Patents

Literature

79results about How to "Good charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

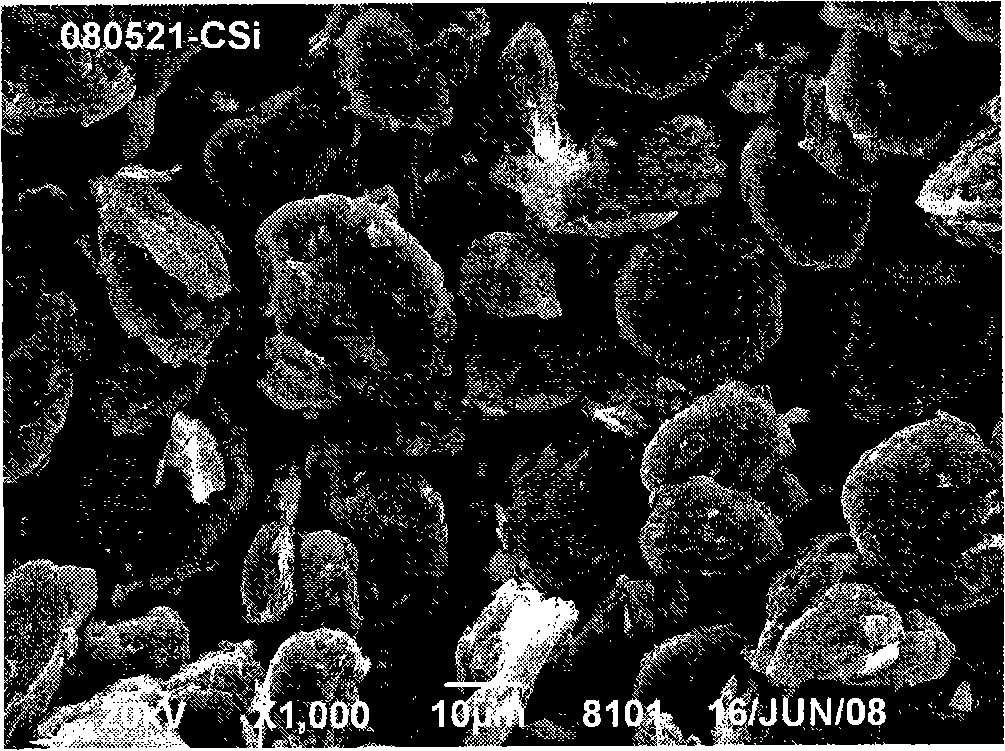

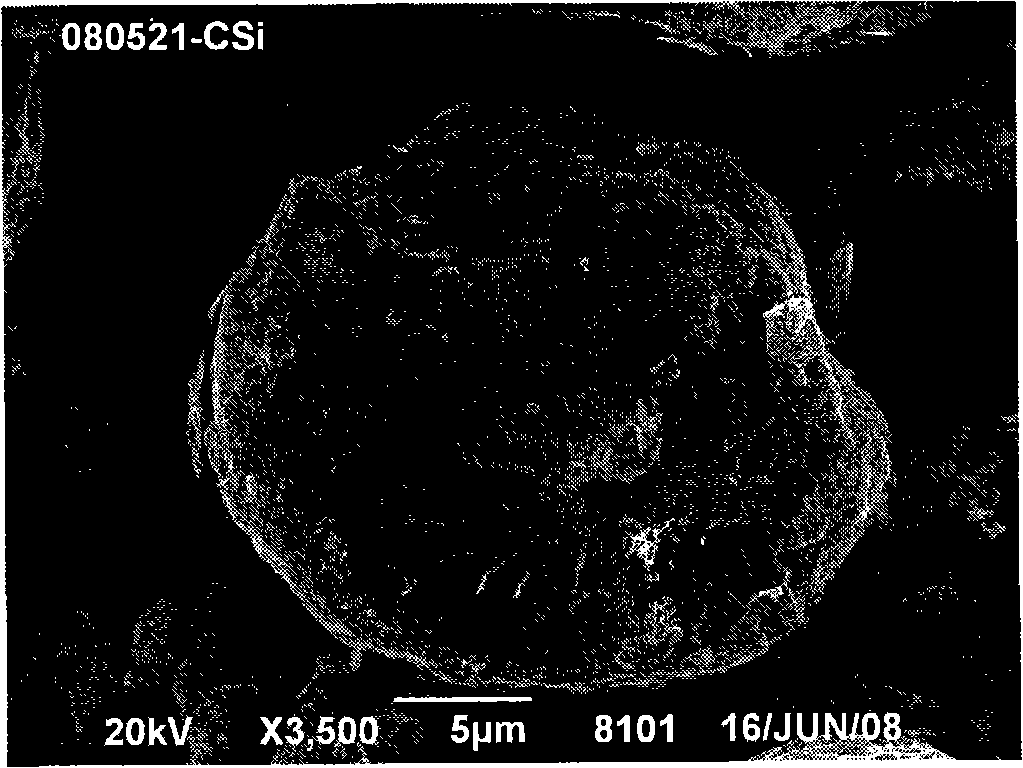

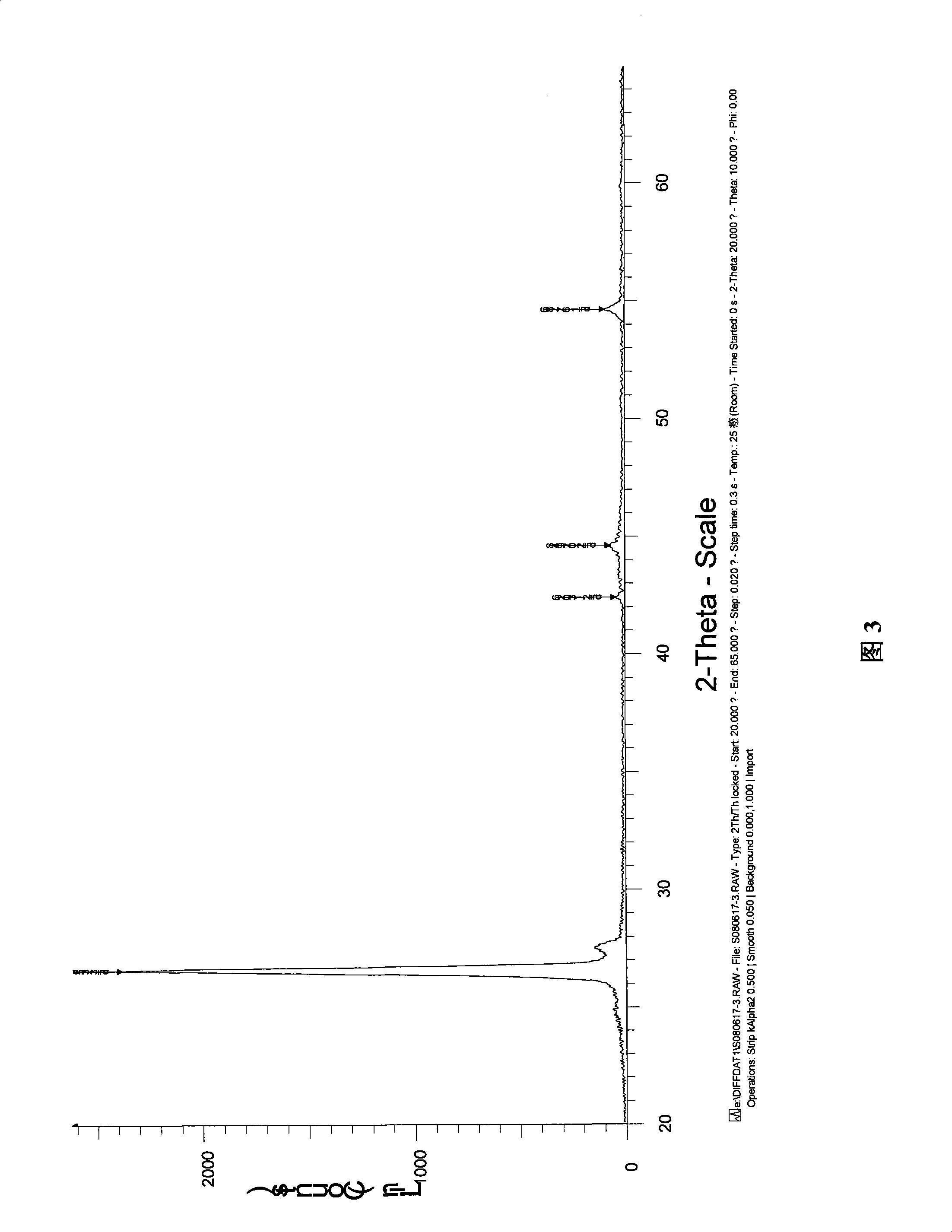

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

Power and energy storage lithium-ion battery and preparation method thereof

ActiveCN103441305AImproved gram capacity playIncrease capacityFinal product manufactureElectrolyte accumulators manufactureGramEngineering

The invention relates to a preparation method of a power and energy storage lithium-ion battery. A negative active substance of the power and energy storage lithium-ion battery comprises soft carbon, hard carbon, a mixed material of soft carbon and graphite and a mixed material of hard carbon and graphite. The designing method of the battery comprises the steps of designing the gram volume of the negative active substance as the primary lithium-embedding gram volume, designing the gram volume of the positive active substance as the primary lithium-removal gram volume, designing the ratio of the capacity of the positive electrode and the capacity of the negative electrode to be (1: 1) to (1.5: 1). By adopting the designing method, the capacity and comprehensive performance of the battery can be remarkably improved, and excellent lithium-embedding and lithium-removal capacity of the soft carbon material and the hard carbon material can be adequately exerted. Compared with the existing lithium battery technology, the prepared power lithium battery has long service life, high multiplying power, high safety performance and excellent low-temperature performance and can be widely applied to the fields such as electric tools, various portable devices, spaceflight, starting power supply and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

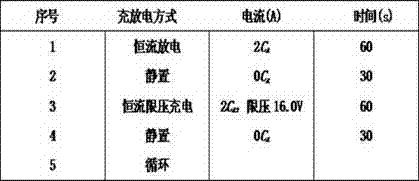

Lithium ion secondary battery

ActiveCN101958428AImprove cycle performance and safety performanceGood charge and discharge performanceCell electrodesFinal product manufactureElectrochemistryLithium electrode

