Patents

Literature

608 results about "Isolation membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

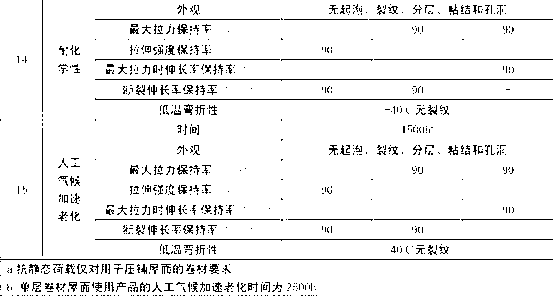

Inventor

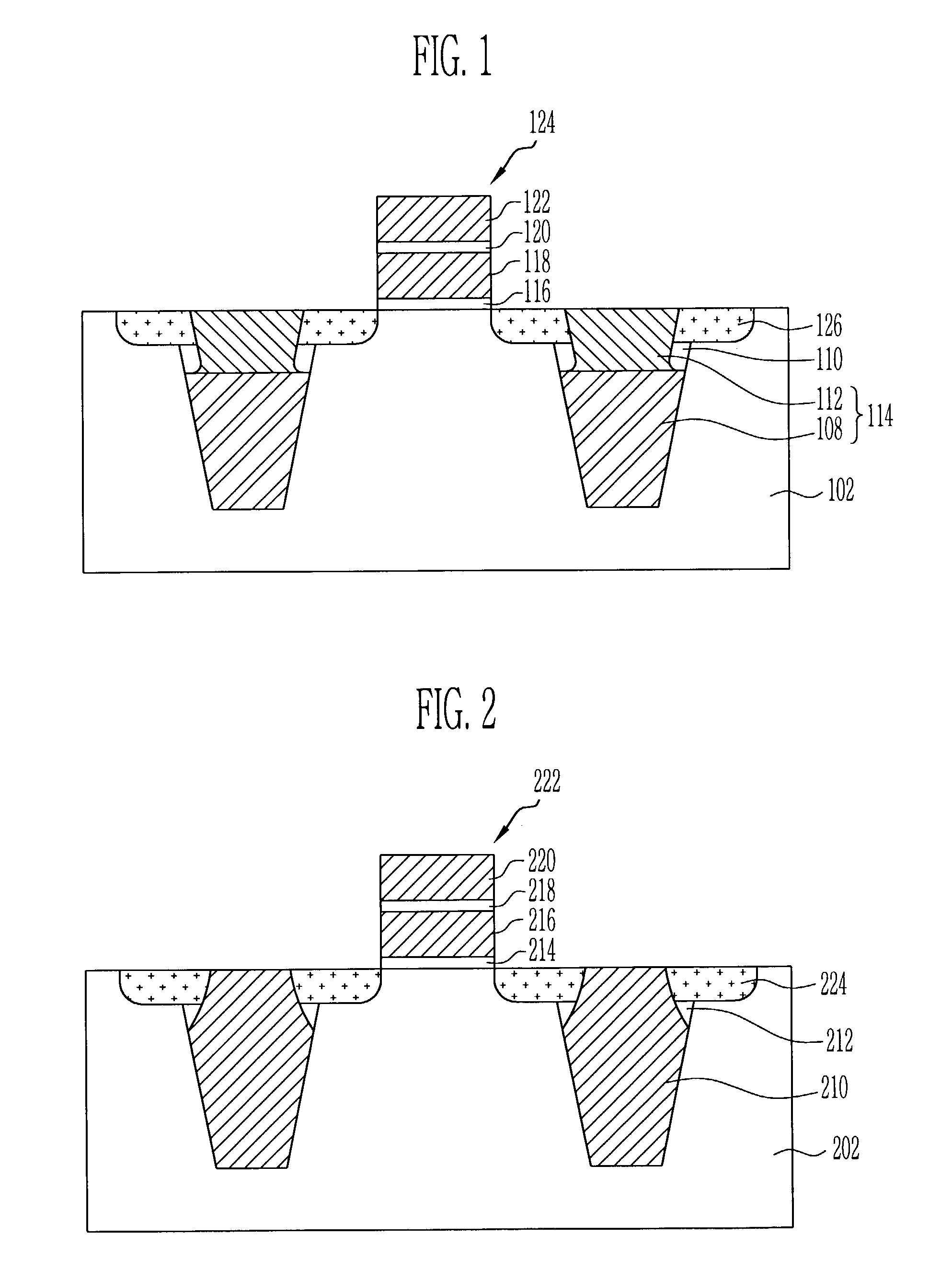

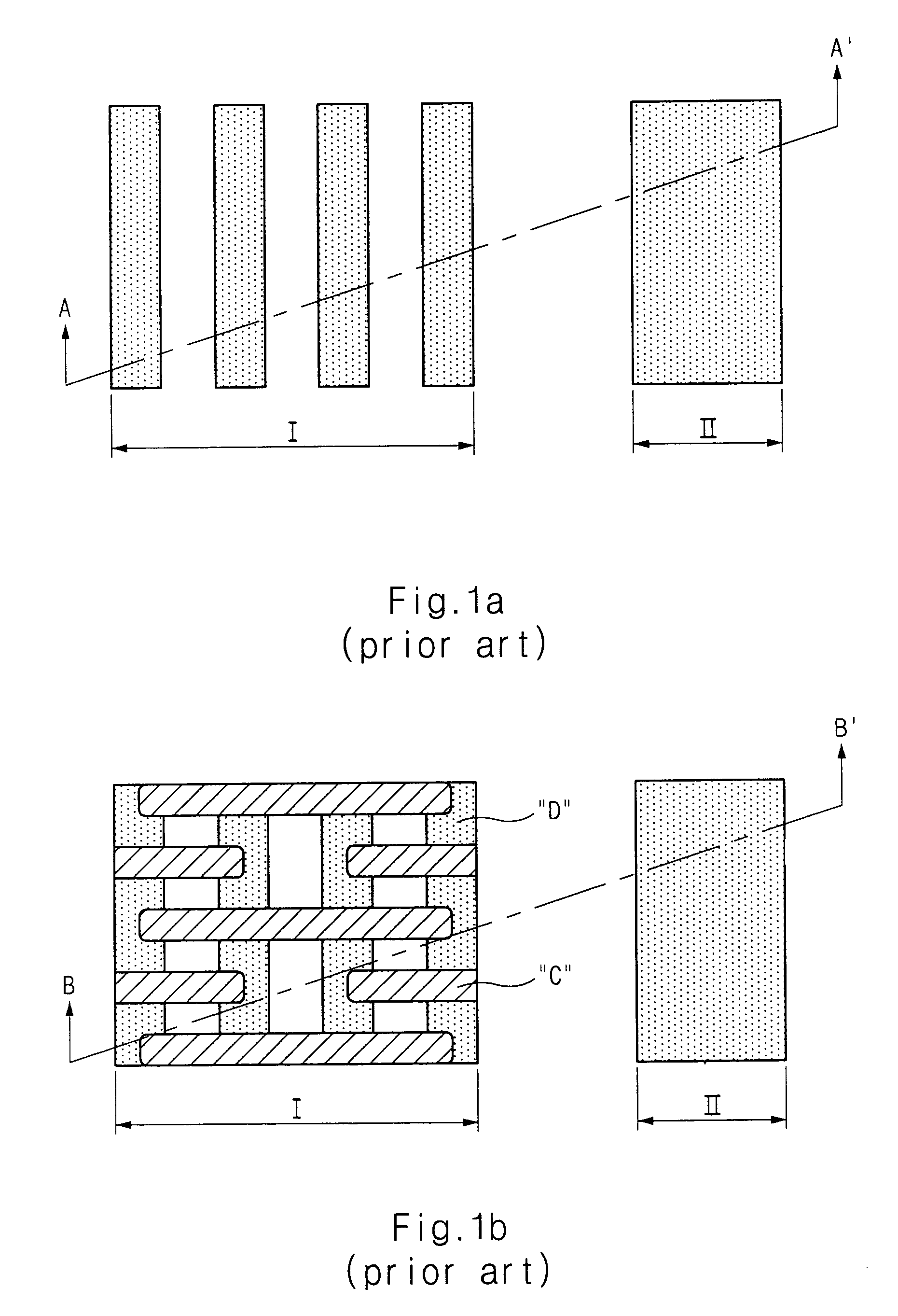

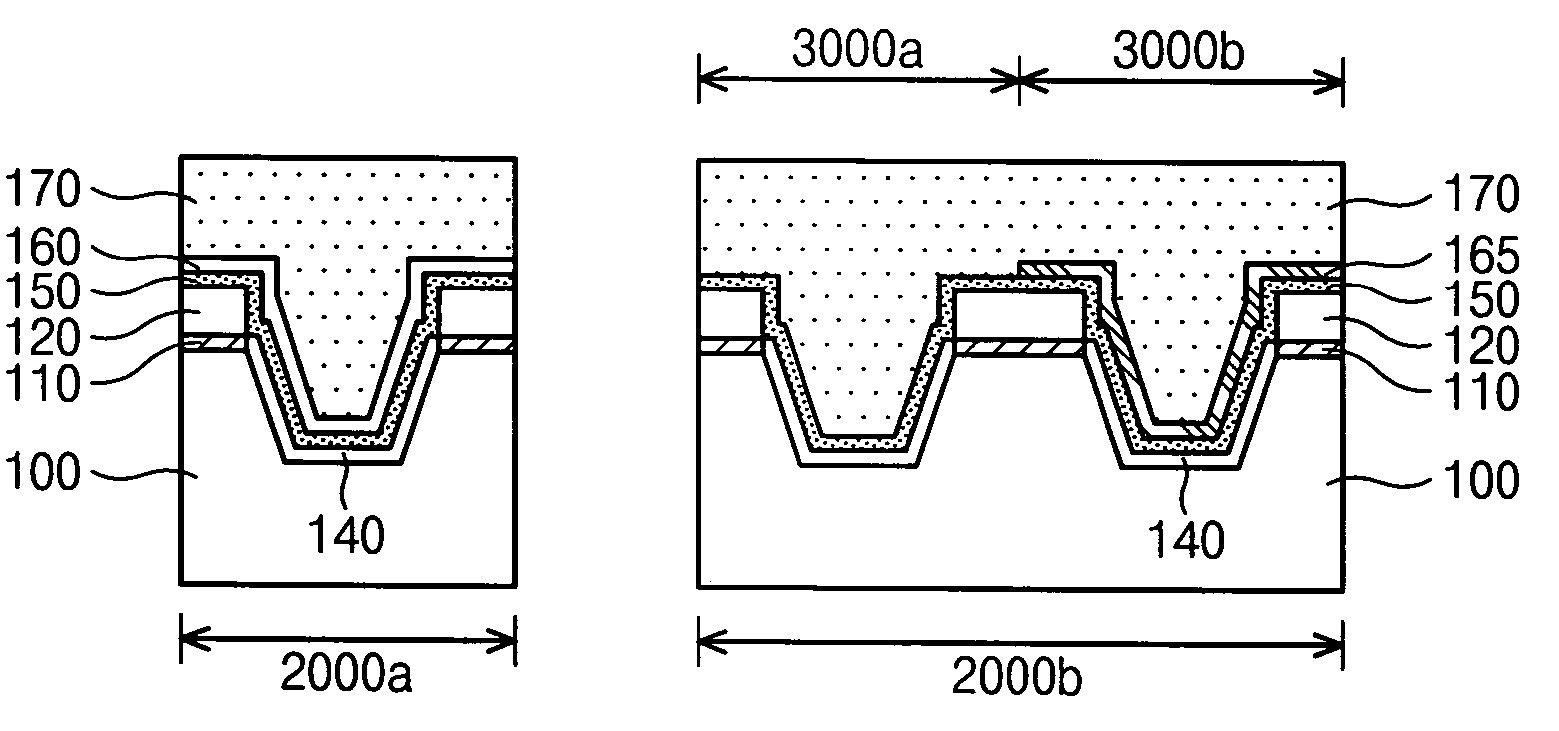

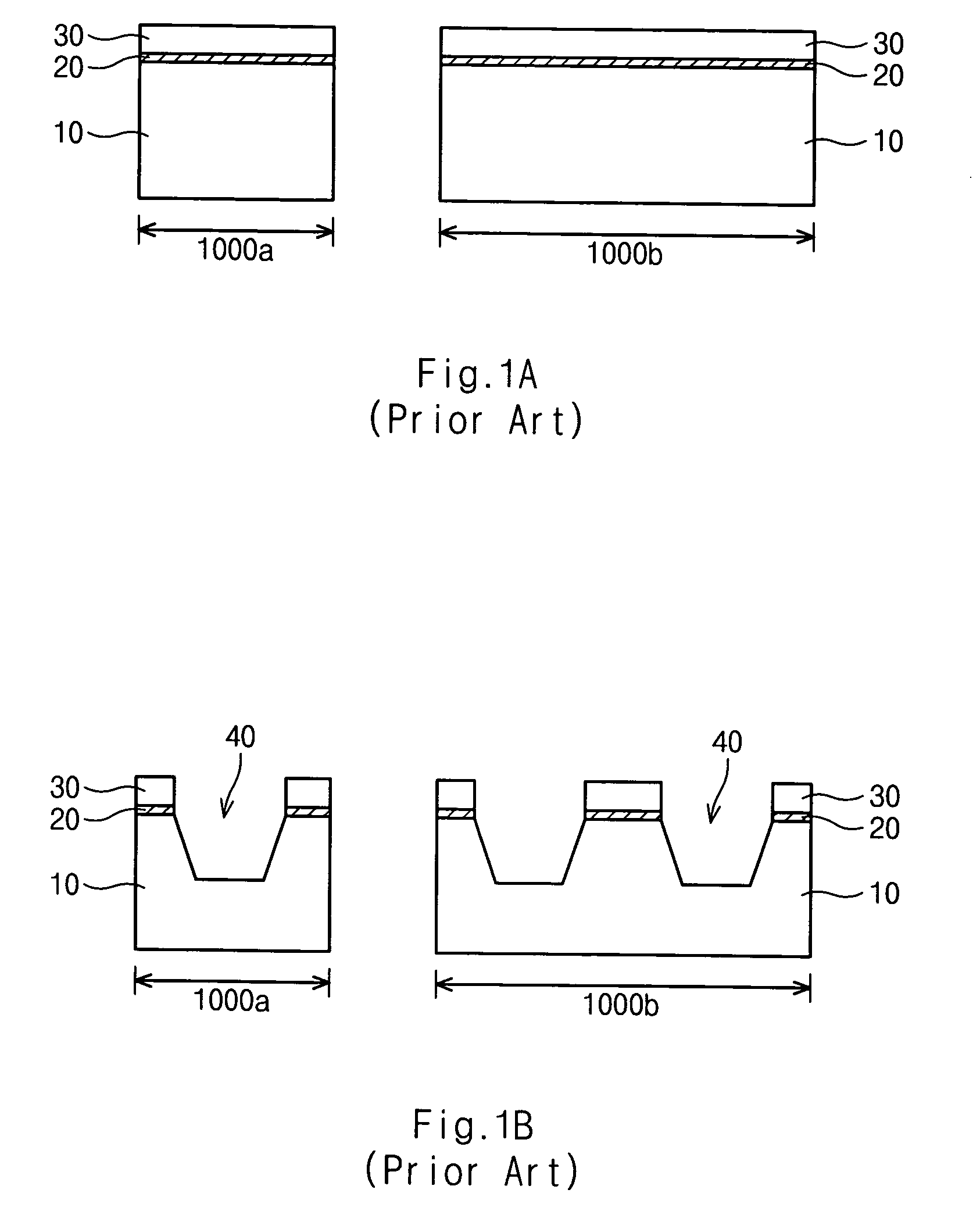

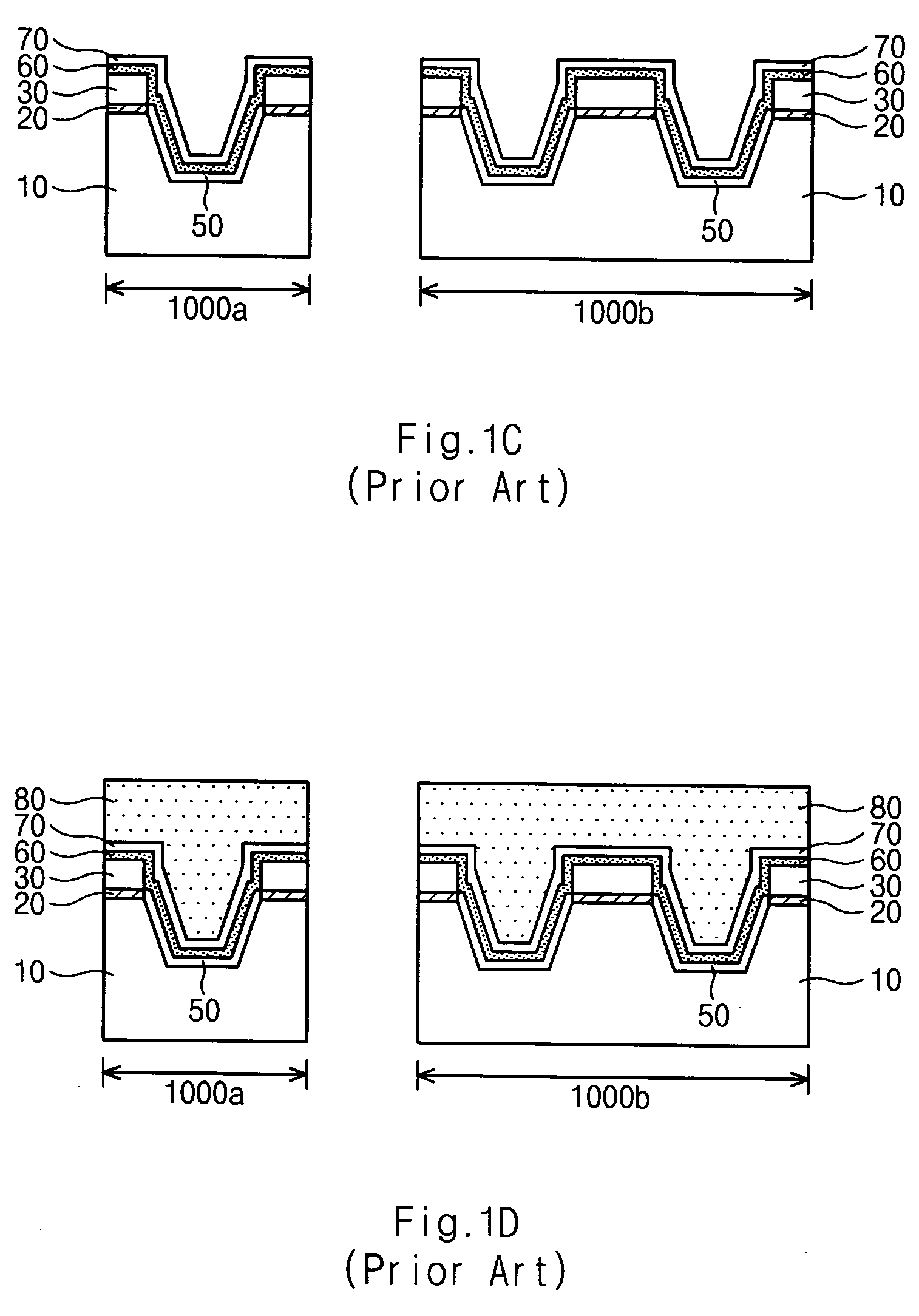

Semiconductor device and method of manufacturing the same

InactiveUS7029989B2Improve level of integrationHighly integratedTransistorSolid-state devicesImpurity diffusionSemiconductor

The present invention relates to a semiconductor device and a method of manufacturing the same. The minimum marginal width of an impurity diffusion layer is defined to reduce by a given width. The reduced width of the impurity diffusion layer is compensated for through a silicon growth layer formed on the top of a device isolation film having a relatively higher degree of freedom than the bottom of the device isolation film. Thus, the degree of integration in the semiconductor device can be improved while keeping intact the minimum marginal width of the impurity diffusion layer.

