Patents

Literature

10728results about How to "Low equipment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

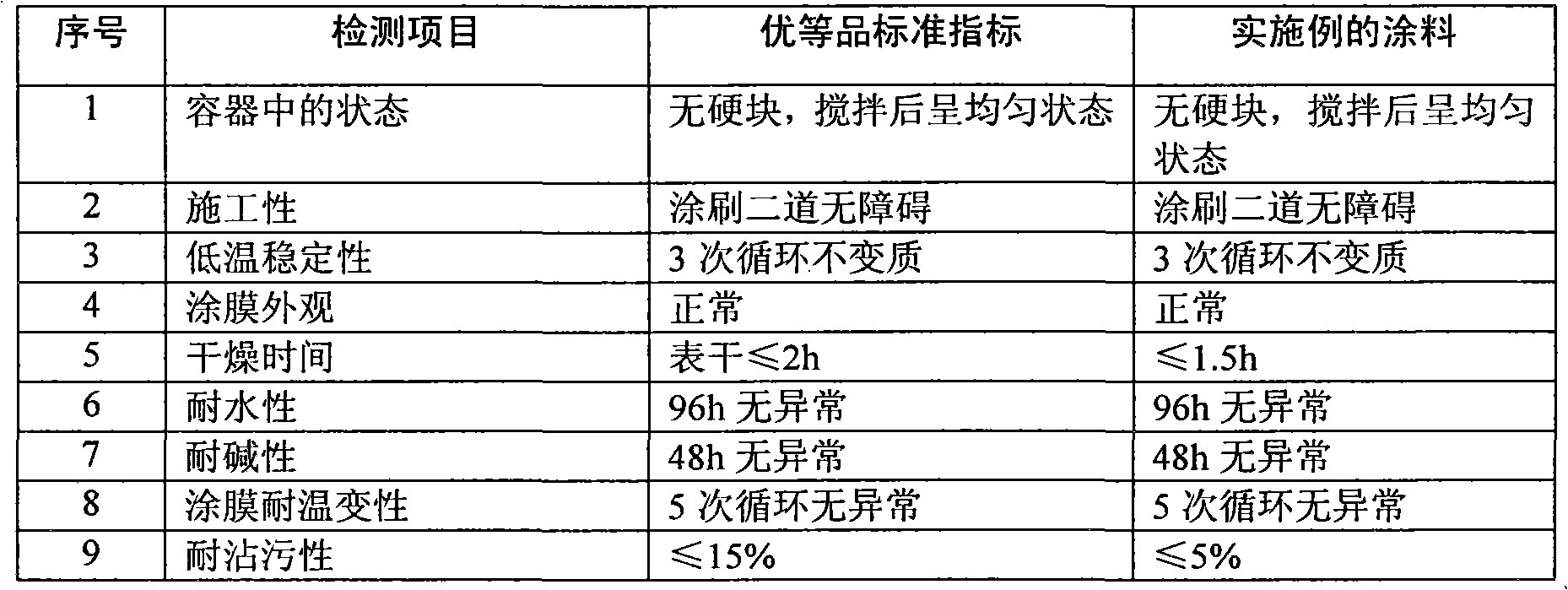

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

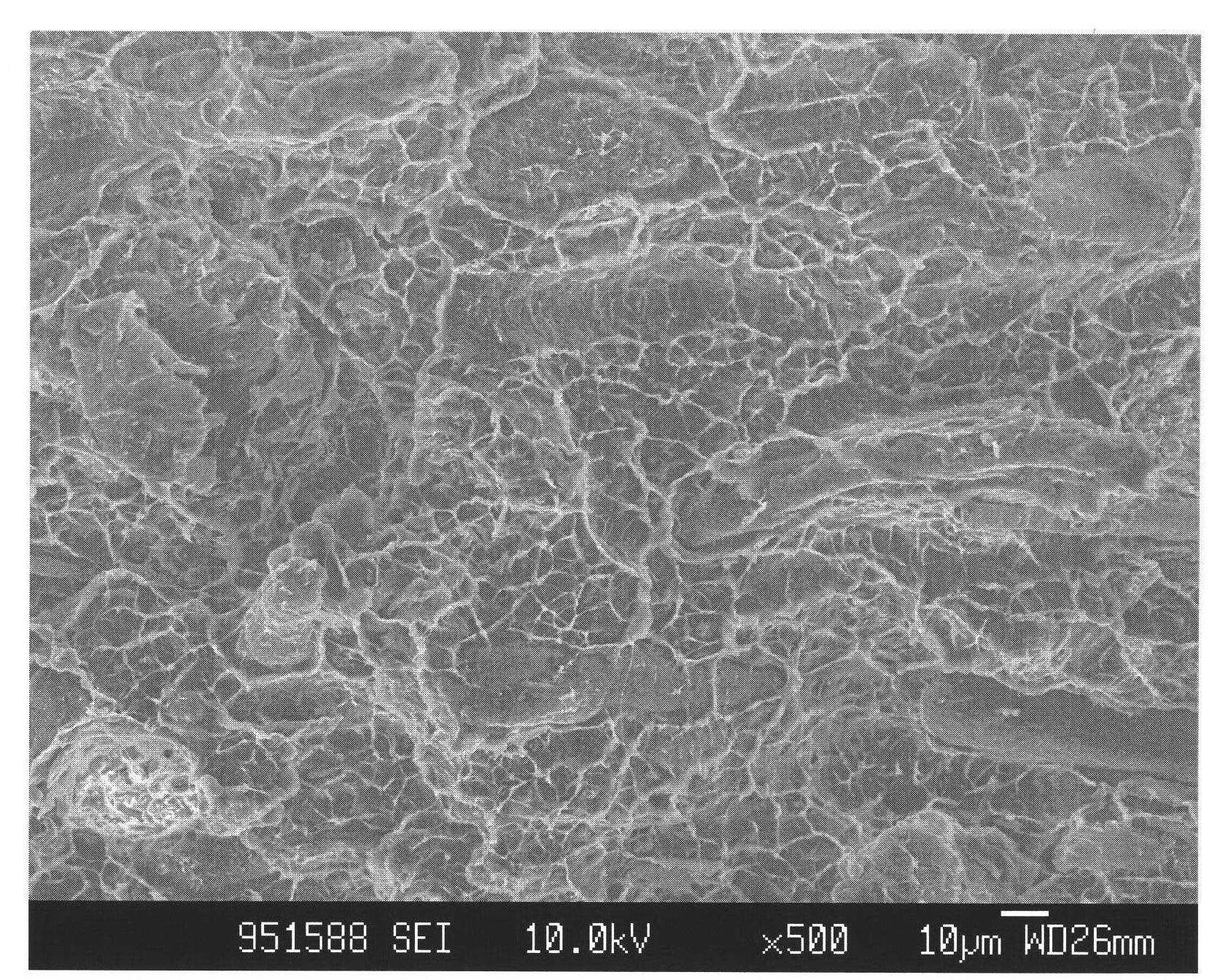

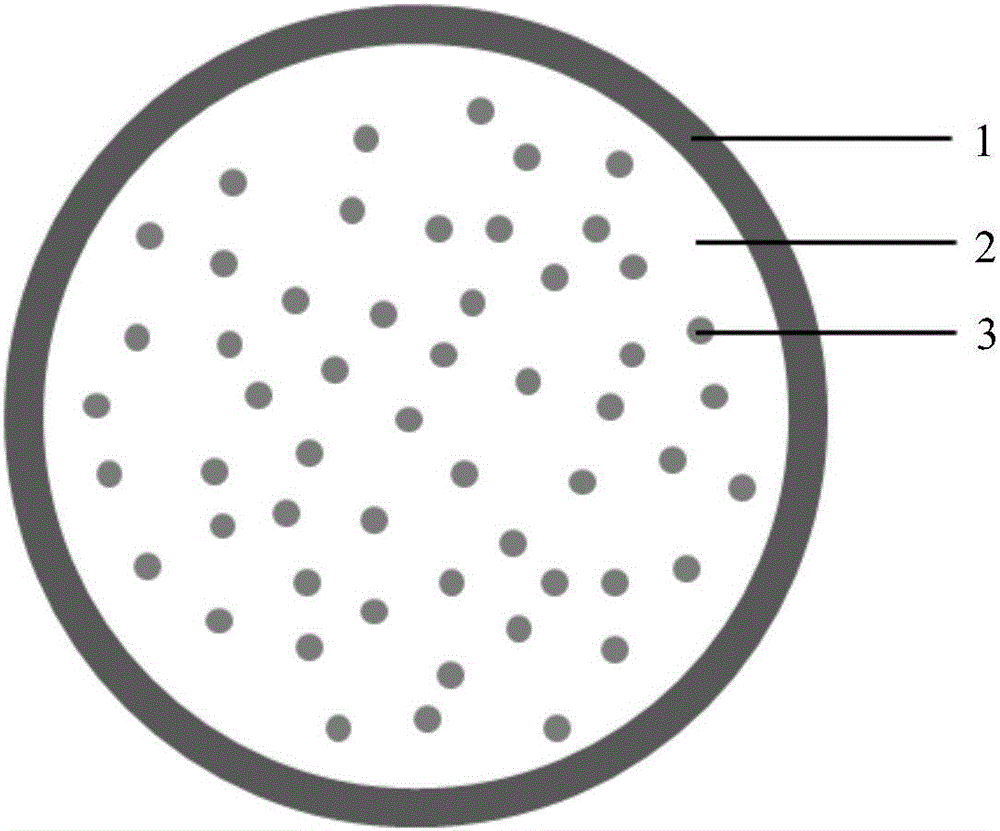

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

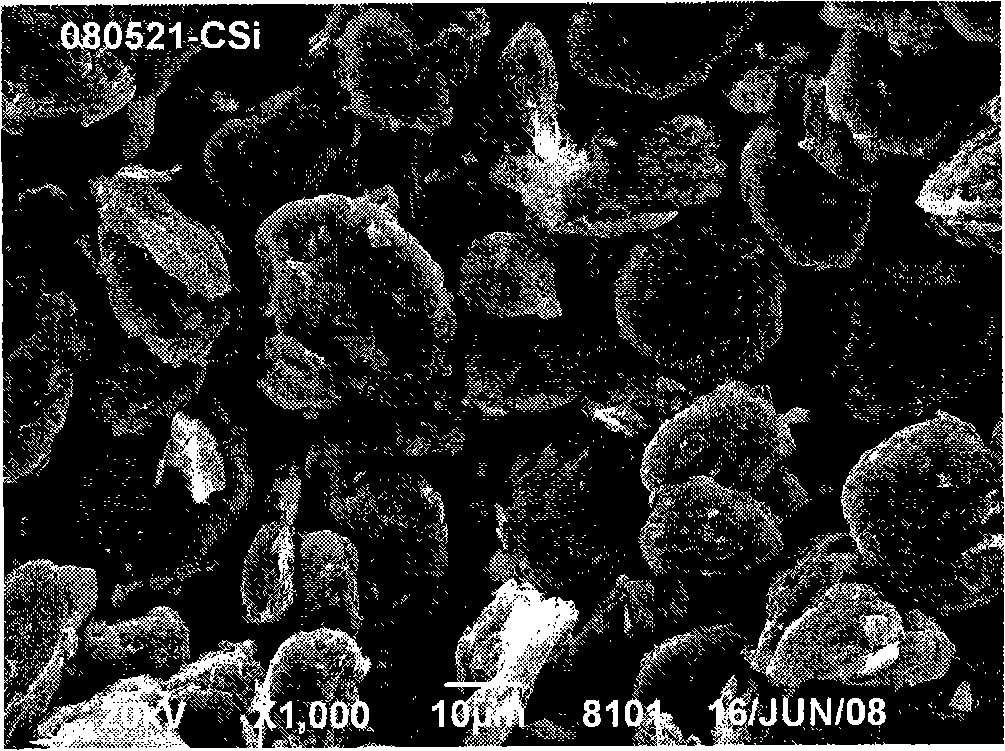

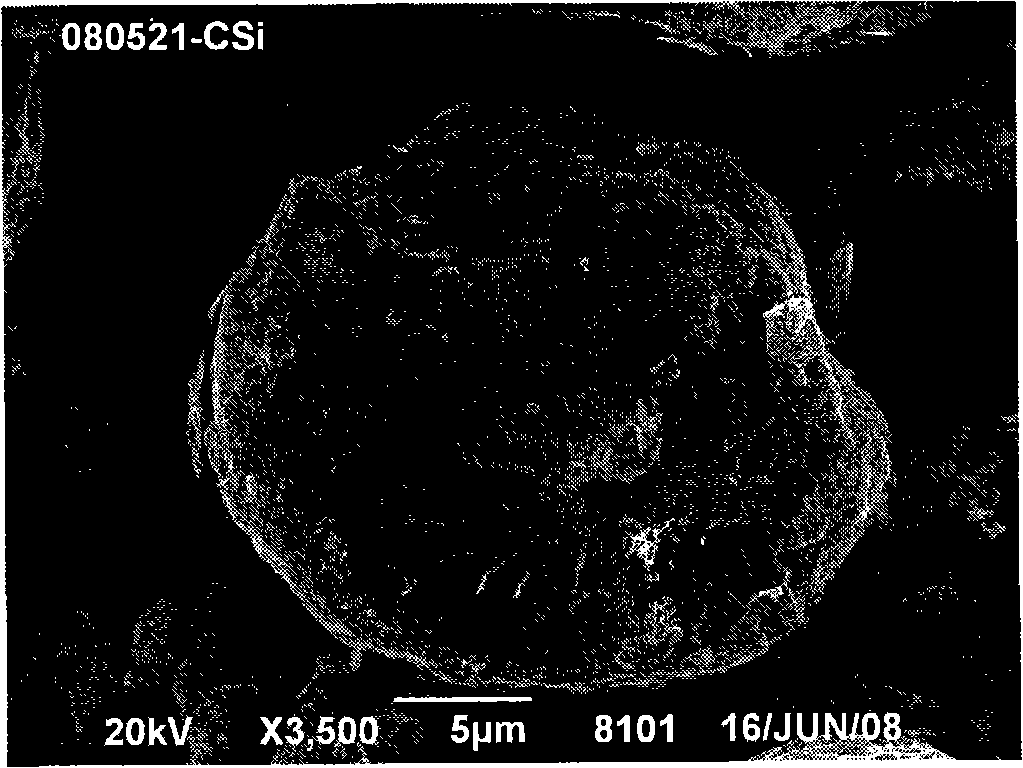

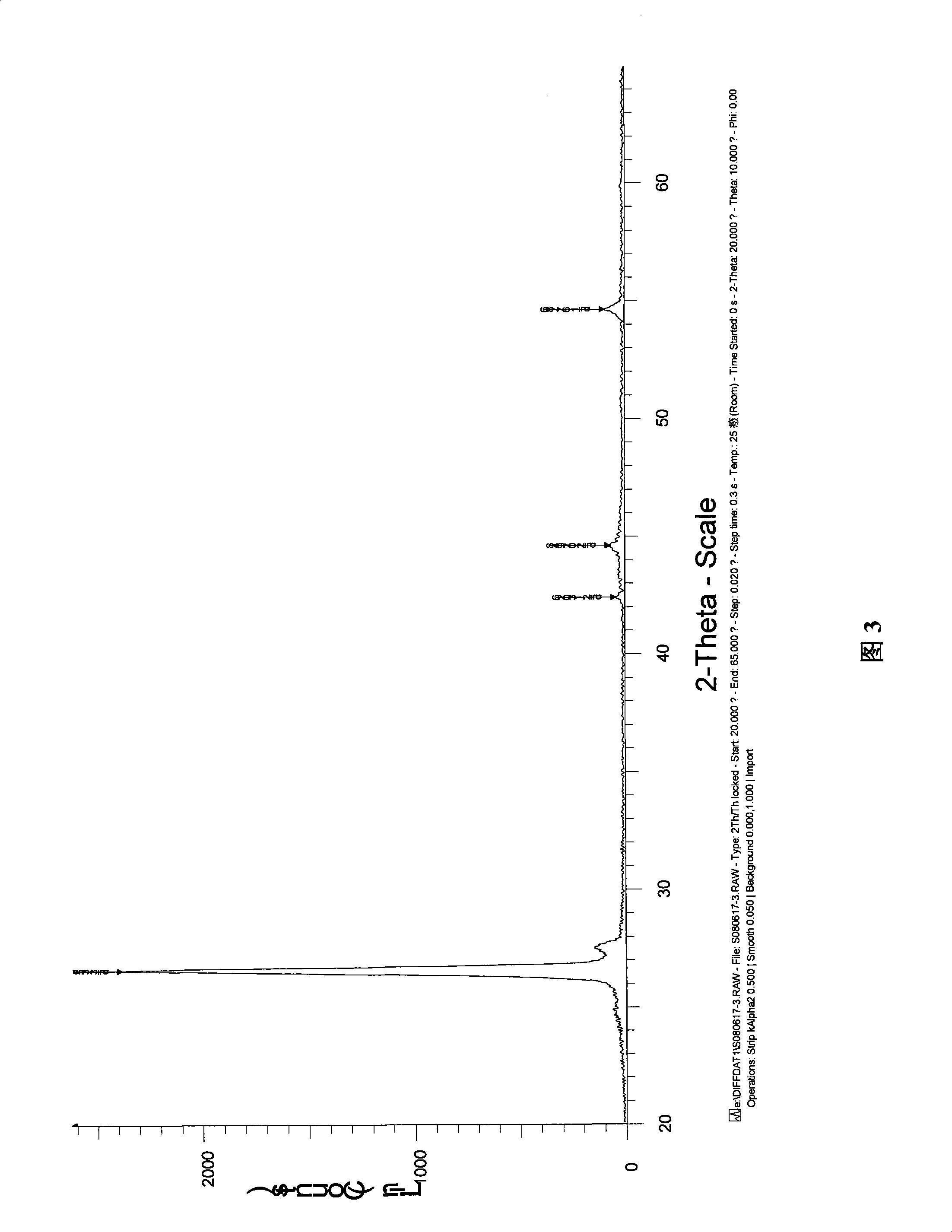

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

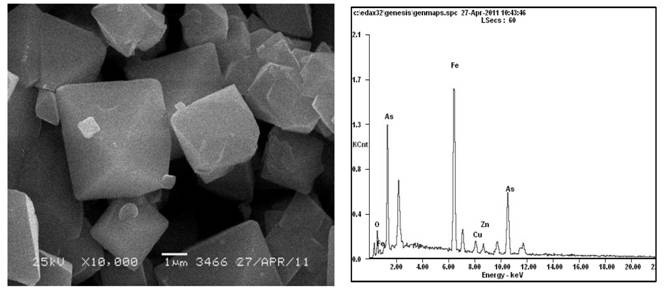

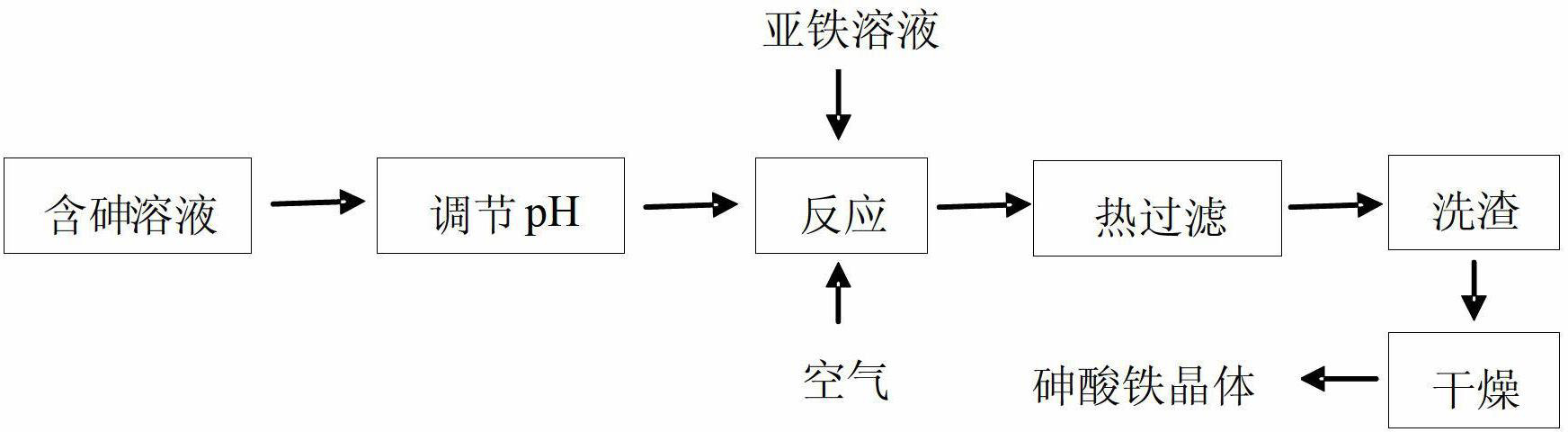

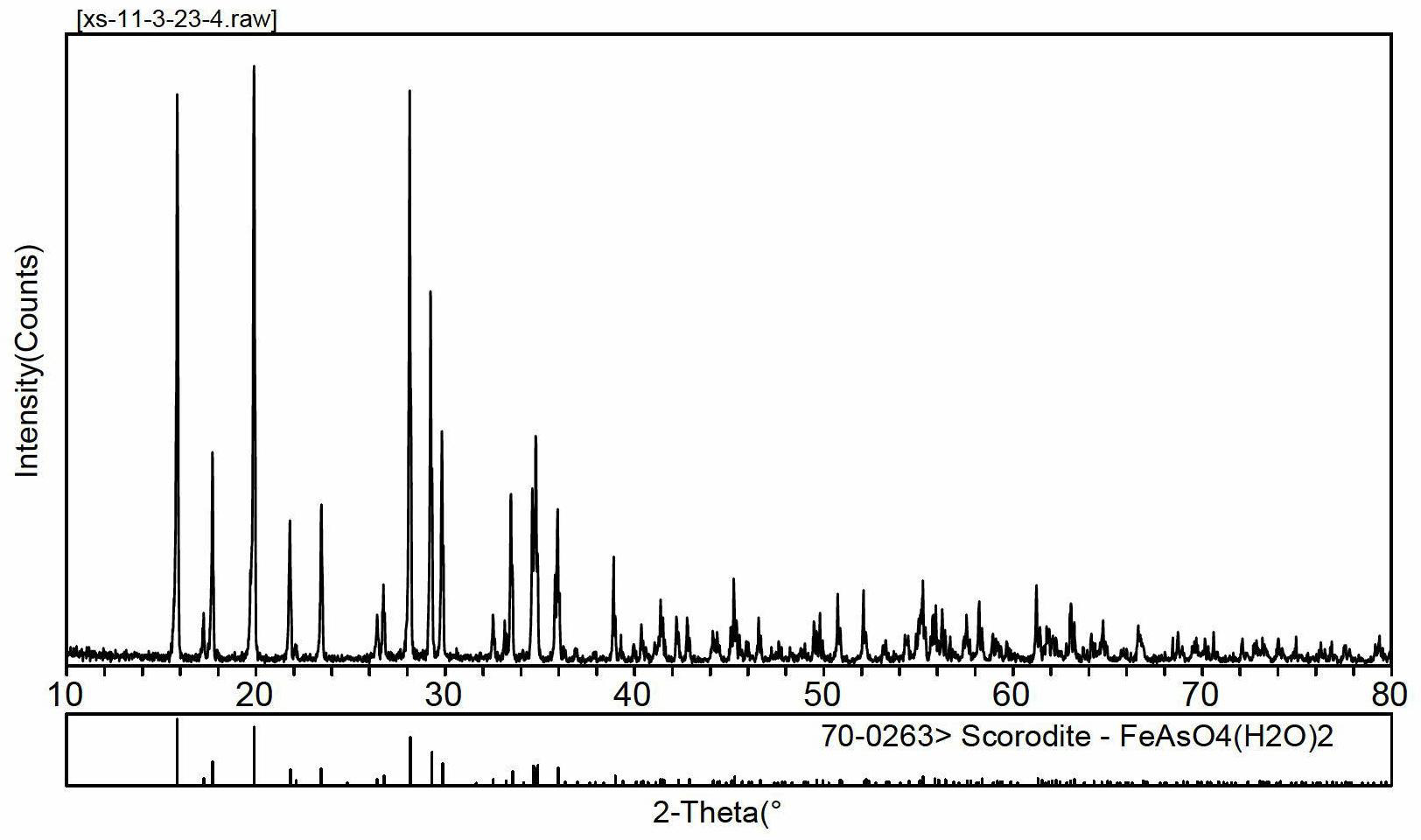

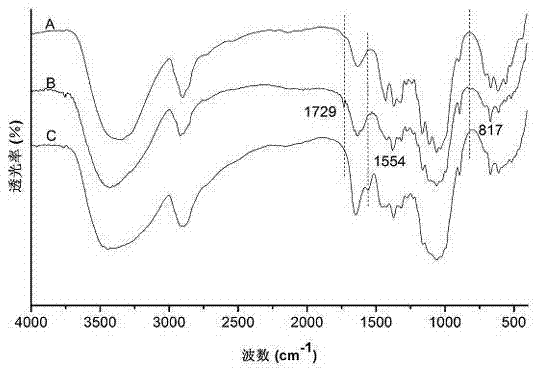

Method for precipitating and stabilizing As from As-containing solution

ActiveCN102674526ASimple preparation processLow equipment requirementsWater contaminantsWater/sewage treatment by oxidationFerrous saltsLimit value

The invention discloses a method for precipitating and stabilizing As from As-containing solution. According to the method, ferrous salt is used as As precipitator; through the air oxidation in the As-containing solution in a weak acid condition, Fe<2+> is oxidized into Fe<3+>; and Fe<3+> reacts with As to generate precipitate with high stability and low As leaching toxicity. The method is simple in technology, and generates the precipitate which is ferric arsenate crystalline compound-scorodite crystal FeAsO4. 2H2O under the conditions that the pH value is 4-6, the temperature is 70-95 DEG C, the molar ratio between Fe and As is 1-1.5, the air flow rate is 120-200L / h and the reaction time is 5-7h; the precipitate As has the leaching toxicity concentration of 1-2mg / L which is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007); and the harmless stabilizing treatment for the As-containing solution can be realized.

