Patents

Literature

2636 results about "Tetraethyl orthosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetraethyl orthosilicate, formally named tetraethoxysilane and abbreviated TEOS, is the chemical compound with the formula Si(OC₂H₅)₄. TEOS is a colorless liquid that degrades in water. TEOS is the ethyl ester of orthosilicic acid, Si(OH)₄. It is the most prevalent alkoxide of silicon.

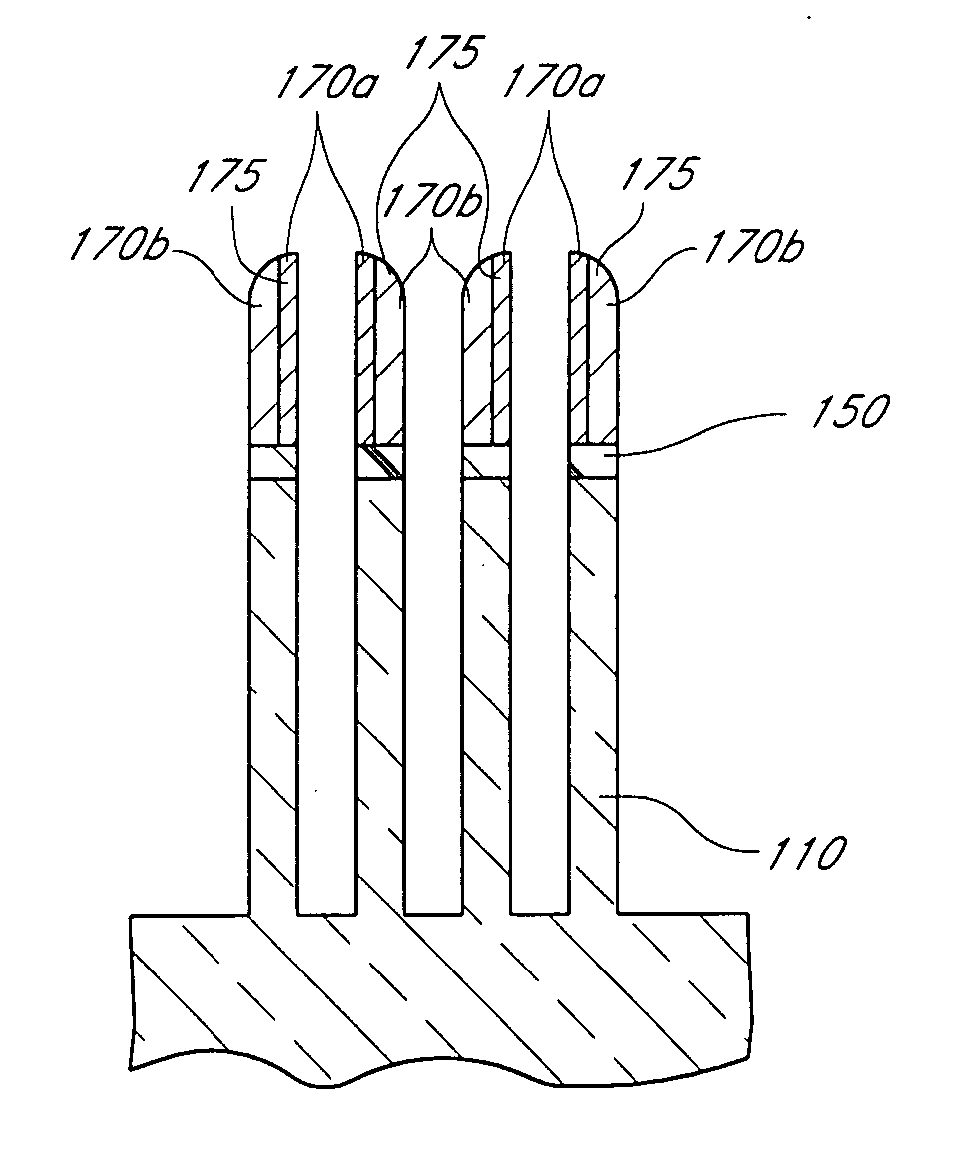

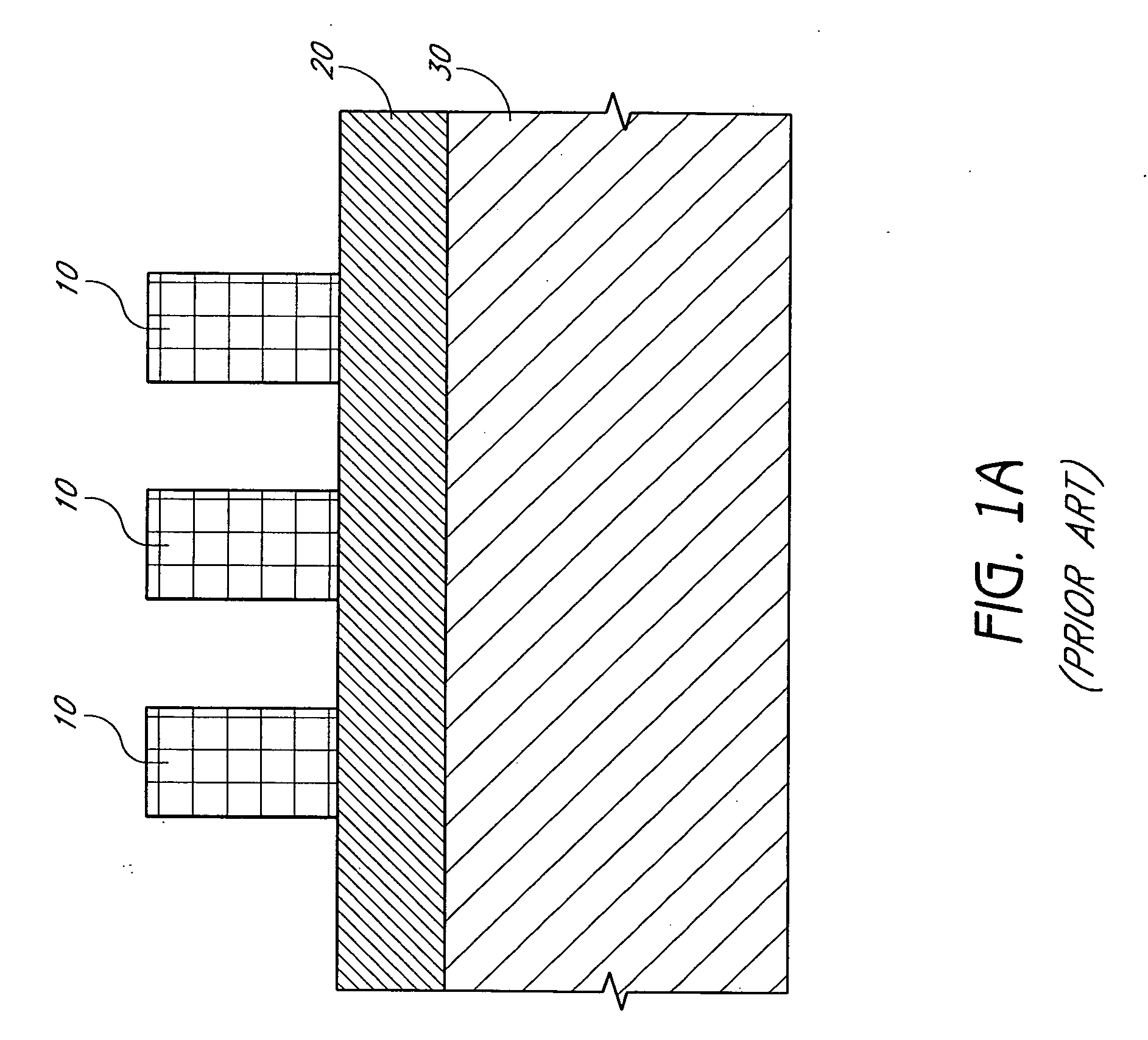

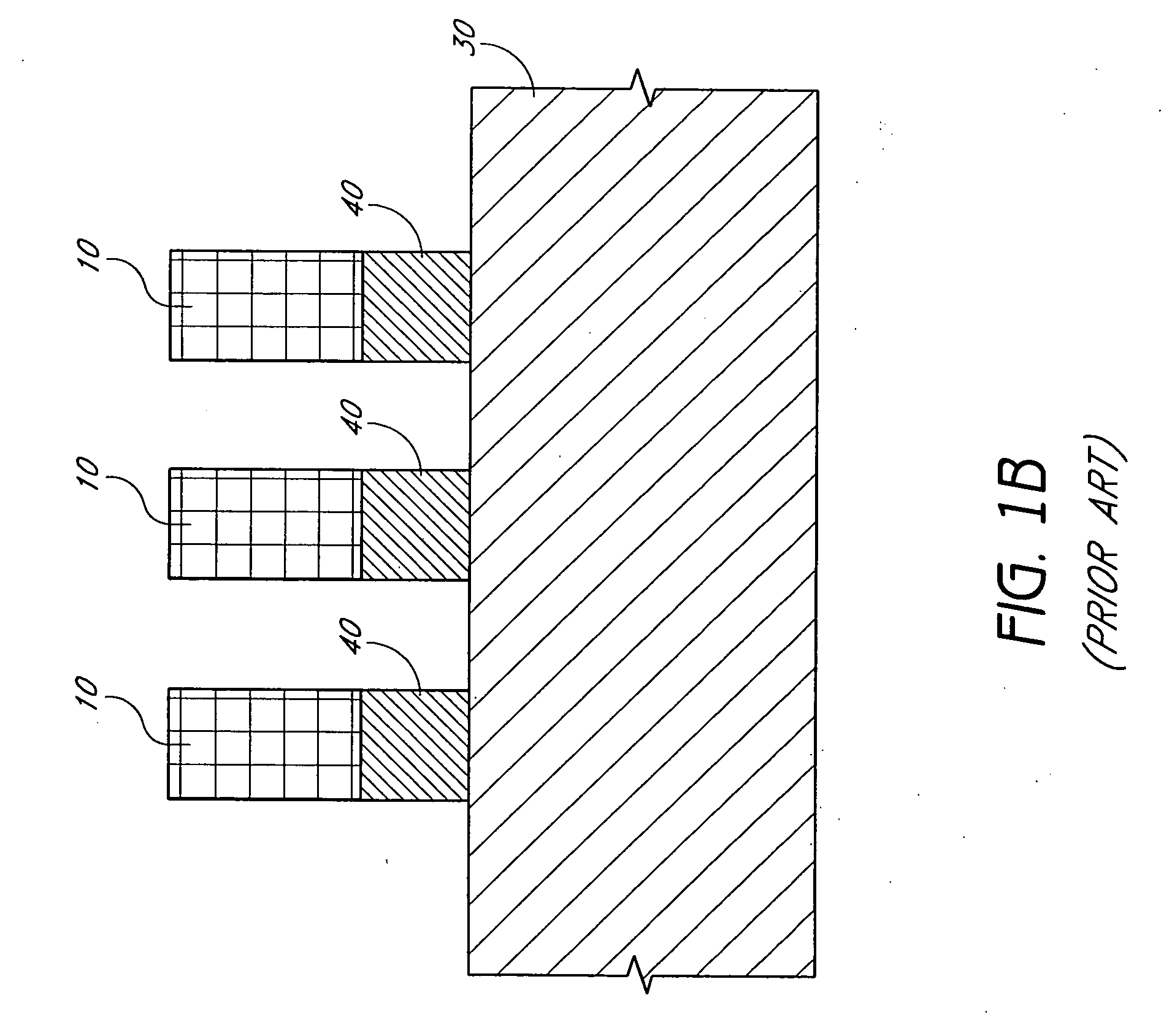

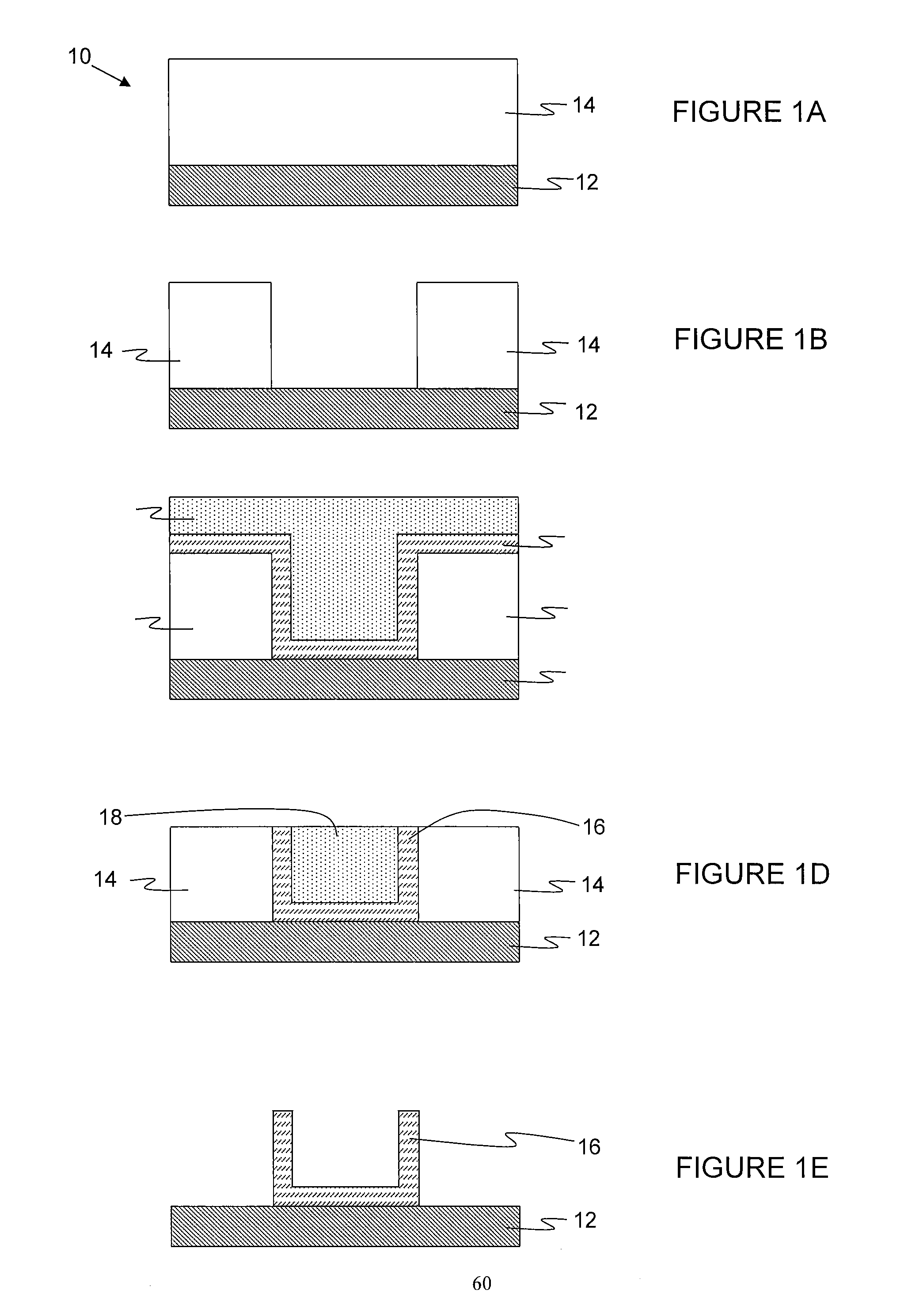

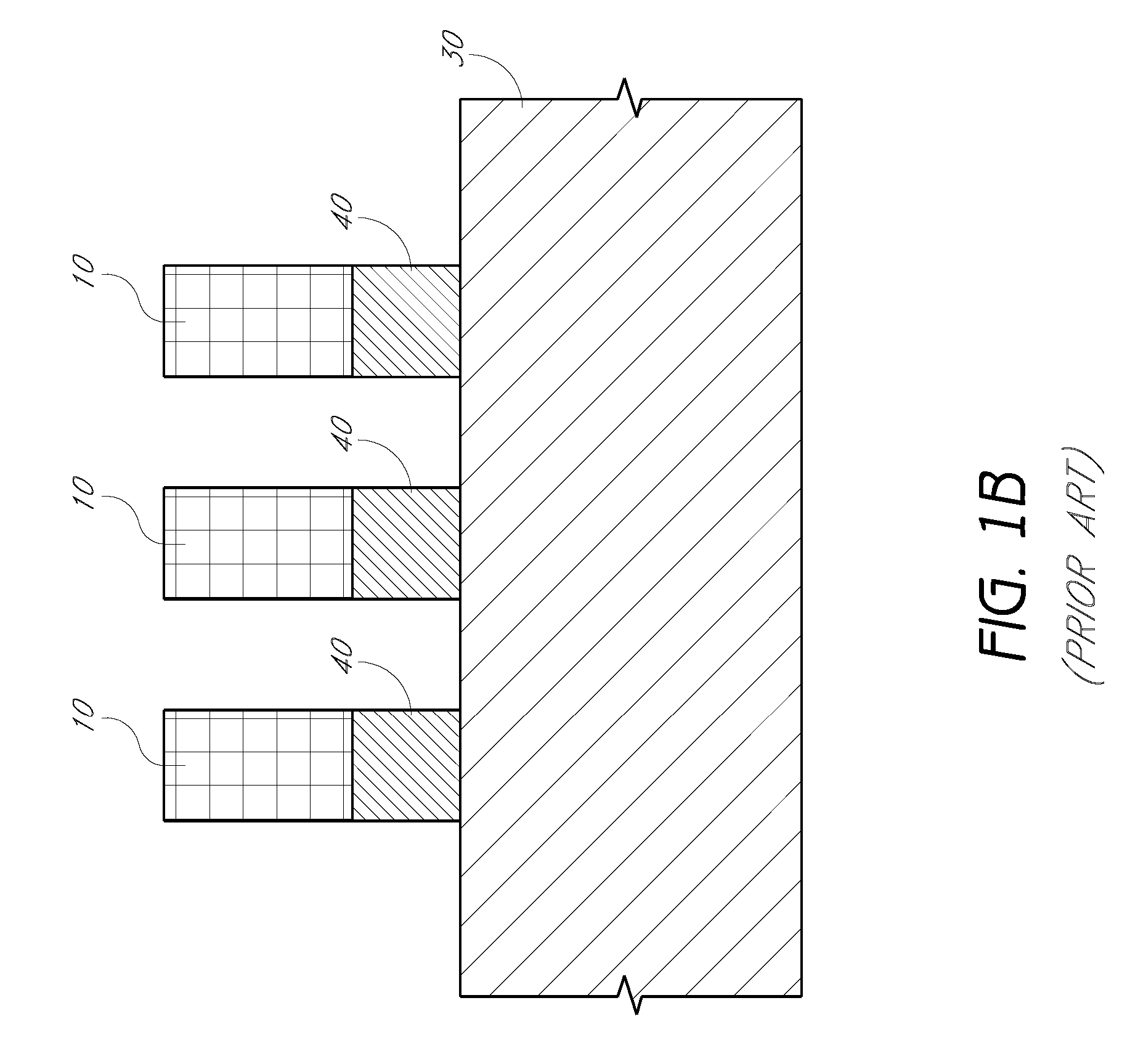

Multiple deposition for integration of spacers in pitch multiplication process

InactiveUS20070049040A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical reactionGas phase

