Patents

Literature

431results about How to "Effective peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

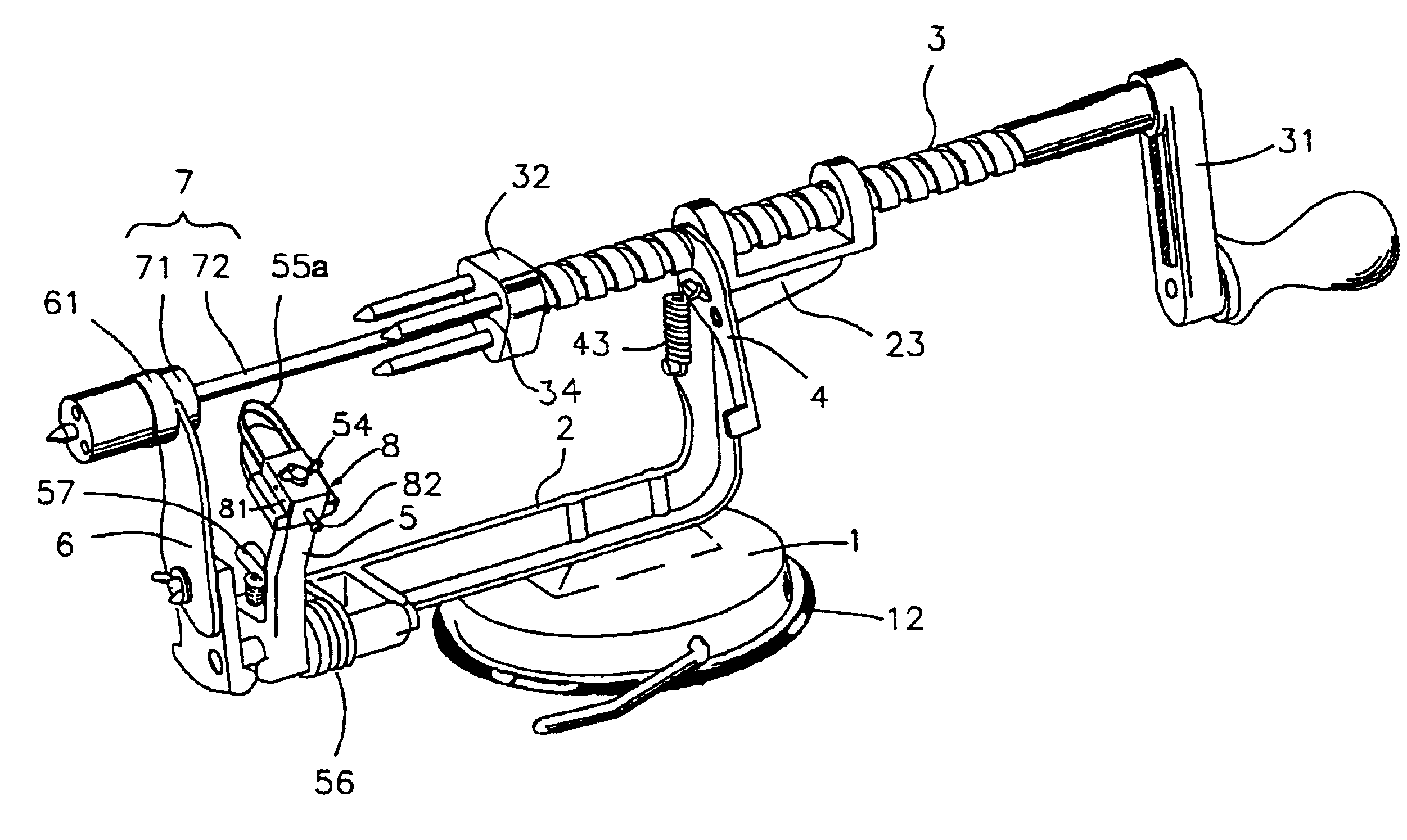

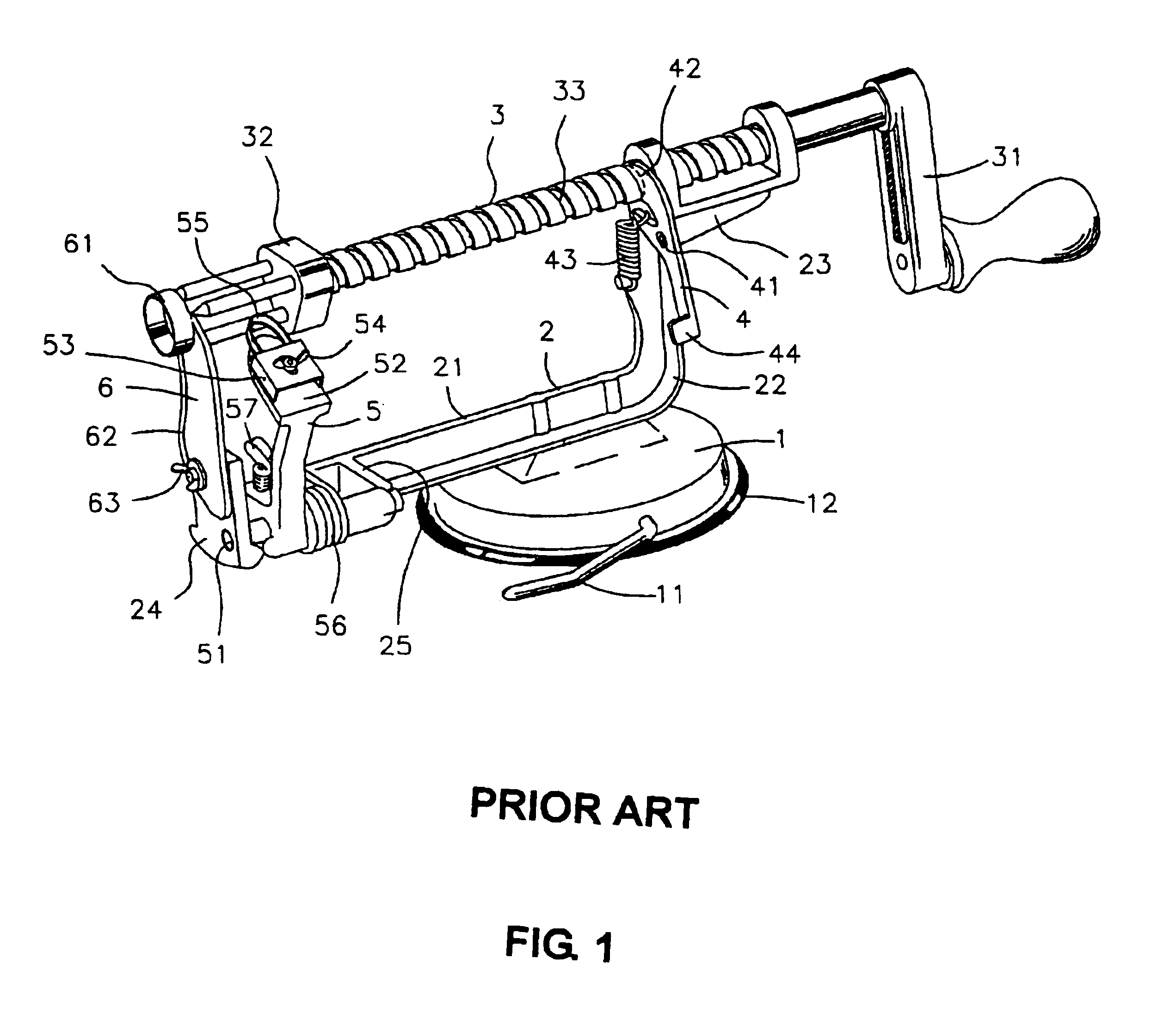

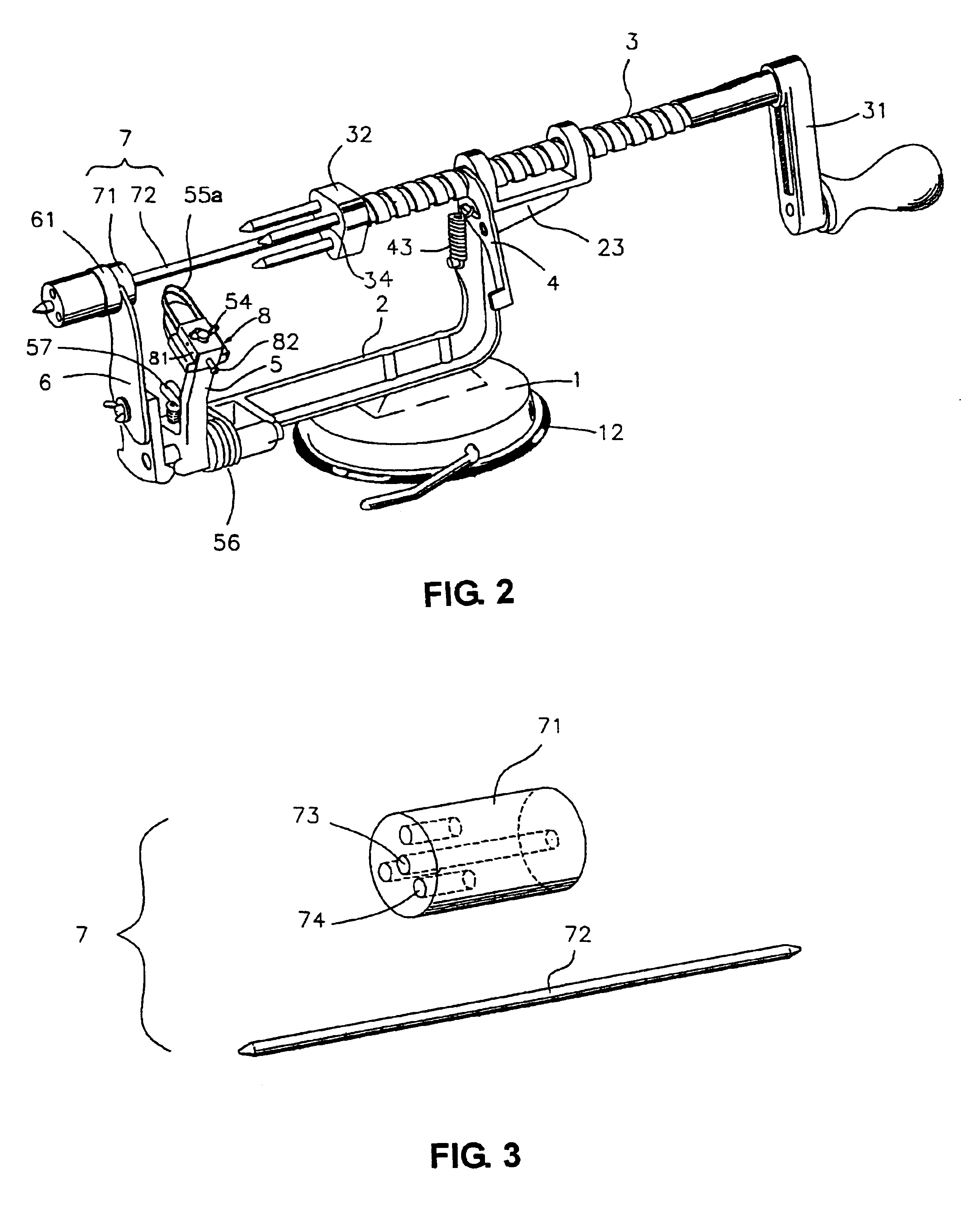

Apple/potato peeler

InactiveUS6854383B2Easy to optimizeEffective peelingFruit coringFruit stoningEngineeringKnife blades

An apple / potato peeler. The peeler includes a base, a main frame mounted to a slightly L-shaped structure on the base, a rotatable and axially movable screw horizontally supported on a screw support member on a vertical frame member disposed at the rear of the main frame, a 3-prong fork fixed to the front end of the screw, a guide piece pivotally mounted on the vertical frame member and being releasably engageable relative to a screw channel of the screw, a resiliently movable peeling arm fore-and aft swingeable pivoted to the front part of the horizontal frame member of the main frame, a U-shaped peeling blade fixed to the upper end of the movable peeling arm by a blade positioning device, and a coring / slicing blade fixed to the front end of the horizontal frame member for cutting flesh of a vegetable fruit held by the 3-prong fork if the screw into continuous spiral slices and for coring fruit.

Owner:WANG PHILIP

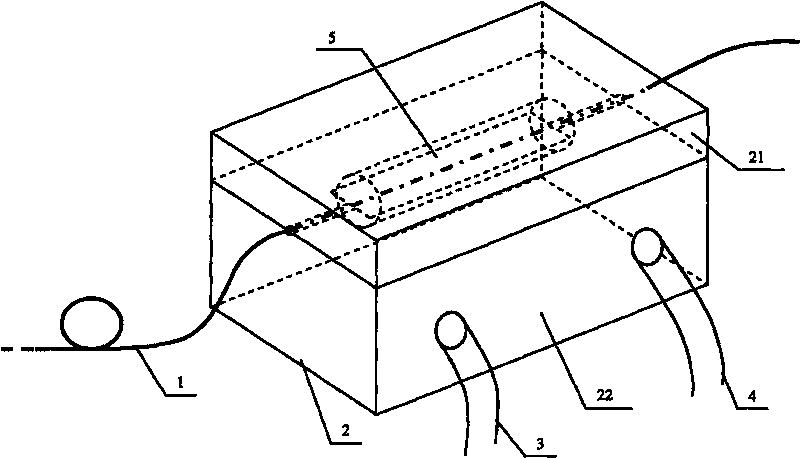

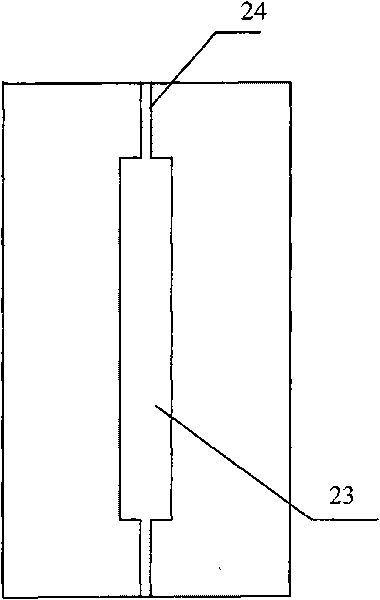

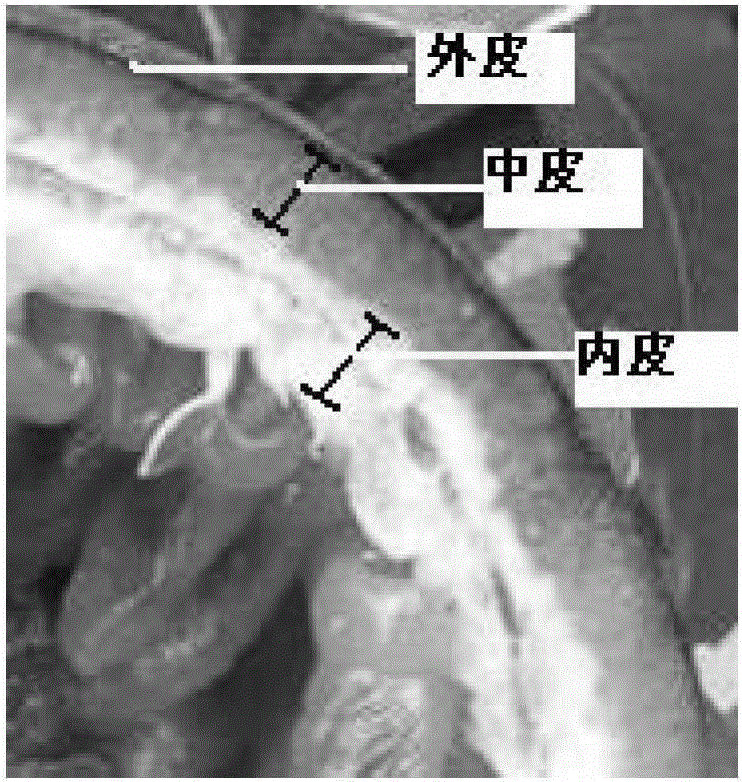

Method for stripping residual pump light in double-coated optical fiber

InactiveCN101718916ASimple structureEasy to implementOptical fibre with multilayer core/claddingNon-linear opticsDouble-clad fiberOptical fiber amplifiers

The invention relates to a method for stripping residual pump light in a double-coated optical fiber, which comprises the steps of: removing an outer coating and a cladding layer of one section of the double-coated optical fiber at the output end of a full optical fiber laser; covering optical gel with high refractive index outside an inner coating of the section of the optical fiber, wherein the refractive index of the optical gel is higher than that of the inner coating of the double-coated optical fiber; leaking light transmitted in the inner coating out through the optical gel, and fully absorbing the leaded pump light with high power by a heat radiating device. The invention has the characteristics of compact structure and convenient integration, and can be applied to a high-power optical fiber laser or high-power optical fiber amplifier.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