Owner:CENT SOUTH UNIV

Preparation method of modified cellulose adsorbents

InactiveCN103480348AWide variety of sourcesLow priceOther chemical processesWater/sewage treatment by sorptionEpoxyPolymer science

The invention discloses a preparation method of modified cellulose adsorbents. The preparation method comprises the following steps: (1) activating cellulose in alkaline aqueous solution to obtain activated cellulose; (2) reacting the activated cellulose with epoxy chloropropane to obtain epoxy cellulose; (3) reacting the epoxy cellulose with an oxidizing agent to obtain epoxy dialdehyde oxidized cellulose; (4) reacting cyclodextrin with epoxy dialdehyde oxidized cellulose to obtain cyclodextrin grafted modified cellulose; and (5) reacting the cyclodextrin grafted modified cellulose with amino-terminated hyperbranched polymer to obtain the modified cellulose adsorbents. The raw material source is wide, the price is low, and the environment-friendly effect is achieved; the preparation method is simple, the reaction condition is mild, the equipment requirement is low and scale production is facilitated; and the prepared adsorbent has stable performance and broad-spectrum adsorption capacity for heavy metal ions, dyes and other organic matters and is environment-friendly, the cellulose additional value is remarkably promoted, and good economic and social benefits are achieved.

Owner:SUZHOU UNIV

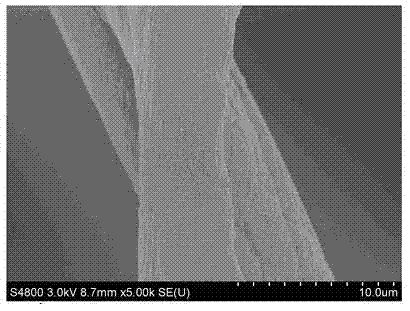

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

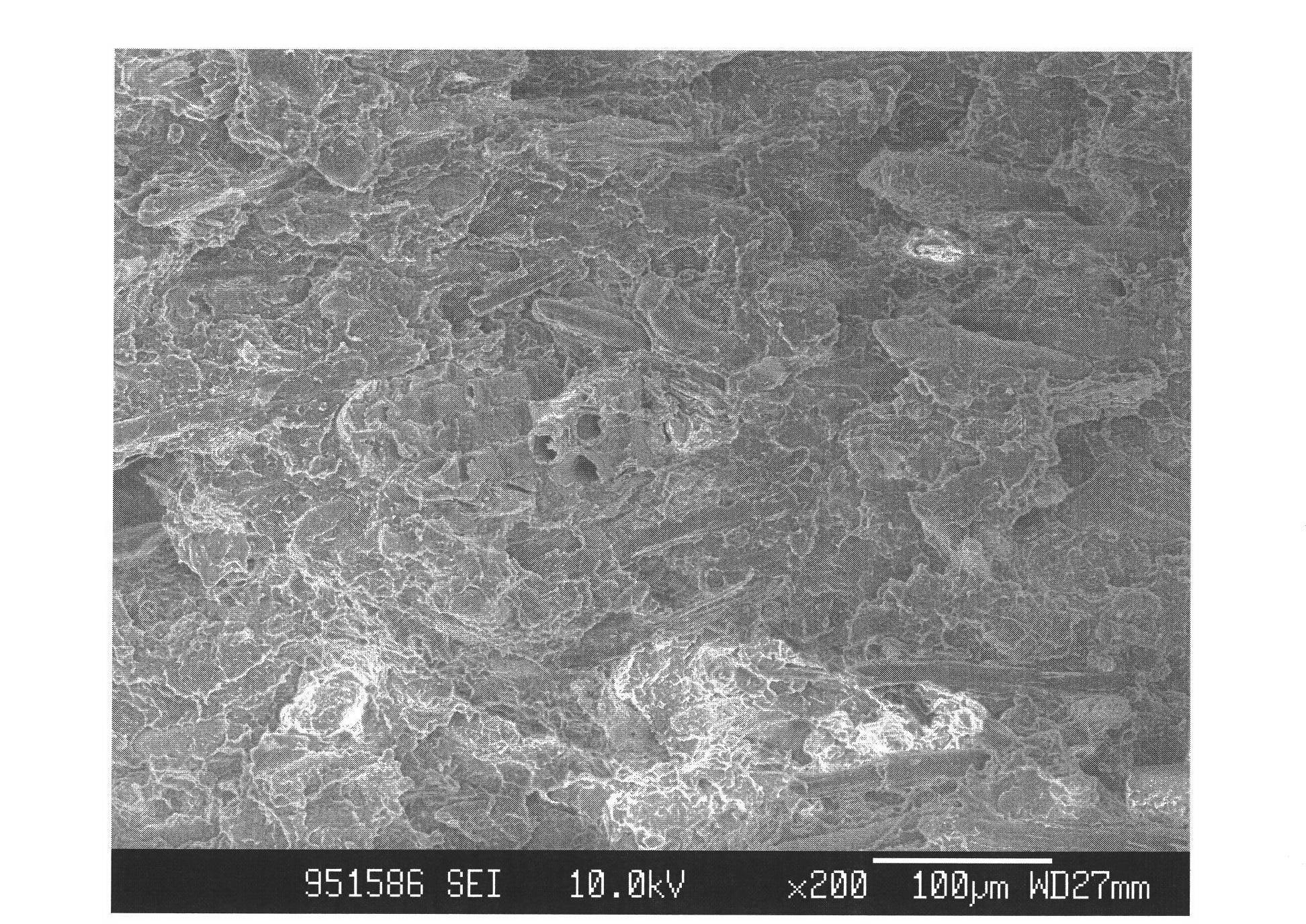

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

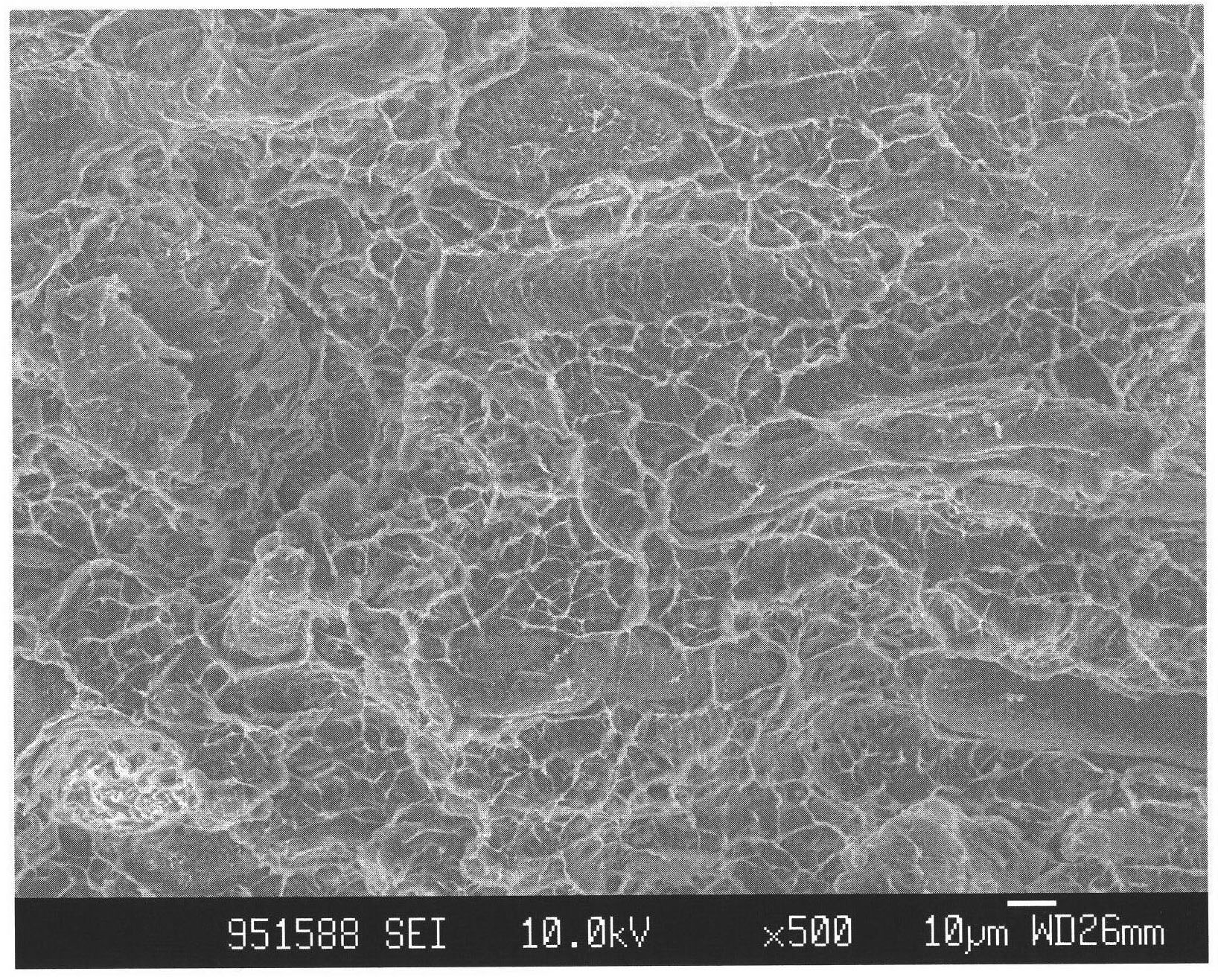

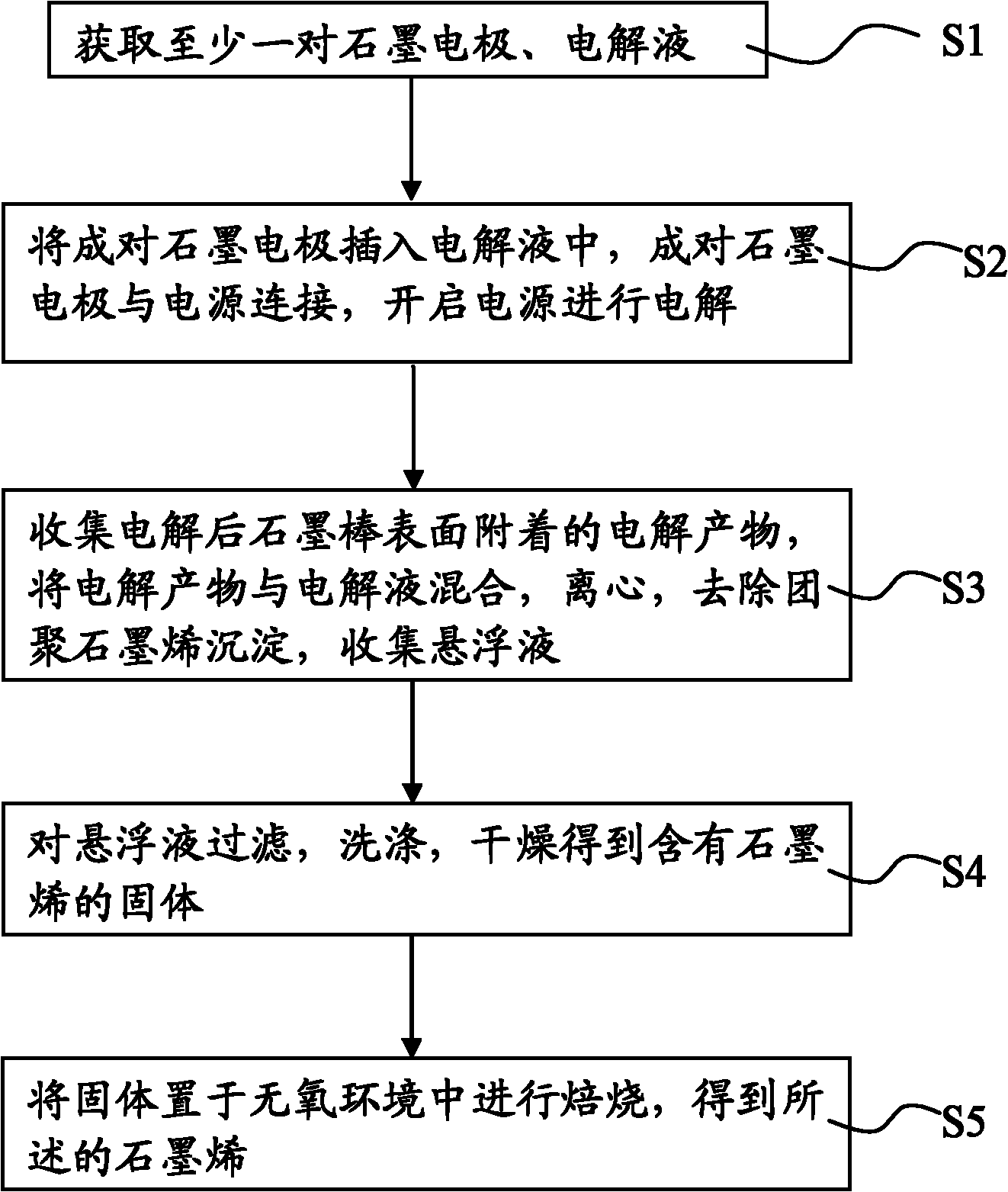

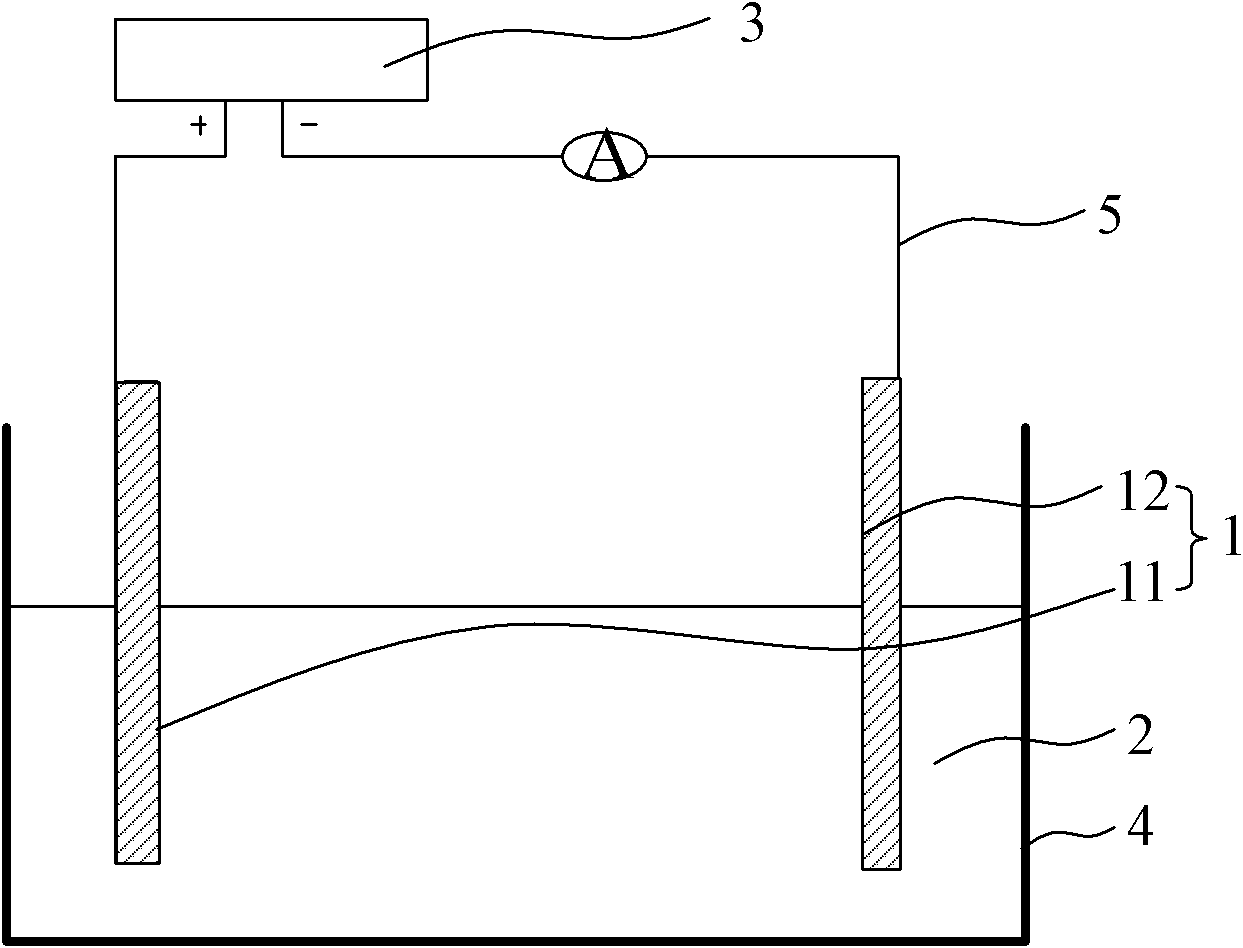

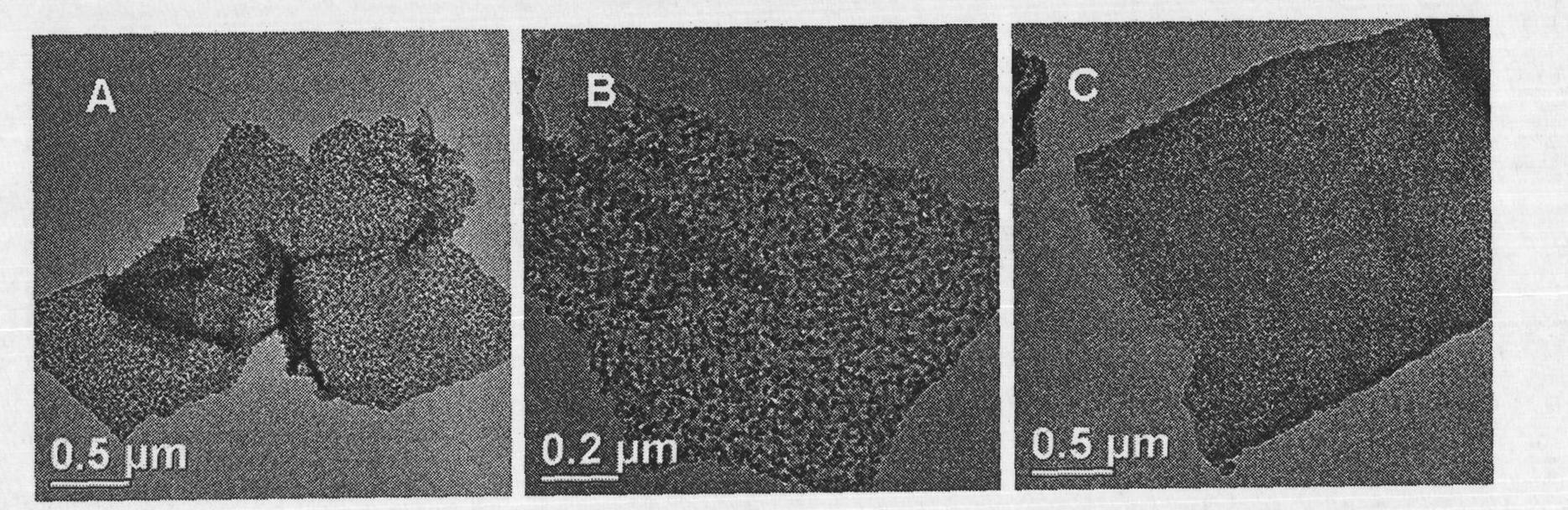

Preparation method of graphene

InactiveCN102465309AImprove productivityLow equipment requirementsElectrolysis componentsProduction rateElectrolysis

The invention discloses a preparation method of graphene. The method comprises the following technological steps of: acquiring at least one pair of graphite rods, an electrolyte and a power supply; inserting the graphite rod pair into the electrolyte, connecting one of the graphite rods with a positive electrode of the power supply, and connecting the other graphite rod with a negative electrode of the power supply, then switching on a power switch for electrolysis; collecting an electrolytic product adhered on the surfaces of the graphite rods, mixing the electrolytic product with the electrolyte, conducting centrifugation, removing an agglomerated graphene sediment, and collecting a suspension; filtering, washing and drying the suspension so as to obtain a graphene-containing solid; roasting he solid in an oxygen-free environment, thus obtaining the graphene. With low requirement for equipment, simple production technology, and strong operability, the method of the invention is suitable for industrial production, and improves graphene productivity. Being economic and environment-friendly, the method provided in the invention can finally generate a graphene product of high purity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

