Patents

Literature

431results about How to "Achieve emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

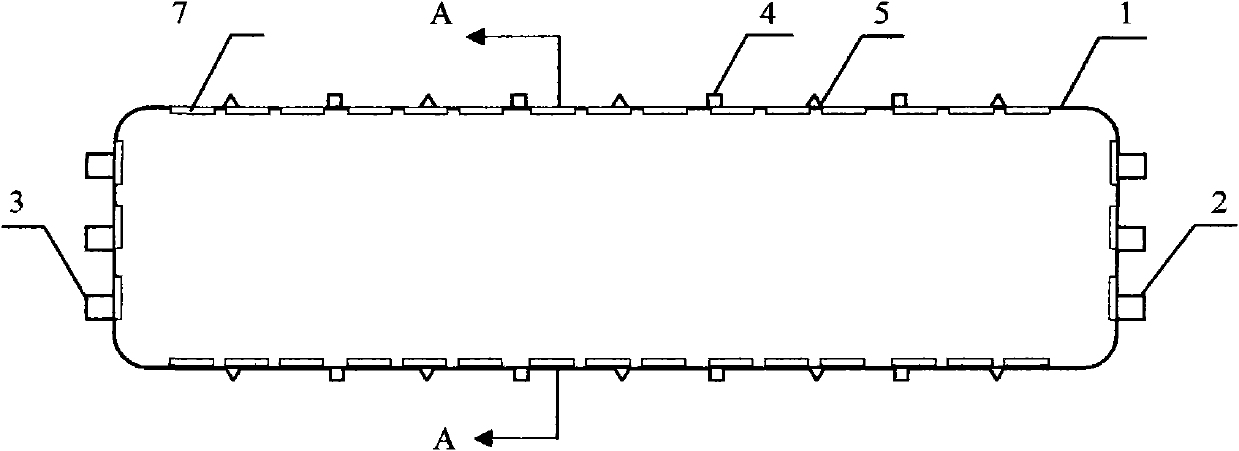

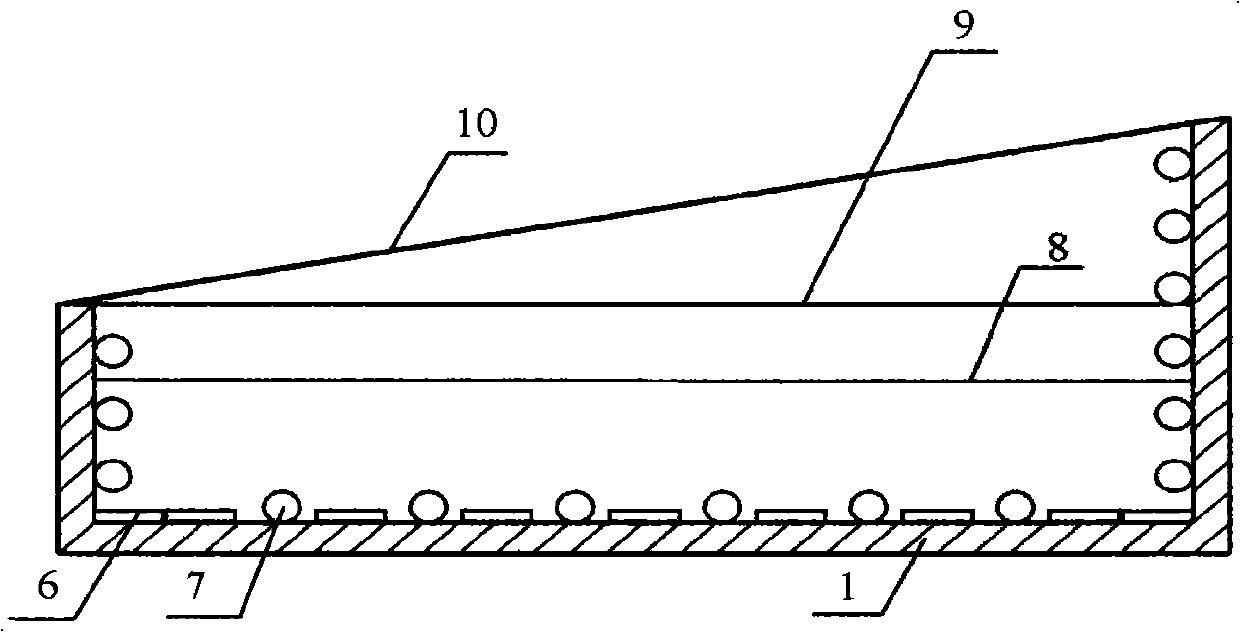

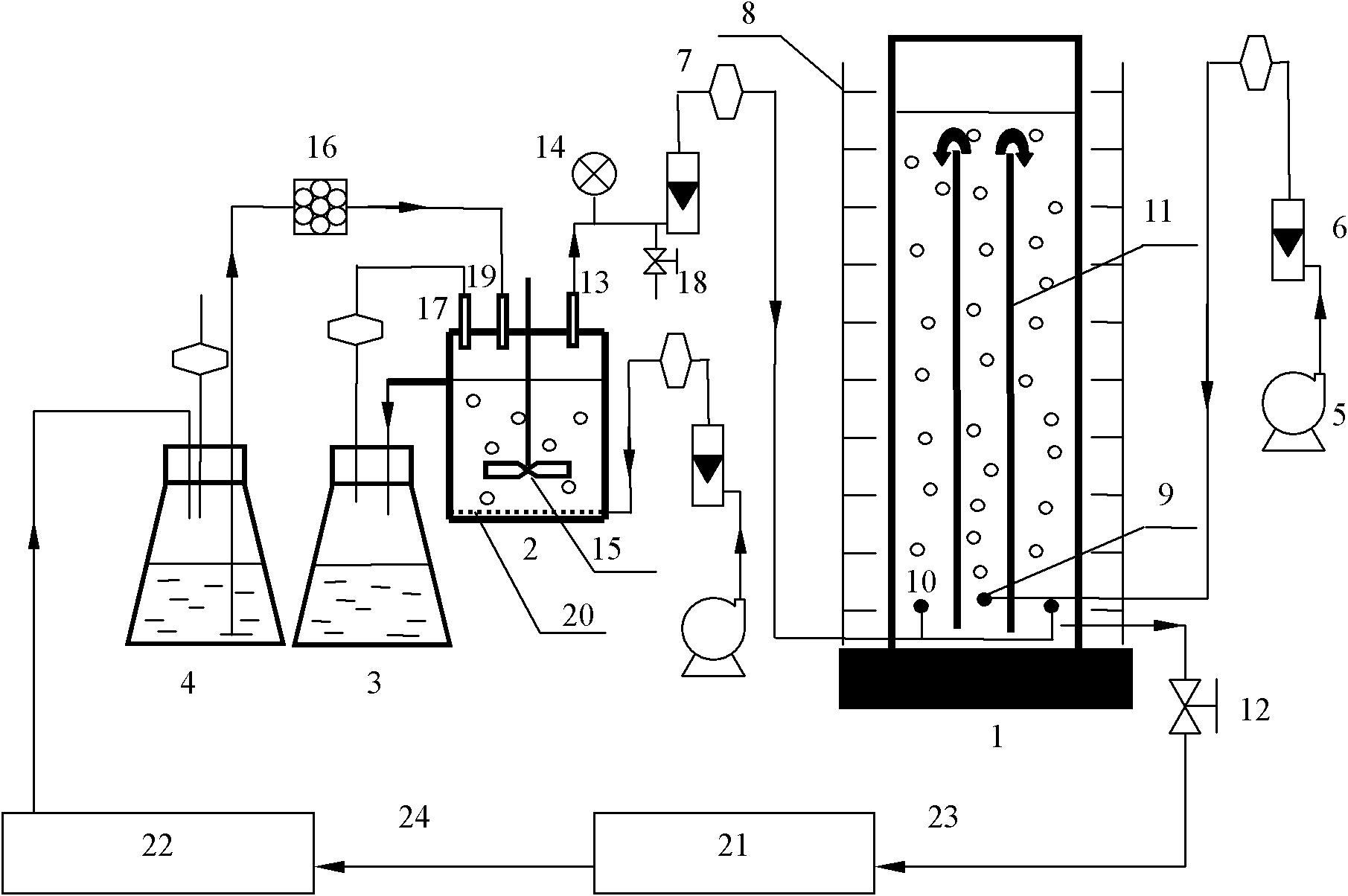

Production unit for microalgae industrialization and method for producing microalgae

InactiveCN101280271AAchieve emission reductionAchieve governanceBioreactor/fermenter combinationsBiological substance pretreatmentsEutrophicationBrick

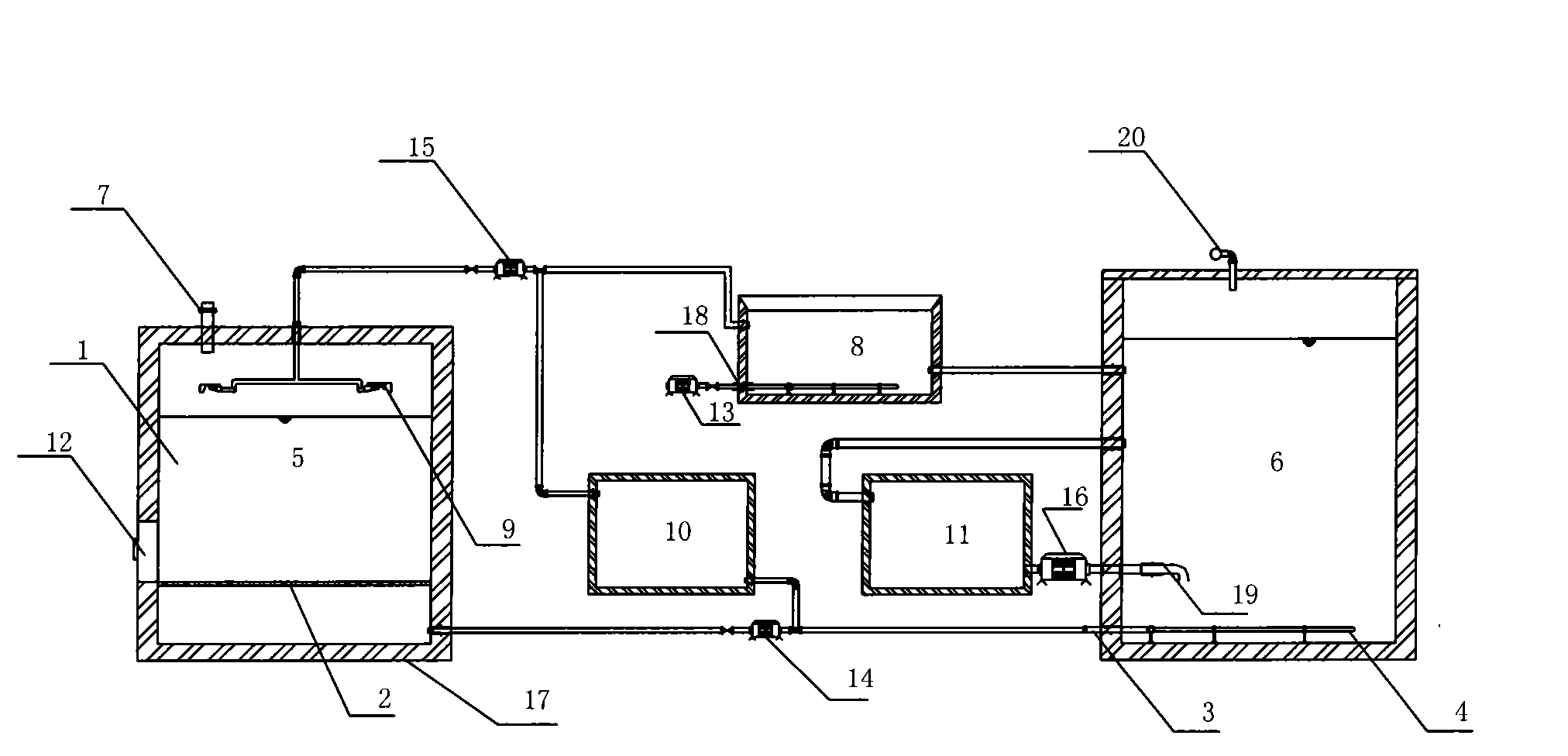

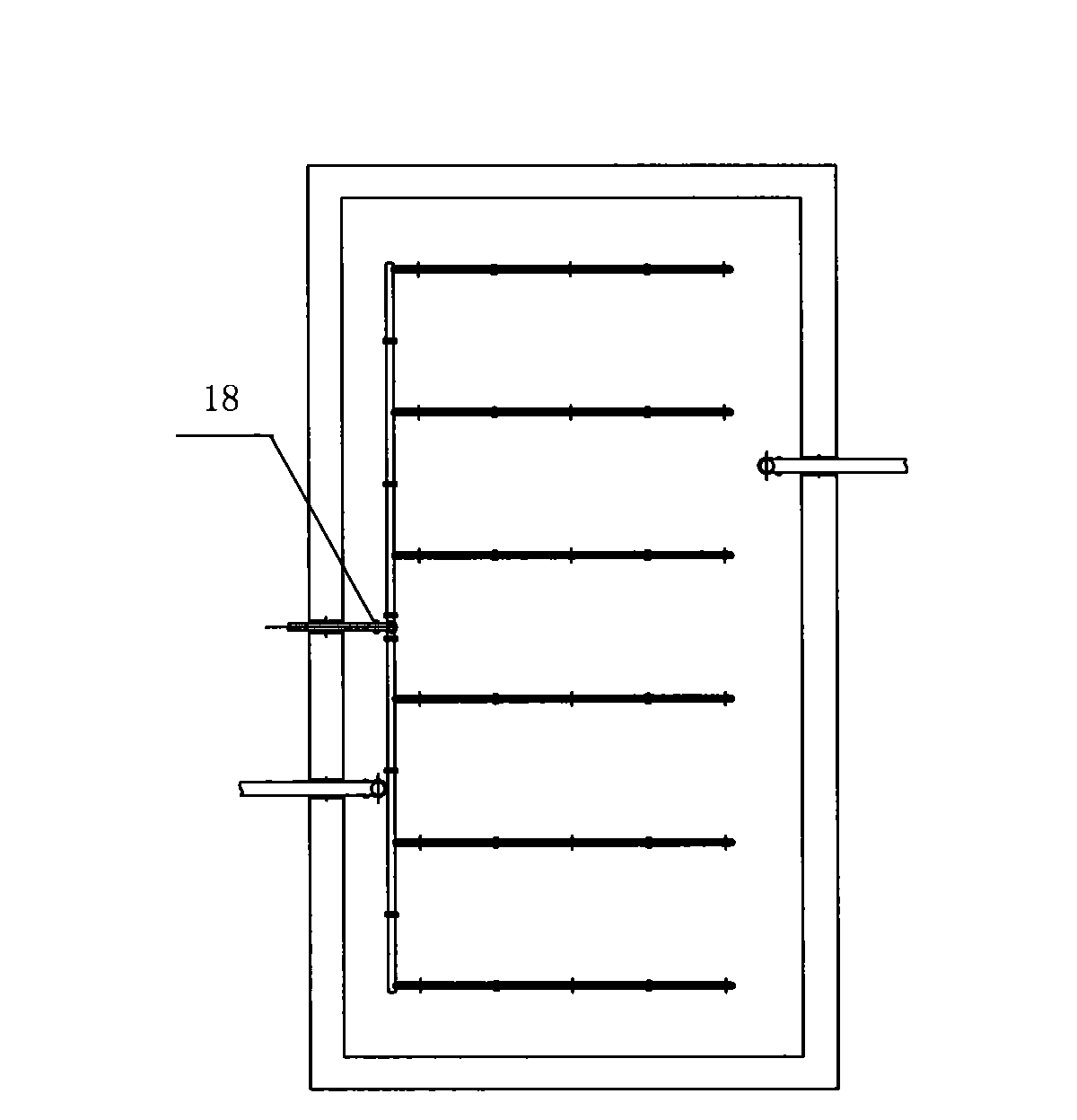

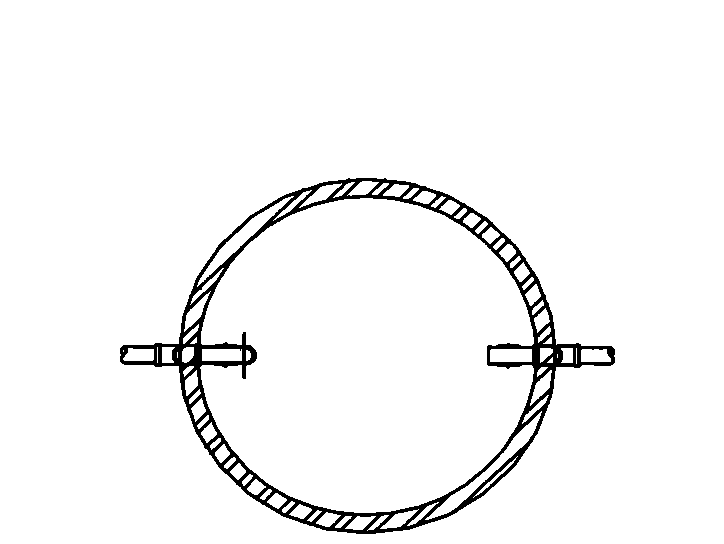

The invention relates to a micro-algae industrialization production device and a method of producing the micro-algae, which belong to the engineering field of the micro-algae culturing and the technical field of the environmental protection. An air-pushed type photobiology reactor unit device is an annular shallow pond built by bricks and concrete, an isolation wall with both ends opened is built in the shallow pond, a liquid drainage pipe and a liquid replacement pipe are arranged in the air-pushed type photobiology reactor unit device, an air inlet pipe is fixed on the isolation wall in the middle part of the air-pushed type photobiology reactor unit device and is connected with a plurality of L-shaped branch pipes, a plurality of micro blowholes are arranged on side walls of the transversal pipes of the branch pipes, the whole air-pushed type photobiology reactor unit device is covered by agricultural film and is provided with a skylight, to form an enclosed type photobiology reactor. The device combines the individual advantage of the open type photobiology reactor and the enclosed type photobiology reactor, by adopting the industrial waste gas and the eutrophication surface water or the industrial wastewater as the main raw material to perform micro-algae culturing in a large scale, especially to culture the micro-algae with high oil percentage, to provide the large or medium sized bio-diesel factory with raw oil, and simultaneously the emission reduction of carbon dioxide and the treatment of polluted water body are realized.

Owner:蔡志武

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

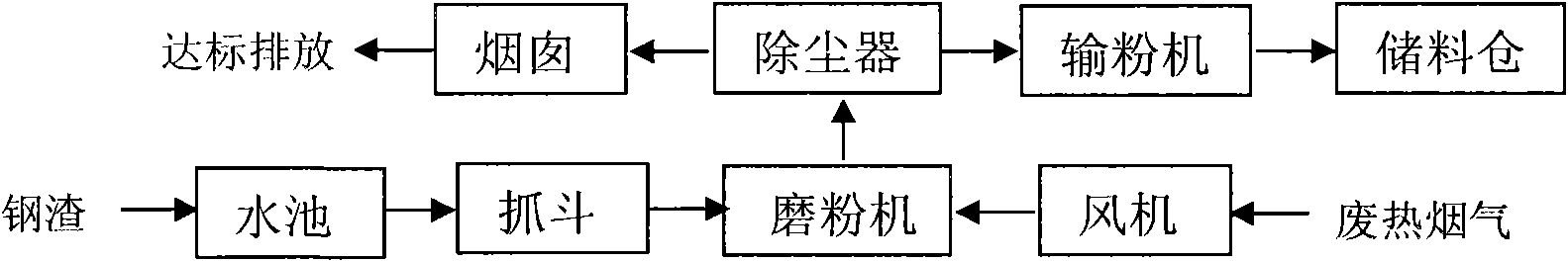

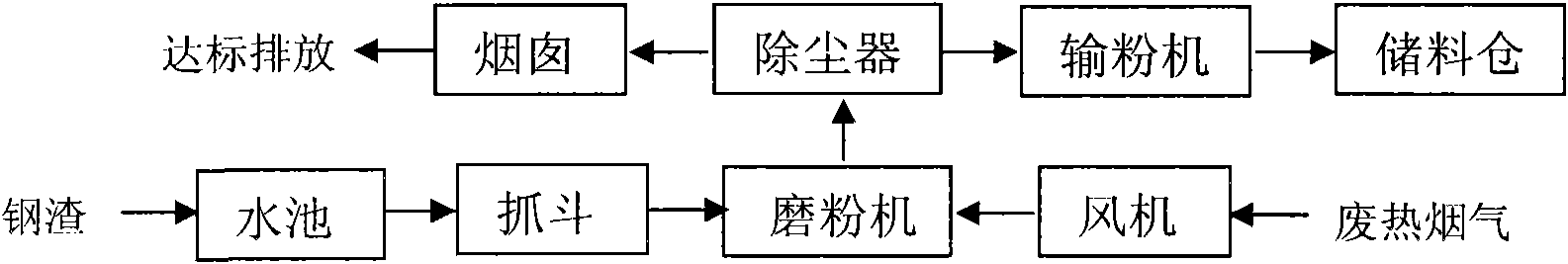

Method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder

InactiveCN101851071AF-CaO content decreasedAchieve stabilizationCalcium/strontium/barium carbonatesGas treatmentSlagResource utilization

The invention relates to a method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder, which belongs to the technical field of the carbon dioxide reduction and the industrial solid waste resource utilization. Converter steel slag is soaked in water, then the steel slag after being soaked in the water is added into a grinding machine, at the same time, waste heat smoke gas containing carbon dioxide is introduced into the grinding machine with the steel slag to carry out the stabilization reaction, and the steel slag is ground and dried; the waste heat smoke gas brings out the steel slag micro powder after being ground and dried from the tail section of the grinding machine to enter a power collection device, and the steel slag micro powder is discharged from the bottom part of the powder collection device; and the temperature of the waste heat smoke gas is 150 to 180 DEG C. The method has the advantages that: carbon dioxide in the waste smoke gas is used for chemically modifying the steel slag micro powder, so the content of the f-CaO is reduced, the chemical stability of the steel slag micro powder is improved, and technical requirements of the national standard GB / T 20491 - 2006 of steel slag powder for cement and concrete can be reached. The carbon dioxide also can be cured, so the exhaustion of the greenhouse gas can be reduced, and the environment-friendly carbon cycling mode can be realized.

