Patents

Literature

1268 results about "Wire brush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wire brush is a tool consisting of a brush whose bristles are made of wire, most often steel wire. The steel used is generally a medium- to high-carbon variety and very hard and springy. Other wire brushes feature bristles made from brass or stainless steel, depending on application. Wires in a wire brush can be held together by epoxy, staples, or other binding. Wire brushes usually either have a handle of wood or plastic (for handheld use) or are formed into a wheel for use on angle grinders, bench grinders, pistol-grip drill motors, or other power tools.

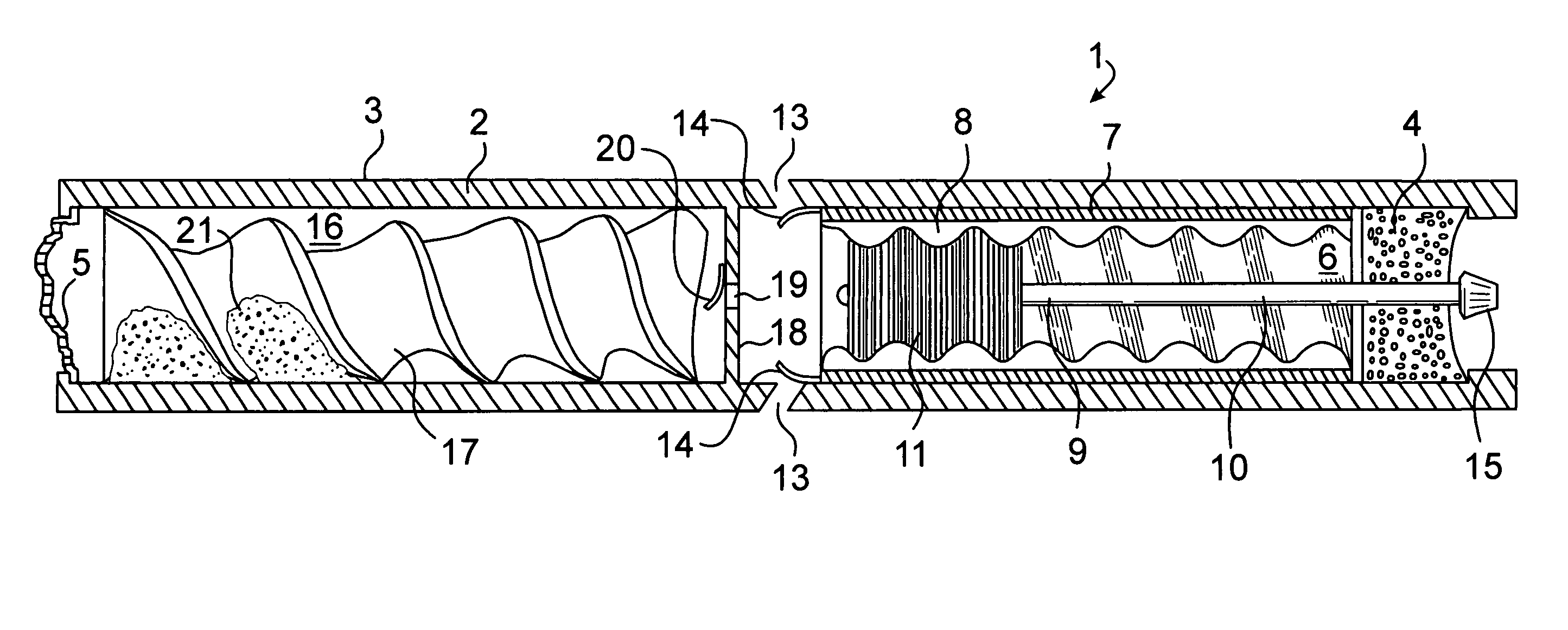

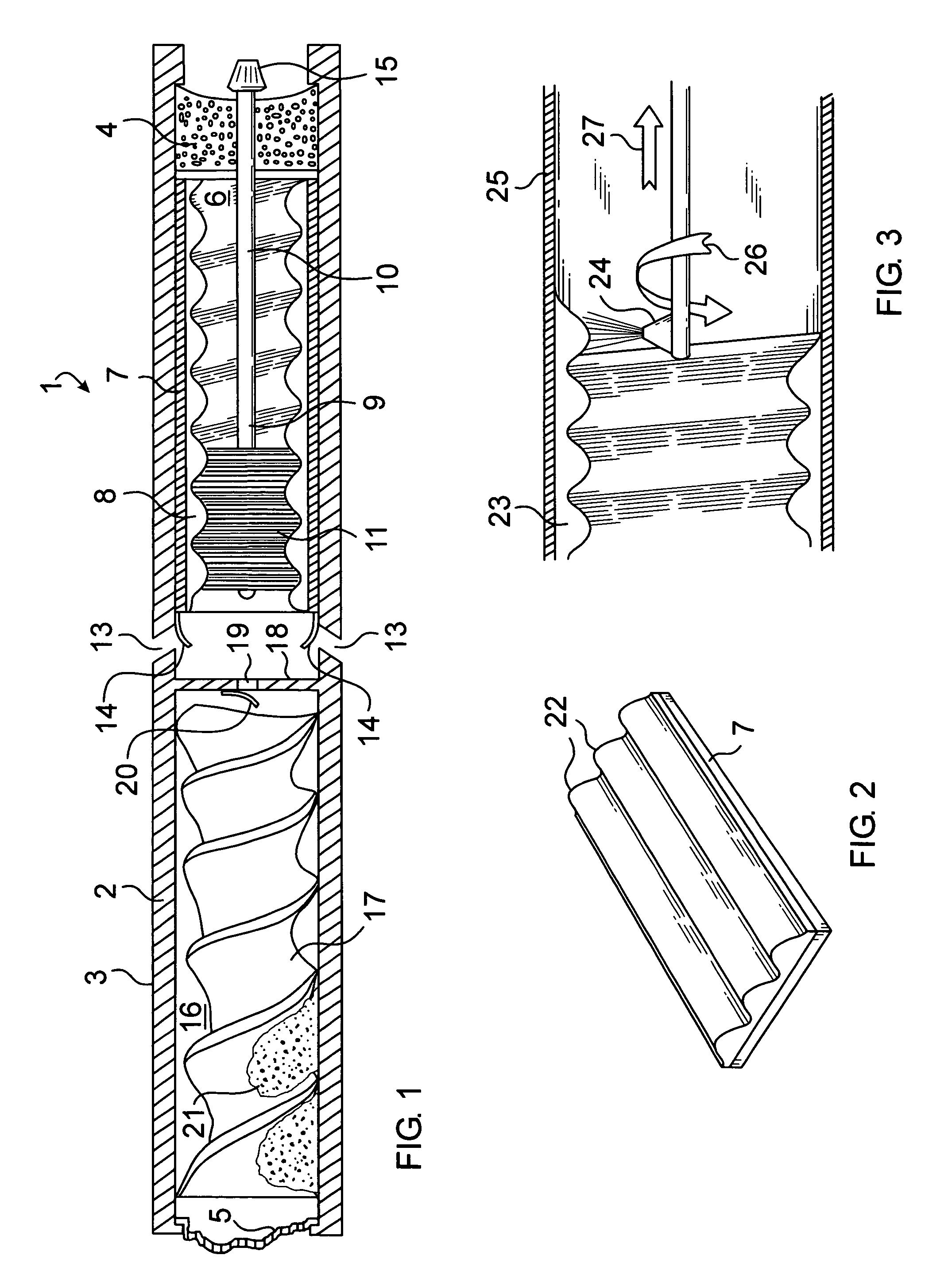

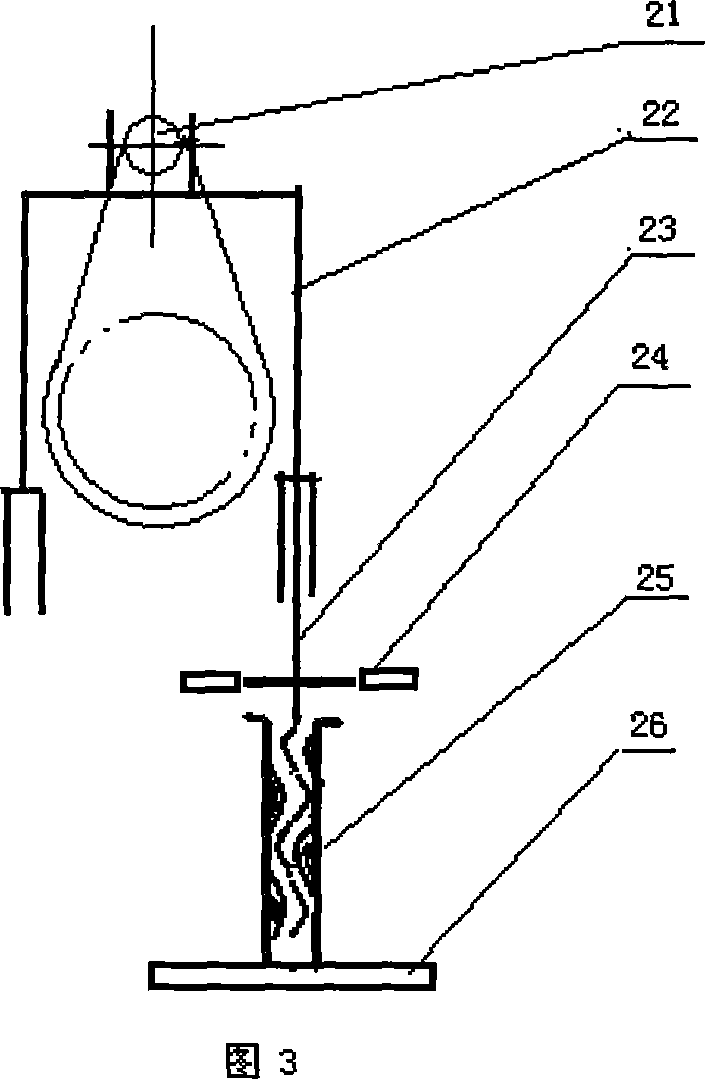

Aromatic cigarette substitute

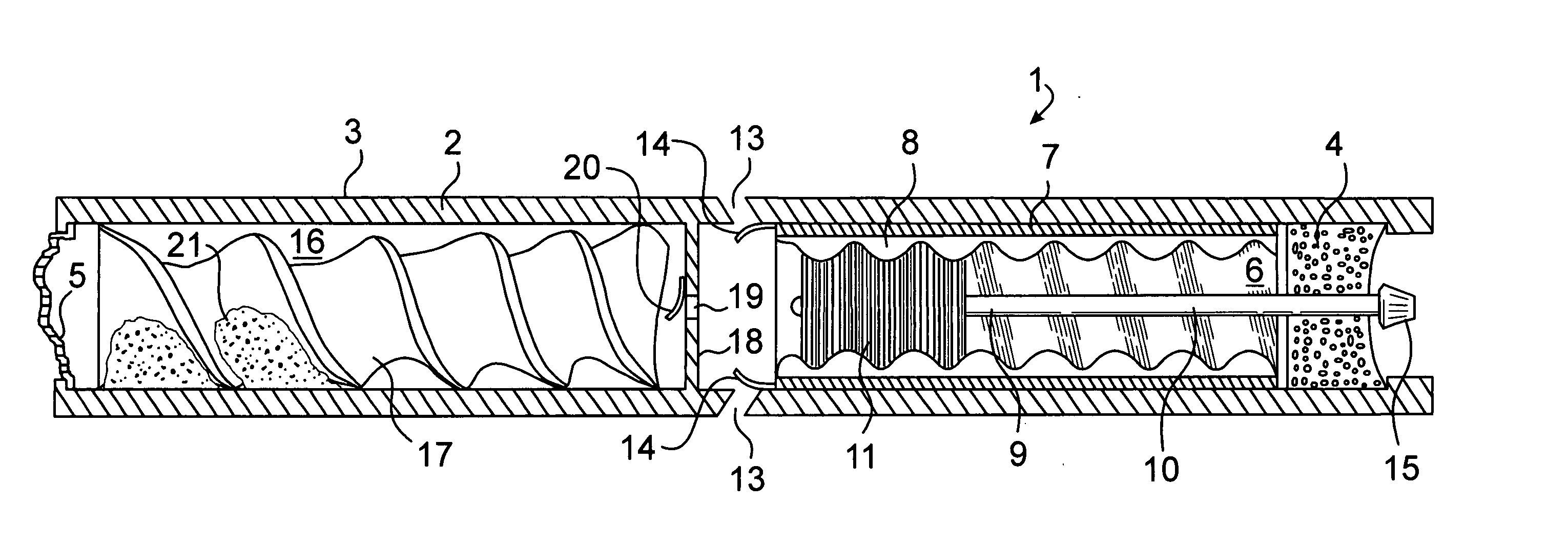

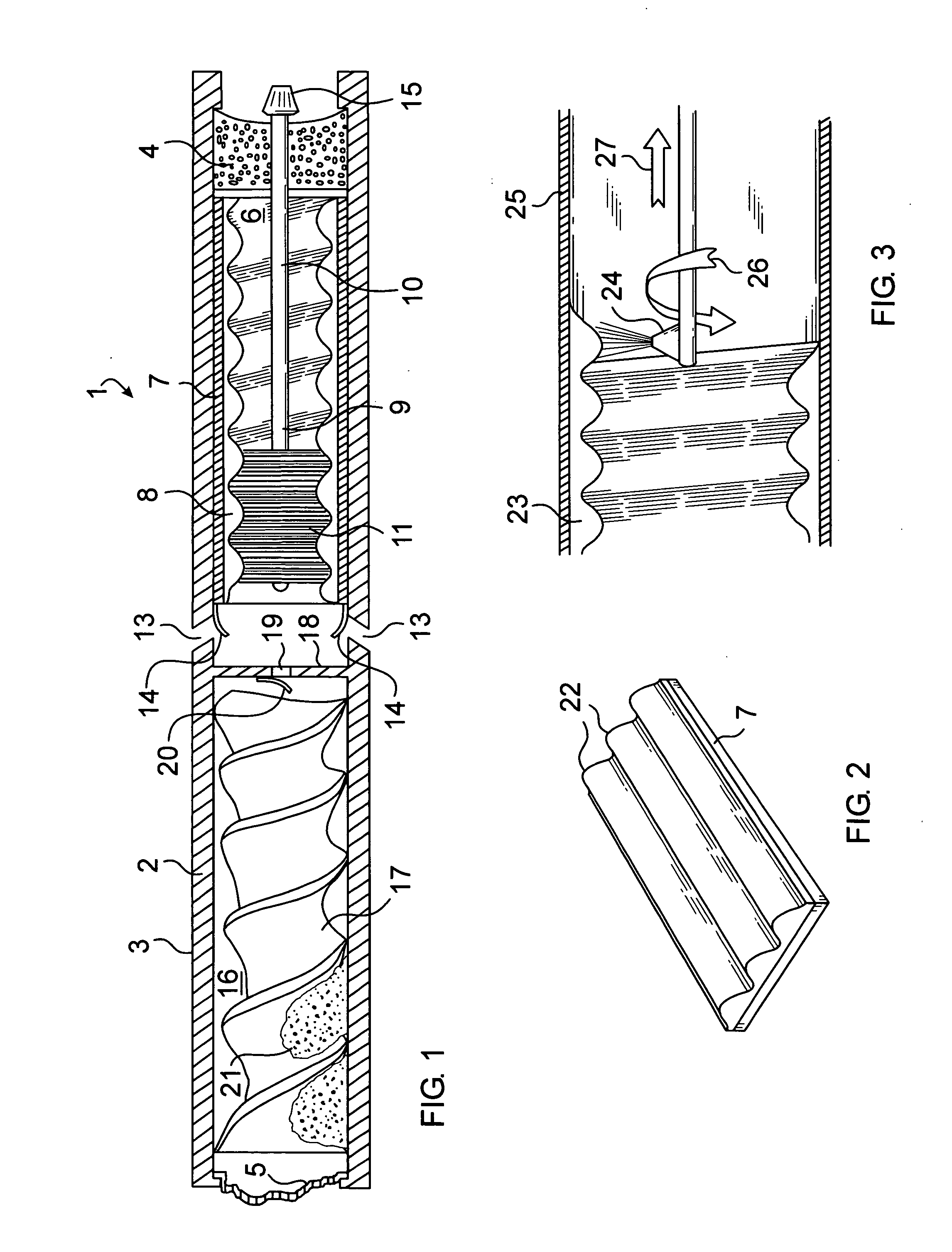

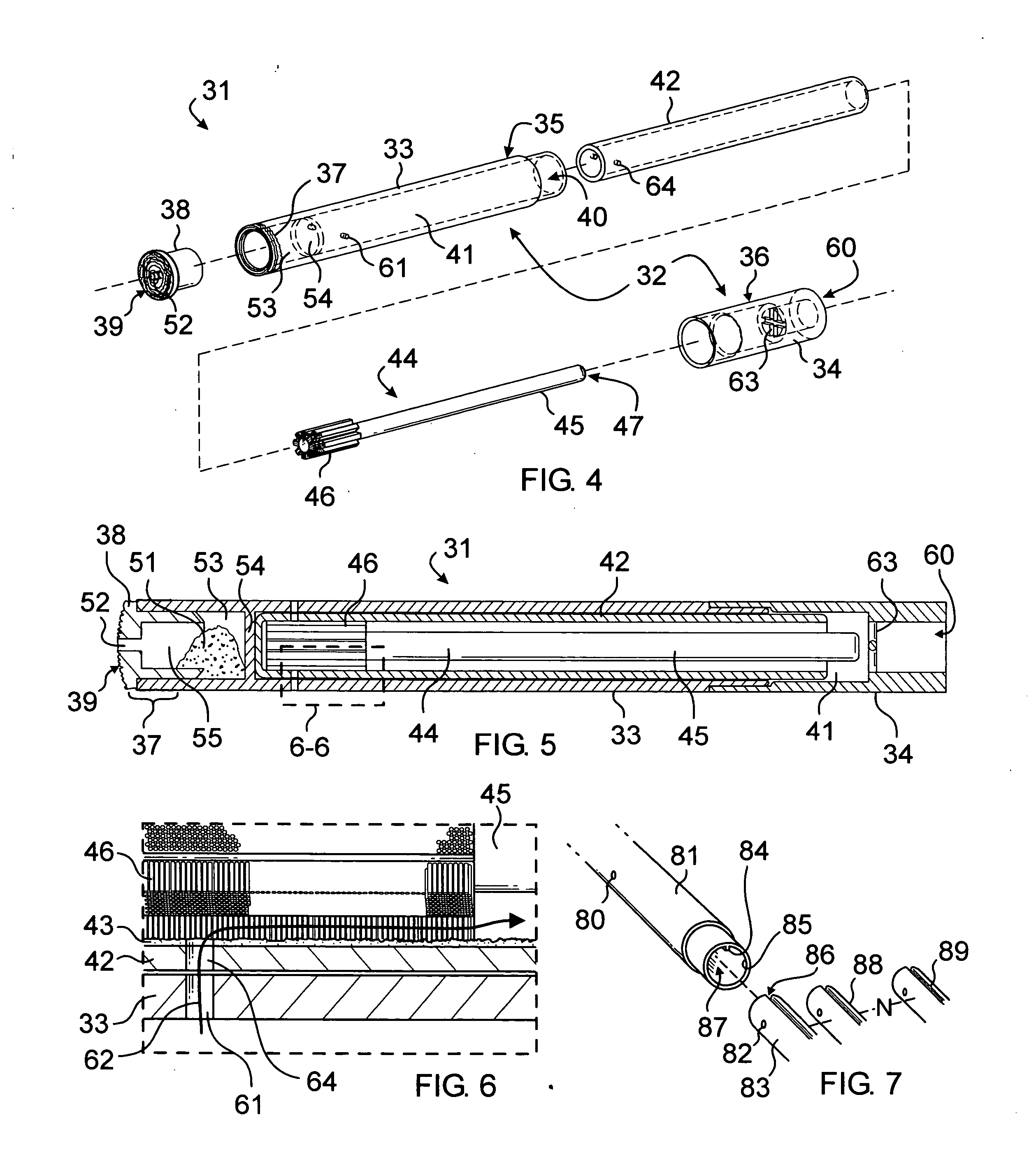

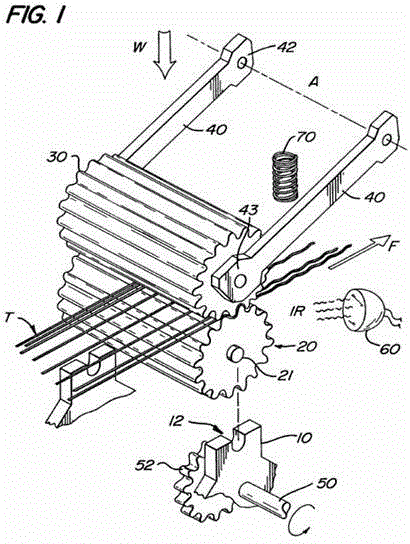

InactiveUS20050016553A1Increased exposed surface areaAvoid inhalationTobacco pipesTobacco devicesFlavorBiomedical engineering

A look-alike substitute for a cigarette, from which a smokeless aroma of burning tobacco or other fragrances can be inhaled and a smoke-simulating aromatized powder can be emitted out, comprises a first chamber lined with a scratch-releasable, flavor-coated insert and a second chamber filled with micrometric powder. The release of the aroma is triggered by scratching the insert with a built-in wire brush. The aromatic compound is preferably deposited on the inner surface of a replaceable hollow tube. A number of different flavored tubes are provided as part of a kit. A specially designed tip gives the appearance of glowing embers.

