Patents

Literature

5722 results about "Ceramic substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curamik® high temperature/ high voltage substrates consist of pure copper bonded to a ceramic substrate such as Al2O3 (Alumina), AlN (Aluminum Nitride), HPS (ZrO2 doped) or silicon based Si3N4 (Silicon Nitride). curamik provides two technologies to attach the substrate with the copper.

System-in packages

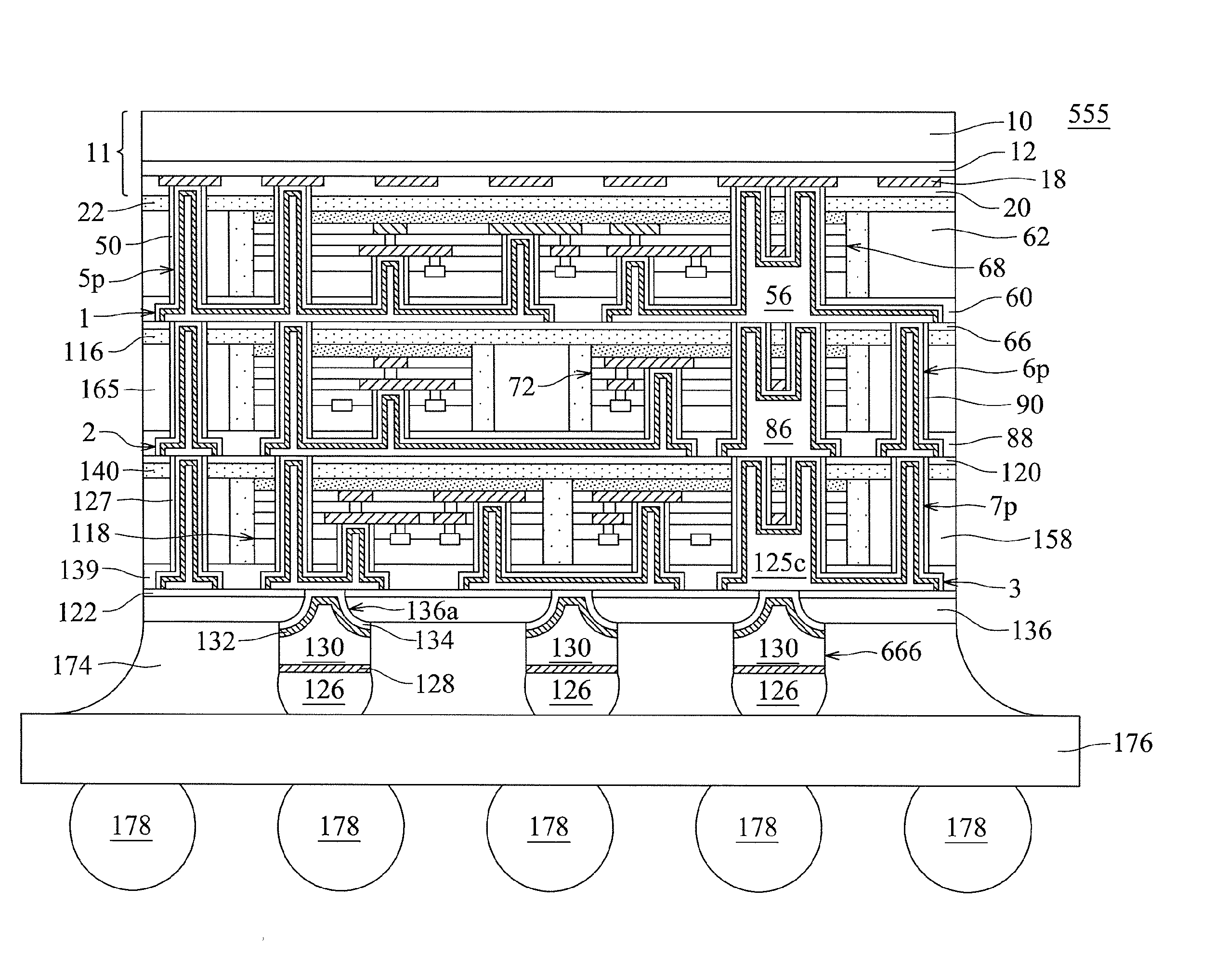

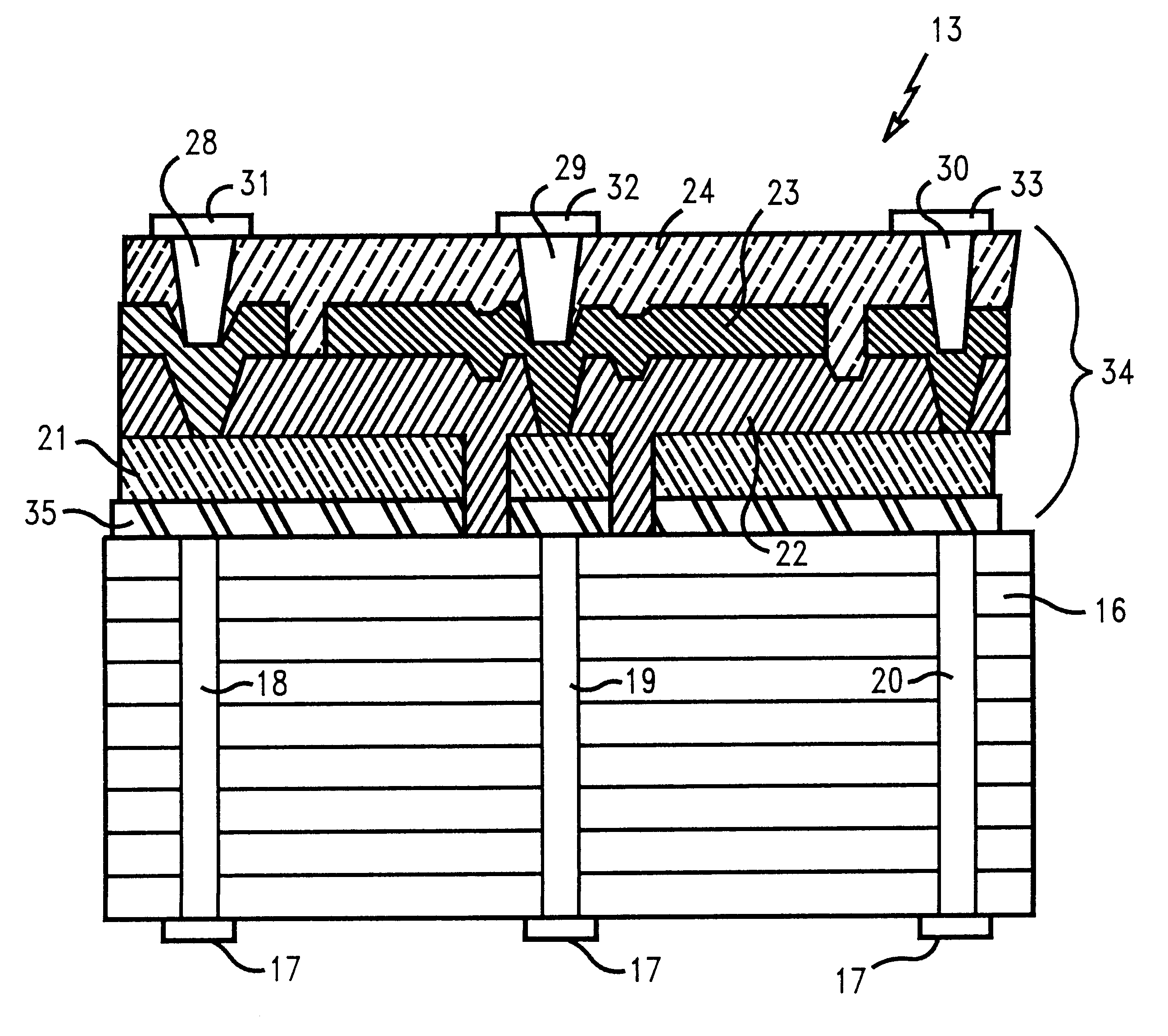

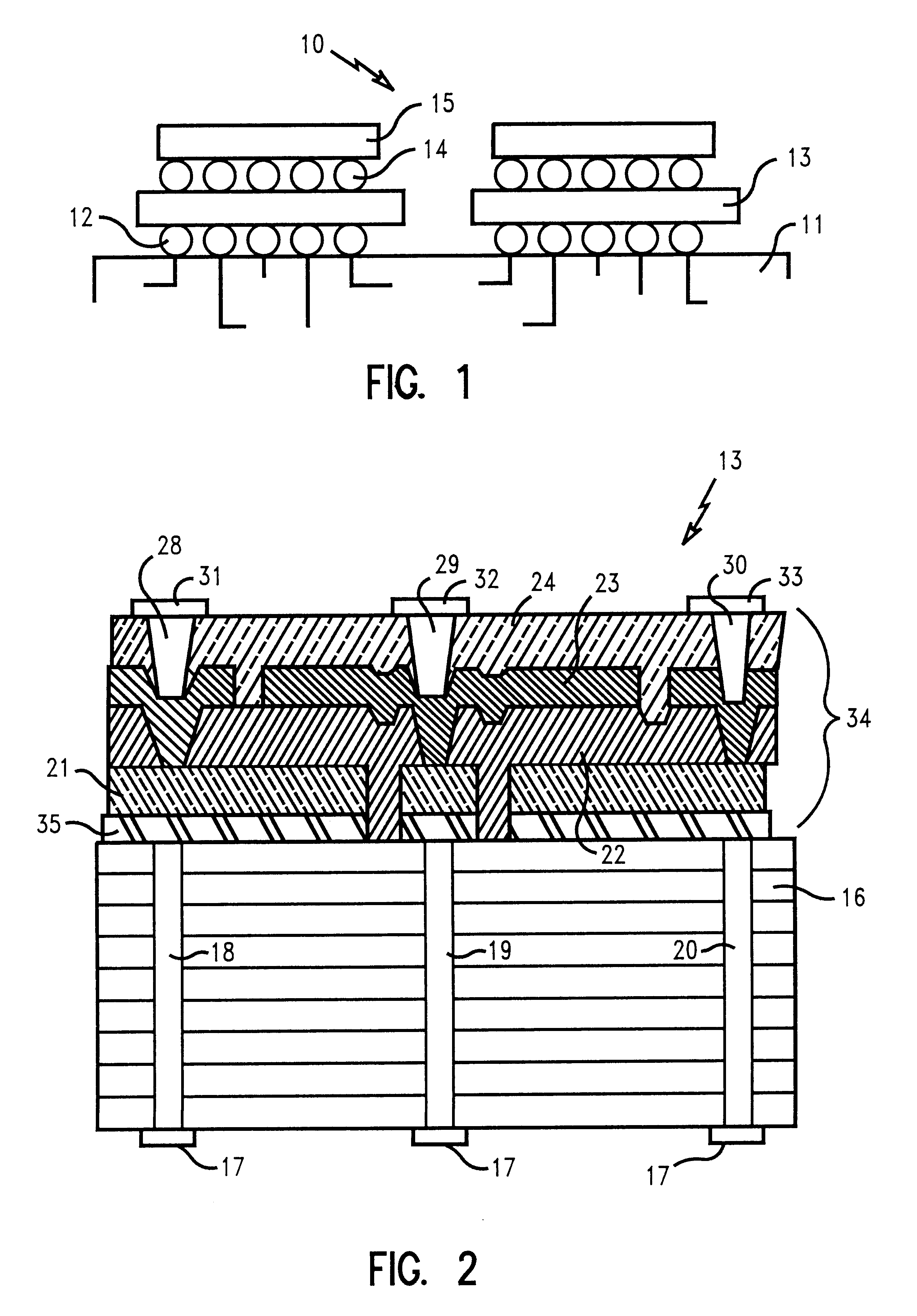

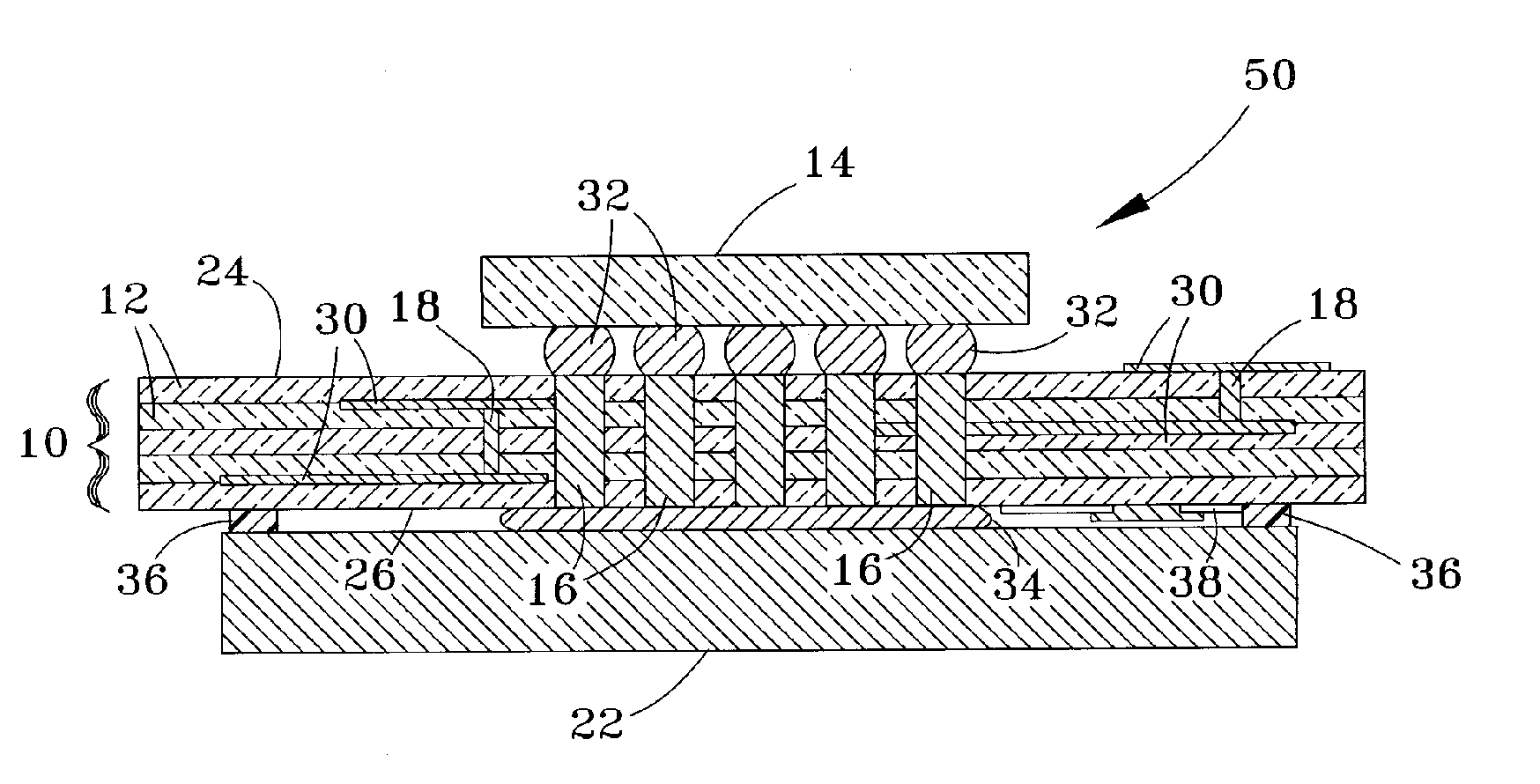

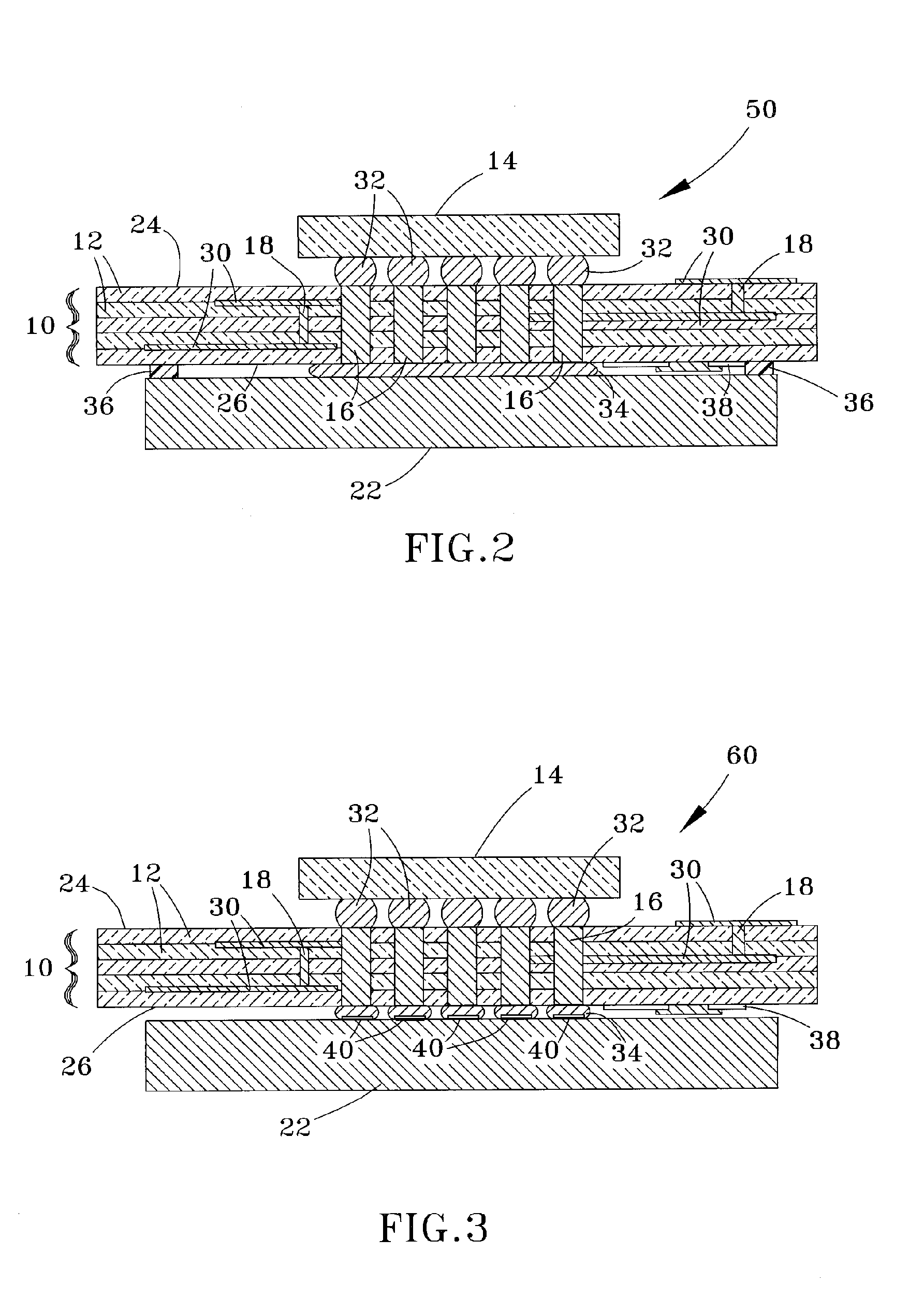

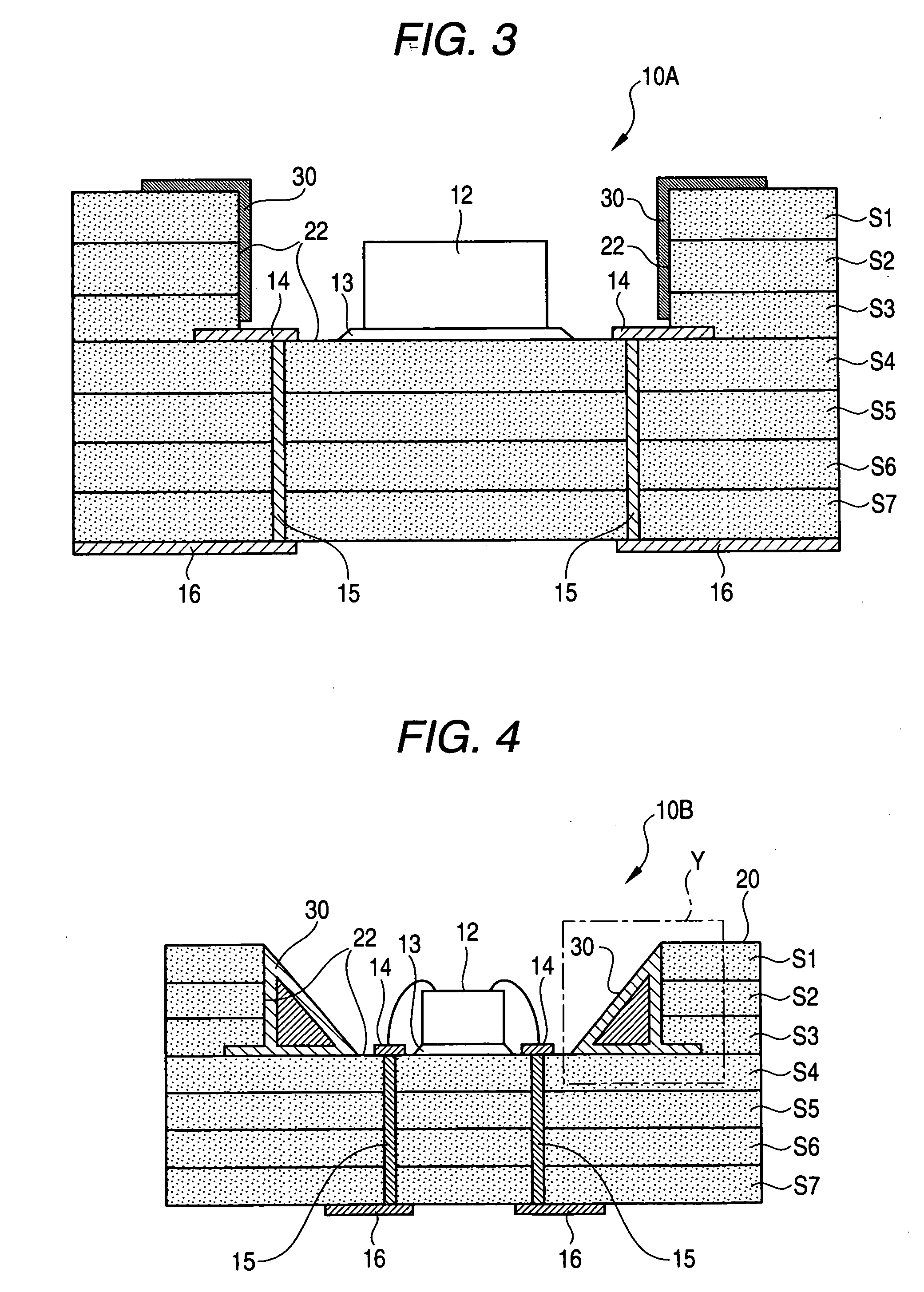

ActiveUS20110026232A1Improve uniformitySemiconductor/solid-state device detailsCircuit arrangements on support structuresMetal interconnectSystem in package

System-in packages, or multichip modules, are described which can include multi-layer chips and multi-layer dummy substrates over a carrier, multiple through vias blindly or completely through the multi-layer chips and completely through the multi-layer dummy substrates, multiple metal plugs in the through vias, and multiple metal interconnects, connected to the metal plugs, between the multi-layer chips. The multi-layer chips can be connected to each other or to an external circuit or structure, such as mother board, ball grid array (BGA) substrate, printed circuit board, metal substrate, glass substrate, or ceramic substrate, through the metal plugs and the metal interconnects.

Owner:QUALCOMM INC

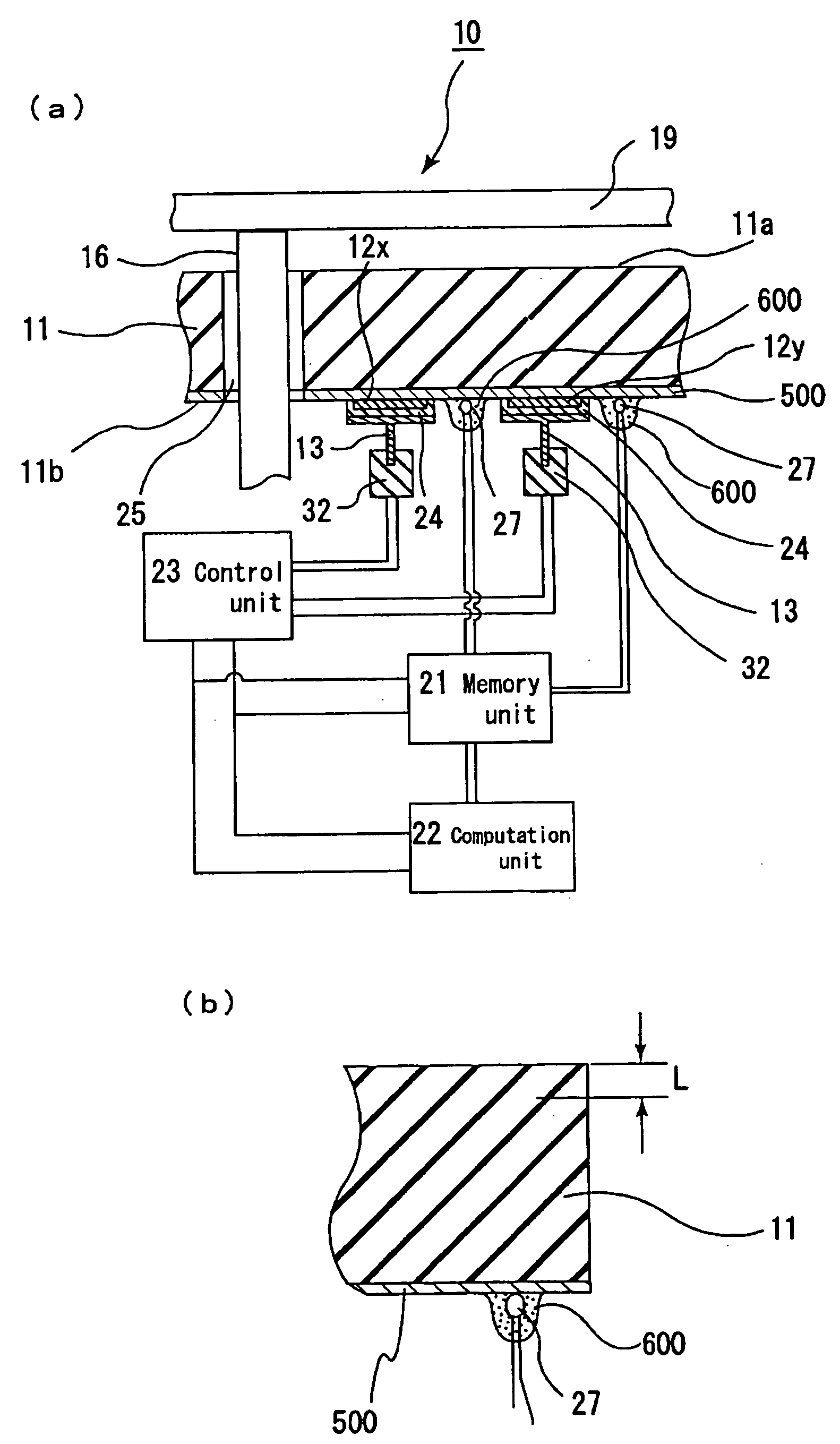

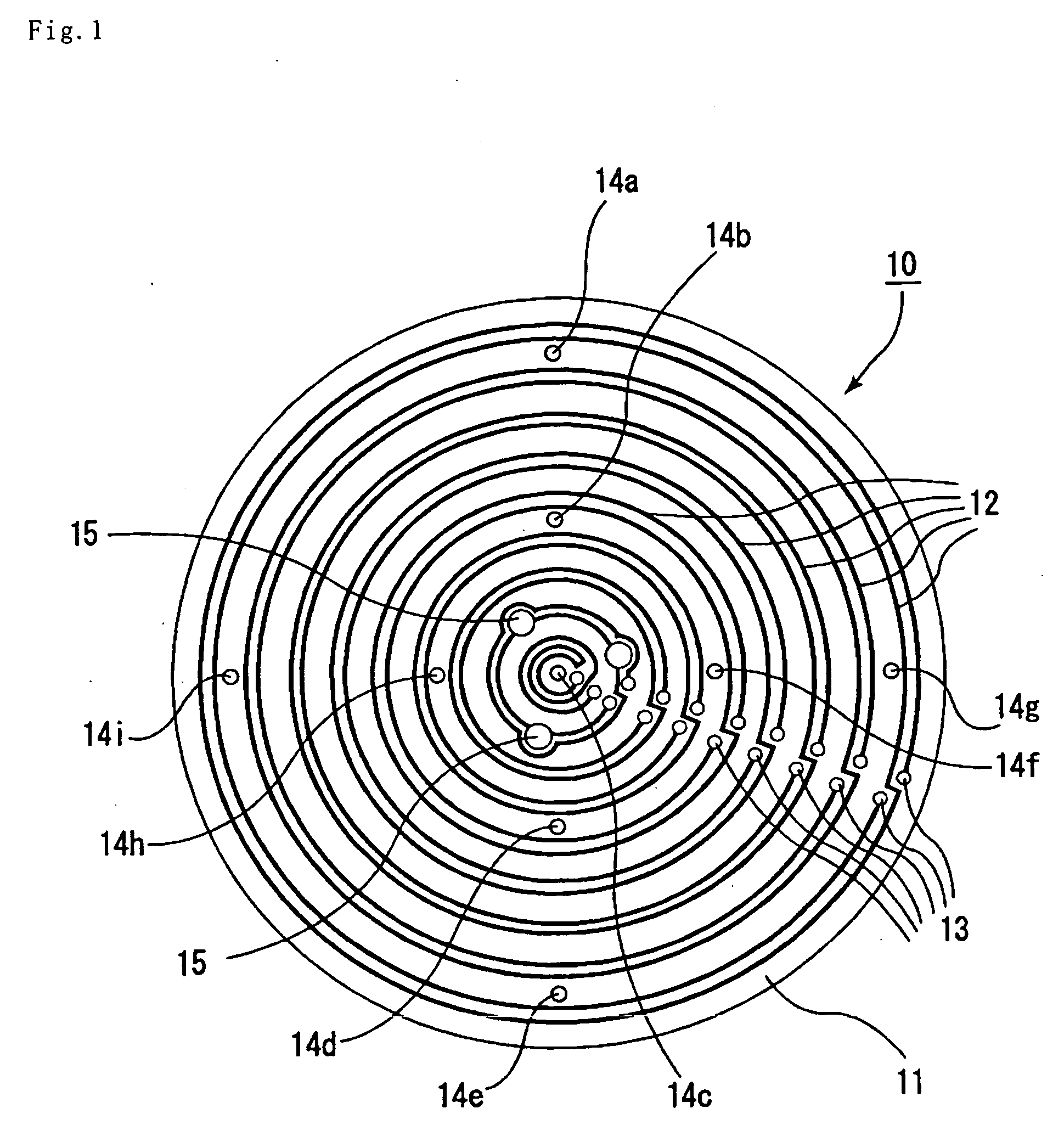

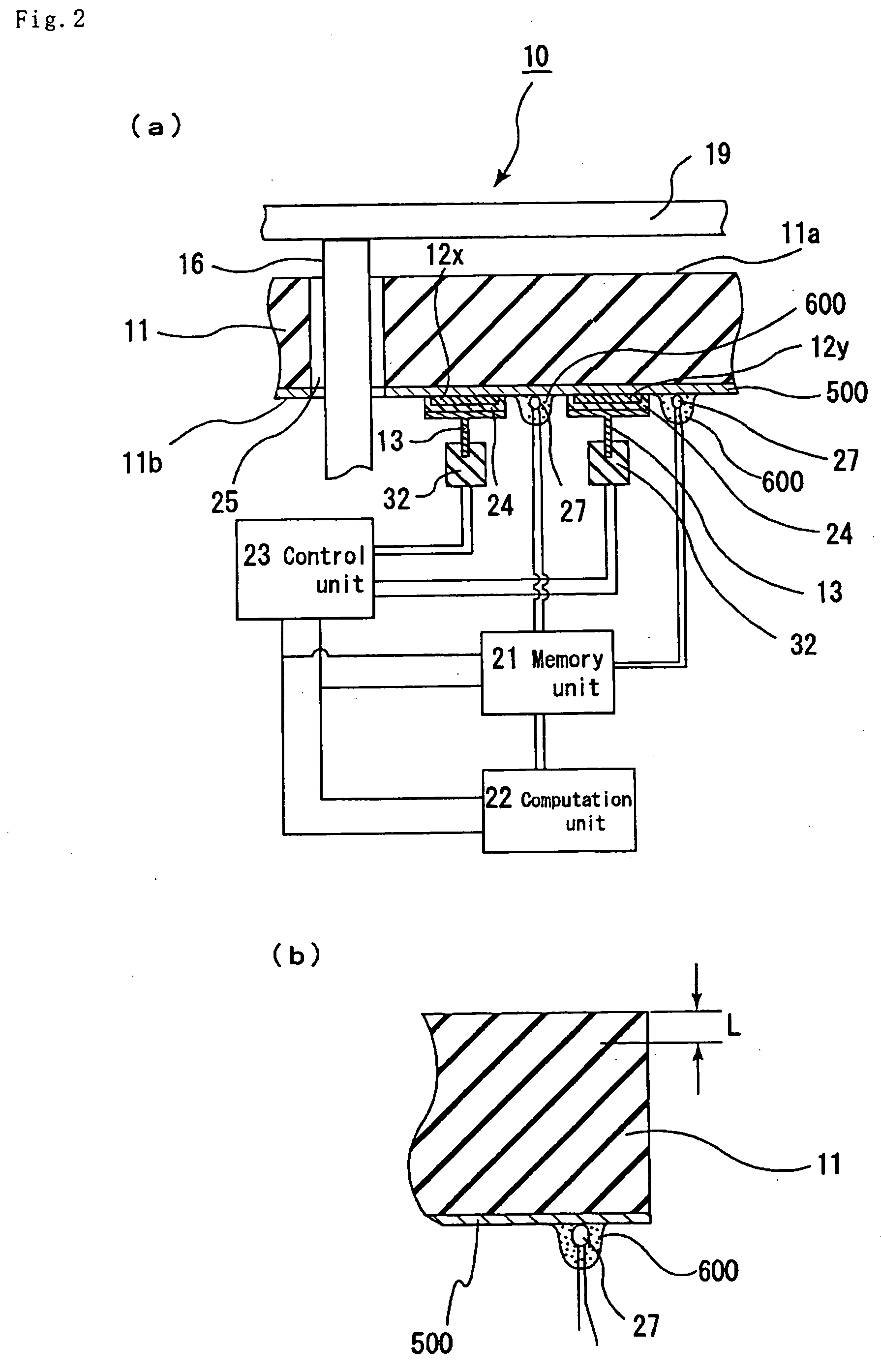

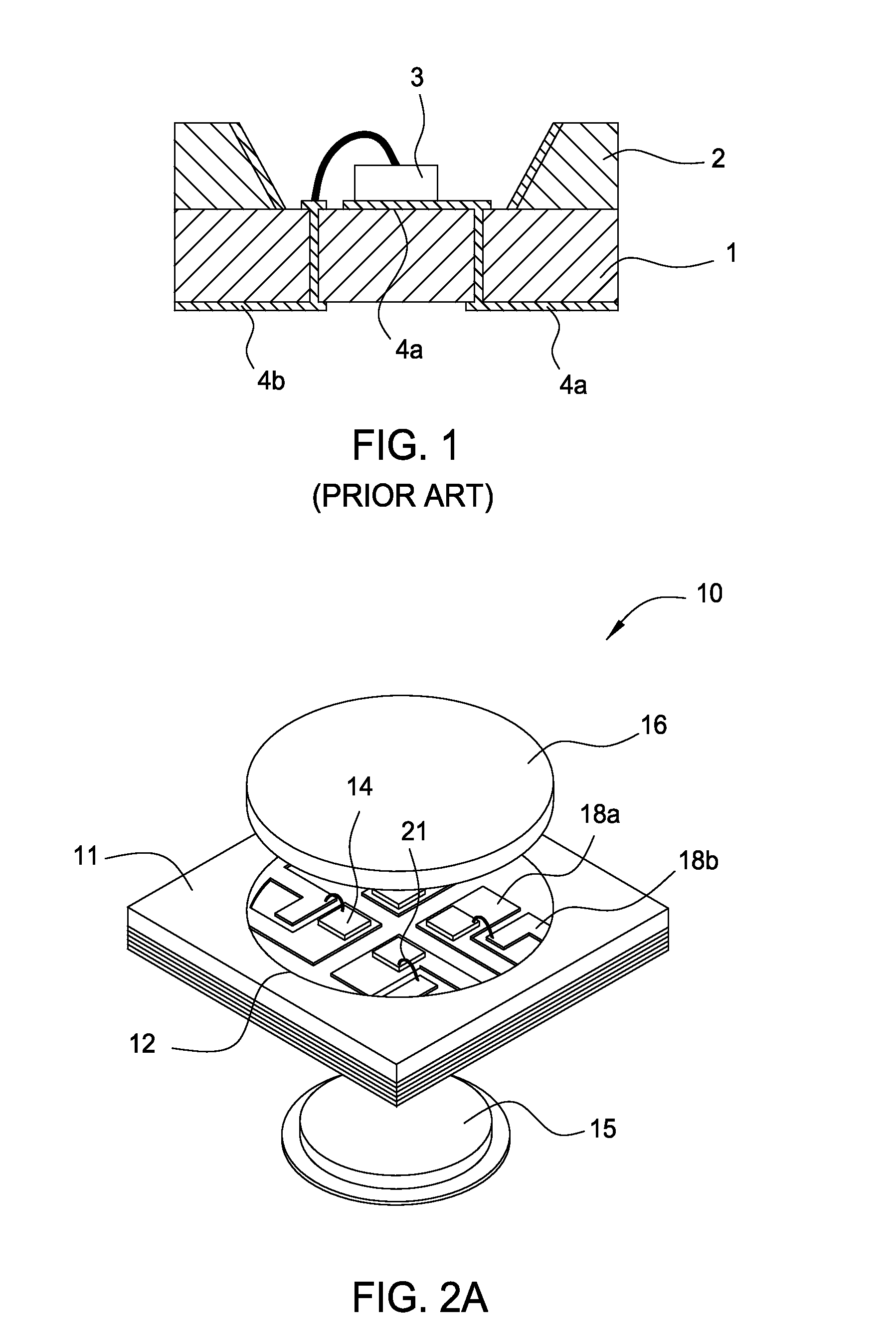

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS20050092733A1Improve responseCausing temperature distributionMuffle furnacesSemiconductor/solid-state device manufacturingMetallurgySemiconductor

A ceramic heater for a semiconductor producing / examining device including a ceramic substrate having a heating surface for receiving a semiconductor wafer, a heating device for generating heat sufficient for producing / examining the semiconductor wafer and formed on the heating surface or inside the ceramic substrate, and a temperature measuring device for measuring a temperature of the heating surface and pressed against the ceramic substrate.

