Reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot melt adhesive, reactive technology, applied in the chemical field, can solve the problems of slow curing speed, poor thermal shock resistance, poor aging resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

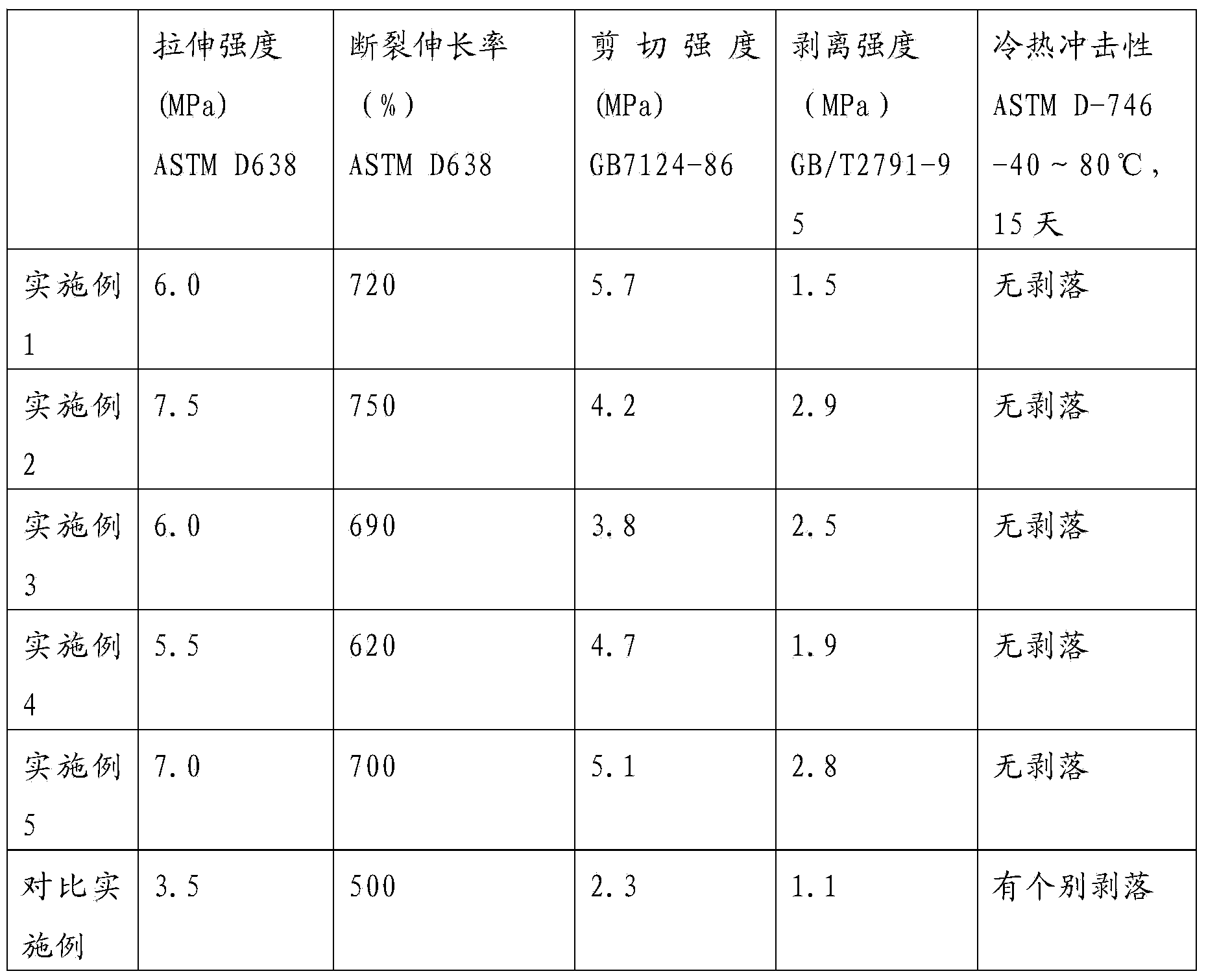

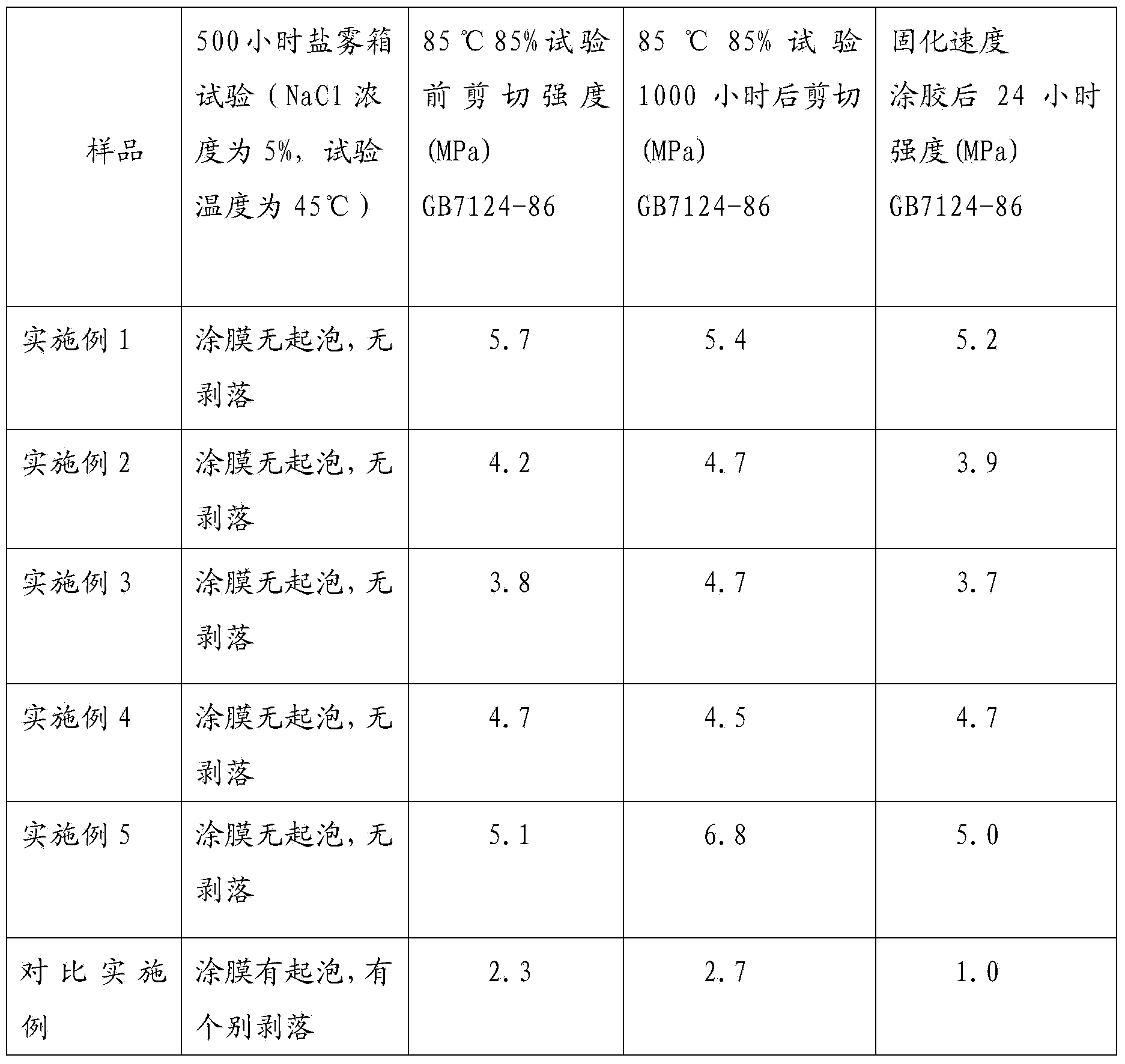

Examples

Embodiment 1

[0028] Add 21 parts of polyether polyol PPG2100 and 43 parts of polyester polyol POL-356T into the reaction kettle, vacuum dehydrate at 120°C for 2 hours, and keep the vacuum at -0.09MPa. Then cool to 80°C, add 10 parts of reactive plasticizer "Nikanol" resin and 14 parts of 4,4'diphenylmethane diisocyanate MDI while stirring, then slowly raise the temperature, control the temperature at 80°C, and fill with nitrogen at the same time Protection, reaction for 2.5 hours. After sampling and analysis, the NCO% content reaches the design value of 2.5%, then add 11 parts of terpene resin, 2 parts of latent curing agent ALT-101, and 0.2 parts of catalyst triethylenediamine. Under the condition that the temperature is 100°C, vacuumize until no air bubbles appear, then discharge, and seal the package. Obtain the PUR glue of the present invention and place it for use.

Embodiment 2

[0030] Add 10 parts of polyether polyol PPG220 and 50 parts of polyester polyol XCP-3000H into the reaction kettle, vacuum dehydrate at 110°C for 2.5 hours, and keep the vacuum at -0.08MPa. Then cool to 80°C, add 8 parts of reactive plasticizer "Nikanol" resin and 13 parts of toluene diisocyanate TDI80 / 20 while stirring, then