Patents

Literature

12144results about "Auxillary shaping apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

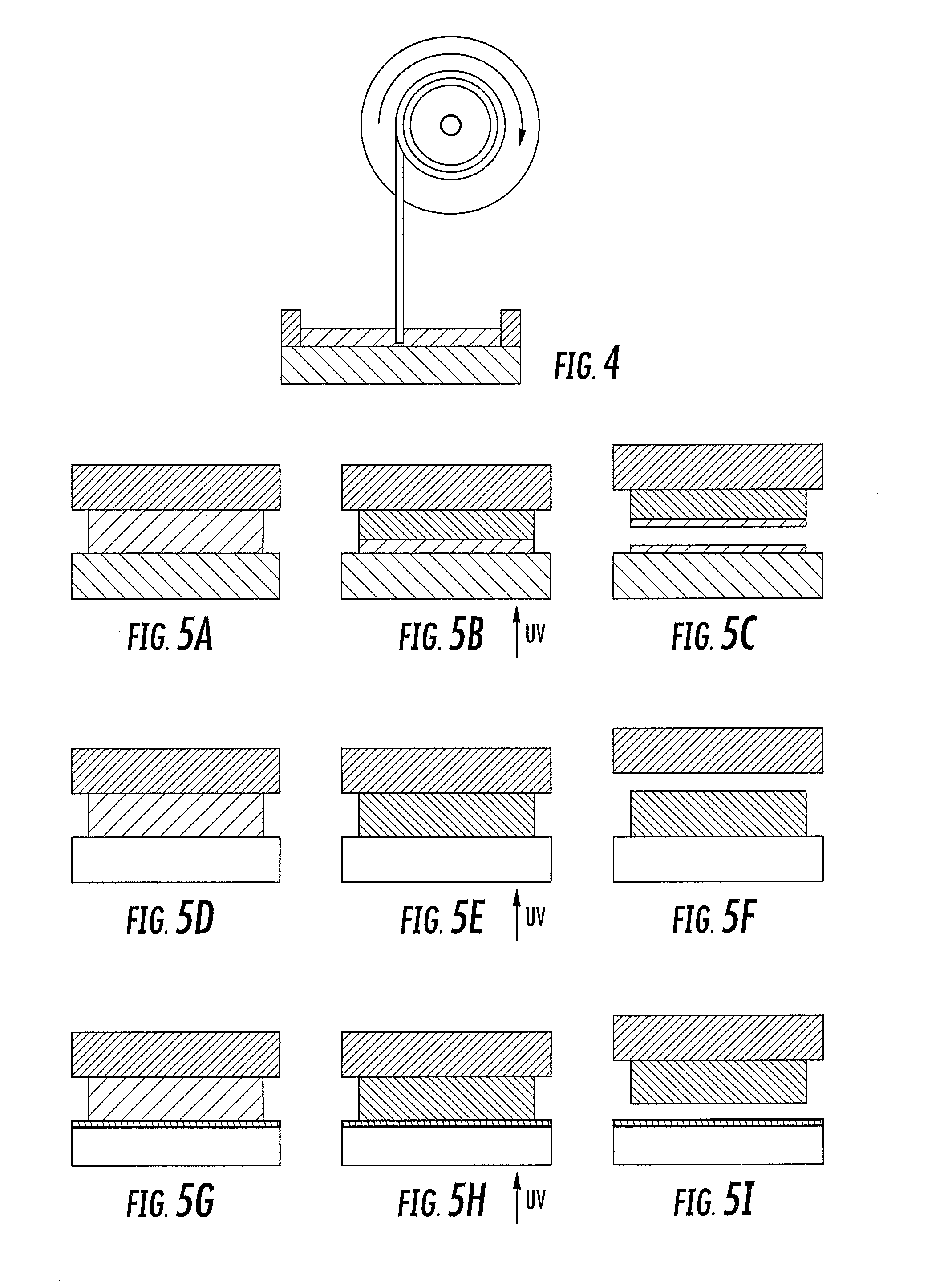

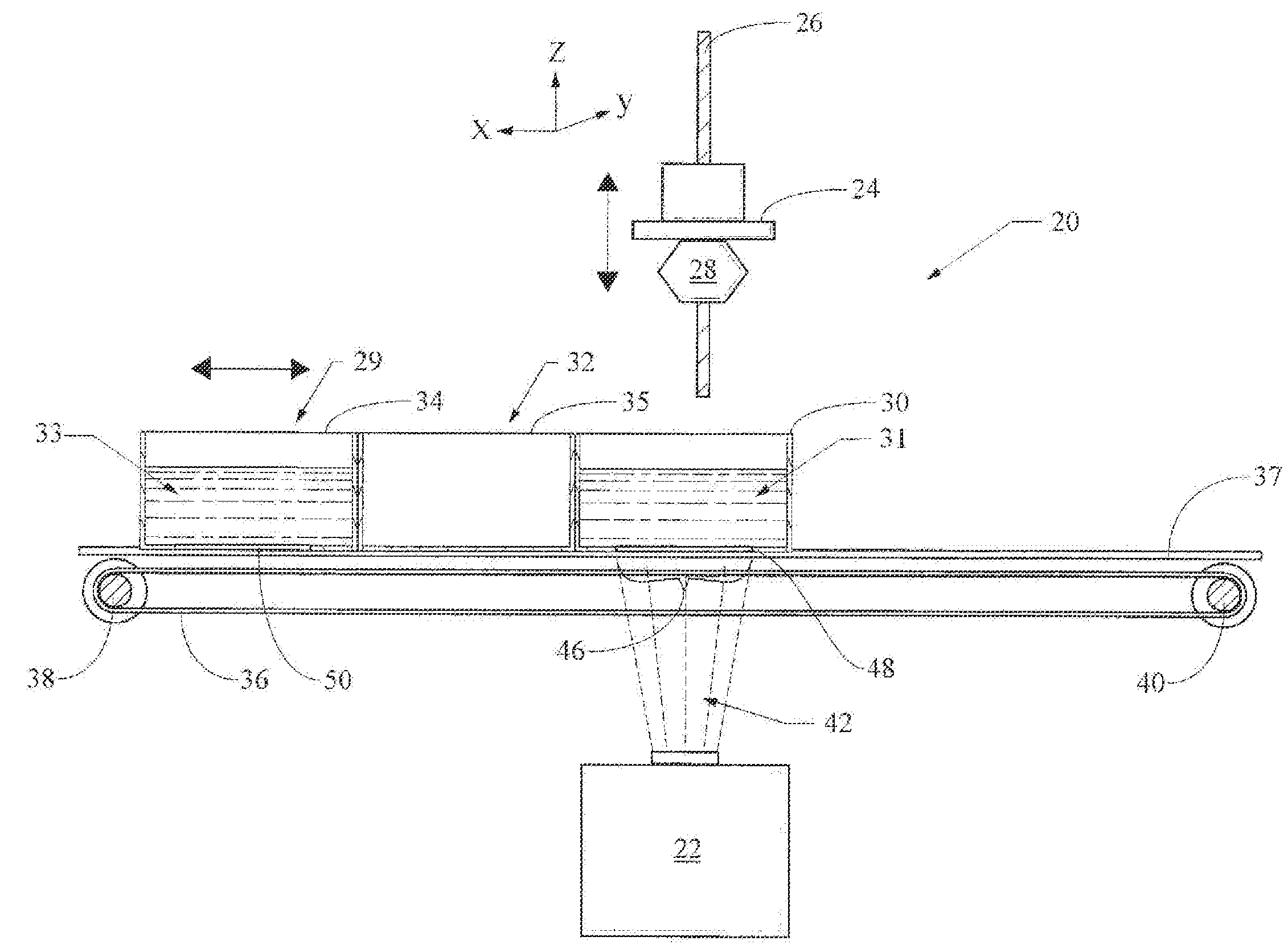

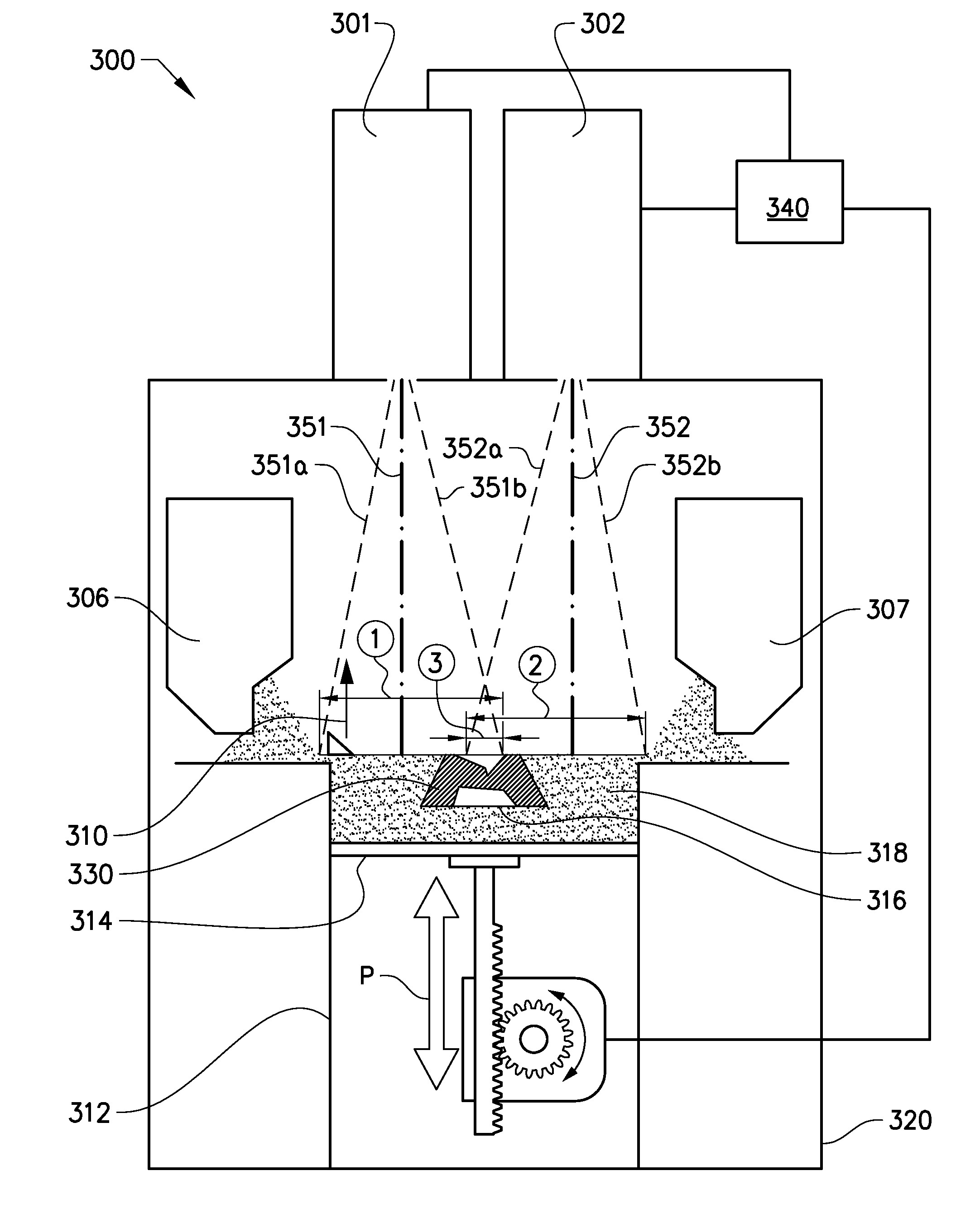

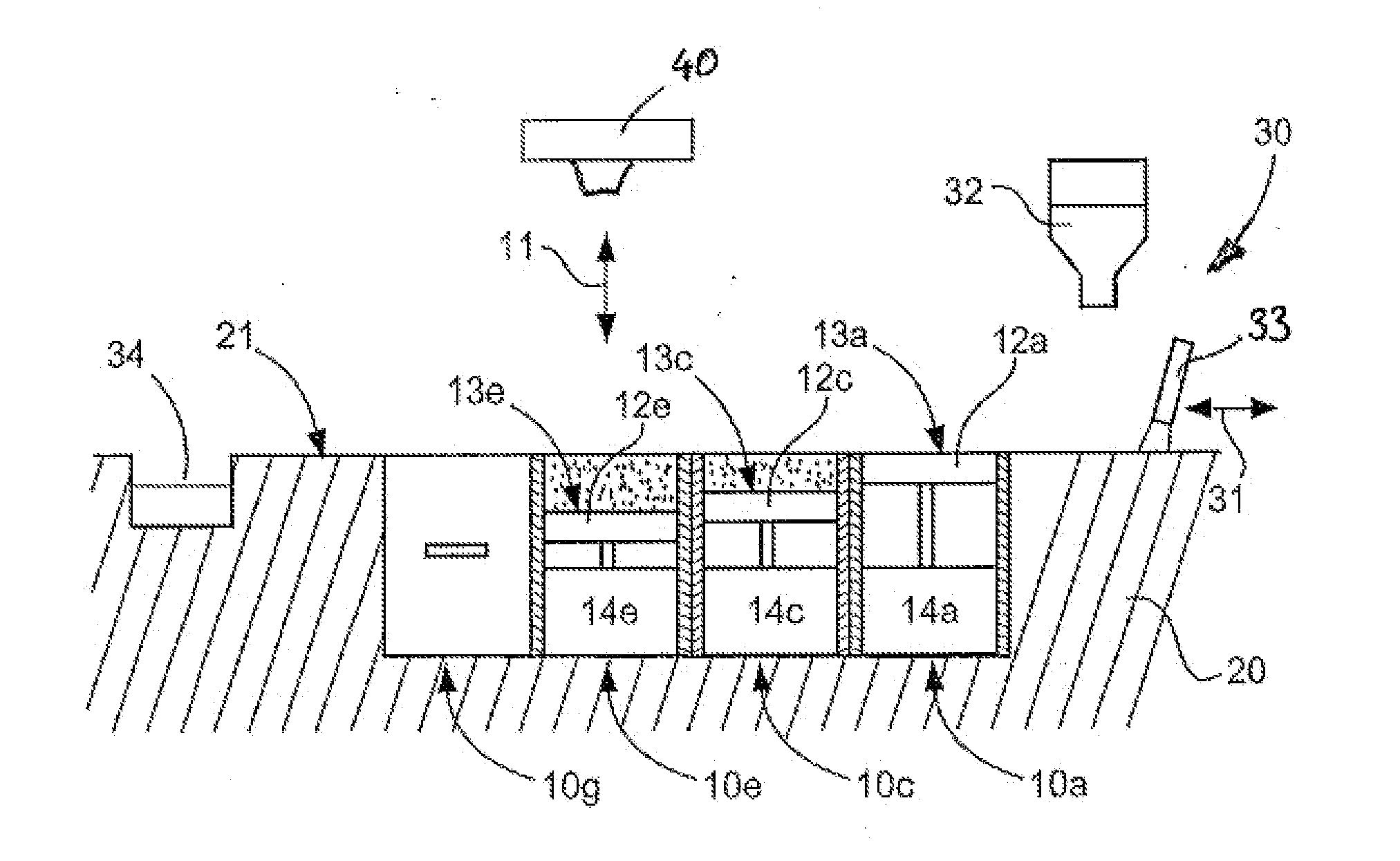

Digital mask-image-projection-based additive manufacturing that applies shearing force to detach each added layer

ActiveUS20130295212A1Additive manufacturing apparatusAuxillary shaping apparatusComputer graphics (images)Projection system

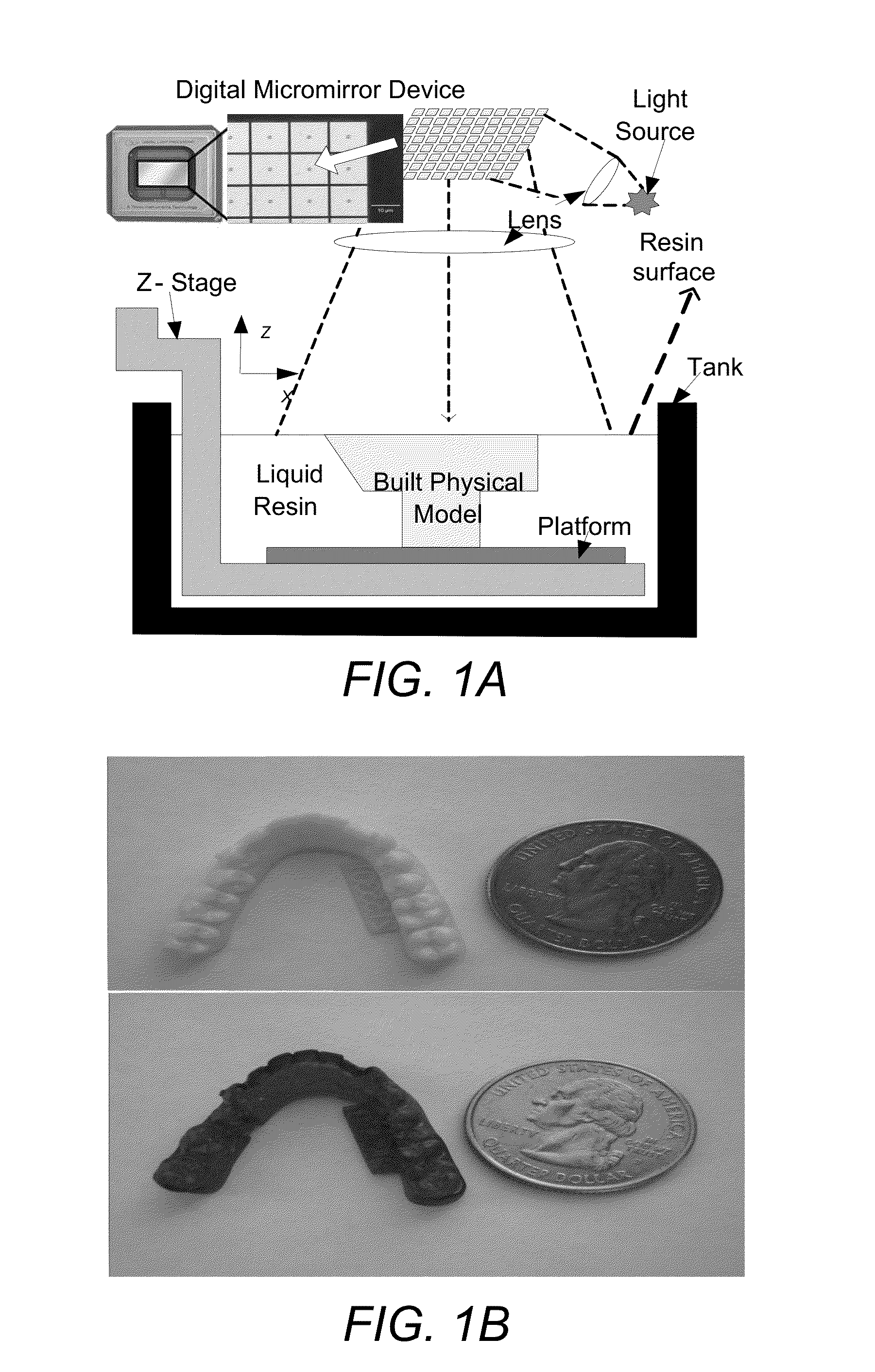

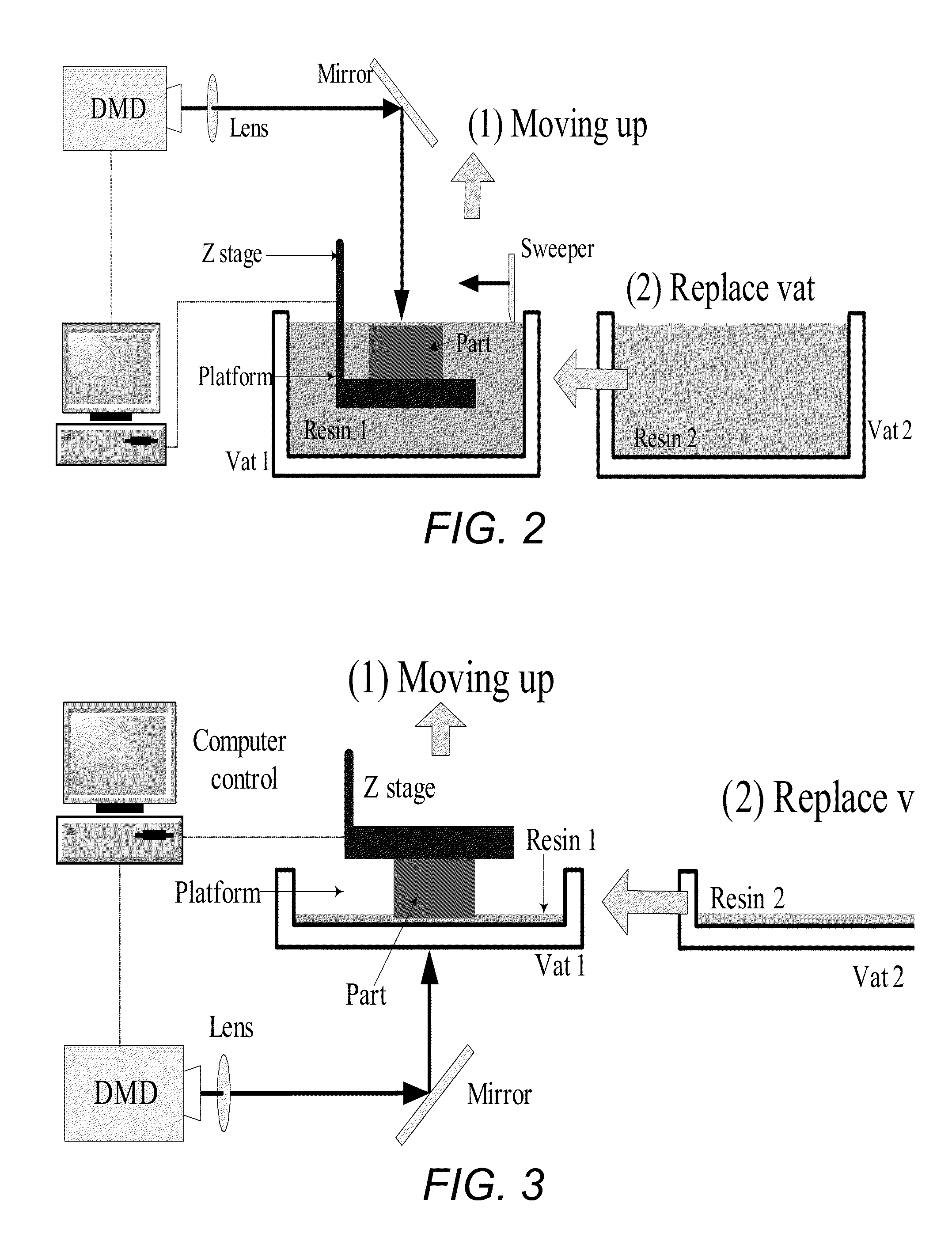

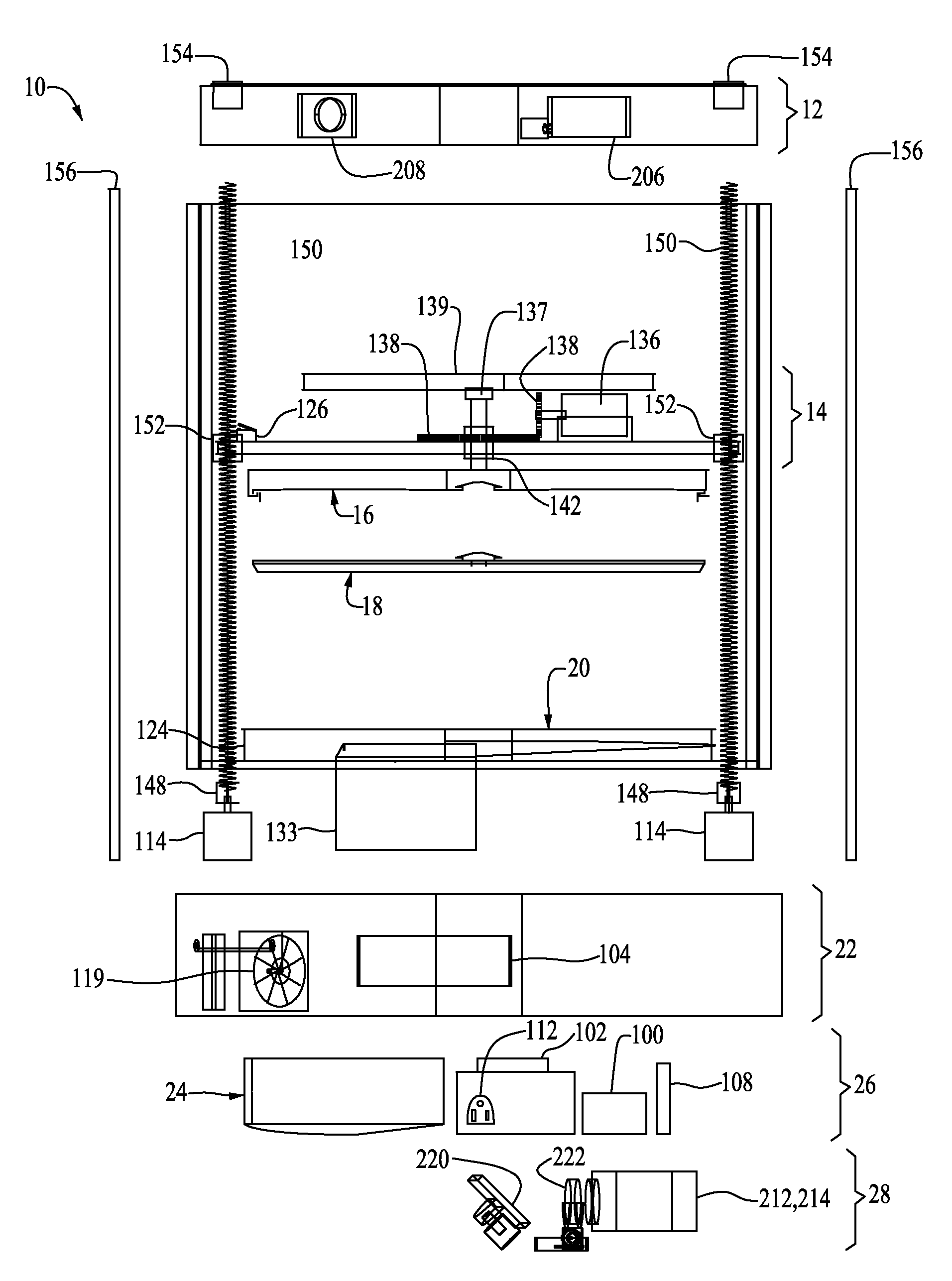

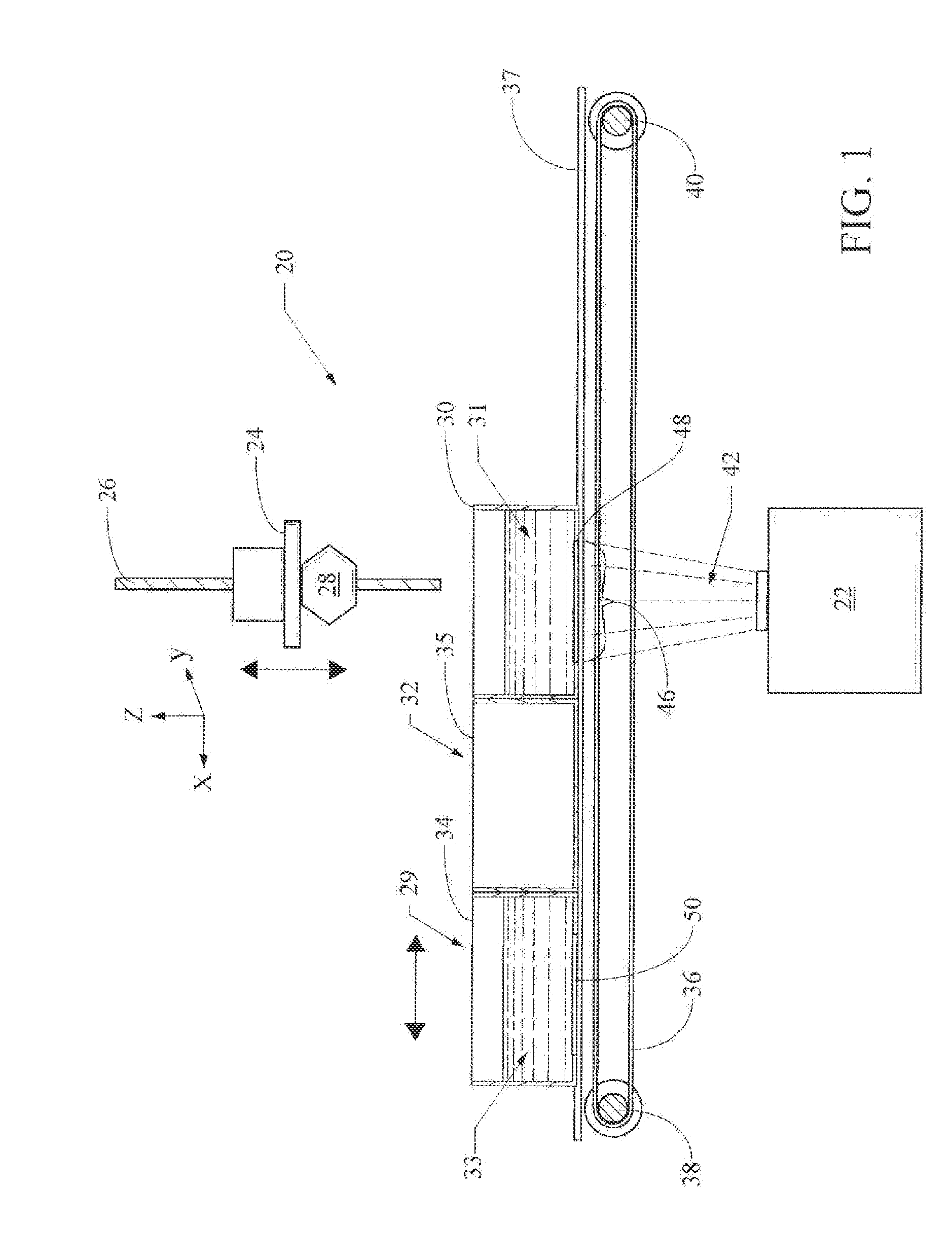

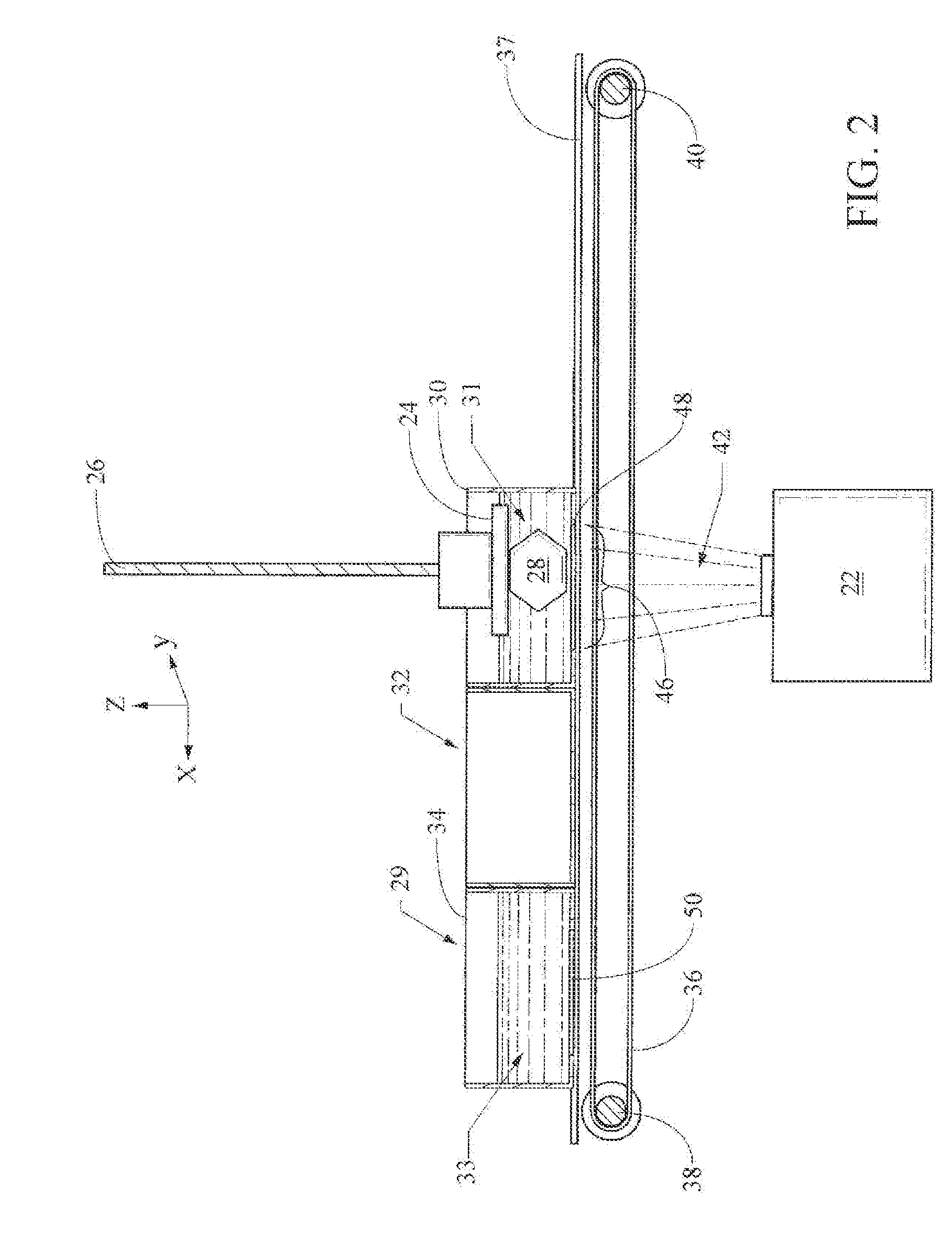

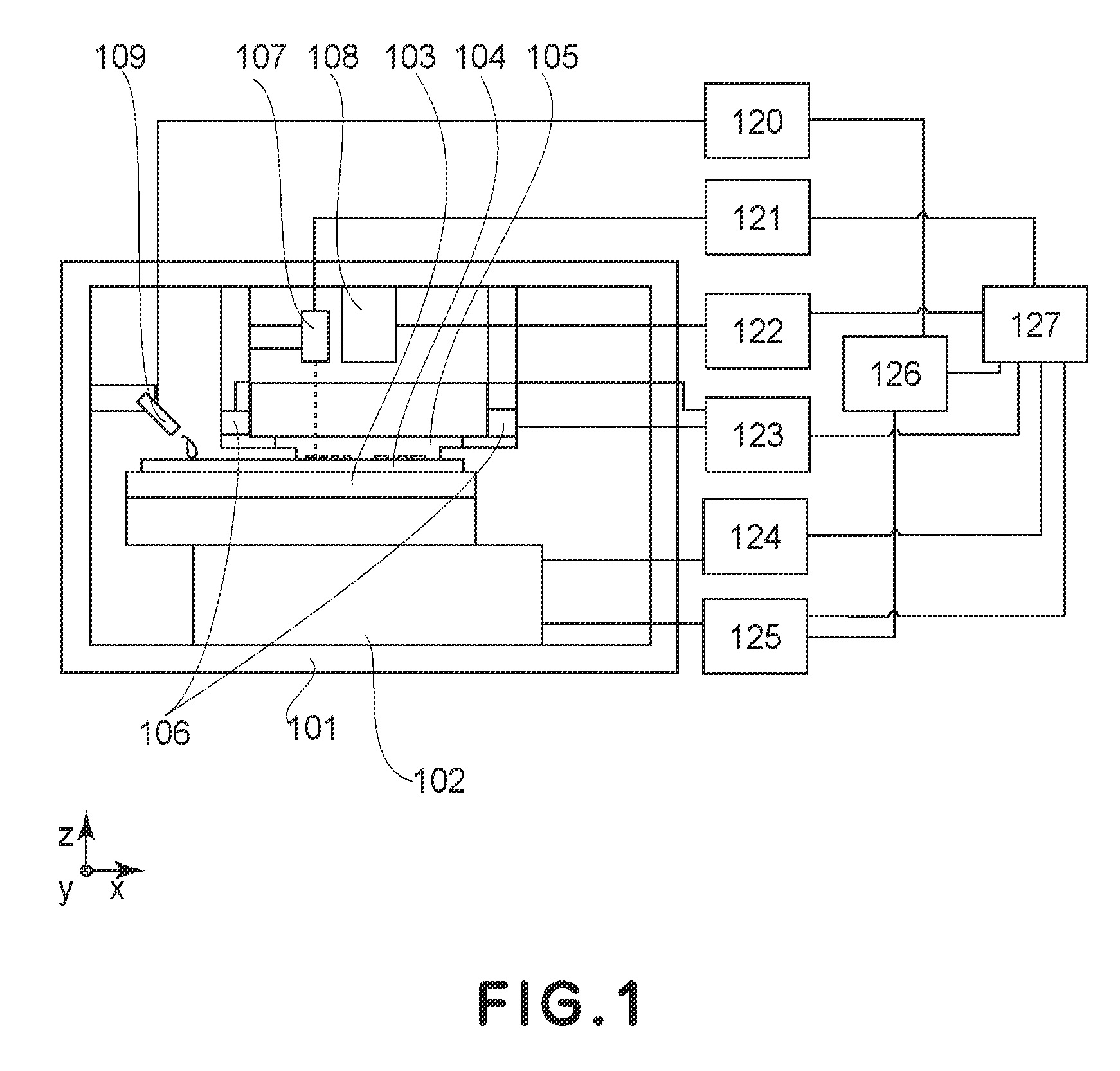

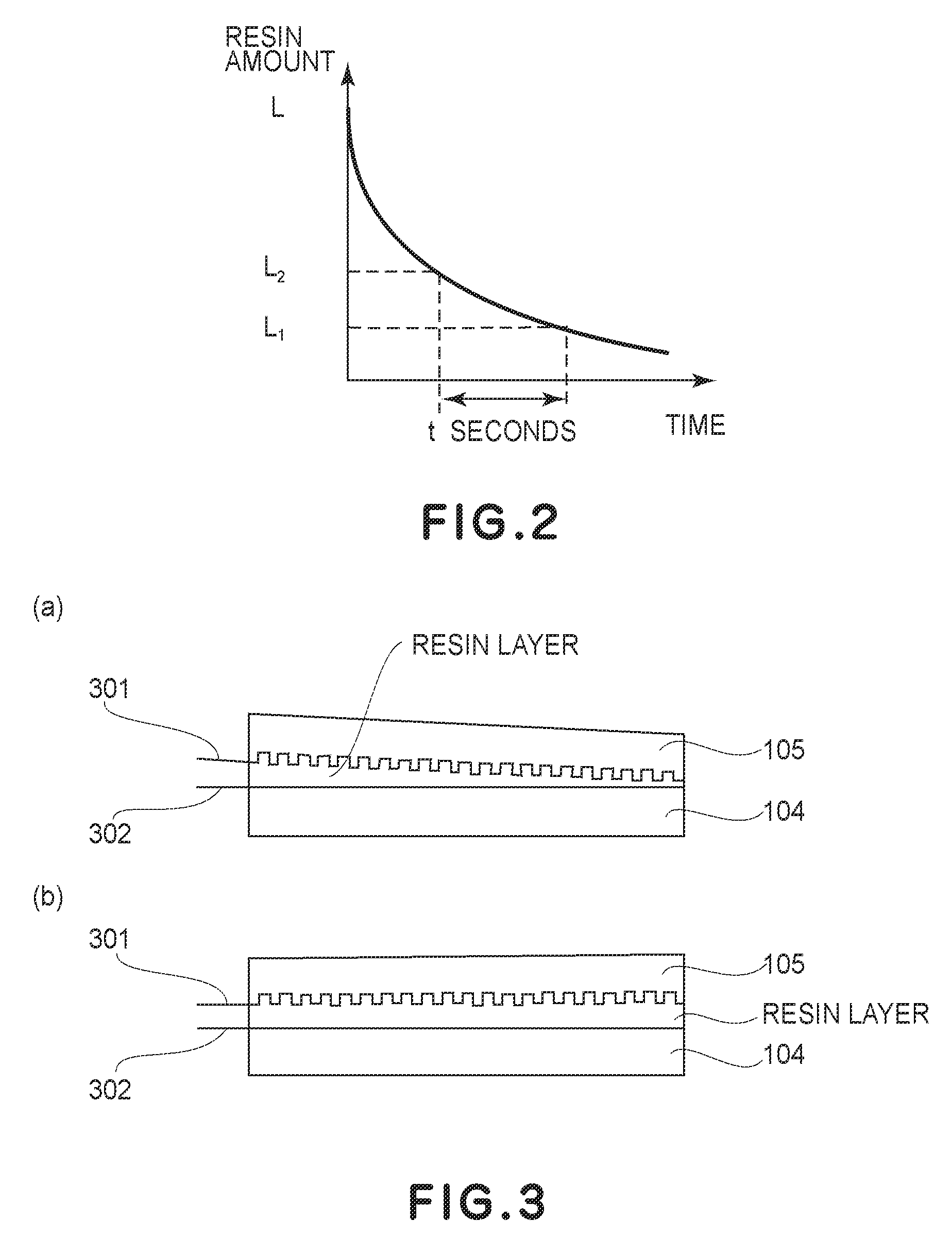

A three-dimensional object may be produced in cascaded layers from a liquid resin that solidifies upon exposure to light. A translation stage may be positioned relative to a vat that is suitable for solidifying the highest un-solidified layer of the three-dimensional object directly beneath any existing, solidified layers of the three-dimensional object. A mask image projection system may project a two-dimensional image of the highest un-solidified layer through a transparent bottom of the vat and into the liquid resin. This may cause at least a portion of the liquid resin to solidify in the shape of the two-dimensional image and to adhere to the bottom of a surface beneath the solidified layer. A shearing force may be applied between the bottom surface of the solidified layer and the surface beneath that is great enough to detach the solidified layer from the surface beneath.