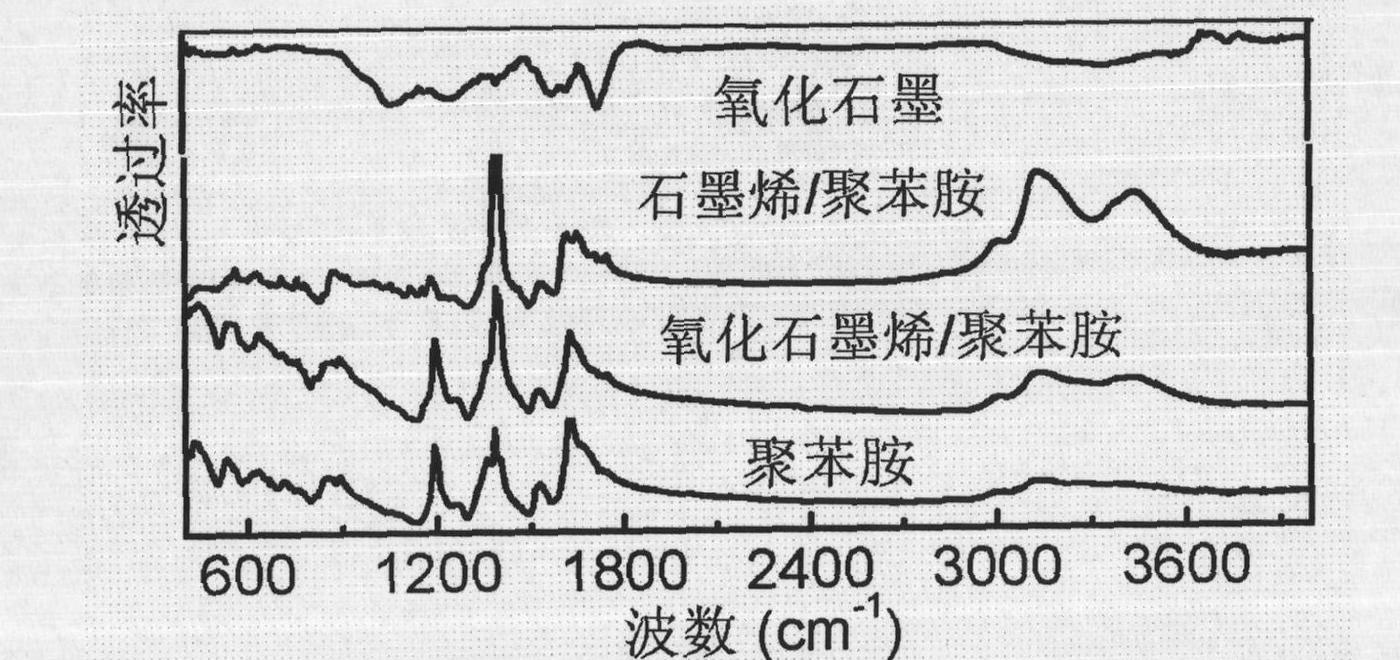

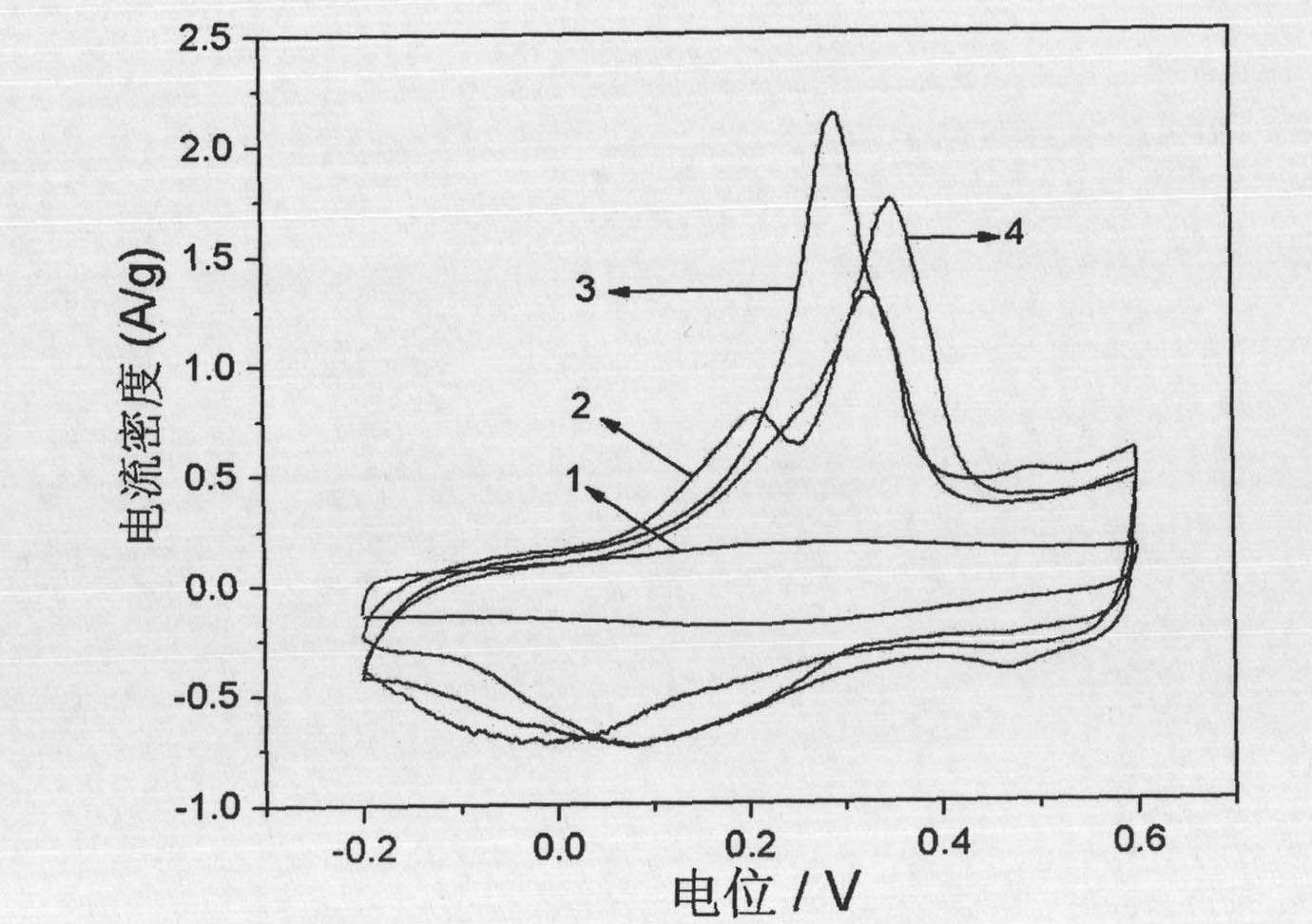

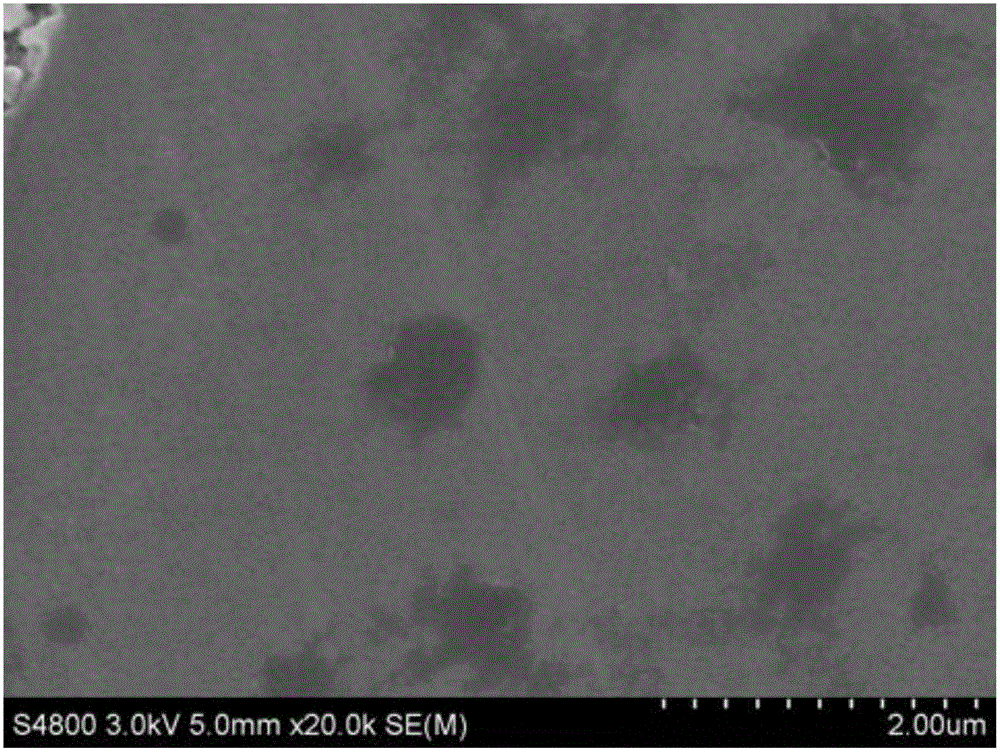

Graphene -organic acid doped polyaniline composite material and preparation method thereof

The invention discloses graphene-organic acid doped polyaniline composite material and a preparation method thereof. The preparation method includes the following steps: adding graphite oxide to dispersing agent for ultrasonic dispersion to form evenly dispersed graphene oxide liquid mixture; adding aniline monomer to the liquid mixture obtained in the first step for further dispersion under room temperature to form liquid mixture, and then blending for certain time; gradually dripping oxidizer and organic doping acid to the liquid mixture obtained in the second step, and blending for polymerization; centrifuging the liquid mixture obtained in the third step, and washing to get graphene oxide-polyaniline composite material; adding concentrated alkaline to the water suspension of the graphene oxide-polyaniline composite material, heating and blending for reaction; and centrifuging the mixture obtained in the fifth step and washing to get graphene-polyaniline composite material. The invention takes the advantage of the big specific surface area of graphene oxide and the capability of the graphene oxide for absorbing aniline on the surface thereof in on organic system to form sandwiched polyaniline / graphene oxide- polyaniline compound through polymerization.

Owner:NANJING UNIV OF SCI & TECH

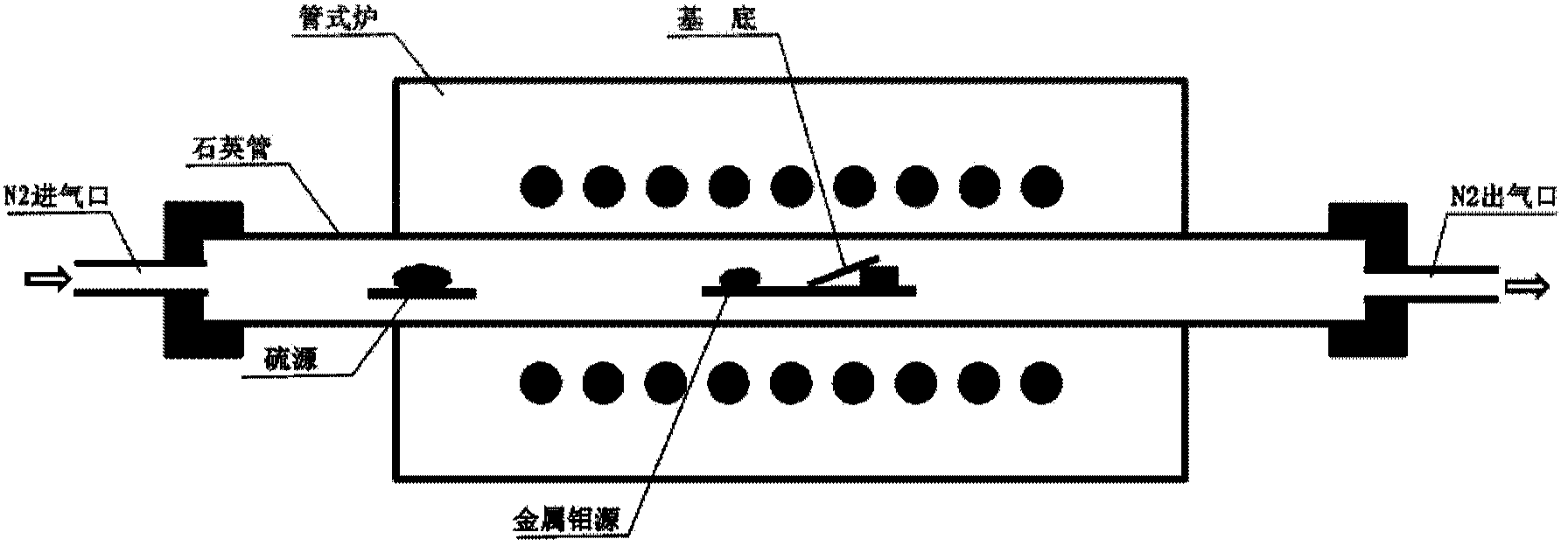

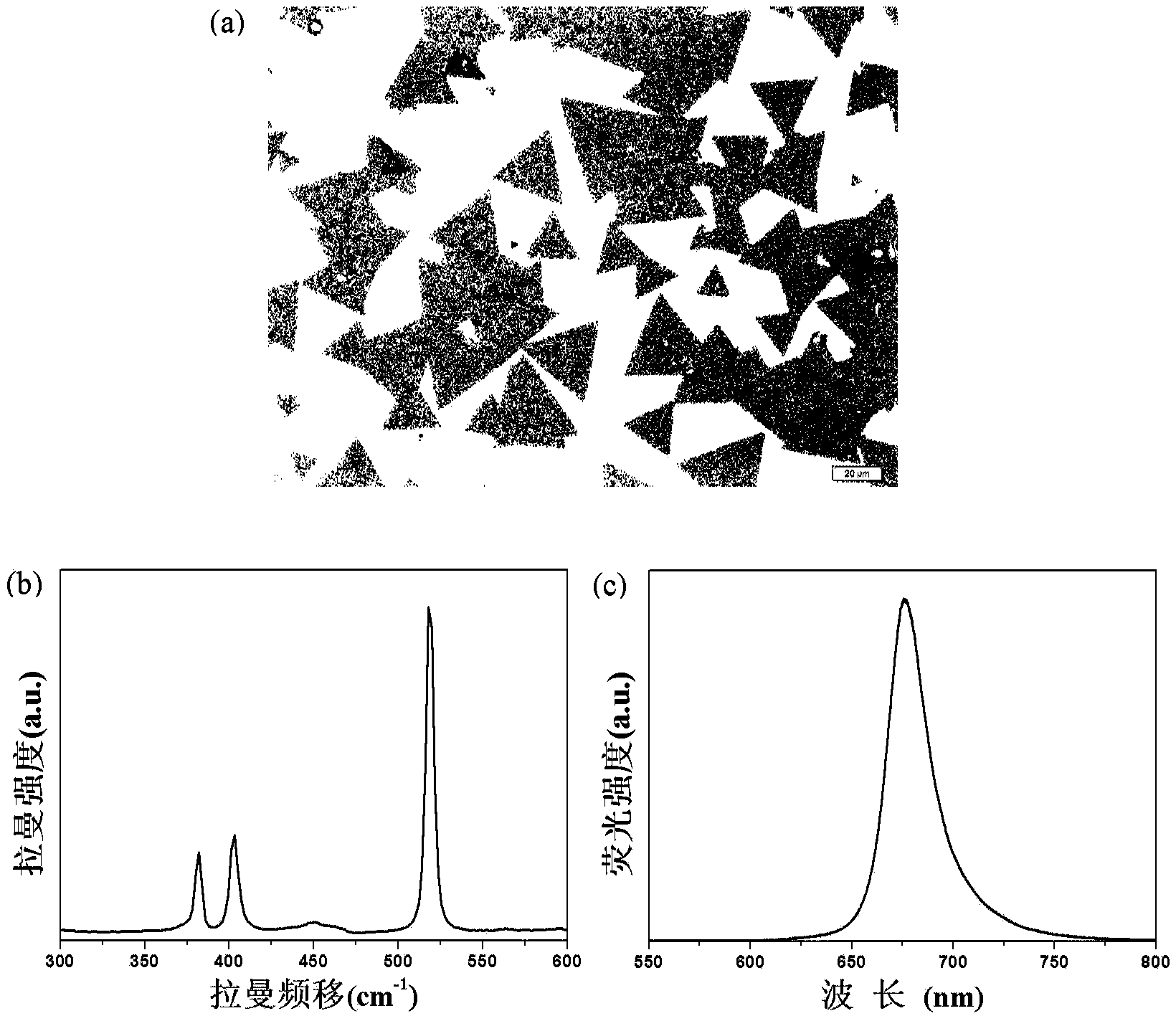

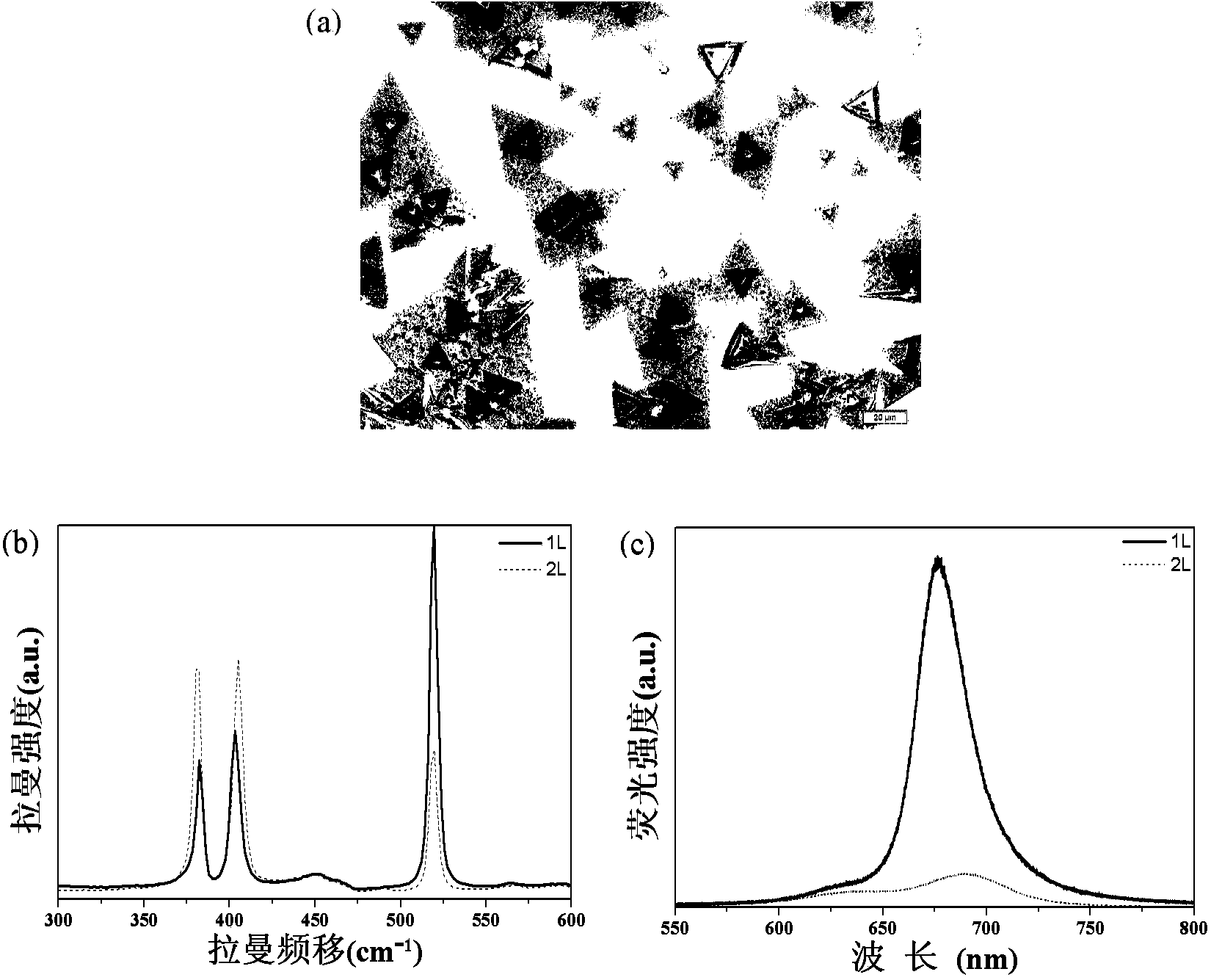

Method for preparing high-quality single/double-layer controllable molybdenum disulfide

ActiveCN104058458AQuality improvementLow equipment requirementsMolybdenum sulfidesDeposition temperatureSulfur

The invention relates to a method for preparing layered molybdenum disulfide. The layered molybdenum disulfide is in a single-layer or double-layer structure, wherein a chemical vapor deposition method is adopted, elemental molybdenum metal and powdered sulfur is taken as a source, two-dimensional molybdenum disulfide is deposited on the surface of a substrate, the preparation parameters such as deposition temperature and growth time are optimized, and controllable growth of the single-layer or double-layer structure of the high-quality molybdenum disulfide is realized.