Owner:IANNUZZI DIANE M

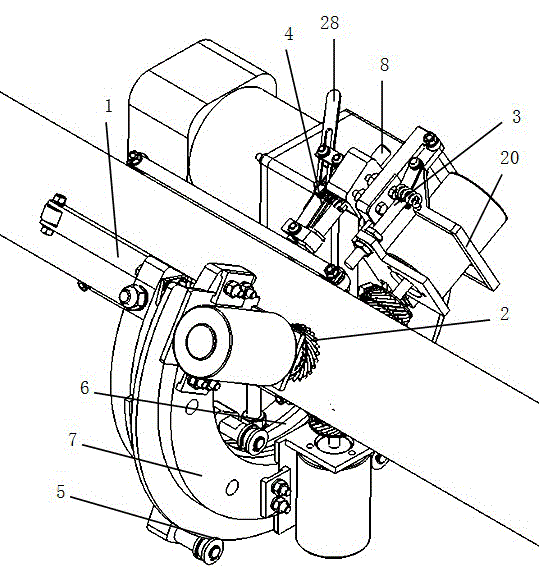

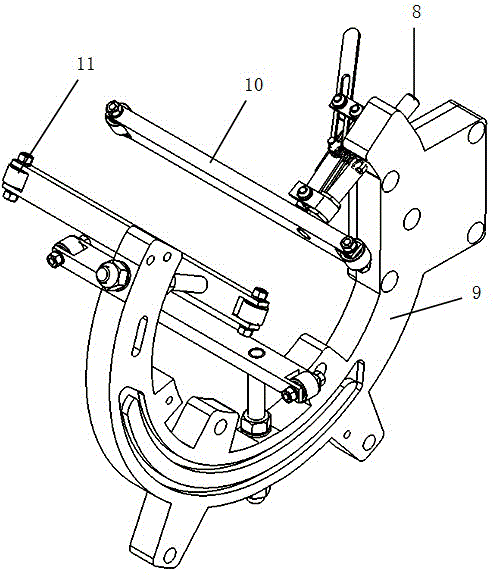

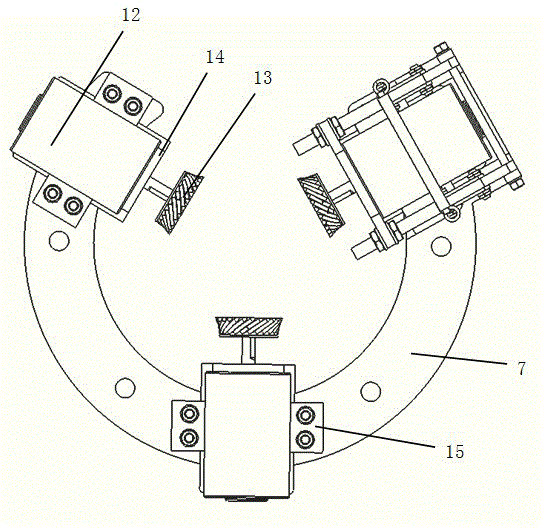

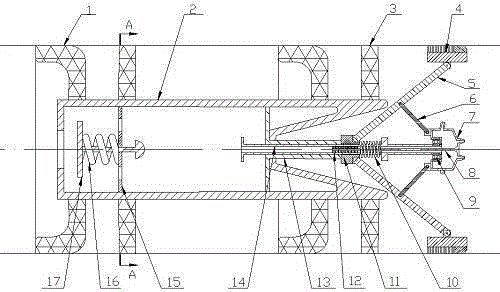

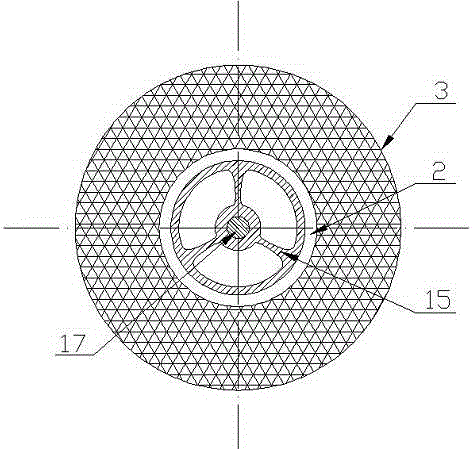

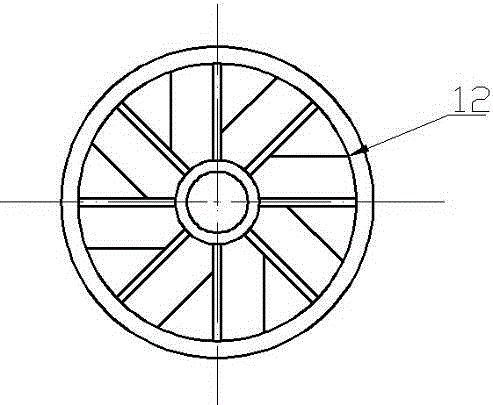

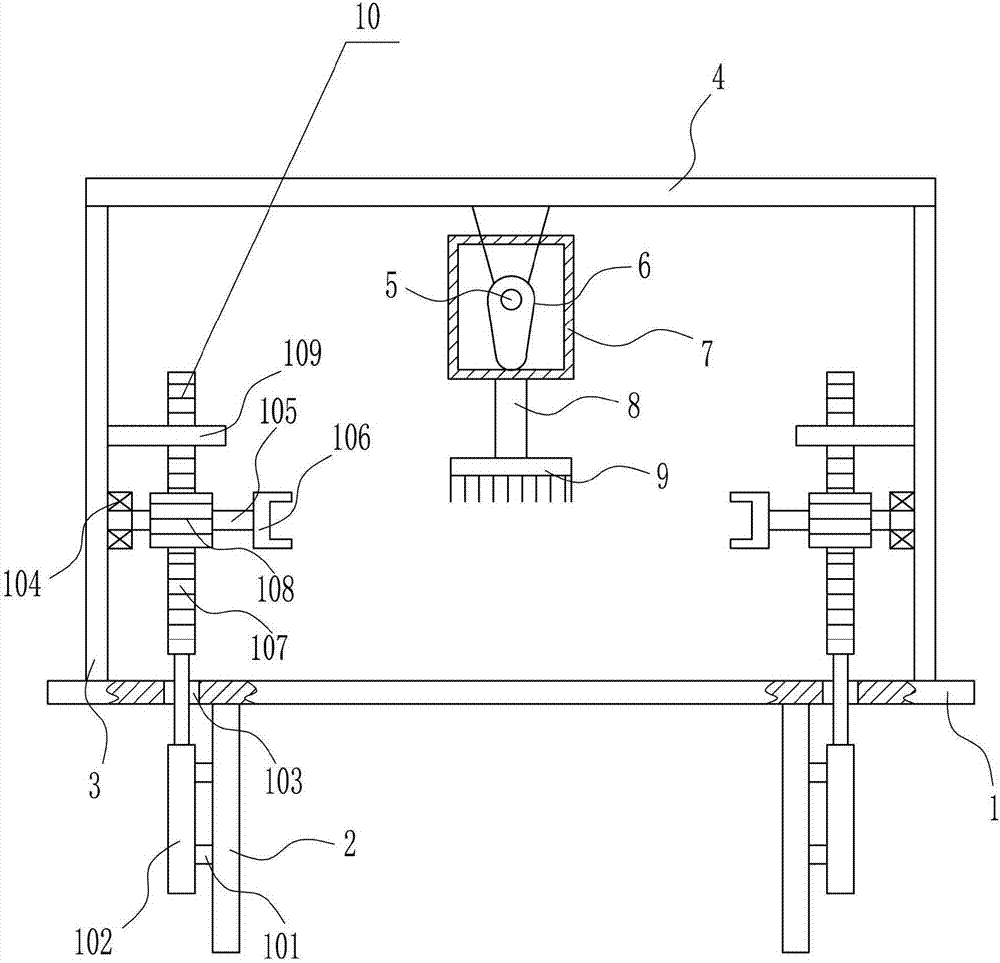

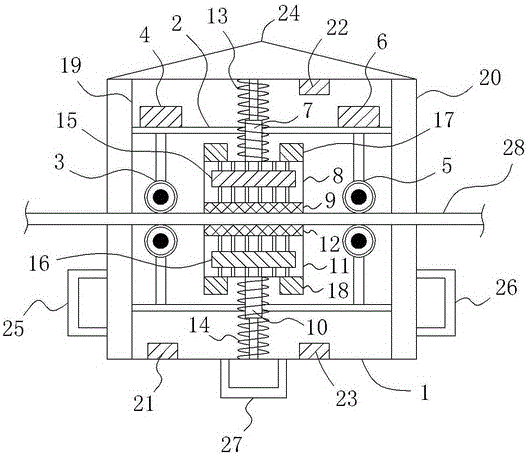

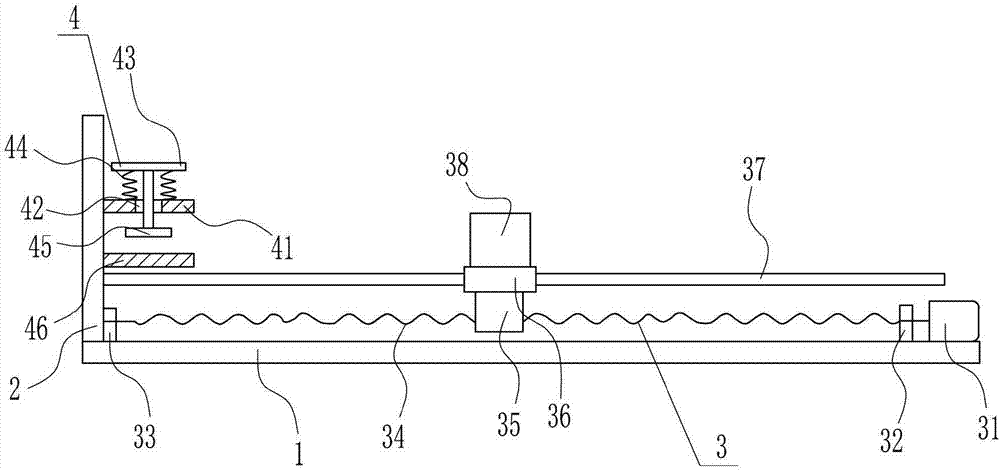

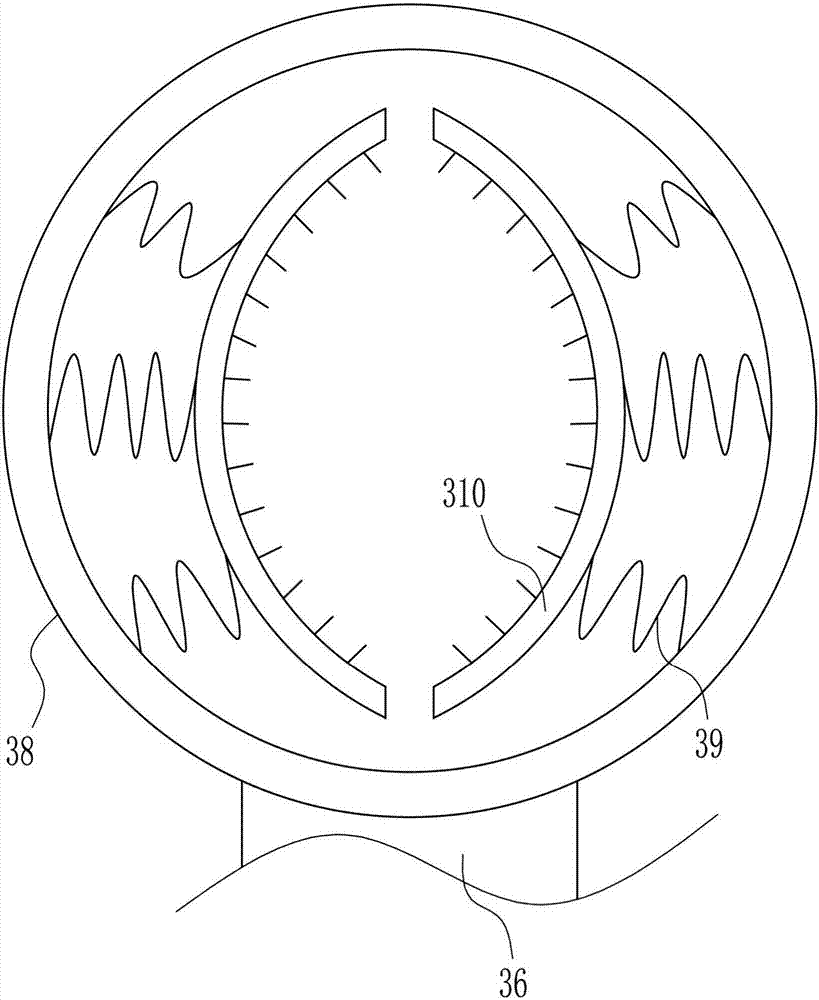

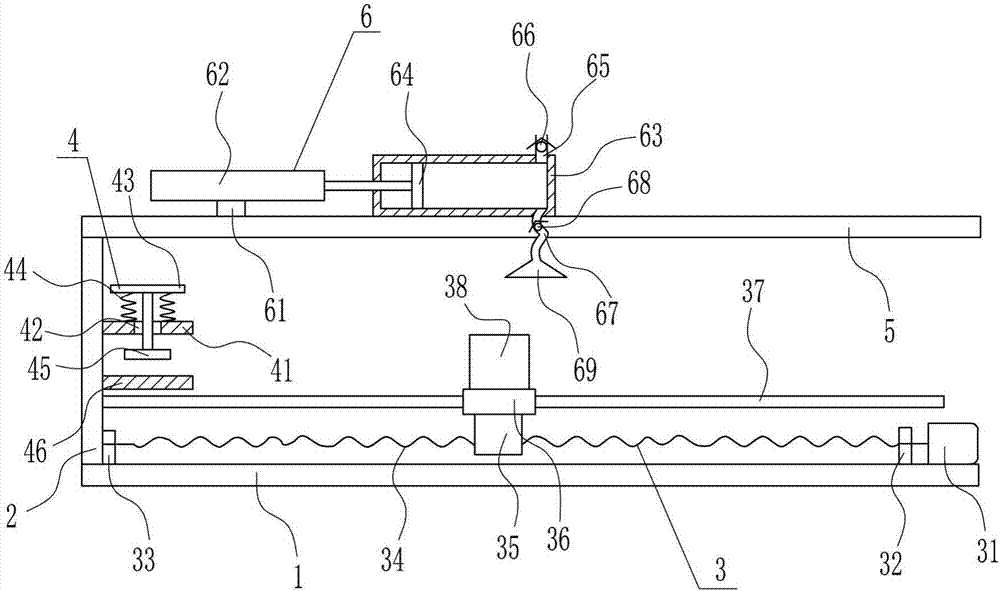

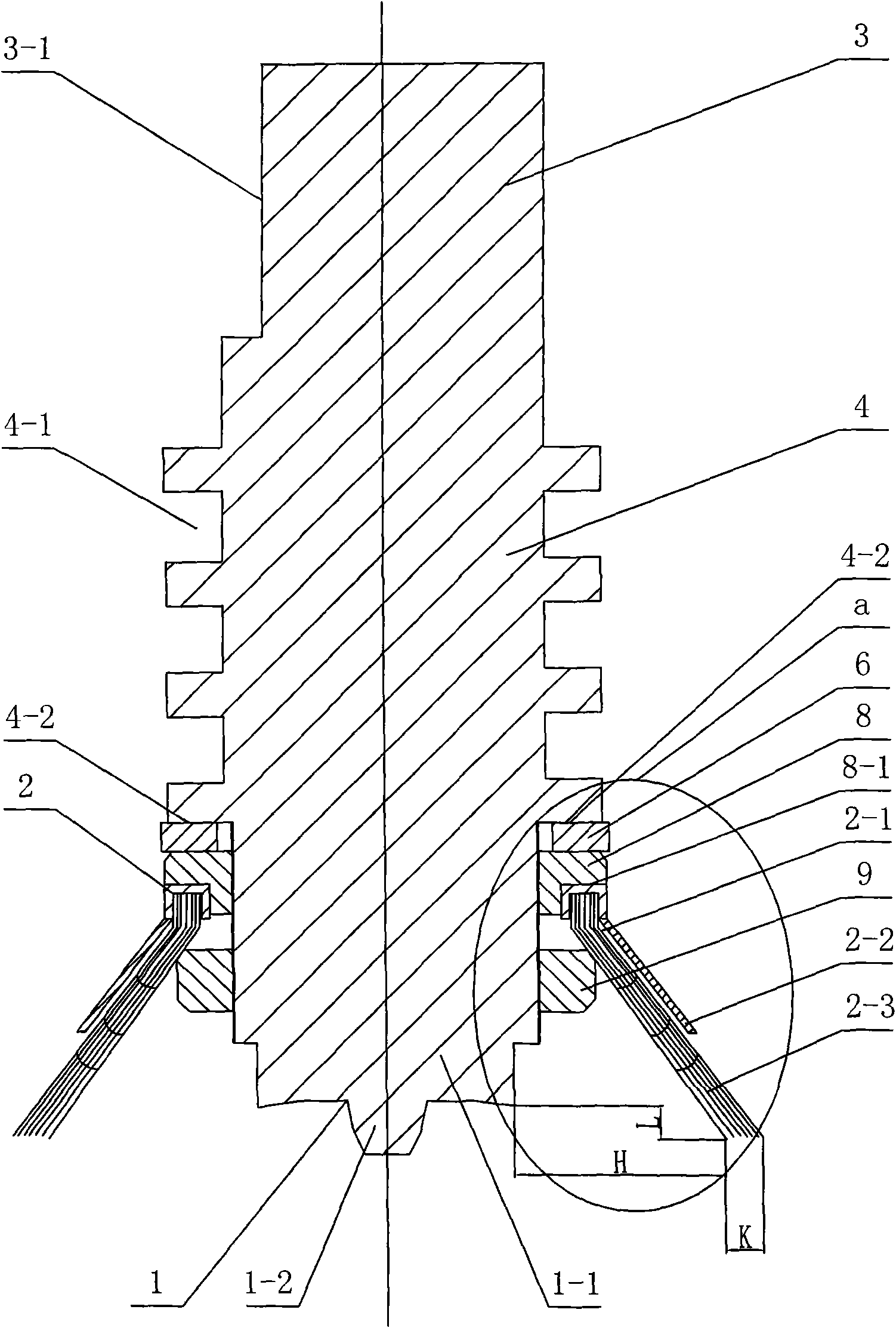

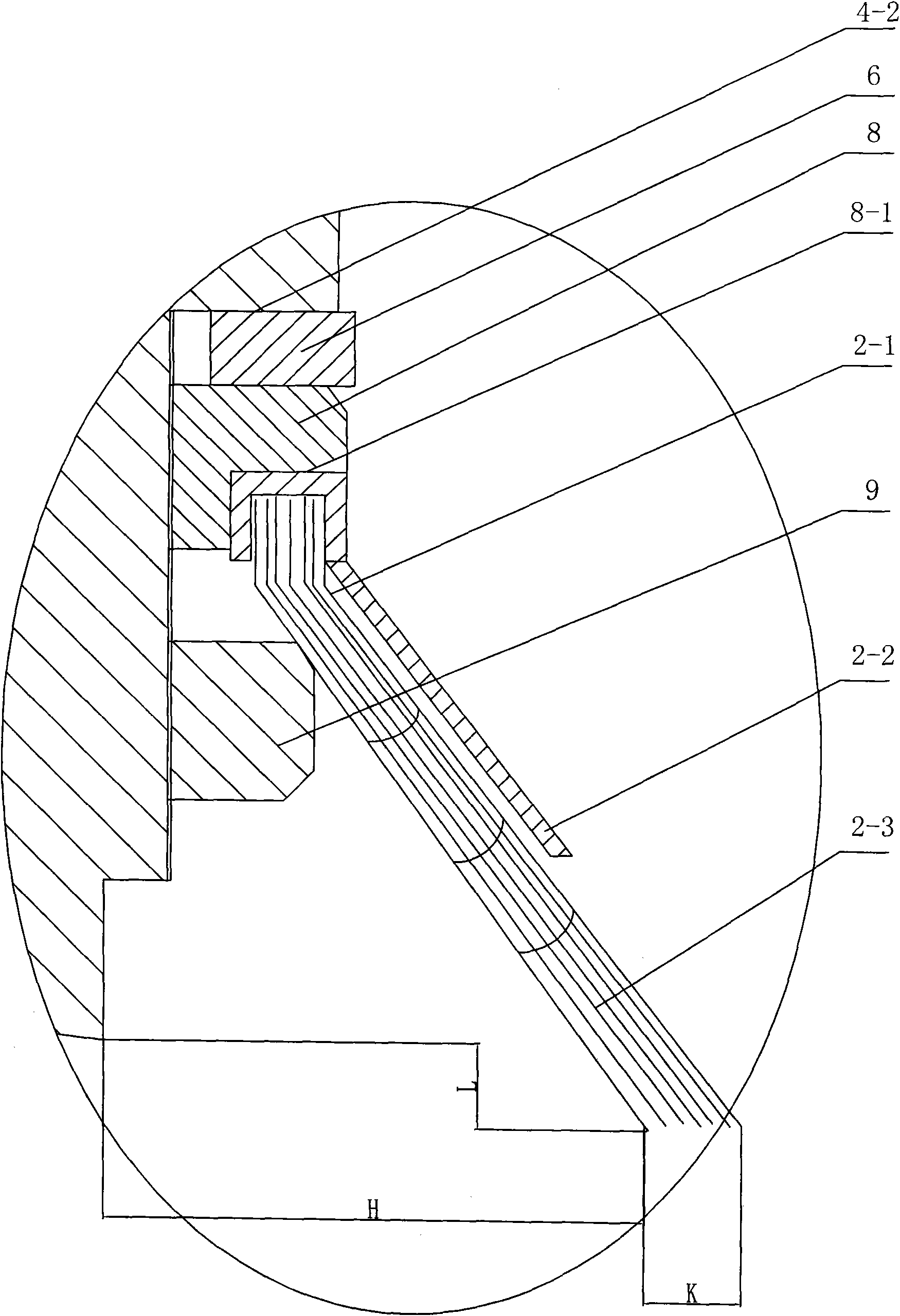

Derusting and polishing device for outer surface of steel pipe

The invention discloses a derusting and polishing device for the outer surface of a steel pipe. The device comprises a rack part (1), a polishing part (2), a polisher locking mechanism (3), a rack locking mechanism (4), a guide rail part (5) and a reciprocating mechanism (6); a high-speed motor drives a steel wire brush to rotate for polishing and derusting the outer surface of the steel pipe, and the reciprocating mechanism (6) drives the polishing part (2) to rotate around a shaft of the steel pipe in a reciprocating manner to achieve the purposes of derusting and polishing the outer surface of the whole circumference of the cylindrical steel pipe; the device is suitable for steel pipes with different diameters due to the adjustable structure; the device is convenient and quick to mount and dismount due to the arrangement of the polisher locking mechanism (3) and the rack locking mechanism (4). The device can be applied to derusting and polishing of the outer surfaces of cylindrical metal guard railings and suspended metal pipelines in public places.

Owner:GUANGDONG UNIV OF TECH

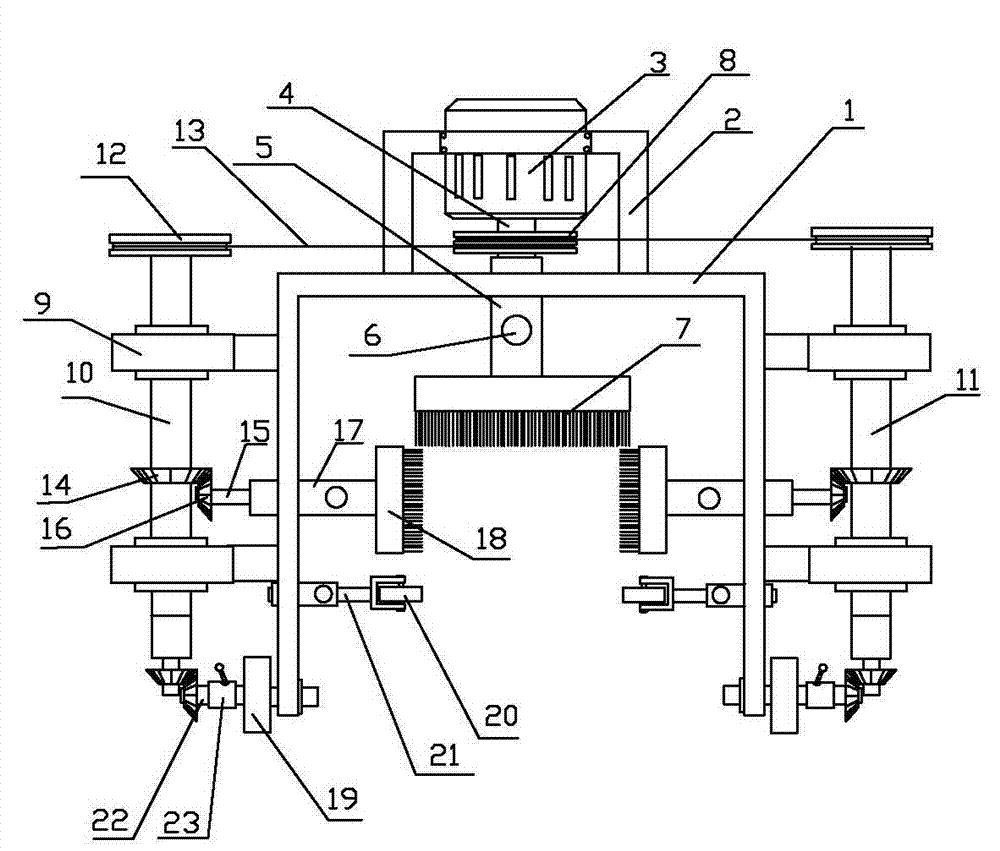

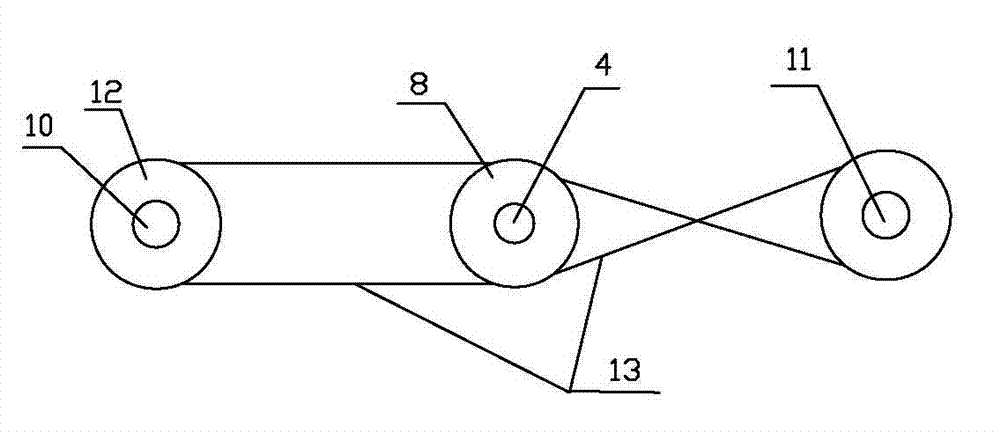

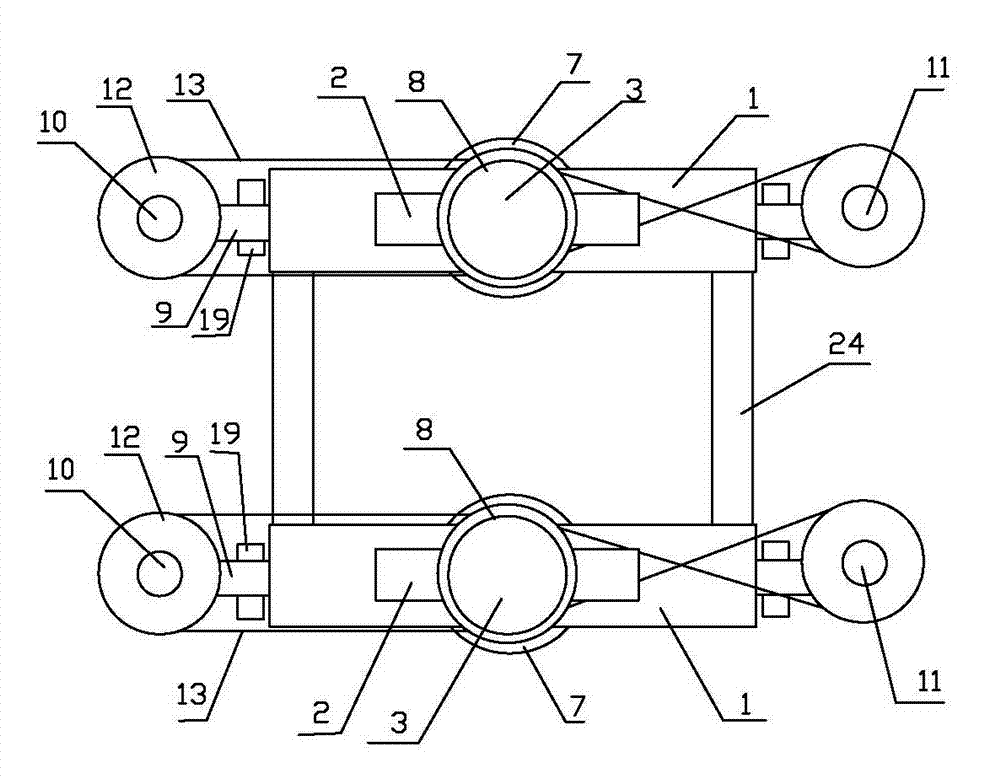

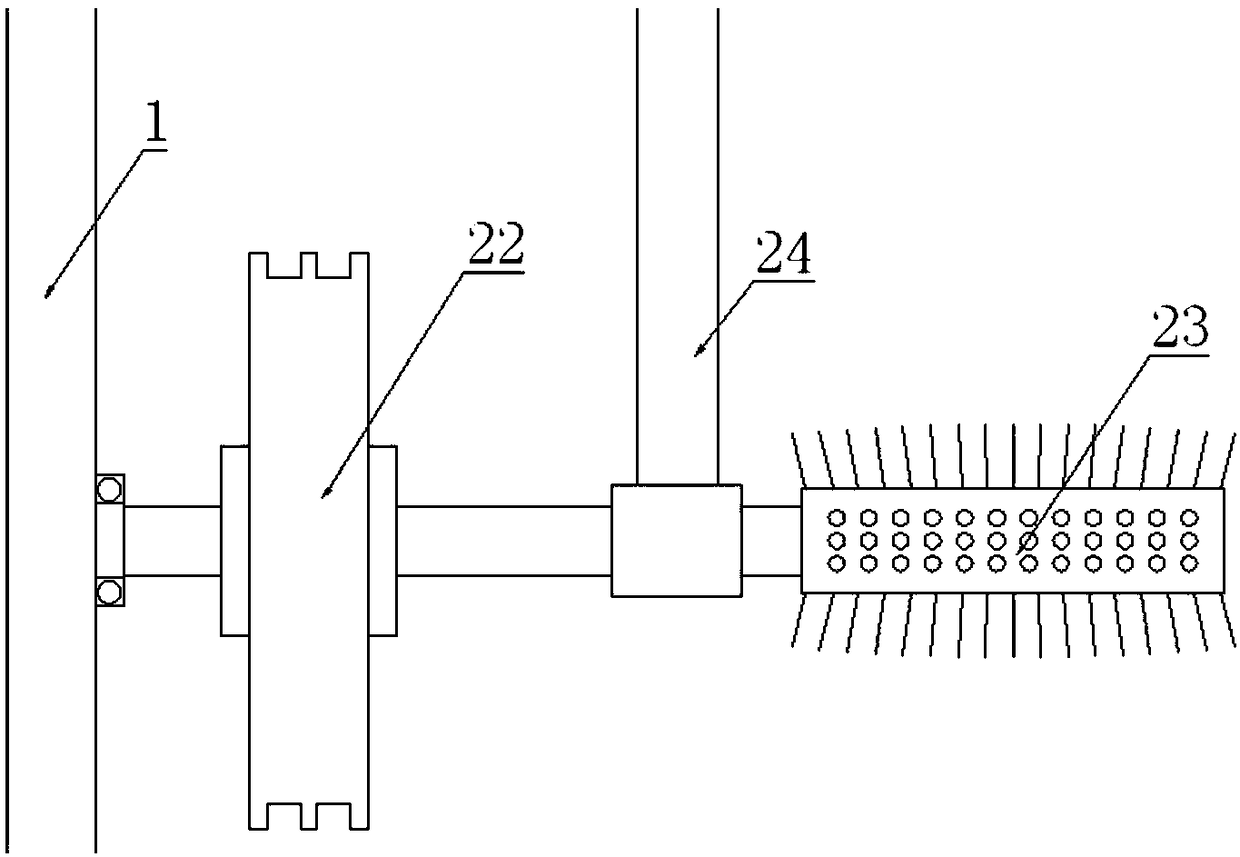

Square tube multiple face synchronous derusting machine

The invention discloses a square tube multiple face synchronous derusting machine. The derusting machine comprises an inverted-U-shaped rack and is characterized in that an upper motor is fixed to the middle of the upper wall of the inverted-U-shaped rack, and an upper horizontal rotating wire brush is fixed to the lower end of a shaft sleeve of a motor spindle, a fixed belt wheel at the upper end of the spindle is connected with driven shafts outside the left wall and the right wall of the inverted-U-shaped rack for transmission, and the middle of the driven shaft on the left and the middle of the driven shaft on the right are respectively meshed with a shaft end bevel gear of a transverse rotating shaft for transmission through a bevel gear; each transverse rotating shaft is provided with a transverse shaft sleeve connected with the transverse rotating shaft in a matched mode through a spline, and an upper perpendicular face rotating wire brush is fixed to the inner end of each transverse shaft sleeve; idler wheels are arranged at the bottom end of the inverted-U-shaped rack; synchronous rotation of the horizontal rotating wire brush and the perpendicular face rotating wire brushes is achieved through one motor, and thus the upper surface and the two side faces of a square tube can be polished and derusted synchronously. Thus, dust on the surface of the square tube can be cleared away fast with the derusting machine, energy is saved, labor efficiency can be improved, and the using effect of the square tube is improved.