Owner:UNIV OF SOUTHERN CALIFORNIA

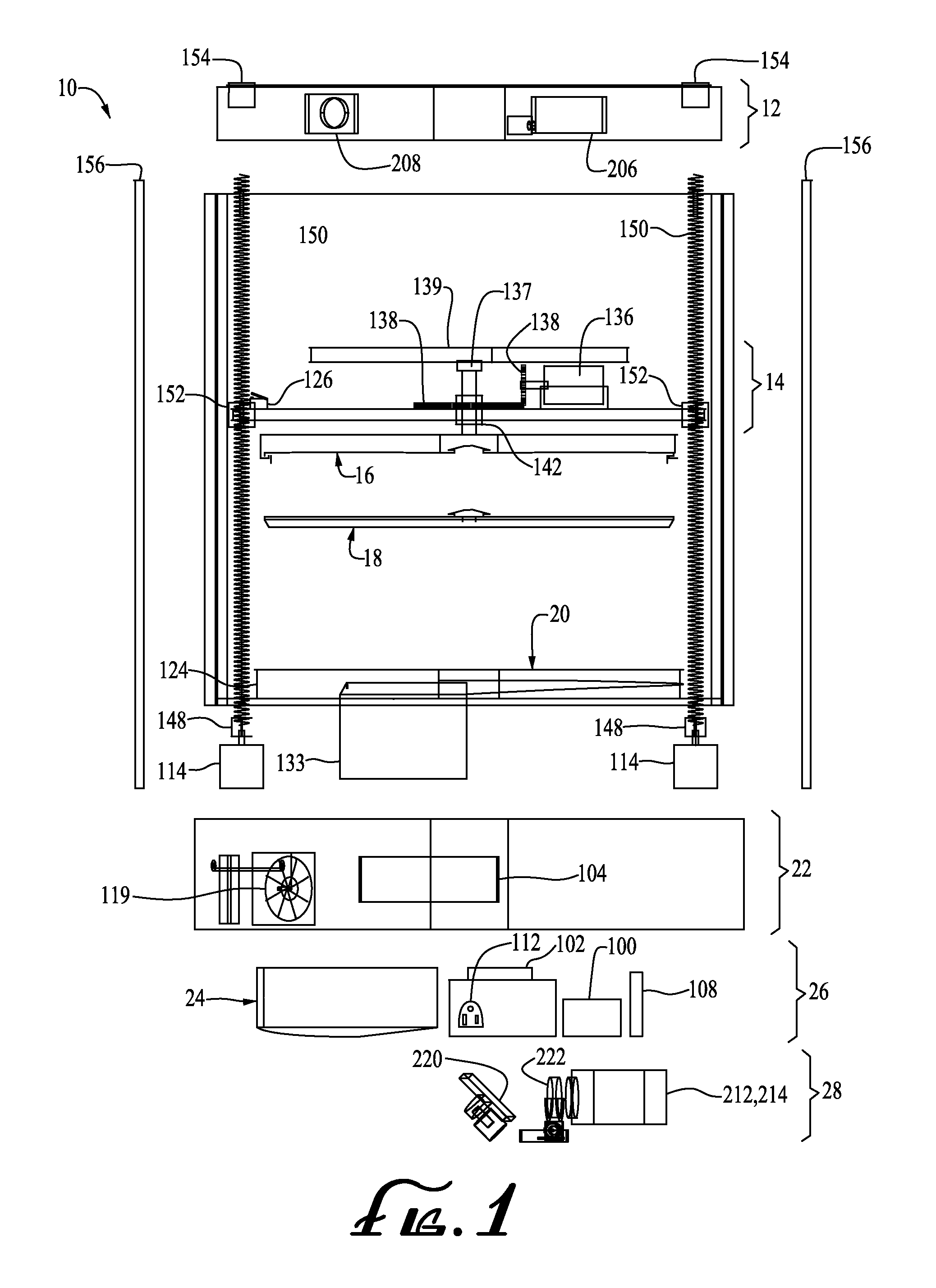

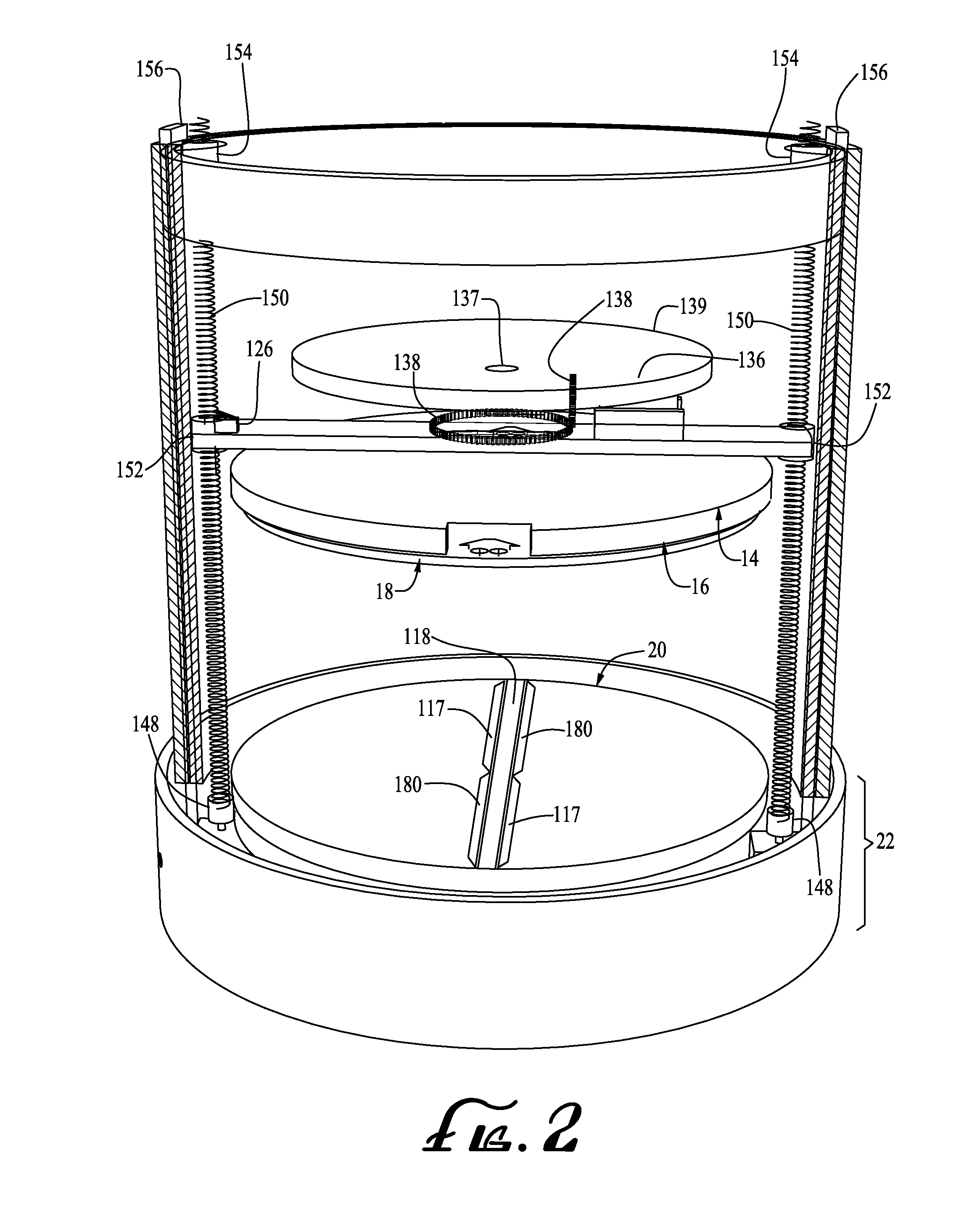

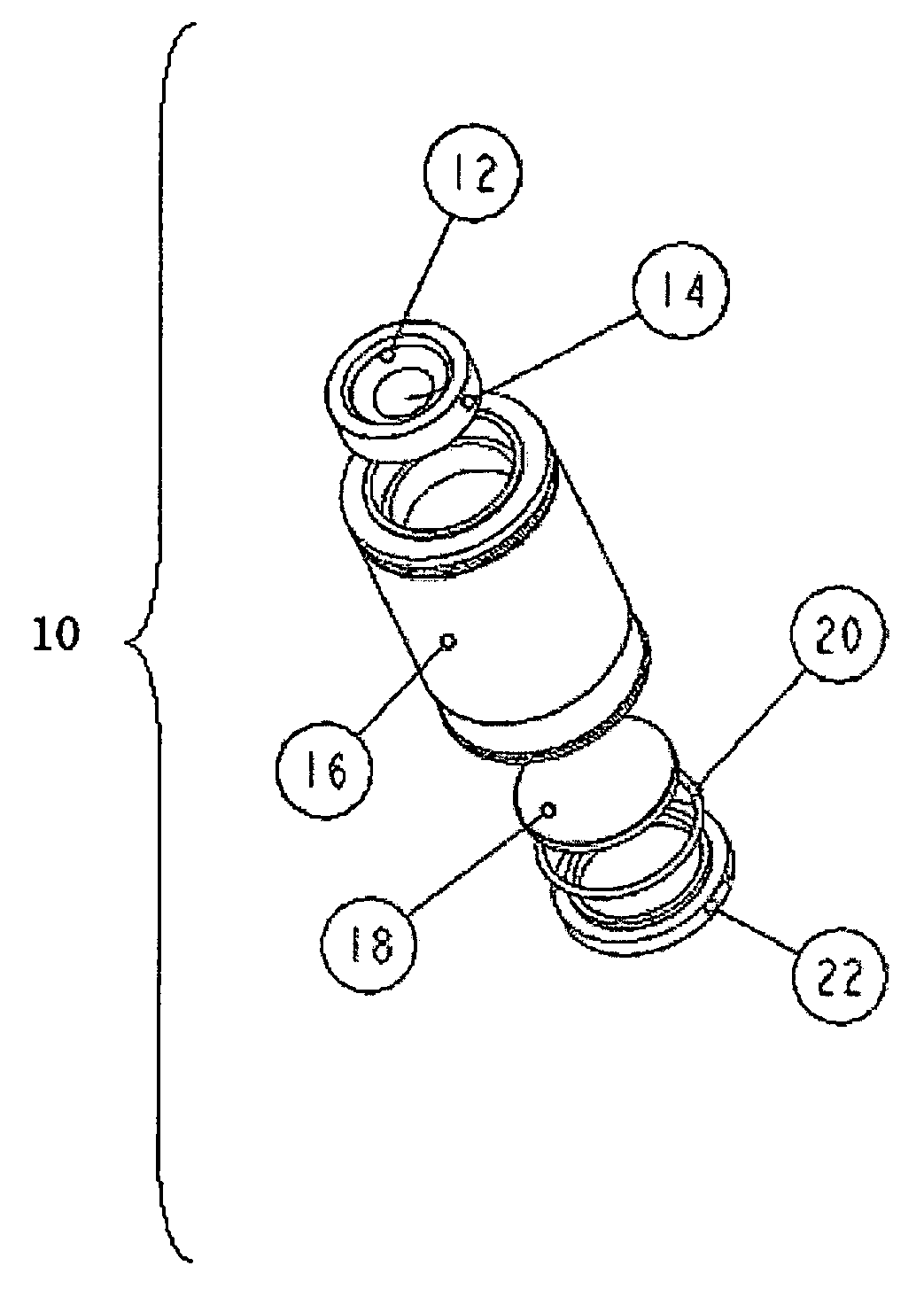

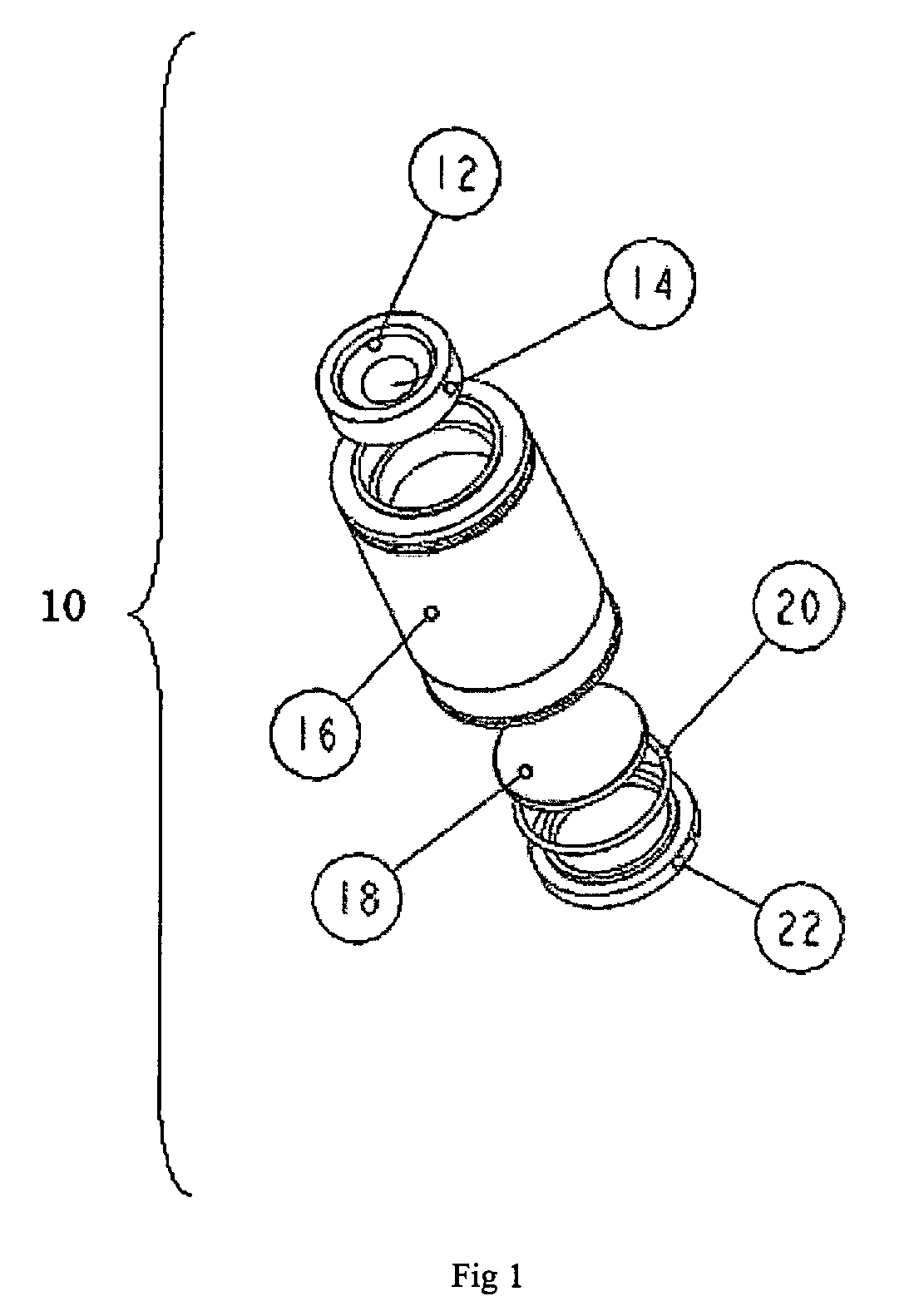

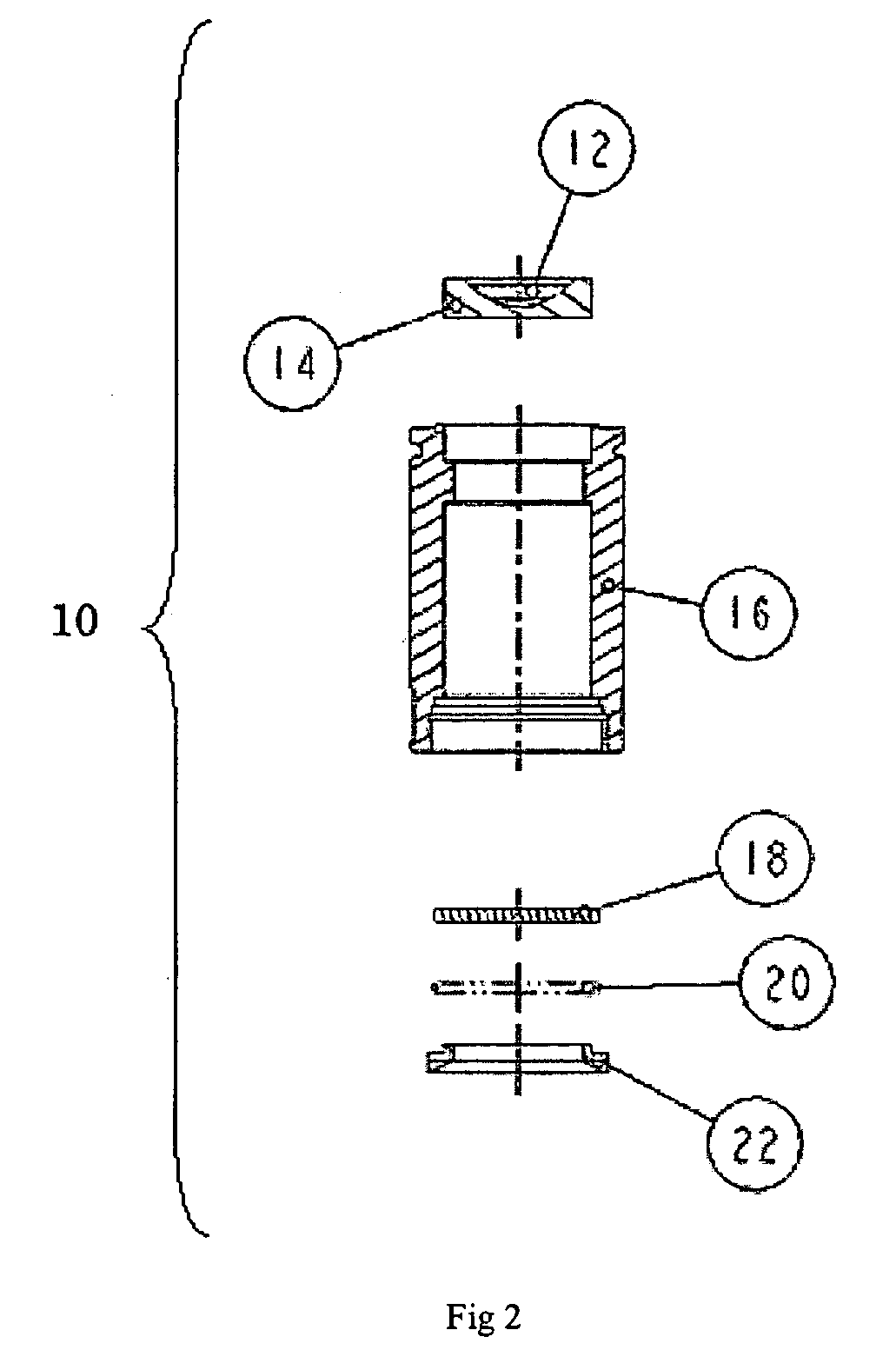

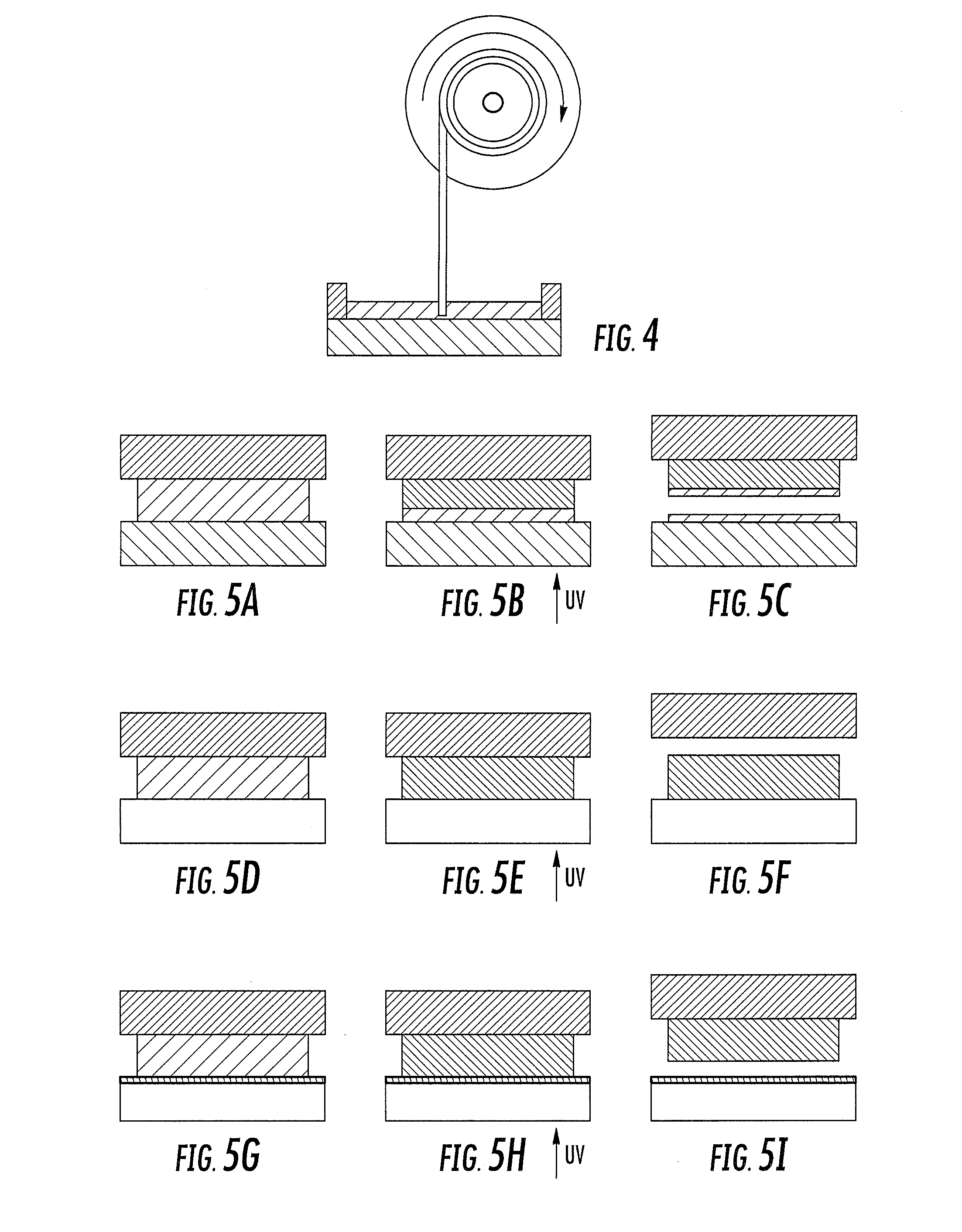

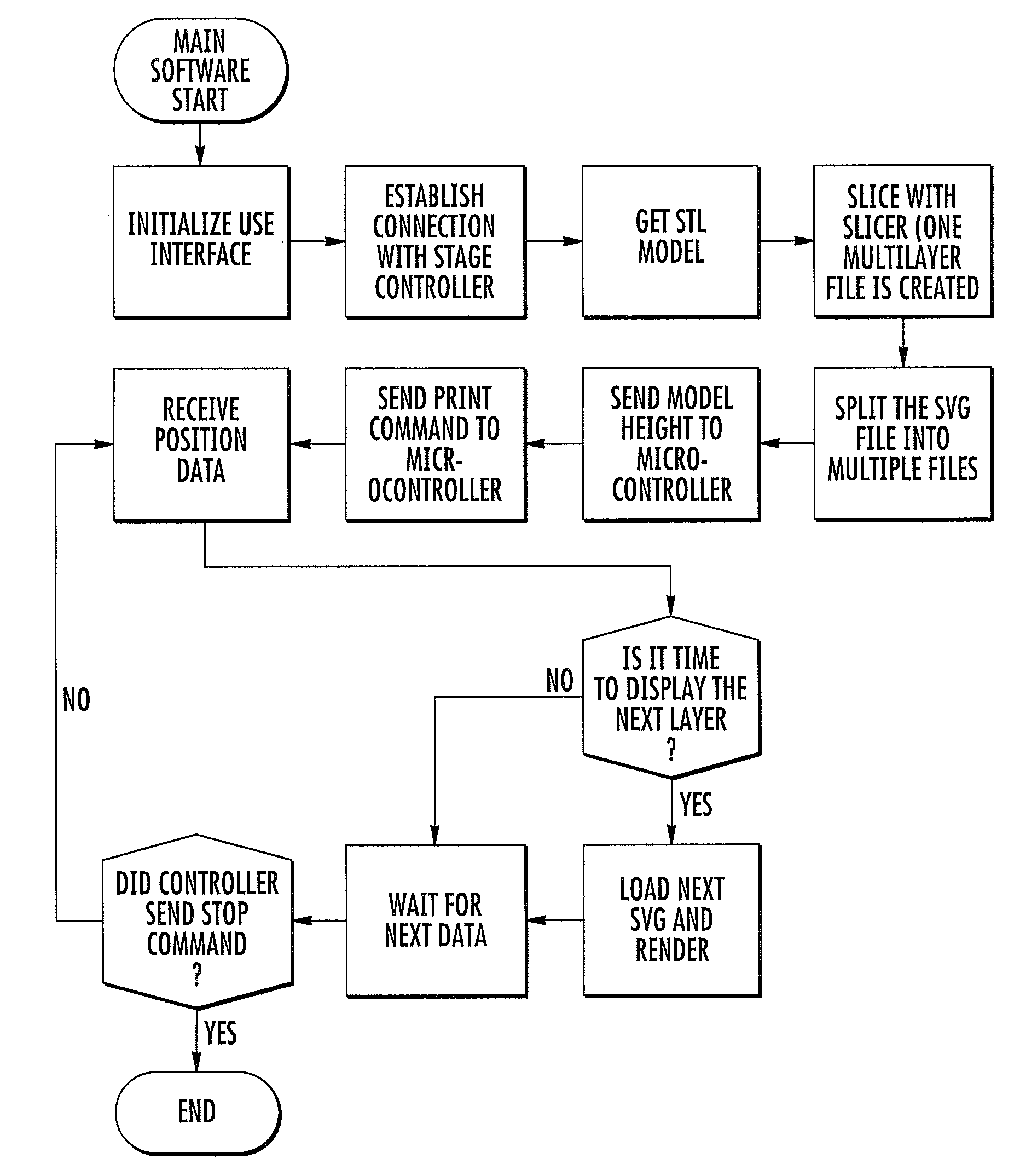

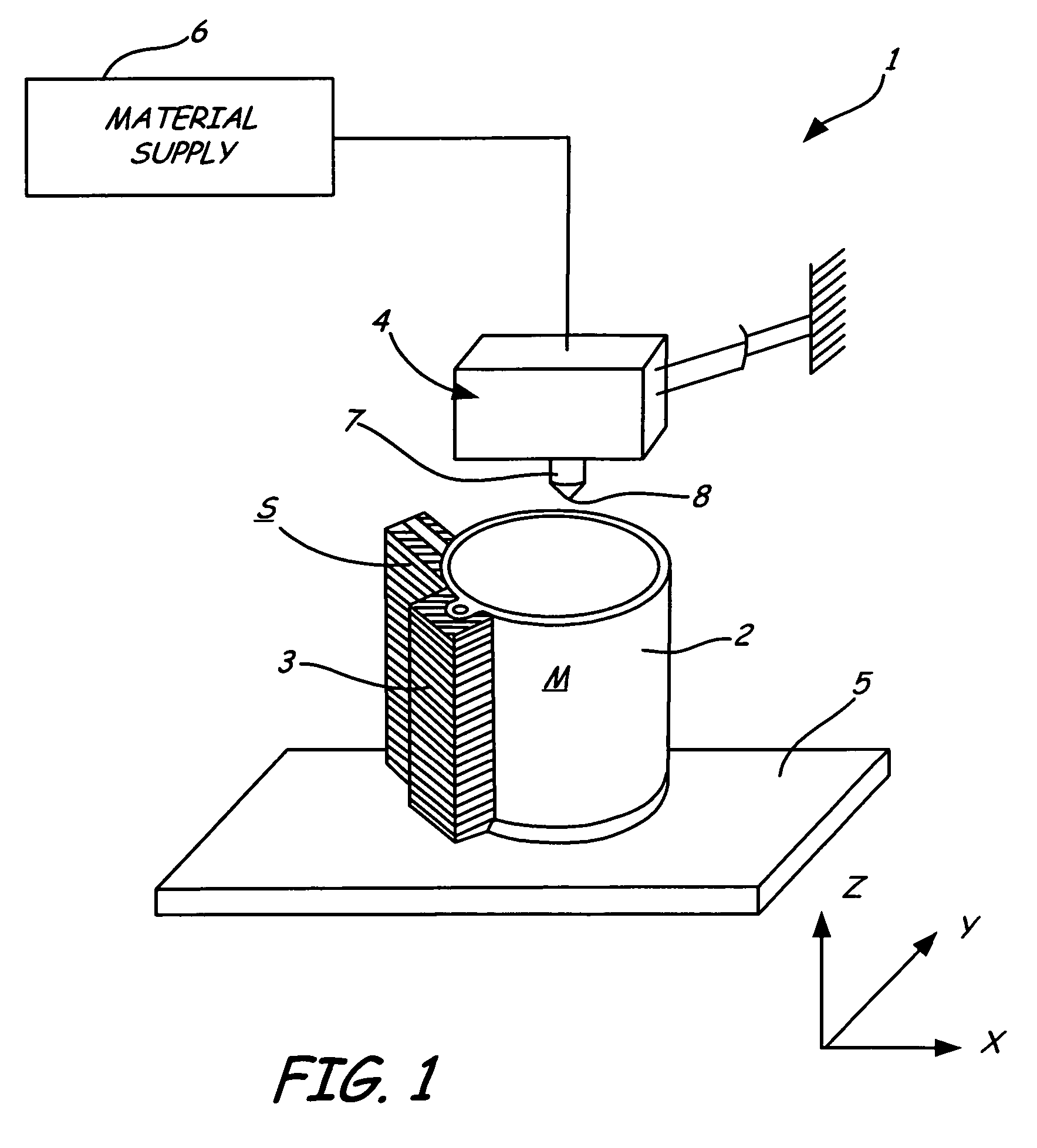

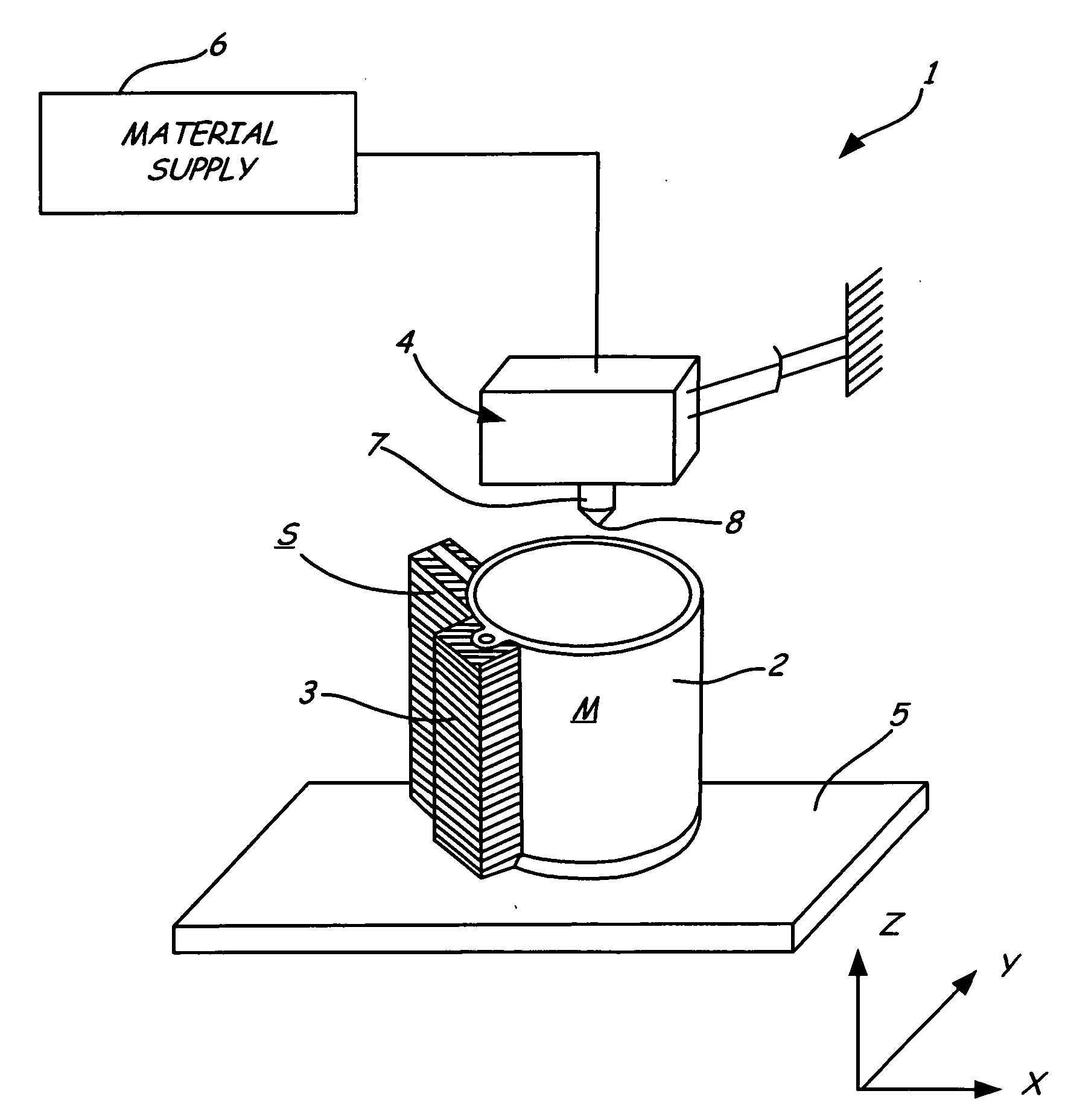

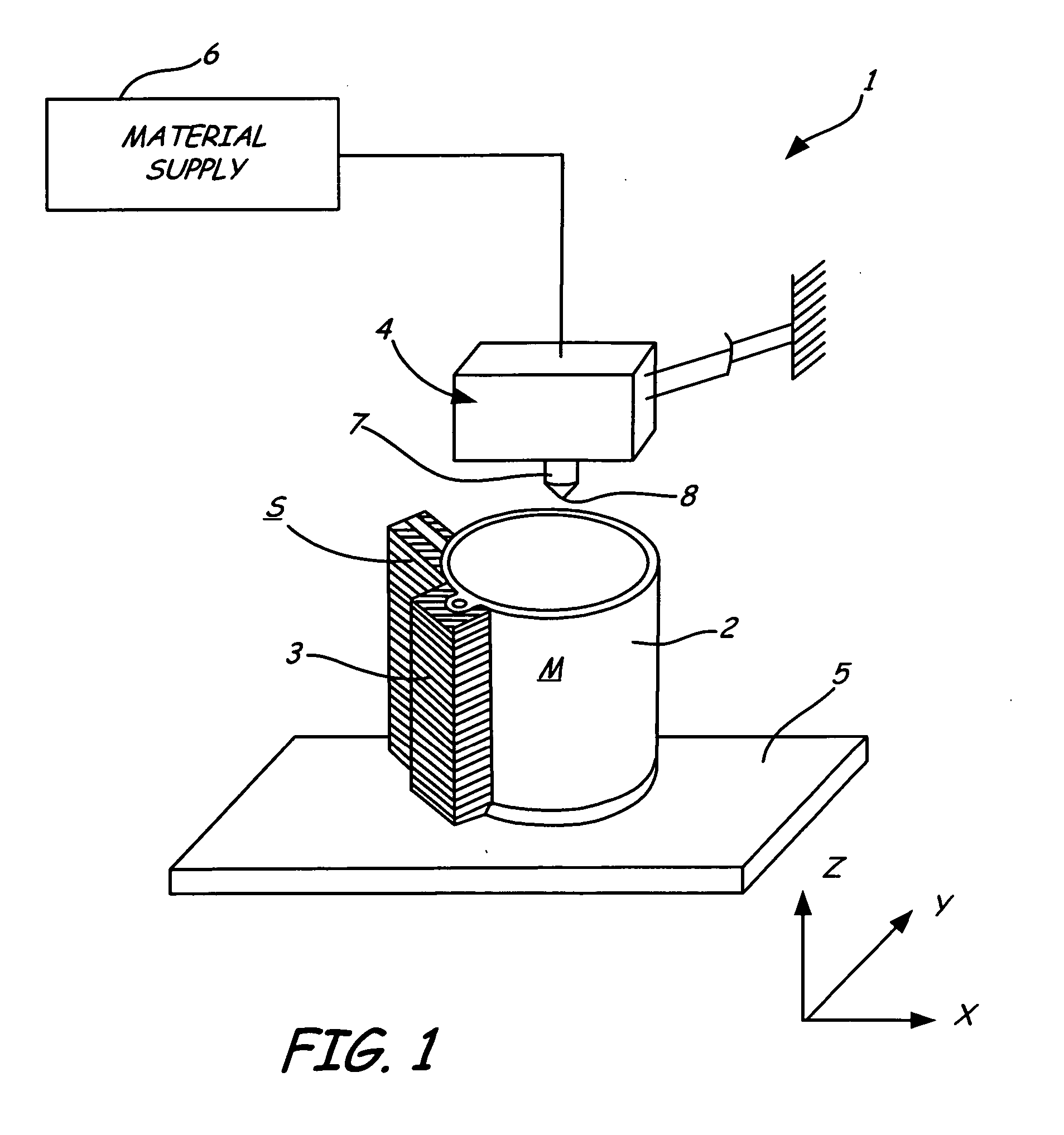

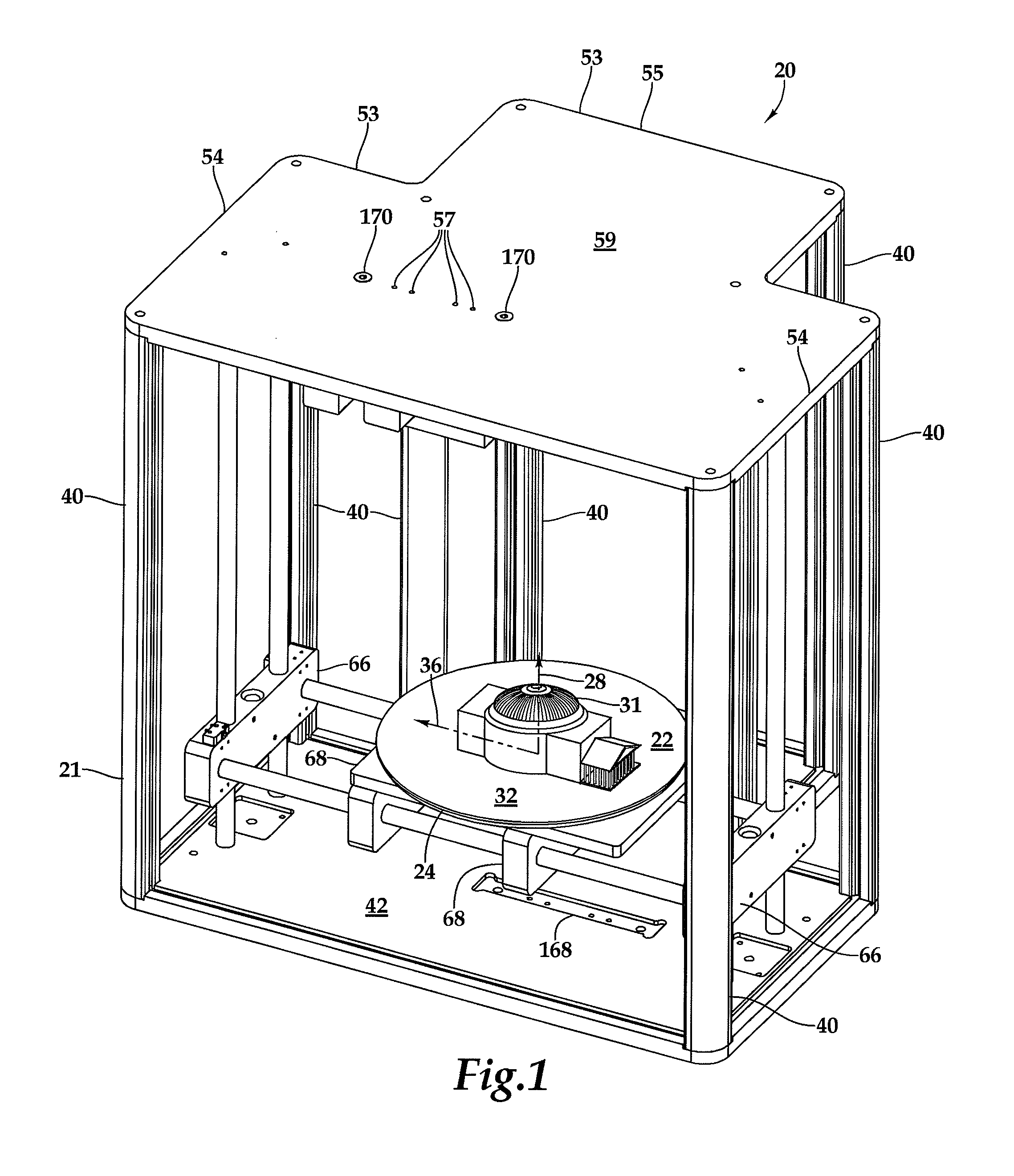

3D printing using spiral buildup

ActiveUS20140265034A1High and accurate level of detailShort timeManufacturing platforms/substratesManufacturing driving meansSingle CenterPhotopolymer

Methods, devices and systems for efficient 3D printing that address conventional inefficiencies while utilizing a single compact device are set forth. Some embodiments utilize a circular-shaped build area revolving symmetrically around a single center point utilizing a continuous helical printing process. In one embodiment a liquid photopolymer for solidification is deposited on a build platform to form the physical object The Build platform is continuously rotated and simultaneously raised in a gradual programmed manner. Focused from below the platform produces a single continuous “layer” of material deposited and bonded in a helical fashion.

