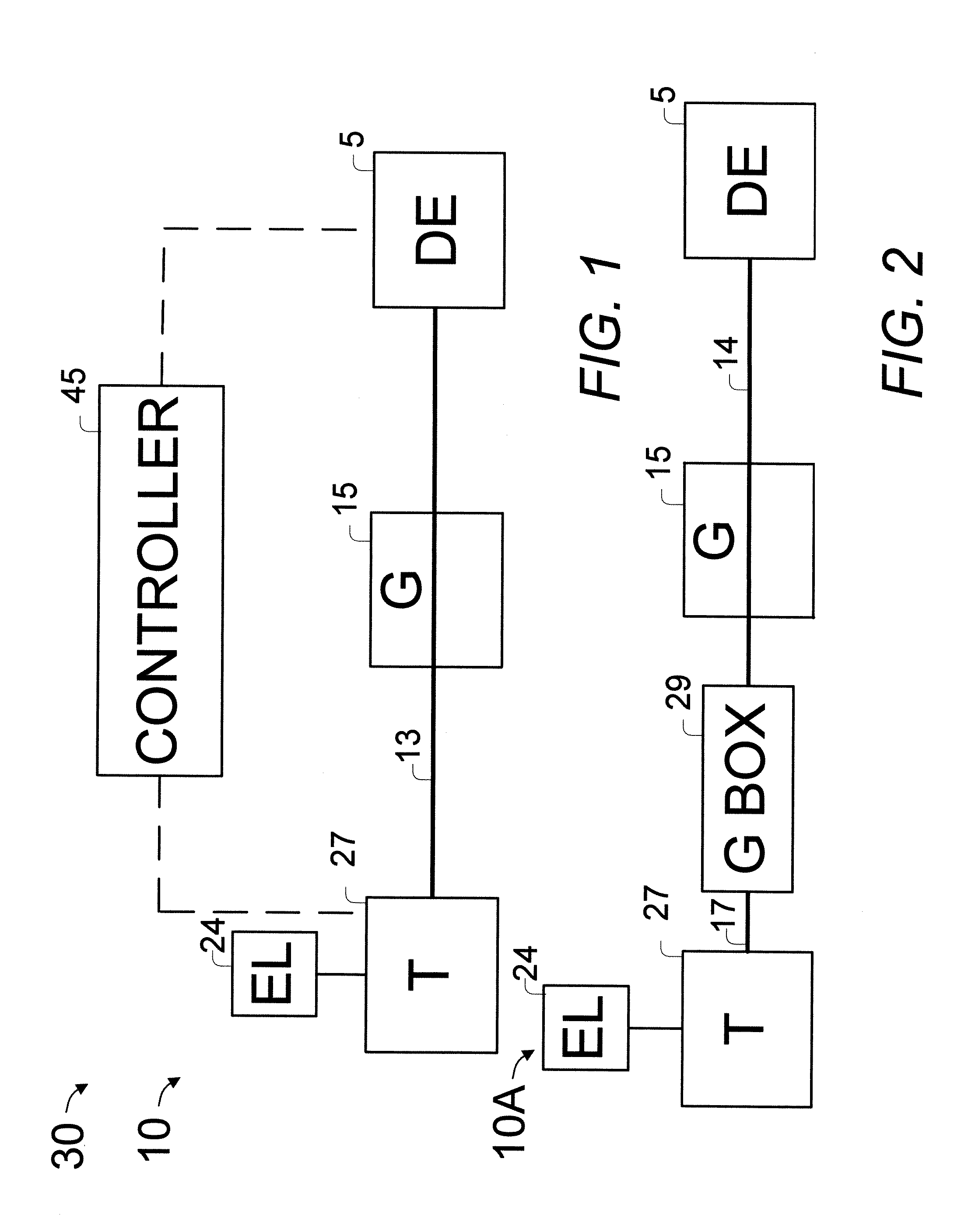

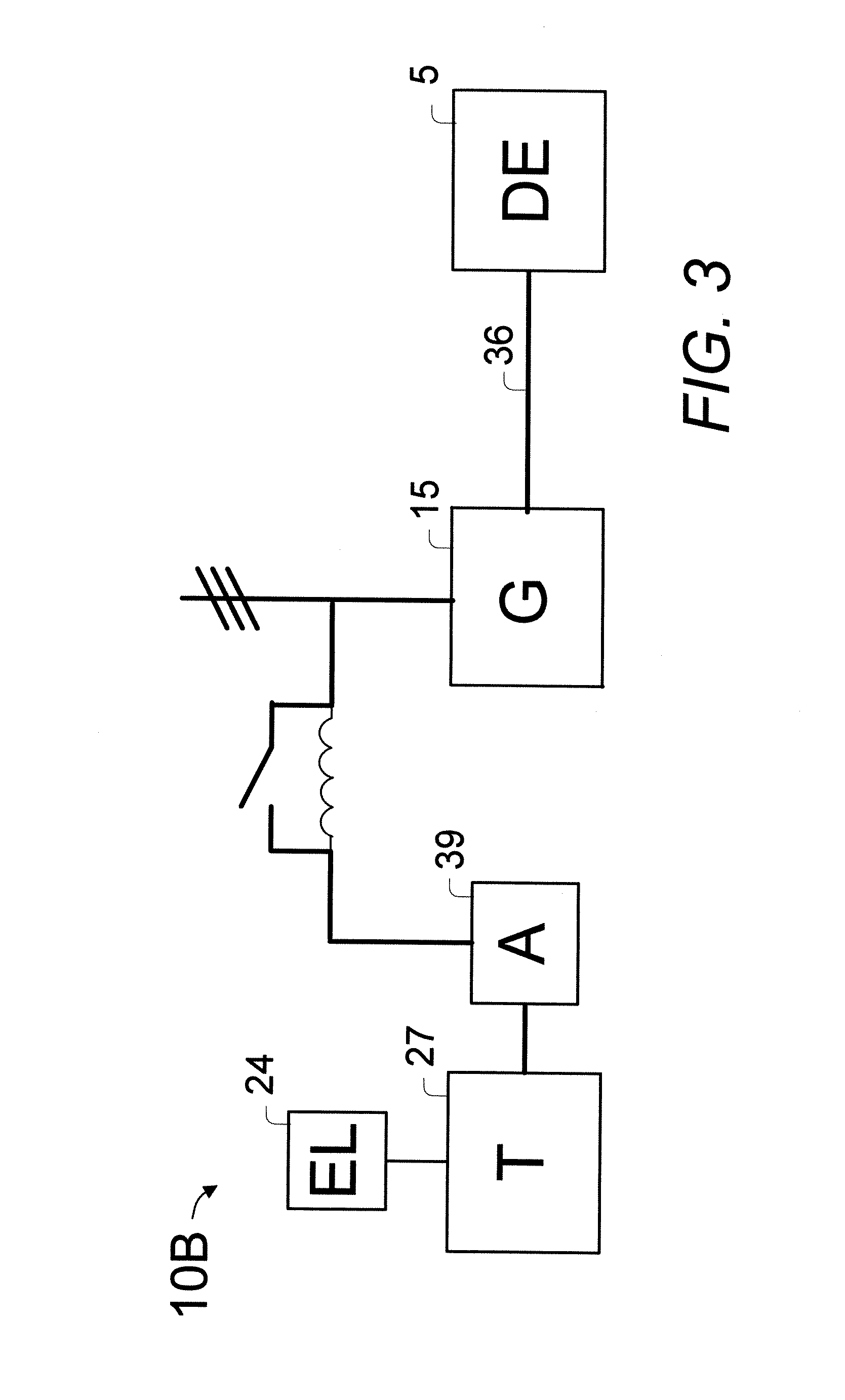

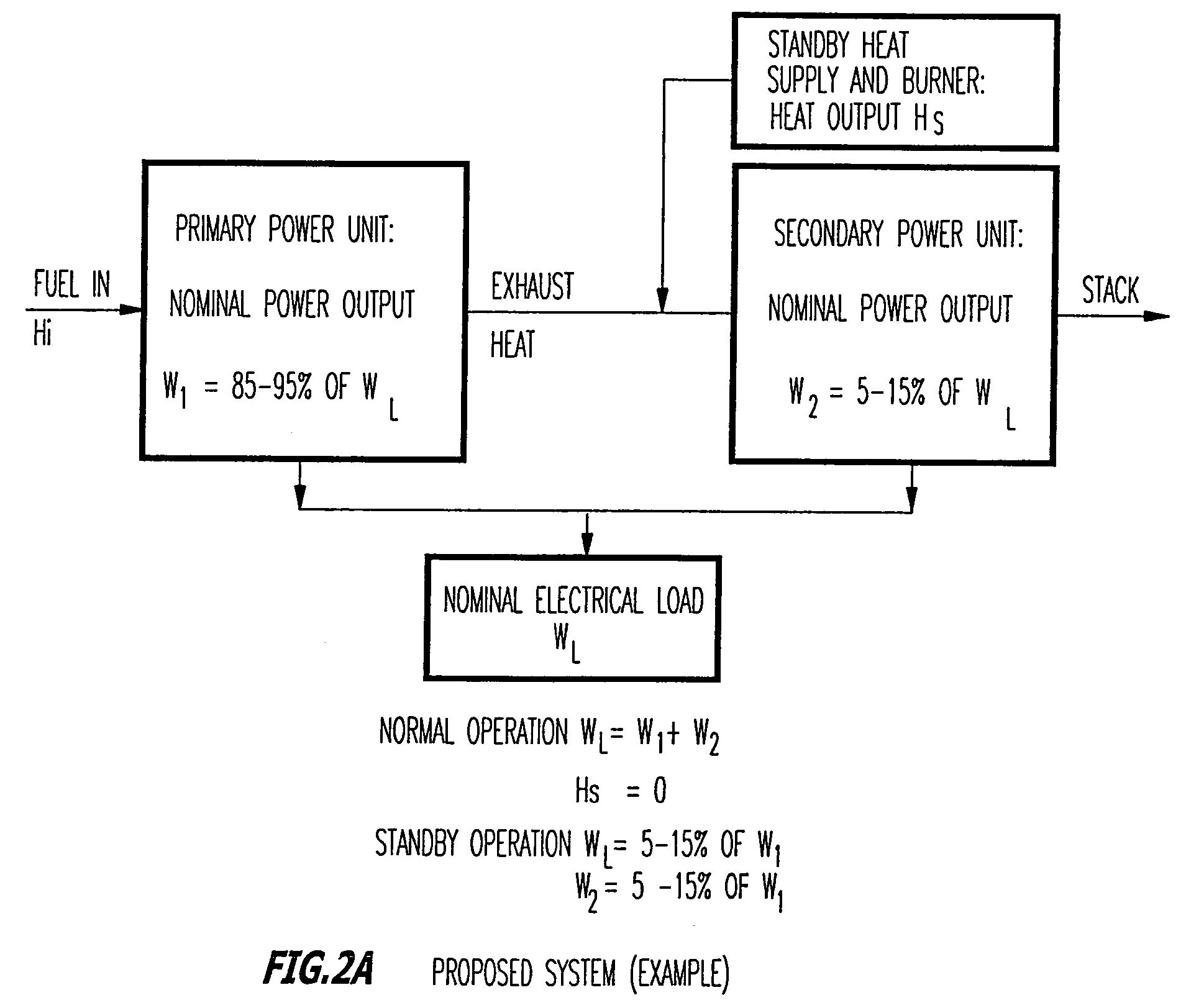

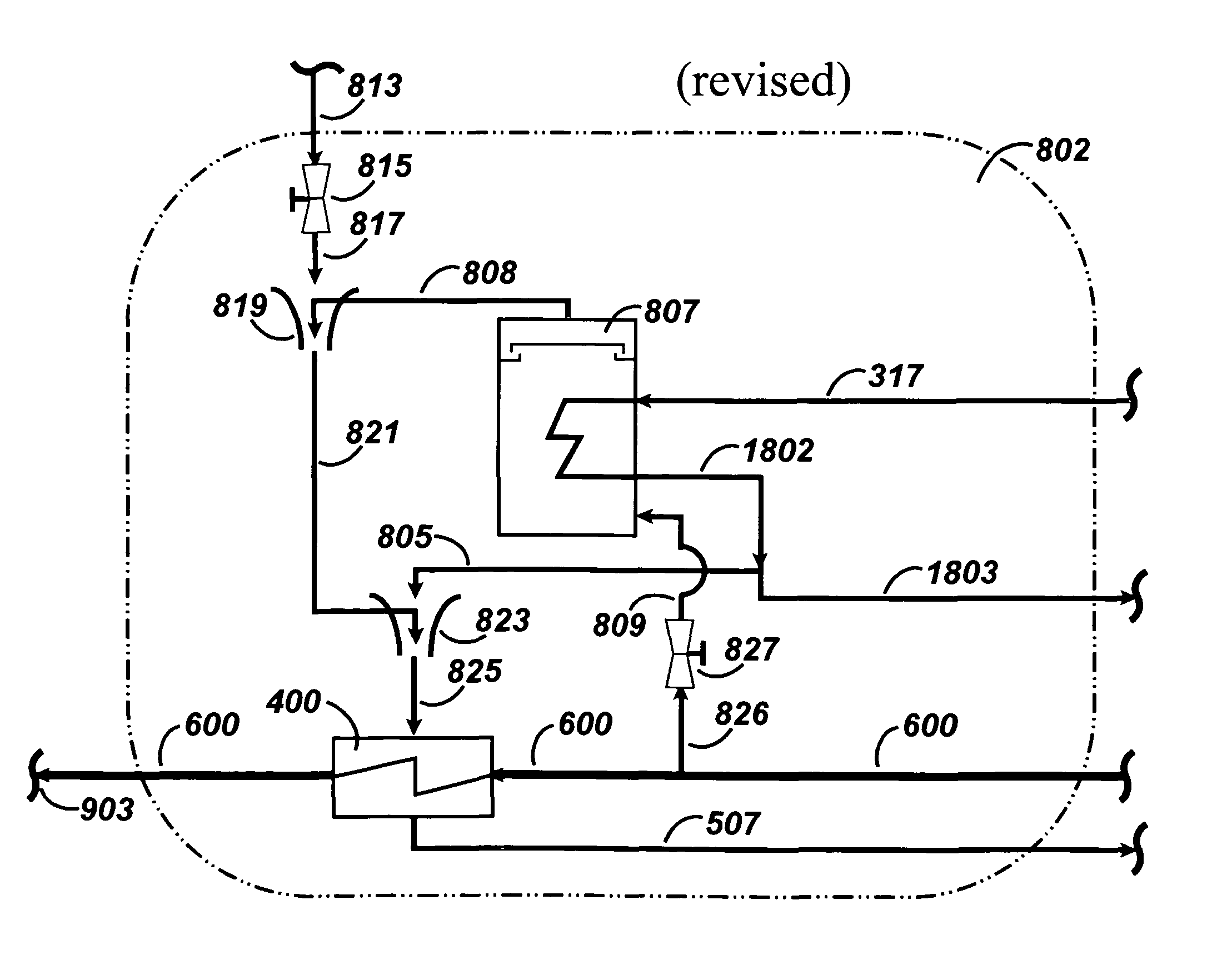

Hybrid power system for continuous reliable power at remote locations

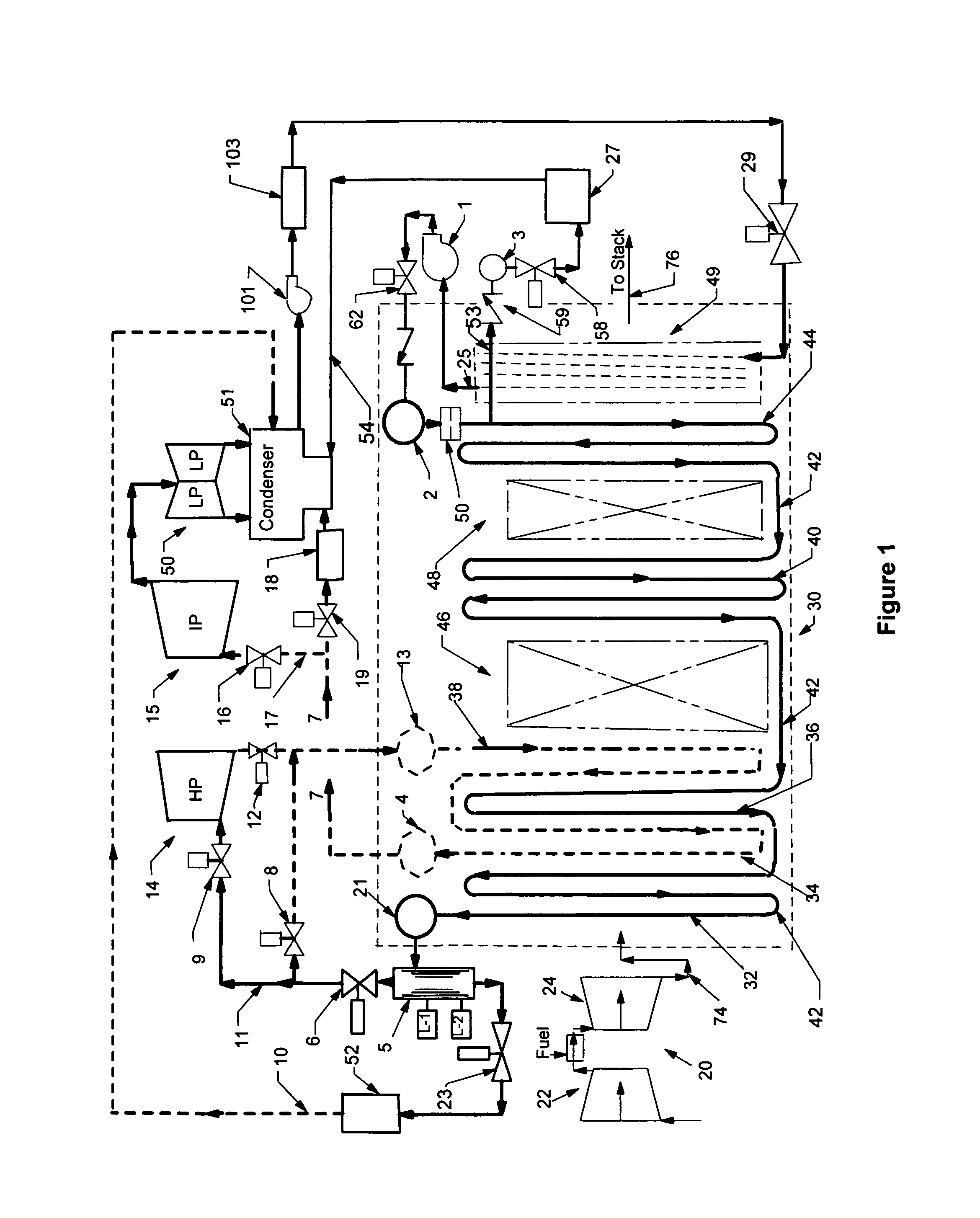

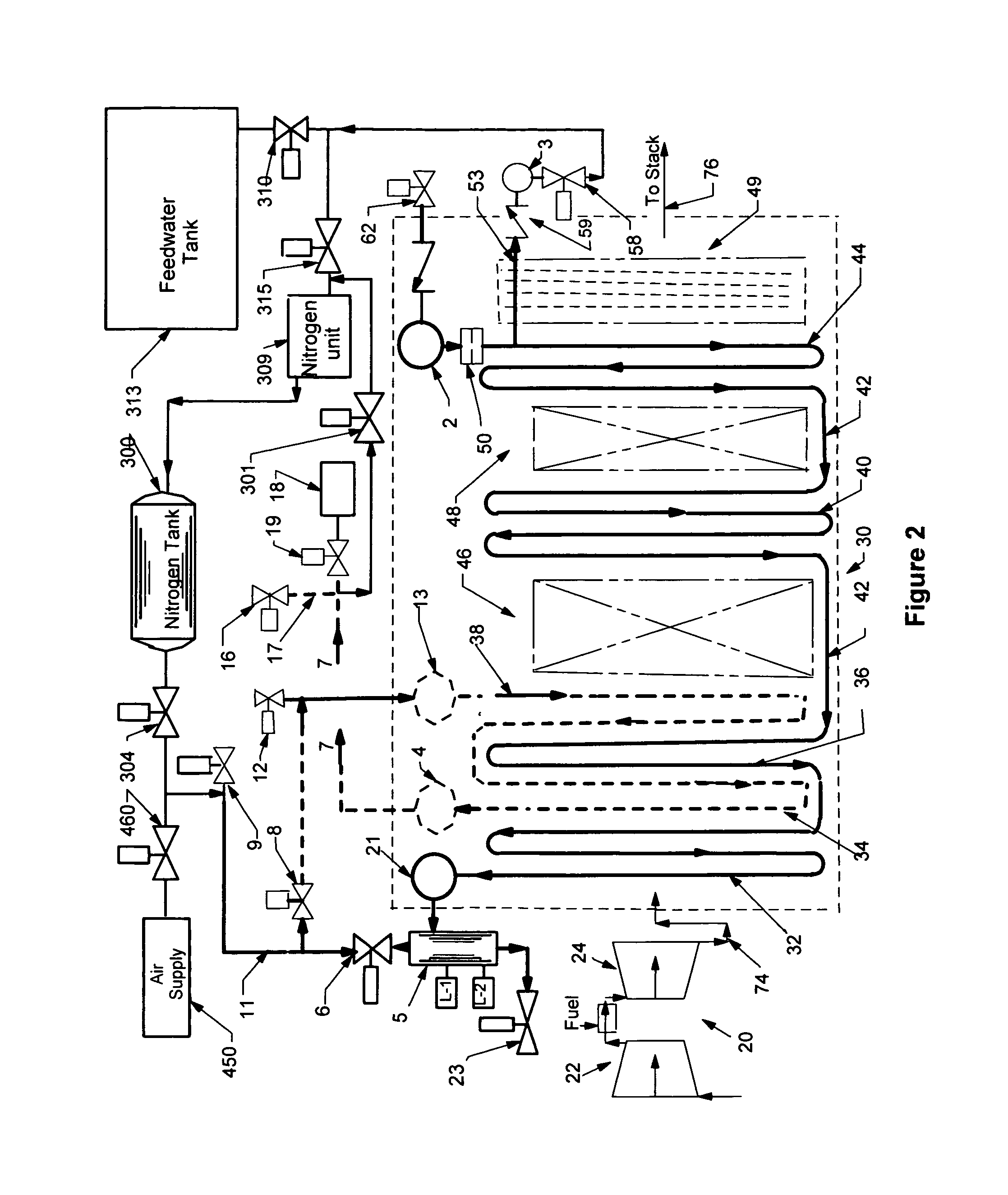

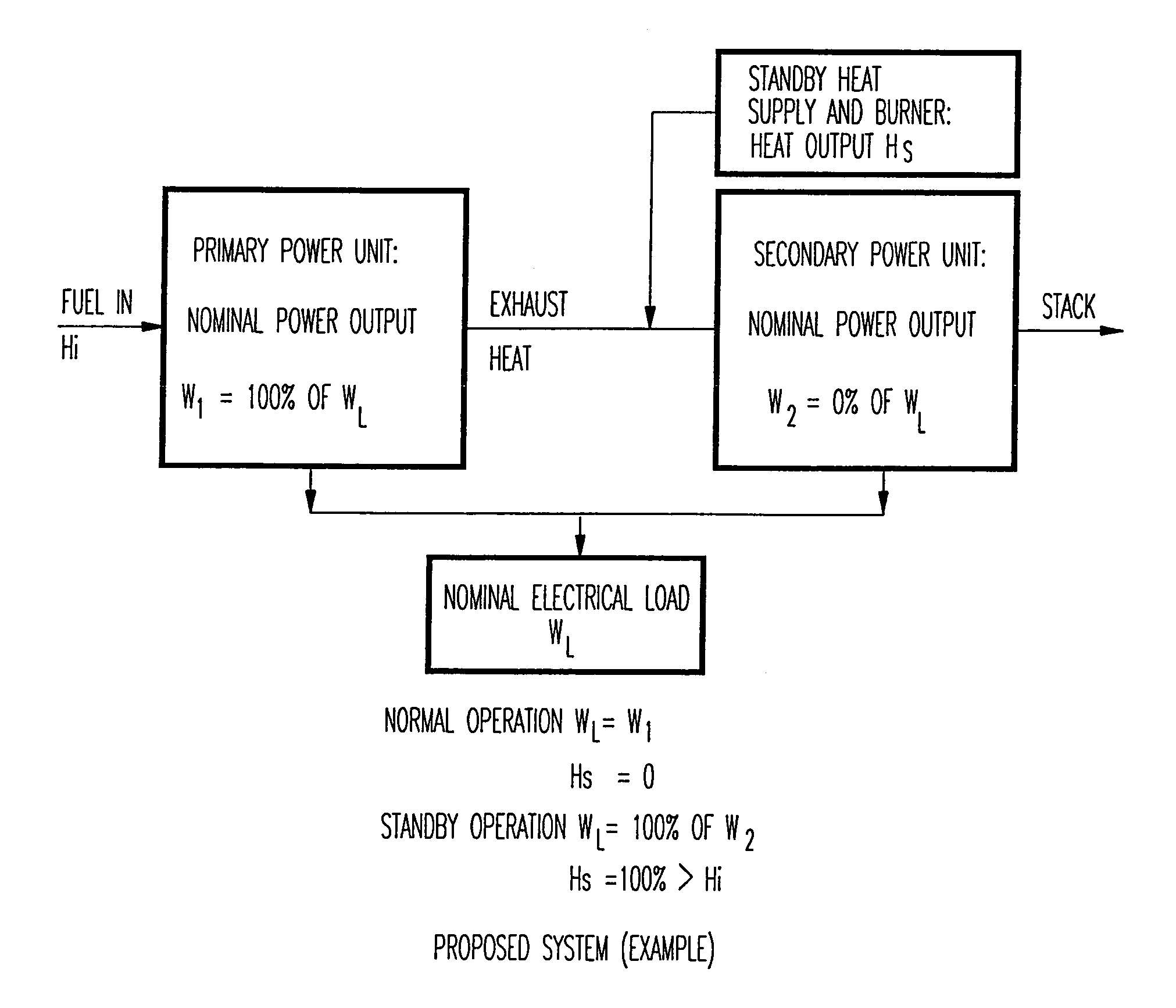

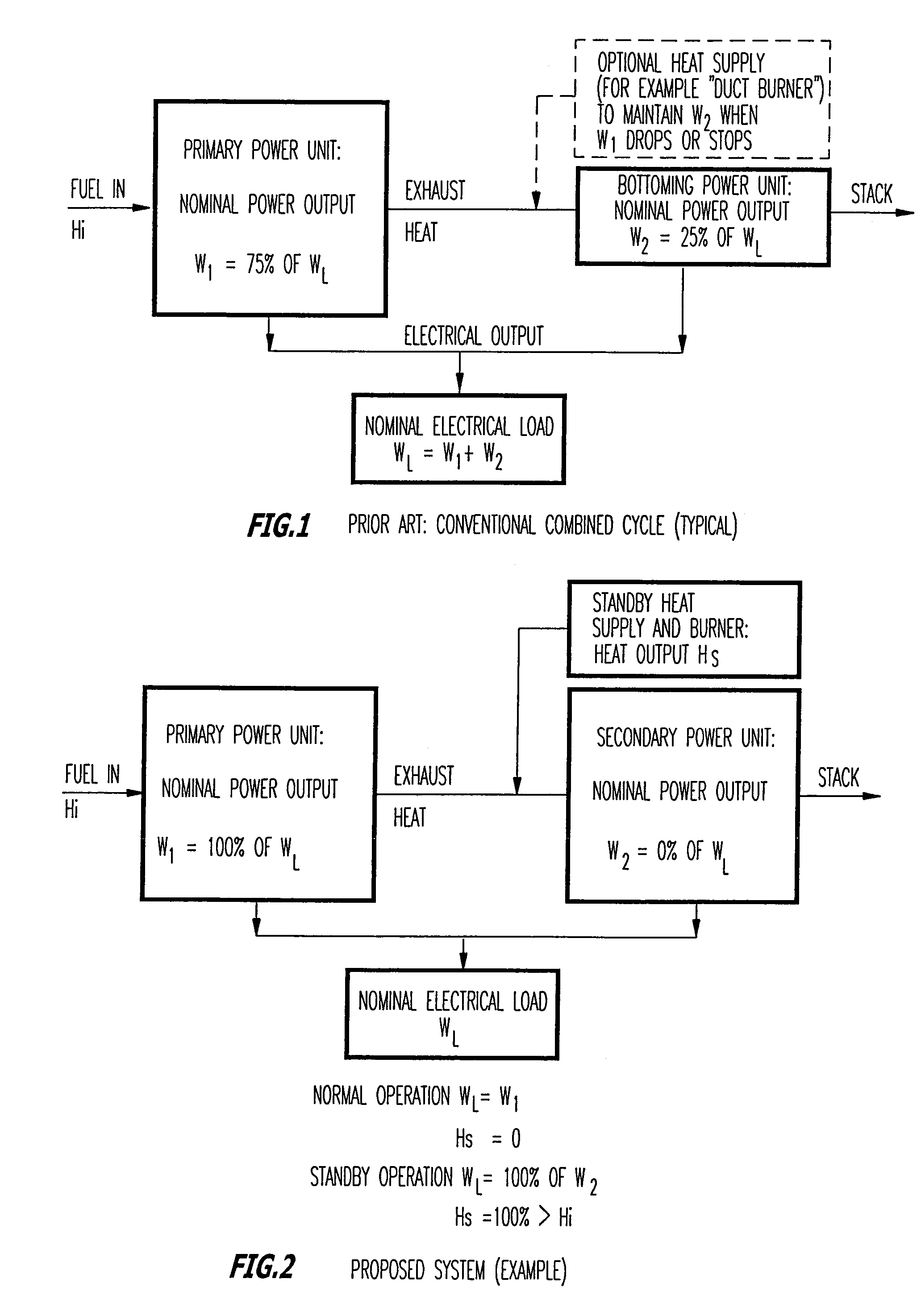

InactiveUS6883328B2Avoid insufficient heatingLiquid degasificationSteam regenerationCombustorElectric power system

The present inventive subject matter is thus drawn to a hybrid ultra reliable power generating system for supplying continuous reliable power at remote locations comprising: a primary power unit producing electric power that is supplied to a load. And a secondary power unit in the form of a closed cycle vapor turbine (CCVT) system that is capable of producing 100% of the electric power that is produced by the primary power unit and which is heated in hot standby by rejected heat of the primary power unit, wherein the vaporizer of the CCVT is maintained during hot standby at a temperature above its nominal operating temperature and the vapor turbine of the CCVT is preferable maintained at idle during hot standby at a rotating speed.Preferably, the CCVT includes a burner that combusts the same fuel as the primary power unit and supplies sufficient heat so that the CCVT produces 100% of power produced by the primary unit to the load once the primary power units stops operation.

Owner:ORMAT TECH INC