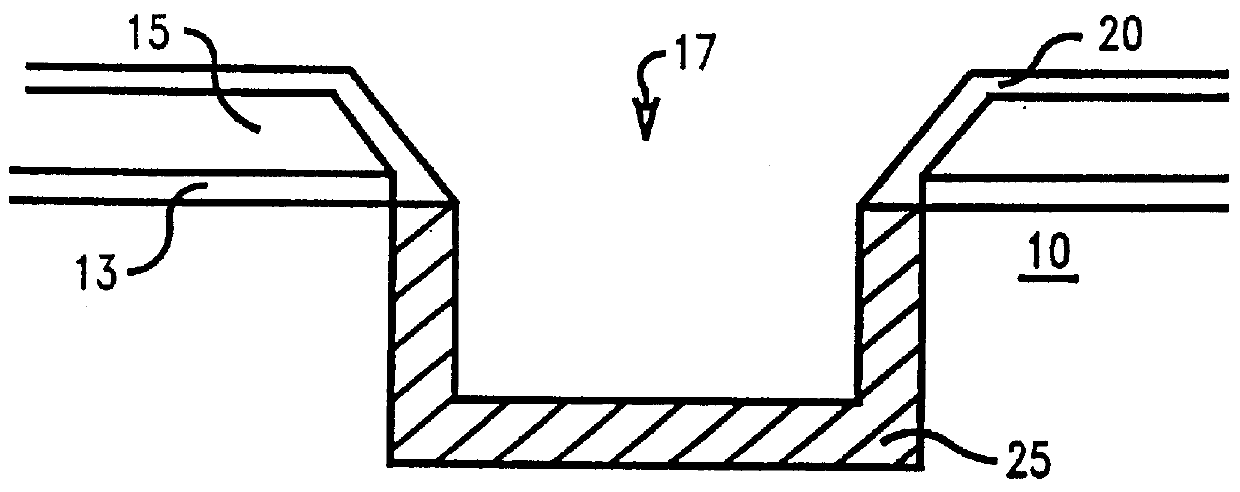

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

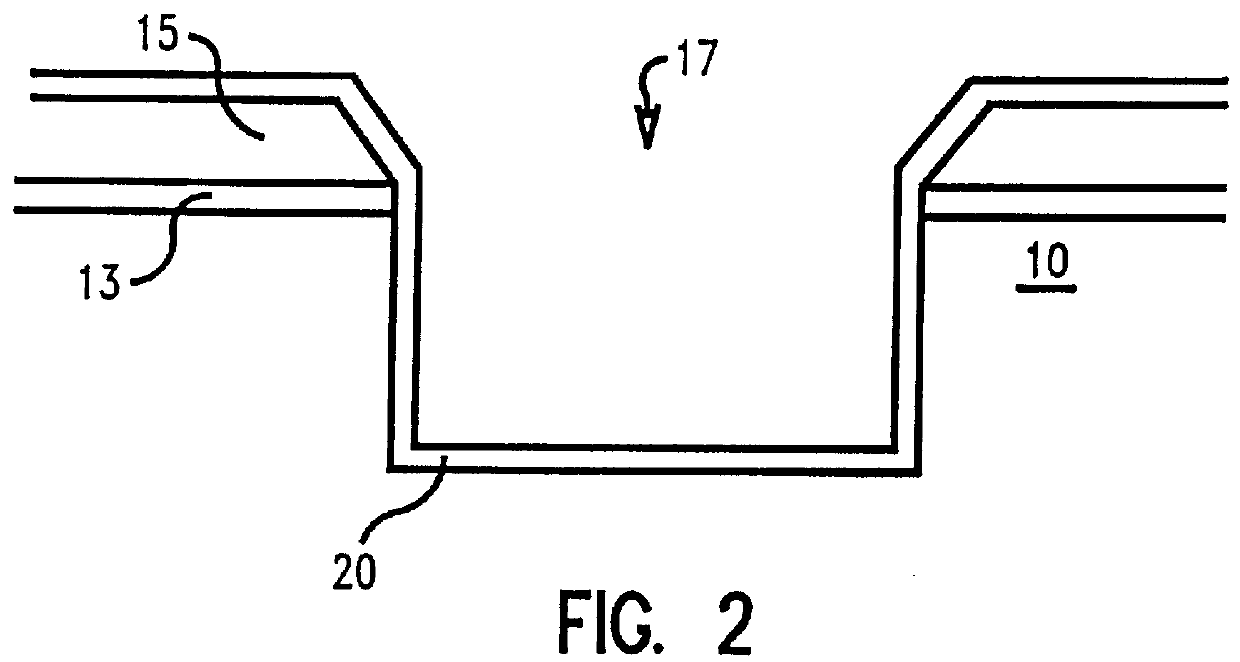

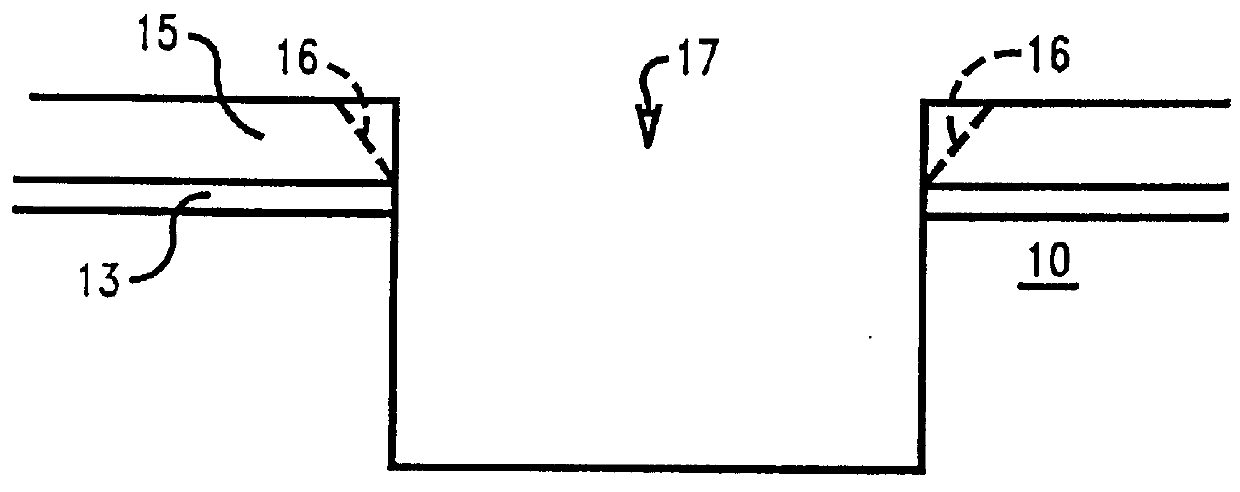

Ozone and teos process for silicon oxide deposition

InactiveUS20090325391A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTetraethyl orthosilicateBatch reactor

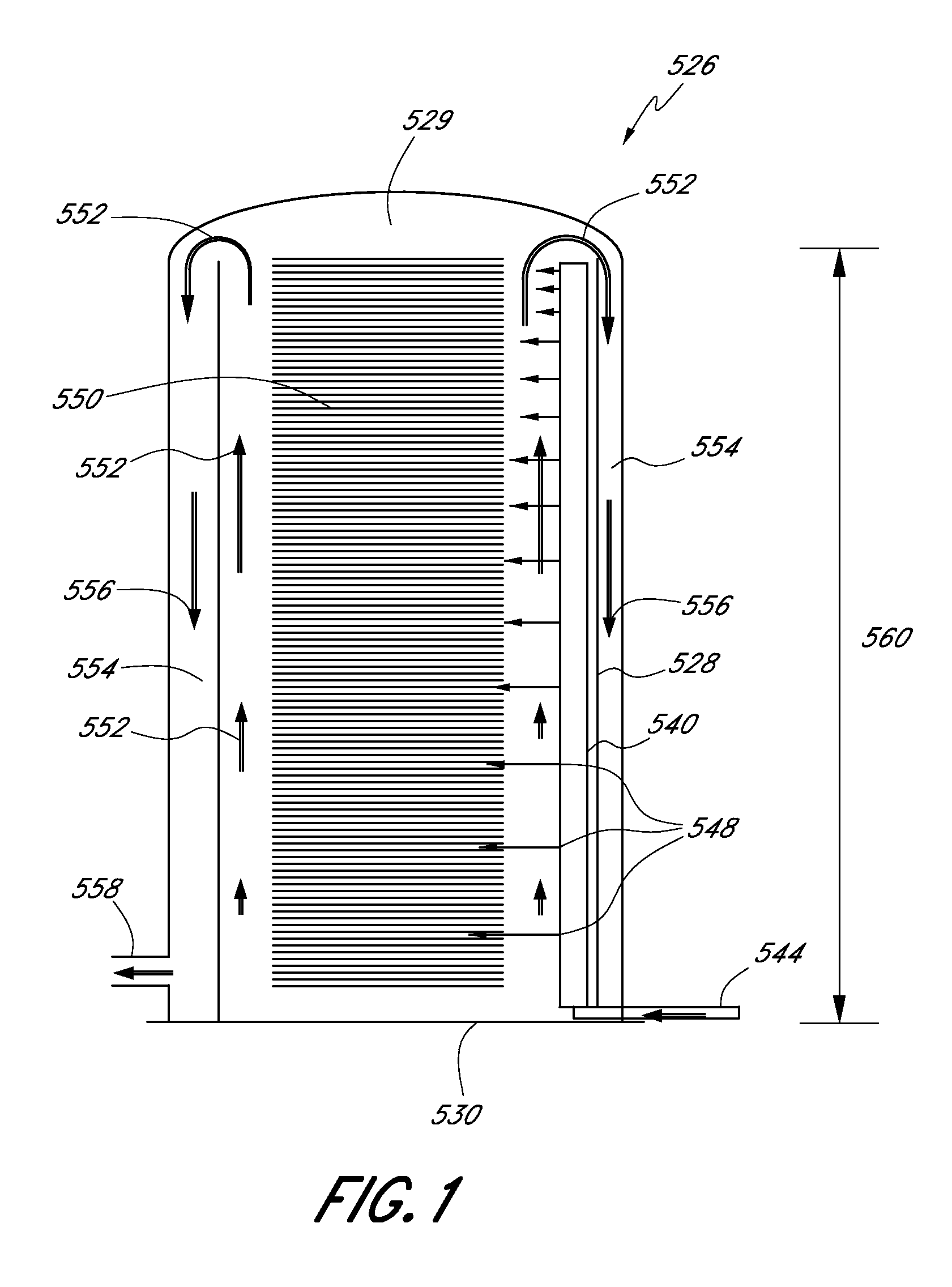

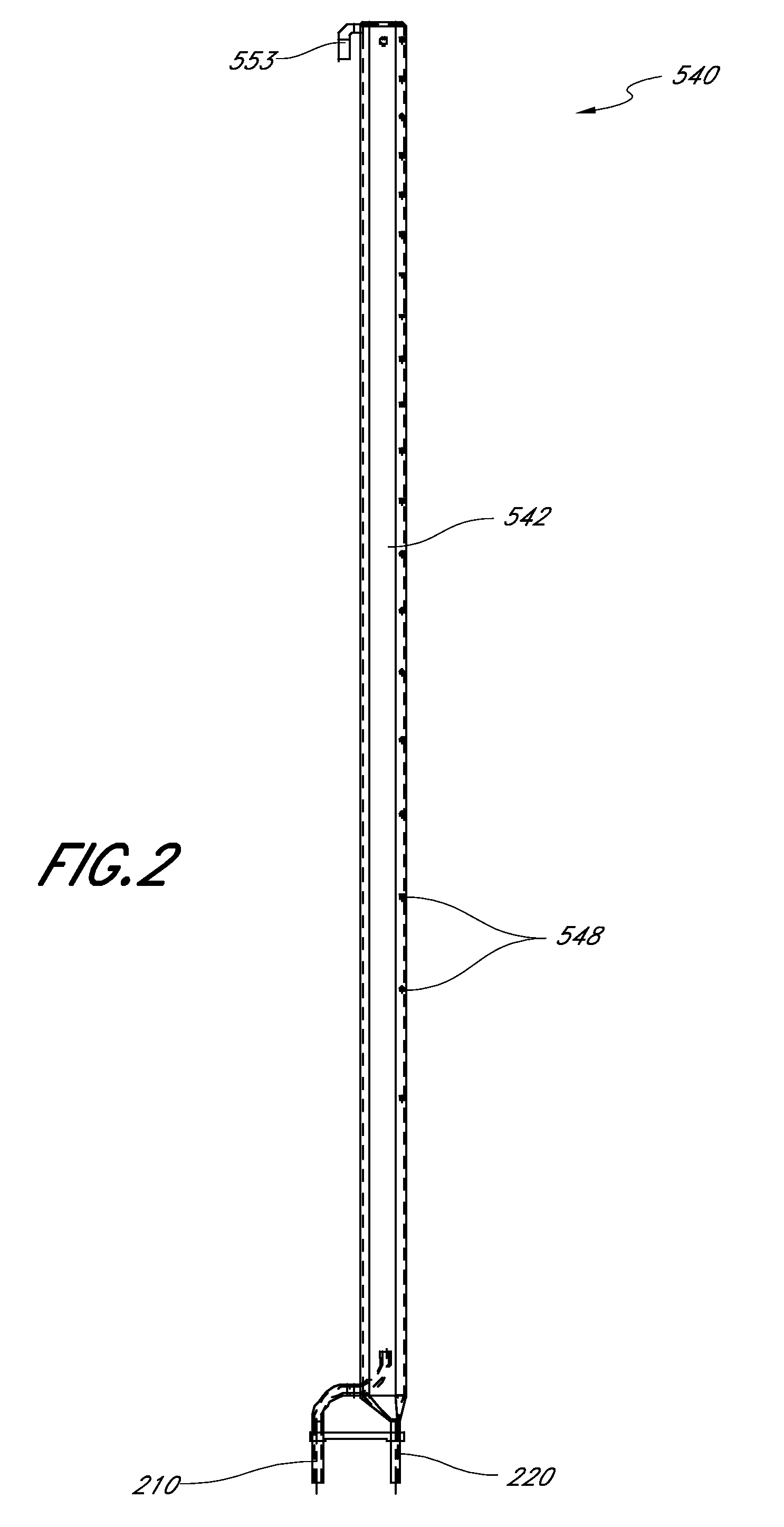

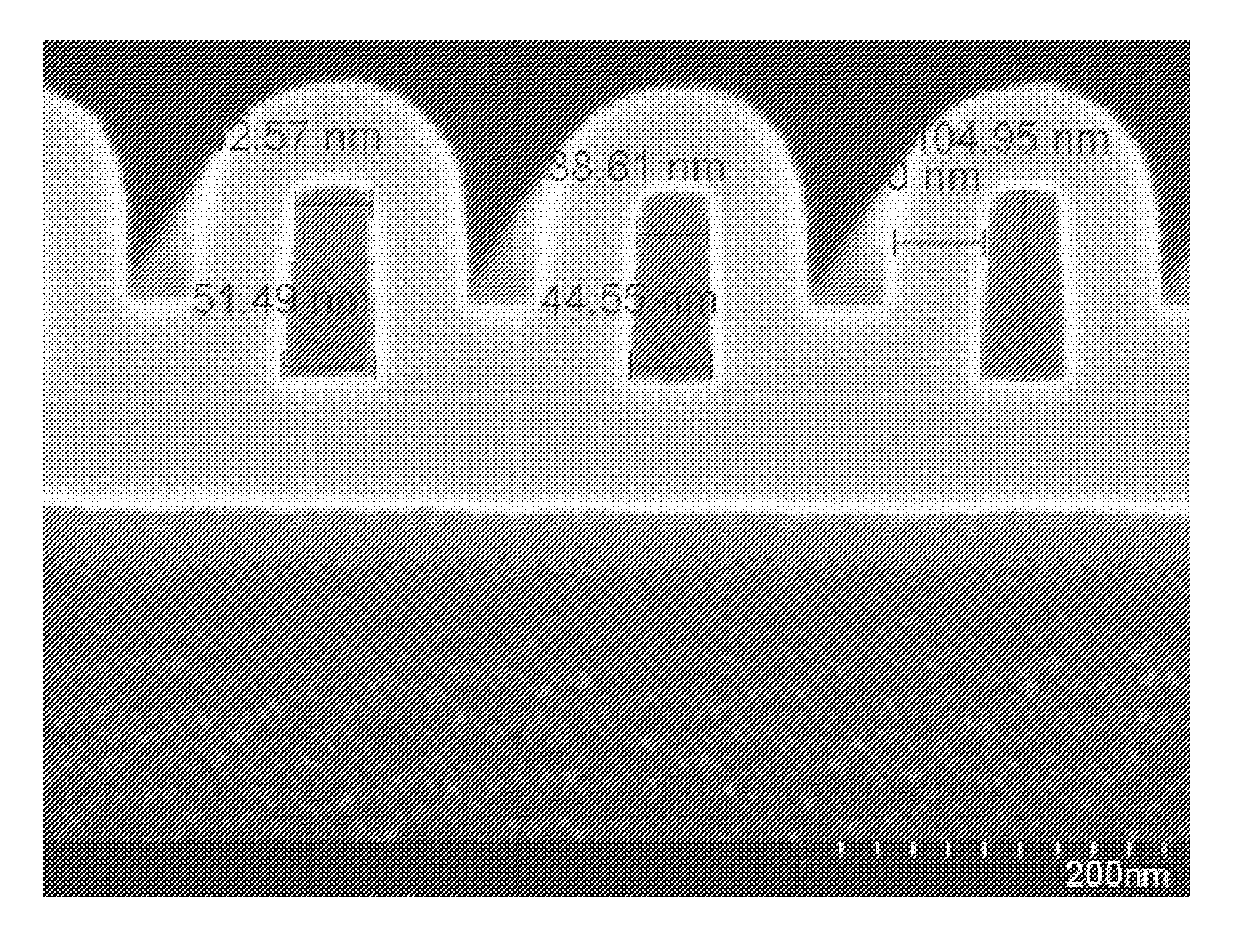

Methods for depositing silicon oxide in a batch reactor are provided. In some embodiments, a plurality of vertically separated substrates is provided in a reaction chamber. Tetraethyl orthosilicate (TEOS) is pulsed into the reaction chamber by direct liquid injection. Ozone is flowed into the reaction chamber simultaneously or alternately with the TEOS. The deposition is performed at about 10 Torr or less to extend the mean free path length of the ozone molecules. According to some embodiments, the deposition allows openings in the substrates to be filled while the occurrence of voids is maintained at a low level.

Owner:ASM INTERNATIONAL

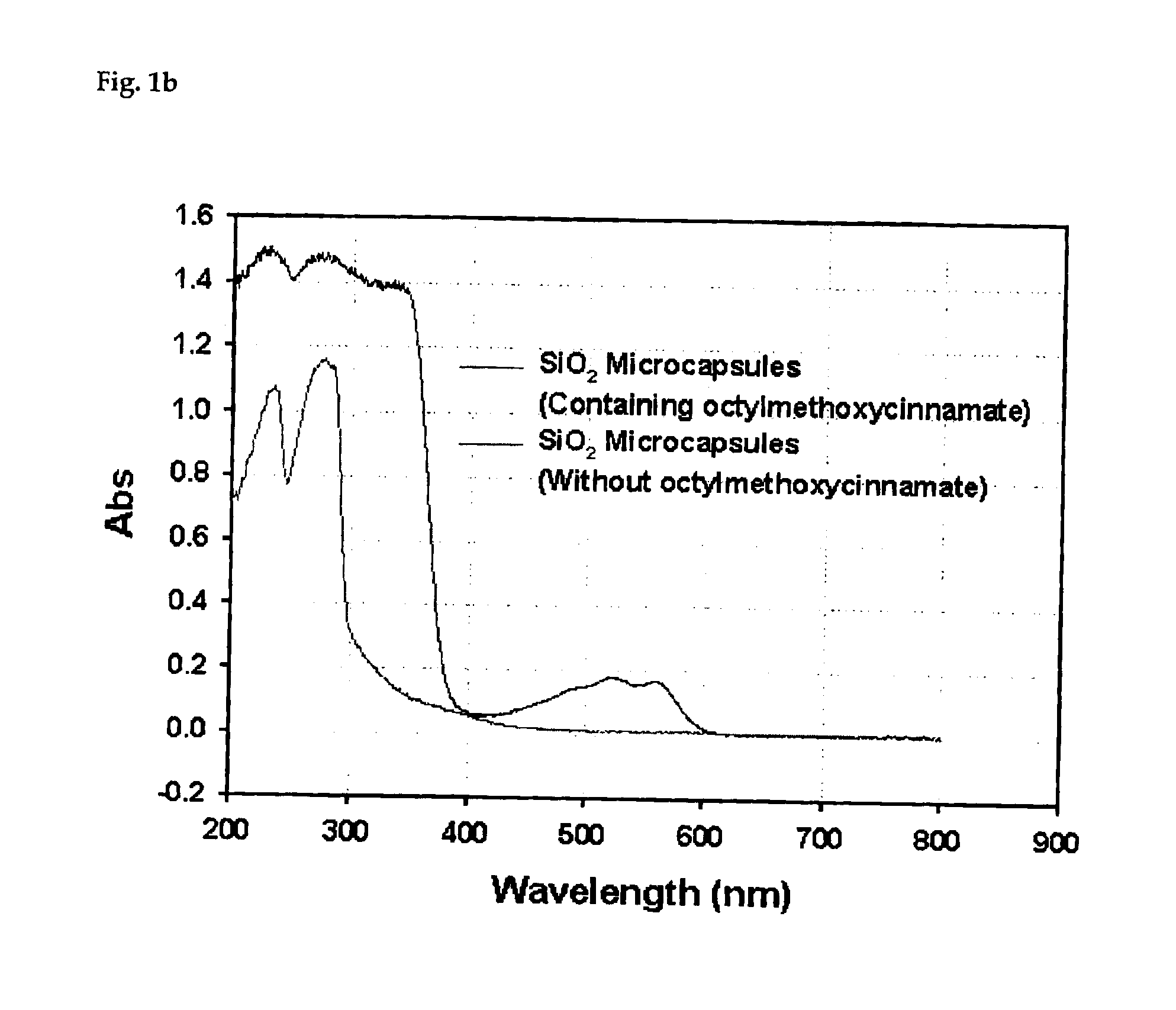

Process for preparing silica microcapsules

InactiveUS6855335B2Reduce environmental pollutionPowder deliveryGlass/slag layered productsAmmonium hydroxideSilica gel

