Patents

Literature

1939 results about "Tape casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tape casting (also called doctor blading and knife coating) is a casting process used in the manufacture of thin ceramic tapes and sheets from ceramic slurry. The ceramic slurry is cast in a thin layer onto a flat surface and then dried and sintered.

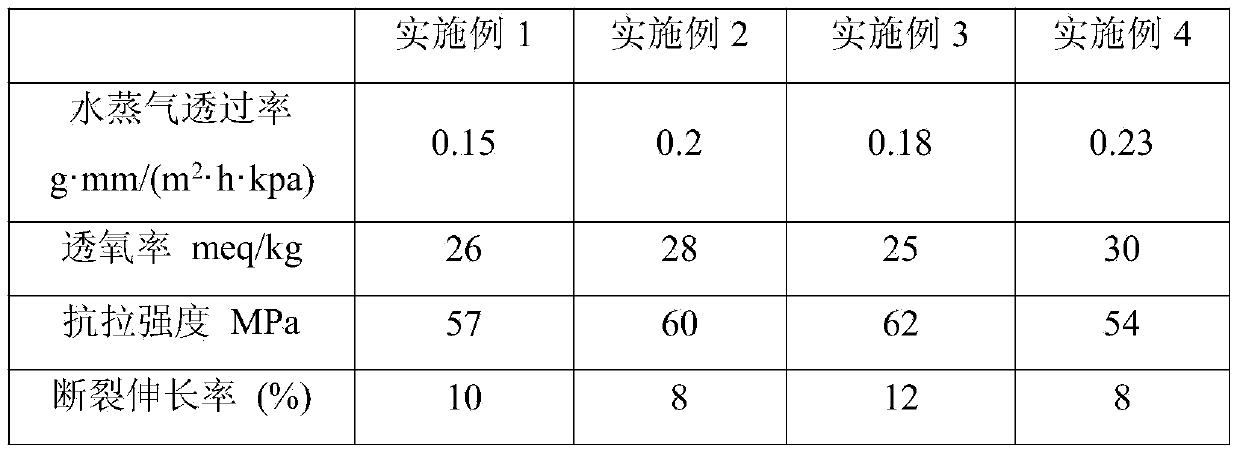

Edible biological preservative film and preparation method thereof

ActiveCN104194354AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersAntioxidantPlasticizer

The invention discloses an edible biological preservative film and a preparation method thereof. The edible biological preservative film comprises the following components in parts by weight: 30-60 parts of a film former, 1-10 parts of a natural antioxidant, 1-10 parts of a natural bacterial inhibitor, 1-4 parts of a plasticizer and 0.5-4 parts of an emulsifier. The preparation method comprises the following steps: mixing the components in proportion to form preservative film liquid, and preparing the preservative film by adopting a tape-casting process. According to the preservative film, excellent film forming performances of materials such as marine polysaccharides, chitosan, gelatin and the like are utilized, the natural antioxidant and the natural bacterial inhibitor are selected and used, and the modification process is carried out through the plasticizer, the emulsifier and the like, so that the prepared preservative film is good in mechanical property, delays the spoilage of an aquatic product and can effectively prolong the shelf life of the aquatic product.

Owner:MARINE BIOLOGY INST OF SHANDONG PROVINCE

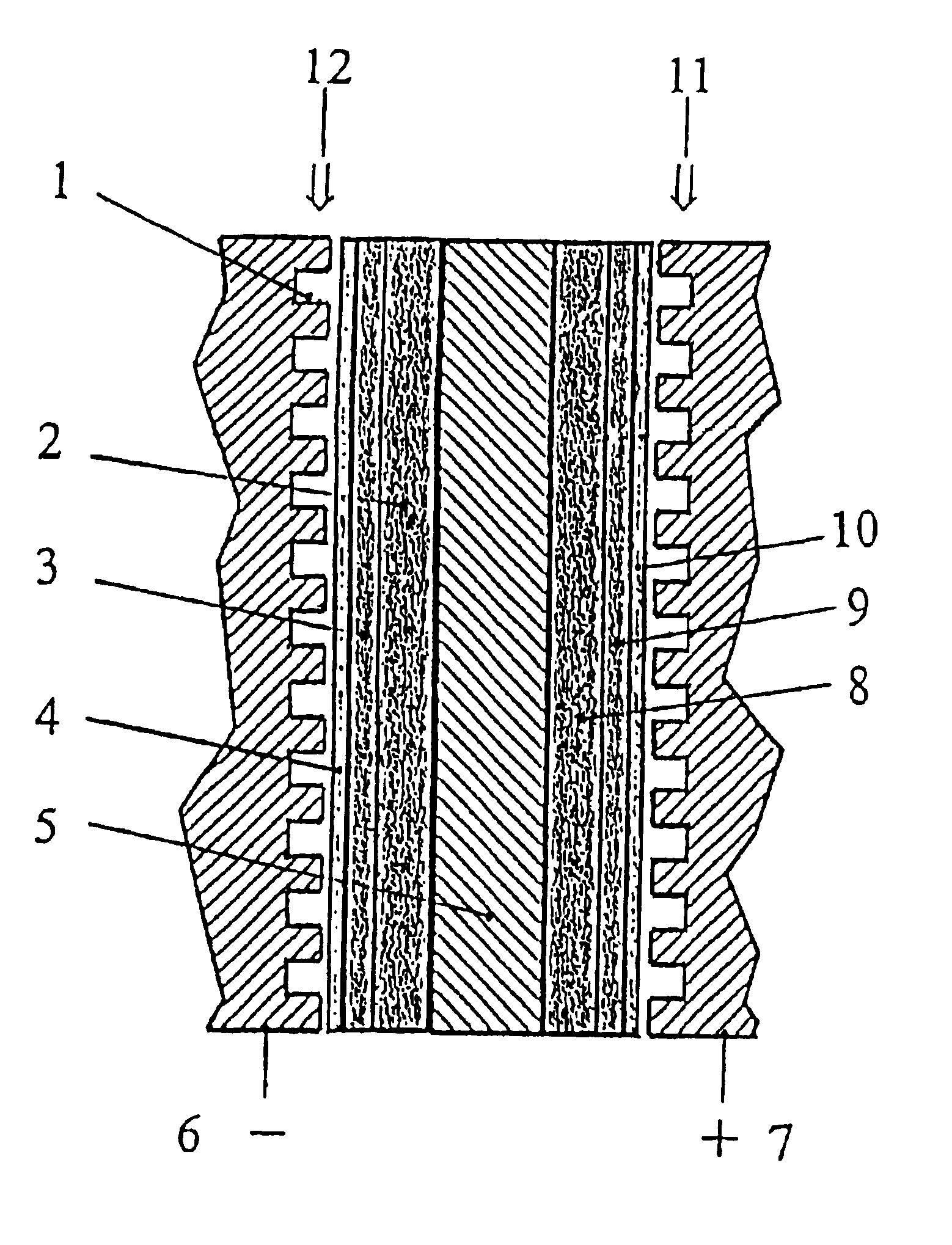

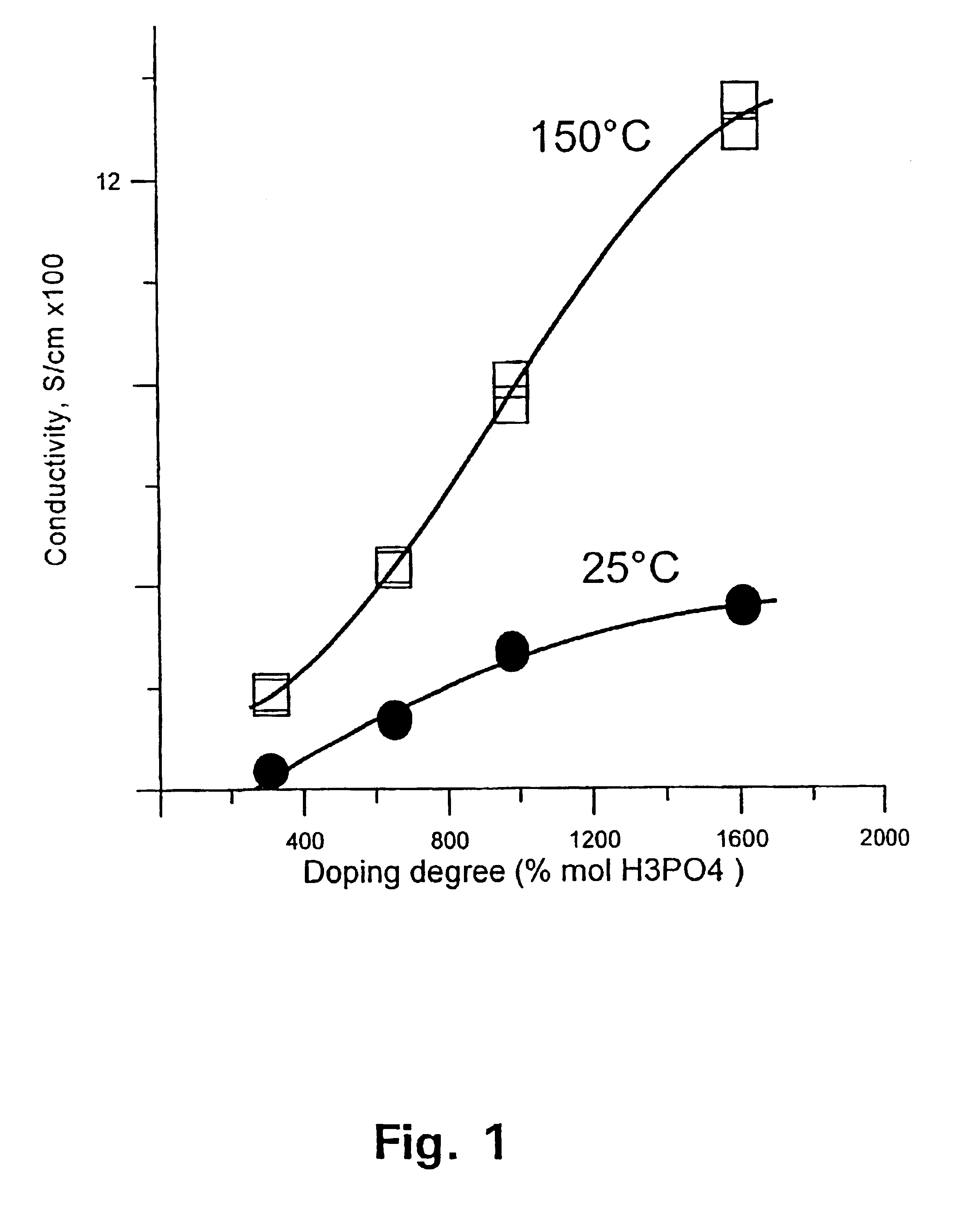

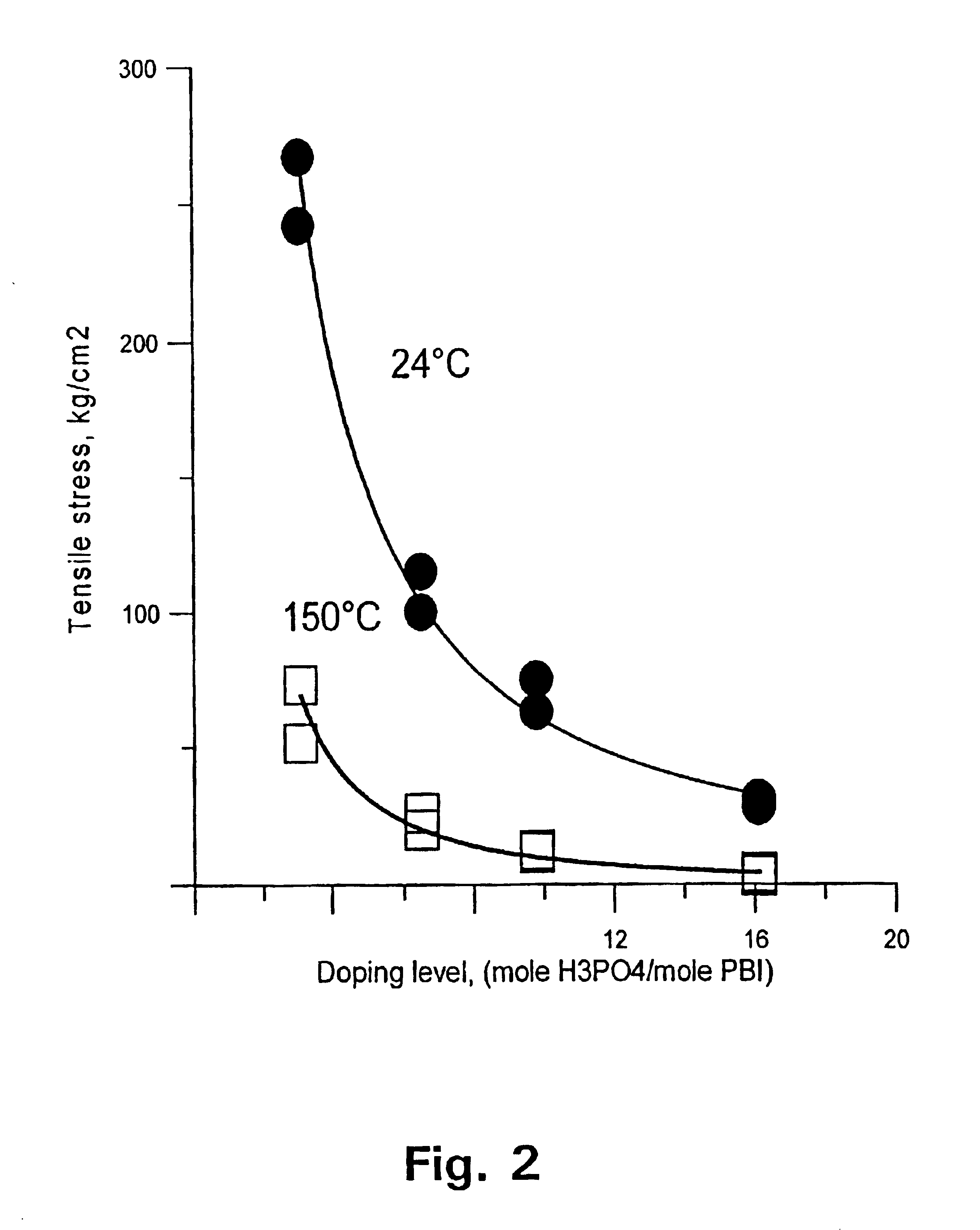

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

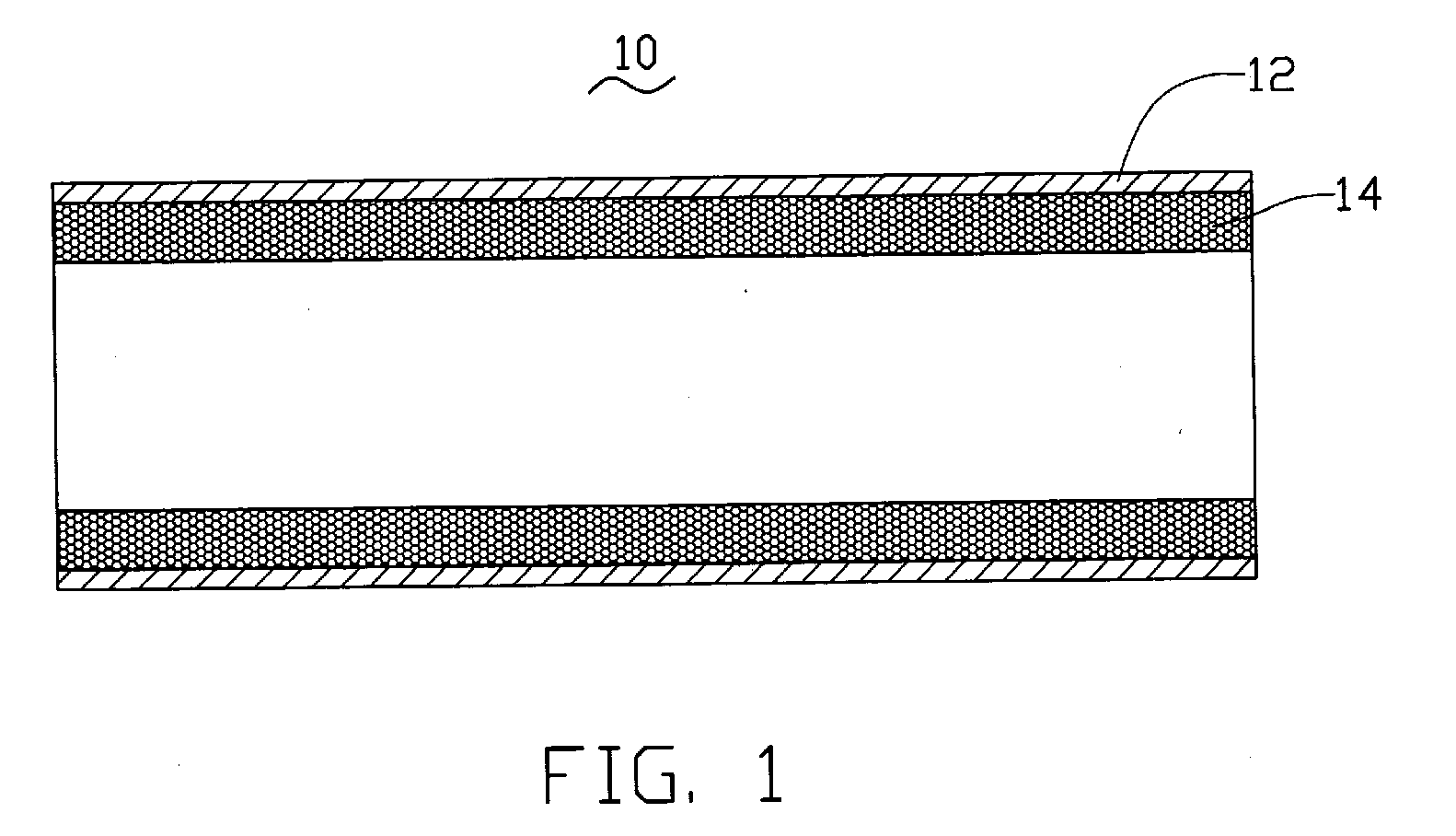

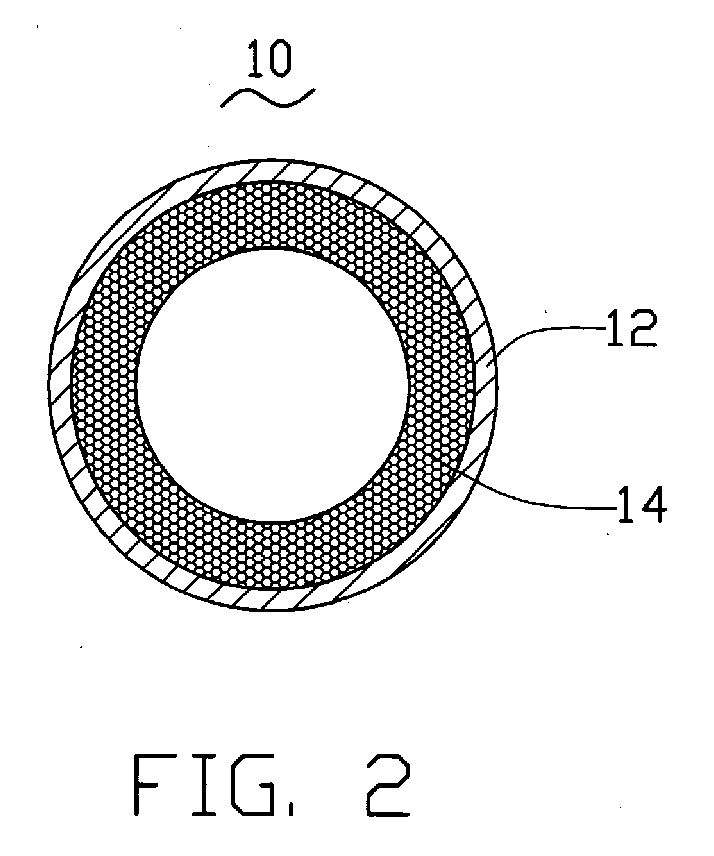

Method of manufacturing heat pipe having sintered powder wick

InactiveUS20060197245A1Improve heat transfer performanceImprove the preparation effectLinings repairLaminationGreen tapeMetallurgy

A method is disclosed to produce a heat pipe with a sintered powder wick formed inside the heat pipe. The method employs tape-casting technology to firstly produce thin sheets of powder and then these sheets are sintered to form the wick. In the tape casting procedure, a slurry of the powders necessary to construct said wick is cast onto a moving surface to form a slurry layer and then the slurry layer is dried to form a green tape. The green tape is rolled onto a mandrel and then is inserted into a hollow casing and sintered to cause the powders in the green tape to diffusion-bond together. Thus, the sintered powder wick is constructed.