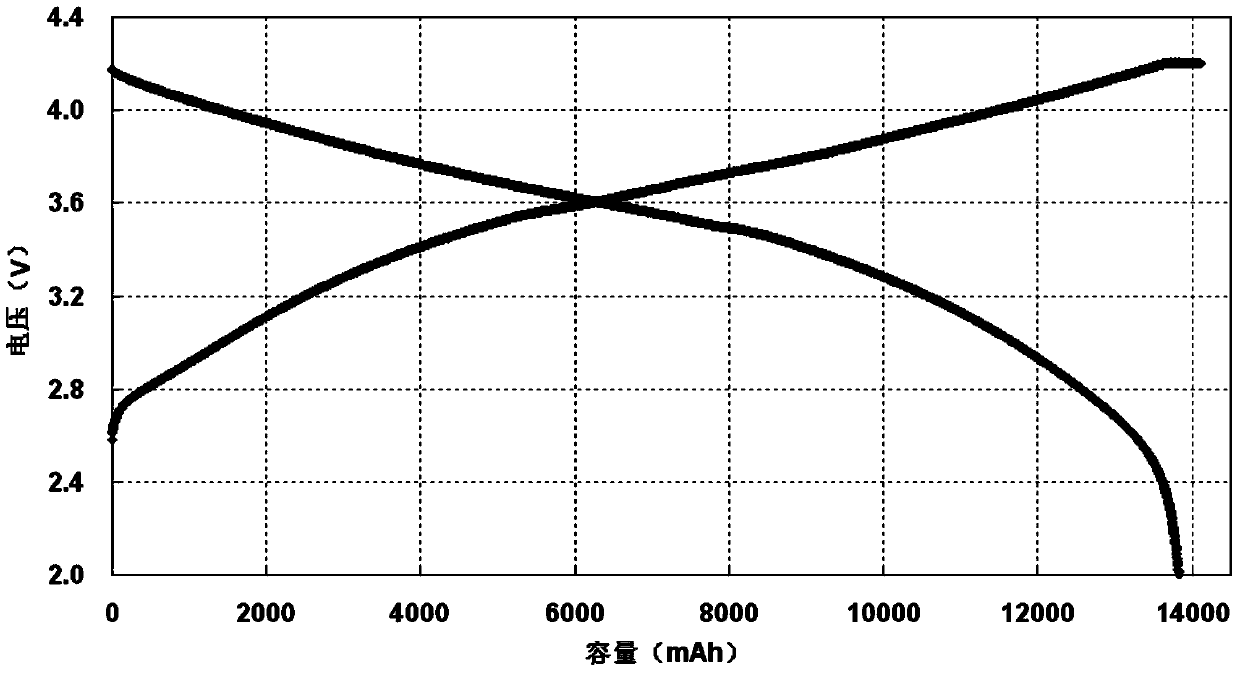

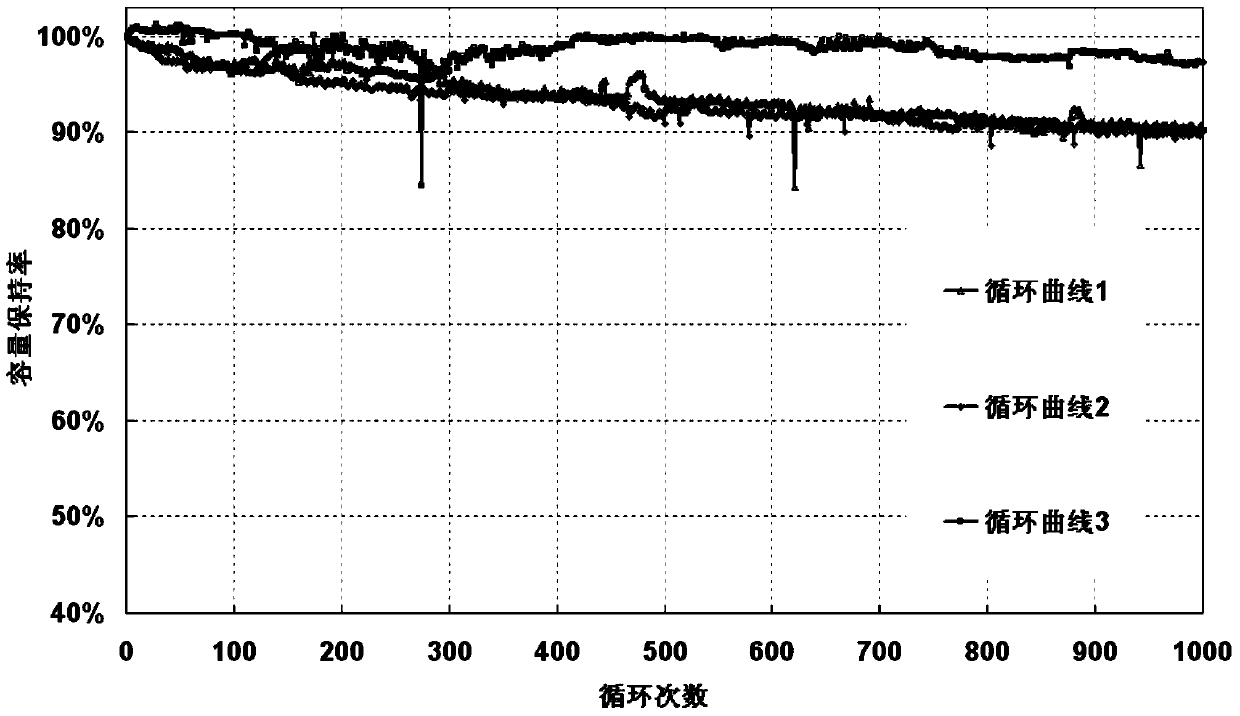

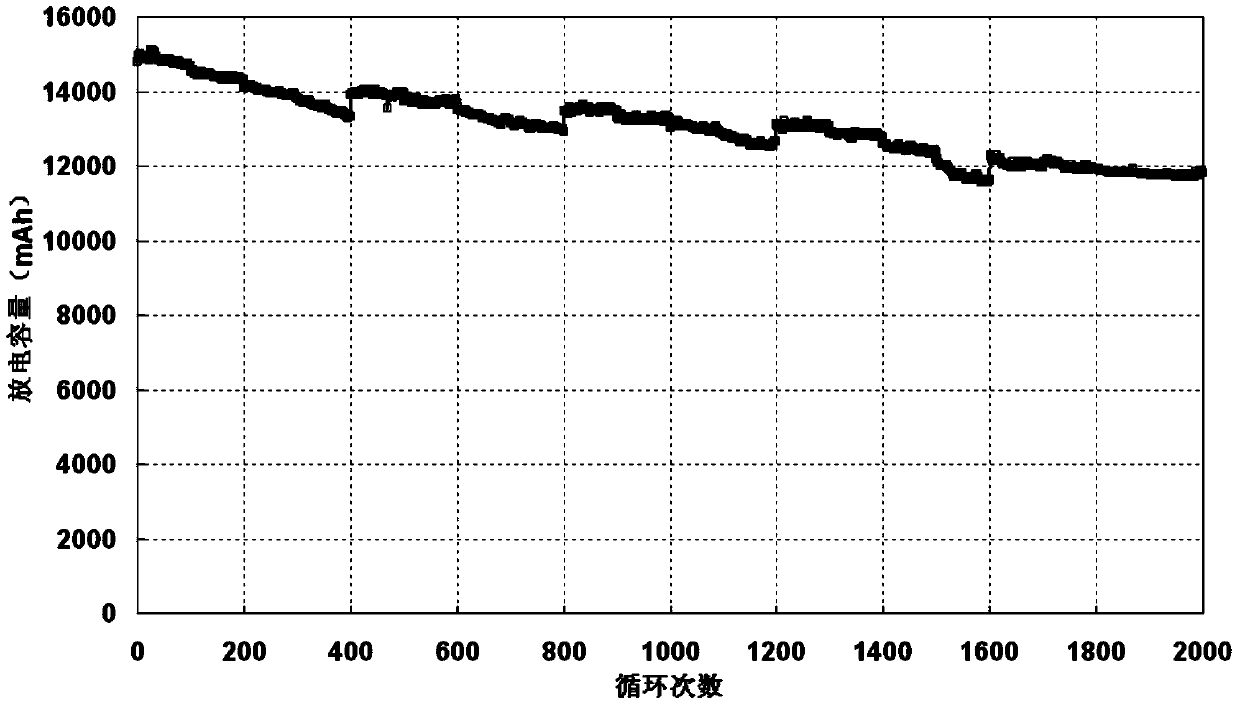

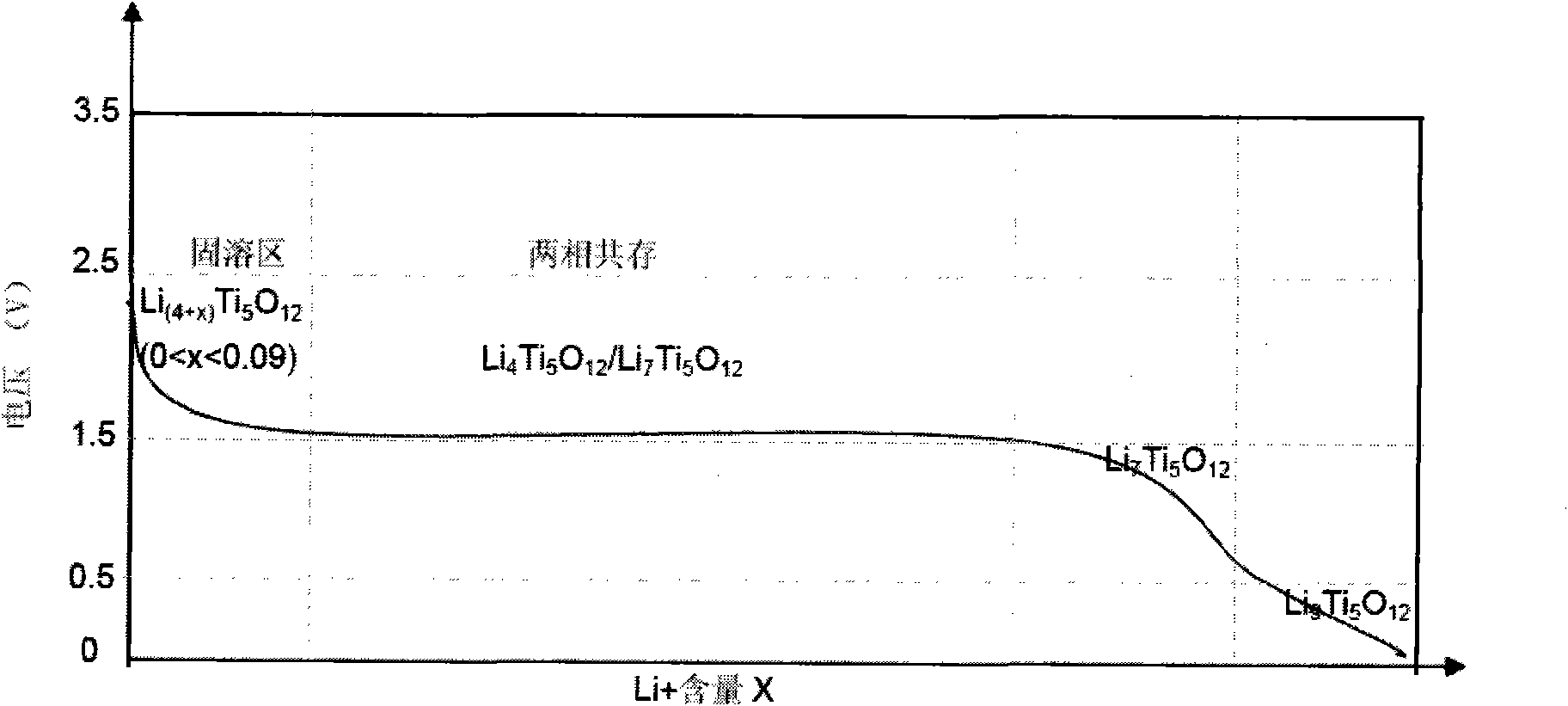

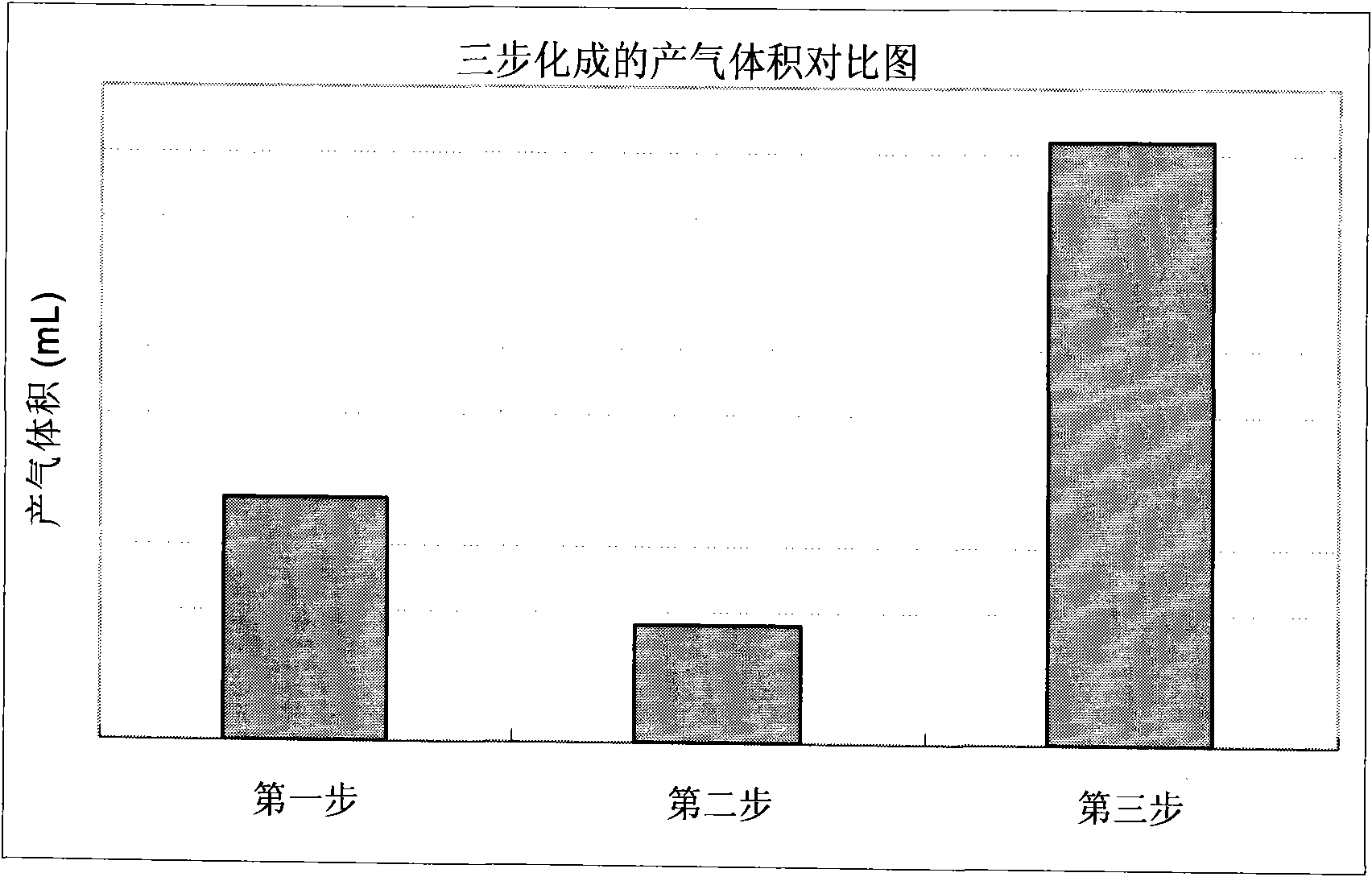

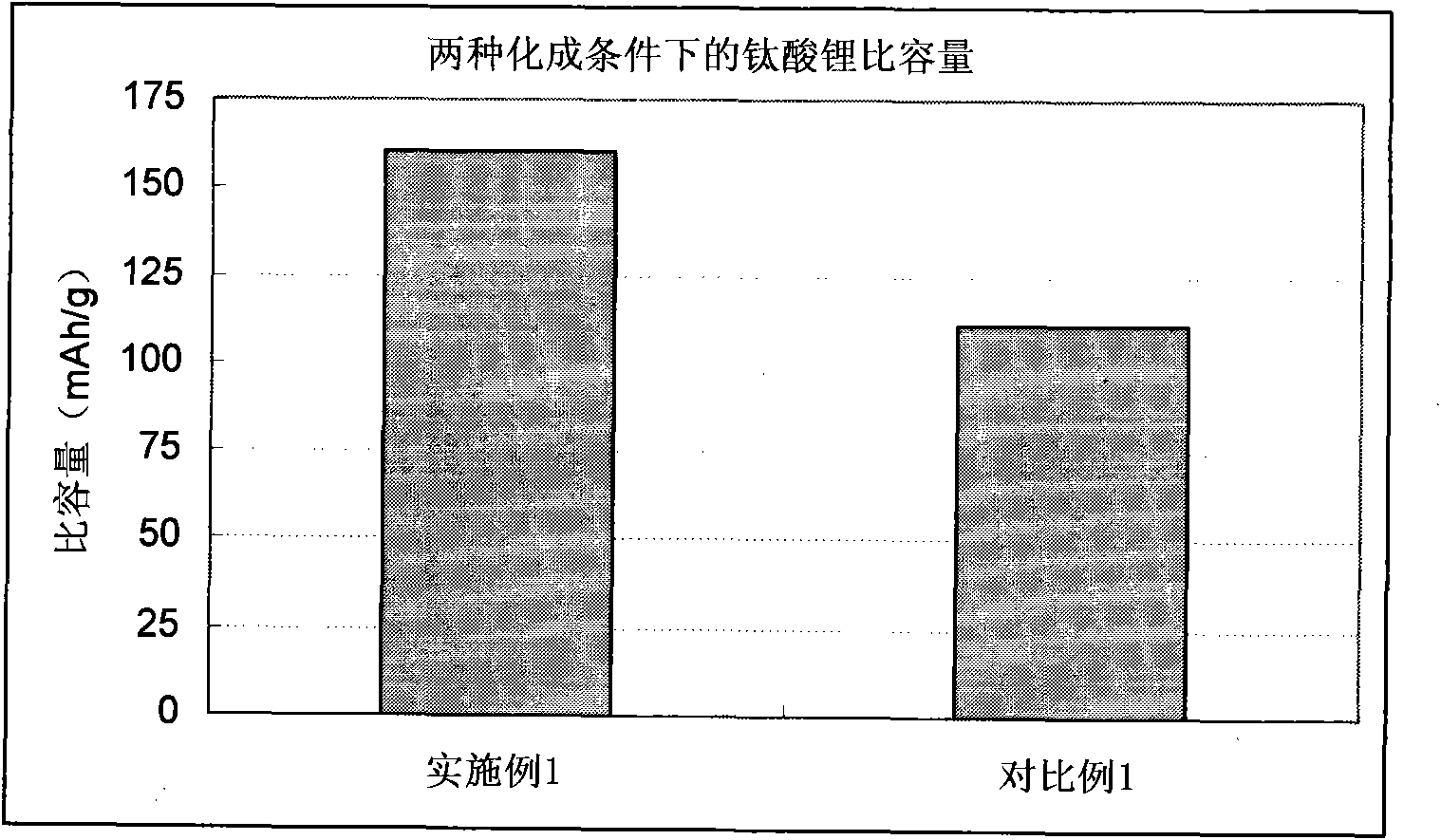

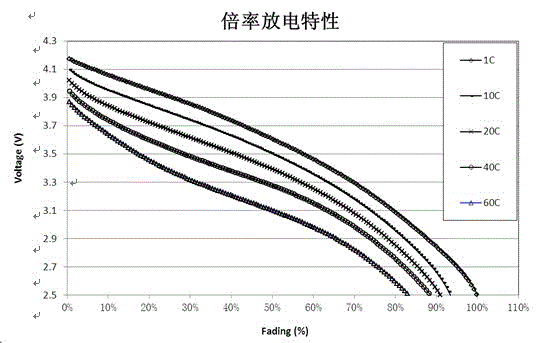

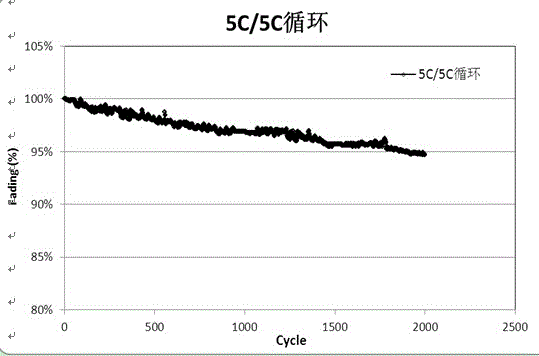

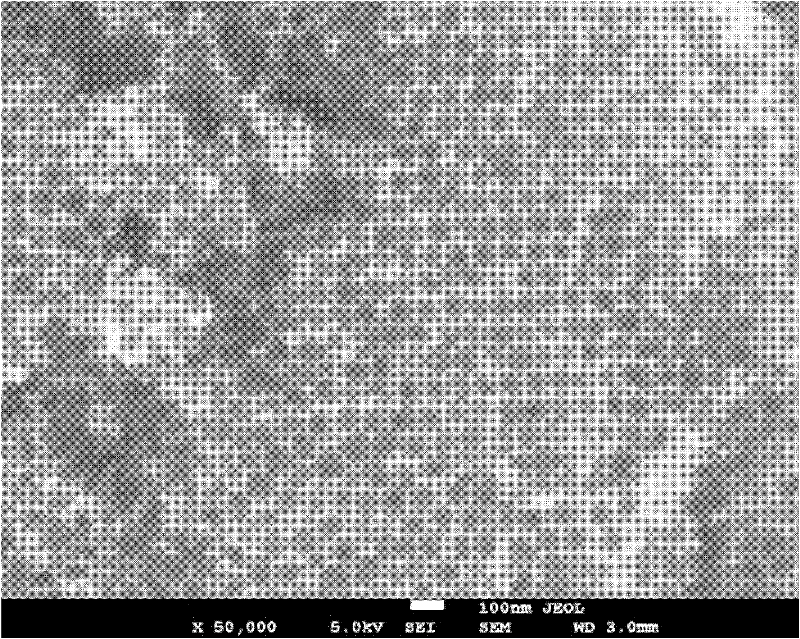

The invention belongs to the technical field of lithium ion batteries, and particularly discloses a lithium ion secondary battery. The lithium ion secondary battery comprises a cathode, an anode, an isolation membrane and electrolyte, wherein the cathode comprises cathode active substance, adhesive and conductive carbon; the anode comprises a lithium titanate active material, adhesive and conductive carbon; base materials for a cathode plate and an anode plate are aluminum foils; and the ratio of the anode capacity to the cathode capacity is 0.70 to 1.00. The lithium ion secondary battery comprises the following activation steps of: 1, charging the battery with constant current of 0.2C to 5C to change lithium titanate into Li4+xTi5O12 from Li4Ti5O12, wherein the x is more than 0.09 and less than or equal to 2.50; 2, charging the battery changed in the first step with constant current of 0.1C to 5C so that the x in the Li4+xTi5O12 is more than 2.50 and less than or equal to 3.00; and 3, charging the battery changed in the second step with constant voltage for 0.2 to 12 hours, and pumping the gas generated in each step until vacuum. The lithium ion secondary battery has excellent electrochemical performance, and meanwhile, the circulation performance and the high-temperature storage performance of the lithium ion secondary battery are improved.

Owner:DONGGUAN AMPEREX TECH

Lithium ion battery capable of being subjected to high-rate charge and discharge and preparation method thereof

InactiveCN102983355AWith high rate charge and discharge characteristicsMeet power requirementsCell electrodesFinal product manufactureFiberHigh rate

The invention discloses a lithium ion battery capable of being subjected to high-rate charge and discharge and a preparation method thereof. The lithium ion battery capable of being subjected to high-rate charge and discharge comprises a positive pole, a negative pole and a diaphragm, wherein the positive pole comprises the following components in percentage by weight: 80-98% of positive active material, 1-19% of conductive agent and 1-19% of binder; the negative pole comprises the following components in percentage by weight: 80-98% of negative active material, 1-19% of conductive agent and 1-19% of binder; the positive active material includes one or two of Li(NiCoMn)O2 and lithium manganate; the negative active material includes one or two of hard carbon and soft carbon; the conductive agent is one of superconducting carbon black, carbon fiber, crystalline flake graphite and a carbon nanotube; and the binder is one of kynar, butadiene styrene rubber, sodium carboxymethylcellulose and hydroxypropyl / carboxymethyl cellulose. According to the lithium ion battery capable of being subjected to high-rate charge and discharge and the preparation method thereof disclosed by the invention, the lithium ion battery has high-rate charge and discharge characteristics, and is good in charge and discharge characteristics, wide in temperature application range, excellent in low-temperature charge performance, long in cycle life and high in safety.

Owner:TIANJIN ENERGIES

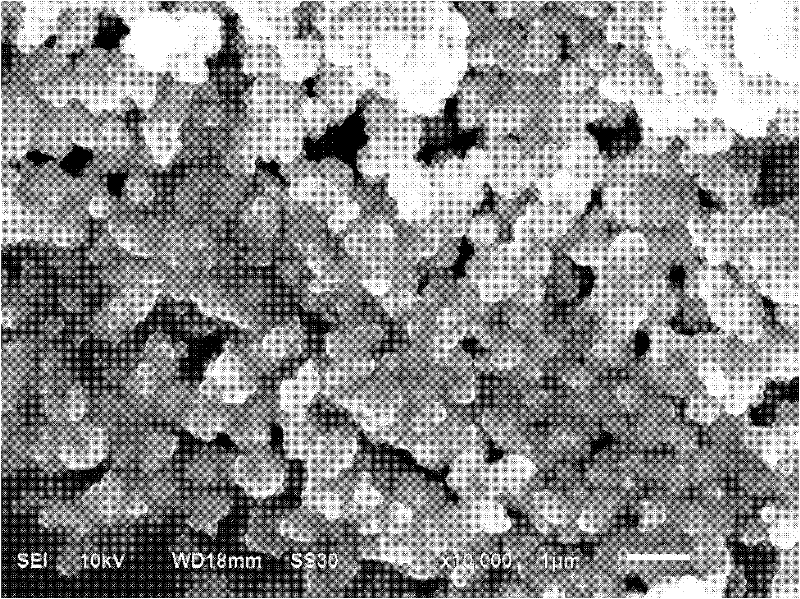

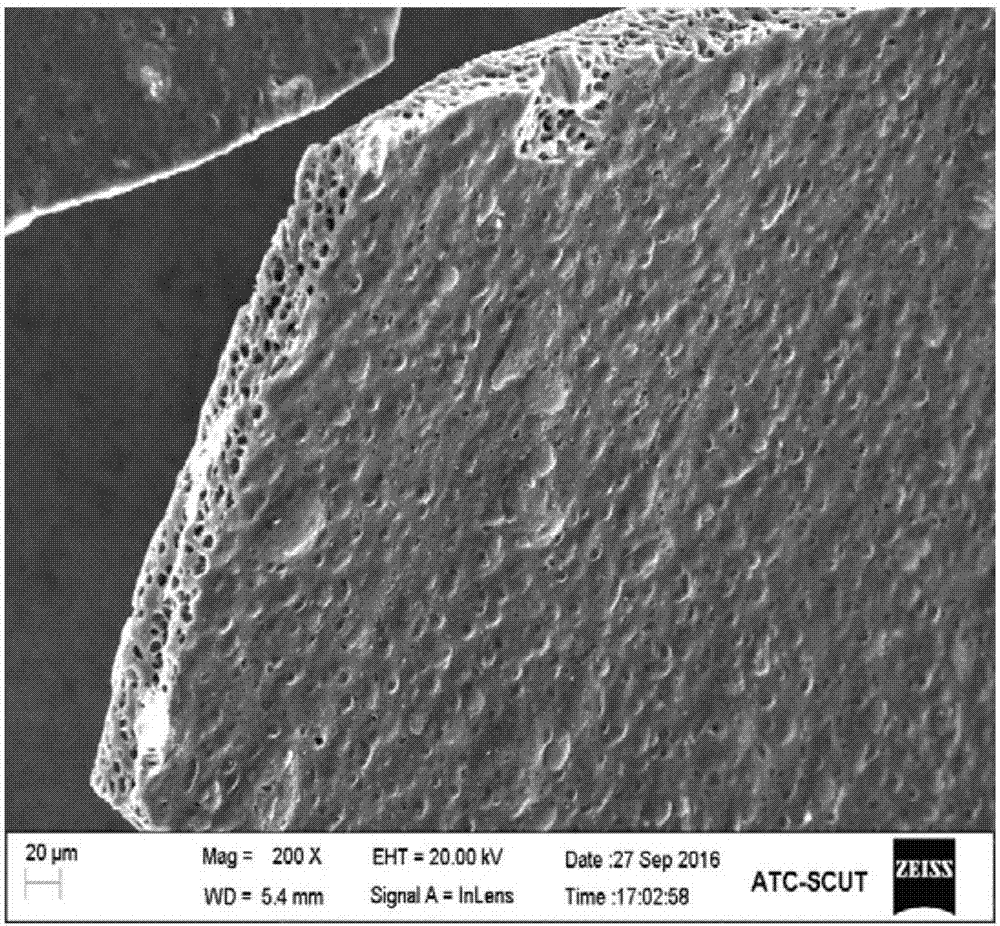

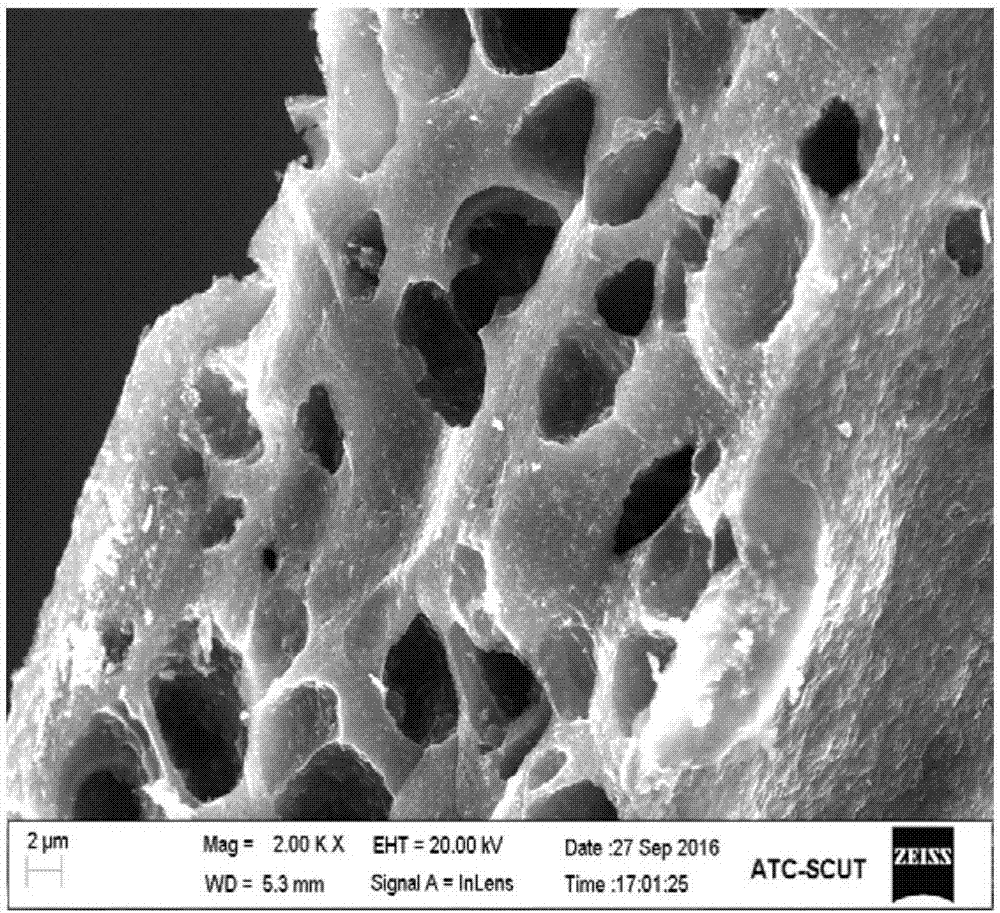

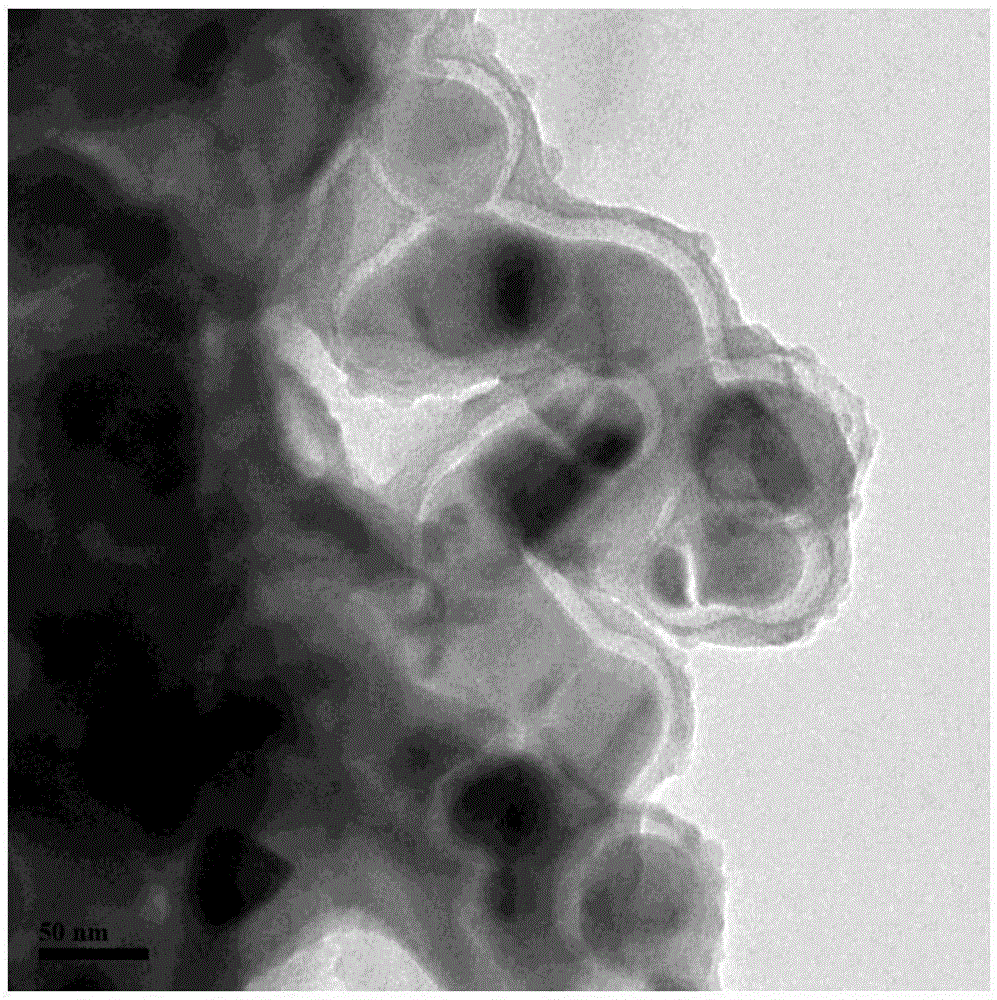

Porous carbon in situ composite lithium iron phosphate cathode material and preparation method thereof

InactiveCN102201576AImprove charge and discharge performanceImprove cycle performanceCell electrodesPorous carbonCharge discharge

The invention, which belongs to the technical field of lithium ion battery cathode materials, discloses a porous carbon in situ composite lithium iron phosphate cathode material and a preparation method thereof. A synthetic process mainly comprises the following steps: dispersing porous carbon; compositing a precursor FePO4.2H2O / porous carbon, and synthesizing the product of the porous carbon in situ coating lithium iron phosphate cathode material. The porous carbon in situ composite lithium iron phosphate cathode material comprises 0.5 to 15 wt% of the porous carbon, 85 to 99.5 wt% of lithium iron phosphate, and 0 to 10 wt% of residual carbon obtained after organic carbon source pyrolysis. Most lithium iron phosphate particles are restricted in the inner of pores of carbon through in situ coating, so obtained composite cathode material particles have small diameters and a good uniformity. Carbon walls of porous carbon allow uniform coating of the lithium iron phosphate particles to be realized and simultaneously particle agglomeration to be largely reduced. The porous carbon in situ composite lithium iron phosphate cathode material has the advantages of good charge-discharge performance, stable circular property, rate capability, novelty, simple synthetic technology and easy large-scale production.

