Square tube multiple face synchronous derusting machine

A technology of descaling machine and frame, which is applied to the parts of grinding machine tools, grinding machines, grinding drive devices, etc., to achieve the effect of improving the use effect, improving labor efficiency, and quickly cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

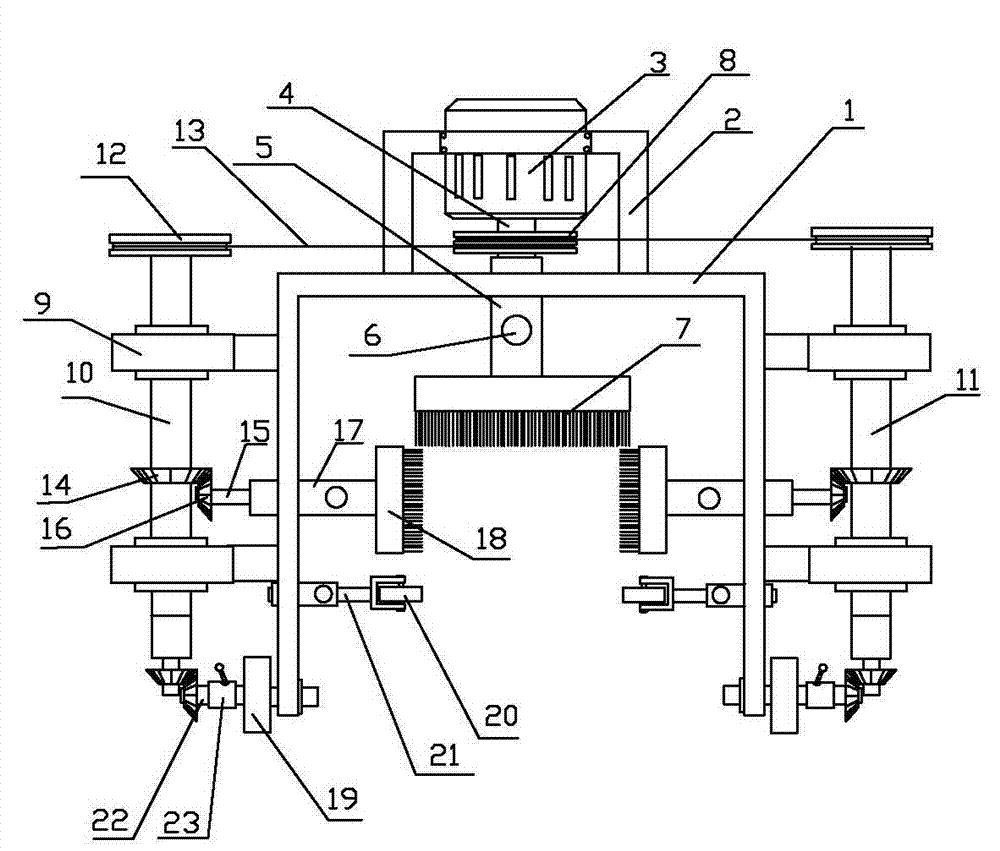

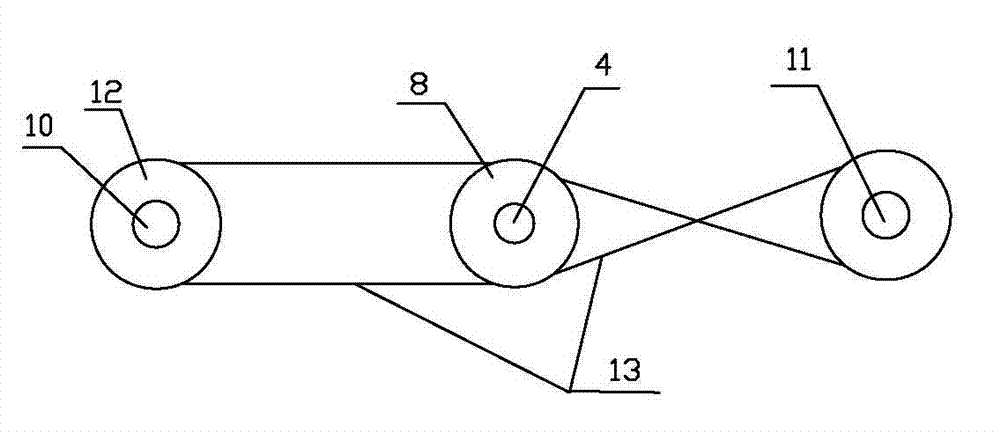

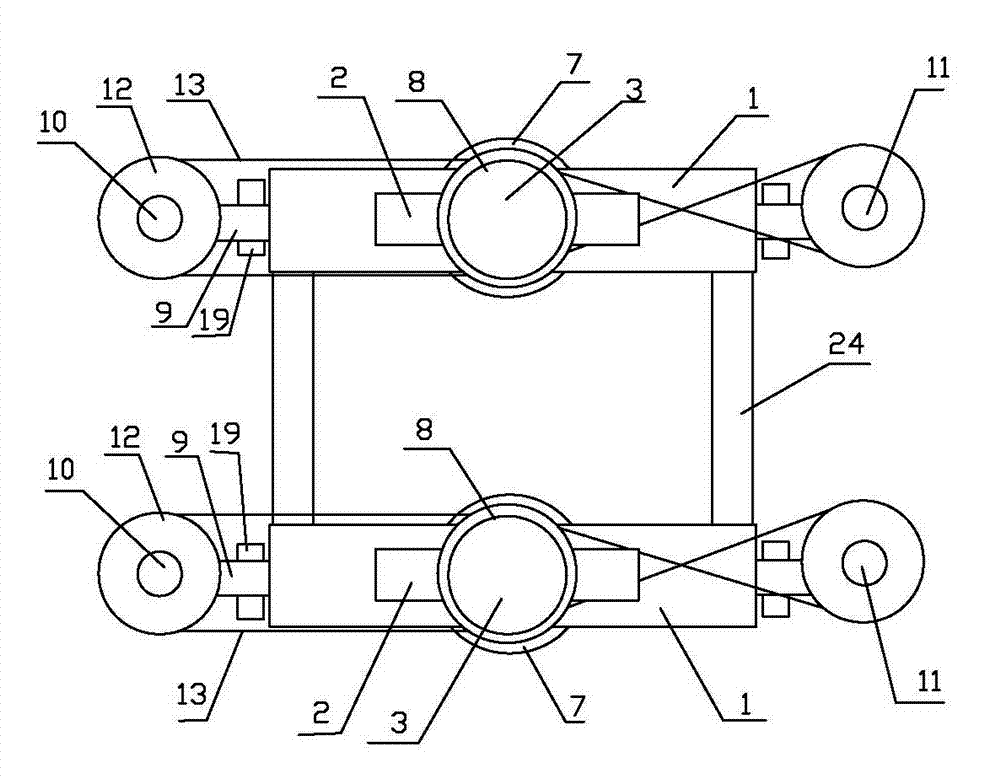

[0016] figure 1 , figure 2 An example is given. refer to figure 1 , figure 2 Make the invention. The square tube multi-faceted synchronous derusting machine includes an inverted "U"-shaped frame 1, which is characterized in that: the middle part of the upper wall of the inverted "U"-shaped frame 1 is fixed with a motor 3 by a support bracket 2, and the motor 3 The main shaft 4 is inserted into the inverted "U"-shaped frame 1 from the through hole in the middle of the upper wall of the inverted "U"-shaped frame 1, and the shaft sleeve 5 is sleeved on the main shaft 4, and the shaft sleeve 5 and the main shaft 4 are matched by splines. The shaft sleeve 5 is provided with a pressure adjusting bolt 6, and a horizontally rotating wire brush 7 is fixed on the lower end of the shaft sleeve 5. Through the rotation of the horizontally rotating wire brush 7, the upper surface of the opposite pipe is polished and derusted, and the shaft sleeve 5 can be moved along the main shaft 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com