Patents

Literature

1350 results about "Deaerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A deaerator is a device that removes oxygen and other dissolved gases from liquids...

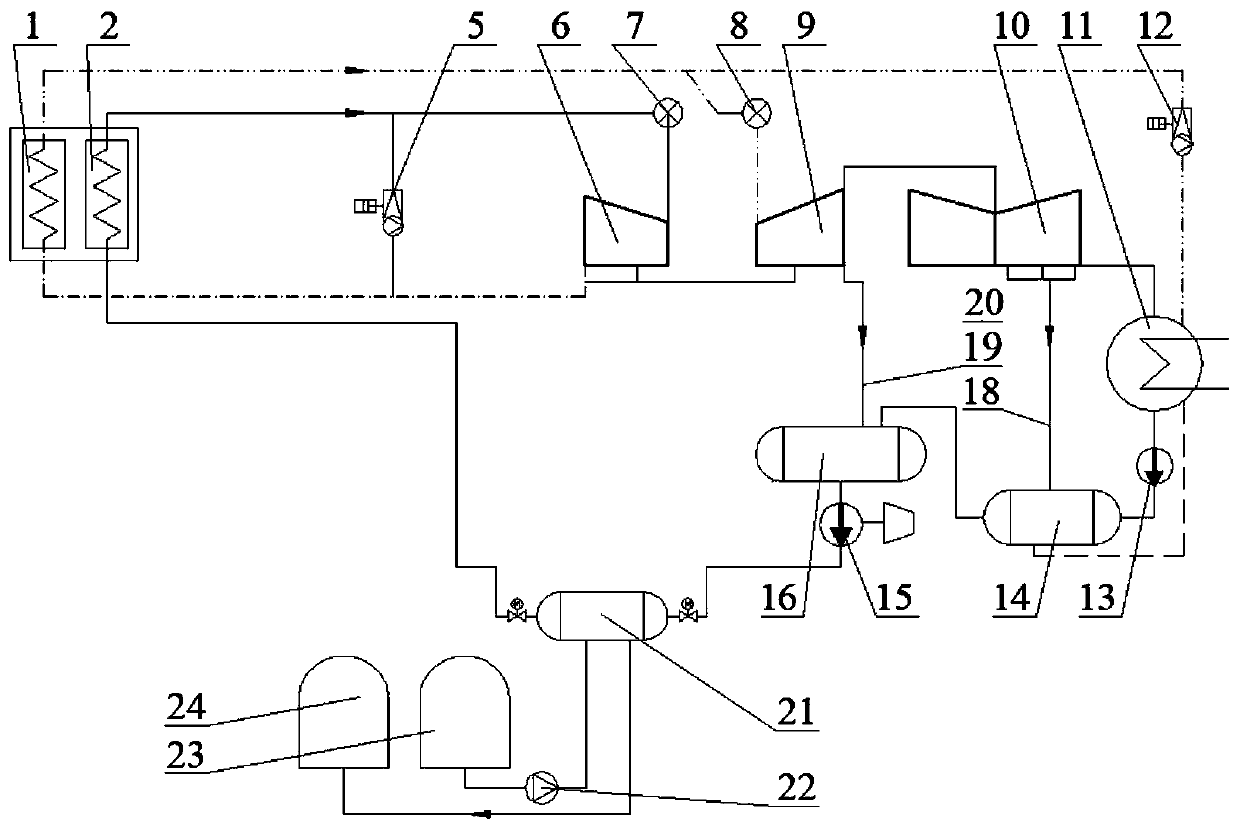

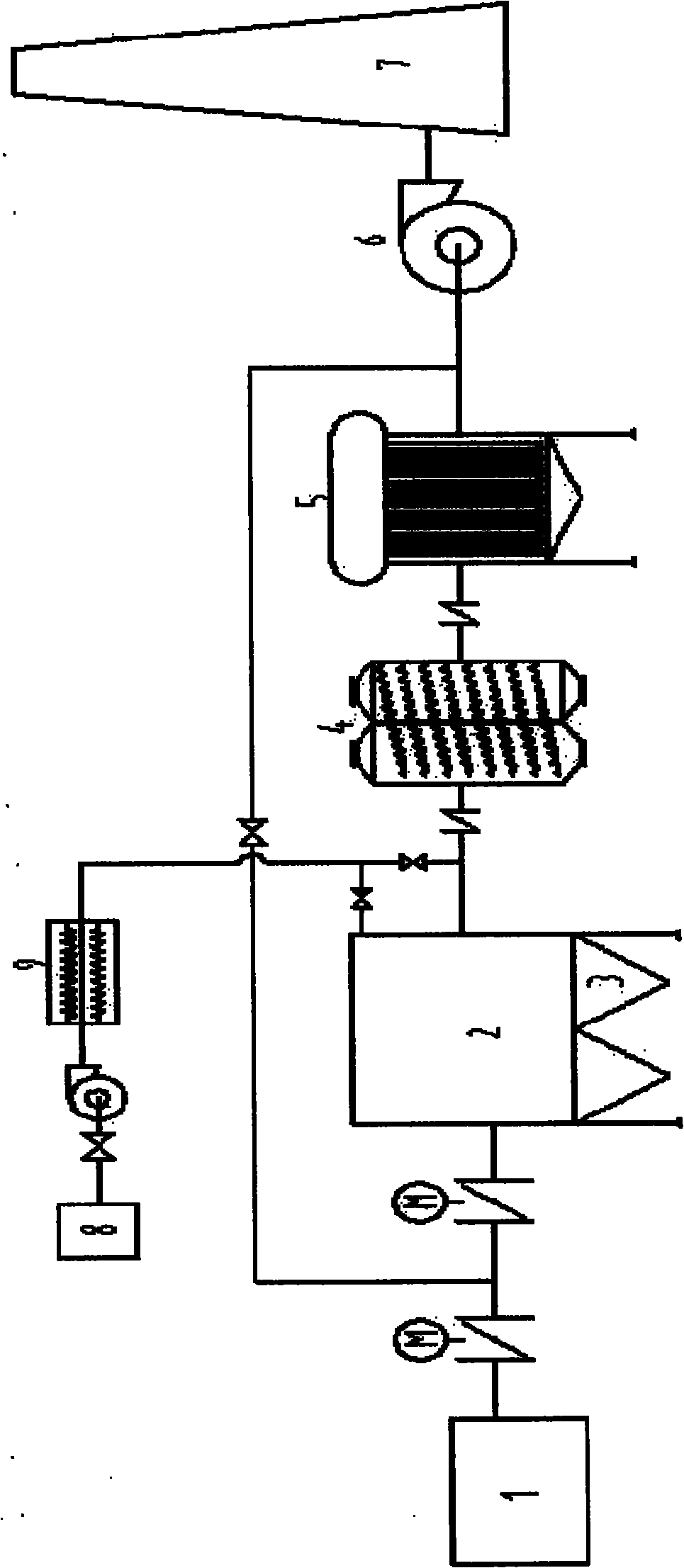

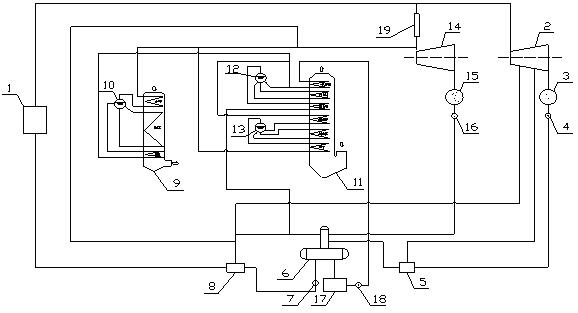

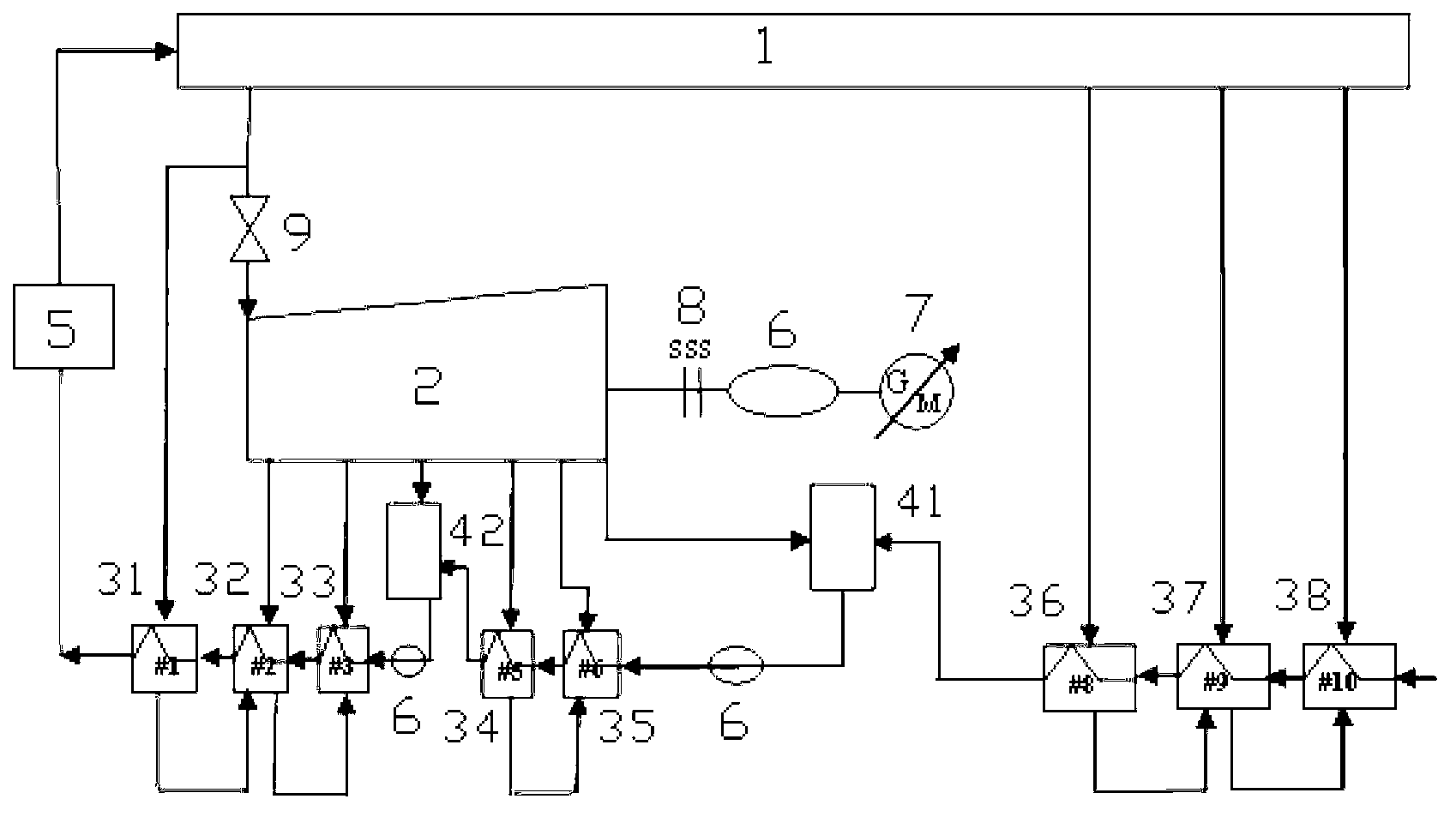

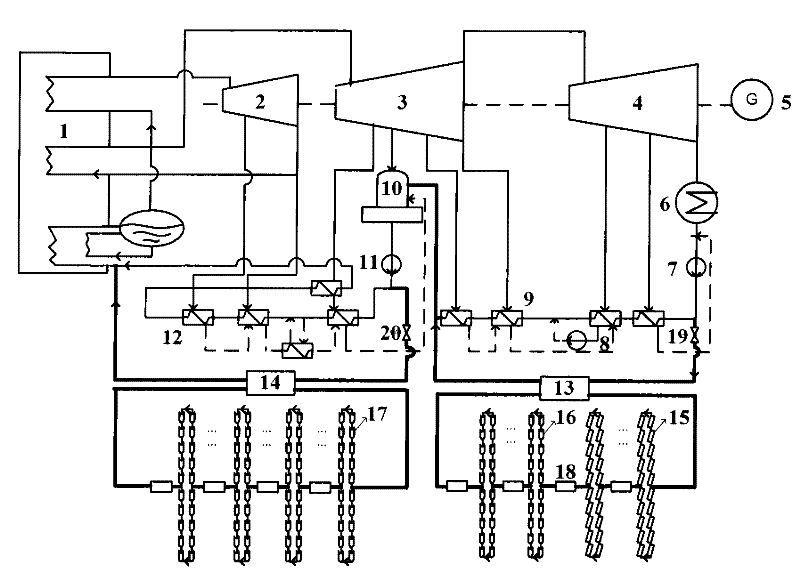

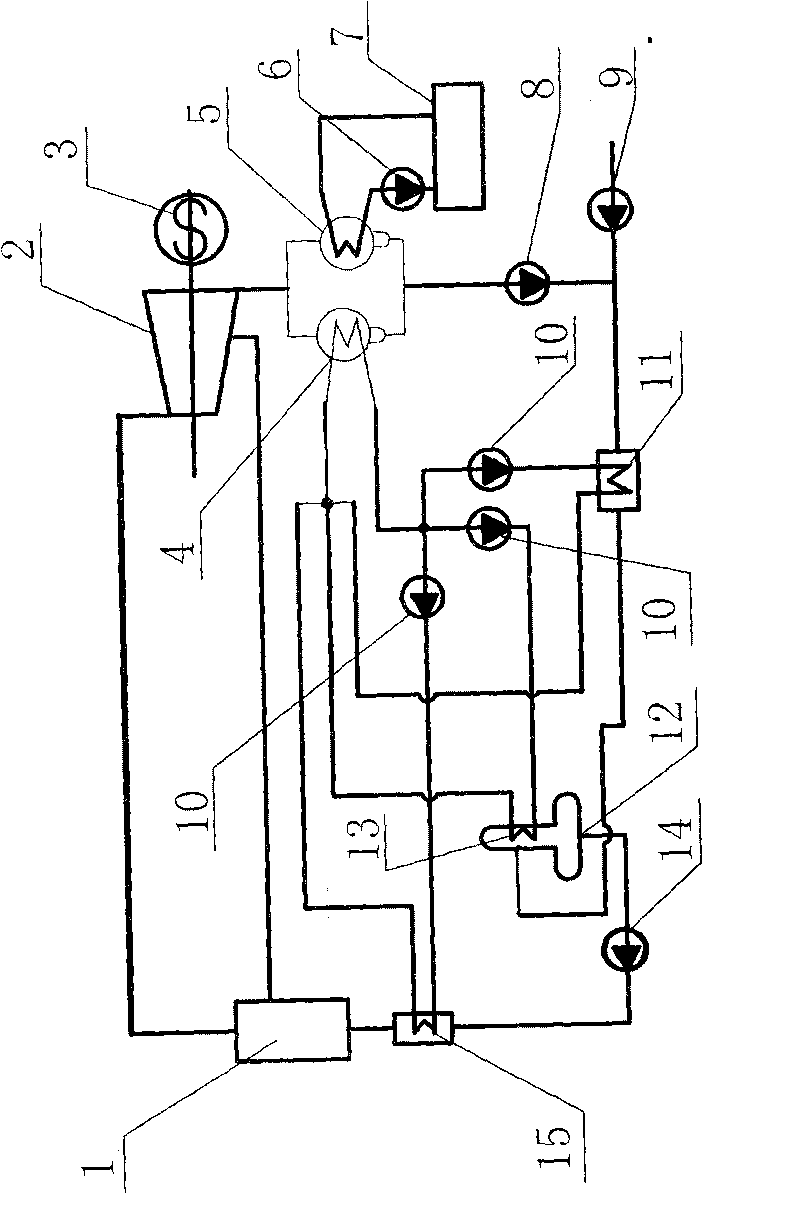

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

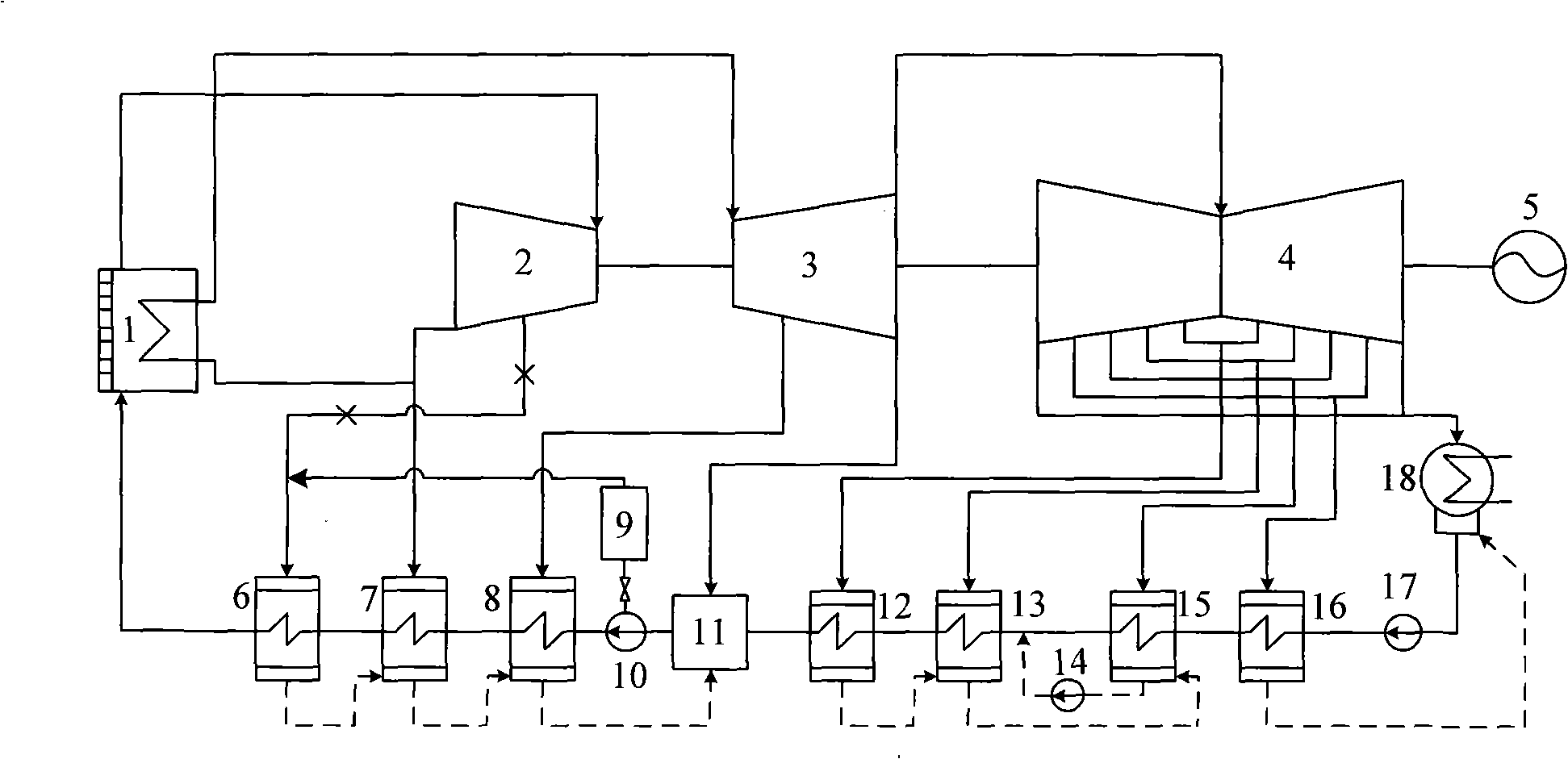

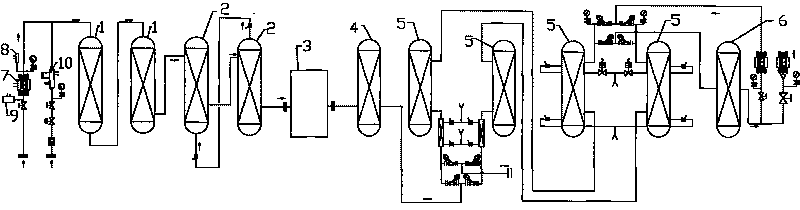

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

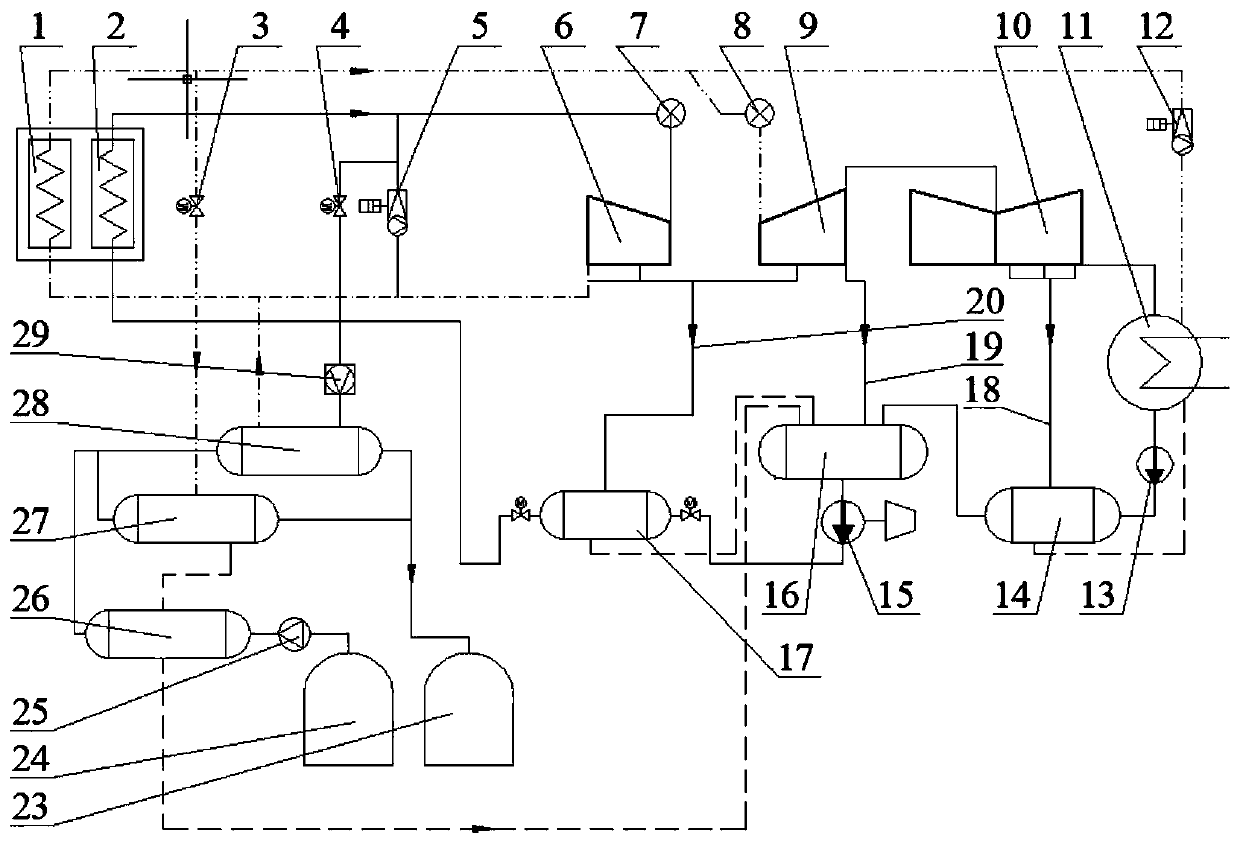

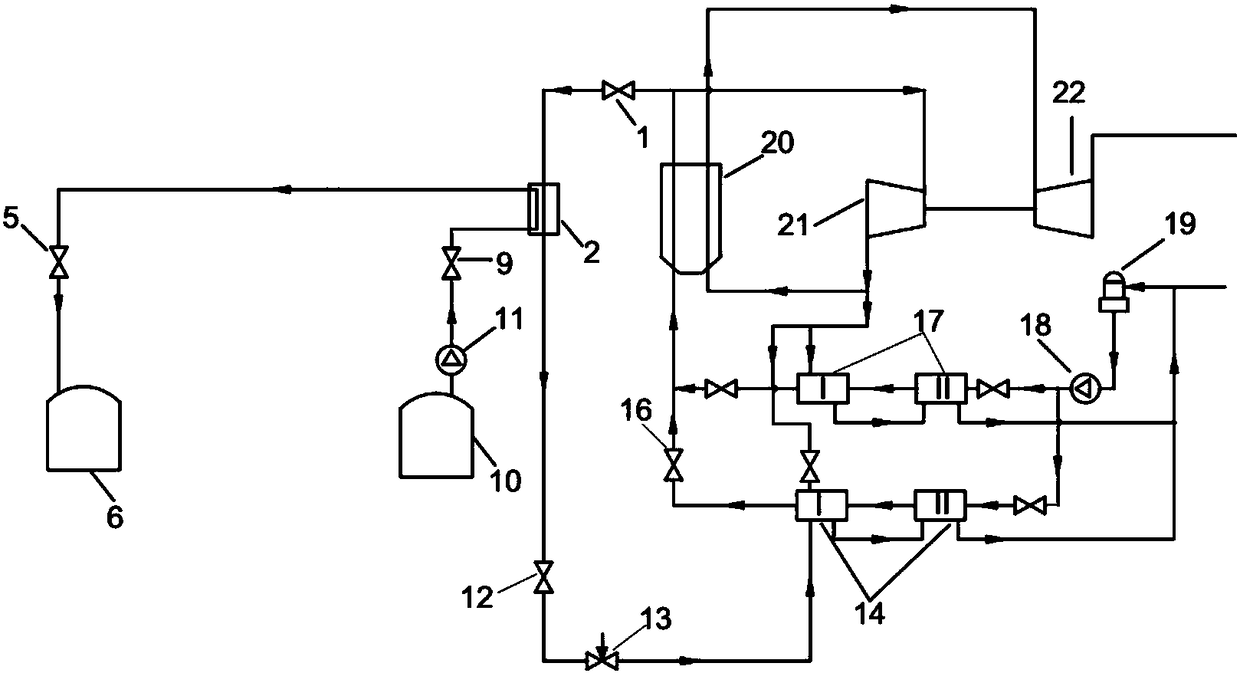

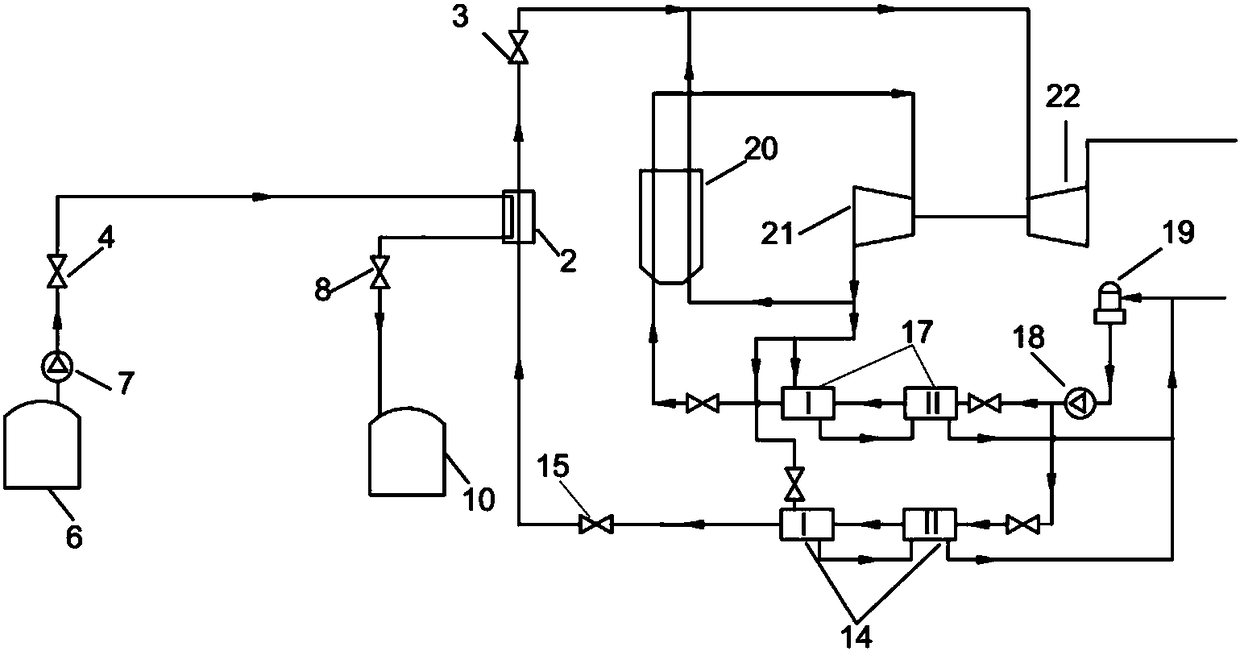

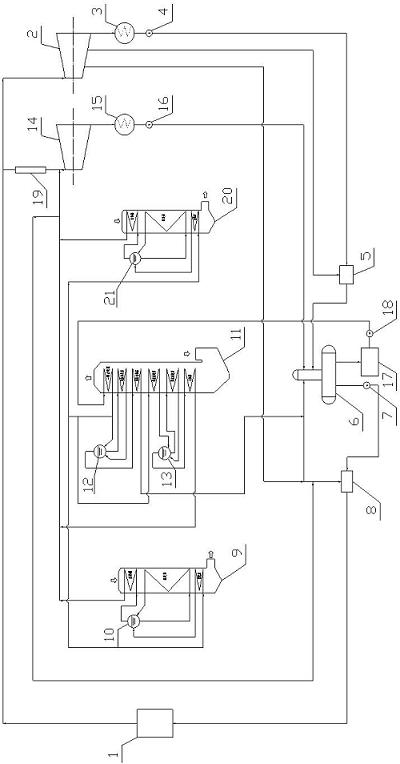

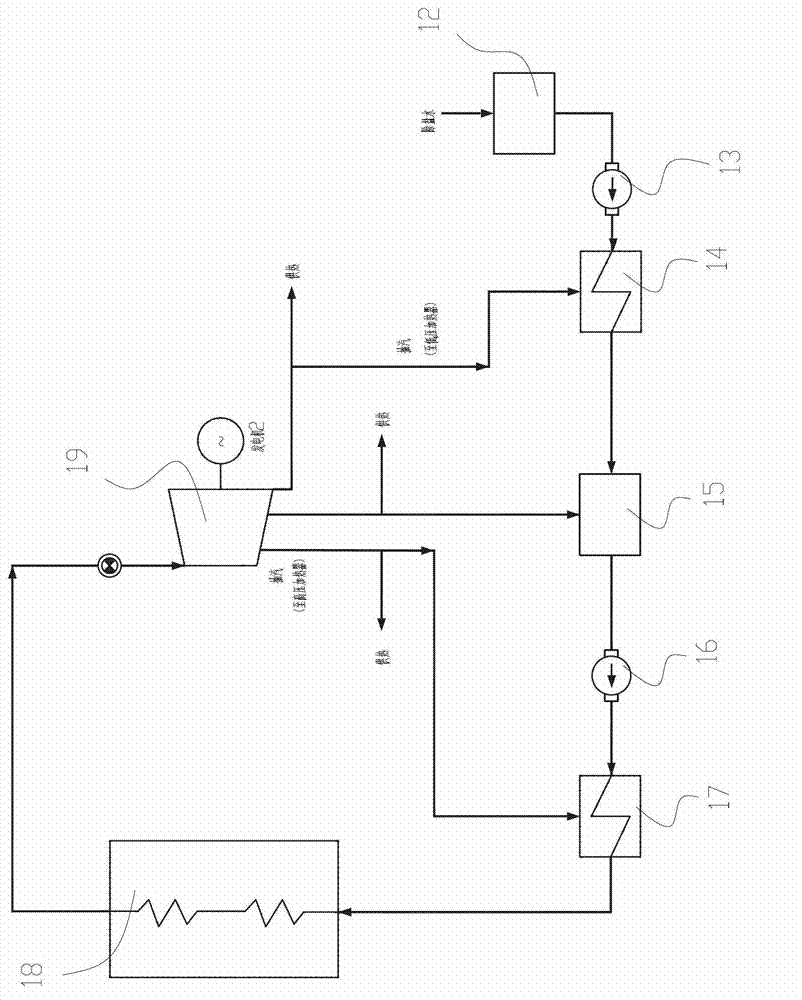

Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

ActiveCN101881191AIncrease energy densityReduce smoke lossDrying solid materials with heatSteam regenerationDeaeratorHigh pressure