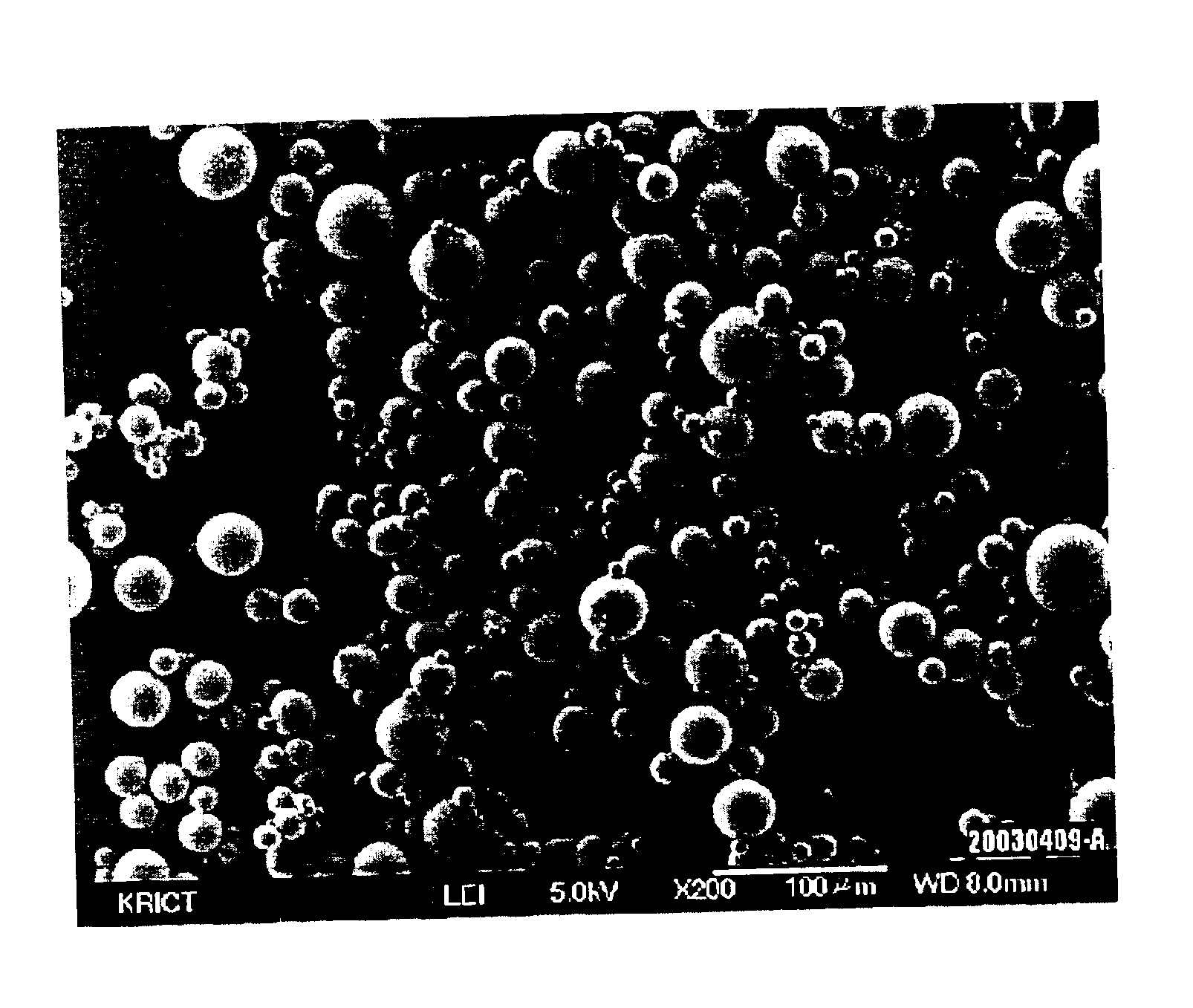

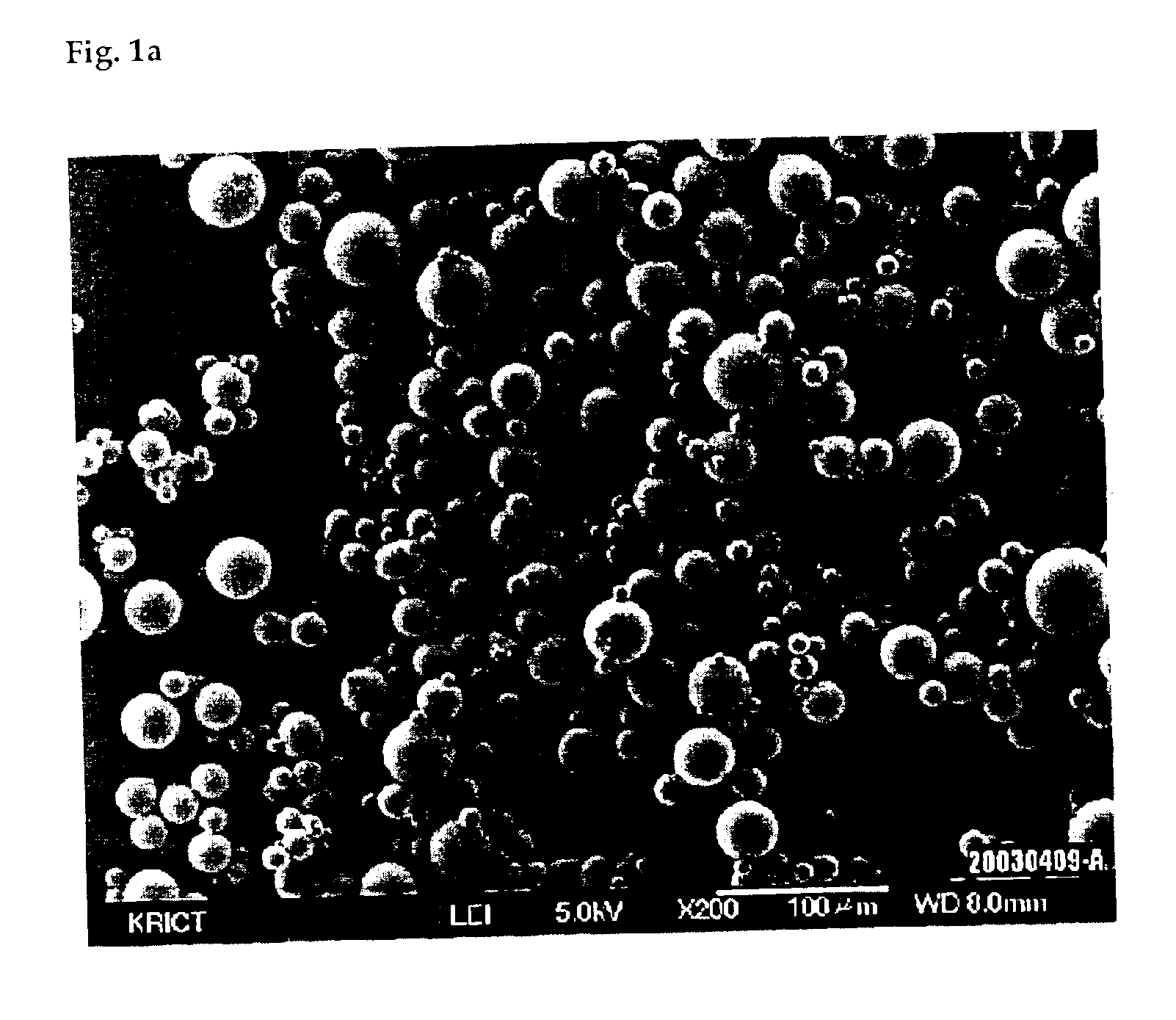

The present invention relates to a process for preparing silica microcapsules and more particularly, to a process for preparing silica microcapsules comprising the steps of dissolving tetraethyl orthosilicate (TEOS) into an aqueous solution containing a hydrolysis catalyst to control a degree of hydrolysis and contribute hydrophilicity or lipophilicity, adding a core material and an appropriate amount of aminopropyltrialkoxysilane(APS) as a gelling agent into the solution, and emulsifying and dispersing the resulting solution to a solution having a polarity opposite to that of the core material to microcapsulate by coating the core material with silica shell via a sol-gel reaction. The process for preparing microcapsules of the present invention reduces environmental pollution compared to conventional processes using an alkali gelling agent such as an ammonia solution, and are suitable for both organic or inorganic core materials having hydrophilic or lipophilic property.

Owner:UNITECH CO LTD (JP)

Formulations for cleaning memory device structures

InactiveUS20080125342A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBorophosphosilicate glassSilicon oxide

A removal composition and process for removing silicon-containing layers from a microelectronic device having said layers thereon. The removal composition selectively removes layers including, but not limited to, silicon oxide, plasma enhanced tetraethyl orthosilicate (P-TEOS), borophosphosilicate glass (BPSG), plasma enhanced oxide (PEOX), high density plasma oxide (HDP), phosphosilicate glass (PSG), spin-on-dielectrics (SOD), thermal oxide, updoped silicate glass, sacrificial oxides, silicon-containing organic polymers, silicon-containing hybrid organic / inorganic materials, organosilicate glass (OSG), TEOS, fluorinated silicate glass (FSG), hemispherical grain (HSQ), carbon-doped oxide (CDO) glass, and combinations thereof, relative to lower electrode, device substrate, and / or etch stop layer materials.

Owner:ADVANCED TECH MATERIALS INC

Shallow trench isolation (STI) with bilayer of oxide-nitride for VLSI applications

A reduction in parasitic leakages of shallow trench isolation vias is disclosed wherein the distance between the silicon nitride liner and the active silicon sidewalls is increased by depositing an insulating oxide layer prior to deposition of the silicon nitride liner. Preferably, the insulating oxide layer comprises tetraethylorthosilicate. The method comprises of etching one or more shallow trench isolations into a semiconductor wafer; depositing an insulating oxide layer into the trench; growing a thermal oxide in the trench; and depositing a silicon nitride liner in the trench. The thermal oxide may be grown prior to or after deposition of the insulating oxide layer.

Owner:QIMONDA +1

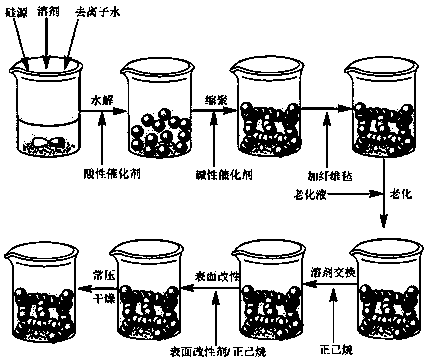

Method for preparing hydrophobic SiO2 aerogel

The invention relates to a method for preparing lyophobic SiO2 aerogel, belonging to the technical field of new material preparation. The method comprises the steps: tetraethyl orthosilicate, absolute ethyl alcohol and oxalic acid solution are firstly mixed in a container for sealing, and then the mixed solution is put into water bath, hydrolyzed under agitation and added with ammonia dropwise; when gel is formed, the absolute ethyl alcohol is added into the gel for exchanging the water in the gel; n-hexane is used for exchanging ethanol in the gel; wet gel which is processed by solvent exchange and aging is dipped into the mixed solution of modifying agent and n-hexane for surface modification, then the n-hexane is added for exchanging the unreacted modifying agent; finally, a test tube is sealed by a aluminum foil provided with a needle hole and is placed into an oven for classified drying under normal pressure, so that the modified SiO2 aerogel is obtained. The SiO2 aerogel prepared by the method has the advantages of high porosity, large specific surface area, good hydrophobic property, etc. The method has the advantages of mild reaction condition, easy control of the reaction as well as simple and convenient process flow.

Owner:YANGZHOU TIANCHEN FINE CHEM +1

Multiple deposition for integration of spacers in pitch multiplication process

Pitch multiplication is performed using a two step process to deposit spacer material on mandrels. The precursors of the first step react minimally with the mandrels, forming a barrier layer against chemical reactions for the deposition process of the second step, which uses precursors more reactive with the mandrels. Where the mandrels are formed of amorphous carbon and the spacer material is silicon oxide, the silicon oxide is first deposited by a plasma enhanced deposition process and then by a thermal chemical vapor deposition process. Oxygen gas and plasma-enhanced tetraethylorthosilicate (TEOS) are used as reactants in the plasma enhanced process, while ozone and TEOS are used as reactants in the thermal chemical vapor deposition process. The oxygen gas is less reactive with the amorphous carbon than ozone, thereby minimizing deformation of the mandrels caused by oxidation of the amorphous carbon.

Owner:ROUND ROCK RES LLC

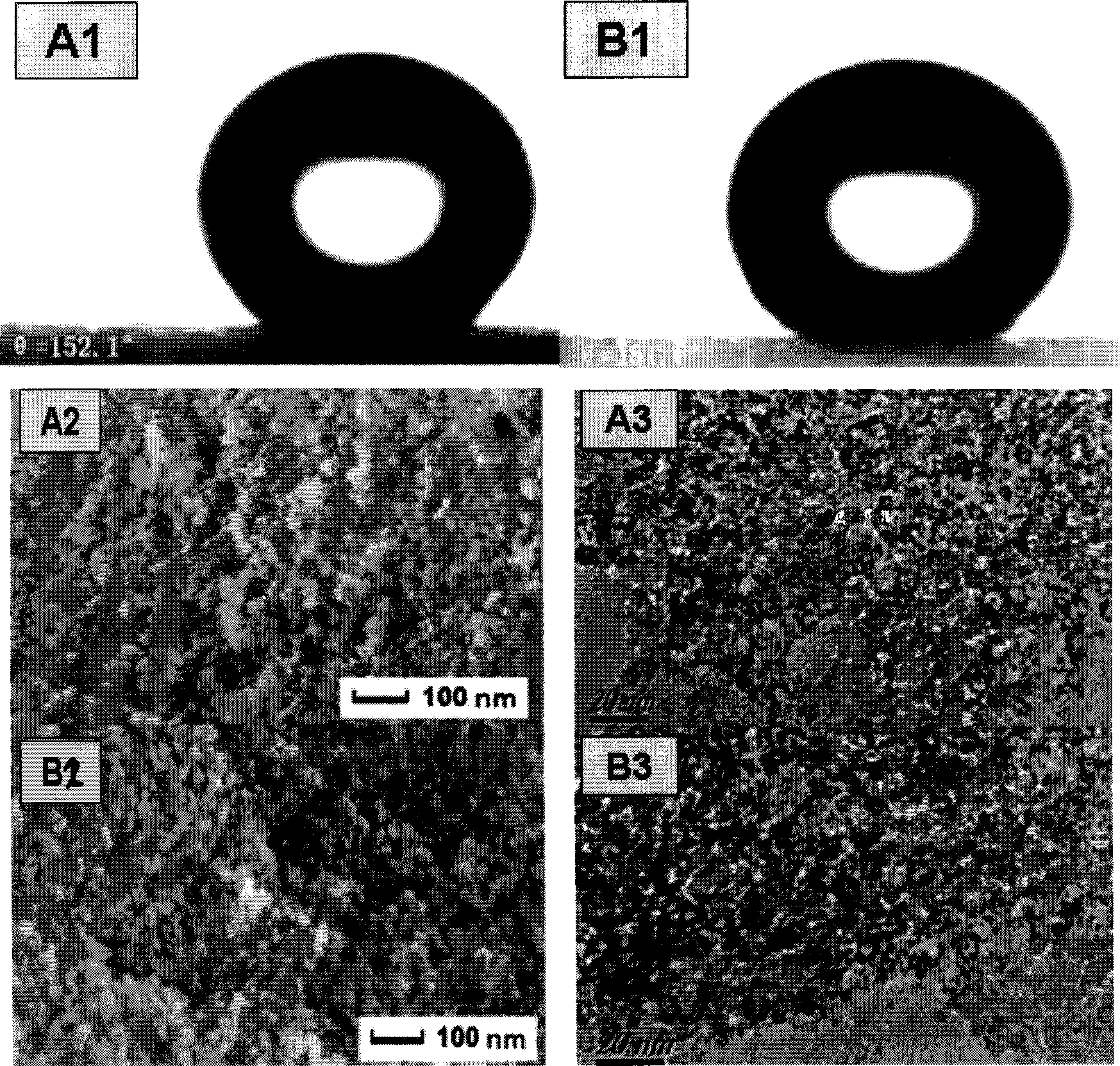

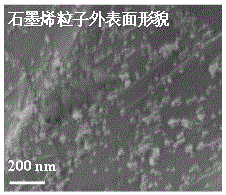

Superhydrophobic composite coating with self-repair function and preparation method thereof

ActiveCN105038439AIncrease storage capacityImprove adsorption capacityCoatingsSuperhydrophobic coatingMaterials science

The invention relates to a superhydrophobic composite coating with self-repair function, which solves the problem of low mechanical strength in the existing self-repair superhydrophobic coating. The superhydrophobic composite coating with self-repair function is prepared from the following raw materials in parts by weight: 1-20 parts of graphene, 1-20 parts of tetraethyl orthosilicate or tetrabutyl titanate, 1-20 parts of ammonia water, 1-5 parts of low-surface-energy modifier, 60-90 parts of low-surface-energy high-molecular polymer, 2-7 parts of pore forming agent, 5-25 parts of deionized water and 60-100 parts of organic solvent. The pore structure constructed inside the coating can keep a coarse structure for a long time in the friction process. The high-strength graphene can enhance the mechanical strength of the coating, thereby keeping high hydrophobicity and oleophobicity of the coating in the friction process. After the rubbed coating is subjected to simple heating treatment, the low-surface-energy substances stored and grafted in the nano storage tank structures among the multilayer graphene can be activated, and thus, can migrate to the coating surface, thereby implementing the hydrophobic and oleophobic repair of the coating.

Owner:NORTHEAST GASOLINEEUM UNIV

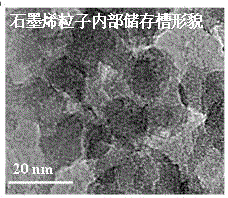

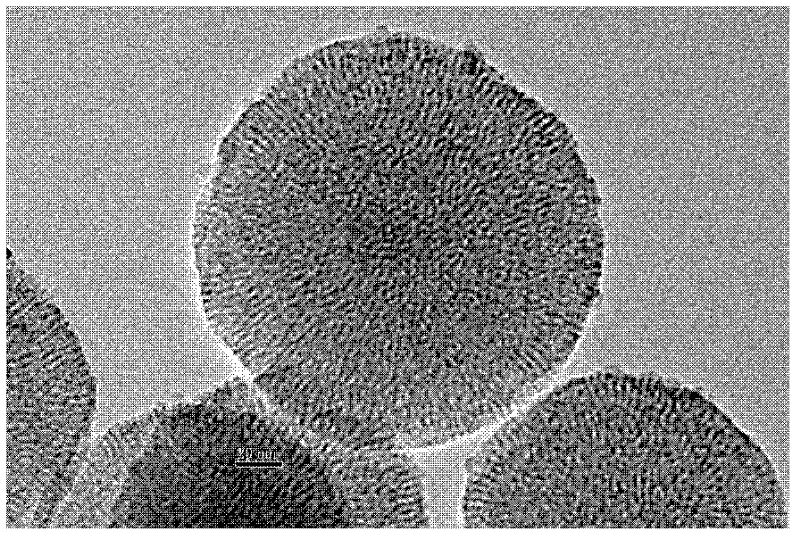

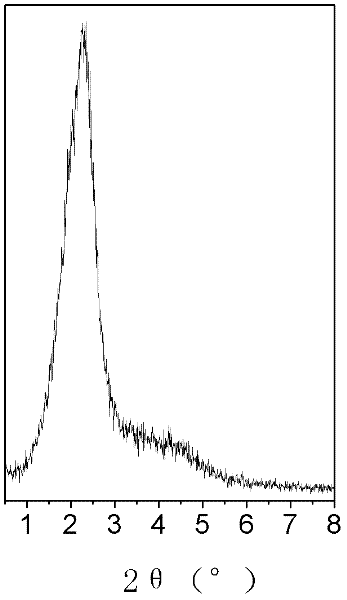

Mono-dispersed spherical mesoporous silicon dioxide nanomaterial and preparation method thereof

InactiveCN102249248AGood monodispersityParticle size controllableSilicaNanotechnologyTetraethyl orthosilicateNanoparticle

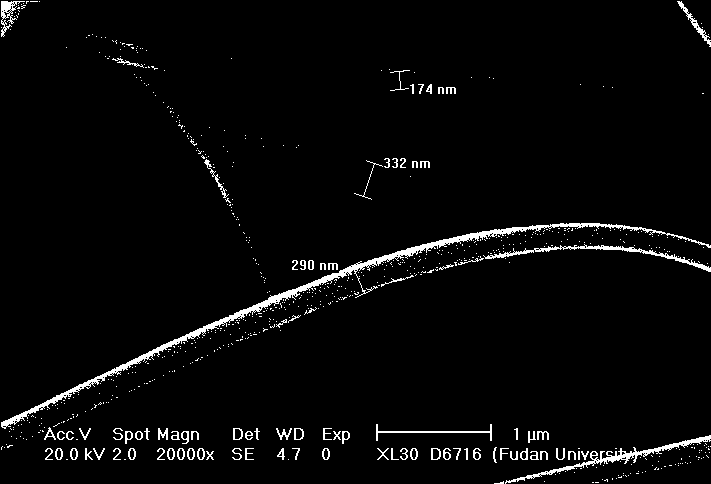

The invention relates to a mono-dispersed spherical mesoporous silicon dioxide nanomaterial, which is characterized in that: the nanomaterial has a spherical structure of which the particle diameter is 80-200 nanometers; the relative standard deviation of the particle diameter is not more than 8 percent; the specific surface area of the material is 1,057-1,379 m<2> / g; the pore volume is 0.74-0.89 cm<3> / g; the mesoporous pore diameter is 2.4-2.6 nanometers; and the nanometer material has a pore canal structure formed radially from the center of a sphere to an outer surface. The mono-dispersed spherical mesoporous silicon dioxide nanomaterial is prepared by hydrolyzing and condensing by taking a cationic surfactant as a template, tetraethyl orthosilicate as a silicon source and alcohol as a cosolvent under alkaline condition. The method has the advantages of simple equipment, easiness of operation, short preparation period, high repeatability, high yield, low cost and environment friendliness. The prepared silicon dioxide material is of spherical nanoparticles which have controllable particle diameters, uniform particle diameter distribution, high mono-dispersity, narrow pore diameter distribution and ordered mesoporous pore canal structures.