Owner:南通通州东大机械有限公司

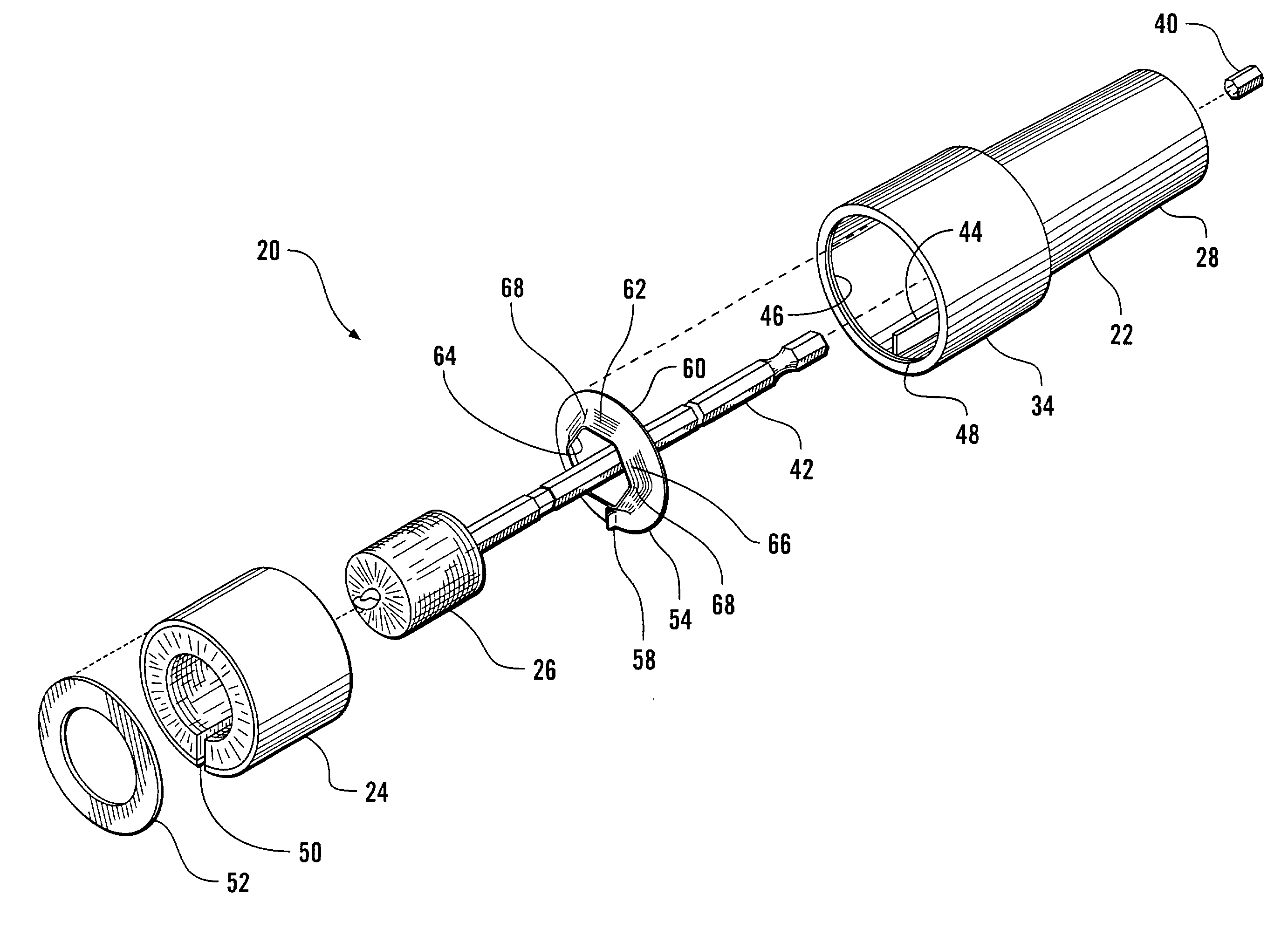

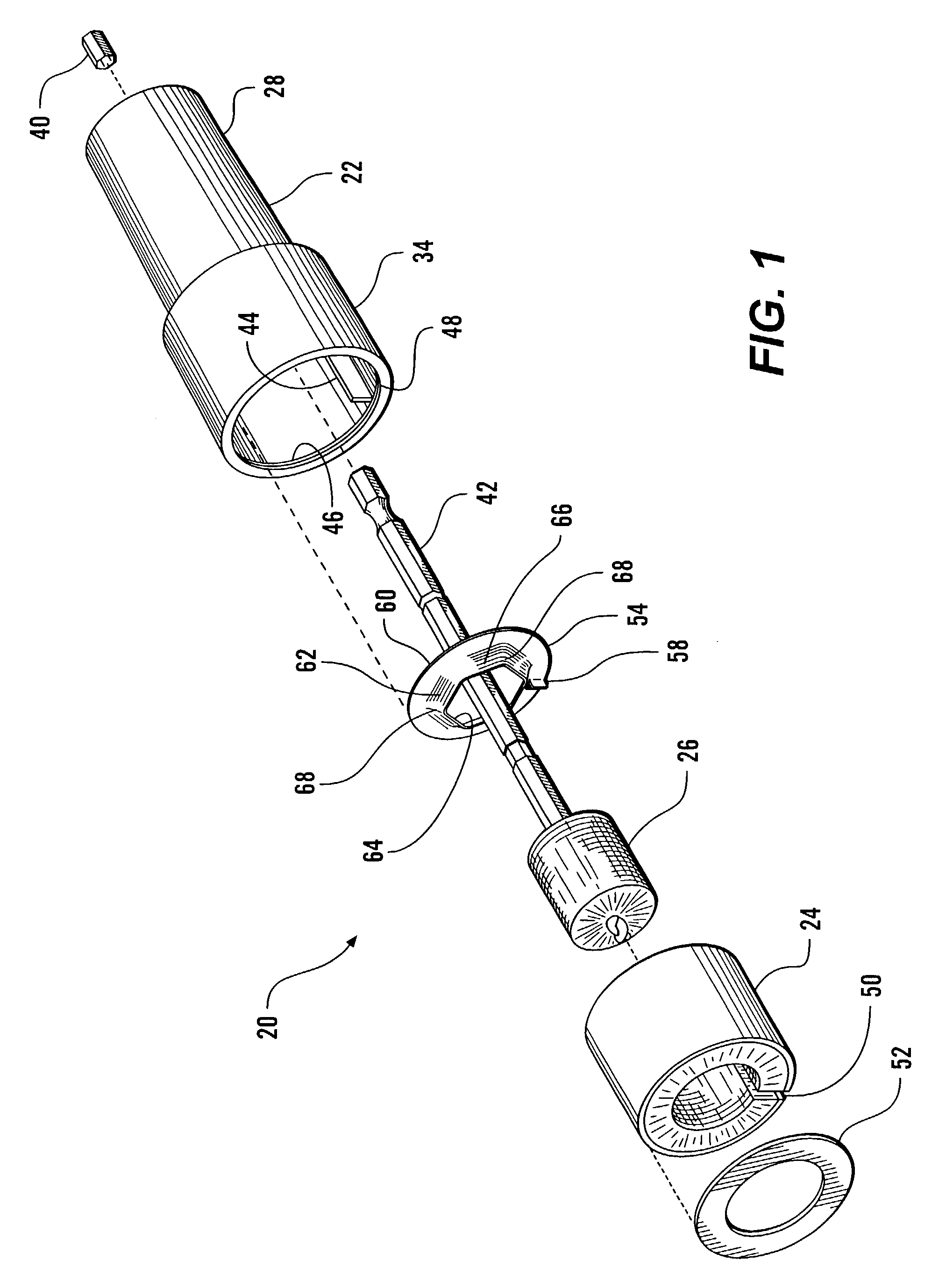

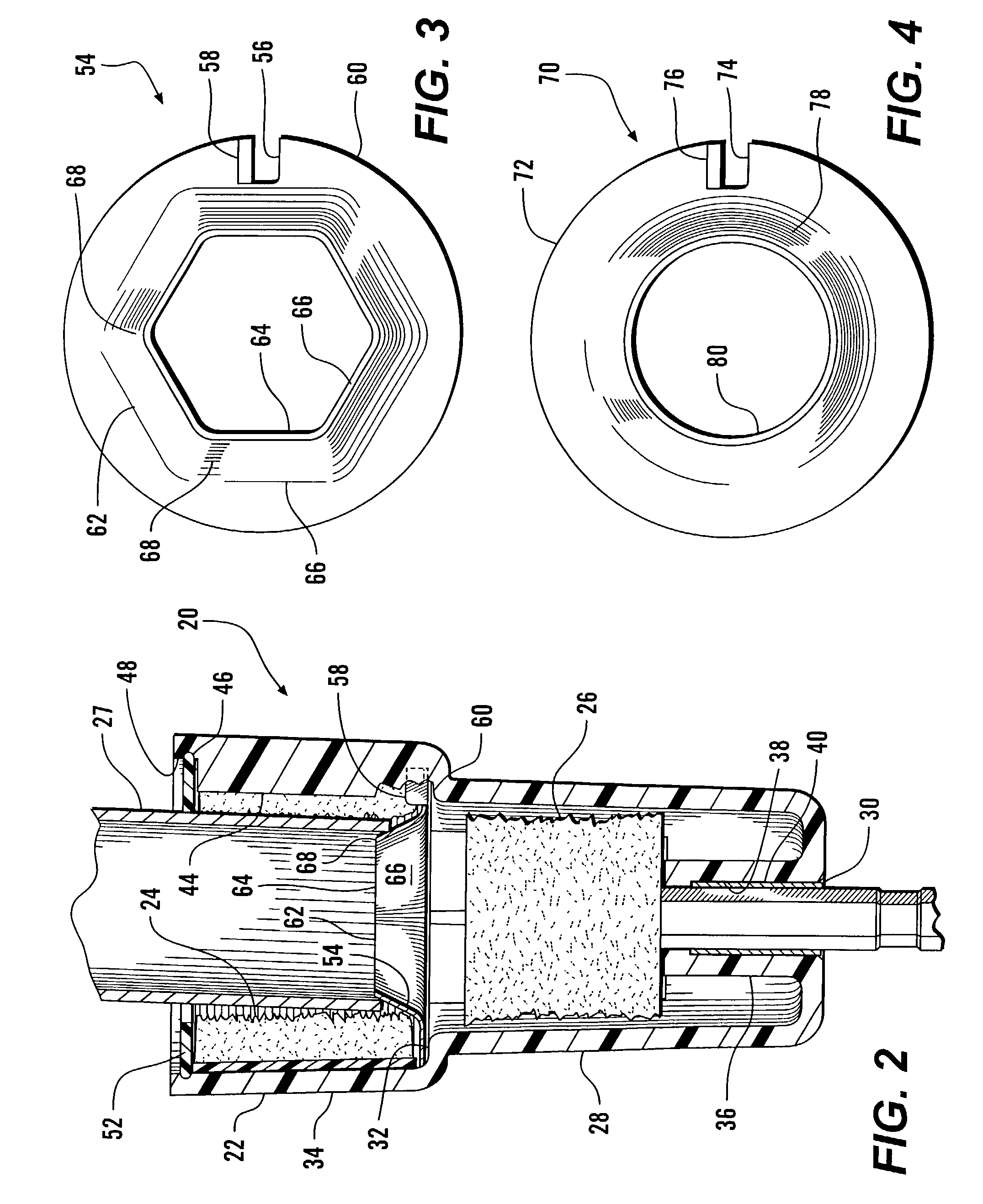

Adjustable fitting and pipe cleaning brush device

The invention outlined in the disclosure is an adjustable wire brush tool for cleaning either the inside or the outside end of a copper pipe or fitting in preparation for soldering the parts together. The tool includes a hollow cylindrical section with a first wire brush on the interior surface of the section. Attached at one end of the cylindrical section is a slightly smaller cylindrical section sized to hold a second cylindrical twisted steel brush having a hexagonal shaft that extends from the smaller section, opposite the larger cylindrical section. The twisted steel brush and attached shaft can be moved to extend the twisted brush beyond the open end of the larger cylindrical section, for insertion into a fitting to clean the fitting interior surface by attaching a power drill to the shaft and rotating the twisted steel brush attached thereto. To clean the outside of a pipe, the twist brush is retracted into the smaller section and secured to that section with an engaging means. The pipe is inserted into the larger section, and the drill is activated to rotate the shaft and attached larger section to clean the pipe outer surface. The tool overcomes the need for separate tools to perform each task and requires but one drill to perform either task as needed. The tool is sized to handle a particular diameter of pipe and fitting, with sizes ranging from one quarter inch to several inches.

Owner:THE MILL ROSE

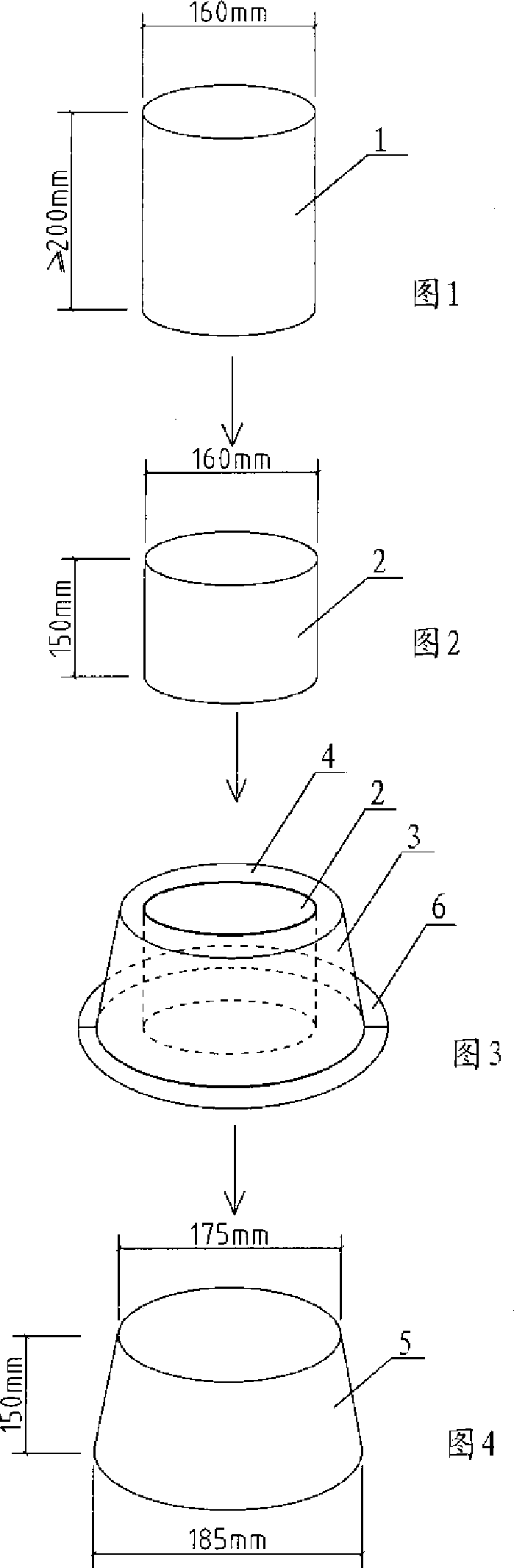

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

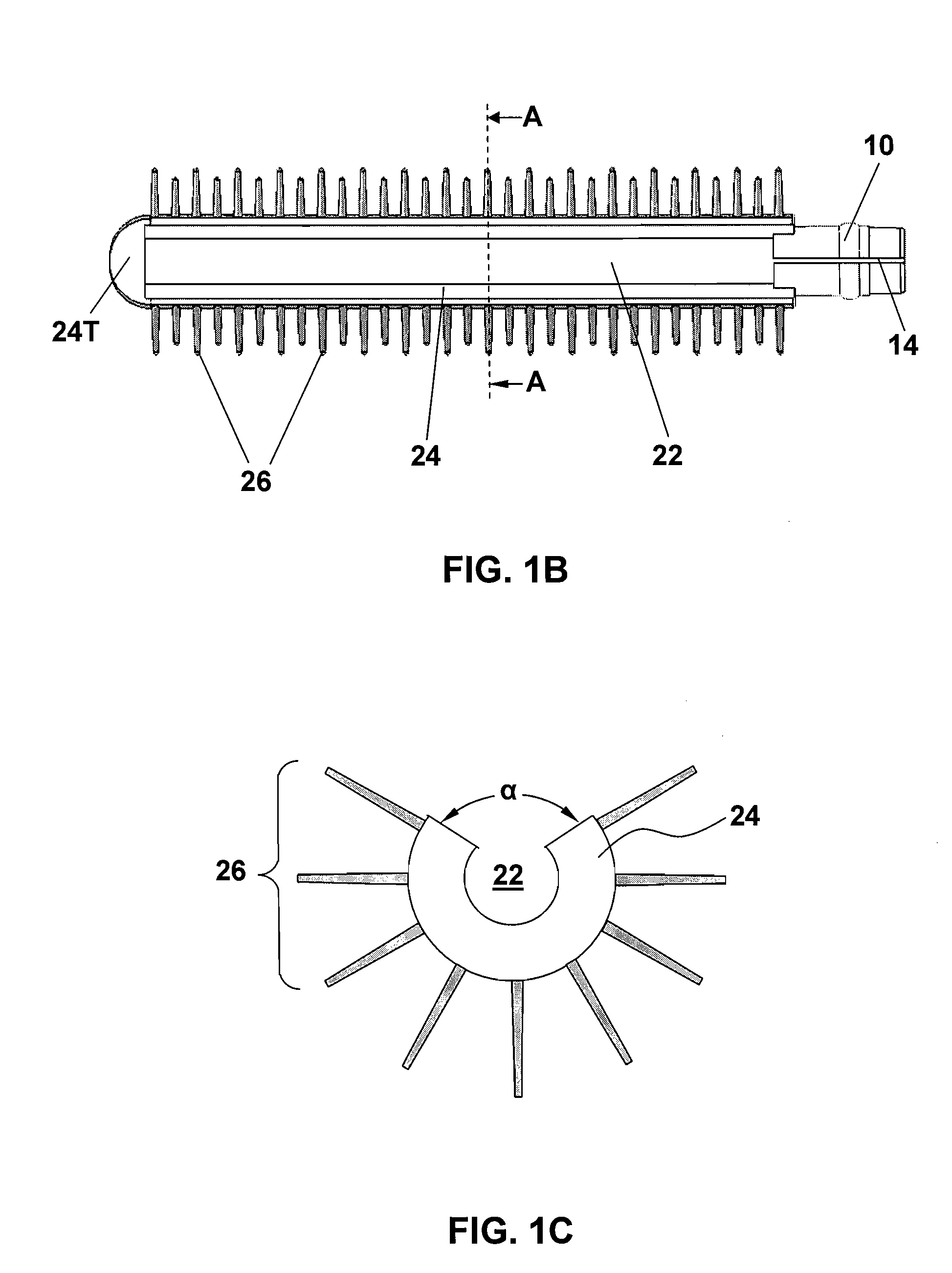

Cosmetic Applicator Assembly

InactiveUS20090276973A1Efficient executionImprove gripBrush bodiesBristleBristleInjection molding process

A cosmetic applicator assembly, which includes a polymeric brush and a twisted wire brush. Specifically, the polymeric brush comprises an elongated polymeric core and multiple polymeric tines protruding from the elongated polymeric core. The elongated polymeric core comprises a first polymeric material of a first tensile modulus, while at least some of the polymeric tines comprise a second polymeric material of a second tensile modulus that is smaller than the first tensile modulus. The twisted wire brush comprises a metal wire core and multiple bristles protruding from the metal wire core. The elongated polymeric core of the polymeric brush is complementarily engaged with at least a portion of the metal wire core of the twisted wire brush to form the cosmetic applicator assembly. The polymeric brush of the present invention is preferably formed by a bi-injection molding process.

Owner:ELC MANAGEMENT LLC

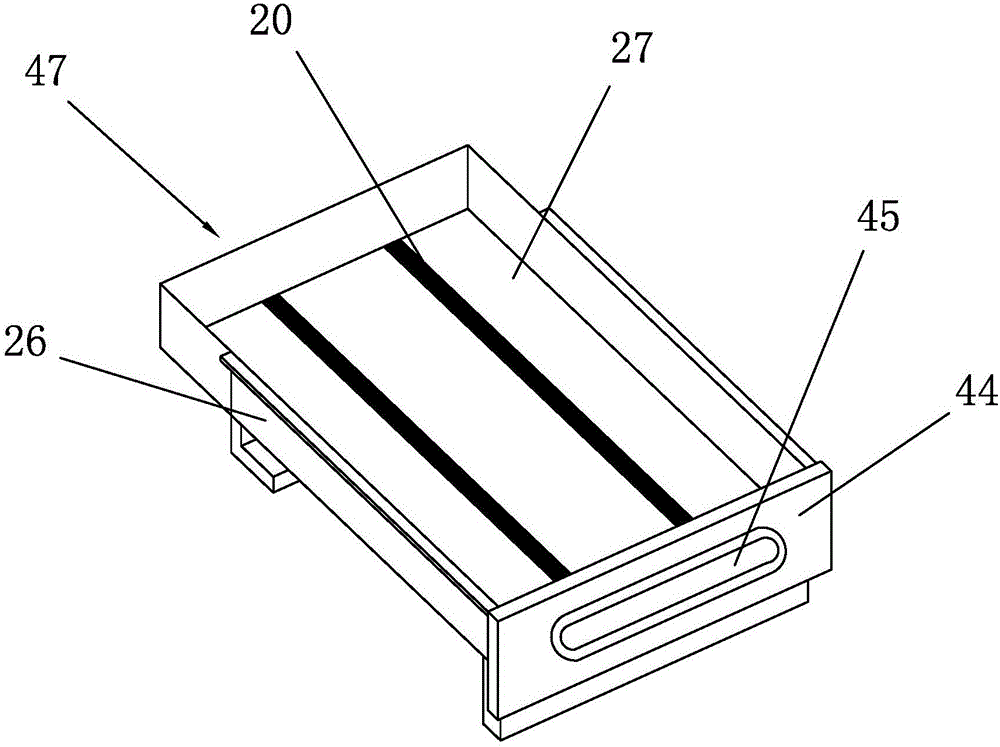

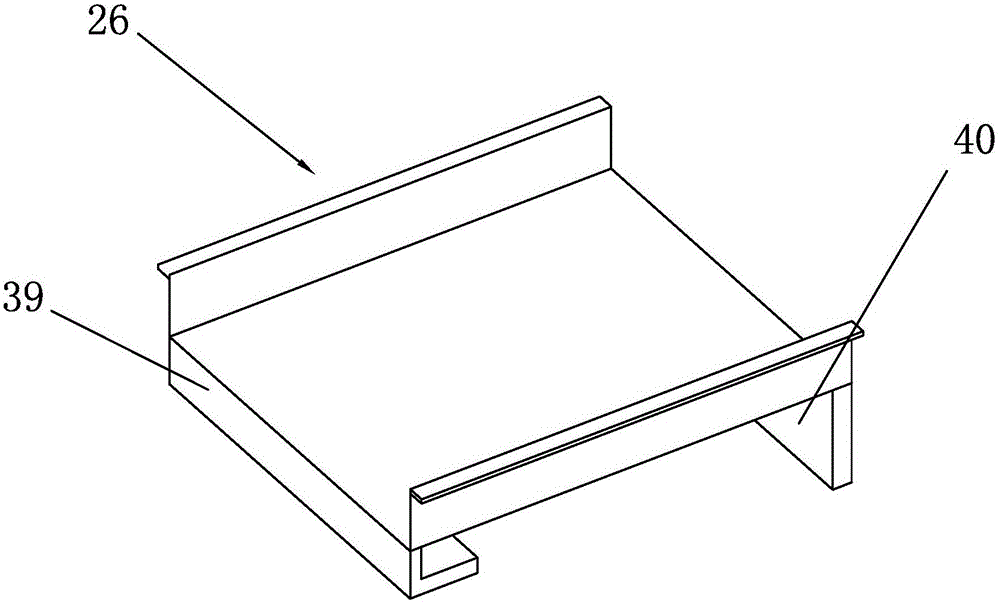

Convenient and fast efficient steel pipe rust removal grinding machine

ActiveCN105150069AAchieve regular recyclingEasy to recycleRevolution surface grinding machinesGrinding feedersArchitectural engineeringWire brush

The invention discloses a convenient and fast efficient steel pipe rust removal grinding machine. The convenient and fast efficient steel pipe rust removal grinding machine comprises a workbench, a motor fixing table, a rust removing device, a scrap iron clearing device and a protective cover. The rust removing device comprises a rust removing brush head and a rust removing roller. The rust removing brush head is connected with the bottom face of the motor fixing table through adjusting rods. The rust removing roller comprises a rust removing barrel body which is evenly provided with installing ports. Steel wire brushes are arranged in the installing ports and fixed through fastening pieces. The scrap iron clearing device comprises a chip removing funnel and a chip collecting device. The convenient and fast efficient steel pipe rust removal grinding machine is simple in structure and high in practicability; by improving the rust removing device, rust removal can be performed on the interior and the surface of a steel pipe at the same time, and operation can be more convenient and easier; due to design of a clamping jaw and a bracket, the steel pipe can be fixed more firmly; meanwhile, by adjusting the clamping jaw and the bracket, rust removal can be performed on steel pipes of different pipe diameters, the using range of the steel pipe rust removal grinding machine is further widened, and comprehensive utilizing efficiency is improved.

Owner:嵊州市恒鑫金属制管有限公司

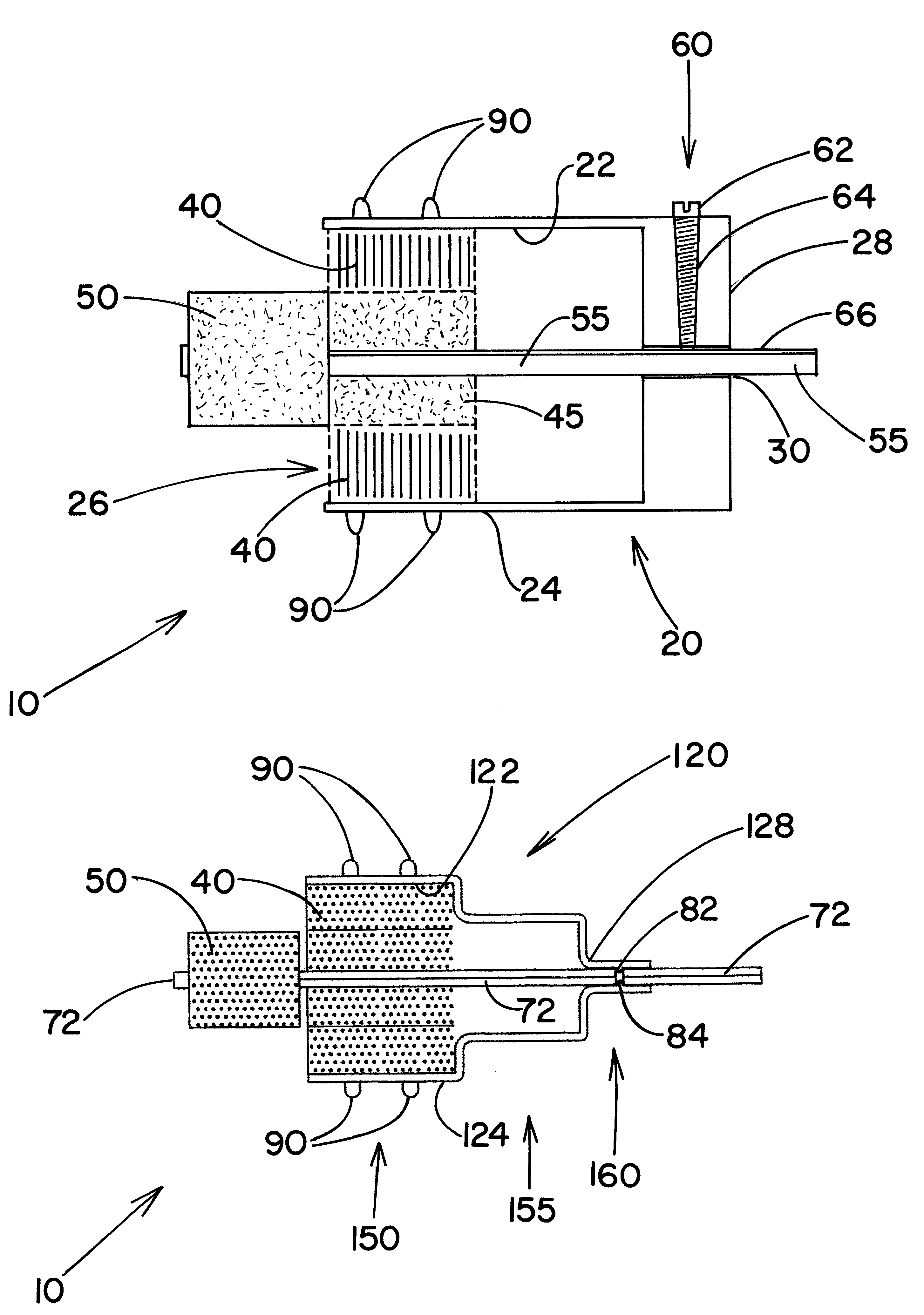

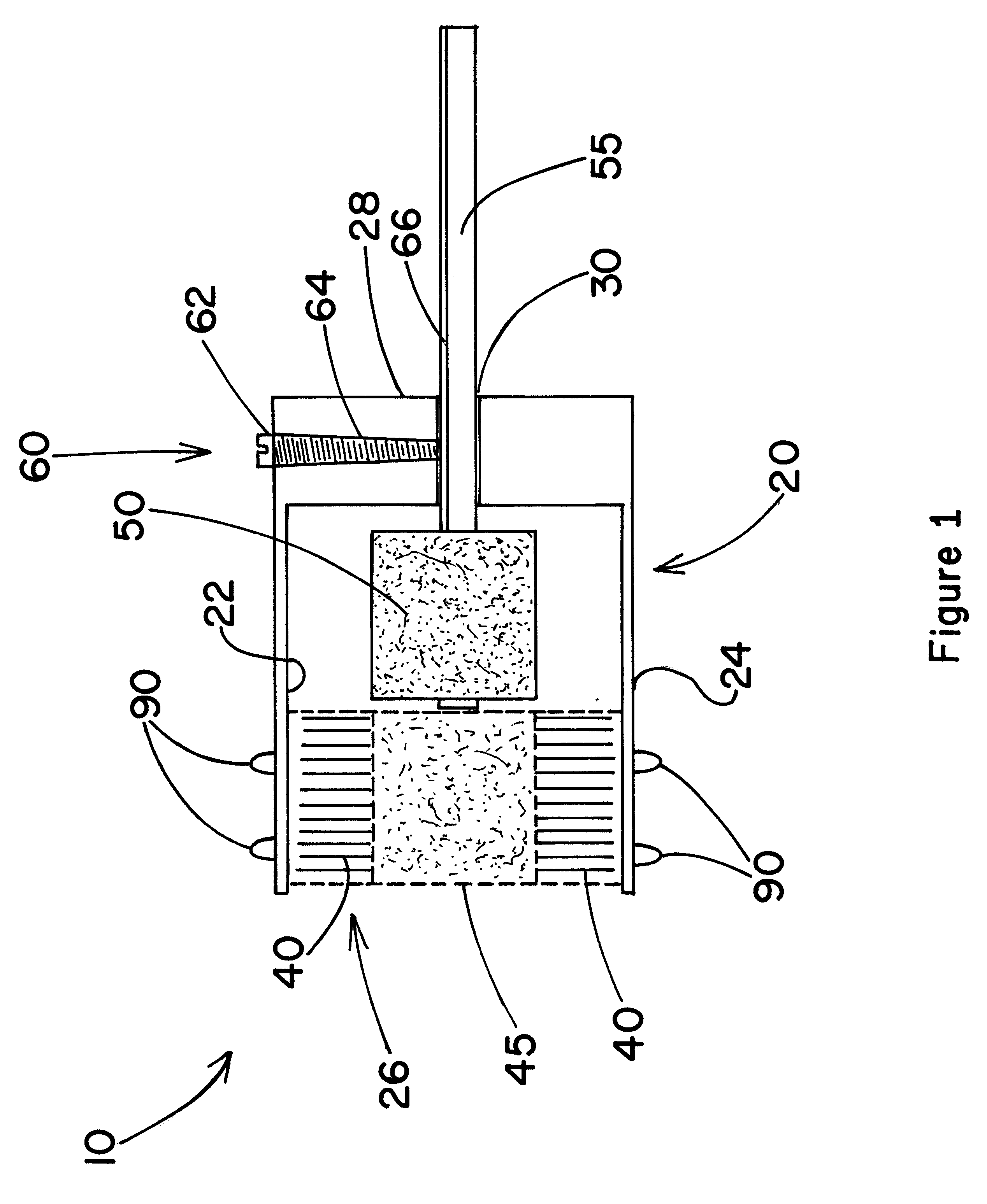

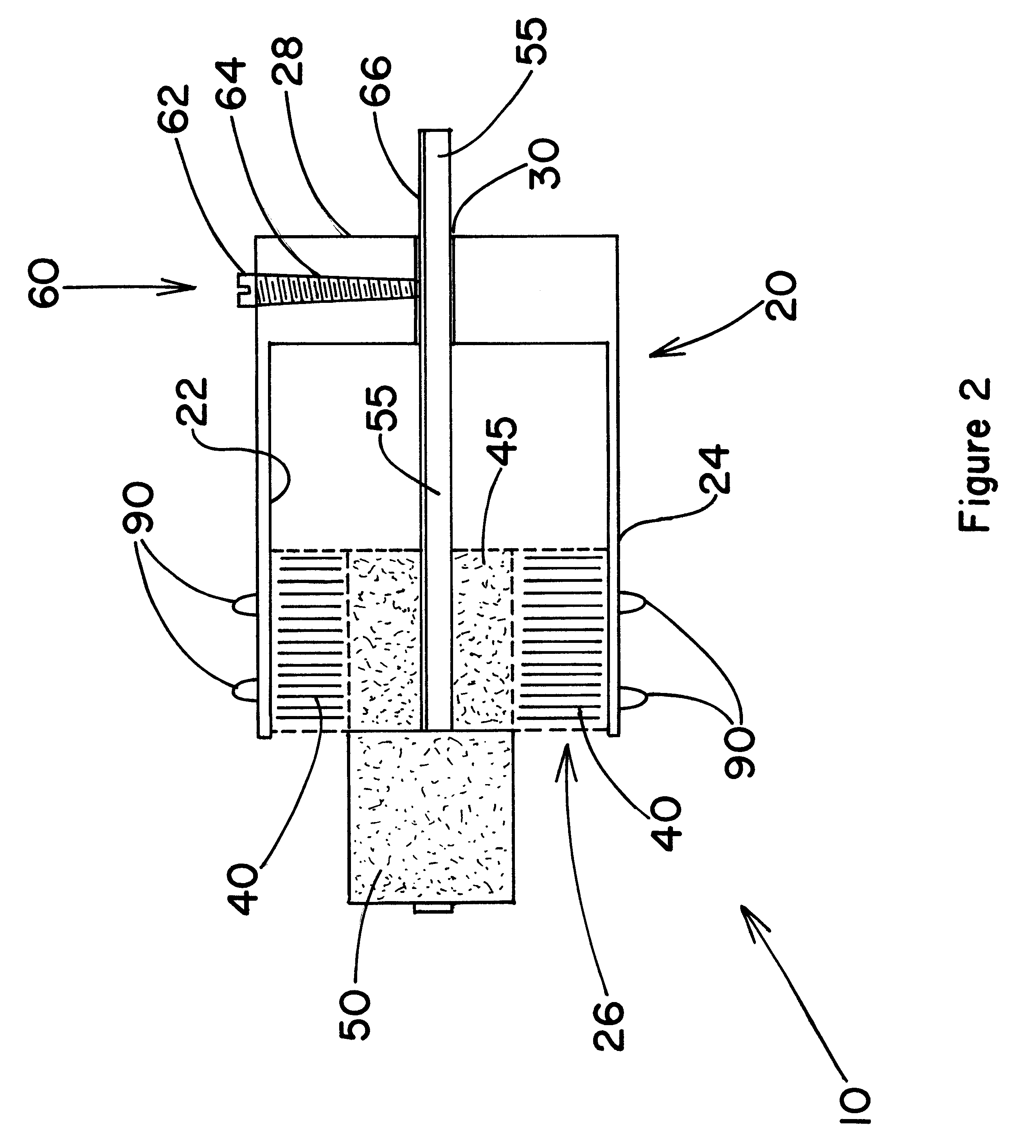

Aromatic cigarette substitute

A look-alike substitute for a cigarette, from which a smokeless aroma of burning tobacco or other fragrances can be inhaled and a smoke-simulating aromatized powder can be emitted out, comprises a first chamber lined with a scratch-releasable, flavor-coated insert and a second chamber filled with micrometric powder. The release of the aroma is triggered by scratching the insert with a built-in wire brush. The aromatic compound is preferably deposited on the inner surface of a replaceable hollow tube. A number of different flavored tubes are provided as part of a kit. A specially designed tip gives the appearance of glowing embers.