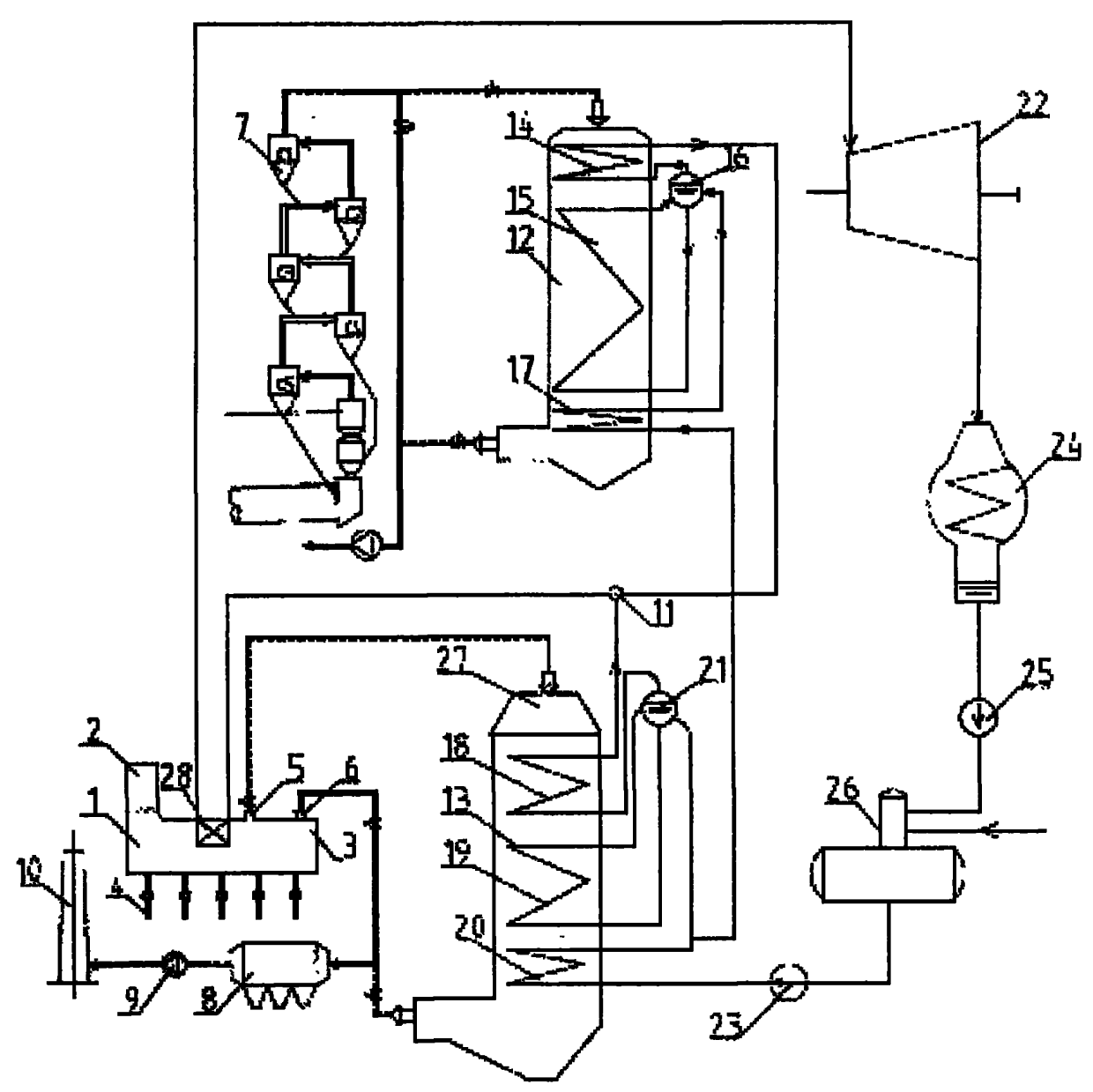

The invention relates to a thermal power generation system based on a high-moisture lignite pre-drying upgrading and recovering technology. The thermal power generation system comprises a boiler, a turbine, a condenser, a condensation pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a wet coal bin, a wet coal feeder and a coal mill and is characterized in that a lignite pre-drying device, a drain pump, a dry coal feeder, a dust remover and a heat energy and waste water recovering device are additionally arranged in the power generation system. The invention improves the energy density of fire coal and accordingly increases the efficiency of the boiler, and is capable of reducing the investment of the boiler and a milling system by a larger extent, simultaneously reducing the plant power utilization ratio, further improving the energy source comprehensive utilization efficiency of a thermal power generation plant, recovering a great deal water by using coal to produce water and saving precious water resources. The invention achieves the effects of high efficiency, energy saving, water saving and emission reduction and accords with the industrial policy of developing the low-carbon economy in China.

