Patents

Literature

1356results about "Mineral oil hydrocarbon copolymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene-vinylacetate copolymer resin hot melt adhesive with high melting point, fast curing and low viscosity

InactiveCN102108269AShort opening hoursMeet the needs of the above purposesMineral oil hydrocarbon copolymer adhesivesWaxPaper filter

The invention relates to an ethylene-vinylacetate (EVA) copolymer resin hot melt adhesive with high melting point, fast curing and low melting viscosity. The hot melt adhesive comprises the following components in parts by weight: 40-60 parts of ethylene-EVA copolymer resin, 20-40 parts of tackifying resin and 10-30 parts of synthetic wax. The hot melt adhesive is especially suitable for splicing the paper filter element of the air cleaner.

Owner:上海理日化工新材料有限公司

Edge sealing hot melt adhesive for furniture and preparation method thereof

ActiveCN101928530AMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWaxPentaerythritol

The invention belongs to the technical field of adhesives and particularly relates to a method for preparing an edge sealing hot melt adhesive for furniture. The method comprises the following specific steps of: putting ethylene-ethylene vinyl acetate (EVA), a tackifying resin, waxes, a 4-[beta-(3,5-ditertiary butyl-4-hydroxy phenyl) propanoic acid] pentaerythritol ester, a filler and dibutyl phthalate into a mixing roll for mixing, heating to raise the temperature to be between 90 and 100 DEG C and mixing the components for 25 minutes; and adding a uniformly mixed product into a double-screw extruder and cooling and pelletizing the extruded product to obtain the edge sealing hot melt adhesive for the furniture. The product greatly lowers production cost and has higher adhesive strength.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

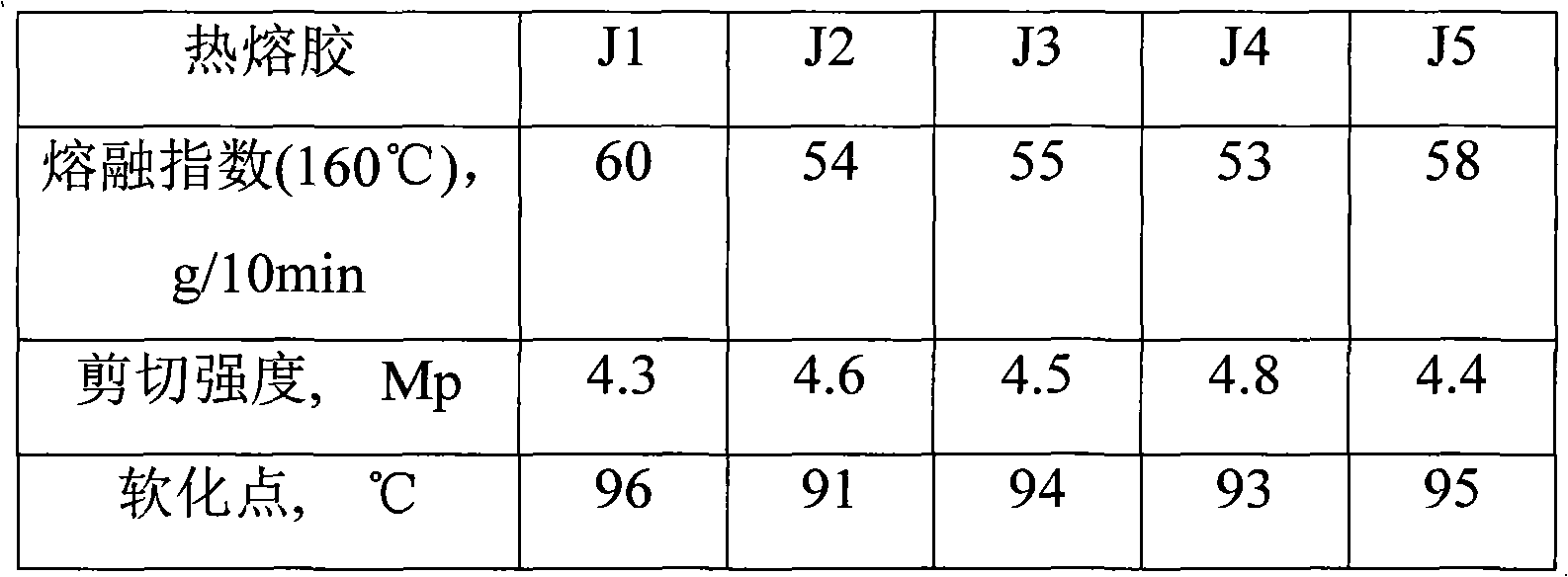

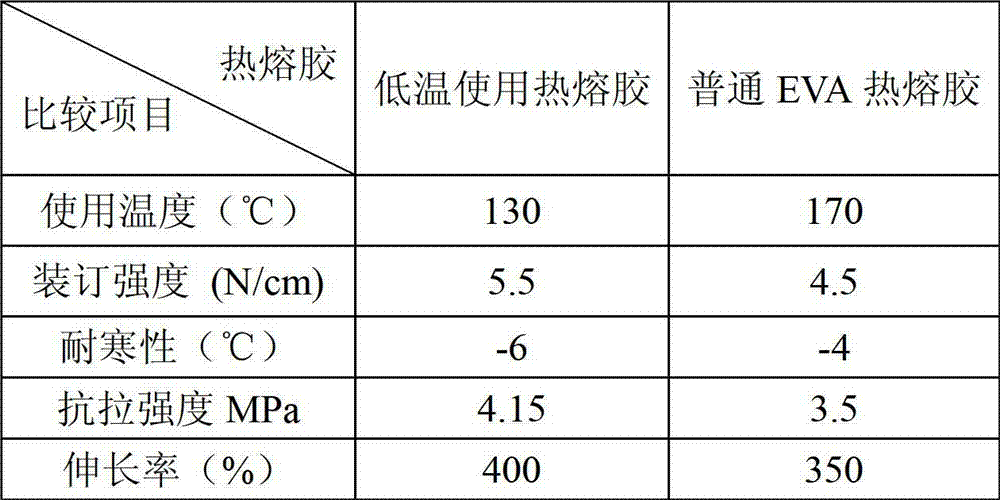

Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

InactiveCN102925080AImprove performanceNot easy to carbonizeMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention relates to hot melt glue and a preparation method thereof, and belongs to the technical field of preparation of hot melt glue. The preparation method comprises the following steps of: starting stirring and opening a heat-conduction oil heating valve; sequentially filling ethylene-vinyl acetate (EVA) resin, a filler, a wax diluents and an antioxygen according to the proportion into a reaction kettle for heating; totally melting each component; adding tackified resin to heat until the tackified resin is totally melted; vacuumizing a reaction system until the reaction system has no bubbles; adding a filter screen and discharging at a discharging port of the reaction kettle; and cooling and forming the materials to obtain a product. The book thermoplastic binding hot melt glue can be used at about 130 DEG C, and is suitable for linkage line production; compared with the traditional book thermoplastic binding hot melt glue, the using temperature is reduced by 30 DEG C to 50 DEG C, so that the production energy consumption (electric energy, heat energy and the like) is reduced, the maintenance cost of equipment is reduced, and the production efficiency is improved; and the glue performance in a glue groove is stable, energy-saving production is facilitated, and the hot melt glue is environment-friendly.

Owner:WUXI WANLI ADHESION MATERIALS

Universal adhesive and preparation technology thereof

InactiveCN102604588AExtended shelf lifeAvoid serious wasteMineral oil hydrocarbon copolymer adhesivesChemical industryHydrocarbon solventsProduction line

The invention relates o a universal adhesive and a preparation technology thereof. The universal adhesive is prepared by using the following raw materials in parts by weight: rubber, a tackifying resin, a hydrocarbon solvent, an ester solvent and a propellant; the preparation technology comprises the following steps of: firstly adding the barreled hydrocarbon solvent and the ester solvent to the stirred vessel through the compressed air of an air compressor, then successively adding the rubber, the tackifying resin and the other additives one by one to prepare a stock solution; and respectively charging the stock solution to iron tanks on an aerosol filling production line, sealing and then filling the propellant to obtain the product. When in use, the universal adhesive provided by the invention is rapid to operate and convenient to use; in addition, environment-friendly solvents such as methyl acetate and ethyl acetate are mainly adopted in the universal adhesive so that the universal adhesive is safer in use and environment-friendly; finally, the aerosol packaging form of the universal adhesive is firstly put forward; the universal adhesive has good packaging leak tightness and is long in the quality guarantee period; the rest of universal adhesive can be stored for long term after the universal adhesive is used, thereby the serious wasting of the universal adhesive is avoided; and the universal adhesive is in line with and abides by the standard requirements of energy saving, emission reduction and environmental protection.