Owner:IBIDEN CO LTD

System-in packages

ActiveUS8503186B2Improve uniformityCircuit arrangements on support structuresSemiconductor/solid-state device detailsMetal interconnectSystem in package

Owner:QUALCOMM INC

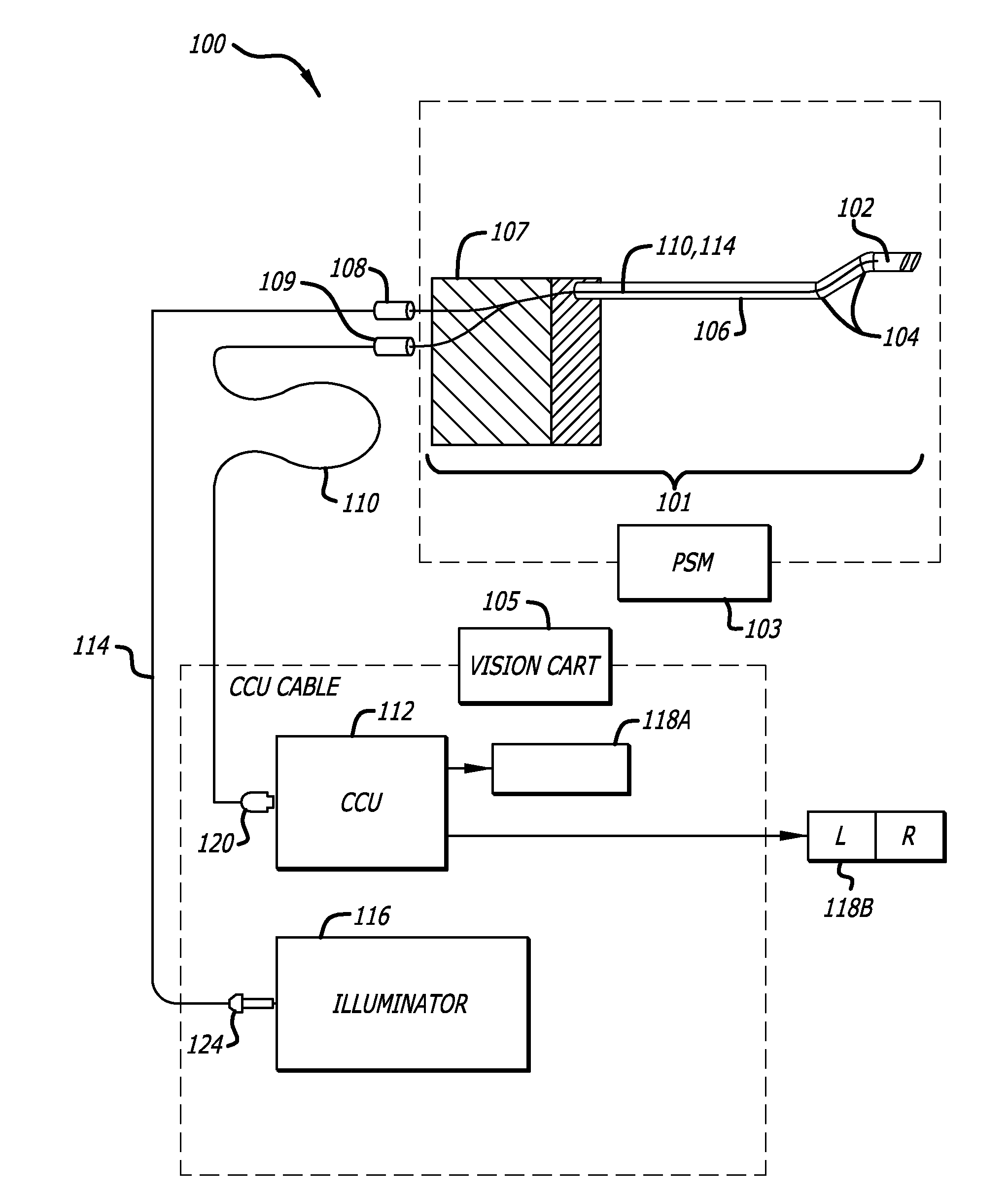

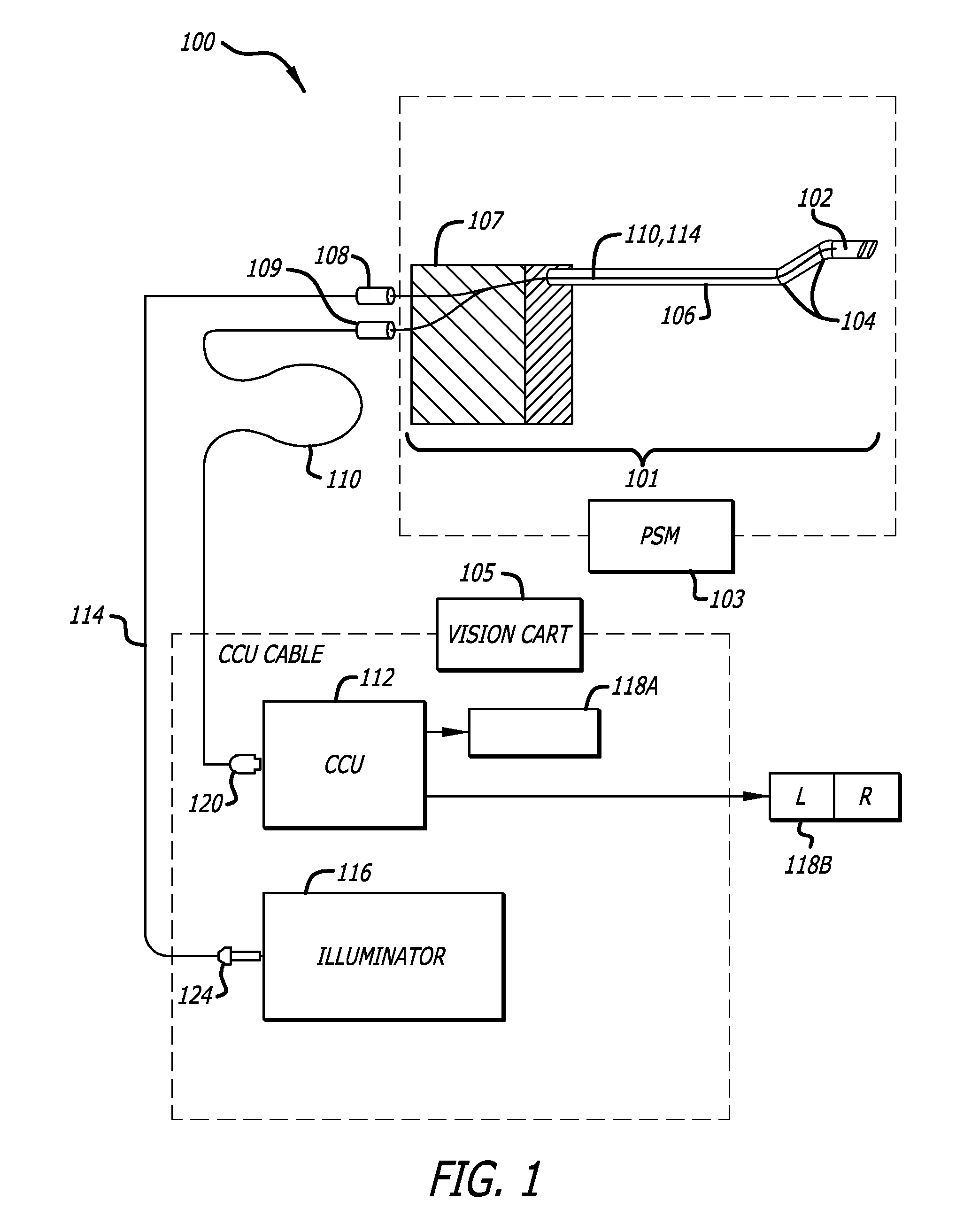

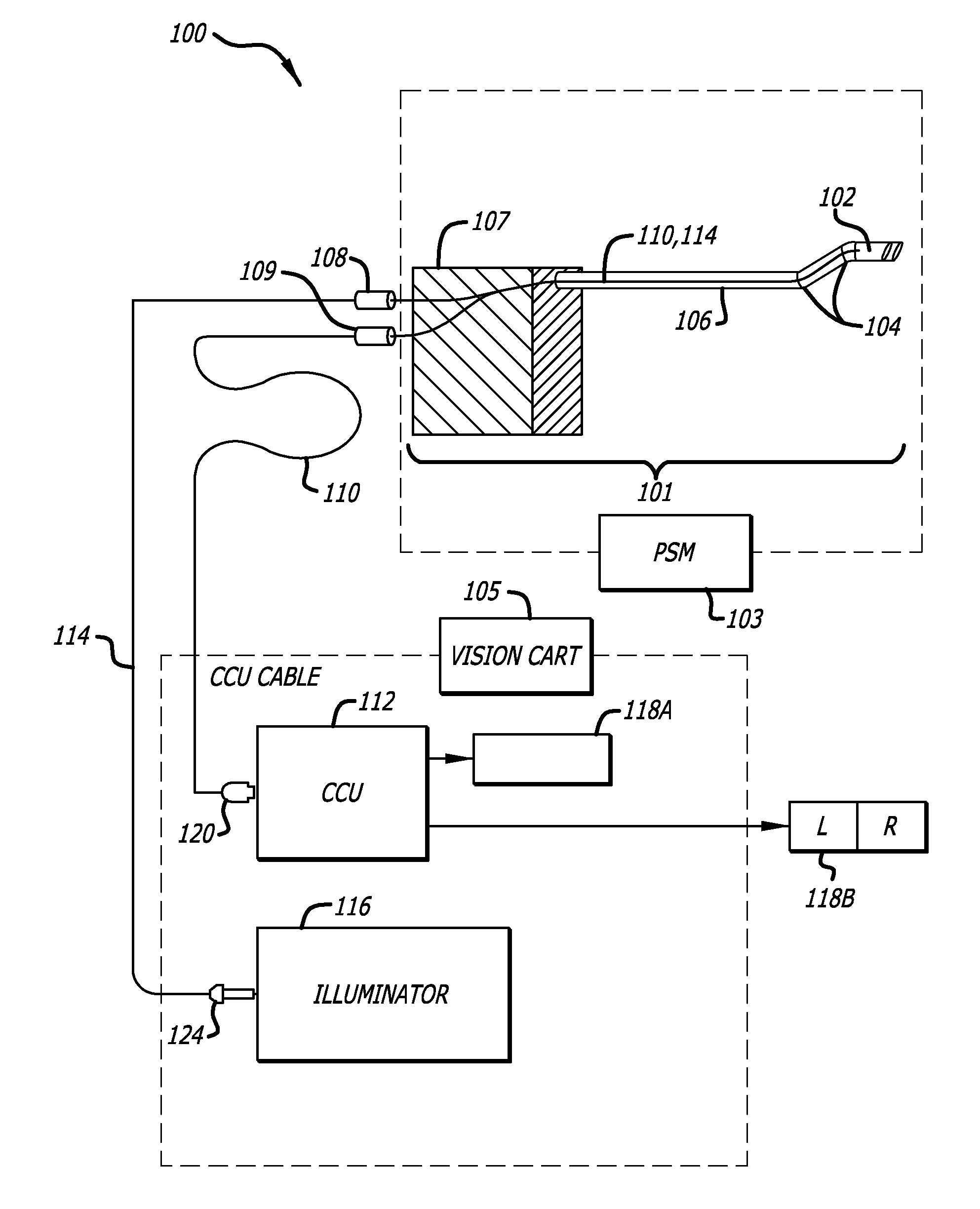

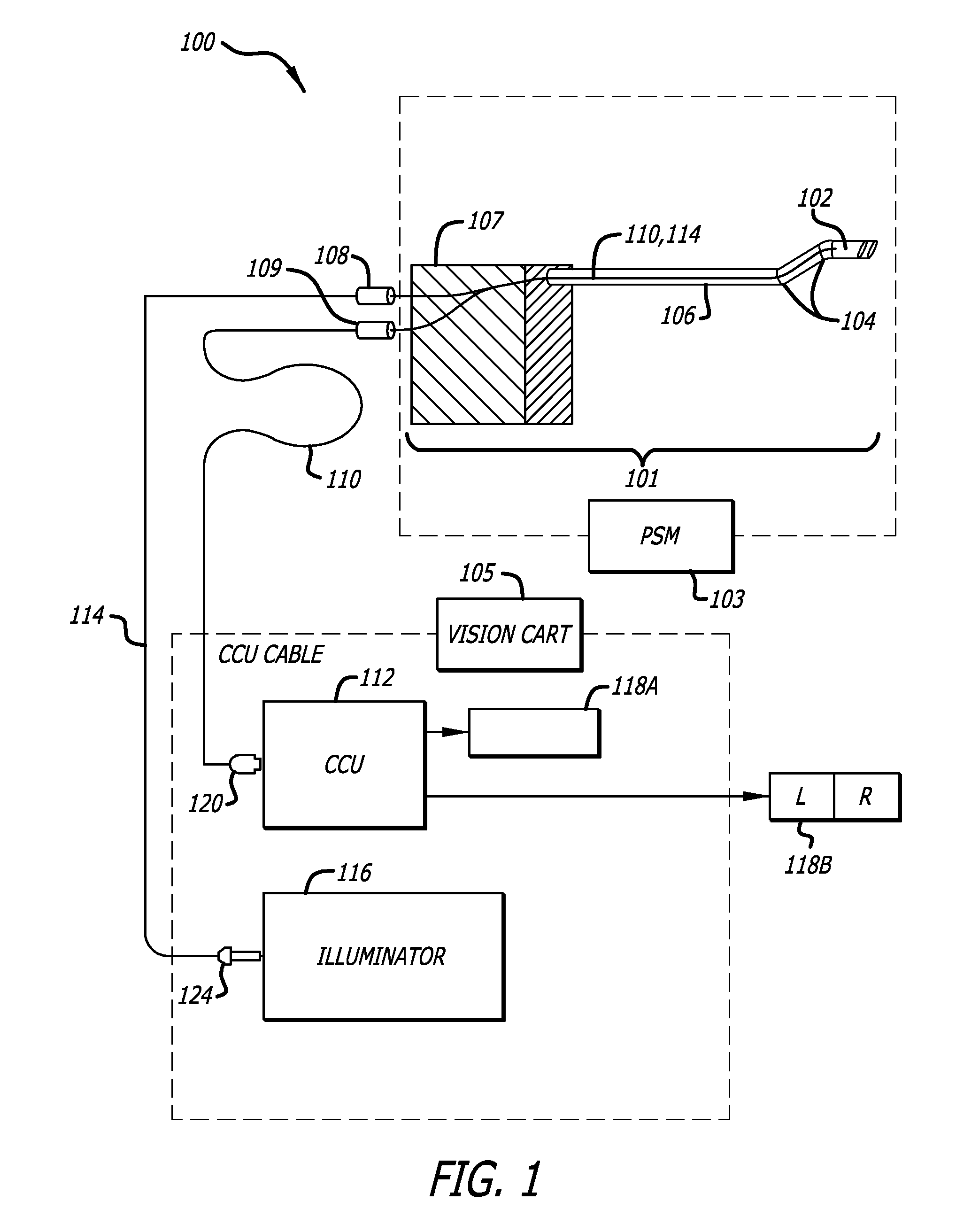

Hermetically sealed distal sensor endoscope

In one embodiment, an endoscopic camera for a robotic surgical system includes a stereo camera module mounted to a robotic arm of a patient side cart. The optical and electro-optic components of the camera module are hermetically sealed within a first housing. Signals from an electro-optic component travel through traces in a ceramic substrate forming one side of the hermetically sealed first housing. A second housing surrounds the first housing and optical fibers are dispersed between the housings to provide lighting in a body cavity. The camera module may be sterilized by an autoclave.

Owner:INTUITIVE SURGICAL OPERATIONS INC

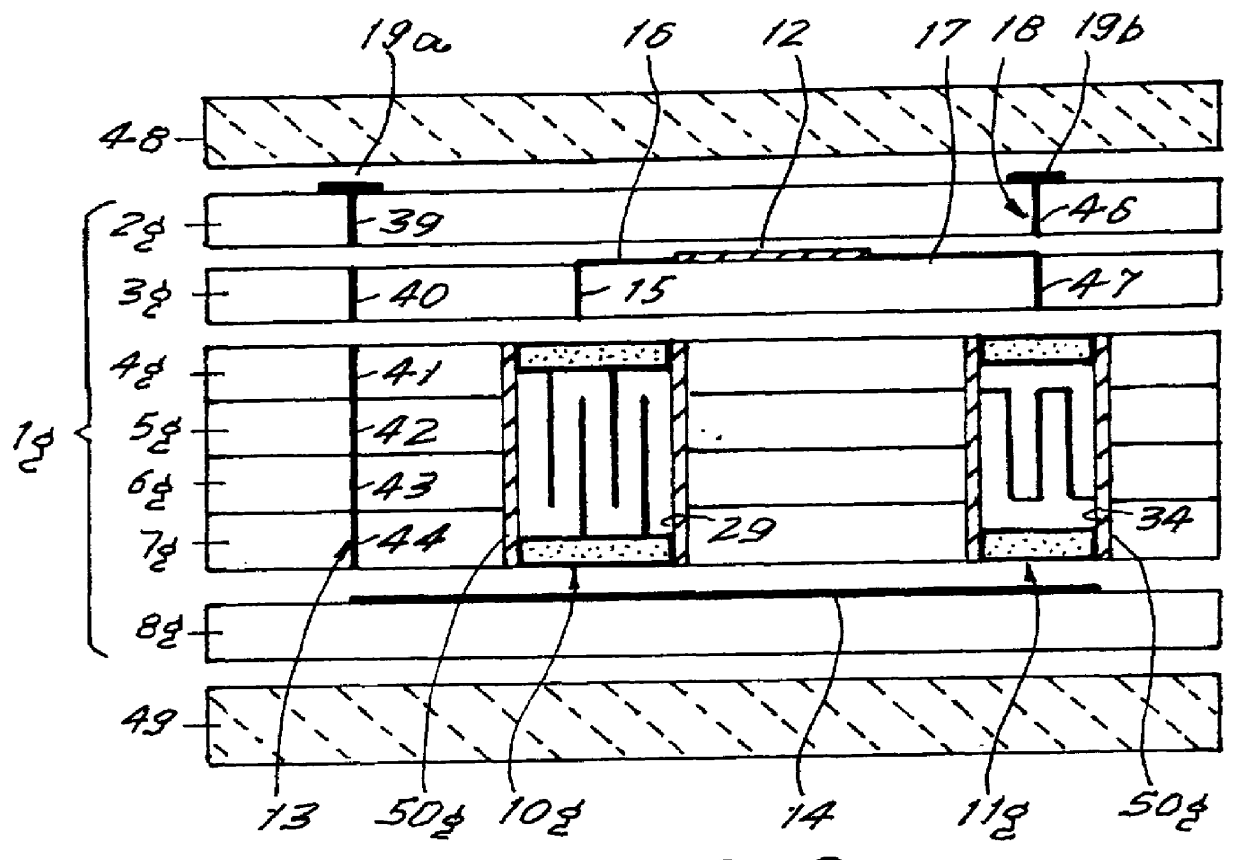

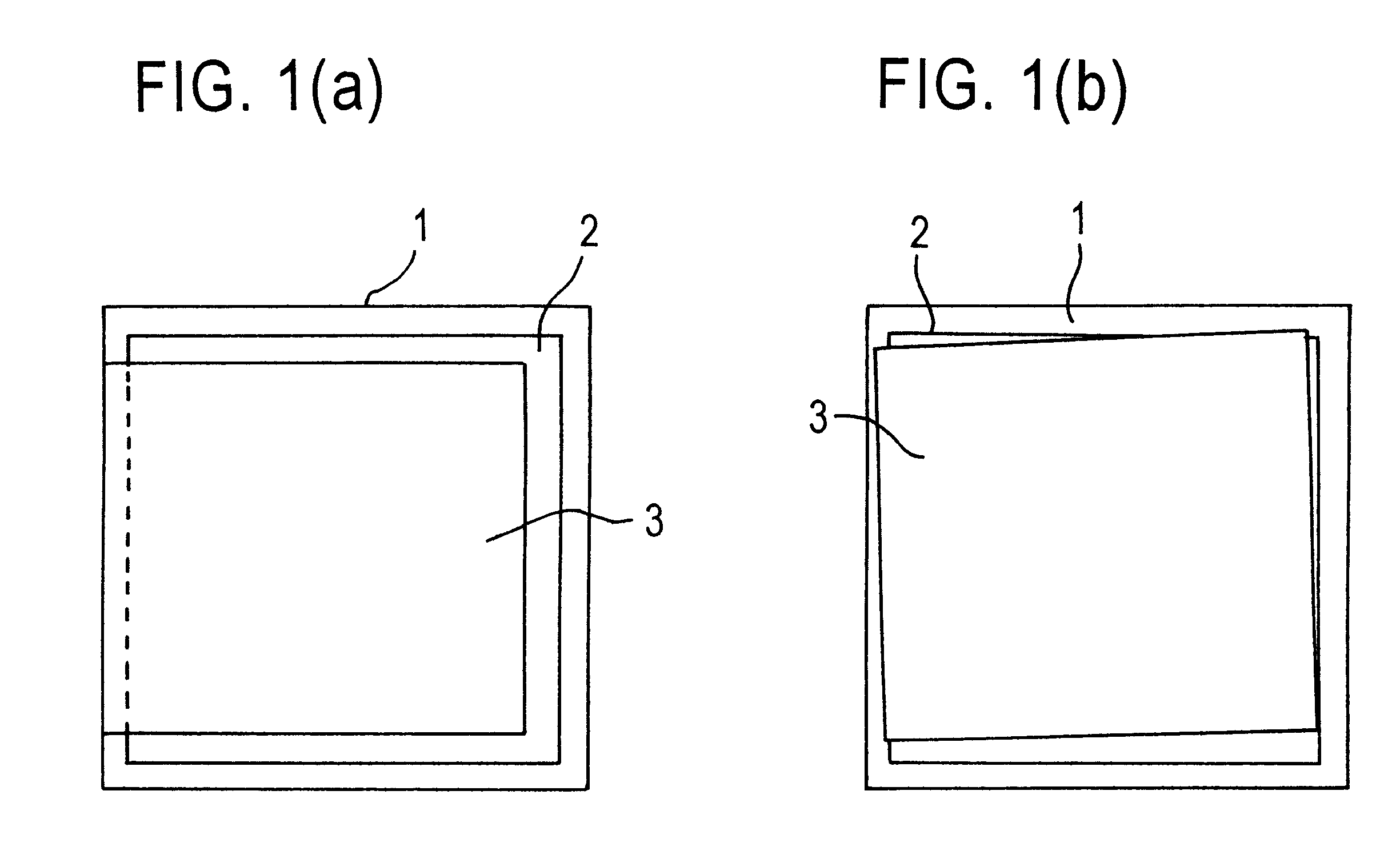

Multi-layer ceramic substrate and method for producing the same

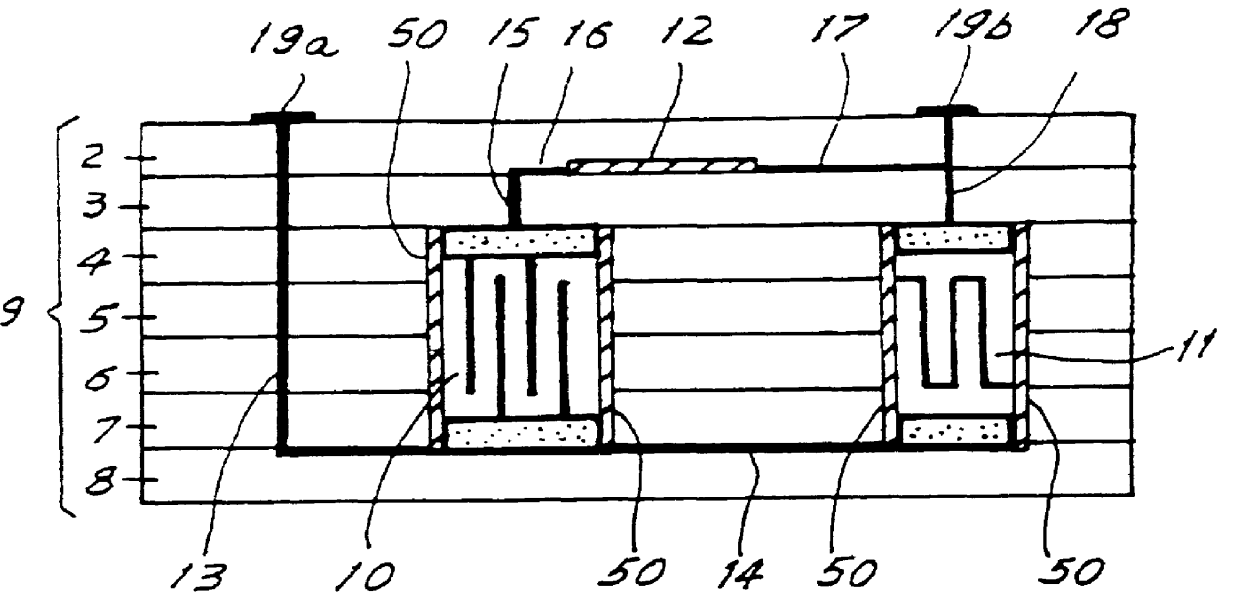

InactiveUS6153290AFinal product manufactureSemiconductor/solid-state device detailsHigh densityInductor

The present invention provides a method for producing a high-density multi-layer ceramic substrate with stable characteristics, the substrate incorporating therein a passive component such as a high-precision capacitor or inductor. The method comprises the steps of providing compact blocks containing a green ceramic functional material to form the passive components; providing a composite green laminate having a plurality of ceramic green sheets comprising a ceramic insulating material and in which the compact blocks are built in pre-disposed spaces and a paste containing a metal inducing, during firing, oxidation reaction accompanied by expansion is provided in space between inside walls of the spaces and the compact blocks; firing the composite green laminate in a state in which the laminate is sandwiched by the sheet-like supports formed of green ceramics that cannot be sintered at the sintering temperature, so as to prevent shrinkage of the laminate; and removing the unsintered sheet-like supports.

Owner:MURATA MFG CO LTD

Electrochemical apparatus with barrier layer protected substrate

ActiveUS20060286448A1Inhibited DiffusionEfficient separationFinal product manufactureElectrode carriers/collectorsElectrochemistrySilicon

The present invention relates to apparatus, compositions and methods of fabricating high performance thin-film batteries on metallic substrates, polymeric substrates, or doped or undoped silicon substrates by fabricating an appropriate barrier layer composed, for example, of barrier sublayers between the substrate and the battery part of the present invention thereby separating these two parts chemically during the entire battery fabrication process as well as during any operation and storage of the electrochemical apparatus during its entire lifetime. In a preferred embodiment of the present invention thin-film batteries fabricated onto a thin, flexible stainless steel foil substrate using an appropriate barrier layer that is composed of barrier sublayers have uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for a LiCoO2 positive cathode.

