Patents

Literature

2493 results about "Walnut Nut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A walnut is the nut of any tree of the genus Juglans (Family Juglandaceae), particularly the Persian or English walnut, Juglans regia.

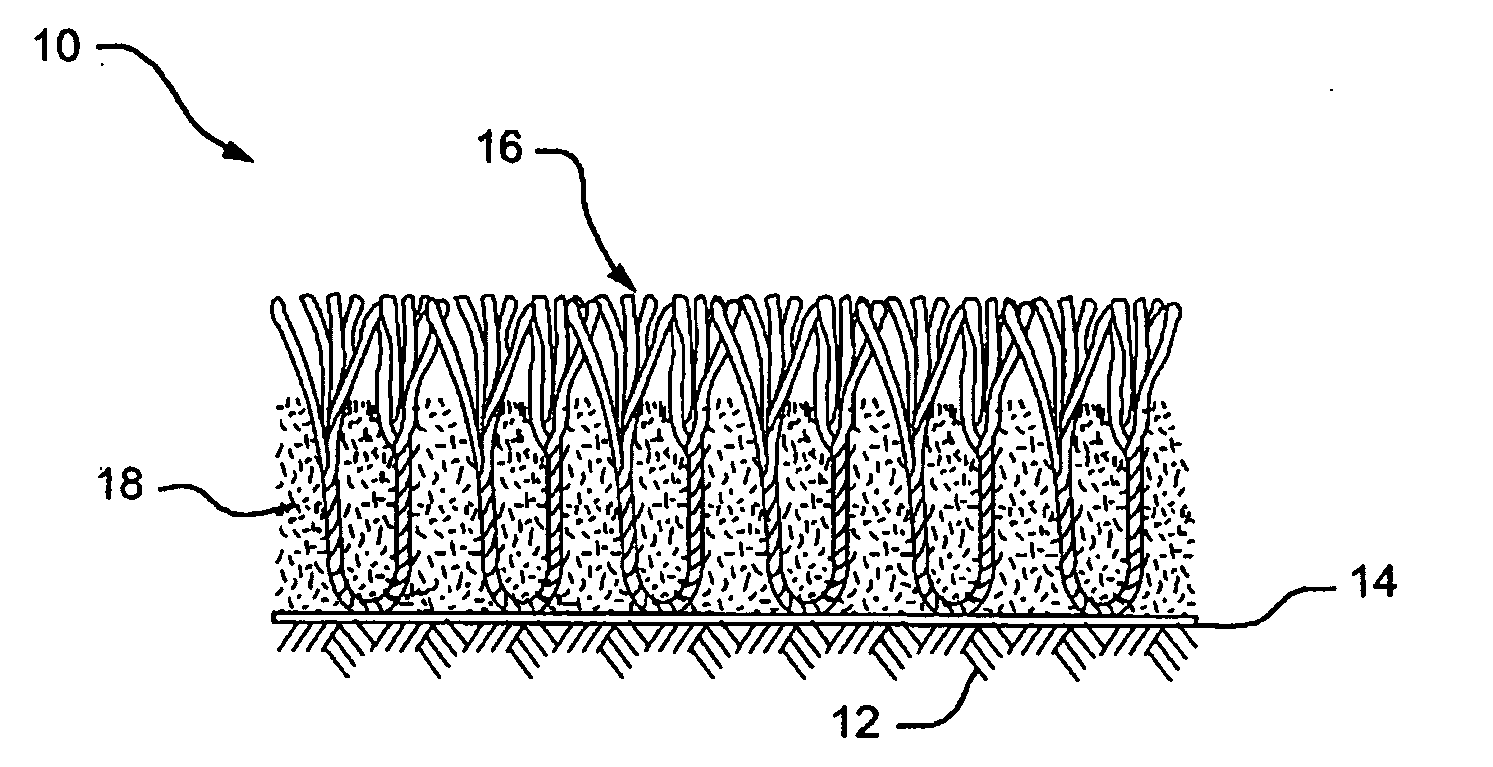

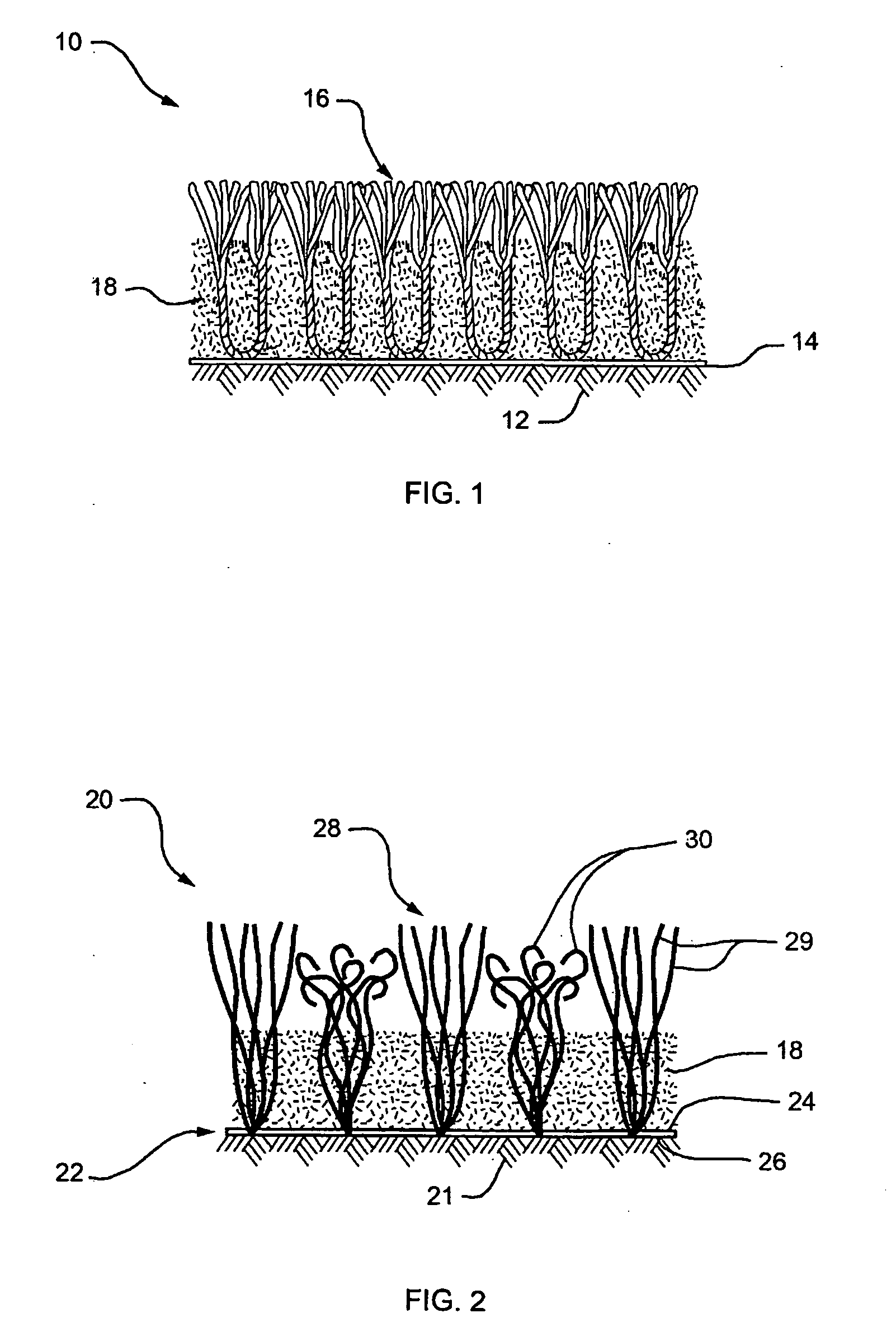

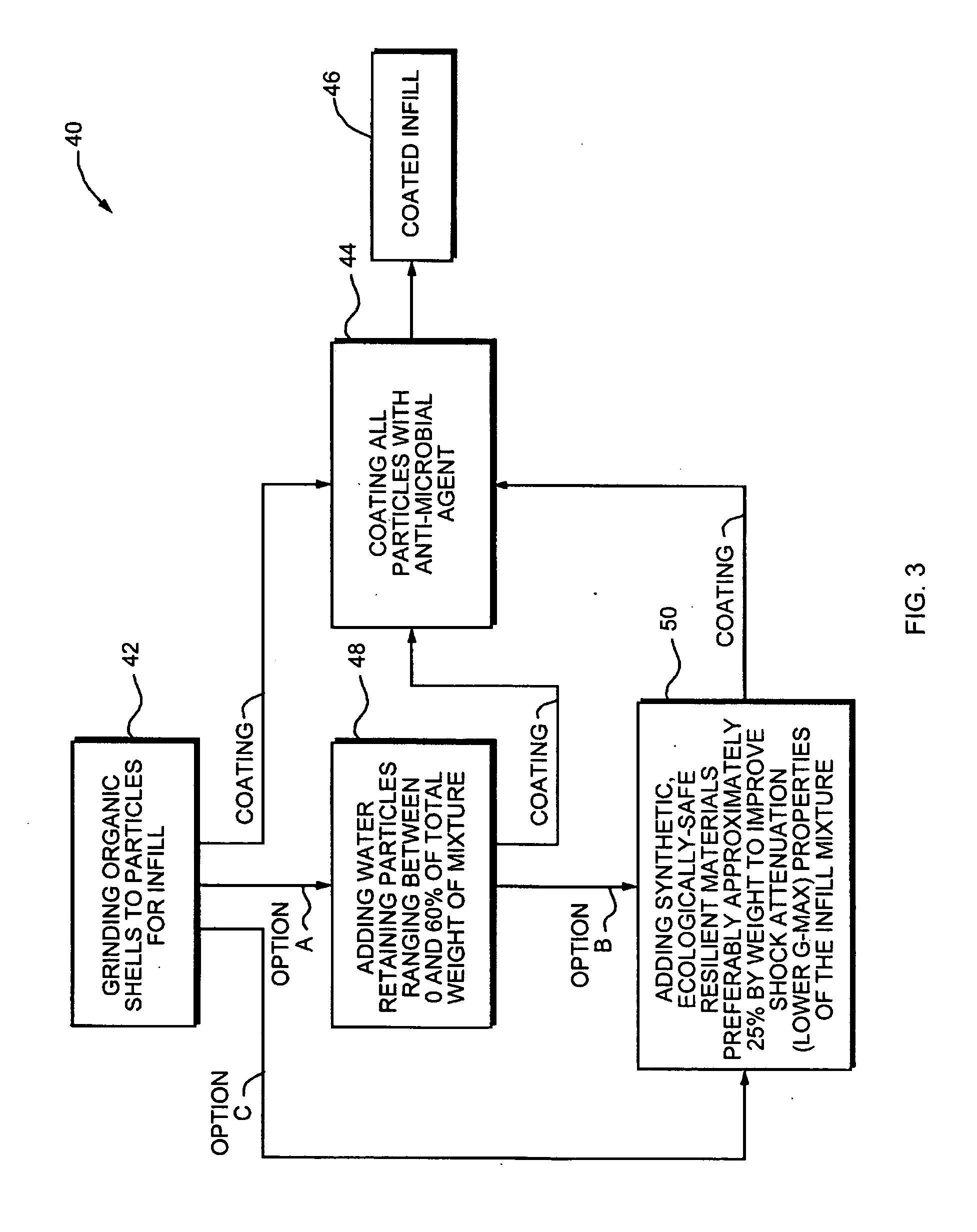

Artificial turf infill

InactiveUS20100055461A1High albedoImprove retention capacitySynthetic resin layered productsCellulosic plastic layered productsWalnut NutUltrasound attenuation

An artificial turf infill comprising an organic material including ground walnut shells having each organic particle completely coated with an anti-microbial agent. Water-retaining particles are added to the infill ranging between 0 and 60% of total weight of the mixture. Synthetic, ecologically-safe resilient granules preferably between approximately 20% and 25% by weight may be added to the infill to improve shock attenuation (lower G-max) properties of the infill mixture. The water-retaining particles and synthetic resilient granules within the infill are completely coated with the anti-microbial agent.

Owner:DALUISE DANIEL A +1

Acidophilus milk and preparation method thereof

InactiveCN101715821ANutritional diversityComprehensive health functionMilk preparationPolygonum fagopyrumCereal grain

The invention relates to an acidophilus milk which comprises the following raw materials in parts by weight relative to total 1000 parts: 50-200 parts of nut, 0-200 parts of pulp, 0-200 parts of grain, 0-15 parts of albumen powder, 70-85 parts of white granulated sugar, 0.5-13.5 parts of stabilizing agent, 0-5 parts of edible essence and the balance of fresh milk. 0.02-0.08 activity unit / kilogram lactobacillus is used for fermenting. The nut is selected from filbert, a pine nut, almond, a Chinese chestnut, a pistachio nut, a sunflower seed, a walnut, anacardium occidentale, a lotus seed, peanut and / or armeniaca. The pulp is selected from coconut, strawberry, a yellow peach, blueberry, mulberry, tangerine, raisin, a grape, cherry, a mango, rubus corchorifolius and / or aloe vera gel. The grain is selected from barley, oat, wheat, rye, buckwheat, rice, wheat seed, broomcorn and maize. A preparation method of the acidophilus milk comprises the steps of inspecting raw milk, mixing, metering volume, homogenizing, sterilizing, cooling, vaccinally fermenting, adding, inspecting and refrigerating. The invention is convenient for the transport and storage of products and ensures the uniformity and completion of added substances.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