Owner:FUJIAN NANAN DAYANG AEROSOL MFG

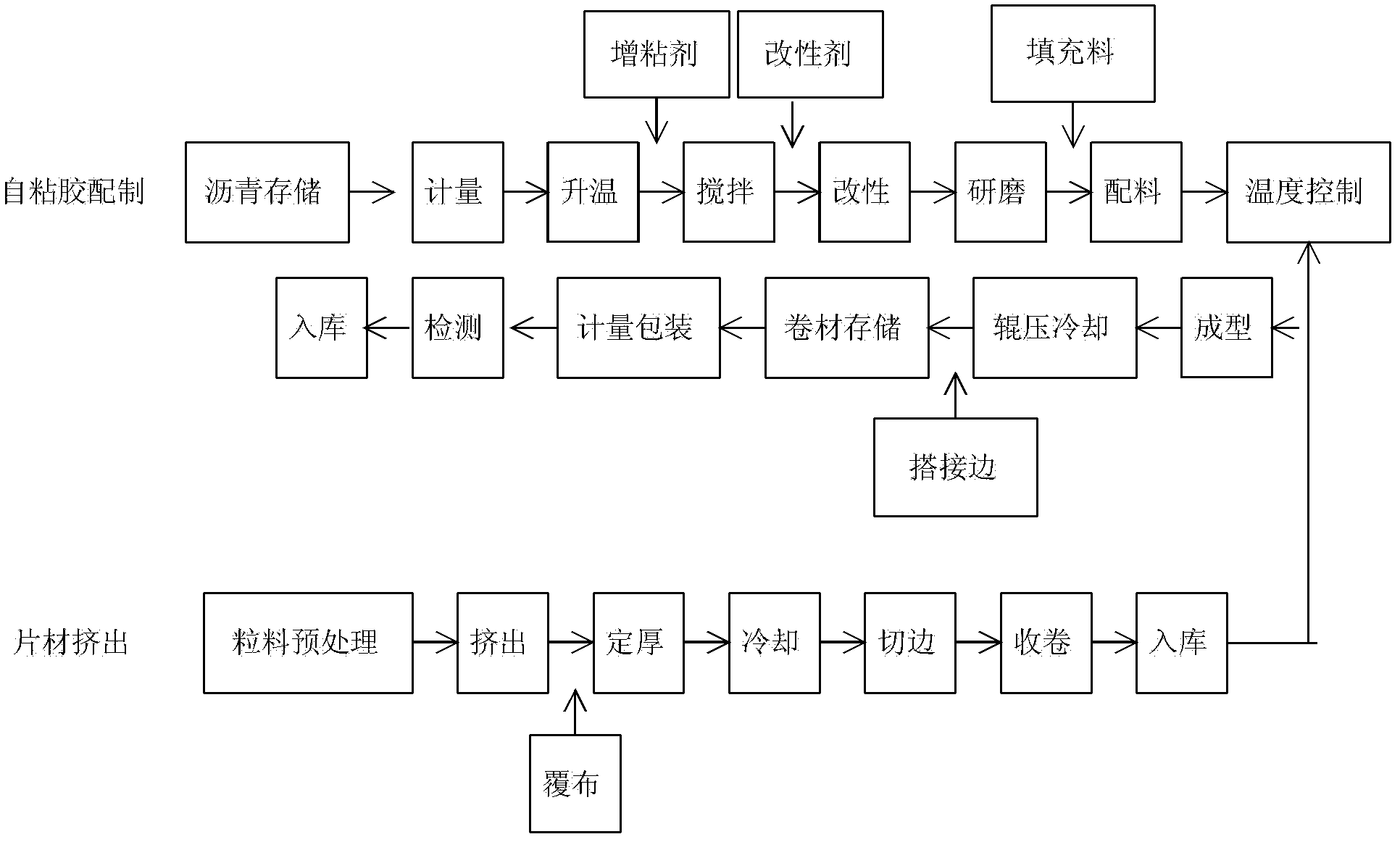

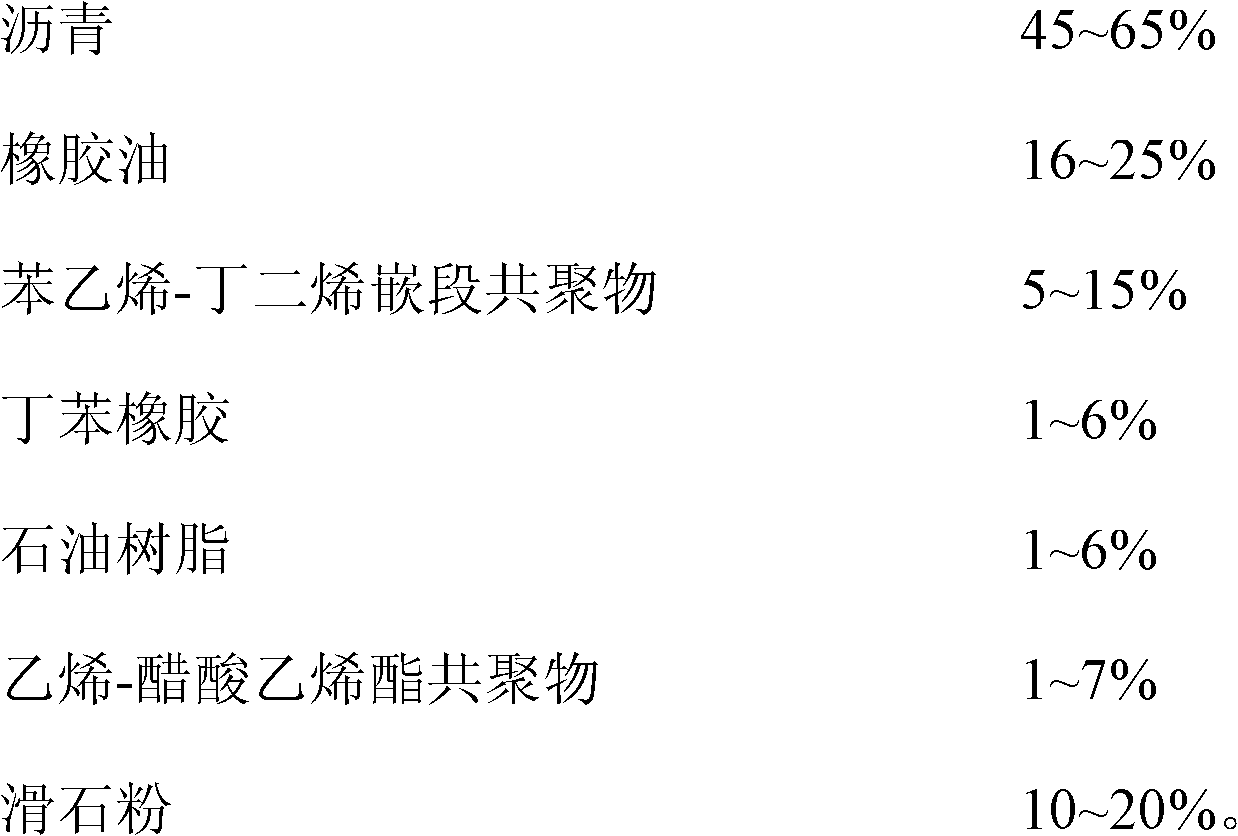

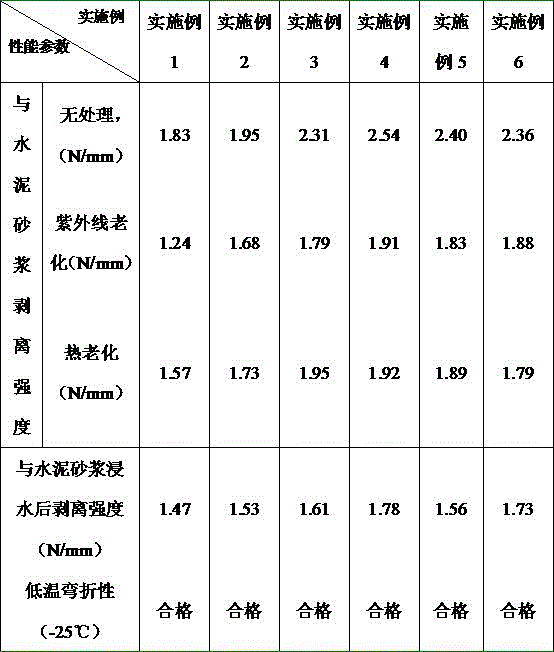

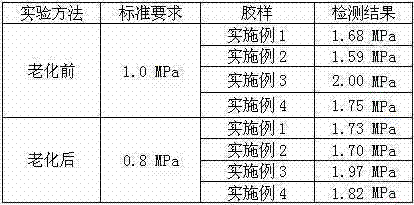

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

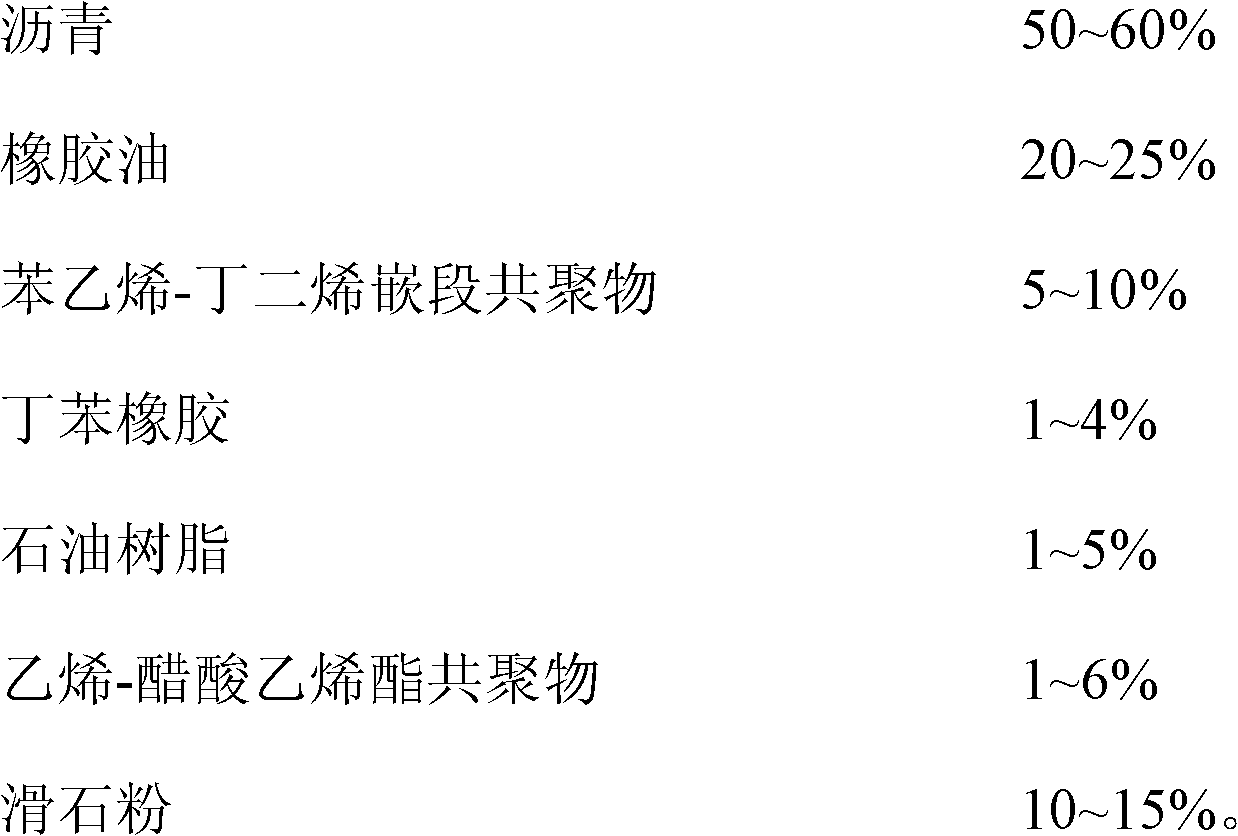

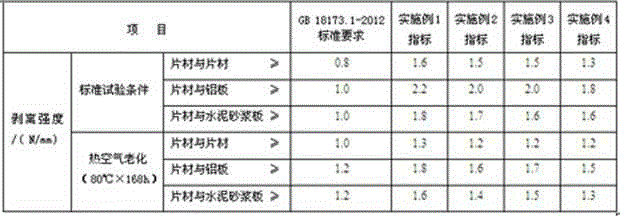

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

Hot-melting pressure sensitive adhesive and preparation method thereof

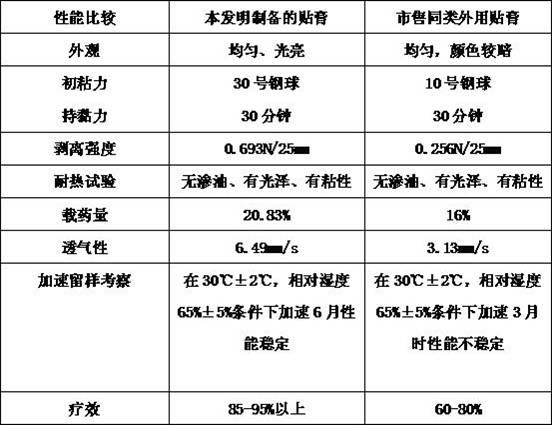

ActiveCN102634307ADoes not cause allergiesImprove anti-agingMineral oil hydrocarbon copolymer adhesivesHydroxy compound active ingredientsPressure sensitiveWeather resistance

The invention relates to a hot-melting pressure sensitive adhesive and a preparation method thereof. The hot-melting pressure sensitive adhesive effectively solves the problems that the compatibility of a pressure sensitive adhesive and medicines is poor, the pressure sensitive adhesive is easy to oxidize, poor in weather resistance, stability and ventilation and can stimulate the skin. The hot-melting pressure sensitive adhesive is prepared from the following raw materials by weight percent: 20%-45% of thermoplastic elastomer SIS (Styrene Isoprene Styrene), 20%-40% of tackifying resin, 15%-35% of softener, 1%-8% of antioxidant and 3%-15% of filler. The preparation method comprises the following steps of: heating, mixing and stirring the thermoplastic elastomer SIS, the softener and 0.25%-2% of antioxidant to the melting state; then adding the tackifying resin and 0.25%-2% of antioxidant, heating, mixing and stirring to the melting state; and adding the filler and 0.5%-4% of antioxidant, and heating, mixing and stirring to the melting state. The hot-melting pressure sensitive adhesive is transparent and environment-friendly, can not cause skin allergy, has good aging resistance and good aerobic degradation effect, and is also applied to emplastrum.

Owner:HENAN LINGRUI PHARMA

Multifunctional glue spray formula and process

ActiveCN102295912AMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceButadiene-styrene rubber