Owner:IANNUZZI DIANE M

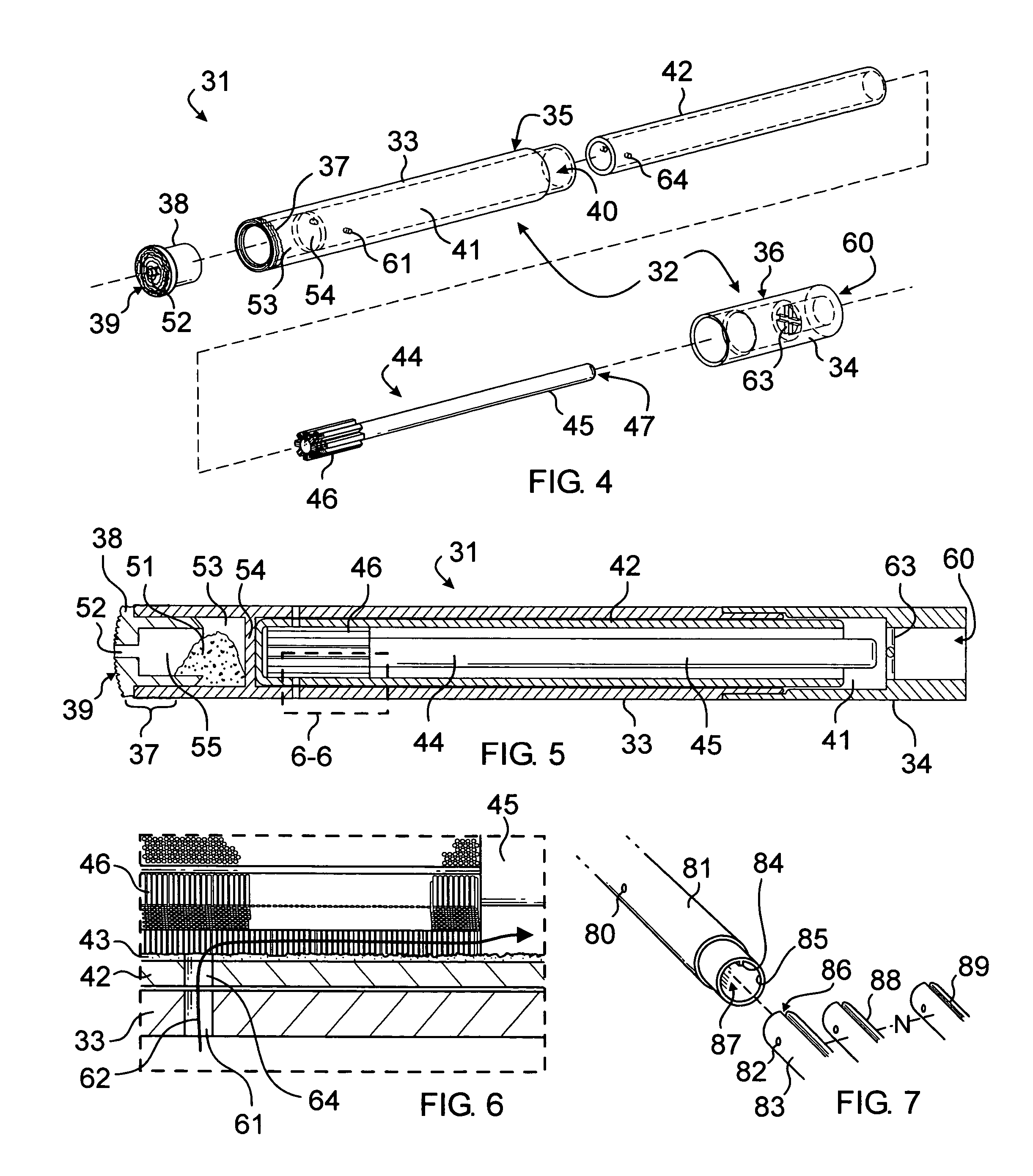

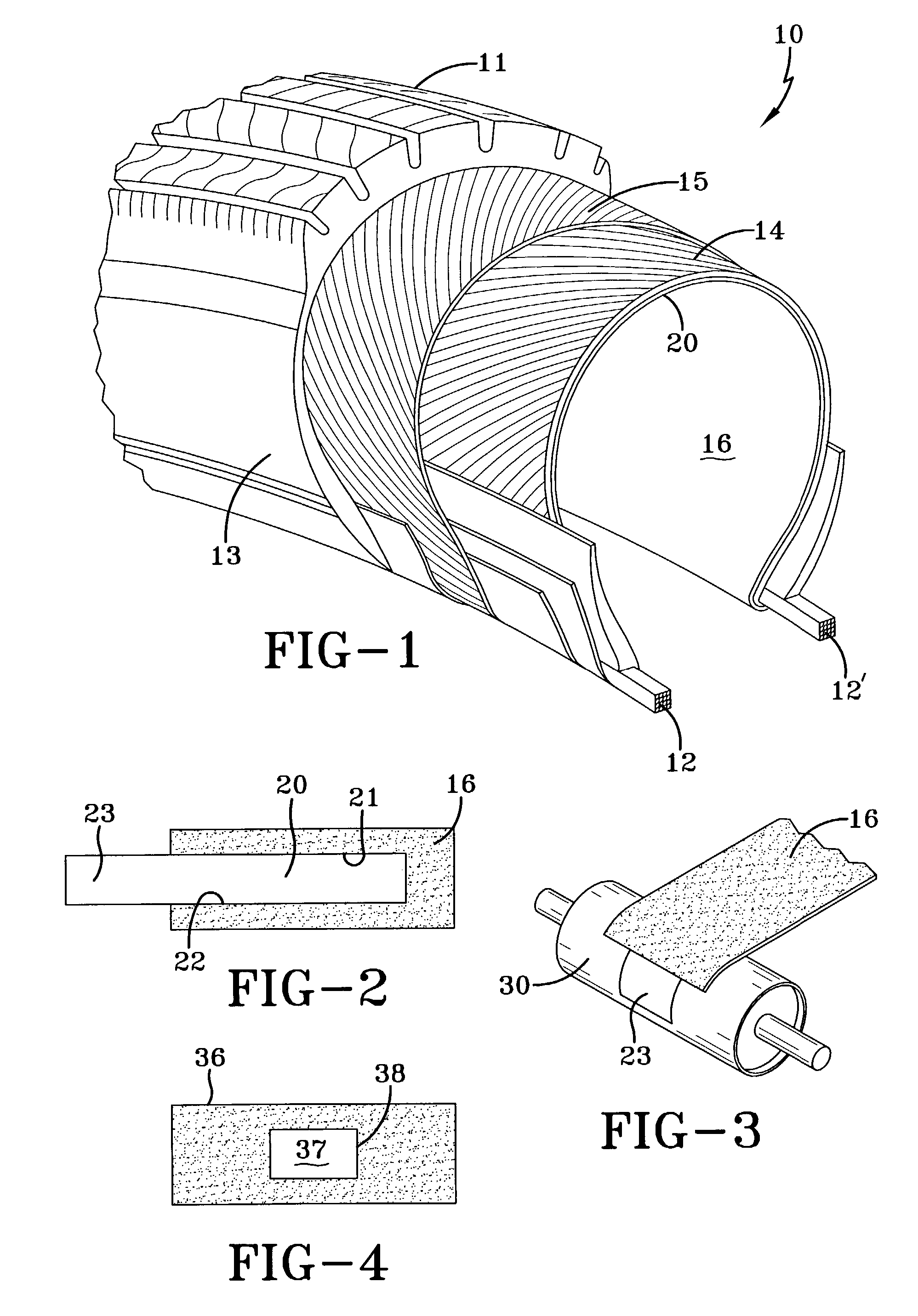

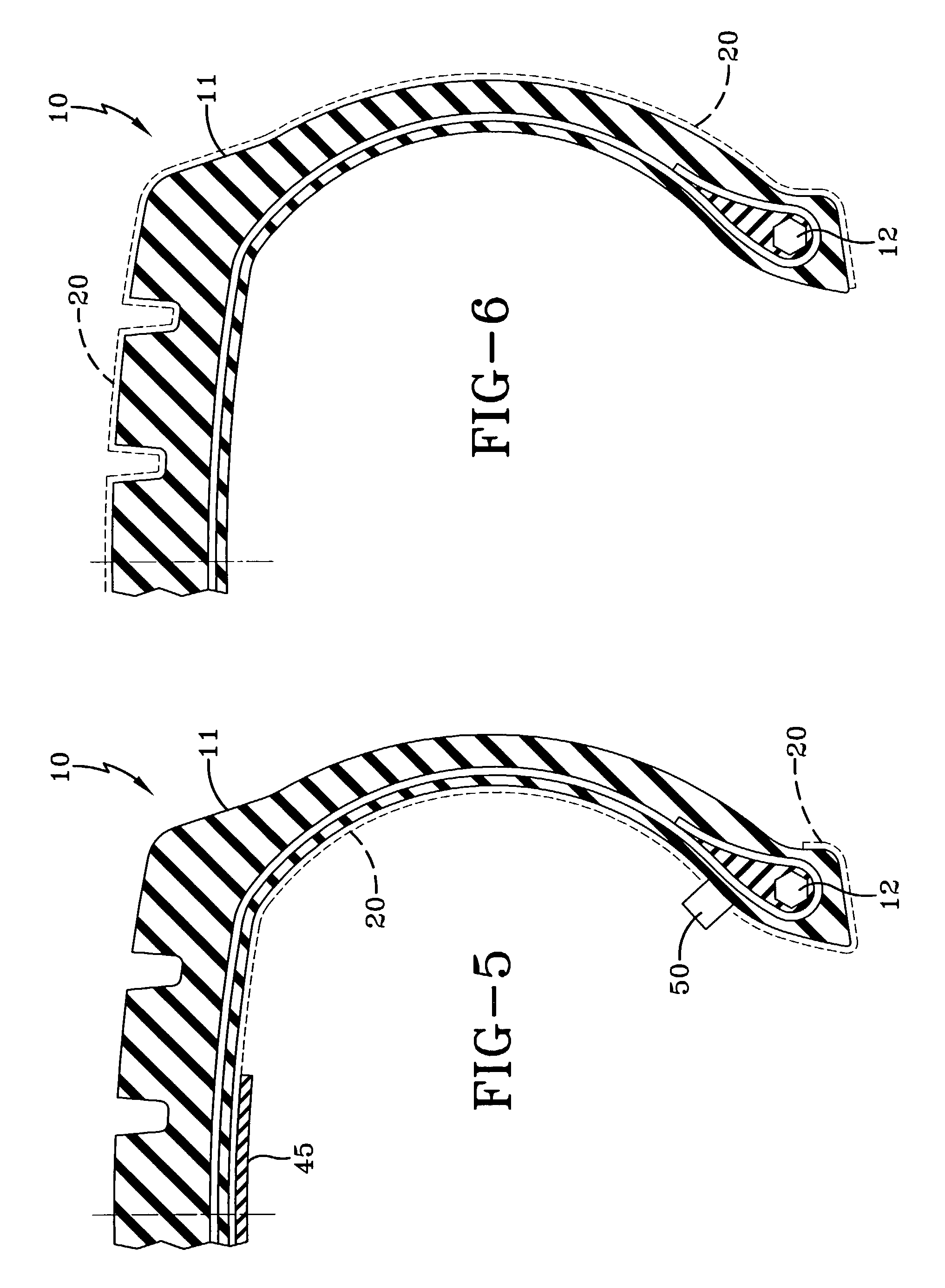

Adherent, removable barrier film for tire carcass

InactiveUS7332047B2Prevent scalingLamination ancillary operationsWithout separate inflatable insertsSulfurEngineering

A bond of a rubbery component to a virgin surface of a tire's cured innerliner which virgin surface has never been contaminated by the remnants of a release agent left after buffing with a wire brush and solvent-cleaning the cured innerliner, is unexpectedly stronger than a bond of the component to the contaminated but “cleaned surface”, cleaned as indicated. As an alternative, buffing with a wire brush results in a textured surface that impairs adhesion of a balance pad. Therefore, a pneumatic tire is provided with a virgin surface protected against contamination by a release agent at the curing temperature of the tire; protection is provided by a self-supporting barrier film of sulfur non-vulcanizable, expandable, thermoformable synthetic resinous material; and, a method is provided for maintaining a virgin cured surface within all or part of either the exterior or interior of a pneumatic tire's rubber carcass which is conventionally cured. The barrier film which is substantially inextensible at ambient temperature, is removable without tearing into pieces from the protected surface of the cured tire. When the interior surface is provided by an innerliner, any component to be included within the interior of the carcass may be adhesively secured to the virgin surface of the innerliner more securely than has been heretofore possible.

Owner:THE GOODYEAR TIRE & RUBBER CO

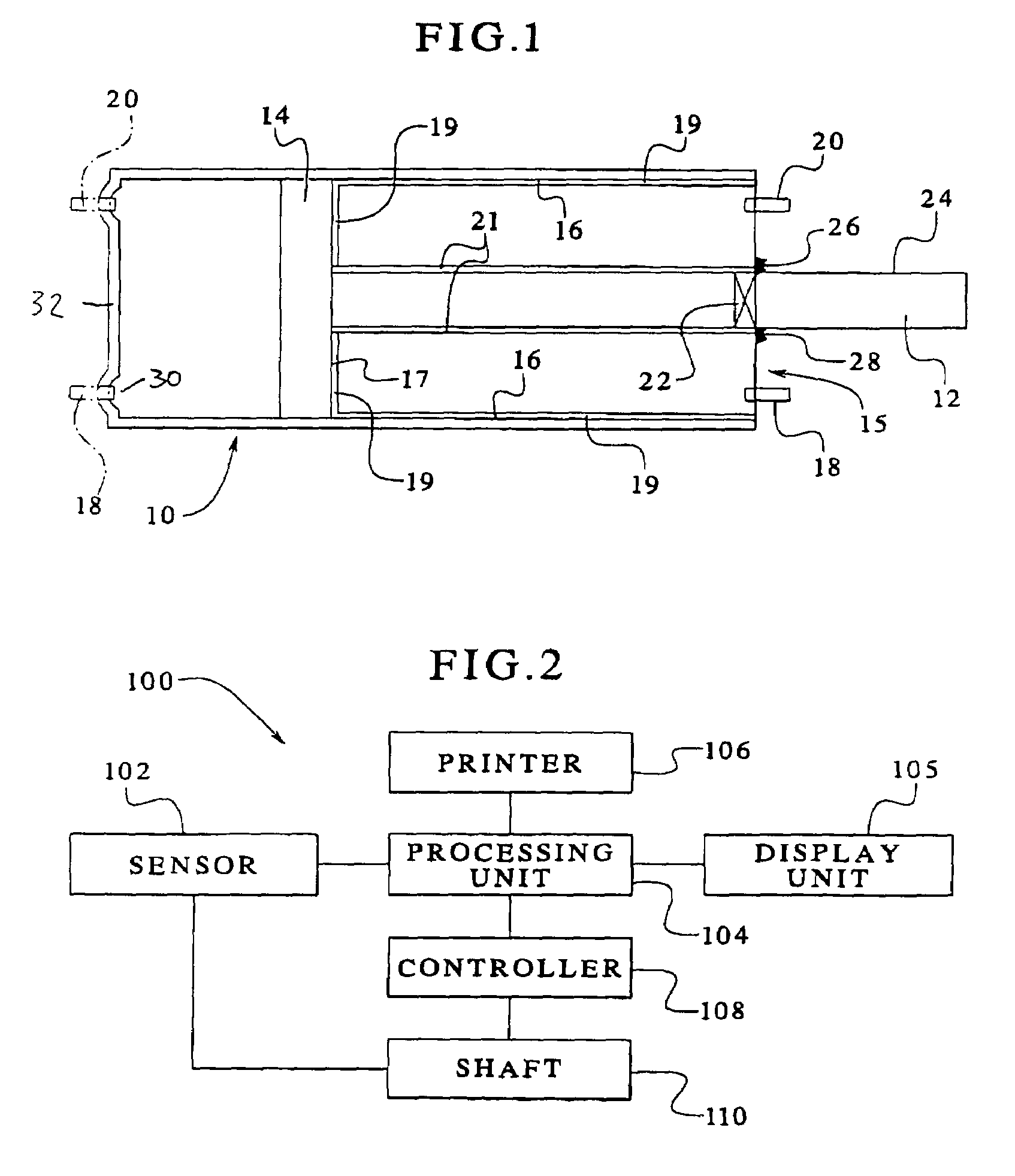

Pipe cleaning and deburring tool

A plastic housing has a front shell with inwardly protruding bristles of an exterior wire brush, and a rear shell which retractably receives the outwardly protruding bristles of an interior wire brush. The interior brush is mounted to a shaft which engages the housing, and which is driven by a motor, such as by a power drill. A ring-like deburring element is mounted to the shell between the front shell and the rear shell, and has an inwardly and frontwardly protruding generally frustoconical first wall forming a deburring element which defines a central opening through which the interior brush may be projected and retracted. The first wall may be planar segments, or may have a circular cross section. The deburring element serves to position a pipe for burnishing by the exterior brush, and also deburrs the end of the inserted pipe.

Owner:RED CEDAR PLASTICS

Rotary washing blockage relieving pipe cleaning device

The invention relates to a rotary washing blockage relieving pipe cleaning device which comprises a main cylinder body, an assistant cylinder body, a pressure control valve and a rotary washing mechanism, as well as a scraping plate and a leather cup mounted on a main shaft of the pipe cleaning device, wherein the assistant cylinder body is fixed at the front end of the main cylinder body; the pressure control valve is fixedly arranged in an inner chamber at the rear part of the main cylinder body; the rotary washing mechanism is mounted on the assistant cylinder body; the pressure control valve is fixed on the inner wall of the main cylinder body through a supporting plate; the supporting plate adopts a hollow structure; the rotary washing mechanism comprises a rotary washing spray head and a wire brush mechanism; rotating nozzles and horizontal nozzles are arranged on the outer wall of the rotary washing spray head; the inner wall of the rotary washing spray head is connected with a turbine group through a power shaft; the turbine group is mounted in an inner chamber of the assistant cylinder body; the wire brush mechanism consists of a crank sliding block mechanism and wire brush heads. The failure of pipeline blocking caused by hard dirt and more sewage can be effectively removed, and the pipe cleaning device reduces energy consumption, and is economical and practical.

Owner:SOUTHWEST PETROLEUM UNIV

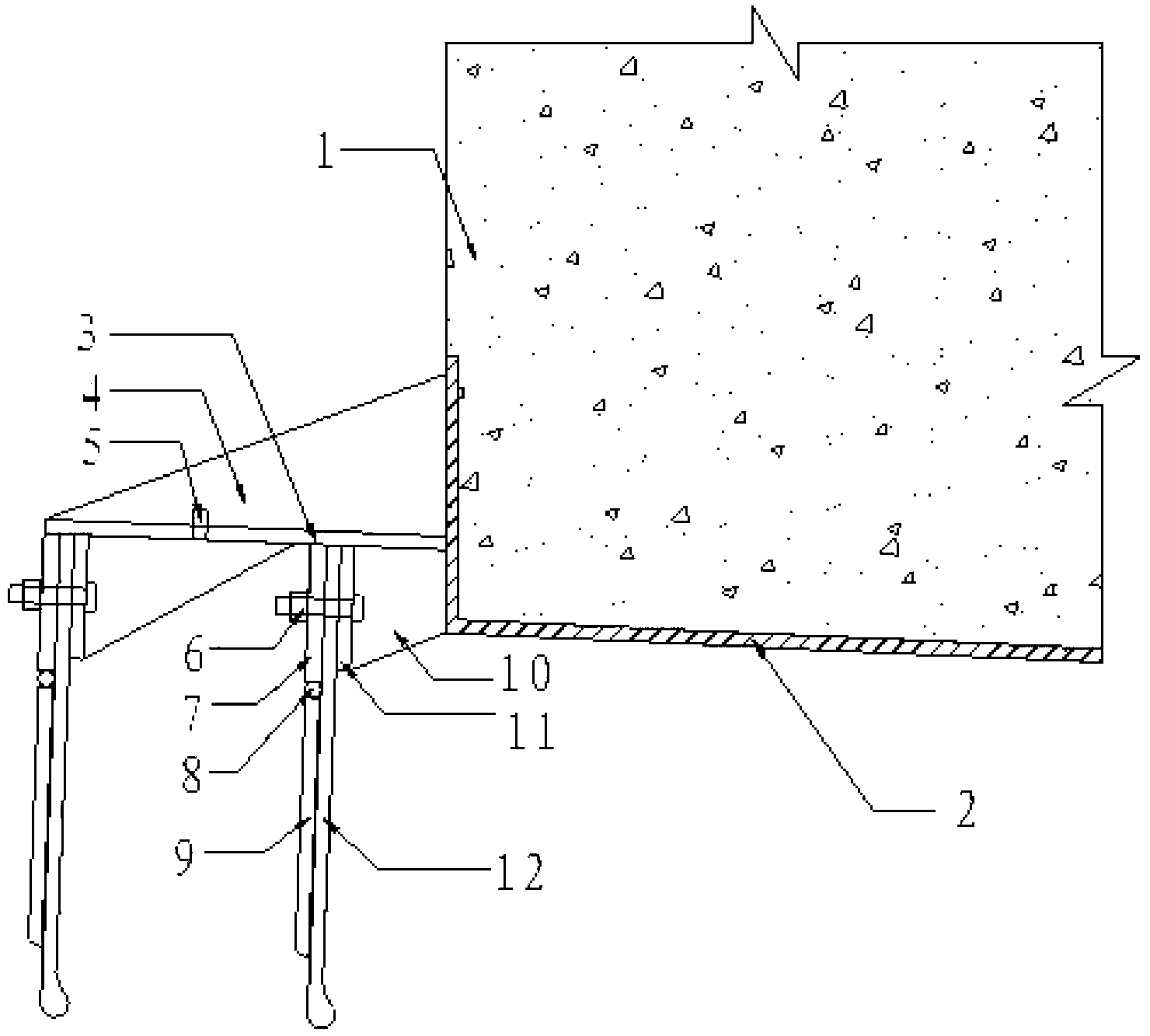

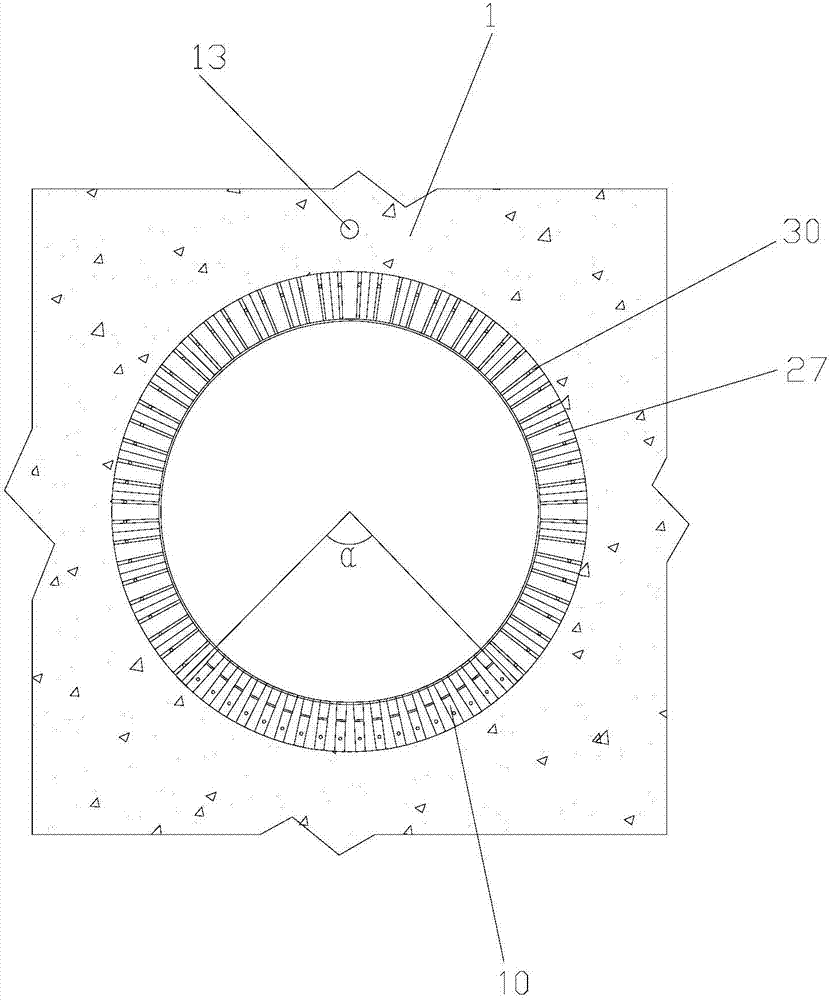

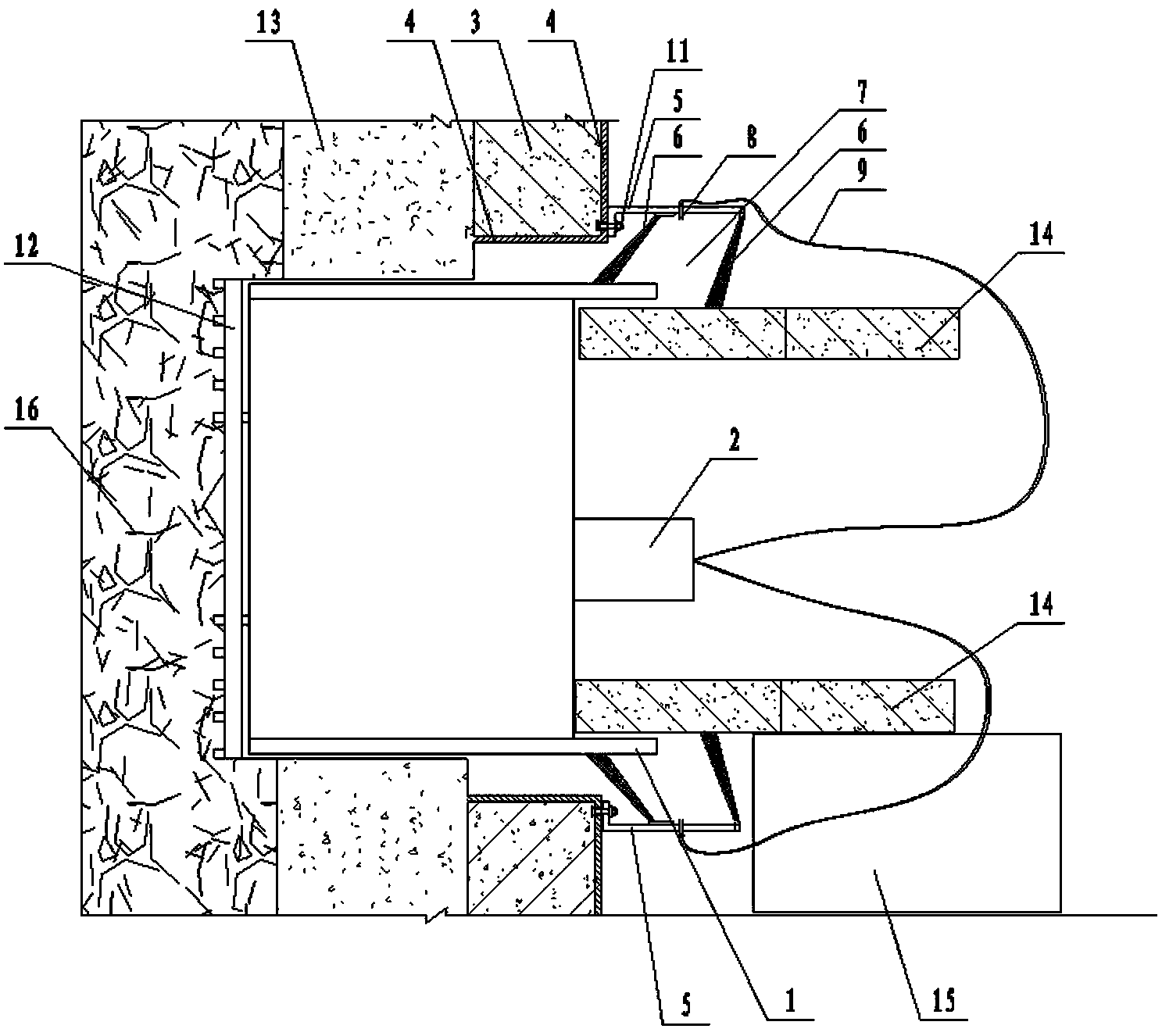

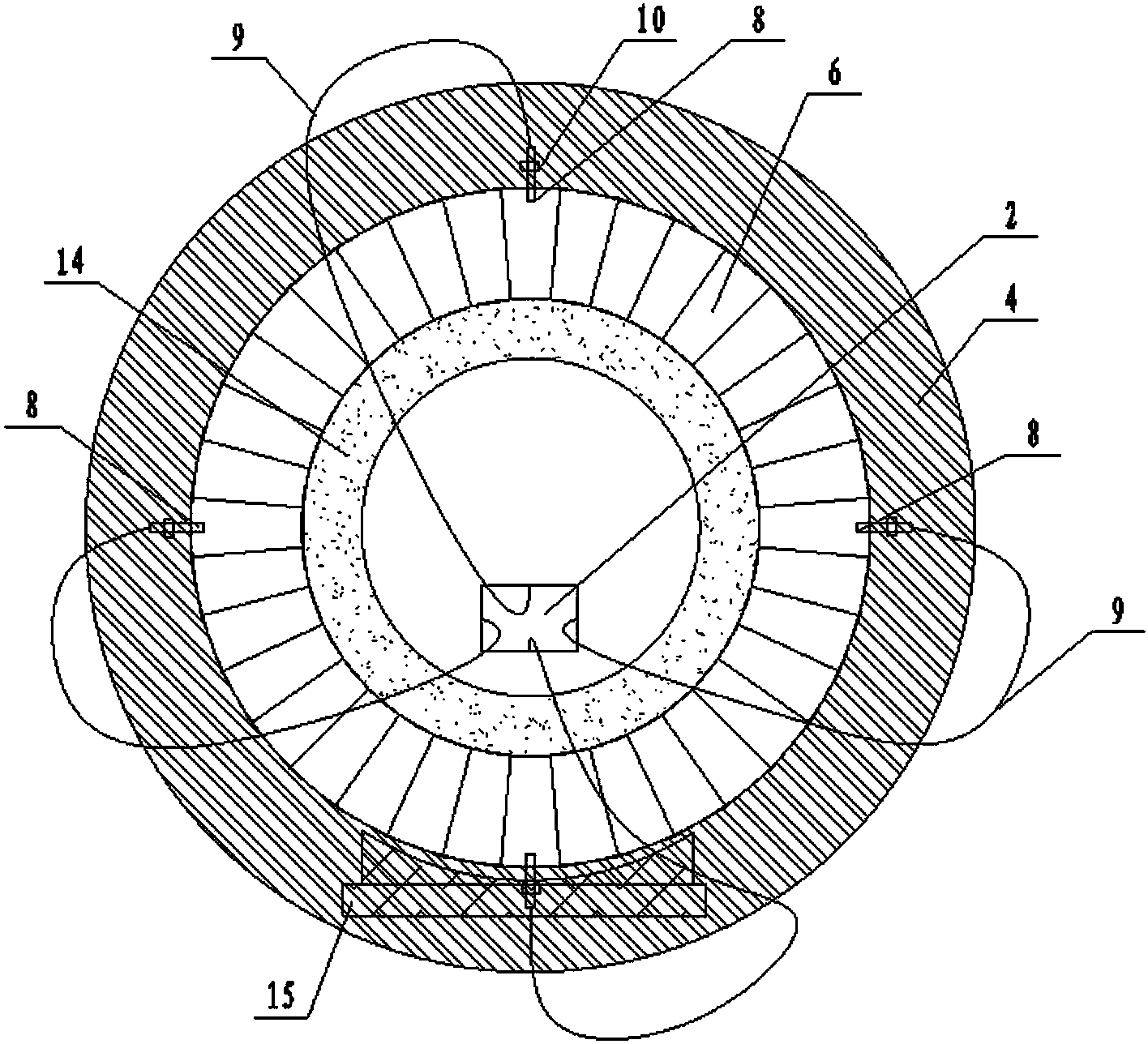

Shield tunnel portal sealing device and shield tunnel portal sealing method

InactiveCN103266898APrevent gushingPrevent water seepageUnderground chambersTunnel liningEngineeringShield tunneling

The invention belongs to the technical field of shield tunnel engineering and particularly relates to a shield tunnel portal sealing device and a shield tunnel portal sealing method. The shield tunnel portal sealing device comprises a lined wall, an embedded steel ring is arranged on the lined wall, a sealing box is arranged on the embedded steel ring and comprises a sealing steel ring, a fixing plate, a fold type support plate and two waterproof structures, a plurality of grease injecting holes are evenly circumferentially reserved in the sealing steel ring between the two waterproof structures, each waterproof structure comprises a steel wire brush and a cord fabric rubber plate, the cord fabric rubber plates are arranged on one side close to the embedded steel ring, and grouting holes are reserved in the lined wall and in the sealing steel ring on the inner sides of the cord fabric rubber plates. The shield tunnel portal sealing device has the advantages that the cord fabric rubber plates are primarily used for sealing to prevent a major part of water and soil from pouring out, so that 'pouring prevention' is achieved; water penetration is prevented as the steel wire brushes secondarily achieve seamless contact with a shield tunneling machine shell or duct pieces; and the grouting holes reserved in the lined wall and the sealing steel ring can achieve grouting sealing timely in emergencies.