Owner:HON HAI PRECISION IND CO LTD

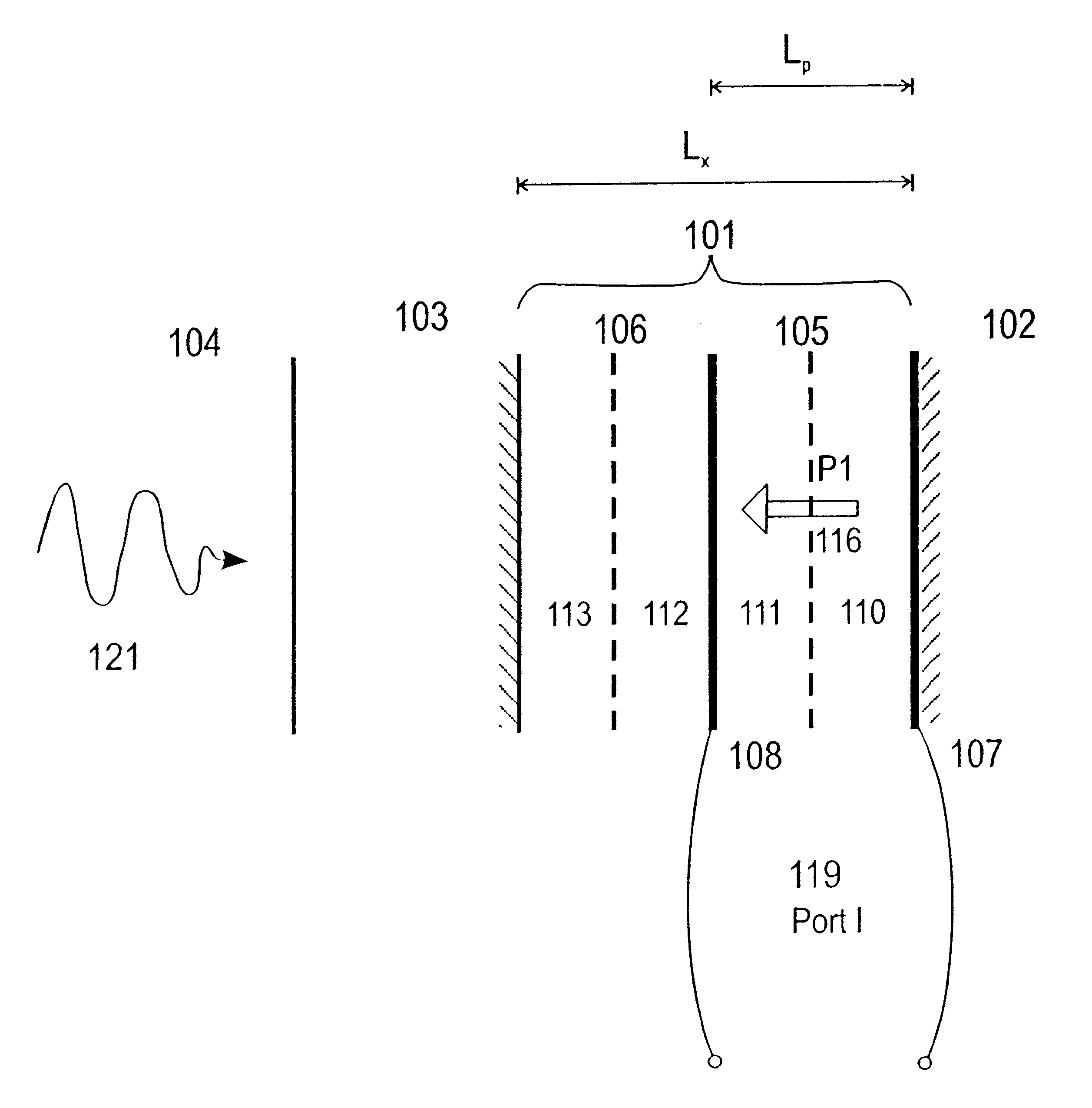

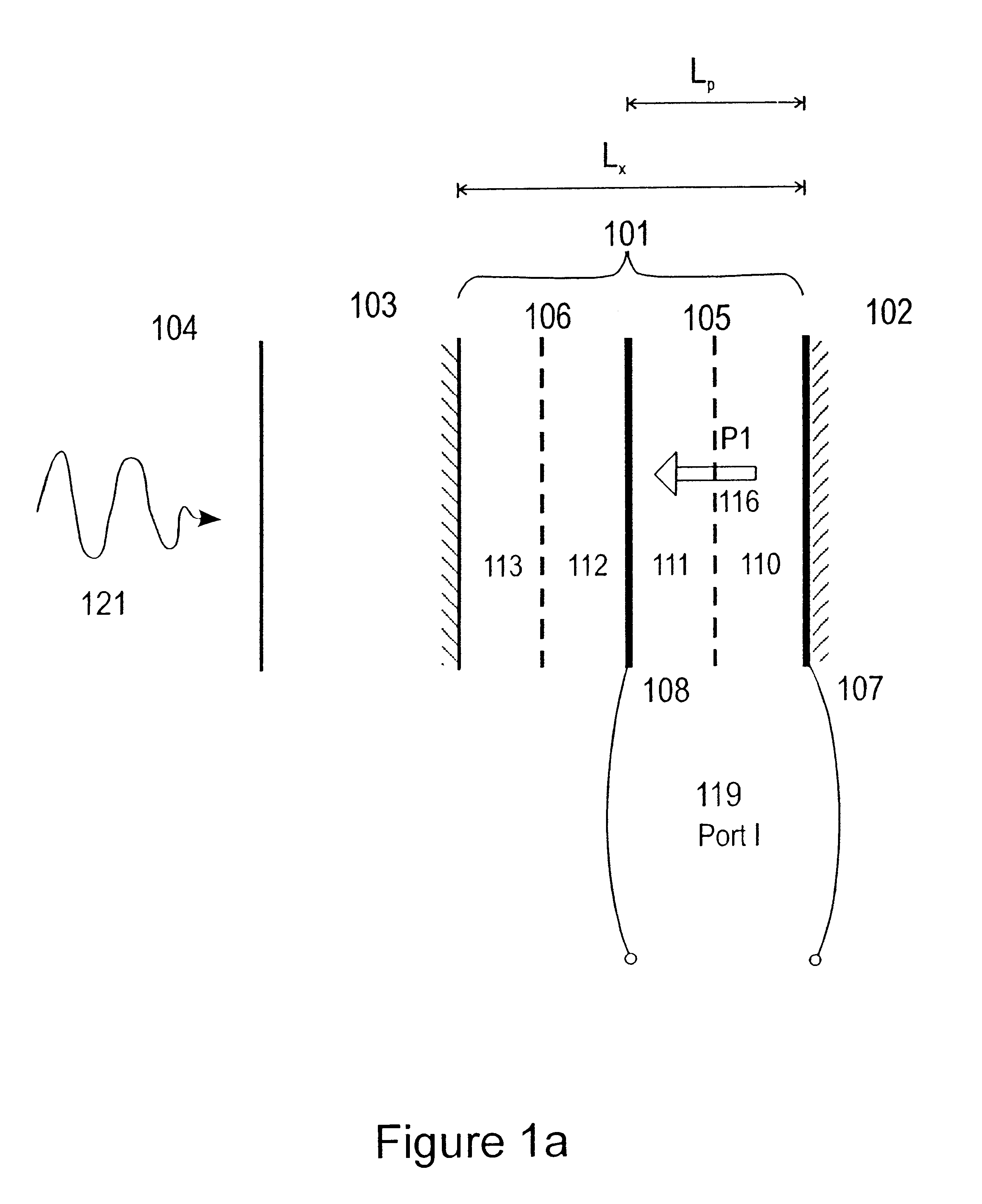

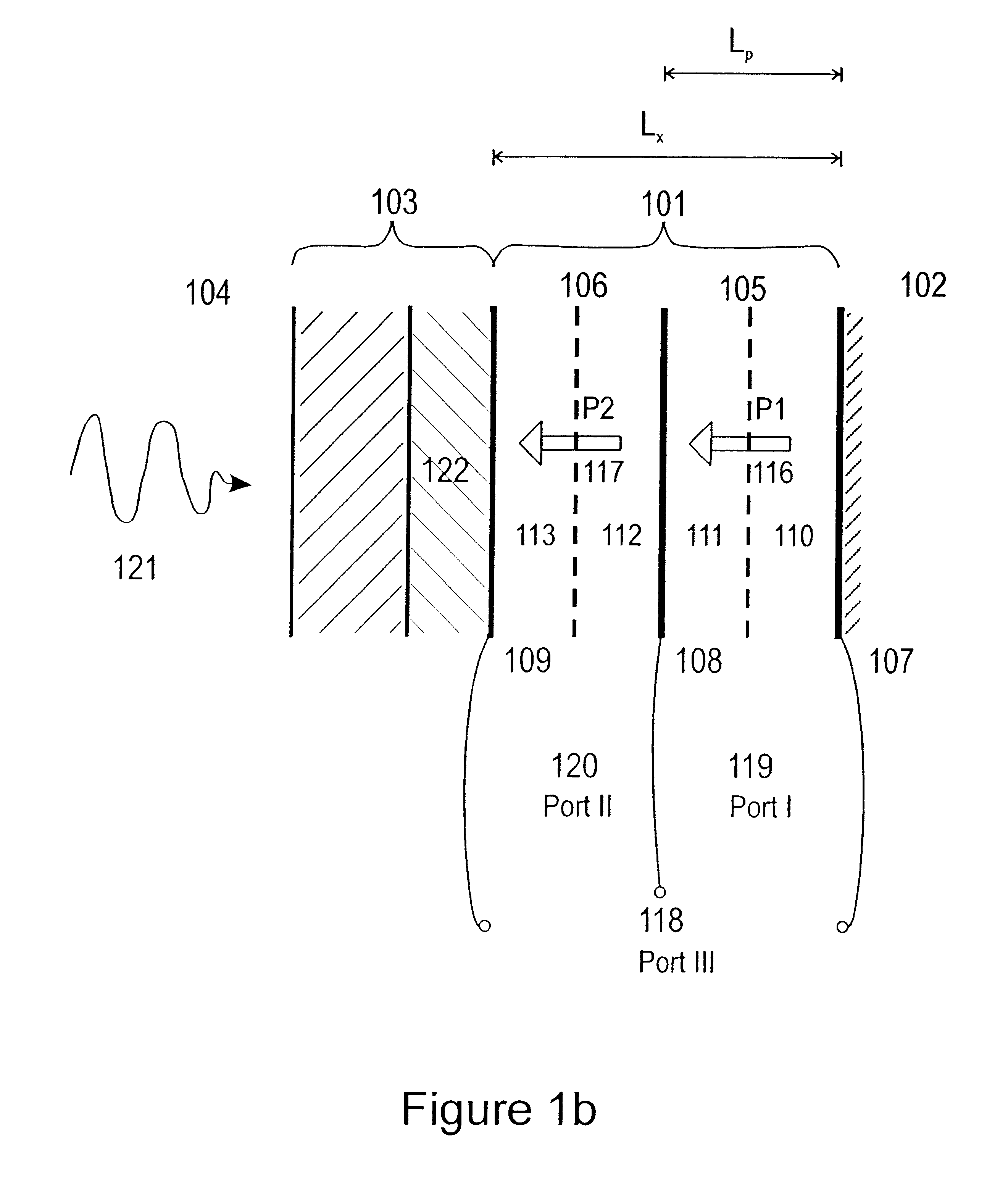

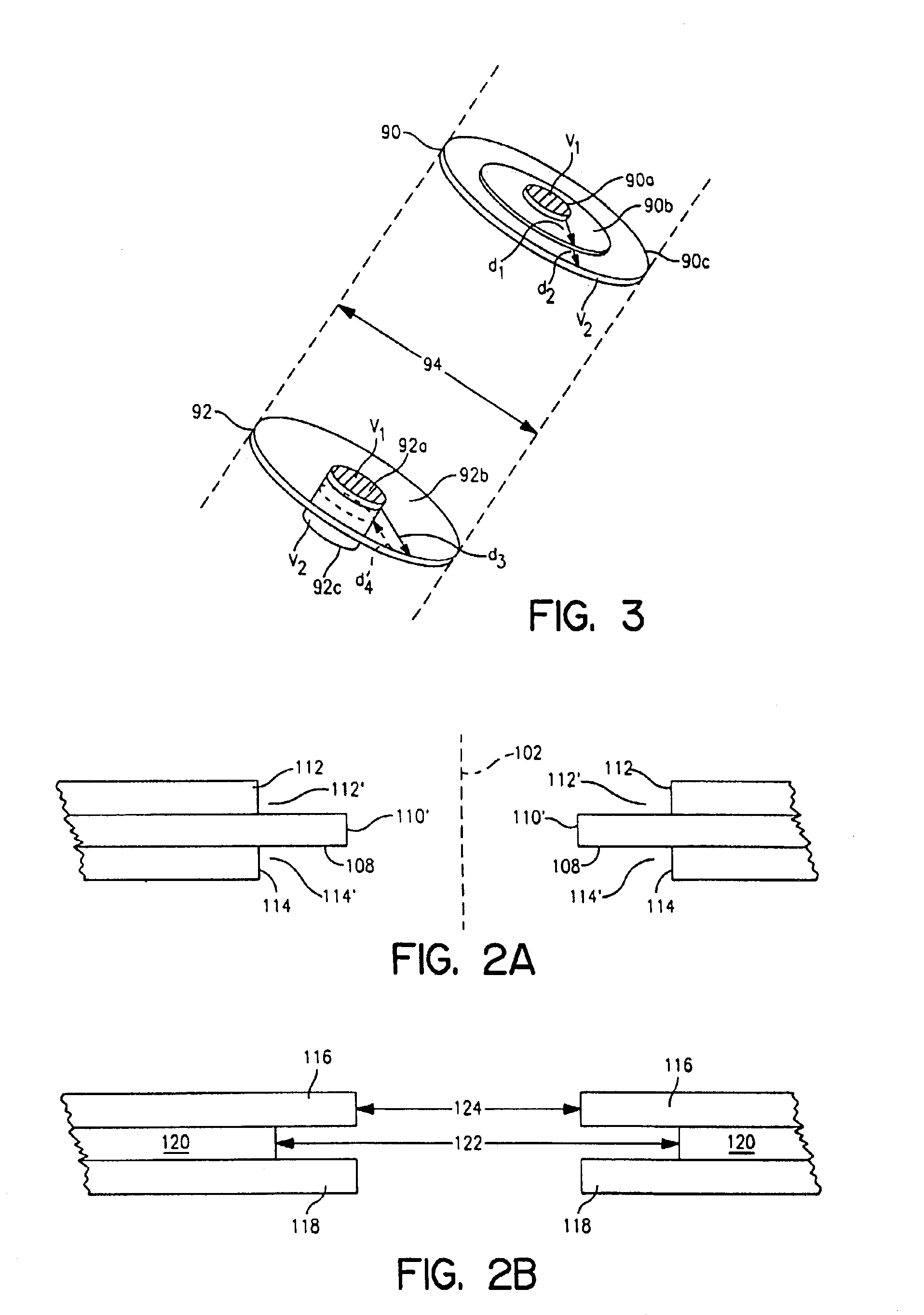

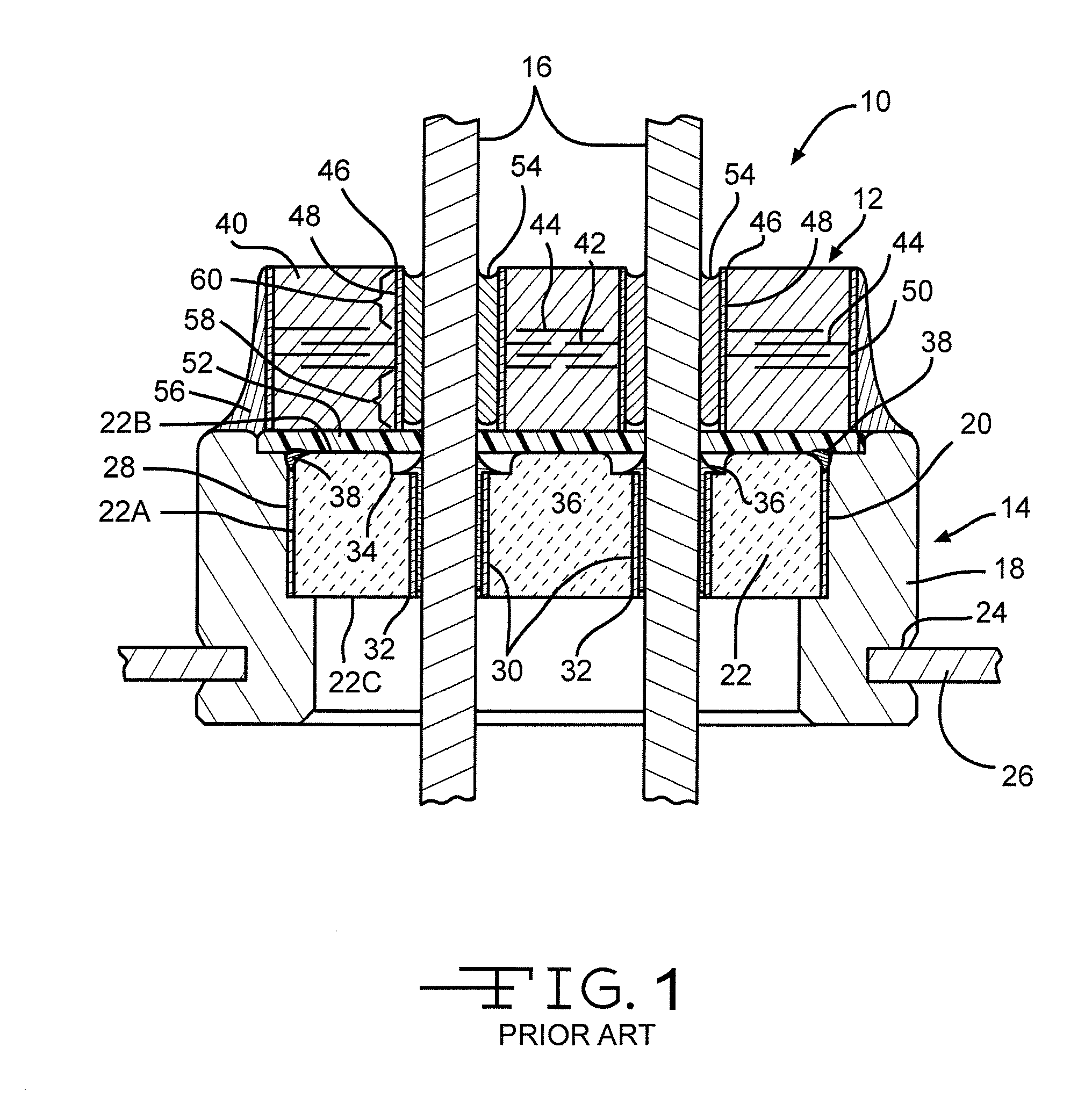

High frequency and multi frequency band ultrasound transducers based on ceramic films

InactiveUS6761692B2Maximizing electromechanical couplingImprove stabilityUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesMulti bandTransceiver

A design and a manufacturing method of ultrasound transducers based on films of ferro-electric ceramic material is presented, the transducers being particularly useful for operating at frequencies above 10 MHz. The designs also involve acoustic load matching layers that provides particularly wide bandwidth of the transducers, and also multiple electric port transducers using multiple piezoelectric layers, for multi-band operation of the transducers over an even wider band of frequencies that covers ~4 harmonics of a fundamental band. A transceiver drive system for the multi-port transducers that provides simple selection of the frequency bands of transmitted pulses as well as transmission of multi-band pulses, and reception of scattered signals in multiple frequency bands, is presented. The basic designs can be used for elements in a transducer array, that provides all the features of the single element transducer for array steering of the focus and possibly also direction of a pulsed ultrasound beam at high frequencies and multi-band frequencies. The manufacturing technique can involve tape-casting of the ceramic films, deposition of the ceramic films onto a substrate with thick film printing, sol-gel, or other deposition techniques, where manufacturing methods for load matching layers and composite ceramic layers are described.