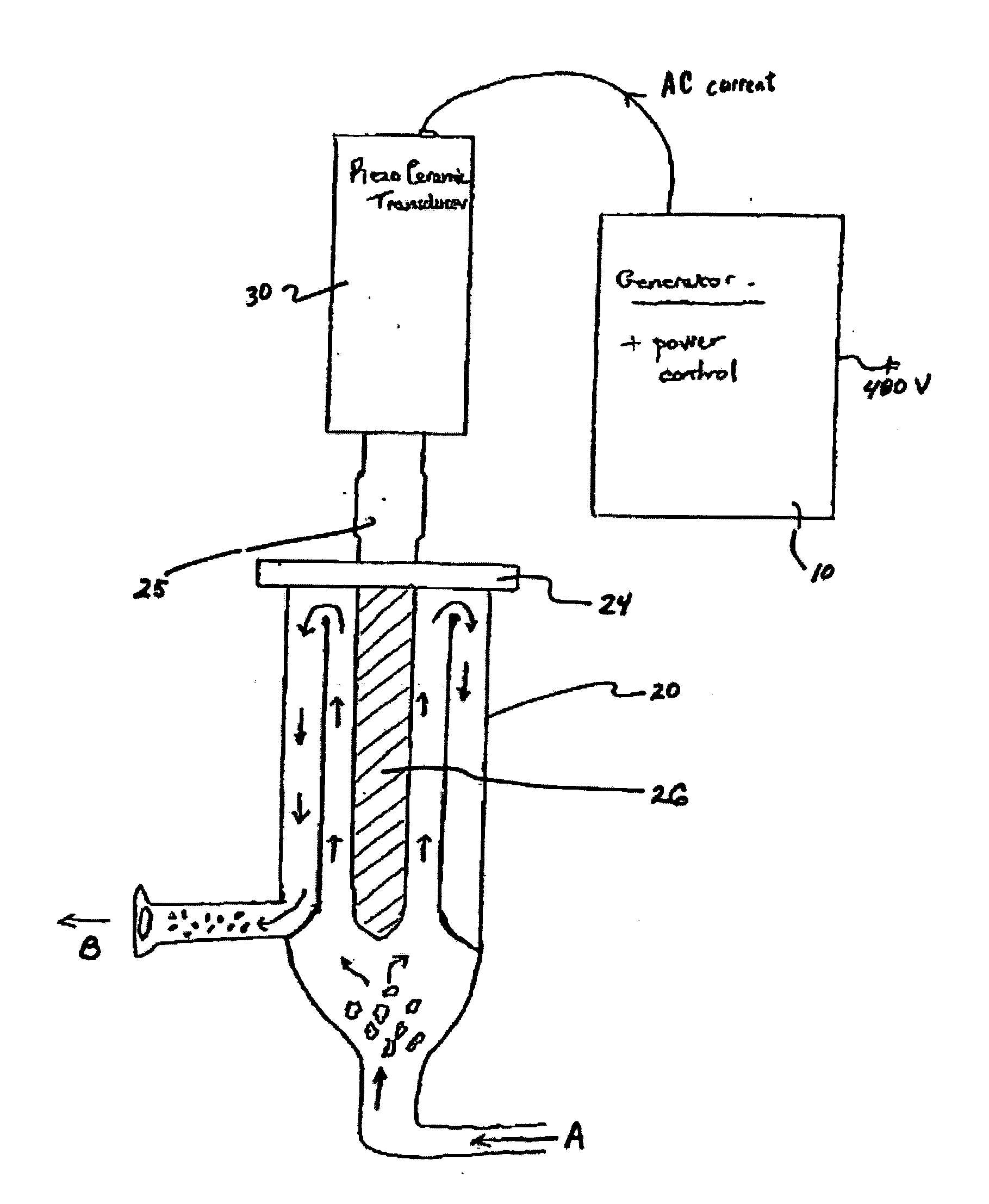

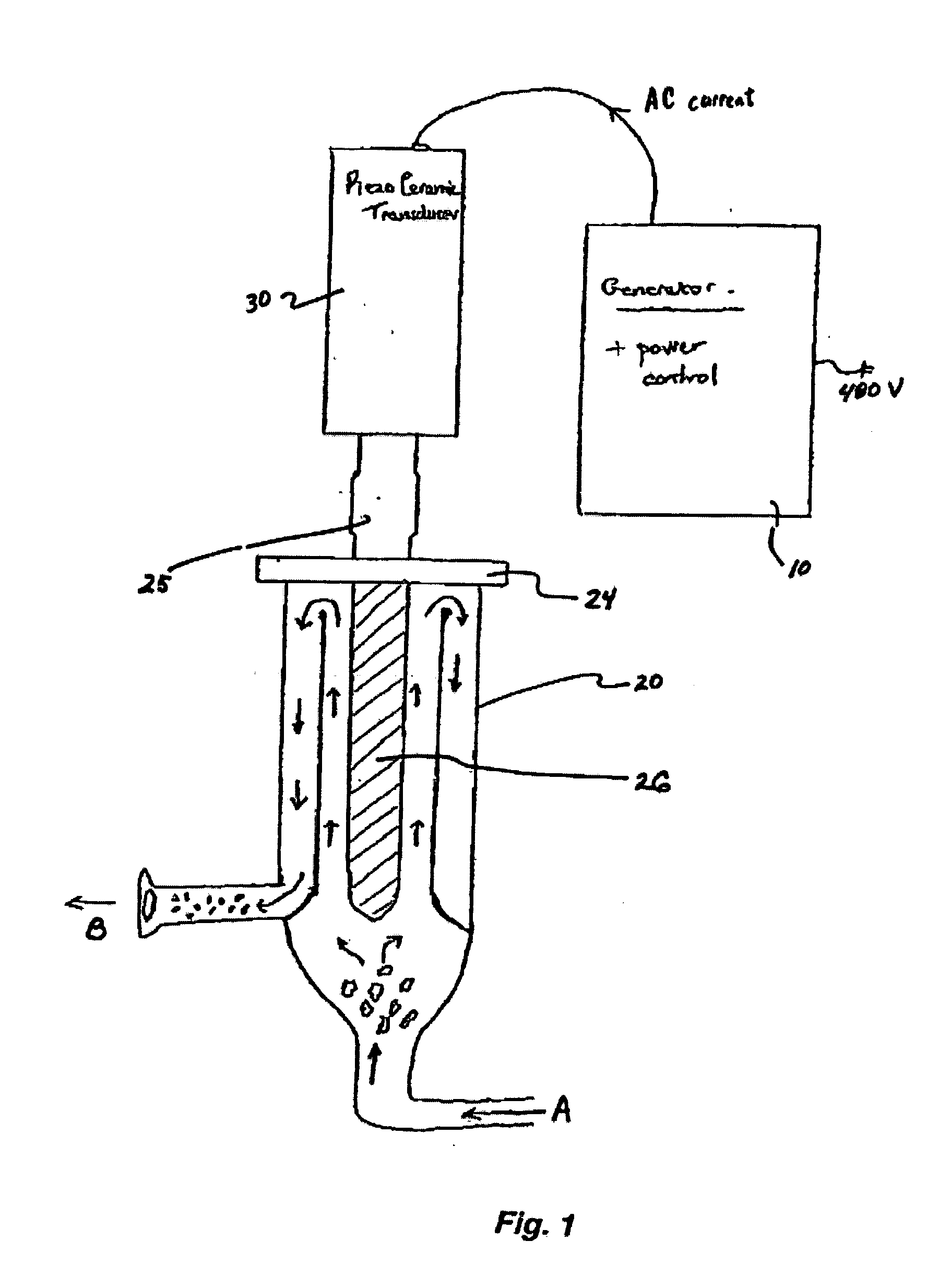

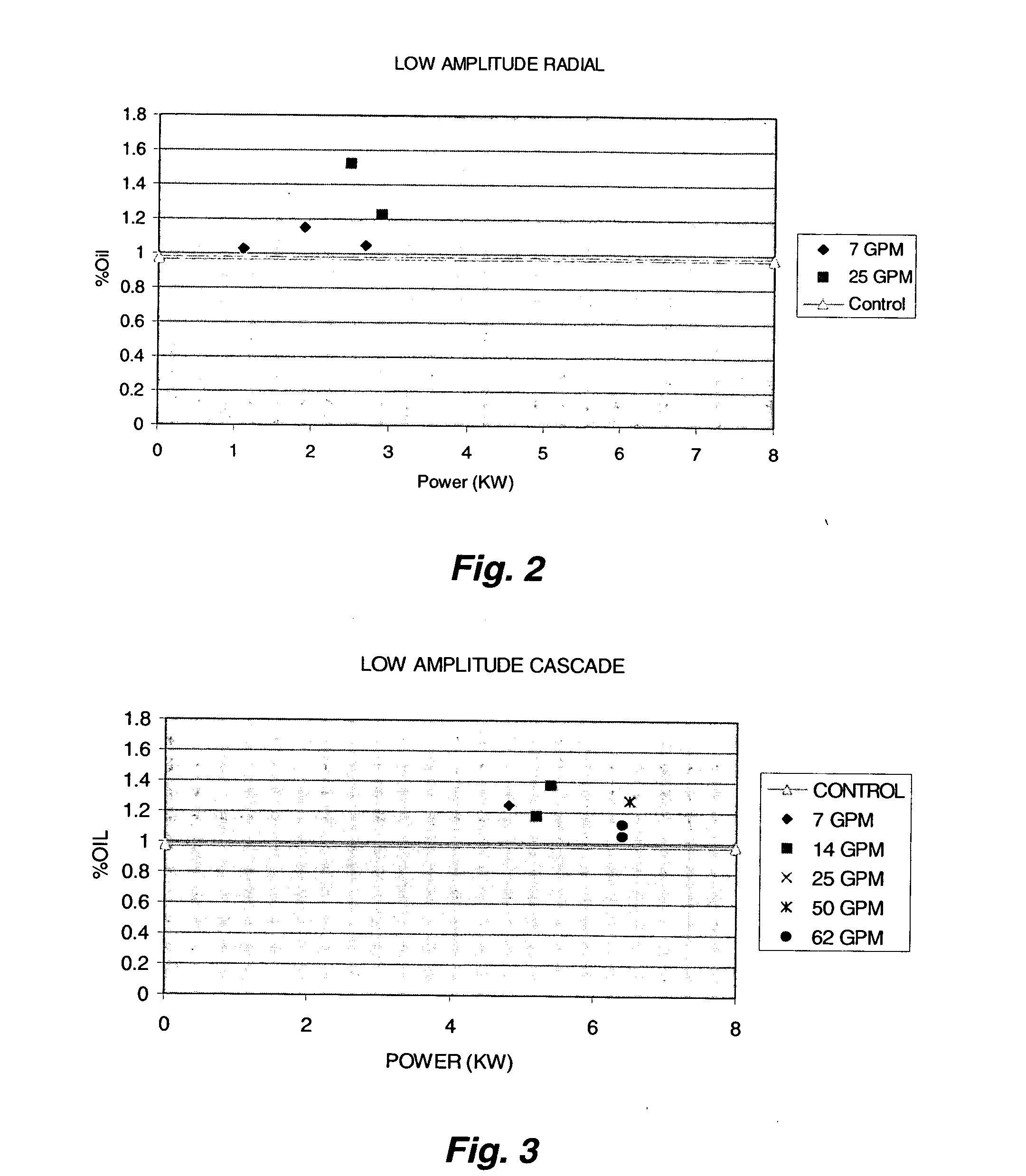

Process and apparatus for enhancing peel oil extraction

InactiveUS20060204624A1Promote recoveryEfficient and cost-effectiveSedimentation separationBakery productsCitrus fruitUltrasonic generator

A process of enhancing peel oil extraction from citrus fruit comprises providing a mixture containing citrus solids and water, subjecting the citrus solids and water mixture to high power ultrasonic energy under conditions sufficient to separate peel oil from the citrus solids, and recovering the peel oil. An apparatus for extracting peel oil from citrus fruit comprises an extractor, a conduit for flowing a citrus mixture containing citrus solids and water, and an ultrasonic generator for subjecting the citrus mixture to high power ultrasonic energy to separate peel oil from the citrus solids. In another embodiment, sonic energy is used to de-emulsify peel oil in a citrus mixture.

Owner:CARGILL INC

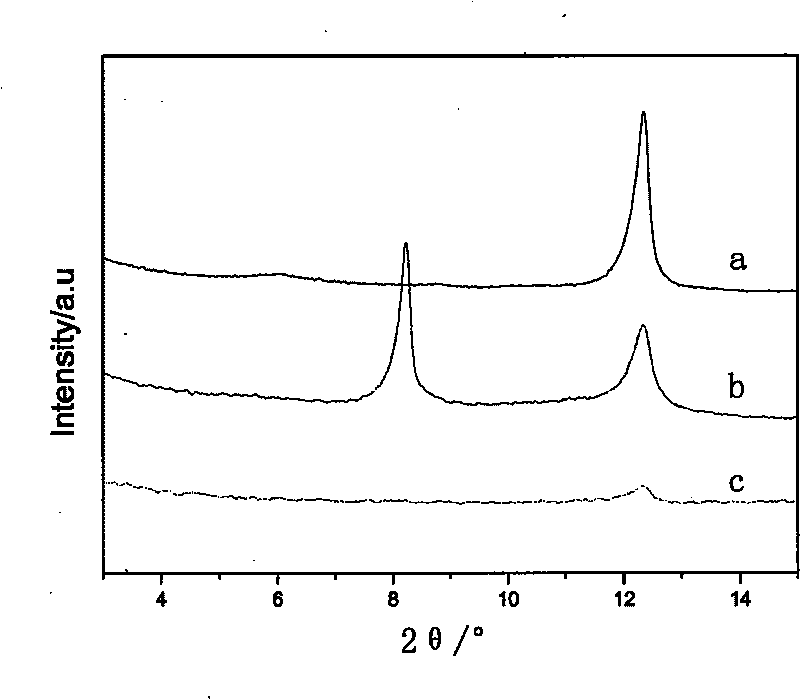

Method for stripping laminated inorganic material

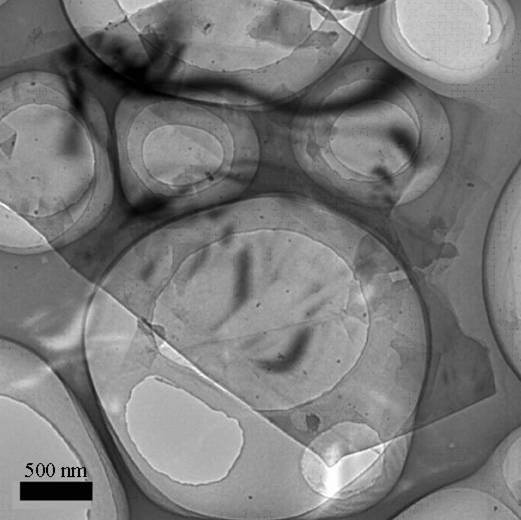

The invention relates to a method for stripping a laminated inorganic material, which comprises the following steps of: firstly preparing a laminated inorganic material organic intercalation compound, then decomposing the organic substance at the interlayer of the solid of the laminated inorganic material organic intercalation compound or the laminated inorganic material organic intercalation compound added into a proper solution within short time under the condition of ultrasonic waves or microwaves, escaping from the interlayer of the laminated inorganic material so as to rapidly strip the laminated inorganic material, and finally separating, washing, drying and grinding to obtain a product. By using the method, not only the laminated inorganic material can be stripped within short time, but also the good crystal structure of the laminated inorganic material can be kept, so that the traditional application of the laminated inorganic material is qualitatively improved, and the value is doubled and redoubled.

Owner:BEIJING UNIV OF CHEM TECH

Microwave method for peeling laminar inorganic material quickly

The invention relates to a method for peeling a laminar inorganic material quickly. The method comprises the following steps of: firstly, preparing laminar inorganic intercalating composite of the laminar inorganic material; secondly, decomposing or evaporating the inter-laminar organic material of the organic intercalating composite solid of the laminar inorganic material in a short time in the presence of microwaves and allowing the inter-laminar organic material to escape from the space between the layers of the laminar inorganic material so as to quickly peal the laminar inorganic material; and finally, performing separation, washing, drying and grinding to obtain the products. The method not only can peal the laminar inorganic material in a short time but also keep a good crystal structure of the laminar inorganic material, so the application of the laminar inorganic material is substantially widened and the use value thereof is multiplied.

Owner:BEIJING UNIV OF CHEM TECH

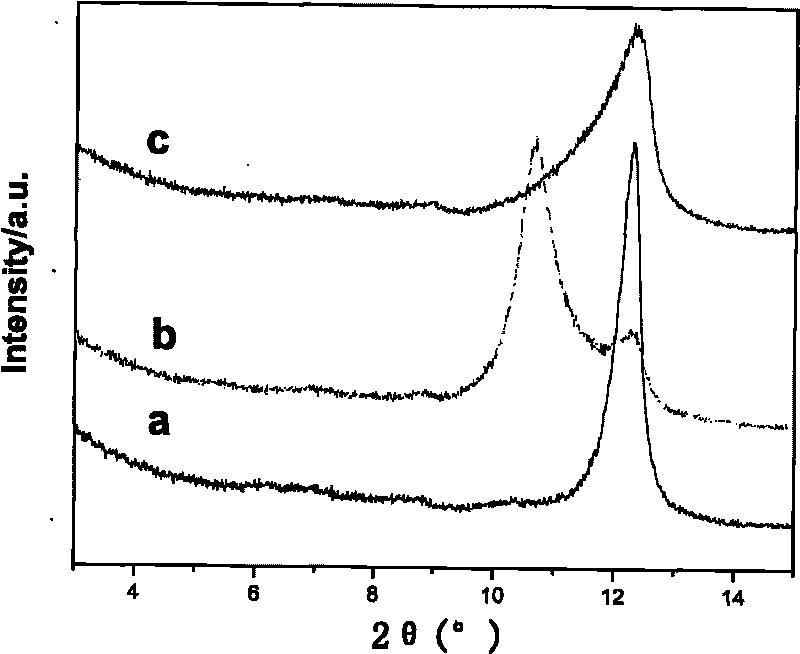

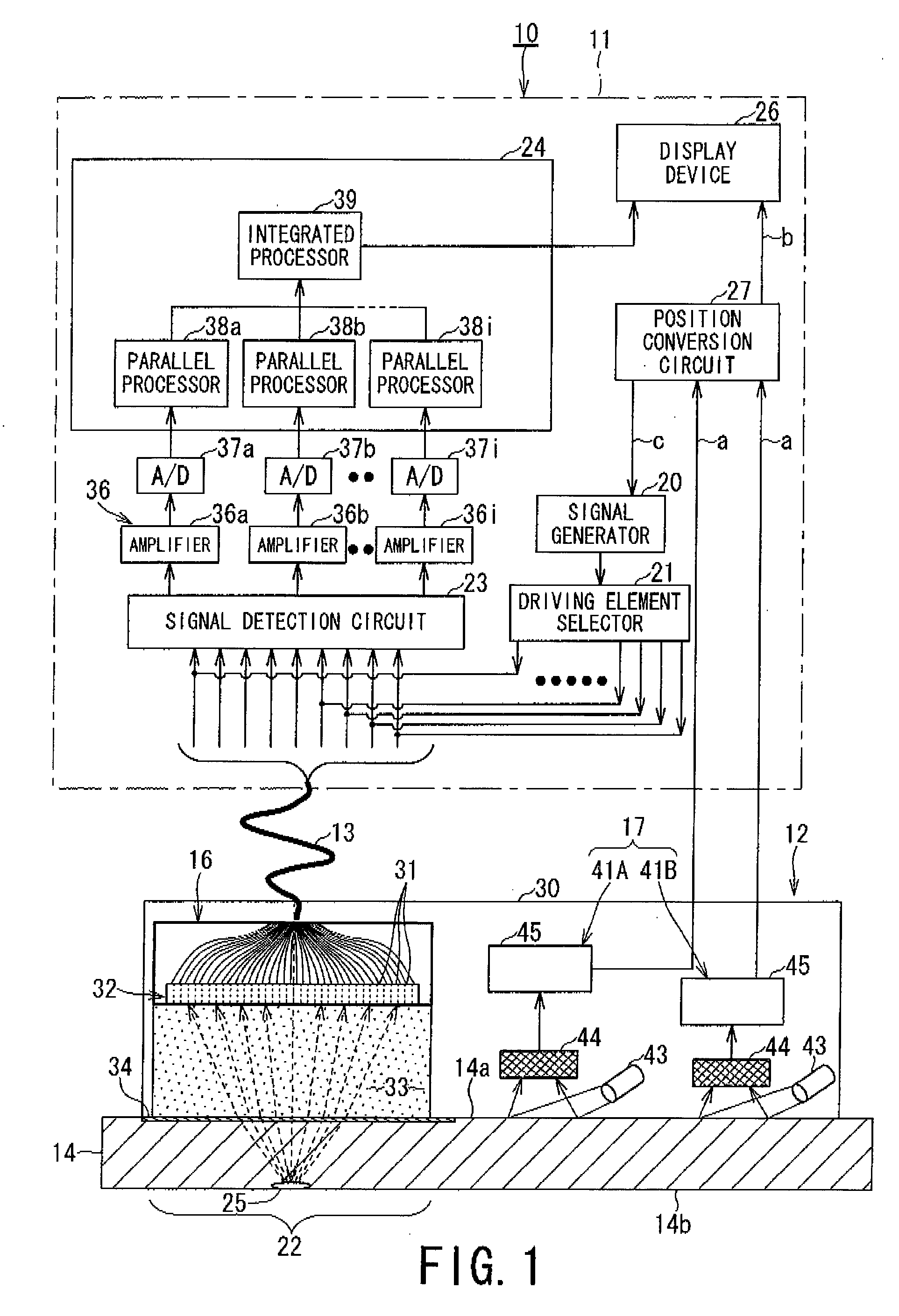

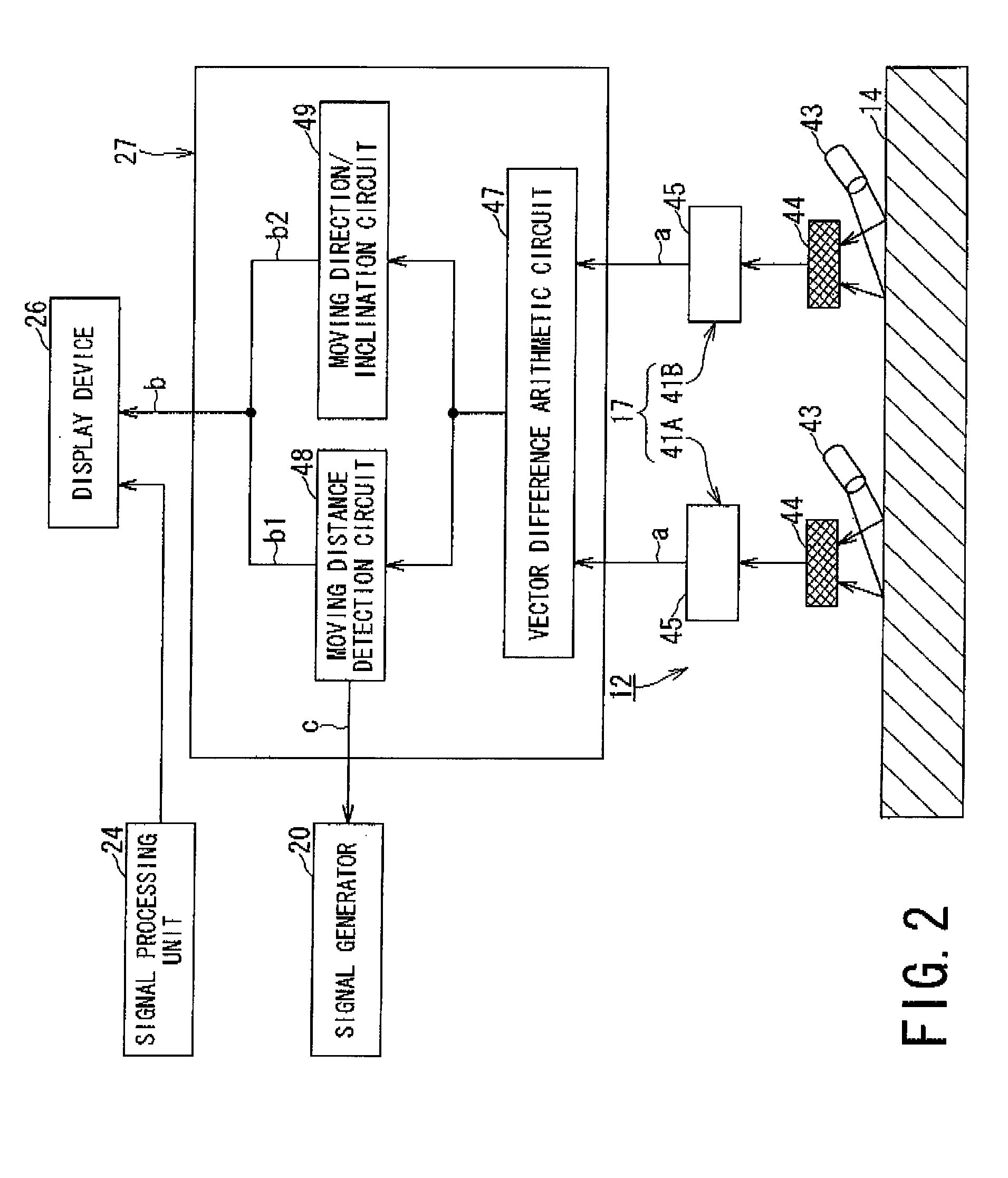

Ultrasonic inspection apparatus and ultrasonic probe used for same

InactiveUS20090126494A1Effective peelingSmall and portableAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansDisplay deviceDriven element

An ultrasonic inspection apparatus includes an ultrasonic probe including an ultrasonic transducer, a position detection device, a drive element selector which is connected to the plurality of piezoelectric elements of the ultrasonic transducer provided so as to select a required piezoelectric element, a signal detection circuit which allows the piezoelectric element selected by the drive element selector to transmit ultrasonic wave to an inspection object through an acoustic transmission medium, which receives reflection echo thereof, and which detects an electric signal of the reflection echo through, a signal processor which generates three-dimensional imaging data inside of the inspection object by processing the electric signal of the detected reflection echo, a position converting circuit which outputs an imaging-start trigger signal to a signal generator in response to a position detection signal, and a display device which displays an imaging result.

Owner:TOSHIBA PLANT SYSTEMS & SERVICES +1

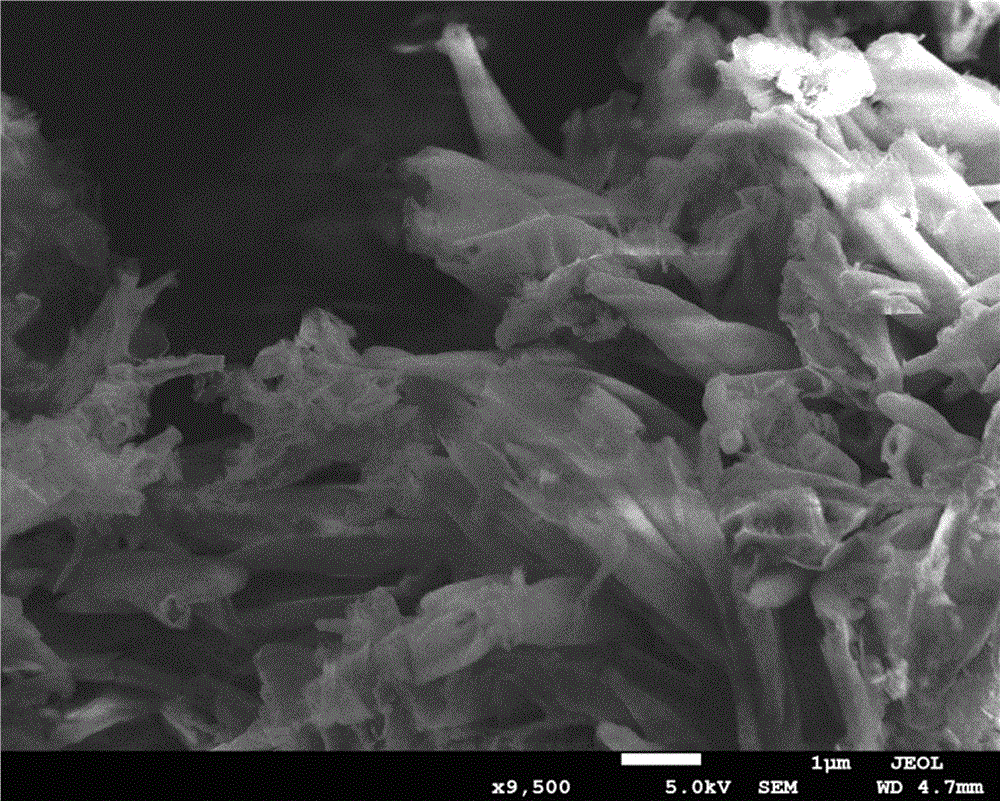

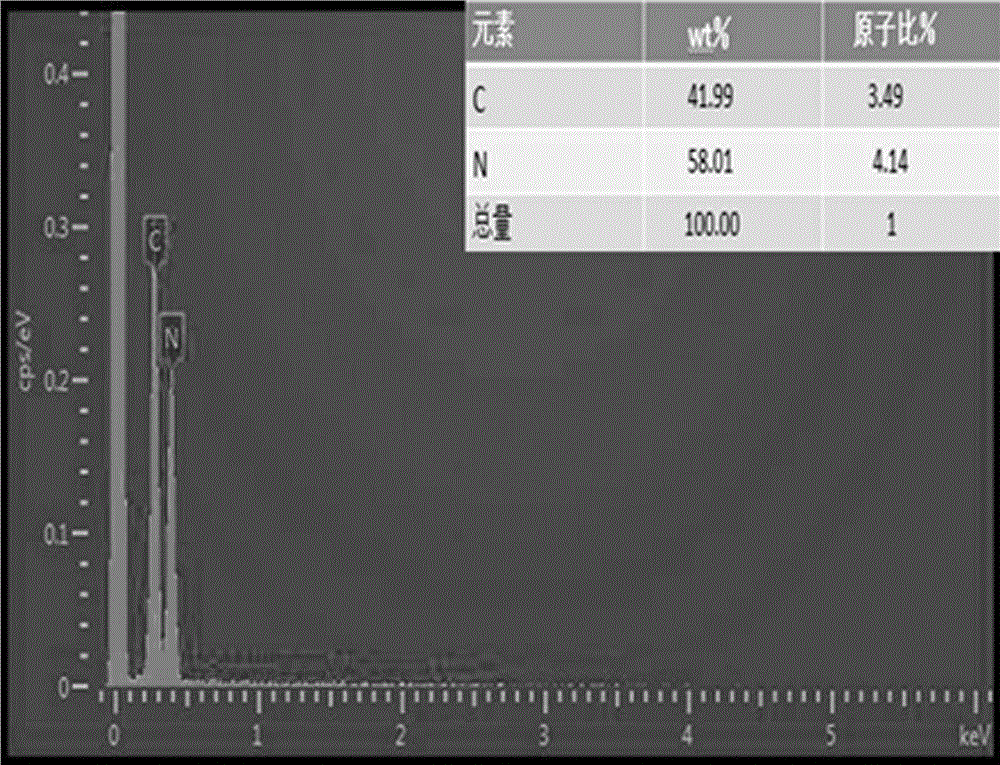

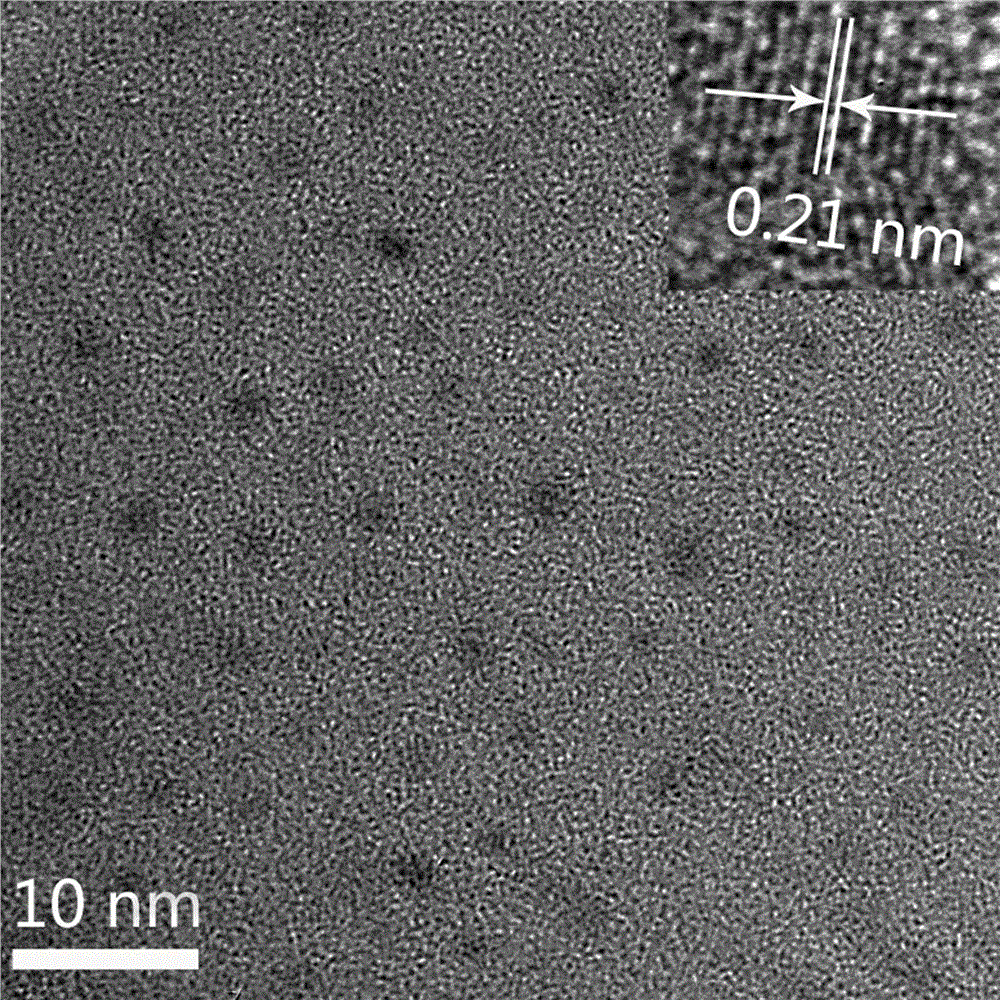

Method for solvothermal preparation of fluorescent carbon nitride quantum dots

InactiveCN106006581AHigh purityHigh yieldMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsDispersityFiltration

The invention belongs to technical field of nanomaterials and discloses a method for solvothermal preparation of fluorescent carbon nitride quantum dots by adoption of melamine as a raw material. The method includes steps: a) calcining melamine in a muffle furnace at a high temperature, and grinding products into yellow graphite-phase carbon nitride powder; b) scattering the graphite-phase carbon nitride powder into an alcohol solvent, adding a certain amount of alkali liquor, dissolving ultrasonically, sealing in a reaction kettle, and reacting for a while at a high temperature; c) cooling to the room temperature, collecting filtrate after vacuum filtration, and dialyzing the filtrate in a dialysis bag with a certain molecular weight cutoff until the filtrate is neutral, so that the fluorescent carbon nitride quantum dots are obtained. The method is simple in process, easy in operation, low in cost and environment friendly, and the prepared fluorescent carbon nitride quantum dots are high in purity and yield, excellent in dispersity and stability and high in fluorescence intensity and have a potential application prospect in fields of bioimaging, solar cells and the like.