Owner:SHOUGANG CORPORATION

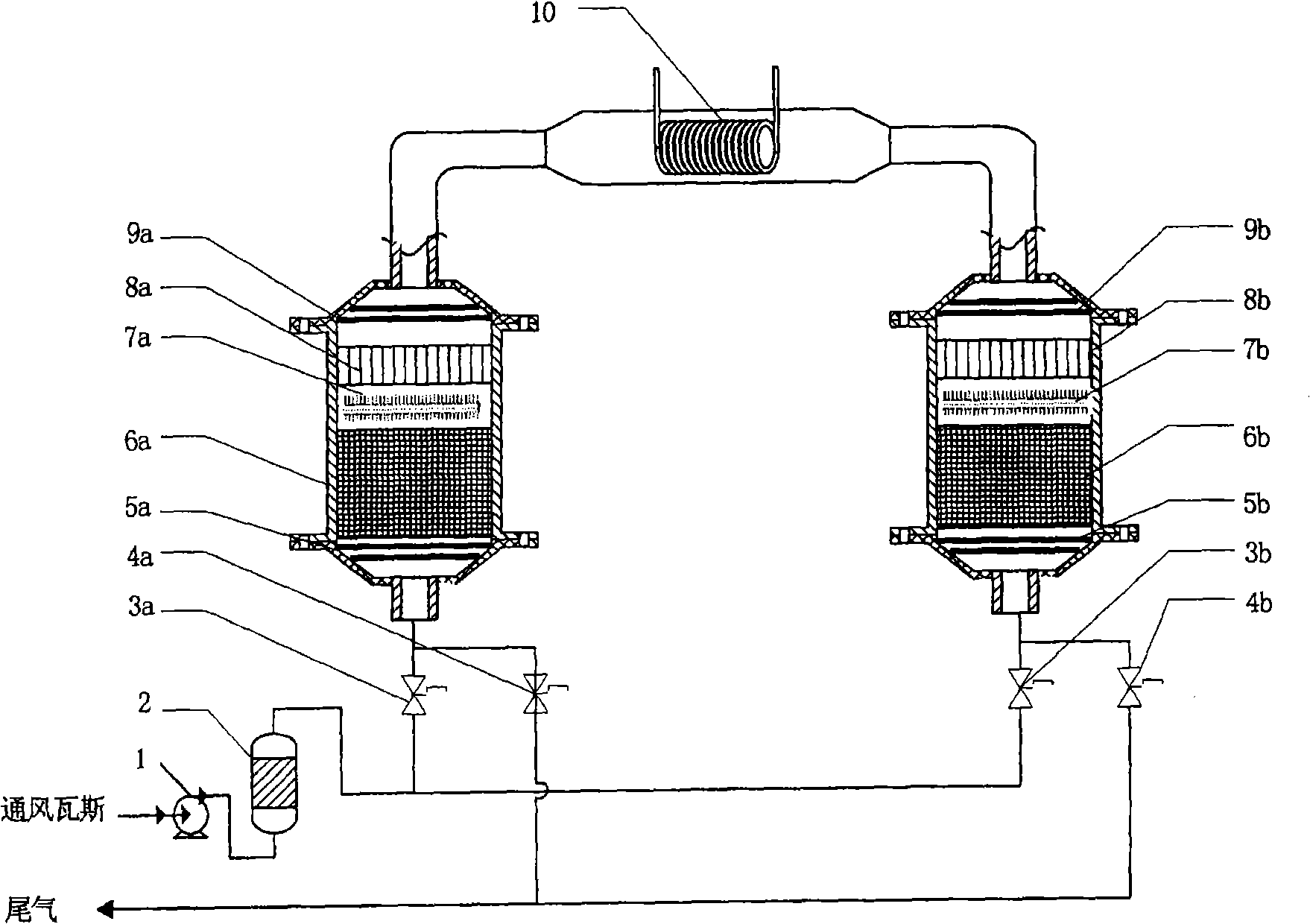

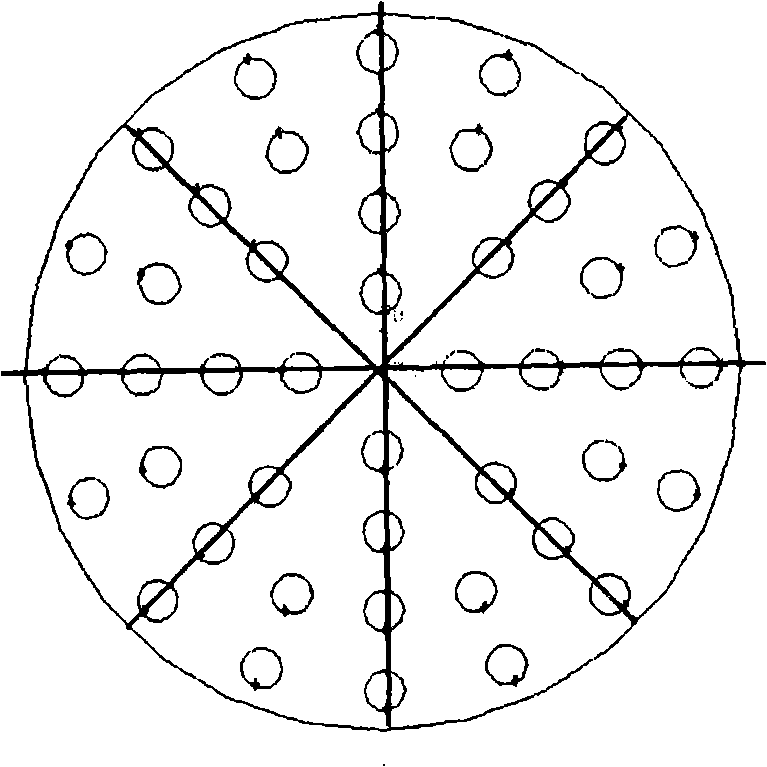

Apparatus for comprehensively utilizing coal mine to ventilate mash gas

InactiveCN101275744AImprove anti-blocking performanceHigh strengthIncinerator apparatusHoneycombProcess engineering

A device for the coal ventilation gas comprehensive utilization, a reactor outlet end with the same structure is connected into a U-shape reactor through a heat taking device; the entrance of the reactor is filled with a honeycomb heat retaining mass; the outlet end is a catalyst bed layer; an electric heater is arranged between the heat retaining mass outlet end and the catalyst bed layer; the entrance of the raw gas is provided with a valve set for controlling the conversion of the current direction in the reactor; the raw gas enters the reactor, and generates the catalytic combustion on the catalyst bed layer; a saddle type bed temperature distribution is realized in the reactor by processing the periodic switch through the current direction of the reaction gas, the burning end gas is fetched out by the heat taking device. The invention has higher heat reclaim efficiency; when the concentration of the methane in the ventilation gas and the flow of the ventilation gas change, the high efficiency selfheating operation can be realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

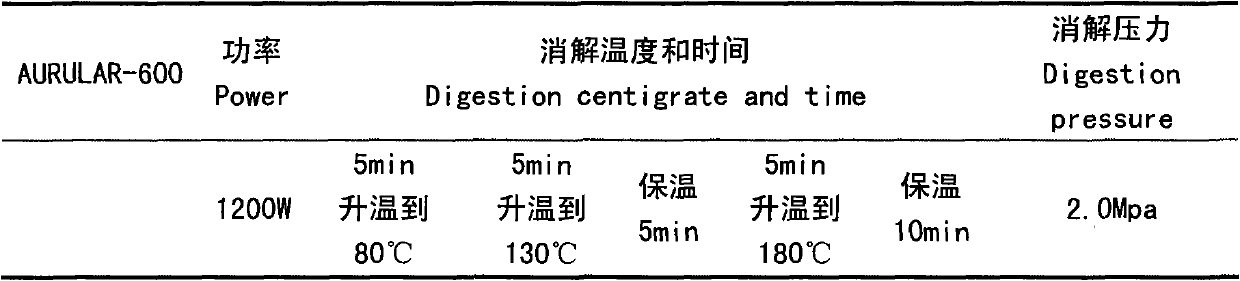

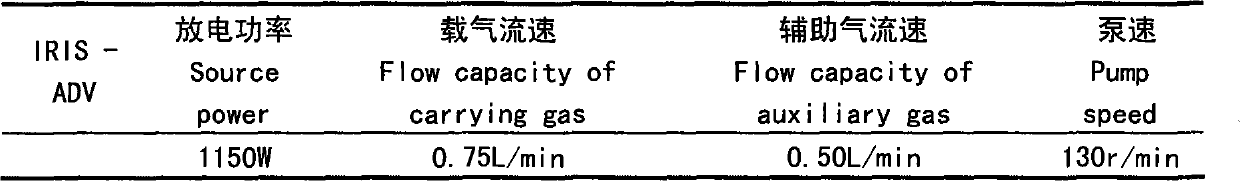

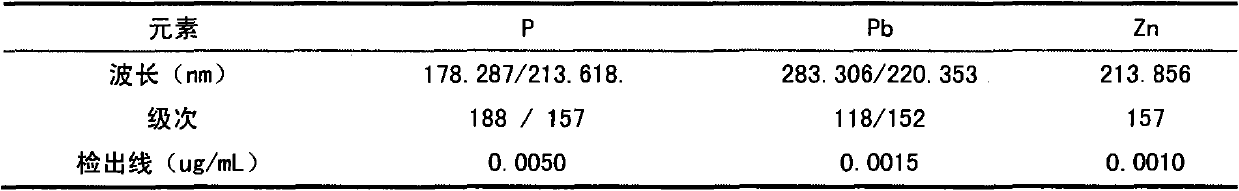

Method for quickly measuring content of phosphorus, lead and zinc in industrial ferrous dust

ActiveCN102564973AEasy to wrapImprove analytical accuracyPreparing sample for investigationColor/spectral properties measurementsPhysicsDecomposition

The invention discloses a method for quickly measuring the content of phosphorus, lead and zinc in industrial ferrous dust. The method comprises the steps of sample decomposition, setting the instrument analysis parameters of an ICP (Inductively Coupled Plasma) spectrometer, interference correction, making a working curve, and analyzing the content of to-be-measured elements in a measured sample by using an ICP spectral method, wherein the sample decomposition comprises sample pre-decarburizing treatment and sample pressure-microwave digestion. The invention provides a new method for improving the speed and the accuracy in a chemical test of hazardous elements in metallurgical dust.

Owner:ANGANG STEEL CO LTD

Chlorella and application thereof

InactiveCN101824386AImprove fixation efficiencyIncrease productionUnicellular algaeDispersed particle separationBiodieselMicrobiology

The invention discloses a strain of chlorella, which is classified to be named as chlorella vulgaris and is preserved in China Centre for Type Culture Collection, and the preservation number is CCTCC NO.: M 209256. The invention also discloses the application of the chlorella in producing microalgae oil and fixing CO2. The chlorella can endure 24.5% of CO2 concentration, the content of grease can reach 17-31%, and the invention has higher CO2 fixing efficiency than ordinary seawater algae, and can obtain high-yield microalgae oil by selecting appropriate culture conditions, so the culture cost of the microalgae can be greatly reduced, and a good production strain is provided for preparing biodiesel by the microalgae oil.

Owner:NANJING UNIV OF TECH

Production process of high-density carbon product

The invention relates to a production process of a high-density carbon product, which is characterized in that the high-density carbon product comprises a high-density prebaked anode, or a high density graphitization electrode, or high-density semi graphitic carbon paste and semi graphitic cathode paste for building carbon blocks; by adopting high density carbon coke with the volume density being greater than 1.6g / cm3 as the main raw material and a large-grain high-density carbon coke whole ball adding mode, the addition amount of powder material and bonding agent coal tar is reduced, the grain structure of the carbon product is changed, and a carbon roasting product with the volume density being larger than 1.6g / cm3 is manufactured; and the production process thereof comprises the following steps of: selecting the raw material; grading the grain size, selecting the bonding agent and controlling the content of the bonding agent; mixing and kneading; shaping, roasting, dipping and graphitizing according to the conventional manufacturing method of the carbon product. By using the high-density carbon product produced by the protection process, the volume density of the carbon sizing product after being roasted is larger than 1.6 / cm3, thus realizing energy saving, emission reduction, high efficiency, low investment and high yield.

Owner:任利华

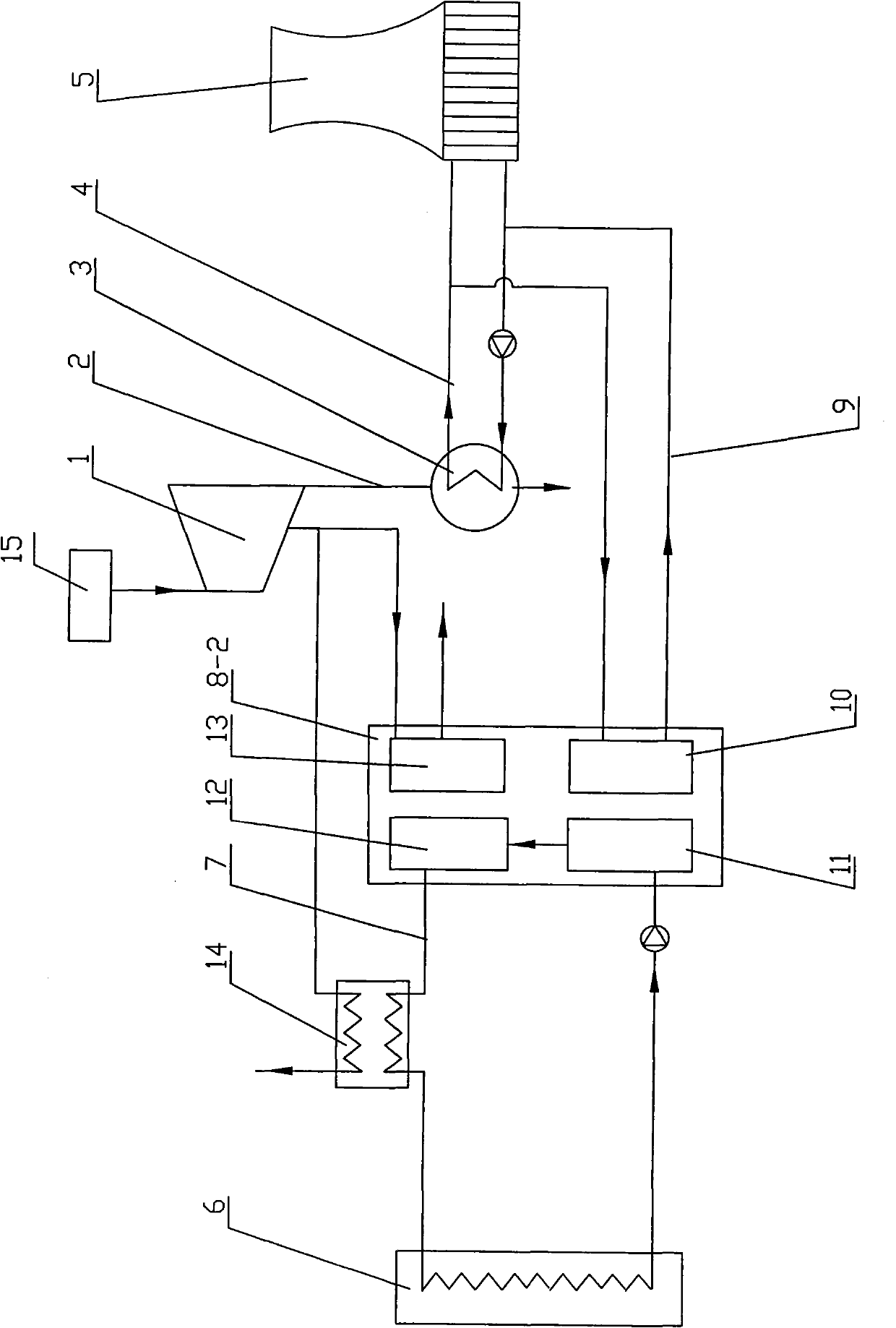

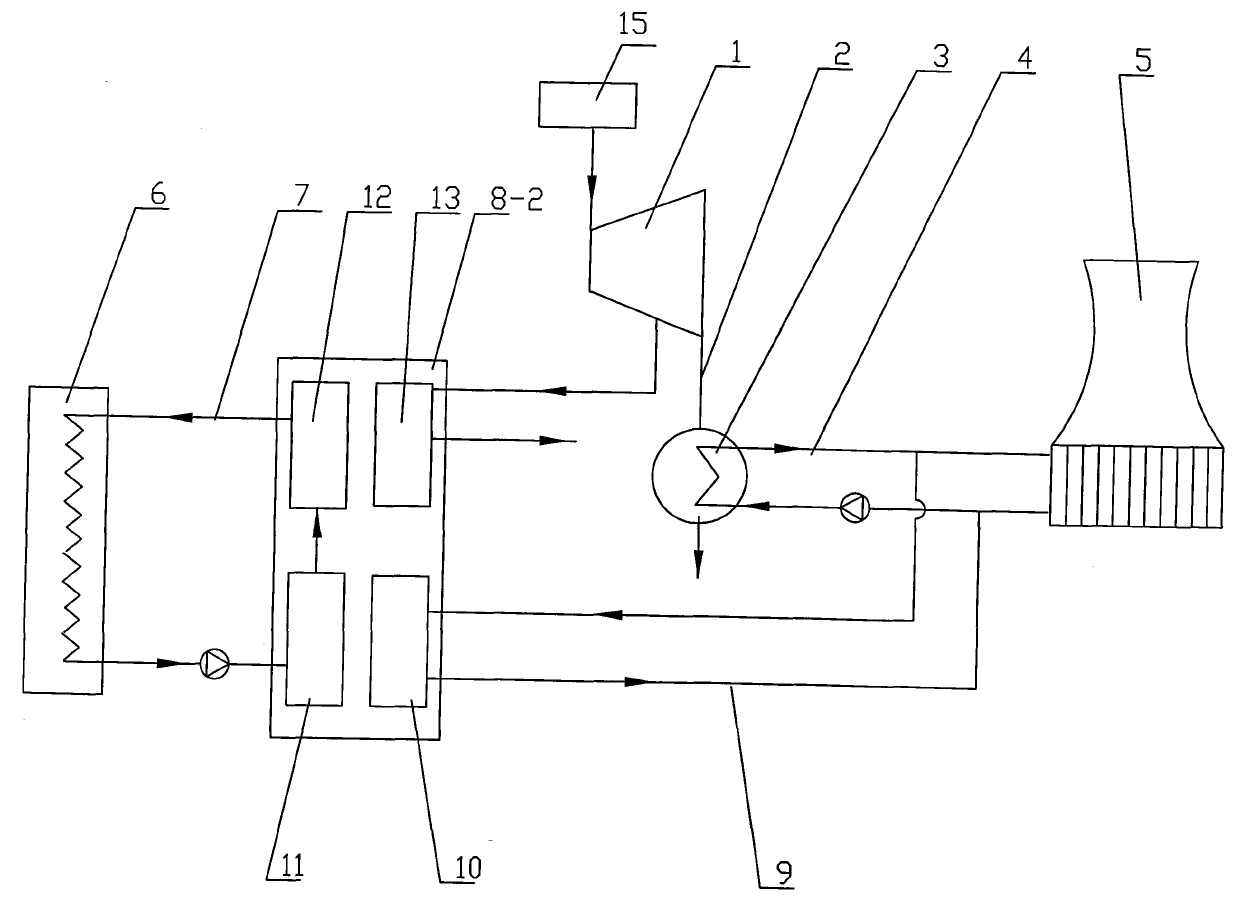

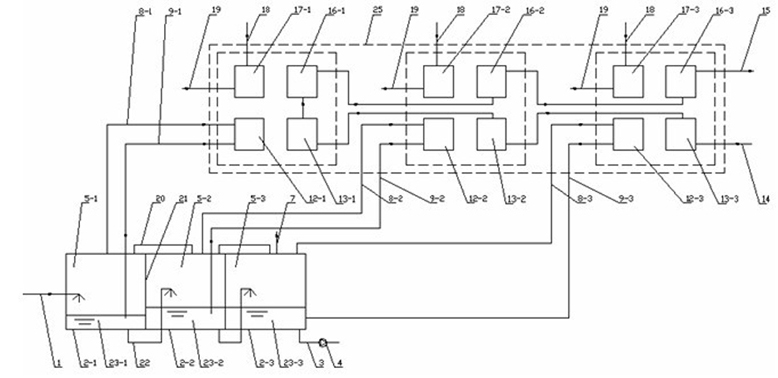

Condensation heat recovery central heating system of power plant indirect air cooling machine set