Owner:OCEAN UNIV OF CHINA

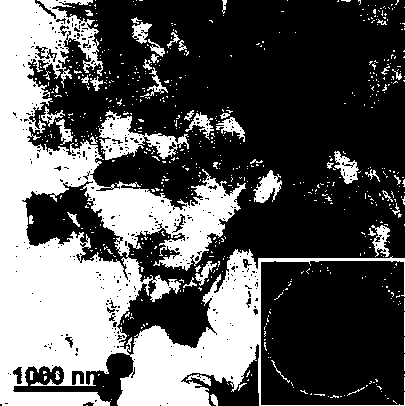

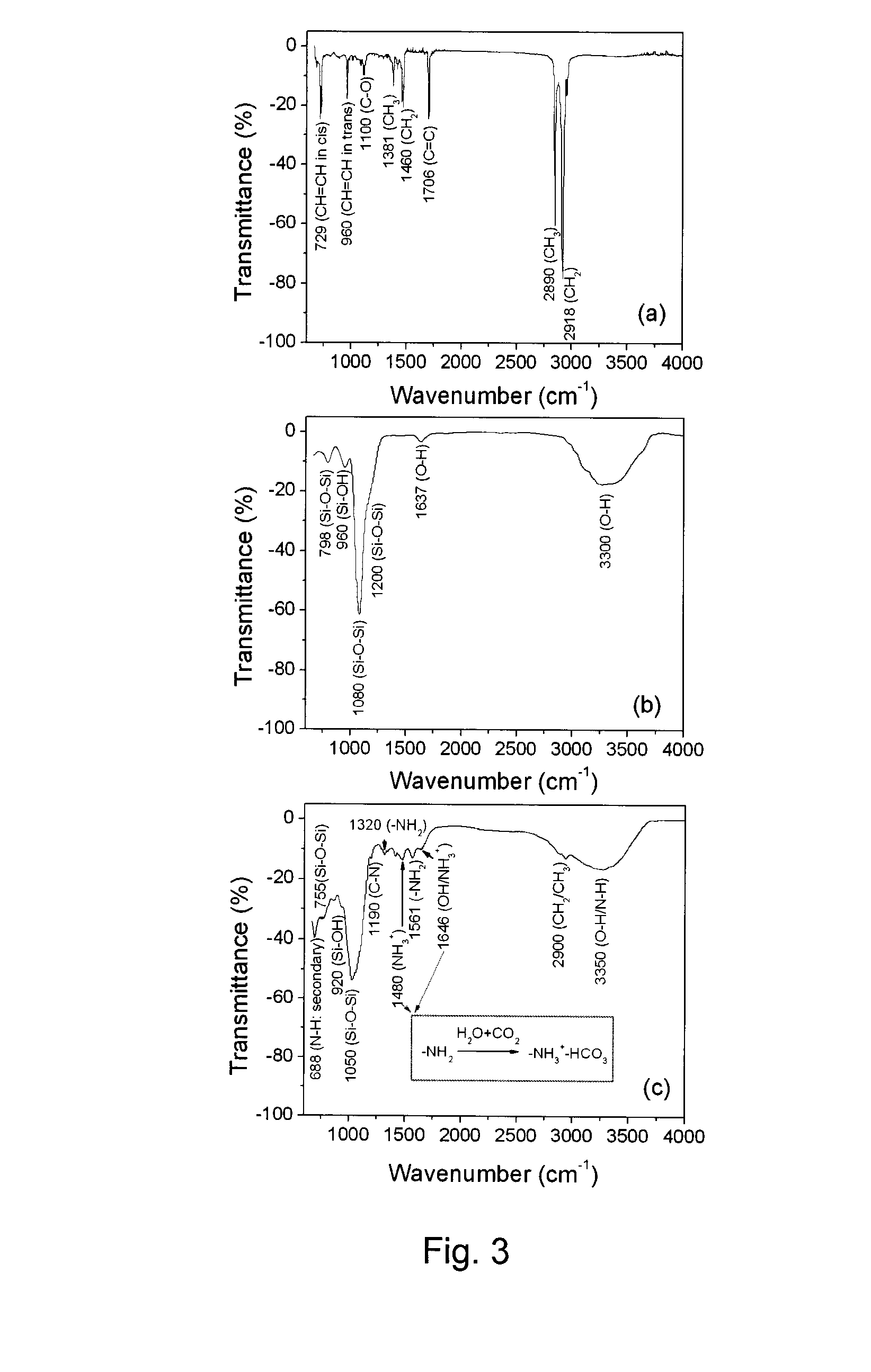

Preparation method of graphene oxide and magnetic mesoporous silica composite material capable of adsorbing pollutants in water

InactiveCN103432996AAdjust the content of magnetic substancesLow costOther chemical processesAlkali metal oxides/hydroxidesAlkanePolyetherimide

The invention relates to a preparation method of a composite material prepared by graphene oxide and magnetic mesoporous silica microspheres through chemical bonding interaction. The magnetic particles are prepared by a hydrothermal process; after acid ultrasonic treatment, the magnetic particles are firstly coated with a thin silicon oxide shell layer by a sol-gel method; after that, long-chain alkane is taken as a pore-forming agent, the magnetic particles are copolymerized with tetraethyl orthosilicate (TEOS) in the sol-gel reaction, and then the pore-forming agent is removed by thermal etching, so that the magnetic mesoporous silica particles with certain hydroxyl on the surfaces can be obtained; polyetherimide (PEI) surface modification is carried out on the magnetic mesoporous silica particles, and strong interaction between PEI and silicon hydroxyl is utilized; finally, the carboxyl on ethylene dichloride (EDC) activated graphene oxide reacts with amino on the PEI, so that the graphene oxide magnetic mesoporous silica composite material can be obtained. The preparation method is simple, convenient and controllable and is favorable for amplification preparation. The composite material has large specific surface area and good magnetic controllability, and can adsorb humic acid and heavy metal ions Pb (II) at the same time by virtue of surface groups.

Owner:TONGJI UNIV

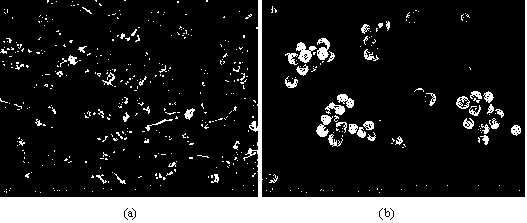

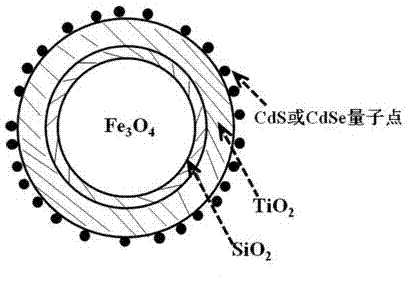

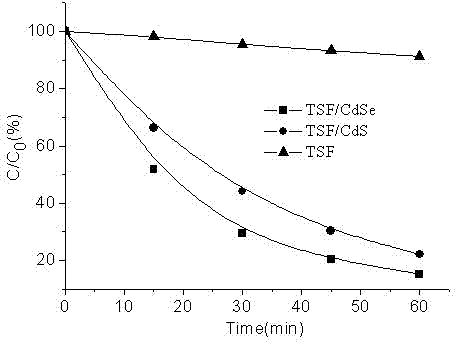

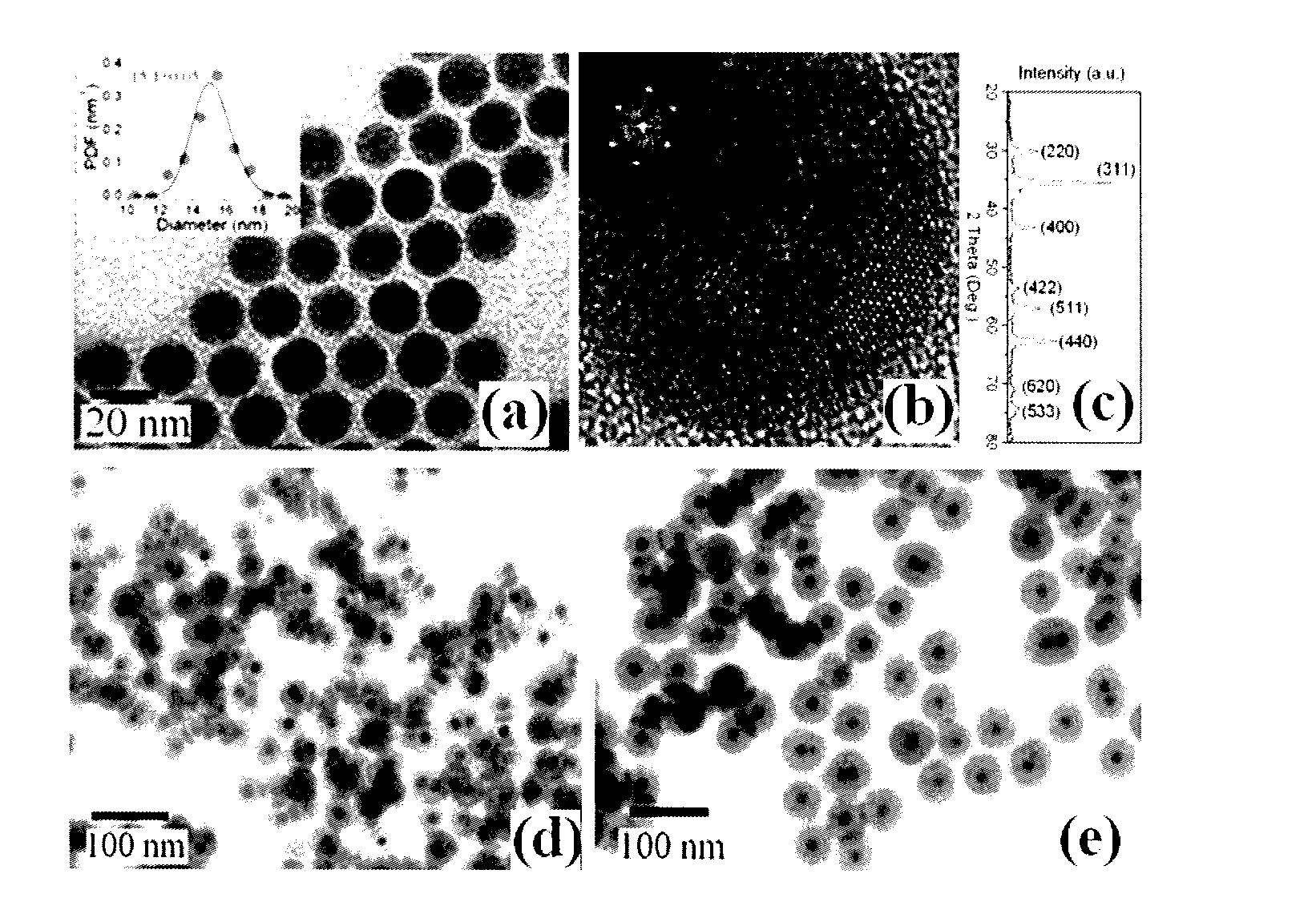

Magnetic Fe3O4/SiO2/TiO2/quantum dot compounded nanometer photocatalyst and preparation method and application thereof

InactiveCN102921435AHigh visible light photocatalytic performancePromote degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationNano catalystVisible light photocatalytic

The invention belongs to the technical field of treatment and application of nanometer materials and industrial and agricultural wastewater, and provides a magnetic Fe3O4 / SiO2 / TiO2 / quantum dot compounded nanometer photocatalyst and a preparation method and application thereof. The preparation method comprises the following steps of: synthesizing an Fe3O4 magnetic nucleus by a coprecipitation method; preparing an SiO2 protective layer by virtue of hydrolysis reaction and polycondensation reaction of TEOS (Tetraethyl Orthosilicate); then preparing a TiO2 layer on the surface of the SiO2 protective layer by a sol-gel method; and finally modifying Fe3O4 / SiO2 / TiO2 nanoparticles by CdS and CdSe quantum dots. The obtained magnetic Fe3O4 / SiO2 / TiO2 / quantum dot compounded nanometer photocatalyst has very good visible-light photocatalytic capability, can be conveniently and fast recovered and reused by an external magnetic field, and can be used for removing organic pollutants of azo dyes contained in the industrial wastewater.

Owner:HUBEI UNIV

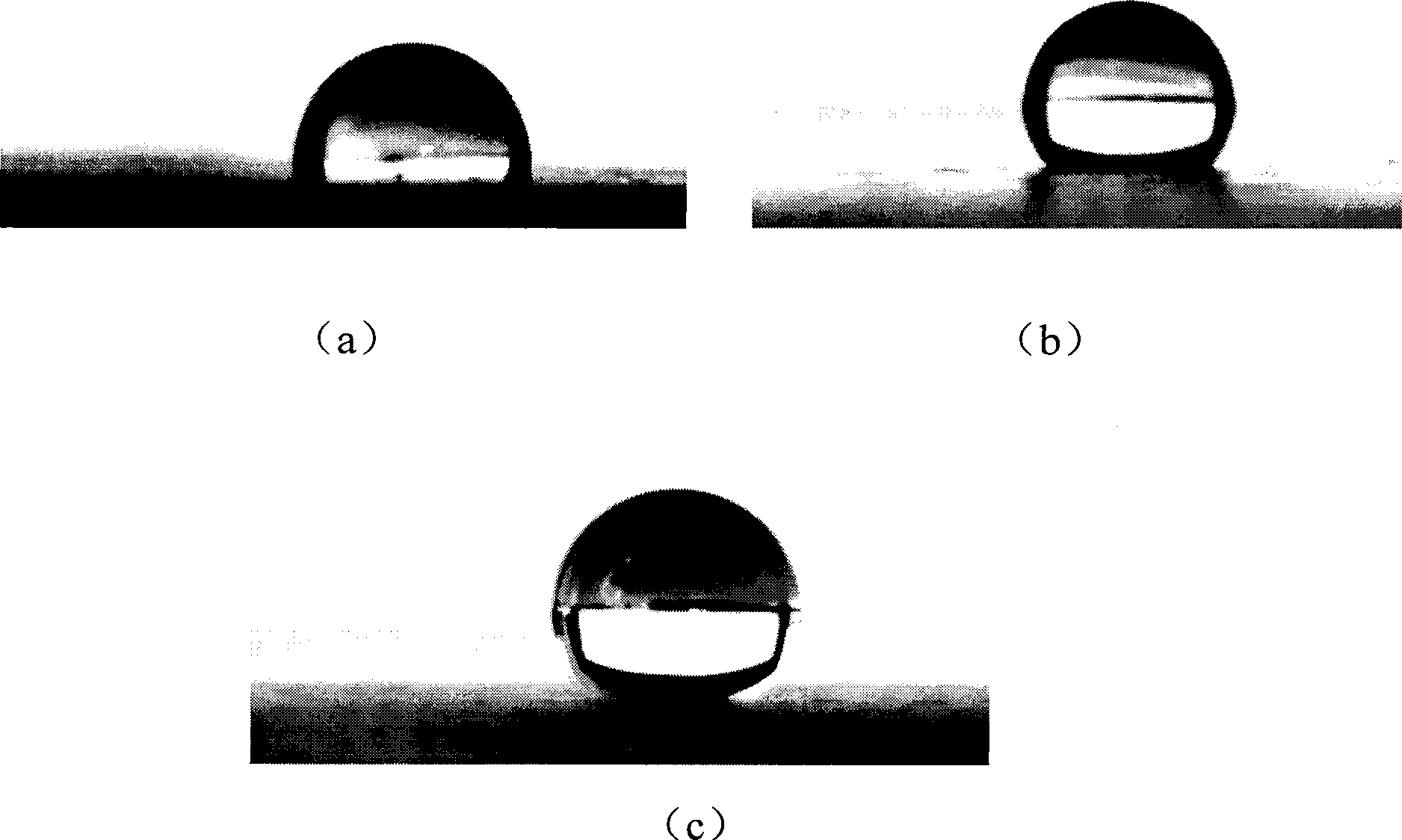

Treatment method and treatment liquid for preparing fluoride-free super-hydrophobic cotton fabric

ActiveCN103290674AMeet the requirementsWide variety of sourcesVegetal fibresTetraethyl orthosilicateFluorine free

The invention provides a treatment method and treatment liquid for preparing a fluoride-free super-hydrophobic cotton fabric. The treatment liquid comprises the following components: 1-8ml of ammonia water of which the mass percent concentration is 25-28%, 80-140ml of ethanol, 5-6ml of tetraethyl orthosilicate, 2-4ml of hexadecyl trimethoxy siloxane, 0.5-3ml of alkane siloxane and 0-4ml of 3-glycidol ether oxy-propyl trimethoxysilane. According to the treatment method, a large amount of modified silicon dioxide nano-particles with water repellency are modified on the surface of the fabric by dipping the fabric in the treatment liquid of modified silicon dioxide sol, so that the contact angle between the prepared fabric and a water drop is more than 150 degrees, the fabric has super-hydrophobic performance, and the physical and mechanical properties of the fabric are not affected. The treatment method and treatment liquid for preparing the fluoride-free super-hydrophobic cotton fabric are environment-friendly in process, simple, convenient, effective and in accordance with ecological textiles, and can meet requirements for industrial mass production.

Owner:MYPOLYMER JIAXING

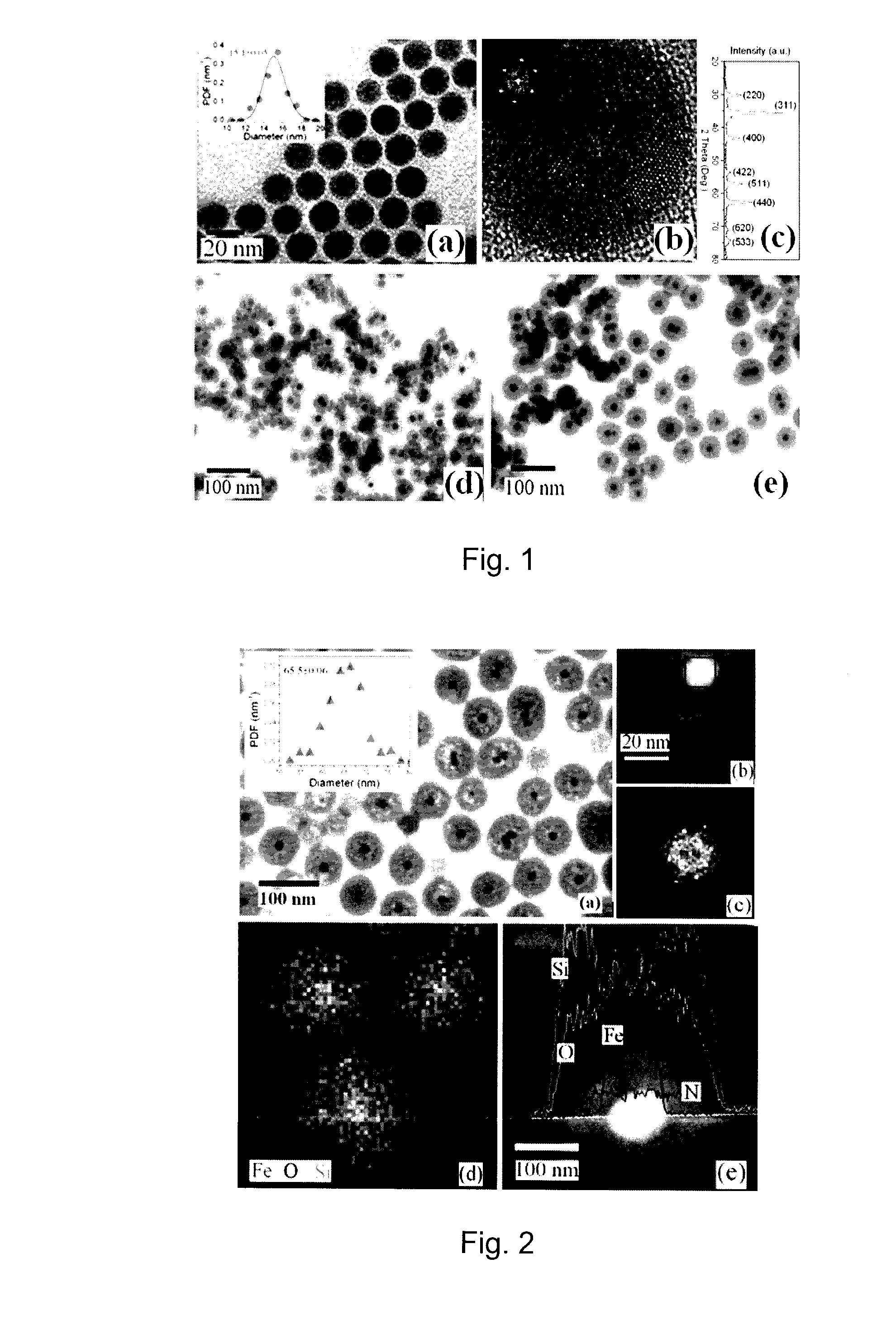

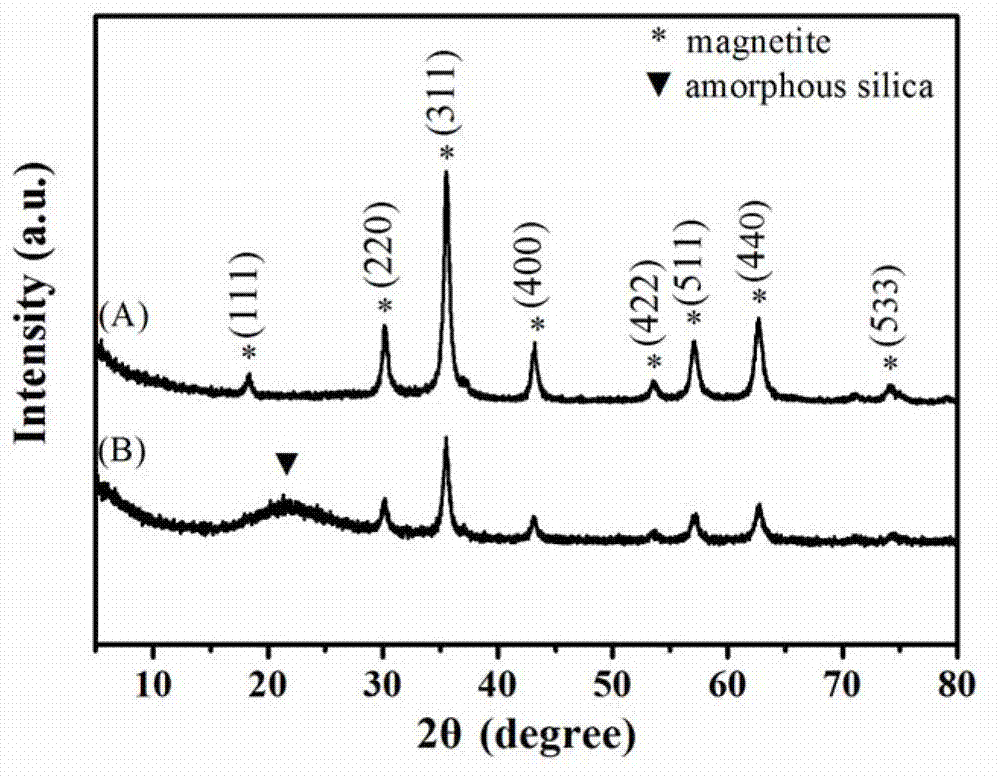

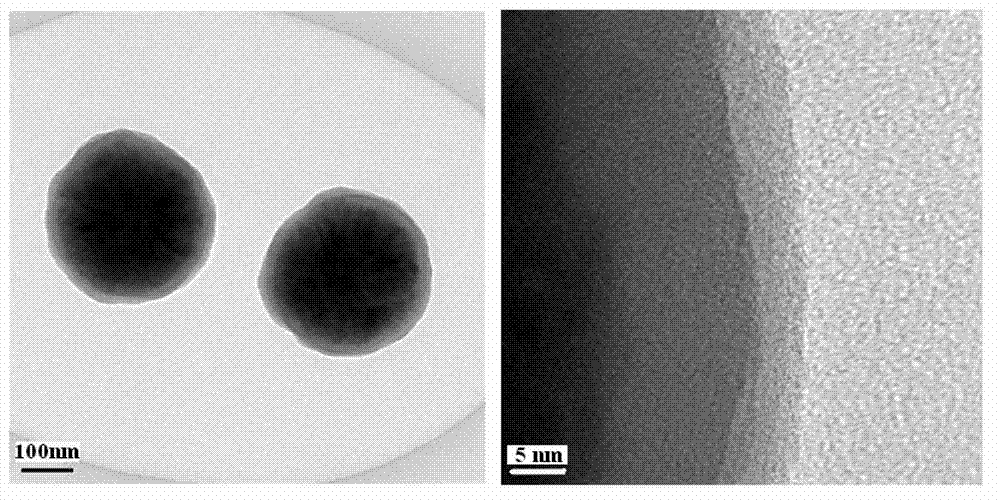

Magnetic Nanoparticles and Uses Thereof

InactiveUS20130089614A1Increase profitGood flexibilityPowder deliveryMaterial nanotechnologyMagnetite NanoparticlesSilica gel

