Preparation method of pyrethroid degradable pesticide insecticide and pesticide insecticide prepared by method

A technology for pyrethroids and pesticide degradation, which is applied in the field of pesticides, can solve problems such as high cost, accumulation of pesticide residues, and difficult degradation of pesticides, and achieves the effects of easy operation, industrialization, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

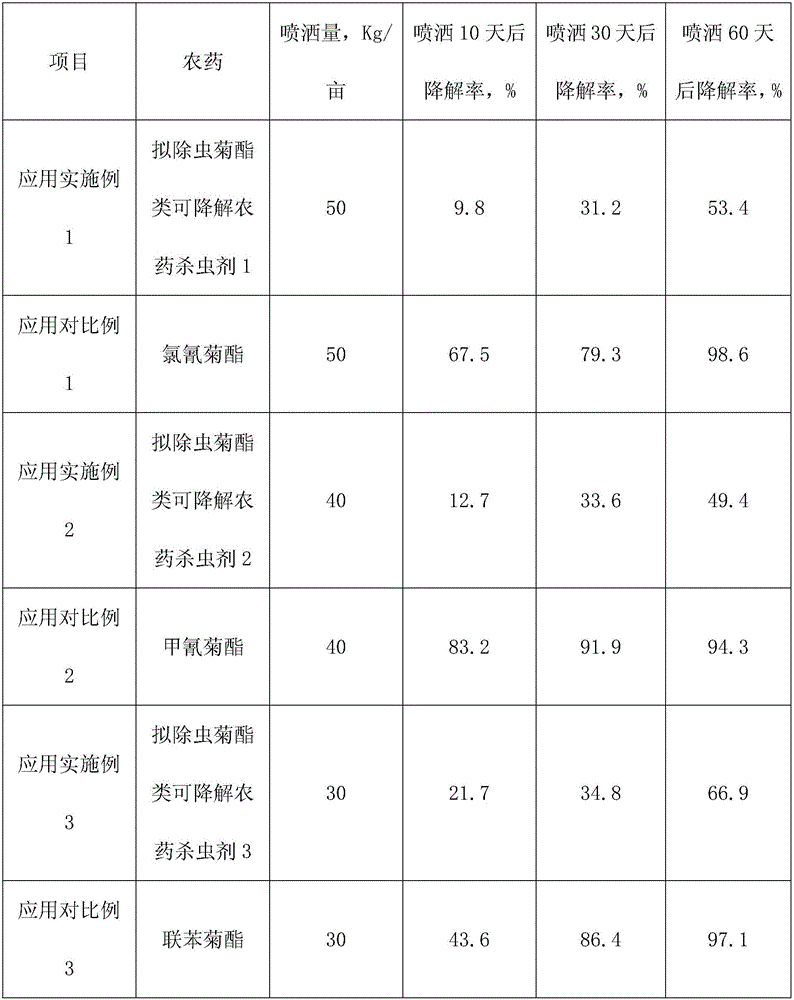

Examples

Example Embodiment

[0023] The present invention provides a method for preparing a pyrethroid degradable pesticide insecticide, which is characterized in that the method comprises: a. Heating the biosorbent in an alcohol solution at 120-200°C for 1-10 hours and then drying , And pulverize to 100-500 nanometers to obtain biosorbent powder; b. Disperse the phosphatase in water at a concentration of 1000-10000 U / g to prepare an aqueous solution of phosphatase; c. The biosorbent obtained in step a The powder and the phosphatase aqueous solution are mixed at 25-35°C and stirred for 5-60 minutes, and the obtained suspension is filtered to obtain the enzyme adsorption powder; d. Dissolve vegetable glue in water to obtain the vegetable glue aqueous solution; e, step d The obtained vegetable glue aqueous solution is sprayed on the surface of the enzyme adsorption powder obtained in step c and then dried to obtain vegetable glue coated powder, wherein the mass ratio of vegetable glue to enzyme adsorption pow...

Example Embodiment

[0036] Example 1

[0037] a. Heat the chitosan in an alcohol solution at 120°C for 9 hours, then dry it and pulverize it to 300 nanometers to obtain a biosorbent powder; b. Disperse the extracted phosphatase of cypermethrin degrading bacteria at a concentration of 3000 U / g Prepare phosphatase aqueous solution in water; c. Mix the biosorbent powder and phosphatase aqueous solution obtained in step a at 25°C and stir for 20 minutes, and the suspension obtained is filtered to obtain enzyme adsorption powder, biosorbent The mixing mass ratio of the powder and the aqueous solution of phosphatase is 1:1; d. Dissolve couma gum in water to obtain an aqueous solution of vegetable glue with a concentration of 3% by mass; e. The aqueous solution of vegetable glue obtained in step d is sprayed in step c The surface of the obtained enzyme adsorption powder is dried to obtain a vegetable gum coated powder, wherein the mass ratio of the vegetable gum to the enzyme adsorption powder is 1:0.04; f...

Example Embodiment

[0038] Example 2

[0039] a. Heat the cellulose in an alcohol solution at 200°C for 2 hours, then dry, and pulverize to 500 nanometers to obtain a biosorbent powder; b. Extract the phosphatase of fenpropathrin degrading bacteria at 10000 U / g Disperse the concentration in water to prepare an aqueous solution of phosphatase; c. Mix the biosorbent powder and the aqueous phosphatase solution obtained in step a at 35°C and stir for 40 minutes, and the suspension obtained is filtered to obtain enzyme adsorption powder. The mixing mass ratio of the adsorbent powder and the aqueous phosphatase solution is 1:5; d. Dissolve flax gum in water to obtain an aqueous solution of vegetable glue with a concentration of 5% by mass; e. Spray the aqueous solution of vegetable glue obtained in step d in step c The surface of the enzyme adsorption powder obtained in step e is dried to obtain a vegetable gum coated powder, wherein the mass ratio of the vegetable gum to the enzyme adsorption powder is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com