InactiveCN101906997AIncrease maximum heating capacityImprove utilization efficiencySteam useCombined combustion mitigationWater circulationAbsorption heat pump

The invention relates to a condensation heat recovery central heating system of a power plant indirect air cooling machine set. The invention is used for recovering surplus heat of exhaust steam of a power plant steam turbine. The system comprises a steam outlet turbine (1), a turbine steam exhaust header pipe (2), a water-cooled condenser (3), a closed cooling circulation water system (4), an indirect air condensation steam system (5), a heat utilization place (6) and a hot water supply pipeline system (7), wherein the exhaust steam of the steam outlet turbine (1) is connected with the water-cooled condenser (3) through the turbine steam exhaust header pipe (2). The system is characterized in that the heating system also comprises an absorption type heat pump machine set (8-2) and a surplus heat water circulation pipeline system (9); the closed cooled circulation water of the water-cooled condenser (3) is divided into two paths, one path is connected with an evaporator of the absorption type heat pump machine set (8-2) through the surplus heat water circulation pipeline system (9), and the other path is connected with the indirect air condensation steam system (5); and a hot water supply outlet of the absorption type heat pump machine set (8-2) is connected with the heat utilization place (6) through the hot water supply pipeline system (7). The heating system can efficiently recover and utilize the low-grade condensation heat of exhaust steam of an indirect air cooling power plant.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

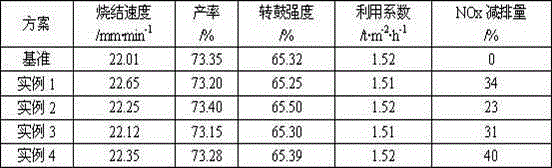

Method for reducing NOx emission in iron ore sintering process

ActiveCN105087906AReduce generationEmission reductionFuel additivesIron ore sinteringMixed materials

The invention discloses a method for reducing NOx emission in the iron ore sintering process. Firstly, conventional sintering fuel coke powder or anthracite is screened into three grain sizes of -1 mm, 1-3 mm and +3 mm; the coke powder or anthracite with the grain size being -1 mm and high-reaction-activity fossil fuel or biomass fuel with the grain size being -1 mm are pressed into fuel particles with the grain size being 1-3 mm; the fuel particles obtained through pressing with the grain size being 1-3 mm and the coke powder or anthracite obtained through screening with the grain size being 1-3 mm are added into fine particle iron ore, part of coarse particle iron ore, flux and return mines to be subjected to granulation in a rotary drum mixer; and the granulated mixed material, modified coke powder or anthracite with the particle size being +3 mm and the remaining coarse particle iron ore are subjected to secondary mixing granulation, and the obtained mixed material is distributed and then ignited and sintered. Generation of fossil fuel NOx in each grain size is controlled specifically according to the features of NOx generated by the fossil fuel in different grain sizes, so that generation of NOx is reduced to a greater extent to reduce NOx emission, and NOx emission is reduced by 20%-40%.

Owner:CENT SOUTH UNIV

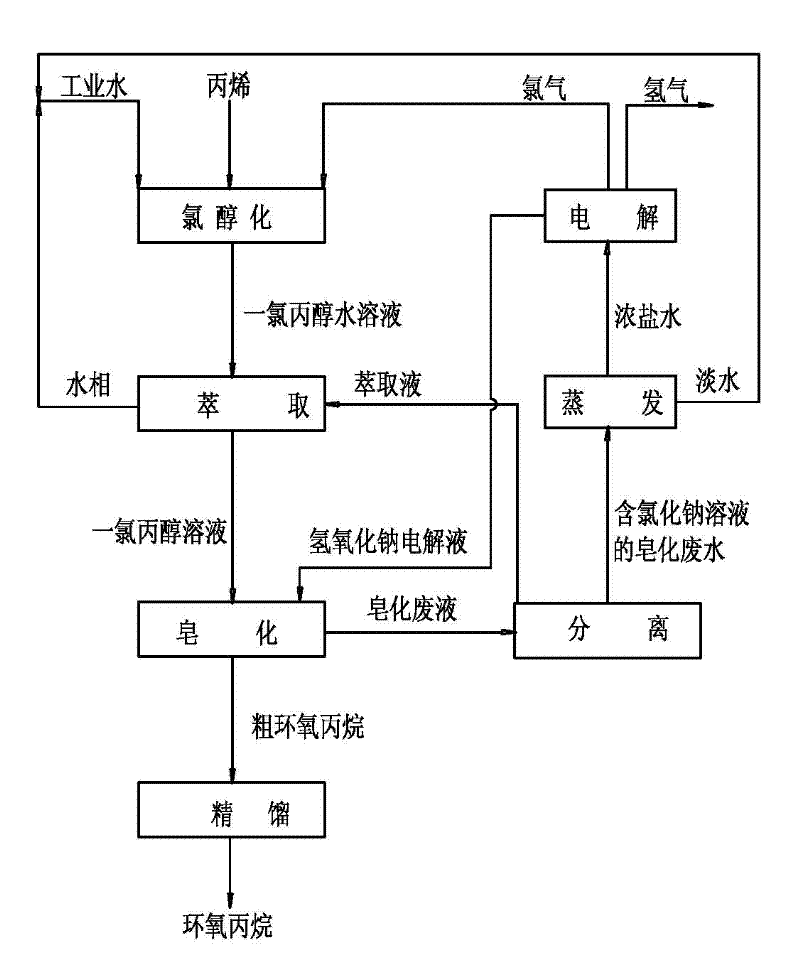

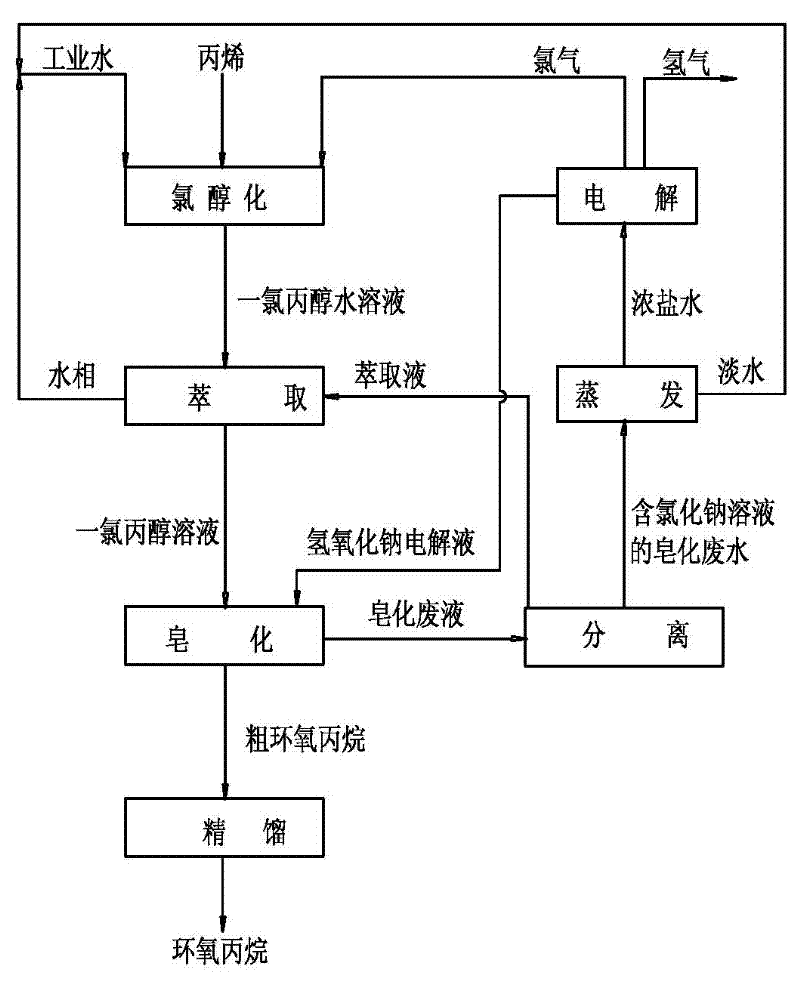

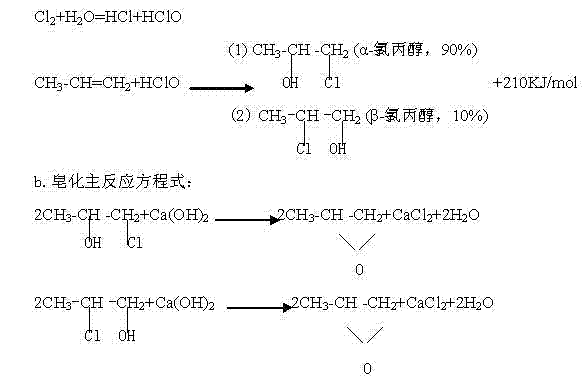

Preparation technology of propylene oxide

ActiveCN102241647AAchieve emission reductionThe production process is clean and environmentally friendlyOrganic chemistryElectrolysis componentsElectrolysisEvaporation

The invention provides a preparation technology of propylene oxide, belongs to the technical field of production of fine chemical intermediates and particularly relates to a preparation technology of propylene oxide. The preparation technology is characterized by comprising the following steps: feeding chlorine, propylene and industrial water into the bottom of a tubular reactor to perform chlorohydrination reaction, thus generating a chloropropanol solution; pumping the chloropropanol solution into the top of an extraction tower, feeding a complexing extractant from the bottom of the extraction tower to perform complexing extraction, thus obtaining a chloropropanol solution; pumping the obtained chloropropanol solution and a sodium hydroxide solution into a saponification reactor to perform saponification reaction, thus generating propylene oxide; and rectifying crude propylene oxide in a rectifying tower, and acquiring the propylene oxide product from the top of the rectifying tower. On the basis of the traditional chlorohydrination method for producing propylene oxide, the processes such as complexing extraction, separation, evaporation and electrolysis are added in the preparation technology; and an emission-reducing, synergistic, clean and environmentally-friendly preparation technology of propylene oxide can be really realized.

Owner:山东昌邑海能化学有限责任公司

Quick-drying explosion-proof castable and producing process thereof

The invention discloses a castable used for an industrial furnace lining and a producing process thereof, and particularly relates to a quick-drying explosion-proof castable used for an industrial furnace lining and a producing process thereof. The producing process comprises four steps of raw material purchasing and testing, burdening, mixing and packaging. The producing process of the invention has the advantages of realizing quick-drying (rapid hardening) and fast stripping of the castable, and rapid baking without burst or explosion. With greatly shortened construction time and baking time, production pace is speeded up, a large quantity of energy is saved, emission of carbon dioxide and nitrogen oxide is significantly reduced and economic and social benefits are prominent.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

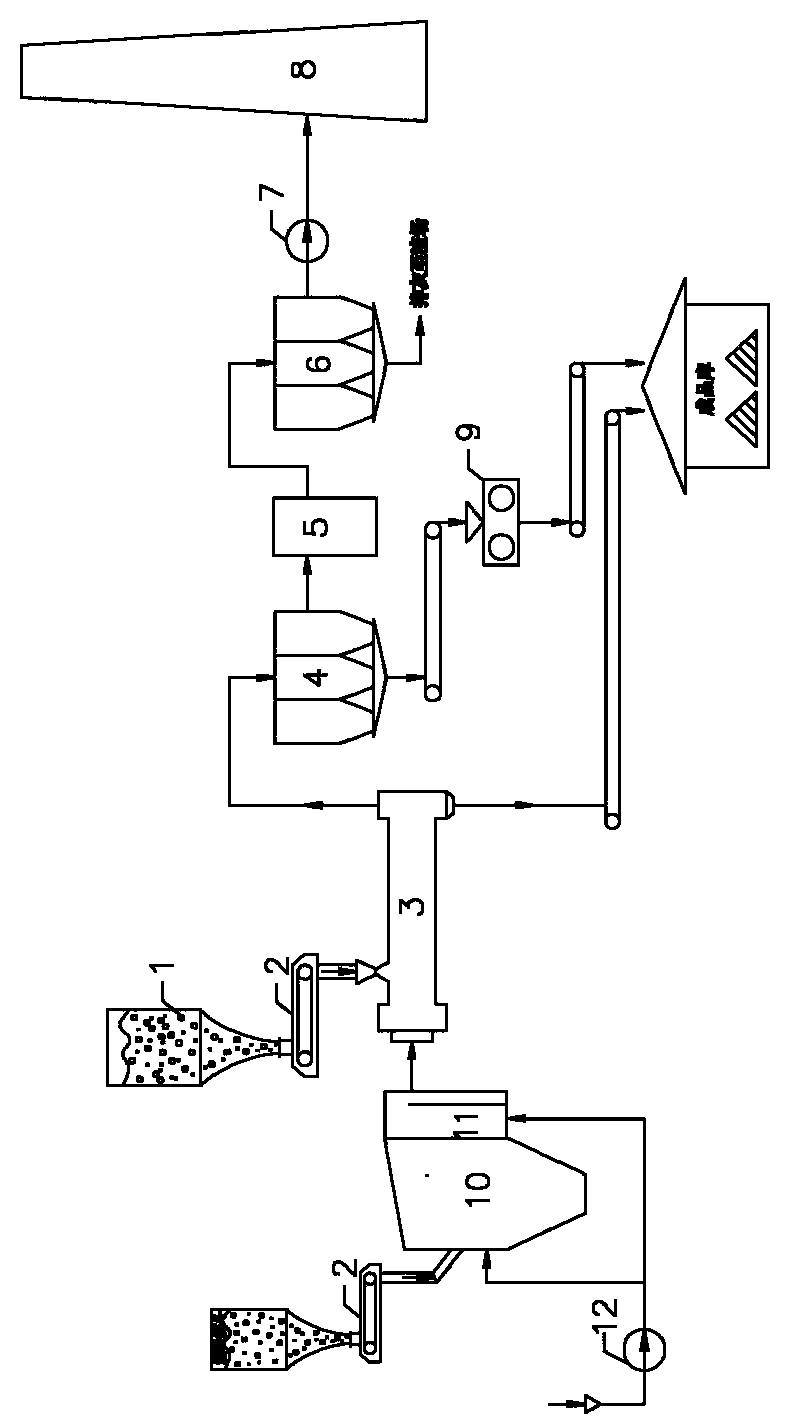

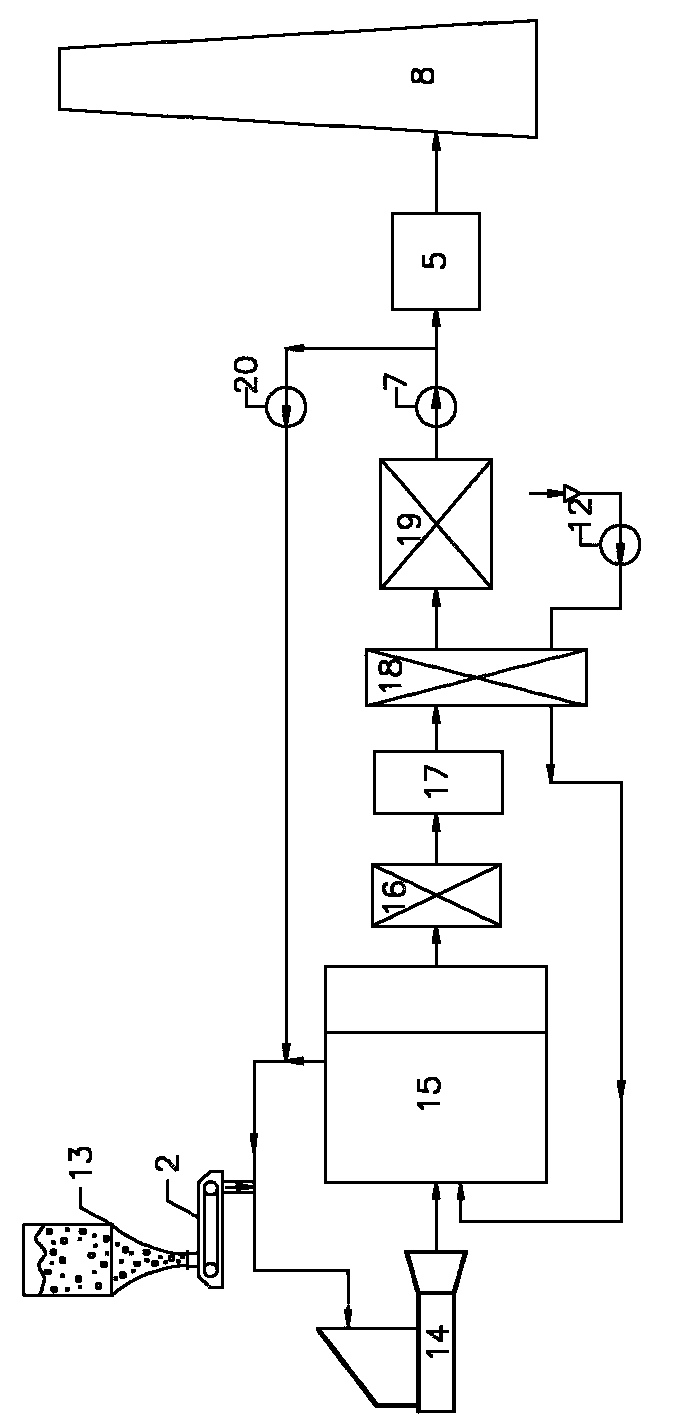

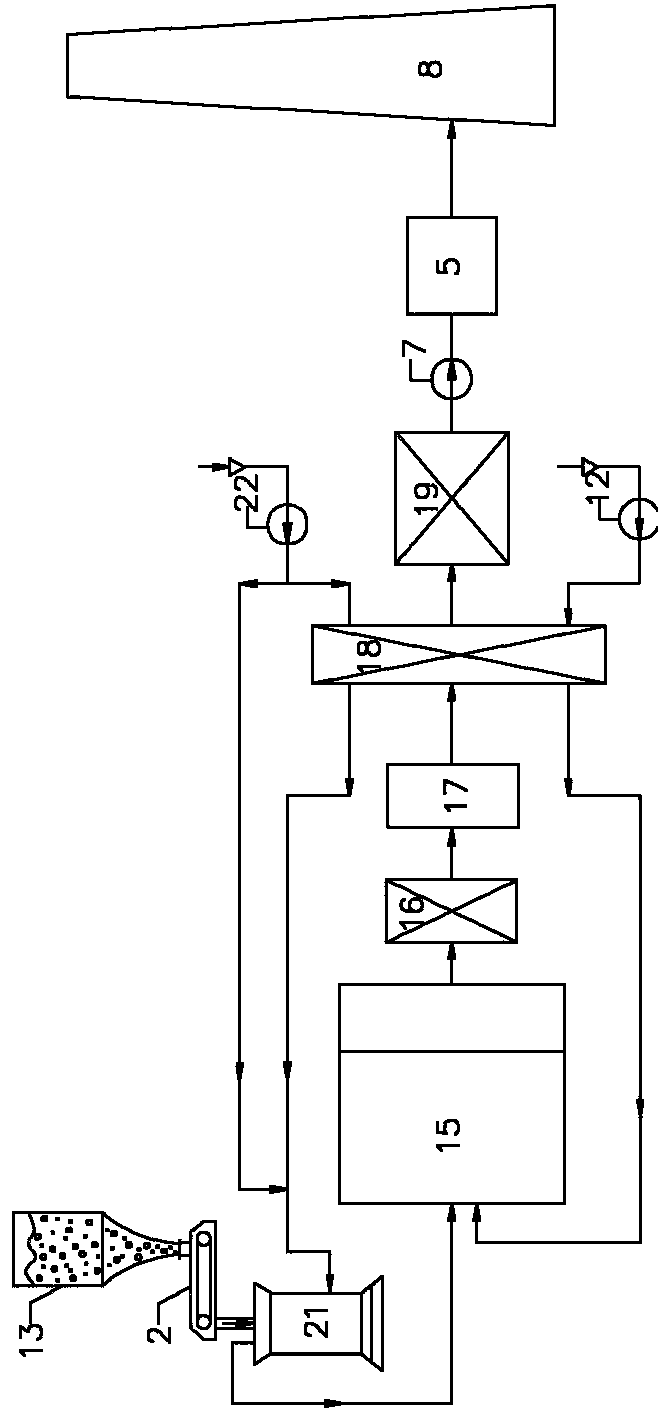

Lignite drum smoke pre-drying power generation integrated system and process

InactiveCN102759118AImprove efficiencyReduce standard coal consumptionDrying gas arrangementsLump/pulverulent fuel feeder/distributionAir preheaterMoisture

The invention discloses a lignite drum smoke pre-drying power generation integrated system and a lignite drum smoke pre-drying power generation integrated process. A lignite drum smoke drying system is combined with a boiler combustion system of a thermal power plant. The lignite drum smoke pre-drying power generation integrated system comprises a boiler coal supply device, a boiler, an economizer, a denitration device, an air pre-heater, a dust collector, an induct draught fan, a desulphurization device, a lignite supply device, a drum dryer, a bag type dust coal collector and a pre-drying booster fan, wherein the boiler coal supply device, the boiler, the economizer, the denitration device, the air pre-heater, the dust collector, the induct draught fan and the desulphurization device are connected in sequence; the lignite supply device, the drum dryer, the bag type dust coal collector and the pre-drying booster fan are connected in sequence; a smoke outlet of the desulphurization device is also connected with a smoke inlet of the drum dryer; a discharge end of the drum dryer is connected with the boiler coal supply device; and an outlet of the pre-drying booster fan is connected with an inlet flue of the desulphurization device. Smoke of the boiler is partially split into the drum dryer to pre-dry the lignite raw material, the waste heat of the smoke of the power plant is fully utilized, the efficiency of the boiler is increased, the emission of combustion pollutants and carbon dioxide is reduced, and the coal moisture after pre-drying is reduced, so that the investment in the boiler and auxiliary equipment thereof is reduced.