Owner:ORANGE MAKER

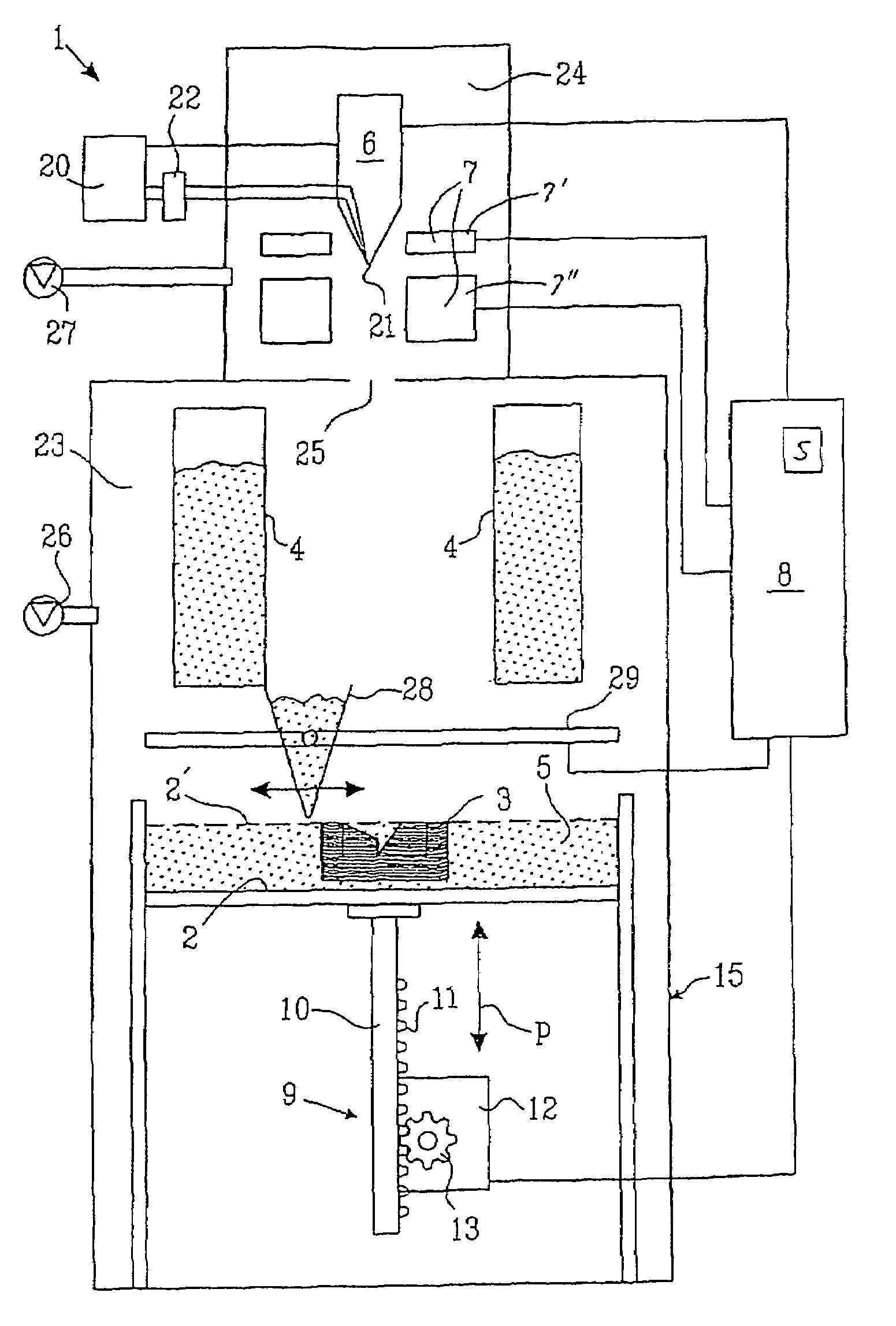

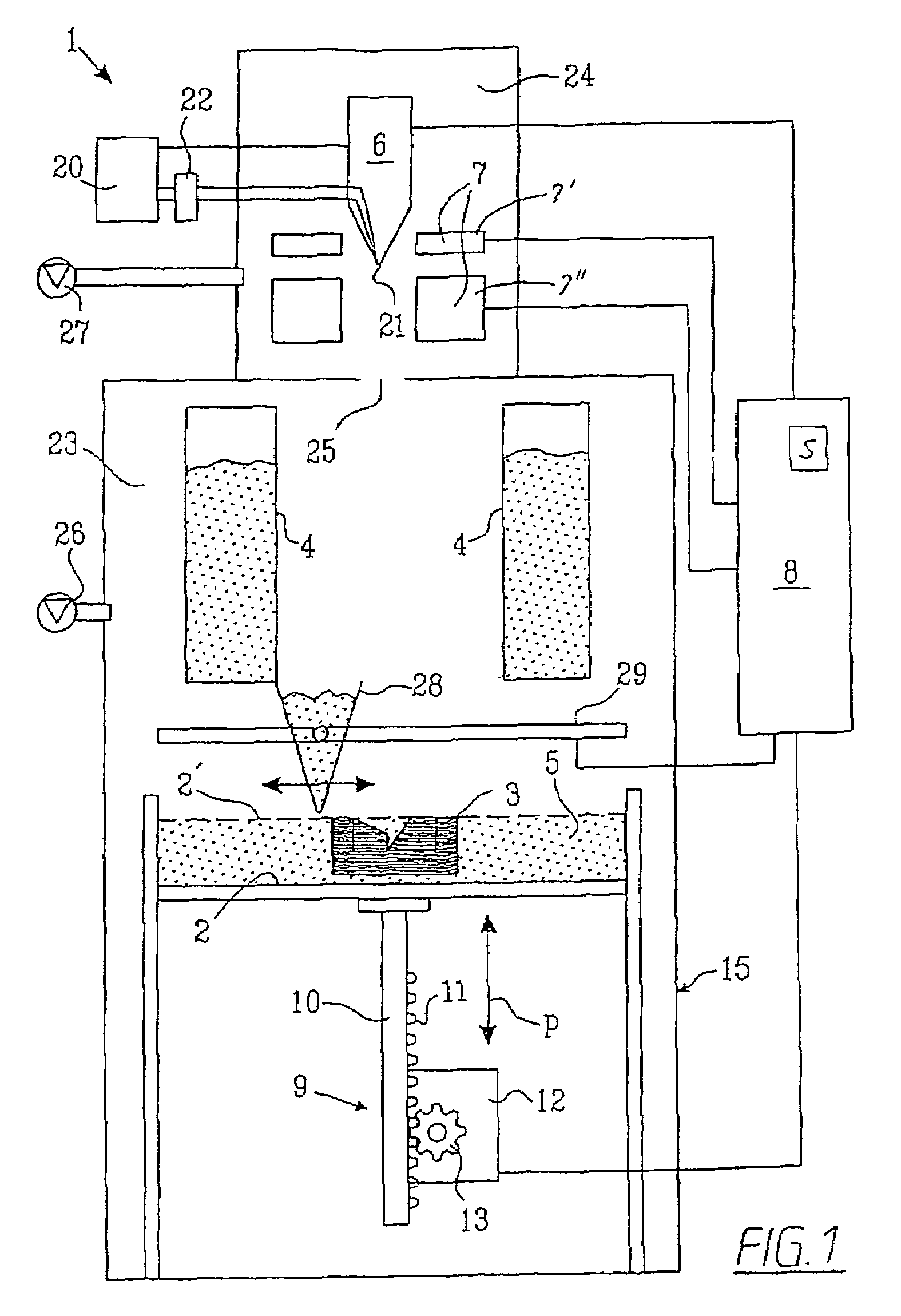

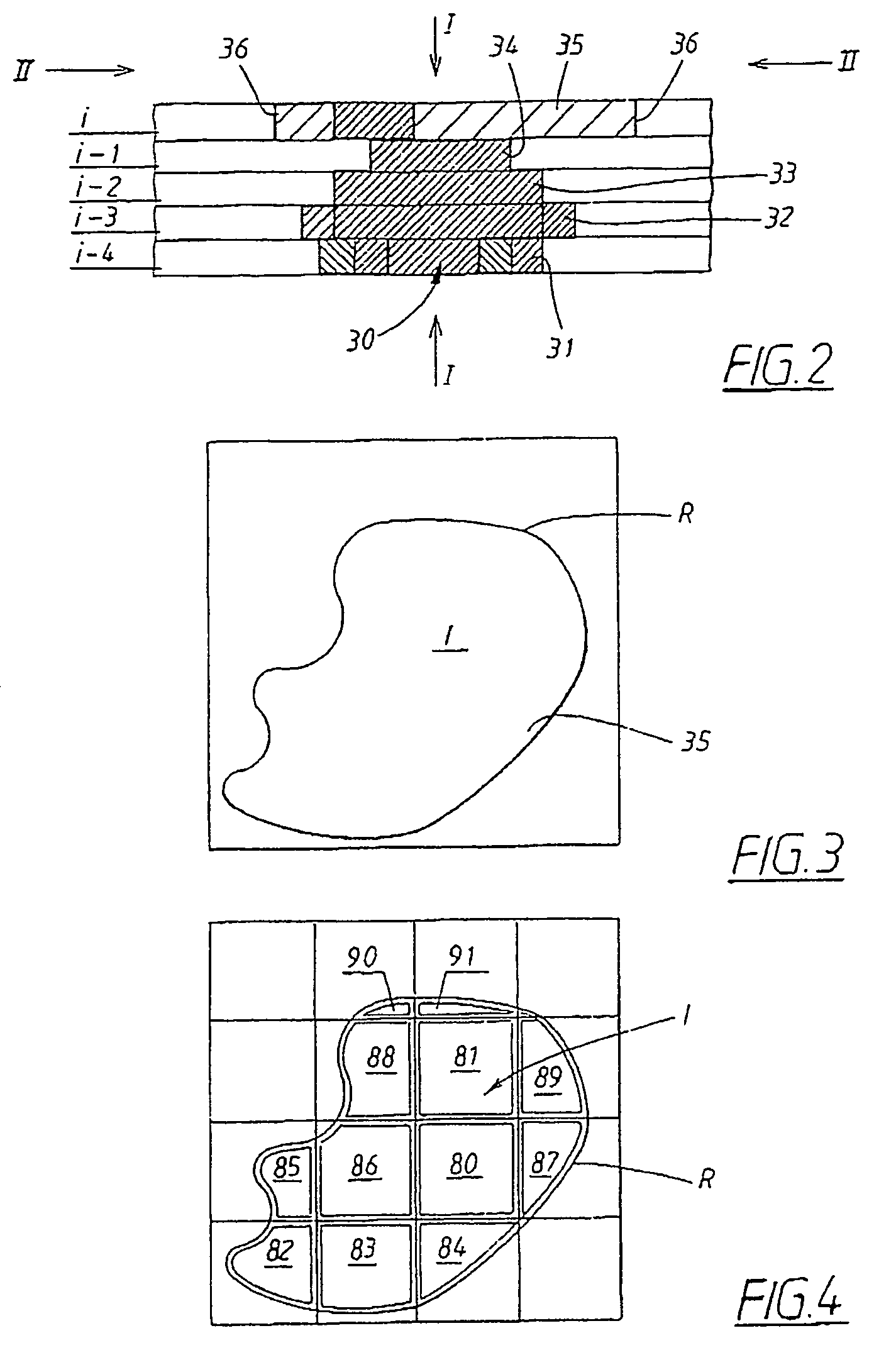

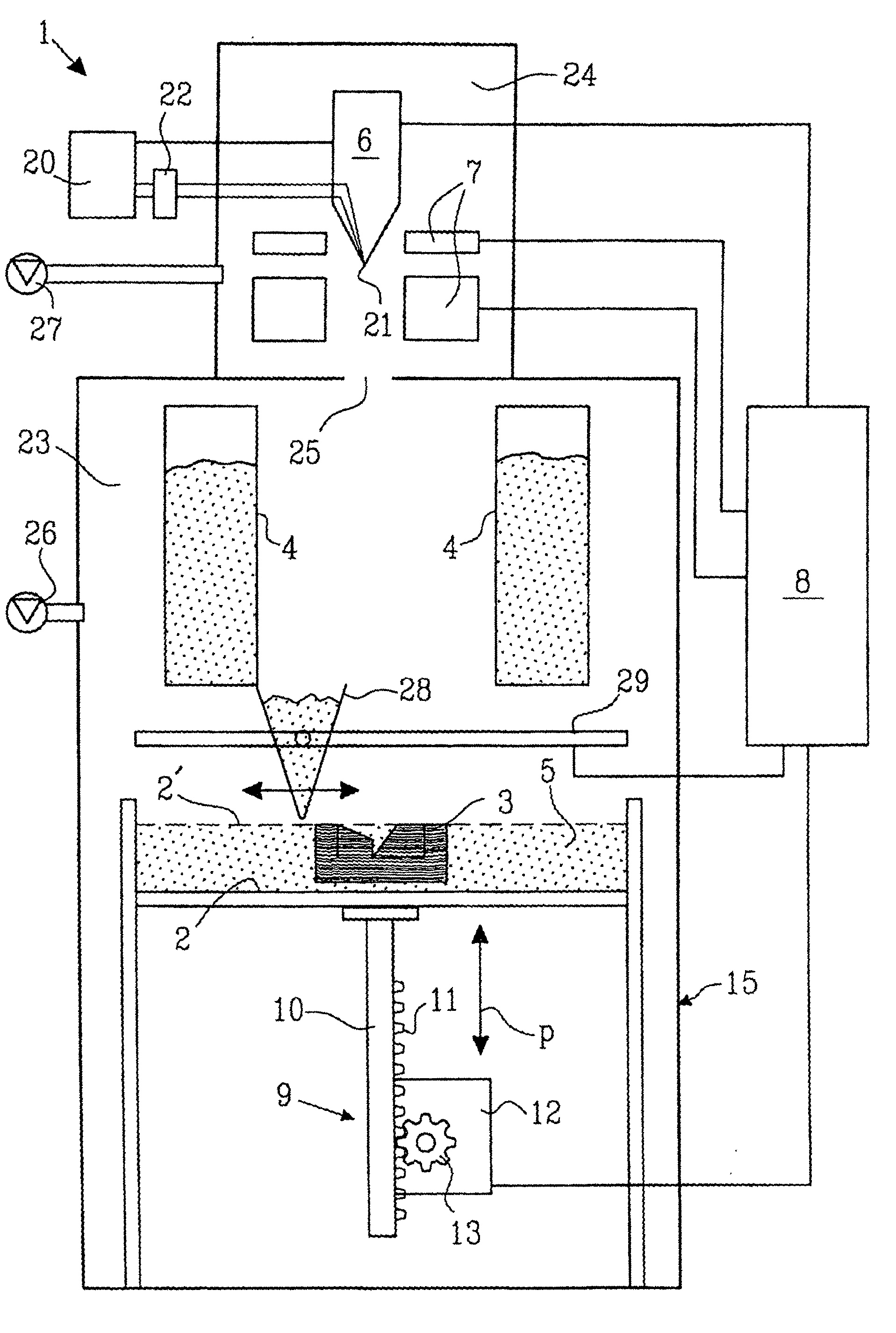

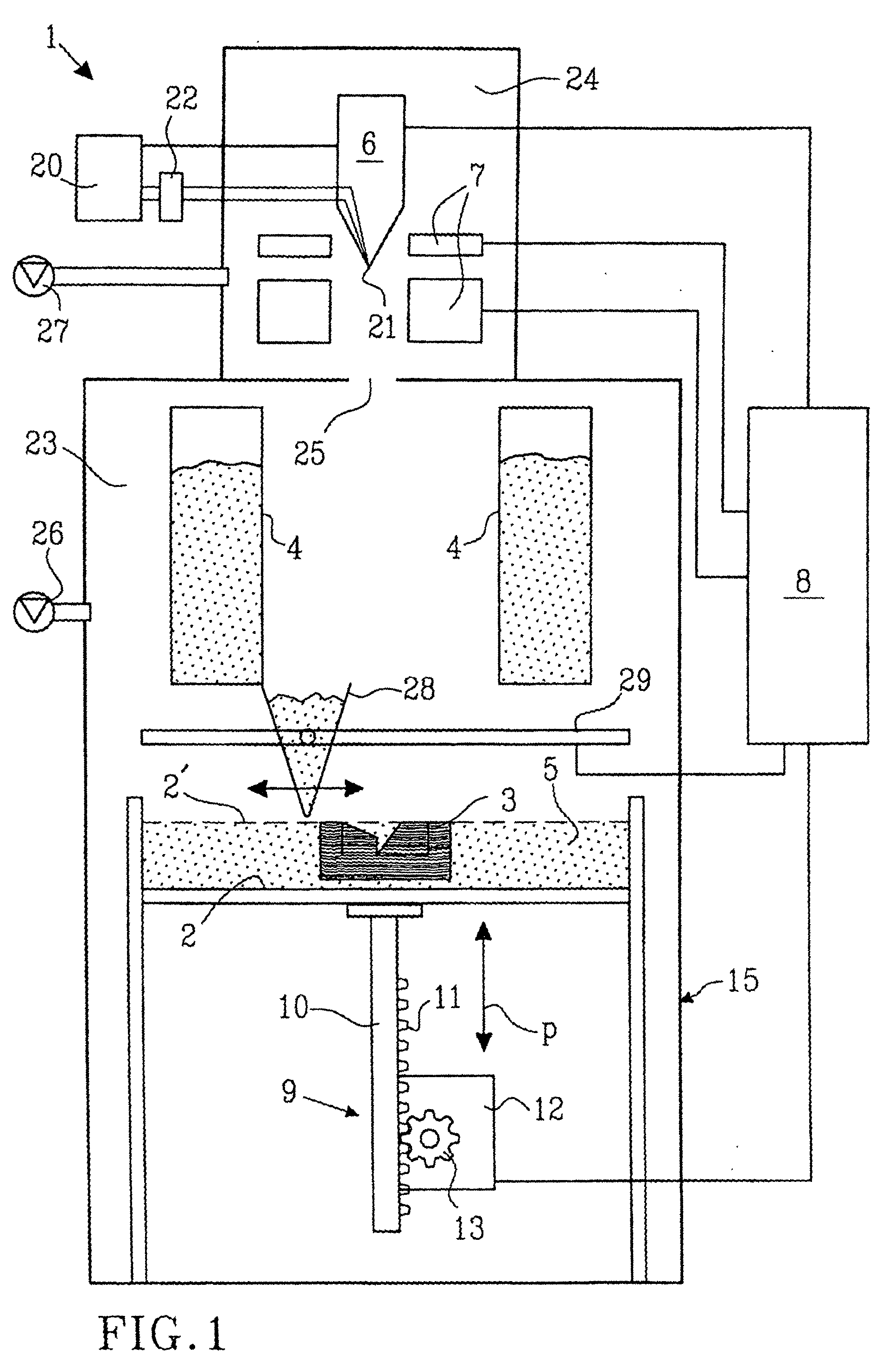

Process and freeform fabrication system for producing a three-dimensional object

ActiveUS8110135B2Increase freedomAdditive manufacturing apparatusAuxillary shaping apparatusEnergy densityElectromagnetic radiation

The present invention describes a process for producing a three-dimensional object, comprising: providing a material to be solidified, the material comprising a filler and a binder; delivering electromagnetic radiation and / or synergistic stimulation in a pattern or an image to a building region for solidifying said material; wherein said delivering of electromagnetic radiation and / or synergistic stimulation is performed selectively to a defined area or volume of said material to be solidified; and wherein an energy density of electromagnetic radiation and / or synergistic stimulation is varied within said pattern or image and / or between patterns or images of different building regions of said material. The present invention may be directed also to a system where different first and second materials are to be solidified. The present invention further provides a freeform fabrication system, and a freeform three-dimensional object having unique properties as well as products derived therefrom, such as sintered products.

Owner:ENVISIONTEC GMBH DE

System and method for curing polymeric moldings

A system and method for forming a polymeric molding. A mold component includes a UV-absorptive material for preventing undesired reflection or transmission of curing energy within the mold cavity, thereby providing more precise control of the edge geometry of the molding.