Owner:MAGNACHIP SEMICONDUCTOR LTD

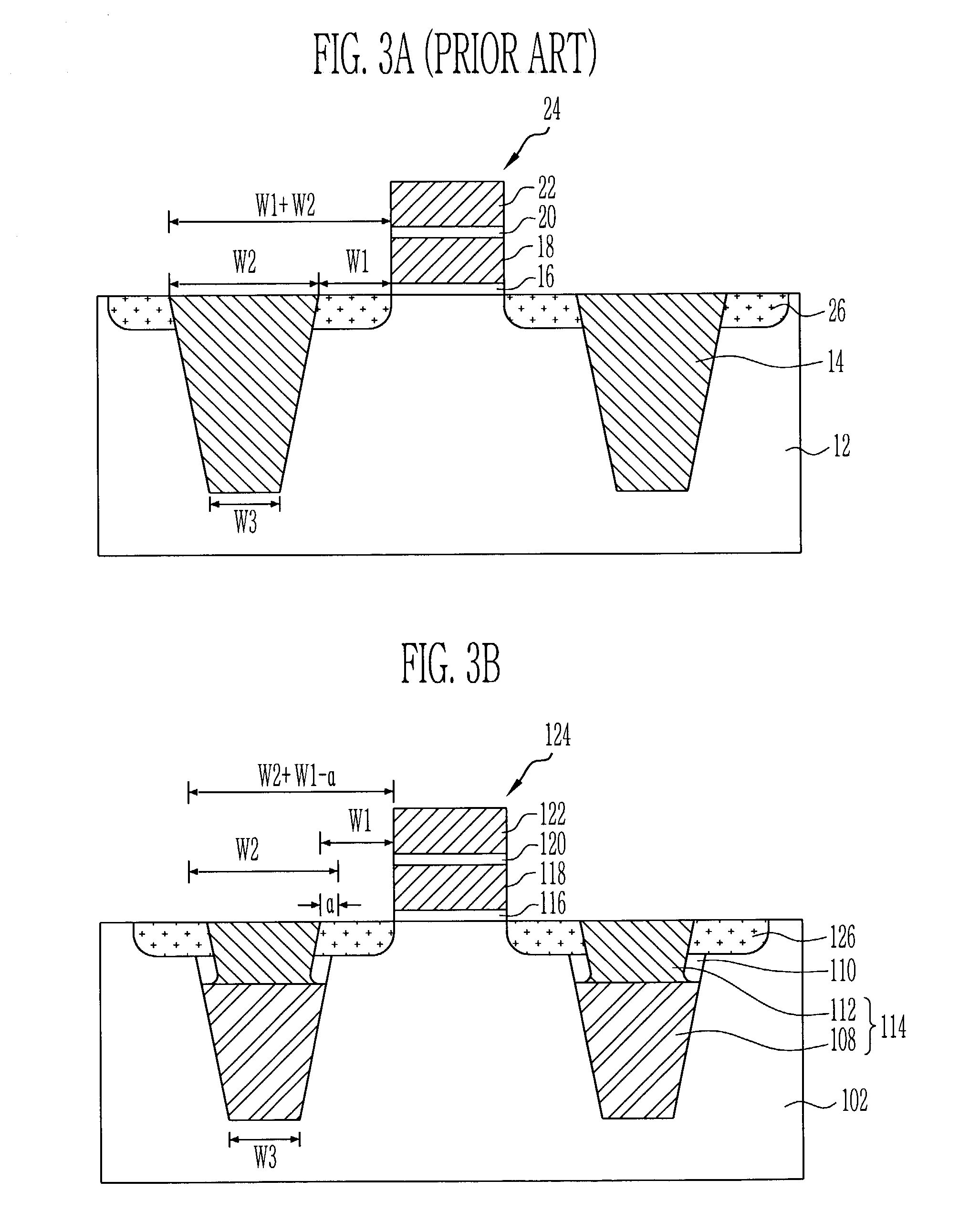

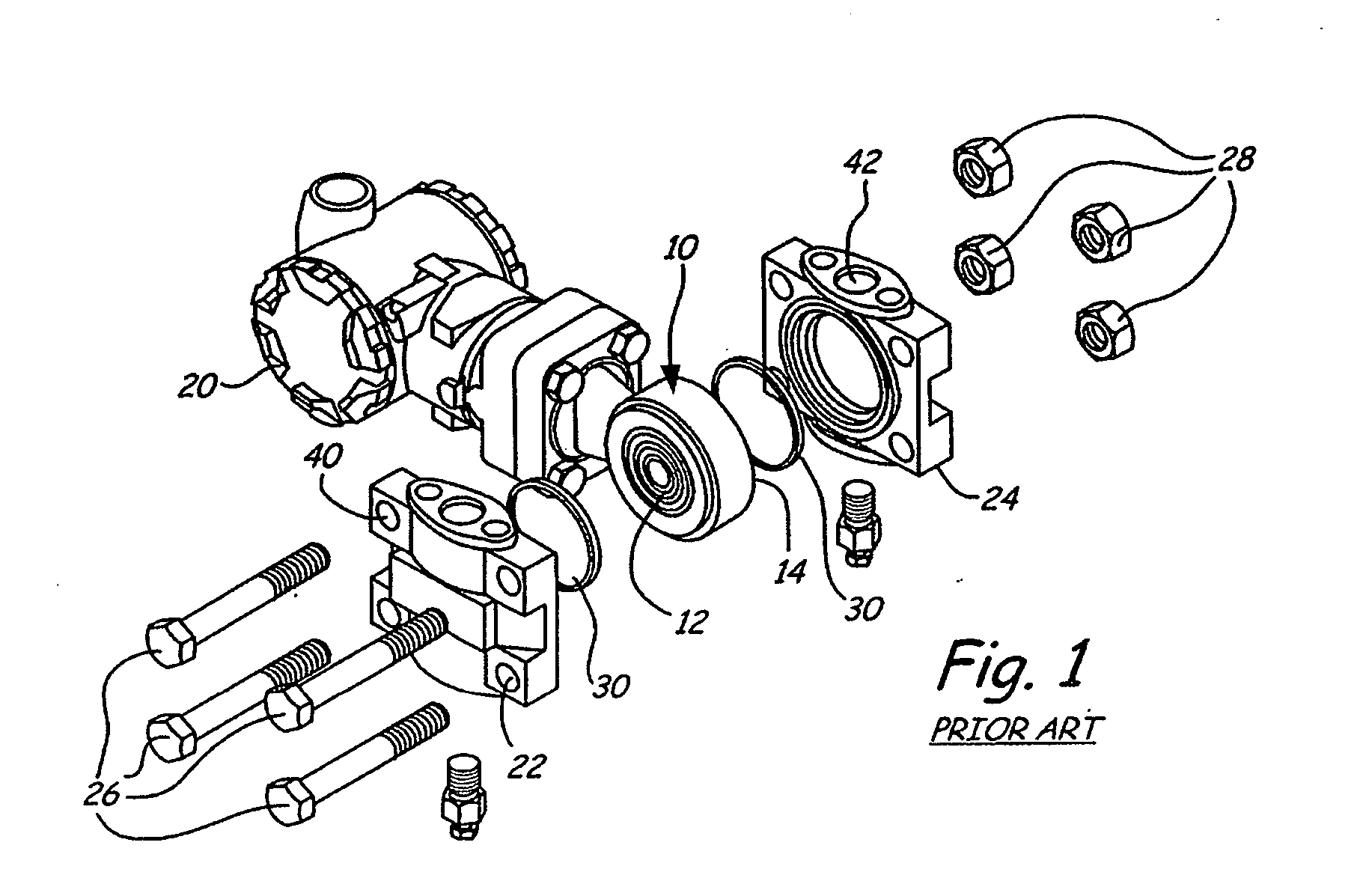

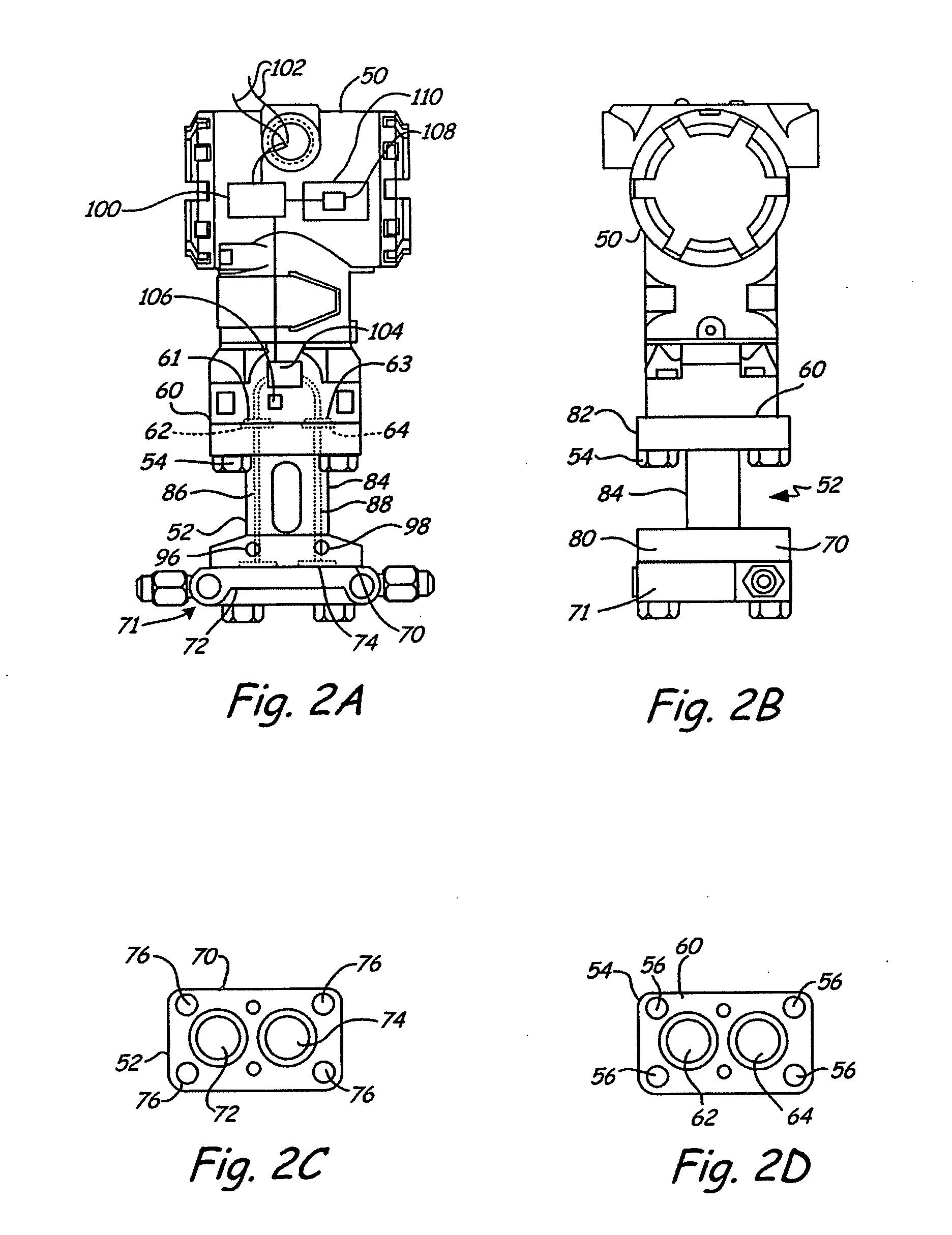

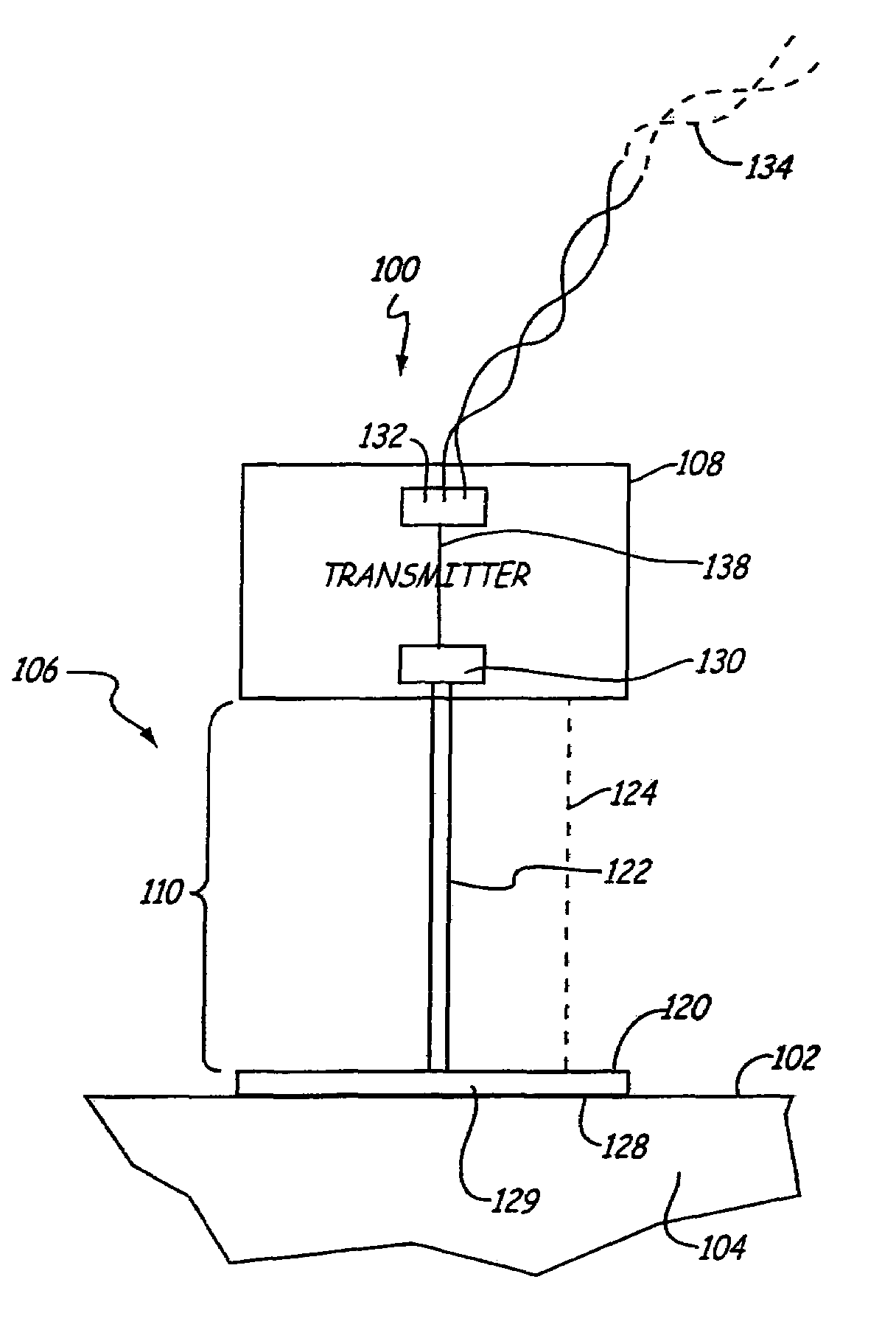

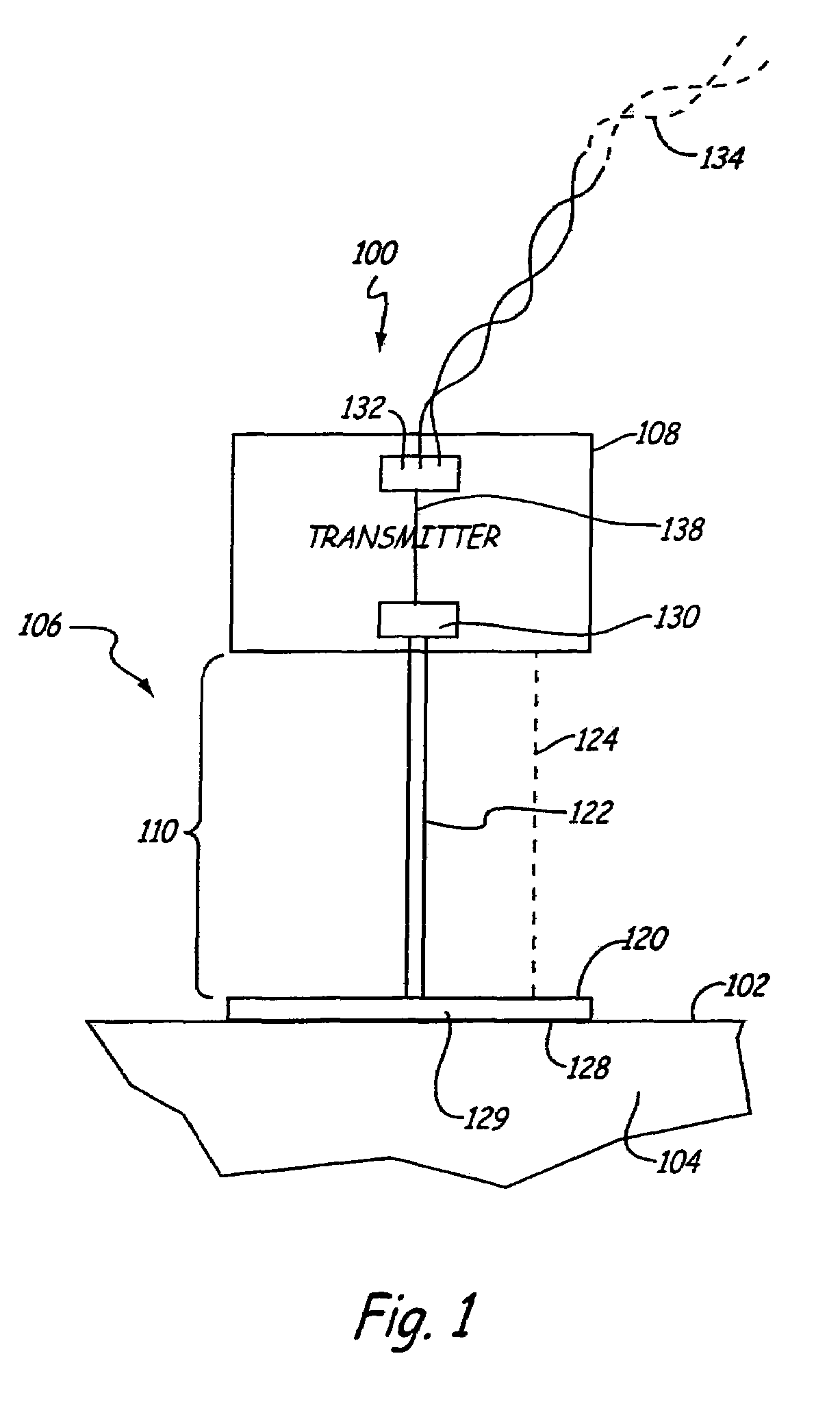

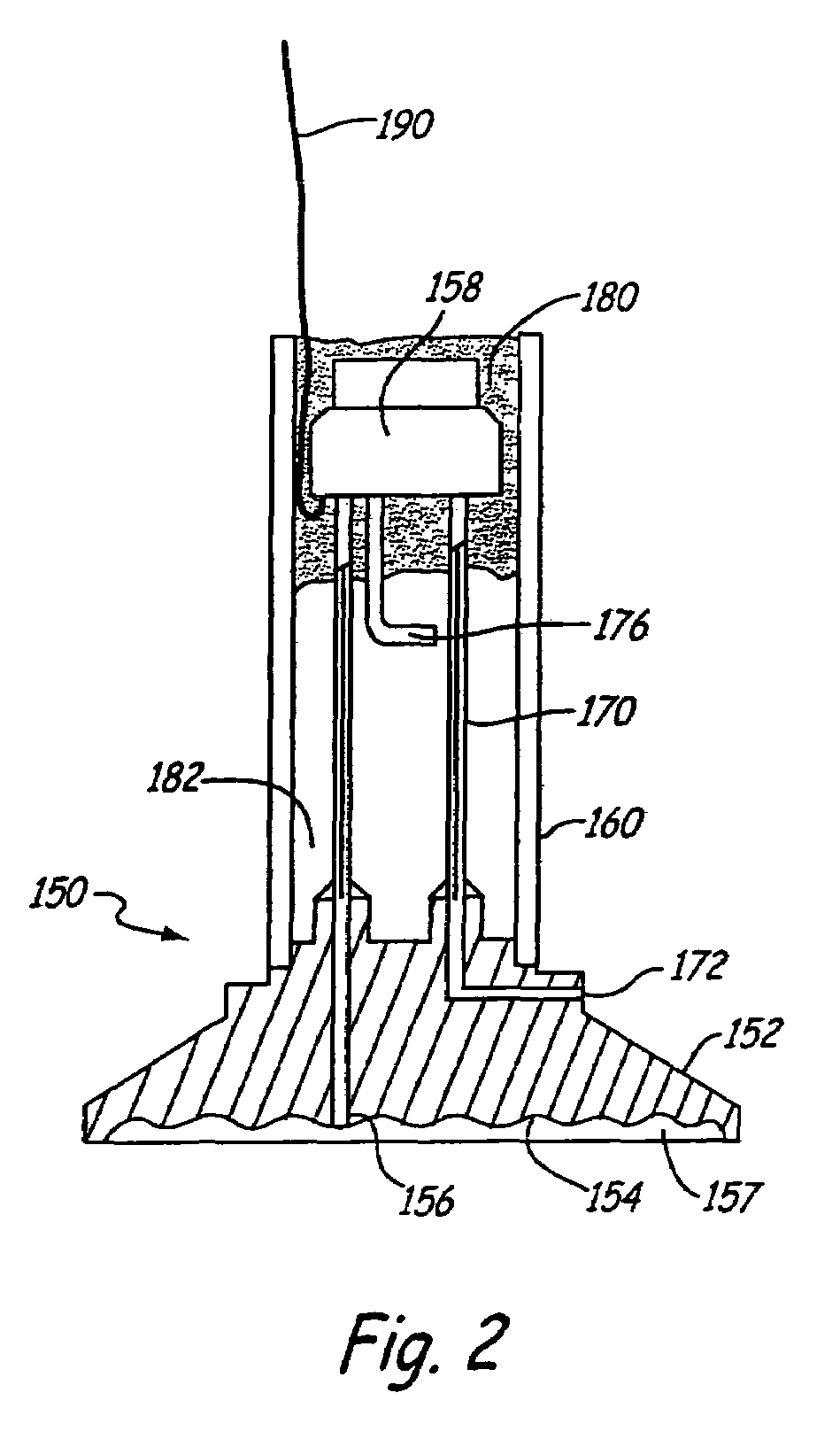

Process transmitter isolation assembly

ActiveUS20060162458A1Mitigating high-temperature effectFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsCouplingEngineering

An isolation assembly for connection to a process transmitter and for mitigating high temperature effects of a process fluid includes a process coupling face having an isolation diaphragm configured to contact process fluid. A transmitter coupling has a pressure coupling configured to couple to a pressure port of the process transmitter. A temperature isolation fluid conduit extends between the process coupling face and the transmitter coupling and carries an isolation fluid which couples a pressure applied to the isolation diaphragm to the pressure coupling to minimize high temperature effects of the process fluid on the process transmitter.

Owner:ROSEMOUNT INC

CMP slurry for semiconductor device, and method for manufacturing semiconductor device using the same

InactiveUS20040123528A1Increase productionHigh affinityPigmenting treatmentOther chemical processesDevice materialEngineering

A CMP slurry for a semiconductor device and a method for manufacturing the semiconductor device using the same, more specifically, a slurry including an additive having high affinity to a nitride film, and a method for polishing a complex film consisting of a polysilicon film and an oxide film or an oxide film using the same are described herein. When the complex film consisting of the polysilicon film and the oxide film removed by using the CMP slurry, a hard mask film which is the nitride film is not removed. Therefore, a polysilicon plug of the semiconductor device can be formed without exposing a word line electrode. In addition, when the oxide film is removed by using the CMP slurry, the slurry includes Al or SiO2 having spherical shaped particles as an abrasive, to form an STI type device isolation film which does not have scratches.

Owner:SK HYNIX INC

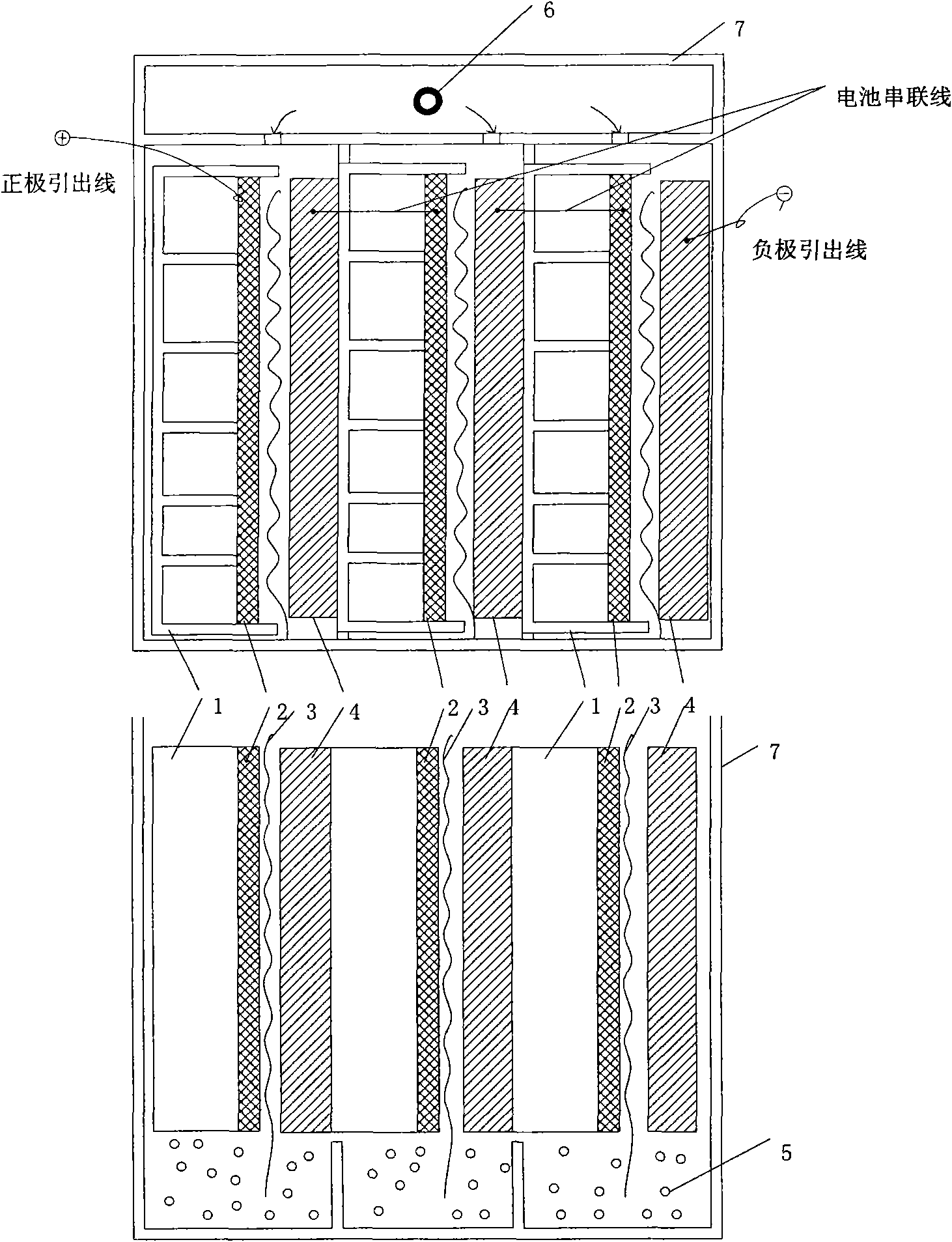

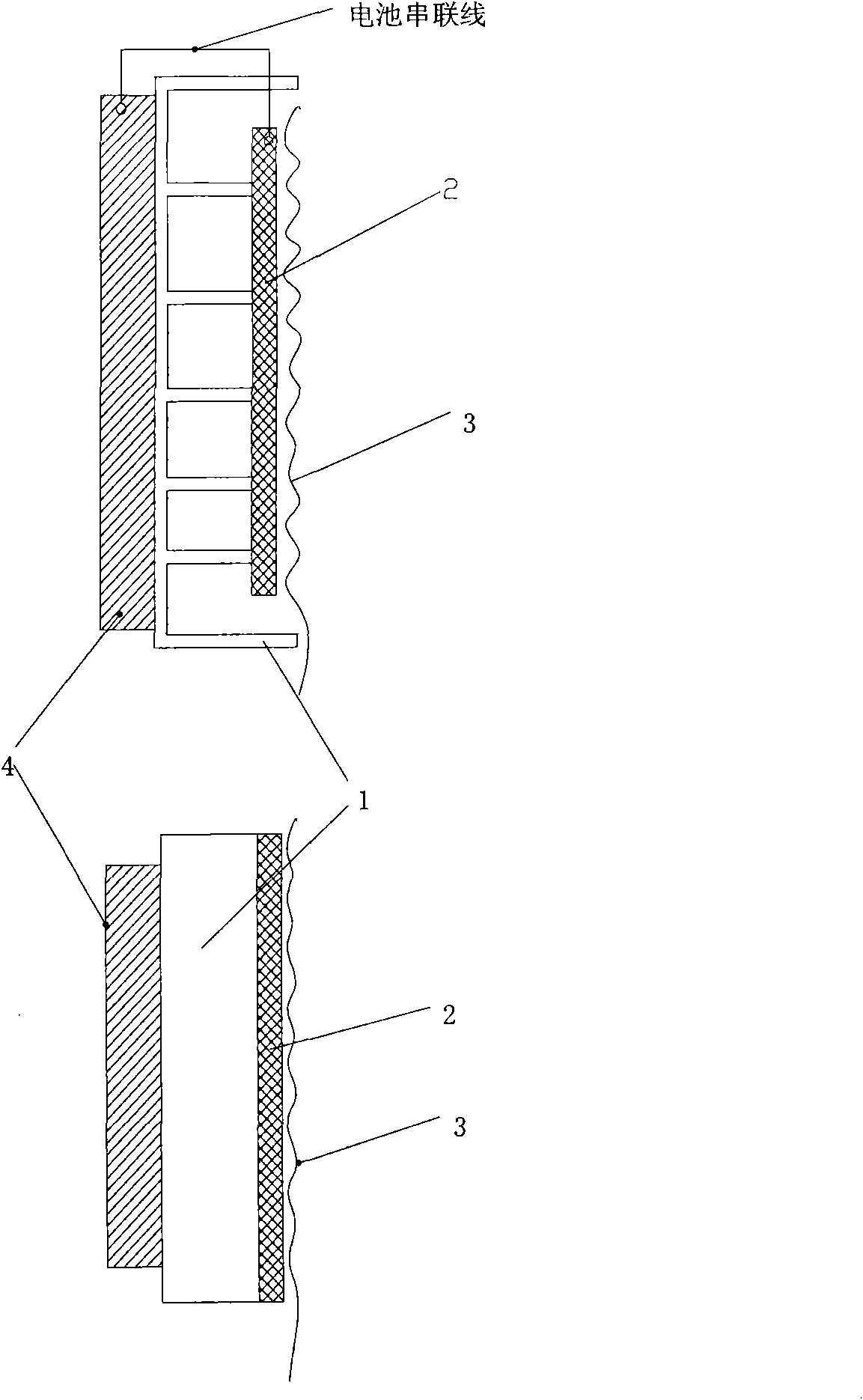

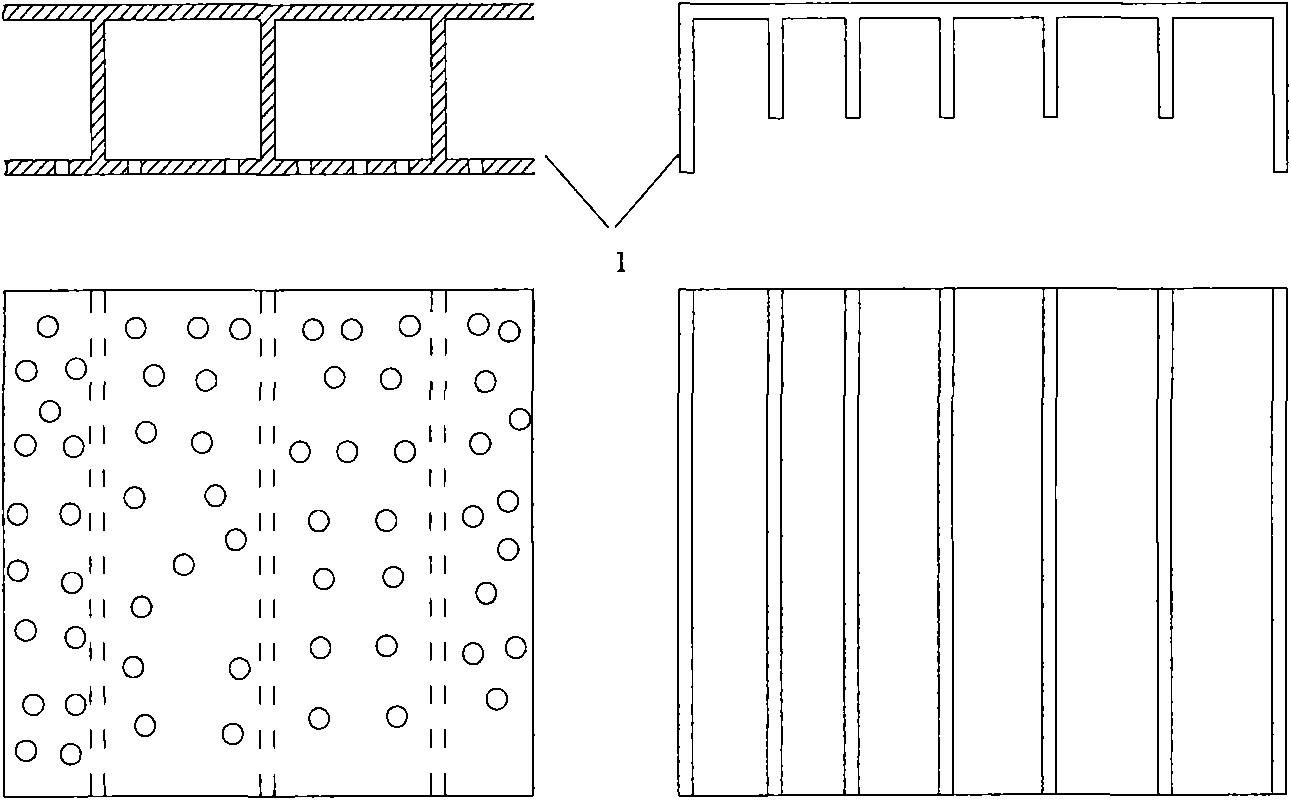

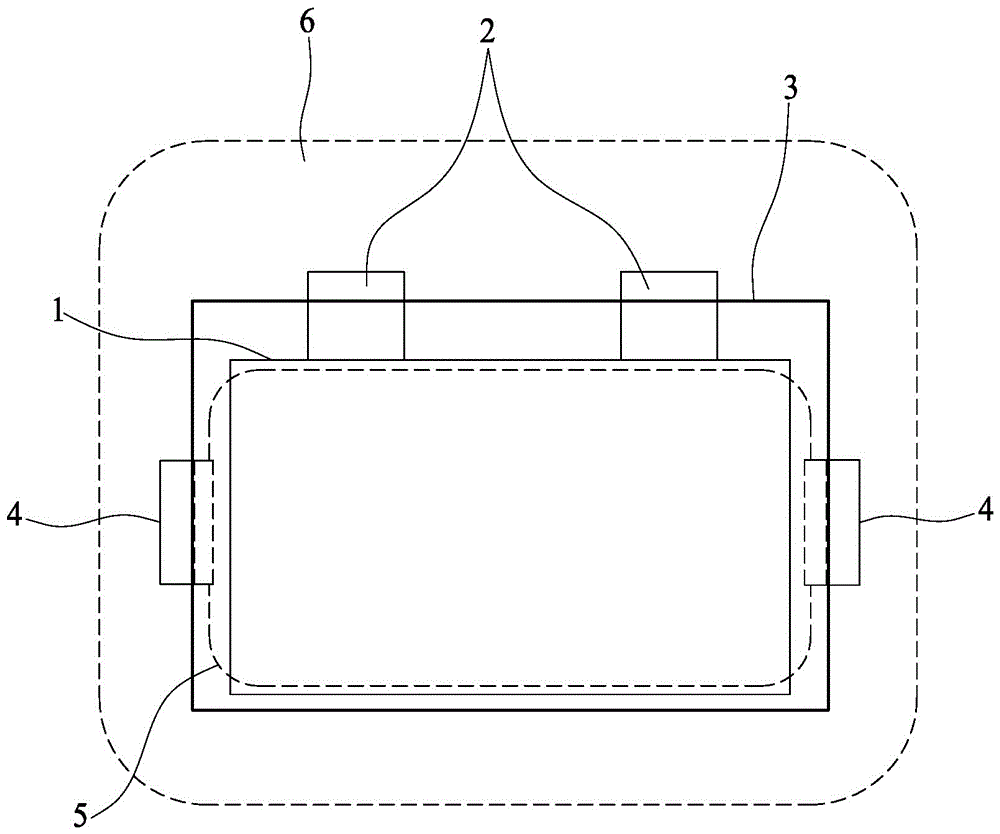

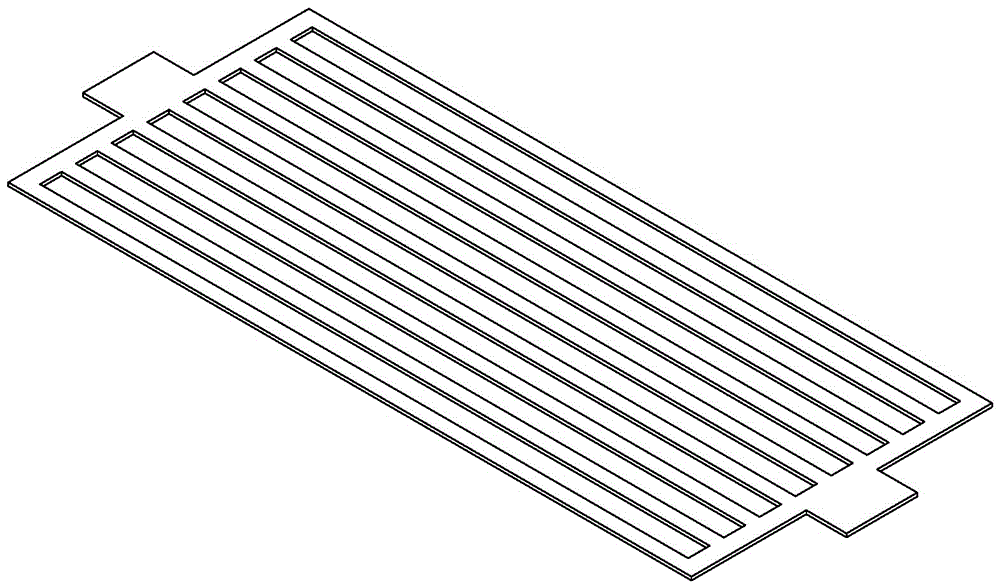

Stack-layered magnesium-air batteries

The application relates to a stack-layered magnesium-air batteries, which is characterized in that a plurality of assembly units is connected in series or in parallel to form the stack layer structure, electrolyte is injected before using, the assembly unit comprises an isolation air feed plate, an air electrode, an isolation membrane, an anode; a plurality of units are repeatedly stacking ordered, winded integrally by a fastener, and assembled into a outer shell; liquid injection pores are disposed on the outer shell, an electrolyte storage slot is disposed on the bottom of the shell, wherein the liquid injection pore is also used as an air inlet pore; the anode is made form magnesium alloy; the electrolyte storage slot is pre-filled with water absorption material; the isolation membrane is made from water absorbing paper dried after water absorbing resin dipping; structure of the isolation air feed plate a hollow plate or a comb-shaped plate with sieve pores, which not only is used as the insulation between batteries, but also functions as a channel for delivering air from external space to the air electrode. The electrolyte needed for the batteries are inputted from the liquid injection pore, stored in the electrolyte storage slot, and distributed to each assembly unit by capillary action of the isolation membrane.

