High-barrier polyester film and its preparation method

A polyester film, high barrier technology, applied in the field of polyester film, can solve the problems of environmental impact, complex manufacturing process, high manufacturing cost, etc., and achieve high barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

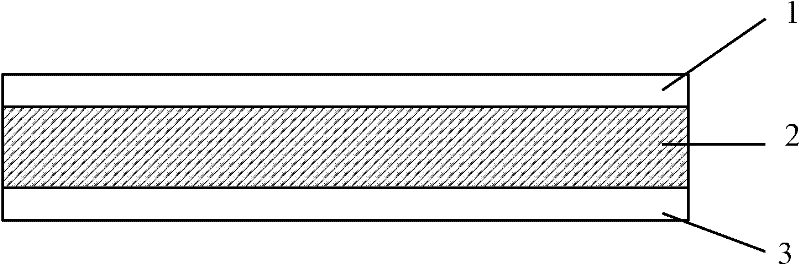

[0022] Such as figure 1 As mentioned above, the high barrier polyester film of the present invention has a three-layer composite structure, and the weight ratio of the core layer to the two-layer skin layer polyester masterbatch is 3-9:1. The skin layer polyester masterbatch contains the following components in weight percentage: 92-98% of PEN polyester chips, 0.2-2% of nucleating agent, and 1-6% of nucleating modifier. Wherein the nucleating agent is sodium benzoate, talcum powder, nano-scale silicon dioxide, montmorillonite, nano-titanium dioxide, 1; 3-2; 4-dilidene (p-methyl) benzyl sorbitol, or Multiple nucleating modifiers are one or more of polyethylene glycol PEG-600, PEG-1000, PEG-2000, PEG-5000, and triphenyl phosphite (TPP). The core layer polyester masterbatch contains the following components by weight percentage: 60-100% of PET polyester chips, 0-40% of PEN polyester chips.

[0023] The preparation method of the three-layer composite high barrier polyester film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com