Owner:ALCON INC

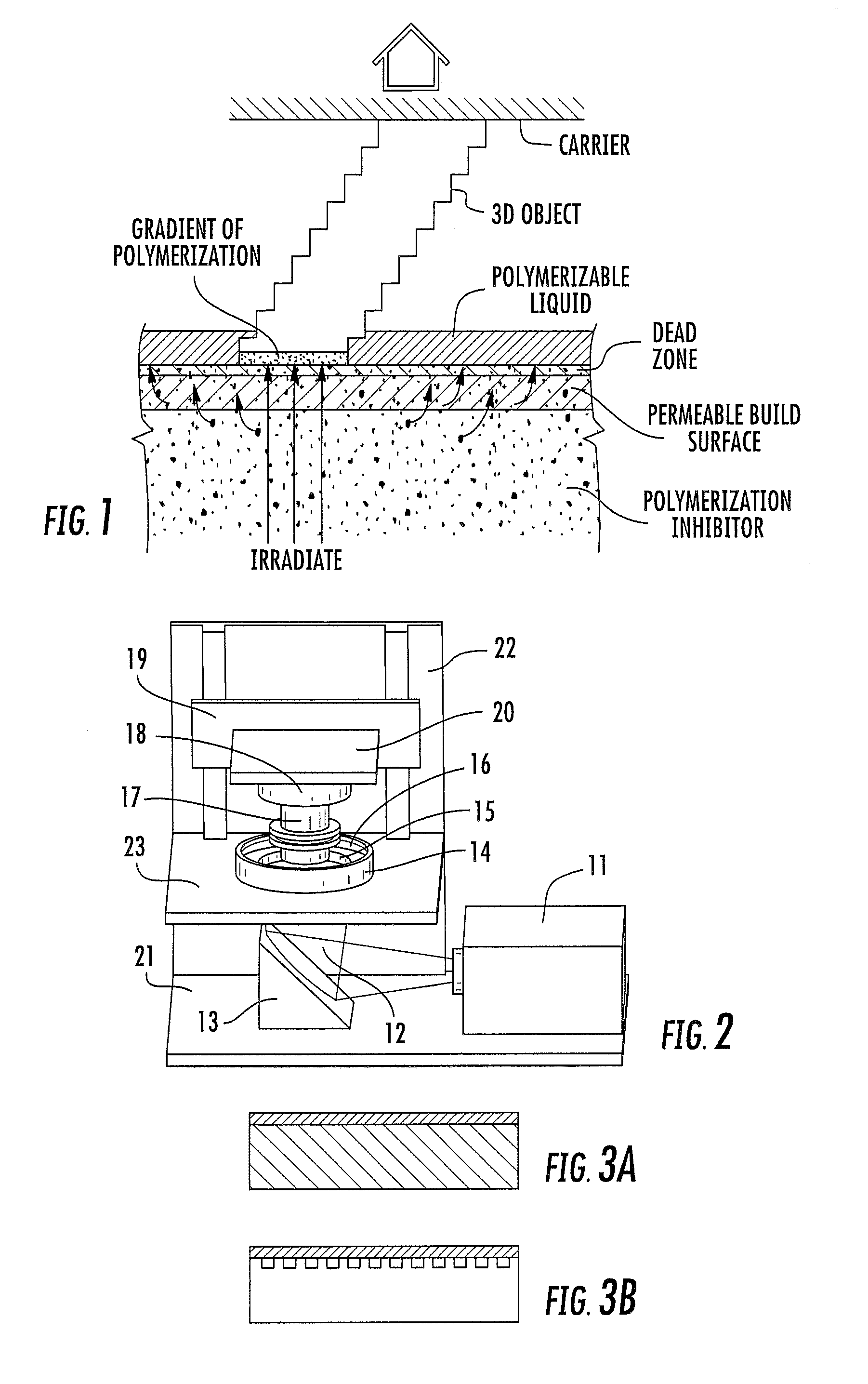

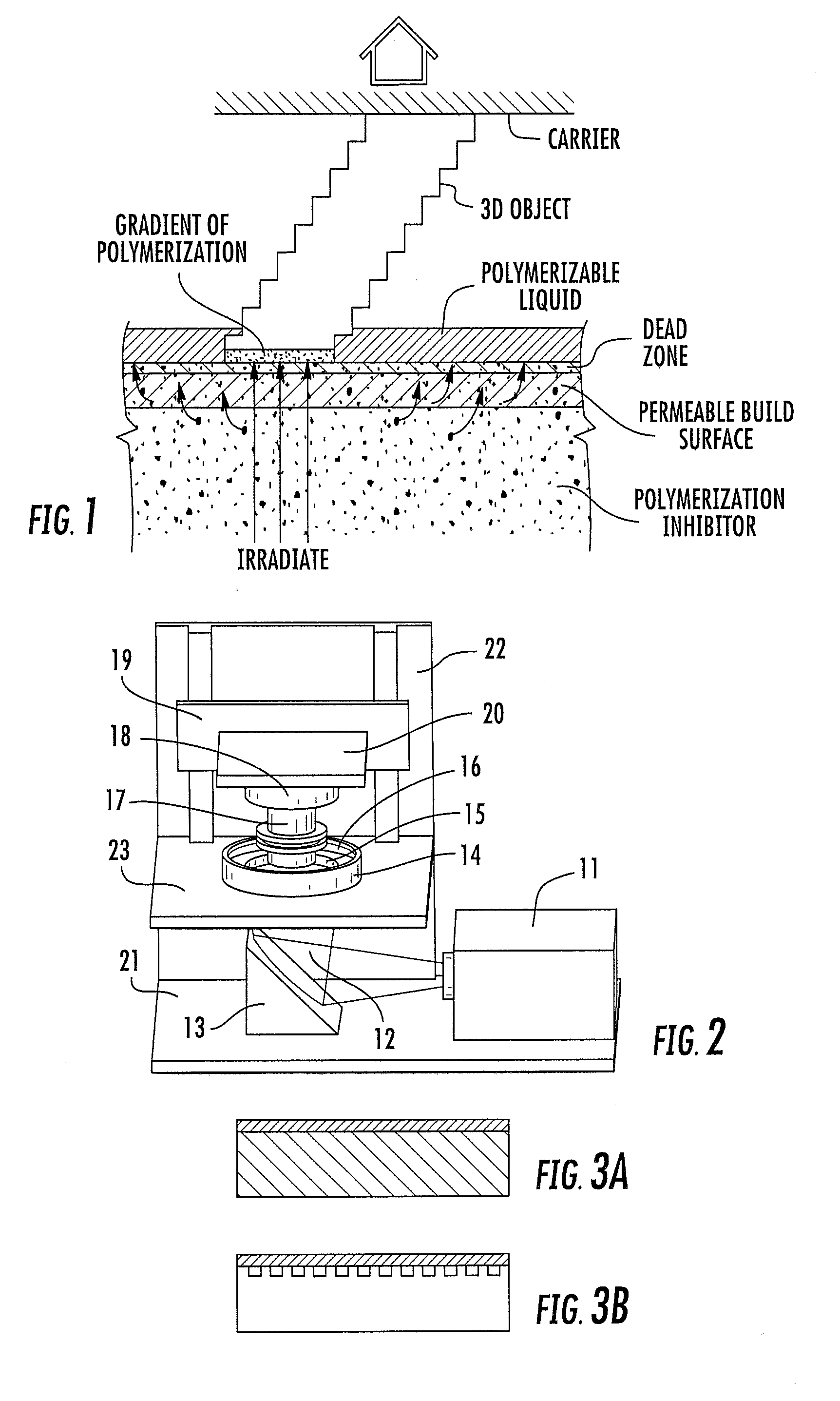

Method and apparatus for three-dimensional fabrication with feed through carrier

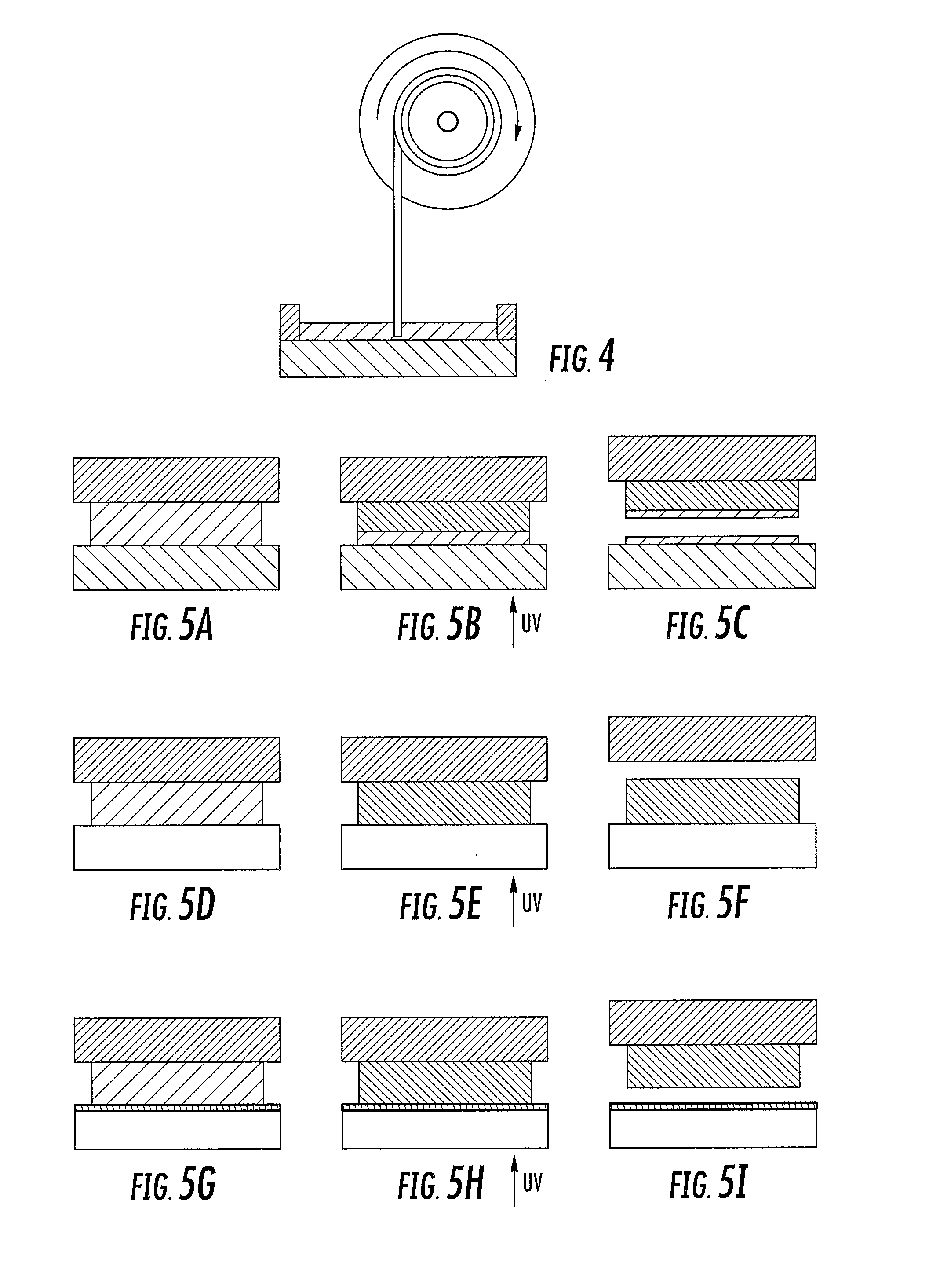

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

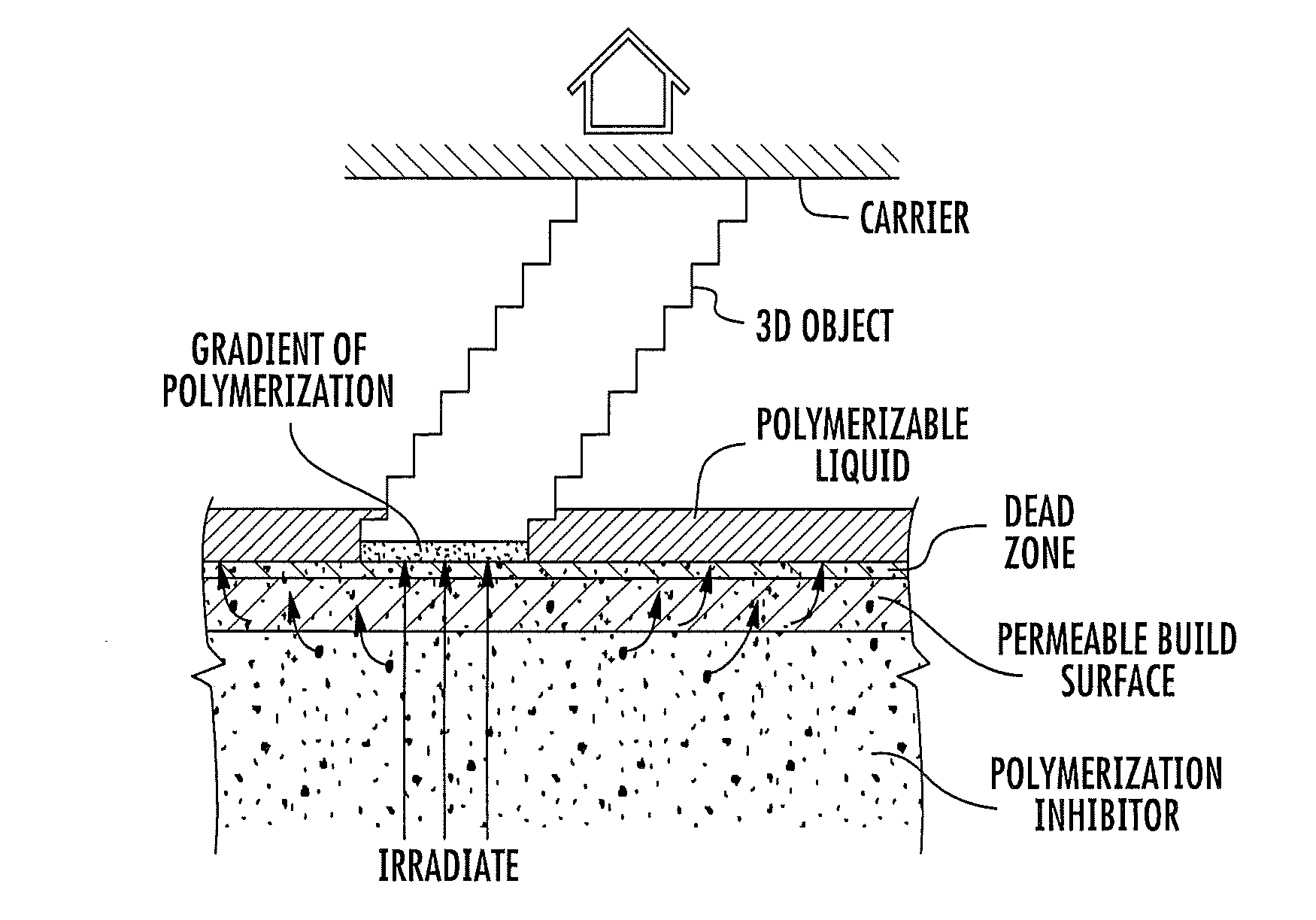

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

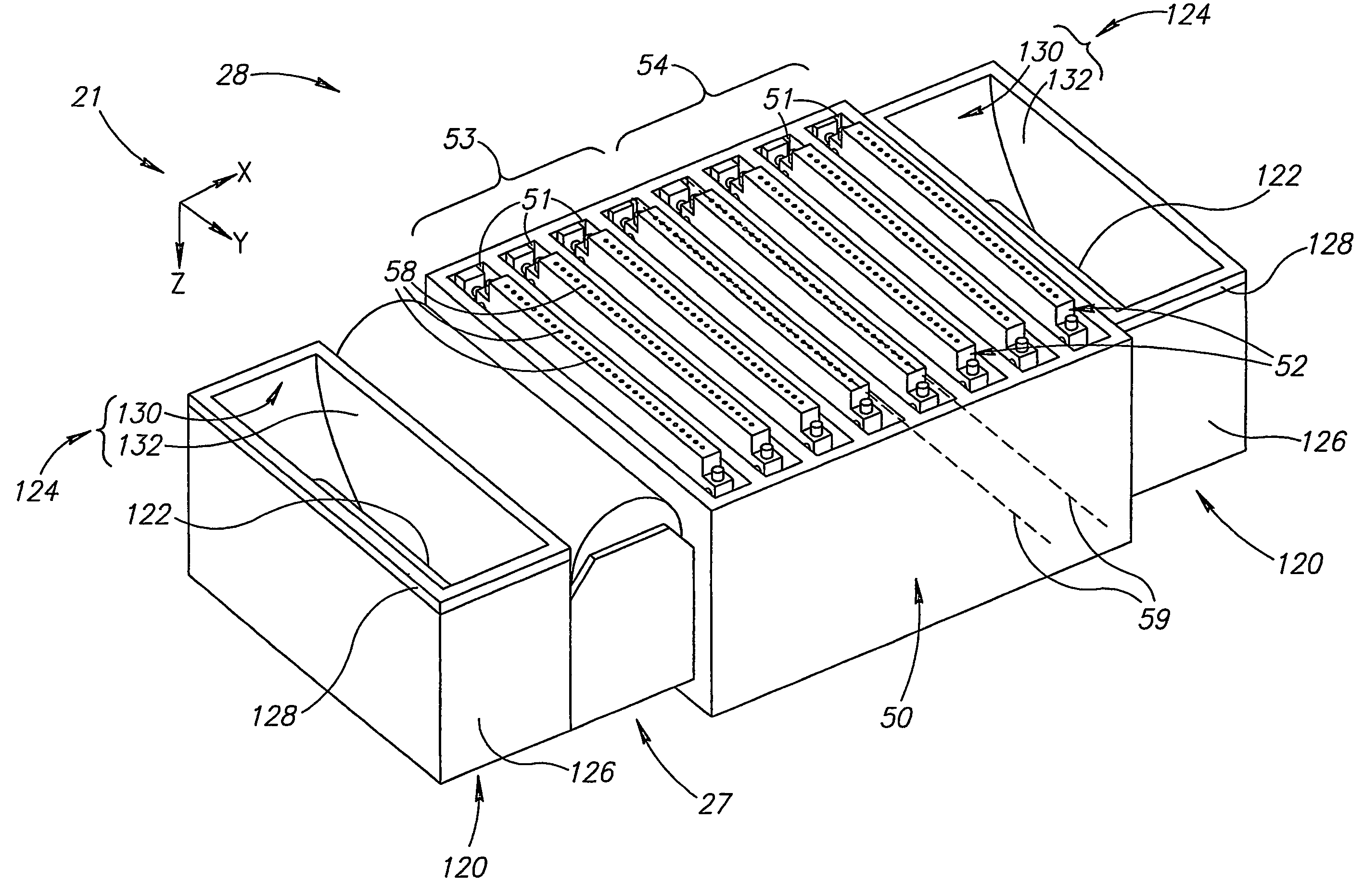

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

Continuous liquid interphase printing

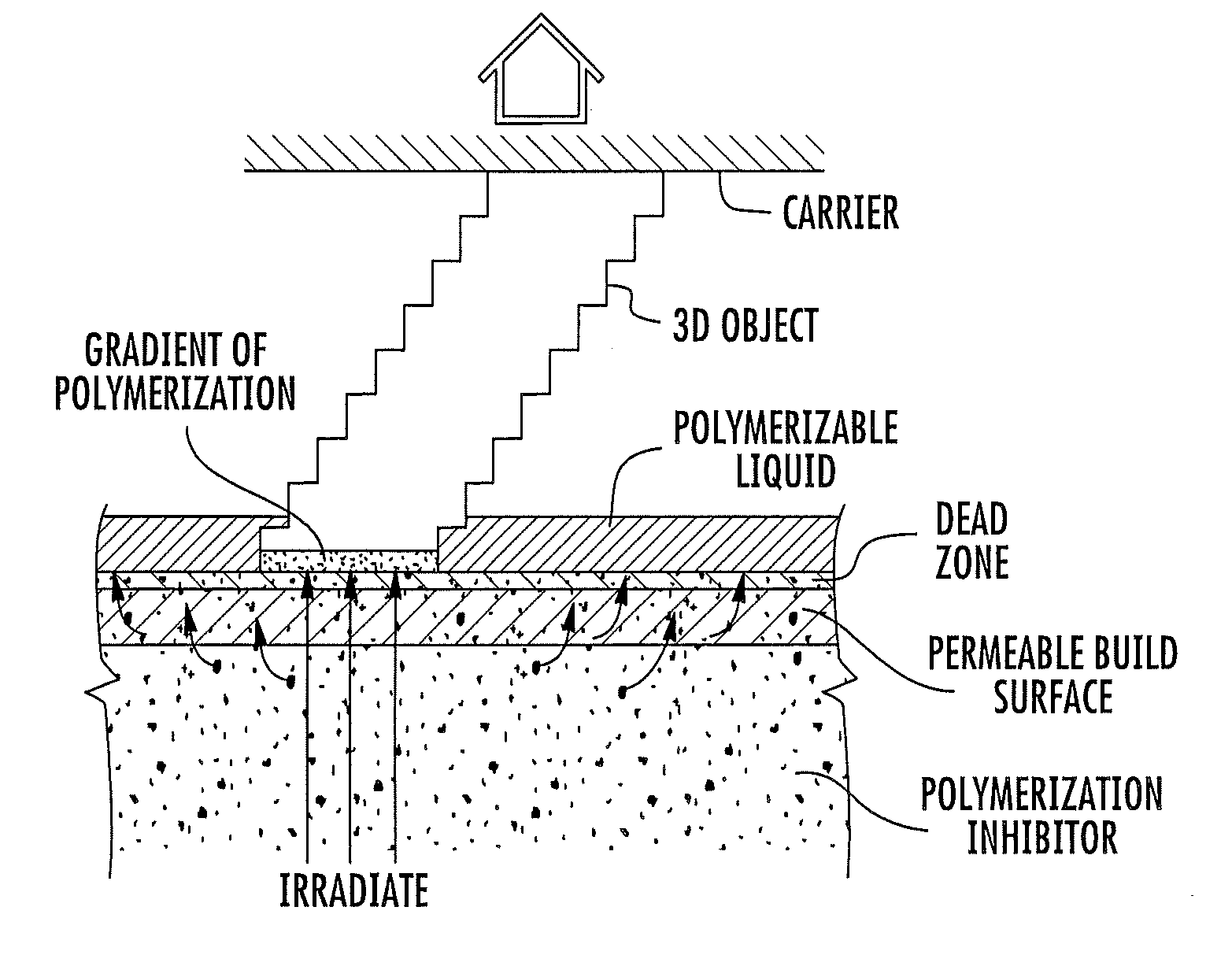

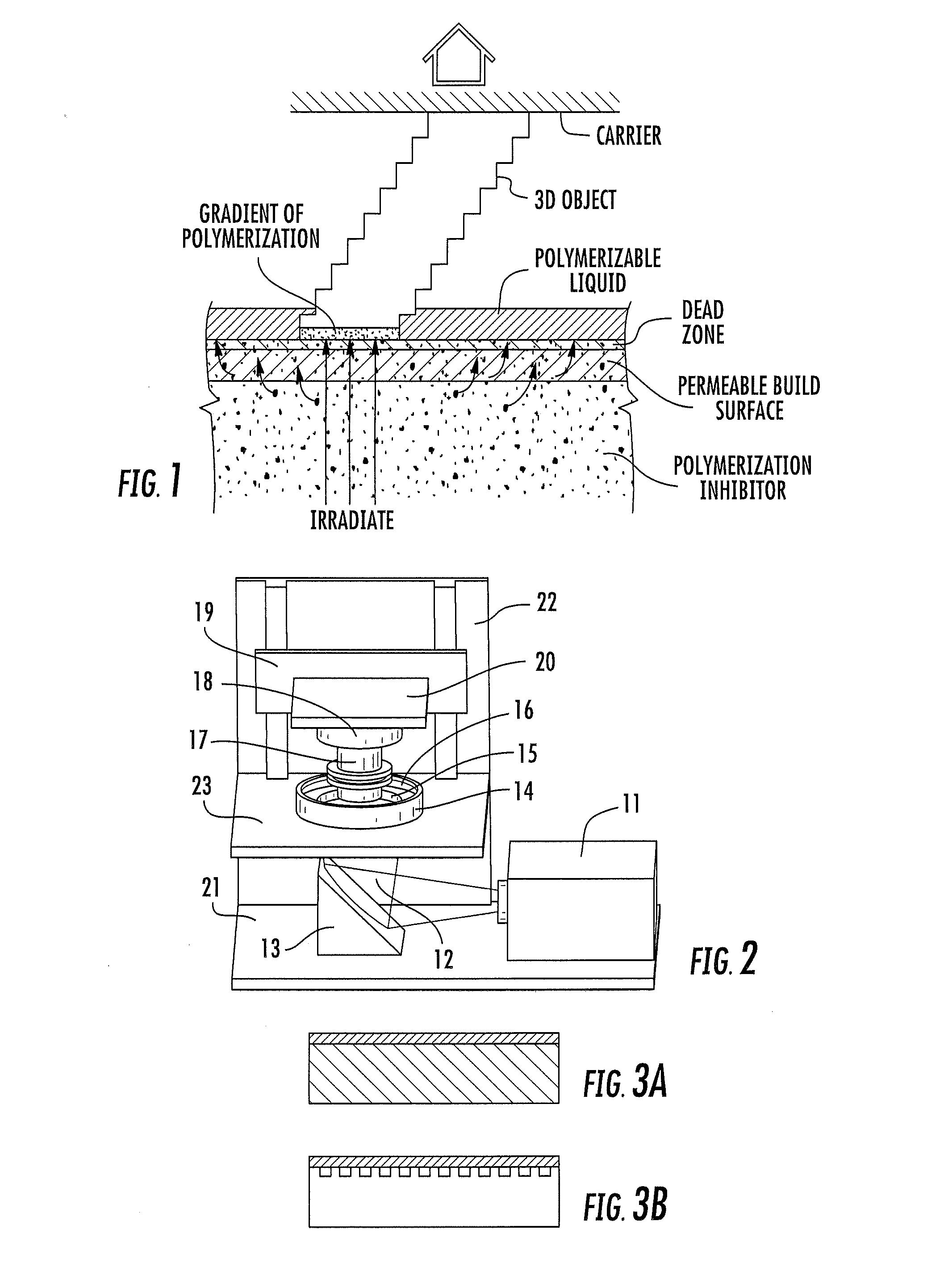

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

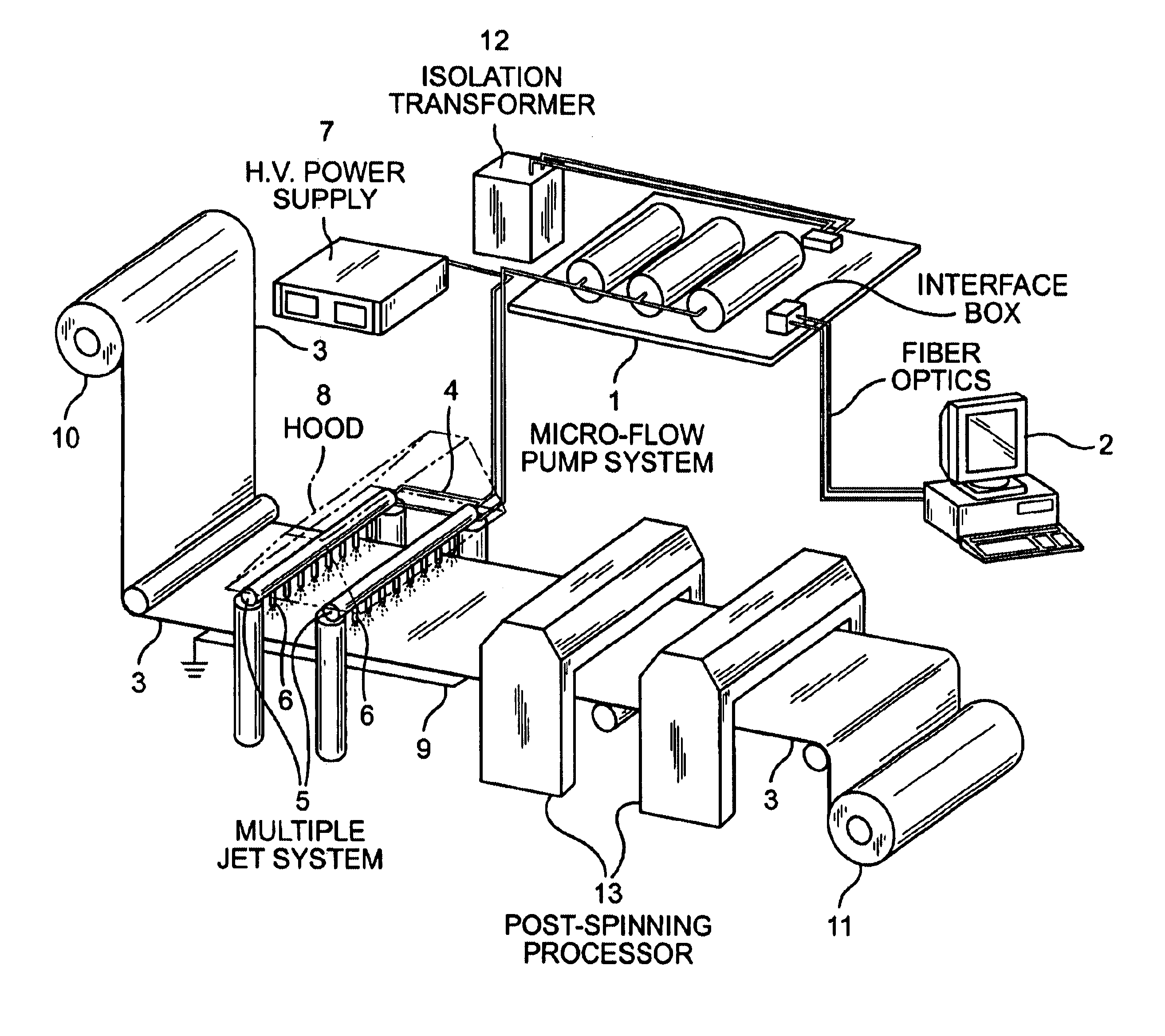

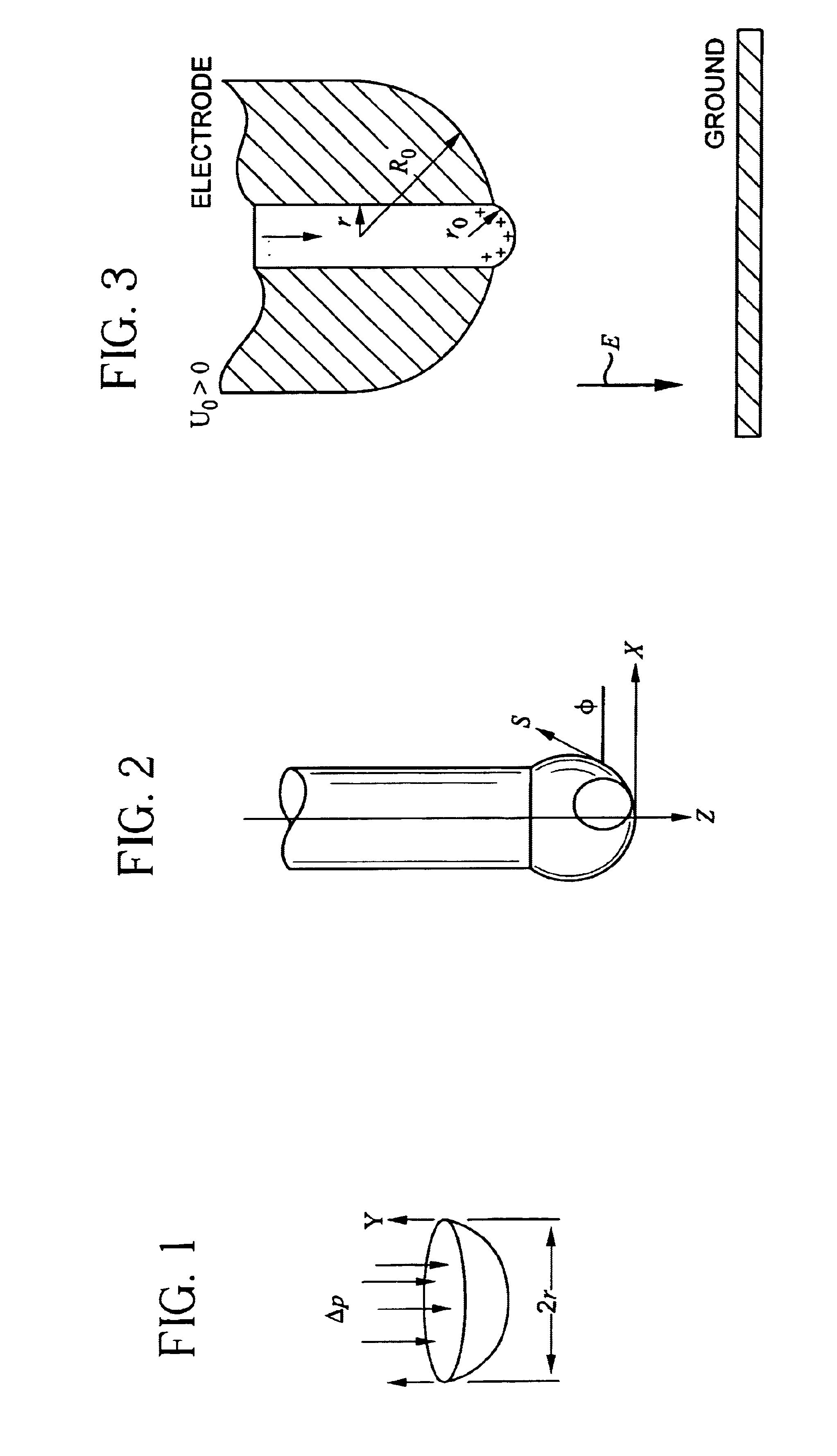

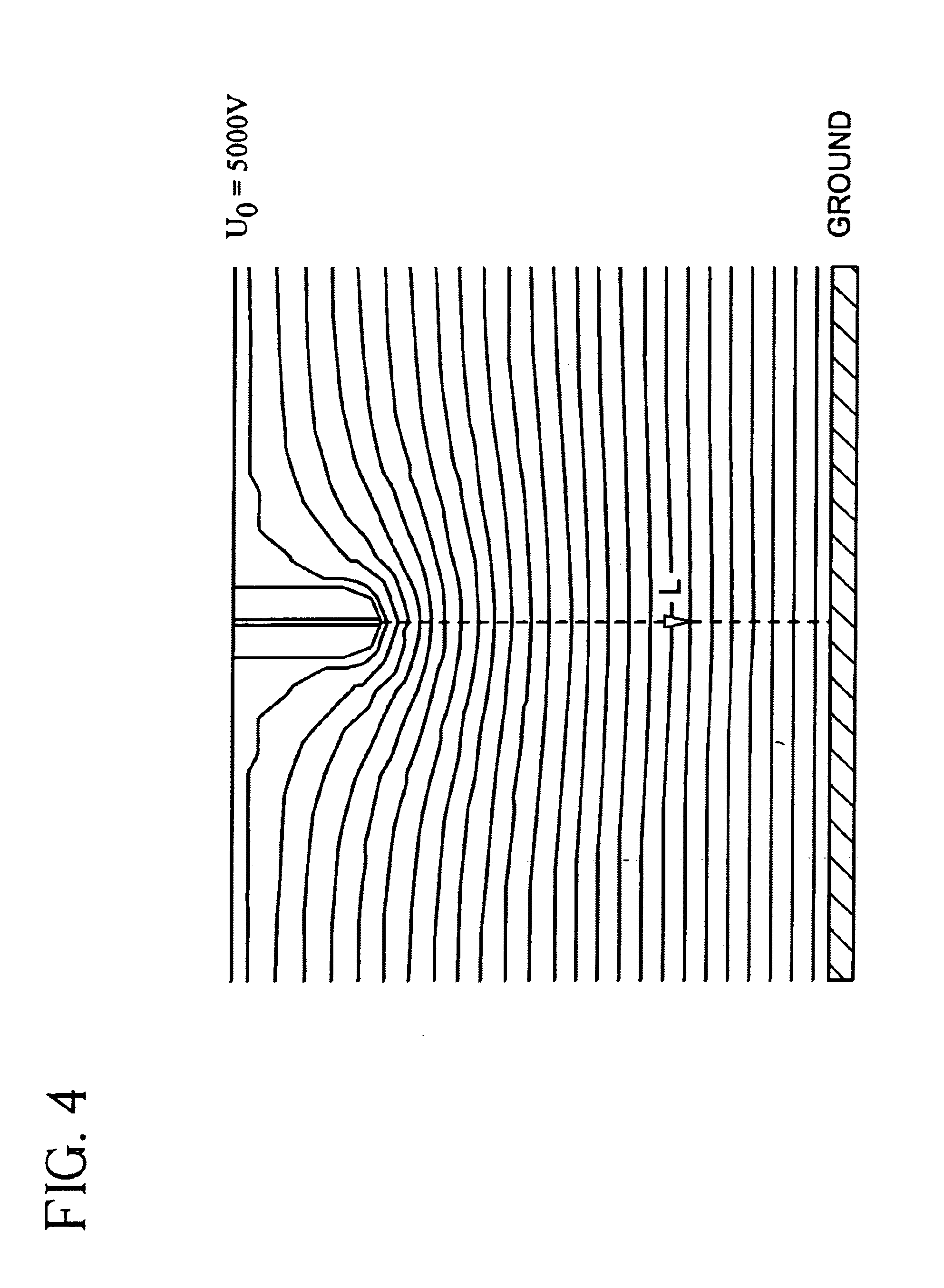

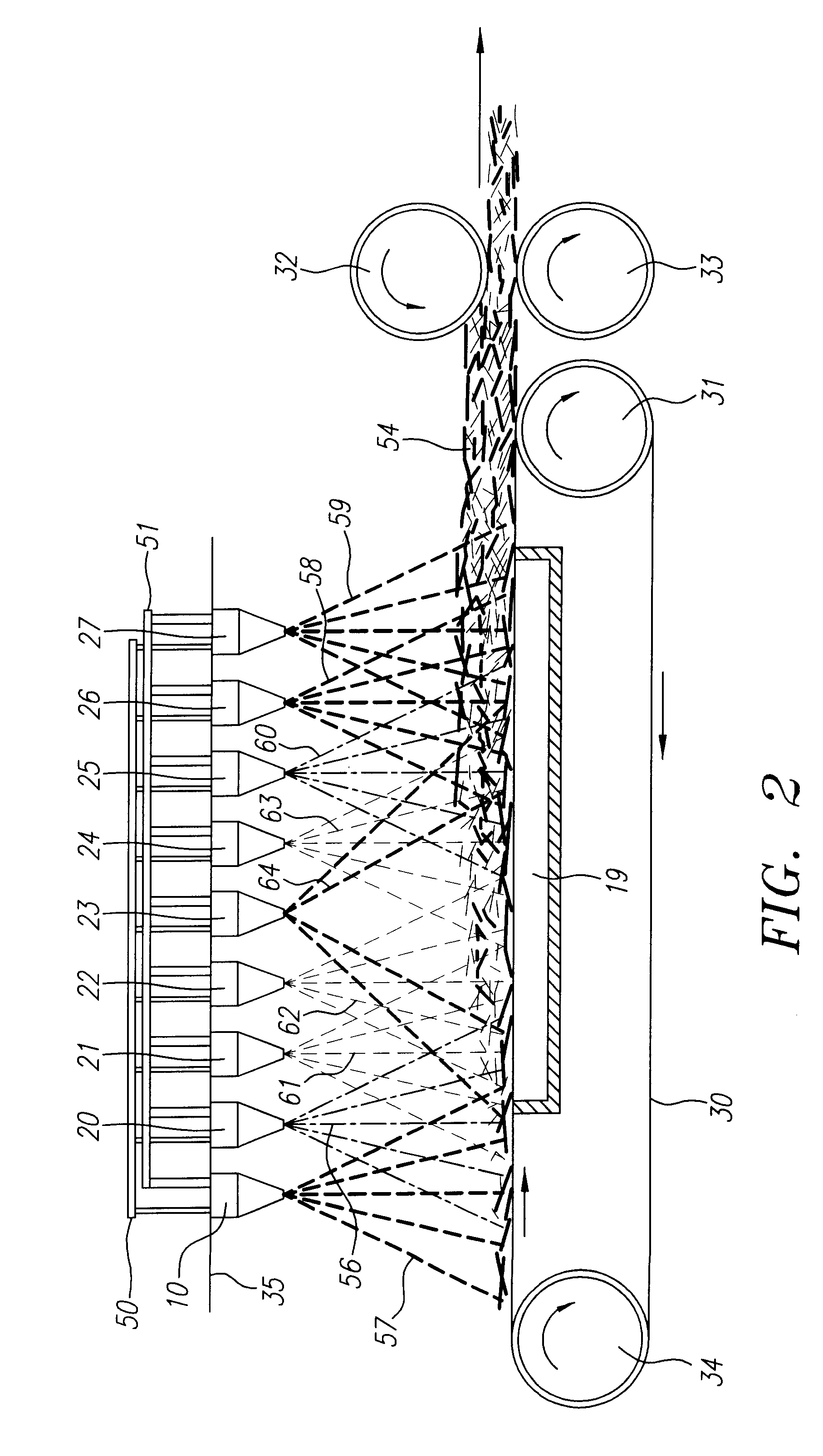

Apparatus and methods for electrospinning polymeric fibers and membranes

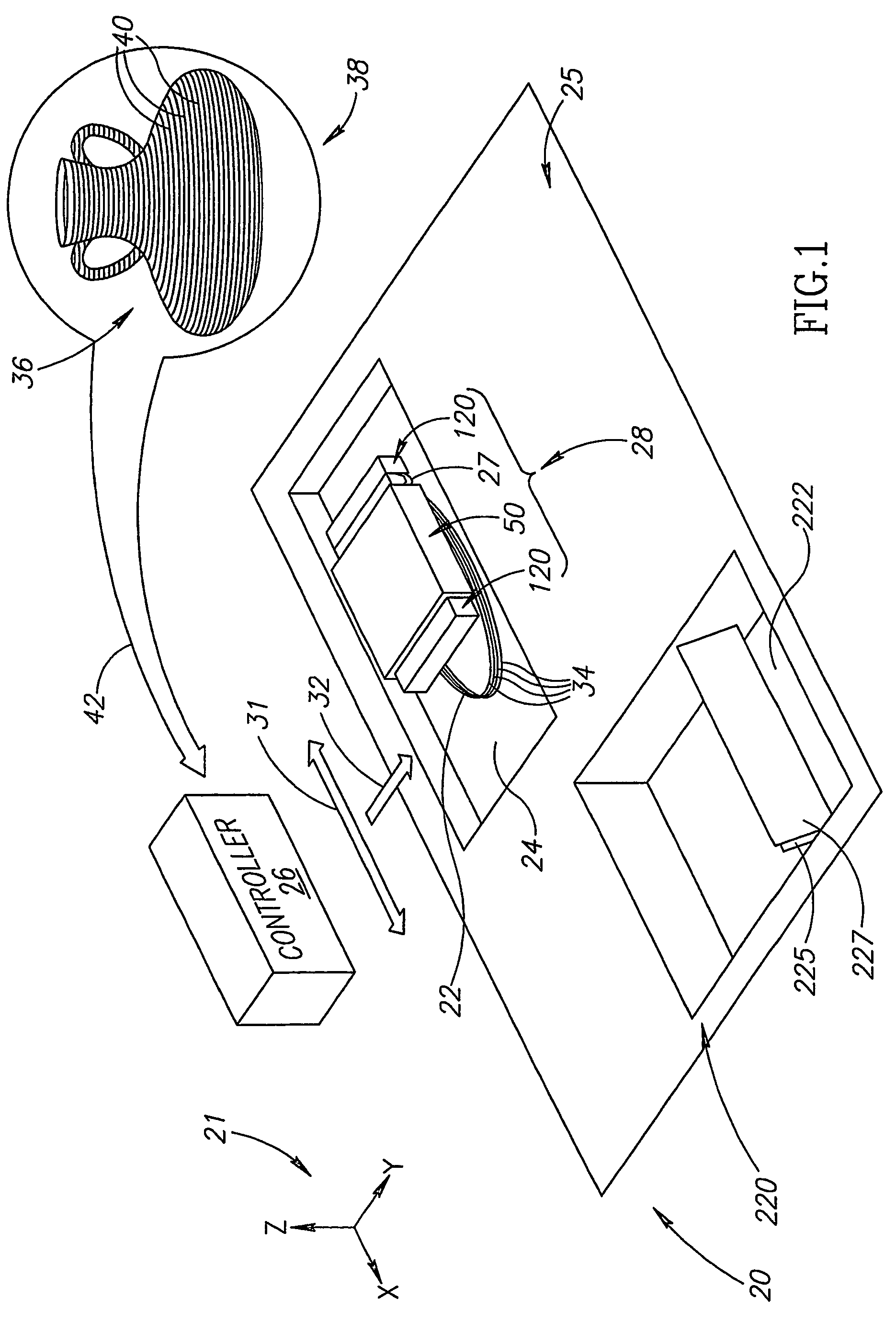

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

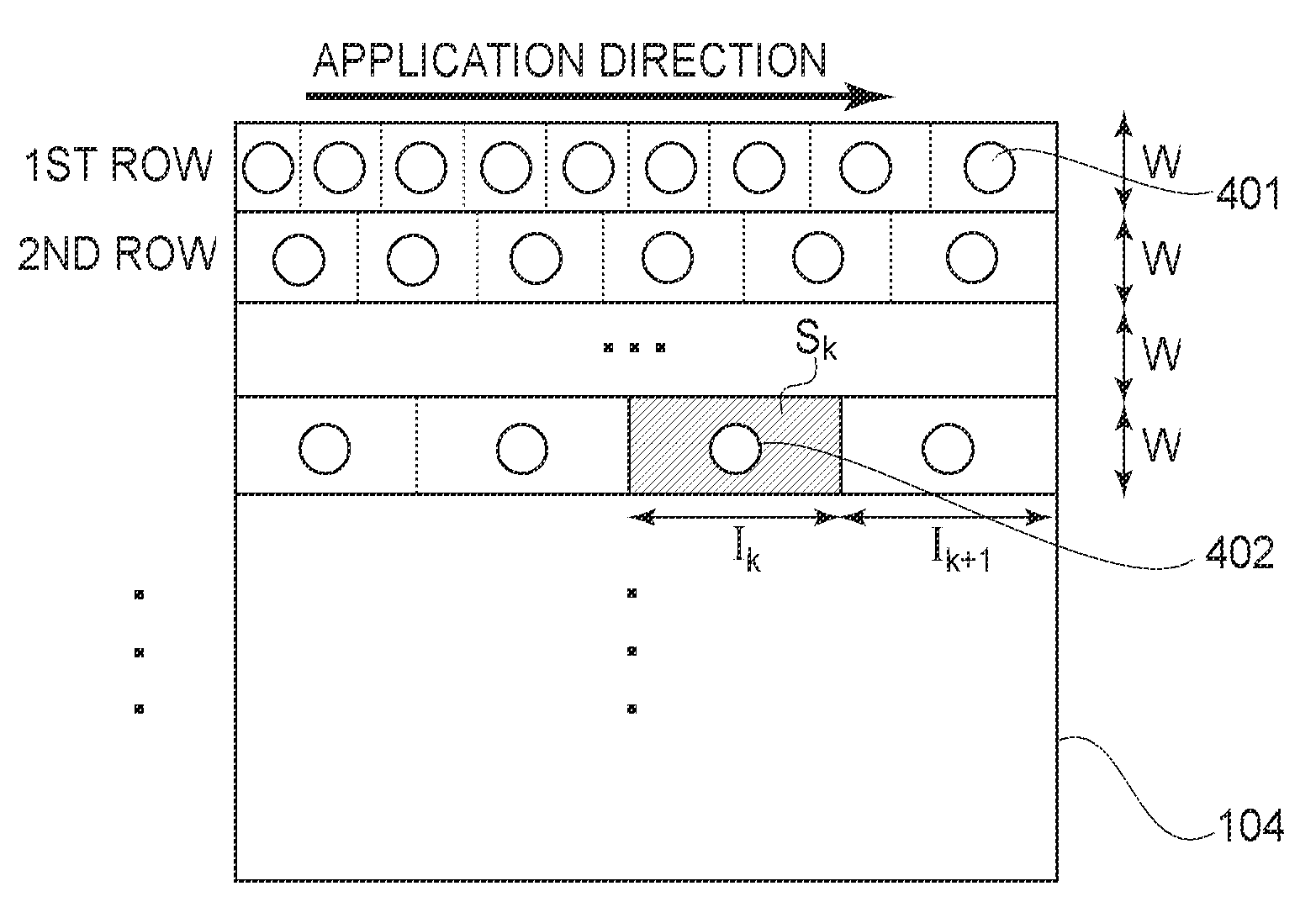

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

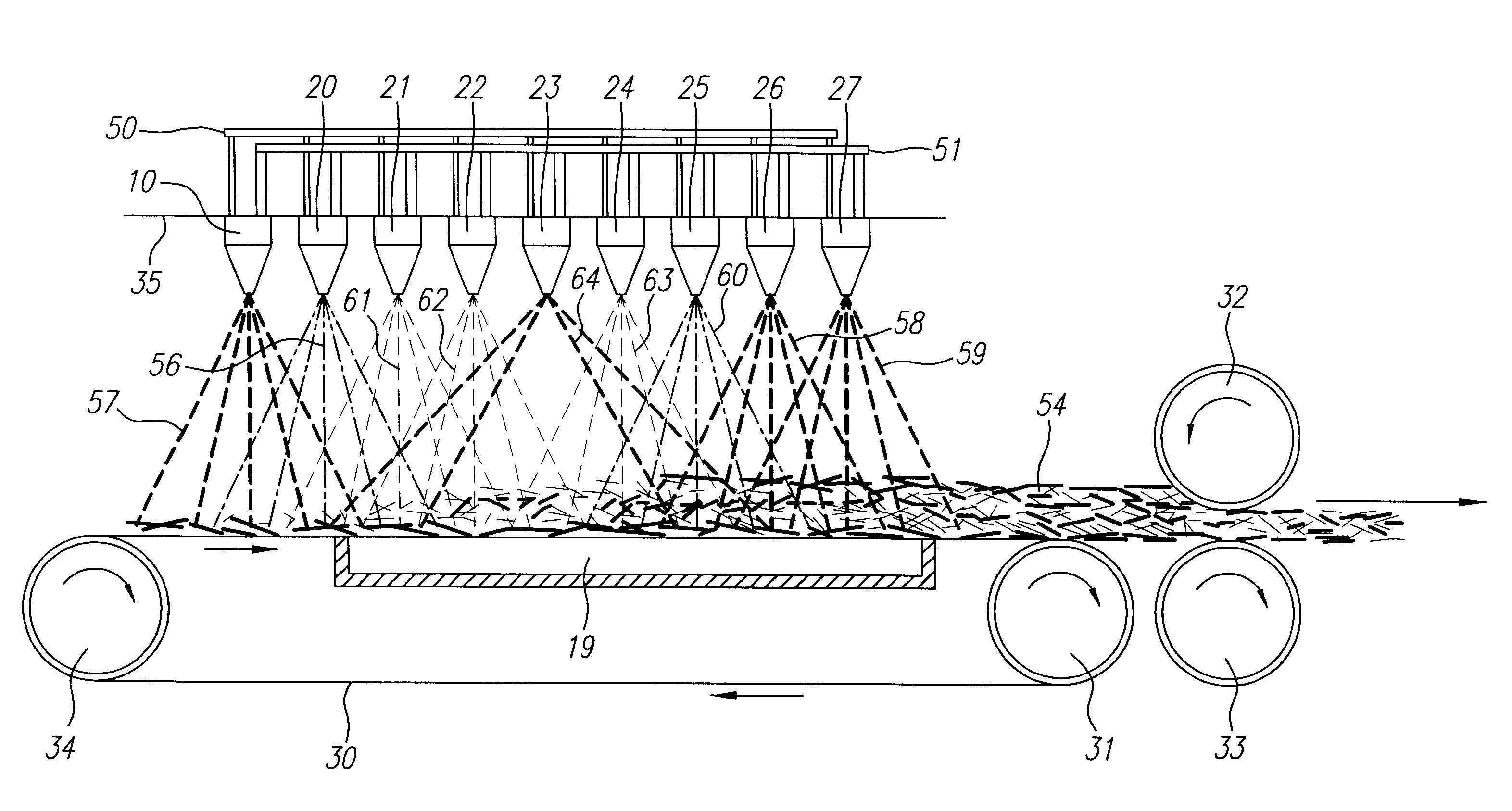

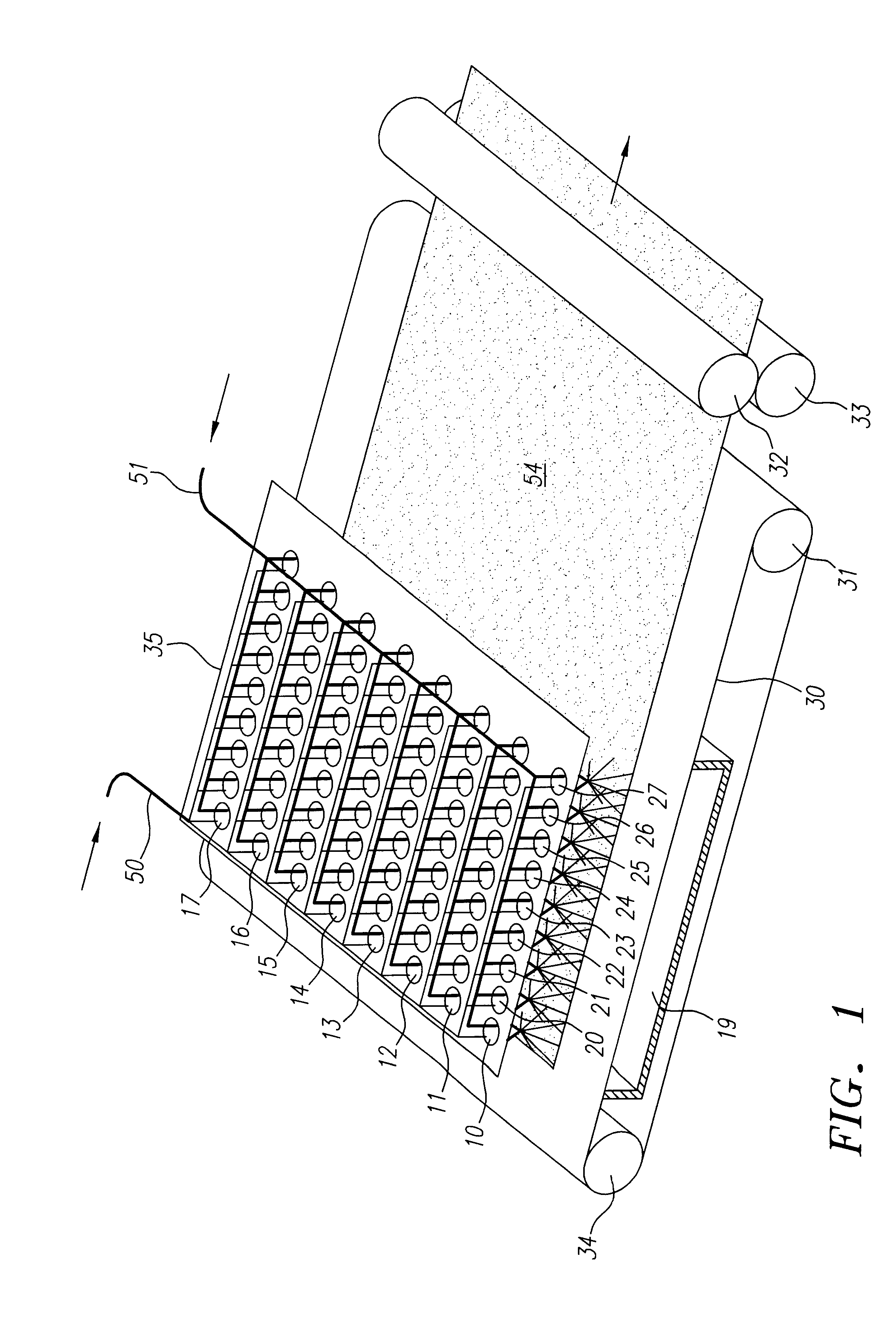

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

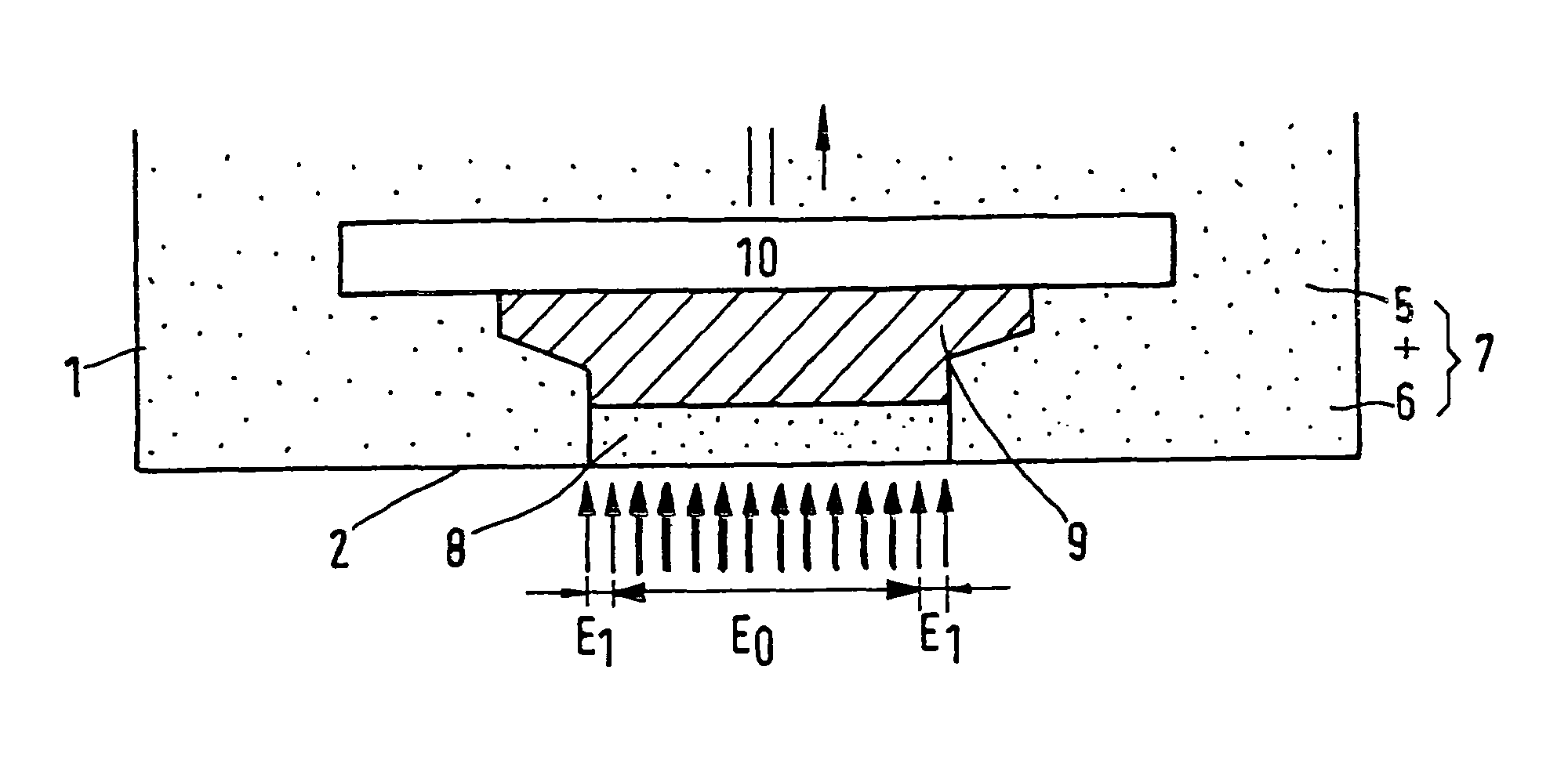

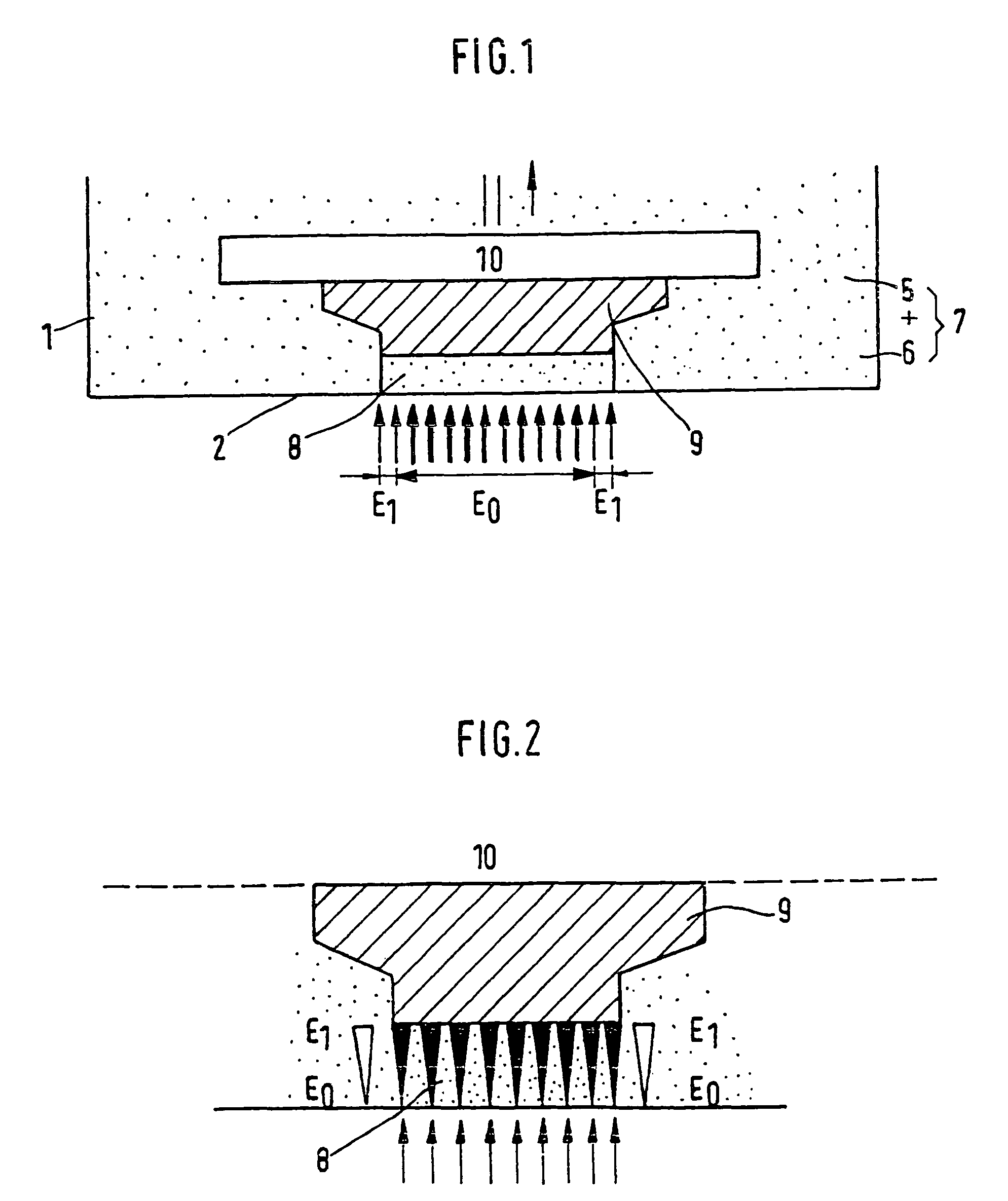

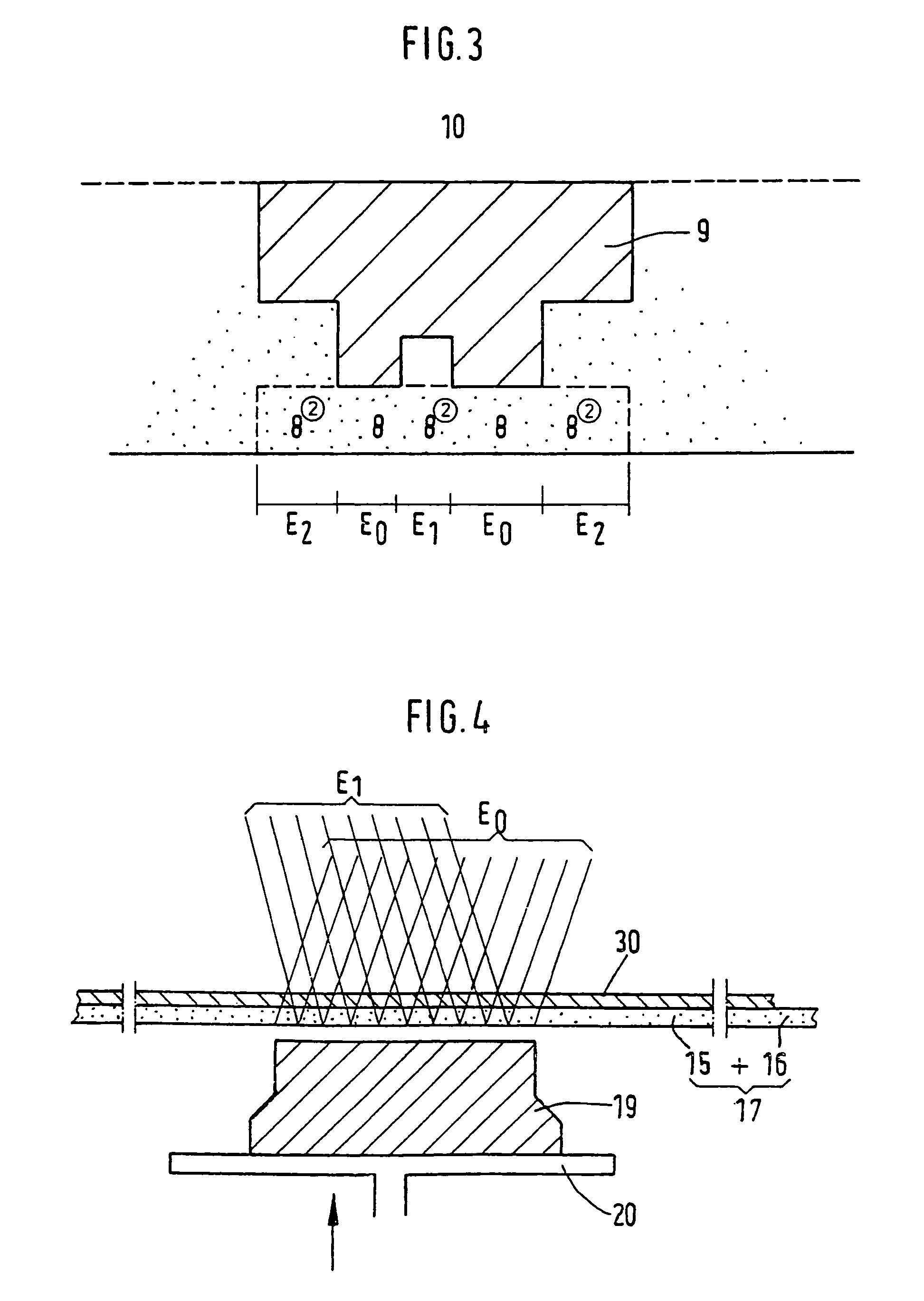

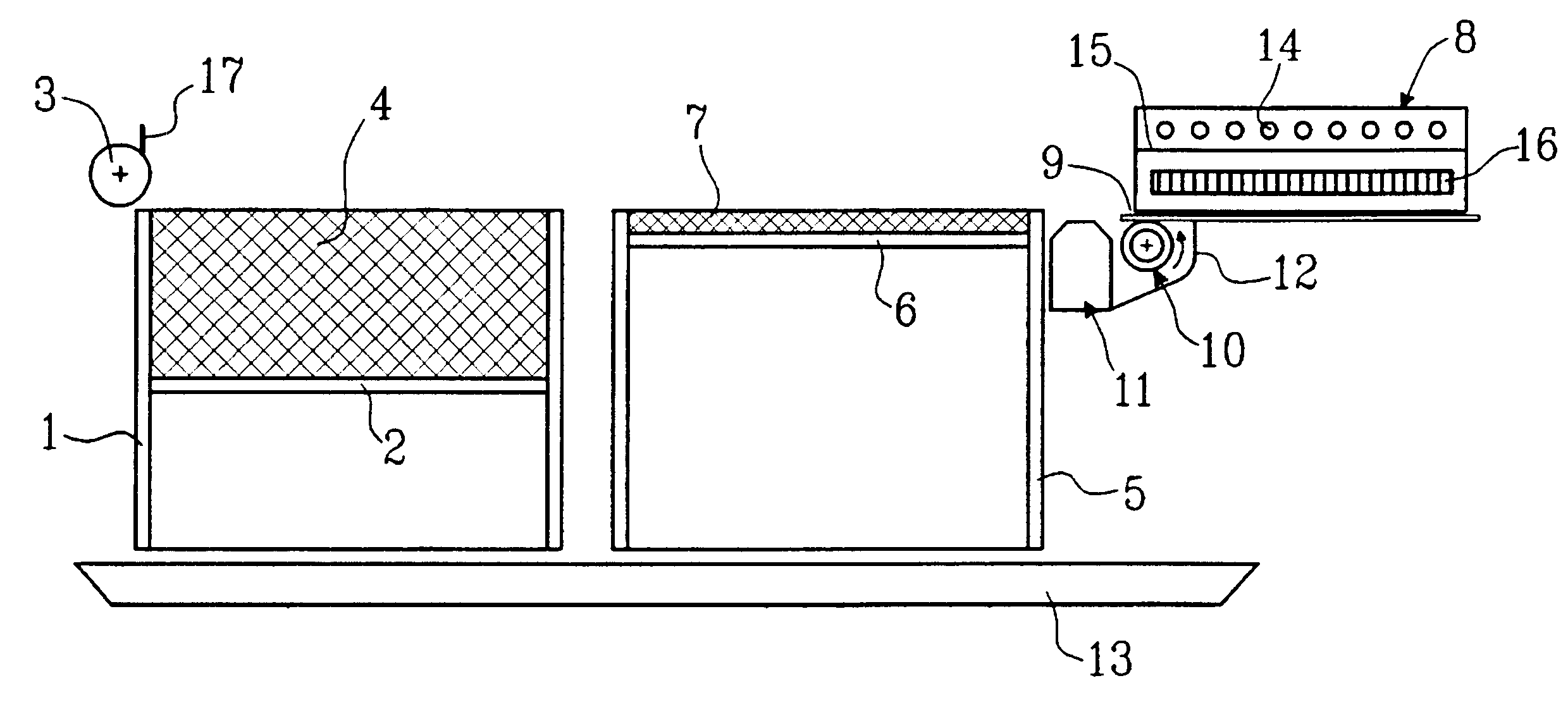

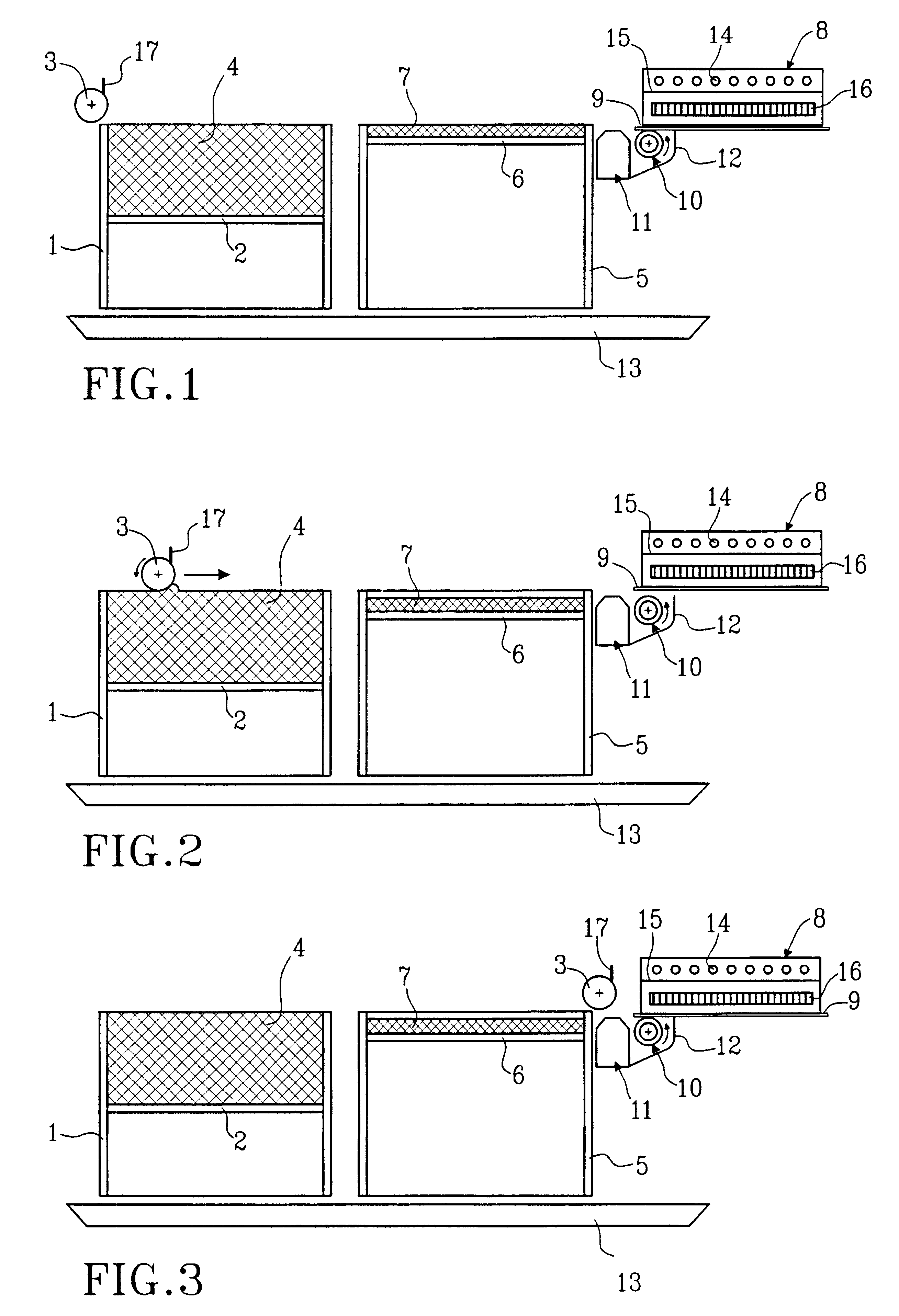

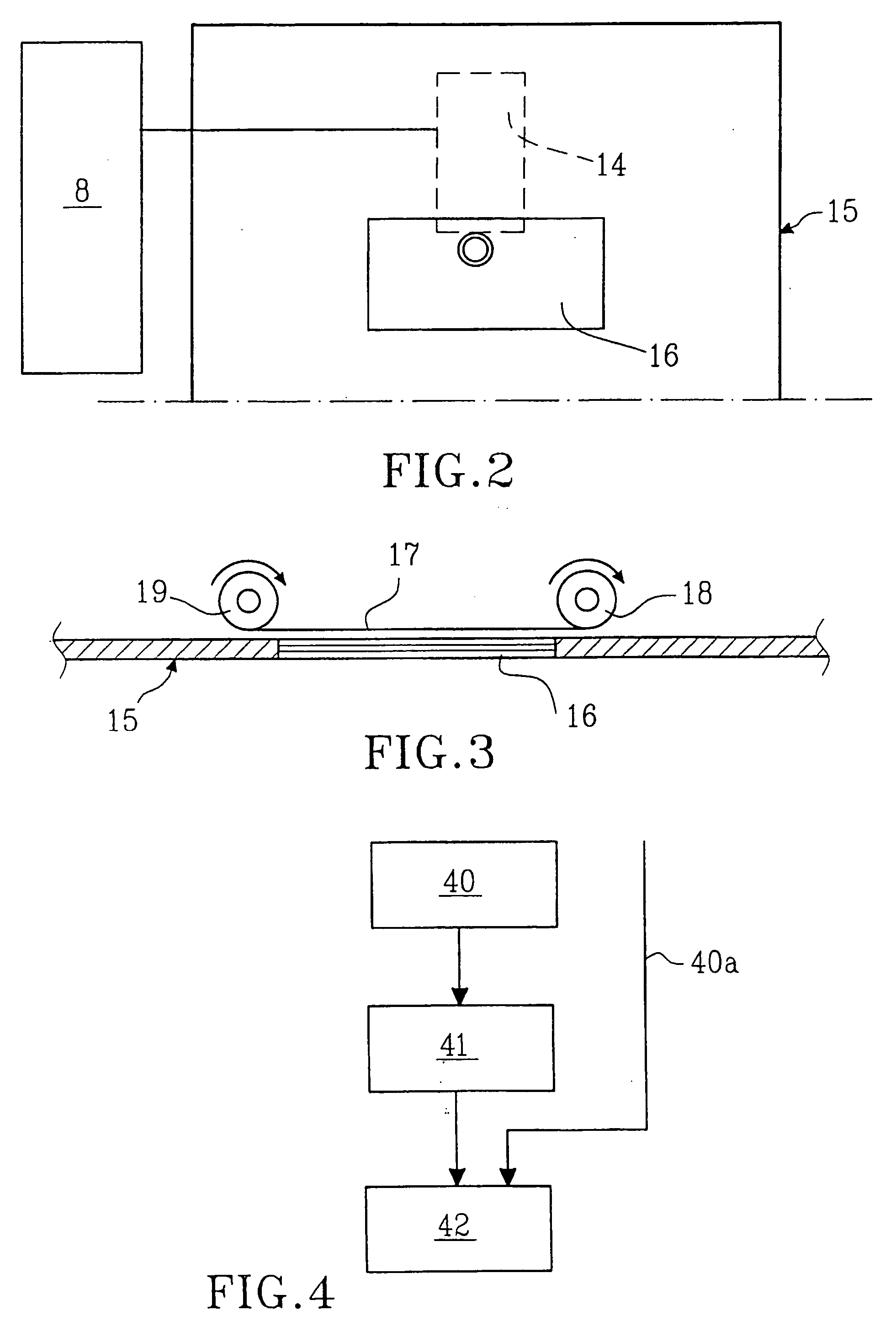

Method and device for manufacturing three-dimensional bodies