Owner:SAPURAST RES

Hermetically sealed distal sensor endoscope

Owner:INTUITIVE SURGICAL OPERATIONS INC

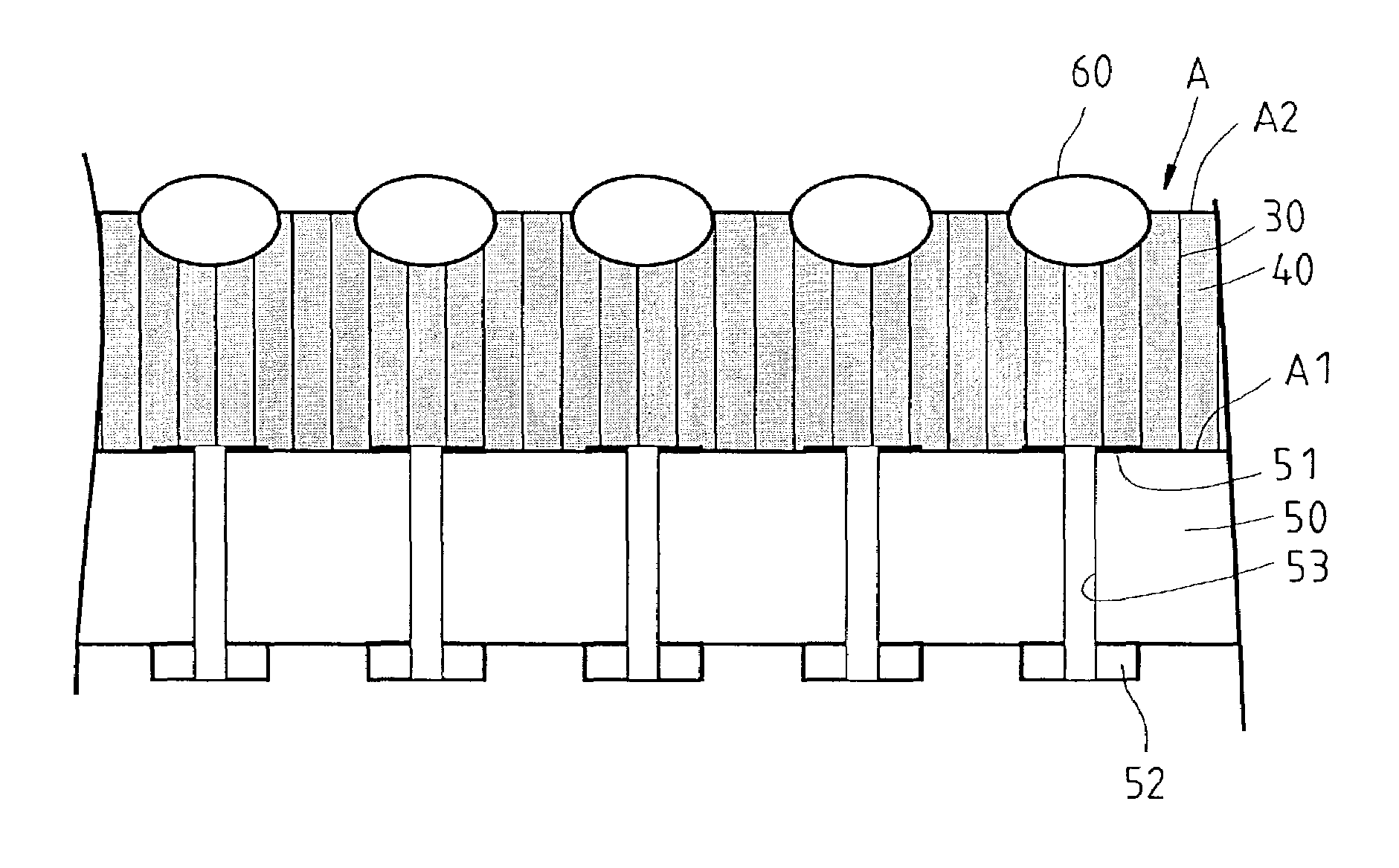

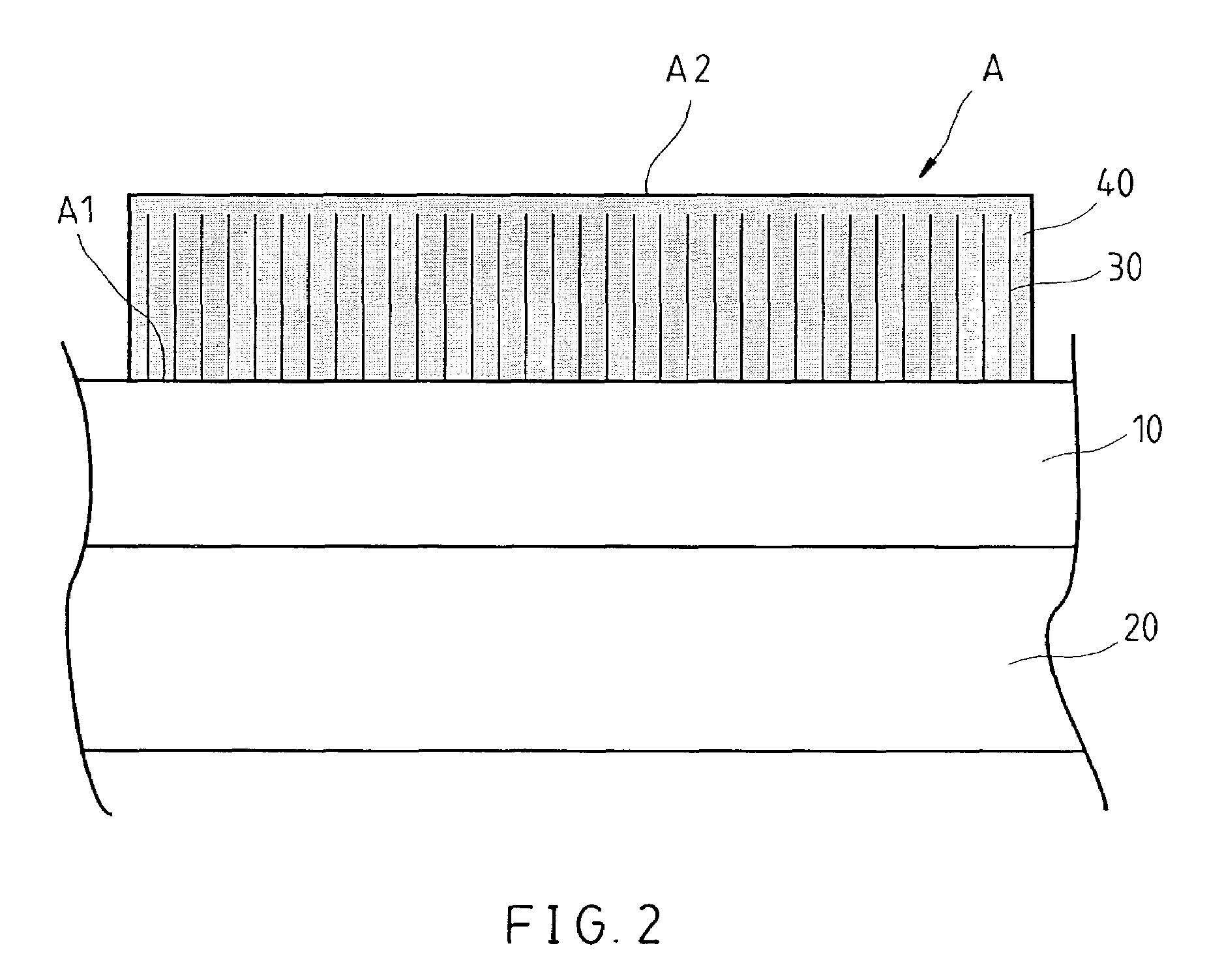

High conducting thin-film nanoprobe card and its fabrication method

InactiveUS7012441B2Compensating for such errorLine/current collector detailsElectrically conductive connectionsPolymer resinNanotube

A conducting thin-film nanoprobe card fabrication method includes the steps of: (a) arranging nanotubes on a substrate in vertical; (b) covering the nanotubes with a liquid polymeric resin and then hardening the polymeric resin to form a conducting nanomembrane; (c) removing a part of the polymeric resin from the conducting nanomembrane to expose one end of each nanotube to outside; (d) removing the substrate and preparing a ceramic substrate having contacts at one side and metal bumps at the other side and plated through holes electrically respectively connected with the contacts and the metal bumps; (e) mounting the nanomembrane on the ceramic substrate to hold the nanotubes in contact with the contacts of the ceramic substrate, and (f) forming recessed holes in the nanomembrane by etching and inserting a metal rod in each recessed hole to form a respective probe.

Owner:IND TECH RES INST

High temperature, conductive thin film diffusion barrier for ceramic/metal systems

A multilayer ceramic substrate having a thin film structure containing capacitor connected thereto is provided as an interposer capacitor, the capacitor employing platinum as the bottom electrode of the capacitor. In a preferred capacitor, a dielectric material such as barium titanate is used as the dielectric material between the capacitor electrodes. The fabrication of the interposer capacitor requires an in-situ or post deposition high temperature anneal and the use of such dielectrics requires heating of the capacitor structure in a non-reducing atmosphere. A layer of a high temperature, thin film diffusion barrier such as TaSiN on the lower platinum electrode between the electrode and underlying multilayer ceramic substrate prevents or minimizes oxidization of the metallization of the multilayer ceramic substrate to which the thin film structure is connected during the fabrication process. A method is also provided for fabricating an interposer capacitor with a multilayer ceramic substrate base and a thin film multilayer structure having at least one capacitor comprising at least one bottom platinum electrode.