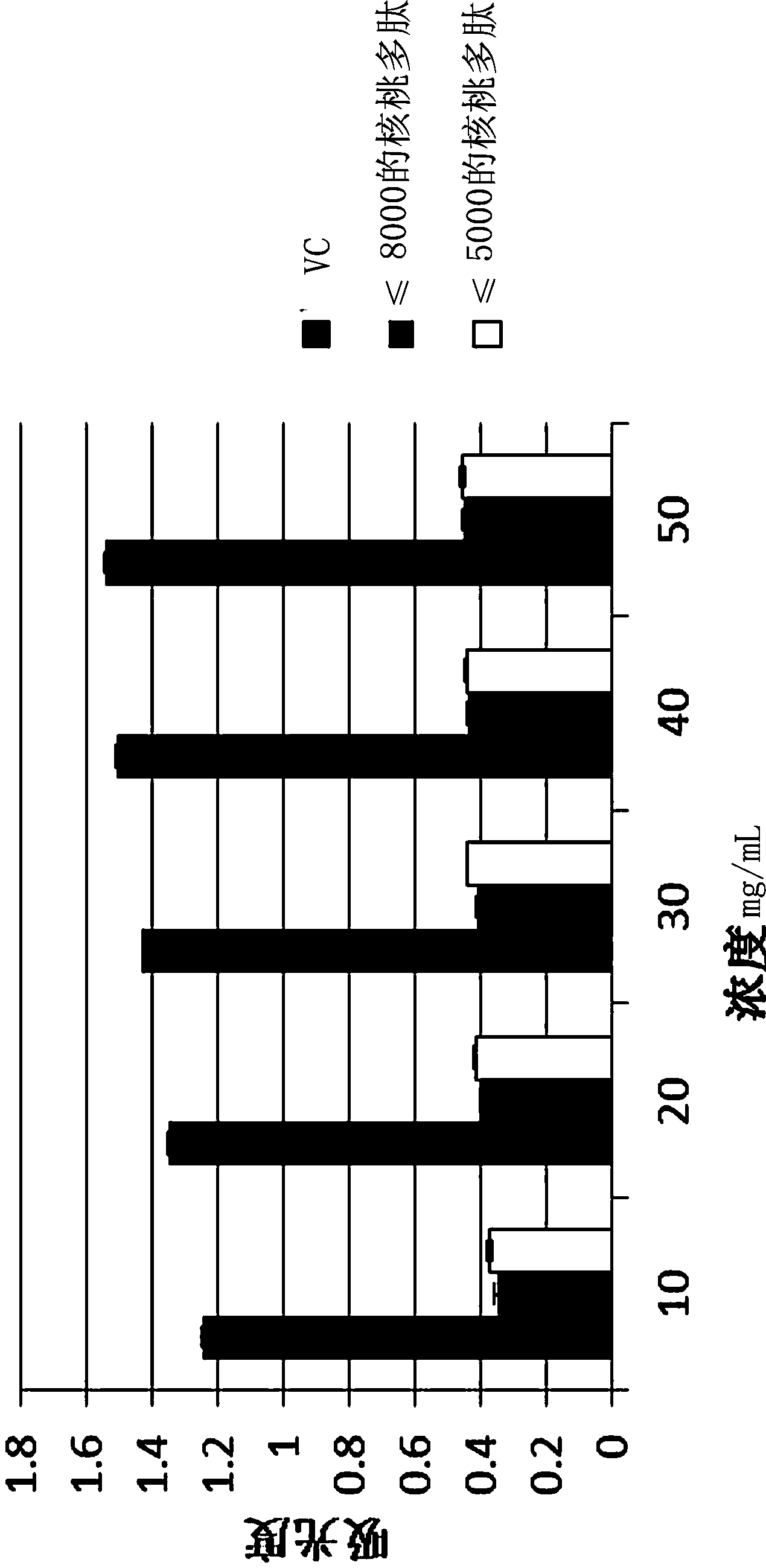

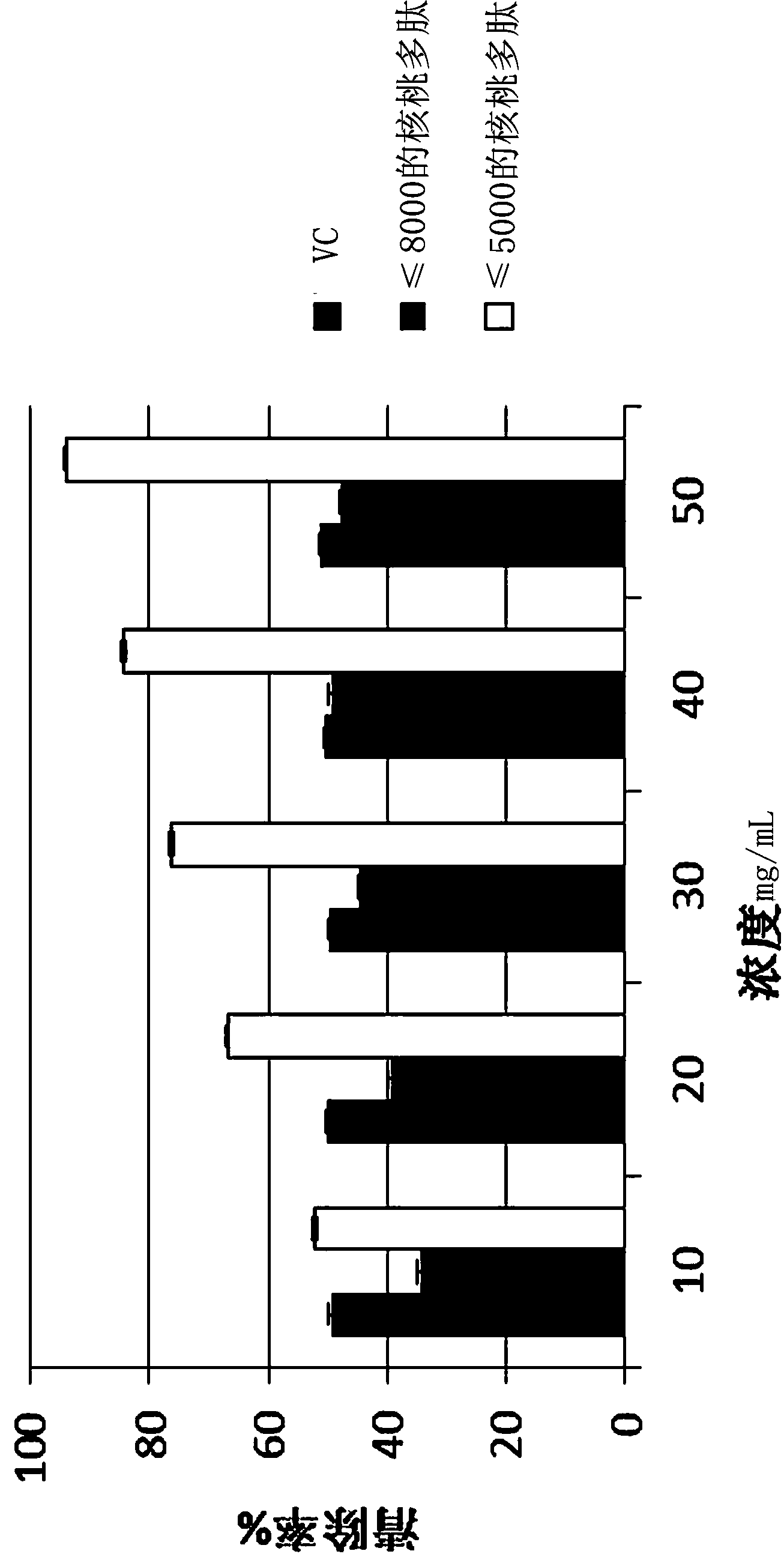

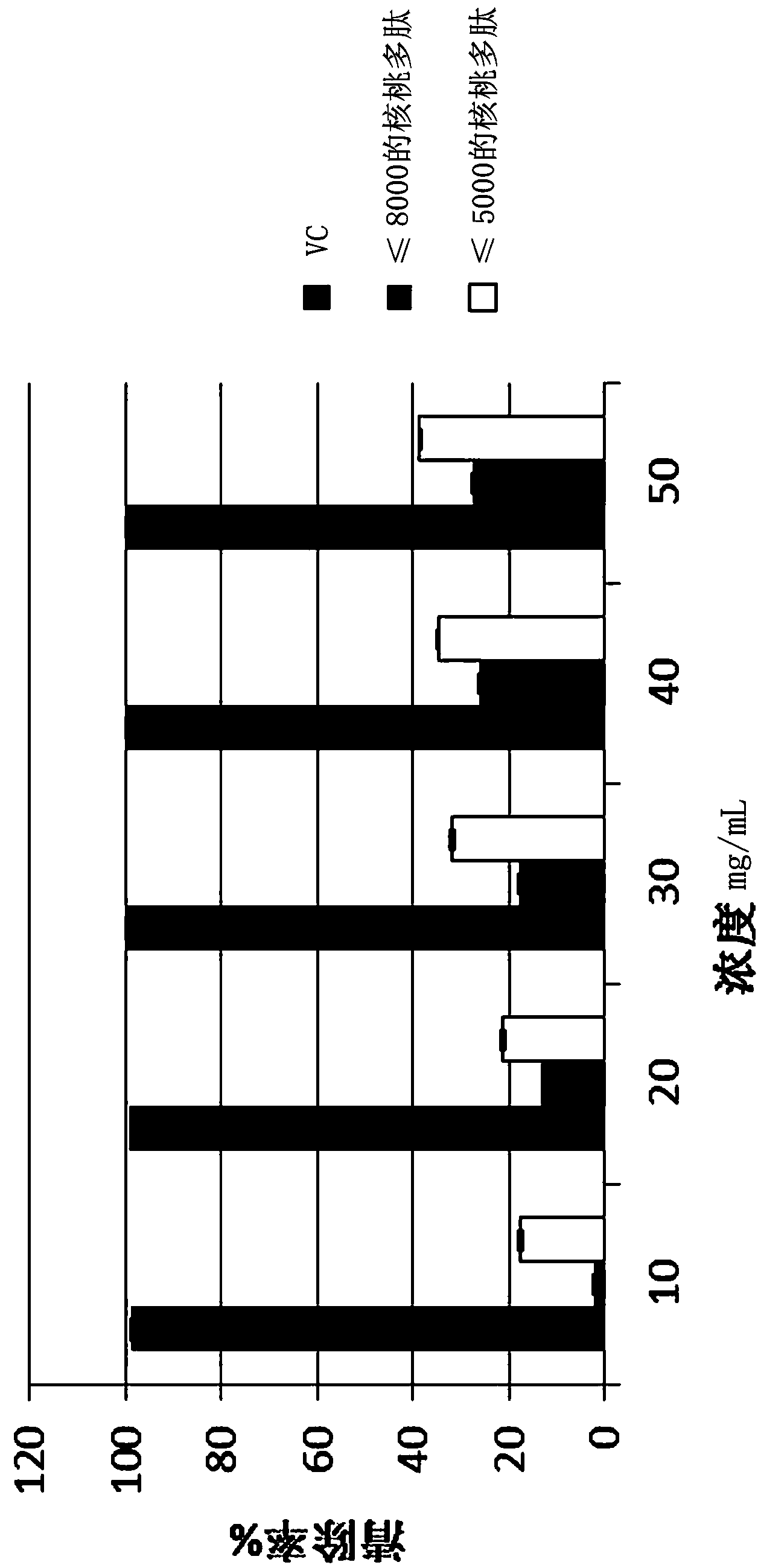

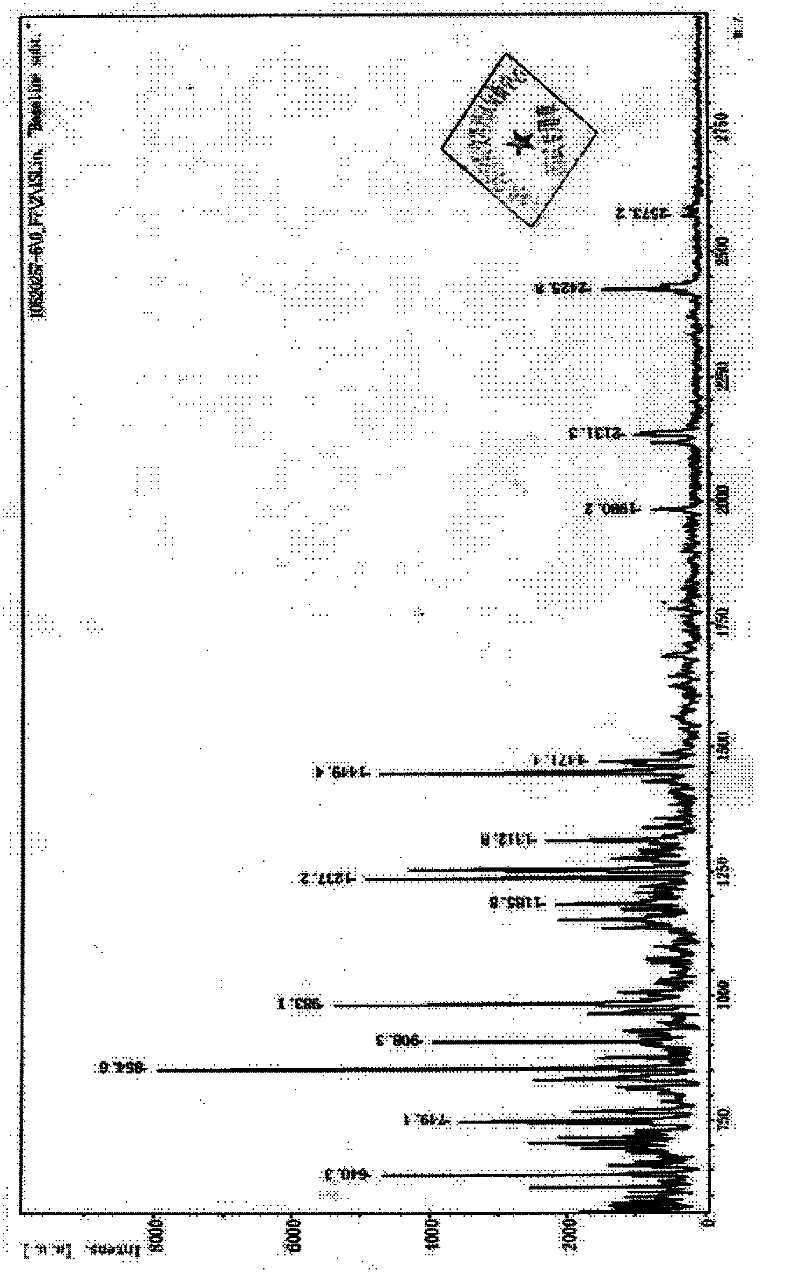

Preparation method of antioxidant walnut polypeptide health product

ActiveCN104293870ALess fatty acidHigh in proteinPeptide preparation methodsChemical recyclingWalnut NutNeutral protease

The invention discloses a preparation method of an antioxidant walnut polypeptide health product. The preparation method comprises the following steps: pre-treating walnut pulp; homogenizing the walnut pulp; extracting walnut proteins; carrying out pre-treatment for enzymolysis; carrying out enzymolysis; separating; desalting; and concentrating and drying to obtain a walnut polypeptide product. Four enzymes: alkaline protease, papain, neutral protease and bromelain are sequentially added in different times in the enzymolysis link. The strength, function and synergy and the like of the effects of the four enzymes which are used for decomposing proteins into polypeptides and amino acids are comprehensively considered and the four enzymes are used for enzymolysis under the optimal enzymolysis conditions, respectively. The reducing capacity of the prepared walnut polypeptide manifests that the absorbancy floats up and down at 0.4, the hydroxyl free radical scavenging rate can reach 95%, the superoxide anion free radical scavenging rate can reach 39.5%, the protein extraction ratio can reach 98.71% and the degree of hydrolysis of the walnut polypeptide can reach 26.37%. Compared with the prior art, those items are greatly enhanced and improved relatively.

