Method for preparing graphene solution based on supercritical carbon dioxide and pyrenyl polymers

A graphene solution, carbon dioxide technology, applied in the production of graphene, nano-carbon, bulk chemicals, etc., can solve problems such as graphene, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

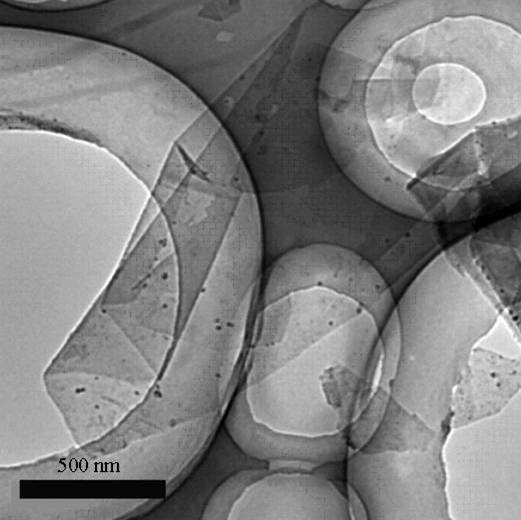

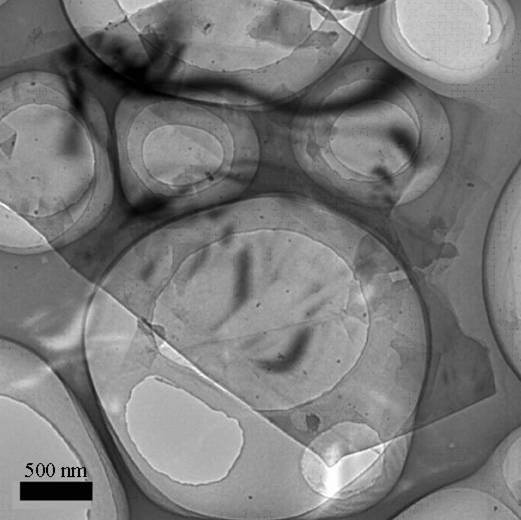

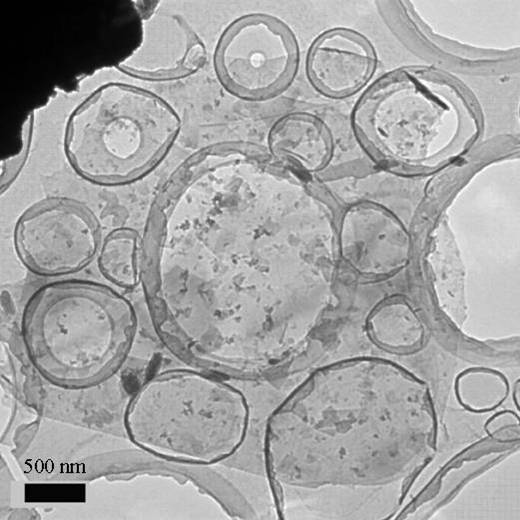

Image

Examples

Embodiment 1

[0021] Pyrene-based polyethylene glycol (pyrene-PEG 2000 and pyrene-PEG 5000 ) preparation: raw materials: 1-pyrenylbutyric acid (purity ≥ 97%) and polyethylene glycol monomethyl ether (m PEG, Mn=2,000 and 5,000). First, polyethylene glycol monomethyl ether was vacuum-dried at 35°C for 24 hours, and then passed through polyethylene glycol monomethyl ether according to the method reported in the literature (Lim, E.-K. et al. Biomaterials, 2010, 31, 9310). The esterification reaction of the hydroxyl group of ether and the carboxyl group of 1-pyrenylbutyric acid prepares pyrene-based polyethylene glycol (pyrene-PEG 2000 and pyrene-PEG 5000 ). Pyrene-PEG 2000 and pyrene-PEG 5000 The molecular structural formula is as follows:

[0022] .

Embodiment 2

[0024] Pyrene-based polycaprolactone (pyrene-PCL 19 and pyrene-PCL 48 ) preparation: raw materials: 1-pyrenylmethanol (purity 98%) and ε-caprolactone (ε-CL, the repeating unit number of monomer caprolactone CL is 19 or 48). Firstly, ε-CL was purified by calcium hydride vacuum distillation, and then according to the method reported in the literature (Li, J. B. 2010, Polymer 51, 1301), 1-pyrenylmethanol (1.314 mmol) was used as the initiator, and ε-CL (26.28 mmol ) ring-opening polymerization to prepare pyrene-based polycaprolactone (pyrene-PCL 19 and pyrene-PCL 48 ), the polymerization reaction temperature was 115°C, and the reaction was stirred for 24h under the protection of nitrogen. Pyrene-PCL 19 and pyrene-PCL 48 The molecular structural formula is as follows:

[0025] .

Embodiment 3

[0027] Based on supercritical carbon dioxide and pyrene-PEG 2000 Preparation of graphene: 20 mg of graphite and 30.8 mg of pyrene-based polyethylene glycol 2000 (pyrene-PEG 2000) was added to 10 ml of dimethyl sulfoxide, ultrasonicated with a low-frequency ultrasonic cleaner (40 kHz, 120W) for 3 h, and the temperature was controlled at about 40 °C to obtain an off-white graphite suspension. The suspension was quickly transferred to a supercritical carbon dioxide reaction device (50 ml stainless steel autoclave) and stirred with a magnet, and carbon dioxide was injected until the pressure was 16 MPa, the temperature was 40 °C, and the pressure holding time was 6 h. Then slowly deflate and release the pressure to take out the sample and continue to sonicate with a low-frequency ultrasonic cleaner (40 kHz, 120W) for 2 h to obtain a dark gray uniform solution (with a part of the precipitate visible to the naked eye). After standing overnight, centrifuge with a centrifuge (9,000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com