The invention relates to the technical field of chemical detergents, in particular to a multifunctional spray glue formula and process. The spray glue formula comprises the following components in percentage by weight: 1-12 percent of rubber, 1.0-15 percent of synthetic resin, 10-40 percent of tackifying resin, 10-60 percent of hydrocarbon solvent, 30-75 percent of propellent, 10-40 percent of chlorine solvent, 3-30 percent of cosolvent, 2-8 percent of plasticizer and 0.05-1 percent of essence. The spray glue is prepared by the following steps of: adding the hydrocarbon solvent, the chlorine solvent and a part of cosolvent such as acetone and the like into a stirring kettle according to formula metering, opening and stirring; adding rubber such as SBS (Styrene-Butadiene-Styrene) thermoplastic elastomer and the like and synthetic resin such as acrylate resin and the like in a stirring state and stirring until the rubber and the synthetic resin are fully dissolved; adding the tackifyingresin such as rosin and the like and stirring until the rosin is fully dissolved; adding remaining cosolvent such as the acetone and the like and the plasticizer and stirring until glue liquid is fully dispersed; and filtering and canning, sealing, and inflating a can. The spray glue formula has the advantages of no toxin, no pollution, super-strong viscosity and adaptation to gluing of various materials, and is white and non-yellowing.

Owner:DONGGUAN DAYANG CHEM

Low-temperature hot-melt pressure-sensitive adhesive for disposable hygienic product and preparation method thereof

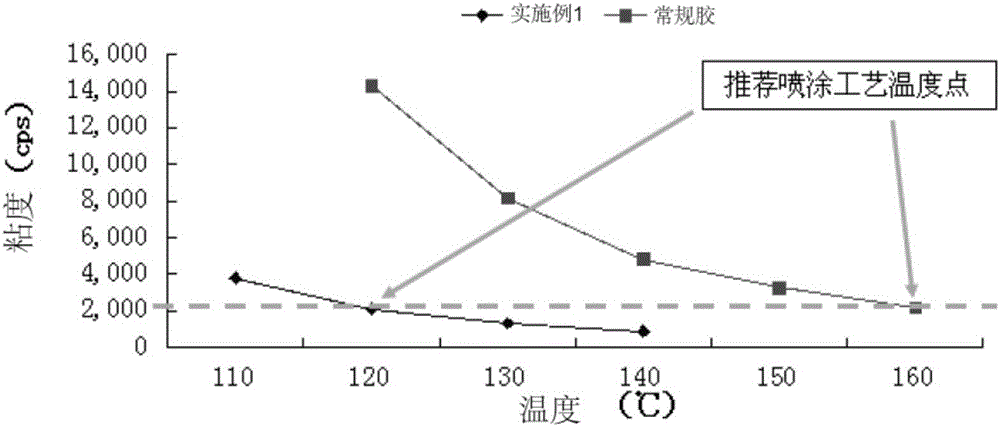

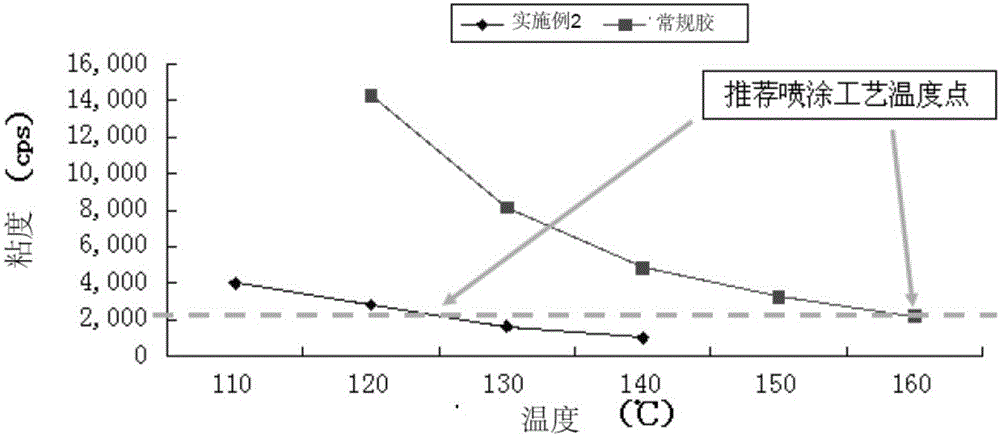

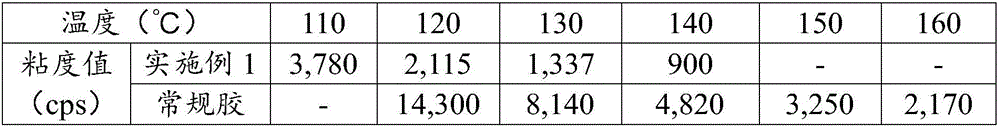

ActiveCN106047287AReduce maintenance costsLow viscosity valueMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWaxDecomposition

The invention discloses a low-temperature hot-melt pressure-sensitive adhesive for a disposable hygienic product. The low-temperature hot-melt pressure-sensitive adhesive is prepared from 10-30wt% of styrenic thermoplastic elastomer, 40-60wt% of tackifying resin, 15-35wt% of naphthenic oil, 0.1-1.0wt% of antioxidant, and selectively 0.1-5wt% of wax. The low-temperature hot-melt pressure-sensitive adhesive has appropriate melt viscosity, good initial bonding performance, persistent bonding performance, operative weldability, heat resistance and the like within the using temperature range from 120 DEG C to 130 DEG C, carbonization is effectively reduced, the equipment failure rate is lowered, the production efficiency is improved, ageing and decomposition of the tackifying resin and the other constituents are reduced, and the environment pollution is reduced. The invention further discloses a preparation method for the hot-melt pressure-sensitive adhesive.