Owner:CHINA POWER ENG CONSULTING GRP +1

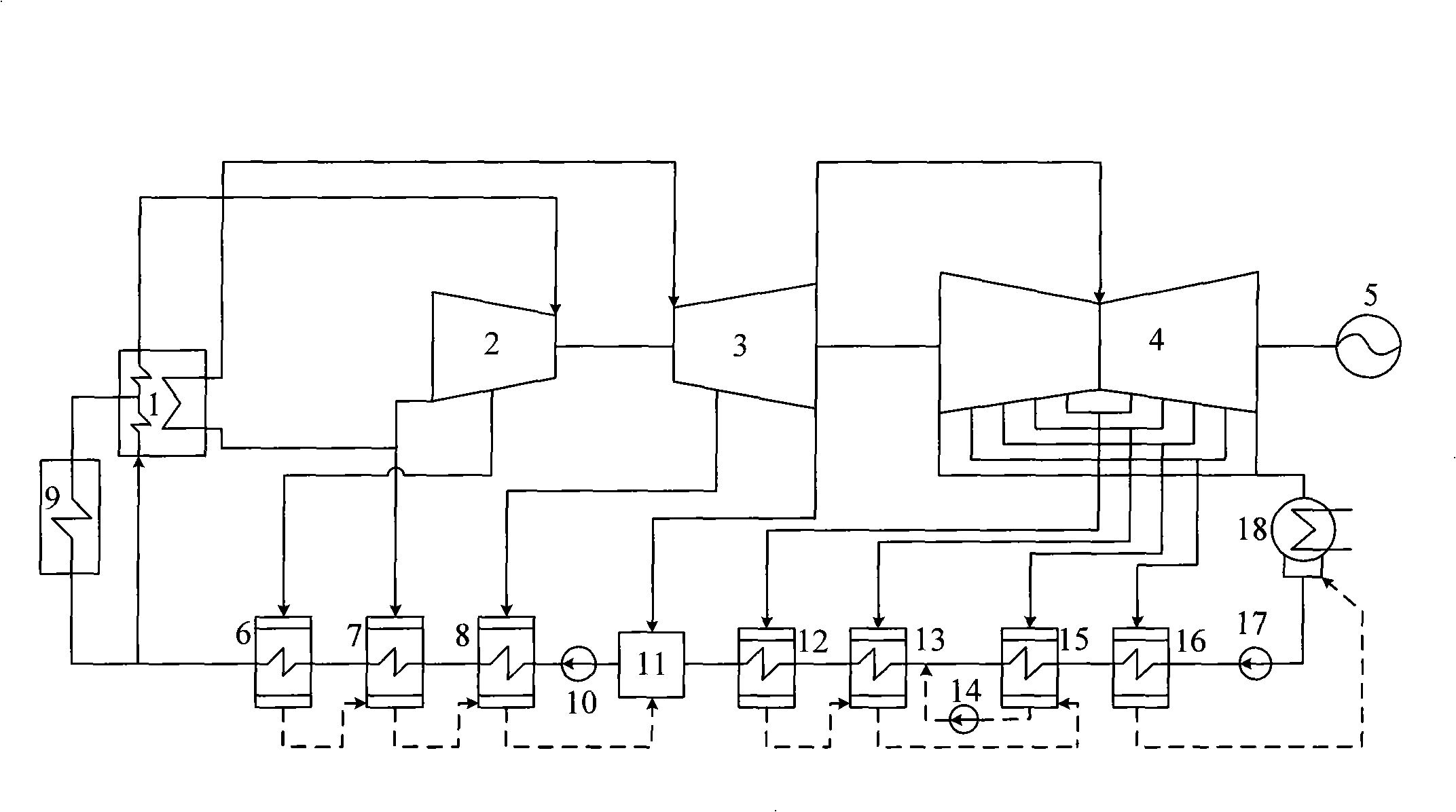

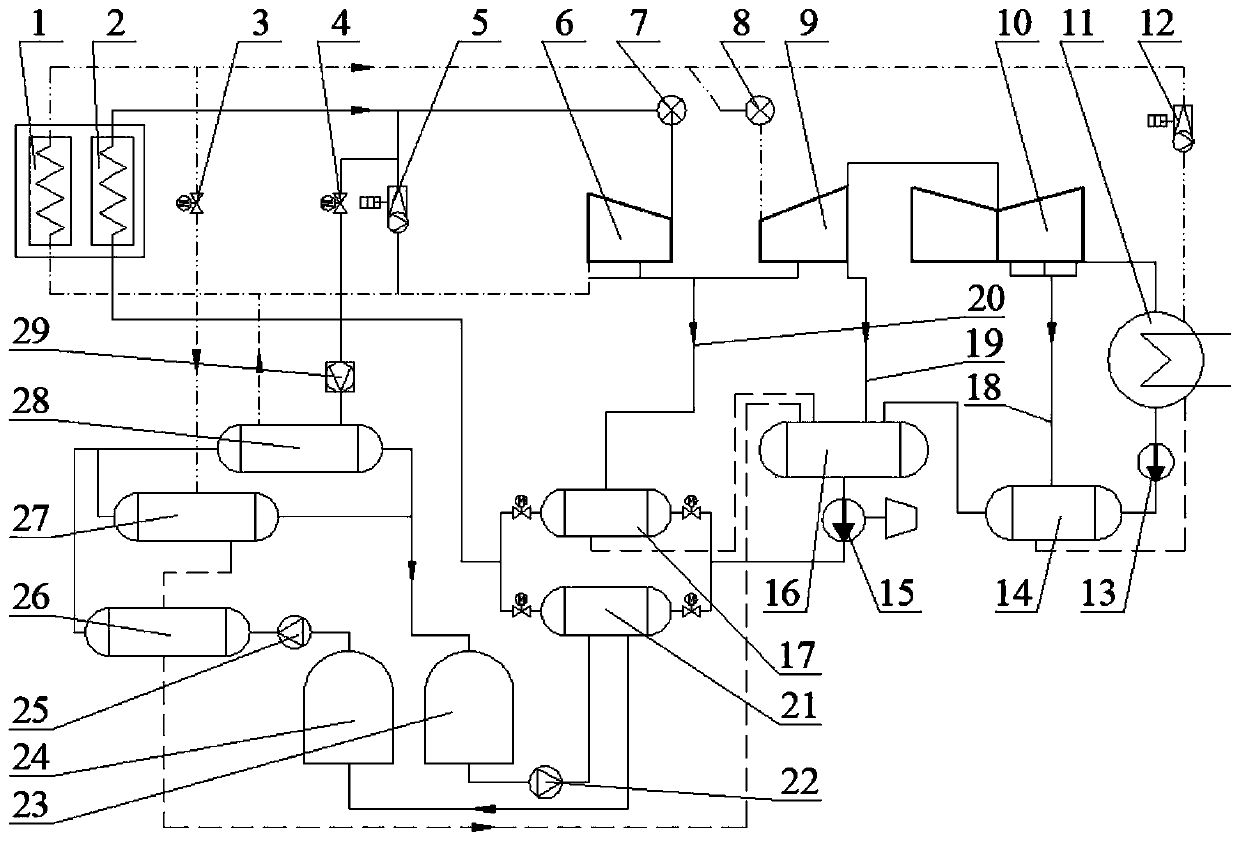

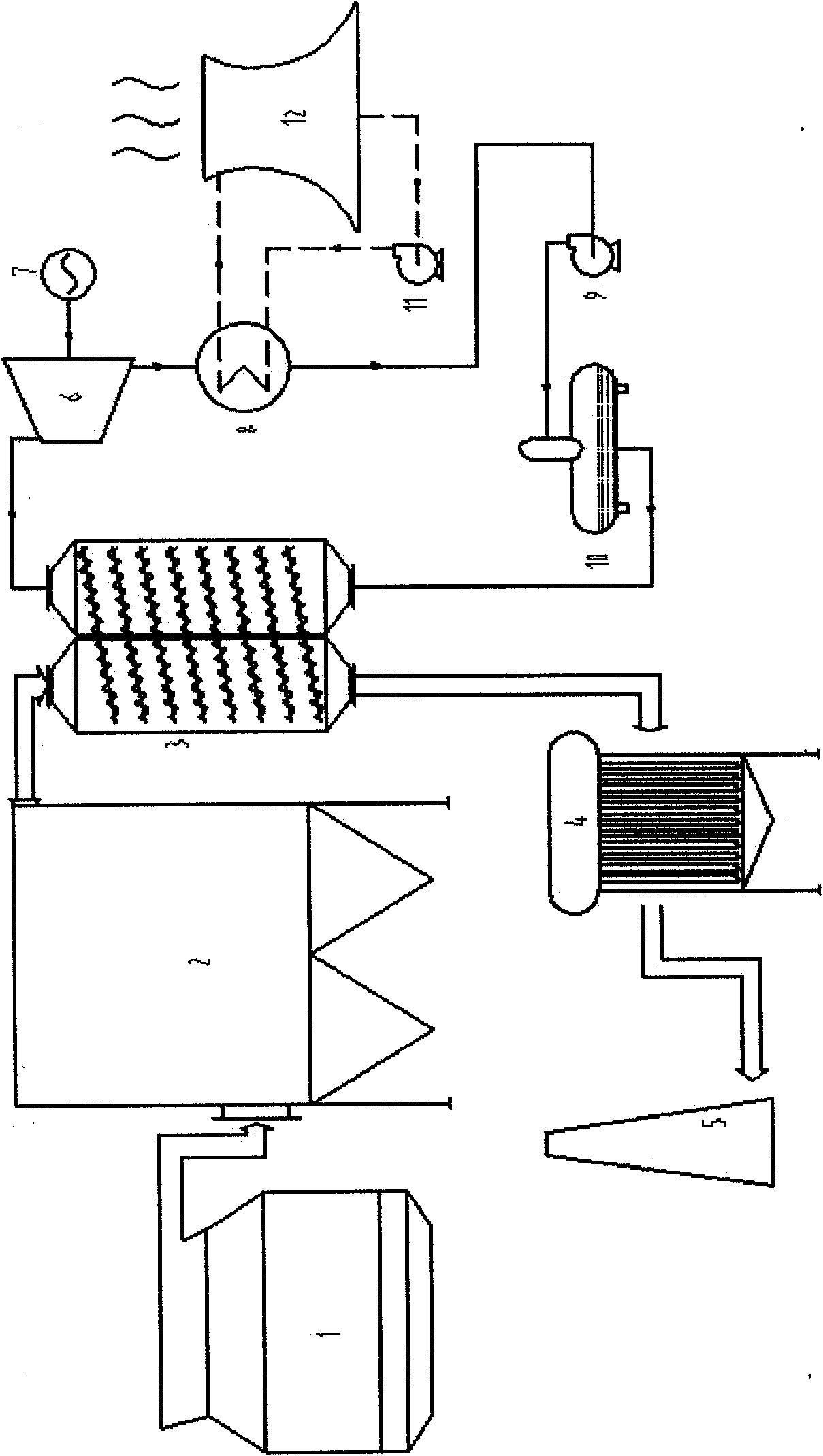

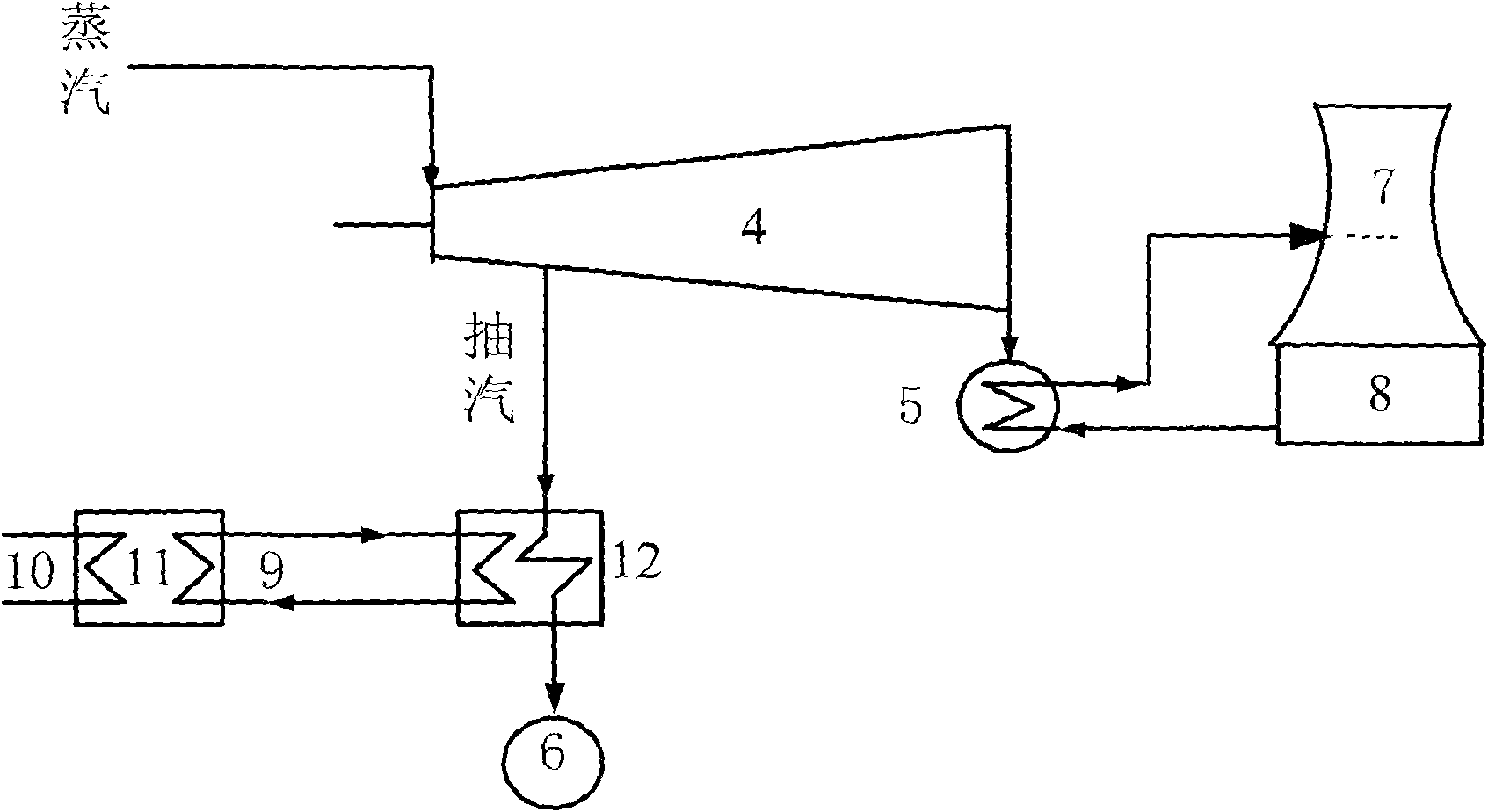

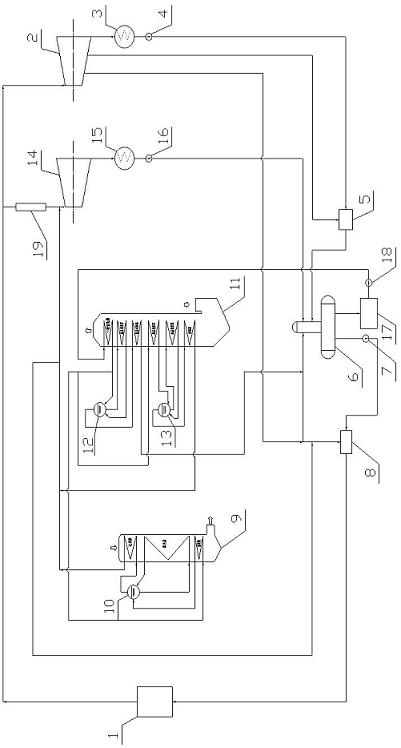

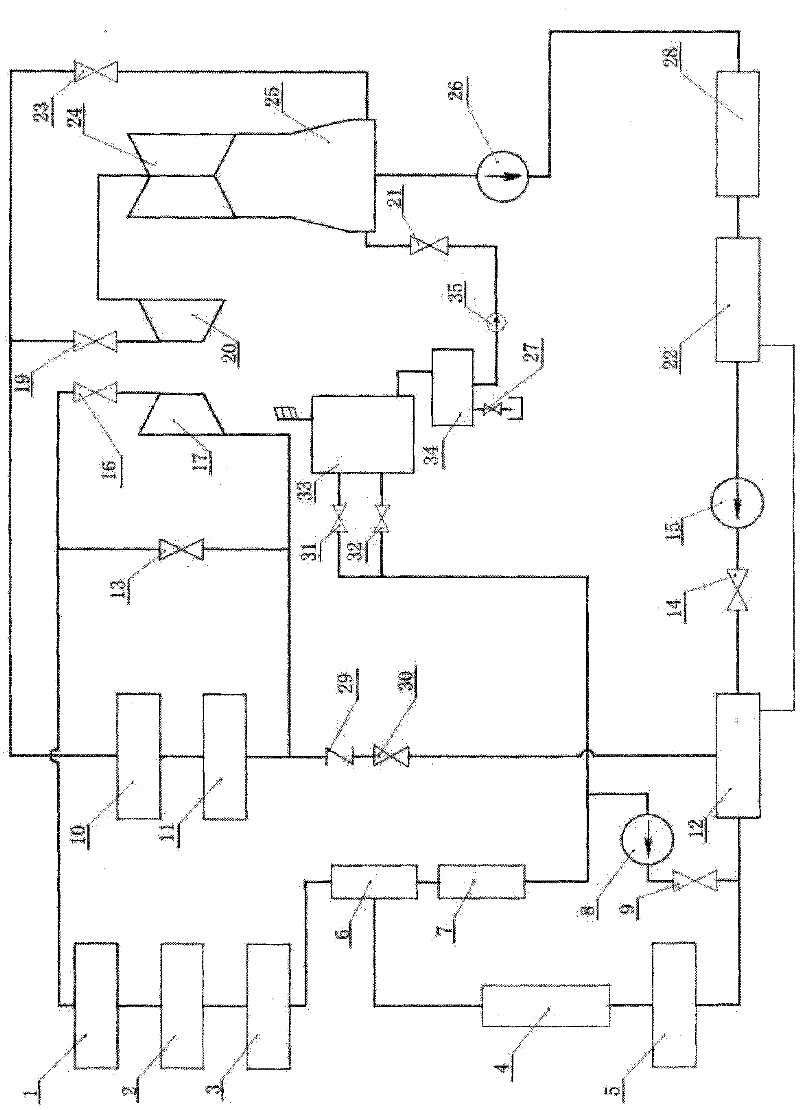

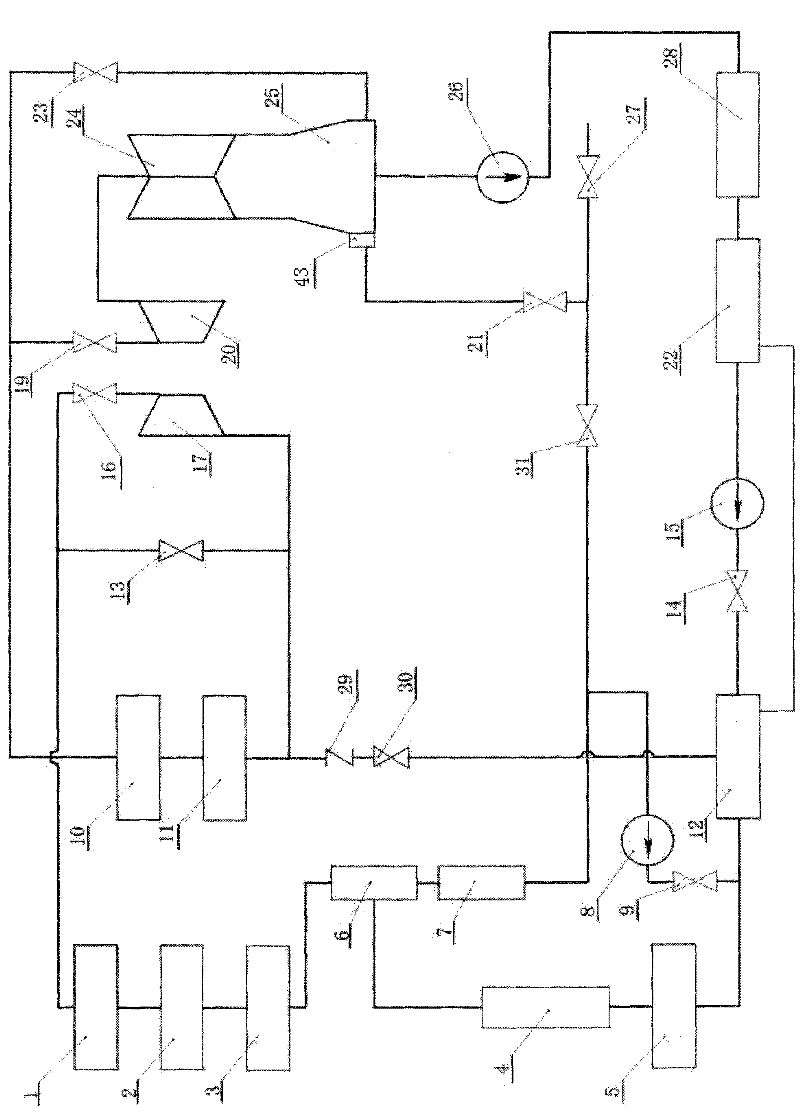

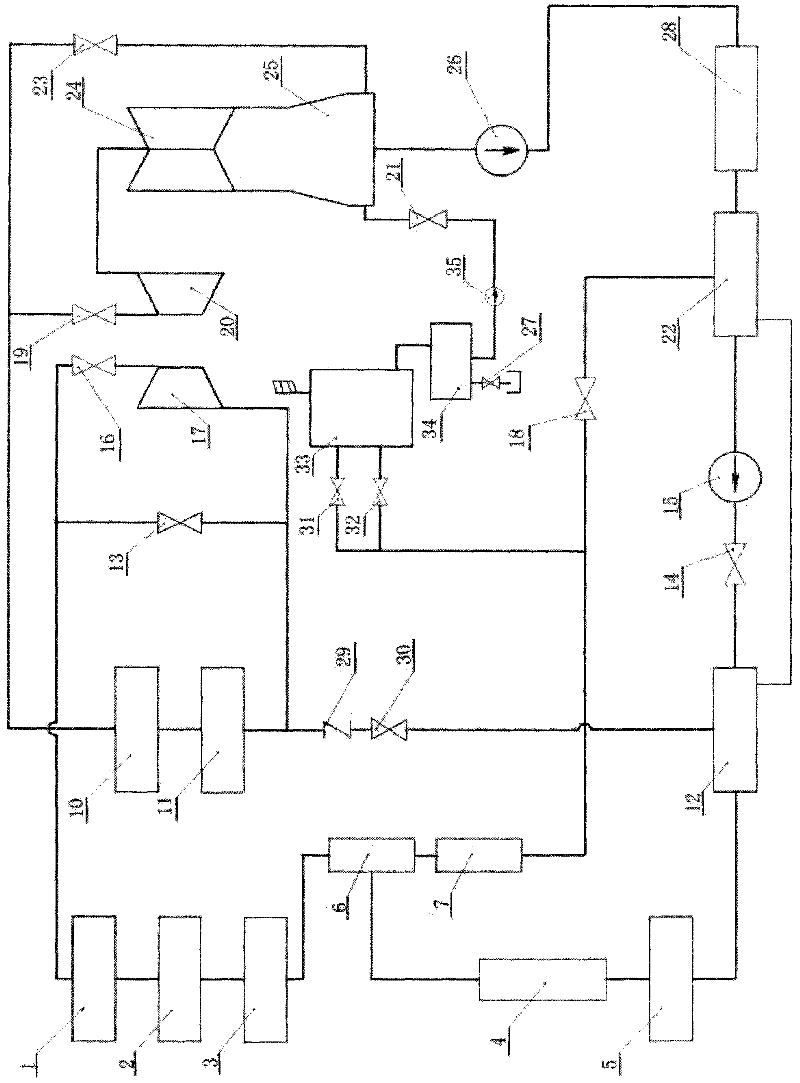

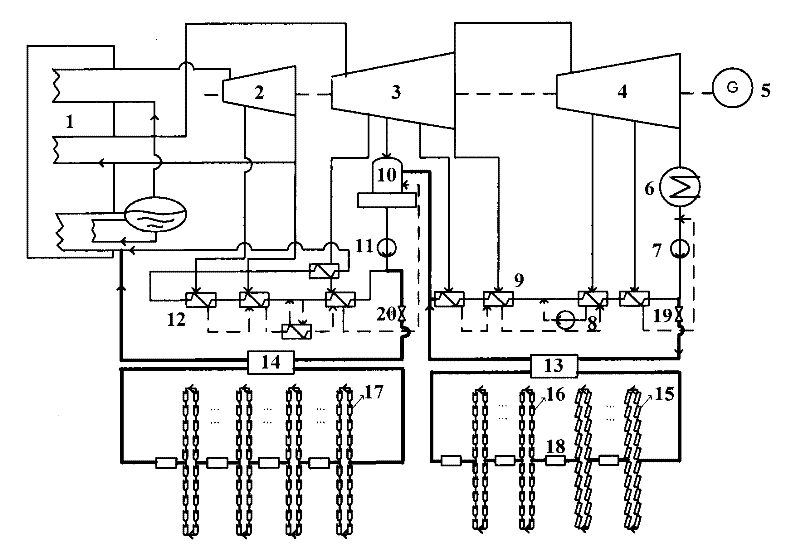

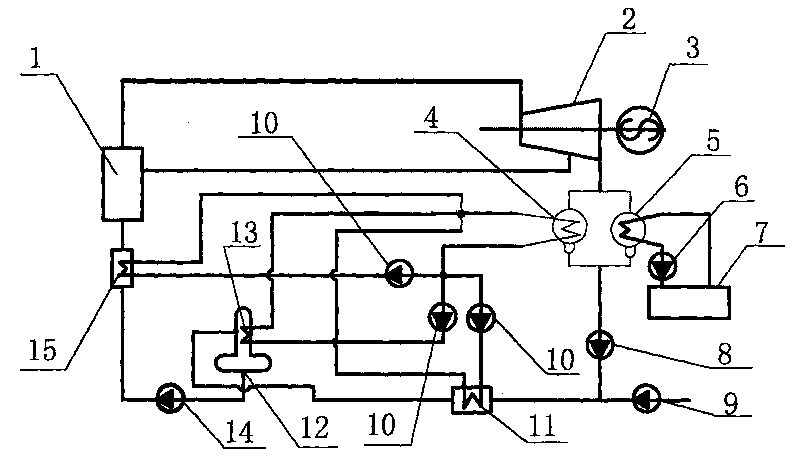

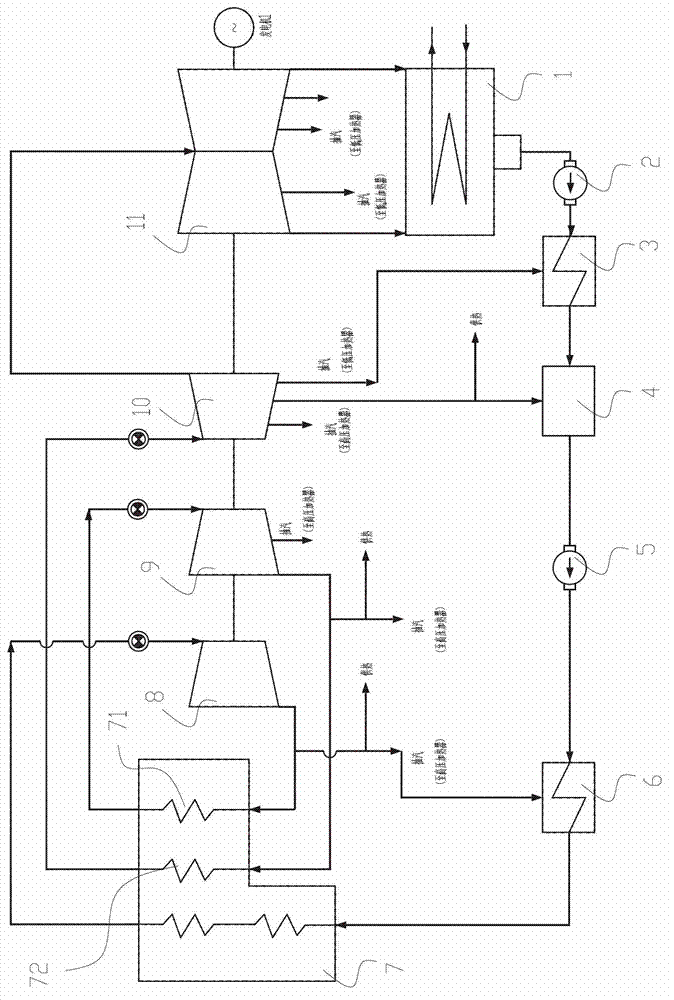

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

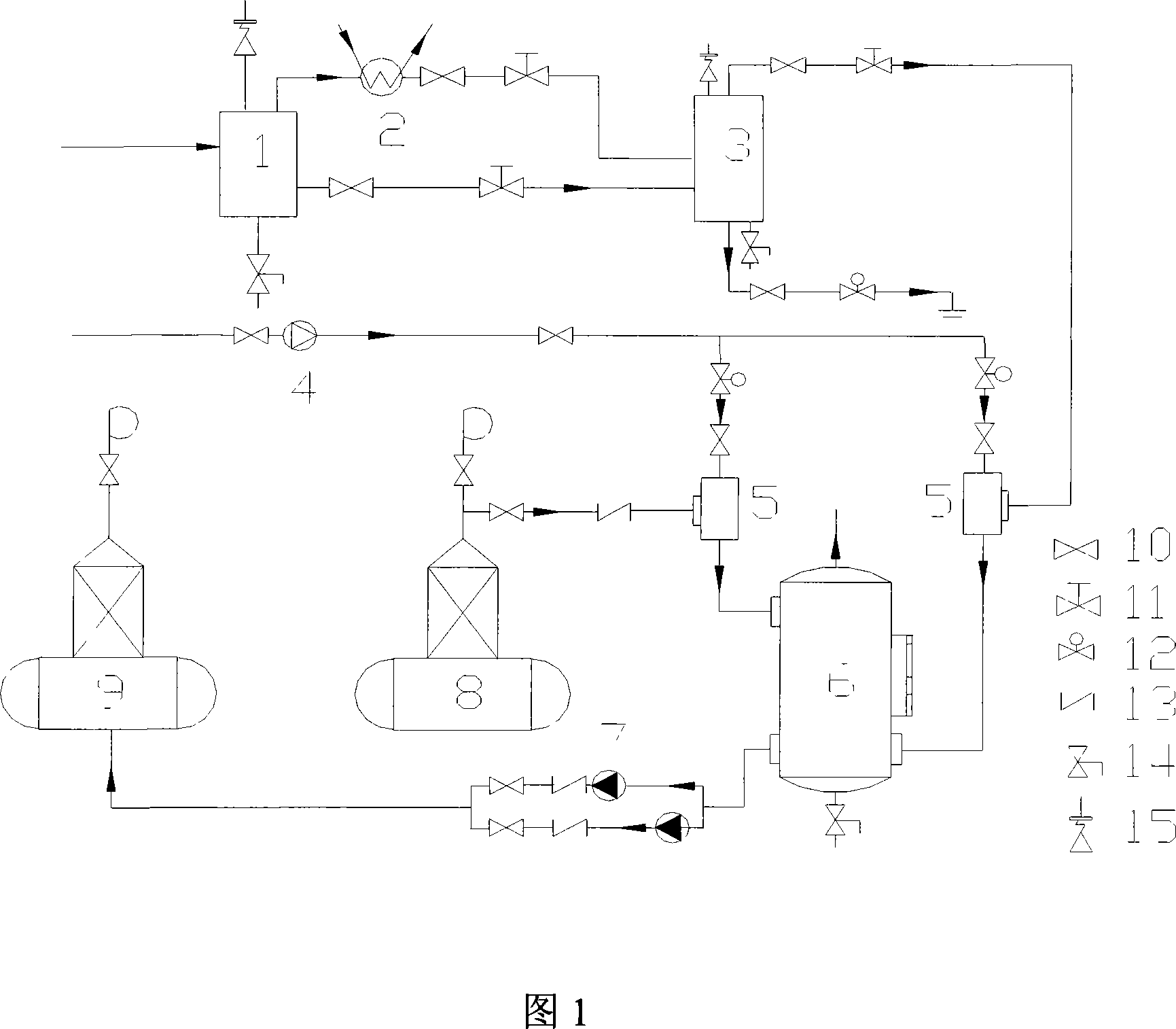

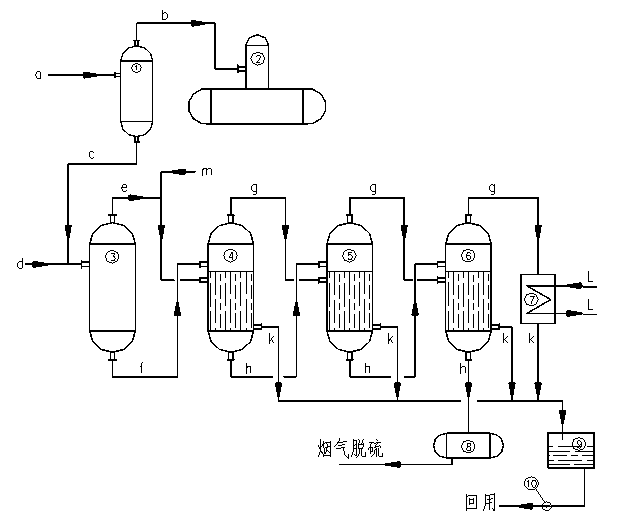

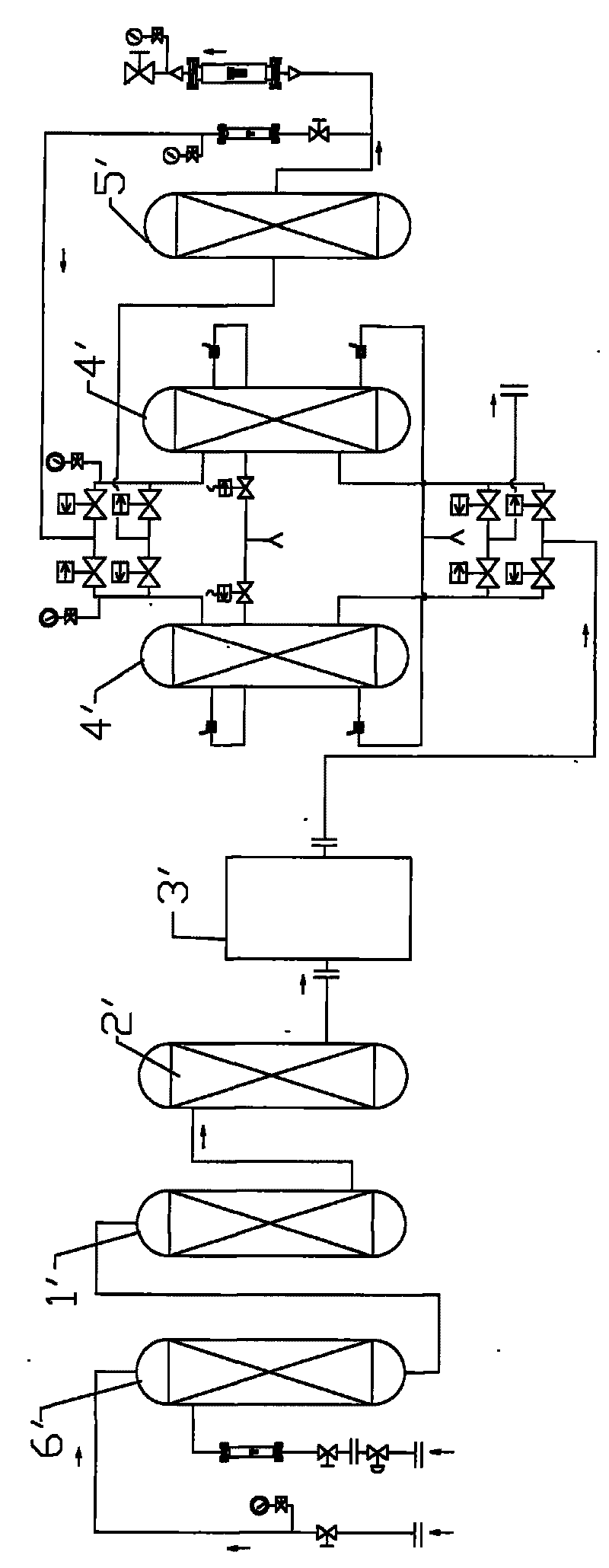

Grey water treatment technology for graded gasification furnace

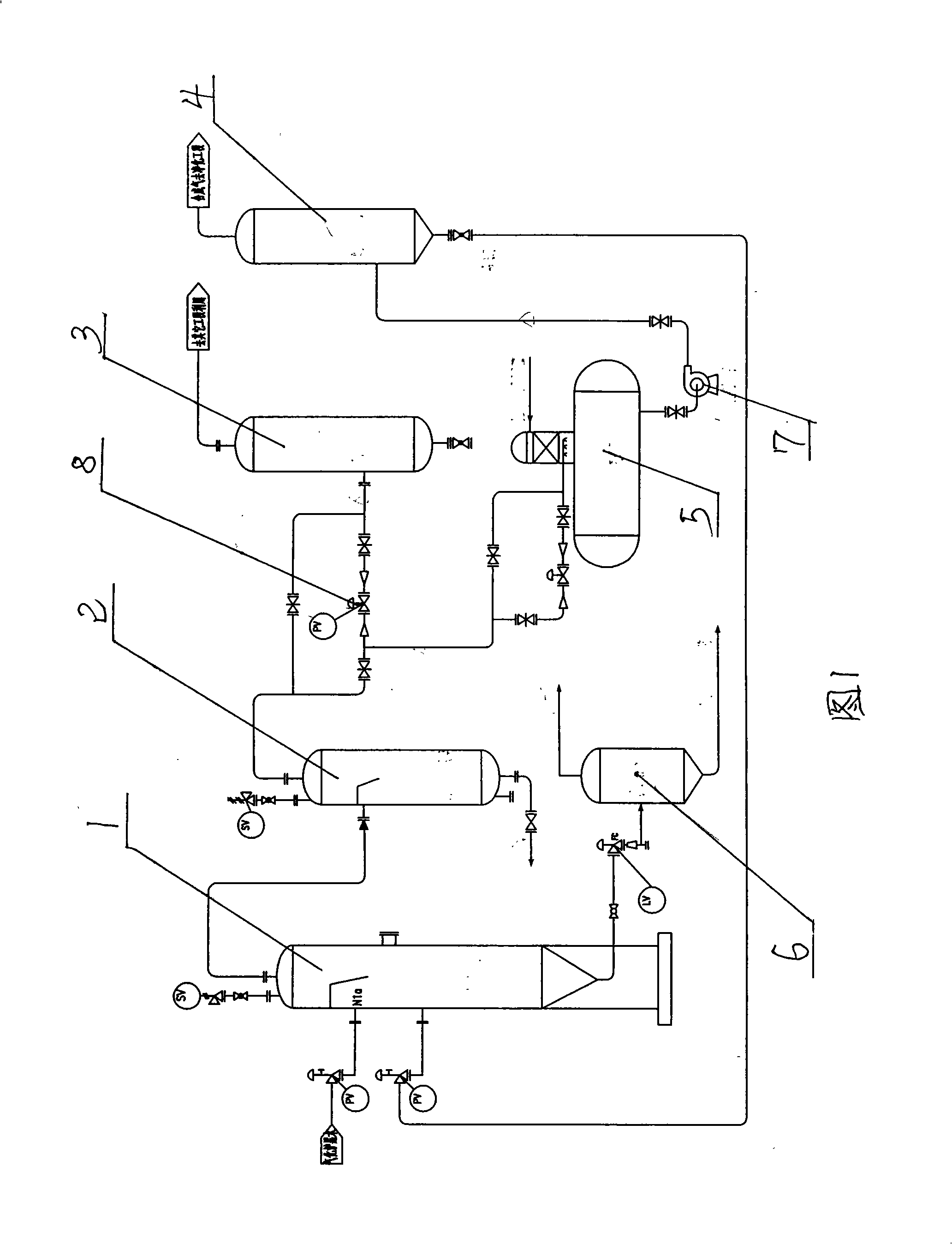

InactiveCN101306899AImprove transfer efficiencyTake advantage ofMultistage water/sewage treatmentWater/sewage treatment by heatingGas phaseDeaerator

The invention belongs to the ash water processing technology for gasification of coal water slurry in gasified ash water, in particular relating to an ash water processing technique applied in a staged gasification furnace. The technique solves the problems in the prior art of complex structure, energy waste, trivial technological operation and so on. The method comprises the following steps that: black water exhausted from the staged gasification furnace and a syngas scrubber respectively enters into a high-pressure flash tank after decompressed by respective pipes; liquid phase after high-flash flash evaporation in the high-pressure flash tank passes through a pressure-reducing valve and enters into a vacuum flash tank for secondary flash evaporation; the liquid phase after vacuum flash evaporation in the vacuum flash tank enters into a settling tank the position of which is lower than that of the vacuum flash tank for settlement by means of gravity action; gas phase after high-flash flash evaporation in the high-pressure flash tank enters into a separator on the top of the high-flash tank for gas-liquid separation; and one part of separated gas phase enters into a deaerator and directly contacts the ash water for heat exchange, and the other part of the steam enters into a steam buffer tank through a pressure control valve. Compared with the prior flow, the adoption of the flow saves equipment investment by 3 million; and about 10 tons of steam is supplied in normal operation.

Owner:山西丰喜肥业(集团)股份有限公司临猗分公司

Automatic control method of 300 MW grading circulating fluidized bed units

ActiveCN101225955AKeep the economy runningAvoid cokingFluidized bed combustionLiquid fuel feeder/distributionAir volumeAutomatic control

The invention relates to an automatic control method of 300MW grade circulating fluid bed unit, which sets the automatic control methods for the coordination of machine and furnace, the deviation of single bed pressure and double bed pressure, the water level of the deaerator and the condenser, the secondary air quantity / oxygen quantity and the secondary air pressure, the boiler bed temperature, the fuel flow and the limerock feeding during making the first 300 MW circulating fluid bed unit as the localization of manufactures, meanwhile, the 300 MW circulating fluid bed unit has the advantages of stable operation, safety, reliable and remarkable economic operation passing through the coordination and control for the system.

Owner:云南电力试验研究院(集团)有限公司

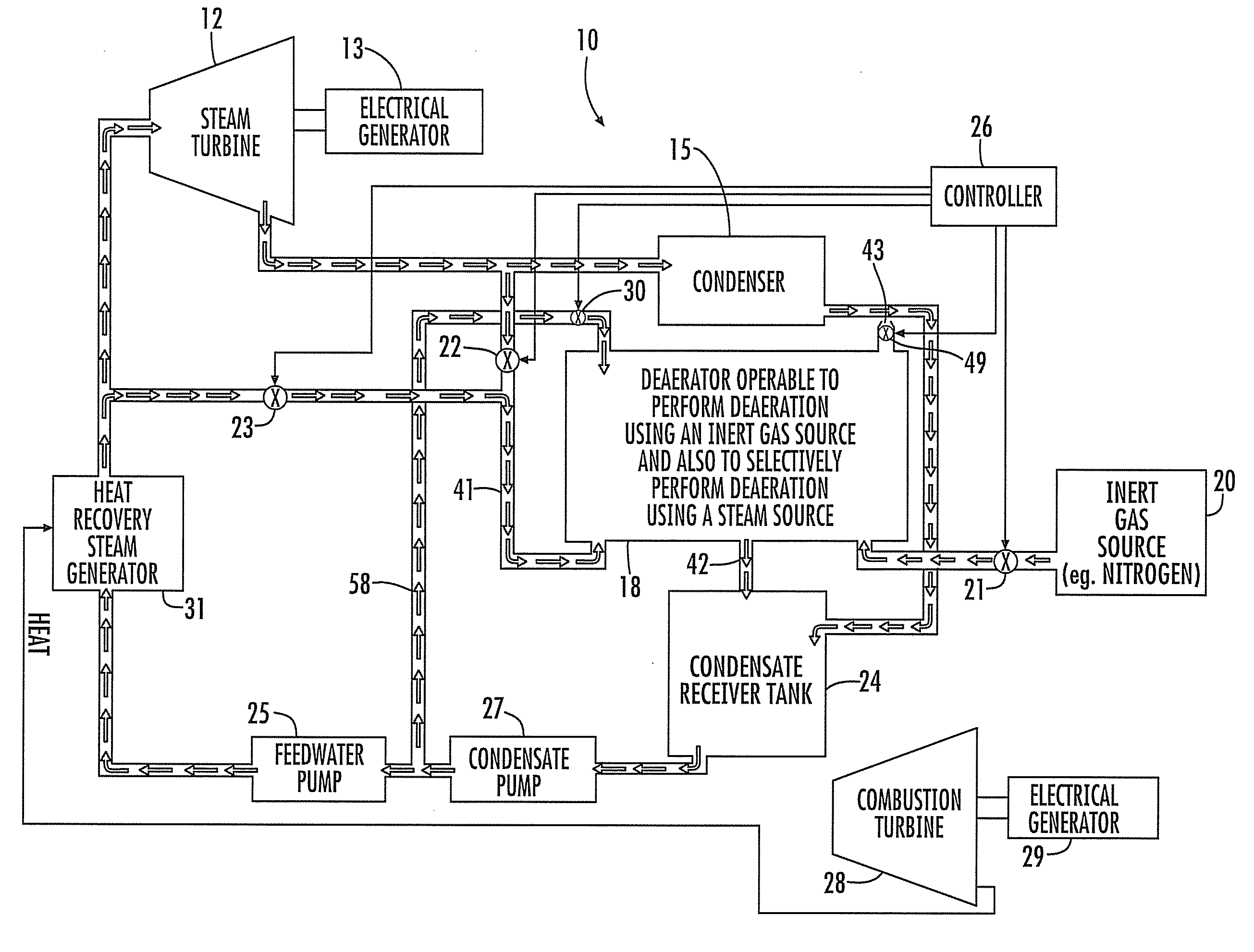

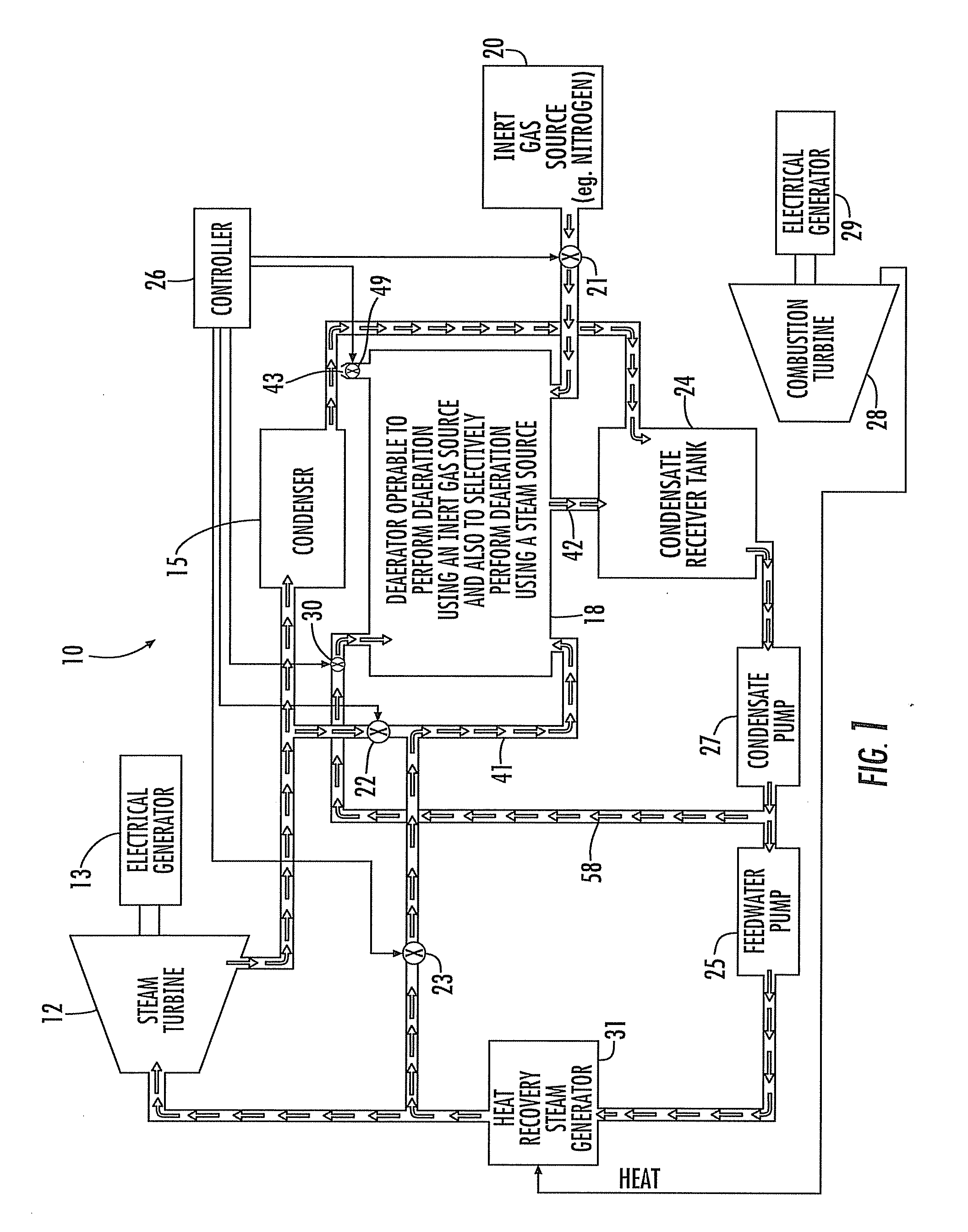

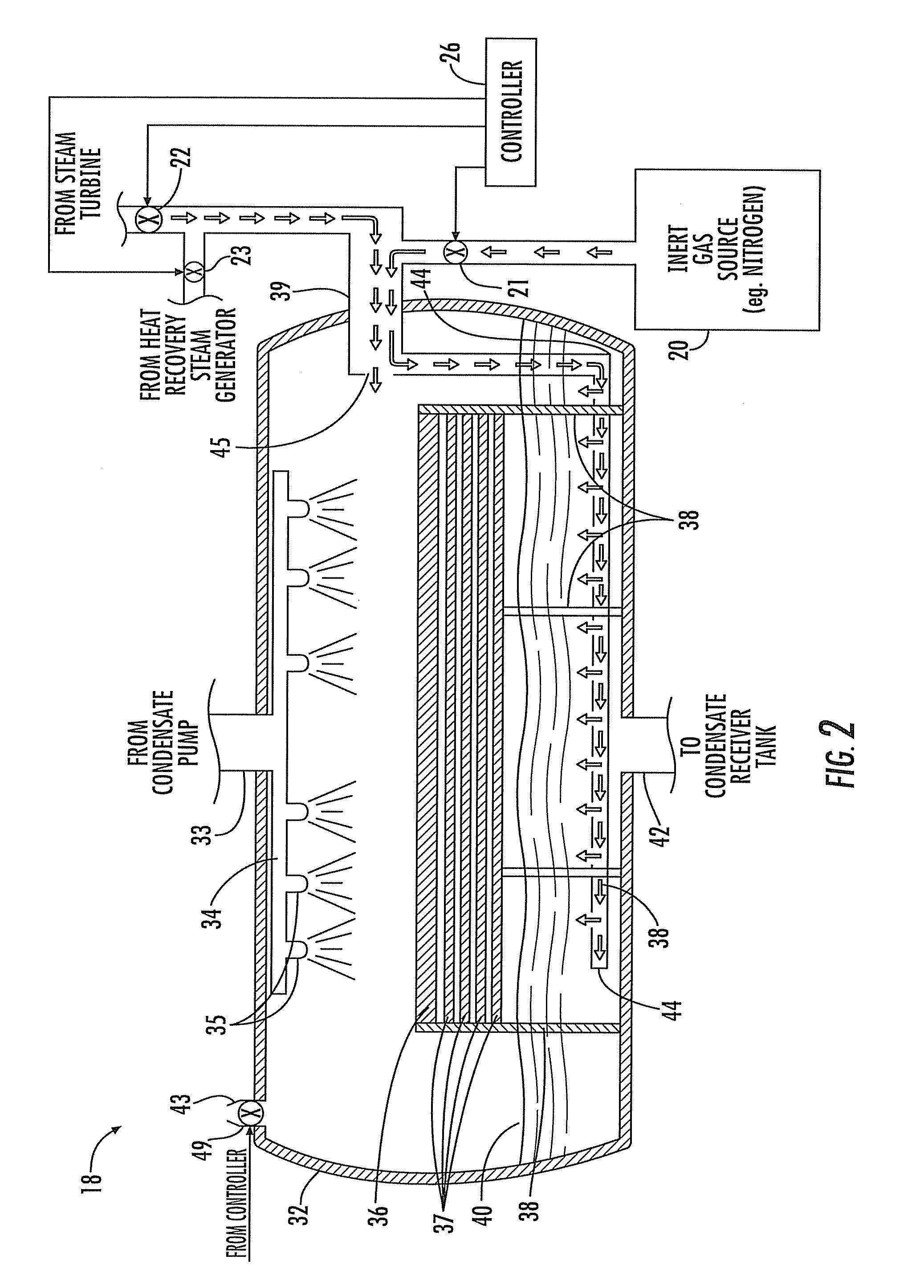

Power Generation Plant Having Inert Gas Deaerator and Associated Methods

InactiveUS20100199670A1Extend lifetimeExtend service intervalSteam regenerationLiquid degasification regulation/controlPower stationEngineering