Magnetic nanoparticles are provided that have a superparamagnetic core and a nanoporous silica shell surrounding the core. The shell is functionalized with amine or S-nitrosothiol groups both inside and outside the nanopores. A process to provide such nanoparticles involves hydrolyzing tetraethoxysilane (TEOS) in a microemulsion of a superparamagnetic nanoparticle to form a superparamagnetic nanoparticle encapsulated by an incompletely hydrolyzed nanoporous silica shell, and hydrolyzing an amine-containing compound or a thiol-containing compound in situ in the presence of the incompletely hydrolyzed nanoporous silica shell before hydrolysis and densification of the silica shell is complete to functionalize the nanoporous silica shell with amine or thiol groups both inside and outside the nanopores and to maintain nanoporosity of the shell. Such magnetic nanoparticles are useful as carriers for chemical or biological species, particularly for magnetic resonance imaging, optical imaging, targeted drug delivery, cell delivery and magnetic separation applications.

Owner:ZHANG XUEFENG +1

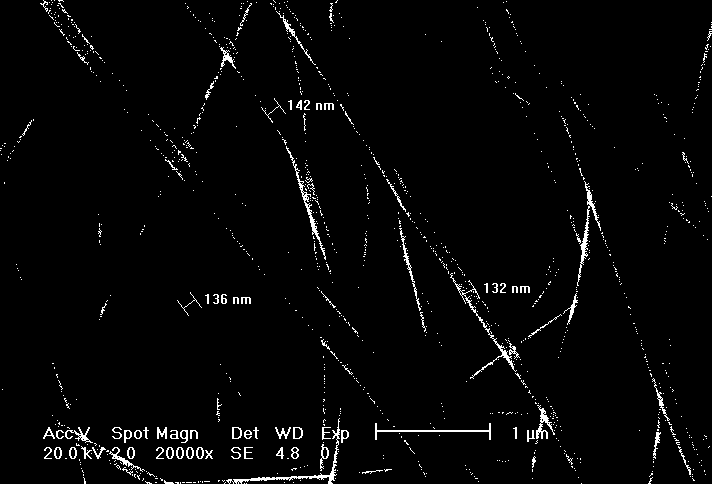

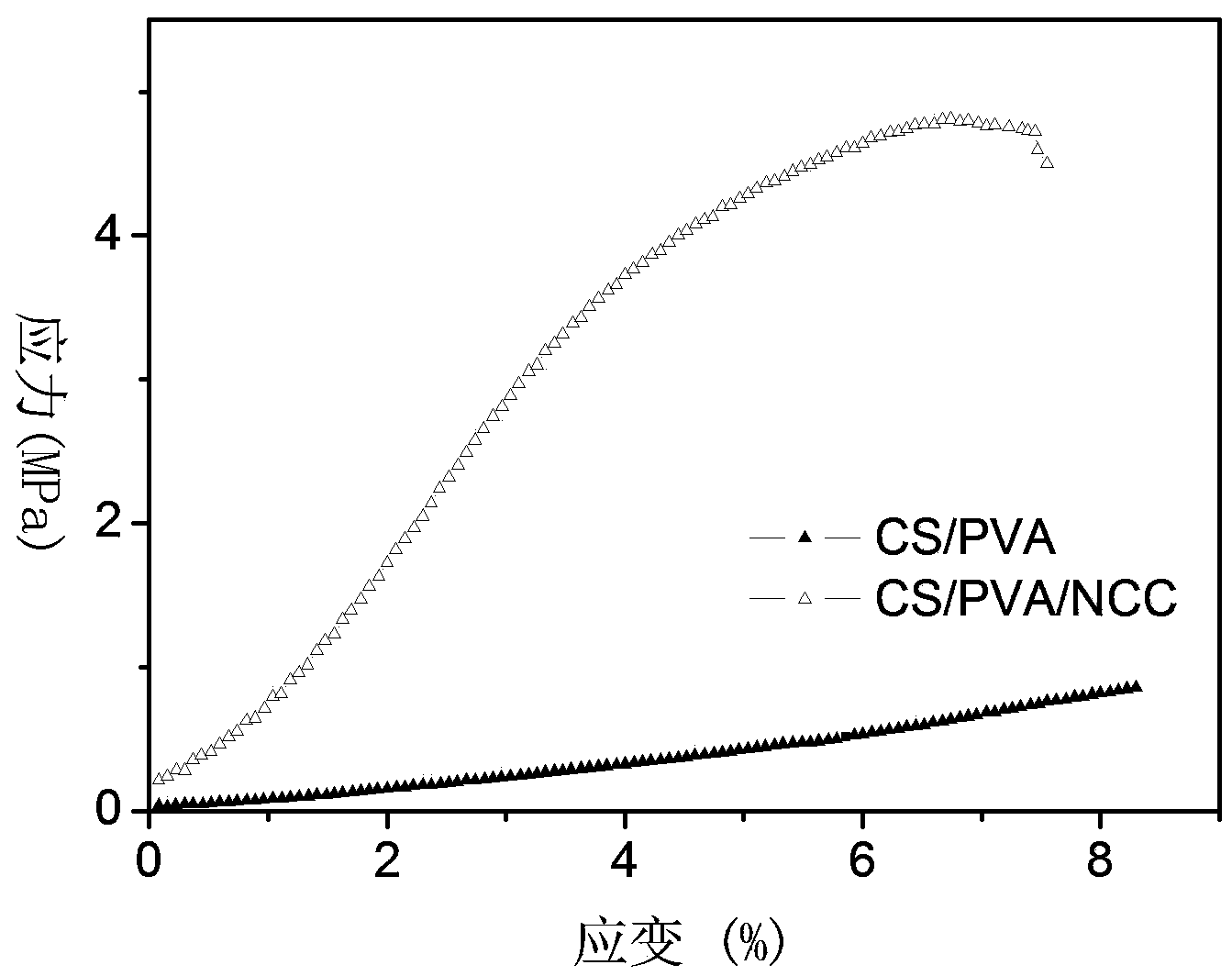

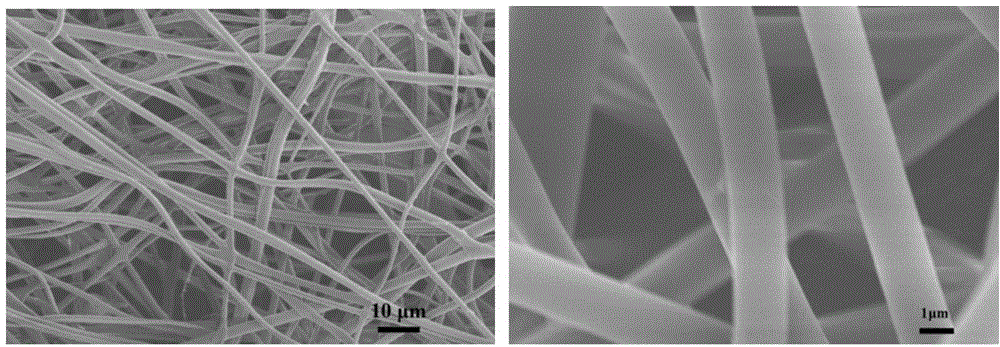

Method for preparing NCC/CS/PVA composite nano-membrane

ActiveCN103866487AAdjustable diameterLarger than surfaceNon-woven fabricsSpinning solutions preparationSpinningSilicic acid

The invention relates to a method for preparing an NCC / CS / PVA composite nanofiber membrane. NCC is rod-shaped particles, wherein the diameter of each particle ranges from 20 nm to 60 nm, and the particles are highly crystallized. The method comprises the steps that (1) an NCC / CS solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.09% to 0.21%; (2) an NCC / PVA solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.4% to 0.8%; (3) an acetic acid solution, tetraethyl orthosilicate, the NCC / CS solution obtained in the step (1) and processed through ultrasound, and the NCC / PVA solution obtained in the step (2) and processed through ultrasound are mixed to obtain a spinning solution, and the nanofiber membrane is obtained through the electrospinning technology, wherein the mass ratio of the acetic acid solution to the tetraethyl orthosilicate to the NCC / CS solution to the NCC / PVA solution is (2.5-3.5):(1.5-2.5):5:5; (4) the obtained nanofiber membrane is immersed in an alkaline solution for 2-6 hours at the normal temperature, and the membrane structure can be stable. The method for preparing the NCC / CS / PVA composite nanofiber membrane has the advantages that the nanofiber material preparation process is simple, the preparation process is environmentally friendly and free of pollution, nanofibers are excellent in mechanical performance, the surface of the nanofiber membrane is rich in modifiable functional groups, and the nanofiber membrane has a remarkable affinity effect on biomacromolecule.

Owner:TONGJI UNIV

Preparation of silastic surface hydrophobic coating

The invention discloses a preparation method of hydrophobic coating on the surface of silicon rubber. The method comprises the following steps: tetraethyl orthosilicate is taken as a precursor, anhydrous alcohol is taken as a solvent so as to prepare silicon dioxide sol under the condition of alkaline catalysis, and the obtained silicon dioxide sol is added with a silane coupling agent for modification process; after the surface is cleaned, a silicone rubber insulator is dipped in the modified silicon dioxide sol to carry out film coating with a pulling method so as to form a one-time coating and obtain a micro-nanometer rough structure which is similar to the leaf of taro; and after dried, the nanometer rough structure is again dripped in self-made fluorosilane sol for a secondary film coating with the pulling method, and then placed in an oven for thermal processing under 100 DEG C to 120 DEG C. The one-time coated micro-nanometer rough structure can obtain the transparent hydrophobic coating with acid and alkali resistance, after being modified by the secondary coating with low-surface fluorosilane sol.

Owner:西安智源电缆料有限公司

Temperature and pH stimuli-responsive intelligent polymer microcapsule and preparation thereof

InactiveCN101838375AGood mutual independenceReduce distractionsPharmaceutical non-active ingredientsMicroballoon preparationSmart polymerInterpenetrating polymer network

The invention relates to a temperature and pH stimuli-responsive intelligent polymer microcapsule and preparation thereof. The microcapsule comprises two polymers sensitive to temperature and pH, and an interpenetrating network structure is formed between the two polymers. Preparation includes the following steps: (1) uniformly blending tetraethyl orthosilicate, aqueous ammonia, water and absolute ethyl alcohol, and then adding surface modifier; (2) adding temperature-sensitive monomer and crosslinking agent into the modified dispersion, and adding initiator for reaction; (3) after diluting the emulsion by five to fifteen times, adding pH-sensitive monomer and crosslinking agent, and adding initiator for reaction; and (4) dispersing the white emulsion of core-shell composite particles with shells formed into a interpenetrating polymer network structure into hydrofluoric acid, and carrying out centrifugal separation or dialysis purification. The microcapsule can respectively respond tothe stimulation of temperature and pH, and moreover, the two types of stimuli responsiveness are independent from each other, and therefore have little interference on each other. The preparation method is simple, and is suitable for industrial production.

Owner:DONGHUA UNIV

Modified ZSM-5 molecular sieve catalyst, preparation method and application in toluene methanol alkylation reaction

InactiveCN102716763AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationHigh activityLarge particle

The invention relates to a modified ZSM-5 molecular sieve catalyst used for toluene methanol alkylation, which takes a ZSM-5 molecular sieve as a matrix, molecular sieve raw powder is taken as a commodity reagent, its scaled silica-alumina ratio (nSiO2 / nAl2O3) is 25, the particle sizes can be divided into two types, the primary particle size of the large particle size (or conventional particle size) ZSM-5 belongs to the micron order, the primary particle size of the small particle size ZSM-5 is about 200 nanometers, tetraethoxysilane (TEOS) is taken as a silicon source, an external surface and hole opening of the molecular sieve can be modified through chemical liquid phase deposition, the SiO2 deposition amount is between 3% and 25%, or chemical modification of Ni and P elements is employed, and the contents of Ni and P elements are 0-1% and 0-8%. According to the invention, the modified ZSM-5 molecular sieve catalyst can be used for preparing xylene by the toluene methanol alkylation with high catalytic activity, the conversion for per pass of toluene can reach more than 30%, in three types of xylene products, the selectivity on xylene is higher than 90%, and the modified ZSM-5 molecular sieve catalyst of the invention is the catalyst possessing high activity and high selectivity.

Owner:NANJING UNIV

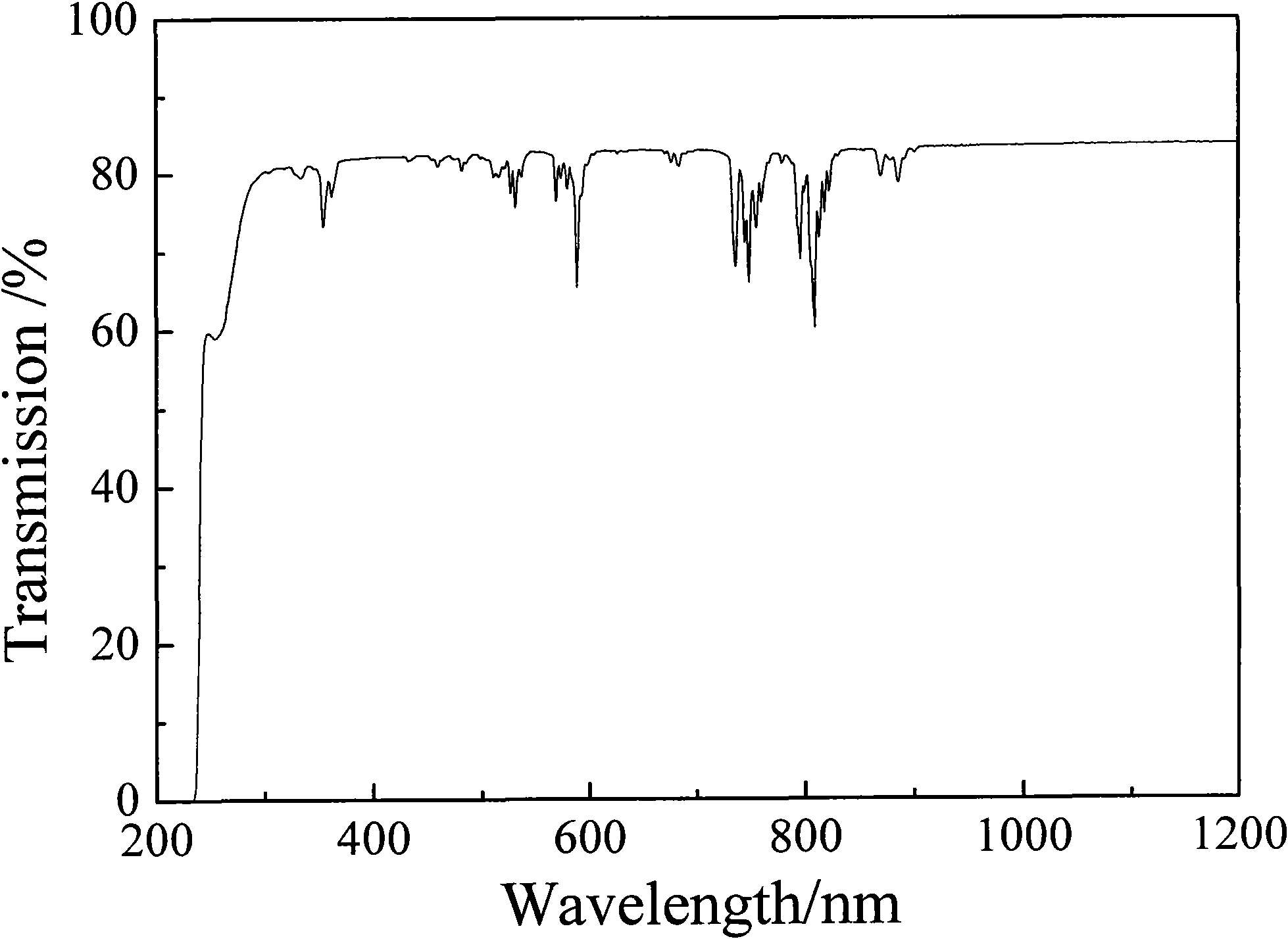

Anti-reflective coating for photovoltaic glass panel

InactiveUS20080241373A1Accelerate the application processReduction in undesirable evaporation of solventPretreated surfacesCoatingsAnti-reflective coatingSilicic acid

A method of making an anti-reflective film comprises preparing a liquid composition with specific amounts of tetraethyl orthosilicate, polyethylene glycol, HCl, ethanol and at least one alcohol having a higher boiling point than ethanol and miscibility with both ethanol and water; applying the liquid composition onto a surface of a substrate to form a liquid film; evaporating the ethanol and the at least one alcohol from the liquid film to form a solid film; and heating the solid film to form a silica film.

Owner:AGC FLAT GLASS NORTH AMERICA INC

Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

ActiveCN101985397AHigh linear transmittanceImprove mechanical propertiesRare-earth elementSpray Granulation

The invention relates to a method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic. In the invention, high-transparency polycrystalline ceramic is prepared by using commercial powdered Y2O3, Al2O3 and Re2O3, of which the purities are over 99.9 percent, as main raw materials and by spray granulation dry pressing molding process and vacuum reaction and sintering, wherein the Re may be one or several of trivalent rare earth elements such as Nd<3+>, Yb<3+>, Cr<3+>, Er<3+>, Ce<3+>, Sm<3+> and Eu<3+>; MgO or CaO or tetraethyl orthosilicate (TEOS) or SiO2 is used as a sintering assistant; a certain amount of bonding agent, plasticizer and dispersant is added; the oxides, sintering assistant and additive are mixed and added into a liquid medium, and the mixture is ball-milled and mixed for 0.5 to 100 hours; after the powder materials are mixed uniformly, the powder is made into spherical or approximately spherical grains; blanks formed by drying pressing isostatic forming are degreased; sintering the blanks in a vacuum sintering furnace; and annealing after sintering. The transmissivity at a laser wavelength of the rare earth-doped yttrium aluminum garnet transparent ceramic prepared by the method is more than or equal to 77 percent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of hydrophobic silica aerogel composite fiber felt material

The invention relates to a preparation method of a hydrophobic silica aerogel composite fiber felt material. The preparation method comprises the following steps: mixing tetraethyl orthosilicate, ethanol, water and an acid catalyst to obtain silica sol; adding an alkali catalyst to the silica sol, uniformly stirring, pouring the mixture into a fiber felt (ceramic or glass fiber felt), immersing, and standing, so as to obtain a gel composite material; ageing the gel composite material in the fiber felt in mother liquor for a certain period of time, and then carrying out solvent exchange, so asto obtain a composite material; immersing the composite material in a solution containing certain concentration of a surface modifier for standing modification, and then drying the composite materialunder atmospheric pressure to obtain the hydrophobic silica aerogel composite fiber felt material. The preparation method has the advantages of simple process, short production cycle, lower cost, lowequipment requirement and excellent product performance, and the hydrophobic silica aerogel composite fiber felt material has superhydrophobic property, strong adsorption property and low thermal conductivity.

