Patents

Literature

10387 results about "Idler-wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An idler-wheel is wheel which serves only to transmit rotation from one shaft to another, in applications where it is undesirable to connect them directly. For example, connecting a motor to the platter of a phonograph, or the crankshaft-to-camshaft gear train of an automobile.

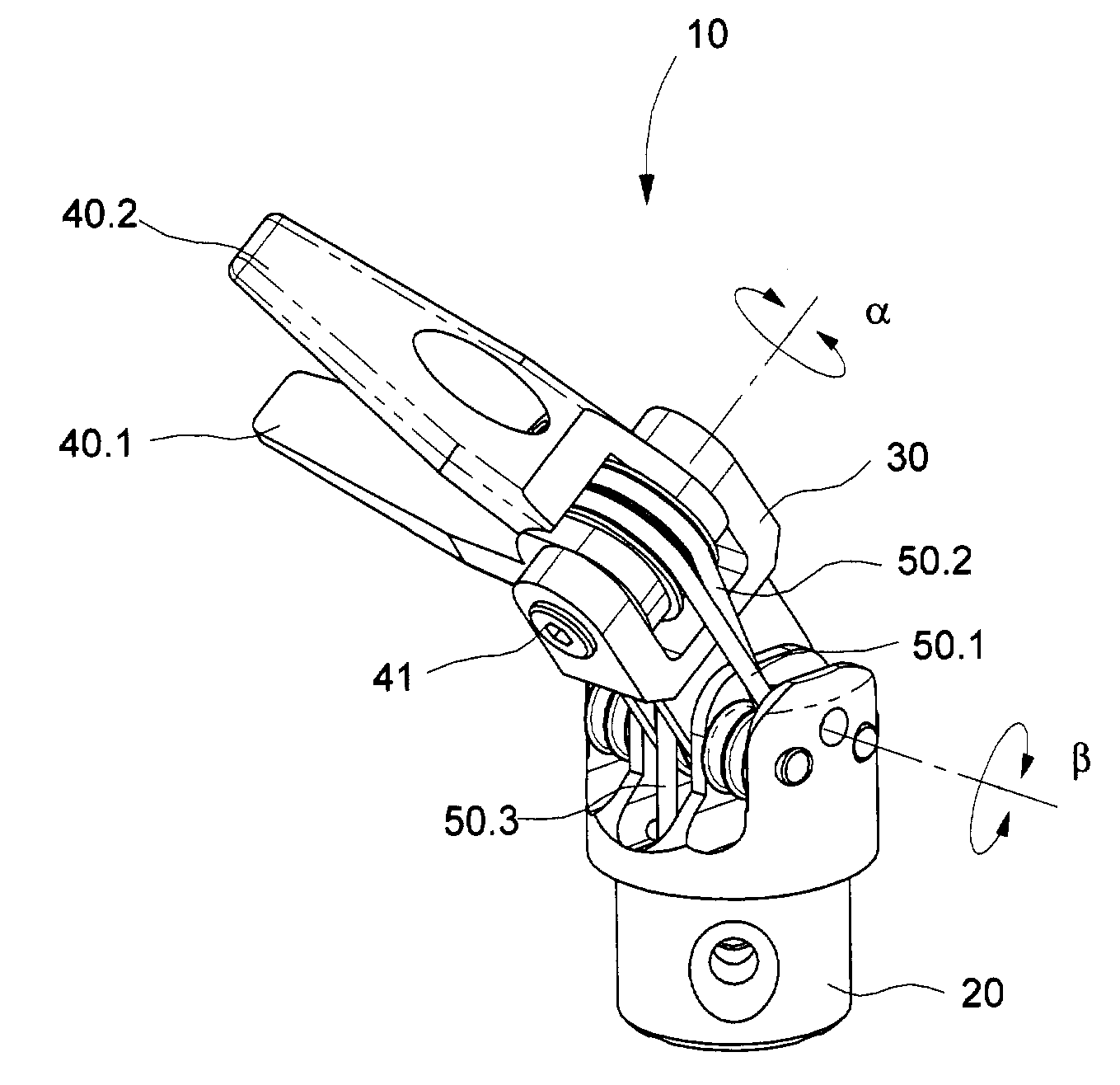

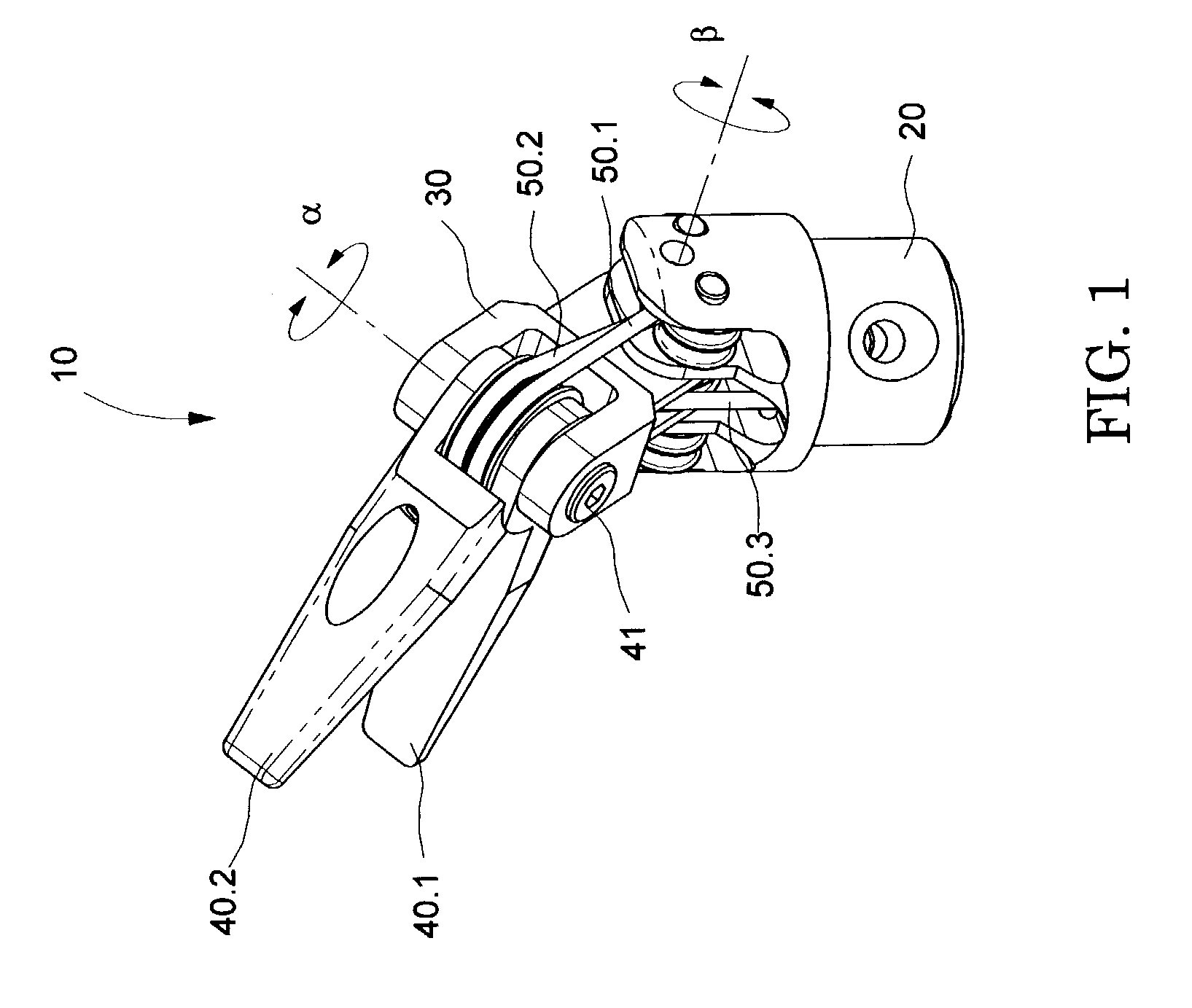

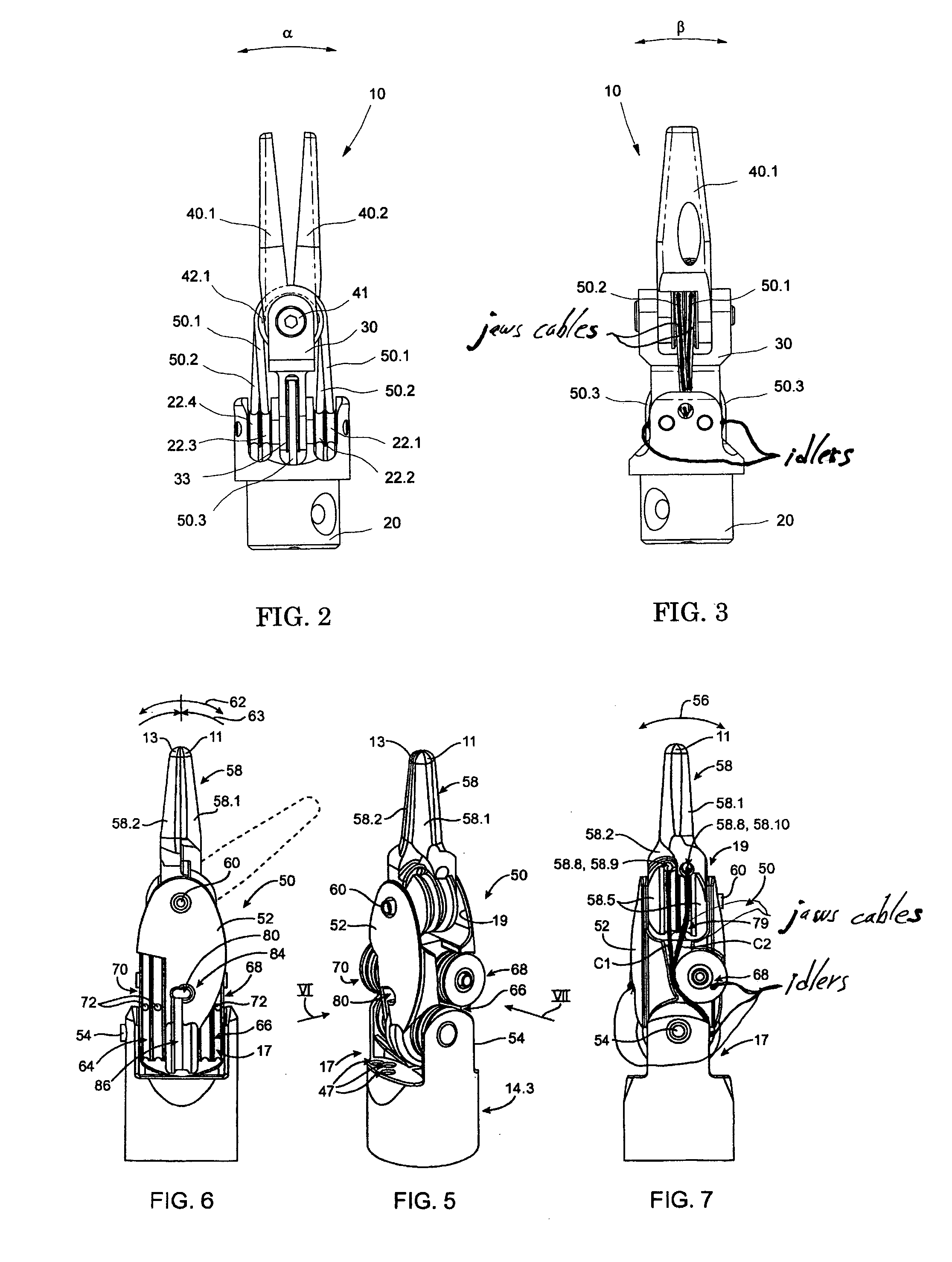

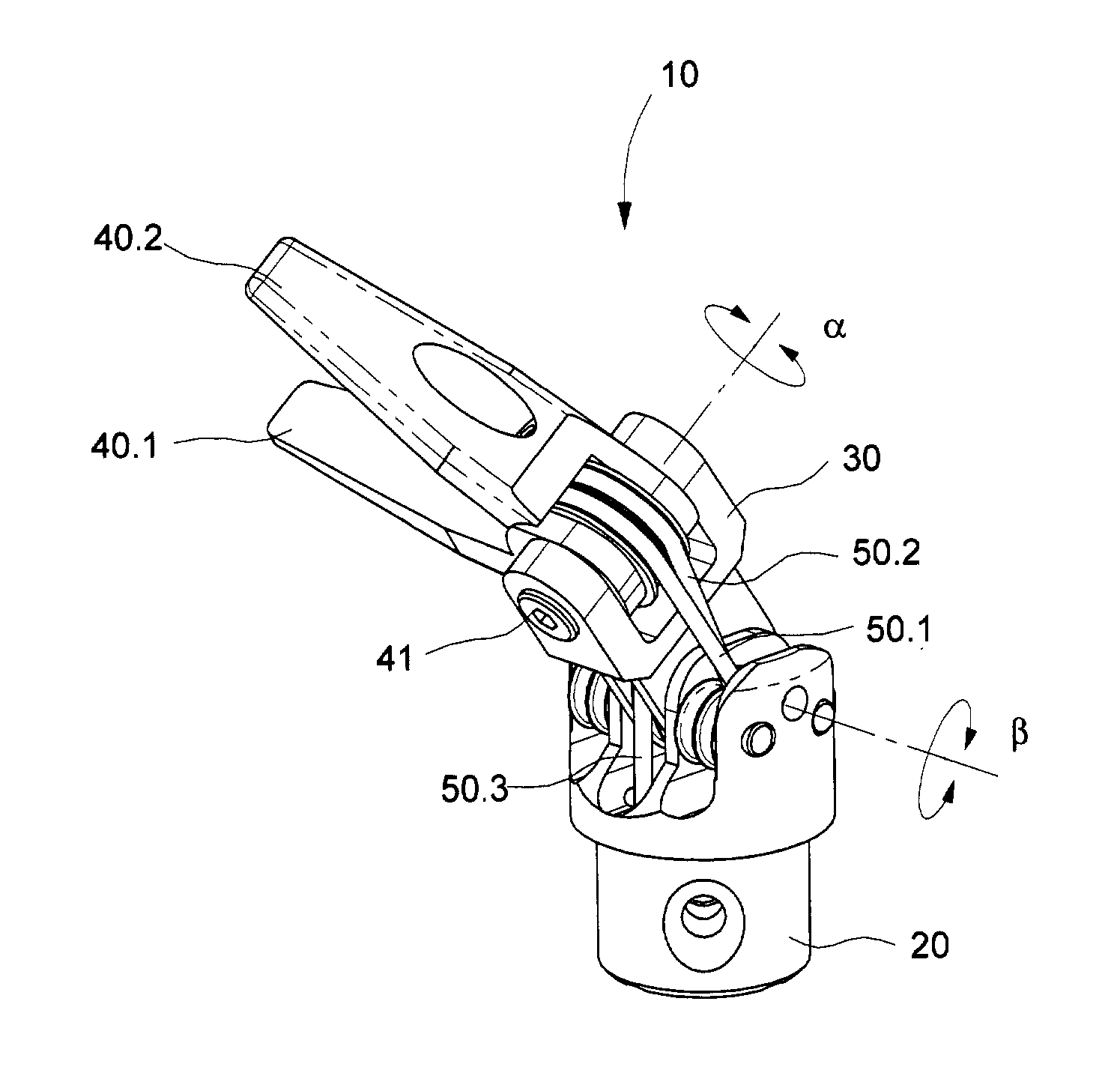

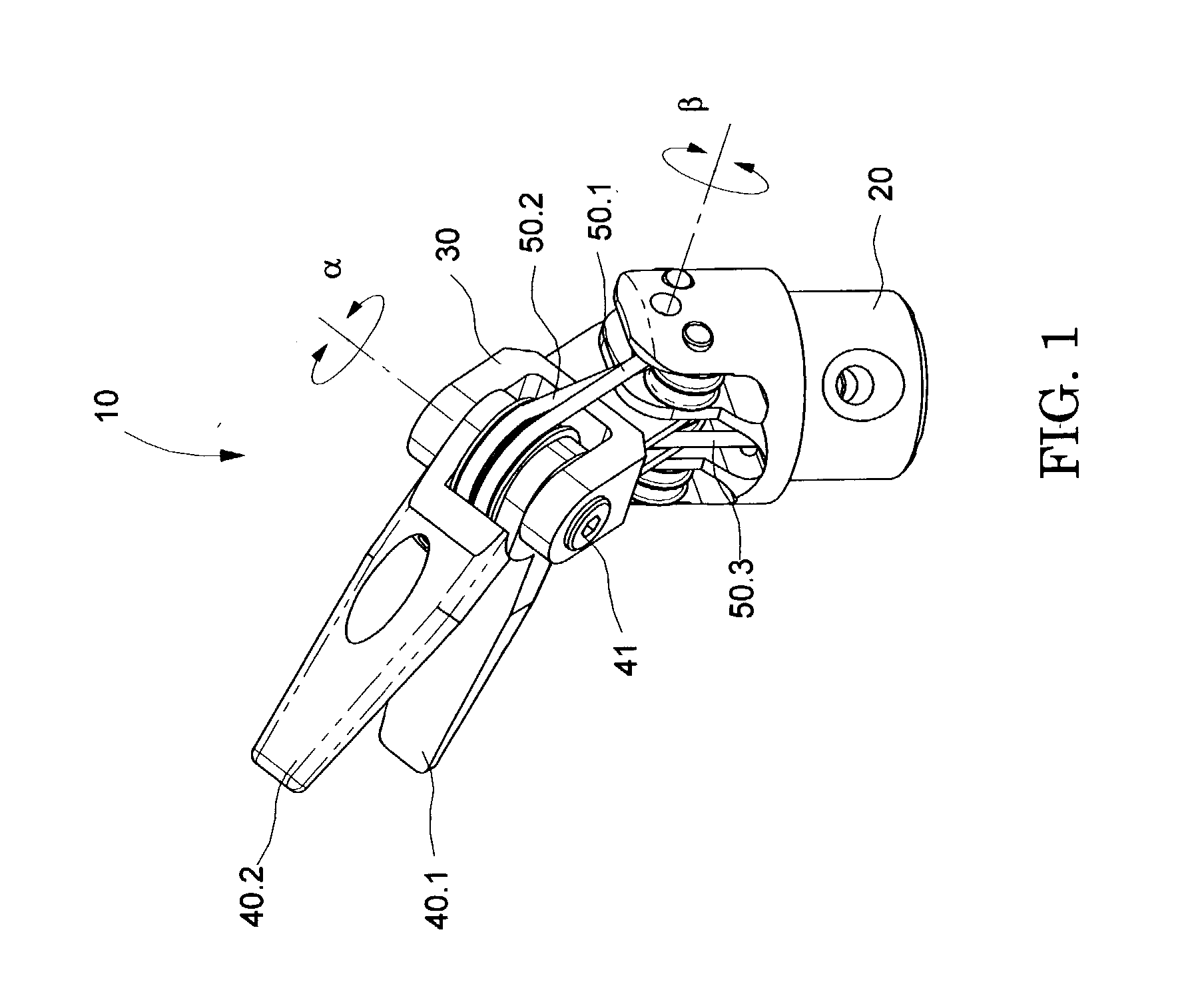

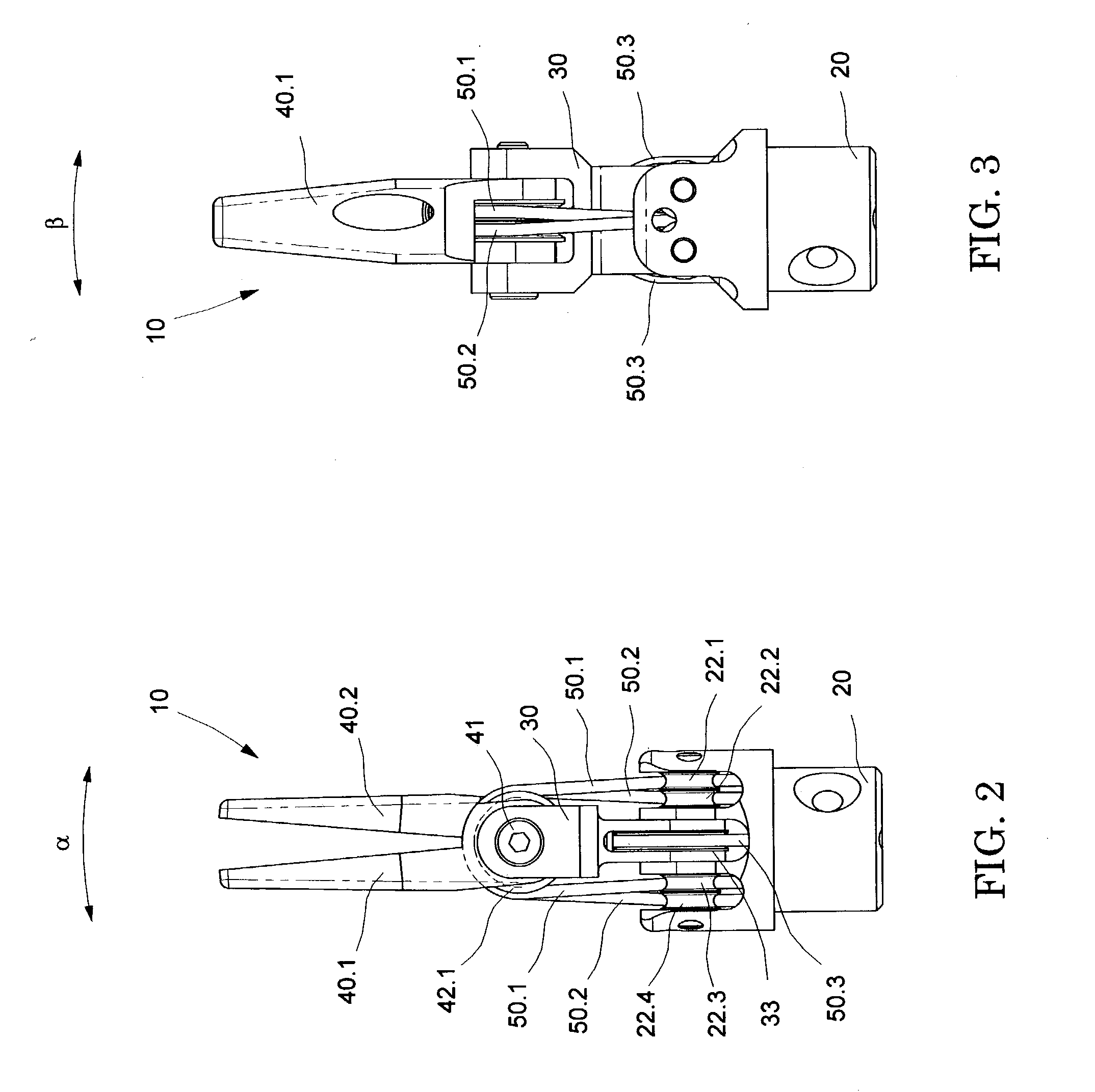

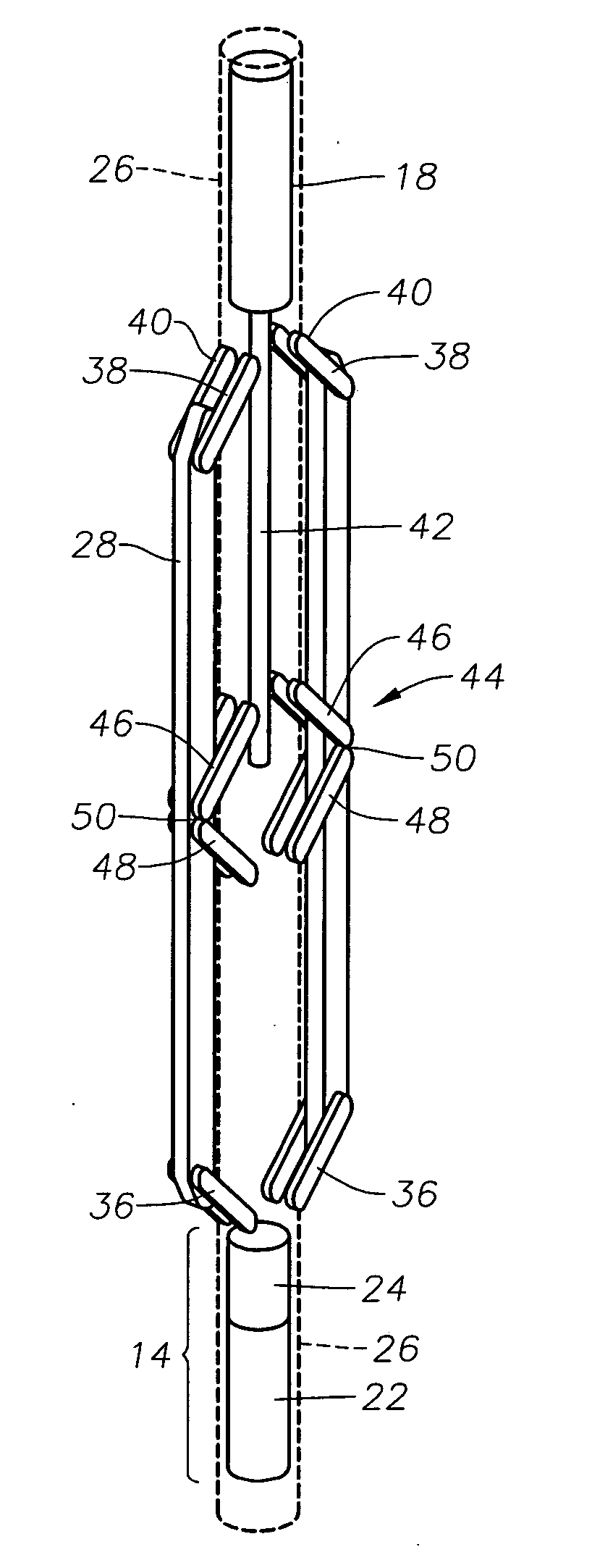

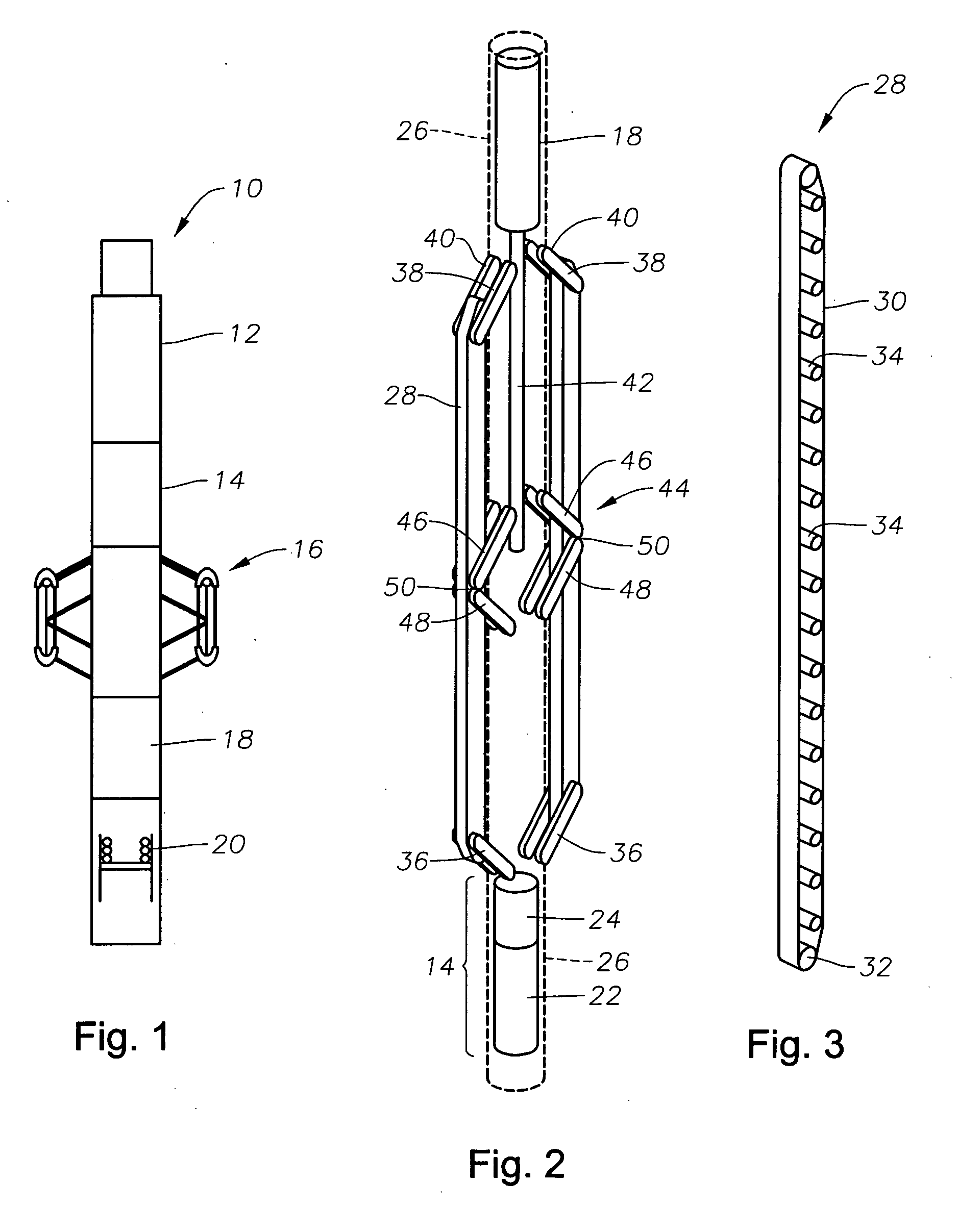

Wrist with decoupled motion transmission

InactiveUS6969385B2Reduce inertiaImprove device performanceMechanical apparatusJointsEngineeringActuator

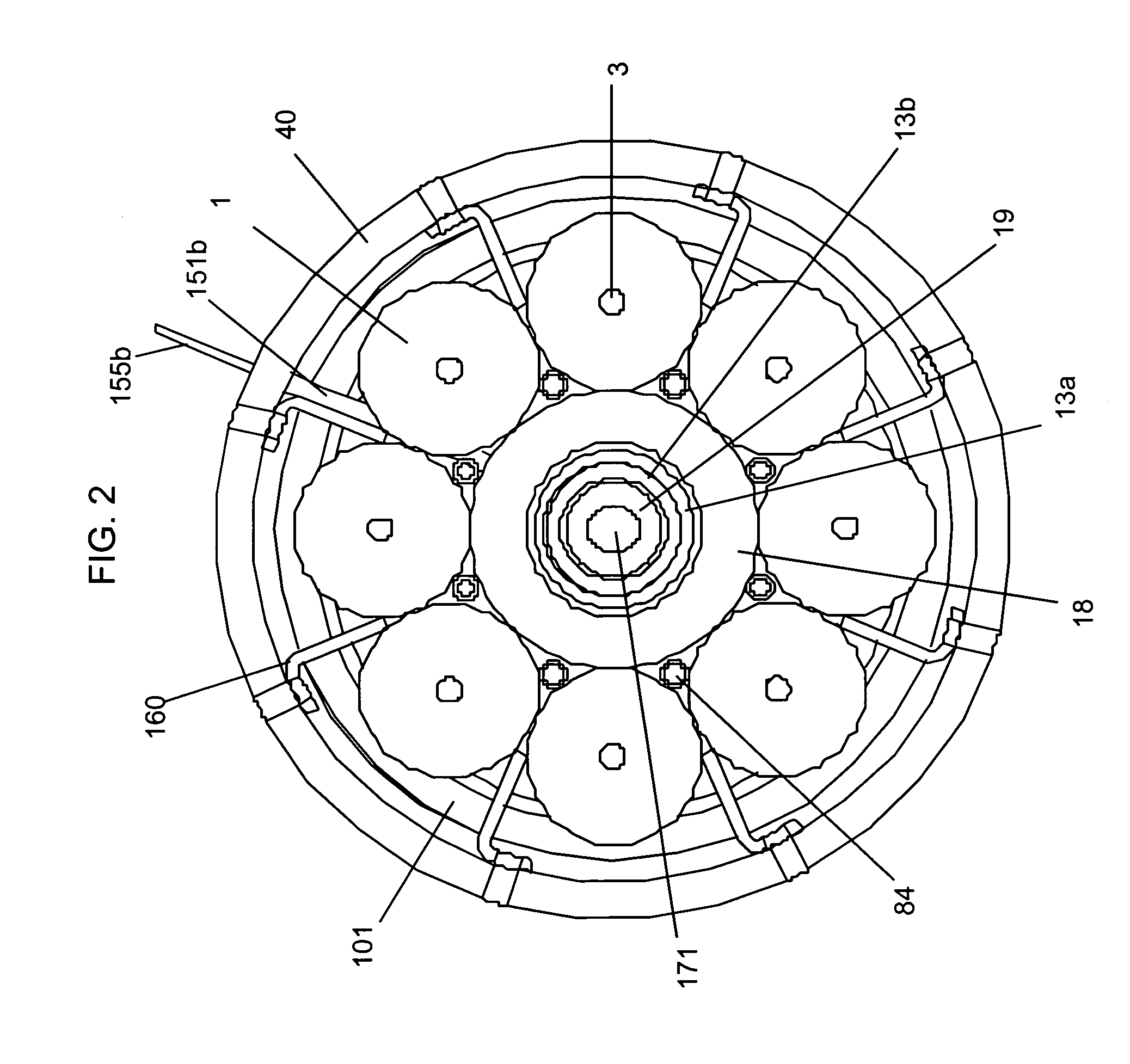

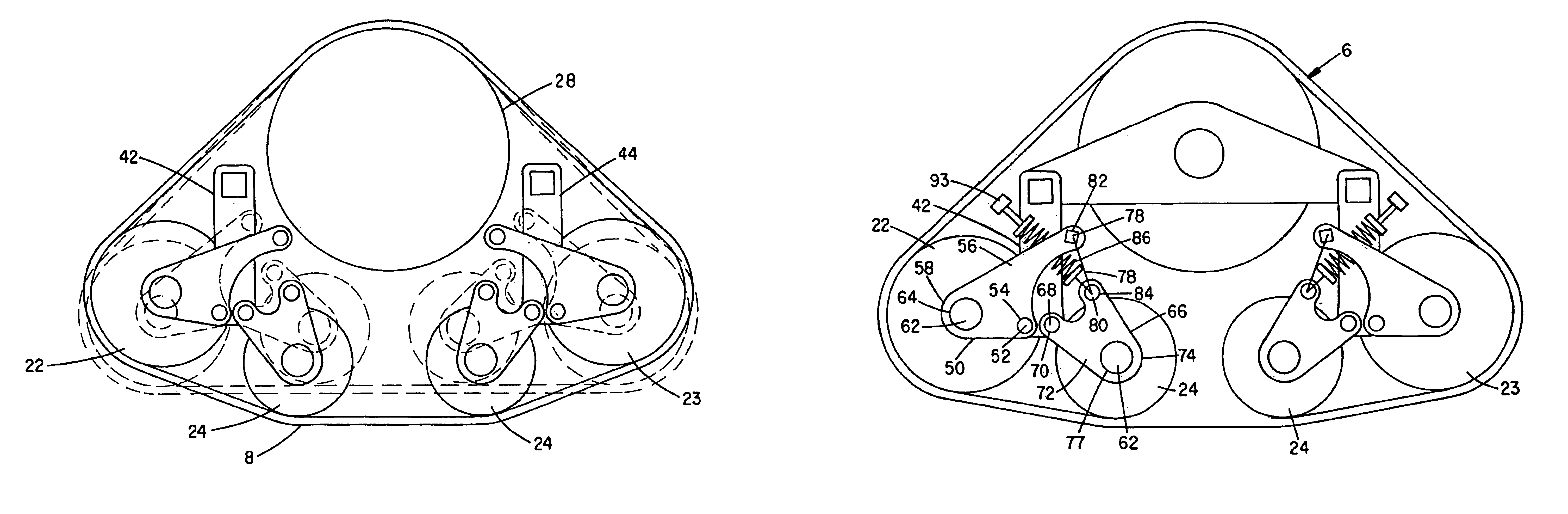

The present invention is a wrist mechanism and a method for making robotic devices in which the transmission of motion, force and / or torque around a revolute joint can be accomplished without coupling. This construction allows mounting the actuators on the base or lower elements of a mechanism, so that only linkage elements move the end-effector. Thus reducing inertia of the moving elements and increasing performance of the device. The decoupled motion of the end-effector or links is achieved by routing their transmission cables around idler pulleys placed parallel to the joint rotation axis on an optimal position such any stretch on the transmission cable is minimized. In particular, this construction can be use for robotic surgical tools that have two independently driven jaws, decoupled and orthogonal from its articulating wrist. This device may be used in grasping, cutting, suturing or alike operations.