Owner:山西银光华盛镁业股份有限公司

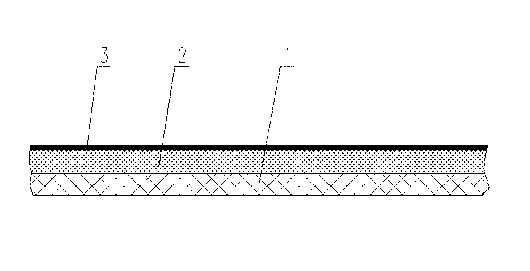

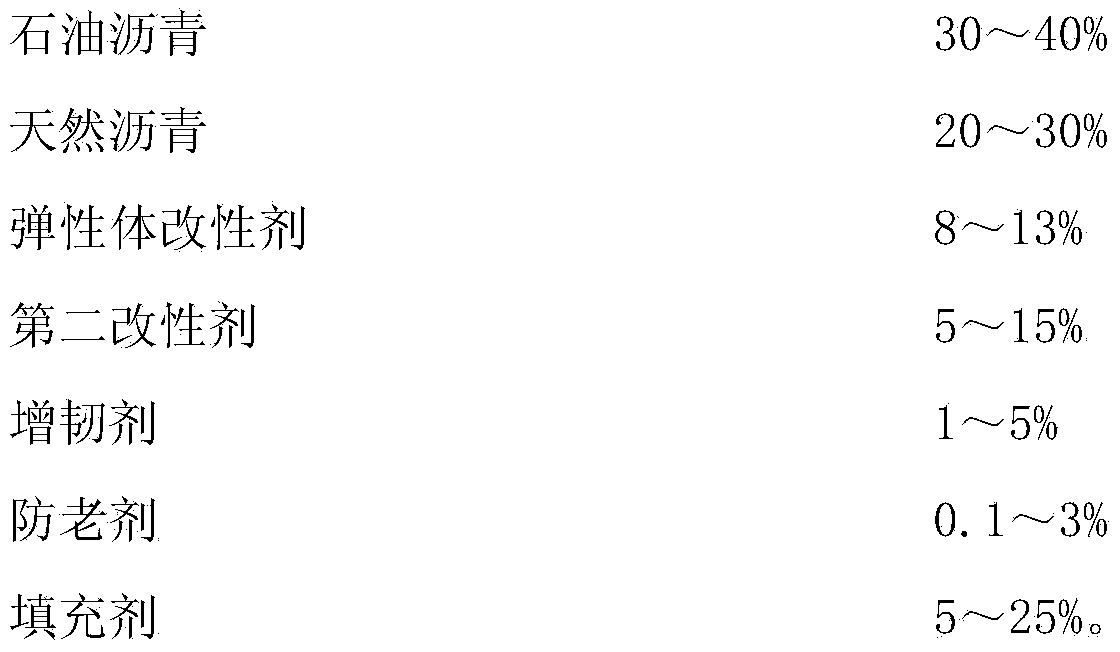

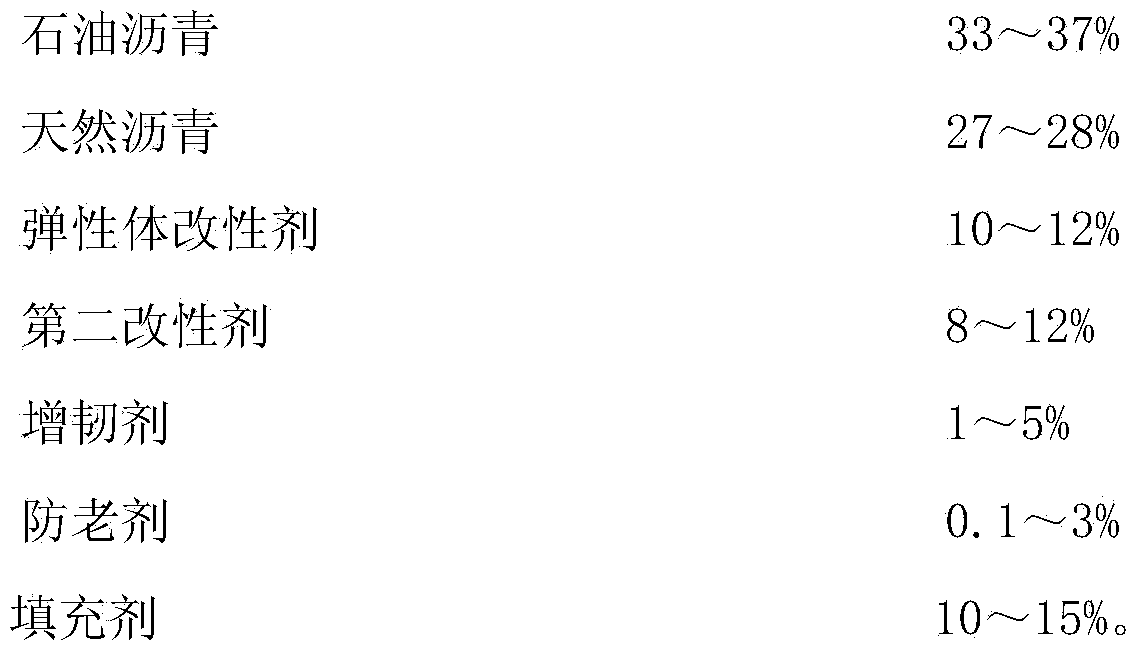

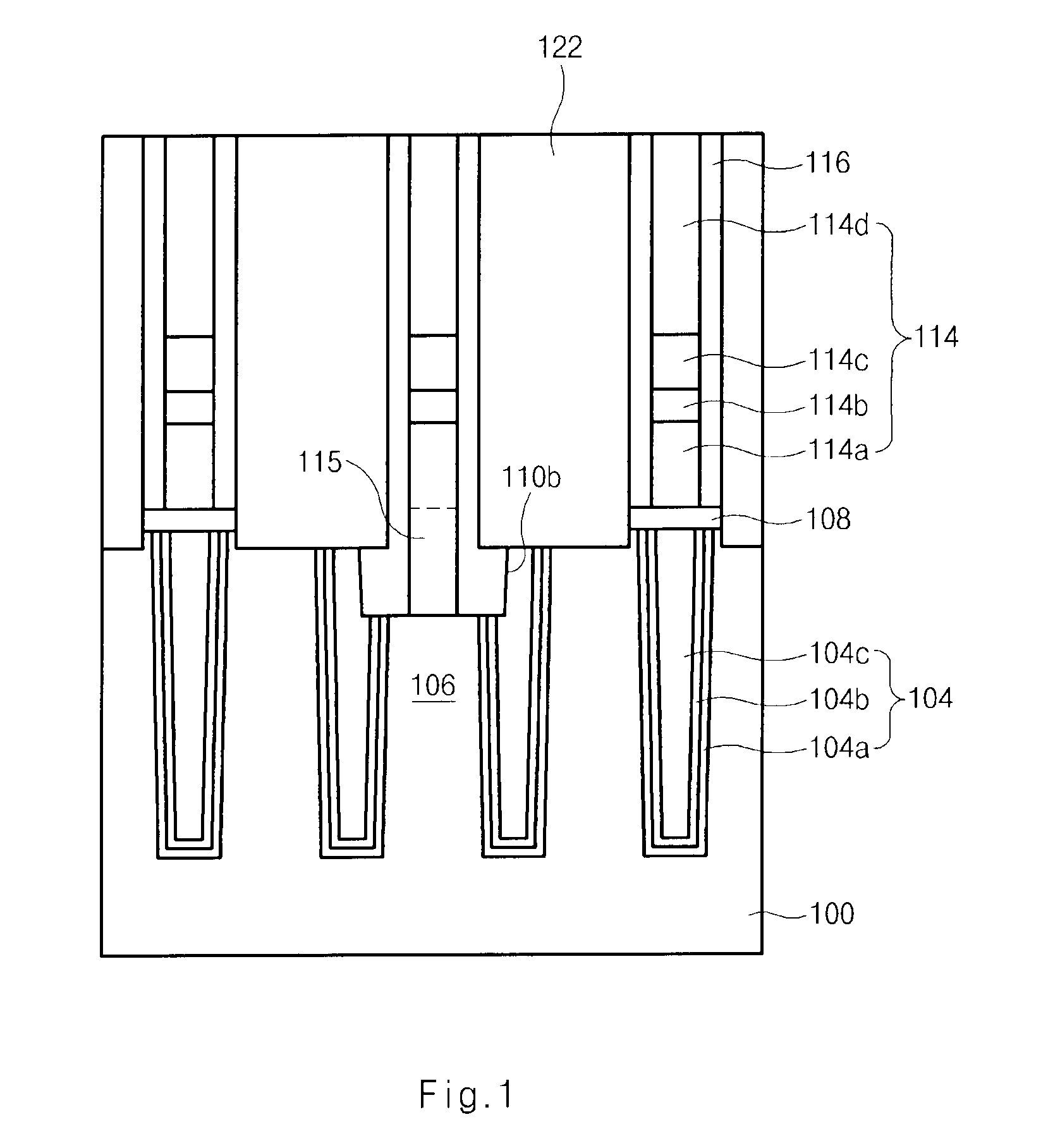

Polyolefin composite modified asphalt wet-laid waterproof roll and production method thereof

ActiveCN102991073AIncrease elasticityGood oil resistanceUnderground chambersRoof covering using flexible materialsElastomerPolymer science

The invention discloses a polyolefin composite modified asphalt wet-laid waterproof roll and a production method thereof. The polyolefin composite modified asphalt wet-laid waterproof roll comprises a modified asphalt binding layer, a binding isolation membrane protecting layer and a polyolefin thermoplastic elastomer material layer which can achieve a chemical crosslinking reaction and a physical mortise-and-tenon collaborative binding action in cooperation with concrete; and the interlayer structure is as follows: the first layer is the polyolefin thermoplastic elastomer material layer, the middle layer is the modified asphalt binding layer, and the lower layer is the isolation membrane protecting layer, and the layers are subjected to thermocompression binding in the production process. The waterproof performance of the waterproof roll is excellent; and the waterproof roll is wriggled and seeped into capillary bores in cement gel and concrete in cement and concrete setting processes by using modified asphalt with reactivity, and has a chemical crosslinking reaction at a contact interface, so that a basal plane reaction layer which is large in binding force, irreversible in binding, concurrently pliable and hard in binding, lasting in binding is formed, thereby achieving a closely and firmly combined and irreversible binding effect as closely linked as flesh and blood.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Self-adhesive waterproof asphalt coil material

ActiveCN104210170AImprove aging resistanceSmooth connectionSynthetic resin layered productsBituminous layered productsElastomerPolyester

The invention discloses a self-adhesive waterproof asphalt coil material. The coil material comprises a mineral aggregate layer, a first high-heat-resistant elastomer modified asphalt size layer, a polyester base layer, a second high-heat-resistant elastomer modified asphalt size layer, a self-adhesive high-heat-resistant asphalt size layer and an isolation membrane layer, which are arranged sequentially from top to bottom. According to the coil material, the remarkable high-temperature resistance of the product is realized by using the mineral aggregate layer, the two high-heat-resistant elastomer modified asphalt size layers and the polyester base layer; the bottom layer is coated with the self-adhesive high-heat-resistant asphalt size layer, so that the construction is convenient, and meanwhile, the high-temperature resistance of the product is further improved.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