Owner:PREXION

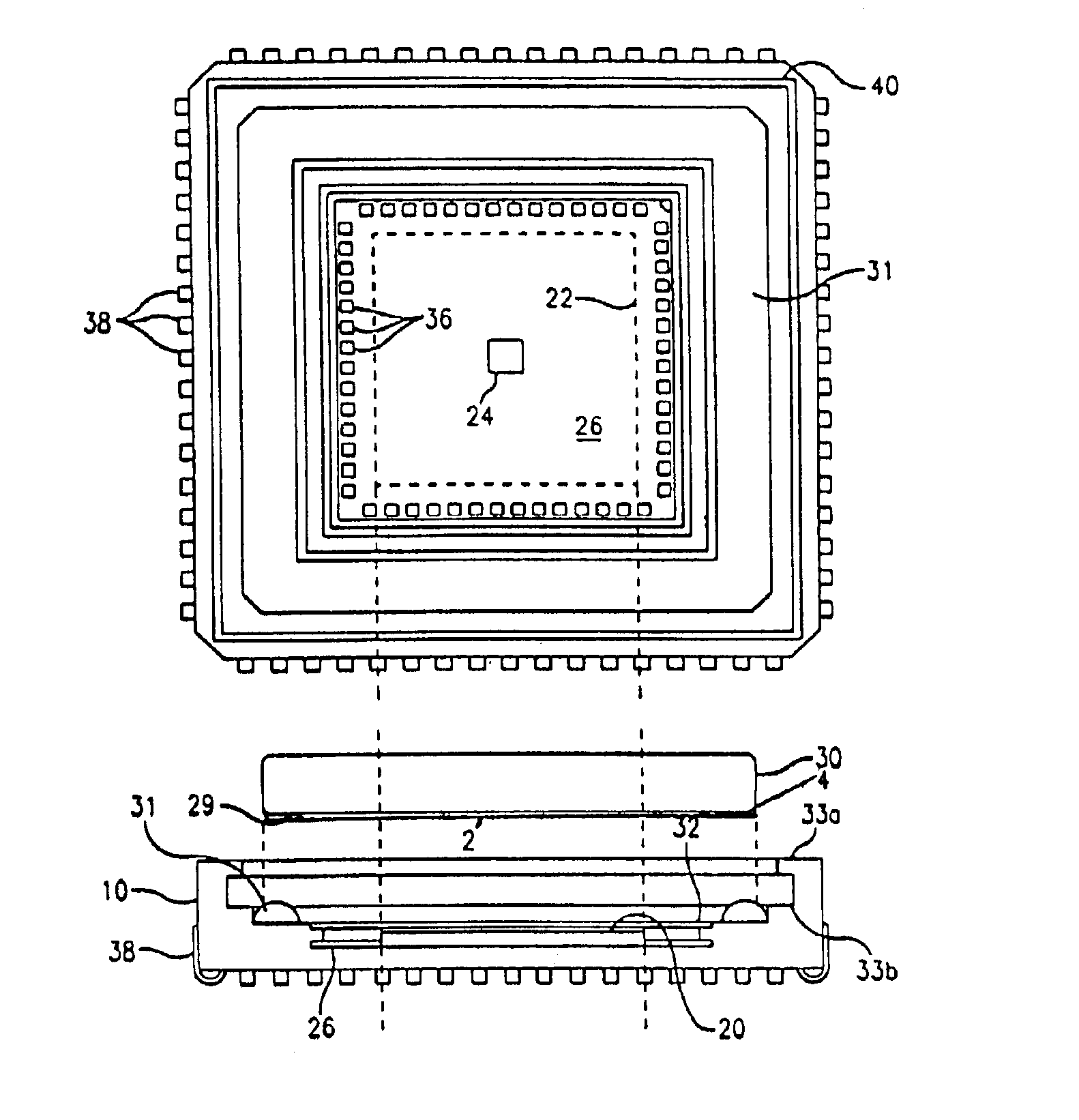

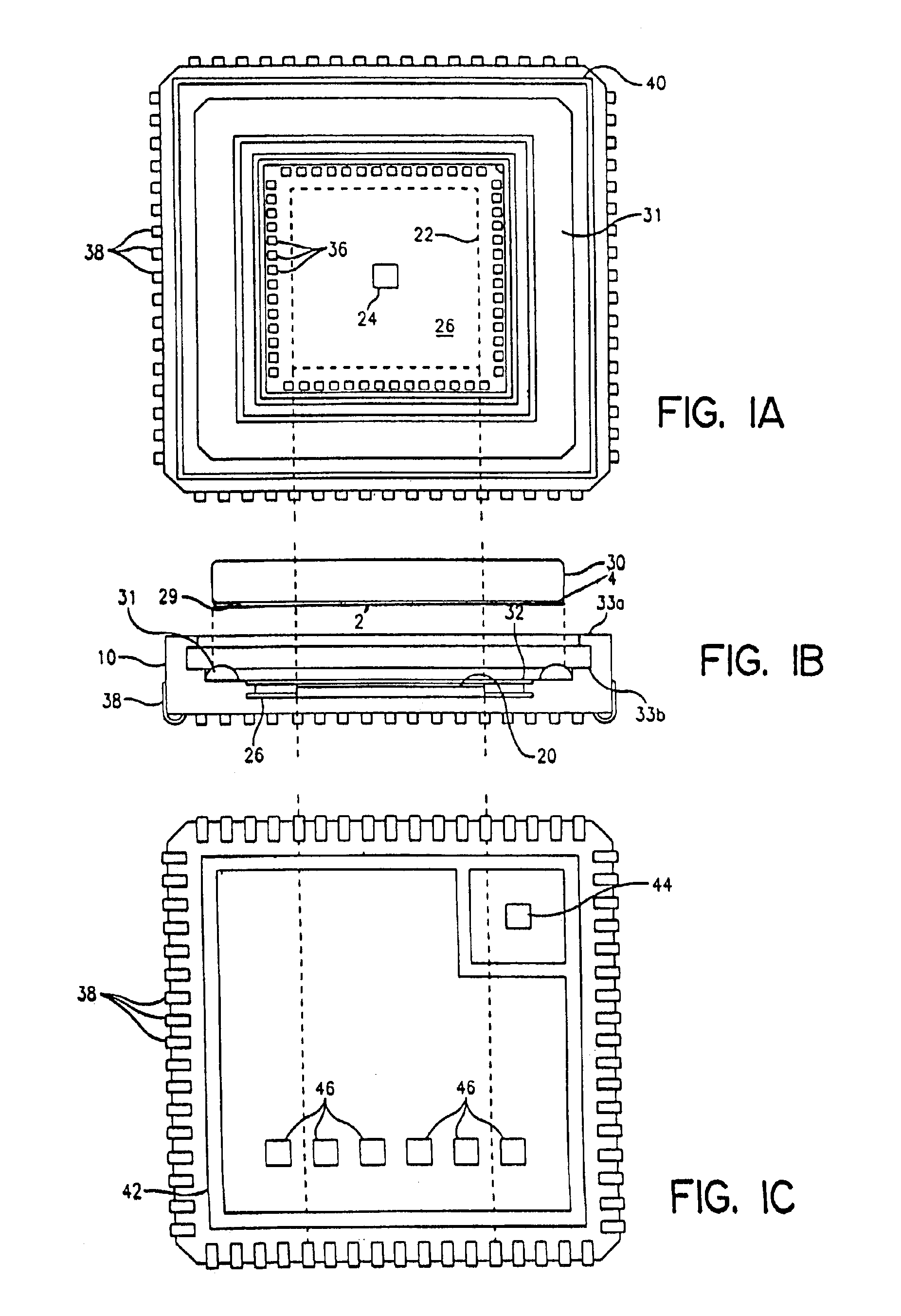

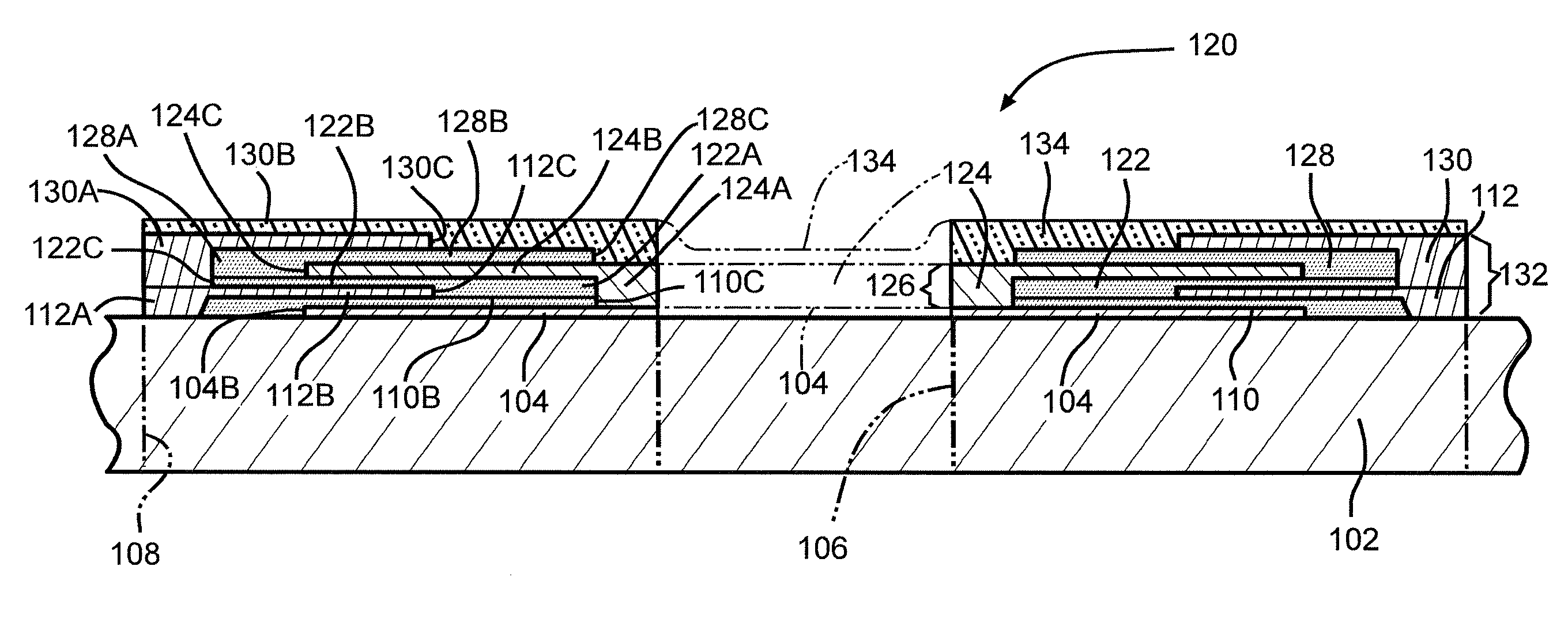

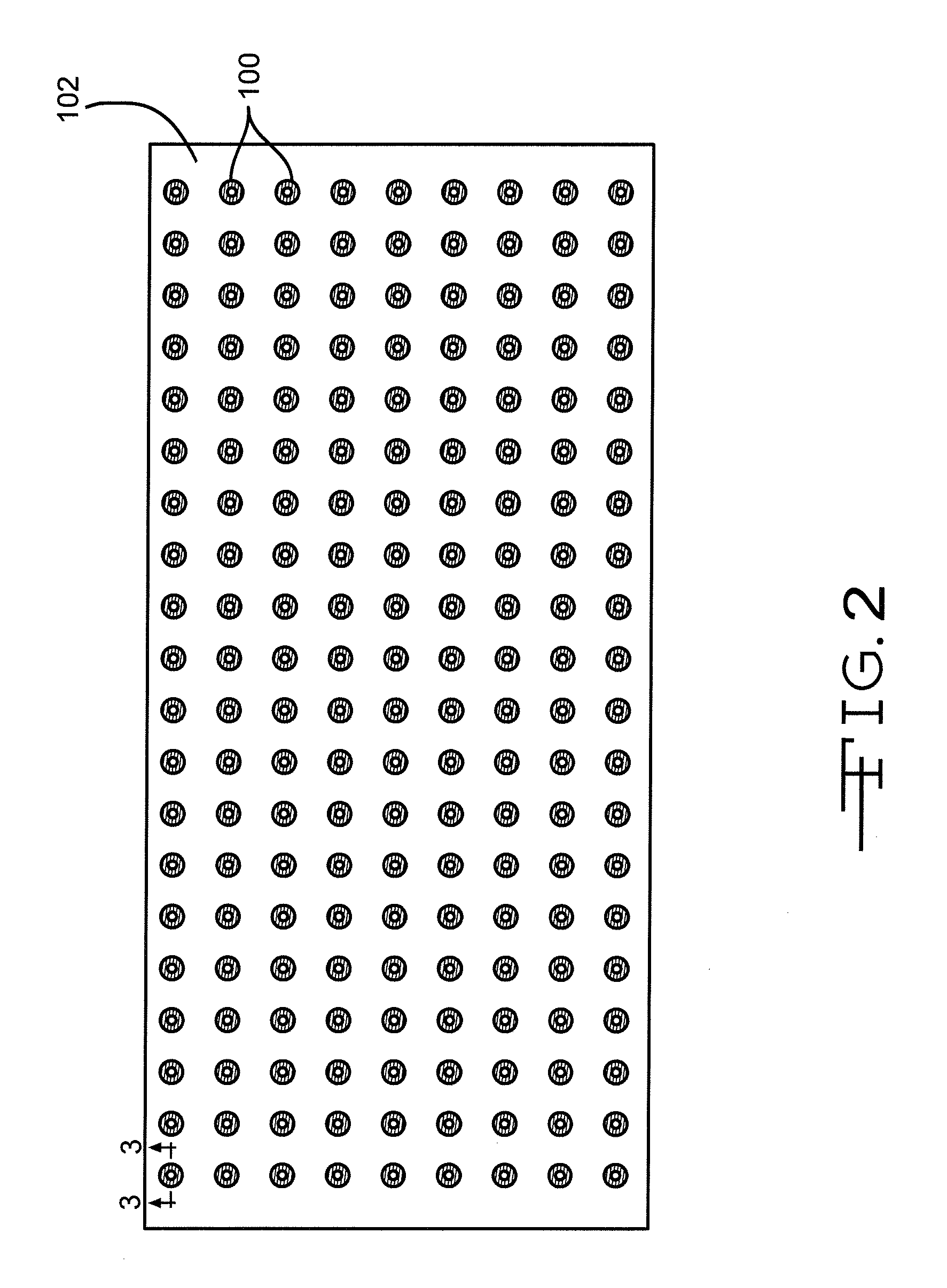

Unitary vacuum tube incorporating high voltage isolation

InactiveUS6837766B2Improve isolationLinear distance increasesGas filling substance selectionCathode-ray/electron-beam tube vessels/containersGreen tapeHigh pressure

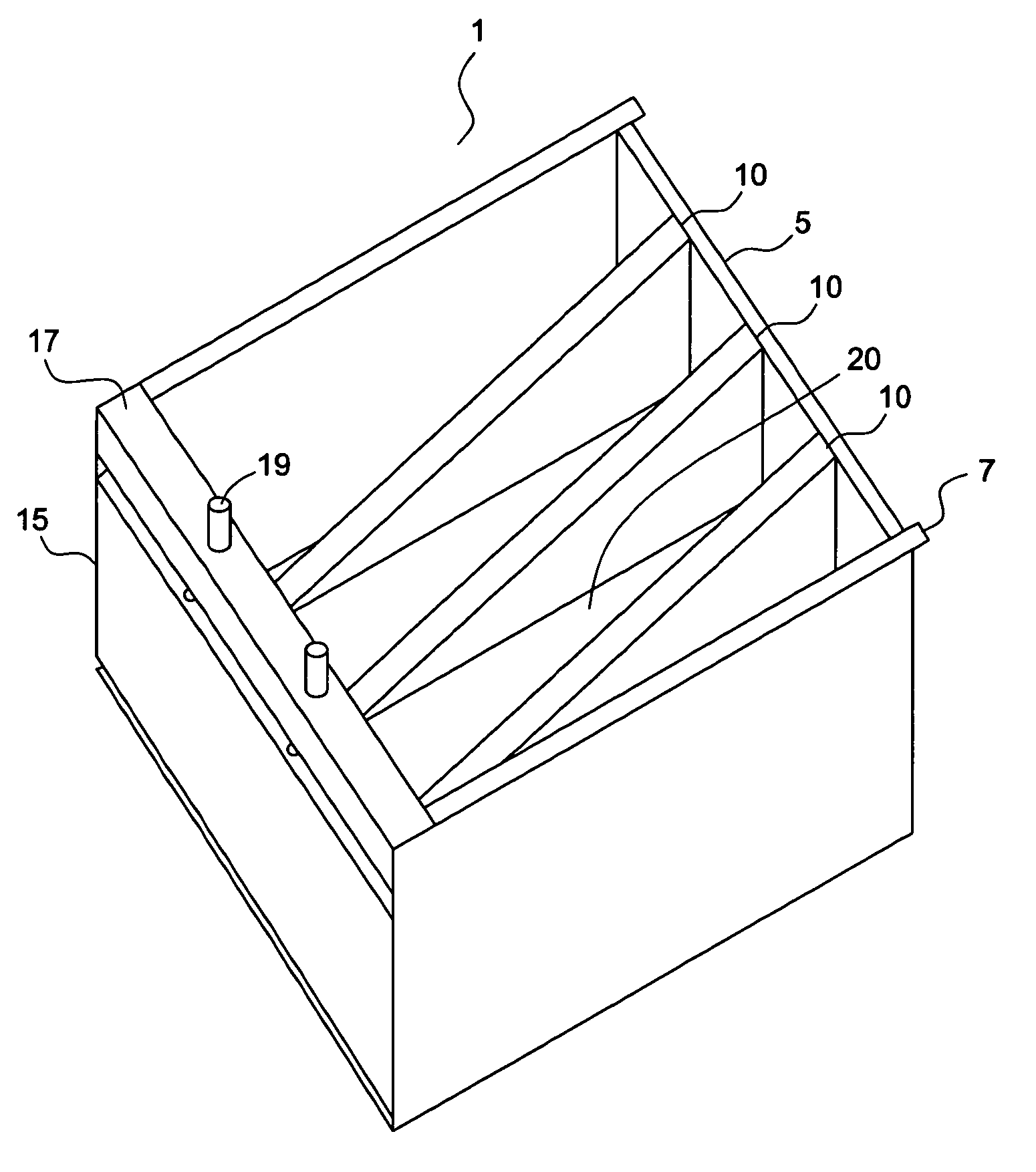

A housing for microelectronic devices requiring an internal vacuum for operation, e.g., an image detector, is formed by tape casting and incorporates leads between interior and exterior of the housing where the leads are disposed on a facing surface of green tape layers. Adjacent green tape layers having corresponding apertures therein are stacked on a first closure member to form a resulting cavity and increased electrical isolation or channel sub-structures are achievable by forming adjacent layers with aperture dimension which vary non-monotonically. After assembly of the device within the cavity, a second closure member is sealed against an open face of the package in a vacuum environment to produce a vacuum sealed device.