Owner:ZHEJIANG UNIV OF TECH

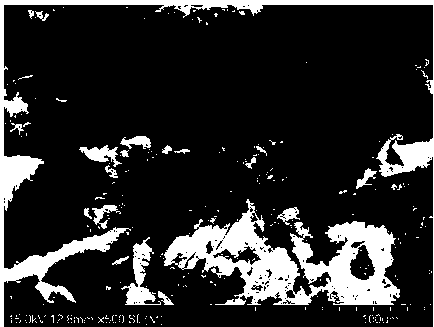

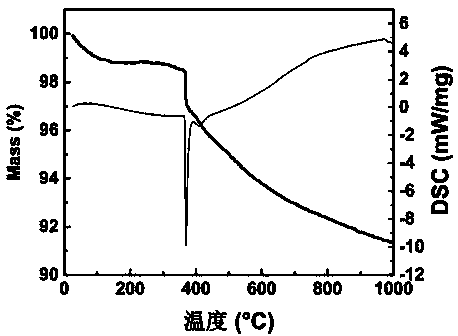

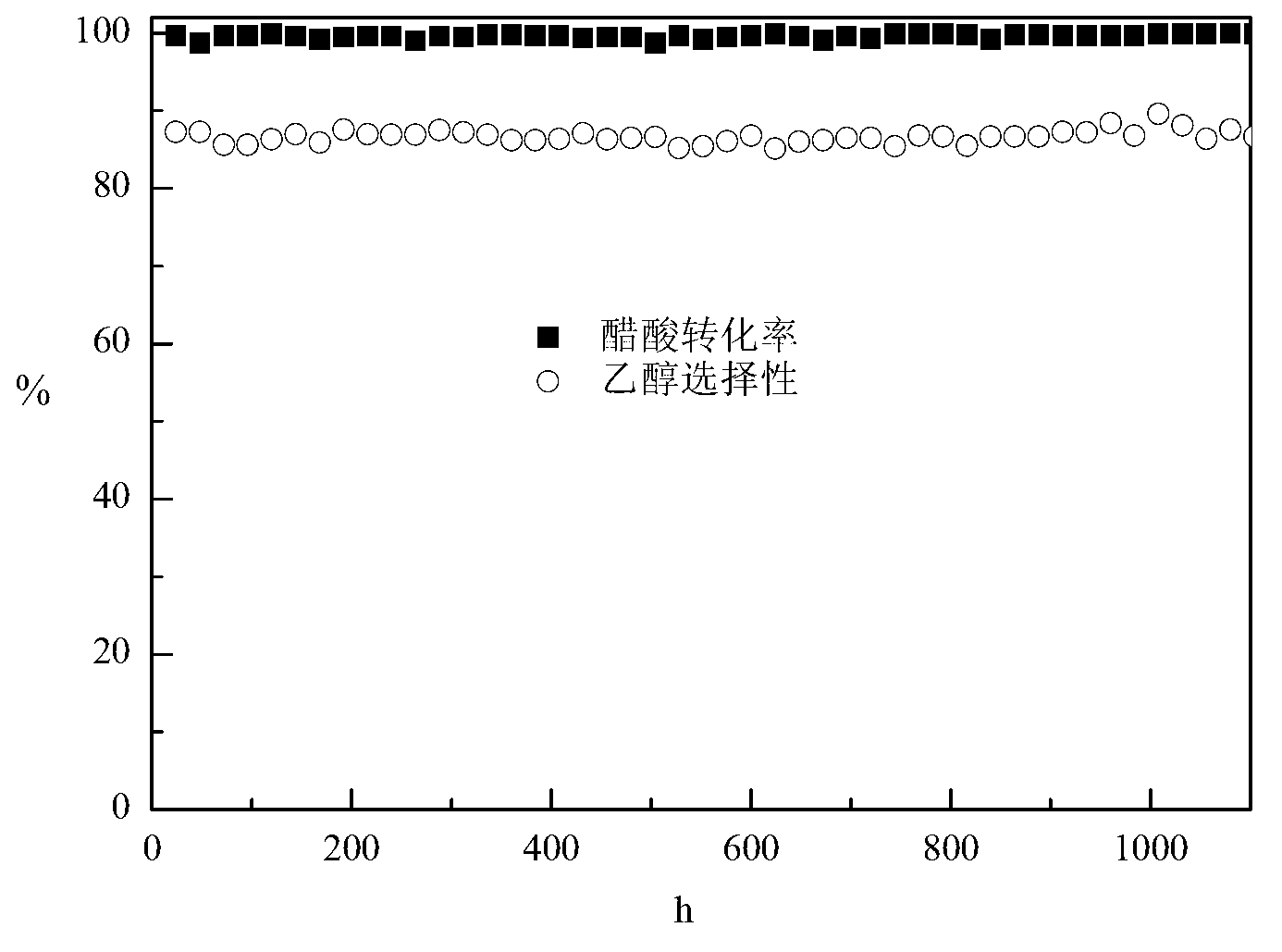

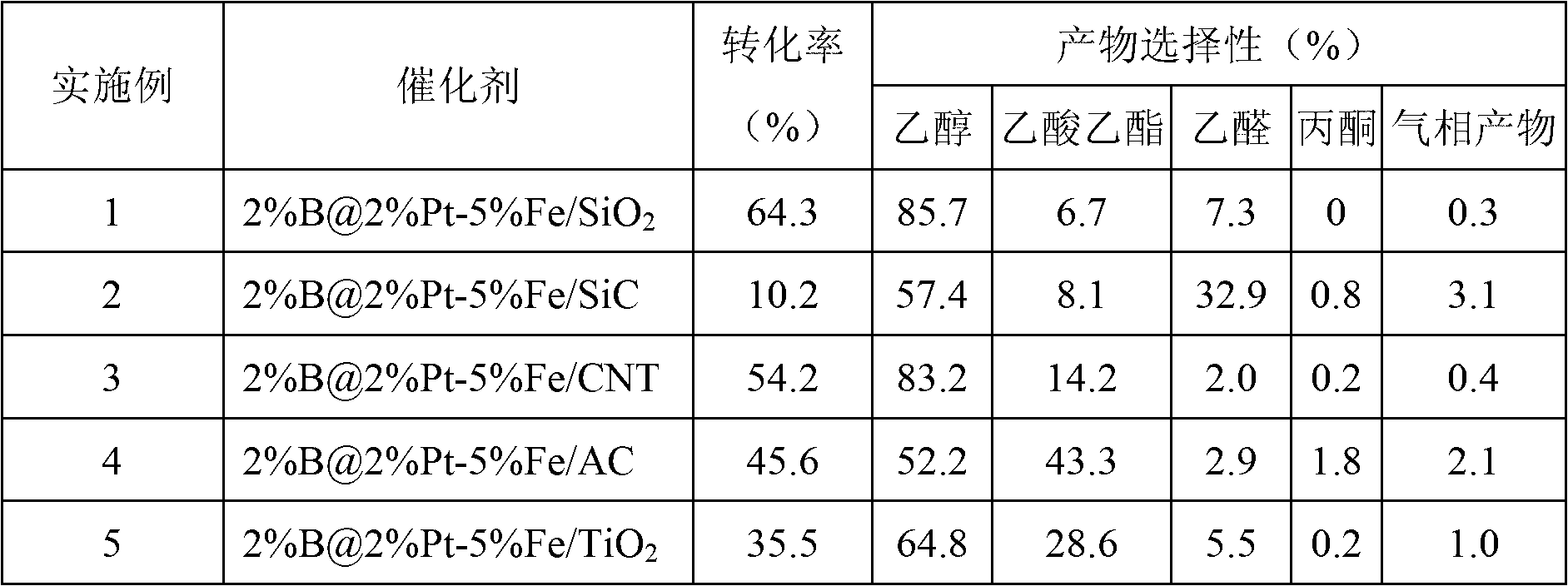

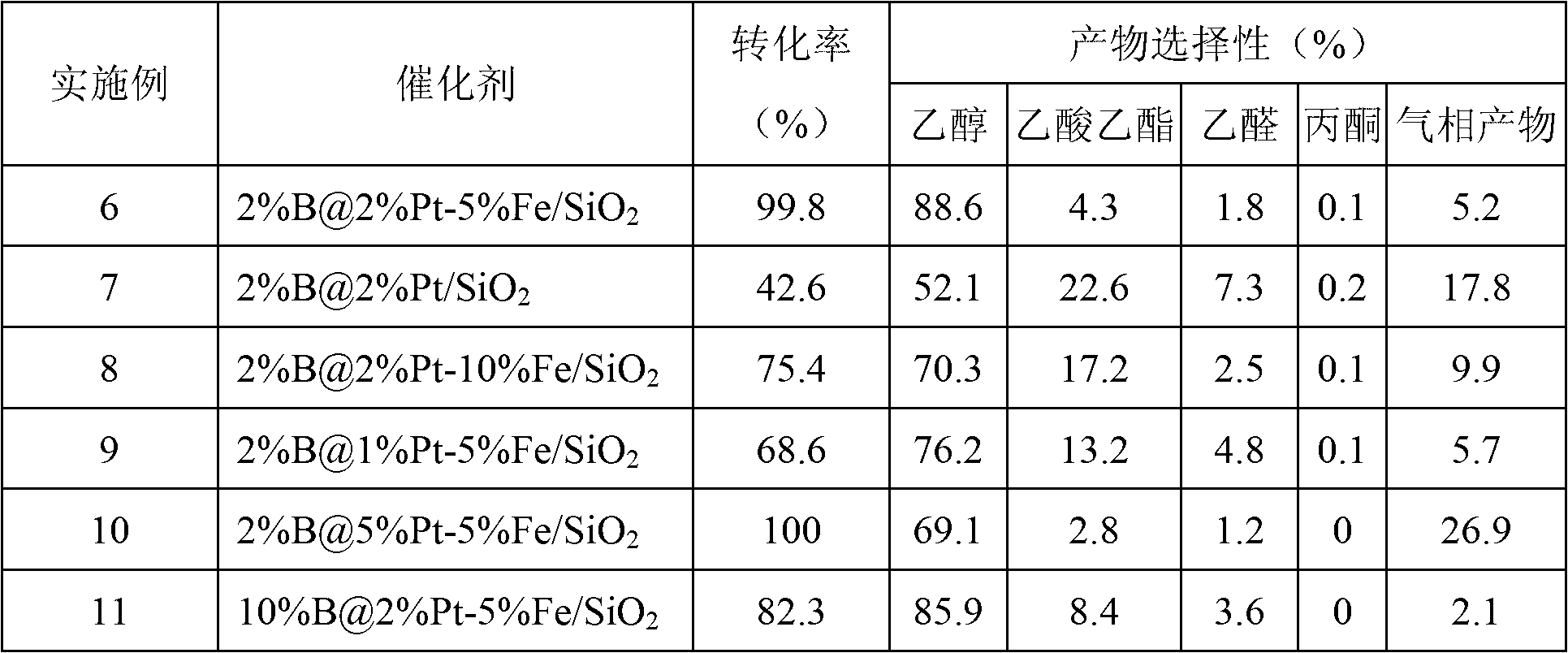

Catalytic agent for preparing ethanol by using acetic acid hydrogenation and preparation method thereof

ActiveCN102847544AImprove thermal stabilityAvoid inactivationOrganic compound preparationHydroxy compound preparationFixed bedCarbon nanotube

A catalytic agent for preparing ethanol by using acetic acid hydrogenation and a preparation method thereof relate to a hydrogenation catalyst and are high in stability and long in service life. The catalytic agent is applicable to a high pressure fixed bed reactor, glacial acetic acid is adopted to serve as raw materials directly, and service life of the catalytic agent is longer than 1000h. The catalytic agent is composed of reactive metal, an accessory ingredient, a protective agent and a carrier, a weight ratio of constitution elements of the reactive metal, the accessory ingredient, the protective agent and the carrier in the catalytic agent is (1-5):(0-10):(0-20):100, the reactive metal is preferentially selected from one of platinum, ruthenium and palladium, the accessory ingredient is preferentially selected from one of Ferrum, cobalt and stannum, the protective agent is preferentially selected from boric acid or tetraethoxysilane, and the carrier is preferentially selected from carbon nano tubes or silica. The catalytic agent is prepared by using an impregnation method. Introduction of the protective agent greatly improves heat stability of the catalytic agent, the method is simple, performance is excellent, stability is high, and the catalytic agent has good industrial application prospects.

Owner:XIAMEN UNIV +1

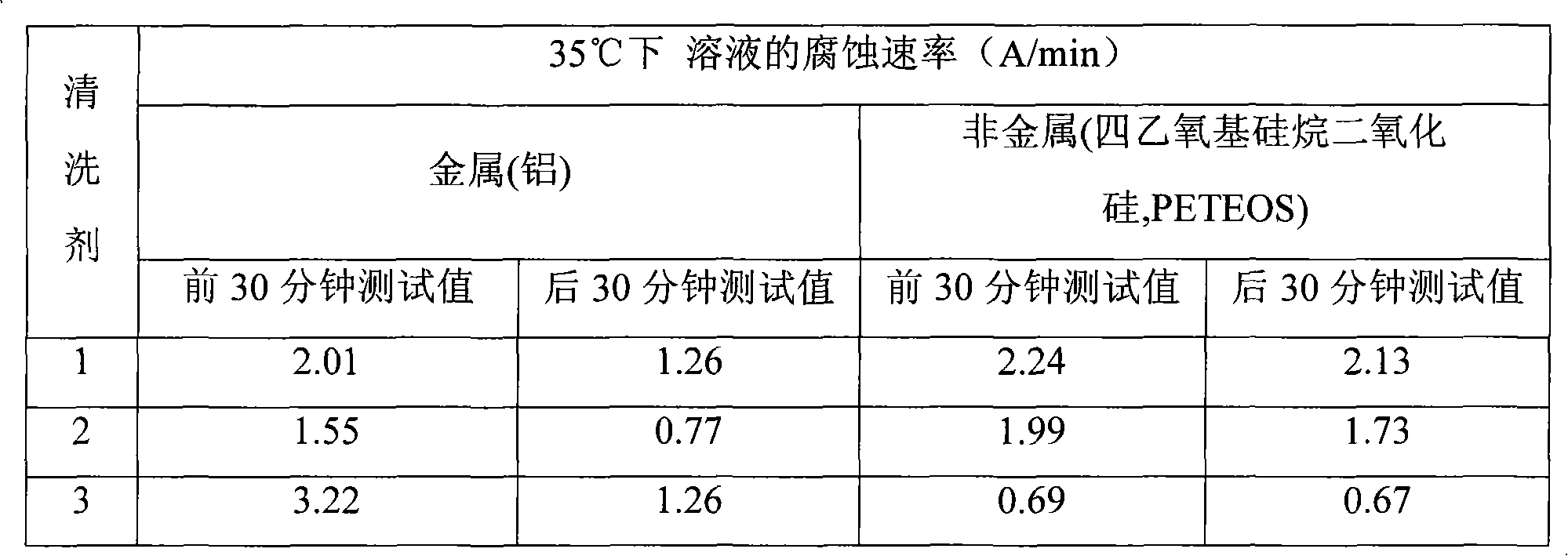

Cleaning fluid for cleaning plasma etching residue

InactiveCN101290482AImprove cleaning efficiencyEfficient and stable cleaning effectNon-surface-active detergent compositionsDetergent mixture composition preparationSilanesSolvent

The invention discloses washing liquid used in the semiconductor industry to wash plasma etching residues. The washing liquid contains citric acid / citrate buffer solution, fluorides, macromoledular corrosion inhibitor, anti-freeze agent and solvent. The washing liquid can effectively wash the plasma etching residues during the process of manufacturing a semiconductor, have low etching velocity on nonmetals and metal substrates such as Si, SiO2, tetraethoxy silane silicon dioxides (PETEOS), low-medium materials, Ti, Al, Cu and so on, is safe and harmless to the environment and the human body, and has good application prospect in the microelectronic field such as washing of semiconductor wafers and so on.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Preparation method of flexible silicon dioxide fiber film

InactiveCN103603136AHigh yieldThe preparation method is simple and feasibleFilament/thread formingFibre chemical featuresFluorescencePhosphoric acid

The invention relates to a preparation method of a flexible silicon dioxide fiber film. The method includes: (1) mixing tetraethyl orthosilicate, ultrapure water and phosphoric acid at room temperature to obtain a transparent and clear silicon source solution; (2) dissolving polyvinyl alcohol in the ultrapure water with stirring at the temperature of 80-90 DEG C for 4-5 hours to obtain a polyvinyl alcohol solution; (3) mixing the silicon source solution with the polyvinyl alcohol solution to obtain a colorless clear spinning solution, standing and ageing prior to electrostatic spinning, and collecting a layer of uniform white fiber film; (4) putting the white fiber film in a muffle furnace, heating to 500 DEG C prior to retaining the temperature for 2-4 hours, then heating to 800 DEG C prior to retaining the temperature for 2-3 hours, and finally naturally cooling to obtain the flexible silicon dioxide fiber film. The preparation method is simple, and the prepared silicon dioxide fiber film is resistant to organic solvents and corrosion, has good flexibility after being subjected to high temperature and has potential application in the fields of catalyst loading and fluorescent films.

Owner:DONGHUA UNIV

Fiber-reinforced flexible SiO2 aerogel heat-insulation material and preparation method thereof

The invention discloses a fiber-reinforced flexible SiO2 aerogel heat-insulation material and a preparation method thereof. Silicon-containing substances such as tetraethyl orthosilicate, tetramethoxysilane, sodium silicate and the like are used as precursors, a fiber felt pad is used as a reinforcing body, fiber / SiO2 composite wet gel is prepared with a sol-gel technology, and the fiber-reinforced flexible SiO2 aerogel heat-insulation material is finally prepared through aging and supercritical drying. The synthesis process is simplified, the preparation cycle is shortened, the cost for synthesis of the SiO2 aerogel composite material is effectively reduced, defects of poor mechanical strength, large brittleness and the like of pure aerogel are overcome, the prepared composite aerogel keeps the excellent performance of the aerogel, the flexibility of the material is obviously improved, the material is better in integrity, capable of being bent at will and very good in heat-insulation effect, the heat conductivity of the material can be decreased to 19 mW / mK, the application range of the aerogel is enlarged, and the material can be applied to actual engineering as an independent bulk composite material.