Owner:GUANGDONG RURGA NEW MATERIAL TECH

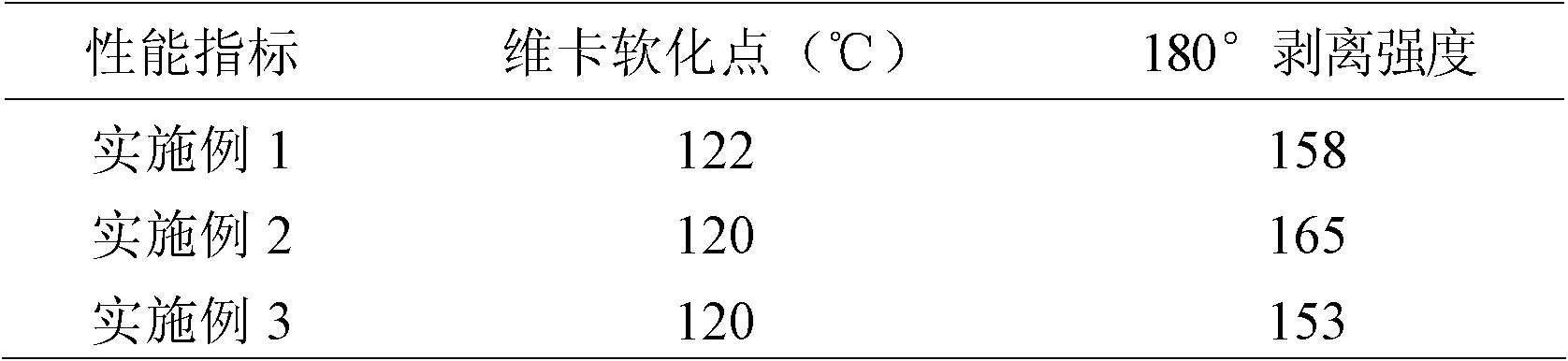

Method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive

InactiveCN101709201ALow costReduce manufacturing costMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolystyreneHot melt

The invention discloses a method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive, which comprises the following steps: orderly weighing polystyrene-polyisoprene-polystyrene ternary segmented copolymer, composite tackifier resin, softening agent and antioxidant in a mass ratio, and stirring the mixture at the rotating speed of 300 to 600 rpm / min; heating, stirring and melting the mixture till forming transparent glue solution at the temperature of between 150 and 180 DEG C after uniformly mixing; and then placing the transparent glue solution on a coating machine preheated at the temperature of between 80 and 120 DEG C, and adhering a piece of isolation paper after coating to obtain the polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive. The method has the advantages of available raw materials, low cost, simplicity and feasibility, environmental protection, excellent comprehensive performance, and suitability for scale industrial production, and provides a new path for the preparation of the hot melt pressure-sensitive adhesive.

Owner:SHANGHAI INST OF TECH

Preparation method of high-polymer self-adhesive waterproof roll

InactiveCN104059553AImprove water resistanceOvercoming technical deficienciesMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyesterSelf-healing

The invention relates to a preparation method of a high-polymer self-adhesive waterproof roll. The technical scheme is as follows: the preparation method comprises the steps of fully coating an SIS (Styrene-Isoprene-Styrene) hot melt pressure sensitive self-adhesive on a main plastic high-polymer waterproof layer by using a hot melt pressure sensitive adhesive coating machine to form an SIS hot melt pressure sensitive self-adhesive layer; then, coating an anti-adhesive isolating membrane on the pressure sensitive self-adhesive layer to prepare a high-polymer self-adhesive waterproof roll product, wherein the main plastic high-polymer waterproof layer is a high-density polyethylene cross laminated film or modified high-density polyethylene film; the anti-adhesive isolating membrane is a silicon oil coated polyurethane isolating membrane. The preparation method has the beneficial effects that firstly, the roll can be permanently and organically combined with the concrete of a structural layer due to the application of the SIS hot melt pressure sensitive self-adhesive, so that no hidden water breakthrough dangers in the intermediate process are caused, and the reliability of a waterproof layer is improved; secondly, the high-polymer self-adhesive waterproof roll is excellent in impact and puncture resistance and capable of bearing the impact of a construction load directly acting on the high-polymer self-adhesive waterproof roll; thirdly, the high-polymer self-adhesive waterproof roll is relatively strong in chemical corrosion resistance and favorable in resistance to alkaline water from concrete; fourthly, the SIS hot melt pressure sensitive self-adhesive is strong in self-healing property.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Reactive butyl rubber self-adhesive layer for waterproof roll and processing technology thereof

ActiveCN103102843ASelf-healingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof. The reactive butyl rubber self-adhesive layer comprises the following components in parts by weight: 20 parts of butyl rubber, 1.0-4.2 parts of ethylene vinyl acetate copolymer, 16.5-20.5 parts of tackifying resin, 18.4-24.0 parts of tackifier, 12-18 parts of carbon black, 9-14 parts of light calcium carbonate, 8.0 parts of functional aid, 1.8 parts of vulcanizing agent, 0.8 part of anti-aging agent and 0.5 part of coupling agent. The butyl rubber self-adhesive layer is prepared by mixing, kneading and extruding forming. Due to the mode, the invention provides a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof, the butyl rubber self-adhesive layer can be chemically reacted with cast-in-place concrete to form a whole, a permanent waterproof layer is formed and has the self-healing performance, the waterproof layer and various high polymer waterproof rolls can be compounded to form a functional waterproof material, and the reactive butyl rubber self-adhesive layer is suitable for various underground waterproof engineering.

Owner:常熟市三恒建材有限责任公司

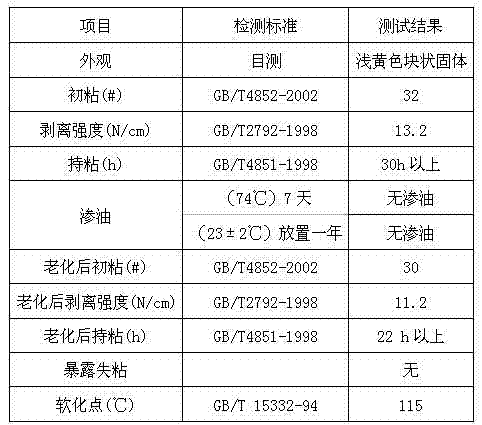

Hot melt pressure sensitive adhesive and preparation method thereof

ActiveCN102504735ASmall temperature changeGood initial adhesionMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesPlasticizerHot melt

The invention provides a hot melt pressure sensitive adhesive and a preparation method thereof, which solve the problems of improving initial tack, oil penetration and die cutting property, etc. The hot melt pressure sensitive adhesive comprises the following components by weight: 25-40 parts of matrix resin, 48-60 parts of tackifier, 12-22 parts of plasticizer and 0.6-1.2 part of a stabilizing agent, wherein the matrix resin comprises triblock copolymer of styrene-isoprene-styrene and diblock copolymer solution-polymerized styrene butadiene rubber of styrene-butadiene in a weight ratio of 1.2-3.1. The hot melt pressure sensitive adhesive provided by the invention has better initial tack, high peel strength and standard holding power; the hot melt pressure sensitive adhesive is free of oil penetration for seven days under heat temperature testing conditions and can be stored for one year at the normal temperature without oil penetration; the adhesive has better die cutting property; and the softening point reaches to 115 DEG C. The hot melt pressure sensitive adhesive of the invention can totally meet the requirement on fabricating back adhesive bags, labels and adhesive tapes.

Owner:河北方大新材料股份有限公司

Leak-blocking adhesive and preparation method thereof

ActiveCN102329585AImprove general performanceGood plugging effectMineral oil hydrocarbon copolymer adhesivesProductsPolymer scienceFoaming agent

The invention relates to a leak-blocking adhesive and a preparation method thereof. The adhesive consists of the following components in part by weight: 15 to 25 parts of synthetic resin, 15 to 30 parts of lubricating grease, 10 to 15 parts of foaming agent, 20 to 35 parts of fibrous filler, 30 to 50 parts of heat-resistant filler and 5 to 10 parts of coloring agent; the synthetic resin, the foaming agent, the heat-resistant filler and the coloring agent are uniformly dispersed and then are added with the lubricating grease and the fibrous filler, the uniformly mixed materials are added into an extruder and are extruded to form a stick shape, and after being cooled to the room temperature, the stick-shaped adhesive is cut. Compared with the prior art, the leak-blocking adhesive can tolerate most of chemical media, is highly universal, can be automatically filled into a neighboring gap when being heated, enhances the leak-blocking effect, prevents the phenomena of adhesive leakage and adhesive spouting, has excellent flowing property before being solidified, is convenient and easy to operate, and has a wide resisted temperature range.

Owner:上海海鹰粘接科技有限公司

Adhesive resin used for steel band reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN102086357AResidue reductionSmall smellMineral oil hydrocarbon copolymer adhesivesRigid pipesMasterbatchChemical reaction

The invention discloses adhesive resin used for a steel band reinforced polyethylene spiral corrugated pipe and a preparation method and applications thereof. The adhesive resin comprises the following raw materials in parts by weight: 20-30 parts of modified grafted polyolefin masterbatch, 55-60 parts of polyethylene, 10-15 parts of tackifying resin, 5 parts of lubricant and 0.3-0.5 part of antioxidant. The preparation method comprises the following steps: mixing the raw materials evenly, performing extrusion reaction, blending and granulating to prepare the finished product. The adhesive resin of the invention has less odor, stable product performance and higher heat resistance and mechanical strength; and the requirements of processing technology of the steel band reinforced polyethylene spiral corrugated pipe can be fully satisfied, and the defects of the products adopting the existing technologies such as high penetrating odor, low heat resistance and mechanical strength and unstable chemical reaction can be overcome.