Owner:EOTECH LLC

Preparation method of edible film with antibacterial and antioxidant functions

InactiveCN103159970AHas antibacterial propertiesAntioxidantFlexible coversWrappersAntioxidantGlycerol

The invention relates to a preparation method of an edible film with antibacterial and antioxidant functions, and belongs to the technical field of edible packaging materials. The preparation method disclosed by the invention comprises the following steps: 1) dissolving and gelatinizing corn starch; 2) dissolving gelatin; 3) dissolving chitosan; 4) adding glycerin and plant essential oil or essential oil components; 5) mixing, homogenizing and refining; 6) degassing; 7) tape-casting; and 8) drying and stripping the film. The preparation method disclosed by the invention has the beneficial effects that the chitosan, the corn starch and the gelatin are taken as base materials of the edible film, the sources of the raw materials are wide, the cost is low, and the prepared edible film has the advantages of strong mechanical properties, high barrier performance and great transparency. Oregano oil, carvacrol and cinnamaldehyde are taken as an antibacterial agent and an antioxidant so as to be added into the edible film, the processing process is simple and easy to operate, the cost is low, the edible film is non-toxic and safe to eat, and the prepared edible film has great antibacterial and antioxidant properties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

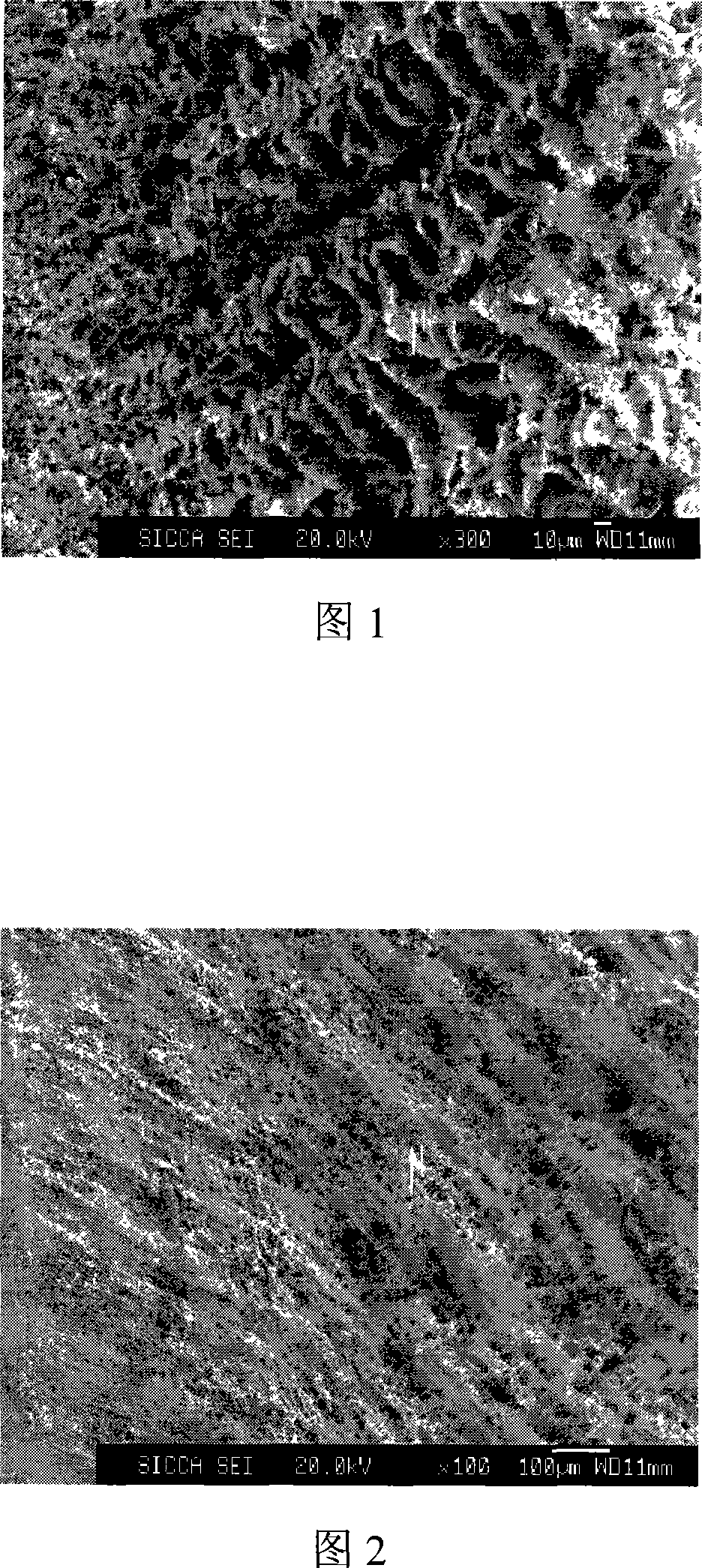

Gradient porous ceramics film and method for preparing the same

The invention relates to a gradient porous ceramic film, the pore diameter size of which is 0.1 micron to 100 microns, the pore rate is 20 percent to 90 percent, and the pores are arranged directionally. The pore has the characteristic of the directional opening communication, and the pore diameters have gradient change along the direction of the thickness. A preparation method is processing for ball milling and mixing according to the weigh ratio of 0.1 to 0.8 portions to 0.2 to 8.0 portions to 0.001 to 0.1 portion to 0.05 to 0.5 portion to 0.05 to 0.8 portion of ceramic powder to deionized water to ammonium polyacrylate to polyvinyl alcohol to polyethylene glycol to obtain slurry for vacuum foam-removal and tape casting at a metal underlay, and a scraper is used for controlling the thickness of the film. A cast film is frozen under low temperature, dried in vacuum, debonded and sintered to obtain the controllable gradient porous ceramic film with high pore rate, which is hopeful for the good application prospect at the fields of a catalyst carrier, a grade absorption catalyzing film, a filter part etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

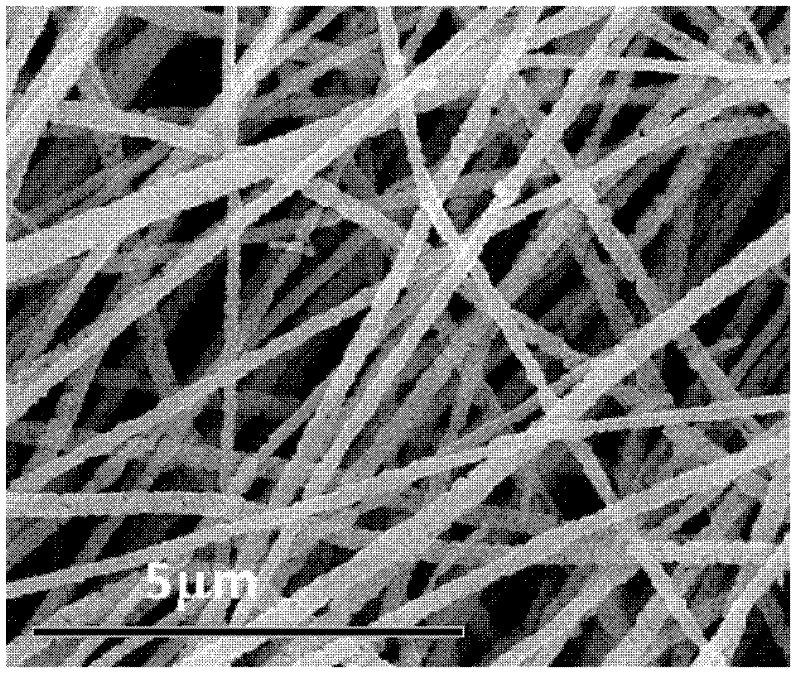

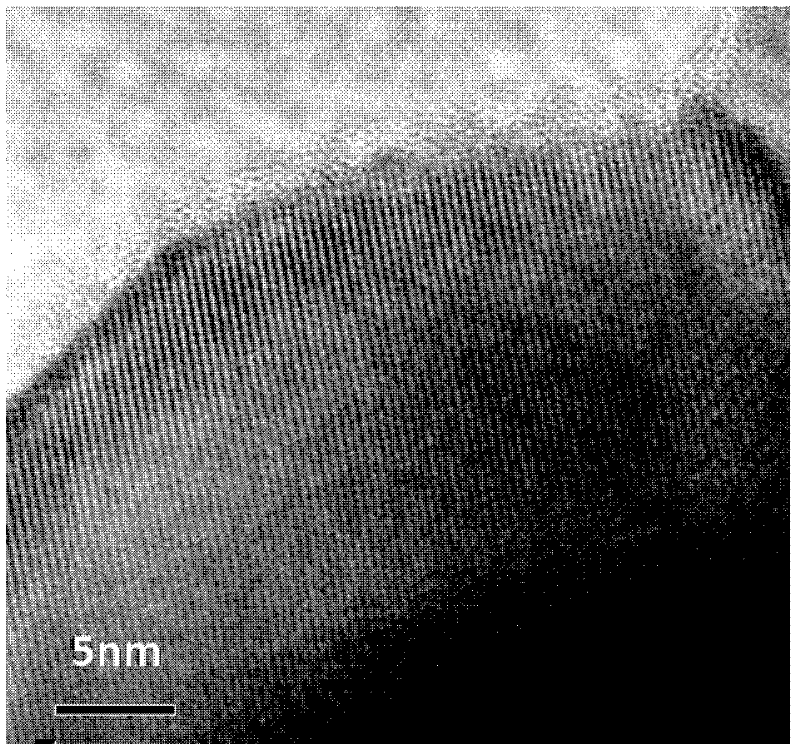

Polymer matrix composite membrane with high energy density and preparation method thereof

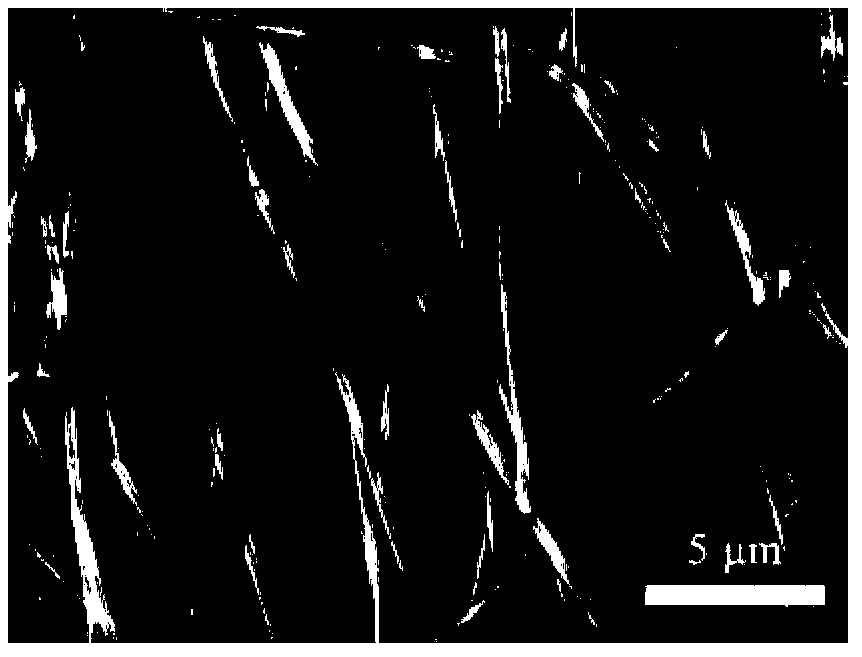

ActiveCN102504449AHigh dielectric constantHigh breakdown field strengthInorganic material artificial filamentsFibre treatmentFiberHigh energy

The invention discloses a high-flexible polymer matrix composite membrane with high energy density and a preparation method thereof. The composite membrane is composed of a polymer matrix and core-shell structured nano-fibre dispersed in the polymer matrix; the core layer of the core-shell structured nano-fibre is ceramic fibre; the shell layer is an organic matter coated layer, wherein the mass percentage of the polymer matrix is 50-95%; and the mass percentage of the core-shell structured nano-fibre is 5-50%. The polymer matrix and the core-shell structured nano-fibre are composited into the membrane by adopting a solution blending and tape casting method or a bidirectional membrane pulling method, so that a flexible polymer matrix composite material having the advantages of being good in dielectric property, high in breakdown field strength and high in energy density is obtained. The dielectric constant of the composite material can be modulated to 10-40 by adjusting the content of nano ceramic fibre; simultaneously, the dielectric loss Tan delta is kept to be less than 5%, the breakdown field strength is more than 210 kV / mm, and the energy density is 2-6 kJ / L; and the composite material is a material which can be used for capacitors and high power static energy storage.