Owner:IBM CORP

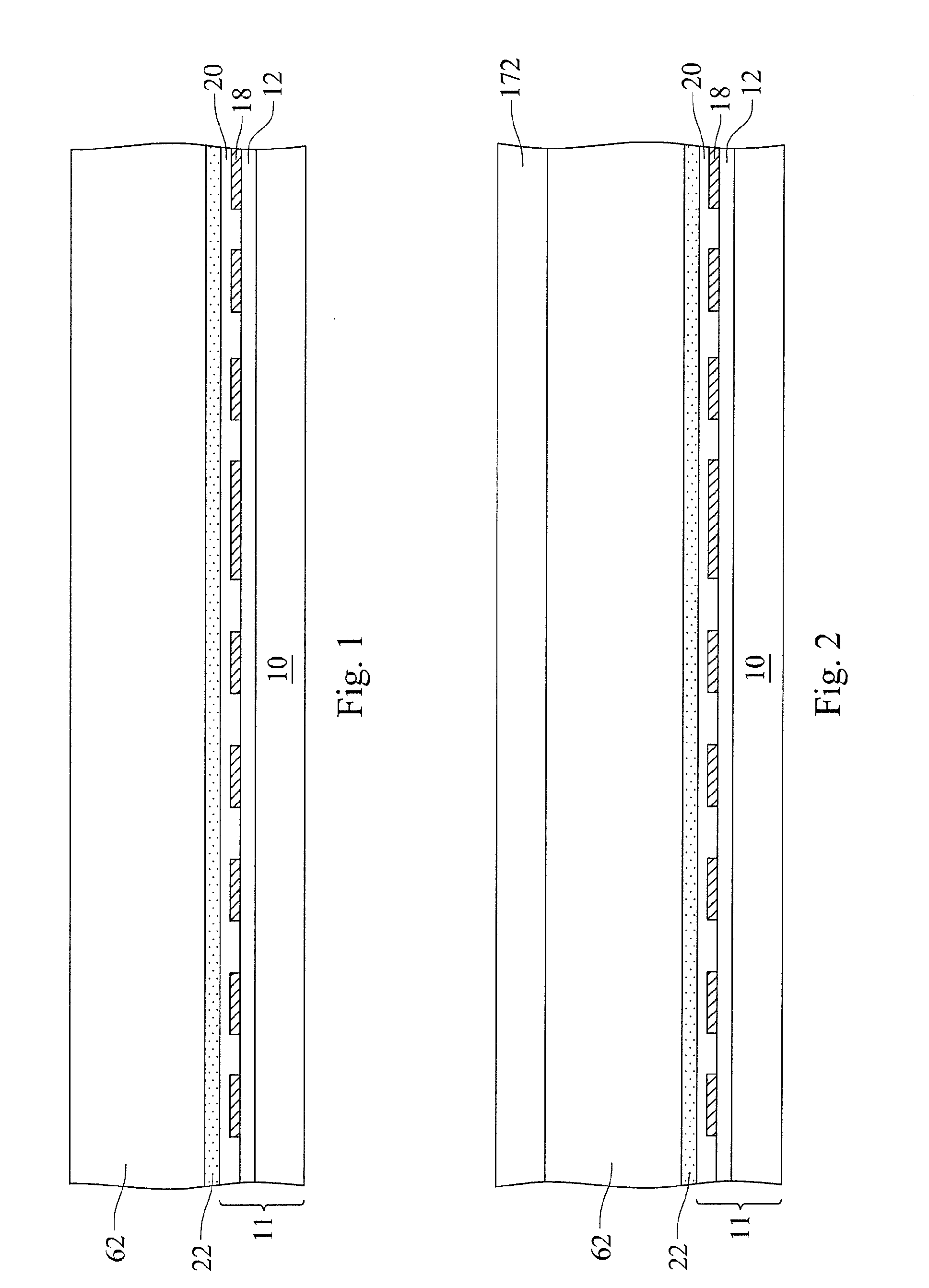

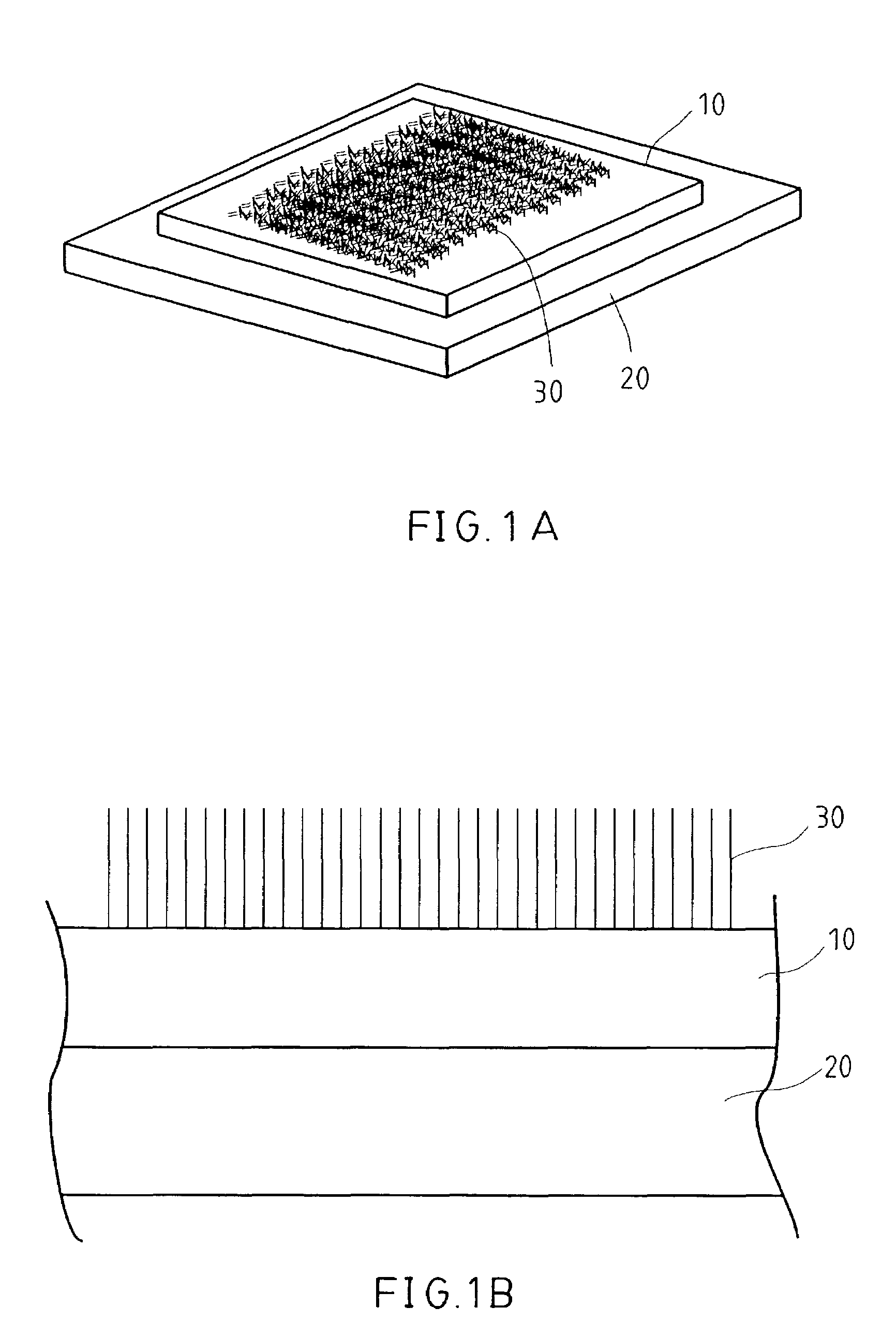

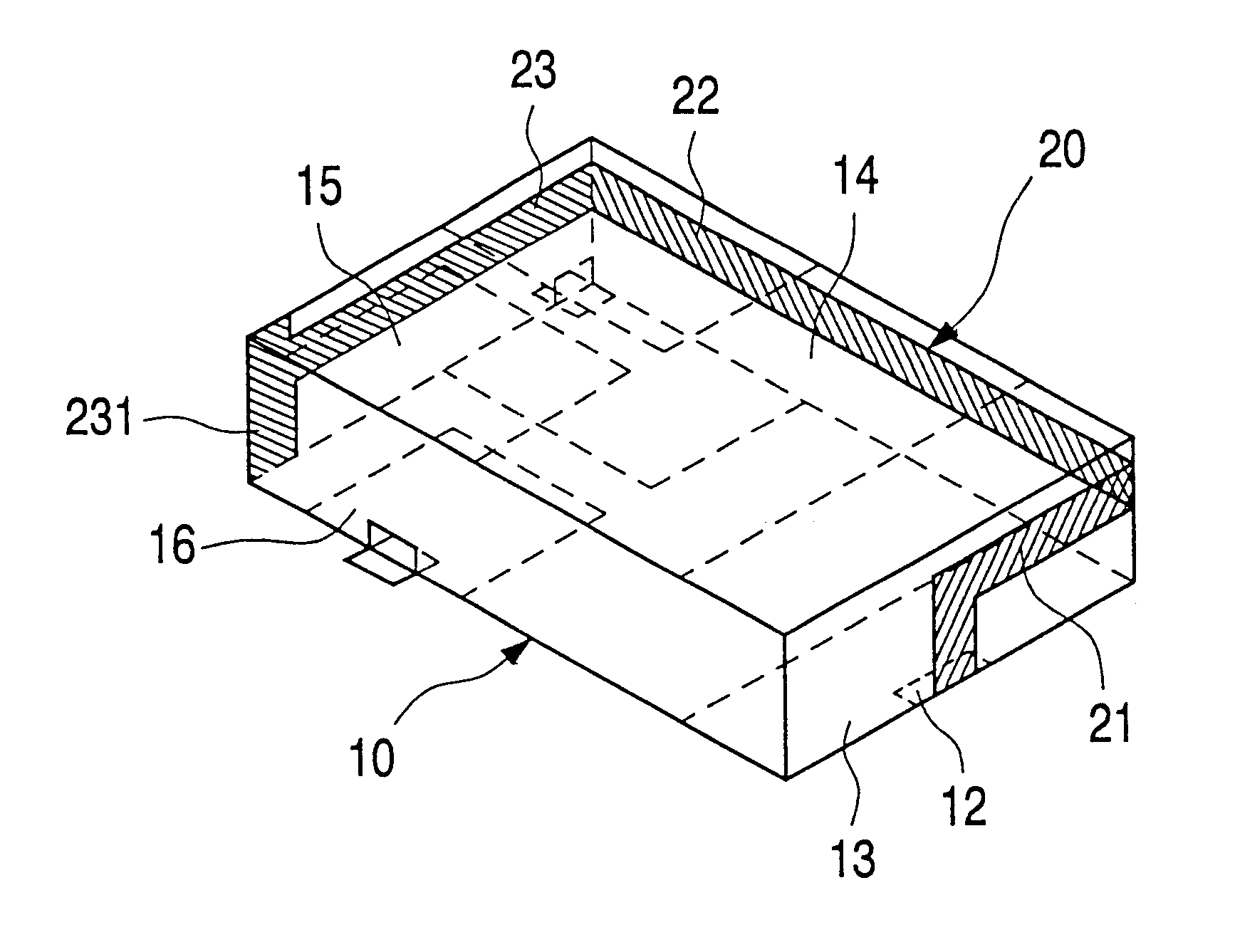

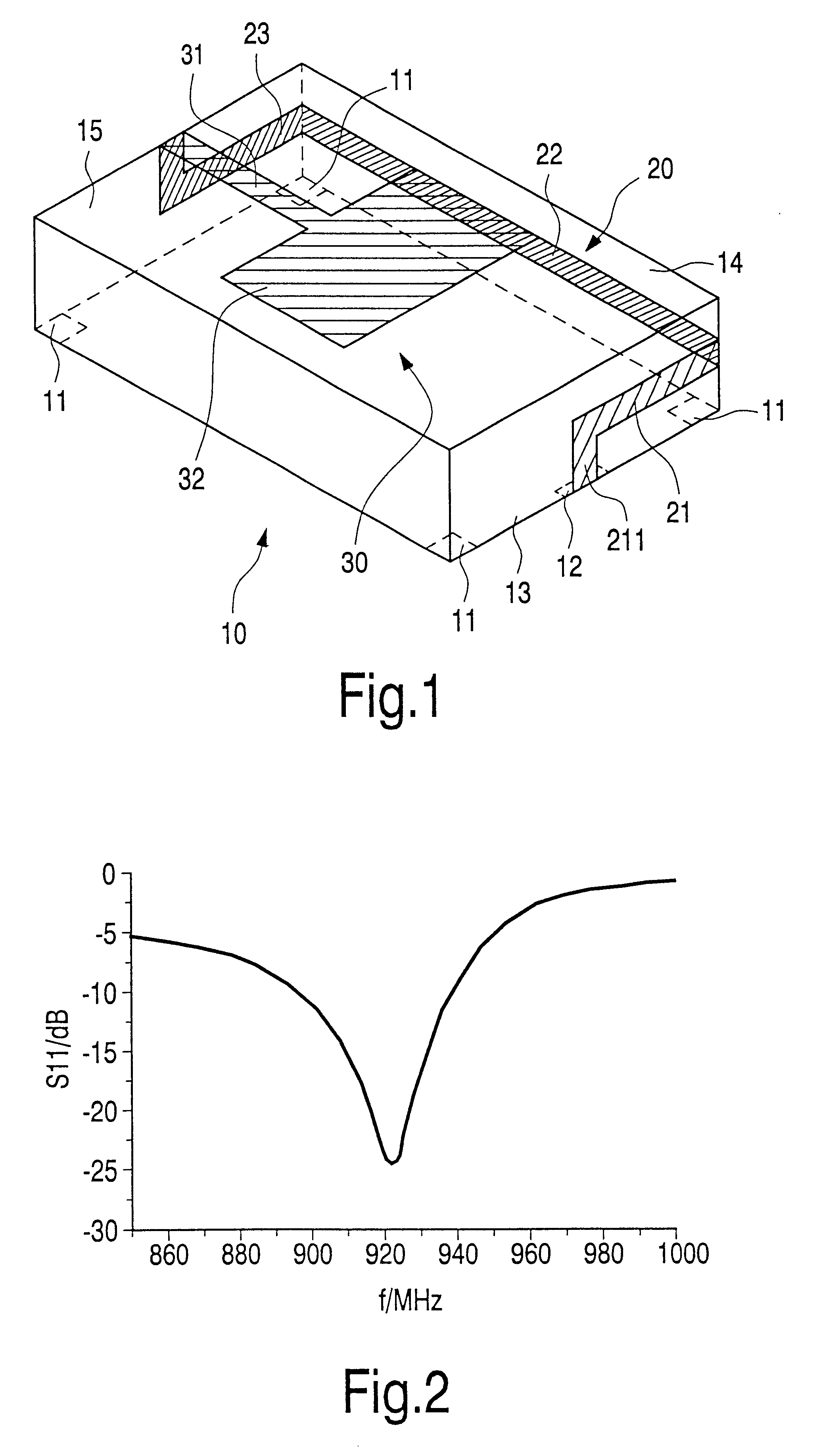

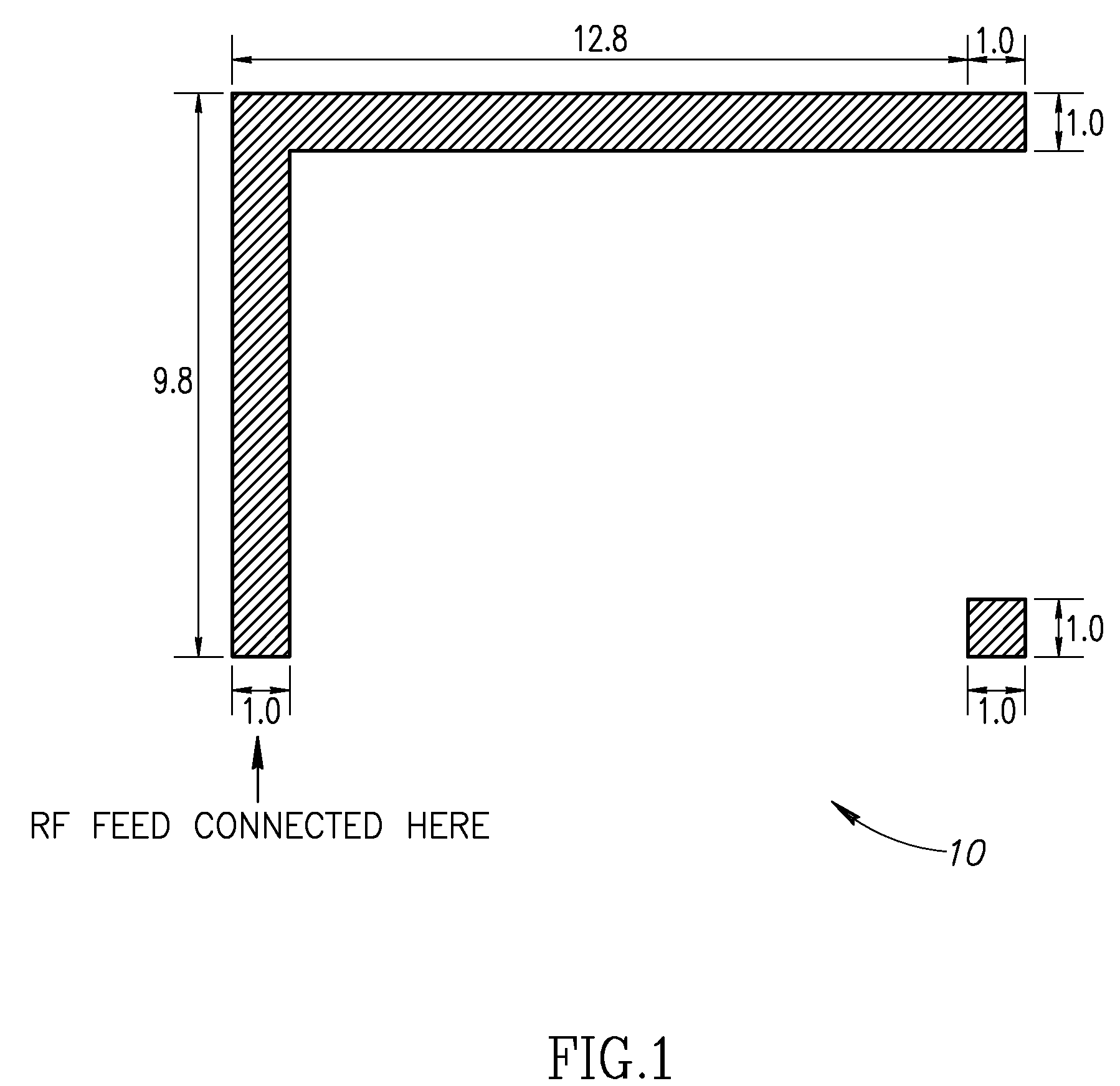

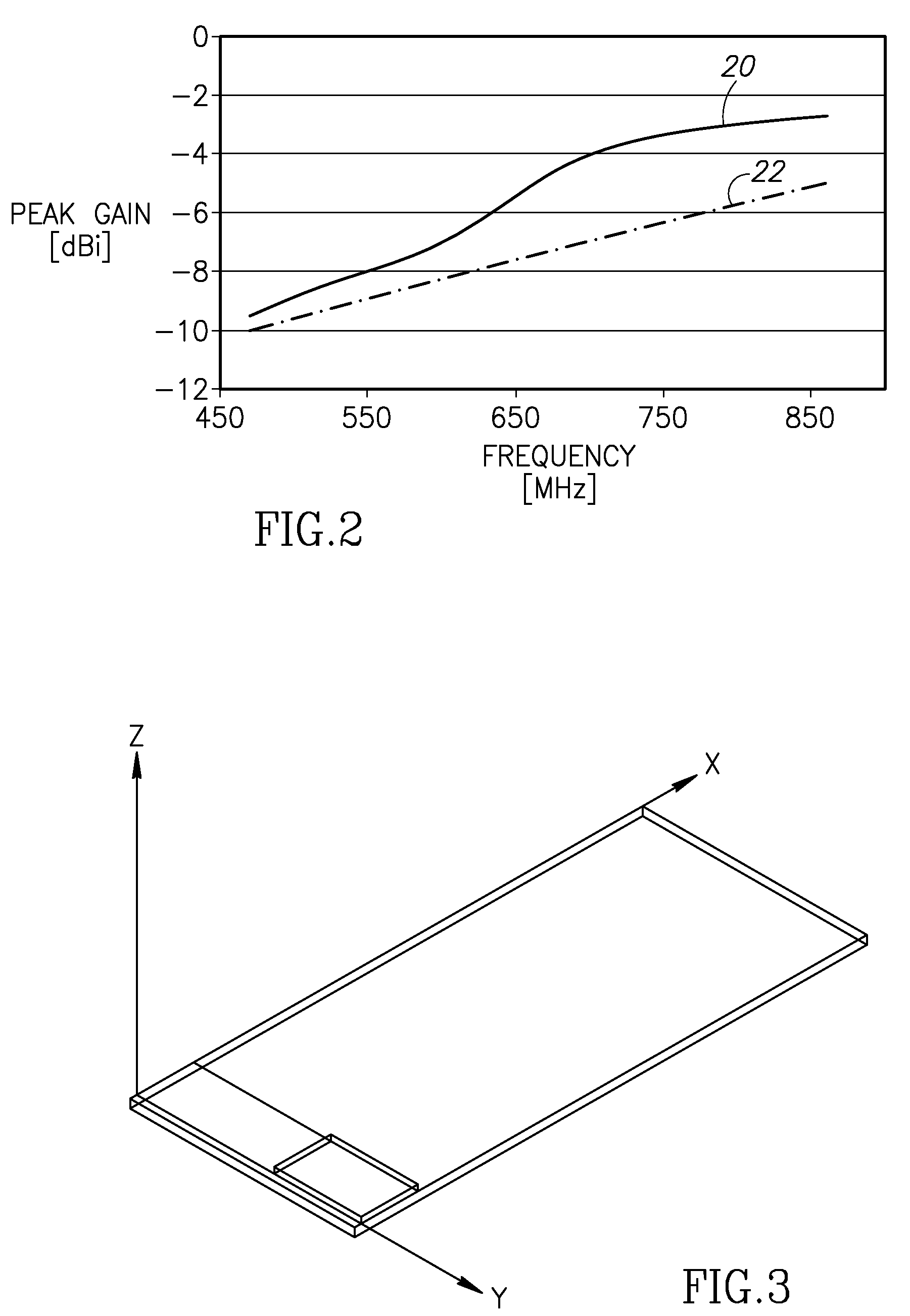

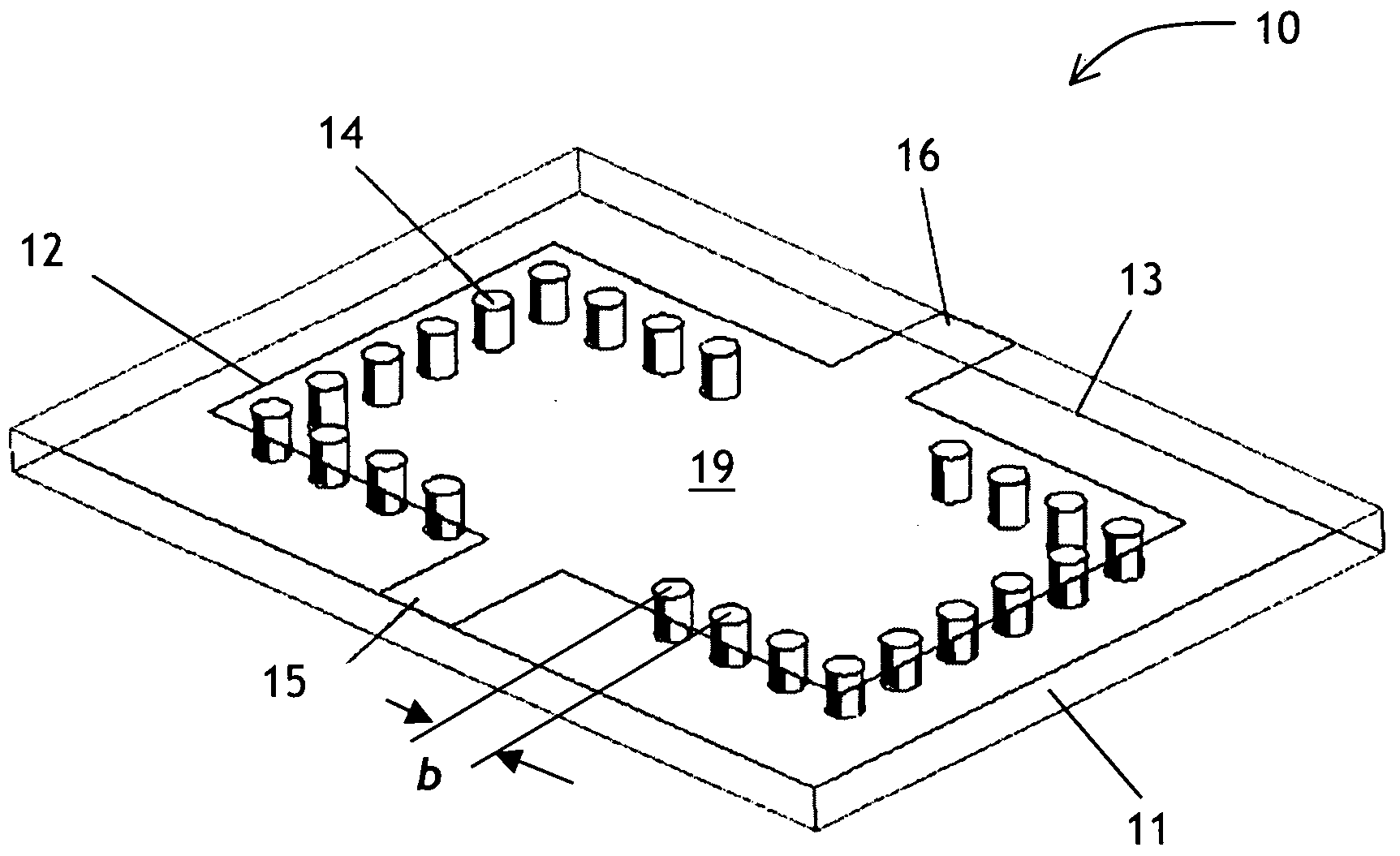

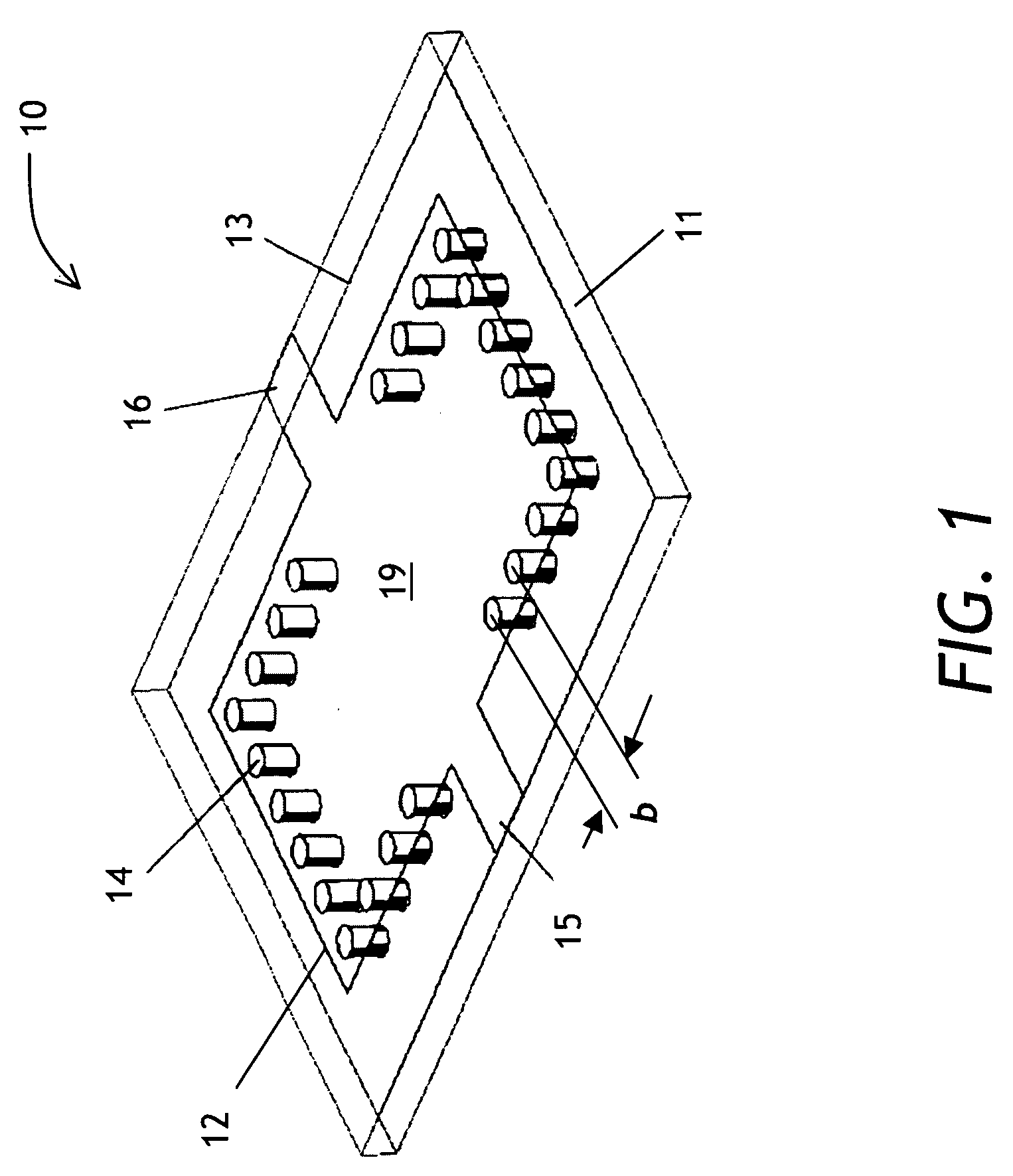

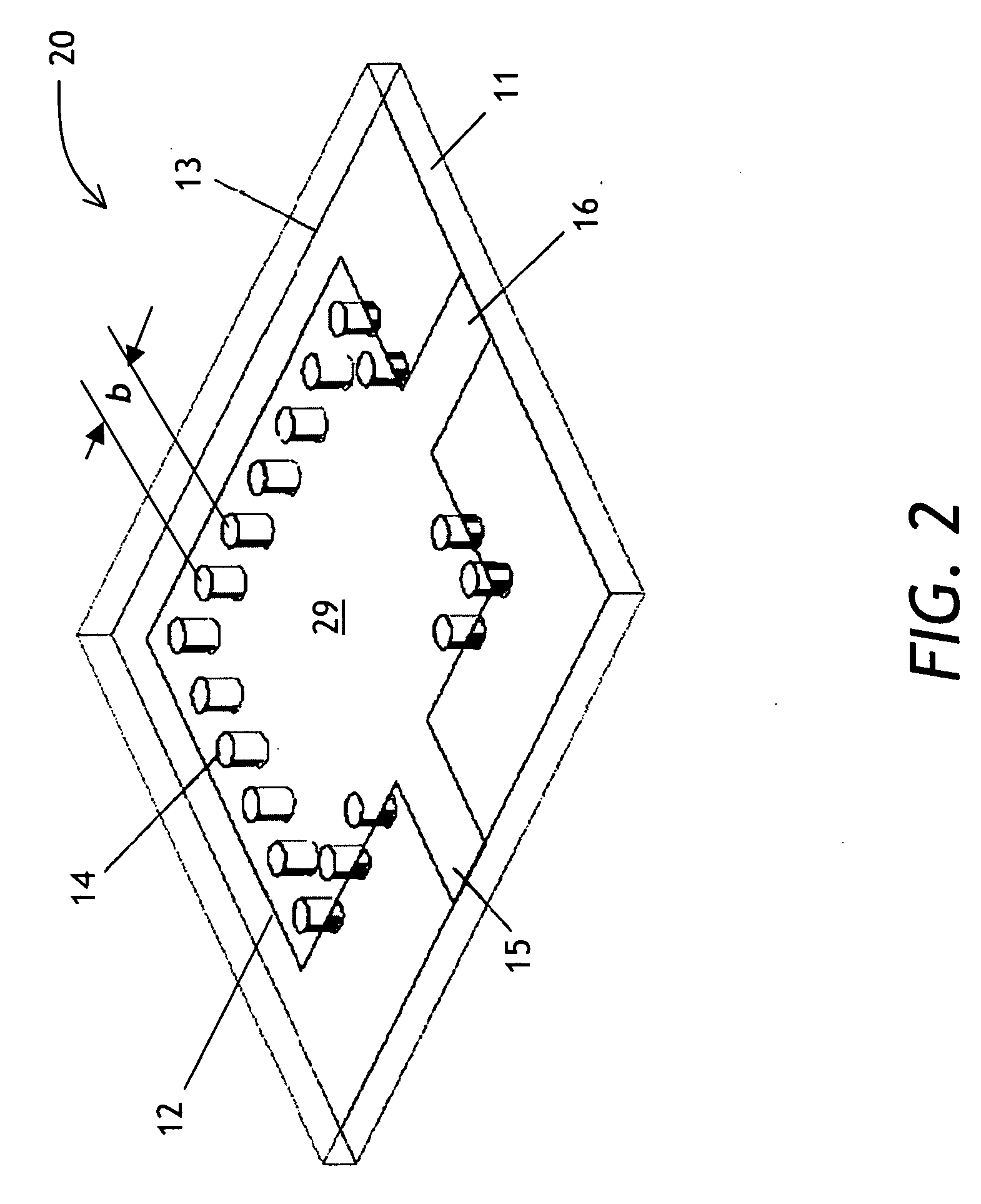

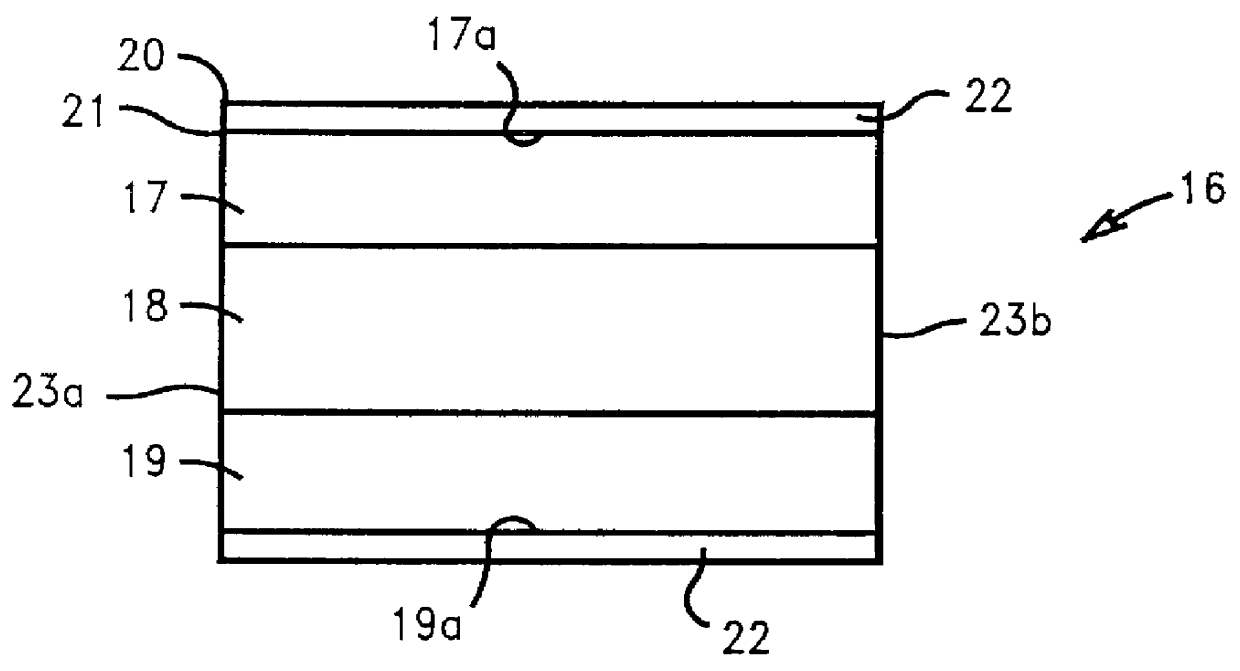

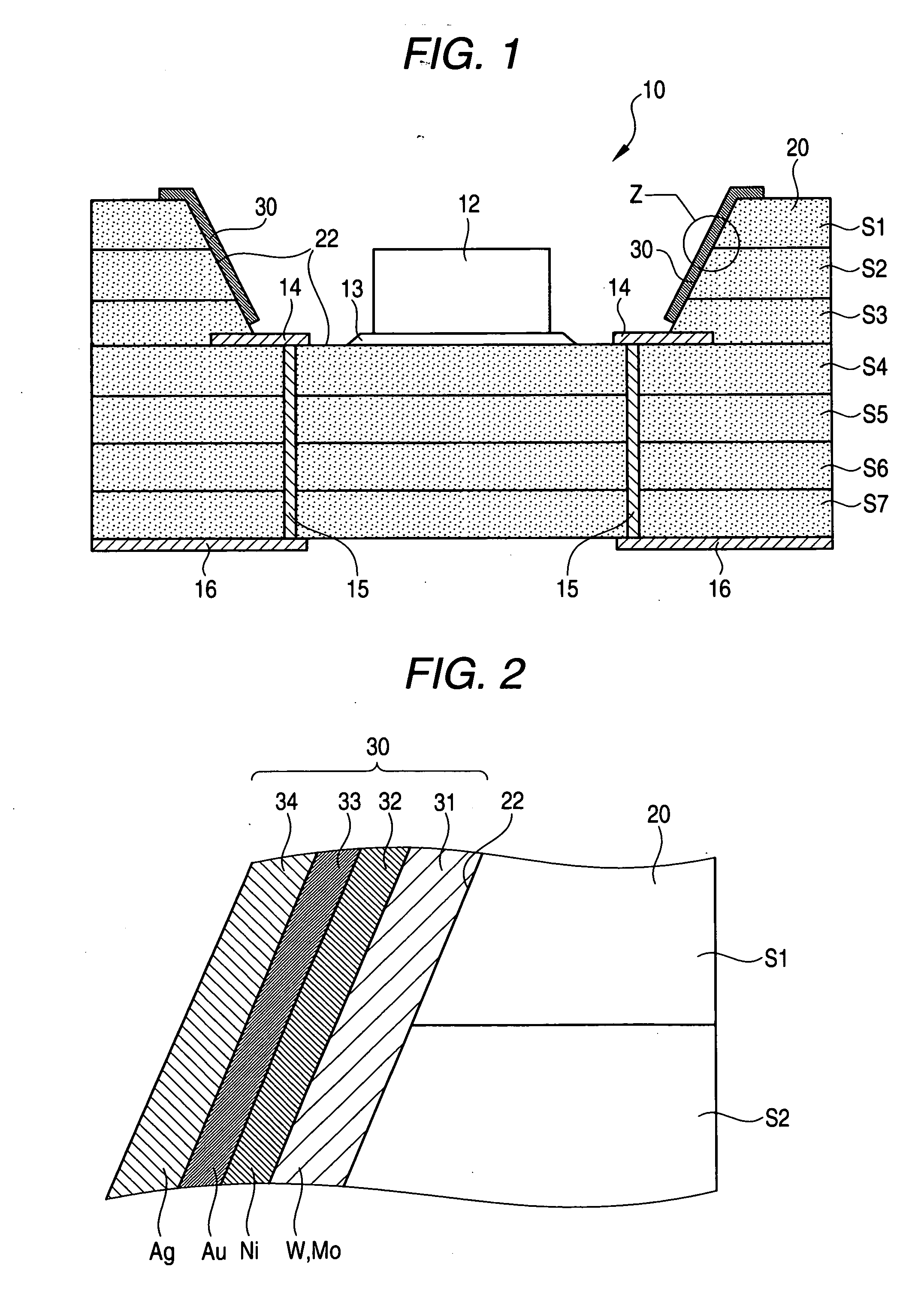

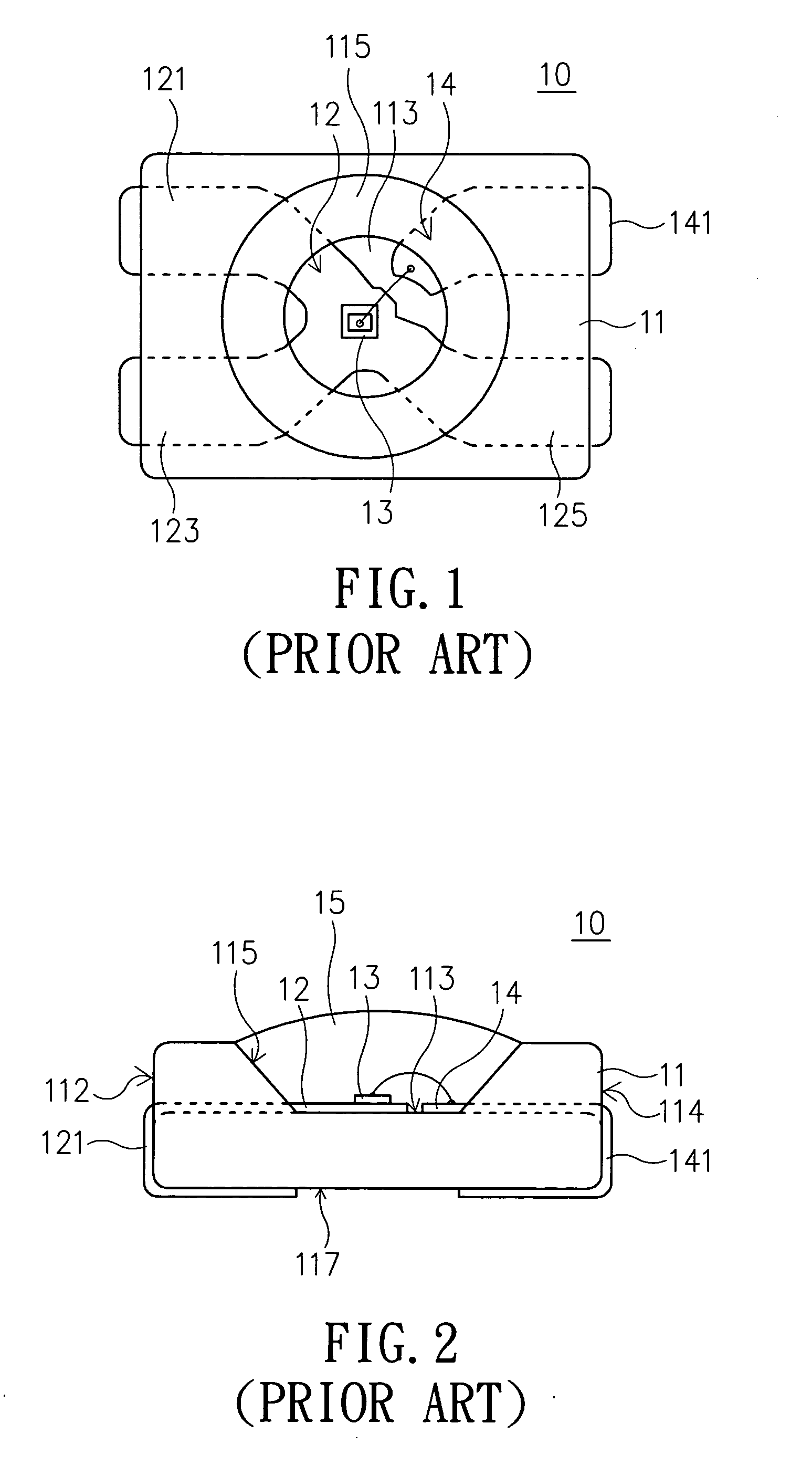

Miniaturized microwave antenna

InactiveUS6680700B2Reduce antenna sizeSmall sizeSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorEngineering

A miniaturized antenna is described with at least a ceramic substrate (10) and a metallization, particularly designed for use in the high-frequency and microwave ranges. The antenna is characterized in that the metallization is a surface metallization which is formed by a feed terminal (12) for electromagnetic energy to be radiated, by at least a first metallization structure (30), and by a conductor track (20) extending along at least part of the circumference of the substrate (10), which track connects the feed terminal to the at least one first metallization structure (30), which first metallization structure (30) comprises a first conductor track portion (31) extending from a side of the substrate lying opposite the feed terminal (12) towards the feed terminal and a first metallization pad (32). The antenna can be provided on a printed circuit board by surface mounting and has a great impedance and radiation bandwidth, so that it is particularly suitable for use in mobile telephones operating in the GSM and UMTS bands.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

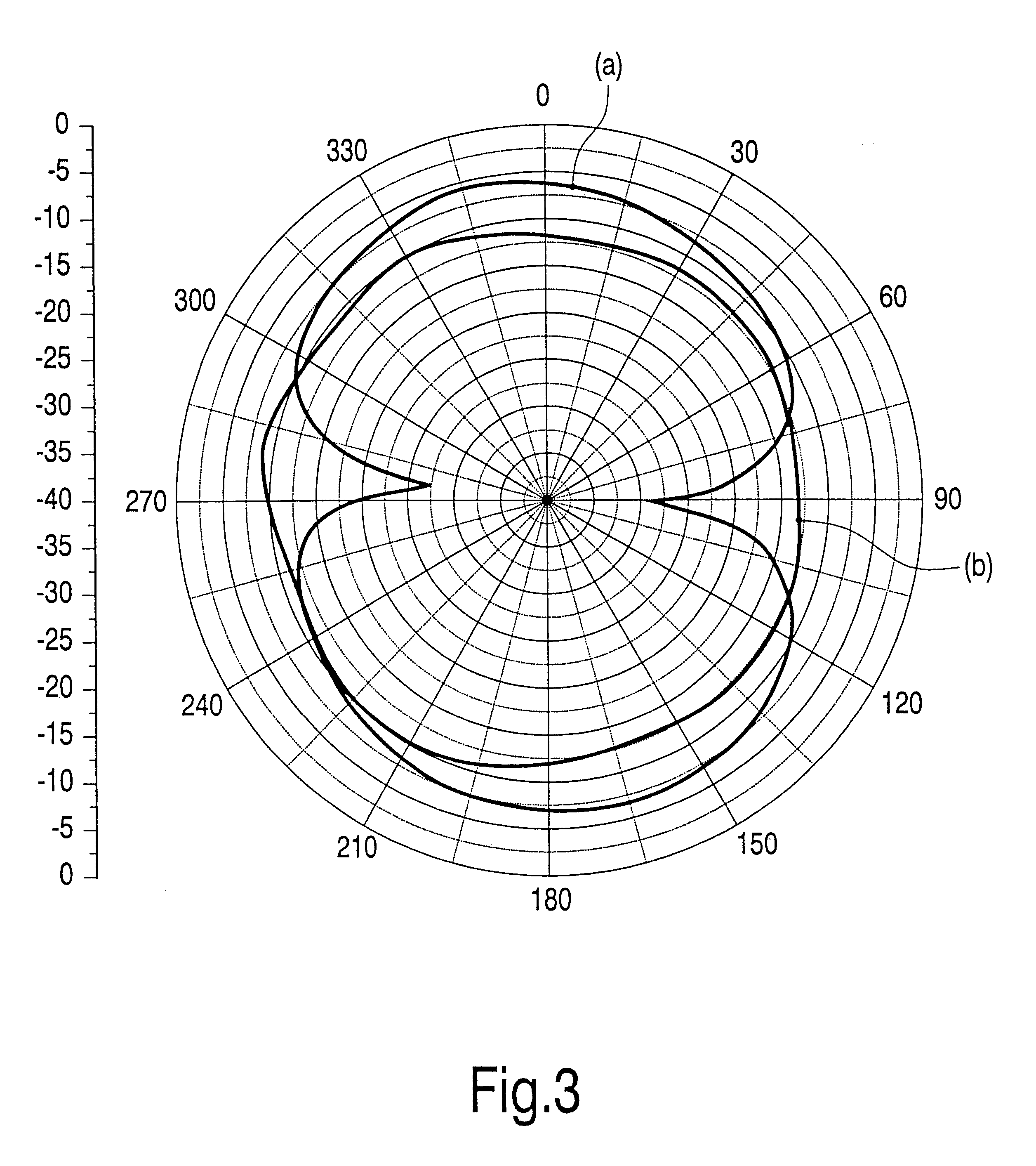

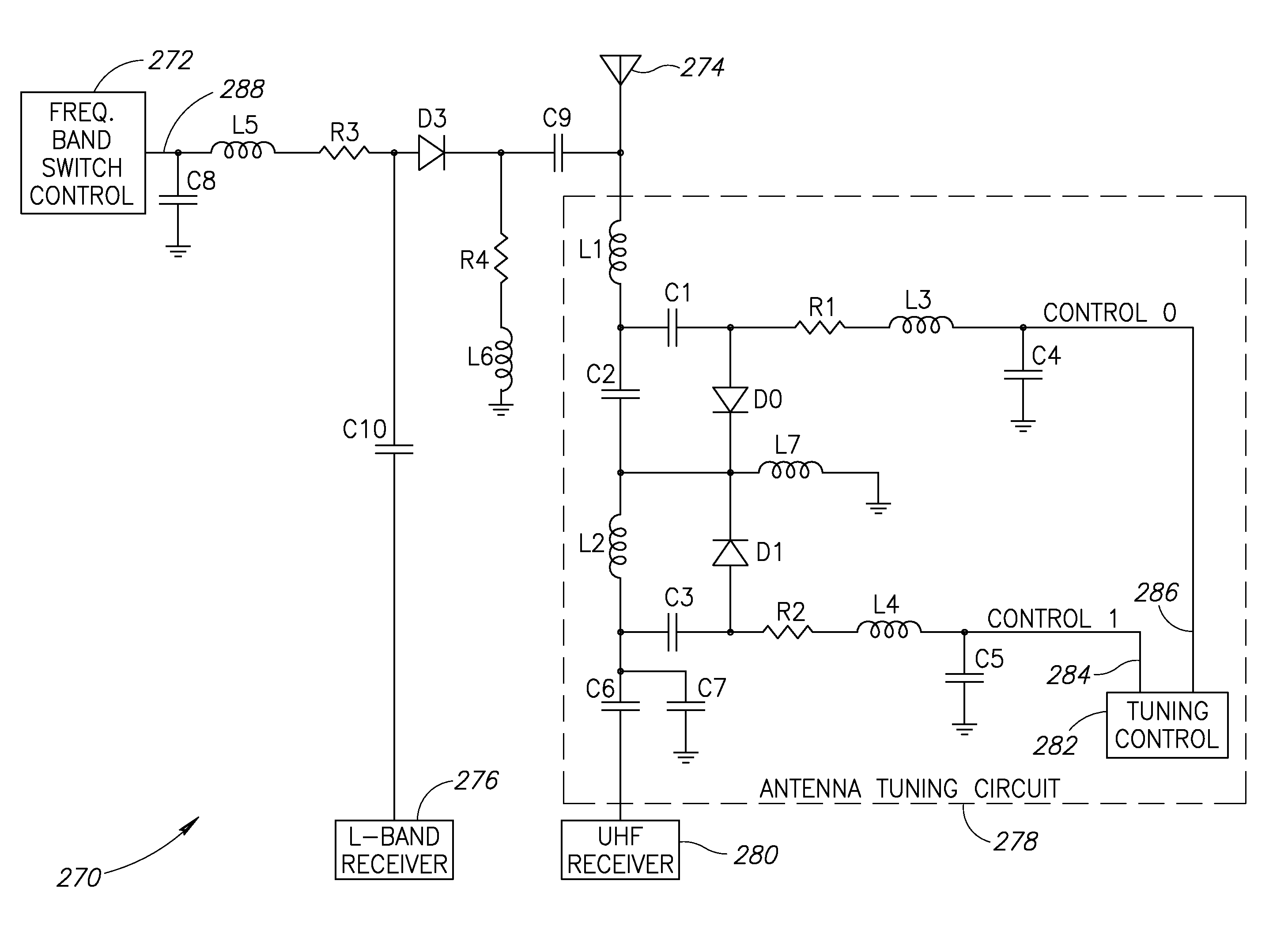

Miniature sub-resonant multi-band vhf-uhf antenna

InactiveUS20080305750A1Low costSmall sizeAntenna supports/mountingsModulation with suppressed carrierMulti bandAntenna design

A novel antenna system for receiving transmissions in the VHF and UHF frequency bands particularly suitable as a miniaturized antenna for UHF reception, such as of digital video broadcasting transmissions. The antenna system utilizes a combination of three techniques including (1) the use of dialect loading using a high dielectric constant ceramic substrate; (2) an antenna dielectrically loaded and tuned to a significantly higher frequency than desired; and (3) use of a tuning circuit to compensate for the frequency offset of the antenna thereby shifting the resonant frequency to cover the entire band. The antenna is intentionally designed to be too small to radiate at the frequency of interest. The antenna element is then ‘forced’ to be tuned to the desired lower frequency using passive (or active) reactive components as part of a tuning circuit. Multi-band operation is achieved by providing a bypass switch to connect the antenna element either to (1) a first receiver without the tuning circuit (i.e. high frequency tuning) or (2) a second receiver with the tuning circuit (i.e. low frequency tuning).

Owner:VISHAY INTERTECHNOLOGY INC

Waveguide filter

InactiveUS20090243762A1Suppress radiation lossHigh out-of-band rejectionWaveguidesBandpass filteringCoplanar waveguide

A waveguide bandpass filter for use in microwave and millimeter-wave satellite communications equipment is presented. The filter is based on a substrate integrated waveguide (SIW) having several cascaded oversized SIW cavities. The filter is implemented in a printed circuit board (PCB) or a ceramic substrate using arrays of standard metalized via holes to define the perimeters of the SIW cavities. Transmission lines of a microstrip line, a stripline or coplanar waveguide are used as input and output feeds. The transmission lines have coupling slots for improved stopband performance. The filter can be easily integrated with planar circuits for microwave and millimeter wave applications.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF IND THROUGH THE COMM RES CENT

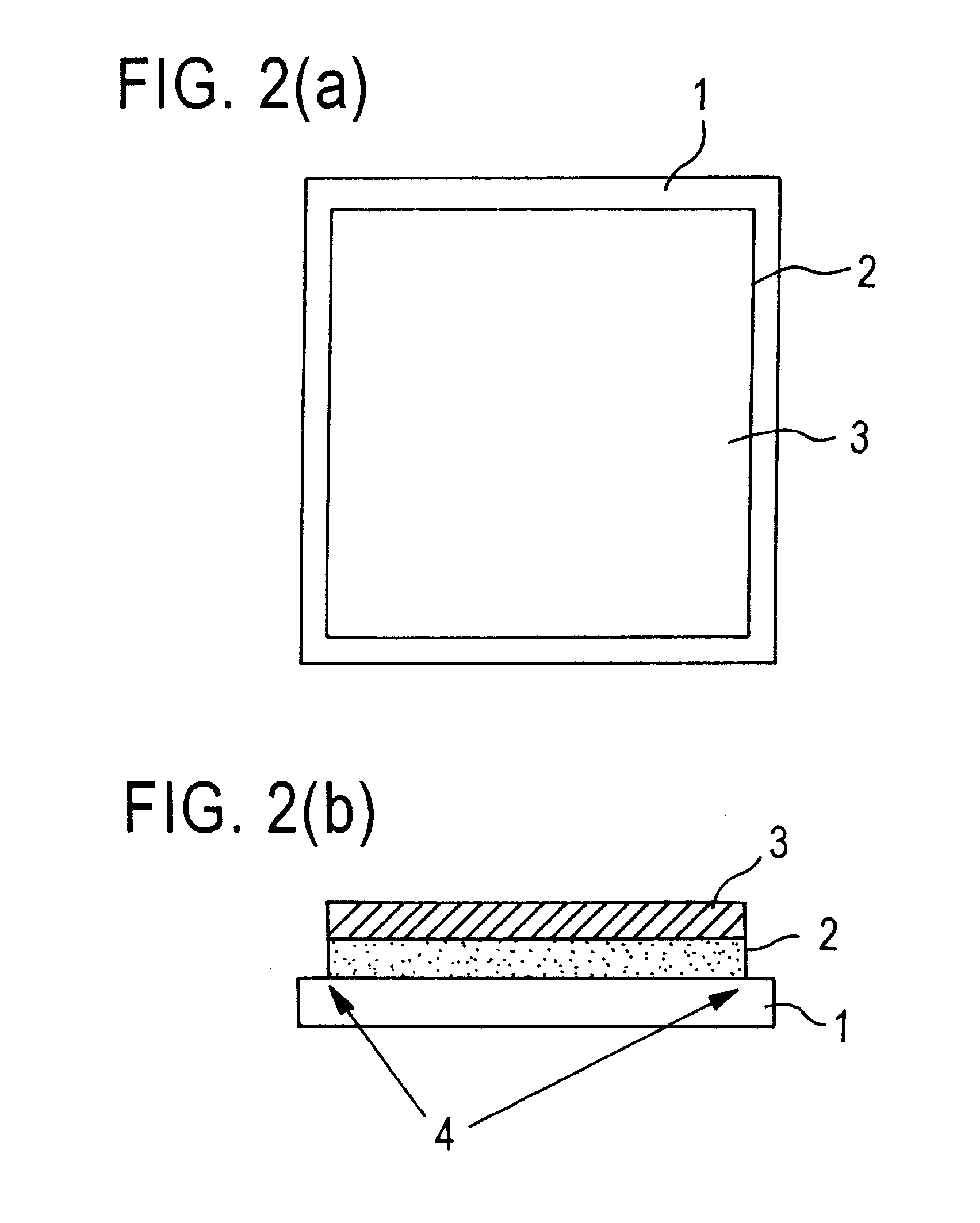

Method for producing ceramic surfaces with easily removable contact sheets

InactiveUS6139666AMinimizing the sharp edgeSemiconductor/solid-state device detailsPrinted circuit aspectsPlasticizerCompressibility

A method for making multilayer ceramic substrates having substantially reduced planar shrinkage and distortion resulting from the firing or sintering process. Contact sheets are employed in the fabrication process on the surface of the multilayer ceramic substrate to be fired with the contact sheets being prepared from a composition containing a non-sinterable non-metallic inorganic material such as alumina having an average particle size approximately about 1 micron or less and an organic binder and preferably a plasticizer. In a preferred embodiment of the invention, the multilayer structure to be fired containing the contact sheet of the invention is provided with a beveled or chamfered edge at an angle of greater than about 60 degrees. A fabrication process employing only chamfering of the edge or the use of a contact sheet of the invention also provides improved multilayer ceramic substrate products. A further feature is a method to control the surface topography of surface metallization by adjusting the compressibility of the contact sheets during fabrication of the substrate.