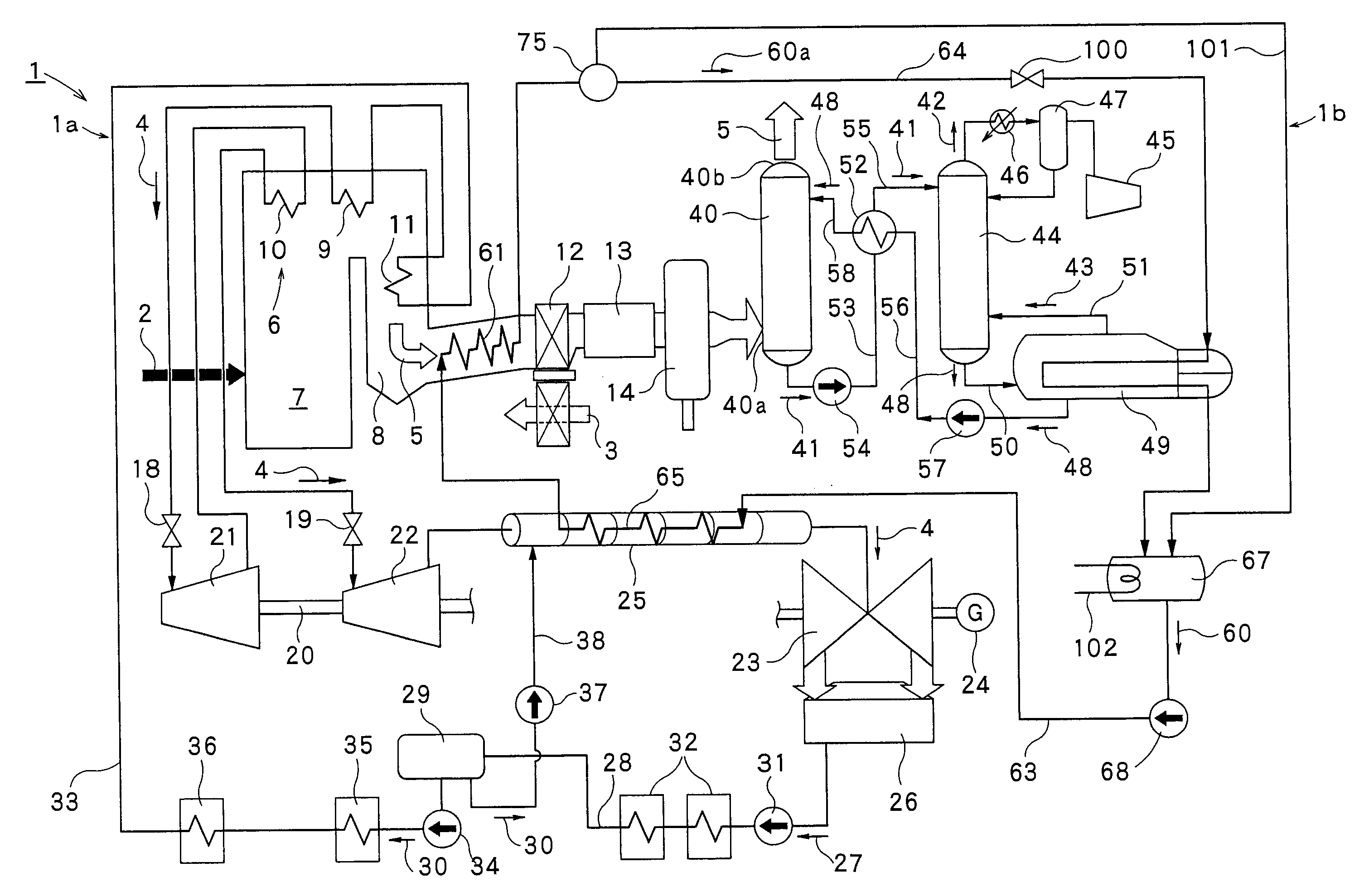

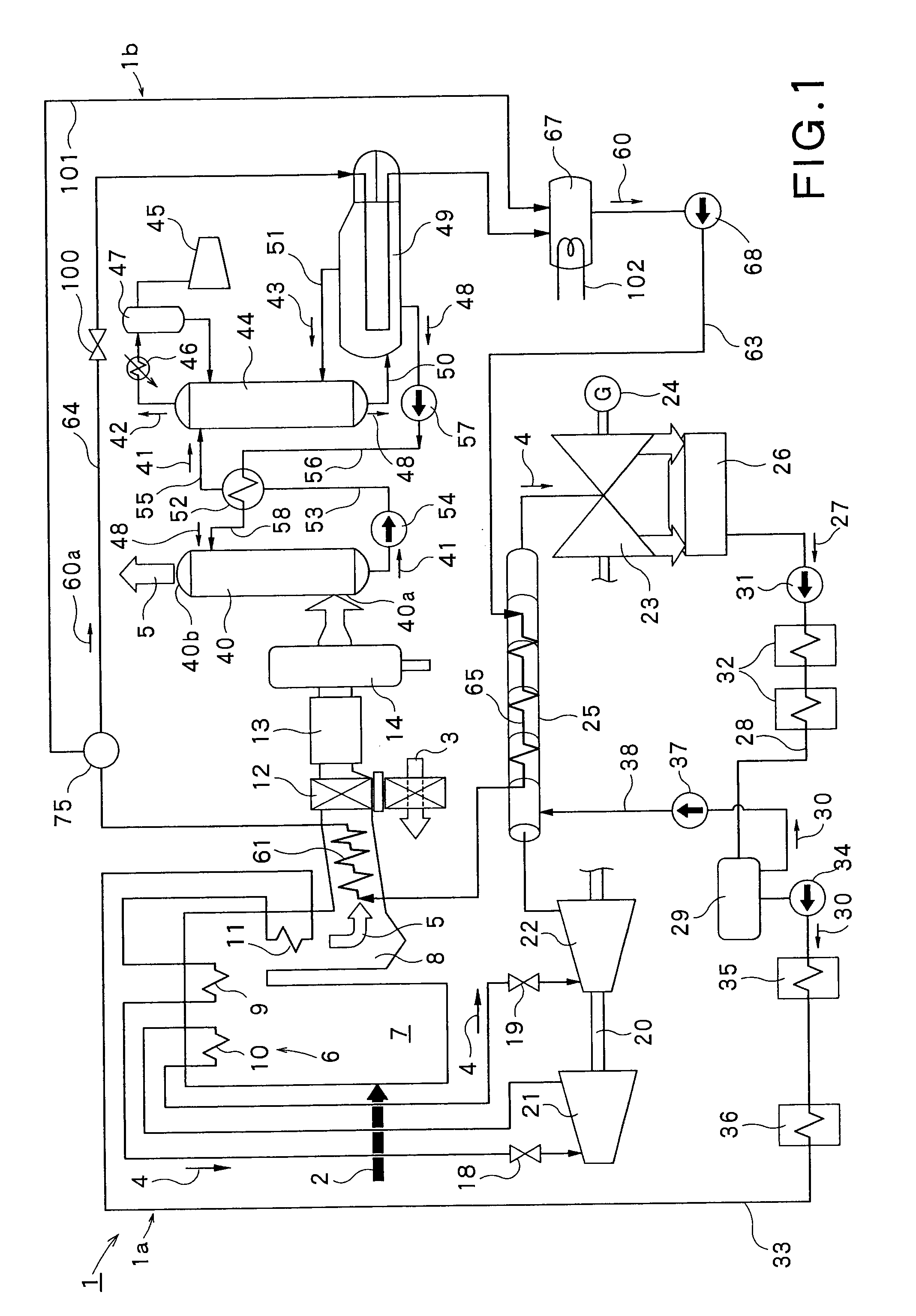

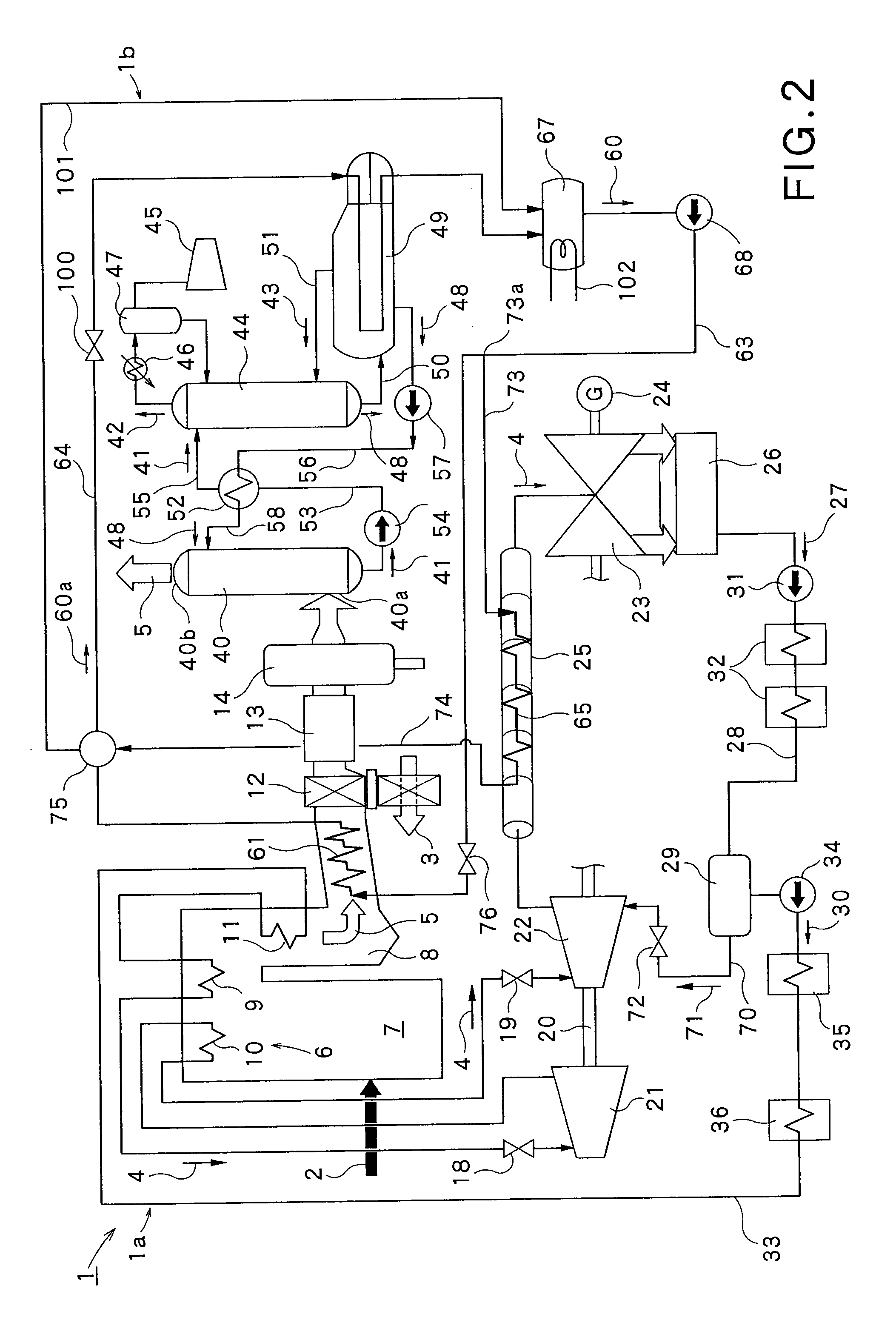

Carbon-dioxide-capture-type steam power generation system

InactiveUS20100050637A1Avoid power generation efficiencyImprove efficiencyLiquid degasificationCarbon compoundsCo2 absorptionReboiler

A carbon-dioxide-capture-type steam power generation system 1 according to the present invention comprises a boiler 6 producing an exhaust gas 5 by combusting a fuel 2 and having a flue 8; an absorbing unit 40 being configured to absorb the carbon-dioxide contained in the exhaust gas 5 into an absorbing solution; and a regenerating unit 44 being configured to release the carbon dioxide gas from the absorbing solution absorbing the carbon dioxide and discharge the released carbon dioxide gas. Further, in this system, a reboiler 49 is provided for receiving a heating-medium as heat source, producing a steam 43 and supplying the produced steam 43 to the regenerating unit 44. Additionally, in the flue 8 of the boiler 6, a boiler-side heat exchanger 61 is provided for heating the heating-medium by the exhaust gas 5 passing therethrough.

Owner:KK TOSHIBA

Electrical power generation method

A method of generating electrical power in which a synthesis gas stream generated in a gasifier is combusted in an oxygen transport membrane system of a boiler. The combustion generates heat to raise steam to in turn generate electricity by a generator coupled to a steam turbine. The resultant flue gas can be purified to produce a carbon dioxide product.