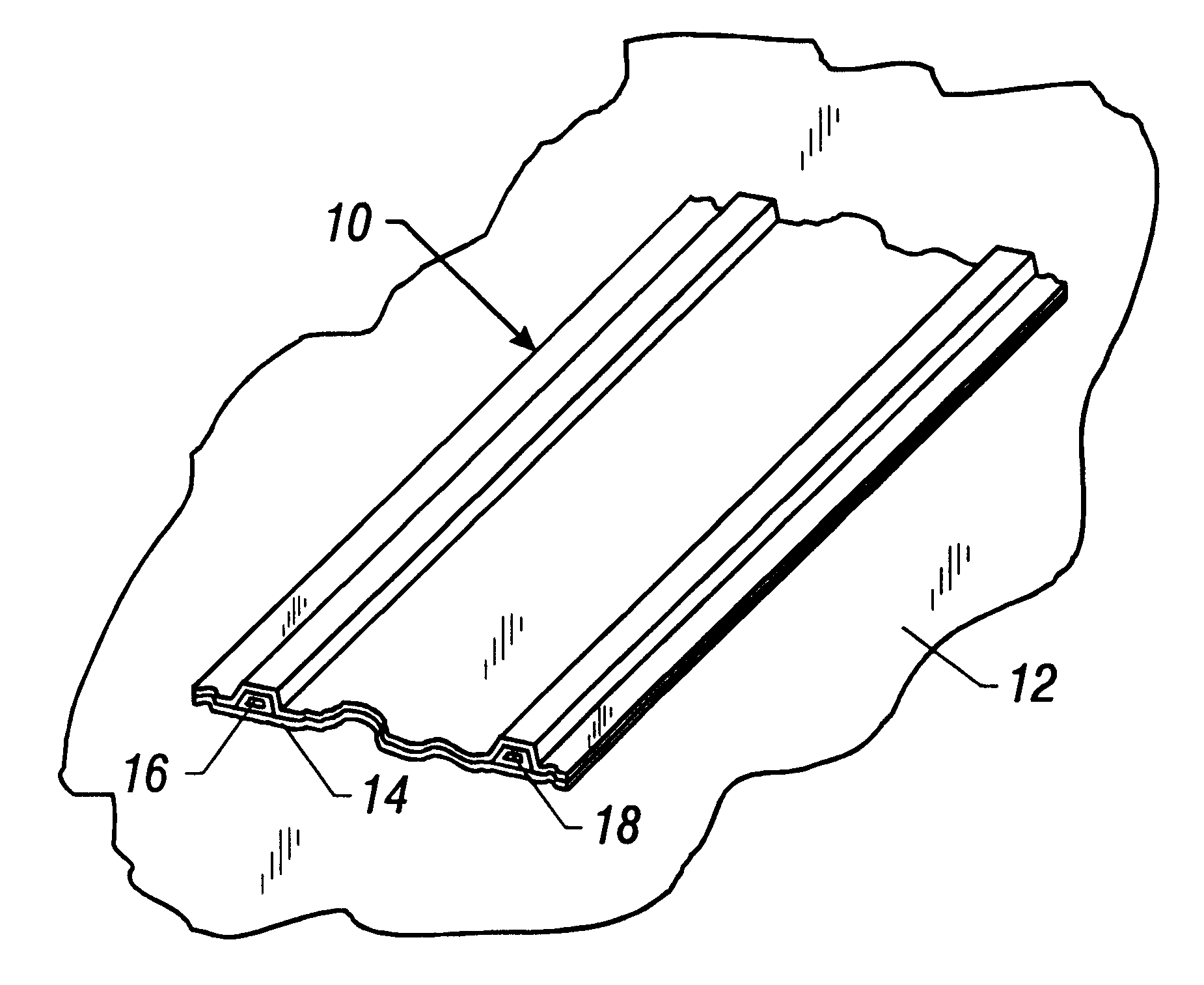

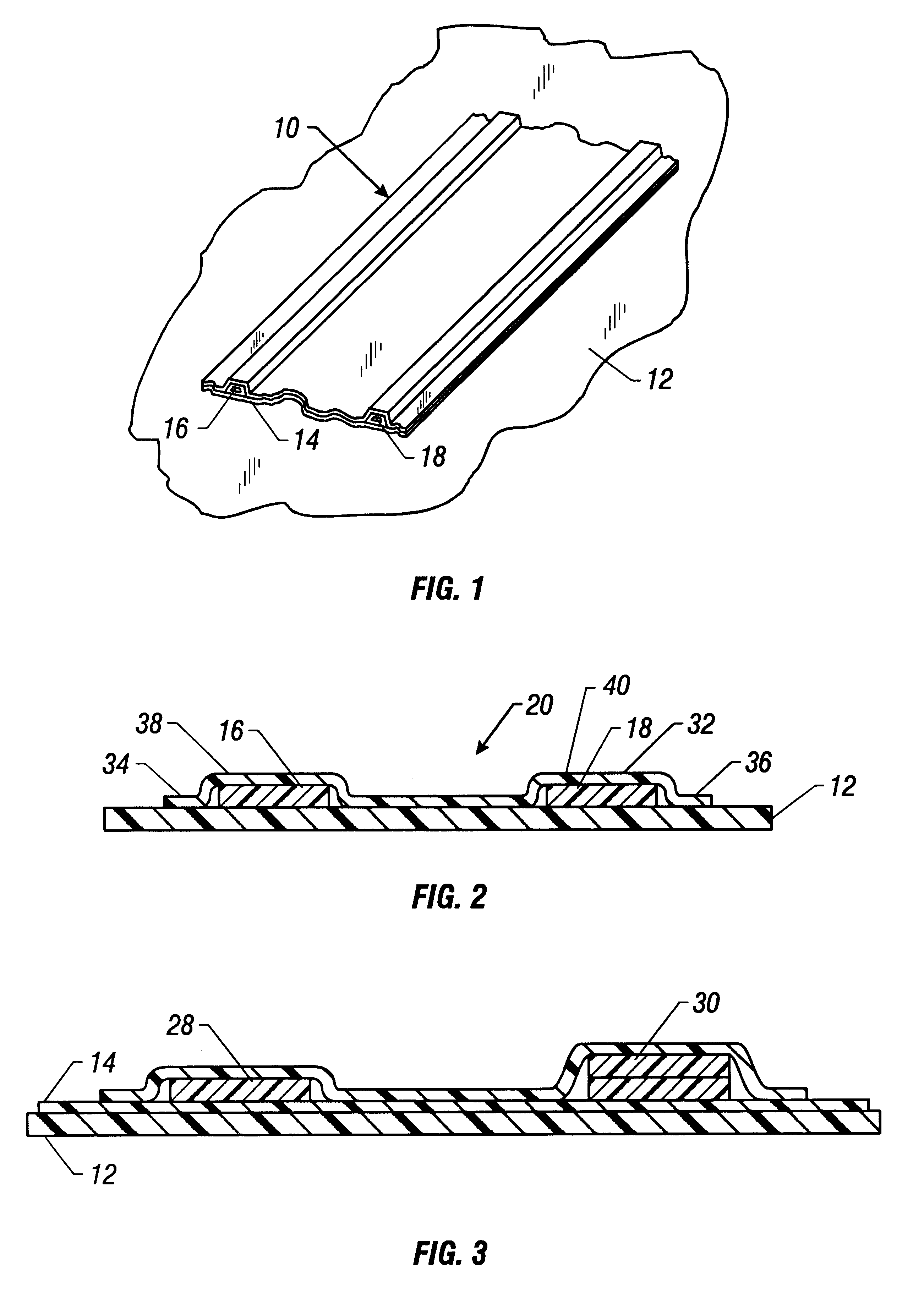

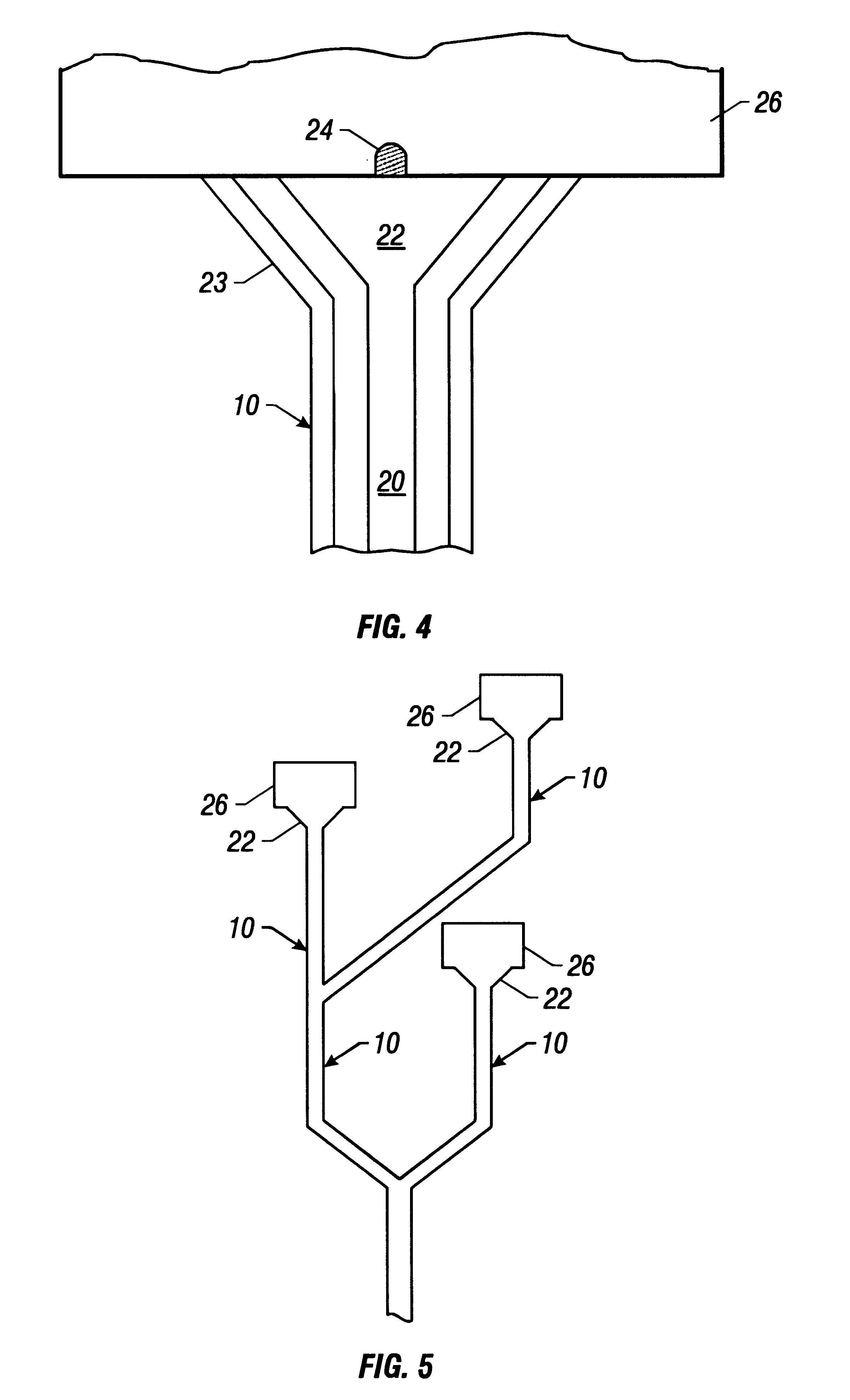

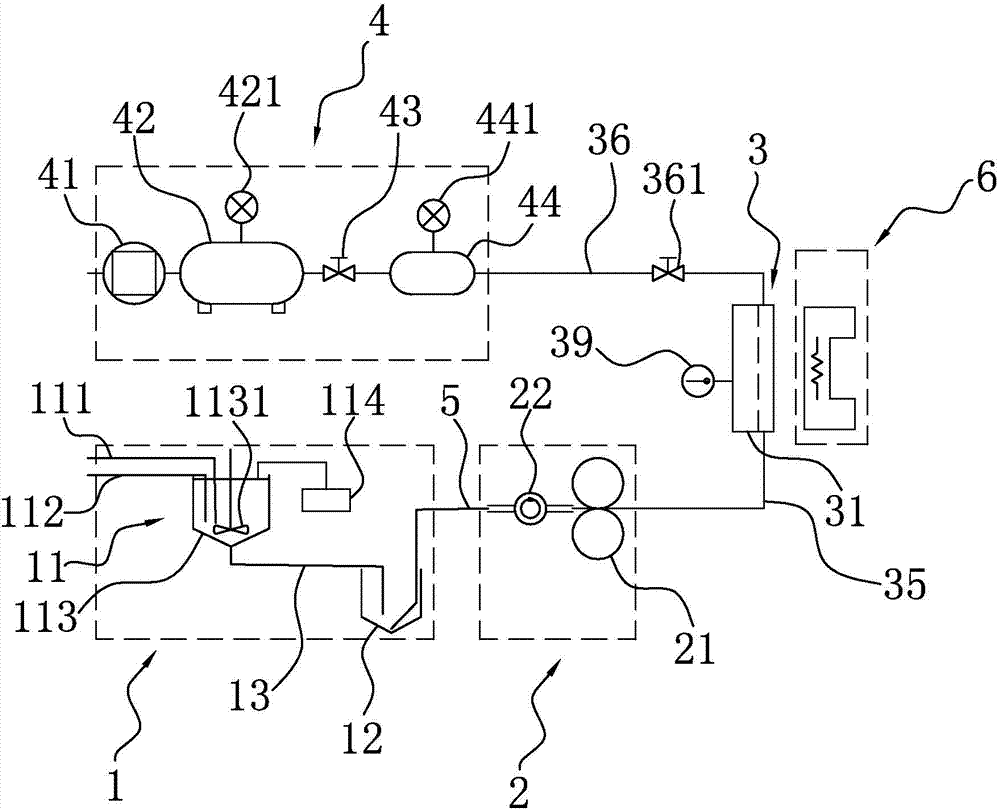

Air conditioning condensation drainage system

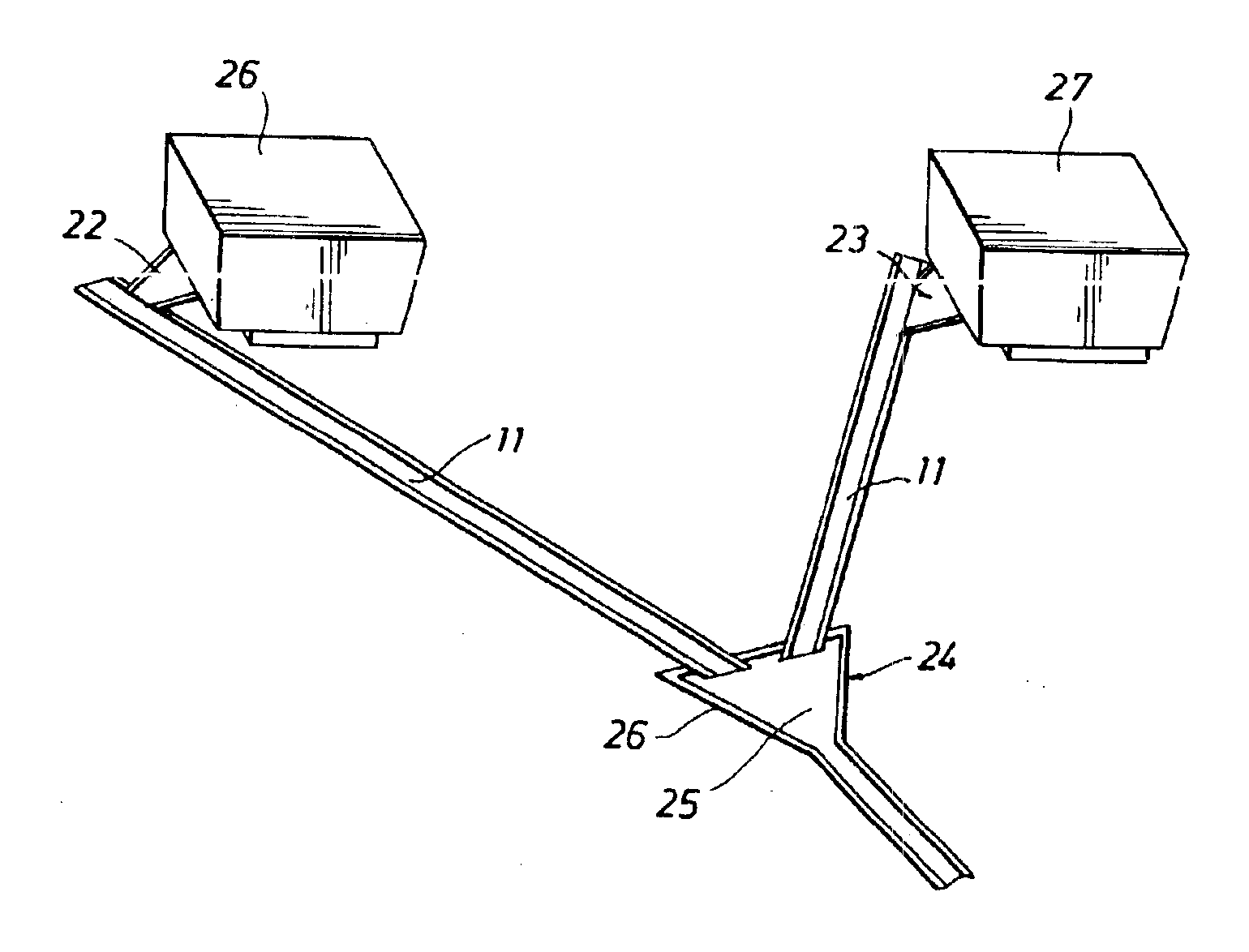

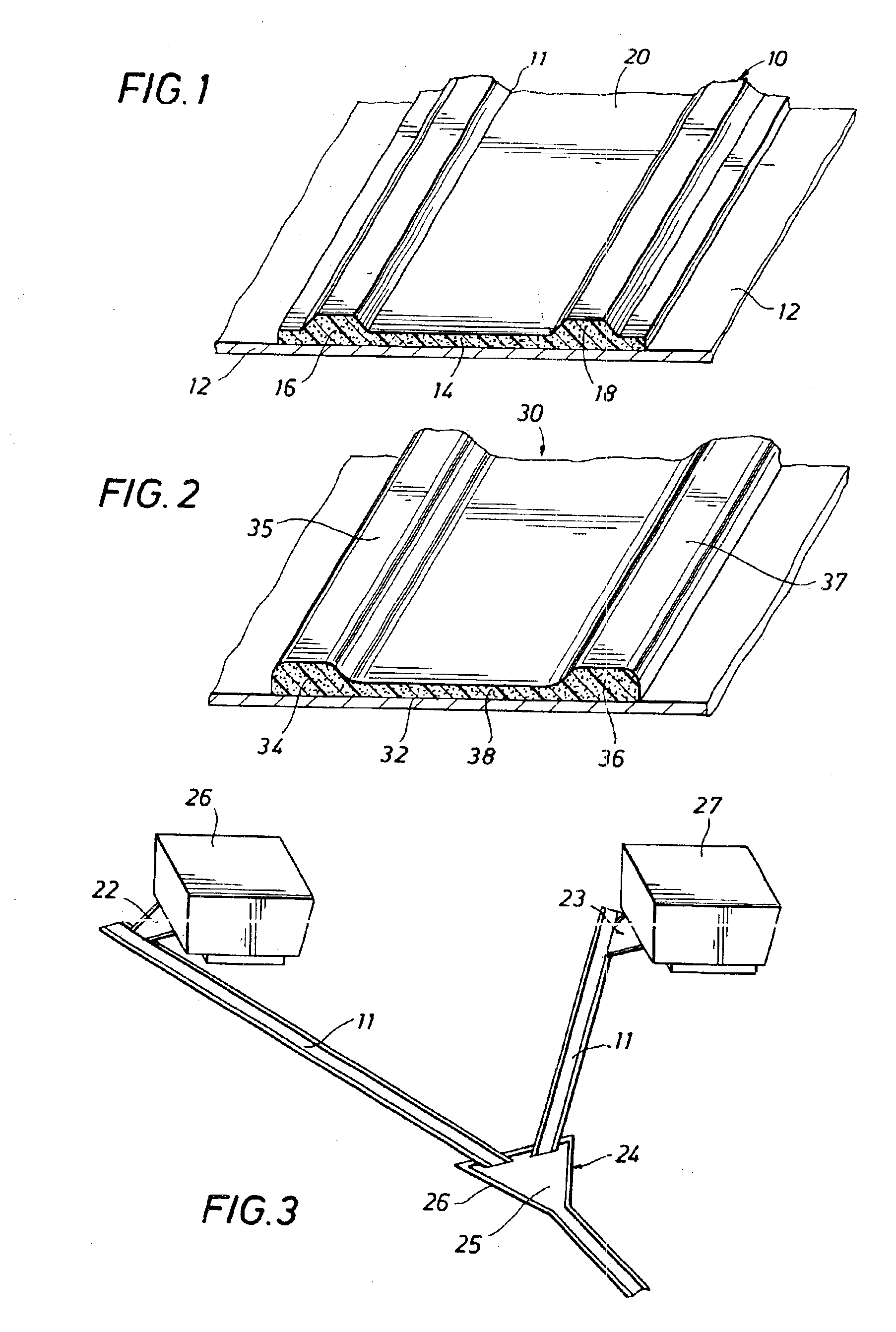

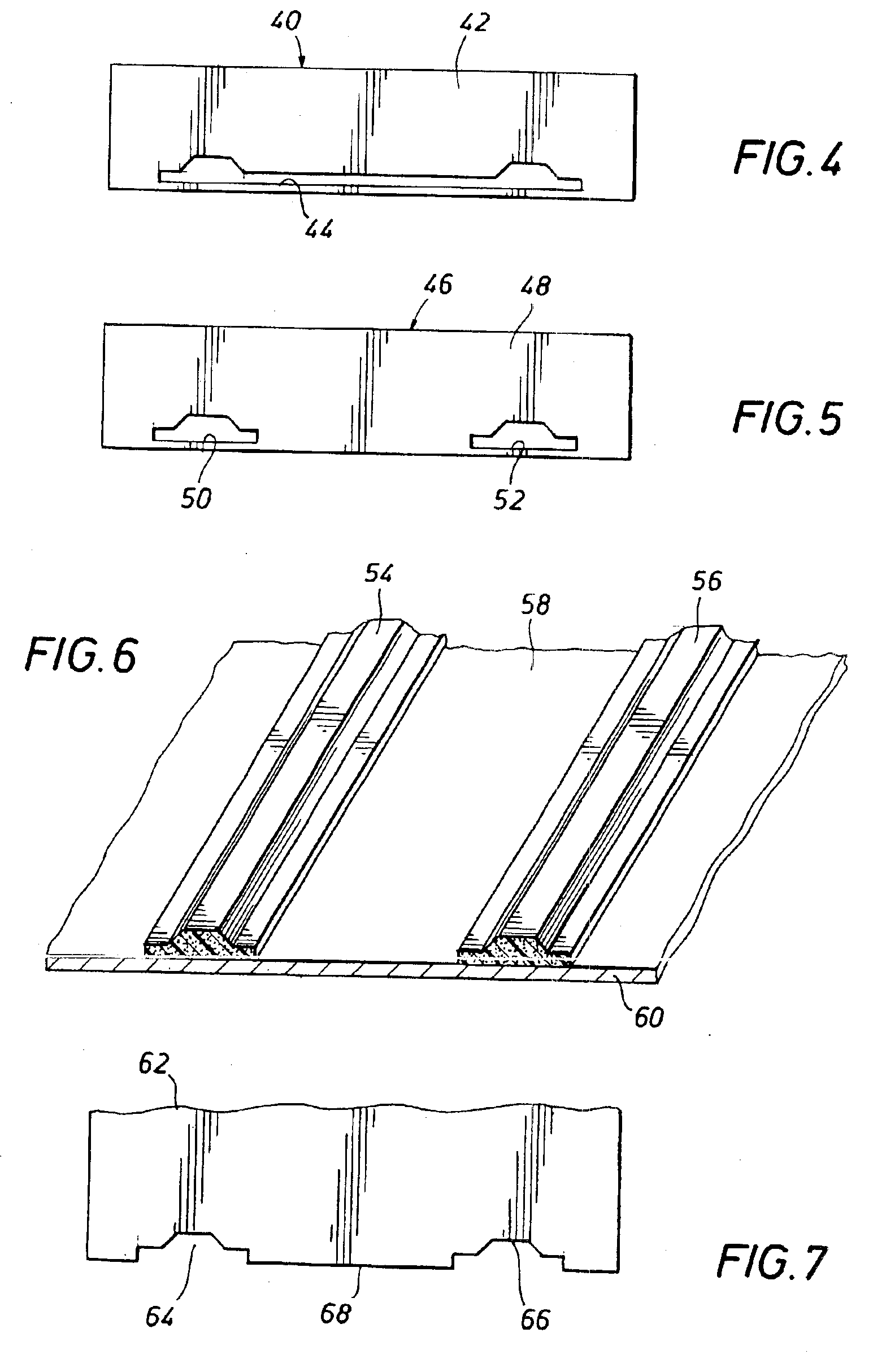

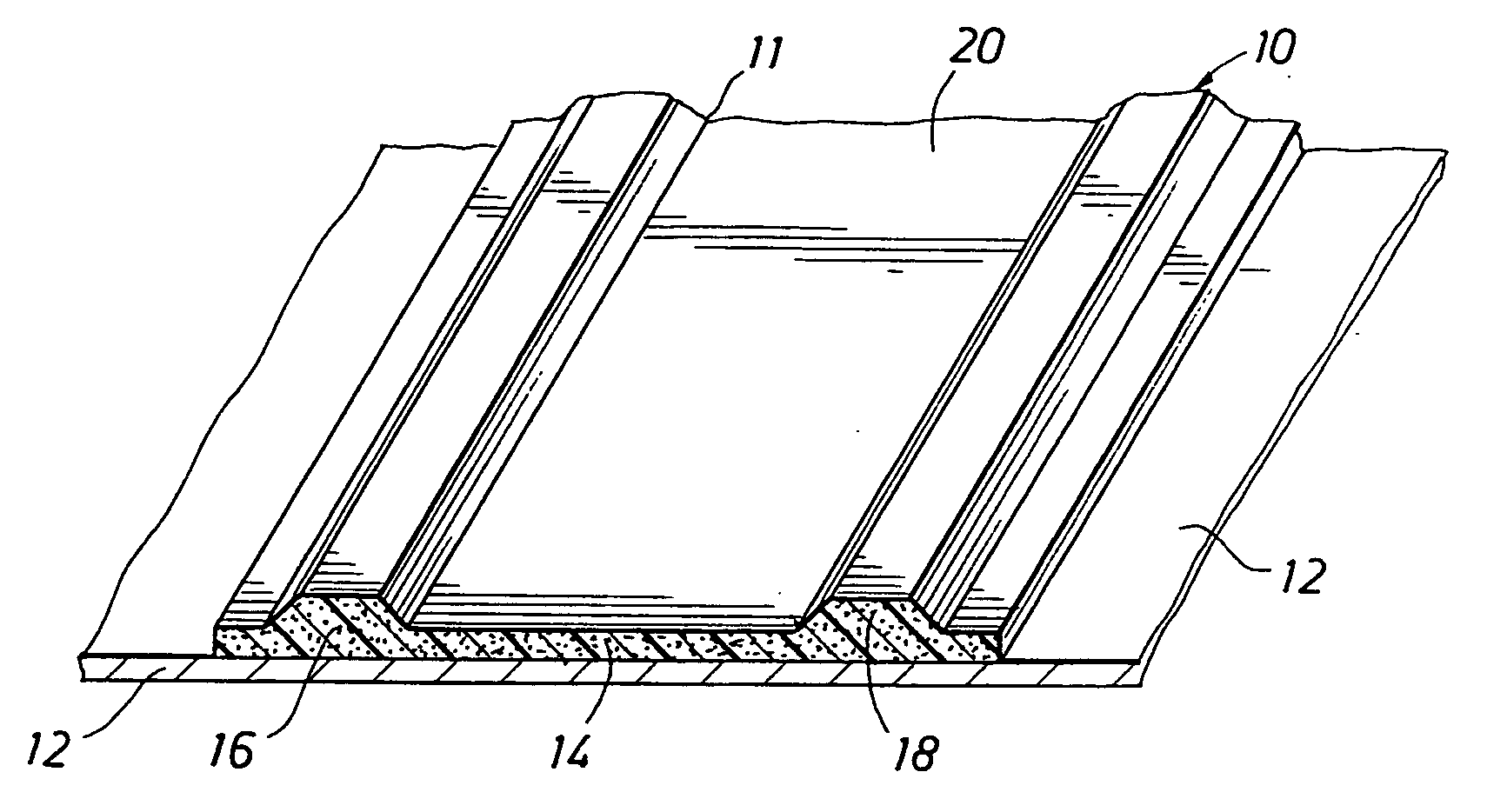

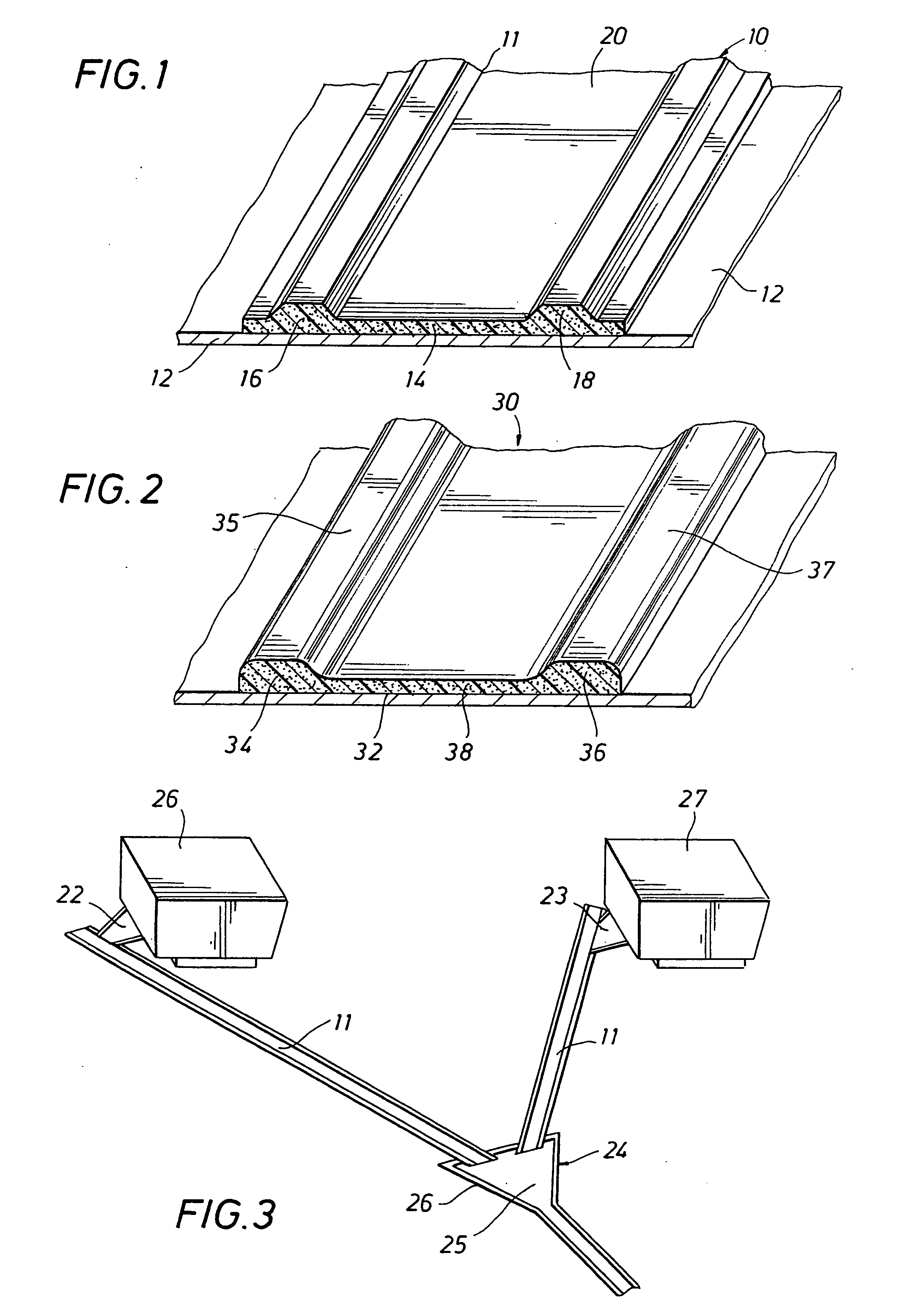

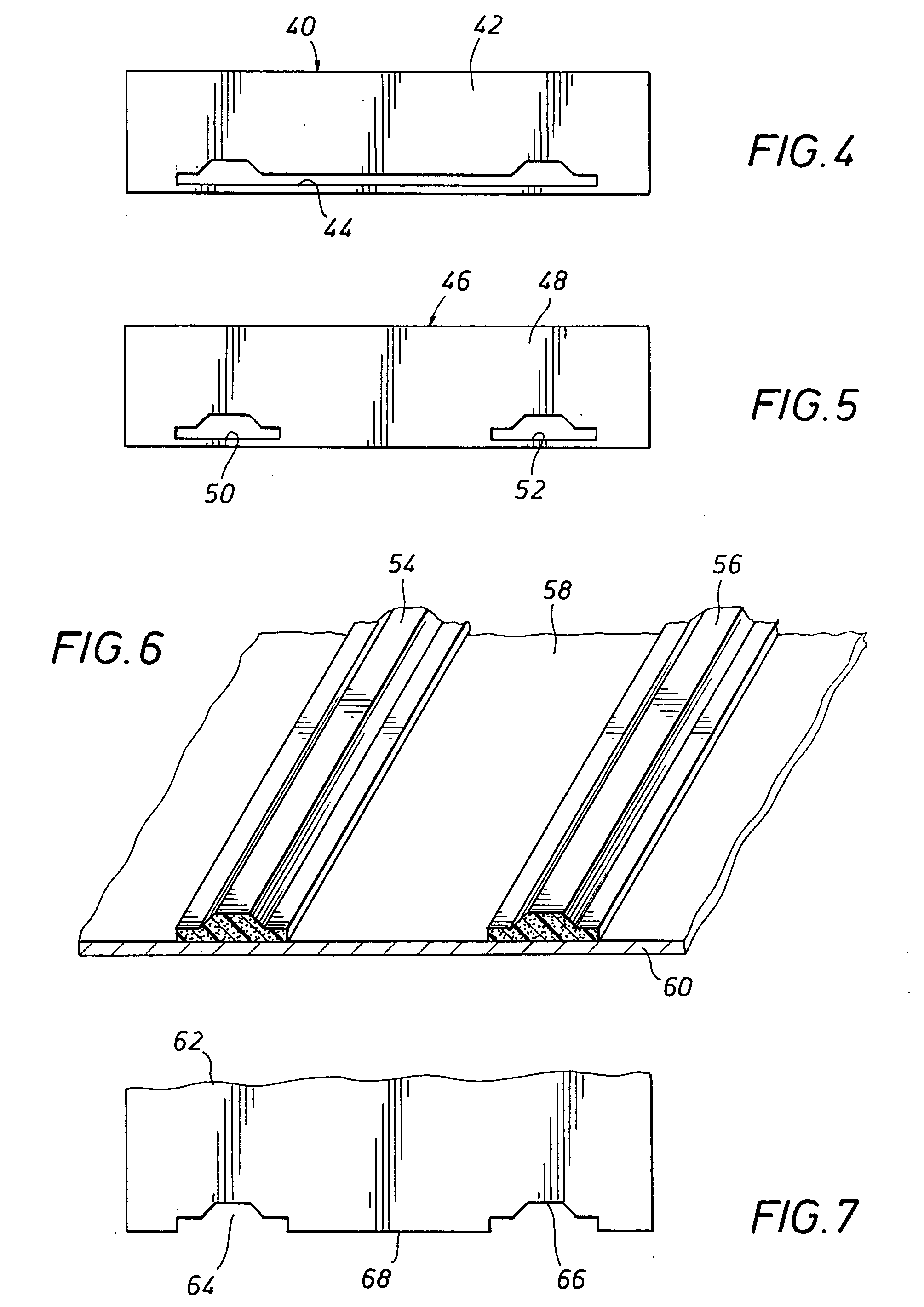

An air-conditioning condensate drainage system for mounting to the roof membrane of the roof structure of buildings or for constructing directly onto the roof membrane of a building structure. The air-conditioning condensate drainage system has an isolation membrane having a bottom surface for assembly to a roof membrane. A pair of ridge structures are disposed in fixed relation with the isolation membrane and are disposed in spaced relation with one another and cooperate with the isolation membrane to define an air-conditioning condensate drainage channel between the spaced ridge structures. Each of the ridge structures has one or more ridge defining elements which is fixed to the isolation membrane and projects above the isolation membrane sufficiently to define a condensate drain channel therebetween. One or more upper membranes may be disposed in covering relation with the ridge defining elements and are conformed to suitable configuration by the ridge forming structures to define spaced condensate containment ridges. The upper membranes are also fixed to the upper surface of the isolation membrane to form an integral condensate drainage unit to conduct a / c drainage from a / c units to an in-roof mounted drain.

Owner:SACKIT

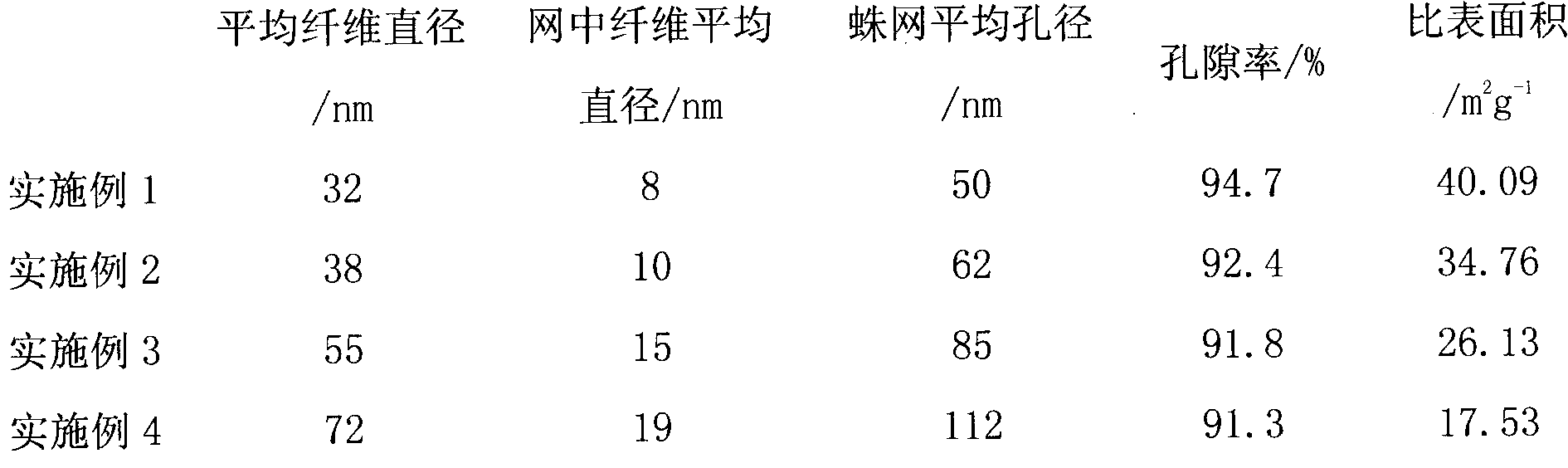

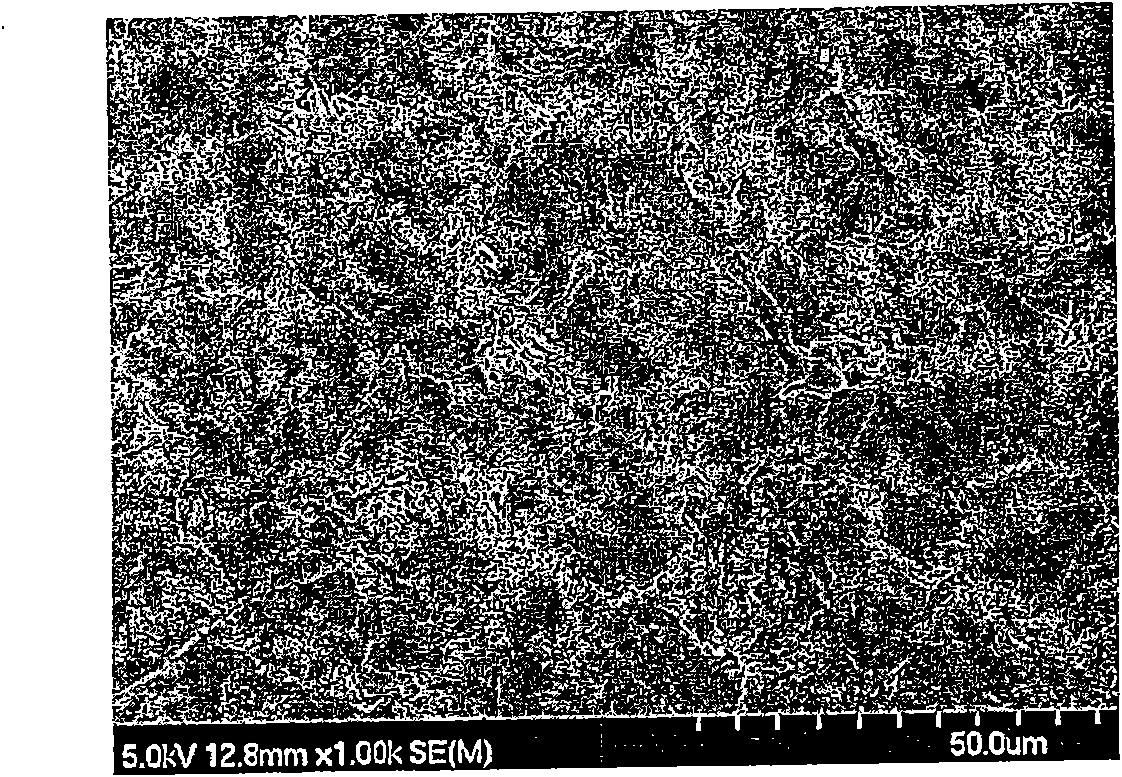

Preparation method of meta-aramid nano-nets fiber membrane

InactiveCN102704028ASmall apertureHigh porosityFilament/thread formingMonocomponent polyamides artificial filamentPorosityOrganic solvent

The invention discloses a preparation method of meta-aramid nano-nets fiber membranes, which comprises the steps that meta-aramid is dissolved in halons and then mixed with organic solvent, thereby obtaining meta-aramid electrospinning material from the prepared ionic liquid solvent system; and the meta-aramid electrospinning material is put into an electrospinning device for electrospinning, thereby obtaining the meta-aramid nano-nets fiber membrane. The preparation method has the advantages that the process of the preparation method is simple, and the prepared meta-aramid nano-nets fiber membrane has smaller fiber diameter, larger specific surface area, smaller bore diameter and higher porosity than the fibers of the common electrospinning fiber membrane, has outstanding high temperature resistance and fire retardancy and good dimensional stability of meta-aramid, and can be widely used in the fields of high temperature filtration, protection, battery isolation membranes, sensing, biomedicine, etc.

Owner:DONGHUA UNIV

Vacuum assistant resin casted protection coating, system and method of permanent magnet motor rotor

InactiveCN104325657AEasy to achieve thickness controlImprove mechanical propertiesManufacturing dynamo-electric machinesDomestic articlesMagnetic polesResin coating

The invention provides a vacuum assistant resin casted protection coating, system and method of a permanent magnet motor rotor. The provided protection coating comprises an enhancing phase, demoulding cloth, and a flow guide net, wherein the enhancing phase, the demoulding cloth and the flow guide net are paved on the surfaces of the magnetic poles of a rotor in sequence. The end part of a resin injection pipeline and the end part of an air suction pipe are fixed on the exterior of the flow guide net. The rotor is hermetically connected to a vacuum isolation membrane, and the vacuum isolation membrane covers the enhancing phase, the demoulding cloth, the flow guide net, the end part of the resin injection pipeline, and the end part of the air suction pipe. Vacuum assistant resin casting and moulding equipment is applied to the magnetic pole protection of permanent magnet motor rotor so as to form a resin coating on the magnetic pole surfaces of a permanent magnet motor rotor; moreover the thickness of the resin coating is easily controlled, and mould sleeve tools are not required. The provided system and method can achieve a good casting effect, and thus the mechanical performance and anticorrosion grade of rotor magnetic poles can be enhanced.