Owner:UNIV OF SCI & TECH BEIJING +1

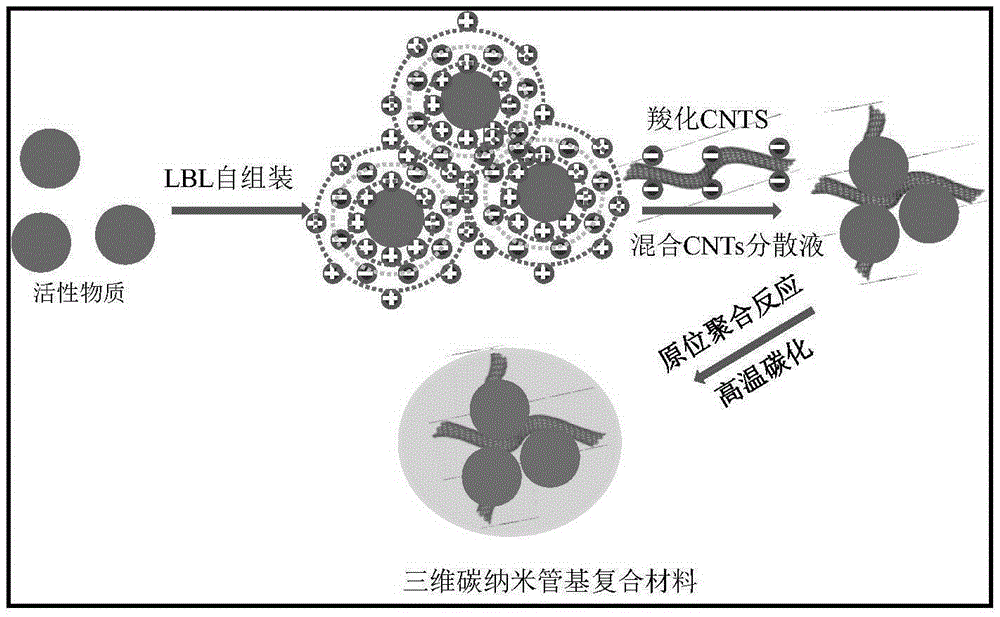

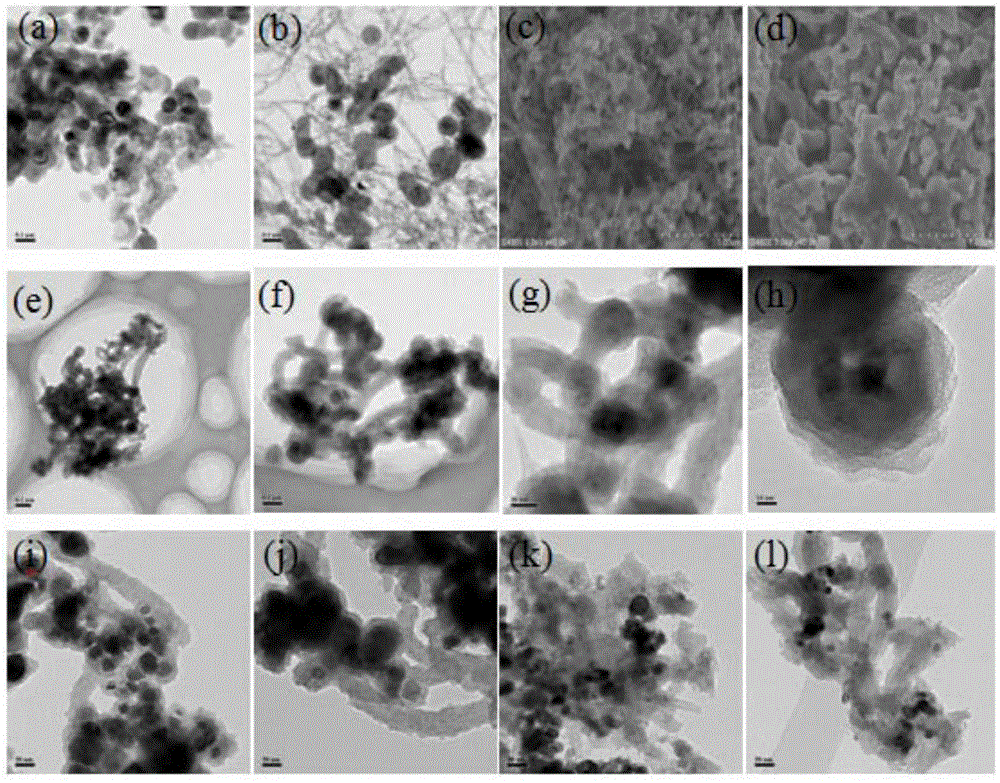

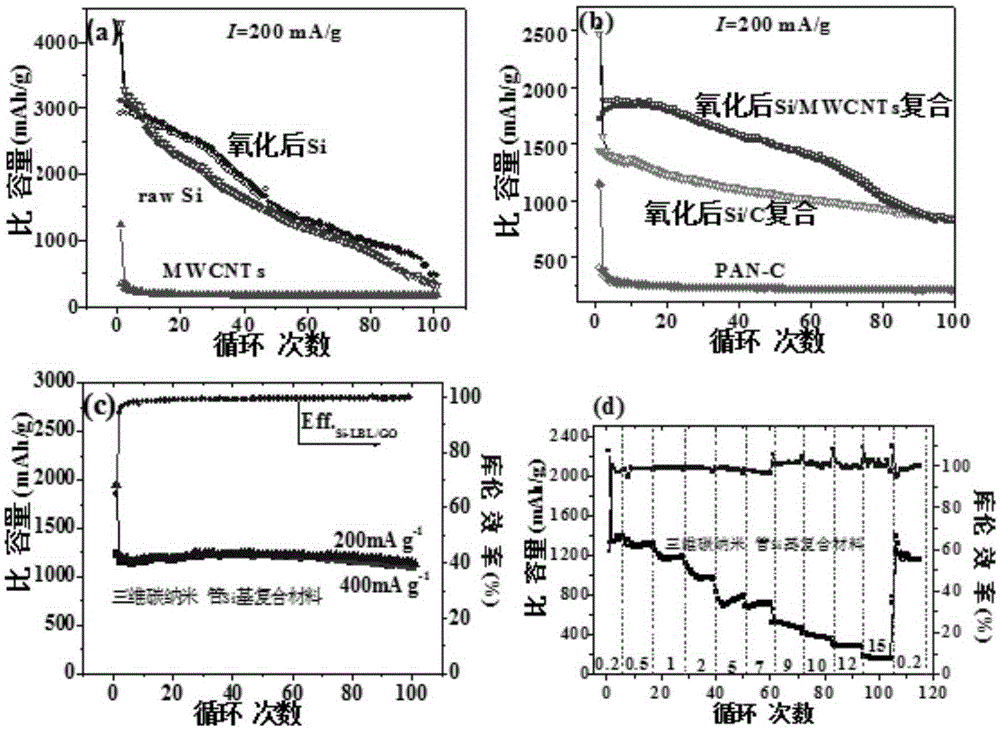

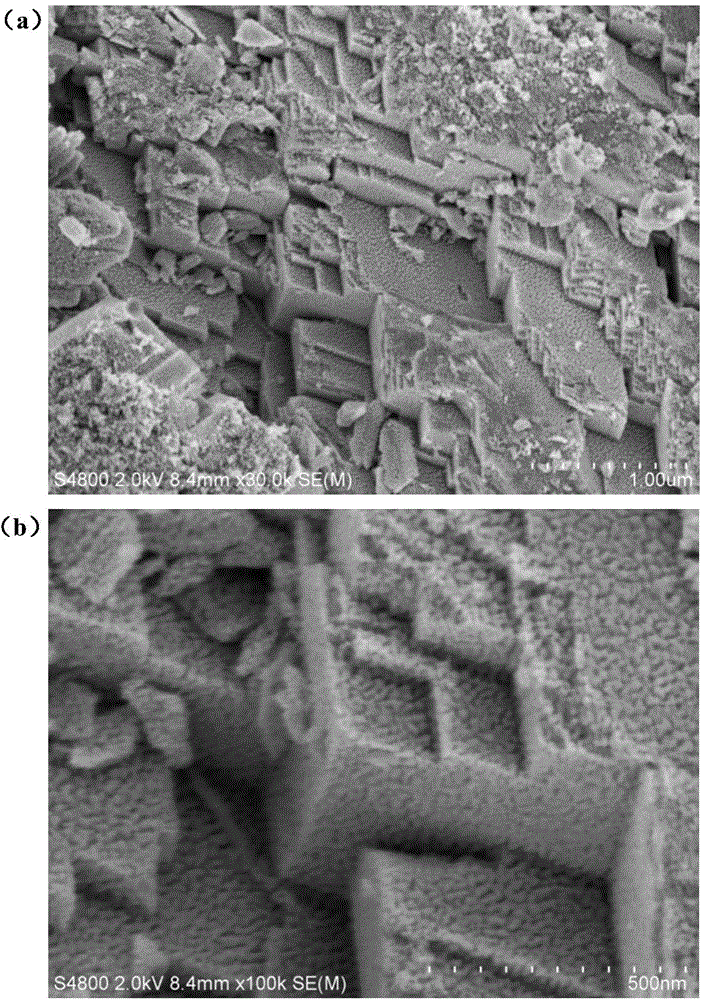

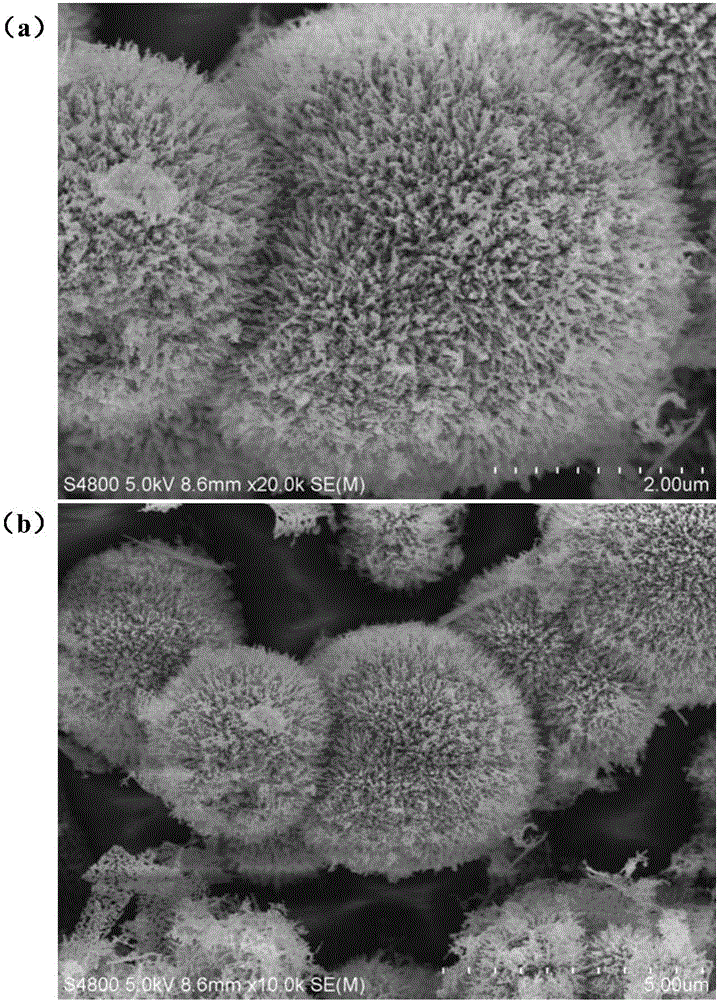

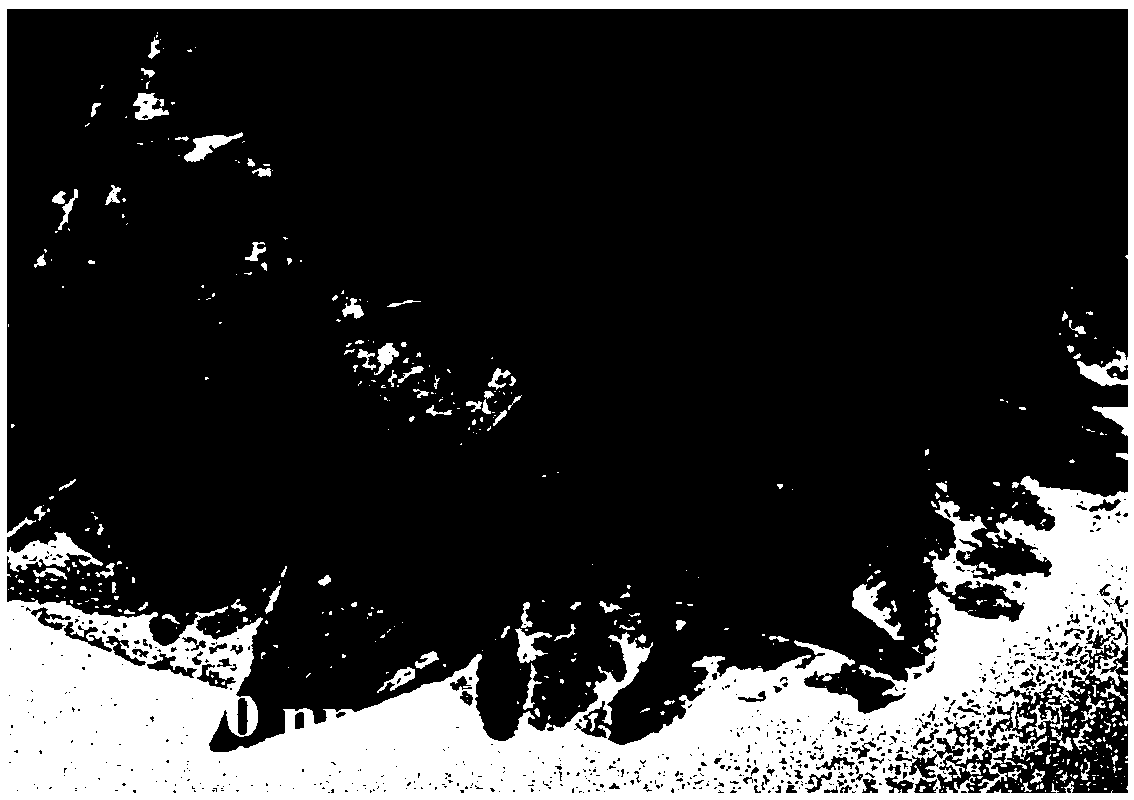

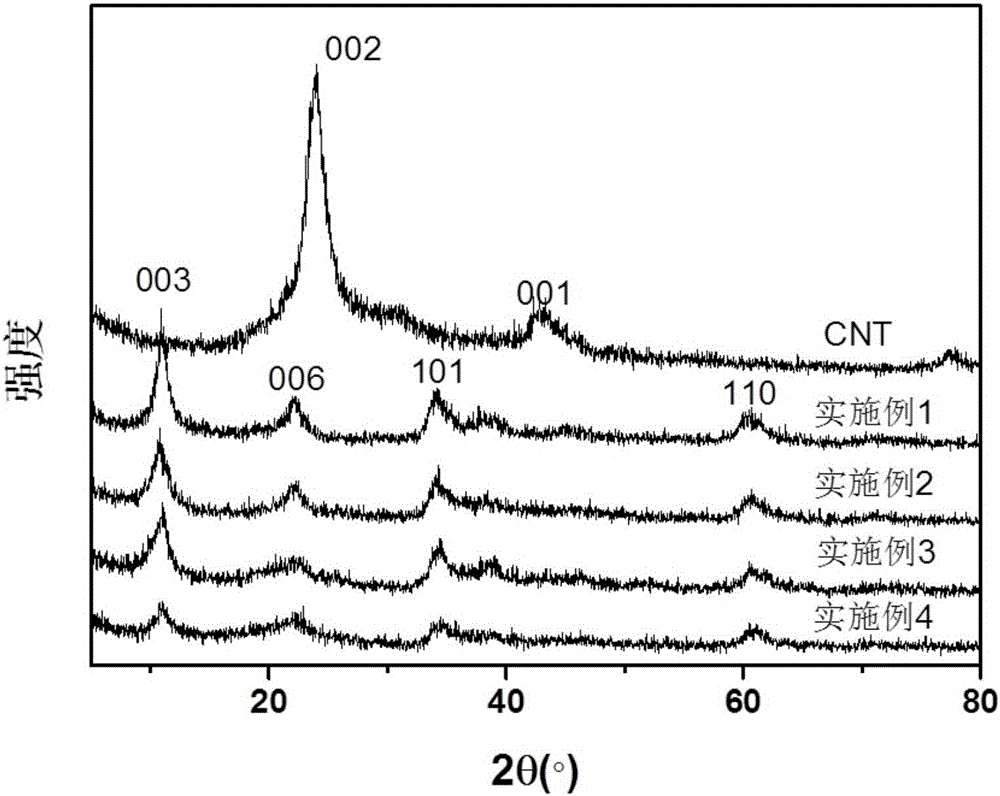

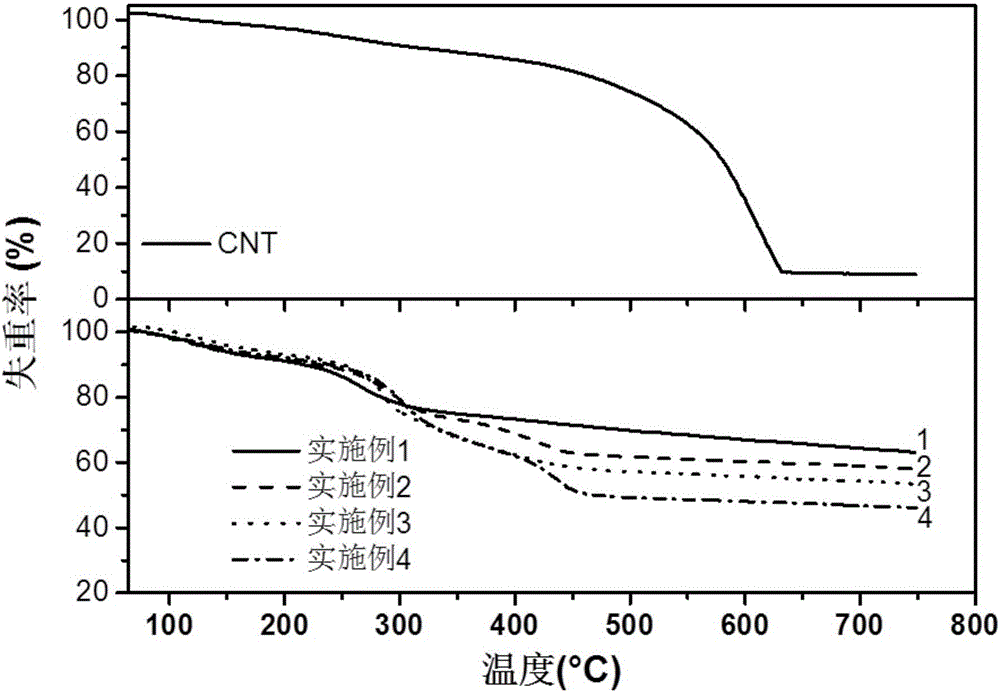

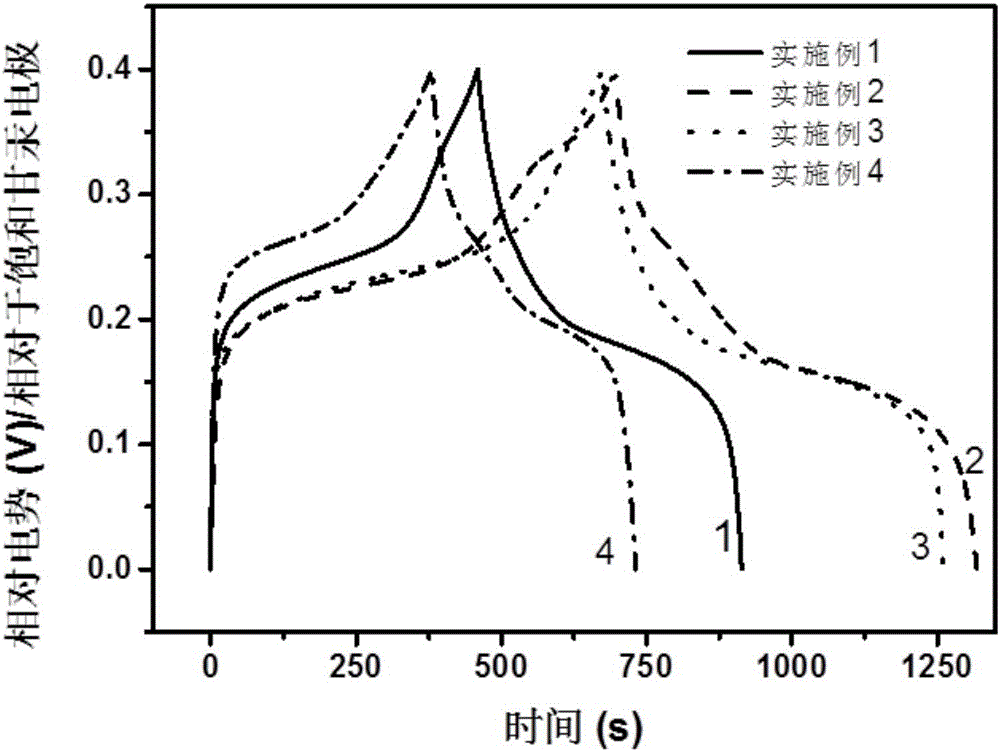

High-performance three-dimensional carbon nanotube composite negative electrode material, preparation method therefor and application thereof

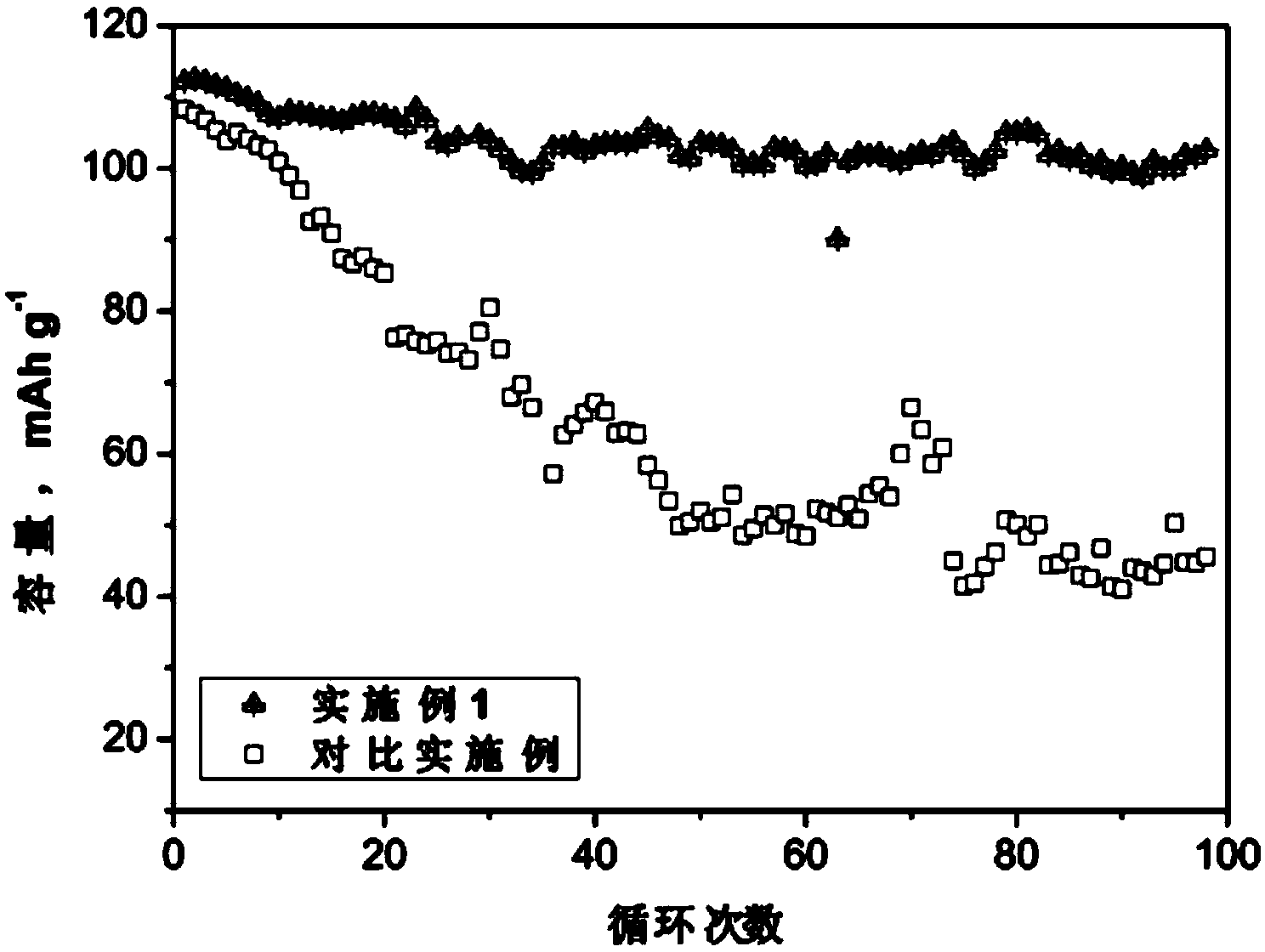

ActiveCN105390687AImprove cycle performanceSignificantly improved cycle performanceMaterial nanotechnologyCell electrodesCarbon nanotubeLayer by layer self assembly

The invention discloses a preparation method for a high-performance three-dimensional carbon nanotube composite negative electrode material. The preparation method comprises: by taking a carboxylated carbon nanotube as a three-dimensional network framework and taking a high-capacity material subjected to layer by layer self-assembly and modification as an active substance, uniformly mixing the carbon nanotube with the active substance under the action of electrostatic attraction; and then performing in-situ coating by taking a mixed element-containing N or S-doped carbon source as a three-dimensional coating layer, and performing high-temperature treatment to obtain the high-performance three-dimensional carbon nanotube composite negative electrode material. The invention furthermore discloses the high-performance three-dimensional carbon nanotube composite negative electrode material and an application thereof. According to the preparation method, the cycle performance of the active substance is remarkably improved, and the capacity of the composite material can be controllably adjusted by controlling a ratio of the carbon nanotube to the active substance. In addition, a solvent used in the method is water, so that the method is environmentally-friendly, good in repeatability and low in cost, and has relatively high potential of large-scale application and good industrialized prospects.

Owner:新疆护翼新材料科技有限公司

Lead-carbon battery anode lead paste for hybrid vehicle, and its preparation method

InactiveCN102738467AImprove cycle lifeGood charge and discharge performanceCell electrodesHybrid carFiber

The invention discloses a lead-carbon battery anode lead paste for a hybrid vehicle. The lead paste is obtained through mixing the following raw materials, by weight, 100 parts of lead powder, 4-15 parts of sulfuric acid, 0.05-5 parts of fumed silica, 0.05-3 parts of a rare earth oxide, 0.1-10 parts of red lead, 0.1-10 parts of Hydrargyri Oxydum Rubrum, 0.1-4 parts of graphite, 0.1-2 parts of a short fiber, and 10-20 parts of water. According to the invention, the fumed silica and the rare earth oxide are added to the lead paste, and other anode additives are also added to prepare the novel lead paste, a pole plate can be coated under a routine lead-acid battery production coating facility condition, the anode is obtained after curing, and there is very good adhesion between an active substances and a plate grid, and one active substance and another active substance, so the electrical properties of the battery are excellent.

Owner:TIANNENG GRP JIANGSU TECH

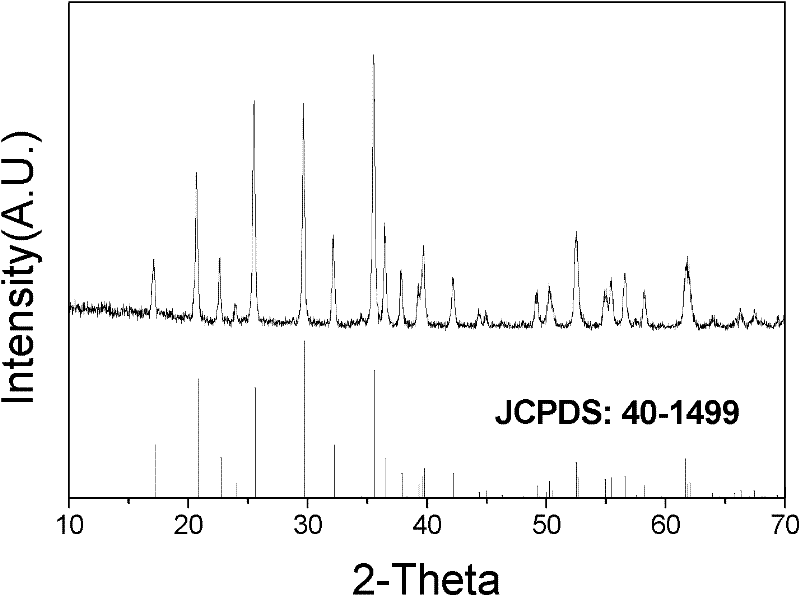

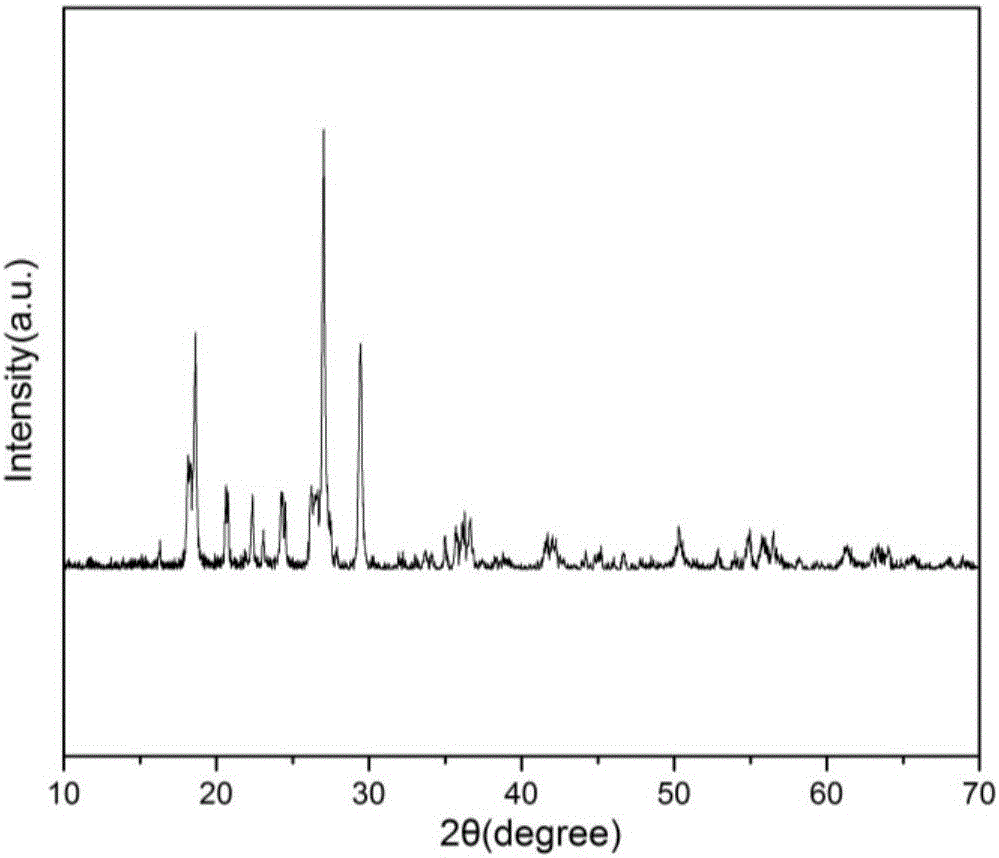

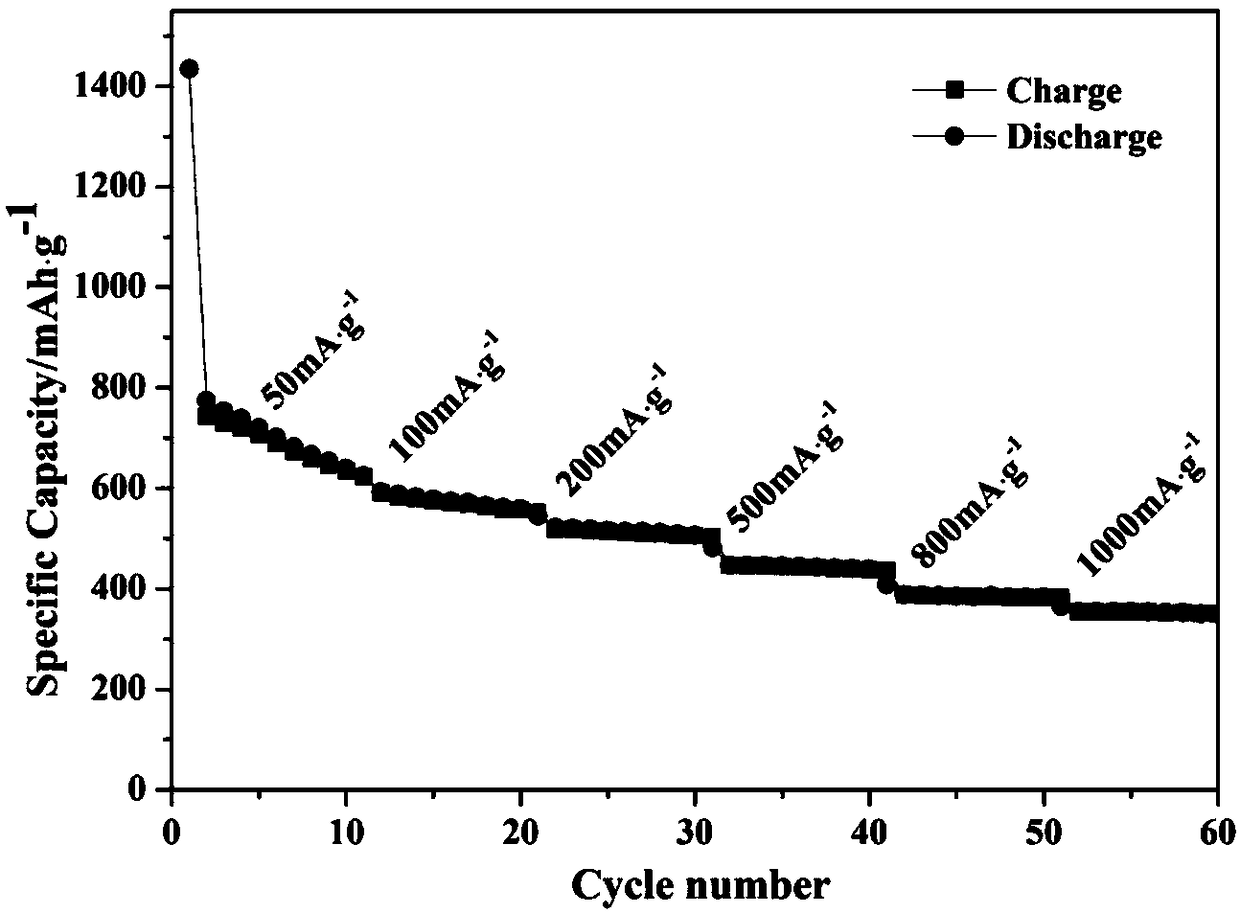

Nickel-cobalt oxide electrode material as well as preparation method and applications thereof