Owner:MOREYRA MANUEL RICARDO

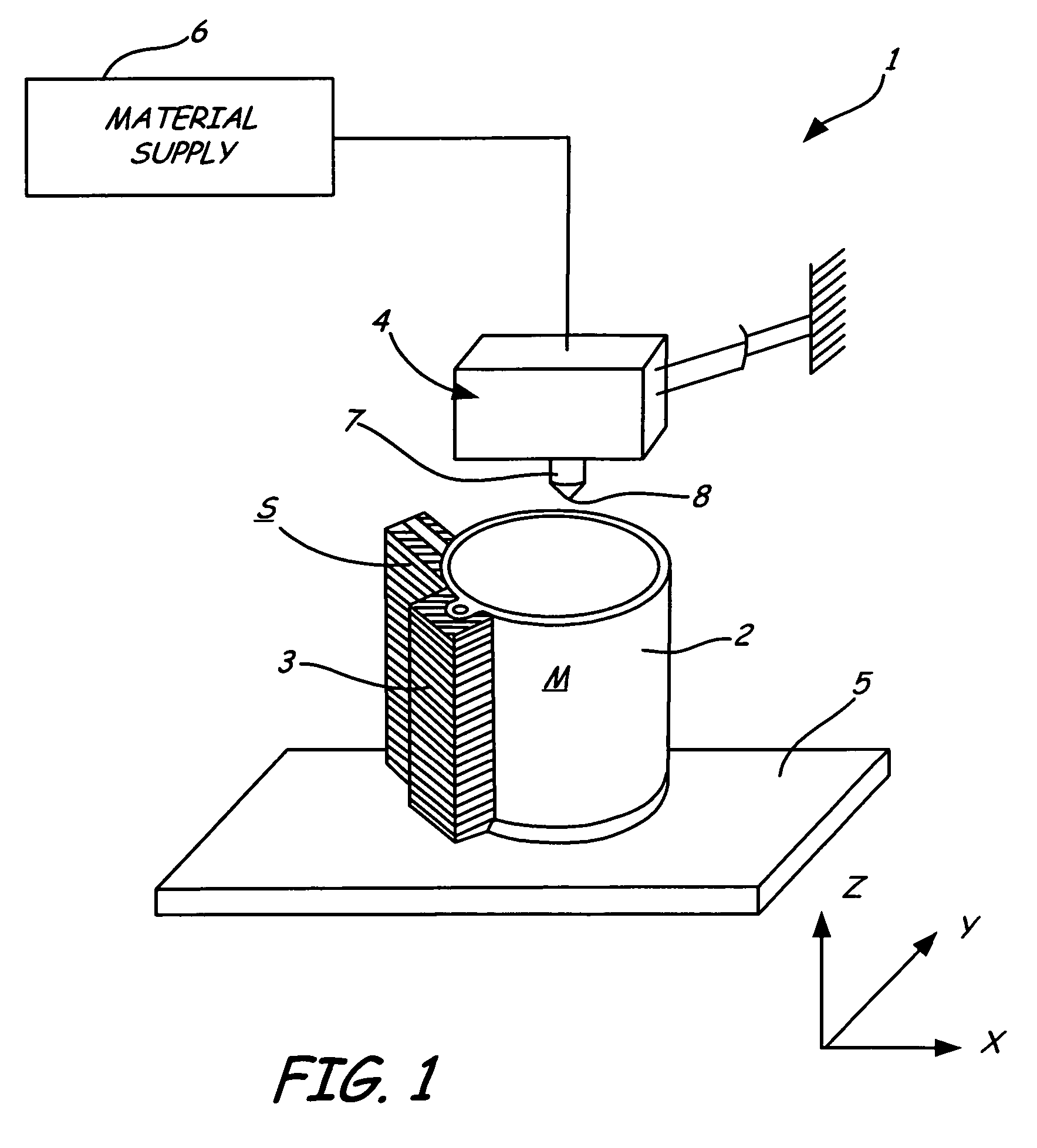

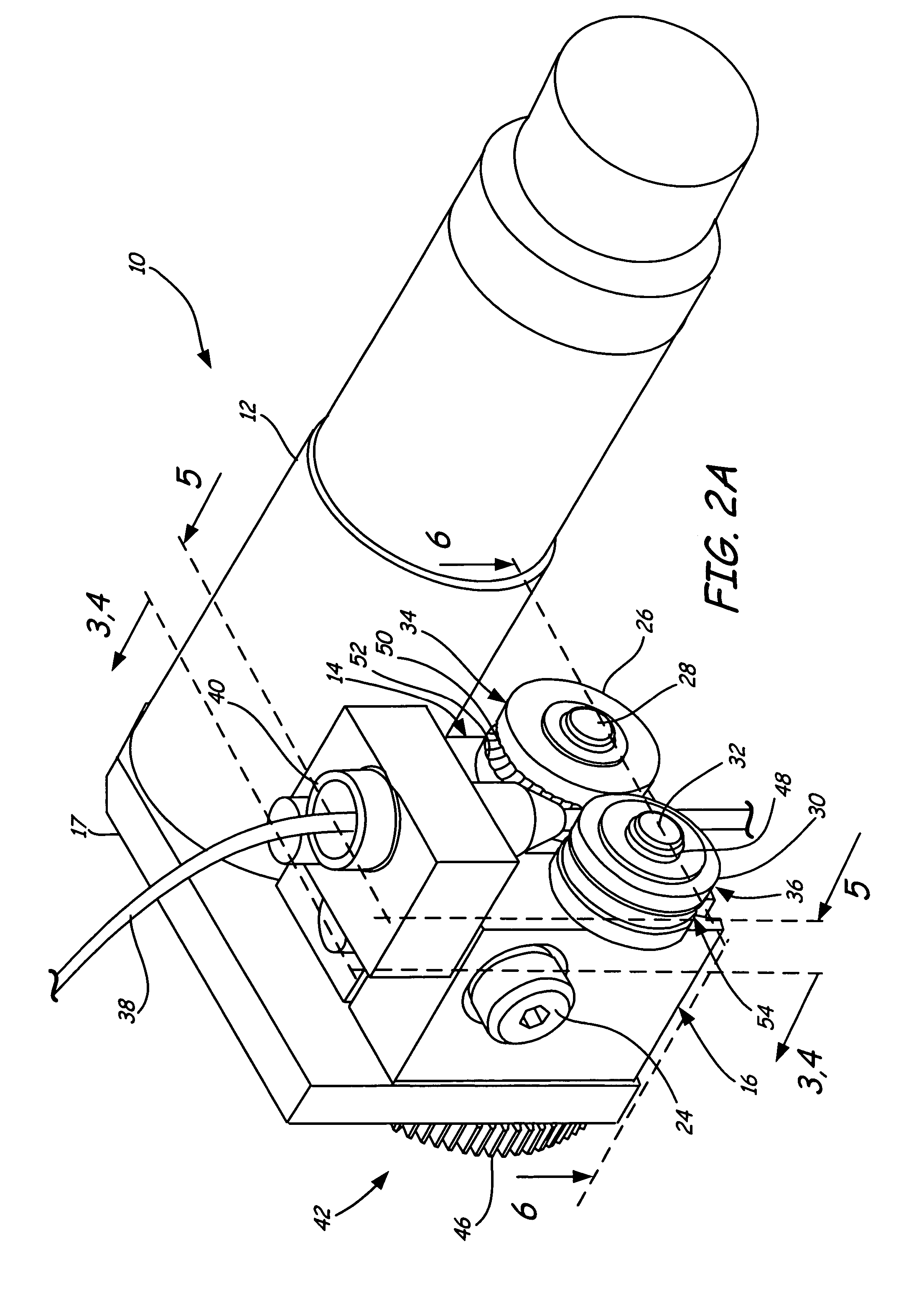

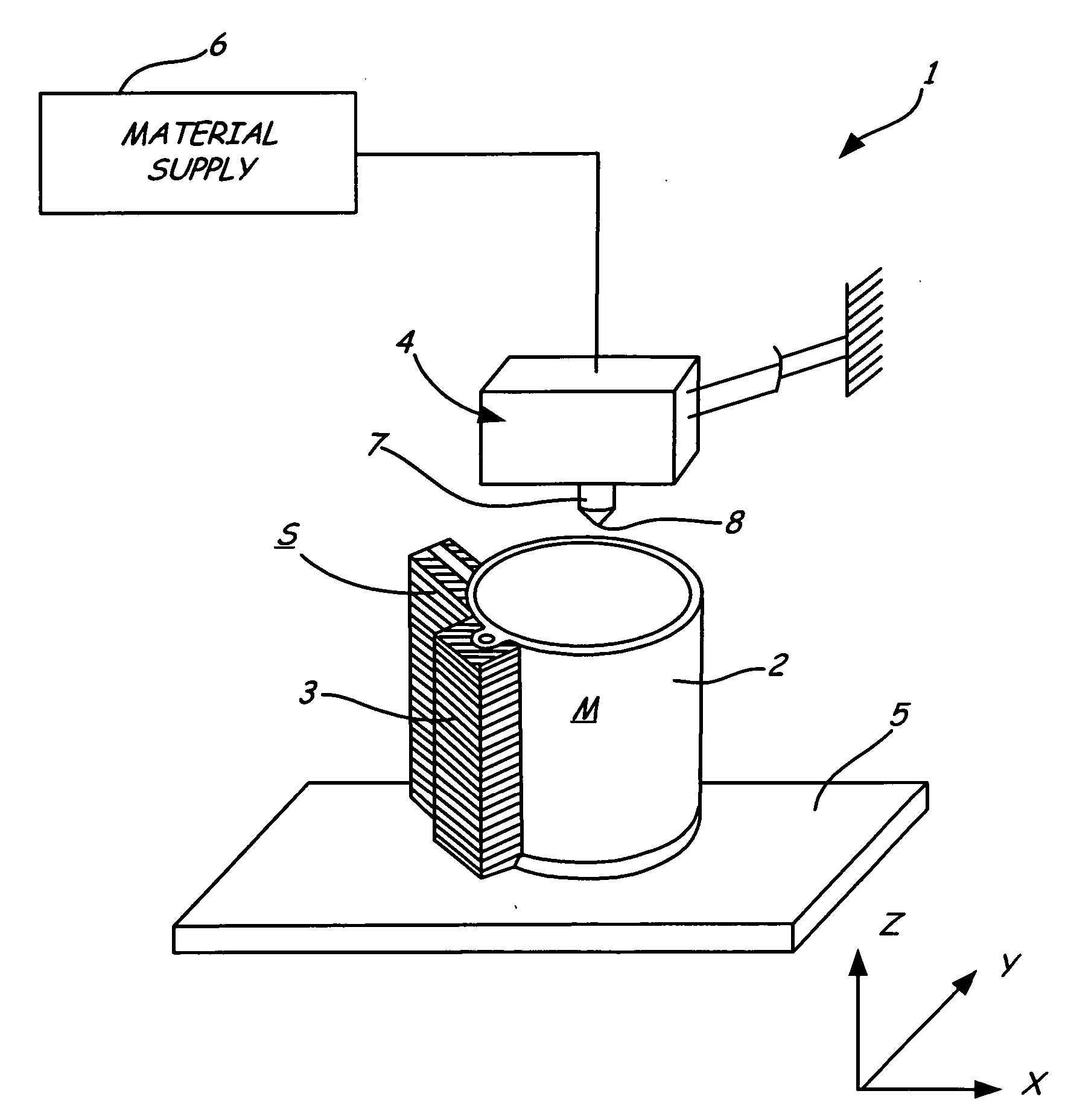

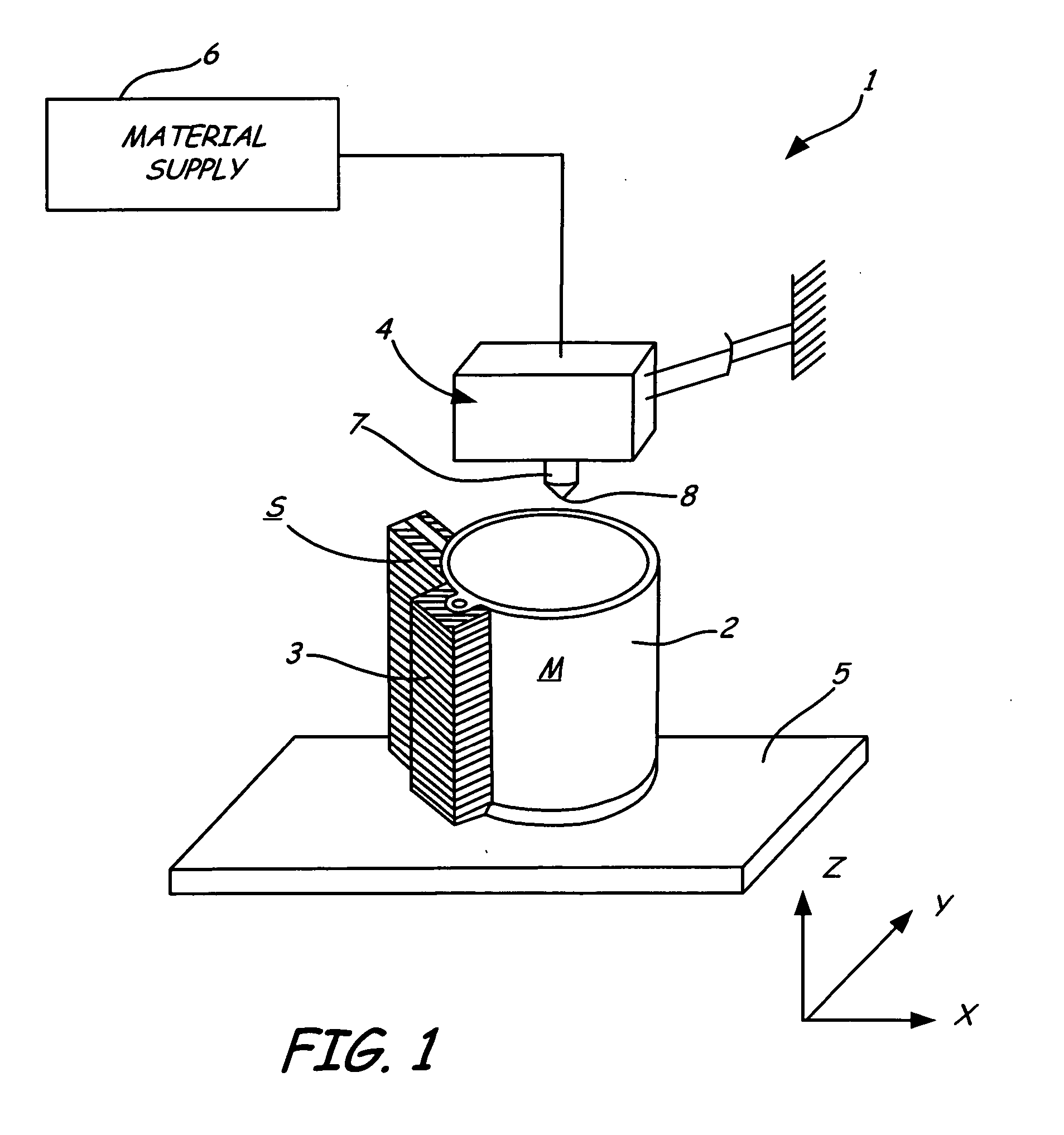

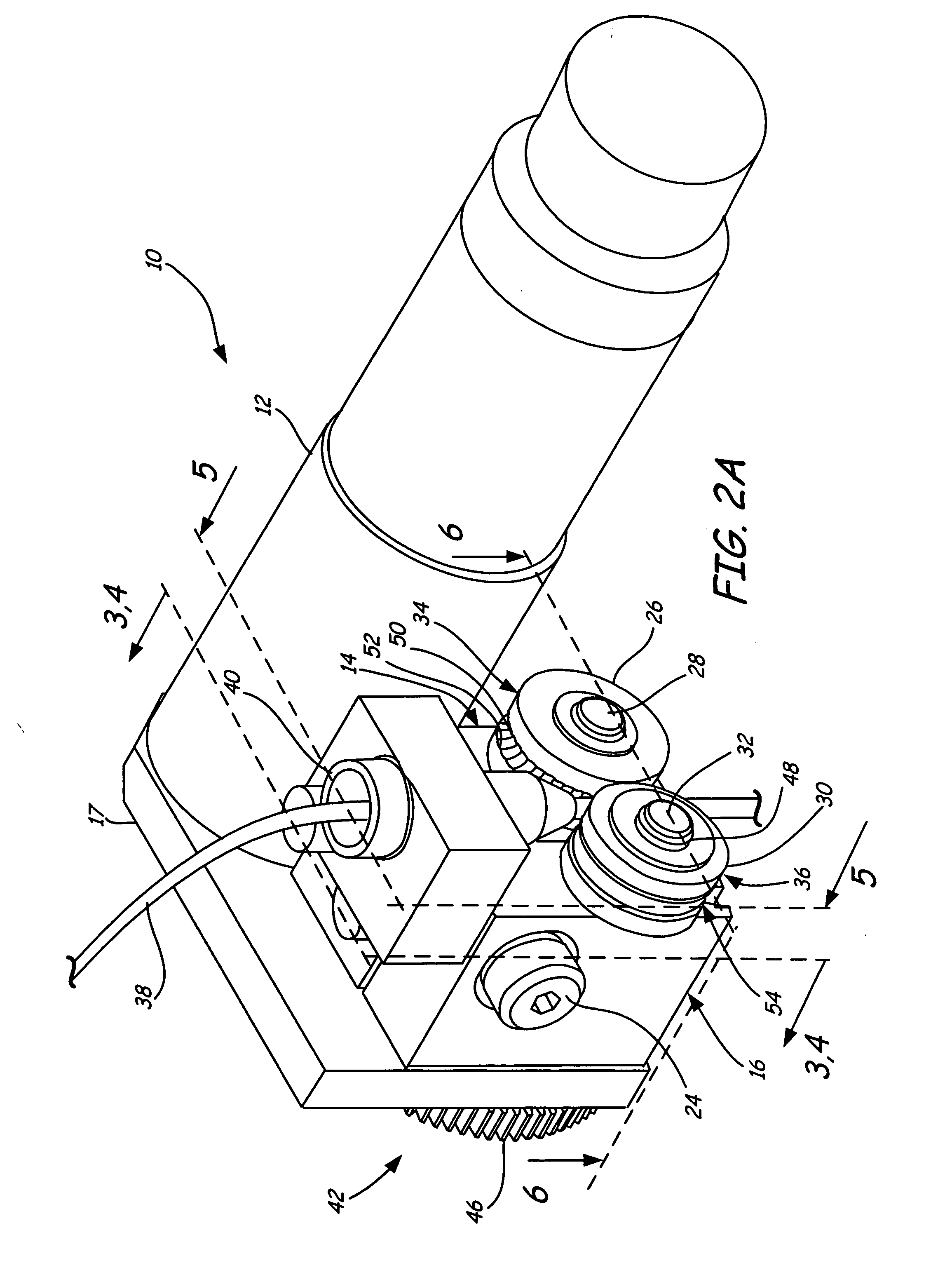

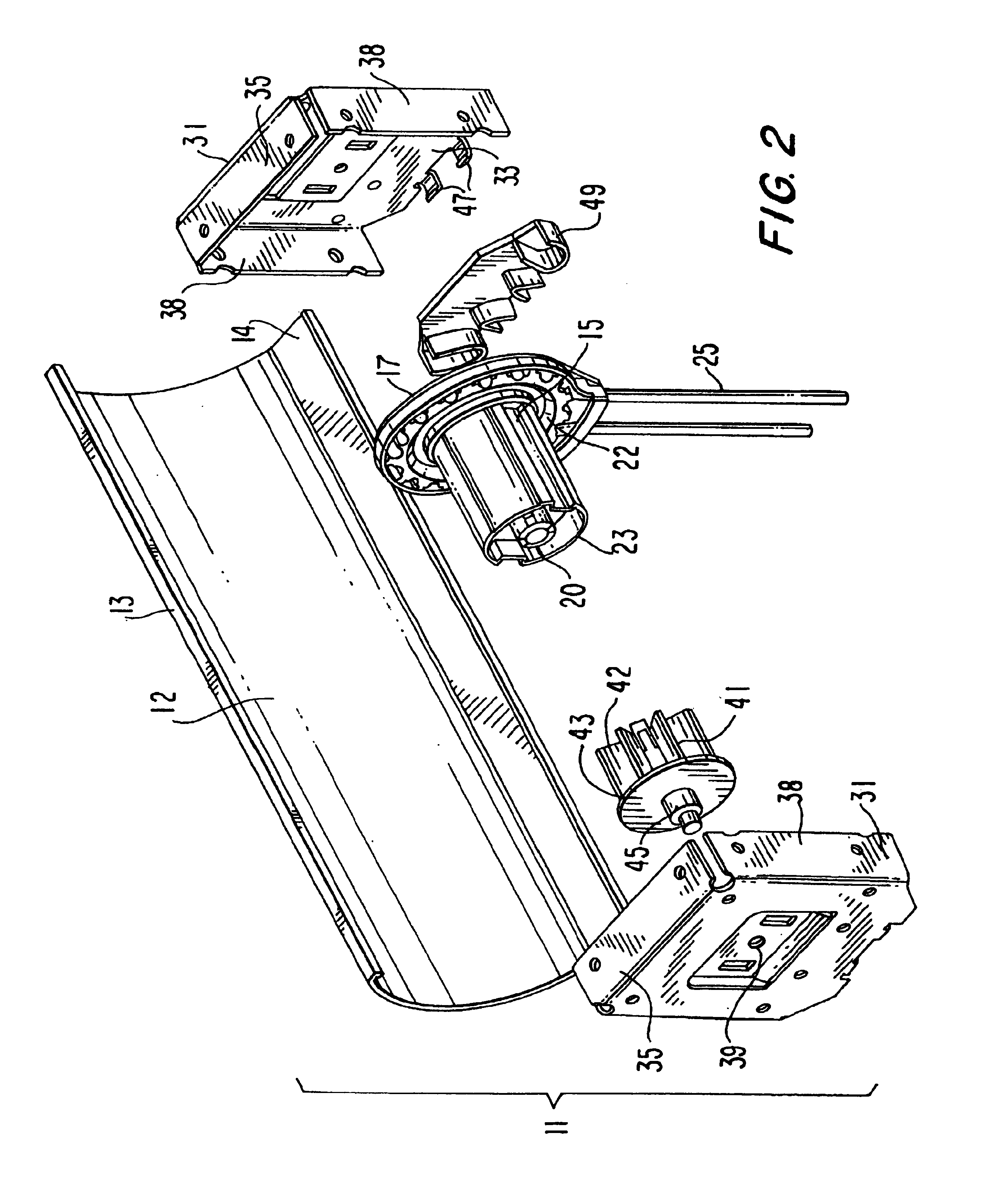

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Wrist with decoupled motion transmission

InactiveUS20030208186A1Reduce inertiaImprove device performanceMechanical apparatusDiagnosticsEngineeringActuator

The present invention is a wrist mechanism and a method for making robotic devices in which the transmission of motion, force and / or torque around a revolute joint can be accomplished without coupling. This construction allows mounting the actuators on the base or lower elements of a mechanism, so that only linkage elements move the end-effector. Thus reducing inertia of the moving elements and increasing performance of the device. The decoupled motion of the end-effector or links is achieved by routing their transmission cables around idler pulleys placed parallel to the joint rotation axis on an optimal position such any stretch on the transmission cable is minimized. In particular, this construction can be use for robotic surgical tools that have two independently driven jaws, decoupled and orthogonal from its articulating wrist.