Owner:XINJIANG GOLDWIND SCI & TECH

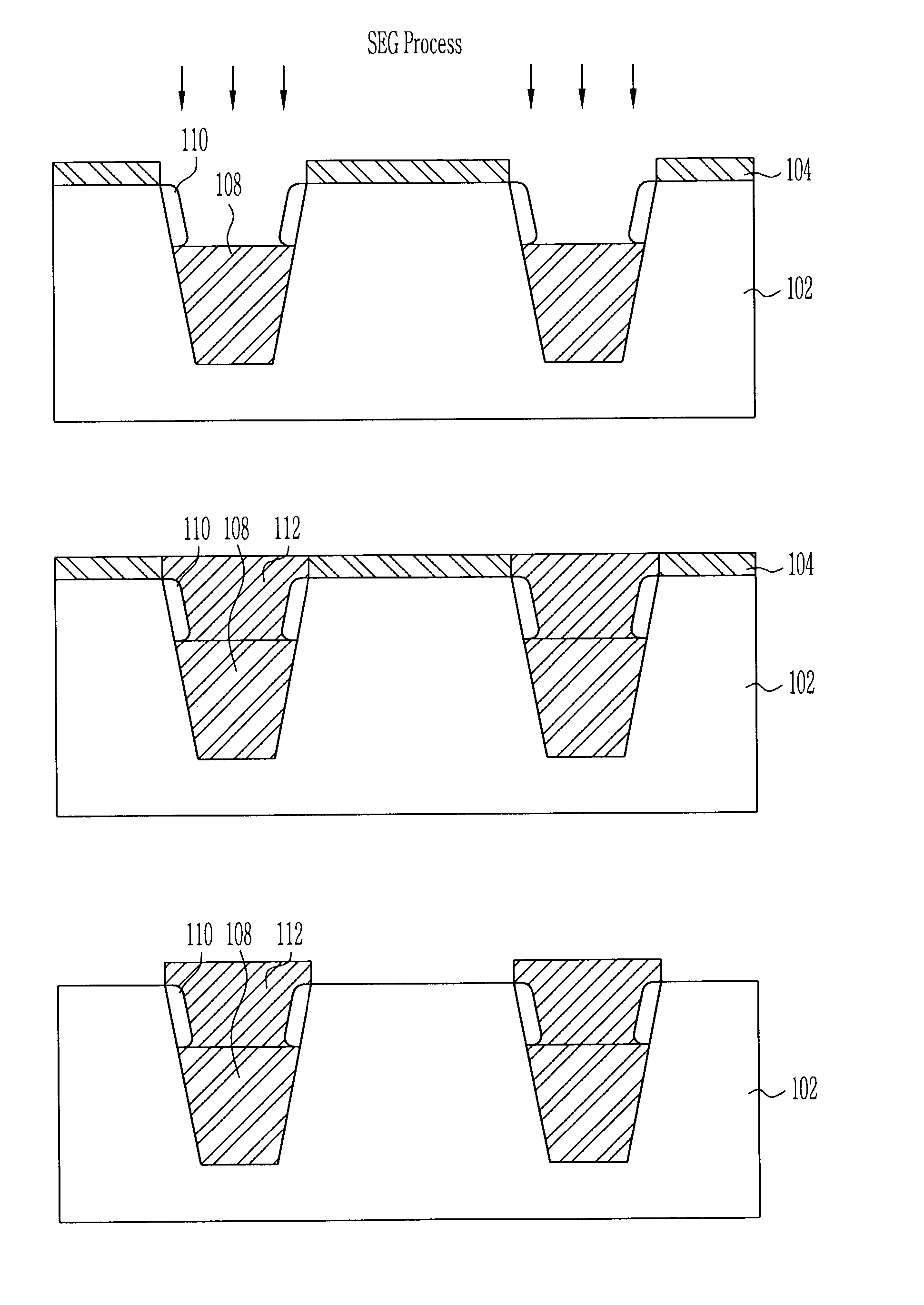

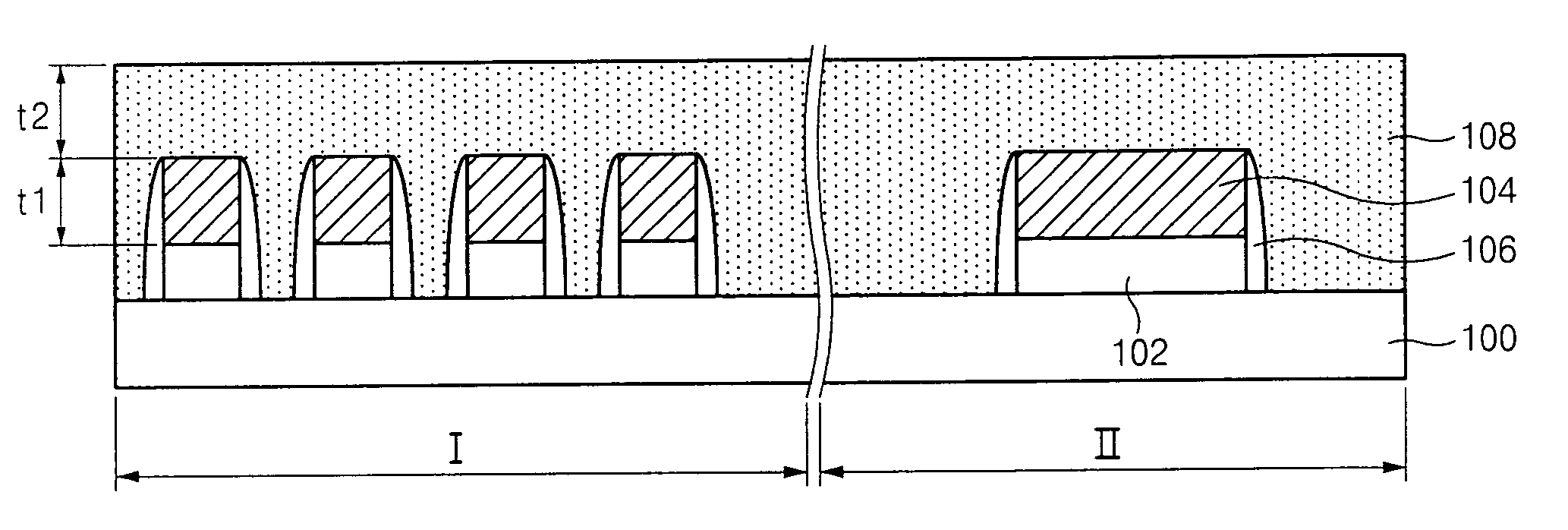

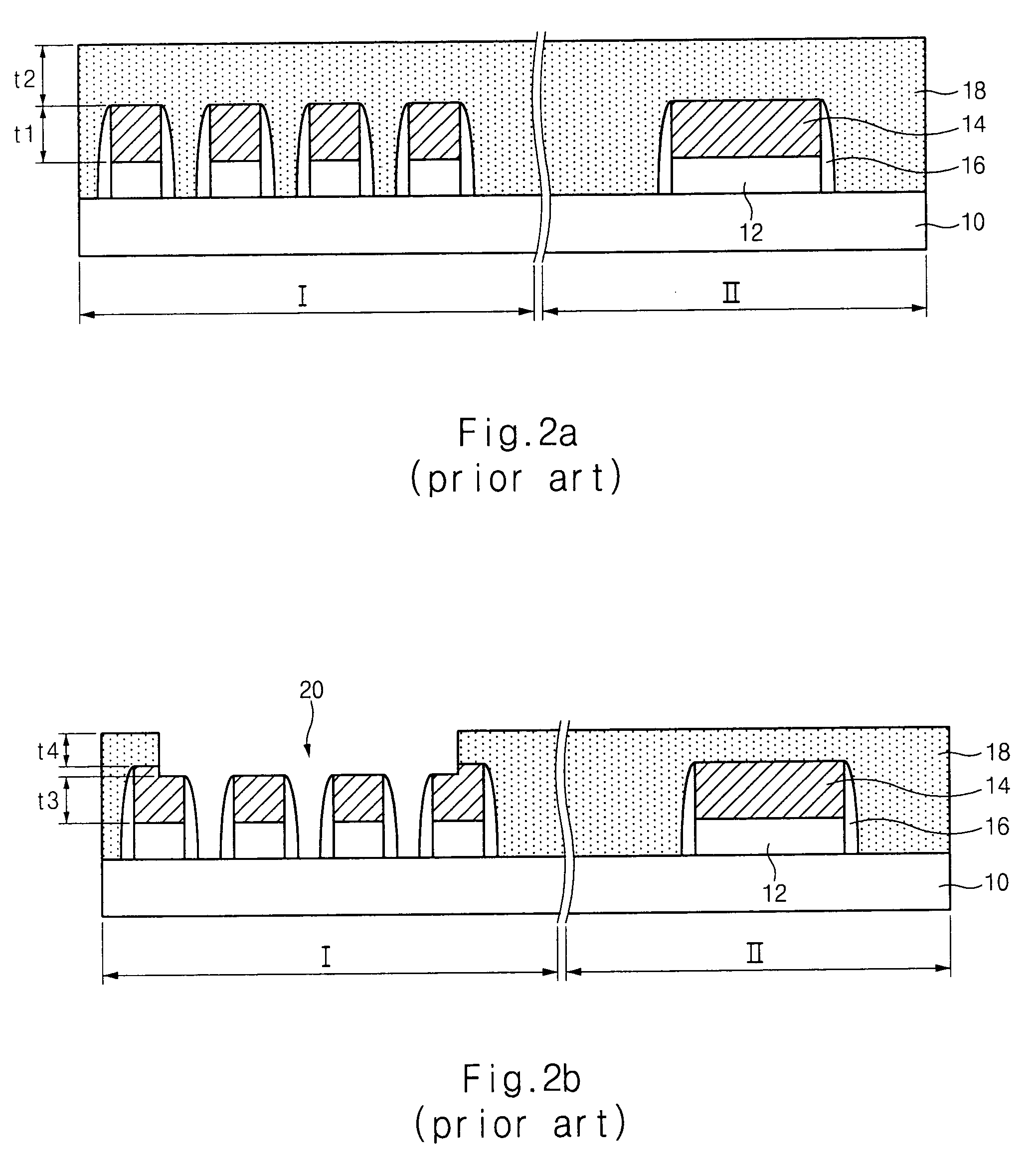

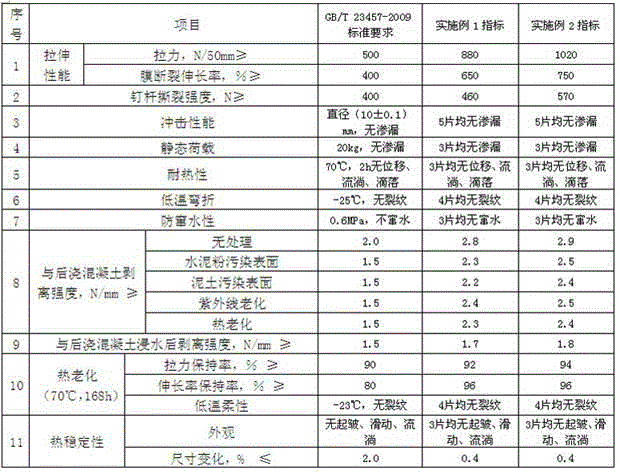

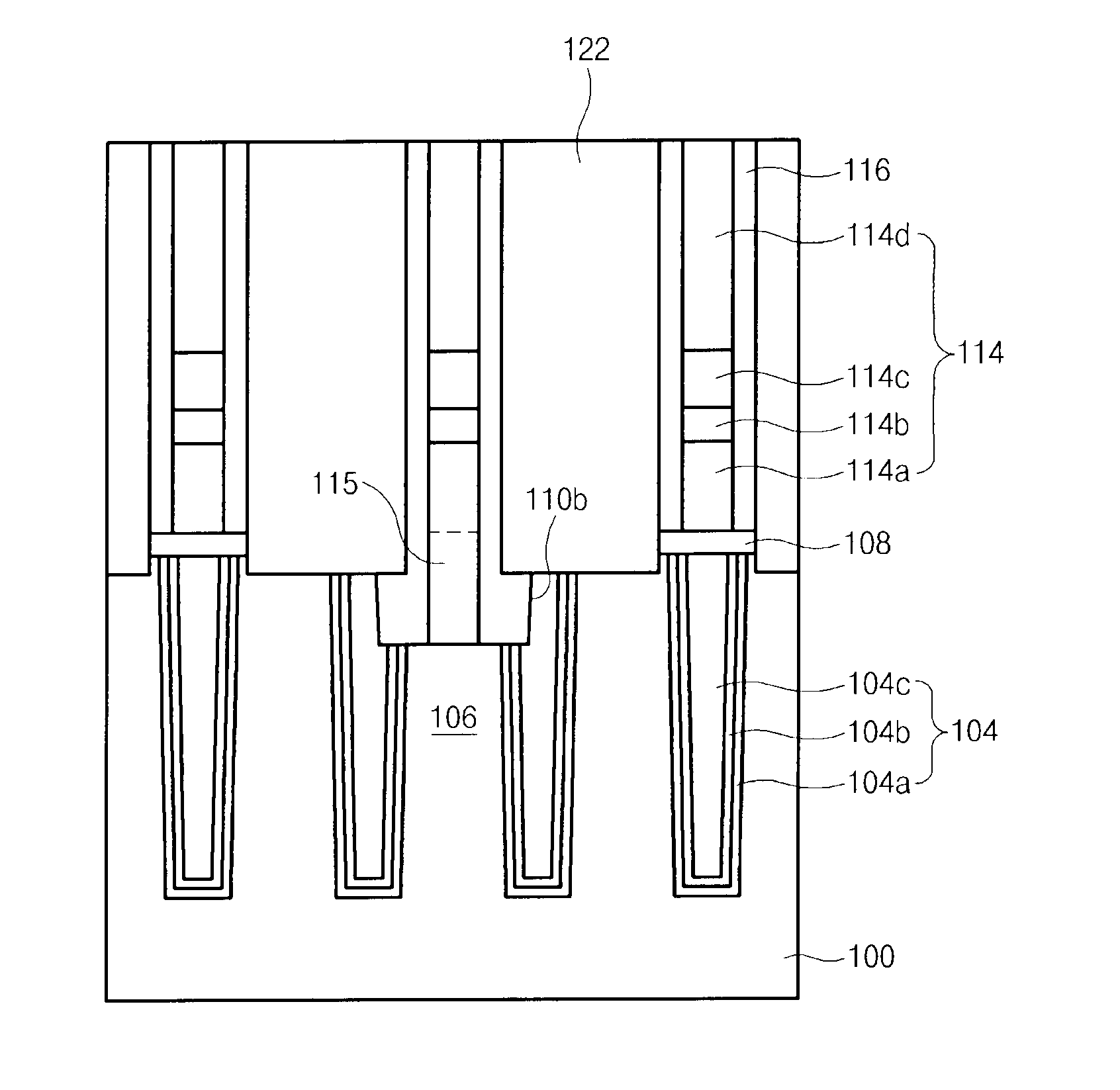

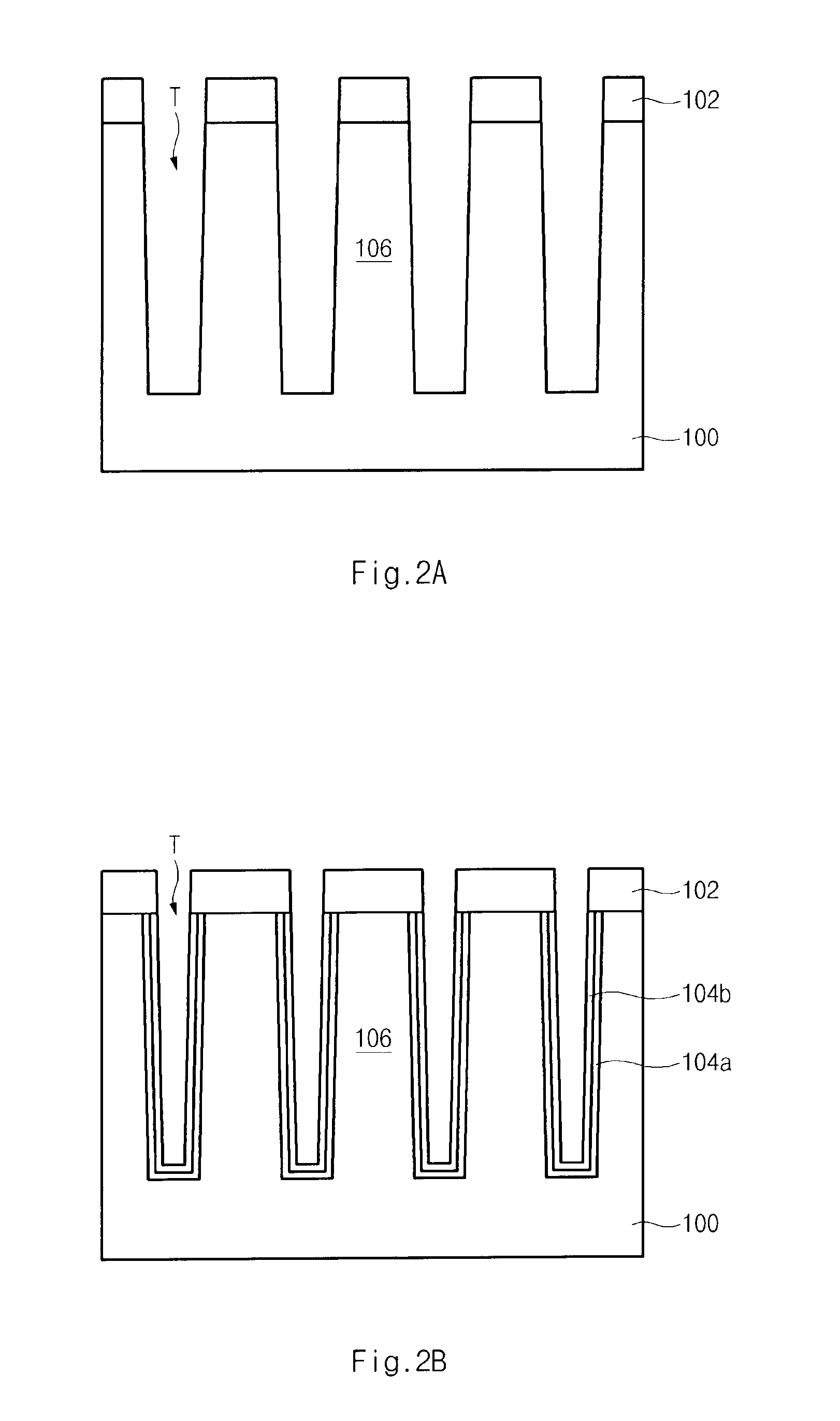

Method for manufacturing device isolation film of semiconductor device

ActiveUS20060024912A1Improving semiconductor device characteristicHEIP phenomenon is reduced or preventedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialTrapping

A method for manufacturing device isolation film of semiconductor device is disclosed. The method utilizes a plasma oxidation of a liner nitride film exposed by etching a liner oxide the film in peripheral region prior to the formation of device isolation film to prevent the generation of a electron trap which causes trapping of electrons at the interface of the oxide film and the nitride film resulting in a HEIP phenomenon.

Owner:SK HYNIX INC

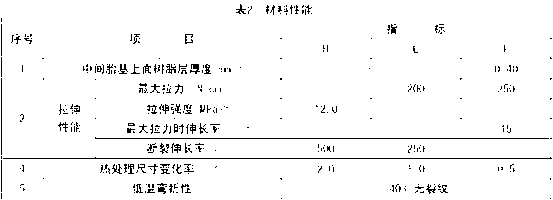

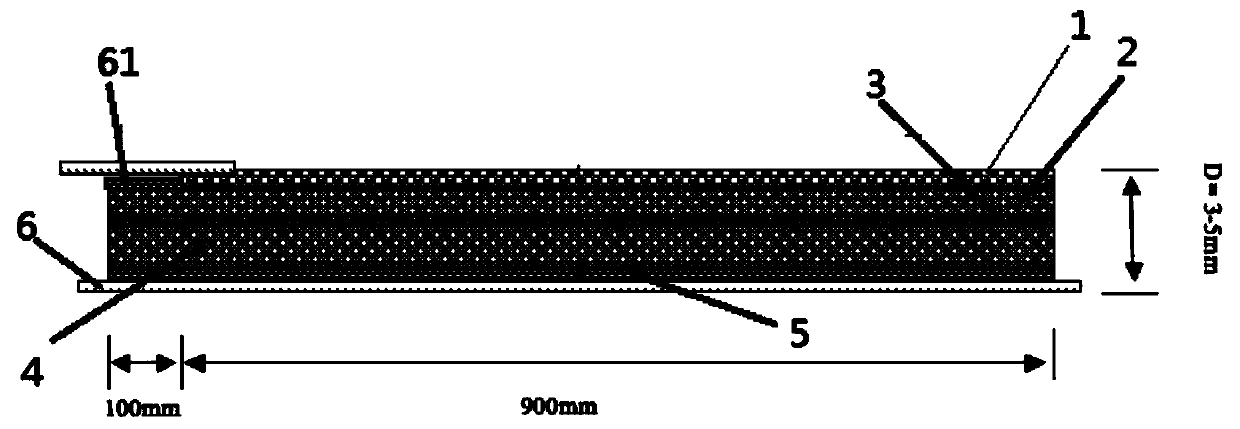

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

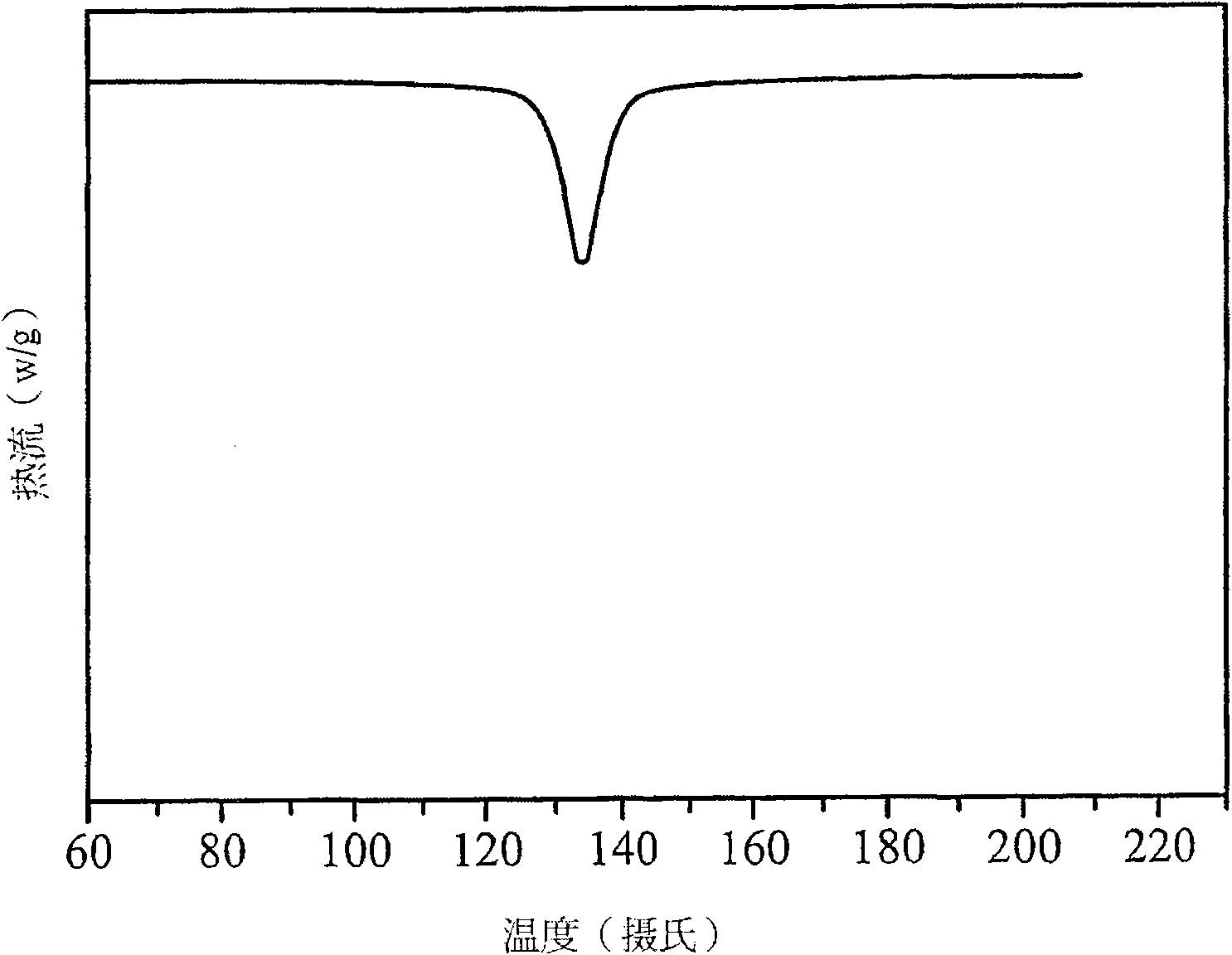

A sulphur-modified polyolefin battery separation film and its making method

ActiveCN101267028AImprove hydrophilicityGood ion conductivityFibre typesCell component detailsPolyolefinIsolation membrane

The invention discloses a polyolefin battery isolation membrane after lfonation modifying, wherein the weight ratios of raw material of the invention are: 60 to 90 percent of polyethylene or polypropylene fiber, graft monument acrylic acid, meth-acrylic acid, 2 to 10 percent of propylene peptide amine or meth-acrylic peptide amine, 5 to 15 percent of enhanced fiber, 1 to 10 percent of sulfonation agent. The polyolefin after lfonation modifying has good hydrophilicity, strong preserving liquid ability, high alkali uptake rate, good chemical stability and strong anti-oxidation property after washing, and can improve electrical property of nickel battery significantly.

Owner:SHENZHEN SENIOR TECH MATERIAL

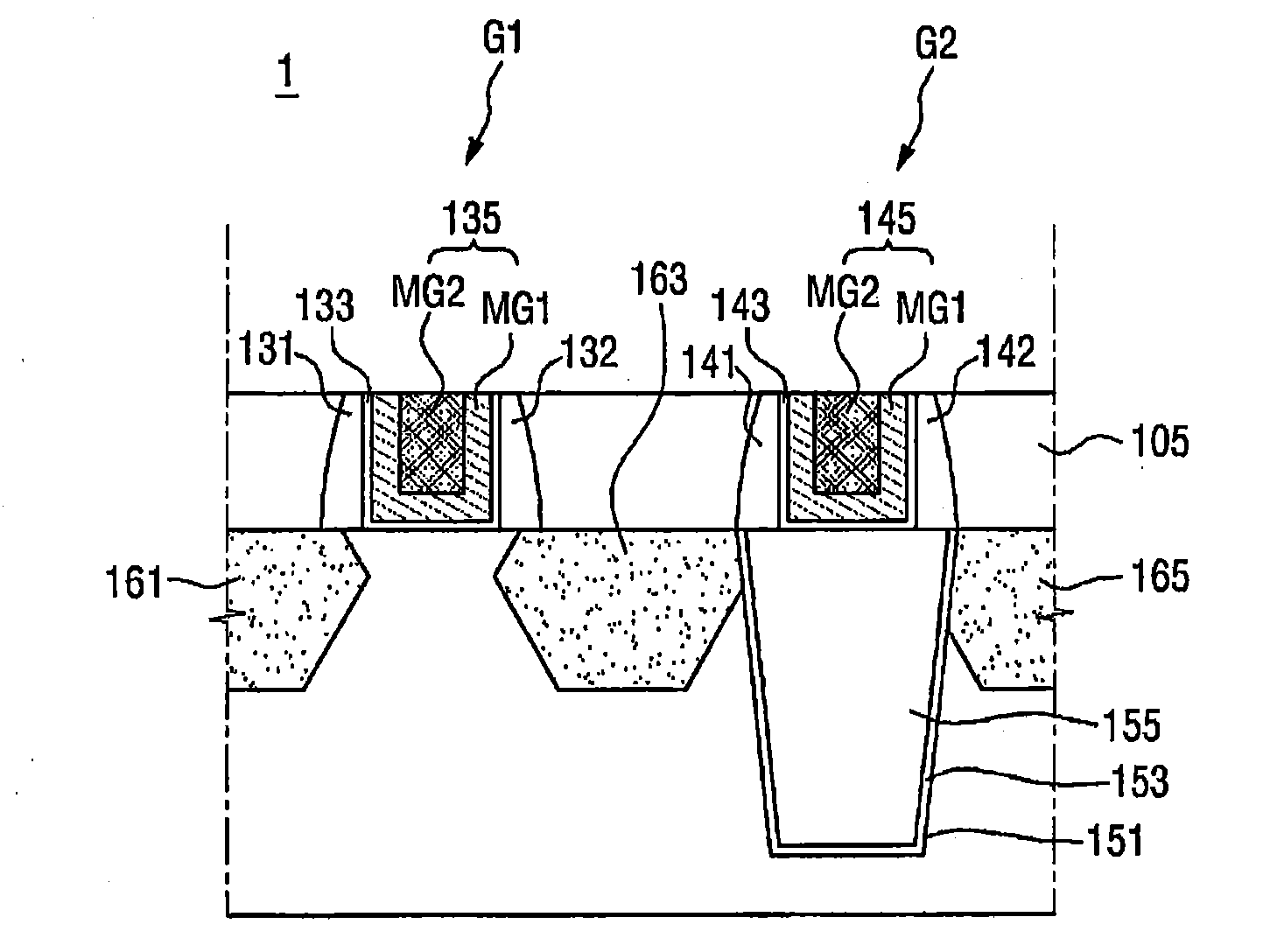

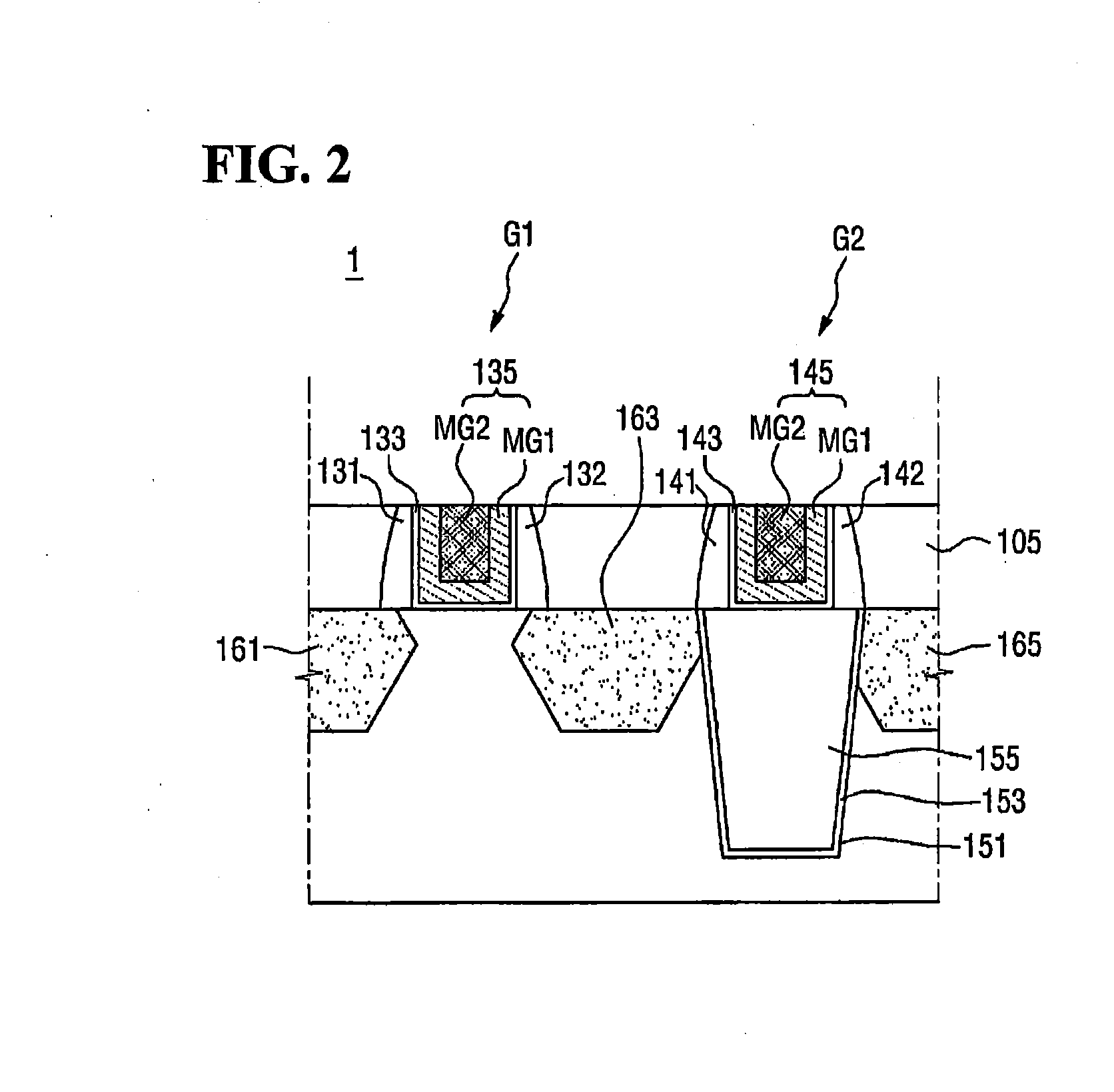

Semiconductor device and method for manufacturinmg the same

ActiveUS20110260238A1Eliminate the problemSolid-state devicesSemiconductor/solid-state device manufacturingBit lineDevice material

A semiconductor device comprises: a semiconductor substrate including an active region defined as a device isolation film; a bit line contact hole obtained by etching the semiconductor substrate; a bit line contact plug having a smaller width than that of the bit line contact hole; and a bit line connected to the upper portion of the bit line contact plug, thereby preventing a short of the bit line contact plug and the storage node contact plug to improve characteristics of the semiconductor device.