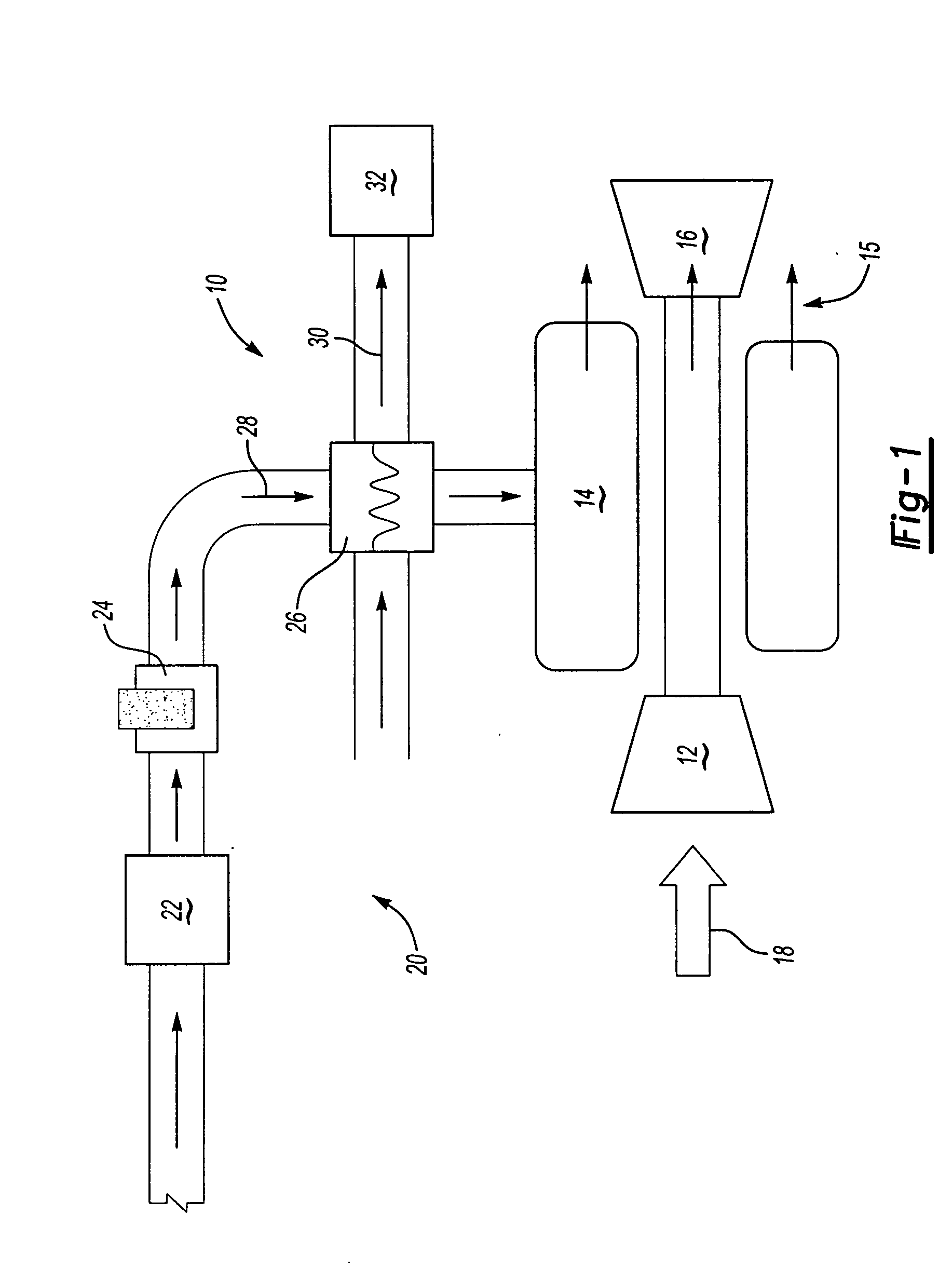

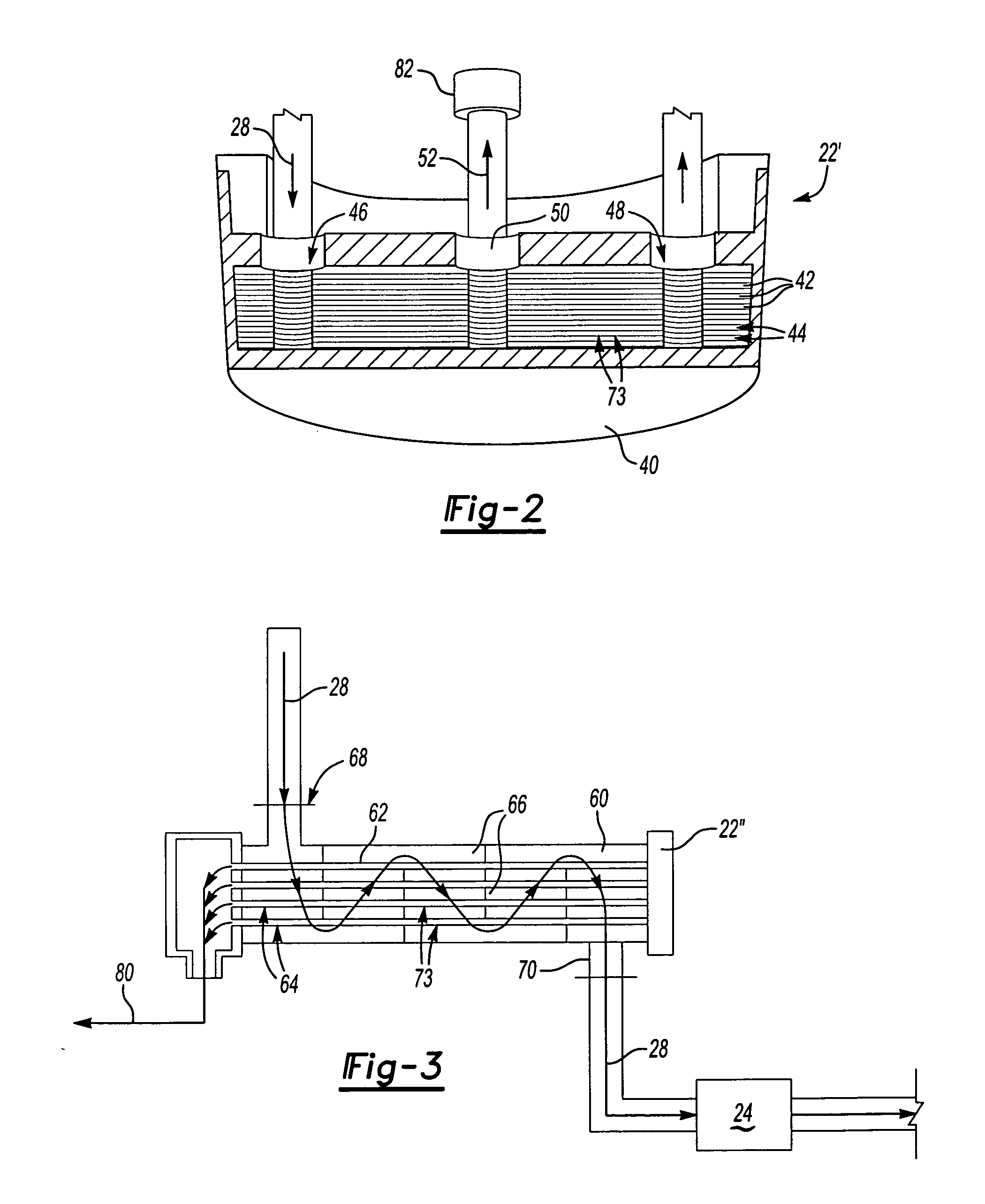

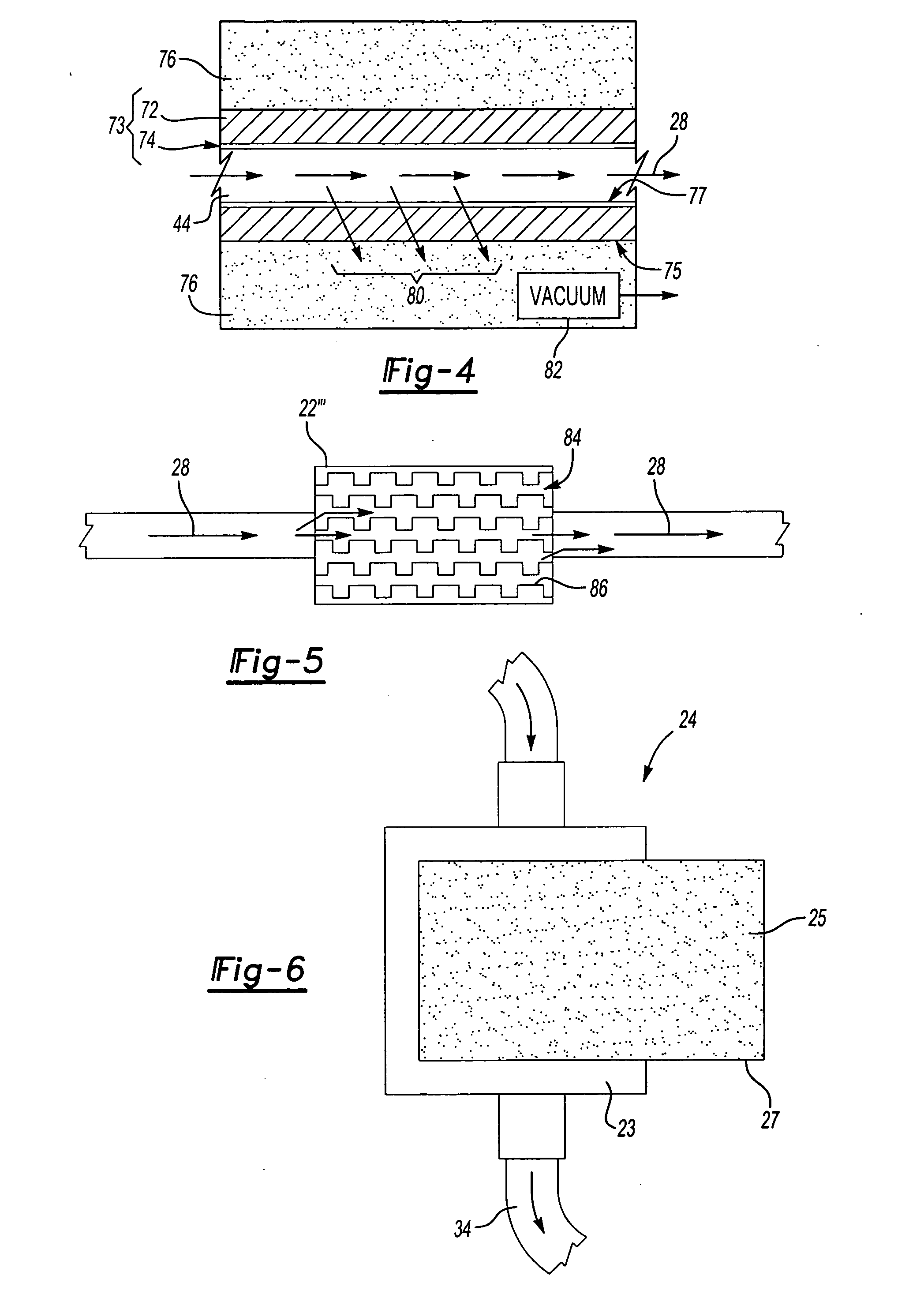

A power generation plant includes a steam turbine and an electrical generator driven thereby. A condenser is downstream from the steam turbine. Moreover, the power generation plant includes a steam source and an inert gas source. A deaerator downstream from the condenser and is operable to perform deaeration using the inert gas source and is also selectively operable to perform deaeration using the steam source.

Owner:SIEMENS ENERGY INC

Method for recycling and regenerating steel plant residual heat boiler saturated steam

InactiveCN101178017AIncrease profitEfficient use ofSteam engine plantsSteam superheatersCooling towerDeaerator

The invention relates to a method to recycle saturated steam from waste heat boiler in steel plant to generate. The method is characterized in that the invention comprises a converter, a converter heat recovery boiler, a steam filtering pressure stabilizer, a saturated steam heating furnace, a heating furnace burner, a low pressure turbine, a motor, a condenser, a condensate pump, a cooling tower, a circulating water pump, a deaerator, a water supply pump, a water supply distributor, a blower, an induced draft fan and a chimney. The invention has the advantages of making full use of the current waste heat boiler of the steel plant, adopting the steam filtering pressure stabilizer and the saturated steam heating furnace, improving efficiency by 140 percent compared with the traditional small-sized medium temperature and medium pressure unit and efficiency being 20 percent up higher than that of the most efficient gas turbine in the world.

Owner:中冶集团华冶资源开发有限责任公司

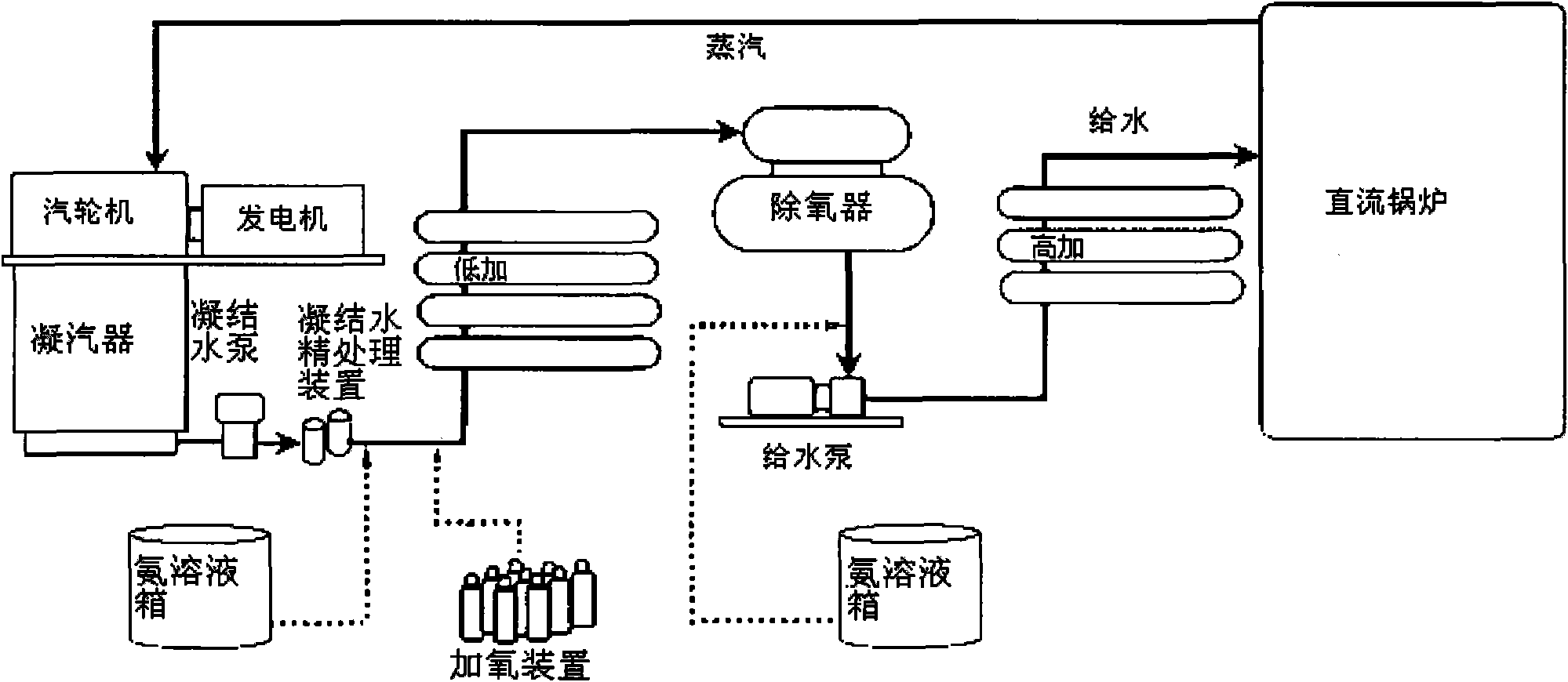

Intrinsically-safe water-feeding and oxygen-adding treatment method of once-through boiler

ActiveCN101880092AAvoid fatigueInhibit sheddingScale removal and water softeningExhaust valveDeaerator

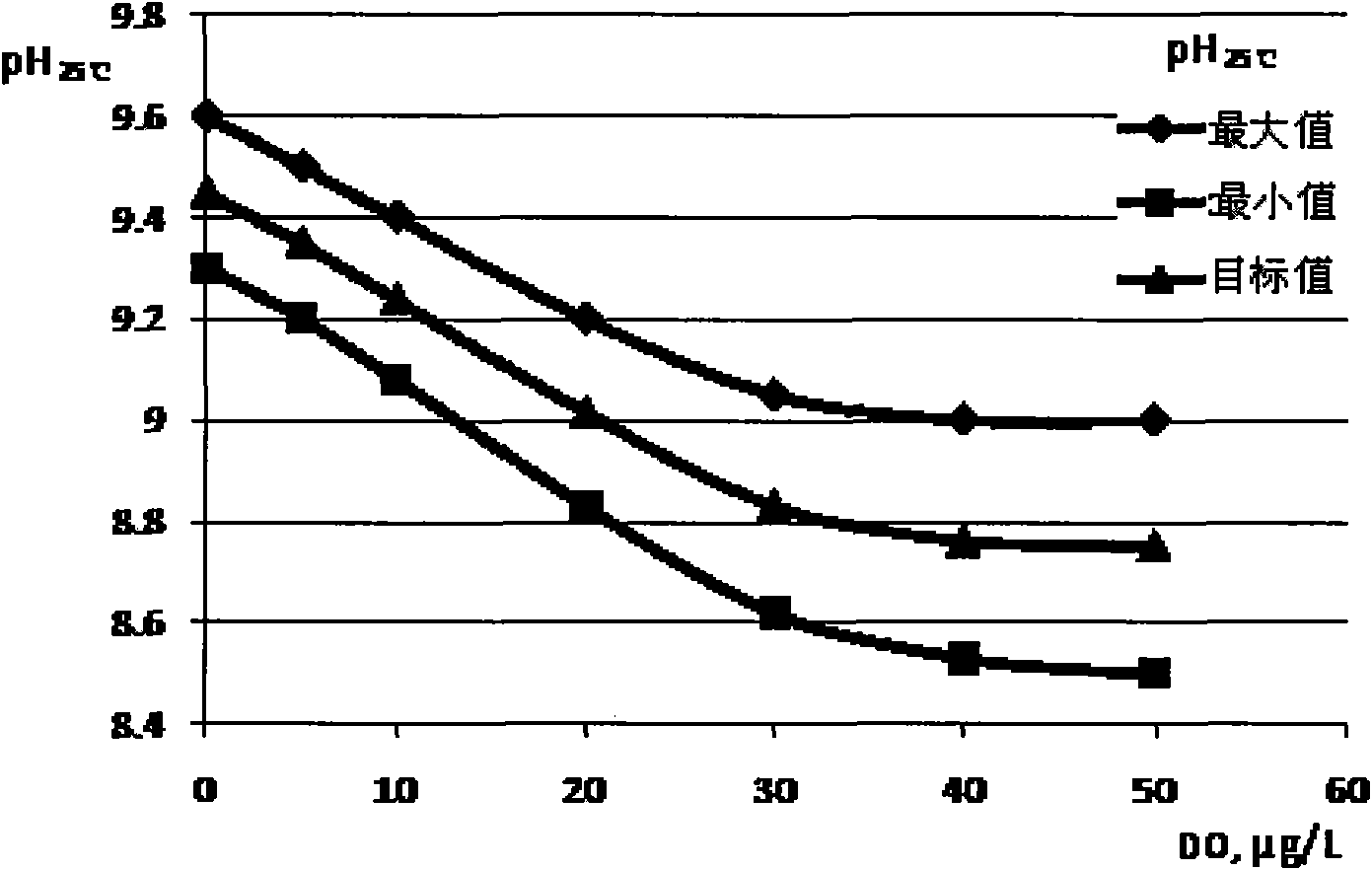

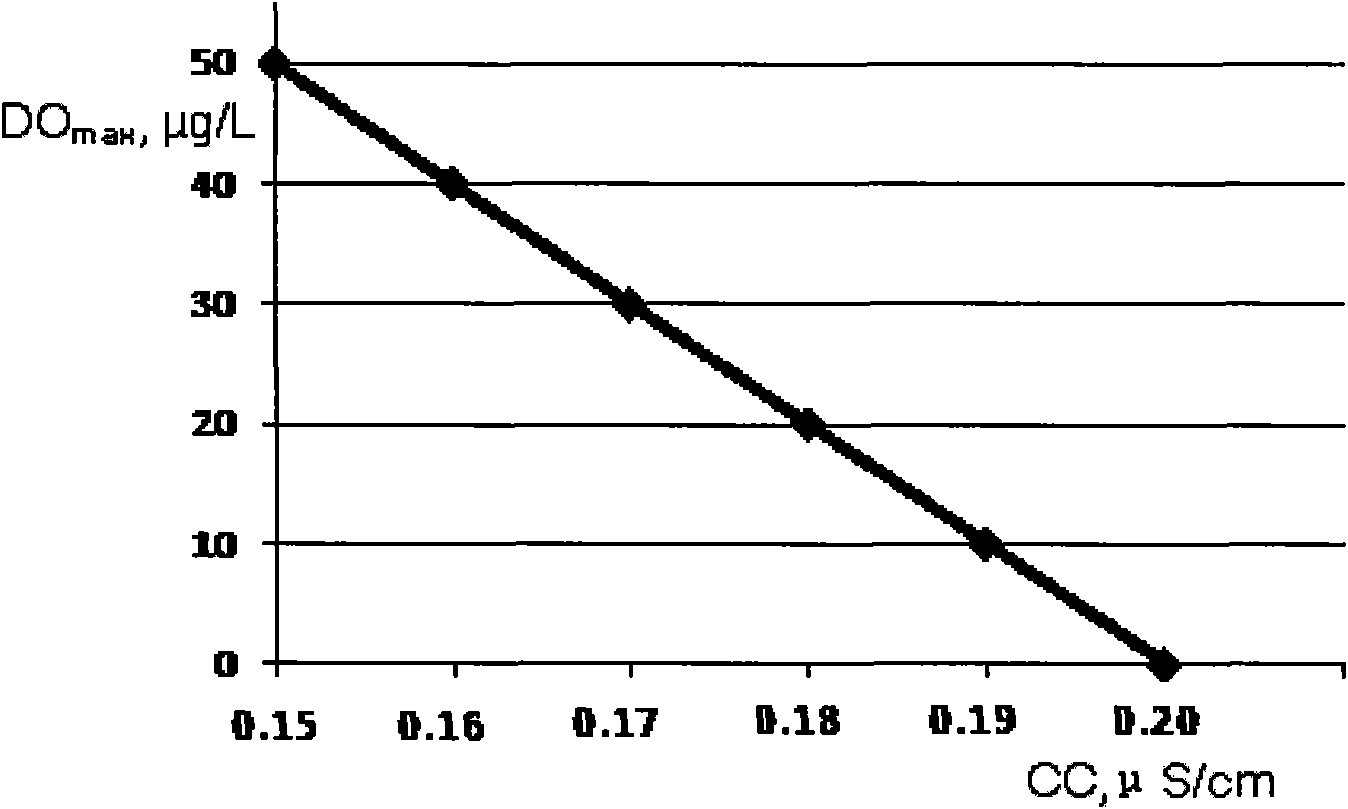

The invention discloses an intrinsically-safe water-feeding and oxygen-adding treatment method of a once-through boiler, comprising the following steps of: (1) adopting independent ammonia-adding treatment as a water-feeding treatment mode before adding oxygen of a copper-free system of a thermal power unit and adjusting the pH value at 25DEG C of water fed before the boiler to be 9.3-9.6 by adding ammonia; (2) closing an exhaust valve of a deaerator after meeting certain conditions; (3) adding oxygen at an oxygen adding point of a condensed water precision treatment outlet of the unit; (4) controlling that the content of dissolved oxygen at an inlet of a coal economizer is in the range of 5-50mu g / L and the oxygen content of main steam is not remarkably increased compared with the before adding oxygen; (5) reducing the control range of the pH value at 25DEG C of water fed before the boiler to be 8.8-9.3 after the electrical conductivity (CC) of anions of water fed before the boiler is reduced to be less than 0.15mu S / cm; (6) improving the pH value at 25DEG C of water fed before the boiler before the unit stops to be 9.3-9.6 until the unit halts; and (7) stopping the operation of the boiler and maintaining. The treatment method can be used for enhancing the buffer capacity of the water-feeding and oxygen-adding treatment and reducing the fluctuation of the dissolved oxygen content of the fed water and other parameters.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

Deep peak shaving system of thermal power plant

PendingCN110006026AImprove operational efficiencyImprove economyLiquid degasificationHeat storage plantsSteam pressureSteam condensation

The invention discloses a deep peak shaving system of a thermal power plant. The deep peak shaving system comprises a superheater, a reheater, a high-pressure cylinder, a reheating steam electric regulating valve, a main steam electric regulating valve, a medium-pressure cylinder, a low-pressure cylinder, a condenser, a condensation water pump, a low-pressure heating water feeding heat exchanger,a water feeding pump set, a deaerator, a high-pressure heating water feeding heat exchanger, a steam turbine low-pressure steam extraction system, four-stage extraction, a steam turbine high-pressuresteam extraction system, a high-temperature molten salt water feeding heat exchanger, a high-temperature molten salt pump, a high-temperature molten salt storage tank, a low-temperature molten salt storage tank, a low-temperature molten salt pump, a molten salt preheater, a steam condensation type heat exchanger, a steam non-condensation type heat exchanger, a steam pressure reduction device and the like. According to the system, the molten salt heat storage technology is utilized, redundant steam heat is stored during load reducing peak shaving of a unit, in the process of load increasing peak shaving of the unit, high-temperature molten salt is used for heating high-pressure fed water to reduce steam extraction of a steam turbine, the output of the steam turbine is increased, the heat efficiency of the unit is improved, and the flexible and deep peak shaving of the thermal power plant is realized.