Owner:MOREYRA MANUEL RICARDO

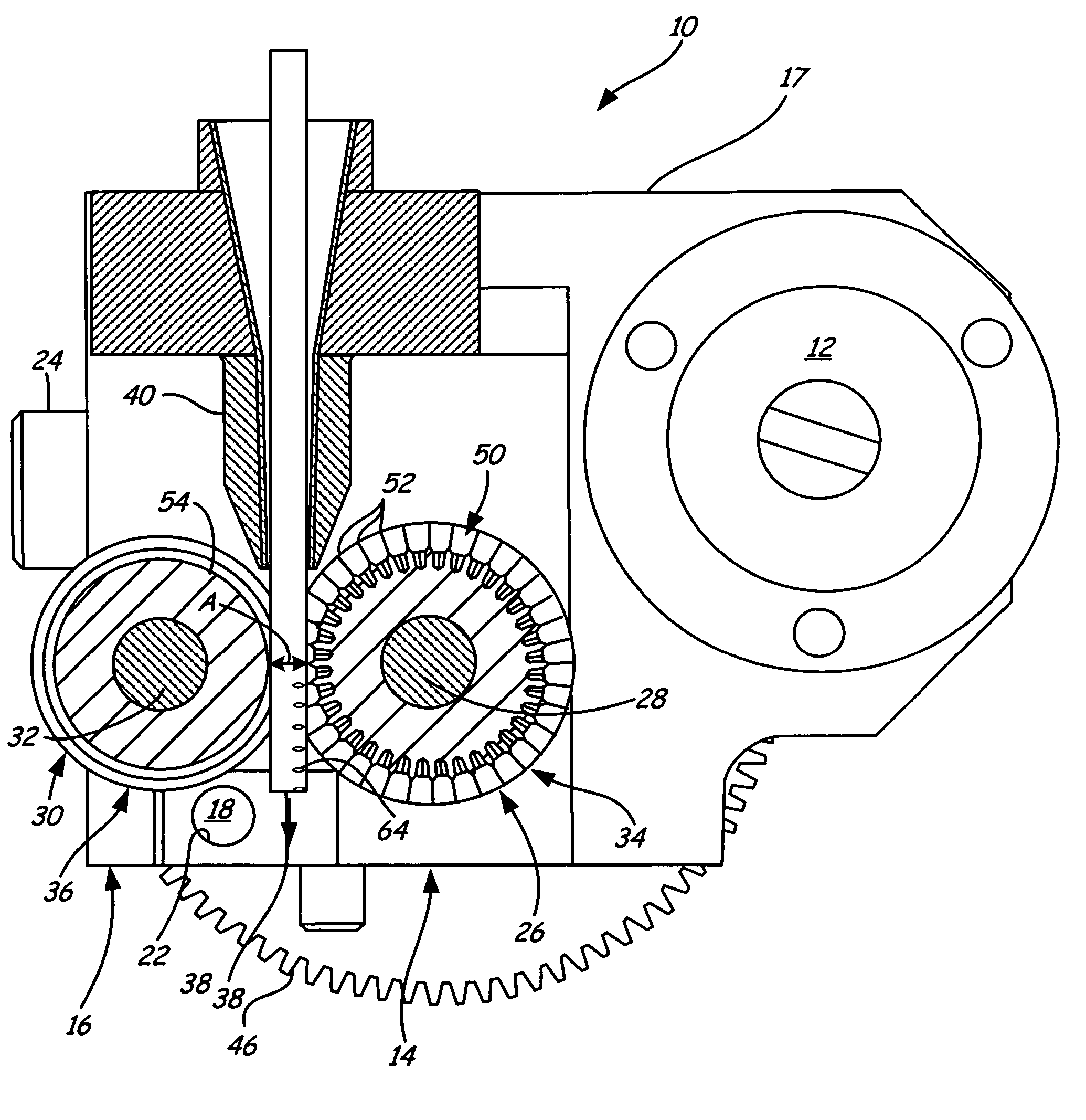

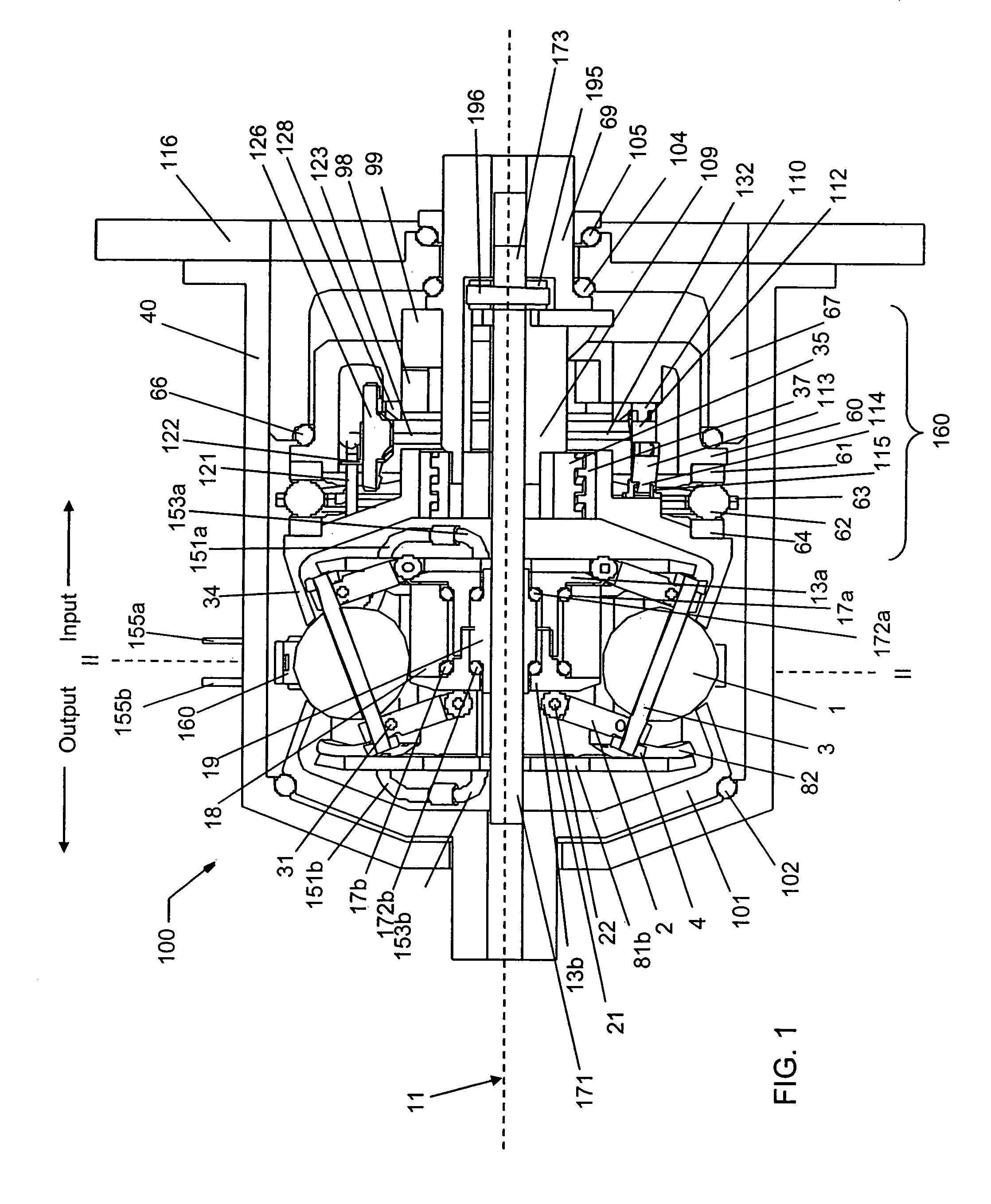

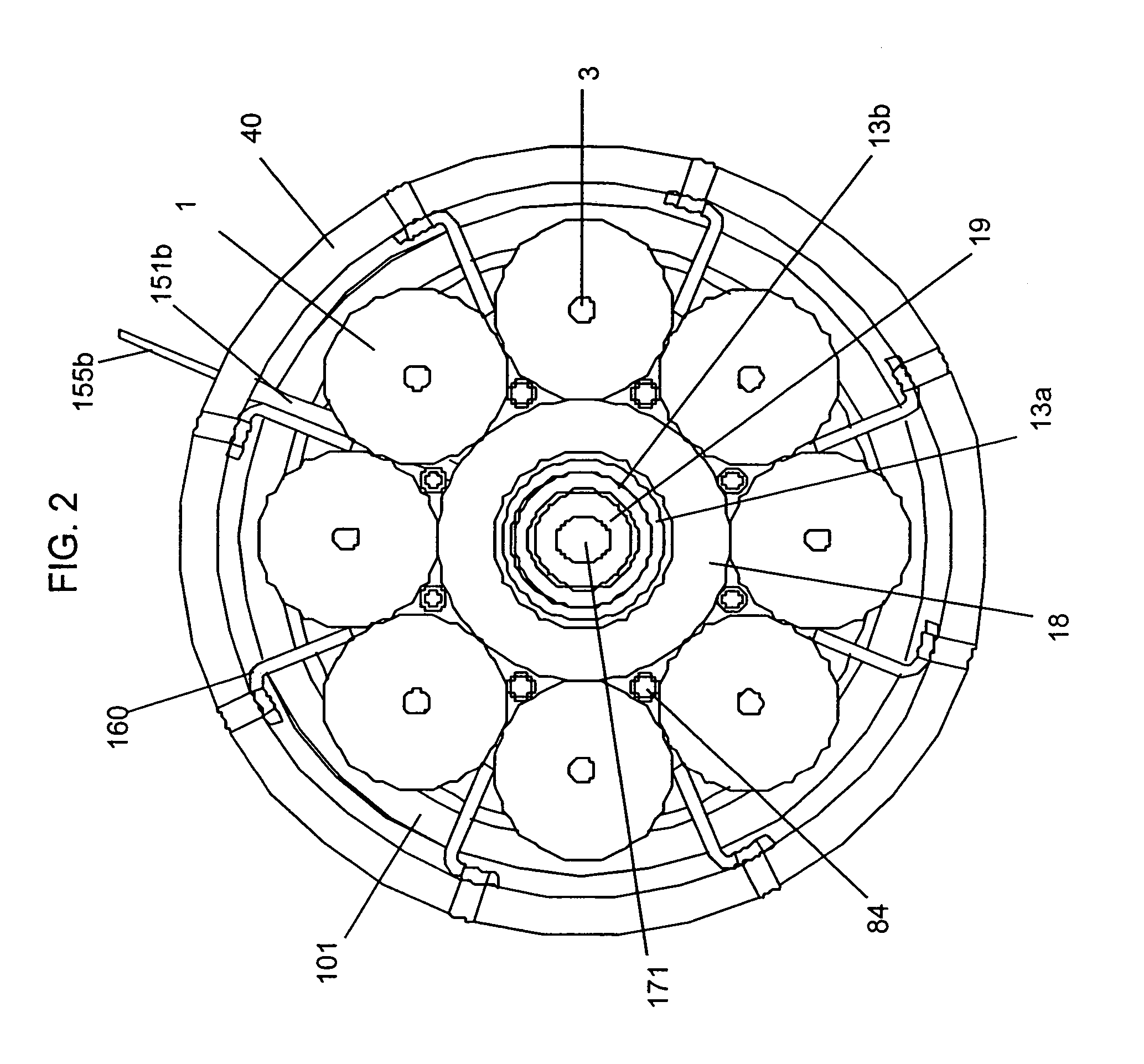

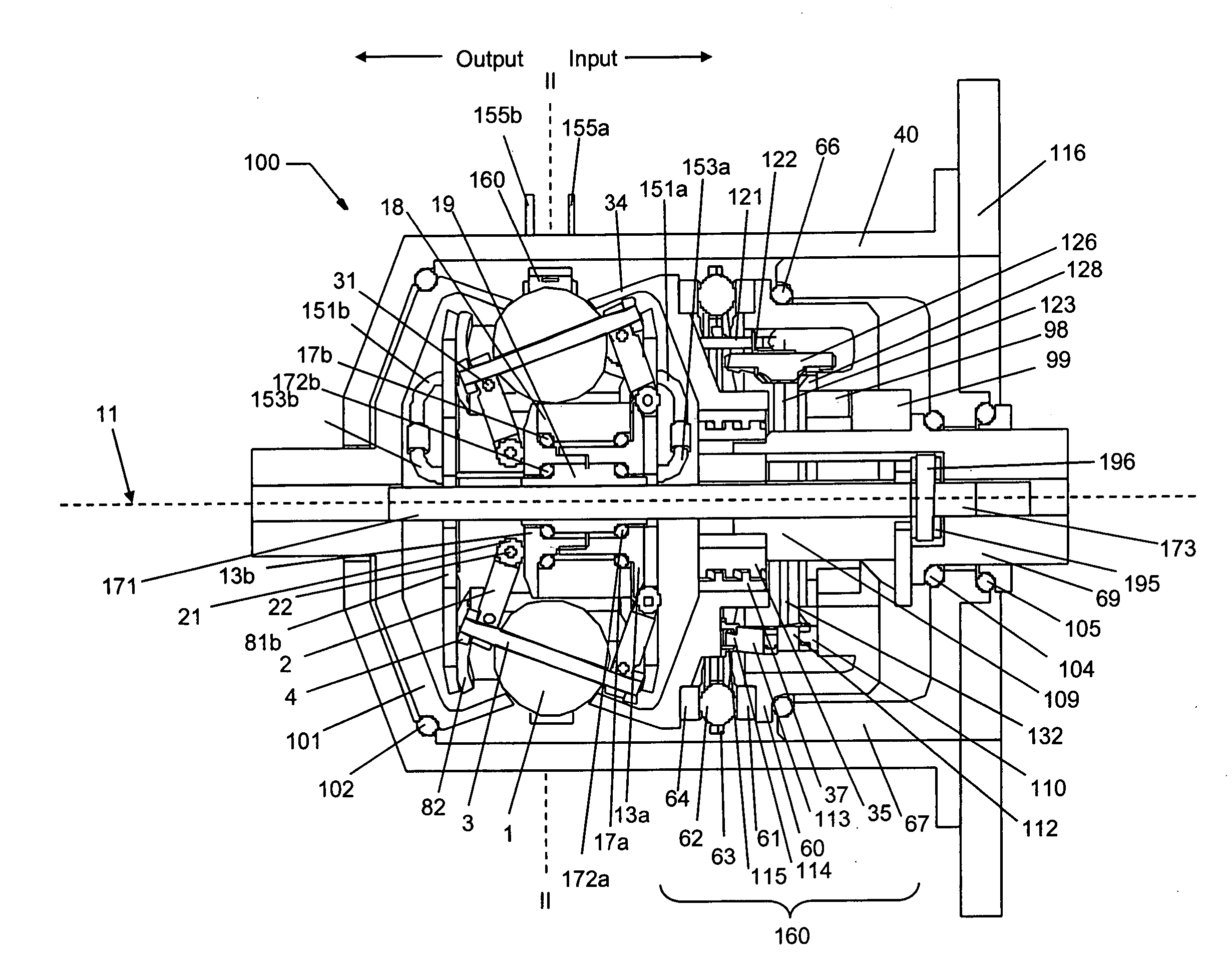

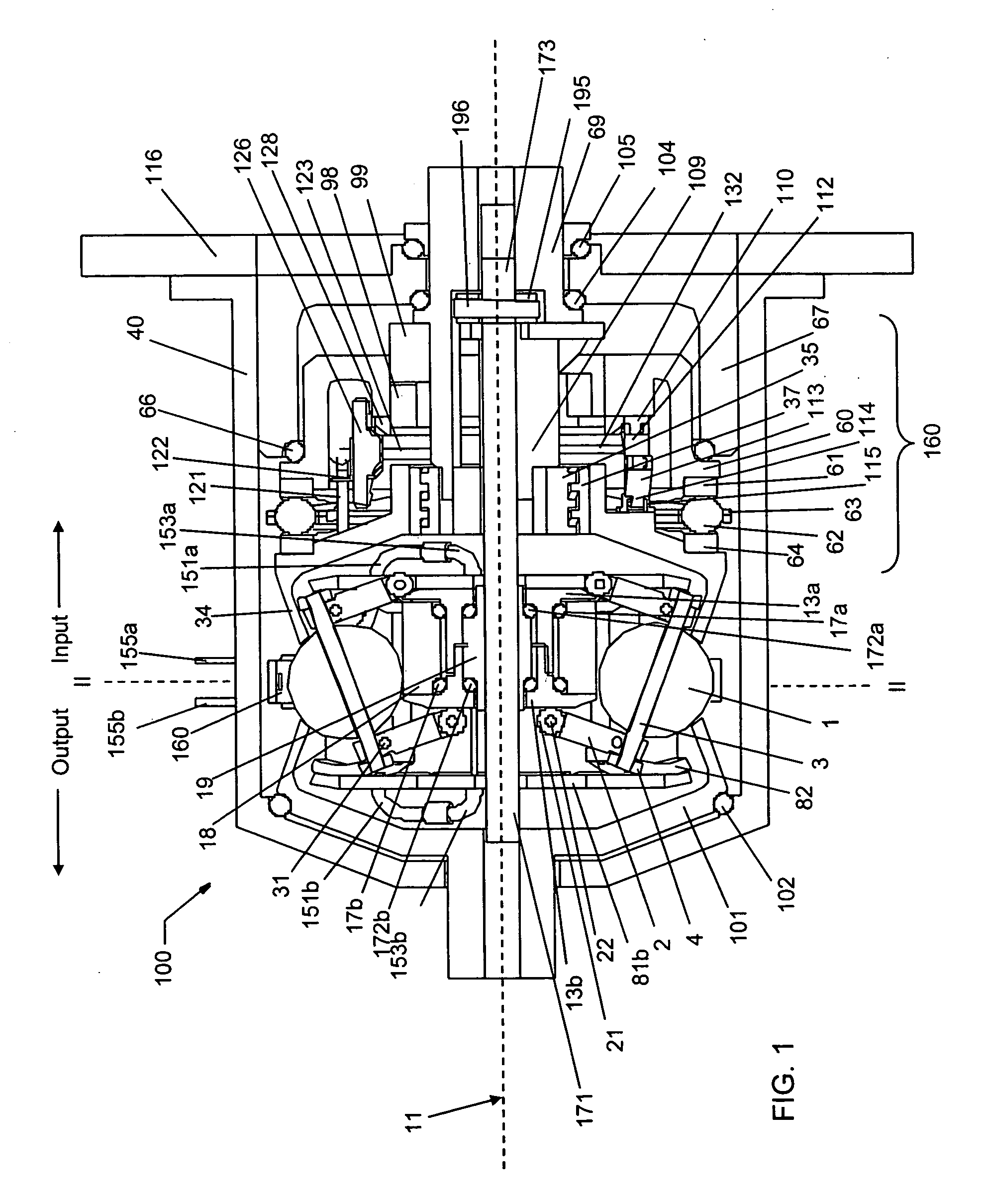

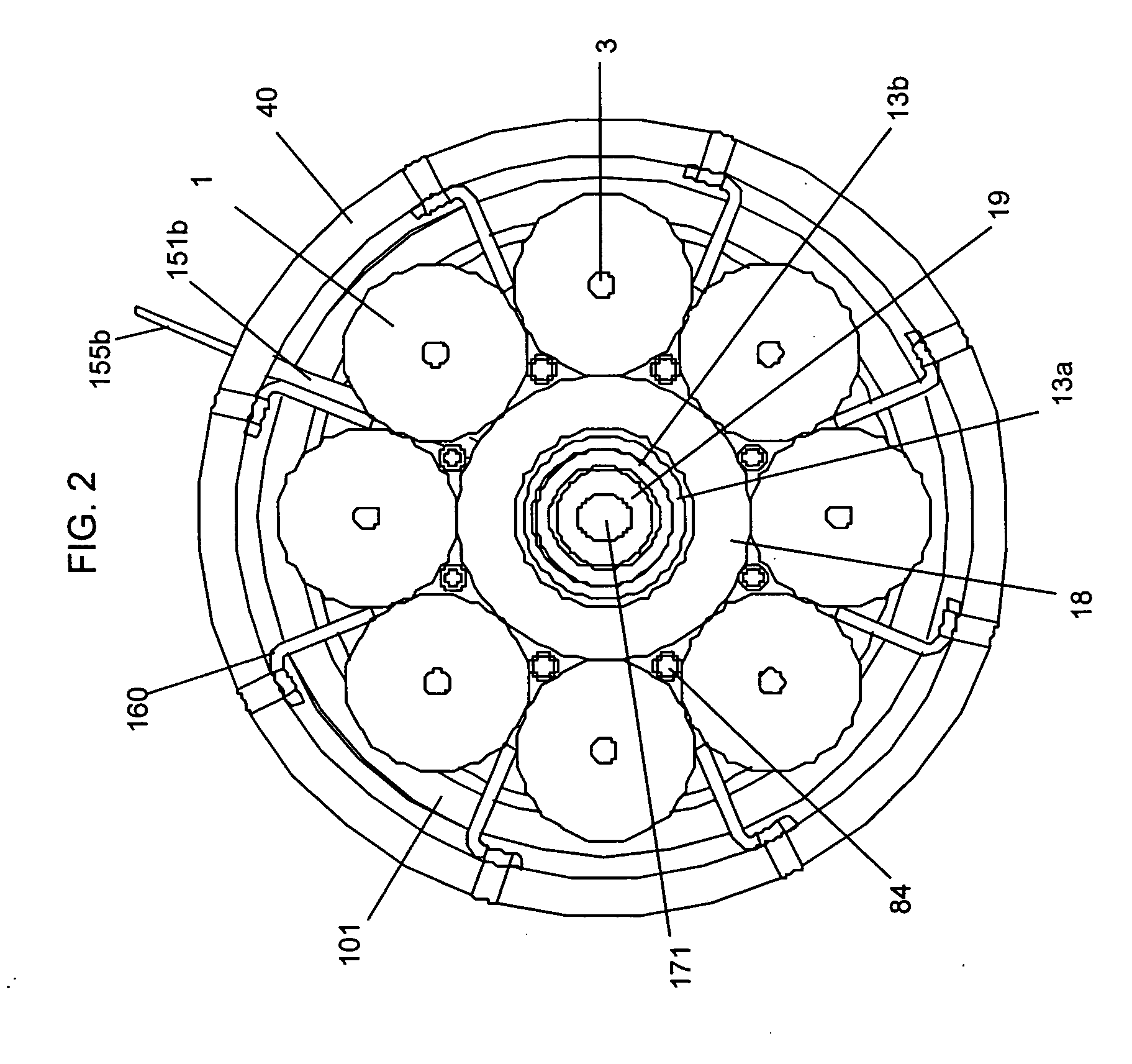

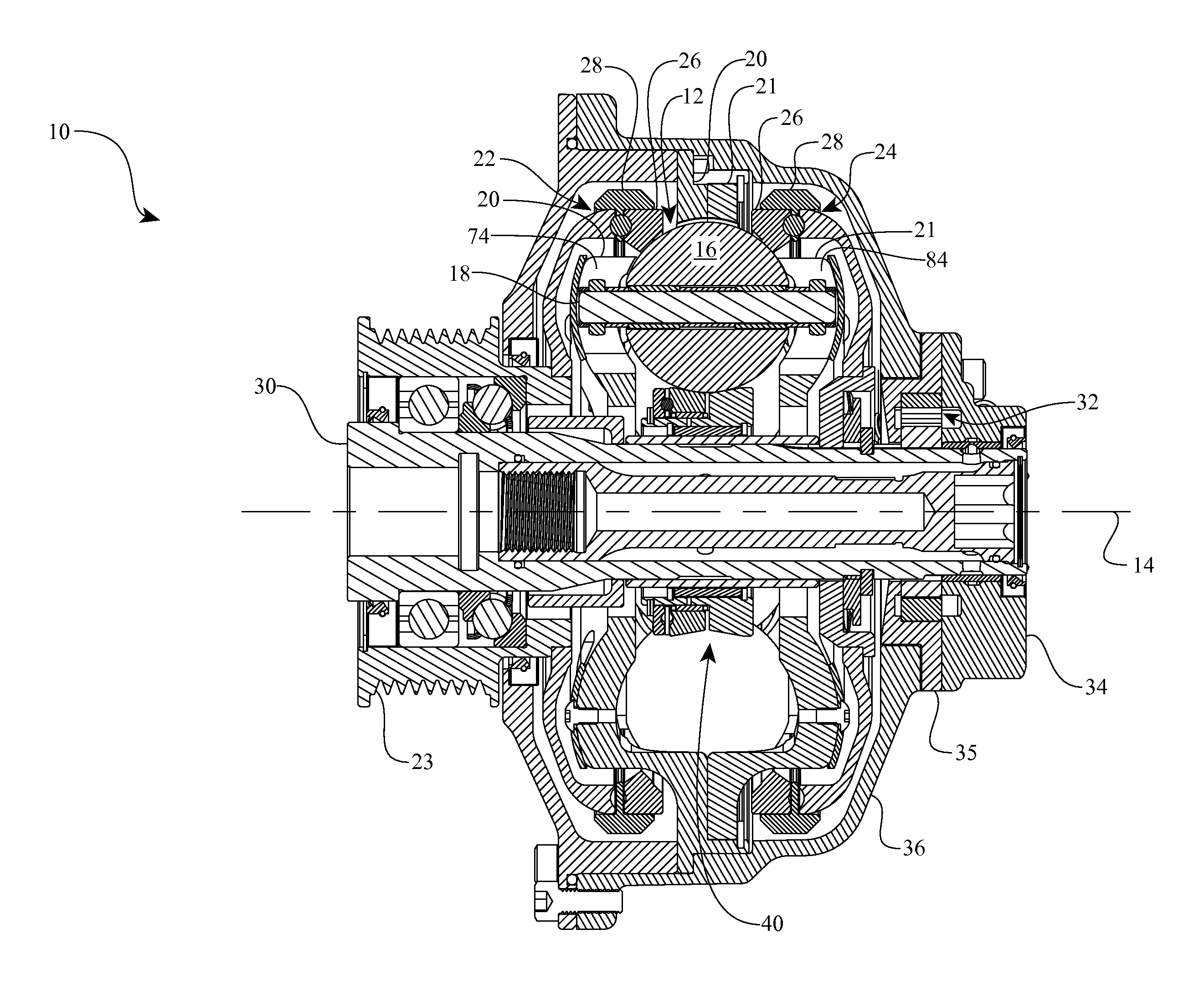

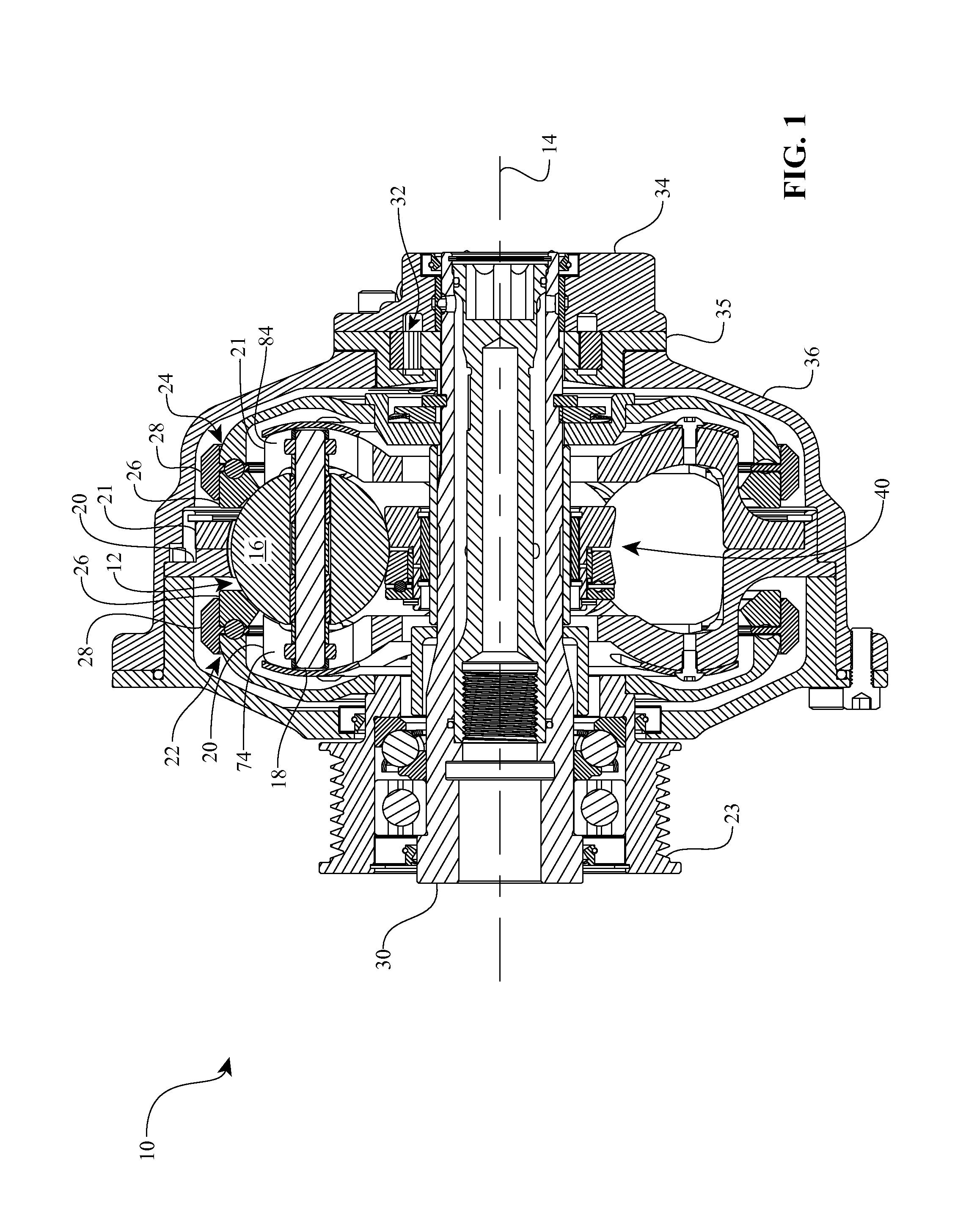

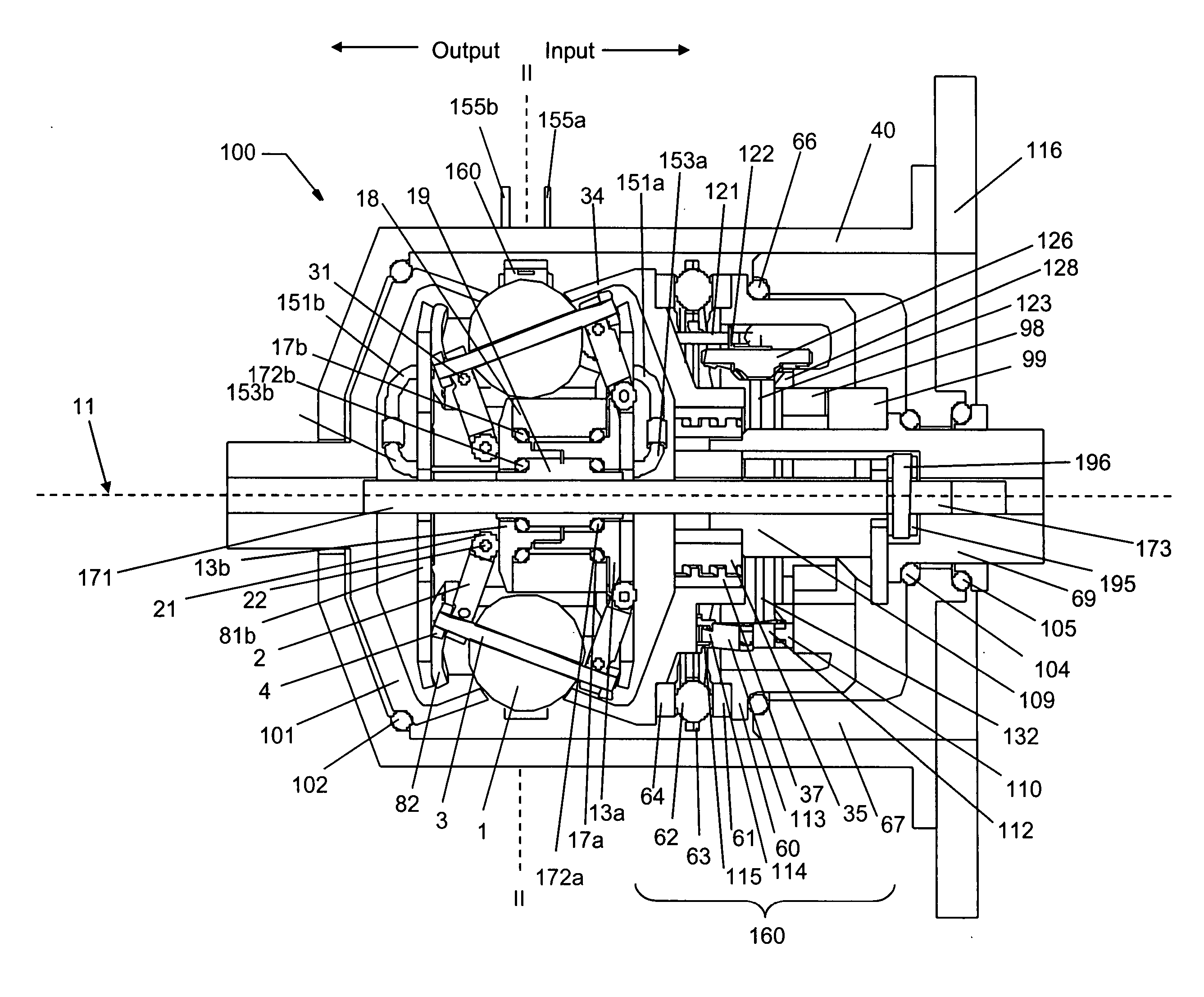

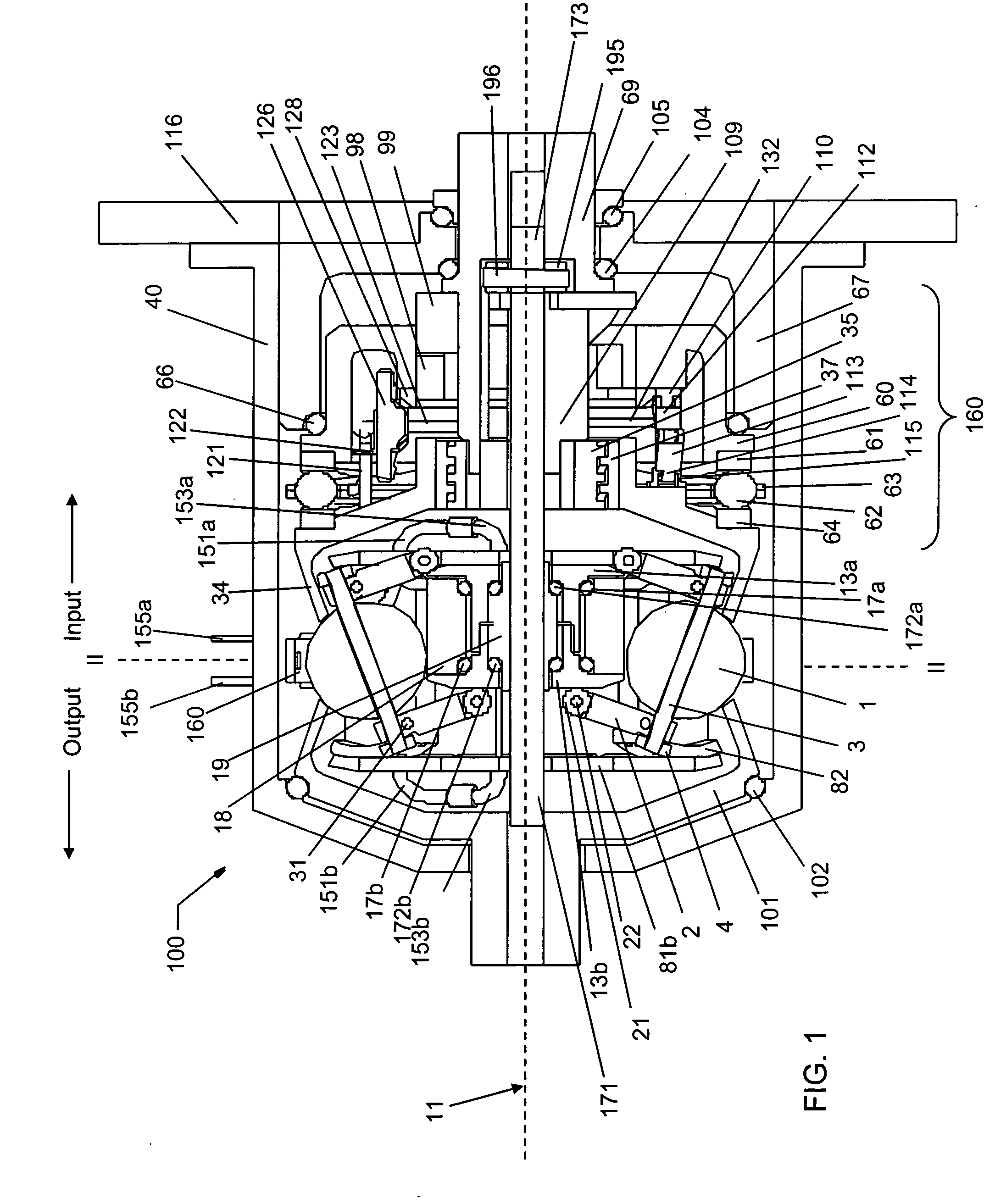

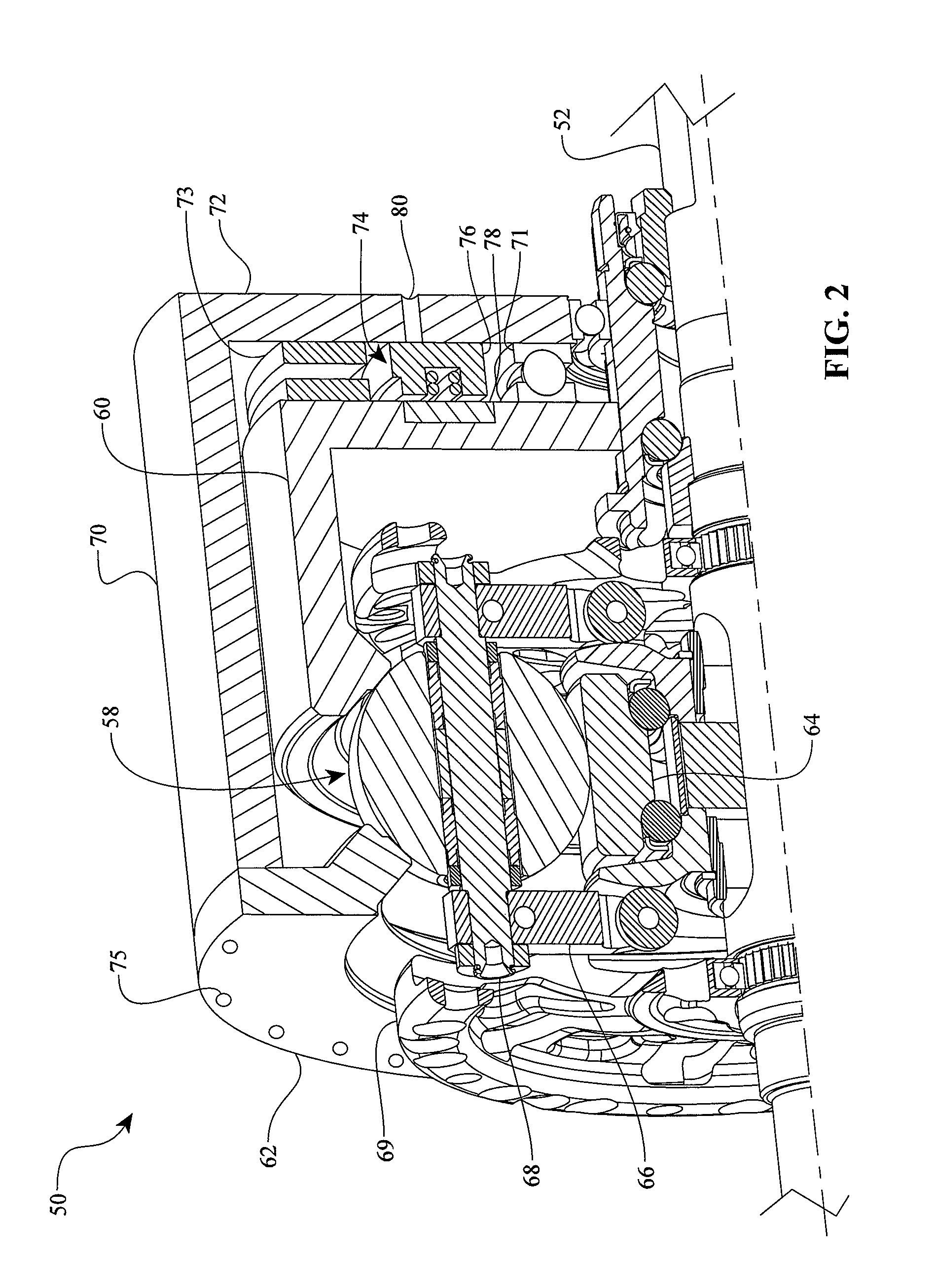

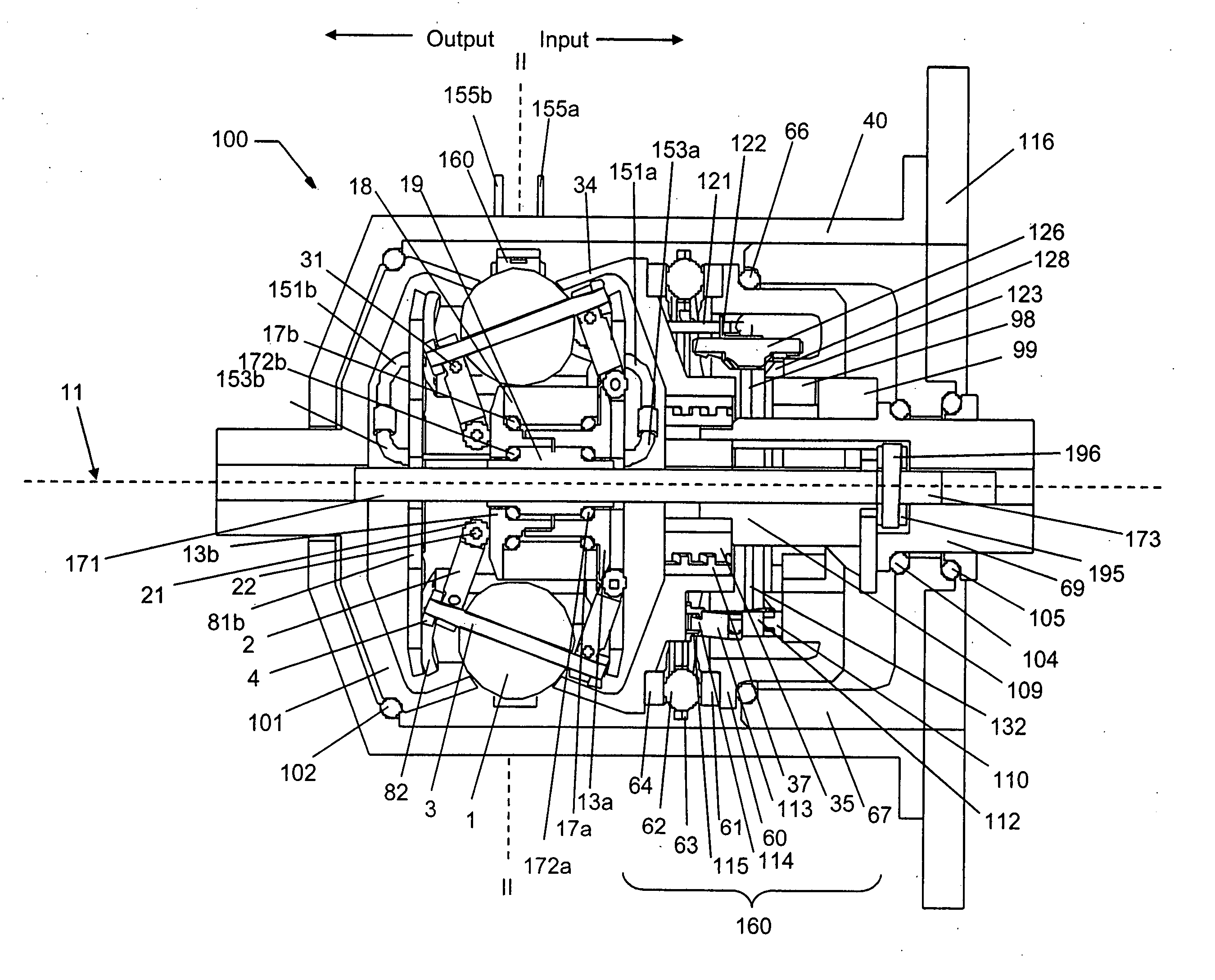

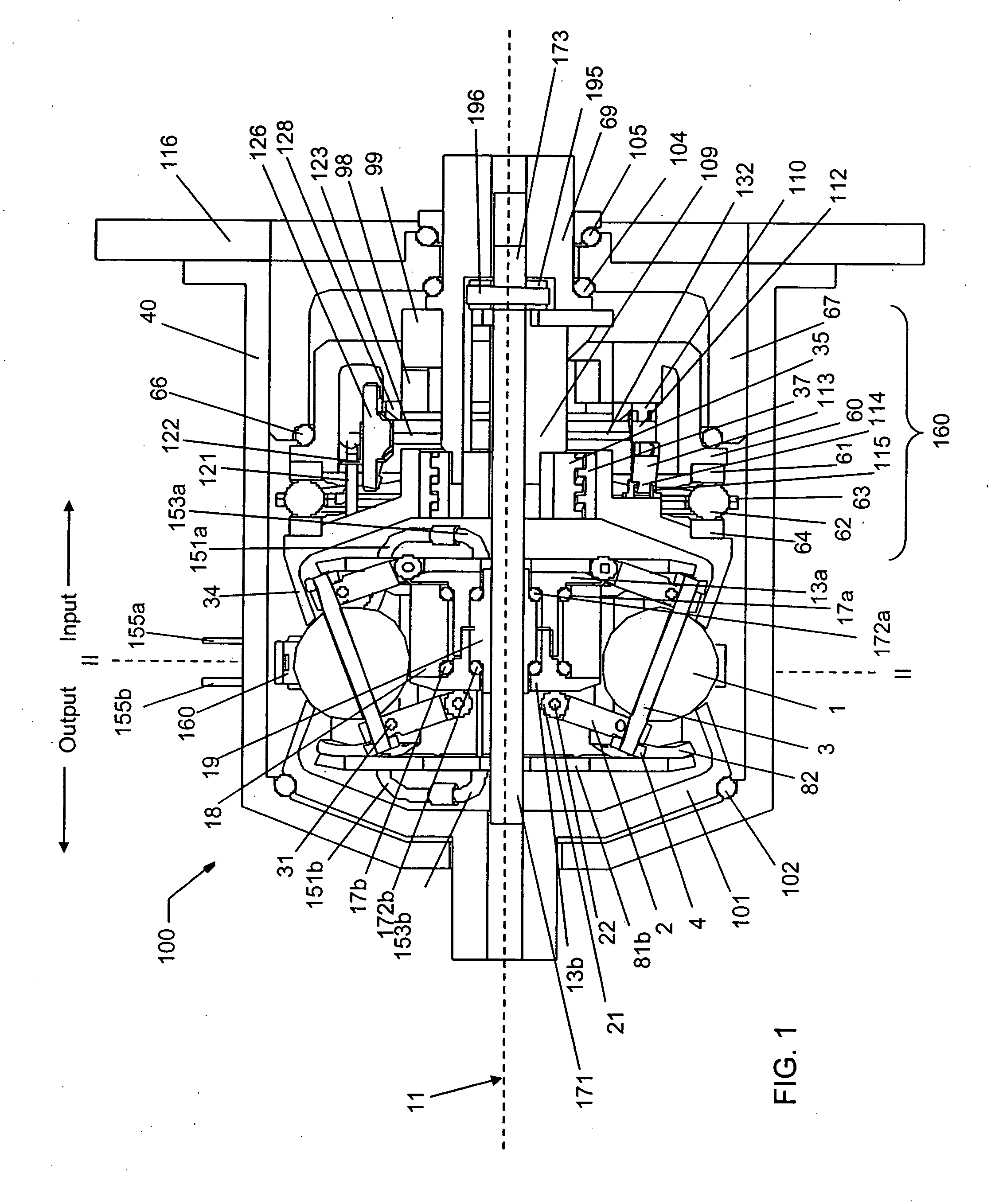

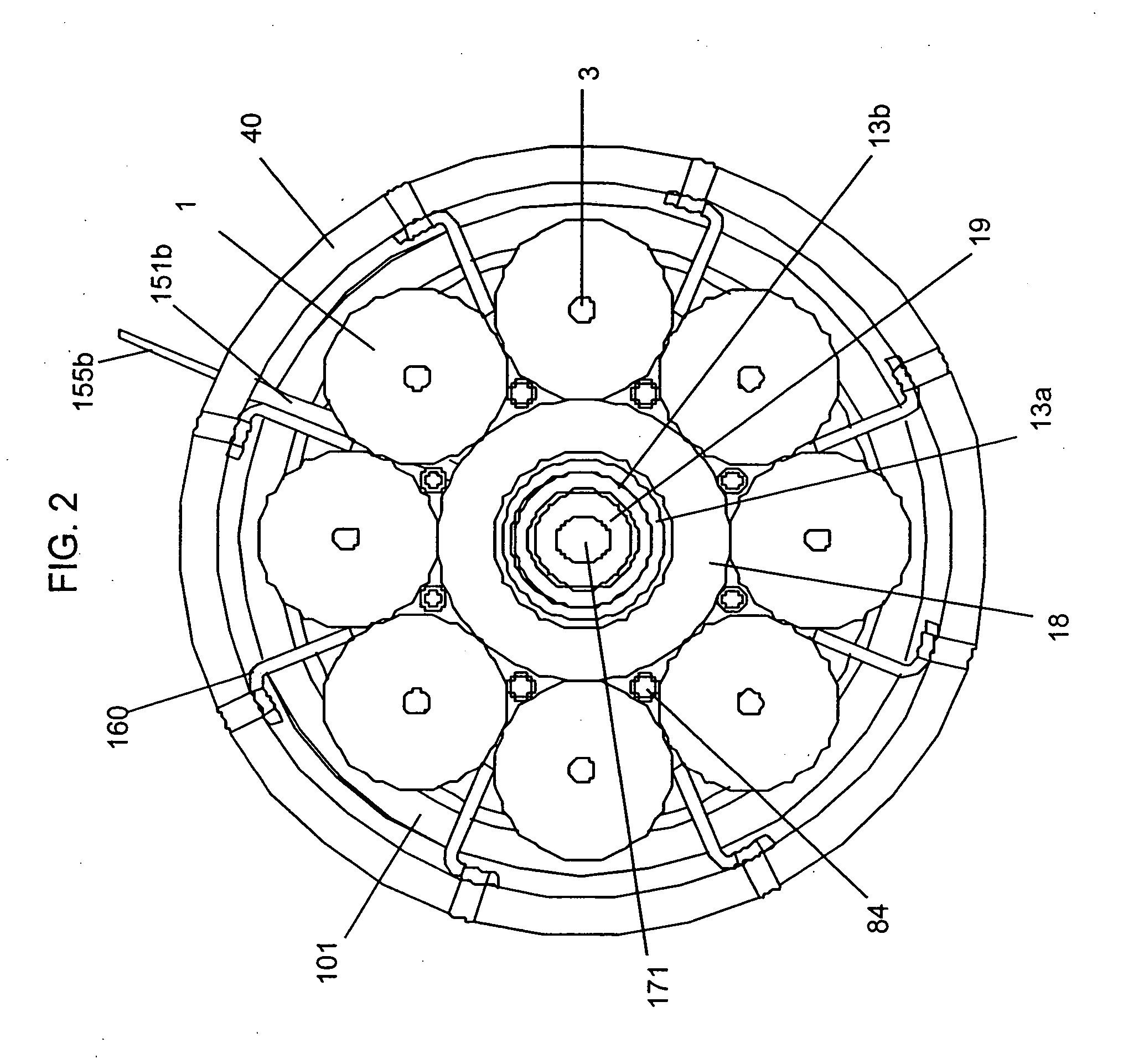

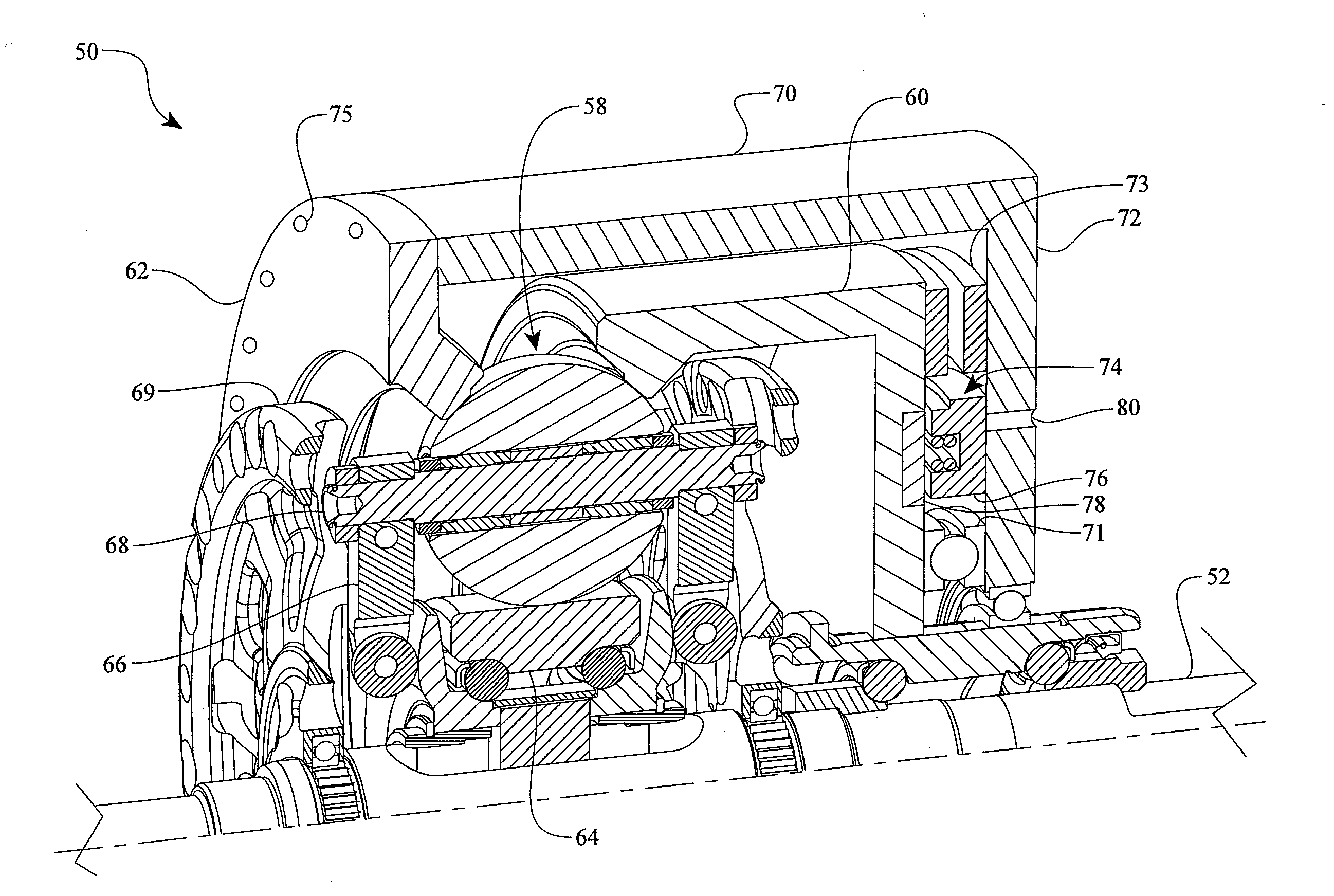

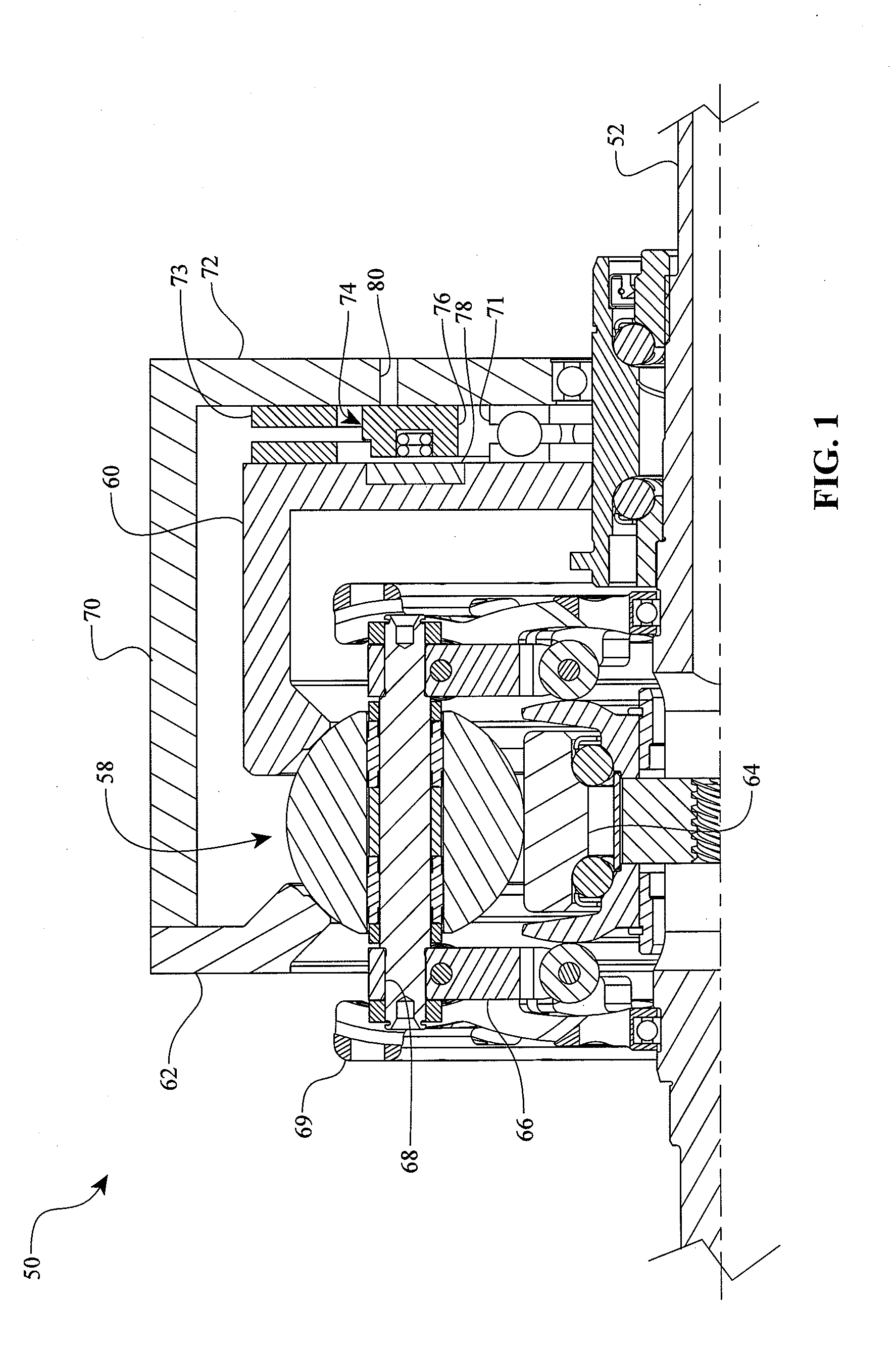

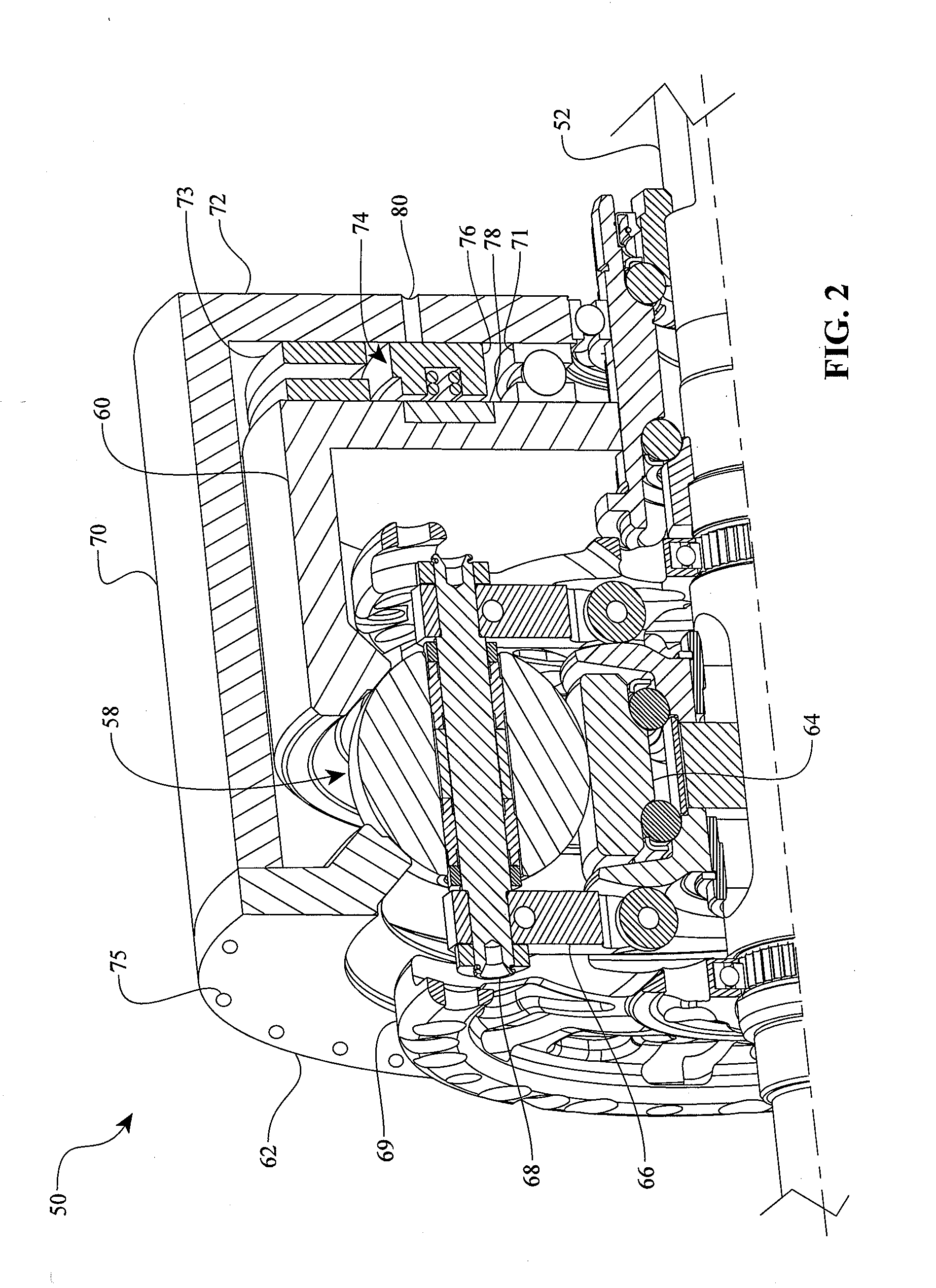

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

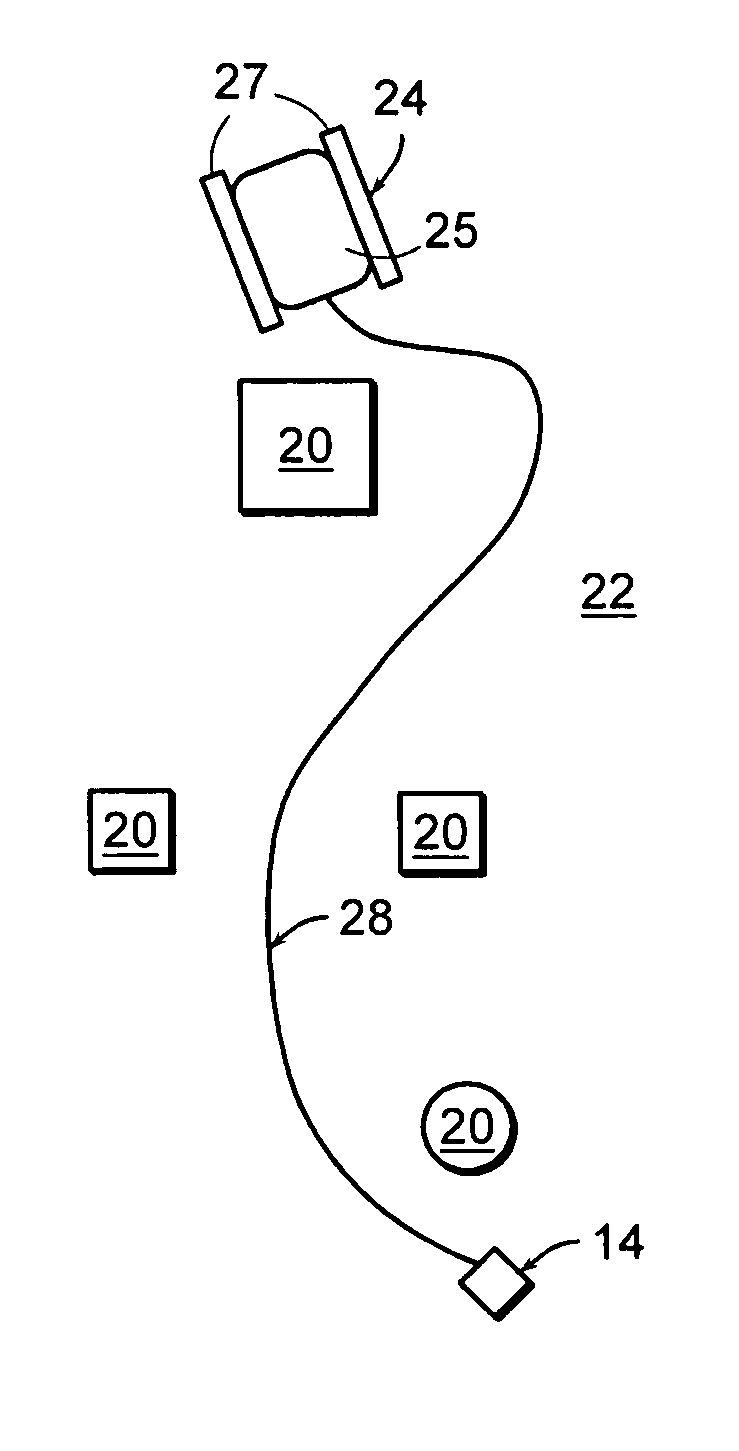

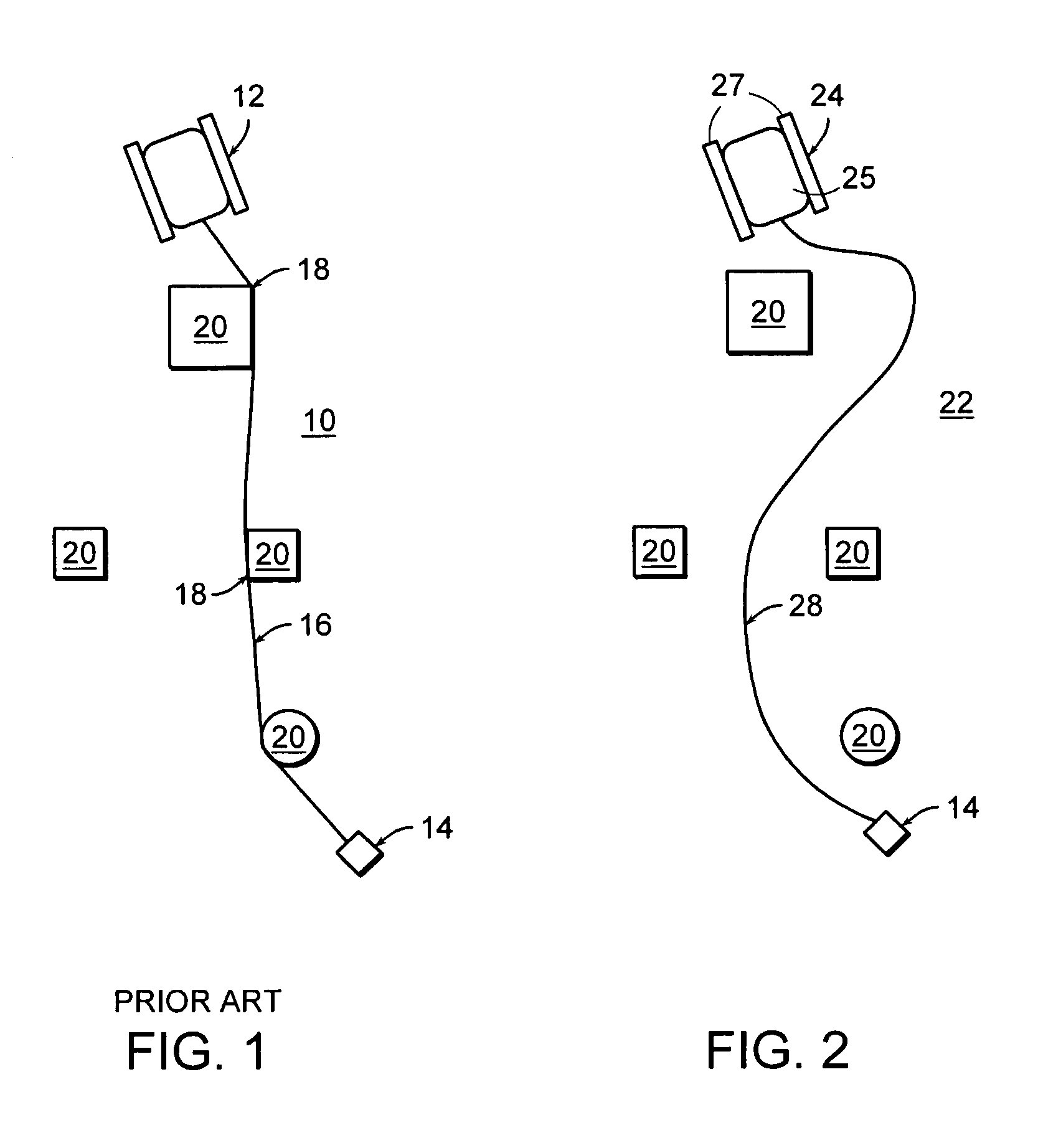

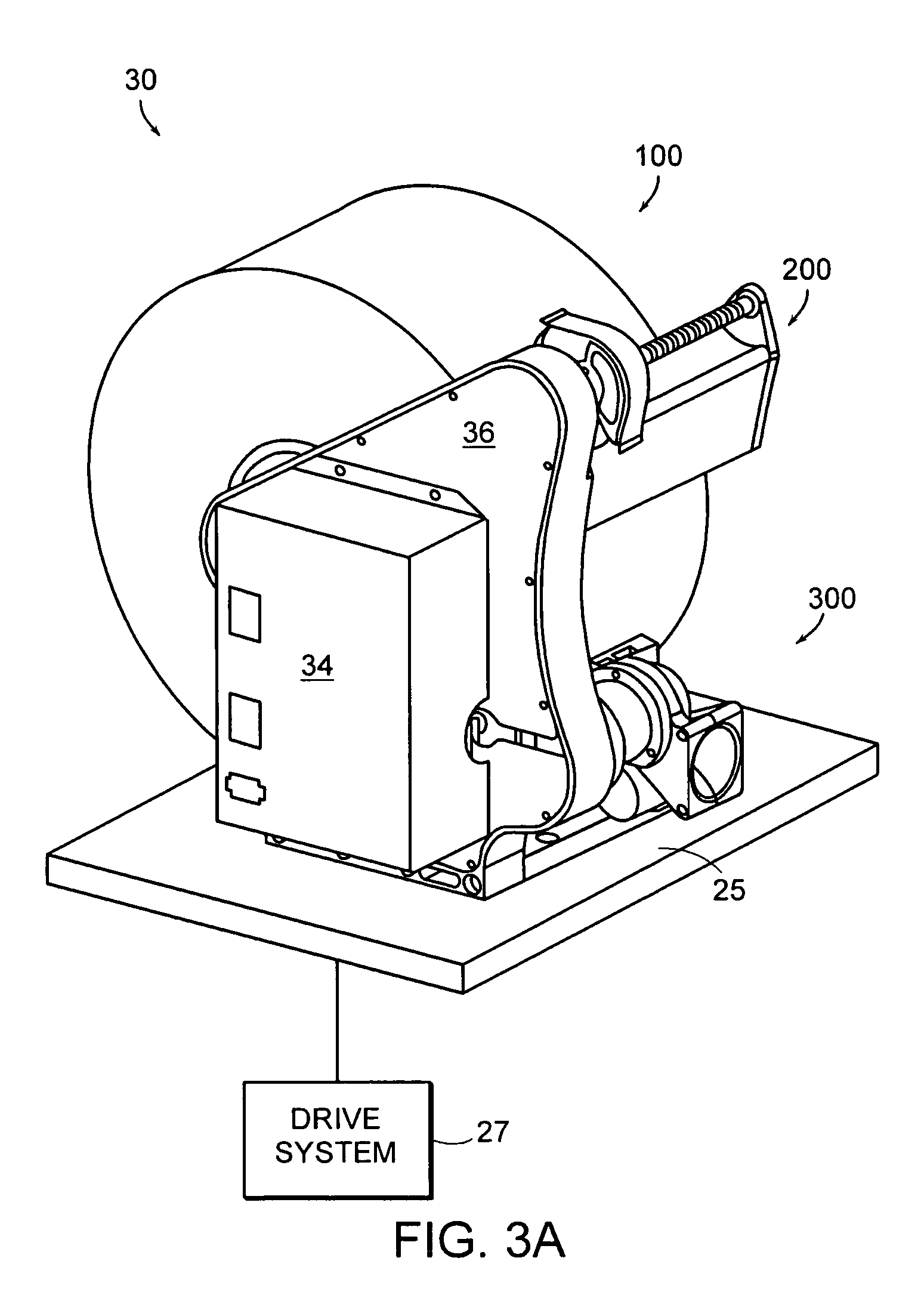

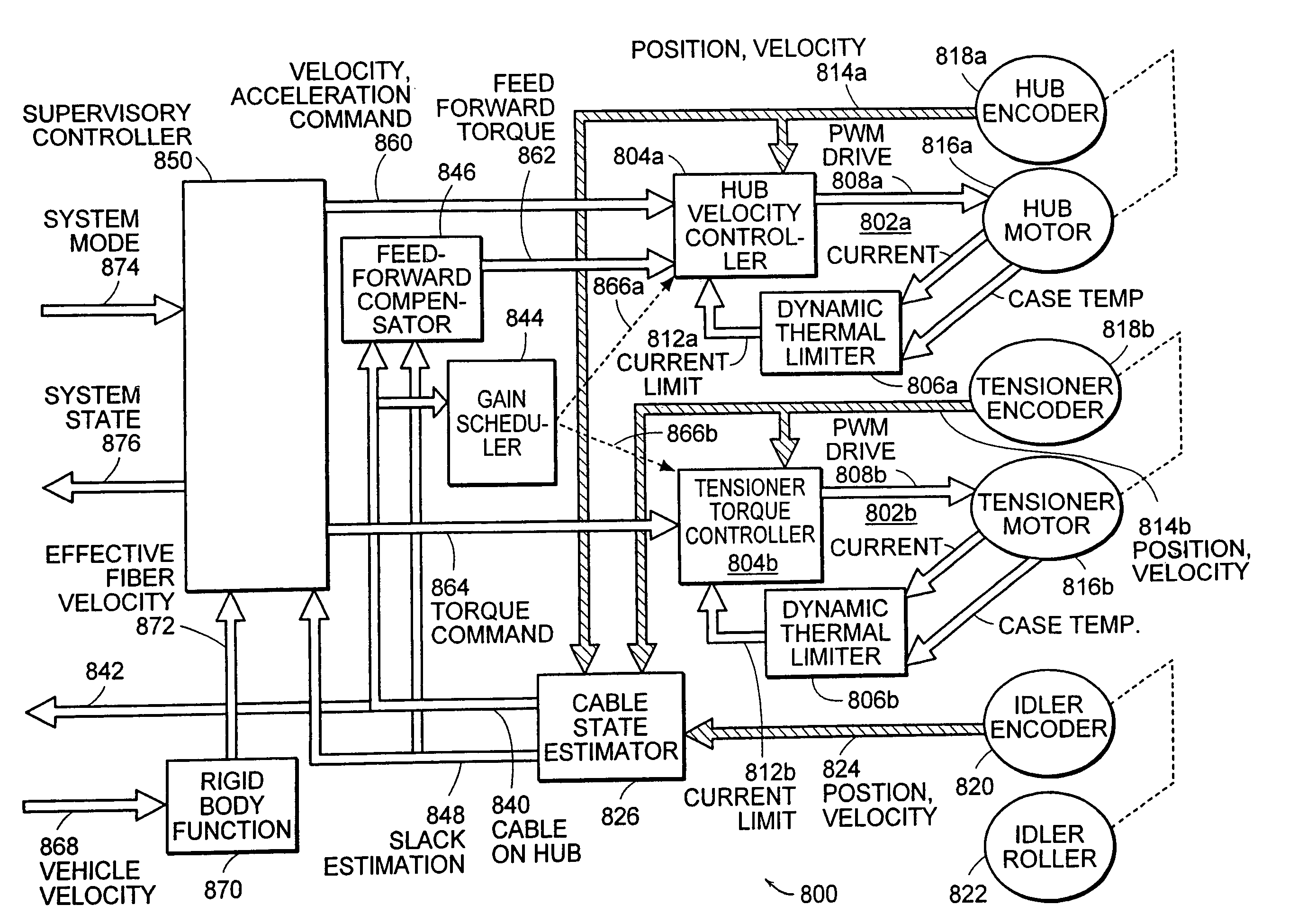

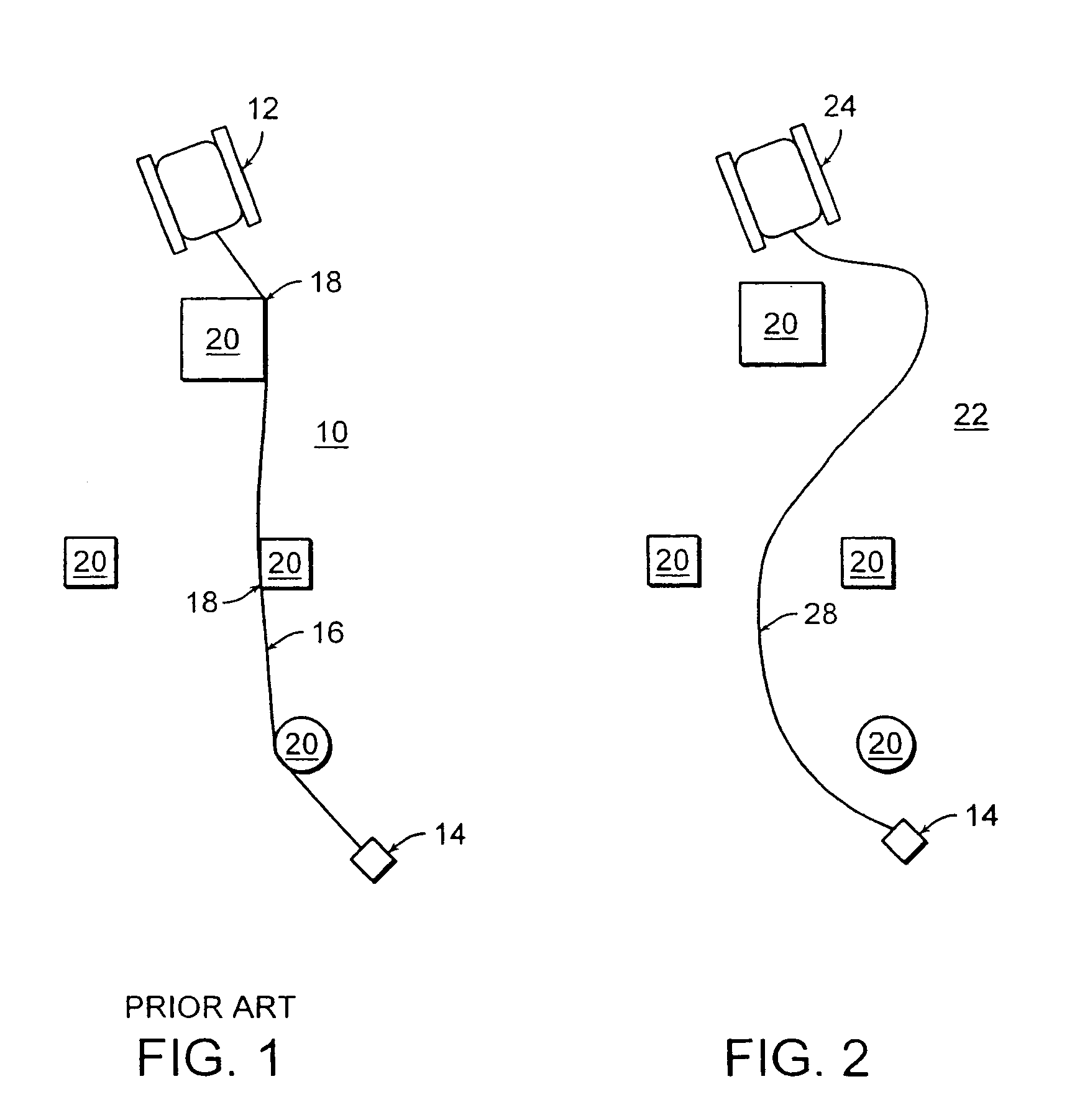

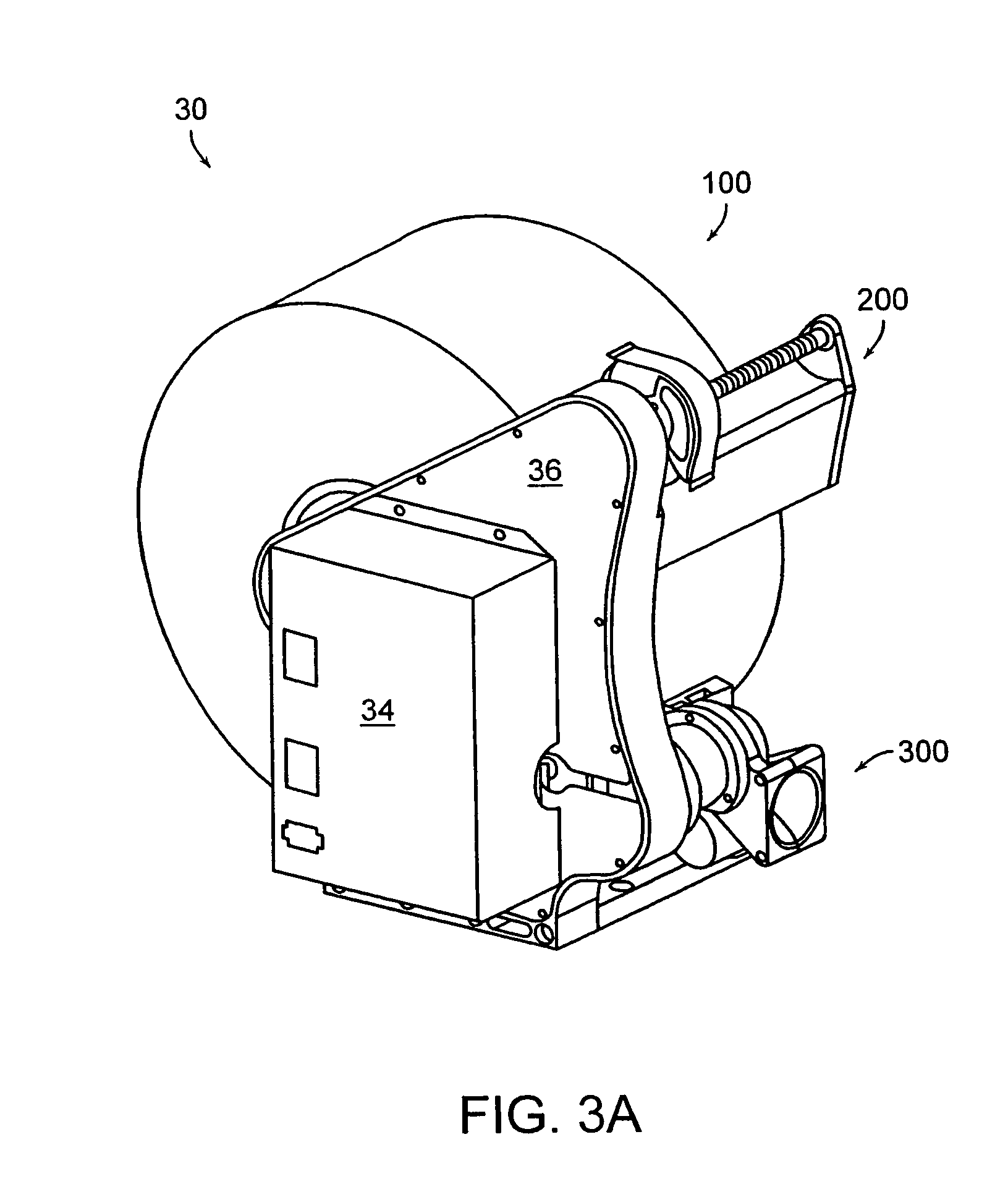

Communications spooler for a mobile robot

A cable handling system mounted to a mobile robot to dispense and retrieve cable at zero tension includes a cable reel drive and a downstream tension roller drive that includes an idler. As a cable passes through the tension roller drive, position along the length of the cable and / or the cable speed is monitored accurately by a sensor attached to the idler. A system controller in communication with the sensor controls the cable reel drive and the tension roller drive for dispensing and retrieving cable downstream of the tension roller drive.