Owner:NORTH CHINA POWER ENG

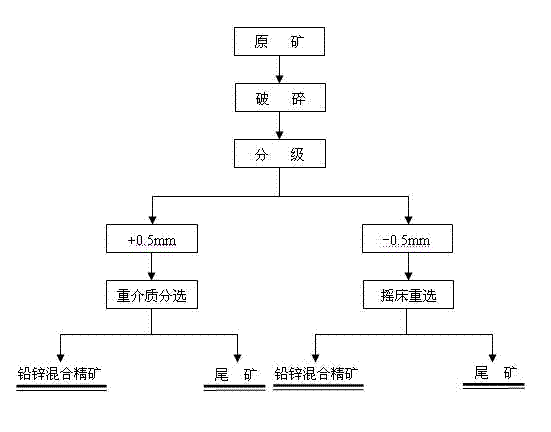

Separation method for treating low-grade refractory zinc lead oxide ores

The invention provides a separation method for treating low-grade refractory zinc lead oxide ores, which adopts a full heavy separation process. The method is implemented in a way that: all raw ores are crushed into particles of which the maximum particle size upper limit is 20-5mm; the crushed ores are screened into two size grades +0.5mm and -0.5mm; and the two size grades of crushed ores are respectively subjected to heavy-media separation and rocker re-separation to obtain lead-zinc mixed concentrate products which can be used as raw materials for the next technical step of oxygen pressure acid leaching. The technical process is simple and easy to operate; and the invention has the advantages of lower ore grinding amount, low separation cost, no need of any reagent, small environmental pollution, favorable technical indexes and the like, can recycle the backwater, greatly enhances the recovery rate of metals lead and zinc, and achieves the goals of energy saving, emission reduction, consumption reduction and comprehensive utilization of resources on the whole.

Owner:青海鸿鑫矿业有限公司

Method for coupling carbon fixation and emission reduction of common nostoc and culturing system for mass culture of common nostoc

InactiveCN101792716AIncrease productionGood yieldBioreactor/fermenter combinationsBiological substance pretreatmentsOxygenLiving environment

The invention relates to a method and a system for the mass production and the coupling carbon fixation and emission reduction of healthy green food common nostoc, which realize large-scale high yield and carbon fixation and emission reduction by using a semiclosed indoor pool on the basis of realizing the high yield of the common nostoc and disclose a structural principle of the pool and optimization conditions of seven basic elements for culturing the common nostoc. The method is suitable for the urban and rural large-scale production, is especially suitable for poor grain lacking regions and is also suitable for the food self-supporting production of global extreme environments and disasters and spaceman living environments. The invention provides a novel healthy green food for human and also realizes the emission reduction, the oxygen generation, and the environment improvement in the food production process.

Owner:张懋

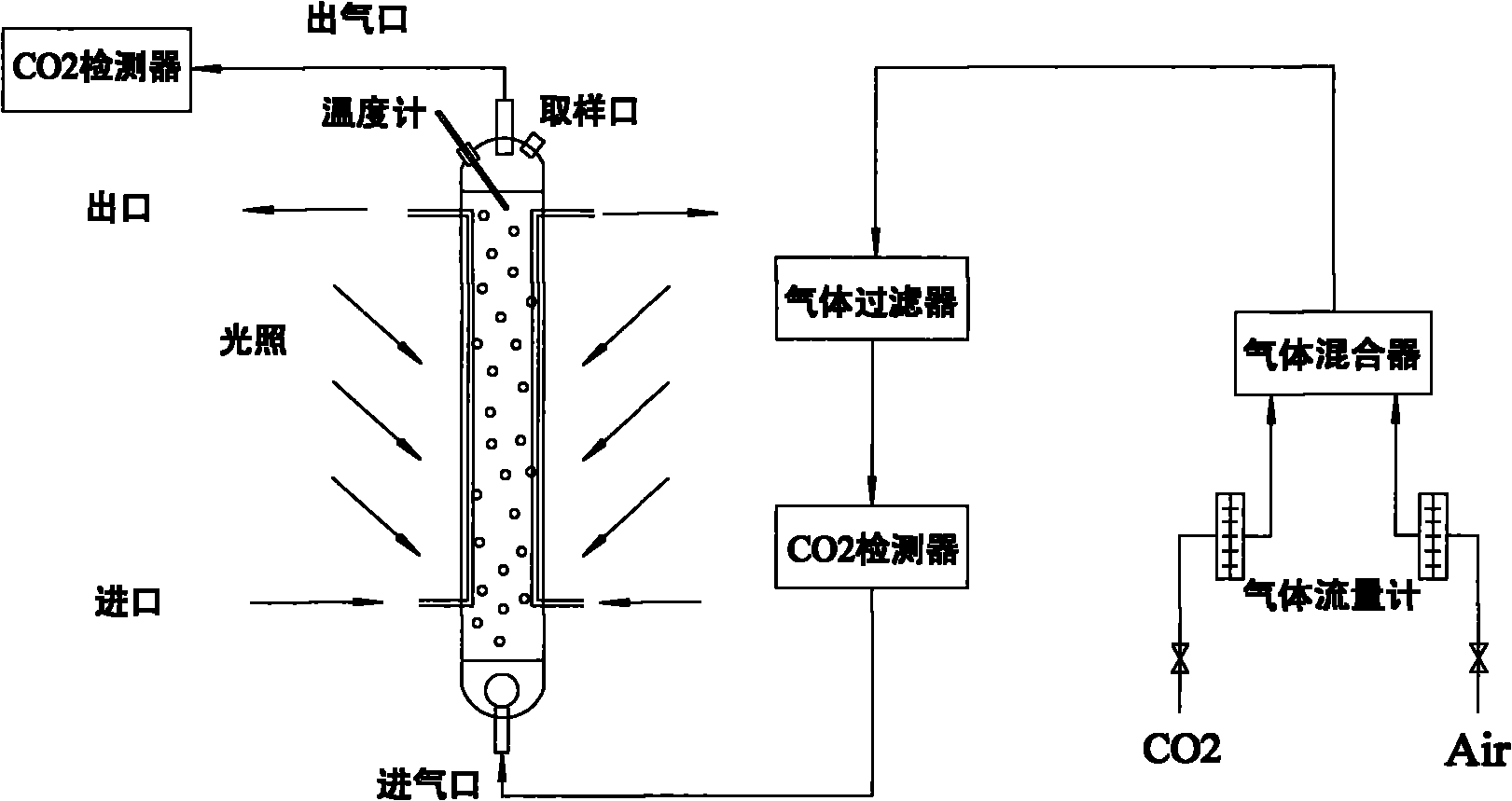

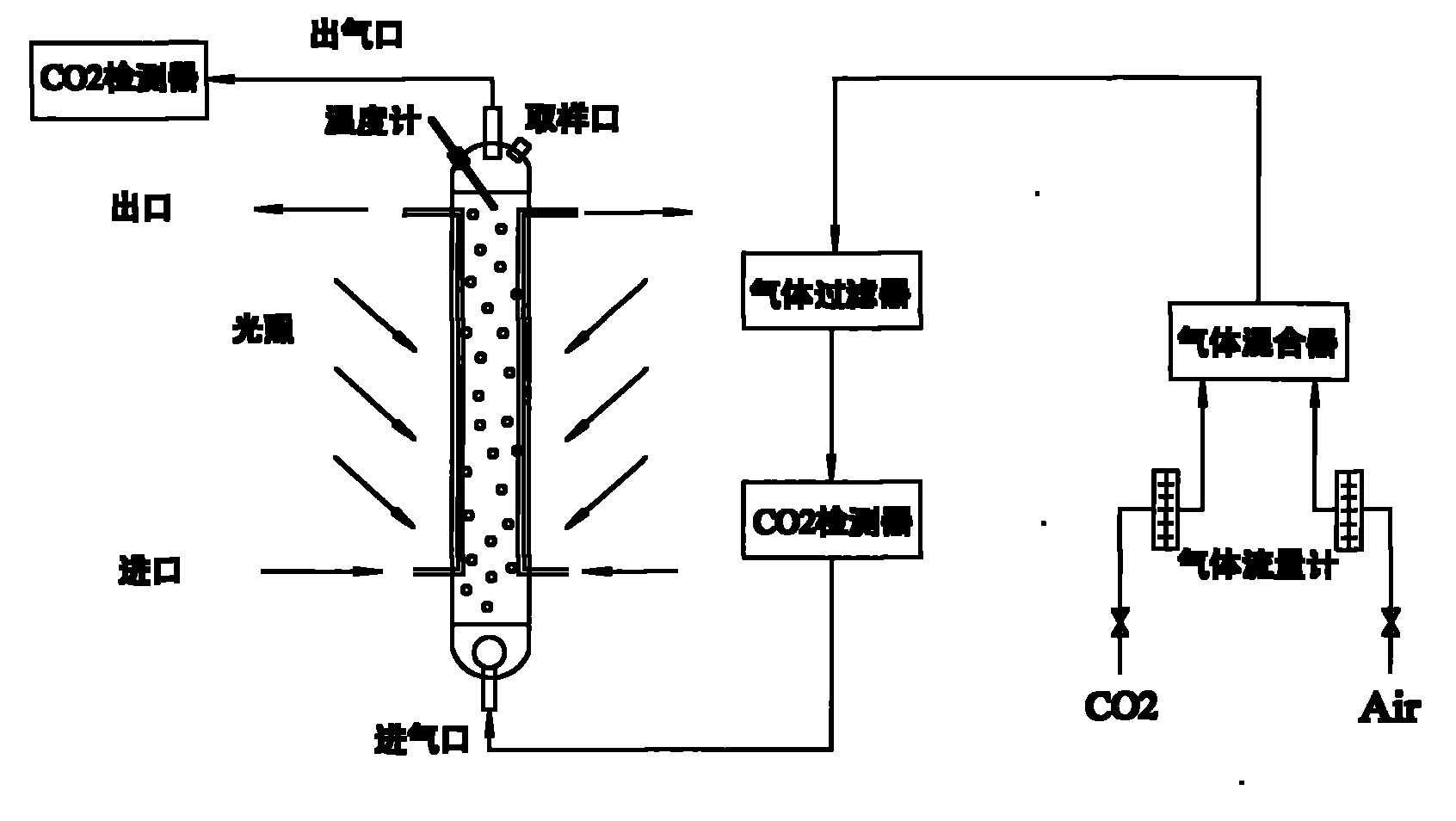

Method for supplementing fermentation raw material by microbial fermentation tail gas CO2 immobilized by microalgae culture

InactiveCN102827775AEnvironmentally friendlyAchieve CO2 emission reductionBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassNitrogen source

The invention relates to CO2 emission reduction and recycling technologies, and discloses a method for adopting microalgae culture immobilized microbe fermentation tail gas CO2 as a supplementation fermentation raw material. According to the invention, tail gas in a microbe fermentation tank is directly introduced into a microalgae culture illumination bioreactor; conditions such as illumination, temperature, and ventilation are controlled; proper inorganic nutrient salts are added; CO2 in microbe fermentation tail gas is adopted as a carbon source for culturing microalgae; biomasses such as carbohydrates and proteins are accumulated; the biomasses are converted into raw materials such as carbon and nitrogen sources needed by fermentation through pretreatment; and the raw materials are delivered back to the microbe fermentation system to be utilized as a fermentation supplementation raw material. With the method provided by the invention, emission reduction and recycling of the microbe fermentation tail gas CO2 are realized; grain raw material consumption of microbe fermentation is reduced; and good environmental and social benefits are provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