A method for producing three-dimensional bodies of a large number of mutually connected layers of a particle-shaped material such as a powder, and where the information of the appearance of each layer is achieved from a computer's CAD-unit or similar. An essentially even particle layer (7) of building material is applied on a support base (6) and on a masking device (9) is arranged a masking pattern in accordance with the information from the CAD-unit, which masking device is led over said particle layer and close to it. A radiation producer (8) is arranged or is led over the masking device (9), whereby the particles which are not covered by the masking pattern are exposed for radiation and thereby are attached to each other. The masking pattern is removed from the masking device and new sequences in accordance with the above are carried through until the three-dimensional body (19) is produced.

Owner:SPEED PART RP

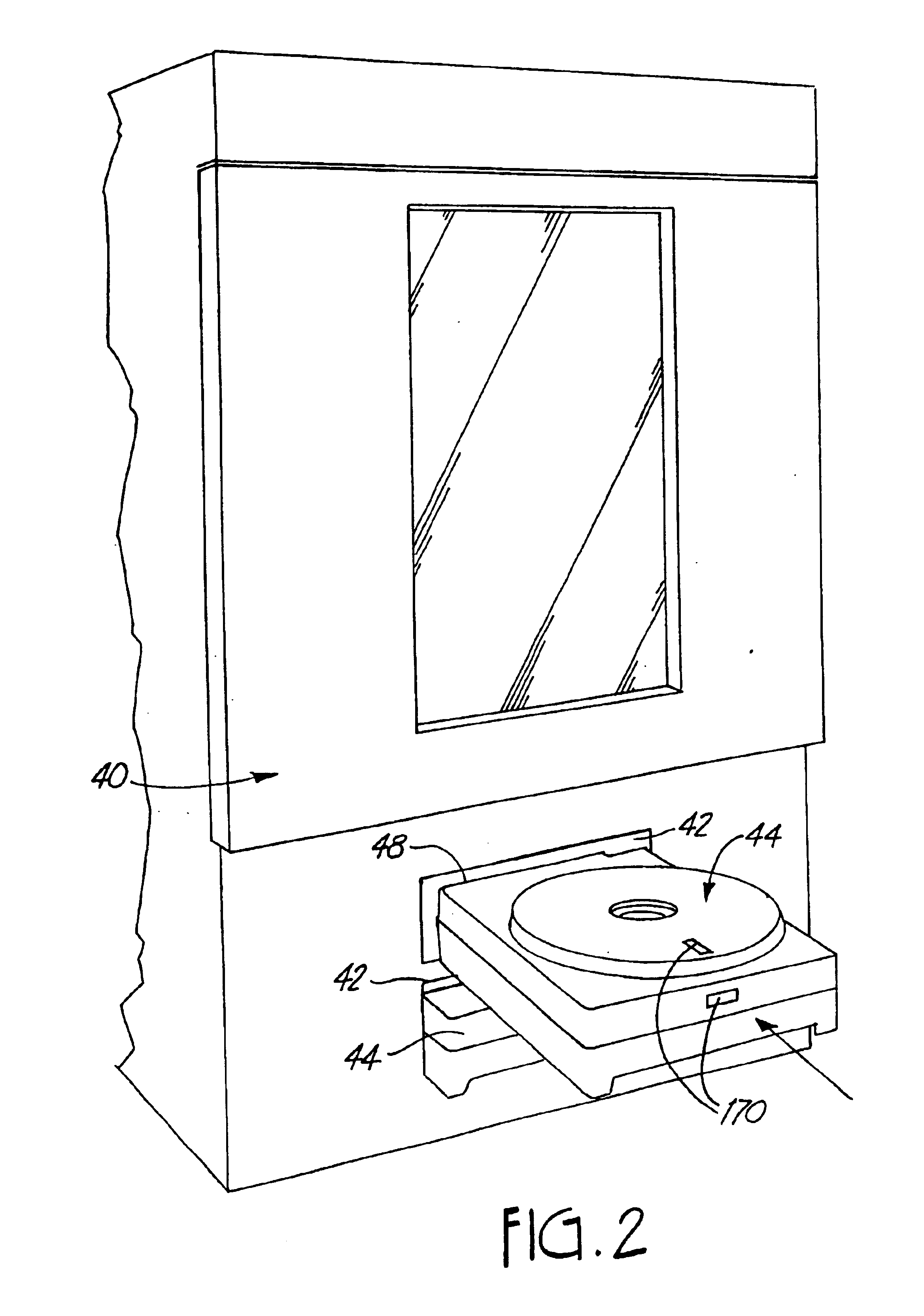

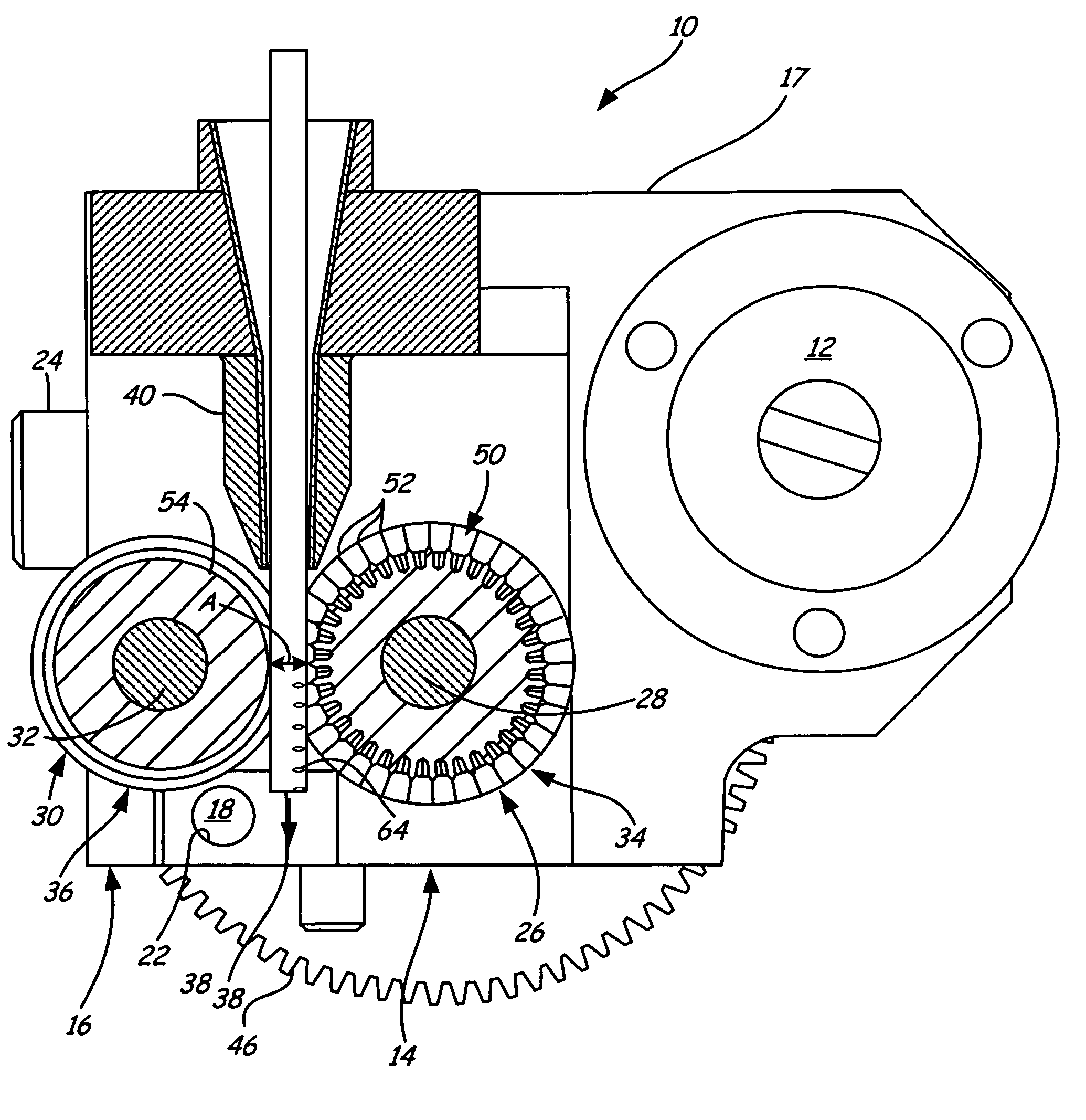

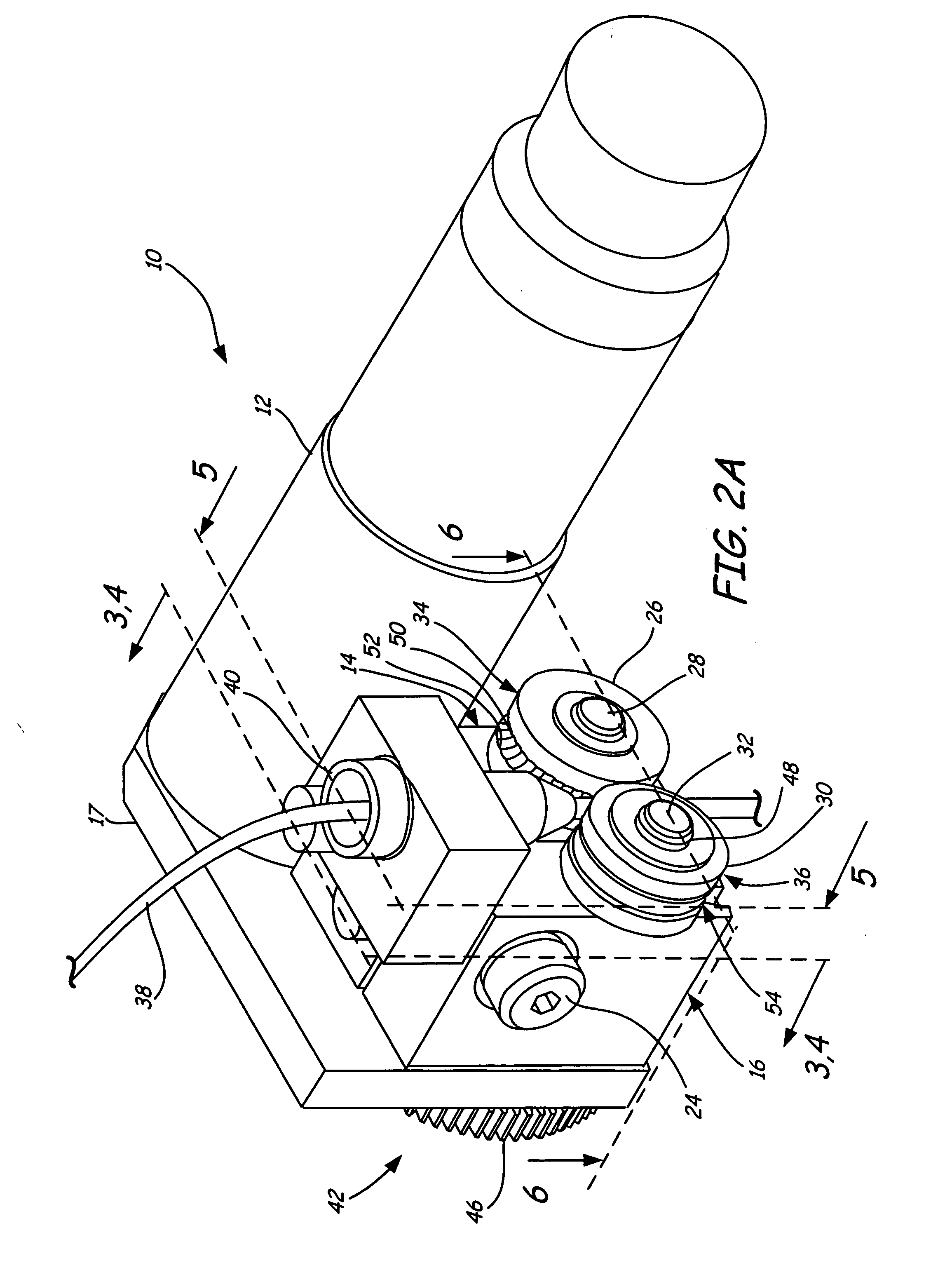

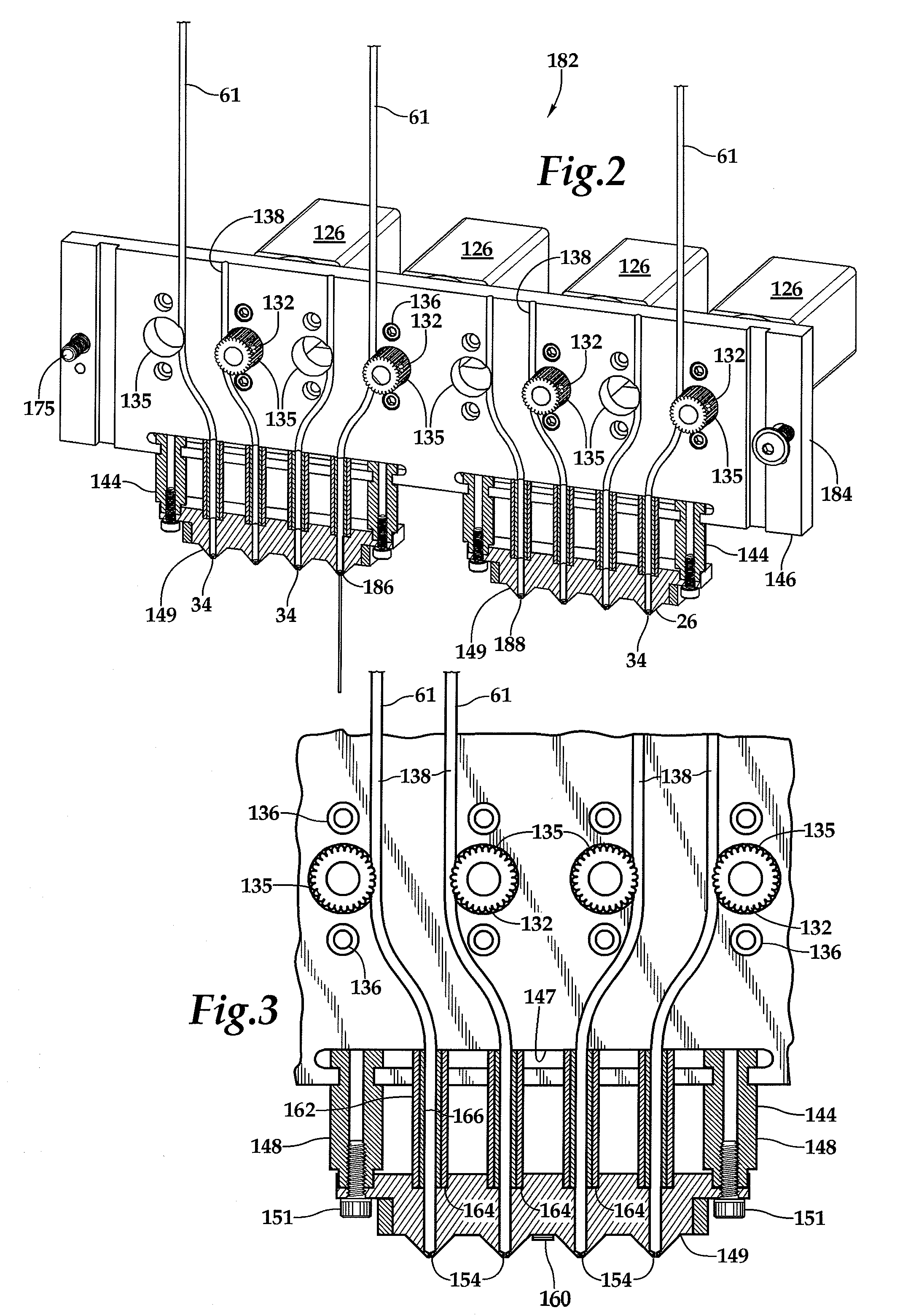

Filament loading system in an extrusion apparatus

InactiveUS6923634B2Protect environmentEasy loadingConfectionerySweetmeatsDrive wheelDimensional modeling

An apparatus which extrudes flowable material from a liquifier includes a system for loading filament supplied in a cassette. The cassette is loaded into a loading bay of the apparatus. A strand of filament from the cassette is engaged and advanced along a path to the liquifier using a drive wheel or roller pair. A conduit having an entrance in the loading bay guides the filament as it is advanced. The filament loading system of the present invention provides a convenient manner of loading and unloading filament in a three-dimensional modeling machine, and can be implemented in a manner that protects the filament from environmental moisture.