Owner:TAIYUAN UNIV OF TECH

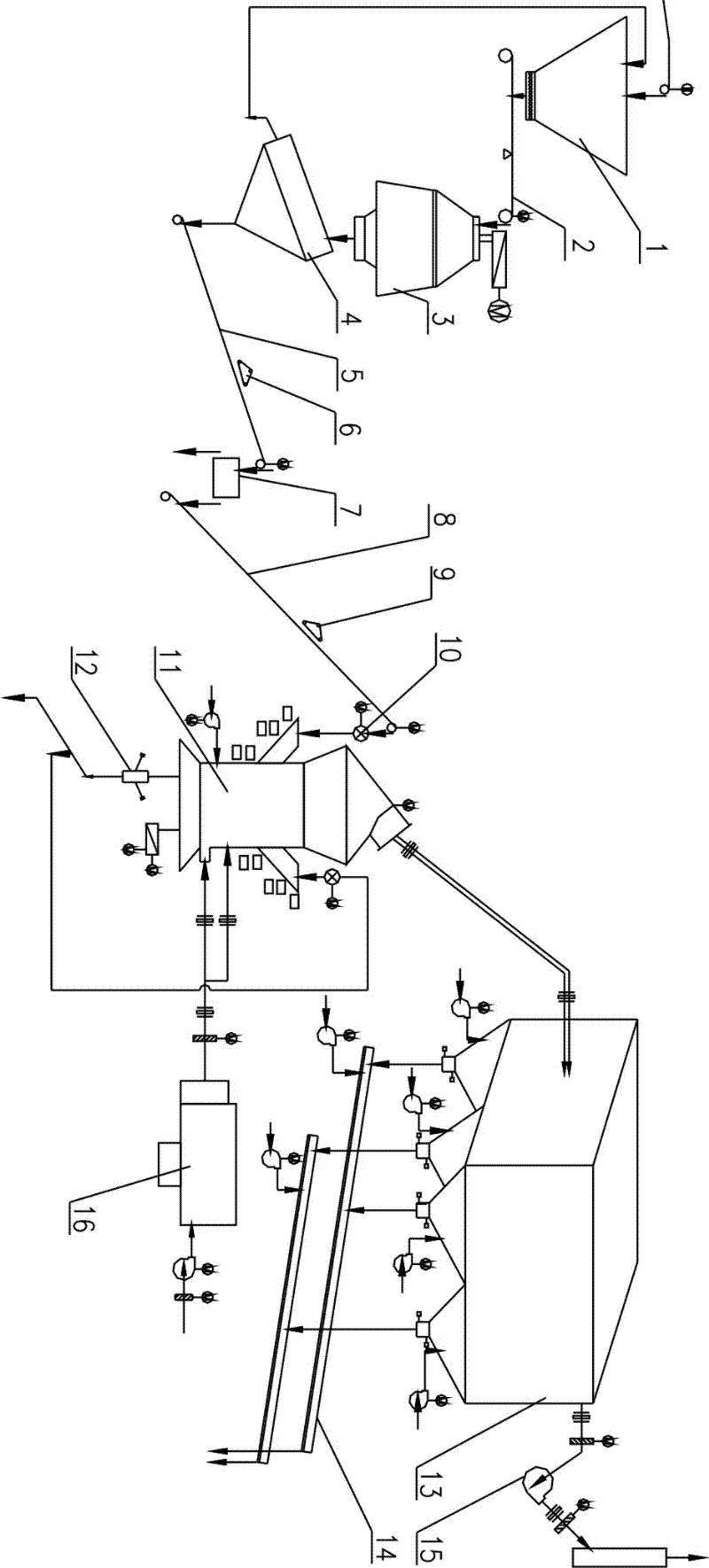

Steel slag grinding production technology and system

The invention discloses a steel slag grinding production technology and system. In the production technology, steel slag of which the moisture is less than or equal to 5% and the granularity is less than 80mm is sent into a column grinder to be grinded to obtain fine powder which contains more than 90% of powder of which the granularity is less than 5mm; the fine powder is screened by a vibrating screen; the screened steel slag fine powder is sent into a strong magnetic separation machine by a belt conveyor to remove iron to ensure that the iron content in the steel slag fine powder is below 2%; and the steel slag fine powder subjected to iron removal is sent into a slag vertical mill to be dried and grinded to obtain a steel slag product of which the specific surface area is 4200-4500cm<2> / g. The production system mainly comprises a charging cabin, a column grinder, a vibrating screen, a belt conveyor, a strong magnetic separation machine and a slag vertical mill. The steel slag grinding production system has the advantages of big yield, high grinding efficiency, low use cost and operation cost and obvious power saving effect, and the economic benefit is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

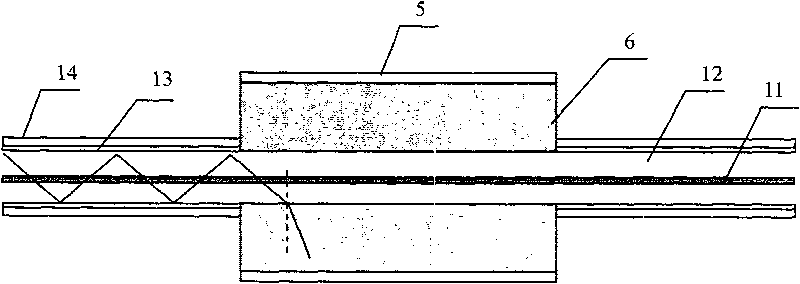

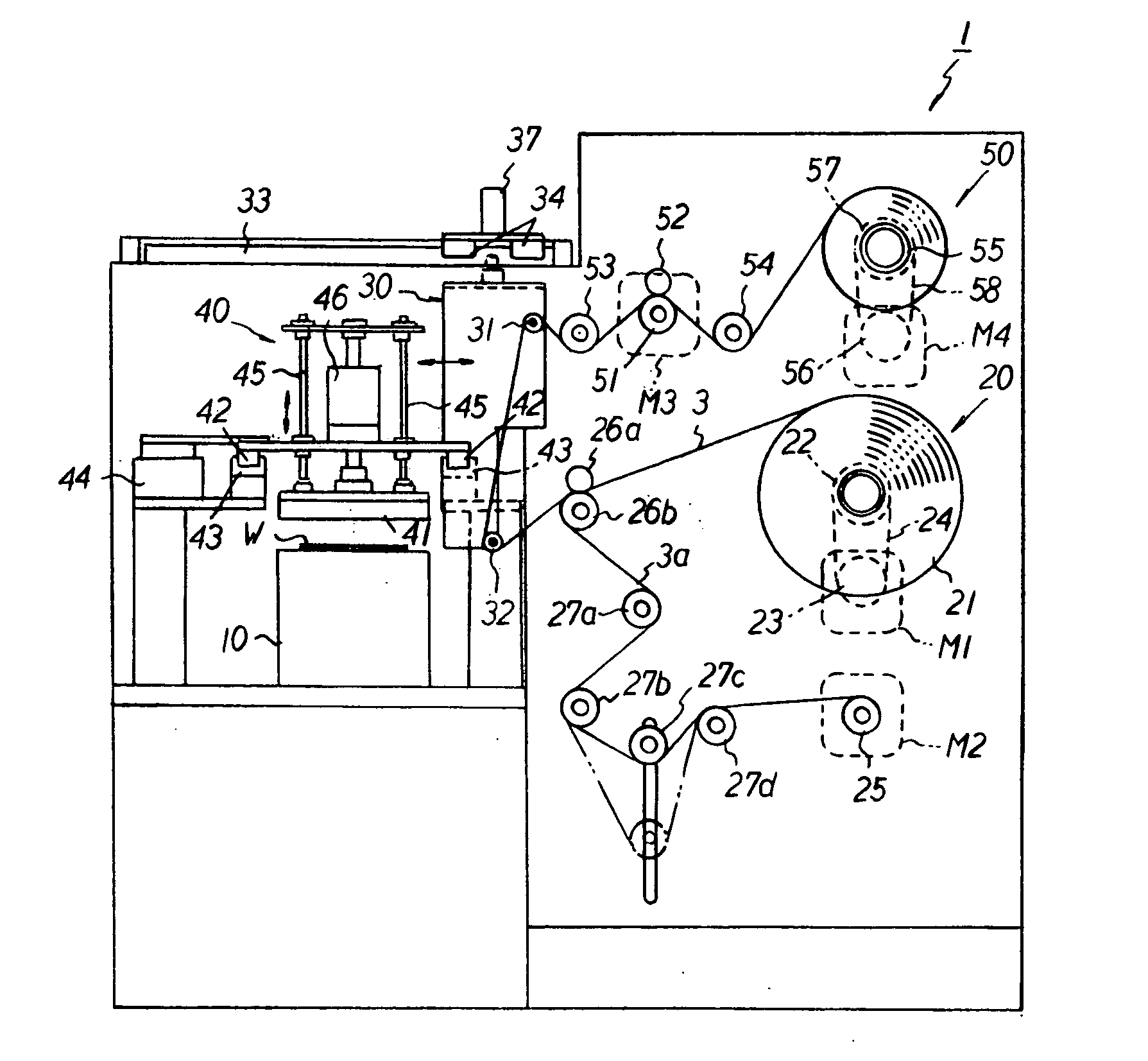

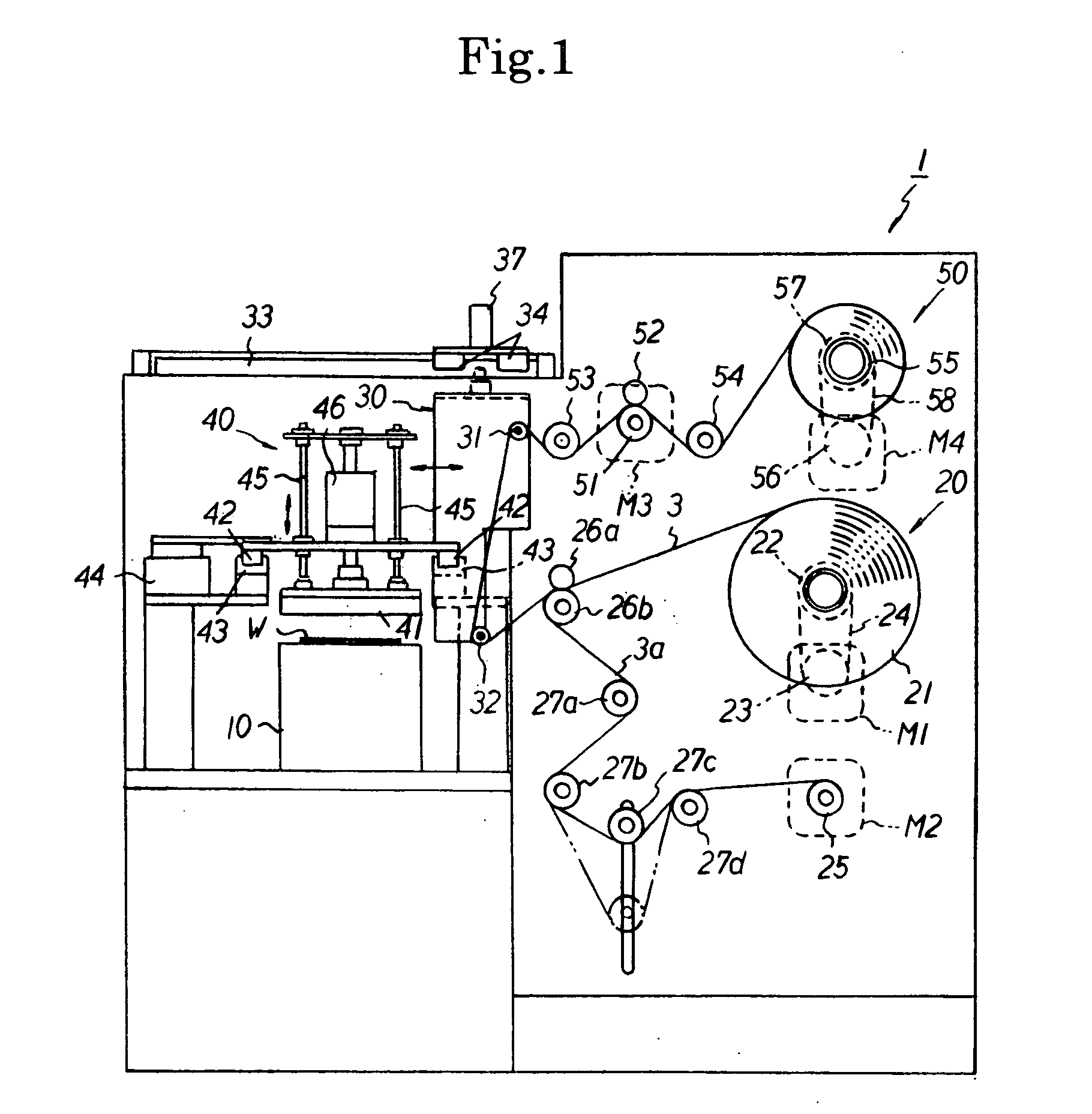

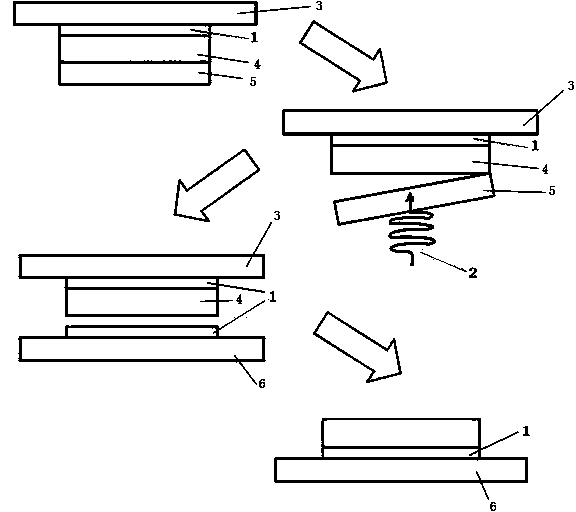

Apparatus for peeling adhesive tape

InactiveUS20070074822A1Easy to peelEfficient executionSolid-state devicesSemiconductor/solid-state device manufacturingAdhesive beltEngineering

An apparatus for peeling an adhesive tape is provided for enabling fragmented adhesive tapes to be readily and efficiently peeled from a plate-shaped member. The apparatus for peeling a surface protection tape (adhesive tape) 2a adhered on the surface of a wafer (plate-shaped member) W and fragmented into chip-size pieces from the wafer W comprises peeling tape supplying means 20 for feeding a peeling tape 3 to the wafer W set on a suction table 10; peeling tape adhering means for adhering the peeling tape 3 fed out by the peeling tape supplying means 20 over the entire surface of the surface protection tape 2a adhered on the surface of the wafer W; heating means for heating the peeling tape adhered over the entire surface of the adhesive tape by the peeling tape adhering means together with the adhesive tape; tape peeling means for peeling the adhesive tape sticking to the peeling tape through the heating by the heating means from the plate-shaped.

Owner:LINTEC CORP

Electrocondution slurry and preparation method and application of electrocondution slurry

InactiveCN103839605AAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Film-transferring printing method

InactiveCN101148127AEffective peelingEfficient transferDecorative surface effectsPattern printingEngineeringPrinting ink

The film transfer printing process includes the following steps: 1. painting polyethylene terephthalate (PET) film with strippable layer of silica and methyl hydrazone acetaldehyde and in pH 7-8, solid content of 45+ / -2 % and proper viscosity; 2. printing graphic context on the PET film with intaglio printing or flexible plate printing ink; 3. painting water soluble glue of vinyl acetate-ethylene emulsion and in pH 8-10, solid content of 52+ / -2 % and proper viscosity; and 4. compounding the PET film to paper material and stripping to transfer the printed graphic context onto the paper material. The present invention can strip and transfer the printed ink layer effectively to obtain printed matter with strong metal texture in less influence of the paper quality on the printed matter quality.

Owner:SHENZHEN JINJIA GRP

Temperature-responsive cell culture substrate on which a straight-chain temperature-responsive polymer is immobilized, and manufacturing method therefor

InactiveUS20120156781A1Effective trainingEffective peelingAnimal cellsCell culture supports/coatingTemperature responseCell culture media

Provided is a temperature-responsive cell culture substrate. A non-crosslinked temperature-responsive polymer having a molecular weight between 10,000 and 150,000 is immobilized on the substrate surface with a density of 0.02 to 0.3 molecular chain per square nanometer. Using the provided temperature-responsive cell culture substrate, cells obtained from various tissues can be efficiently cultured. This culturing method makes it possible to efficiently peel off a cell sheet by just changing the temperature, without causing damage.

Owner:TOKYO WOMENS MEDICAL UNIV

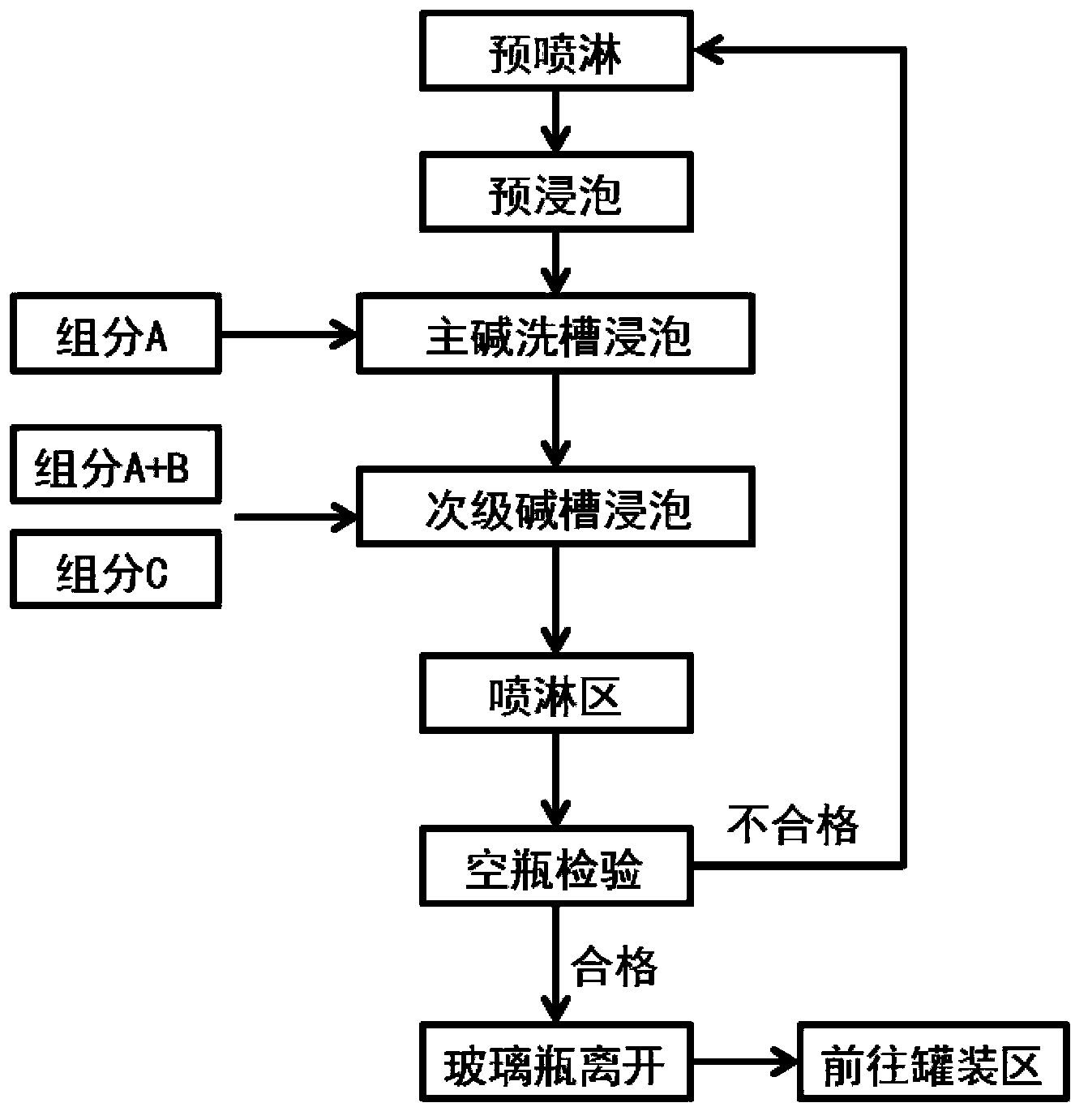

Passion fruit jam and preparation method thereof

InactiveCN105010918AEfficient peelingIncrease productivityFood ingredient as colourFood preparationBiotechnologyPreservative

The invention discloses a passion fruit jam and a preparation method thereof. The preparation method comprises the following steps: selecting and cleaning passion fruit; freezing; scalding; carrying out cold leaching to remove outer skin; soaking to keep freshness; separating and collecting; circularly pulping; and seasoning. Through physical methods of freezing, scalding and cold leaching, the outer skin which is relatively hard in surface texture and coarse and dry in taste is efficiently removed from the fresh passion fruit; the jam which is free of a preservative or other pigment additives, pleasant in sweetness and sourness and abundant in nutrient is prepared from middle skin, inner skin, pulp and juice of the passion fruit; the production method is simple; the production cost is relatively low; and the passion fruit jam is economical, environment-friendly and suitable for large-scale industrial production.