Owner:FLIR DETECTION

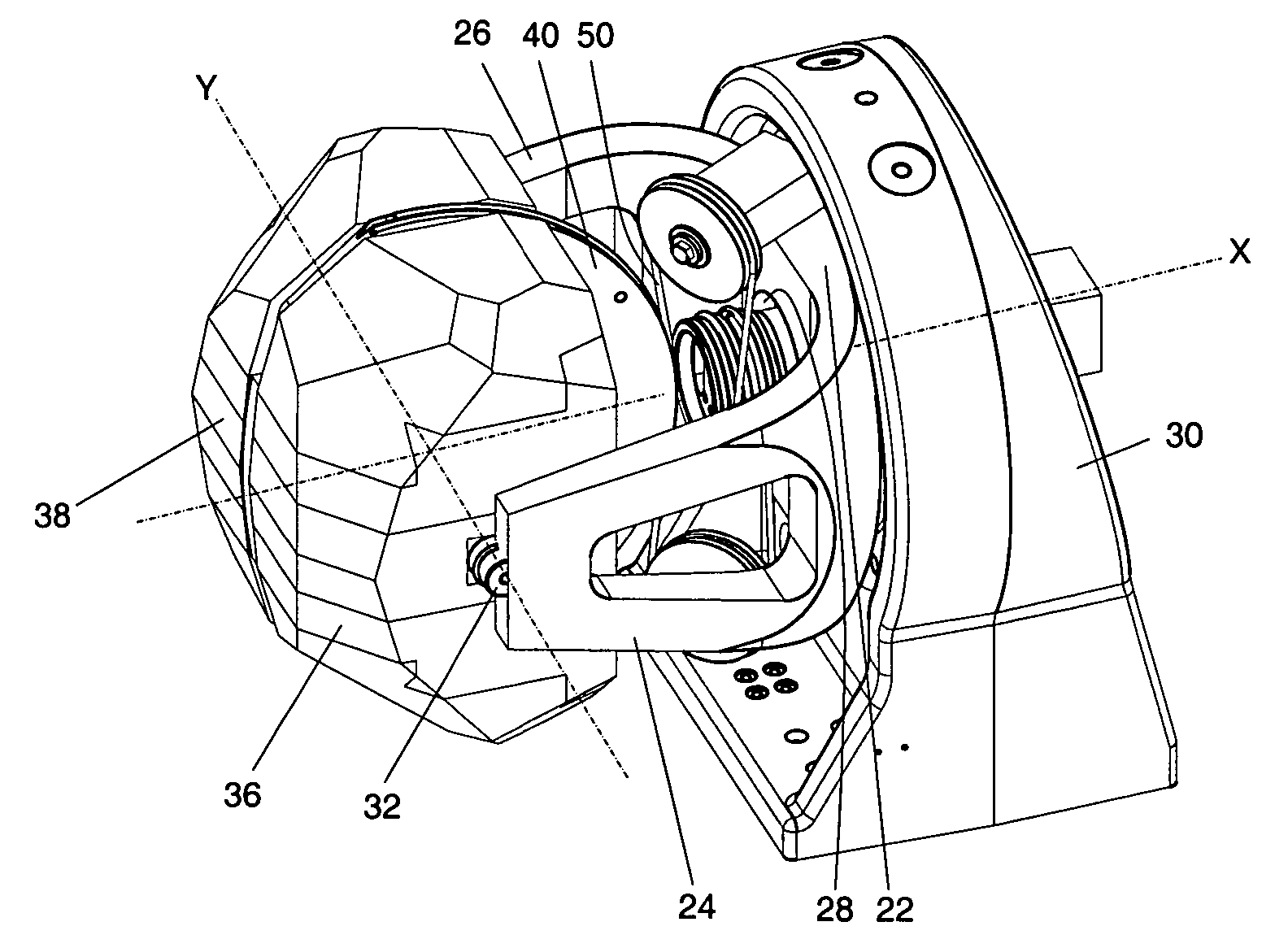

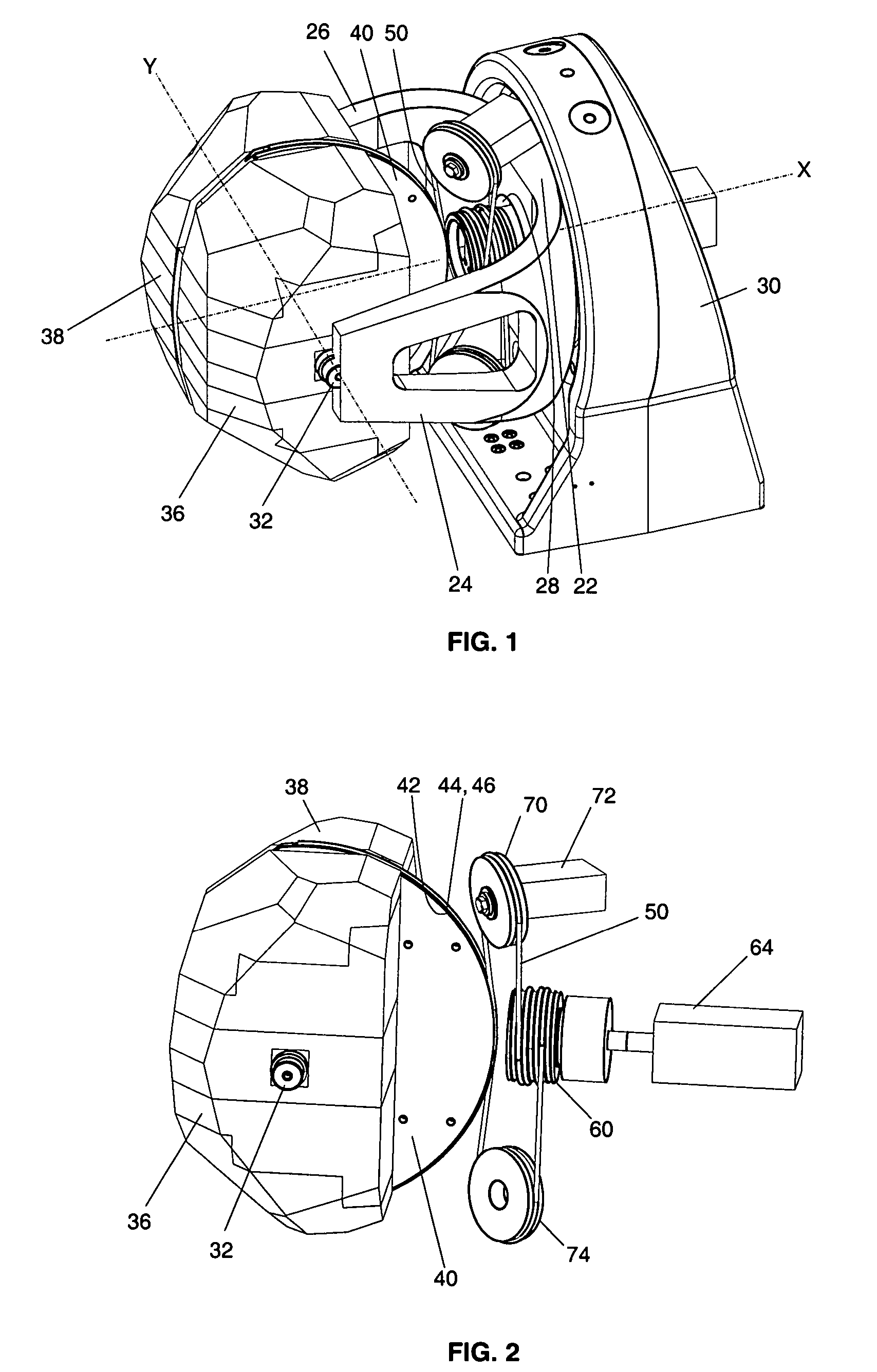

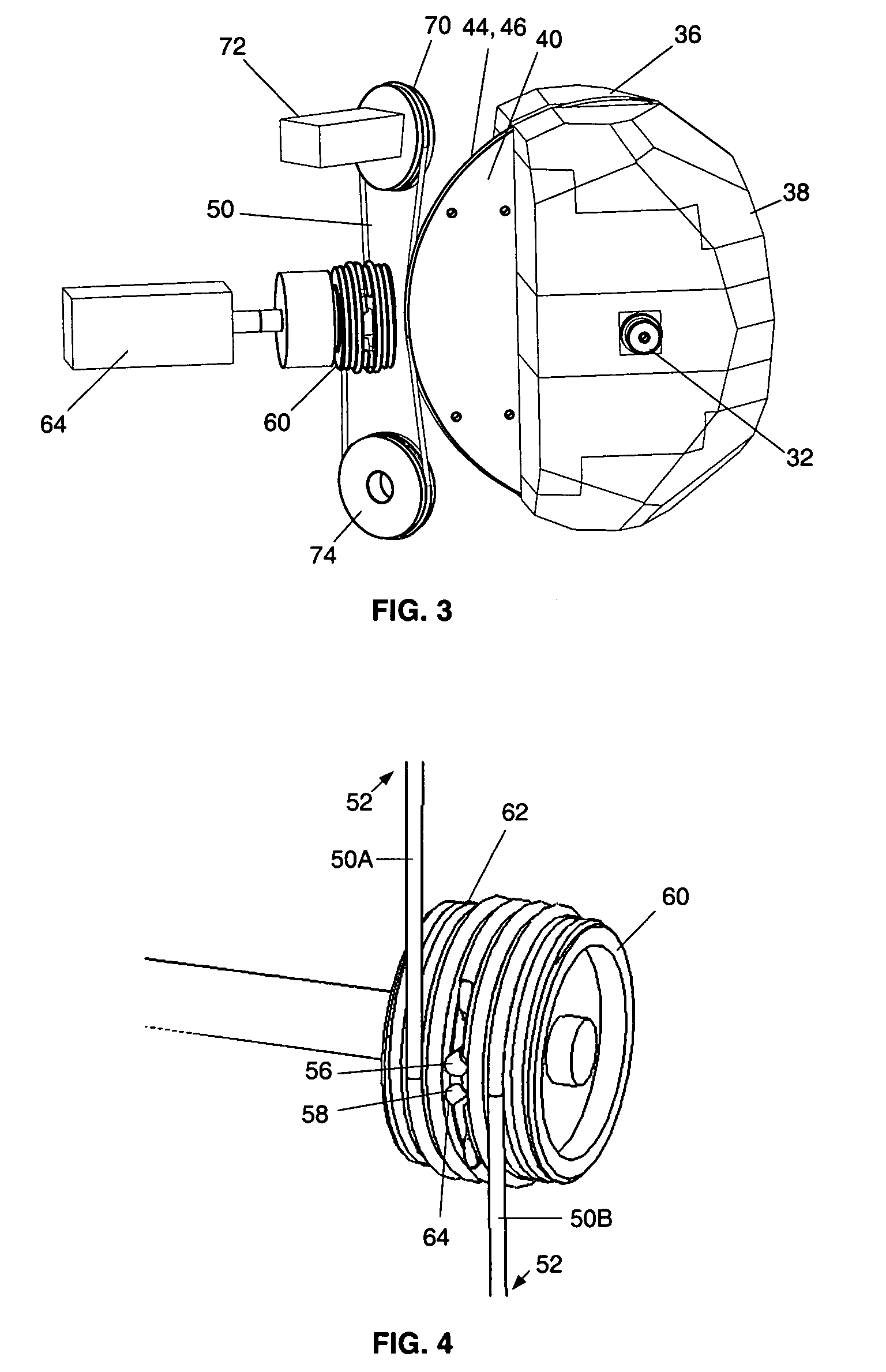

Apparatus for pivotally orienting a projection device

An apparatus that provides for rotation about two axes orthogonal to each other includes a gimbal having two arms adjoining a portion that is mounted to a base for rotation about a first axis. A shaft defining a second axis orthogonal to the first pivotally couples a mounting plate to the arms. The mounting plate has an arcuate edge with first and second parallel grooves therein adapted to receiving a drive cable. A drive cable that is engaged with a drive pulley is aligned by at least one idler pulley with the first and second grooves of the mounting plate. The drive cable has opposing free ends that are received in the first and second grooves of the mounting plate. A motor is coupled to the drive pulley for controlling the drive cable travel, to accordingly rotate the mounting plate to provide for orientating a device in a desired direction.

Owner:STEREOTAXIS

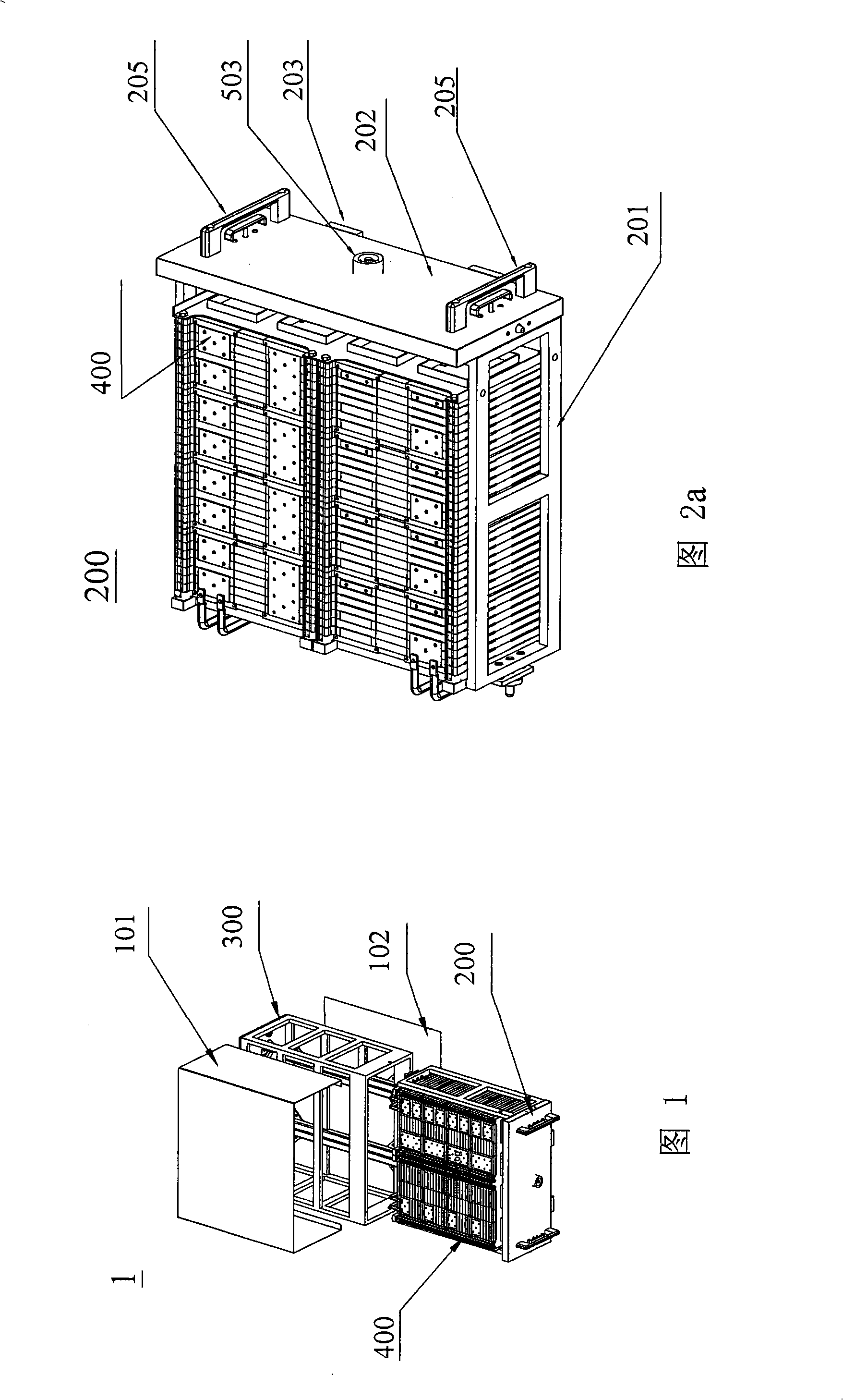

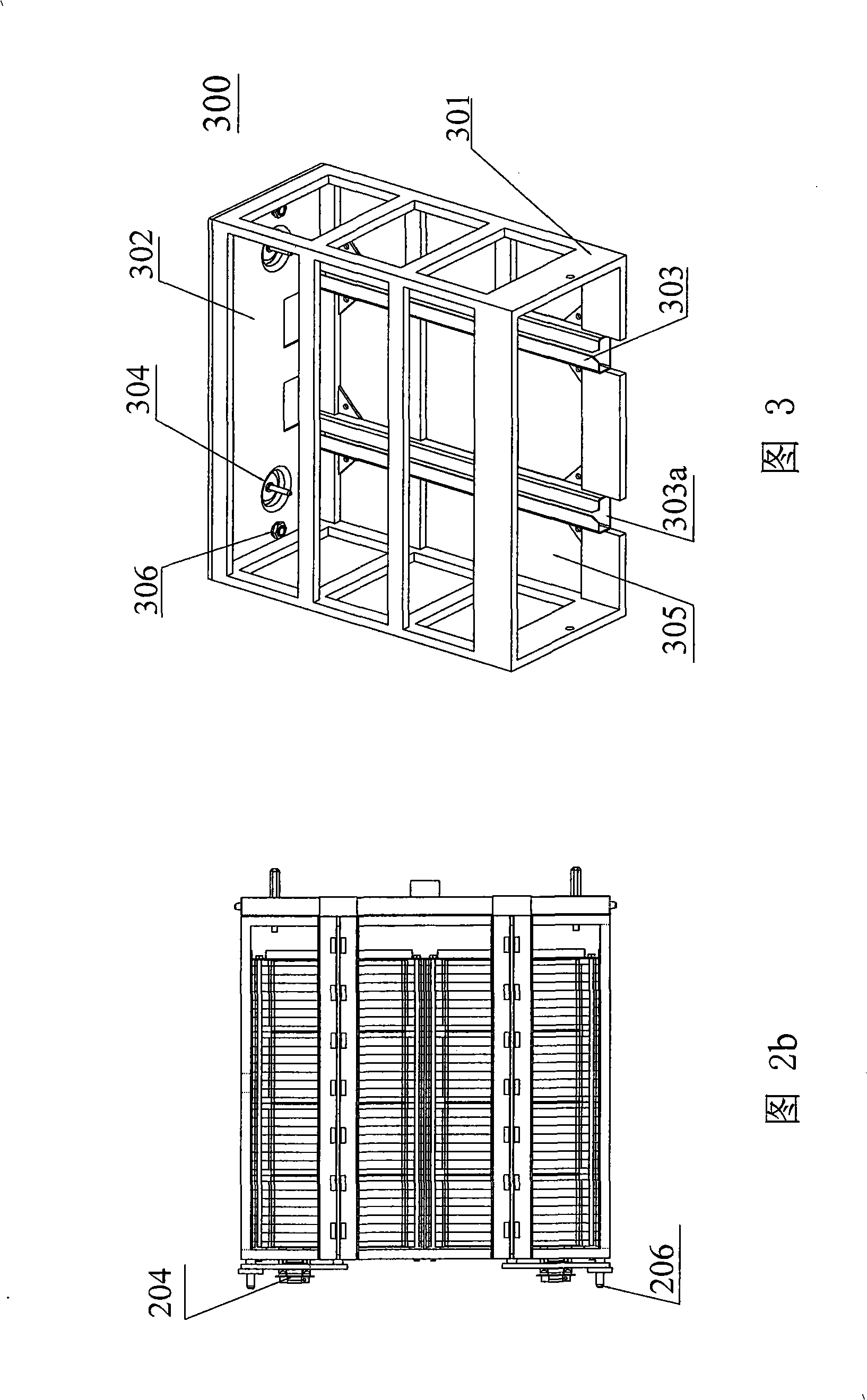

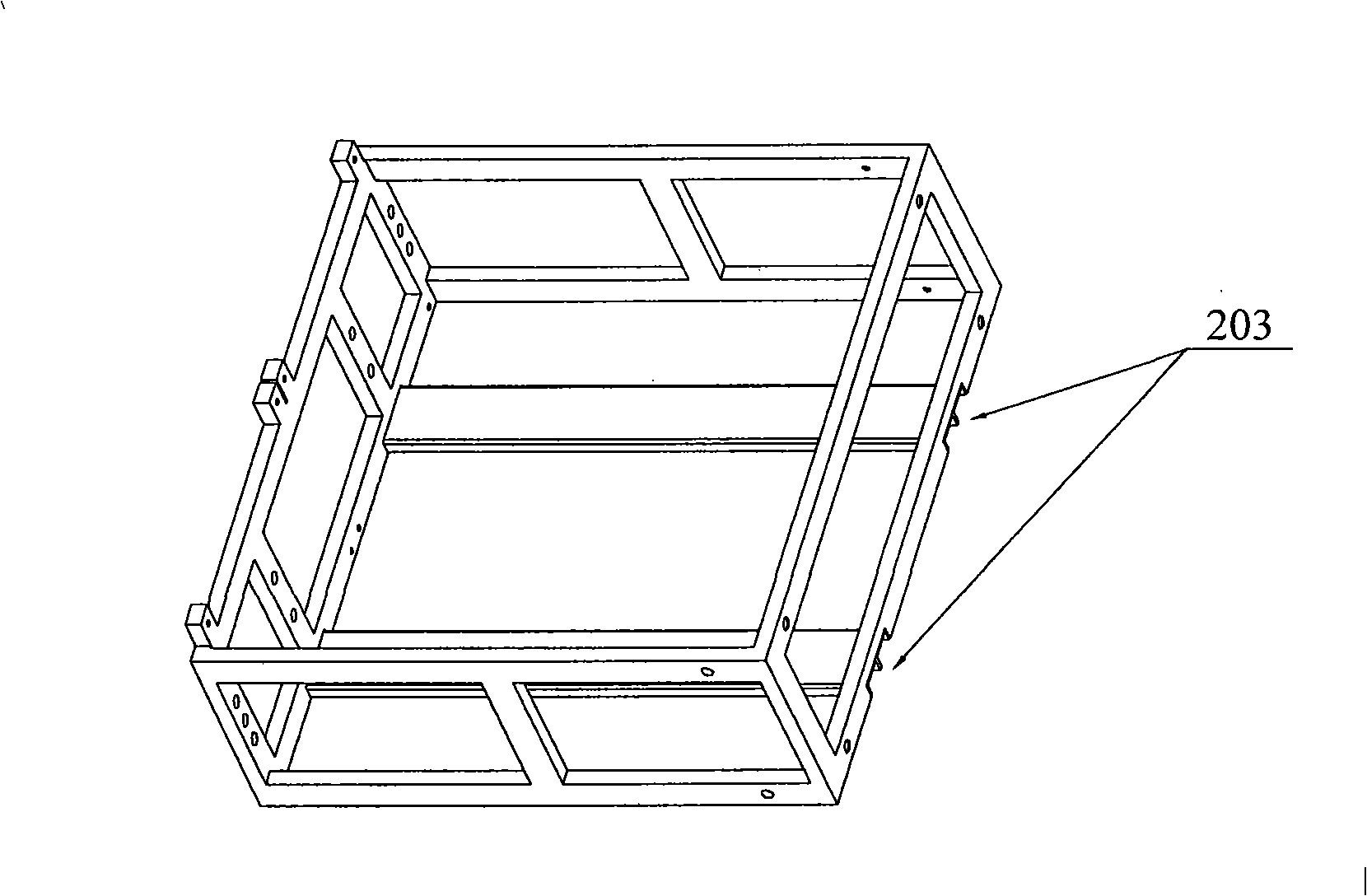

Quick replaceable electric motor vehicle cell box

ActiveCN101289056ANormal transmission workSolve the problem of safe useElectric propulsion mountingCell component detailsEngineeringIdler-wheel