Owner:PRAXAIR TECH INC

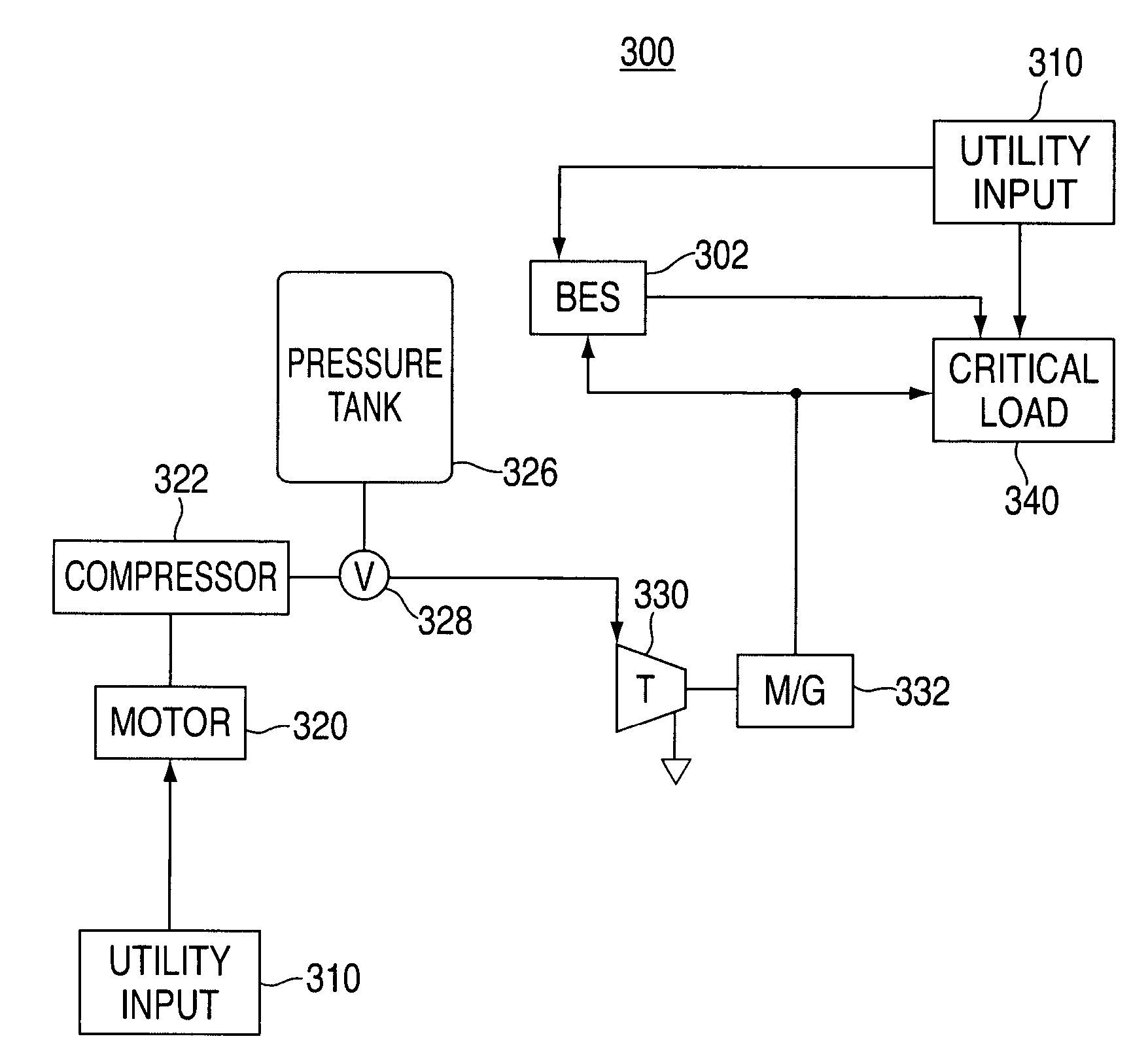

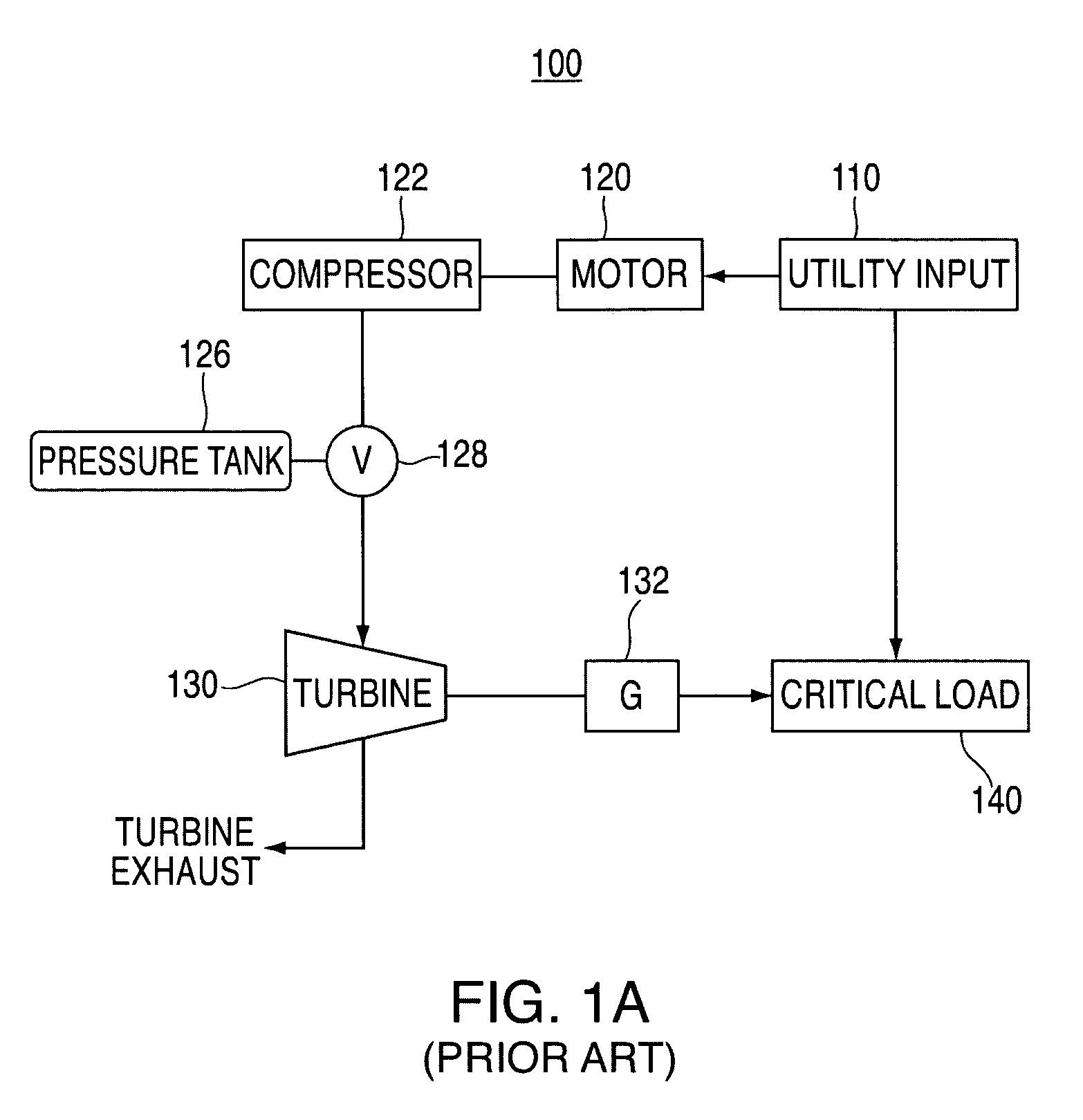

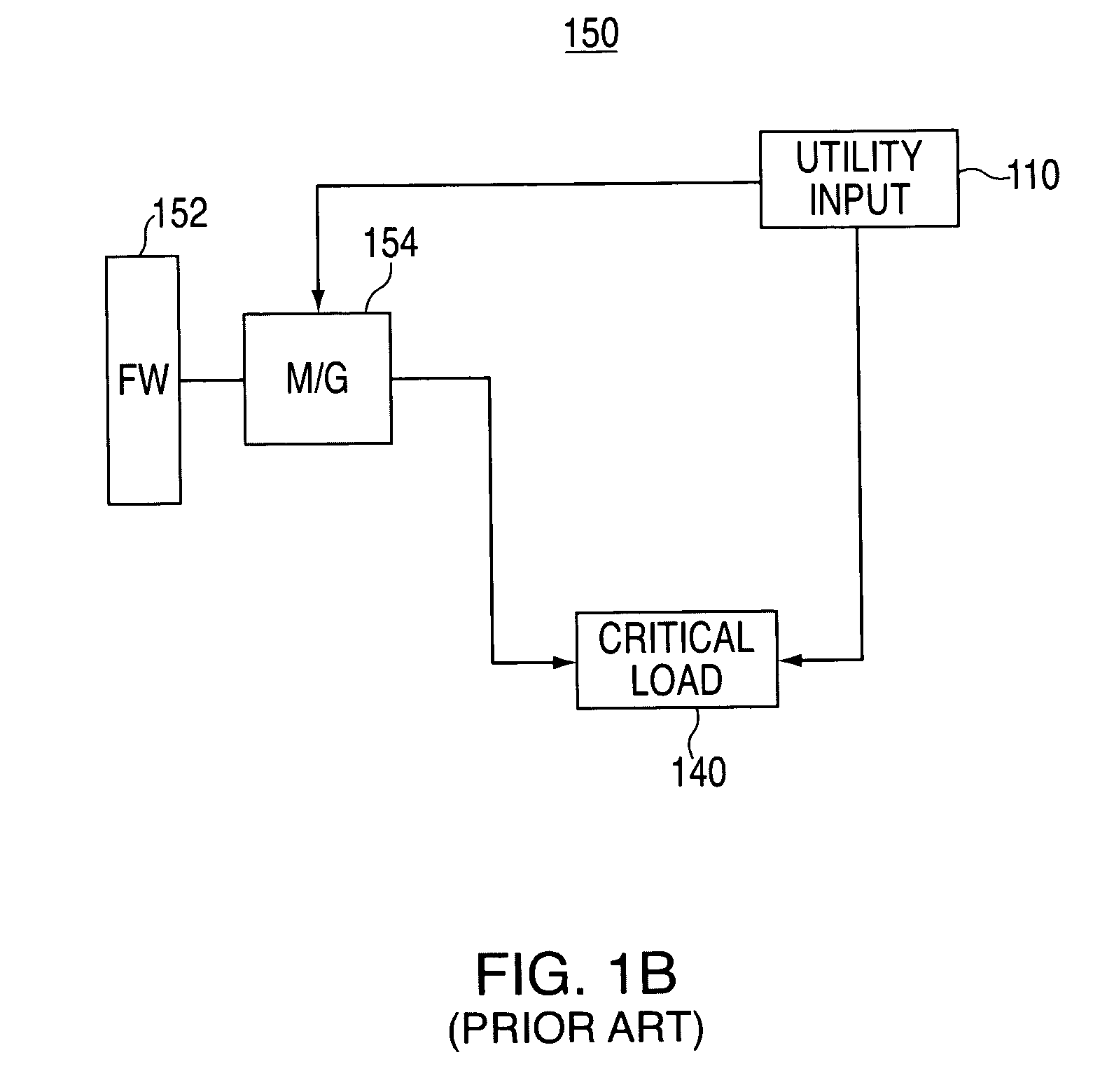

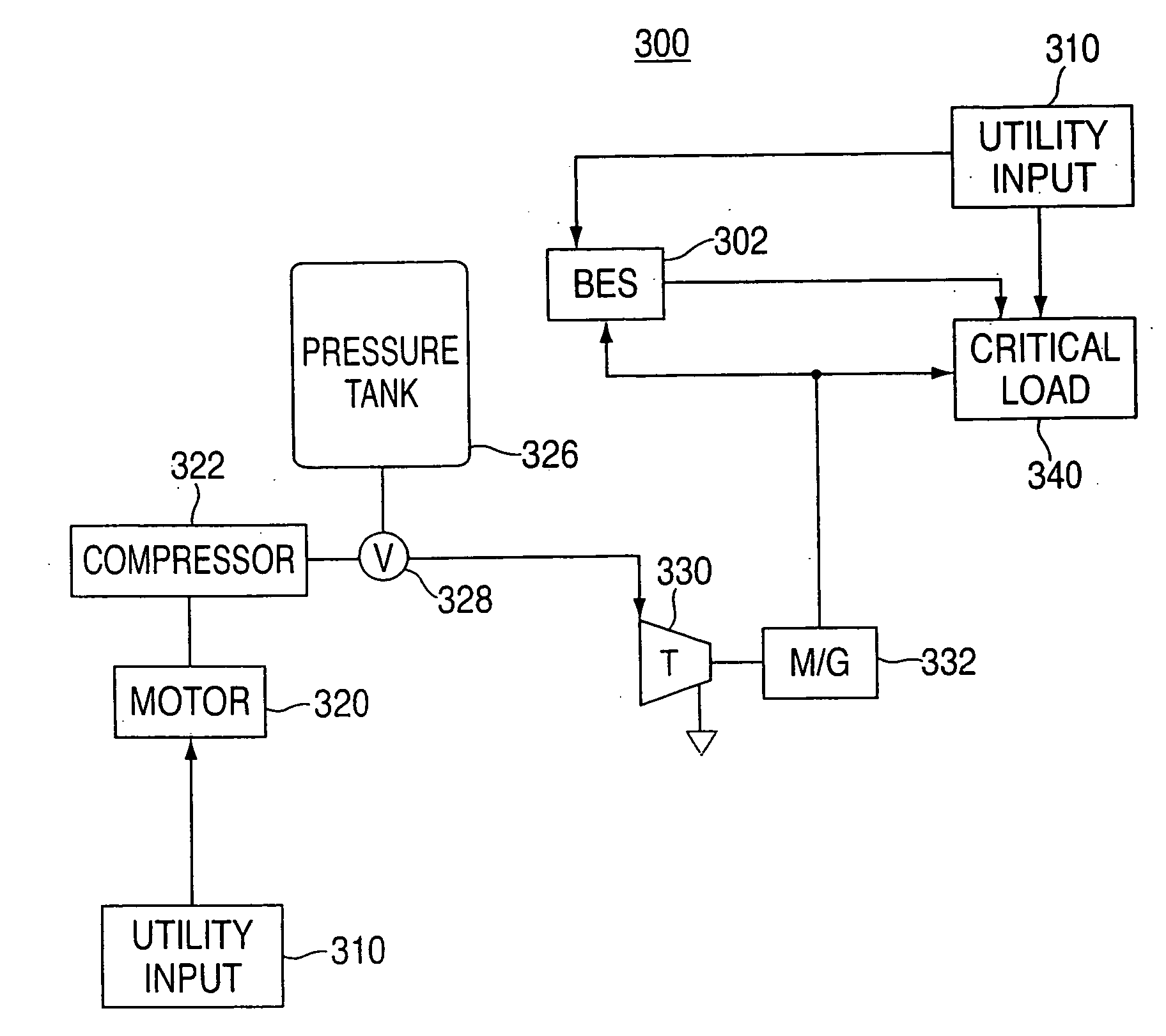

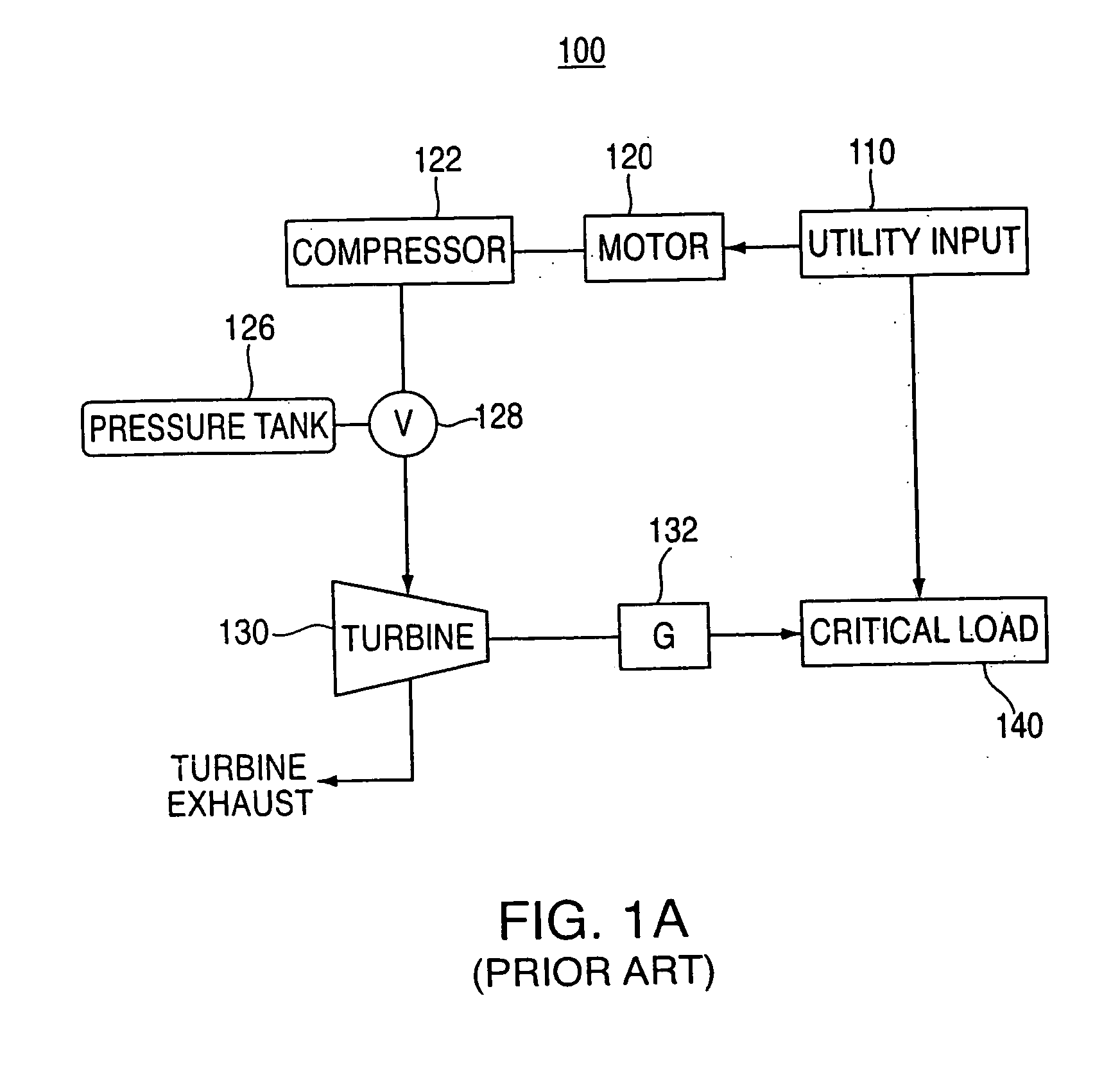

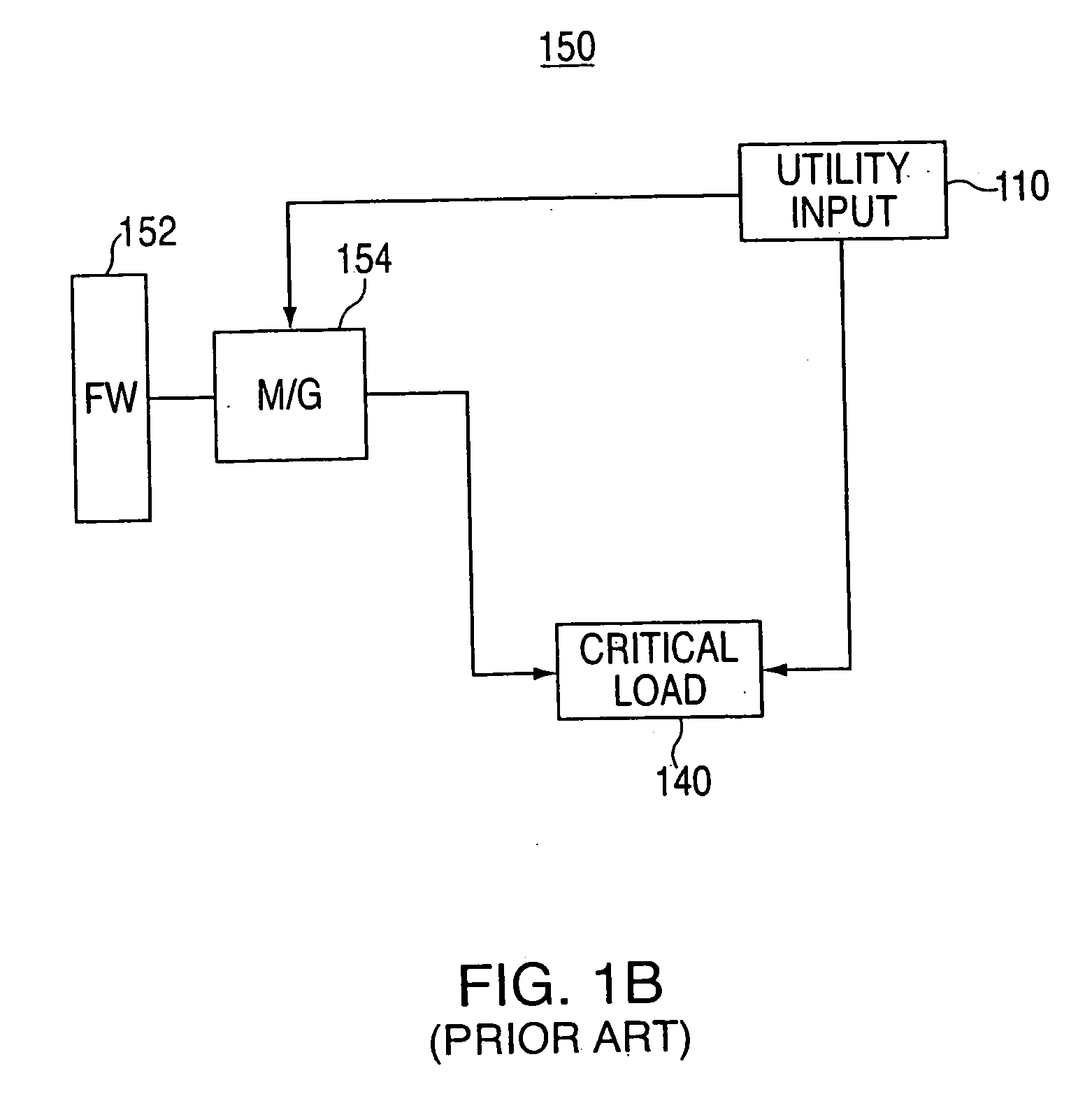

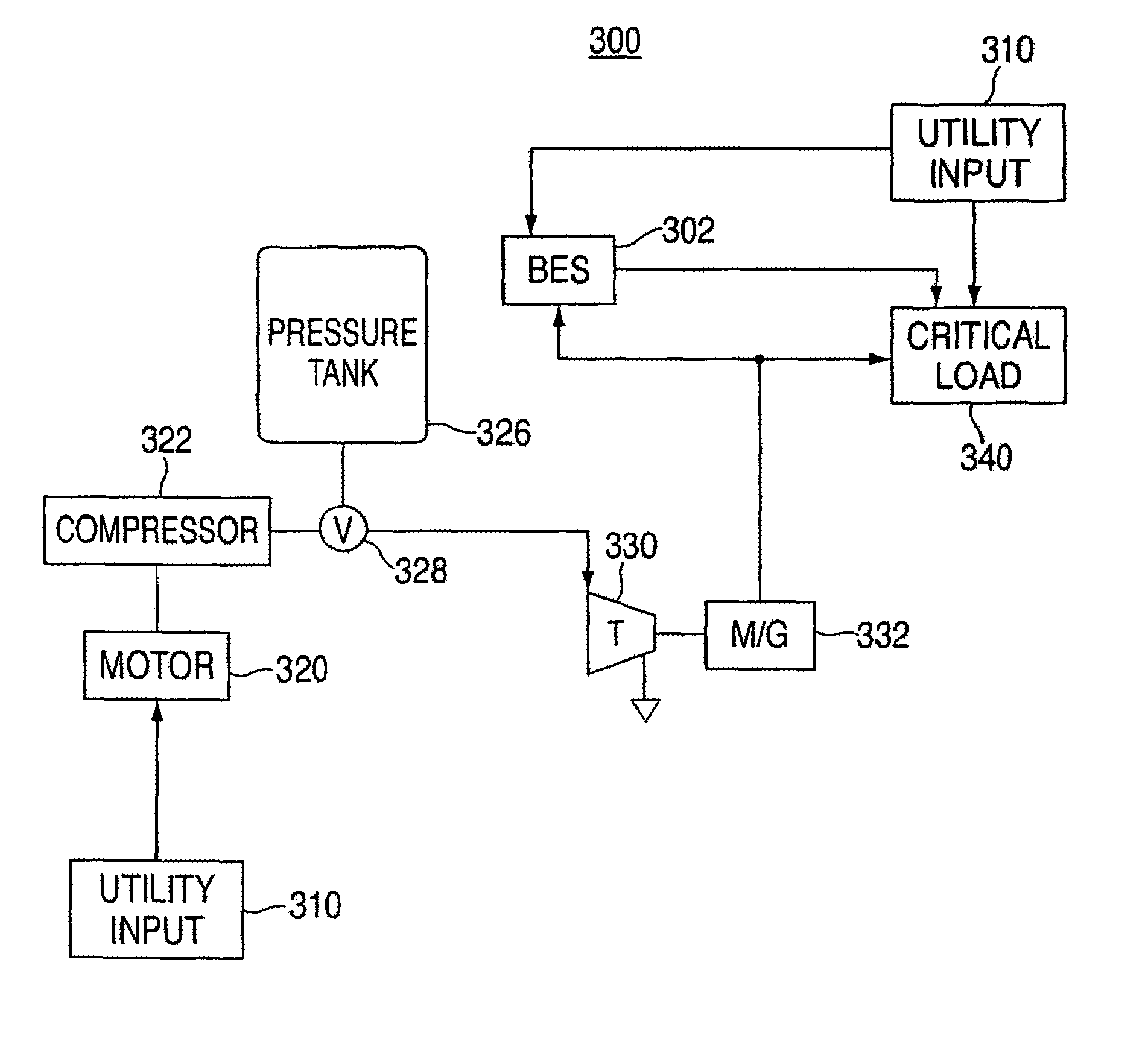

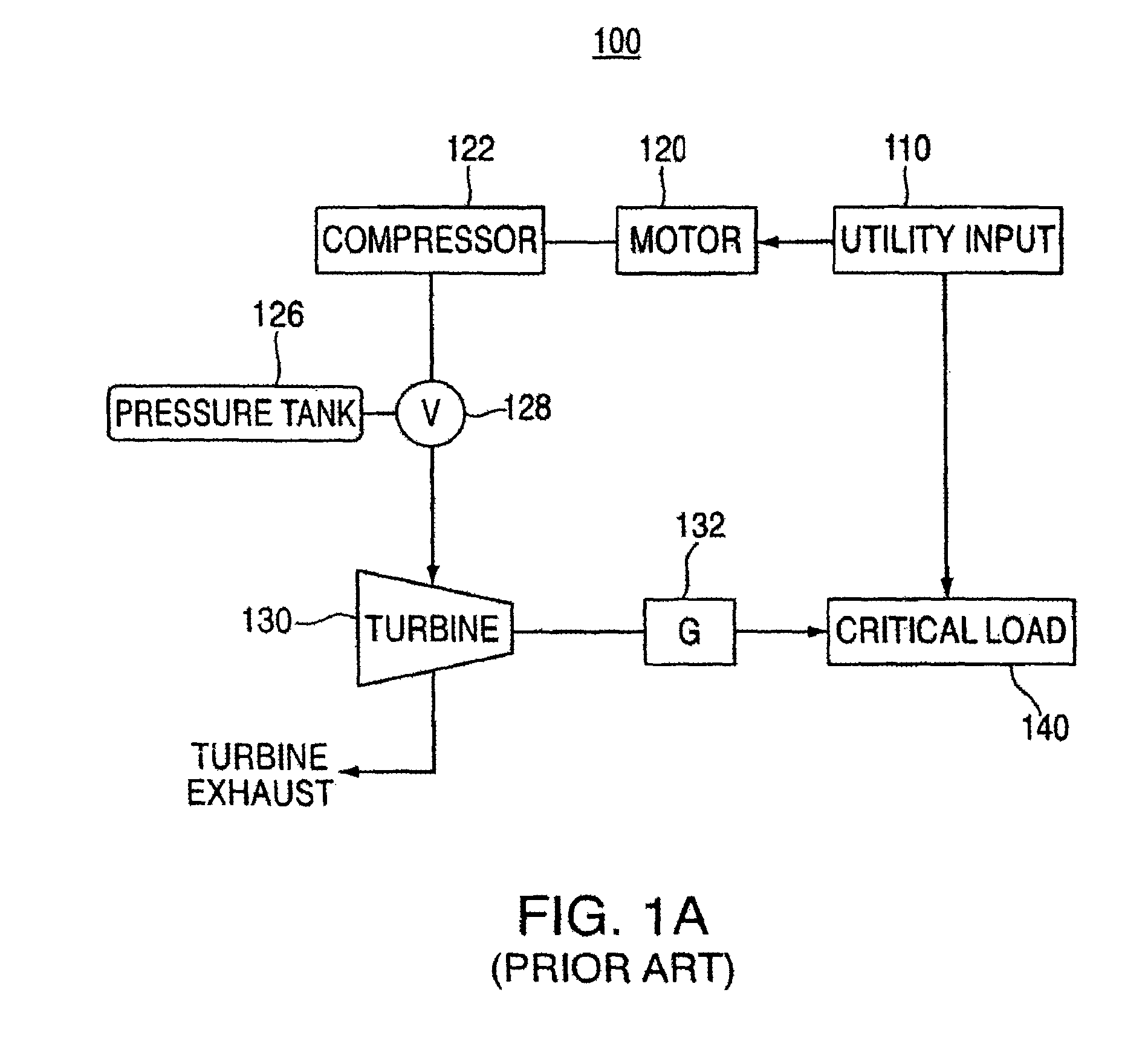

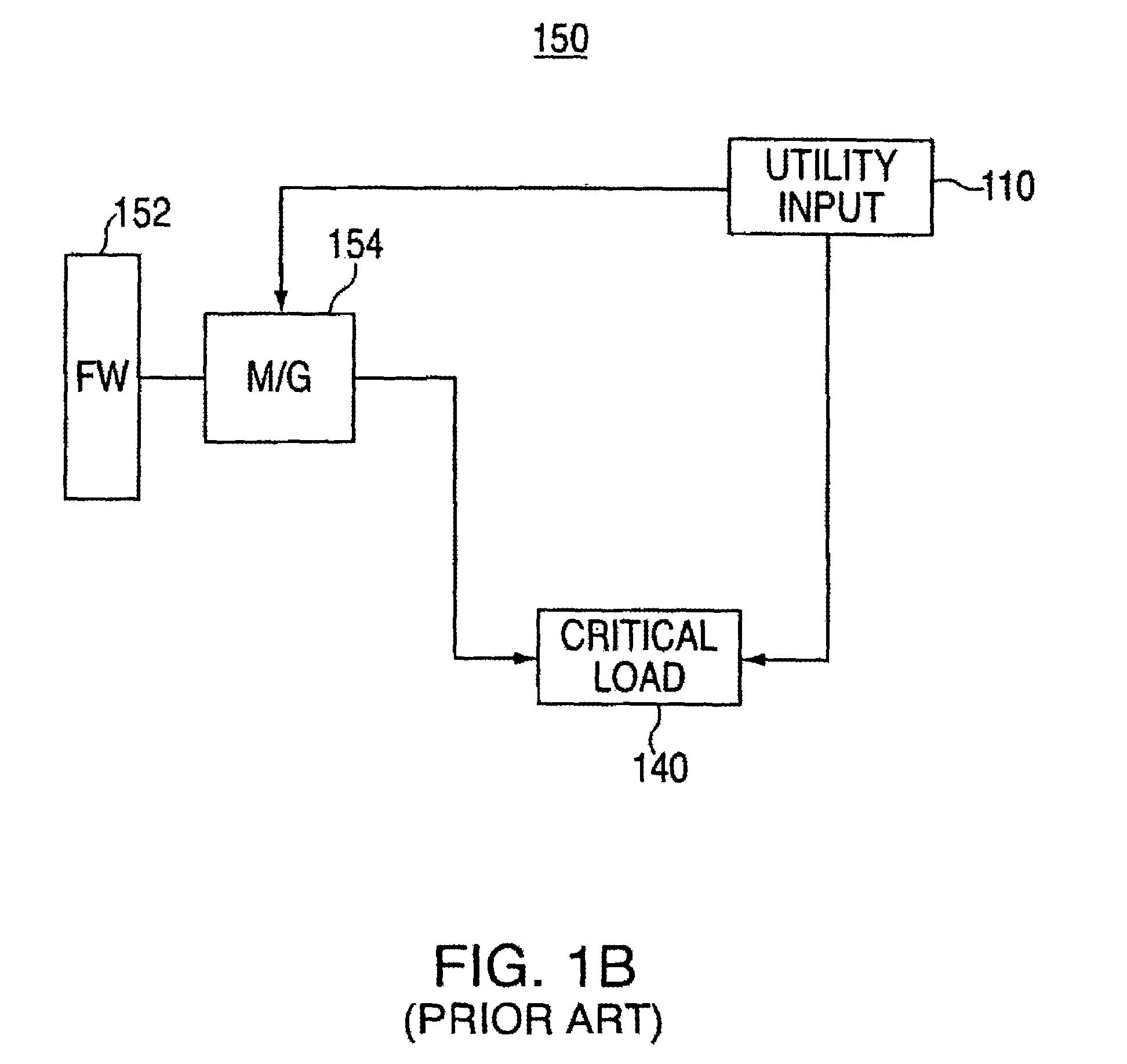

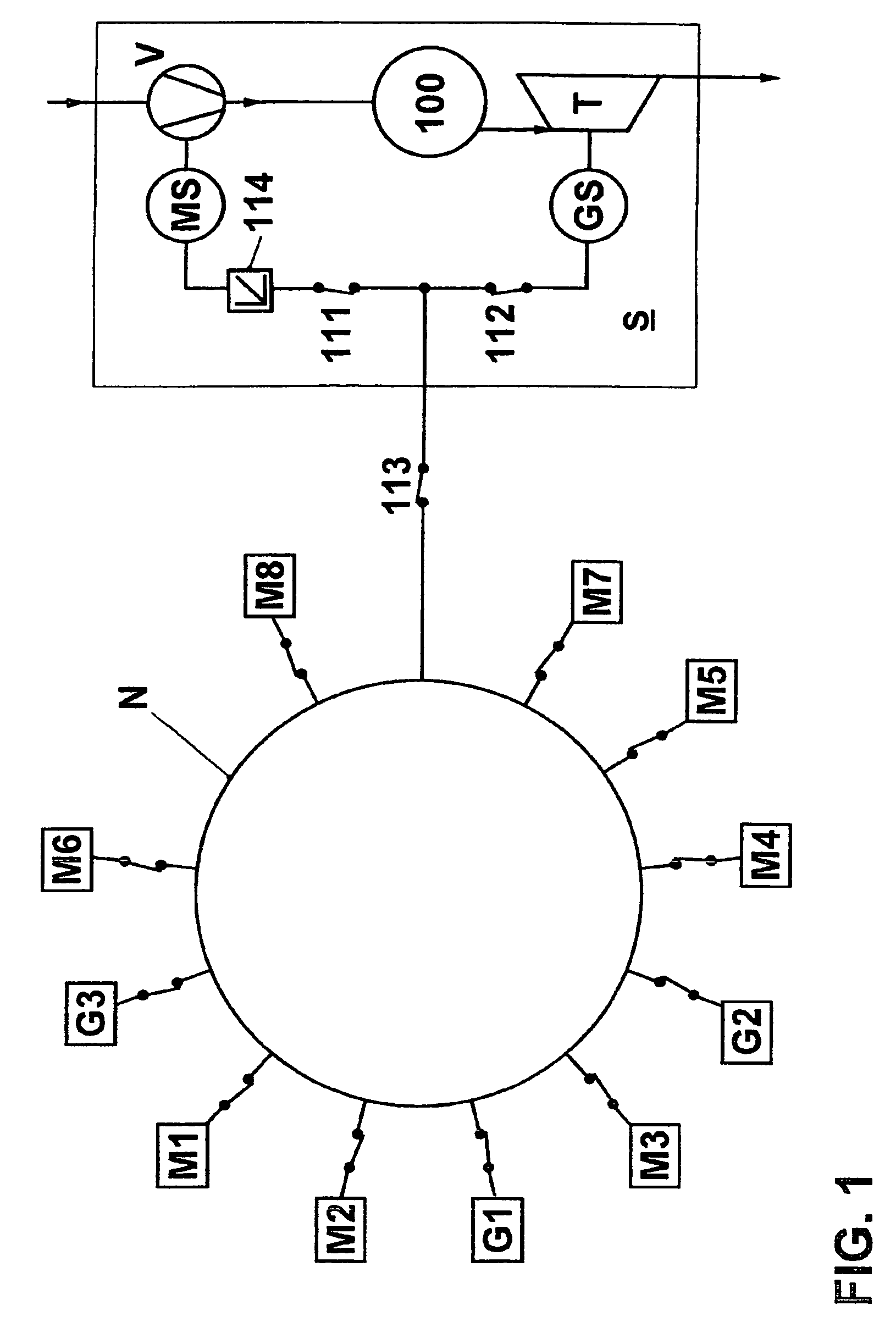

Systems and methods for providing backup energy to a load

Backup energy systems utilizing compressed air storage (CAS) systems and bridging energy systems to supply backup power to a load are provided. During a power failure, the bridging energy system provides backup power to the load at least until the CAS system begins supplying adequate power. In various embodiments, backup power capability is enhanced through the use of one or more exhaustless heaters, which are used to heat compressed air. The compressed air, in turn, drives a turbine which is used to power an electrical generator. In various embodiments, ambient air heat exchangers or other types of heat exchangers are used to heat compressed air prior to the compressed air being routed to the turbine, thereby increasing system efficiency. Backup power and backup HVAC are also provided by utilizing turbine exhaust, heat exchangers and various resistive heating elements.

