Patents

Literature

141 results about "Regenerative cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of regenerative cycle. : a cycle in a steam engine using heat that would ordinarily be lost: such as. a : a multiple-expansion steam-engine cycle in which the receivers are used as successive feed-water heaters.

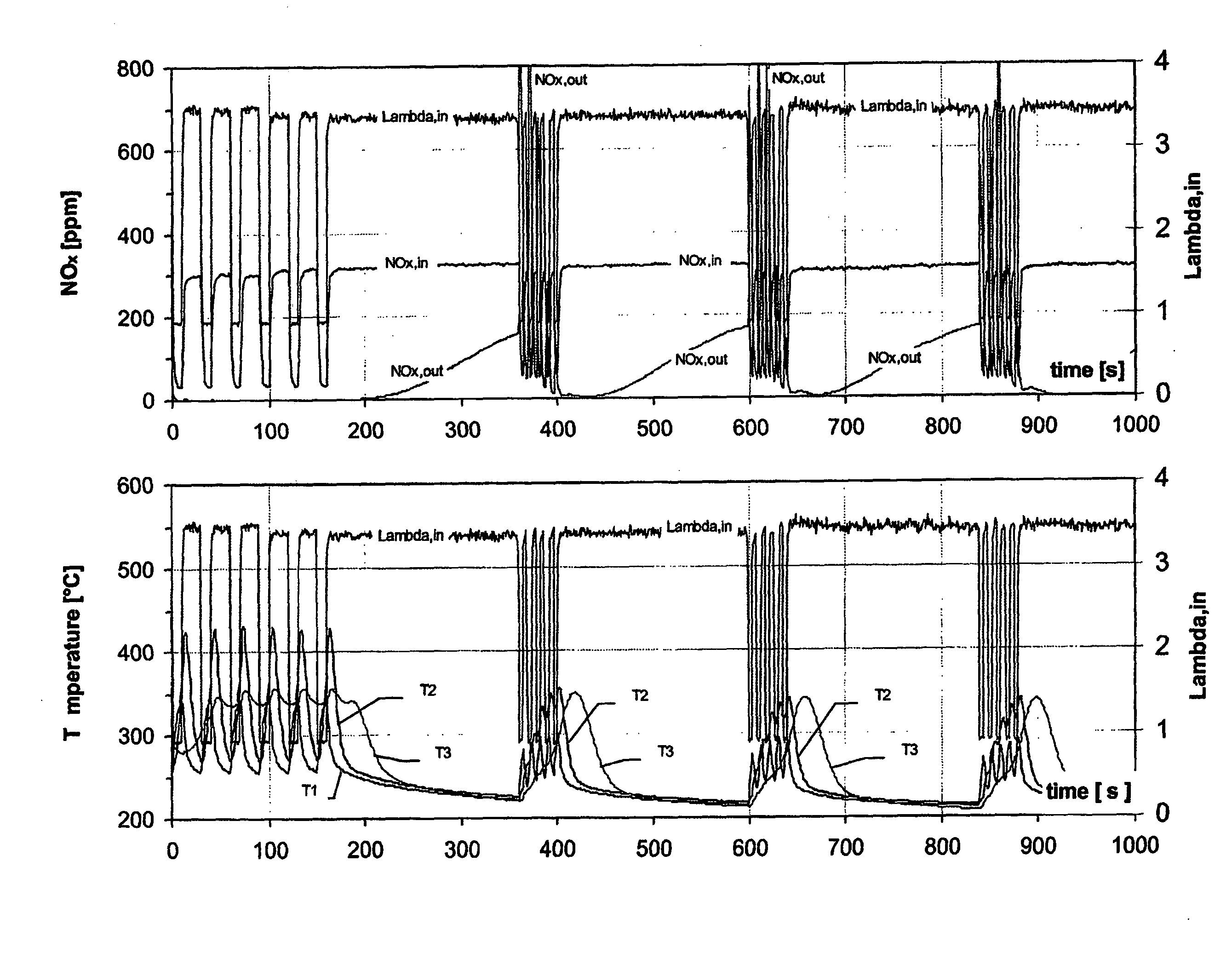

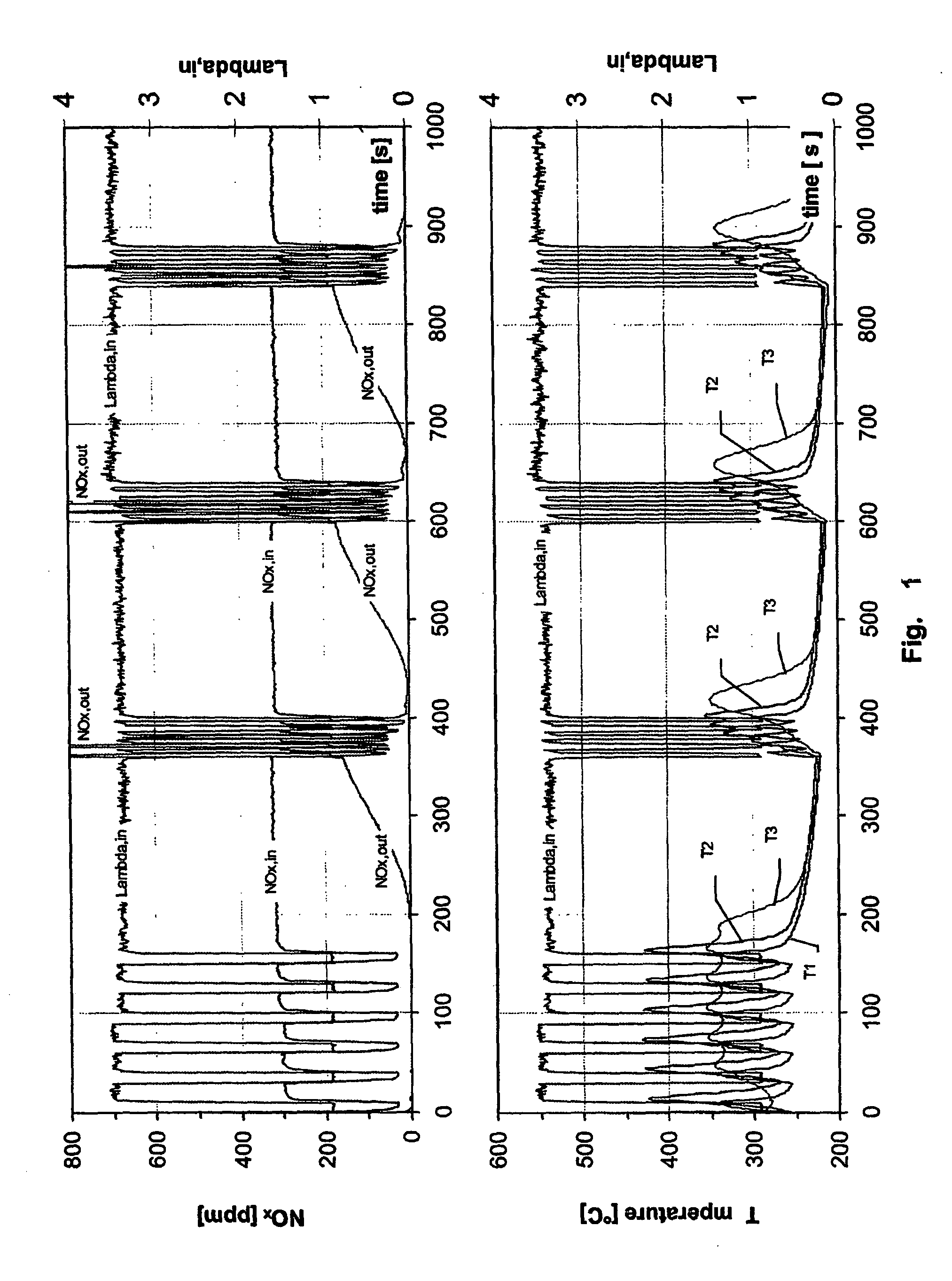

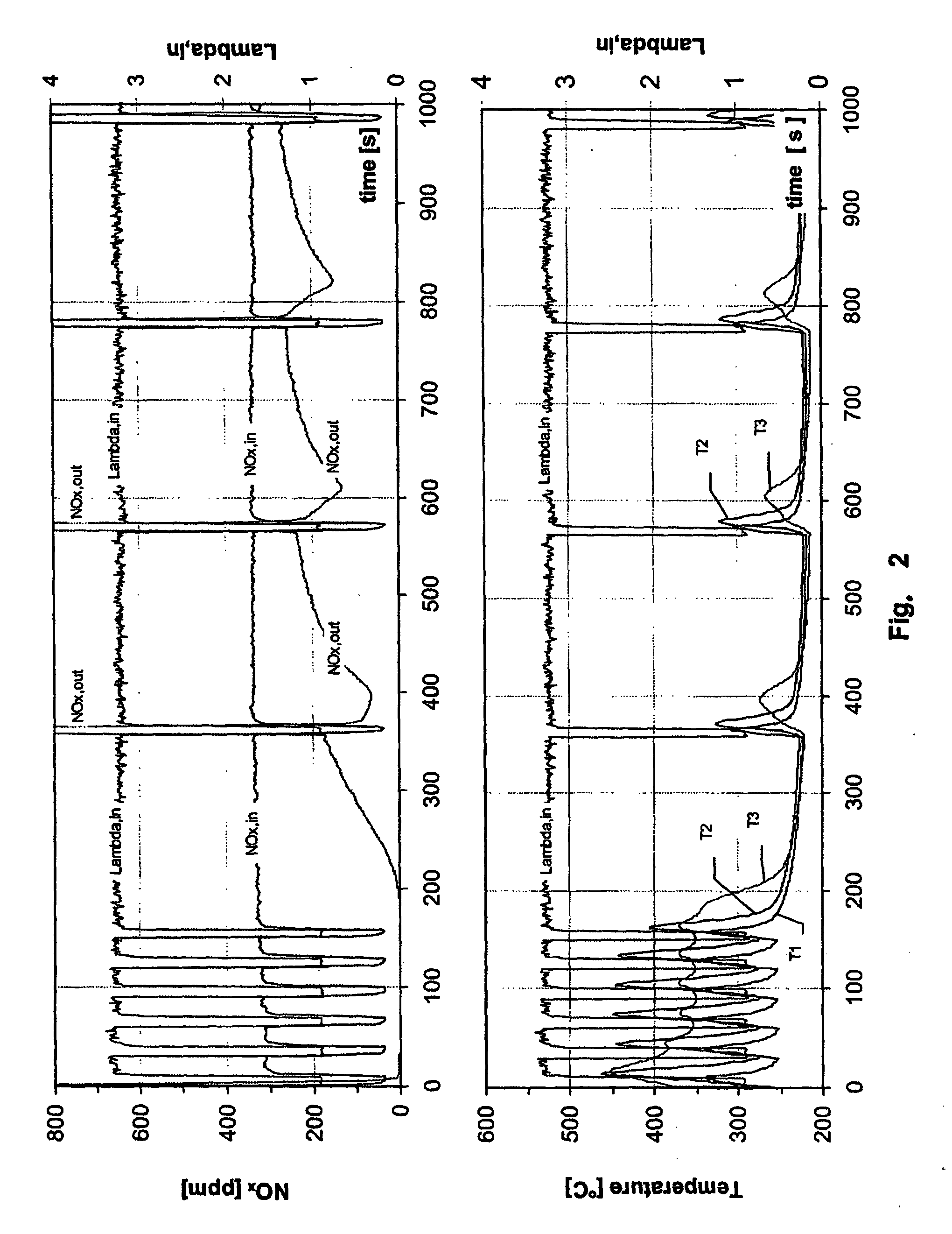

Process for regenerating a nitrogen oxides storage catalyst

InactiveUS20040055285A1Electrical controlInternal combustion piston enginesNitrogen oxidesPtru catalyst

The present invention provides a process and a device for regeneration of a nitrogen oxide storage catalyst in the exhaust system of a diesel engine. The process comprises a first and a second regeneration strategy. The first regeneration strategy is applied when the exhaust gas temperature is above a threshold value and comprises changing the air / fuel-ratio from a lean to a rich value during a first regeneration period. The second regeneration strategy is applied when the exhaust gas temperature is below a threshold value and comprises switching the air / fuel-ratio back and forth between lean and rich air / fuel-ratios, forming a sequence of between 2 and 10 rich pulses and between 2 and 10 lean pulses during a second regeneration period.

Owner:OMG AG & CO KG

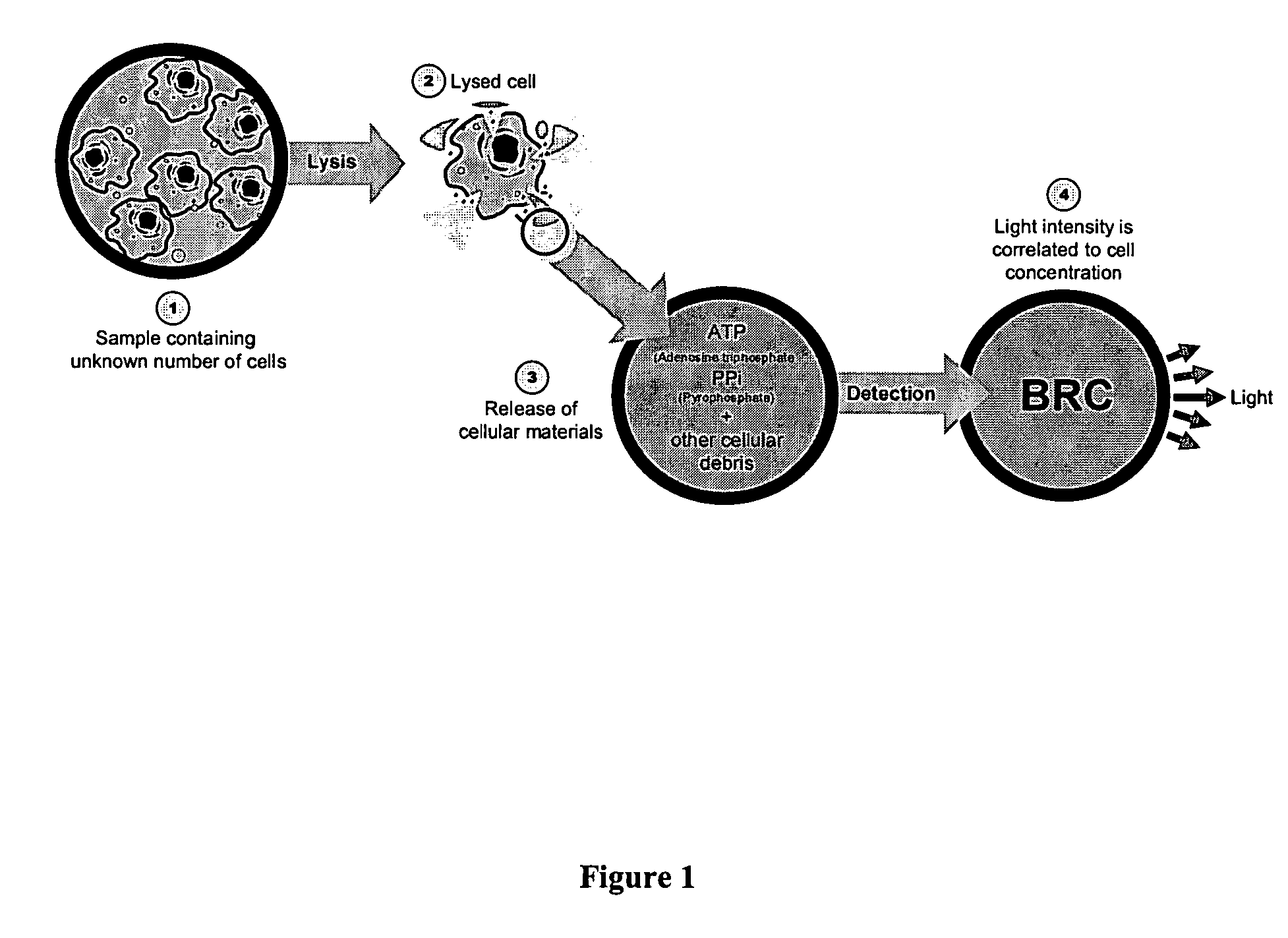

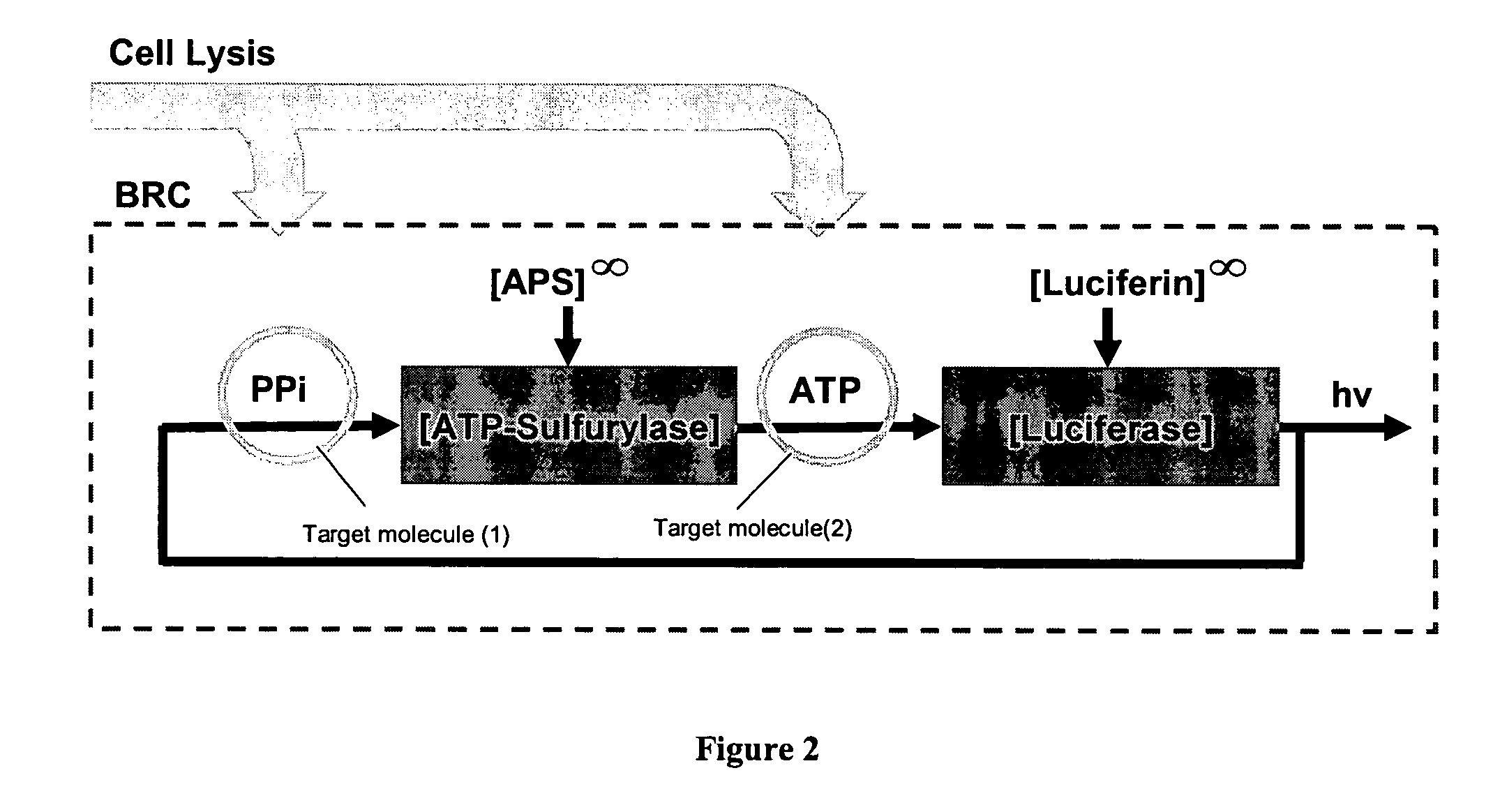

Methods for cellular or microorganism capture and quantification using bioluminescence regenerative cycle (BRC) assays

InactiveUS20050112601A1High detection sensitivityLong integration timeBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismAssay

The methods, apparatus and compositions disclosed herein concern the detection, identification and / or quantification of target cells and / or microorganisms in samples. The assays are based on light emission detected from a bioluminescence regenerative cycle (BRC). Light emission may be related to cell and / or microorganism number through the number of ATP and PPi molecules per cell or microorganism. In certain embodiments of the invention, specific target cells and / or microorganisms may be separated from samples using one or more capture molecules, such as antibodies. The cells and / or microorganisms may be lysed, the contents purified in whole or in part and the ATP and PPi contents determined by BRC. Other embodiments of the invention concern apparatus comprising a series of chambers connected by a monodirectional flow channel, each chamber comprising an affinity matrix with one or more binding moieties attached. In certain embodiments, a multiplex assay may be performed using both antibodies and oligonucleotide probes specific for a pathogen of interest.

Owner:XAGROS TECH

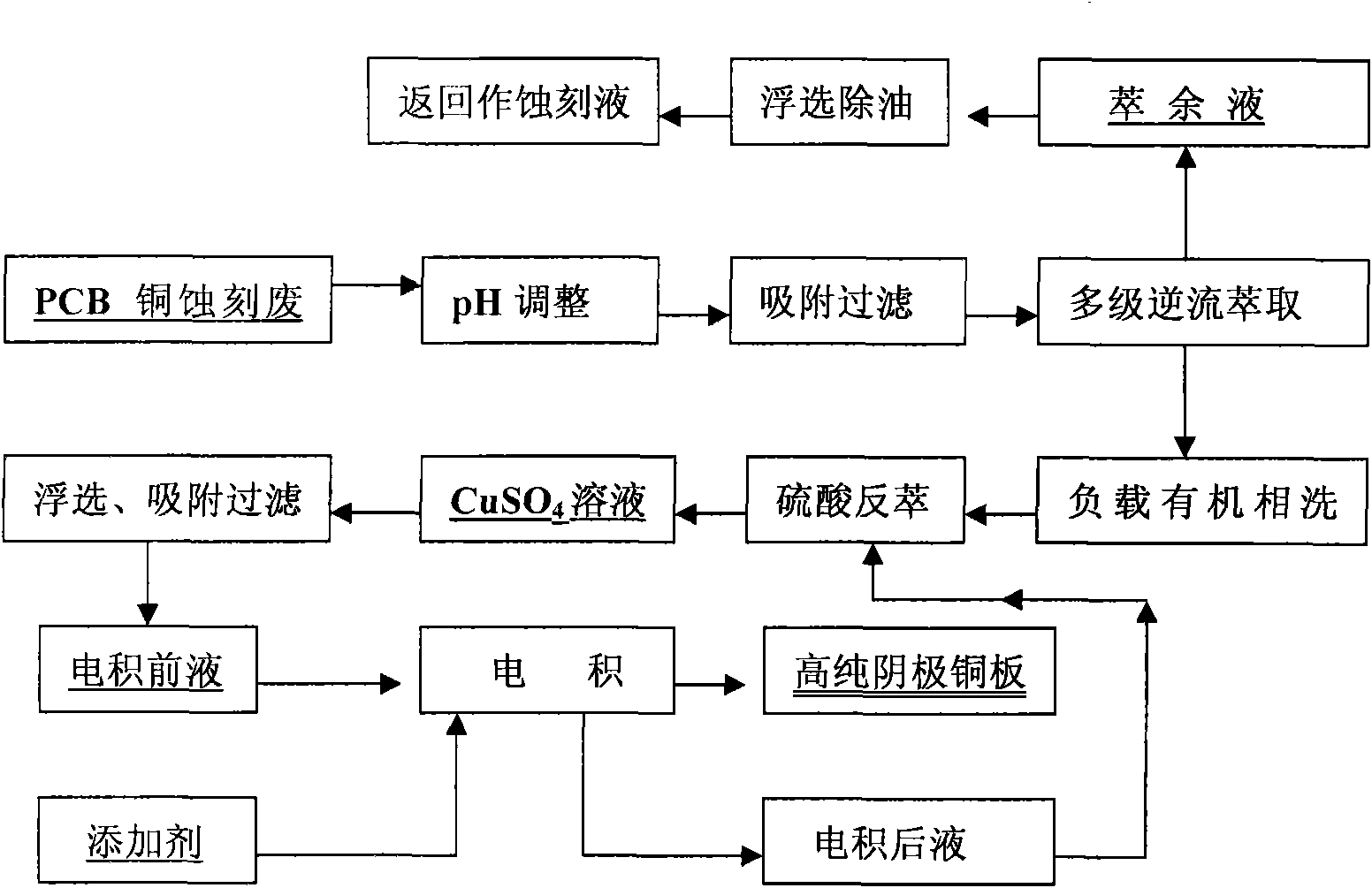

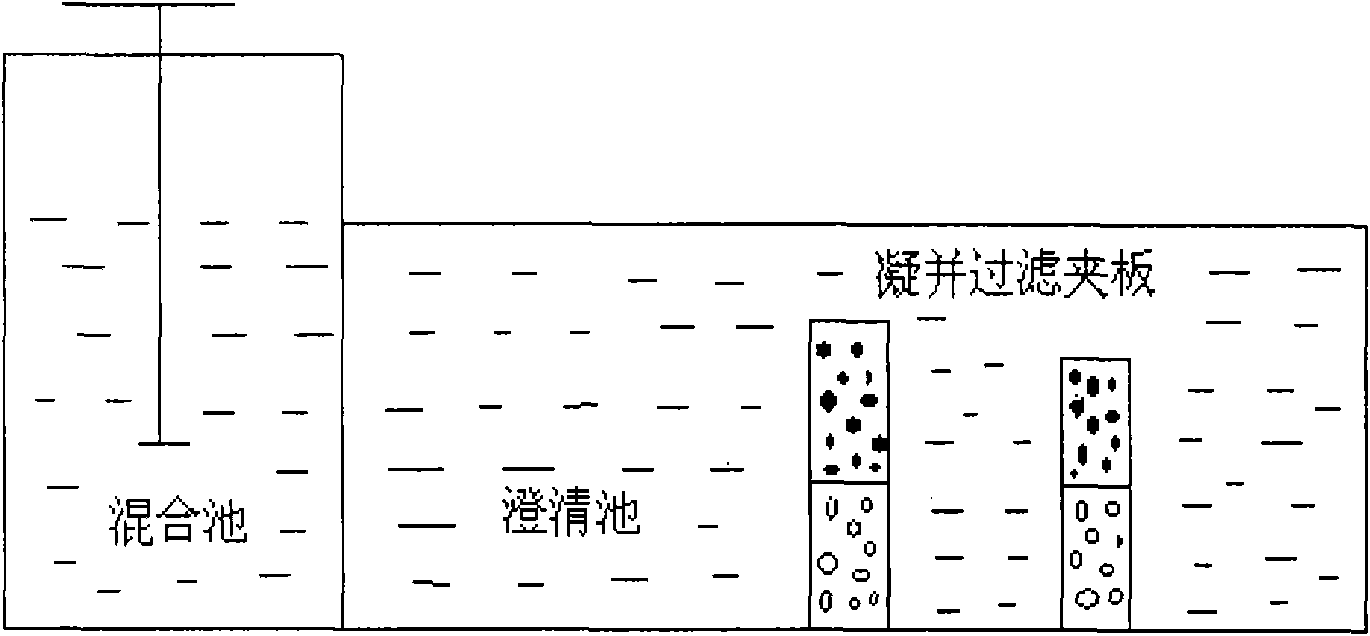

Method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage

InactiveCN101550488AHigh purityReduce entrainmentPhotography auxillary processesProcess efficiency improvementIonRegenerative cycle

The present invention disclose a method of preparing high pure cathode copper by using PCB acid chlorine copper etching solution sewage, the main technical characteristics include applying sewage preprocess procedure to satisfy extraction need better, programming multi-extraction to improve extraction recovery rate of cooper, applying extractant with high selectivity avoid extraction entrainment design, washing procedure etc. to reduce carried impurity and dispel affect of chloride ion to electrodeposition. The electrodeposition applies additive to improve copper crystallinity, simultaneity, utilize residual useful ingredient in raffinate to prepare copper etching solution, arriving the objective of both prepare high pure cathode copper effectively and regenerative cycle use of the etching solution. The purity of the prepared cathode copper reaches 99.99%.