The invention relates to an electric car battery box, which comprises a battery, an inner box body, an outer box body and an emersion slideway; wherein, the slideway is arranged between the inner box body and the outer box body and comprises an upper slideway and a lower slideway; the upper slideway and a framework of the inner box body are welded together; the lower slideway and a framework of the outer box body are welded together; the upper slideway is inserted in the lower slideway to form drawer type assembly and disassembly of the battery; the upper slideway comprises a plurality of idler wheels; while the lower slideway comprises a lower slideway slot; a plurality of idler wheels of the upper slideway can move in the lower slideway slot. The battery box of the invention realizes the fast assembly and disassembly of the whole battery; which is convenient to be maintained, enlarges the continuous running mileage and is suitable for fission charging.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

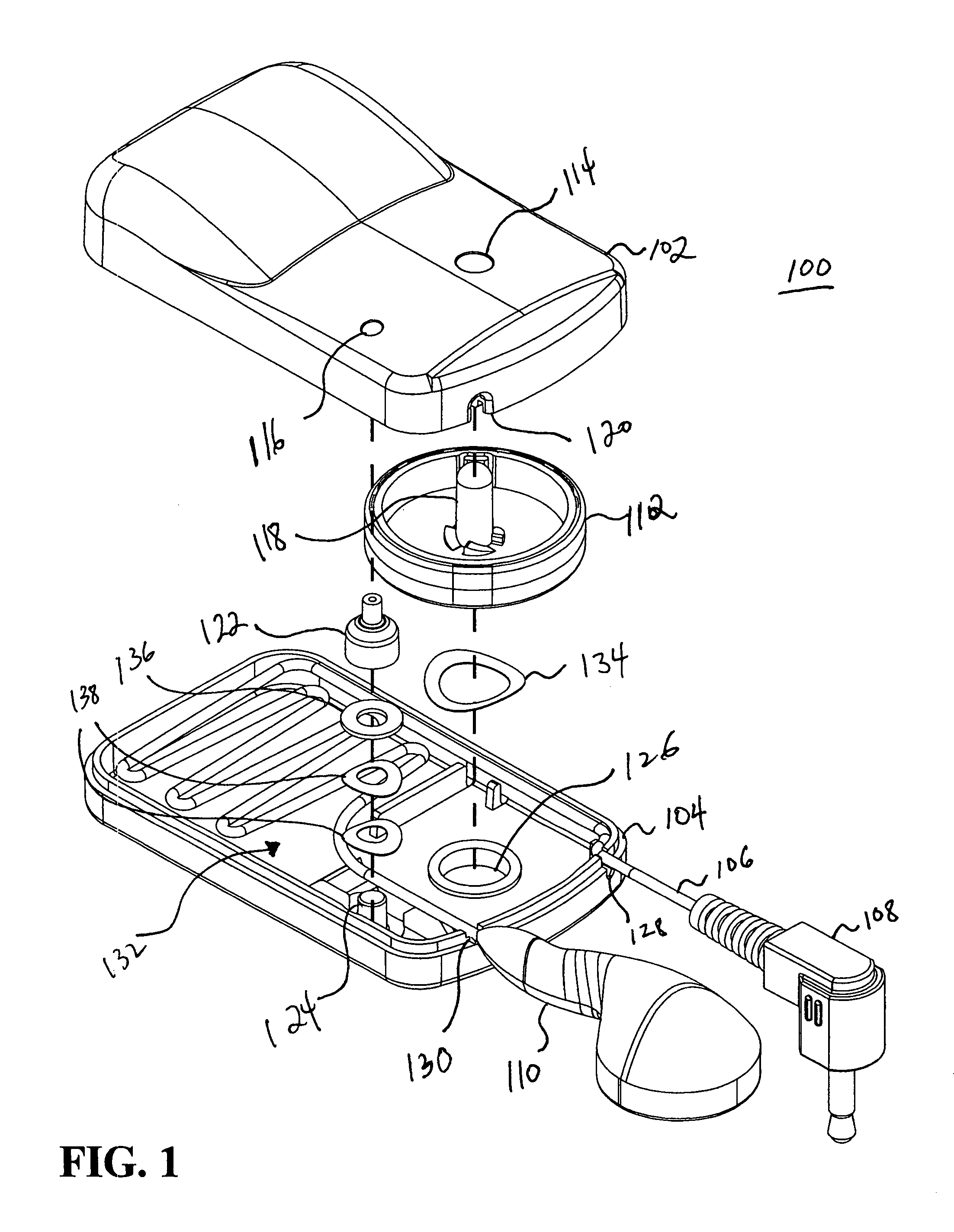

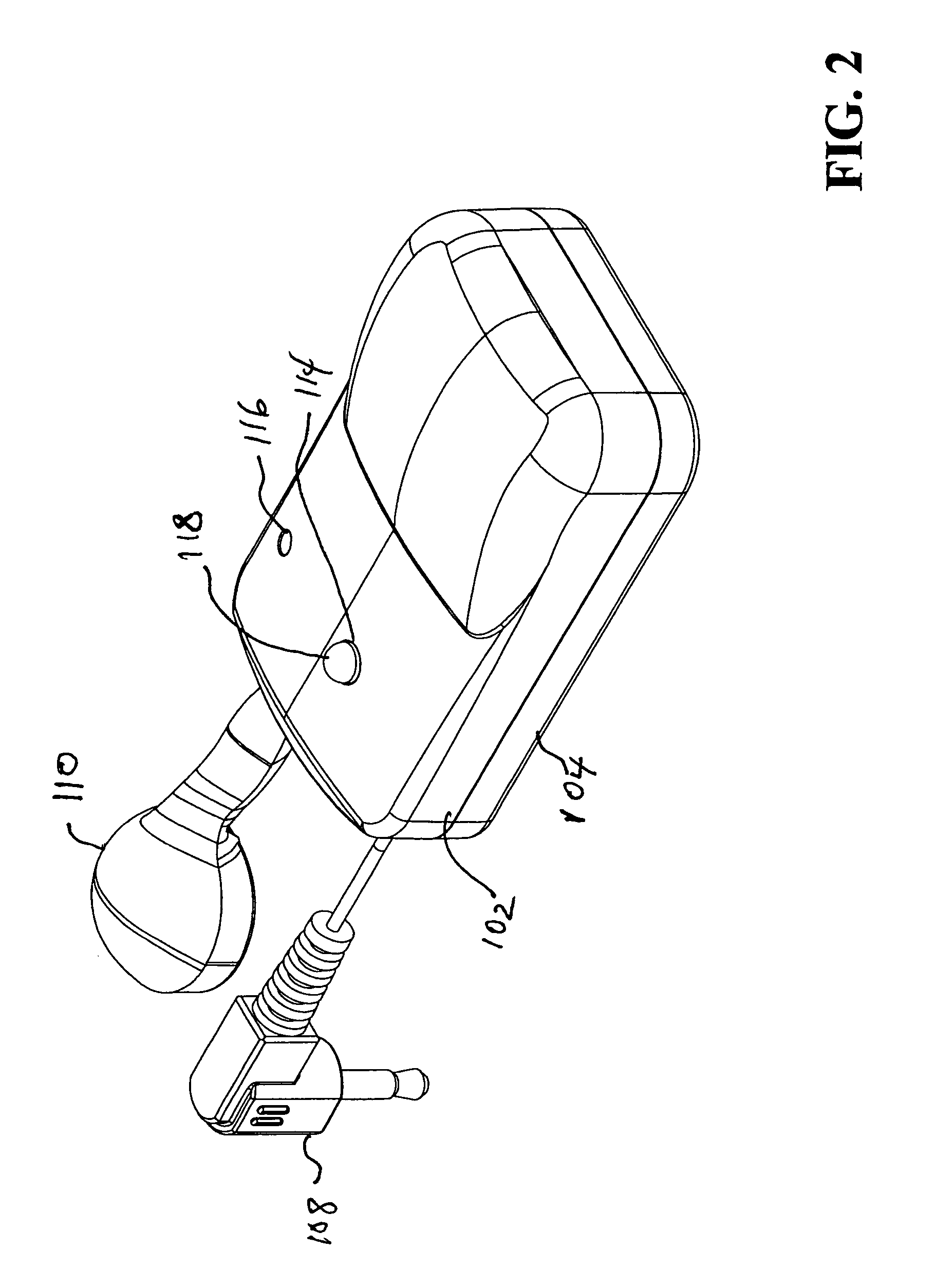

Headset cable retraction system

InactiveUS7086512B2Arrangements using take-up reel/drumTelephone set constructionsDrive wheelEngineering

A headset cable retraction system and device is described, the system including a housing, the housing having a cavity. In addition, the system includes a cord capable of transmitting an electrical signal, wherein a portion of the cord is contained in the cavity. The system further includes an earpiece attached to the cord; and, a retracting mechanism in the housing, the retracting mechanism including a drive wheel, a spring coupled to the drive wheel and a idler wheel, the cord being pressed between the drive wheel and the idler wheel; wherein when the cord is extracted from the cavity, the spring becomes tensioned. A method for using the system and device is also described.

Owner:CAHP

Continuously variable transmission

Owner:FALLBROOK INTPROP COMPANY

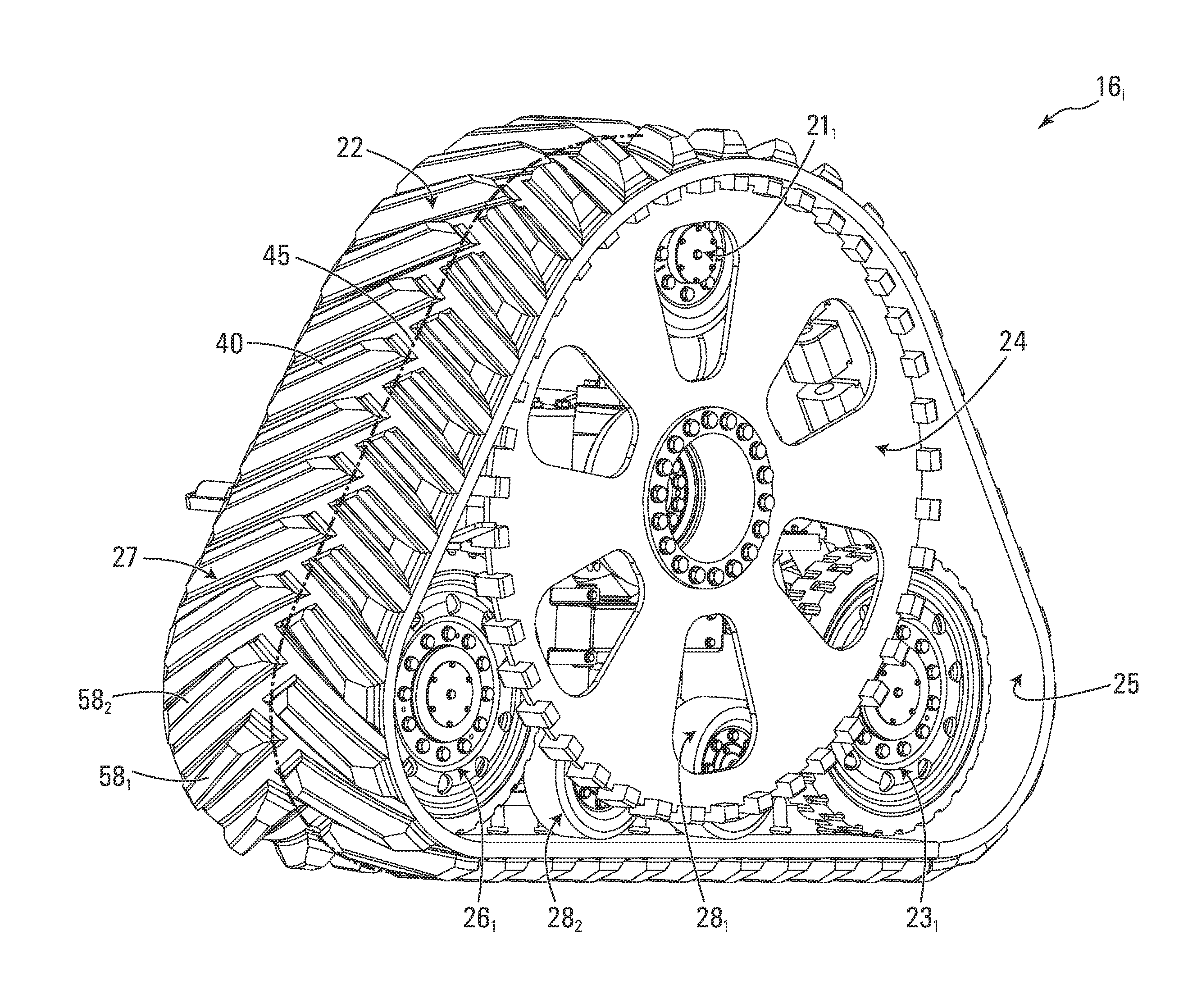

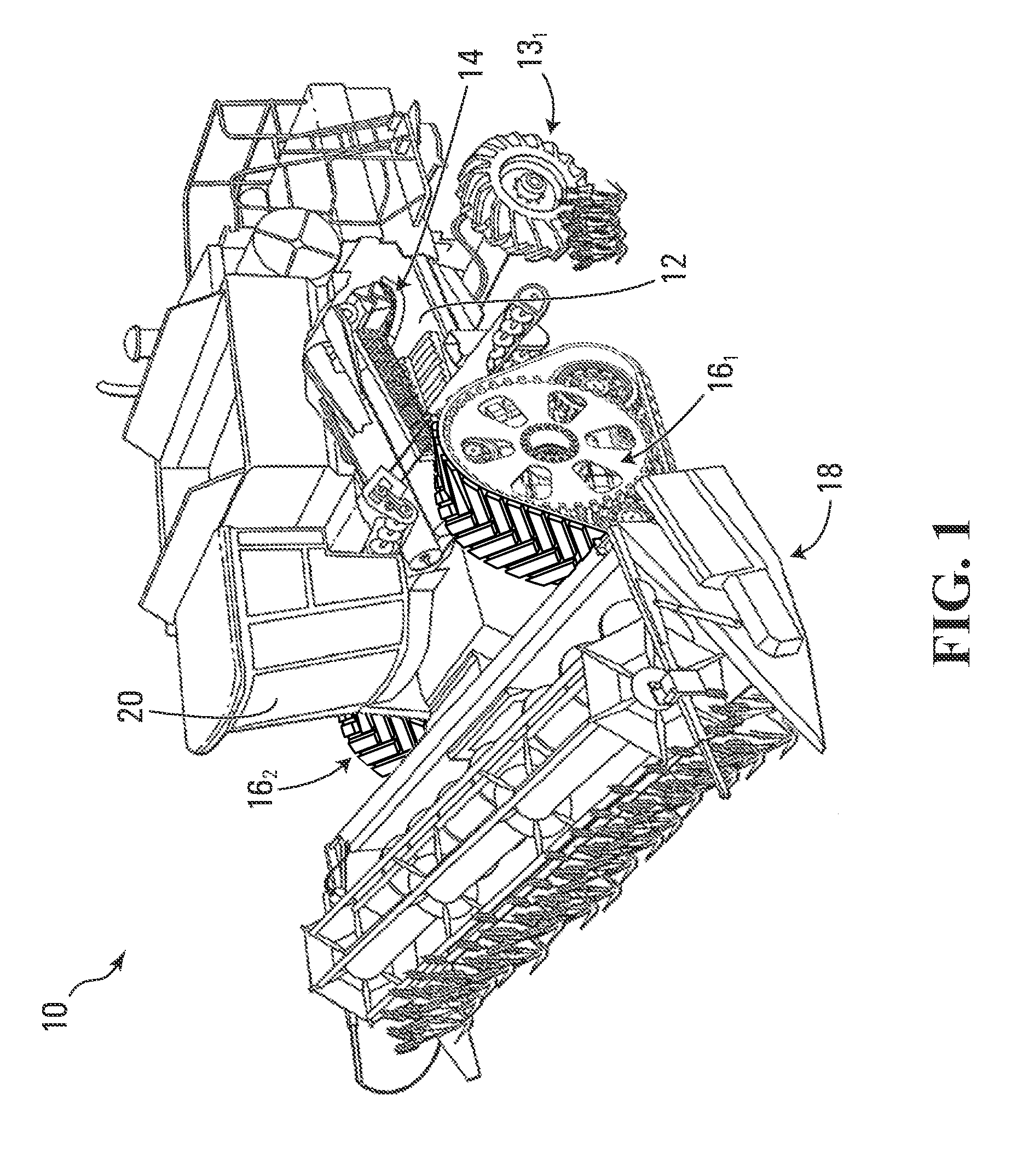

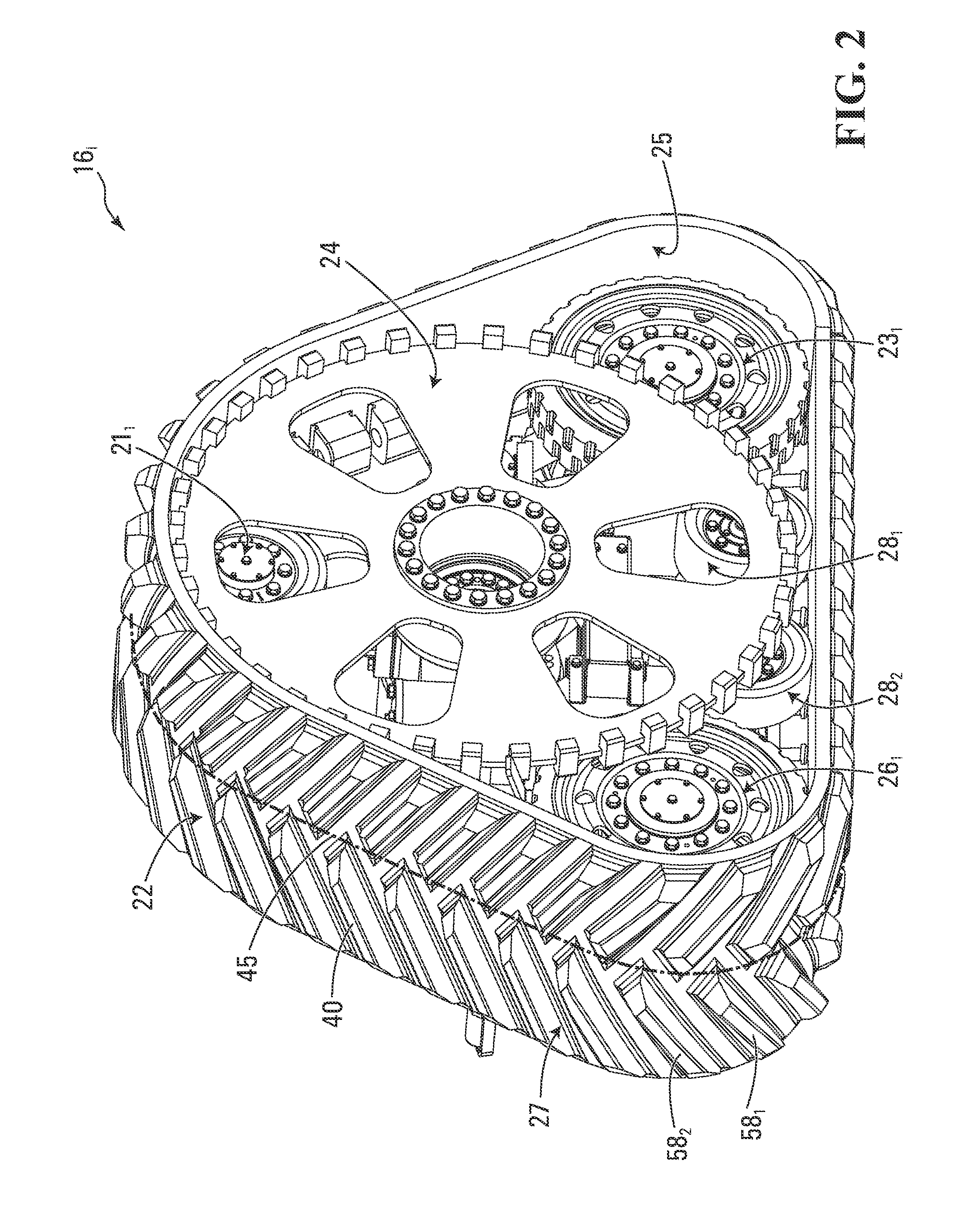

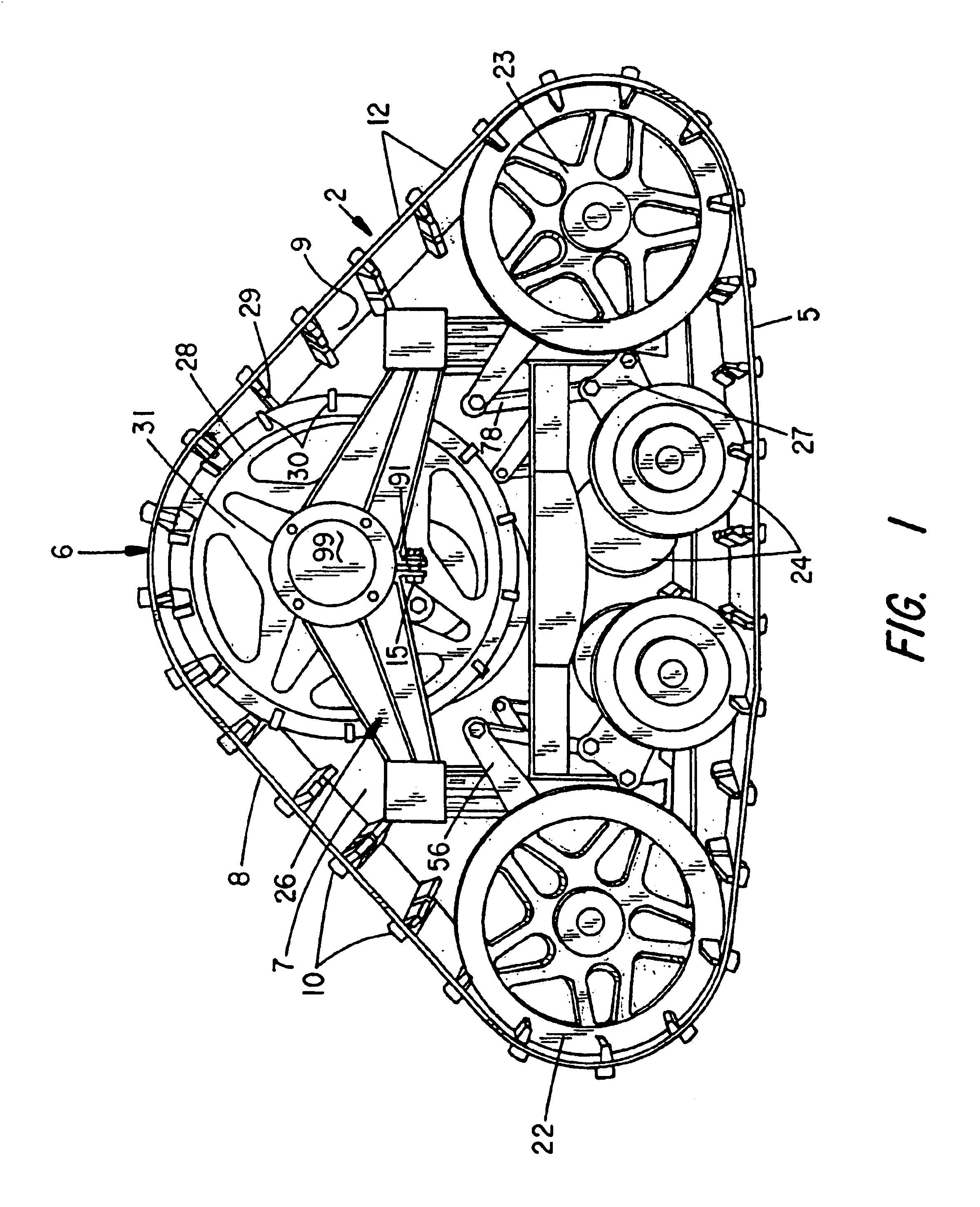

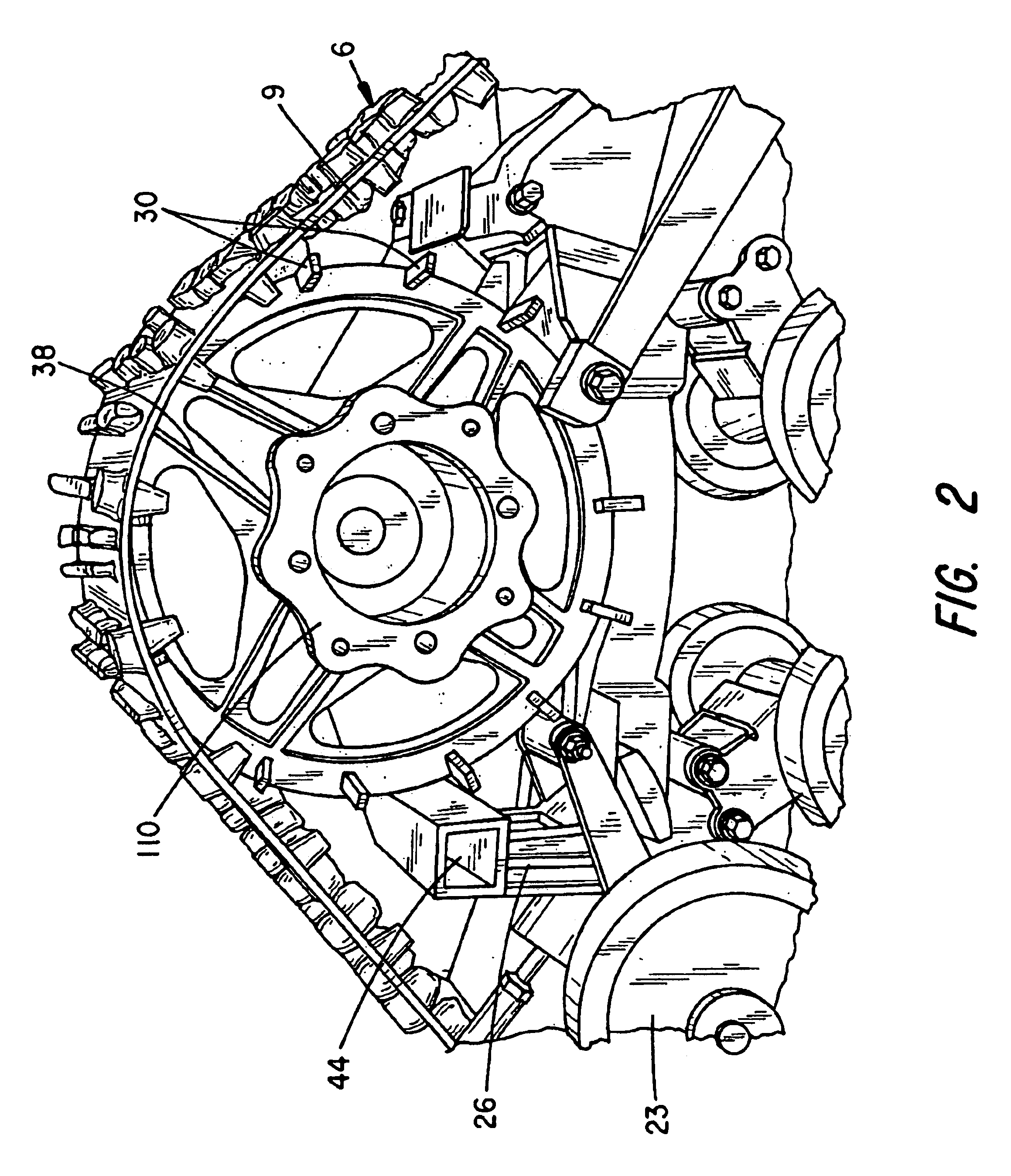

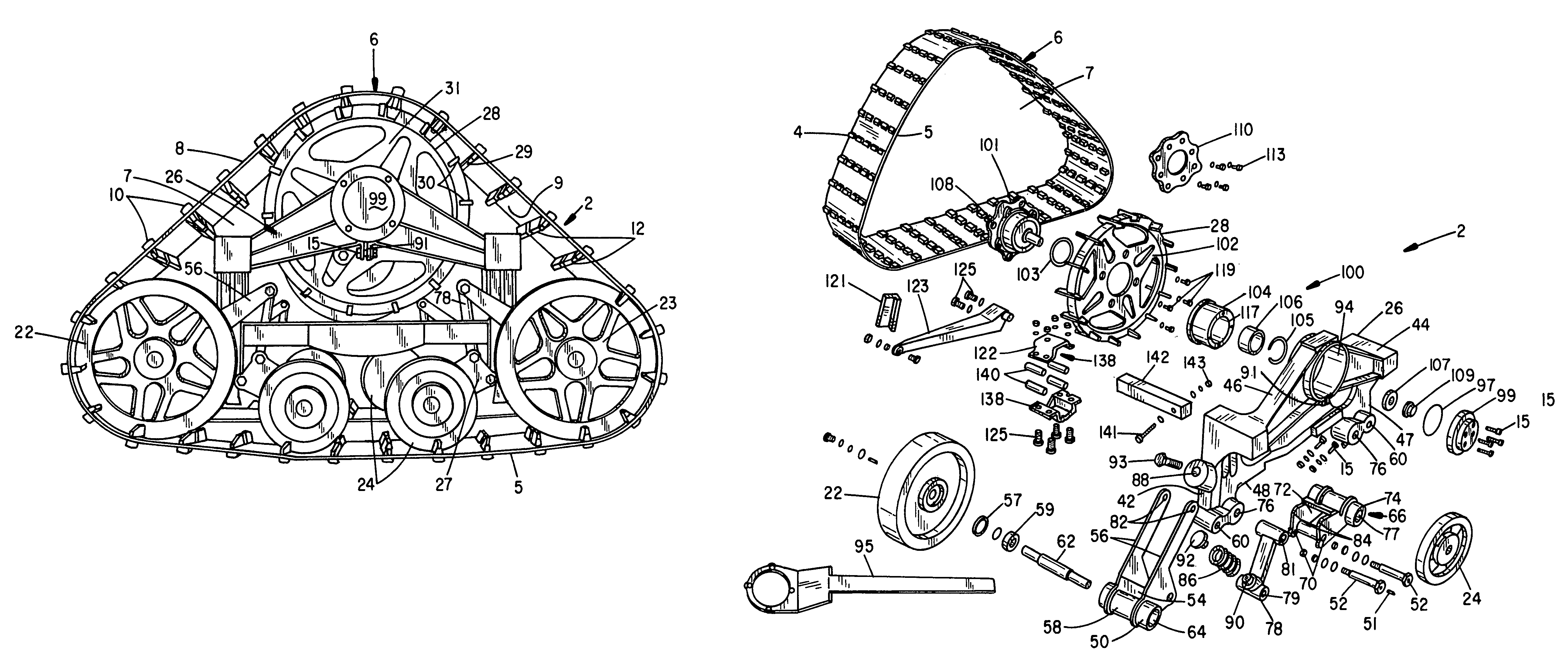

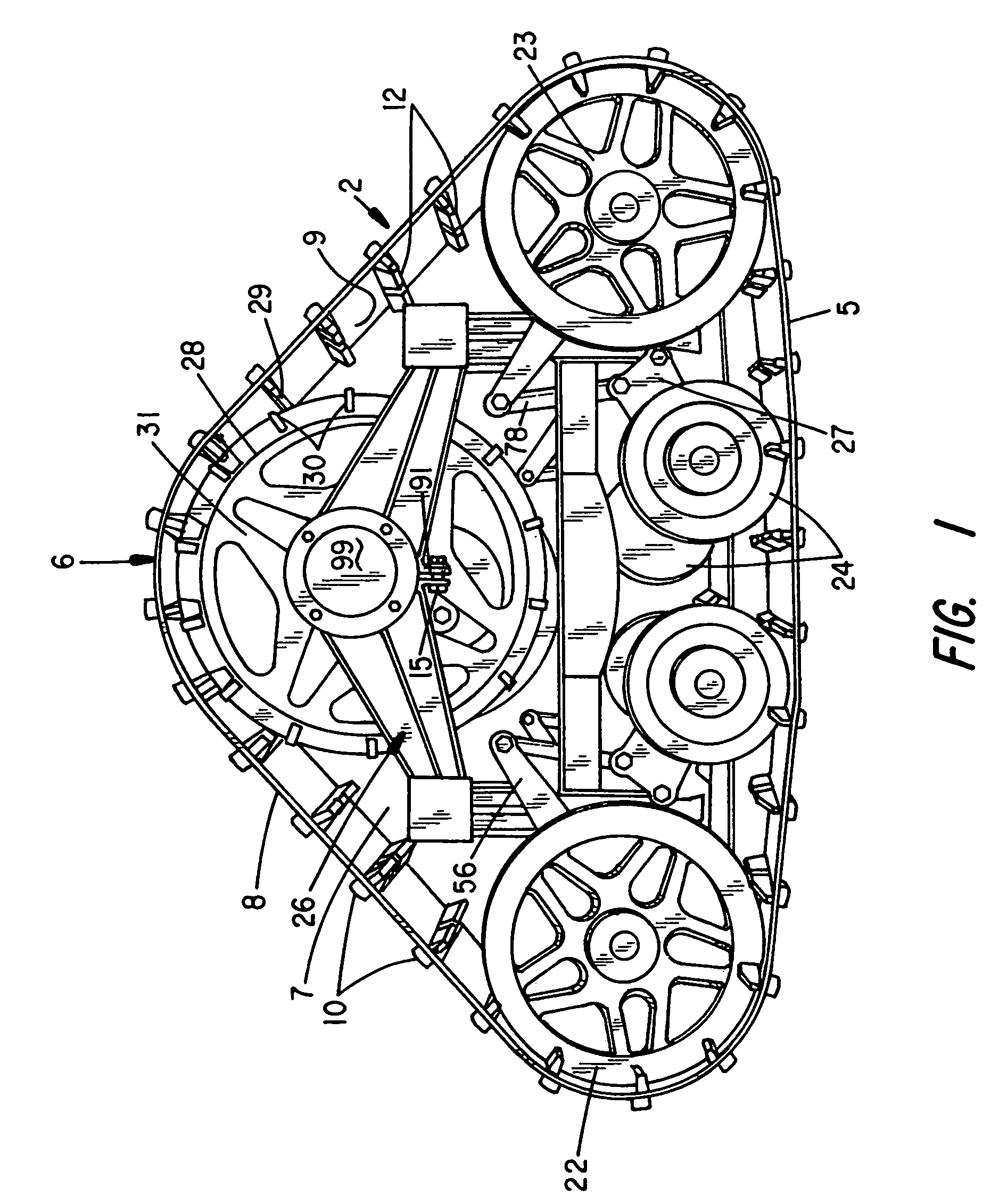

Track Assembly for Traction of a Vehicle

A track assembly for providing traction to a vehicle, such as an agricultural vehicle, a construction vehicle, or another work vehicle The track assembly is mountable to an axle of the vehicle The track assembly comprises a plurality of wheels comprising a leading idler wheel and a trailing idler wheel spaced apart in a longitudinal direction of the track assembly, an axis of rotation of the axle of the vehicle being located between an axis of rotation of the leading idler wheel and an axis of rotation of the trailing idler wheel in the longitudinal direction of the track assembly, and a driver wheel for rotating when the axle of the vehicle rotates The track assembly also comprises an endless track disposed around the wheels The endless track comprises an inner side facing the wheels and a ground-engaging outer side for engaging the ground The endless track engages the driver wheel such that rotation of the driver wheel imparts motion to the endless track.

Owner:CAMOPLASY INC

Continuously variable planetary gear set

ActiveUS20040224808A1Reduce amountEasy to removeHybrid vehiclesChain/belt transmissionRadial positionEngineering

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

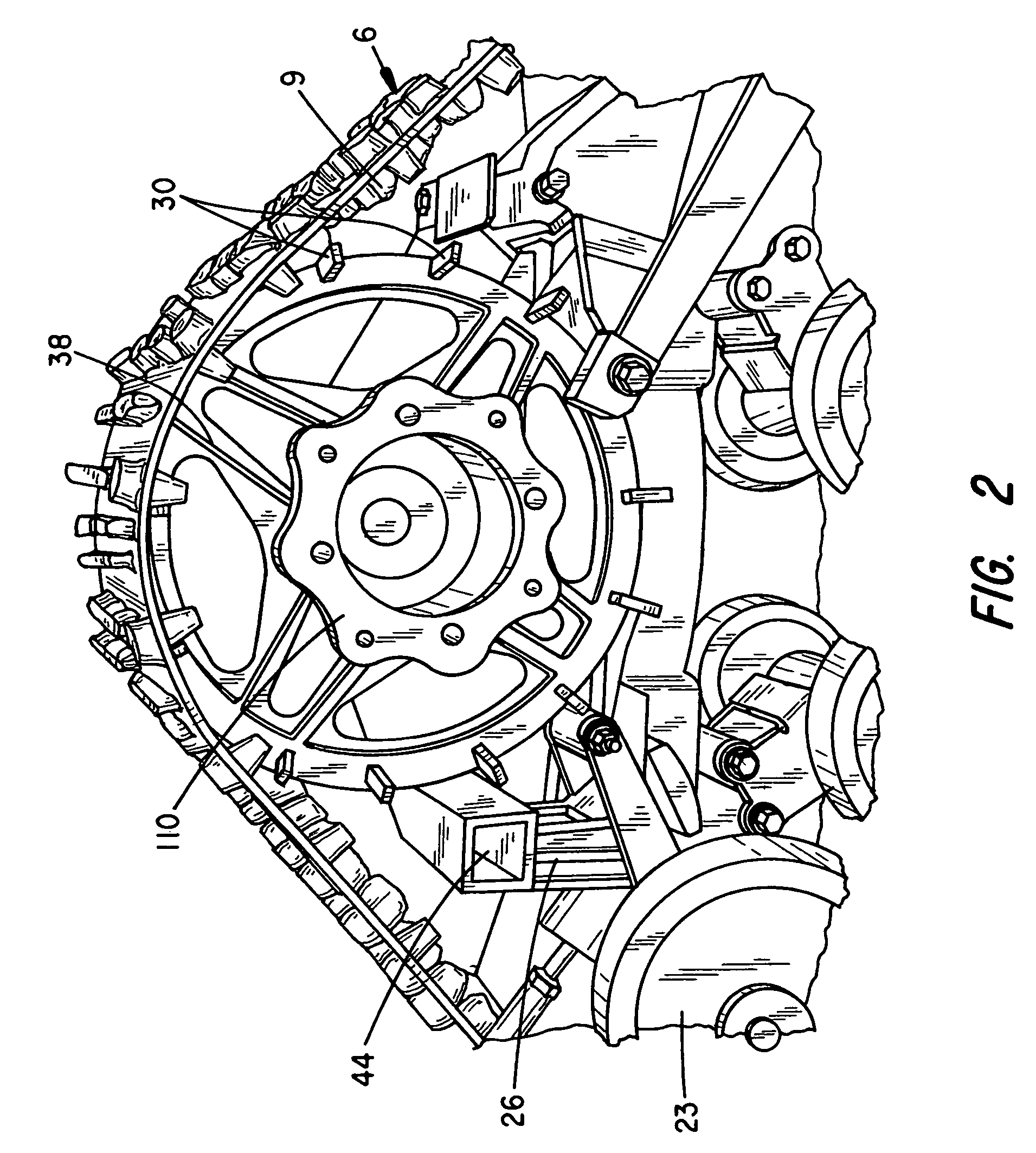

Terrain conforming track assembly

An endless track assembly that mounts to a wheeled vehicle. The assembly provides 1) a track suspension having fixed or adjustable, independently biased sets of idler wheels to vary the track contour without affecting track tension, 2) an eccentric bearing housing at a drive sprocket controls track tension, 3) a contoured peripheral edge at the drive sprocket prevents ice and mud buildup, 4) rubber-coated, plastic idler wheels facilitate track movement, 5) a multi-vehicle compatible adapter mounting plate accommodates a variety of vehicles, 6) a rotation limited torsion coupler and / or rotation limiting coupler arms prevent track contact with the vehicle, 7) a locking steering arm coupler prevents loss of steering control, and 8) shaped track lugs and channels clear and direct debris away from the track suspension and drive assembly. The improved suspension particularly supports sets of idler wheels in pivotal relation to the track support frame and resiliently biases a pre-tensioned rocker arm that links adjacent suspension arms mounted to the adjoining idler wheels. Suspension arm movement induces expansion and contraction of tension springs coupled to the rocker arms to augments shape changes at the track contact surface to optimize traction and steering control.