Owner:STRATSYS INC

Pattern forming method and pattern forming apparatus

Owner:CANON KK

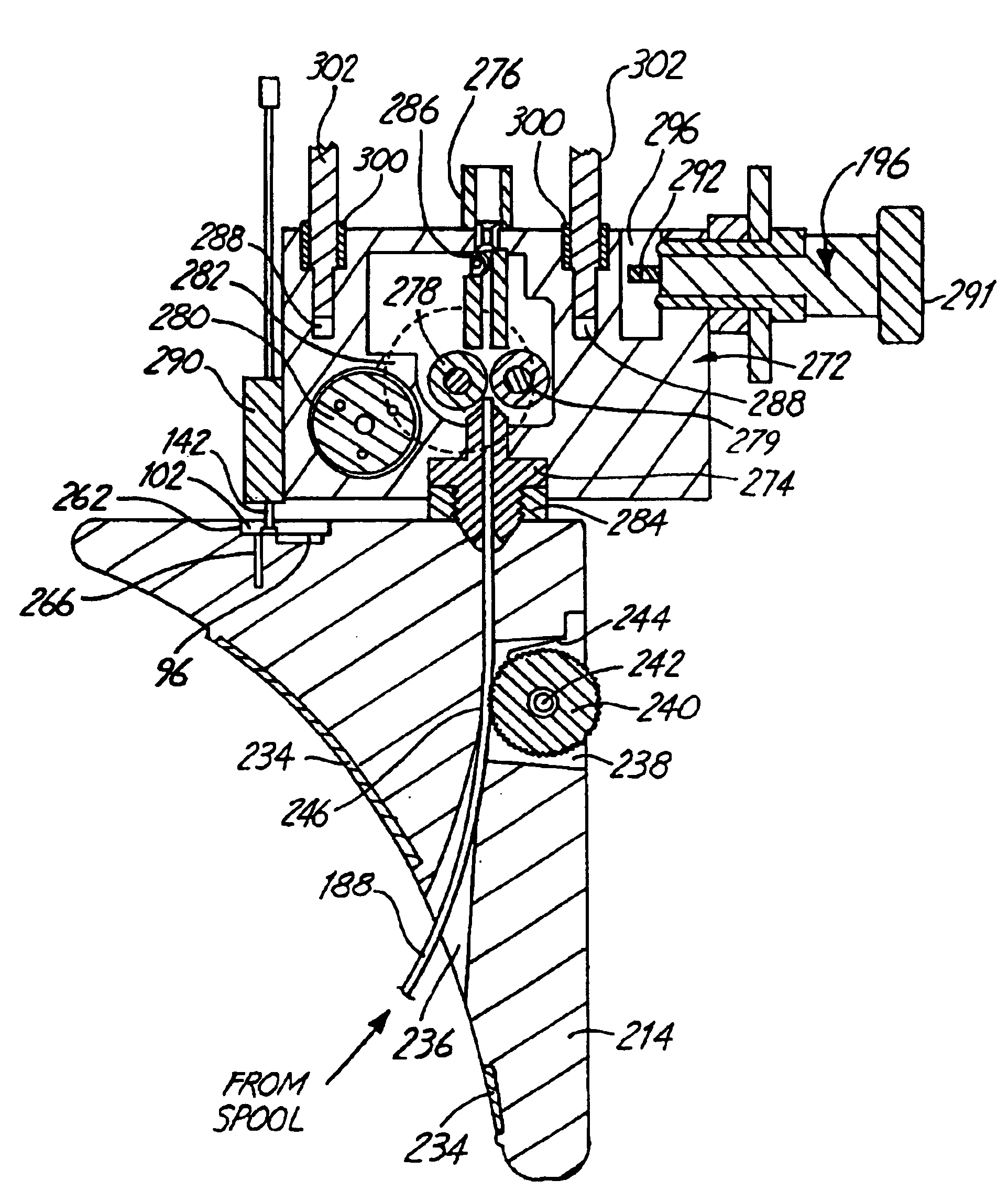

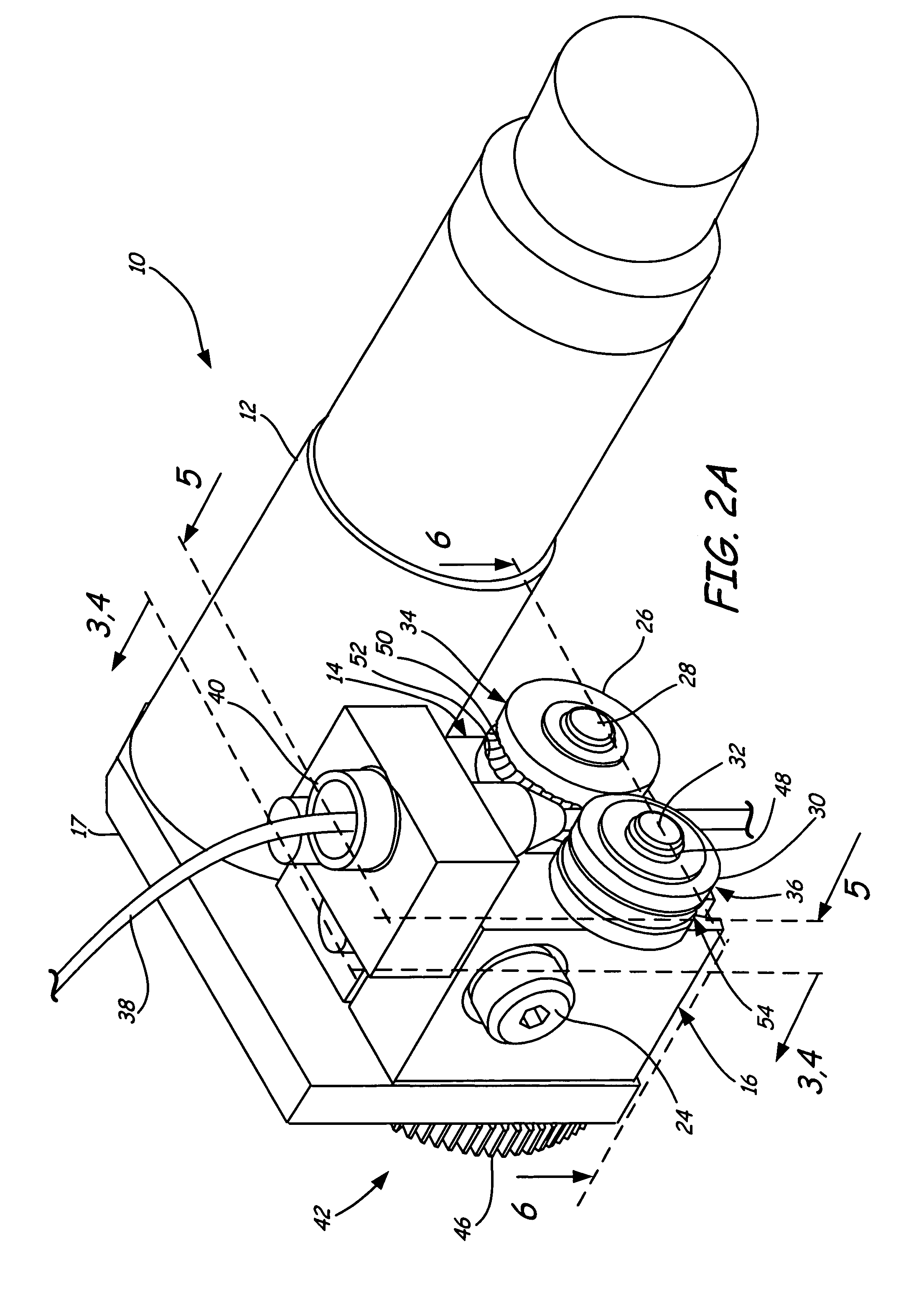

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

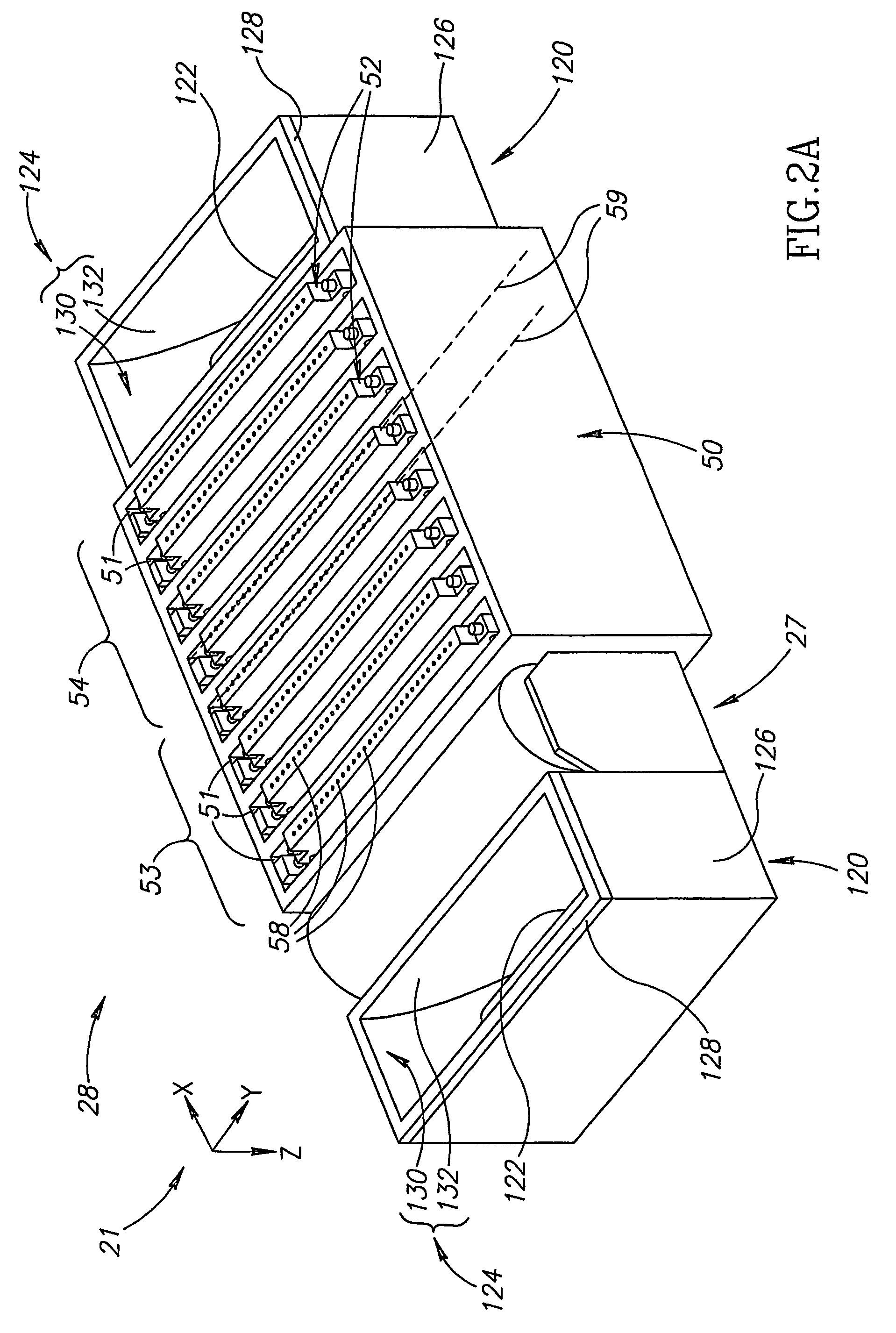

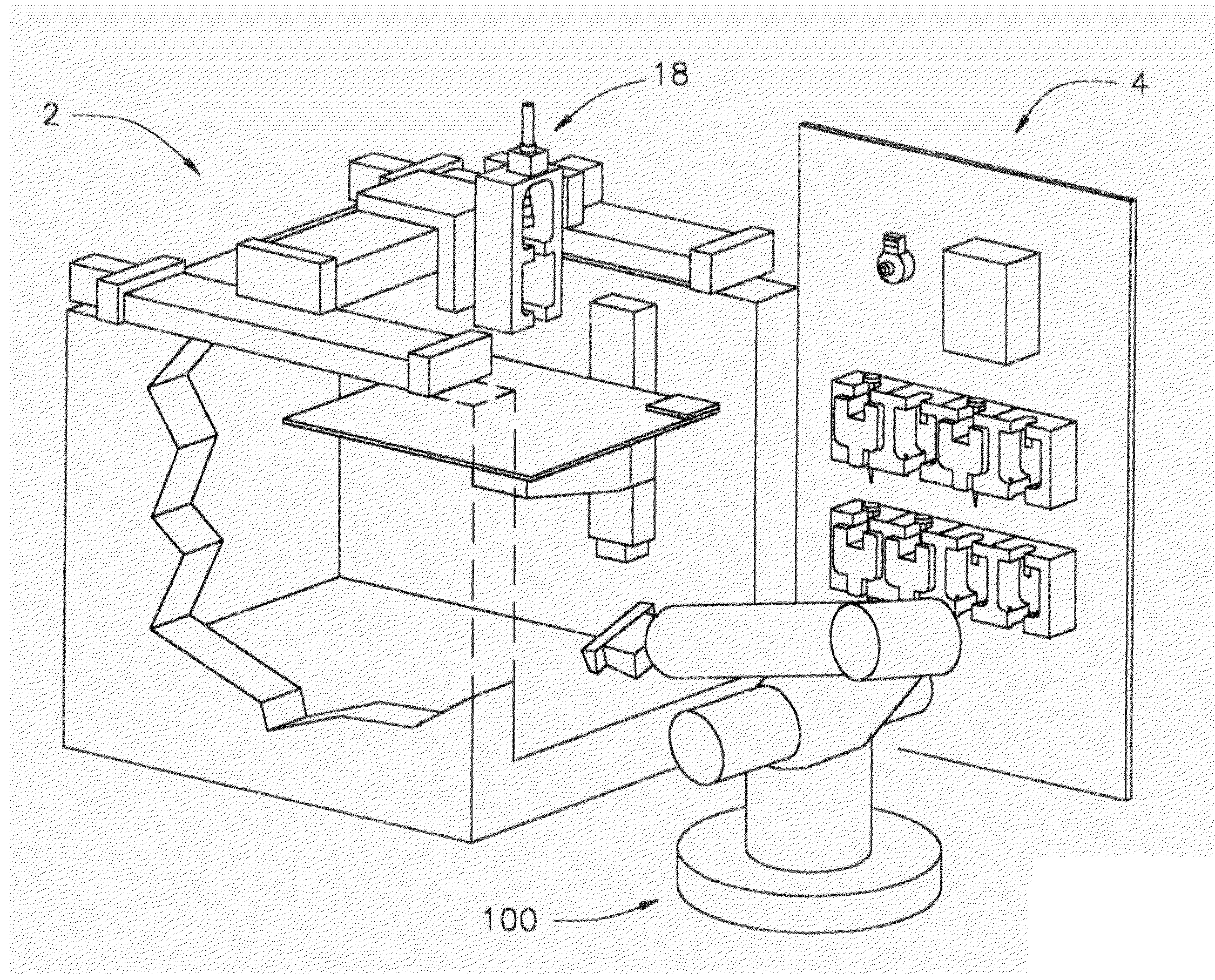

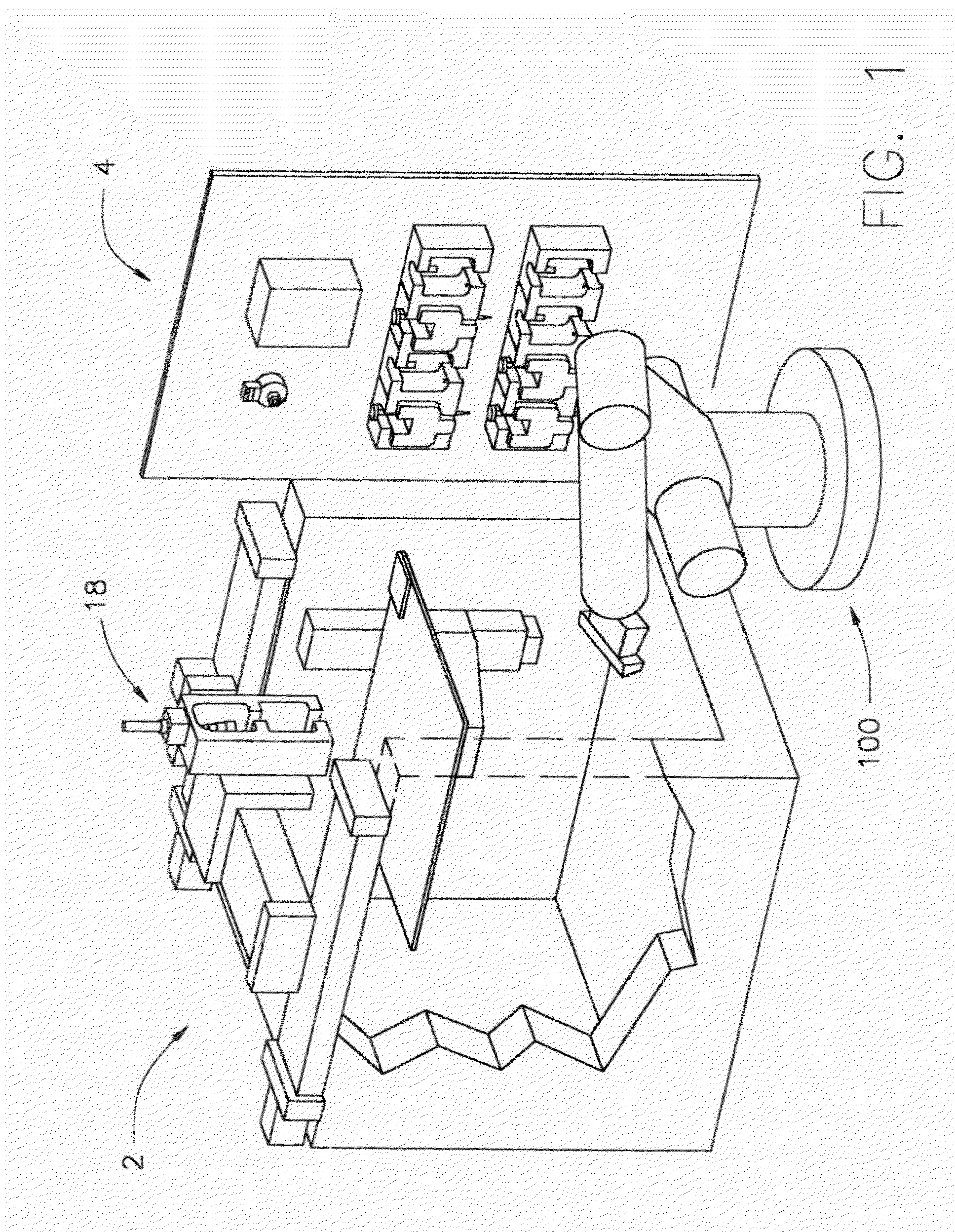

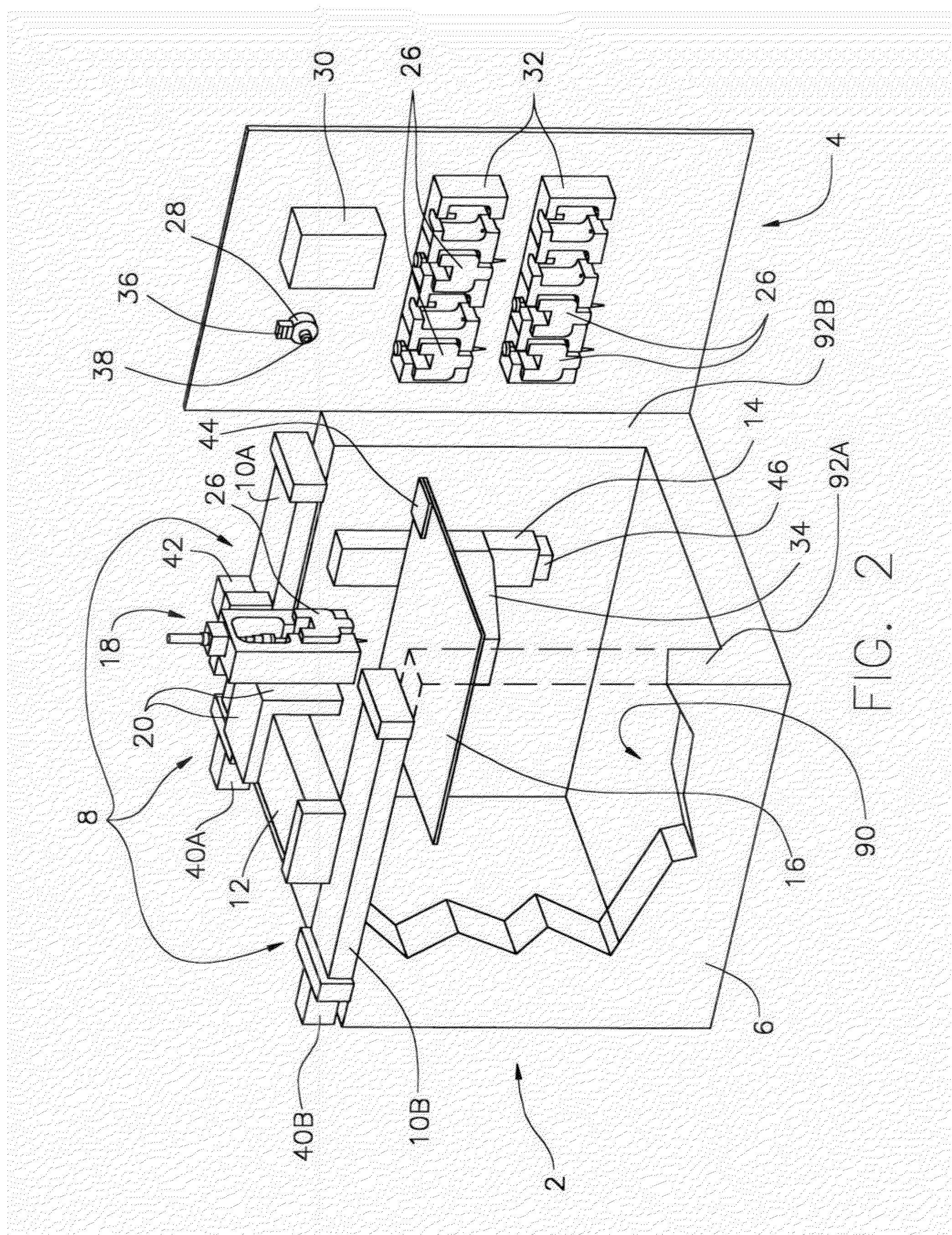

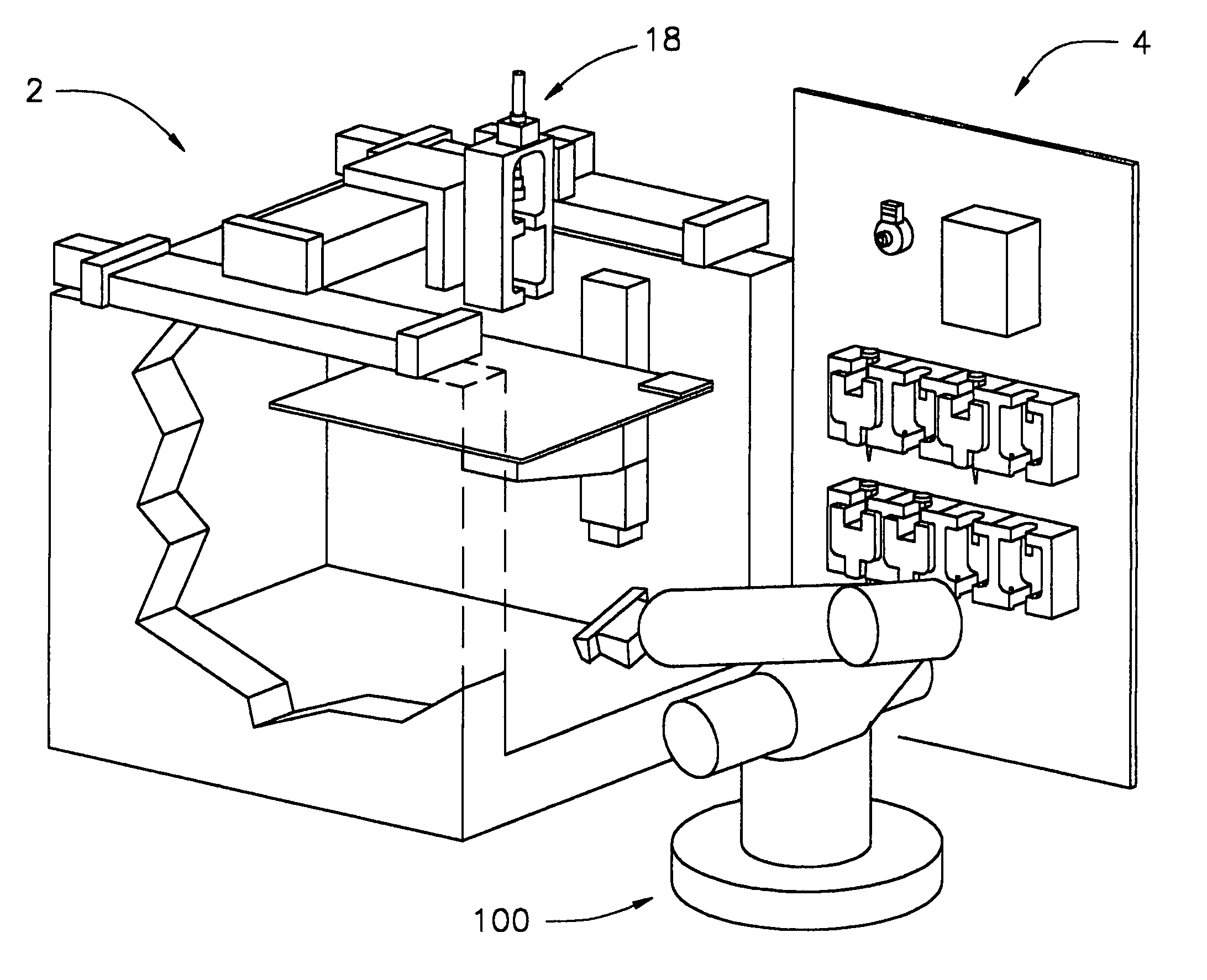

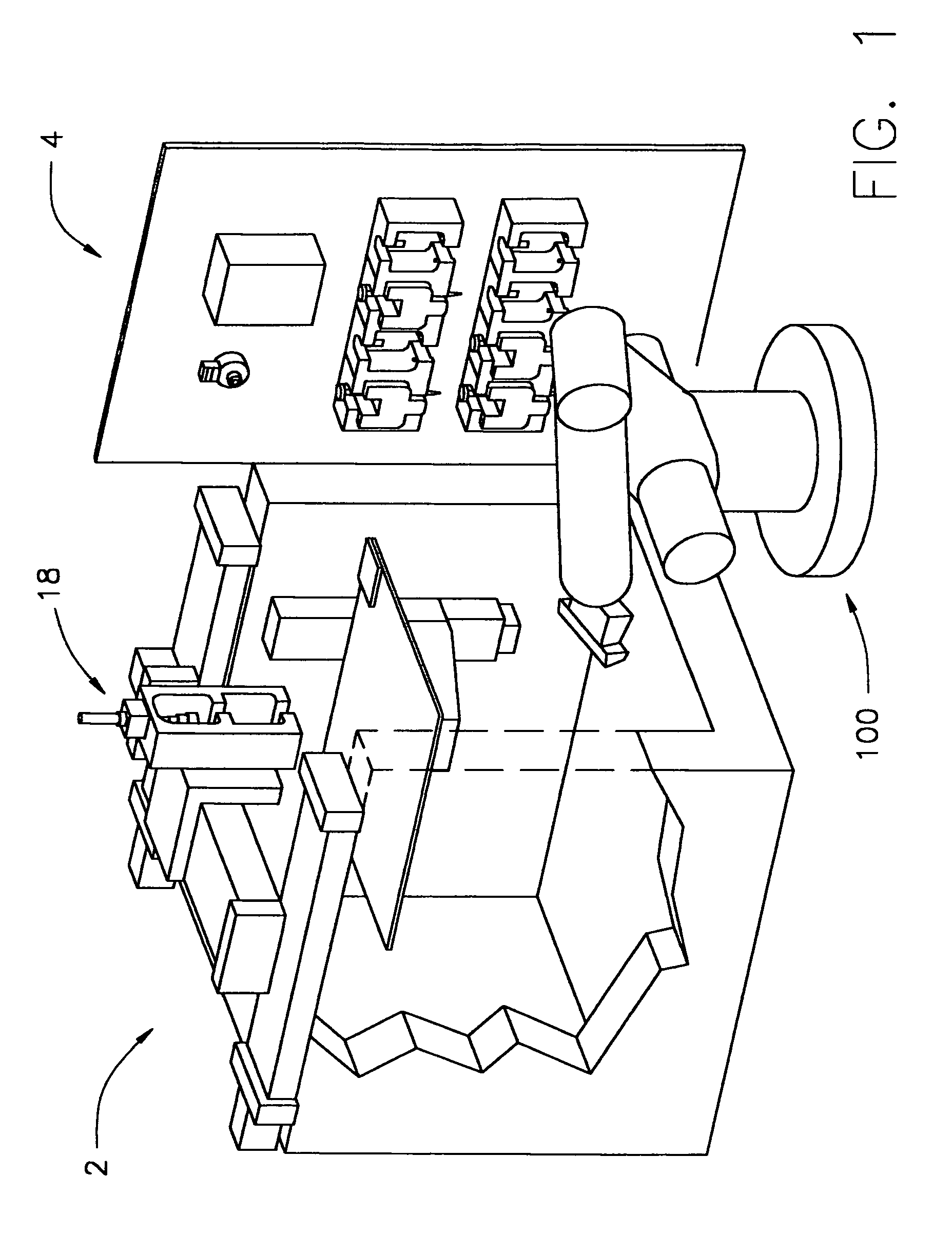

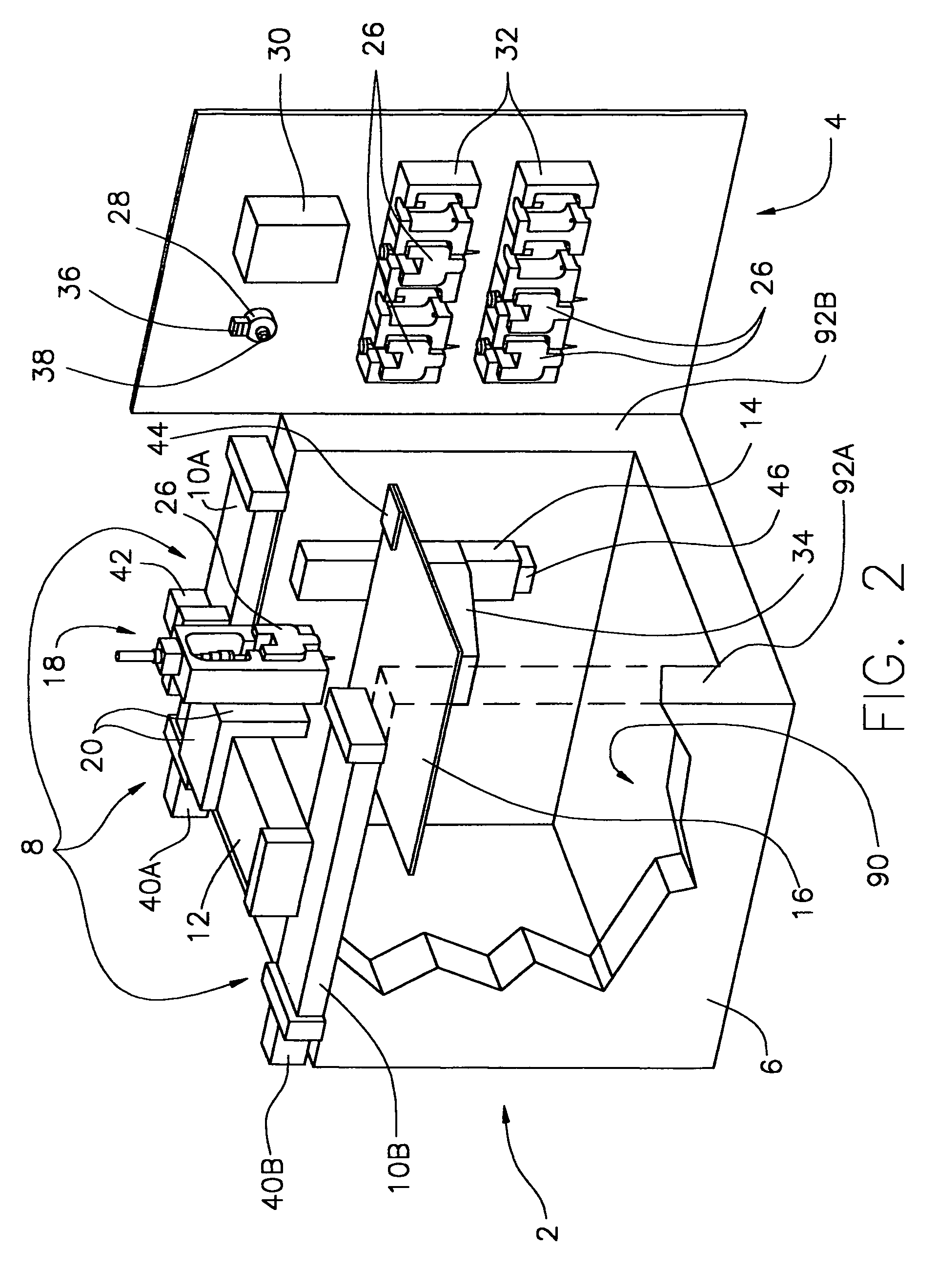

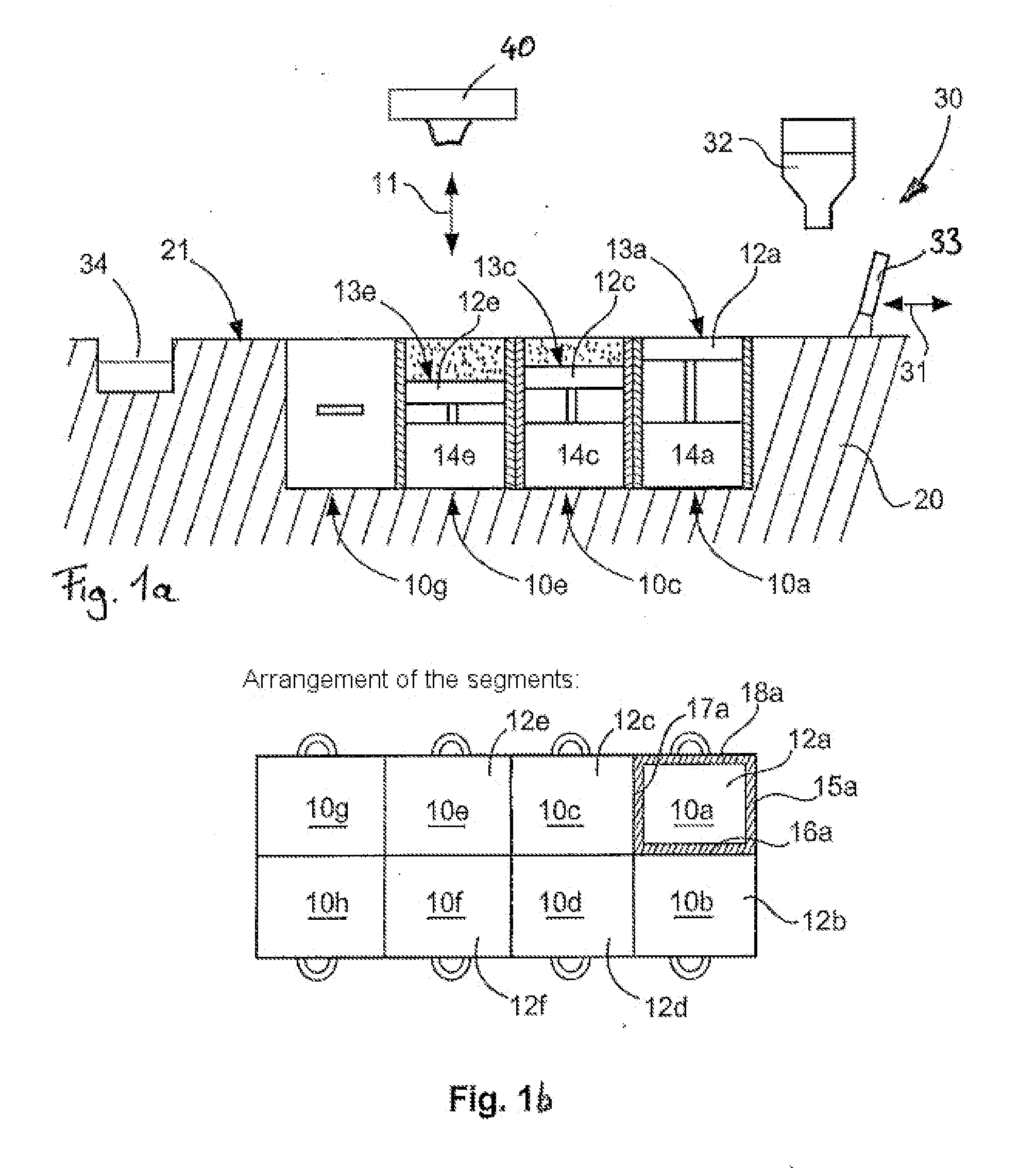

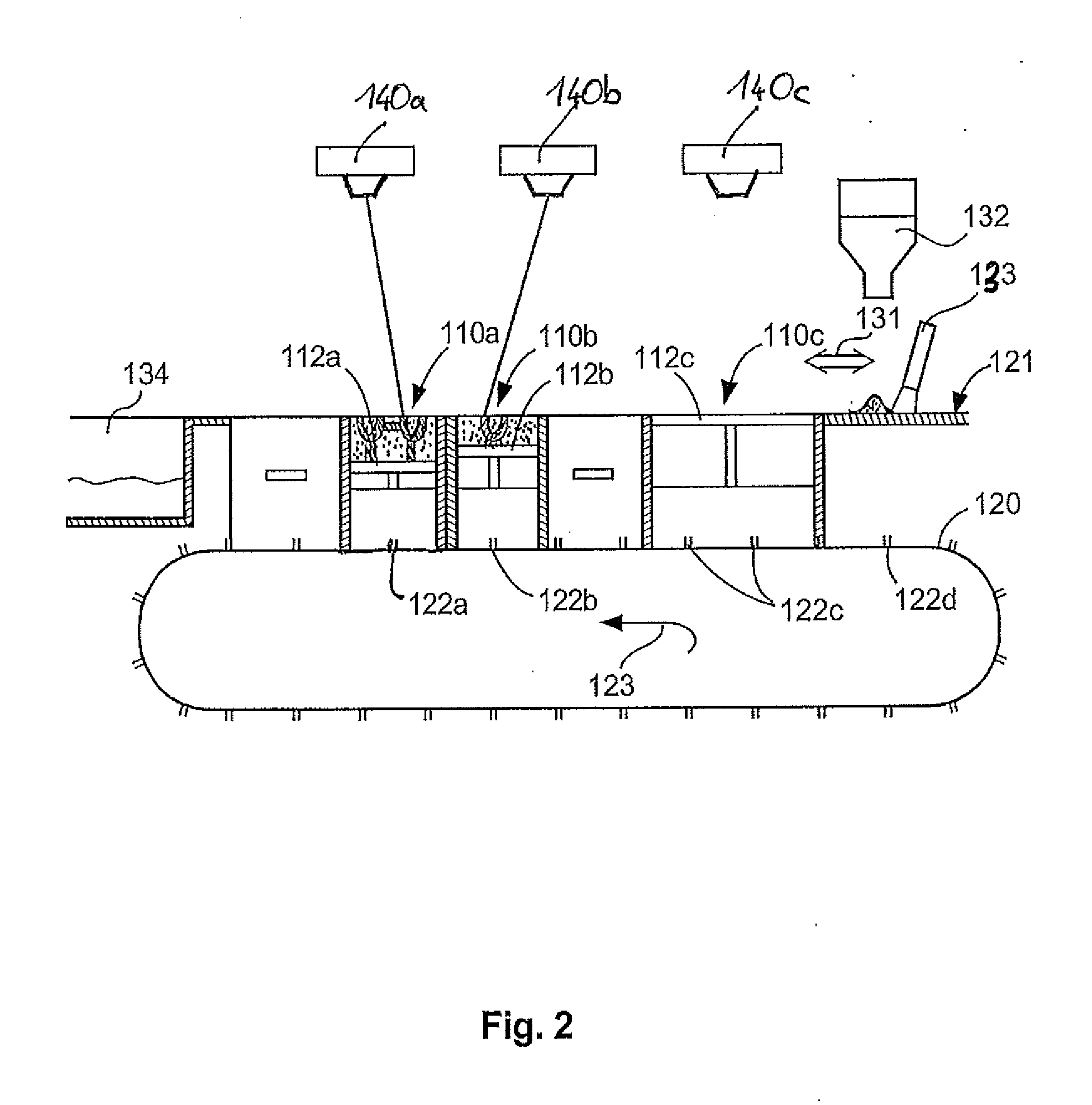

Modular fabrication systems and methods

ActiveUS20130089642A1Improve throughputHigh-throughput applicationsReady-for-oven doughsAuxillary shaping apparatusEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating edible foodstuffs.