Owner:CENT SOUTH UNIV +1

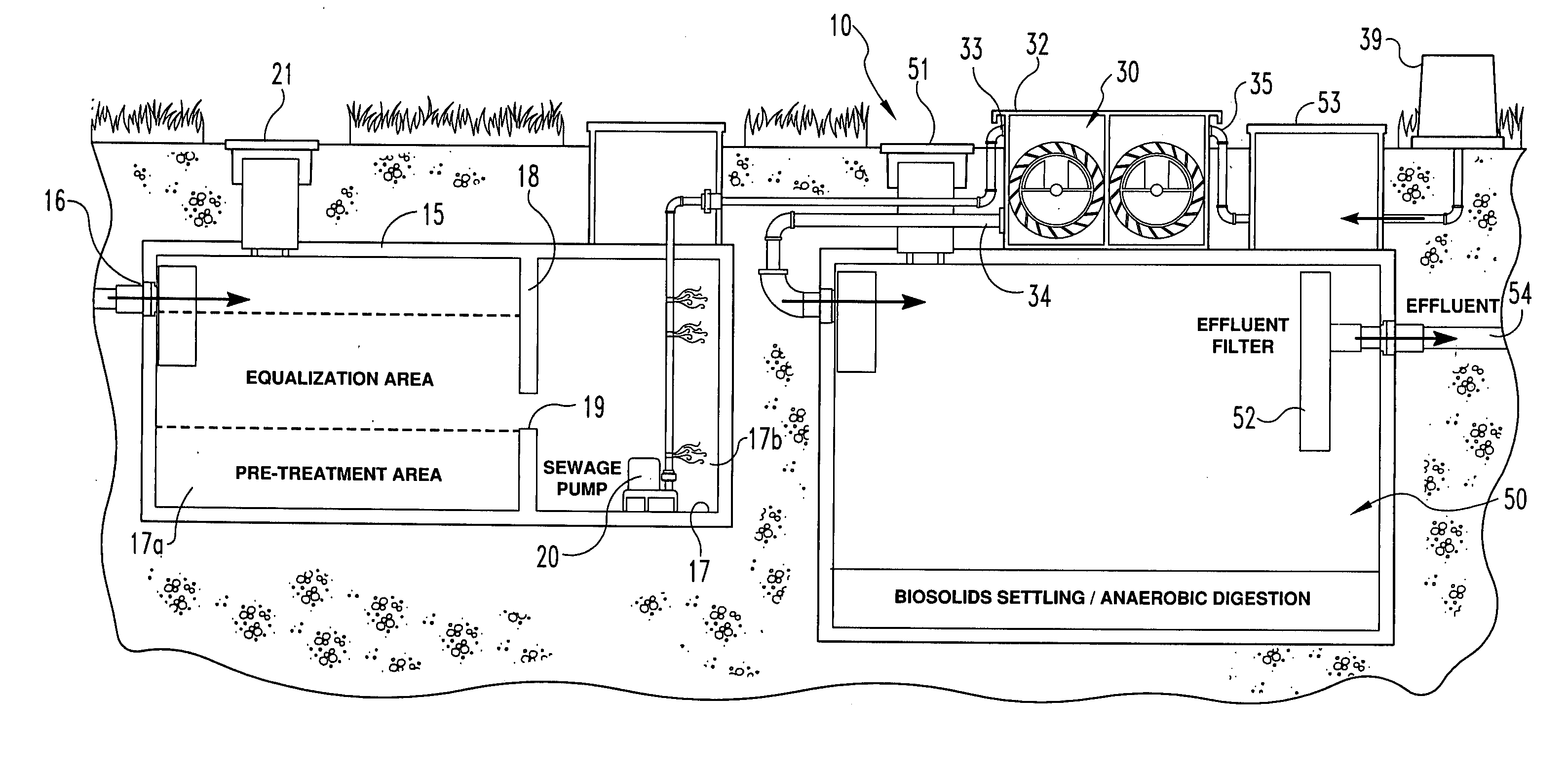

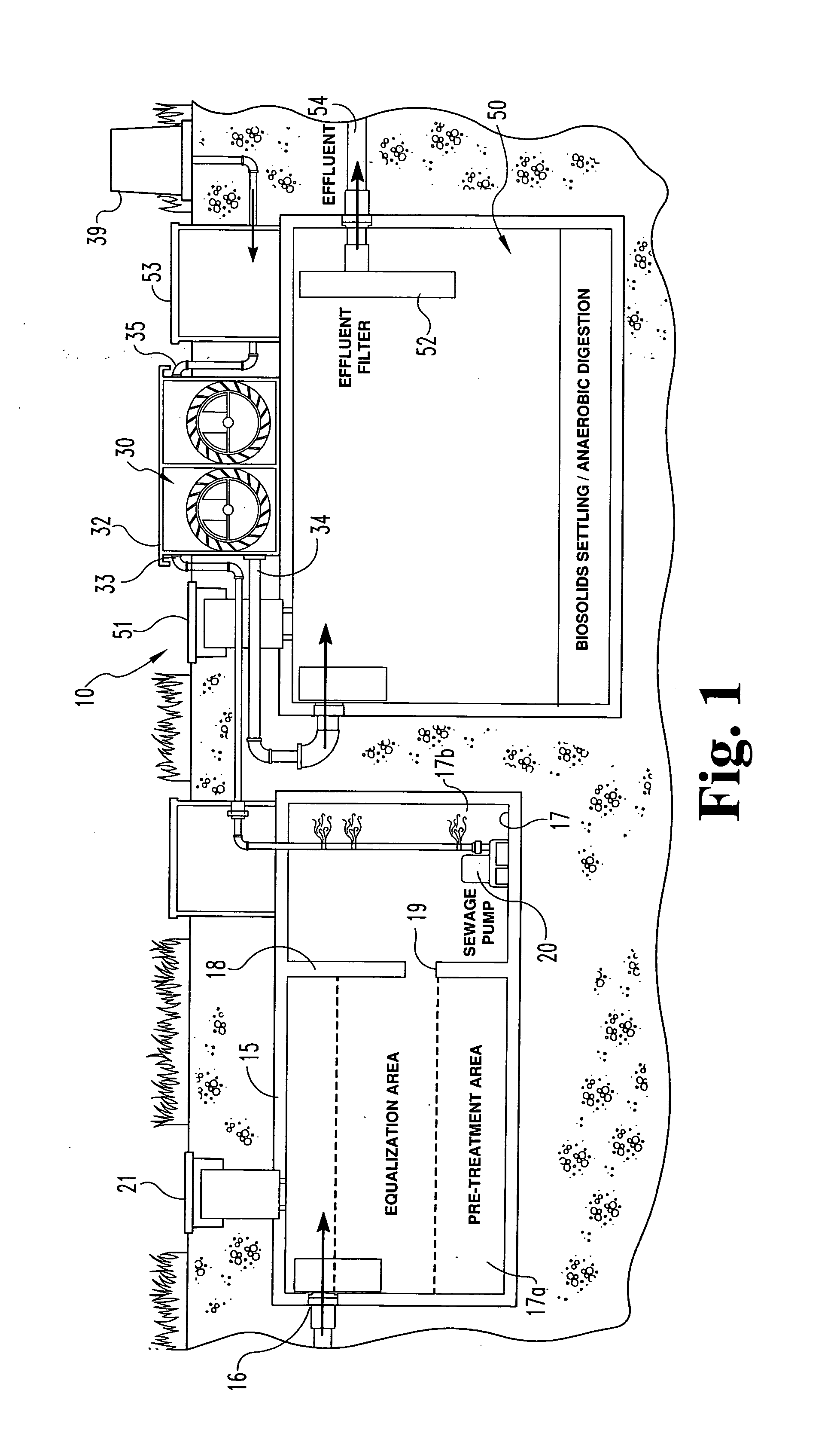

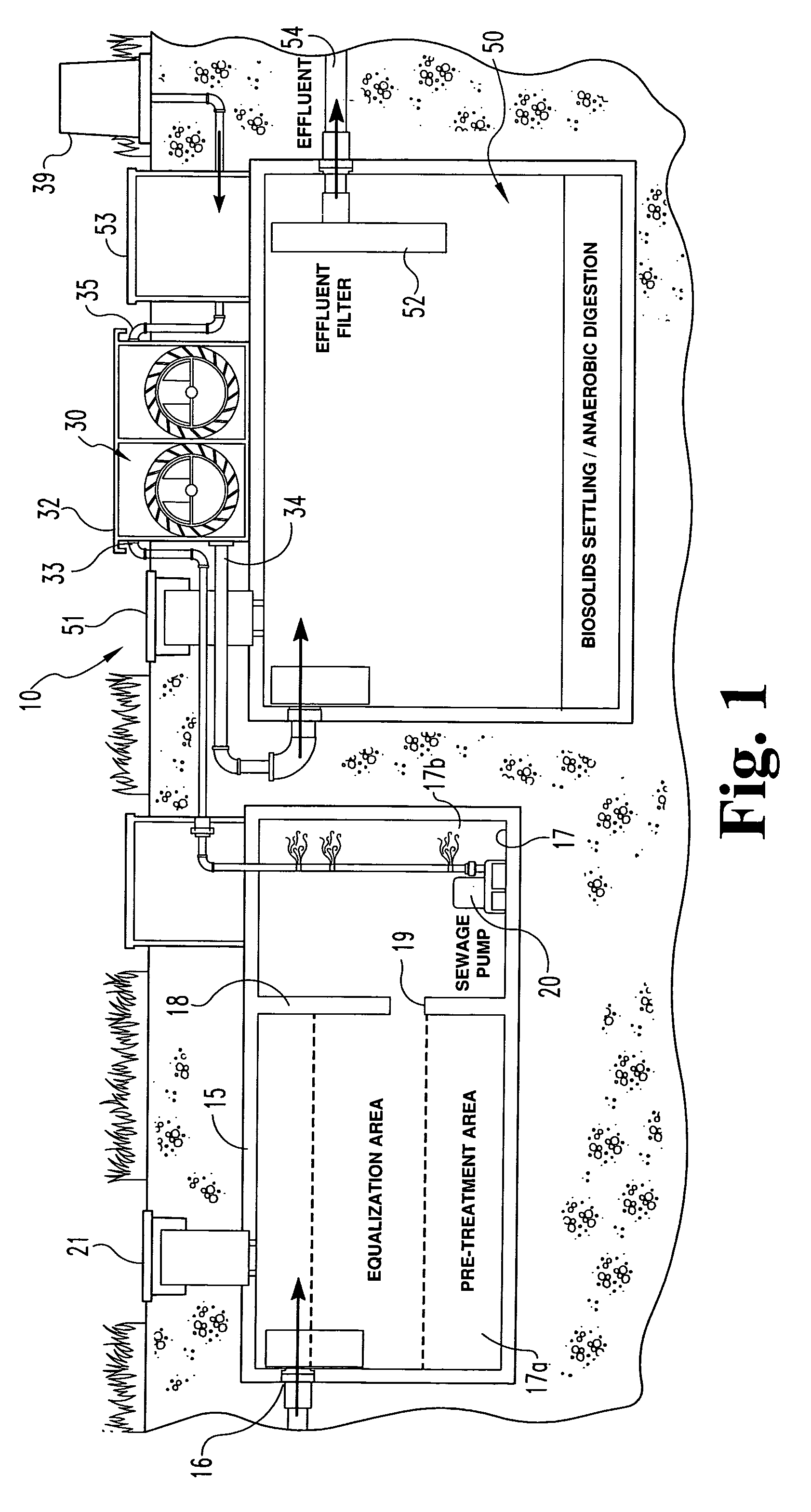

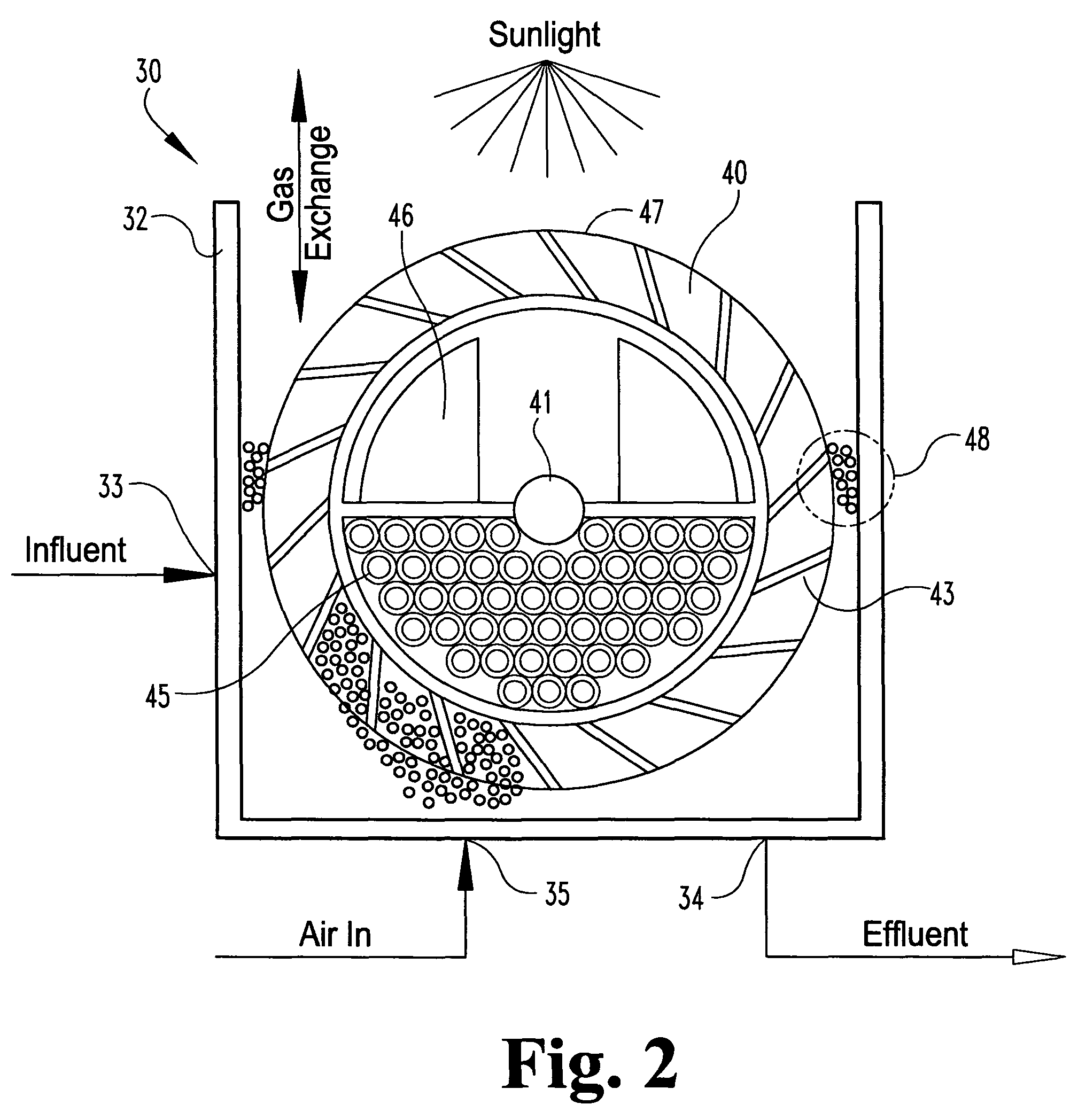

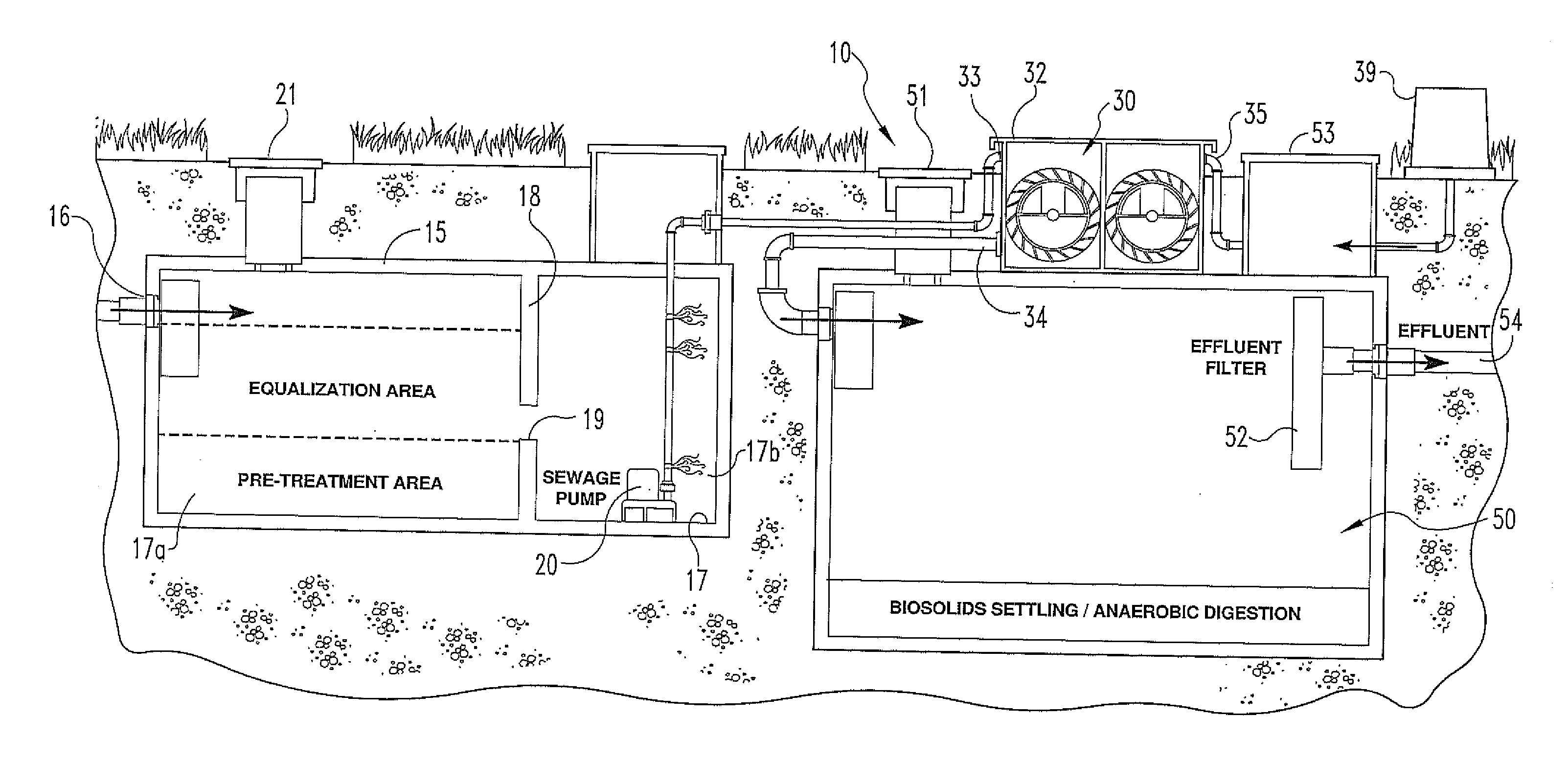

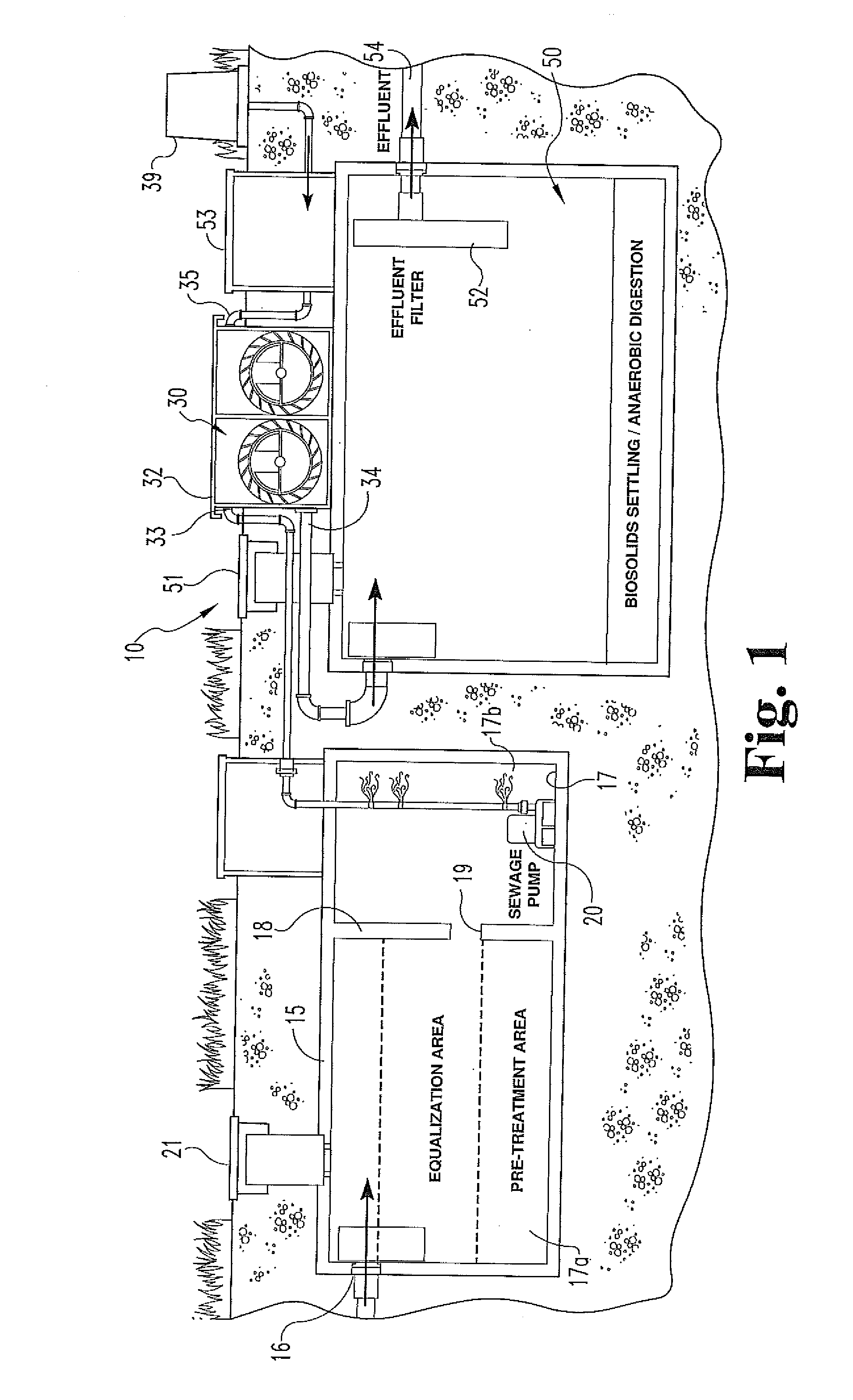

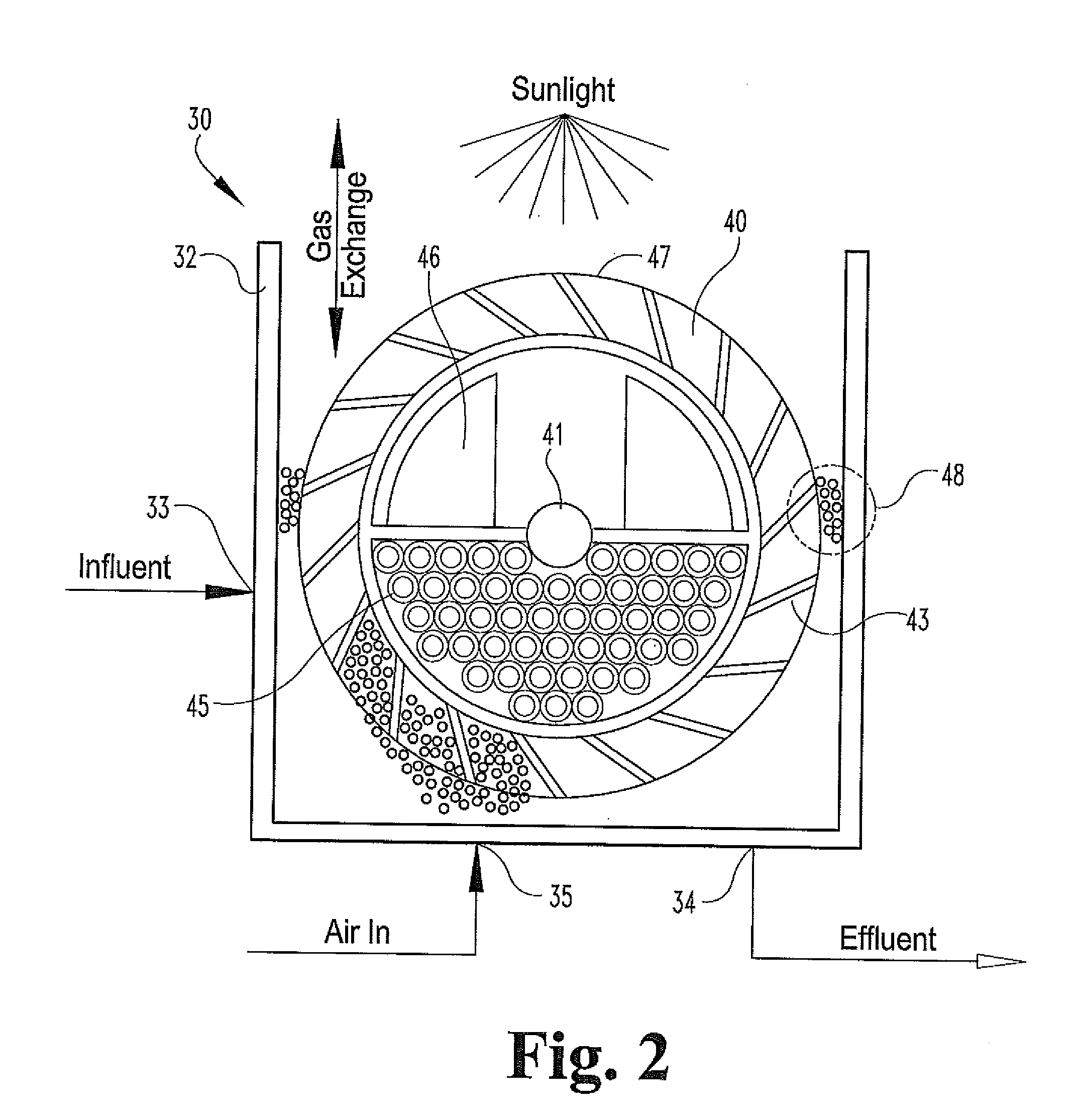

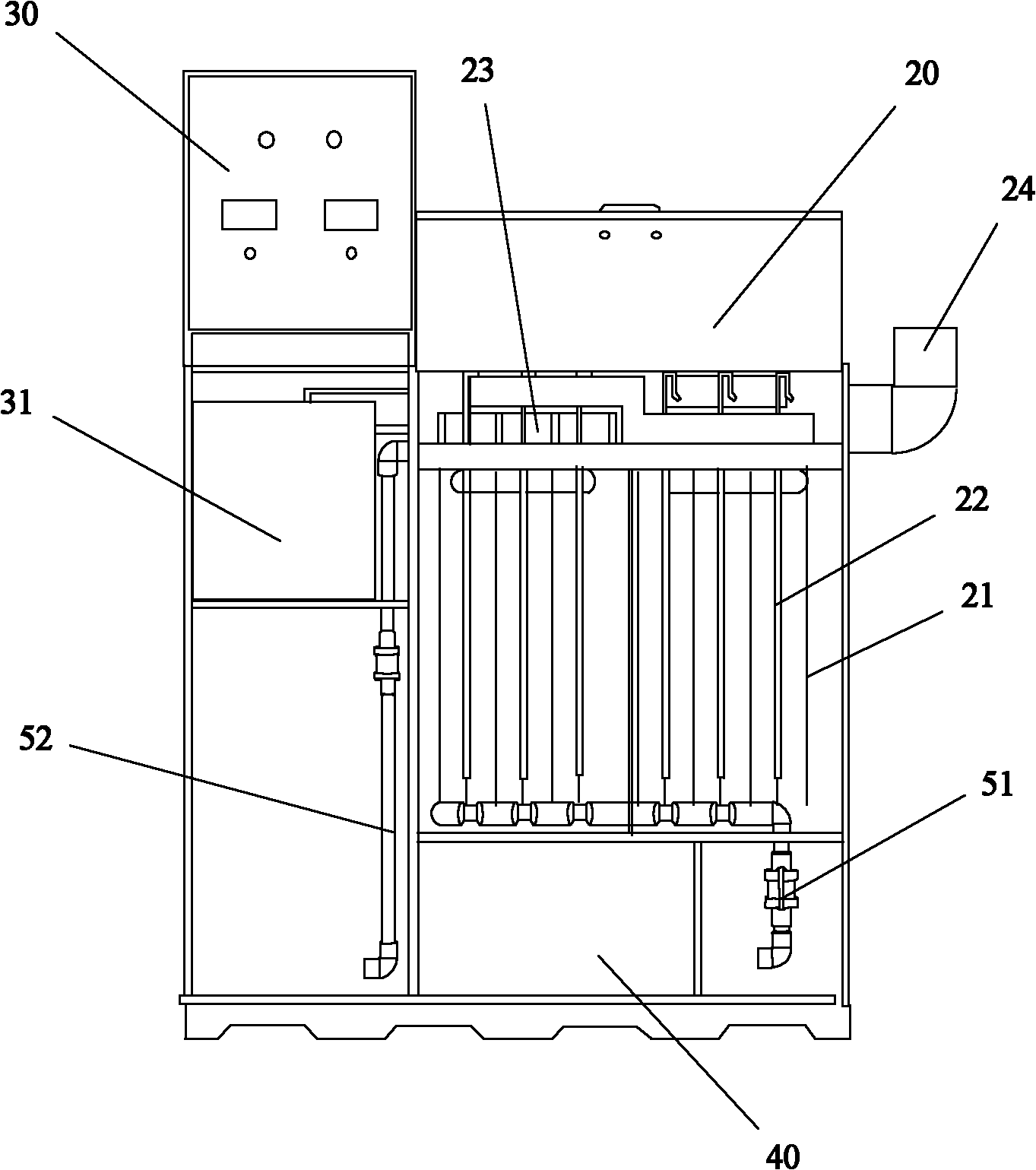

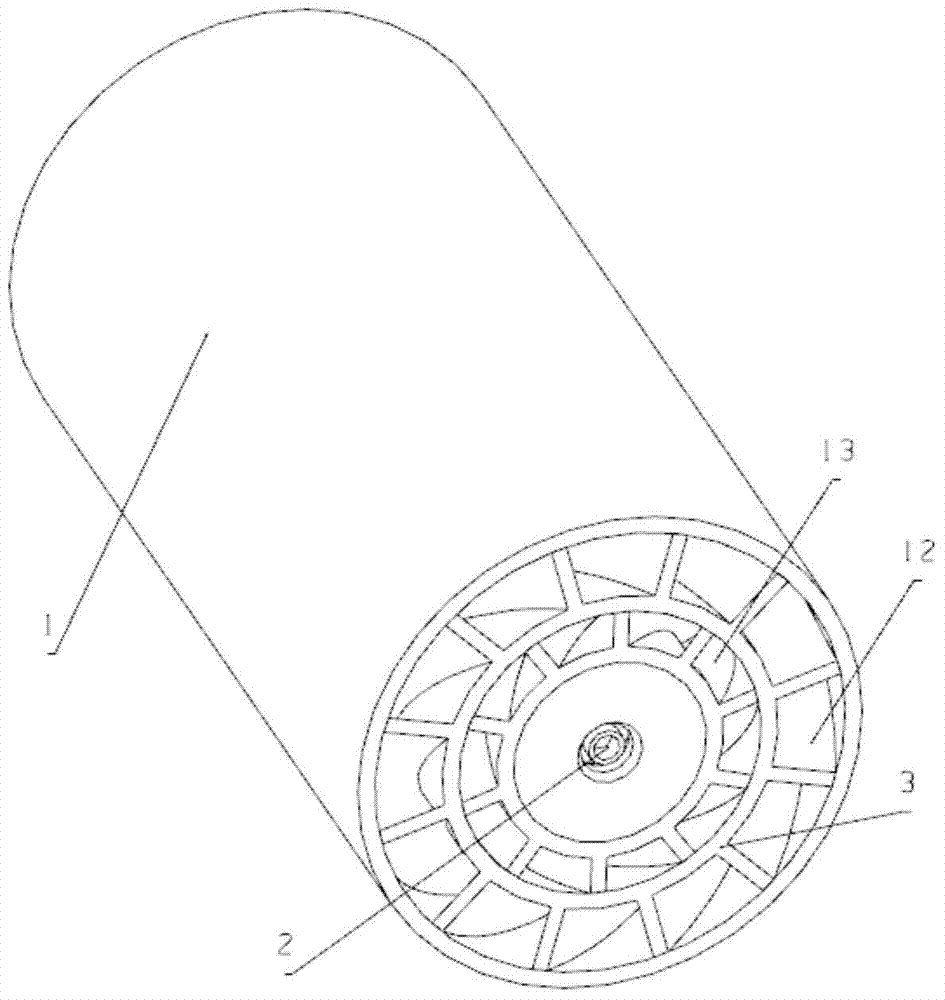

System and Method for Biological Wastewater Treatment and for Using the Byproduct Thereof

