Composite TiO2-SiO2 aerogel and application thereof

A composite airgel and wet gel technology, applied in the field of photocatalytic degradation, can solve problems such as difficult recycling and reuse, easy deactivation, and easy aggregation of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

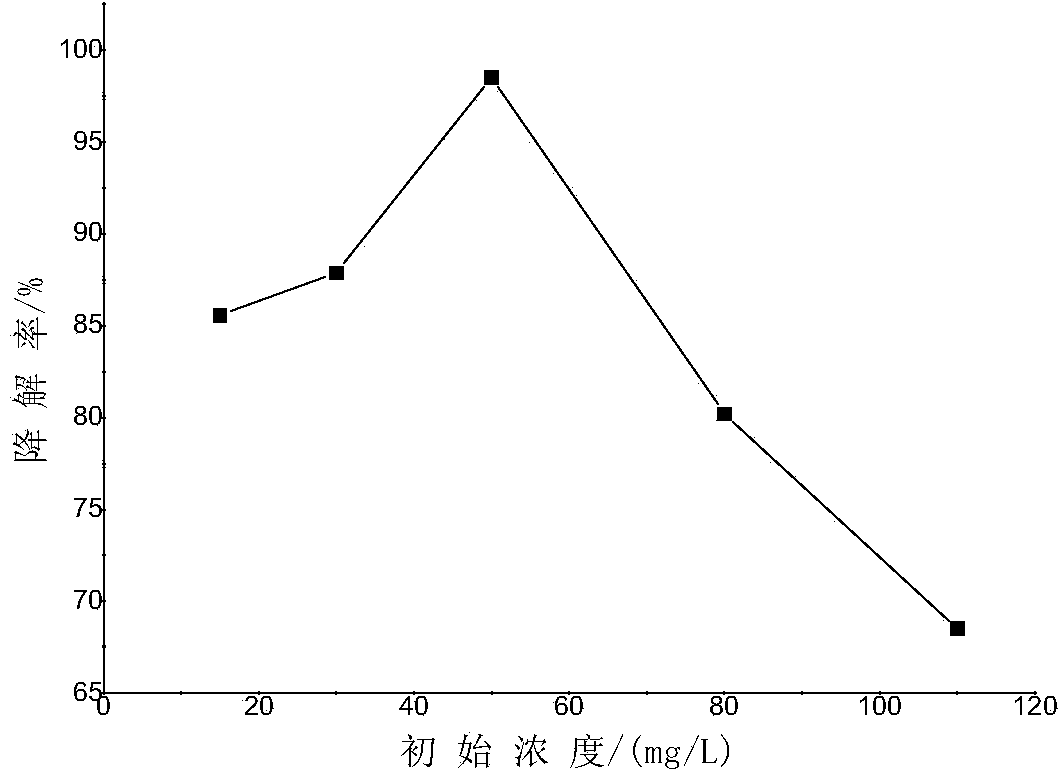

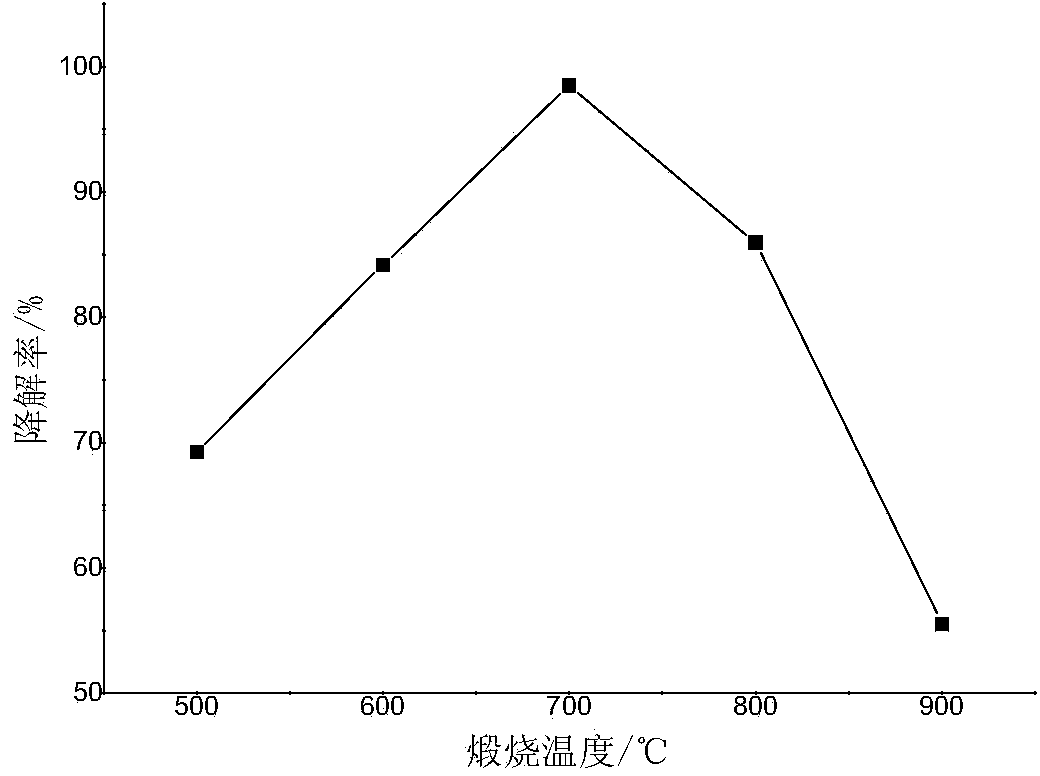

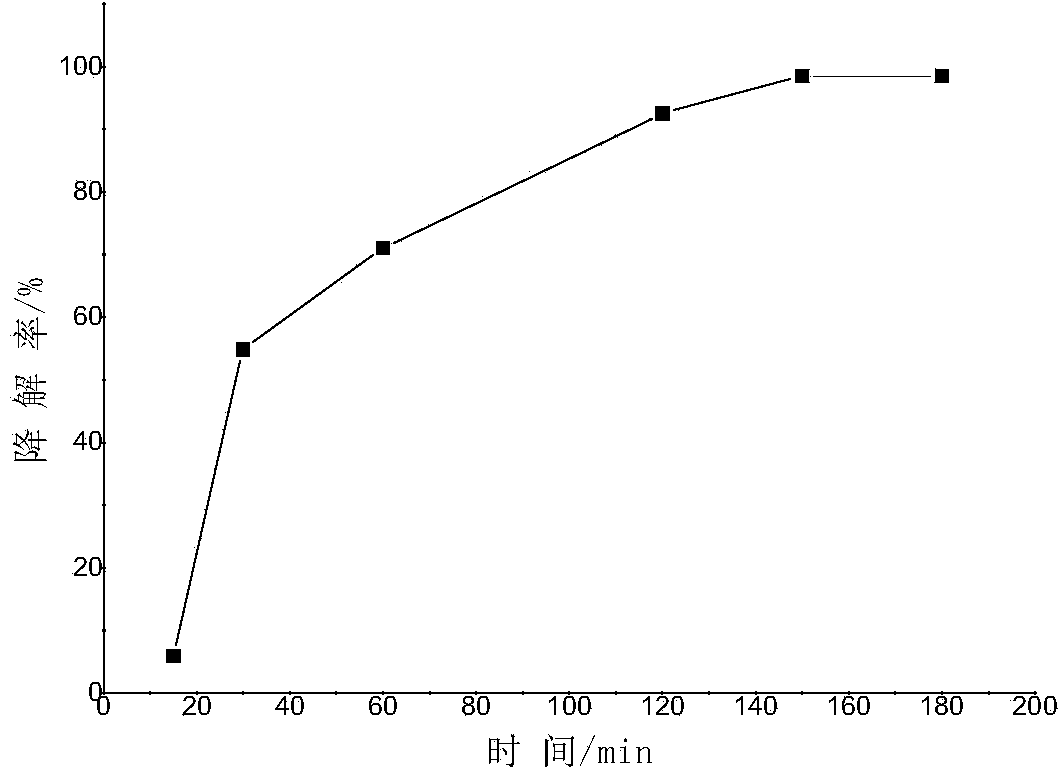

[0030] Example 1 Tetraethyl orthosilicate, absolute ethanol, and deionized water were uniformly mixed in a volume ratio of 1:1.32:0.21, and 1.2mol / L HNO 3 Adjust the pH value of the solution to 3.2, hydrolyze at 33°C for 3.5h, and keep stirring to obtain SiO 2 Sol; Tetrabutyl titanate and absolute ethanol are uniformly mixed at a volume ratio of 1:2.3, and 1.2mol / L HNO 3 Adjust the pH value of the solution to 3.1 to obtain solution A, mix absolute ethanol and deionized water at a volume ratio of 4.2:1, and use 1.2mol / L HNO 3 Adjust the pH value of the solution to 3.1 to obtain solution B. Add solution B dropwise to solution A at a speed of 0.3ml / s under stirring. The volume ratio of solution A and solution B is 4.2:1. Hydrolyze