Owner:IBM CORP

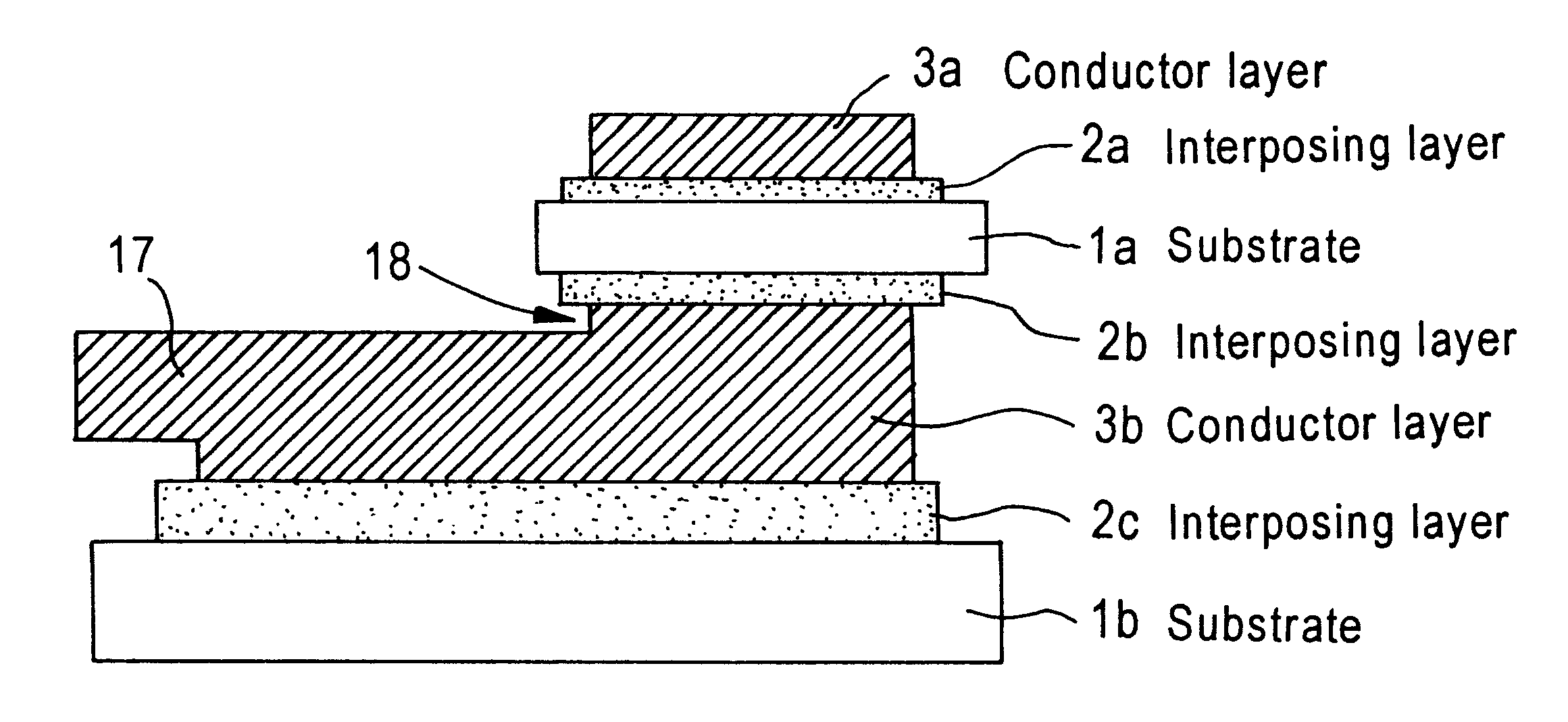

Copper circuit junction substrate and method of producing the same

InactiveUS6261703B1Avoid discharge phenomenonHigh concentration of thermal stressInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorCopper oxide

A highly reliable copper circuit-joined board that, in mounting a semiconductor element, a lead frame or the like on a ceramic substrate, enables the semiconductor element, the lead frame or the like to be strongly joined to the substrate without breaking or deformation of the substrate found in conventional joining methods, such as brazing and joining using a copper / copper oxide eutectic crystal. Any one of an interposing layer comprising a brazing material layer comprising silver and / or copper as a main component and an active metal or an interposing layer having a two-layer structure comprising a first interposing layer comprising the brazing material layer or a high-melting metallizing layer and a second interposing layer, having a melting point of 1000.degree. C. or below, comprising Ni, Fe, Cu as a main component in that order from the substrate side, is formed on a ceramic substrate, and a conductor layer, comprising copper as a main component, which, in both the lengthwise and widthwise directions, is at least 0.05 mm shorter than the interposing layer, is formed on the interposing layer to prepare a copper circuit-joined board. The copper circuit-joined board may comprise the base board having thereon an outer layer comprising Ni as a main component. A semiconductor element is mounted on the copper circuit-joined board to prepare a semiconductor device.

Owner:SUMITOMO ELECTRIC IND LTD

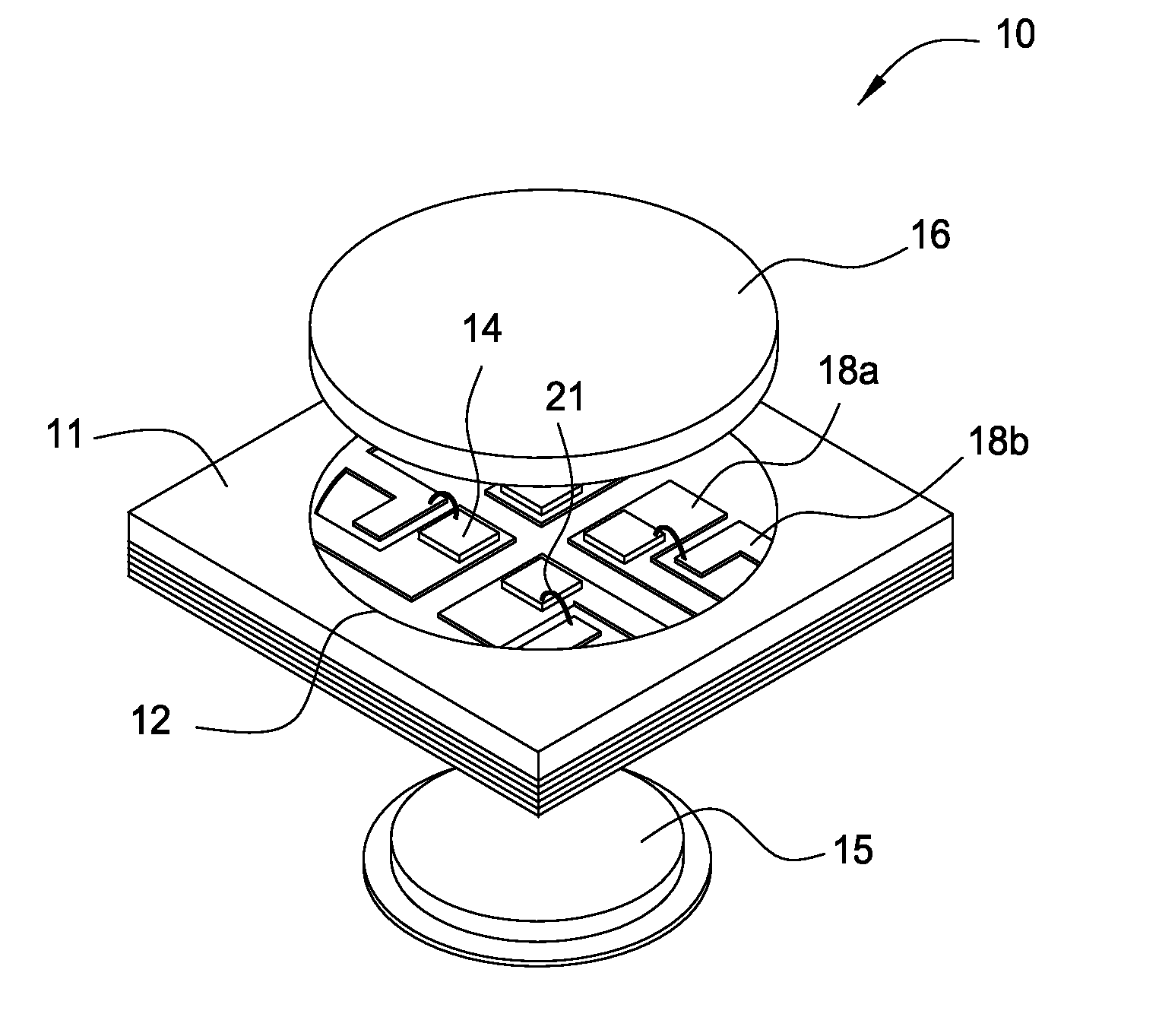

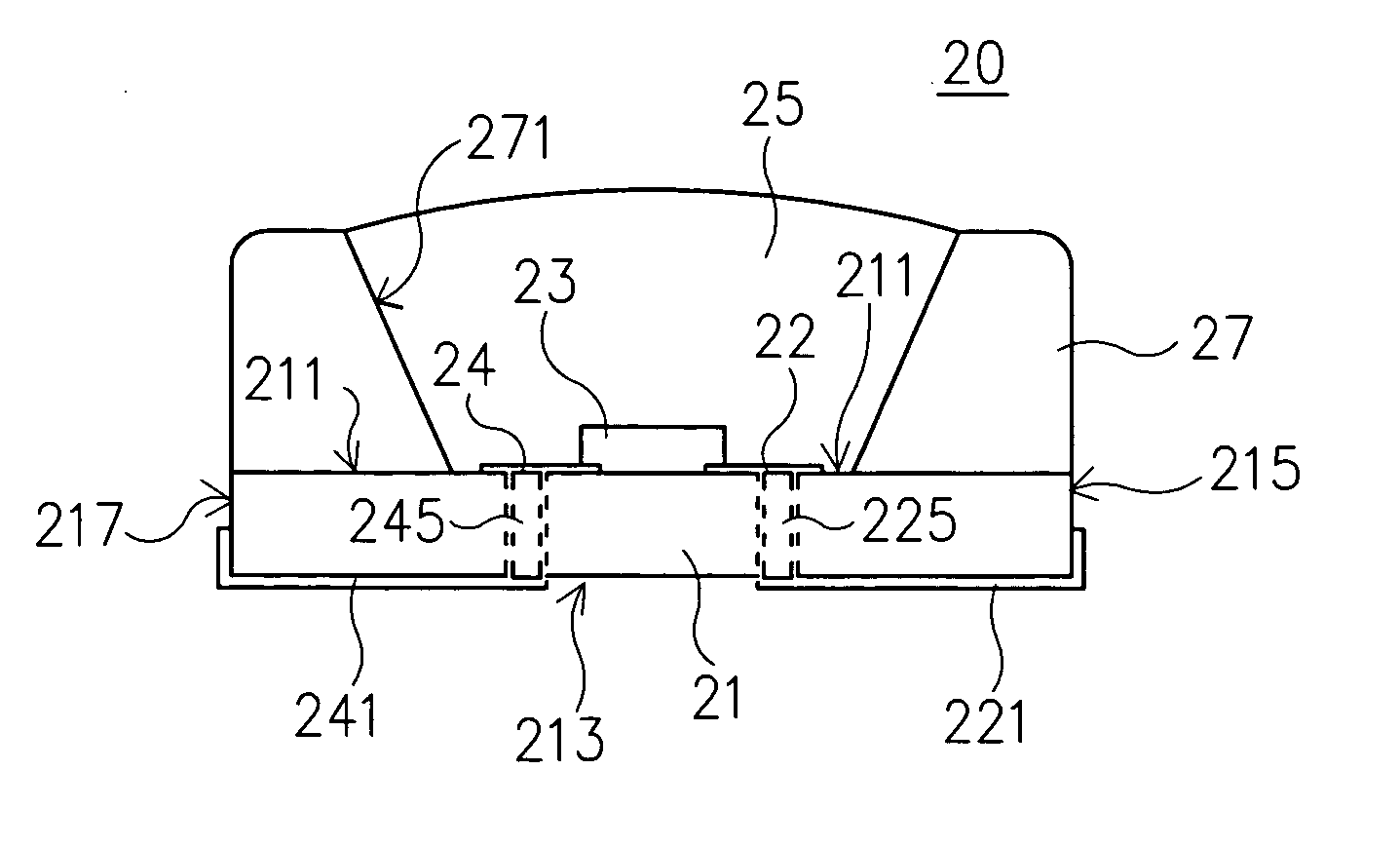

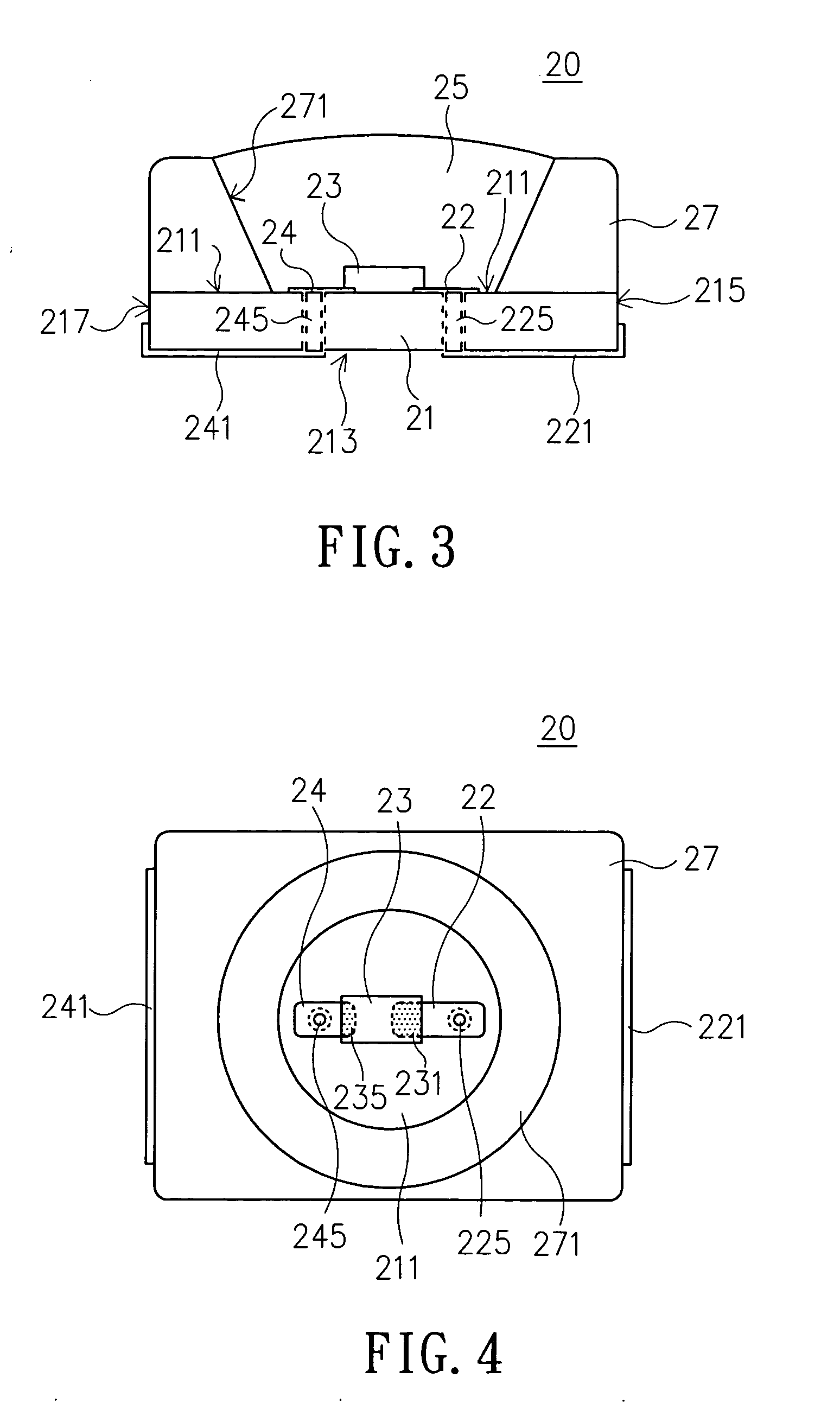

Ceramic LED package

InactiveUS20080179618A1Circuit optical detailsPrinted circuit aspectsLight-emitting diodeCeramic substrate

Light-emitting diode (LED) packages with improved heat transfer paths for LED dies encased therein when compared to conventional LED packages are provided. For some embodiments, the LED package includes a ceramic substrate having a top cavity with one or more LED dies disposed within and having a bottom cavity for receiving a metallic insert to dissipate heat away from the LED dies. For other embodiments, an LED package is provided that includes a ceramic substrate having a heat spreader coupled to thermal vias filled with a highly thermally conductive composite.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

Electrochemical apparatus with barrier layer protected substrate

InactiveUS20080003496A1High crystallinityMore flexibleCell electrodesBattery isolationDiffusion barrierElectrochemistry

The present invention relates generally to fabricating well performing thin-film batteries onto metallic substrates, polymeric substrates, and doped and undoped silicon substrates. More specifically, the invention may include fabricating an appropriate diffusion barrier layer between the substrate and the battery part of the present invention that separates said two parts chemically during the entire battery fabrication process and the operation and storage conditions of the electrochemical apparatus during its entire lifetime. In one embodiment of the present invention, thin-film batteries fabricated onto a thin, flexible, stainless steel foil substrate using an appropriate diffusion layer show uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for the LiCoO2 positive cathode.

Owner:SAPURAST RES

Thermal management of surface-mount circuit devices on laminate ceramic substrate

InactiveUS20060109632A1Improved thermal managementSemiconductor/solid-state device detailsPrinted circuit aspectsSurface mountingPower circuits

Owner:DELPHI TECH INC

Ink providing etch-like effect for printing on ceramic surfaces

ActiveUS8163077B2Other chemical processesDuplicating/marking methodsCeramic substrateComposite material

The invention relates to an ink-jet ink composition for printing on a ceramic substrate comprising: (a) a liquid vehicle; (b) sub-micron particles of binding composition having a melting point below 6000 C; and (c) sub-micron particles causing an etch-like effect, said sub-micron particles are selected from metal oxide particles, high melting point frit particles, and a combination thereof, said sub-micron particles causing an etch-like effect have a melting point of at least 500 C above the melting point of said sub-micron particles of binding composition. The invention further relates to a printing process using such ink and to a ceramic substrate printed with a pattern or image having an etch-like effect, by means of the printing process.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

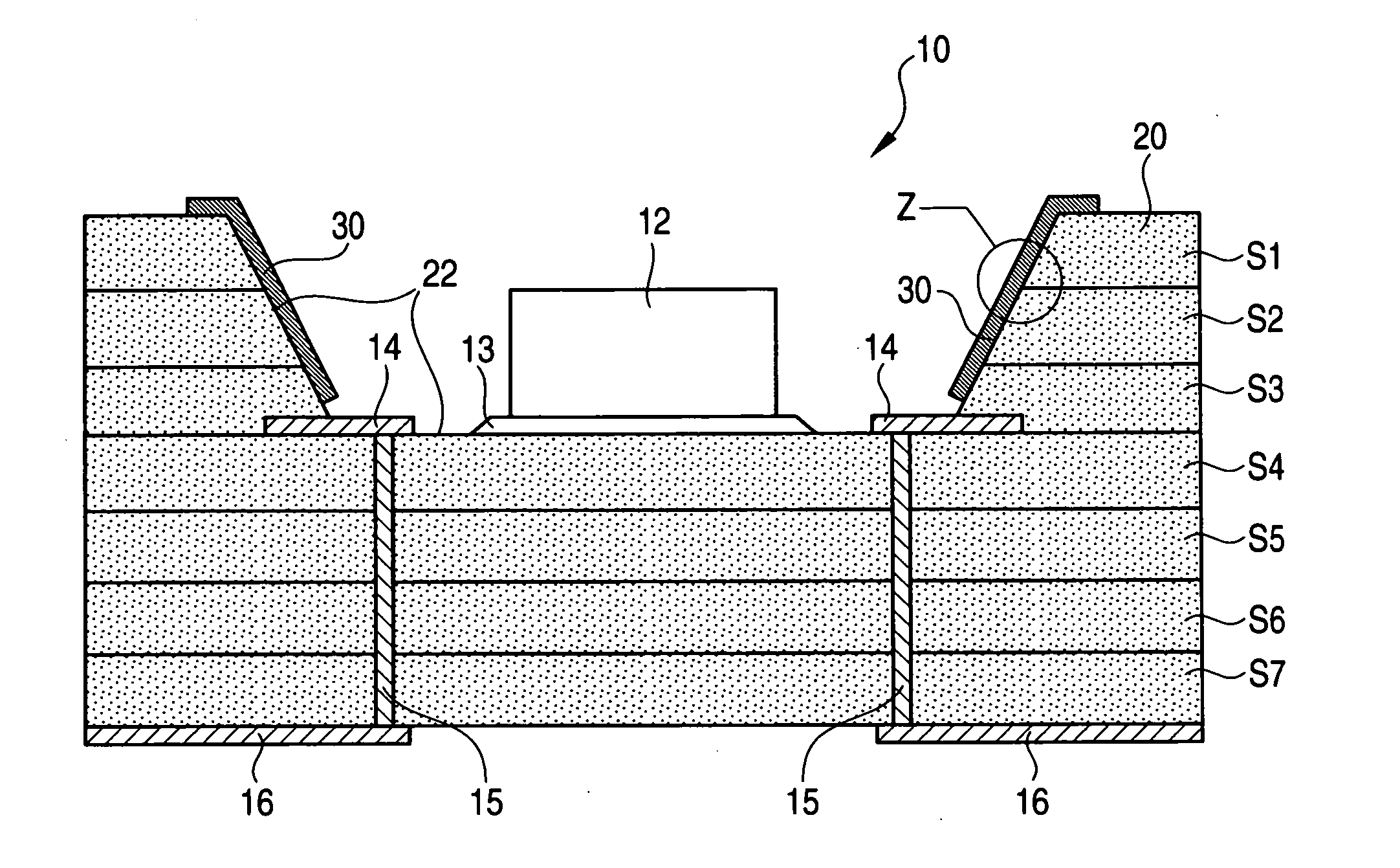

Ceramic substrate, ceramic package for housing light emitting element

InactiveUS20060147746A1Reduce smoothnessIncrease costExtrusion containersSolid-state devicesGold layerCeramic substrate

A ceramic substrate comprising a metallic layer on its surface, wherein said metallic layer includes: a silver layer containing silver; a gold layer containing gold; and a nickel layer containing nickel, in this order from an outermost layer of said metallic layer.