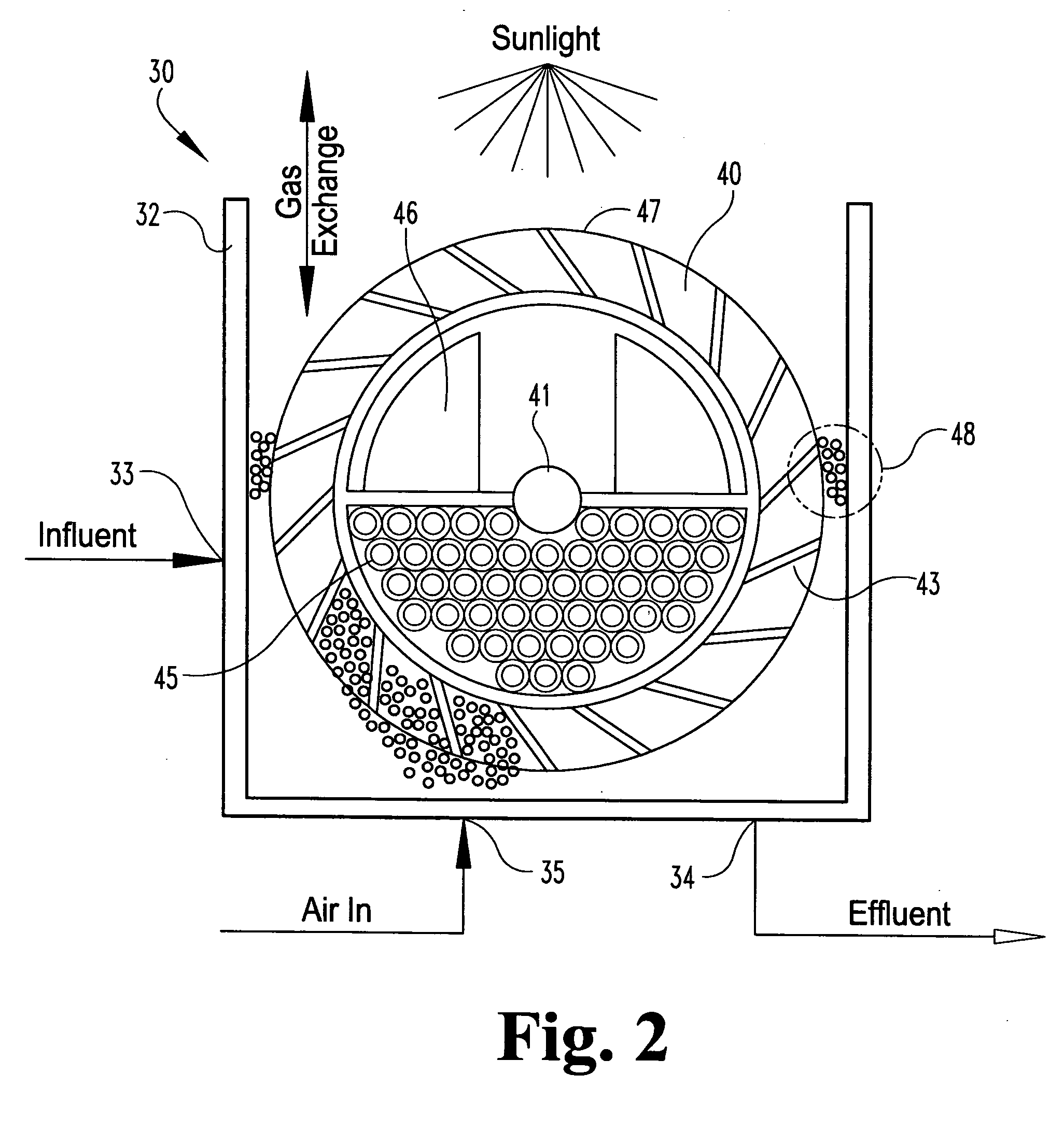

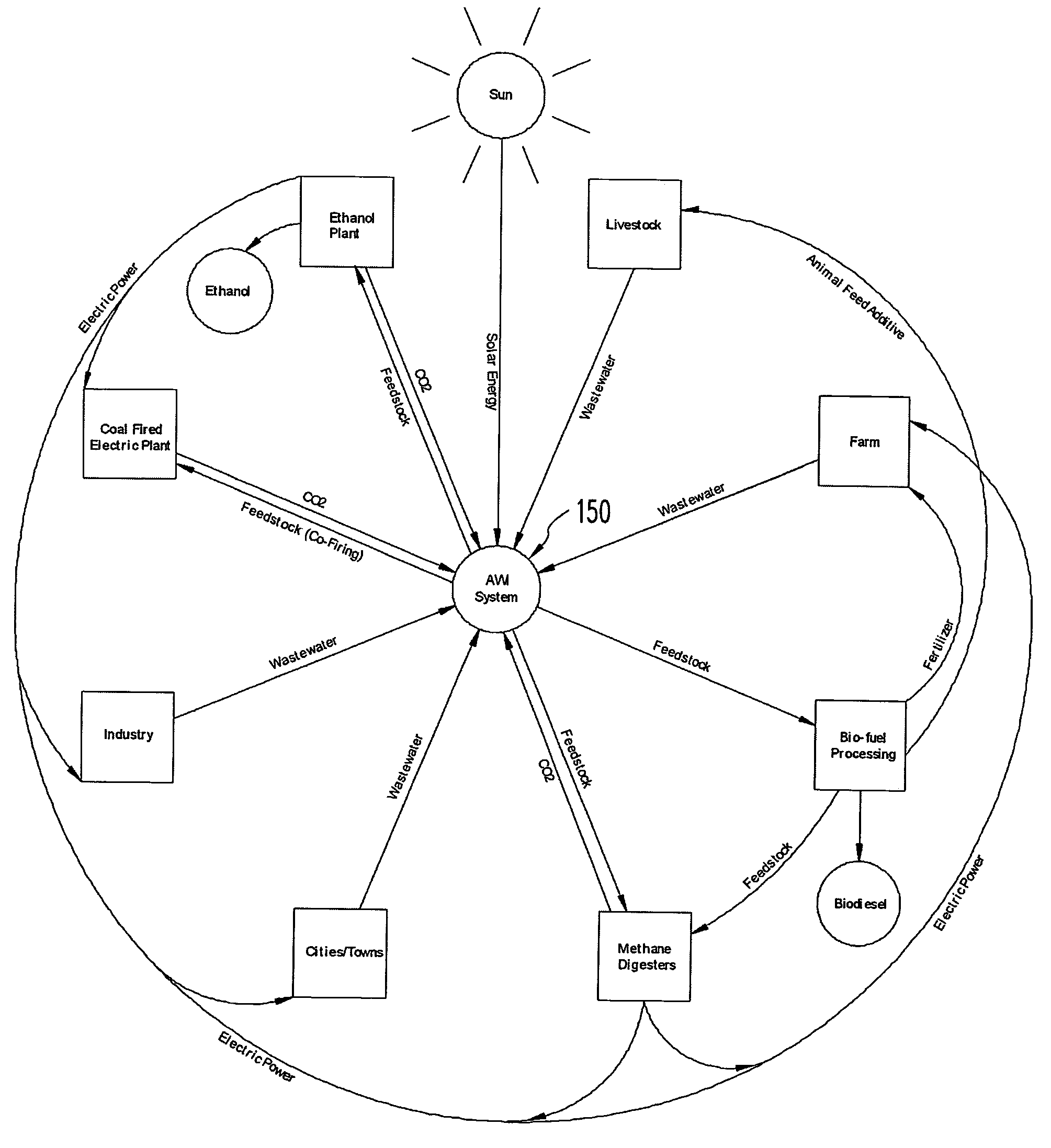

ActiveUS20080135475A1Facilitates growth of bacteriaImprove responseBioreactor/fermenter combinationsBio-organic fraction processingBiodieselAlgal growth

A wastewater treatment system and process biologically treats wastewater to produce substantially clean water effluent and byproducts. The treatment system includes an array of media wheels that rotate into and out of exposure to sunlight for sustained algae growth. One byproduct is algae removed from the rotating media wheels, which may be provided to other processing facilities to produce, for instance, bio-diesel fuel. Waste CO2 from the processing facility may also be returned to the treatment system for enhanced algae growth. Bacteria is provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. Large scale facilities may integrate the treatment systems in a regenerative cycle in which the biomass obtained from the algal colonies is used in a separate facility and byproducts of the operation of the separate facility are used by the treatment system to fuel further algal growth.

Owner:LIMCACO CHRISTOPHER A

System and method for biological wastewater treatment and for using the byproduct thereof

ActiveUS7736508B2Cost effectiveFree energyBioreactor/fermenter combinationsBio-organic fraction processingBiodieselToxic material

A wastewater treatment system and process biologically treats wastewater to produce substantially clean water effluent and byproducts. The treatment system includes an array of media wheels that rotate into and out of exposure to sunlight for sustained algae growth. One byproduct is algae removed from the rotating media wheels, which may be provided to other processing facilities to produce, for instance, bio-diesel fuel. Waste CO2 from the processing facility may also be returned to the treatment system for enhanced algae growth. Bacteria is provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. Large scale facilities may integrate the treatment systems in a regenerative cycle in which the biomass obtained from the algal colonies is used in a separate facility and byproducts of the operation of the separate facility are used by the treatment system to fuel further algal growth.

Owner:LIMCACO CHRISTOPHER A

Device and method for combined ejection refrigeration and vapor compression refrigeration cycle

InactiveCN101825372AImprove the cooling factorImprove energy savingRefrigeration machinesEngineeringRefrigeration

The invention relates to a device and a method for the combined ejection refrigeration and vapor compression refrigeration cycle, aiming at improving the running efficiency of the refrigeration system and solving the problems that the unit power and the unit condensation rate of the compressor increase and the air transmission rate and the refrigeration coefficient decrease due to the regenerative cycle adopted in the vapor compression refrigeration cycle to make the refrigerant have a certain supercooling degree. On the vapor compression refrigeration cycle side, the air exhaust opening of a compressor (2) is connected with the refrigerant inlet of a generator (5), the refrigerant inlet of the generator (5) is connected with the inlet of a first condenser (3), the outlet of the first condenser (3) is connected with the refrigerant inlet of a supercooler (6), the refrigerant outlet of the supercooler (6) is connected with the refrigerant inlet of an evaporator (1) through a throttle valve (4), and the outlet of the evaporator (1) is communicated with the air suction opening of the compressor (2). The ejection refrigeration cycle and the vapor compression refrigeration cycle are combined in the device, and two refrigeration systems are connected through one generator and one supercooler.

Owner:SOUTHEAST UNIV

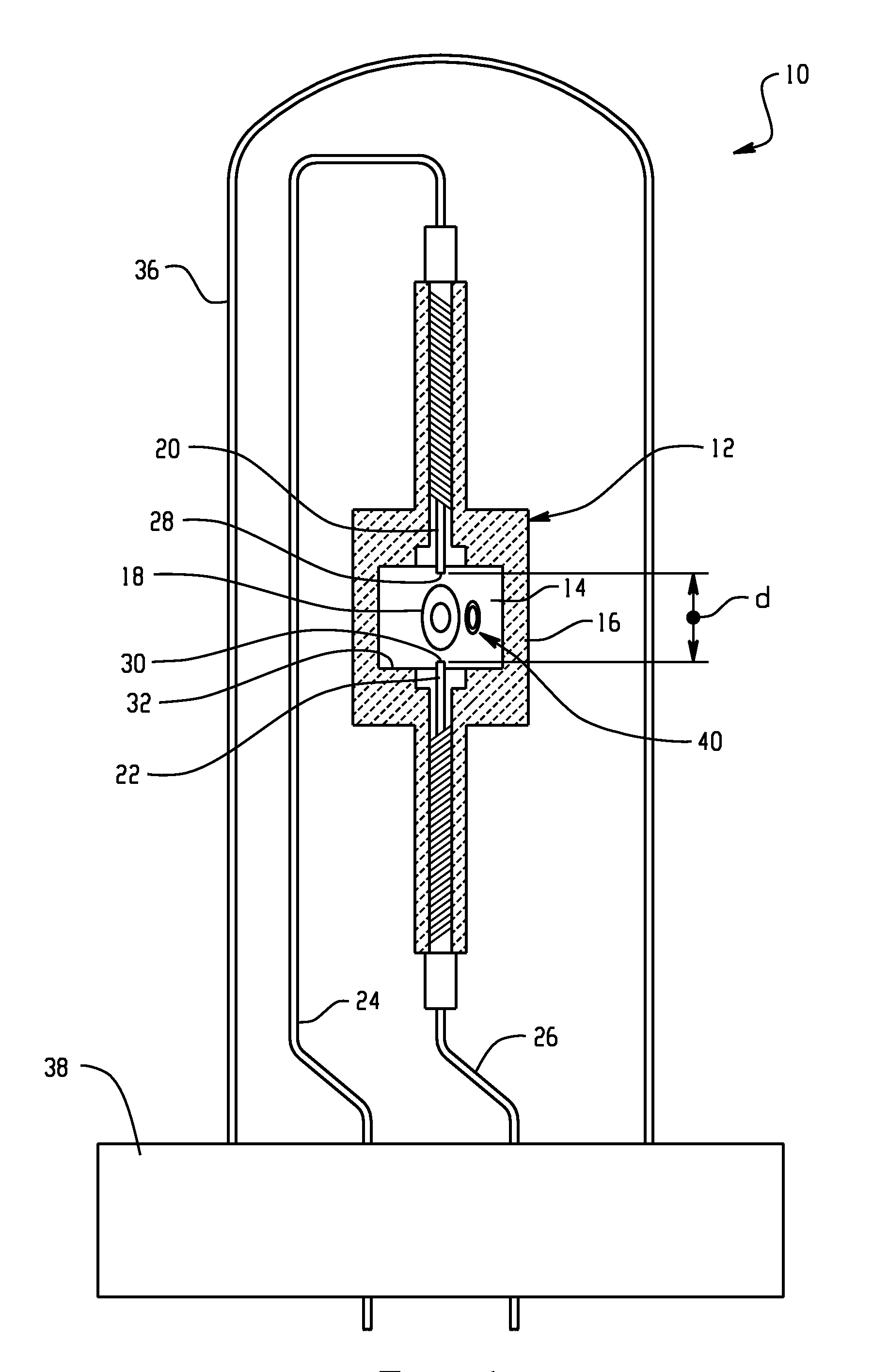

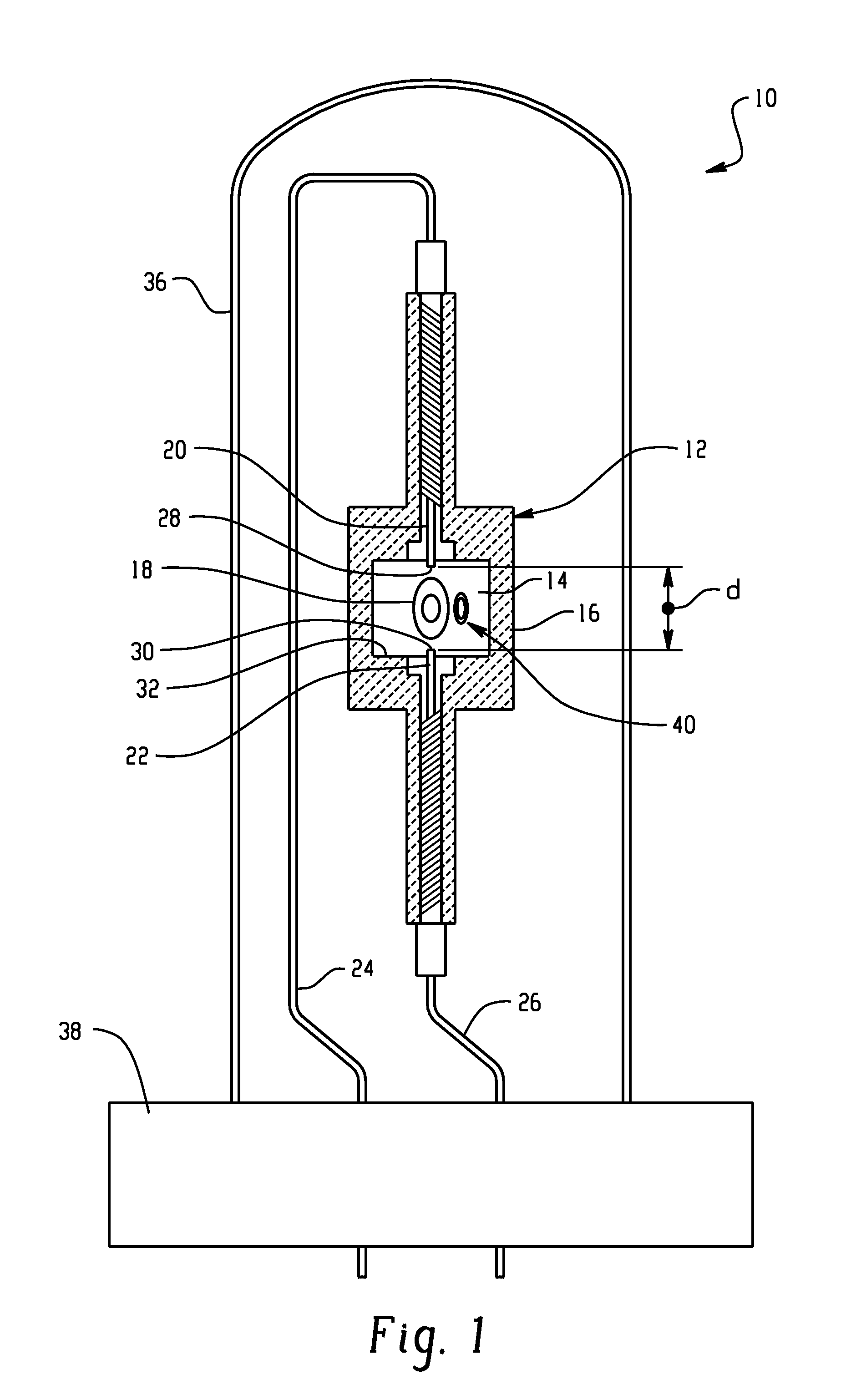

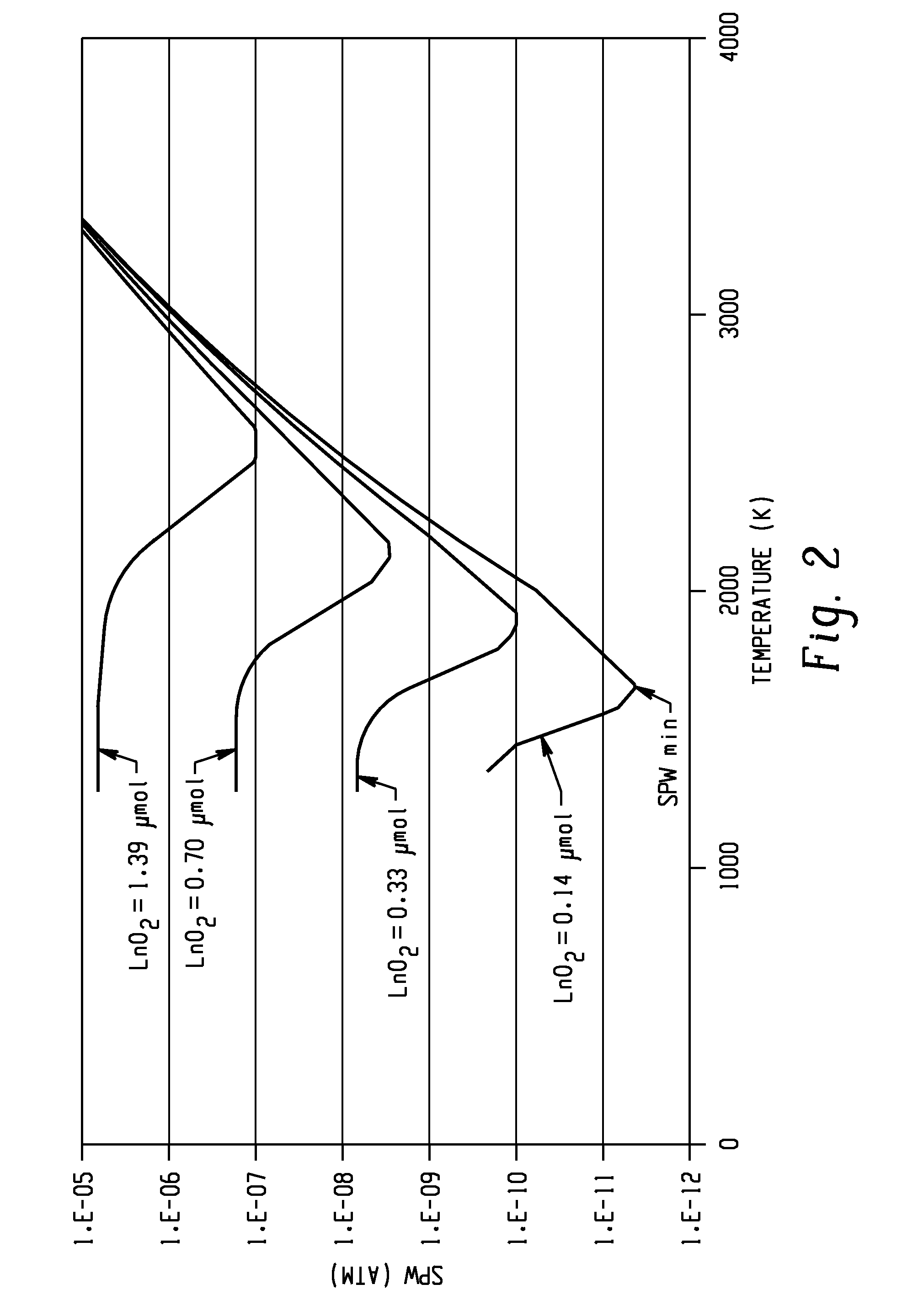

Lanthanide oxide as an oxygen dispenser in a metal halide lamp

InactiveUS20090146570A1Improve lumen maintenanceImprove performanceElectric lighting sourcesX-ray tube gas fillingMetal-halide lampRare earth

A lamp includes a discharge vessel. Tungsten electrodes extend into the discharge vessel. An ionizable fill is sealed within the vessel. The fill includes a buffer gas and a halide component that includes a rare earth halide. A source of oxygen which includes a lanthanide oxide is present in the discharge vessel. The source of oxygen provides oxygen for a regenerative cycle which reduces blackening of the lamp walls by tungsten from the electrodes.

Owner:GENERAL ELECTRIC CO

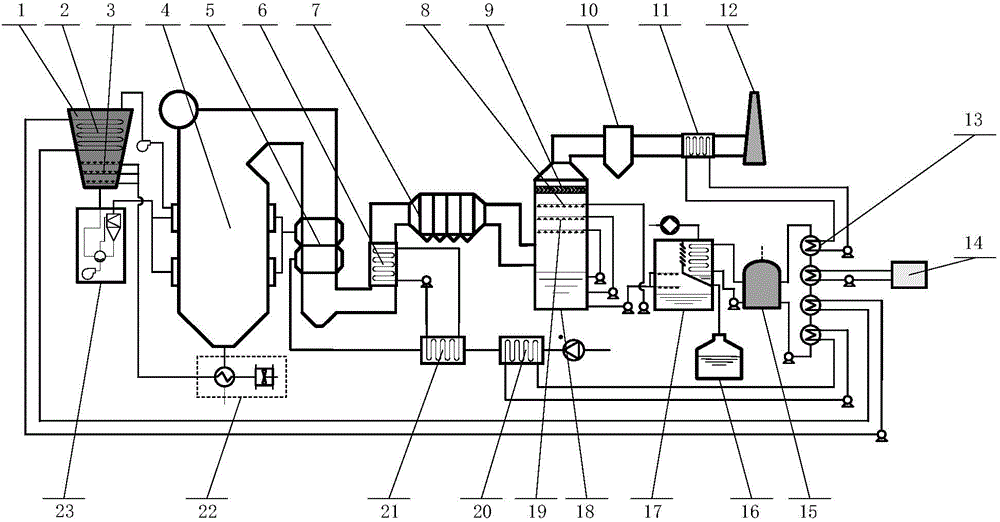

Coal-fired power plant flue gas heat regenerative system and energy-saving water-saving ultra-clean discharging method

ActiveCN104930539AImprove solubilityImprove desulfurization efficiencyIndirect carbon-dioxide mitigationLump/pulverulent fuel preparationSlurryWater vapor condensation

The invention discloses a coal-fired power plant flue gas heat regenerative system and an energy-saving water-saving ultra-clean discharging method. The temperature of the flue gas is reduced to about 90-110 DEG.C through a low-temperature coal economizer, and the recycled flue gas heat heats primary and secondary wind entering a boiler through a steam air heaters, so that the first stage of heat regenerative cycles is achieved. The temperature of the flue gas at the outlet of a desulfurization tower is reduced to 30-40 DEG.C through a vacuum flash evaporation and solidification device and a low-temperature heat pump heat exchange device, and a part of water vapor of the flue gas is condensed and collected, so that water is saved. The low-temperature heat pump heat exchange device absorbs the latent heat released in flue gas sensible heat and condensation processes, and dry as-fired coal and air are heated, so that the second stage of heat regenerative cycles is achieved. A boiler slag discharge system recycles the waste heat of heat slag, and the as-fired coal is heated, so that the third stage of heat regenerative cycles is achieved. When the waste heat is not used up, the remained waste heat can be utilized, so that energy is saved. Low-temperature desulphurization slurry led out from the vacuum flash evaporation and solidification device is injected into the desulfurization tower, so that the desulphurization efficiency is improved, and an ultra-clean discharging objective is achieved.