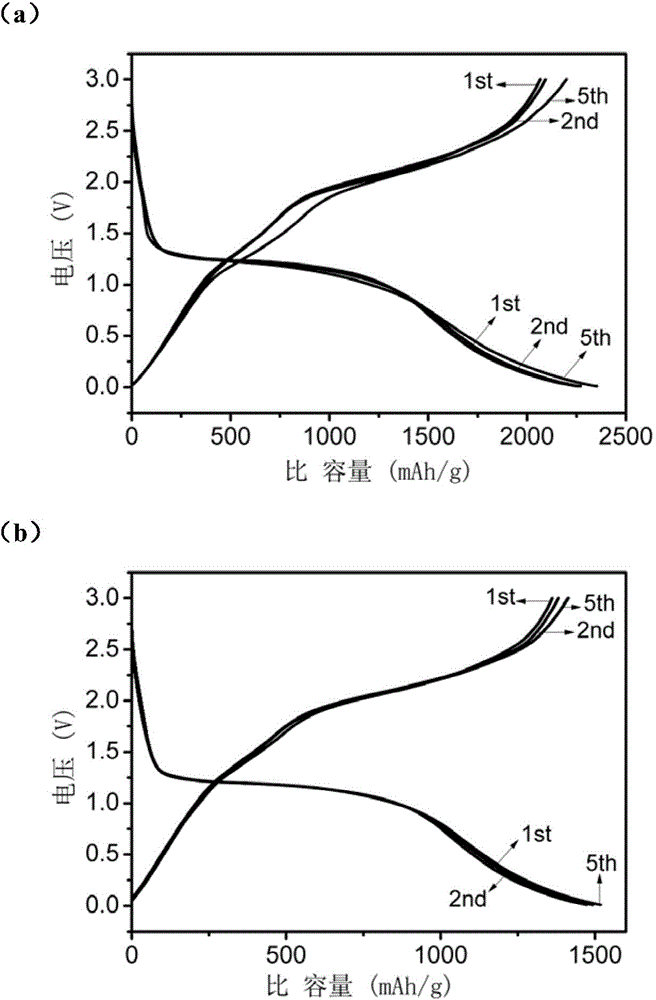

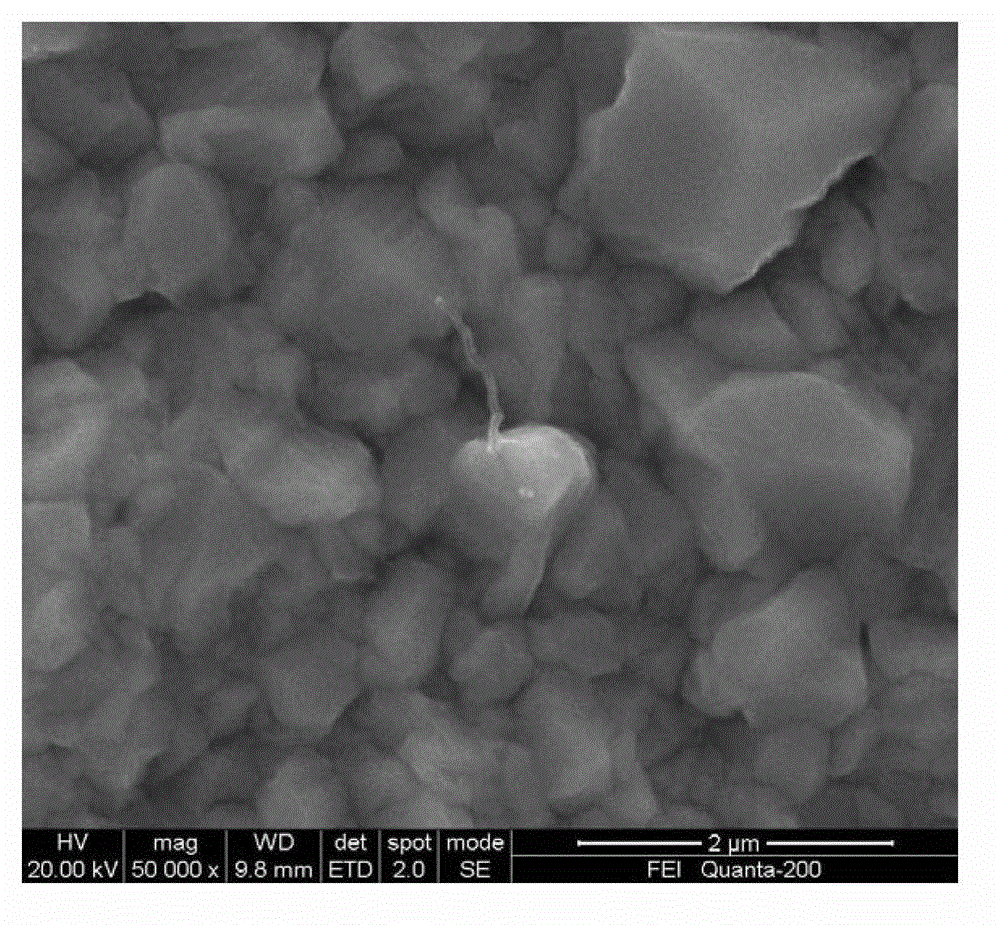

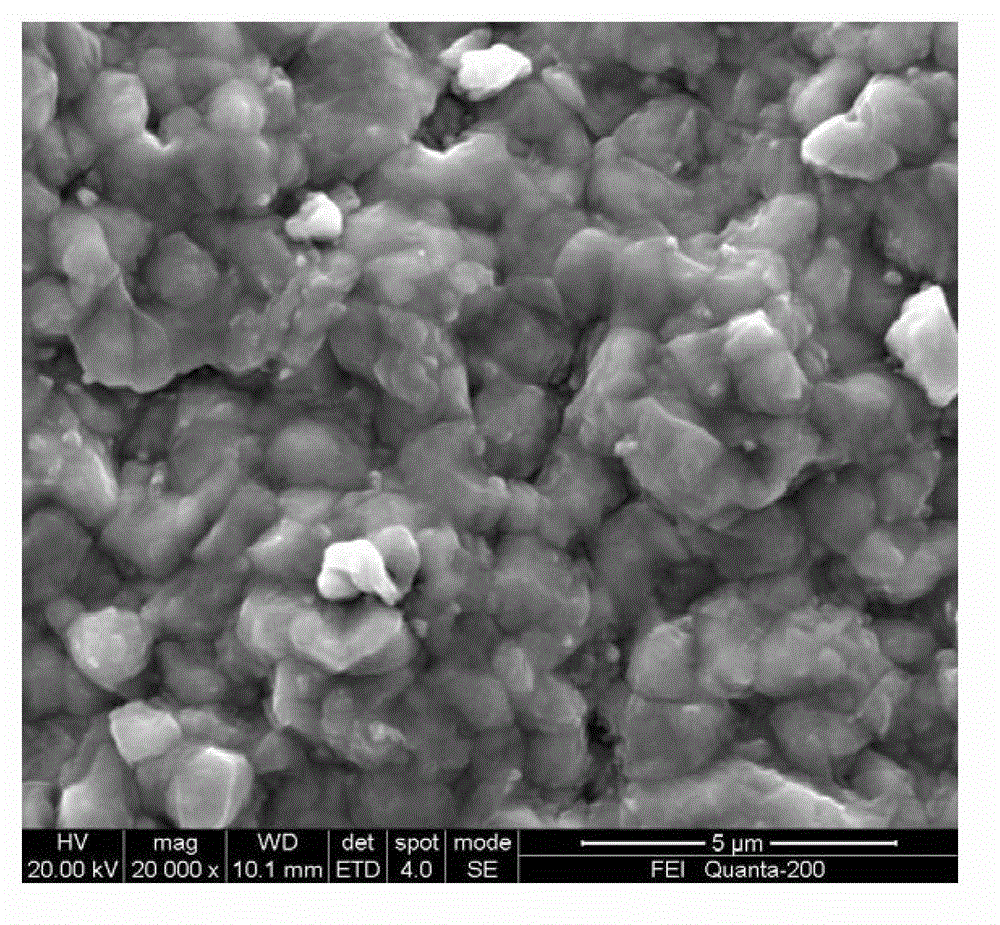

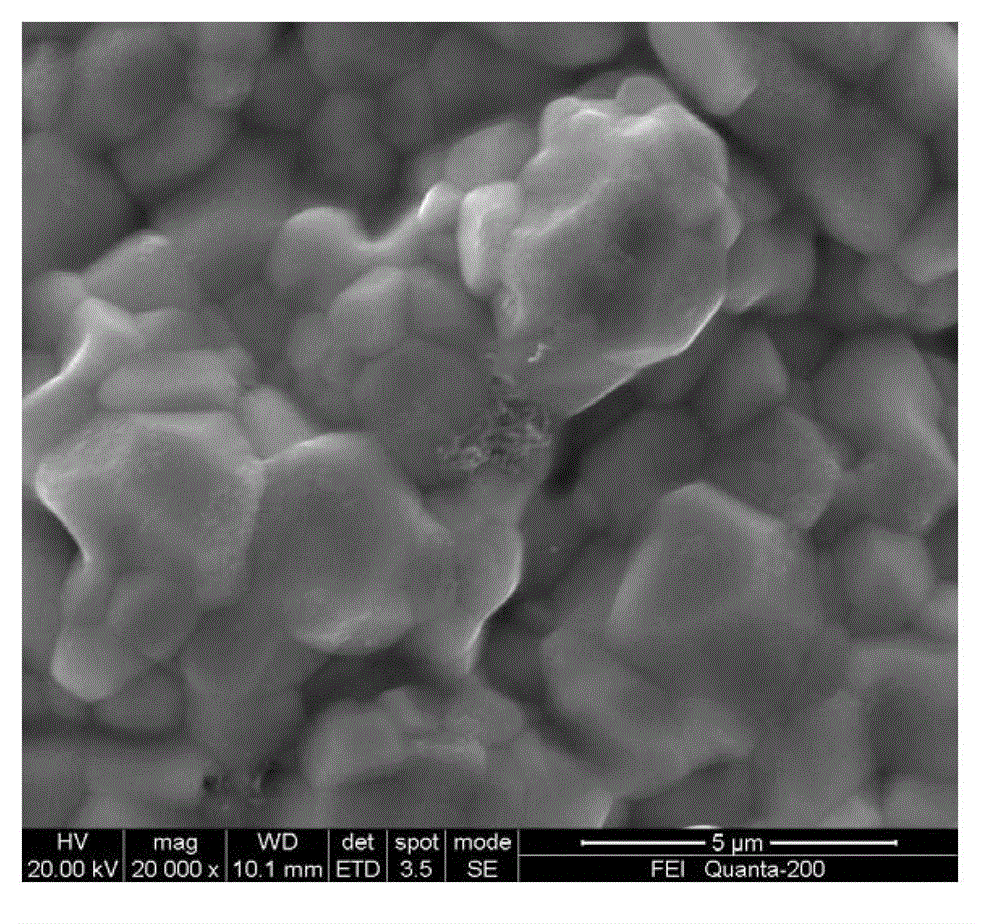

The invention discloses a nickel-cobalt oxide electrode material as well as a preparation method and applications thereof. The nickel-cobalt oxide electrode material is NiCo2O4 oxide prepared by adopting a hydrothermal method. The method concretely comprises the following steps: adding nickel nitrate (Ni(NO3)2.6H2O) and cobalt nitrate (Co(NO3)2.6H2O) into distilled water and fully mixing, adding urea and methanol to provide hydroxyl groups, and adding PVP as a complexing agent, and reacting in a reaction kettle to obtain NiCo2O4 oxide. Different material shapes can be obtained by adopting different reaction parameters, so that different lithium ion battery performances can be realized. The method has the advantages of being simple in technology, wide in the sources of raw materials, capable of performing large-scale production, and the like. The first discharge capacity of the lithium ion battery cathode material prepared from the material can achieve 2000mAh / g, the capacity has no obvious change after being circulated for 20 times, and the charging and discharging performances are excellent. By adopting the lithium ion battery prepared, the capacity is high, the cyclic performance is good and the lithium ion battery can be used for industrial production.

Owner:WUHAN UNIV

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

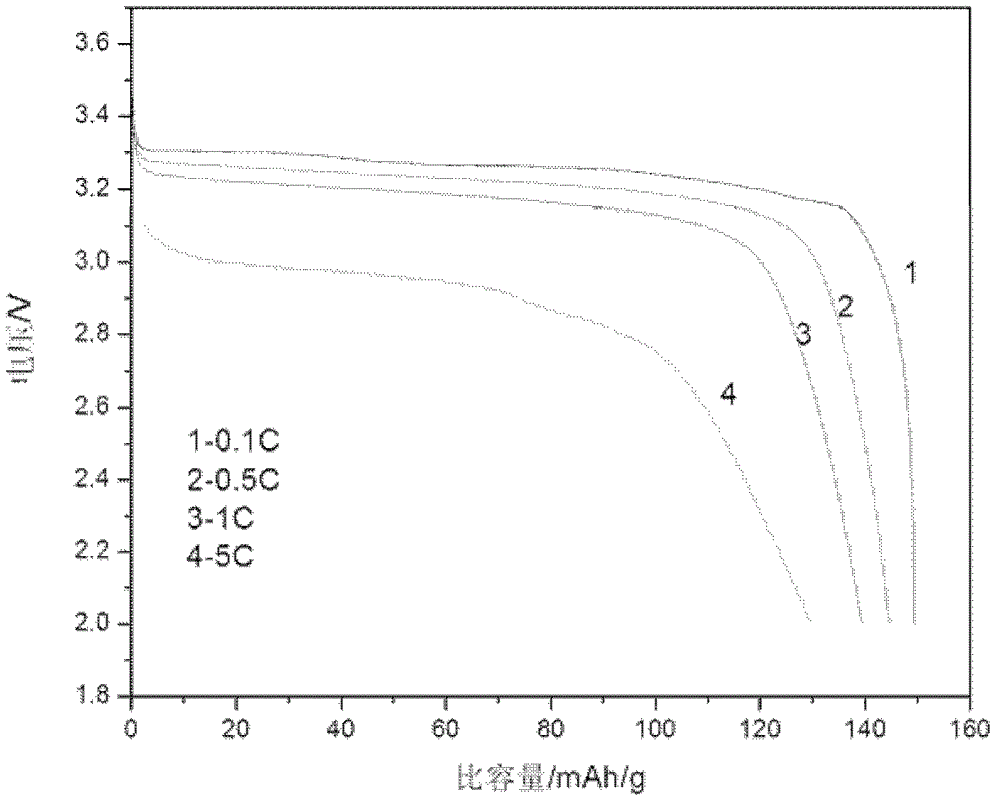

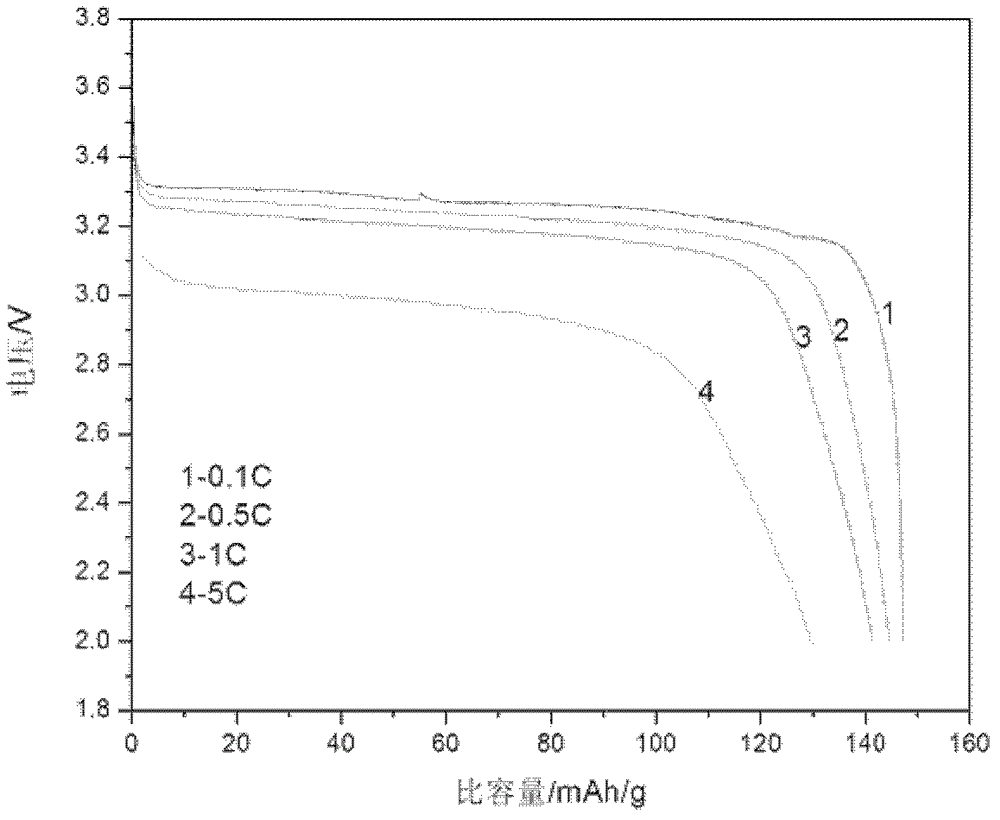

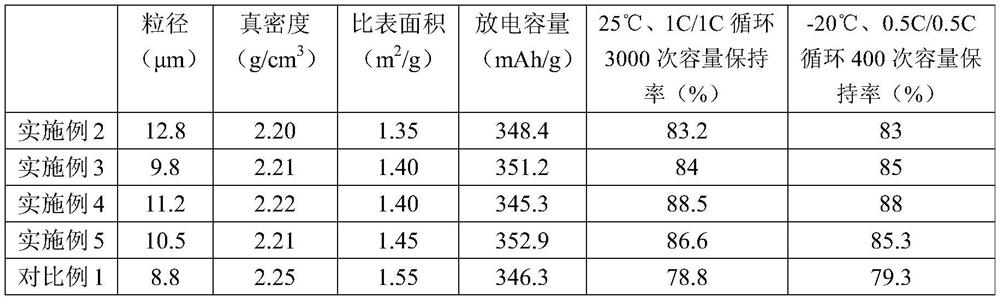

LiFePO4 composite type positive pole material and preparation method thereof

The invention relates to a LiFePO4 composite type positive pole material and a preparation method thereof. The invention adopts the essentials that the LiFePO4 composite type positive pole material consists of a Nasicon lithium superionic conductor crystal nucleus and an LiFePO4 / C shell. The preparation method comprises the following steps of: preparing a Nasicon lithium superionic conductor by adopting a sol-gel method; with the Nasicon lithium superionic conductor as a crystal nucleus, adding a certain quantity of FeC2O4.2H2O, NH4H2PO4, Li2CO3 and glucose to an alcohol medium, ball milling for 4-8 hours for uniformly mixing, and drying; and sintering at 400-600 DEG C for 4-8 hours in an inert atmosphere; sieving and then sintering at 600-800 DEG for 10-24 hours in the inert atmosphere; and cooling and porphyrizing to obtain the like spherical LiFePO4 composite type positive pole material. The LiFePO4 composite type positive pole material has the advantages of good conductivity, highmultiplying power and good heavy-current charge / discharge properties; and the like spherical structure improves the energy density and the pole piece processing property of the material.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