Owner:汾州裕源土特产品有限公司

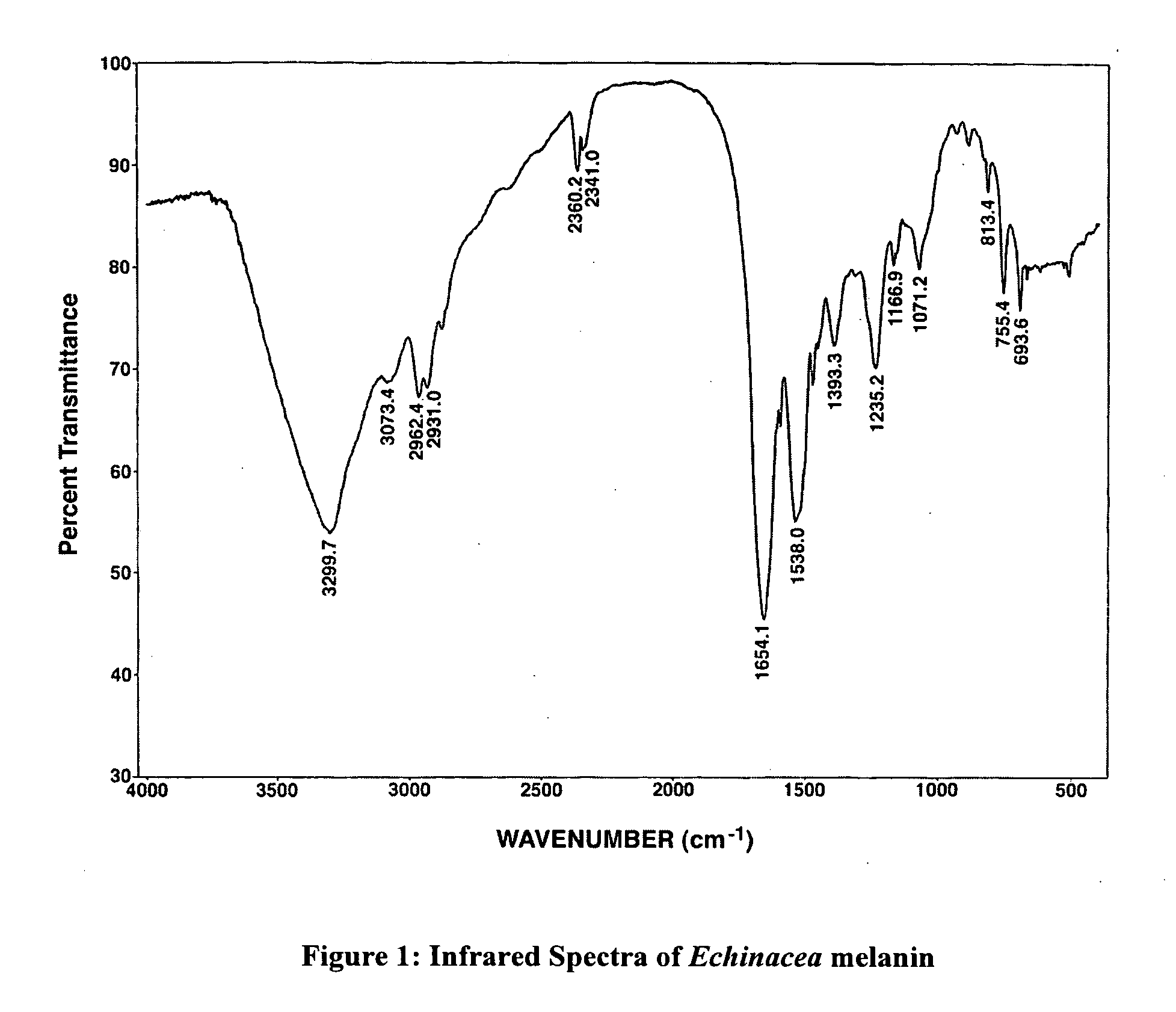

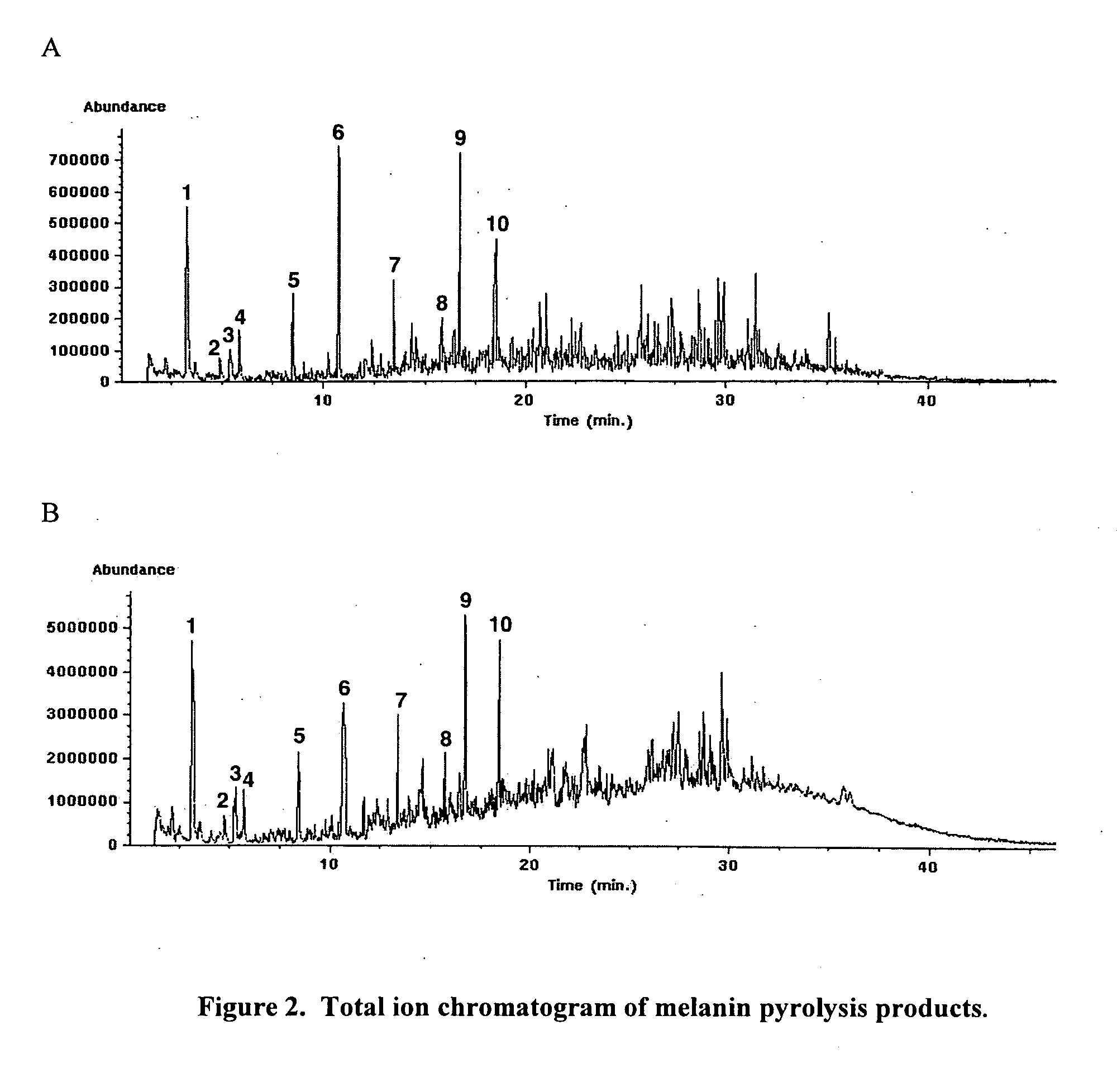

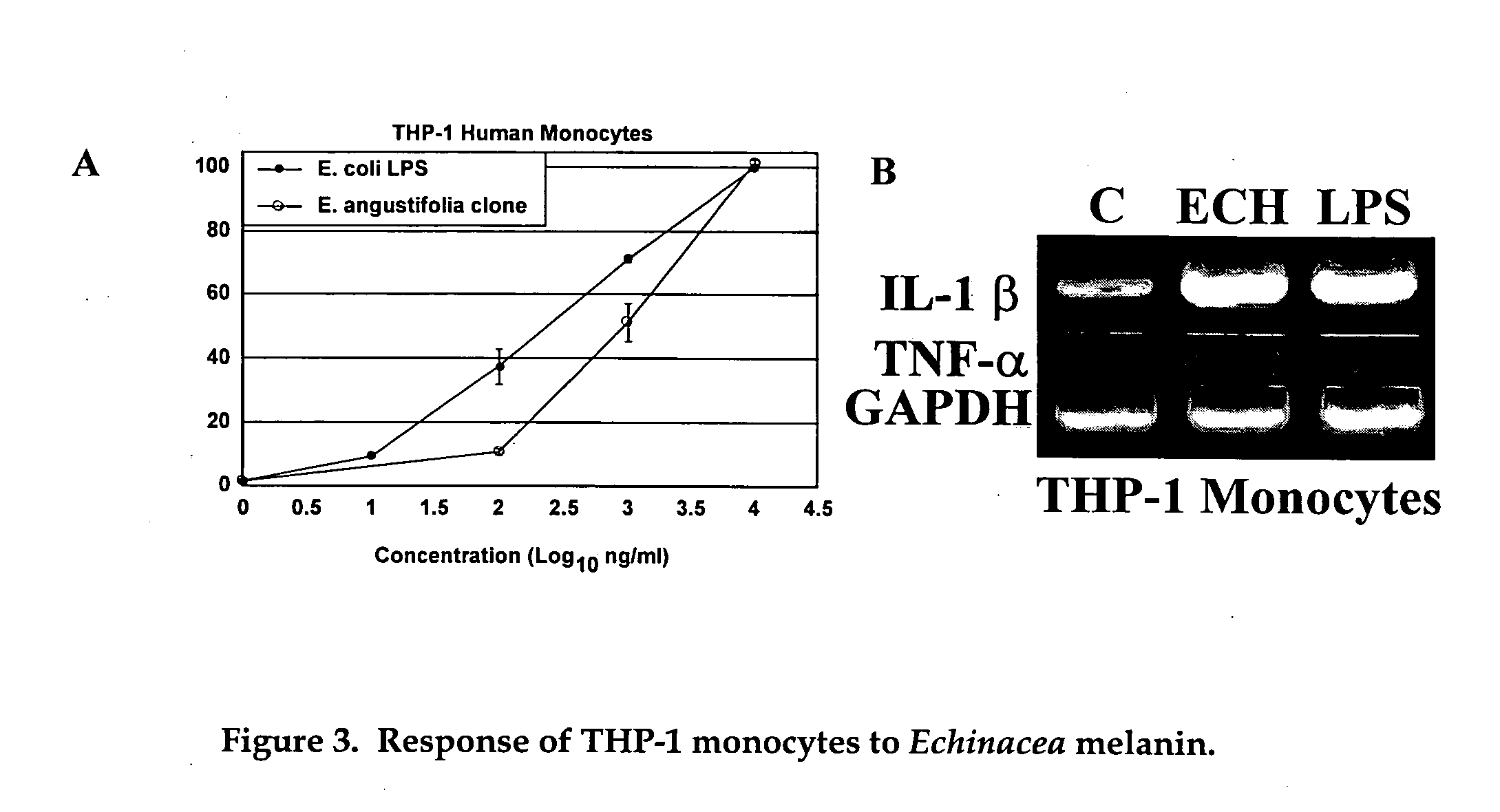

Immunostimulatory agents in botanicals

InactiveUS20050002962A1Improved immunostimulatory activityHigh activityBiocideLichen medical ingredientsRed CloverBlack cohosh

A melanin preparation as an immunostimulatory agent from at least one of the following botanicals: Echinacea, American ginseng, black walnut, green tea, Parthenium integrifolium, Korean ginseng, alfalfa sprouts, ginger, goldenseal, red clover, dandelion, black cohosh, licorice, chamomile, milk thistle, alfalfa, horsetail, astragalus, gotu kola, feverfew, valerian, hawthorn, rosemary, saw palmetto, ephedra, pau d'arco, ginkgo, garlic, St. John's wort, Agaricus bisporus (common mushroom), Agaricus bisporus brown strain (portabella mushroom), Lentinus edodes (shiitake mushroom) or Boletus edulis (porcini mushroom). Also disclosed is methods of treating a subject requiring immune mediation comprising administering to said subject a therapeutically effective amount of a melanin preparation from any one of the following botanicals: Echinacea, American ginseng, black walnut, green tea, Parthenium integrifolium, Korean ginseng, alfalfa sprouts, ginger, goldenseal, red clover, dandelion, black cohosh, licorice, chamomile, milk thistle, alfalfa, horsetail, astragalus, gotu kola, feverfew, valerian, hawthorn, rosemary, saw palmetto, ephedra, pau d'arco, ginkgo, garlic, St. John's wort, Agaricus bisporus (common mushroom), Agaricus bisporus brown strain (portabella mushroom), Lentinus edodes (shiitake mushroom), Boletus edulis (porcini mushroom).

Owner:UNIVERSITY OF MISSISSIPPI

Methods and related systems and formulations to normalize and improve human body chemistry and healing ability

InactiveUS20080260708A1Improve the situationImprove abilitiesBiocidePeptide/protein ingredientsSodium BentoniteOlive leaf

Methods, systems and formulations for normalizing and improving human body chemistry and the body's natural ability to heal itself. In one embodiment a system including effective amounts of a digestive enzyme, soluble and insoluble fiber, laxative, probiotics, vitamin C, potassium, protease enzymes, lipase, lysine, taurine, proline, choline, inositol, inositol hexaphosphate, policosanol, charcoal, bentonite clay, thyme, ascorbic acid, magnesium citrate, calcium citrate, methylsulfonyl methane, cayenne pepper, magnesium, potassium, ester-c, ginger and niacin, lysine calcium, stevia leaf, citric acid, a tincture of bayberry bark, juniper berries, yam root, cramp bark, golden seal root, fennel seed, uva ursi leaves, ginger root, lobelia herb, catnip herb, and peppermint leaf, golden seal root, Echinacea angustifolia root, ginger root, and licorice root, a tincture of black walnut hulls, venus fly trap, chaparral, wormwood, licorice root, slippery elm, cloves and comfrey root, burdock root, sheep sorrel, rhubarb root, slippery elm, olive leaf and yarrow flower is provided.

Owner:HALL MICKEY A

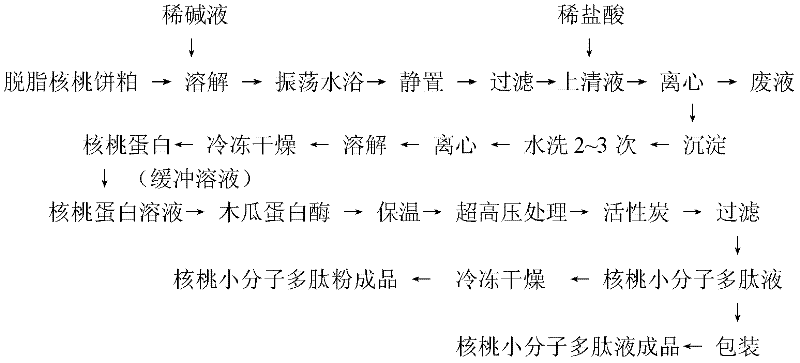

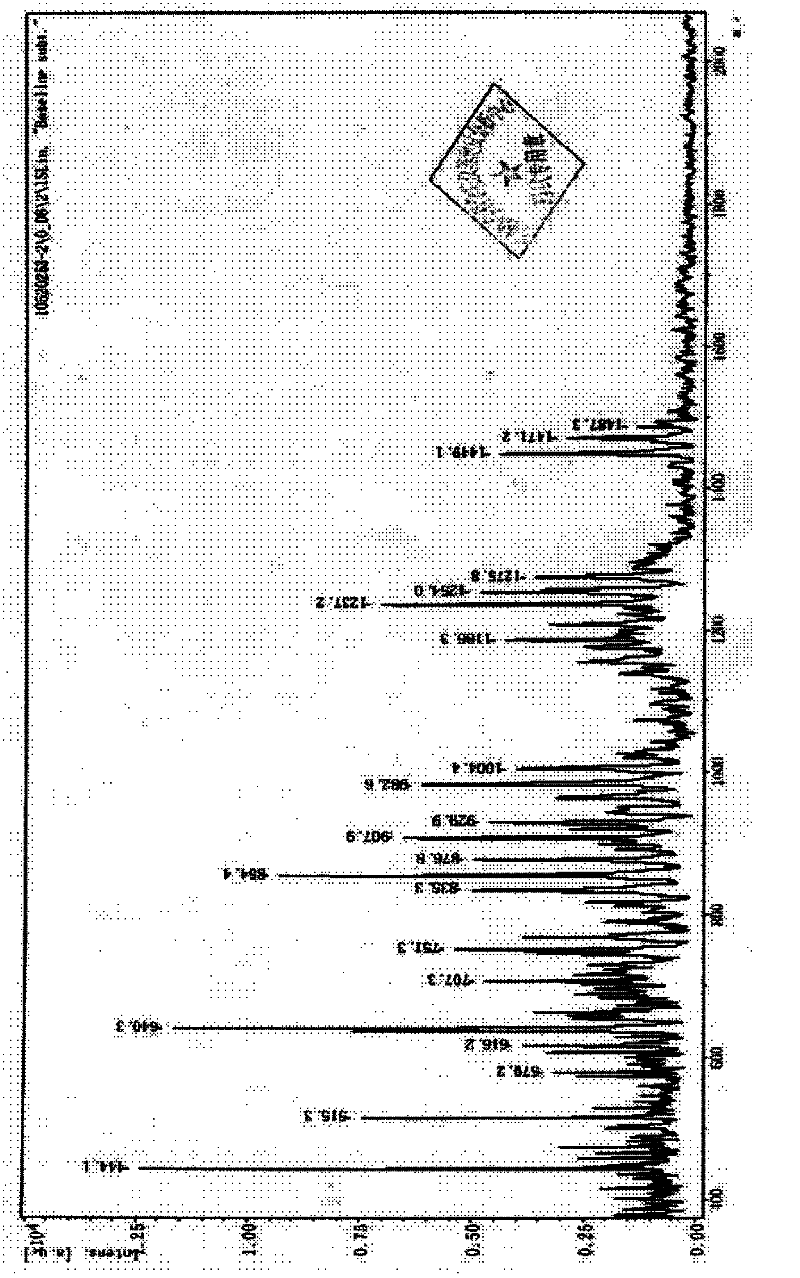

Walnut low molecular weight polypeptide and preparation method thereof

ActiveCN102406050ASimple compositionRaise the ratioProtein composition from vegetable seedsFood additiveFreeze-drying

The invention discloses a walnut low molecular weight polypeptide and a preparation method thereof. The preparation method comprises the following steps: hydrolyzing walnut albumen powder through a high static pressure technique combined with a biological enzyme; decoloring and adsorbing to remove bitter substances in the walnut low molecular weight polypeptide, and then preparing the walnut low molecular weight polypeptide with high purity, good quality and high low molecular weight peptide proportion; and directly packaging or carrying out freeze drying to obtain the finished walnut low molecular weight polypeptide product. The walnut low molecular weight polypeptide disclosed by the invention can be widely applied to medicine raw materials, medicaments, food, health care products, foodadditives and the like. By using the method disclosed by the invention, the hydrolysis degree of protein is improved so that the proportion of the walnut low molecular weight polypeptide is improved,thereby being more beneficial to the absorption and utilization of walnut polypeptide, enhancing the nutrition and health care effects of walnut and improving the product additional value of walnut. Thus, the walnut low molecular weight polypeptide has a good market application prospect.

Owner:厦门元之道生物科技有限公司

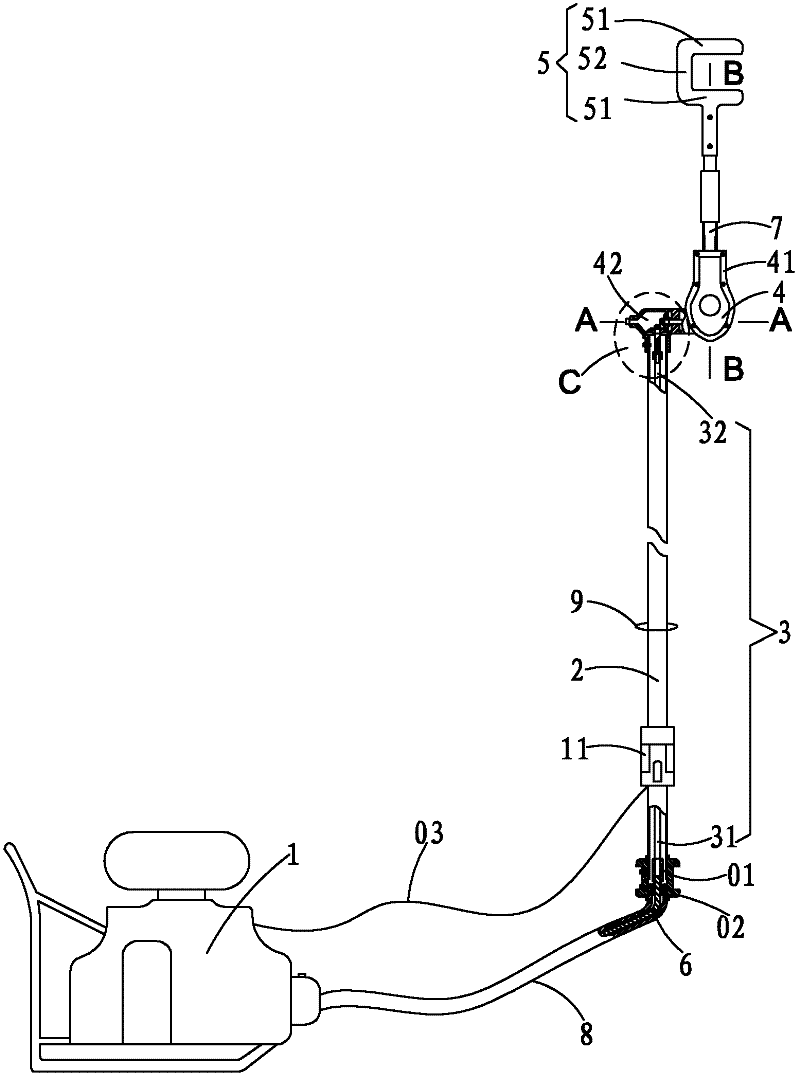

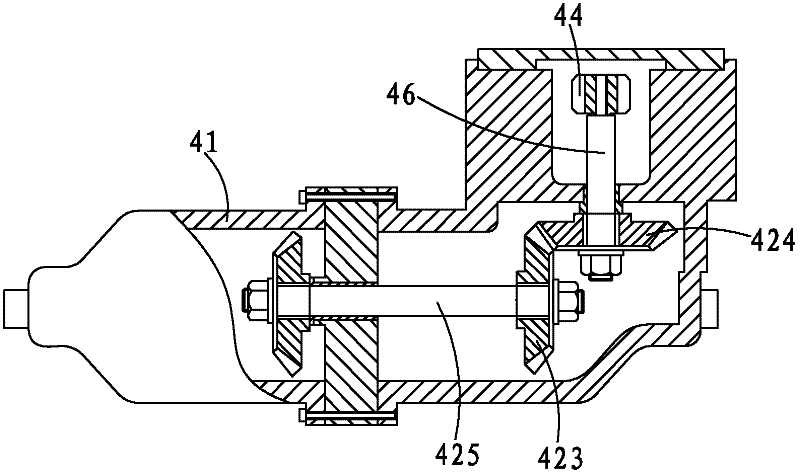

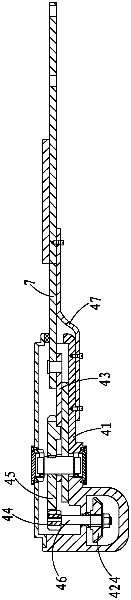

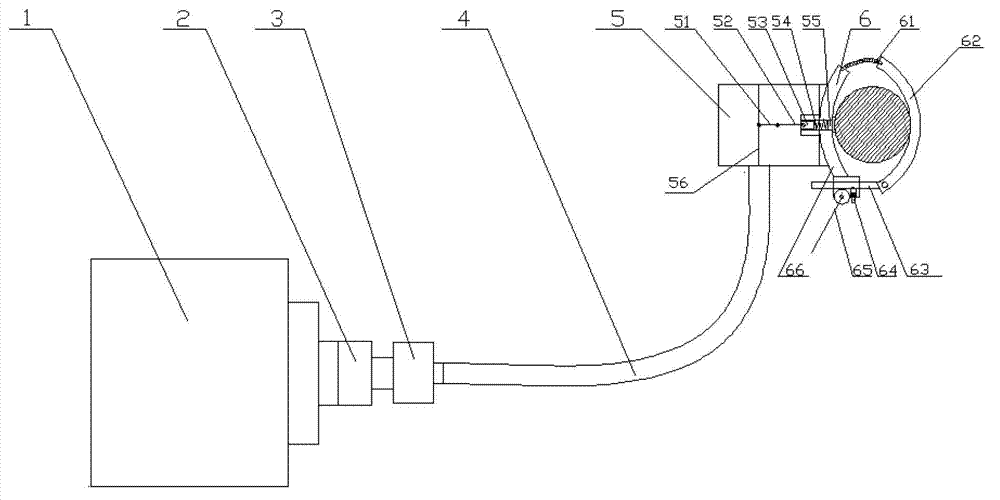

Portable walnut picking device

The invention relates to a portable walnut picking device. The device comprises a power source with an accelerator control part, a picking rod, a transmission shaft, a vibration mechanism and a picking chuck, wherein the transmission shaft is sleeved in the picking rod; the power source is connected with a lower end of the transmission shaft by a wire flexible shaft; the vibration mechanism comprises a shell and a buffer unit, a push rod, a pinion and an eccentric gearwheel which are all arranged in the shell; the eccentric gearwheel is meshed with the pinion; the buffer unit is connected with an upper end of the transmission shaft and is connected with the pinion by a first shaft; the eccentric gearwheel is connected with the push rod; and the picking chuck is connected with the push rod by a connecting rod. The picking device has the following advantages: the picking device has low cost and small volume, is easy to carry and can efficiently pick the walnuts on the primary branches through vibration.