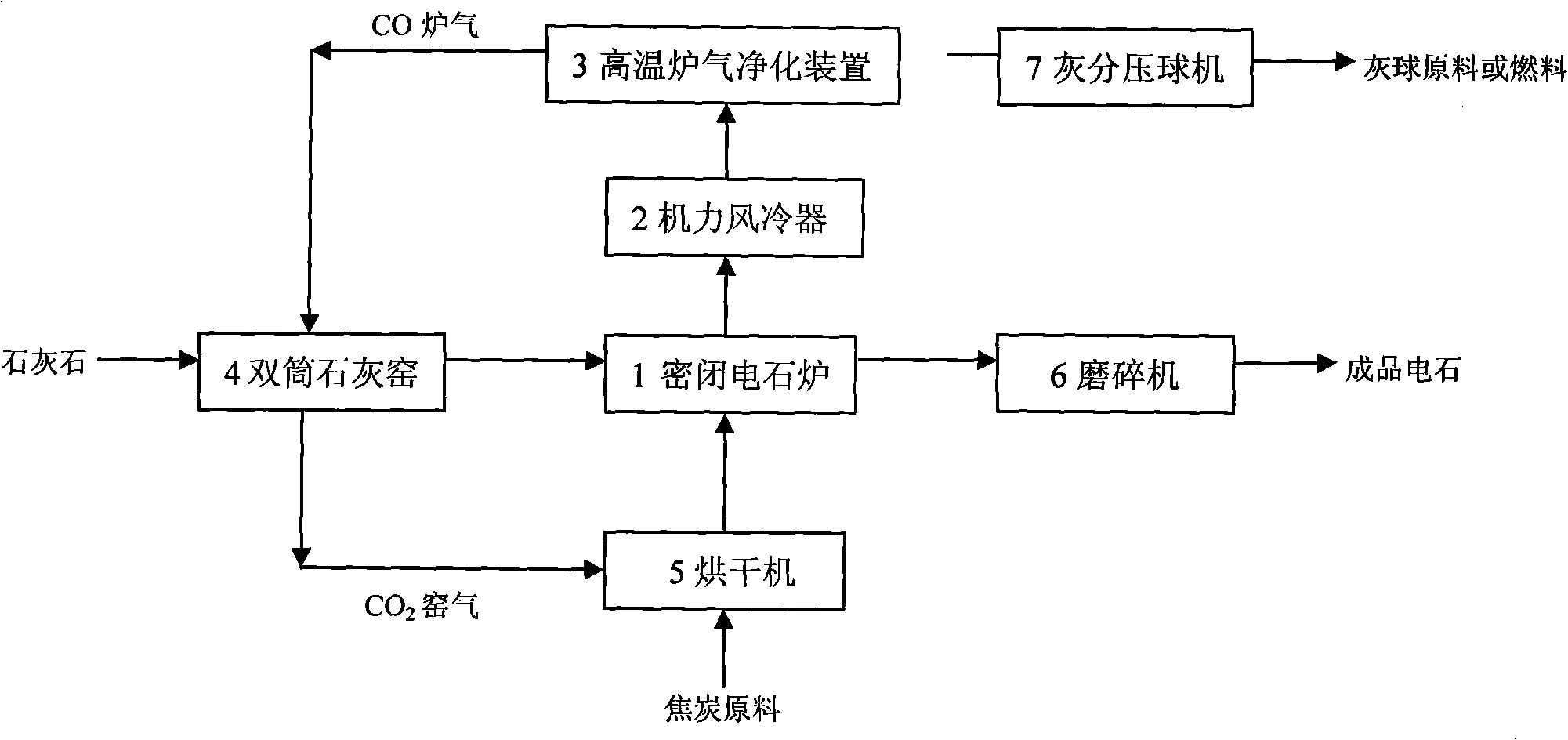

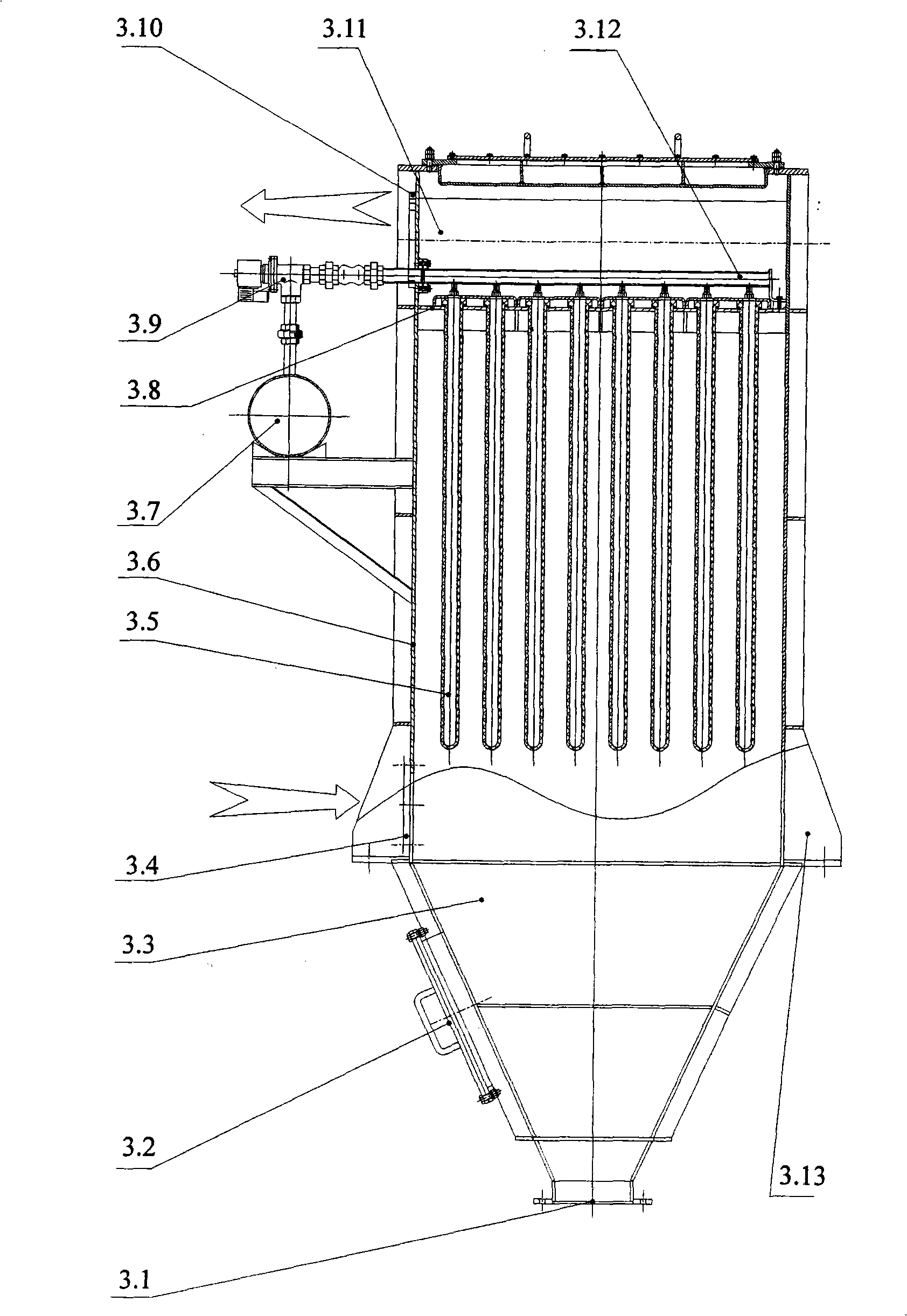

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

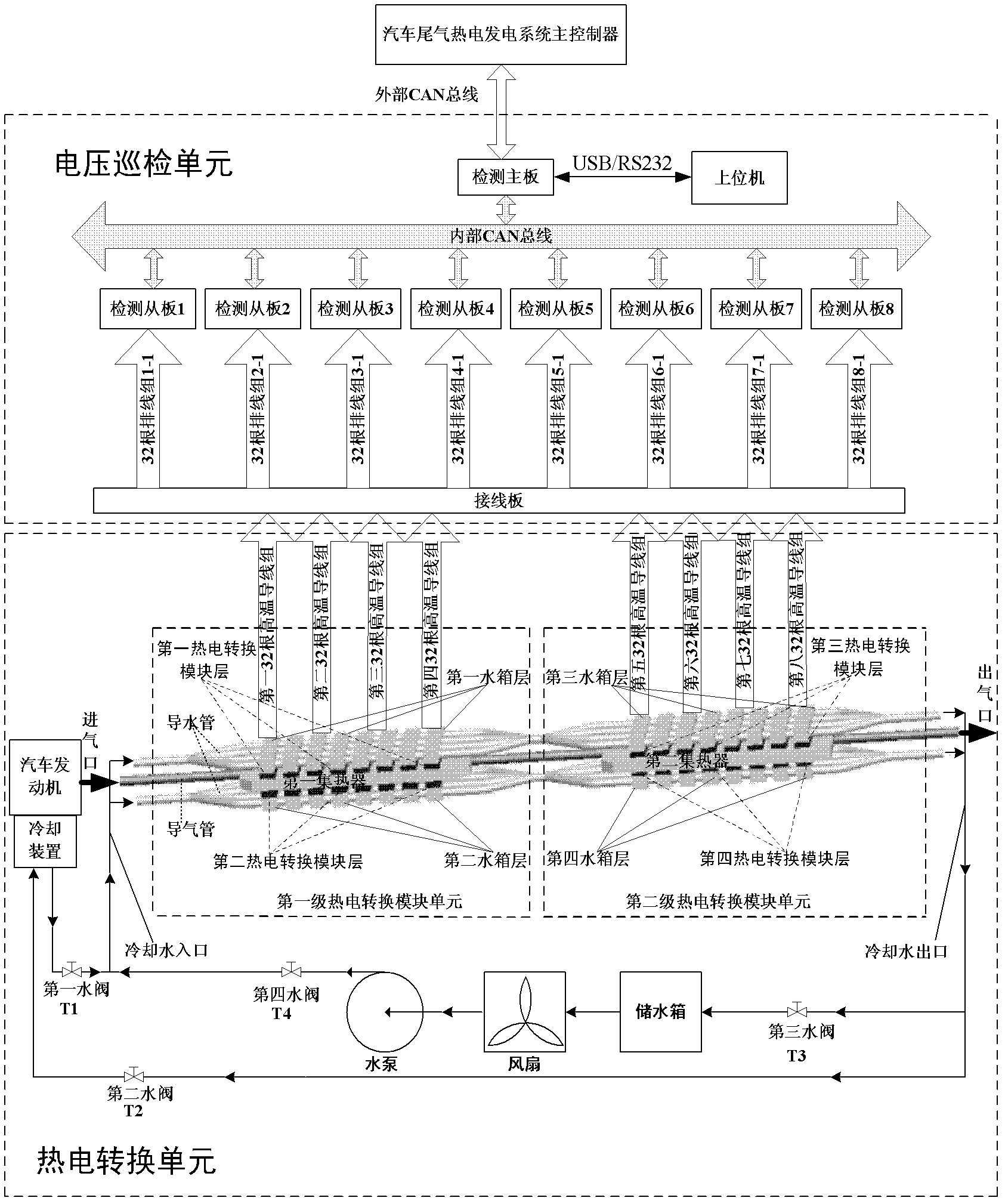

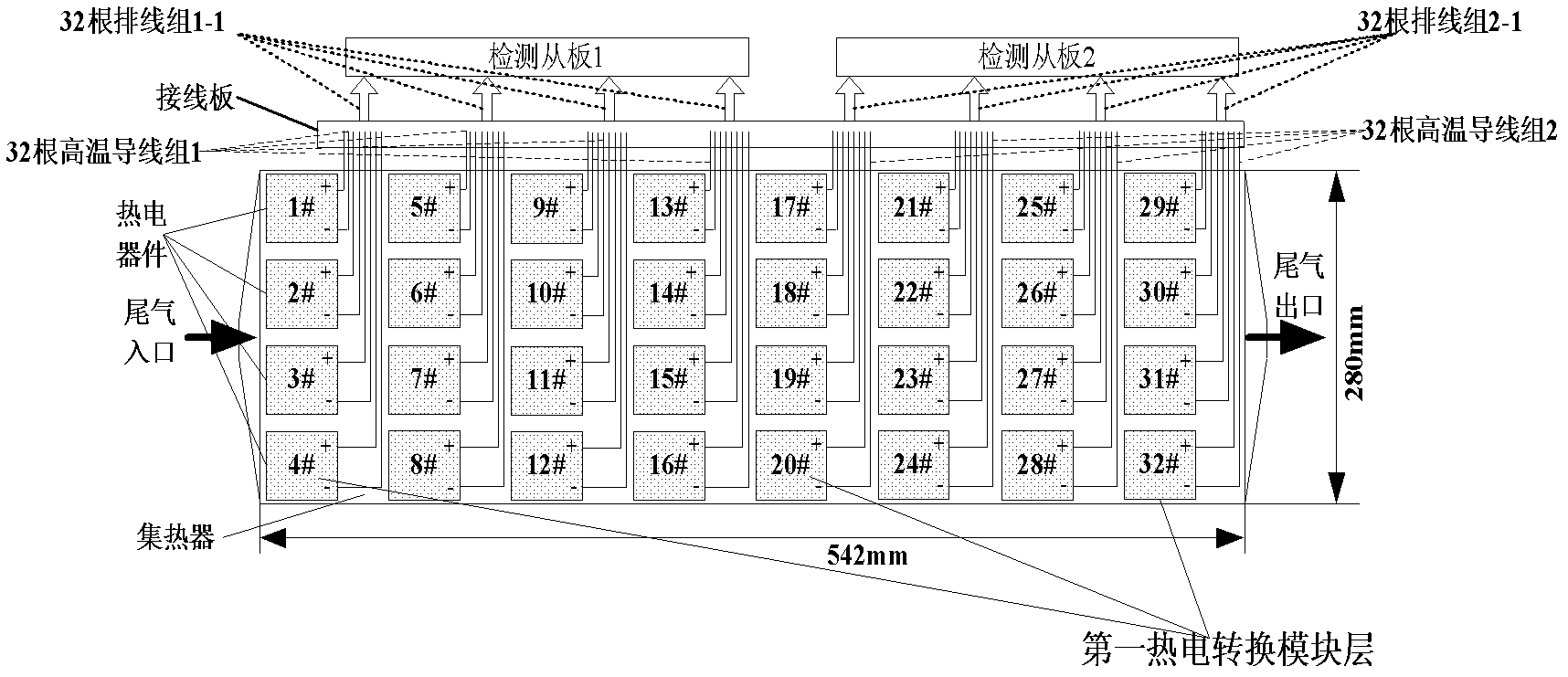

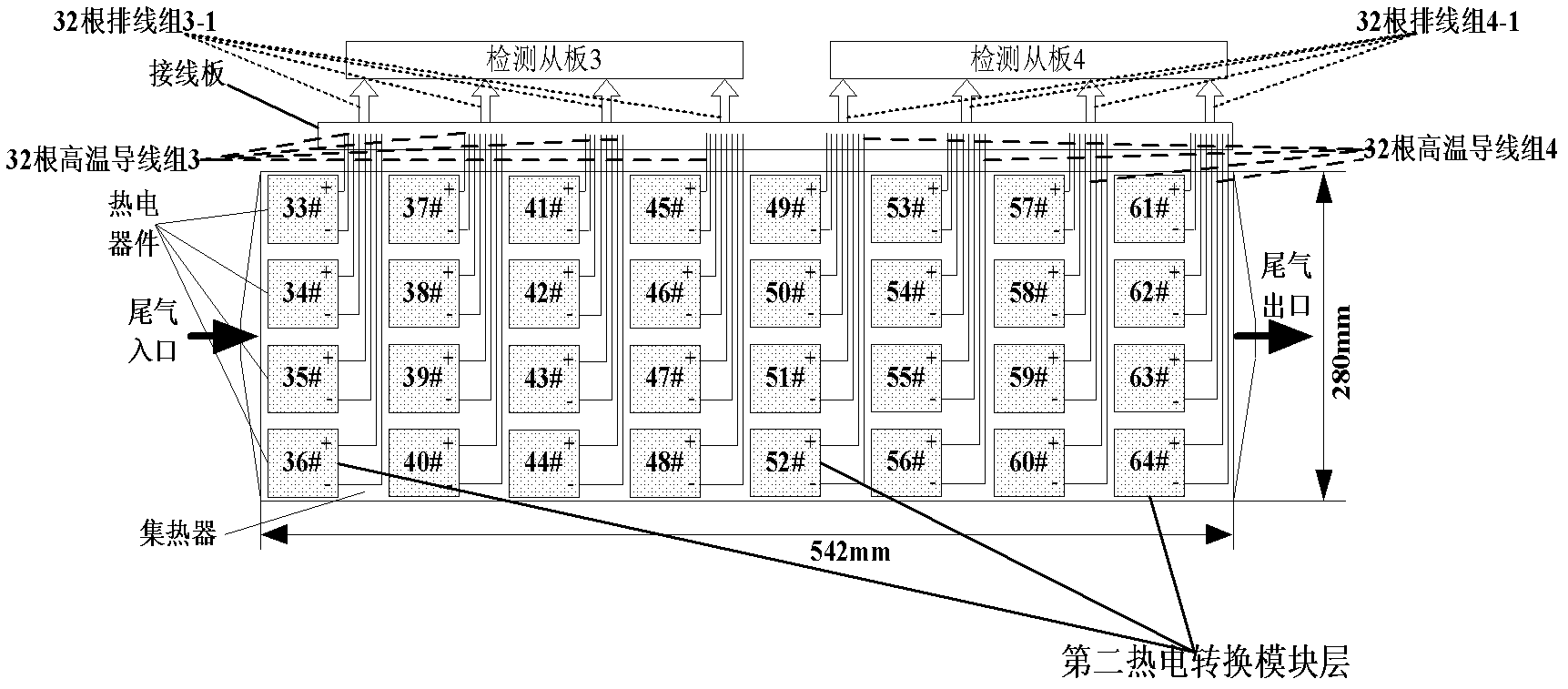

Single-module independent water-cooled type automobile tail gas thermoelectric conversion device and method

InactiveCN102427319AIncrease output powerRaise the temperature differenceInternal combustion piston enginesExhaust apparatusLoop designTemperature difference

The invention relates to a single-module independent water-cooled type automobile tail gas thermoelectric conversion device and method. The device consists of a thermoelectric conversion unit and a voltage polling unit and is characterized in that: an engine exhausts high-temperature tail gas; in a plurality of thermoelectric conversion modules of the thermoelectric conversion unit, the hot ends absorb the heat of the high-temperature tail gas and the cold ends cling to an independent small water tank; the temperature difference between the hot ends and the cold ends is increased by cooling water of a cooling device of the engine or a cooling water loop designed externally and independently, so that direct-current electric energy is generated; the voltage polling unit detects the direct-current voltage generated by each thermoelectric conversion module; and optimal series and parallel combination is performed according to the output characteristic of each thermoelectric conversion module, so that output power and conversion efficiency of the automobile tail gas thermoelectric conversion device can be improved to the maximum degree. The temperature difference between the hot ends and the cold ends is increased by the single-module independent water-cooled mode; the heat of the waste gas exhausted by the automobile is effectively utilized; and the generated electric energy is applied to vehicle-mounted equipment, so energy conservation and emission reduction of the automobile are facilitated.

