Lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems affecting the gram capacity and cycle performance of active materials, and the inability to form SEI films, etc., to improve safety performance and cycle performance, reducing gas production sources, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

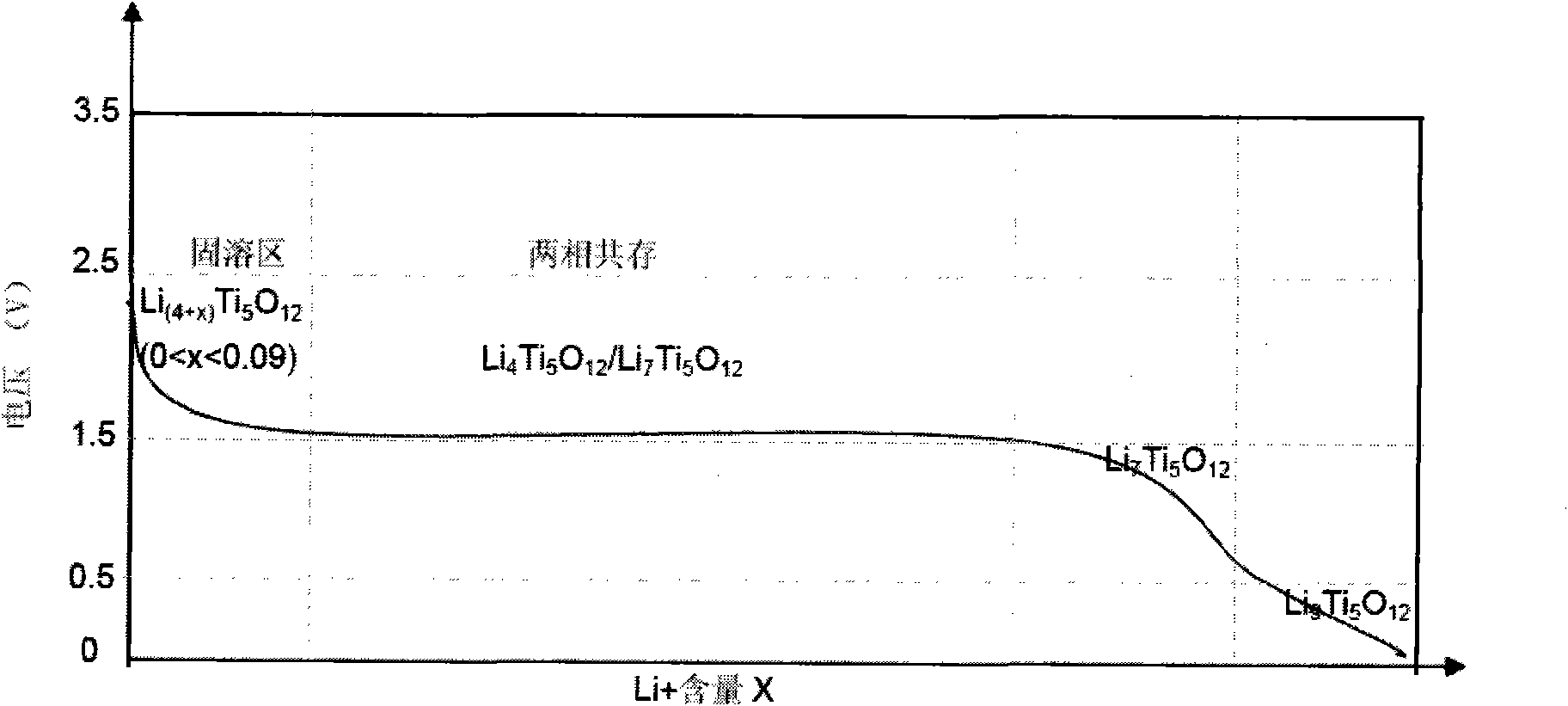

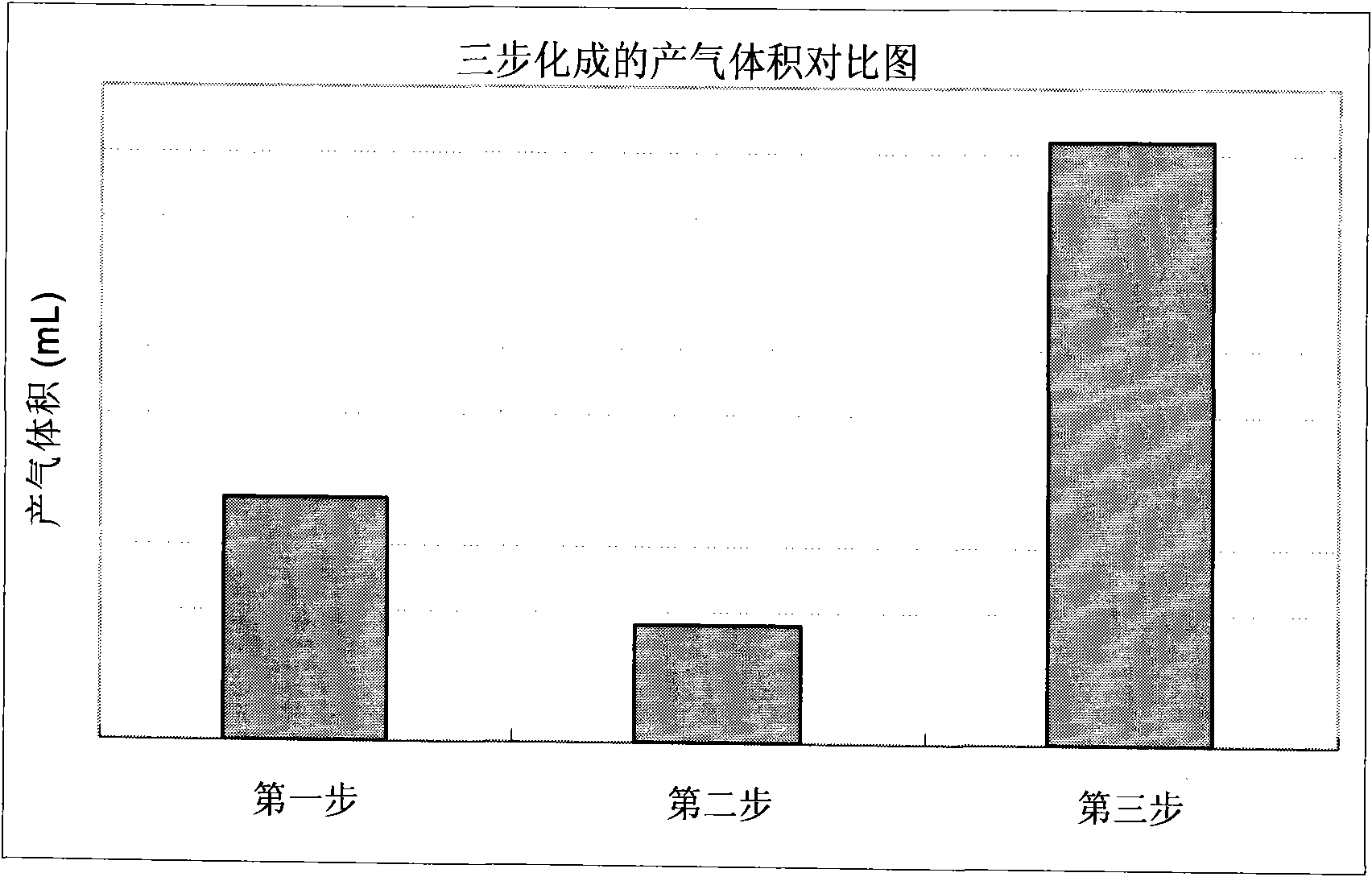

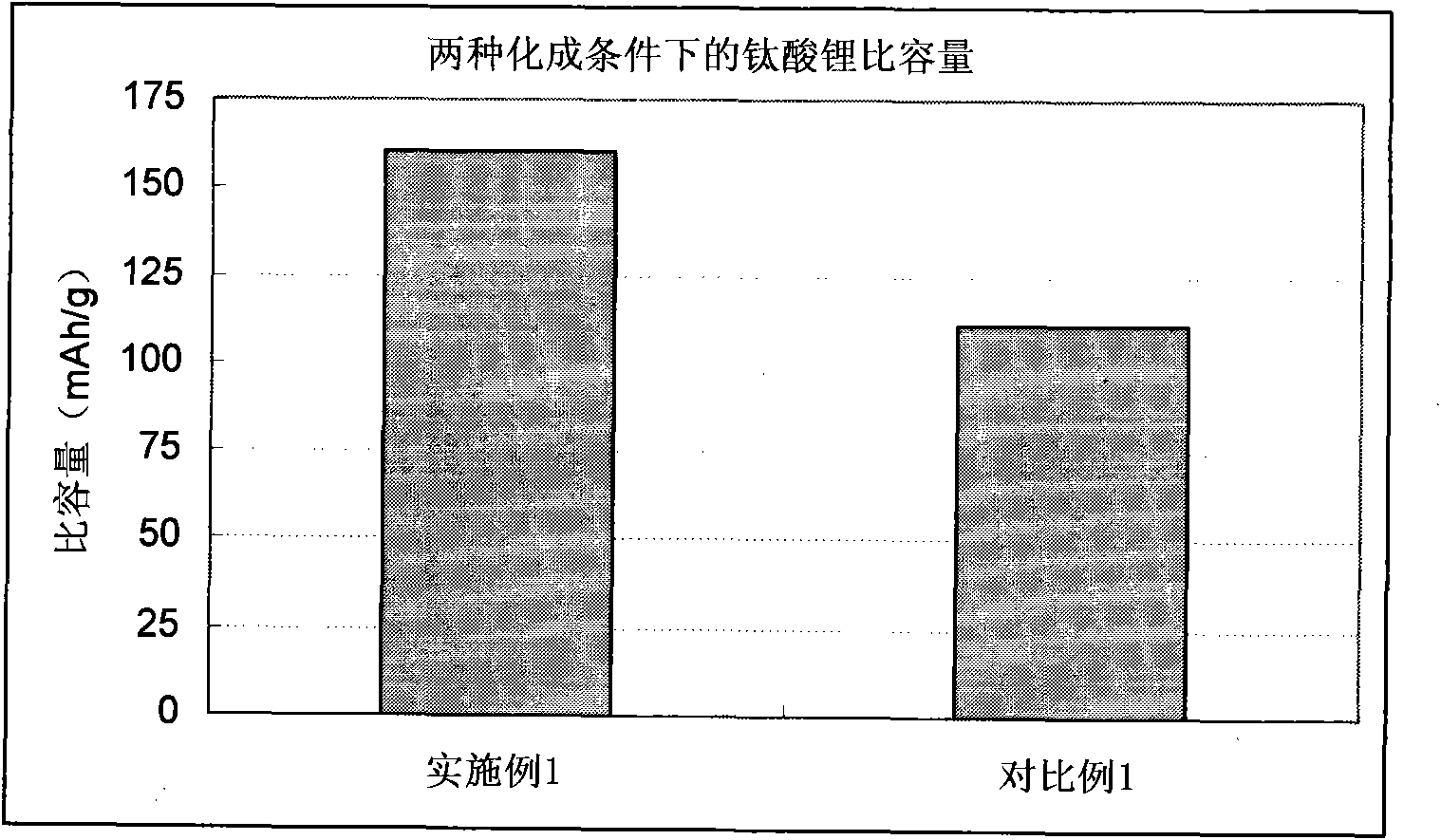

[0050] See Figure 3-4 And 6-8, with aluminum foil as the base material of the anode pole piece, lithium titanate as the anode active material, nickel cobalt lithium manganese oxide as the cathode active material, the anode capacity / cathode capacity of the pole piece is 0.8, and the lithium Assembly of ion secondary batteries. The prepared