Owner:SK HYNIX INC

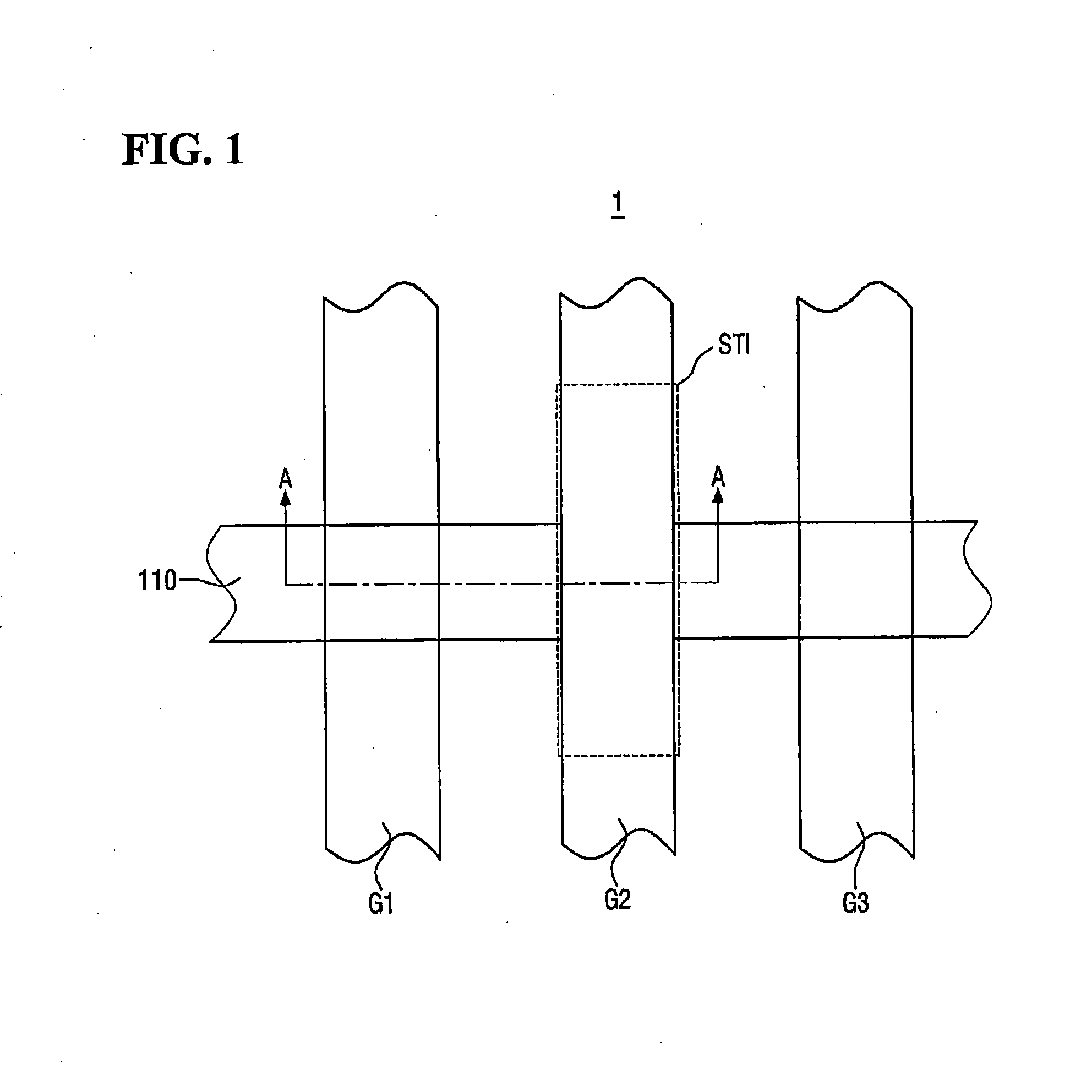

Semiconductor devices including shallow trench isolation (STI) liners

Semiconductor devices including STI liners are provided. The semiconductor devices may include a STI trench that defines an active region in a substrate, a STI liner that extends conformally along side walls and a bottom surface of the STI trench, a device isolation film that is on the STI liner and fills up at least a part of the STI trench, a first gate structure that is disposed on the active region, and a second gate structure that is spaced apart from the first gate structure. The second gate structure may include a gate insulating film contacting the device isolation film, a gate electrode on the gate insulating film, and spacers on both sides of the gate electrode. Lower surfaces of the spacers may contact an upper surface of the STI liner.

Owner:SAMSUNG ELECTRONICS CO LTD

Air conditioning condensation drainage system

InactiveUS6883336B2Quantity minimizationCondensate preventionCompression machines with non-reversible cycleIsolation membraneAir conditioning

An air-conditioning condensate drainage system for mounting to the roof membrane of the roof structure of buildings or for construction thereof directly onto the roof membrane of a building structure. The air-conditioning condensate drainage system is defined by one or more strips of material having an isolation membrane having a bottom surface for assembly to a roof membrane. A pair of spaced ridge elements project upwardly from the isolation membrane and cooperate with the isolation membrane to define an air-conditioning condensate drainage channel. In the alternative, ridge strips may be disposed in spaced relation and fixed directly to a roof membrane to define condensate drain channels along the roof membrane to in-roof drains. The condensate drain strip or ridge strips may be molded or extruded and maybe formed directly on and adhered to or fixed to the roof membrane to define the condensate drain channels.

Owner:CROSSD HLDG +1

Air conditioning condensation drainage system

InactiveUS20050183346A1Quantity minimizationRoof covering using slabs/sheetsRoof covering using tiles/slatesIsolation membraneAir conditioning

An air-conditioning condensate drainage system for mounting to the roof membrane of the roof structure of buildings or for construction thereof directly onto the roof membrane of a building structure. The air-conditioning condensate drainage system is defined by one or more strips of material having an isolation membrane having a bottom surface for assembly to a roof membrane. A pair of spaced ridge elements project upwardly from the isolation membrane and cooperate with the isolation membrane to define an air-conditioning condensate drainage channel. In the alternative, ridge strips may be disposed in spaced relation and fixed directly to a roof membrane to define condensate drain channels along the roof membrane to in-roof drains. The condensate drain strip or ridge strips maybe molded or extruded and maybe formed directly on and adhered to or fixed to the roof membrane to define the condensate drain channels.

Owner:DUDLEY WILLIAM E +1

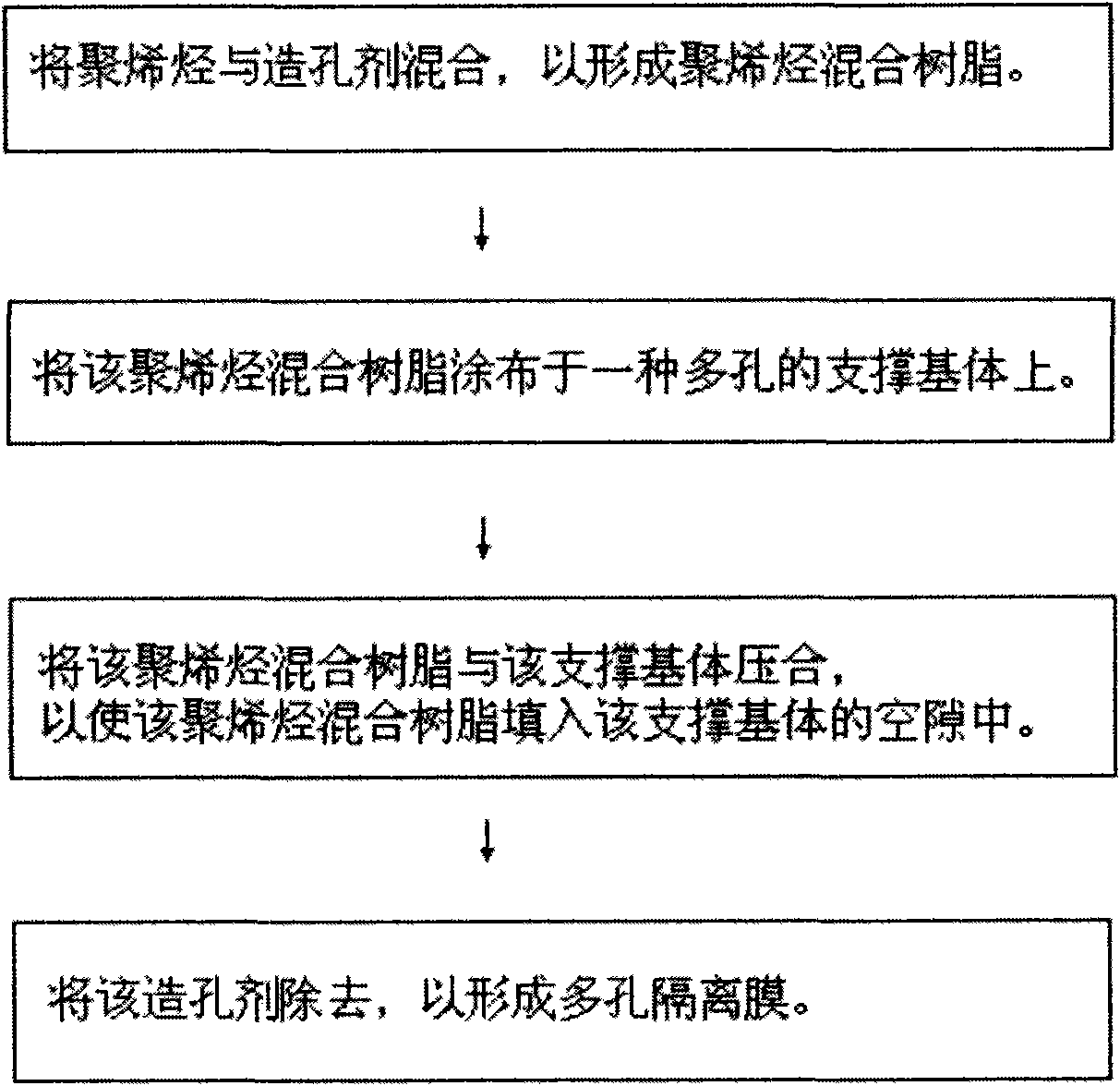

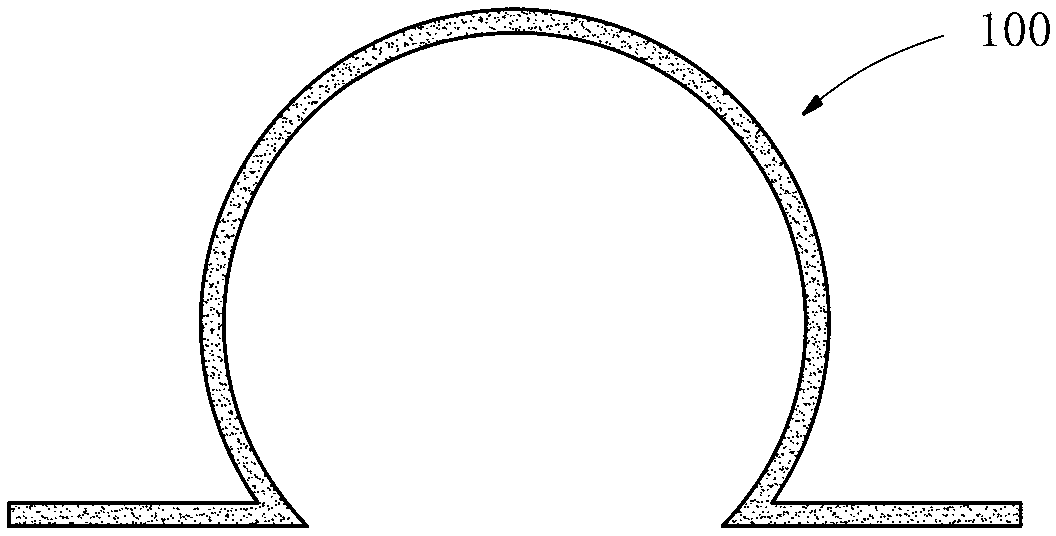

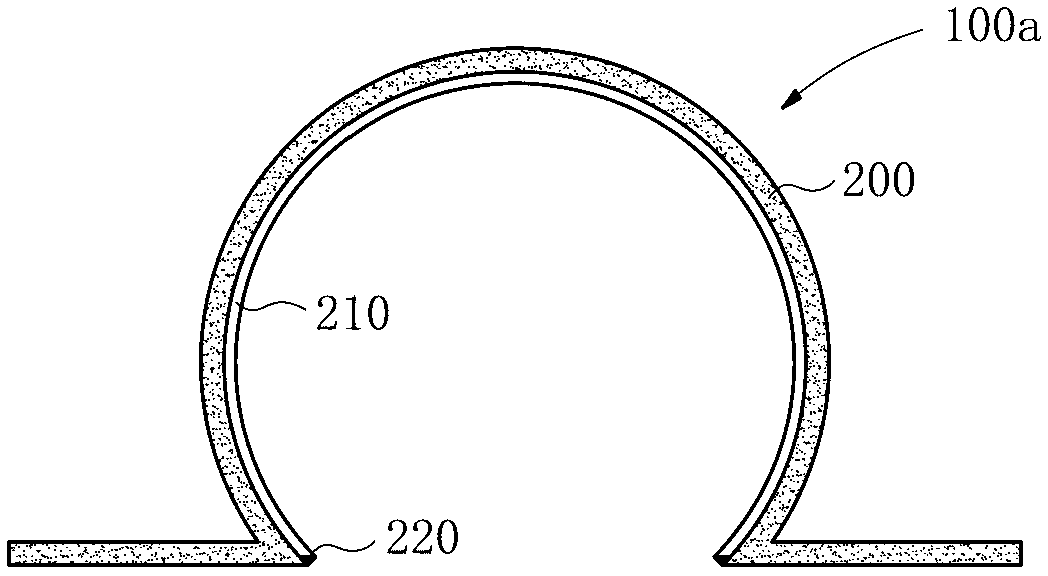

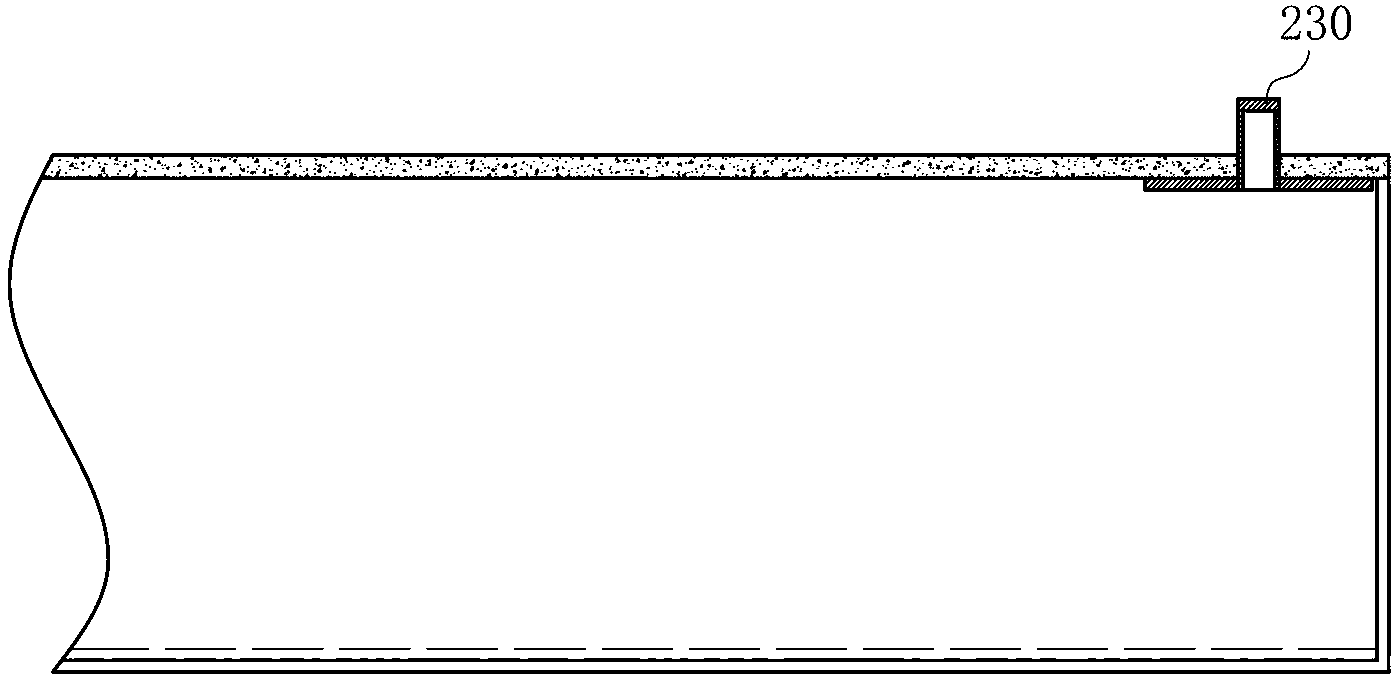

Lithium battery isolation membrane and method for manufacturing same

The invention provides a lithium battery isolation membrane and a method for manufacturing same. The lithium battery isolation membrane comprises a porous support substrate made of fibers, and porous polyolefin resin filled into gaps of the substrate. The invention also provides the method for manufacturing the lithium battery isolation membrane, which comprises the following steps: mixing polyolefin with a pore-forming agent to form the polyolefin mixed resin; coating the polyolefin mixed resin on the porous support substrate; pressing the polyolefin mixed resin and the support substrate to fill the polyolefin mixed resin into the gaps of the support substrate; and removing the pore-forming agent to form the porous isolation membrane.

Owner:IND TECH RES INST

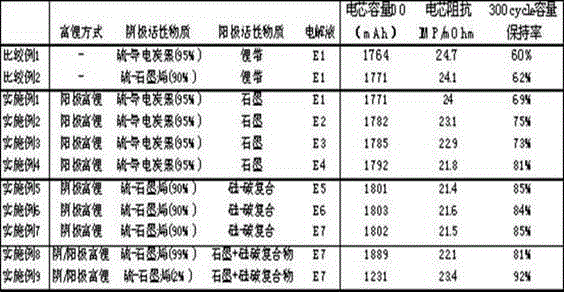

Lithium-sulfur battery and preparation method thereof

InactiveCN104659410AImprove performanceFinal product manufactureCell electrodesLithium metalLithium–sulfur battery

The invention belongs to the field of lithium-sulfur batteries and particularly relates to a lithium-sulfur battery and a preparation method thereof. The lithium-sulfur battery comprises a cathode, an anode, an isolation film, an electrolyte and an outer packing, wherein the cathode and the anode adopt lithium-deficient electrode materials; by using a carbon material, an alloy type material and other anode active substances, many problems of a lithium metal anode are solved, and through a lithium-rich technology, lithium-rich treatment is performed on the electrode, so that the problem that the sulfur cathode cannot provide a lithium source is solved; and a film-forming additive is introduced into the electrolyte, so that the anode active substance, such as the carbon material, the alloy type material and other particles can form a high-quality solid electrolyte film (SEI film) on the surface, and the lithium-sulfur battery with excellent performance is finally prepared.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

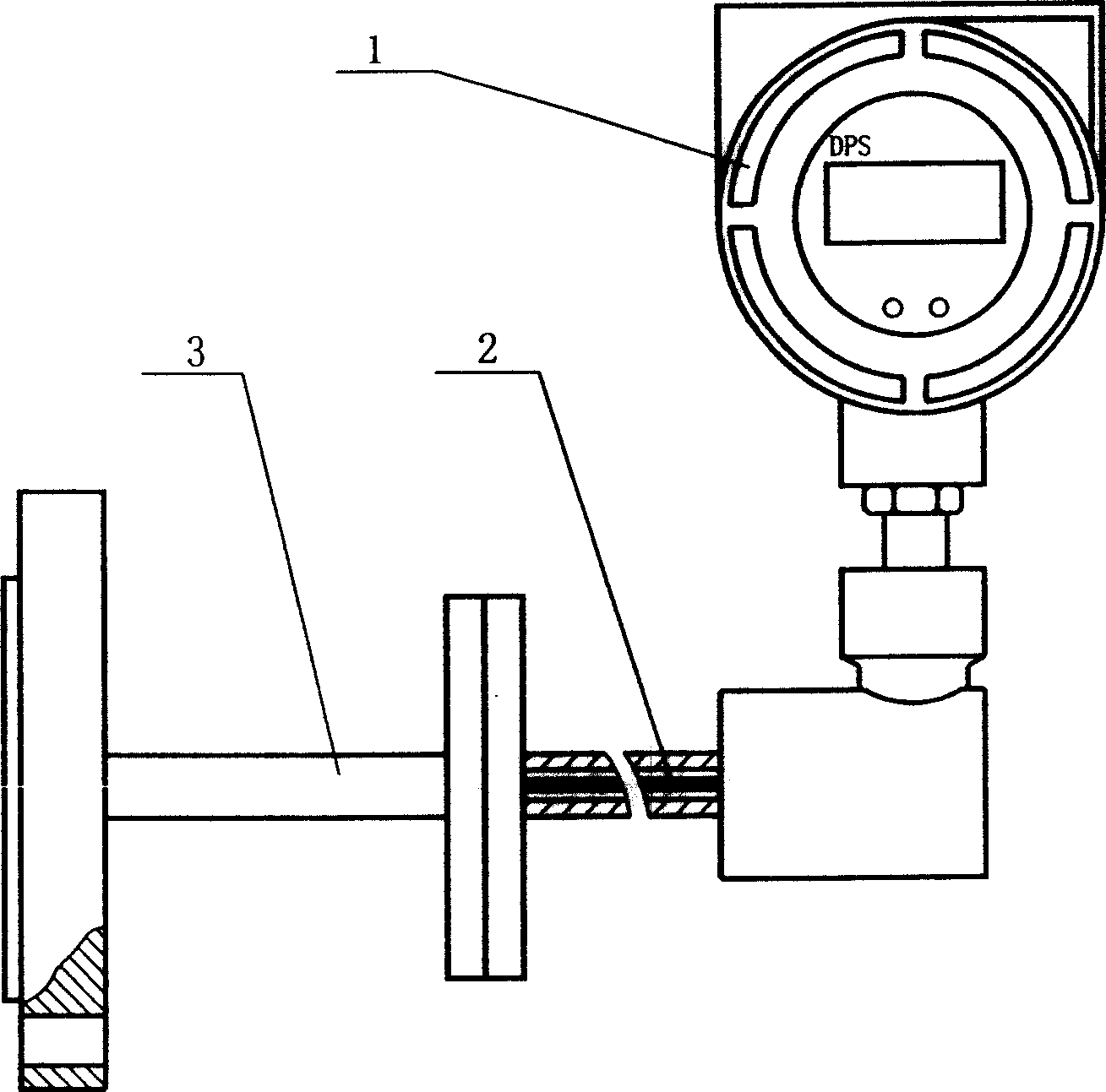

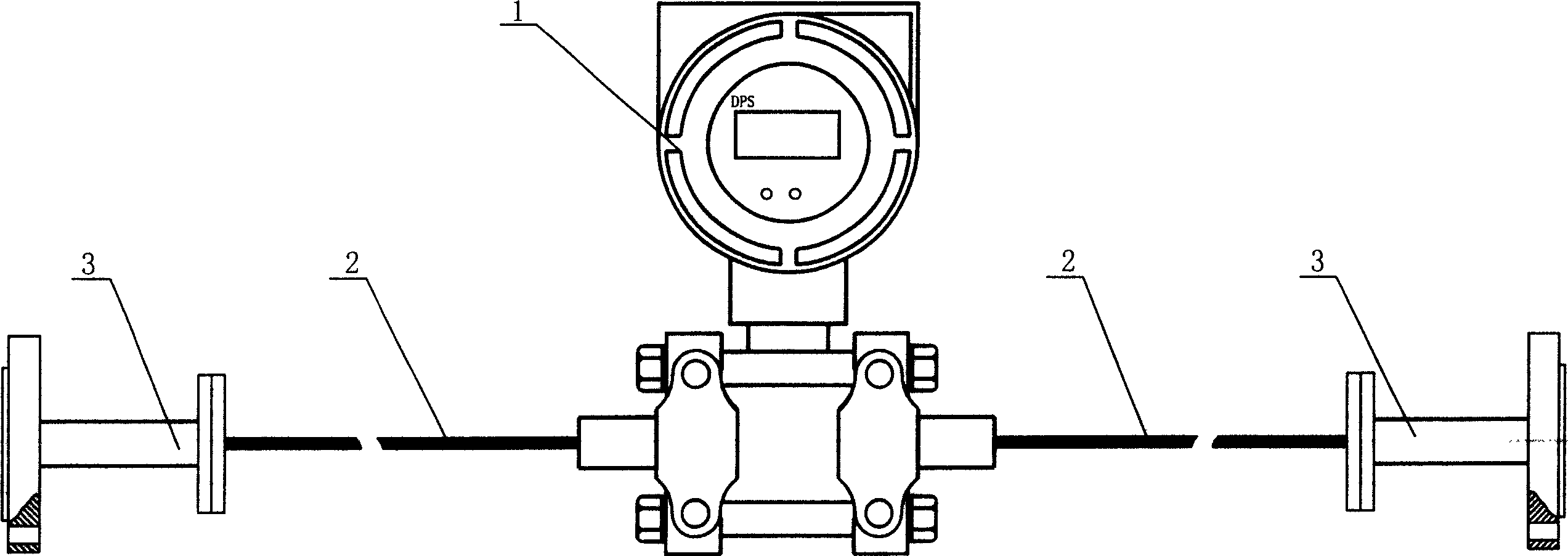

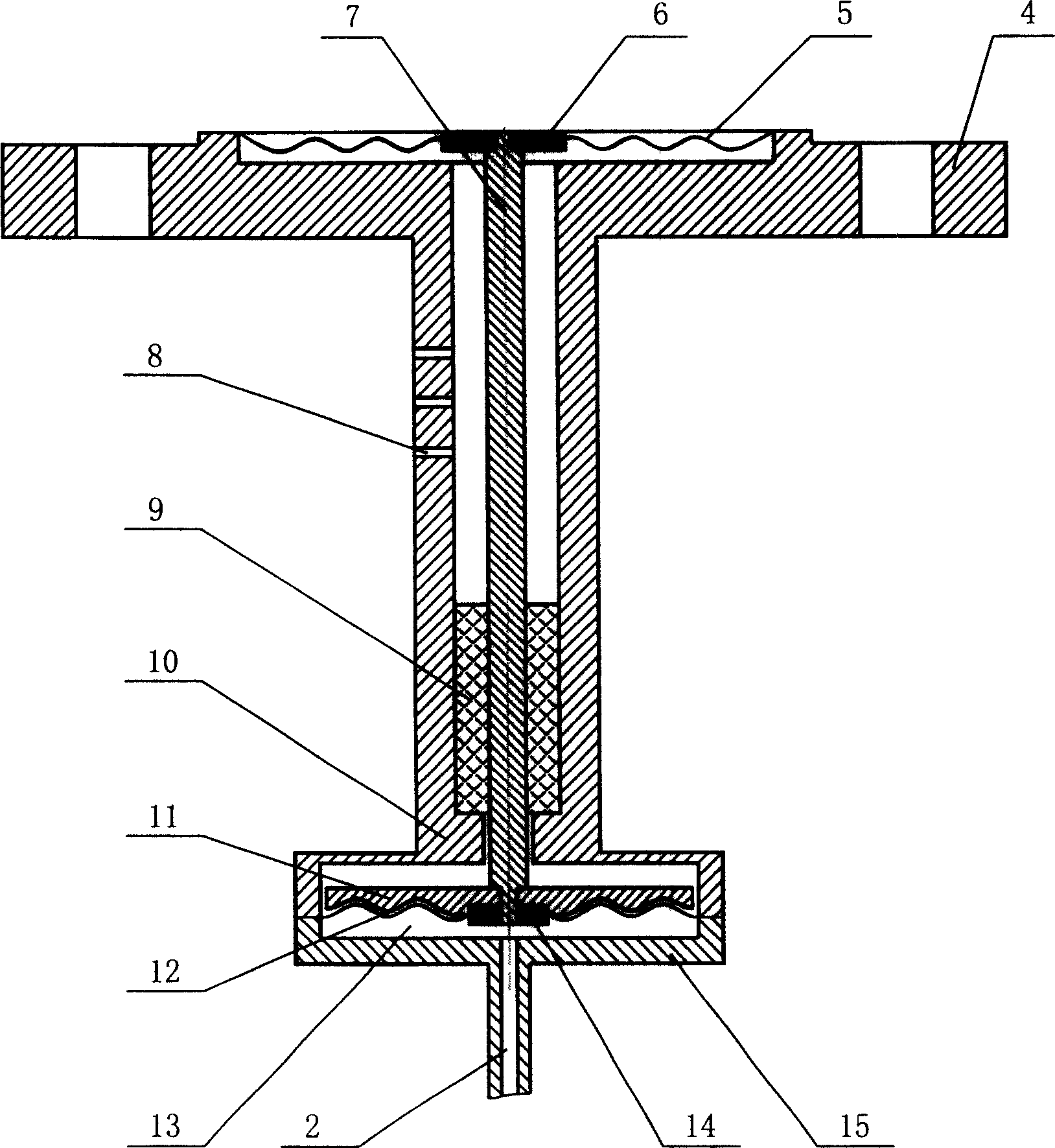

Telemetering high-temp pressure resistant / differential pressure sensor

InactiveCN1651891AReasonable structural designReasonable operationFluid pressure measurement by electric/magnetic elementsDifferential pressureTransducer

The present invention relates to a remote transferred high temperature resstant pressure / differential pressure transducer. Said invention includes the following components: transducer, measuring membrane, isolating diaphragm, membrane hard core, connecting flange, rigid stress bar and membrane box. Said invention also provides their connection mode, and said invented transducer can raise accuracy of measurement, and can prolong its service life.