Owner:谭强

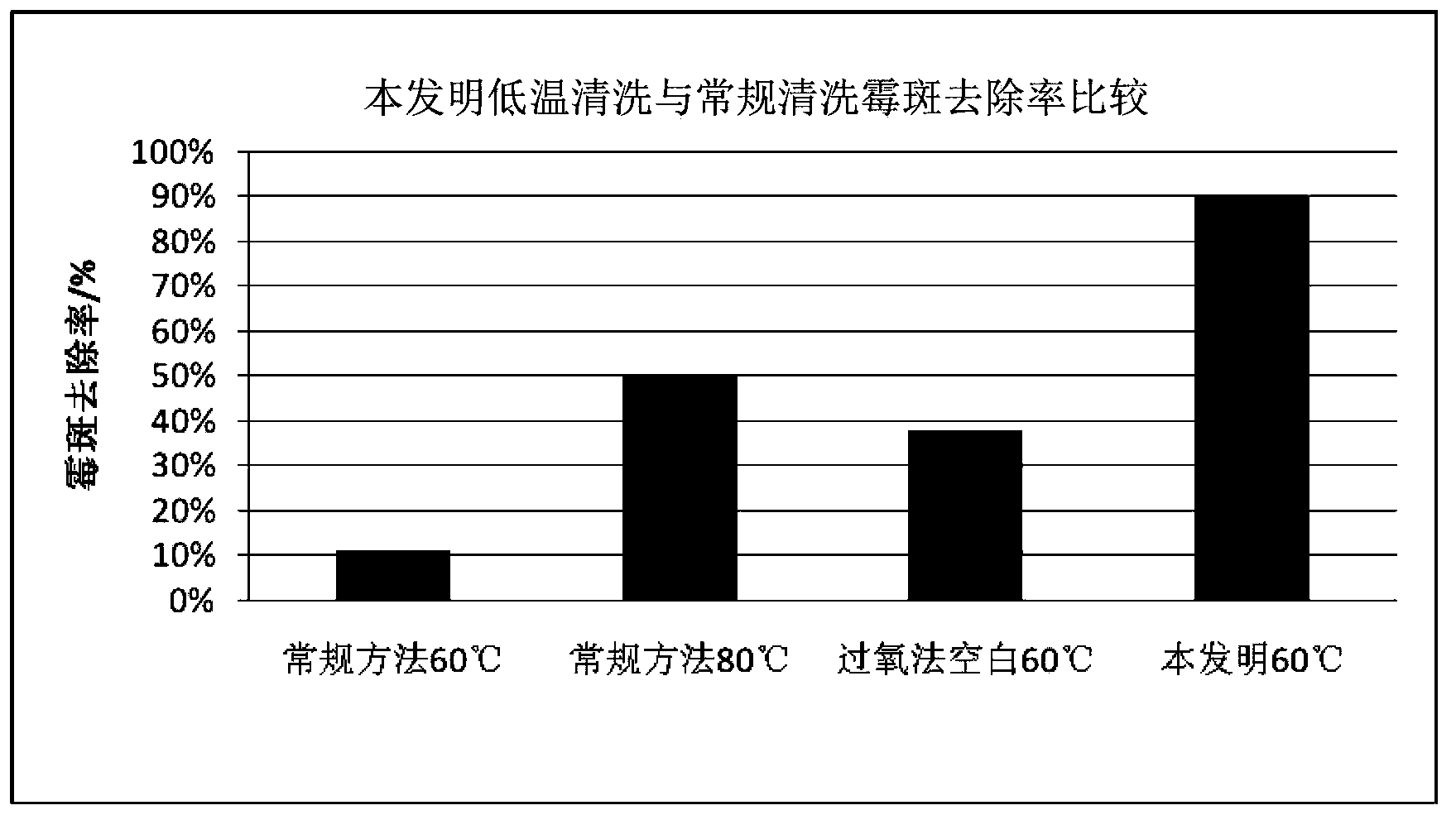

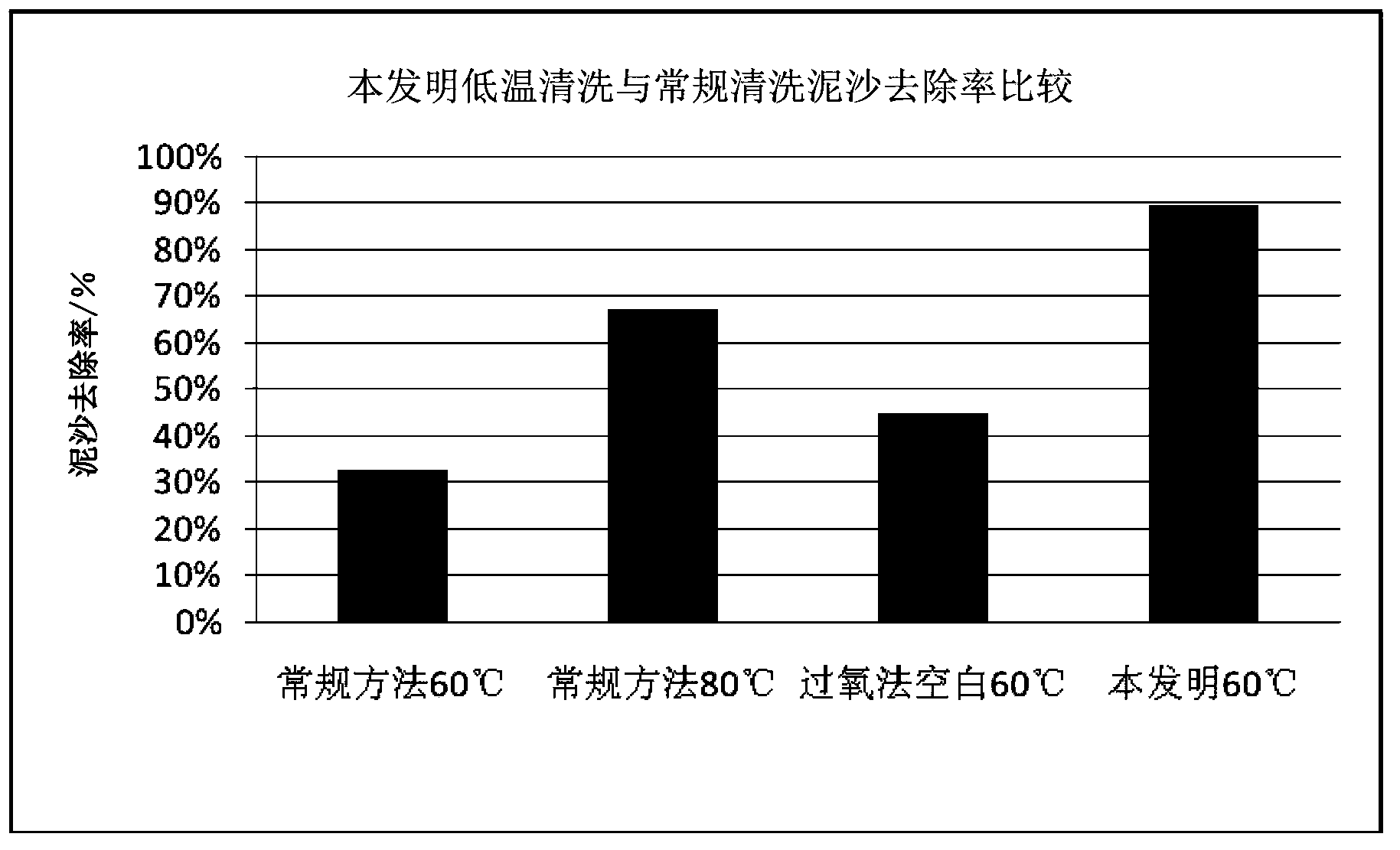

Cleaning additive and cleaning method adopting the cleaning additive

InactiveCN103849498AImprove solubilityLess corrosiveNon-ionic surface-active compoundsNon-surface-active detergent compositionsOrganic phosphorusBottle

The invention discloses a cleaning additive for glass bottles and a cleaning method of the glass bottles. The cleaning method and the cleaning additive are used for glass bottle cleaning by a primary alkaline bath and a secondary alkaline bath. The cleaning additive comprises a component A, a component B and a component C, wherein the component A comprises an organic phosphorus chelating agent, the component B comprises peroxide, the component C comprises a defoaming agent, the component A is added into the primary alkaline bath, the component B is selectively added into the primary alkaline bath, the component A and the component B are added into the secondary alkaline bath, and the component C is selectively added into the primary alkaline bath or the secondary alkaline bath. Based on the weight of alkaline solution in the primary alkaline bath or the secondary alkaline bath where the component is added, the adding amount of the component A is 0.05-5%, the adding amount of the component B is 0.1-0.5%, and the adding amount of the component C is 0-0.5%. The alkaline solution in the primary alkaline bath and the secondary alkaline bath is sodium hydroxide solution having a concentration of 1.5-3%. The cleaning additive and the cleaning method can achieve stable and good cleaning effects at a relatively low temperature that is usually 50-70 DEG C.

Owner:ECOLAB USA INC

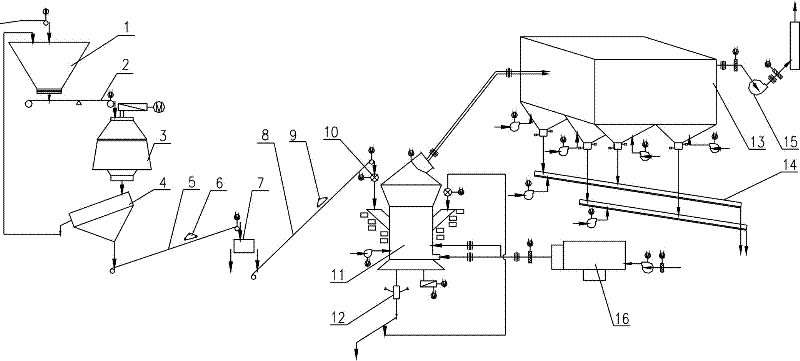

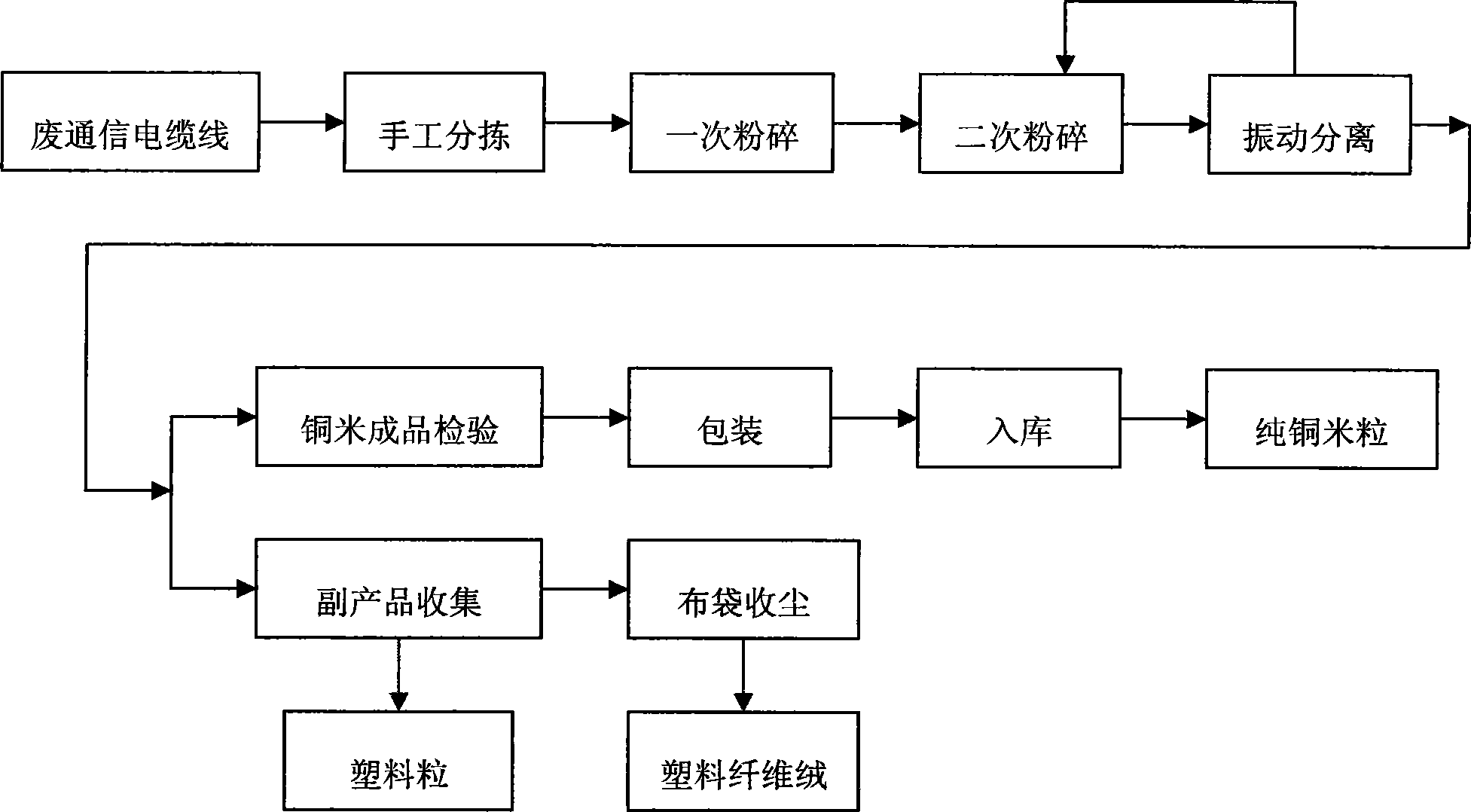

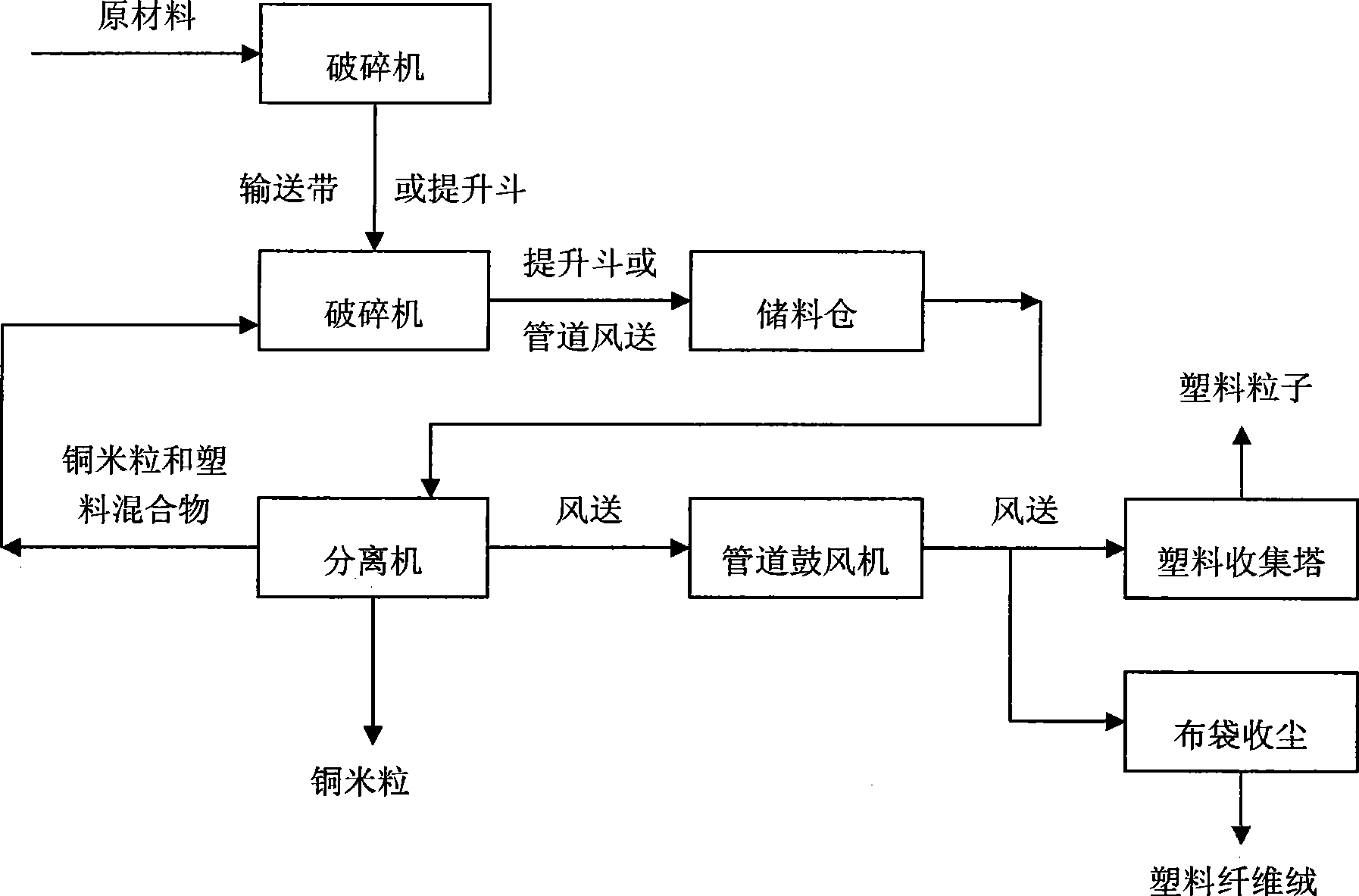

Process for recycling and manufacturing copper granule from waste and old electric wire and cable

InactiveCN101367084ALow costReduce energy consumptionSievingSolid waste disposalEngineeringMixed materials

The invention discloses a technological method for producing copper rice grains by recovering waste wires and cables based on an improvement of the prior production mode that the waste wires and cables recover copper raw materials. The technological method has low cost, small energy consumption, less discharge and no waste pollution, meets the requirement of circular economy development, and can obtain a copper rice grain product the purity of which reaches 99.9 percent. The technological process comprises the steps of classification inspection, loading, primary crushing, secondary crushing, and vibration separation; the angle of a vibration sieve is adjusted according to the content of copper and the wire diameter, and the copper rice grains and plastic are subjected to optional separation through vibration sieving; a material from a mixed material port flows into an air suction pipe, and is sent for secondary crushing through a circulating air pipe; the air suction pipe above the vibration sieve sucks plastic fibers and other dust in the space of the vibration sieve to a dust collector for treatment; the qualified copper rice grains obtained at a copper outlet flow into a packing bag; and the finished product inspection is performed, namely the obtained copper rice grains enter a warehouse through the inspection.

Owner:南京东南铜业有限公司

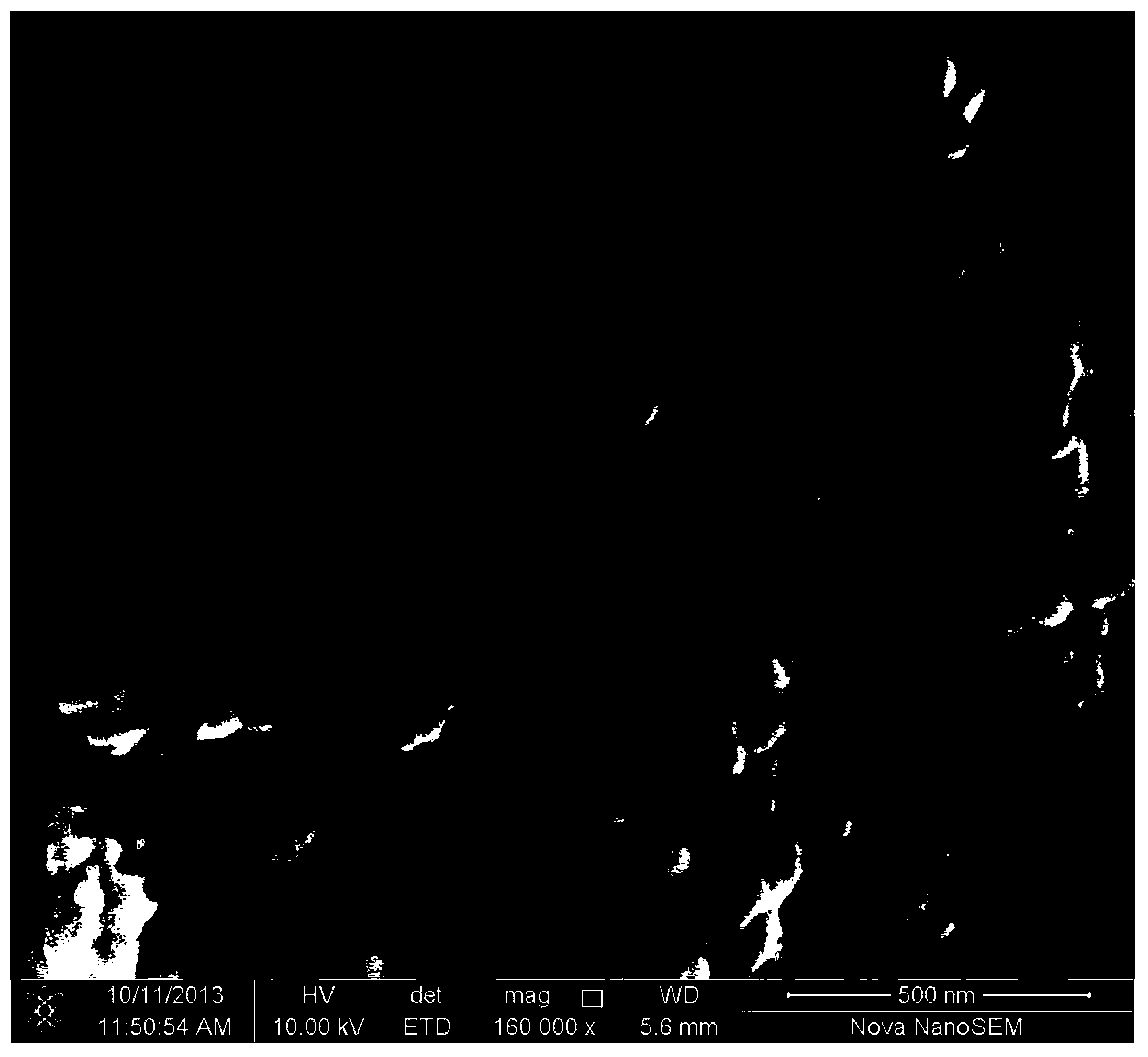

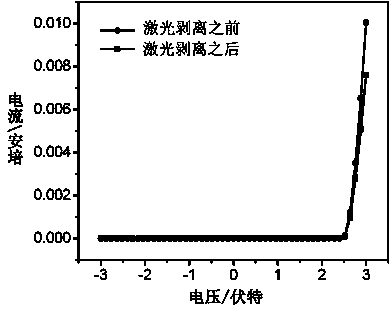

Laser lift-off method for flexible electronic application of sapphire substrate of gallium nitride LED

The invention discloses a laser lift-off method for flexible electronic application of a sapphire substrate of a gallium nitride LED. According to the laser lift-off method, lasers with high power and very short action time are emitted, and sufficient heat is generated in an interface area, so that gallium nitride is decomposed into metal gallium and nitrogen; besides, due to the fact that the action time of the lasers is very short, the heat is concentrated, only the gallium nitride which is hundreds of nanometers thick nearby an interface is decomposed, and a core area of the gallium nitride LED cannot be damaged; after being irradiated, the interface area only has one layer of the metal gallium left after decomposition of the gallium nitride, and the metal gallium enables the sapphire substrate to be connected with the gallium nitride; heating is conducted so that the gallium nitride and the sapphire substrate can be separated; a diluted hydrochloric acid solution is used for removing the residual metal gallium on the gallium nitride after separation. Compared with the prior art, the sapphire substrate of a whole LED array can be lifted off and transferred effectively without change by means of the simple and rapid laser lift-off method.

