Drill column vibration and hydraulic pulse coupling downhole drilling tool

A hydraulic pulse and drilling tool technology, which is used in vibration drilling, driving devices for drilling in wellbore, drilling equipment, etc., can solve the problem of pressurized tool life that cannot be effectively solved, drilling speed decline, drill bit mud bag, etc. problems, to achieve the effect of improving the efficiency of hydraulic energy utilization, reducing drilling costs, and increasing ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

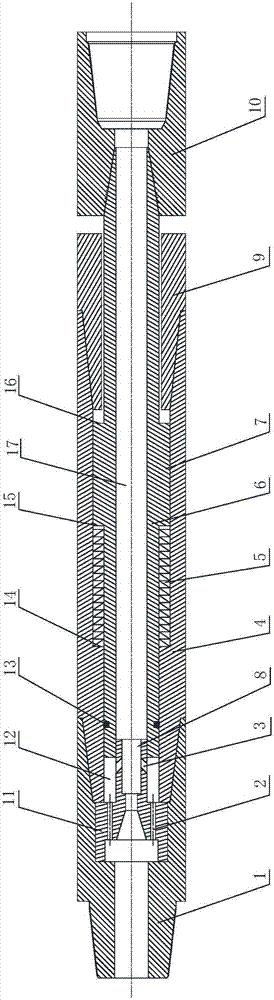

[0016] With reference to the accompanying drawings, a drill string vibration and hydraulic pulse coupling downhole drilling tool includes an upper joint 1 connected to a drill pipe, an outer cylinder 4, a lock nut 9, a mandrel 6 and a lower joint 10 connected to a drill bit. The upper joint 1, the outer cylinder 4, the lock nut 9, and the mandrel 6 are installed along the axial direction in sequence. The upper joint 1 is threadedly connected with the upper end of the outer cylinder 4, the mandrel 6 is installed inside the outer cylinder 4, and the outer cylinder 4 and the mandrel 6 adopt a sliding key fit mode to transmit the upper torque. The sliding key 7 is arranged on the mandrel 6, and the inner side of the outer cylinder 4 is vertically provided with a sliding key groove matched with the sliding key. The mandrel 6 can move up and down relative to the outer cylinder 4, and the outer cylinder 4 can drive the mandrel 6 to rotate. Torque is transmitted to spindle 6 . An ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com