Owner:SHENYANG SENSOR TECH INST

High temperature pressure transmitter assembly

ActiveUS7373831B2Increases cost and complexityConvenient and accurateFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsThermal isolationCoupling

A pressure transmitter assembly for measuring a pressure of a process fluid includes an isolation diaphragm assembly configured to couple to a process fluid. A pressure sensor is coupled to the isolation diaphragm assembly and is configured to sense a pressure. An isolation diaphragm coupling flange is provided to carry the isolation diaphragm assembly and includes a cutaway portion to provide thermal isolation.

Owner:ROSEMOUNT INC

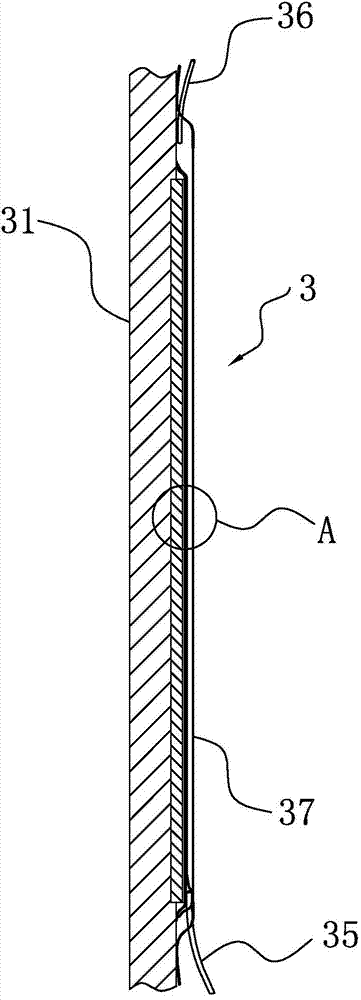

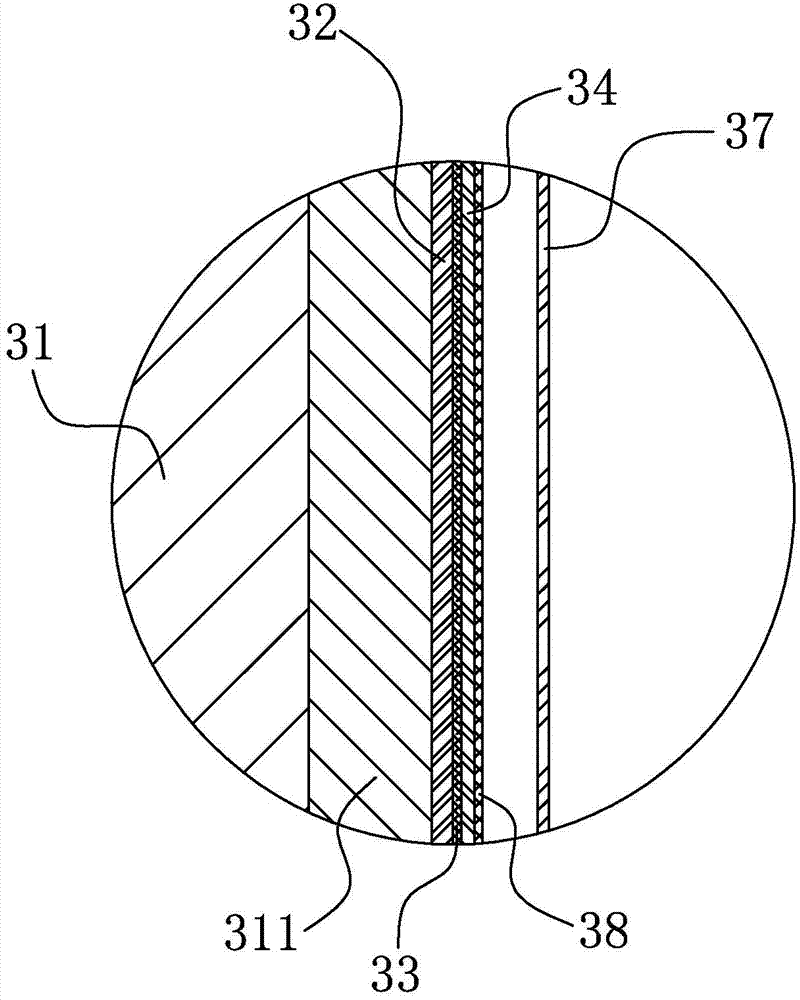

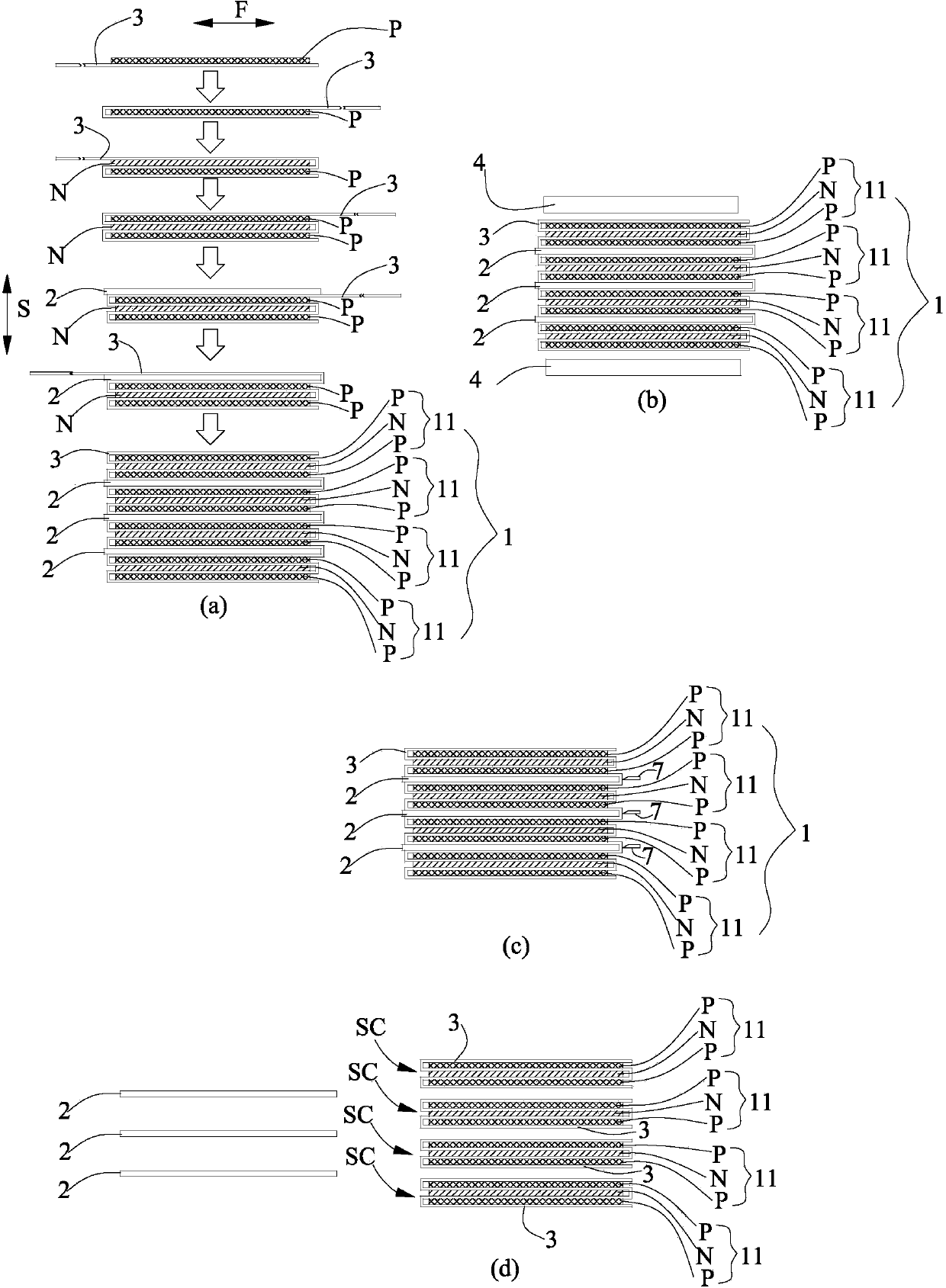

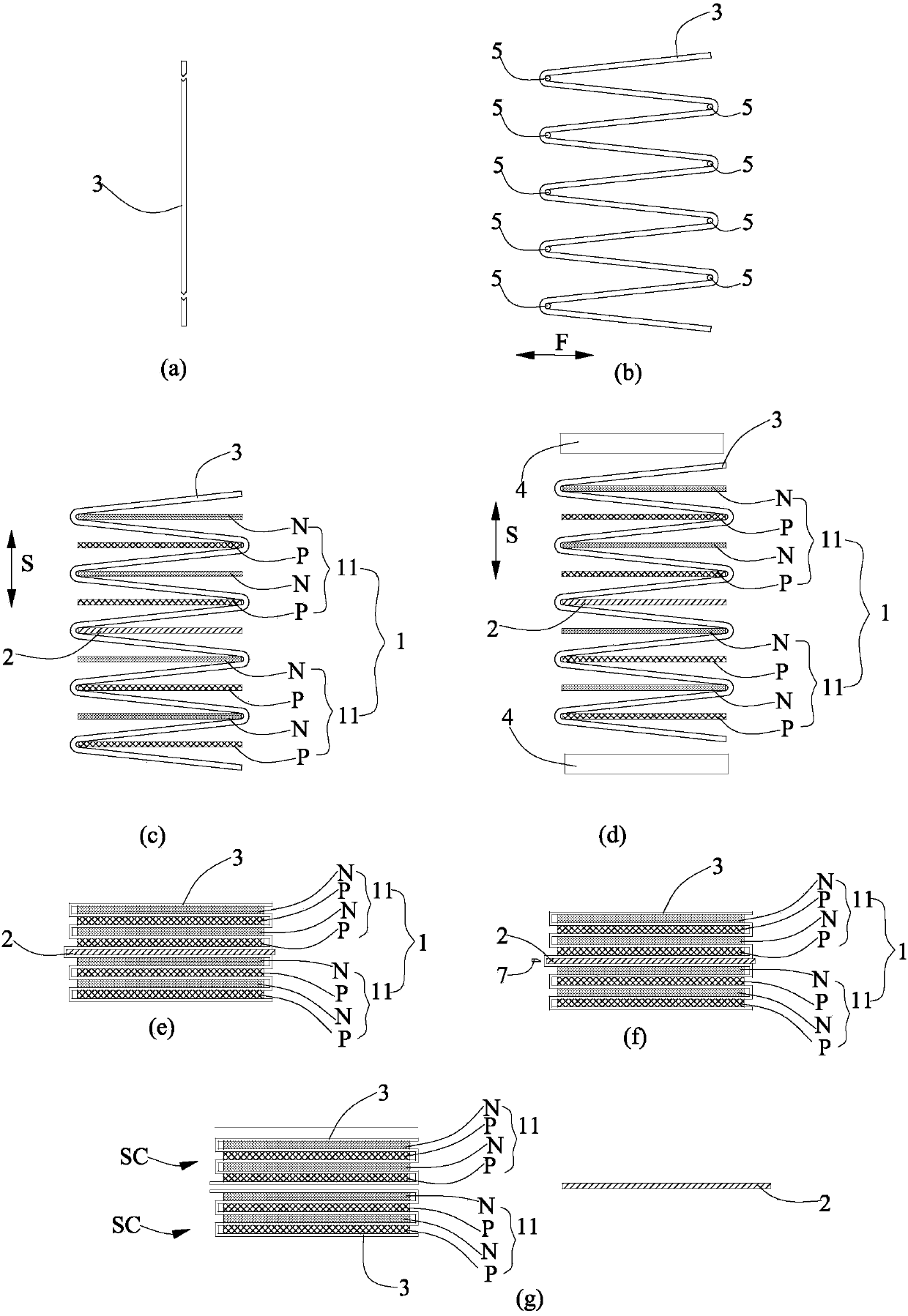

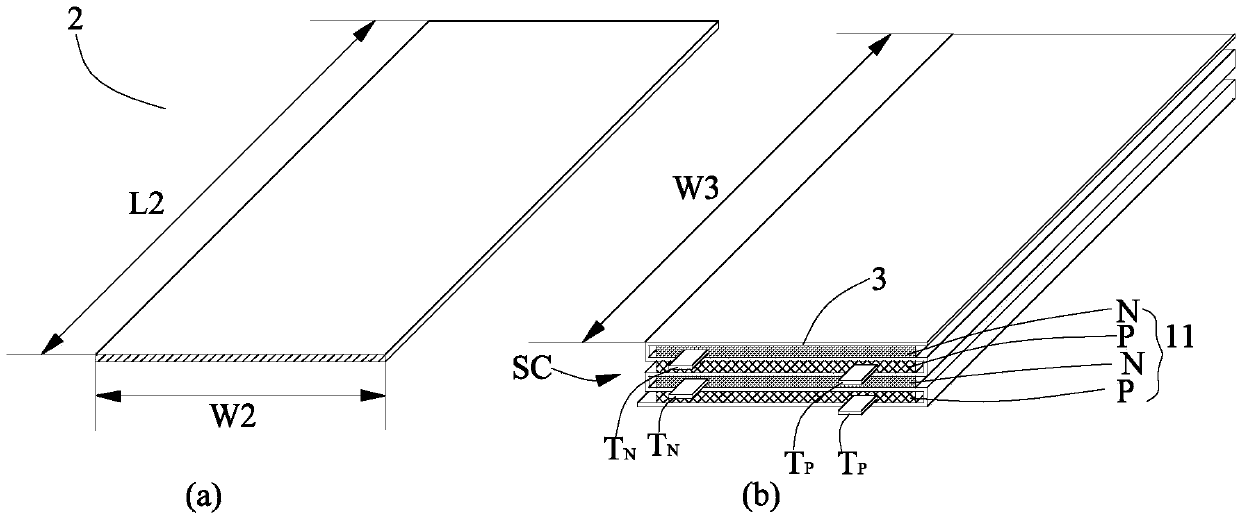

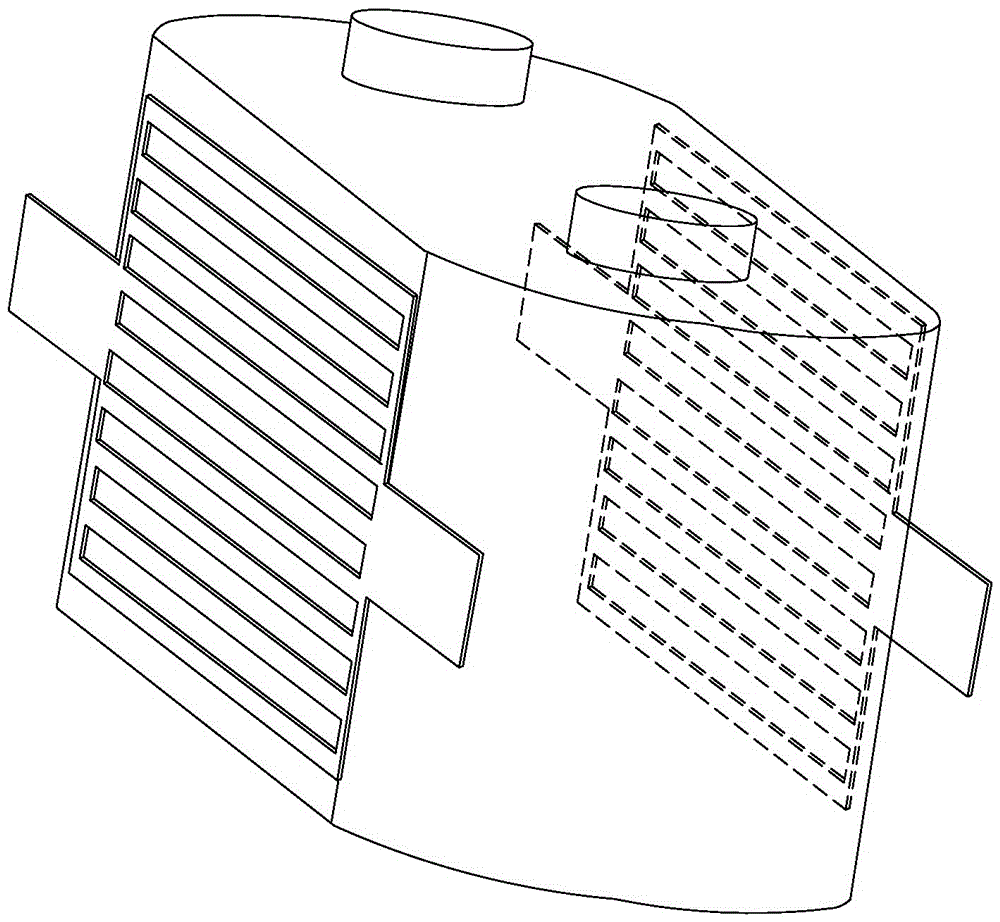

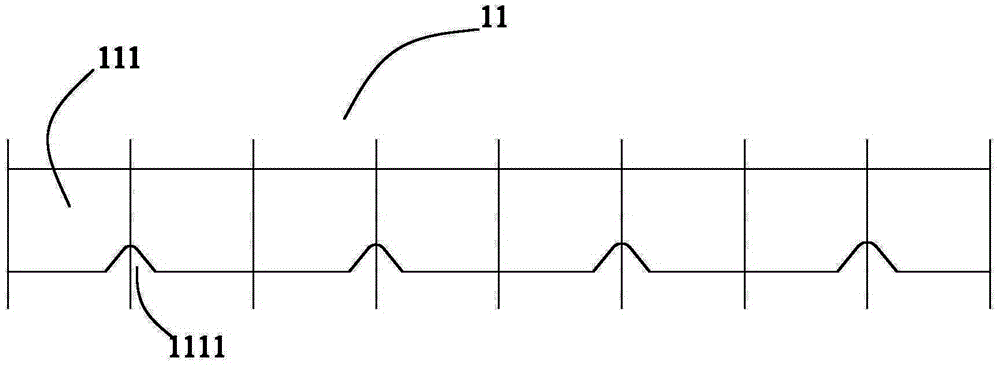

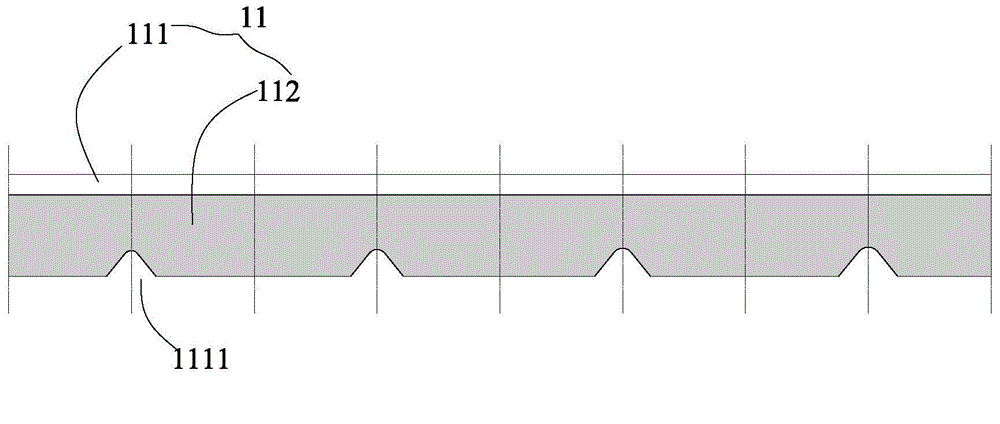

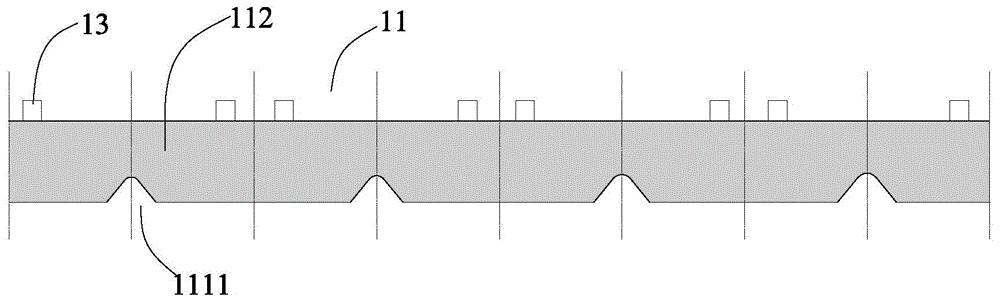

Preparation method of lamination battery cell

ActiveCN104051793AReduce auxiliary timeImproving the efficiency of preparing laminated cellsFinal product manufactureLi-accumulatorsIsolation membranePole piece

The invention provides a preparation method of a lamination battery cell. The preparation method of the lamination battery cell comprises the following steps: a lamination pile comprising n lamination groups is arranged, wherein each lamination group comprises m pole piece elements, n is more than or equal to 2, and m is more than or equal to 2, and gaskets are arranged between the adjacent lamination groups; the pole piece elements of all the lamination groups of the lamination pile and the gaskets between the adjacent lamination groups are sequentially positioned in a Z-shaped isolation membrane along the piling direction; each gasket separates the upper and lower parts of the adjacent isolation membranes; forming a lamination battery cell is formed, namely, the isolation membranes are disconnected at one end of each gasket, positioned in the isolation membranes, so that each gasket and each lamination group can be separated, and further, the lamination battery cell formed by the pole piece elements in each lamination group and corresponding isolation membrane can be obtained, wherein each lamination battery cell comprises an anode pole piece and a cathode pole piece, or a monomer battery cell, or a monomer battery cell, or the combination of the monomer battery cell and the anode pole piece and / or cathode pole piece, so that the efficiency of the lamination battery cell is improved greatly.

Owner:NINGDE AMPEREX TECH

Method for continuously producing jelly of ultra-high molecular weight polyethylene porous membrane

ActiveCN101618295AEasy to useHigh strengthSemi-permeable membranesSwelling capacityVolumetric Mass Density

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

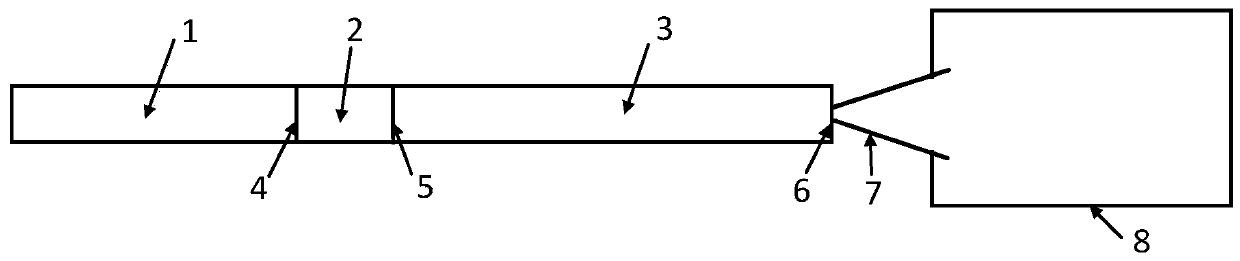

Shock tunnel with isolation device

The invention discloses a shock tunnel with an isolation device. The shock tunnel with the isolation device disclosed by the invention comprises a driving section, an isolation section, a driven section, a spray pipe and a test section, which are sequentially connected from front to back, wherein a main membrane is installed between the driving section and the isolation section, an isolation membrane is installed between the isolation section and the driven section, and a throat membrane is installed between the driven section and the spray pipe. According to the shock tunnel with the isolation device disclosed by the invention, a segment of isolation section filled with nitrogen is added in a pipe body of the shock tunnel for isolating the flue gas in the driving section from the in the driven section, so as to suppress contact surface combustion and to improve the test reliability of the shock tunnel.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Vacuum infusion process and drainage tube used for vacuum infusion process

The invention provides a vacuum infusion process and a drainage tube used for the vacuum infusion process. The process comprises the following steps of: paving glass fiber textile, release cloth, a perforated isolation membrane and a drainage mesh; paving the drainage tube, wherein the drainage tube comprises a drainage tube main body, a film lining or film bag and an injection port; paving a resin glue inlet tube, a glue inlet three-way tube and a vacuum tube; paving a vacuum bag so as to seal at a proper position of the component; opening a valve of the resin glue inlet tube so as to perform vacuum infusion; when the infusion process is about to be completed, connecting the injection port of the drainage tube main body by utilizing a connecting tube so as to inject a packing medium to enable the film lining or the film bag to be expanded, thus squeezing out resin inside the drainage tube main body; and infusing the remaining part of a product by utilizing the resin squeezed out, and then curing. The vacuum infusion process can solve the problems of material waste and the like caused by resin residual inside the drainage tube, and is beneficial to cleaning and recovery utilization of the drainage tube.