Owner:P10 IND INC

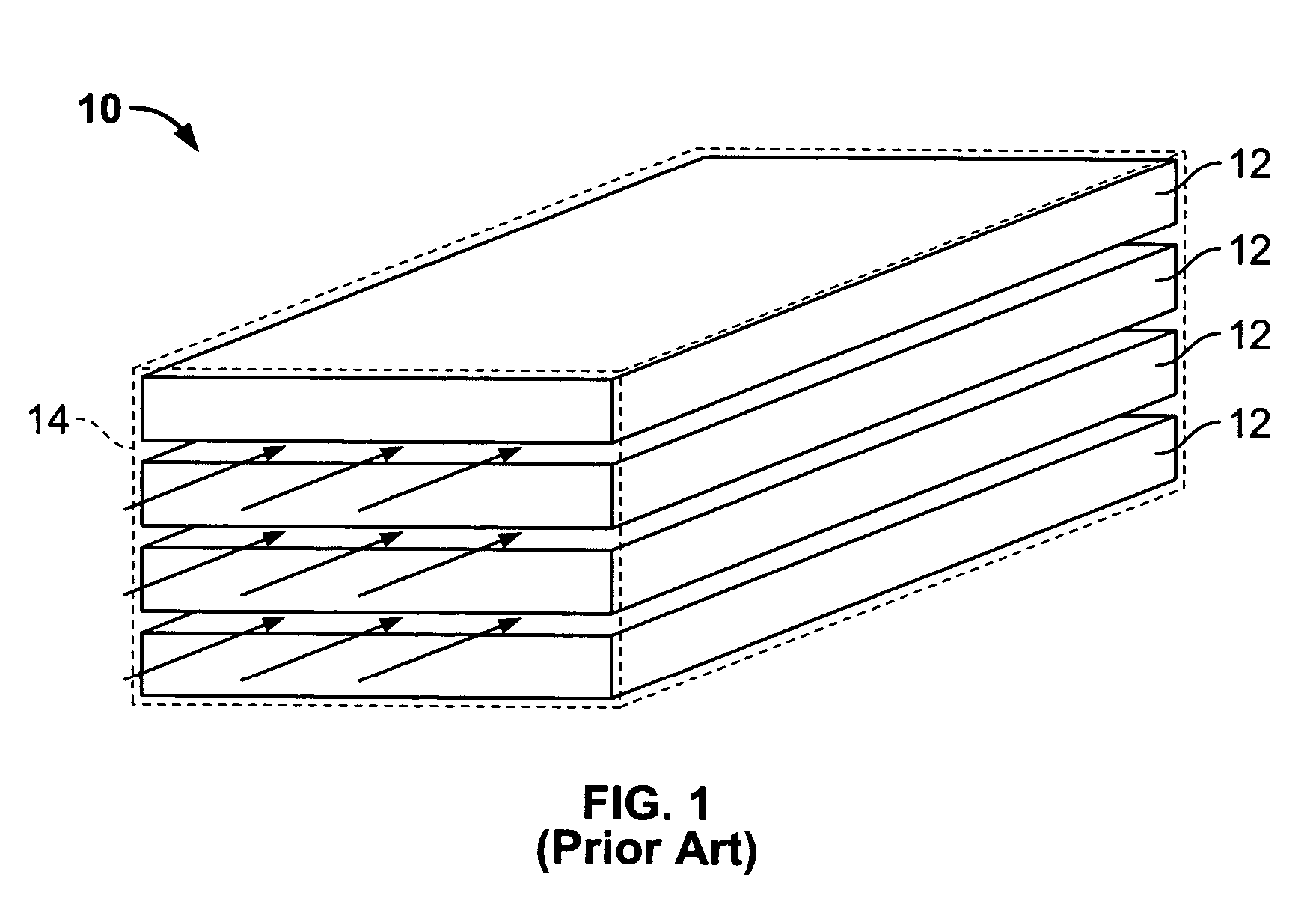

Thermal storage unit and methods for using the same to heat a fluid

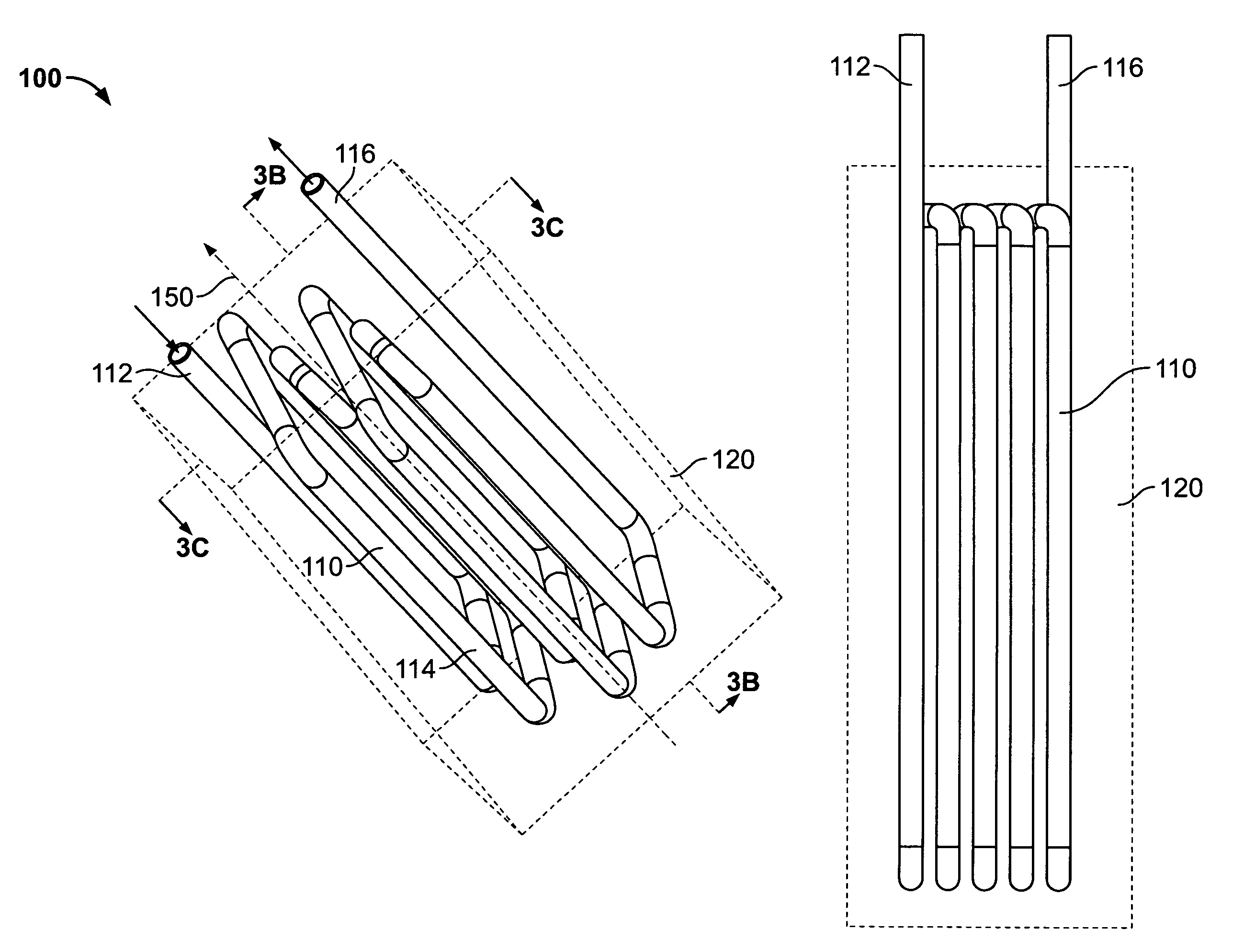

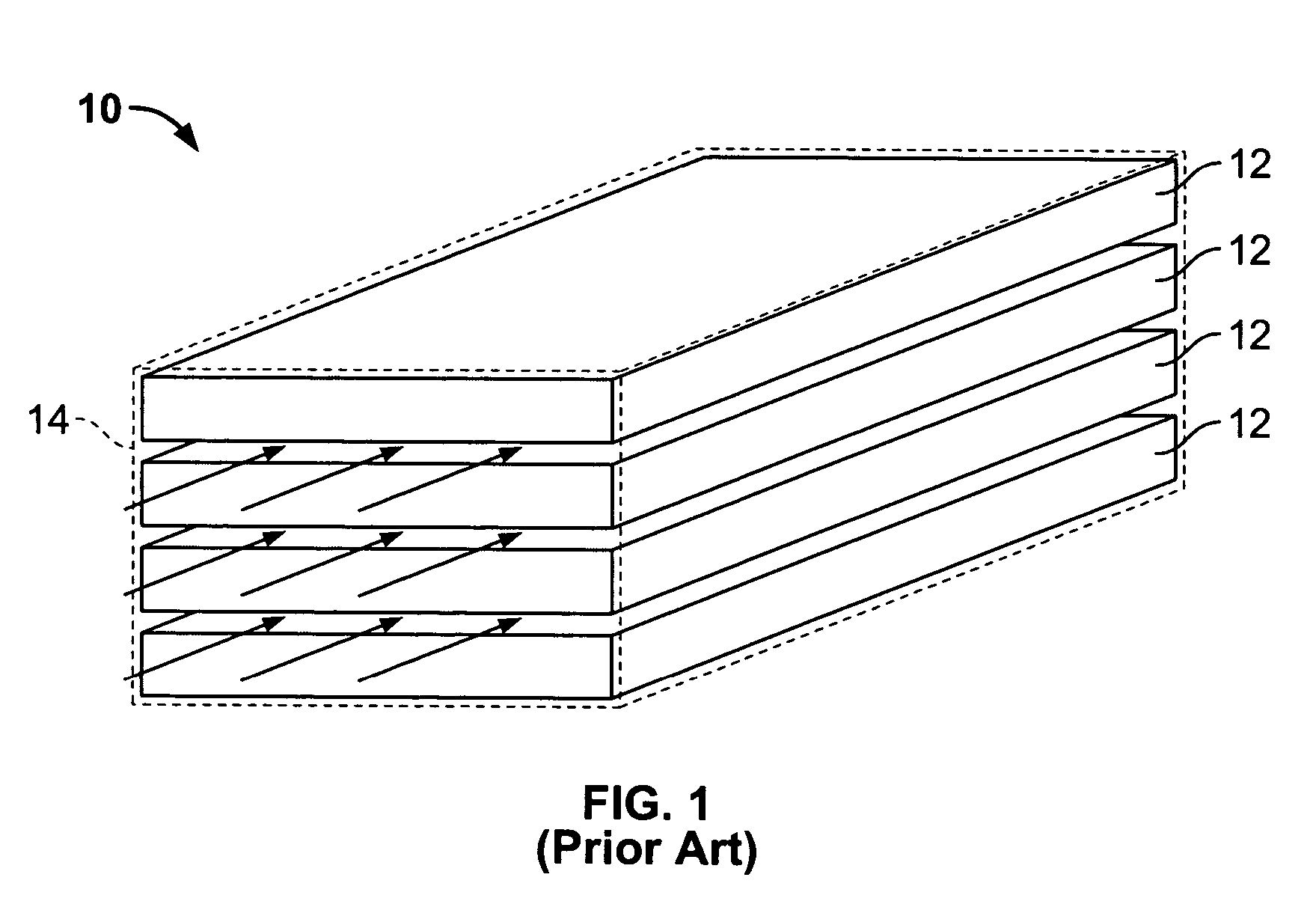

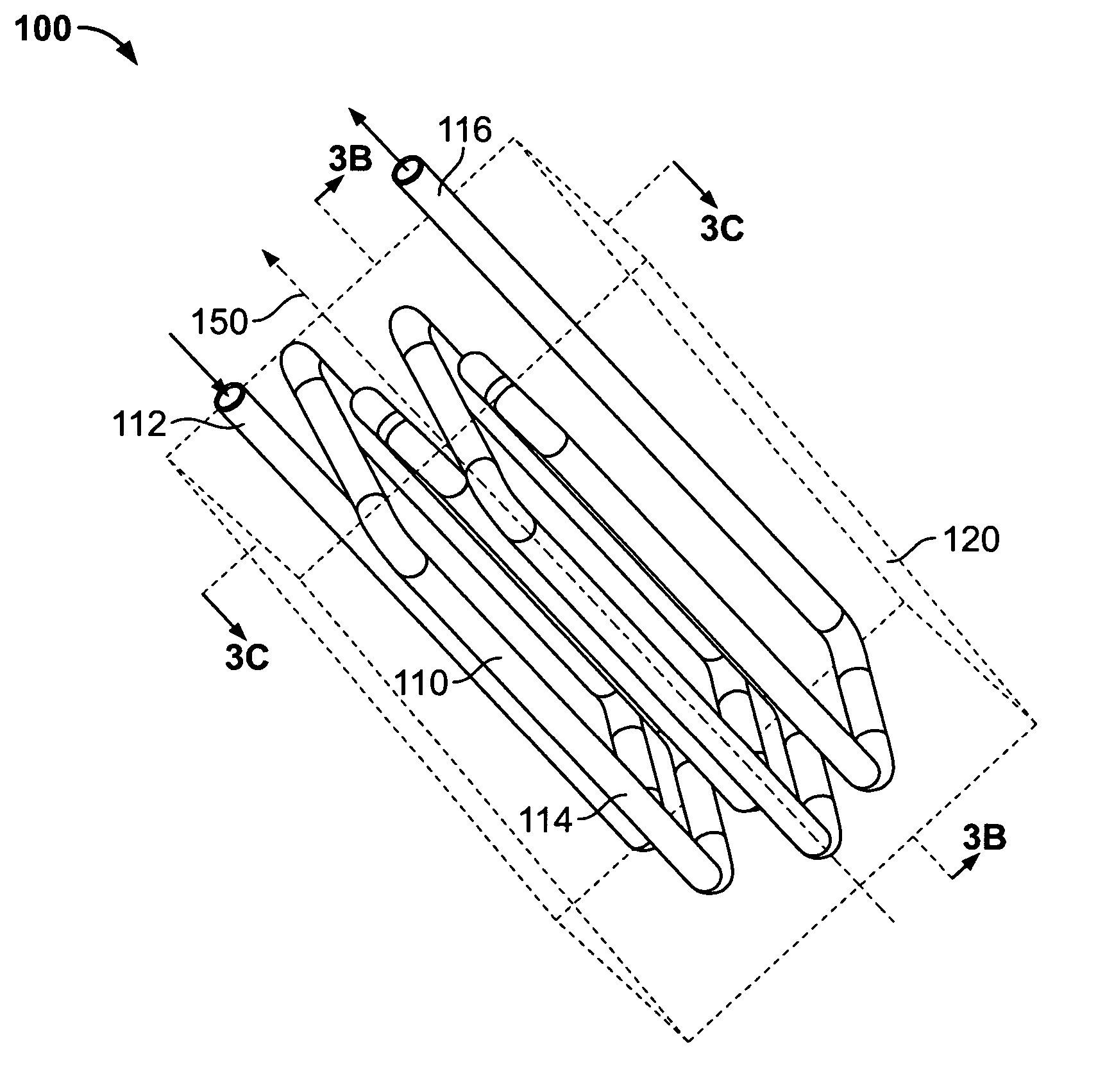

ActiveUS7693402B2Desirable thermal mass and thermal storage propertyInexpensive to fabricateLiquid degasificationCentral heating with accumulated heatEngineeringMultiple pass

A thermal storage unit having at least one conduit around which a cast is made is provided. The thermal storage unit uses conventional piping or tubing to create conduits that economically maximize the surface area of flow in contact with the thermal mass by proving multiple passes for the fluid through the cast. This enables the thermal storage unit to economically provide heat storage as well as effective heat delivery and pressure containment for a fluid flowing through the conduit.

Owner:P10 IND INC

Thermal storage unit and methods for using the same to heat a fluid

ActiveUS20060107664A1Desirable thermal mass and thermal storage propertyInexpensive to fabricateLiquid degasificationCentral heating with accumulated heatEngineeringMultiple pass

A thermal storage unit having at least one conduit around which a cast is made is provided. The thermal storage unit uses conventional piping or tubing to create conduits that economically maximize the surface area of flow in contact with the thermal mass by proving multiple passes for the fluid through the cast. This enables the thermal storage unit to economically provide heat storage as well as effective heat delivery and pressure containment for a fluid flowing through the conduit.

Owner:P10 IND INC

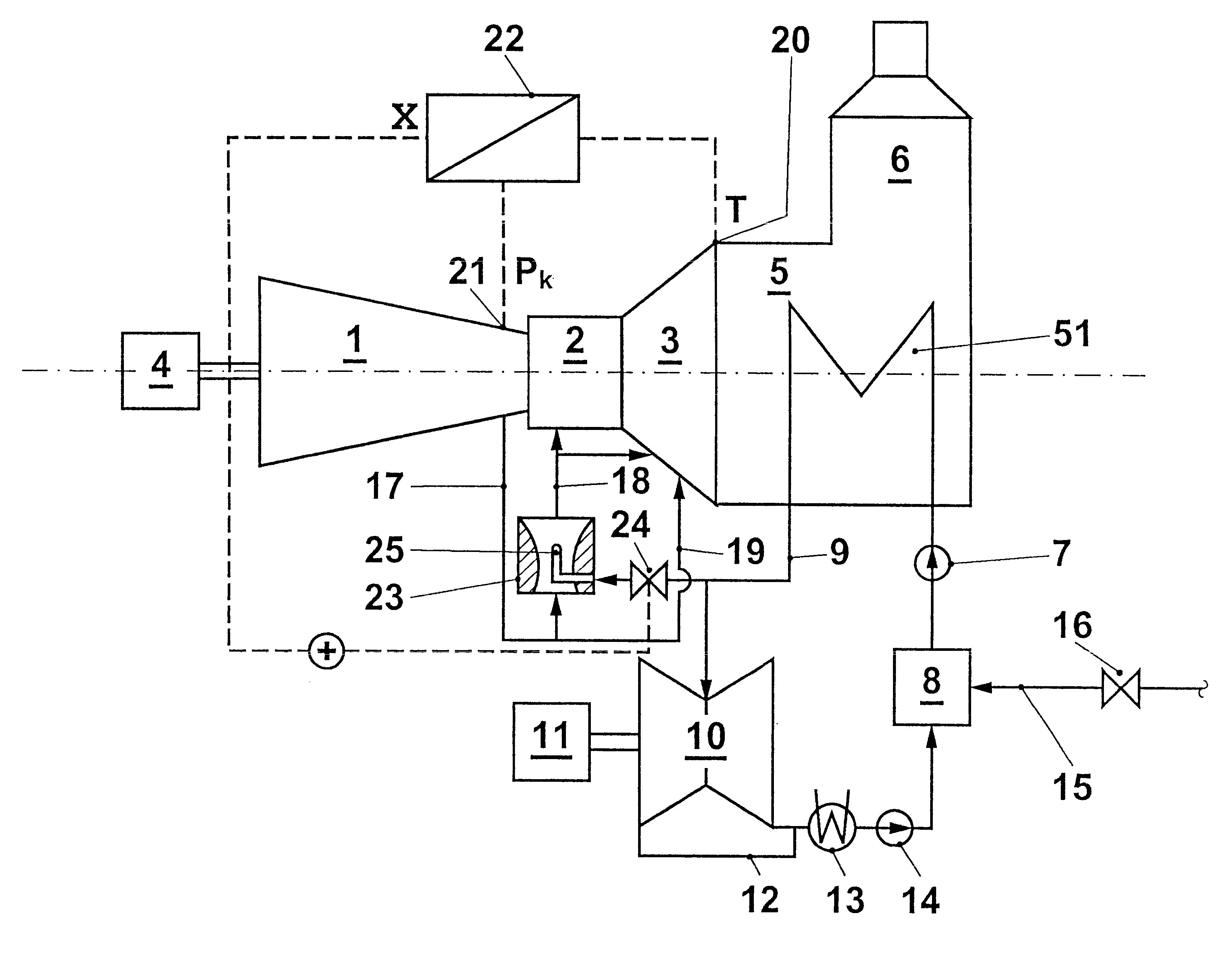

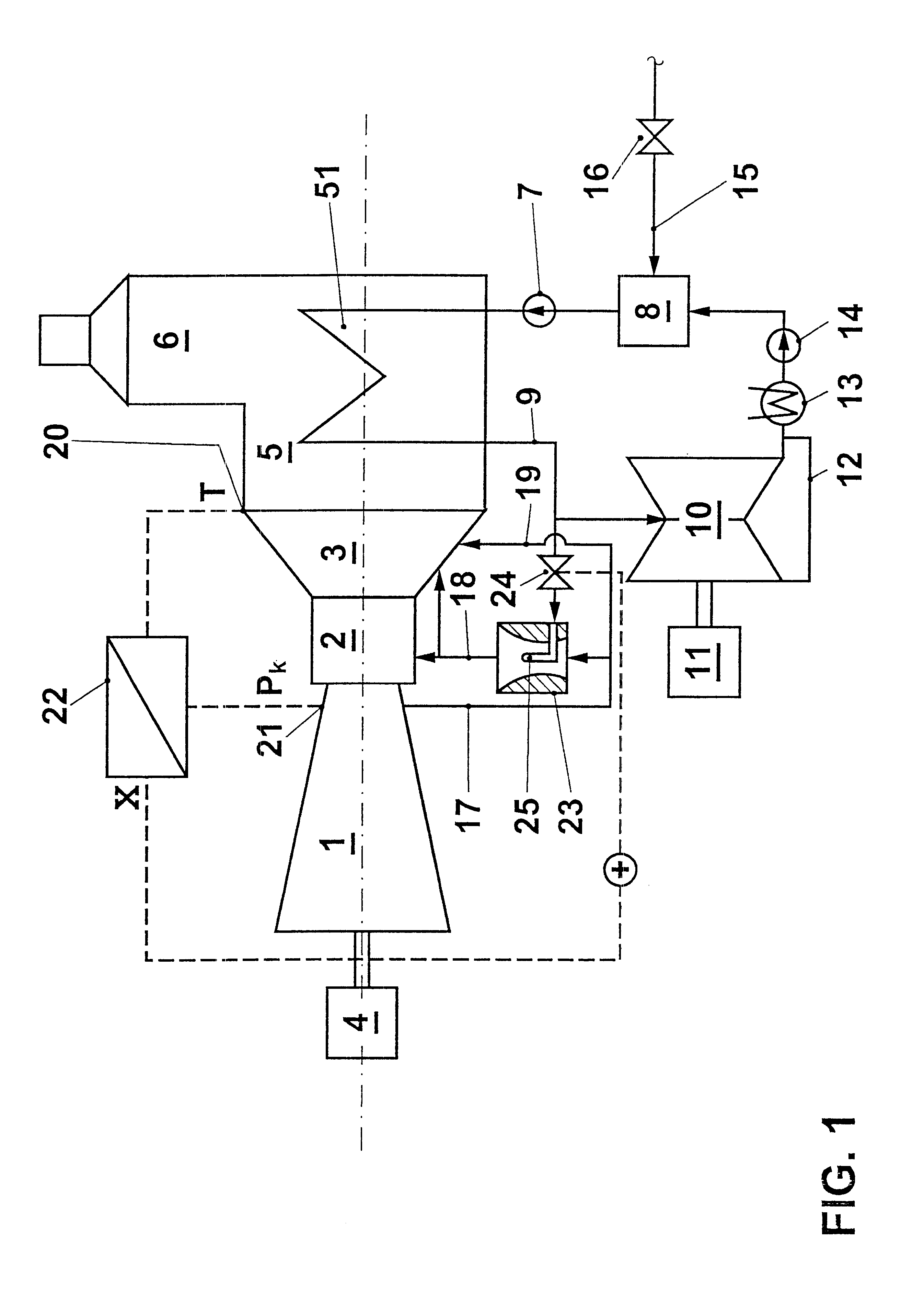

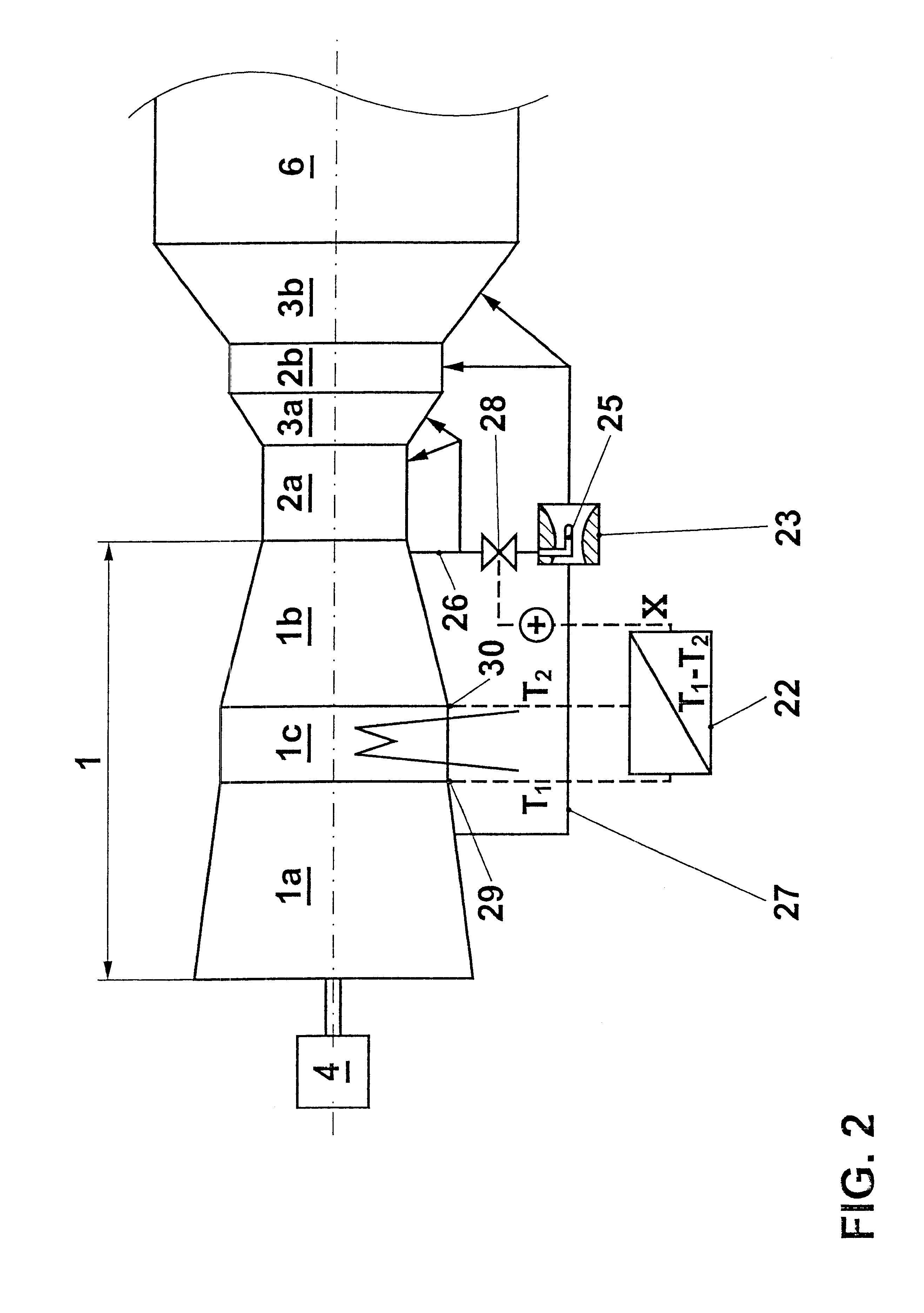

Process for controlling the cooling air mass flow of a gas turbine set

The invention gives a process for the control of the amount of cooling air of a gas turbine set (1, 2, 3). Suitable means (32, 33) are provided in the cooling system (26, 27) to enable the amount of cooling air to be varied. The control of this means takes place in dependence on an operating parameter (X). This is determined in a computer unit (22) by suitable combination of measured machine data (p1, p2).