Owner:UNIV OF SCI & TECH OF CHINA

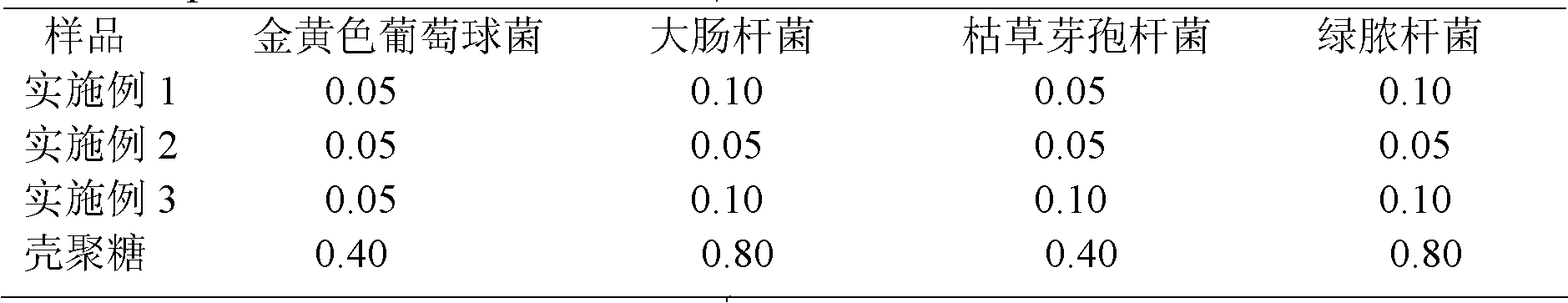

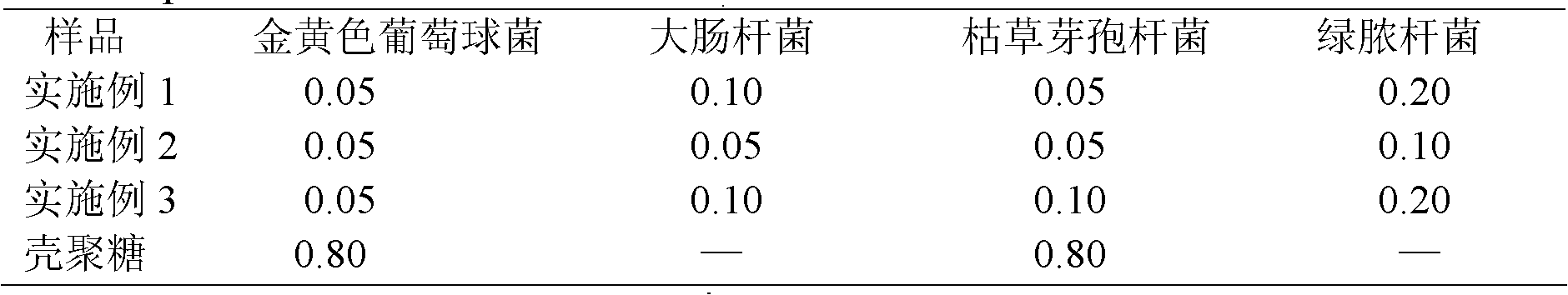

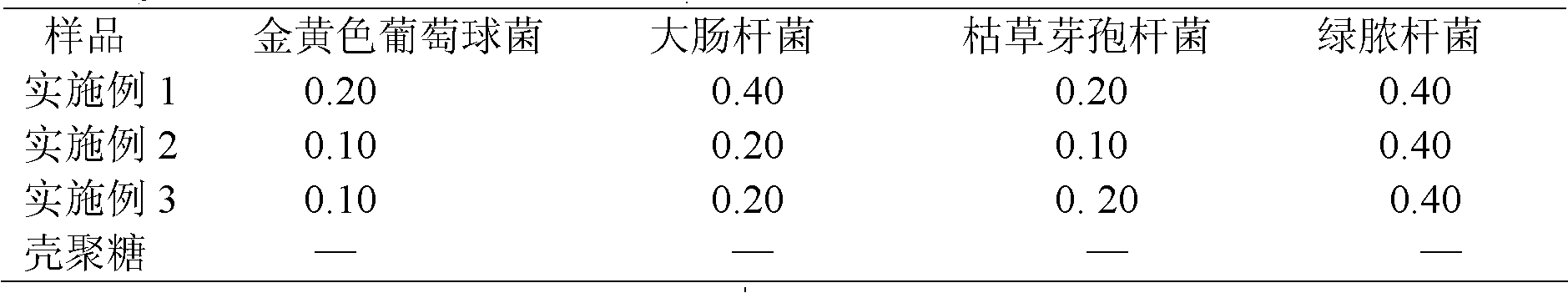

Carboxymethyl chitosan quaternary ammonium salt as well as preparation and application thereof in preparing natural cosmetic antibacterial agent

ActiveCN102040670ASimple methodLow equipment requirementsCosmetic preparationsToilet preparationsChemistryMethyl group

The invention discloses a carboxymethyl chitosan quaternary ammonium salt as well as preparation and an application thereof in preparing a natural cosmetic antimicrobial agent. The method for preparing the carboxymethyl chitosan quaternary ammonium salt comprises the following steps: alkalifying carboxymethyl chitosan by using organic alcohol, and adding a quaternized reagent to react, thereby obtaining the carboxymethyl chitosan quaternary ammonium salt, wherein the degree of quaternization of the carboxymethyl chitosan quaternary ammonium salt is 0.69-1.05, the viscosity-average molecular weight is (0.92-2.36)*104g / mol, and the degree of substitution of carboxymethyl group is 0.26-0.72. The carboxymethyl chitosan quaternary ammonium salt has the advantages of simple preparation method and low requirements on equipment. The obtained carboxymethyl chitosan quaternary ammonium salt, an amino acid surfactant and a chelator are compounded according to the mass ratio of (0.5-0.7):(0.2-0.3): (0.1-0.2) to obtain an antimicrobial agent. The antimicrobial agent has the advantages of strong antimicrobial performance, wide antimicrobial spectrum and no stimulation, can be used as an antimicrobial preservative in cosmetics, can be completely biodegraded, and can not cause environmental pollution.

Owner:FROG PRINCE (FUJIAN) BABY & CHILD CARE PROD CO LTD

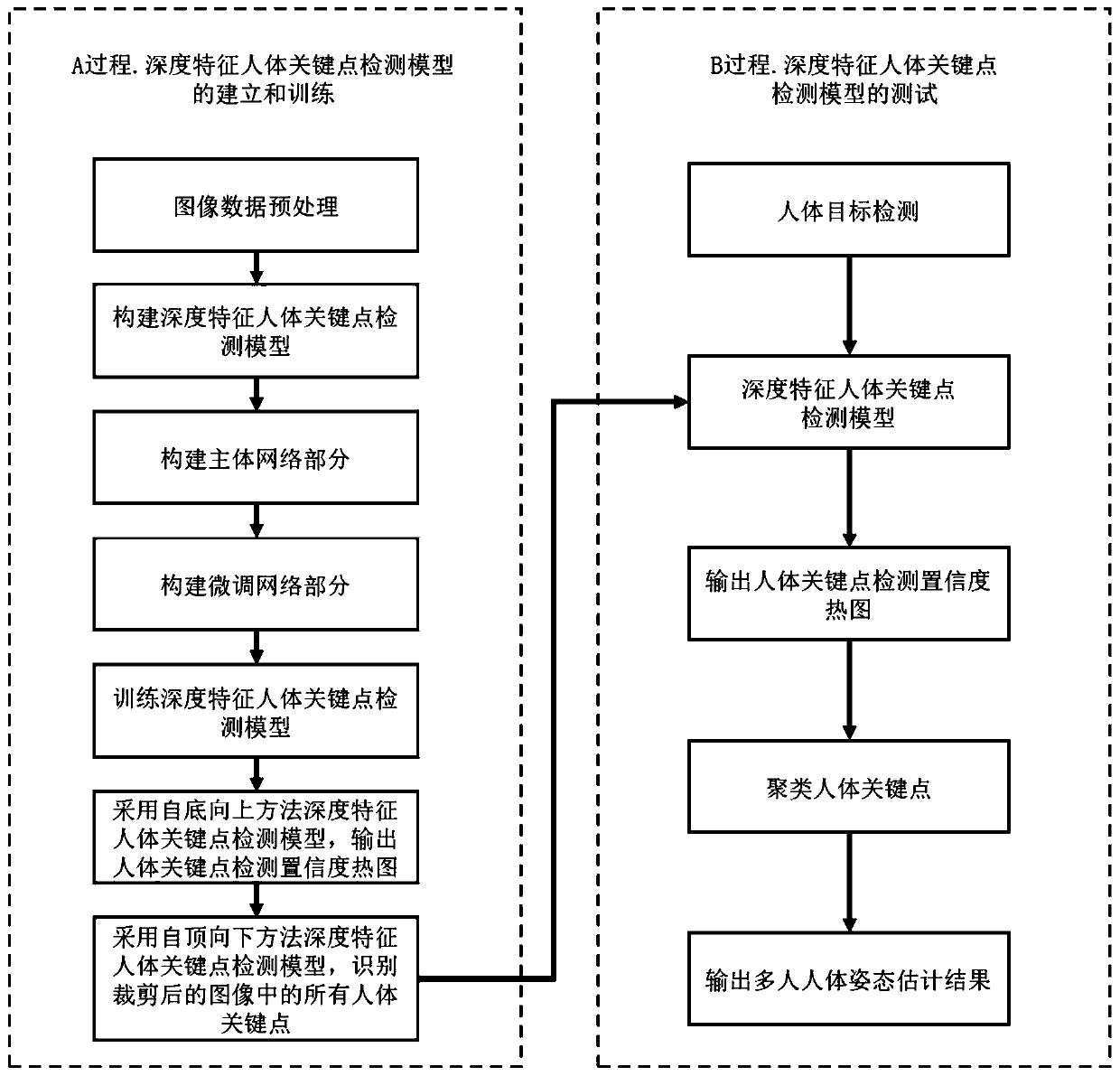

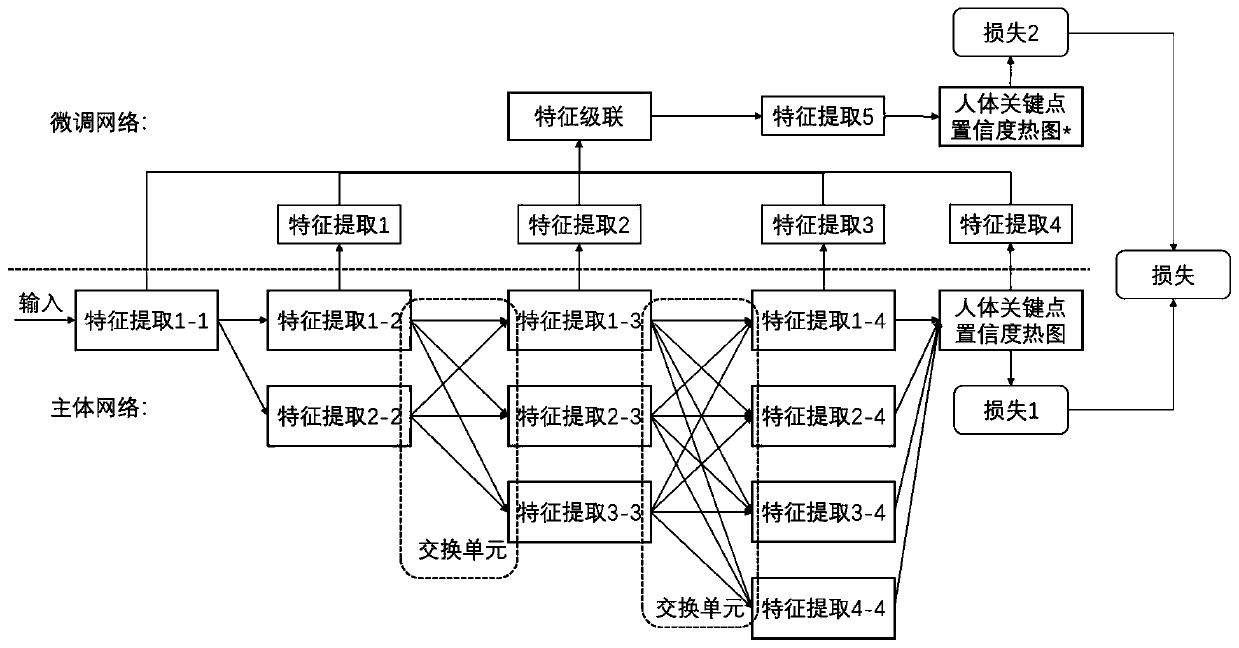

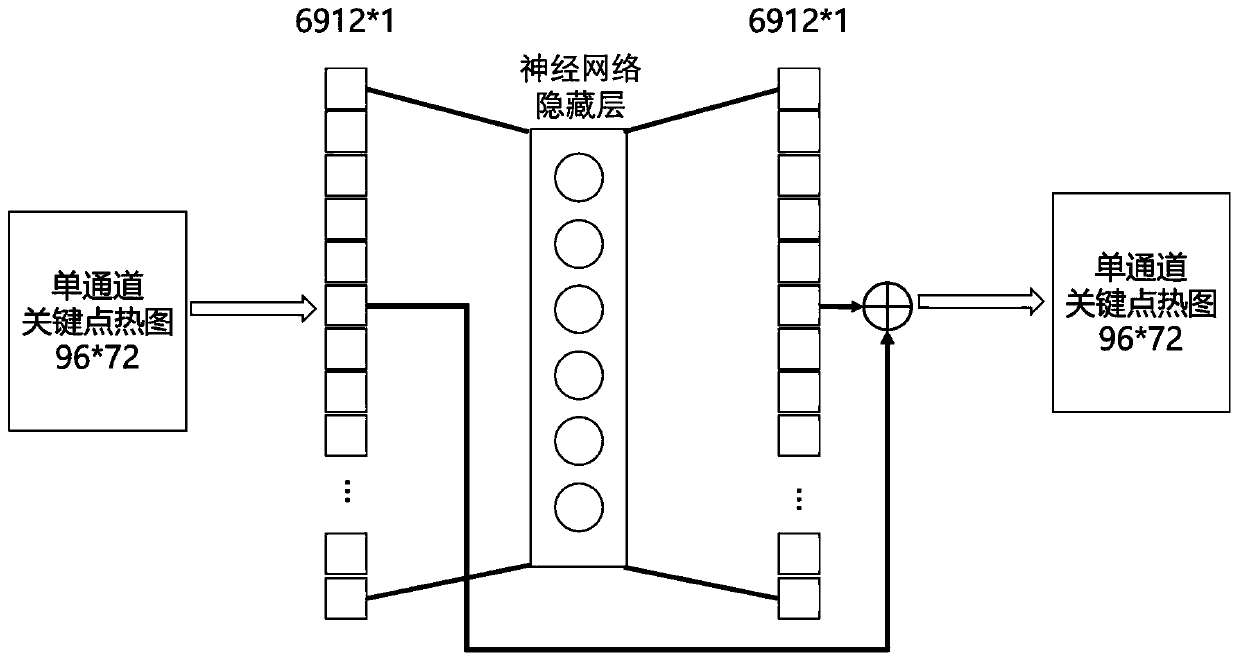

Multi-person human body posture estimation method

ActiveCN111339903AImprove recognition rateAvoid interferenceImage enhancementImage analysisPattern recognitionHuman body

The invention discloses a multi-person human body posture estimation method, and relates to processing of a recording carrier for identifying graphics. The method is a multi-person human body postureestimation method based on depth features. According to the method, a depth feature human body key point detection model composed of a main body network and a fine tuning network is constructed; a depth feature human body key point detection model is trained by adopting a two-stage training method combining a bottom-up method and a top-down method; finally, the human body key points are detectedby using a depth feature human body key point detection model trained in two stages. Redundant key points which do not belong to a target person are removed through human body key point clustering processing, then a multi-person human body posture estimation result is output, and the defects that in the existing multi-person human body posture estimation method technology, under the condition thatcrowds are dense, the target human body shielding interference robustness is poor, and the human body key point detection accuracy is low are overcome.

Owner:HEBEI UNIV OF TECH

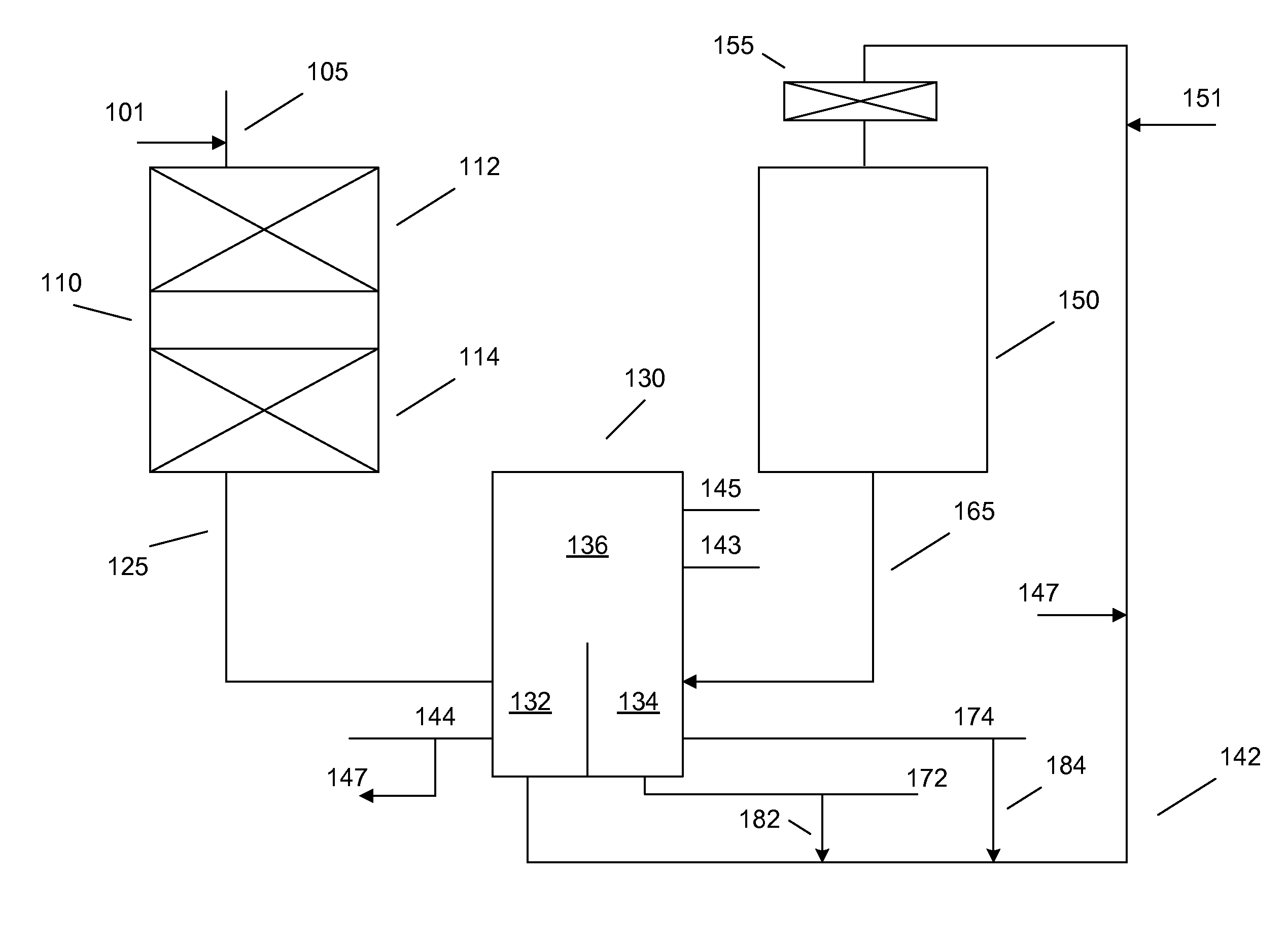

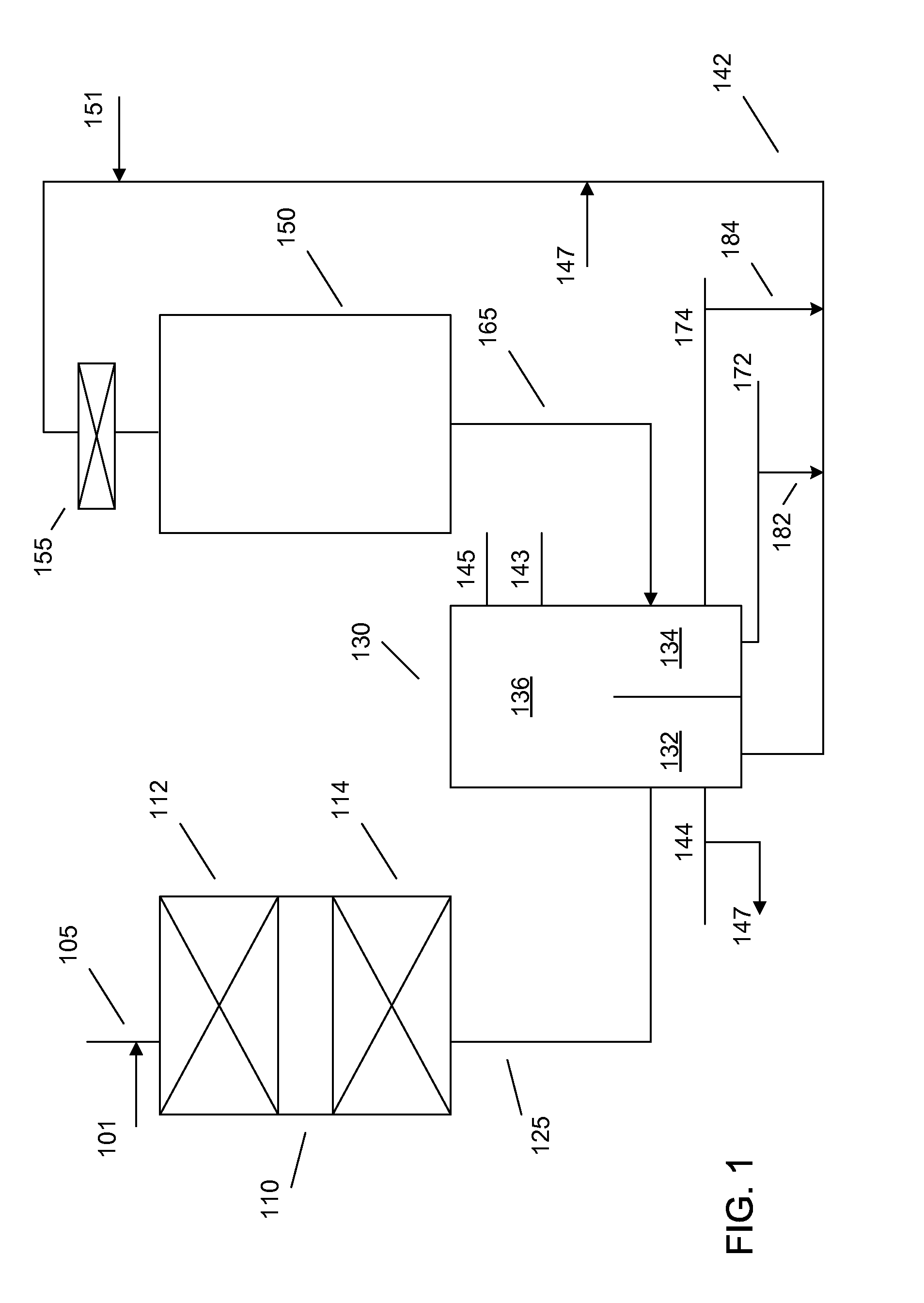

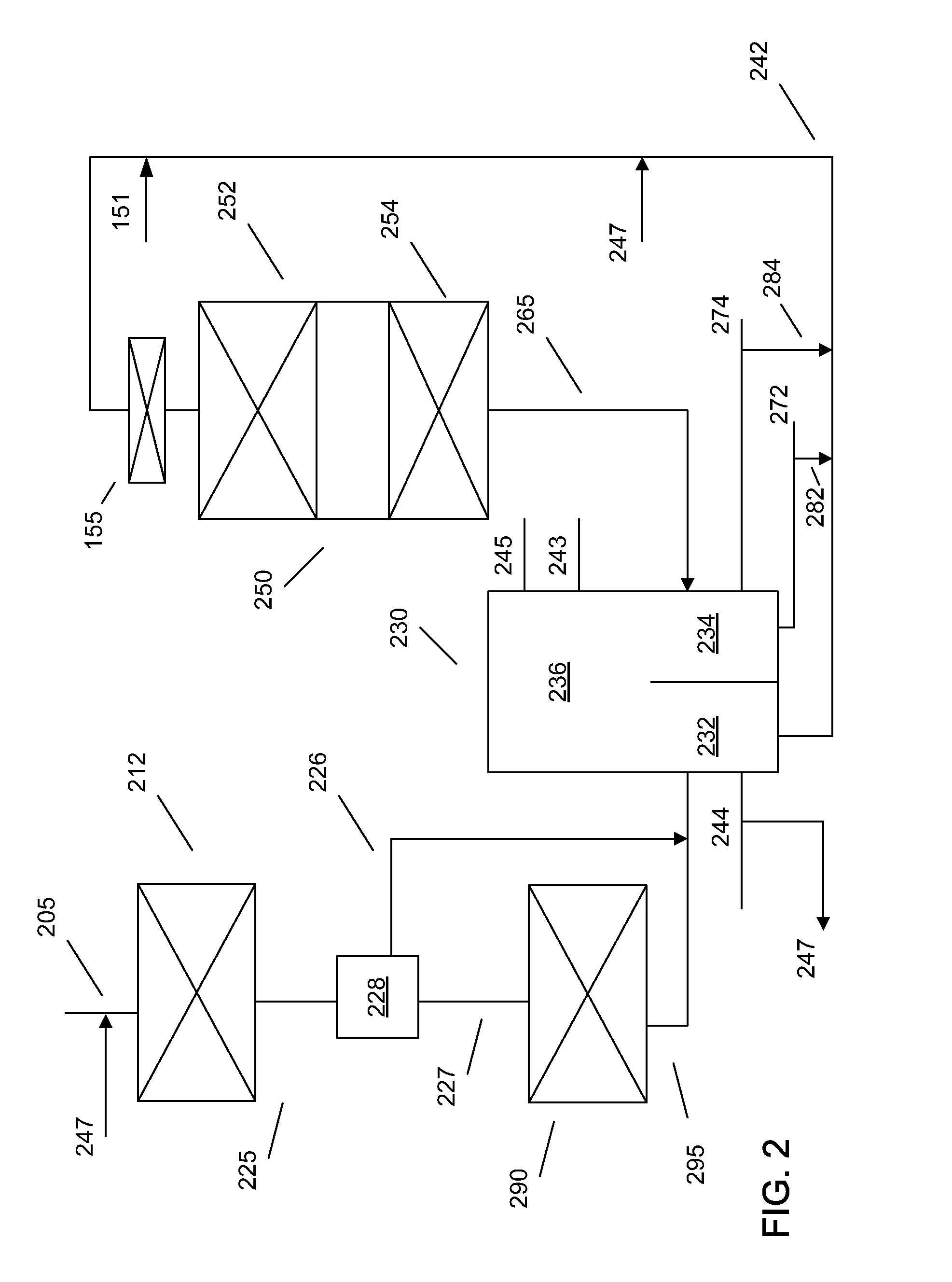

Two stage hydroprocessing with divided wall column fractionator

InactiveUS20120004478A1Low sulfurImprove propertiesCoke ovensHydrocarbon distillationFractionationReaction system

A divided wall column can allow for fractionation of multiple streams while maintaining separate product qualities. Effluents from multiple stages of a reaction system can be processed in a single divided wall column. The divided wall column can produce multiple cuts from each separated area, as well as at least one output from a common area. At least one reaction stage can advantageously have a continuous liquid phase environment.