Owner:SHANDONG UNIV +2

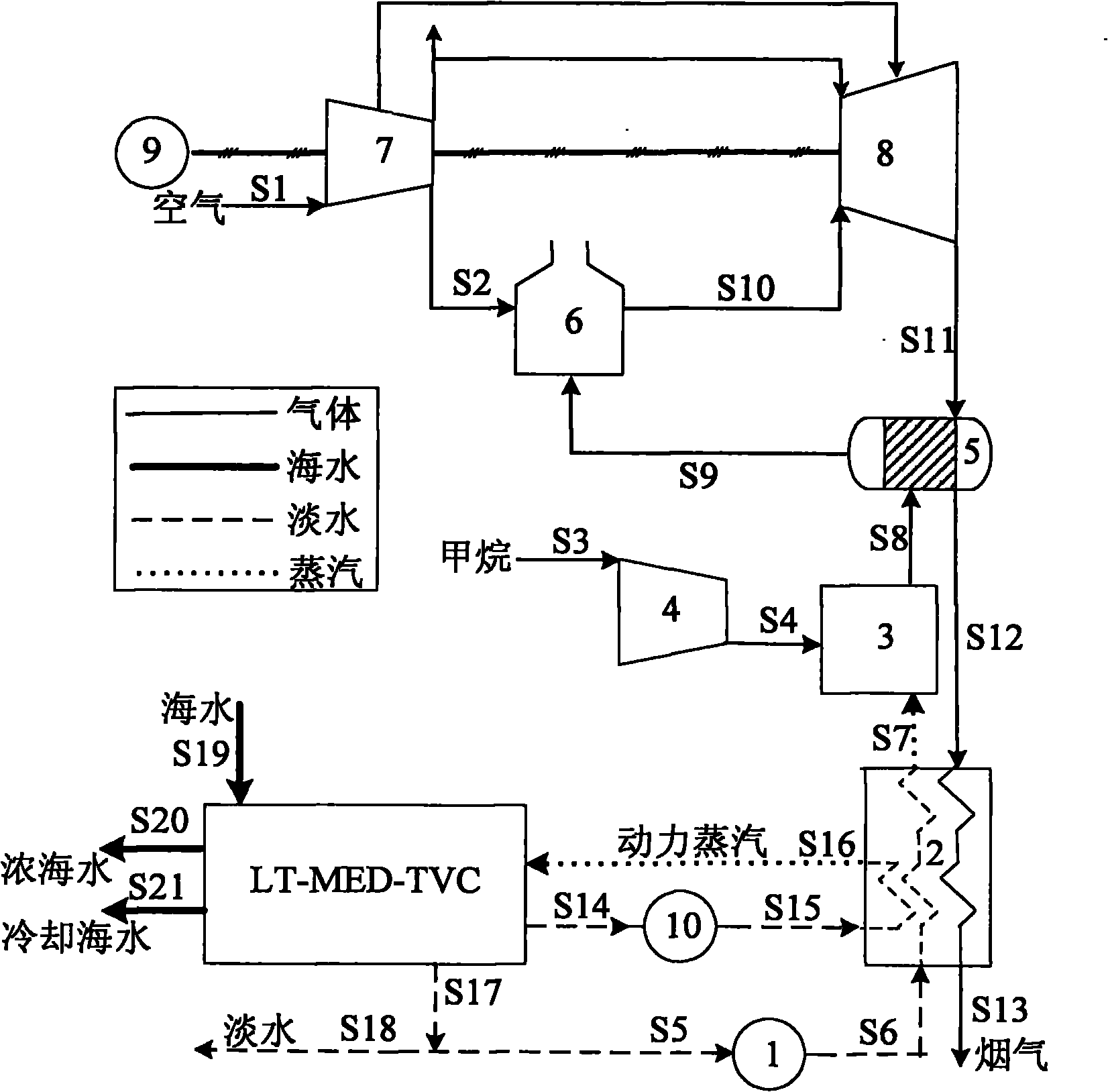

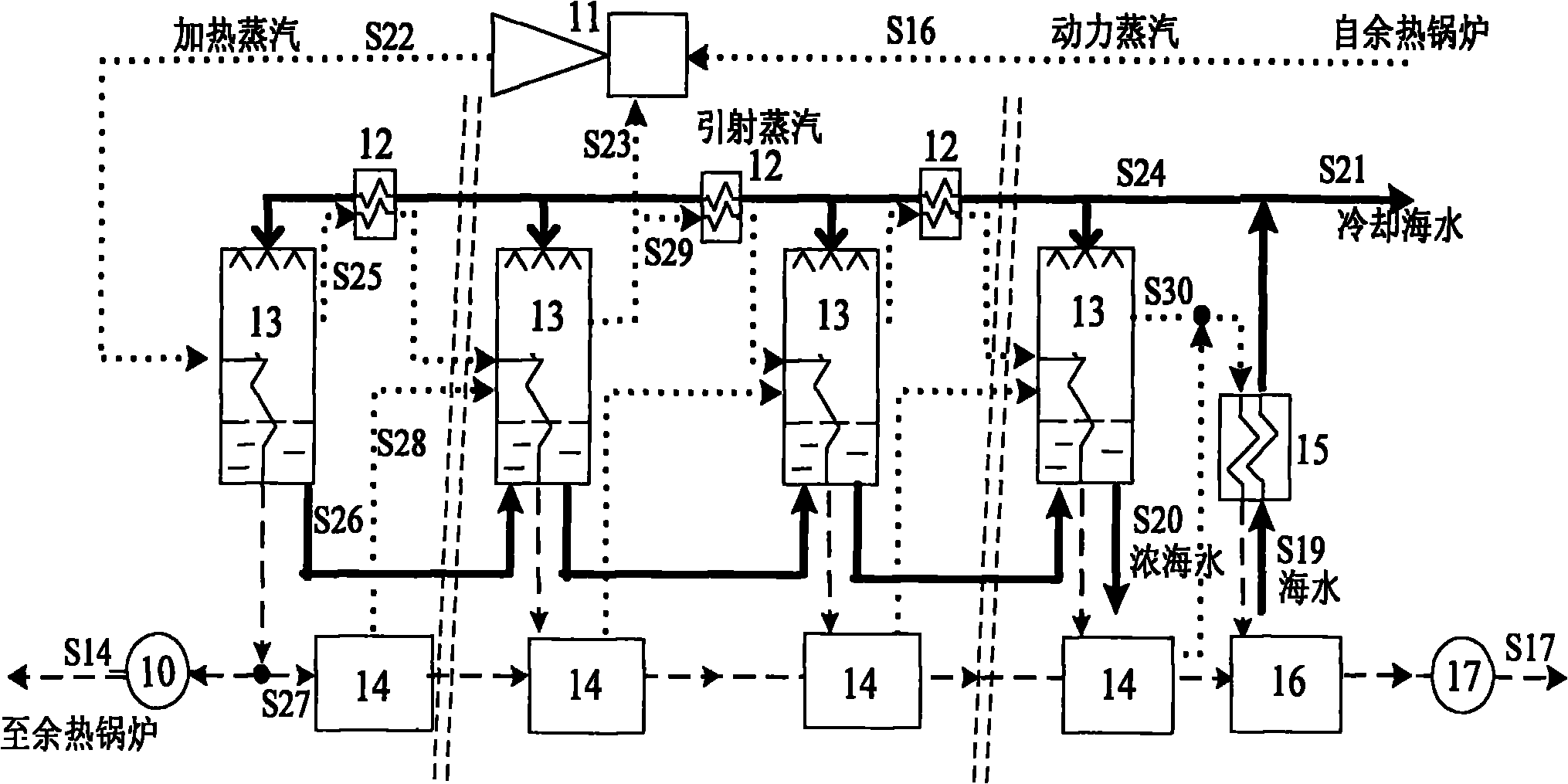

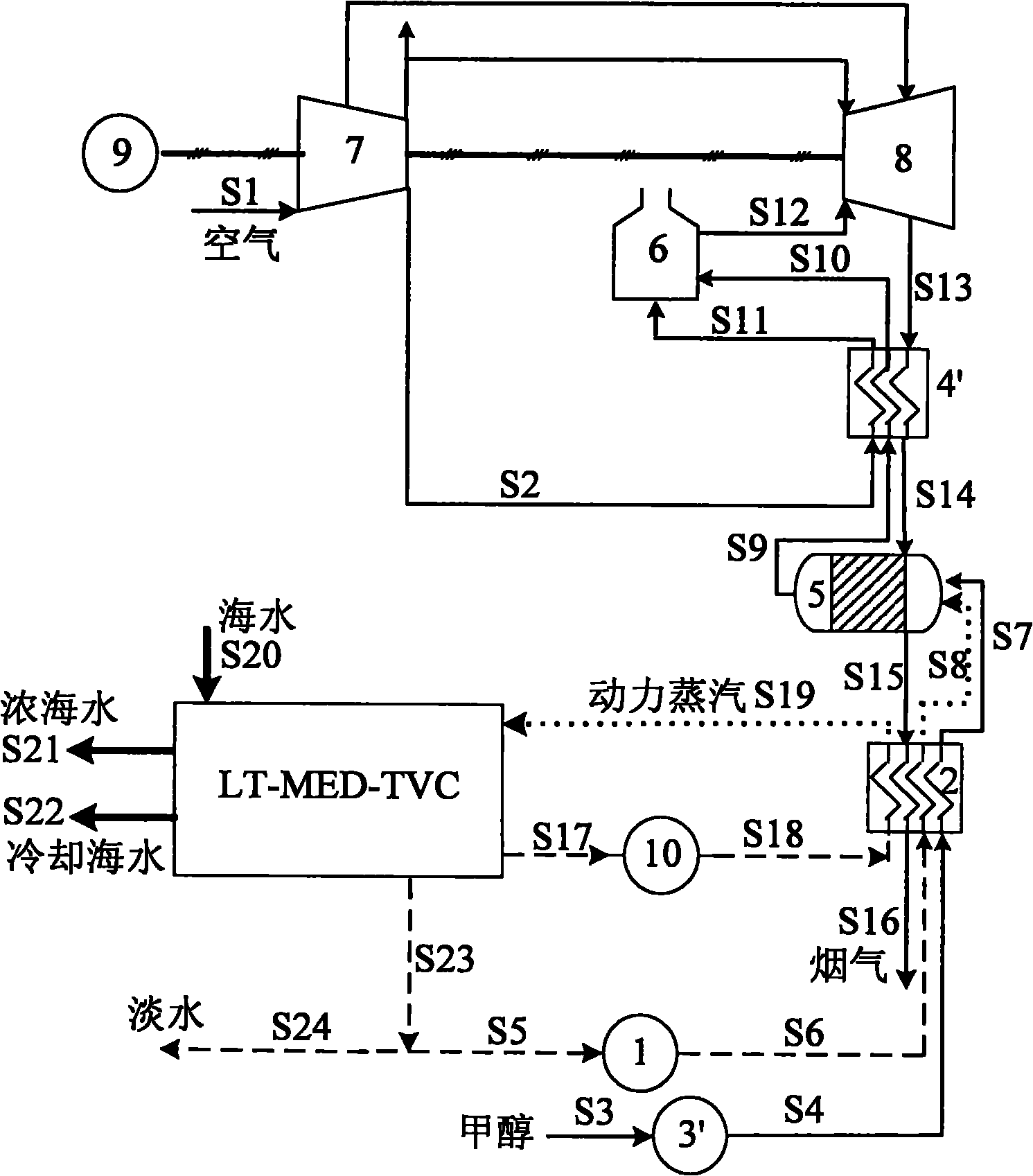

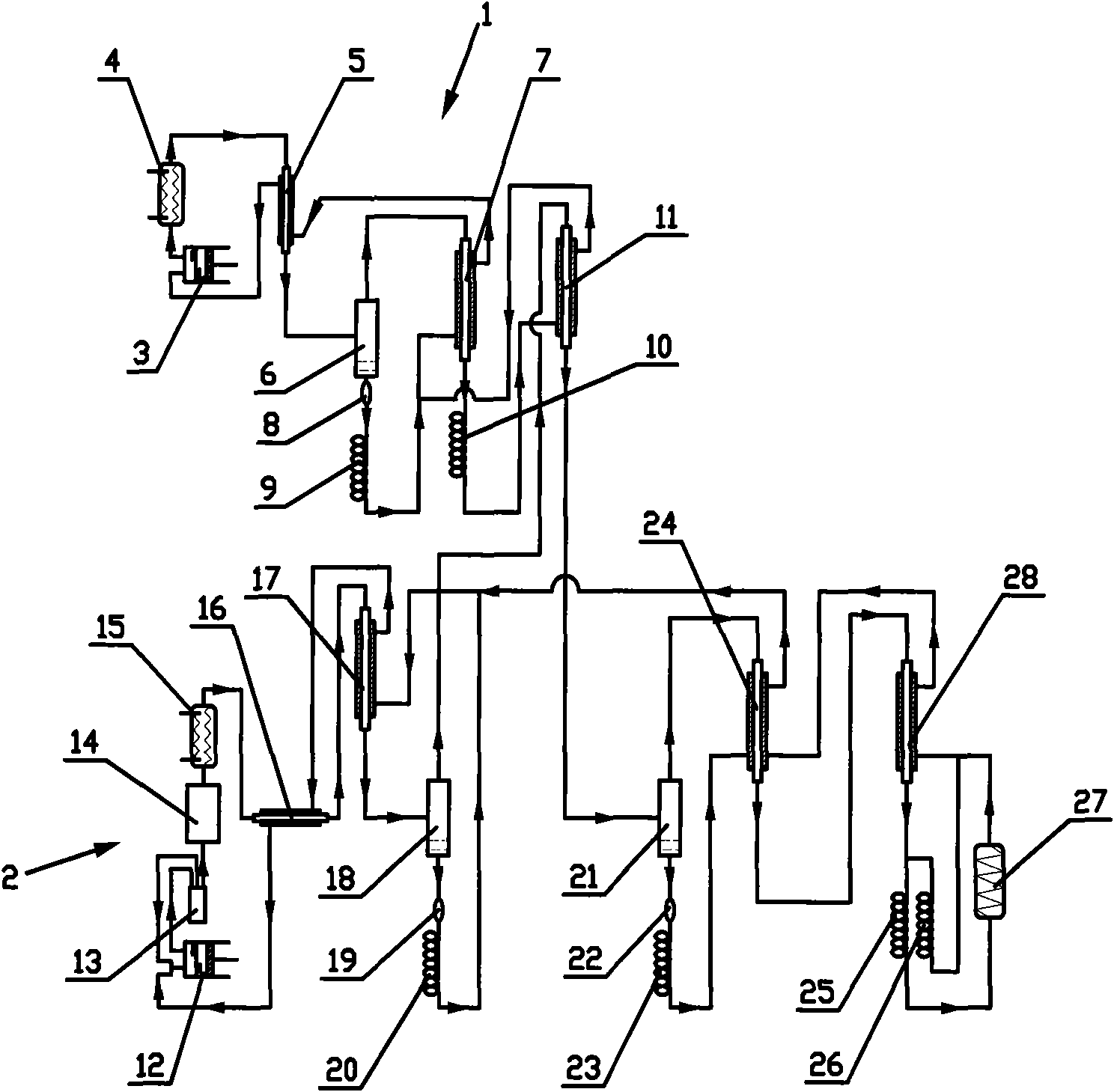

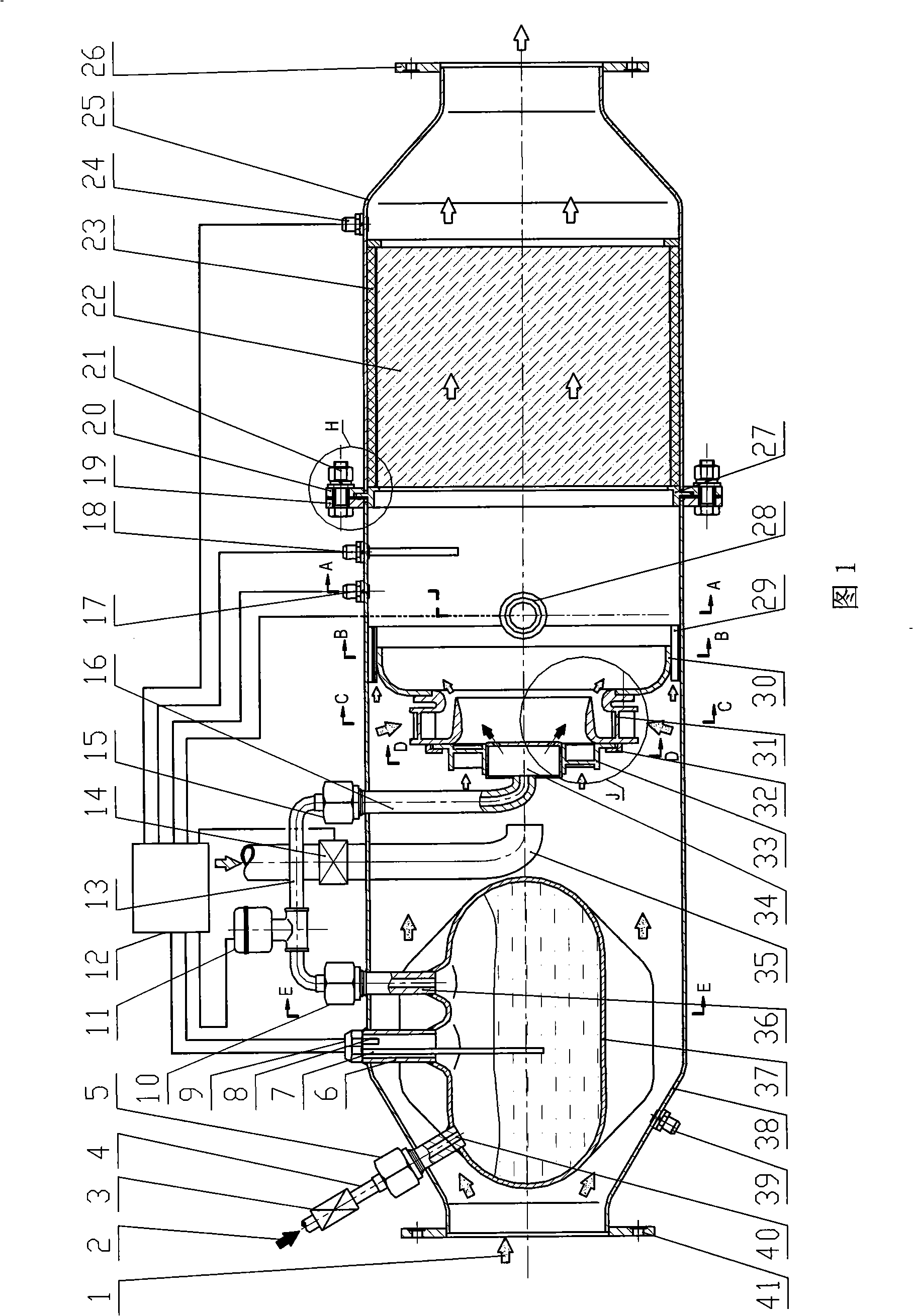

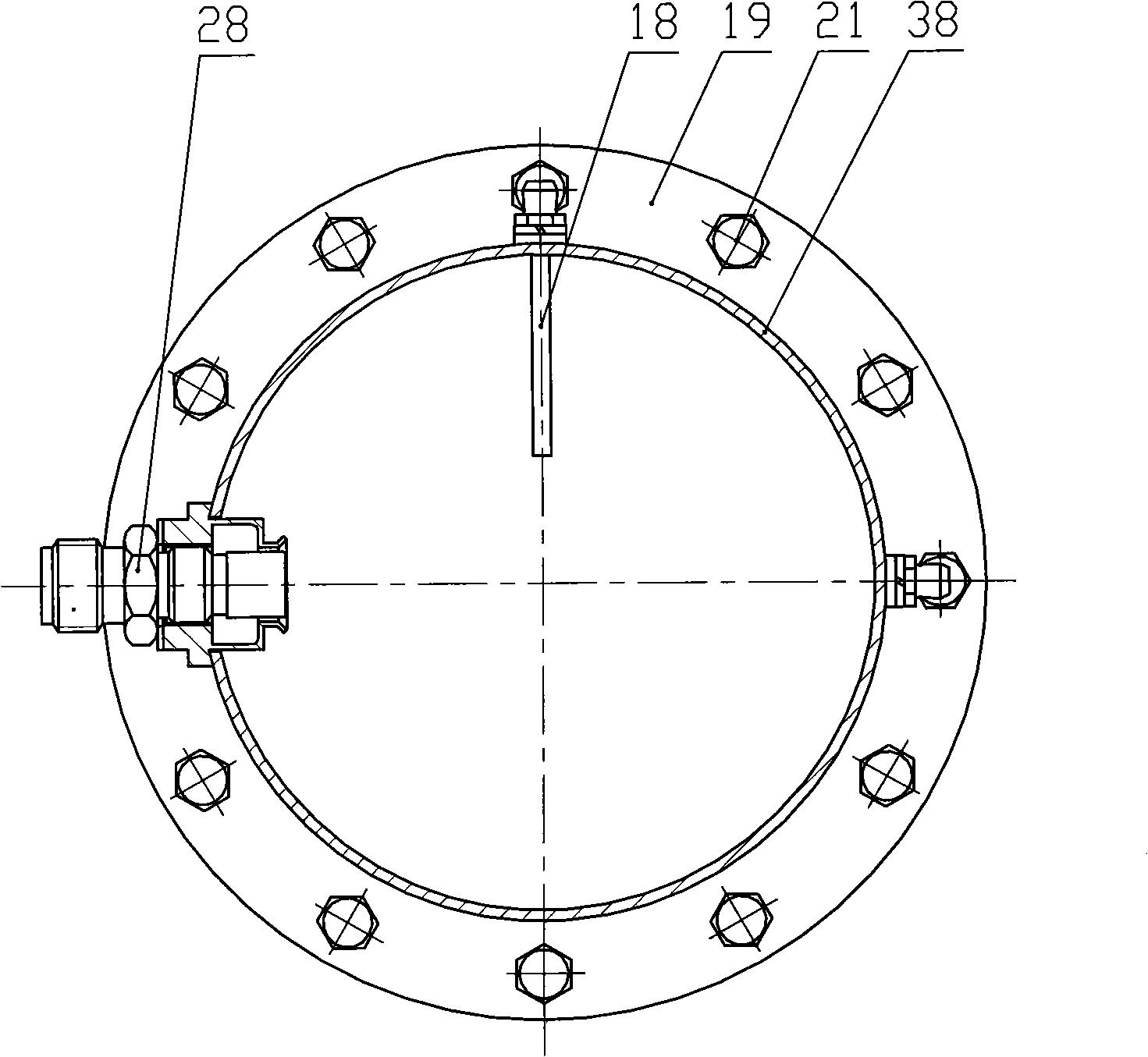

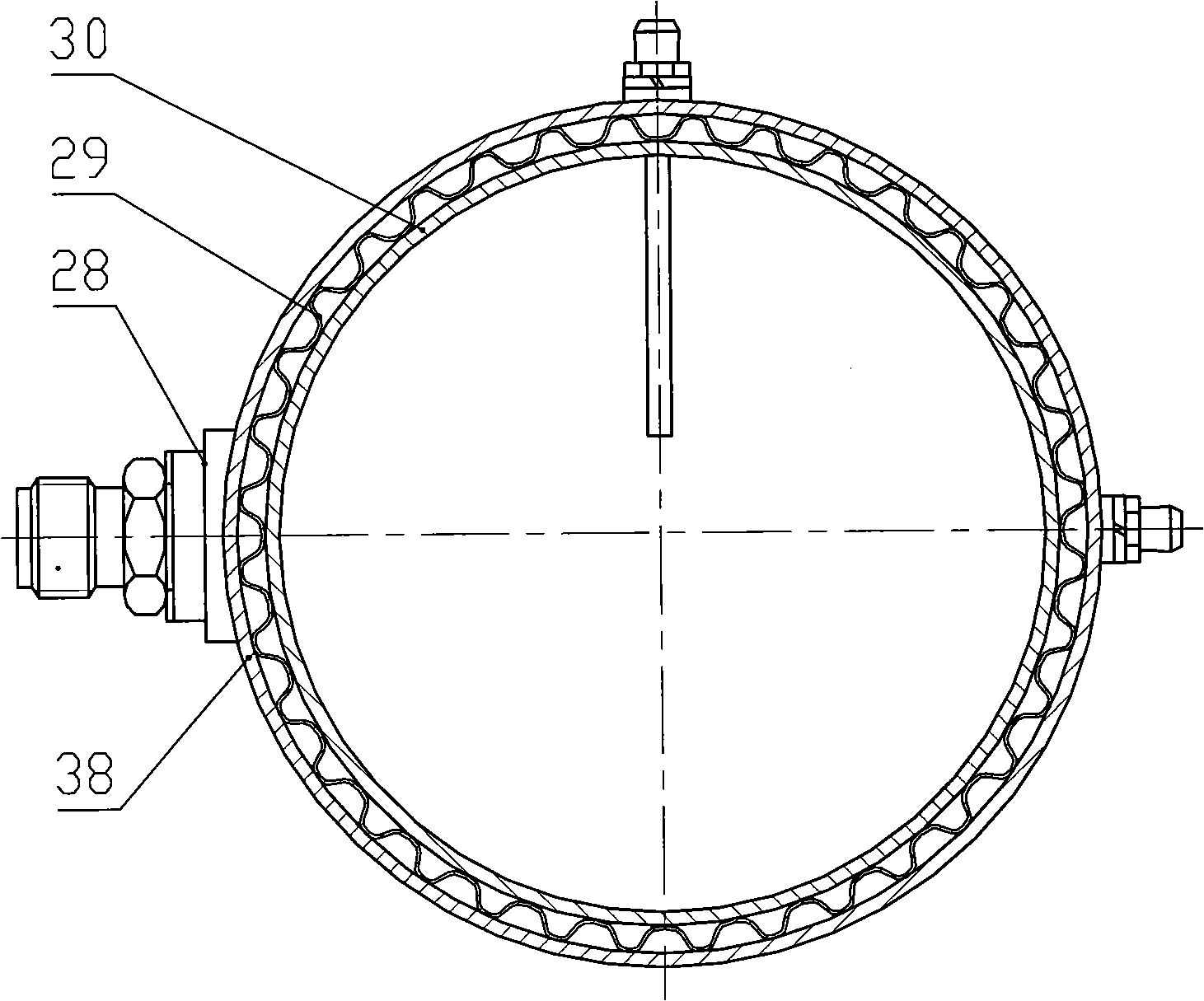

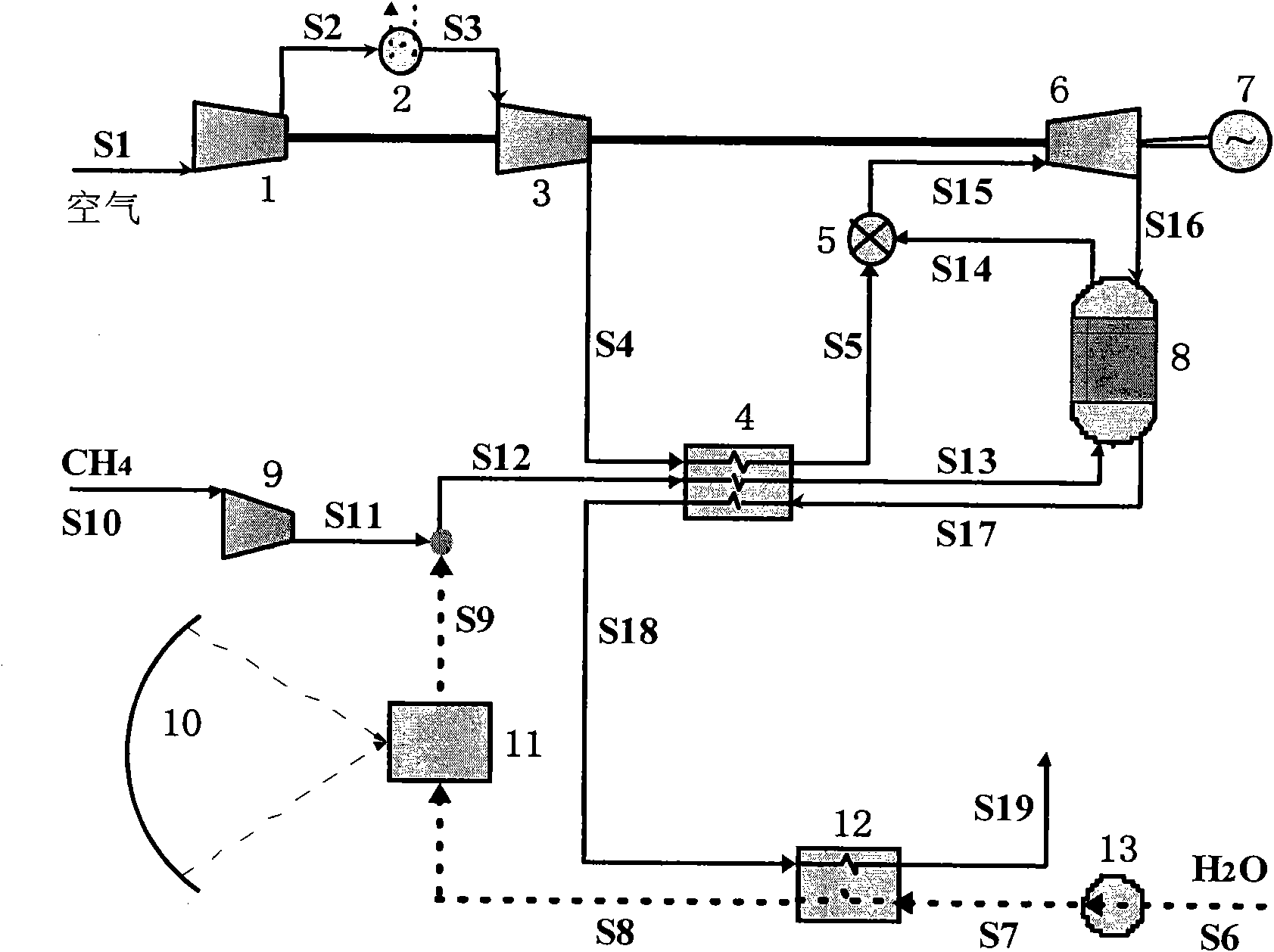

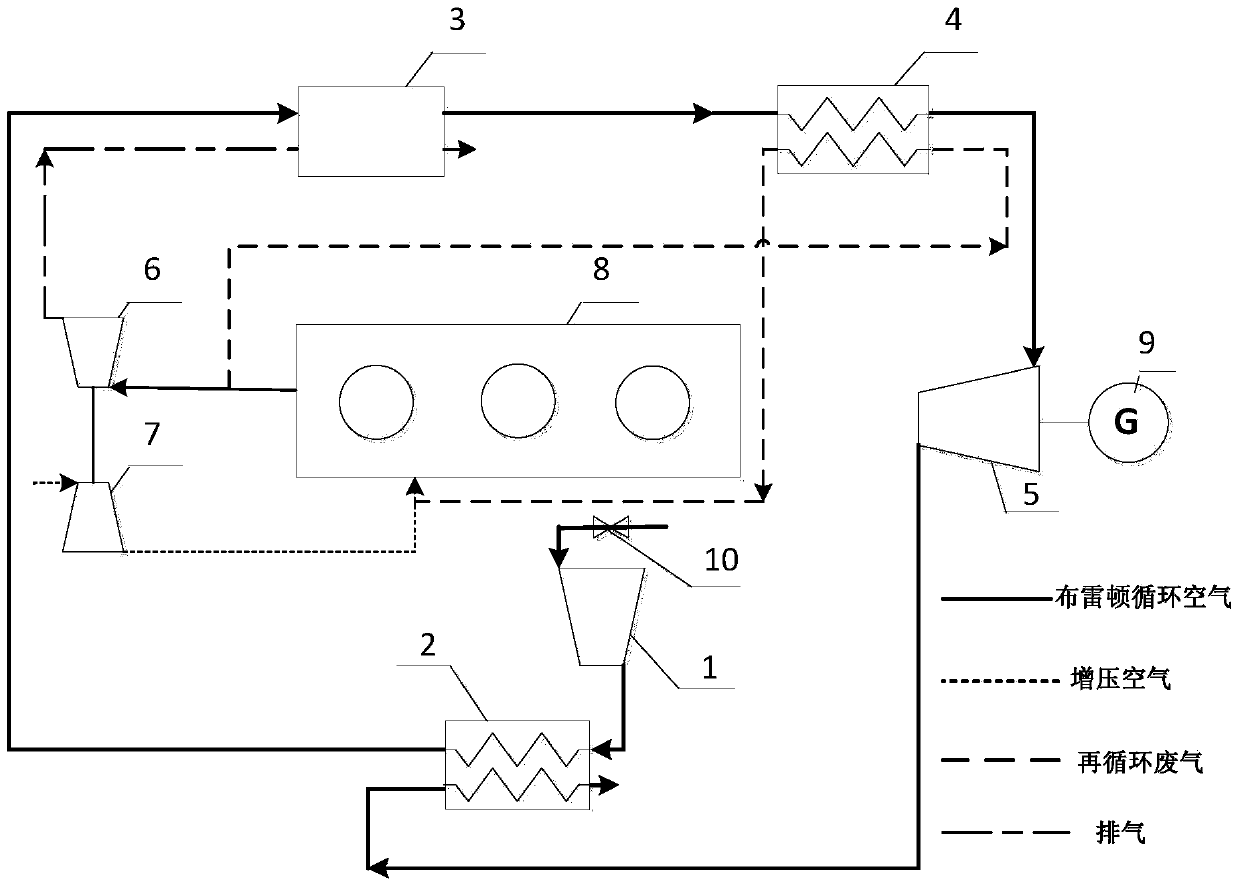

Regenerative cycle and low-temperature multi-effect distillation seawater desalinization thermodynamic cycling device and method

ActiveCN102060267ASolve the problem of large water consumption in chemical reheating cycleHydrogenGeneral water supply conservationDistillationSeawater

The invention discloses a regenerative cycle and low-temperature multi-effect distillation seawater desalinization thermodynamic cycling device, which is formed by coupling a chemical regenerative cycle and a low-temperature multi-effect distillation seawater desalinization system, wherein the flue gas waste heat of the chemical regenerative cycle is used for producing steam power to drive the low-temperature multi-effect distillation seawater desalinization system; fresh water produced by the low-temperature multi-effect distillation seawater desalinization system is supplied to satisfy the needs of reaction in the chemical regenerative cycle; the advantages of the chemical regenerative cycle and the low-temperature multi-effect distillation seawater desalinization system are complemented; and the system realizes integrated optimization. In the process of recycling the flue gas waste heat, a regenerator, a reformer and a waste heat boiler are arranged according to temperature corresponding and energy cascade-utilization principles, and as reforming temperatures of different fuels such as natural gas and methanol, a system structure is required to be correspondingly regulated to realize optimal heat exchange matching. Compared with a separate production system with the same output, the system can improve the efficiency by 5 to 9 percent and save 11 to 19 percent of fossil fuels. Therefore, the device has high economy and vast engineering application prospect.