Owner:CCCC SECOND HARBOR ENG

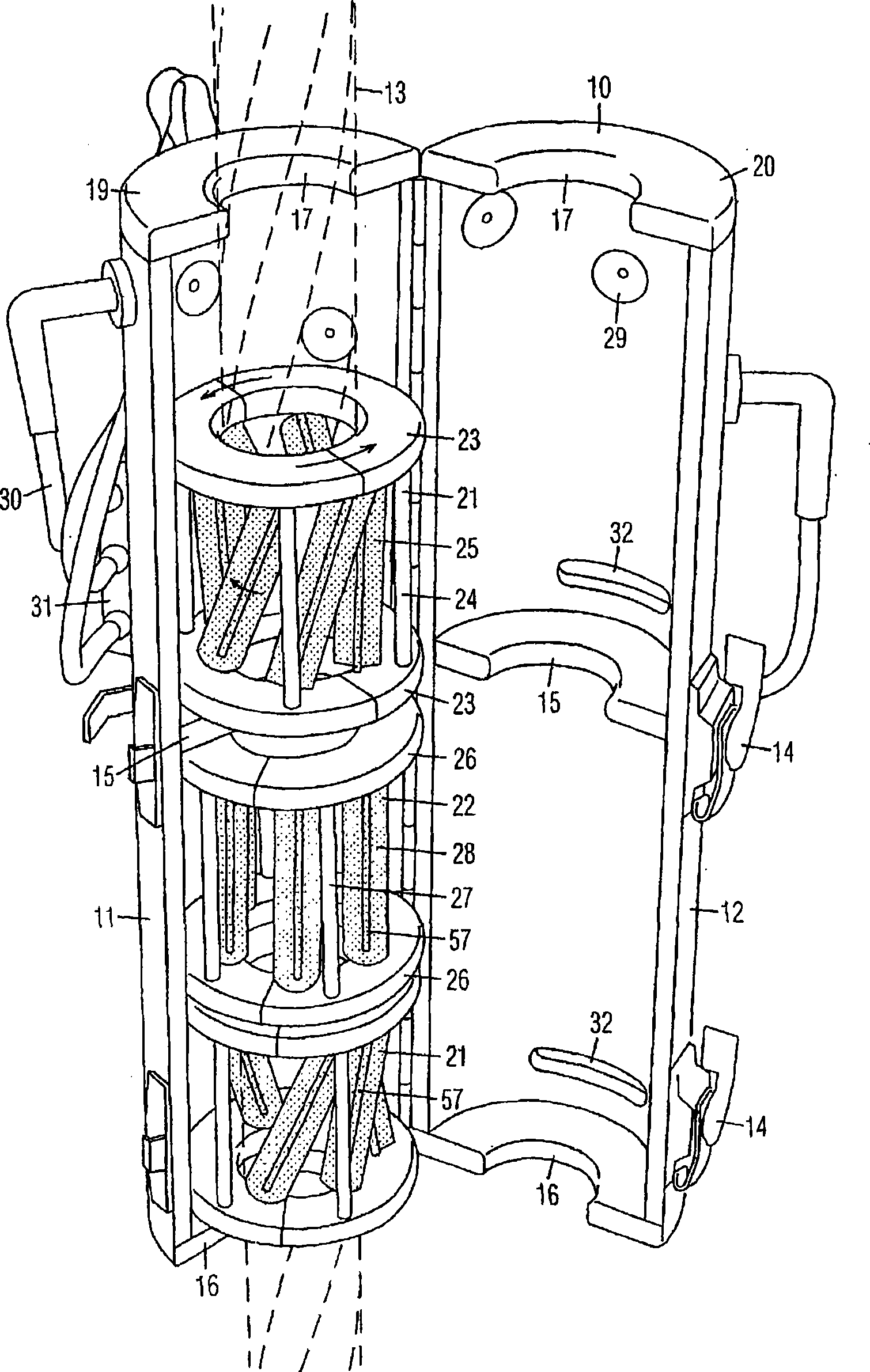

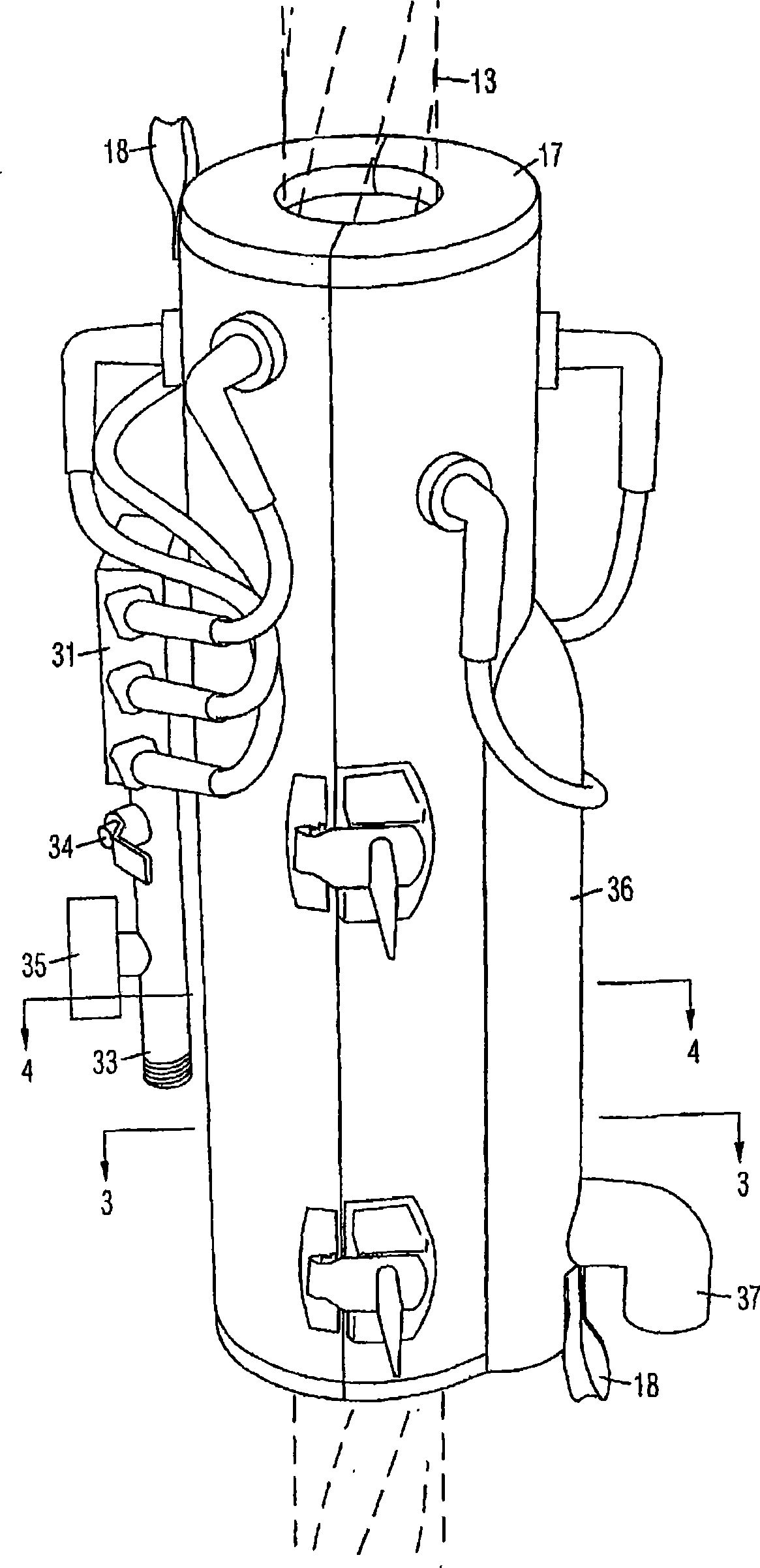

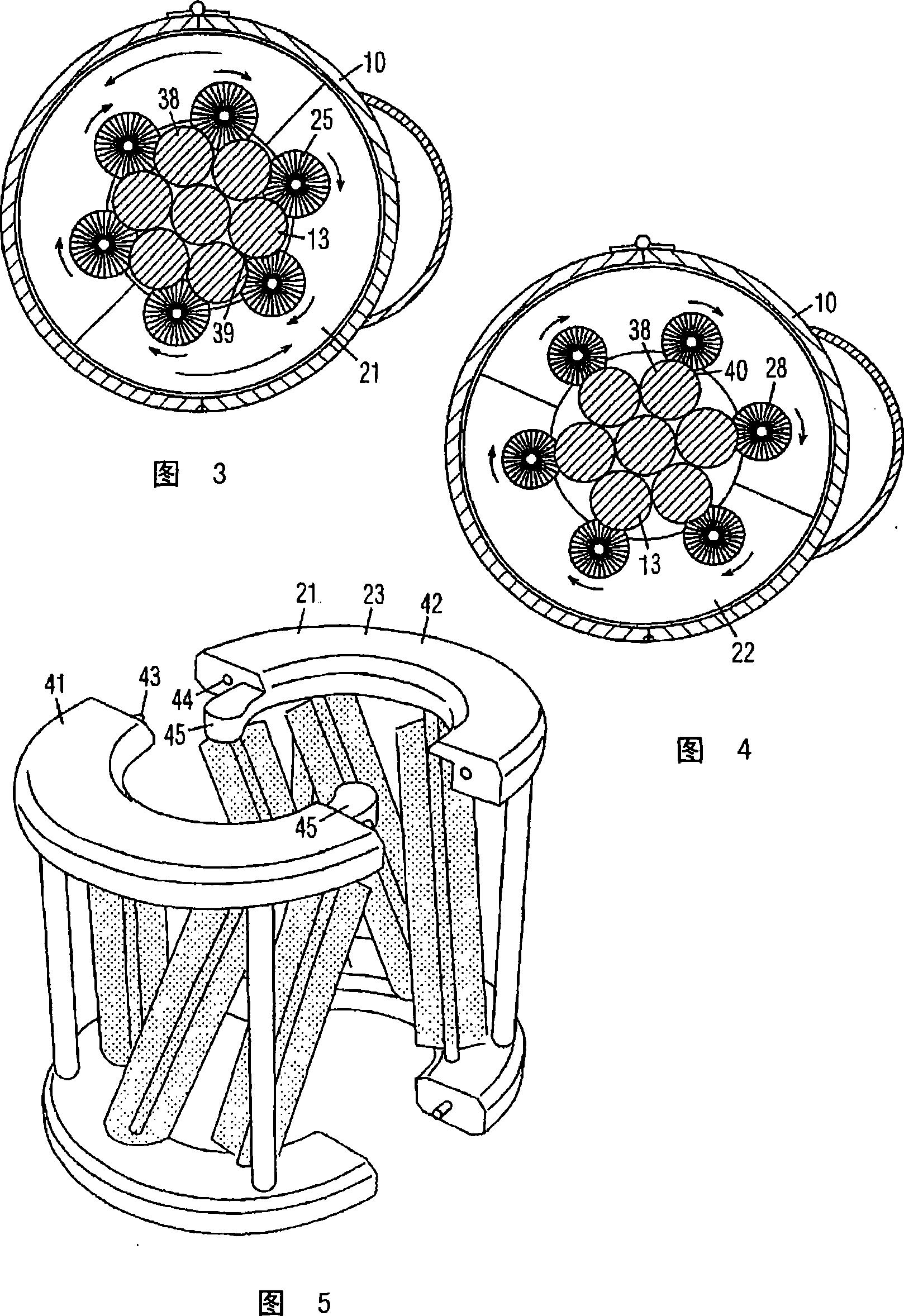

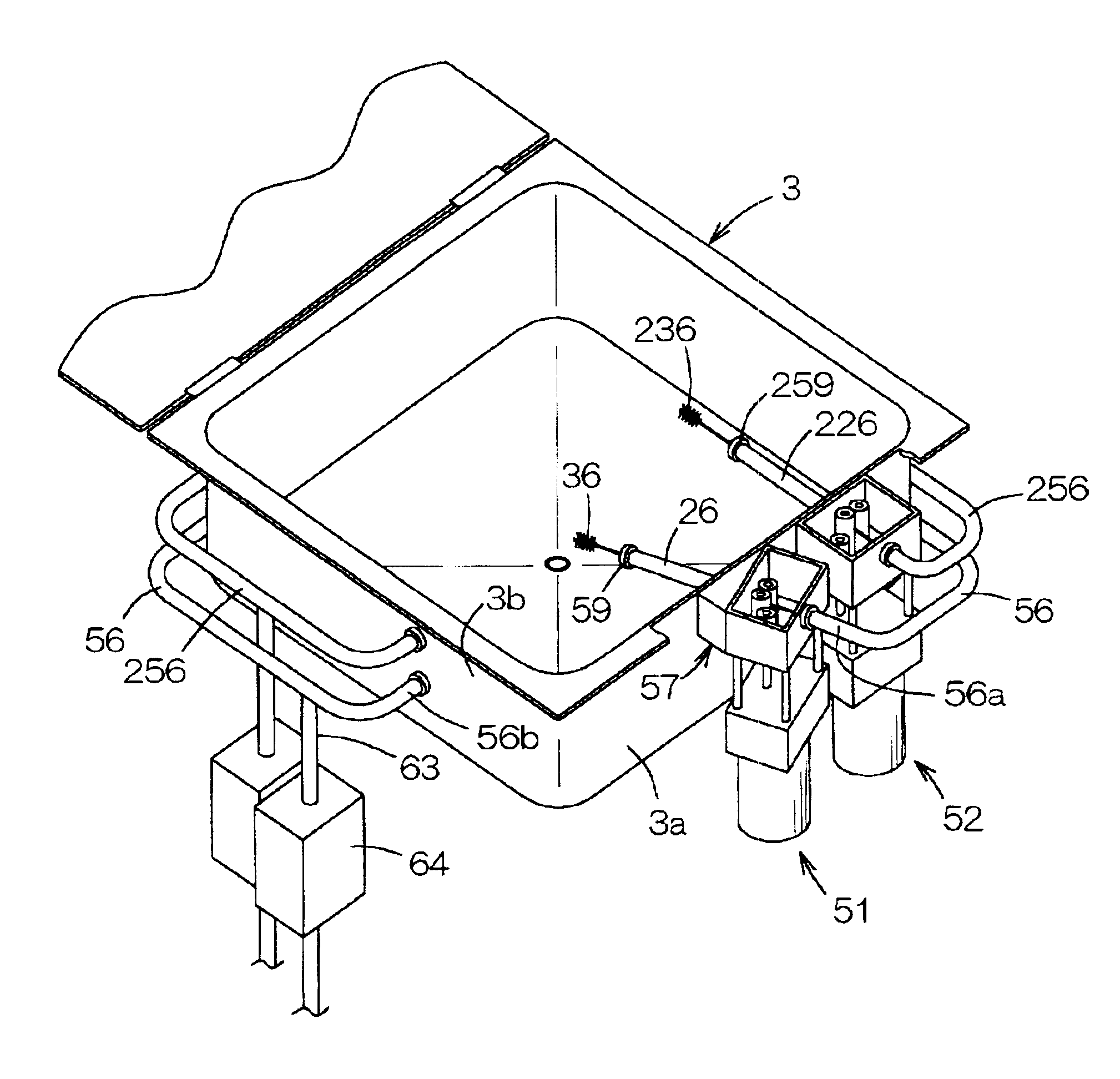

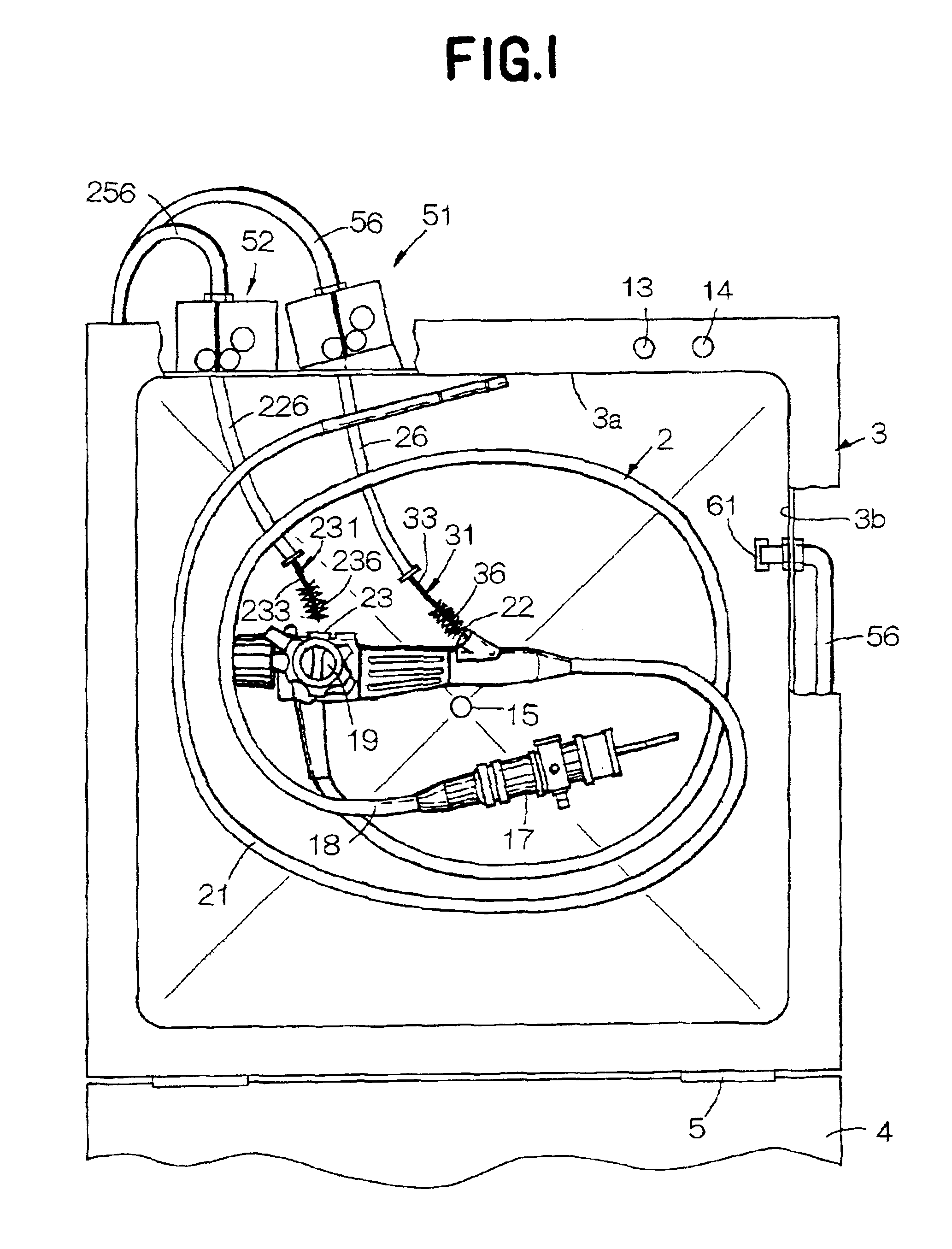

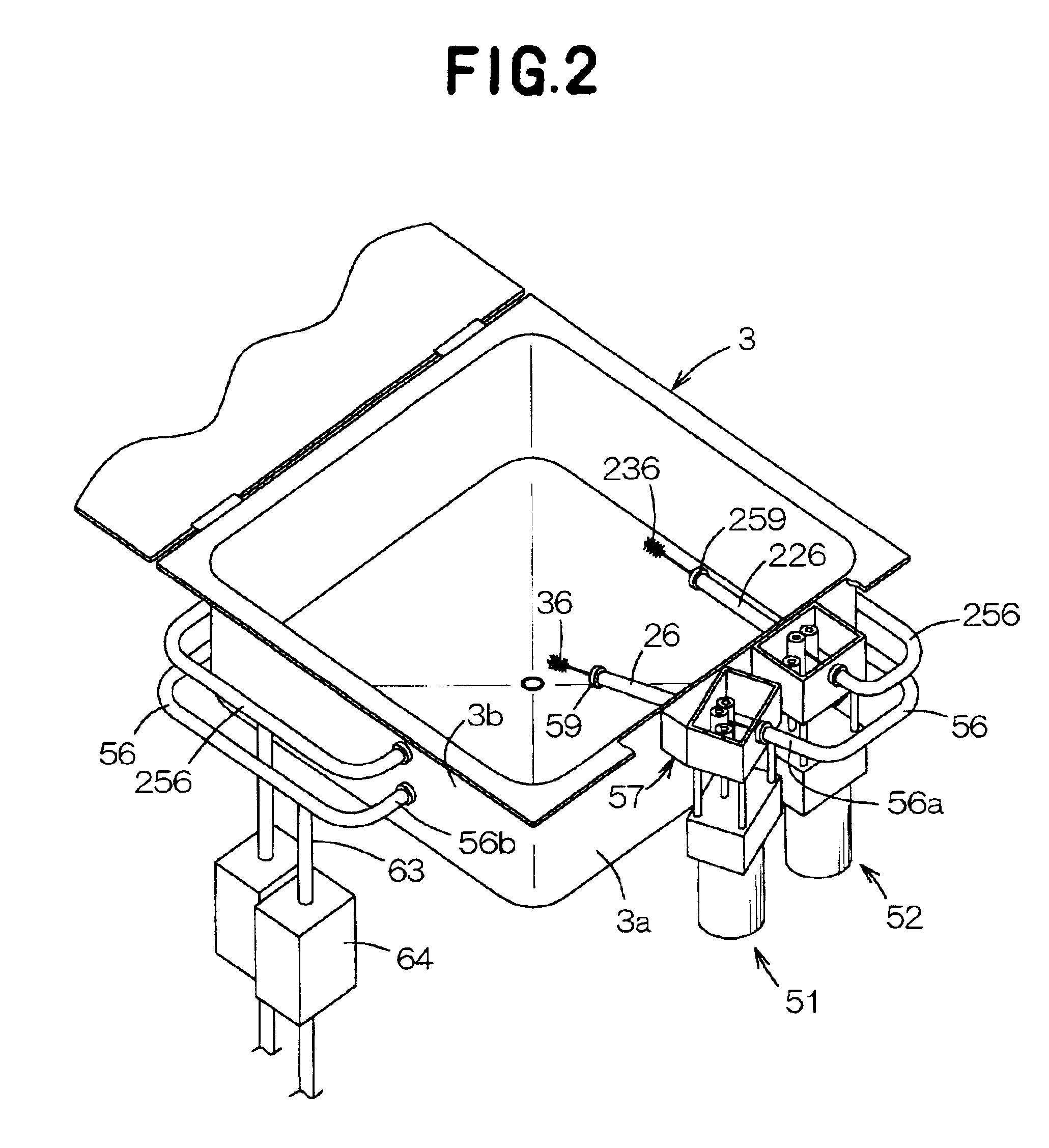

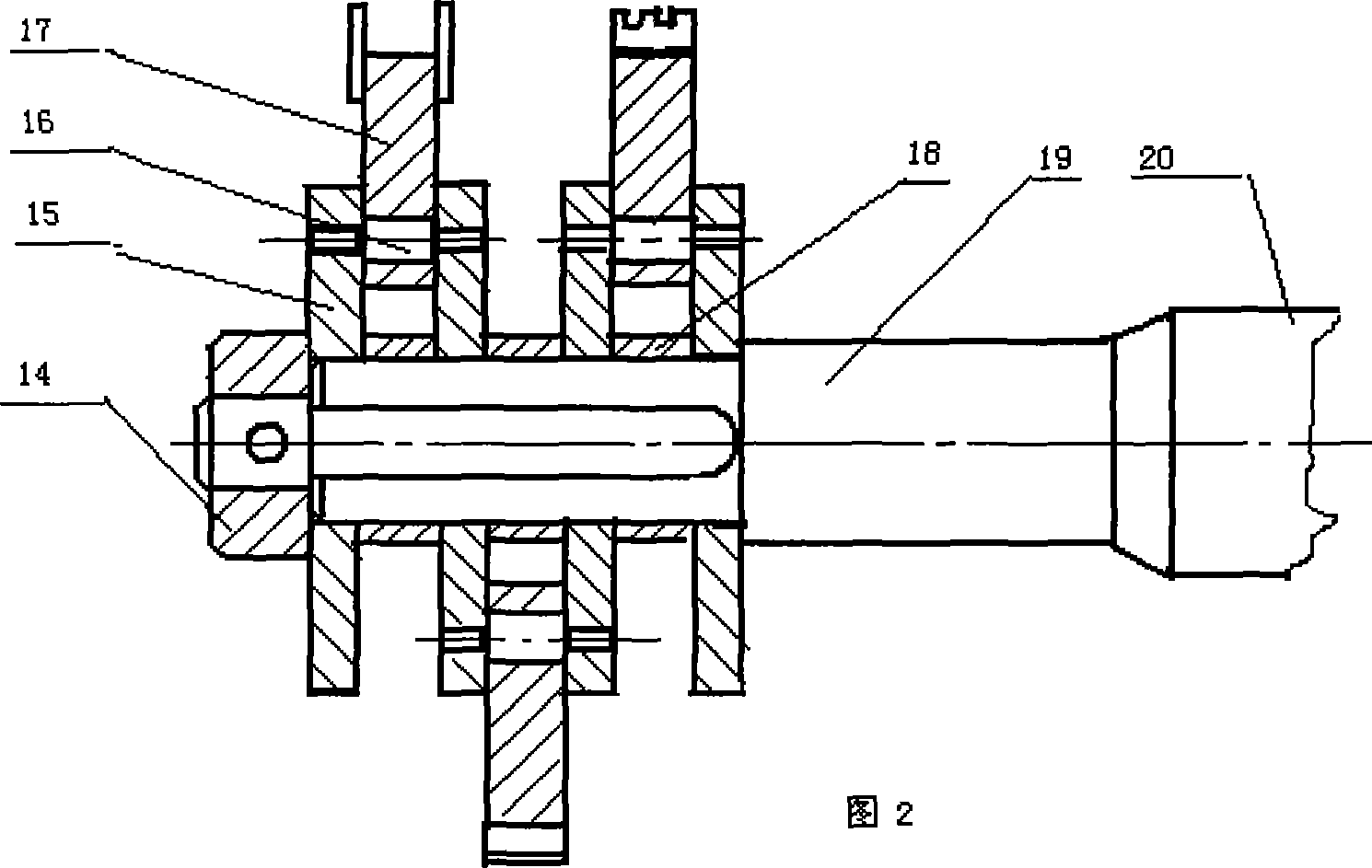

Cylindrical member maintenance device

A cylindrical member maintenance device is comprised of a housing (10) comprised of two hinged halves (11, 12) for being closed around a cylindrical member (13), such as a stranded steel cable. A rotary helical brush assembly (21) and a rotary longitudinal brush assembly (22) are positioned in the housing and rotatable about an axis of the housing. Each rotary brush assembly is comprised of coaxial split rings (23, 26) with rotary cylindrical wire brushes (25, 28) connected in between and which are independently rotatable about their own axes. Nozzles (29) are positioned on the inside of the housing for applying a cleaning fluid or paint to the cylindrical member. Apertures (32) in the housing are for connecting to a suction device for removing debris, cleaning fluid, and paint to avoid contaminating the environment. Loops (18) on the housing are for attaching to cables for moving the housing along the cylindrical member.

Owner:H & H ENG

Method for detecting solid concrete impermeability by core boring sampling

InactiveCN101149368AReal reflection of impermeabilitySimple and fast operationMaterial testing goodsPermeability/surface area analysisEngineeringDrill

A kind of drill sample method to detect the impermeability of solid concrete structure, using the drill sample method to get the concrete cylinder in the detected solid concrete structure; cuts the concrete cylinder into cylinder core board; puts the cylinder core board in the center of the cylinder test module; pulls the grouting material in the space between the cylinder test module and the cylinder core board to mold; uses the steel wire brush brush away the grout film in the end after demoulding, then doing standard maintain to it; takes six cylinder impermeability piece as a group, besmears a flat of melt airproof material in their side face, and then push down to the sample cover which has been preheat by the oven, test them at the impermeability instrument; the water pressure of the test begin at 0.1 megapascal, observe the water penetration situation of the cylinder impermeability piece end at any moment, when three of the six cylinder impermeability piece water penetrates, stopping the test, record the water pressure value of the time, calculates the impermeability grade according to the formula. It can really reflect the impermeability of solid concrete.