Owner:EXXON RES & ENG CO

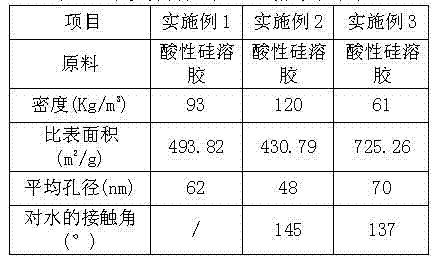

Method for preparing silicon dioxide aerogel by using acidic silica sol

ActiveCN102642842ALow cost of preparationSimple processSilicaBulk chemical productionSolventOrganosilicon

The invention discloses a method for preparing silicon dioxide aerogel by using acidic silica sol and belongs to the field of preparation of inorganic heat-insulating materials. The method comprises the following steps of: directly forming gel under actions of acid and alkali catalysts by using acidic silica sol as a raw material, wherein the process for preparing the gel does not involve organic solvent so as to improve the security of production; and preparing SiO2 aerogel through supercritical or constant pressure drying after the gel is subjected to solvent replacement and surface silylation. According to the method, the process for preparing the sol by using organic silicon as raw material and a complicated process for removing salt in water glass are avoided; and because the acidic silica sol with low cost and stable performance is used as the raw material, the method has the advantages that the process is simple, the production cycle is short, the reaction process is controlled, and the requirement and investment of the equipment are low, so that the industrial production of SiO2 aerogel can be realized.

Owner:纳诺科技有限公司

Synthetic method of visible light catalyst Bi2MoO6

InactiveCN101254463AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsMolybdateSynthesis methods

A synthetic method of a novel visible light photocatalyst Bi2MoO6 (bismuth molybdate) is provided. The method includes the following steps: weighing Bi(NO3)3*5H2O and (NH4)6Mo7O24*4H2O solids at the theoretical ratio by mass of 14:1, dispersing the weighed solids into an appropriate amount of deionized water, stirring to obtain white curdy precipitates, placing the precipitates in a magnetic stirrer and stirring at normal temperature for 30 minutes, subjecting to ultrasonic treatment with a ultrasonic generator for 30 minutes to allow intensively mixing, allowing reactions of the treated white precipitates at 150-200 DEG C under sealed conditions, filtering the reaction product to collect flavescent precipitates, washing, drying, and grinding to obtain Bi2MoO6 (bismuth molybdate) photocatalyst. The photocatalyst has good photodegradation effect on target pollutants; and when the temperature of hydrothermal synthesis is 160 DEG C, the removal rate of target pollutant 4BS after photodegradation for 90 minutes reaches 99.5%. The inventive synthetic method has the advantages of simple process and low requirement for equipment, and is suitable for the synthesis of highly-active visible light photocatalyst Bi2MoO6 (bismuth molybdate).

Owner:NANJING UNIV

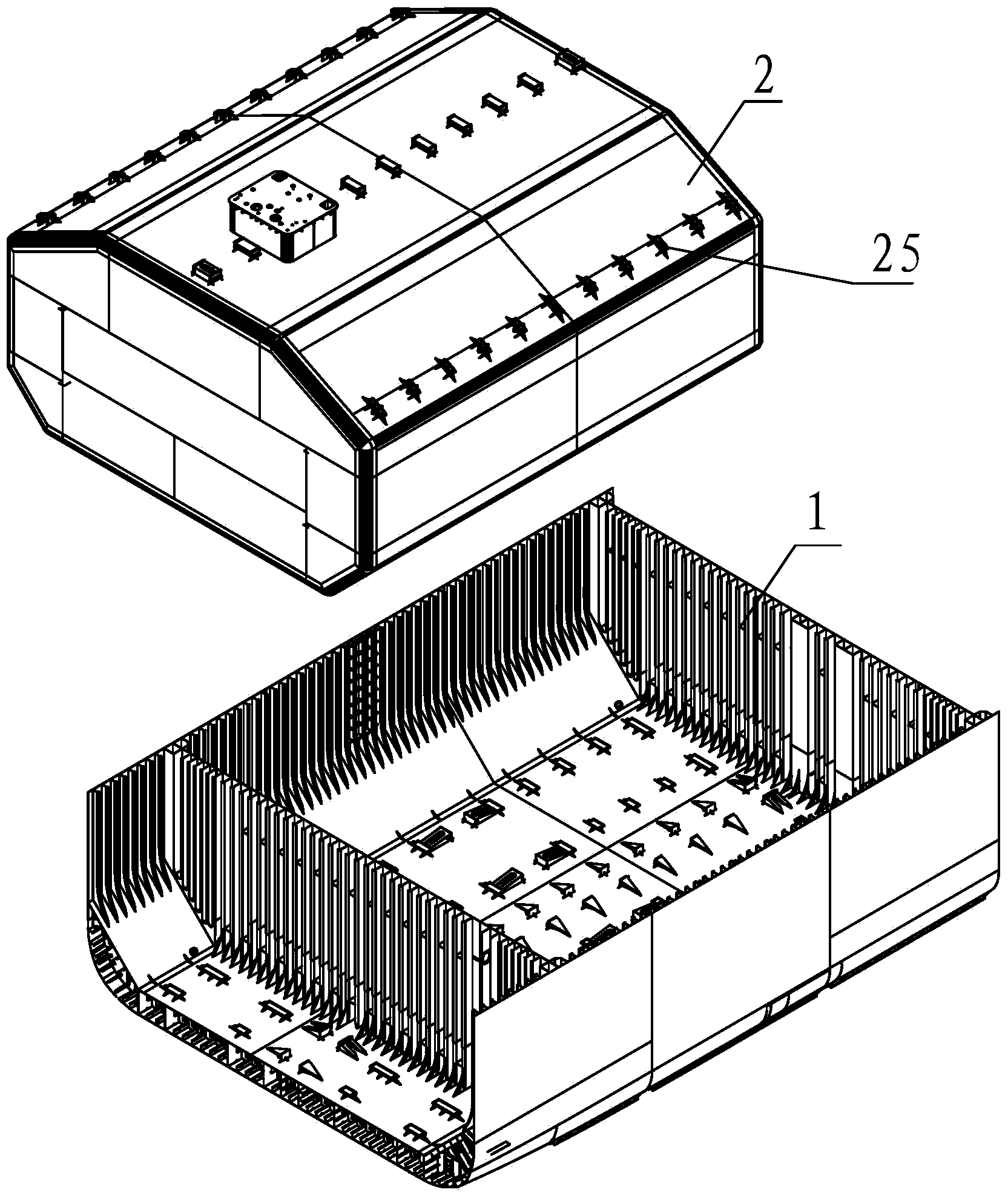

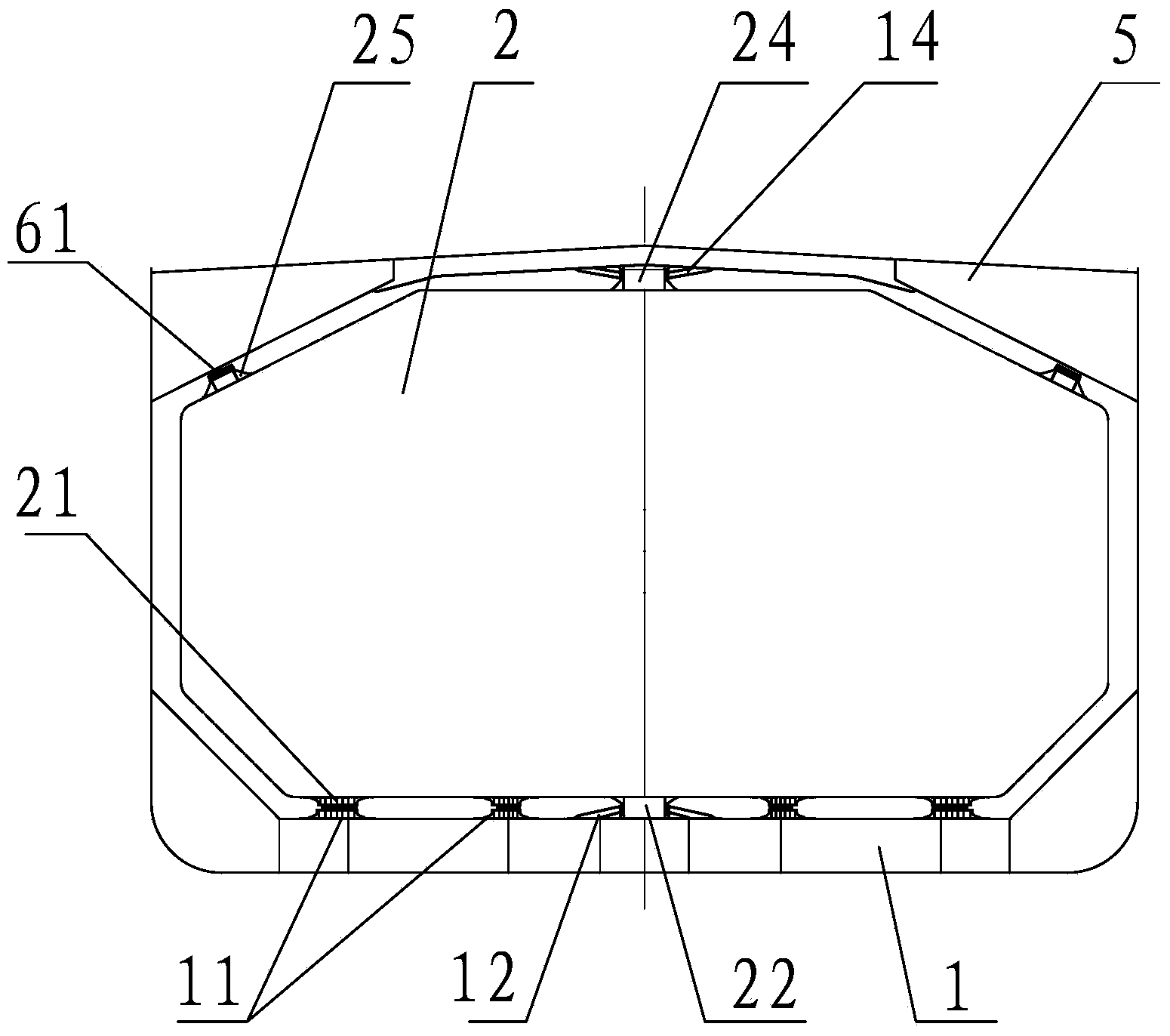

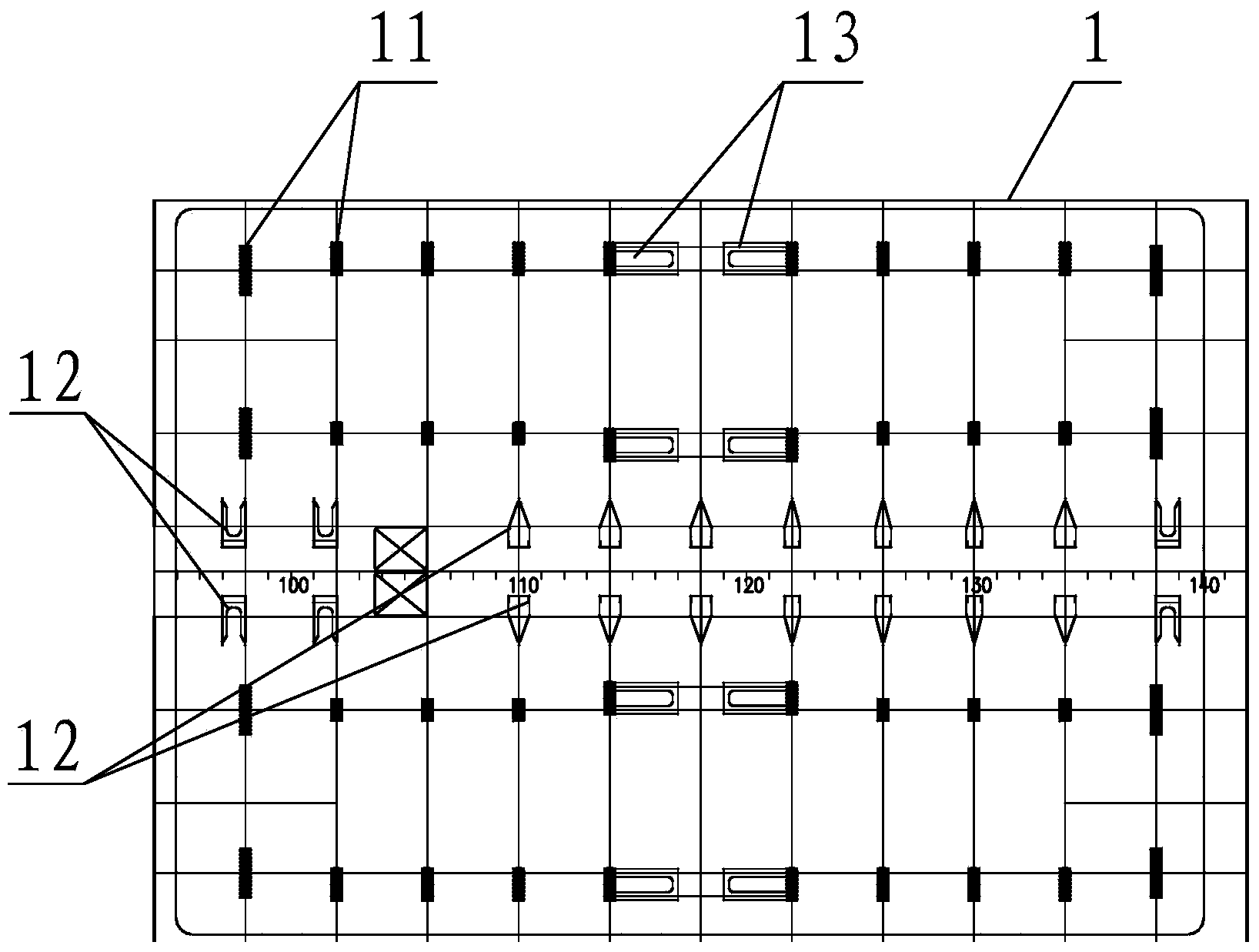

Installing structure of liquid tank of large liquefied gas carrier and installation locating method of liquid tank

ActiveCN103832543ALow equipment requirementsSimple and fast operationHull interior subdivisionLarge containersCollections dataLiquid tank

The invention provides an installing structure of a liquid tank of a large liquefied gas carrier and an installation locating method of the liquid tank. According to the installing structure of the liquid tank of the large liquefied gas carrier, a liquid tank cabin of the large liquefied gas carrier is mainly provided with a bottom perpendicular supporting base, a bottom transverse-shake preventing support, a top transverse-shake preventing support and a bottom longitudinal-shake preventing support, wherein the bottom perpendicular supporting base is used for supporting a whole liquid tank, the bottom transverse-shake preventing support and the top transverse-shake preventing support are used for preventing the liquid tank from transversely shaking relative to a hull, and the bottom longitudinal-shake preventing support is used for preventing the liquid tank from longitudinally shaking relative to the hull. In the actual working process of installing the liquid tank in the liquid tank cabin, according to the installation locating method of the liquid tank, the data collection step, the three-dimensional simulation step, the epoxy resin thickness calculation step, the locating datum line assignment step, the supporting positioning step and the like are carried out in sequence, and finally the liquid tank is installed in the liquid tank cabin. By the adoption of the installation locating method of the liquid tank, installation locating work of the liquid tank can be rapidly and accurately accomplished, the utilization rate of tools is high, the using time of a crane is short, and the construction cost of an enterprise is greatly reduced.

Owner:JIANGNAN SHIPYARD GRP CO LTD

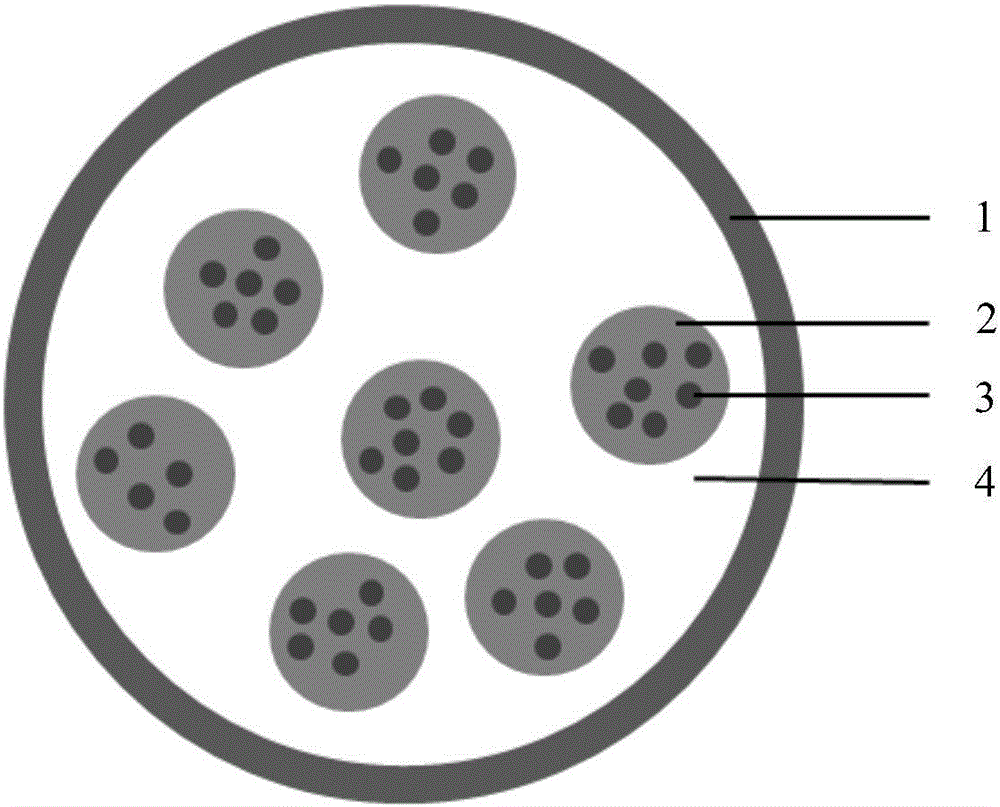

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Expandable polypropylene beading, preparation method thereof, and its foaming beading and foaming molding products

The invention provides an expandable polypropylene bead and a preparation method of the expandable polypropylene beads, and also provides foaming beads and foaming molding products of the expandable polypropylene beads, which relates to the resin expandable beads technical field. Random copolymerized polypropylene is used as basic resin, so that melting intensity can reach to an ideal range when in foaming with high melting intensity polypropylene and low density polyethylene resin being added. Expandable beads are prepared in a closed reactor without external pressure with pentane being used as foaming agent. The expandable beads contain 1 to 15 parts by weight of the high melting intensity polypropylene, 1 to 10 parts by weight of the low density polyethylene, 1.0 to 3.8 parts by weight of the foaming agent and 0.1 to 10 parts by weight of nucleating agent on the basis of 100 parts by weight of the random copolymerized polypropylene. The expandable polypropylene beads are easy to foam, whose foaming rate can reach to 16 times with uniform cells and whose foam volume weight is about 0.05 to 0.12g / cm3. The invention adopts a low-pressure method to produce the polypropylene foaming products in different shapes according to the requirement with low equipment requirement and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