Owner:BEIJING UNIV OF TECH

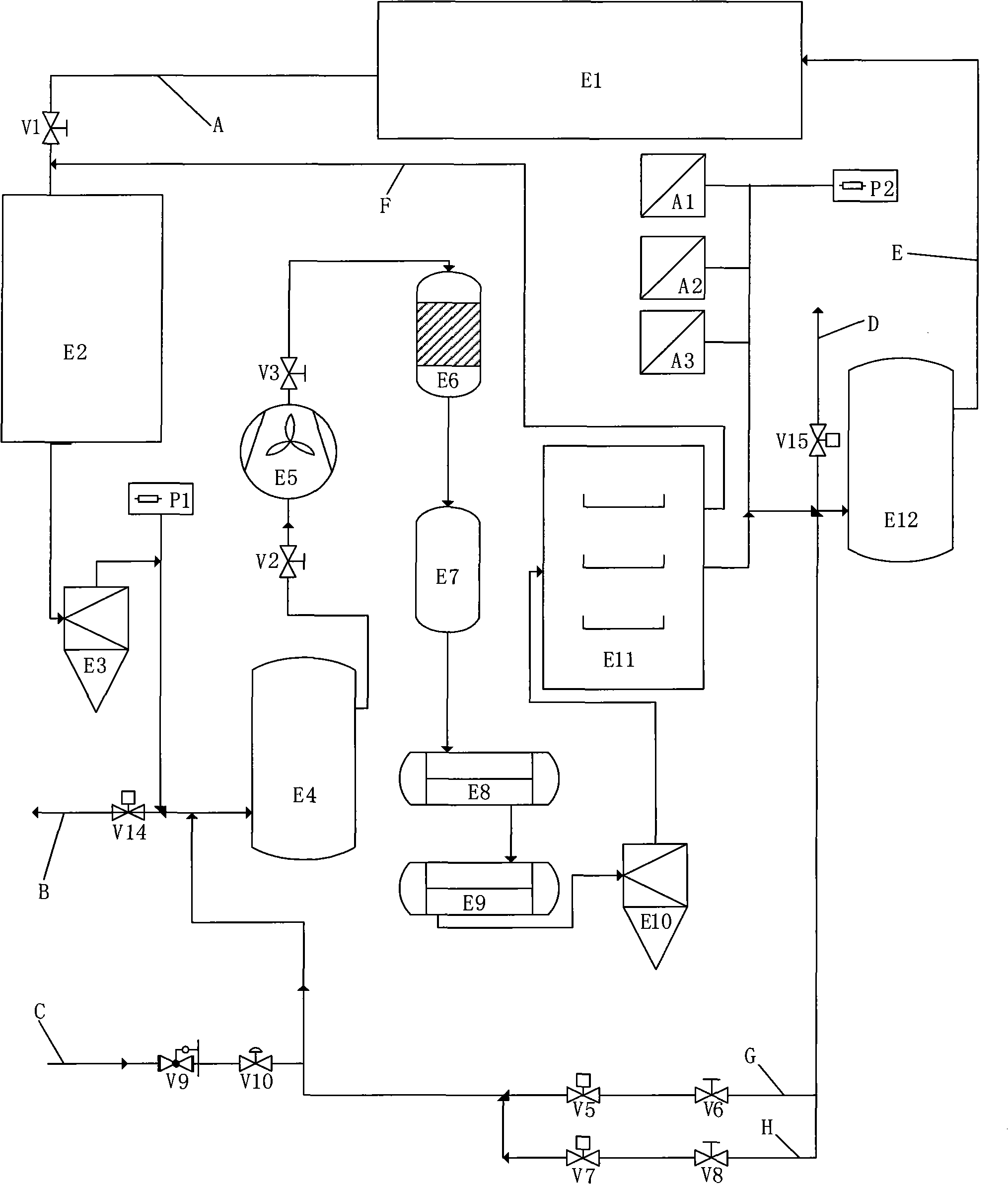

Boiler low grade residual heat combined reclamation method and device

InactiveCN101165399ASelf-utilizationAchieving joint recyclingLiquid degasificationFeed-water heatersRecovery methodWater storage tank

This invention relates to a waste heat combined recovery method of power station boiler and its device composition. It mainly recovers the sewage of boiler, the waste heat and cleaning water of the discharged gas from high pressure deaerator. The device includes flash tank, jet type mixed heater, degas water storage tank, frequency converting pump, softening water pump, pipeline and valve. Softened water is used as working medium. It condenses the flash steam and discharged gas from high pressure deaerator through jet type mixed heater. In the degas water storage tank, the air in the discharged gas from high pressure deaerator is removed. The heat water in the water storage tank is transported into the low pressure deaerator through frequency converting pump. Thus, it fulfills the self-using of recovered heat. This invention only brings in softened water from outside and does not change the original thermal system.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

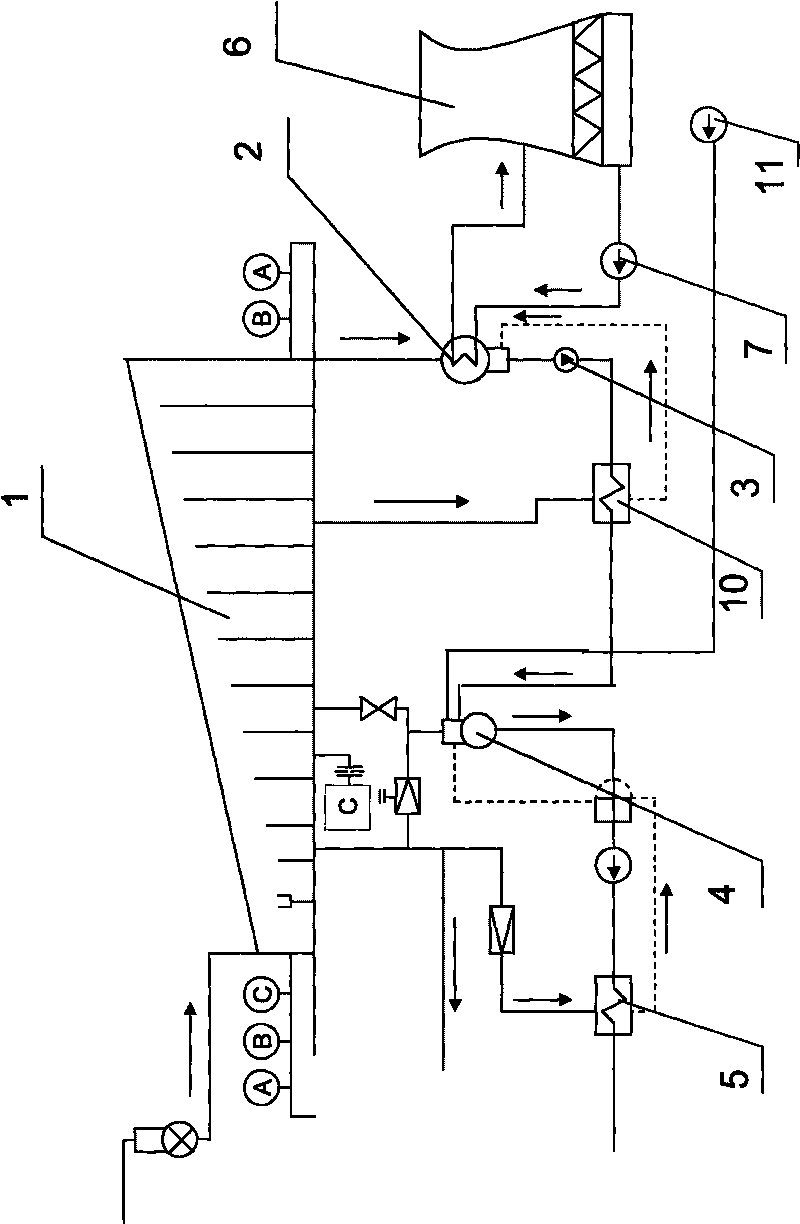

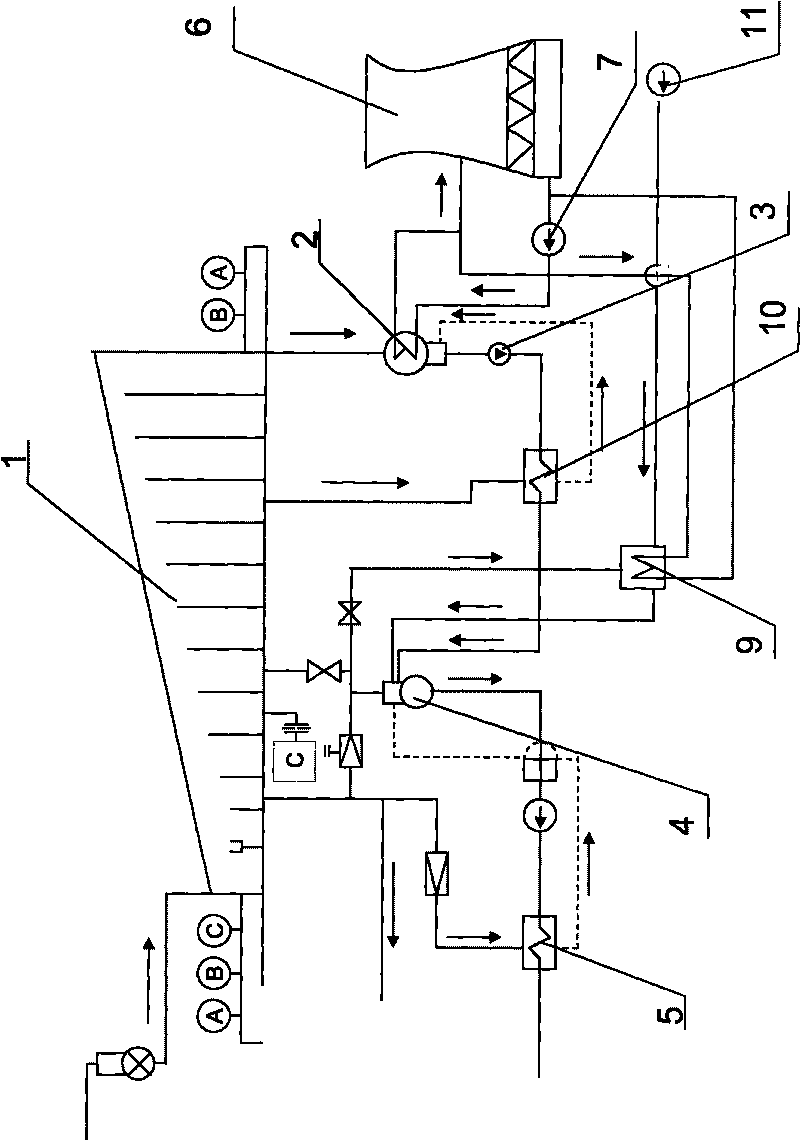

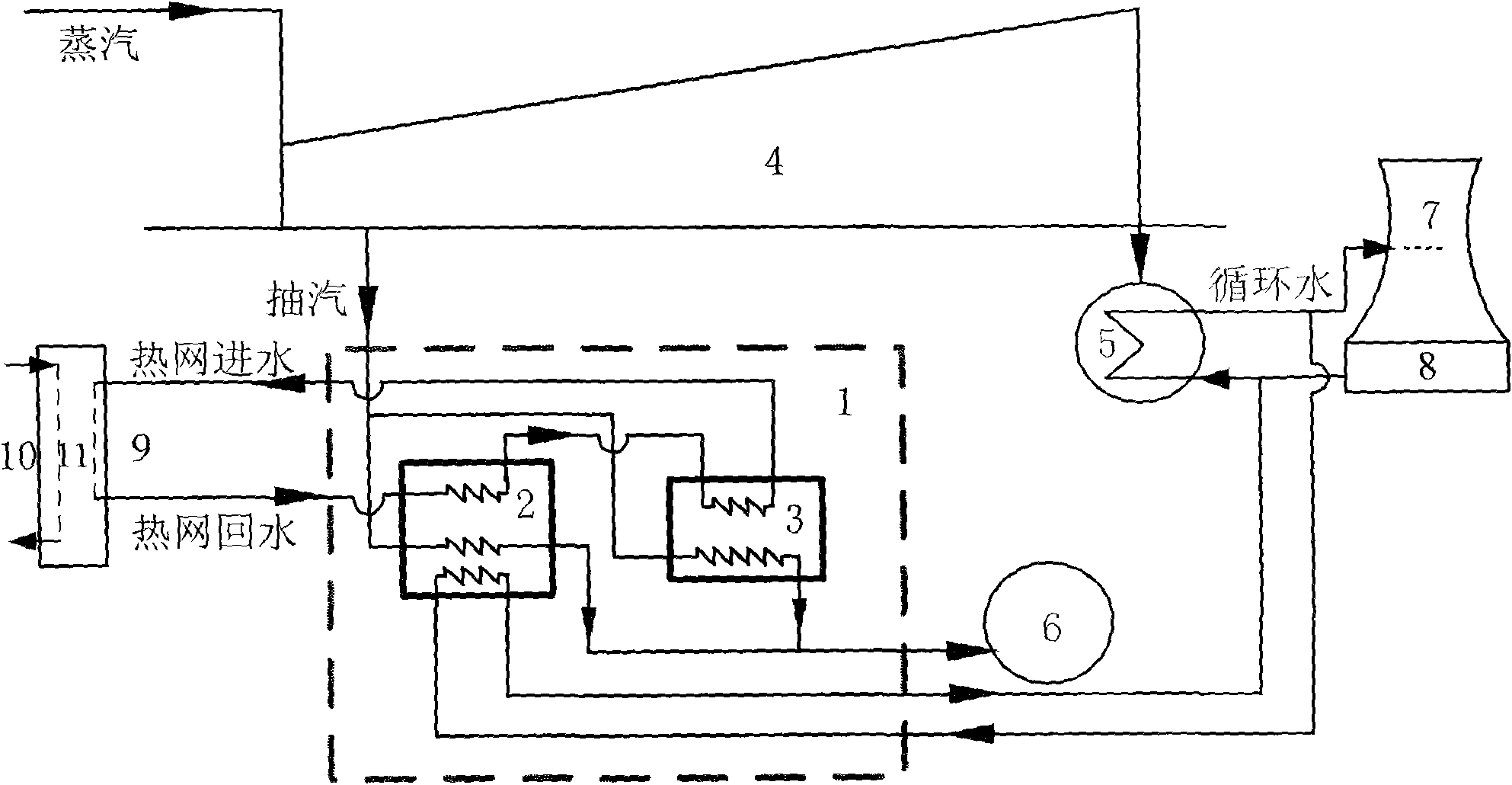

Low-temperature heat energy recovering apparatus of heat and electricity co-generation and recovering method thereof

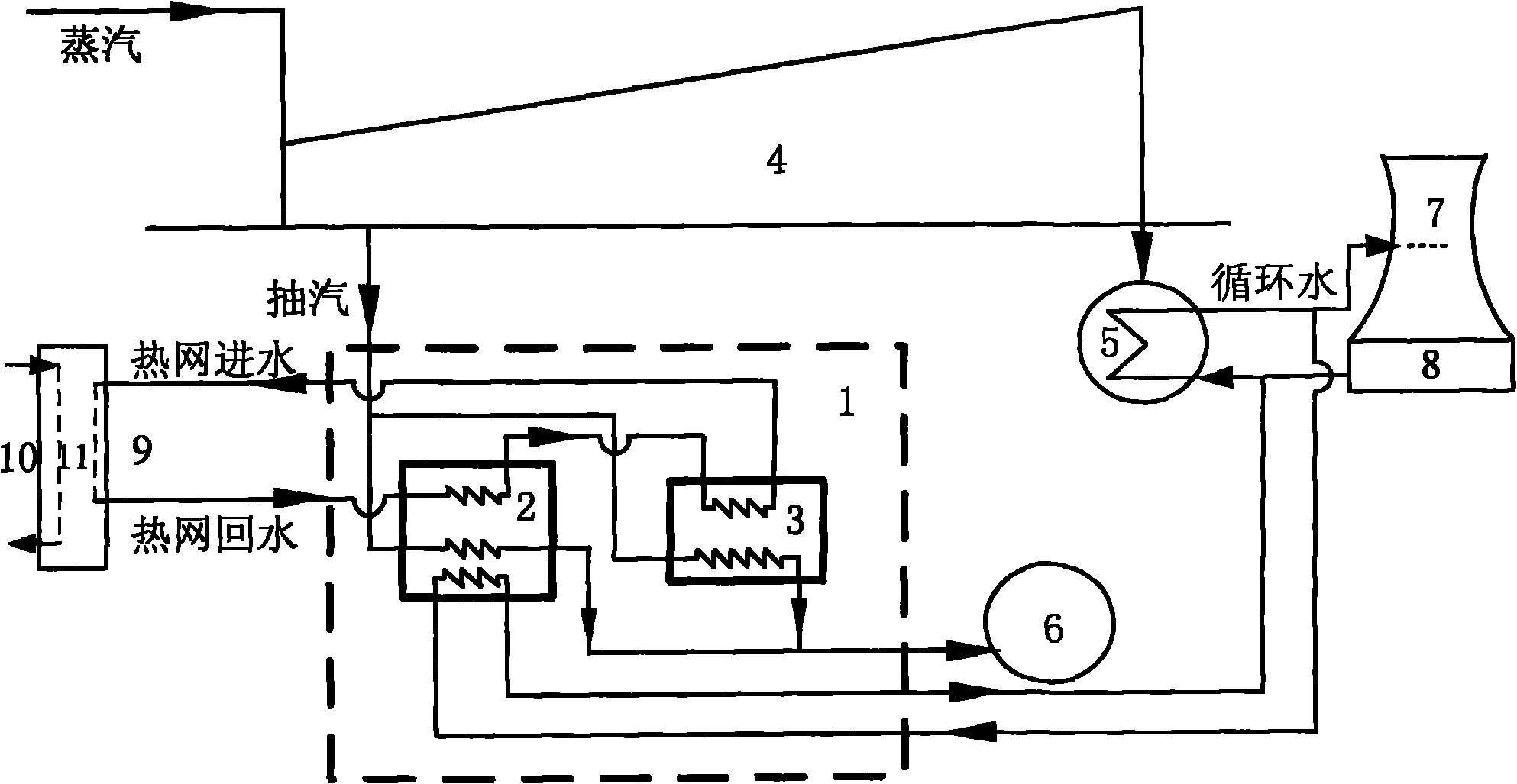

ActiveCN101696643AIncrease small loopReduce heat transfer irreversible lossLiquid degasificationSteam regenerationCooling towerAutomatic control

The invention relates to a low-temperature heat energy recovering apparatus of heat and electricity co-generation and a recovering method thereof. The apparatus comprises a steam boiler, a steam turbine, a generator, a condenser, a deaerator, a high-pressure heater, a cooling tower and a demineralized water pump. The steam turbine is connected with the condenser through an exhaust cylinder. The condenser is connected with the cooling tower through pipelines to form a water channel large circulation. The device is characterized by also comprising a water supplementing mixer and a heat pump type feed water heater, wherein the water supplementing mixture is respectively connected with the condenser and the demineralized water pump through pipelines, the heat pump type feed water heater is respectively connected with the water supplementing mixer and the deaerator through the pipelines. The condenser and the feed water heater are connected with the cooling tower through pipelines to form water channel small circulation. The heat pump type feed water heater is driven by steam extracted by the steam turbine. The apparatus further comprises an automatic control apparatus. The invention can reduce the cold source loss and improve the comprehensive heat efficiency.

Owner:联合优发生物质能源徐州有限公司

Integrated waste heat generating and heating system and process flow thereof

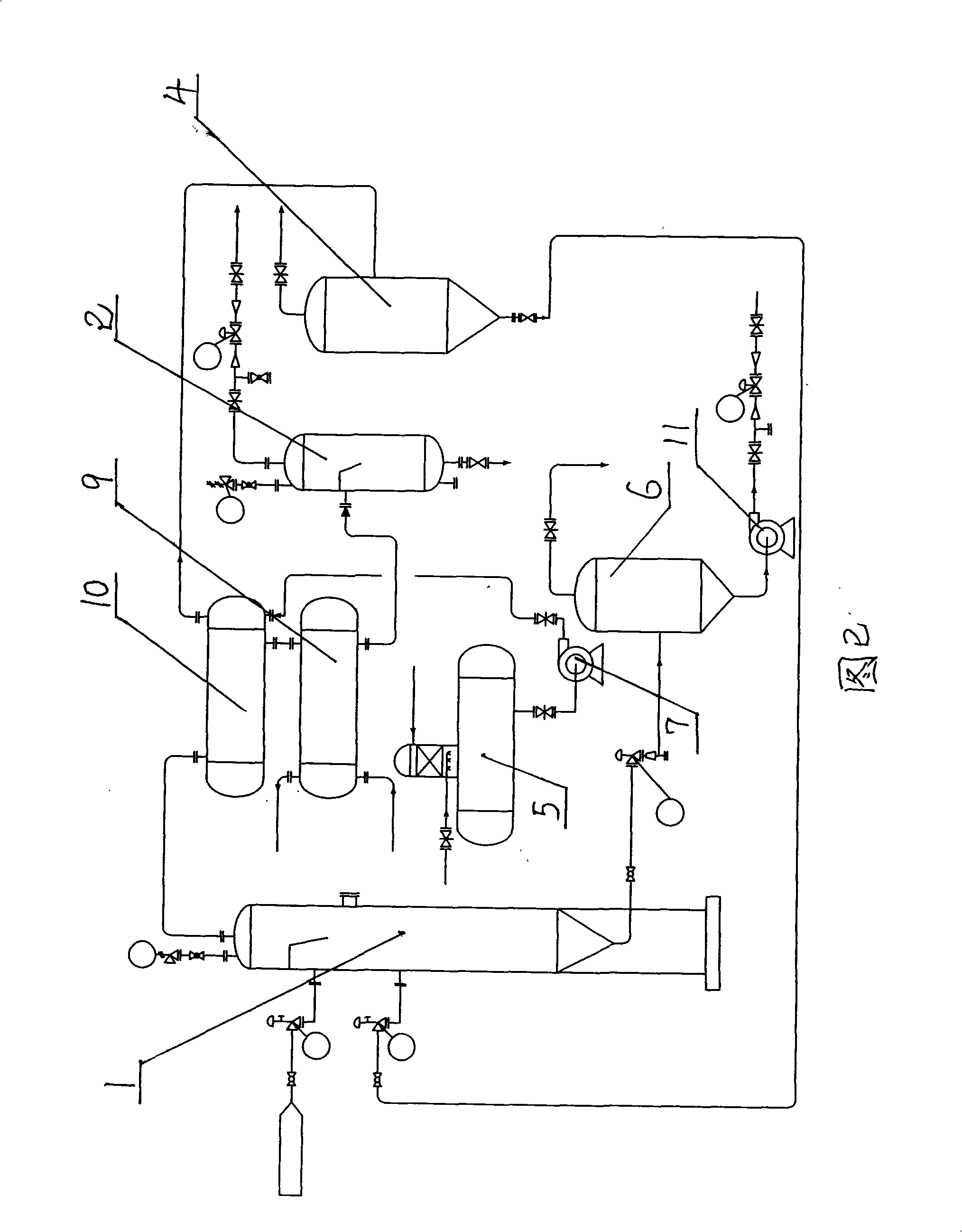

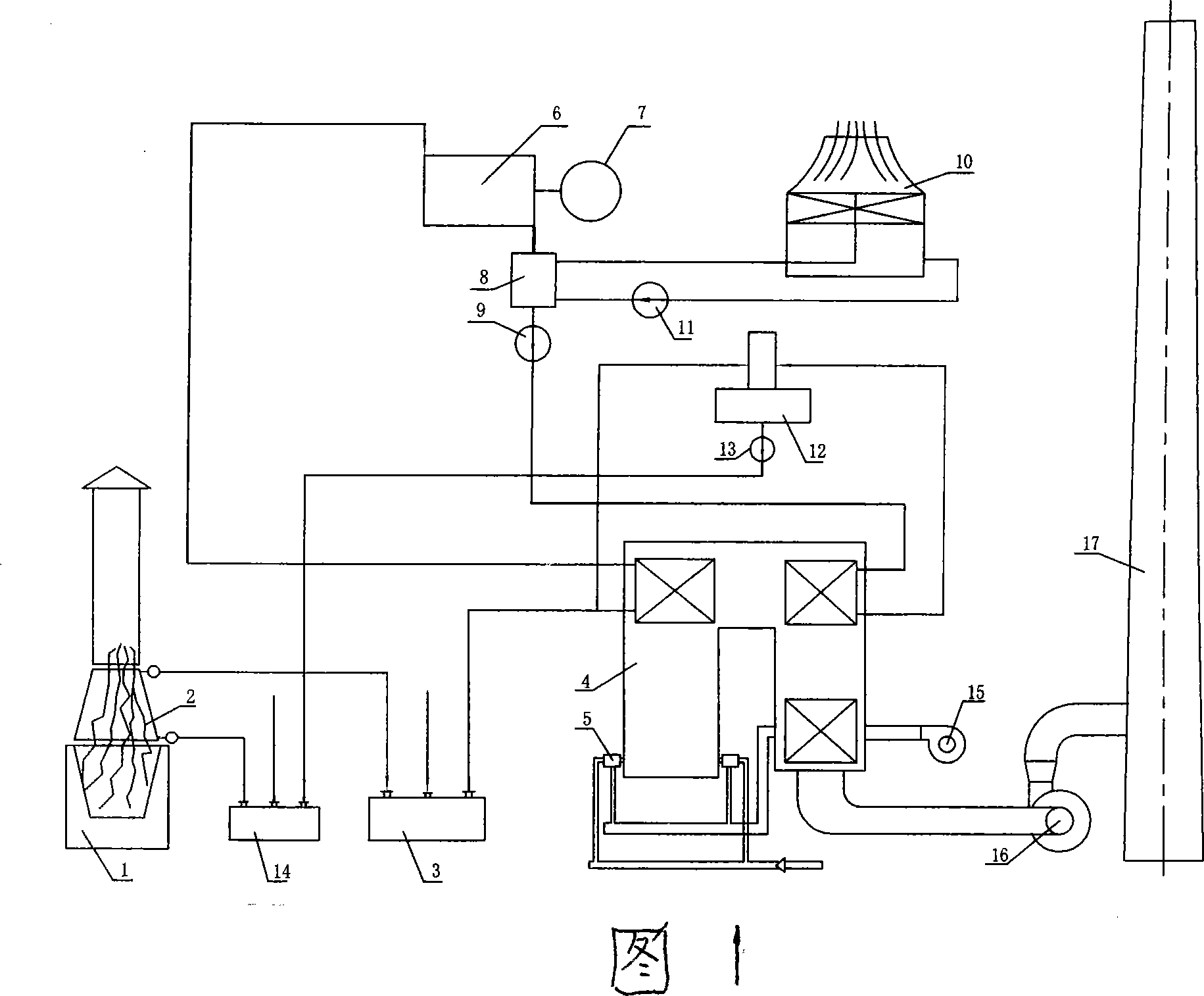

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

Fused salt heat accumulating peak regulating system for heat-engine plant heating by means of main steam

PendingCN108548168AGet the most out of your utilizationImprove economyLiquid degasificationSteam generation plantsEngineeringHigh pressure

The invention relates to a fused salt heat accumulating peak regulating system for a heat-engine plant heating by means of main steam and belongs to the technical field of heat accumulating peak regulating of heat-engine plants. The system comprises a main steam regulating valve, a high pressure steam-fused salt heat exchanger, a reheated steam regulating valve, a high temperature fused salt tank,a high pressure fused salt pump, a low temperature fused salt tank, a low temperature fused salt pump, a throttling valve, a high pressure heater, a water delivery pump, a deaerator, a boiler, a highpressure cylinder and a medium pressure cylinder. When the electrical load is reduced, the utilization ratio of the boiler is fully exerted; a fused salt heat accumulating system is additionally arranged to store heat of residual stem of the boiler in the high temperature fused salt through the high pressure steam-fused salt heat exchanger; in the electrical peak stage, the high temperature fusedsalt is extracted from the fused salt tank to be fed to the high pressure steam-fused salt heat exchanger again to heat the boiler feed water and generate high temperature high pressure steam and issent to a turbine to increase the generating capacity of the turbine and play a peak regulating role on a unit. Residual steam generated by the boiler can be recovered when the electrical load is relatively low, so that the utilization ratio and the operating safety of the boiler are improved, and the purpose of being energy-saving is achieved.