Owner:ZHEJIANG FORESTRY UNIVERSITY

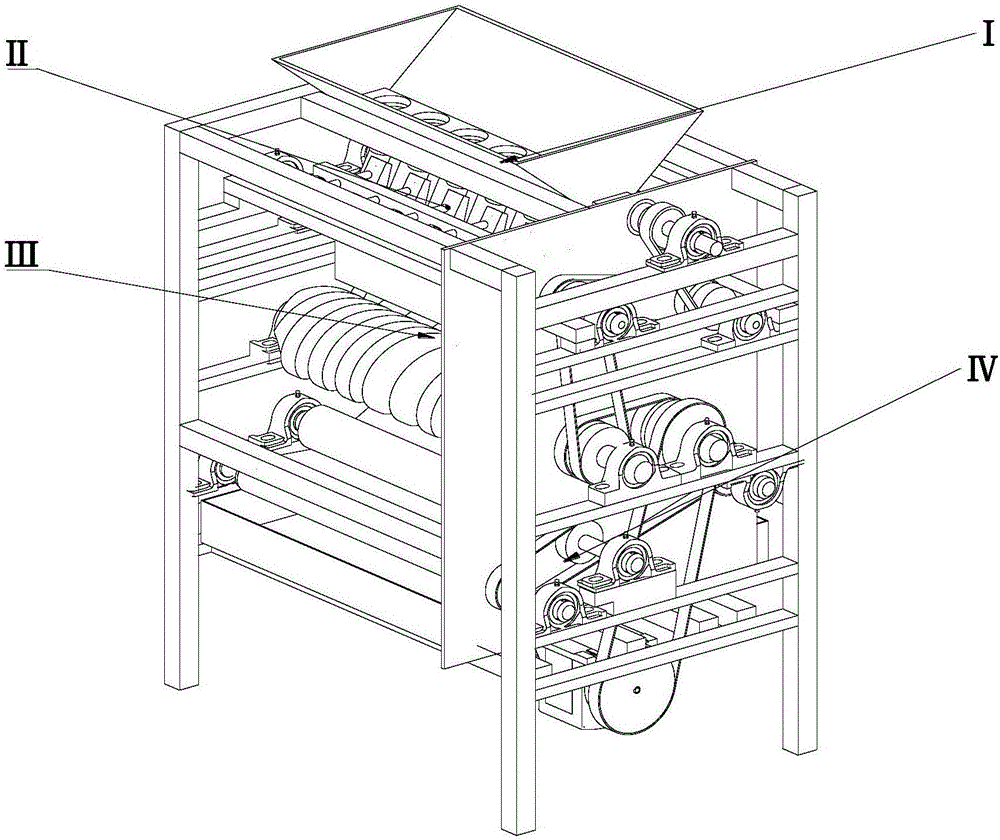

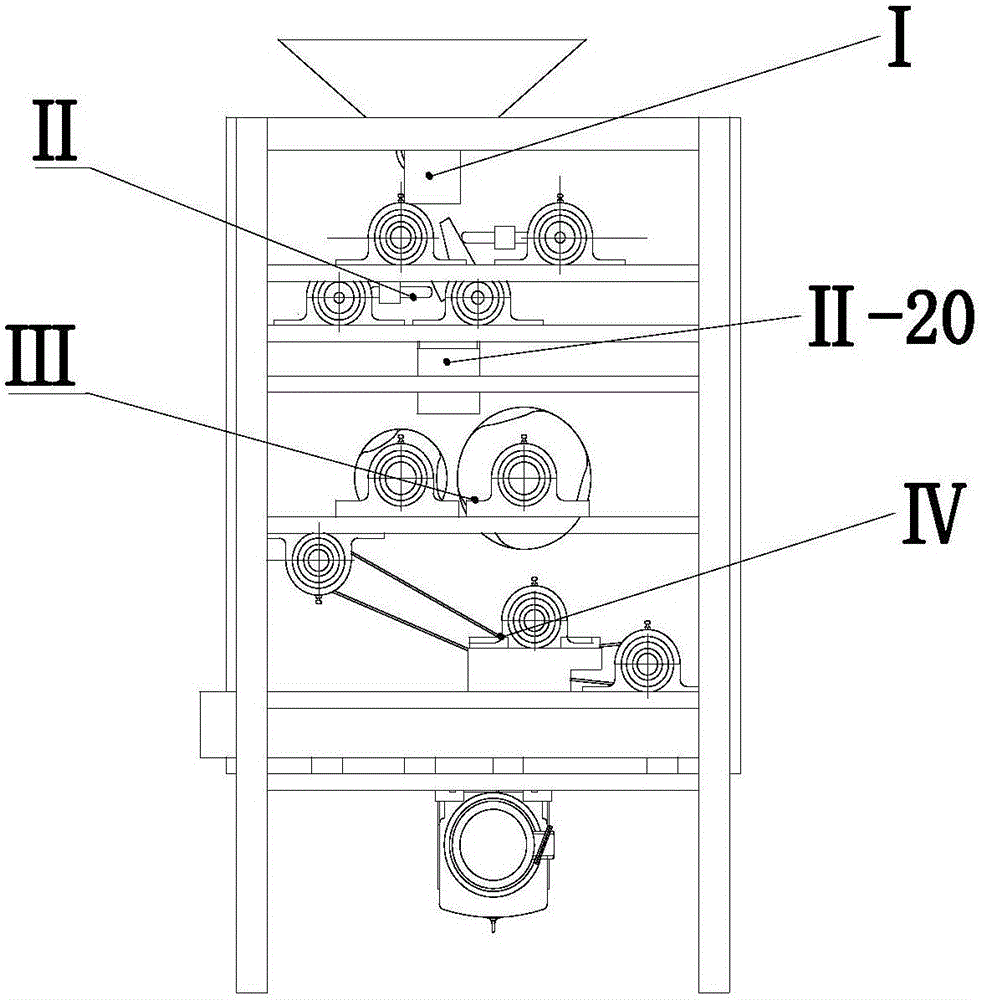

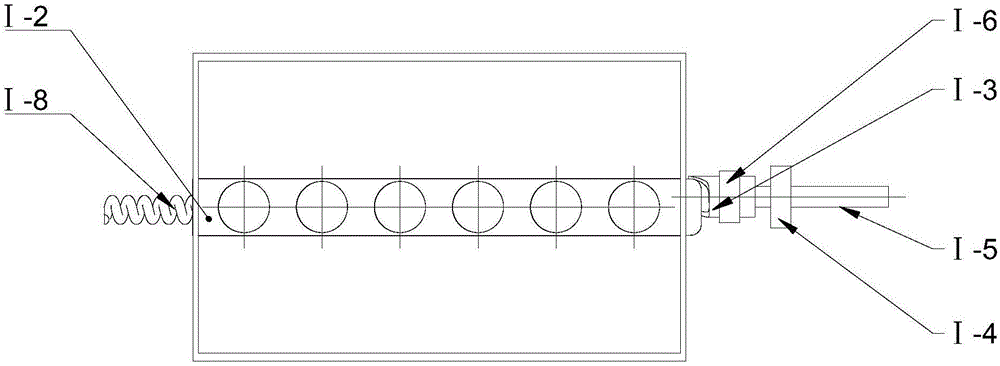

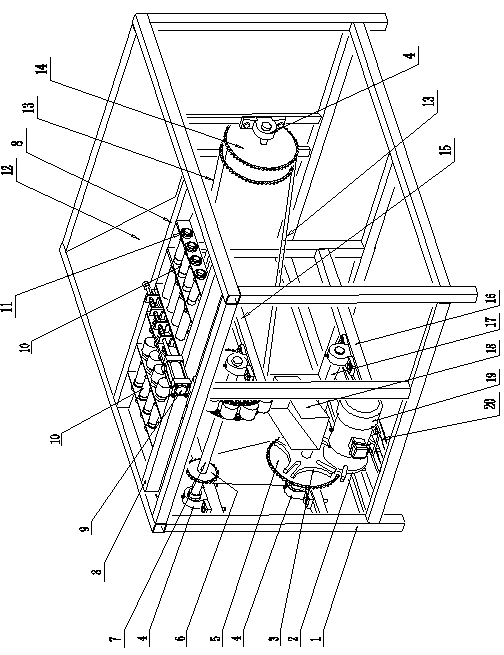

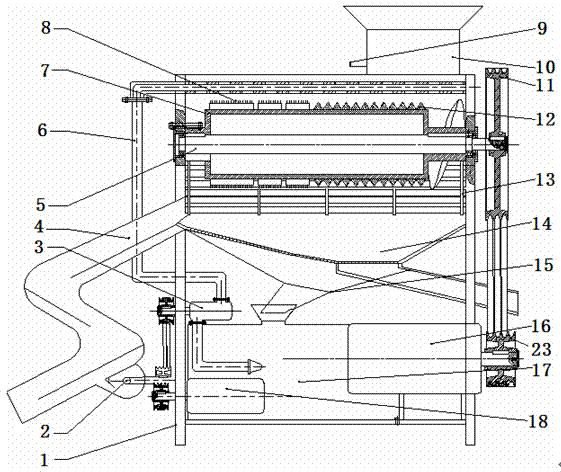

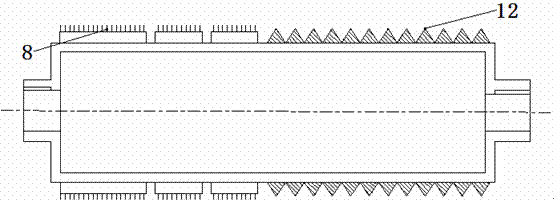

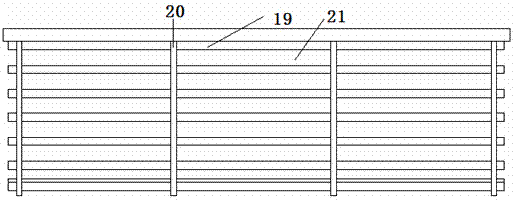

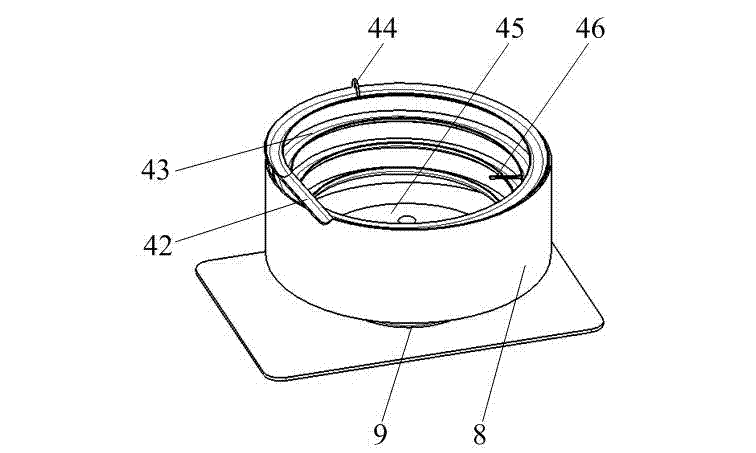

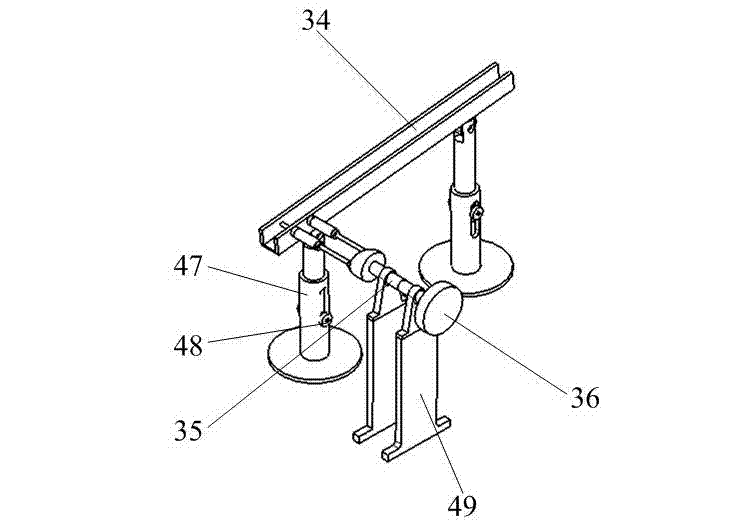

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

Health-care coarse-grain flour, dried noodle, and preparation processes thereof

ActiveCN102349553AGuaranteed not to break downGuaranteed conditioning functionDough treatmentFood preparationBiotechnologyGizzard

The invention discloses health-care coarse-grain flour which is prepared from the following raw materials in parts by weight: (1) coarse cereals: 60-70 parts of wheat, 4-6 parts of corn, 4-6 parts of polished round-grained rice, and 4-6 parts of barley; (2) auxiliary raw materials: 0.2-1 parts of walnut, 0.1-0.8 parts of cattle blood, 0.15-0.6 parts of goose blood, 0.1-0.6 parts of yam, and 0.1-0.8 parts of endodermis of chicken gizzard; meanwhile, the auxiliary raw materials of the health-care coarse-grain flour disclosed by the invention further comprise0.1-0.8 parts of pig blood, 0.1-0.6 parts of edible fungus, 0.2-1 parts of peanuts, and 0.2-1 parts of cassia seeds; in addition, the coarse-grain flour also can comprises 8-12 parts of one of tapioca, broad bean meal, peameal, soybean meal and millet or sorghum flour, or an arbitrary mixture thereof. The invention discloses a process for preparing the health-care coarse-grain flour. Meanwhile, the invention also discloses a health-care coarse-grain dried noodle prepared from the health-care coarse-grain flour above and a preparation process thereof.

Owner:SHEHONG YIMIN FOOD

Lipolysis stimulator

The present invention is directed to a lipolysis stimulator and a slimming agent which stimulate or facilitate lipolysis of accumulated adipose tissue, to thereby exert the body slimming effect. The lipolysis stimulator or the slimming agent of the present invention contains as an active ingredient any form of a plant or an extract thereof, the plant being selected from among common juniper, togenashi, rosehip, areca, polygala root, plantago herb, calumba, zuikorodoku, garden nasturtium, kidachiumanosuzukusa, bayberry, cogon grass, kohon, shoyokanzo, Japanese white birch, tanjin, kikubafuro, white mustard, common sunflower, ground ivy, Chinese wolfberry, Japanese pagota tree, sennenken, common fig, kankatto, Chinese hibiscus, usubaakaza, fenugreek, English walnut, sozuku, koniwa-zakura, gardenia, shima-kan-giku, akamino-akane, futaba-mugura, karoou, schizonepeta spike, purslane, karabyakushi, and prostrate knotweed.

Owner:KAO CORP

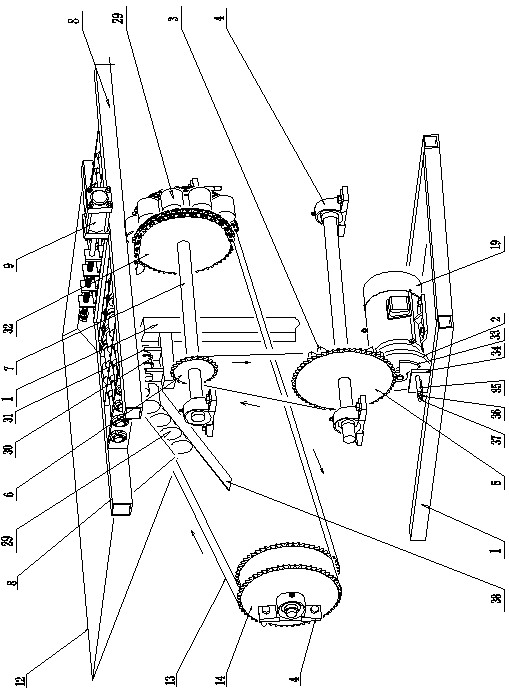

Pneumatic walnut hull breaking machine

The invention provides a pneumatic walnut hull breaking machine and belongs to the field of forest fruits. The pneumatic walnut hull breaking machine consists of a machine frame, a transmission control device, a feeding mechanism and a hull breaking device. The hull breaking device is installed on the machine frame and consists of impact cylinders and holding cylinders which are installed among partition plates of a working rack in a connecting mode. The transmission control device is installed under the front portion of the machine frame and consists of an electric motor, a poking wheel, a control cam, a driving chain wheel, a grooved wheel, side-by-side front end chain wheels, a driven chain wheel, side-by-side back end chain wheels, a clamping switch, a holding switch and a strike switch, wherein the poking wheel, the control cam and the electric motor are sleeved coaxially, the driving chain wheel and the grooved wheel are sleeved on a lower shaft, the side-by-side front end chain wheels and the driven chain wheel are sleeved on an upper shaft, the side-by-side back end chain wheels are installed at the back portion of the machine frame, and the clamping switch, the holding switch and the strike switch are installed at the lower portion of the machine frame at intervals. The driving wheel, the driven wheel, the front end chain wheels and the back end chain wheels are respectively linked through chains, a material box is installed at the back portion of the working rack, a slot is arranged on one wall of the box, and the feeding mechanism is arranged under the position tightly close to the slot and consists of the side-by-side chains, rotary rollers installed on the chains at intervals in a connecting mode, rolling plate supporting the rotary rollers and tensioning chain wheels. The pneumatic walnut hull breaking machine is strong in adaptability on walnut types, complete in walnut hull separation, few in broken walnut nuts and high in hull breaking efficiency.

Owner:XINJIANG AGRI UNIV

Walnut rich in selenium and organic fertilizer rich in selenium for walnut rich in selenium

ActiveCN103918520ASave resourcesEasy to produceFertilising methodsCultivating equipmentsOrganic fertilizerMicrogram

The invention belongs to the field of agricultural technologies and particularly relates to a walnut rich in selenium and organic fertilizer rich in selenium for the walnut rich in selenium. The walnut and the organic fertilizer are mainly used for solving the technical problems that the fertilization amount of existing fertilizer for producing subsidiary agricultural products rich in selenium is difficult to control, the environment is polluted, dependence of crops is prone to generation, land is barren, and cost is high. According to the technical scheme, the walnut rich in selenium is obtained through fertilization of the self-made organic fertilizer rich in selenium, the selenium content of a walnut kernel ranges from 200 microgram per kilogram to 800 microgram per kilogram, and the walnut and the organic fertilizer have the advantages of being environmentally friendly, free of pollution and low in cost.