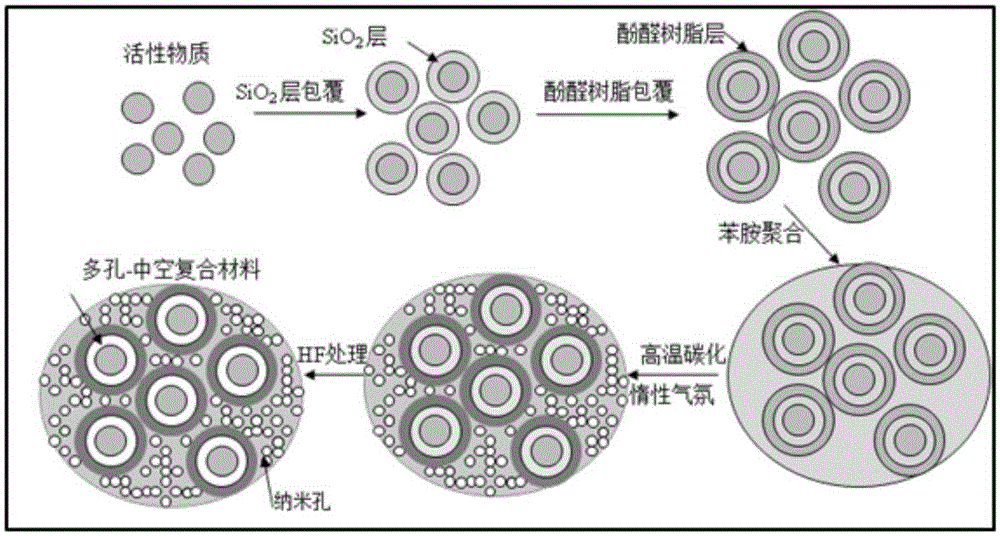

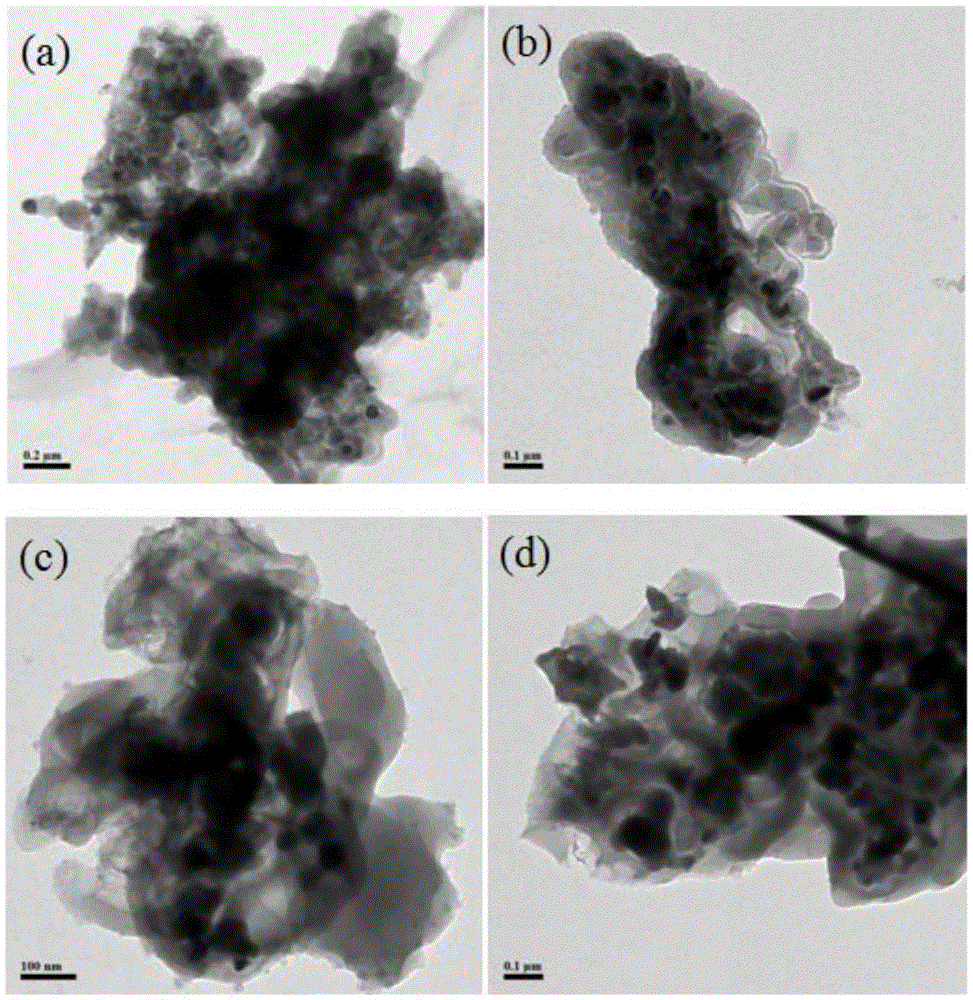

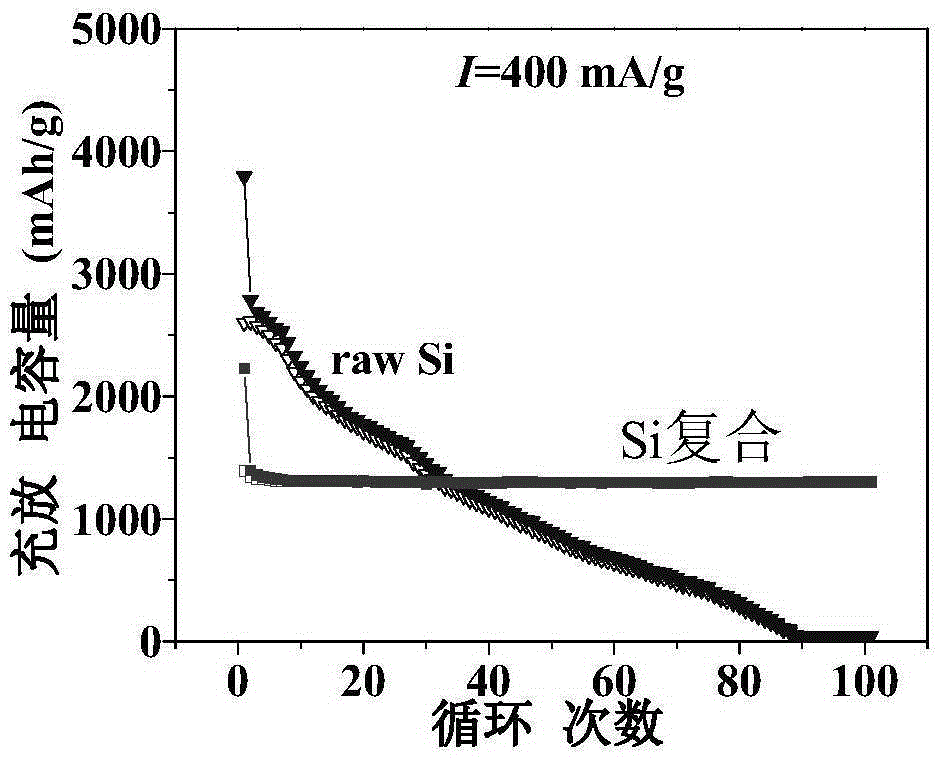

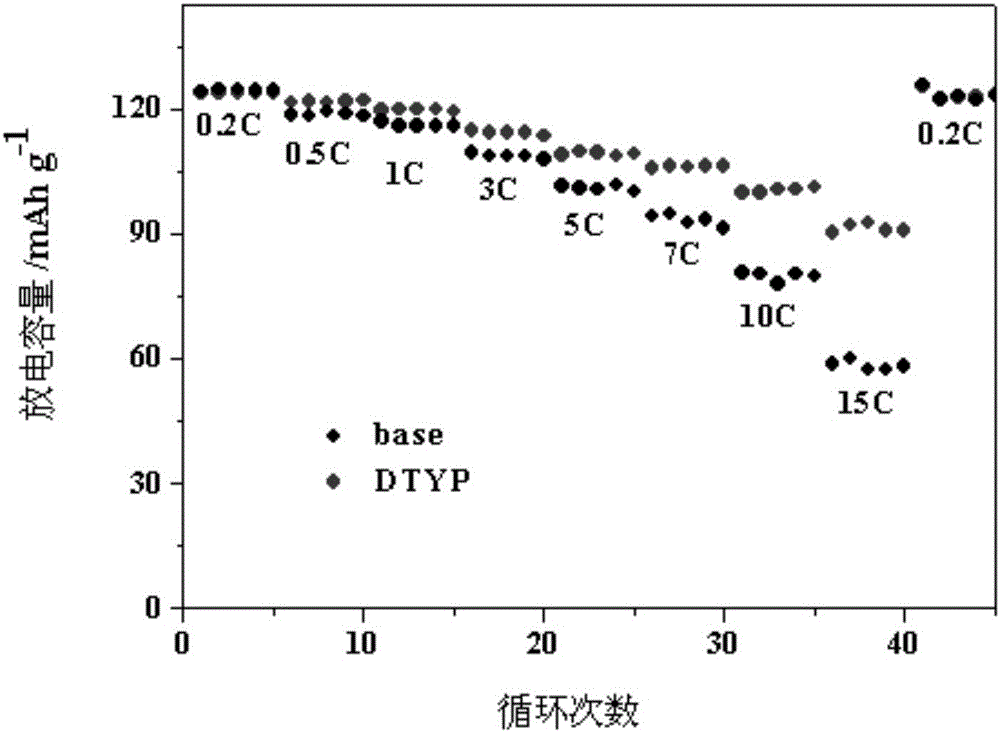

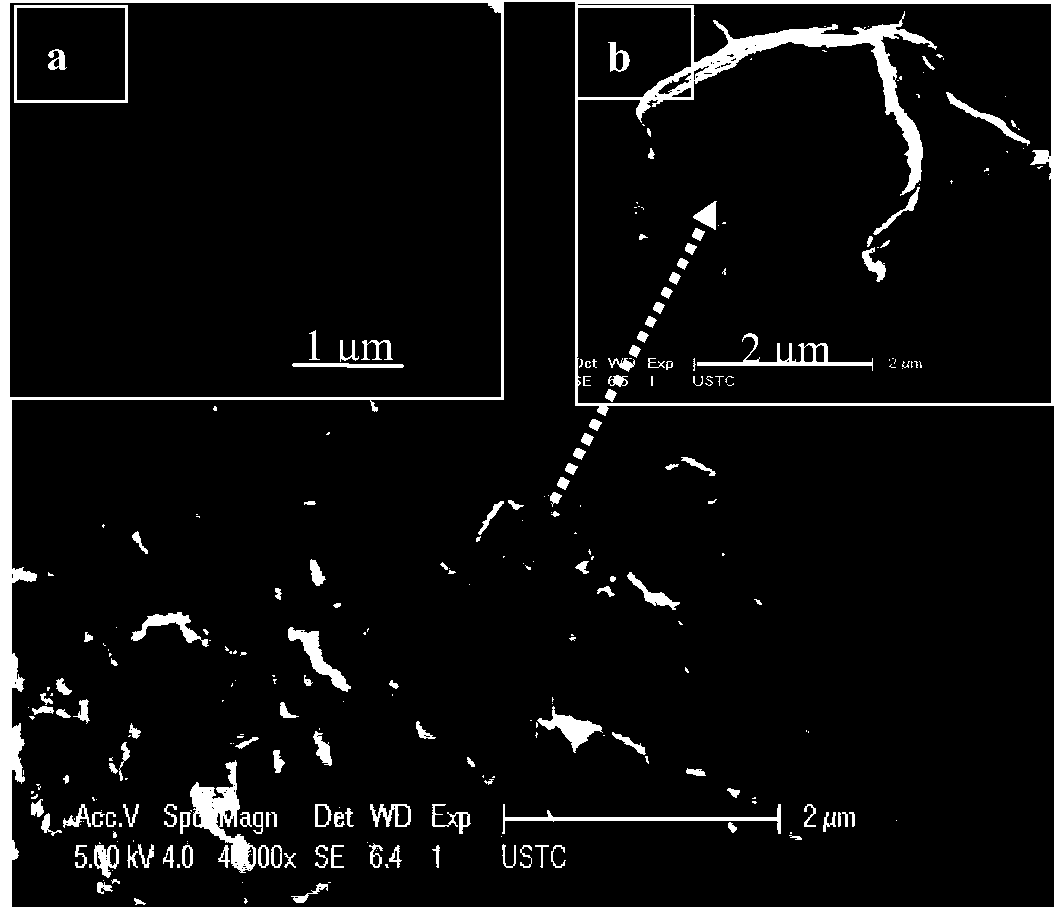

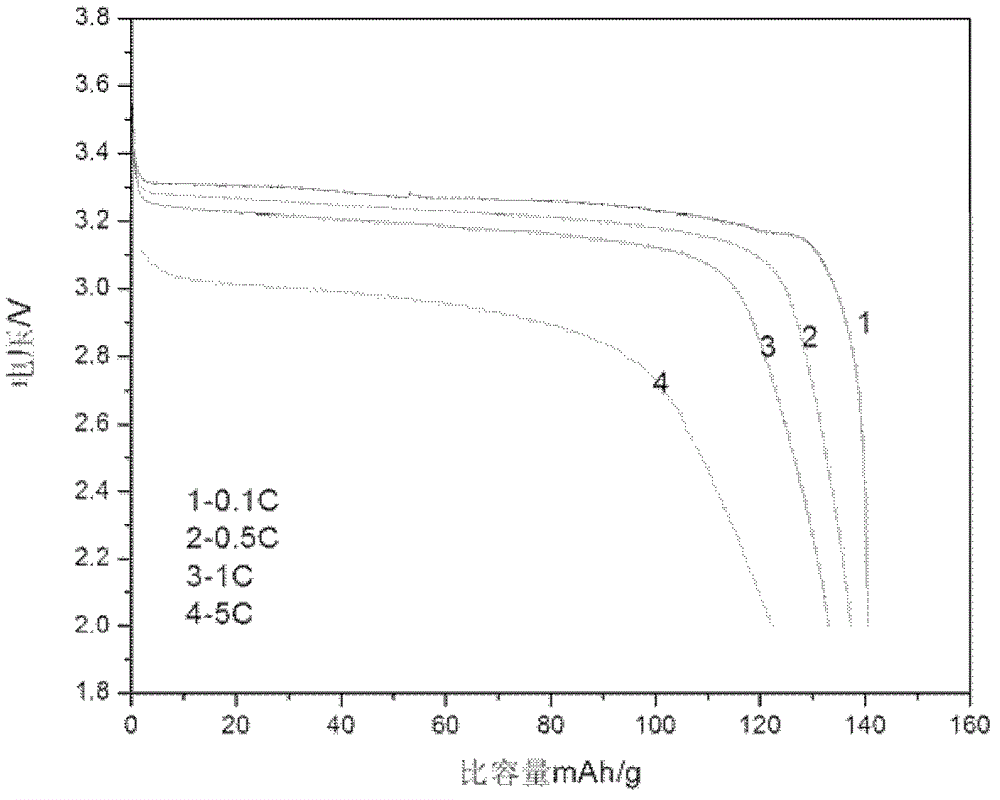

High-performance porous-hollow composite anode material and preparation method and application thereof

ActiveCN105428611AGood charge and discharge performanceImprove cycle performanceCell electrodesSecondary cellsCross-linkCarbon layer

The invention discloses a preparation method of a high-performance porous-hollow composite anode material. An SiO<2> layer is introduced into the surface of a high-capacity nano anode material as a sacrificial layer; a uniform carbon layer is introduced through in situ polymerization of phenolic resin; a high-molecular polymer and a soft template are subjected to cross-linking polymerization on the surface; and the high-performance porous-hollow composite anode material is prepared through high-temperature carbonization and template removal methods. The invention further discloses the high-performance porous-hollow composite anode material and an application thereof. According to the characteristics of a lithium battery anode material in charge and discharge cycles, the uniform carbon layer coats the outside of an intermediate layer of an active material, and a uniform mesoporous structure is designed in the middle of the outer carbon layer, so that the electrochemical properties of the electrode material are effectively improved. The high-performance porous-hollow composite anode material is cheap in preparing raw materials, simple in operation process and high in yield; the charge and discharge properties of the material are excellent; and industrial production is facilitated.

Owner:盐城卓越电子材料有限公司

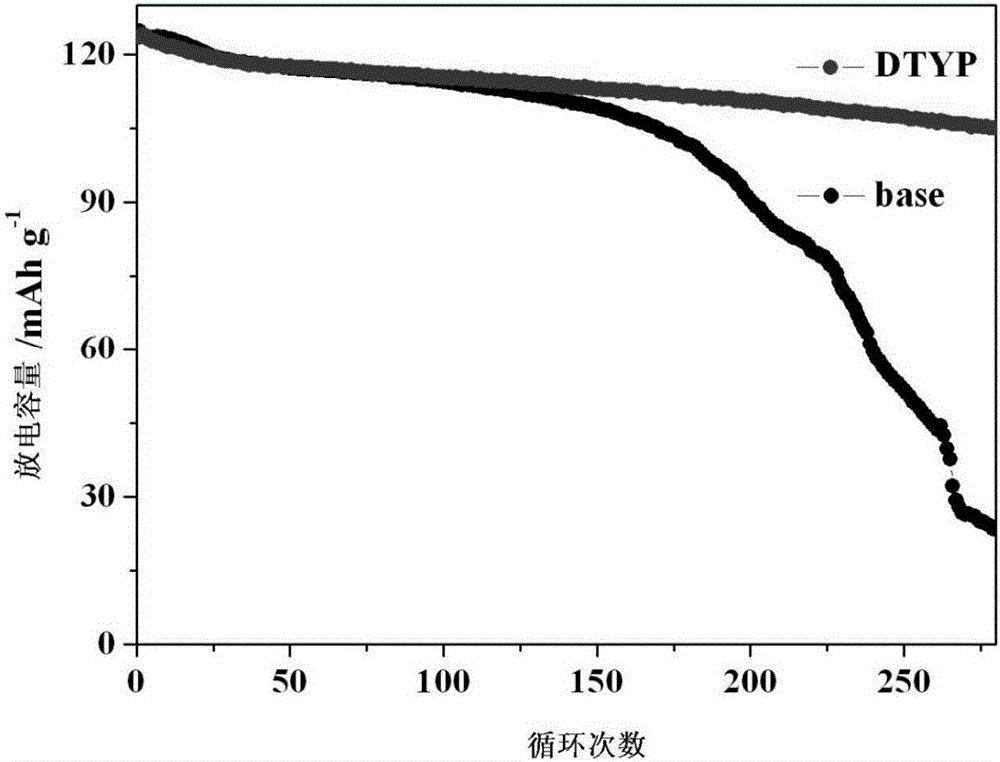

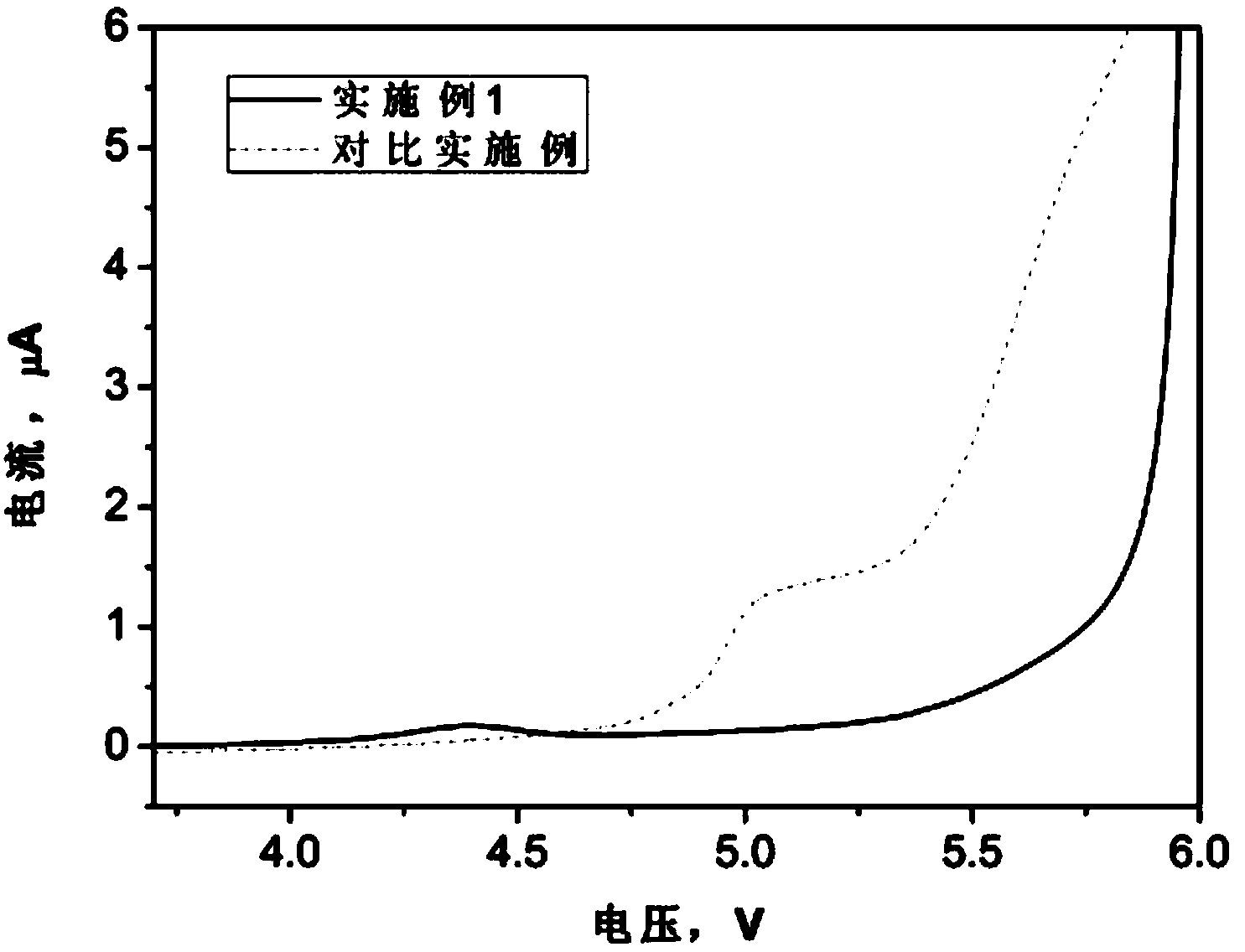

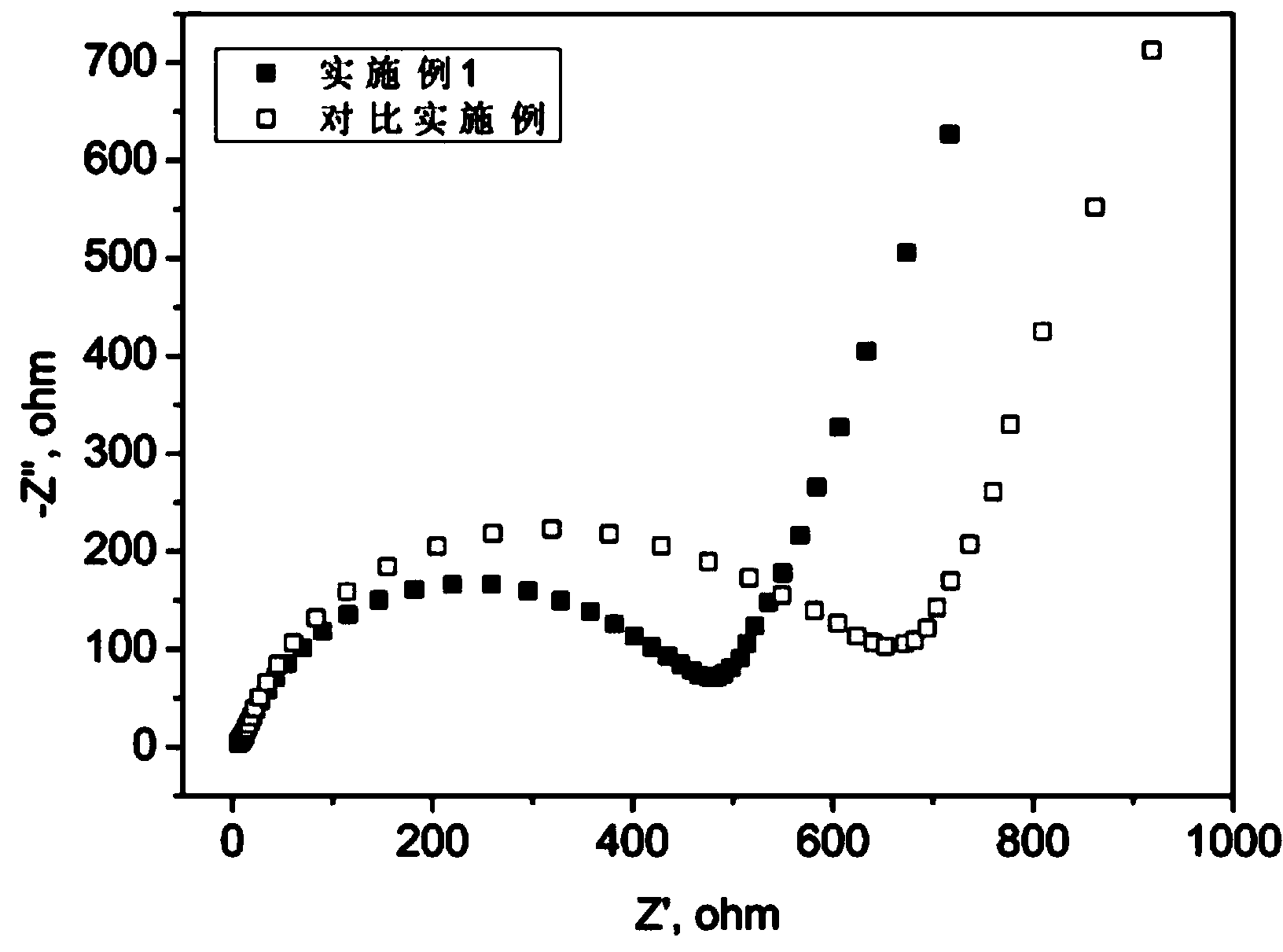

High-voltage functional electrolyte and preparation method and application therefor

ActiveCN105870501AGood charge and discharge performanceInhibit surface activityFinal product manufactureElectrolyte accumulators manufacturePhosphateRoom temperature

The invention belongs to the technical field of the lithium ion battery, and discloses a high-voltage functional electrolyte and a preparation method and an application therefor. The high-voltage functional electrolyte is prepared by adding a functional additive into the common electrolyte, wherein the functional additive accounts for 0.25-5% of the common electrolyte based on mass percentage; and the structural formula of the functional additive is as shown in the formula (1). The functional additive which is diethyl (thiophene-2-methyl) phosphate can be used as the high-voltage film-forming agent and the flame-retardant additive of the lithium ion electrolyte; the electrolyte containing the functional additive is non-combustible; and the room-temperature and high-temperature cycling performances of the lithium ion battery prepared from the electrolyte are both improved under 3-5.0V, so that the high-voltage functional electrolyte is wide in the application prospect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