Owner:XINJIANG GOLDWIND SCI & TECH

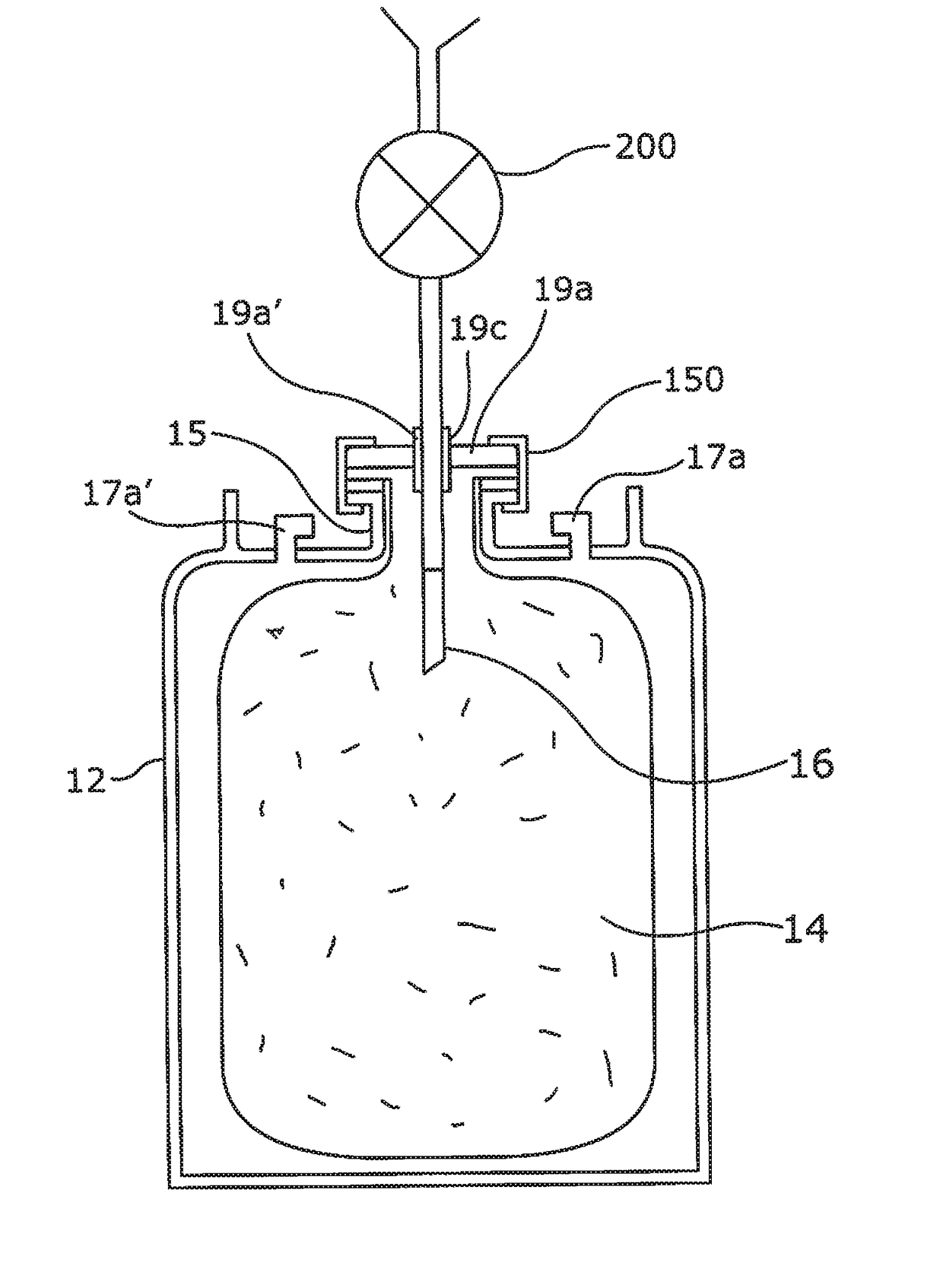

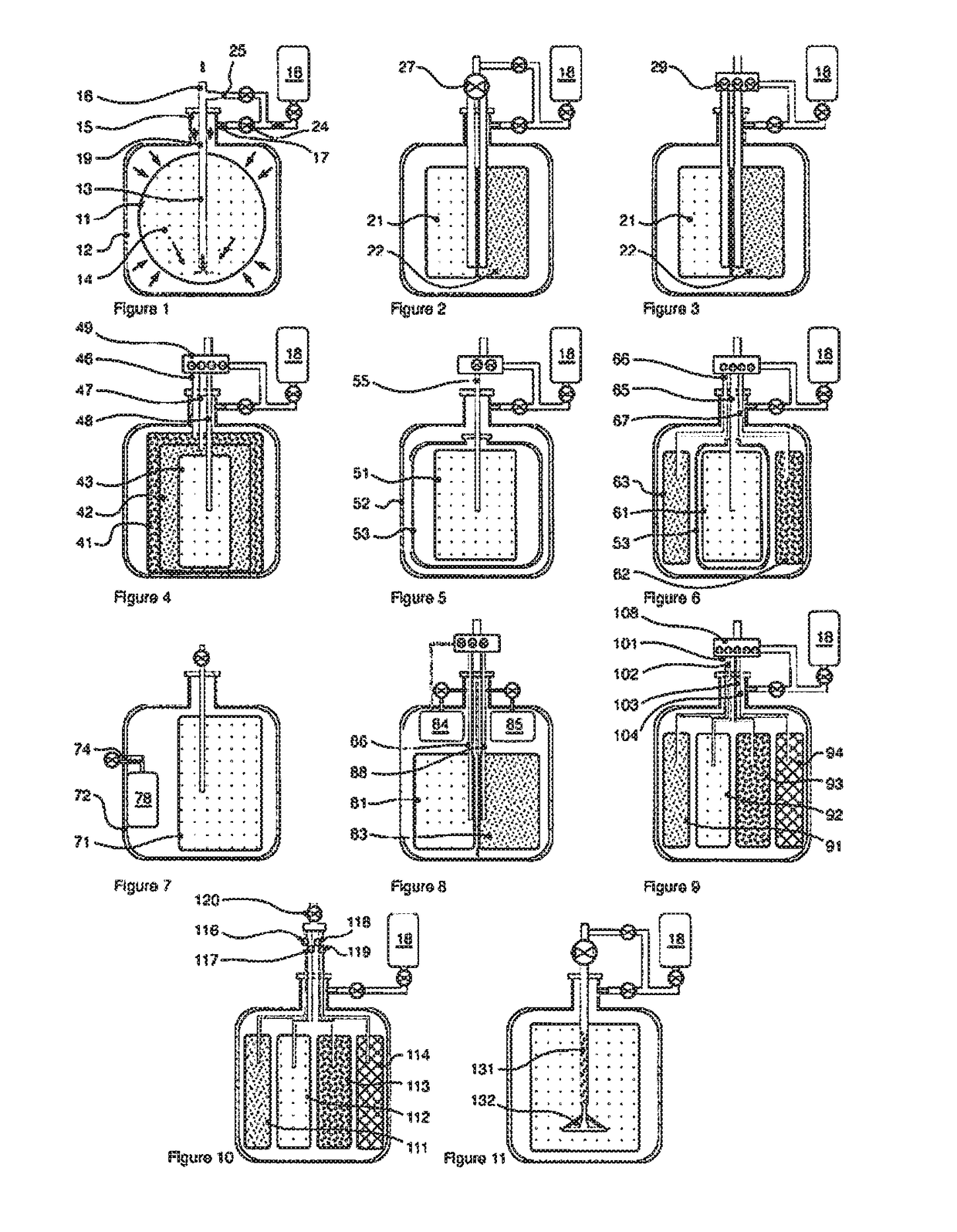

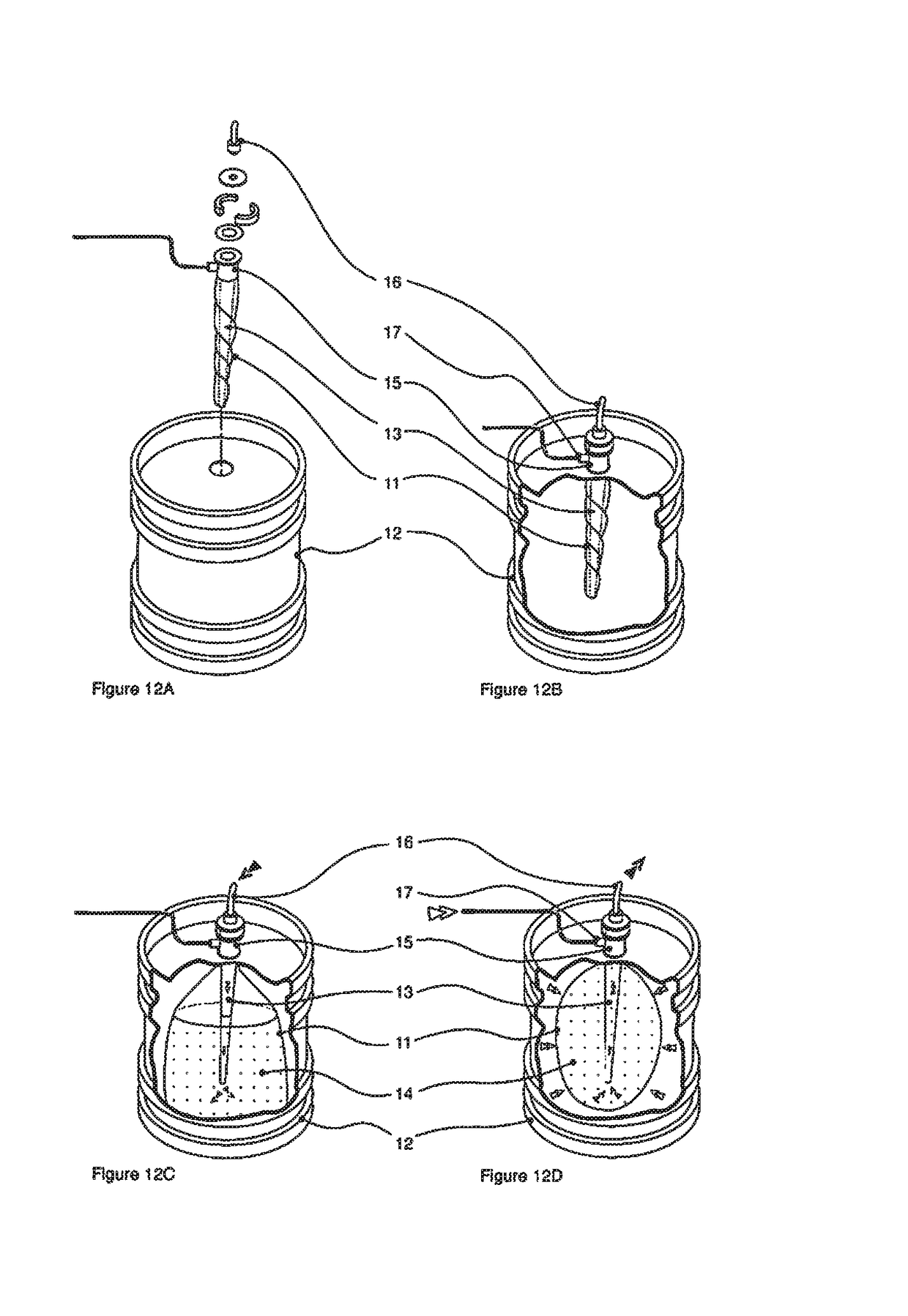

Fluid dispenser with isolation membrane

ActiveUS20180029864A1Reduce assemblyEase and safetyLiquid transferring devicesLinings/internal coatingsEngineeringIsolation membrane

The combination of a container of a first volume and a fluid containment and dispensing apparatus includes a flexible bag having an inner wall, an outer wall and a collar. The collar comprises a plurality of components, including a collar body, a flange that is attached to the bag, and a top plate having a first aperture therein configured to for connection to a first fluid carrying conduit, the fluid carrying conduit providing for egress of fluid from the bag. The container comprises walls the walls having inner and outer surfaces, and the collar body extends from a wall of the container. The container provides at least one second aperture providing for ingress and egress of fluid to and from a space situated between the outer surface of the bag and the inner surface of the container and the apparatus further comprises fastening means to fasten the collar components together.

Owner:BLACKBURN RAYMOND WILSON

Rapid heating battery

PendingCN106532190AImprove the heating effectTwo do not delay workCell temperature controlCurrent channelMetal foil

The invention discloses a rapid heating battery, which mainly comprises a battery shell, a battery core (comprising a positive plate, a negative plate, an isolation membrane, an electrolyte and the like), a metal foil body heating plate, a working terminal and a heating terminal, wherein the battery core is an electrochemical working system; the battery core completes conversion between electric energy and chemical energy in charging and discharging processes; the working terminal is a channel through which the electric energy and the chemical energy can pass in and out of the battery core; the metal foil body heating plate, the heating terminal and the battery shell are auxiliary components of the battery; the metal foil body heating plate is mainly used for heating the battery core; the heating terminal is a current channel of the metal foil body heating plate; and the battery shell is mainly used for packaging the battery core and the metal foil body heating plate. When the temperature of the battery core is relatively low, an external power supply provides the metal foil body heating plate with the electric energy through the heating terminal and the metal foil body heating plate converts the electric energy into heat energy for heating the battery core. The rapid heating battery has the advantages that the battery core and the metal foil body heating plate are packaged in the battery and the heating efficiency is high; and the working terminal of the battery core and the heating terminal of the metal foil body heating plate are mutually independent and input and output can be independently controlled.

Owner:XIAMEN HUARONG ENERGY TECH

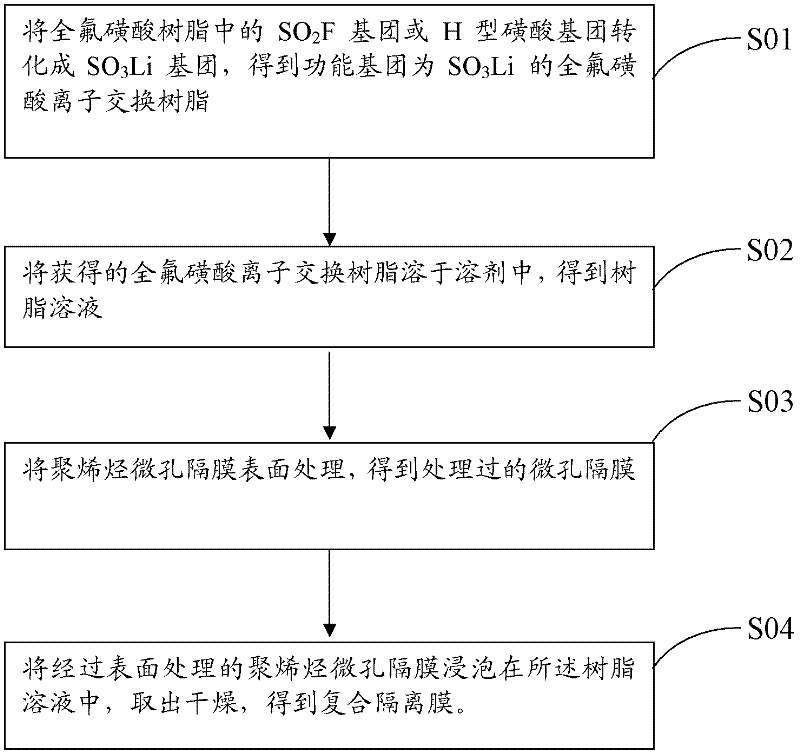

Composite isolation membrane and formation method thereof

ActiveCN102311559AImprove liquid absorption capacityImprove heat resistanceCell component detailsAbsorption capacityPolyolefin

The invention provides a composite isolation membrane and a formation method thereof, and the method comprises the following steps: transforming a SO2F group or a H-type sulfonic group in perfluorosulfonate resin into a SO3Li group to obtain a perfluorosulfonate ion exchange resin with a SO3Li functional group; dissolving the obtained perfluorosulfonate ion exchange resin in a solvent to obtain a resin solution; performing surface treatment of a polyolefin micropore diaphragm to obtain a treated micropore diaphragm; soaking the polyolefin micropore diaphragm after surface treatment in the resin solution, taking the diaphragm out and drying to obtain a composite isolation membrane. According to the invention, by combining the perfluorosulfonate ion exchange resin which has a Li ion exchange function after ion transformation with the polyolefin micropore diaphragm after surface treatment, the polyolefin micropore diaphragm is modified; because of the high thermal stability, hydrophilicity, and ion exchange capability of the perfluorosulfonate ion exchange resin, the liquid absorption capacity, heat resistance and ion penetration capability of the isolation membrane are increased.

Owner:SHENZHEN SENIOR TECH MATERIAL

Preparation method of electric core

ActiveCN104157912AGuaranteed performanceLow costFinal product manufactureWound/folded electrode electrodesIsolation membraneEngineering

The invention provides a preparation method of an electric core. The method comprises the following steps: cutting a first gap of a linear array at the edge of and / or in a first current collector along the longitudinal direction, coating a first paste containing a first active material, drying, and conducting cold pressing to obtain a first pole piece; cutting a second gap of the linear array along the vertical direction of a second current collector, wherein the a second gap is on a position on the second current collector and corresponding to the first current collector, and corresponds to and matches with the gap of the first current collector, coating a second paste containing active material, drying, and conducting cold pressing to prepare a second pole piece; arranging a first pole ear and a second polar ear; arranging an isolation membrane to form a laminated body; reeling the laminated body into an electrical core, so that corresponding first gap of the first pole piece and the second gap of the second pole piece form a cut loss portion, and the corresponding first gap of the first pole piece and the second gap of the second pole piece have aligned corresponding edges. The preparation method of the electric core is simple and low in cost and ensures the performance of the electric core.

Owner:DONGGUAN AMPEREX TECH +1

Lithium ion battery

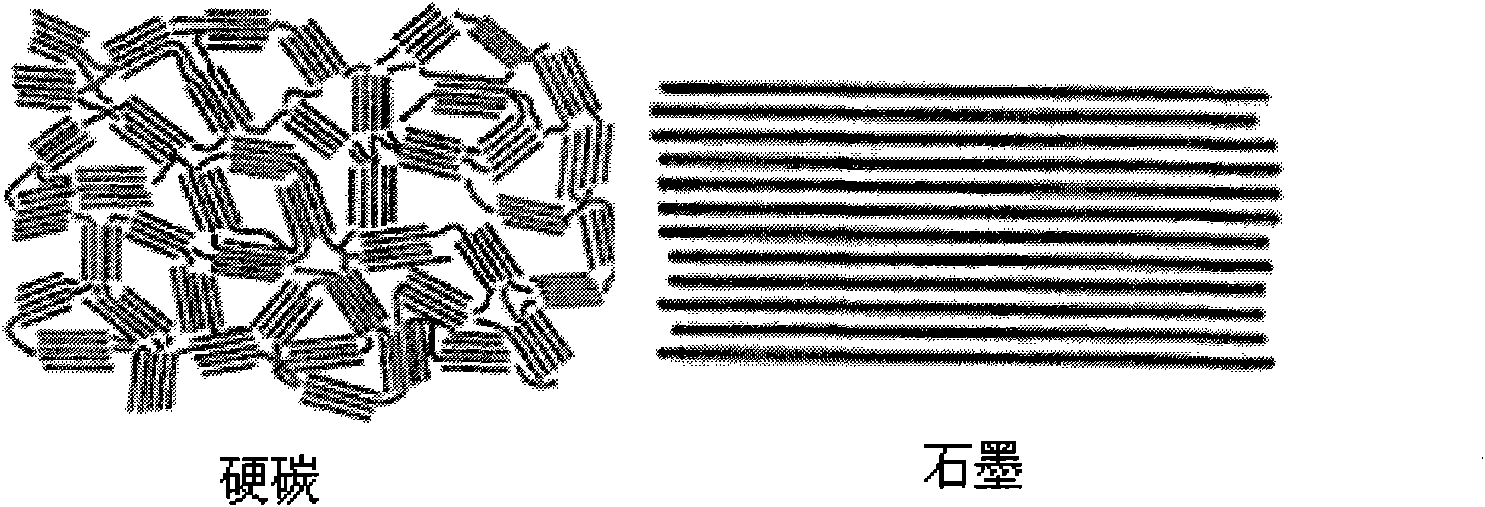

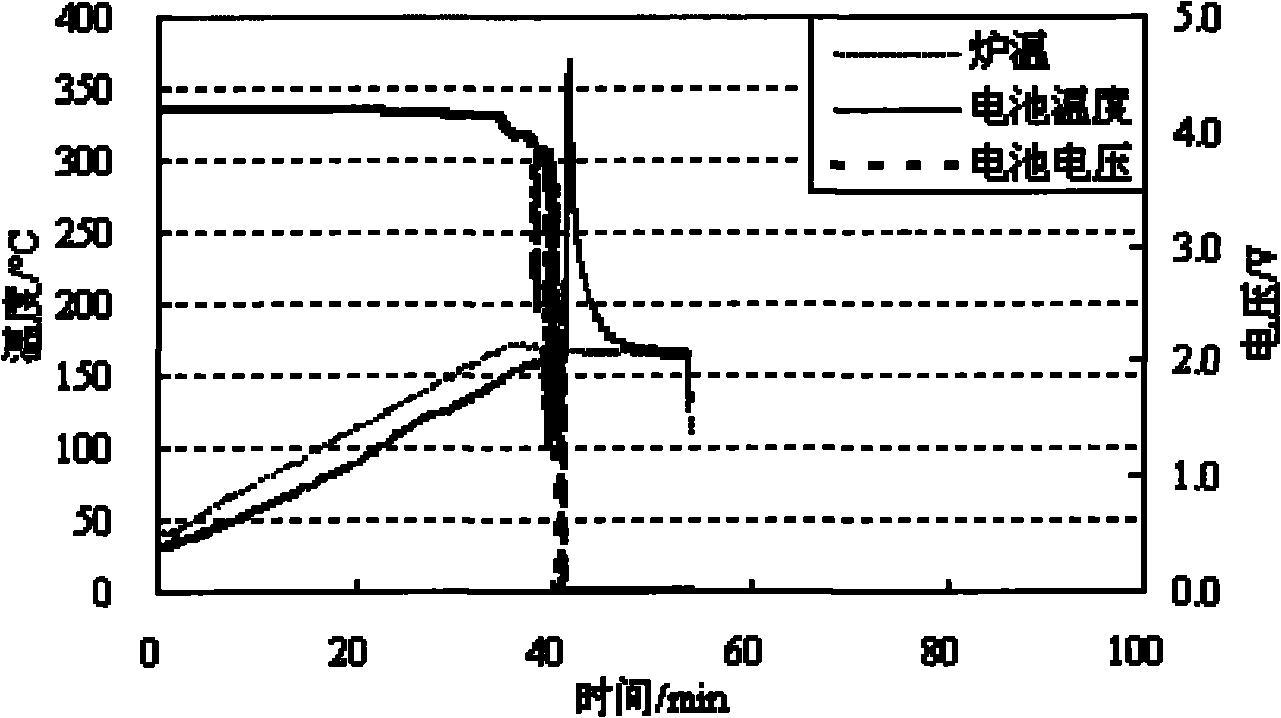

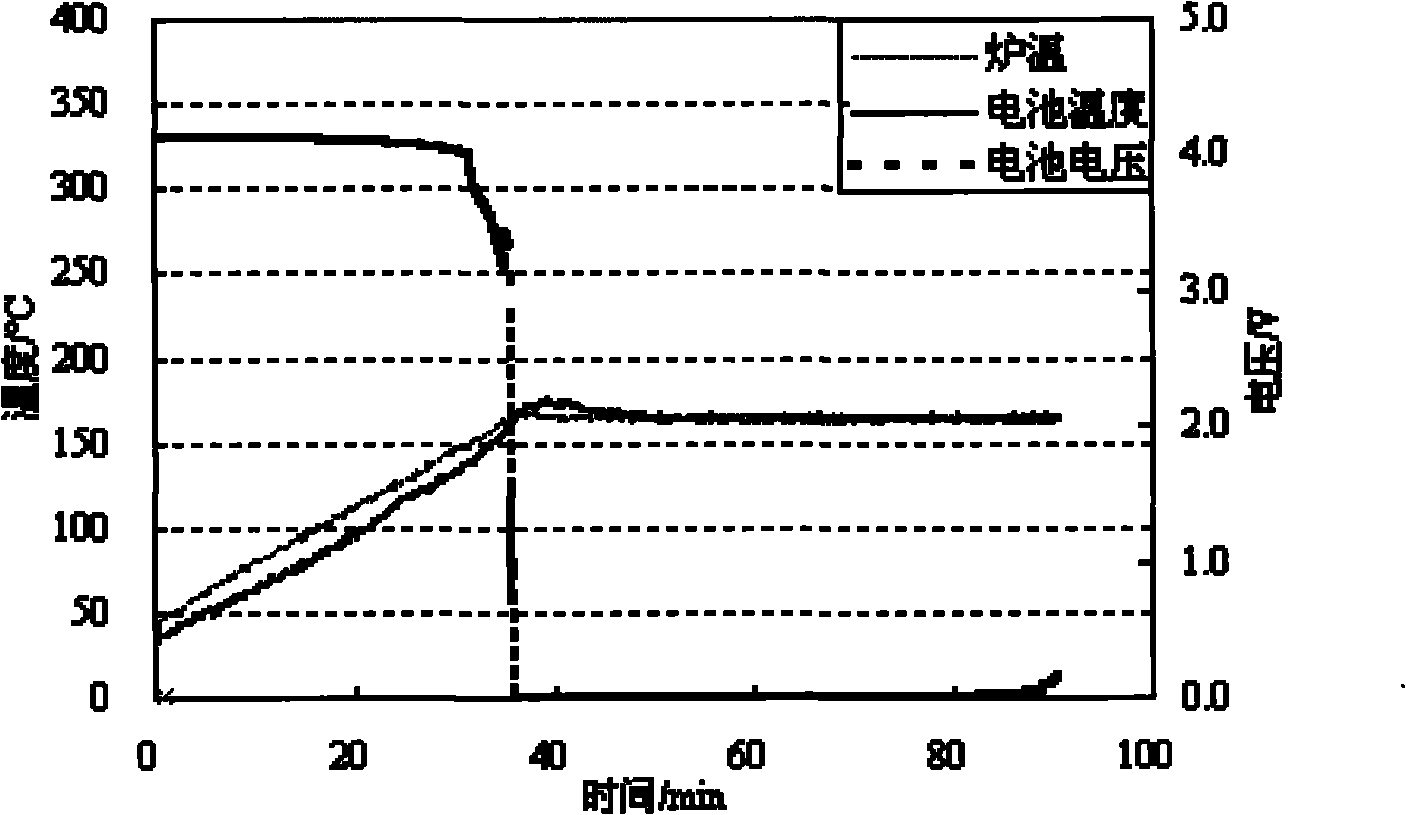

InactiveCN101924243AImprove securityImprove electrochemical performanceCell electrodesSecondary cellsCarbon layerDimethyl methylphosphonate

The invention discloses a lithium ion battery. The lithium ion battery comprises a positive plate, a negative plate, an isolation membrane arranged between the positive plate and the negative plate and an electrolyte, wherein the positive plate comprises a positive current collector and a positive diaphragm which is attached to the positive current collector and contains a positive active substance; the negative plate comprises a negative current collector and a negative diaphragm which is attached to the negative current collector and contains a negative active substance; an electrolyte solvent contains dimethyl methylphosphonate; and the negative active substance is hard carbon. In the lithium ion battery, a structure that carbon layers of the hard carbon are randomly arranged reduces the destruction of the dimethyl methylphosphonate, and weakens a reduction reaction of the hard carbon and the dimethyl methylphosphonate in the formation process; and the first charge-discharge efficiency and capacity of the lithium ion battery are not reduced substantially due to the addition of the dimethyl methylphosphonate, and the safety of the lithium ion battery is improved.

Owner:DONGGUAN AMPEREX TECH

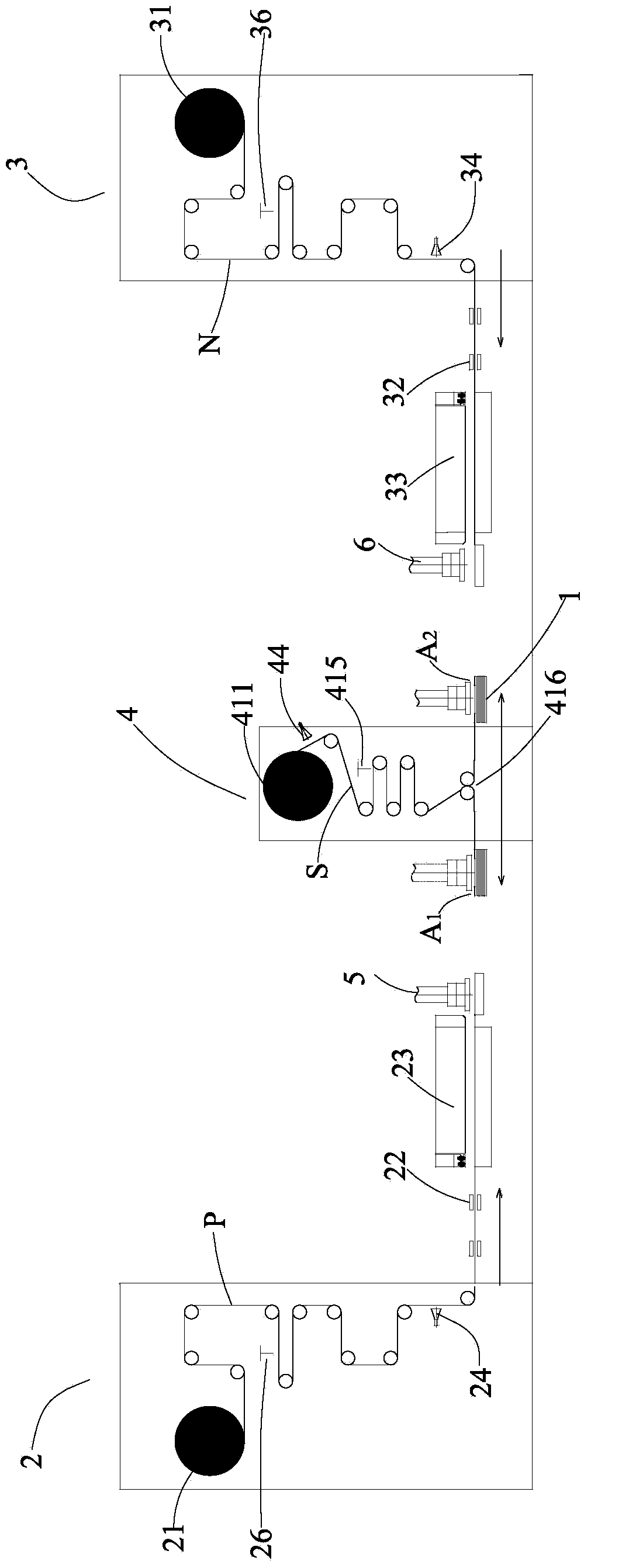

Laminated battery cell preparation device

ActiveCN104241700AOmit the repositioning stepEasy to produceLamination plant layoutLamination ancillary operationsIsolation membraneEngineering

The invention provides a laminated battery cell preparation device which comprises a laminating platform, an anode strip preparation mechanism used for positioning and preparing anode strips one by one, a cathode strip preparation mechanism used for positioning and preparing cathode strips one by one, an isolation membrane providing mechanism used for positioning isolation membranes and directly providing the isolation membranes for the laminating platform, an anode strip mechanical hand used for picking the prepared anode strips from the anode strip preparation mechanism one by one and directly providing the anode strips for the laminating platform, and a cathode strip mechanical hand used for picking the prepared cathode strips from the cathode strip preparation mechanism and directly providing the cathode strips for the laminating platform, wherein the anode strips, the isolation membranes and the cathode strips are laminated without location at the laminating platform in a manner of arranging the isolation membranes between the anode strips and the cathode strips to form a laminated battery cell. According to the laminated battery cell preparation device, the production efficiency of the laminated battery cell can be improved and the production yield of the laminated battery cell can be increased.

Owner:DONGGUAN AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com