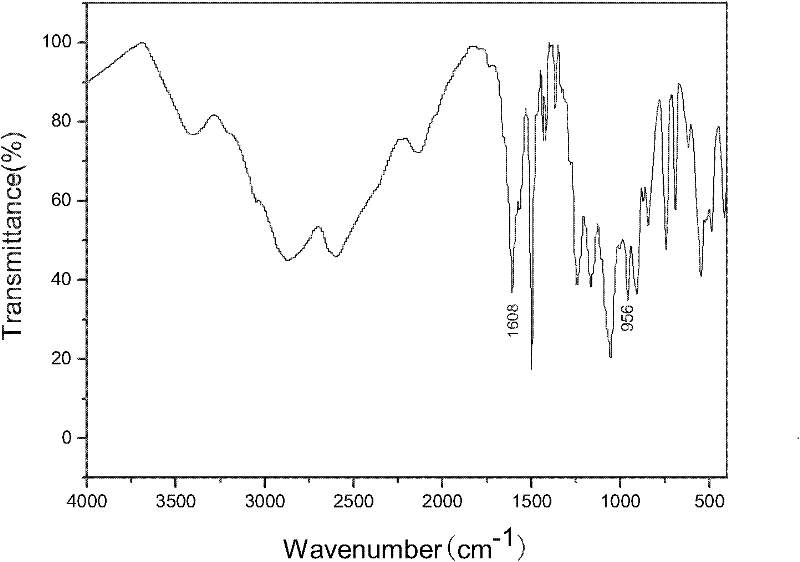

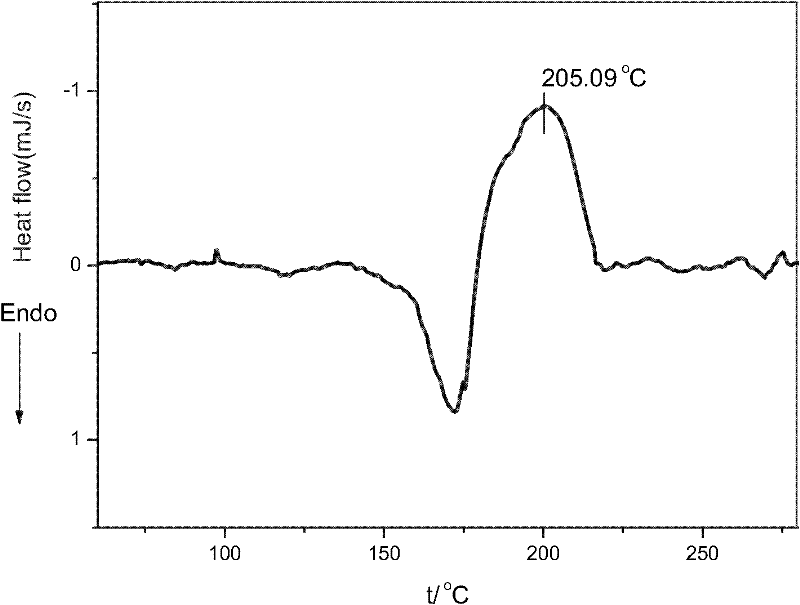

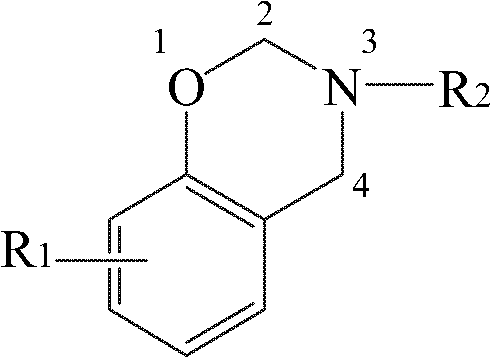

Dibenzoxazine containing oxazole ring and preparation method thereof

InactiveCN102250117ASimple preparation processLow equipment requirementsLiquid crystal compositionsOrganic chemistrySolventOrtho-aminophenol

The invention relates to a dibenzoxazine containing an oxazole ring and a preparation method thereof. The preparation method comprises the following two steps of: 1: mixing ortho-aminophenol hydrochloride and para-hydroxybenzoic acid, adding polyphosphoric acid as a solvent, reacting at 60-180 DEG C for 24-60 hours, and washing by using deionized water, filtering and drying to obtain diphenol containing an oxazole ring structure; and 2: mixing the diphenol containing the oxazole ring structure, phenylamine and paraformaldehyde, reacting at 80-110 DEG C for 40-80 minutes, then filtering and precipitating, washing 4-8 times by using alkali liquor, and then washing, filtering and drying to obtain the product. The dibenzoxazine disclosed by the invention has the advantages of very good mechanical property because the high temperature resistant oxazole ring structure is introduced to a benzoxazine molecule structure, dielectric constant of only 1.6-2.3, simple process, lower equipment requirement and suitability for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

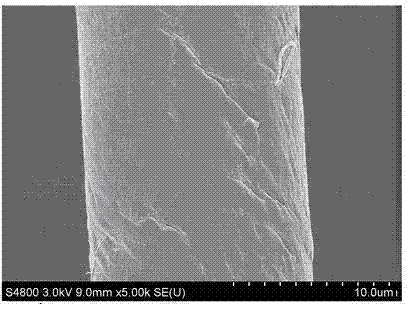

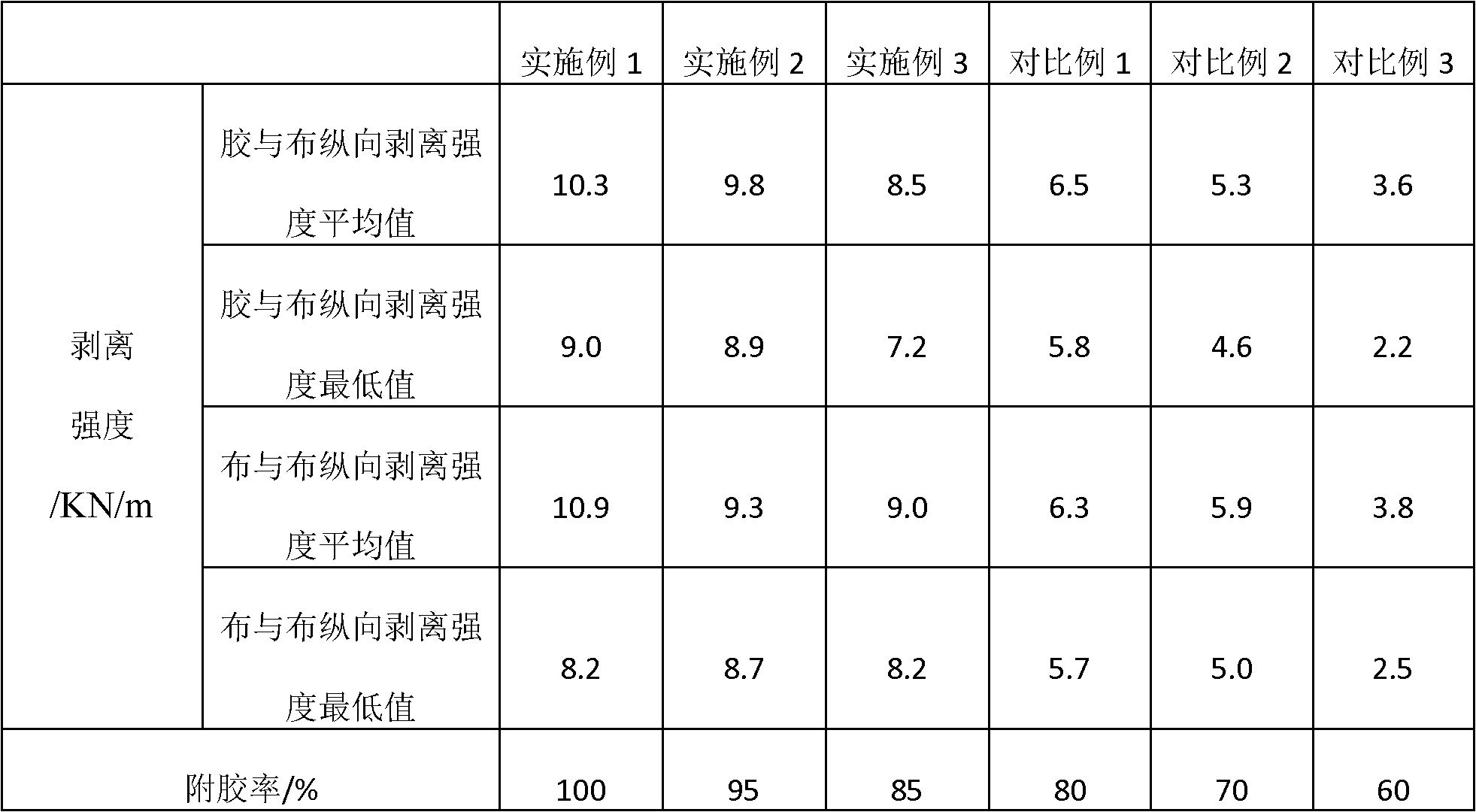

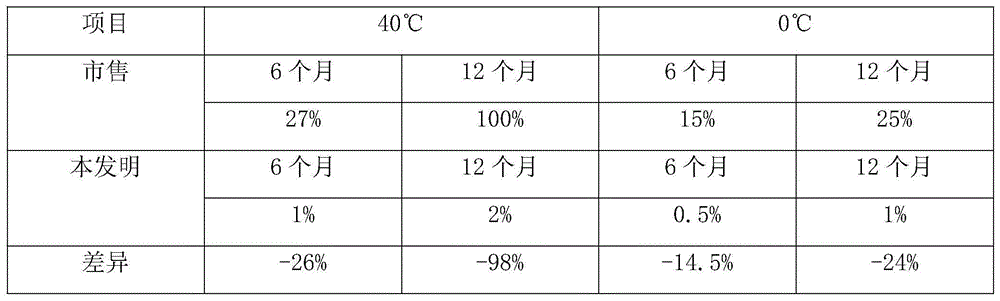

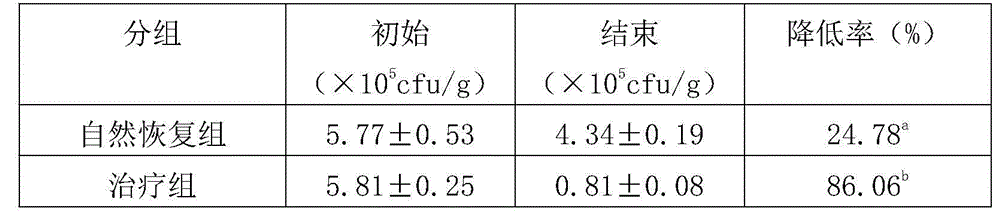

Method for pretreating fibers

The invention relates to a method for pretreating fibers, comprising the following steps of: performing surface activation on fibers by a dopamine hydrochloride biomimetic modification method, and then performing impregnation treatment on the fibers by using impregnation solution composed of rubber latex and phenolic resin, aiming to improve the interface adhesion property of the fibers with rubber so that the fibers are more suitable for tyres, conveyor belts, high-pressure rubber tubes and transmission belts. The method solves the experimental problem caused by high toxicity of isocyanate and avoids damage on the fibers caused by high-temperature treatment; and the process flow is simplified and the production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH

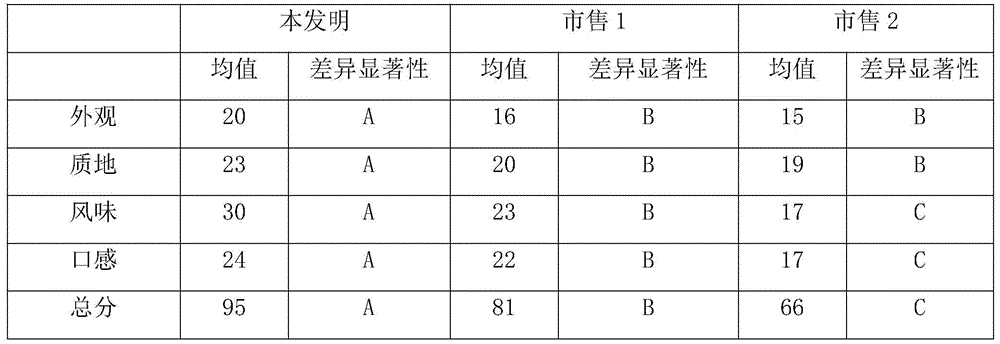

Medlar and red date enzyme and preparation method thereof

InactiveCN104872674AKeep natural colorImprove biostabilityNatural extract food ingredientsFood ingredient functionsRipeningHigh pressure

The invention discloses a medlar and red date enzyme and a preparation method thereof, which belong to the technical field of enzyme preparation. Multi-strain composite fungi powder is adopted as a leavening agent; the medlar and the red date are adopted as main raw materials; dietary fiber, pectin hydrolyzate, seasoner extracting liquor, Chinese herbal medicine extracting liquor, enzyme stabilizer and other multifunctional auxiliary raw materials are scientifically compounded and modified; low-temperature processing technology such as ultrasonic cleaning, cryogenic grinding, microwave-assisted high-voltage pulse electric field processing and ultrasonic ripening are mainly adopted in the whole process, so that the natural colors, the flavor, the taste and the content of the active materials of the medlar and the red date are maintained furthest, the biological stability, the non-biological stability and the biological activity of the medlar and red date enzyme are obviously enhanced, the introduction of chemical addition agent is reduced, and the juicing rate of the medlar and the red date as well as the food safety of the enzyme are improved. Finally, the medlar and red date enzyme with high biological activity, strong stability, strong taste, flavor and appetite, long expiration date and edible safety is prepared.

Owner:NINGXIA JINSHANGQI BIOTECH

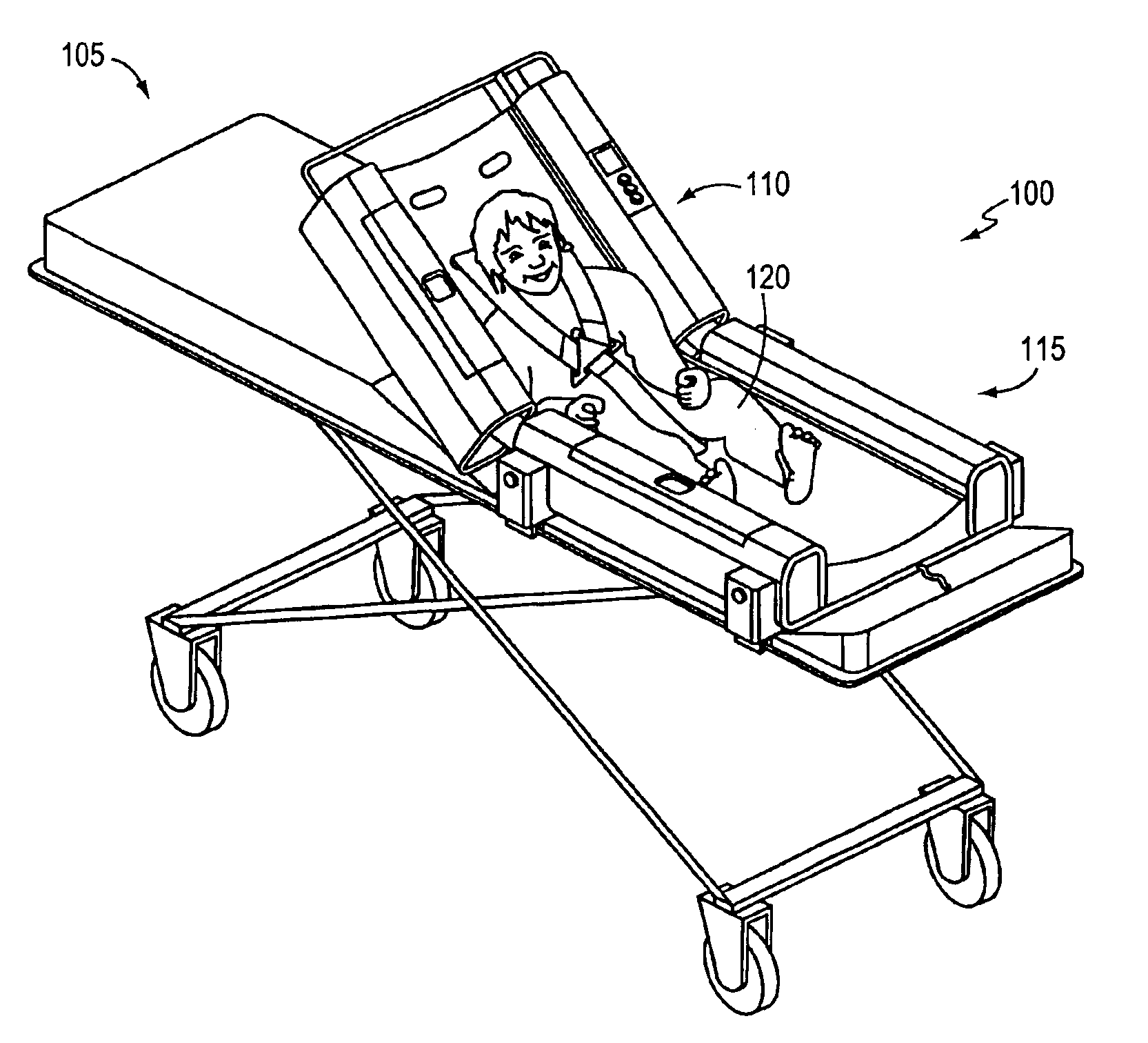

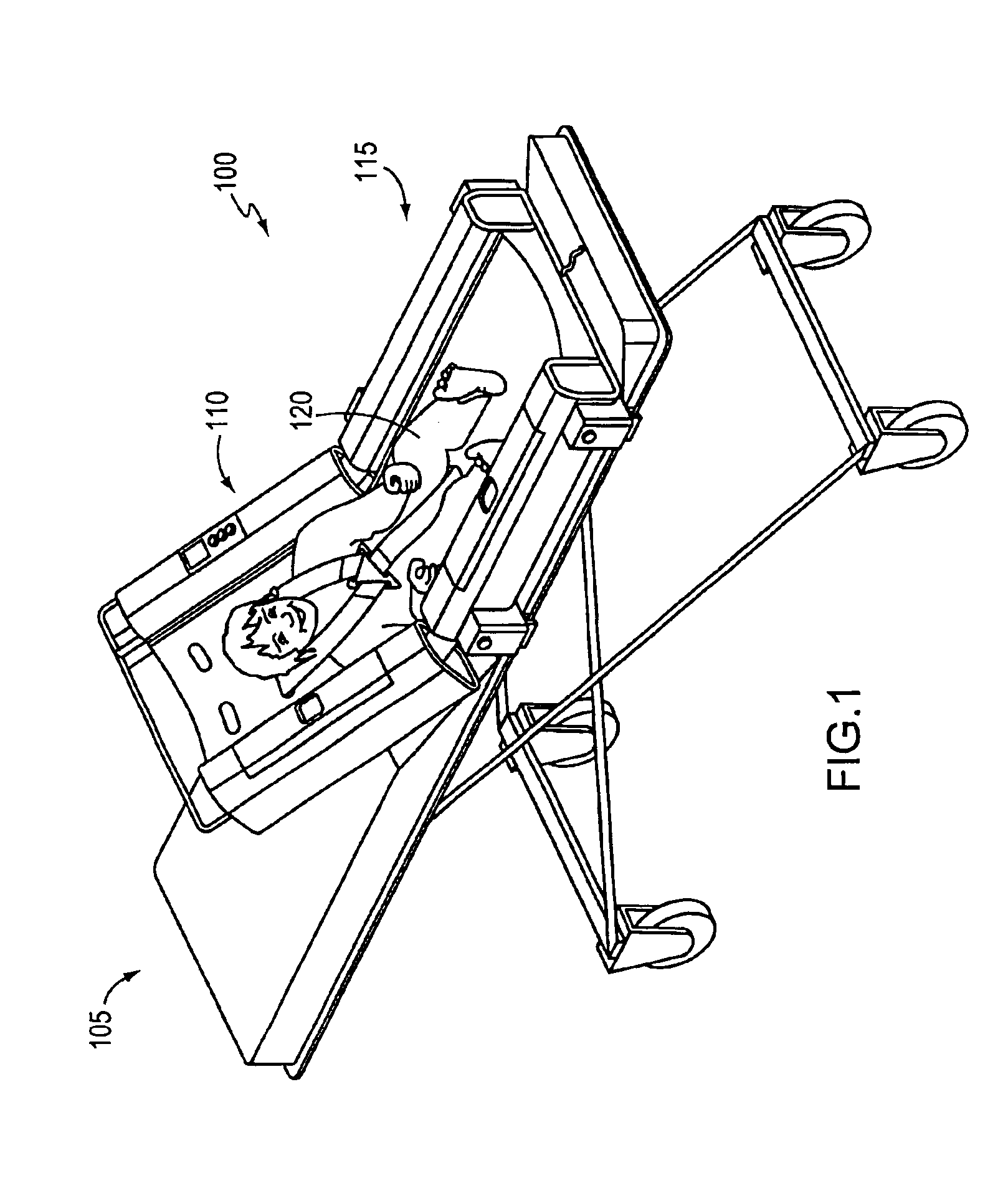

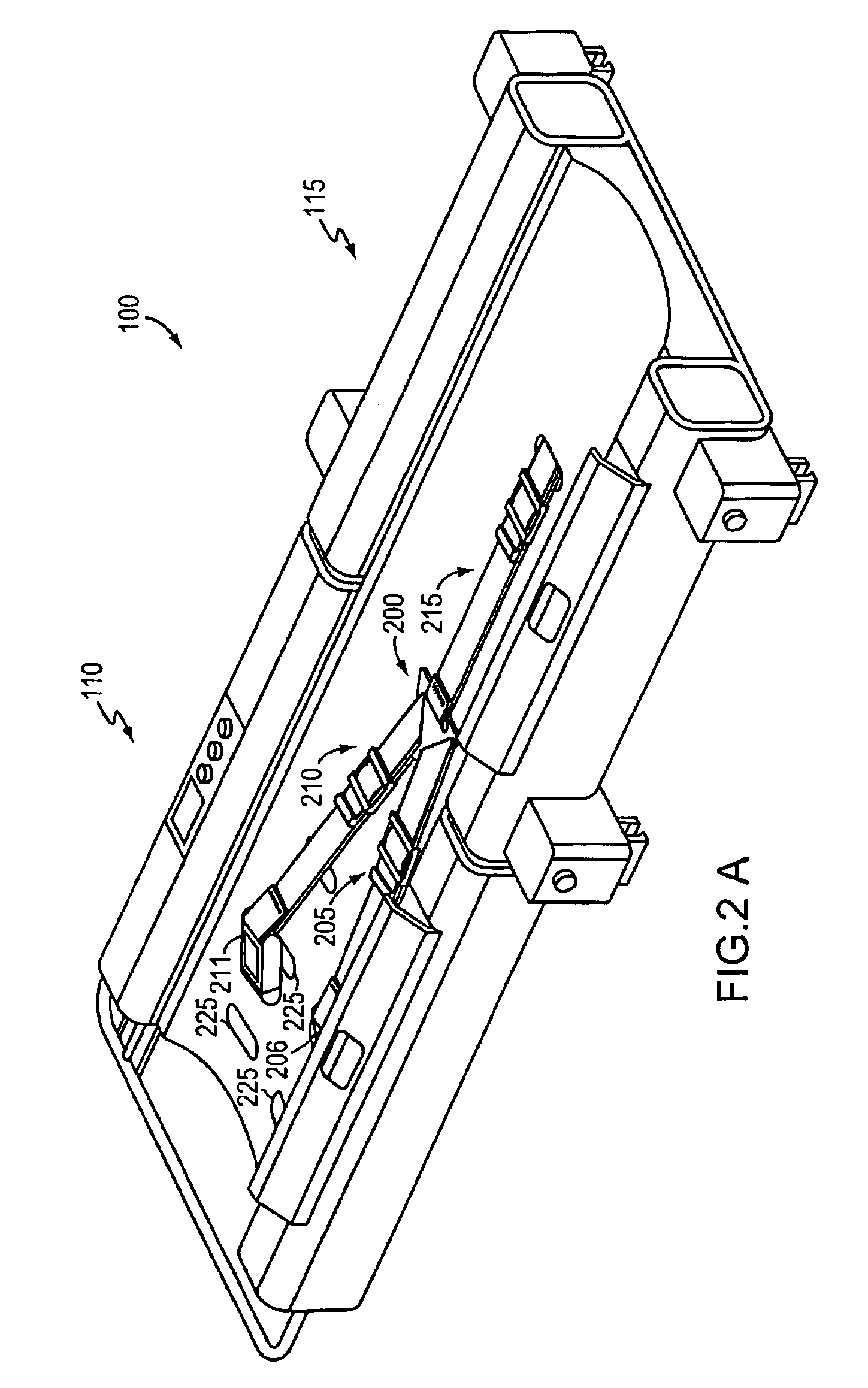

Device for emergency transport of pediatric patients

InactiveUS6898811B2Effectively aid in administration of medical procedureAdd equipmentStretcherSofasPediatric patientDevices fixation

A device for emergency transport of pediatric patients that safely and efficiently transports a pediatric patient to a medical facility. To confine the patient to the device frame, it includes a child restraint in the form of a restraining belt assembly. The device accommodates children of varying size using the restraining belt assembly. The device also includes a hinge assembly that controls the relative rotation of portions of the frame. A clamp that can releasably attach to an object with a rail, such as a medical transport device is also described. To increase efficiency, the clamp includes a width accommodation feature and a universality feature. These features enable it to secure the device to objects of varying shapes and widths.