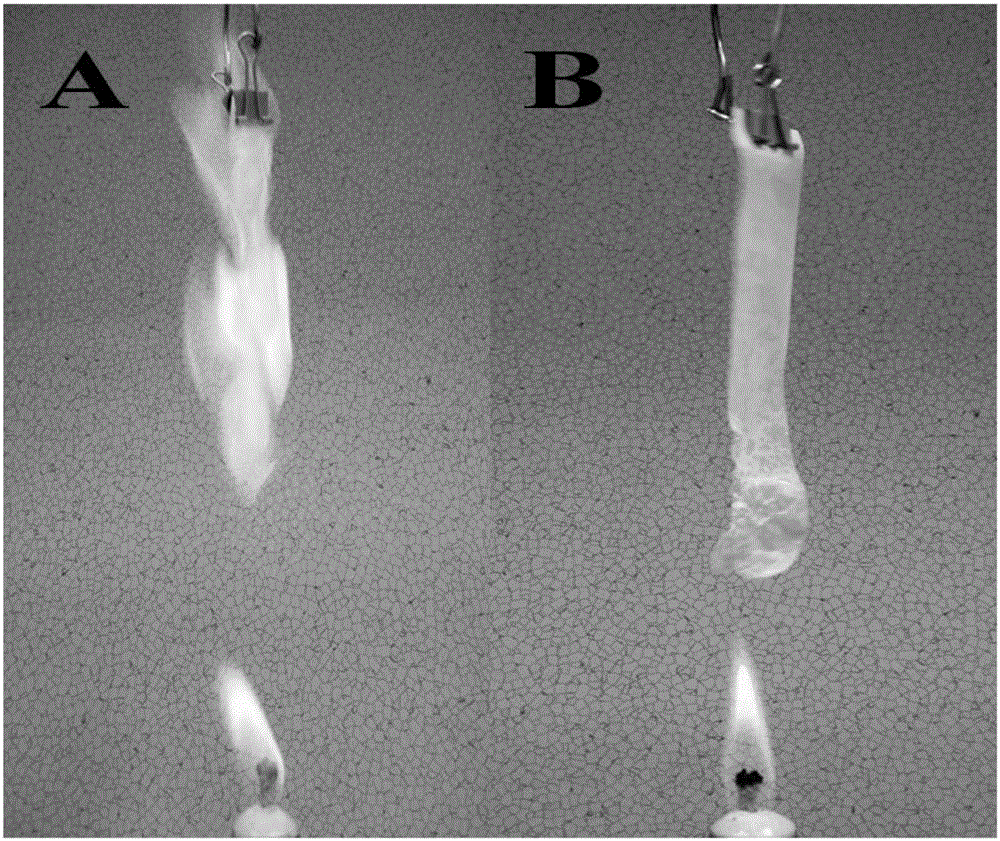

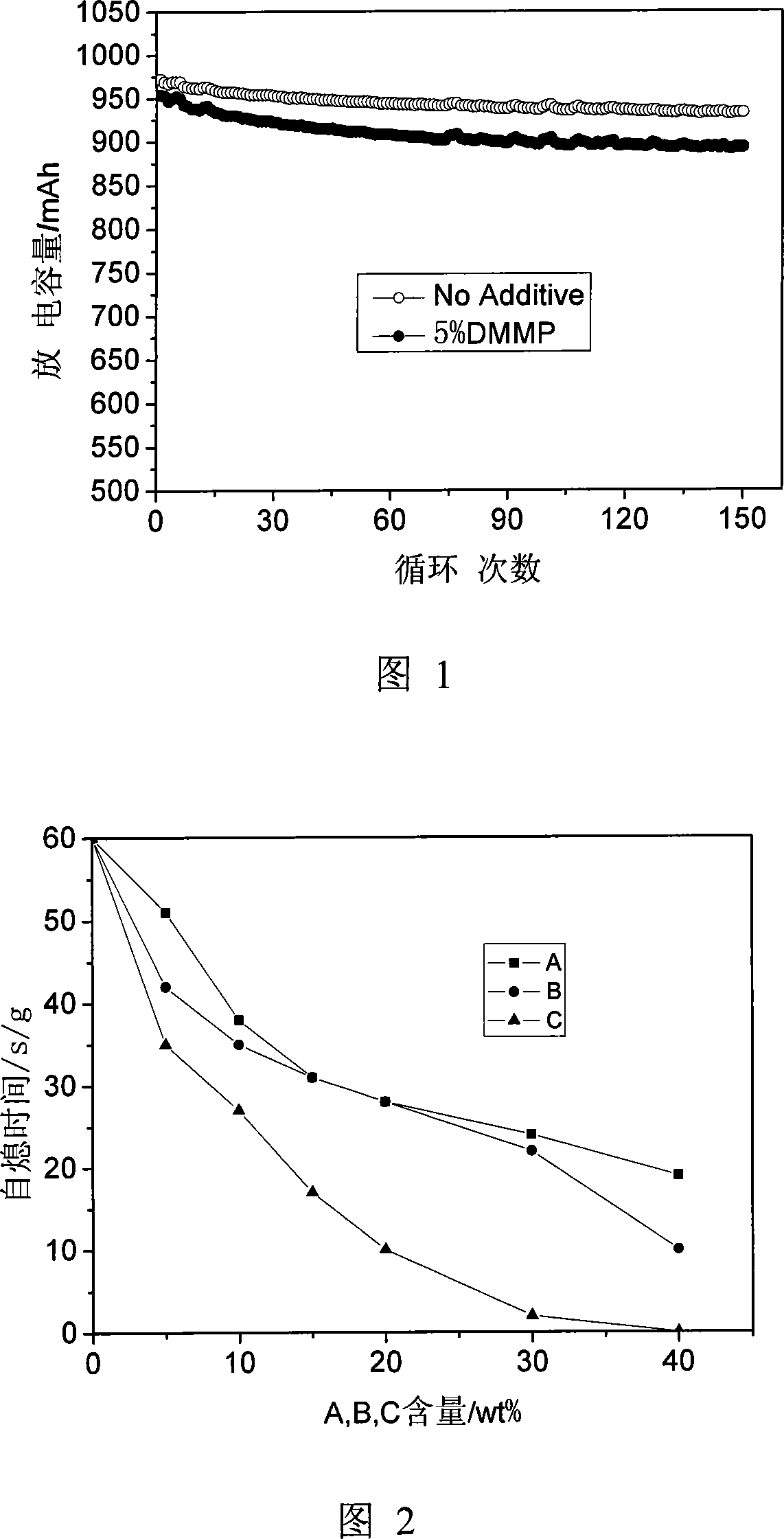

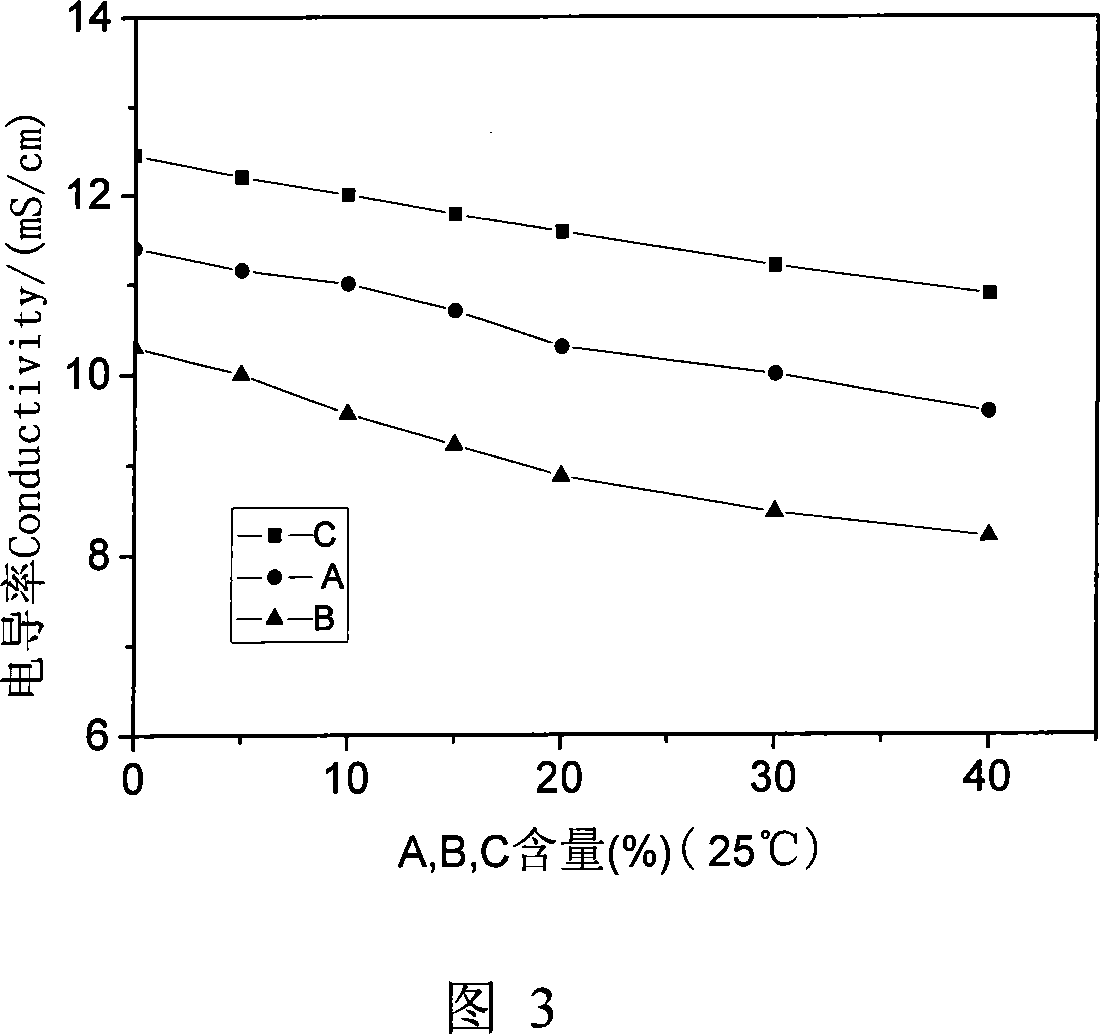

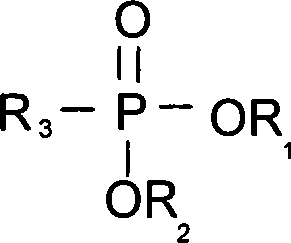

Phosphorus-contained flameproof additive agent for lithium ion cell electrolysing solution and method of use thereof

InactiveCN101083345AHigh in phosphorusImprove flame retardant performanceSecondary cellsHeat-exchange elementsPole pieceStructural formula

The invention publishes a phosphoric flame-resistant additive which is used in the solution of the lithium ion battery, which is a phosphoric organic compound, its basic structural formula likes right, or is the isometry body of the state structure; of which R1, R2, R3 are alkyl CnH2n+1 or alkene base CnH2n-1, and the carbon atom number of R1, R2, R3 is 1<=n<=4. The application method of the phosphoric flame-resistant additive is adding the phosphoric flame-resistant additive in the ordinary lithium ion battery solution; its quantity is the 5 to 40wt% of the lithium ion battery solution weight. The phosphoric flame-resistant additive has high phosphoric quantity, the good flame-resistant effect, and low viscosity, not only enables the electrolyte to have the good flame retardance, simultaneously has little influence of viscosity, conductivity of electrolyte, has good wettability with positive and negative pole piece and the membrane, and has good charging and discharging performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method of vanadium nitride

InactiveCN102070130AAvoid reunionImprove supercapacitor characteristicsNitrogen-metal/silicon/boron binary compoundsVanadium nitridePhysical chemistry

The invention provides a preparation method of vanadium nitride, which comprises the steps of: mixing vanadium oxide with an organic nitrogen compound, carrying out heat treatment with a solvent to obtain vanadium-nitrogen chelate, crystallizing, filtering and then calcining in a protective gas to obtain the vanadium nitride. The vanadium nitride prepared according to the method provided by the invention has small grain diameter, high specific capacitance and excellent cycle performance. The preparation method of vanadium nitride, provided by the invention, has mild reaction conditions and low reaction temperature as well as effectively prevents agglomeration of vanadium nitride nano particles; and after crystallization and filtration, the excessive oxygen-free organic nitrogen compounds can be recovered and used repeatedly, thereby saving energy and lowering production cost.

Owner:庄晓曦

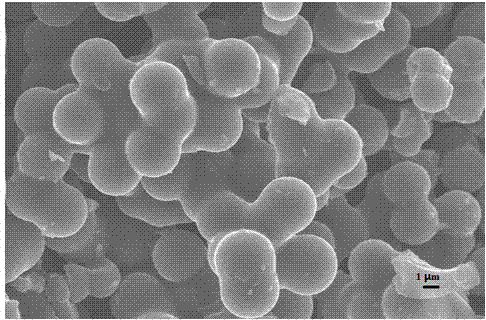

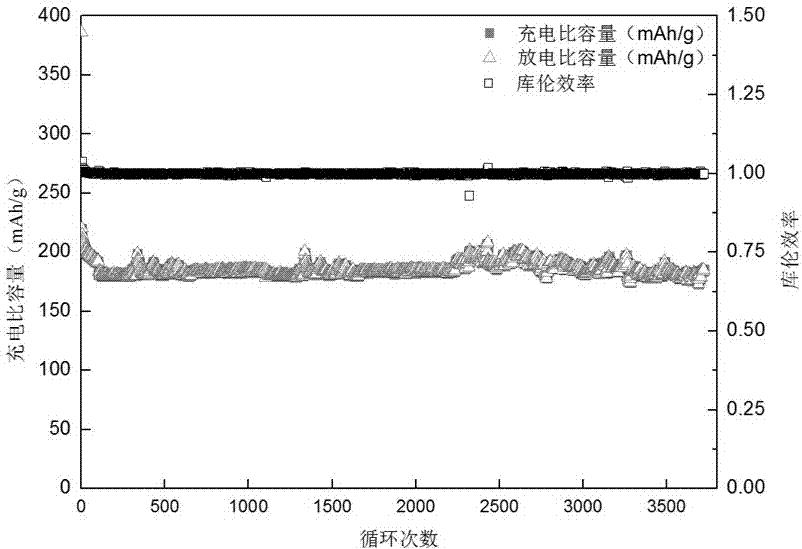

Negative electrode material phosphorus-sulfur double-doped hard carbon microsphere for sodium ion battery and preparation method of negative electrode material

InactiveCN106972162AGood charge and discharge performanceHigh reversible capacityCell electrodesSecondary cellsSucroseMicrosphere

The invention belongs to the technical field of a sodium ion battery, and particularly relates to a negative electrode material phosphorus-sulfur double-doped hard carbon microsphere for a sodium ion battery and a preparation method of the negative electrode material. The negative electrode material for the sodium ion battery is a sucrose-based hard carbon material doped with elements sulfur and phosphorus and is an irregularly-shaped microsphere body, and the diameter of the microsphere is 3-10 micrometers. The material is prepared by hydrothermal reaction and high-temperature solid-phase reaction, metal sodium is used as a counter electrode, and in the sodium ion battery packaged from the material, the reversible capacitor of the sodium ion battery is about 340mAh / g under the current density being 30mA / g, and the specific capacity still can be maintained at (170-340)mAh / g after 3,500 circles and under a large current being 600mA / g. The electrode material has the advantages of high specific capacity, good rate performance, simple preparation method and low cost in raw material, and is applicable to a power type sodium ion battery.

Owner:FUDAN UNIV

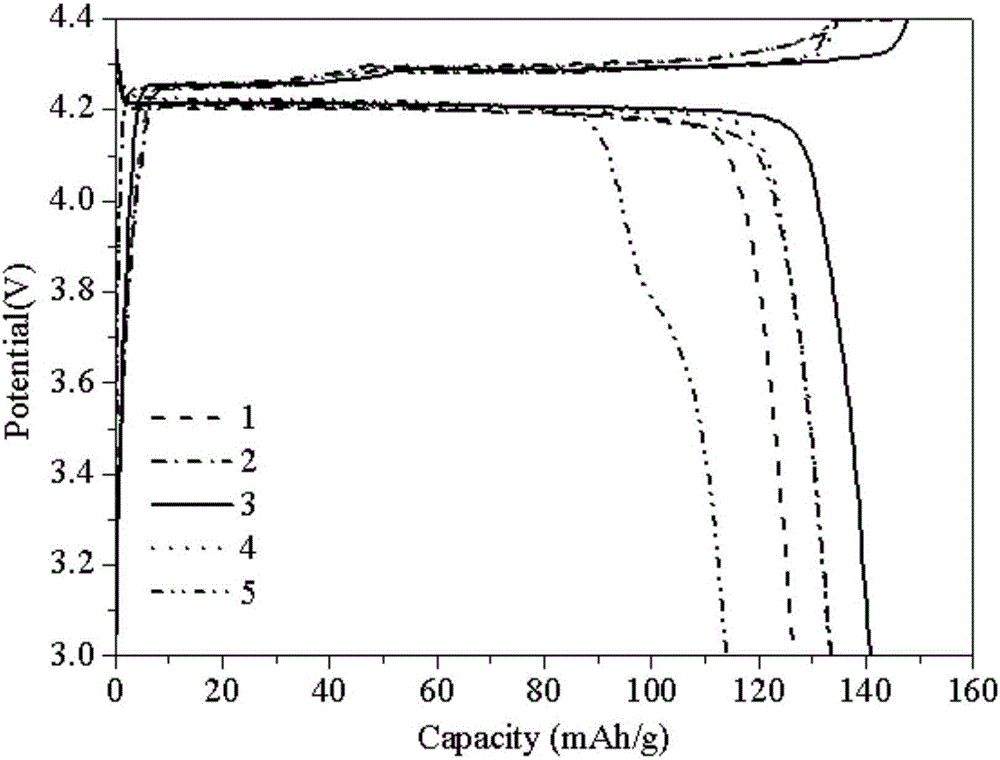

Method for preparing anode material doped with LiVPO4F for lithium ion battery

ActiveCN106602044AGood charge and discharge performanceExcellent rate performanceCell electrodesSecondary cellsTube furnaceElectrochemistry

The invention discloses a method for preparing an anode material doped with LiVPO4F for a lithium ion battery. The method comprises the following steps: weighing a lithium source, a vanadium source, a phosphorus source, a fluorine source, doping elements and a reducing agent according to a certain stoichiometric ratio, quickly and completely reducing V5 + into to V3 + to form a green porous material, performing grinding and sieving, placing the material in a vacuum tube furnace, heating the material to 650-850 DEG C in an inert atmosphere, performing heat preservation for 2-14 h, and performing natural cooling to obtain a modified LiVPO4F composite material. The problems of poor circulatory stability of the LiVPO4F material and the like are solved, meanwhile the particle size distribution of the sample is uniform after being doped, the electrical conductivity is higher, the electrochemical performance of the material is improved, the production process is simplified, and industrialized production is easy to realize.

Owner:HUNAN UNIV

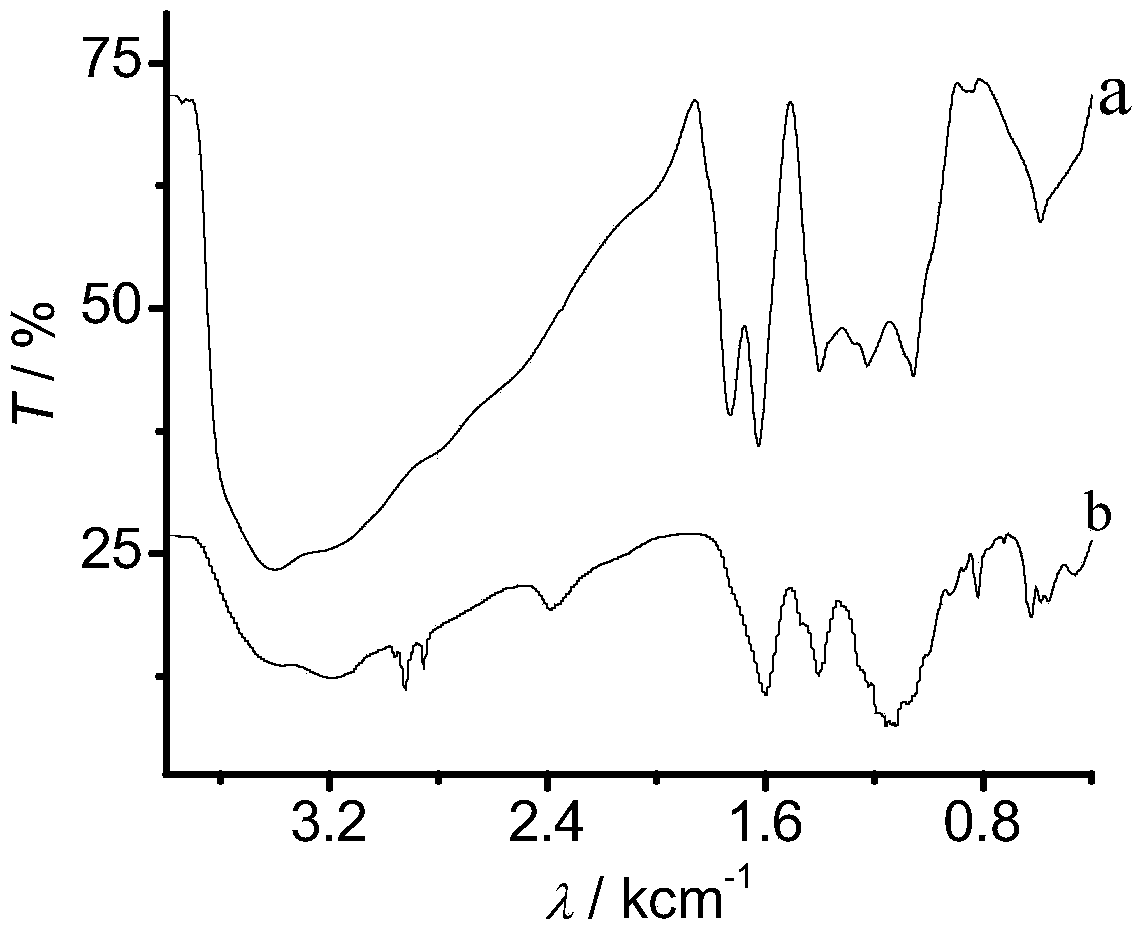

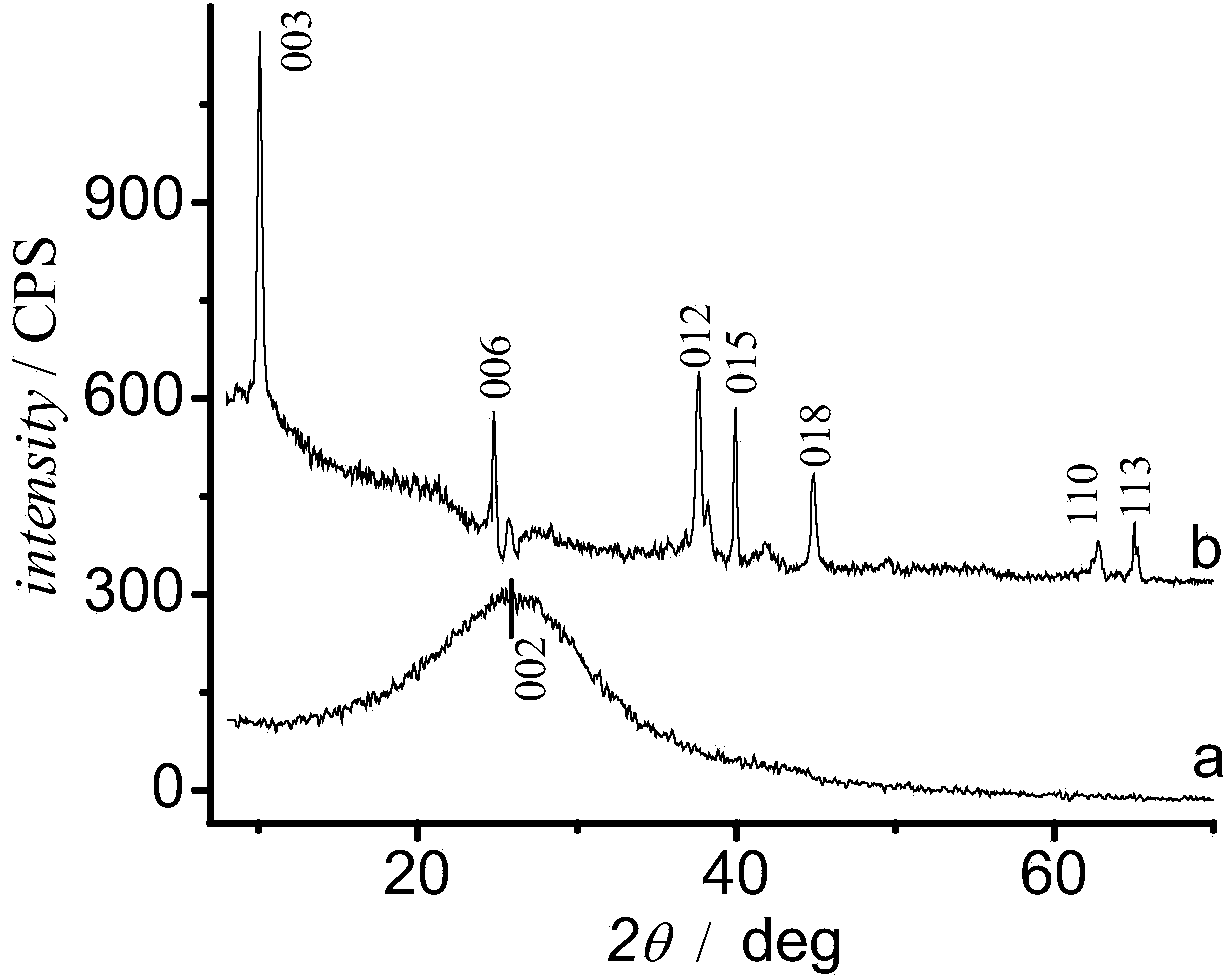

Method for efficiently and rapidly recovering nickel and phosphorus in chemical nickel-plating waste liquid

InactiveCN103449422AExcellent electrocatalytic oxidation performanceGood charge and discharge performanceCarbon compoundsNickel oxides/hydroxidesChemical oxygen demandMaterials science

The invention discloses a method for efficiently and rapidly recovering nickel and phosphorus in a chemical nickel-plating waste liquid. The method comprises the following steps of: adding inorganic aluminium salt and graphene oxide in the chemical nickel-plating waste liquid as auxiliary raw materials; performing oxidation demulsification by an oxidizing agent, and oxidizing metaphosphate radical into a phosphate radical; preparing by an ultrasonic-assisted coprecipitation method to obtain a GO / NiAl-LDHs composite material; and recovering nickel and phosphorus in the chemical nickel-plating waste liquid by virtue of the GO / NiAl-LDHs composite material. According to the method disclosed by the invention, pollutants such as Ni and P in the chemical nickel-plating waste liquid can be adsorbed in situ during the preparation process for the GO / NiAl-LDHs composite material; the recovery rates of the nickel element and the phosphorus element in the chemical nickel-plating waste liquid achieve more than 93% and 90% respectively; and the decrease rate of chemical oxygen demand achieves more than 90%. The GO / NiAl-LDHs composite material prepared by the method disclosed by the invention is excellent in electrocatalytic oxidation performance for methyl alcohol and ethyl alcohol, excellent in charge-charge performance, and capable of being used as a capacitor material.

Owner:HEFEI UNIV OF TECH

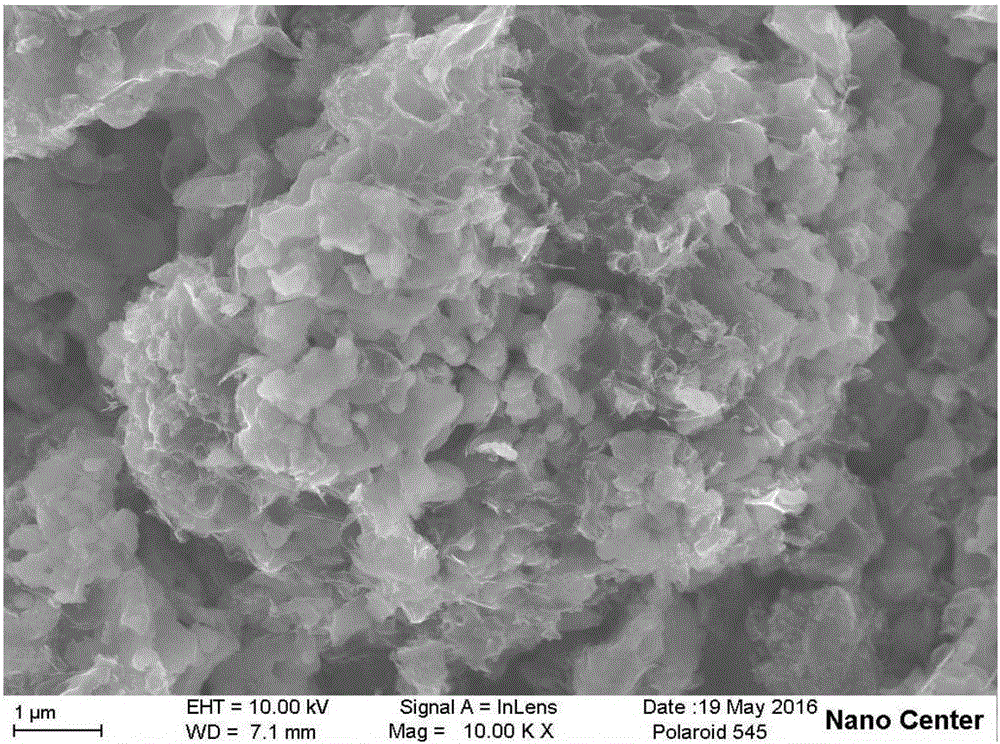

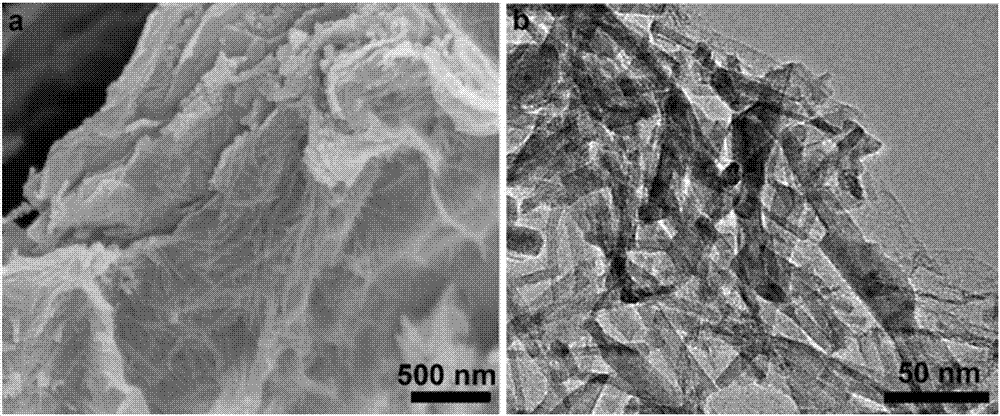

Preparation method of nanosheet self-assembled three-dimensional nano flower tin sulfide/graphitized carbon nitride lithium ion battery anode material

ActiveCN109286009AControllable growthUniform size distributionMaterial nanotechnologyCell electrodesVacuum dryingMaterials science

The invention discloses a preparation method of a nanosheet self-assembled three-dimensional nano flower tin sulfide / graphitized carbon nitride lithium ion battery anode material. Melamine is kept at450-650 DEG C for 2-6 hours, is naturally cooled to room temperature, is ground for prepare use, and is dispersed in ethanol to obtain a suspension, the suspension is centrifuged and washed several times with deionized water and absolute ethanol, vacuum drying is conducted to obtain a product g-C3N4, the product g-C3N4 is dissolved in the deionized water, after stirring, the product g-C3N4 is ultrasonically dispersed to form a suspension A, PVP is added to the suspension A, stirring is conducted until the product g-C3N4 is completely dissolved to form a solution B, TAA and SnCl4 2H2O are addedto the solution B, stirring is uniformly conducted to form a solution C, the solution C is subjected to a microwave hydrothermal reaction, after the reaction is completed, a precursor is obtained, the precursor is centrifuged and washed several times with the deionized water and the absolute ethanol, and vacuum drying is conducted to obtain a nanosheet self-assembled three-dimensional nano flowerSnS2 / g-C3N4 battery material.