at 33°C 0.5h, keep stirring to obtain TiO 2 Sol; under stirring state, according to n(Si):n(Ti)=1:1, mix SiO with the speed of 0.3ml / s 2 The sol was added dropwise to TiO 2 In the sol, take it out after stirring evenly, and let it stand at 33°C unti...

example 2

[0032] Example 2 Mix water glass, absolute ethanol, and deionized water in a volume ratio of 1:1.45:0.36, and use 2.3mol / LHNO 3 Adjust the pH value of the solution to 4, hydrolyze at 40°C for 4 hours, and keep stirring to prepare SiO 2 Sol; Tetrabutyl titanate and absolute ethanol are uniformly mixed at a volume ratio of 1:2.6, and 2.3mol / L HNO 3 Adjust the pH value of the solution to 4.2 to obtain solution A, mix absolute ethanol and deionized water at a volume ratio of 4.5:1, and use 2.3mol / L HNO 3 Adjust the pH value of the solution to 4.1 to obtain solution B, add solution B dropwise to solution A at a speed of 0.45ml / s under stirring, the volume ratio of solution A and solution B is 4.5:1, and hydrolyze at 40°C 0.7h, keep stirring to make TiO 2 Sol; under stirring state, according to n(Si):n(Ti)=1:5, mix SiO with the speed of 0.45ml / s 2 The sol was added dropwise to TiO 2 In the sol, take it out after stirring evenly, and let it stand at 40°C until it coagulates to ob...

example 3

[0034] Example 3 Mix silica sol, absolute ethanol, and deionized water uniformly at a volume ratio of 1:1.59:0.5, adjust the pH of the solution to 4.8 with 3mol / L HCl, hydrolyze at 48°C for 4.5h, and keep stirring to obtain SiO 2 Sol; Titanium tetrachloride and absolute ethanol are uniformly mixed in a volume ratio of 1:2.9, and the pH value of the solution is adjusted to 4.8 with 3mol / L HCl to obtain solution A, and anhydrous ethanol and deionized water are mixed in a volume ratio of 4.9:1 Mix evenly, adjust the pH value of the solution to 4.8 with 3mol / L HCl to obtain solution B, add solution B dropwise to solution A at a speed of 0.6ml / s under stirring, and the volume ratio of solution A to solution B is 4.9 : 1, hydrolyzed at 50°C for 1h, and kept stirring to obtain TiO 2 Sol; under stirring state, according to n(Si):n(Ti)=1:8, mix SiO with the speed of 0.6ml / s 2 The sol was added dropwise to TiO 2 In the sol, take it out after stirring evenly, and let it stand at 50°C u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com