Owner:合诚技术股份有限公司

Double sticky tape for lithium battery and preparation method for double sticky tape

ActiveCN104610883AMeet the production process requirementsGuaranteed performanceMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrochemical responseLithium-ion battery

The invention relates to a double sticky tape for a lithium battery. The double sticky tape comprises a first sealed hot-melting pressure-sensitive adhesive layer, a basic film layer, a second sealed hot-melting pressure-sensitive adhesive layer, a normal temperature cohesion-less sealed adhesive layer, and a two-sided silicon-free release film layer, which are sequentially connected from top to bottom, wherein one side of the double sticky tape for the lithium battery has the cohesiveness to an aluminium foil and a polyethylene film at normal temperature, and the other side is free of cohesiveness to the polyethylene side when the temperature is 80 DEG C or below, so that the double sticky tape meets the requirement on production technology of the lithium battery; the adhesive layers of the double sticky tape are free of release agent and other impurities, so that the purity of the adhesive layers can be kept; when the adhesive layers are immersed in electrolyte, the double sticky tape is still high in stability, good in corrosion resistance against the electrolyte and free of electrochemical reaction, so that the performance of the lithium battery can be maintained, and the service life of the lithium battery can be prolonged.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

High speed cigarette mouth building hot melt adhesive and preparation method thereof

InactiveCN101538450AEasy to dryMeet the requirements of high-speed cigarette operationMineral oil hydrocarbon copolymer adhesivesRosin adhesivesAntioxidantSolvent

The invention belongs to the technical field of novel cigarette materials, in particular relates to a high speed cigarette mouth building hot melt adhesive and a preparation method thereof. The cigarette mouth building hot melt adhesive is prepared from ethylene-vinyl acetate copolymer, tackifying resin, nanometer silicon dioxide and antioxidant, and includes the following components according to percentage by weight: 25 to 35 percentages of ethylene-vinyl acetate copolymer, 35 to 45 percentages of tackifying resin, 20 to 40 percentages of viscosity modifier, 5 to 10 percentages of nanometer silicon dioxide and 0.1 to 0.5 percentage of antioxidant, wherein the components are heated and melted by a reaction kettle and are sequentially added and uniformly stirred. The cigarette adhesive prepared by the method has strong quick-drying performance, the ring and ball softening point nearly ranges from 95 to 105 DEG C, the softening range is from 5 to 8 DEG C, the operation of adhesion can be accomplished in 5 seconds, and the cigarette adhesive has the characteristics of no solvent, no absorption of moisture, corrosion resistance, aging resistance, and the like; the flowability and the wetting quality of the adhesive can be controlled by changing the parameters of wax, the method is suitable for the preparation of different cigarettes, and the adhesive and the method have good value of market popularization and application.

Owner:SHANGHAI JENTAI NANO SCI & TECH CO LTD

Removable hot-melt pressure-sensitive adhesive tape for temporary fixation

InactiveCN102702990AAchieve quantitative coatingImprove affinity and applicabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesSilicone tapePlasticizer

The invention belongs to the field of adhesive tapes and particularly relates to a removable hot-melt pressure-sensitive adhesive tape for temporary fixation. The removable hot-melt pressure-sensitive adhesive tape for the temporary fixation comprises a base material and a hot-melt pressure-sensitive adhesive which is hot-molten and coated on the base material, and is characterized in that the hot-melt pressure-sensitive adhesive consists of the following components in percentage by mass: 40 to 60 percent of thermoplastic rubber, 20 to 40 percent of tackifying resin, 2 to 16 percent of plasticizers and 0.1 to 4 percent of antioxidant and other aids. The tackifying resin is added when the hot-melt pressure-sensitive adhesive tape is prepared, so that the adhesion is improved, and the viscosity of the system is reduced to ensure that the coating is convenient; a plurality of kinds of plasticizers are added, so that soft segment phases (B, I, EB and EP) and a hard segment phase (PS) in elastomer rubber are softened and plasticized, and the affine application property of an adhesive tape product is improved; by using the antioxidant, an adhesive is prevented from pyrolysing and deteriorating in the heating process, so that the adhesion of an adhesive product is stable, the adhesive product can be peeled at high and low rates and can be repeatedly pasted, and the trace of adhesive residue is avoided; and a heating and molten coating process is adopted, so that the release of a volatile organic solvent and the high-temperature energy consumption of an end-of-life process are avoided, and the cost of materials is reduced.