Owner:四川睿光科技有限责任公司

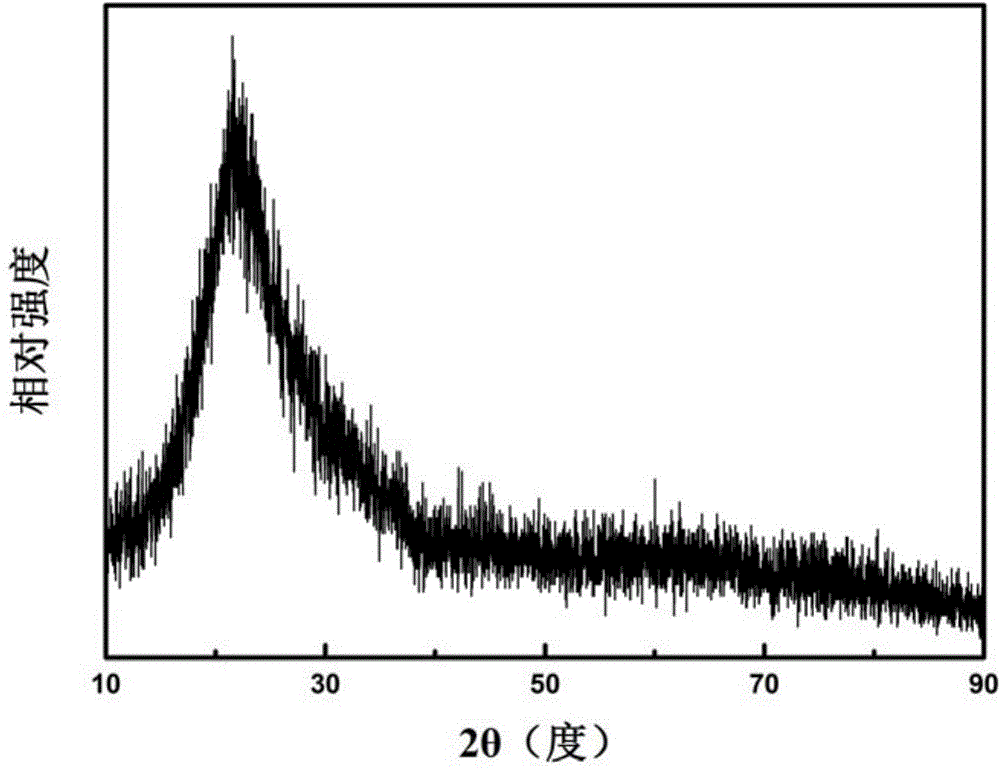

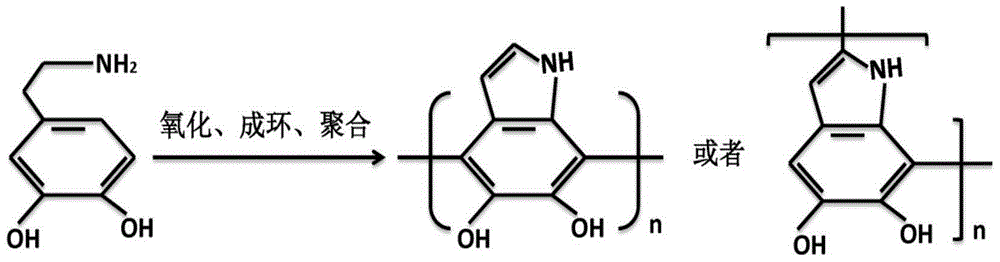

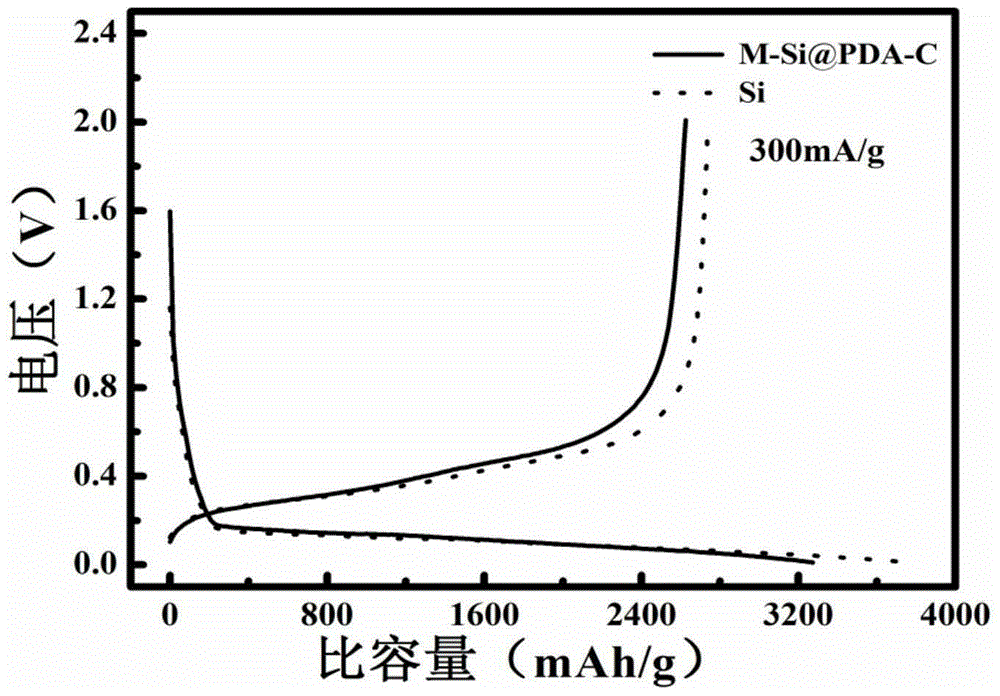

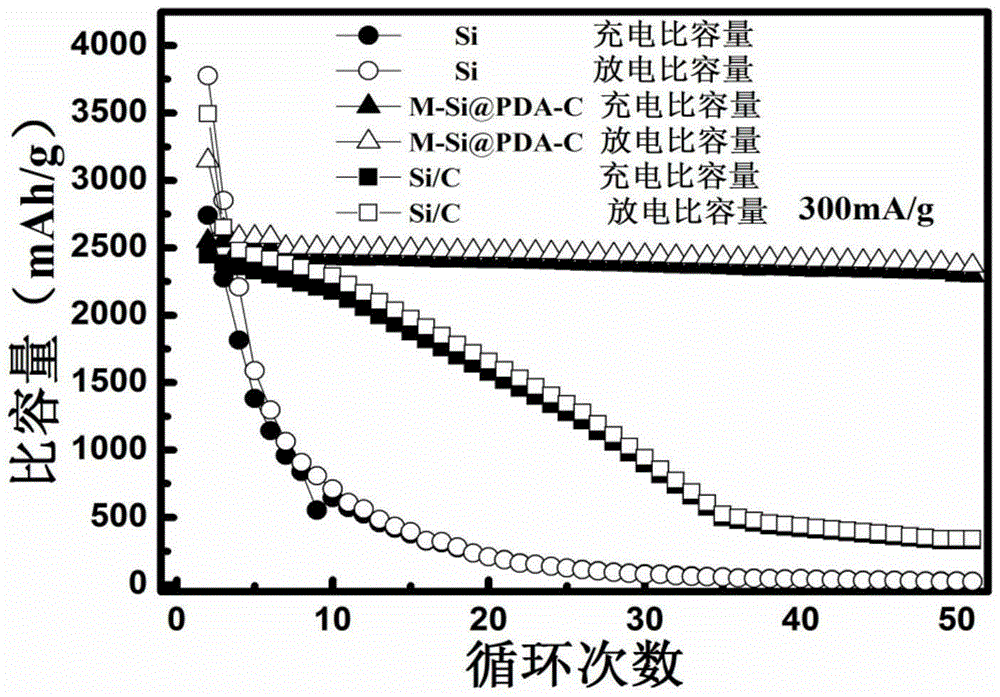

Preparation method of silicon-based anode material for lithium ion battery

The invention discloses a preparation method of a silicon-based anode material for a lithium ion battery. The preparation method comprises the following steps of using tetraethyl orthosilicate as a silicon source and nanometer aluminum oxide as a template agent to prepare a silicon dioxide coated nanometer aluminum oxide material, and then carrying out magnesiothermic reduction and acid treatment to obtain hollow porous silicon; coating the surface of the hollow porous silicon with a layer of polydopamine by means of self-polymerization of dopamine; and carrying out thermal treatment to prepare hollow porous silicon coated with a polydopamine pyrolytic carbon layer, namely the silicon-based anode material for the lithium ion battery. A porous silicon hollow structure can be used for providing a certain expansion space for volume changes during the charging and discharging process of silicon, a nitrogen-doped carbon layer formed after thermal treatment on the polydopamine has higher mechanical property and electrical conductivity than conventional carbon layers, thus, the silicon-based anode material disclosed by the invention has favorable cycle performance and rate performance, and the retention rate of the charge specific capacity of the silicon-based anode material is still kept 90% after 50 times of cycling.

Owner:CENT SOUTH UNIV

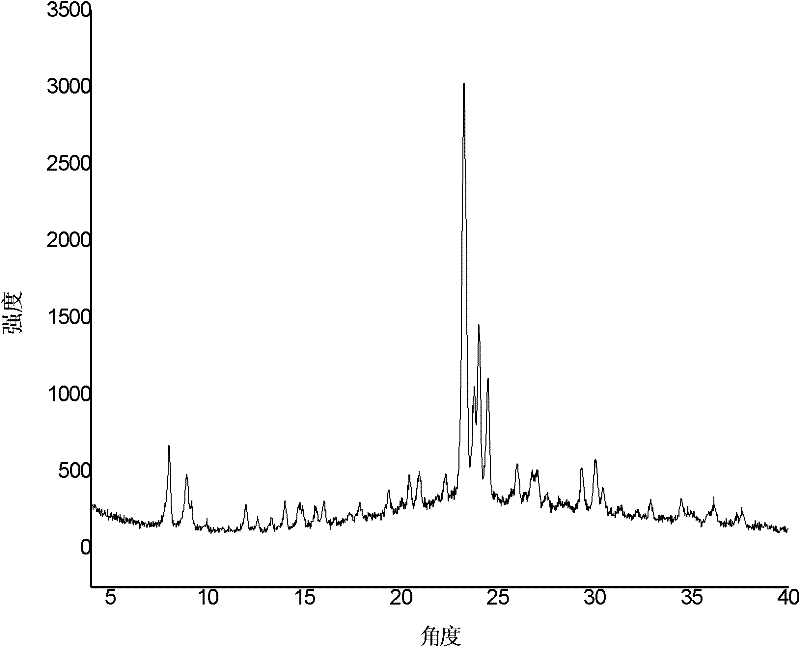

Preparation method of ZSM-5 molecular sieve nanosphere with multi-level pore hollow structure

ActiveCN102689911AEasy and quick to makeSave reaction timePentasil aluminosilicate zeoliteMicrowaveCrystallization temperature

The invention relates to a preparation method of a ZSM-5 molecular sieve nanosphere with a multi-level pore hollow structure. The method comprises: taking 64ml of tetraethyl orthosilicate, 0.54g of aluminum isopropoxide and 2.24g of sodium hydroxide (1mol / L) as starting raw materials, adopting 100g of a 15.7% tetrapropylammonium hydroxide aqueous solution as a template agent, controlling the crystallization temperature at 100DEG C-200DEG C, and subjecting the obtained product to drying and roasting so as to obtain a nano-ZSM-5 molecular sieve; adding a nano-ZSM-5 molecular sieve crystal into an alkaline solution, carrying out microwave treatment and centrifugal drying, thus obtaining multi-level pore ZSM-5 molecular sieve nanosphere with a macropore-micropore or mesopore-micropore structure, with the microwave treatment time controlled at 1-25s, the microwave output power controlled at 400-900w, and the concentration of the alkaline solution maintained at 0.1-2 mol / L. By changing the microwave treatment time, the aperture of a ZSM-5 molecular sieve nanosphere hollow pore can be adjusted in the range of 30-150nm.

Owner:PETROCHINA CO LTD +1

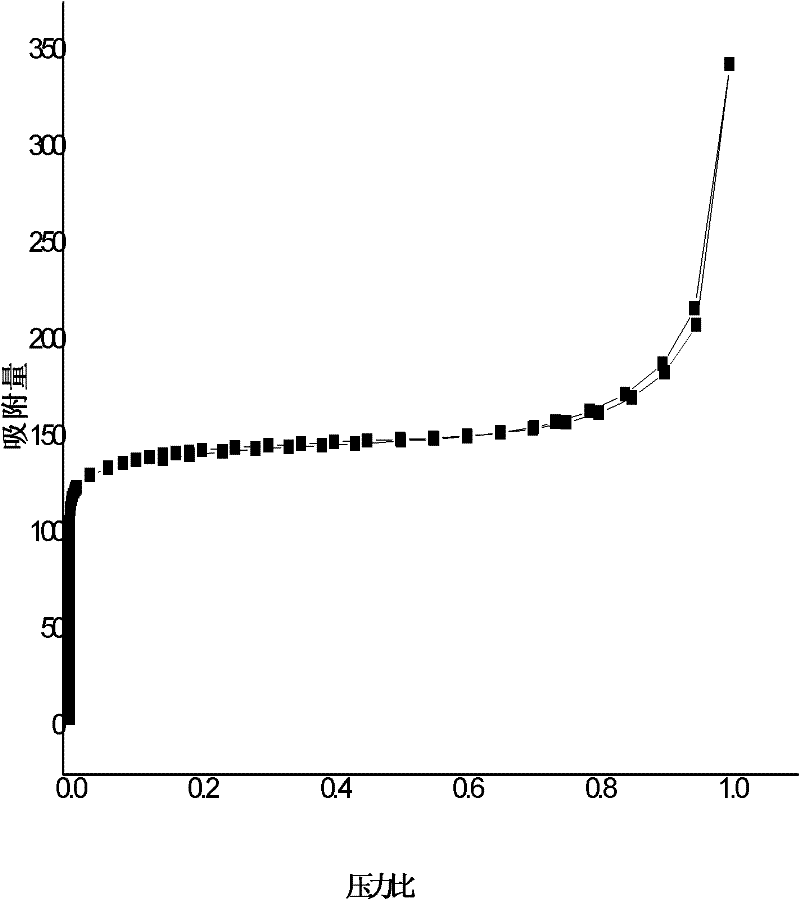

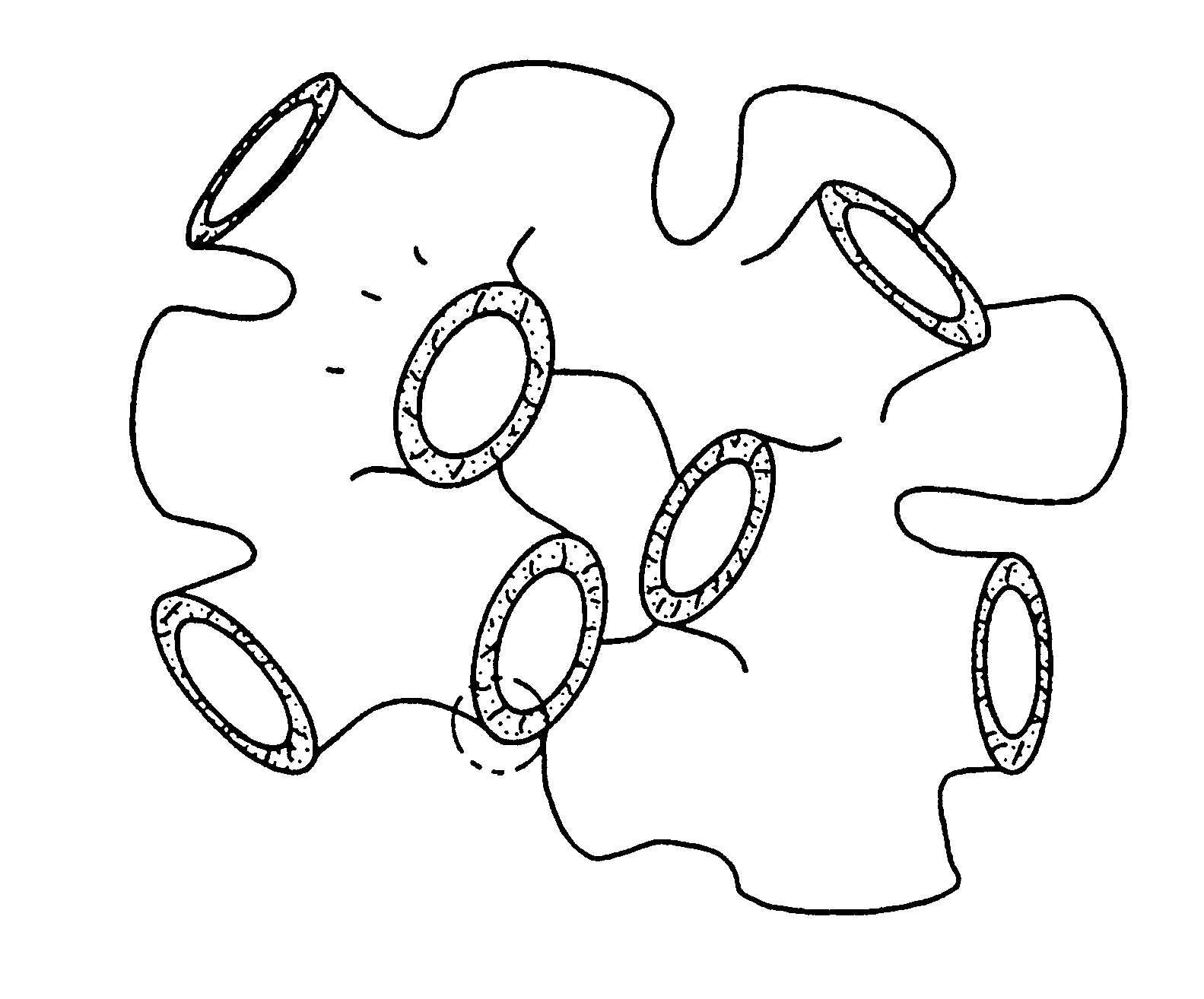

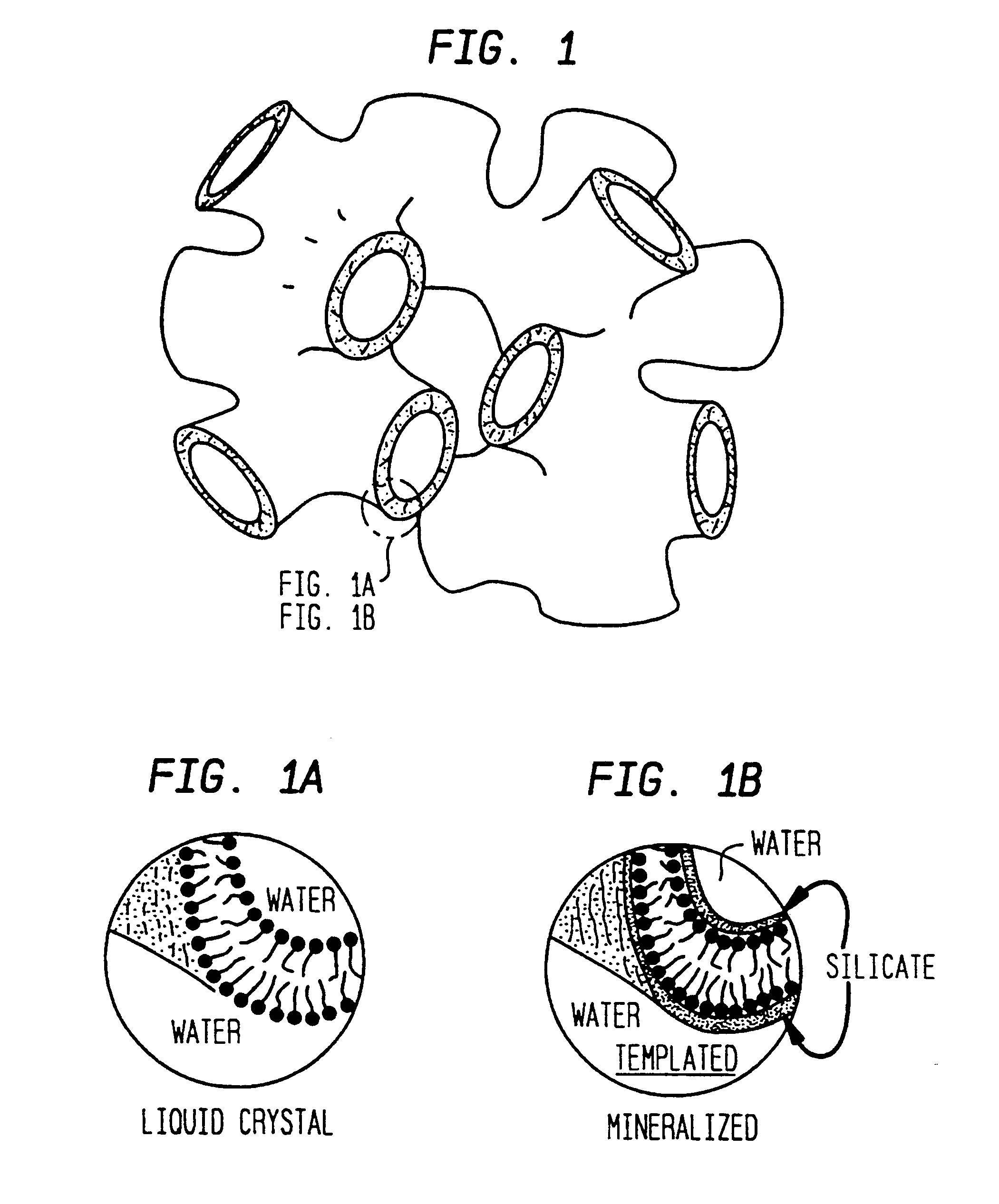

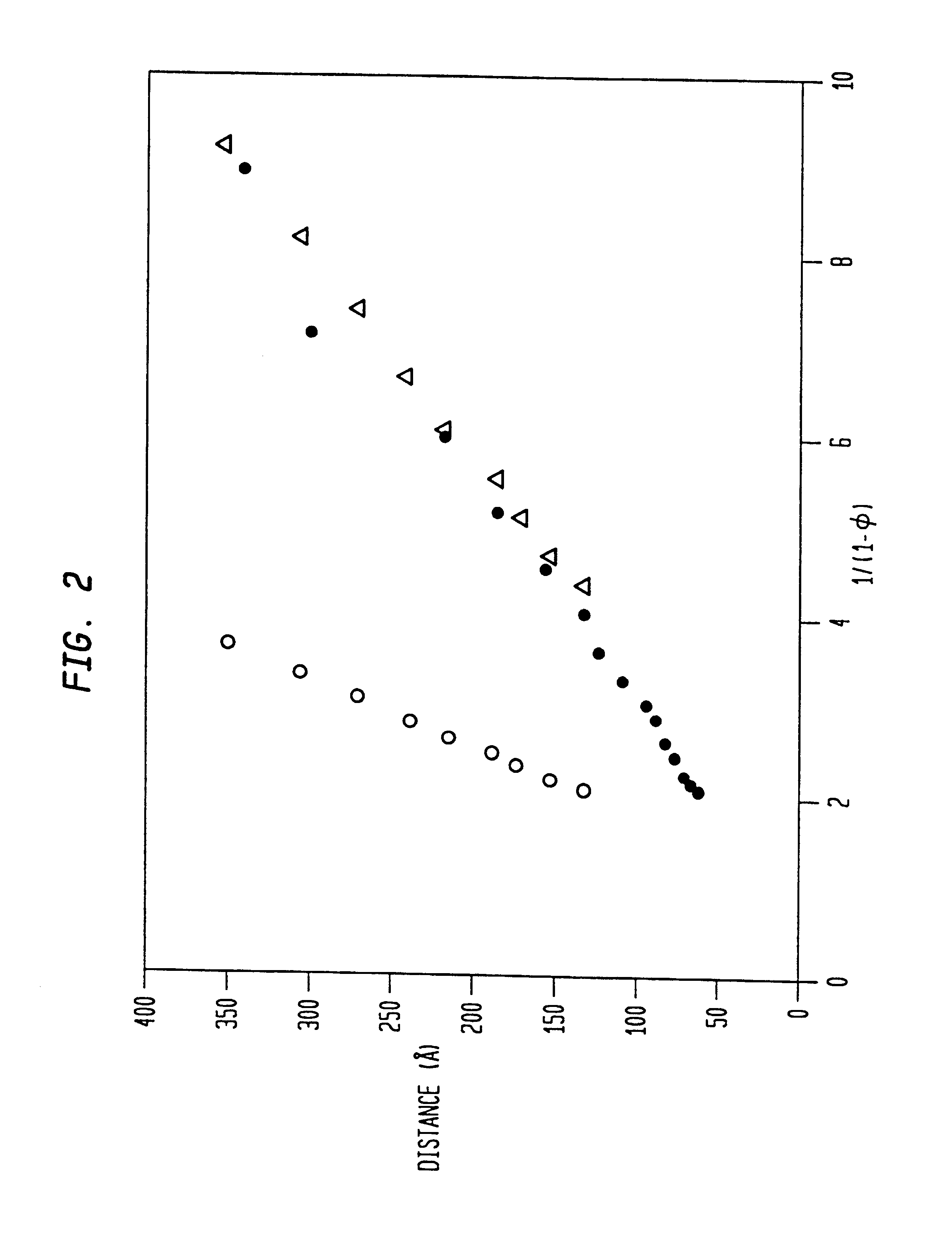

Lyotropic liquid crystalline L3 phase silicated nanoporous monolithic composites and their production

InactiveUS6638885B1Easy to changeEasy to disassembleMaterial nanotechnologyIon-exchanger regenerationLiquid crystallineNanometre

A mesoporous ceramic material is provided having a pore size diameter in the range of about 10-100 nanometers produced by templating with a ceramic precursor a lyotropic liquid crystalline L3 phase consisting of a three-dimensional, random, nonperiodic network packing of a multiple connected continuous membrane. A preferred process for producing the inesoporous ceramic material includes producing a template of a lyotropic liquid crystalline L3 phase by mixing a surfactant, a co-surfactant and hydrochloric acid, coating the template with an inorganic ceramic precursor by adding to the L3 phase tetramethoxysilane (TMOS) or tetraethoxysilane (TEOS) and then converting the coated template to a ceramic by removing any remaining liquids.