Owner:汾州裕源土特产品有限公司

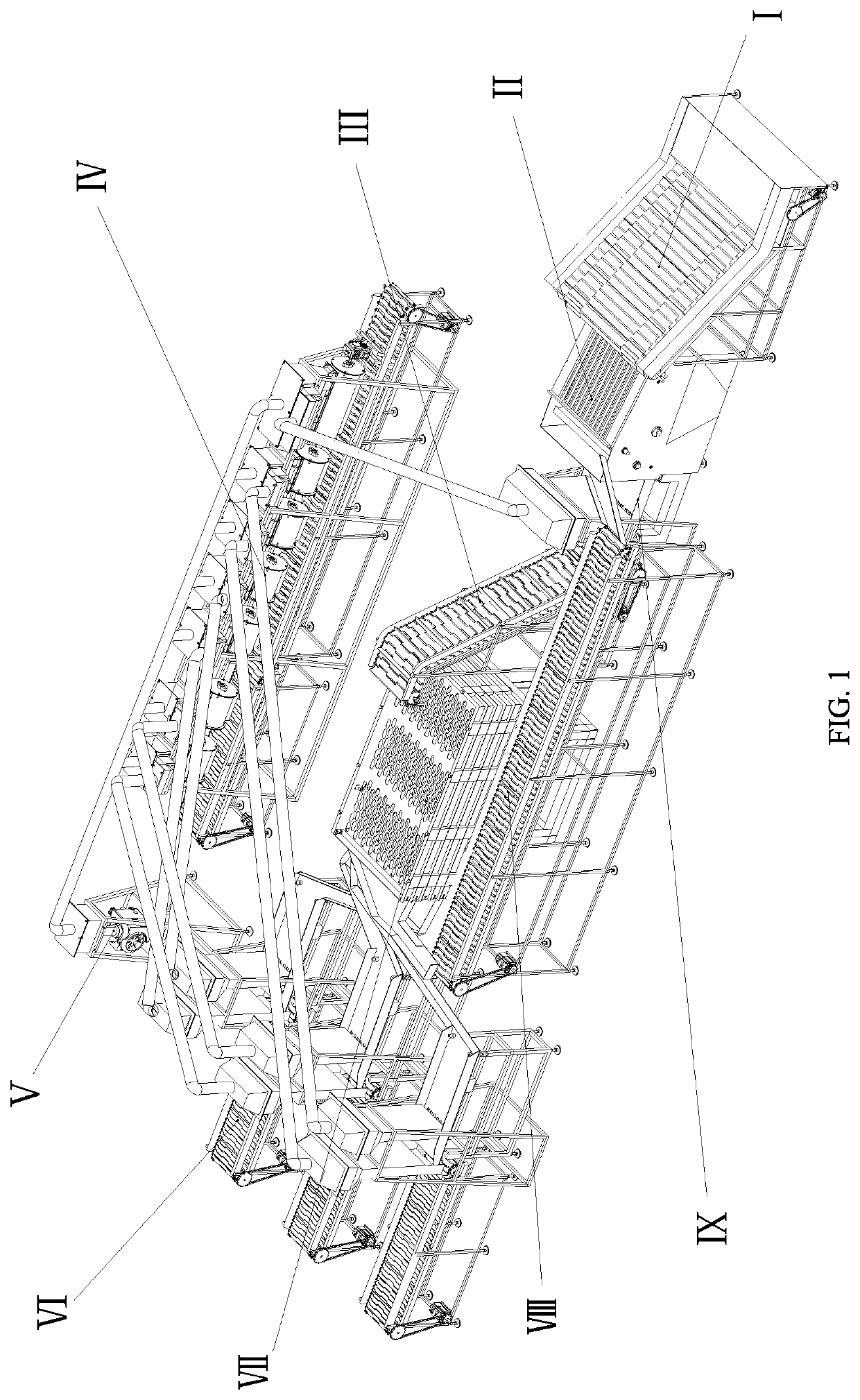

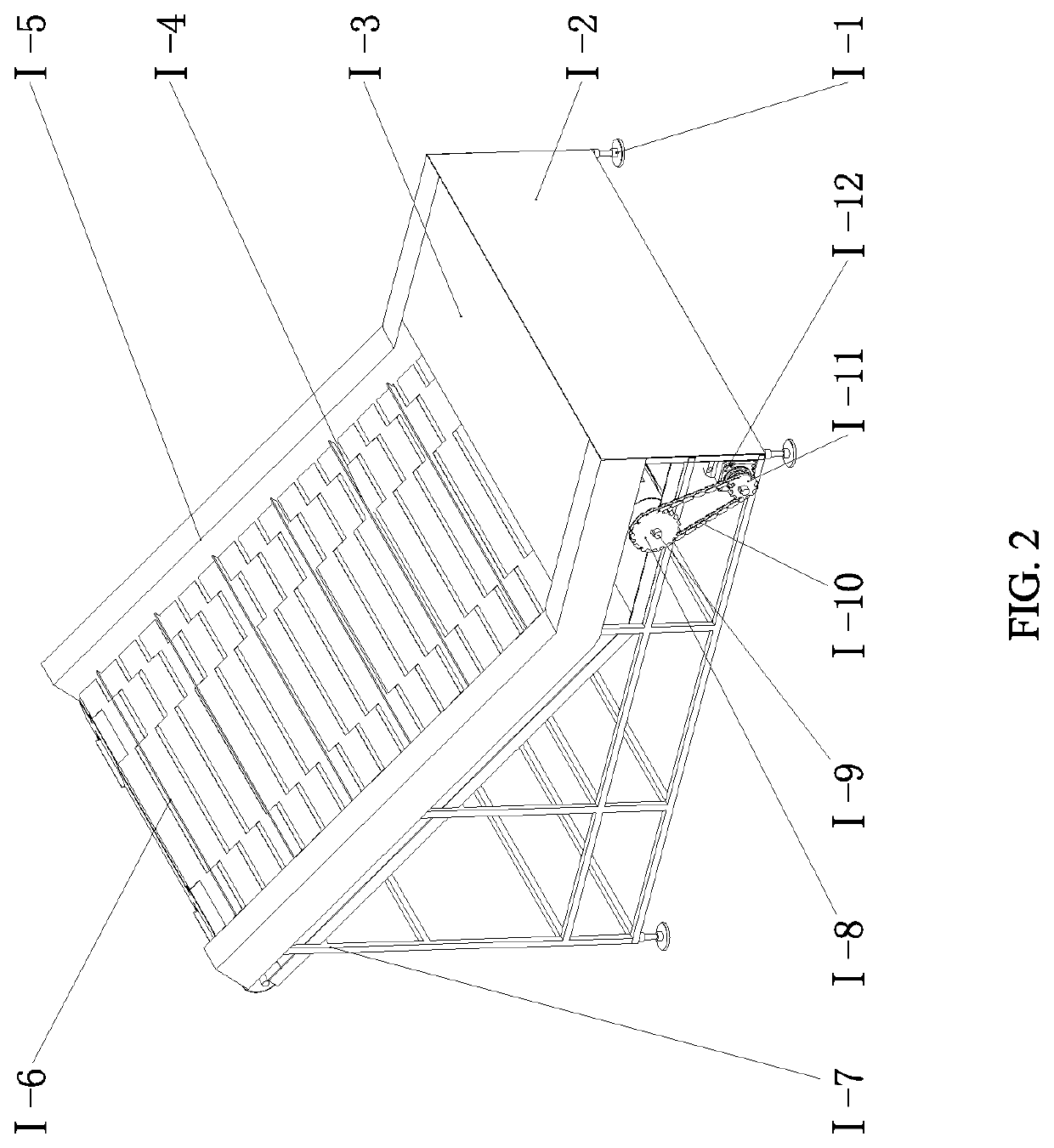

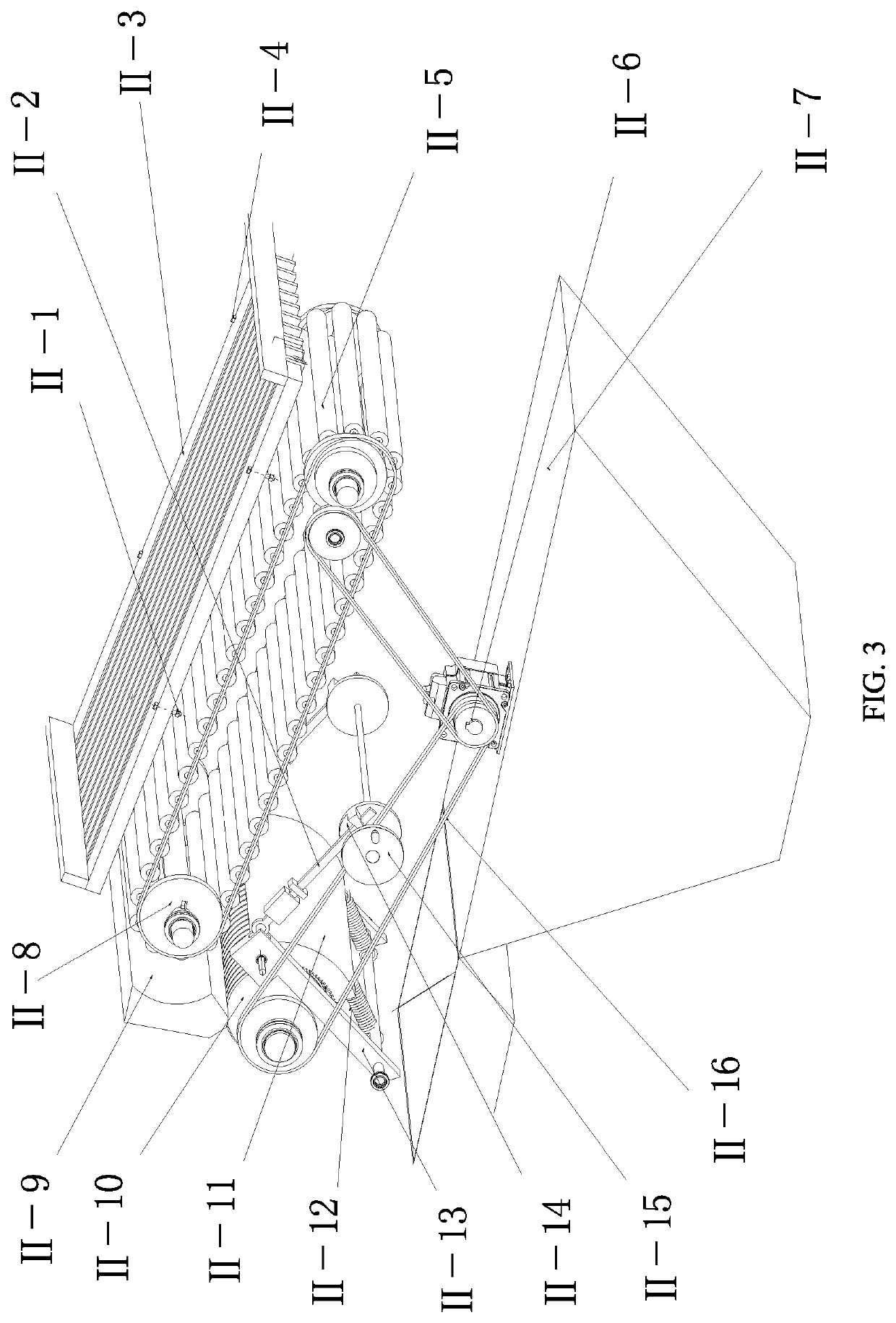

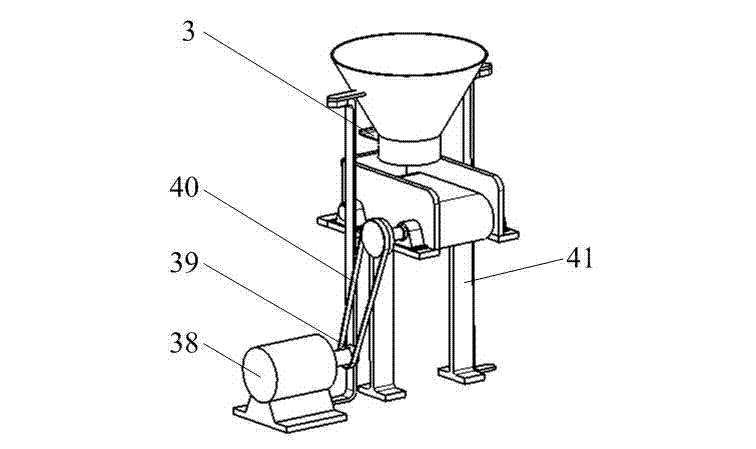

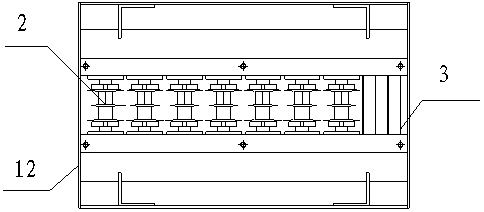

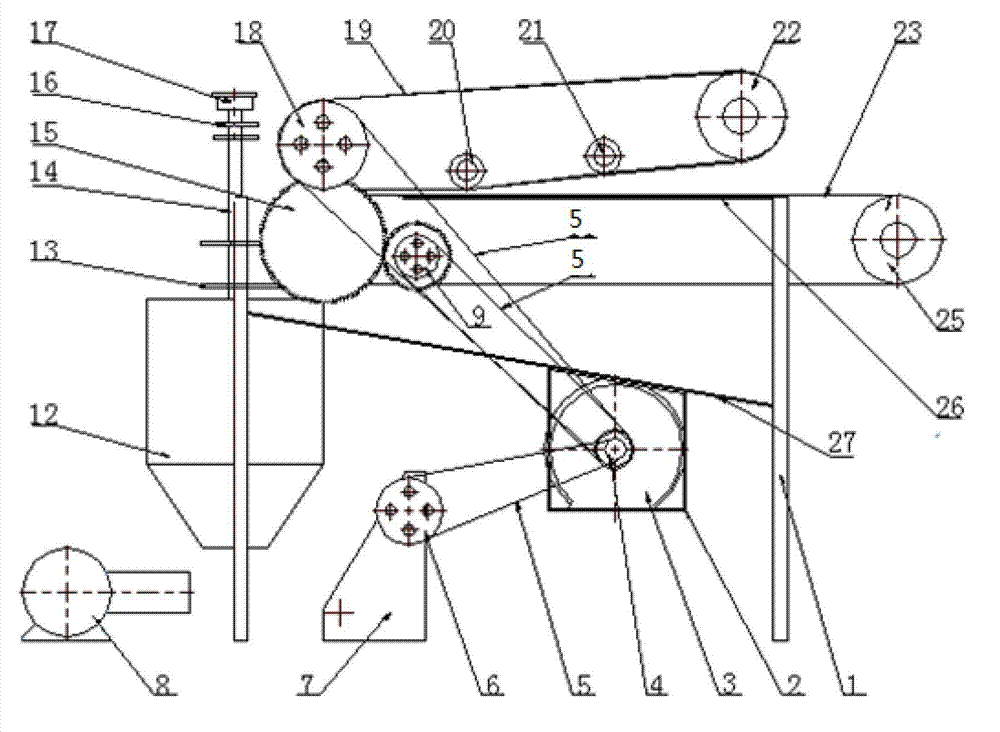

Automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation

PendingUS20200138083A1High speedHigh-efficiency walnut shell-breakingGas current separationHuskingWalnut NutProcess engineering

The disclosure discloses an automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation, solving the problem that the existing walnut shell breaking device cannot adapt to walnuts having different sizes and shell breaking rate and shell breaking efficiency cannot be ensured. The system can realize efficient shell-breaking, kernel-taking and shell-kernel separation on different varieties of walnuts, is quick in production speed and high in automation degree, and meanwhile is capable of improving entire kernel rate and kernel obtaining rate, reducing the damage rate of the walnut kernel and ensuring the high shell-breaking efficiency and thoroughness of shell and kernel separation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Method of cultivating edible fungus using walnut shell as base material

InactiveCN100999418AIncrease productionHigh biological efficiencyFungiOrganic fertilisersWater qualityWater immersion

This invention relates to a method of using walnut shell as matrix for mushroom cultivation. Walnut shells contain vegetable tannin that inhibit reproduction of true fungus, so ignore possibility of it as mushroom medium. This method includes medium heat sterilization, vaccination. Medium preparation methods are : (1) smash the walnut shell, in size of diameter below 1 mm to 10mm, at room temperature water immersion walnut shells 24-72 hours to reduce tannin content, walnut shells and water quality ratio (1 : 2) - (1:8); (2) take walnut shell, wood and wheat bran as compost, quality ration of: the walnut shell 50% -70%, 10% -38% sawdust, wheat bran 18% -10%, by adding glucose 0.5% -1% and Gypsum 1%. This invention use abandoned walnut shells as materials, not rely on higher-value raw materials, will brought facilitating role for walnut producing farmers, walnut processing enterprises and mushroom cultivation.

Owner:SOUTHWEST FORESTRY UNIVERSITY

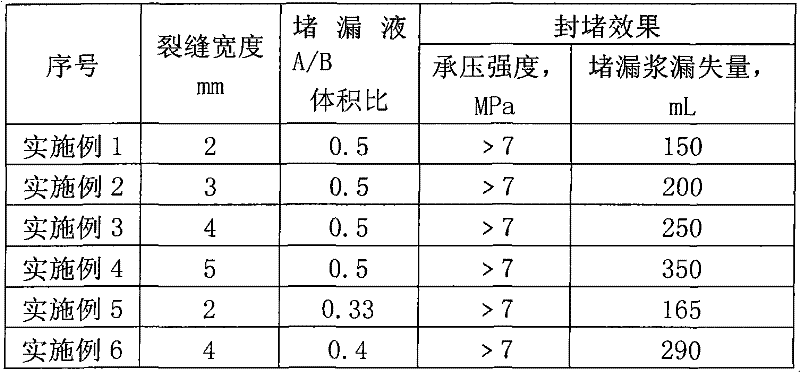

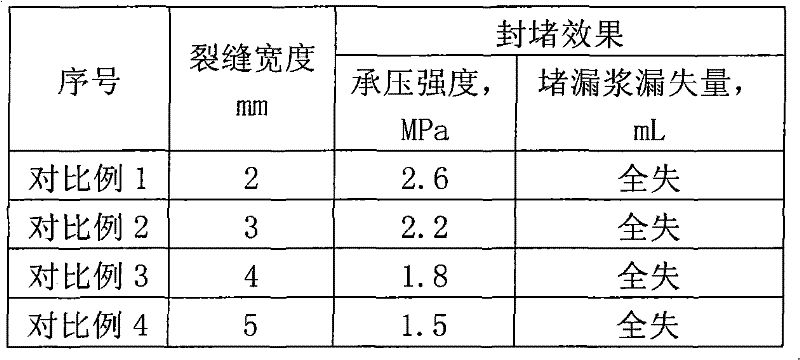

Leak-stopping agent for petroleum drilling, preparation method, and application thereof

The present invention discloses a leak-stopping agent for petroleum drilling, a preparation method, and an application thereof. The leak-stopping agent comprises a leak-stopping liquid A and a leak-stopping liquid B, wherein the leak-stopping liquid A comprises, by weight, 0.5-0.8 parts of alginate, 0-5 parts of walnut shells and 100 parts of water, the leak-stopping liquid B comprises, by weight, 200-250 parts of oil well cement, 0.5-1 parts of fiber, and 100 parts of water, and a volume ratio of the leak-stopping liquid A to the leak-stopping liquid B is 1:2-1:3. The preparation method comprises: a, dissolving the alginate in the water to prepare a solution, and adding the walnut shells to the solution to prepare the leak-stopping liquid A; b, preparing the oil well cement and the waterinto the cement slurry, and adding the fiber to the cement slurry to prepare the leak-stopping liquid B. With the leak-stopping agent of the present invention, the problem of the poor leak-stopping effects under complex geological conditions of cracks and holes can be solved, and the leak-stopping effects of the stratum with the cracks and the large holes can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

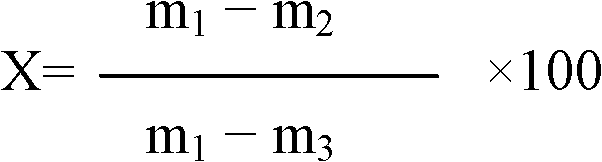

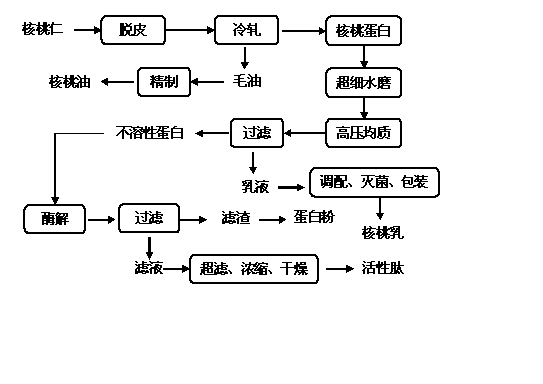

Deep processing method for preparing low-fat walnut milk, active peptide and protein powder by comprehensively utilizing walnut kernels

The invention aims at the high-value processing of walnut protein. A deep processing method comprises the following steps: firstly, separating out walnut oil by a low-temperature cold-rolling method to obtain walnut kernel protein; secondly, dissolving the soluble protein to prepare walnut milk drink through micro-grinding and homogenizing processes; thirdly, performing enzymatic hydrolysis on the insoluble walnut protein to obtain the active peptide through enzymatic degradation; and finally, developing the rest of protein residues into walnut powder so as to realize full-value utilization of the walnut protein.