Owner:CORNELL UNIVERSITY

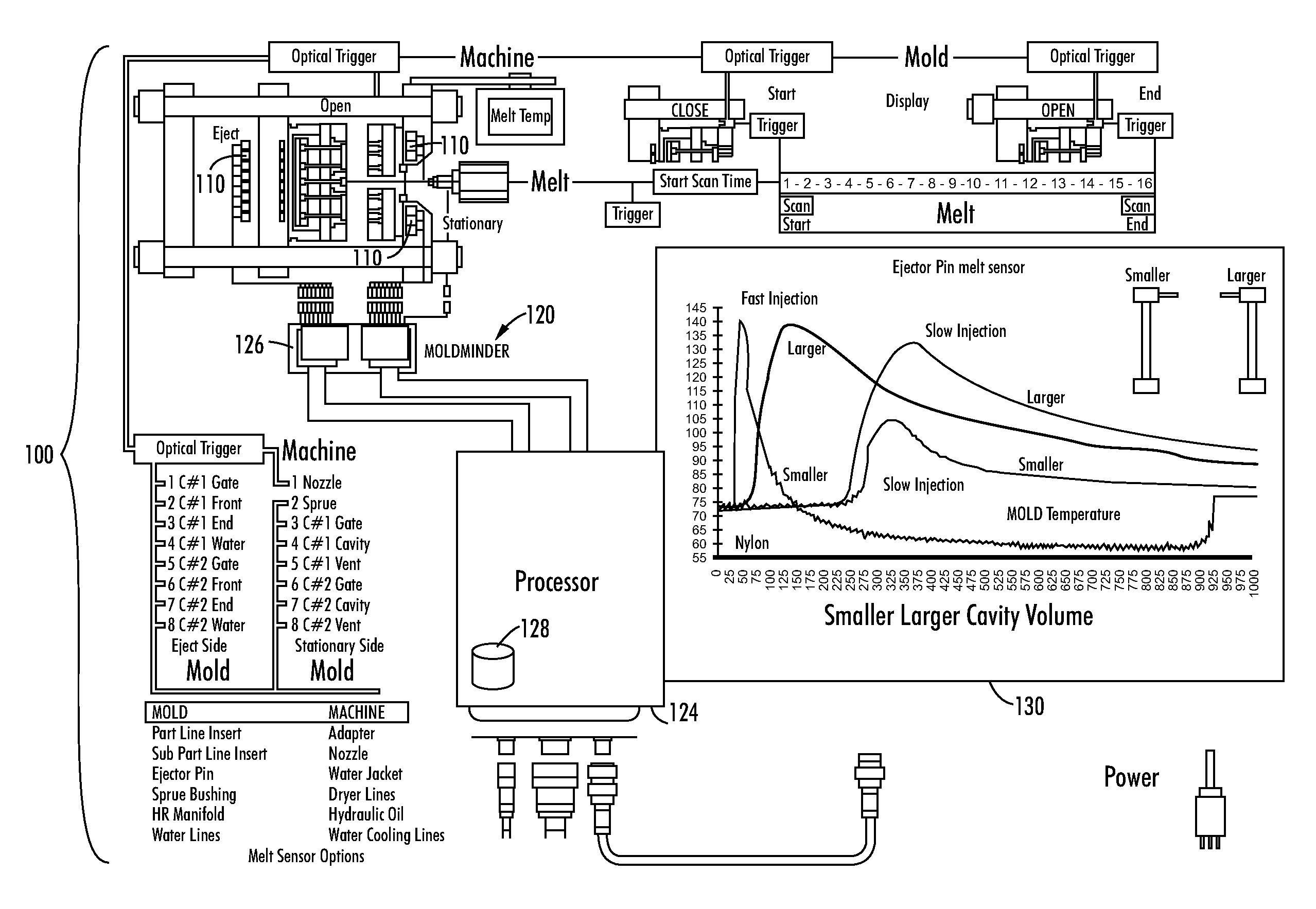

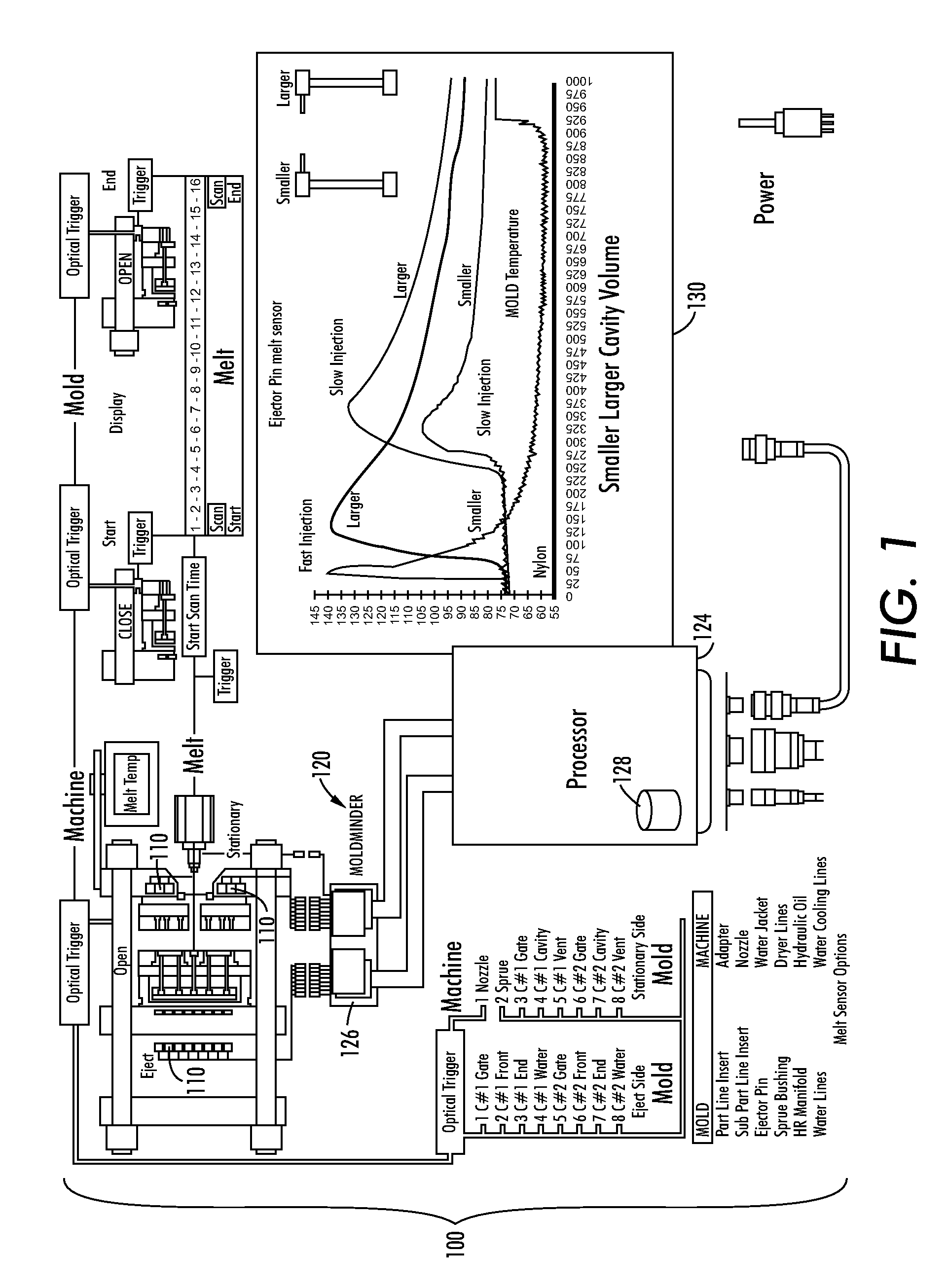

System for monitoring temperature and pressure during a molding process

Disclosed are systems and methods for the use of a micro-bead EMF junction in the sensing and control of an injection molding process, whereby the improved junction is able to reliably sense and indicate temperature and pressure changes in a molding process.

Owner:BUJA FREDERICK J

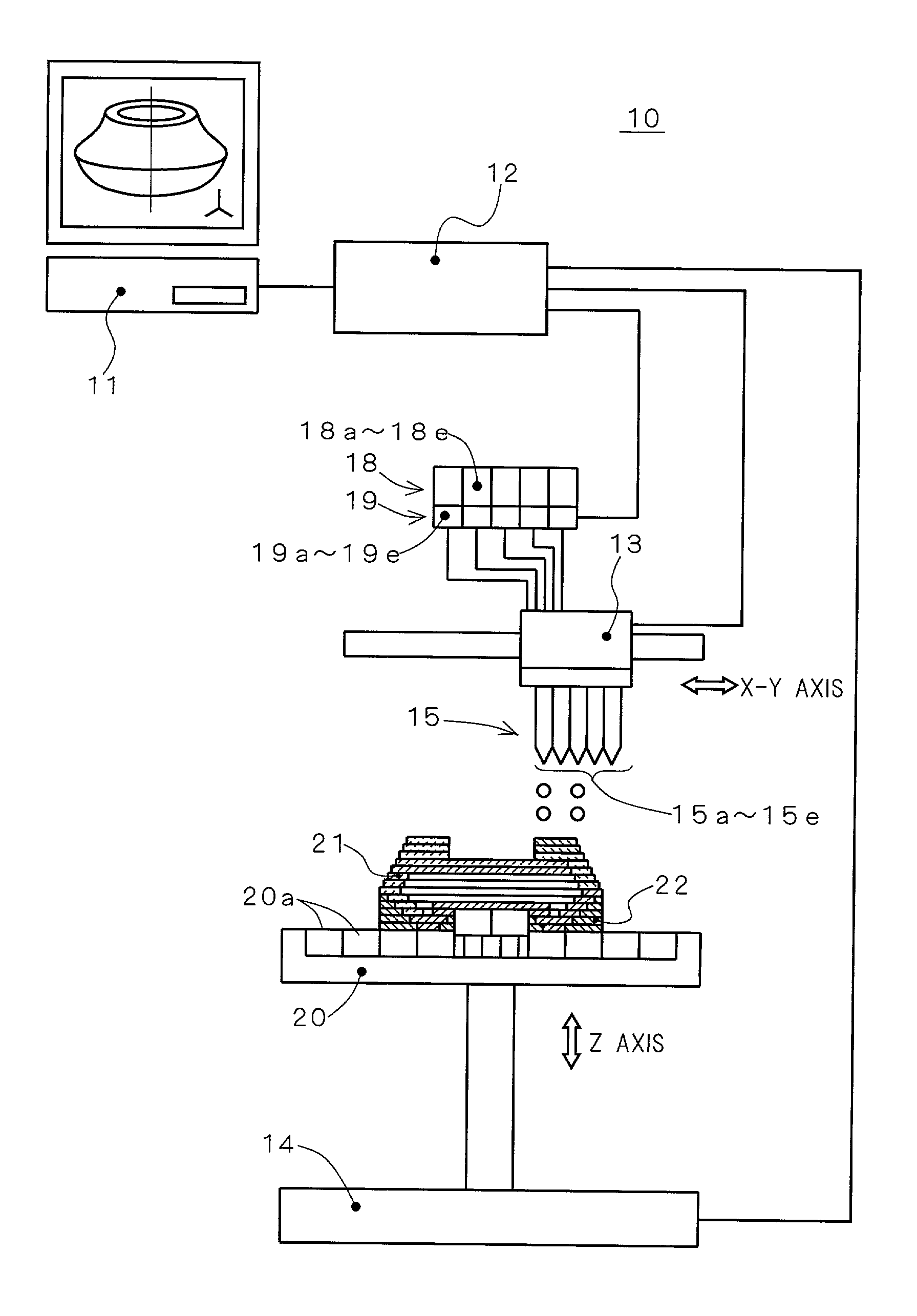

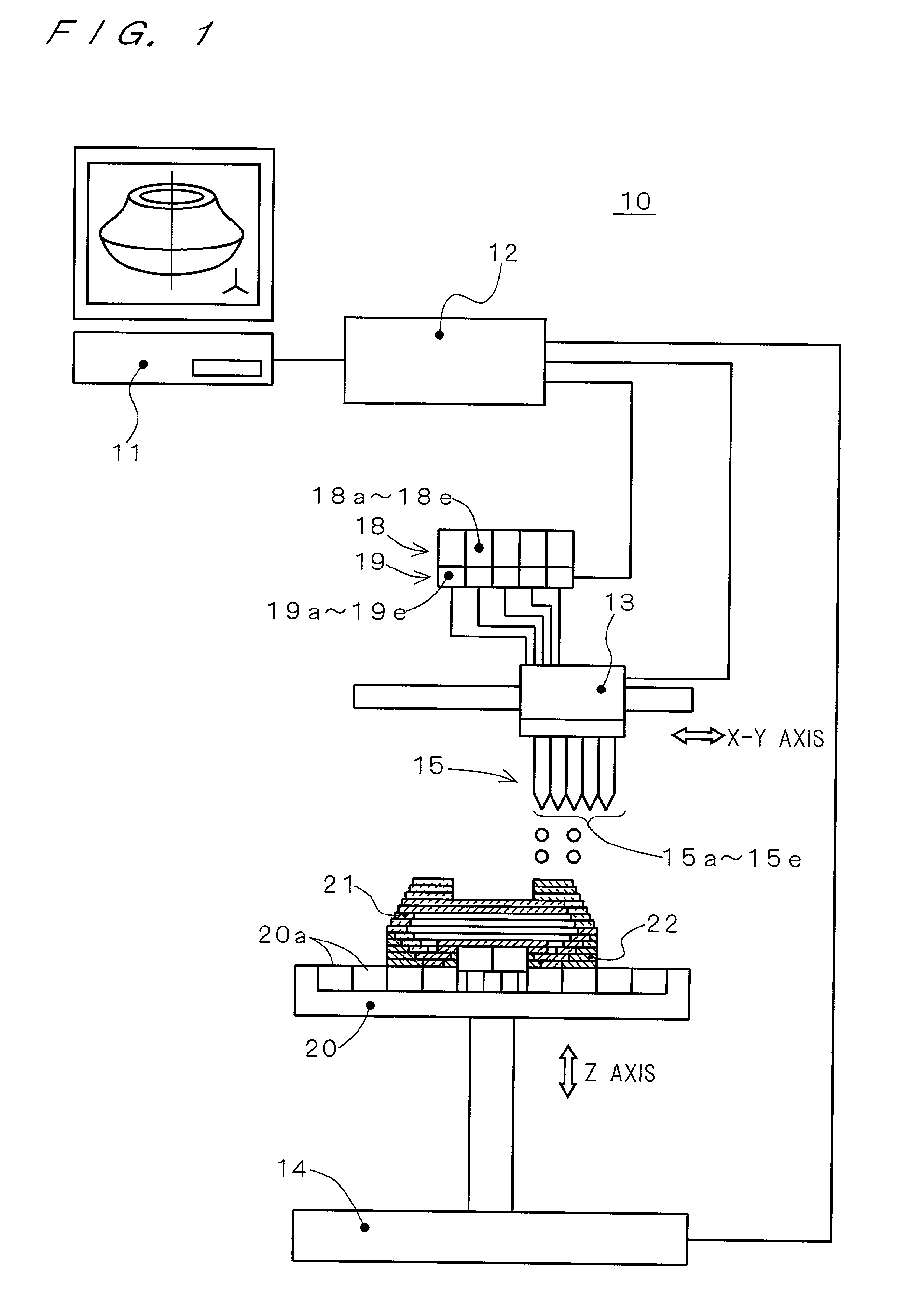

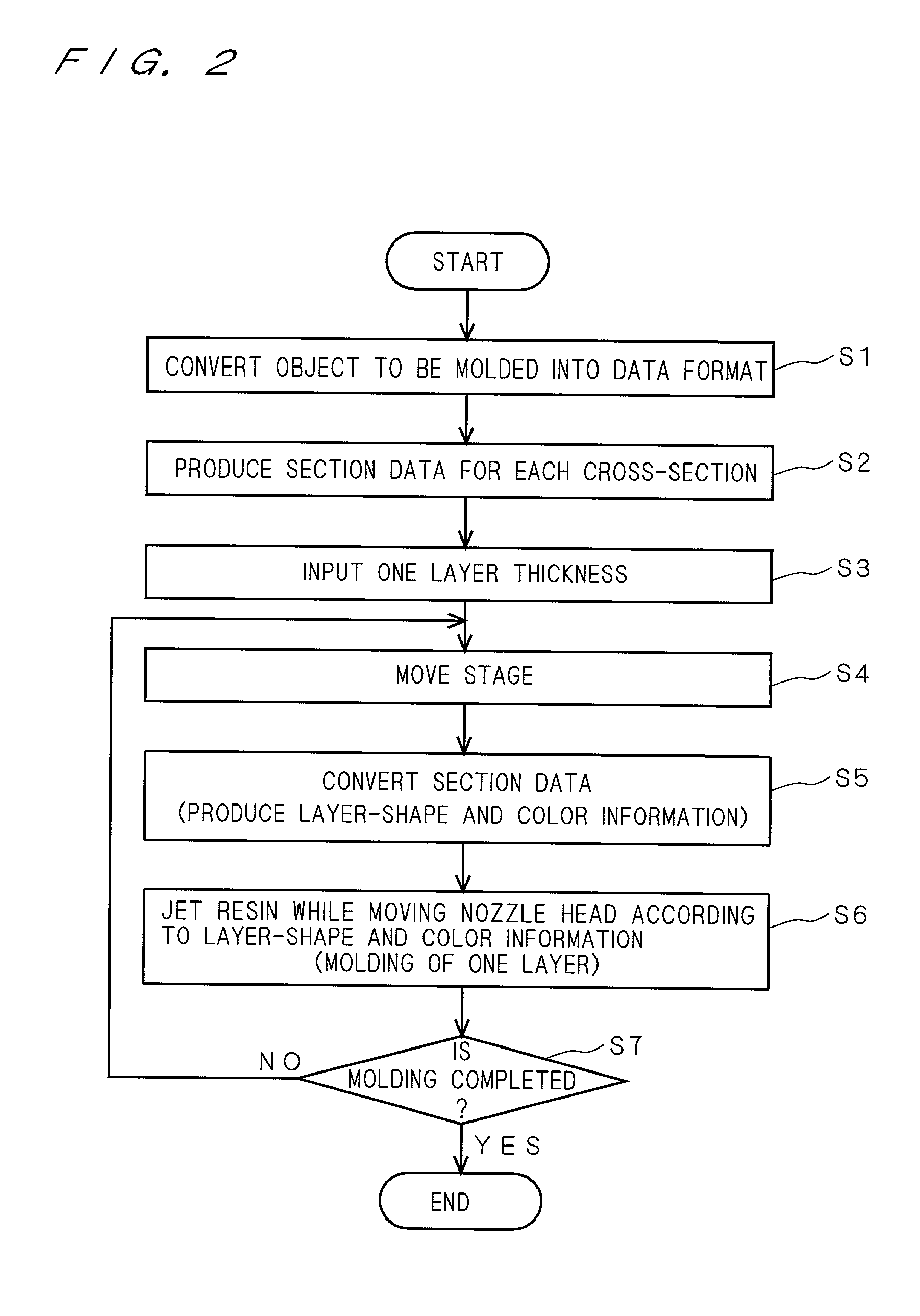

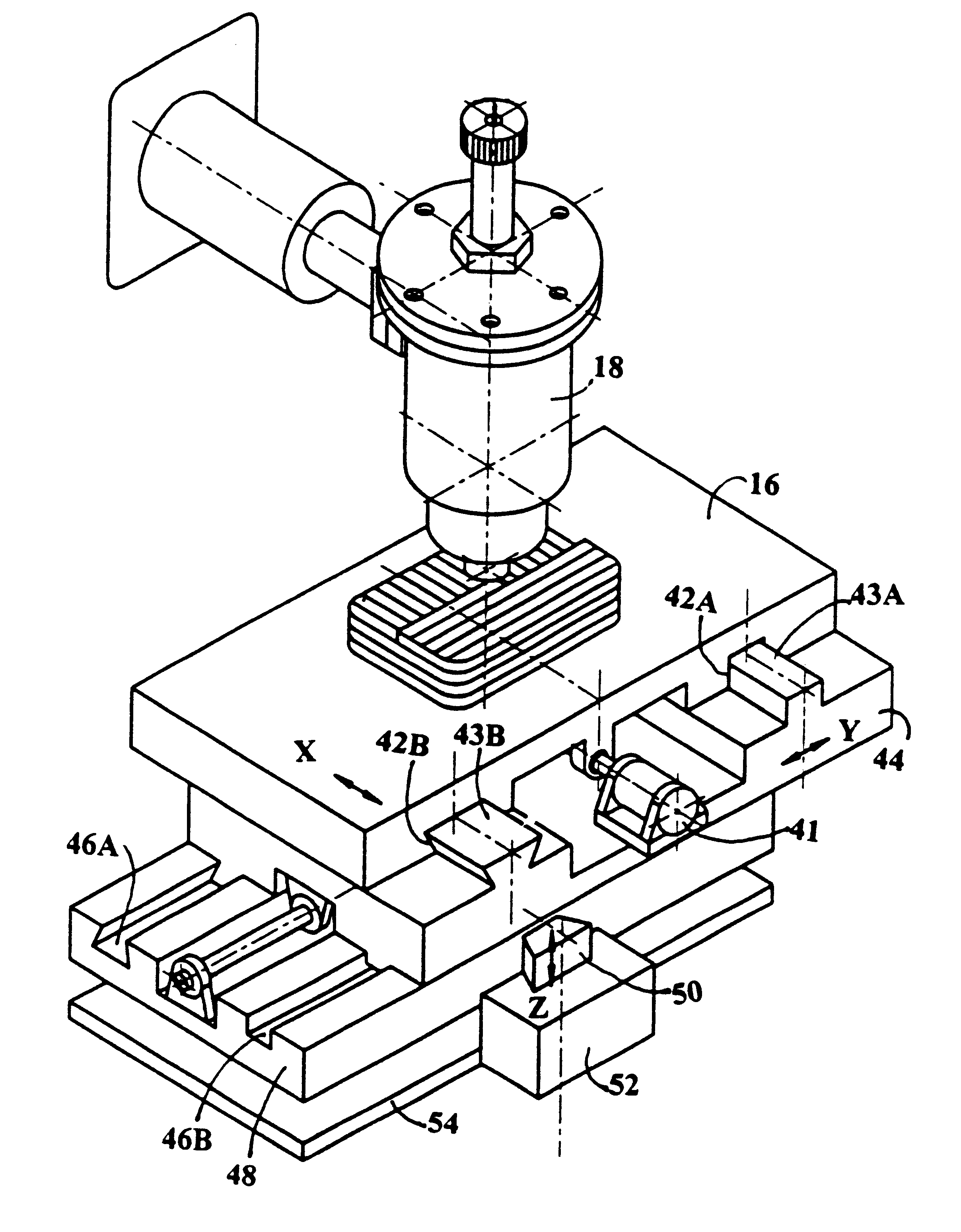

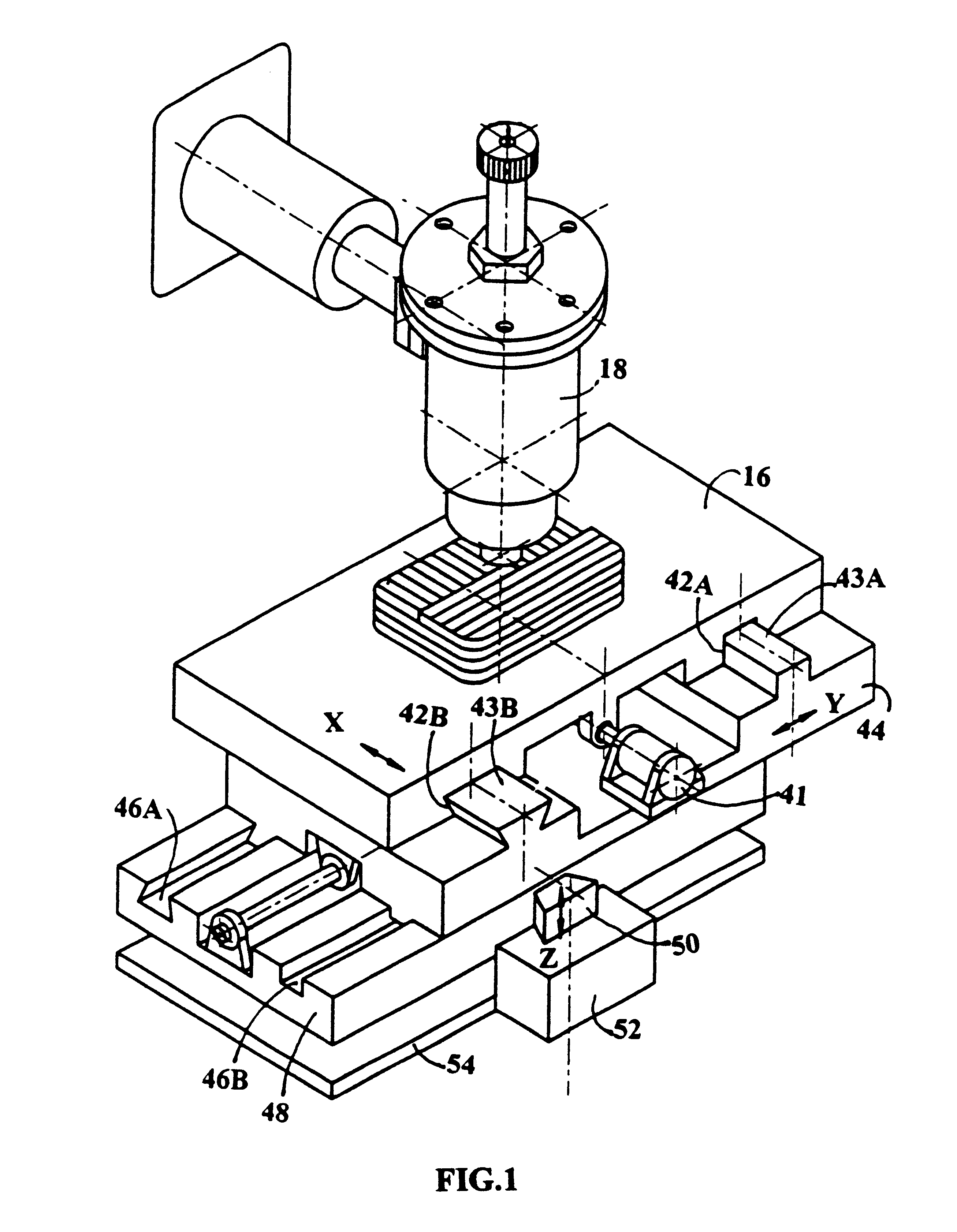

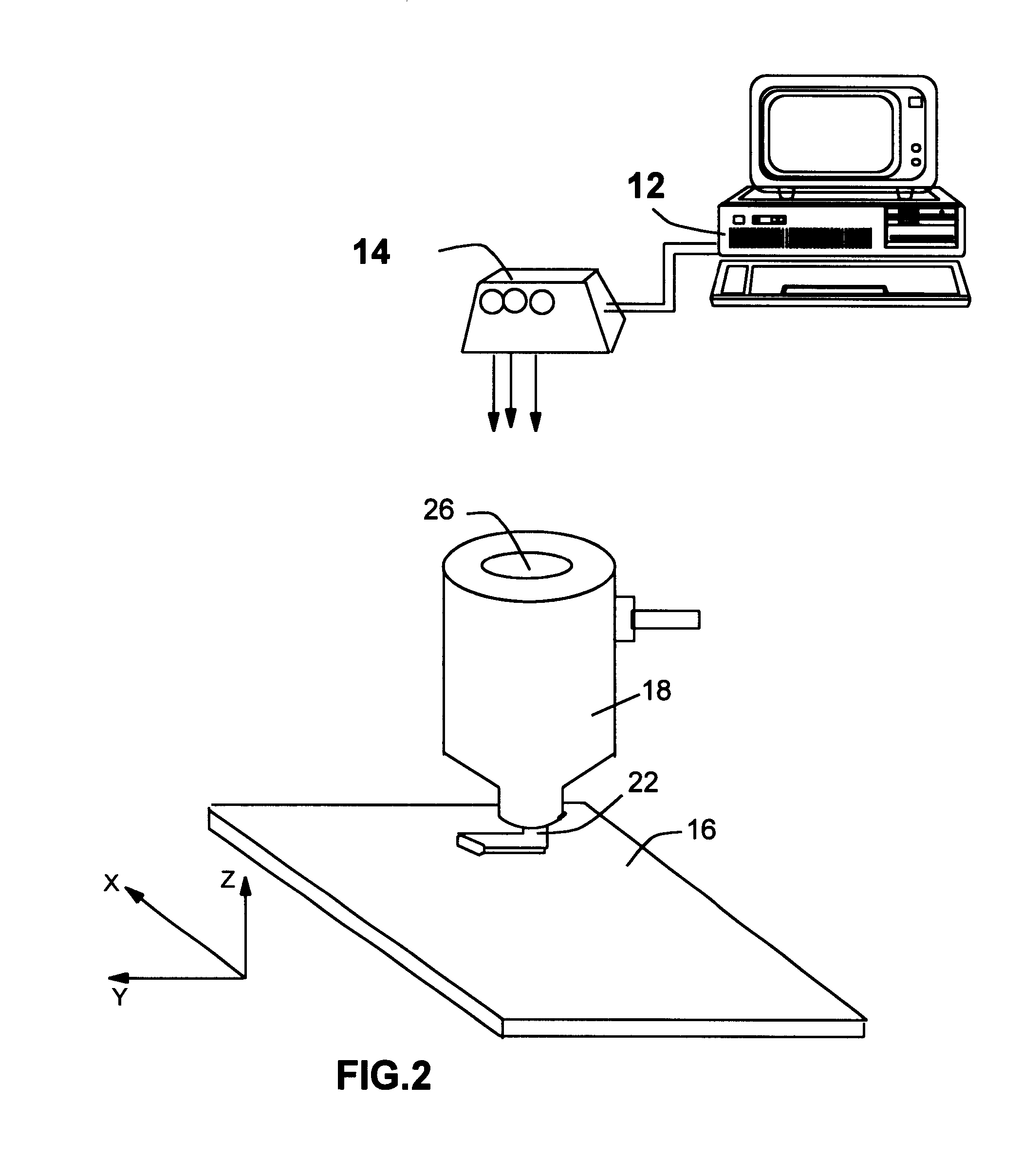

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

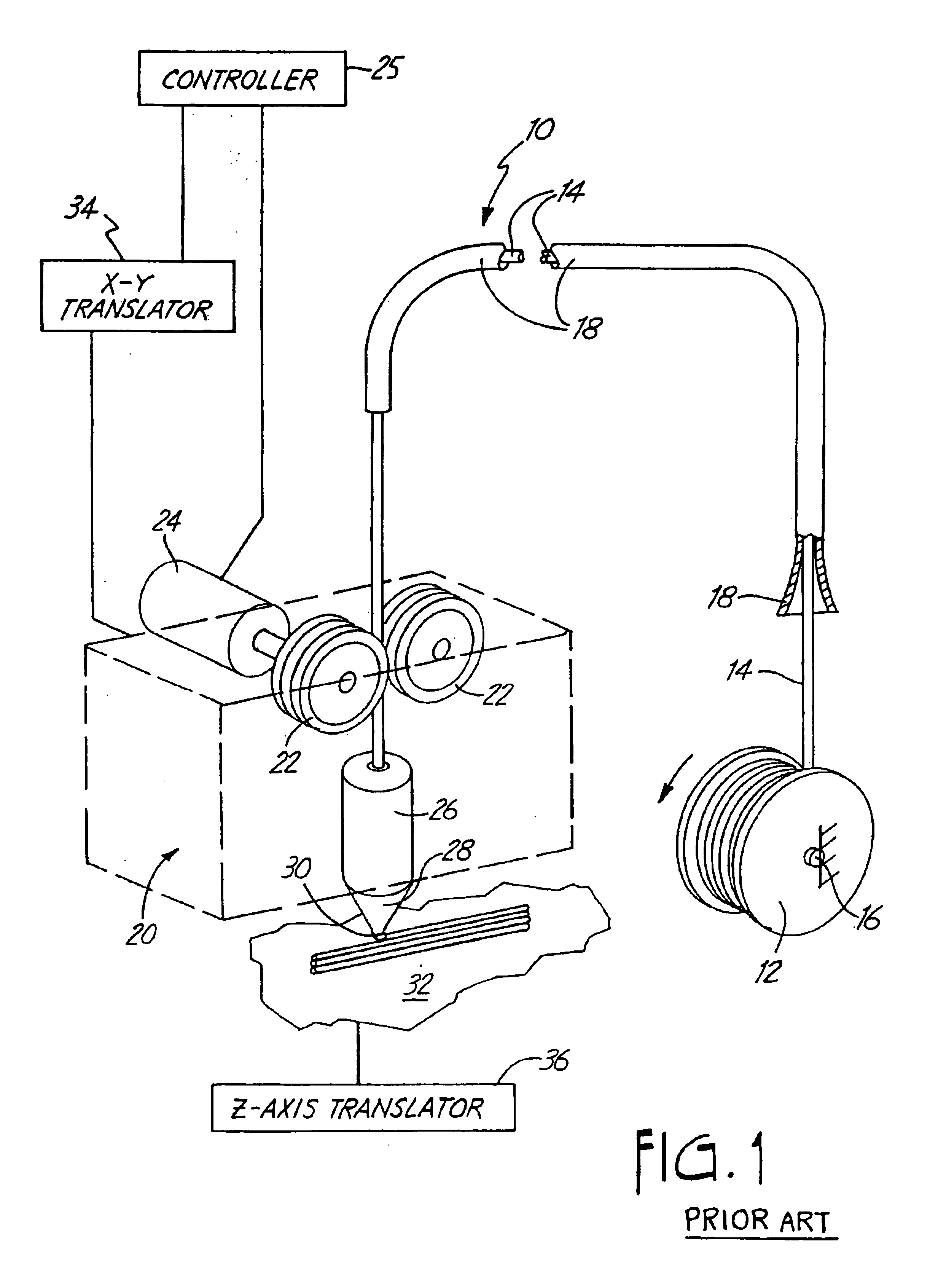

Rapid prototyping and fabrication method for 3-D food objects

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

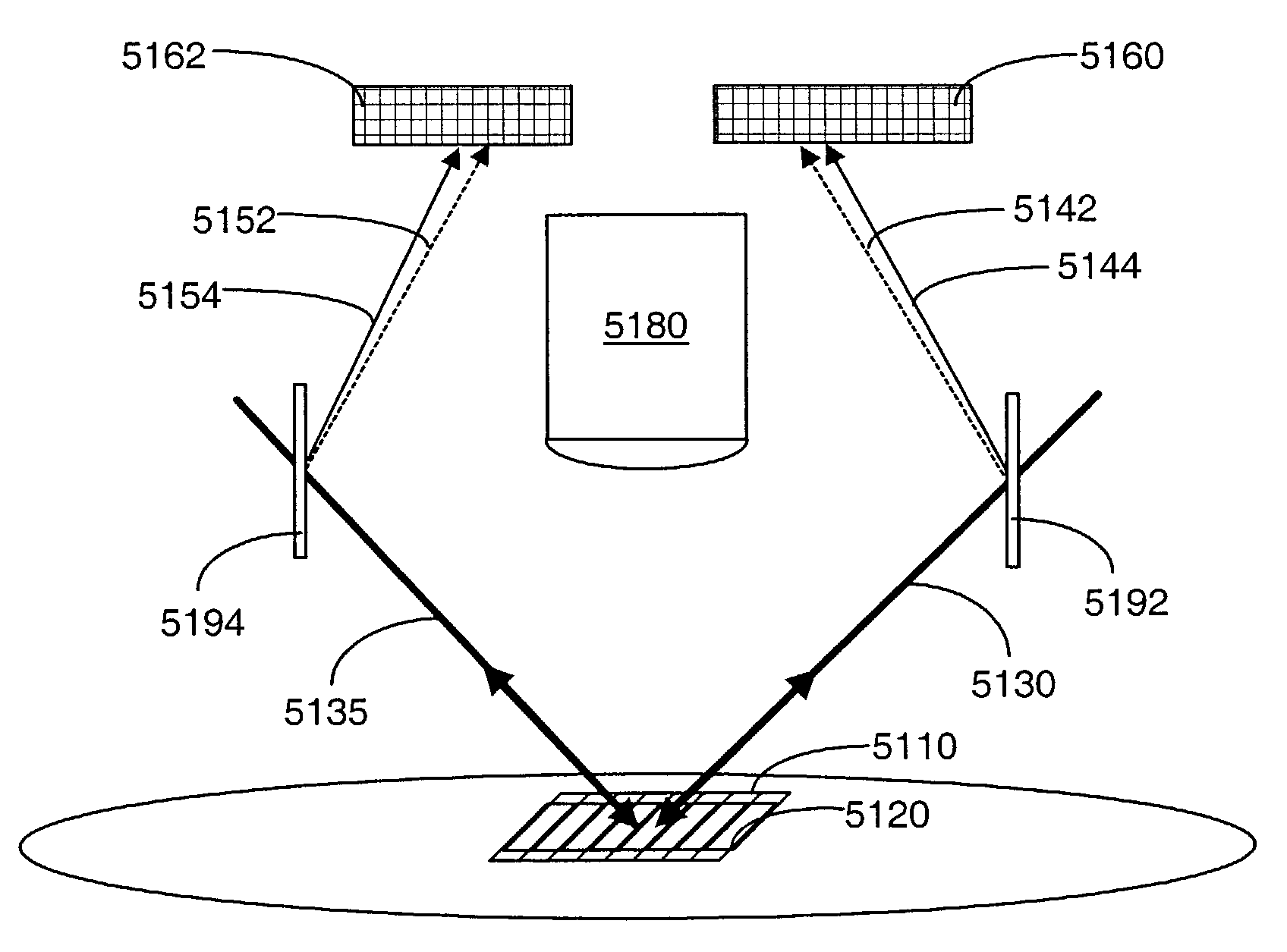

Alignment systems for imprint lithography

Described are systems for patterning a substrate by imprint lithography. Imprint lithography systems include an imprint head configured to hold a template in a spaced relation to a substrate. The imprint lithography system is configured to dispense an activating light curable liquid onto a substrate or template. The system includes a light source that applies activating light to cure the activating light curable liquid. Multiple optical imaging devices are used to align the template with the substrate.