Owner:WUHAN UNIV OF TECH

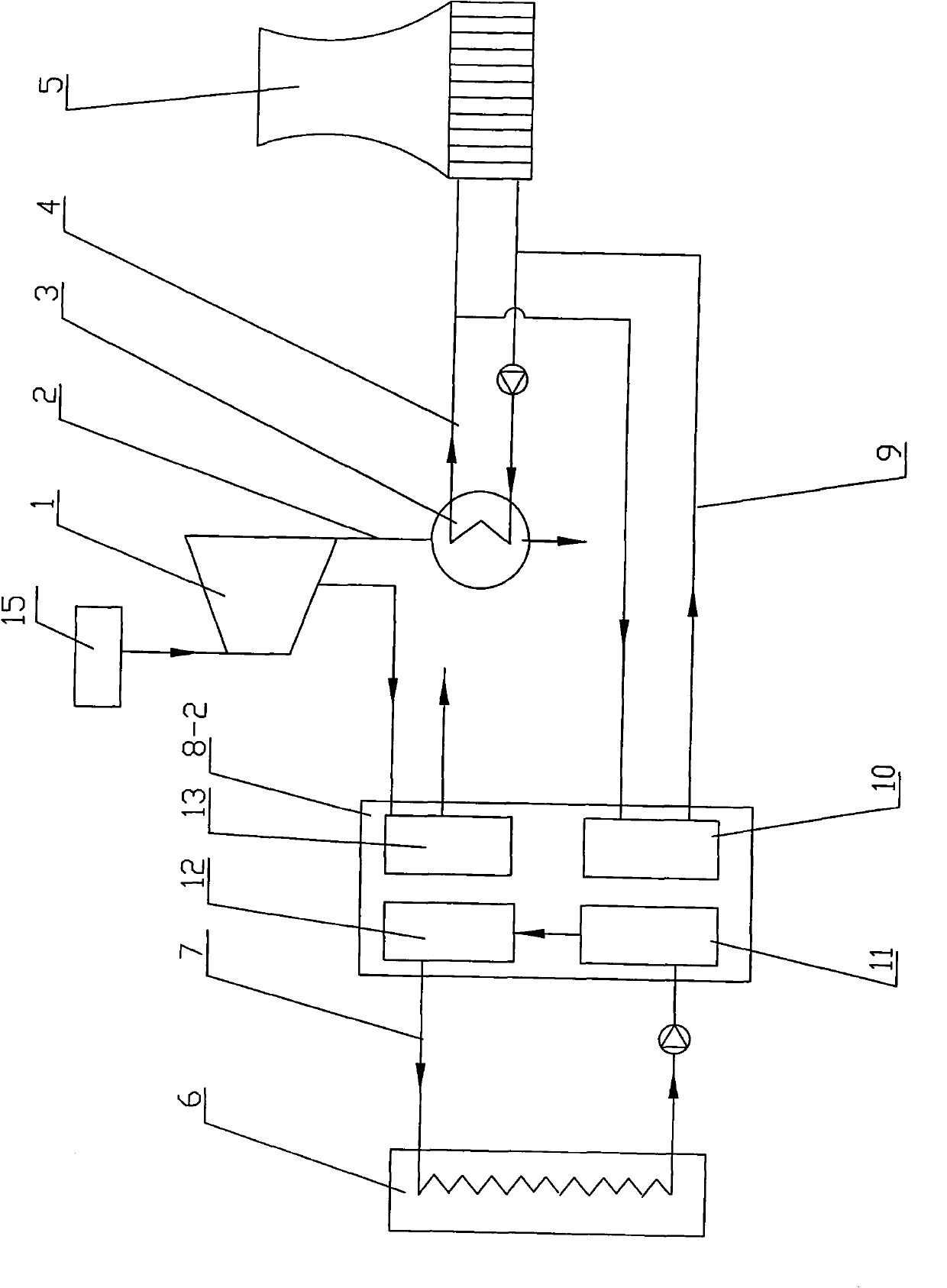

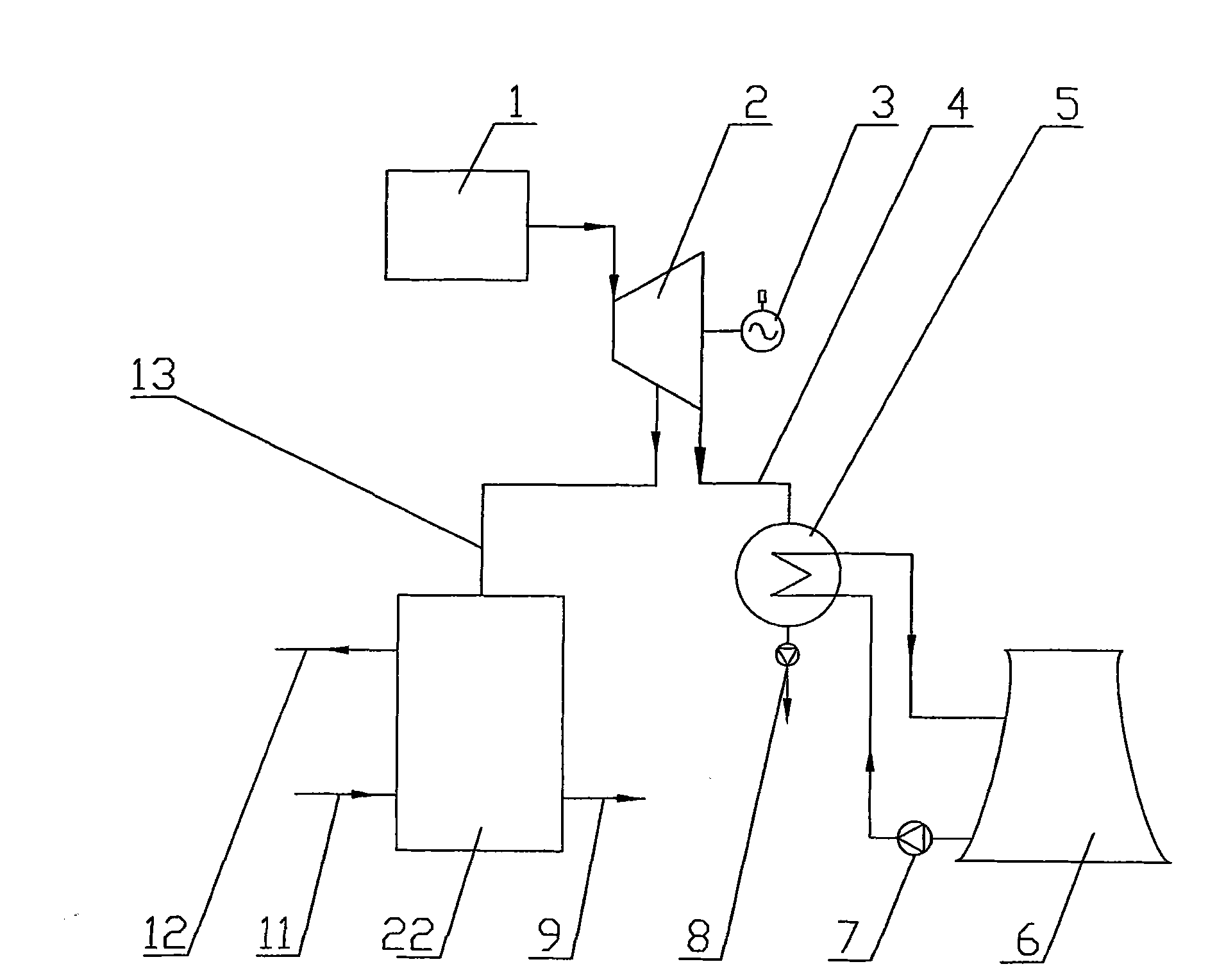

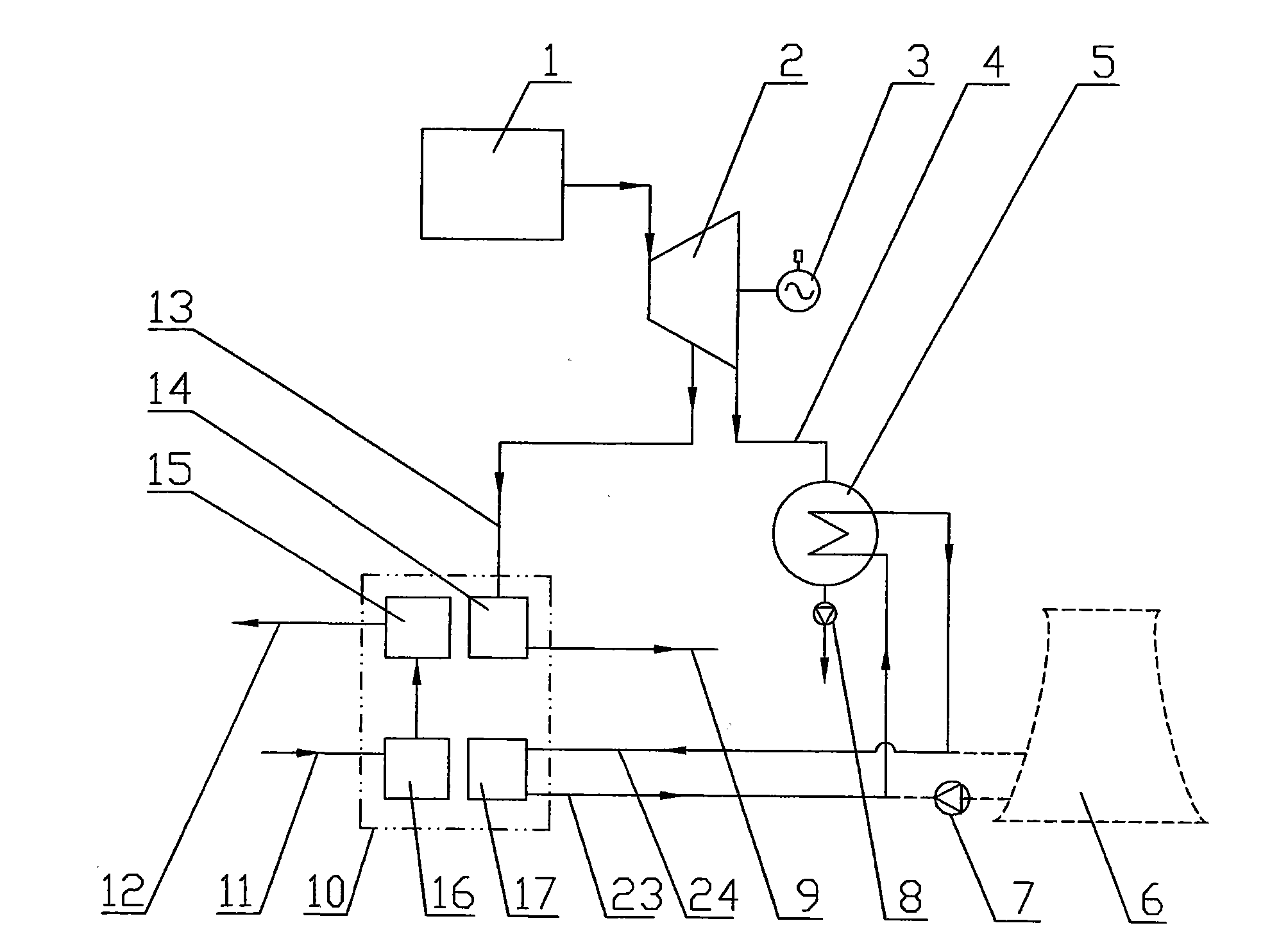

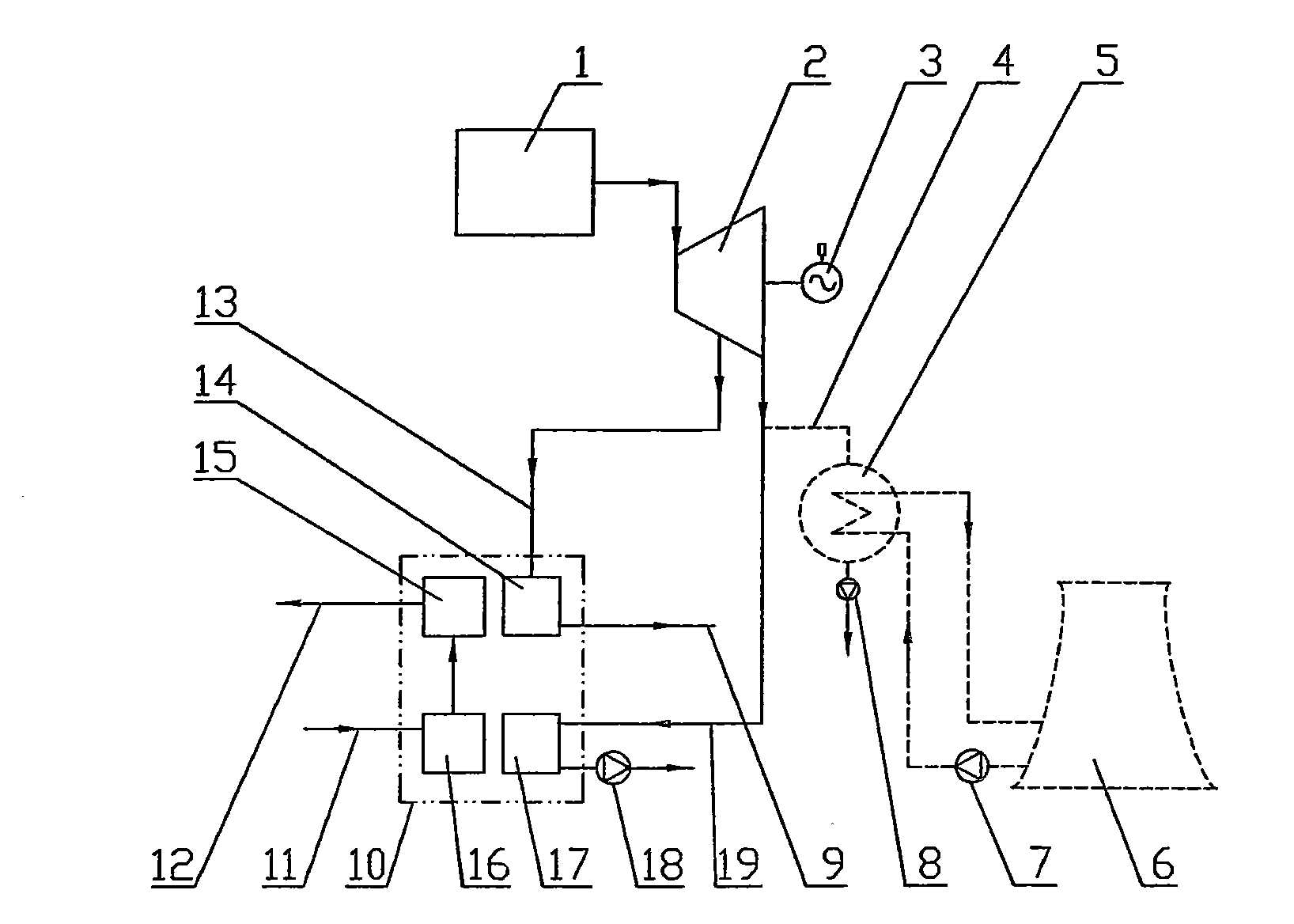

Combined heat and power system for directly recovering exhaust afterheat of power station steam turbine by absorption heat pump

InactiveCN101793171AEfficient use ofImprove utilization efficiencySteam useCombined combustion mitigationCooling towerEngineering

The invention relates to a combined heat and power system for directly recovering exhaust afterheat of a power station steam turbine by an absorption heat pump, which is used for recovering the exhaust afterheat of the power station steam turbine. The combined heat and power system comprises a power plant boiler (1), the steam turbine (2), an electric generator (3), a steam turbine exhaust pipe (4), a condenser (5), a cooling tower or an air cooling system (6), a water circulating pump (7), an exhaust condensate pump (8), a steam extraction and water condensation boiler pipe (9), the absorption heat pump (10), a hot water return pipe (11), a hot water outlet pipe (12) and a steam turbine extraction pipe (13), wherein the absorption heat pump (10) comprises a generator (14), a condenser (15), an absorber (16) and an evaporator (17). The combined heat and power system is characterized in that: low-pressure steam pipes discharged by the steam turbine (2) are divided into two paths, wherein one path is connected with the condenser (5) through the steam turbine exhaust pipe (4), while the other path is connected with the evaporator (17) of the absorption heat pump (10) through a steam turbine exhaust evaporator tube (19). The combined heat and power system can more effectively recycle low-grade exhaust condensation heat of a power plant, and reduces the temperature loss, improves the supply water temperature of hot water, and reduces the system investment and operating cost on the premise of not changing the exhaust back pressure.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

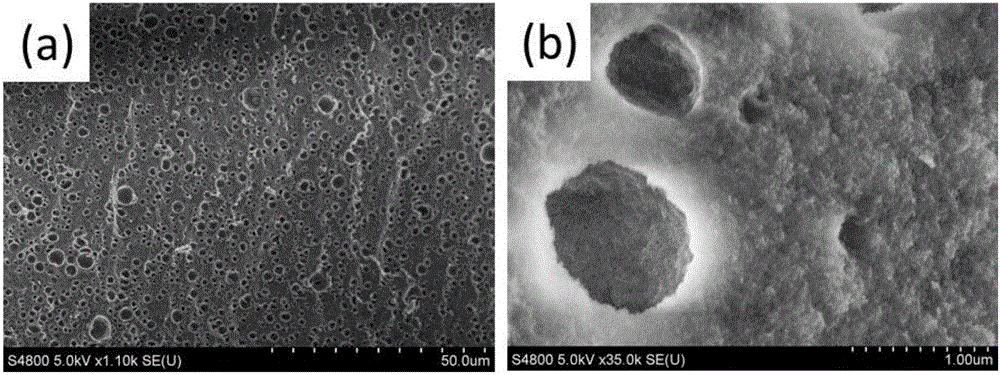

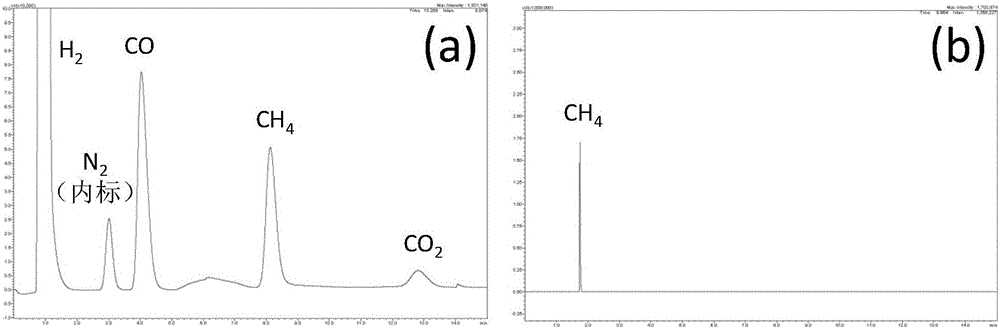

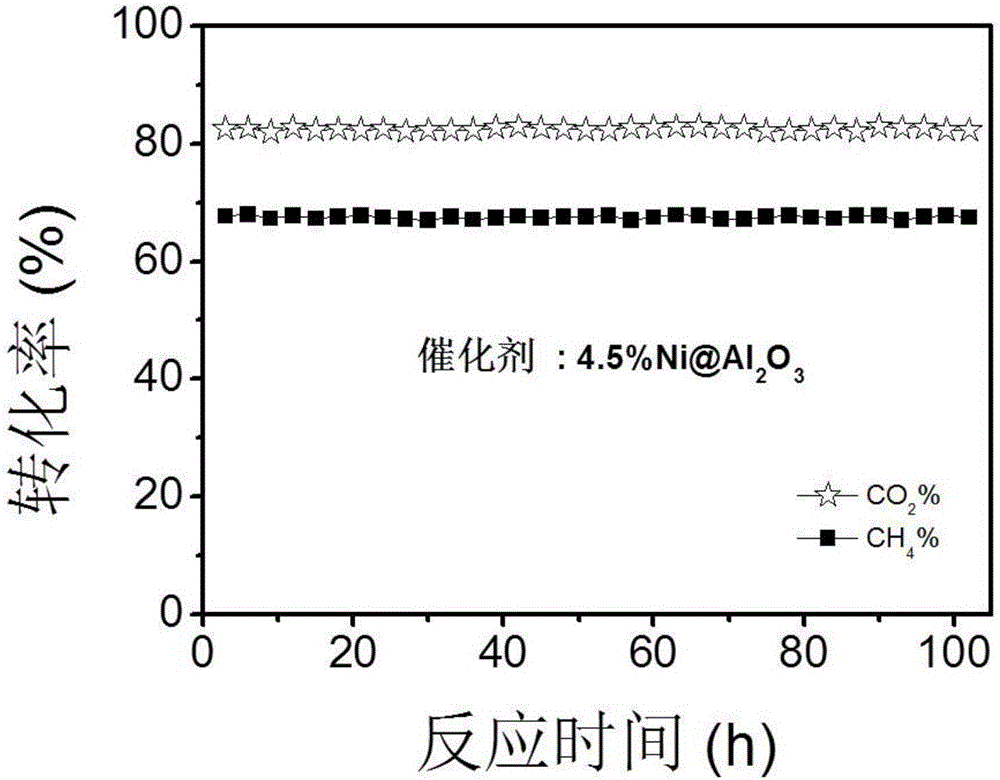

Hierarchical porous supported nickel-based catalyst, preparation method and application

ActiveCN106000405AIncreased diffusion and mass transfer ratesGood anti-sintering and anti-coking propertiesHydrogenCatalyst activation/preparationChemistryCarbon dioxide

The invention discloses a hierarchical porous supported nickel-based catalyst, a preparation method and application of the catalyst to a carbon dioxide methane reforming reaction. The hierarchical porous supported nickel-based catalyst is prepared from a carrier and an active ingredient dispersed on the carrier. The catalyst is characterized in that the carrier is selected from at least one of inorganic oxides and contains macropore with the average pore size larger than 50 nm and mesopore with the average pore size of 1 nm-50 nm, and nickel is adopted as the active ingredient. The hierarchical porous supported nickel-based catalyst is used for the carbon dioxide methane reforming reaction, has the excellent sintering resistance and carbon deposition resistance and has the important realistic significance on promoting industrialization of the carbon dioxide methane reforming reaction.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

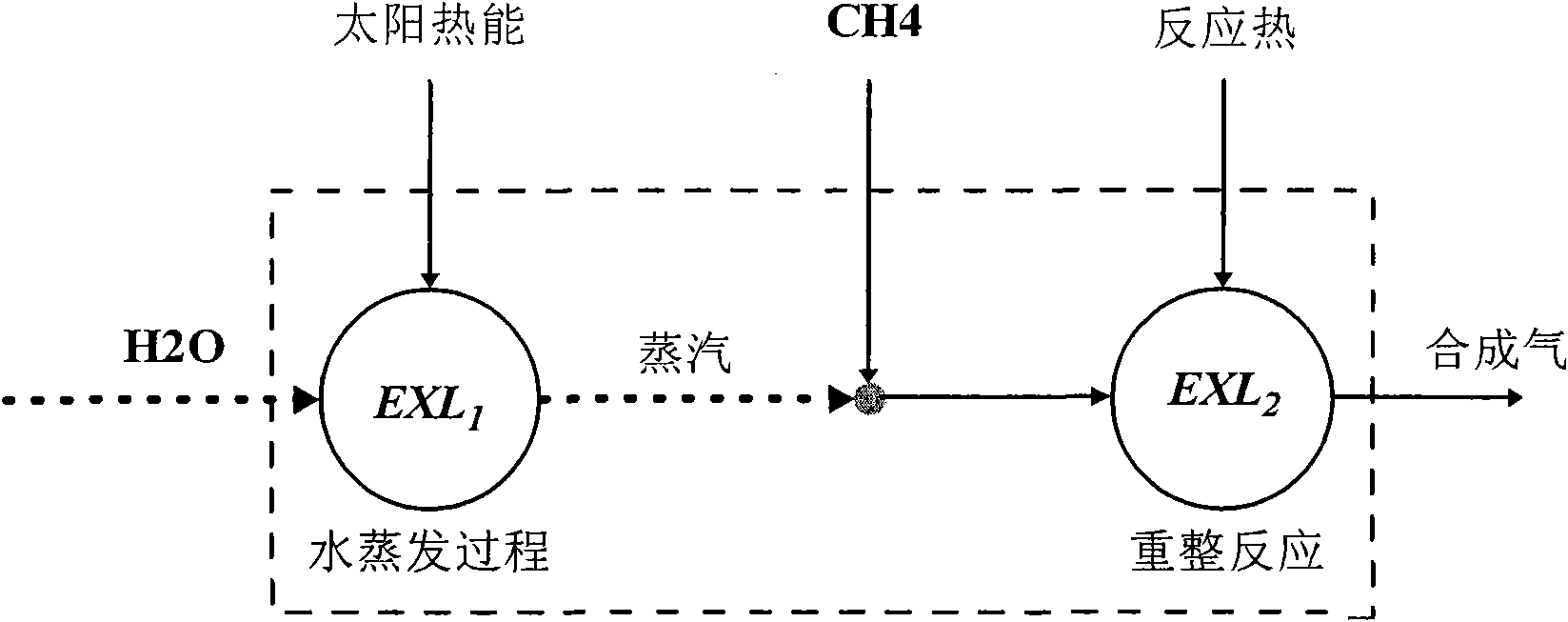

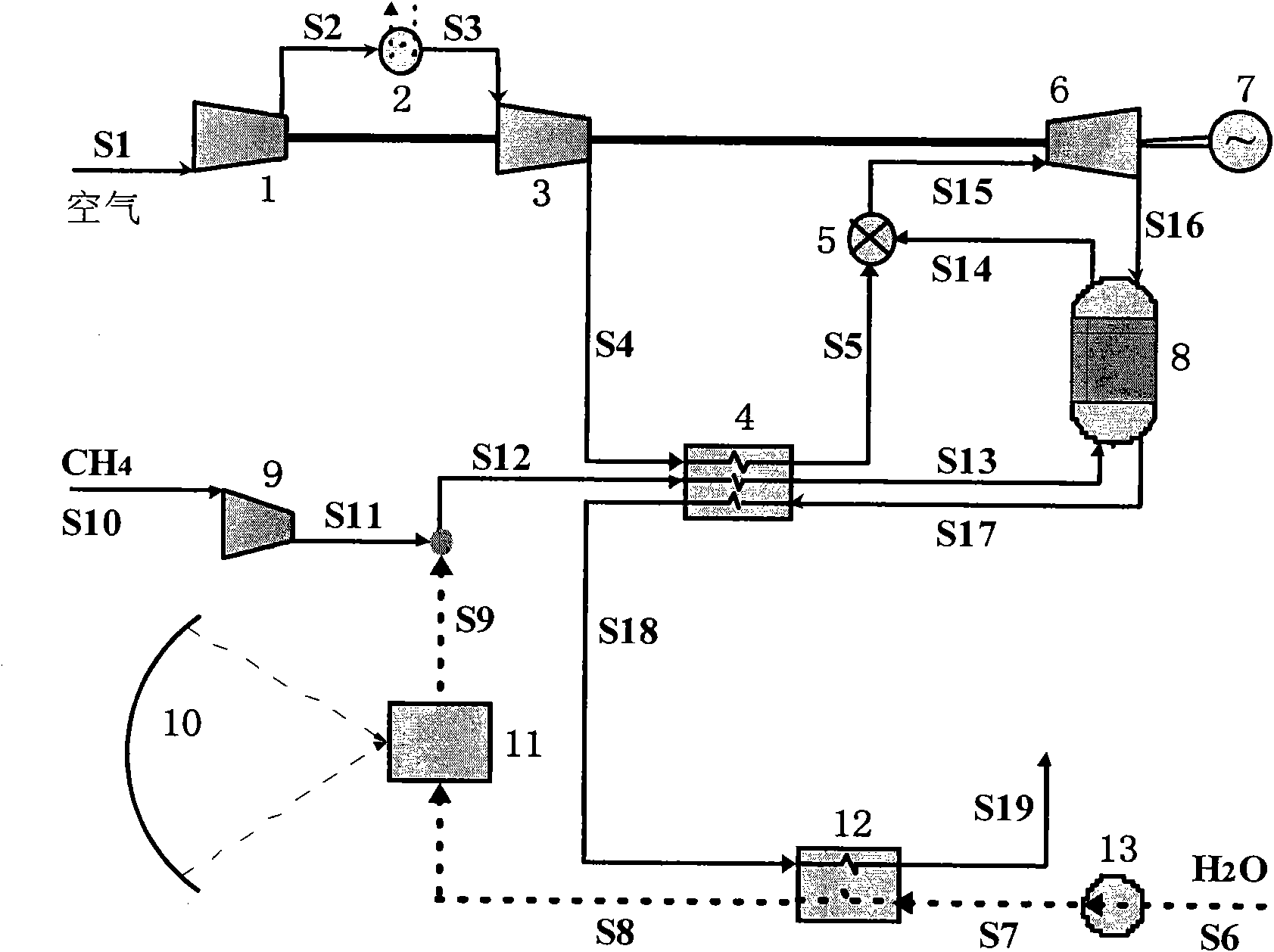

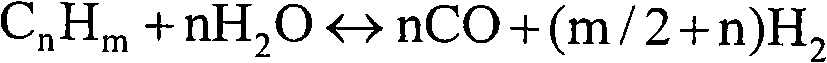

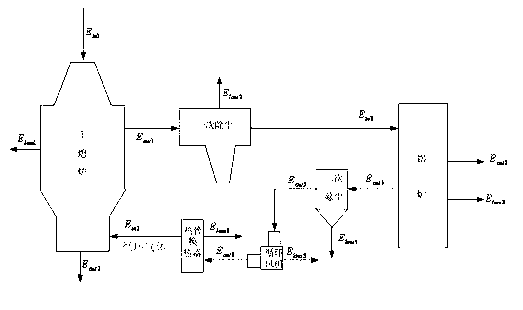

Method and device for indirectly promoting medium and low temperature solar heat energy grades

InactiveCN102061994AAchieve emission reductionImprove efficiencyTurbine/propulsion fuel supply systemsGas turbine plantsThermal energyEvaporation

The invention discloses a method for indirectly promoting medium and low temperature solar heat energy grades, which comprises the following steps of: introducing medium and low temperature solar heat energy in chemical regenerative cycle, converting the solar heat energy into steam internal energy by means of steam evaporation latent heat, converting the steam internal energy into synthetic gas chemical energy by reforming reaction with the participation of steam to realize grade promotion, and finally implementing heat power conversion in a combustion gas turbine system. Because of the introduction of solar energy, turbine exhaust waste heat reclamation is improved, fossil energy consumption is reduced, meanwhile, steam yield is increased, and chemical regeneration and physical regeneration benefits are increased. The solar energy heat-to-power net efficiency can reach 25 to 30 percent; and compared with the conventional chemical regenerative cycle, the efficiency is improved by 5.7 percent, the fossil energy can be saved by 20 to 30 percent, and meanwhile, CO2 emission reduction is realized. Therefore, the method has good economic efficiency and broad engineering application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