Owner:SCHNEE SANDY +1

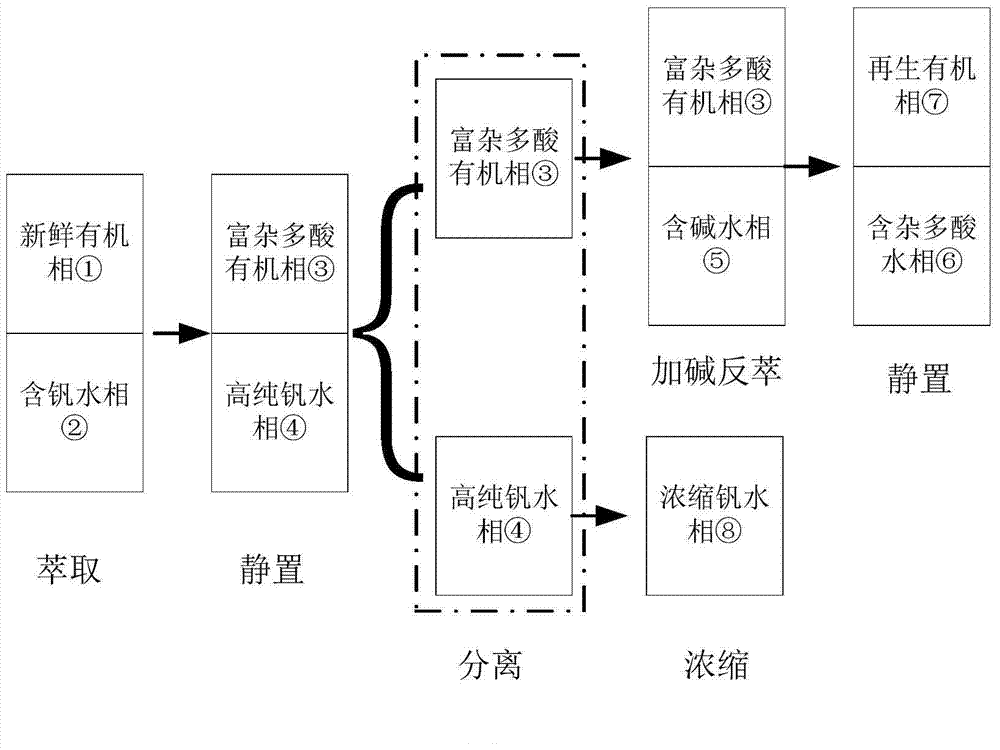

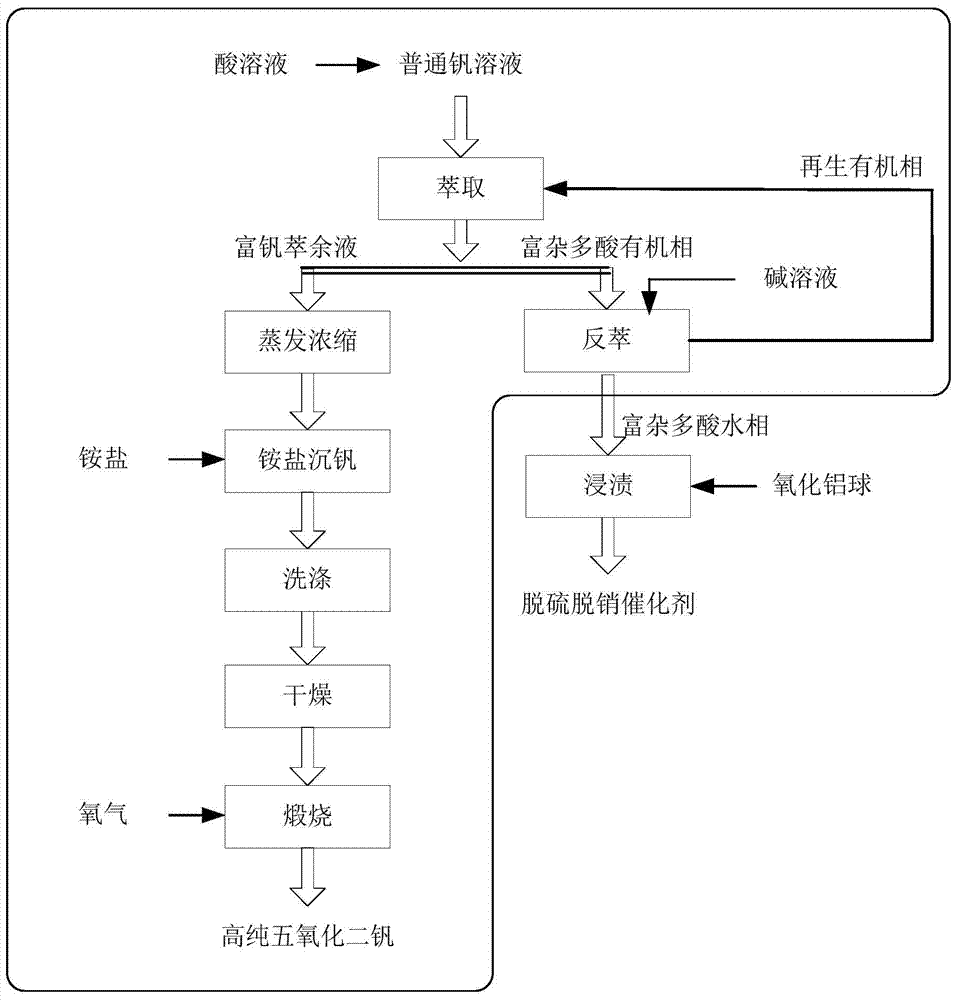

Method for preparing high-purity vanadium from heteropolyacid impurity in amine extraction mode

ActiveCN103540745AIncrease added valueImprove thermal stabilityProcess efficiency improvementAmmonium metavanadateRaffinate

The invention relates to a method for preparing high-purity vanadium from heteropolyacid impurities in an amine extraction mode. Generally an ordinary vanadium solution is doped with impurities such as chromium, silicon, phosphorus, tungsten, molybdenum and arsenic, if acid is added into the solution, heteropolyacids such as phosphorus tungsten, phosphorus vanadium tungsten, silicon tungsten, phosphorus molybdenum tungsten, silicon molybdenum tungsten, molybdenum vanadium arsenic and tungsten arsenic can be formed, the impurities in the solution are removed by carrying out compounding synergic extraction on the heteropolyacids in the ordinary vanadium solution by using amines and a synergist so as to obtain a purified vanadium-containing raffinate, subsequently the vanadium-containing raffinate is evaporated and concentrated to be the concentration that each liter of the solution contains 40g vanadium, ammonium salt is further added into the concentrated liquid to obtain ammonium metavanadate solid, vanadium pentoxide with the purity greater than 99.9% is obtained through washing in pure water, drying and calcining in an oxygen atmosphere, the organic phase after the heteropolyacid is extracted is subjected to reverse extraction by using an alkali solution so as to form a heteropolyacid water phase, and the organic phase is recycled and circulated. The method has low requirement on equipment, and is simple to operate, key extraction agents are good in thermal stability and not sensitive in acid and alkali, and a recycling and circulating method is simple and easy to be industrialized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

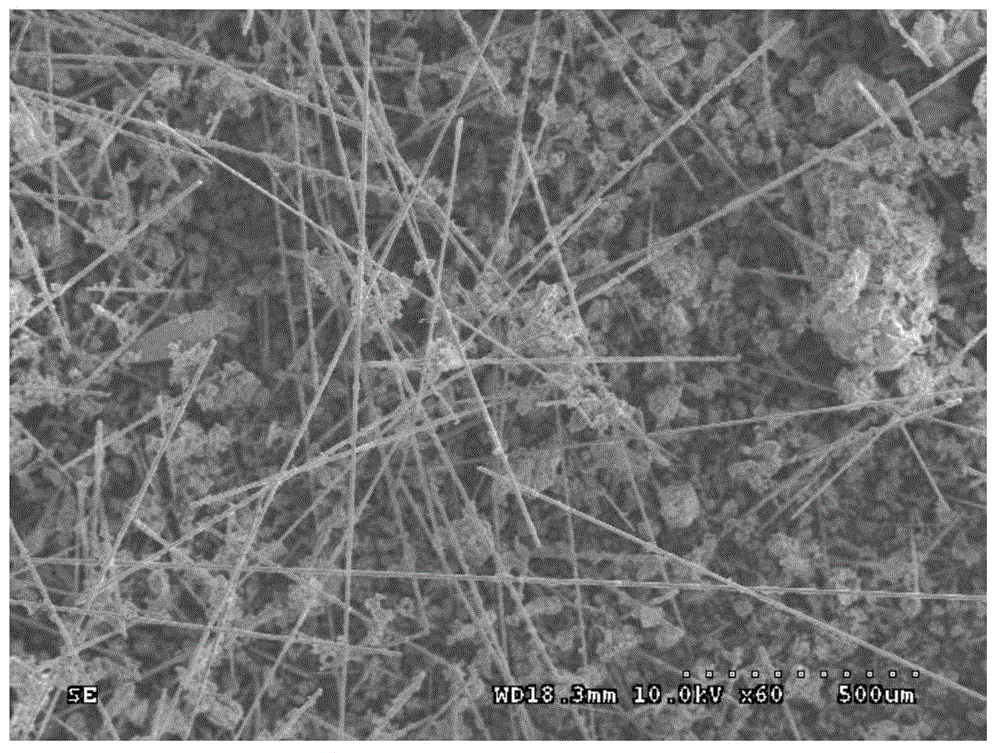

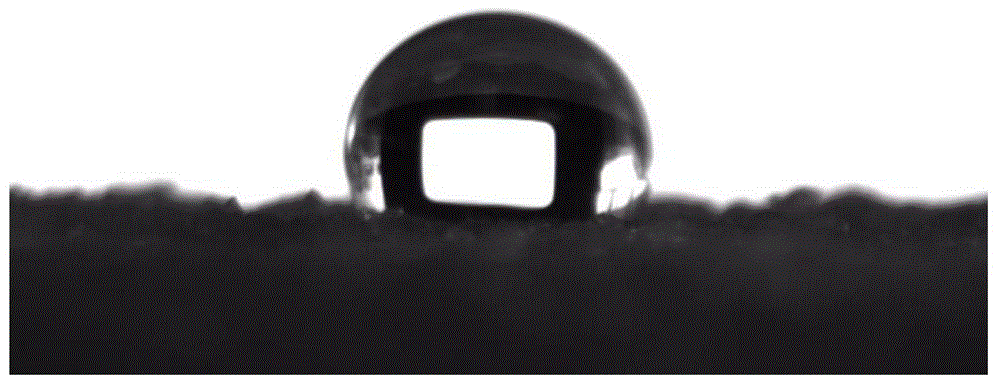

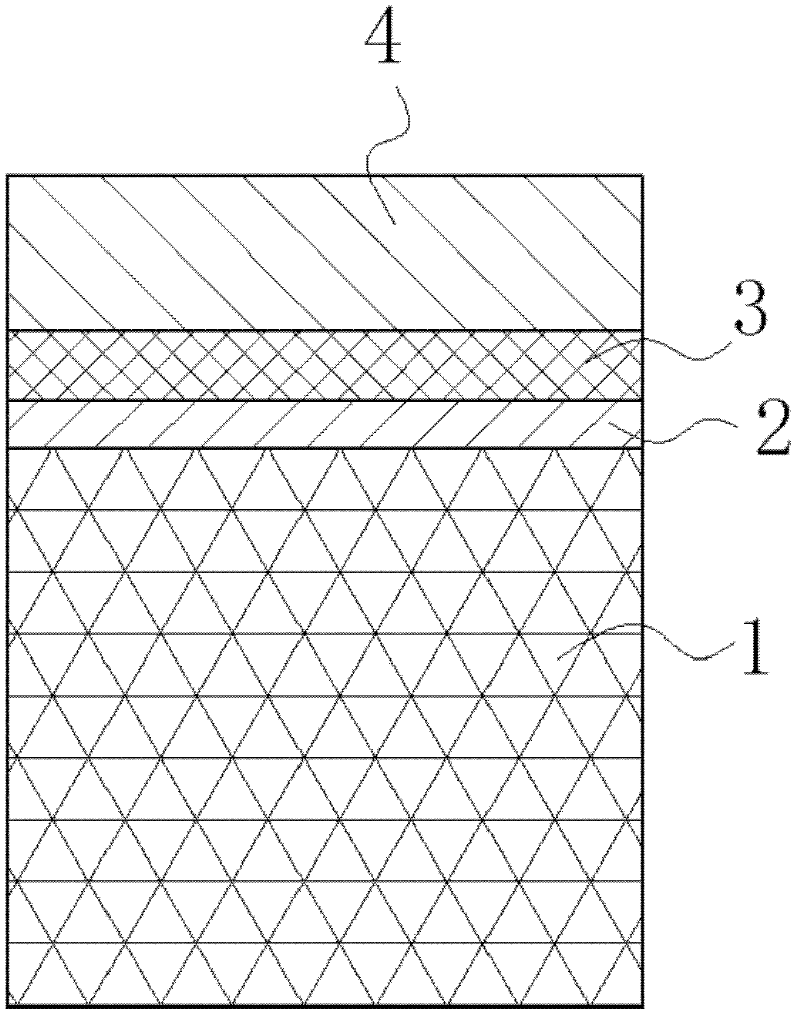

Preparation method of fiber felt enhanced silica aerogel composite panel

The invention discloses a preparation method of a fiber felt enhanced silica aerogel composite panel. The method comprises the following steps: with industrial-grade water glass as a silicon source, carrying out alkylation on a silica gel surface with a silane modifier, and drying at ordinary pressure, so as to prepare silicon dioxide aerogel particles; mixing and doping the prepared silica aerogel powder with hot melt adhesive powder in a fiber felt at the ratio, and carrying out thermo-compression formation, so as to prepare the silica aerogel composite panel, wherein the mass content of aerogel is 39%-61%; the density of the composite panel is 98-260kg / m<2>; the compressive strength can be up to 2.9-3.7MPa; the breaking strength is 1.9-3.3MPa; the heat conductivity coefficient is less than 0.023-0.035W / (m.K); and the hydrophobic angle reaches 129-153 DEG. The preparation method is low in silicon source cost, simple in synthetic process, and low in equipment demands; the prepared silica aerogel composite panel does not come off; and the fiber felt enhanced silica aerogel composite panel has self-supporting ability, and can be applied to the fields of heat preservation, heat insulation, fire protection, sound isolation, oil absorption and the like.

Owner:中知在线股份有限公司

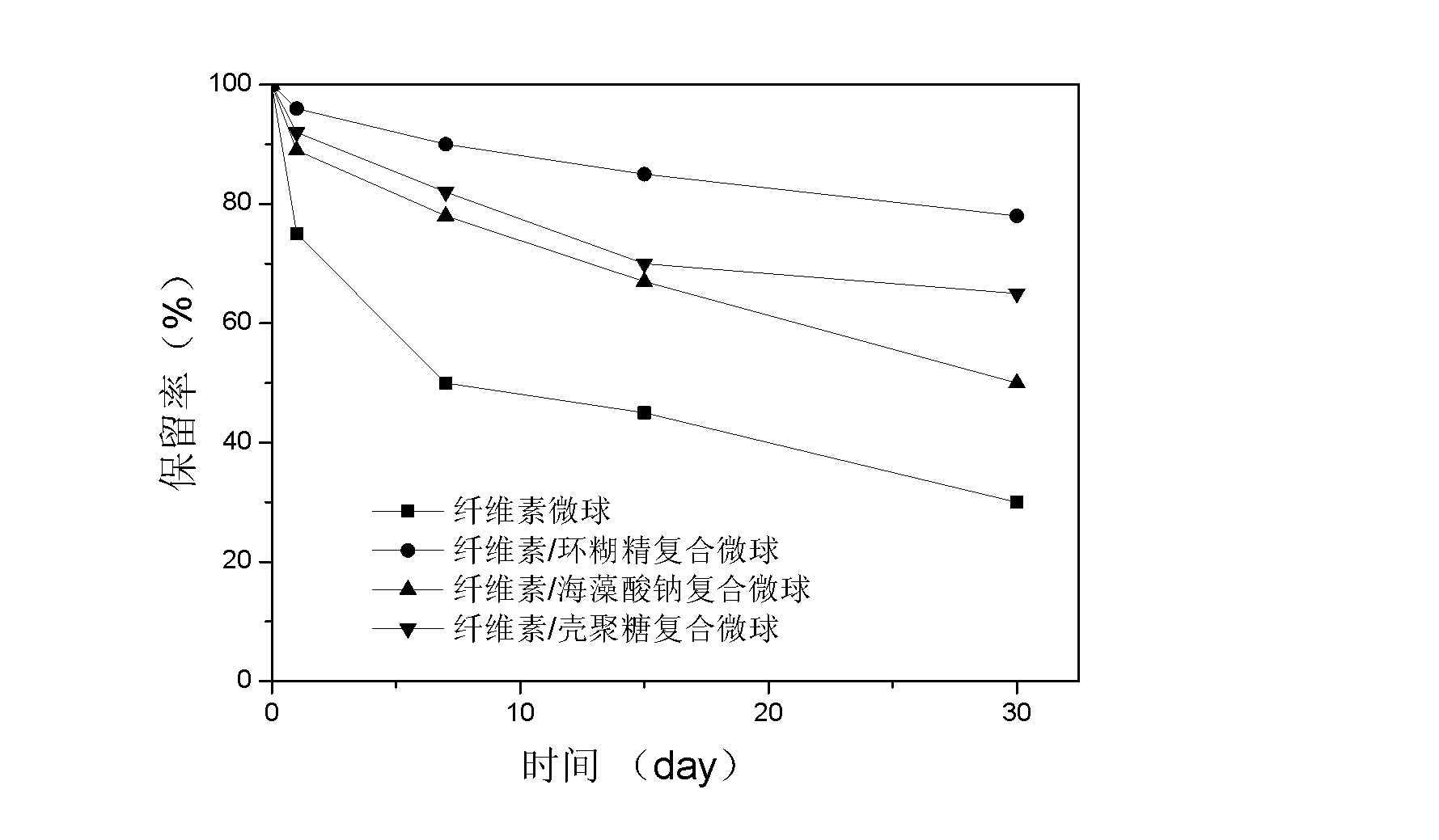

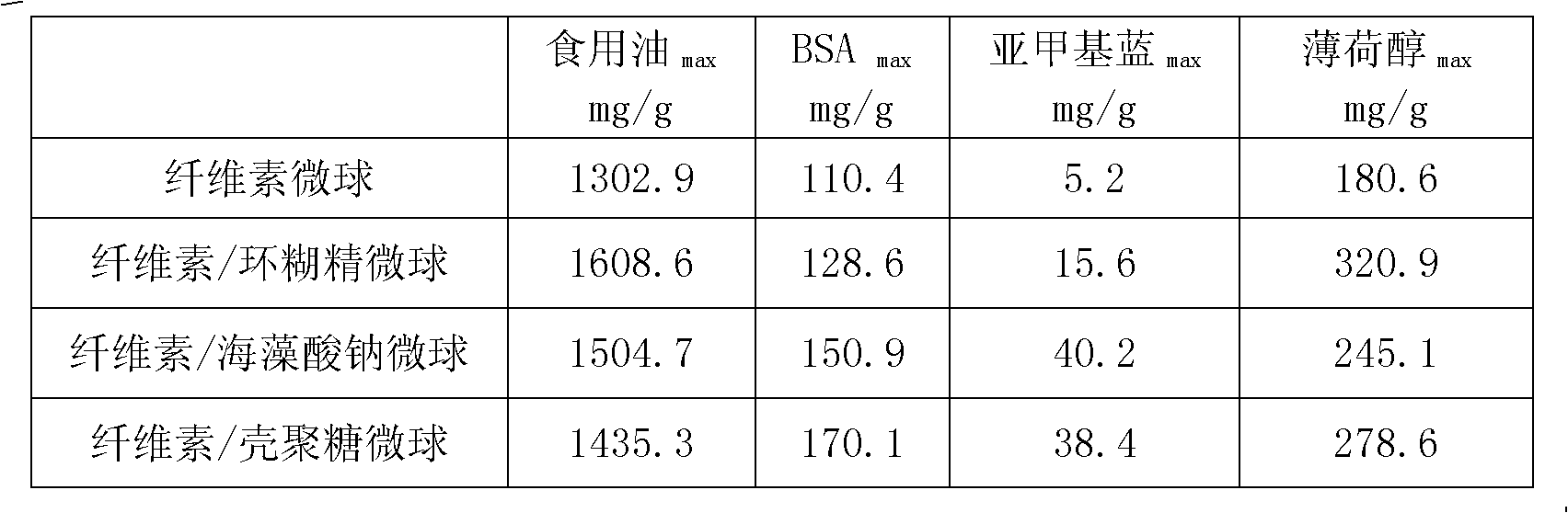

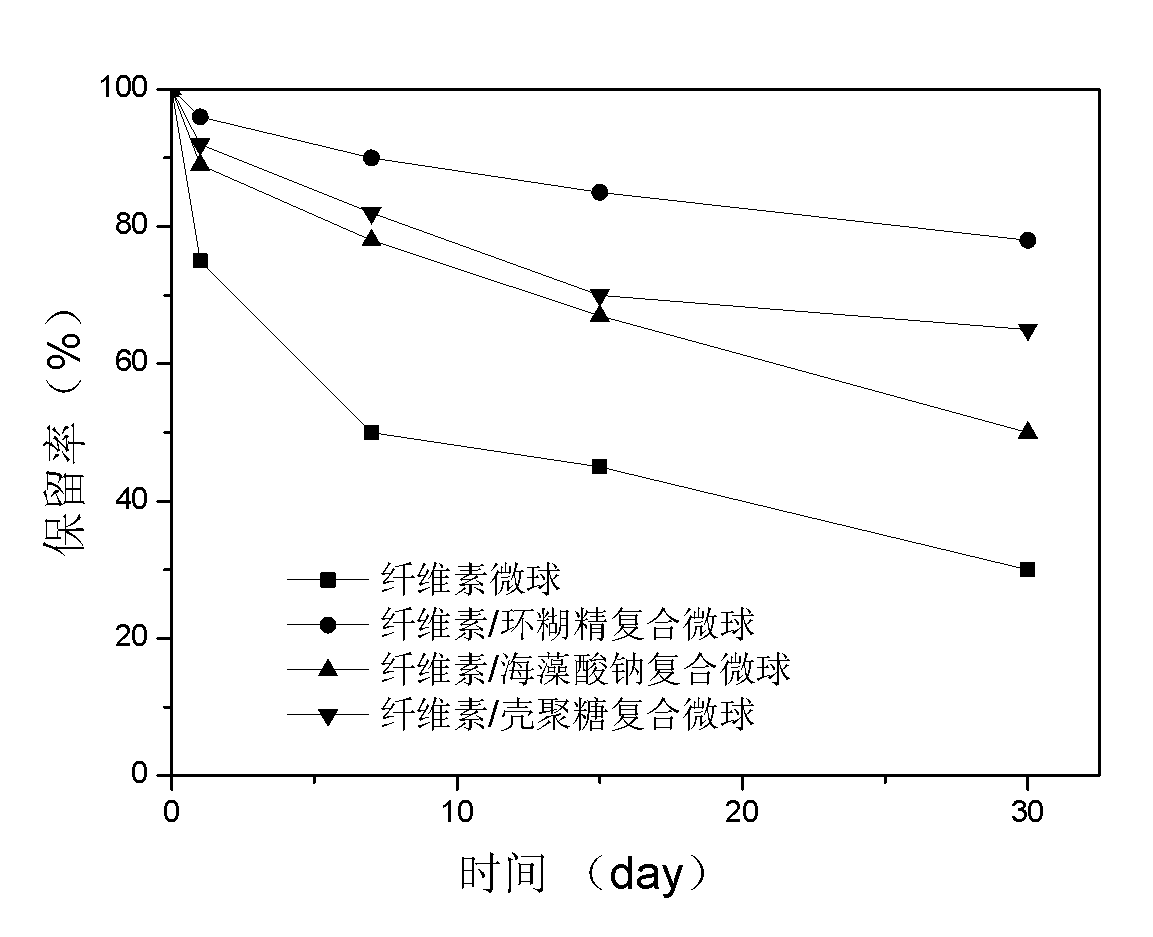

Cellulose composite microsphere and preparation method thereof

InactiveCN102553545ALarge specific surface areaHigh porosityOther chemical processesAlkali metal oxides/hydroxidesSolventUrea