slowly raise the temperature, control the temperature at 70°C, and fill with nitrogen protection at the same time, react for 2.5 hours . After sampling and analysis, the NCO% content reaches the design value of 2.0%, then add 6 parts of petroleum tackifying resin, 3 parts of latent curing agent ALT-101, and 0.1 part of catalyst dibutyltin dilaurate. Under the condition that the temperature is 90° C., vacuumize until no air bubbles appear, and then discharge the material and seal the package. Obtain the PUR glue of the present invention and place it for use.

Embodiment 3

[0032] Add 30 parts of polyether polyol PPG204 and 30 parts of polyester polyol POL-356T into the reactor, vacuum dehydrate at 110°C for 3.5 hours, and keep the vacuum at -0.09MPa. Then cool to 80°C, add 18 parts of reactive plasticizer "Nikanol" resin and 16 parts of 4,4'diphenylmethane diisocyanate MDI while stirring, then slowly raise the temperature, control the temperature at 80°C, and fill with nitrogen at the same time Protection, reaction for 2.5 hours. After sampling and analysis, the NCO% content reaches the design value of 2.8%, then add 10 parts of terpene tackifying resin and 10 parts of petroleum tackifying resin, 1 part of latent curing agent ALT-101, 0.1 part of catalyst dibutyltin dilaurate and three 0.3 parts of ethylene diamine. Under the condition that the temperature is 110° C., vacuumize until no air bubbles appear, and then discharge the material and seal the package. Obtain the PUR glue of the present invention and place it for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com