Owner:SHAANXI UNIV OF SCI & TECH

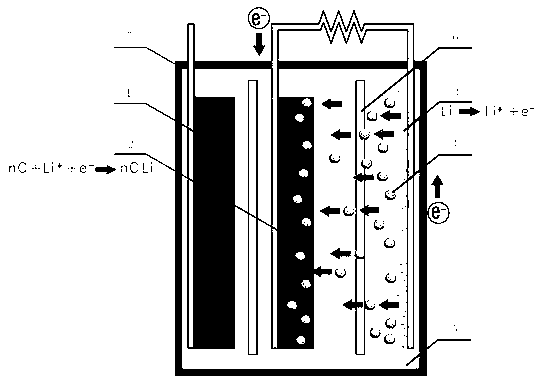

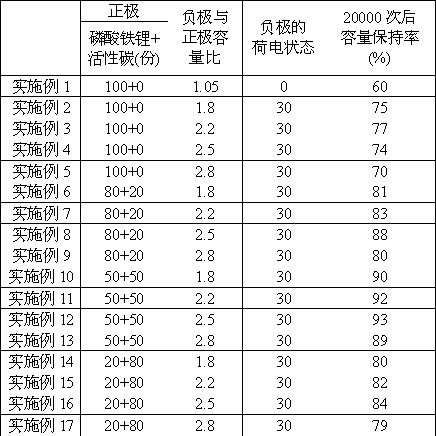

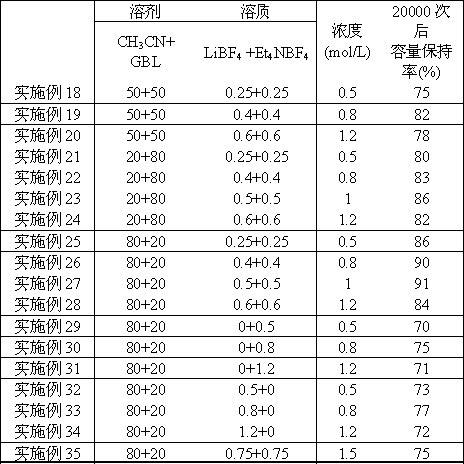

Chemical power supply

InactiveCN102842703AGood charge and discharge performanceLong cycle lifeElectrolytic capacitorsCell electrodesLithium electrodeSupercapacitor

The invention provides a chemical power supply. The chemical power supply comprises an anode, a cathode, an isolation film and electrolyte, and is characterized by being formed by mixing a lithium ion battery and the inner part of a super capacitor, wherein the cathode is subjected to the pre-doping lithium process, so that the SOC (State of Charge) of the cathode is 30%. According to the chemical power supply, particularly the lithium titanate-based chemical power supply provided by the invention, not only is high-multiplying power charging and discharging performance good, also the cycle service life is long, the internal resistance can not be increased, and the gas expansion can be occur after the long-term use of the chemical power supply, the safety is high, and the circulation performance and the power performance are good, so that the chemical power supply has wide application field.

Owner:SHANGHAI AOWEI TECH DEV

High-voltage solid state LIC (Li-ion Capacitor)

InactiveCN106876146AGood charge and discharge performanceHigh rate cycling stabilityHybrid capacitor electrodesDouble layer capacitorsIonCurrent collector

The invention discloses a high-voltage T-Nb<2>O<5> / RGO solid state LIC (Li-ion Capacitor). The solid state LIC comprises a solid state gel electrolyte, a positive electrode and a negative electrode; each of the positive electrode and the negative electrode is composed of a current collector layer and an electrode material layer attached on the current collector layer; and a preparation method of directly blending an ionic liquid and a polymer into a film is selected by the solid state gel electrolyte. The solid state LIC has excellent properties such as high specific capacity, high energy density, high power density, and fast charging and discharging, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

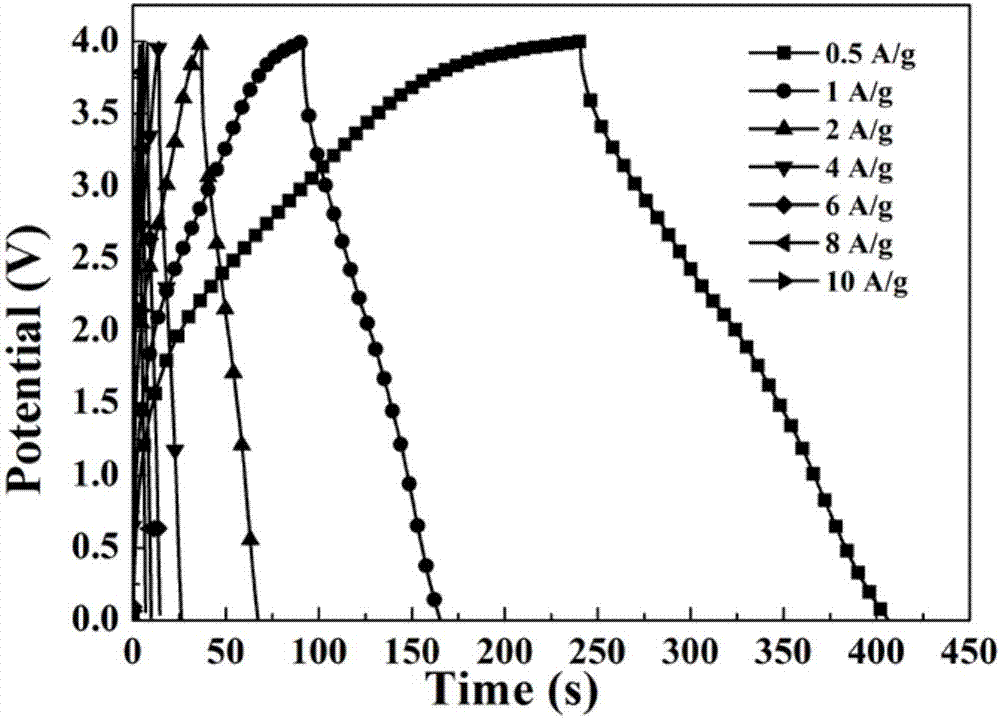

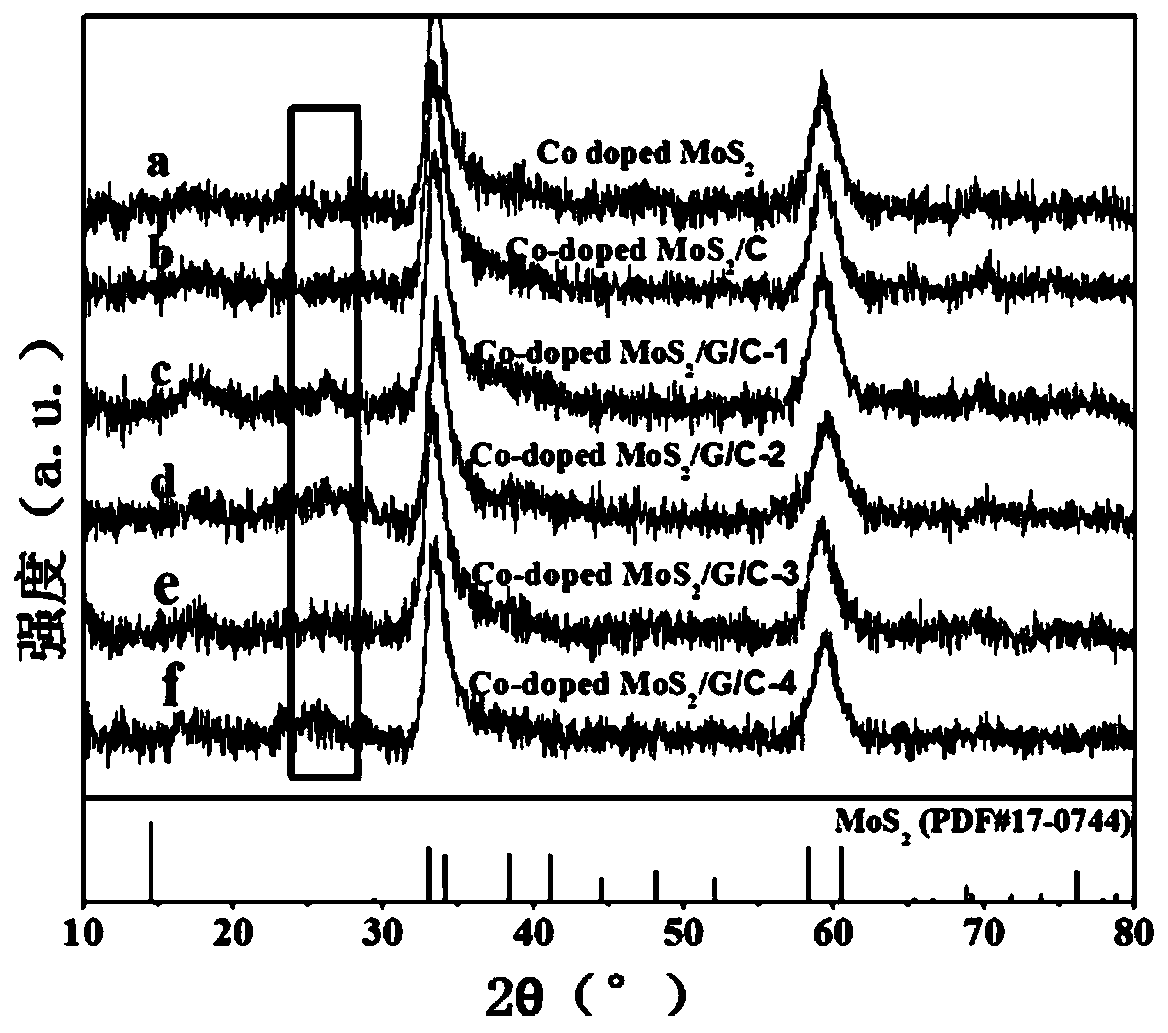

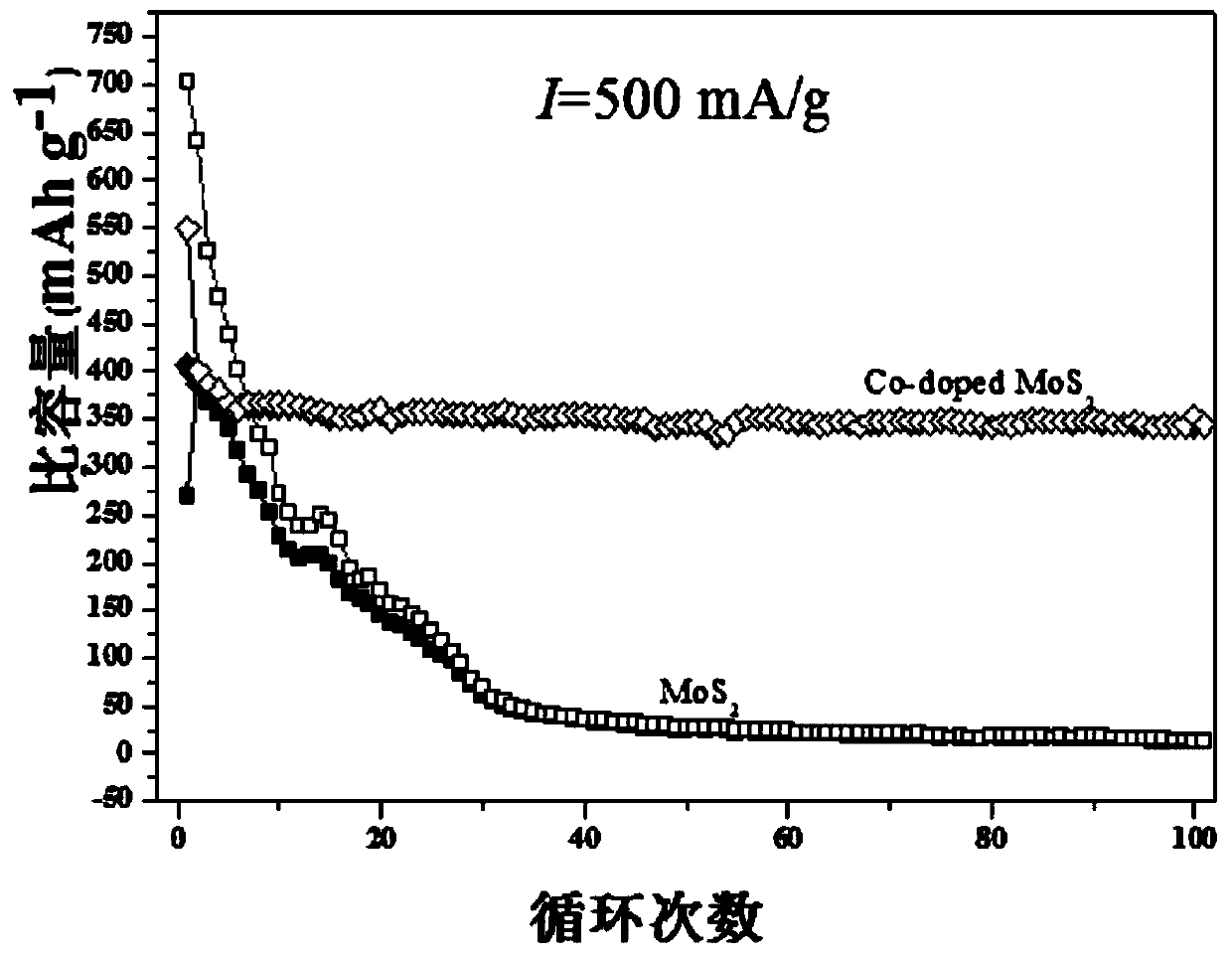

Cobalt-doped molybdenum sulfide-graphene-carbon composite material, and preparation method and application thereof

InactiveCN109713258AGood charge and discharge performanceImprove conductivityCell electrodesSecondary cellsCarbon compositesThiourea

The invention discloses a cobalt-doped molybdenum sulfide-graphene-carbon composite material, and a preparation method and application thereof. The method comprises proportionally adding cobalt salt,sodium molybdate, a graphene oxide aqueous solution and thiourea into an aqueous solution of sugar; uniformly ultrasonically mixing the mixture; transferring the mixed solution to a hydrothermal reaction kettle for a hydrothermal reaction at a fixed temperature; and obtaining the cobalt-doped molybdenum sulfide-graphene-carbon composite material by washing, drying and sintering. The invention alsodiscloses the composite material and the application thereof. The method, based on the characteristic of the molybdenum sulfide used as a sodium battery negative electrode material, uses the grapheneand carbon having excellent electrical conductivity as a composite medium, utilizes cobalt doping to greatly improve electronic conductivity and sodium storage capacity of the composite material, andprepares the molybdenum sulfide-based composite electrode material having a high specific capacity and a long cycle life in one step. The material is cheap in raw materials, simple in operation process, high in yield, excellent in charge and discharge performance, convenient for industrial production, and easy to promote.

Owner:YANCHENG INST OF TECH

High voltage lithium ion battery functional electrolyte and preparation method and application

InactiveCN103928707AGood charge and discharge performanceDissolution inhibitionFinal product manufactureElectrolyte accumulators manufactureElectrical batterySolvent

The invention belongs to the field of chemistry and chemical engineering, in particular to high voltage lithium ion battery functional electrolyte and a preparation method and application. The high voltage lithium ion battery functional electrolyte is obtained by adding a functional addictive with the mass equivalent to 0.1-5% of the mass of ordinary electrolyte into the ordinary electrolyte, the ordinary electrolyte is formed by cyclic carbonate solvent, linear carbonate solvent and conductive lithium salt. The functional addictive is dialkyl phenyl phosphonic acid salt, the structural formula of the ordinary electrolyte is shown as formula 1, wherein 0<=n<=5. The high voltage lithium ion battery functional electrolyte can remarkably improve circulating stability of a high voltage lithium ion battery under the condition of high temperature and high potential and can be widely applied to the field of lithium ion battery manufacture. (Please find the formula in the specification).

Owner:SOUTH CHINA NORMAL UNIVERSITY

Nickel cobalt base-carbon nanotube composite electrode material and preparation method thereof

InactiveCN106847530AEasy to prepareGood charge and discharge performanceHybrid capacitor electrodesHybrid/EDL manufactureDouble-layer capacitanceCapacitance

The invention discloses a nickel-cobalt bimetallic hydroxide / carbon nanotube novel composite electrode material for super capacitors and a preparation method thereof. The method comprises finishing the surface of a carbon nanotube to form an aqueous solution with good dispersity; adding nickel salt, cobalt salt and an additive, and then adding an appropriate quantity of an alkali source, performing suction filtration, washing, and drying after reaction in an oil bath with a mild condition so as to obtain highly uniformly dispersed nickel-cobalt bimetallic hydroxide / carbon nanotube novel composite. The nickel-cobalt bimetallic hydroxide / carbon nanotube novel composite is used as the electrode material of the super capacitor so that both the double-layer capacitance of the carbon nanotube and the pseudocapacitance of the hydroxide can be used and the carbon nanotube has good electrical conductivity, dispersion promoting performance and mechanical strength. The optimized and synthesized novel composite electrode material has a specific capacitance value of 1558F / g when having a current density of 1A / g. When the current density is increased to 10A / g, the specific capacitance value is still maintained at 1358F / g, thereby achieving a retention rate of 87. 2% so that the novel composite electrode material has good magnification and good charge and discharge cycle stability. The method for synthesizing the material is simple, mild in condition, and cheap in raw material and is a good preparation method. The electrode material has excellent performance.

Owner:SICHUAN UNIV

Chemical nickel plating solution and preparation method thereof, method for carrying out nickel plating on nano-LiFePO4/C composite material by using chemical nickel plating solution, and resulting product thereof

InactiveCN102747344AGood charge and discharge performanceImprove rate discharge performanceLiquid/solution decomposition chemical coatingHigh rateNickel plate

The present invention discloses a chemical nickel plating solution and a preparation method thereof, a method for carrying out nickel plating on a nano-LiFePO4 / C composite material by using the chemical nickel plating solution, and a resulting product thereof. The chemical nickel plating solution comprises the following components, 25-35 g / L of nickel sulfate, 20-30 g / L of sodium hypophosphite, 10-30 g / L of sodium acetate, 10-50 g / L of an organic hydroxy acid, and 5-20 g / L of an amino acid. An ammonia water is adopted to adjust the pH value of the chemical nickel plating solution to 4-7. After the chemical nickel plating solution of the present invention is adopted to carry out nickel plating on a nano-LiFePO4 / C composite material, elementary nickel content in the resulting composite material formed by coating the metal nickel on the surface of the nano-LiFePO4 / C composite material is 0.5-12 (wt)%, and the resulting composite material has characteristics of excellent charge-discharge performance (especially excellent high rate discharge performance), low internal resistance, excellent electrical conductivity, and high tap density.

Owner:GUANGXI NORMAL UNIV +1

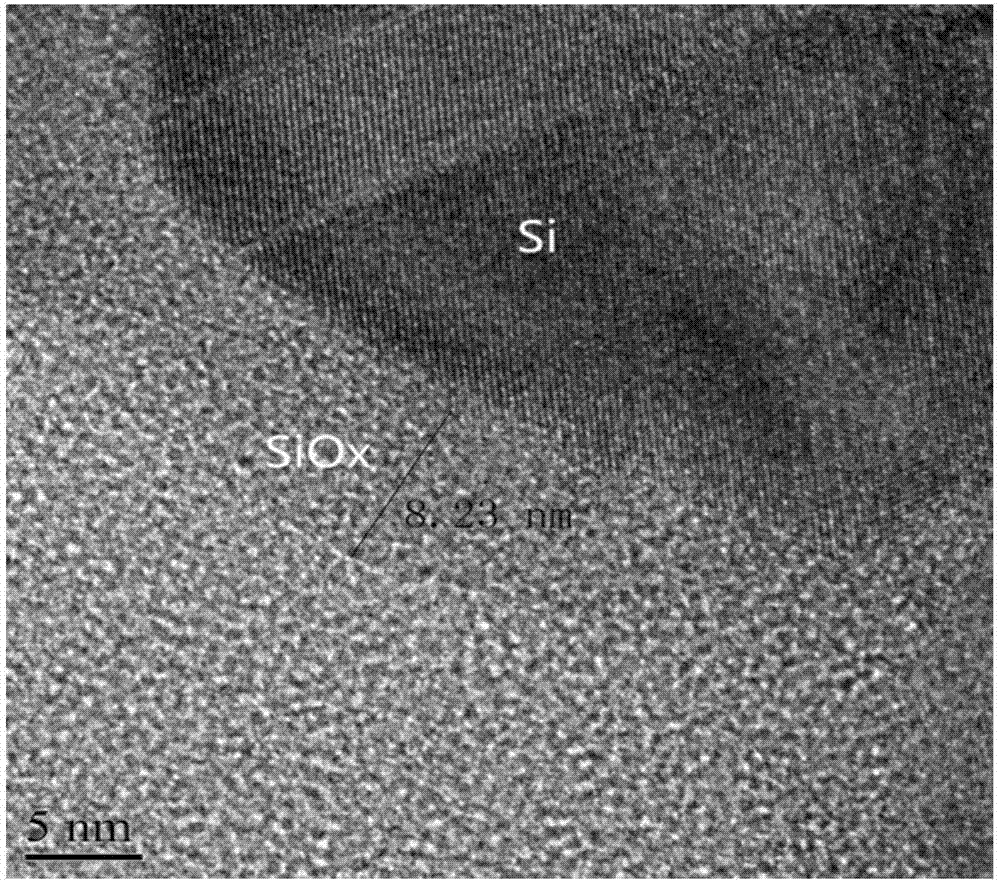

Lithium ion battery silicon doped carbon porous composite film and preparation method thereof

ActiveCN107579203AHigh bonding strengthImprove stabilityMaterial nanotechnologyCell electrodesCarbon compositesComposite film

The invention discloses a lithium ion battery silicon doped carbon porous composite film and a preparation method thereof. The preparation method comprises the following steps: firstly, oxidizing monatomic silicon, modifying the oxidized monatomic silicon through organo-siloxane so as to obtain modified monatomic silicon, preparing a silicon doped carbon composite film through a mixed solution prepared from the organo-siloxane modified monatomic silicon, a carbon-based polymer, a foaming pore forming agent and an organic solvent, and by taking hydrocarbon as a carbon source and an inert gas asa carrier gas, depositing a carbon nano material on the silicon doped carbon composite film by using a chemical vapor deposition method, and performing a method of sublimation pore forming with a foaming agent, thereby obtaining the lithium ion battery silicon doped carbon porous composite film. When the lithium ion battery silicon doped carbon porous composite film is used as a lithium ion battery cathode material, the primary lithium insertion capacity of the material is up to 1027.6mAh / g, the primary lithium removal capacity of the material is 997mAh / g, the coulombic efficiency of the material is 97.02%, the coulombic efficiency of the material is 91.31% after 100 times of circulation, and excellent charge and discharge properties are achieved.