Owner:CHINA CONSTR FOURTH ENG DIV +1

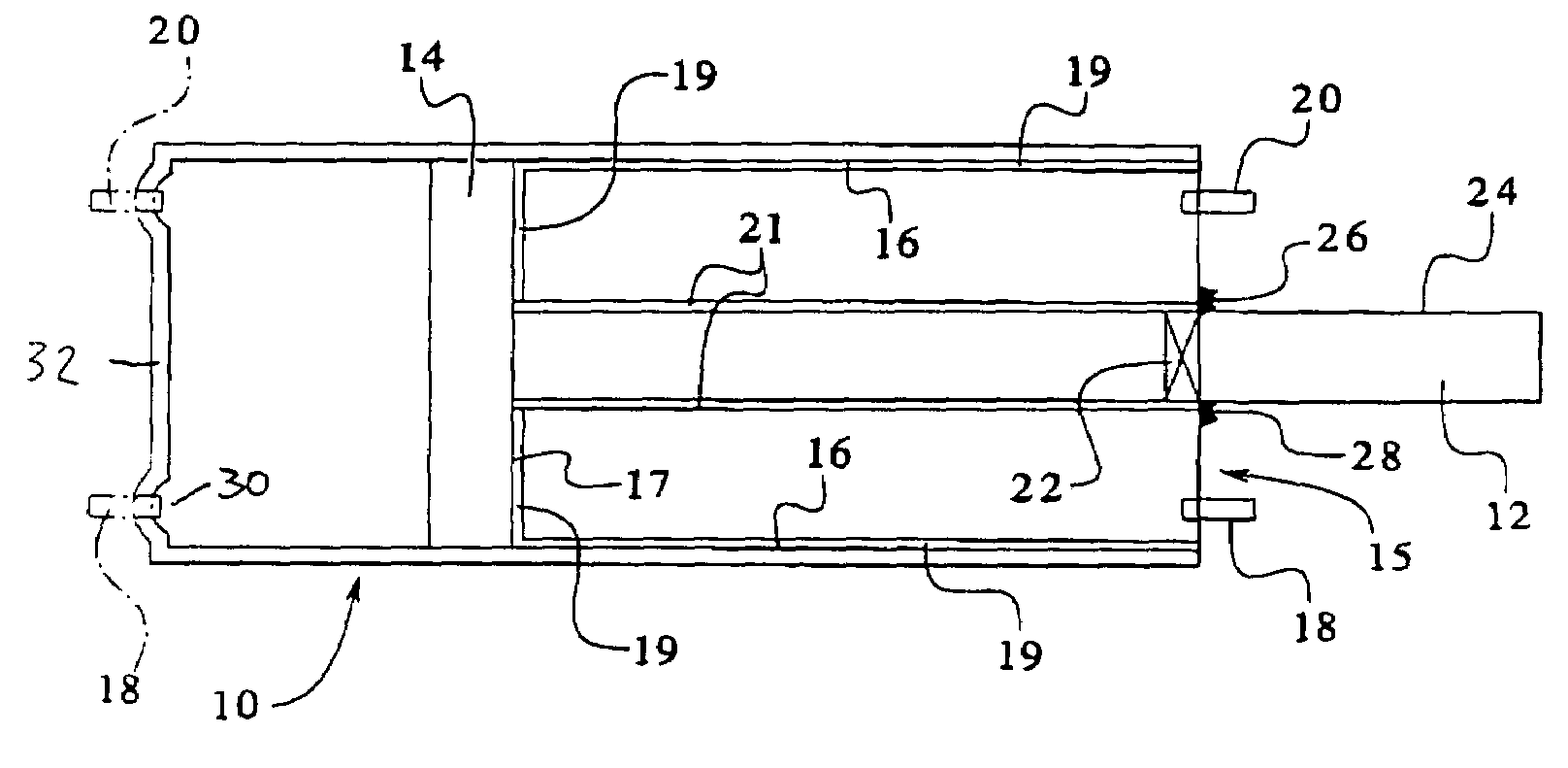

Apparatus, a system and a method for monitoring a position of a shaft element in a cylinder and an apparatus, a system and a method for cleaning of the shaft element

InactiveUS6952009B1Indication of overall efficiencyLong-term useMaterial analysis by optical meansMachines/enginesEngineeringBronze

An apparatus, a system and a method are provided for monitoring position of a machine element within a mechanical system and / or cleaning a machine element. A light source and sensor may be positioned within a cylinder. The sensor may detect the intensity of light within the cylinder as a shaft element moves laterally throughout the cylinder. The measurement may indicate the position of the shaft element within the cylinder. In addition, a seal, a wire brush and / or a bronze brush may be placed near an end wall of a cylinder. The seal may surround the shaft element. Furthermore, the shaft element may be coated with a compound, such as a nitrile compound or a ceramic compound or the like. The wire brush and bronze brush may be in contact with the shaft element and may scrape any contaminants, such as weld spatter, which may be deposited on the shaft element.

Owner:MOTION CONTROLS

Washing apparatus for endoscope

InactiveUS6928686B2Easy to controlPromote exchangeHollow article cleaningSurgeryEngineeringMechanical engineering

A washing apparatus for an endoscope includes a wire brush, a region for housing the wire brush and a driver adapted to advance and retract the wire brush. The wire brush is received in a pipe section of the wire housing region so that the wire brush may be selectively advanced out or retracted in this pipe section which is, in turn, provided along its front end portion and a rear end portion with position sensors to detect a position of a wire component of the wire brush.