Owner:WUXI JINGKAI TECH

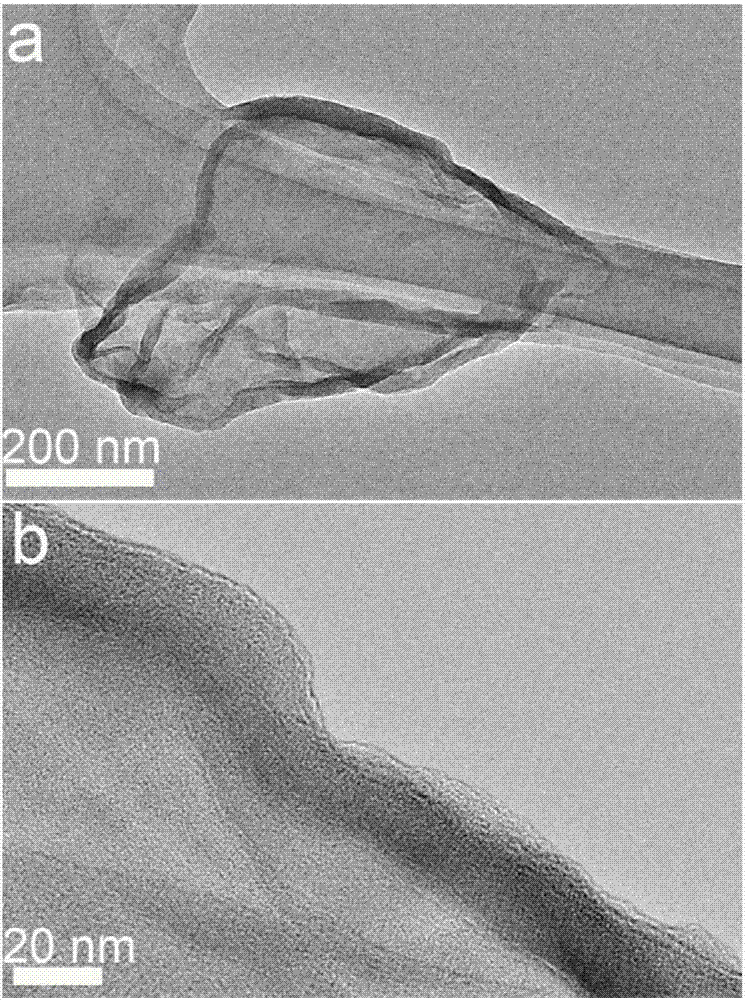

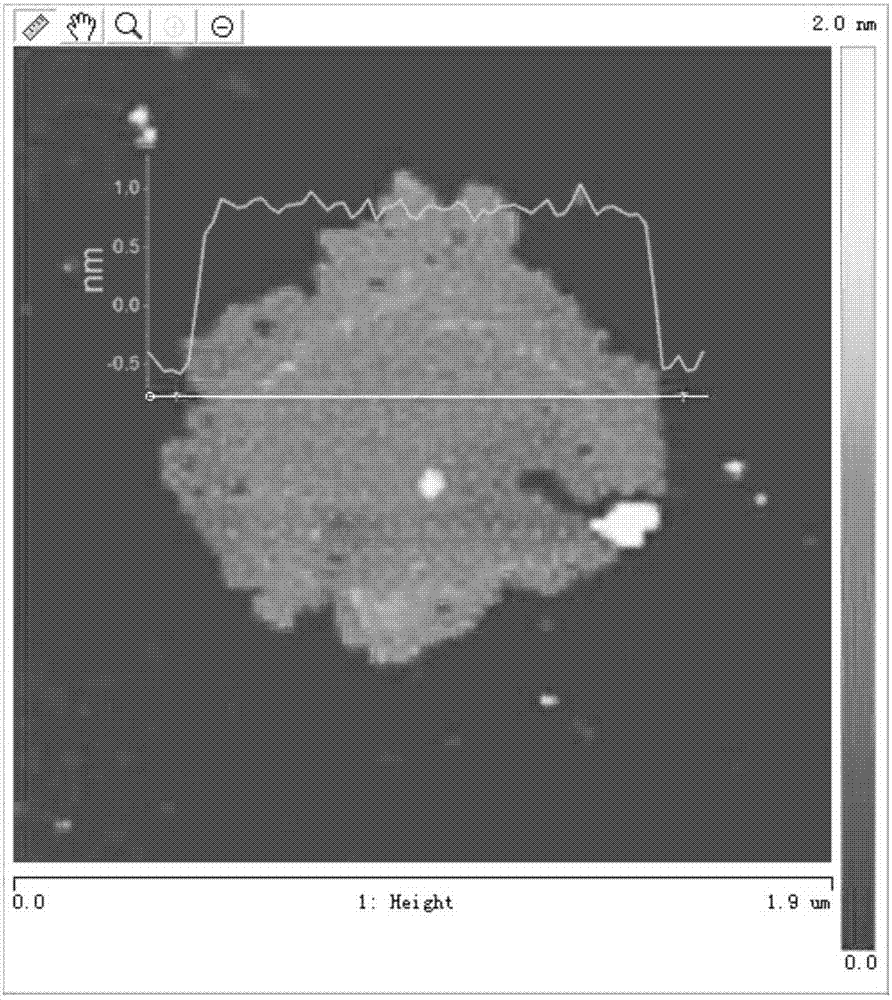

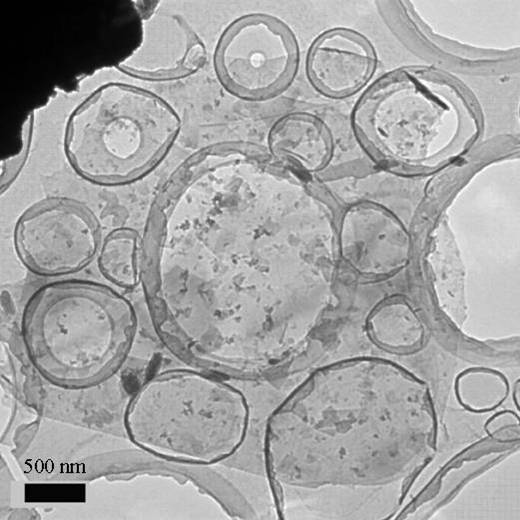

Hydrophilic boron nitride nanosheet and preparation method and application thereof

InactiveCN107337185AReduce pollutionEffective dispersionMaterial nanotechnologyNitrogen compoundsAlkali ionsWater dispersible

The invention belongs to the technical field of nanomaterials, and discloses a hydrophilic boron nitride nanosheet and a preparation method and application thereof. The preparation method specifically comprises the following steps that firstly, hexagonal boron nitride powder is dispersed in an alcohol solvent, and a certain quantity of alkali saturated aqueous solution is added; secondly, the alcohol dispersion solution of the boron nitride powder is put into a reaction kettle to be sealed, and reacts for a period of time under a high-temperature closed condition; thirdly, after the product is cooled to the room temperature, the product is washed with deionized water to be neutral after vacuum suction filtration, and freeze drying is conducted to obtain alkali ion intercalated boron nitride compound powder; fourthly, the composite powder is re-dispersed in deionized water, ultrasonic treatment is conducted for 10 minutes, and an aqueous dispersion solution of the boron nitride nanosheet can be obtained after dialysis and purification. The preparation method is simple in process, easy to operate, low in cost and environmentally friendly, the yield of the obtained boron nitride nanosheet is high, and the boron nitride nanosheet has good water dispersibility and stability. The hydrophilic boron nitride nanosheet has potential application prospects in the fields of drug carriers, biological sensing and the like.

Owner:SOUTH CHINA AGRI UNIV

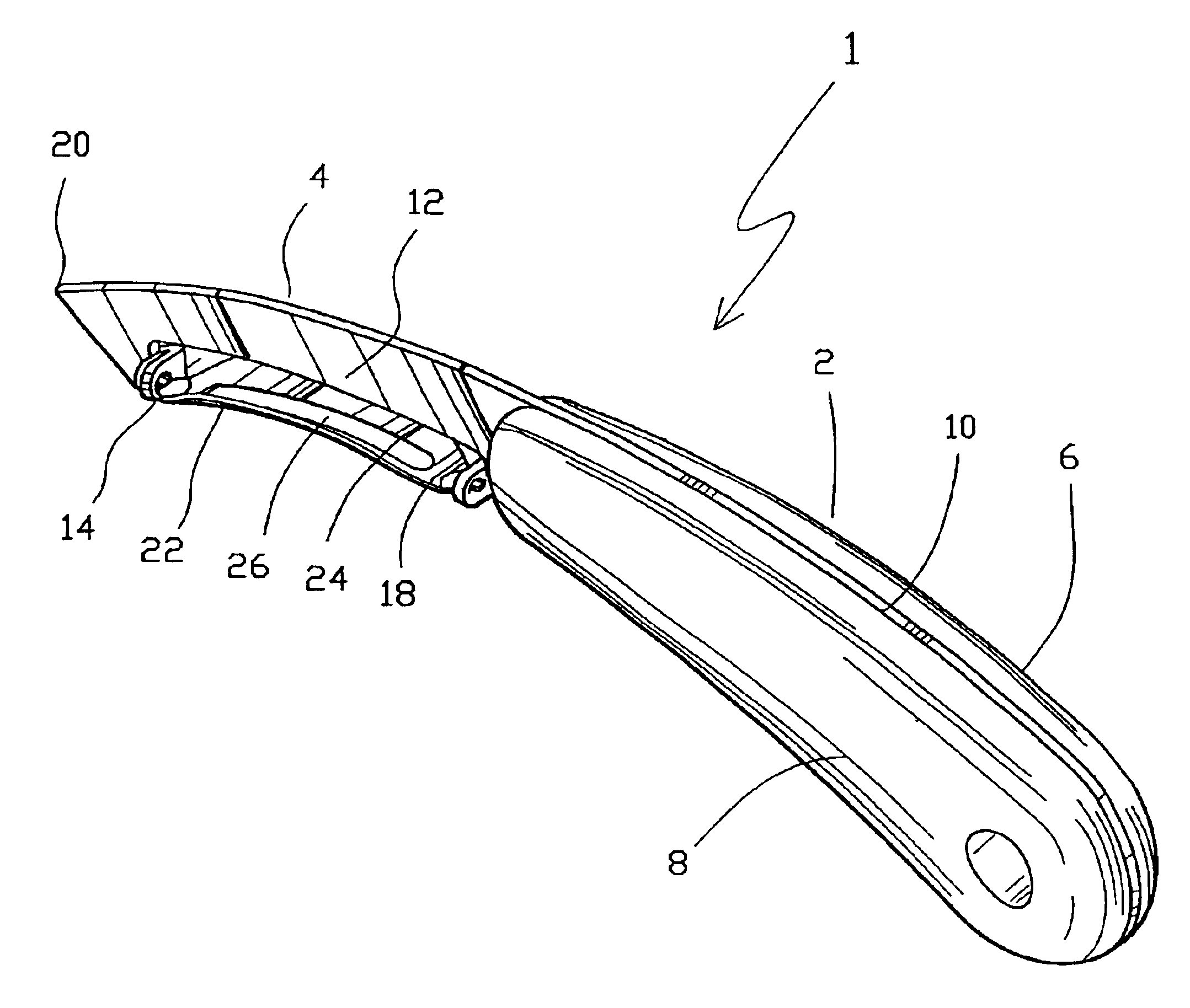

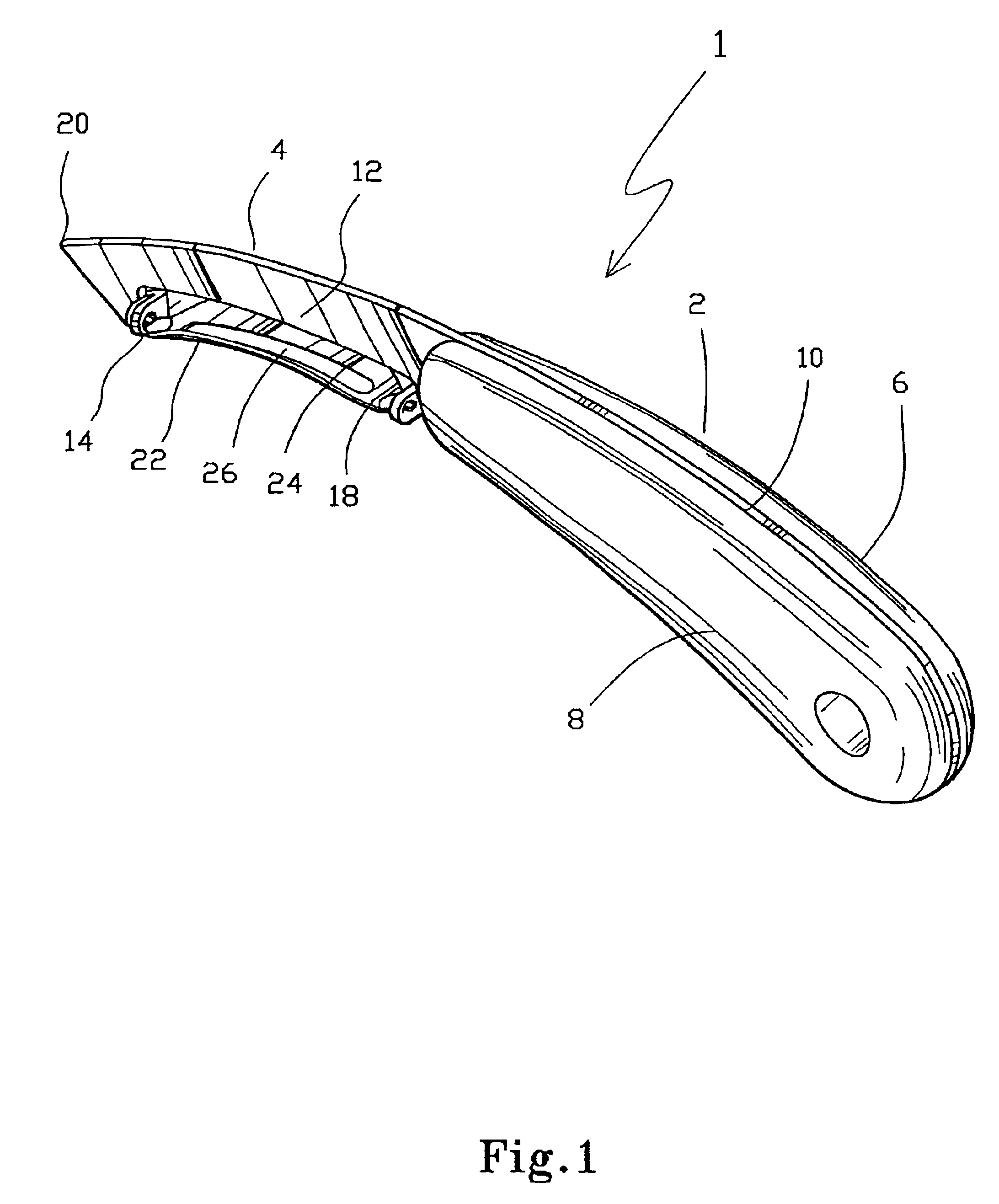

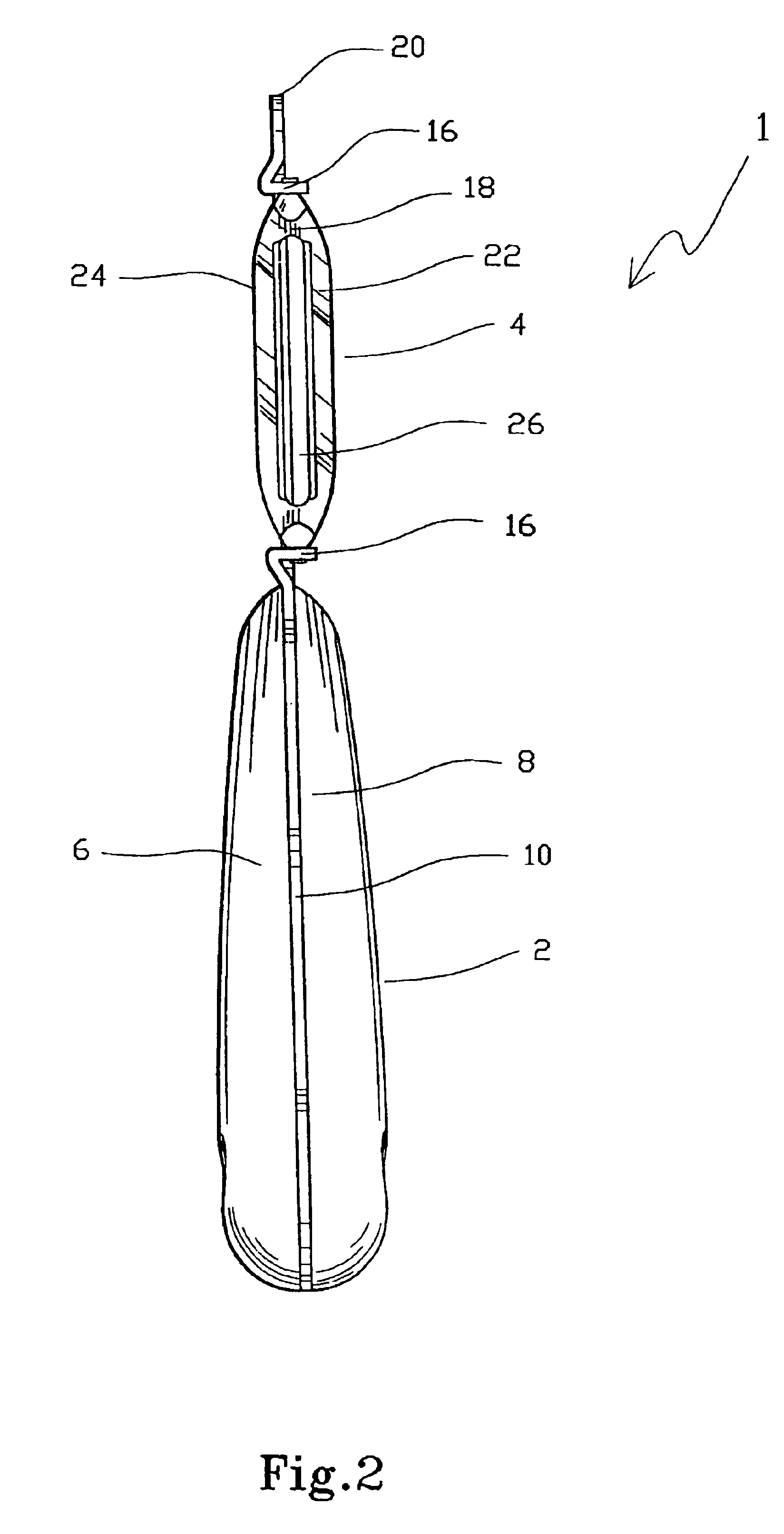

Culinary peeler

InactiveUS6874236B2Effective peelingEasy and fast processingVegetable peelingHand equipmentsKnife bladesBiomedical engineering

A culinary peeler having an elongate blade bent or curved in its lateral dimension having at least one longitudinal opening extending along its length with a sharp cutting region adjacent the opening, wherein the blade is of curved form in its longitudinal direction.

Owner:MAXPAT TRADING & MARKETING FAR EAST LTD

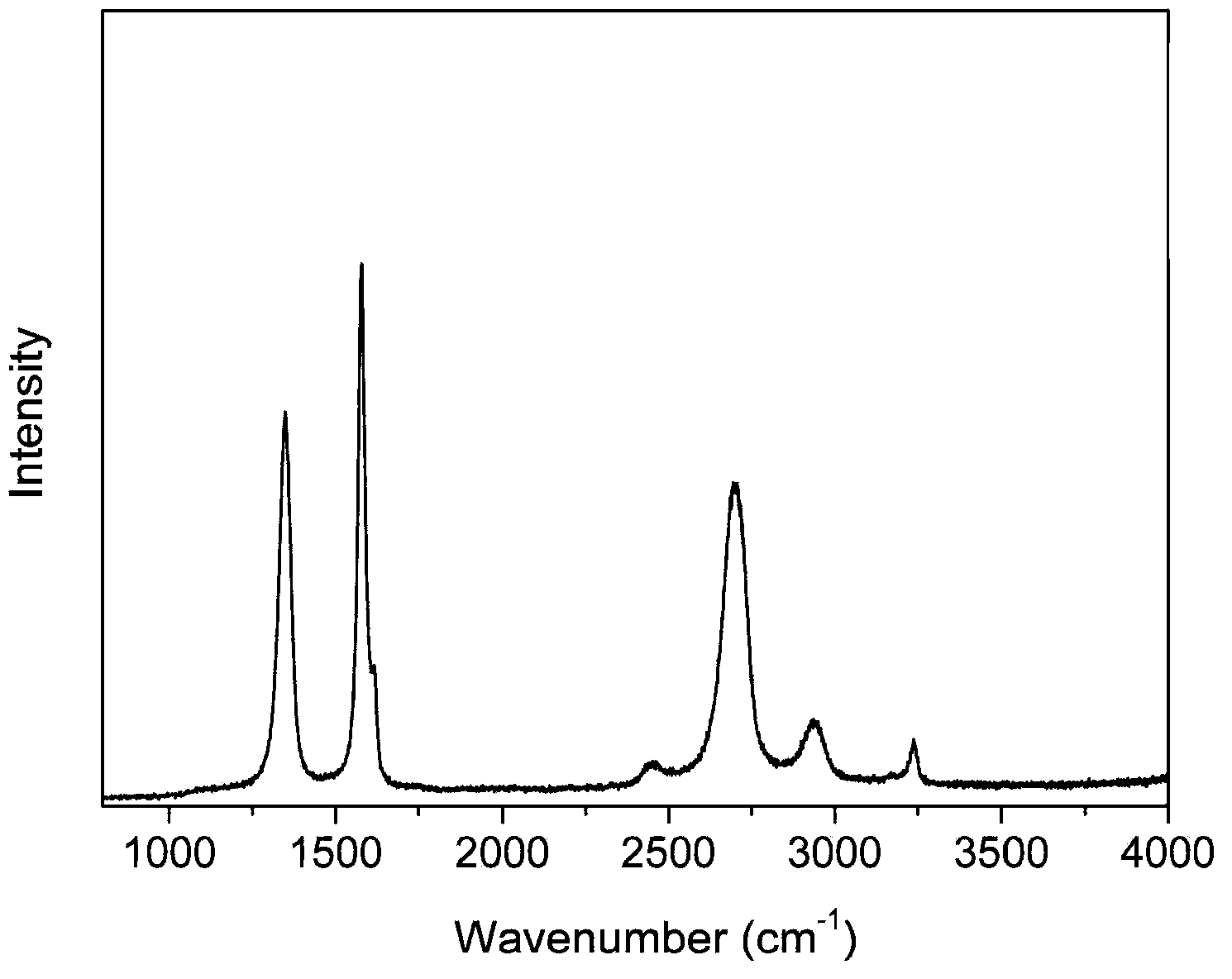

Method for preparing graphene solution based on supercritical carbon dioxide and pyrenyl polymers

InactiveCN102502607AEffective peelingImprove diffusion abilityGrapheneBulk chemical productionHigh concentrationDefective graphene

The invention belongs to the technical field of graphene preparation, and discloses a method for preparing graphene solution based on supercritical carbon dioxide and pyrenyl polymers. Graphites of 10 to 20 mg and the pyrenyl polymers of 15.4 to 30.8 mg are dispersed in dimethyl sulfoxide of 5 to 10 ml; then obtained suspending liquid containing the graphites and the pyrenyl polymers is put in a supercritical carbon dioxide reaction device, is stirred and reacts for 3 to 6 hours under the temperature ranging from 40 to 45 DEG C and the pressure ranging from 12 to 16 MPa, and then is processedthrough pressure relief; obtained liquid reactant is separated to remove supernatant; sediments are repeatedly washed through solvent so as to remove unreacted pyrenyl polymers, and then are dispersed in the same type of solvent renewedly; and finally, the graphites that are not exfoliated are removed, and then graphene solution is obtained. The method solves the problem that high-concentration uniform graphene solution is difficult to prepare at present, can achieve the high-yield and high-quality preparation and the functionalization of graphene in one step, can enable the output of non-defective graphene layers to be high to 51.8 wt percent, and is a simple and effective method for preparing graphene solution.