Owner:NGK SPARK PLUG CO LTD

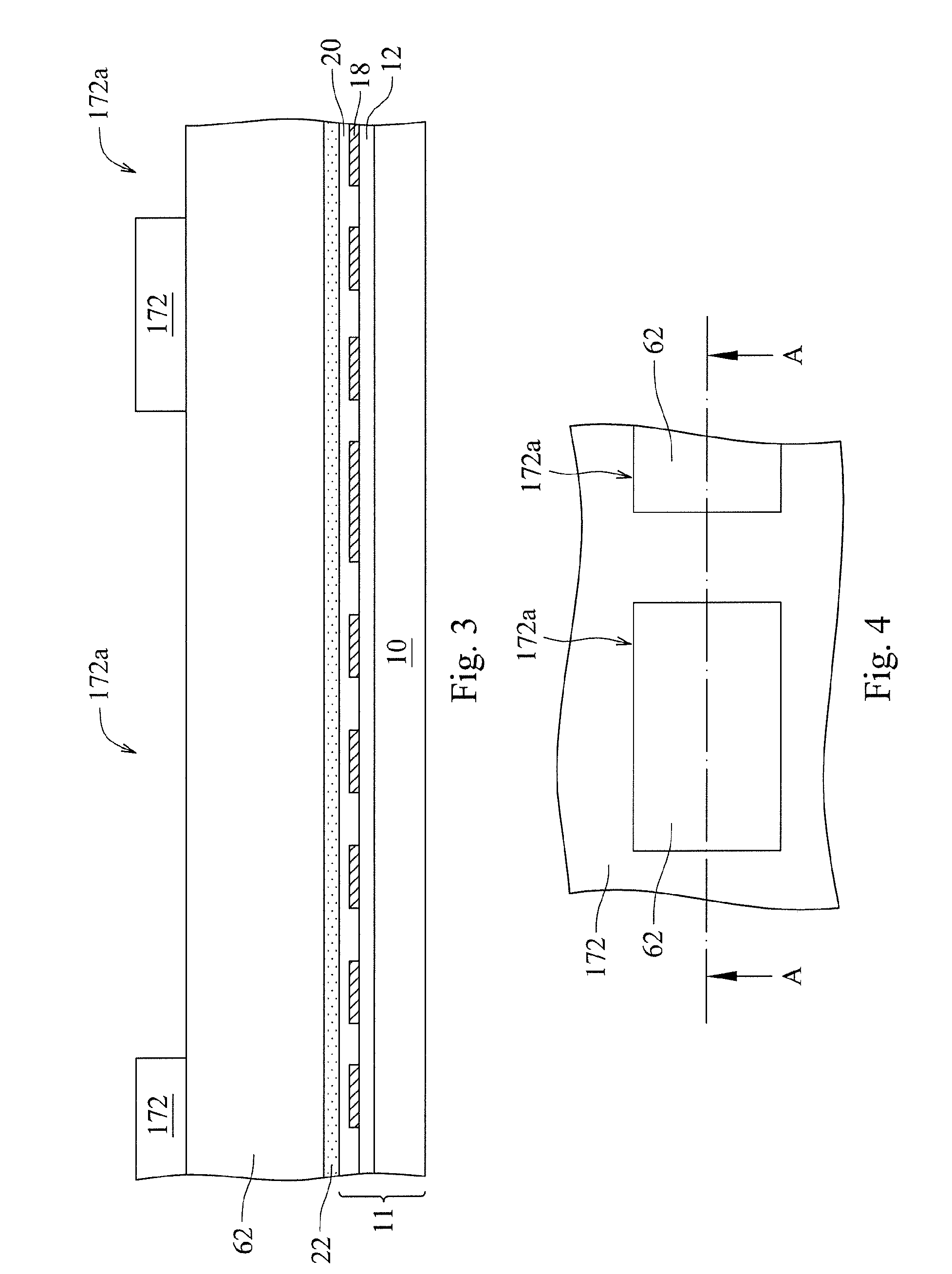

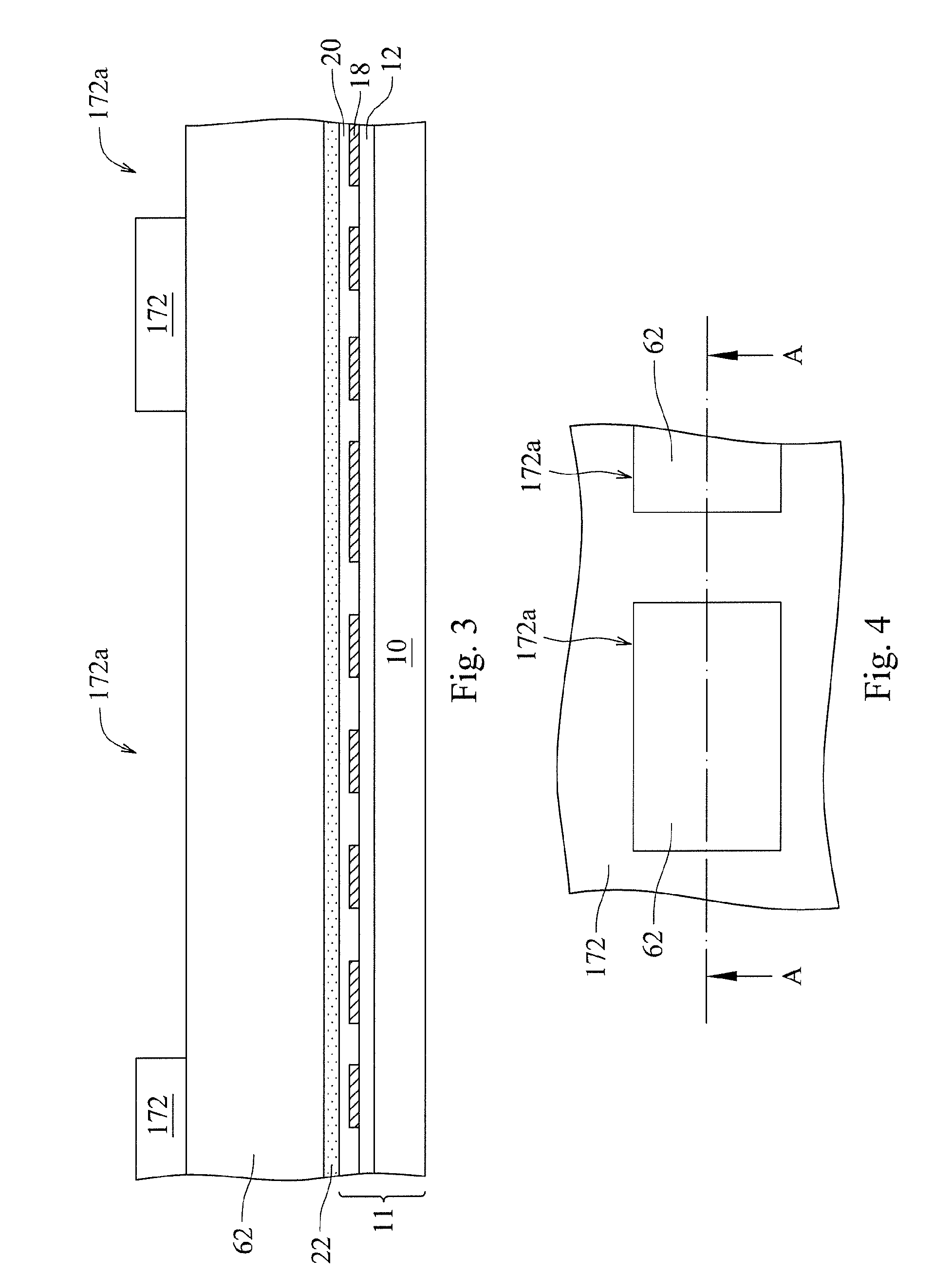

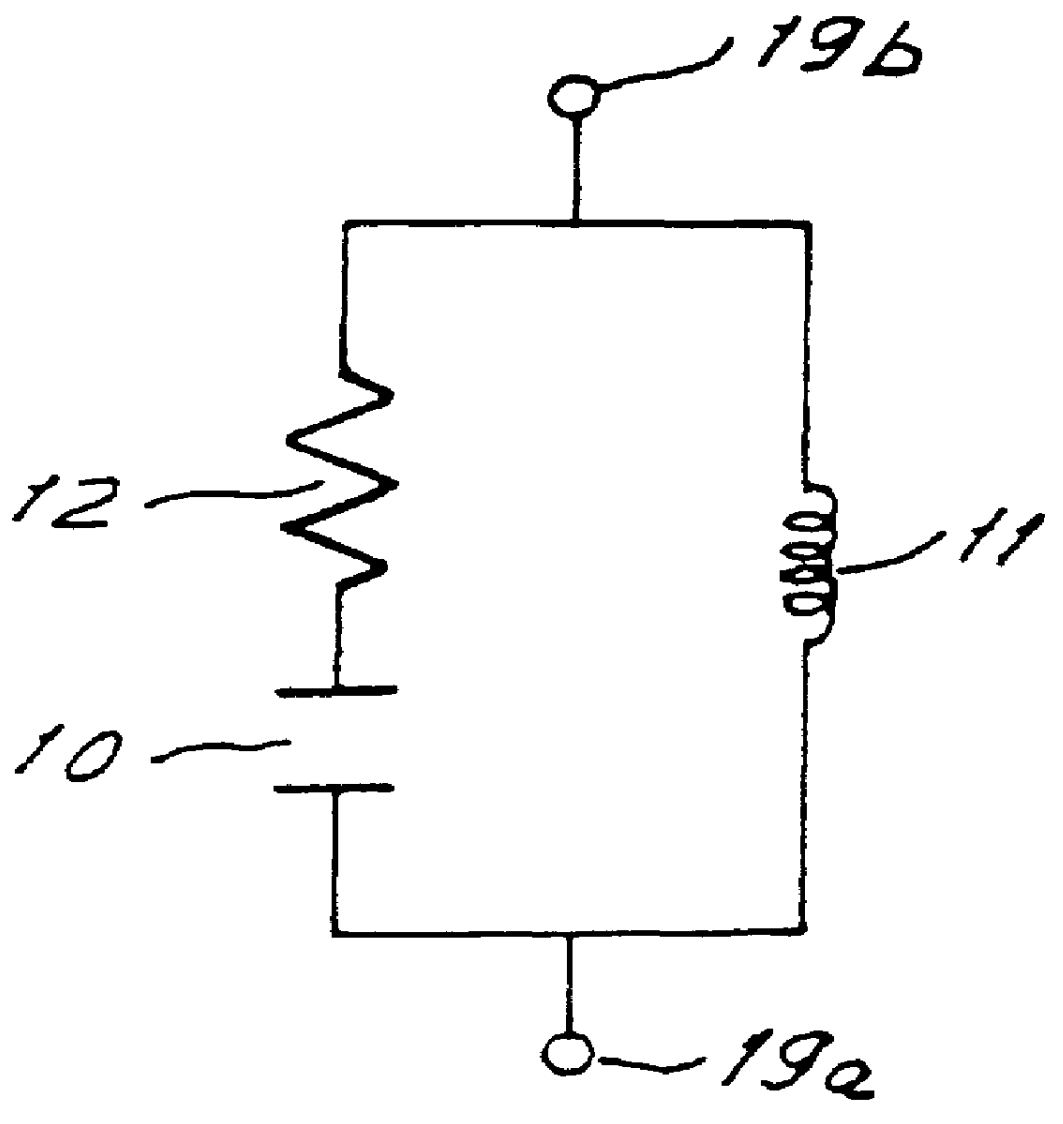

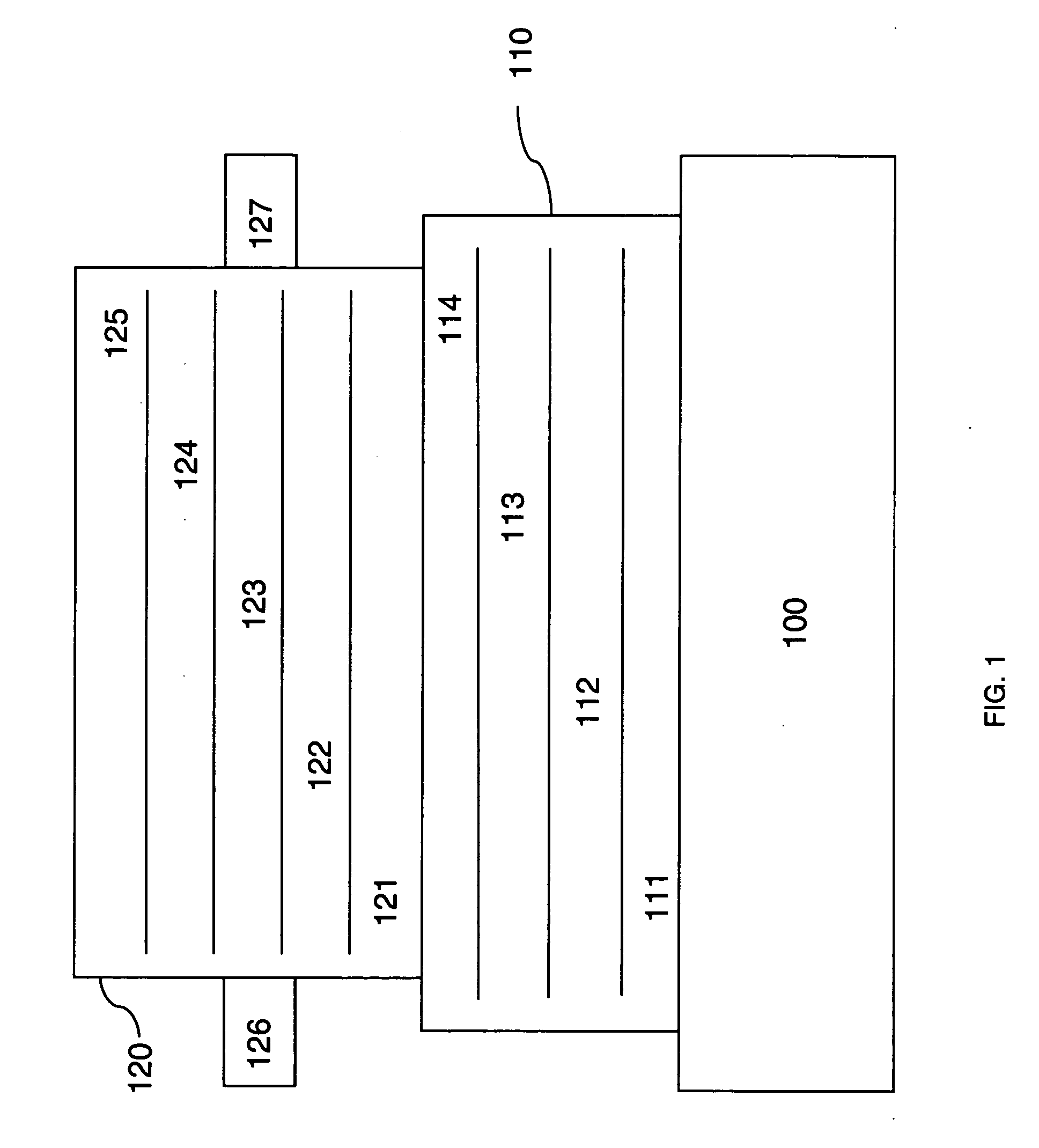

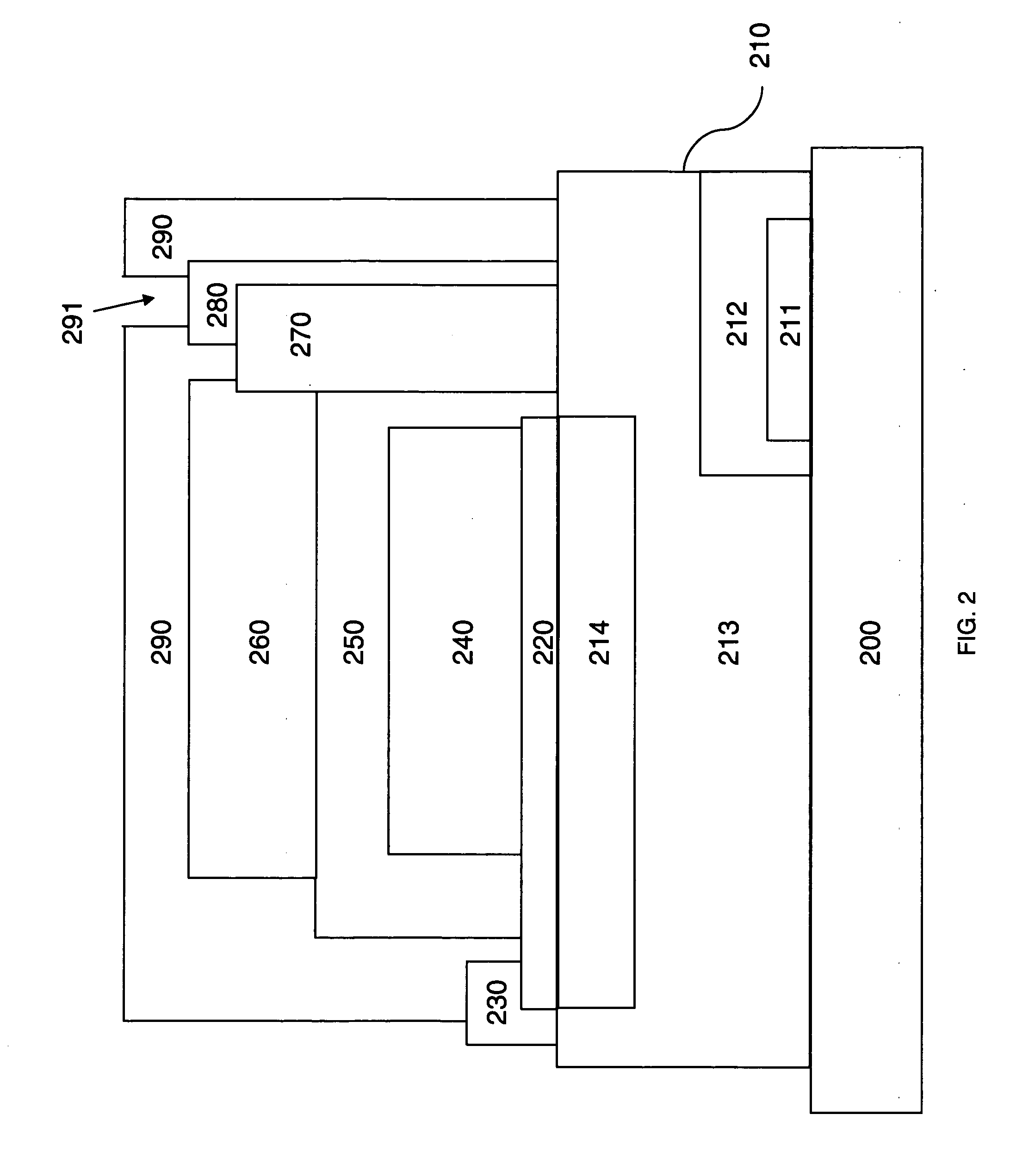

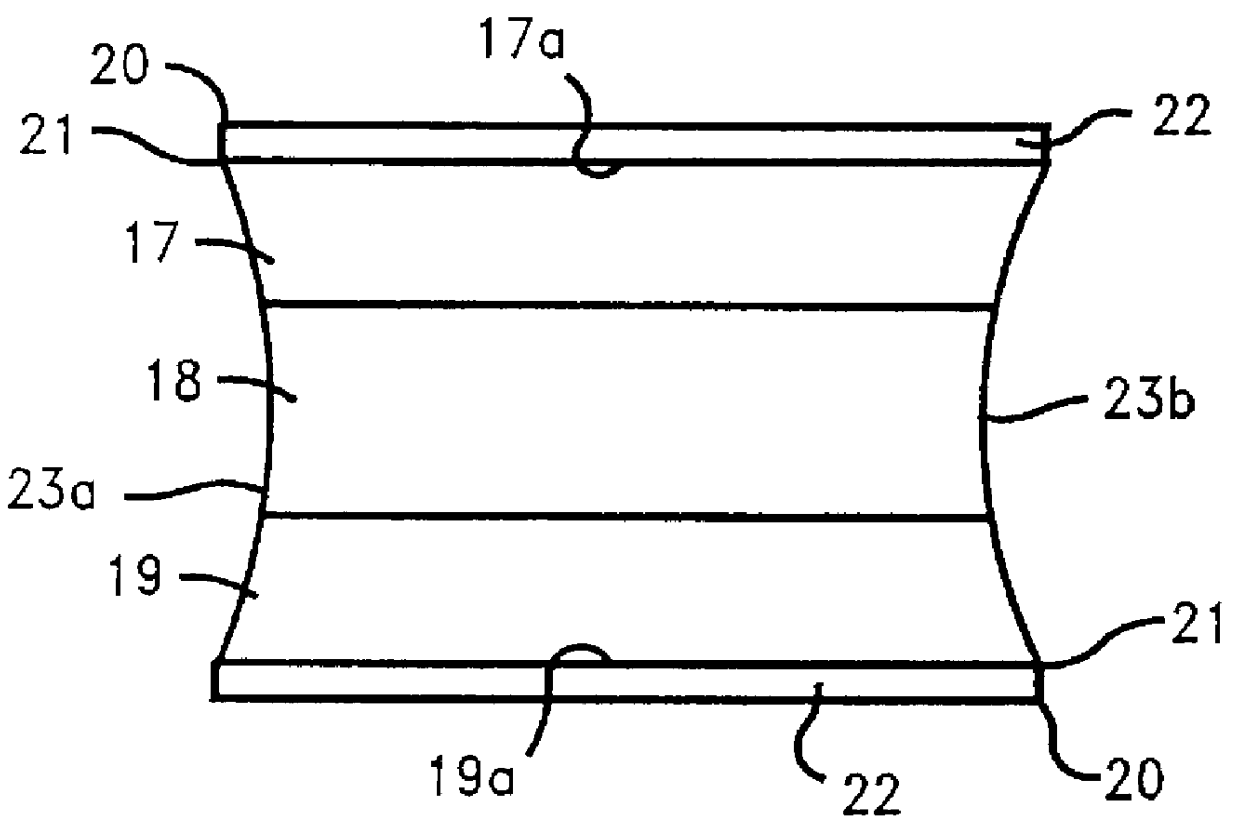

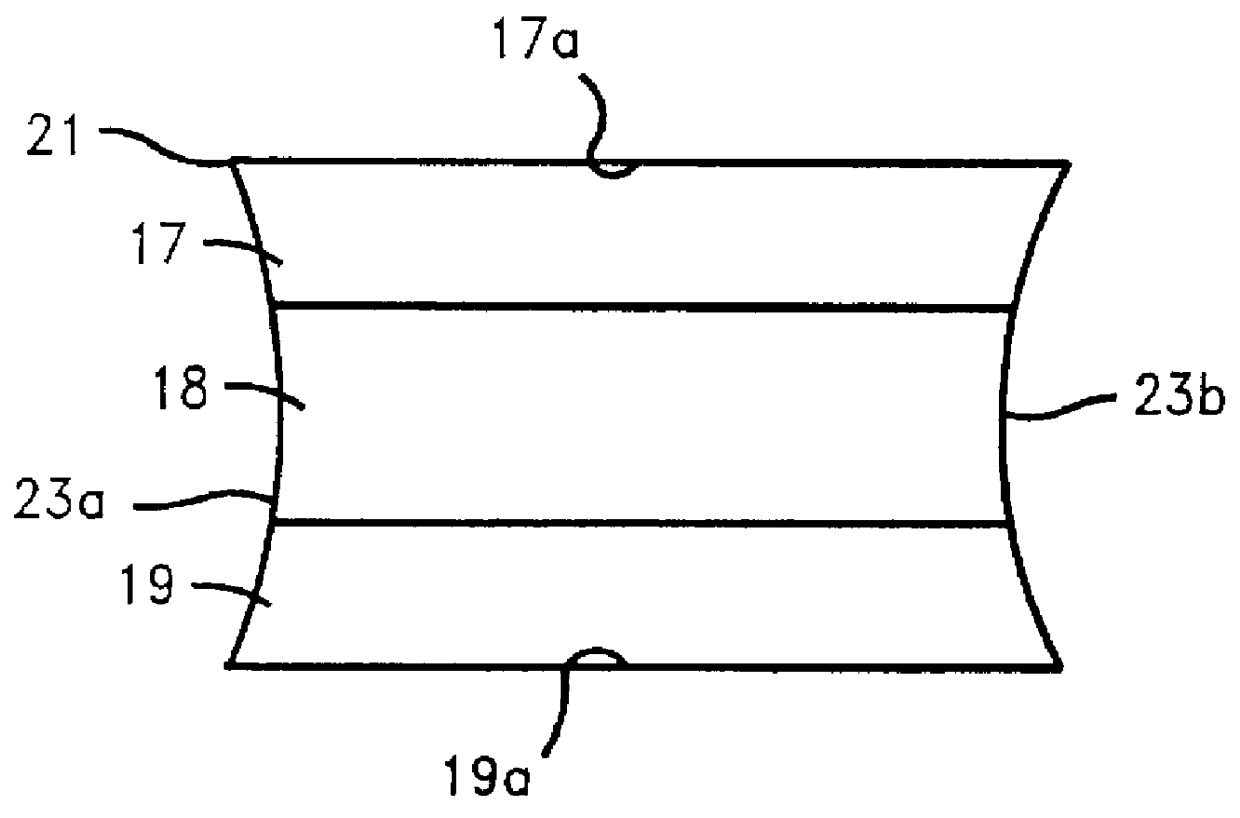

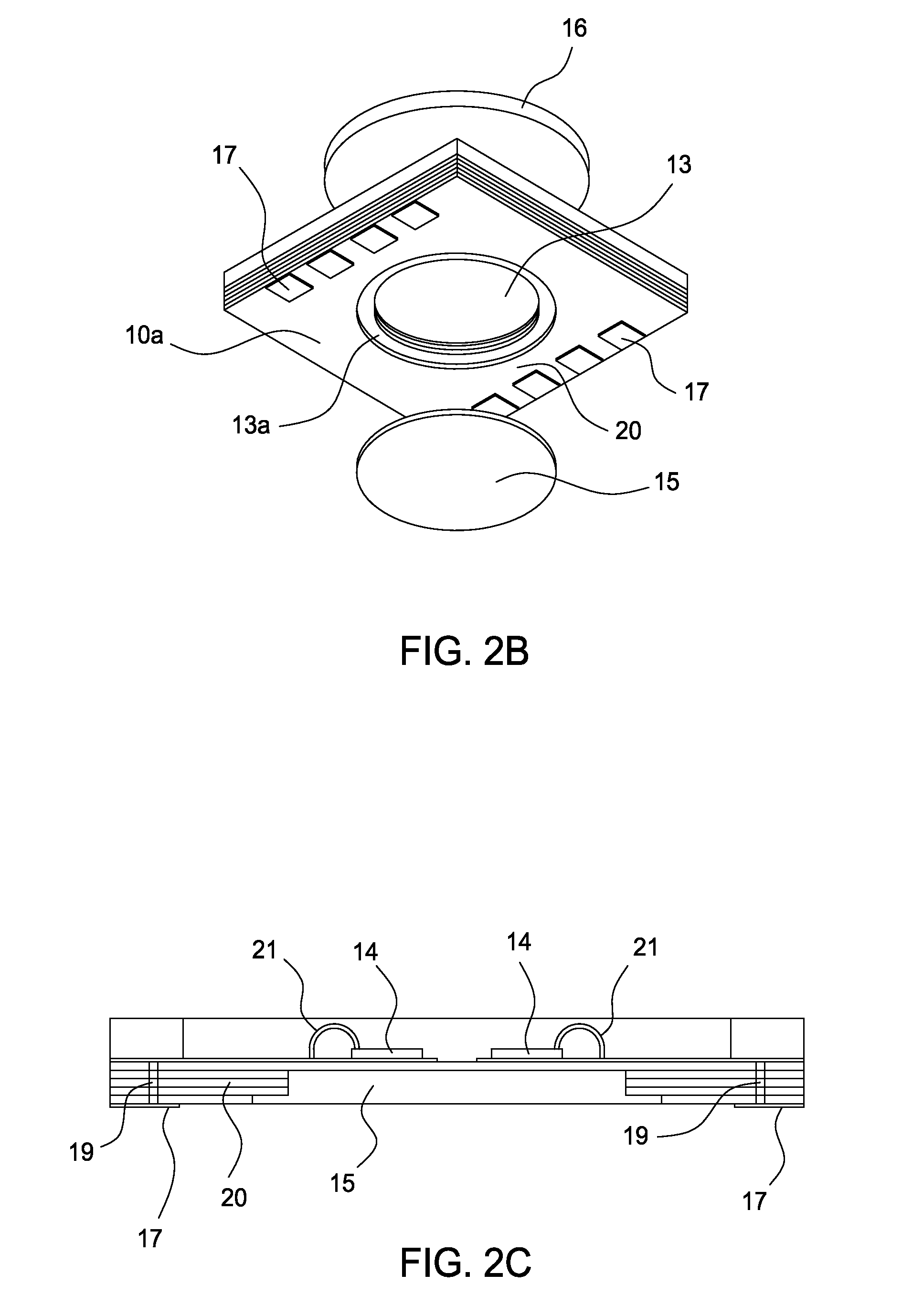

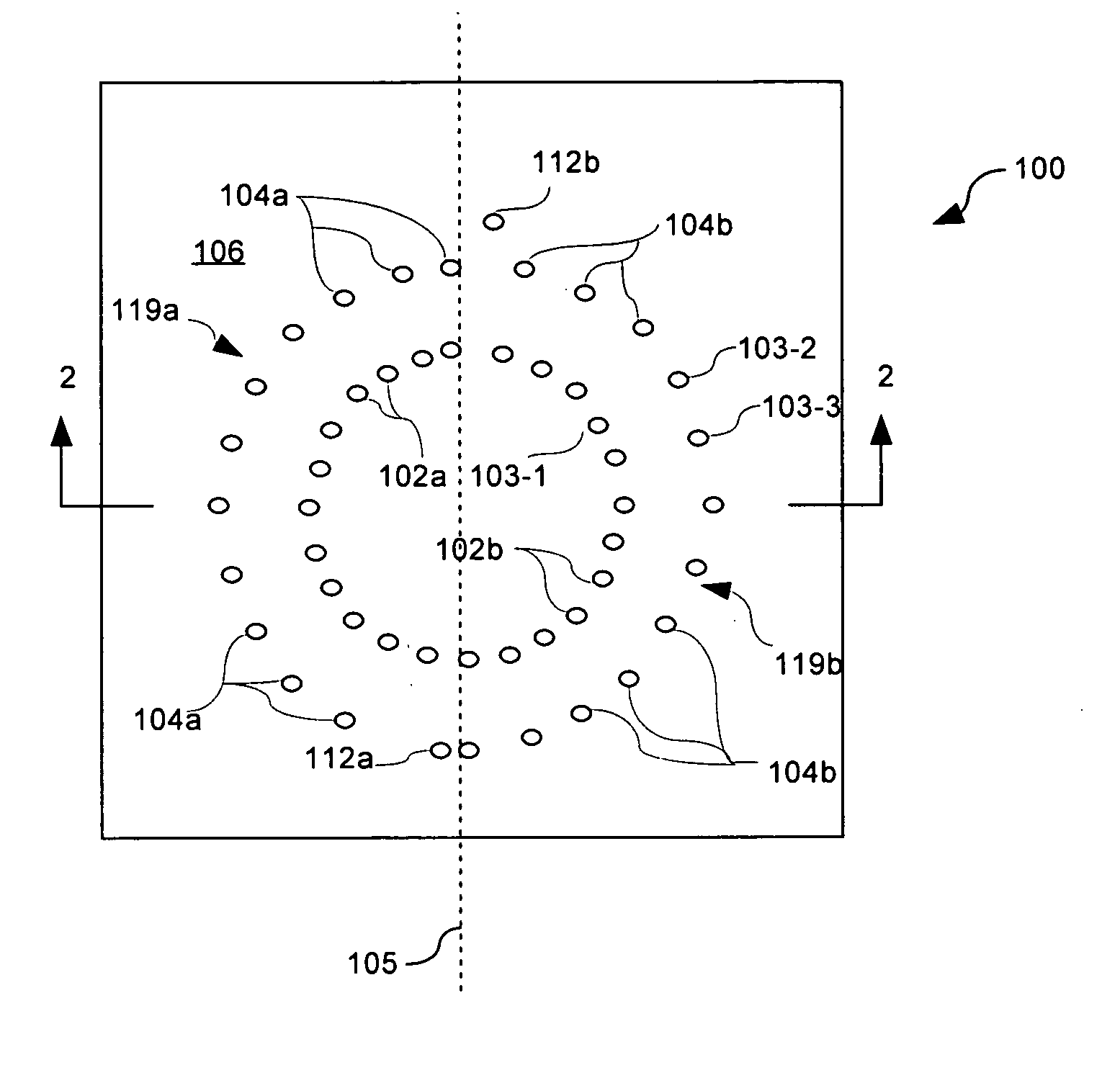

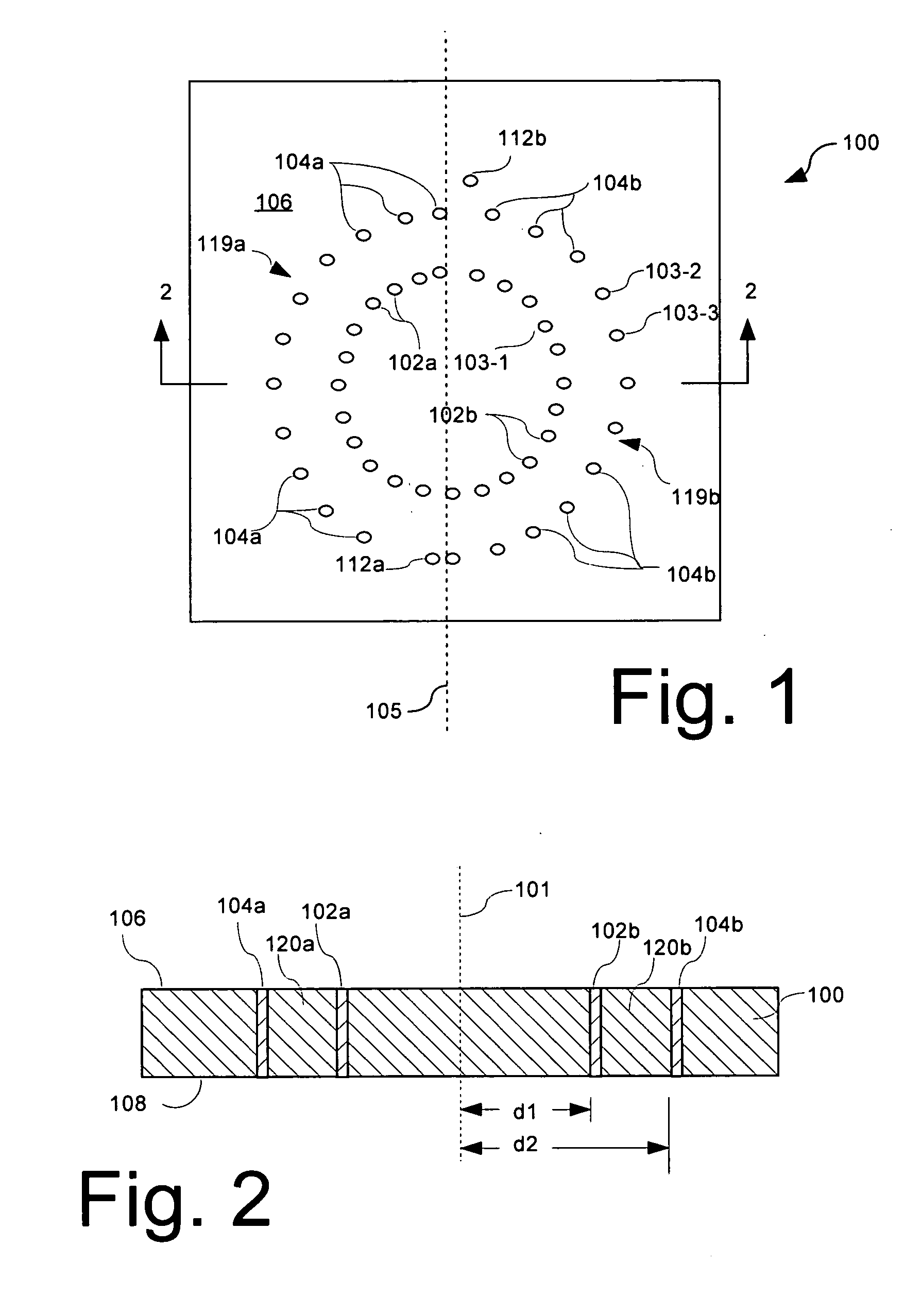

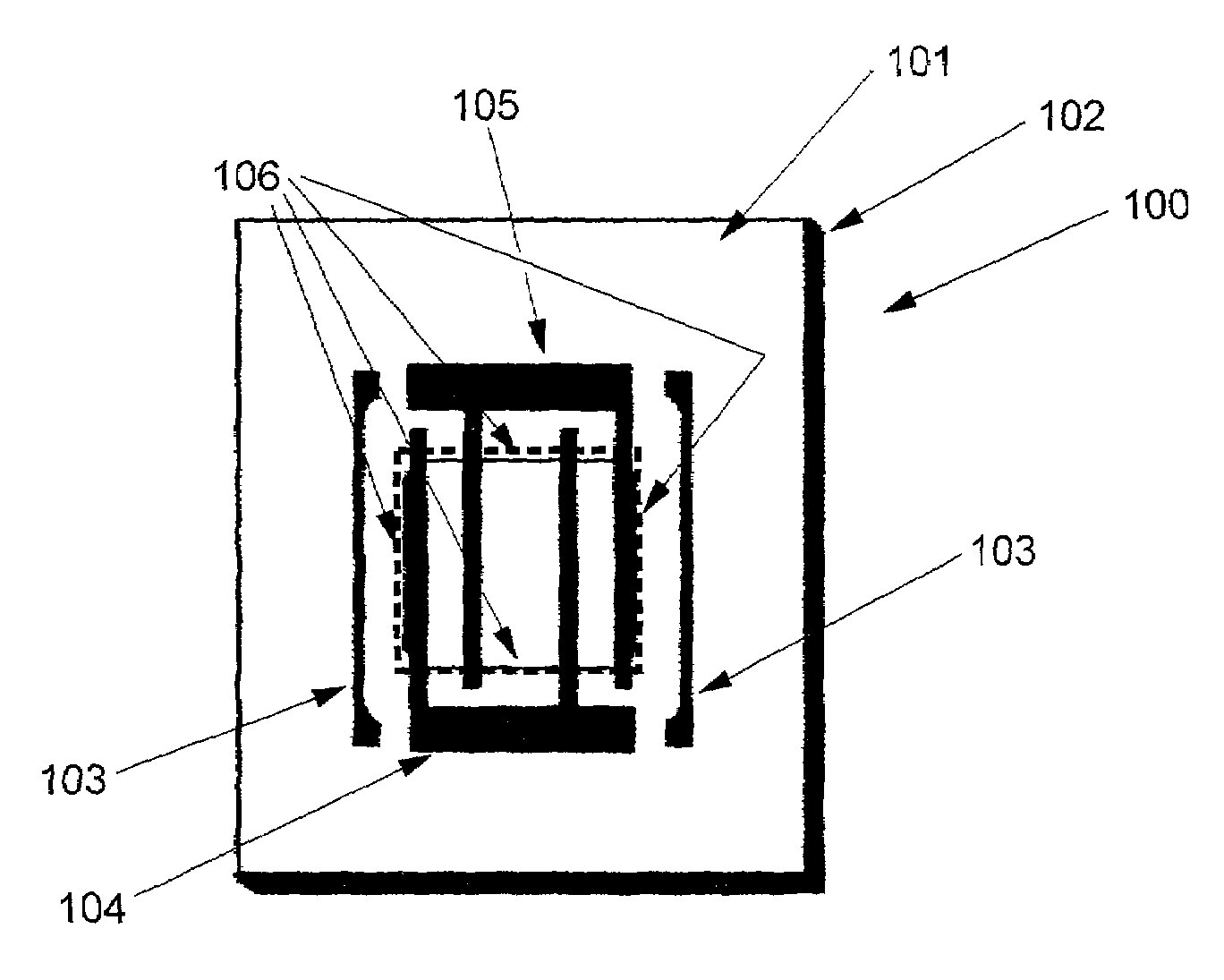

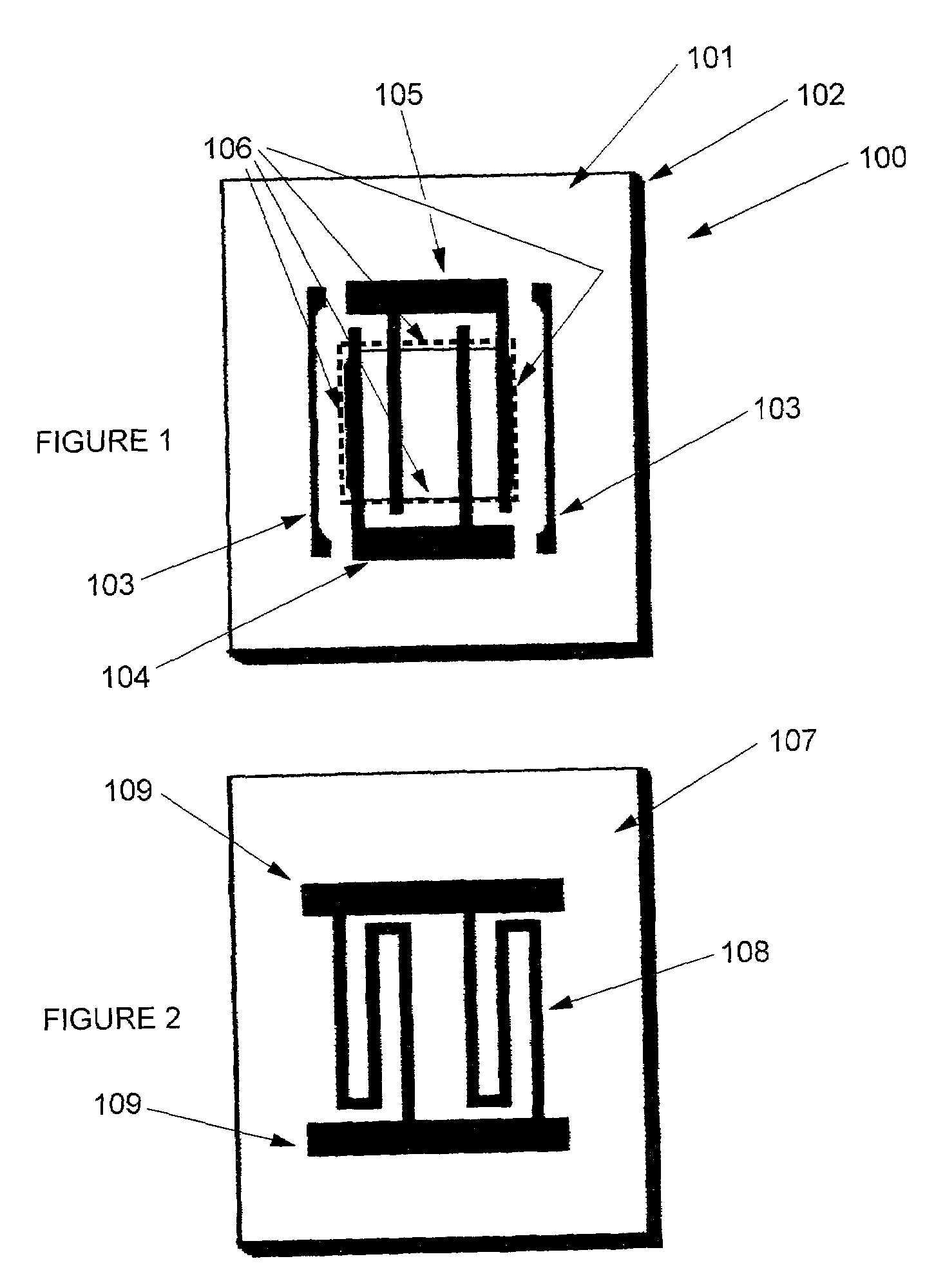

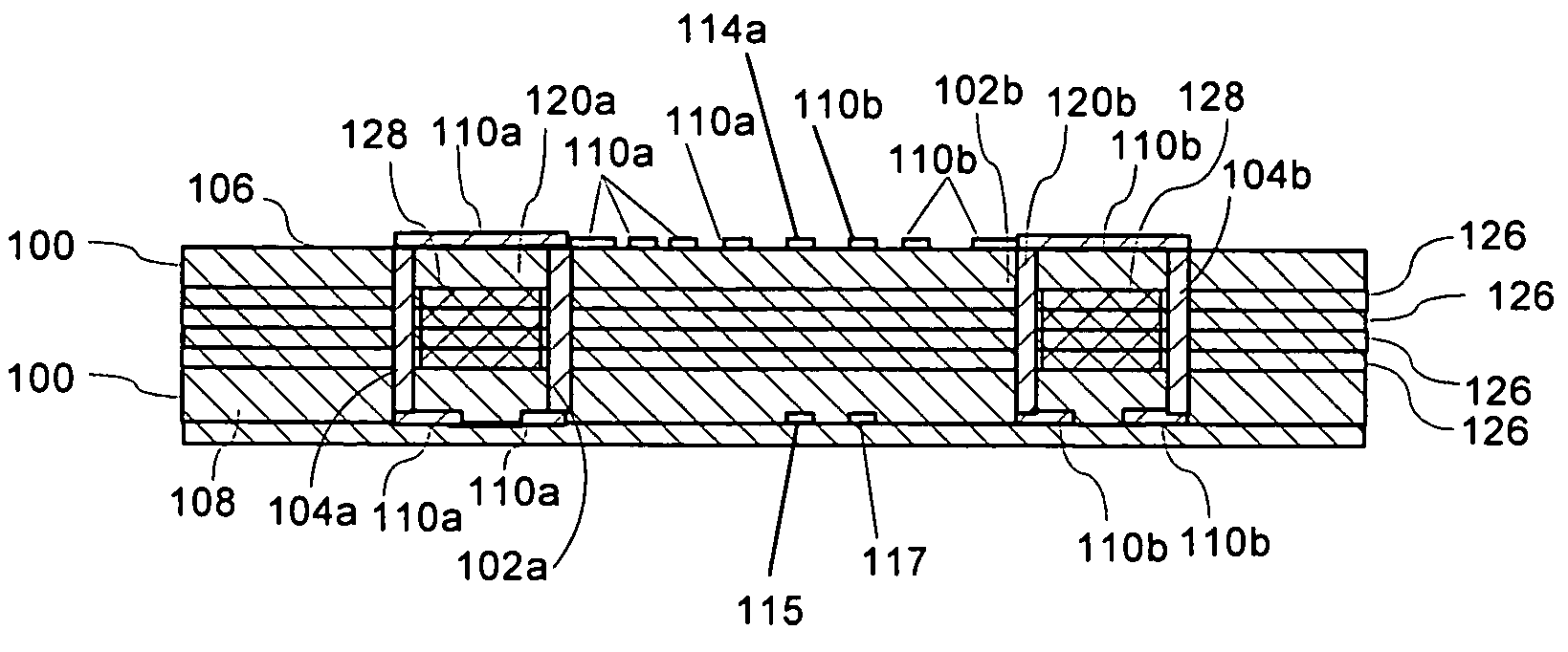

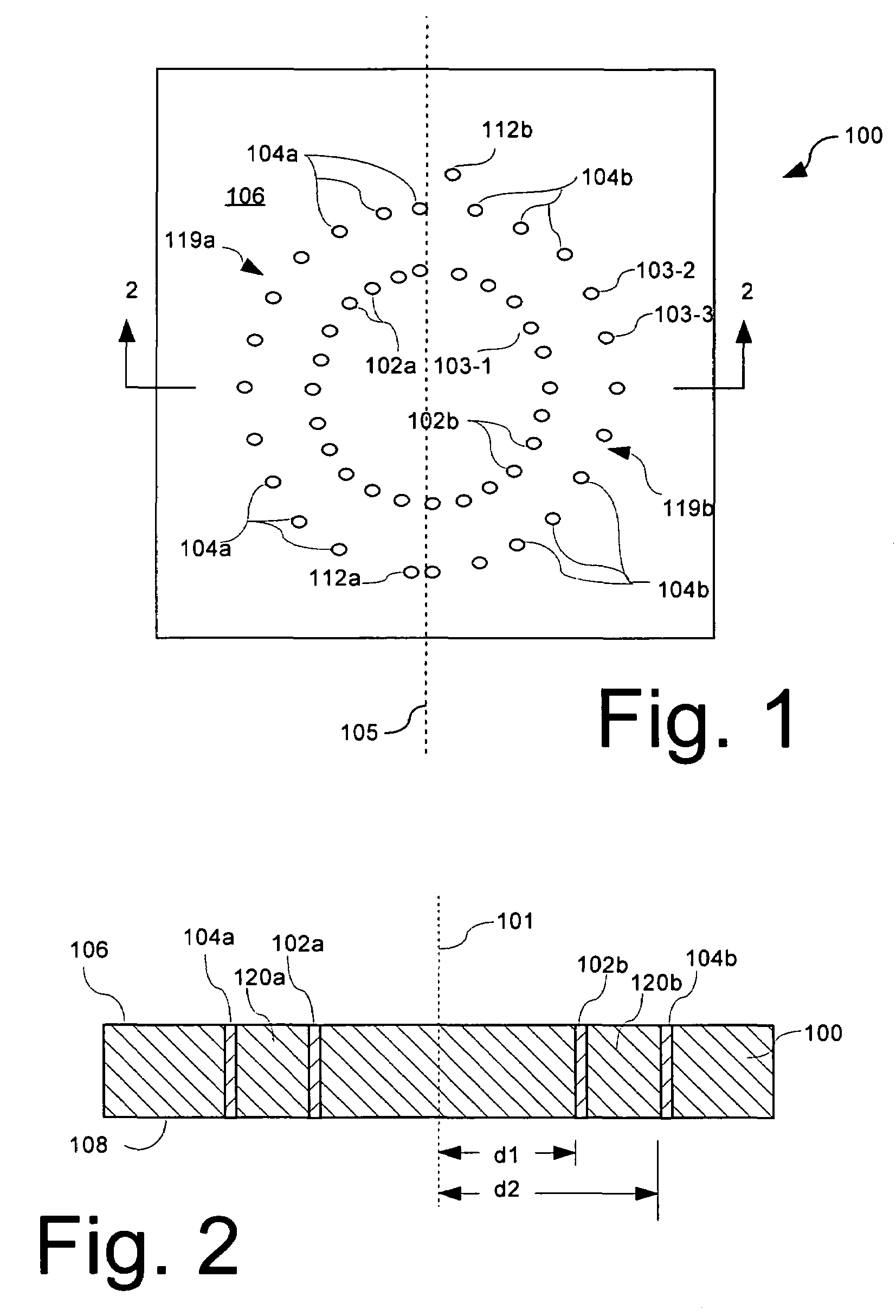

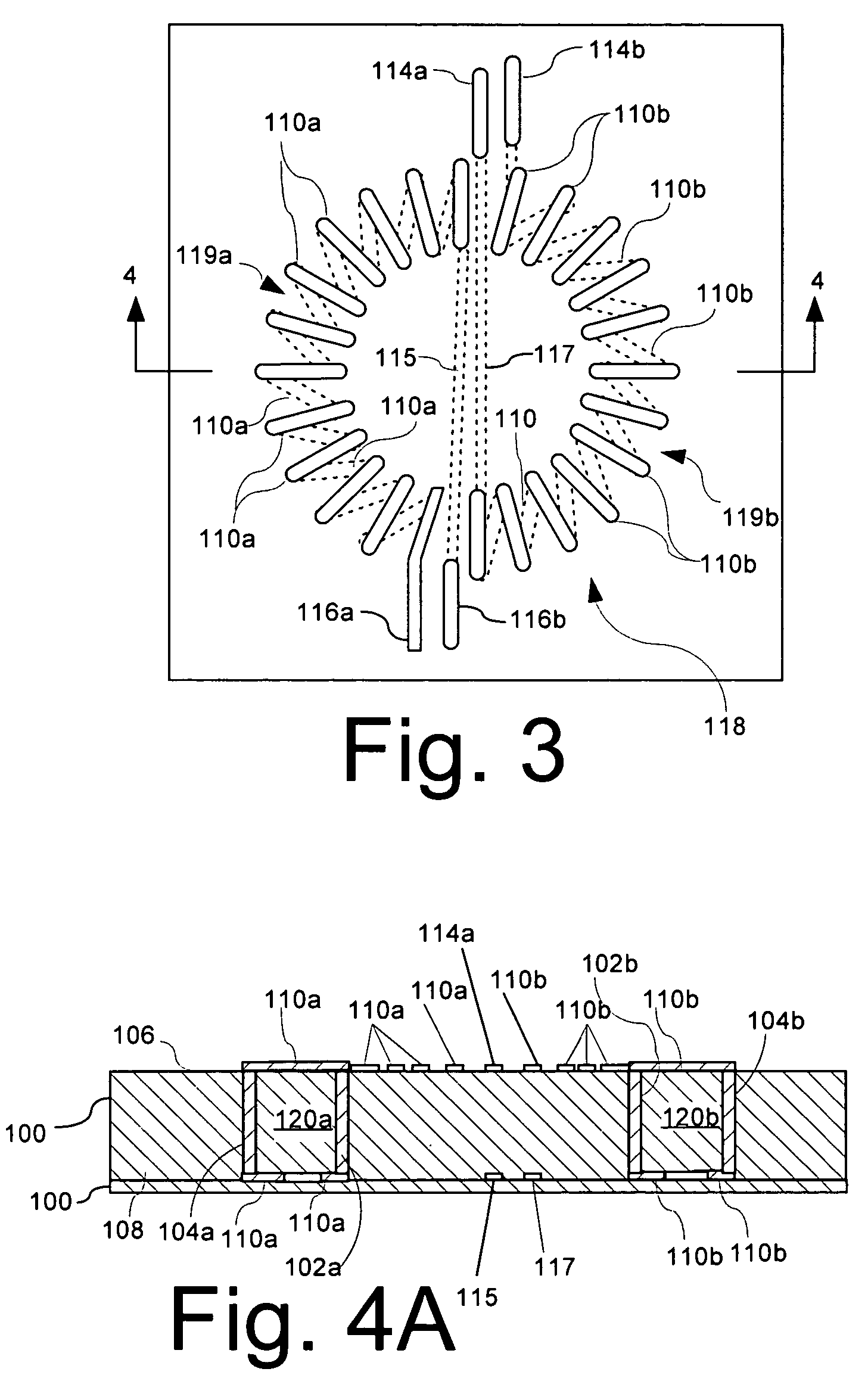

Embedded toroidal transformers in ceramic substrates

ActiveUS20050212642A1Semiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsMetallurgyTransformer

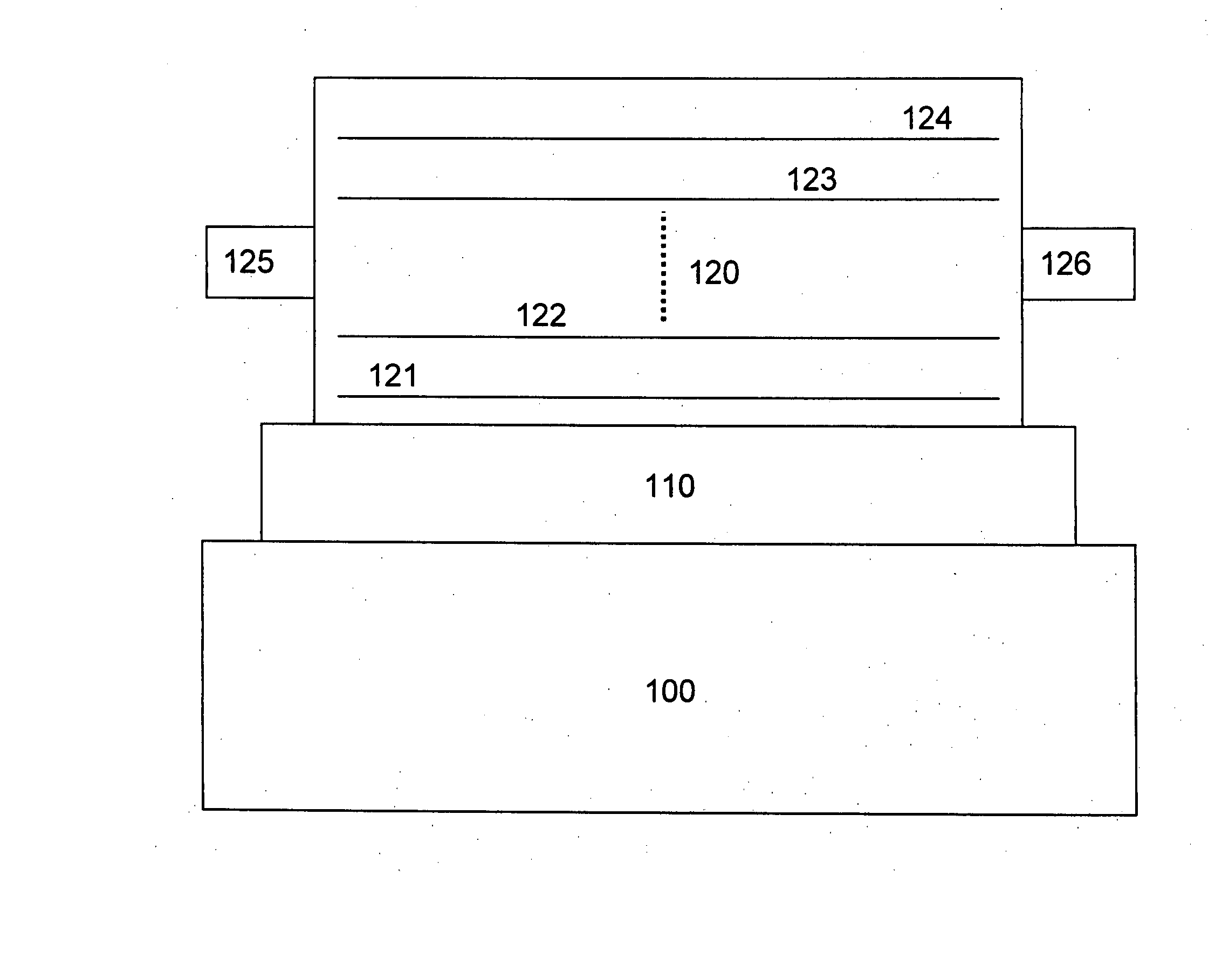

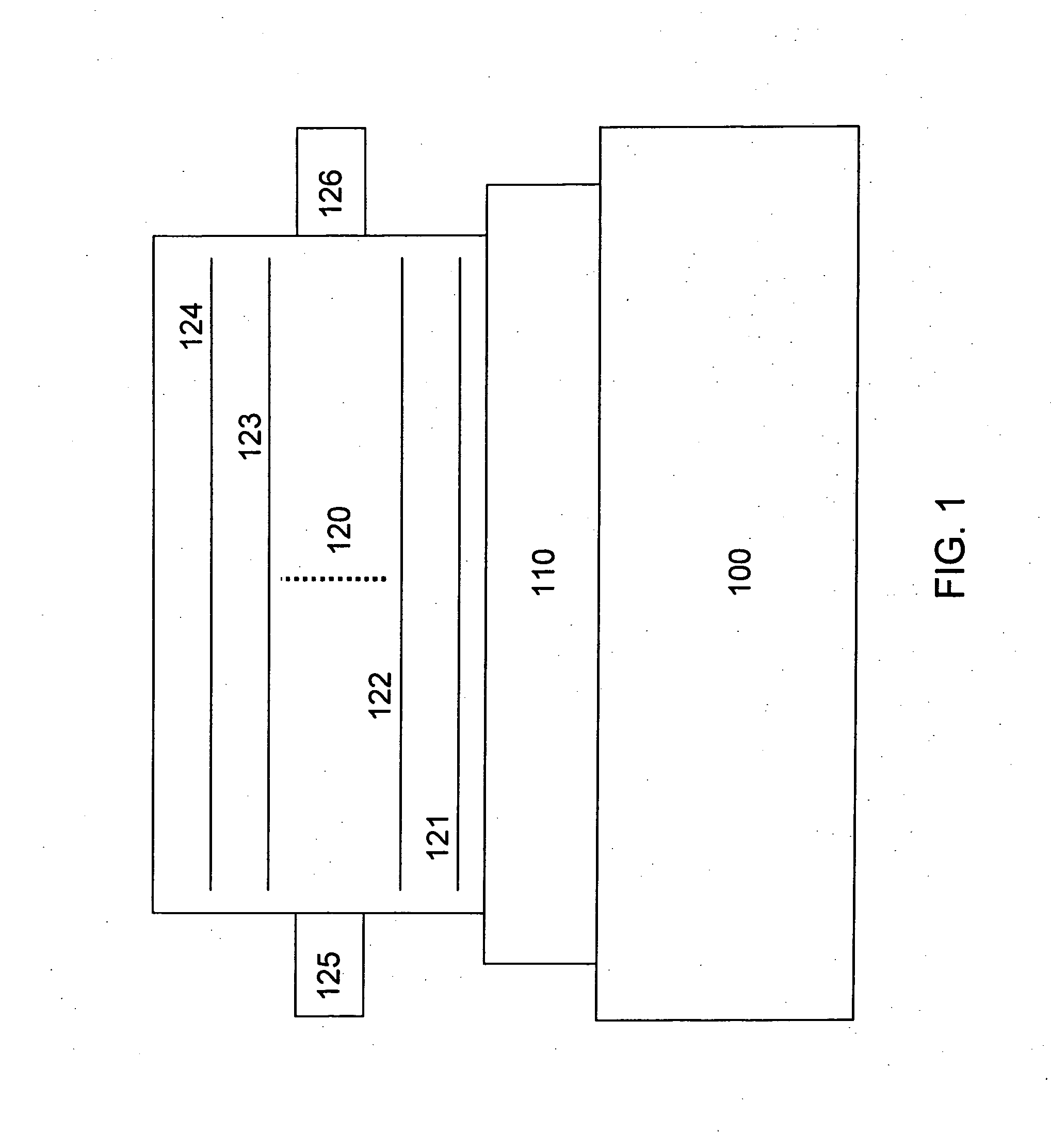

Method for forming a transformer (118) in a ceramic substrate. The method can include the steps of forming at least one conductive coil (119a, 119b) comprising a plurality of turns about an unfired ceramic toroidal core region (120a, 120b) defined within an unfired ceramic substrate (100). The method can also include the step of co-firing the unfired ceramic toroidal core region (120a, 120b), the unfired ceramic substrate (100), and the conductive coil (119a, 119b) to form an integral ceramic substrate structure with the conductive coil at least partially embedded therein.

Owner:HARRIS CORP

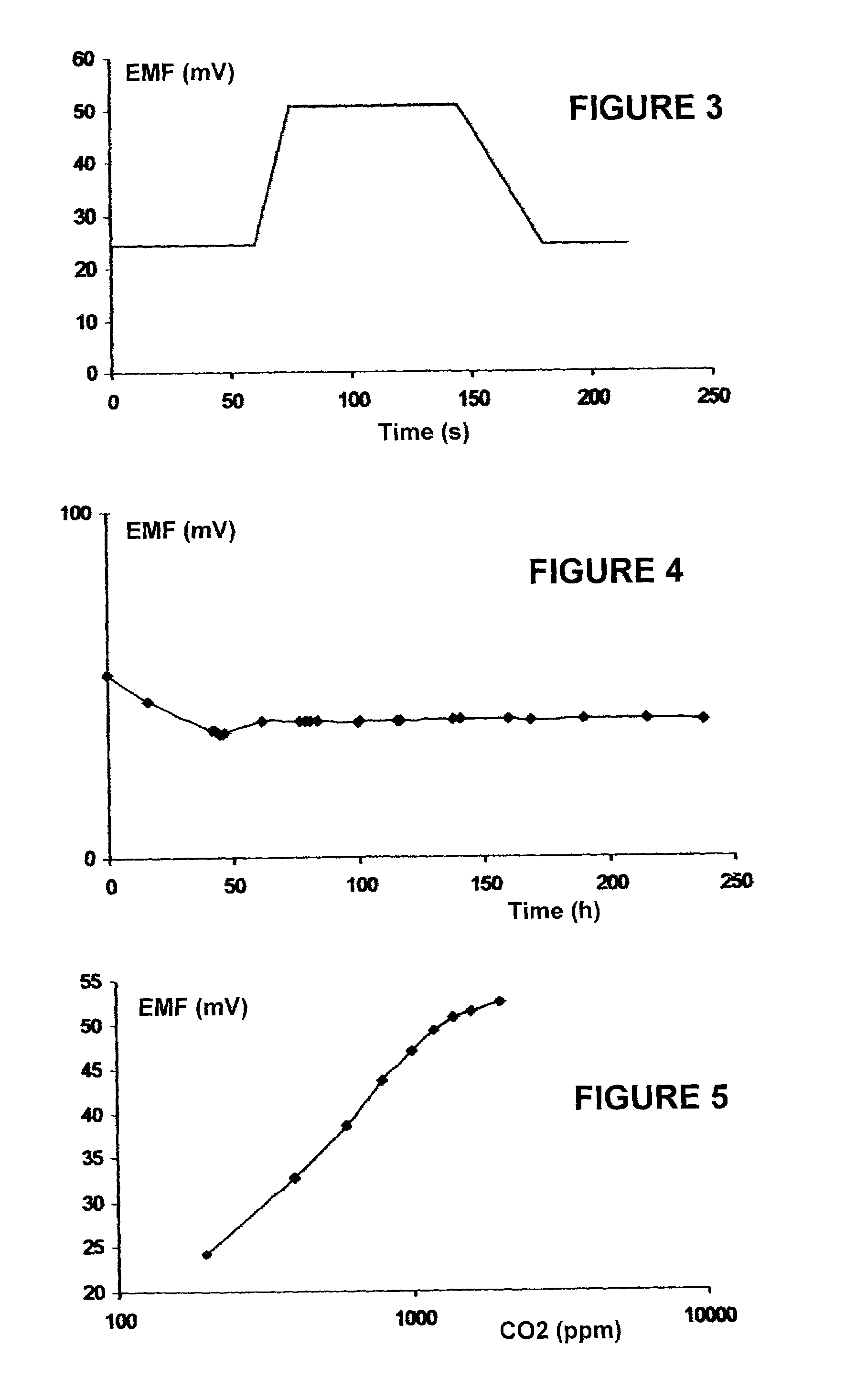

Gas component sensor for gas oxides

InactiveUS7001495B2Additional sensorExcellent chemical stability and thermal compatibilityWeather/light/corrosion resistanceElectrolytic capacitorsElectrochemical responseGas composition

The present invention is a gas component sensor comprising novel electrolyte compositions. The electrolyte compositions in bulk, sintered or thin film embodiments are capable of forming with different-metal sensing and reference electrodes a highly stable gas oxide sensors. The novel electrolyte composition changes electrochemical reactions at the sensing and reference electrodes and the overall reaction of the electrodes and electrolyte. The novel electrolyte compositions have: (1) excellent chemical stability and thermal compatibility as to the electrodes and a preferred ceramic substrate, (2) excellent chemical stability with the environment as to the reference and sensing electrodes, which need not be sealed against the atmosphere to be sensed, (3) effective adherence to the substrate and electrode metals.

Owner:AIR Q