Owner:BRAZIER GLEN

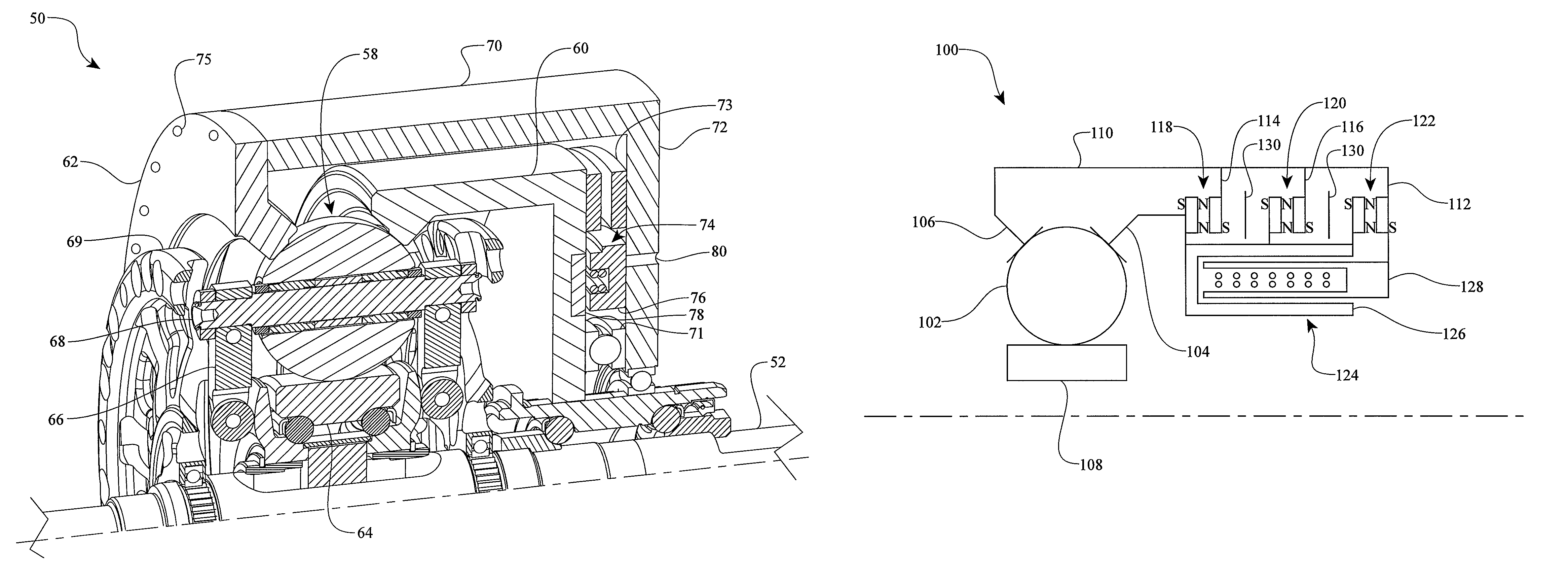

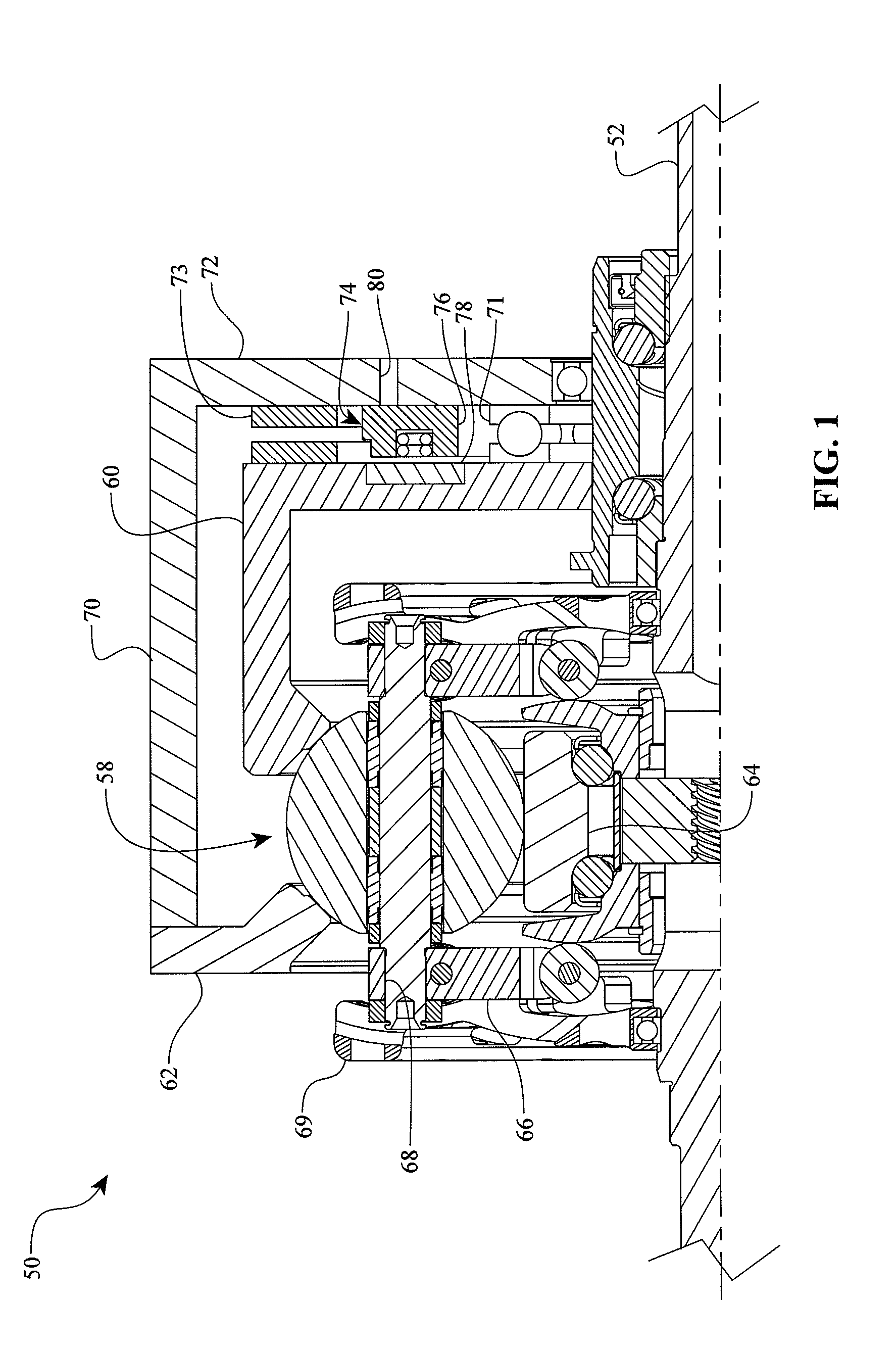

Assemblies and methods for clamping force generation

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

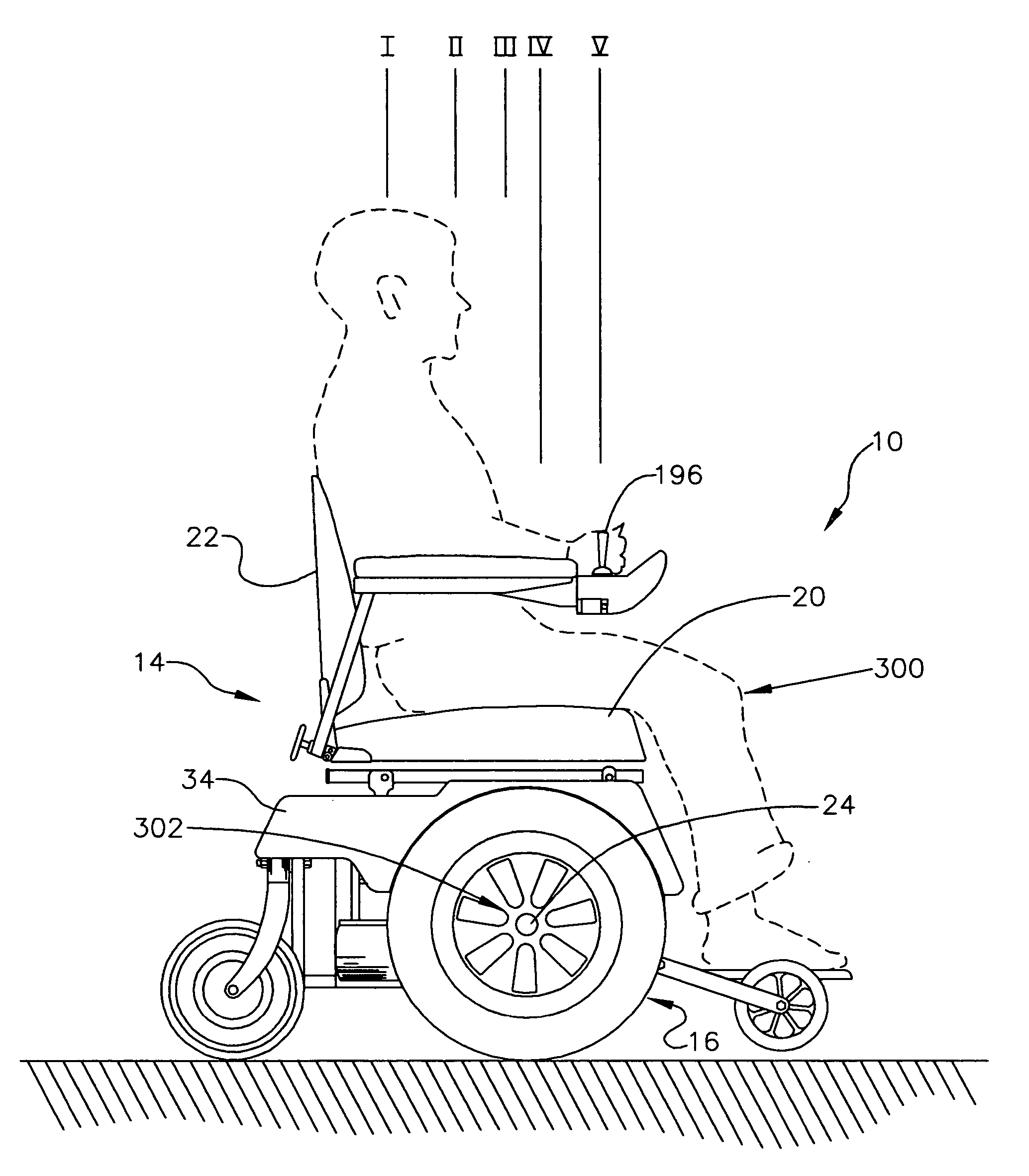

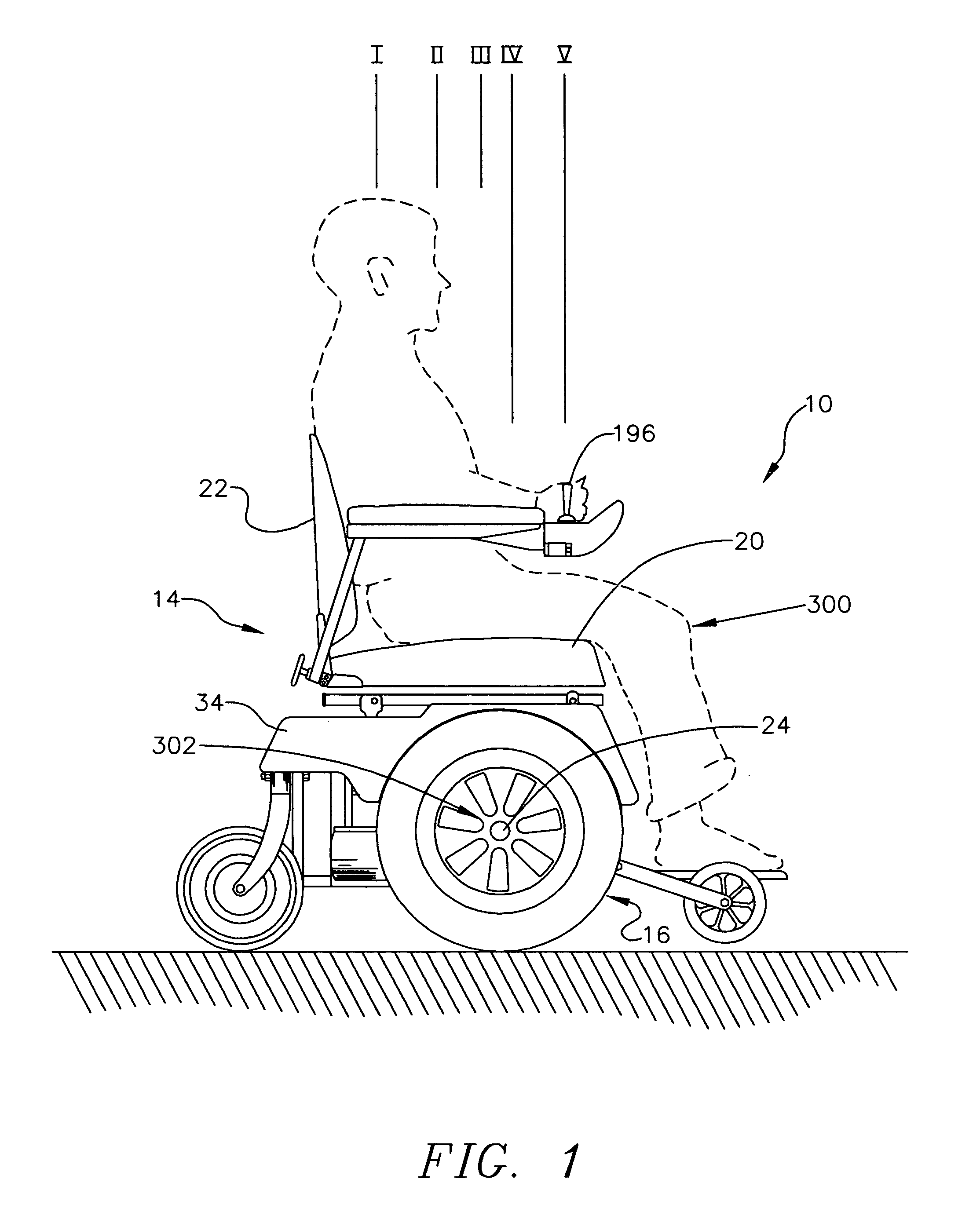

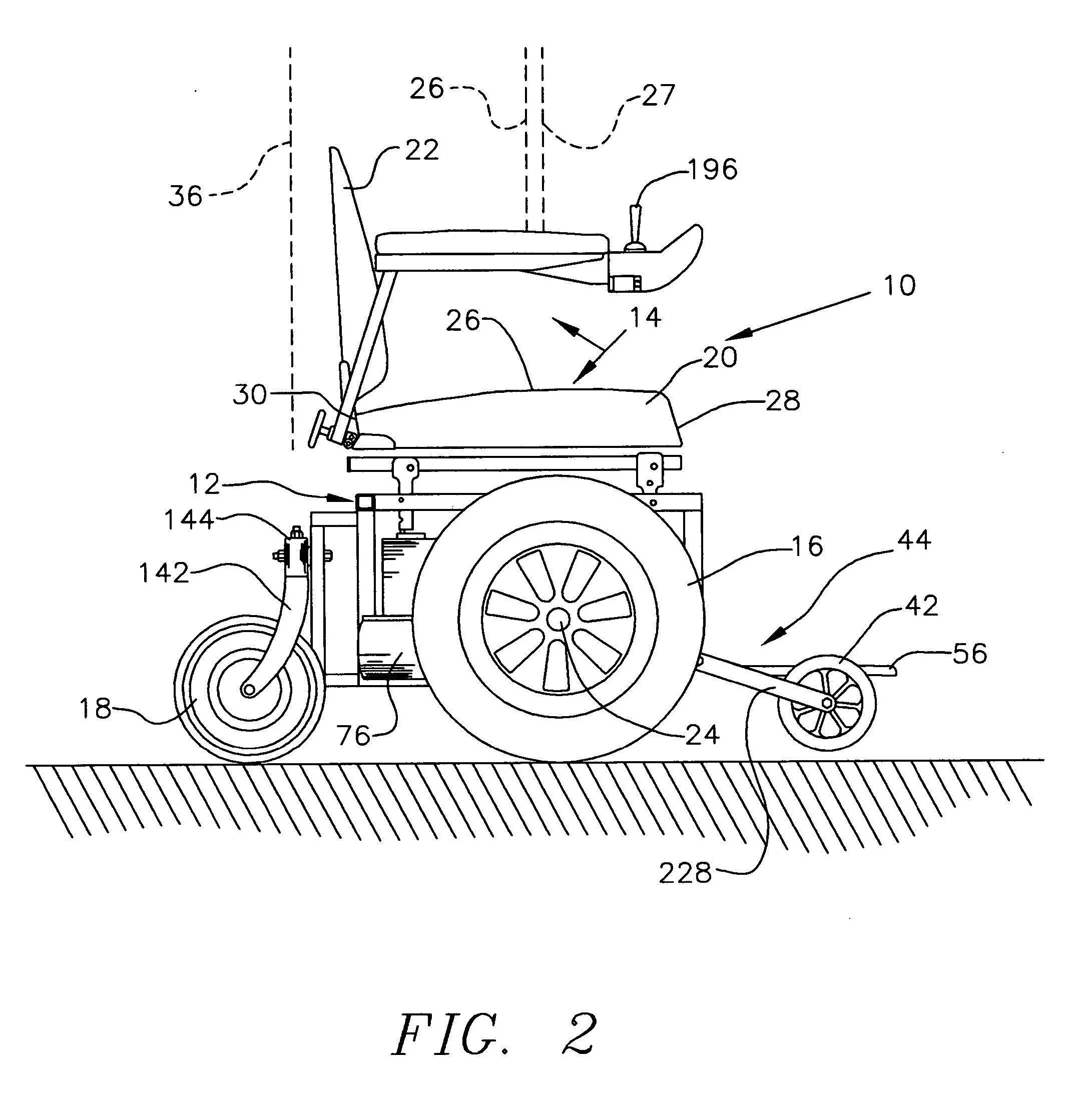

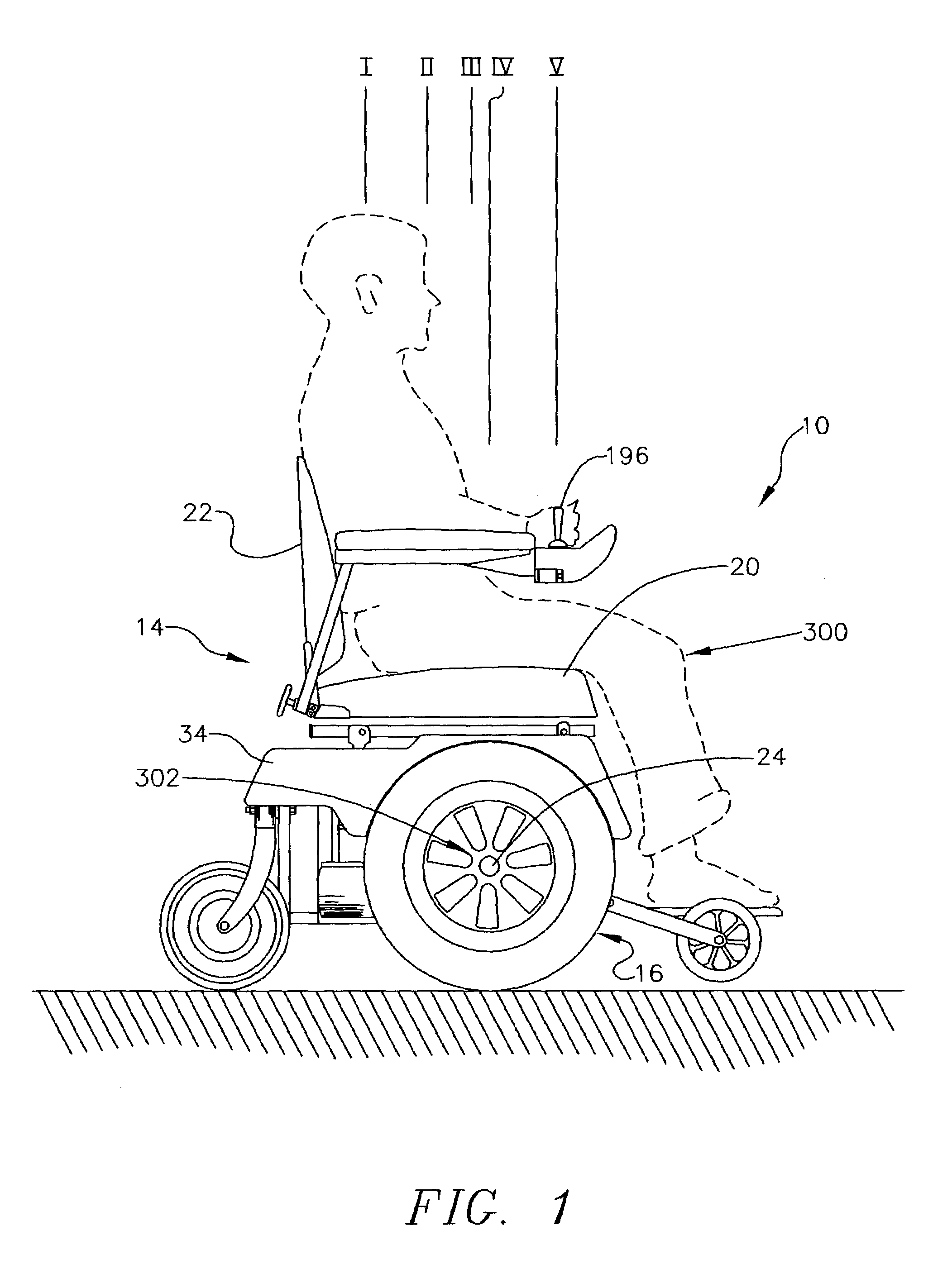

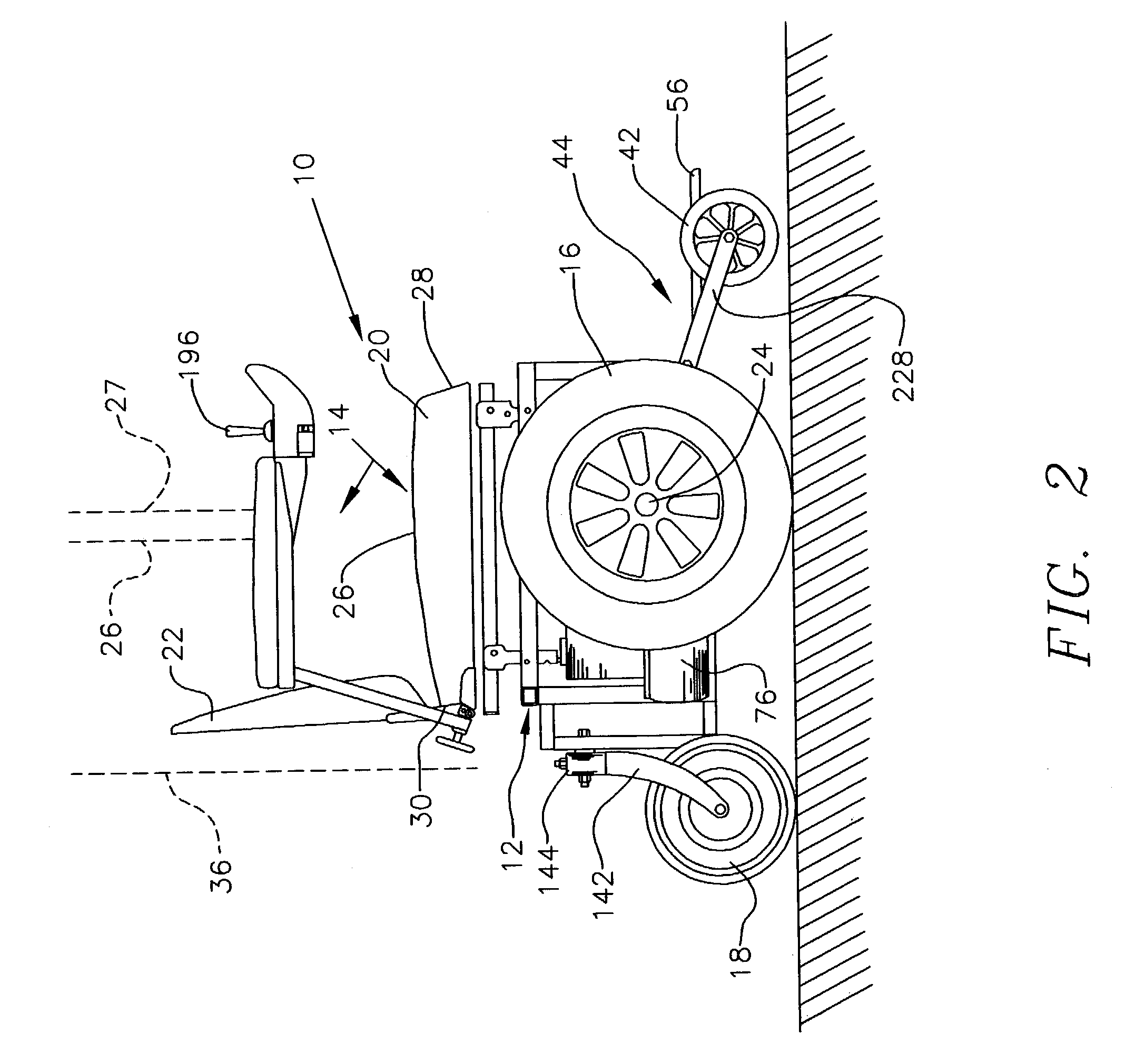

Curb-climbing power wheelchair

ActiveUS20050127631A1Pedestrian/occupant safety arrangementElectric propulsion mountingWheelchairDrive wheel

A mid-wheel drive power wheelchair for use by handicapped and disabled persons is provided having a frame, a seat supported by the frame, a pair of drive wheels supported on the frame under the seat, drive means for causing rotation of the drive wheels, power means for supplying power to the drive means, a rearward idler wheel, a forward anti-tip device and a resilient suspension supporting the forward anti-tip device, the suspension being attached to the drive means rearward of the front portion of the frame.

