Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

A shell breaking device and self-positioning technology, which is applied in the fields of shelling, pod removal, food science, etc., to achieve the effect of reducing the positioning process, high kernel rate, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be further described below in conjunction with the drawings and embodiments.

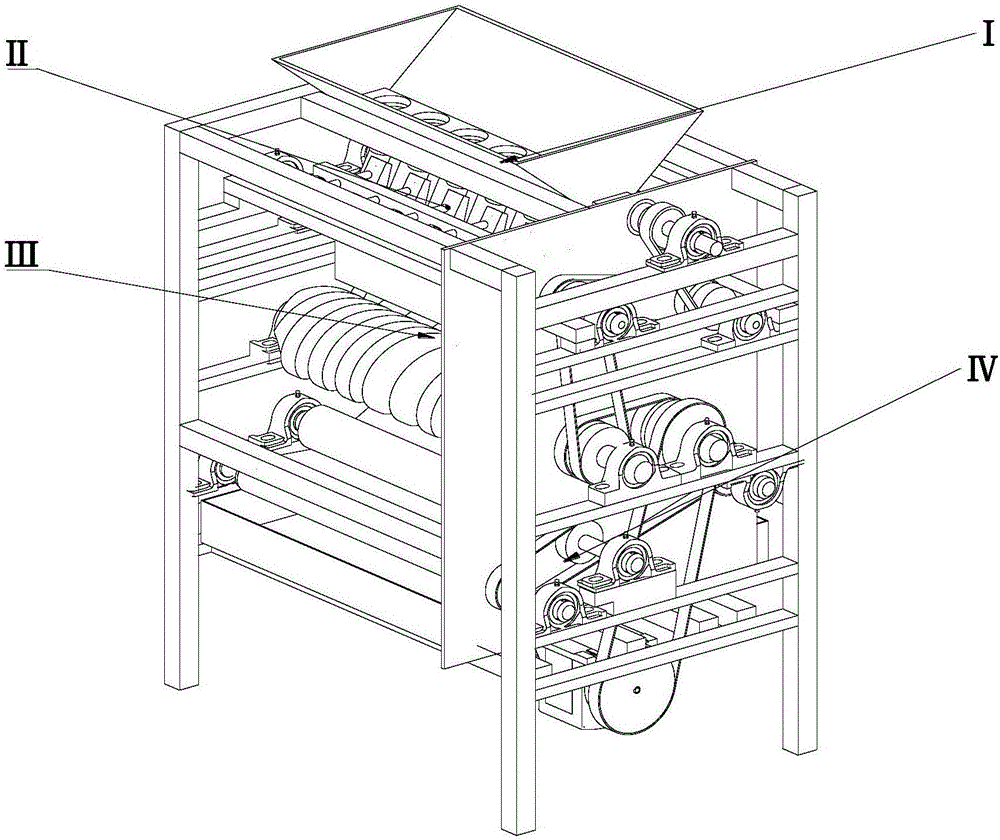

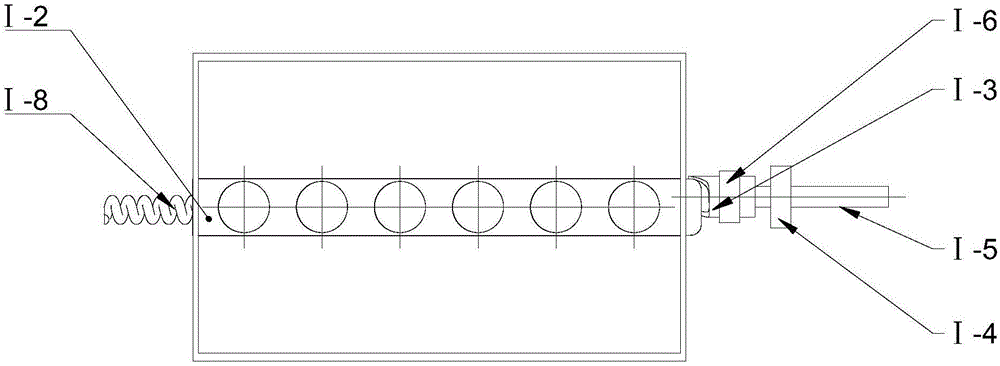

[0095] Such as figure 1 Shown is an isometric view of the device of the present invention. It can be seen from the figure that the present invention includes four major parts. From top to bottom, they are intermittent feeding device I, V-shaped block self-positioning pre-crushing device II, Co-rotating double spiral roller self-grading flexible shell breaking device III, pressure roller friction belt separation device IV.