Owner:ANSALDO ENERGIA IP UK LTD

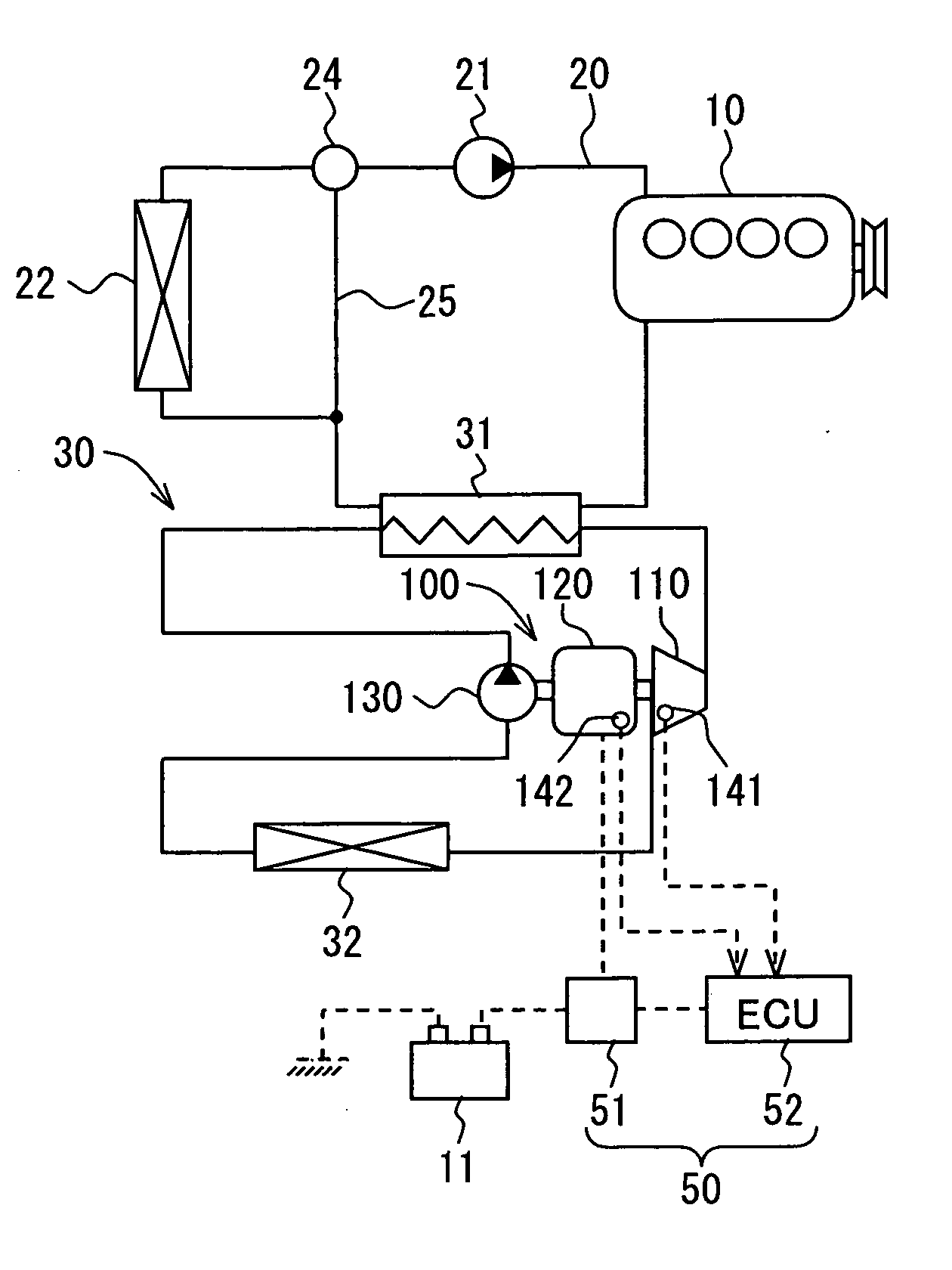

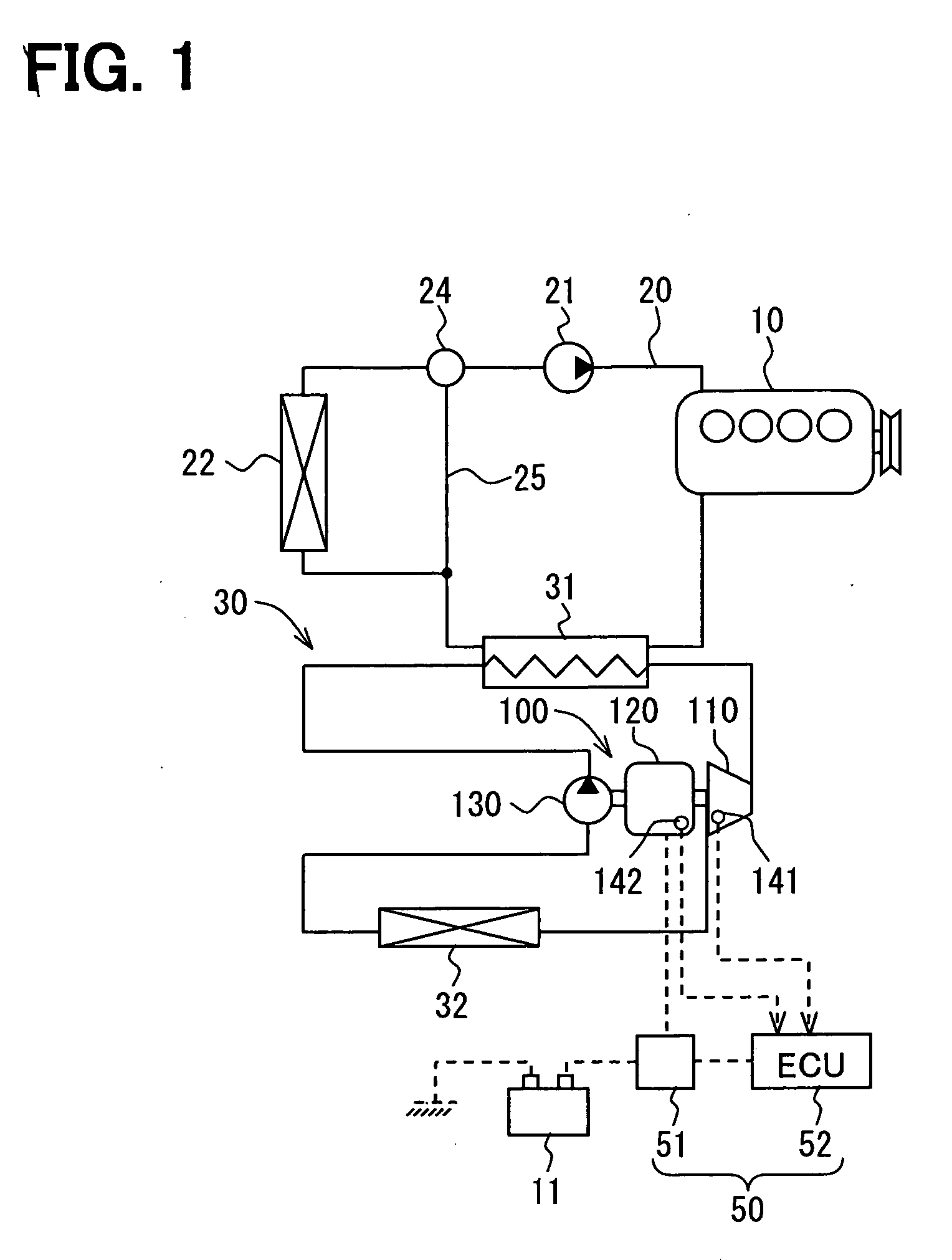

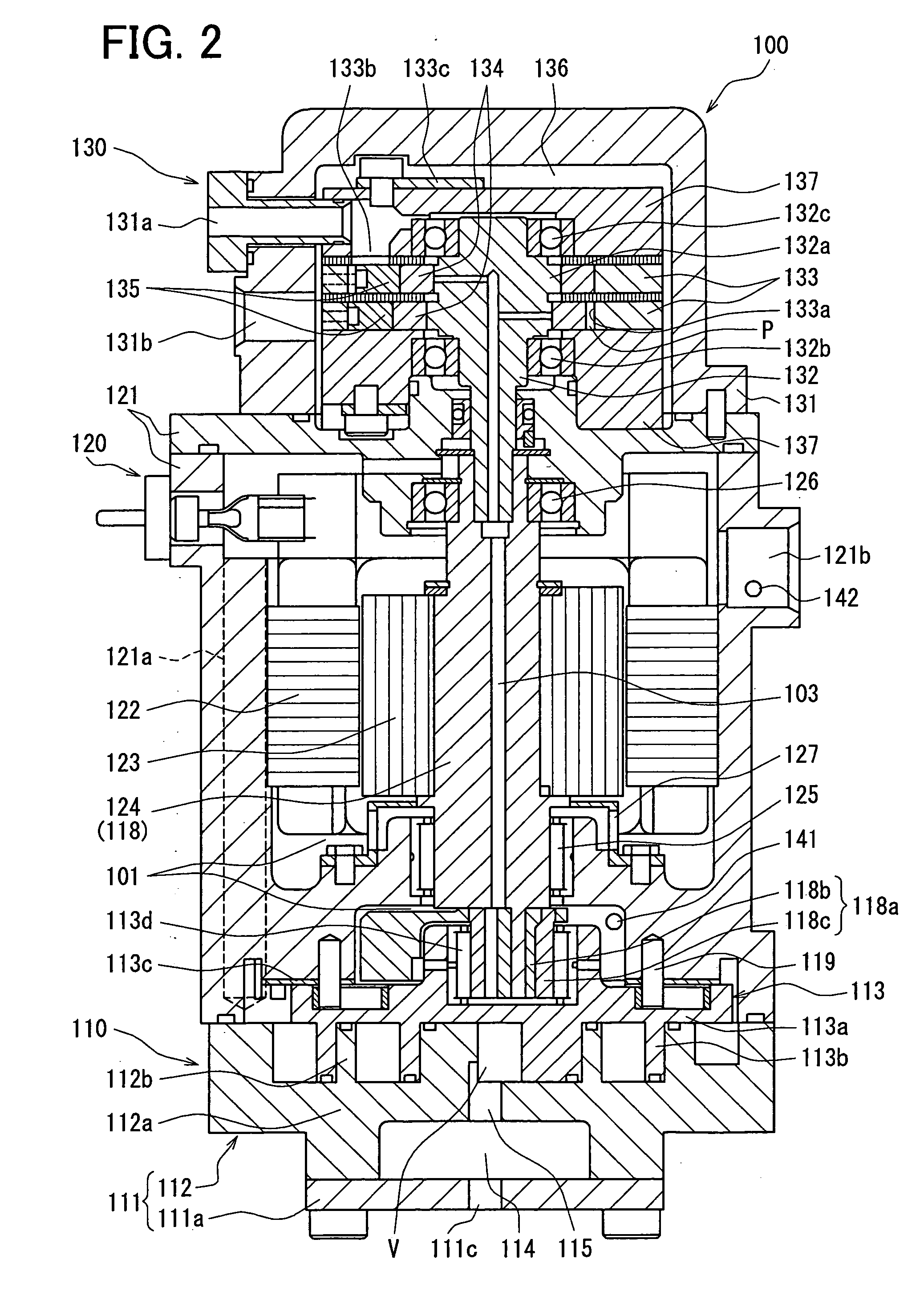

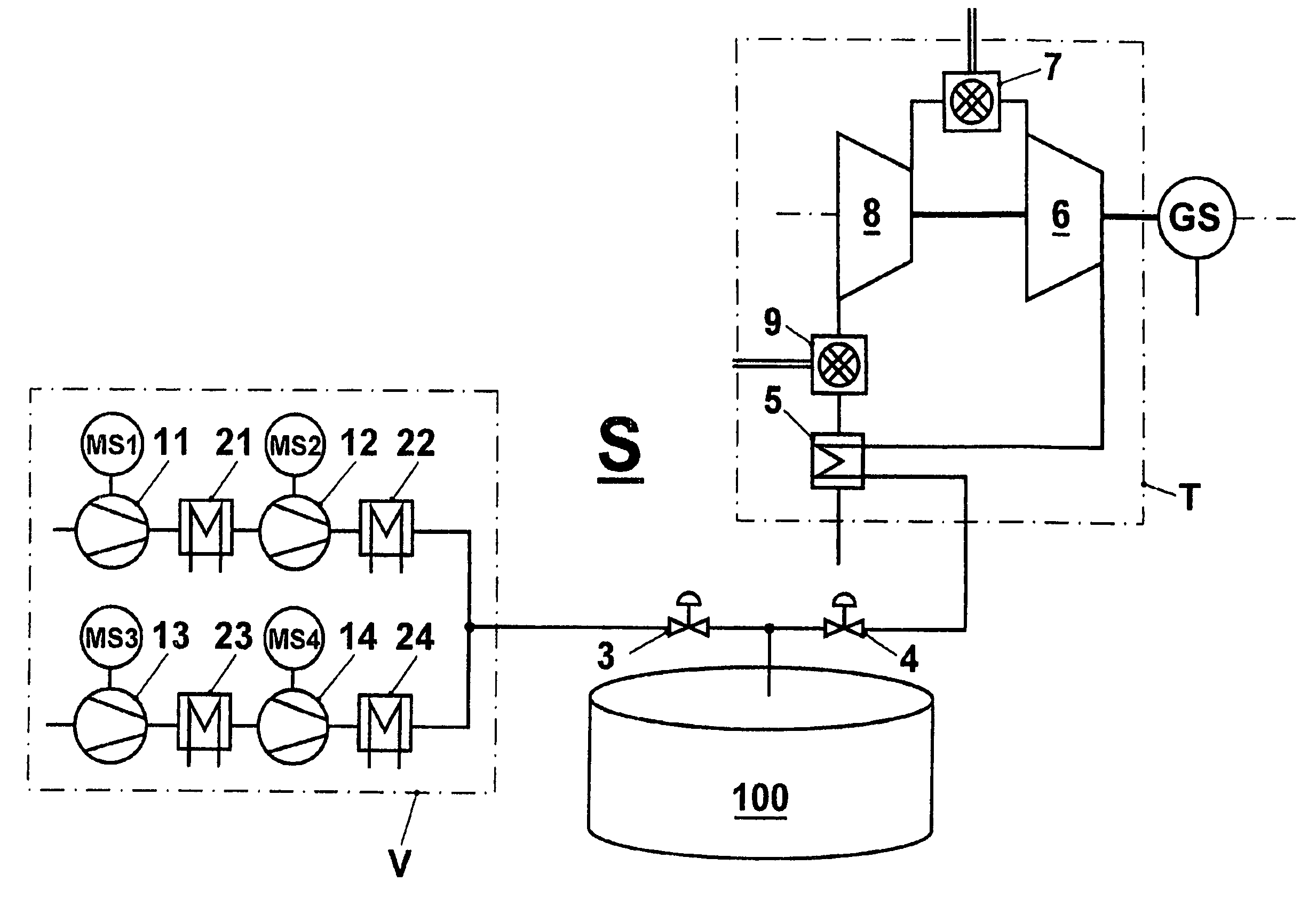

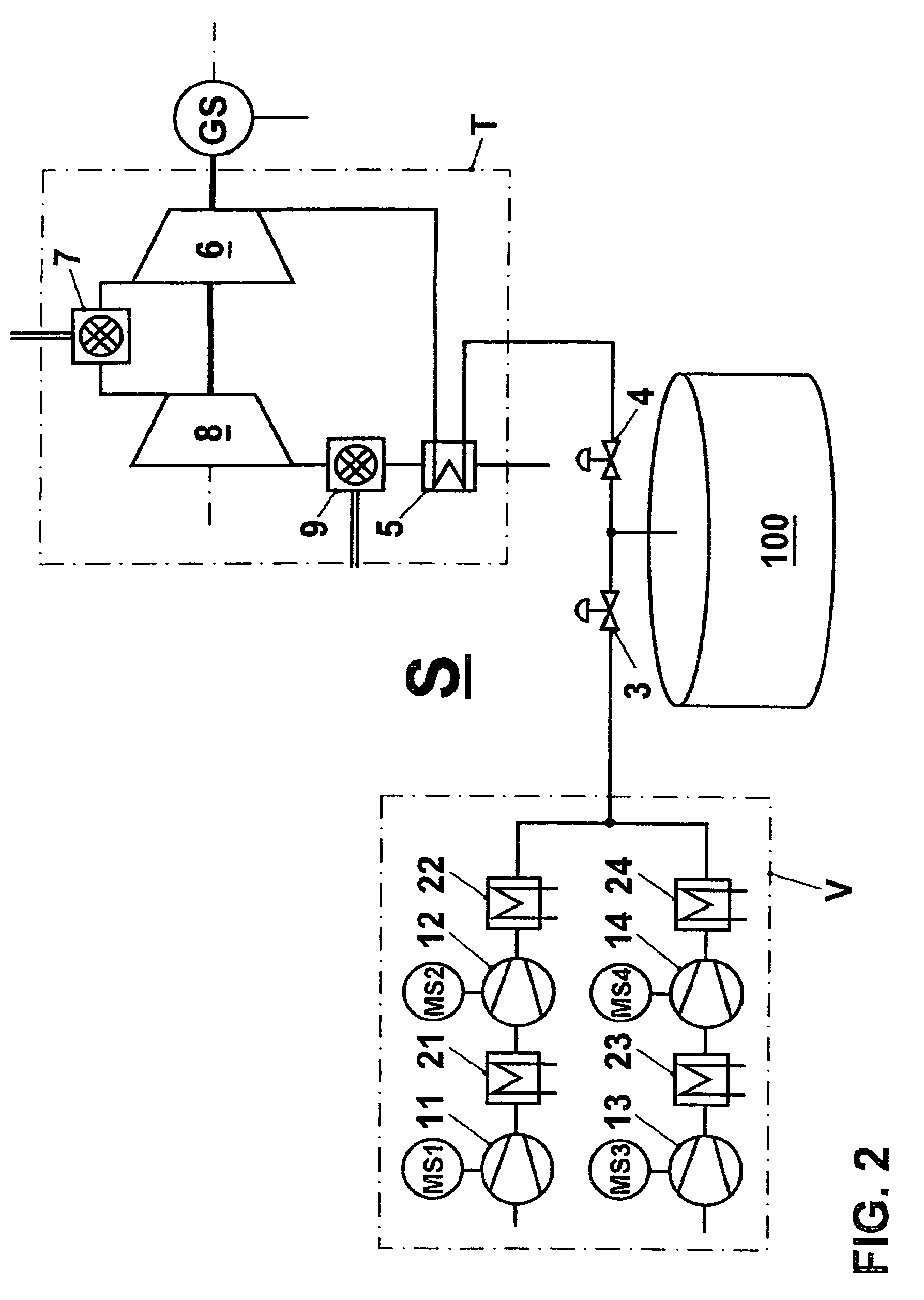

Fluid machine for Rankine cycle

InactiveUS20070175212A1Easily equalizedSafely and surely stopLiquid degasificationEngine of arcuate-engagement typeWorking fluidGas phase

It is an object to provide a fluid machine, which is simple in structure and in which lubricating oil containing smaller amount of the working fluid is supplied to sliding portions of an expansion device. The fluid machine has the expansion device for generating a driving force by expansion of the working fluid, which contains the lubricating oil and is heated to a gas phase condition. The fluid machine further has an electric power generating device driven by the driving force of the expansion device and generating electric power. An oil pooling portion is formed in a fluid passage, through which the working fluid discharged from the expansion device flows, such that the lubricating oil contained in the working fluid is brought into contact with at least one of sliding portions of the expansion device and the electric power generating device. And a heating unit is provided to heat the working fluid in the oil pooling portion.

Owner:DENSO CORP +1

Systems and methods for providing backup energy to a load

InactiveUS20070022755A1Liquid degasificationLighting and heating apparatusElectrical resistance and conductancePower capability

Backup energy systems utilizing compressed air storage (CAS) systems and bridging energy systems to supply backup power to a load are provided. During a power failure, the bridging energy system provides backup power to the load at least until the CAS system begins supplying adequate power. In various embodiments, backup power capability is enhanced through the use of one or more exhaustless heaters, which are used to heat compressed air. The compressed air, in turn, drives a turbine which is used to power an electrical generator. In various embodiments, ambient air heat exchangers or other types of heat exchangers are used to heat compressed air prior to the compressed air being routed to the turbine, thereby increasing system efficiency. Backup power and backup HVAC are also provided by utilizing turbine exhaust, heat exchangers and various resistive heating elements.

Owner:ACTIVE POWER INC

Systems and methods for providing backup energy to a load

Backup energy systems utilizing compressed air storage (CAS) systems and bridging energy systems to supply backup power to a load are provided. During a power failure, the bridging energy system provides backup power to the load at least until the CAS system begins supplying adequate power. In various embodiments, backup power capability is enhanced through the use of one or more exhaustless heaters, which are used to heat compressed air. The compressed air, in turn, drives a turbine which is used to power an electrical generator. In various embodiments, ambient air heat exchangers or other types of heat exchangers are used to heat compressed air prior to the compressed air being routed to the turbine, thereby increasing system efficiency. Backup power and backup HVAC are also provided by utilizing turbine exhaust, heat exchangers and various resistive heating elements.

Owner:P10 IND INC

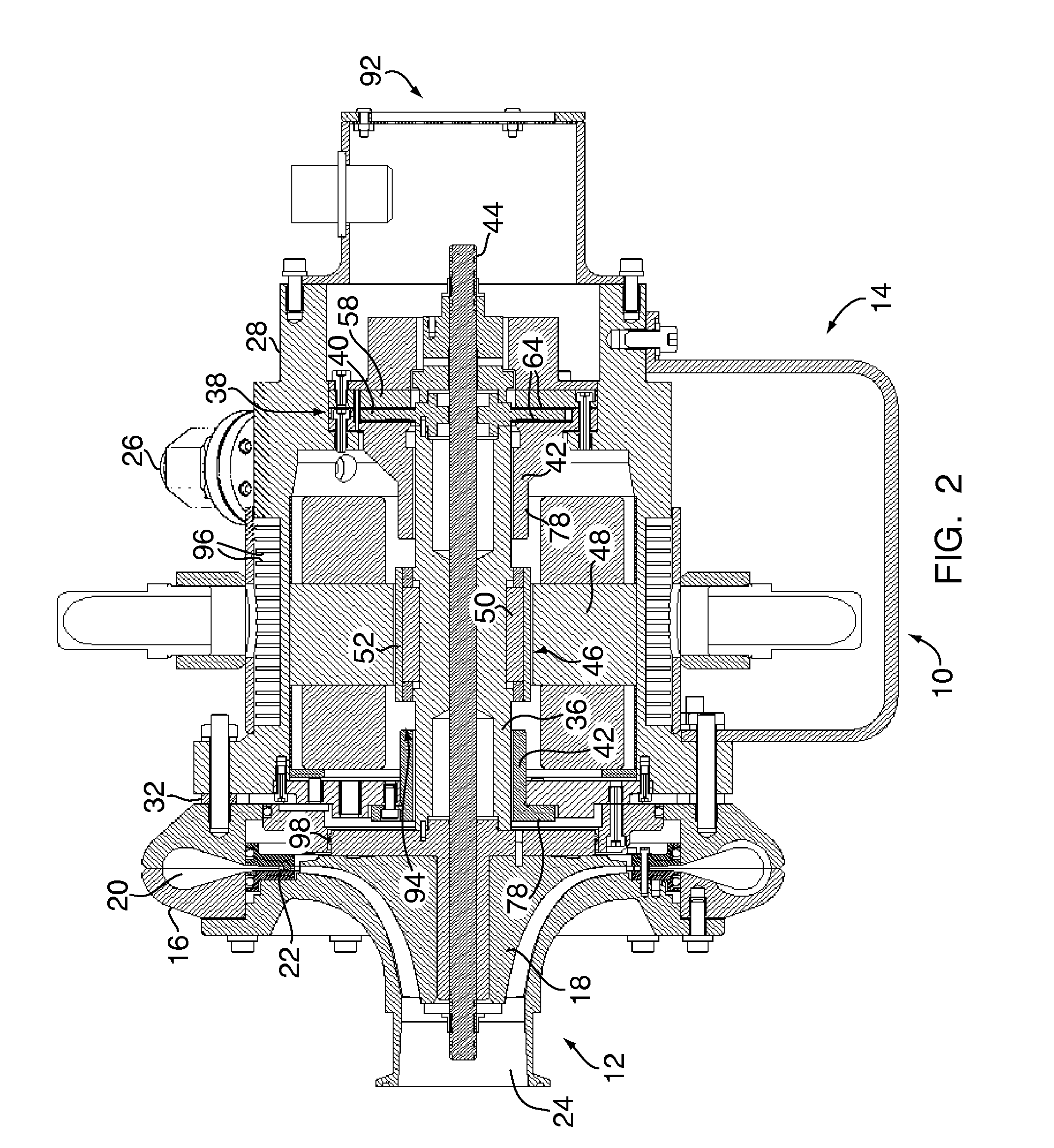

Integrated engine generator rankine cycle power system

InactiveUS20070240420A1Improve efficiencyLiquid degasificationSteam regenerationWorking fluidLubrication

The present invention provides an integrated engine generator Rankine cycle power system which increases the efficiency of the use of its power output. The system comprises a closed Rankine cycle power generating unit through which working fluid flows and an engine generator, the closed Rankine cycle power generating unit including a waste heat boiler for vaporizing said working fluid by means of exhaust gases discharged from the engine generator, an expander in which the vaporized working fluid expands and performs work to drive a shaft for producing mechanical power, or an electric generator coupled thereto and adapted to produce electrical power, from both the engine generator and the expander, and an external lubrication system in fluid communication with the expander wherein one or more closed Rankine cycle power generating unit components are operationally connected to the electric generator.