Owner:ZHENGZHOU UNIV

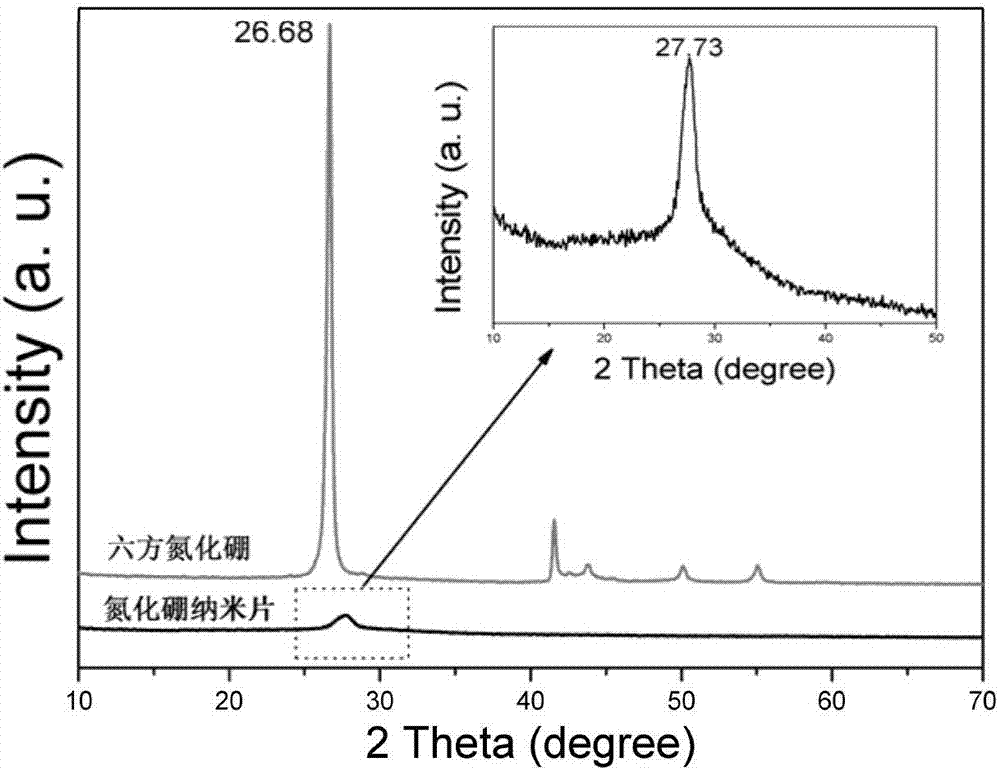

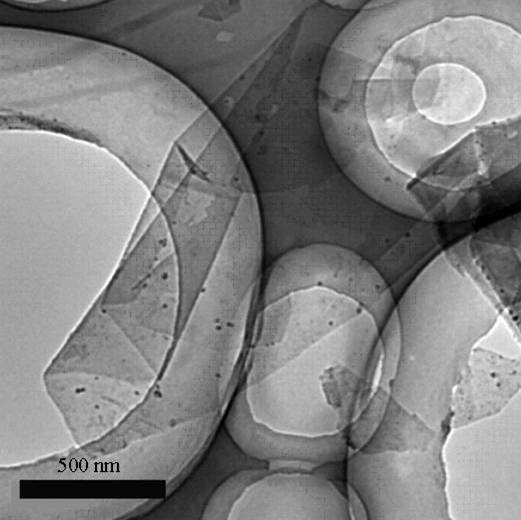

Method for large-scale preparation of graphene and two-dimensional boron nitride crystal materials

ActiveCN103570003AComplete structureHigh purityNitrogen compoundsGrapheneHexagonal boron nitrideFiltration

The invention relates to a method for large-scale preparation of graphene and two-dimensional boron nitride crystal materials. The method is characterized in that in the presence of NH3BH3 as a ball milling assistant, a solid mixture having a mass ratio of an inorganic layered material to NH3BH3 of 1: 0.5-5 is subjected to ball milling treatment by a mechanical ball milling technology so that high-efficiency peeling on the inorganic layered material such as graphite and hexagonal boron nitride is realized; and the products are washed and filtered for NH3BH3 removal and the filtration products are dried so that the single-layer or multiple-layer graphene and two-dimensional boron nitride crystal materials are obtained. The graphene and two-dimensional boron nitride crystal materials have high purity and complete structures. The method has the advantages of easy acquisition of raw materials, operation simpleness, safety and low cost and is suitable for large-scale preparation of the graphene and two-dimensional boron nitride crystal materials.

Owner:中科榆林能源技术运营有限责任公司

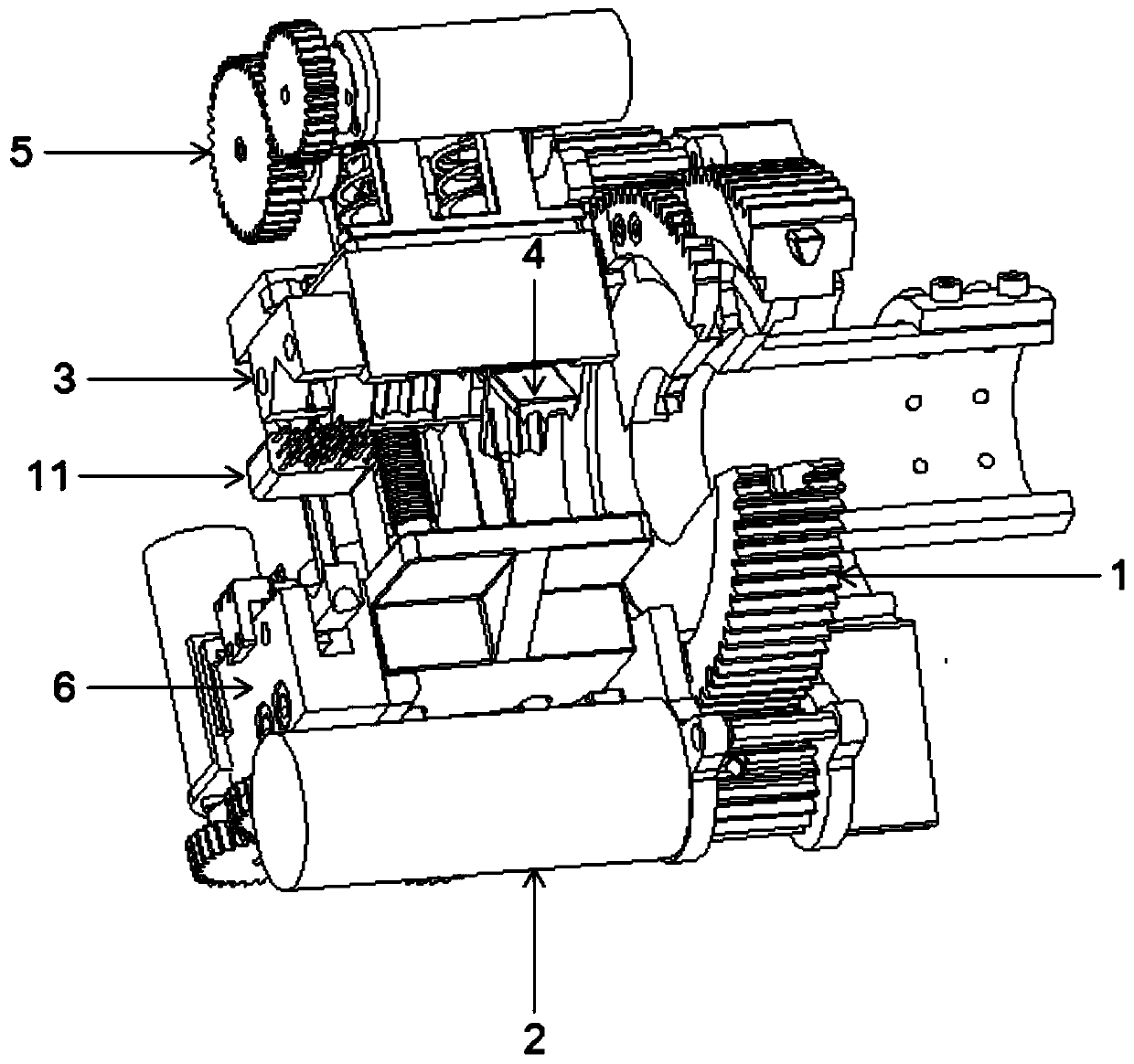

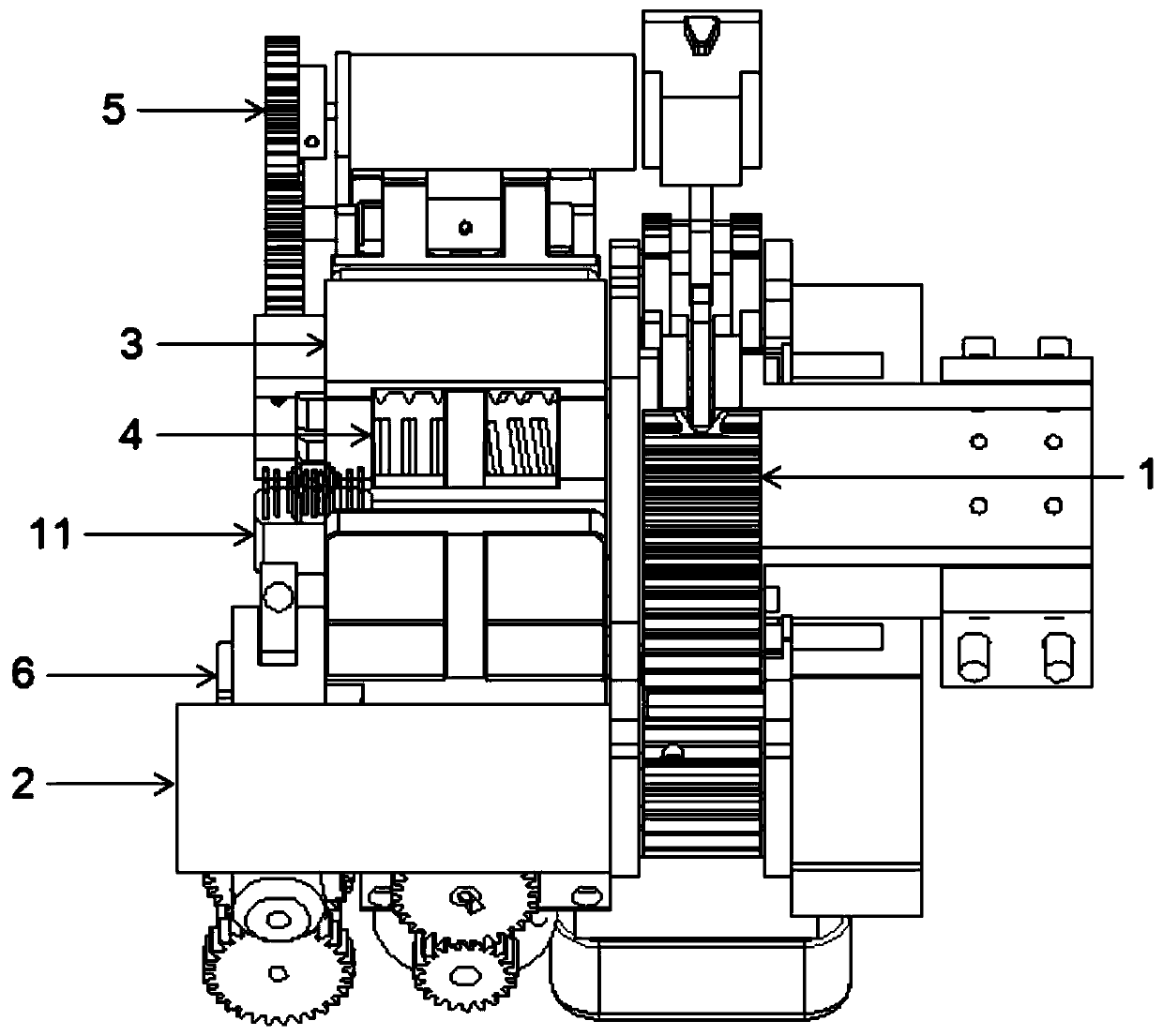

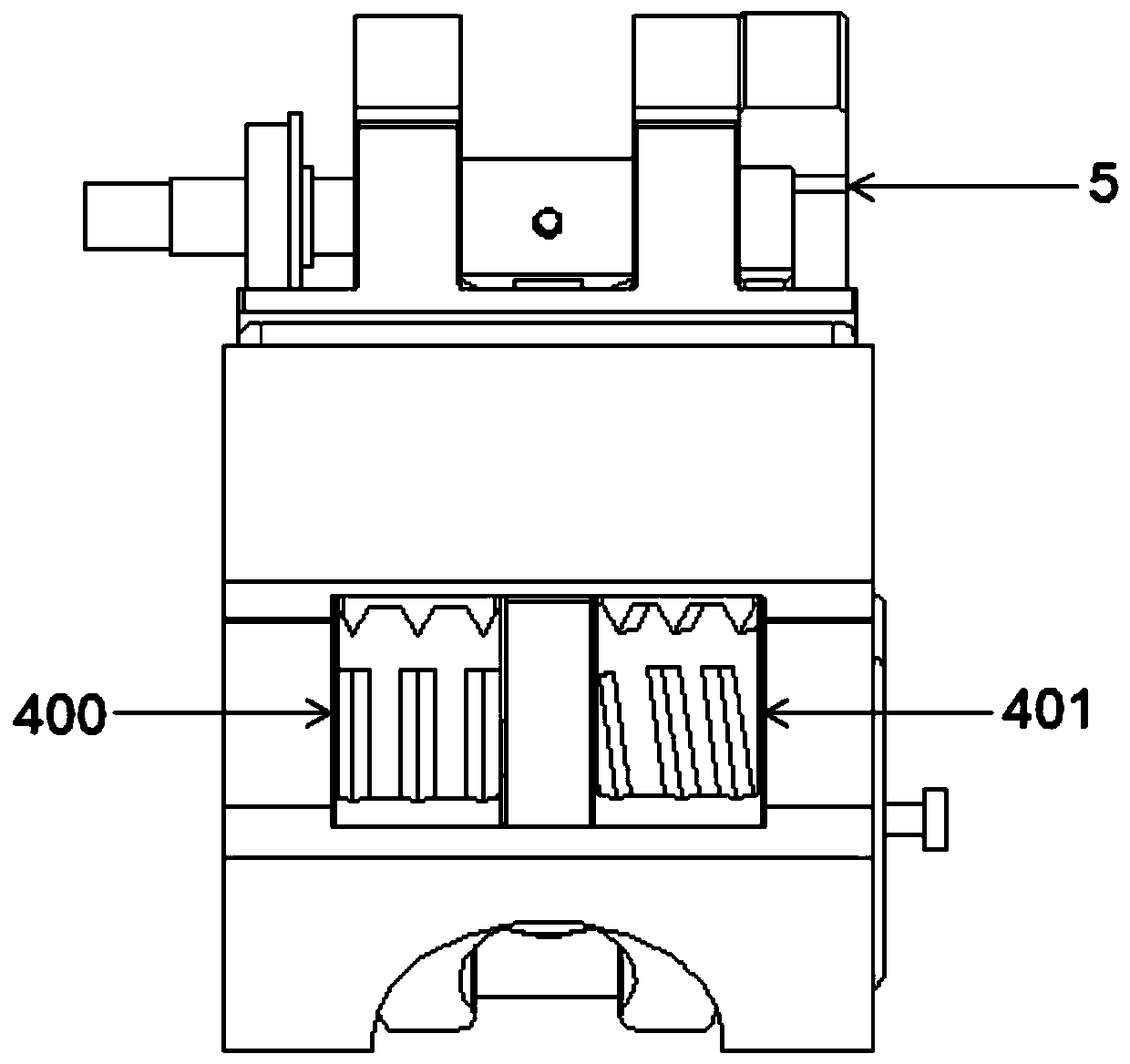

Wire stripping device and wire stripping system

ActiveCN110729672APeeling safetyQuick peelApparatus for removing/armouring cablesElectronic waste recyclingEngineeringMechanical engineering

The invention belongs to the field of electric power operation and discloses a wire stripping device. The wire stripping device comprises a fixed part (1), a rotating part (2), a clamping part (3), and a cutting part (6); the rotating part (2) rotates relative to the fixed part (1); the clamping part (3) is used for clamping a wire; the clamping part (3) is fixedly connected with the rotating part (2); and the clamping part (3) is provided with clamping blocks (4) and a clamping block adjusting mechanism (5) used for changing the states of the clamping blocks (4); and the clamping part (3) isfixedly connected with the rotating part (2) and the cutting part (6) and is used for cutting the insulating layer of the wire. The wire stripping device is provided with the fixed part, the rotatingpart rotating relative to the fixed part, the clamping part connected with the rotating part and the cutting part; the wire stripping device clamps the wire through the clamping part and drives the cutting part through the rotating part so as to strip the wire; and therefore, manual operation is not needed, and safe, rapid and efficient stripping can be achieved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

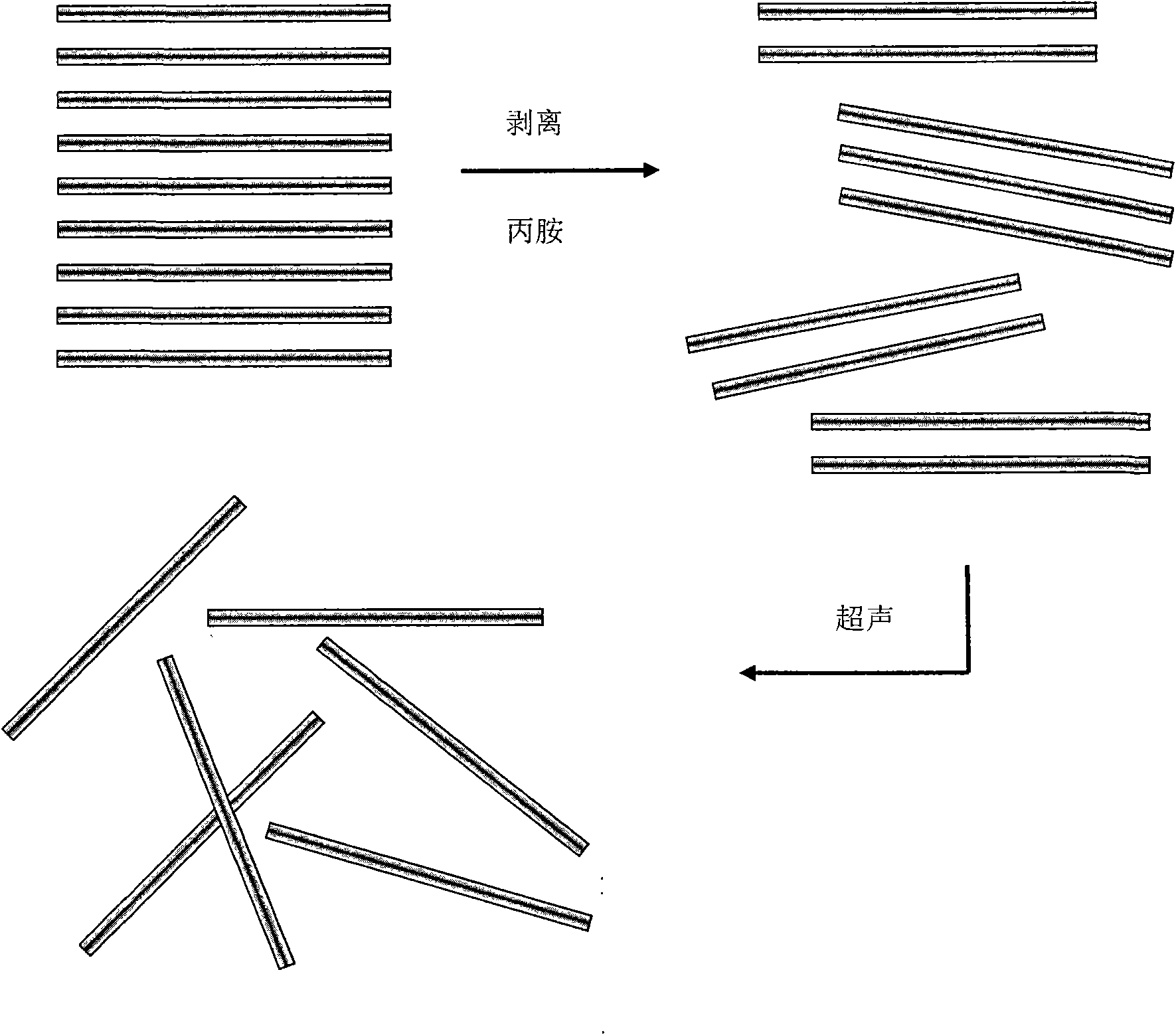

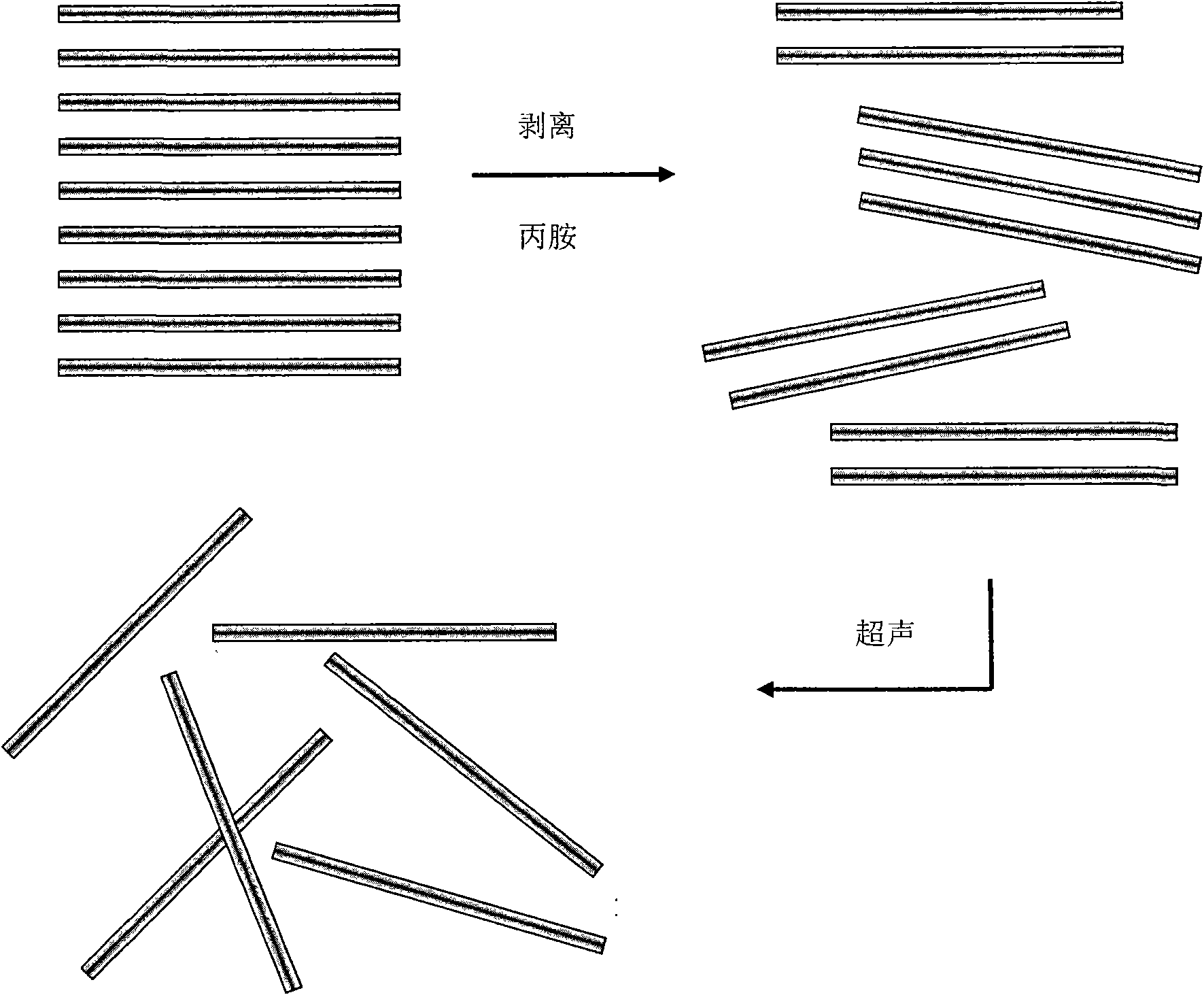

Method for efficiently-stripped laminar inorganic material

InactiveCN101898766AThin layer thicknessImprove stripping efficiencyOxygen/ozone/oxide/hydroxideSilicon compoundsInorganic materialsMaterials science

The invention relates to a method for efficiently-stripped laminar inorganic material. The method comprises the following steps of: firstly, stripping the laminar inorganic material by using organic micro-molecules; and secondly, completely stripping the stripped laminar inorganic material under the ultrasonic wave condition. The method can ensure that the laminar inorganic material is completely stripped and also can keep a good crystal structure of the laminar inorganic material, so that the use of the laminar inorganic material is radically improved and the value of the laminar inorganic material is multiplied.