Owner:JIANGNAN UNIV +1

Biophysical method for removing endopleura of walnut

InactiveCN102972850AEasy to operateMild treatment conditionsFood preservationHuskingPectinaseWalnut Nut

The invention provides a biophysical method for removing the endopleura of a walnut. The walnut with the shell is soaked by tap water for 12 to 24 hours, the shell is removed, the kernel is taken out, pectinase with the activity being 30000 IU is dissolved into disodium hydrogen phosphate-citric acid buffer liquid with the pH being 3.2 to 3.8, and 3 percent to 5 percent of pectic enzyme liquid is prepared and is heated to 50 DEG C. The soaked walnut kernel is soaked in the pectic enzyme liquid and is placed into an ultrasonic generator with the power being 250W and the work frequency being 40KHZ, the enzymolysis and the ultrasonic treatment are carried out for 2.5 to 5 hours at the constant temperature being 50 DEG C, the walnut kernel is fished out and is sprayed and flushed by flowing water with the pressure being 7 to 10 MPa until the endopleura is completely removed, the walnut kernel with the advantages that the color and the luster are opacified, the kernel fruit is complete, the texture is flexible, the mouth feeling and the flavor are pure and sweet as those of the fresh walnut kernel can be obtained, and when the walnut kernel is in vacuum package and freezing storage, a fresh walnut kernel storage method is obtained. The biophysical method adopts the advanced biological enzyme technology to be combined with the ultrasonic physical technology and has the obvious characteristics that the operation is simple, the processing condition is mild, no chemical pollution exists, the kernel and the nutrition are kept complete, and the sensory quality is good.

Owner:BEIJING UNION UNIVERSITY

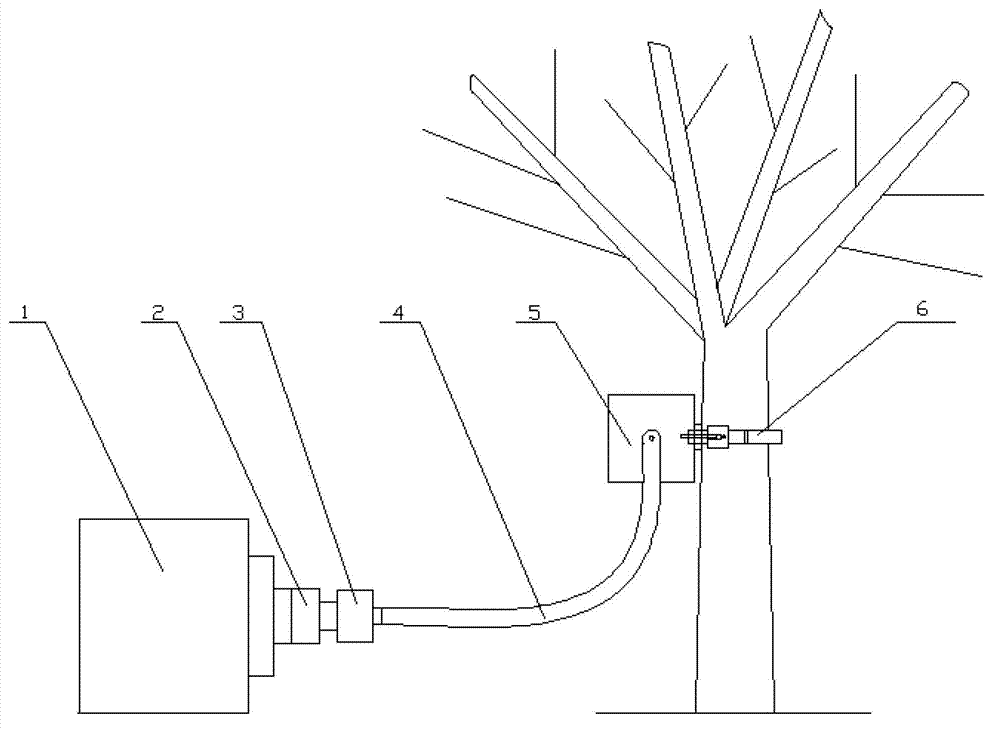

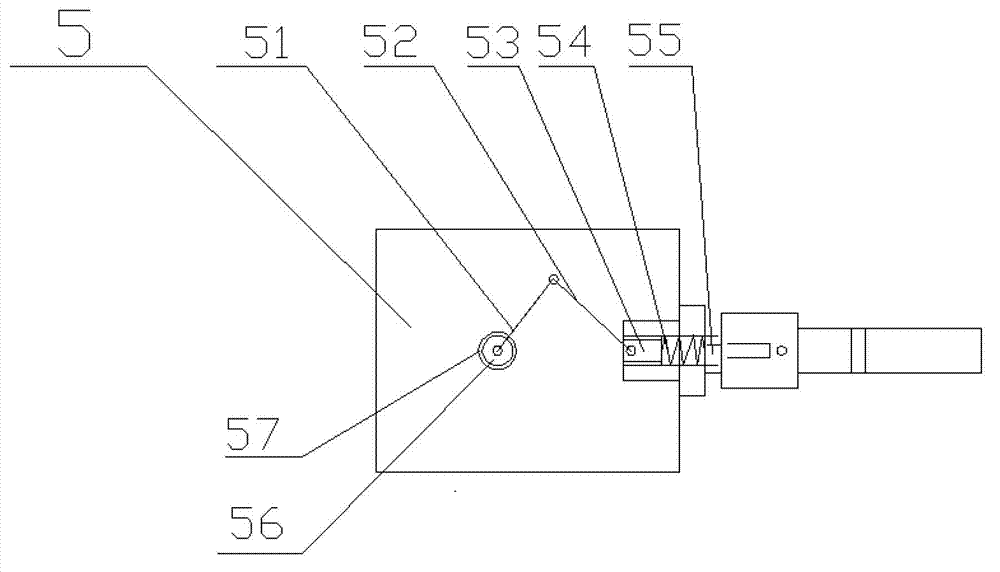

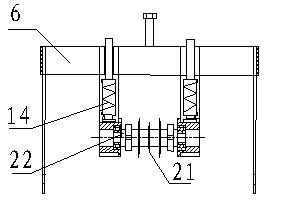

Portable walnut picker

InactiveCN103039199AMeet the needs of clamping and pickingAvoid damagePicking devicesFruit treeWalnut Nut

The invention provides a portable walnut picker which comprises a driving device, a transmission flexible shaft, a vibration device and a trunk clamping device. One end of the transmission flexible shaft is connected with the driving device, and the other end of the transmission flexible shaft is connected with the vibration device which is fixed on the trunk clamping device and comprises a push-shake rod used for knocking trunks. The picker transmits power through the flexible shaft to realize multidirectional and wide-range movement of the trunks clamped by the clamping device, so that the portable walnut picker can meet needs of clamping and picking fruit trees at different positions, with different distances, at different heights and with different maturity degrees, and has the advantages of convenience, flexibility and efficiency in operation, convenience for carrying, small required working space and the like; and in addition, picking is completed by knocking the trunks by the push-shake rod, so that damages to the fruit trees are small.

Owner:SHAANXI UNIV OF SCI & TECH

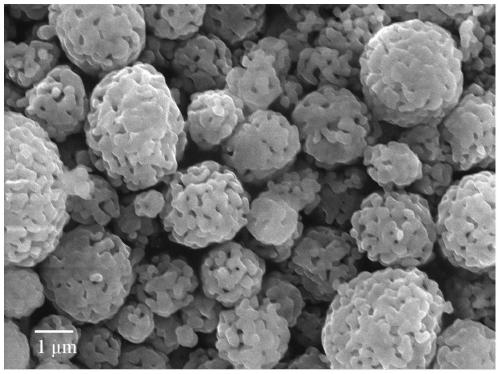

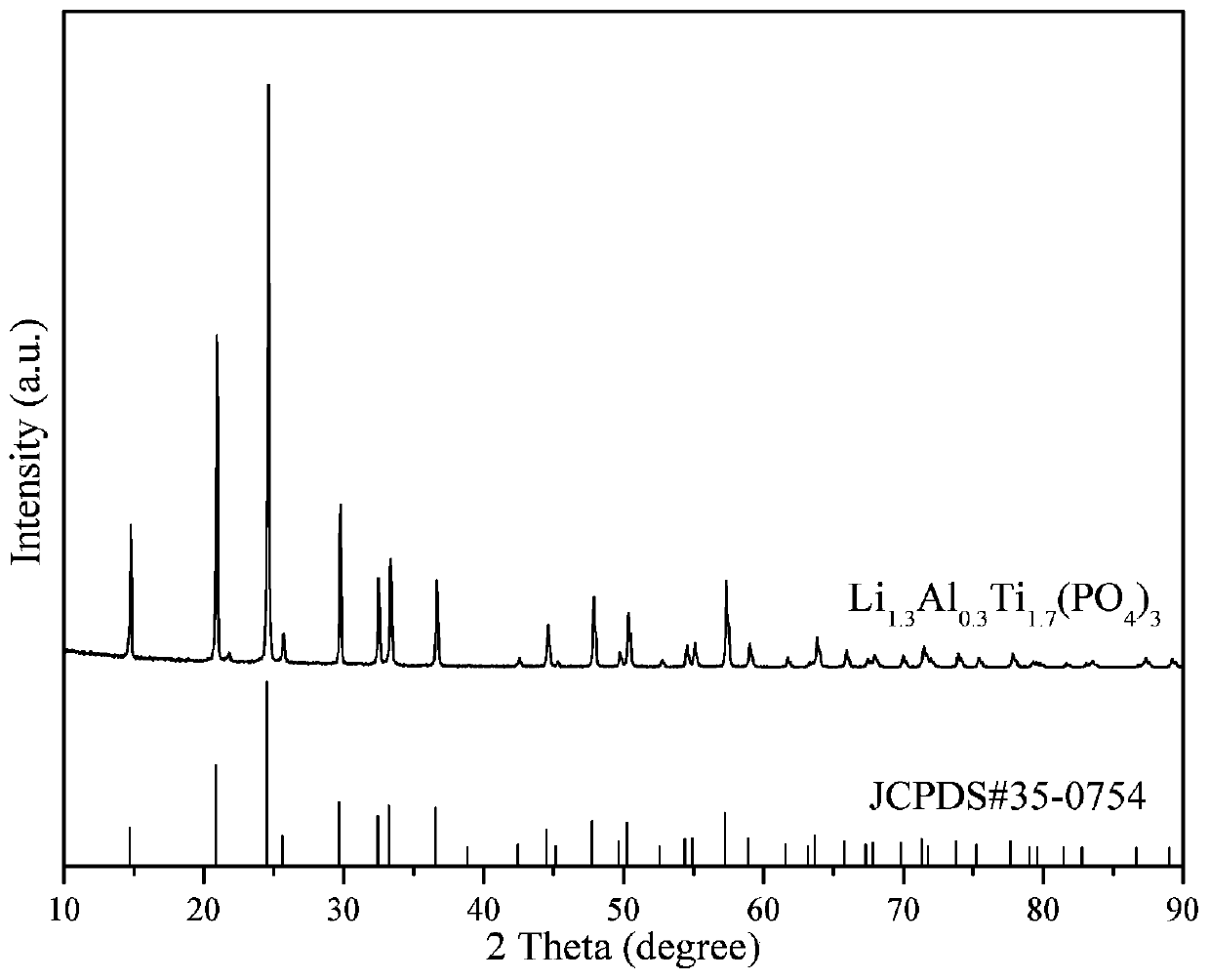

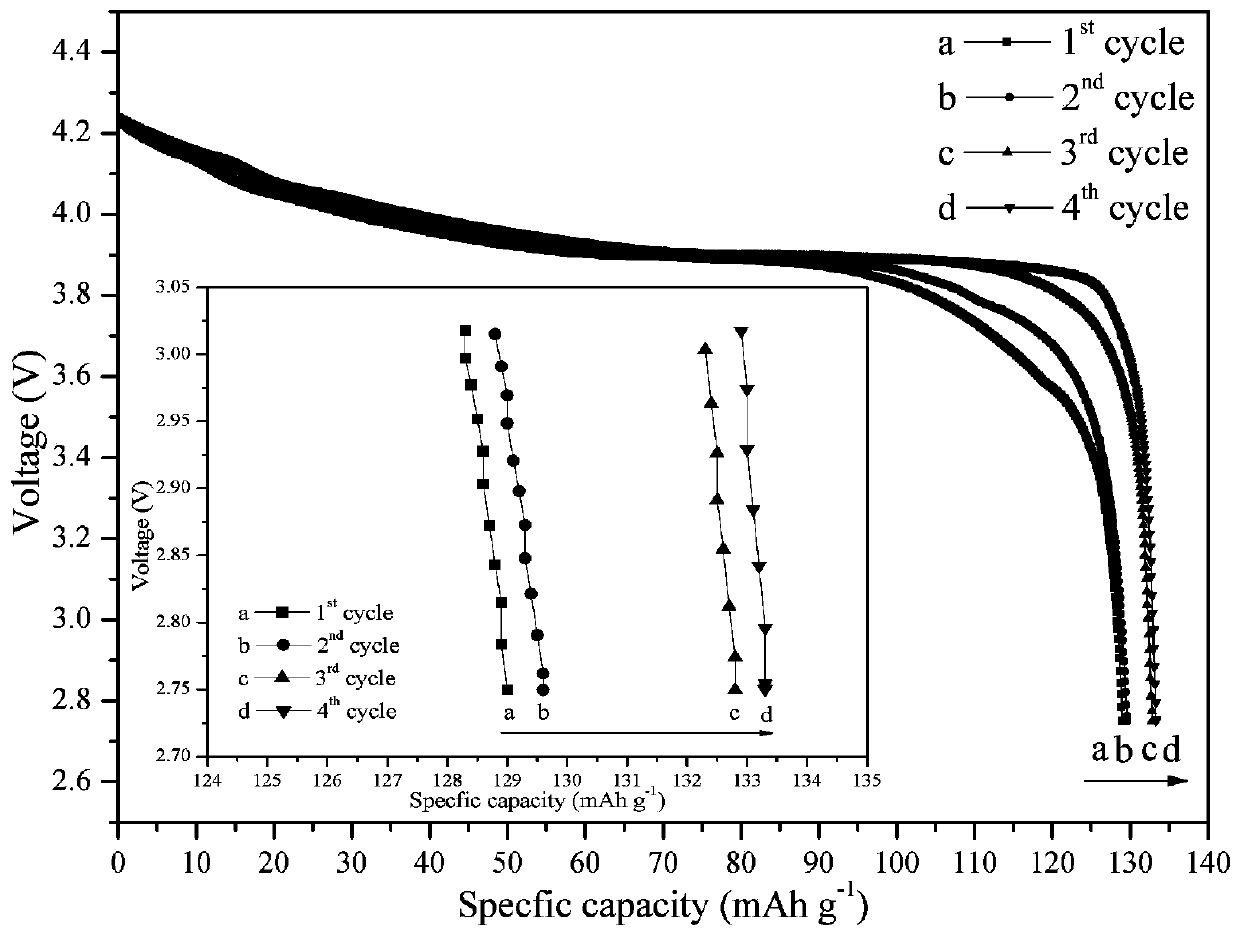

All-solid-state lithium ion electrolyte material and preparation method thereof

InactiveCN109721042AImprove conductivityEvenly dispersedSecondary cellsPhosphorus compoundsAir atmosphereElectrical conductor

The invention provides an all-solid-state lithium ion electrolyte material and a preparation method thereof. The method specifically comprises the following steps: (1) adding a lithium source, an aluminum source, a titanium source and a phosphorus source into a water solution of ethanol according to a stoichiometric ratio of Li<1+x>Al<x>Ti<2-x>(PO4)3, wherein x is greater than 0 and less than or equal to 1, then adding a complexing agent, and carrying out hydrolyzing to obtain a uniform solution, sol or turbid liquid; (2) carrying out spray drying on the solution, sol or turbid liquid obtainedin the step (1); and (3) heating the product obtained in the step (2) to 600-1200 DEG C in an air atmosphere, carrying out temperature-control calcinations for 2-10 hours, and then carrying out natural cooling to obtain the walnut-like fast-ion conductor material titanium aluminum lithium phosphate. The all-solid-state lithium ion electrolyte material prepared by the preparation method is in a special morphology, is distributed in a monodisperse manner and has relatively high room-temperature ionic conductivity and excellent rate and cycle performance; and no other impurity elements are introduced, so that the product purity is high.