Owner:SOUTH CHINA UNIV OF TECH

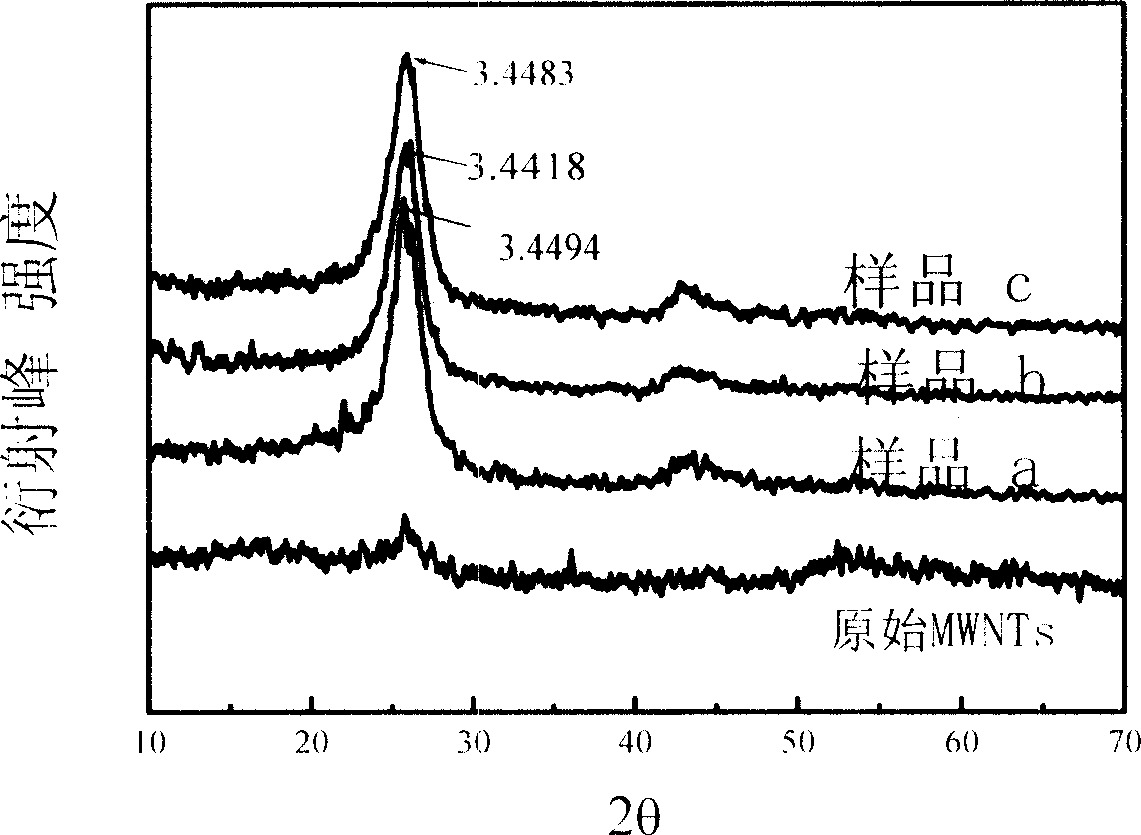

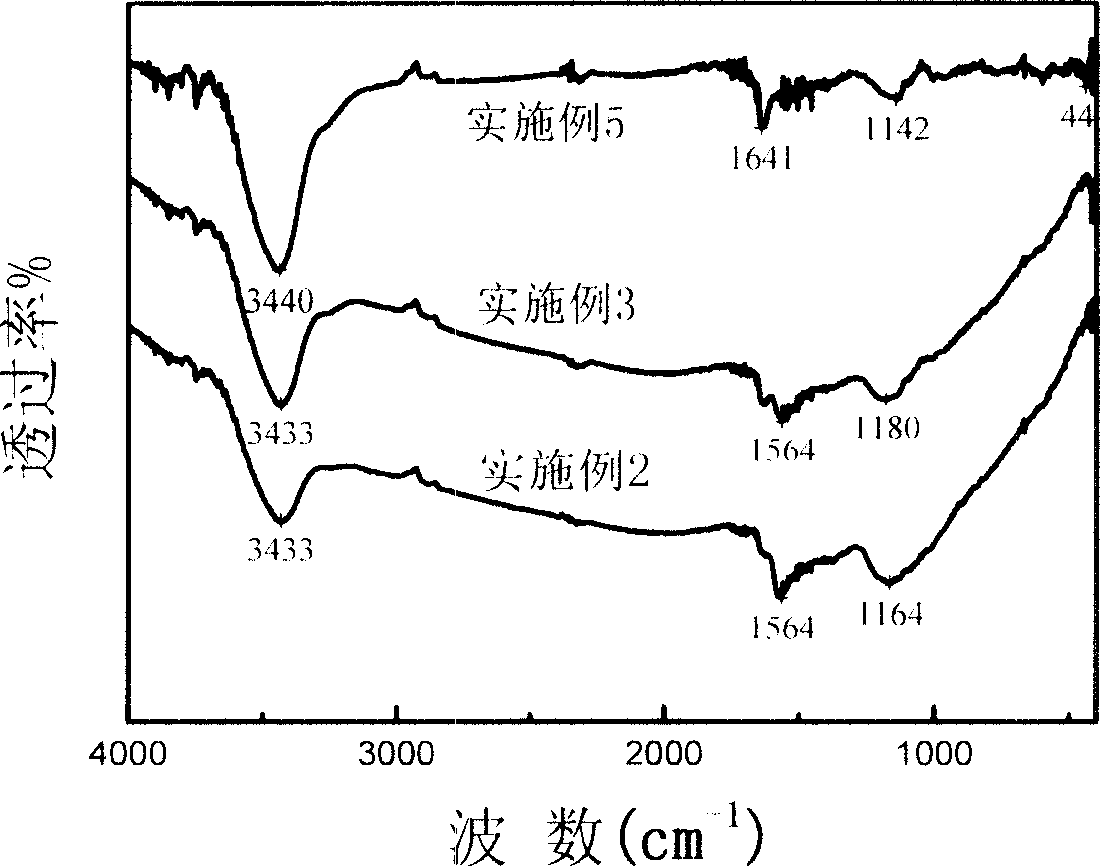

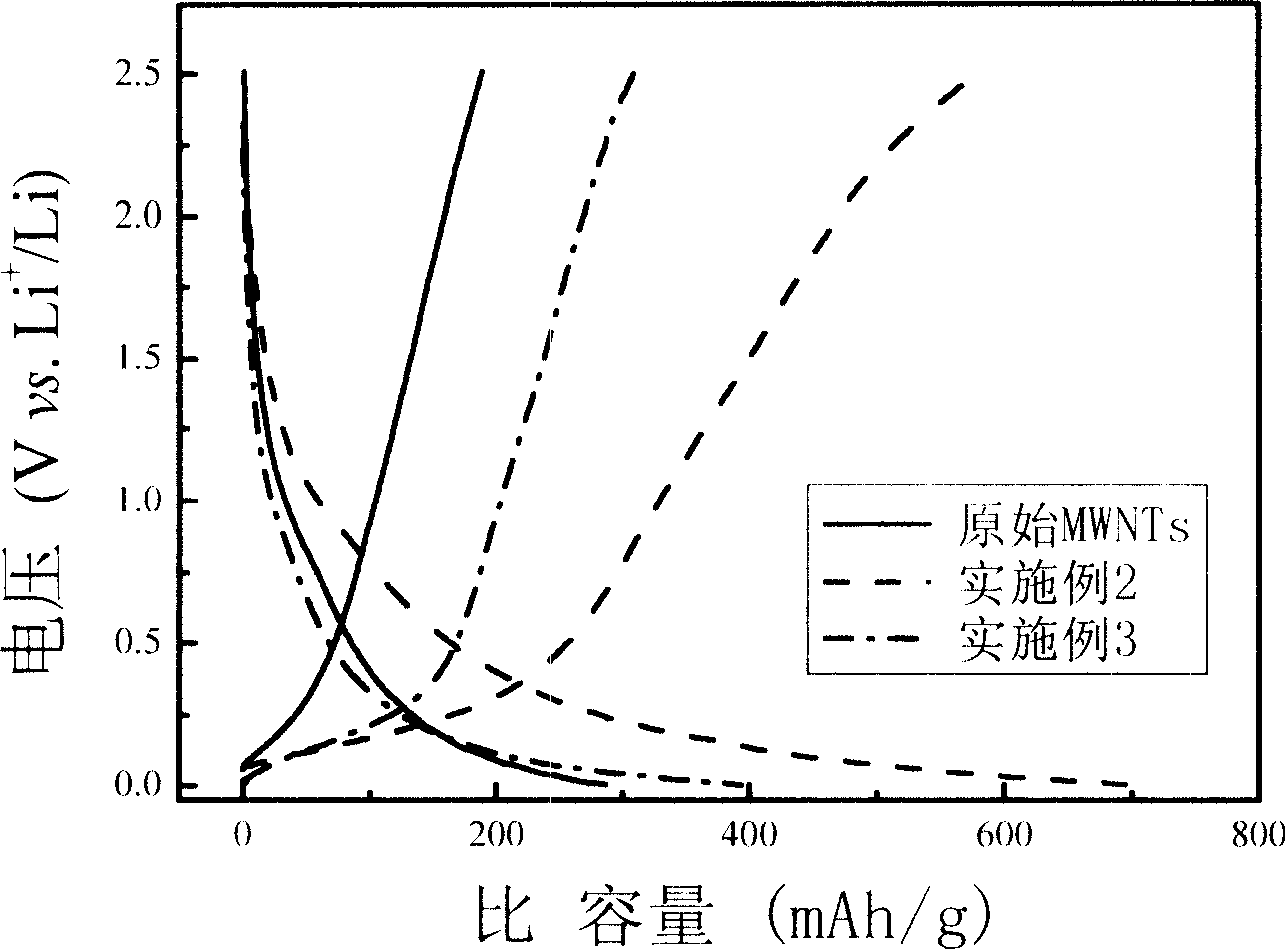

Method for increasing electrochemical lithium storage content of nano-carbon tube

InactiveCN1688046AIncrease spacingIncrease profitElectrode manufacturing processesGas phaseCarbon nanotube

This invention discloses a method for increasing electrochemical Li-storage capacity of carbon nm tubes, which processes the original MWNTS raw material prepared with chemical gas phase deposition method including: first of all, the original MWNTS is supersonic-vibrated, mechanical mixed and dipped under room temperature in different matched volumes of H2SO4 and HNO3 mixed solution, the reacted product is cleaned with deionized water to neutral and put in a tube oven to be heated under 200-500deg.C to be cooled and dipped in Li2CO3 or LiOH solution, the obtained sample is cleaned with deionized water, filtered and dried in vacuum. The gap of quasigraphite layer of the processed MWNTS is expanded, the electrochemical Li capacity is increased.

Owner:TSINGHUA UNIV

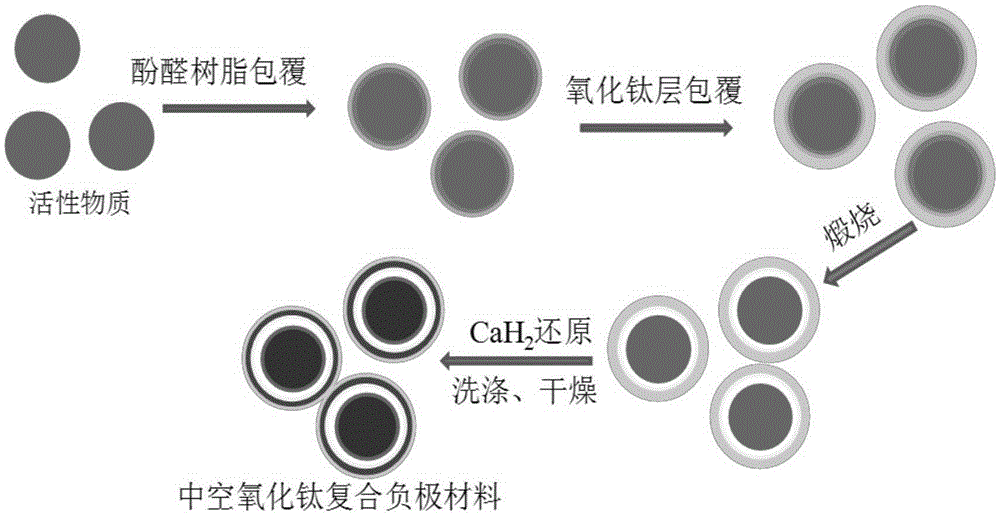

Hollow titanium oxide composite material, and preparation method and application thereof

ActiveCN105406041AThe electrochemical performance is significantly improvedThe process steps are simpleCell electrodesSecondary cellsOxygen vacancyCharge discharge

The invention discloses a hollow titanium oxide composite material, and a preparation method and application thereof in a lithium ion battery. The surface of an active substance is coated with a phenolic resin layer serving as a sacrifice template and then coated with a porous titanium oxide material, and the active substance coated hollow titanium oxide composite material containing rich oxygen vacancies is obtained by template removing and CaH2 treatment. The hollow titanium oxide composite material prepared according to the method can be used as a negative electrode material of the lithium ion battery. The hollow titanium oxide composite material, the preparation method and the application thereof, disclosed by the invention, have the advantages of simplicity in process step, short reaction time, high repeatability, high yield and low cost, and have the favorable large-scale application potential; with a hollow structure of the hollow titanium oxide composite material and the existing of a titanium oxide coating layer containing the rich oxygen vacancies, the electrochemical performance of the active substance can be obviously improved; and when used for preparing a lithium ion electrode, the hollow titanium oxide composite material has favorable cycle stability and excellent charging-discharging performance.

Owner:江苏久荣智能科技有限公司

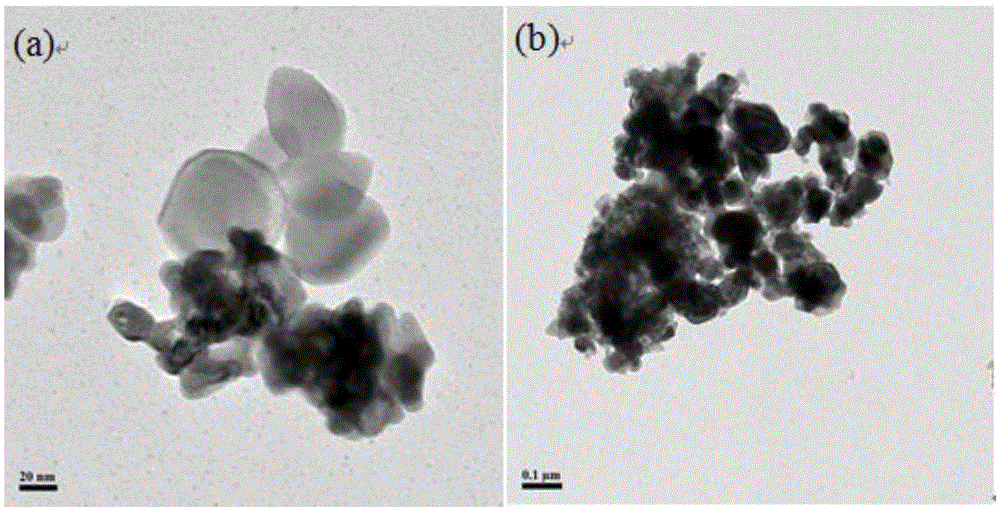

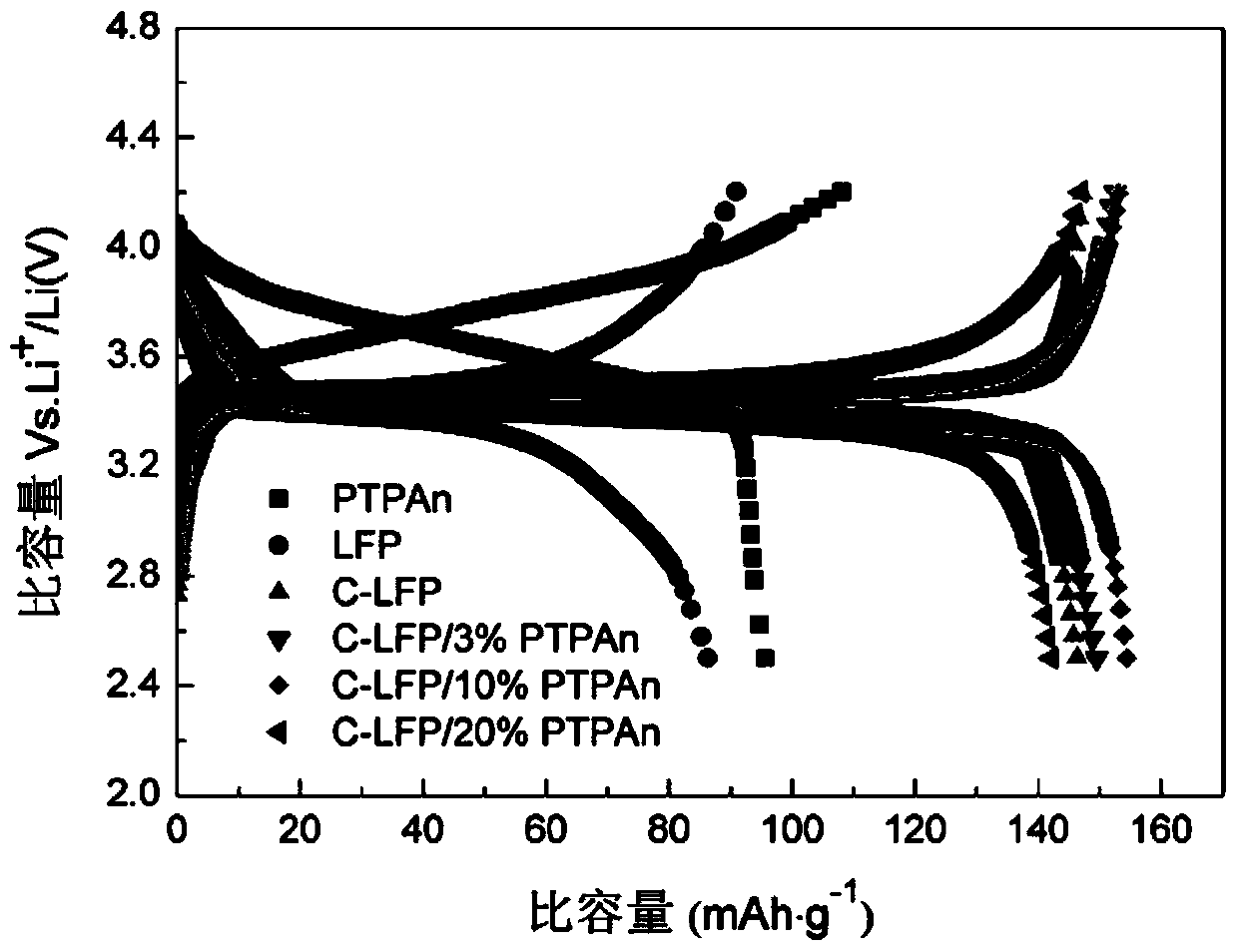

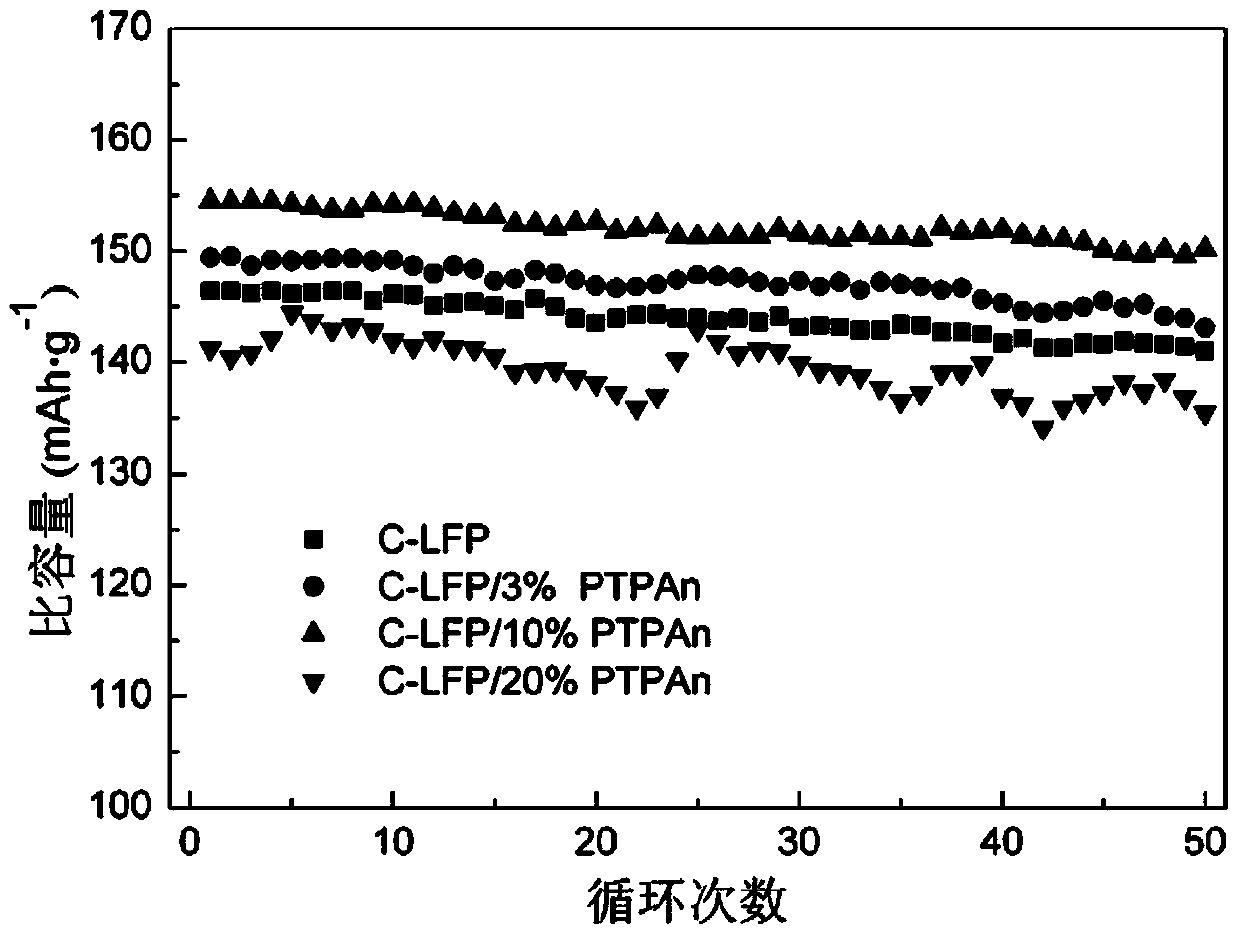

C-LiFePO4/PTPAn composite material, its application and lithium battery produced by composite material thereof

InactiveCN103746094AGood charge and discharge performanceHigh charge and discharge capacityCell electrodesSecondary cellsIonCharge and discharge

The invention provides a C-LiFePO4 / PTPAn composite material, its application and a lithium battery produced by the composite material thereof. The C-LiFePO4 / PTPAn composite material is characterized by taking a carbon-coated LiFePO4 material and PTPAn as raw materials and prepared by a solution blending method. The C-LiFePO4 / PTPAn composite material which is taken as a lithium ion batteries cathode material has good charge and discharge performances, cycle stability and high magnification performance.

Owner:ZHEJIANG UNIV OF TECH

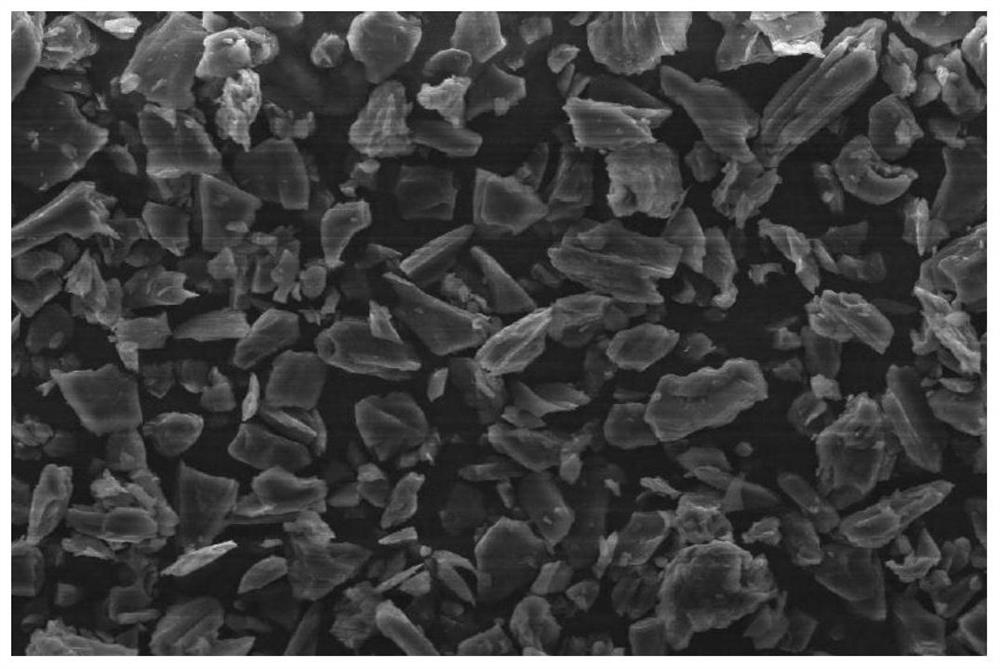

Preparation method of high-magnification quick-charging graphite negative electrode material

ActiveCN112289986AImprove defectsImprove the rate of fast charging performanceCell electrodesSecondary cellsGraphitePetroleum coke

The invention discloses a preparation method of a high-magnification quick-charging graphite negative electrode material. The method comprises the following steps: carrying out coarse crushing and fine grinding on one or more of needle coke, petroleum coke and pitch coke, carrying out spheroidizing shaping treatment, mixing with a first carbon source, heating to carry out surface coating, and carrying out high-temperature carbonization; then carrying out high-temperature graphitization treatment to obtain an artificial graphite powder; and mixing the obtained artificial graphite powder with asecond carbon source, heating for surface coating, and carbonizing at a high temperature to obtain the high-magnification quick-charging graphite negative electrode material. The graphite negative electrode material prepared by the invention has the advantages of a high charge-discharge rate, a large discharge gram capacity and good cycle performance, and a battery prepared from the graphite negative electrode material has excellent comprehensive performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

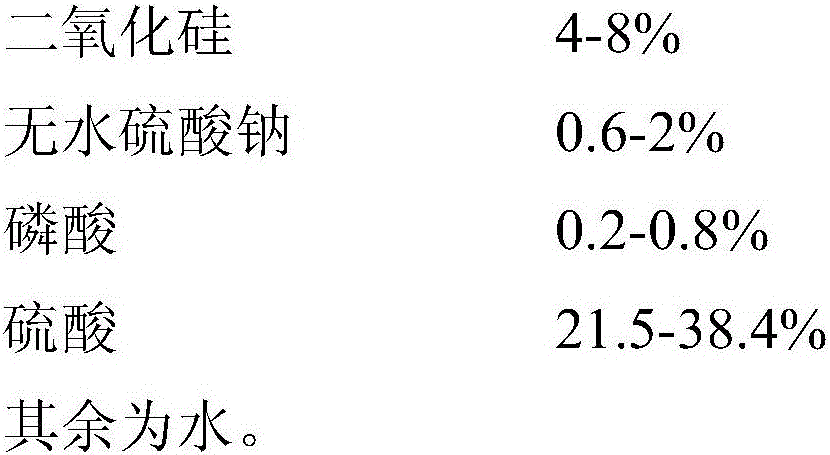

Gel battery electrolyte and preparation method therefor

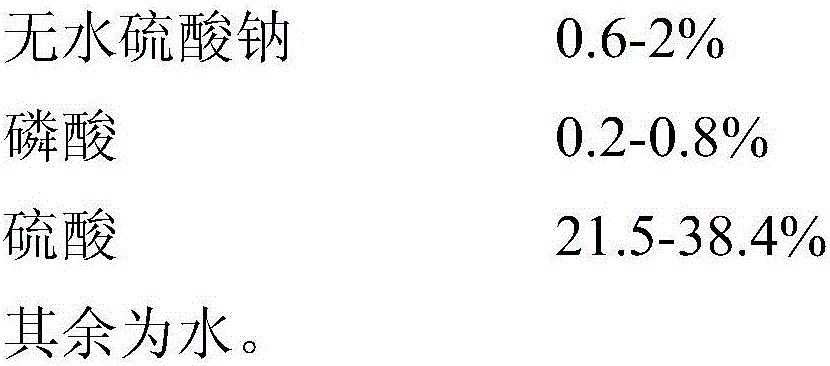

InactiveCN106025379AReduce dehydrationLong cycle lifeLead-acid accumulatorsPhosphoric acidCharge discharge

The invention discloses a gel battery electrolyte. The gel battery electrolyte comprises the ingredients in percentage by mass: 4-8% of silicon dioxide, 0.6-2% of anhydrous sodium sulfate, 0.2-0.8% of phosphoric acid, 21.5-38.4% of sulfuric acid and the balance of water. The invention also discloses a preparation method for the gel battery electrolyte, wherein the preparation method comprises the steps of (1) mixing silicon dioxide with water, and preparing a gel mother liquid under a high-speed shearing effect; (2) preparing a dilute sulfuric acid solution, and adding anhydrous sodium sulfate and phosphoric acid to obtain a mixed solution; and (3) adding the obtained gel mother liquid into the mixed solution, and rapidly stirring to obtain the gel battery electrolyte. Due to the synergetic cooperation and the reasonable adding sequence of the materials with the proportion, the prepared electrolyte is capable of effectively eliminating hydration layering, long in cycle life and excellent in charging-discharging performance at a low temperature environment; and meanwhile, the electrolyte system is stable, low in cost, and good in the operational performance.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com