Edible biological preservative film and preparation method thereof

A technology of biological freshness preservation and food habit, applied in the direction of flexible covering, meat/fish preservation with coating protection layer, packaging, etc., can solve the problems of harming the health of consumers, achieve the purpose of inhibiting the growth of microorganisms, avoiding secondary pollution, and enhancing The effect of mechanical properties and barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

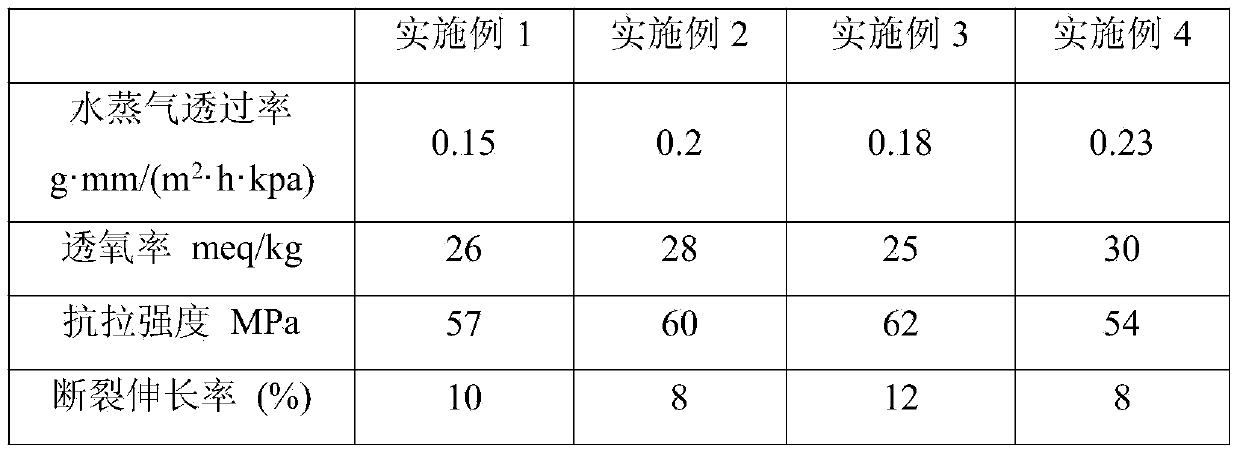

Examples

Embodiment 1

[0025] Weigh 1g of gelatin and dissolve in 50ml of distilled water, weigh 0.75g of sodium alginate and dissolve in 50ml of distilled water, respectively stir at 60°C for 1h, then let stand for 30min to obtain transparent gelatin solution and sodium alginate solution. Measure 50ml each of the gelatin solution and sodium alginate solution, blend them, and stir them evenly with a magnetic force; add 0.5g of ascorbic acid and 0.1g of clove oil to fully dissolve them, and stir them evenly with a magnetic force; add 0.1g of glycerin and 0.1g of Tween-80 respectively , fully mixed, stirred with a magnetic stirrer for 1 hour, and ultrasonically degassed for 10 minutes to obtain a transparent edible biological preservative film liquid.

[0026] The edible biological preservative film solution is poured into a PVC plate by casting method, and dried at room temperature to form an edible biological preservative film. Finally, the dried preservative film is peeled off, placed in a desiccat...

Embodiment 2

[0028] Weigh 1.2g of chitosan and dissolve it in 50ml of 0.5% acetic acid aqueous solution, weigh 1g of sodium alginate and dissolve it in 50ml of distilled water, stir at 60°C for 1h, and then let it stand for 30min to obtain a transparent chitosan solution and seaweed Sodium acid solution. Measure 50ml each of chitosan solution and sodium alginate solution, blend, stir evenly with magnetic force; add 0.5g tea polyphenol and 0.1g lysozyme to fully dissolve, stir evenly with magnetic force; add 0.2g sorbitol and 0.05g lysozyme respectively Tween-80, mix well, stir with a magnetic stirrer for 1 hour, and ultrasonically degas for 10 minutes to obtain a transparent edible biological preservative film solution.

[0029] The edible biological preservative film solution is poured into a PVC plate by casting method, and dried at room temperature to form an edible biological preservative film. Finally, the dried preservative film is peeled off, placed in a desiccator with a relative ...

Embodiment 3

[0031] Weigh 1g of carrageenan and dissolve in 50ml of distilled water, weigh 1.5g of agar and dissolve in 50ml of distilled water, stir at 60°C for 1 hour, then let stand for 30 minutes to obtain transparent carrageenan solution and agar solution. Measure 50ml each of carrageenan solution and agar solution, blend them, and stir evenly with magnetic force; add 0.5g phytic acid and 0.3g polylysine to dissolve them fully, and stir them evenly with magnetic force; add 0.1g glycerin and 0.08g polylysine respectively Tween-80, mix thoroughly, stir with a magnetic stirrer for 1 hour, and ultrasonically degas for 15 minutes to obtain a transparent edible biological preservative film solution.

[0032] The edible biological preservative film solution is poured into a PVC plate by casting method, and dried at room temperature to form an edible biological preservative film. Finally, the dried preservative film is peeled off, placed in a desiccator with a relative humidity of about 65% t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com