Owner:CANON KK

Method and apparatus for additive manufacturing

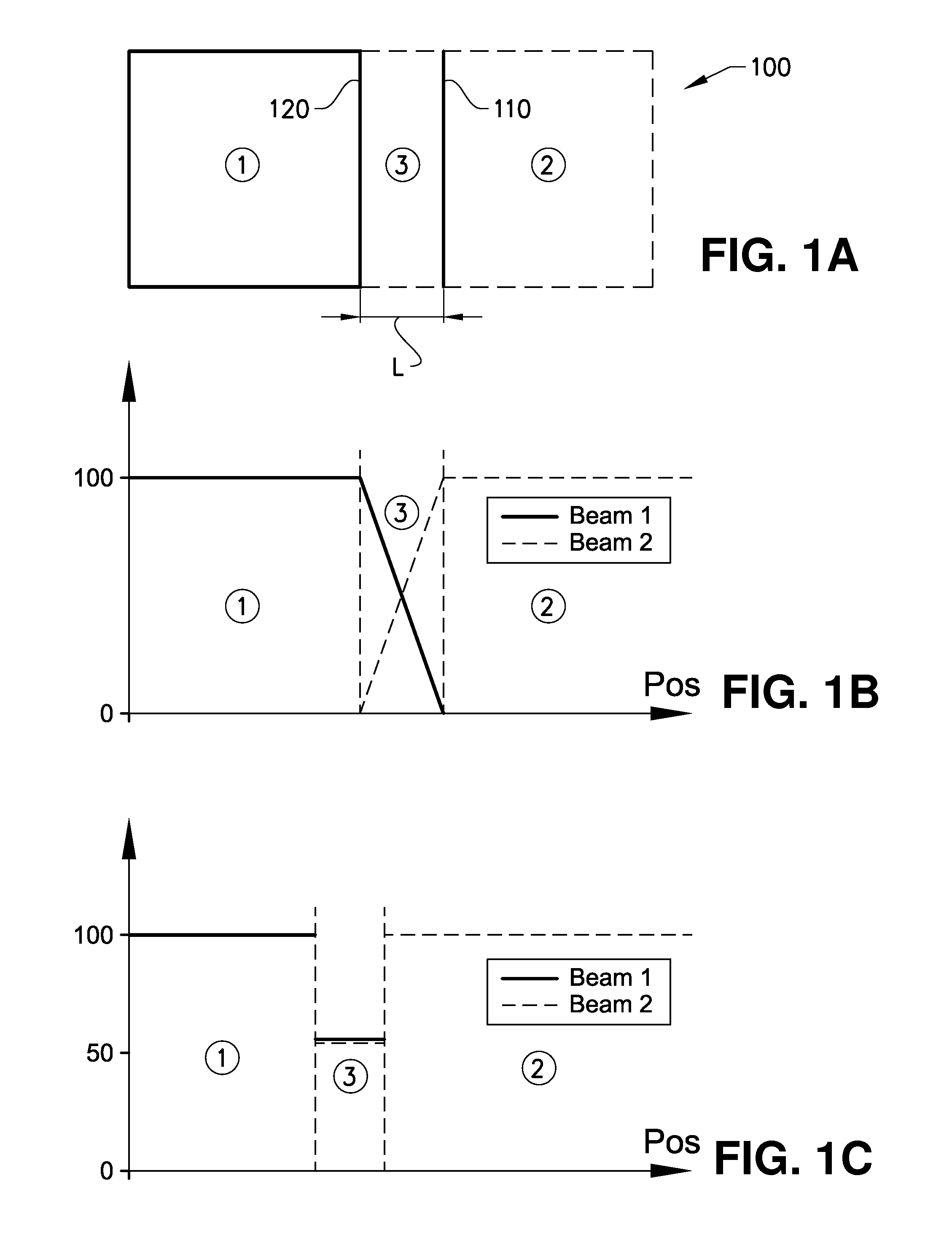

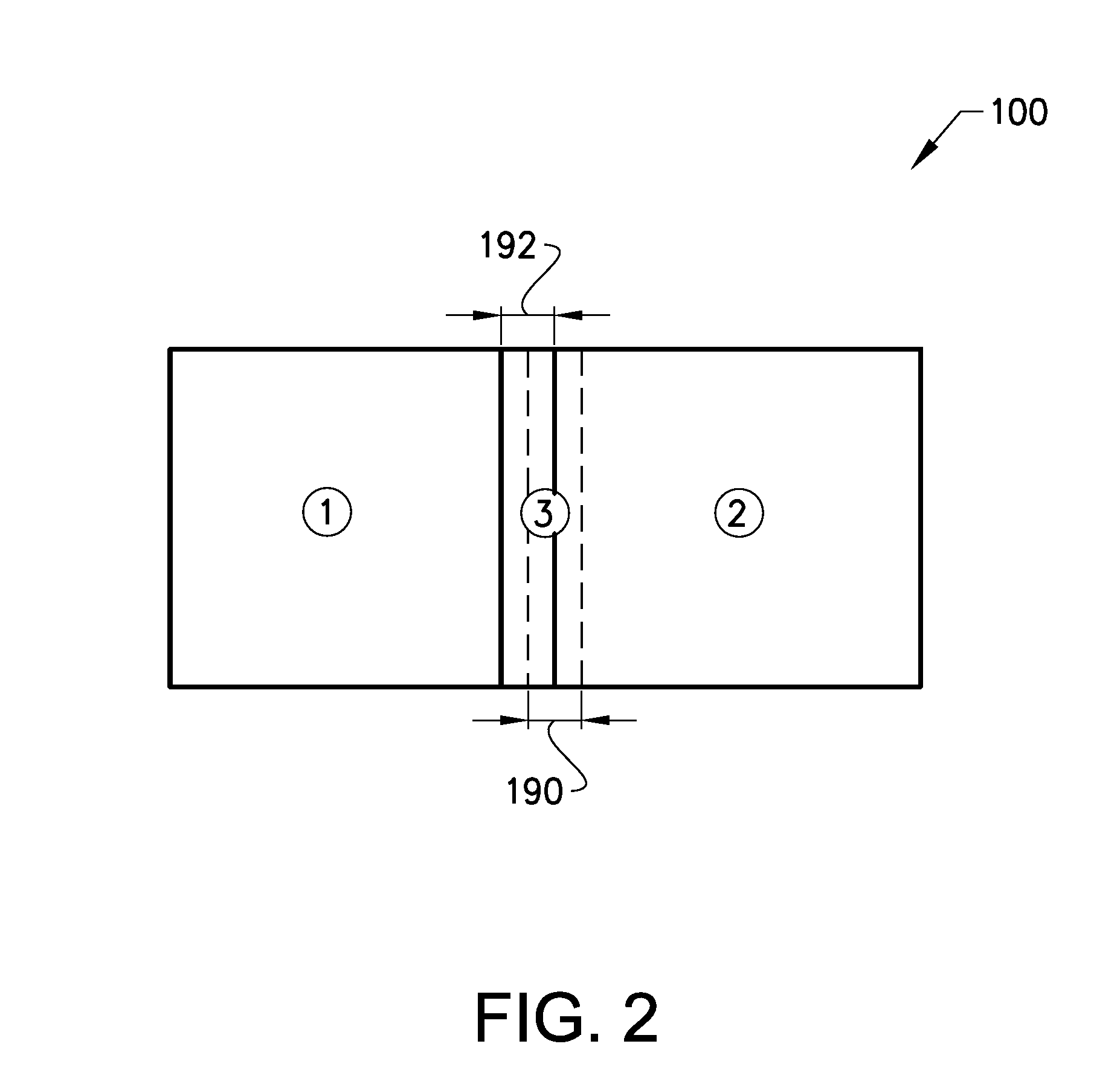

ActiveUS20140348691A1Large build volumeSacrificing qualityAdditive manufacturing apparatusAuxillary shaping apparatusBeam sourceEngineering

A method for forming a three-dimensional article through successive fusion of parts of a powder bed, which parts corresponds to successive cross sections of the three-dimensional article, said method comprising the steps of: providing a model of said three dimensional article, providing a first powder layer on a work table, directing a first energy beam from a first energy beam source over said work table causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, directing a second energy beam from a second energy beam source over said work table causing said first powder layer to fuse in second selected locations according to said model to form the first cross section of said three-dimensional article, wherein said first and second locations of said first powder layer are at least partially overlapping each other.

Owner:ARCAM AB

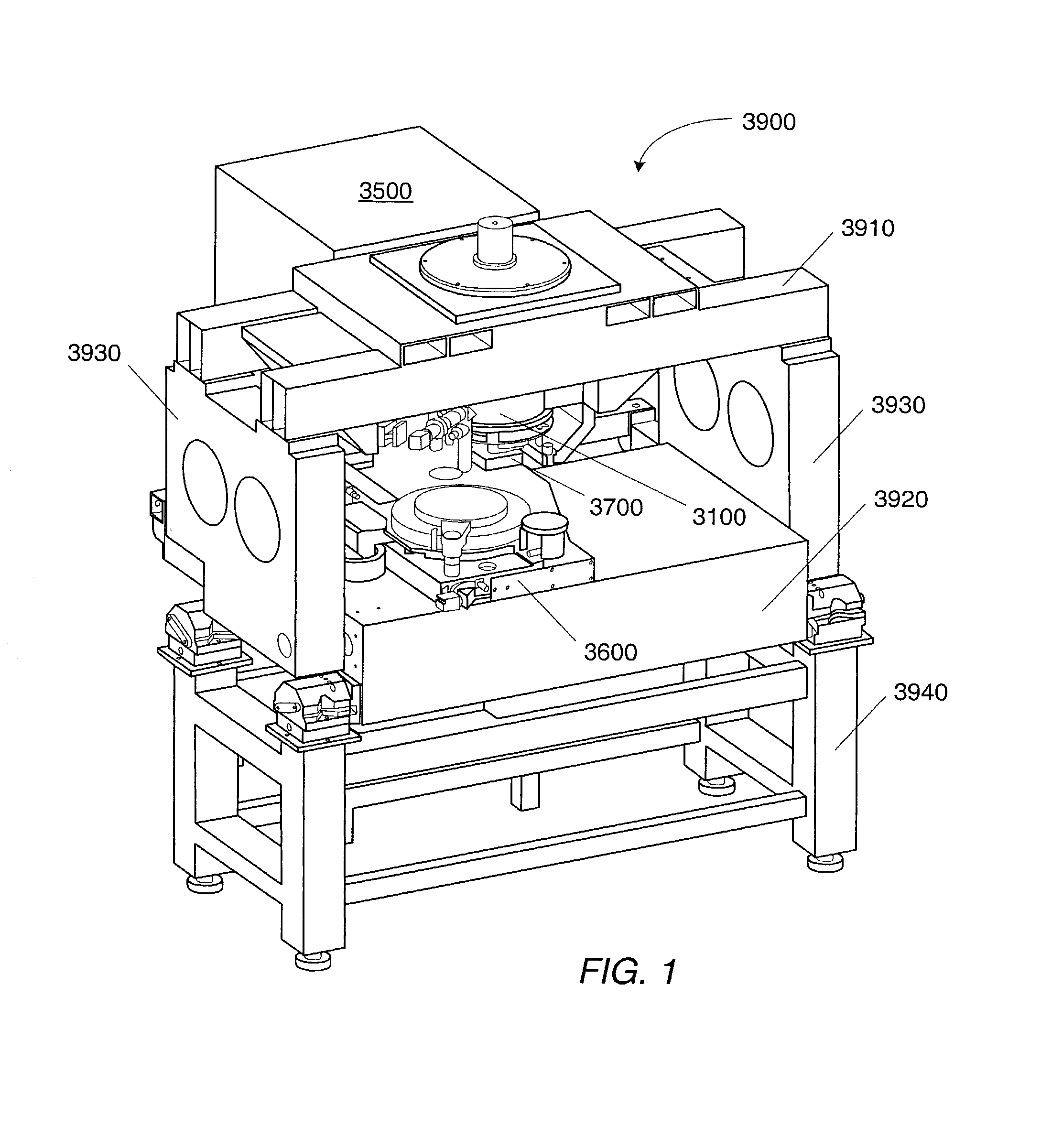

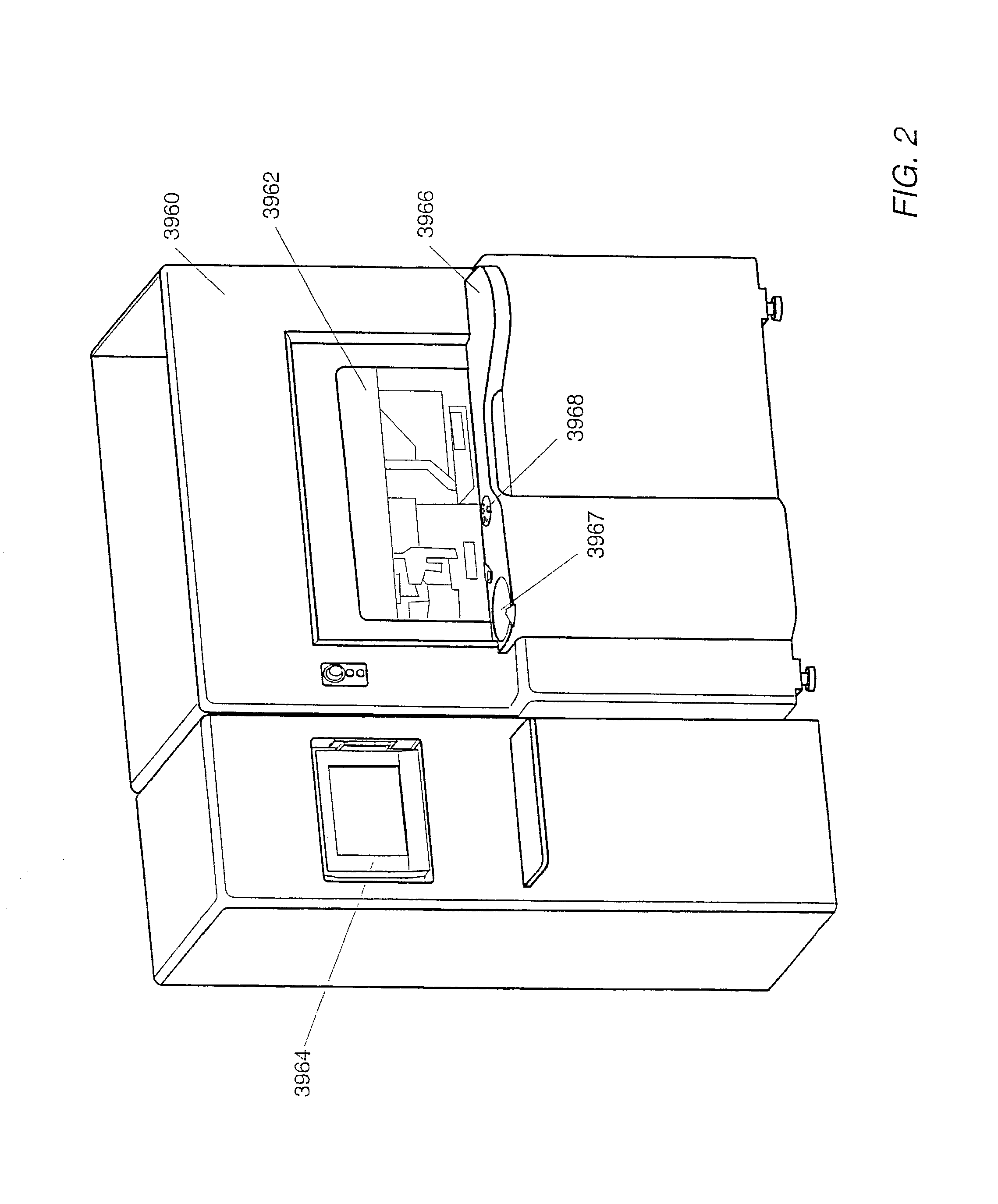

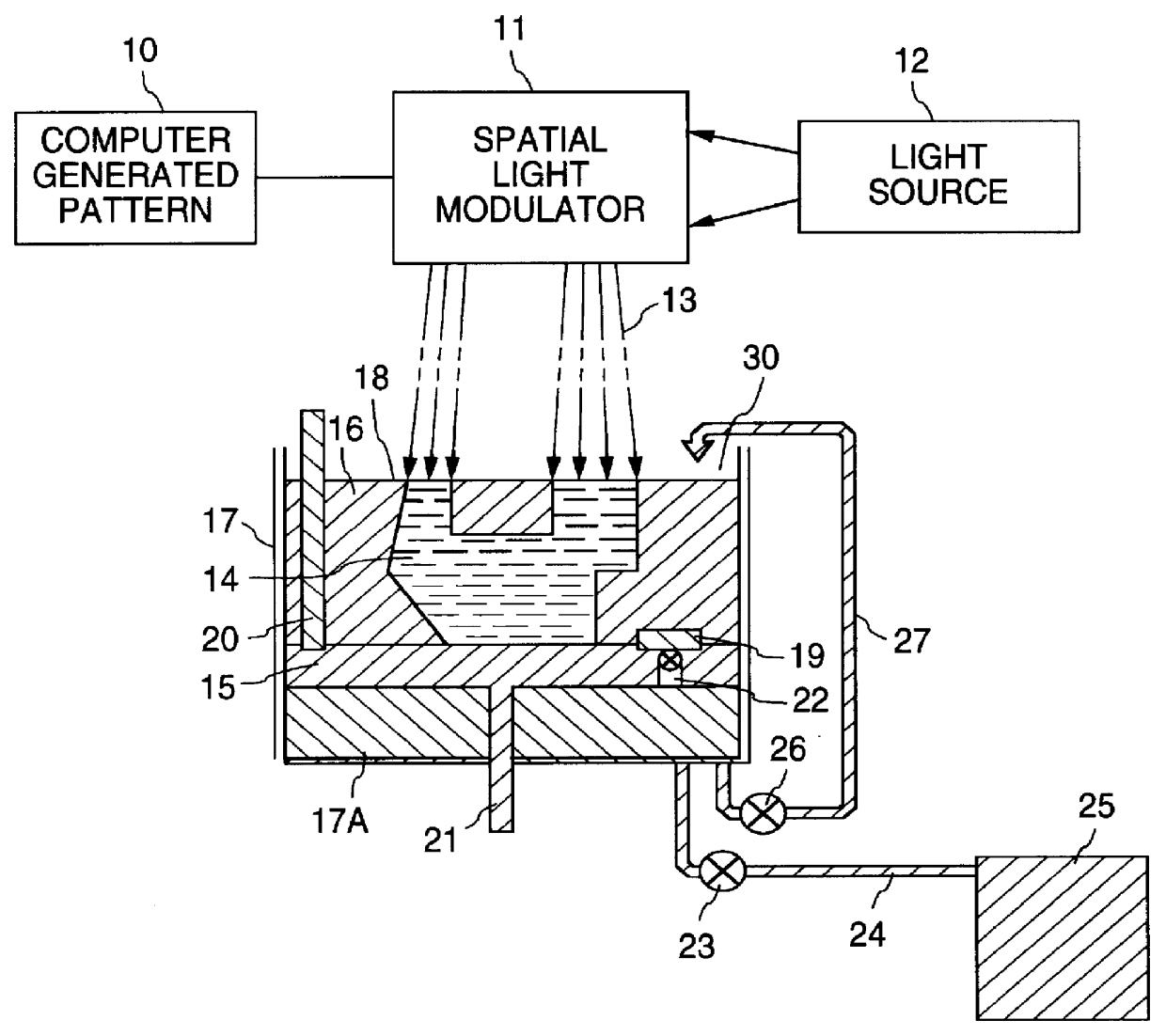

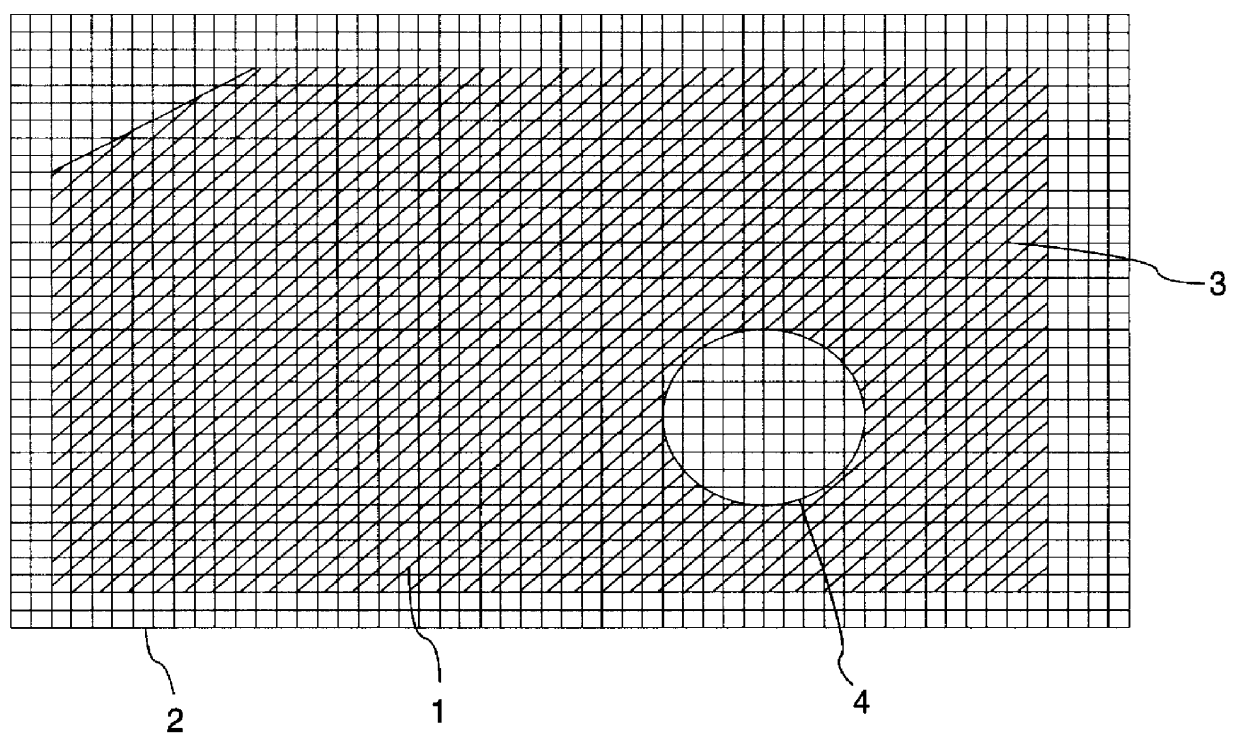

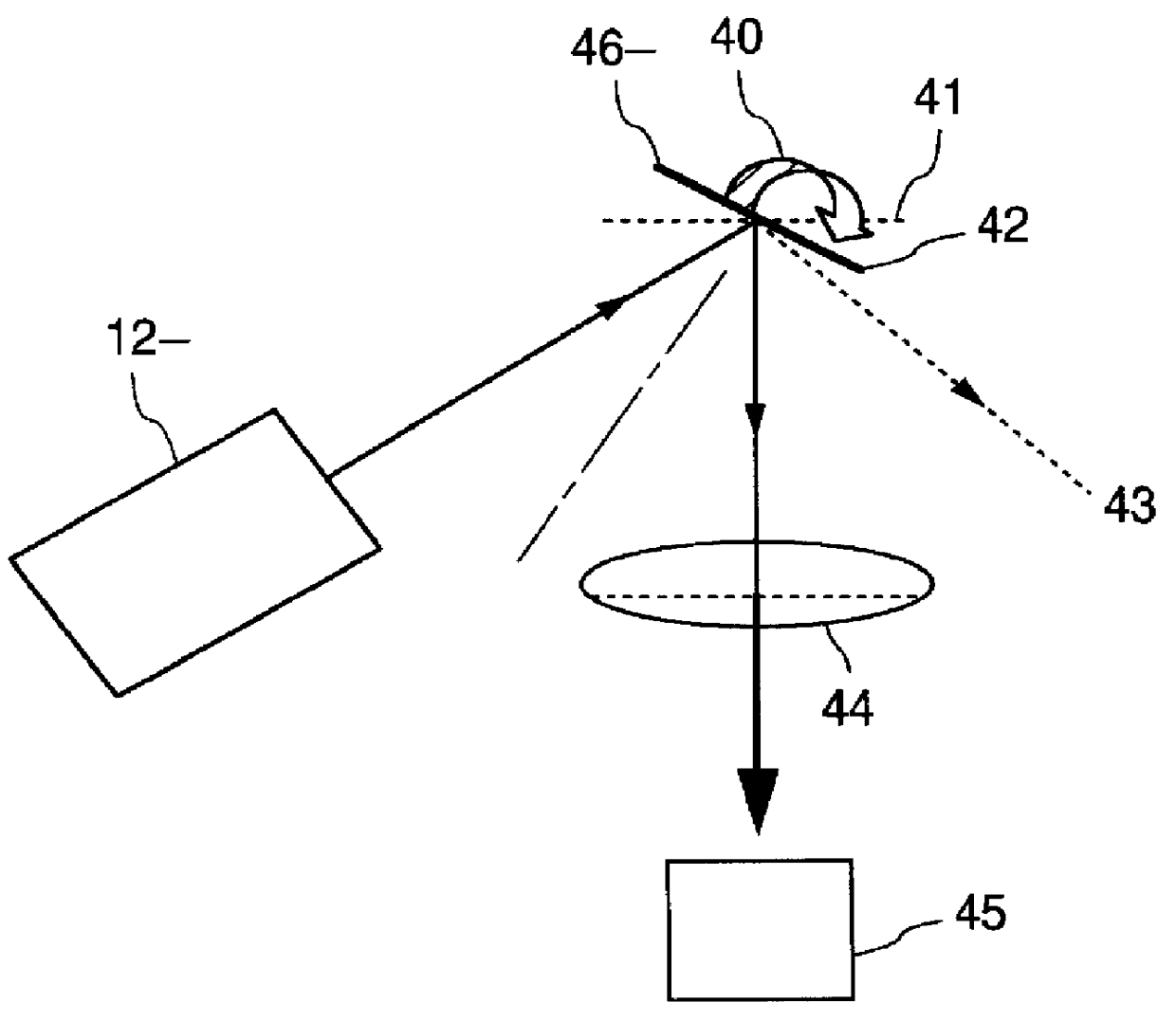

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

Arrangement and method for producing a three-dimensional product

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating scheme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for producing three-dimensional product using such an arrangement.

Owner:ARCAM AB

Modular fabrication systems and methods

ActiveUS7625198B2Improve throughputAdapt to a wide rangeLiquid surface applicatorsConfectioneryEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

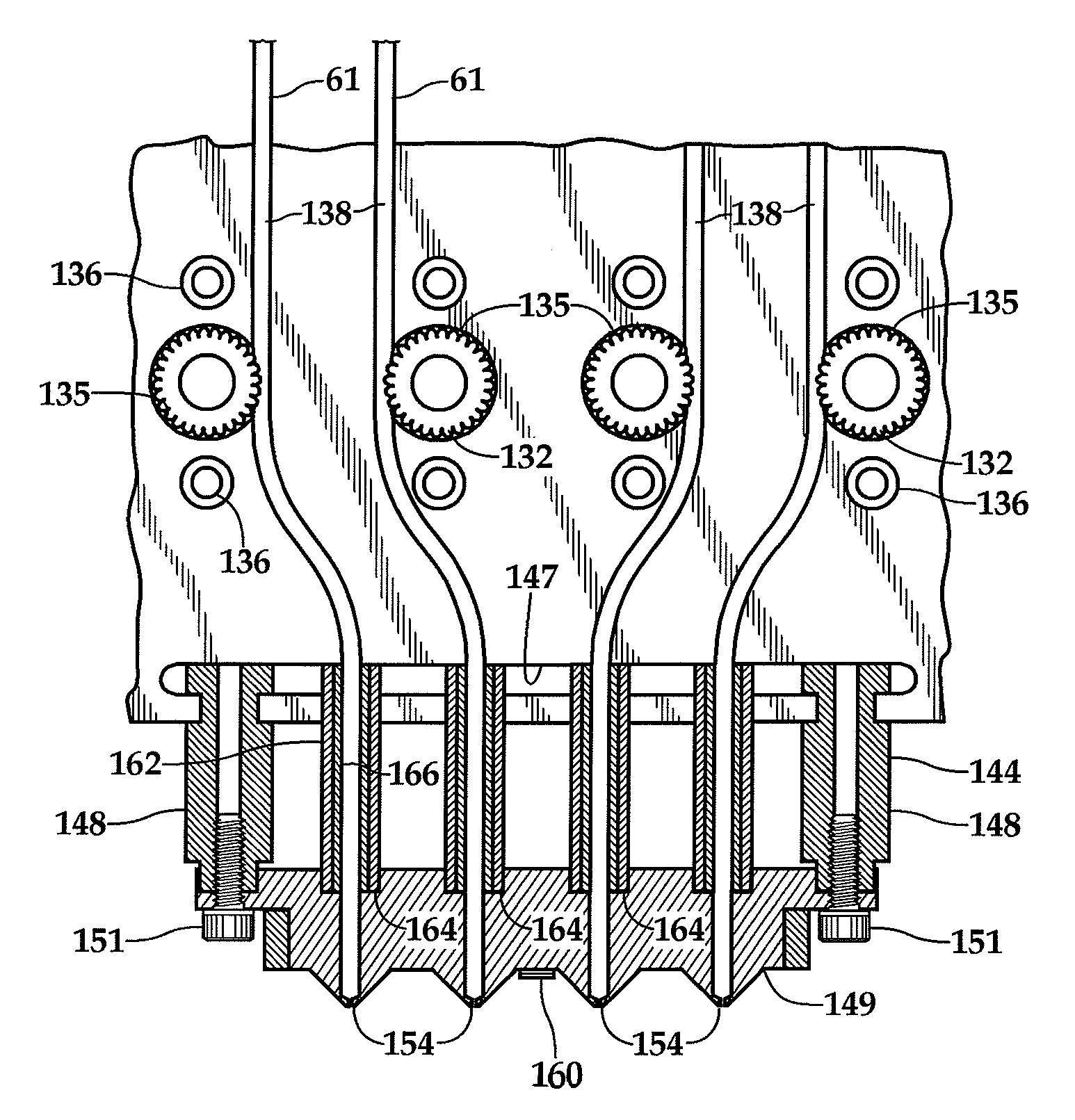

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

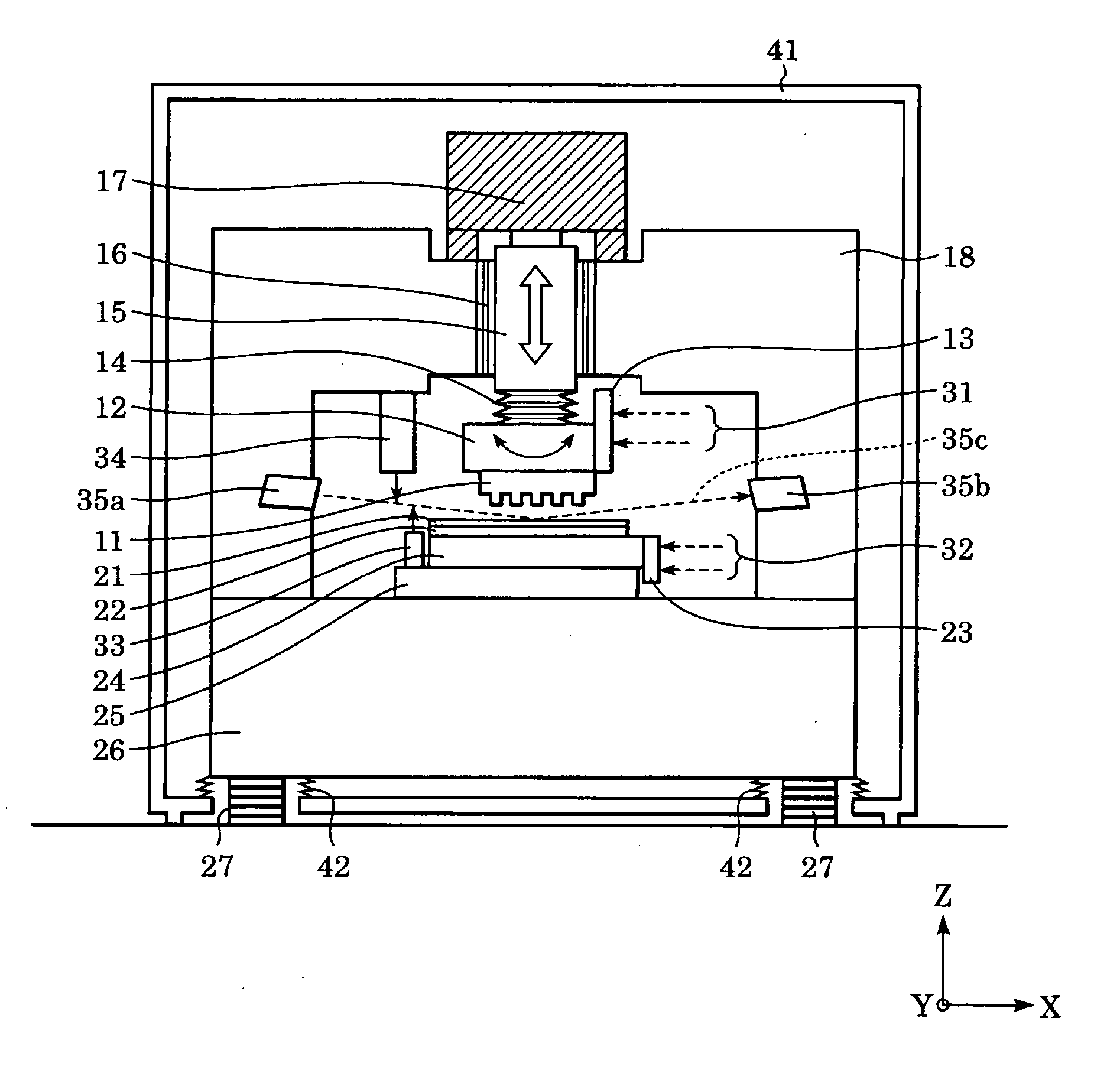

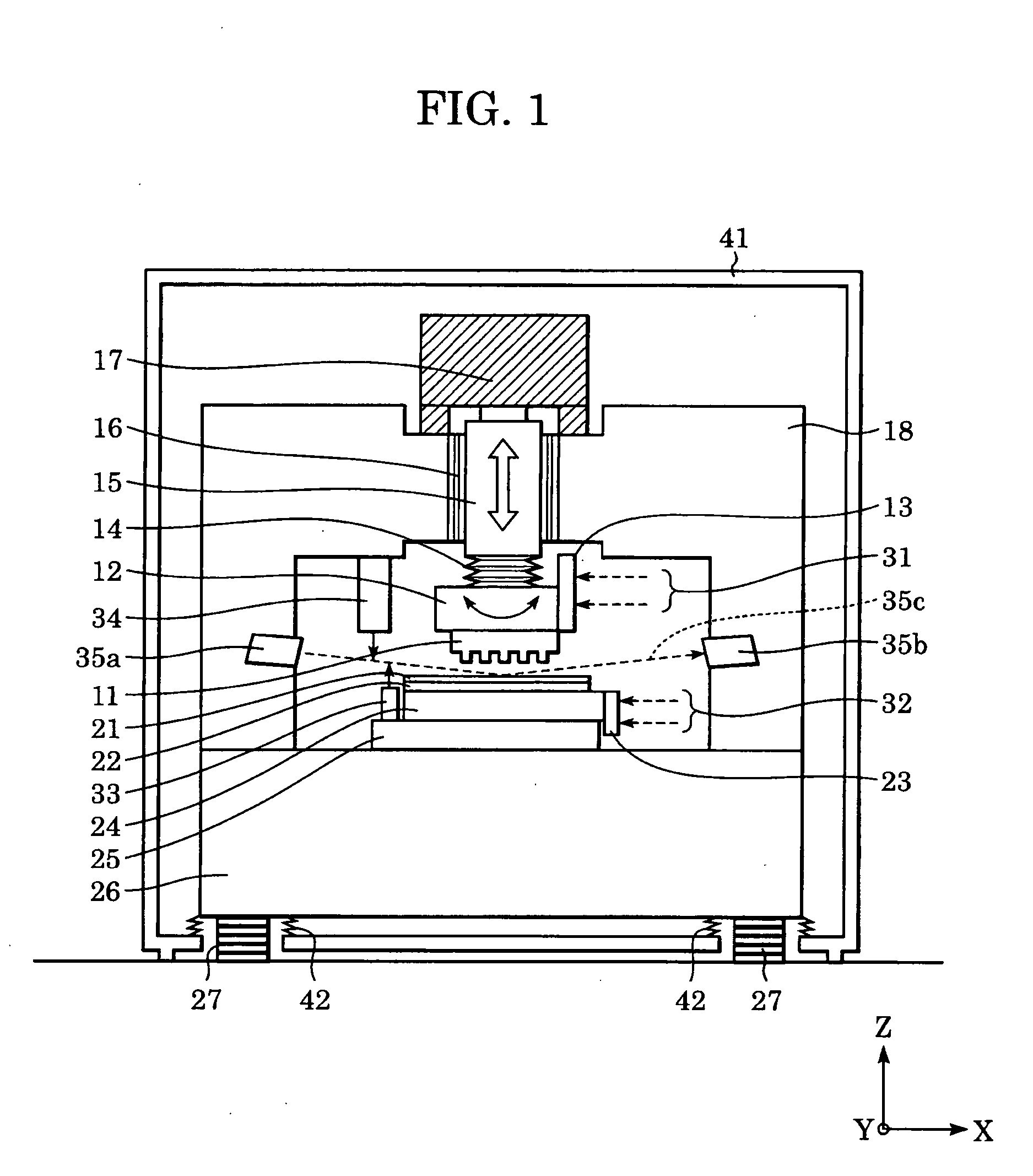

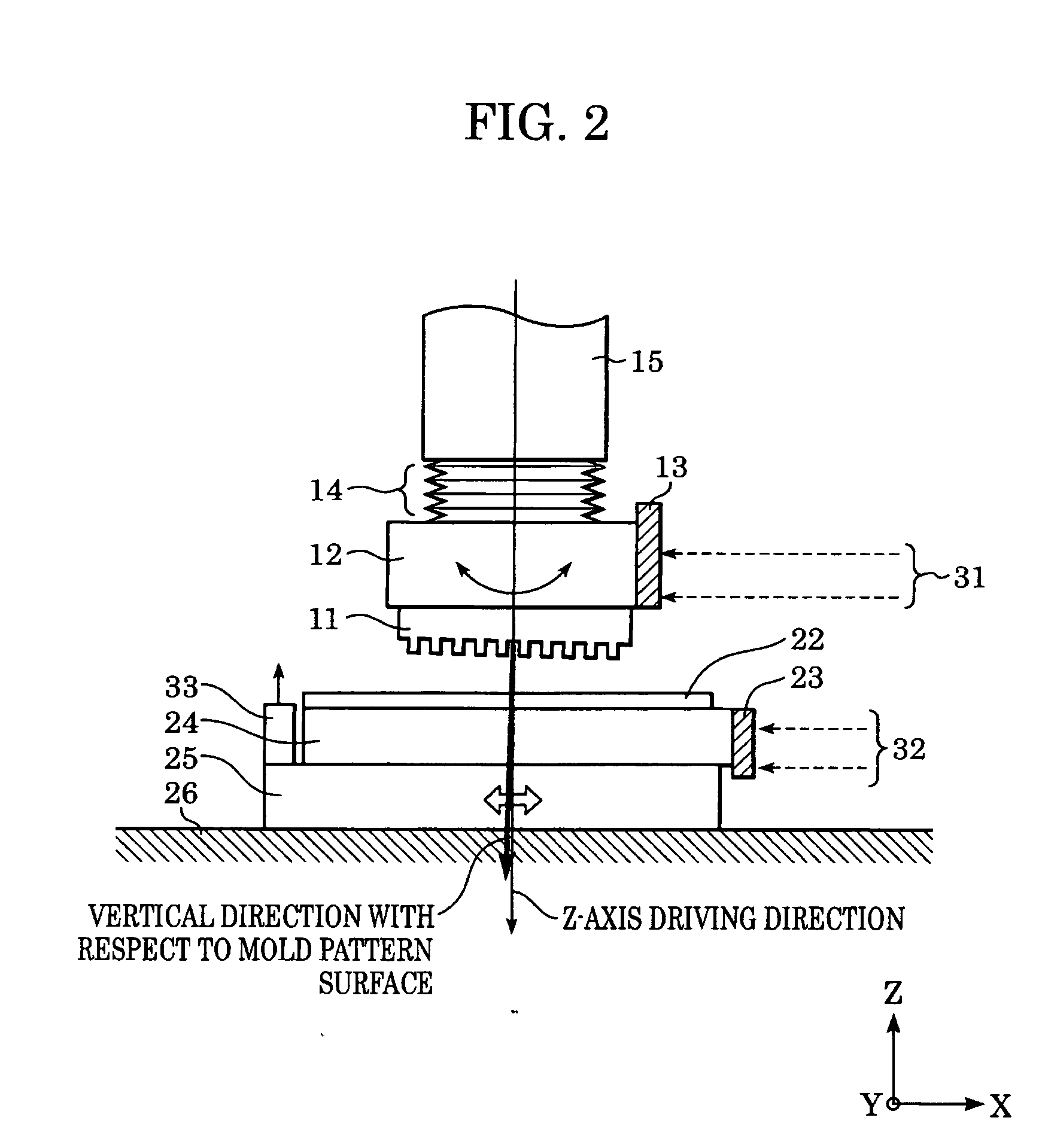

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com