Owner:THE TRUSTEES FOR PRINCETON UNIV

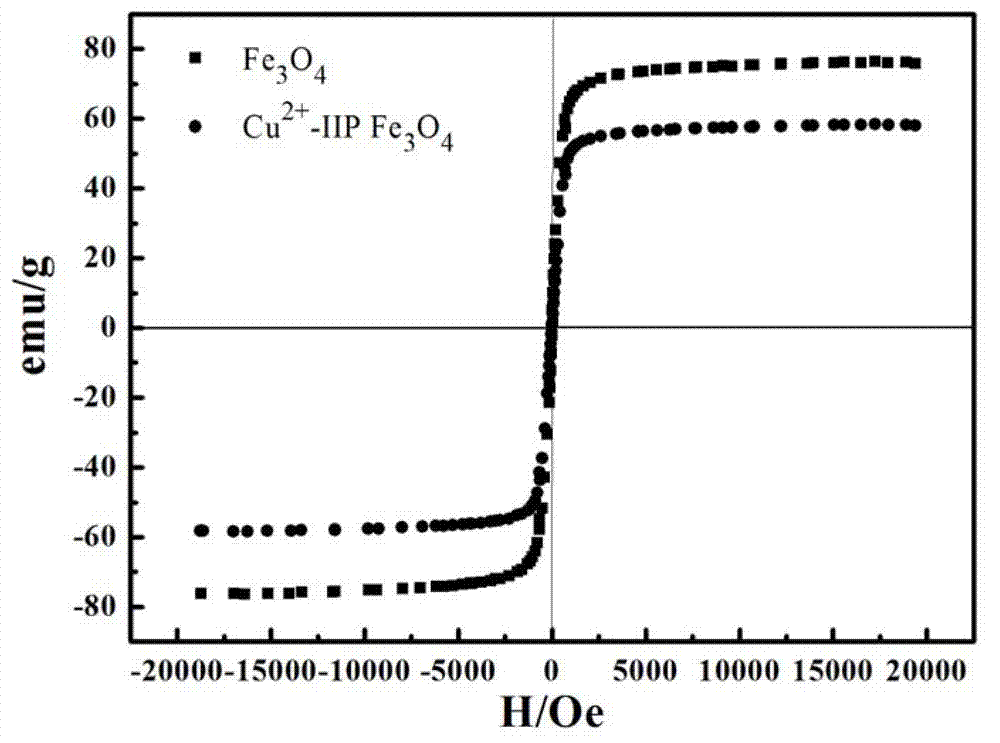

Preparation method of magnetic copper ion imprinting silica gel material

InactiveCN102784615ALarge specific surface areaImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The invention relates to a preparation method of a magnetic copper ion imprinting silica gel material, which comprises the steps of: firstly preparing Fe3O4 nano particles by a hydrothermal method; then preparing magnetic nano particles Fe3O4.SiO2 with a compact silicon shell layer structure by hydrolysis reaction of tetraethoxysilane (TEOS); and finally depositing a porous Cu<2+> ion imprinting silicon gel layer by using Cu<2+> ions as template ions, a nitrogenous silylating reagent (aapts, H2NCH2CH2NHCH2CH2CH2Si(OMe)3) as a functional monomer, cetyl crimethyl ammonium bromide (CTAB) as a porogenic agent, and TEOS as a cross-linking agent on the surface of Fe3O4.SiO2. The agnetic copper ion imprinting silica gel material obtained by the method provided by the invention can enrich Cu<2+> ions quickly and selectively, and has excellent regenerability and acid resistance.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

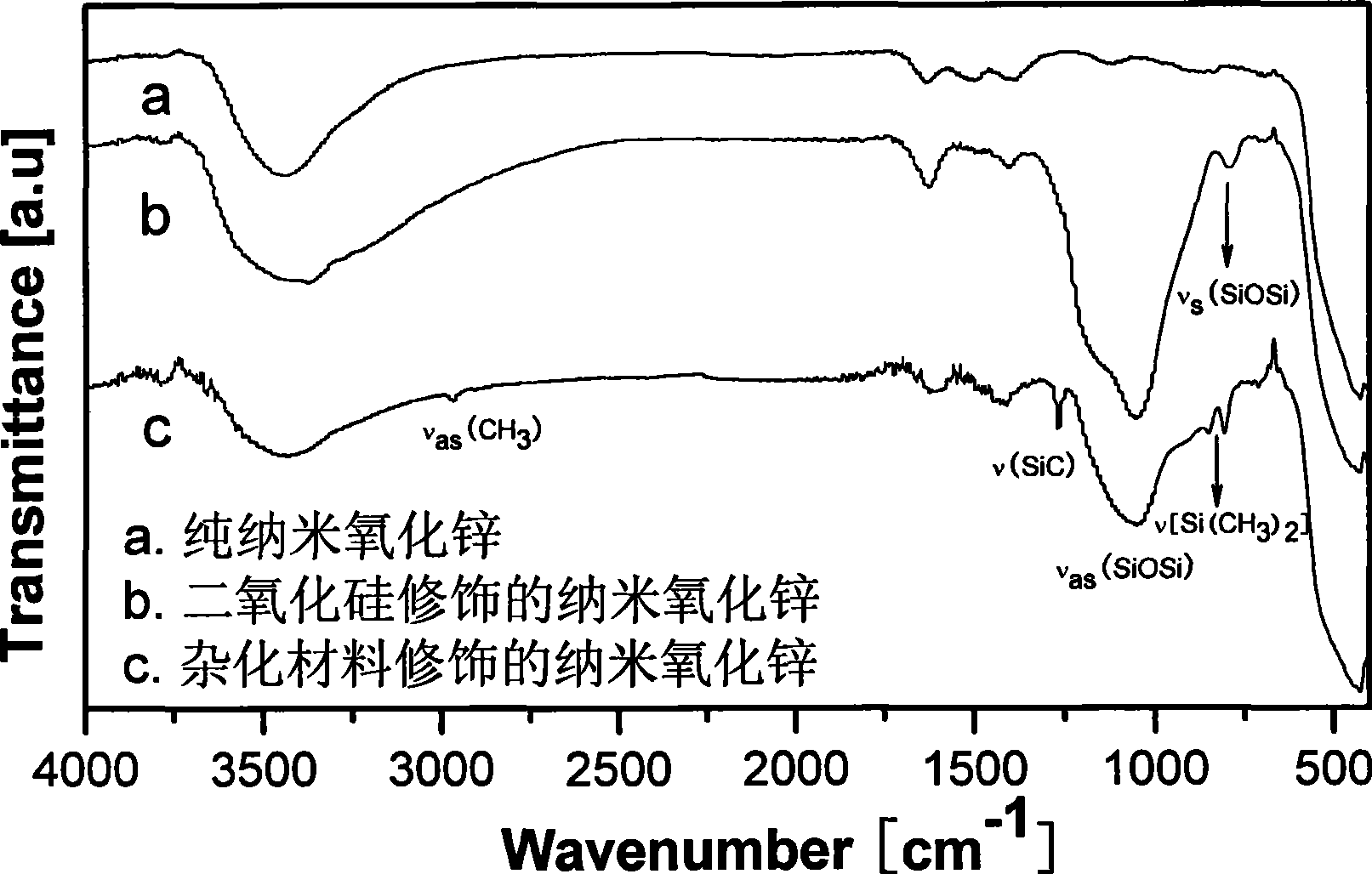

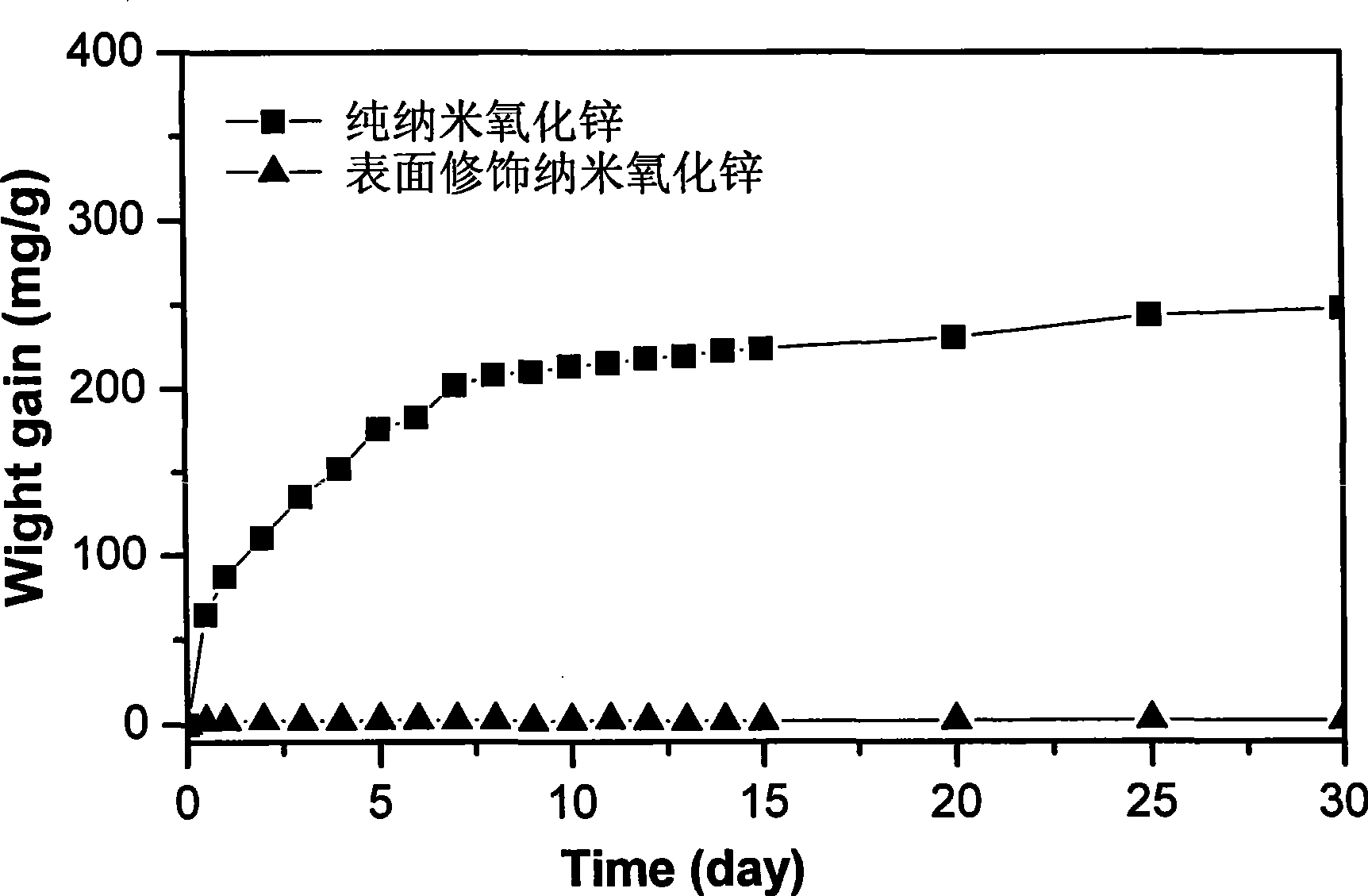

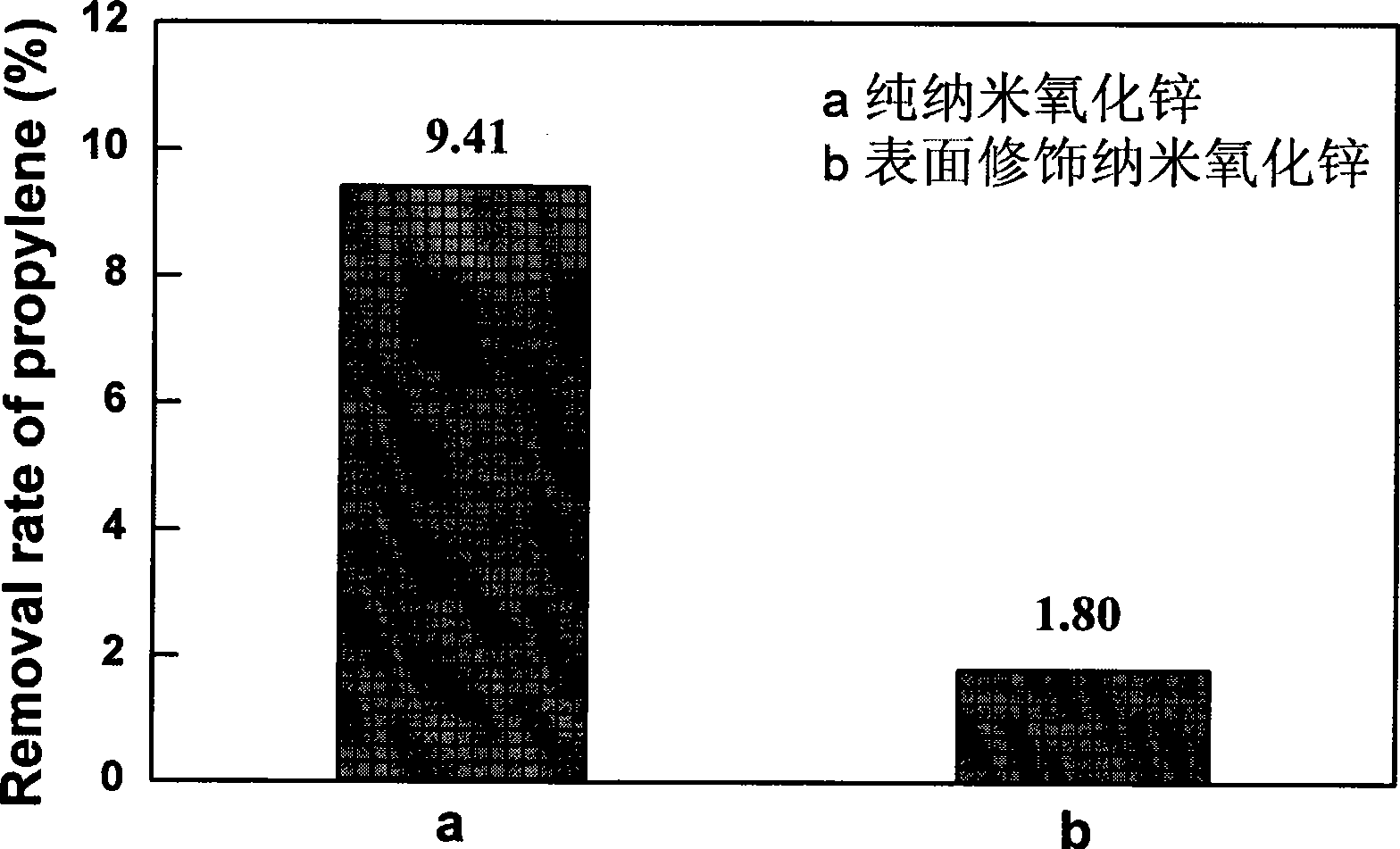

Nano zinc oxide surface modifying method

ActiveCN101543466ASimple processEasy to industrializeCosmetic preparationsToilet preparationsChemical reactionReaction temperature

The invention relates to a nano zinc oxide surface modifying method, which adopts the technical proposal comprising the following steps that: 1) nano zinc oxide powder is fully dispersed in mixed solution of deionized water and latent solvent to form slurry; and 2) a modifier consisting of tetraethyl orthosilicate and / or methyl silicate and organosilane is evenly mixed with the latent solvent, the mixture is added into the slurry in stirring, pH value is adjusted to be between 8 and 12 for reaction, the reaction temperature is about 90 DEG C and the reaction time is between 3 and 12 hours, wherein the organosilane is polydimethylsilane or / and silane coupling agent. The method adopts a common aqueous-phase chemical reaction method, uses common devices, can complete the surface modification on the nano zinc oxide powder of an organic-inorganic hybrid material through a one-step reaction, and has simple process and easy industrialization. Prepared products improve compatability with organic substrates, make the photocatalytic activity inhibited, and are particularly suitable to be used as a UV blocking agent in sun-screen cosmetics.

Owner:HENAN UNIVERSITY

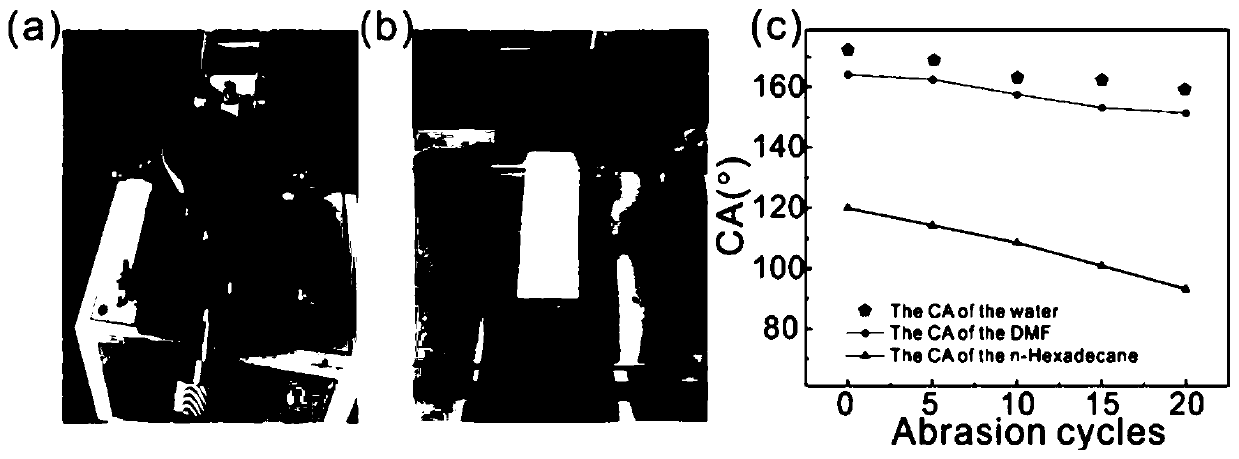

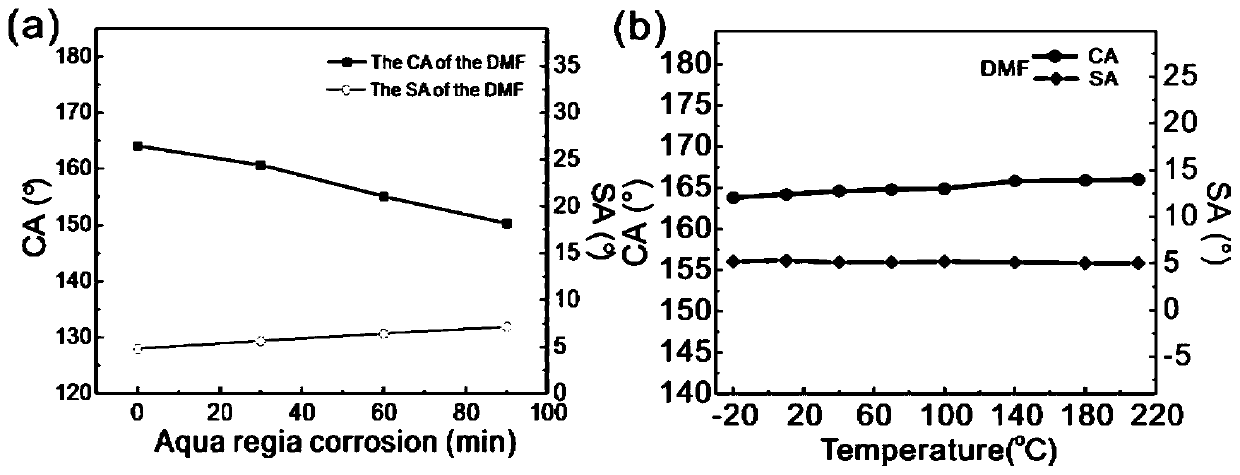

Preparation and application of super-hydrophobic/oleophobic coating layer with excellent performance

The invention relates to preparation and application of a super-hydrophobic / oleophobic coating layer with excellent performance, wherein the preparation comprises the steps: dispersing nanoparticles and cellulose in an alkaline substance-containing alcoholic solution, and adding tetraethyl orthosilicate and fluorine-containing organosilane for hydrolytic coating to form a solution A; dispersing epoxy resin in an alcoholic solution to form a solution B; uniformly mixing the solution A and the solution B, and then adding tetraethyl orthosilicate and fluorine-containing organosilane to react to generate polysiloxane, to obtain a solution C; dissolving a fluorine-containing amine compound in an alcoholic solution to obtain a solution D; and uniformly mixing the solution C and the solution D, spraying the mixture on a substrate, and curing to obtain the product. A multi-stage micro-nano hierarchical structure is constructed; the super-hydrophobic / oleophobic coating layer has good chemical stability, can achieve a complete repelling effect on N,N-dimethylformamide liquid drops (34.4 mN / m), has a contact angle of 120 degrees on n-hexadecane (27.1 mN / m), is simple in preparation method, can be sprayed on a large scale, and paves a road for industrialization of the super-hydrophobic / oleophobic coating layer.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com