Owner:YANGTZE UNIVERSITY

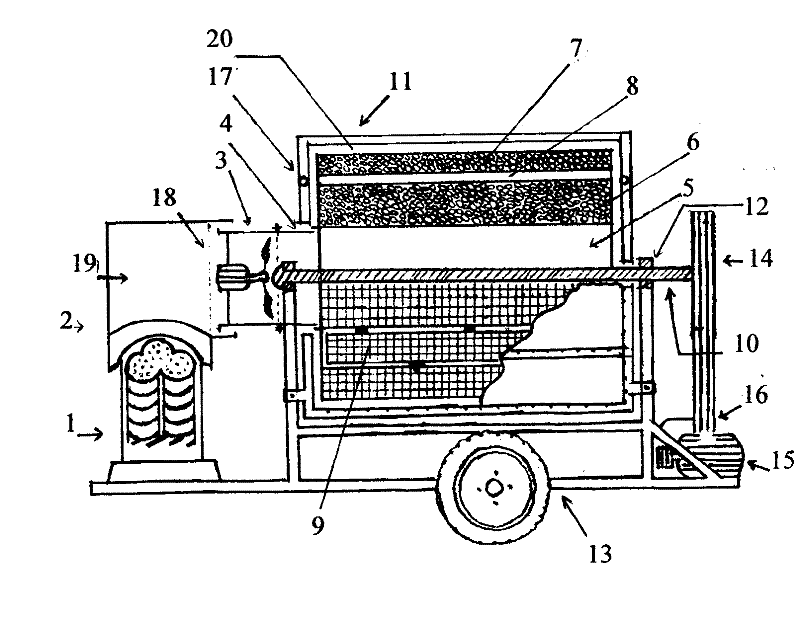

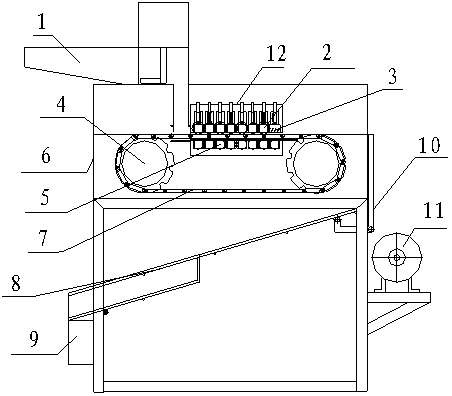

Peeling-cleaning all-in-one machine for green walnuts

InactiveCN104256858ARealize mechanized productionShorten the timeClimate change adaptationHuskingWalnut NutWater storage

The invention relates to a peeling-cleaning all-in-one machine for green walnuts, and belongs to the technical field of processing mechanical equipment for agriculture products. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention comprises a peeling device, an impurity removal and cleaning device, and a drying device, wherein the peeling device comprises a rack, a central main shaft, a peeling rotary drum, a charge port, a concave-plate sieve and a first motor; the impurity removal and cleaning device comprises a water pump, an S-shaped discharge tube, a water tube, a residue collection device, a water collection bucket, a water storage box and a second motor; the drying device comprises a hot-air device and the S-shaped discharge tube. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention is capable of meeting peeling and cleaning requirements on green walnuts, and ensuring the quality of peeling, thorough in peeling, complete in cleaning, high in automation degree, capable of realizing the cyclic utilization of water resources and primary drying for walnuts, low in cost, stable in running, and wide in market prospect.

Owner:KUNMING UNIV OF SCI & TECH

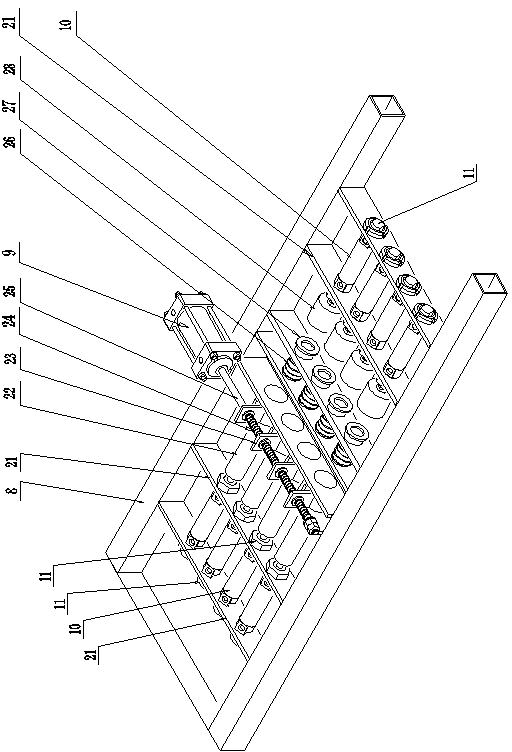

Walnut feeding, conveying, isolating and shelling all-in-one machine

The invention discloses a walnut feeding, conveying, isolating and shelling all-in-one machine which consists of a main machine seat, a feeding and conveying device, a vibrating and conveying device, an isolating device, a shelling device and a power transmission. The feeding and conveying device, the vibrating and conveying device, the isolating device, the shelling device and the power transmission are mounted on the main machine seat. Compared with the prior art, the walnut feeding, conveying, isolating and shelling all-in-one machine has the following advantages that an integrated design method integrating feeding, conveying, isolating and shelling is adopted, and mechanization, automation and integration degrees of the total machine are high; walnuts are supplied by the aid of a conveying belt, a vibrating disc, an isolating device and a conveying disc, so that supplying speed is flexible and adjustable, labor cost is effectively reduced, and processing efficiency is improved; and the linear reciprocating latch type isolating device and the cylindrical cam indexing type conveying disc are adopted, so that coordinated, orderly and efficient running is realized in a walnut shelling process, and the walnut feeding, conveying, isolating and shelling all-in-one machine is applicable to industrialized, standard and large-scale production. In addition, a work mode is reliable, shelling efficiency is high, and accordingly the walnut feeding, conveying, isolating and shelling all-in-one machine is popularized and applied conveniently.

Owner:SHANDONG UNIV OF TECH

Hawthorn dried beef

InactiveCN103932211ASimple preparation processFull of nutritionNatural extract food ingredientsFood preparationRabdosia serraSmoked Plum

The invention relates to hawthorn dried beef, which consists of the following raw materials by weight part: 120-130 of beef, 150-160 of cola, 130-150 of hawthorn, 40-50 of smoked plum, 30-40 of sunflower seed kernel, 20-25 of walnut kernel, 10-15 of laver powder, 3-5 of Chinese wolfberry powder, 70-80 of flour, 4-6 of wheat germ, 4-6 of prunella vulgaris, 3-5 of safflower, 3-5 of cactus, 2-3 of Rabdosia serra, 3-5 of lettuce seeds, and 2-3 of rape flower, etc. The preparation process of the hawthorn dried beef provided by the invention is simple. Added with laver powder, walnut and other food materials, the hawthorn dried beef has rich nutrition and good taste. Also added with wheat germ, prunella vulgaris, safflower, cactus and other Chinese herb extracts, the hawthorn dried beef has certain health care efficacy, and is suitable for most people to eat.

Owner:广州市三道食品有限公司

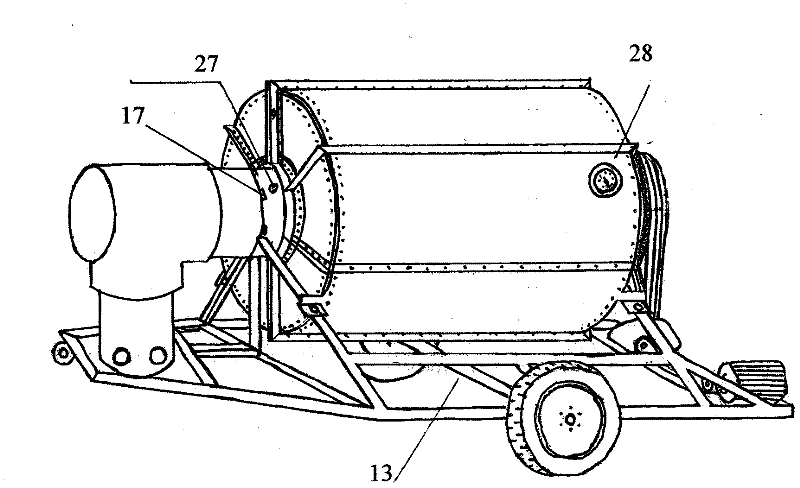

Movable multi-use drying machine

InactiveCN102538414ADry fastConsistent dryDrying gas arrangementsSeed preservation by dryingWalnut NutReducer

The invention relates to a drying device, in particular to a movable multi-use drying machine for dried fruits such as a walnut, a pepper, a Chinese chestnut and the like and a variety of traditional Chinese medicines as well as grains. The movable drying machine comprises a heating part, a main body part and a transmission part, wherein the heating part comprises a coal ball stove, a hot air cover and an axial-flow fan; the main body part comprises an inner drying box, an outer drying box and an insulation cover; and the transmission part comprises a main shaft, a bearing, a chassis frame, a big belt wheel, a motor and a speed reducer. According to the movable multi-use drying machine provided by the invention, dried matters can be rotated by 360 degrees in the drying boxes. In addition, the movable multi-use drying machine has the effects of realizing multiple functions and saving labor intensity.

Owner:尹雄虎

Health wine for invigorating kidney and strengthening yang

InactiveCN101879276AEnhance youthful vitalityImprove immunityAnthropod material medical ingredientsDigestive systemPenisOfficinalis

The invention discloses a health wine for invigorating kidney and strengthening yang, which is characterized by comprising the following components: 20g deer velvet, 50g ginseng, 60g lucid ganoderma, 60g herba epimedii, 50g rhizoma polygonati, 40g Tuckahoe, 60g Chinese dae, 50g cynomorium songaricum, 50g root of bidentate achyranthes, 50g Chinese angelica, 50g lotus seed, 30g tortoise plastron, 50g Morida officinalis, 60g fleece-flower root, 60g desert cistanche, 50g walnut, 50g medlar, 50g semen allii tuberosi, 50g Rehmannia Glutinosa, 50g dogwood, 50g Astragalus mongholicus, 30g Odobenus rosmarus, one penis cervi, 5 pairs of gecko, 100 Male silkworm moth, 2000g honey and 20000g 50-degree pure grain spirit. The health wine has ingenious concept and excellent formula, can invigorate the kidney and strengthen the Yang, can supply vital essence and marrow, can nourish brain and activate the blood, can improve the immunity, and can strengthen the young blood of the body.

Owner:毛成艺

Walnut peeling device

The invention discloses a walnut peeling device which comprises a rack, a feed hopper, a pair of chain wheels, a transmission chain, a chain wheel drive device, a carriage saddle, a cutting device, a grid-type blade, a separation sieve and a discharge port, wherein the pair of chain wheels and the transmission chain which is meshed with the pair of chain wheels form a conveying belt, the cutting device and the grid-type blade are arranged on the carriage saddle, the cutting device is formed by an upper cutting device and a lower cutting device which are respectively arranged on the upper side and lower side of the conveying belt, and the grid-type blade is arranged on the tail end of the cutting device. The walnut peeling device can be suitable for peeling walnuts with different sizes, so that miss peeling can be prevented from being generated. Because a cutting mode but an extruding mode is adopted, the walnuts can be effectively prevented from being crushed, and the peeled walnuts can be enabled to be complete without fracture.

Owner:张庆明

Walnut shelling and picking device

The invention discloses a walnut shelling and picking device which comprises a rack, wherein a case is arranged on the rack; a compression grinding device is arranged in the case; the discharge port of the compression grinding device is provided with a stirring device; the discharge port of the stirring device is provided with a sorting unit; a power device is fixed on the lower wall of the case, and is respectively connected with the sorting unit and the compression grinding device through a V-shaped belt; and the compression grinding device is firstly used for cracking the walnut, then through the hammering of the stirring device and the wind force separation, velvet strip adhesion and other functions of a separating device, the kernel is shelled out, so the automatic kernel-husk separation is realized. A height-adjustable device is adopted, the device can be adaptive to treatment of different types of walnuts, thus the walnut shelling and picking device can be used for mass production, so the labor time is shortened, the labor is saved, the processing cost is lowered, and the problems that the walnut is difficult to shell and depends on manual shelling are better solved; and moreover, the shelling rate and kernel yield are improved, so efficient low-consumption low-cost green and clean production is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