Owner:TSINGHUA UNIV

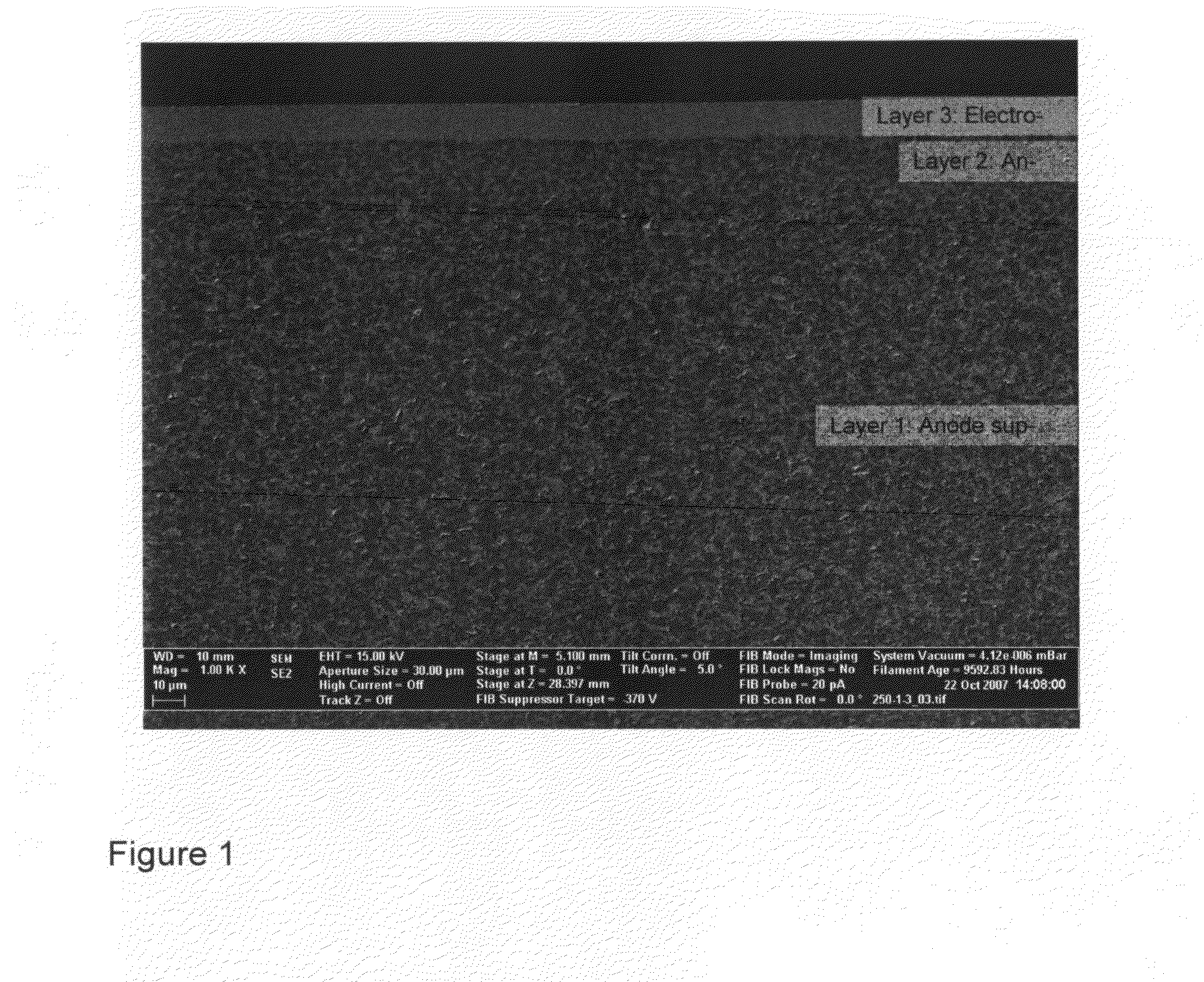

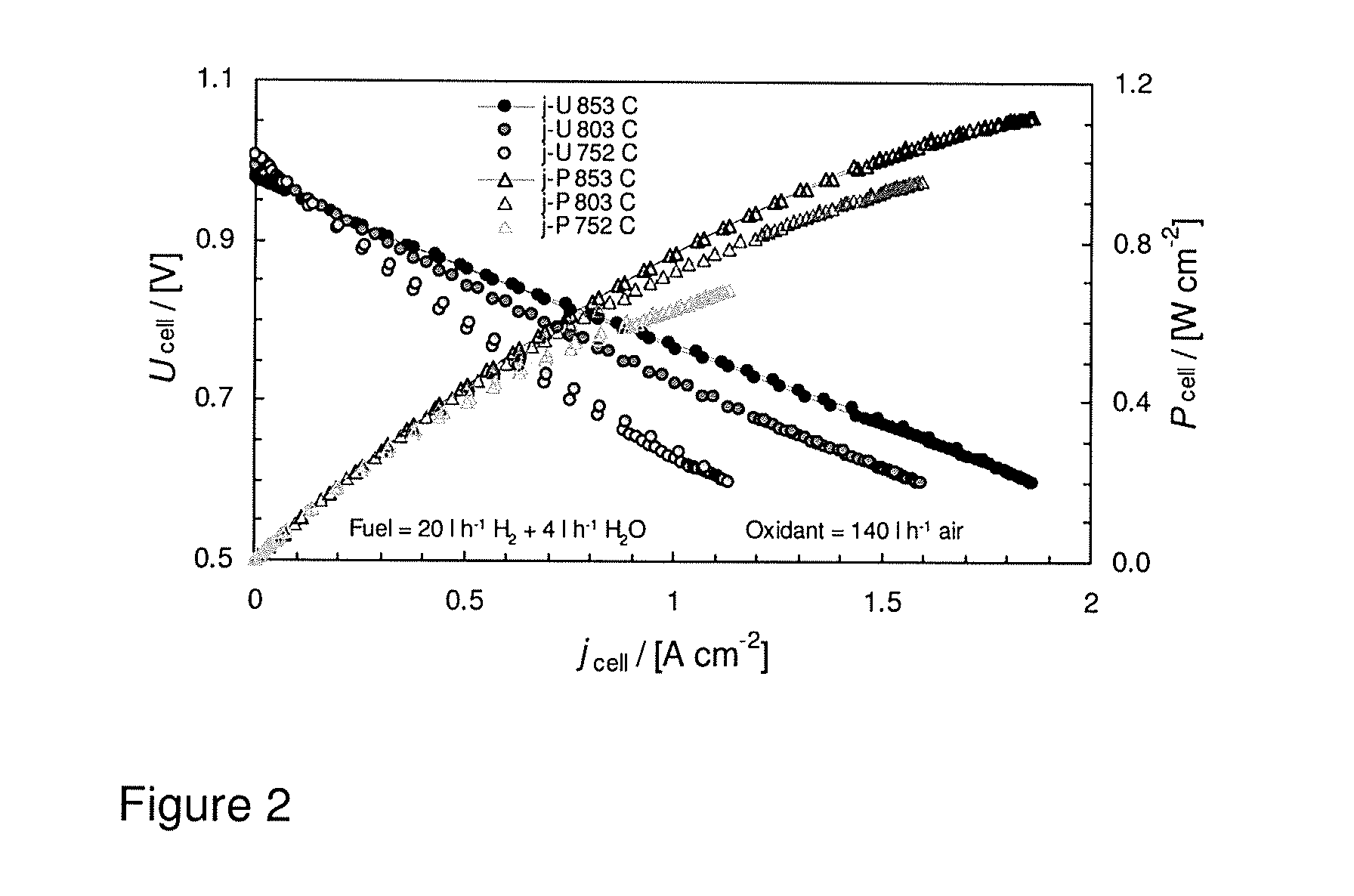

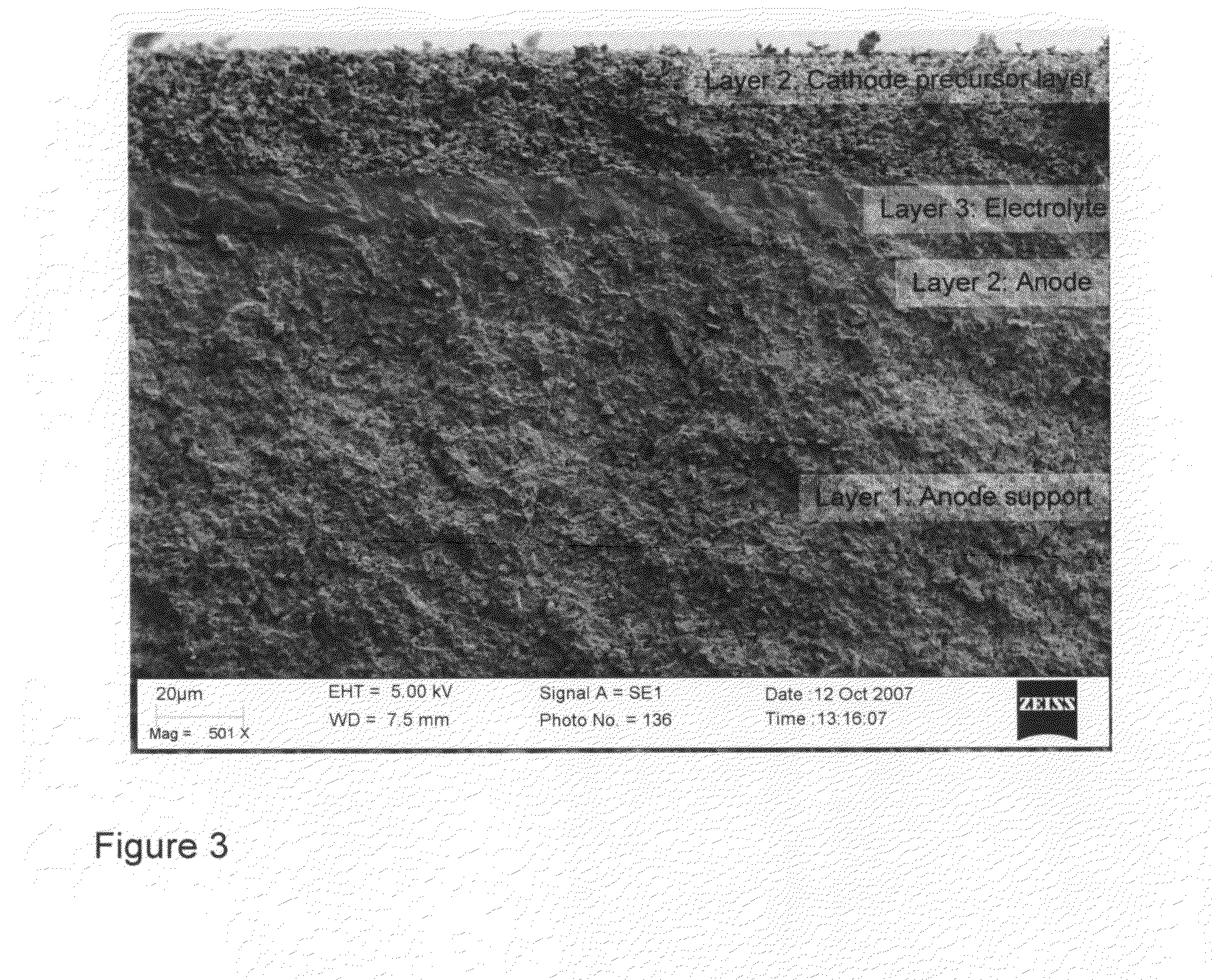

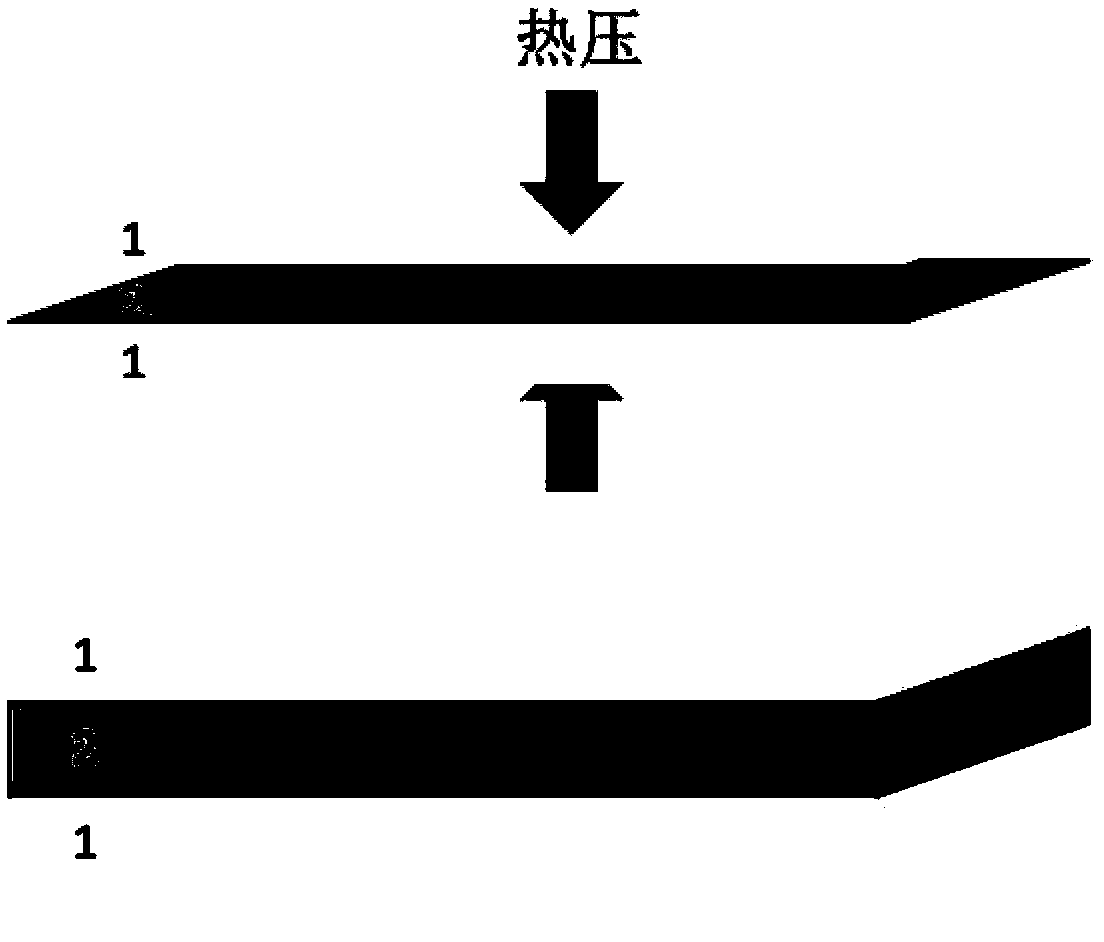

Method for the manufacture of reversible solid oxide cells

InactiveUS20080124602A1Lamination ancillary operationsFinal product manufactureOptoelectronicsElectrolyte

A method of producing a reversible solid oxide cell. The method includes the steps of tape casting an anode support layer on a support (1); tape casting an anode layer on a support (2); tape casting an electrolyte layer on a support (3); and either laminating said anode layer on top of said anode support layer; removing said support (2) from said anode layer; laminating said electrolyte layer on top of said anode layer; and sintering the multilayer structure; or laminating said anode layer on top of said electrolyte layer; removing said support (2) from said anode layer; laminating said anode support layer on top of said anode layer; and sintering the multilayer structure.

Owner:DANMARKS TEKNISKE UNIV

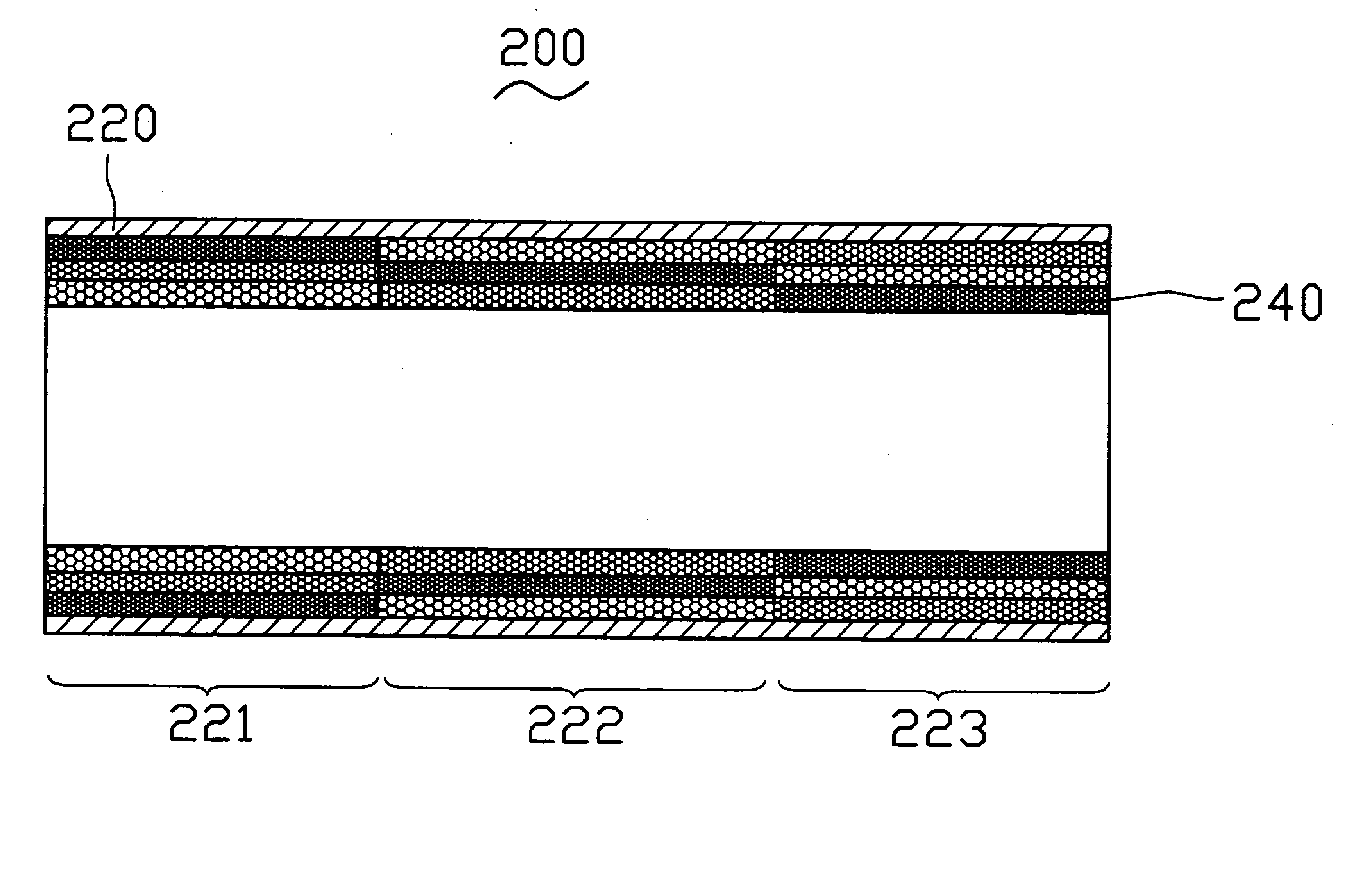

Laminated-structure polymer-based dielectric energy-storage composite material and preparation method thereof

ActiveCN104044318ALow breakdown field strengthImprove electrical polarization characteristicsInorganic material artificial filamentsSynthetic resin layered productsFiberComposite film

The invention discloses a laminated-structure polymer-based dielectric energy-storage composite material and a preparation method thereof. The composite material is a laminated thin film having at least three thin film layer structures. The laminated thin film is formed by a composite membrane, composed of nanometer fibers and a polymer, and a composite membrane, composed of nanometer particles and a polymer, in an alternately laminated manner. According to the invention, a tape casting method is employed for manufacturing a single-layer composite thin film and then a laminated hot-pressing method is employed for manufacturing the laminated composite material, or a multistage tape casting method is employed for flowing out multiple thin film layers successively to obtain a laminated structure. An experimental result proves that the laminated composite material has a relative high dielectric constant, a relative low dielectric loss, relative high breakdown field intensity and a relative high energy-storage density. The laminated composite material is expected for being applied in an embedded capacitor, a static accumulator, a large-power capacitor and the like.

Owner:TSINGHUA UNIV

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

Biodegradation time controlled plastic film and preparation method thereof

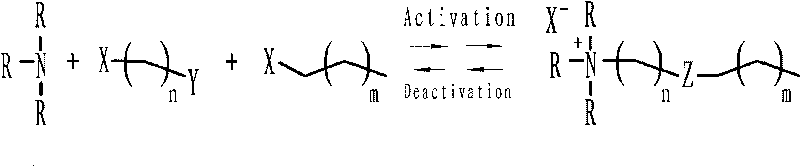

ActiveCN101735636ASimple production processCause harmFlat articlesCoatingsBlow moldingAmmonium compounds

The invention discloses a biodegradation time controlled plastic film and a preparation method thereof. The biodegradation time controlled plastic film can be prepared through a blow molding method or a tape casting method; and the biodegradation time controlled plastic film mainly comprises a degradative resin and a time controlled soft antibacterial agent. The soft antibacterial agent is a long-chain quaternary ammonium compound consisting of three parts, namely long-chain alkyl, an easily-adjusted spacer and a terminal polar group (quaternary ammonium salt), and the inactivation half-life thereof at the temperature of 60 DEG C is at least more than 3h.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

Preparation method of polyether-ether-ketone/graphene oxide nano-composite film

InactiveCN102827386ASolve the problem of fragmentationSimple processPolymer sciencePoly ether ether ketone

The invention belongs to a preparation method of a functional polymer and relates to a preparation method of a polyether-ether-ketone / graphene oxide nano-composite film. The polyether-ether-ketone / graphene oxide nano-composite film is prepared by blending graphene oxide treated by a silane coupling agent, and sulfonated polyether-ether-ketone by a tape casting method, and has high strength and good anti-wear and friction reduction effects. The polyether-ether-ketone / graphene oxide nano-composite film obtained by the preparation method solves the problem of organic and inorganic interface dispersion caused by other preparation methods, and realizes organic / inorganic nano-material compounding in a molecular level. The preparation method has simple processes, is convenient for operation, can be industrialized easily, and has potential application values in fields of structural materials, friction materials, heat-resistant materials and barrier materials.

Owner:JIANGSU UNIV

Hand-held terminal product appearance ceramic thin type member and production method thereof

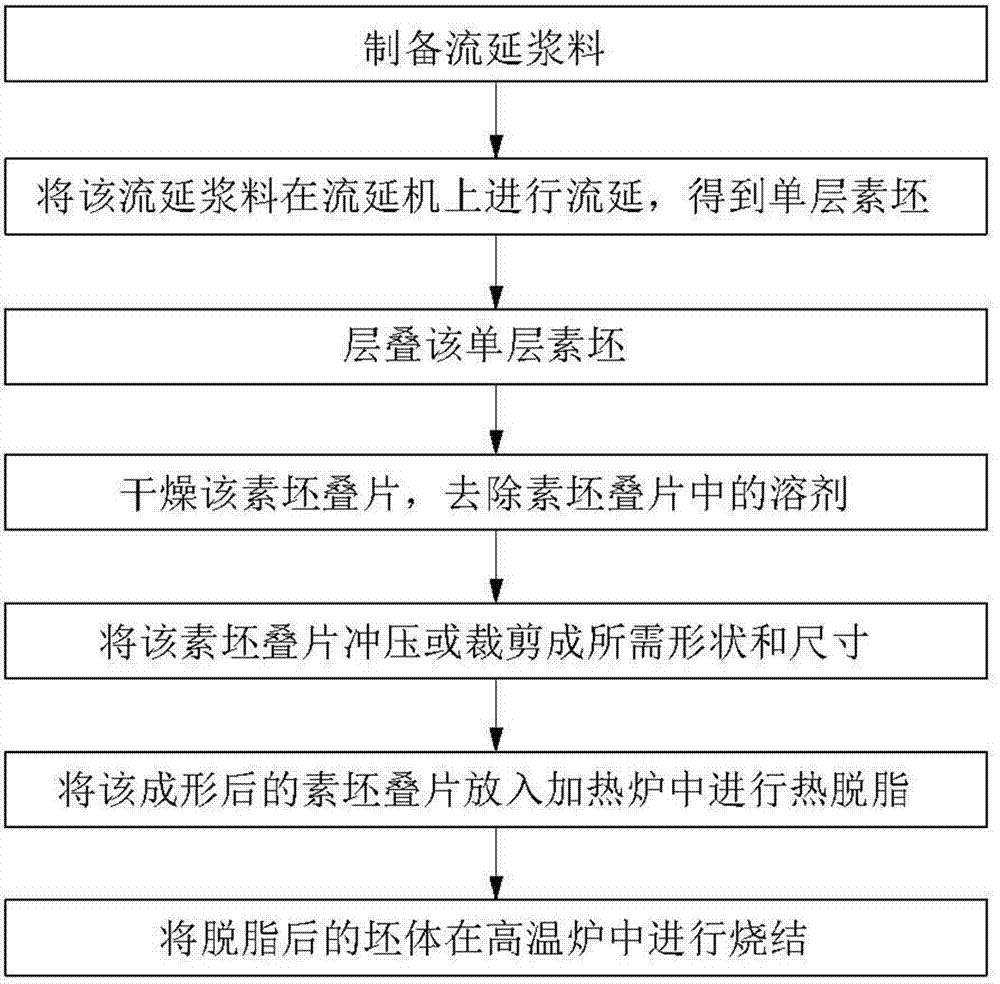

A method for making a thin ceramic part involves making a casting slurry including a ceramic powder, a solvent, a binder, a plasticizer, and a dispersant. The casting slurry is tape casted to achieve a single layer green tape. At least two single layer green tapes are laminated to form a green tape lamination. The green tape lamination is dry pressed, dried, shaped, degreased, and fired to achieve the exterior component required.

Owner:TSINGHUA UNIV +1

High temperature gas seals

A flexible seal for use in a solid oxide fuel cell stack is formed from a ceramic fibre matrix impregnated with a plurality of metallic or semi-metallic particles which are then converted to a corresponding ceramic particle, such as by oxidation. The seal may be formed by dipping the fibre matrix into a slurry, suspension or sol-gel of the particles in an alcohol, and then firing the seal to oxidize the metal particles. The seal may also be formed by tape casting a slurry formed from metallic or semi-metallic particles, ceramic fibres and / or ceramic particles.

Owner:FUELCELL ENERGY LTD

High-strength aluminum nitride ceramic substrate and manufacturing method thereof

The invention relates to a ceramic substrate and provides a high-strength aluminum nitride ceramic substrate having high bending strength and heat conductivity and a manufacturing method of the high-strength aluminum nitride ceramic substrate. The high-strength aluminum nitride ceramic substrate is prepared from tape-casting slurry by tape casting and high-temperature sintering, wherein the tape-casting slurry comprises the following components in parts by weight: 95-105 parts of aluminum nitride powder, 4-8 parts of rare earth oxide, 0.05-0.5 part of silicon-containing oxide, 40-45 parts of solvent, 1-3 parts of dispersing agent, 8-12 parts of bonding agent and 3-7 parts of plasticizer.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Screen-printed filter capacitors for filtered feedthroughs

InactiveUS7569452B2Prevent leakageAvoid spreadingAnti-noise capacitorsFeed-through capacitorsScreen printingDielectric layer

A filter capacitor comprising a pre-sintered substrate supporting alternating active and ground electrode layers segregated by a dielectric layer is described. The substrate is of a ceramic material that maintains its shape and structure dimensions even after undergoing numerous sintering steps. Consequently, relatively thin active and ground electrode layers along with the intermediate dielectric layer can be laid down or deposited by a screen-printing technique. Using a relatively thin over-glaze in comparison to a thick upper dielectric layer finishes the capacitor. Consequently, a significant amount of space is saved in comparison to a comparably rated capacitor or, a capacitor of a higher rating can be provided in the same size as a conventional prior art capacitor. The pre-sintered ceramic substrate is used instead of conventional tape cast technology for the base dielectric.