Owner:苏州联科纳米净化科技有限公司

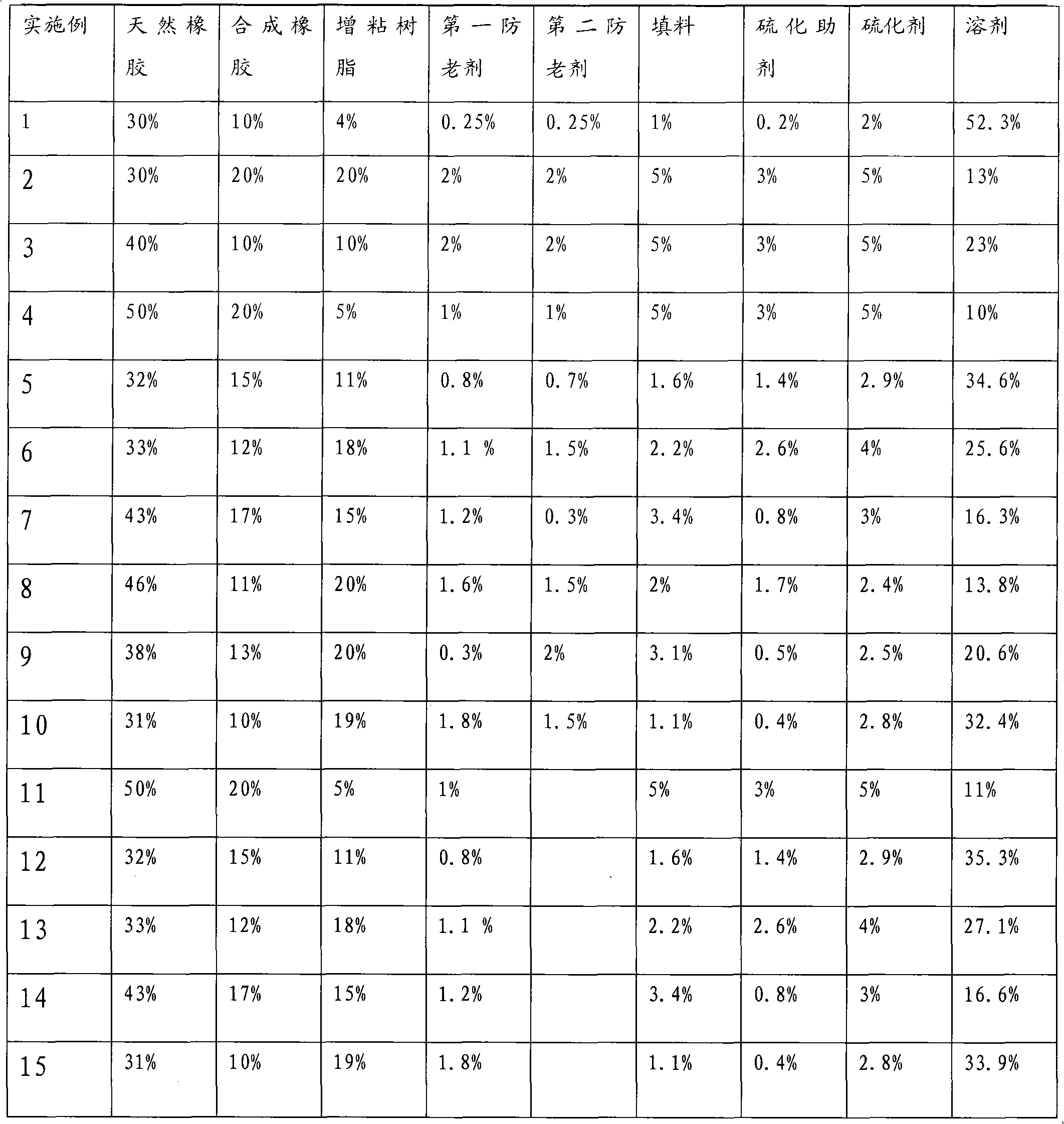

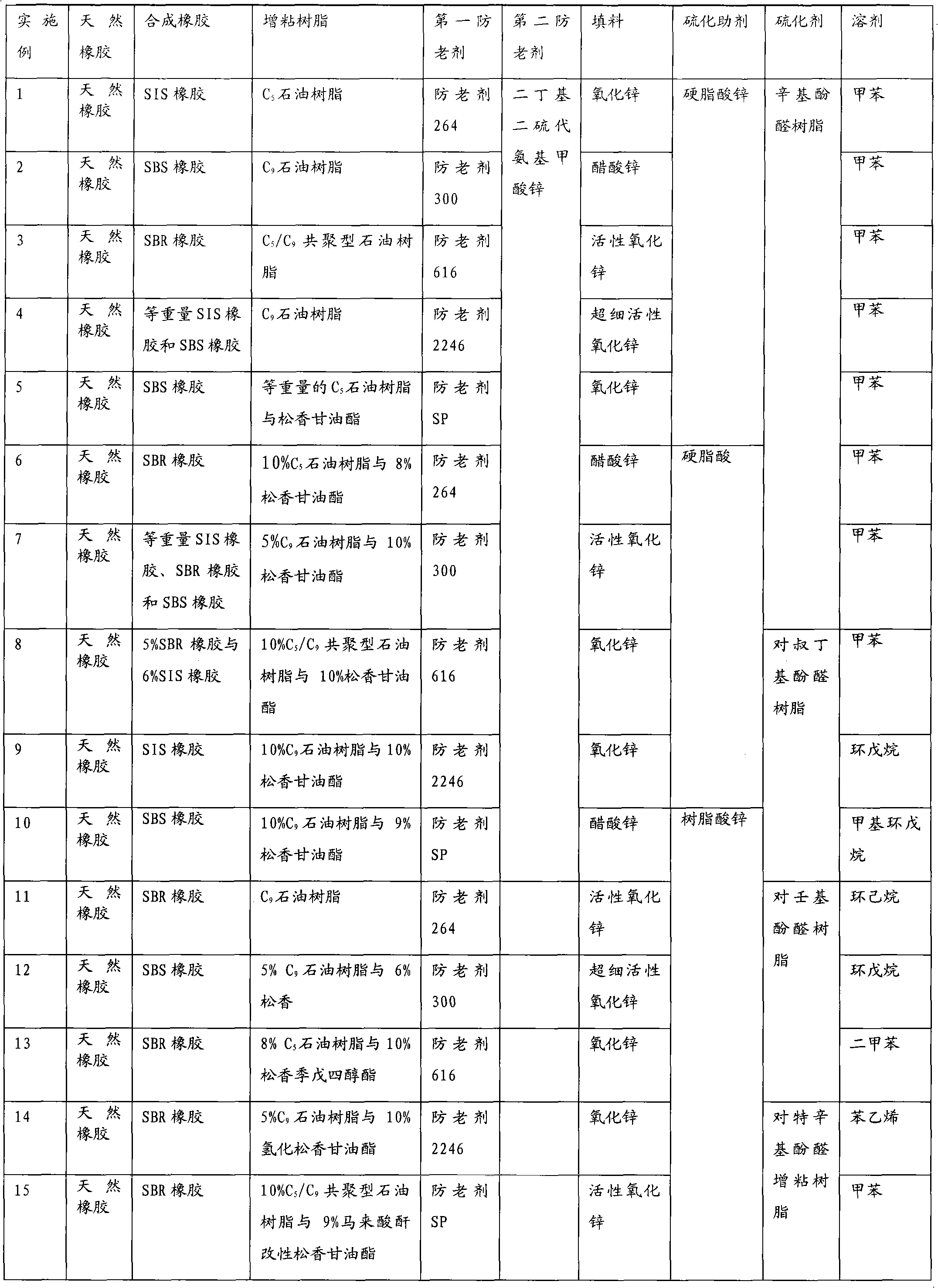

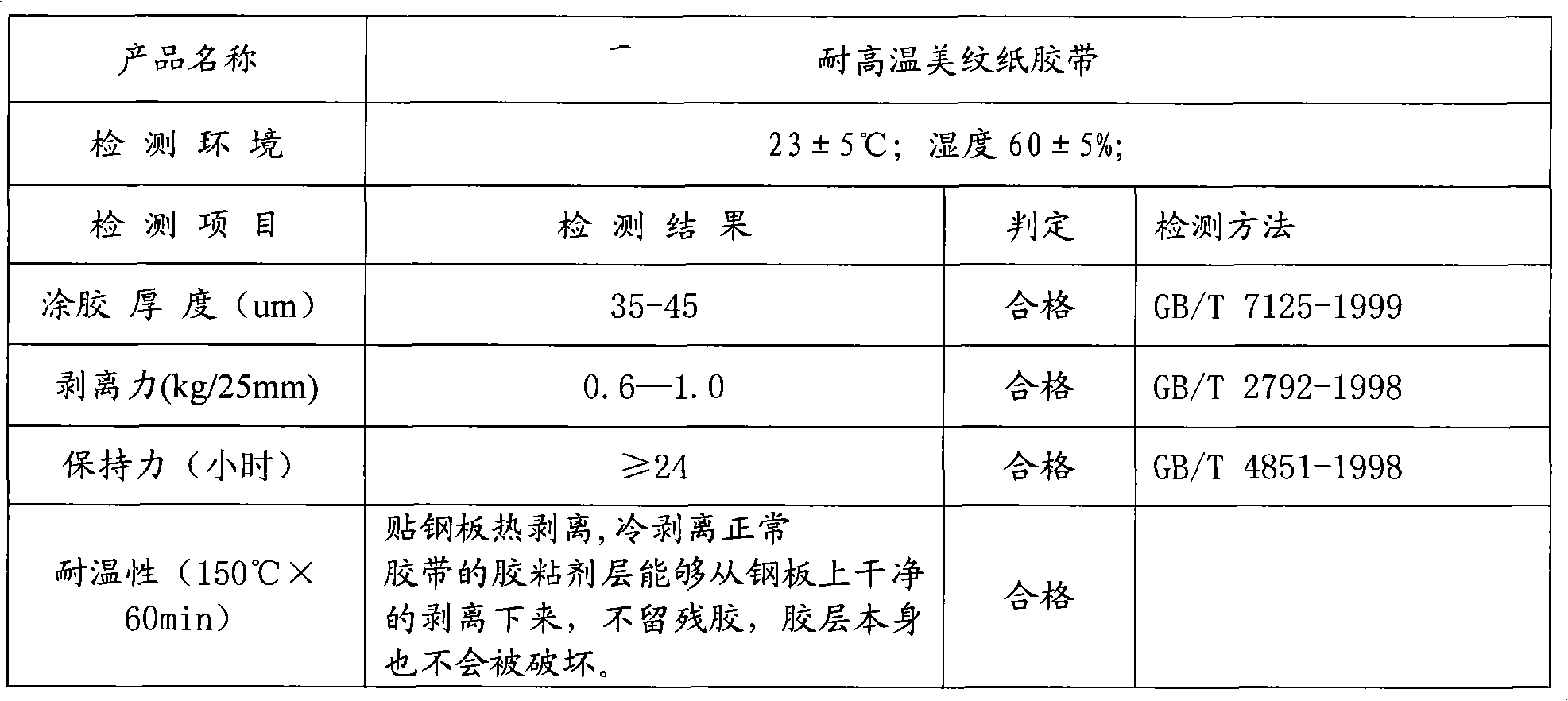

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

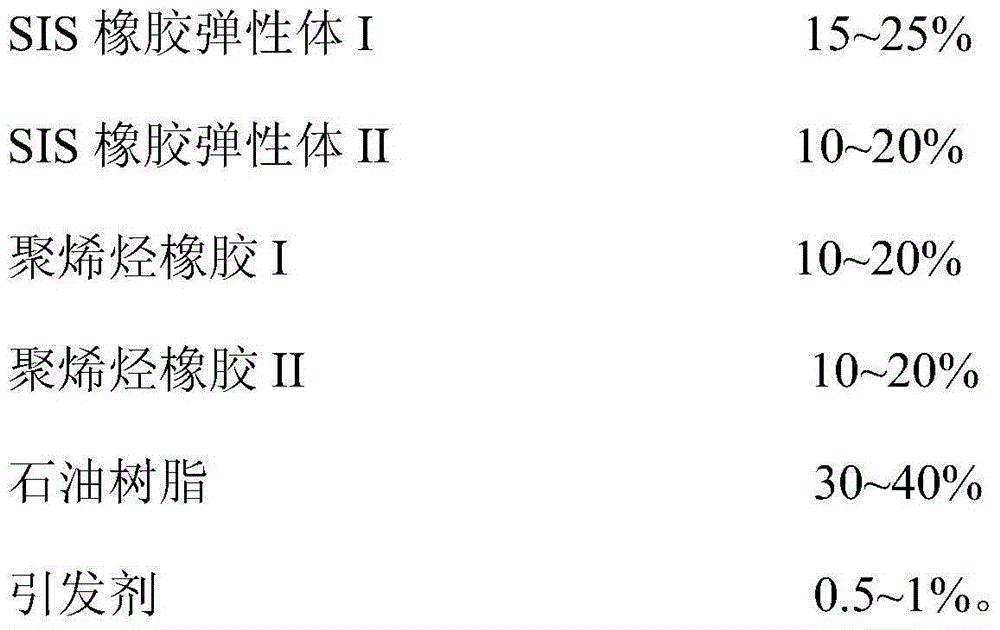

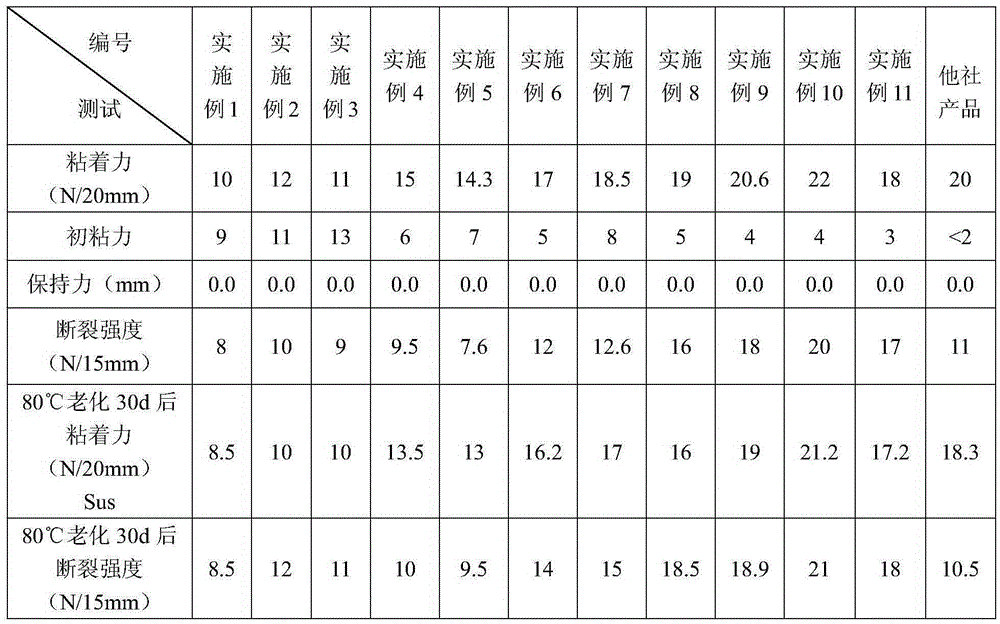

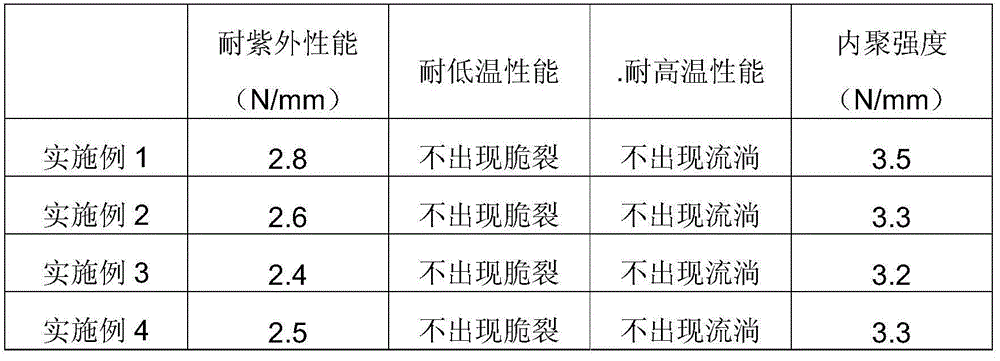

High-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN105694776AImprove heat aging resistanceAccelerated agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerButadiene-styrene rubber