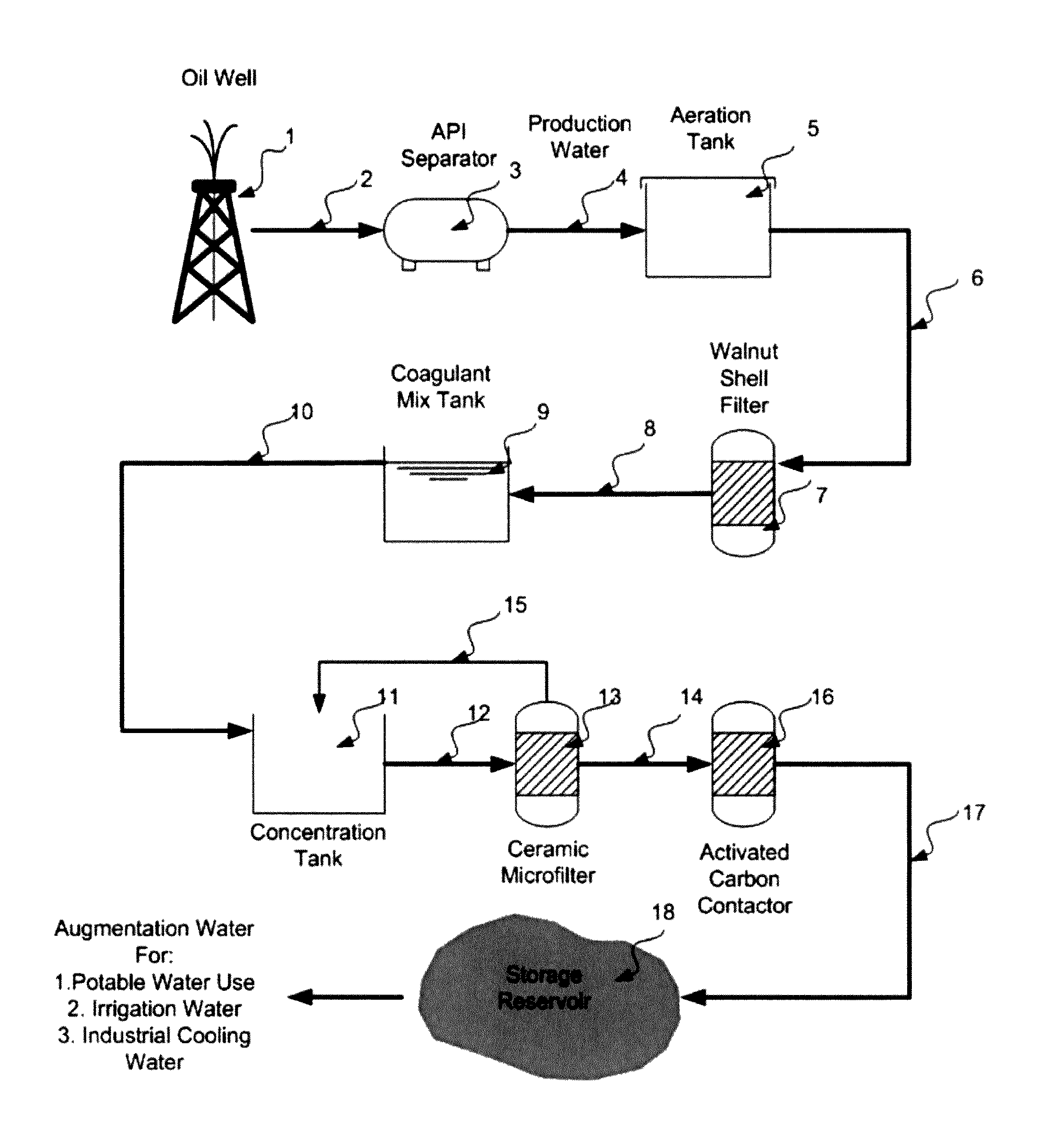

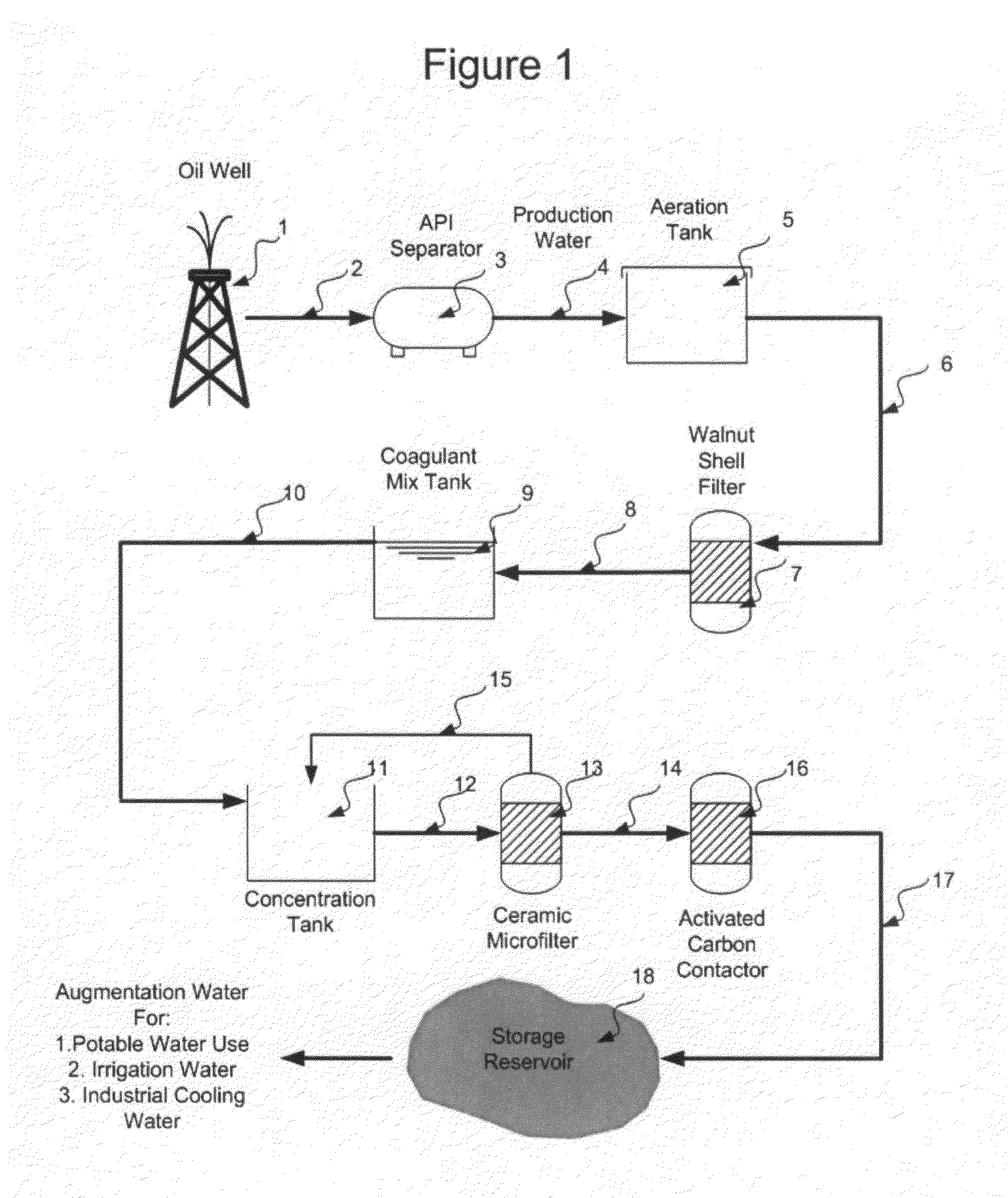

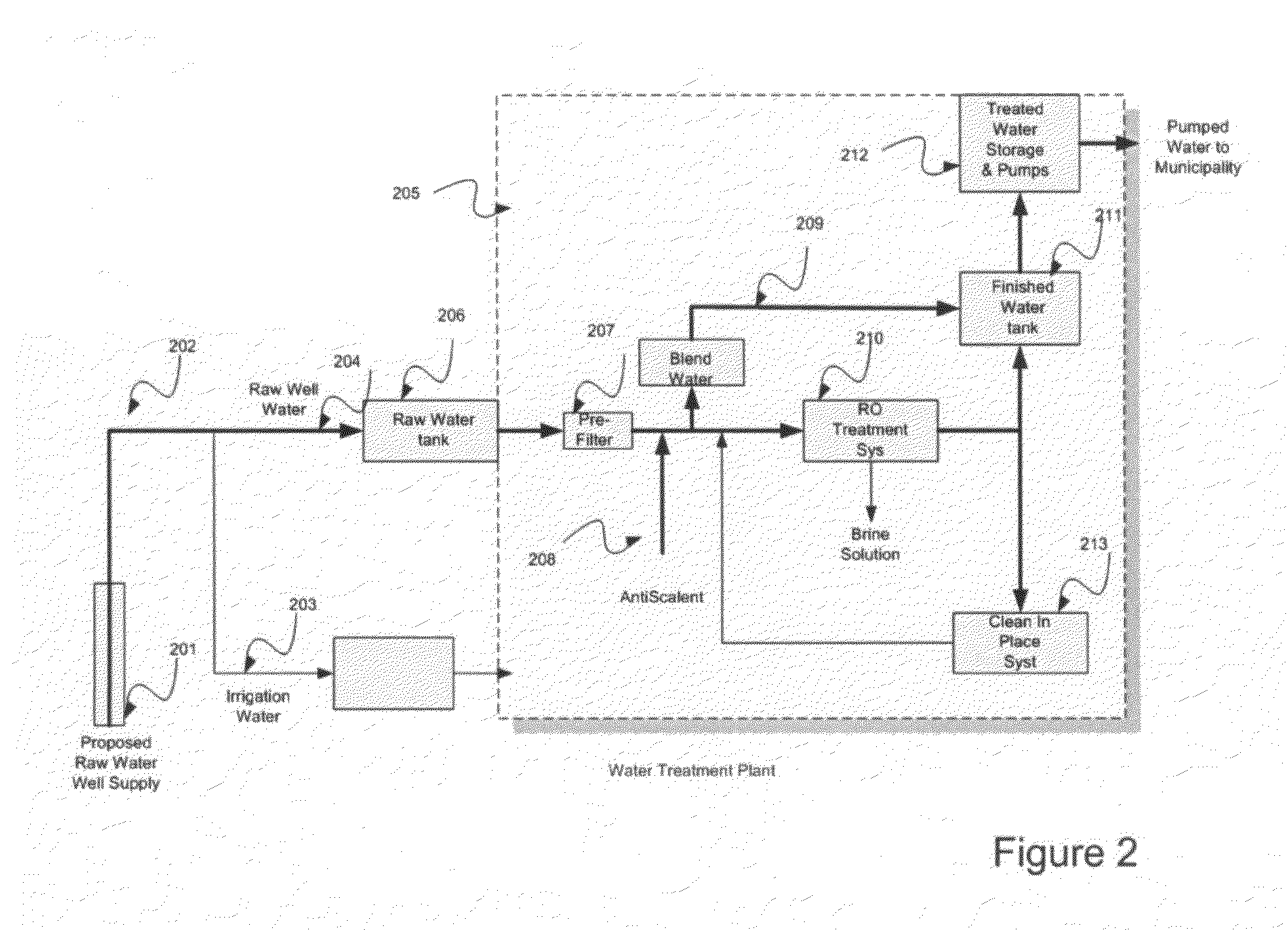

Purification of oil field production water for beneficial use

A method and system for purifying production water obtained from oil and gas operations so that the purified water need not be disposed of by forced injection back into the geological formation but can be put to a beneficial use such as agriculture, irrigation, industrial or municipal or potable applications. The production water is treated in a ceramic microfilter after it has been pretreated (preferably by aeration and with a walnut shell filter) to remove volatile hydrocarbons and heavier oils, such as paraffins and asphaltenes, that could foul the ceramic filter. The permeate from the ceramic microfiltration can then be treated with activated charcoal or otherwise treated to meet the specific requirements for the intended beneficial use.

Owner:PRODD WATER DEV

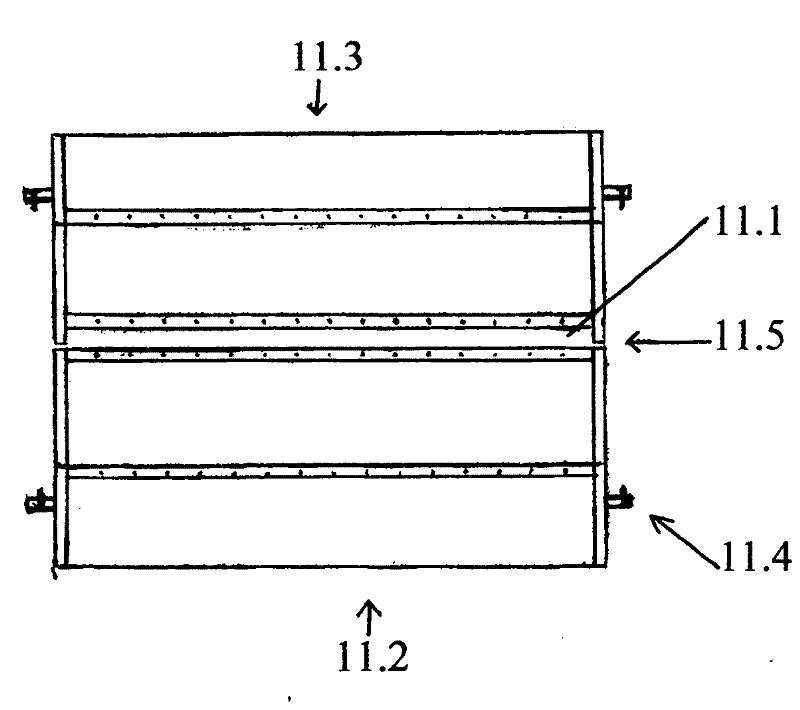

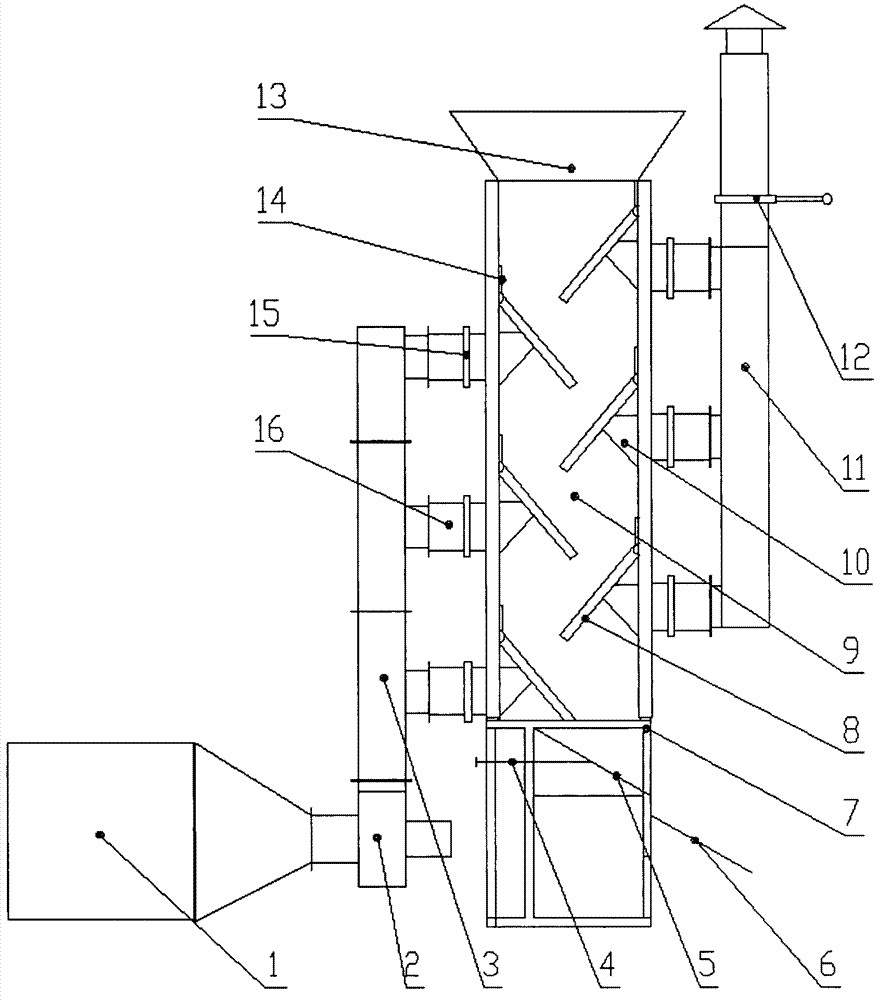

Cross-flow type layered drying machine

InactiveCN103115484AAvoid collusionStrong penetrating powerDrying gas arrangementsDrying chambers/containersWalnut NutCuticle

The invention discloses a cross-flow type layered drying machine, relates to an agricultural product processing machine and belongs to the technical field of agricultural product processing. The cross-flow type layered drying machine aims at solving the problems that when a drying machine is used for drying materials, uneven drying and damage of the cuticles of the materials are easy to occur, the cuticles of the materials are burst when drying temperature is high and the like. The materials enter into the drying machine are separated into material layers with the same thickness due to the fact that baffles with holes are mounted in an intersect-arrayed mode and an inclined mode, self-flow and slow rolling of the materials are achieved by using the self-weight of the materials when hot wind crosses the layered material layer transversely, the cross section position of a moisture-exhaust adjusting plate relative to a moisture-exhaust channel is controlled, drying speed of the materials is controlled, the burst of the material when in a drying process can be avoided. The cross-flow type layered drying machine is simple in structure, high in work efficiency and good in evenness of material drying and can achieve continuous drying operation of the materials. The cross-flow type layered drying machine is suitable for drying operation of granular agricultural products such as dates and walnuts.

Owner:XINJIANG AGRI UNIV

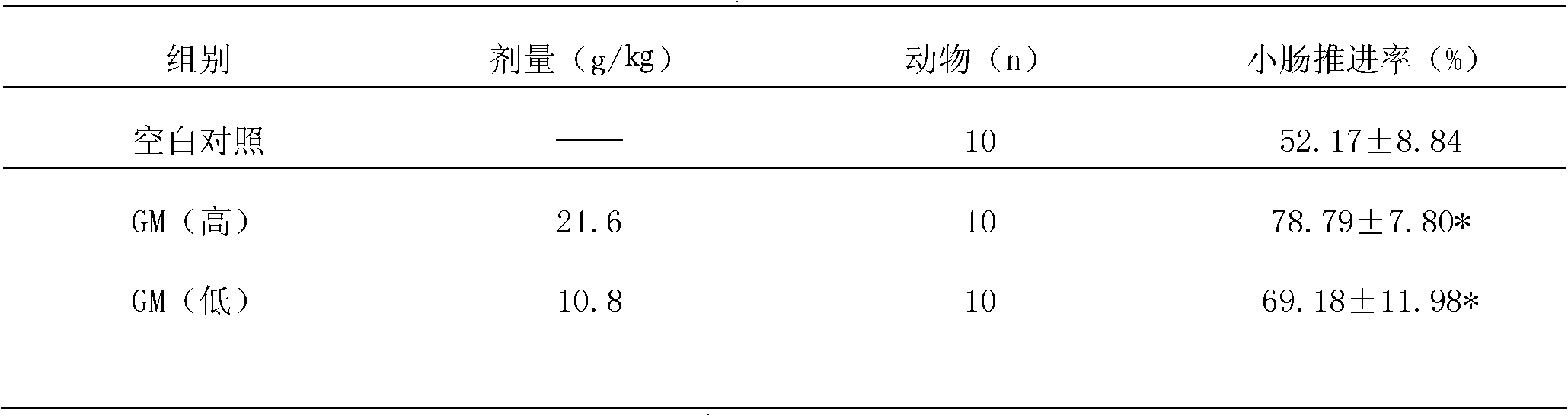

Life nourishing biscuits and a preparation method thereof

InactiveCN104814092APromote precipitationProtect nutritionDough treatmentBakery productsBiotechnologyFood additive

The present invention discloses life nourishing biscuits and a preparation method thereof. The biscuits are made from the following raw materials in parts by weight: wheat flour 60-80 parts, soybean powder 8-15 parts, purple sweet potato powder 8 -12 parts, Chinese yam powder 5-15 parts, vegetable oil 10-20 parts, yacon micro powder 10-15 parts, eggs 5-10 parts, milk powder 6-15 parts, persian walnuts 4-10 parts, pistachios 5-8 parts, baking soda 0.5-1.5 parts, ammonium bicarbonate 1-2 parts, red dates 3-9 parts, Chinese wolfberries 1-5 parts, grape seeds 2-10 parts, honey 8-18 parts, xylitol 1-8 parts, food additives 2-5 parts, table salt 3-10 parts and a proper amount of water. The preparation method is simple and environment-friendly, the produced biscuits are delicious and tasty, and also can promote gastrointestinal peristalsis, promote digestion, regulate gastrointestinal environment, strengthen and tonify spleen, nourish essence and reinforce kidney, resist oxidation, lower blood fat, blood pressure and cholesterol, nourish liver and moisten lung, maintain beauty and preserve countenance and resist fatigue and other functions.

Owner:ANHUI YOUYUAN FOOD

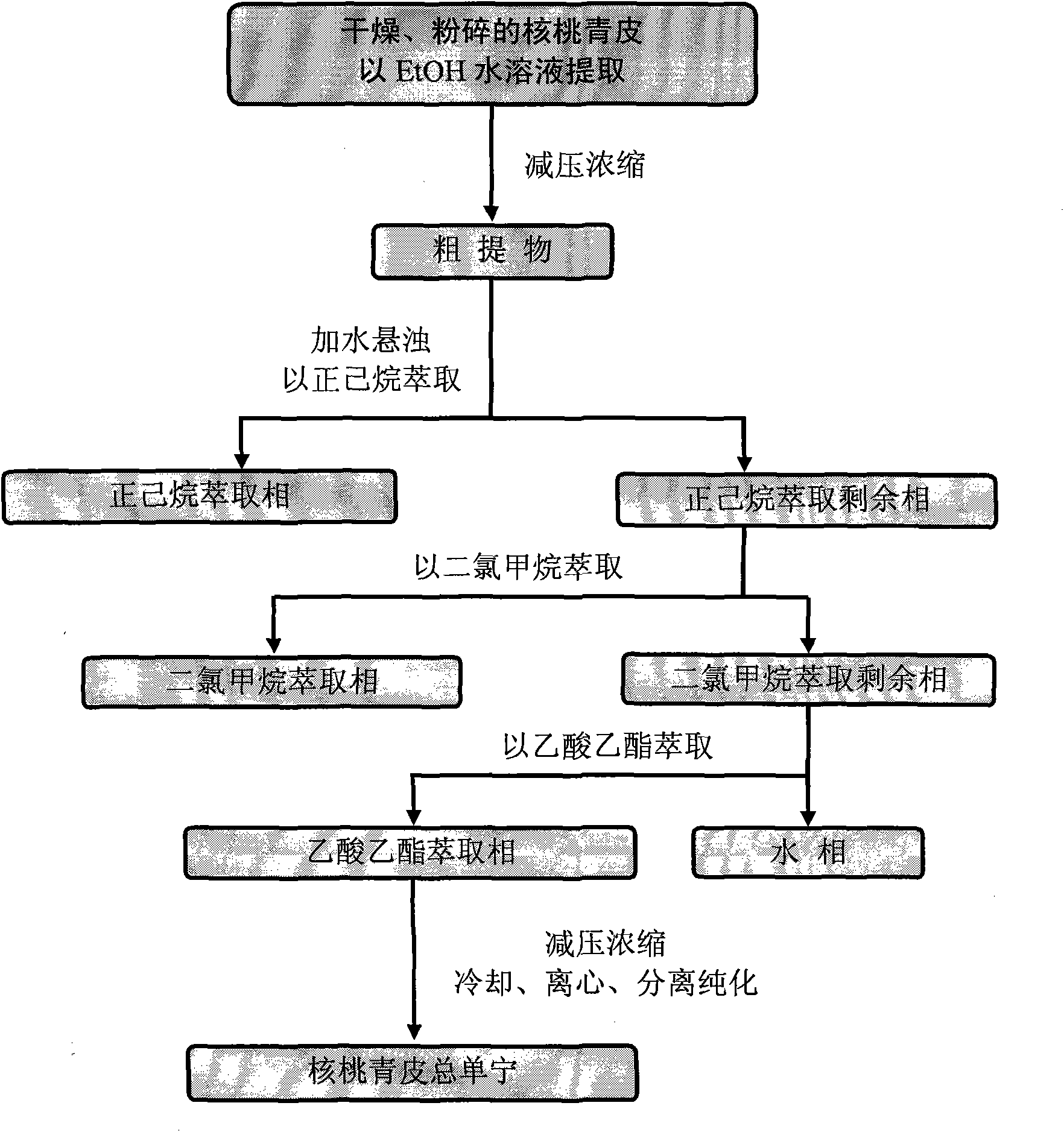

Preparation method of walnut green husk total tannin and application of same to antineoplastic medicines

The invention belongs to the technical field of natural medicines, in particular to a preparation method of a walnut green husk total tannin and an application of the same in antineoplastic medicines. The walnut green husk total tannin is prepared by using walnut green husk as raw material and extracting, leaching, precipitating, separating and purifying the raw material, has light color and high purity, and the preparation method has the advantages of high yield, low production cost and simple and standard process. The walnut green husk total tannin prepared by the invention can remarkably inhibit the growth of tumor cells and can be used for preparing the antineoplastic medicines.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com