battery is activated: the battery is charged with a constant current at a constant temperature of 60 ° C, so that lithium titanate is converted from Li 4 Ti 5 o 12 become Li 6.5 Ti 5 o 12 , the charging current is 0.5C; after pumping, the battery is charged at a constant current, so that Li 5 Ti 5 o 12 become Li 7 Ti 5 o 12 , the charging current is 1C; finally, the battery is charged at a constant voltage for 12 hours, then vacuum-sealed, and finally, the resulting battery is used for standby.

Embodiment 2

[0053] Example 2: see Figure 5 , the present embodiment differs from Example 1 in that: first, the cathode active material is lithium cobalt oxide; second, the anode capacity / cathode capacity of the pole piece is 0.7; third, the prepared battery is Activated at a temperature of 80°C, the constant current charging current is 0.5C, so that lithium titanate is charged by Li 4 Ti 5 o 12 become Li 5.5 Ti 5 o 12 ; In the fourth place, the battery is charged at a constant current after pumping, and the charging current is 5C, so that Li 5 Ti 5 o 12 become Li 7 Ti 5 o 12 ; Fifth, finally charge the battery at a constant voltage for 8 hours. Others are the same as those in Embodiment 1, and will not be repeated in this embodiment.

Embodiment 3

[0057] See Figure 6 , The difference between this embodiment and Embodiment 1 is that: the anode capacity / cathode capacity of the pole piece is 0.9, and the others are the same as Embodiment 1, and this embodiment will not repeat them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com