Owner:SCHAFFNER WALTER E

Terrain conforming track assembly

Owner:BRAZIER GLEN

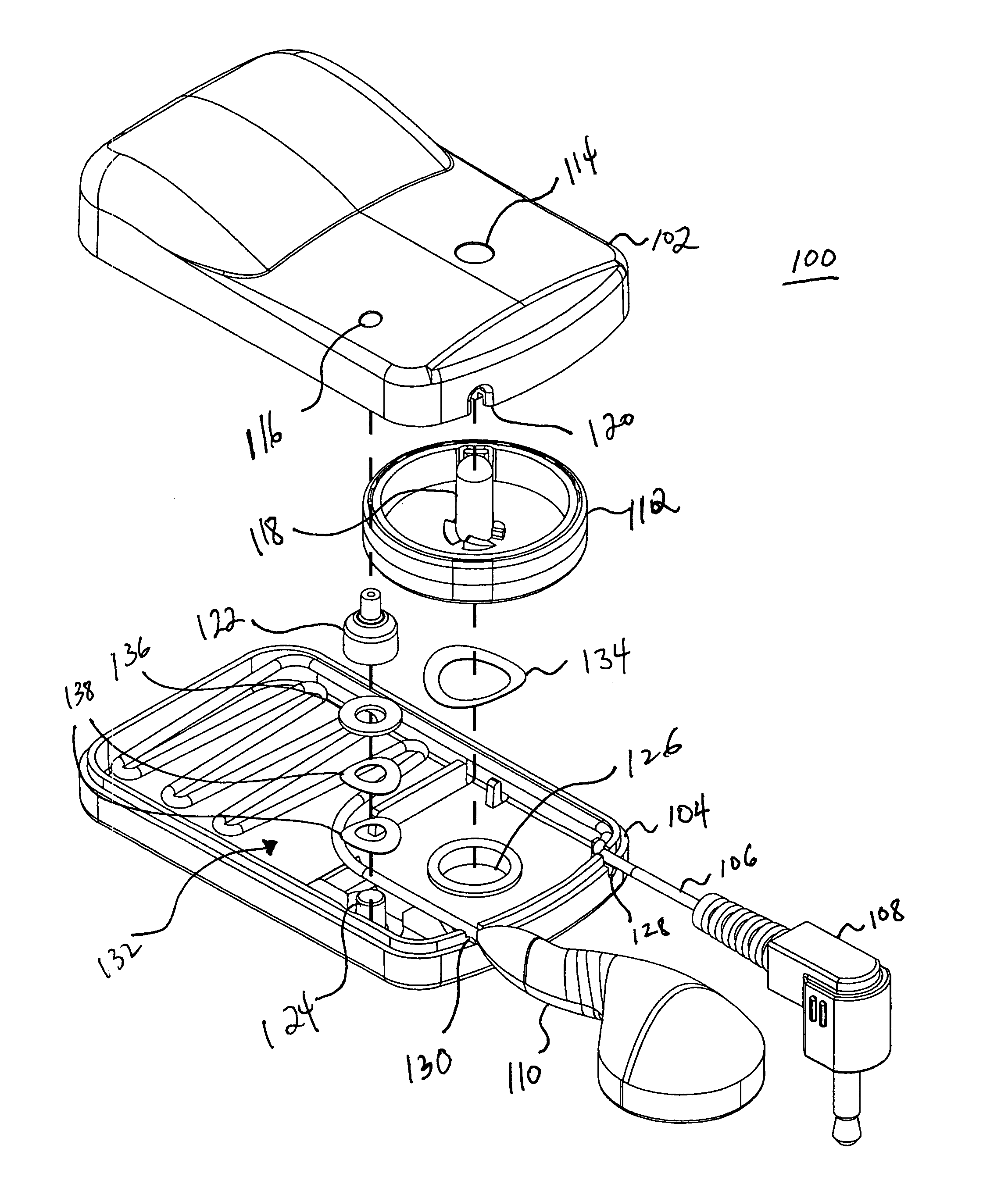

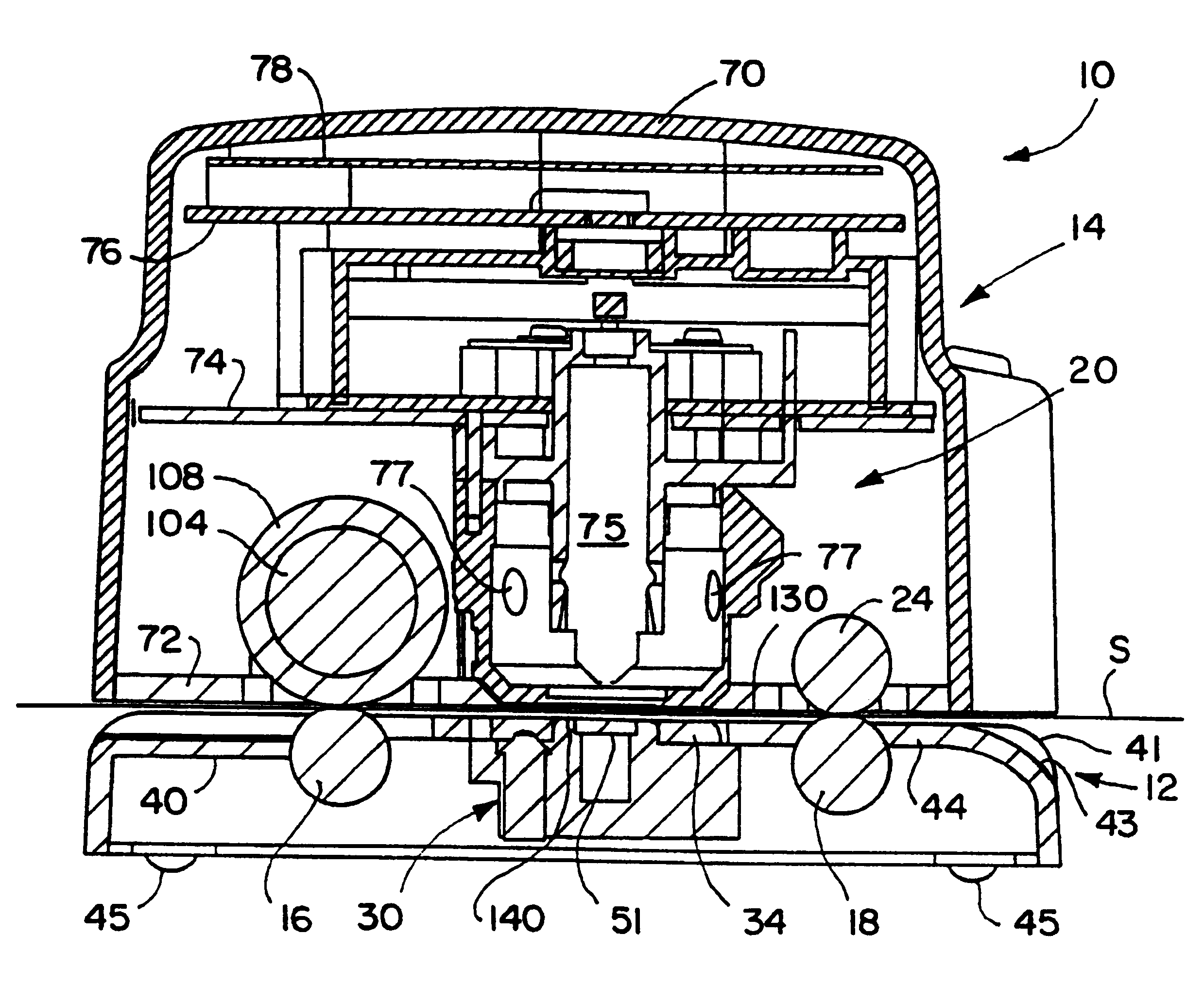

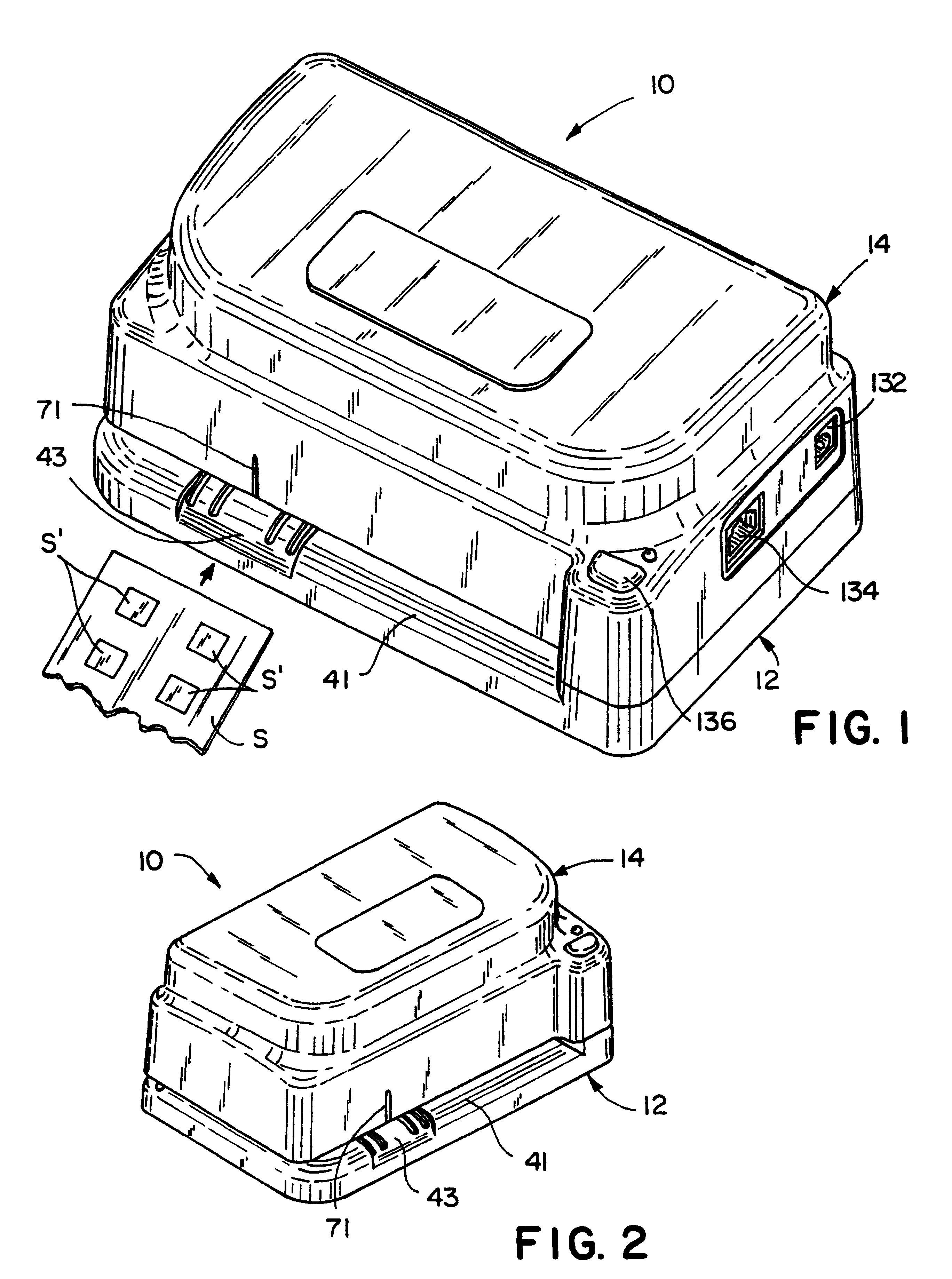

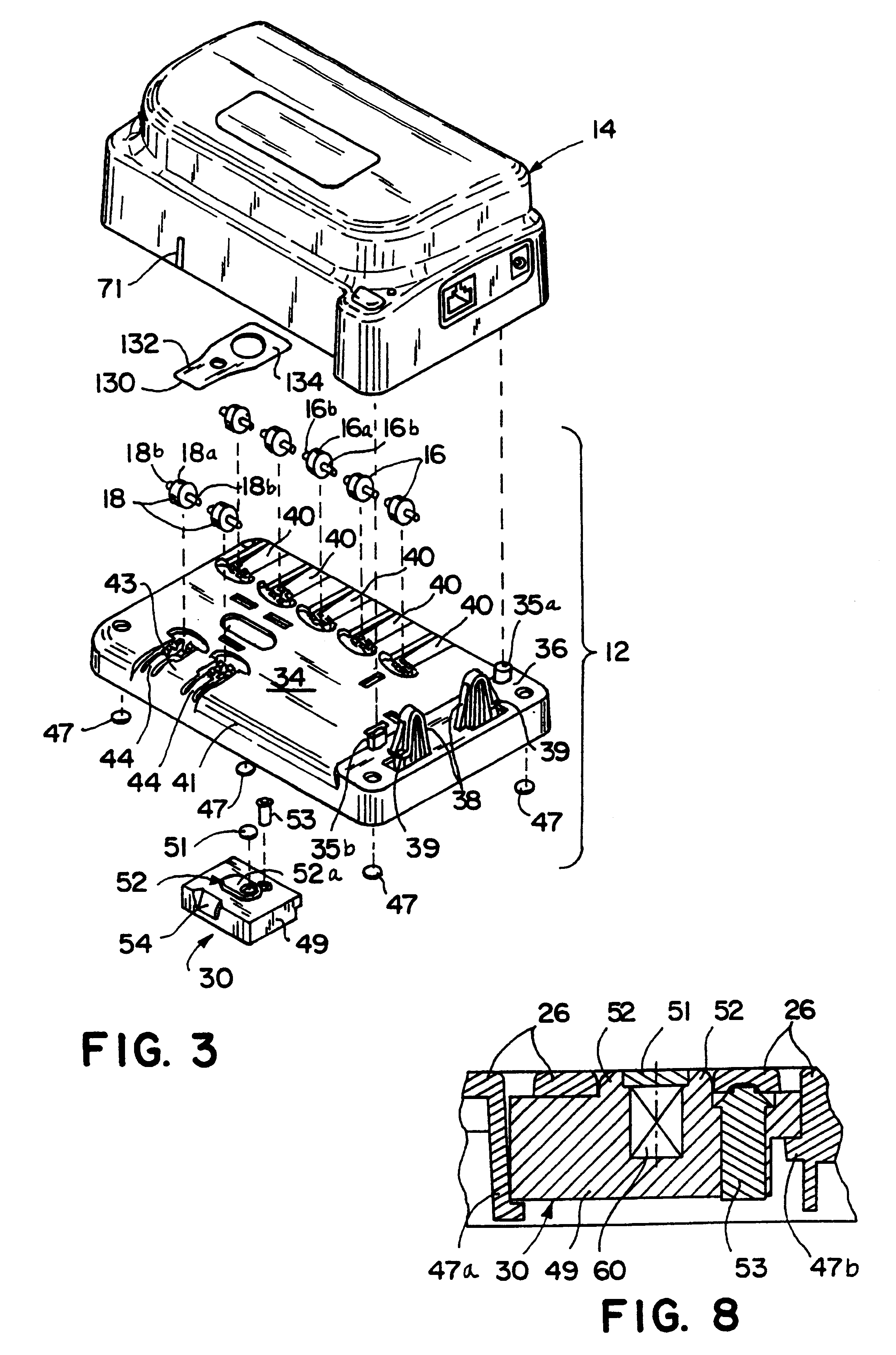

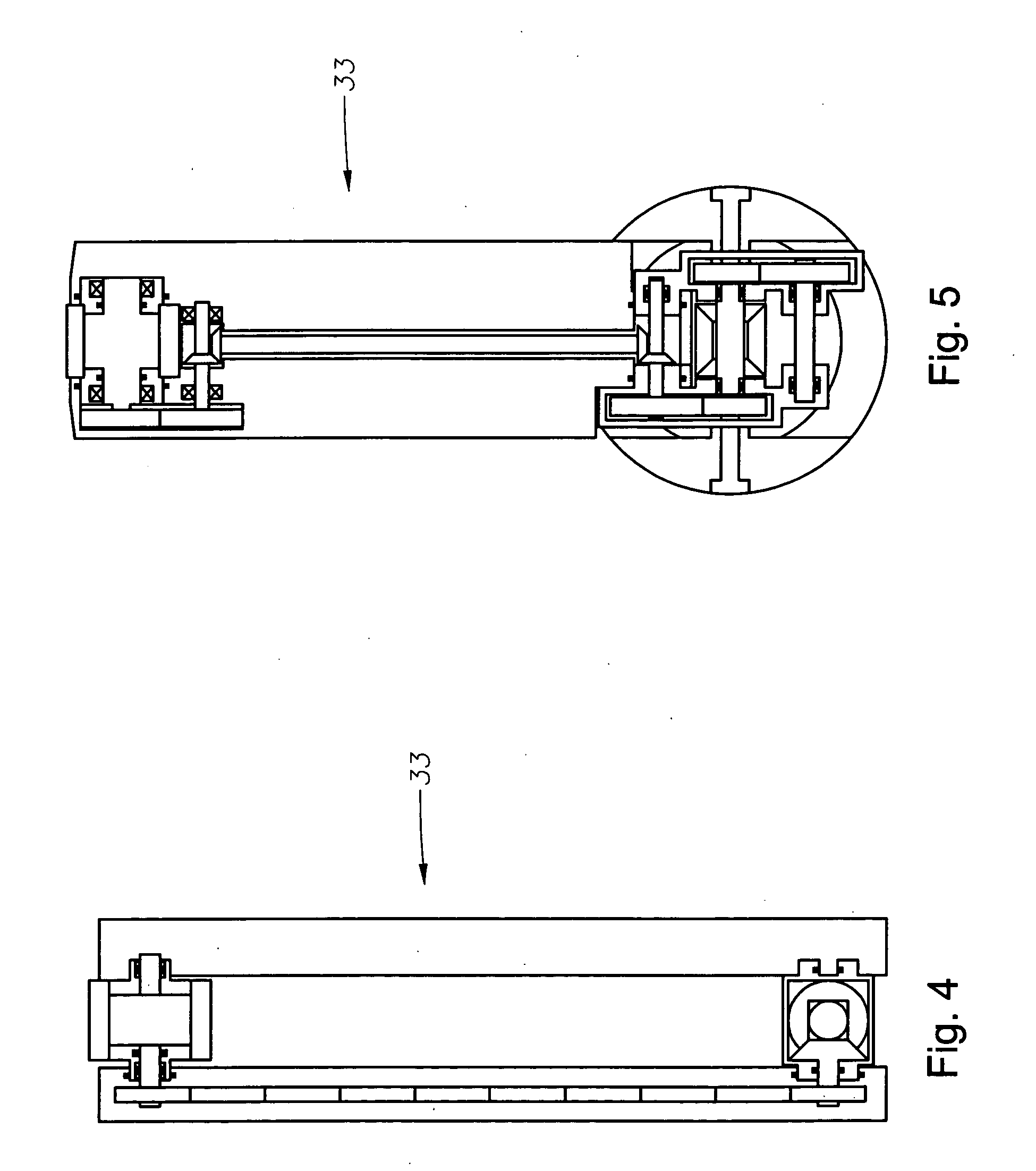

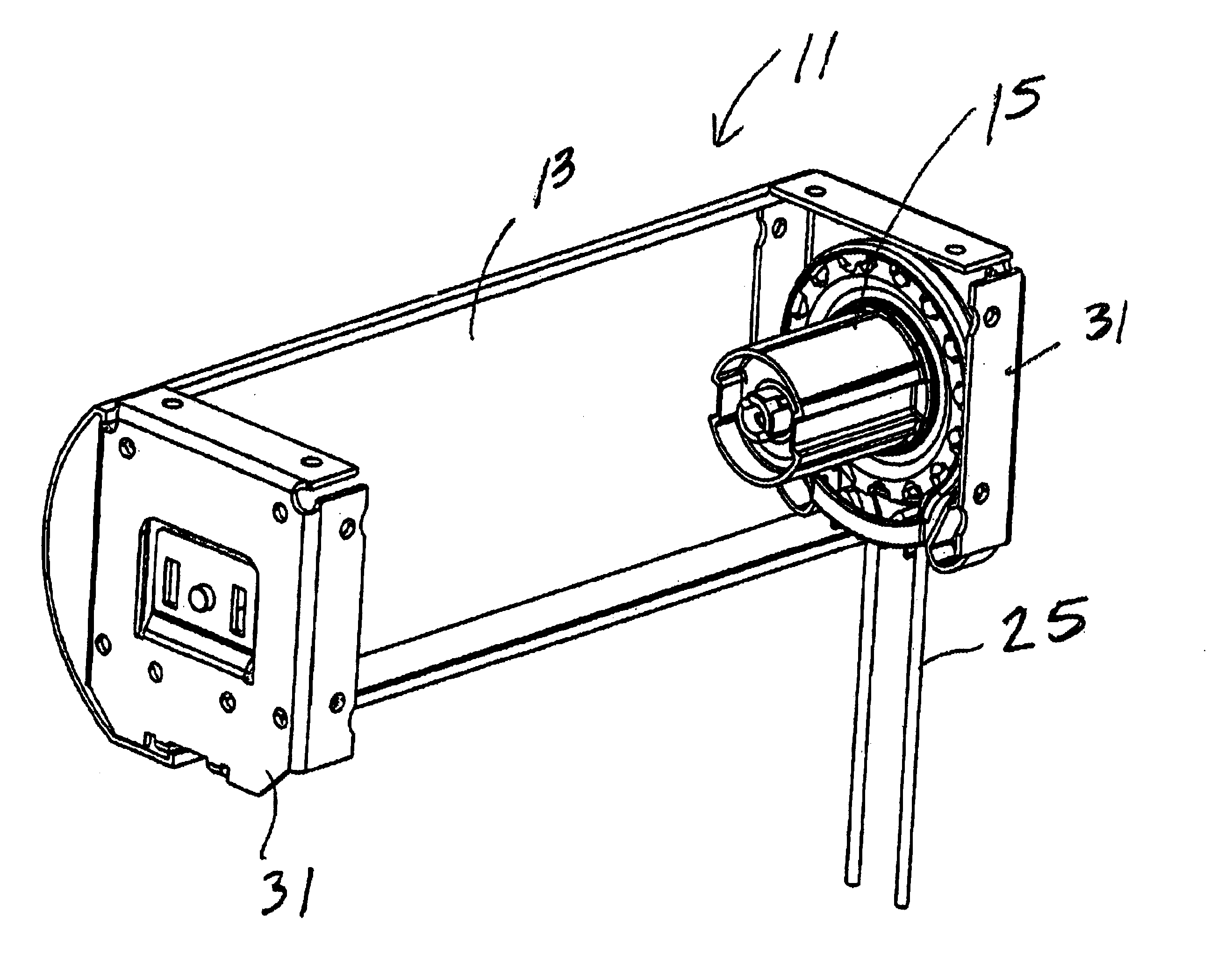

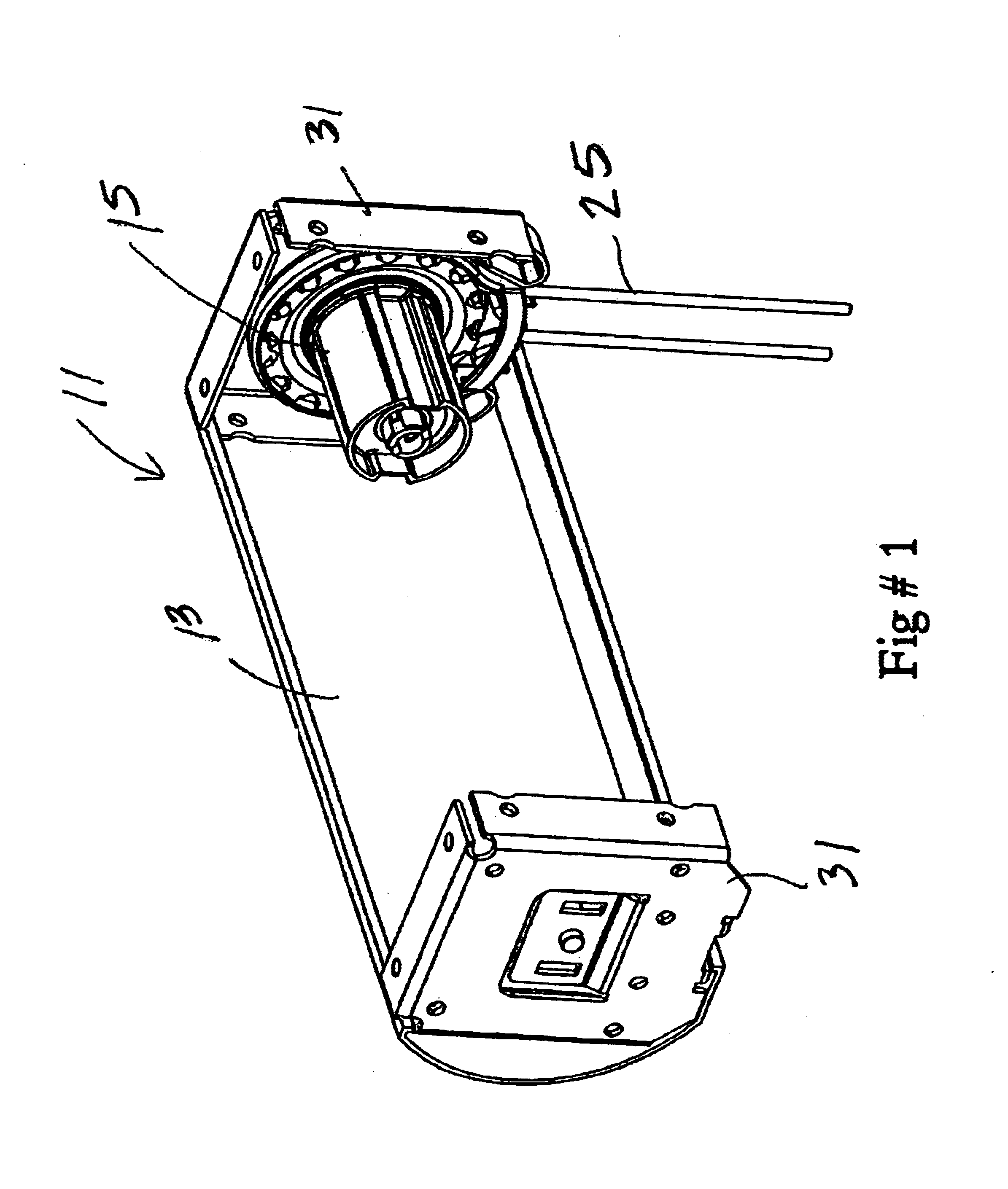

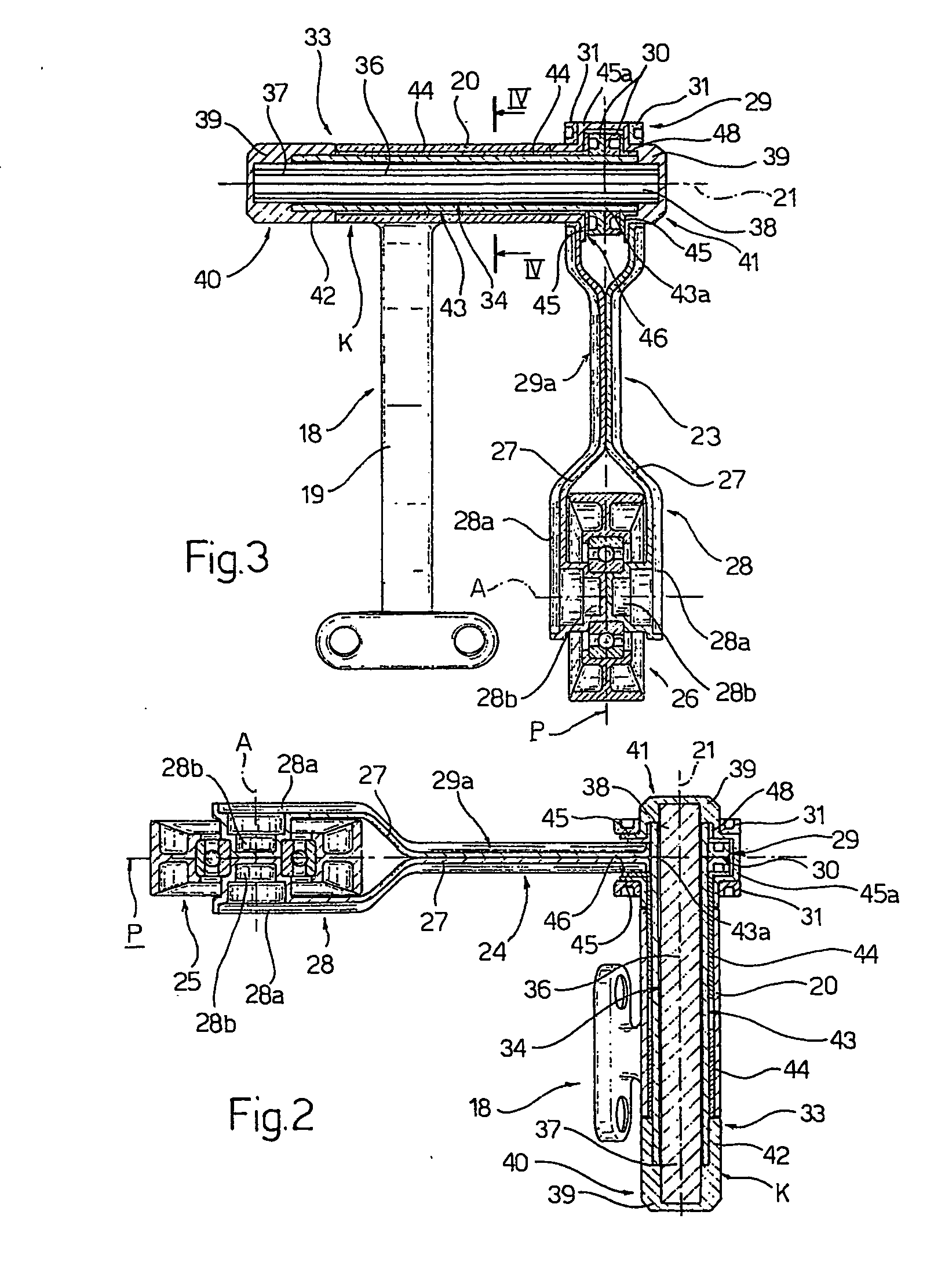

Portable scanning spectrophotometer

InactiveUS6198536B1Easy maintenanceConvenient registrationRadiation pyrometryMaterial analysis by optical meansEngineeringVarying thickness

Owner:X-RITE

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

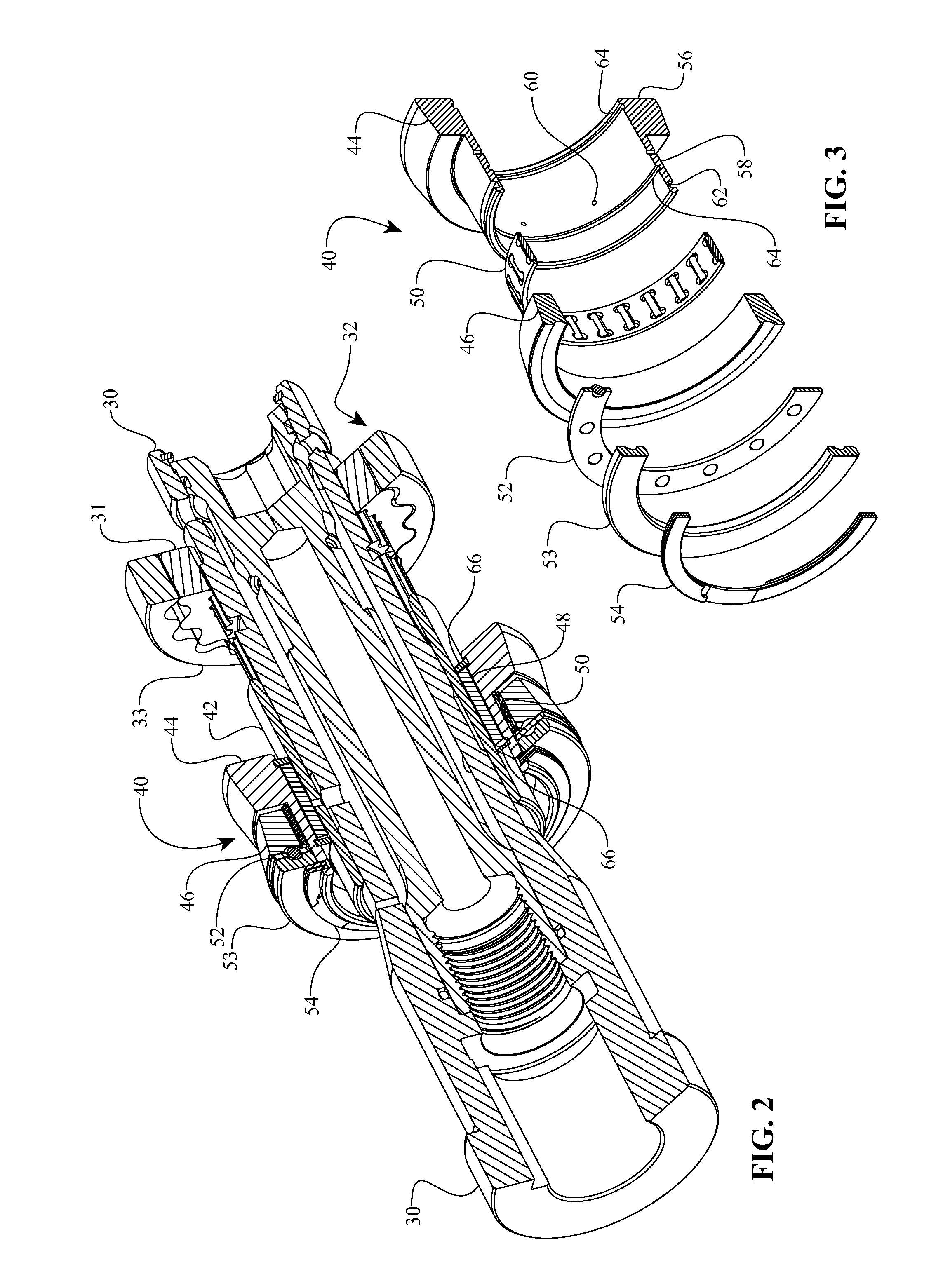

Open hole tractor with tracks

A downhole tractor is provided that may be used in open or cased wells, and is also designed for use in open holes having a variety of soil / formation consistencies (e.g., soft, firm, rigid, etc.), varying diameters and non-uniform and irregular bore profiles. The tractor may include a track assembly including a plurality of idler wheels and a continuous track rotatably disposed around the idler wheels. A motor may be adapted to rotate the track around the idler wheels. Upper and lower arms may be pivotally connected to opposite ends of the track assembly and pivotally connected to a tractor housing. An actuator arm or link assembly may be provided to impart an outward force to the track assembly to move the track assembly outwardly into an open position and a retracting force to retract the track assembly into a closed position. A rotatable screw may be connected to a second motor, or a rod may be connected to a hydraulic system, to actuate the actuator arm or link assembly.

Owner:SCHLUMBERGER TECH CORP

Assemblies and methods for clamping force generation

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

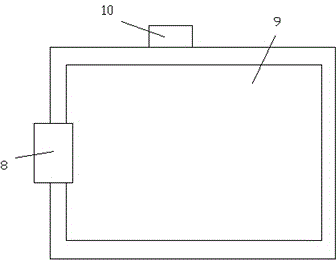

Circuit board plug-in subassembly with LED indicator light

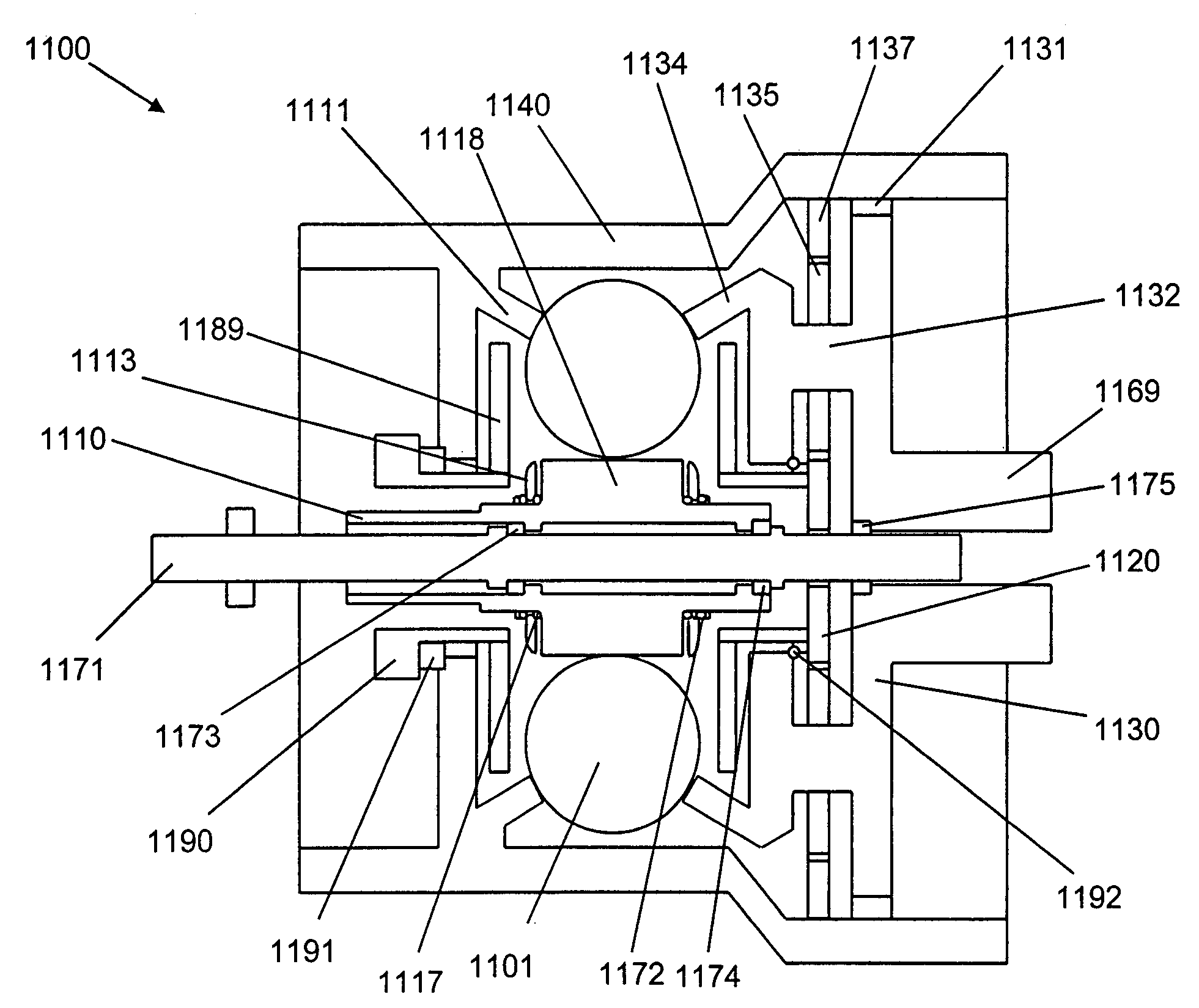

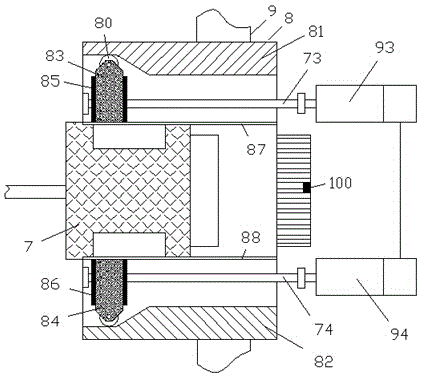

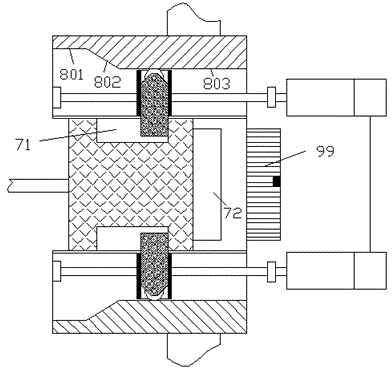

InactiveCN104836087ASmooth side to side movementAchieve lockingCoupling device detailsIdler-wheelPin array

A circuit board plug-in subassembly with an LED indicator light of the invention comprises circuit board equipment (9) and an interface device (8) which is arranged at the left side of the circuit board equipment (9). The LED indicator light (10) is arranged at the top of the circuit board equipment (9), and the interface device (8) comprises a shell which is composed of an upper outline part (81) and a lower outline part (82). A contact pin array (99) is arranged at the part of the plate of the circuit board equipment (9) adjacent to the inner side of the shell and is used for engaging with a jack array (72) which is inserted into a plug (7) between the upper outline part (81) and the lower outline part (82) of the interface device (8), and the upper outline part (81) and the lower outline part (82) are respectively engaged with idler wheels (80), which are arranged on an upper sliding block subassembly (83) and a lower sliding block subassembly (84).

Owner:汪贤女

Universal brackets for roller shade

Generally speaking, in accordance with the invention, an improved window treatment system is provided. The system includes a head rail, a spring clutch disposed at one end of the head rail and an idler disposed at the other end of the head rail. Significantly, a pair of universal brackets, one coupled to the spring clutch and the other coupled to the idler, are used. Each bracket is suitable for fixedly mounting either the clutch or the idler at either end of the head rail. The brackets are identical.

Owner:ROLLERASE INC

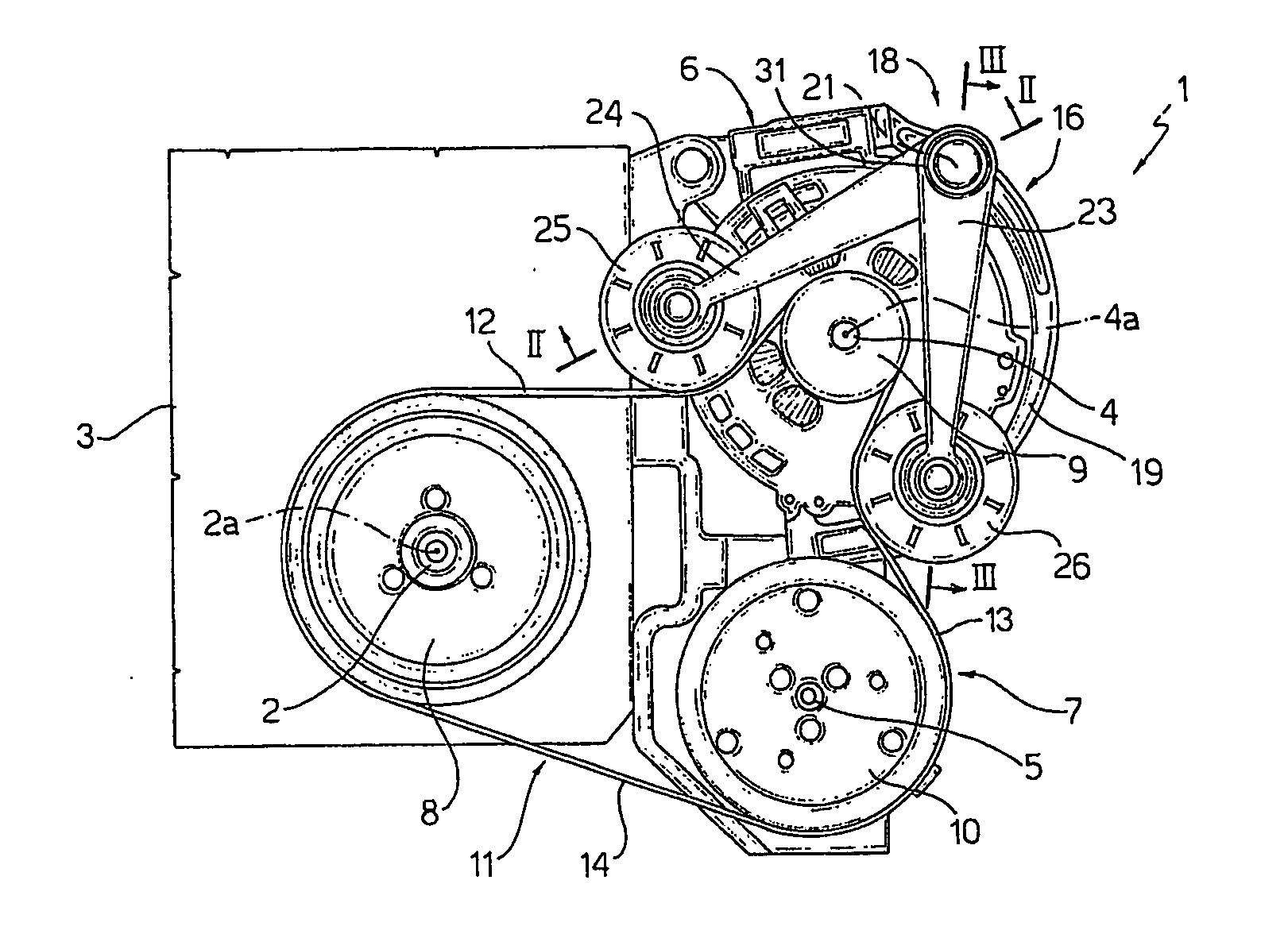

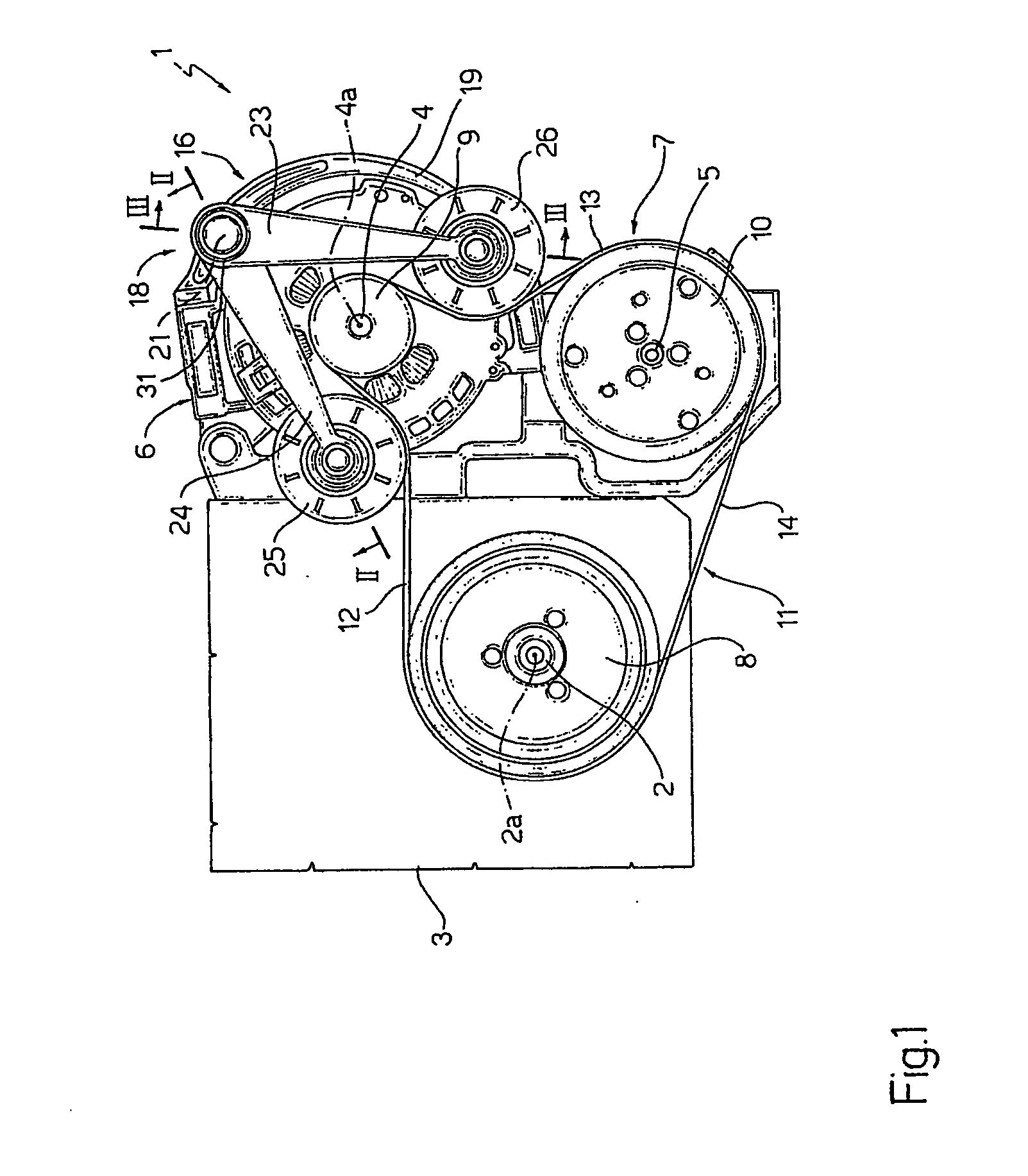

Two-arm belt tensioner

ActiveUS20070037648A1Easy and cheap to produceGearingMachines/enginesInternal combustion engineIdler-wheel

Owner:DAYCO EURO +1

Small epicyclic magnetron with controlled radial sputtering profile

InactiveUS6852202B2Improve uniformityMore target utilizationCellsElectric discharge tubesSputteringSection plane