Owner:WILSON GREATBATCH LTD

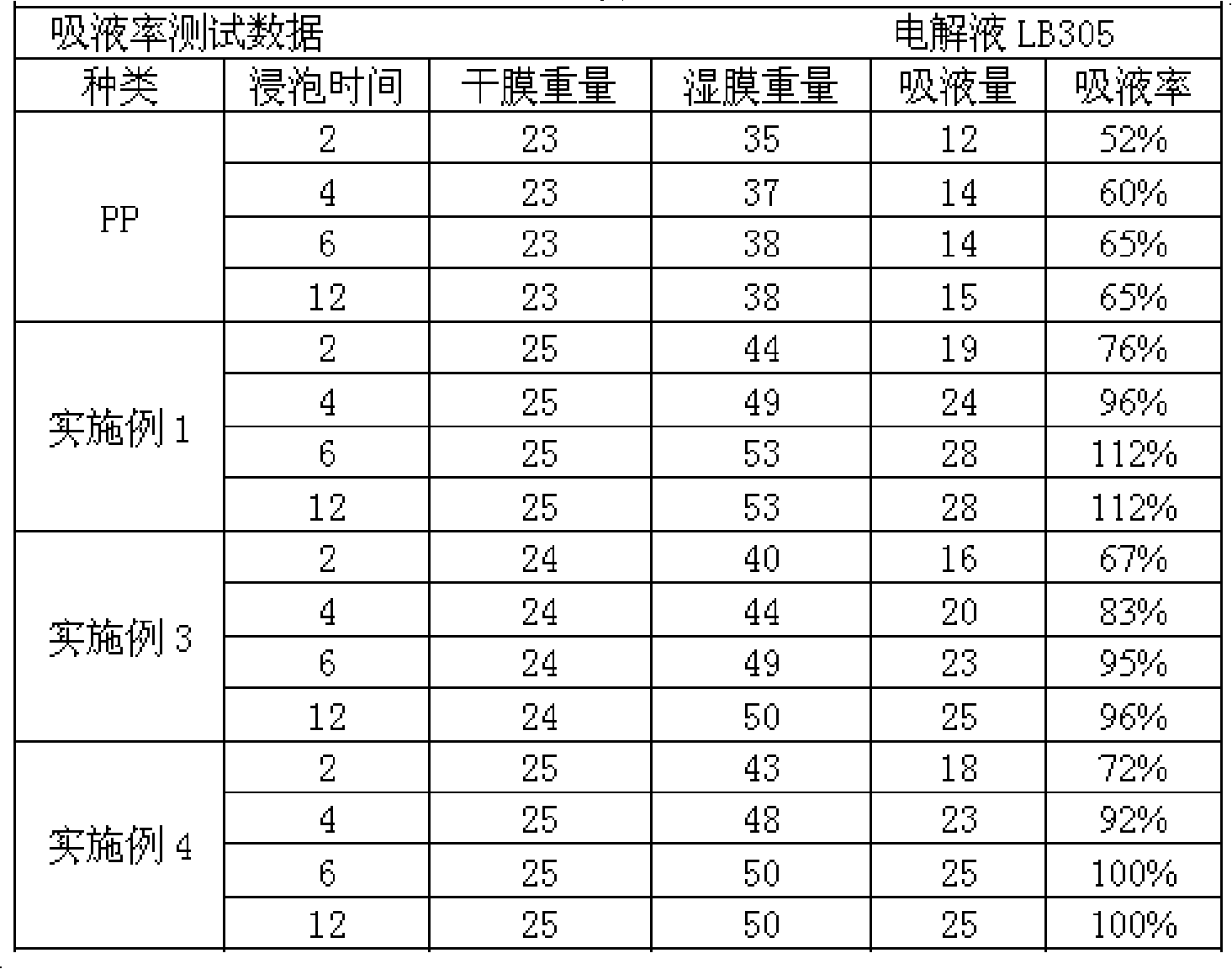

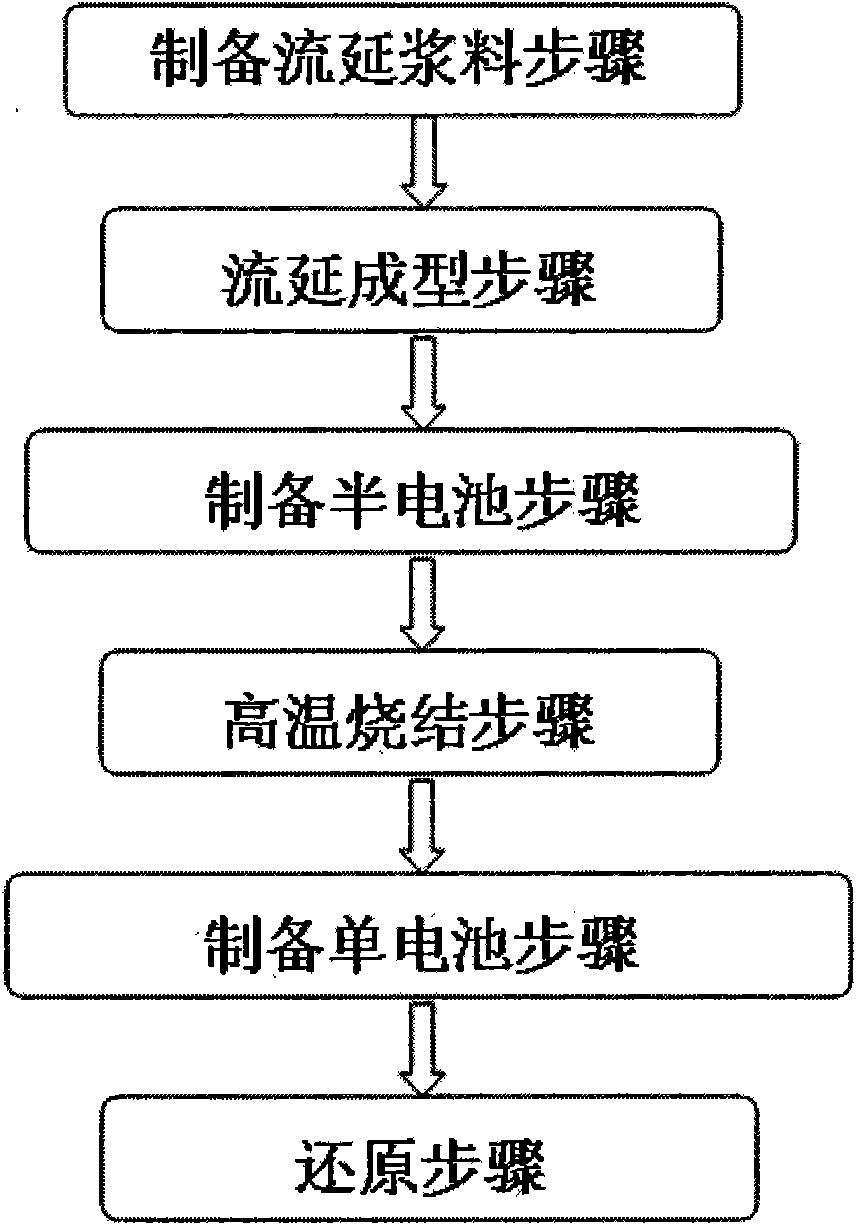

Microporous polymer isolating film for Li-ion battery and method for producing the same

ActiveCN101212036AIncrease surface areaHigh porositySolid electrolytesFinal product manufactureHydrophilic monomerPolymer science

The invention relates to a diaphragm used for power maintaining device as a lithium ion secondary battery and a preparation method thereof, which belongs to a field of manufacturing battery and capacitor. The diaphragm of the invention takes water as reaction medium; polymers colloid and emulsion are obtained through polymerization reaction generated by polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer with an initiator in water solution; by adopting tape-casting and coating process, the polymers colloid and emulsion are coated on a plastic baseband; the diaphragm is obtained through stripping after drying. The diaphragm has good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability; and the prepared lithium ion battery is characterized by good cycle stability and long service life.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

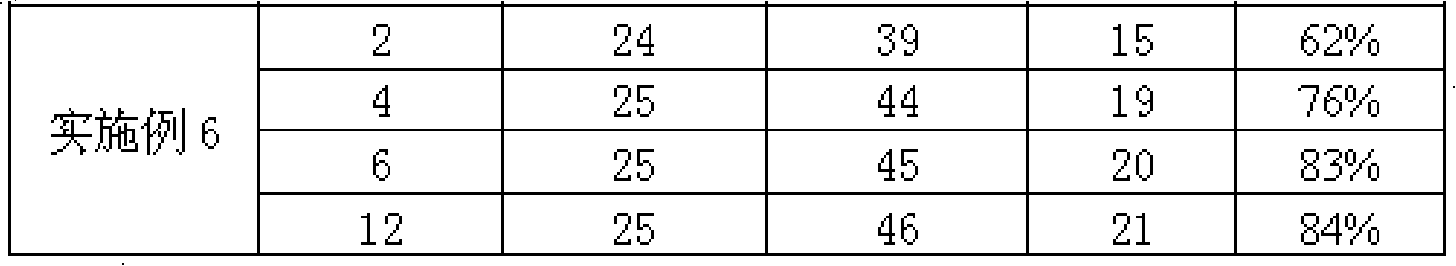

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

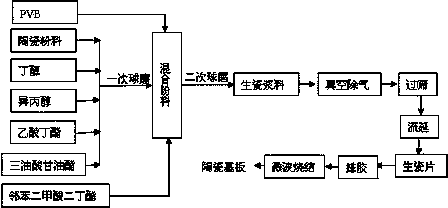

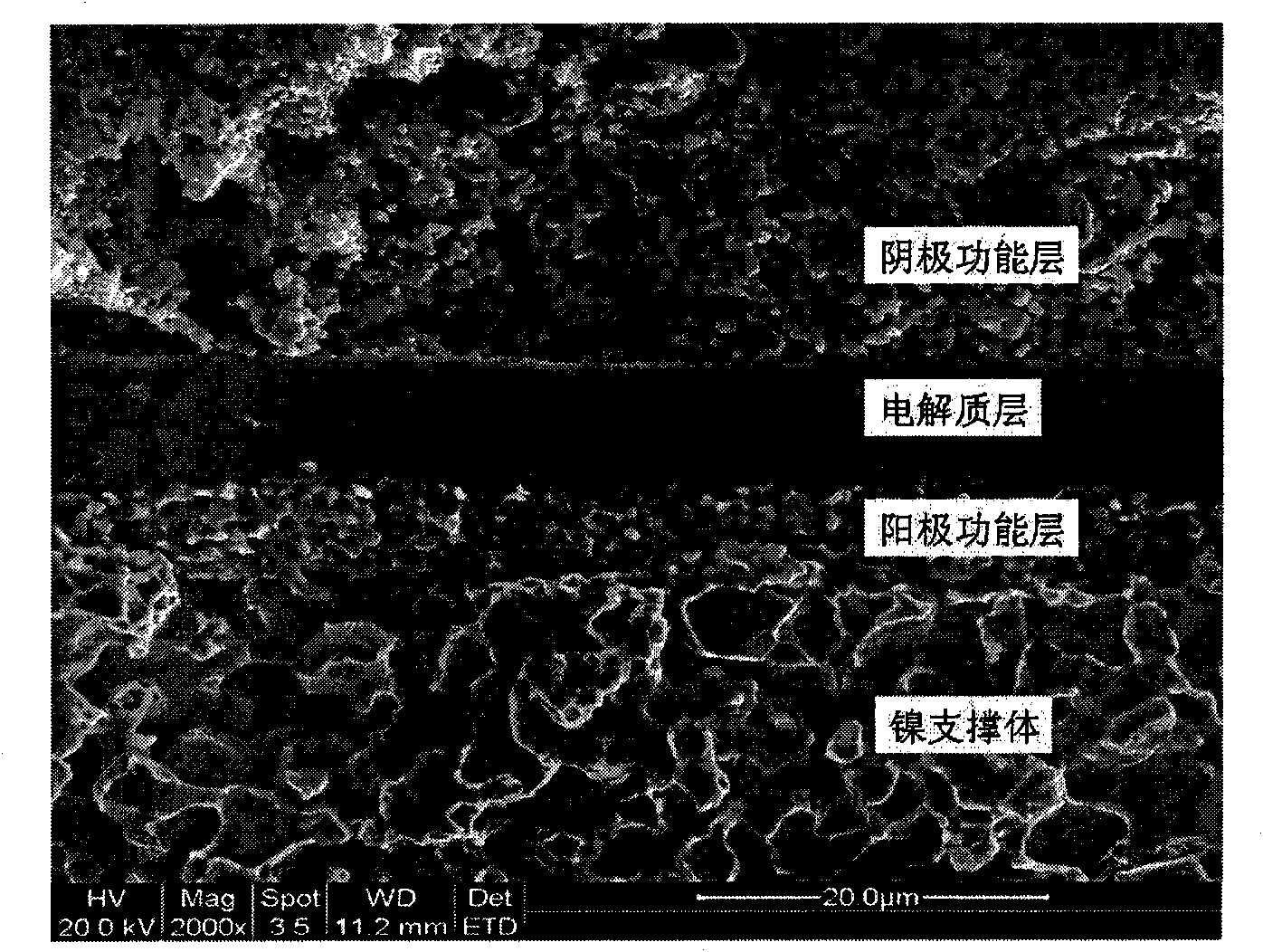

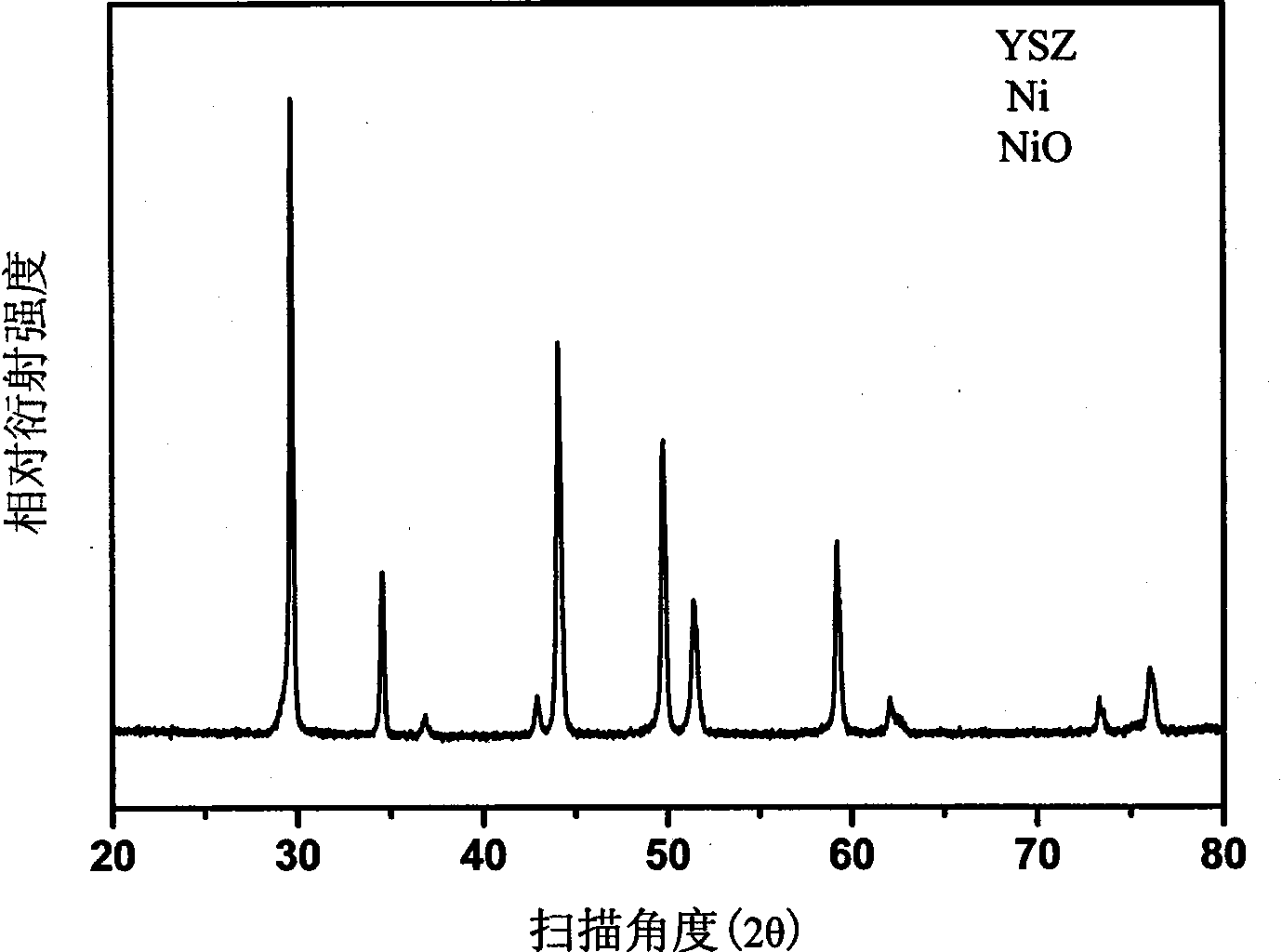

Method for preparing metallic support type solid oxide fuel cell

InactiveCN101562255AAvoid defects such as crackingAvoid cathodic activity reductionFinal product manufactureSolid electrolyte fuel cellsFuel cellsSlurry

The invention provides a method for preparing a metallic support type solid oxide fuel cell, and belongs to a method for preparing a solid oxide fuel cell (SOFC). The invention aims to simplify process, lower cost and prepare the fuel cell with excellent electric property. The method comprises the following steps: (1) a tape casting slurry preparation step; (2) a tape casting formation step; (3) a half cell preparation step; (4) a high-temperature sintering step; (5) a monocell preparation step; and (6) a reducing step. The method has the advantages of wide raw material source, simple preparation process and low cost; and the open-circuit voltage of the prepared SOFC, which is measured at a temperature of 750 DEG C, is 1.01V, the maximum power density is 0.64w / cm, so that the SOFC can be applied to the preparation of the large-area metallic support type solid oxide fuel cell.

