Self-adhesive waterproof asphalt coil material

A kind of asphalt waterproof membrane and self-adhesive technology, which is applied in the direction of asphalt layered products, layered products, synthetic resin layered products, etc. It can solve the problems that self-adhesive membranes cannot be used on roofs, only 70°C, and fire hazards. , to achieve the effect of increasing compactness, reducing surface tension and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

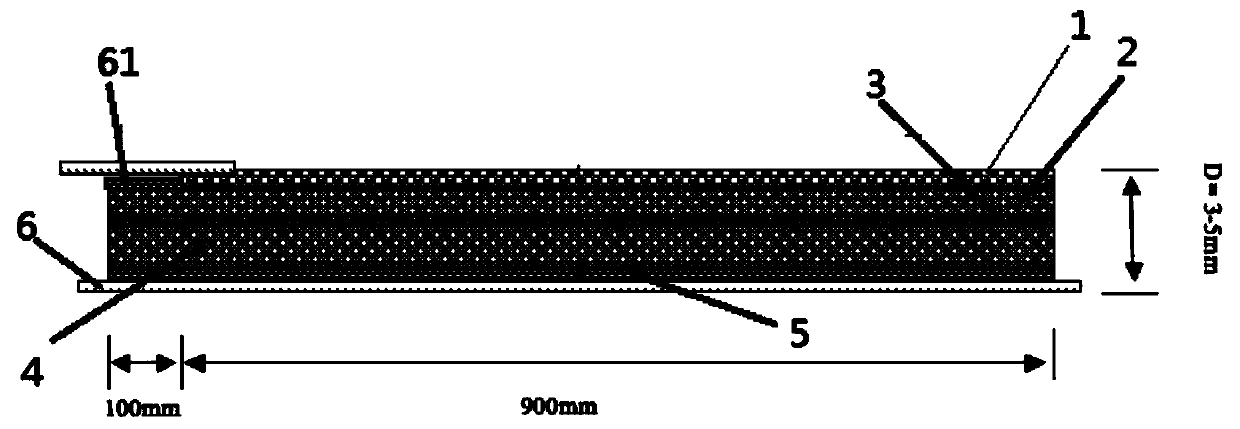

Image

Examples

Embodiment 1

[0045] Polyester tire specification selection weight is 140g / m 2 , the thickness is 0.6mm; the thickness of the mineral granular layer is 0.7mm, the thickness of the high heat-resistant elastomer modified asphalt compound layer is 1.1.2mm, the thickness of the self-adhesive polymer modified asphalt compound is 0.6mm, and the isolation film layer is 0.3mm.

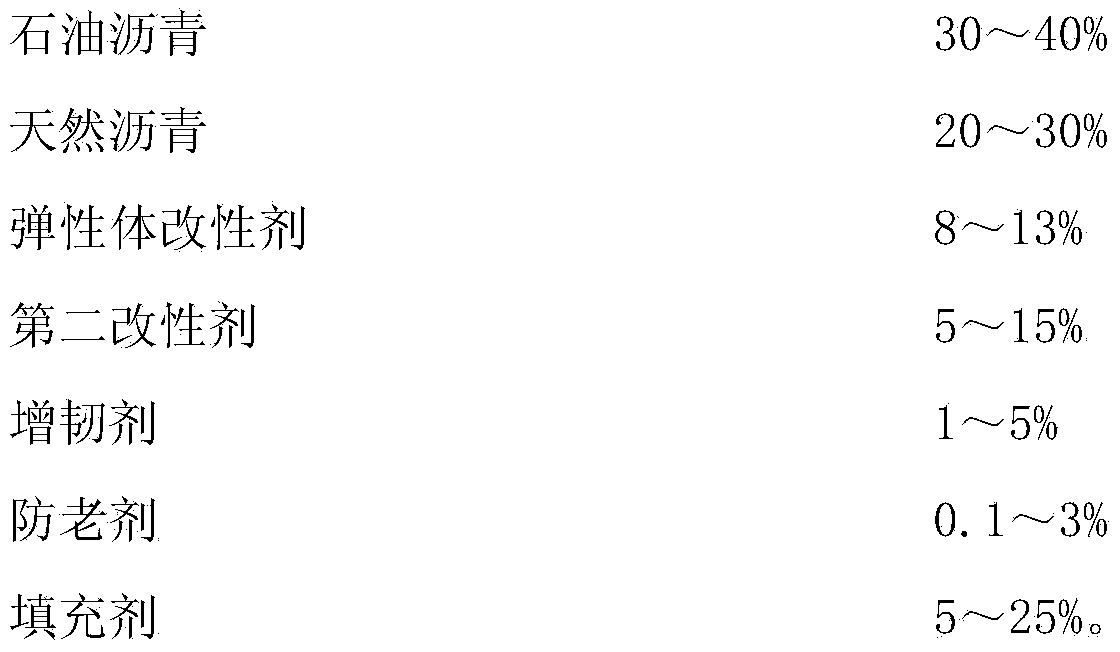

[0046] The composition of the first and second high heat-resistant elastomer modified bituminous compounds is as follows:

[0047]

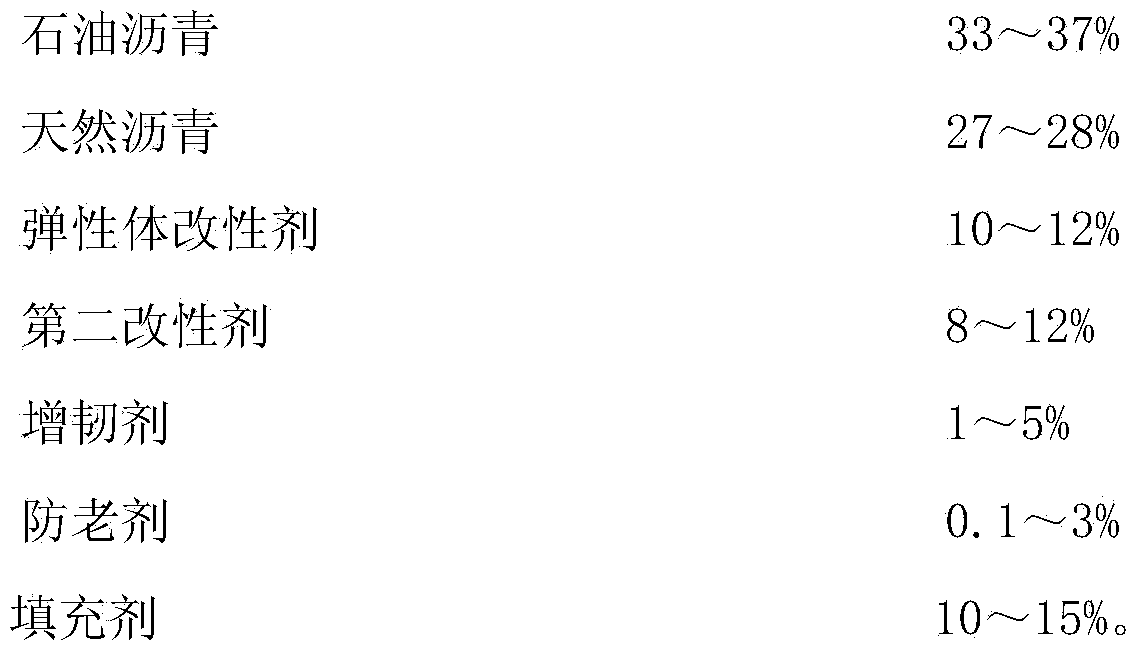

[0048] The chemical composition of high heat-resistant self-adhesive asphalt compound is:

[0049]

[0050]

[0051] The applicant has tested the physical and chemical properties of the waterproof coiled material of the present invention, and it shows that the above-mentioned waterproof coiled material has no cracks or cracks at -30°C. The upper surface can withstand high temperatures up to 130°C, and the lower surface can reach 110°C. 1000N / 50mm, the peeling strength with the alumin...

Embodiment 2

[0053] Polyester tire specification selection weight is 160g / m 2 , the thickness is 0.7mm; the thickness of the mineral granular layer is 1.0mm, the thickness of the high heat-resistant elastomer modified asphalt compound layer is 0.8mm, 1.2mm, the thickness of the self-adhesive polymer modified asphalt compound is 1.2mm, and the isolation film layer is 0.1mm .

[0054] The composition of the first and second high heat-resistant elastomer modified bituminous compounds is as follows:

[0055]

[0056] The chemical composition of high heat-resistant self-adhesive asphalt compound is:

[0057]

[0058]

[0059] The applicant has tested the physical and chemical properties of the waterproof coiled material of the present invention, and it shows that the above-mentioned waterproof coiled material has no cracks or cracks at -30°C. The upper surface can withstand high temperatures up to 140°C, and the lower surface can reach 115°C. 1500N / 50mm, the peel strength with the al...

Embodiment 3

[0061] Polyester tire specification selection weight is 180g / m 2 , the thickness is 0.7mm; the thickness of the mineral granular layer is 1.1mm, the thickness of the high heat-resistant elastomer modified asphalt rubber layer is 0.9mm, the thickness of the self-adhesive polymer modified asphalt rubber layer is 1.0mm, and the isolation film layer is 0.2mm.

[0062] The composition of the first and second high heat-resistant elastomer modified bituminous compounds is as follows:

[0063]

[0064]

[0065] The chemical composition of high heat-resistant self-adhesive asphalt compound is:

[0066]

[0067] The applicant has tested the physical and chemical properties of the waterproof coiled material of the present invention, and it shows that the above-mentioned waterproof coiled material has no cracks or cracks at -30°C. The upper surface can withstand high temperatures up to 140°C, and the lower surface can reach 115°C. 1500N / 50mm, the peel strength with the aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com