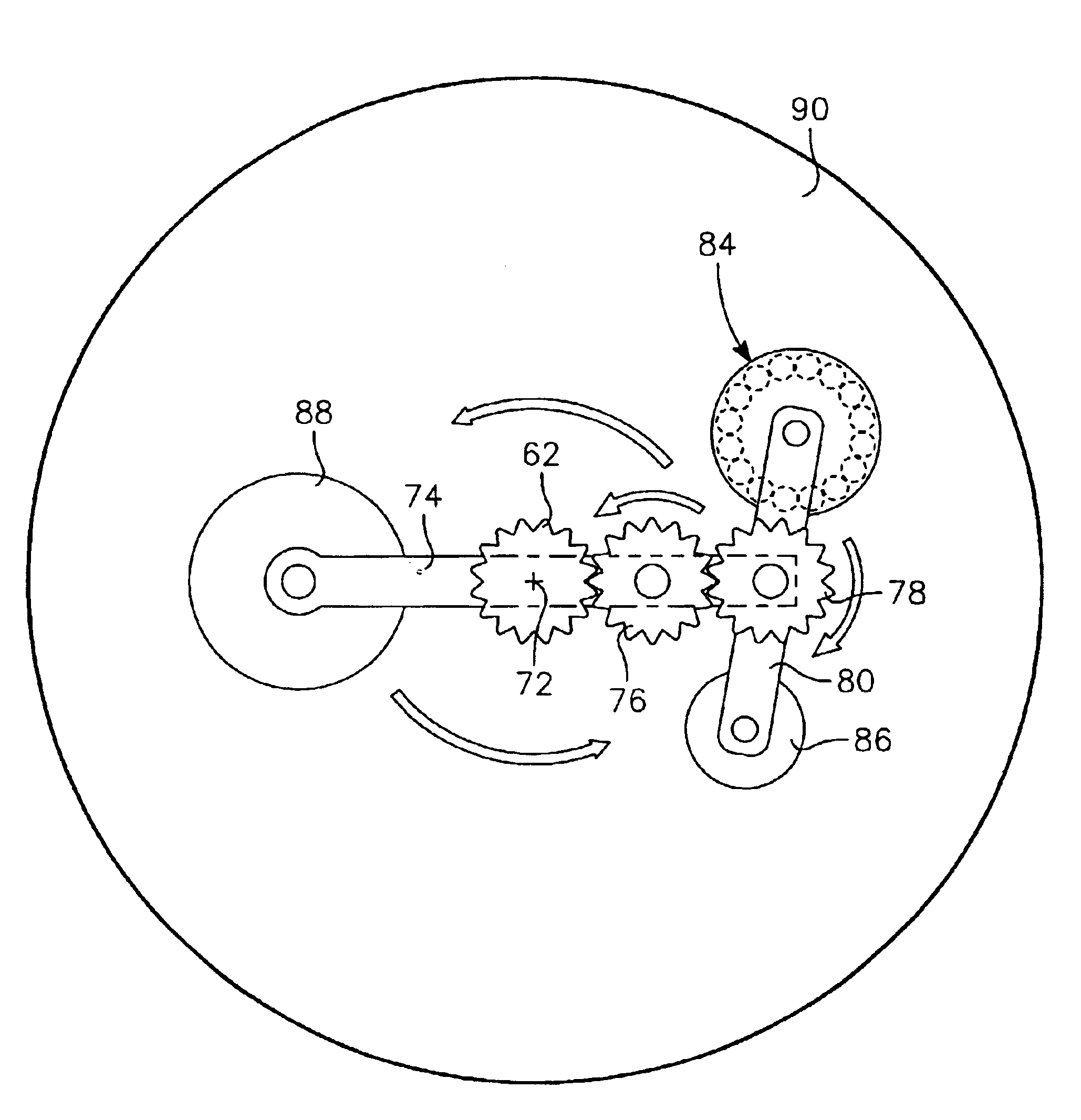

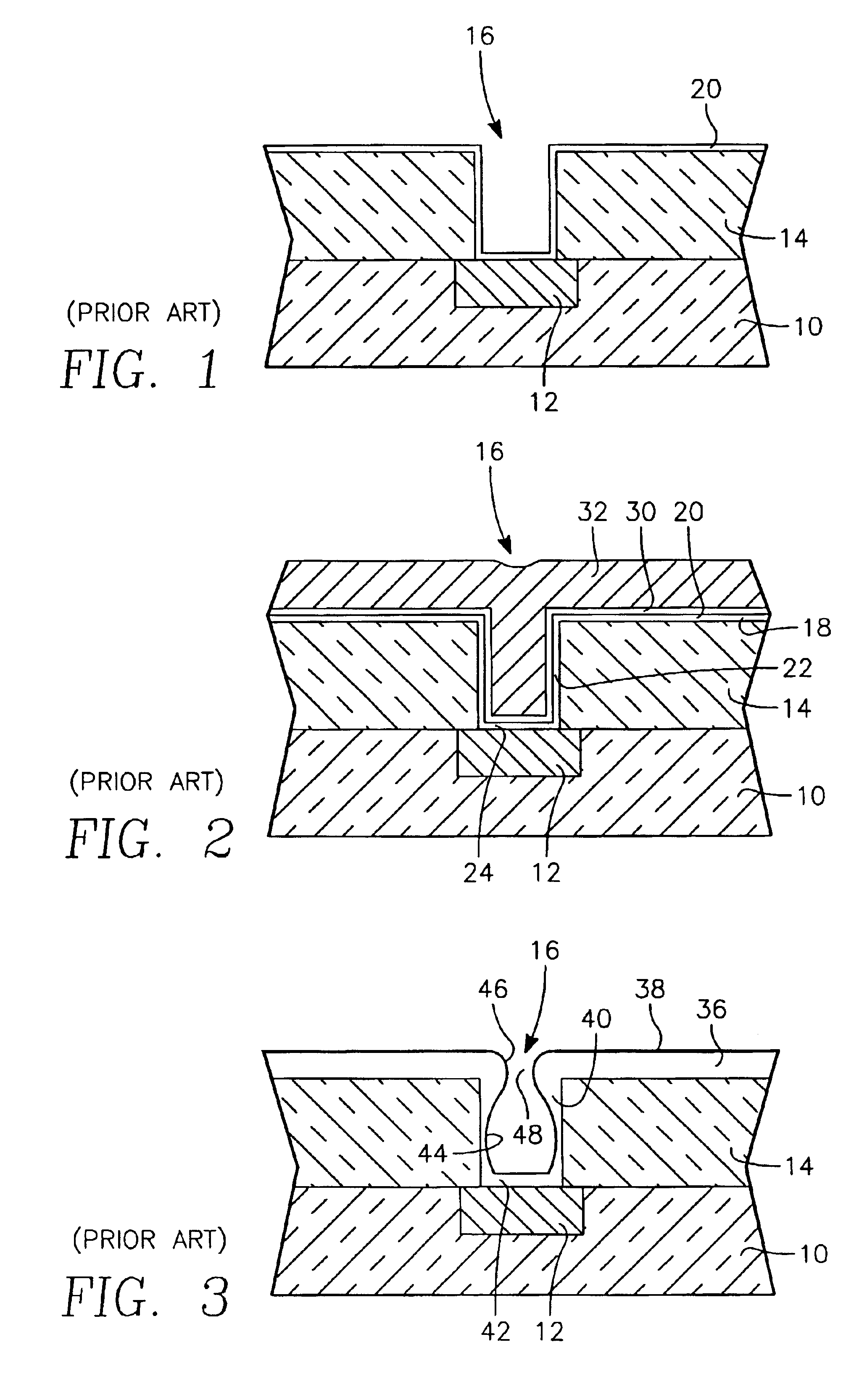

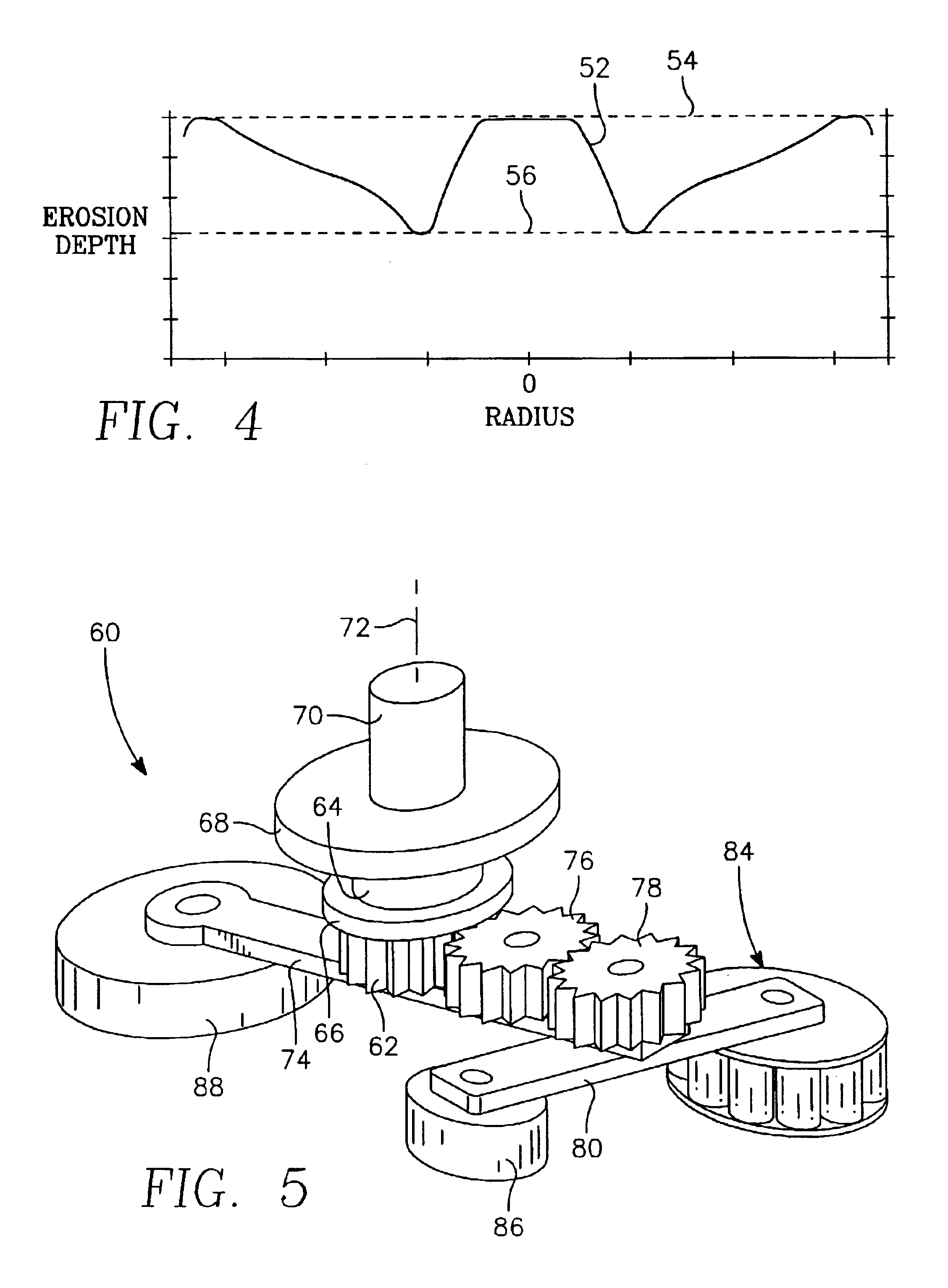

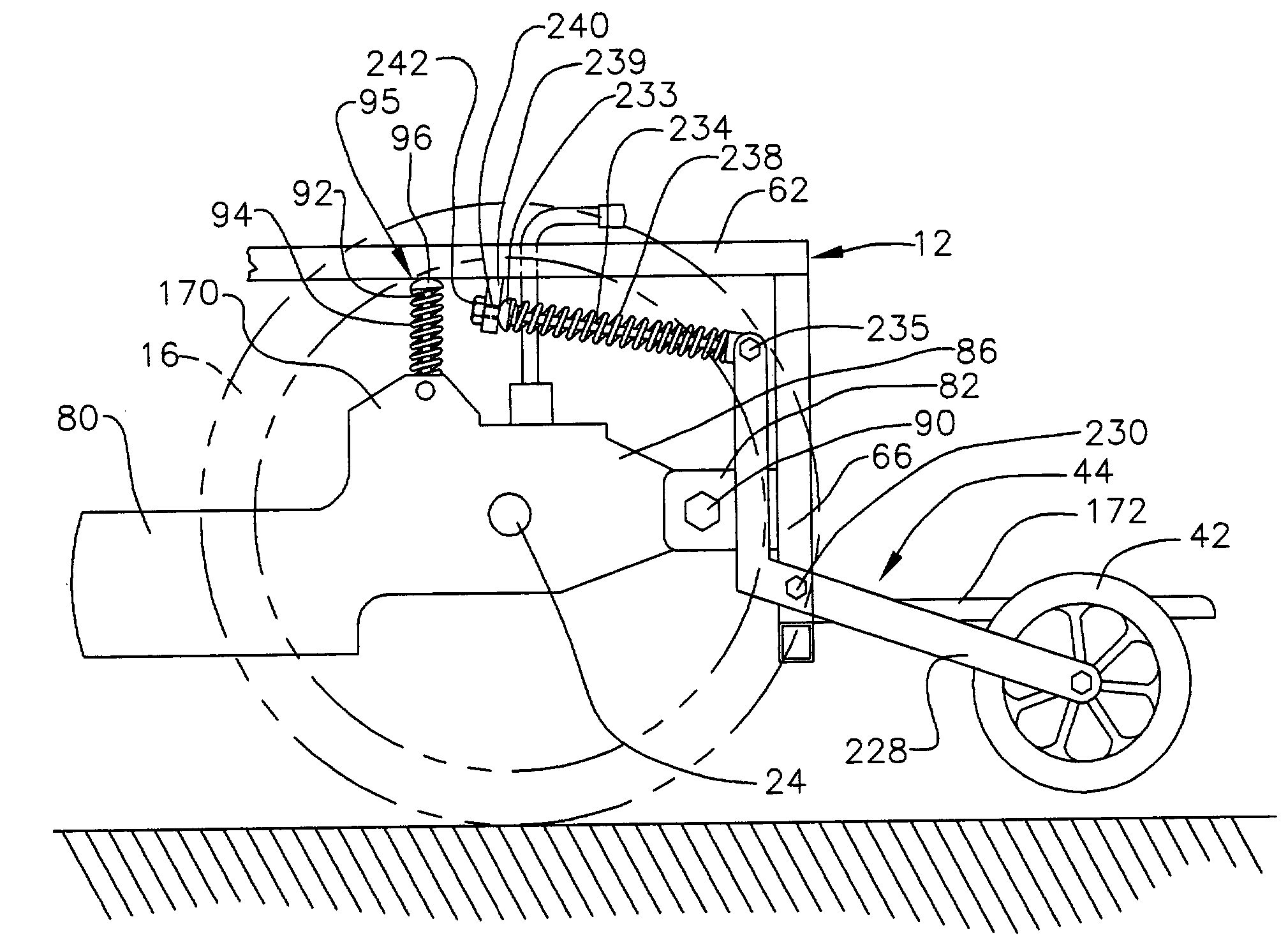

A small unbalanced magnet assembly is scanned in a retrograde planetary or epicyclic path about the back of a target being plasma sputtered including an orbital rotation about the center axis of the target and a planetary rotation about another axis rotating about the target center axis. The magnet assembly may pass through the target center, thus allowing full target coverage. A geared planetary mechanism may include a rotating drive plate, a fixed center gear, and an idler and a follower gear rotatably supported in the drive plate supporting a cantilevered magnet assembly on the side of the drive plate facing the target. The erosion profile may be controlled by varying the rotation rate through the rotation cycle or by modulating the target power. A second planetary stage may be added or non-circular gears be used. Auxiliary electromagnetic coils may create a focusing magnetic field.

Owner:APPLIED MATERIALS INC

Power wheelchair

InactiveUS7104346B2Pedestrian/occupant safety arrangementElectric propulsion mountingWheelchairDrive wheel

Owner:SCHAFFNER WALTER E

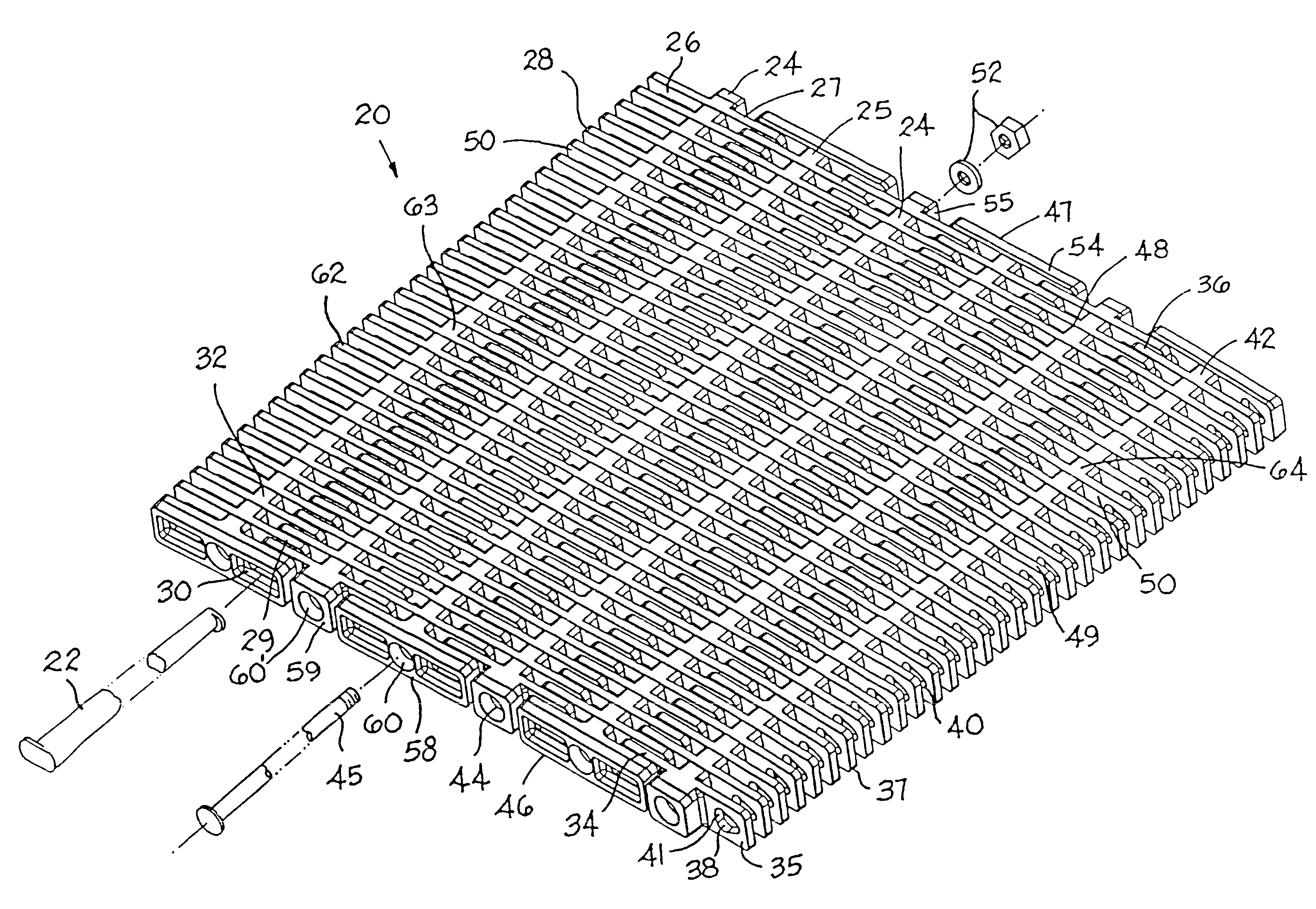

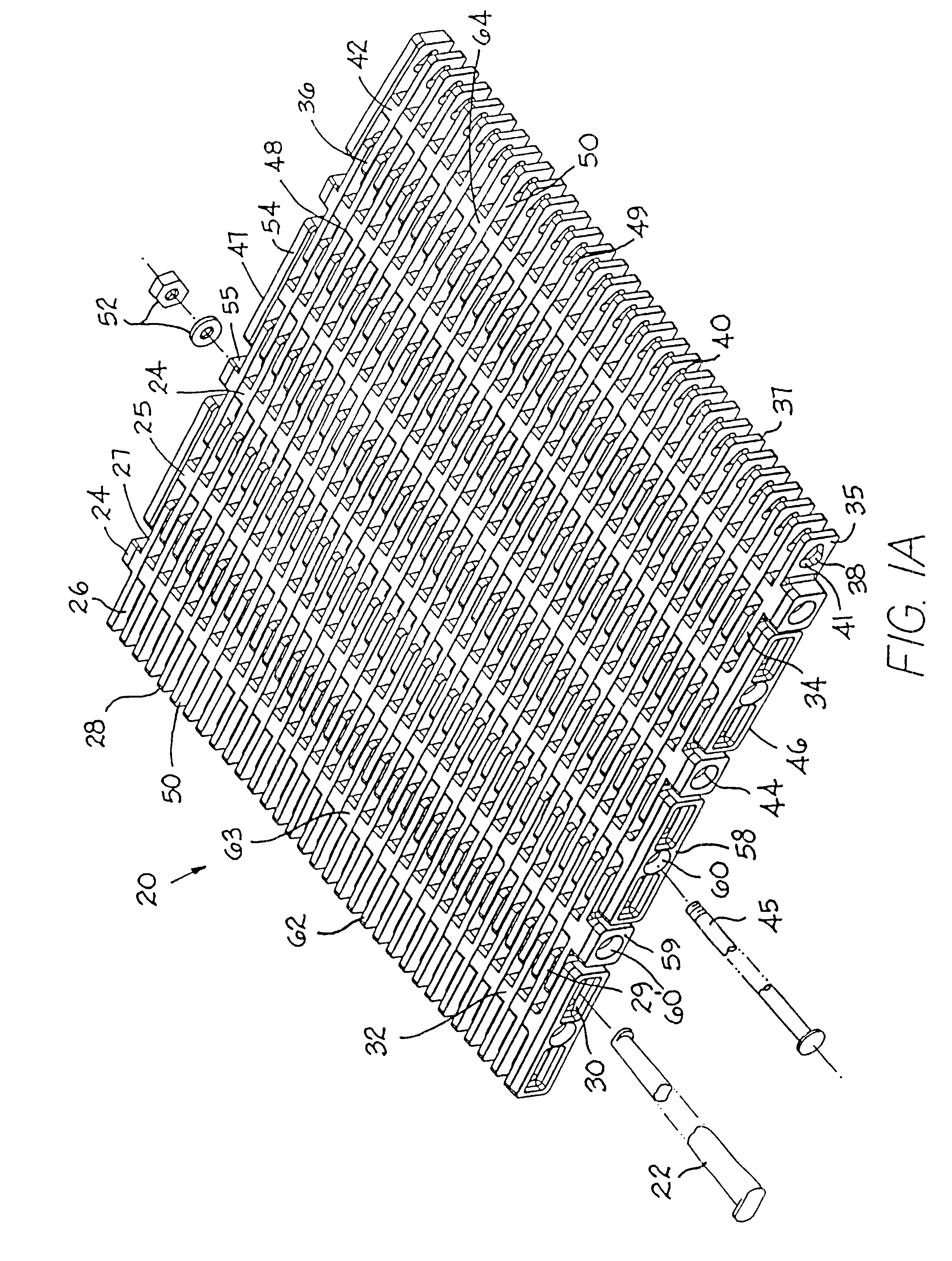

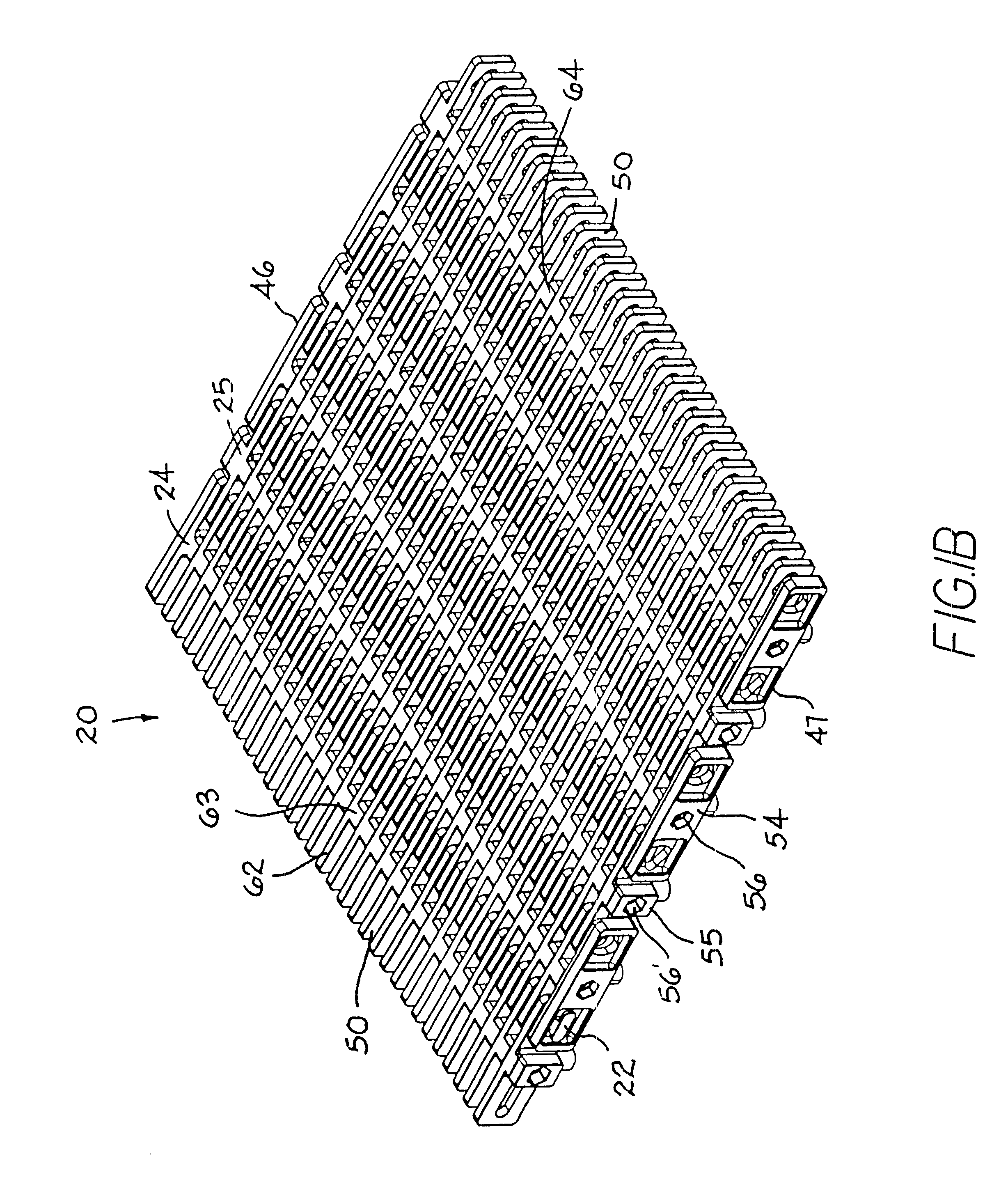

Modular belt with tapered oblong hinge pins

A modular conveyor belt (20) constructed of a series of rows (24, 25) of belt modules hingedly interlined by tapered oblong hinge pins (22) and suitable for following straight or curved conveyor paths. Aligned slots (30) formed in one set of hinge elements between successive rows are elongated in the direction of belt travel to allow the belt to fan out in turns. Fan-shaped apertures (38) formed in interleaved hinge elements of an adjacent row and aligned axially with the slots to admit a hinge pin (22) allow the belt to pivot at the hinge to articulate about a sprocket (181) or idler (186) or to enter and exit an incline. The oblong hinge pin has a first region at a first end (88) with a constant long axis to share the belt load among hinge elements encompassing the first region on straight runs. A second region of the hinge pin at an opposite second end (89) has a tapered oblong cross section, the long axis of which increases with distance from the second end to define a variable pitch and to spread the belt tension among the hinge elements at the outside of a turn encompassing the second region. Each belt row can be constructed of individual links stacked together on a support element (45) and retained by fasteners (52) or of integrally molded modules each comprising a transverse connecting member from which leading and trailing hinge elements extend. Accessory attachments, such as teeth (160) or sideguards (150), can be added to the belt. The belt can be driven by a cog, a roller chain, or other driving means driving lugs (172) extending from the bottom of the belt. The drive surfaces of the lugs can be obliquely arranged for better load sharing.

Owner:HARTNESS INT INC +1

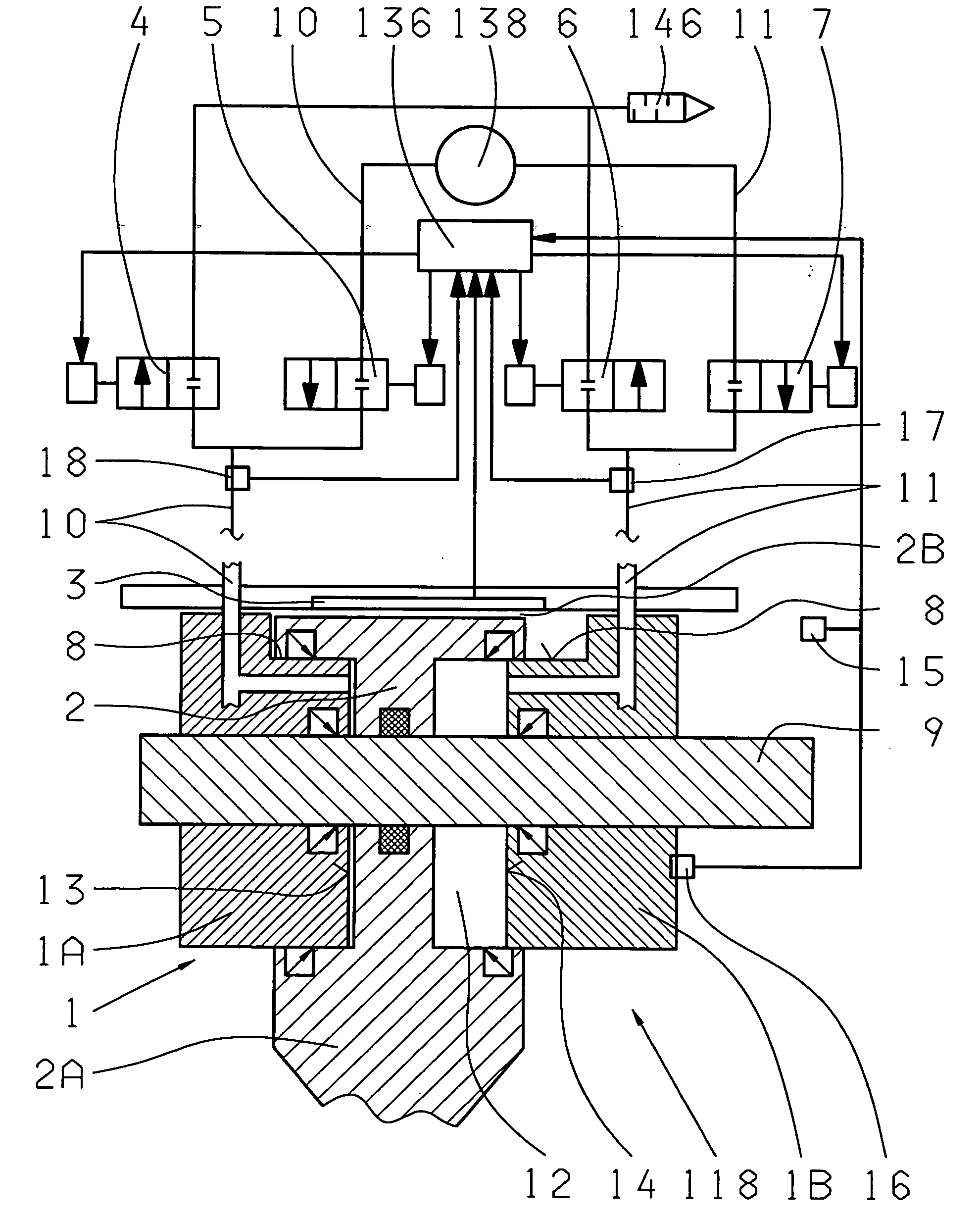

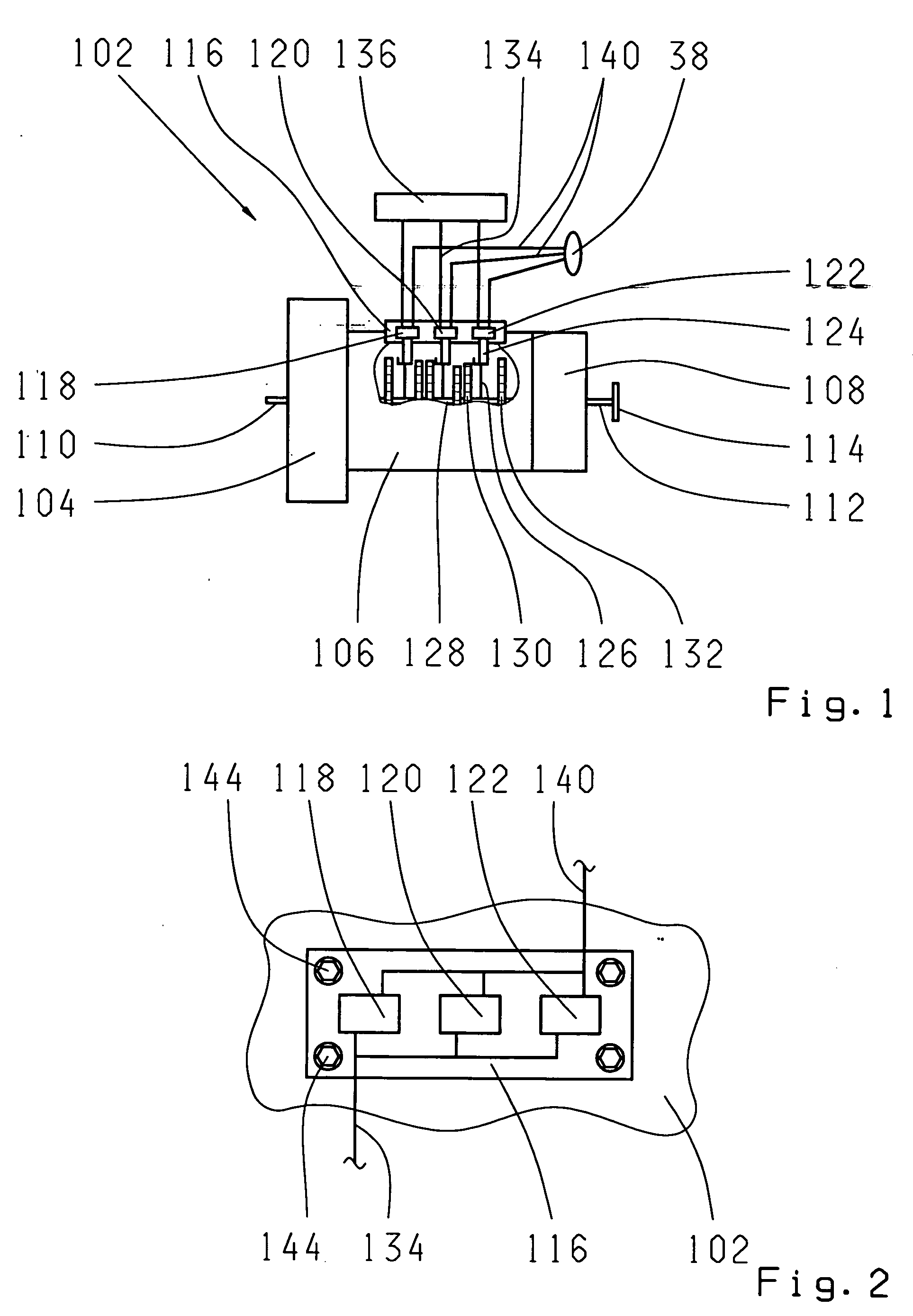

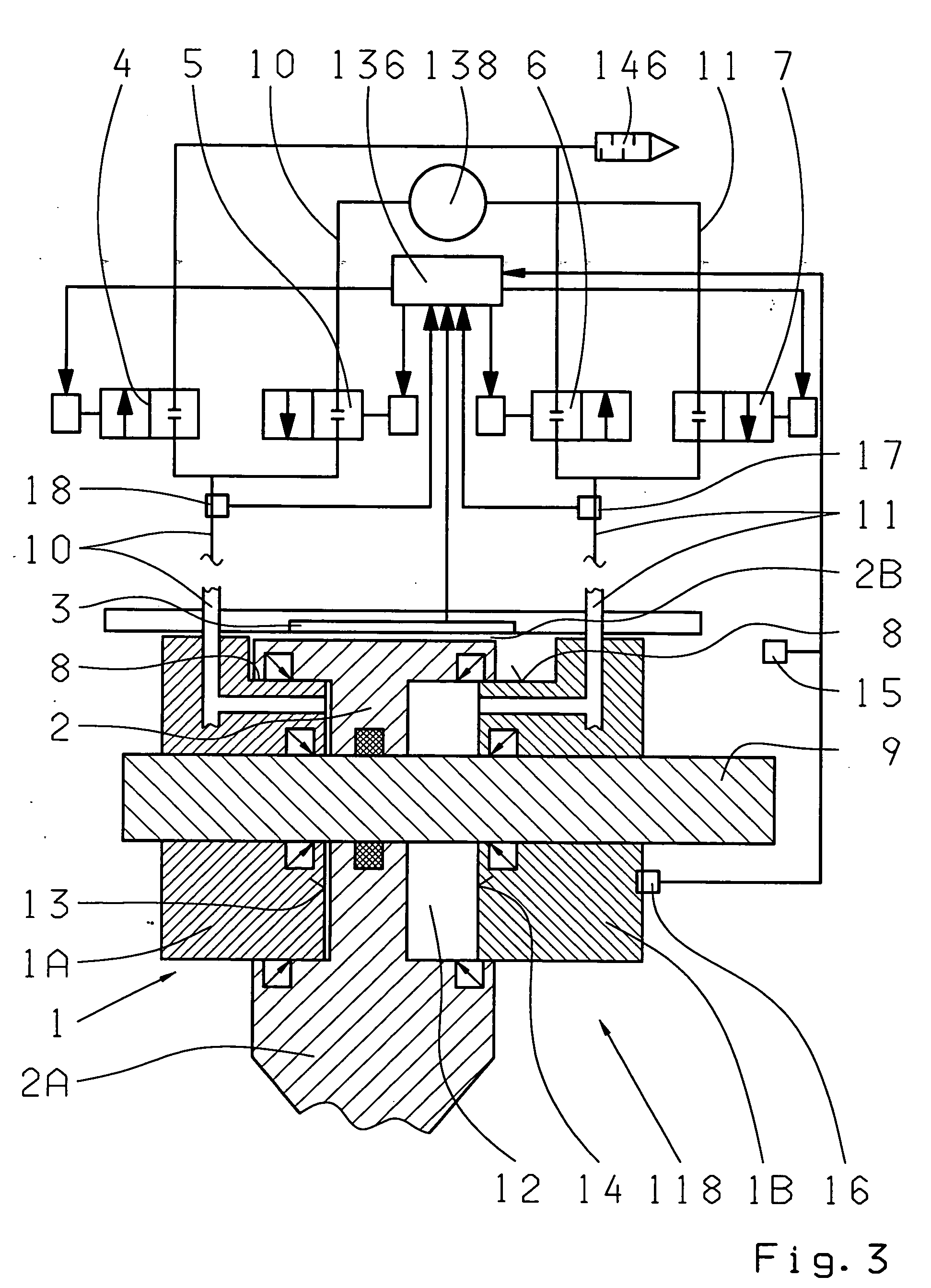

Method for the control of operational sequencing in an automatic transmission of auxiliary construction

InactiveUS20060213300A1Fluid actuated clutchesMagnetically actuated clutchesAutomatic transmissionEngineering

A method for controlling operational sequencing of gears in an automatic transmission (102) which has been built in an auxiliary mode. In the case of such a shifting transmission it is possible that during the engagement of its transmission gear stage, impact noises or contact noises are present in the shifting procedure. This can occur by the generation of a tooth-on-tooth positioning between the toothing of a sliding collar (126) and the come-along toothing of an idler gear (130, 132). Provision is made for the control of the activation movement of the sliding collar (126) carried out in such a manner that an activation condition impact of the transmission parts, which are partakers in the shifting associated transmission part onto other transmission parts with the least possible impact force and / or with a least possible impact noise level.

Owner:ZF FRIEDRICHSHAFEN AG

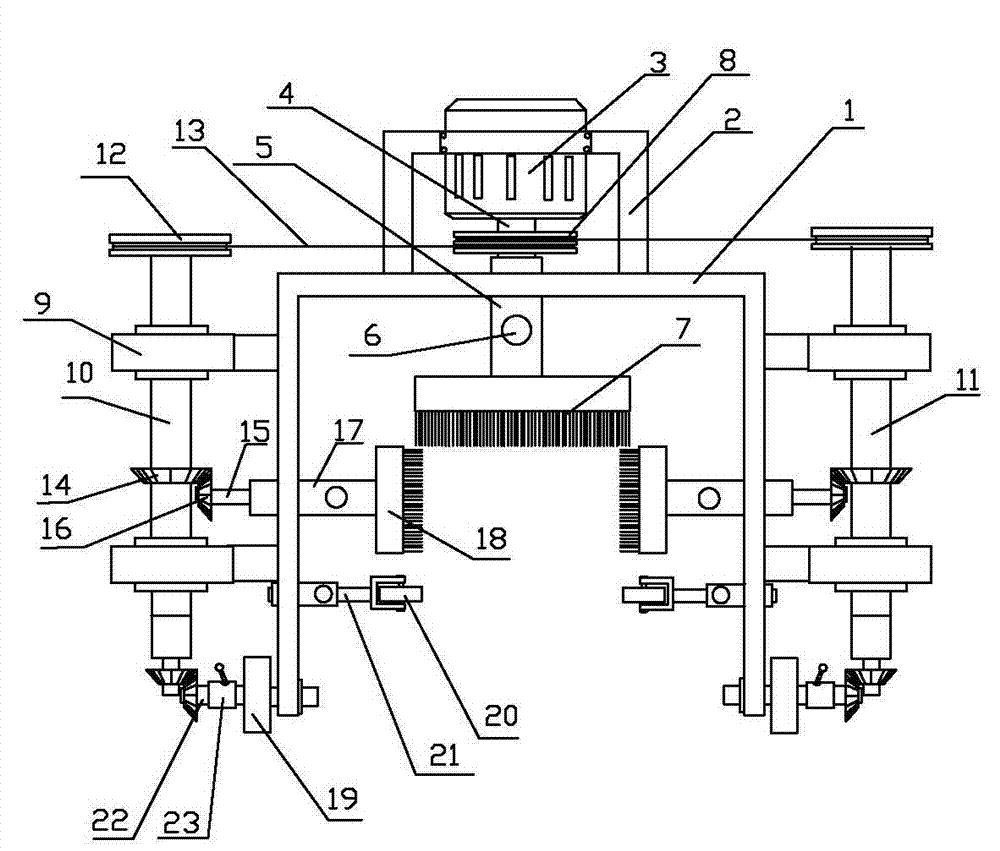

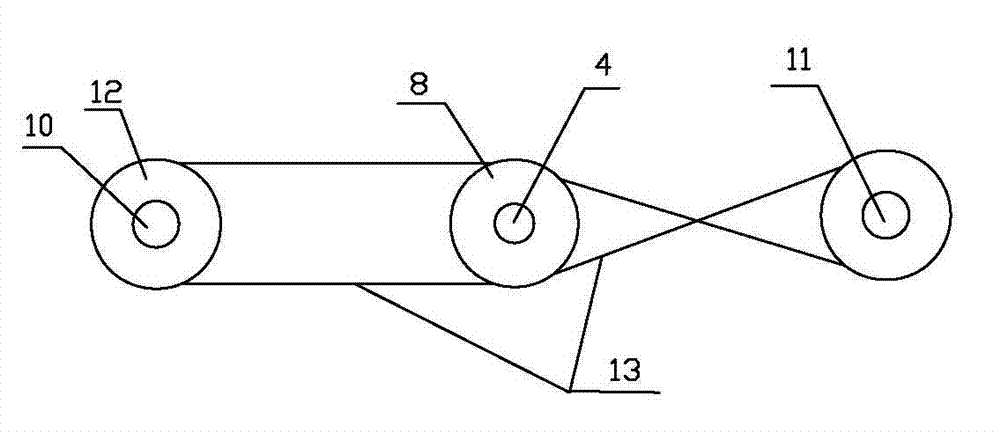

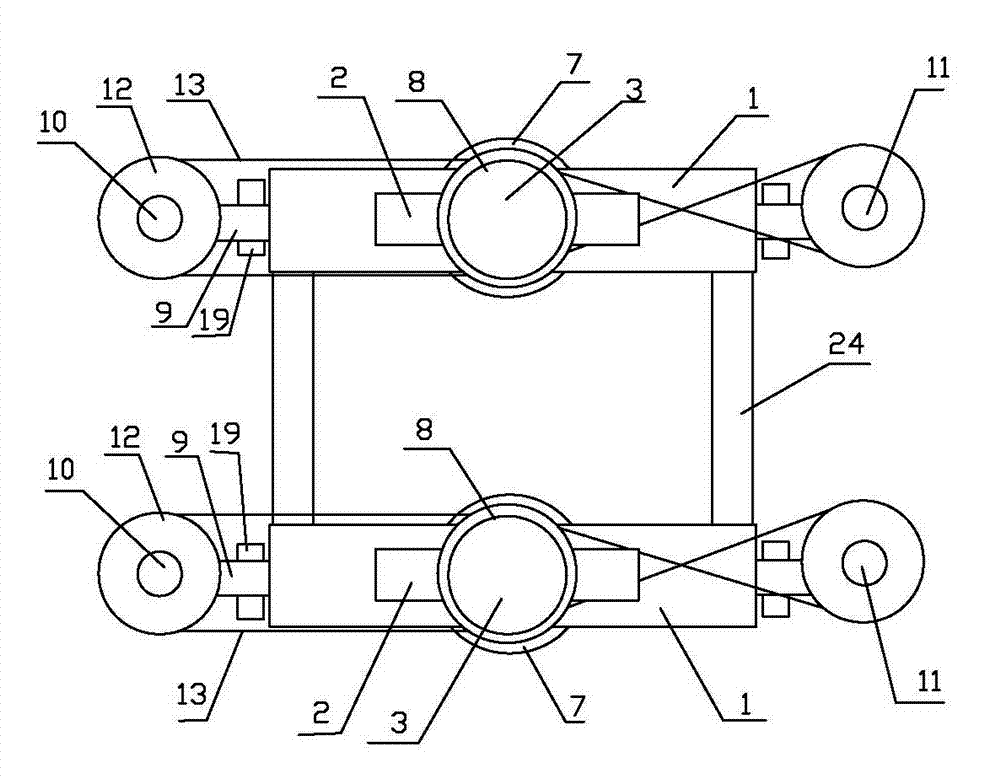

Square tube multiple face synchronous derusting machine

The invention discloses a square tube multiple face synchronous derusting machine. The derusting machine comprises an inverted-U-shaped rack and is characterized in that an upper motor is fixed to the middle of the upper wall of the inverted-U-shaped rack, and an upper horizontal rotating wire brush is fixed to the lower end of a shaft sleeve of a motor spindle, a fixed belt wheel at the upper end of the spindle is connected with driven shafts outside the left wall and the right wall of the inverted-U-shaped rack for transmission, and the middle of the driven shaft on the left and the middle of the driven shaft on the right are respectively meshed with a shaft end bevel gear of a transverse rotating shaft for transmission through a bevel gear; each transverse rotating shaft is provided with a transverse shaft sleeve connected with the transverse rotating shaft in a matched mode through a spline, and an upper perpendicular face rotating wire brush is fixed to the inner end of each transverse shaft sleeve; idler wheels are arranged at the bottom end of the inverted-U-shaped rack; synchronous rotation of the horizontal rotating wire brush and the perpendicular face rotating wire brushes is achieved through one motor, and thus the upper surface and the two side faces of a square tube can be polished and derusted synchronously. Thus, dust on the surface of the square tube can be cleared away fast with the derusting machine, energy is saved, labor efficiency can be improved, and the using effect of the square tube is improved.

Owner:南通通州东大机械有限公司

Communications spooler for a mobile robot

A cable handling system mounted to a mobile robot to dispense and retrieve cable at zero tension includes a cable reel drive and a downstream tension roller drive that includes an idler. As a cable passes through the tension roller drive, position along the length of the cable and / or the cable speed is monitored accurately by a sensor attached to the idler. A system controller in communication with the sensor controls the cable reel drive and the tension roller drive for dispensing and retrieving cable downstream of the tension roller drive.

Owner:FLIR DETECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com