Owner:青岛艳阳天环保科技有限公司

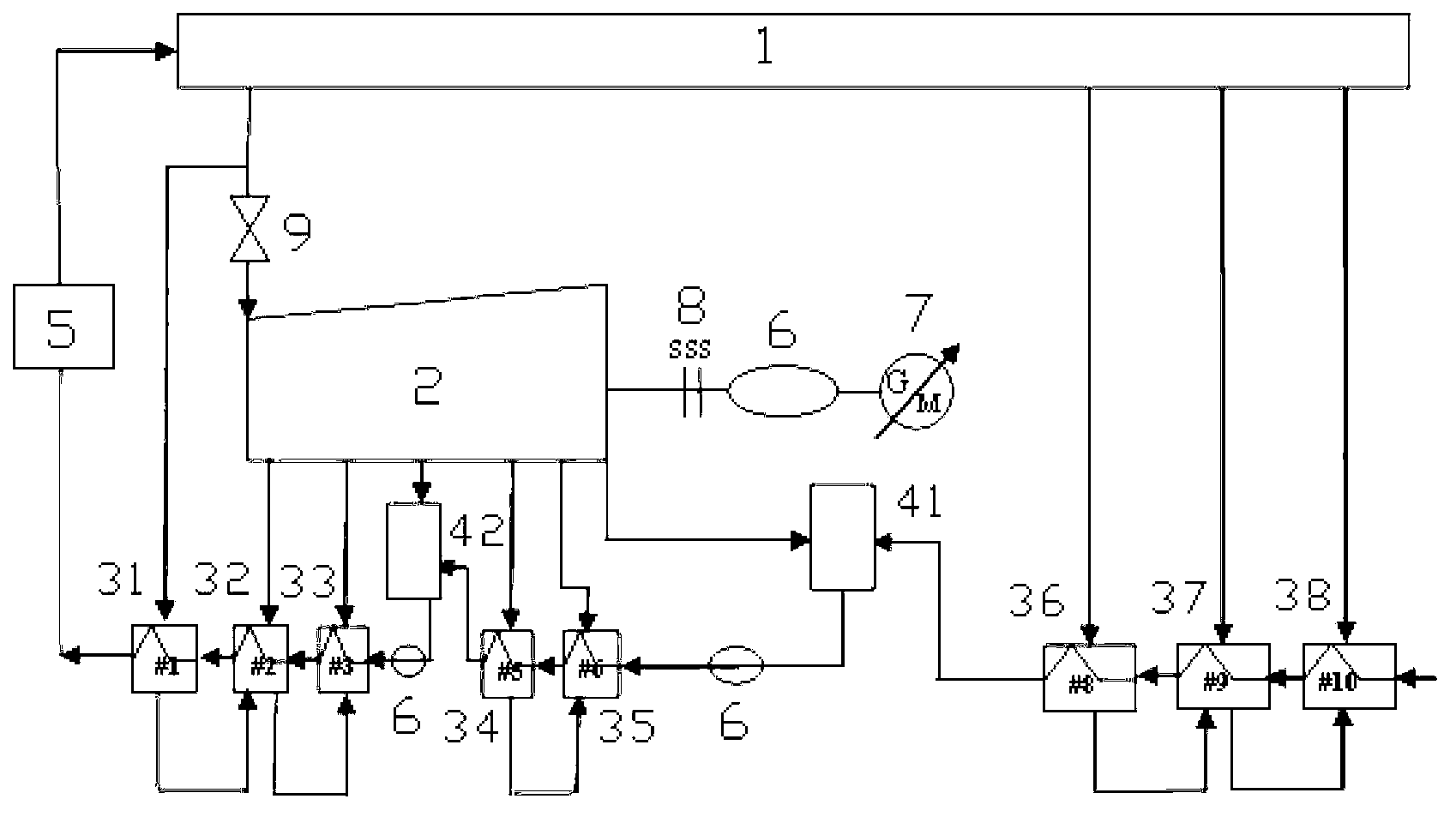

Double-turbine steam thermodynamic system with regenerative steam extraction function

InactiveCN103195521AImprove flow efficiencyReduce axial sizeSteam useCombined combustion mitigationEngineeringDeaerator

The invention provides a double-turbine steam thermodynamic system with a regenerative steam extraction function. The double-turbine steam thermodynamic system comprises a large steam turbine, a small steam turbine and a regenerative cycle unit. The regenerative cycle unit comprises one or a plurality of high-pressure heaters, one or a plurality of medium-pressure heaters, one or a plurality of low-pressure heaters and two deaerators, and a water circulating pipeline is communicated with a boiler via the low-pressure heaters, the low-pressure deaerator, the medium-pressure heaters, the high-pressure deaerator and the high-pressure heaters sequentially. The double-turbine steam thermodynamic system with the regenerative steam extraction function has the advantages that medium-pressure cylinders of the large steam turbine do not need to be provided with steam extraction openings for regenerative steam extraction owing to the double-deaerator structure, medium-pressure cylinder structures of the large steam turbine are greatly simplified, the axial dimension of an integral unit is reduced, and the through-flow capacity of the large steam turbine is improved; and sufficient flow and sufficient power for the small steam turbine can be guaranteed, a complicated logic balance system for the power of the small steam turbine is omitted, and accordingly the integral system is simple and reliable.

Owner:SHANGHAI TURBINE

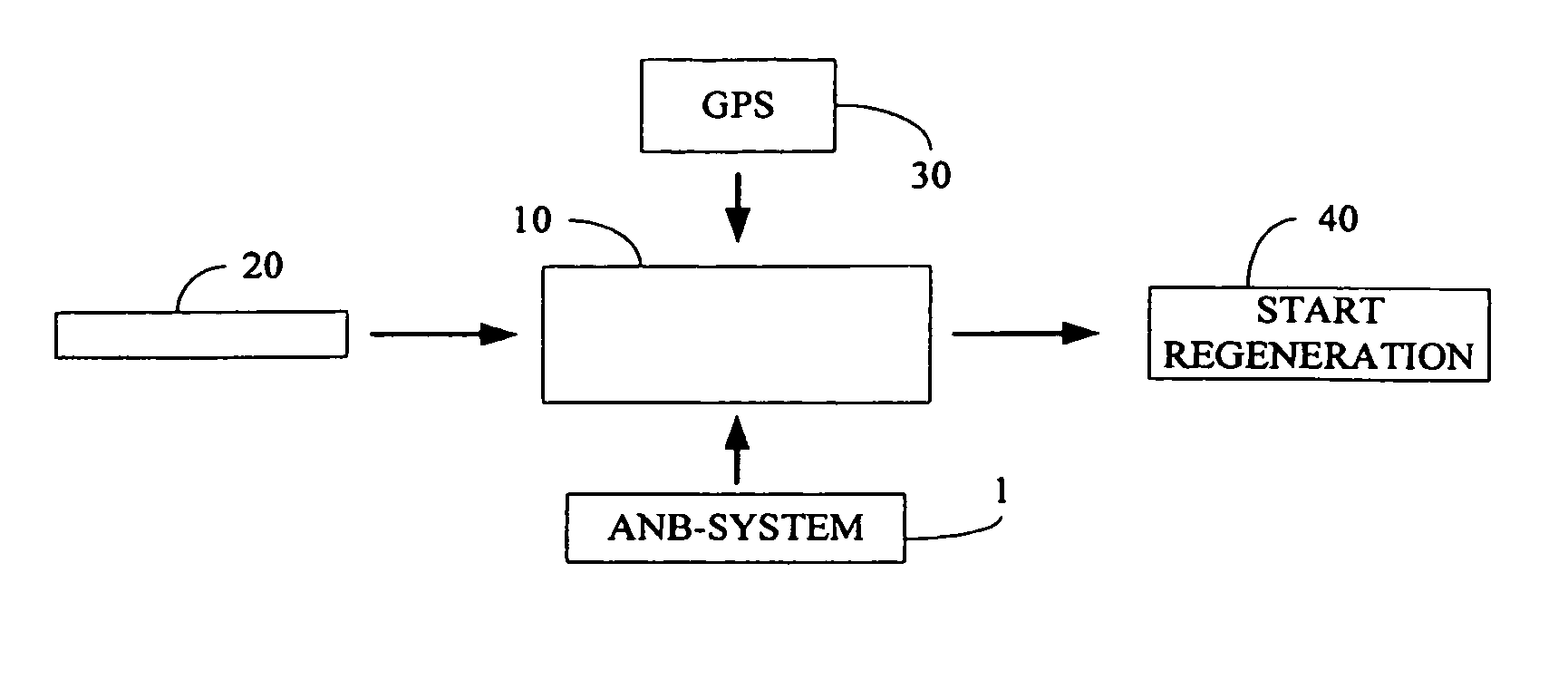

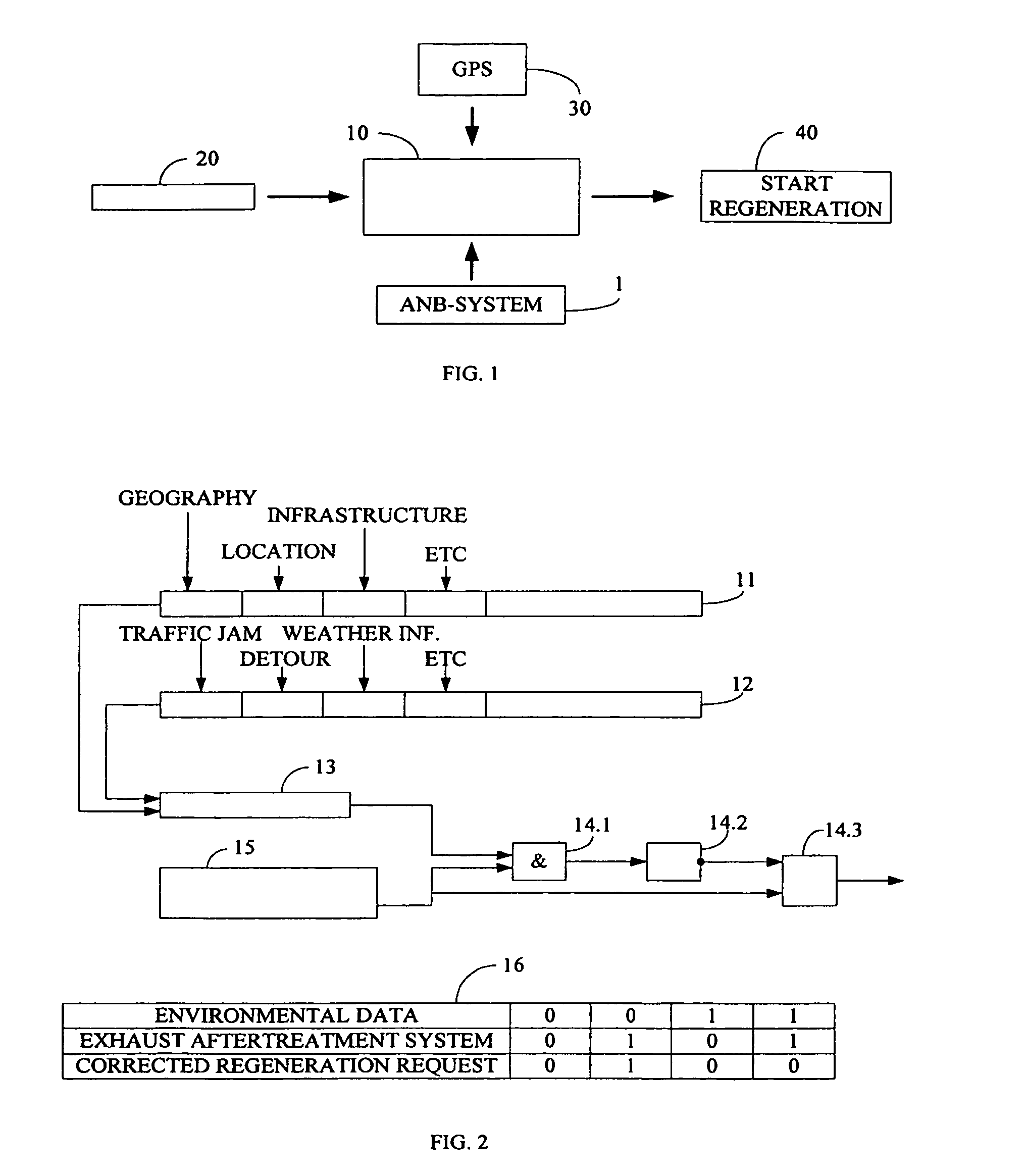

Method for regenerating an exhaust aftertreatment system

InactiveUS8015805B2Low installation expenditureImprove overall utilizationAnalogue computers for vehiclesElectrical controlCycle controlInternal combustion engine

Owner:ROBERT BOSCH GMBH

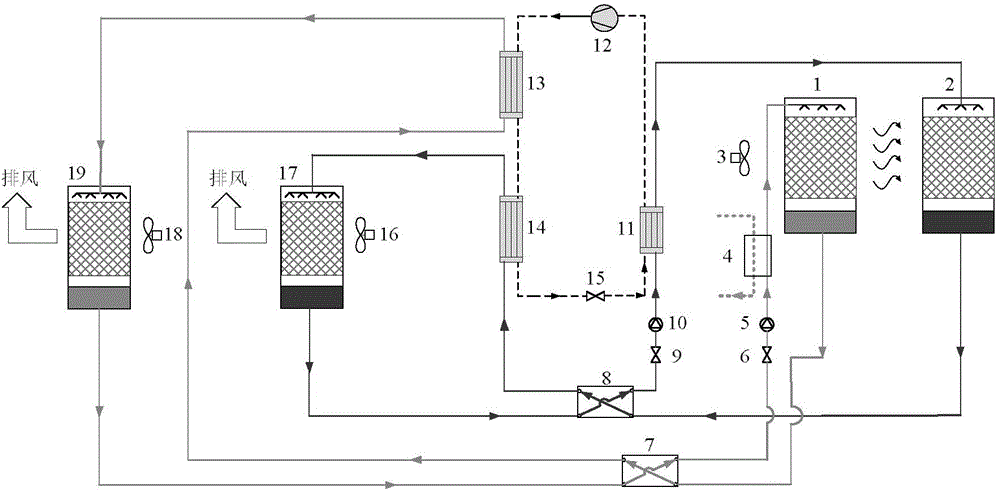

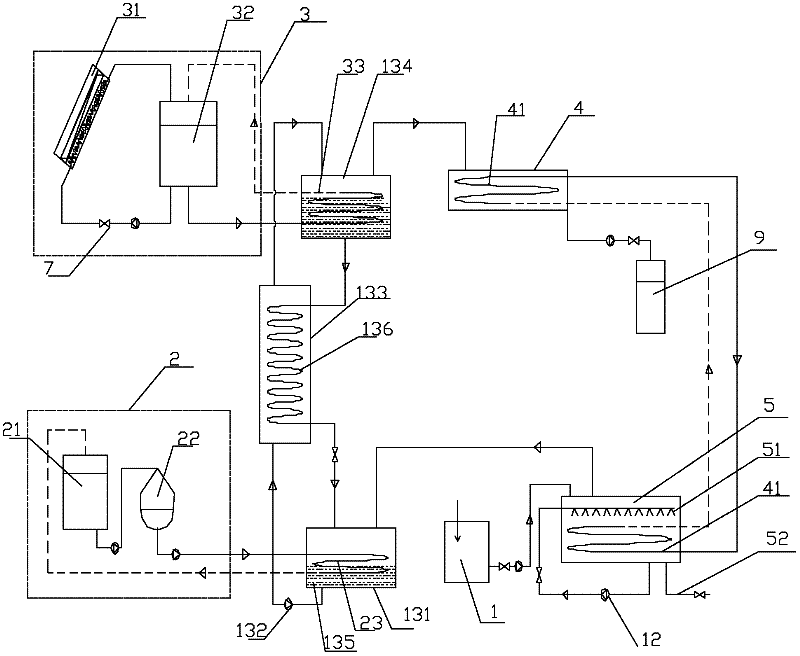

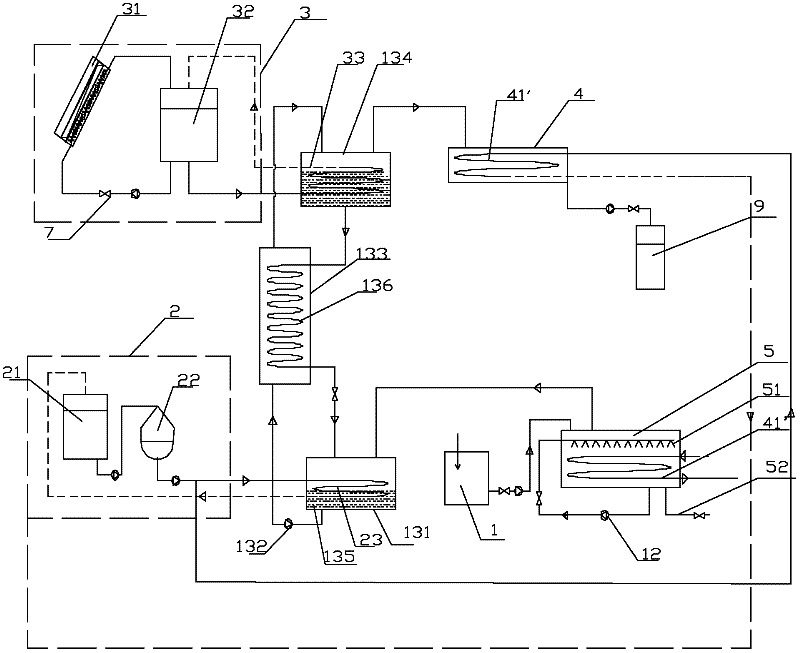

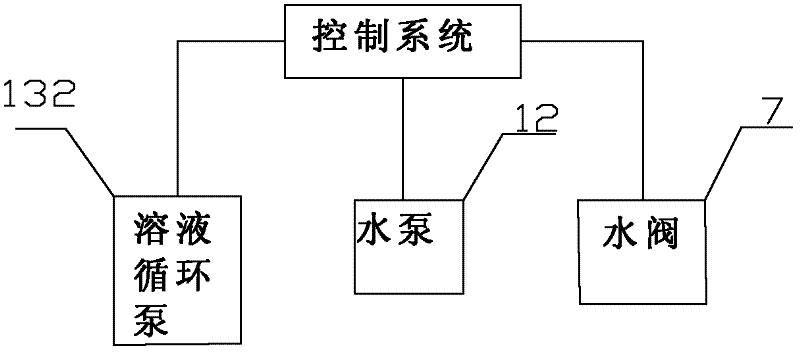

Two-stage high and low temperature liquid desiccant air-conditioning system driven by heat pump and controlling method

ActiveCN104061634AHigh trafficEasy to useSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir conditioning

The invention discloses a two-stage high and low temperature liquid desiccant air-conditioning system driven by a heat pump and a controlling method. The two-stage high and low temperature liquid desiccant air-conditioning system driven by the heat pump is characterized by comprising a first level liquid desiccant regenerative circulating system, a second level liquid desiccant regenerative circulating system, a heat pump circulating system and a first draught fan, wherein the first level liquid desiccant regenerative circulating system comprises a first level dehumidifier and a first reproducer; the liquid outlet of the first level dehumidifier is communicated to the liquid inlet of the first reproducer, and the liquid outlet of the first reproducer is communicated to the liquid inlet of the first level dehumidifier, which constitute a first level liquid desiccant regenerative cycle; the second level liquid desiccant regenerative circulating system comprises a second level dehumidifier and a second reproducer; the liquid outlet of the second level dehumidifier is communicated to the liquid inlet of the second reproducer, and the liquid outlet of the second reproducer is communicated to the liquid inlet of the second level dehumidifier, which constitute a second level liquid desiccant regenerative cycle; the heat pump circulating system comprises a first condenser, a throttle valve, a compressor and an evaporimeter; the liquid outlet of the second reproducer is cooled through the evaporimeter and communicated to the liquid inlet of the second level dehumidifier.

Owner:SOUTHEAST UNIV

Self-overlapping refrigeration system

ActiveCN101576329AReduce the temperatureSelf-cascading implementationCompression machines with non-reversible cycleCompression machines with cascade operationIntermediate heat exchangerBoiling point

The invention relates to a self-overlapping refrigeration system provided with at least one high-temperature self-overlapping loop (1) and at least one low-temperature self-overlapping loop (2), wherein the high-temperature self-overlapping loop (1) and the low-temperature self-overlapping loop (2) are respectively an independent and closed refrigeration circulation loop, and the high-temperatureself-overlapping loop carries out temperature-reduction fractional condensation for the second time to a gas refrigerant of the low-temperature self-overlapping loop after fractional condensation forthe first time by an intermediate heat exchanger. The invention enables the medium temperature of a refrigeration working medium to be lower, reduces the pressure of a low-temperature level system, obviously reduces the exhaust temperature and the exhaust pressure at the previous period of starting-up and temperature reduction, enhances the temperature-reduction speed simultaneously and enables alow-temperature level to obtain much larger refrigerating capacity. The invention enhances the effects of fractional condensation and separation by utilizing the evaporation of a working medium with high boiling point and a mixed regenerative cycle mode of a low-temperature flow-reversal working medium in the low-temperature level, and can ensure that components with high boiling points are more completely separated out.

Owner:QINGDAO HAIER BIOMEDICAL CO LTD

System and Method for Biological Wastewater Treatment and for Using the Byproduct Thereof

ActiveUS20100276361A1Cost effectiveFree energyBio-organic fraction processingSolid sorbent liquid separationBiodieselToxic material

A wastewater treatment system and process biologically treats wastewater to produce substantially clean water effluent and byproducts. The treatment system includes an array of media wheels that rotate into and out of exposure to sunlight for sustained algae growth. One byproduct is algae removed from the rotating media wheels, which may be provided to other processing facilities to produce, for instance, bio-diesel fuel. Waste CO2 from the processing facility may also be returned to the treatment system for enhanced algae growth. Bacteria is provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. Large scale facilities may integrate the treatment systems in a regenerative cycle in which the biomass obtained from the algal colonies is used in a separate facility and byproducts of the operation of the separate facility are used by the treatment system to fuel further algal growth.

Owner:LIMCACO CHRISTOPHER A

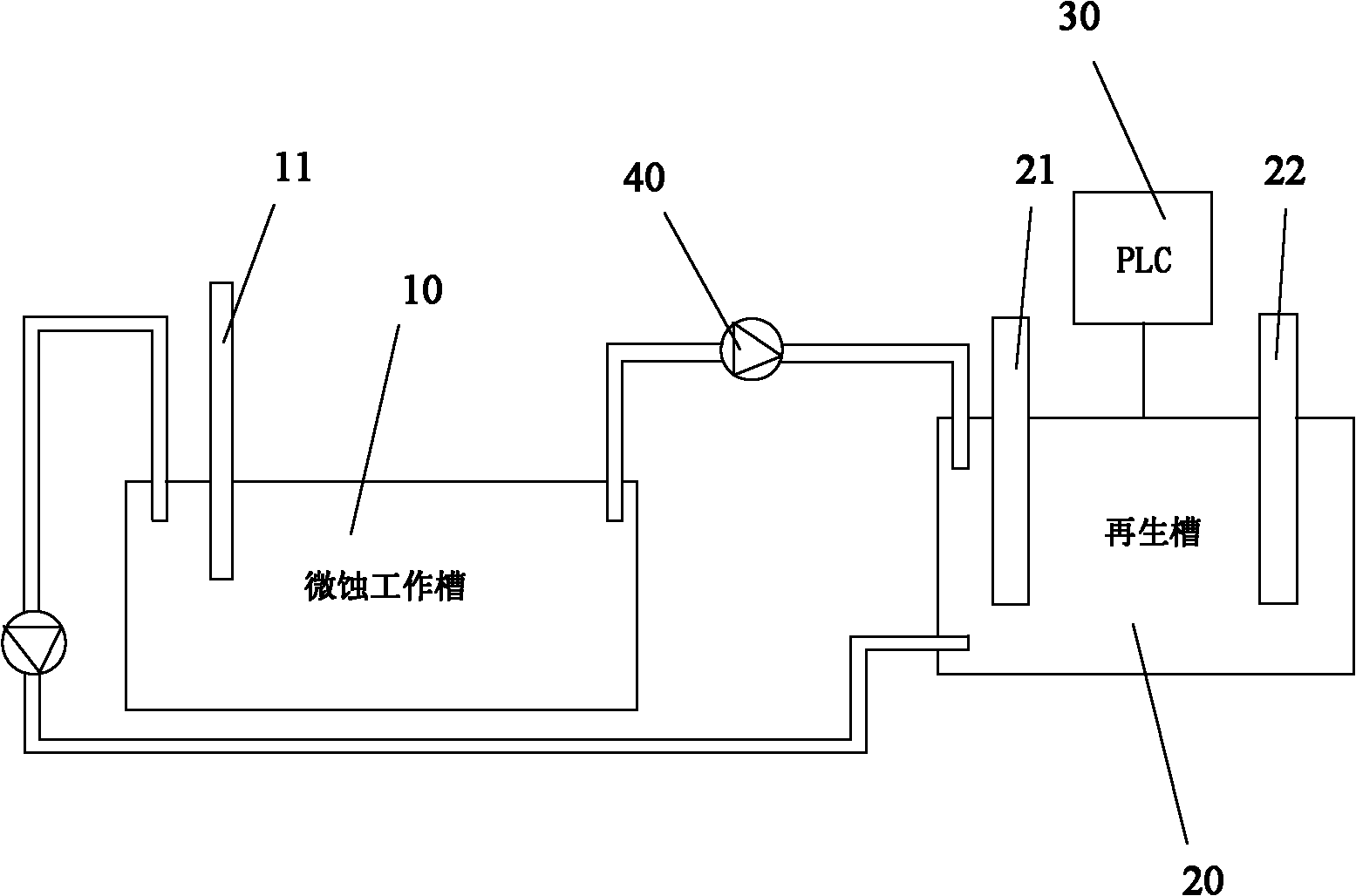

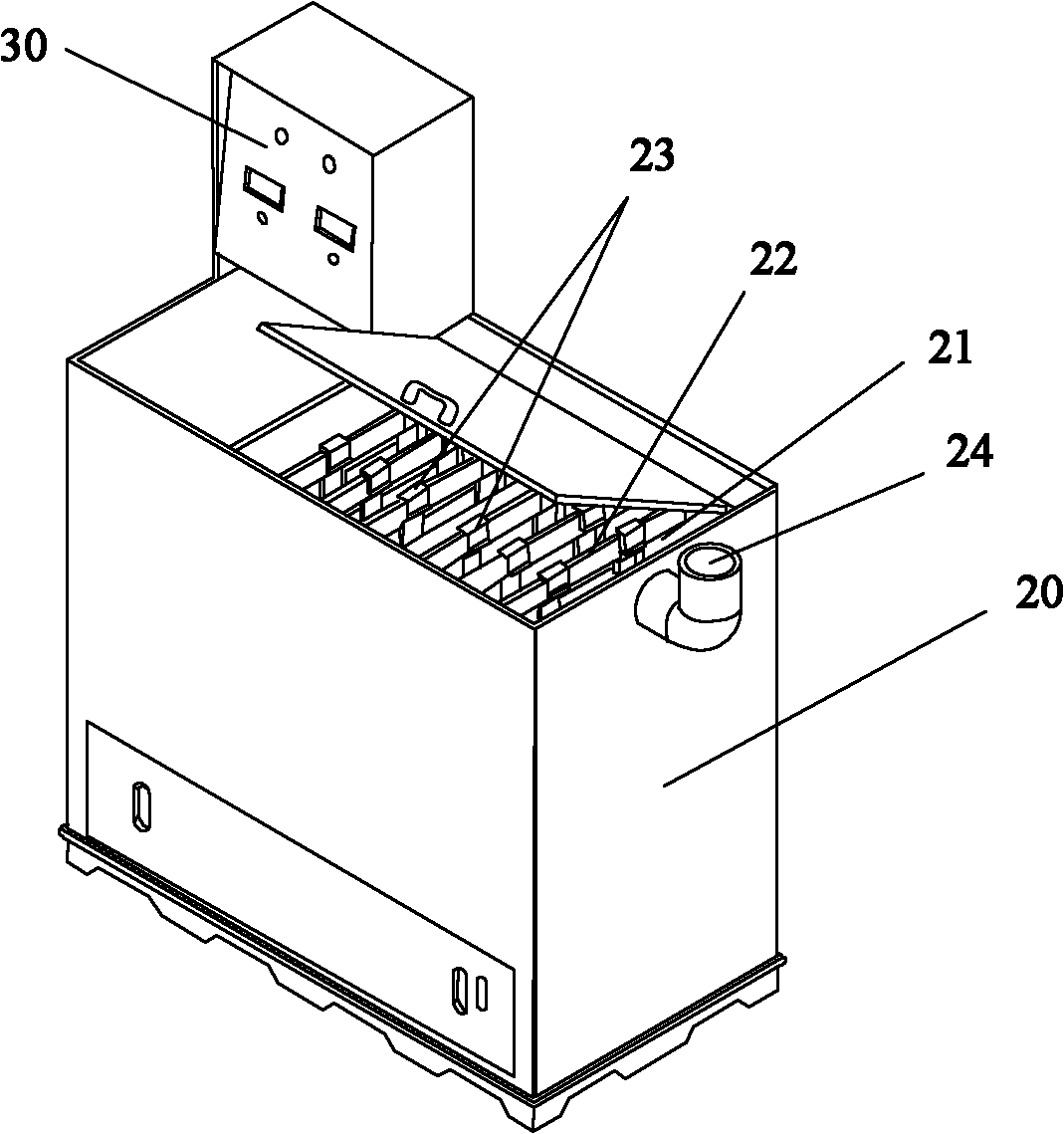

Treating agent and treating system for micro-etching surfaces of recyclable copper and copper alloys

InactiveCN102181865ASuperior Surface MicrostructureIncrease uniform roughnessElectrolysisAutomatic control

The invention discloses a treating agent and treating system for micro-etching surfaces of recyclable copper and copper alloys. The treating agent comprises the following components by weight: 1-20% of sulfuric acid or / and nitric acid, 1.5-35% of ferric sulfate or / and ferric nitrate, 0.005-0.2% of anionic fluorinated surfactant, 0.005-5% of additive and the balance of deionized water. Besides, the treating system comprises a micro-etching working tank, an electrolytic drug regeneration and copper recovery system and an automatic control system for connecting the micro-etching working tank with the electrolytic recovery and regeneration tank and realizing automatic stable control. The circuit board micro-etching regenerative cycle process and equipment have the beneficial effects of reducing the production cost of the micro-etching process, improving the level of the process for micro-etching the surfaces of the copper and copper alloys and achieving the aims of cleaner production and zero emission.