The invention discloses a cellulose composite microsphere, a preparation method thereof and application. The particle size of the cellulose composite microsphere is 1mum-1200mum, the specific surface area of the cellulose composite microsphere is 100m<2> / g-500m<2> / g, and the aperture of the cellulose composite microsphere is 200nm-900nm. The preparation method comprises the following steps of: preparing a mixture solution of cellulose and a composite material by using the cellulose as a matrix, a polymer material as composite material and a water solution of alkali / urea or alkali / thiourea as a solvent, and obtaining the cellulose composite microsphere through sol-gel phase transition and cross-linking agent cross linkage. The advantages of cellulose microsphere are reserved by the cellulose composite microsphere, and due to the adding of the composite material, new functional groups are simultaneously added for the surface of the microsphere and further decoration and modification are facilitated. An organic solvent used in the preparation method disclosed by the invention can be reused, the whole preparation technology is simple, low in time consuming, undemanding for equipment and convenient for industrial production, and the prepared cellulose composite microsphere has a good flow property and mechanical property and a wide application.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

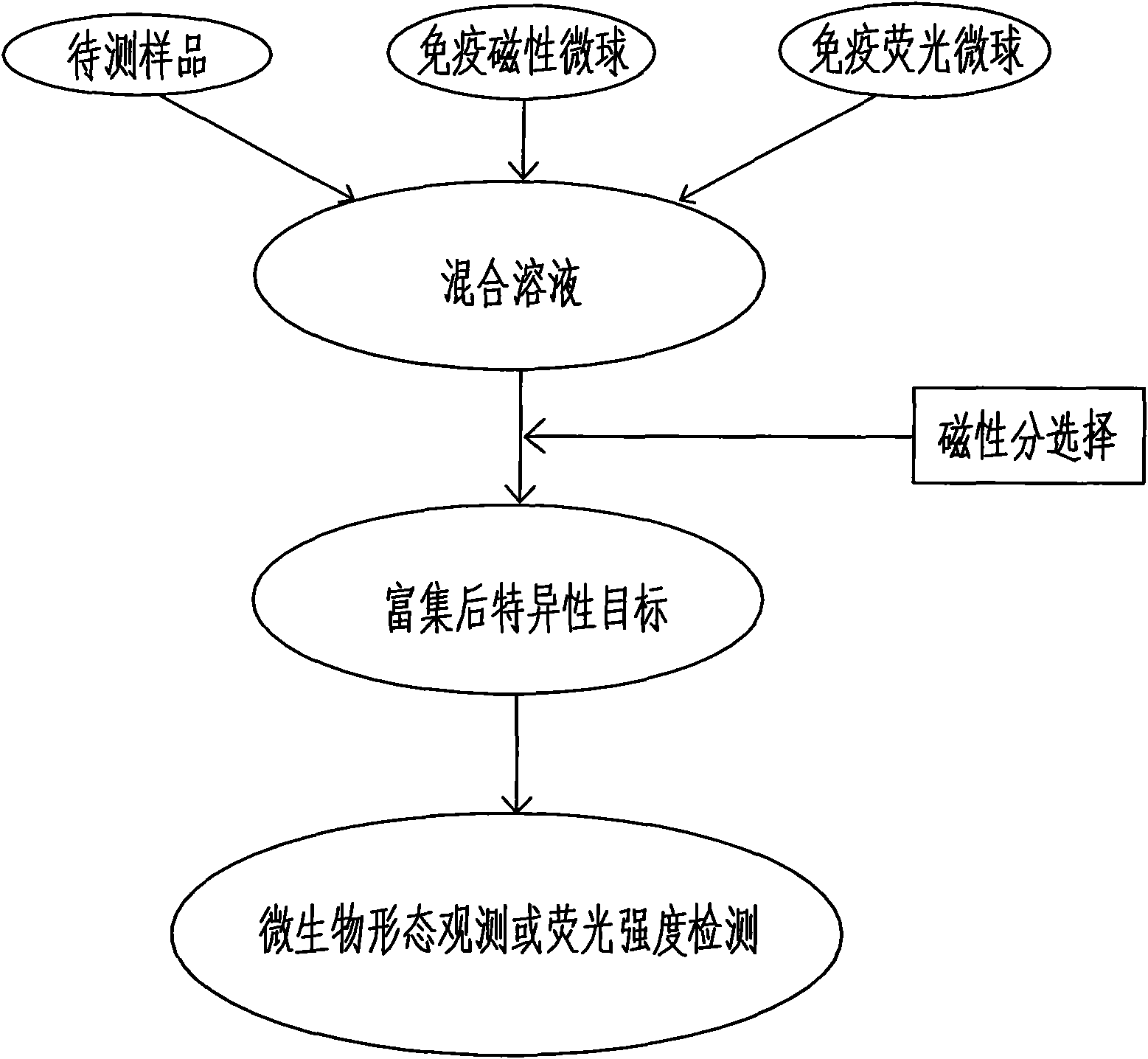

Magnetic fluorescent kit for rapidly detecting microbes as well as preparation method and use method thereof

InactiveCN102253193AEfficient separationRapid Quantitative AnalysisBiological testingFluorescence/phosphorescenceImmunofluorescenceMicrosphere

The invention discloses a magnetic fluorescent kit for rapidly detecting microbes as well as a preparation method and a use method thereof. The kit comprises two components: 1) immunomagnetic microspheres specifically bound with the microbes to be detected; and 2) immunofluorescent microspheres specifically bound with the microbes to be detected. The preparation method comprises the following steps: (1) preparation of the immunomagnetic microspheres; and (2) preparation of the immunofluorescent microspheres. The use method comprises the following steps: (1) adding the sample to be detected, lyophilized powder of the immunomagnetic microspheres and the immunofluorescent microspheres to a buffer solution; (2) ensuring the surfaces of the identified microbes to have antigenic determinants simultaneously bound with the immunomagnetic microspheres and the immunofluorescent microspheres; (3) enriching the microbes bound with the immunomagnetic microspheres through magnetic separation of the immunomagnetic microspheres; and (4) qualitatively and quantitatively judging the microbes by measuring the fluorescence intensity of the immunofluorescent microspheres bound with the separated and enriched microbes. The kit, the preparation method and the use method have the advantages of rapidness, quantitative property and wide scope of application.

Owner:EMERGING THERAPEUTICS SHANGHAI CO LTD

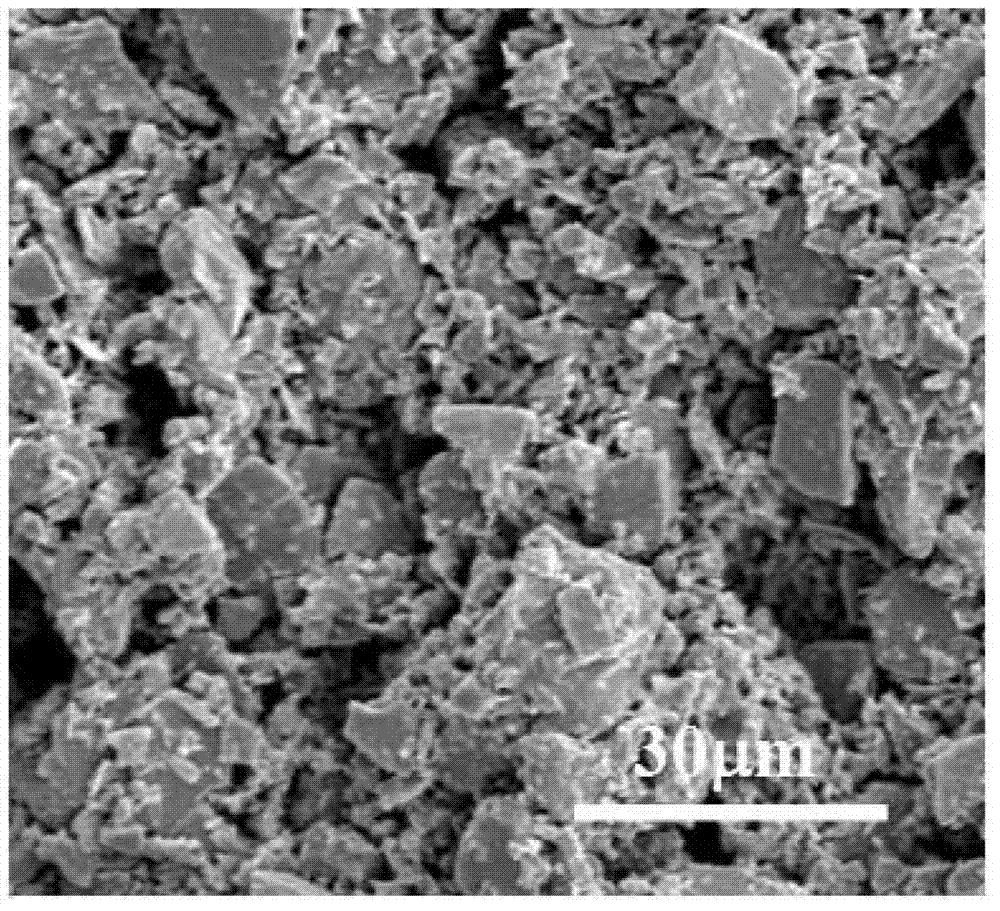

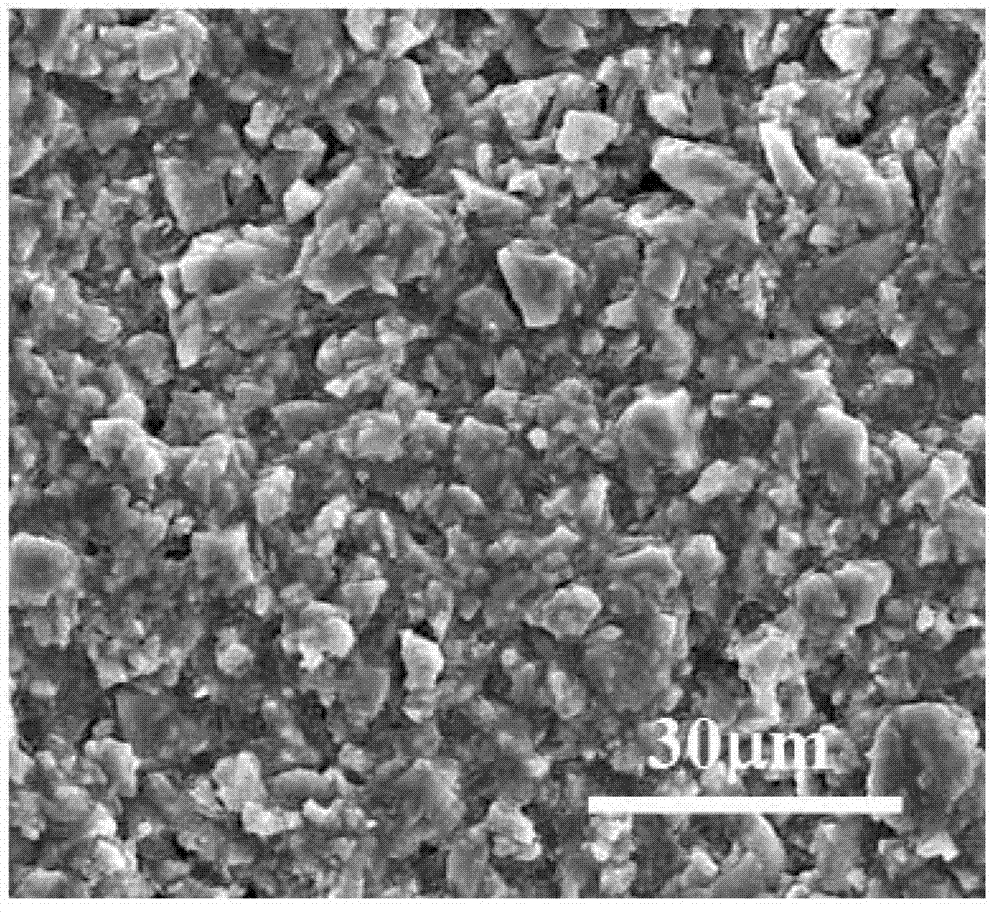

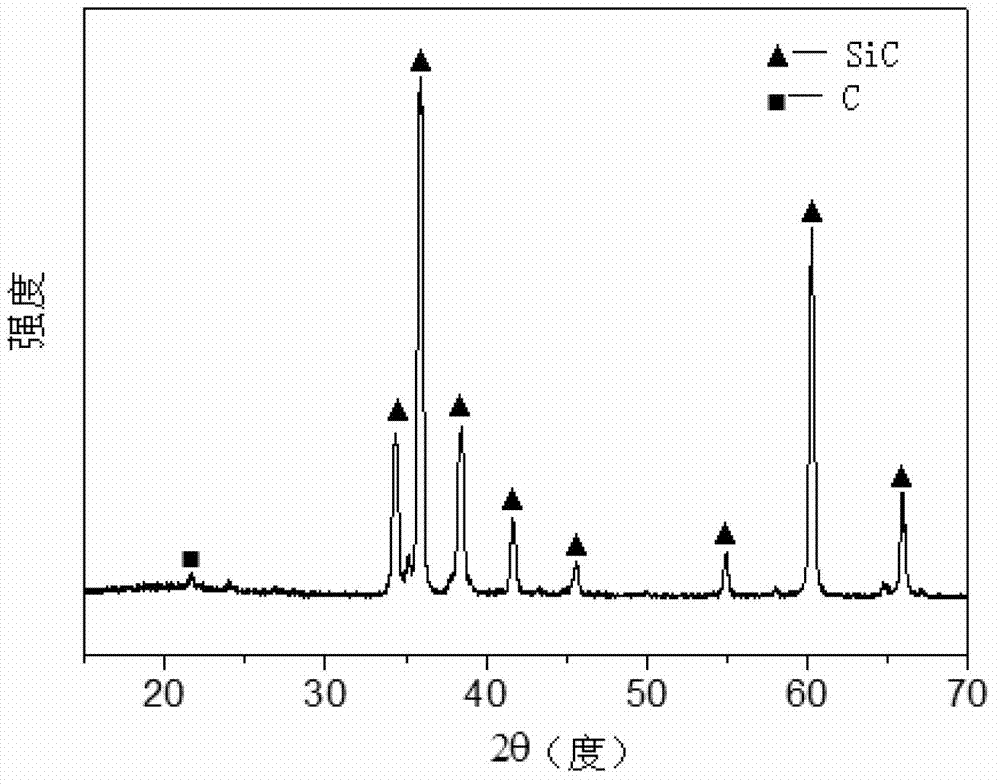

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

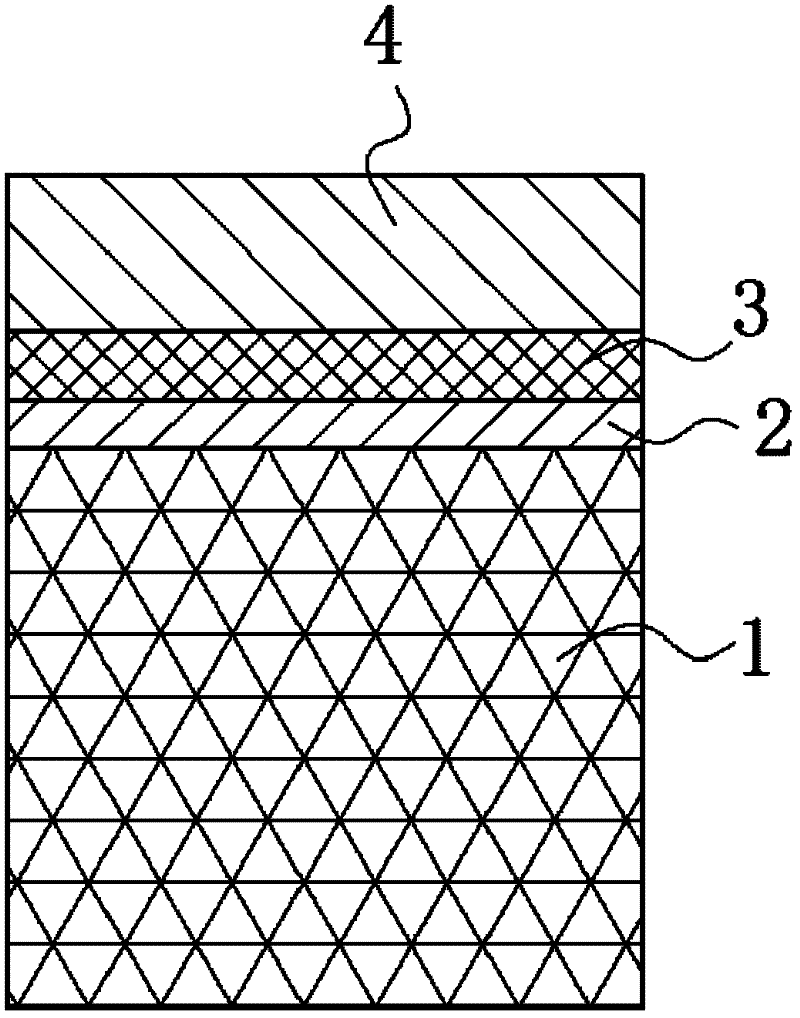

Multilayer silicon nitride antireflection film of crystalline silicon solar cell and preparation method of multilayer silicon nitride antireflection film

InactiveCN102339872AImprove conversion efficiencyImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingCrystalline siliconSemiconductor

The invention discloses a multilayer silicon nitride antireflection film of a crystalline silicon solar cell and a preparation method of the multilayer silicon nitride antireflection film, belonging to the technical field of manufacturing of semiconductor crystalline silicon and solar cells. The multilayer silicon nitride antireflection film comprises at least three silicon nitride films which are deposited on a silicon substrate, the refraction indexes of all the silicon nitride films are sequentially reduced from bottom to top, and the thicknesses of all the silicon nitride films are sequentially increased from bottom to top. According to the invention, the passivation effect of a coating film is effectively improved, the antireflection effect of the antireflection film is improved, thepassivation effect of the antireflection film is enhanced, and the photoelectric conversion efficiency of the solar cell is increased.

Owner:湖南红太阳新能源科技有限公司

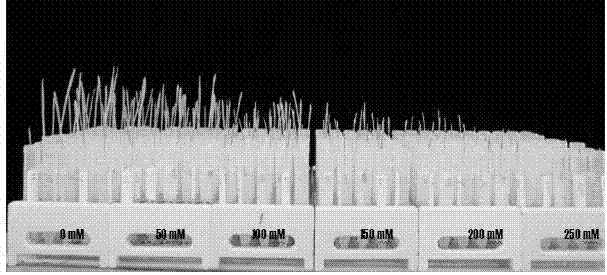

Salt-tolerance determining method for barley at seedling stage

InactiveCN102860159AReduce the impactSimple methodSeed and root treatmentHorticulture methodsAgricultural scienceQuantitative trait locus

The invention relates to a determining method for indicating salt tolerance of different varieties of barleys at seedling stages and belongs to the field of agriculture. The determining method includes adopting a water culturing manner to simulate salt environment artificially, investigating salt damage degree of samples to be tested under the condition of salt stress compared with the blank control condition by measuring seedling height, root length and fresh weight of each seedling of different treatment, and finally determining salt tolerance of the variety. The determining method can be widely applied to screening and evaluation of plant stress resistance genetic resources, particularly used for screening of barley salt-tolerance variety resources, salt-tolerance QTL (quantitative trait locus) genetic analysis, salt-tolerance gene positioning and seed selection of salt-tolerance barley varieties. The determining method has the advantages of simplicity, easiness in mastering and reliable results, the whole salt-tolerance determining process is under control and is slightly affected by the environment, requirements for equipment are low so that only one common illumination culturing box is required.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Preparation method of hydrogel with adsorption and catalysis functions

ActiveCN103524965AEasy to prepareLow equipment requirementsWater/sewage treatment by irradiationOther chemical processesOrganic dyePrecious metal

The invention discloses a preparation method of a hydrogel with adsorption and catalysis functions. The preparation method comprises the following steps of: preparing the hydrogel, and loading at least one noble metal to a hydrogel carrier; drying the obtained loaded type hydrogel. The preparation process of a loaded type hydrogel material is simple, moderate in condition and suitable for industrial production; an obtained product can be used for effectively degrading the organic dyes which are contained in a water body and include anionic and cationic dyes and still has better catalytic property after being recycled for multiple times.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Wood softener, and preparation method and application thereof

ActiveCN102303332ALow elastic modulusShorten the timeWood treatment detailsWood impregnation detailsPolymer scienceAlcohol

The invention provides a wood softener, wherein components included in the wood softener and the weight percentage of each component are as follows: 10-80% glycerol, 0.2-3% anionic penetrating agent, and rest being water. The invention also provides a preparation method of the wood softener, wherein the following process is adopted: proportionally and evenly mixing glycerol with anionic penetrating agent and water, and stirring the mixture using a stirrer at 25-40 DEG C and at a speed ranging from 50-200 r / min for 1-3 min. The invention further provides a method for performing softening treatment on the wood, comprising the following steps of: adding the prepared softener to a container; putting small wood pieces in the softener; and heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h. The invention additionally provides a method for processing wood slices, comprising the following steps of: adding the prepared softener to the container; heating to a range of 70-100 DEG C and keeping the temperature for 3-10 h; and then putting the softened wood pieces into mixed solution of absolute ethyl alcohol and anhydrous glycerol, and oscillating for 0.5-5 hours, thereby forming the wood pieces into wood slices. The wood slice is processed by the wood softener, which is used for identifying the type of wood.

Owner:山东省纤维检验局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com