Owner:BEIJING UNIV OF CHEM TECH

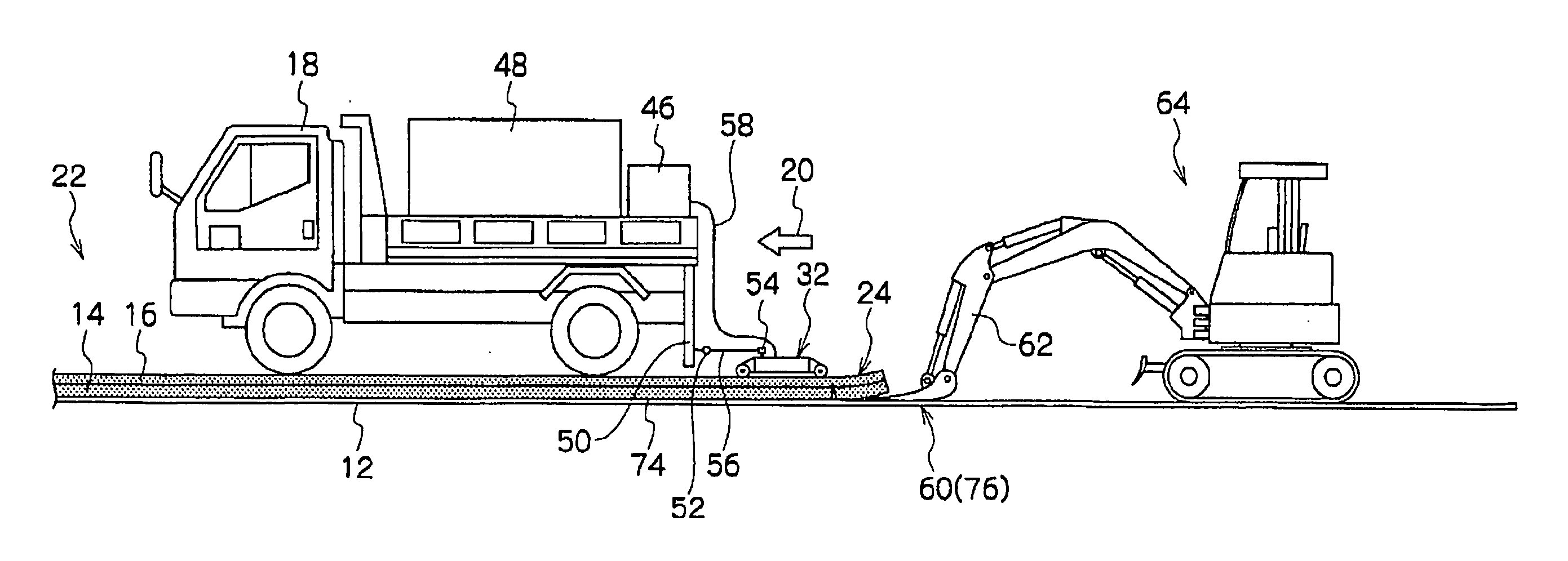

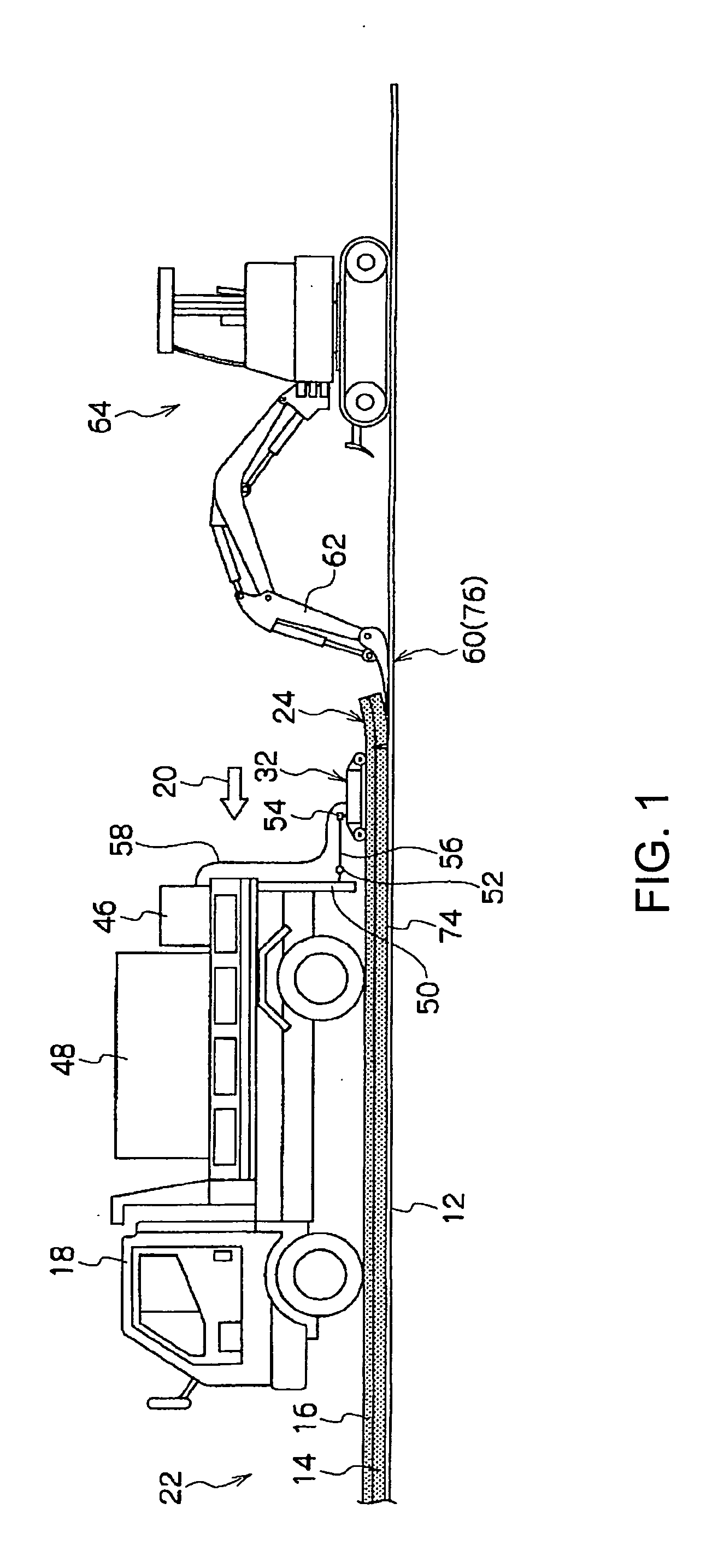

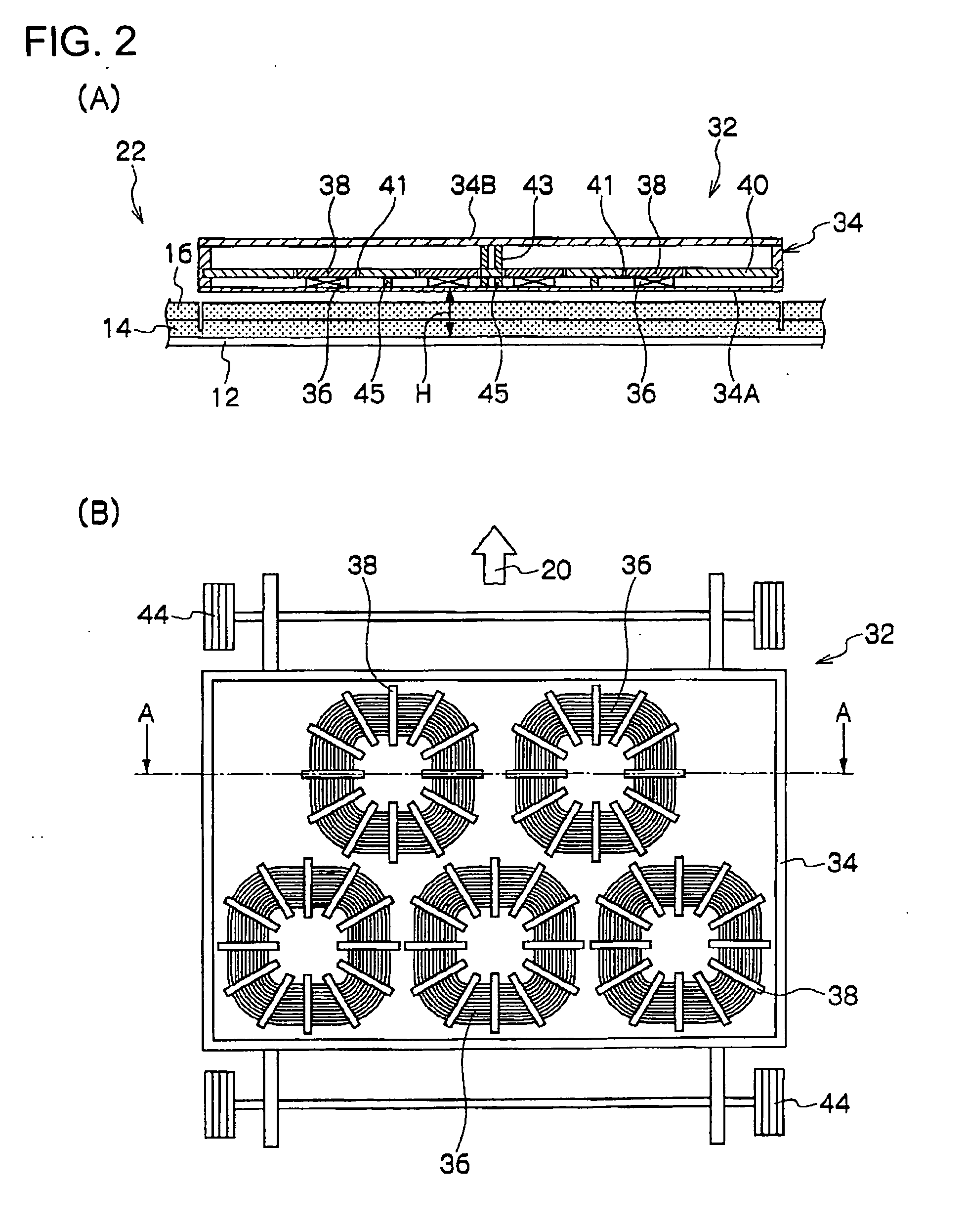

Method for Removing Asphalt Pavement, System for Removing Asphalt Pavement, Electromagnetic Induction Coil Unit, Apparatus for Removing Asphalt Pavement, and Method for Peeling off Asphalt Pavement

ActiveUS20090297268A1Big vibrationEffective peelingIn situ pavingsCoil arrangementsRoad surfaceCopper

It is intended to allow an asphalt pavement to be peeled off efficiently with a relatively small amount of electric power without generating large vibration and noise, and handled in the form of a block. An electromagnetic induction coil 36 is positioned above an asphalt pavement 22 provided on a copper plate (12) to melt a lower surface of the asphalt pavement 22. Then, a wedge-shaped thermally-conductive peeling member 60 having a peeling layer formed on an upper surface thereof is inserted into a melted layer (74) of the lower surface of the asphalt pavement 22 to peel off the asphalt pavement 22 from the steel plate 12. This makes it possible to peel off the asphalt pavement 22 with a relatively small amount of electric power and handle the peeled asphalt pavement 22 in the form of a block.

Owner:GREEN ARM

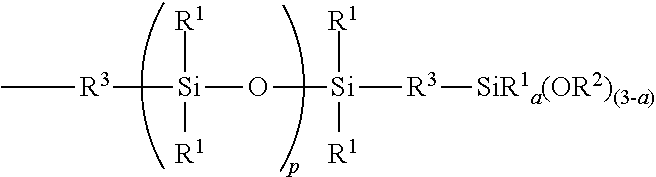

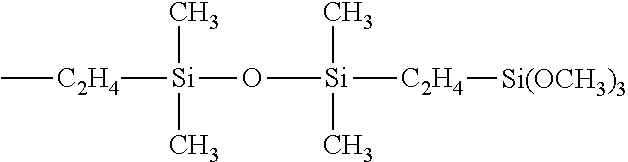

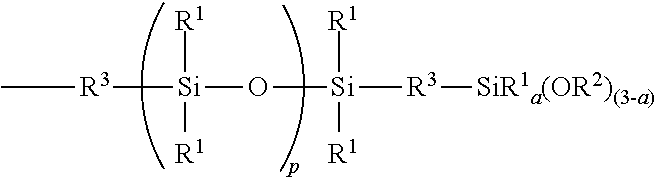

Room-temperature-curable silicone rubber composition, the use thereof, and method for repairing electronic device

ActiveUS20170037287A1Good adhesionGood releasabilityOther chemical processesChemical recyclingCondensation reactionRoom temperature

A room-temperature-curable silicone rubber composition which exhibits good adhesion to a substrate contacted during curing and which forms a silicone rubber cured product that can be efficiently peeled is disclosed. The room-temperature-curable silicone rubber composition comprises: (A) an organopolysiloxane having in each molecule at least two specified alkoxysilyl-containing groups on silicon atoms in the molecular chain, (B) a diorganodialkoxysilane or partially hydrolyzed condensate thereof, and (C) a condensation-reaction catalyst.

Owner:DOW TORAY CO LTD

Mango and passion fruit jam and preparation method thereof

InactiveCN105166614AStomachicAnti-inflammatory and pain-relievingFood preparationBiotechnologyPassion fruit

The invention discloses mango and passion fruit jam and a preparation method thereof. The jam comprises raw materials as follows: 10 parts of mango pulp by weight, 1-100 parts of peeled passion fruits by weight, 4-110 parts of a sweetening agent by weight and 0.5-10 parts of an acidulant by weight. The preparation method of the jam comprises steps as follows: (1) mangoes are selected, peeled and subjected to color protection for use; (2) passion fruits are selected, washed, frozen, unfrozen, peeled and soaked for preservation; (3) the mangoes are pulped or diced, the passion fruits are pulped and homogenized for use, mango pulp or dices are added to passion fruit pulp, and boiling concentration, seasoning, sterile canning, degassing and cold storage are performed. Peels of the passion fruits are effectively removed with a simple physical method of freezing and thawing. The jam which contains no additive and is sour, sweet, delicious and rich in nutrition is prepared from the mango pulp or dices as well as remaining peels, pulp and juice of the passion fruits; the production method is simple, economical, environment-friendly, suitable for mass industrial production and lower in production cost.

Owner:谭强

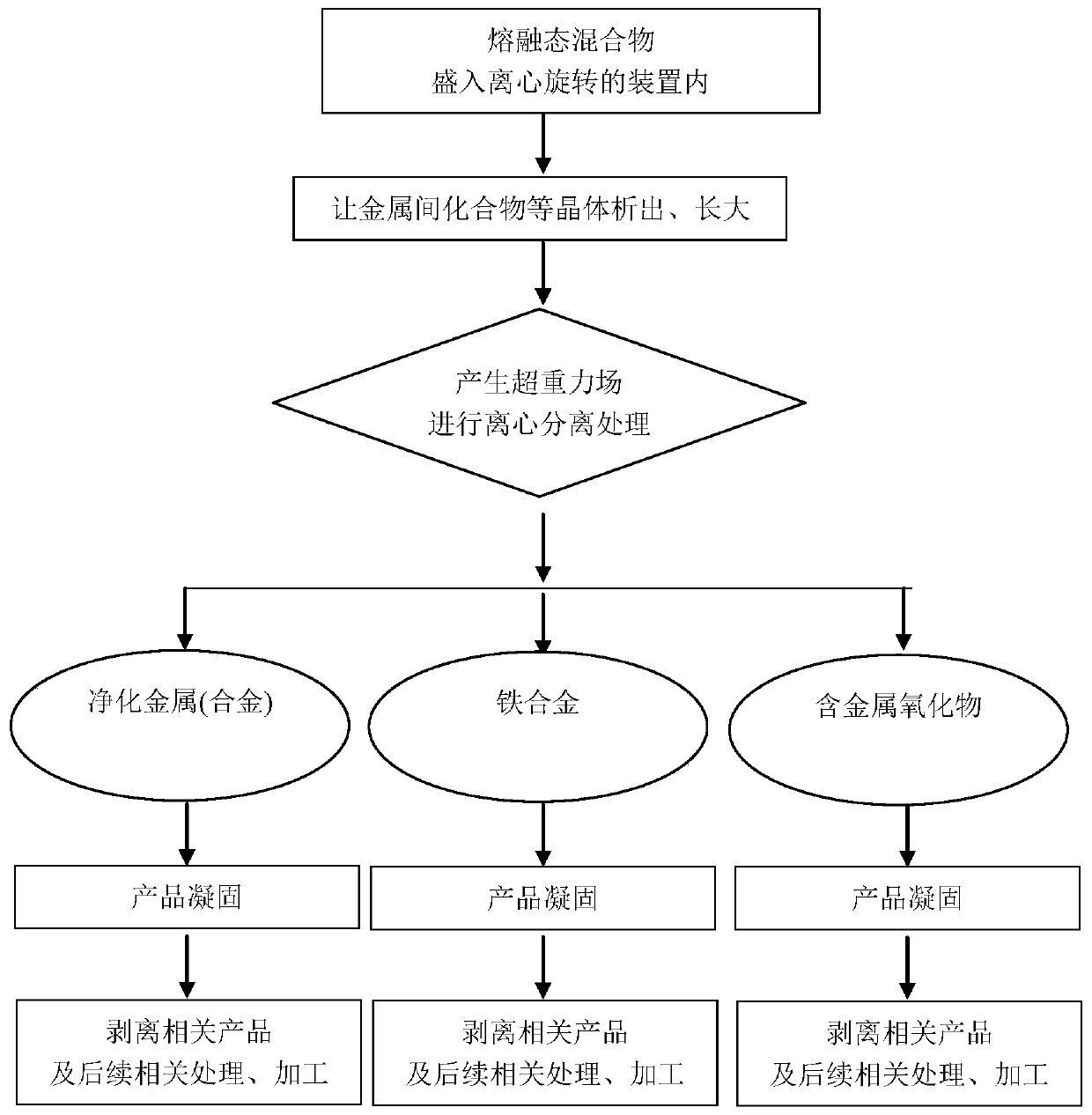

Method for centrifugally removing harmful elements and impurities in iron-containing mixture

InactiveCN110904340AEfficient separationLow costProcess efficiency improvementFluid phaseIngot casting

The invention relates to a method for centrifugally removing harmful elements and impurities in an iron-containing mixture. The method comprises the following steps that (1), the molten mixture at thetemperature of exceeding 650 DEG C is put into a centrifugal rotating device; (2), the centrifugal rotating device completely contains the molten mixture, and intermetallic compound crystals are precipitated and grow up; (3), centrifugal separation treatment is carried out on the molten mixture manufacturing supergravity field in the device; and (4), various products are stripped by using a manual or mechanical method, and subsequent remelting and ingot casting or refining are carried out. According to the method, substances such as solid-phase compounds are precipitated when the mixture is subjected to liquid phase cooling, the mixture and the impurities are separated by means of the supergravity effect generated by centrifugal rotating motion by utilizing the difference between the density of the intermetallic compounds and the like and the density of the liquid-phase metal, and then a plurality of products are obtained through the method of settling, floating, peeling and the like.

Owner:武翠莲

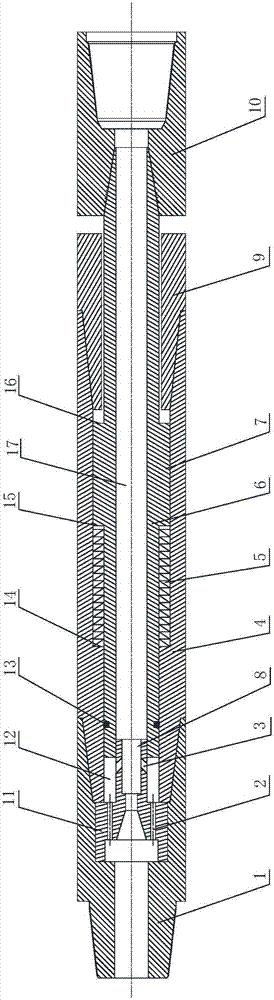

Drill column vibration and hydraulic pulse coupling downhole drilling tool

ActiveCN107100547AEasy to cleanHarm reductionLiquid/gas jet drillingBorehole drivesCouplingUpper joint

The invention discloses a drill column vibration and hydraulic pulse coupling downhole drilling tool which comprises an upper joint, an outer cylinder, a locking nut, a core shaft and a lower joint. The outer cylinder and the core shaft are in sliding key fit; a disc-shaped spring is arranged between the outer cylinder and the core shaft; a pressurized flow dividing structure is arranged at the upper end of the core shaft; a main flow hole channel of the pressurized flow dividing structure communicates with a fluid channel in the center of the core shaft; flow diving hole channels are formed in the periphery of the main flow hole channel; the upper portion of the outer cylinder, a pressurized flow dividing channel and the upper portion of the core shaft form an annular pressurized cavity; the flow diving hole channels communicate with the annular pressurized cavity; the annular pressurized cavity communicates with the main flow hole channel through a jet flow hole channel; and when the outer cylinder and the core shaft relatively move, the size of the annular pressurized cavity can be changed, and the jet flow hole channel is closed periodically. According to the drill column vibration and hydraulic pulse coupling downhole drilling tool, through alternating load coupling generated by a hydraulic pulse jet flow and drill column vibration, shaft bottom rock is effectively stripped from the shaft bottom, meanwhile, the pulse jet flow improves the cleaning ability of rock debris, and thus the drilling speed is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

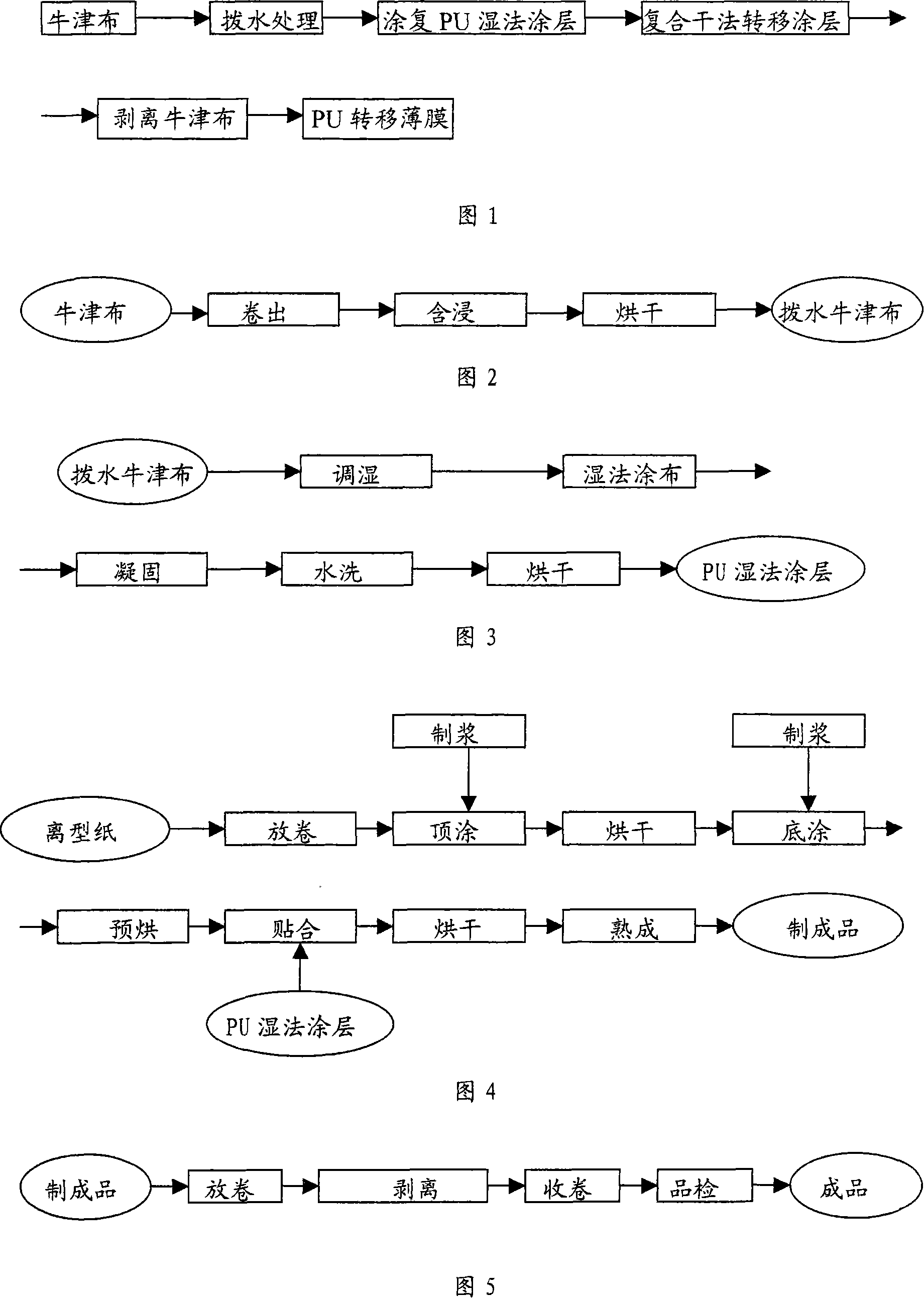

Producing method of PU divert film

ActiveCN101204867AFeel goodIncrease elasticityLamination ancillary operationsLaminationChemistryPlain weave