Owner:BEIJING UNIV OF TECH

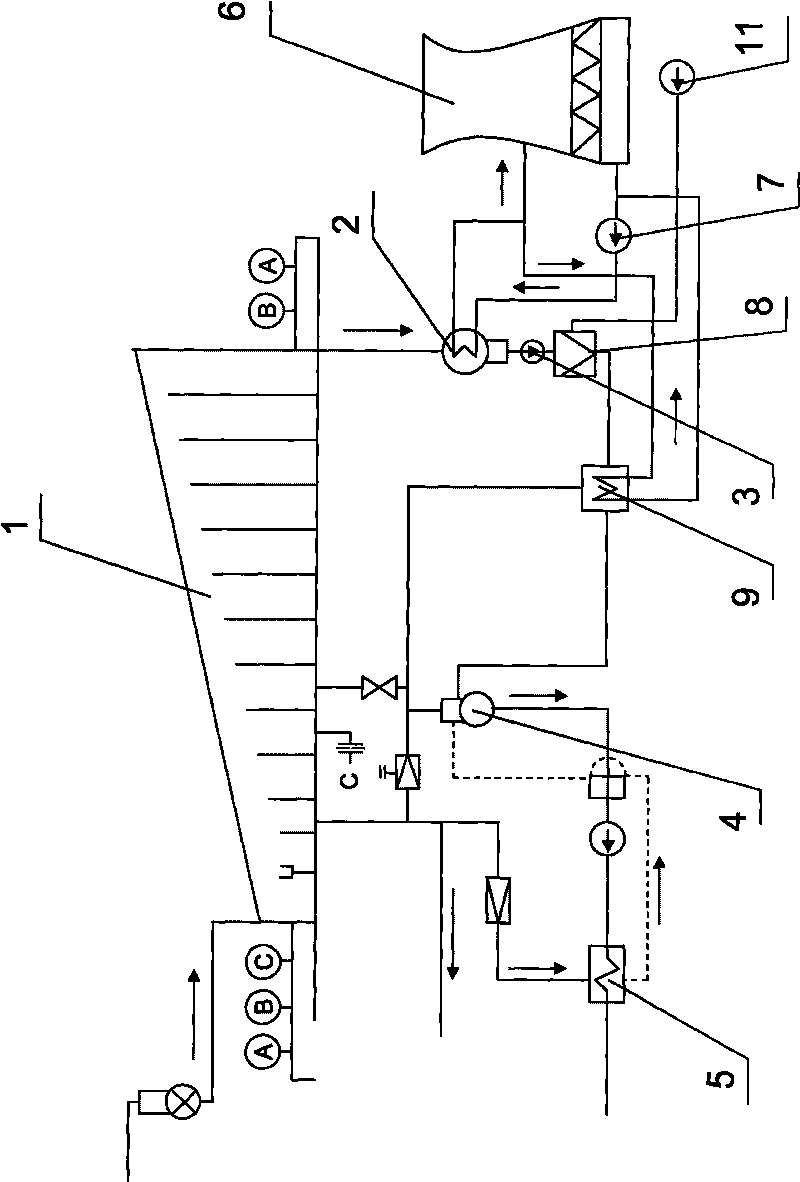

Thermoelectricity co-generation energy-saving device for supplying heat by using waste heat and energy-saving method thereof

InactiveCN101943435AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

The invention provides a thermoelectricity co-generation energy-saving device for supplying heat by using waste heat and an energy-saving method thereof. The device comprises a steam boiler, a turbine, an electric generator, a steam condenser, a deaerator and a cooling tower, wherein the turbine is connected with the steam condenser by an exhaust hood, and the steam condenser is connected with the cooling tower to form a big circulation of waterway; the device also comprises a waste heat utilization hot water heater comprising an absorbing type heat pump and a heat exchanger; a steam inlet of the absorbing type heat pump is connected with an extraction opening of the turbine, a water inlet of the absorbing type heat pump is connected with a water returning end of a hot water pipe network, and the steam condenser, absorbing type heat pump and cooling tower are connected to form a small circulation of waterway; a steam inlet of the heat exchanger is connected with the extraction opening of the turbine, a water inlet end of the heat exchanger is connected with a water outlet end of the absorbing type heat pump, and the water outlet end of the heat exchanger is connected with a water inlet end of the hot water pipe network; and the water drainage ends of the heat exchanger and the absorbing type heat pump are joined and then connected to the deaerator. The device of the invention has the advantages of reducing loss of a cold source, improving comprehensive heat efficiency and electric heating ratio and lowering coal consumption of the machine set in power generation.

Owner:北京联合优发能源技术有限公司

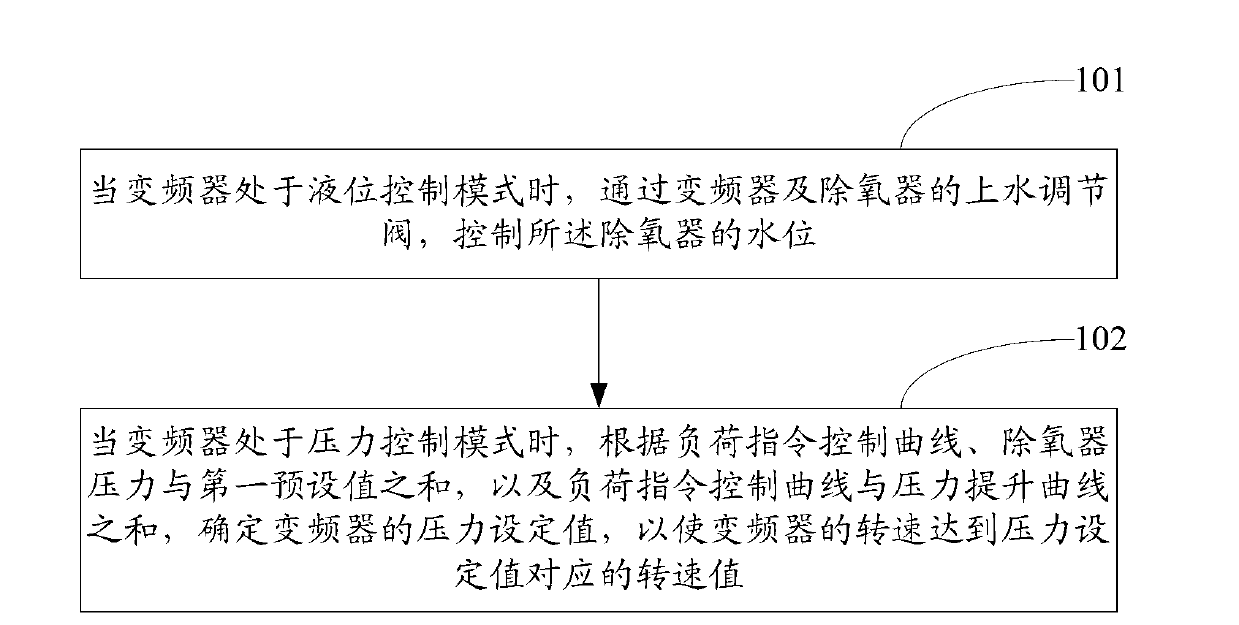

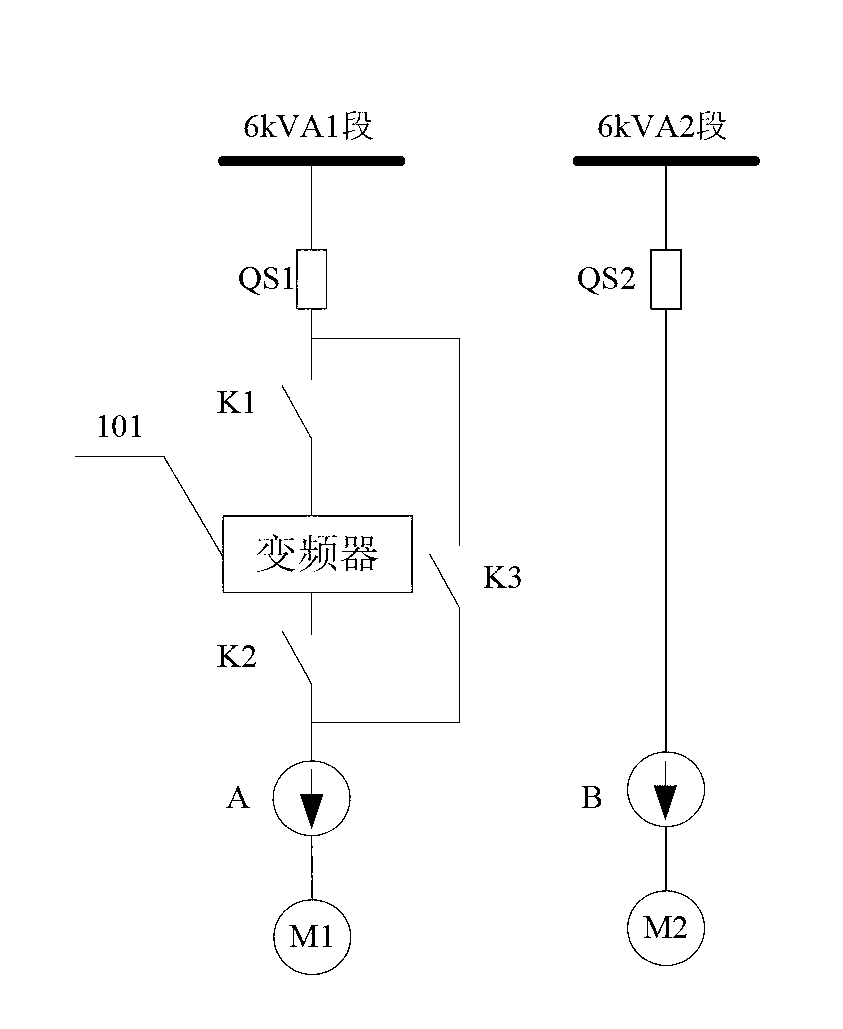

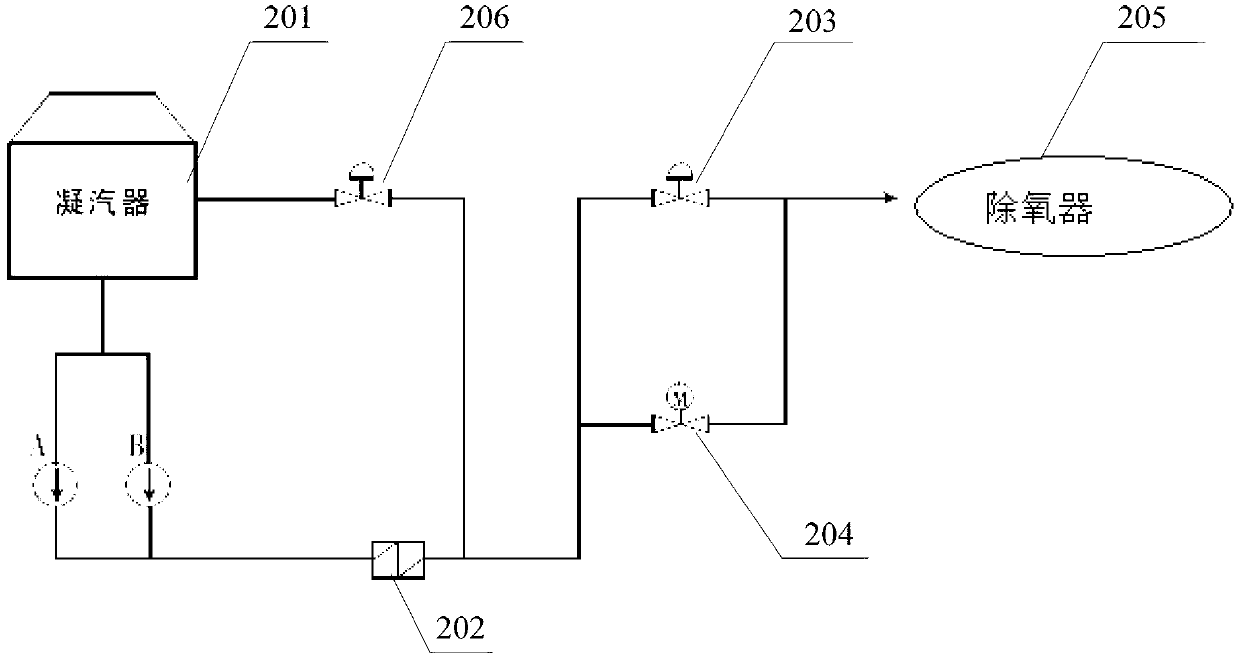

Frequency converting control method and system of condensate pump of condensed steam generator set

ActiveCN103133319AReduce speedOutput frequency adjustablePump controlPositive-displacement liquid enginesFrequency changerDeaerator

The invention discloses a frequency converting control method and system of a condensate pump of a condensed steam generator set. When a frequency converter is in a liquid control mode, the water level of a deaerator is controlled by the frequency converter and a water adjusting valve on the deaerator, and the frequency converter controls the water level of the deaerator by adjusting the rotating speed. A water feeding main adjusting valve on the deaerator is maintained at certain aperture according to the load of a machine unit; and under the same load, when the machine unit is in a load up stage, the aperture of the water feeding main adjusting valve is maintained to be small, and when the machine unit is in a load down stage, the aperture of the water feeding main adjusting valve is maintained to be large. Simultaneously certain load space can be generated by control of two clamped curves during load up and load down, and frequent aperture changing of the water feeding adjusting valve caused by small load fluctuation can be avoided. The rotating speed of the frequency converter can be lower, the current is small, the output frequency of the frequency converter is in the adjustable and economical range, and energy consumption of the frequency converter is reduced.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

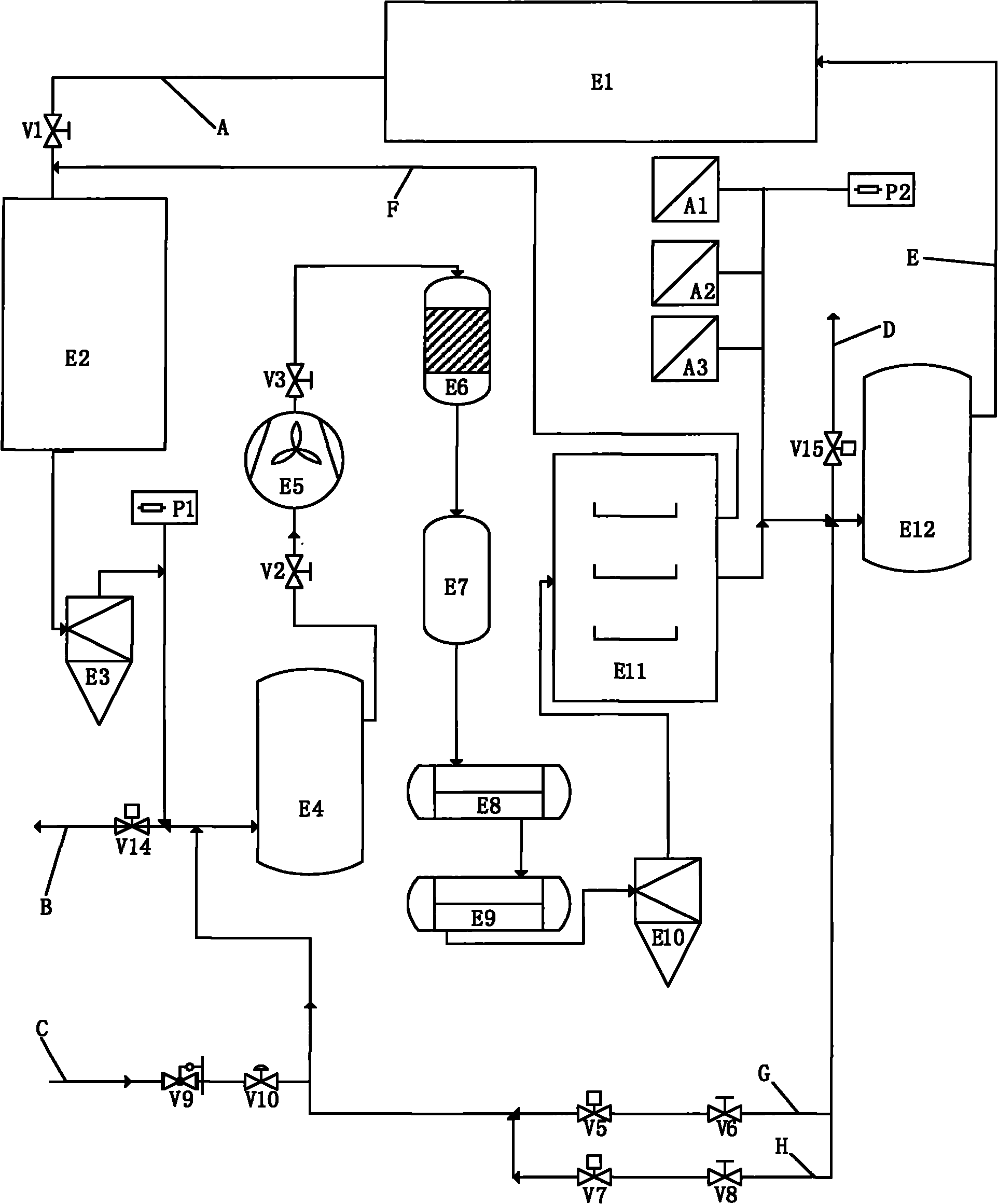

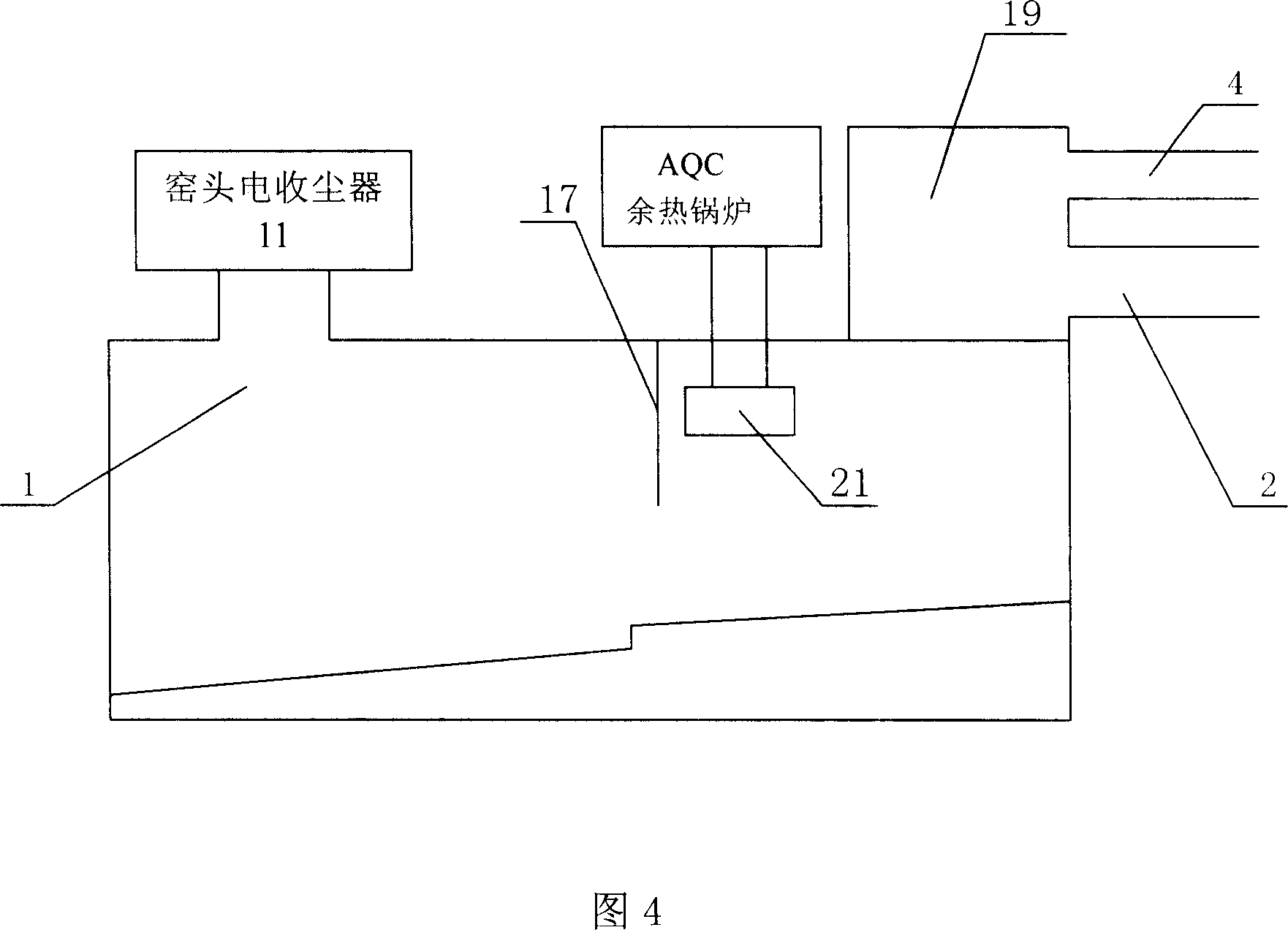

Coal-fired power generation and waste heat power generation coupling system for private station of cement kiln

ActiveCN102080582AReduce non-adjusted steam extractionImprove stabilityEnergy industryIncreasing energy efficiencyEngineeringDeaerator

The invention discloses a coal-fired power generation and waste heat power generation coupling system for a private station of a cement kiln, comprising a coal-fired boiler, a kiln head waste heat boiler, a kiln tail waste heat boiler, a kiln head steam pocket, a kiln tail steam pocket, a condensing steam turbine, a condensate pump, a heater, a deaerator, a water feeding pump and related auxiliary devices, wherein the kiln head waste heat boiler utilizes a dual-pressure system; a primary economizer of the low-pressure system is used as a public economizer for the waste heat power generation; the high-pressure steam and the steam generated by the kiln tail waste heat boiler are collected to the main steam pipeline of the waste heat power generation system; one path of the main steam pipeline is connected with a steam turbine of the waste heat power generation system while the other path thereof is connected with non-adjustable extraction steam of a coal-fired steam turbine; one path ofthe main steam pipeline of the coal-fired unit is connected with the coal-fired steam turbine while the other path thereof is connected with the waste heat steam turbine. In the invention, the coal-fired power generation is rationally coupled with waste heat power generation system so that the problem that the stability of the waste heat power generation system of the cement kiln is low is solved, and the whole thermal circulating efficiency of the private station can be largely increased.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

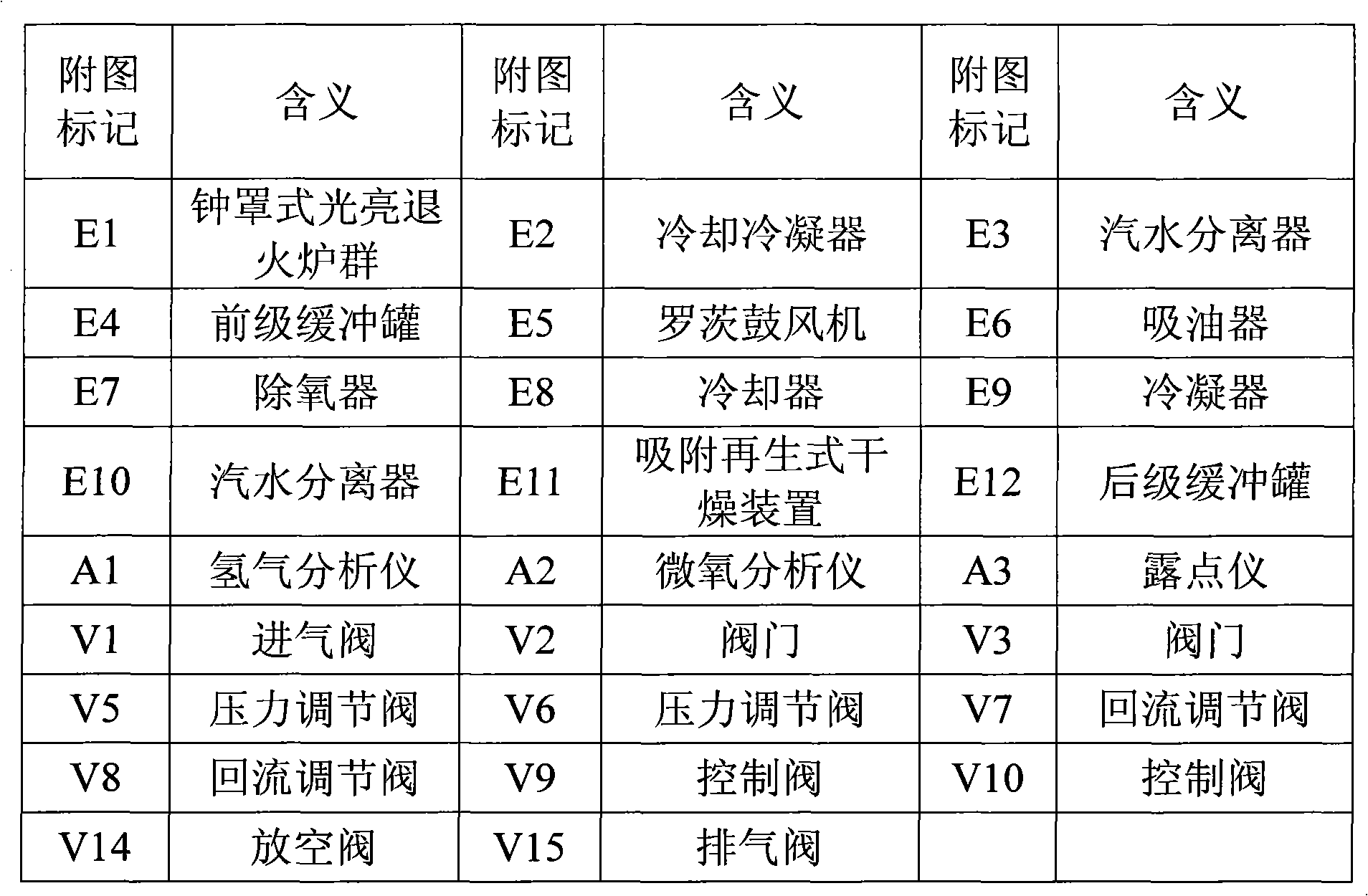

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061AAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator to generate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, the refluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