The invention discloses a high-polymer waterproof coiled material hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by mass: 30-200 parts of elastomer composition, 40-100 parts of tackifying resin, 20-70 parts of plasticizer, 0.3-5 parts of stabilizer and 0.1-3 parts of additive. The elastomer composition is selected from SIS (styrene-isoprene-styrene) / SEPS (styrene-ethylene / propylene-styrene), SIS / SBS (styrene-butadiene-styrene), and / or SBS / SEBS (styrene-ethylene-butadiene-styrene). The mass ratio of the two components in the elastic composition is 1-20; the styrene in the SIS in the elastic composition accounts for 15-30 wt%, the styrene in the SEPS accounts for 10-30 wt%, the styrene in the SBS accounts for 20-50 wt%, and the styrene in the SEBS accounts for 10-40 wt%. The hot-melt pressure-sensitive adhesive has the characteristics of excellent ultraviolet aging resistance, favorable thermal aging resistance, high peel strength, simple technique and low cost.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Pressure-sensitive adhesive tape and pressure-sensitive adhesive composition

InactiveUS20060182958A1Mineral oil hydrocarbon copolymer adhesivesOperating means/releasing devices for valvesRosinAcrylic polymer

A pressure-sensitive adhesive tape is characterized by containing at least (A) an acrylic polymer, (B) a petroleum resin, and (C) a rosin-based resin, wherein the component (B) and the component (C) are contained in proportions of from 1 to 50 parts by weight and from 1 to 50 parts by weight, respectively based on 100 parts by weight of the component (A). In addition, it is preferable that the total sum of the component (B) and the component (C) is not more than 60 parts by weight based on 100 parts by weight of the component (A). As the rosin-based resin (C), a rosin ester-based resin is preferable.

Owner:NITTO DENKO CORP

A kind of glue spray formula and process

ActiveCN102277130AToxin-freeNo pollution in the processMineral oil hydrocarbon copolymer adhesivesFibre treatmentThermoplastic elastomerAdhesive

The invention, relating to the technical field of chemical spray adhesive, especially relates to a spray adhesive formula and a technology thereof. The spray adhesive comprises the following ingredients: 1-12 wt% of rubber, 1-5 wt% of dispersant, 10-40 wt% of tackifying resin, 10-60 wt% of varsol, 10-55 wt% of chlorinated solvent and 35-70 wt% of propellent. The technology of preparing the spray adhesive comprises the following steps: (1) adding varsol and chlorinated solvent in a stirring tank according to the amount in the formula, starting the stirring tank for stirring; (2) adding SBS thermoplastic elastomer and other rubbers with stirring until the rubbers completely dissolve; (3) then adding rosin and other tackifying resin with stirring until rosin completely dissolves, then addingorganic bentonite dispersant, continuously stirring until organic bentonite completely disappears; and (4) filtering and then canning, and carrying out sealing and then inflating the tank. The spray adhesive has no toxins and no pollution, and can be used on white fabrics without yellowing or blackening with ideal bonding effect.

Owner:吕大洋

Silencing film for automobile

InactiveCN101497768AEasy to break awayGood workmanshipMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrophoresisCar manufacturing

The invention relates to a binding material, in particular to an automobile sound deadening film which is used on metal plates for locally reinforcing the metal plates and particularly on automobile doors to reduce noises generated by the vibration of a running automobile. The automobile sound deadening film is prepared by mixing and extruding 10-25 percent of synthetic rubber, 5-15 percent of thermoplastic resin, 5-20 percent of thickening resin, 10-25 percent of plasticizing agent, 25-50 percent of vibration damping and sound deadening agent, 10-20 percent of oil absorbing and filling agent and 5-10 percent of reinforcing filling material. The automobile sound deadening film can be used for the large-area sound deadening and vibration damping of the metal plates during the automobile manufacturing process. When being used, the automobile sound deadening film can be operated by hands, is innoxious and odorless, is easy to separate from release paper, has good manufacturability, can not shift after being pasted, is less susceptible to oil washing, phosphating process, electrophoresis, paint spraying and drying, and other subsequent automobile body manufacturing processes and is convenient to use.

Owner:广州市东明扬汽车部件有限公司

Environment-friendly and decorative nail-free glue and preparation method thereof

ActiveCN103484043AReduce contentNo pollution in the processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention belongs to environment-friendly and decorative glue, particularly relates to environment-friendly and decorative nail-free glue and a preparation method thereof. The environment-friendly and decorative nail-free glue comprises the following components: 5.0 to 20.0 percent of rubber elastomers, 10.0 to 30.0 percent of tackifying resin, 15.0 to 35.0 percent of reinforcing fillers, 2.0 to 8.0 percent of a thixotropic agent, 10.0 to 40.0 percent of a solvent and 0.1 to 1.0 percent of anti-oxidant; the preparation method of the environment-friendly and decorative nail-free glue comprises the following steps: putting the solvent into a high-speed stirrer, sequentially adding the rubber elastomers and the tackifying resin after a stirrer is started, stirring for 2 to 8 hours until all materials are dissolved to be a uniform liquid, then slowly adding the enhancing fillers and stirring uniformly so as to prepare a flowable slurry mixture, then adding the thixotropic agent and the anti-oxidant, and stirring uniformly so as to prepare the environment-friendly and decorative nail-free glue. The environment-friendly and decorative glue provided by the invention is environmental-friendly, is convenient to use, has high product bonding intensity and is excellent in durability.

Owner:GLEIHOW NEW MATERIALS CO LTD

Alcohol-soluble composite film adhesive and preparation method thereof

InactiveCN101818033AThe impact of small resource pricesNo waste problemMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceComposite film

The invention discloses an alcohol-soluble composite film adhesive and a preparation method thereof, belonging to the field of an adhesive. The adhesive is prepared from the following components in percentage by weight: acrylate polymer, tackifying resin and solvent, wherein the acrylate polymer is polymerized from 20-50wt% of acrylate hard monomer, 40-70wt% of acrylate soft monomer and 1-10wt% of acrylate functional monomer by a solution polymerizing method under the actions of an initiator and the solvent. The glass transition temperature of the acrylate polymer is -10 to -40 DEG C. As the acrylate hard monomer and the acrylate soft monomer are reasonably matched, and a certain acrylate functional monomer is matched to participate into the polymer, the molecular chain of the acrylate polymer in the composite film adhesive has multiple chemical bond structures of -COH, -OH, -NH and the like, multiple intermolecular action force can be formed, the adhesive can be adhered to various composite materials with good adhesion property and wide adhesion range. The prepared composite film adhesive can use the alcohol as the main solvent and has the advantages of little toxicity and low cost.

Owner:BEIJING COMENS NEW MATERIALS

Hot-fusible adhesive and method for preparing same

ActiveCN101307214AReduce melt viscosityHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesWaxPlasticizer

The invention provides a high temperature resistant hot melt adhesive which is made from an elastic body, synthesized high melting-point wax, synthetic resin, a plasticizer and an antioxidizer. The hot melt adhesive has high softening point, strong adhesive attraction and penetrability, and appropriate viscosity. The hot melt adhesive is used to splice a device; and the use method is simple and convenient, the device splicing is firm, and the high temperature resistant property and the anti-aging property are good. The product does not contain a poisonous solvent, thereby belonging to an environmental-friendly product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adhesive tape for encapsulating an organic electronic arrangement

ActiveUS20150162568A1Improve barrier propertiesReduce water contentMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEngineeringGetter

The invention relates to a method for protecting an electronic arrangement which is disposed on a substrate and comprises organic constituents, where a cover is applied to the electronic arrangement in such a way that the electronic arrangement is at least partly covered by the cover, the cover being bonded at least over a partial area to the substrate and / or to the electronic arrangement, the adhesive bond being produced by means of at least one layer of an adhesive in an adhesive tape, characterized in that the adhesive comprises a getter material which is capable of at least one permeable substance, the getter material being present in the adhesive in a proportion of not more than 2 wt %, based on the adhesive with the getter material.

Owner:TESA SE

Back glue for books and magazines and production method thereof

InactiveCN102838949ASolve the difficulty of sticking, opp filmSolve the problem that the pet film cannot stickMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesParaffin waxPolyethylene vinyl acetate