Owner:GUANGDONG SKYCHEM TECH LTD

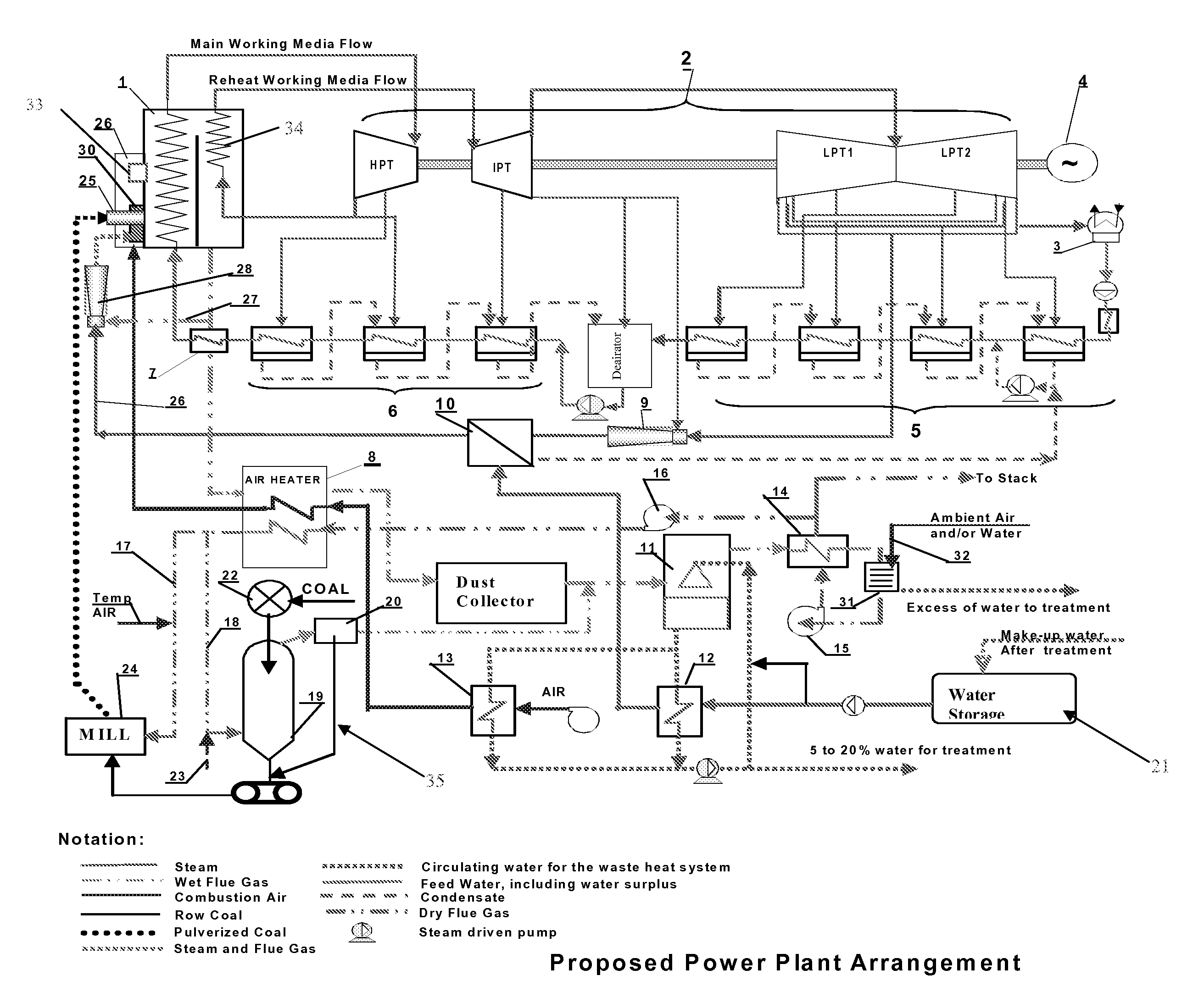

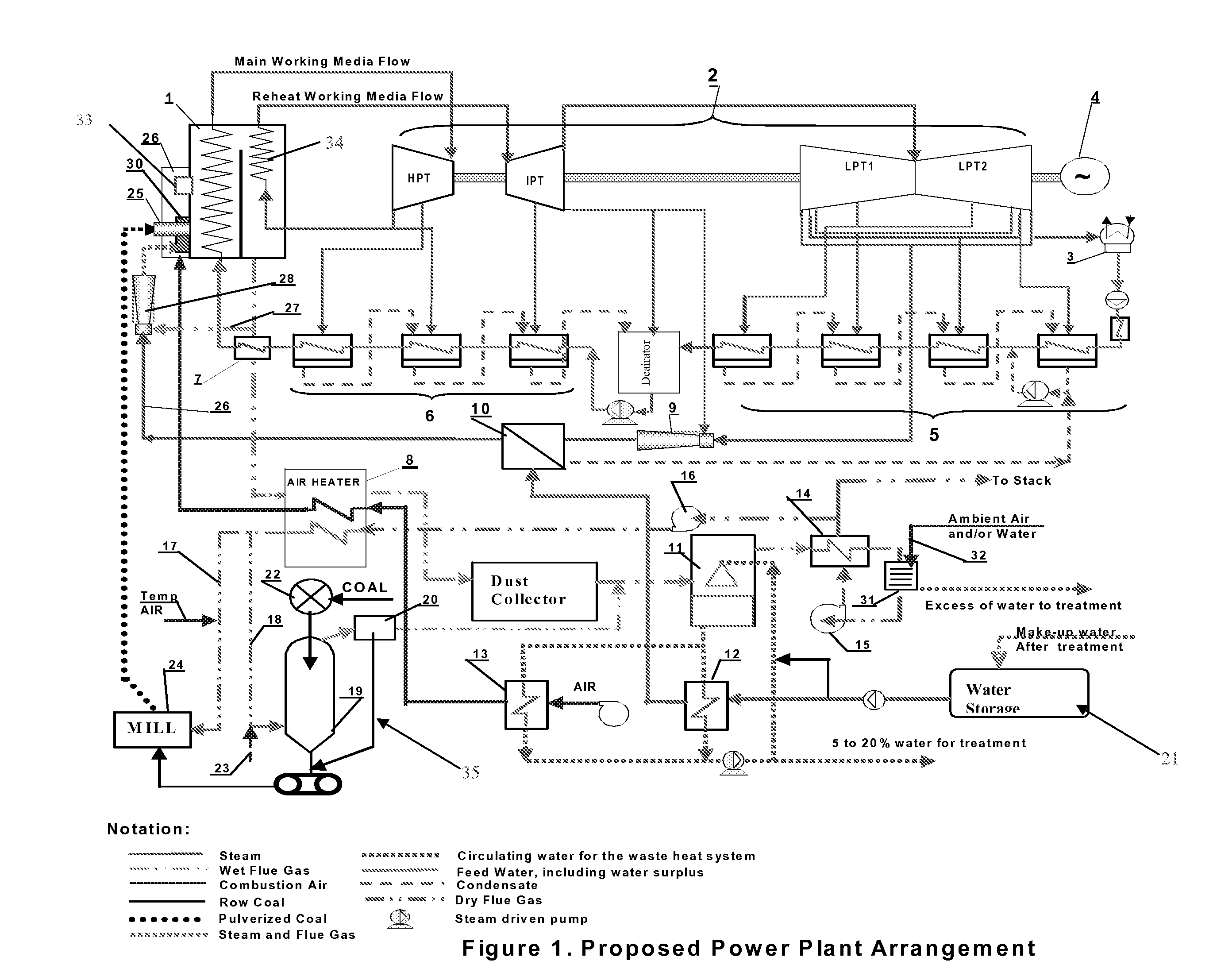

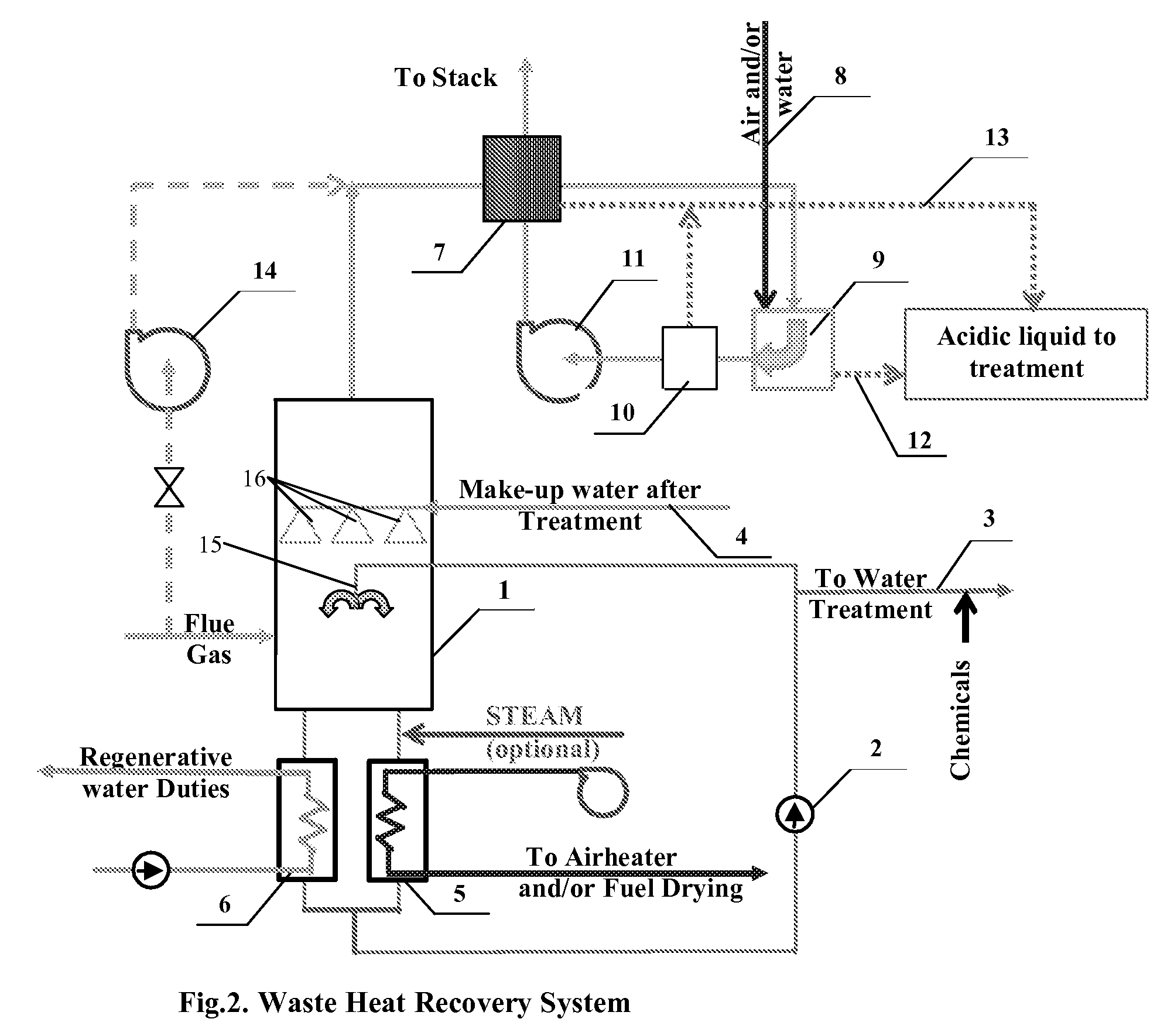

Method of efficiency and emissions performance improvement for the simple steam cycle

InactiveUS7690201B2Reduce disadvantagesSpeed up the conversion processSteam generation heating methodsSteam accumulatorsThermal energyEngineering

A method for improvement of a fossil fuel energy conversion into electrical energy for the simple sub- and supercritical steam cycle is proposed through introduction of additional regenerative cycle duties to improve the evaporation rate per unit of fuel burned, thus minimizing condenser heat loss of the working media. The additional duties provide a supplemental energy credit in the form of heat input to a steam generator where a modified combustion process is realized to convert fossil fuel into carbon monoxide and hydrogen at atmospheric pressure and thus achieving an essential reduction of nitrogen oxides (NOx) formation. The additional duties also involve a direct contact heat transfer to recover latent and thermal energy, contained in the discharged combustion products to provide yet another energy credit that satisfies both conventional and / or added regenerative cycle duties. A water surplus is also achieved in the said process of heat recovery from the combustion products to significantly improve water usage of the simple steam plant. The proposed heat recovery process also minimizes coolant usage while achieving a complete water recovery from combustion products and maintaining draft capabilities in the stack.

Owner:VERITASK ENERGY SYST

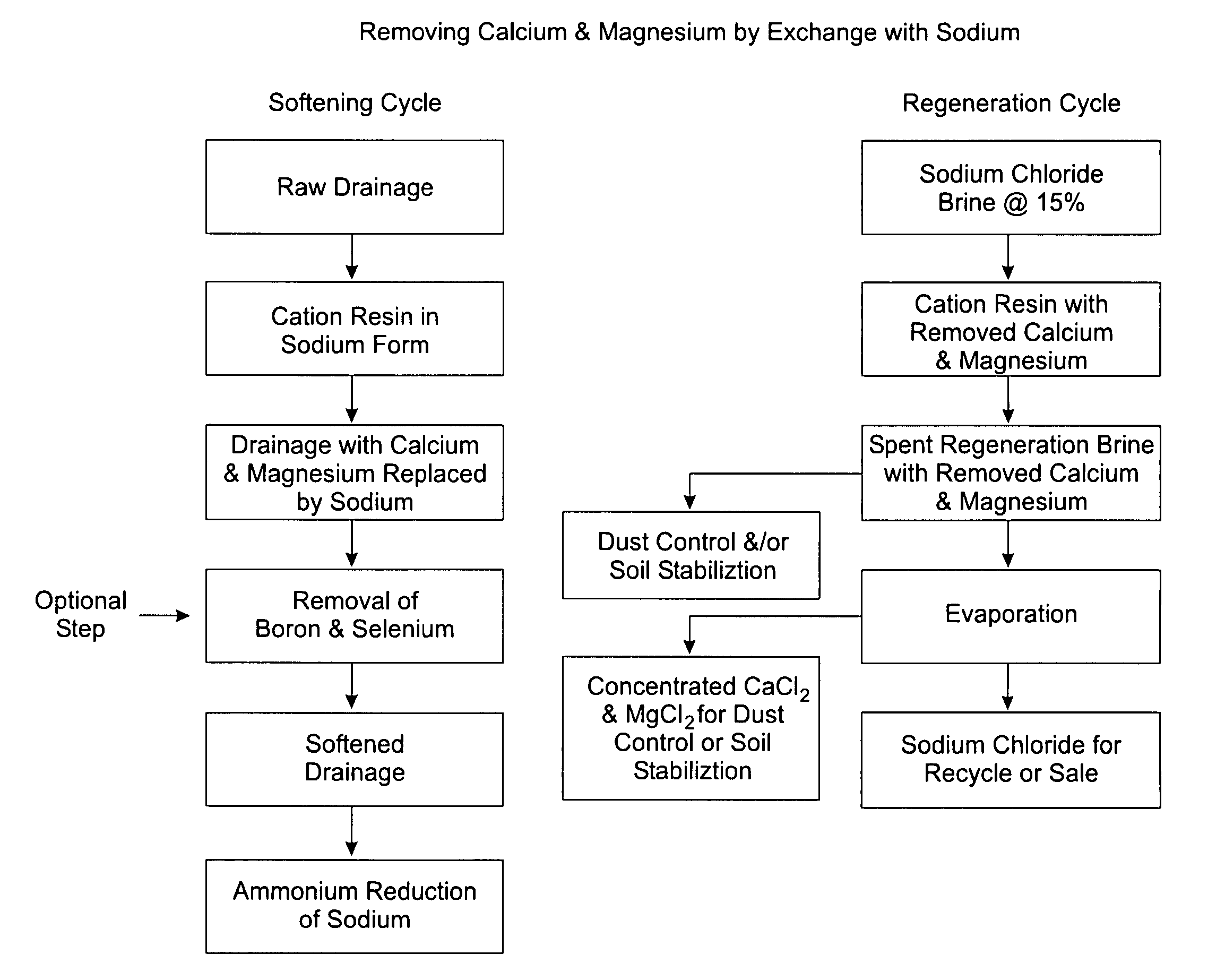

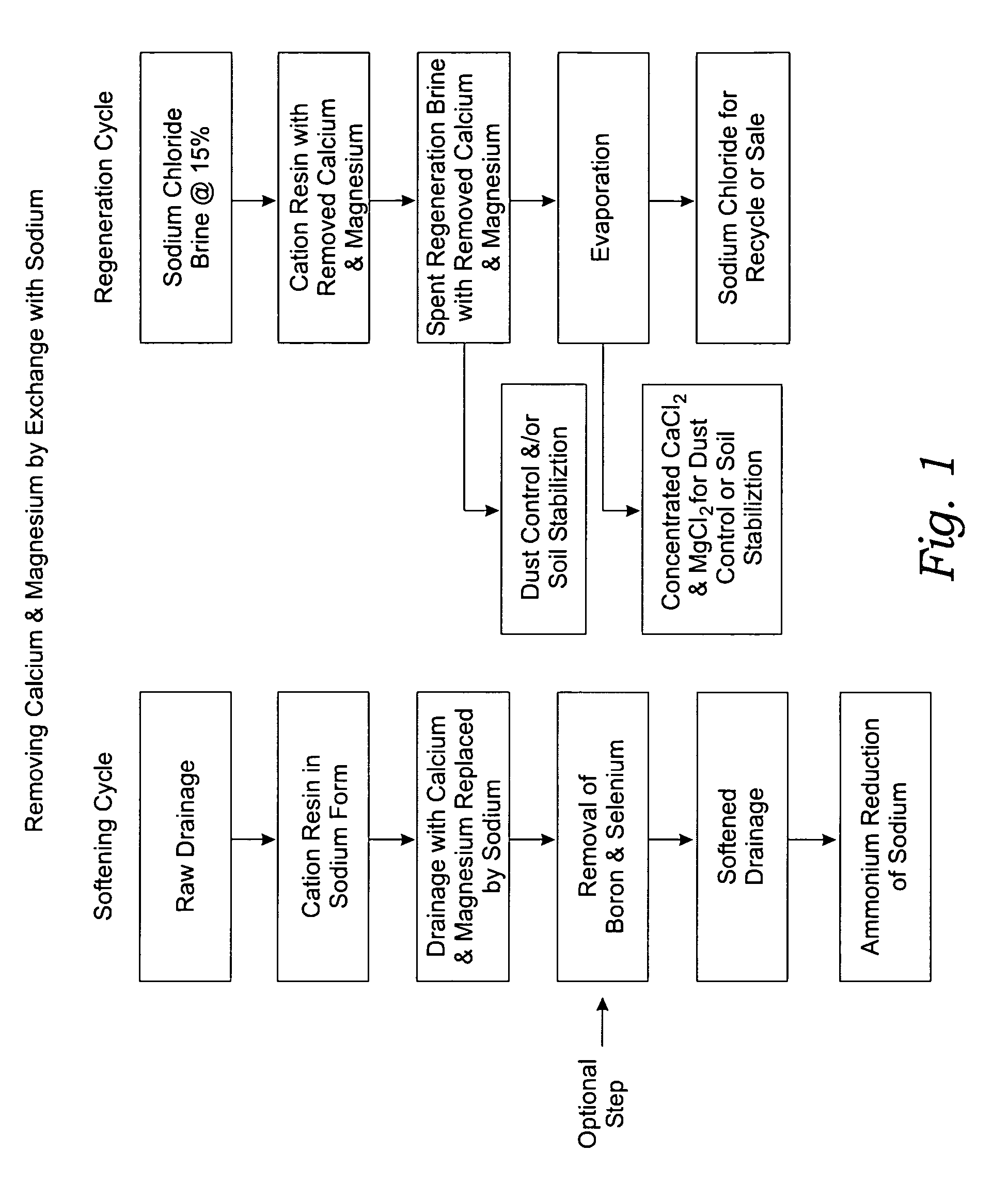

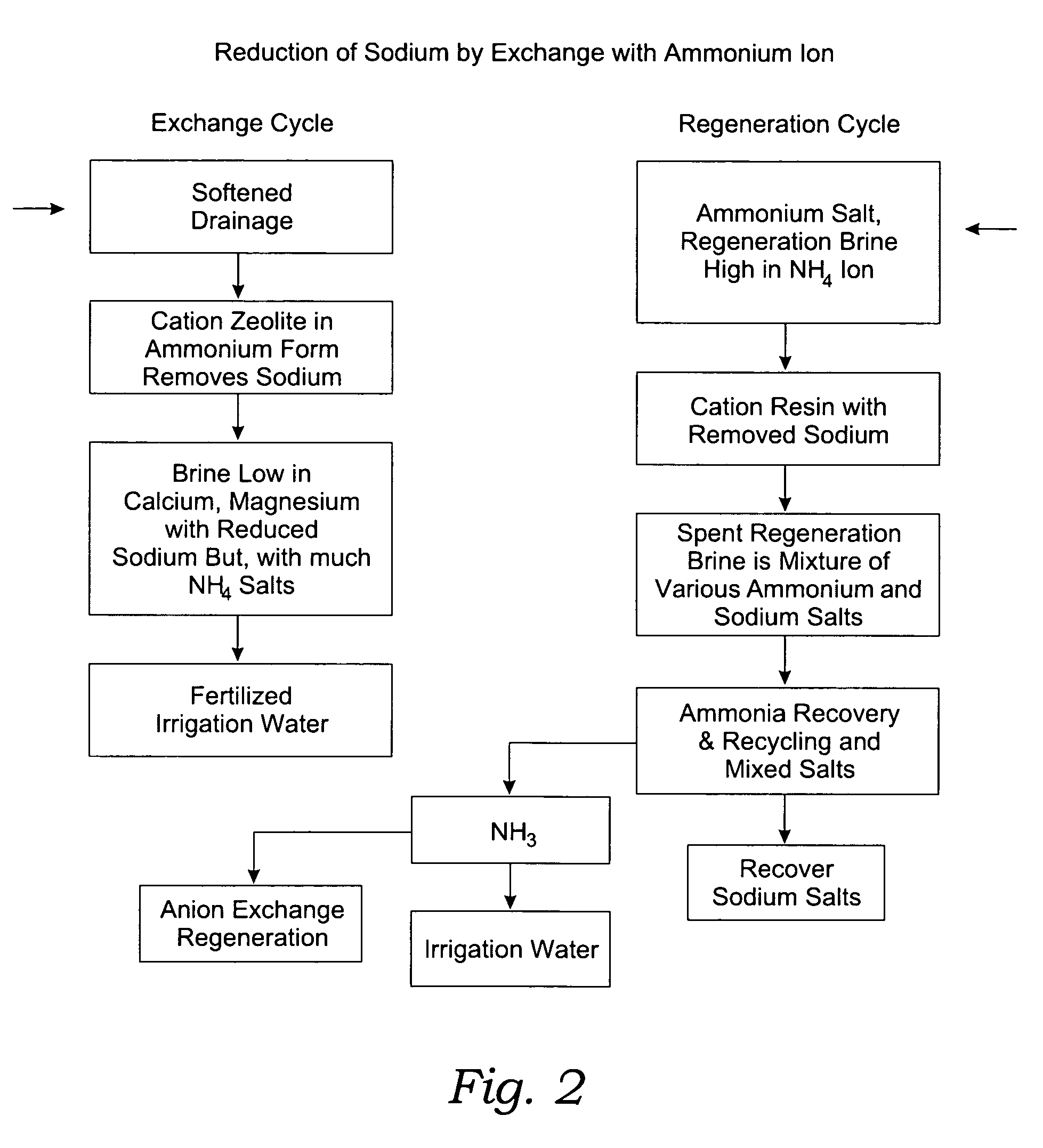

Methods of the purification and use of moderately saline water particularly for use in aquaculture, horticulture and, agriculture

InactiveUS20070023359A1Economically and efficiently purifyingIon-exchange column/bed processesIon-exchanger regenerationIon exchangeAmmonium nitrate