Owner:KOKEN CO LTD

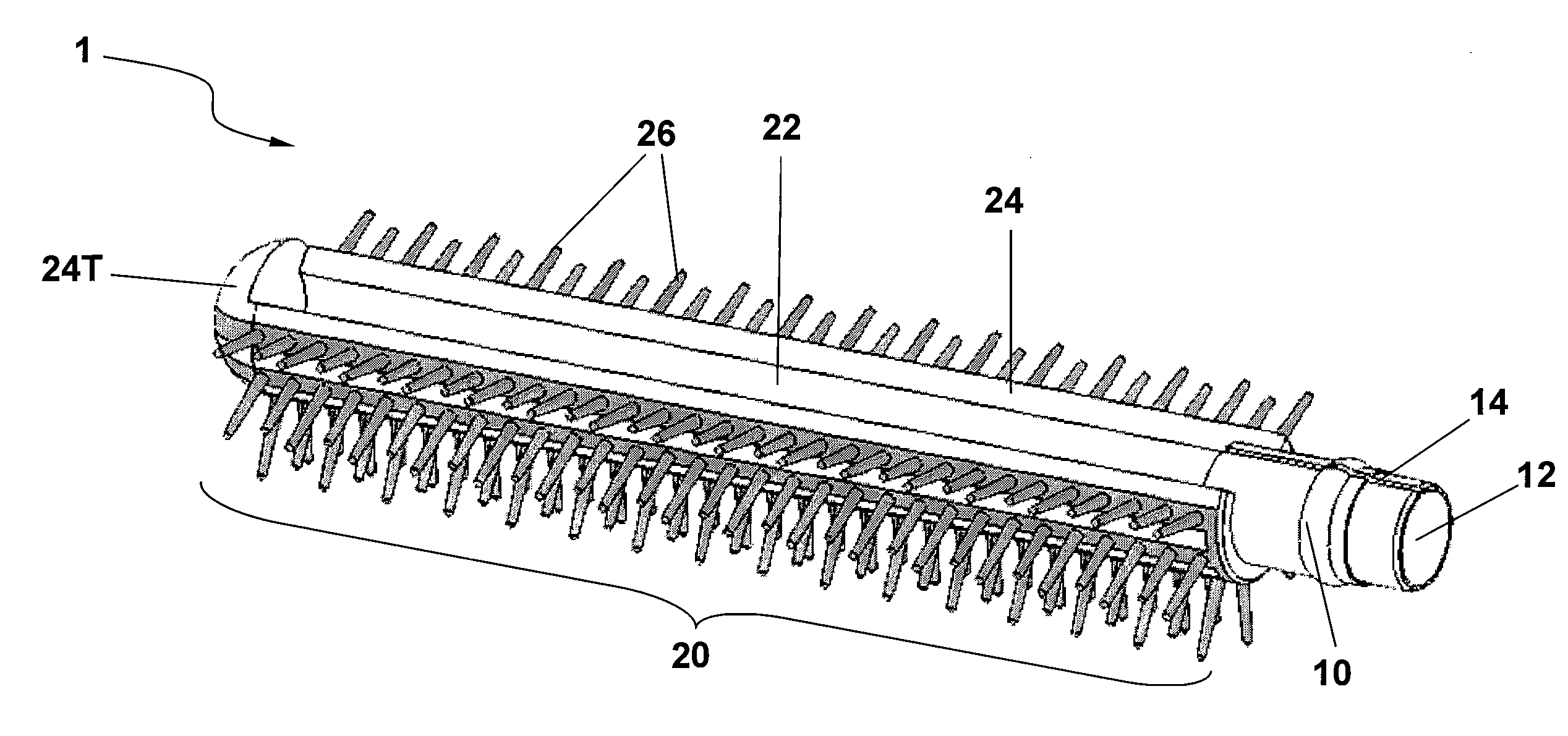

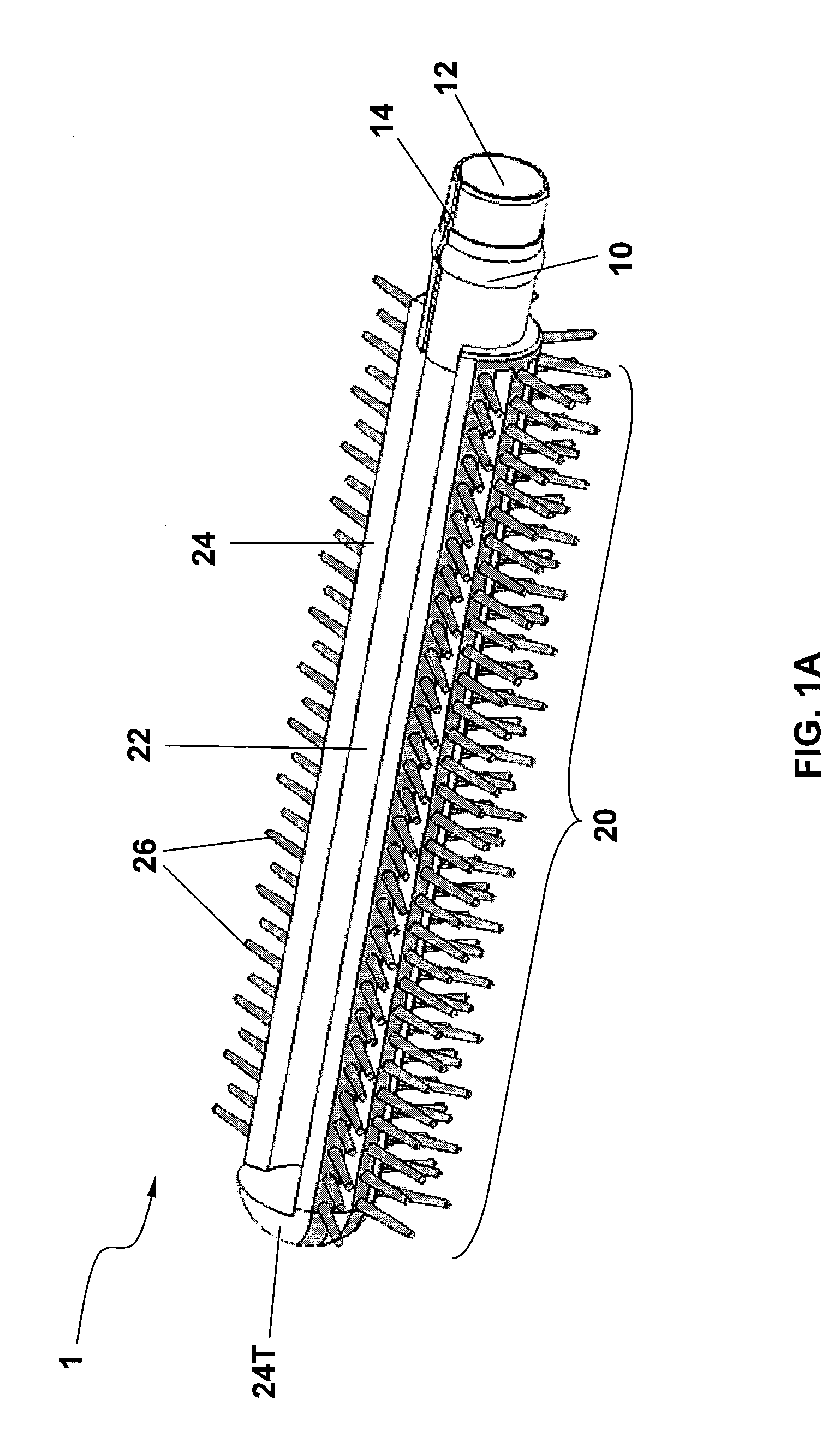

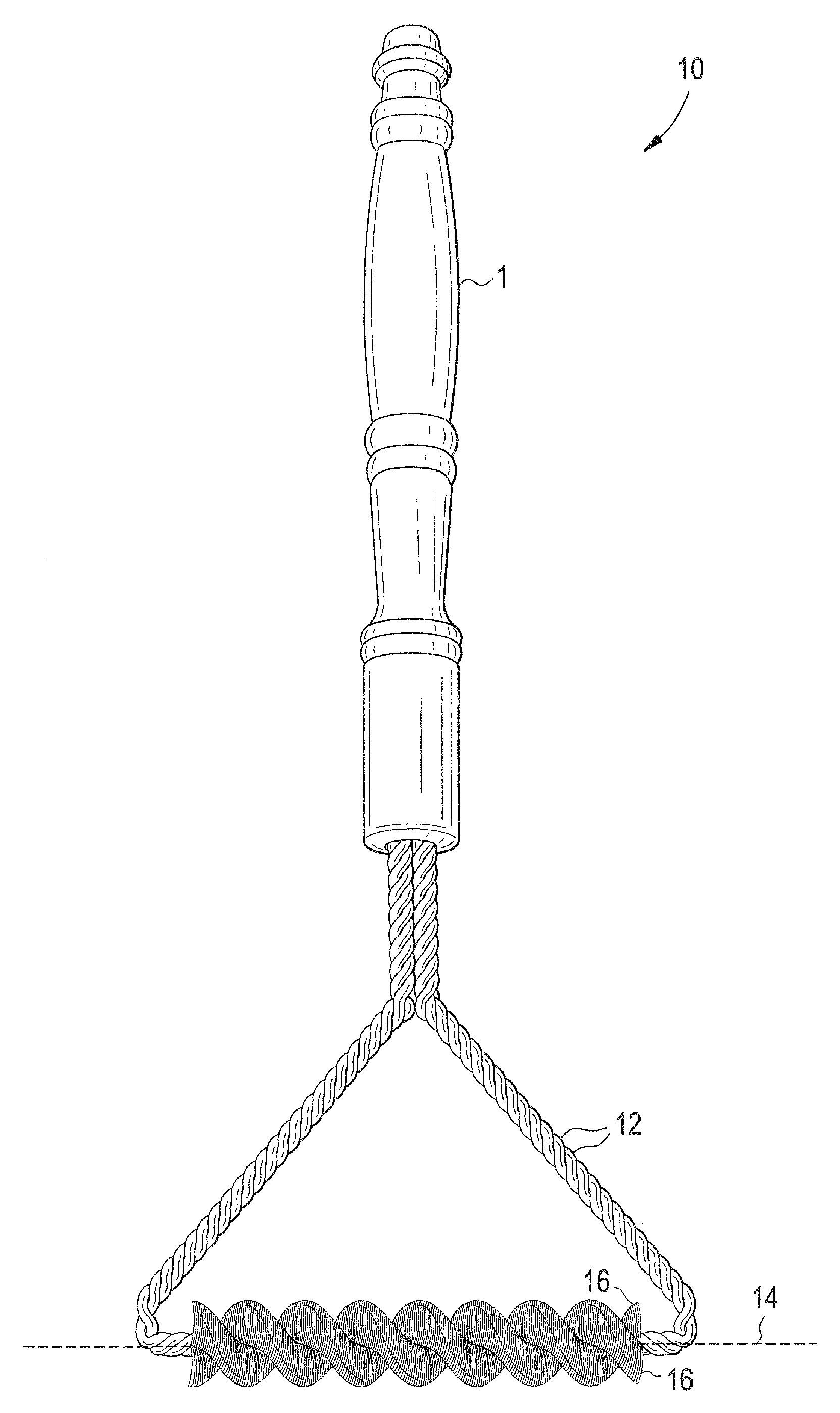

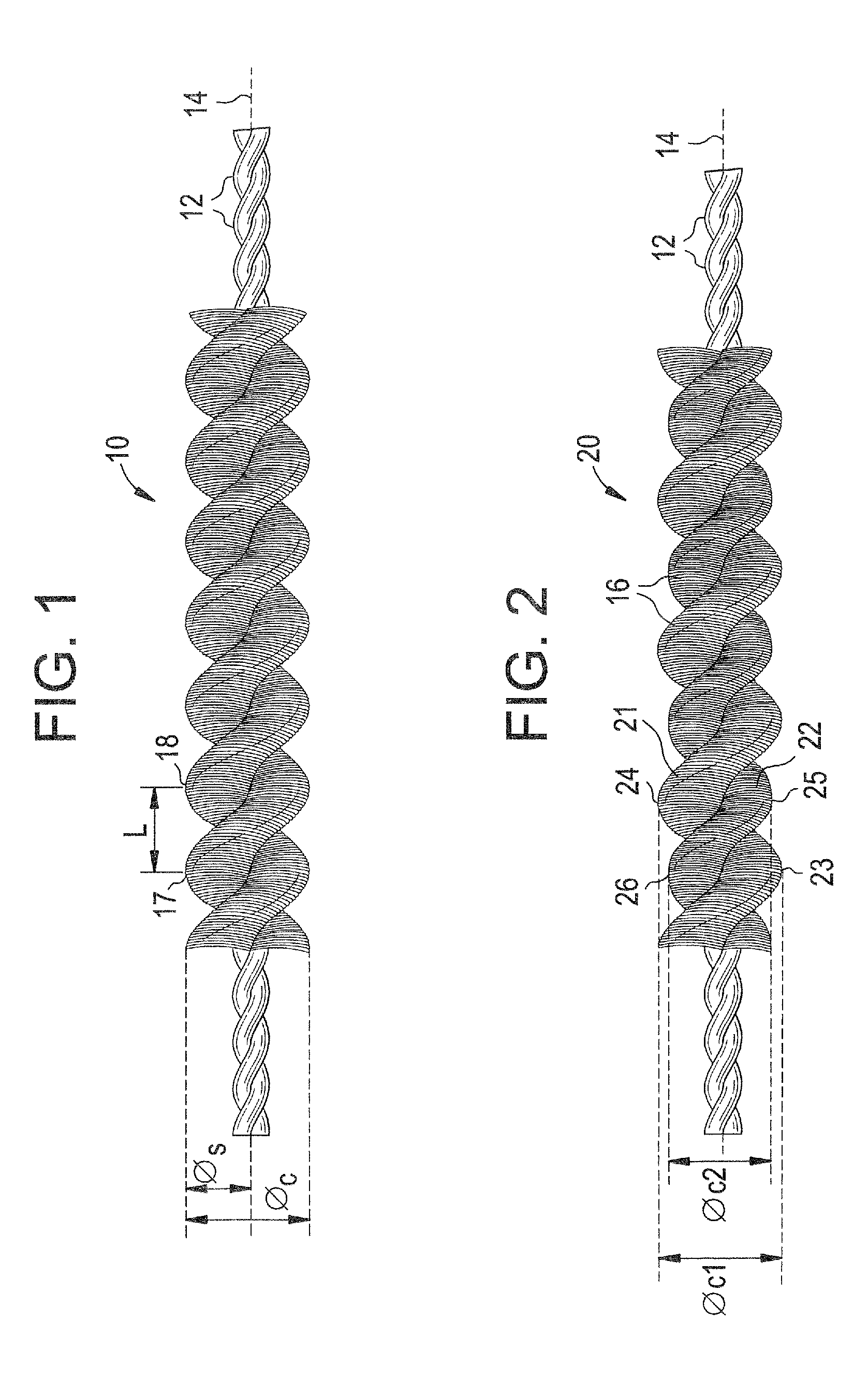

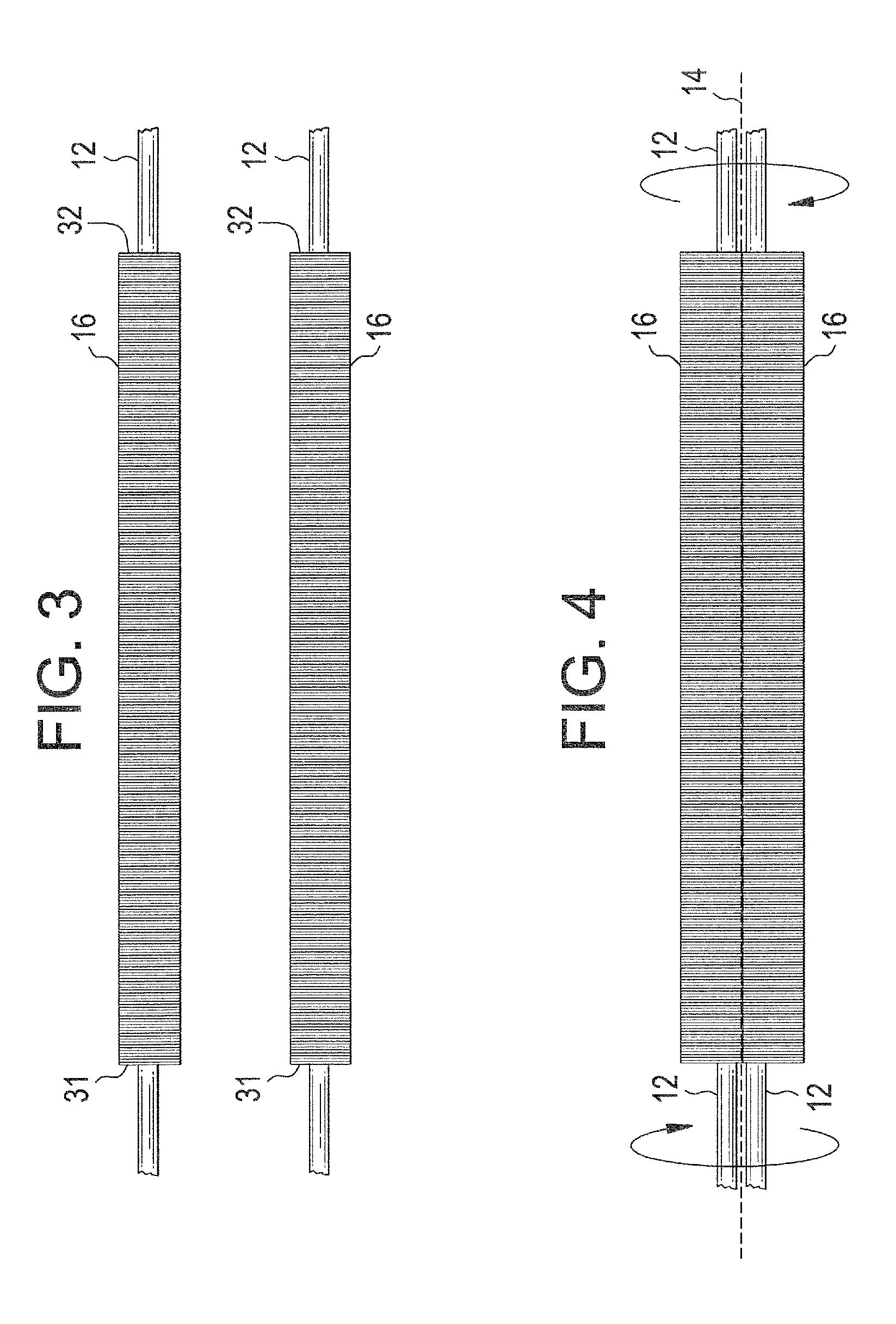

Twisted wire brush and method of making

Owner:BRUSHTECH

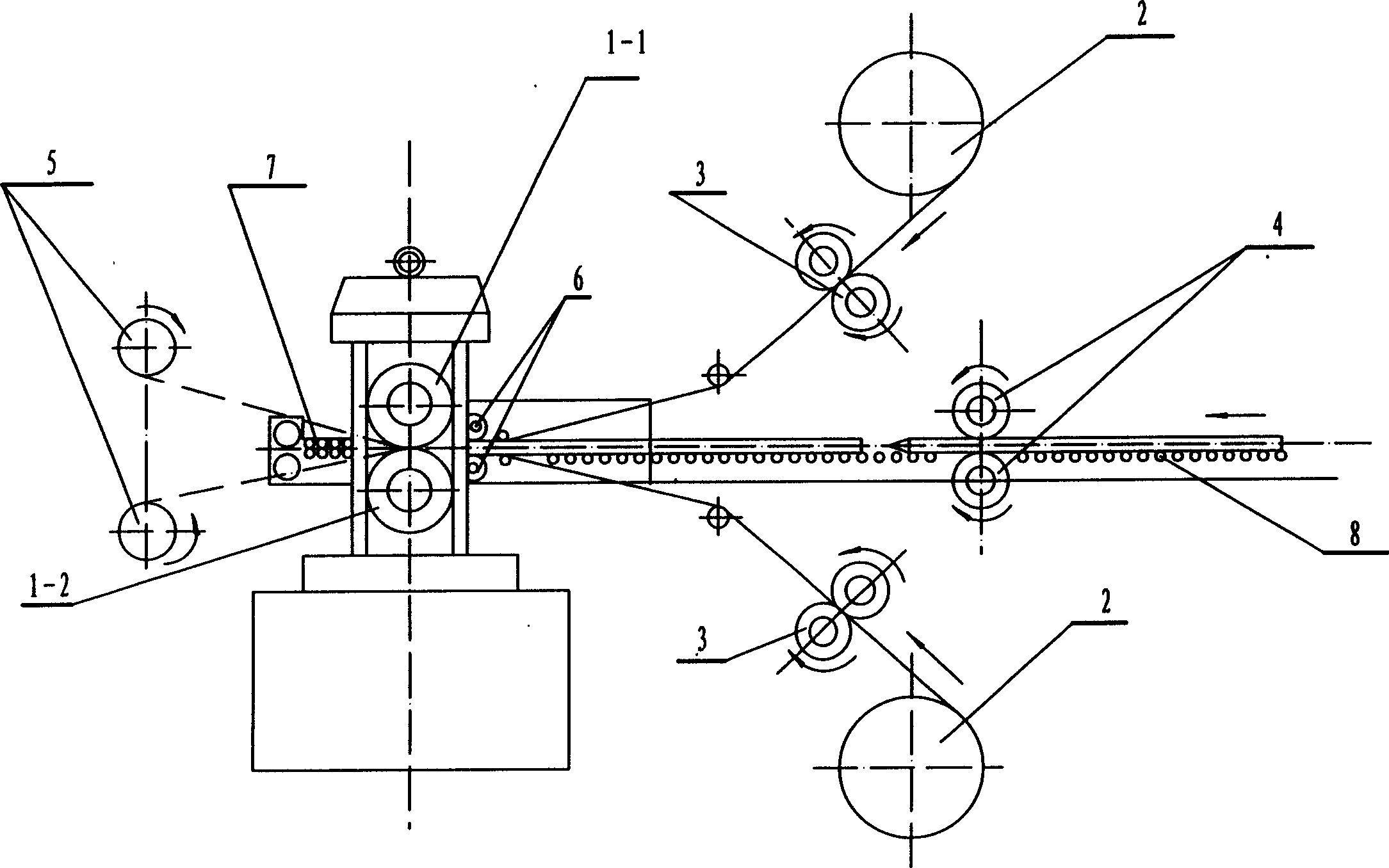

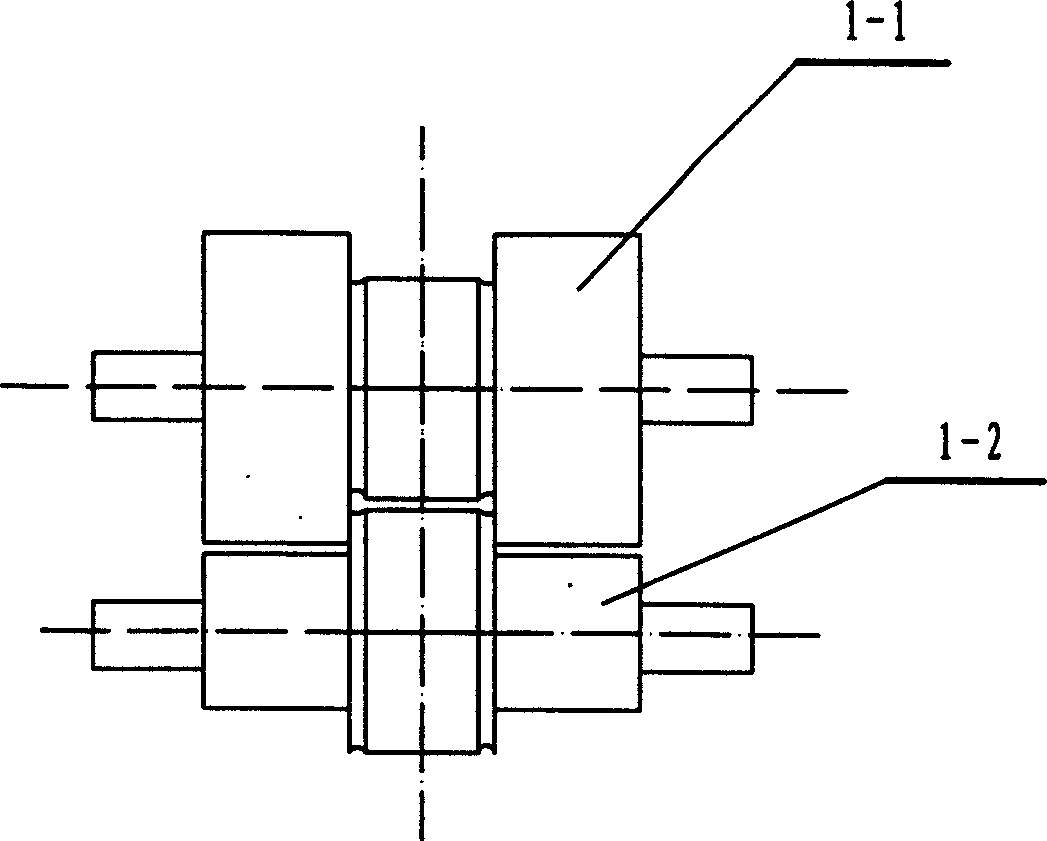

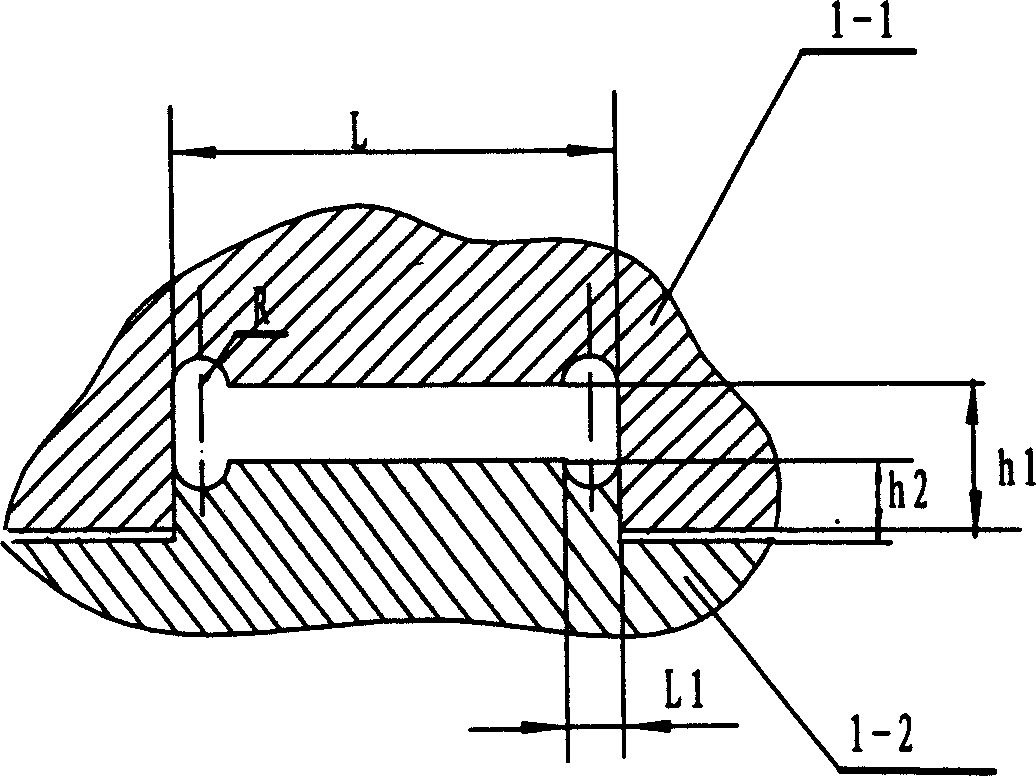

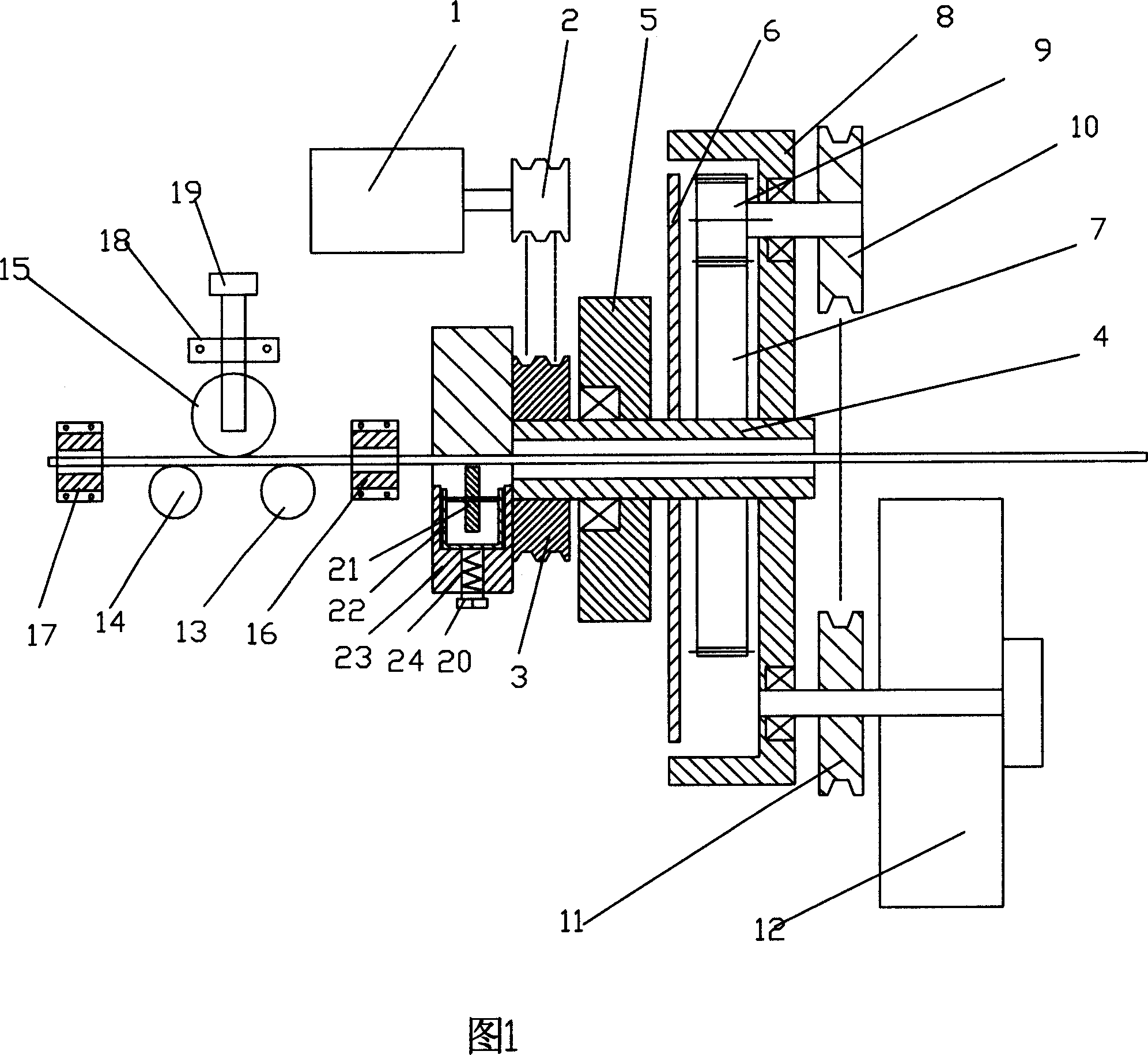

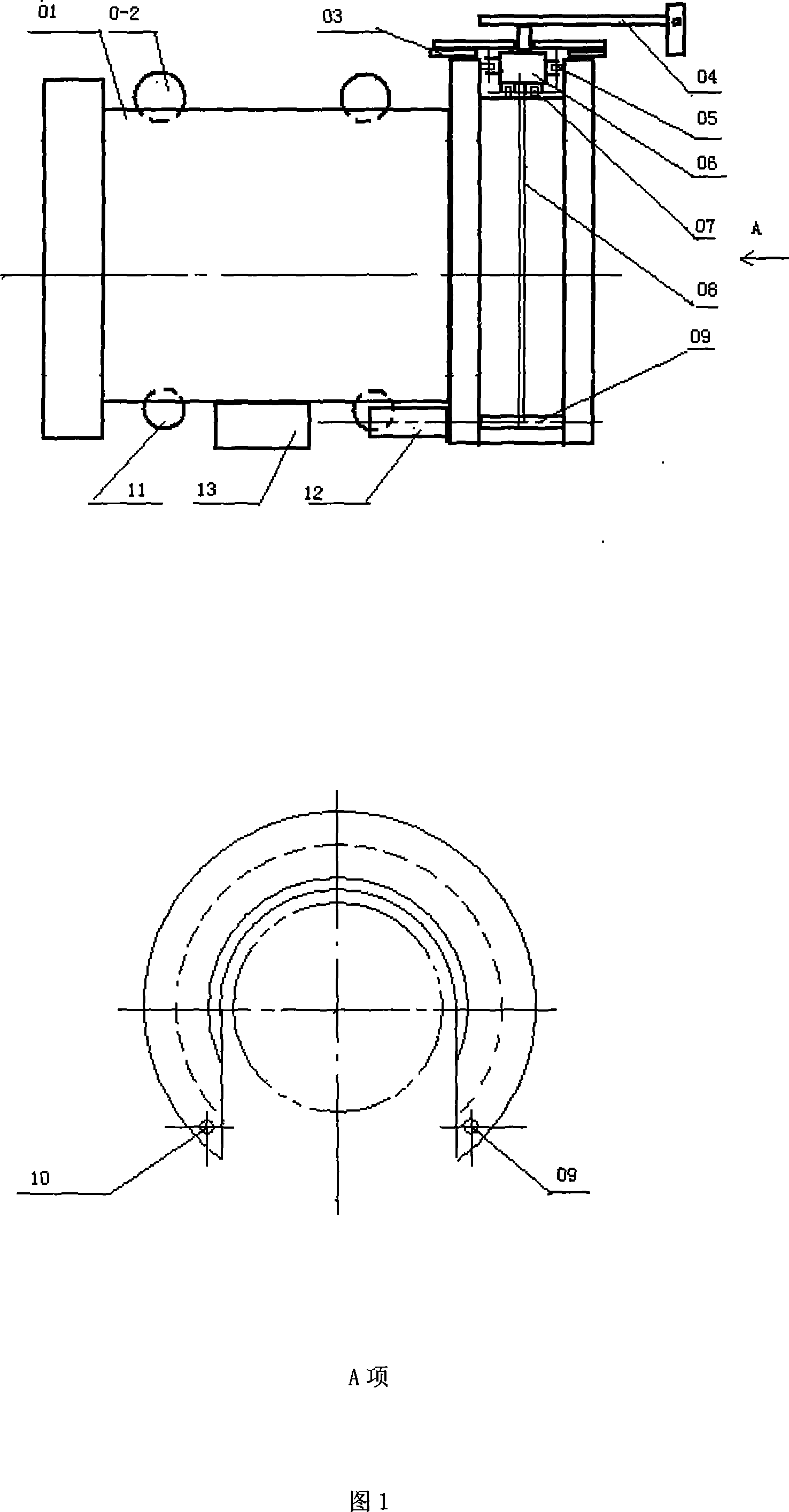

Steel wire rust cleaning method and device

InactiveCN1935396ANo need to deal withNo heating requiredCleaning using toolsExtrusion cleaning devicesIt equipmentMaterials science

The present invention relates to a steel wire rust-removing method and its equipment. Said method mainly includes the following two steps: firstly, mechanically-loosening rusty steel wire by utilizing a group of stripping rollers to make the rust on the steel wire surface be loosened; then brushing the rusty steel wire surface by adopting a steel wire rust-removing device. Said steel wire rust-removing equipment includes the following several portions: a supporting frame, a hollow main shaft, a rotary disk, a rust-removing roller, a pair of front guide sleeves and a pair of rear guide sleeves and a group of stripping rollers.

Owner:王一

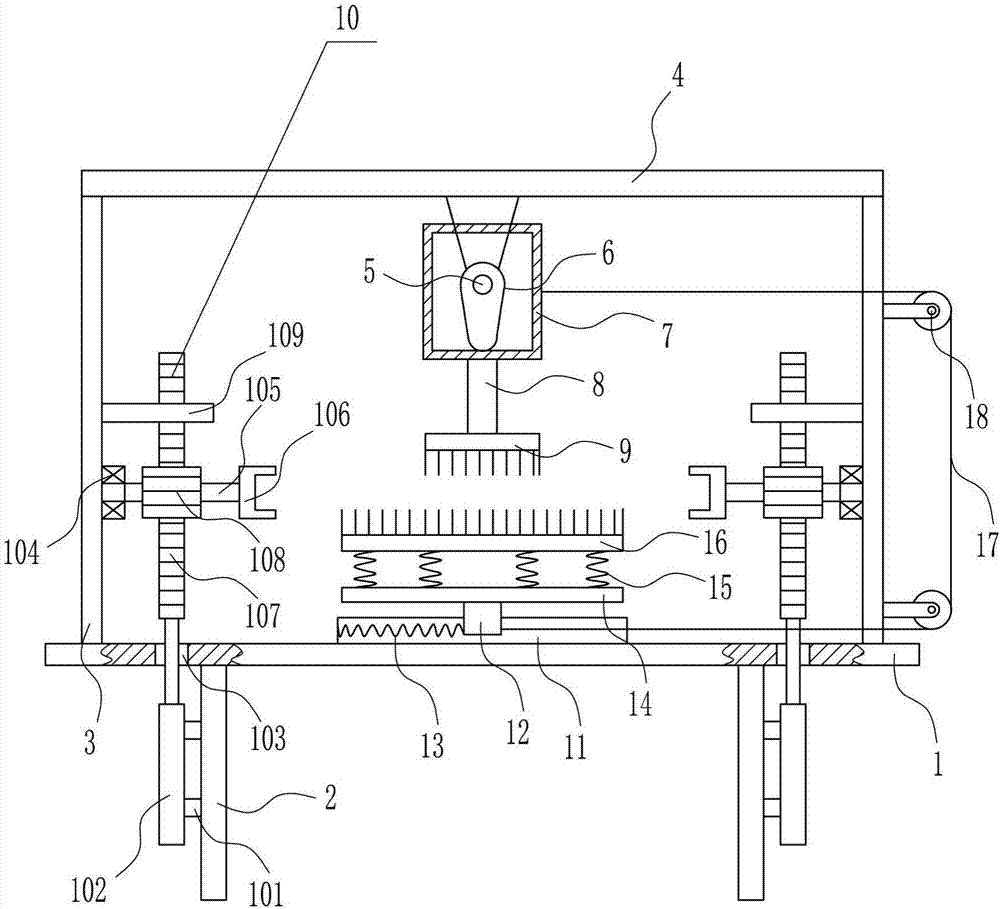

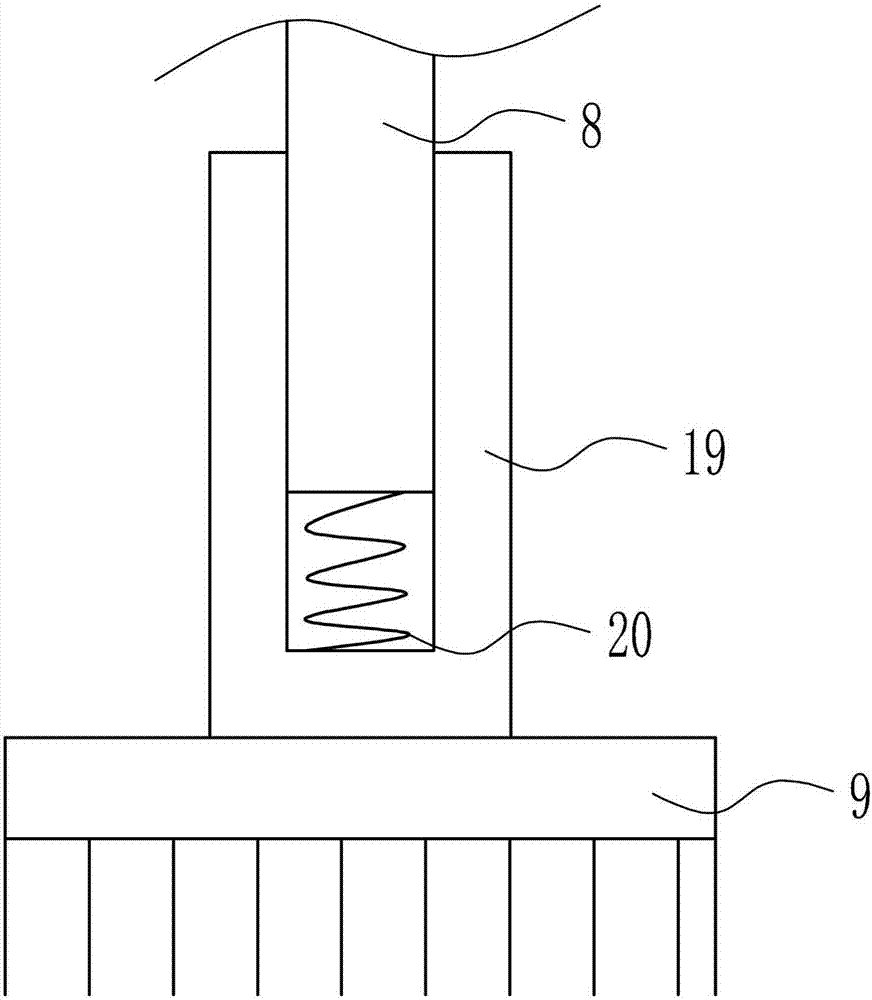

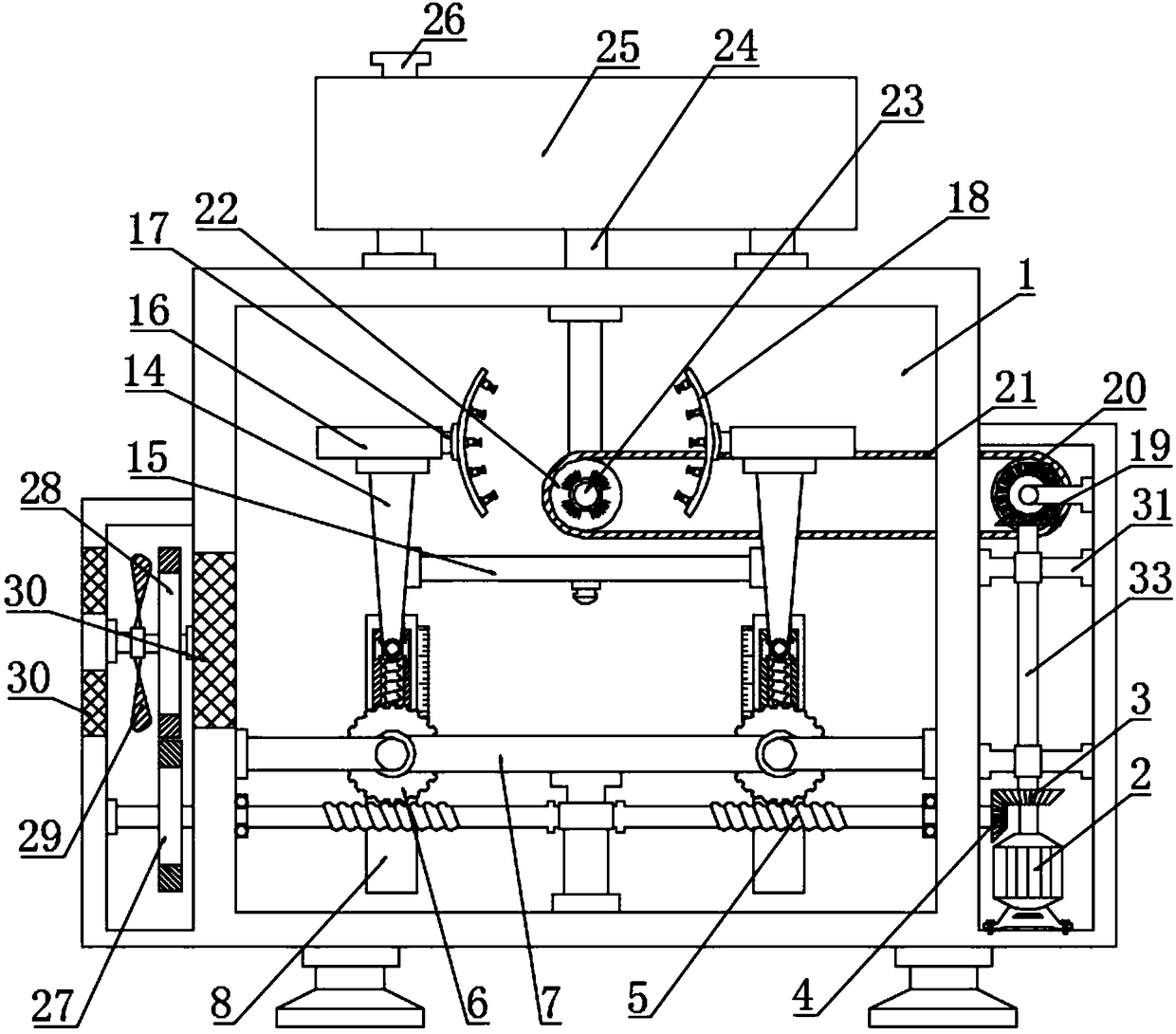

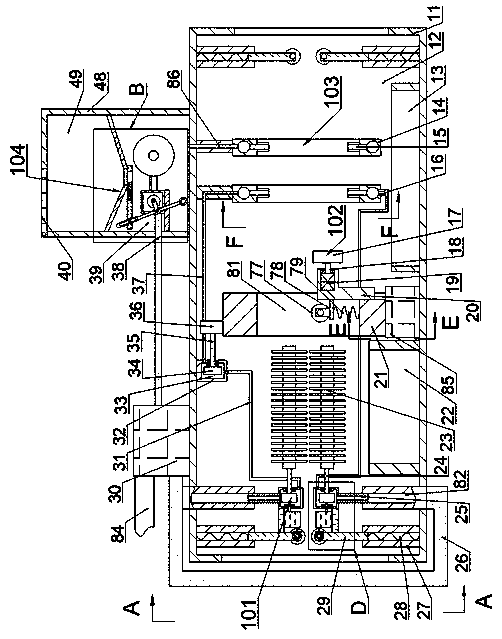

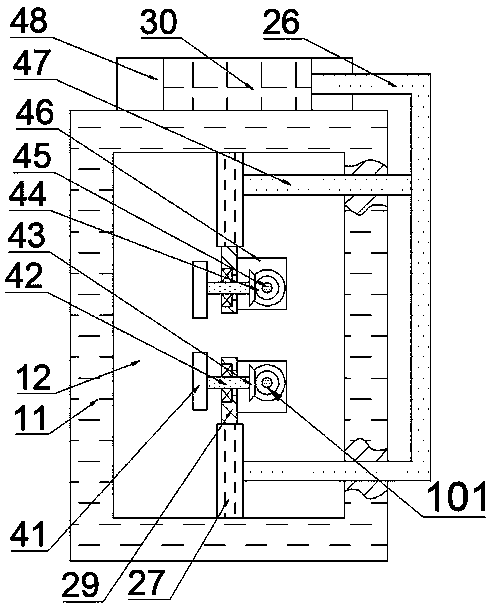

Efficient steel bar rust removing equipment for construction

InactiveCN106944908AComprehensive rust removalImprove rust removal effectGrinding carriagesGrinding drivesArchitectural engineeringEngineering

The invention relates to a derusting device for steel bars for construction, in particular to a high-efficiency derusting device for steel bars for construction. The technical problem to be solved by the present invention is to provide a high-efficiency derusting equipment for building steel bars that does not require a large amount of labor, has short derusting time, and is not easy to be injured during the derusting process. In order to solve the above technical problems, the present invention provides such a high-efficiency derusting equipment for steel bars for construction, which includes a bottom plate, legs, support plates, top plate, first motor, cam, frame, vertical bar, etc.; Outriggers are installed on the sides by bolts, support plates are installed on the left and right sides of the top of the bottom plate by bolts, and a top plate is installed on the top of the support plate by bolts. In the present invention, the first steel wire brush and the second steel wire brush move left and right to double derust the steel bar, so that the derusting effect of the steel bar is better, and at the same time, the rotation of the steel bar is improved.

Owner:孔军玲

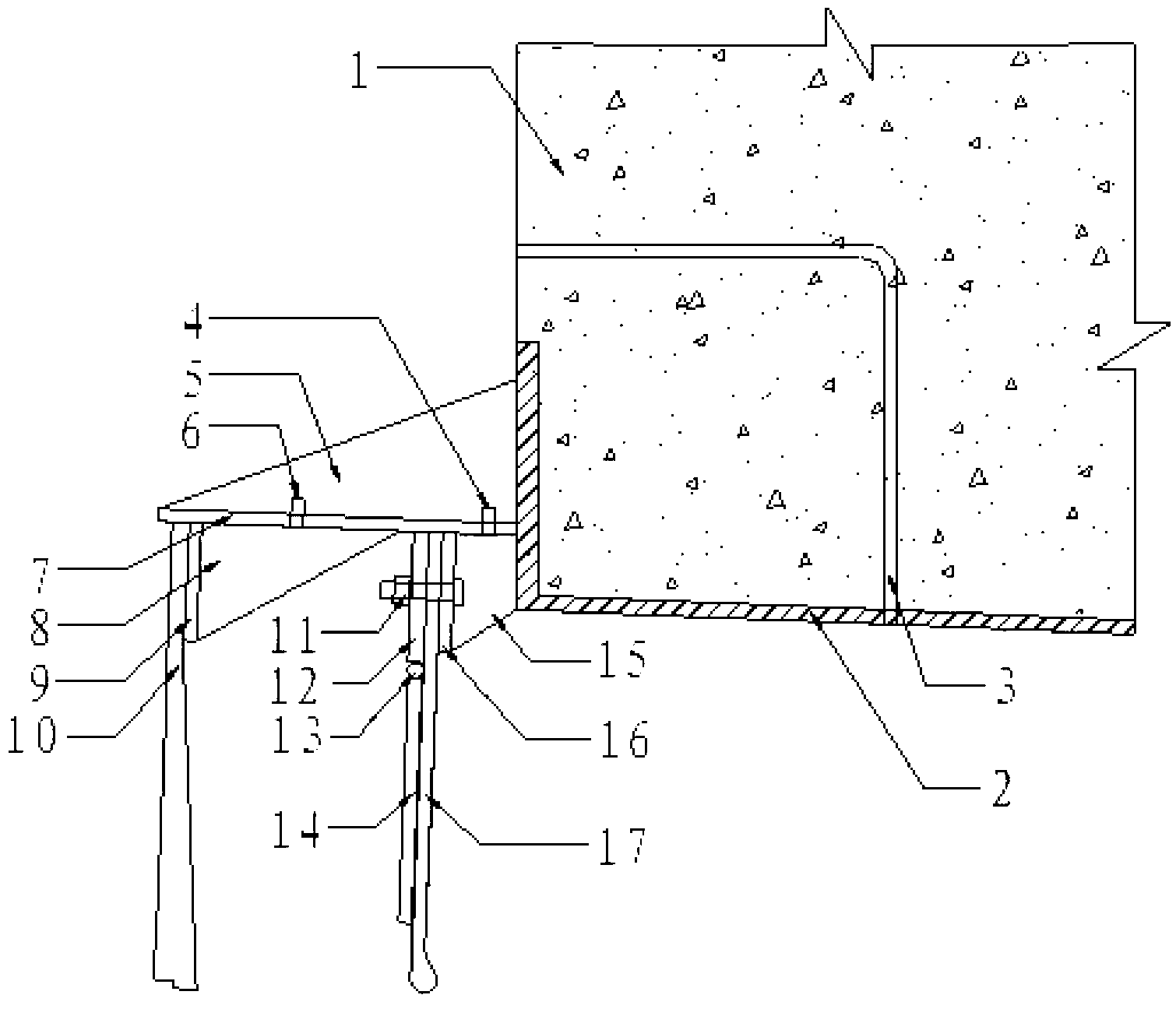

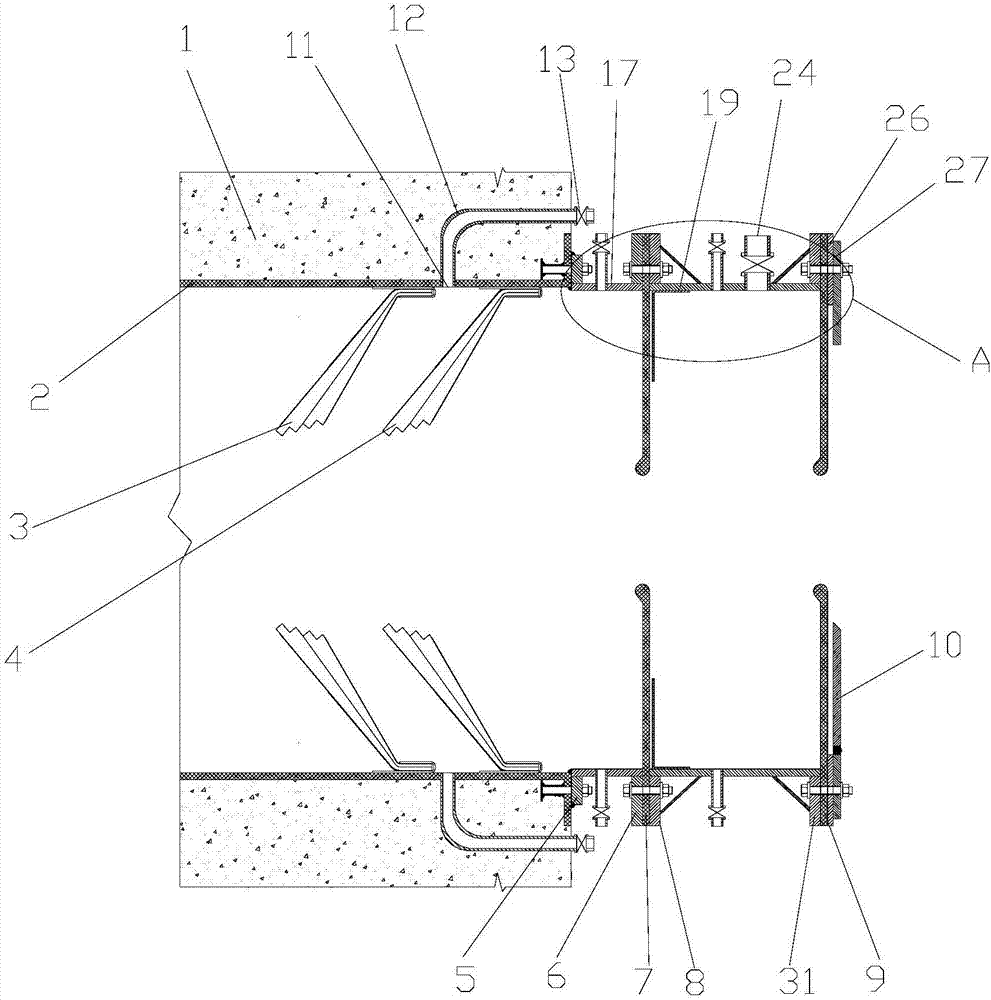

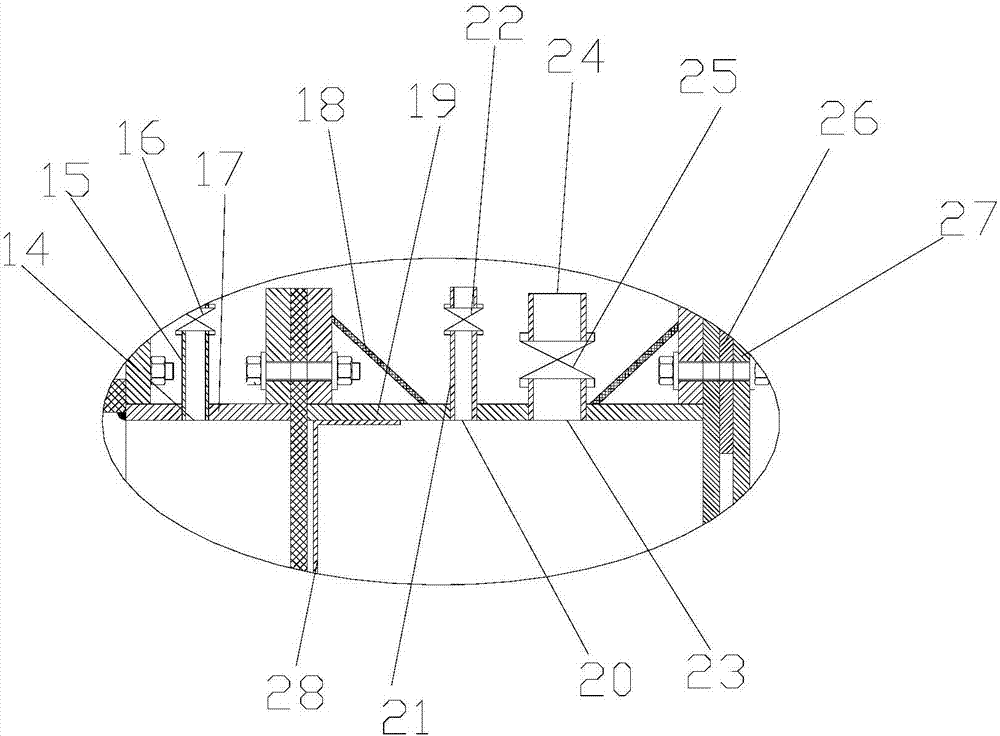

Slurry shield starting tunnel portal sealing structure and construction method thereof

ActiveCN106948829AEnsure safetyAvoid instabilityUnderground chambersHydro energy generationArchitectural engineeringStructural engineering

The invention discloses a slurry shield starting tunnel portal sealing structure and a construction method thereof. The sealing structure comprises two streaks of steel wire brushes, two streaks of cord fabric rubber plates and sealing slurry poured in three sealing cavities formed among the two streaks of steel wire brushes, the two streaks of cord fabric rubber plates and a shield tunneling machine and used for sealing a tunnel portal. The construction method comprises the steps of first, tunnel portal steel ring mounting, second, mounting of the first streak of steel wire brushes and the second streak of steel wire brushes, third, first extending steel ring mounting, fourth, mounting of the first steak of cord fabric rubber plates and a second extending steel ring, fifth, mounting of the second steak of cord fabric rubber plates and a fixing steel ring, sixth, cord fabric pressing plate assembly mounting, and seventh, contacting of the shield tunneling machine and the tunnel face, and sealing slurry pouring. The sealing effect can be improved greatly, the situation that slurry overflows when a shield tunneling machine starting slurry bin is built can be avoided effectively, the phenomenon that the slurry overflows, so that a soil body is unstable is avoided, the safety of slurry shield starting is guaranteed, and the construction method is simple in step, reasonable in design and short in construction period.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Novel power line deicer

The invention relates to a new type of power line deicer, which includes a box body and a bracket. There are left and right wire holes on the left and right sides of the box body. The left end of the bracket is equipped with a first wheel set and the first motor. Two wheels and the second motor, the center of the top wall of the box is equipped with an upper telescopic rod, an upper pressing block and an upper wire brush, and the center of the bottom wall of the box is equipped with a lower telescopic rod, a lower pressing block and a lower wire brush, and the upper and lower telescopic There are upper and lower coil springs on the outside of the rod. There are upper and lower pressure block through holes on the upper and lower pressure blocks. There are upper and lower electric heating tubes embedded inside. The top of the upper pressure block is equipped with an upper fan. There is a lower fan, the vertical side wall of the box includes inner and outer layers, the upper part of the inner layer and the lower part of the outer body are distributed with inner and outer ventilation holes, and the inside of the box is equipped with a temperature sensor, a microcontroller and a wireless transmitter , By adopting the above structure, the present invention can quickly and thoroughly perform deicing operation, and also effectively avoid damage to the circuit.

