Hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls, and preparation method thereof

A polymer waterproof, base pre-laid technology, used in non-polymer adhesive additives, adhesives, layered products, etc., can solve the problems of slow curing speed, unstable hot melt adhesive force, and high cost. Achieve excellent low temperature resistance, excellent UV resistance, good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A non-asphalt-based hot-melt adhesive for pre-paved polymer waterproof membrane, the composition ratio of which is:

[0059] 25 parts naphthenic oil,

[0060] Antioxidant 1 part,

[0061] 0.5 part of silane coupling agent,

[0062] 0.5 parts of nanoscale titanium dioxide,

[0063] 0.5 parts of nano-scale zinc oxide,

[0064] 28 parts of styrene-isoprene-styrene copolymer,

[0065] 4 parts of styrene-hydrogenated isoprene-diblock copolymer,

[0066] 25 parts of C5 / C9 copolymerized petroleum resin,

[0067] 30 parts of C5 hydrogenated petroleum resin.

[0068] Wherein, the naphthenic oil is high-pressure hydrogenated naphthenic oil; the styrene content in the styrene-isoprene-styrene copolymer is 15wt%, and the diblock content of styrene-isoprene is 50wt%, and the melt index of the styrene-isoprene-styrene copolymer is 10g / 10min (200°C / 5kg); the styrene in the styrene-hydrogenated isoprene diblock copolymer The content of styrene-hydrogenated isoprene diblock is 37w...

Embodiment 2~6

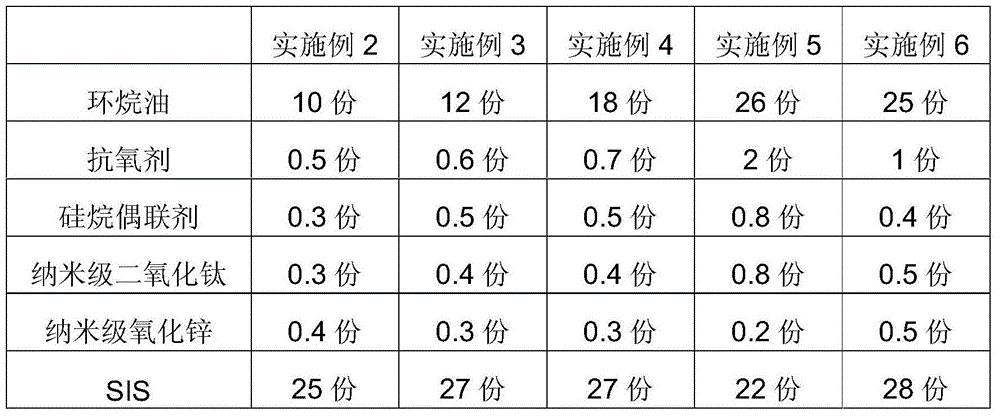

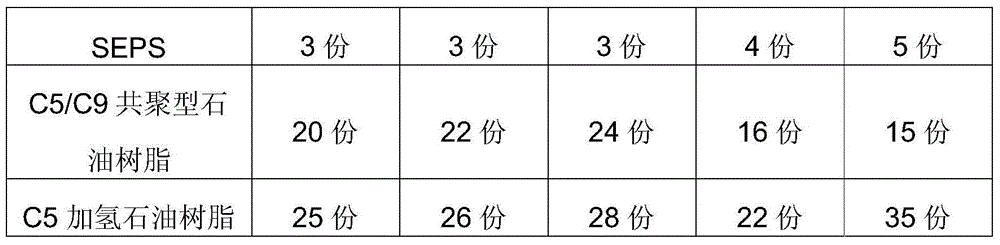

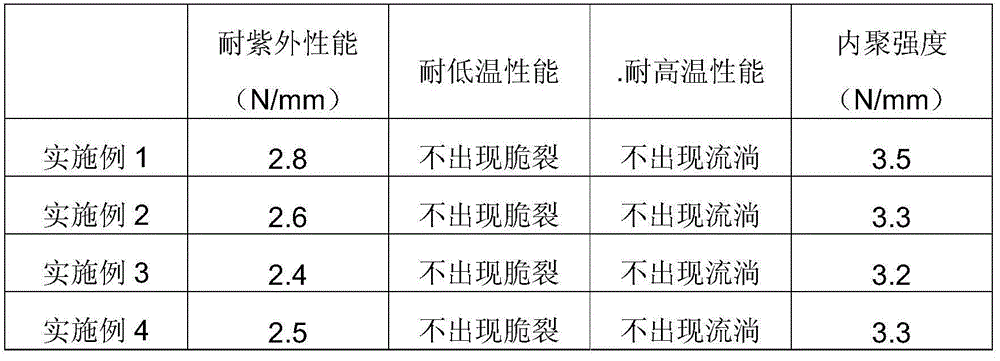

[0071] The difference between Examples 2-6 and Example 1 is that the composition ratio is different, see Table 1 for details.

[0072] The composition ratio of the non-asphalt-based pre-paved polymer waterproof membrane hot melt adhesive provided by Table 1 embodiment 2-6

[0073]

[0074]

Embodiment 7

[0076] Embodiment 7 differs from Embodiment 1 in that:

[0077] The styrene content in the styrene-isoprene-styrene copolymer is 18wt%, the diblock content of styrene-isoprene is 55wt%, and the styrene-isoprene-styrene The melt index of copolymer is 12g / 10min (200 ℃ / 5kg); The content of styrene in the described styrene-hydrogenated isoprene diblock copolymer is 42wt%, and described styrene-hydrogenated isoprene The melt index of the diblock copolymer is 0.5g / 10min (200°C / 5kg); the weight ratio of the C5 cut and the C9 cut in the C5 / C9 copolymerized petroleum resin is 75:11, and the C5 / C9 copolymerized petroleum resin The softening point of petroleum resin is 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com