Owner:GROTT GERALD J

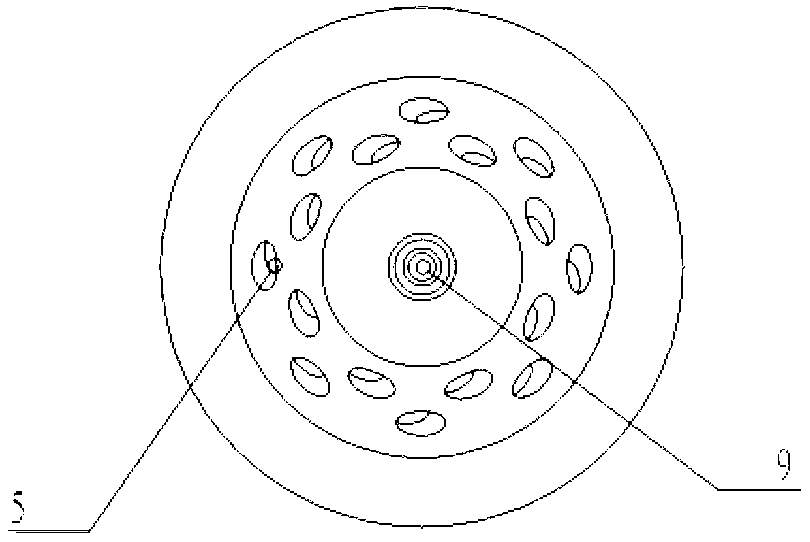

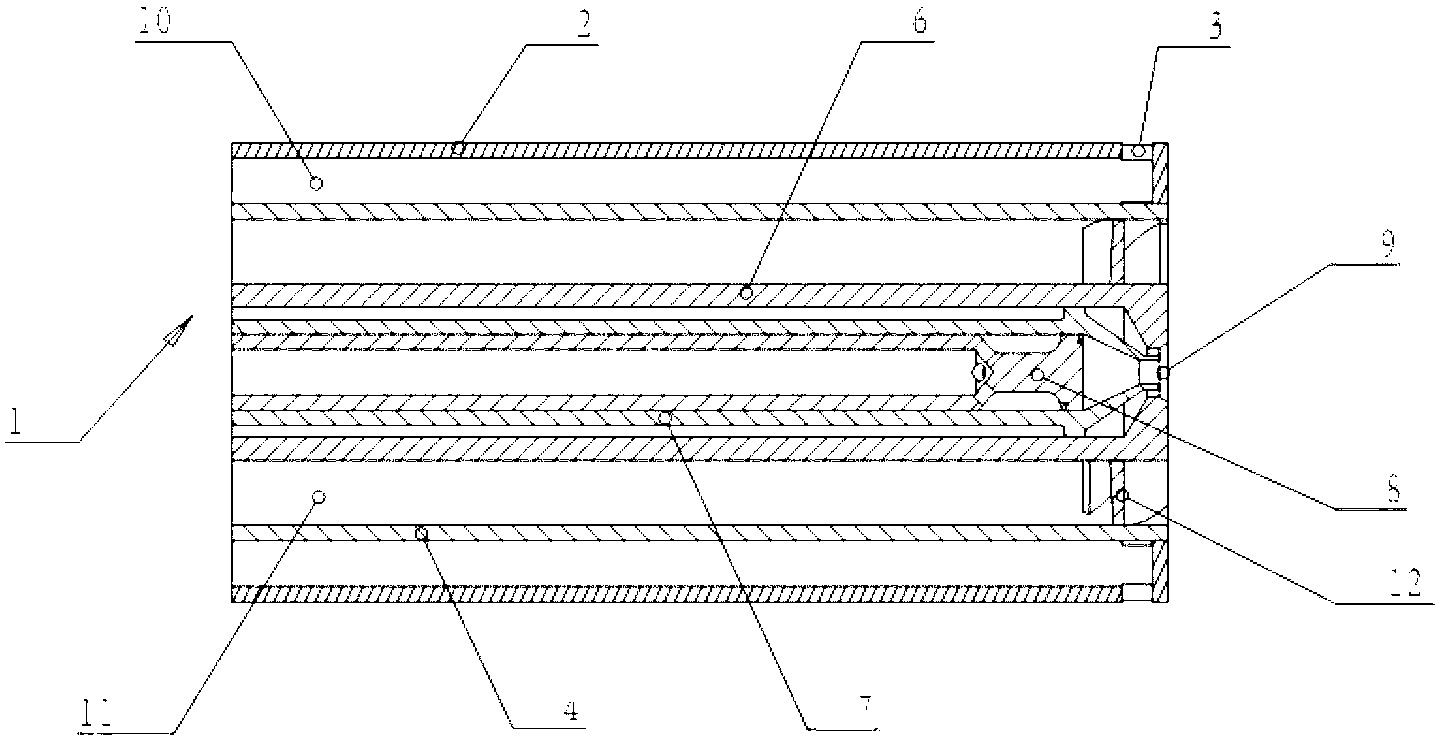

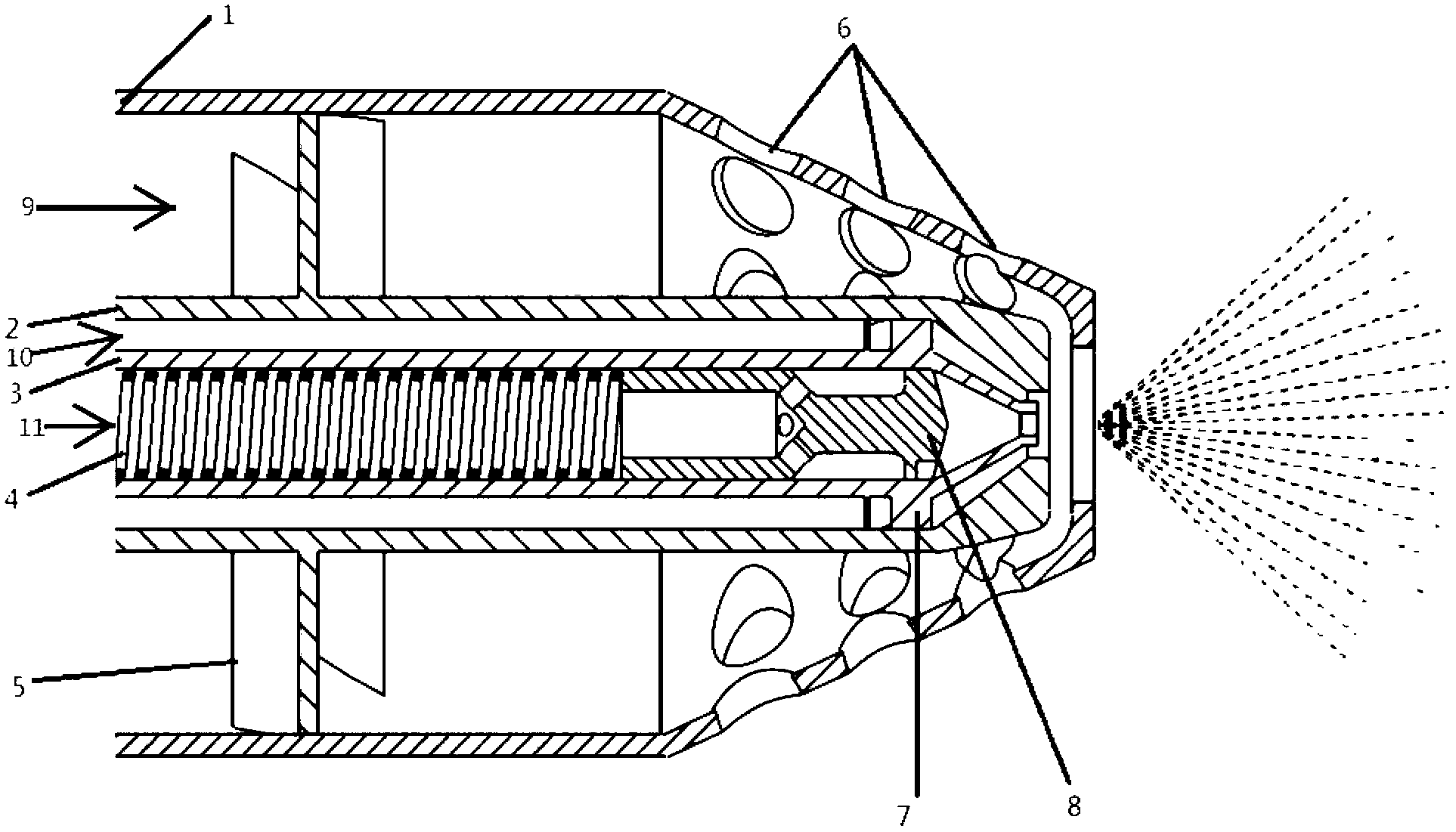

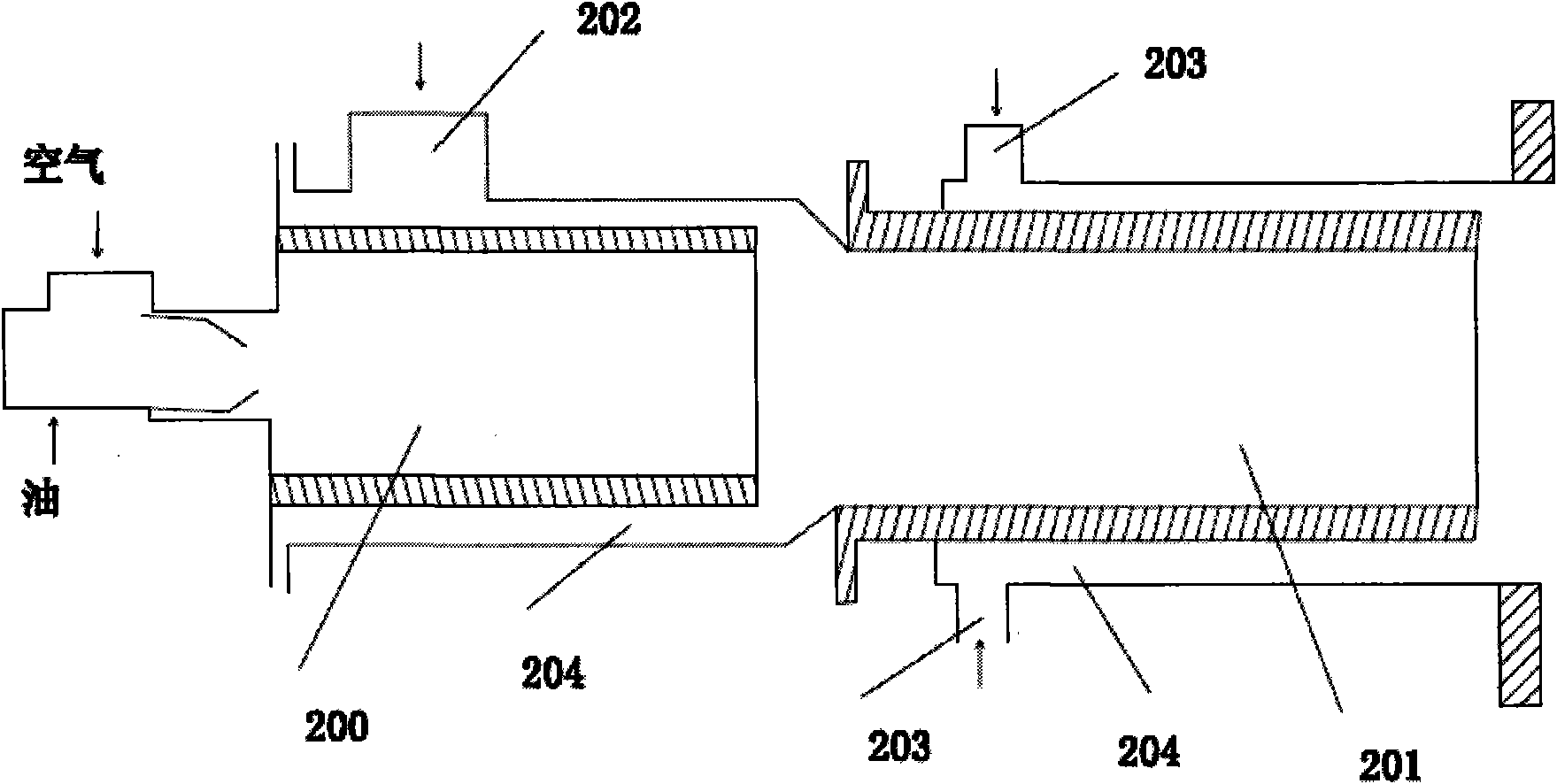

Dual-fuel nozzle used for chemical regenerative cycle

InactiveCN103175220AEfficient blendingWell mixedContinuous combustion chamberCombustorCombustion chamber

The invention provides a dual-fuel nozzle used for a chemical regenerative cycle. The dual-fuel nozzle used for the chemical regenerative cycle comprises a water vapor channel outer wall, a gas fuel channel outer wall, a main oil path pipeline, an auxiliary oil path pipeline and an oil path spout. The gas fuel channel outer wall is arranged in the water vapor channel outer wall. The main oil path pipeline is arranged in the gas fuel channel outer wall. The auxiliary oil path pipeline is arranged in the main oil path pipeline. A water vapor channel is formed between the water vapor channel outer wall and the gas fuel channel outer wall. A gas fuel channel is formed between the gas fuel channel outer wall and the main oil path pipeline. A main oil path is formed between the main oil path pipeline and the auxiliary oil path pipeline. An auxiliary oil path is arranged in the auxiliary oil path pipeline. An auxiliary oil path swirler is arranged on the end portion of the auxiliary oil path pipeline. The main oil path and an outlet of the auxiliary oil path swirler are communicated with the oil path spout. According to the dual-fuel nozzle used for the chemical regenerative cycle, water vapor and air are well mixed, emissions of a combustor are reduced, and a flameout phenomenon is avoided. Due to the fact that gas fuel and the air are well mixed, a combustion flame can be effectively shortened, and combustion efficiency can be improved.

Owner:HARBIN ENG UNIV

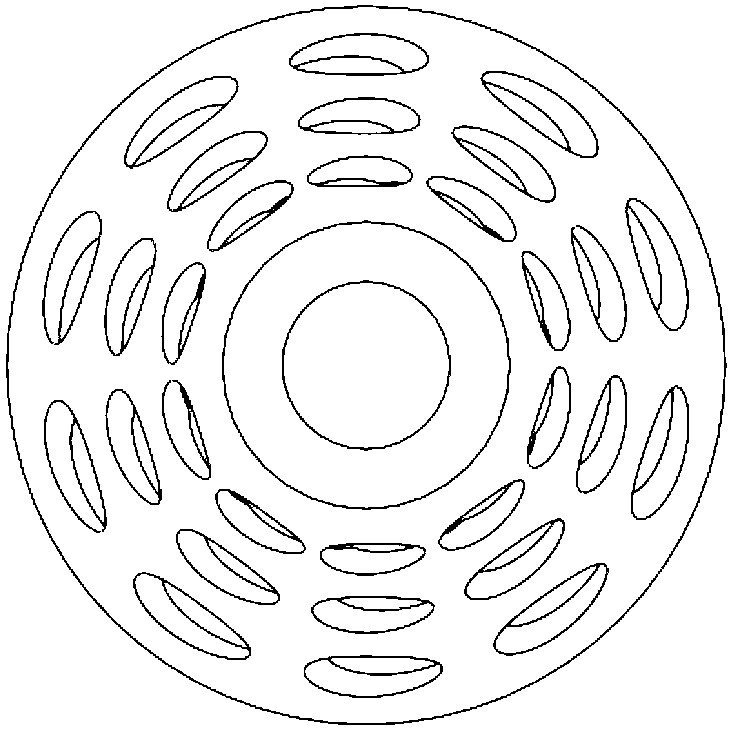

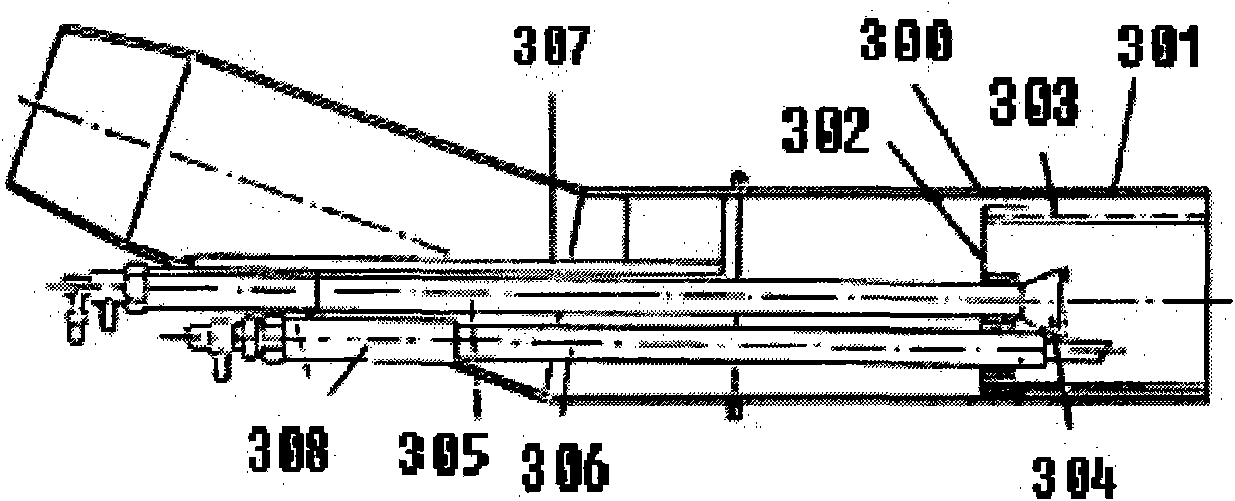

Double-swirl dual-fuel nozzle used for chemical regenerative cycle

InactiveCN103939943AImproved swirlEnhanced blendingContinuous combustion chamberSpray nozzleEngineering

The invention aims to provide a double-swirl dual-fuel nozzle used for a chemical regenerative cycle. The double-swirl dual-fuel nozzle comprises an auxiliary oil-path channel wall, a main oil-path channel wall, a first-level gas-path inner wall, a second-level gas-path inner wall and a gas-path outer wall, wherein the auxiliary oil-path channel wall, the main oil-path channel wall, the first-level gas-path inner wall, the second-level gas-path inner wall and the gas-path outer wall are arranged from inside to outside. An auxiliary oil-path channel is formed inside the auxiliary oil-path channel wall, and an auxiliary oil-path swirler is arranged at the end of the auxiliary oil-path channel wall and communicated with an oil-path spout. A main oil-path channel is formed between the auxiliary oil-path channel wall and the main oil-path channel wall and communicated with the oil-path spout. A first-level gas-path channel is formed between the first-level gas-path inner wall and the second-level gas-path inner wall, a second-level gas-path channel is formed between the second-level gas-path inner wall and the gas-path outer wall, the end, located on one side of the oil-path spout, of the first-level gas-path channel is provided with first-level swirl vanes, and the end, located on one side of the oil-path spout, of the second-level gas-path channel is provided with second-level swirl vanes. According to the double-swirl dual-fuel nozzle, the swirl vanes are adopted, the two levels of the swirl vanes have the opposite rotation angles, and mixing of gas fuel and air is enhanced.

Owner:HARBIN ENG UNIV

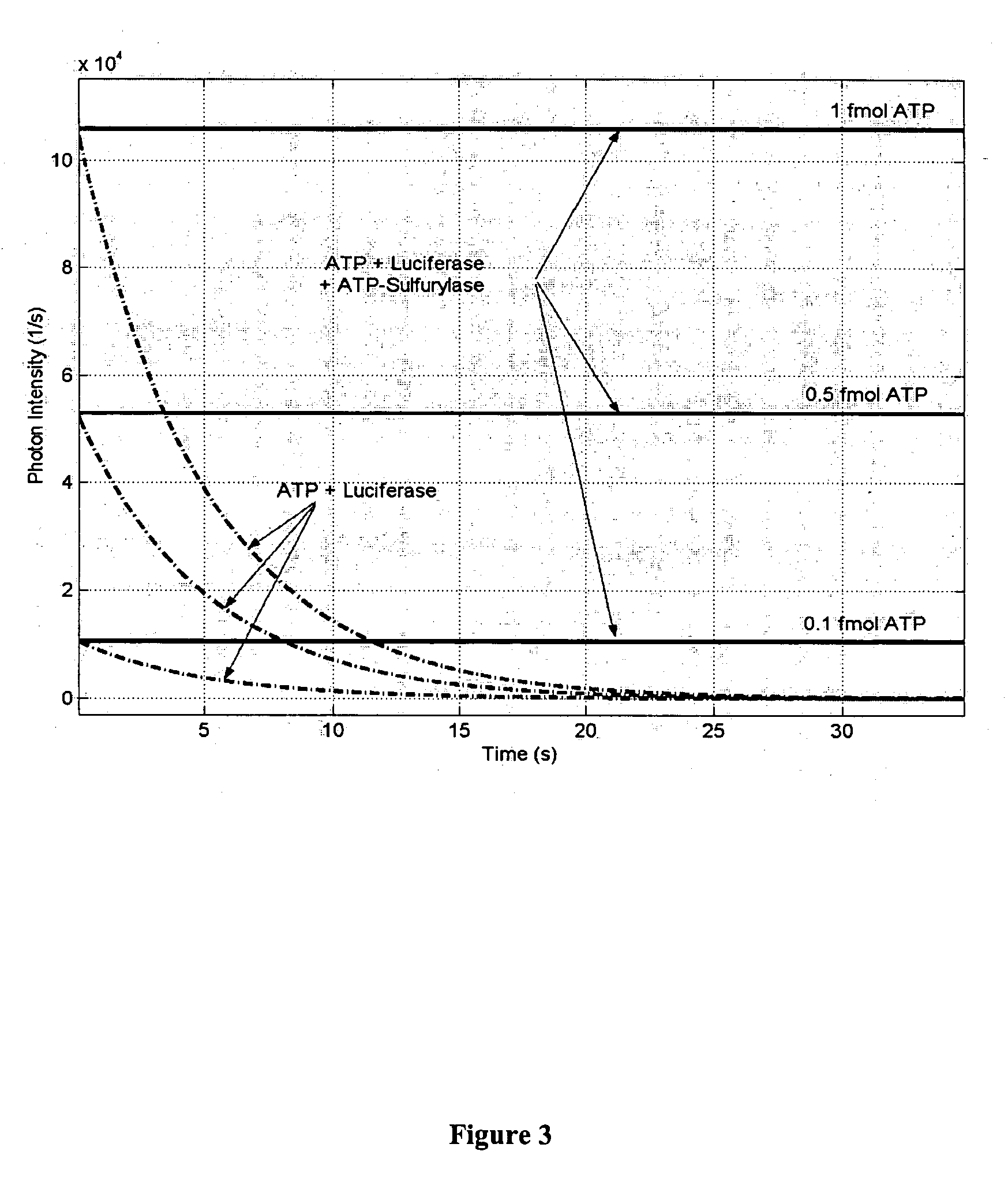

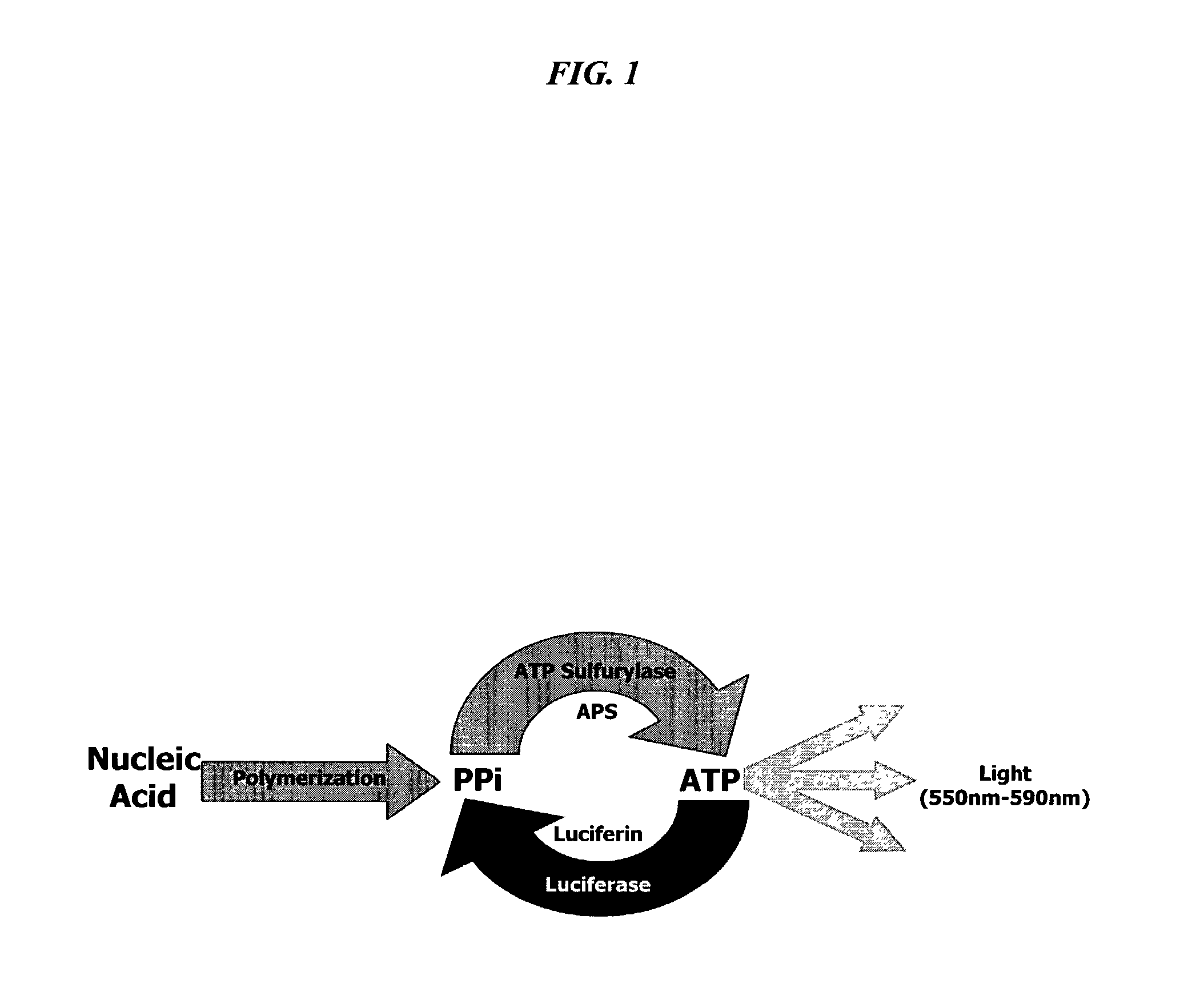

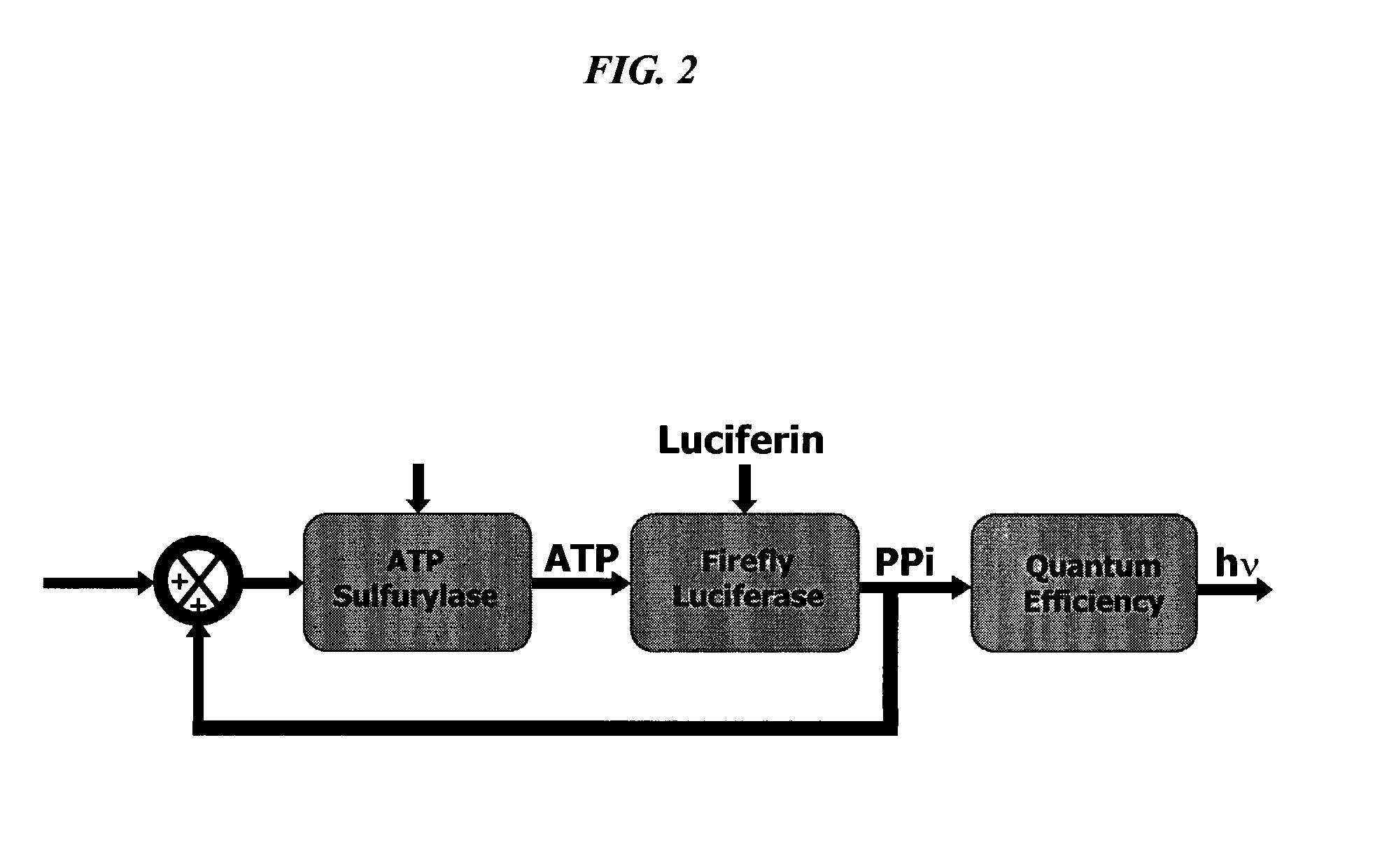

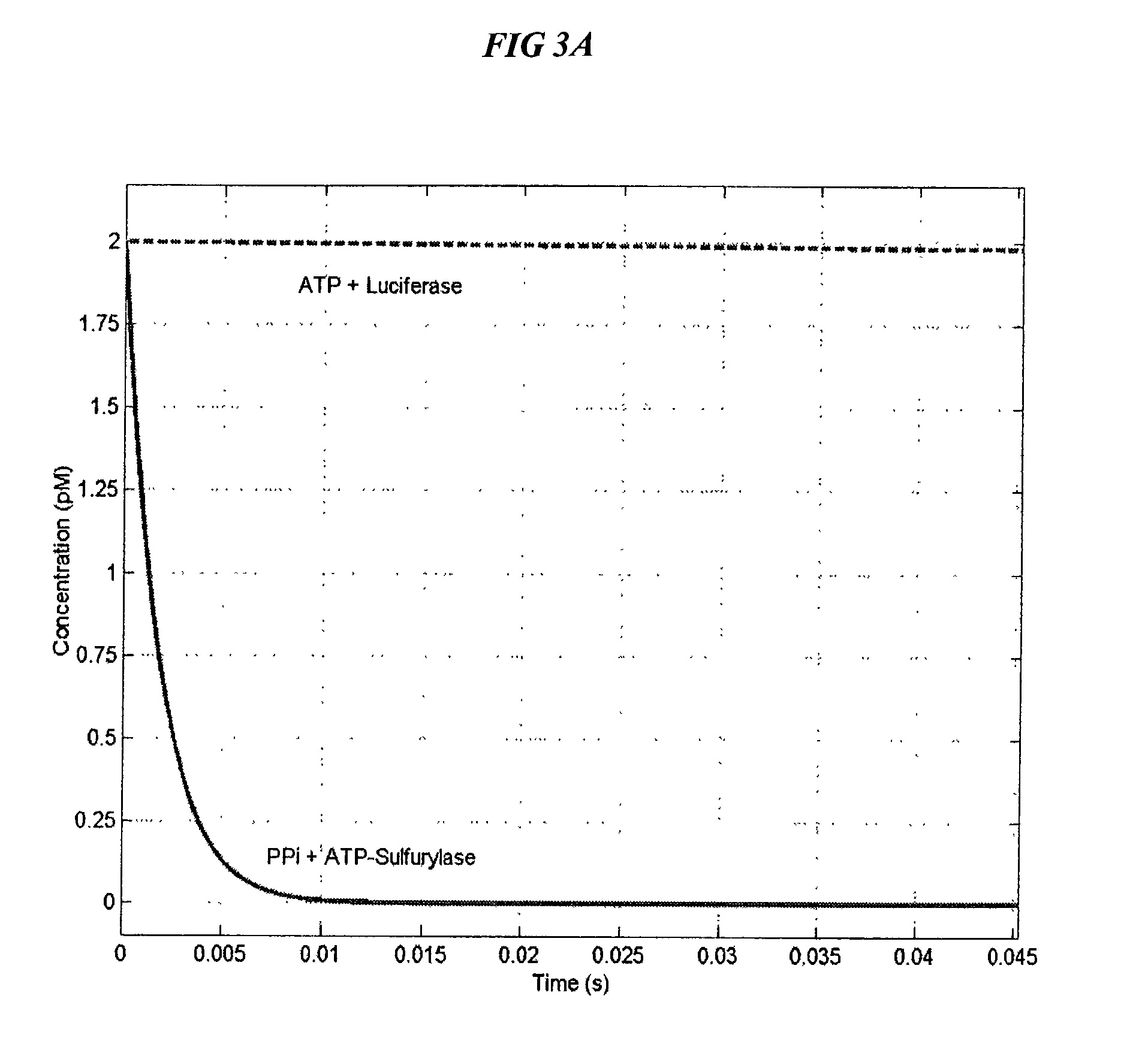

Bioluminescence regenerative cycle (BRC) for nucleic acid quantification

InactiveUS7141370B2High sensitivityImprove dynamic rangeMicrobiological testing/measurementBiological testingGeneration ratePyrophosphate

The present invention concerns methods of quantifying nucleic acids using a bioluminescence regenerative cycle (BRC). In BRC, steady state levels of bioluminescence result from processes that produce pyrophosphate. Pyrophosphate reacts with APS in the presence of ATP sulfurylase to produce ATP. The ATP reacts with luciferin in a luciferase-catalyzed reaction, producing light and regenerating pyrophosphate. The pyrophosphate is recycled to produce ATP and the regenerative cycle continues. Because the kinetic properties of ATP sulfurylase are much faster than luciferase, a steady state results wherein concentrations of ATP and pyrophosphate and the rate of light production remain relatively constant. Photons are counted over a time interval to determine the number of target molecules present in the initial sample. The BRC process has a controllable dynamic range up to seven orders of magnitude and is sensitive enough to detect a few thousand molecules of target nucleic acid.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

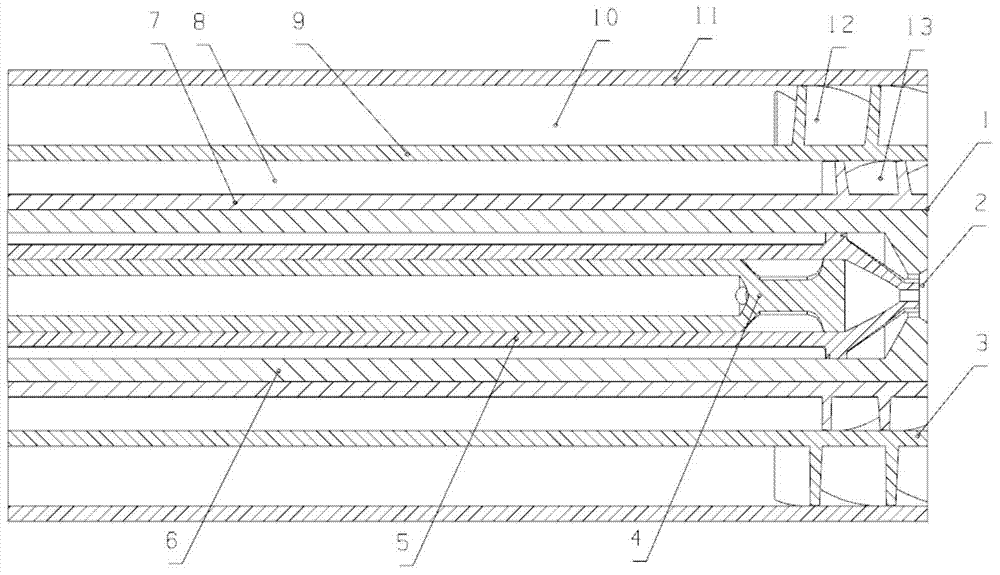

Active heat reclaiming method and device for diesel engine particulate drip catcher

InactiveCN101270685AAvoid the defect that it is not easy to igniteImprove ignition performanceExhaust apparatusSilencing apparatusParticulatesLiquid fuel

The invention relates to an active thermal regenerative method and a device of a collector for diesel micro particle. The method is as follows: liquid fuel, the boiling point of which is higher than normal temperature, is put into the tail gas of an engine or made into high pressure fuel vapor by being heated by electricity; after CPU sends a regeneration instruction, the oxygen content of regenerative environment is adjusted by supplementing auxiliary air and the fuel under high temperature steam enters combustion zone; meanwhile, an ignition plug begins to jump spark; fuel vapor is ignited Under the action of a twin-stage reverse whirl cone, premised flame is fixed on a proper position; heat from fuel burning makes gas flow temperature rise until the temperature of microparticle on filter element is above inflammation point; the microparticle on deposit is ignited when high temperature air flow passes by the filter element; the fuel should be continuously supplied until the microparticle on the deposit is burnt out; and a regenerative cycle is finished. In order to avoid the extreme high temperature of primary chamber part outside the collector, a gaseous film cooling structure is arranged. The active thermal regenerative method and device of the collector for diesel microparticle is easy to be ignited and has the characteristics of stable burning, efficient burning, strong anti-interference ability, little secondary pollution and stable action.