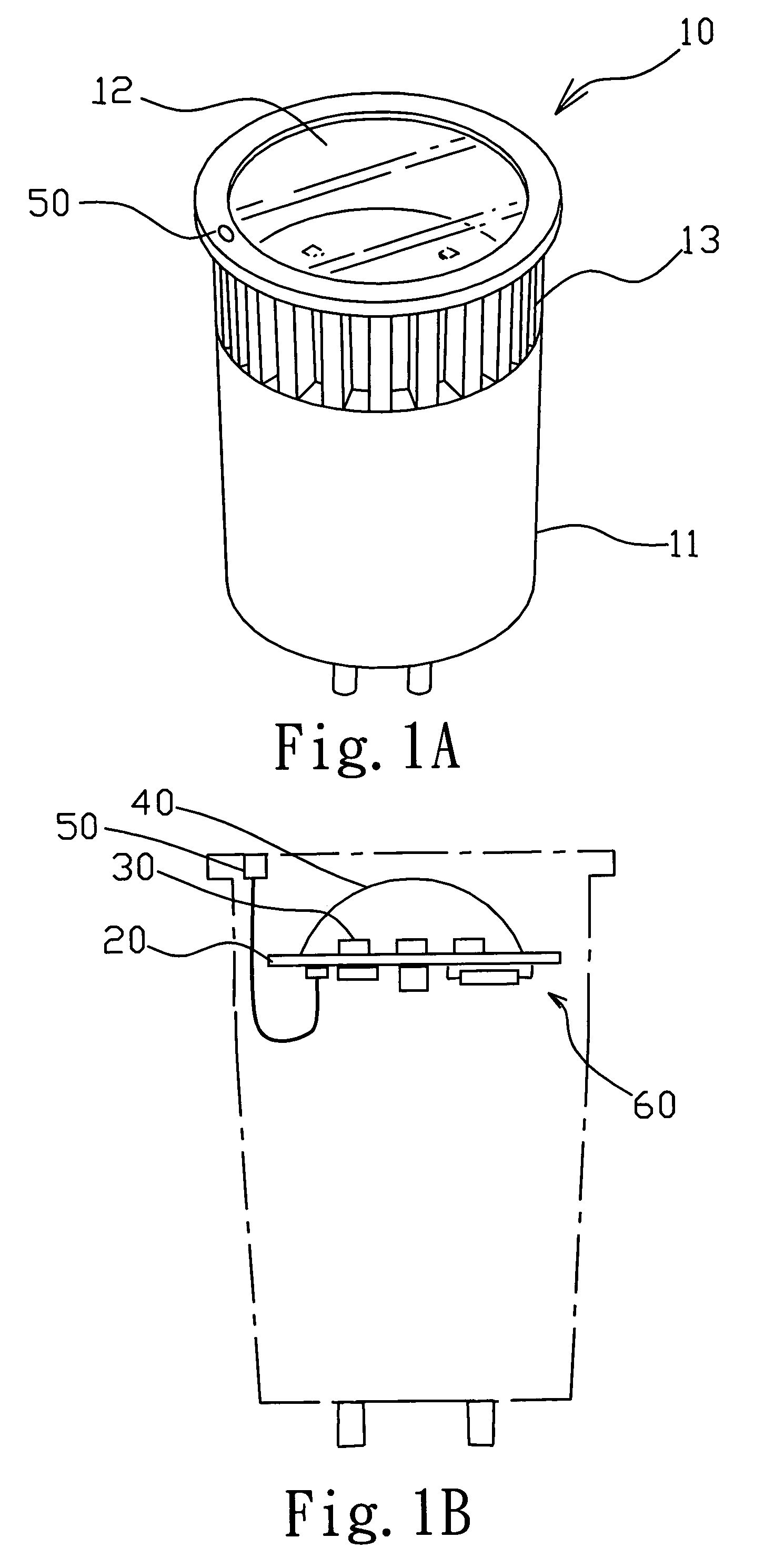

Light-emitting device with high heat-dissipating efficiency

InactiveUS20050199900A1Ensure safe operationReduce manufacturing costSolid-state devicesSemiconductor devicesOptical reflectionLight guide

A light-emitting device with high heat-dissipating efficiency, includes a ceramic substrate having at least one pair of power-supply circuits mounted at a specific location of the substrate, a light-emitting die fixedly mounted on the ceramic substrate by flip-chip mounting, wherein the two electrodes of the light-emitting die are electrically connected to a corresponding power-supply circuit, respectively, and an optical reflector which is adjacently mounted in the periphery of the light-emitting die and made up of a metallic material or a material with a high coefficient of thermal conductivity for increasing the heat-dissipating area and providing a light-guiding mechanism.

Owner:OPTO TECH

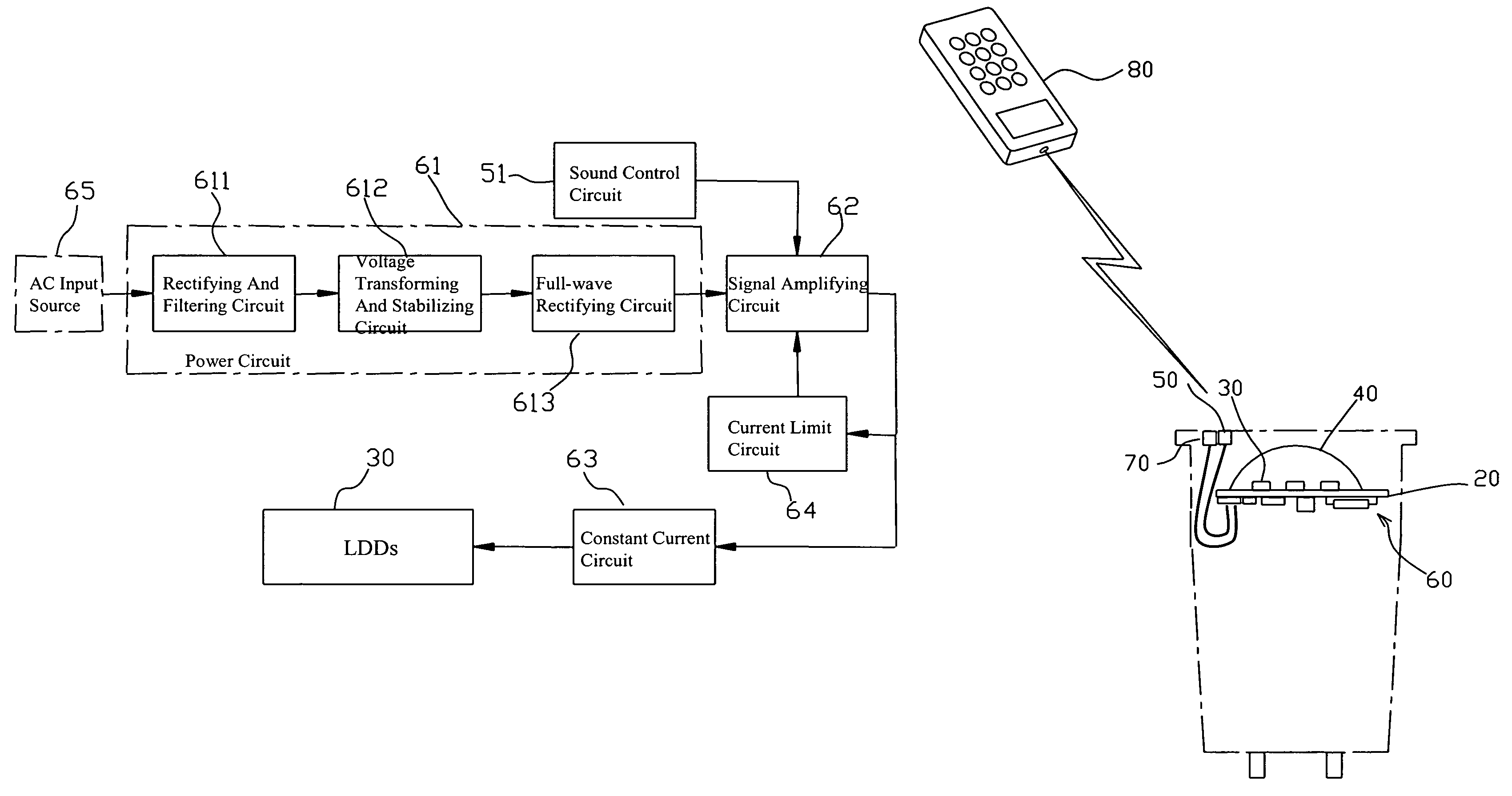

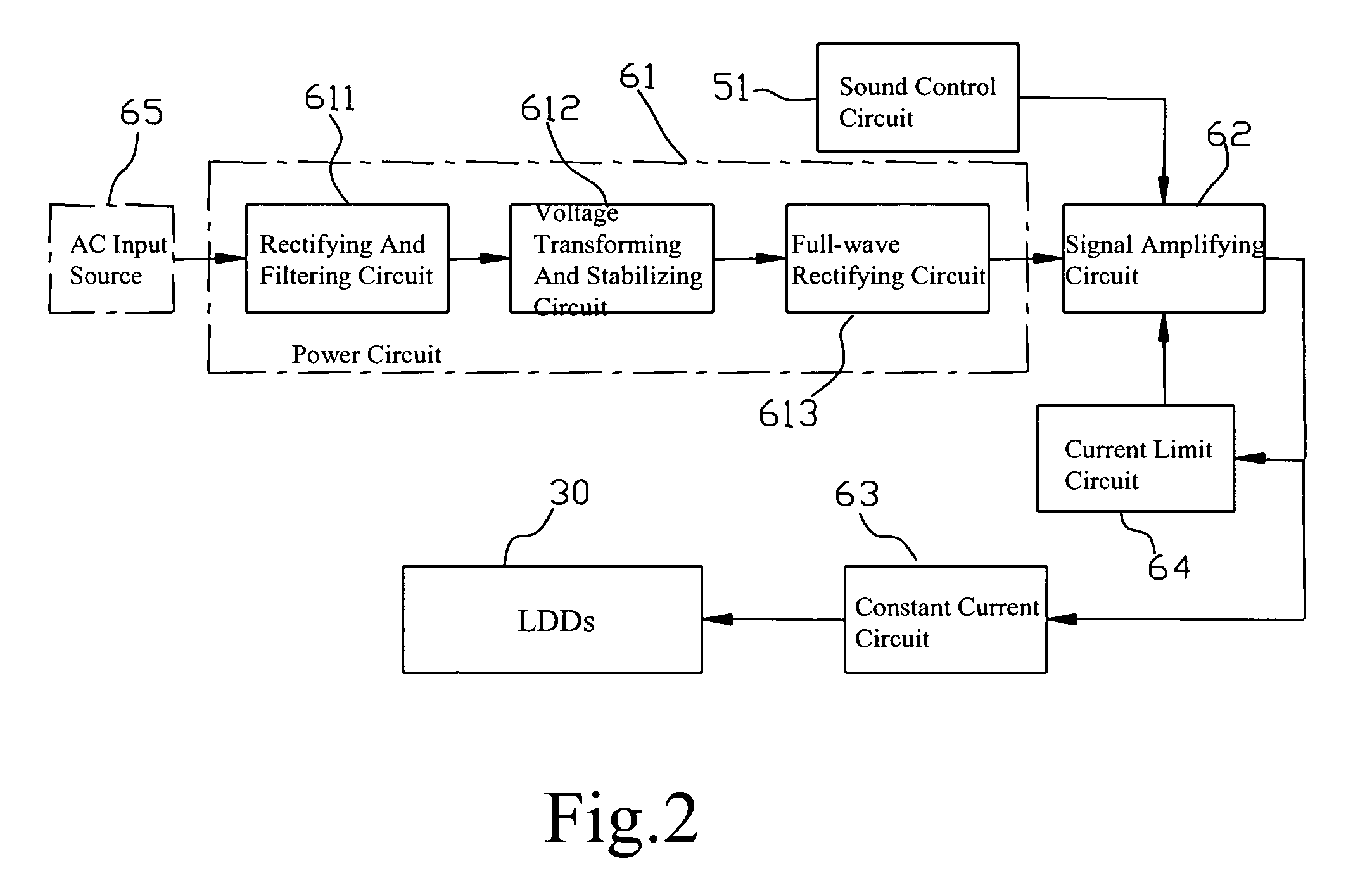

Sound control for changing light color of LED illumination device

InactiveUS7211959B1Lift time can be increasedSave energyElectrical apparatusElectric light circuit arrangementControl circuitBrightness perception

A LED (light emitting diode) illumination device includes a ceramic substrate to integrate a plurality of LED dies and a control circuit together so that a volume of the LED illumination device can be reduced and the heat dissipation of the LED illumination device can be enhanced. The LED illumination device utilizes sound control to change the light emitted from each LED die, so that the illuminating light mixed from the emitting light of the LED dies of the LED illumination device can vary in color and brightness according to the tempo and volume of music, for example, to provide more cheerful and joyful feeling.

Owner:CHOU PETER

Embedded toroidal transformers in ceramic substrates

ActiveUS7196607B2Semiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsTransformerMetallurgy

Method for forming a transformer (118) in a ceramic substrate. The method can include the steps of forming at least one conductive coil (119a, 119b) comprising a plurality of turns about an unfired ceramic toroidal core region (120a, 120b) defined within an unfired ceramic substrate (100). The method can also include the step of co-firing the unfired ceramic toroidal core region (120a, 120b), the unfired ceramic substrate (100), and the conductive coil (119a, 119b) to form an integral ceramic substrate structure with the conductive coil at least partially embedded therein.