Owner:CHENGDU KECHUANG JIASI TECH

Pipeline external wall cleaning machine

InactiveCN101185930AMovement Speed MatchRotation speed matchingHollow article cleaningLine tubingDrive wheel

The invention relates to a cleaning machine used for washing external wall of pipes, which pertains to the special equipment of industrial production and is suitable for cleaning the external wall of the petroleum chemical pipeline, removing scale, rust and the vitiated old anticorrosion coating, and spaying. The invention mainly consists of a frame, a driving wheel, protective strips, working parts, lateral wheels, sliders, a radial wheel wire rope, a wire rope driving wheel, a wire rope driven wheel, a driven wheel, a governor and counterweight. The working parts comprise a hydraulic water nozzle, an impactor, a wire brush, a polishing wheel and a paint gun. The invention is characterized in that the cleaning machine which is used for washing external wall of pipes can walk on the pipes and work continuously with high efficiency. A plurality of cleaning ways can be combined for use or a single cleaning way can be used. The invention has good washing effect.

Owner:李树

Portable steel bar rust cleaner for building

ActiveCN106863094AComprehensive rust removalNot easy to get hurtGrinding machine componentsGrinding machinesArchitectural engineeringRebar

The invention relates to a steel bar rust cleaner for a building, and in particular relates to a portable steel bar rust cleaner for a building. The portable steel bar rust cleaner for the building is time and force saving, hardly damaged during the rust cleaning, and simple and convenient to operate. The portable steel bar rust cleaner for the building comprises a bottom plate, etc., wherein a left side plate is mounted at the left side of the top part of the bottom plate in a bolt connecting manner; a left and right moving device is arranged on the top part of the bottom plate; a fixing device is arranged at the right side of the left side plate. According to the portable steel bar rust cleaner for the building, steel wire brushes arranged at the inner front side and the inner rear side of an annular block are utilized to completely clean the rust on a steel bar; meanwhile, scrap iron falling during the rust cleaning of the steel bar can be blown away through air as an air port moves left and right.

Owner:ZHEJIANG XINHUA CONSTR

Abrasive wire brush component and method for producing abrasive wire brush component

The invention discloses an abrasive wire brush and a production method thereof. The wire brush comprises three components, namely a base material, a plastic additive and a grinding material, wherein the base material refers to a nylon material. The method for producing the abrasive wire brush comprises the following fifteen steps: selecting the materials, proportioning and mixing the materials, selecting a mold, selecting a wire brush twin-screw extruder, performing mixing extrusion in the twin-screw extruder, cooling in a cold water tank, drawing in a drawing machine, performing secondary drawing, performing third drawing and wire brushing, changing straight wire brushing into curved wire brushing, setting the wire brush in a drying box, rolling, recovering, performing jet coding, weighing, boxing and the like. The wire brush disclosed by the invention has extremely high safety, long service life and stable quality, the production process is easy to control, and the machining precision is high.

Owner:苏州生光塑料机械有限公司

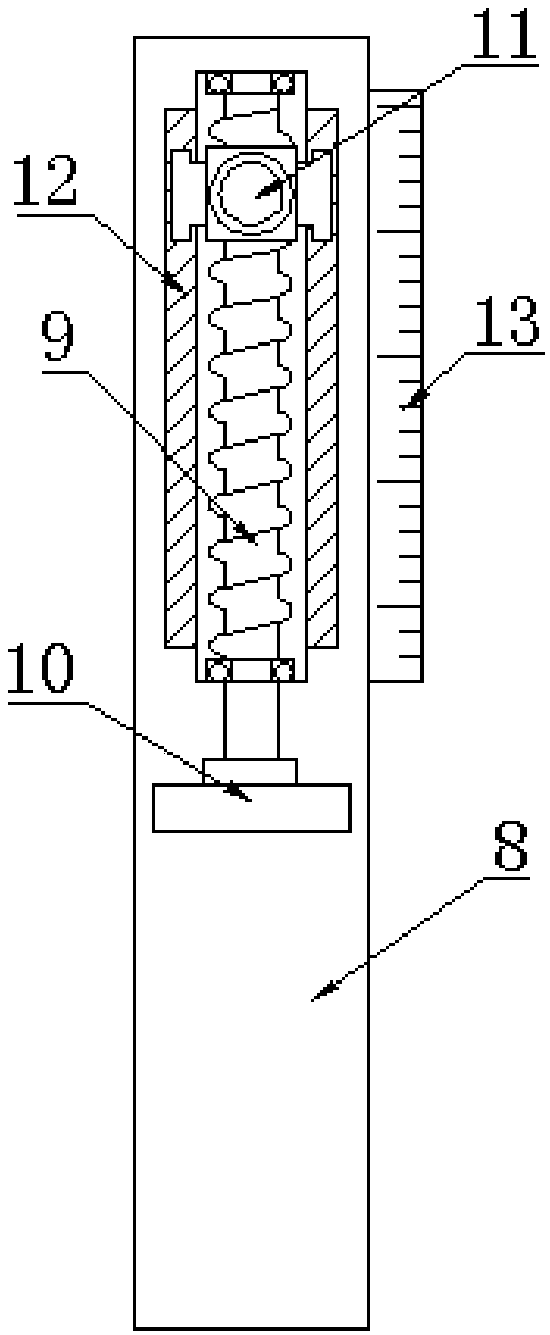

Adjustable-inner-diameter construction steel pipe cleaning device

InactiveCN108160624AImprove the cleaning efficiency of the inner wallReasonable structural designGrinding drivesHollow article cleaningDrive shaftGear wheel

The invention discloses an adjustable-inner-diameter construction steel pipe cleaning device. Worms are engaged with worm gears correspondingly. The rear portions of the worm gears are fixedly connected with the centers of regulating devices correspondingly. The worm gears and the regulating devices are rotationally connected with a transverse plate. The upper end of a driving shaft is fixedly connected with a third bevel gear. A fourth bevel gear is in rolling connection with the right end of a conveying belt. The rear portion of a belt pulley is rotationally connected with the back of a device body, and the front end of the belt pulley is fixedly connected with a rotary shaft. The front end of the rotary shaft is fixedly connected with a steel wire brush roll. Bearings on the upper portions of the regulating devices are rotationally connected with lead screws correspondingly. The lead screws are in threaded connection with sleeve blocks correspondingly. The two ends of the sleeve blocks are in sliding connection with guide grooves correspondingly. According to the device, a bevel gear set drives the belt pulley to rotate so as to drive the steel wire brush roll to rotate for cleaning, clamping rings are used for clamping a steel pipe, so that the interior of the steel pipe rotates around the steel wire brush roll for cleaning and brushing, the sleeve blocks are driven to moveup and down by rotating the lead screws, accordingly, the diameter of circular motion of the steel pipe is regulated, and steel pipes with different inner diameters can be cleaned and brushed. The device is reasonable and applicable in structural design, capable of adapting to the steel pipes with the different pipe diameters, and high in flexibility.

Owner:长沙双合盛企业管理有限公司

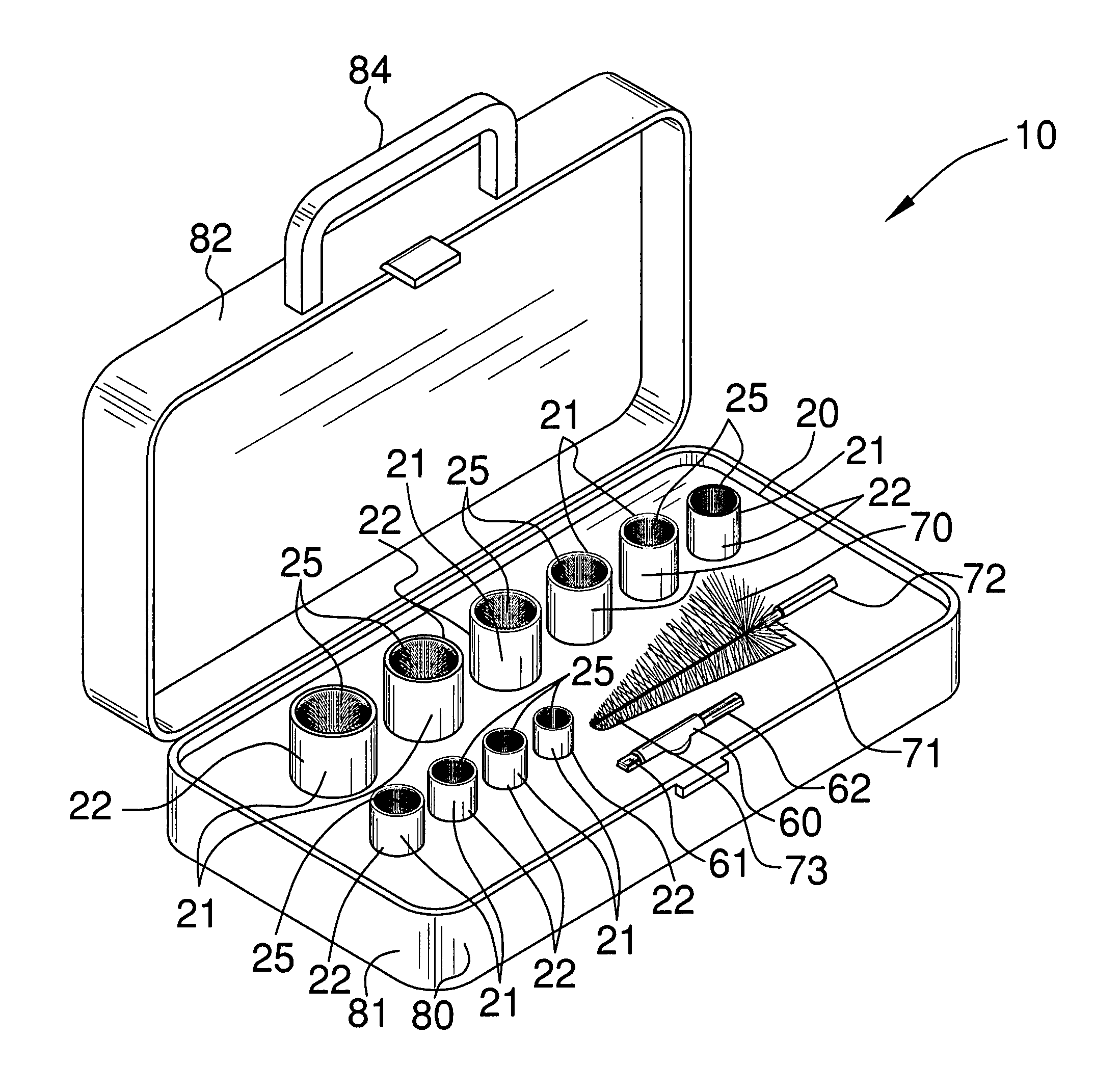

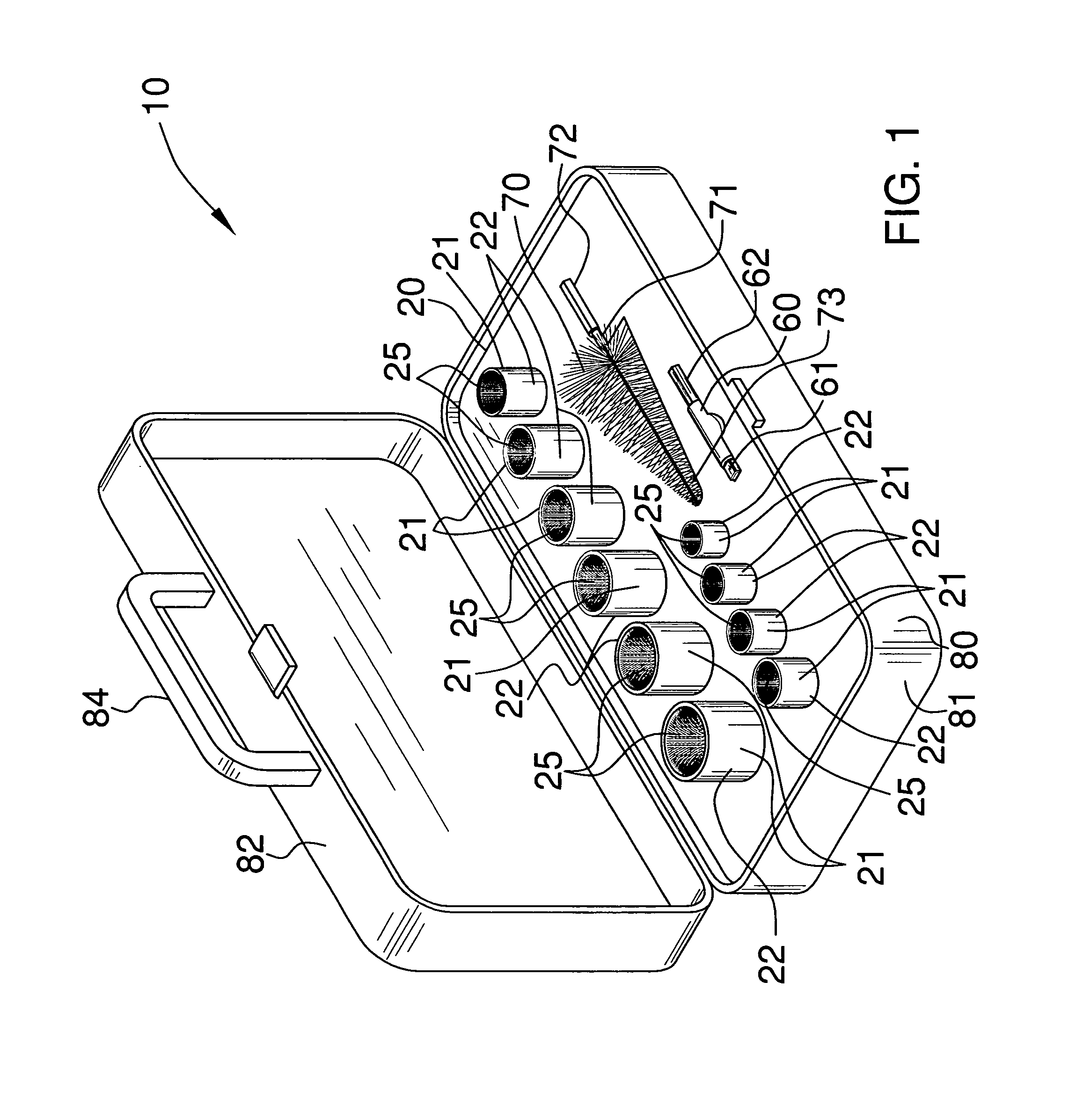

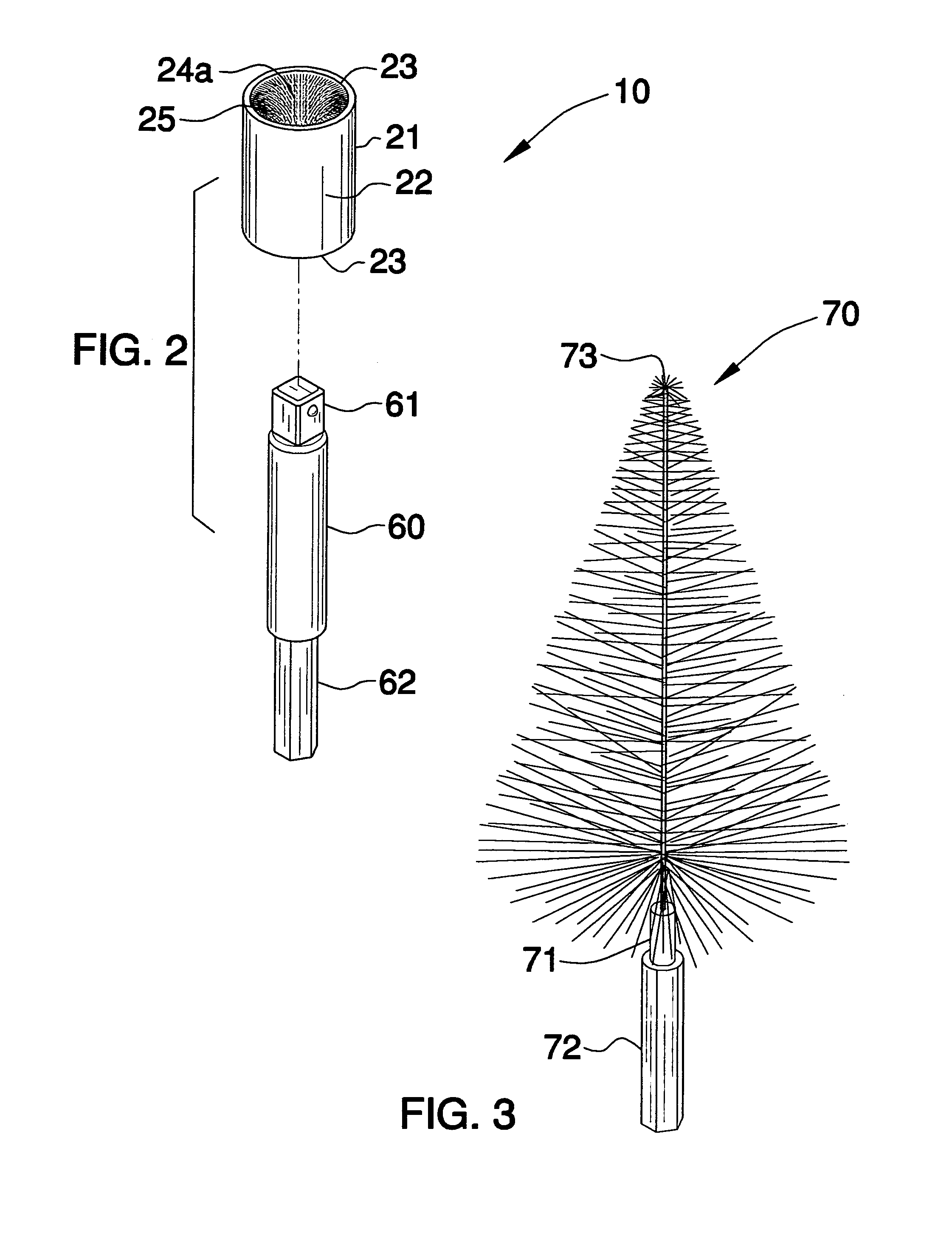

Pipe cleaning kit

A cleaning kit operable by a tool for cleaning pipes and fittings to prepare same for soldering. The cleaning kit includes a plurality of sockets including wire bristles attached thereto and for receiving the outer surface of a pipe therealong. The plurality of pipes are maintain in continuous contact with a pipe surface for cleaning same while a tool rotatably engages the plurality of sockets about the pipe. The cleaning kit also includes a shank for receiving the plurality of sockets therein and for removably connecting to a tool respectively. A wire brush including a lower end portion and a second shank connected thereto is removably attachable to a tool so that the wire brush can rotatably engage an interior of a pipe and thereby clean same.

Owner:JADYDY EMYR

Sealing device for slurry shield starting of water-rich sand layer and sealing control method for starting

The invention relates to the field of tunnel shield construction, in particular to a sealing device for slurry shield starting of a water-rich sand layer and a sealing control method for the starting, and solves the problem that the conventional sealing devices are poor in effect, and high in risk, and water leakage and grout leakage are easy to occur during a shield starting process. Grease distributing valves are additionally arranged on shield tail grease filling pipes; an external steel loop is connected with a tunnel portal steel loop; two wire brushes are arranged in the external steel loop; grease injection holes with gate valves are reserved between the wire brushes; after the shield is assembled on a starting base, grease is smeared on the wire brushes of the external steel loop; a cutter head is pushed to a station space enclosing structure; the grease injection pipes are connected with the grease injection holes reserved in the external steel loop and the grease distributing valves; the grease injection gate valves are opened to enable the grease to be injected between the two wire brushes from the grease injection holes reserved in the external steel loop to fill the interspace; slurry balance is built to conduct shield starting. According to the invention, slurry shield safe starting is realized; slurry shield starting technology is simplified greatly; the technology is simple; the technique is advanced; the practicability is high.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

Steel bar grinding and descaling equipment for building construction

InactiveCN110216569AImprove rust resistanceAvoid secondary rustRevolution surface grinding machinesLiquid spraying apparatusArchitectural engineeringEngineering

The invention discloses steel bar grinding and descaling equipment for building construction. The equipment comprises a descaling box; the descaling box is internally provided with a descaling cavitywhich is through left and right; the descaling cavity is internally provided with a descaling device for conveying steel bars and preliminarily descaling the steel bars; the descaling cavity is internally provided with a grinding device located on the right side of the descaling device; the descaling cavity is internally provided with a spraying device located on the right side of the grinding device; and the end surface of the upper side of the descaling cavity is provided with a mixing device located on the upper side of the spraying device. The conveying device and the descaling device canautomatically adapt to the steel bars of different diameters through a telescopic mechanism, steel wire brushes are adopted by the descaling device for rapidly and preliminarily descaling the steel bars, the steel bars are further ground and descaled through a grinding wheel mechanism, thus, the descaling uniformity and descaling quality can be improved, and descaling liquid is sprayed to the descaled steel bars through the spraying device, so that the equipment has good descaling quality and can descale the steel bars.

Owner:LISHUI ZHONGYING MACHINERY TECH CO LTD

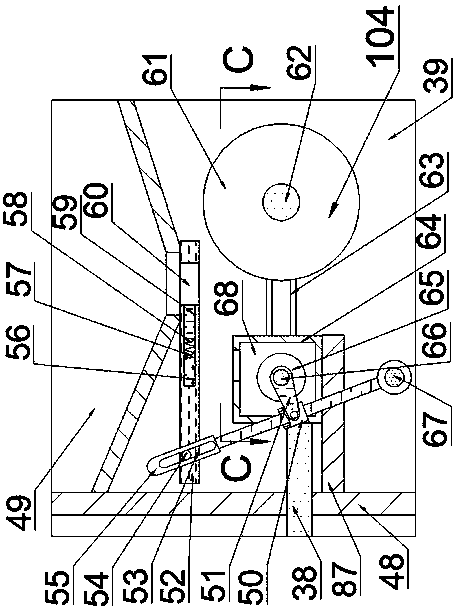

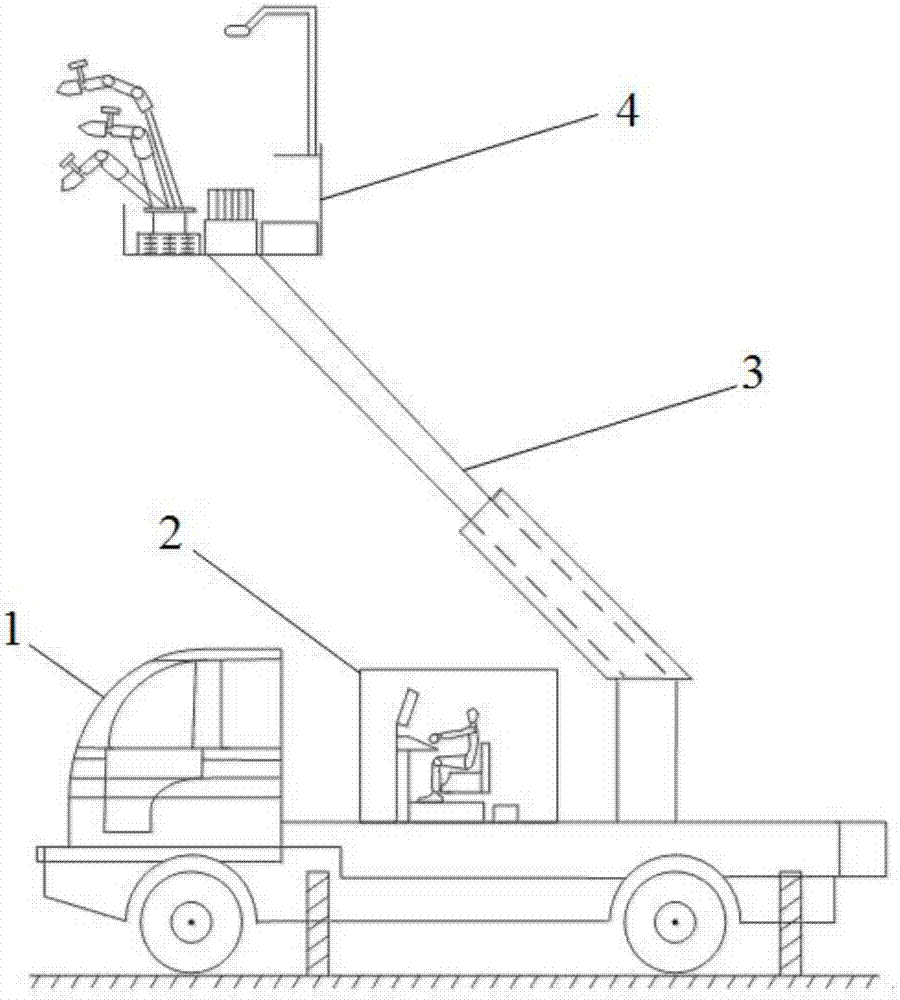

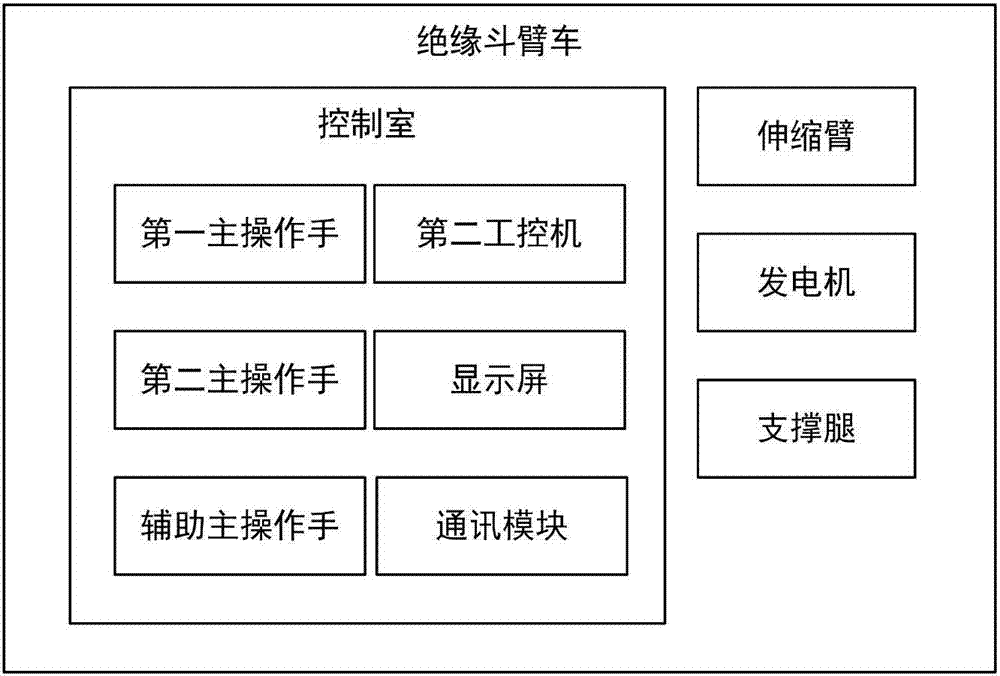

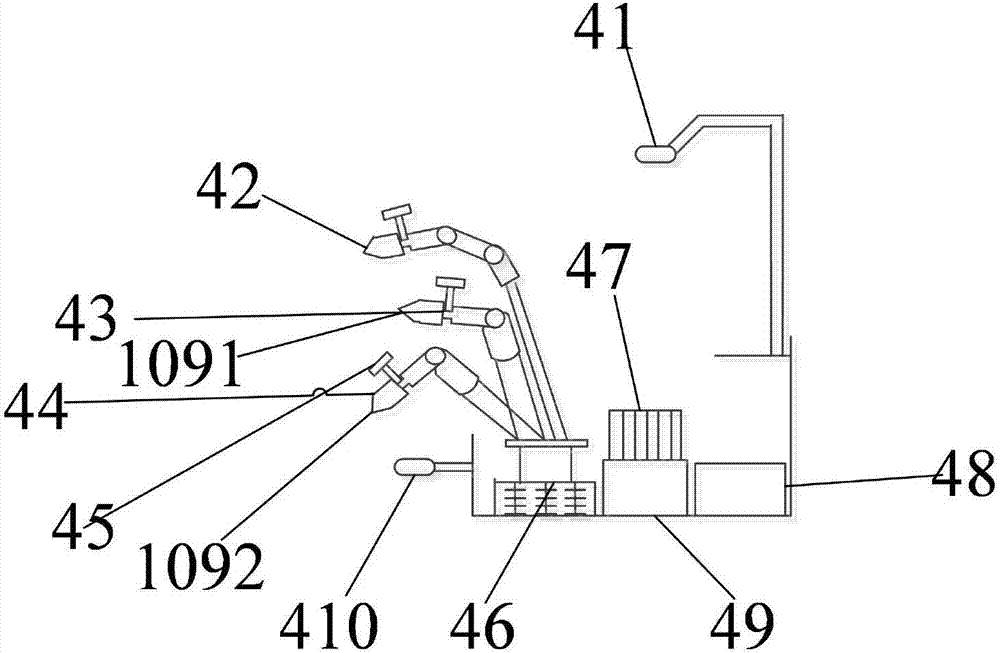

Overlapping method for branched connecting line of hot-line robot

InactiveCN107053188AAvoid negative effectsReduce outage timeManipulatorApparatus for overhead lines/cablesConductive pasteControl data

The invention provides an overlapping method for a branched connecting line of a hot-line robot. Mechanical arms of the robot respond to control data. A gasoline cotton cloth brush, a steel wire brush, a conductive paste paint brush and a C-shaped wire clamp are carried to the position nearby a to-be-overlapped wire. The auxiliary mechanical arm clamps the to-be-overlapped wire. The first mechanical arm and the second mechanical arm complete cleaning of the to-be-overlapped wire, and then the to-be-overlapped wire is connected with the branched connecting line in a hooking mode. According to the overlapping method, the mechanical arms of the hot-line robot are overlapped with the branched connecting line in the mode of remote operation or autonomous working, the danger caused when operators work nearby live high-voltage lines is avoided, and the operating steps are simplified.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com