Owner:HUNAN UNIV

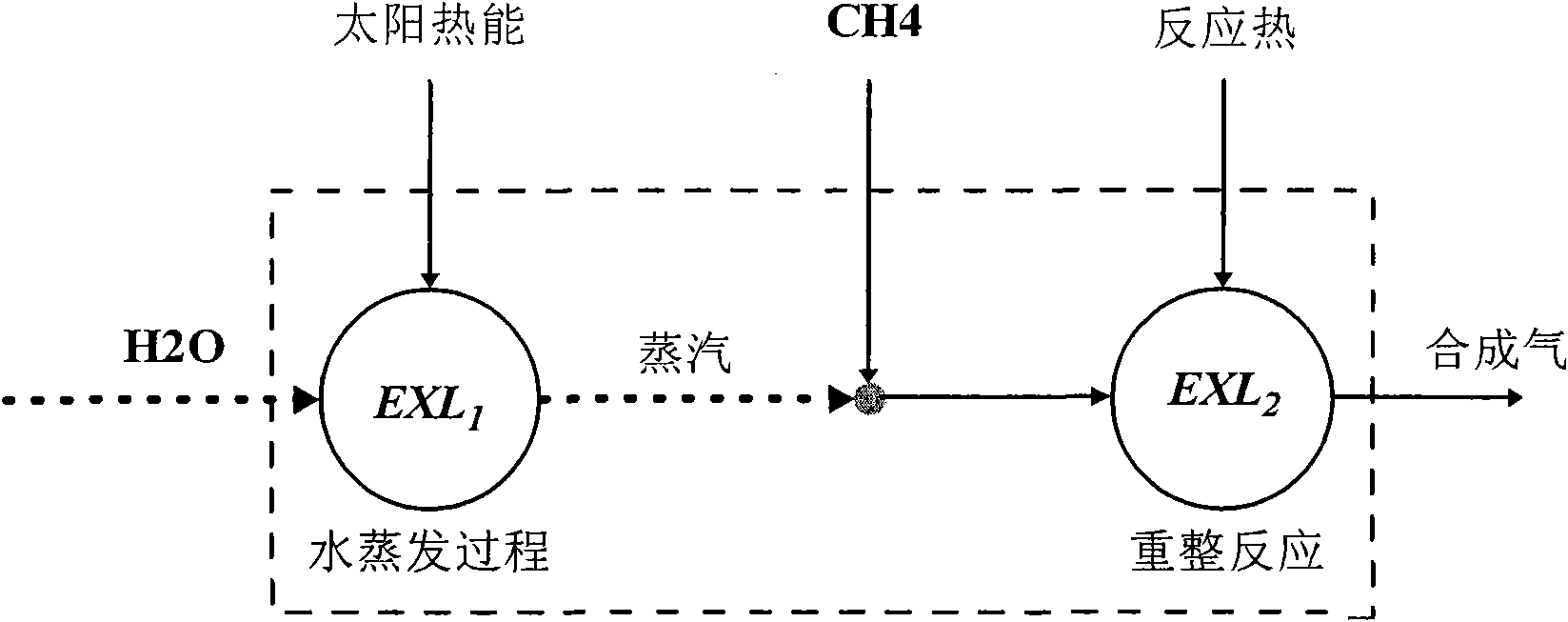

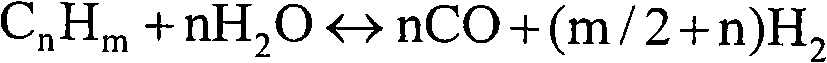

Method and device for indirectly promoting medium and low temperature solar heat energy grades

InactiveCN102061994AAchieve emission reductionImprove efficiencyTurbine/propulsion fuel supply systemsGas turbine plantsThermal energyEvaporation

The invention discloses a method for indirectly promoting medium and low temperature solar heat energy grades, which comprises the following steps of: introducing medium and low temperature solar heat energy in chemical regenerative cycle, converting the solar heat energy into steam internal energy by means of steam evaporation latent heat, converting the steam internal energy into synthetic gas chemical energy by reforming reaction with the participation of steam to realize grade promotion, and finally implementing heat power conversion in a combustion gas turbine system. Because of the introduction of solar energy, turbine exhaust waste heat reclamation is improved, fossil energy consumption is reduced, meanwhile, steam yield is increased, and chemical regeneration and physical regeneration benefits are increased. The solar energy heat-to-power net efficiency can reach 25 to 30 percent; and compared with the conventional chemical regenerative cycle, the efficiency is improved by 5.7 percent, the fossil energy can be saved by 20 to 30 percent, and meanwhile, CO2 emission reduction is realized. Therefore, the method has good economic efficiency and broad engineering application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

High-temperature waste heat recovery system for diesel engine

InactiveCN104265500APerformance impactCause harmNon-fuel substance addition to fuelInternal combustion piston enginesAtmospheric airAir compressor

The invention discloses a high-temperature waste heat recovery system for a diesel engine. The technical scheme is that an air compressor, a regenerator, a thermo-electric generator, an EGR heat exchanger and an expander are sequentially connected to form a Brayton air regenerative cycle system, and an airflow regulating valve is connected with the air inlet of the air compressor; high-temperature exhaust gas discharged by an engine is output in two ways: one part sequentially passes through a turbine and the thermo-electric generator and then is discharged to the atmosphere, the other part is mixed with supercharged air from a supercharger through the EGR heat exchanger, and the mixture enters the air inlet of the engine; and Brayton circulating air serves as the cold end of the thermo-electric generator, exhaust passing through the turbine serves as the hot end, and the thermo-electric generator pre-heats the Brayton circulating air while outputting power. The high-temperature waste heat recovery system can efficiently utilizes high-temperature waste heat of an internal combustion engine, thereby improving the fuel economy of the internal combustion engine and lowering the heat load of the system. Meanwhile, the system has a relatively simple composition, ensures safe and environment-friendly running, is convenient and flexible in layout, and can be easily implemented in the internal combustion engine.

Owner:TIANJIN UNIV

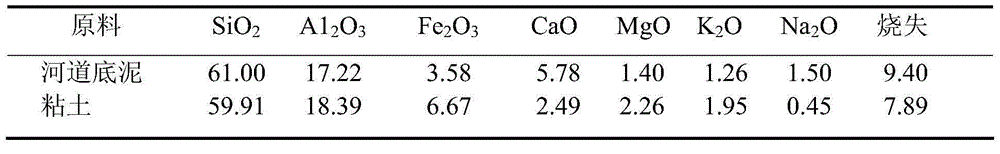

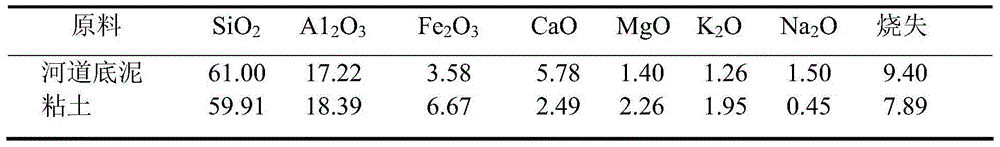

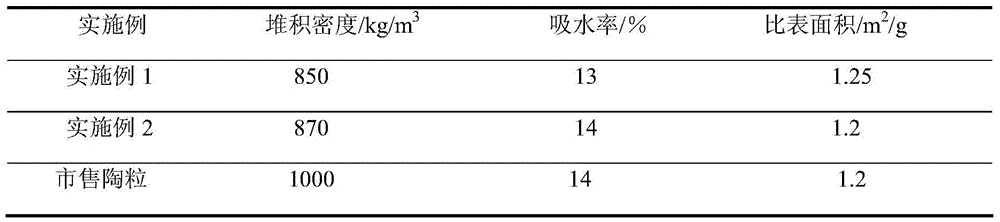

Preparation method of iron-carbon micro-electrolysis ceramsite filler for water treatment

InactiveCN104961201AReduce accumulationHarm reductionWater/sewage treatmentTreatment effectElectrolysis

The invention provides a preparation method of iron-carbon micro-electrolysis ceramsite filler for water treatment, which is characterized by comprising the following steps: 1, mixing iron scrap, waste circuit board powder, river sediment powder of loess cliff section of Xiaofu river in Zibo city of Shandong province and clay, the mass ratio is (15 to 20) to (55 to 60) to (10 to 15) to (10 to 15), and the mixture is formed; 2, adding the mixture into a granulating disc, additionally adding binder diluent for granulating, and the mass of the binder diluent is 25 to 30 percent, the spheroidal particles with each diameter of Phi 3 to 5 mm are prepared; 3, calcining and cooling under oxygen-free atmosphere after the spheroidal particles are dried, and obtaining the iron-carbon micro-electrolysis ceramsite filler. The iron-carbon micro-electrolysis ceramsite filler is prepared by solid waste such as waste iron scrap and waste circuit board powder as the main raw materials, the resources and energy are saved, using waste to treat waste and energy conservation and emission reduction are realized. The wastewater treatment effect is obviously superior to the existing ceramsite, especially for the iron-carbon micro-electrolysis reduction treatment effect of highly toxic wastewater containing hexavalent chromium; and the iron-carbon micro-electrolysis ceramsite filler is long in service life, simple in maintaining, and easy in utilization of regenerative cycle.

Owner:SHANDONG UNIV OF TECH

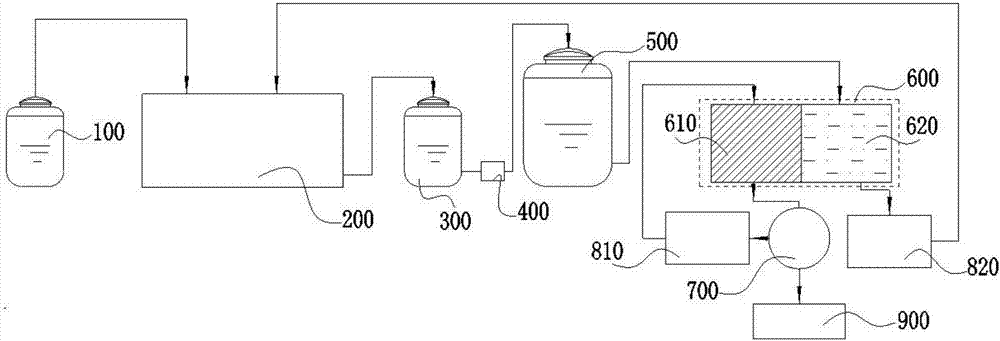

Solar absorption type sea water desalination device with regenerative cycle

InactiveCN102344179AHigh yieldImprove utilization efficiencyGeneral water supply conservationSeawater treatmentWater desalinationCooling tower

The invention discloses a solar absorption type sea water desalination device with regenerative cycle. The device comprises a cooling water tank, a cooling tower, a cooling pipeline, a solar heat collector, a hot water tank, a heating pipeline, a sea water tank, a sea water degassing device, an evaporator and an absorption type circulation system, wherein the cooling water tank, the cooling tower and the cooling pipeline are circularly communicated with one another; the solar heat collector, the hot water tank and the heating pipeline are communicated with one another; the sea water tank, the sea water degassing device and the evaporator are communicated with one another; a spray nozzle is formed in the evaporator and is communicated with the evaporator; a water outlet pipeline is connected outside the evaporator; an absorber, a solution circulating pump, a solution heat exchanger and a generator are arranged in the absorption type circulation system and are communicated with one another; lithium bromide solution is filled in the absorber and the generator; a water passing pipeline is formed in the solution heat exchanger and is communicated with the absorber and the generator; the solution circulating pump is connected with a control system; the cooling pipeline is arranged in the absorber; the heating pipeline is arranged in the generator; a condenser is communicated with a fresh water collection tank; and the pump is arranged on the connecting pipe and is connected with the control system. Thus, fresh water yield is increased, and corrosion of sea water on equipment is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

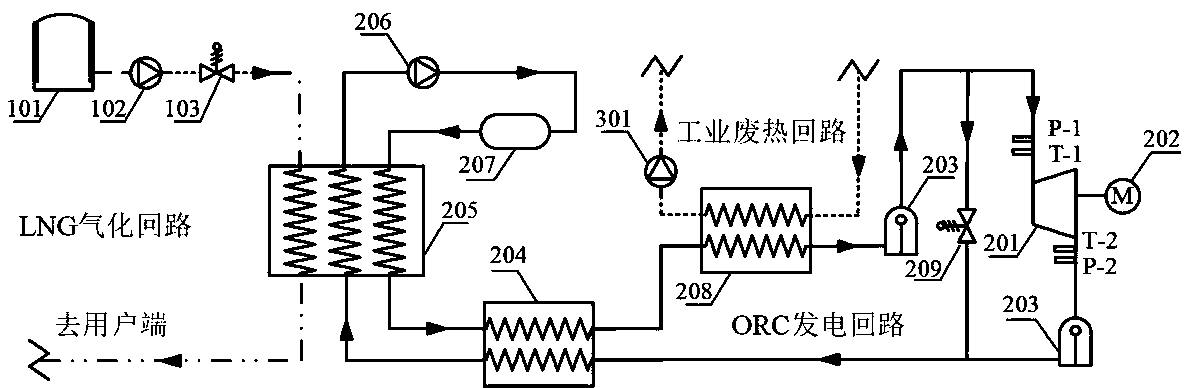

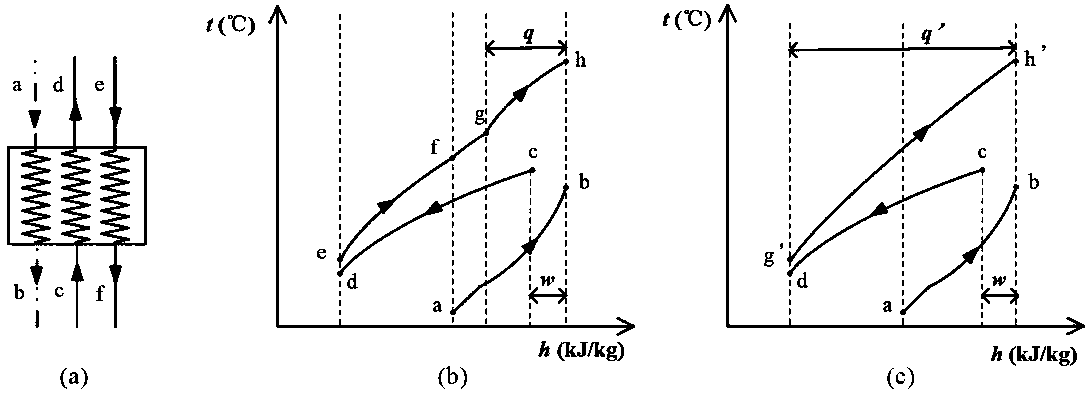

Regenerative cycle type ORC (organic Rankine cycle) power generation system utilizing LNG (liquid nature gas) cold energy and industrial waste heat

ActiveCN109098809ALow running costRaise the evaporation temperatureSteam engine plantsThermal energyOrganic Rankine cycle

The invention discloses a regenerative cycle type ORC (organic Rankine cycle) power generation system utilizing LNG (liquid nature gas) cold energy and industrial waste heat. The system comprises an LNG gasification loop, an ORC power generation loop and an industrial waste heat loop. Cold energy in the LNG gasification loop and heat energy in the industrial waste heat loop are utilized in the ORCpower generation loop, and a bypass loop is arranged in the ORC power generation loop to ensure safety high-efficiency running of an expansion machine. The regenerative cycle type ORC power generation system utilizing the LNG cold energy and the industrial waste heat has the advantages that an LNG cold energy recovery method is improved on the basis of existing ORC, the cold energy released in anLNG gasification process is fully utilized through a three-fluid heat exchanger and a heat regenerator, thermal stress during LNG cold energy utilization and thermal load of an evaporator are reduced, and the efficiency of the ORC power generation system is effectively improved. The regenerative cycle type ORC power generation system can be widely applied to the fields of power generation by theLNG cold energy and industrial waste heat recovery.

Owner:SHANGHAI MARITIME UNIVERSITY

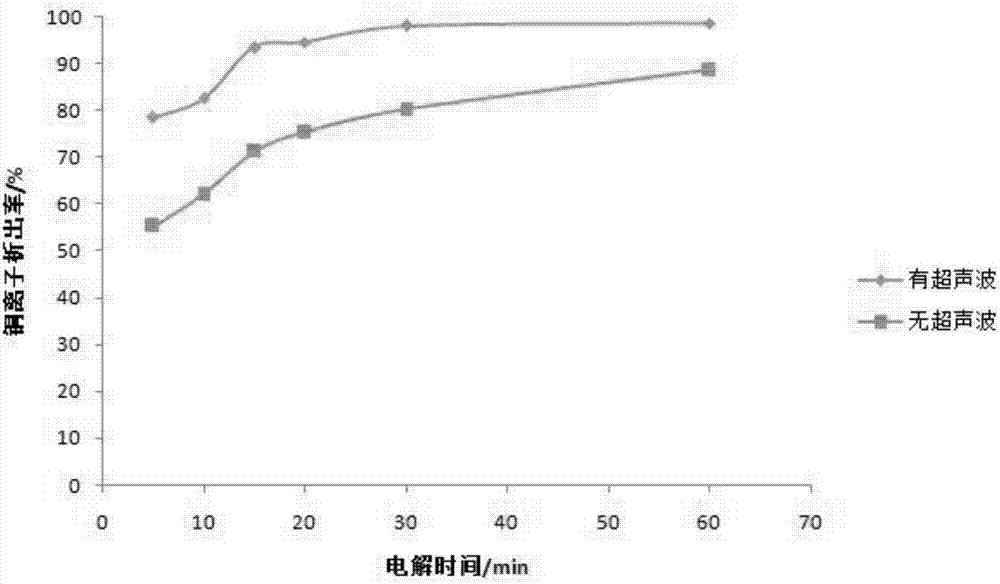

Acid etching liquid regenerative cycle method and system

ActiveCN107012466APrecise etching effectIncrease precipitation speedPhotography auxillary processesAcid etchingElectrolysis

The invention provides an acid etching liquid regenerative cycle method. The method comprises the steps of collection of acid etching liquid, filtration and mixing of the acid etching liquid, ultrasonic-assisted electrolysis, copper sheet decomposition, anolyte cycle using and the like. According to the acid etching liquid regenerative cycle method, ultrasonic catalyzed electrolysis is adopted, the concentration of the acid etching electrolyte, the electrolytic current density and electrolytic temperature are precisely adjusted and controlled, copper ions in the acid etching liquid can be converted to be copper sheets with the purity reaching up to 99%, the separation-out speed of the copper ions is greatly improved, production efficiency is improved, and meanwhile production energy consumption is lowered. The invention further provides an acid etching liquid regenerative cycle system matched with the acid etching liquid regenerative cycle method. The ultrasonic technology is combined with the ion film technology, the copper ion separation-out speed can be increased, the copper ion separation-out purity can be further improved, and the high-purity copper sheets with the purity being 99.8% or above can be obtained.

Owner:丰顺佳丰电子有限公司

Acidic waste water treatment agent capable of regenerative cycle use and preparation method thereof

InactiveCN1919748ASimple preparation processGood effect in treating acid wastewaterWater/sewage treatment by neutralisationWastewaterHydrotalcite

The invention discloses a renewable industrial acid waste water disposing agent and preparing method, which is characterized by the following: adopting magnesium hydrotalcite as former; sintering to obtain the magnesium composite metal oxide; adopting hydrotalcite material structure to dispose acid waste water.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

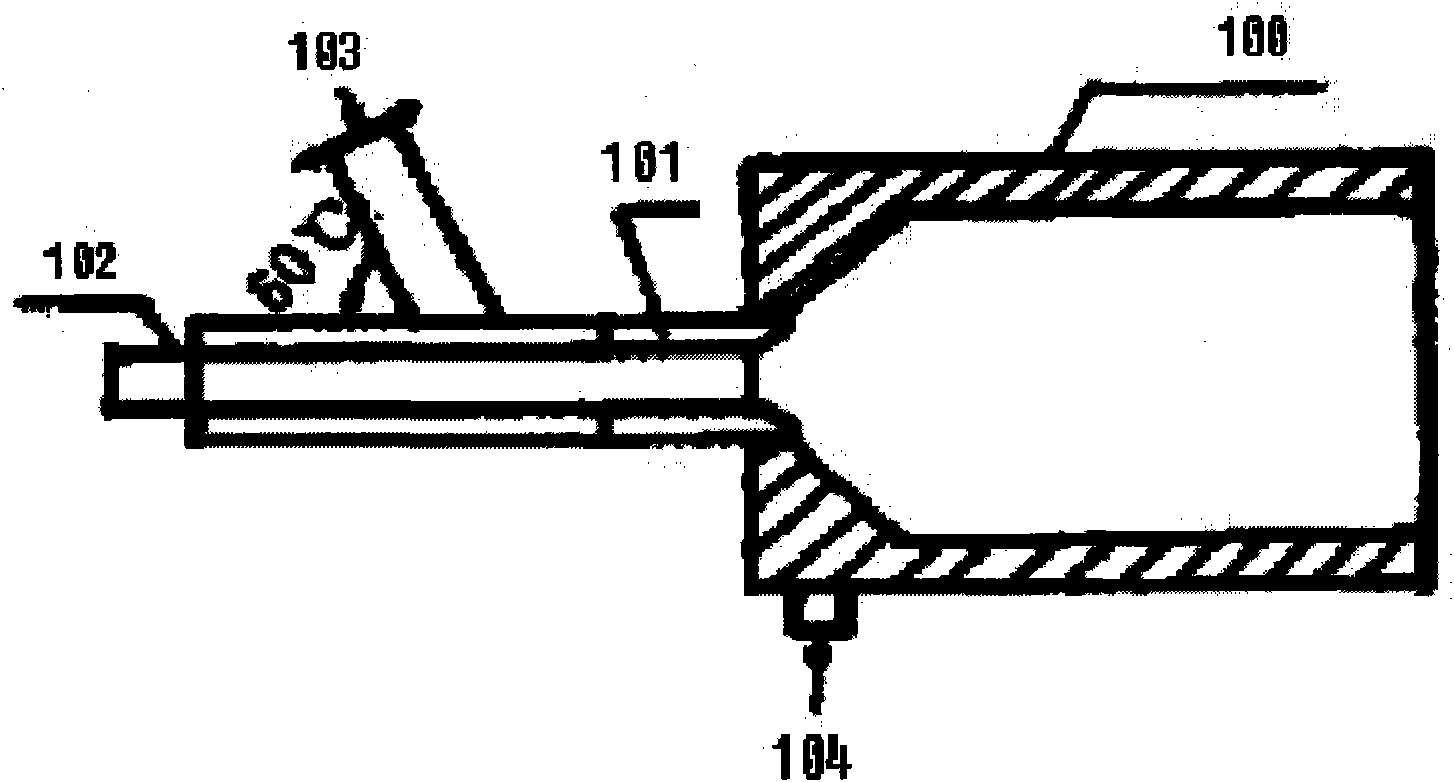

Gas-assisted dual-fuel nozzle used for chemical regenerative cycle

InactiveCN103175221AImprove atomization effectPrevent backflowContinuous combustion chamberCombustion chamberCombustor

The invention provides a gas-assisted dual-fuel nozzle used for a chemical regenerative cycle. The gas-assisted dual-fuel nozzle comprises a pyrolysis gas channel outer wall, a pyrolysis gas channel inner wall and a main oil path inner wall. A pyrolysis gas channel is formed between the pyrolysis gas channel outer wall and the pyrolysis gas channel inner wall. A main oil path is formed between the pyrolysis gas channel inner wall and the main oil path inner wall. An auxiliary oil path is arranged in the main oil path inner wall. A spring and an auxiliary oil path swirler are mounted in the auxiliary oil path, wherein the spring abuts against the auxiliary oil path swirler to enable the auxiliary oil path swirler to be coaxial with the main oil path inner wall. A main oil path rotational flow groove is formed in the end portion of the main oil path. An outlet of the auxiliary oil path swirler is communicated with an outlet of the main oil path rotational flow groove. The cross section of the end portion of the pyrolysis gas channel outer wall is a trapezoid, wherein a spout is formed in the upper surface of the trapezoid, and a pyrolysis gas outlet is formed in each of waists of the trapezoid. The gas-assisted dual-fuel nozzle used for the chemical regenerative cycle combines the advantages of pressure swirl atomization and pneumatic nebulization, thereby being good in atomization effect and capable of meeting the requirements of full working conditions of a combustor.

Owner:HARBIN ENG UNIV

Oxygen-enriched burner

InactiveCN101556039ASave high-grade energySaving grade energyChemical industryDispersed particle separationCombustorFlue gas

The invention discloses an oxygen-enriched burner which comprises a burner communicated with a hearth and an oxygen-enriched gas generator that includes an air separator, an air inlet pipe, a nitrogen outlet pipe and an oxygen-enriched gas outlet pipe; wherein, the air inlet pipe, the nitrogen outlet pipe and the oxygen-enriched gas outlet pipe are respectively connected with three ports of the air separator; the burner comprises an inner bushing, a middle bushing, an outer bushing and a connecting pipe between the inner and the outer bushings, wherein, the inner bushing is arranged inside the middle bushing which is positioned inside the outer bushing, one end of the inner bushing is connected with one end of the outer bushing by the connecting pipe between the inner and the outer bushings, the other end of the inner bushing is communicated with an inlet of the hearth, and the other end of the outer bushing is an inlet of regenerative cycle flue gas; one end of the middle bushing is communicated with an inlet of the hearth, and the other end thereof is an inlet of coal dust and oxygen-enriched gas. The oxygen-enriched burner leads the oxygen-enriched gas and the coal dust to be fully and evenly mixed together, and improves the heat exchange efficiency of preheating the coal dust by back-flow gas, so as to overcome the defects of the existing oxygen-enriched combustion technology.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com