Owner:中博源仪征新能源科技有限公司

Low-temperature co-fired ceramic tape casting material and preparing method and application thereof

The invention relates to a low-temperature co-fired ceramic tape casting material and a preparing method and application of the low-temperature co-fired ceramic tape casting material. The low-temperature co-fired ceramic tape casting material comprises, by weight, 35-50% of inorganic-phase components and 50-65% of organic-phase components. The inorganic-phase components include borosilicate glass powder and aluminum oxide ceramic powder, wherein the weight ratio of the borosilicate glass powder to the aluminum oxide ceramic powder is 2:3-3:2, and the borosilicate glass powder includes CuO which accounts for less than 3% of the power in weight. The organic-phase components include a solvent, an adhesion agent, a plasticizing agent and a dispersing agent, wherein the solvent is an alcohol-ester mixed solvent, and alcohol accounts for 20-70% in the mixed solvent in weight.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

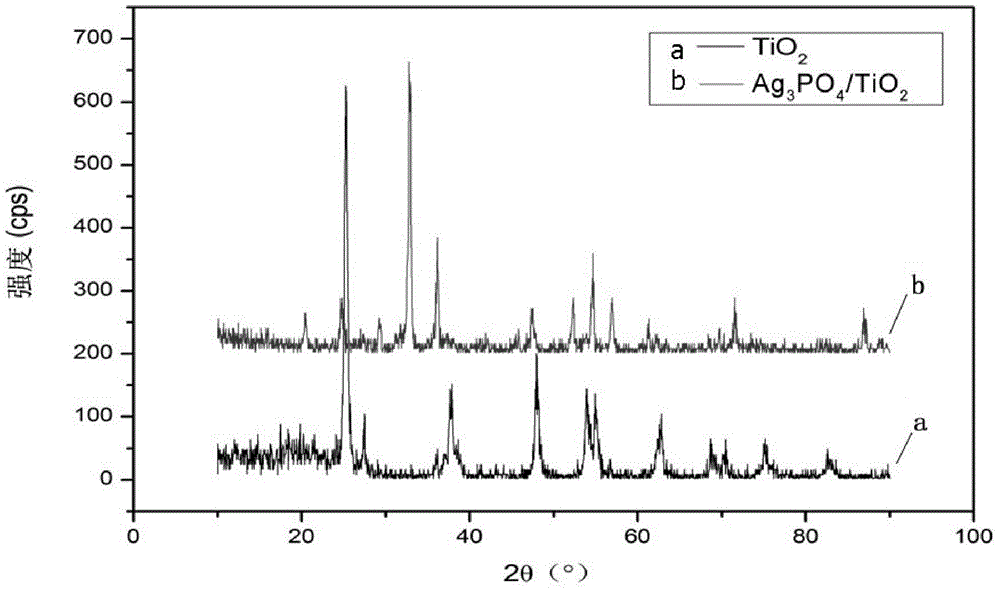

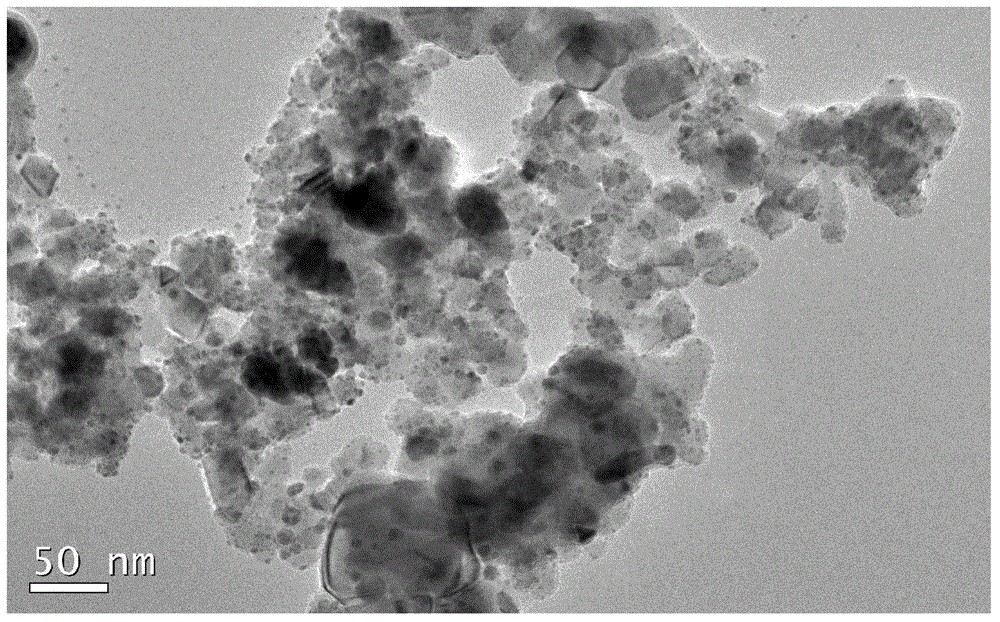

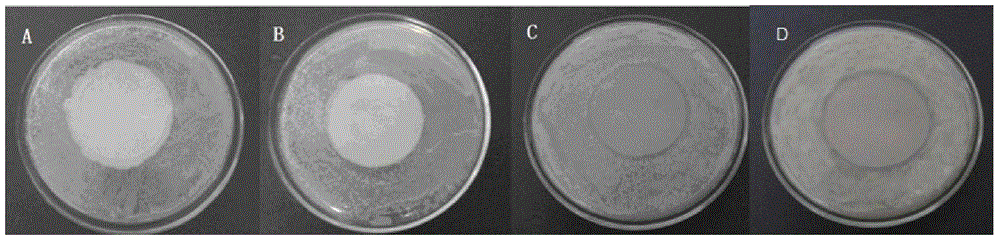

Visible-light-response antibacterial and antifouling polyvinylidene fluoride film and preparation method thereof

InactiveCN104383820AWith visible light catalytic antibacterial and antifouling propertiesEasy to manufactureSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsModified ultrafiltrationGlass sheet

The invention belongs to the technical field of modified ultrafiltration films, and discloses a visible-light-response antibacterial and antifouling polyvinylidene fluoride film and a preparation method thereof. The preparation method comprises the following steps: firstly depositing Ag3PO4 nanometer particles on the surface of TiO2 by using a in-situ deposition method to obtain an Ag3PO4 / TiO2 compound; then dissolving polyvinylidene fluoride powder, a pore-foaming agent and the Ag3PO4 / TiO2 compound in an organic solvent, mixing to enable the polyvinylidene fluoride powder, the pore-foaming agent and the Ag3PO4 / TiO2 compound to be uniformly dispersed, and then performing decompressing defoaming to obtain a casting film solution; and finally, scraping the film by using a scraper, tape-casting the casting film solution on a clean glass plate, and immersing in a coagulating bath after standing in air to obtain the visible-light-response antibacterial and antifouling polyvinylidene fluoride film. The visible-light-response antibacterial and antifouling polyvinylidene fluoride film has double performances of hydrophilcity and bacterium and fouling resistance, and can be used for lightening the situation that the surface of the polyvinylidene fluoride is polluted when water is treated, and effectively inhibiting the growth and the reproduction of bacteria and microorganisms on the surface of the film.

Owner:SOUTH CHINA NORMAL UNIVERSITY

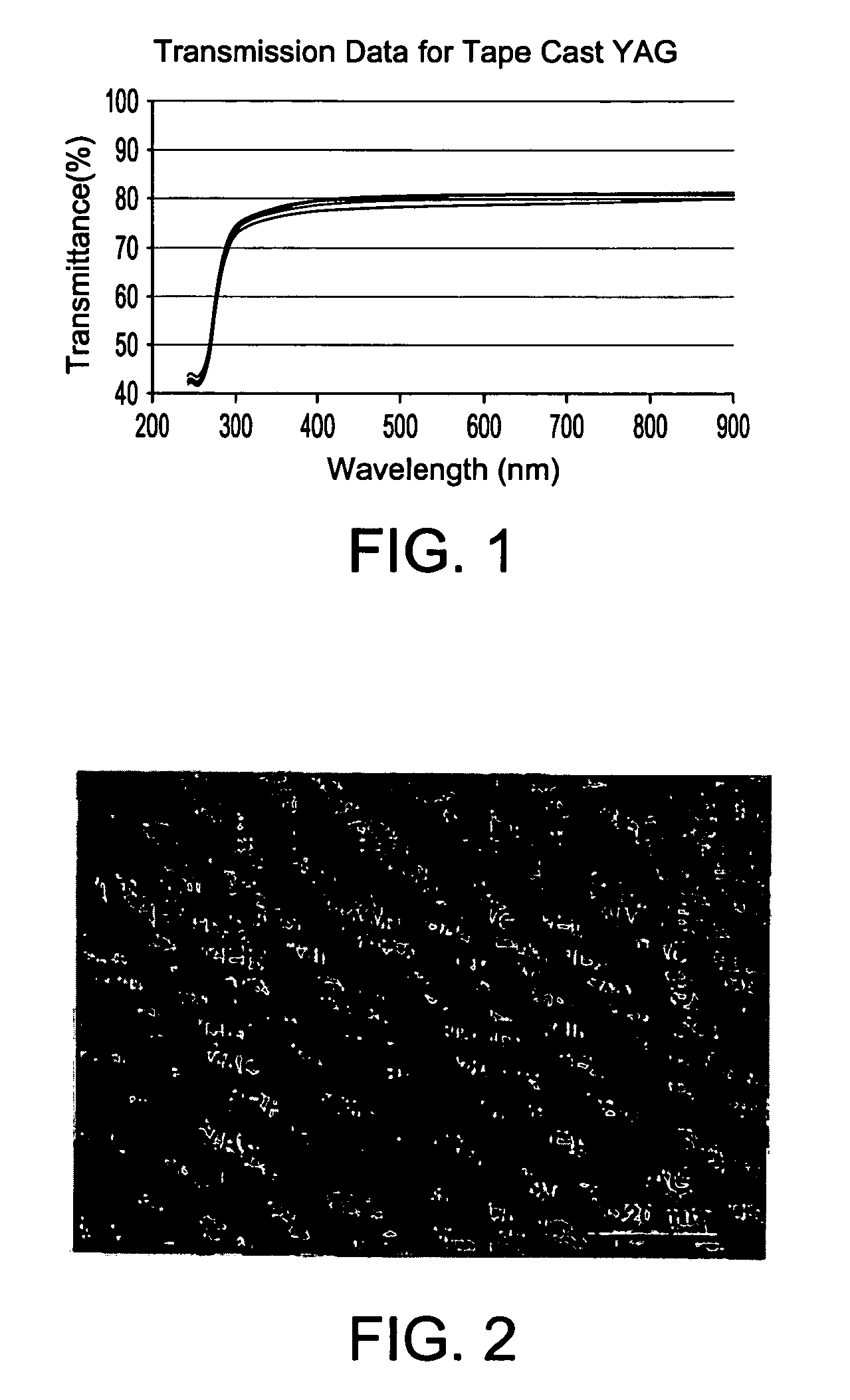

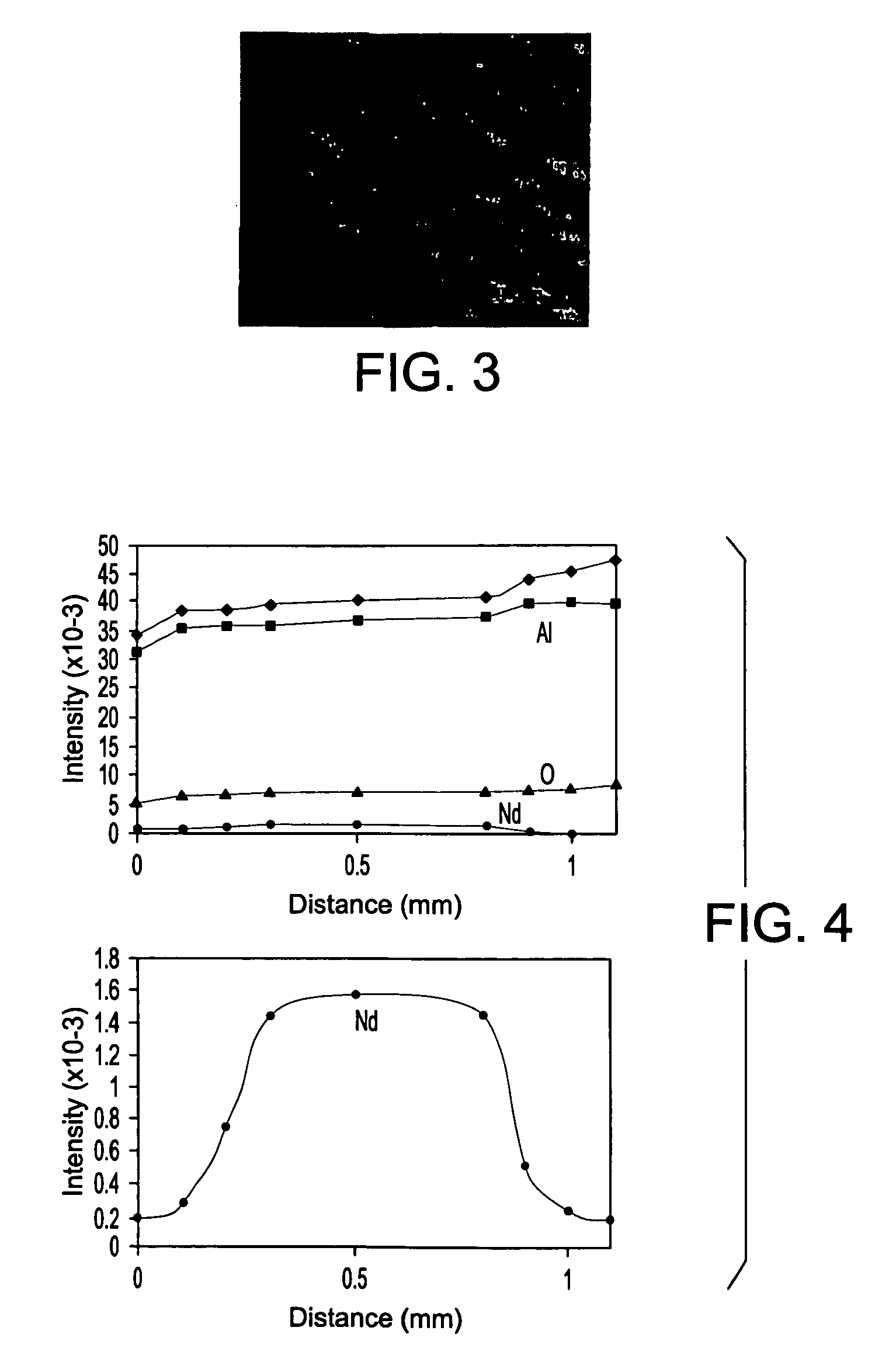

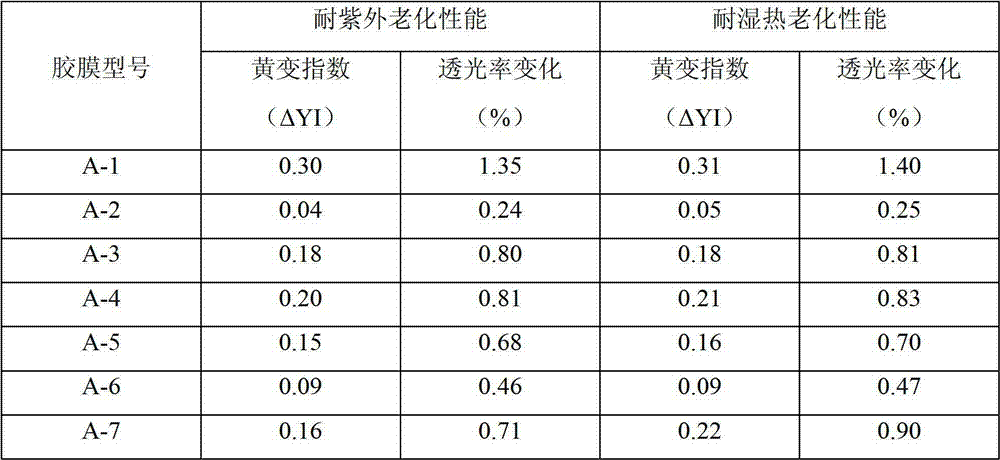

Method for manufacture of transparent ceramics

The disclosed invention relates to a method of manufacture of transparent ceramics such as yttrium aluminum garnet by tape casting. The method entails forming a mixture of ceramic oxide, dispersant and organic solvent, milling the mixture to produce a first slurry, mixing the first slurry with an organic binder and a plasticizer to form a treated slurry, milling the treated slurry to produce milled slurry, tape casting the milled slurry to produce cast tape, drying the cast tape to produce dried tape, stacking portions of dried tape to form an assembly, compressing the assembly to produce a preform, heating the preform to produce a green preform, and sintering the green preform to produce transparent yttrium aluminum garnet. The method may be used to produce a unitary ceramic product having differing transparent sections as well as transparent ceramic product having a dopant gradient across a portion of the thickness of the product.

Owner:PENN STATE RES FOUND

Method for preparing metal soft magnetic compound material by tape casting

ActiveCN104073660AHigh saturation flux densityHigh resistivityMagnetic materialsOrganic solventPlasticizer

The invention discloses a method of preparing a metal soft magnetic compound material by tape casting. The method mainly comprises the following steps: 1) mixing a passivant and a solvent according to a mass fraction of the passivant being 0.1-0.5% to obtain a passivation liquid, mixing the passivation liquid with magnetic metal powder according to a mass ratio of 0.01-1, stirring and drying to obtain passivation powder; 2) mixing the passivation powder with an organic solvent, a dispersant, a binder and a plasticizer, uniformly stirring, filtering through a screen and defoaming to prepare uniformly dispersed slurry; 3) tape casting; and 4) drying and curing. The method disclosed by the invention has the advantages that the metal soft magnetic compound material prepared by tape casting has the characteristics of high electrical resistivity and higher saturation flux density than conventional ferrite. By means of a mature tape casting process, the production process of the metal soft magnetic compound material is simplified and the cost is lowered; and the metal soft magnetic compound material has a wide application prospect in preparation of electron devices such as thin-film inductors.