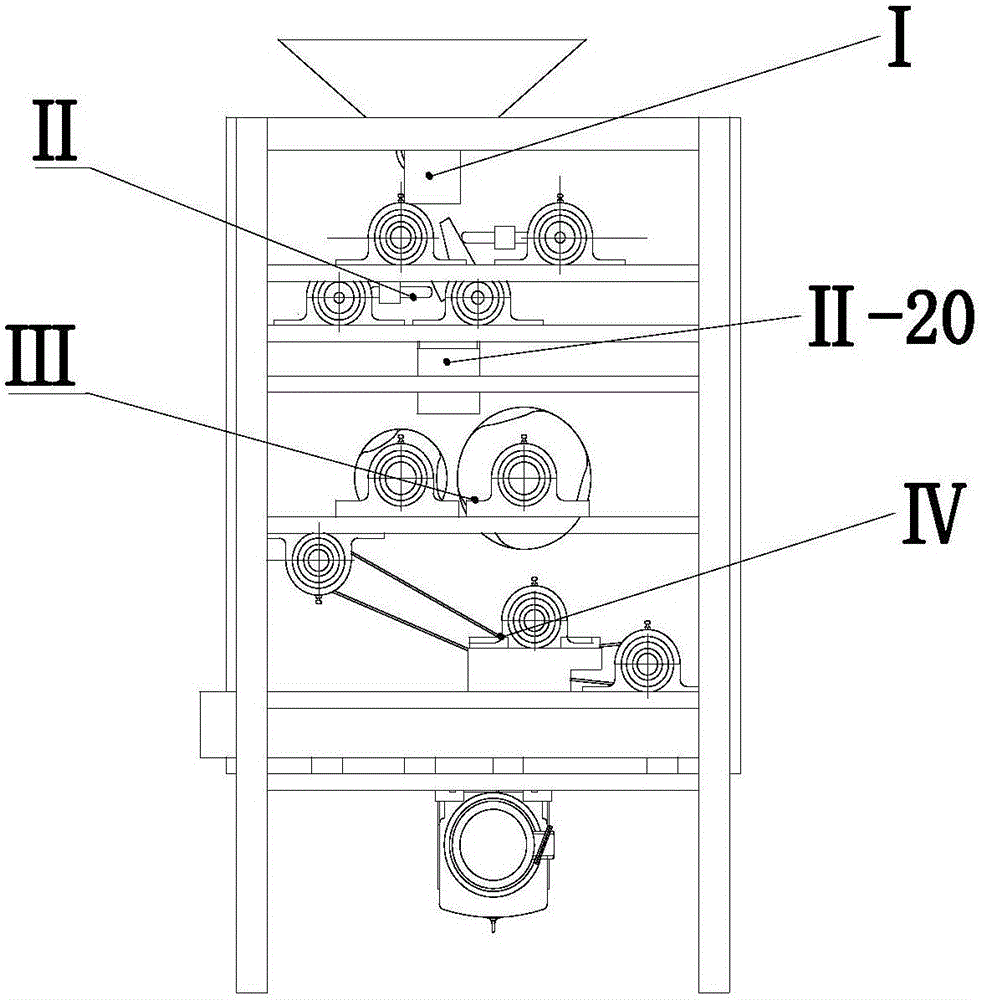

[0096] Such as figure 2 Shown is the left side view of the device of the present invention. From the figure, the up and down arrangement of the various parts of the present invention and the transmission between the various devices can be seen more clearly. The intermittent feeding device I is installed on the upper part of the overall device for intermittent batch feeding; the V-shaped block self-positioning pre-cracking device II is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com