The invention relates to a method for preparing a PU transfer membrane, which comprises that: (a) water-poking treatment is applied to plain woven oxford cloth; (b) a wet-process polyurethane (PU) coating is plated on the plain woven oxford cloth; (c) a PU dry-process transferring coating with a leather grain is compounded on the wet-process polyurethane coating; (d) the plain woven oxford cloth is stripped and the PU transfer membrane is prepared. The water-poking treatment for the oxford cloth reduces the adhesive force between the PU transfer membrane and the oxford cloth; thereby the purpose of stripping is achieved effectively. Hand feel, flexibility and permeability of the membrane are improved by a microspore structure inside the wet-process polyurethane coating. The dry-process transfer coating is a PU coating with a leather grain, thus increasing the effect of leather imitation. The PU transfer membrane prepared by the method can be used as materials for car interior decoration such as an attaching leather membrane for a panel mesa. The PU transfer membrane can also be compounded with such substrates as underlayer oxhide, micro fiber leather, etc. to the surface of which the PU wet-process coating is hardly applied, thus the PU transfer membrane is manufactured into imitating leather with good leather effect.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD +1

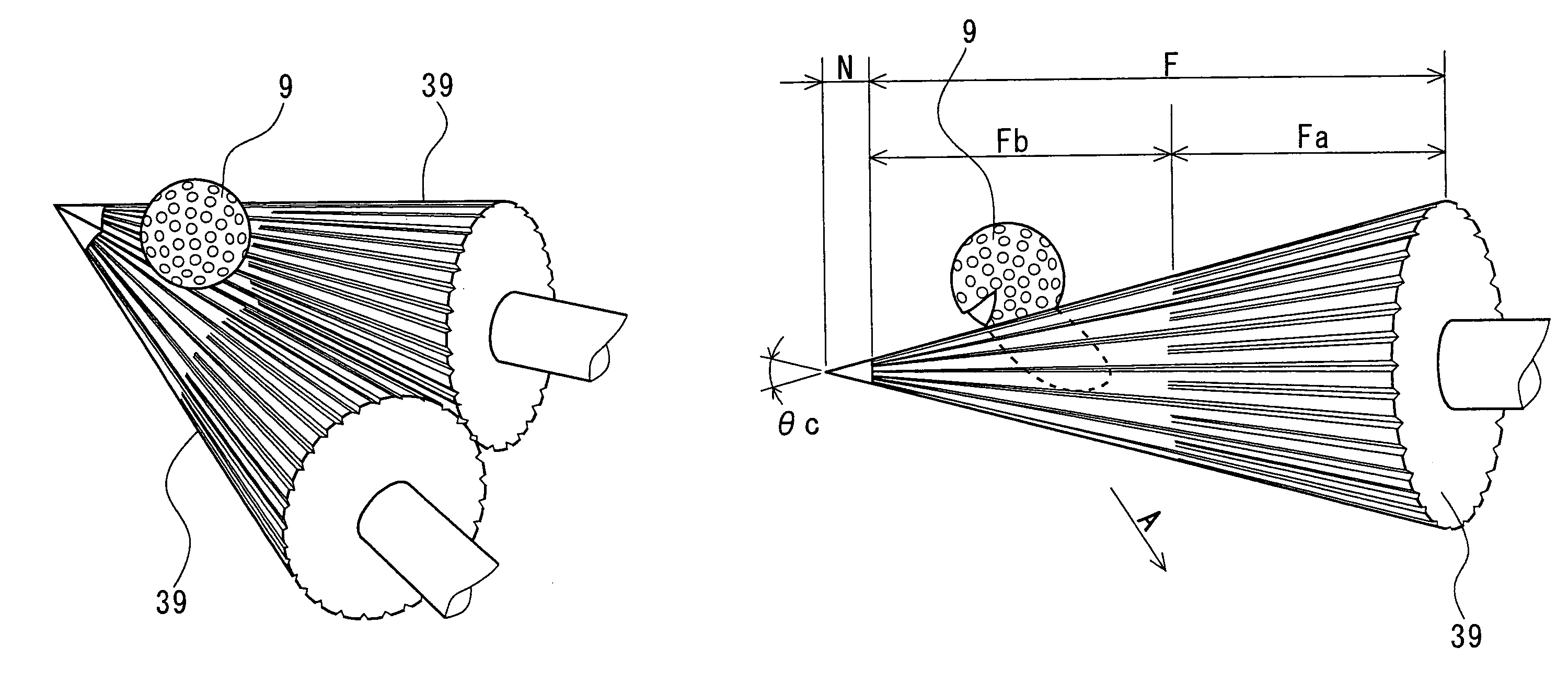

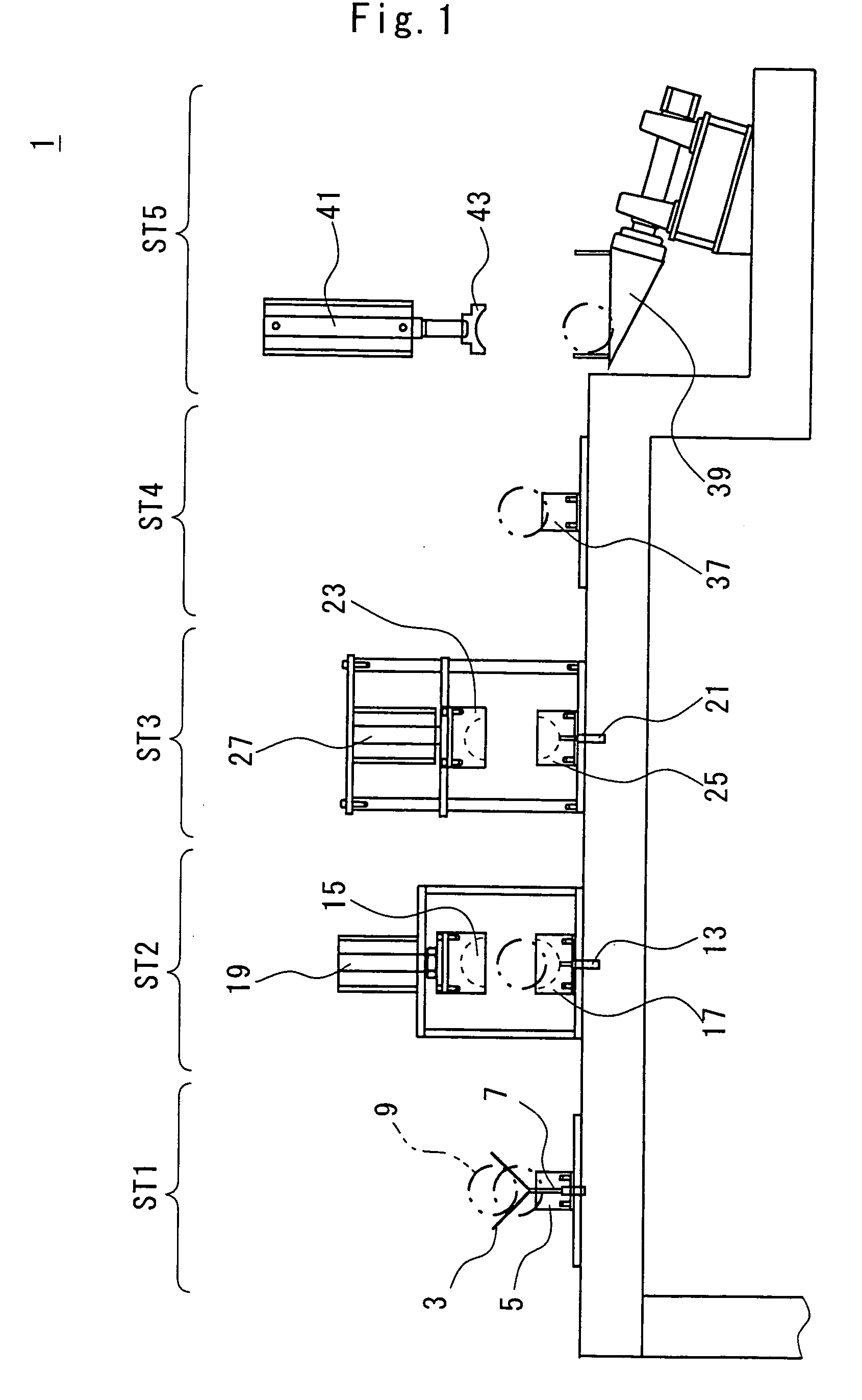

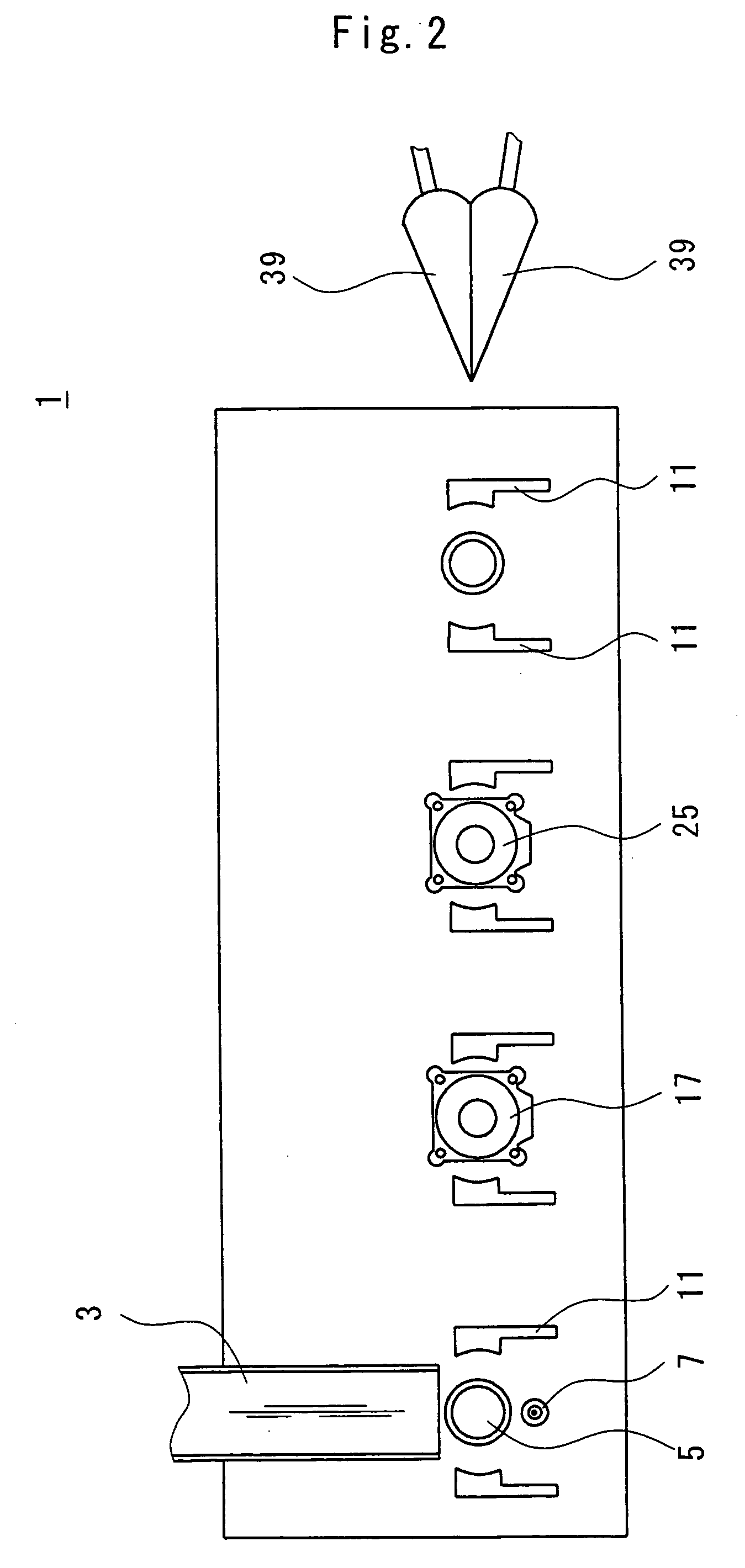

Apparatus for removing cover of golf ball from core

A cover peeling machine includes a pair of rolls. The roll has an almost conical shape. Both of the rolls are rotated in a reverse direction. The direction of the rotation is an inward direction as seen from above. A golf ball is put close to a tip of the roll. In the vicinity of the tip, a distance between a nip of the roll and the golf ball is short. Therefore, a clip portion formed on the golf ball can be easily bitten between the rolls. With the rotation of the roll, a cover is peeled from a core. A groove formed on a surface of the roll can prevent the roll and the cover from slipping. After the removal, the cover and the core are recycled respectively.

Owner:DUNLOP SPORTS CO LTD

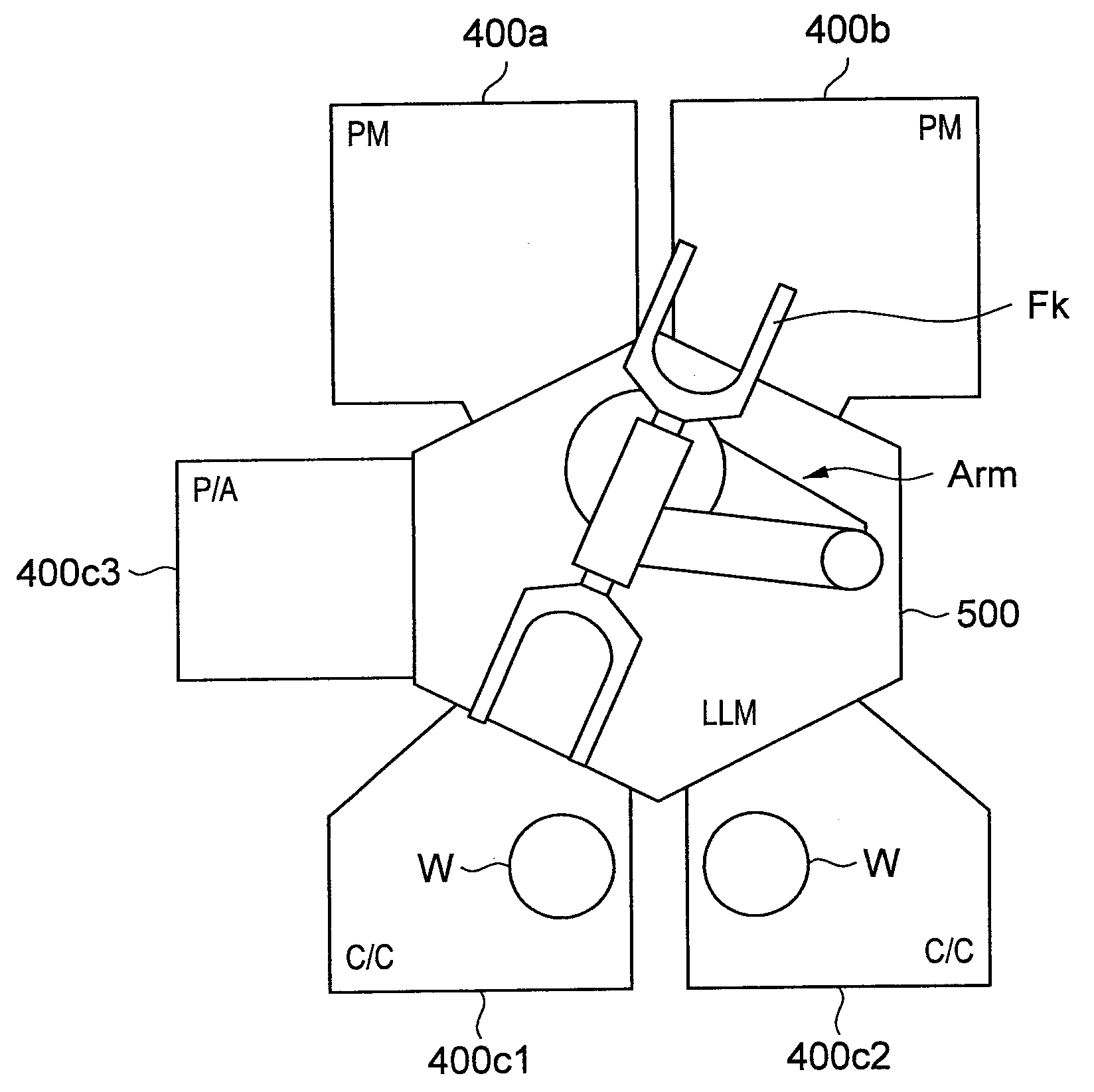

Method for cleaning vacuum apparatus, device for controlling vacuum apparatus, and computer-readable storage medium storing control program

InactiveUS20080154410A1Peel off the depositsEffective peelingSemiconductor/solid-state device manufacturingProgram controlProcess engineeringHigh pressure

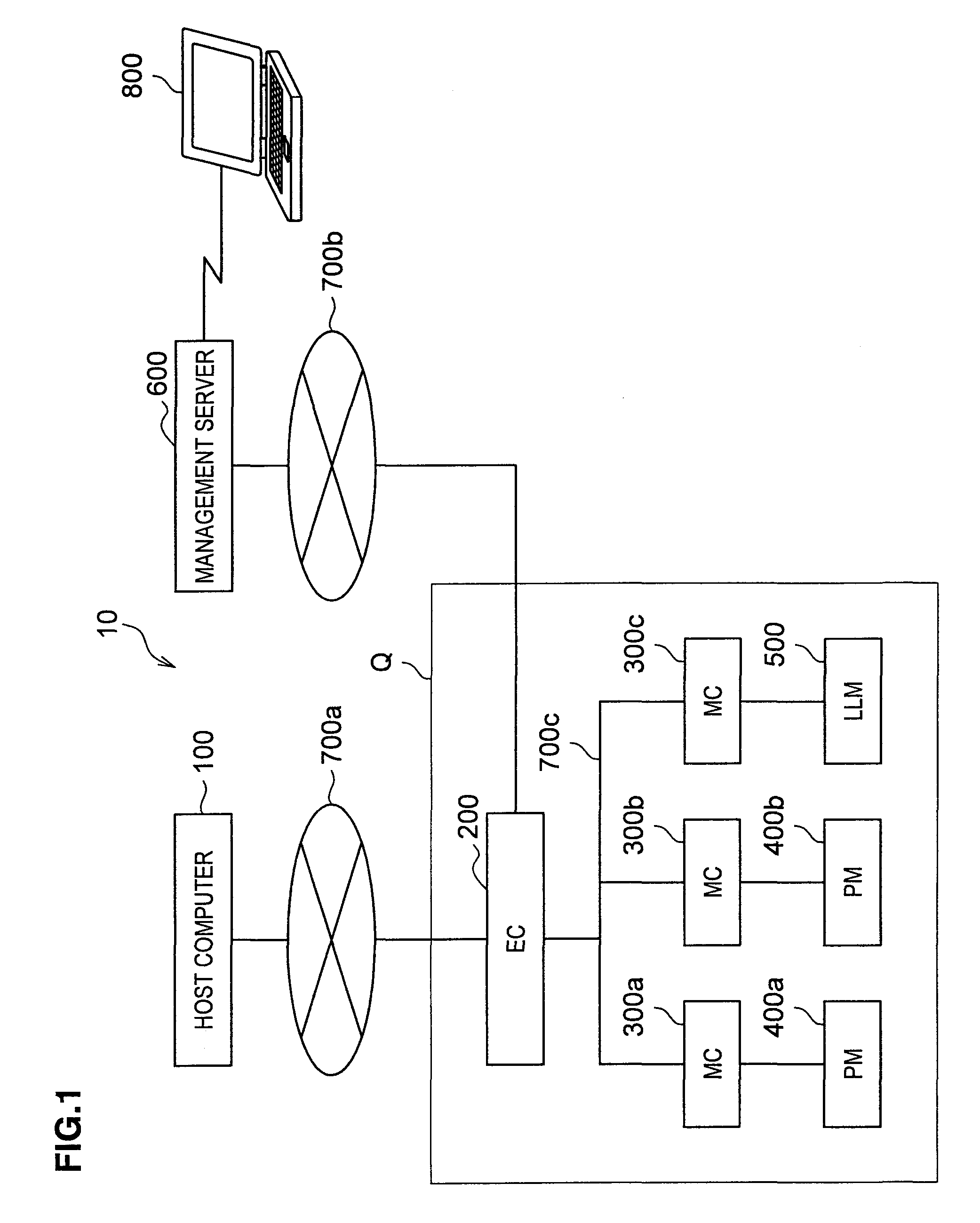

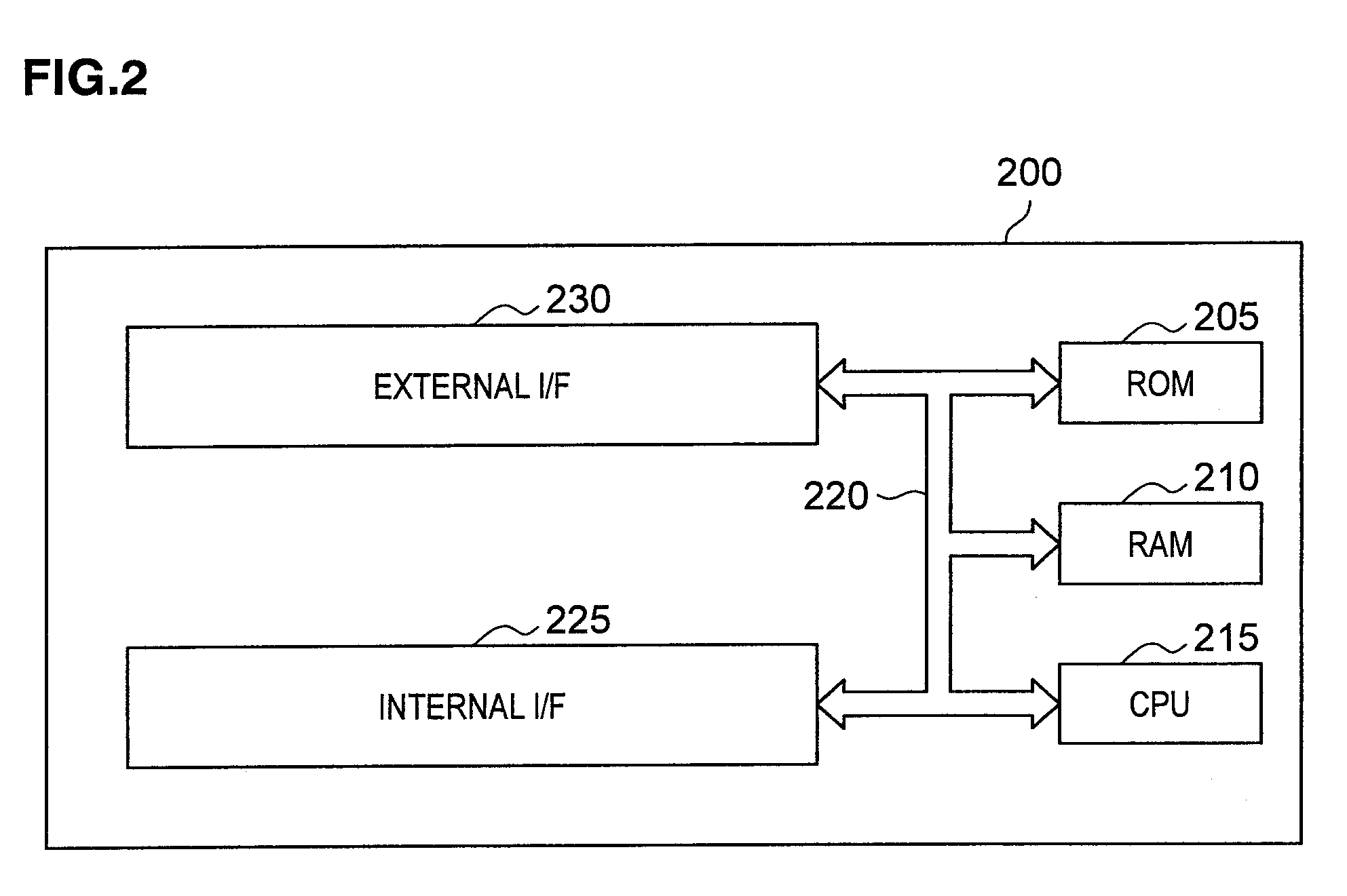

A vacuum apparatus such as PM 400 or LMM 500 includes: a chamber to transfer or process a wafer; a plurality of movable parts in the chamber; a high-voltage power supply 485 to introduce a high voltage HV to the chamber; a gas supply unit 445 to supply a gas to the chamber; and an exhaust mechanism 490 to exhaust a purge gas in the chamber. The vacuum apparatus is cleaned by supplying the purge gas from the gas supply unit 445 and exhausting the purge gas in the chamber via the exhaust mechanism 490, repeating a motion of each movable part, and controlling the purge-gas pressure to be equal to or more than a predetermined pressure before and / or during and / or after the repeated motions of each movable part, and / or allowing the power supply 485 to intermittently output the HV before and / or after the motions of each movable part.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com