Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

A calcium carbide furnace and high-temperature furnace technology, applied in furnaces, furnace components, climate sustainability, etc., can solve problems such as large filtration resistance, unstable operation, burning bags, etc., to reduce furnace gas emissions, avoid air mixing, Reasonable effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

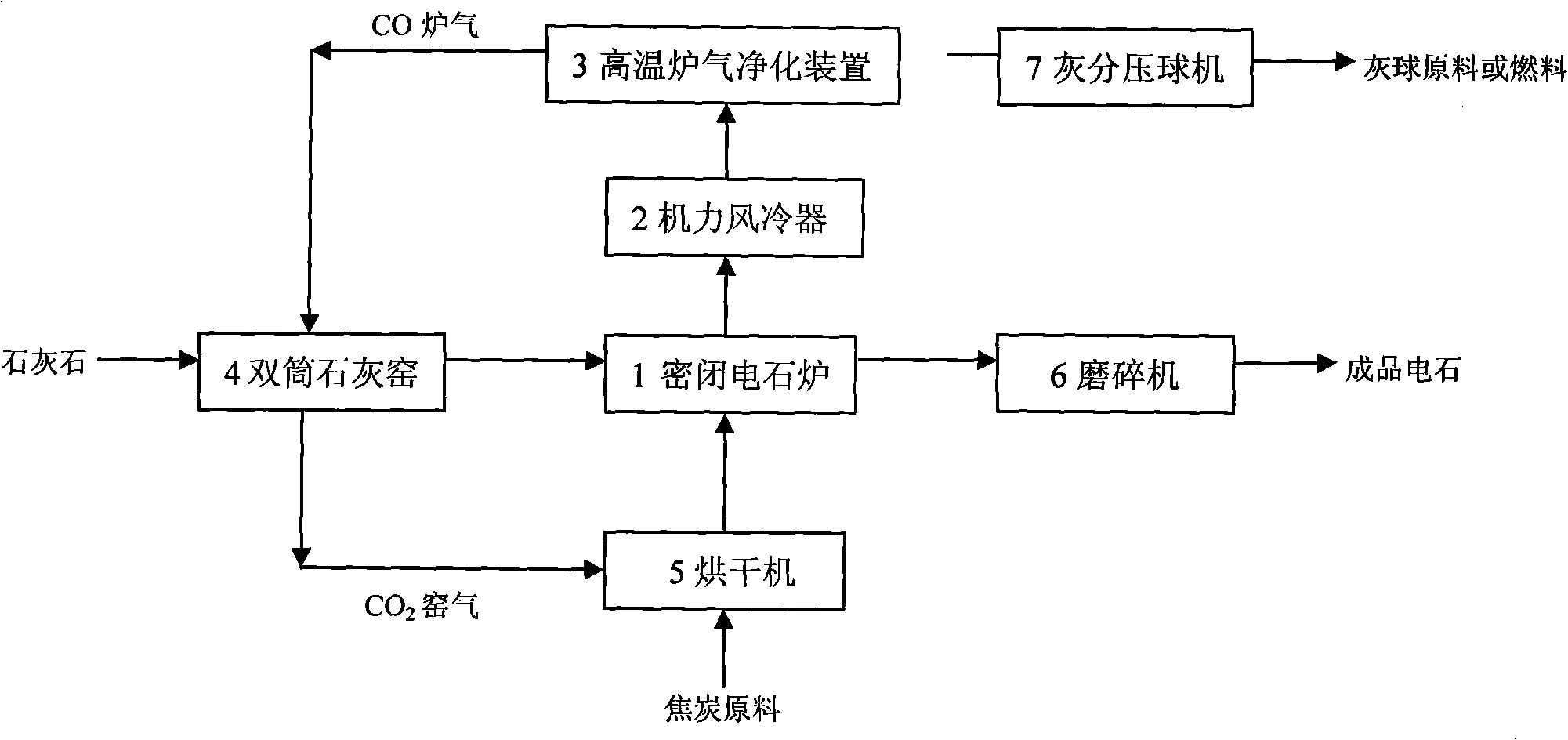

[0016] Such as figure 1 As shown, in the airtight calcium carbide furnace high-temperature furnace gas comprehensive utilization system of the present invention, the two inlets of the airtight calcium carbide furnace 1 are respectively connected with the double-tube lime kiln 4 for supplying quicklime and the dryer 5 for supplying coke, and the airtight calcium carbide furnace 1 One outlet is connected to a grinder 6 for calcium carbide crushing. The inlet and outlet of the mechanical air cooler 2 are respectively connected with another outlet of the sealed calcium carbide furnace 1 and the inlet of the high-temperature furnace gas purification device 3, and the two outlets of the high-temperature furnace gas purification device 3 are connected with the double-tube lime kiln 4 respectively. One inlet is connected with the ash pellet machine 7, and the double-tube lime kiln 4 is also connected with one inlet of the dryer 5. Except for the high-temperature furnace gas purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com