Steel wire rust cleaning method and device

A technology of steel wire and steel rust, which is applied in the field of surface derusting of mechanical steel wire materials before cold drawing and extension, can solve problems such as environmental pollution, polluted water and air, and incomplete treatment, and achieves simple structure of the device, good treatment effect, and high treatment efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

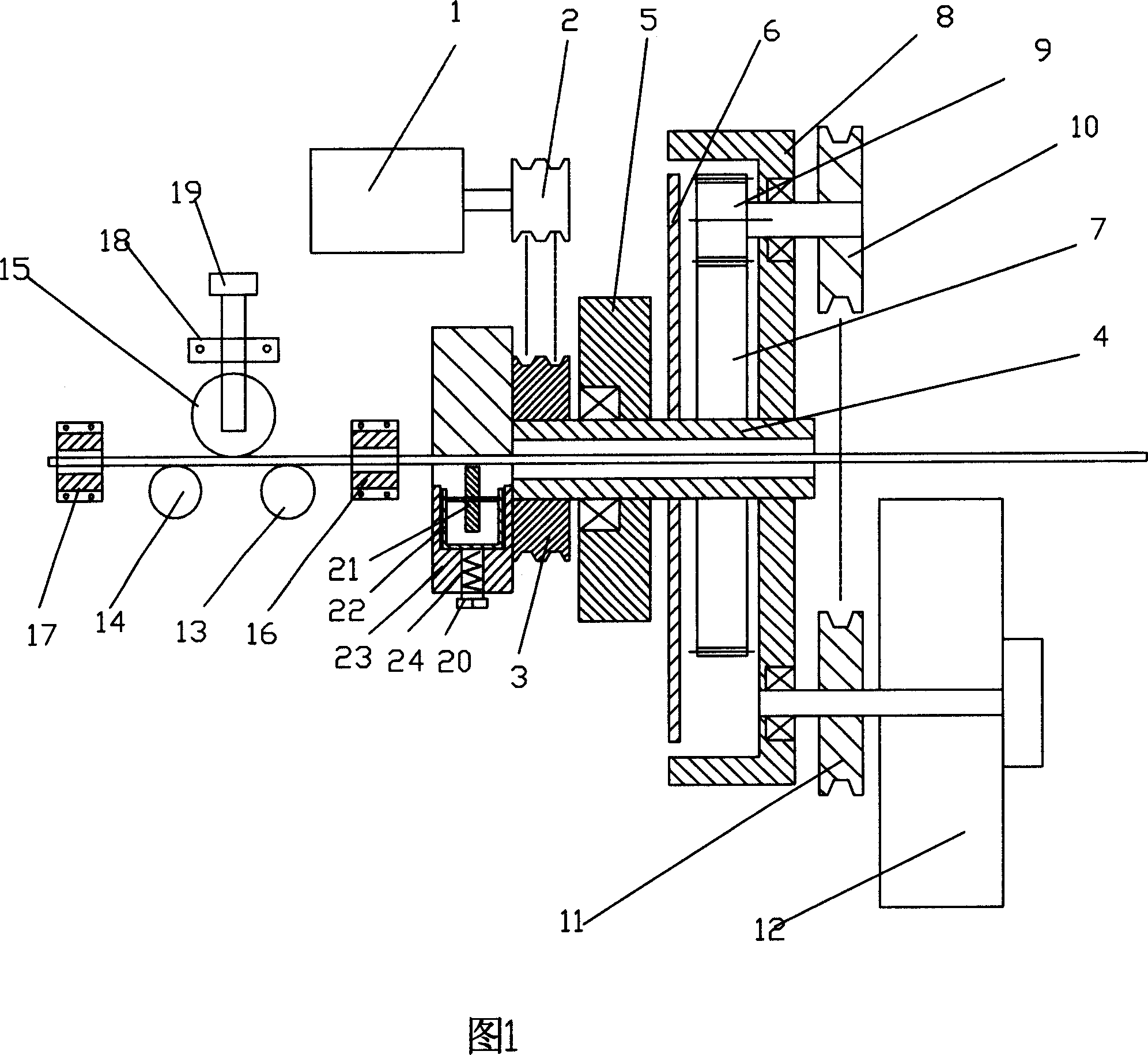

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: the method of the present invention at least includes the following two steps, first the mechanical loosening of steel wire surface rust is carried out, and secondly the loose steel wire surface rust is cleaned and derusted .

[0016] The mechanical loosening treatment is to use at least one set of peeling rollers to act on the incoming steel wire material, causing it to be bent and deformed under force, so as to loosen the rust attached to the surface of the steel wire; the cleaning and rust removal is to use a Steel wire rust removal device, that is, a rotating roller with a wire brush to clean and remove loose steel rust.

[0017] The device of the steel wire derusting method according to the present invention at least includes a support, a hollow main shaft 4 is installed on the support 5, a turntable 8 is arranged at one end of the main shaft, and a descaling mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com