Owner:ORMAT TECH INC

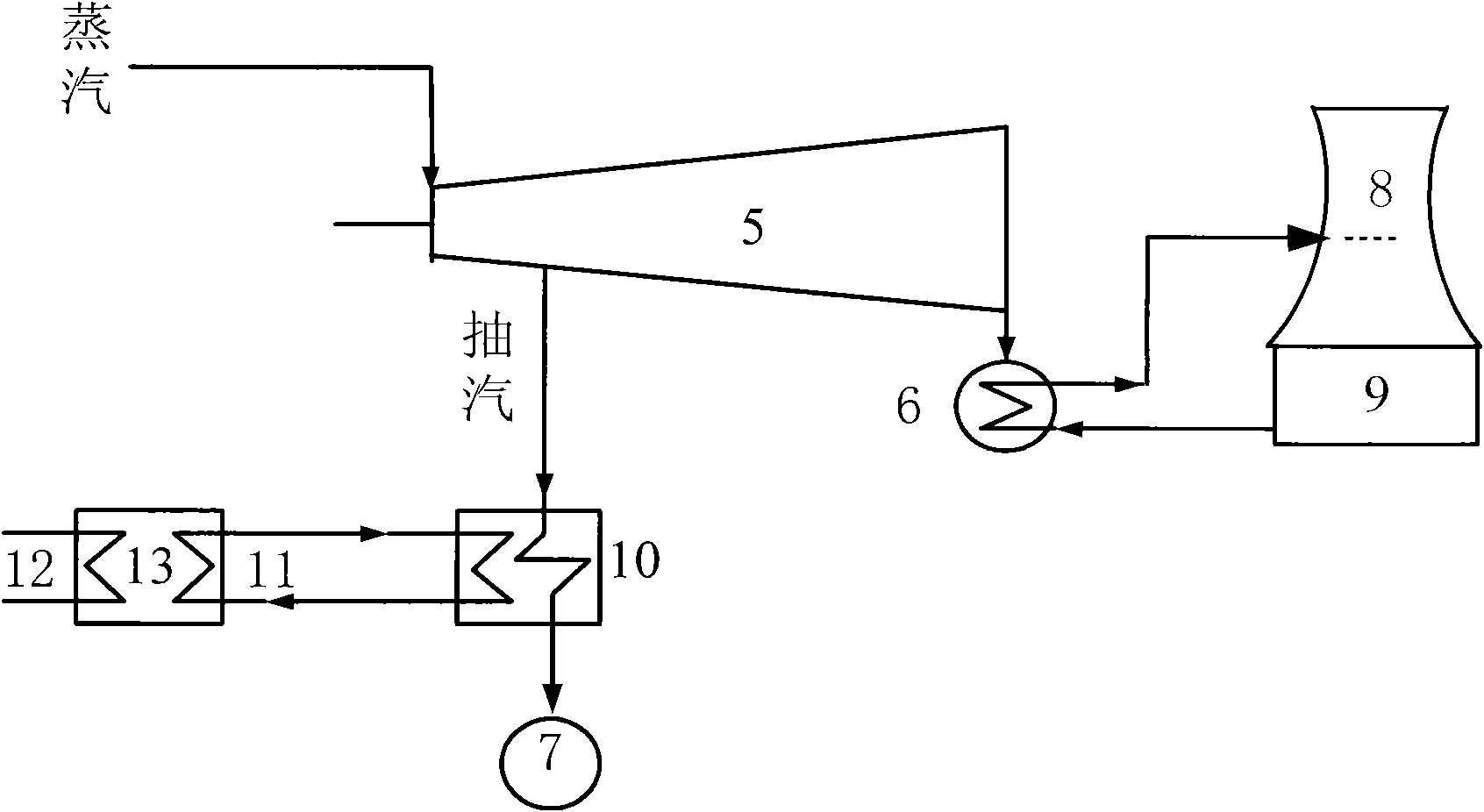

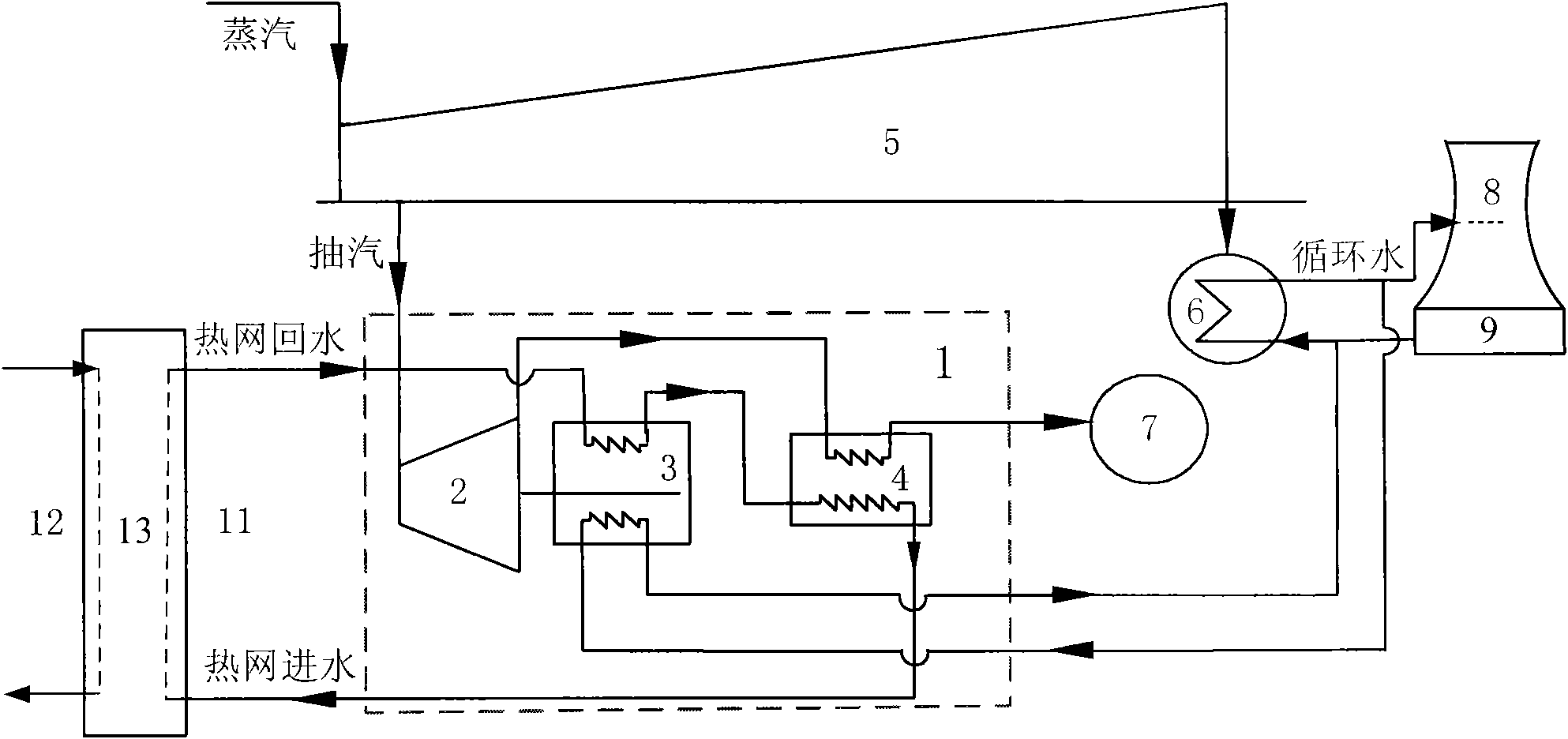

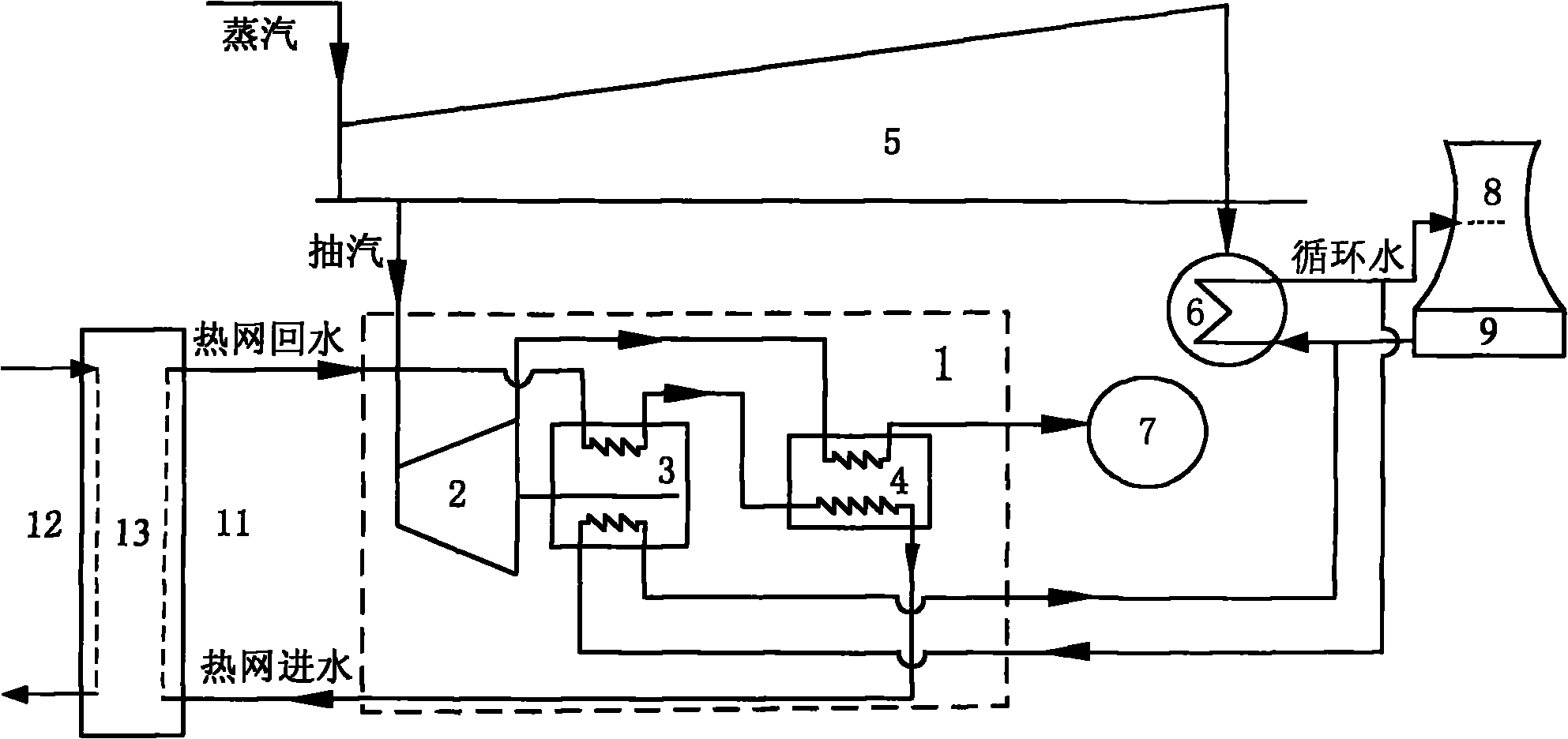

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

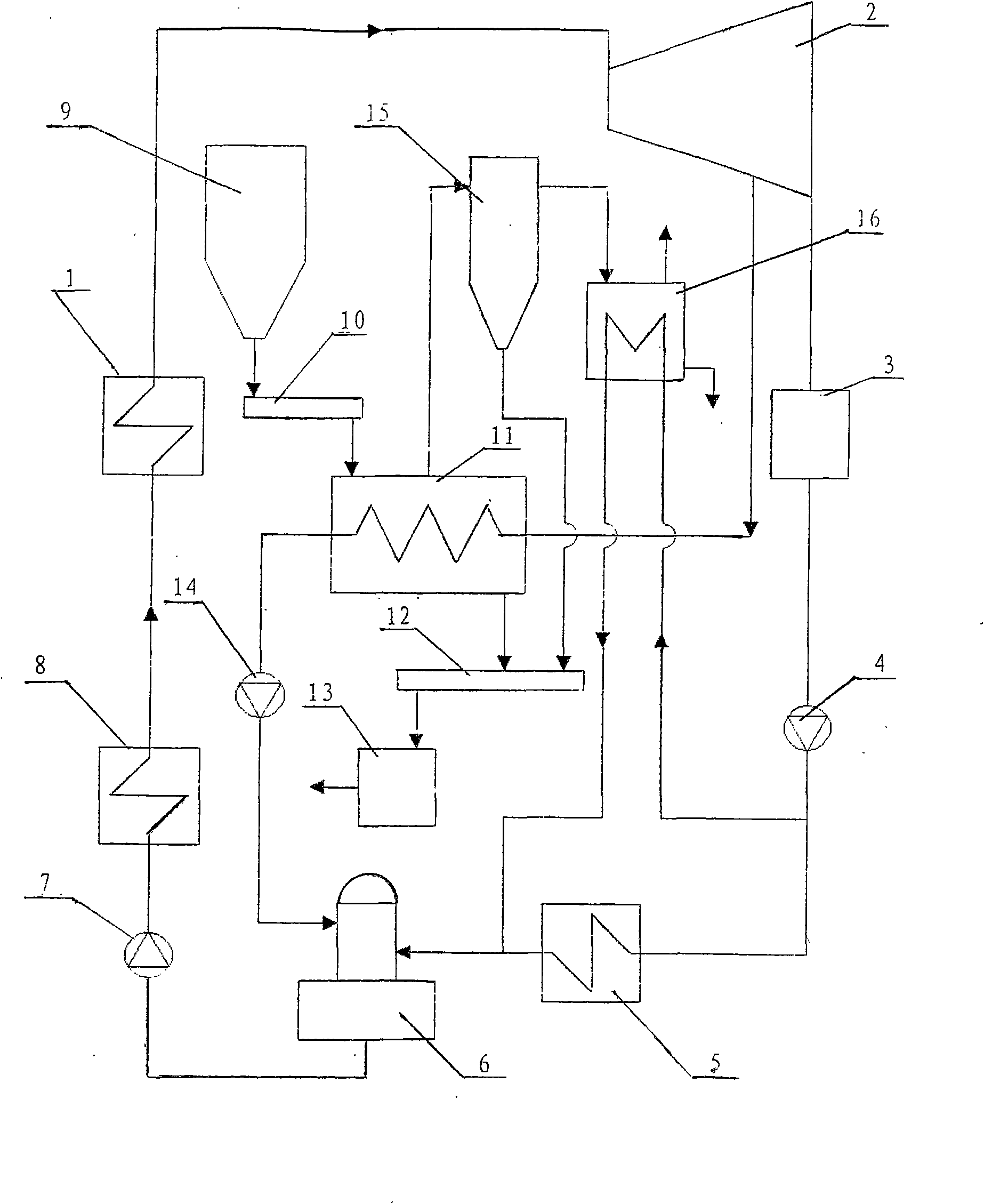

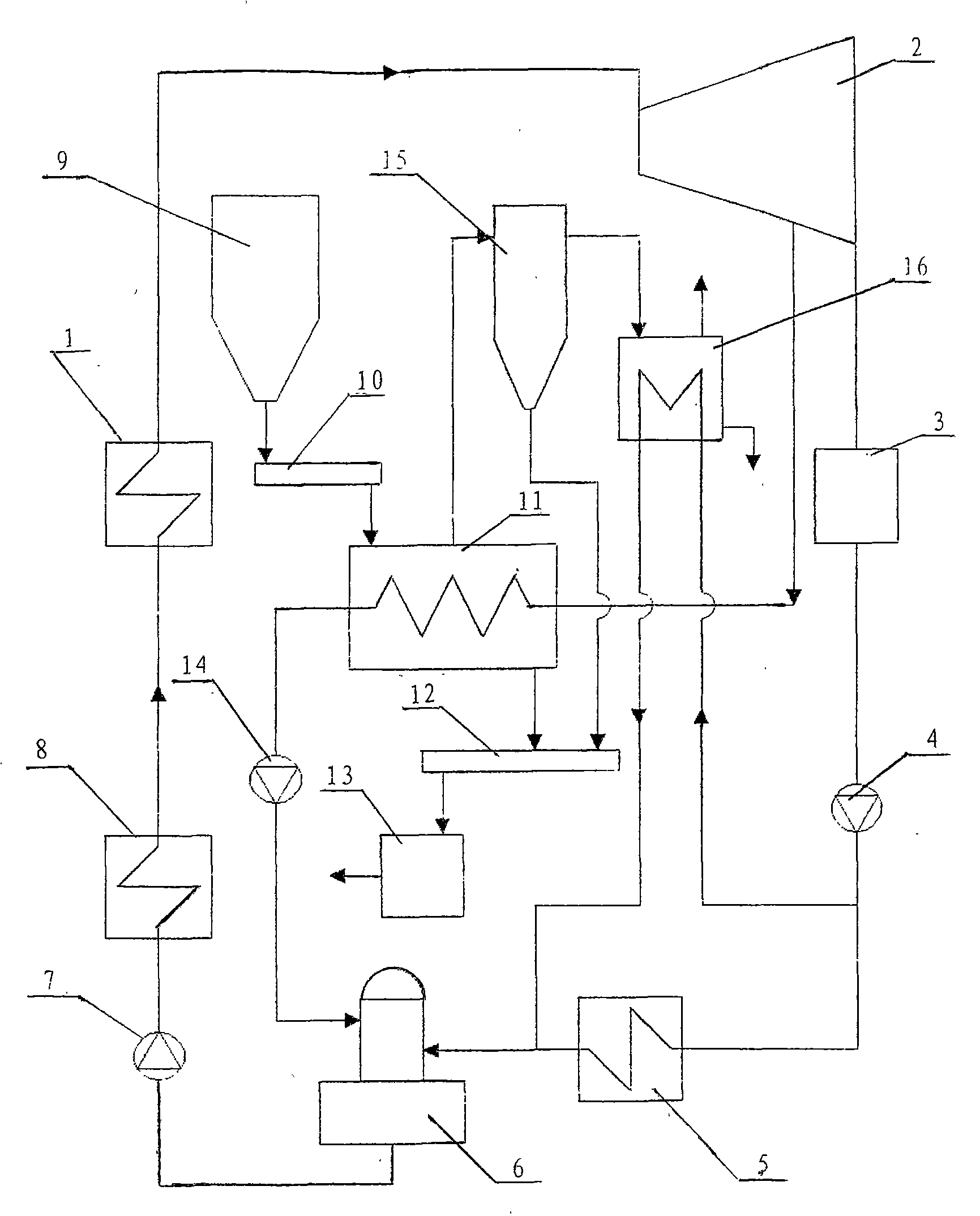

Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

ActiveCN101881191AIncrease energy densityReduce smoke lossDrying solid materials with heatSteam regenerationDeaeratorHigh pressure

The invention relates to a thermal power generation system based on a high-moisture lignite pre-drying upgrading and recovering technology. The thermal power generation system comprises a boiler, a turbine, a condenser, a condensation pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a wet coal bin, a wet coal feeder and a coal mill and is characterized in that a lignite pre-drying device, a drain pump, a dry coal feeder, a dust remover and a heat energy and waste water recovering device are additionally arranged in the power generation system. The invention improves the energy density of fire coal and accordingly increases the efficiency of the boiler, and is capable of reducing the investment of the boiler and a milling system by a larger extent, simultaneously reducing the plant power utilization ratio, further improving the energy source comprehensive utilization efficiency of a thermal power generation plant, recovering a great deal water by using coal to produce water and saving precious water resources. The invention achieves the effects of high efficiency, energy saving, water saving and emission reduction and accords with the industrial policy of developing the low-carbon economy in China.