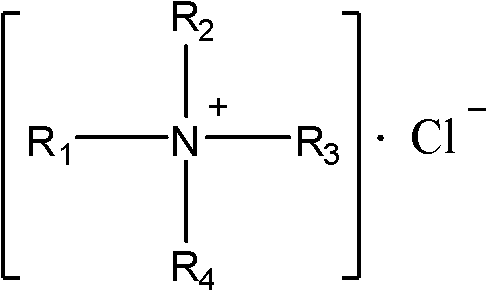

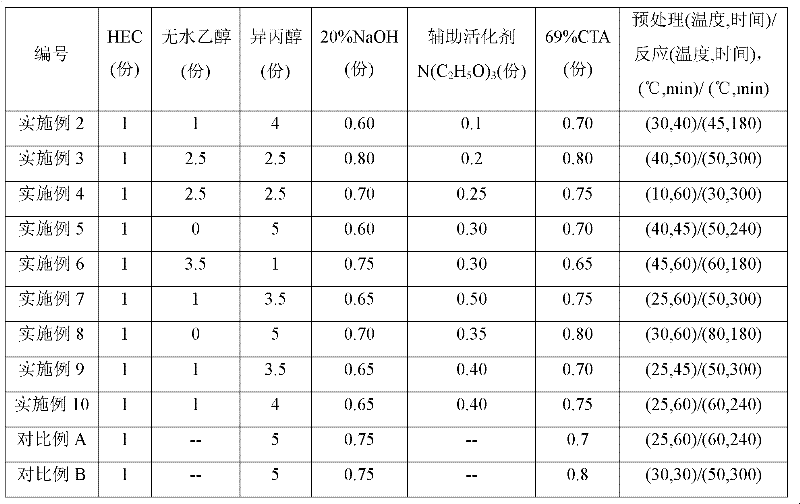

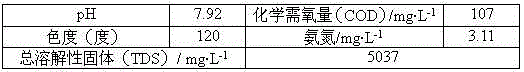

Preparation method of cationic hydroxyethyl cellulose ether

The invention discloses a preparation method of cationic hydroxyethyl cellulose ether. The method comprises the following steps: adding 1 part of hydroxyethyl cellulose, 0.6-0.8 part of 20-35wt% sodium hydroxide solution and 0-0.5 part of amine alkali coactivator in a mixed solution composed of 0-5 parts of absolute alcohol and 0-5 parts of isopropanol and stirring at 10-45 DEG C for 20-60 minutes to obtain liquid A; stirring the liquid A while controlling the temperature to 30-80 DEG C, adding 0.6-1.4 parts of cationic etherifying agent to react for 3-5h to obtain liquid B; cooling the liquid B to 25-35 DEG C, adjusting the pH value, filtering, extracting and drying to obtain the cationic hydroxyethyl cellulose ether. The cationic substitution degree of the method is 0.30-0.50, the cationic reaction efficiency is 42%-75%, the technological process does not require other intermediate links, the production cost is reduced and energy saving and emission reduction are realized in the production process.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

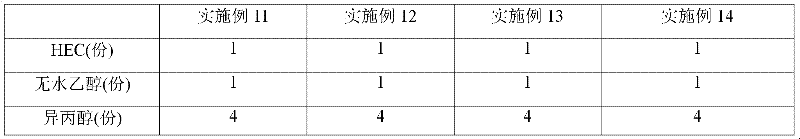

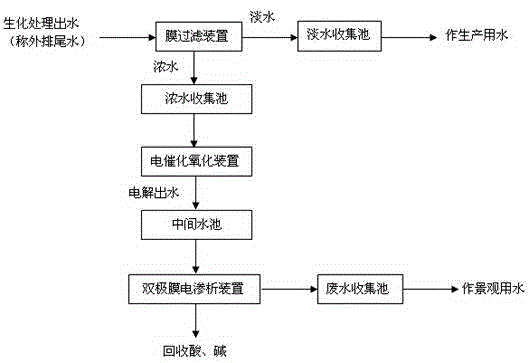

Wastewater advanced treatment method coupling membrane and electricity

ActiveCN104944646AImprove conductivityEmission reductionMultistage water/sewage treatmentWater useFiltration

A wastewater advanced treatment method coupling membrane and electricity belongs to the technical field of wastewater treatment. The treatment method comprises the following steps: discharged wastewater is filtered through a membrane filtration device to obtain fresh water and concentrated water; the fresh water is recycled, the concentrated water is conveyed into an electrocatalysis and electrooxidation device, and the organic pollutants and organisms in the concentrated water are treated and decomposed by electrocatalysis and electrooxidation; the obtained reclaimed water is conveyed into a bipolar membrane electrodialysis device, and the inorganic salt in the reclaimed water is transformed into acid and alkali, so that resource utilization is achieved; the wastewater with the inorganic salt separated by the bipolar membrane electrodialysis device is adopted as scenic environmental water. According to the treatment method, membrane and electricity are coupled, so that advanced treatment of wastewater, material recycling and emission reduction of pollutants are achieved; all water quality indexes of the fresh water and the concentrated water treated through the treatment method respectively meet the standards of GB / T 19923-2005 The Reuse of Urban Recycling Water-Water Quality Standard for Industrial Uses and GB / T 18921-2002 The Reuse of Urban Recycling Water-Water Quality Standard for Scenic Environment Use.

Owner:ZHEJIANG UNIV OF TECH

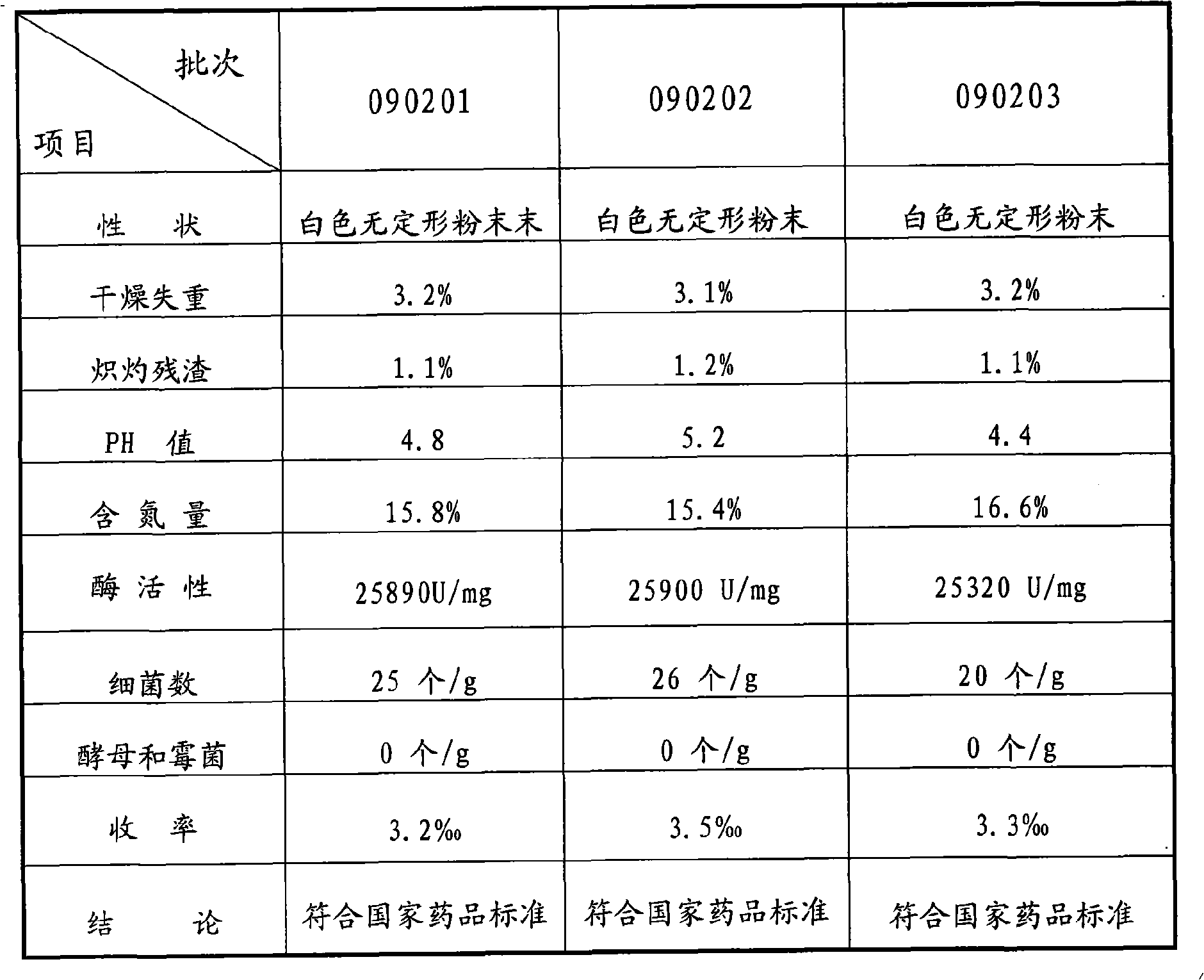

Preparation method of lysozyme

ActiveCN101603038AAchieve emission reductionImprove separation efficiencyEnzymesChemistryChromatography column

The invention provides a preparation method of lysozyme, comprising the following steps: a. pretreating: separating egg white from egg yolk and facilitating the egg white to enter a raw material storage tank after sterilizing; b. separating and purifying: carrying out ultrafiltration separation on homogenized egg white liquid by an ultrafiltration membrane with molecular weight cutoff of 30000D to obtain filtered solution; sending the filtered solution to an ion exchange resin chromatography column for chromatography, carrying out elution after chromatography, collecting qualified elution solution and filtering the elution solution by an ultrafiltration membrane with molecular weight cutoff of 5000D to obtain concentrated solution cutoff; c. drying: spray drying the concentrated solution cutoff and preparing the finished product of lysozyme after drying. The product prepared by the method has higher enzyme activity than the enzyme activities of current domestic products, short production cycle and high yield, can be used as enzyme reagents of pharmaceutical raw materials and biochemical tools and can be also used as preservatives of high-grade organisms and food additives. Each index of the product reaches or exceeds the state pharmaceutical standard.

Owner:SHANDONG LUBEI PHARMA

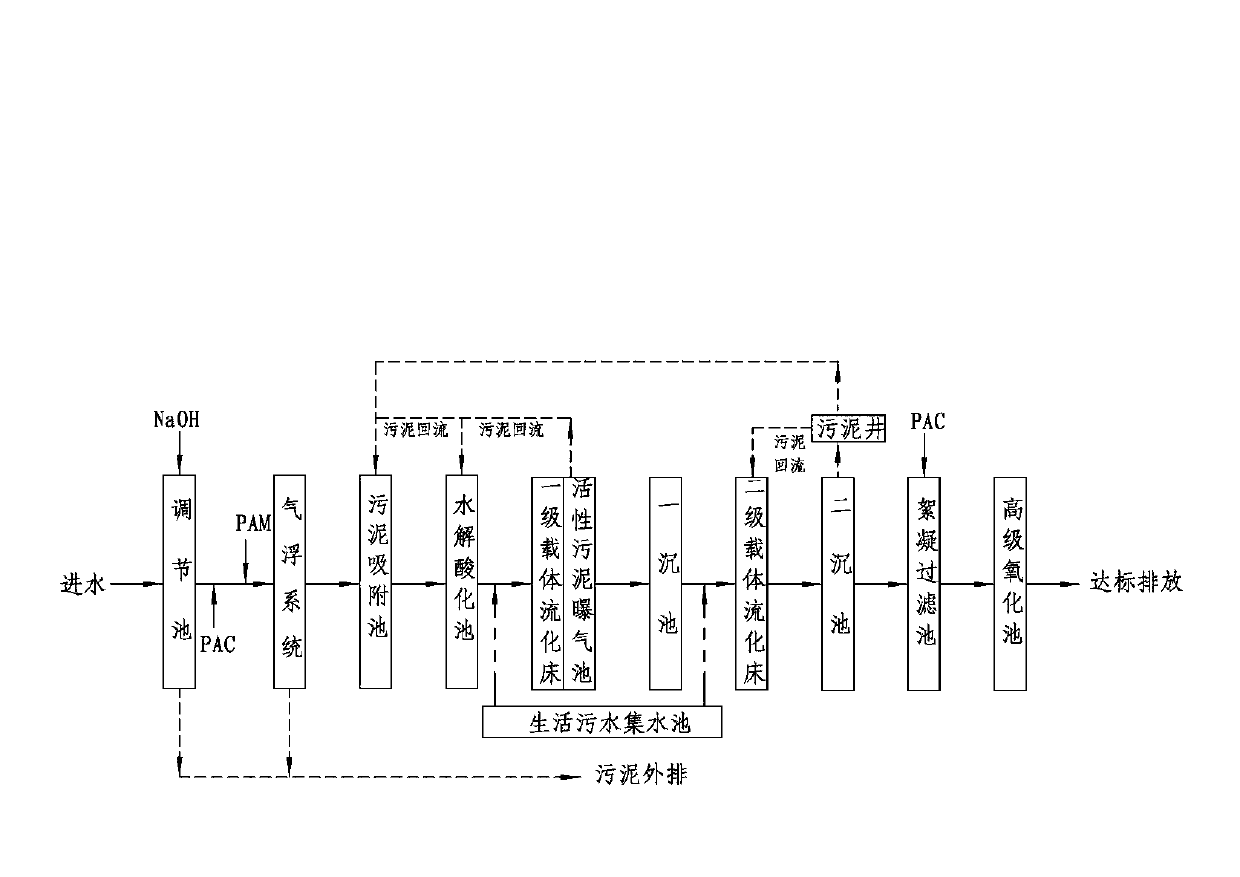

Sewage treatment method in synthetic rubber production

ActiveCN102730862ASafe and reliable operationStable effluent qualityMultistage water/sewage treatmentChemistrySewage

The invention relates to a sewage treatment method in synthetic rubber production and belongs to the technical field of industrial sewage treatment. The method comprises steps in the following order: sewage pretreatment, sludge adsorption, hydrolytic acidification, aerobic biochemical treatment and advanced oxidation treatment, inclusive of domestic sewage and synthetic rubber production sewage blended treatment. By the adoption of the method, biodegradation rate and degradation effect are effectively raised. Iron-carbon microelectrolysis technology is adopted in the advanced oxidation stage, thus greatly reducing treatment cost and effectively removing pollutants of COD, NH3-N the like in the synthetic rubber production sewage. COD of an effluent obtained after the treatment is less than or equal to 60mg / L, and NH3-N is less than or equal to 5mg / L. therefore, the method achieves the standard of discharge and is of great realistic significance. In addition, the treatment cost of the sewage per ton can be reduced to 0.5 yuan. The economic benefit is great.

Owner:CHINA PETROLEUM & CHEM CORP

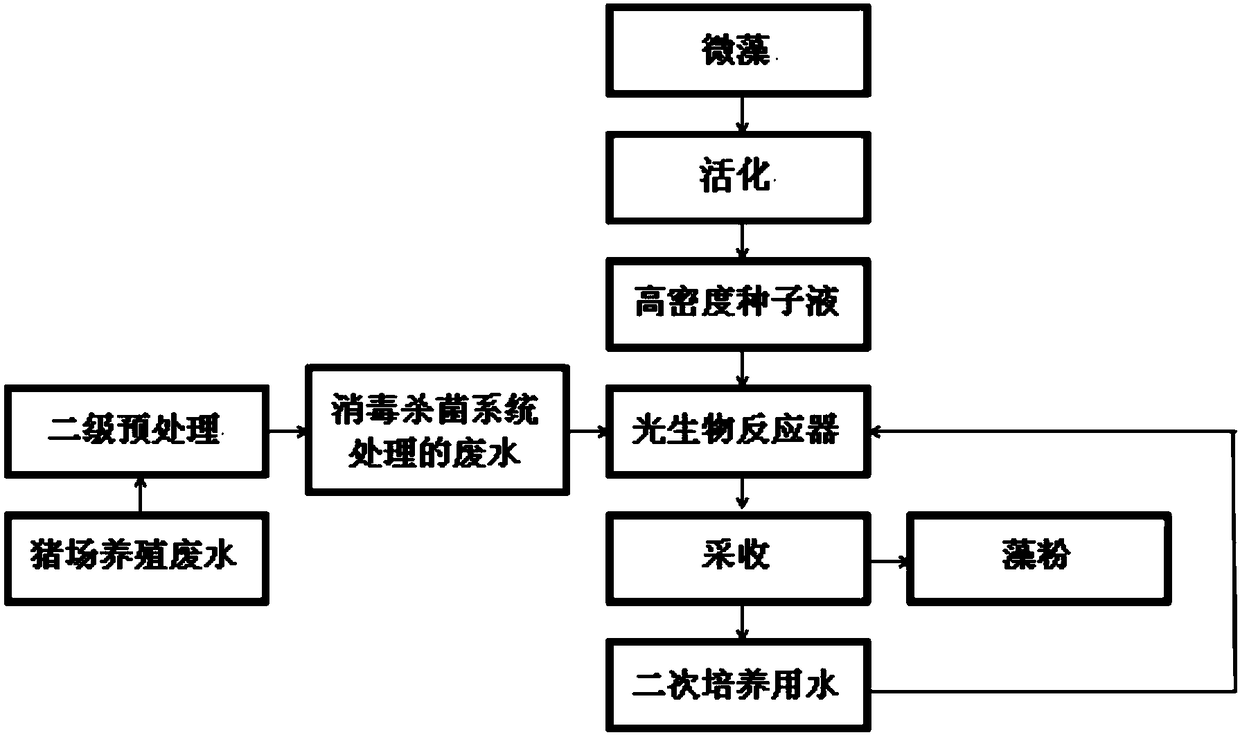

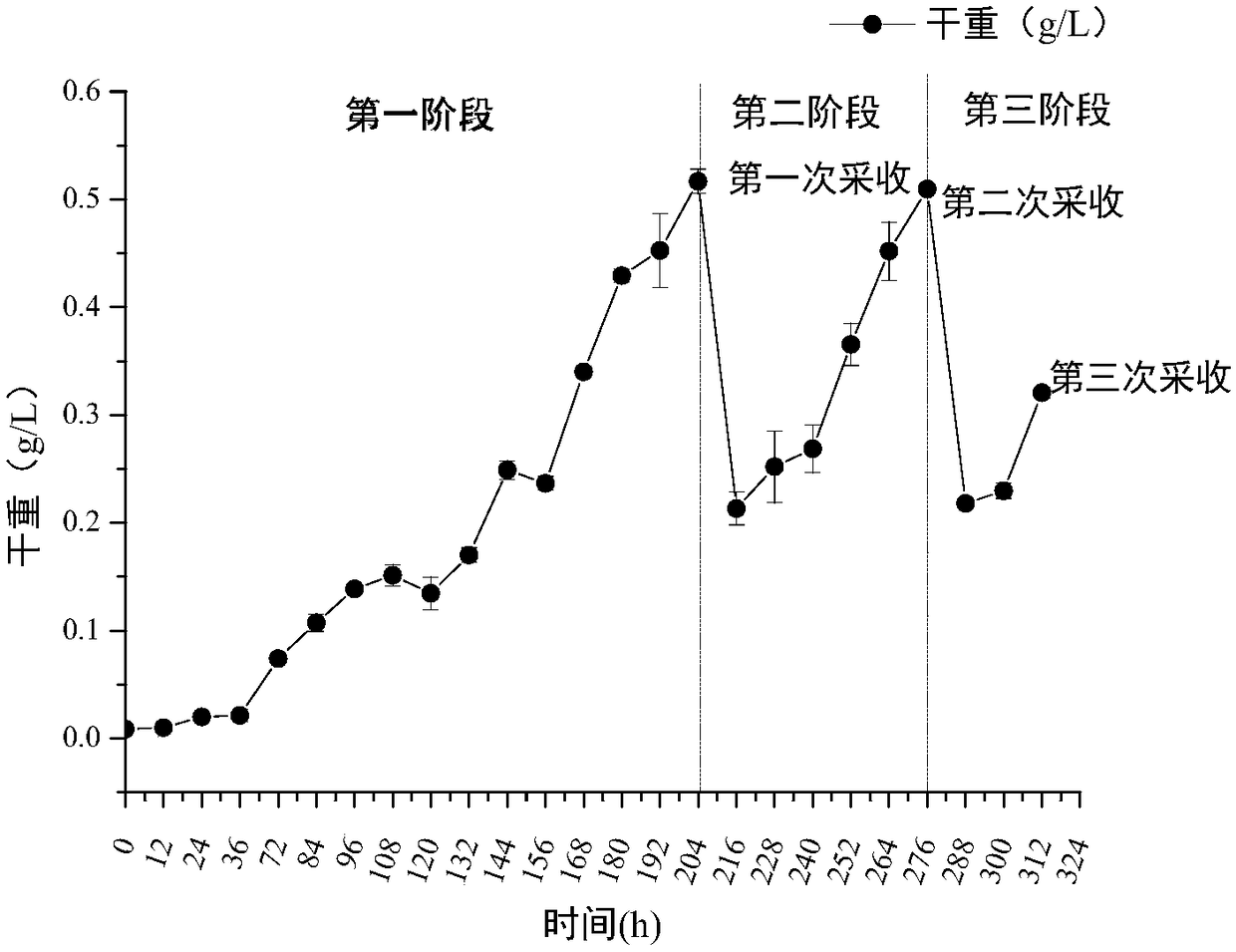

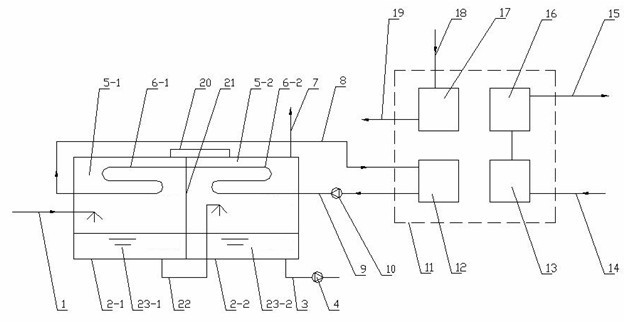

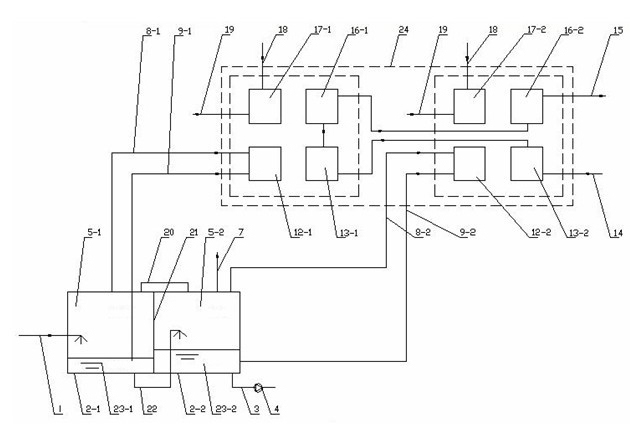

Apparatus and process for treating breeding wastewater in pig farm and producing algal powder by utilizing microalgae