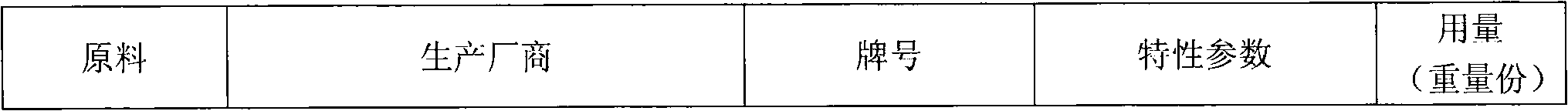

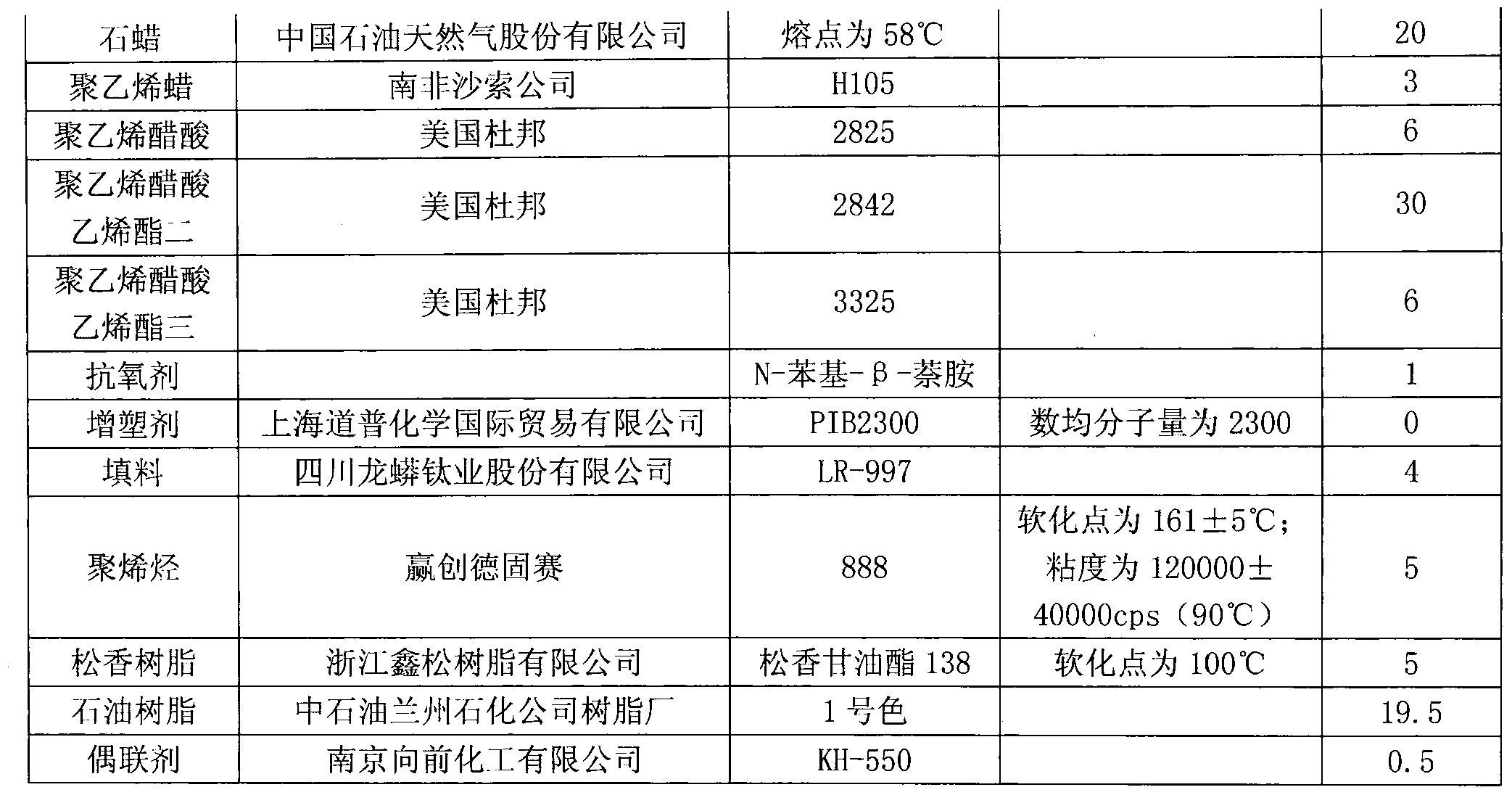

The invention discloses back glue for books and magazines and a production method thereof. The back glue is characterized by comprising the following materials in parts by weight: 10-20 parts of paraffin wax, 0-10 parts of polyethylene wax, 5-30 parts of polyethylene vinyl acetate I, 5-30 parts of polyethylene vinyl acetate II, 5-30 parts of polyethylene vinyl acetate III, 0.1-1.5 parts of antioxidant, 0-5 parts of plasticizing agent, 1-10 parts of filler, 1-10 parts of polyolefin, 5-30 parts of rosin resin, 5-30 parts of petroleum resin and 0.1-1 part of coupling agent. The back glue is a hot-melt glue adopting EVA as a main material, is solvent-less and nontoxic, belongs to an environmentally-friendly product, solves the problems of difficult sticking to ink and incapability of opp membranes and pet membranes for long term by adding the polyolefin and special composite coupling agent, and can be used as back glue for unsewn binding of books, or materials such as high-grade paper, high-gram coated paper and dual laminating membranes.

Owner:浙江固特新材料科技股份有限公司

Medical hot melt pressure sensitive adhesive substrate and preparation method thereof

InactiveCN102676100AIncrease polarityHigh drug loadingMineral oil hydrocarbon copolymer adhesivesPharmaceutical non-active ingredientsPolymer scienceAntioxidant

The invention discloses a medical hot melt pressure sensitive adhesive substrate and a preparation method thereof, and belongs to the technical field of hot melt adhesives. According to the hot melt pressure sensitive adhesive substrate, 40 to 60 weight parts of epoxidation modified styrene-dialkene-styrene block copolymer thermoplastic elastomer is taken as a main body, partial double bonds of the copolymer are converted into epoxide groups, 30 to 70 weight parts of tackifier, 30 to 60 weight parts of plasticizer and 1 to 10 weight parts of antioxidant are added, and a hot melt pressure sensitive adhesive is prepared and is stirred to be fused under the protection of nitrogen. The hot melt pressure sensitive adhesive is transparent, high in polarity and medicine-loading rate, has moisture-penetrability, is attached to skin to ensure that the skin is comfortable, and contains 100 percent of solid content without solvent.

Owner:BEIJING UNIV OF CHEM TECH

Transfer tape

ActiveCN105400440AEasy to operateImprove adhesion strengthMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesElastomerUltimate tensile strength

The invention provides a transfer tape which comprises an adhesive layer with the thickness of 80-800 [mu]m, wherein raw materials for preparation of the adhesive layer comprises the following components in parts by weight: 40-50 parts of rubber elastomer, 50-60 parts of tackifying resin, 0-5 parts of a softening agent, 0-5 parts of a plasticizing agent, 1-10 parts of an antioxygen and 0-5 parts of color paste. The transfer tape has the characteristics of being large in sticking strength and long in fixing of the common double-sided adhesive tape, and can be moved only by being pulled out by 0-60 degree when an electronic product is disassembled in maintenance, and so that not only damage to electronic devices of battery and the like in maintenance is avoided, but also great convenience is brought to maintenance personnel.

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

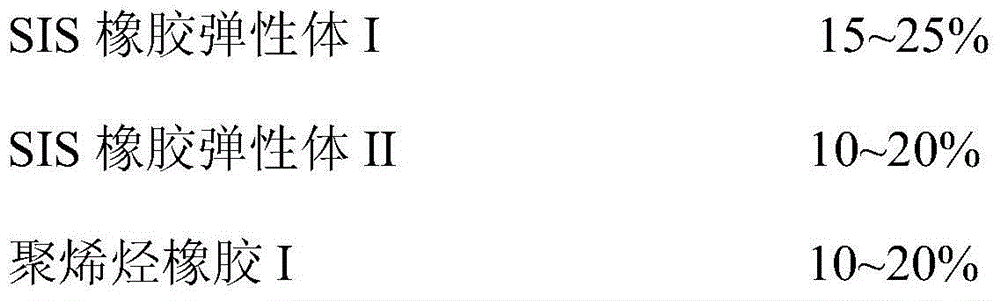

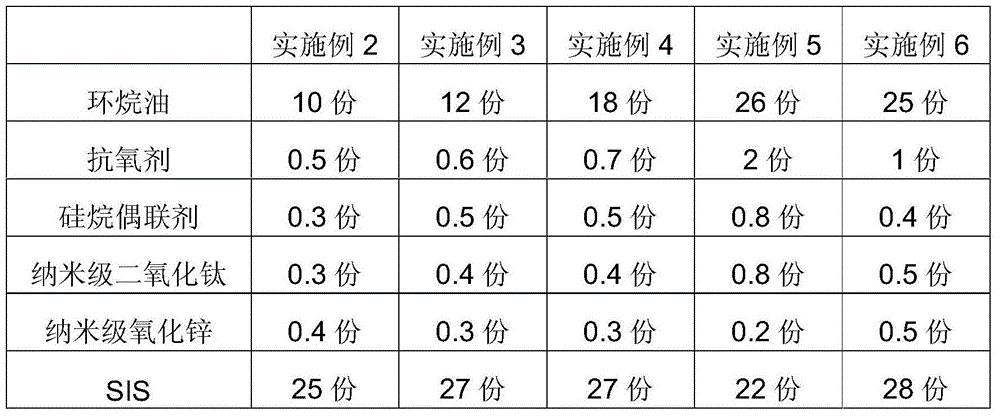

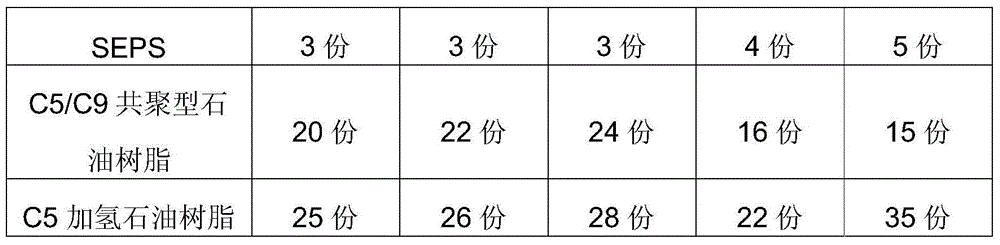

Hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls, and preparation method thereof

ActiveCN105086895AImproves UV resistanceImprove low temperature resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantTemperature resistance

The invention provides a hot melt adhesive for hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The The hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls comprises 10-30 parts of naphthenic oil, 0.1-3 parts of an antioxidant, 0.1-1 part of a silane coupling agent, 0.1-1 part of nanometer titanium dioxide, 0.1-1 part of nanometer zinc oxide, 20-32 parts of a styrene-isoprene-styrene copolymer, 1-5 parts of a styrene-hydrogenated isoprene-diblock copolymer, 15-30 parts of C5 / C9 copolymerized petroleum resin and 20-35 parts of C5 hydrogenated petroleum resin. The invention also provides a preparation method of the hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The hot melt adhesive has the advantages of excellent ultraviolet resistance, good low temperature resistance, good high temperature resistance, and appropriate cohesion strength, initial adhesion and peel strength, can be firmly pasted to a base material, can be firmly pasted to reaction sand particles spread on the surface of the base material, and has good weatherability.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com