Owner:ZHEJIANG UNIV +1

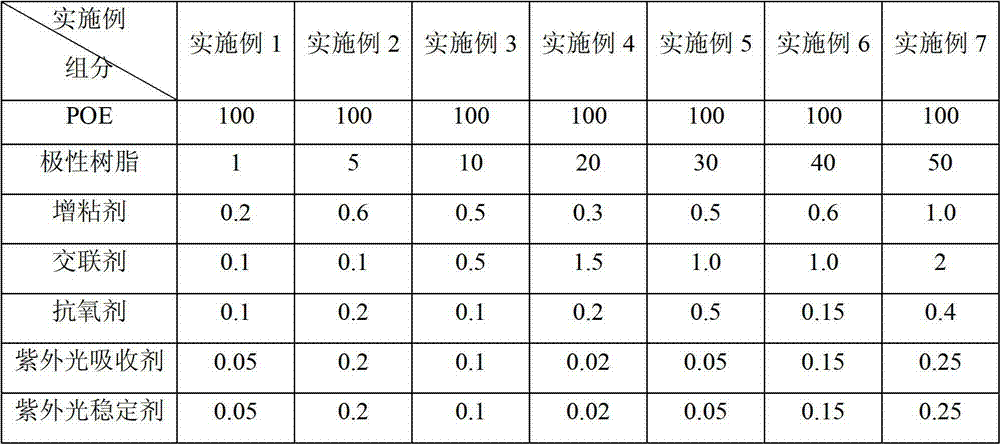

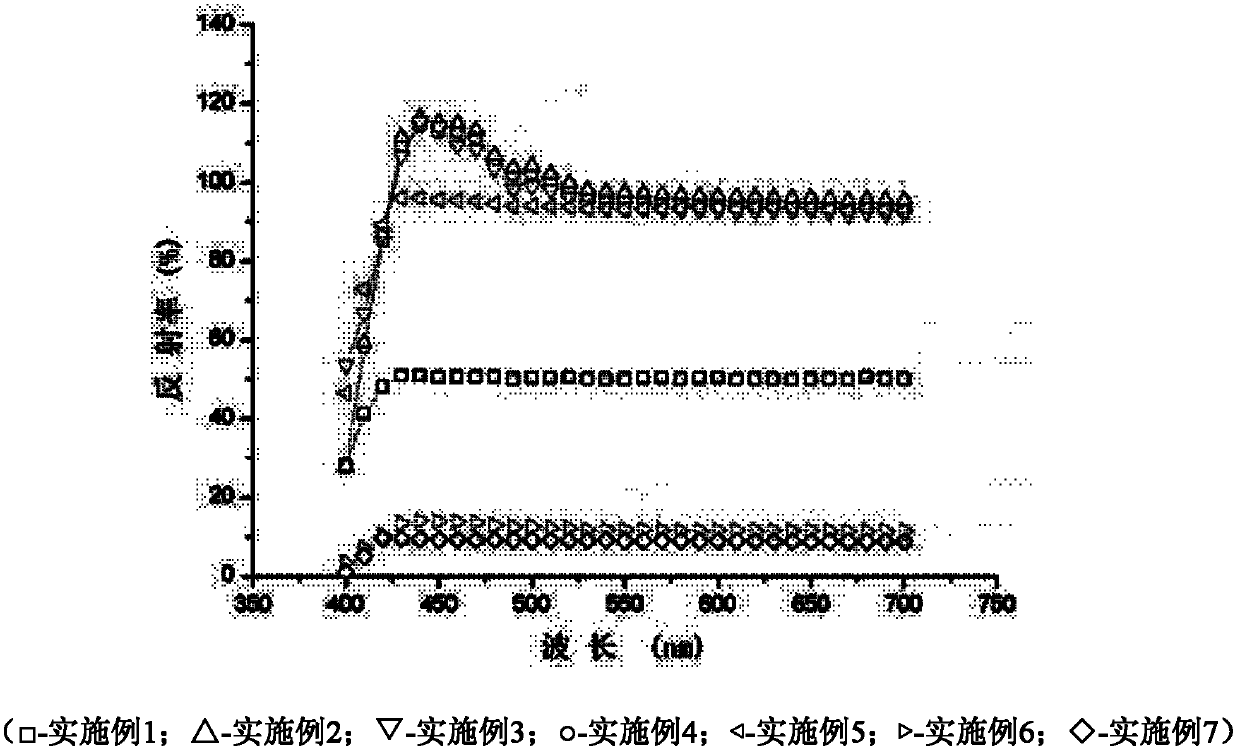

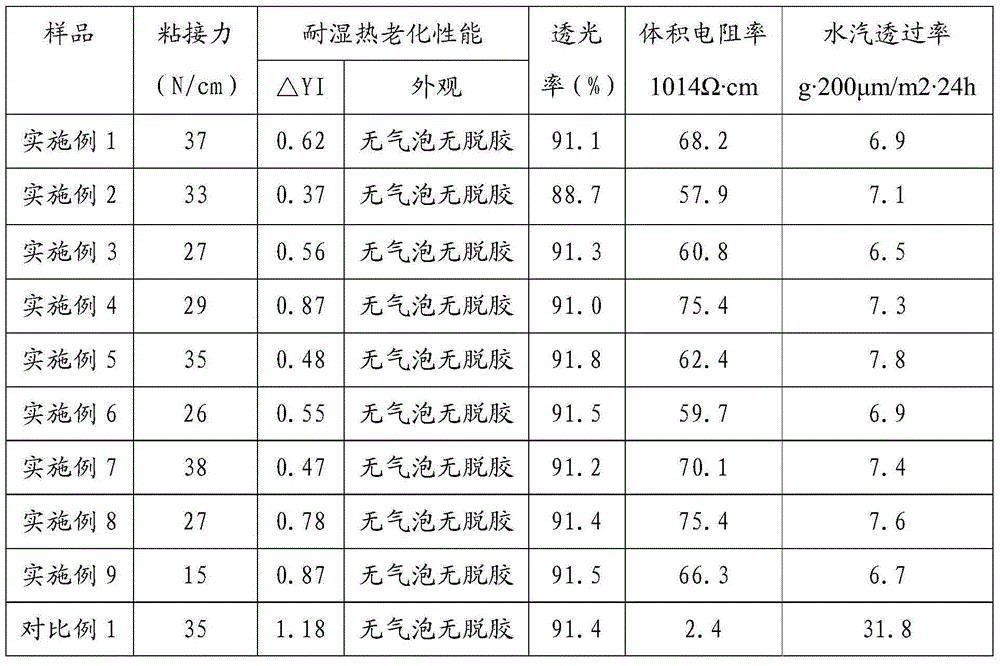

Aging-resistant glue film for packaging solar cell and preparation method for glue film

ActiveCN102876246AImprove aging resistanceImprove anti-yellowing effectNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerMelt flow index

The invention relates to an aging-resistant glue film for packaging a solar cell and a preparation method for the glue film. The glue film is prepared from the following raw materials in part by mass: 100 parts of polyethylene octene elastomer (POE), 1 to 50 parts of polarity resin, 0.1 to 1.0 part of tackifier, 0.1 to 2 parts of cross-linking agent, 0.1 to 0.5 part of antioxidant, 0.05 to 0.25 part of ultraviolet absorber, and 0.05 to 0.25 part of ultraviolet stabilizer, wherein the melt flow index of POE is 0.5 to 30g / 10min, and the light transmittance of POE is more than or equal to 80 percent; the preparation method comprises the following steps of: uniformly mixing raw materials, putting mixed raw materials into an extruder, and blending; performing tape casting on the obtained extrudate, and rolling to obtain a film; cooling and drawing for shaping; and winding to obtain the glue film. The glue film for packaging the solar cell is aging-resistant, and cannot be yellowed easily; by using the glue film, the service life of the solar cell can be prolonged; the preparation method is simple; the glue film is low in cost and can be produced on large scale; and the production efficiency is high.

Owner:宁波威克丽特功能塑料有限公司

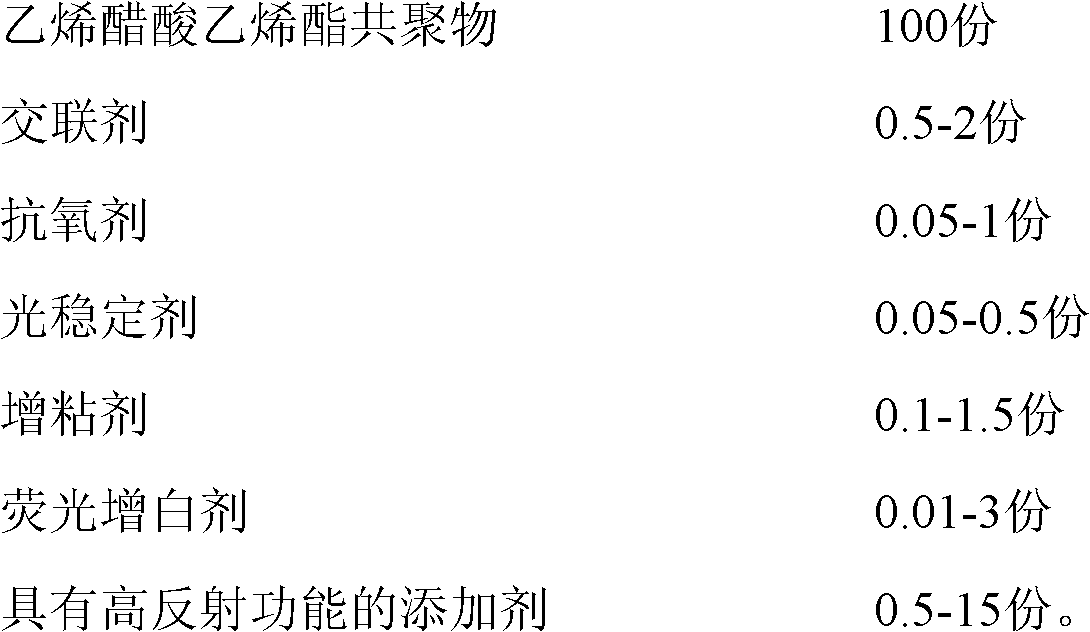

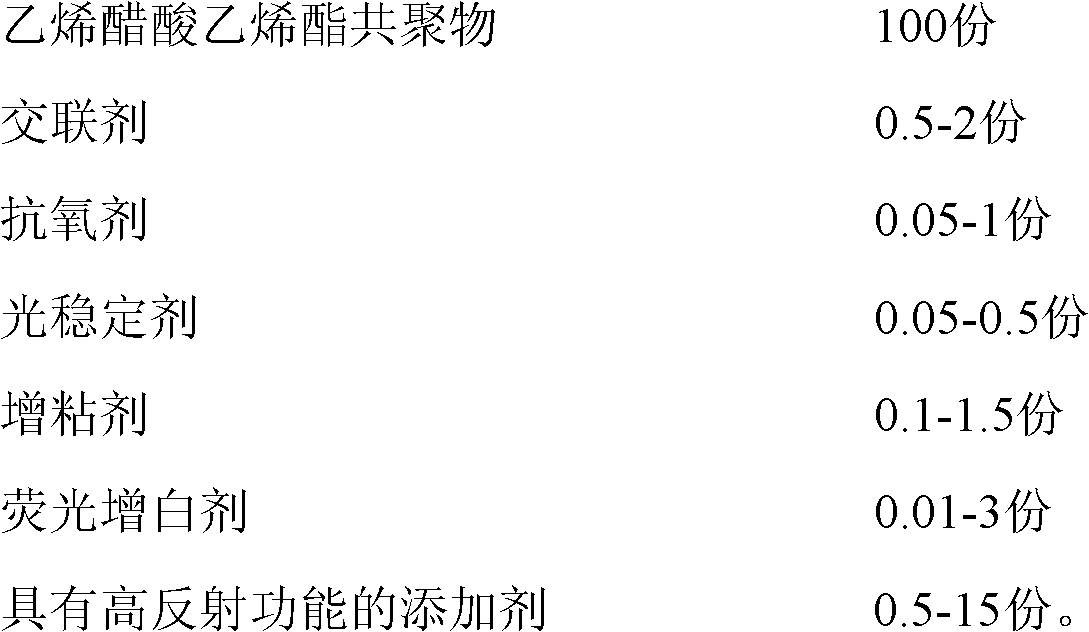

Preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition

InactiveCN102533163AImproves UV resistanceIncrease profitNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceWhitening Agents

The invention discloses a preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition, which is characterized by containing the following components by weight proportion: 100 parts of ethylene-vinyl-acetate copolymer, 0.5-2 parts of cross-linking agent, 0.05-1 part of antioxidant, 0.05-0.5 part of light stabilizer, 0.1-1.5 parts of tackifier, 0.01-3 parts of fluorescent whitening agent and 0.5-15 parts of additive with a high reflection function. The ethylene-vinyl-acetate copolymer and the other functional additives are performed with premixing, fusing extruding and tape casting or calendaring for film forming, and finally are wound up to manufacture a high reflection rate ethylene vinyl acetate copolymer (EVA) packaging glue film. The preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition does not add organic ultraviolet absorber, thereby reducing yellowing effect on the glue film caused by the ultraviolet absorber. In addition, the preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition improves yellowing resistance and ultraviolet radiation resistance of the glue film by adding fluorescent whitening agent and high reflection additive. Simultaneously, reused ratio of light rays is increased, and finally long period service life of a photovoltaic assembly can be prolonged and photoelectric conversion efficiency of the photovoltaic assembly can be improved.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Absorbable bone screw and preparation method thereof

InactiveCN102247624AImprove biological activityPromote degradationSurgeryInjection molding machineUltimate tensile strength

The invention discloses an absorbable bone screw and a preparation method thereof. The absorbable bone screw comprises: by mass, 5 to 40% of nanoscale calcium carbonate and 95 to 60% of a polylactic acid. The preparation method comprises mixing nanoscale calcium carbonate powder and a polylactic acid in a solution form, uniformly dispersing the nanoscale calcium carbonate powder in a polymer matrix through a rapid tape-casting drying method, and carrying out a molding process by an injection molding machine. The absorbable bone screw has the advantages of good biological activity and degradability, and high strength.

Owner:ZHONGAO HUICHENG TECH CO LTD

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

InactiveUS20030119656A1Improved propertyLow cost productionLayered productsFixed capacitor dielectricBreakdown strengthMicrowave

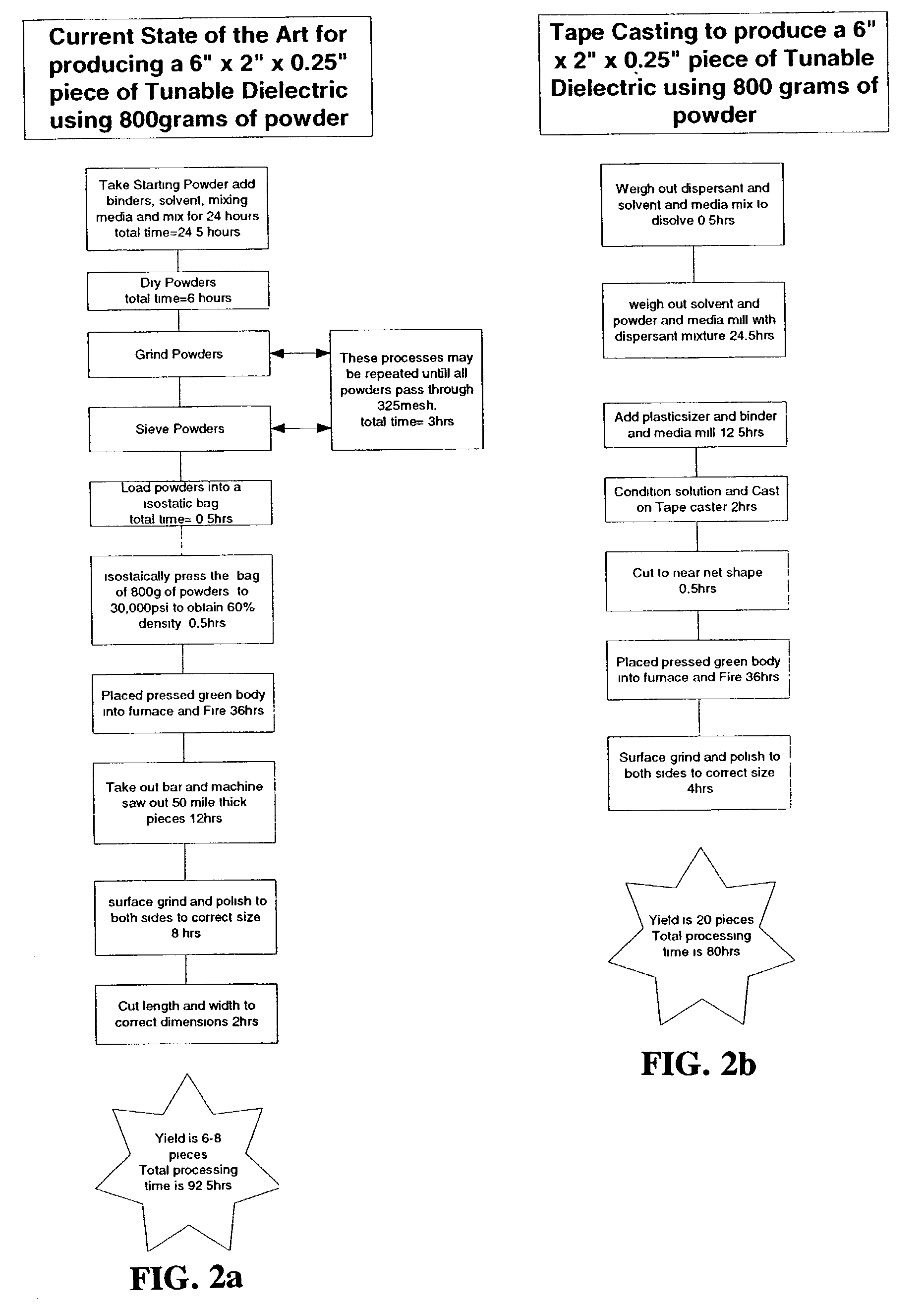

The production of low-loss, tunable composite ceramic materials with improved breakdown strengths is disclosed. The composite materials comprise ferroelectric perovskites such as barium strontium titanate or other ferroelectric perovskites combined with other phases such as low-loss silicate materials and / or other low-loss oxides. The composite materials are produced in sheet or tape form by methods such as tape casting. The composite tapes exhibit favorable tunability, low loss and tailorable dielectric properties, and can be used in various microwave devices.

Owner:NXP USA INC

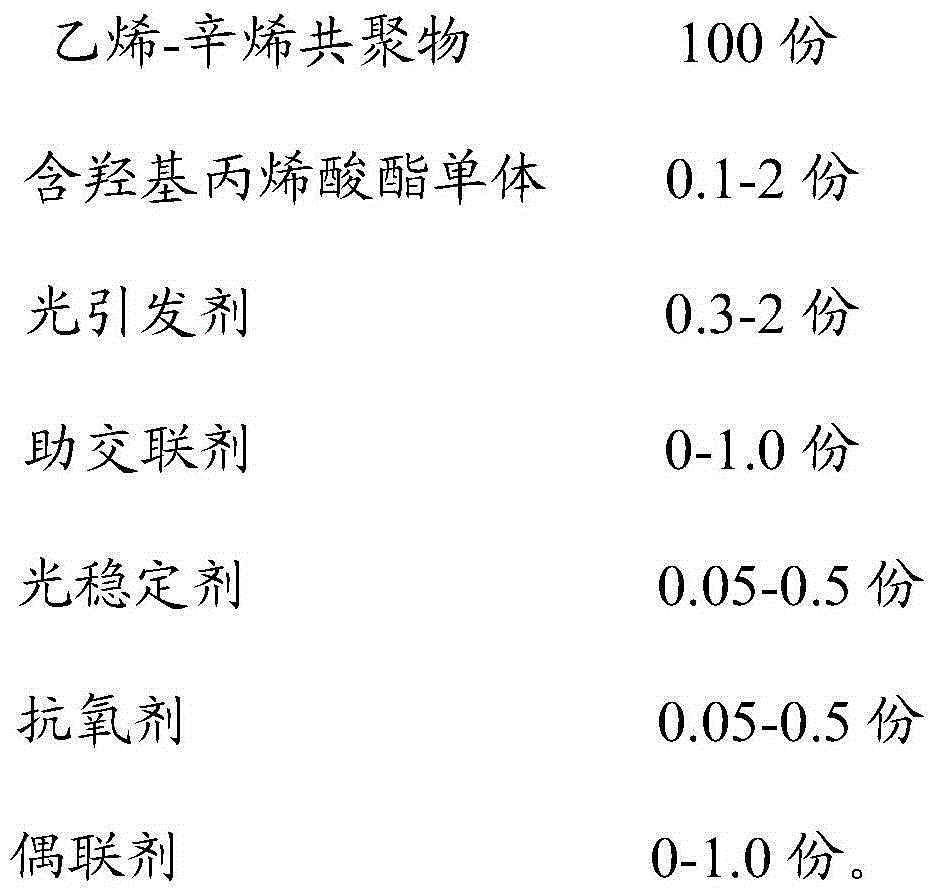

UV-curable polyolefin optical film and preparation method thereof

ActiveCN104356967ANot easy to produceSimple processNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolyolefin

The invention discloses a UV-curable polyolefin optical film and a preparation method thereof. The UV-curable polyolefin optical film is prepared by pre-mixing 100 parts by weight of an ethylene / octene copolymer, 0.1-2 parts by weight of a hydroxyl acrylic monomer, 0.3-2 parts by weight of a photoinitiator, 0-1.0 part of an assistant crosslinker, 0.05-0.5 part by weight of a light stabilizer, 0.05-0.5 part by weight of an antioxidant and 0-1.0 part of a coupling agent by a cone-shaped blender and then performing tape casting. The UV-curable polyolefin optical film and the preparation method have the advantages that the process is simple, the processing is convenient, the operation is easy, the production efficiency is high, and the prepared UV-curable polyolefin optical film not only has the characteristics of being easy to process and capable of reworking, but also has an excellent water vapor barrier property, an excellent insulating property, an excellent adhesive property and excellent non-corrosion performance. When the UV-curable polyolefin optical film is used, the curing crosslinking can be completed through special UV-irradiation after laminating and prepressing.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Polysaccharide-protein composite membrane and preparation method thereof

The invention provides a polysaccharide-protein composite membrane and a preparation method thereof. The polysaccharide-protein composite membrane is prepared from the following raw materials by mass percent: 20-80% of polysaccharide and 80-20% of protein. The method comprises the following steps: by taking plant polysaccharide as a raw material, adding soy isolate protein; carrying out tape casting to form a film after evenly mixing and reacting, and drying at high temperature, so as to obtain the composite membrane. The polysaccharide-protein composite membrane is prepared from natural renewable resources, is wide in material source, safe and non-toxic, has certain moisture-retarding and oxygen-retarding effects, and can be naturally degraded. The materials disclosed by the invention can be applied to packing materials, daily-use chemical industry and farming, forestry and gardening.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com