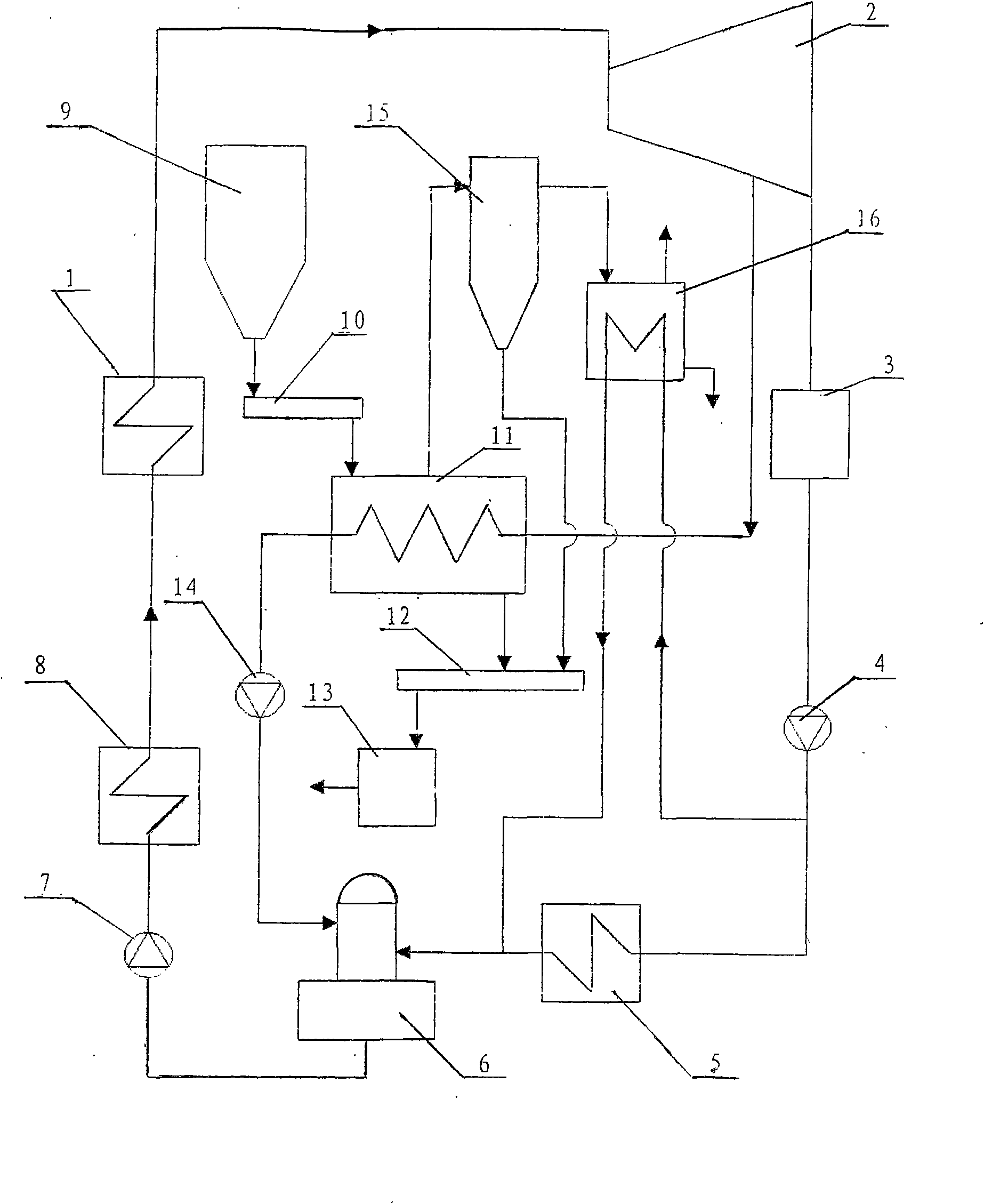

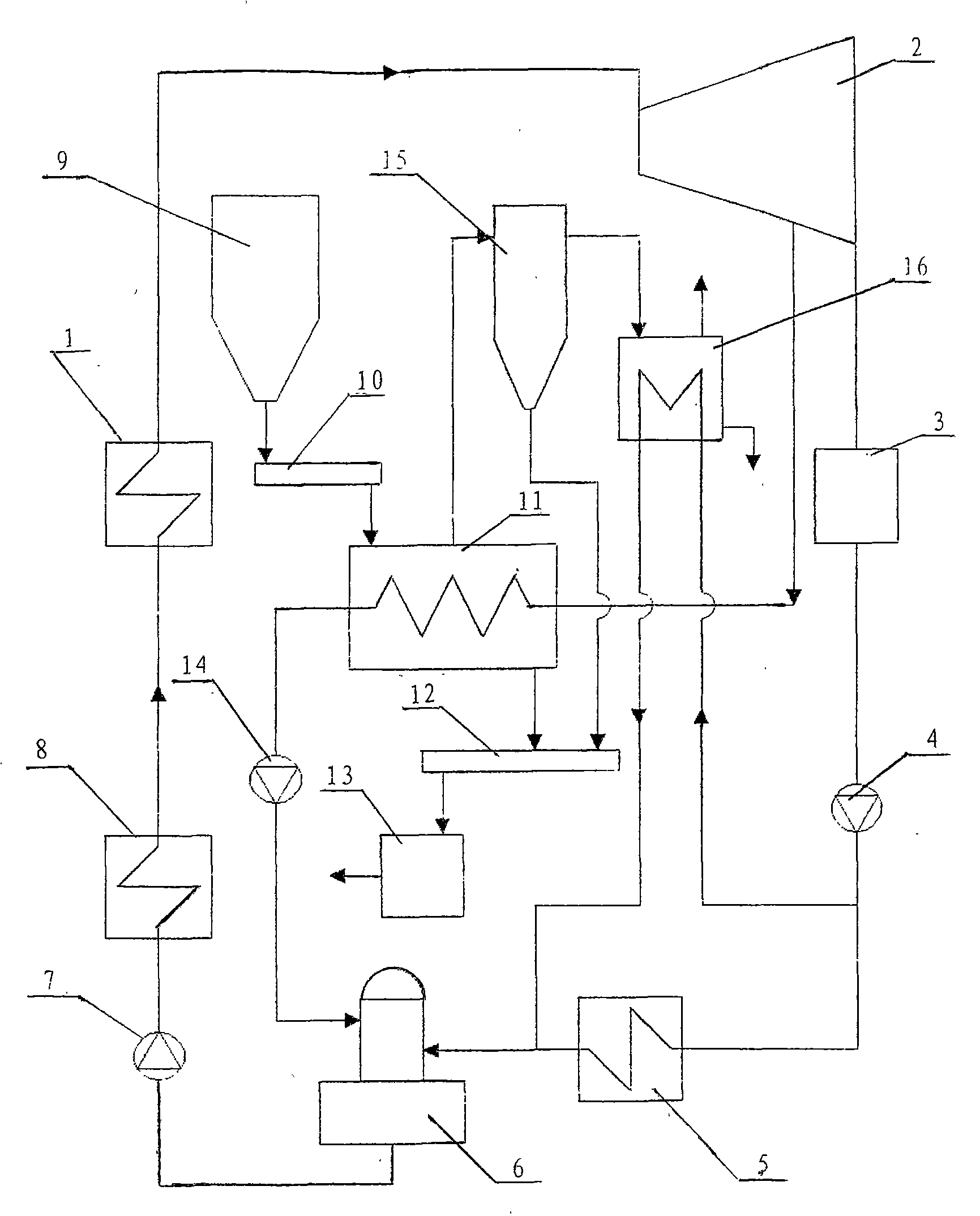

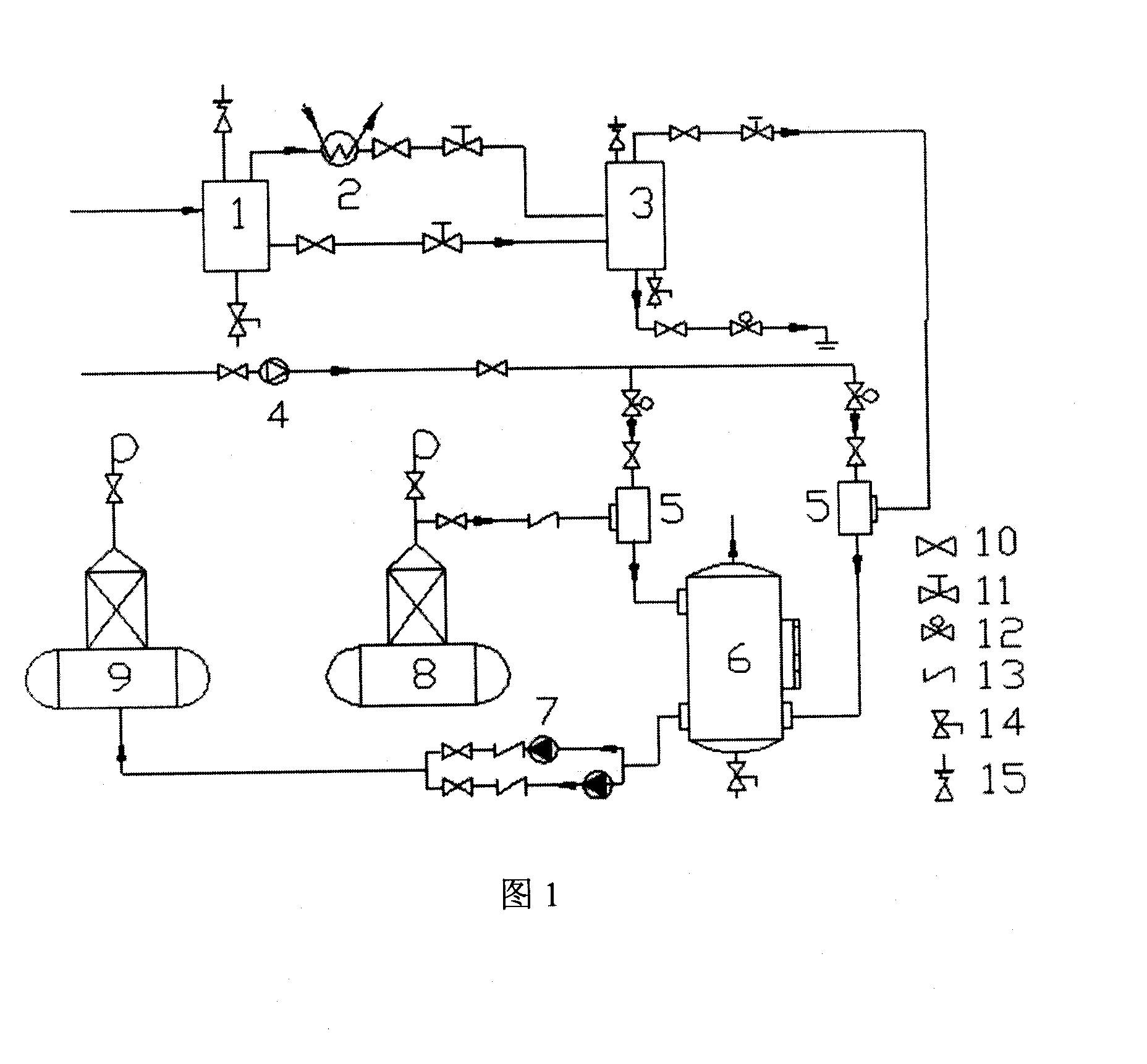

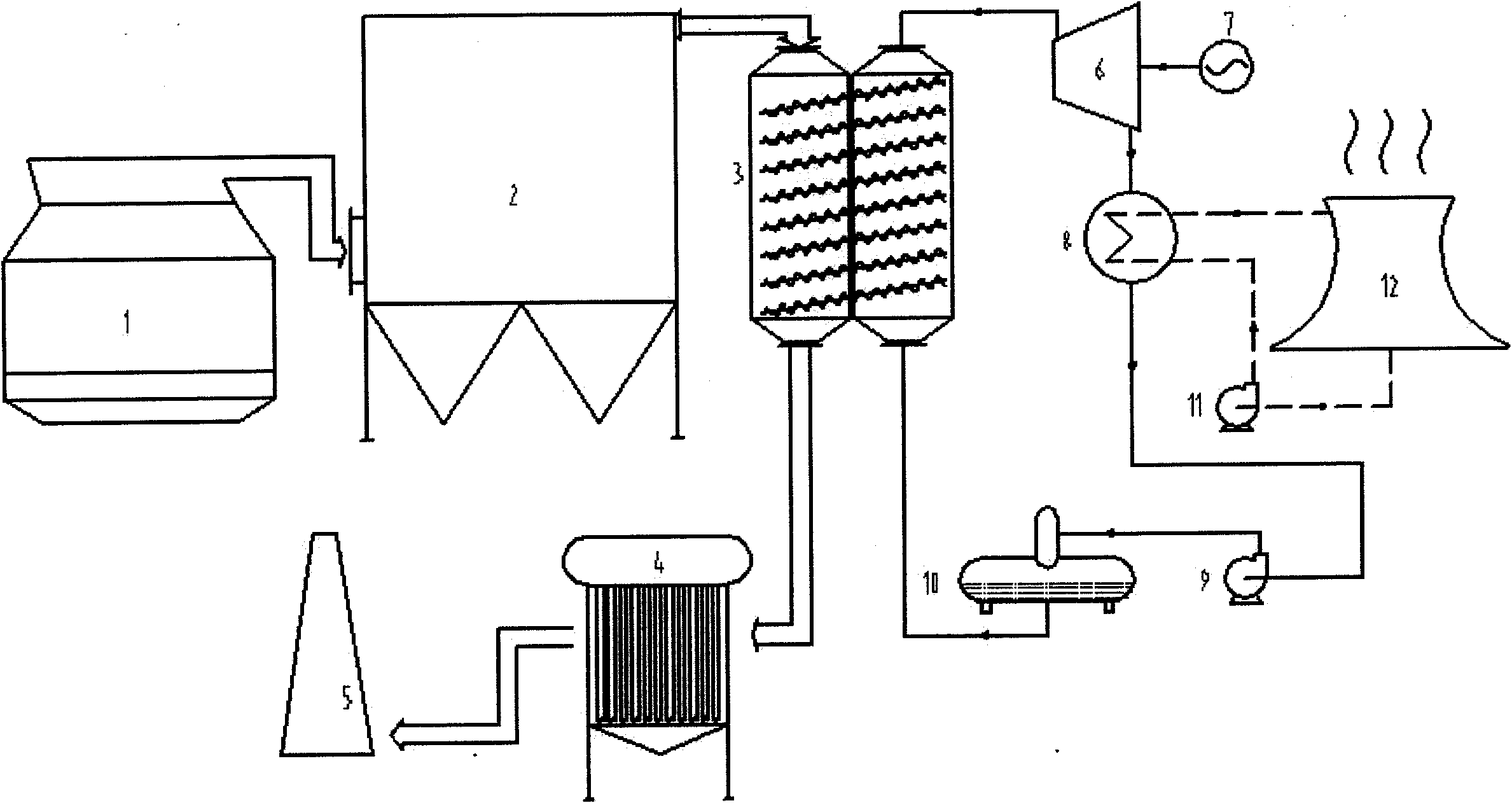

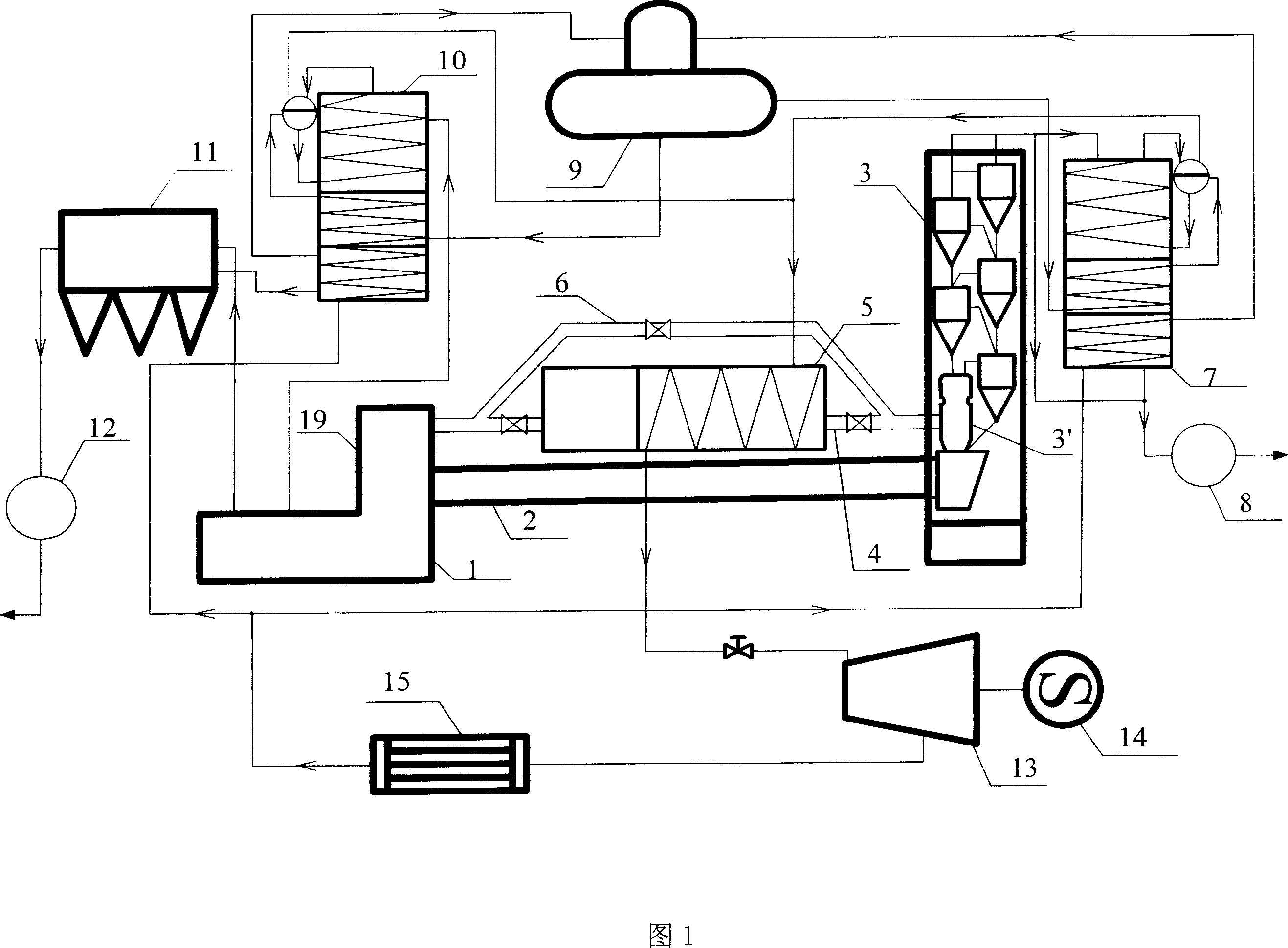

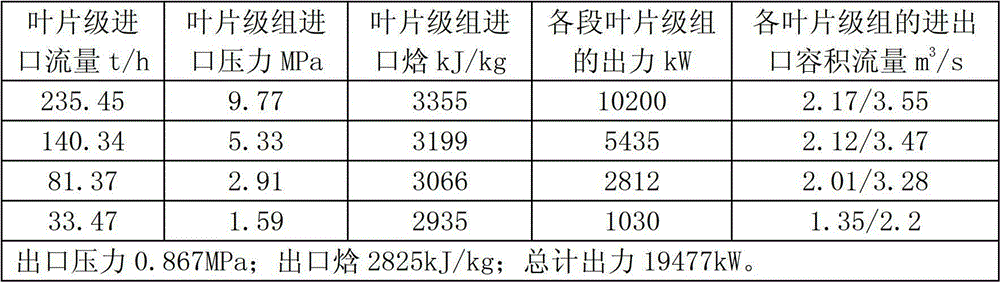

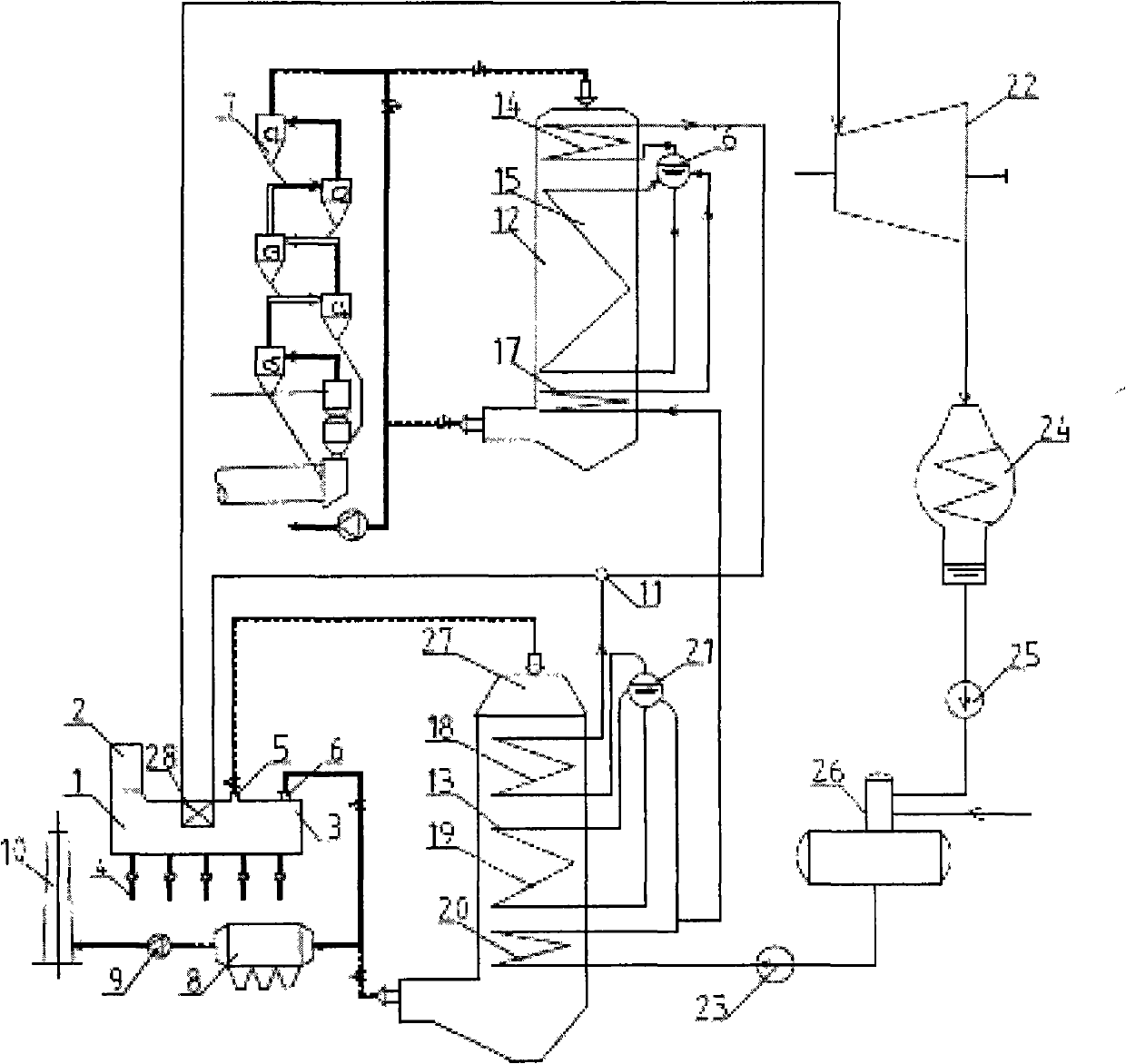

Residual heat generating system used for new type nonaqueous cement production line

ActiveCN101013002AMeet production needsIncrease profitIncreasing energy efficiencyClinker productionDeaeratorSuperheated steam

The invention discloses an abundant generating system used in dry cement product line, comprising a grog cooler, a AQC abundant heat boiler, a cement rotary furnace, a head frame of cement rotary furnace, a third-stage wind tube, a cement preheating device, a cement predissociation furnace, a SP abundant heat boiler, a fan, a deaerator, a condenser, and a generator of turbine. The third-stage wind tube is between the head frame and the predissociation furnace. The head frame is communicated with the grog cooler. The invention is characterized in that third-stage wind tube is arranged with a third-stage wind abundant-heat boiler with bypass wind channels; the medium inlet of the third-stage wind abundant-heat boiler via the tube is connected with the AQC abundant-heat boiler and the SP abundant-heat boiler, while the medium outlet is connected with the turbine generator. The invention can completely absorb the abundant heat of product line, to supply overheated steam to the generator, while the electricity generation is higher than 40kwh.

Owner:BEIJING LIULIHE CEMENT +1

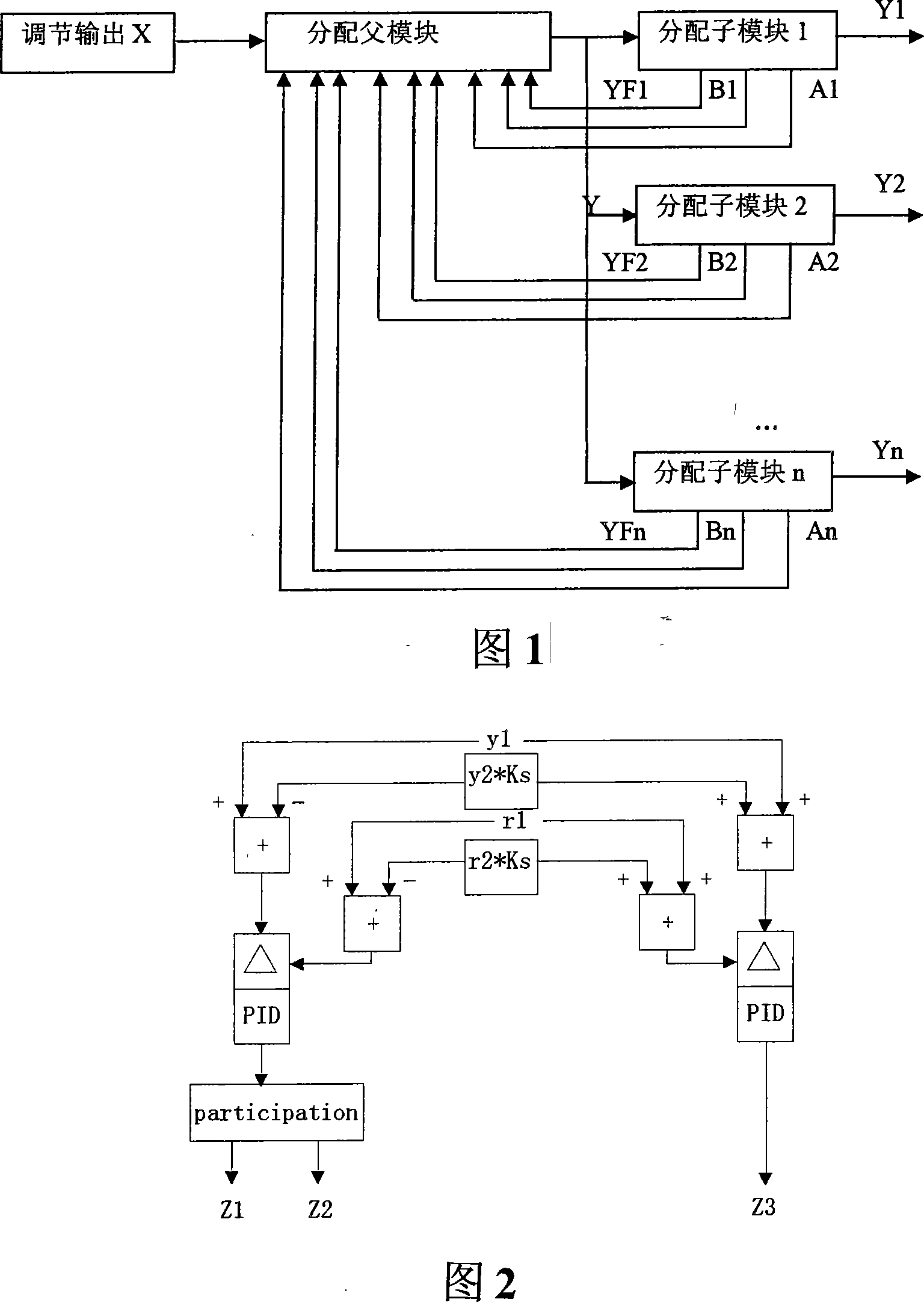

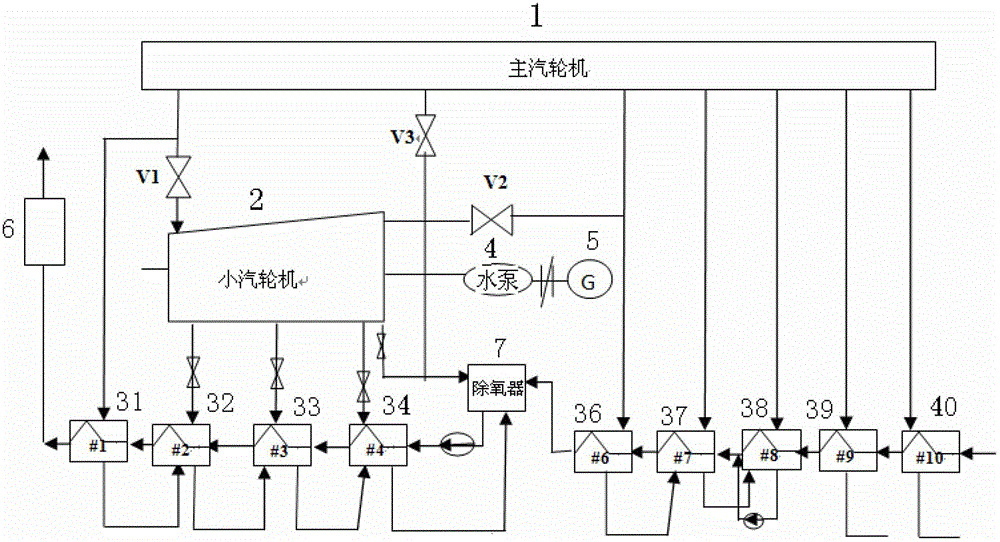

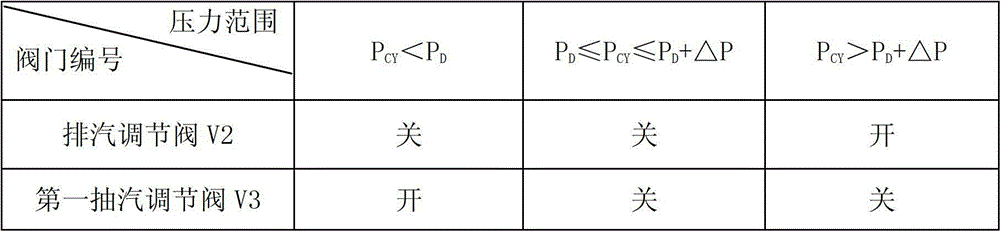

Control method for steam thermal system with dual-machine backheating steam extraction

ActiveCN102720551ASafe and stable jobEnsure balanceLiquid degasificationCombination enginesControl mannerEngineering

The invention provides a control method for a steam thermal system with dual-machine backheating steam extraction. When the pressure of a deaerator is lower than the steam extraction pressure at a heat supply steam extraction port of a deaerator on a main steam turbine, a first steam extraction control valve is opened; when the pressure of the deaerator is higher than the steam extraction pressure at the heat supply steam extraction port of the deaerator on the main steam turbine, the first steam extraction control valve is closed and a steam exhaust control valve is opened. According to the control method, the deaerator is connected with a small steam turbine exhaust pipe and a heat supply steam extraction port of the deaerator on a large steam turbine respectively; through controlling the switches of corresponding control valves, on one hand, synchronisms of the pressure of the deaerator and the steam extraction pressure at the heat supply steam extraction port of the deaerator on the large steam turbine under different running conditions are ensured, and on the other hand, the balance of backheating steam extraction flow is achieved on the premise that the output balance between the small steam turbine and the system auxiliary equipment is ensured. Therefore, by adopting the control method, the balance of the backheating steam extraction flow is ensured, and the small steam turbine is enabled to work safely and stably for a long time.