Owner:CHINA POWER ENG CONSULTING GRP +1

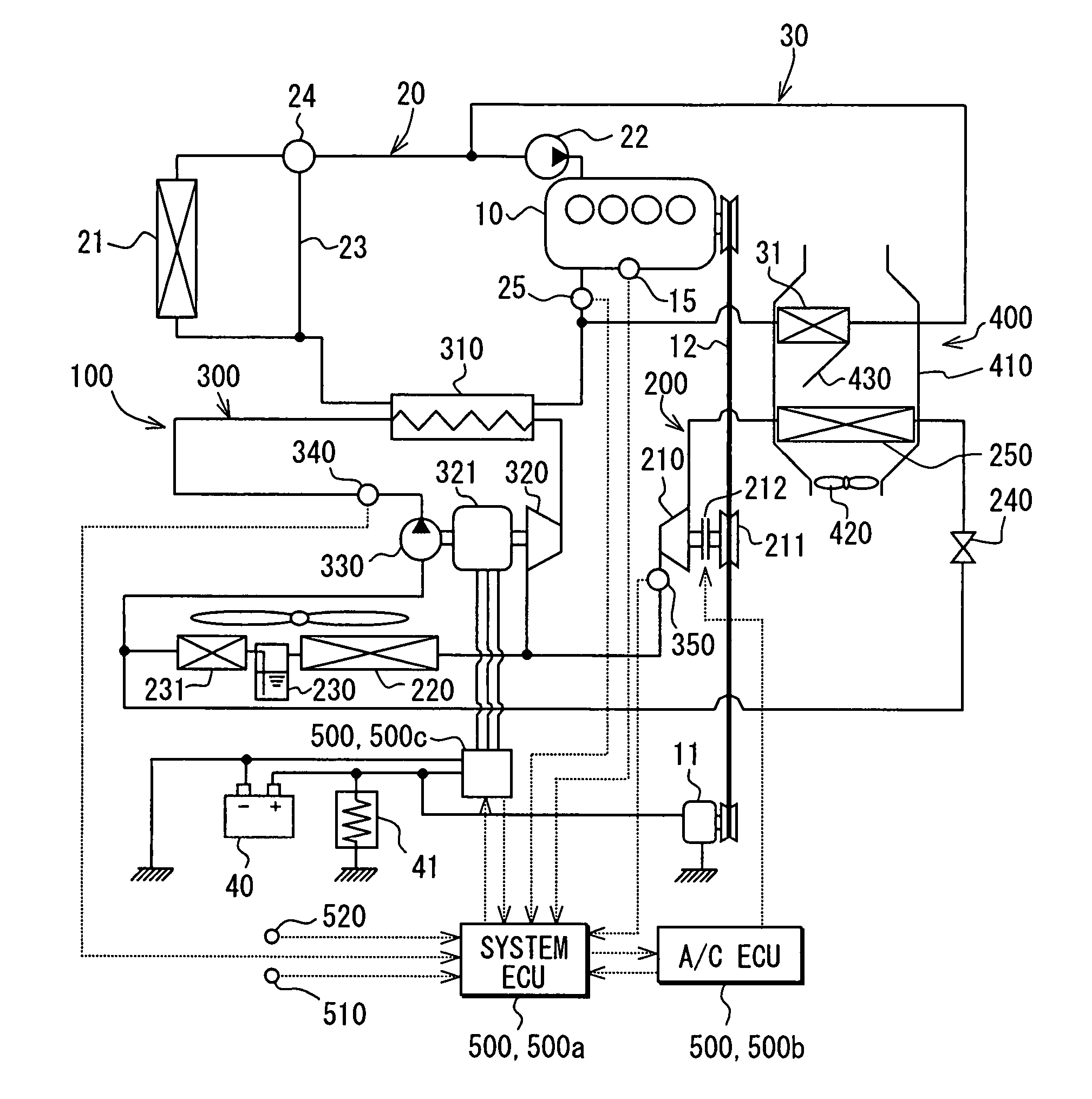

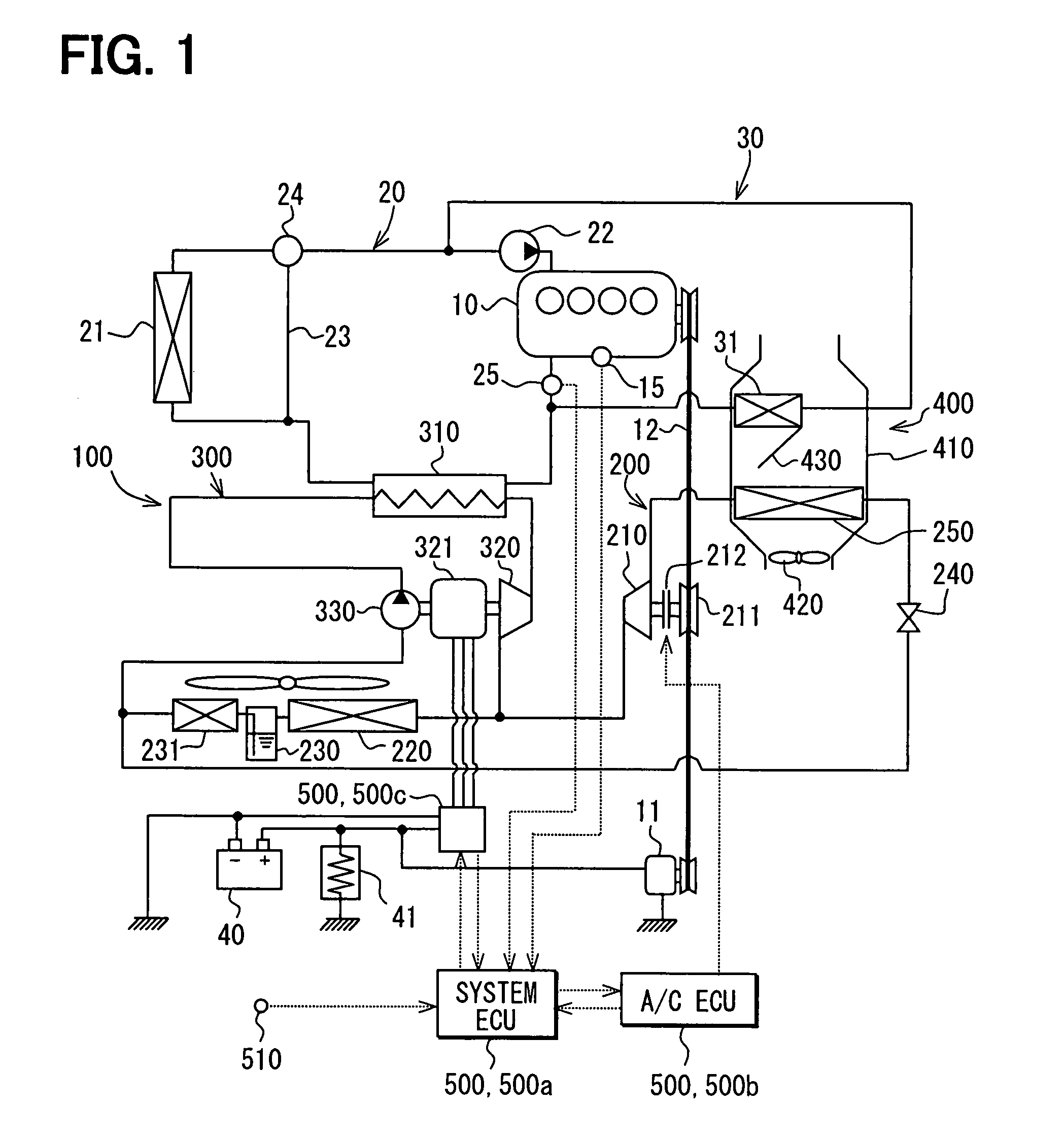

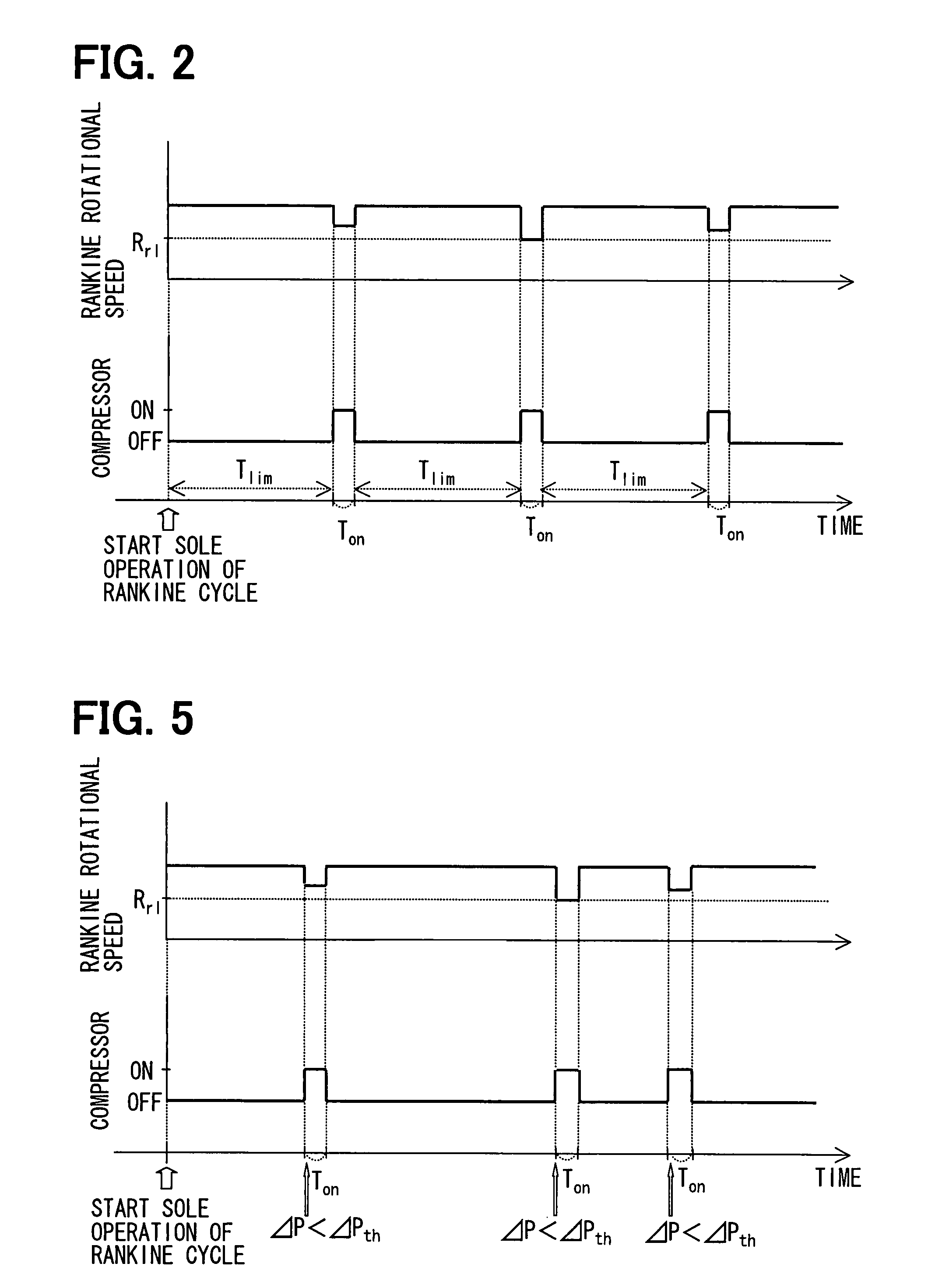

Refrigeration system including refrigeration cycle and rankine cycle

A controller reduces a rotational speed of a Rankine cycle from a predetermined normal rotational speed during an operation of a compressor in a predetermined state when the controller determines that a predicted refrigerant flow quantity, which is predicted by assuming that the compressor is operated in a sole operation of the Rankine cycle at the predetermined normal rotational speed of the Rankine cycle, exceeds a predetermined flow quantity. The predetermined state is a state that satisfies a predetermined condition, which relates to the sole operation of the Rankine cycle.

Owner:DENSO CORP +1

Method for operation of a power generation plant

InactiveUS7464551B2Increase power generationIncrease powerElectrical storage systemLiquid degasificationPower stationPower grid

Owner:GENERAL ELECTRIC TECH GMBH

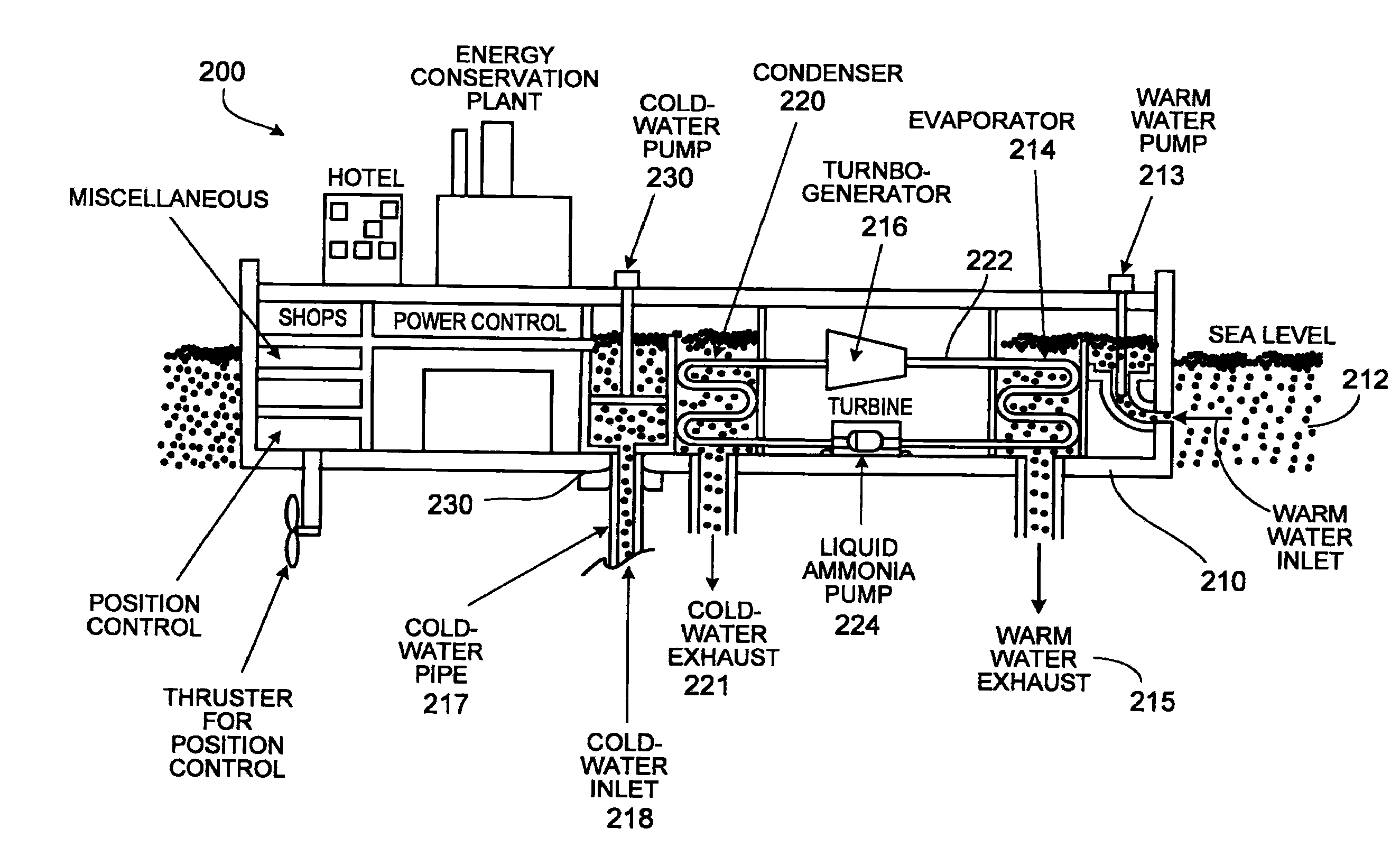

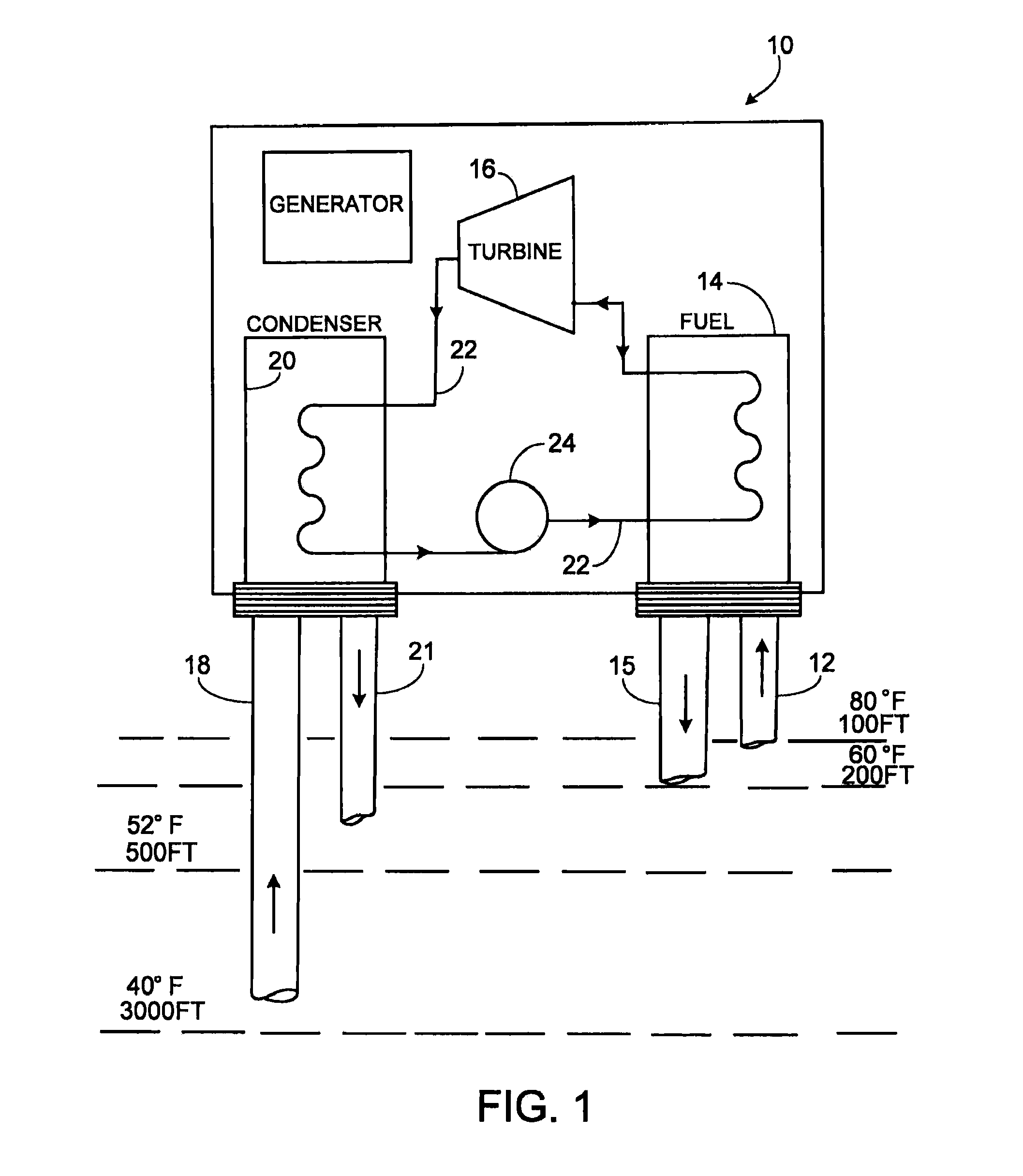

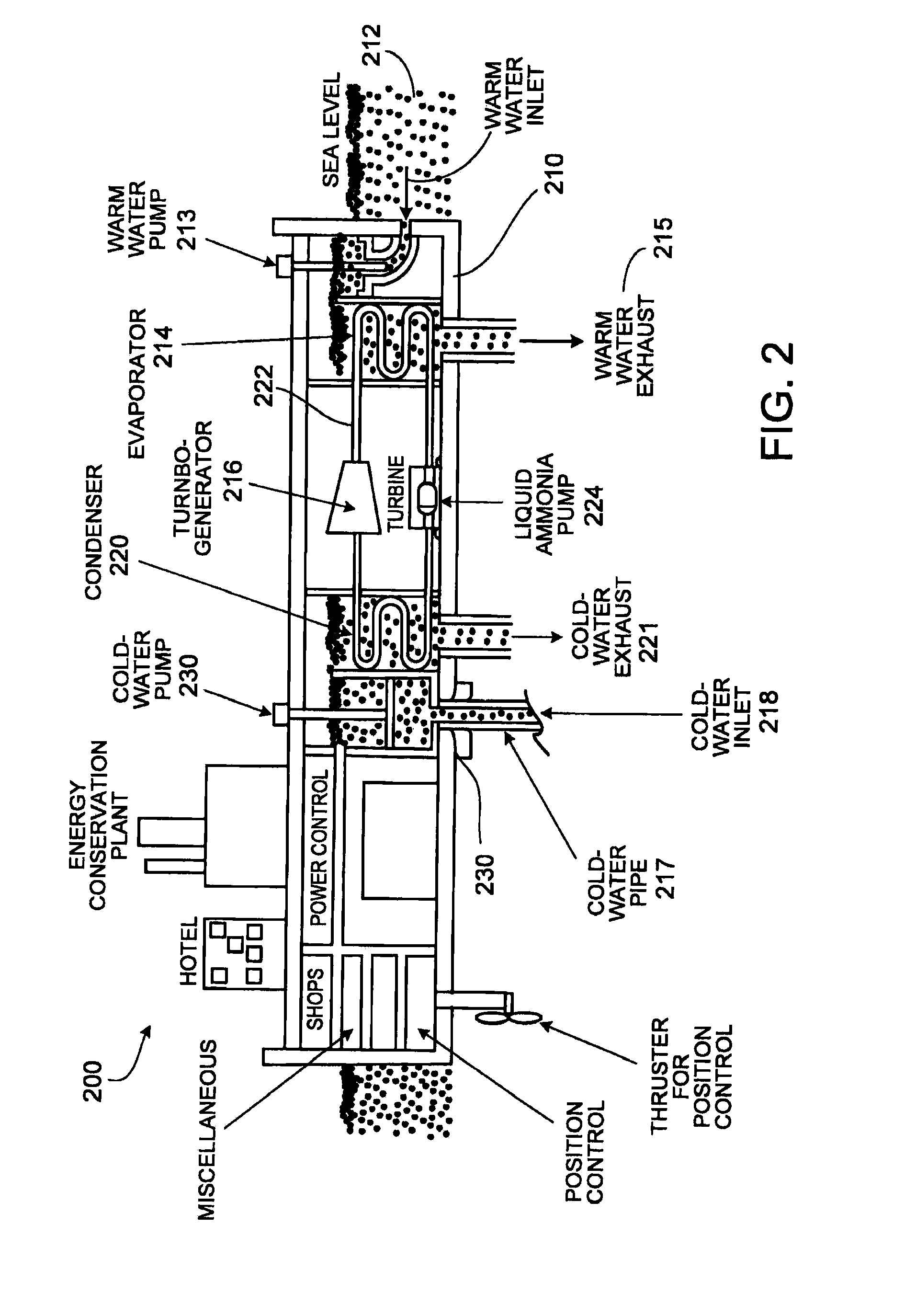

Ocean Thermal Energy Conversion Plant

ActiveUS20110173979A1Minimal pressure lossMinimal movementSteam regenerationIndirect heat exchangersThermal energyOcean thermal energy conversion

An offshore power generation structure comprising a submerged portion having a first deck portion comprising an integral multi-stage evaporator system, a second deck portion comprising an integral multi-stage condensing system, a third deck portion housing power generation equipment, cold water pipe; and a cold water pipe connection. The heat exchangers in the evaporator and condenser systems include a multi-stage cascading heat exchange system. Warm water conduits in the first deck portion and cold water conduits in the second deck portion are integral to the structure of the submerged portion of the offshore platform.

Owner:THE ABELL FOUND INC

Heat recovery steam generator and method for fast starting combined cycles

ActiveUS8820078B1Control moisture contentPossible leakageLiquid degasificationSteam generation heating methodsEngineeringSuperheater

A once-through high pressure steam generator and reheater configured to eliminate the majority of components limiting cyclical life of fast start conventional HRSGs. Two remaining problematic components in conventional designs the final superheater and reheater tubes overheat while their headers remain colder in fast starts. In this inventive HRSG the critical components are arranged and started by a method that limits these damaging temperature differentials. At ignition when exhaust gas surges into a wet superheater steam flow starts minutes before conventional systems. This early steam flow cools the tubes while heating the headers, thereby reducing life damaging stresses. Steam temperature is controlled through the start and warms the rest of the plant earlier without attemperators with their problematic thermal stress history. Faster starts than conventional result without damaging fatigue life depletion with this low cost innovation.

Owner:DUFFY THOMAS EDWARD

Hybrid power system for continuous reliable power at locations including remote locations

The present inventive subject matter is drawn to a hybrid ultra reliable power generating system for supplying continuous reliable power at remote locations comprising: a primary power unit producing electric power that is supplied to a load. Also a secondary power unit is included in the form of a closed cycle vapor turbine (CCVT) system that is capable of producing 100% of the electric power that is produced by the primary power unit and which is heated in hot standby by rejected heat of the primary power unit, wherein the vaporizer of the CCVT is maintained during hot standby at a temperature above its nominal operating temperature and the vapor turbine of the CCVT is preferable maintained at idle during hot standby at a rotating speed. Furthermore, the present inventive subject matter is drawn to an apparatus that combines a fuel efficient primary power generation unit system such as a high temperature fuel cell with a secondary power unit that is a very high reliability closed cycle vapor turbine (CCVT) which operates according to a Rankine cycle using organic working fluid that is capable of producing approximately 5-15% of the electric power that is produced by the primary power unit and which is heated by rejected heat of the primary power unit, wherein working fluid in the vaporizer of the CCVT is heated by the heat rejected by the primary power unit.

Owner:ORMAT TECH INC

Method and apparatus for controlling the final feedwater temperature of a regenerative Rankine cycle using an exergetic heater system

ActiveUS8091361B1Power Loss MinimizationImprove system reliabilitySteam regenerationSteam useWorking fluidPower station

This invention relates to a method and apparatus for increasing the final feedwater temperature associated with a regenerative Rankine cycle, said cycle commonly used in thermal systems such as conventional power plants, whose steam generators are fired with a fossil fuel and whose regenerative Rankine cycle employs a reheating of the working fluid. This invention involves the placement of an Exergetic Heater System in the feedwater path of the regenerative Rankine cycle. The Exergetic Heater System conditions and heats feedwater such that the temperature of the cycle's final feedwater as it enters the steam generator has reached a desired value. The Exergetic Heater System receives its driving steam from an Intermediate Pressure turbine extraction.

Owner:EXERGETIC SYST

Turboalternator with hydrodynamic bearings

ActiveUS7948105B2Low efficiencyOptimum powerLiquid degasificationPump componentsStored energyAlternator

Owner:R & D DYNAMICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com