InactiveCN108249574AShort processing cycleAchieve recyclingBioreactor/fermenter combinationsBiological substance pretreatmentsPig farmsUltrafiltration

The invention discloses apparatus and a process for treating breeding wastewater in a pig farm and producing algal powder by utilizing microalgae. The device comprises a wastewater pool, a filtering device, a pipeline type photobioreactor, a spraying device, a gas supply device, an ultrafiltration device, a centrifuge and a clear water pool; and the process comprises the following steps: (1) performing secondary pretreatment on the breeding wastewater in the pig farm, placing the treated wastewater into the photobioreactor, and performing treatment by using a disinfection sterilization system;(2) performing inoculation in the photobioreactor having the wastewater in the pig farm by using the microalgae, performing cultivation, and performing harvesting, wherein the photobioreactor includes an on-line detection water datum system: an in-situ carbon supplementation-pH feedback control device, a spray automatic cooling system and a dissolved-oxygen detection system; and (3) performing centrifugation on the harvested algal liquid to obtain algal mud, and performing drying to obtain the algal powder. The method provided by the invention eliminates or reduces discharge of waste to a maximum limit, achieves the purposes of energy conservation, emission reduction, efficiency enhancement and resource recovery, is applied to large-scale purification treatment of the wastewater in the pig farm and production of the algal powder, and realizes sustainable development and utilization of resources.

Owner:SOUTH CHINA UNIV OF TECH

Heat supply system for directly recovering sewage multi-section flashing steam waste heat by using multiple sections of absorption heat pumps

ActiveCN102072592ALess power consumptionEliminate power consumptionHeat pumpsEngineeringAbsorption heat pump

The invention relates to a heat supply system for directly recovering sewage multi-section flashing steam waste heat by using multiple sections of absorption heat pumps, which is used for recovering sewage flashing steam waste heat. The system comprises 1, 2, ..., and N independent sealing chambers and the multiple sections of absorption heat pumps, wherein the multiple sections of absorption heat pumps comprise respective 1, 2, ..., and N generators, 1, 2, ..., and N condensers, 1, 2, ..., and N absorbers and 1, 2, ..., and N evaporators; water steam which is formed by flashing sewage in the 1, 2, ..., and N independent sealing chambers and has different pressure from high pressure to low pressure enters 1, 2, ..., and N evaporator tubes sequentially by 1, 2, ..., and N flashing steam and is directly connected with the 1, 2, ..., and N evaporators of the multiple sections of absorption heat pumps; and flashing steam condensate outflows the 1, 2, ..., and N evaporator tubes and reflows to respective 1, 2, ..., and N liquid phase areas of the 1, 2, ..., and N independent sealing chambers sequentially by respective 1, 2, ..., and N flashing steam condensate. The system can reduce heat loss, improve the water-supply temperature of hot water and reduce investment and running cost.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

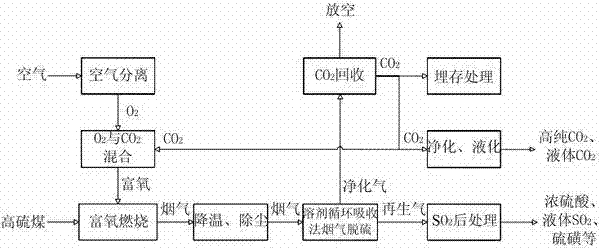

Oxygen-enriched combustion of high-sulfur coal and comprehensive flue gas treatment process

InactiveCN102261647AImprove heat transfer performanceIncrease oxygen contentCarbon compoundsChemical industryChemical industryFlue gas

The invention relates to the oxygen-enriched combustion of high-sulfur coal and the comprehensive treatment process of flue gas. Through the integration and application of various technologies such as oxygen-enriched combustion technology and solvent circulation absorption method flue gas desulfurization technology, a high thermal efficiency, low energy consumption, and low Pollution, good economic characteristics, and taking into account flue gas desulfurization, decarbonization, dust removal treatment and SO2 pollutants, CO2 pollutants recovery and utilization of high-sulfur coal oxygen-enriched combustion and flue gas comprehensive treatment process, so as to provide a clean environment for high-sulfur coal A feasible way has been found. The technical content of the invention can be widely used in the combustion and utilization of high-sulfur coal by coal-fired furnaces in thermal power, chemical industry, building materials and other industries and the comprehensive treatment of SO2 and CO2 in the flue gas.

Owner:成都华西工业气体有限公司

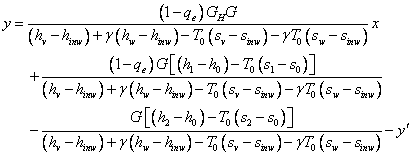

Method for measuring dry-quenching burning loss rate based on exergy balance

InactiveCN102759542AReduce manufacturing costSimple calculationMaterial heat developmentCokeIndustrial engineering

The invention discloses a method for measuring a dry-quenching burning loss rate based on an exergy balance. The method comprises the following steps of: establishing an exergy balance model for a dry-quenching burning system after analyzing a dry quenching process, operating situations and related factors for affecting the dry-quenching burning loss rate; and obtaining a relationship between the dry-quenching burning loss rate and a steam yield through the analysis of the exergy balance model. According to the method disclosed by the invention, the dry-quenching burning loss rate can be simply, conveniently, effectively and quickly calculated out by using the relationship; and besides, the method has important meanings for reducing the dry quenching production cost and improving the dry quenching yield and efficiency.

Owner:CHANGSHA CHANGZHI ELECTRICAL

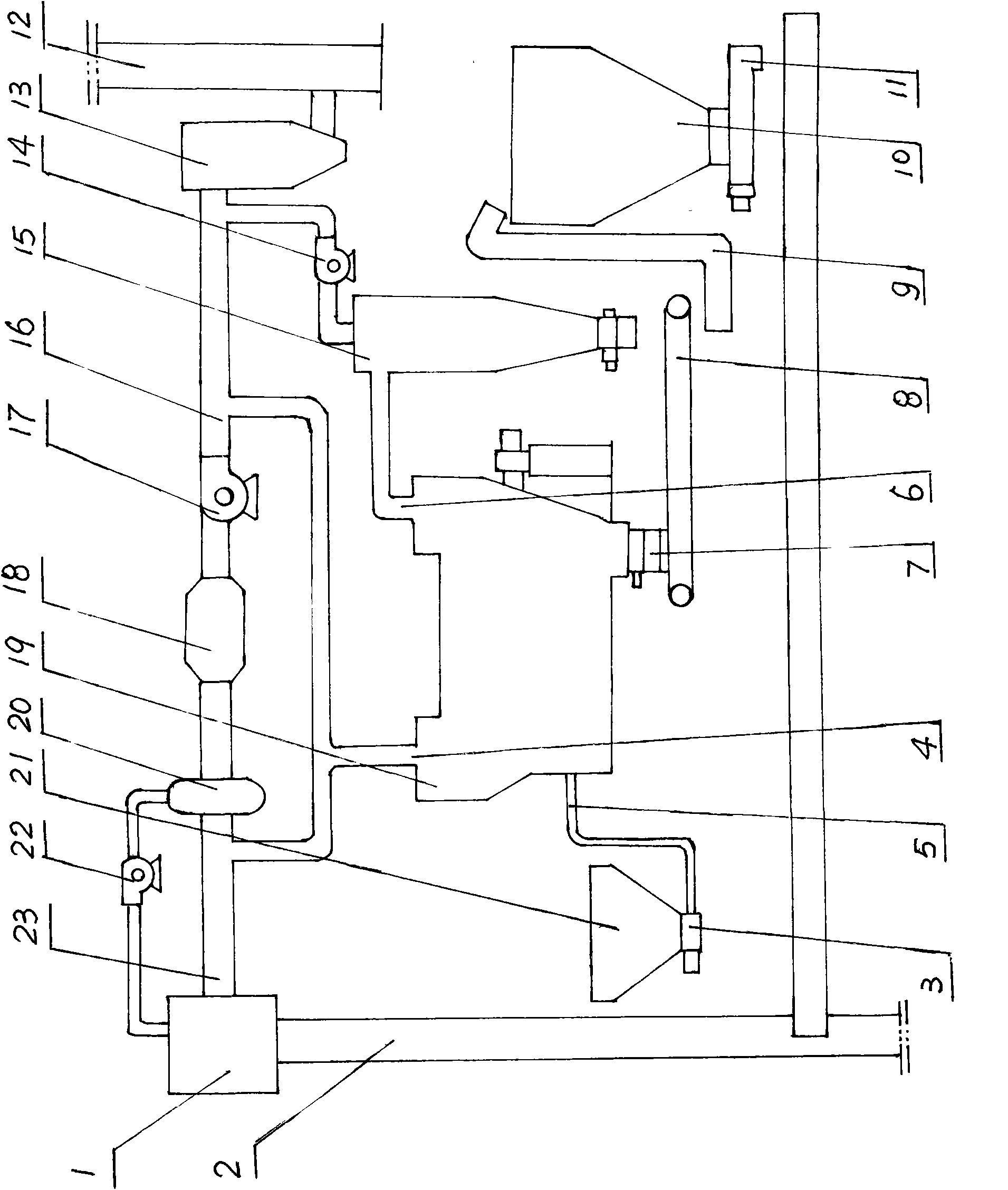

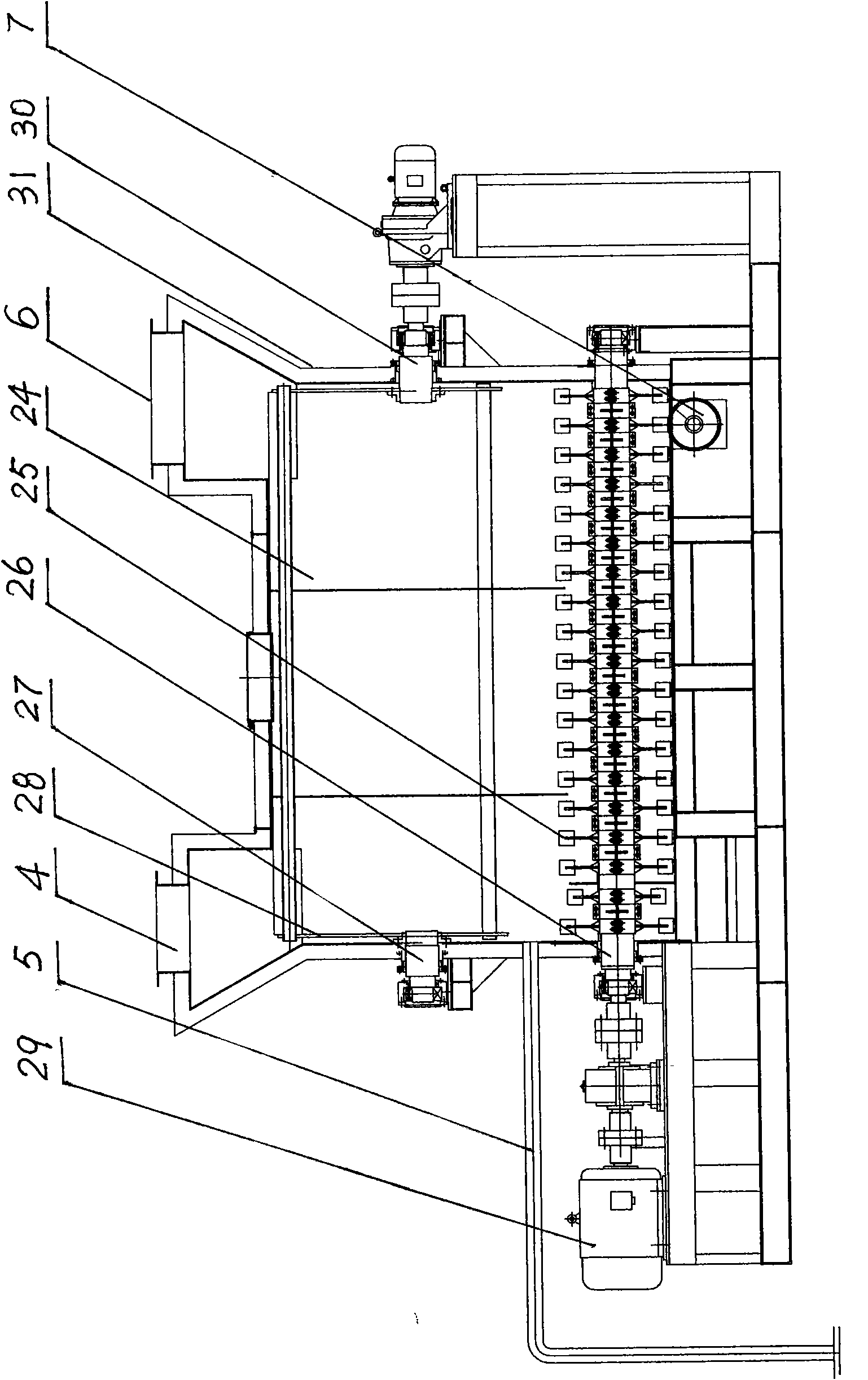

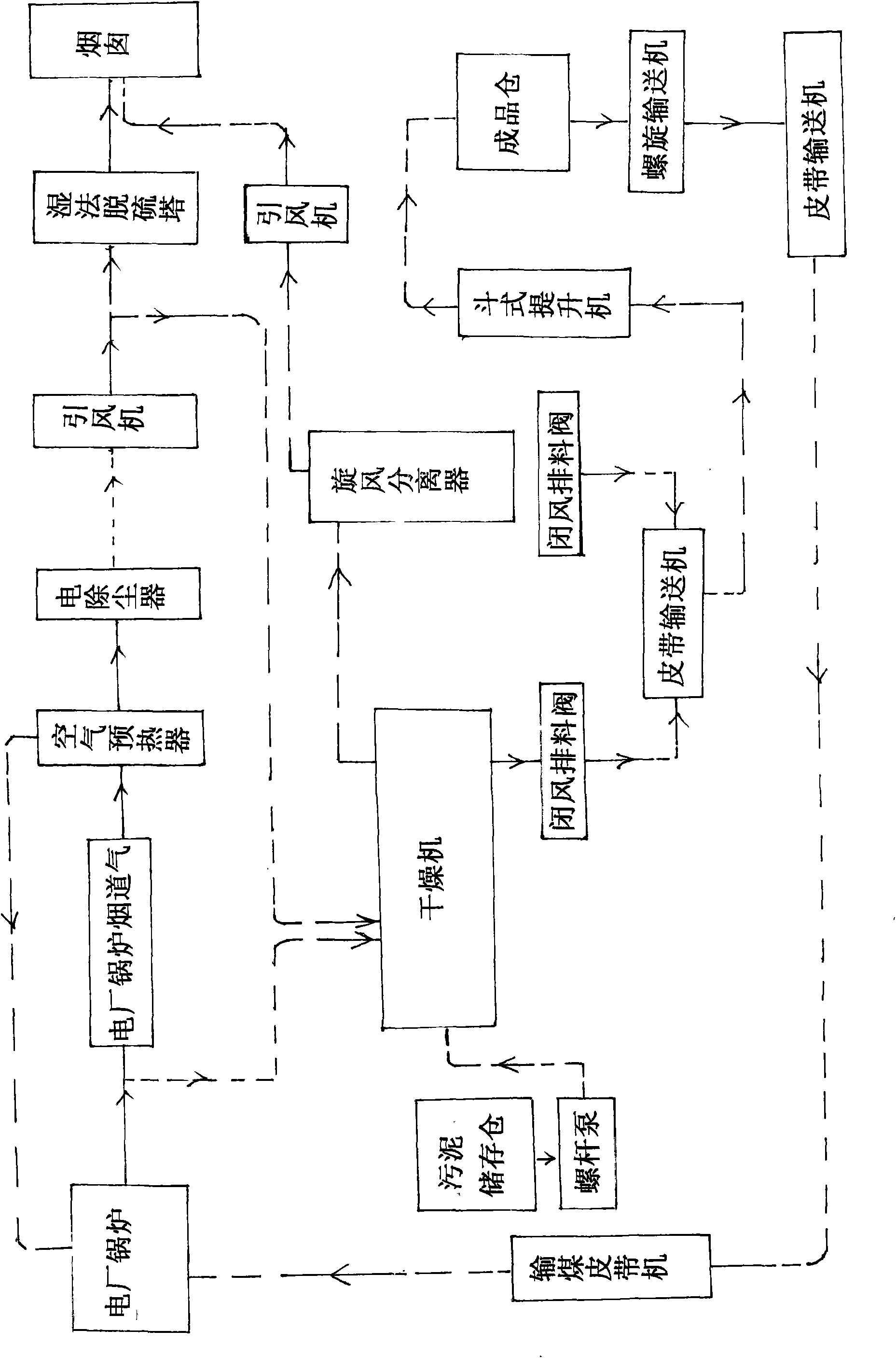

Sludge treatment device using waste heat of boiler and treatment process thereof

ActiveCN101885573AReduce the temperatureTake advantage ofSludge treatment by de-watering/drying/thickeningDispersed particle separationCombustionSludge

The invention provides a sludge treatment device using waste heat of a boiler and a treatment process thereof, relates to a sludge treatment device using waste heat of a boiler and improvement of a treatment process thereof, in particular to a sludge treatment device using waste heat discharged by fume of a boiler and a treatment process thereof. The sludge treatment device comprises the boiler, wherein the boiler is respectively connected with a coal conveying belt device and a fume discharge treatment device. The sludge treatment device is characterized in that the fume channel of a fume discharge device is connected with a drier through an induced draft fan and a cyclone separator; the side of the drier is connected with a sludge storage warehouse; the drier and the bottom of the cyclone separator are connected with a finished product warehouse through a belt conveyer; and the finished product warehouse is connected with the coal conveying belt device through a spiral conveyer. The treatment process comprises the following steps: firstly, introducing fume in the fume discharge channel of the boiler into the drier to dry sludge; and sending tail gas in the dried sludge into the fume discharge channel of the boiler, and then returning the residual sludge to the boiler to participate in combustion.

Owner:沈阳禹华环保有限公司

Dry manure two-phase anaerobic digestion system for pig farm

InactiveCN101654321AAchieve enrichmentEmission reductionBiological substance pretreatmentsGas production bioreactorsPig farmsSlurry

The invention discloses a dry manure two-phase anaerobic digestion system for a pig farm belonging to the technical field of environment engineering and energy, which uses a hydrolytic acidification and methane production two-phase anaerobic digestion system as a main body. The system is characterized in that the dry manure in the pig farm is treated by integrating aeration biogas slurry reflux, external culture of acid producing bacteria and methane producing bacteria, and activity maintaining device so as to solve the problem that the prior two-phase process cannot effectively treat high solid concentration pig manure and has lower efficiency, thoroughly solve the problem of large water consumption of the conventional anaerobic treatment, realize biogas slurry concentration, reduce the discharge amount of the biogas slurry, greatly reduce subsequent treatment load of biogas engineering, and realize quick degradation and efficient gas production of organic waste. After application, the system improves the comprehensive economic benefit by 20 percent compared with the prior anaerobic system; and the improvement on efficiency ensures that the biogas engineering of the dry manure pigfarm realizes self supply of energy, and maintains normal operation of the biogas engineering of the pig farm in winter, thereby achieving multiple aims of saving water, reducing discharge, protecting environment and producing energy and fertilizer.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com