Owner:SHANGHAI TURBINE

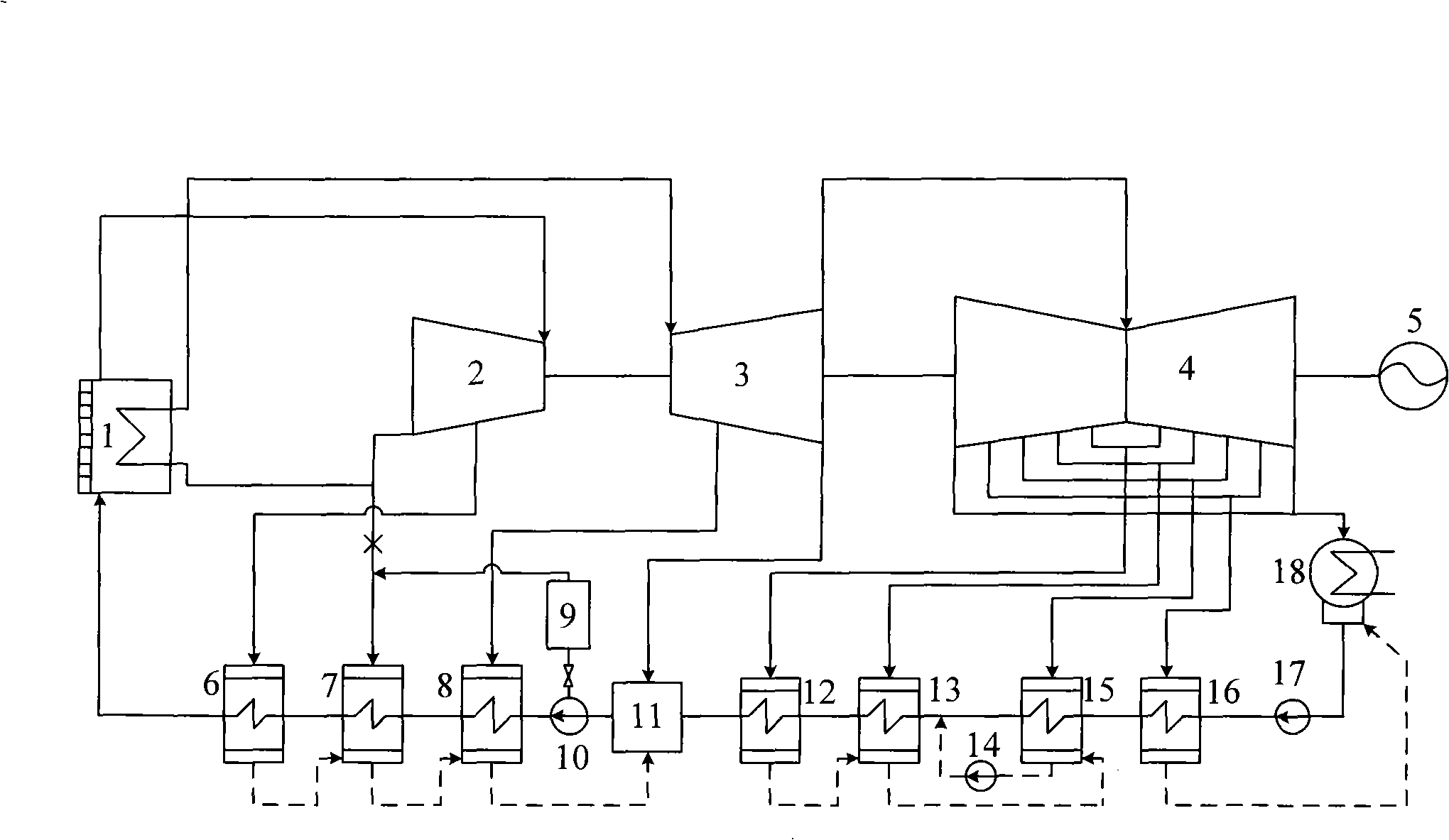

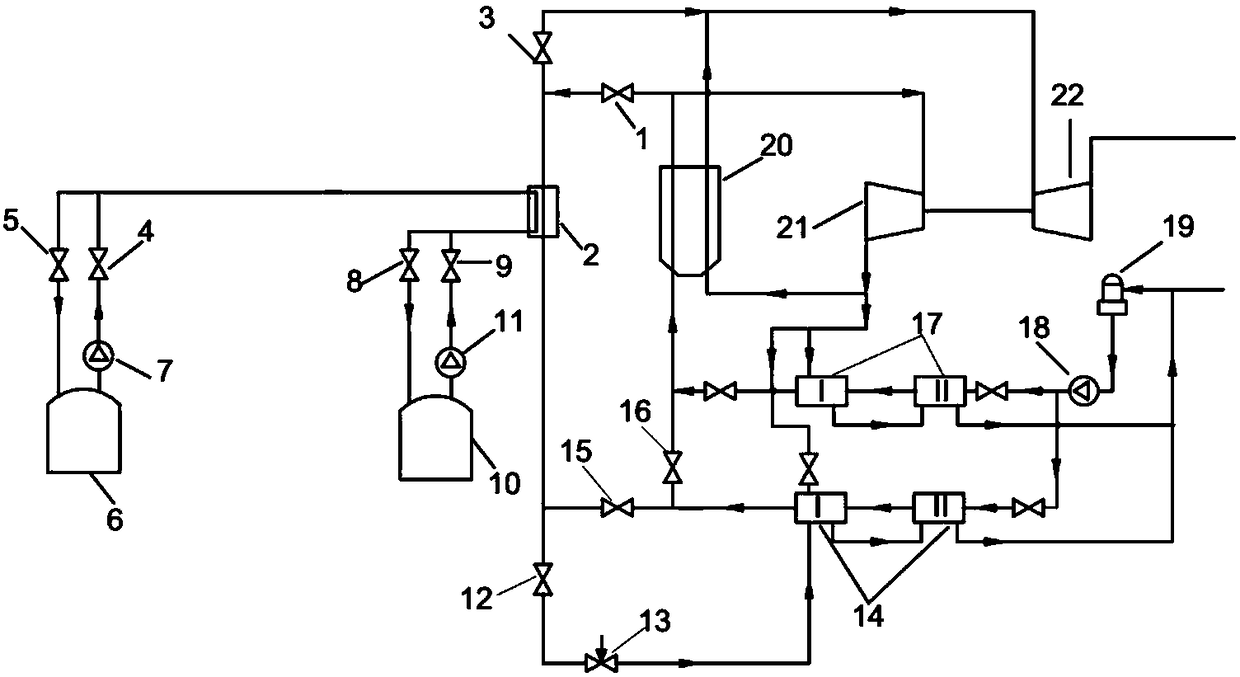

Double-turbine steam thermodynamic system with regenerative steam extraction function

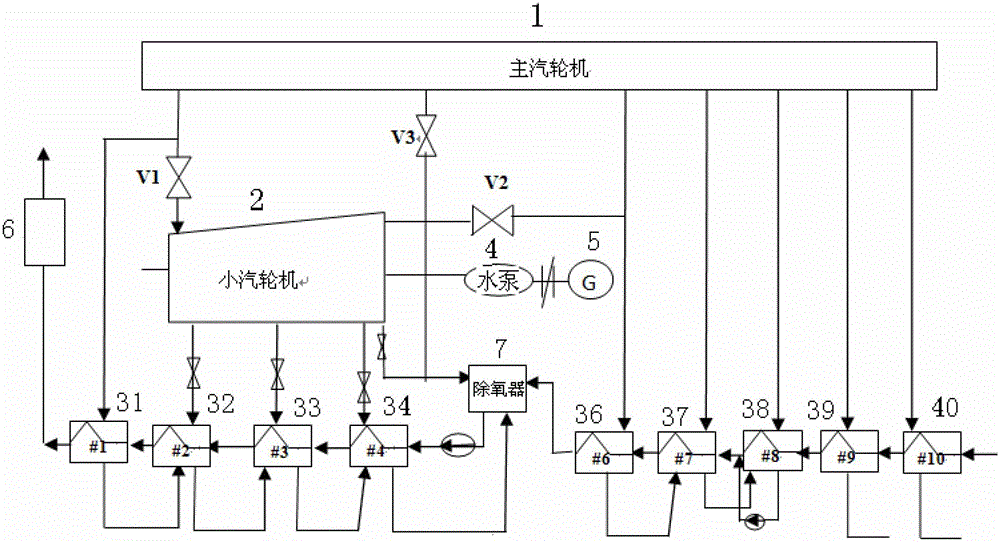

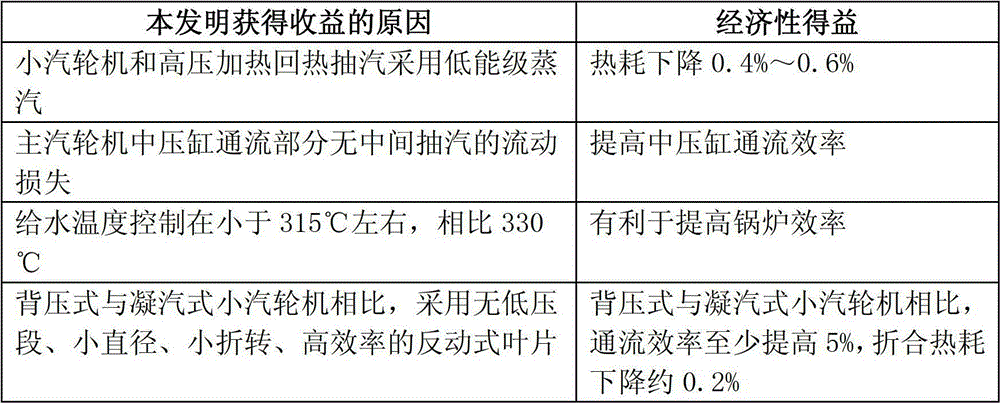

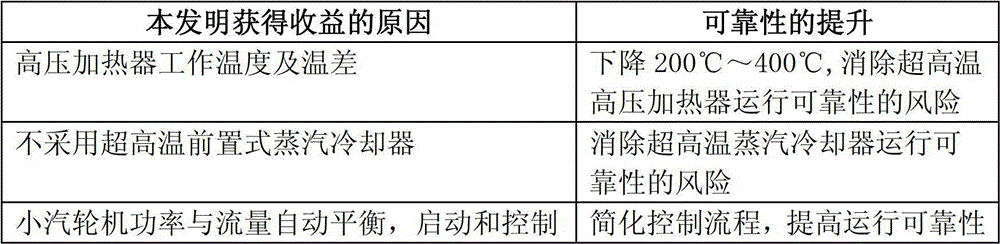

InactiveCN103195521AImprove flow efficiencyReduce axial sizeSteam useCombined combustion mitigationEngineeringDeaerator

The invention provides a double-turbine steam thermodynamic system with a regenerative steam extraction function. The double-turbine steam thermodynamic system comprises a large steam turbine, a small steam turbine and a regenerative cycle unit. The regenerative cycle unit comprises one or a plurality of high-pressure heaters, one or a plurality of medium-pressure heaters, one or a plurality of low-pressure heaters and two deaerators, and a water circulating pipeline is communicated with a boiler via the low-pressure heaters, the low-pressure deaerator, the medium-pressure heaters, the high-pressure deaerator and the high-pressure heaters sequentially. The double-turbine steam thermodynamic system with the regenerative steam extraction function has the advantages that medium-pressure cylinders of the large steam turbine do not need to be provided with steam extraction openings for regenerative steam extraction owing to the double-deaerator structure, medium-pressure cylinder structures of the large steam turbine are greatly simplified, the axial dimension of an integral unit is reduced, and the through-flow capacity of the large steam turbine is improved; and sufficient flow and sufficient power for the small steam turbine can be guaranteed, a complicated logic balance system for the power of the small steam turbine is omitted, and accordingly the integral system is simple and reliable.

Owner:SHANGHAI TURBINE

Pump-free direct current furnace starting system capable of recycling working medium and heat comprehensively

The invention relates to a pump-free direct current furnace starting system capable of recycling a working medium and heat comprehensively, and provides a direct current furnace starting system which is used for a supercritical direct current furnace without a starting furnace water circulation pump at a power station and can recycle the working medium and heat comprehensively. According to the invention, during the starting period of the direct current furnace, three high-pressure heaters at the side of a turbine are utilized as a water heat exchanger, heat is emitted in echelon by the starting of the drainage with high enthalpy, pressure is reduced, thus the enthalpy is reduced to be suitable for the safe recovery by a deaerator; double control logic of the high-pressure heater by a machine set DCS (data conversion system) with special design ensures each high-pressure heater to complete the starting whole process of the direct current furnace and a heat regenerative system working pattern safely and economically under two different working patterns; the working medium and heat can be recycled comprehensively by each starting working condition and starting whole process, and therecycled effect is superior to the direct current furnace starting system with a starting furnace water circulation pump; and the maintaining expense of the infrastructural construction investment and operation can be reduced greatly by the starting furnace-free circulation pump and a subsystem thereof.

Owner:章礼道

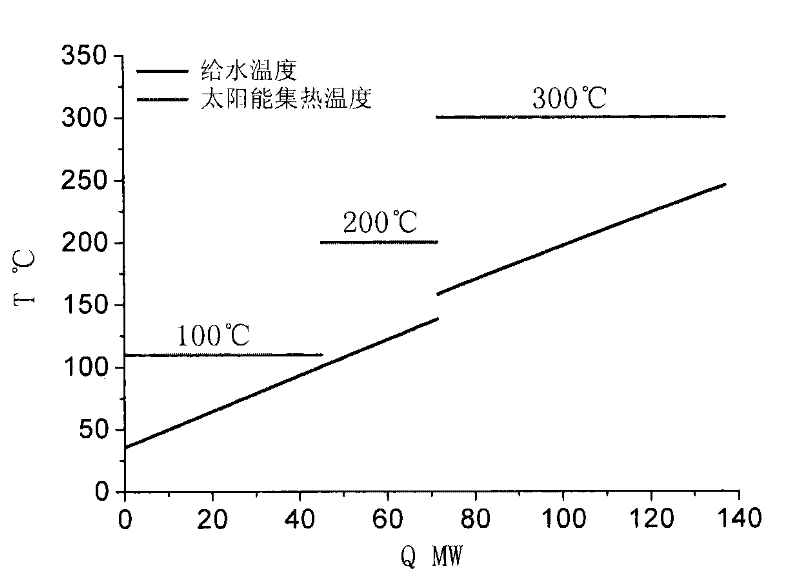

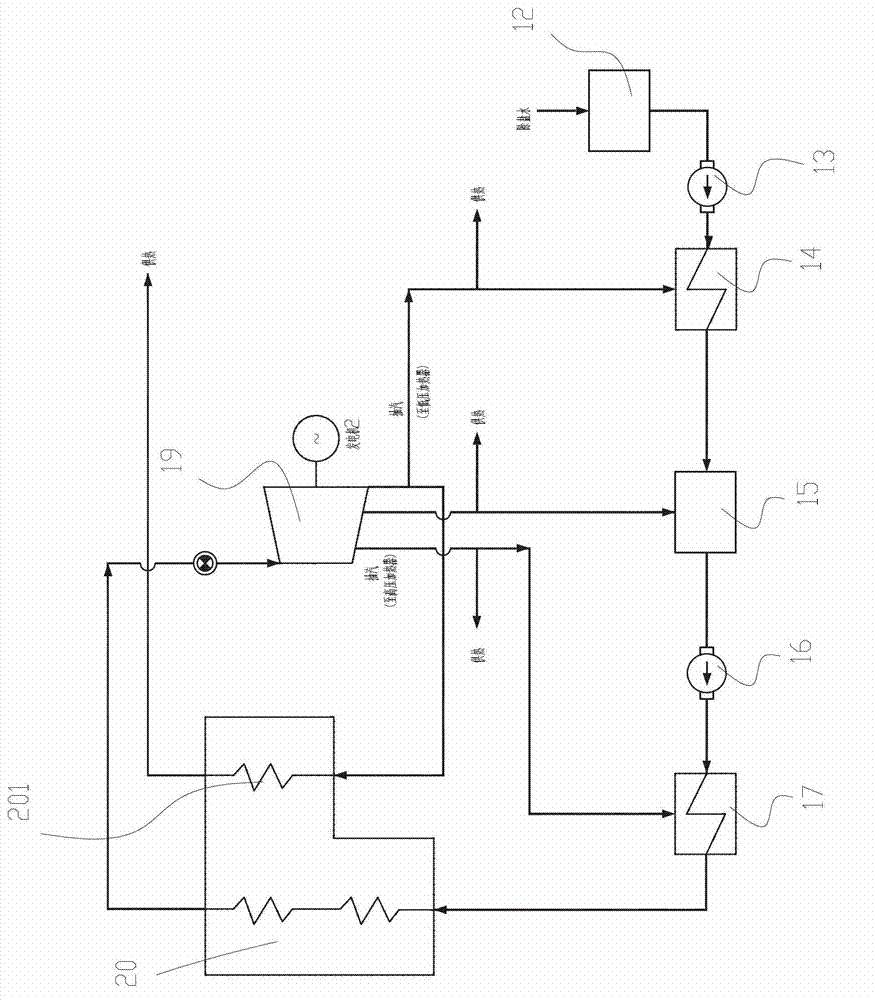

Board slot combined solar energy and thermal power station complementary generating system

ActiveCN102454440AReduce irreversibilityHigh thermal efficiencySteam generation heating methodsSolar heat devicesWater vaporDeaerator

The invention discloses a board slot combined solar energy and thermal power station complementary generating system which comprises a coal-fired boiler, a steam turbine, a generator, a condenser, a condensate pump, an oil-water heat exchanger of a low-pressure solar feed water heater, a flat-plate solar collector, a first parabolic trough type solar collector, a deaerator, a high-pressure water pump, an oil-water heat exchanger of a high-pressure solar feed water heater and a second parabolic trough type solar collector, wherein the steam turbine comprises a high-pressure cylinder, an intermediate-pressure cylinder and a low-pressure cylinder; high-temperature and high-pressure steam generated in the coal-fired boiler does work by expansion in the high-pressure cylinder, the intermediate-pressure cylinder and the low-pressure cylinder of the steam turbine to drive a generator to rotate and output an electrical load externally. The generating system can be used for realizing the capacity expansion and consumption reduction of thermal power stations and solving the problem that the solar energy is unstable and discontinuous, and is beneficial to low-cost transformation of the thermal power stations and large-scale application and popularization of a solar energy technology.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Comprehensive utilization method of thermal power plant boiler wastewater

The invention provides a comprehensive utilization method of thermal power plant boiler wastewater. The comprehensive utilization method comprises the following process steps: (1) continuous boiler wastewater goes into a continuous blowdown flash tank for reduced-pressure flashing; secondary steam generated after flashing is guided out of the upper part of the continuous blowdown flash tank and into a deaerator; (2) the hot wastewater at the bottom of the continuous blowdown flash tank is guided into a boiler periodic blowdown flash tank for further reduced-pressure flashing together with regular boiler wastewater; (3) the secondary steam generated by flashing from the periodic blowdown flash tank serves as a heat source and is guided into a low-temperature multiple-effect evaporator group, and bottom salt-containing wastewater also goes into the low-temperature multiple-effect evaporator group as the evaporated liquid; (4) the condensed water generated by the low-temperature multiple-effect evaporator group and the steam condensed water out of a cooler are collected to a condensed water tank by use of a condensation header and then fed into a boiler water supply system by use of a condensed water pump to be recycled; a thickened liquid generated by performing multiple-effect evaporation on the salt-containing wastewater is recycled into a thickened liquid recovery tank and then fed into a wet boiler flue gas desulphurization system used as a desulfurizing agent for desulphurization.

Owner:CHINA CEC ENG

Self-coupling cold source heat pump circulating device of low-temperature exhaust heat power generating system in low temperature exhaust steam condensation process

ActiveCN101705849AReduce lossesReduce power consumptionSteam engine plantsSteam condensationDeaerator

The invention relates to the technical field of low-temperature exhaust heat power generation at low temperature, in particular to a self-coupling cold source heat pump circulating device of a low-temperature exhaust heat power generating system in the low temperature exhaust steam condensation process. The self-coupling cold source heat pump circulating device comprises a conventional low-temperature exhaust heat power generating heat circulation system, a heat pump type condenser which is arranged parallel with a water-cooled condenser is arranged at an exhaust steam outlet of a lower pressure cylinder of a steam turbine; a gaseous state working medium outlet of the heat pump type condenser is divided into three paths which respectively pass through a heat pump system compressor, wherein a first path passes through a heat pump condensed water heater, a second path passes through a heat pump deoxidized heater and a third path passes through a heat pump water feeding heater and then returns to a liquid state working medium input of the heat pump type condenser; the heat pump water feeding heater is arranged between a condensing water pump and a deaerator; the heat pump deoxidized heater is arranged on the deaerator; and the heat pump water feeding heater is arranged at a water feeding inlet of a water feeding pump and an exhaust heat boiler. The invention substantially improves the exhaust heat utilization efficiency of the low-temperature exhaust heat power generating system and enables the system to produce more power energy under the condition that exhaust heat sources are the same.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Preparation method of vitamin A microcapsules

InactiveCN102198116AFree from destructionWon't breakHydroxy compound active ingredientsMetabolism disorderAntioxidantDissolution

The invention relates to a preparation method of more stable vitamin A microcapsules, comprising the following steps of: firstly, preparing a vitamin A oil solution containing an antioxidant from vitamin A and the antioxidant in the absence of oxygen, adding chitosan and stirring evenly, after stirring fully, filtering and removing the chitosan to obtain the vitamin A oil solution; adding octenyl succinic acid modified starch to purified water deaerated by a thermal spray deaerator, heating for dissolution; mixing the prepared octenyl succinic acid modified starch solution and the vitamin A oil solution in a certain proportion, emulsifying quickly by an on-line emulsifying machine, and instantly cooling by a cooler; and performing hot air spray drying on the emulsion to obtain stable vitamin A microcapsules. The storage life of the product prepared in the invention reaches two years.

Owner:何德海

Nitrogen purification method

The invention discloses a nitrogen purification method, wherein nitrogen and hydrogen both mixed with oxygen impurities are fed into a deaerator in which combustion reaction can be formed between the oxygen in the deaerator and the hydrogen to generate water, after the nitrogen mixed with steam is cooling-dewatered by a multistage cooler, freezing-dried by a freezing drier, dewatered by a gas-water separator and drying-dewatered by a multistage dryer, the dew-point temperature of the nitrogen can be lowered to about minus 80 degrees, in this case, the nitrogen hardly contains water, and in the end, the impurities like dust, particles, etc. in the nitrogen are removed by a filter to obtain nitrogen with the purity of 99.999%.

Owner:NANTONG TIANYUAN GAS

Multi-stage fuel deoxygenator

InactiveUS20050137441A1Increased usable cooling capabilityImprove rendering capabilitiesSemi-permeable membranesOther chemical processesNuclear engineeringDeaerator

A fuel delivery system for an energy conversion device includes a fuel deoxygenator and an oxygen scavenger module for removing dissolved oxygen and increasing the usable cooling capability of a fuel. Fuel emerging from the fuel-deoxygenating device flows into the oxygen-scavenging module where a second portion, smaller than the first portion of oxygen is removed from the fuel. The combination of the oxygen scavenger and the fuel deoxygenator provides an increase in removal of dissolved oxygen relative to the use of either device alone. The combination provides the desired increase in deoxygenation of fuel without the corresponding increase in device size.

Owner:UNITED TECH CORP

Thermal power plant and united thermodynamic system for thermal power plant

ActiveCN102828791AImprove thermal cycle efficiencyReduce consumptionSteam useCombined combustion mitigationPollutant emissionsDeaerator

The invention discloses a thermal power plant and a united thermodynamic system for the thermal power plant. The thermal power plant comprises a secondary reheating coagulated steam unit and a backpressure unit; the united thermodynamic system comprises a thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; a reheating system from a condenser to a deaerator is shared by the thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; the condensed water of the secondary reheating coagulated steam unit and the replenished desalted water of the backpressure unit pass through the shared reheating system and then are divided into two paths; one path enters the secondary reheating coagulated steam unit; and the other path enters the backpressure unit. The united thermodynamic system provided by the invention can meet the industrial requirements of large capacity and high parameter heat supply; the thermodynamic cycle efficiency is greatly increased; the fuel consumption is reduced; the pollutant emission is reduced; and meanwhile, the investment of the thermal power plant is greatly reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

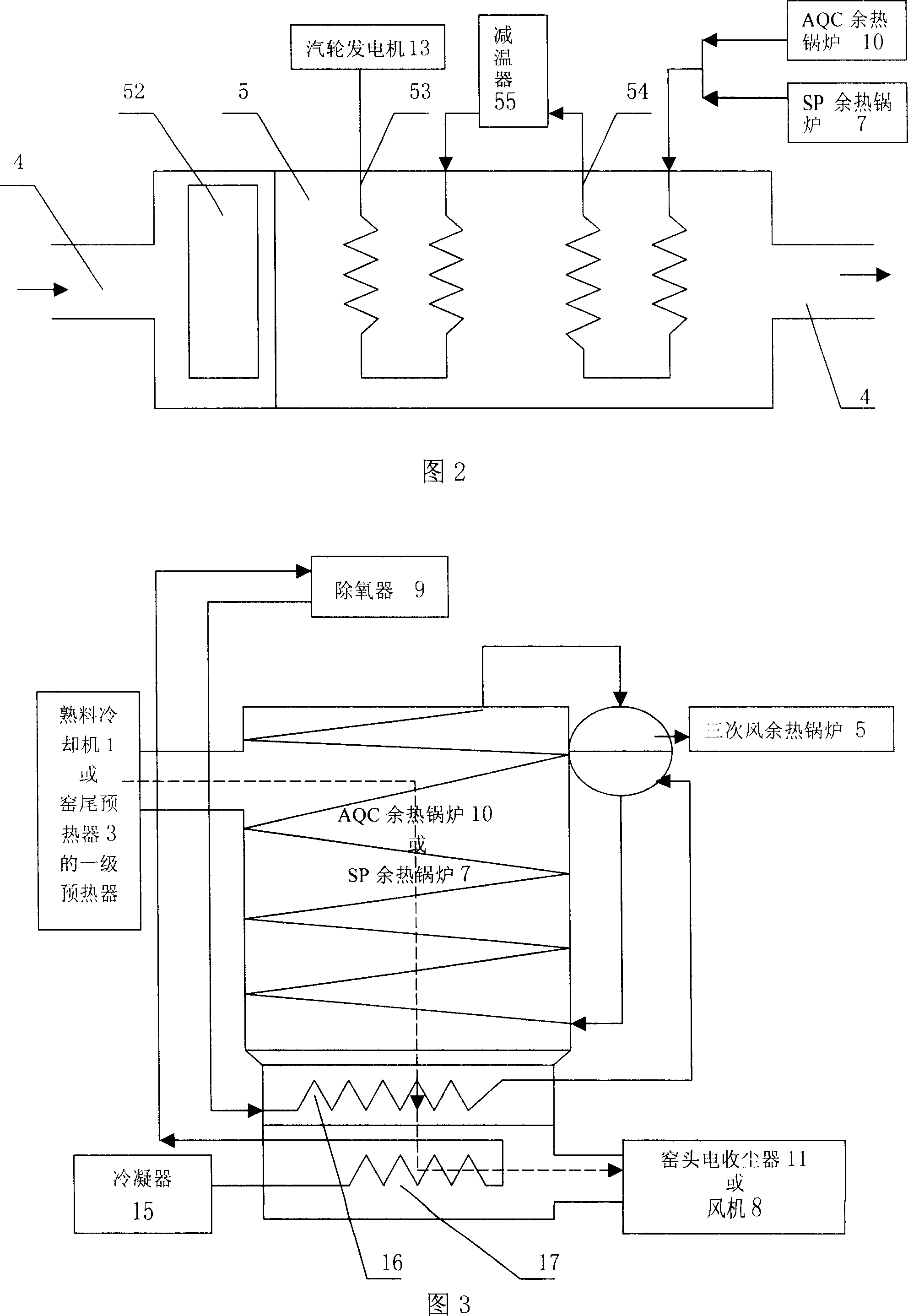

Pure medium-low temperature waste heat generating system in cement kiln

InactiveCN101793467AIncrease temperatureIncrease enthalpyFeed water supplyIncreasing energy efficiencySuperheaterDeaerator

The invention relates to a pure medium-low temperature waste heat generating system in a cement kiln. The invention is characterized in that an AQC boiler is arranged at the kiln head to generate low-temperature low-pressure steam; an SP boiler is arranged at the kiln tail to generate low-temperature low-pressure steam; the low-temperature low-pressure steam generated by the two waste heat boilers are mixed by a steam distributor and then goes into a common high-temperature superheater arranged in the front end of a grate cooler at the kiln head, the low-temperature low-pressure steam generated by the AQC boiler and the SP boiler is superheated into high-temperature high-pressure steam and then goes into a condensing steam turbine, the dead steam after the action of the steam turbine goes into a condenser, condensation water goes into a vacuum deaerator through a condensation water pump and a pipeline to deoxidize, and the deoxidized water goes into the AQC boiler and the SP boiler through a boiler feed pump. By reasonably using the waste steam temperature in the cement kiln and carrying out the cascading use of the waste steam heat based on the temperature, the invention reduces or avoids the entropy phenomena, and enables the temperature of the superheated steam at the inlet of the steam turbine to be raised, thereby realizing the pure medium-low temperature waste heat generating system in the cement kiln, of which the generating capacity is improved.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

Dual-machine regenerative steam extraction steam thermodynamic system

ActiveCN102720550AReduce the temperatureImprove efficiencySteam useEnergy industryEngineeringIntermediate stage

The invention provides a dual-machine regenerative steam extraction steam thermodynamic system. In the system, the intermediate stage of a high pressure cylinder of a main steam turbine is provided with a high pressure steam extraction opening, the high pressure steam extraction opening is respectively connected with a steam inlet of a small steam turbine and one high pressure heater with the highest steam inlet parameter in a plurality of high pressure heaters through high pressure steam extraction pipelines, the intermediate stage of the small steam turbine is provided with a plurality of regenerative steam extraction openings which are connected with the rest high pressure heaters except the high pressure heater with the highest steam inlet parameter through regenerative steam extraction pipelines, and a steam exhaust port of the small steam turbine is connected with a deaerator through a steam exhaust pipeline of the small steam turbine. According to the system disclosed by the invention, a high-temperature preposed steam cooler can be omitted, and the feed-water temperature of a boiler is reduced, which helps to improve the efficiency of the boiler and reduce the heat consumption of a machine set; and flow loss can be effectively reduced, the circulation efficiency is improved, and the cost of equipment is reduced.

Owner:SHANGHAI TURBINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com