Owner:HARRIS CORP

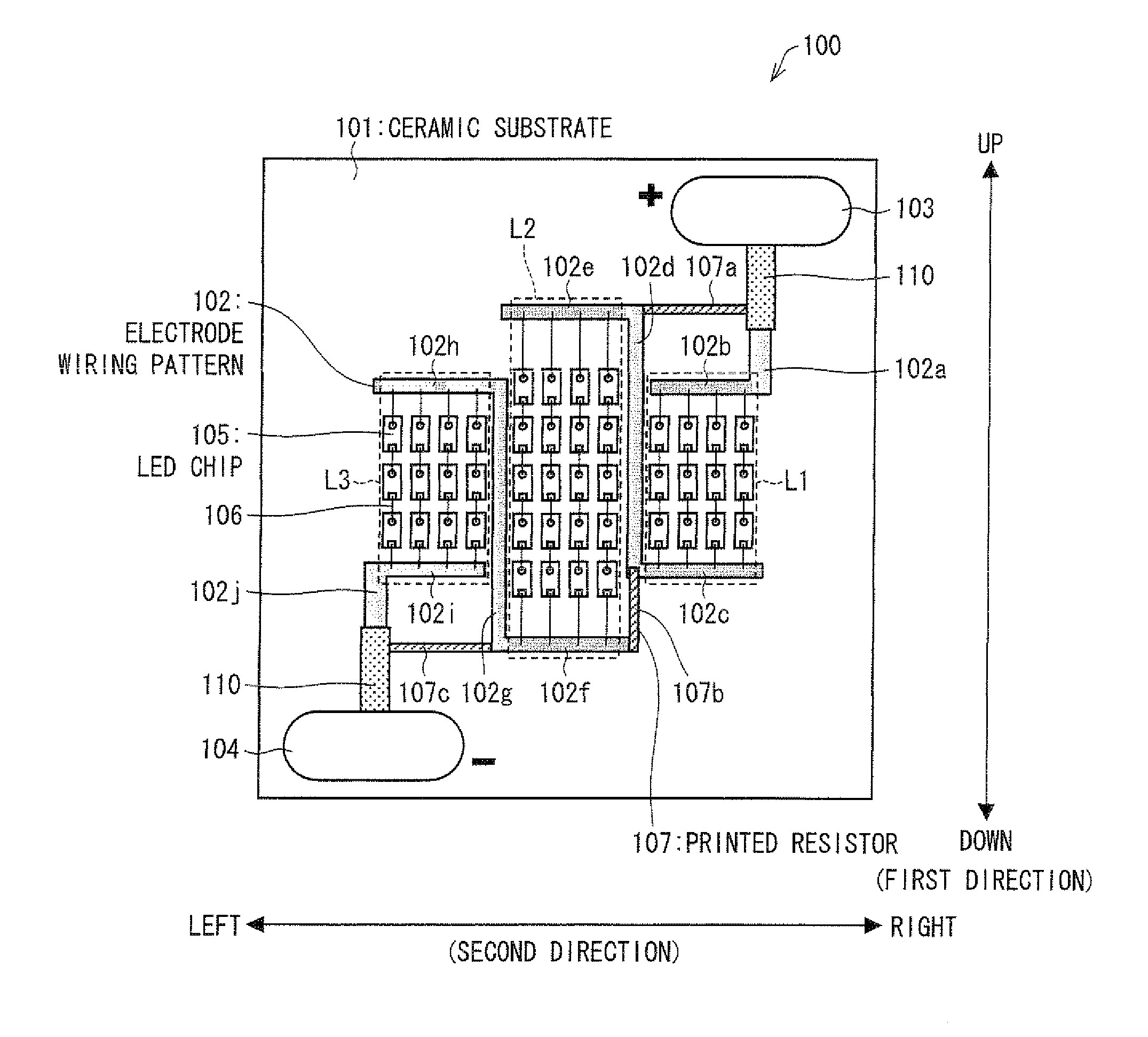

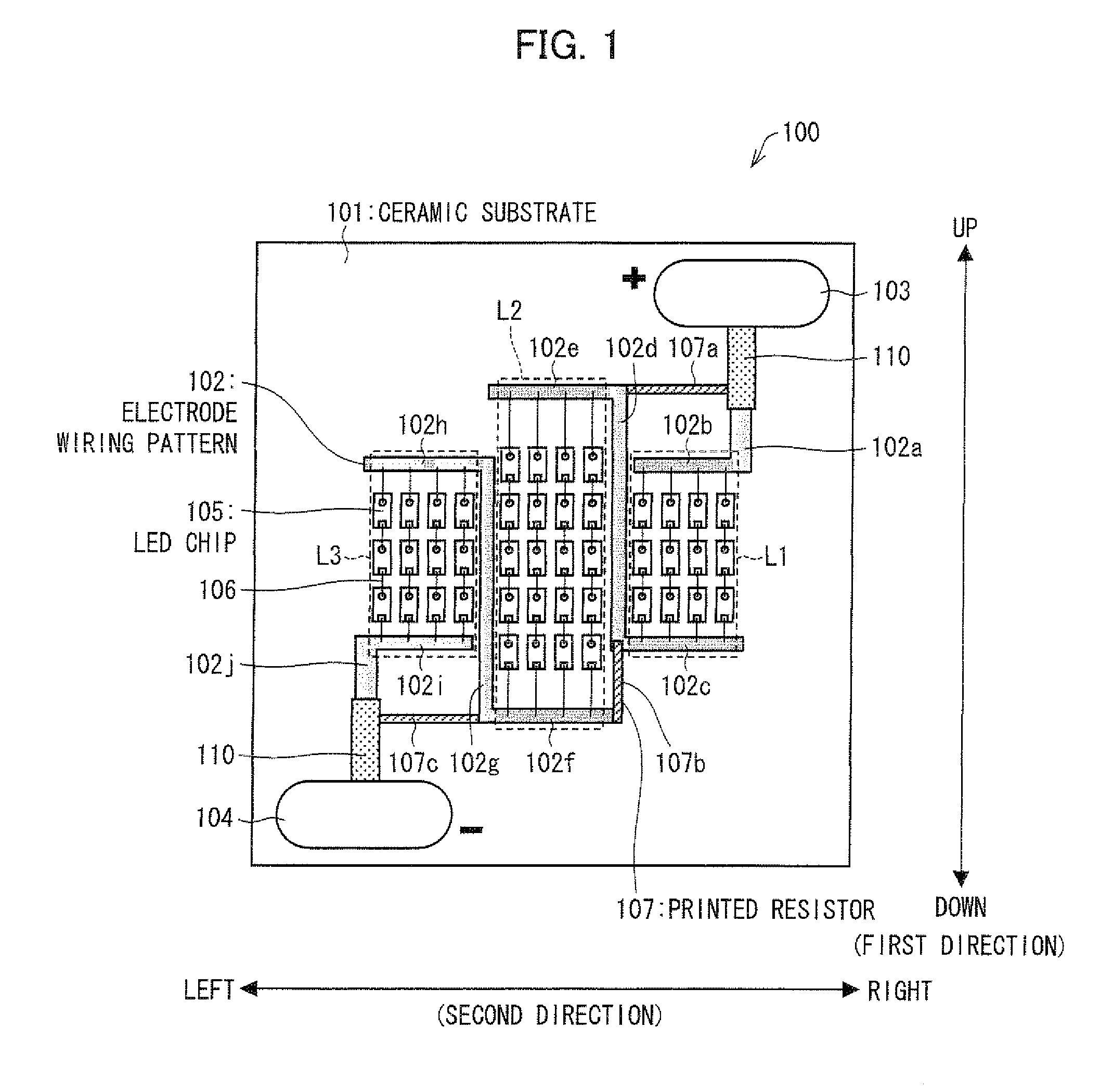

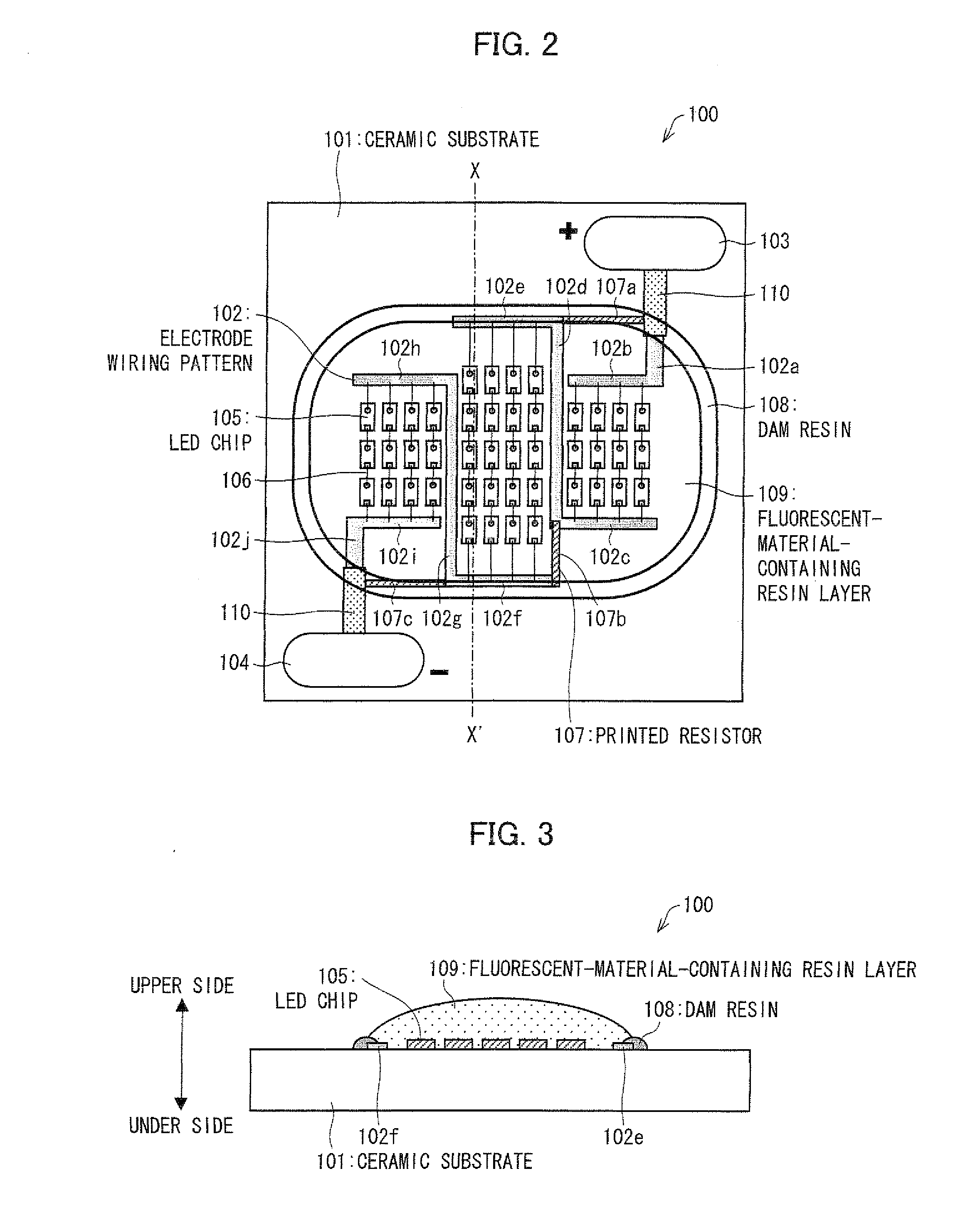

Light emitting device

ActiveUS20110180817A1Reduce distanceHigh optical densityPoint-like light sourceLighting heating/cooling arrangementsOptical transmittanceLight emitting device

A light emitting device includes: a ceramic substrate; a plurality of LED chips; a printed resistor(s) connected in parallel with the plurality of LED chips; a dam resin made of a resin having a low optical transmittance; a fluorescent-material-containing resin layer; and an anode-side electrode and a cathode-side electrode, (a) which are provided on a primary surface of the ceramic substrate so as to face each other along a first direction on the primary surface and (b) which are disposed below at least one of the dam resin and the fluorescent-material-containing resin layer. With the configuration in which a plurality of LEDs, which are connected in a series-parallel connection, are provided on a substrate, it is possible to provide a light emitting device which can achieve restraining of luminance unevenness and an improvement in luminous efficiency.

Owner:HEAVY DUTY LIGHTING LLC

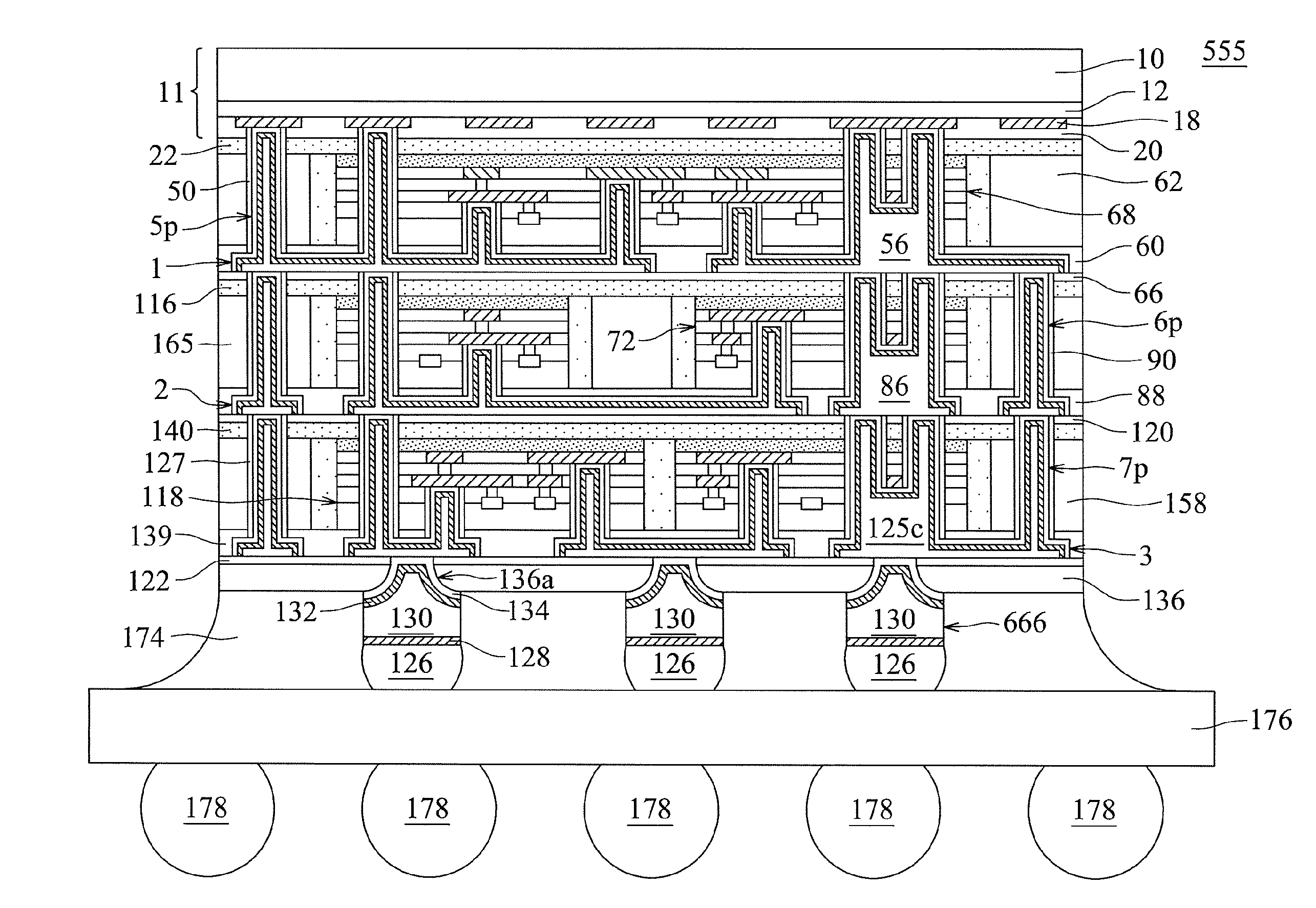

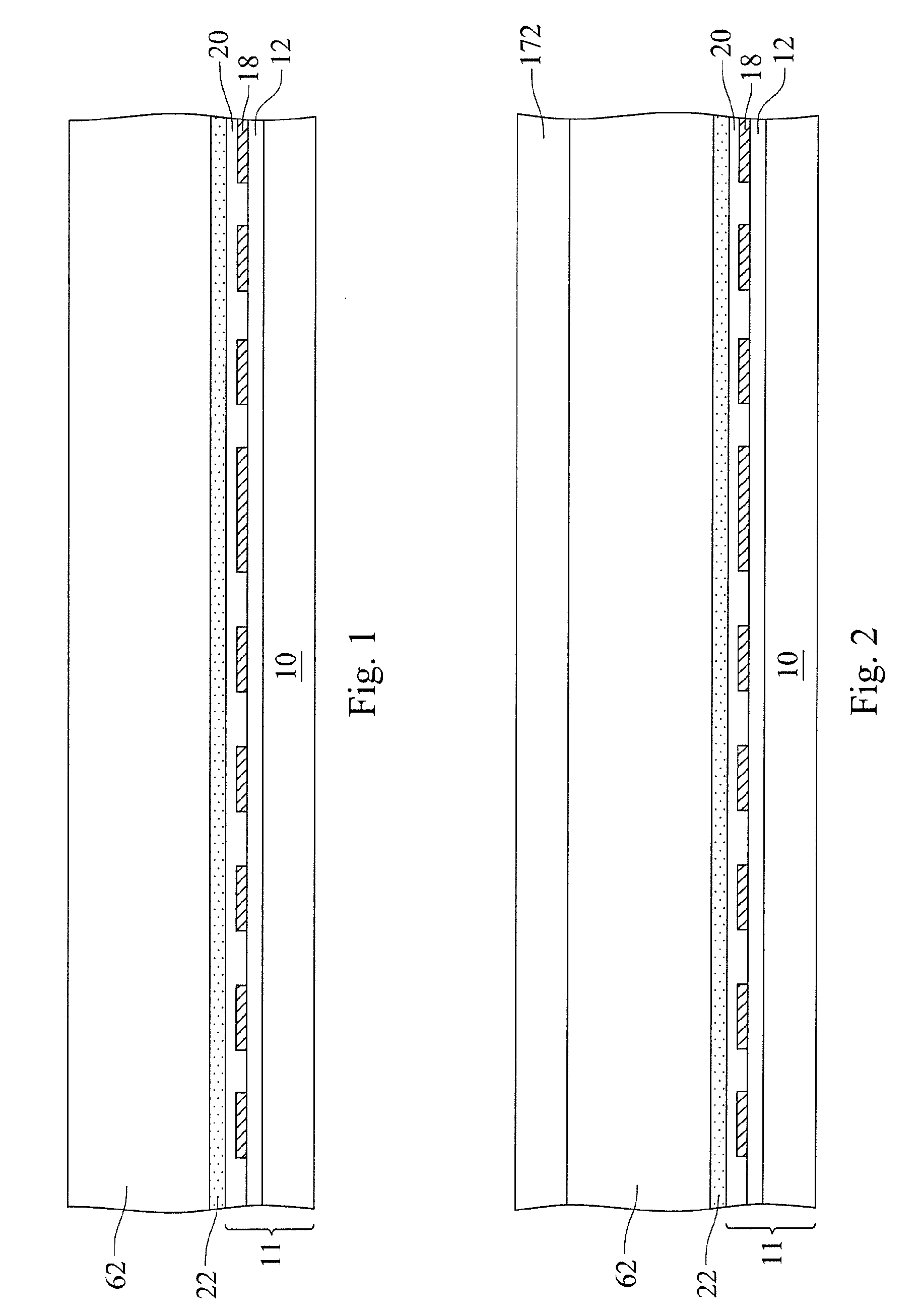

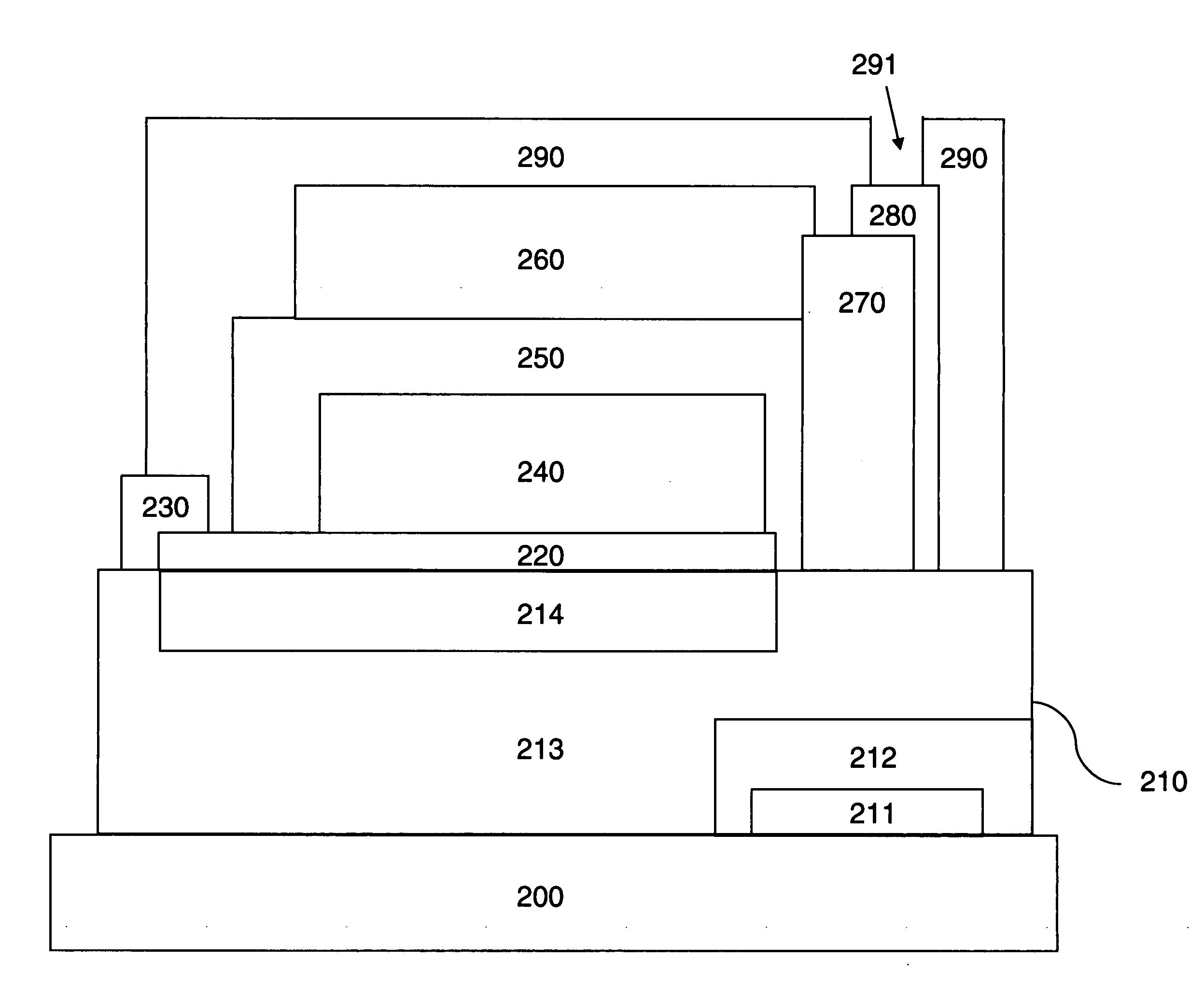

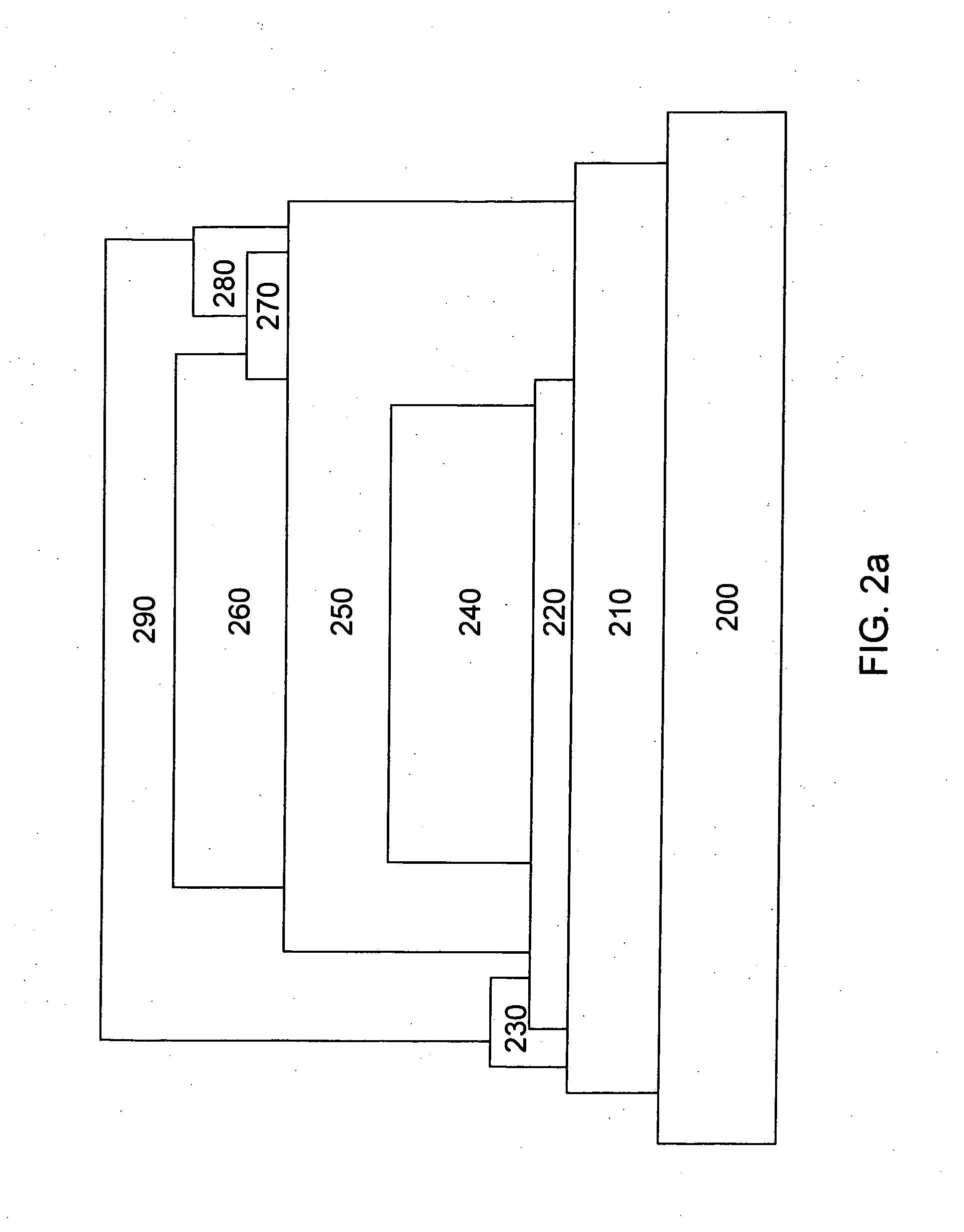

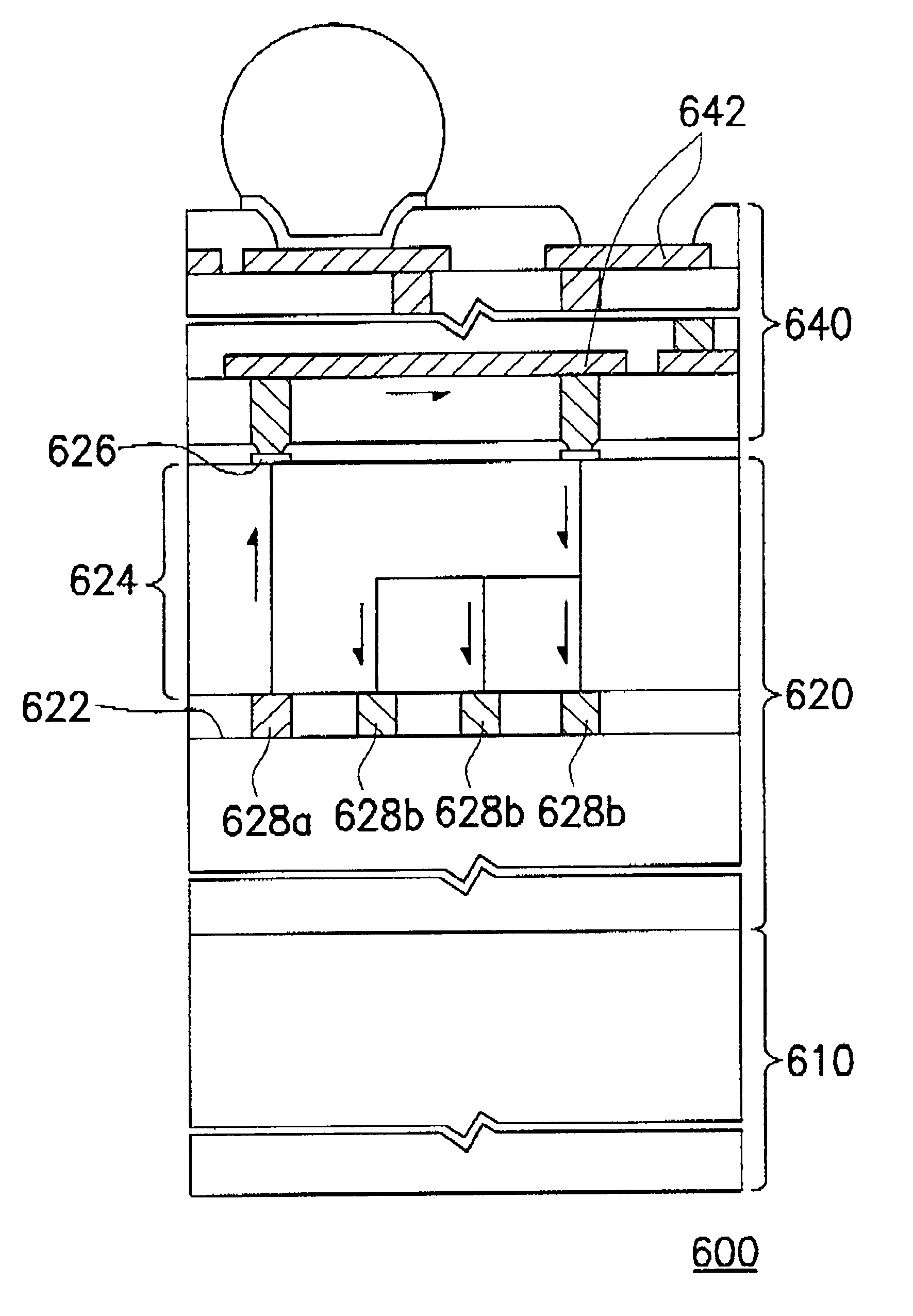

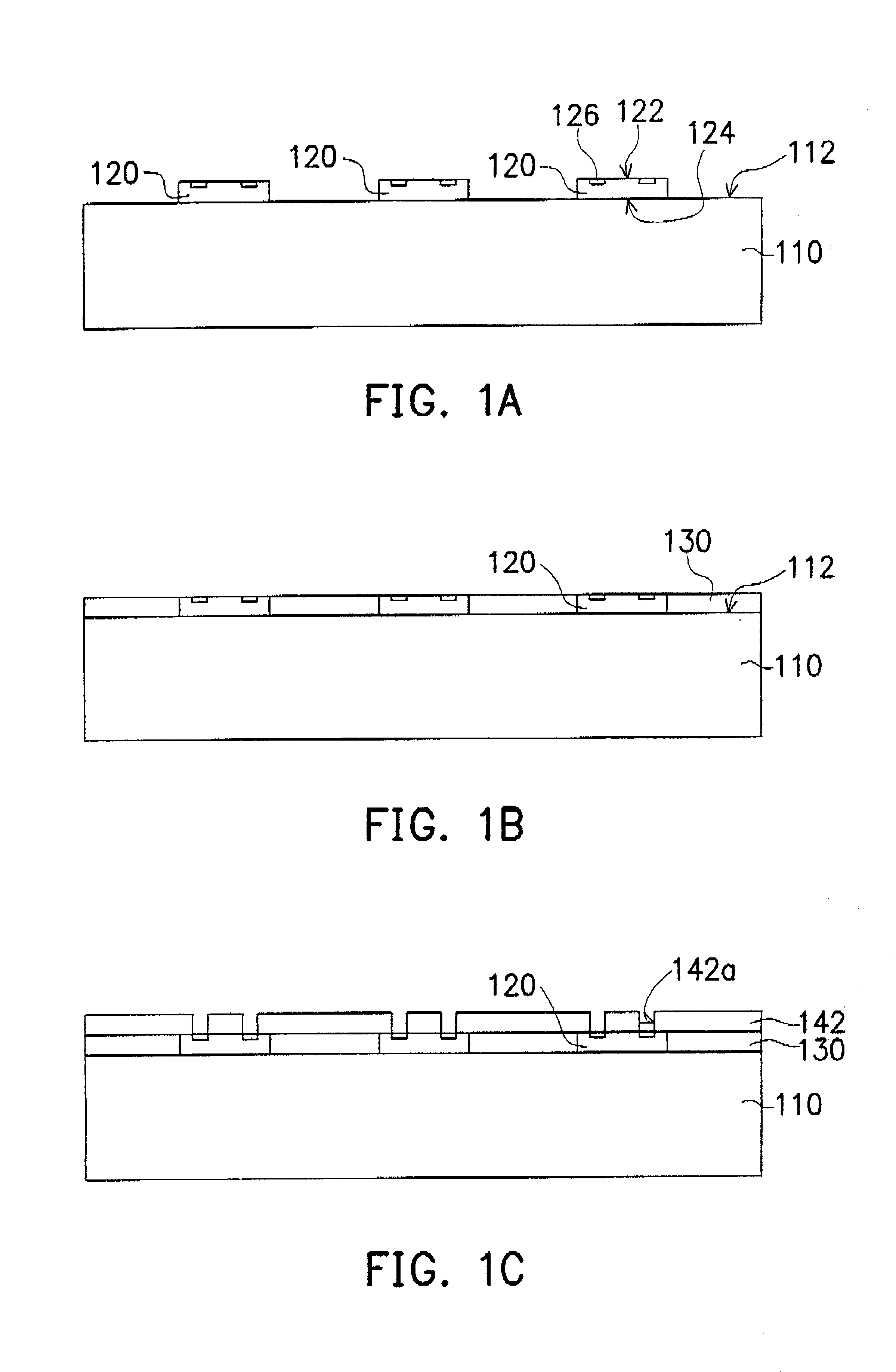

Integrated chip package structure using ceramic substrate and method of manufacturing the same

InactiveUS6800941B2Semiconductor/solid-state device detailsSolid-state devicesThin film circuitsExternal circuit

An integrated chip package structure and method of manufacturing the same is by adhering dies on a ceramic substrate and forming a thin-film circuit layer on top of the dies and the ceramic substrate. Wherein the thin-film circuit layer has an external circuitry, which is electrically connected to the metal pads of the dies, that extends to a region outside the active surface of the dies for fanning out the metal pads of the dies. Furthermore, a plurality of active devices and an internal circuitry is located on the active surface of the dies. Signal for the active devices are transmitted through the internal circuitry to the external circuitry and from the external circuitry through the internal circuitry back to other active devices. Moreover, the chip package structure allows multiple dies with different functions to be packaged into an integrated package and electrically connecting the dies by the external circuitry.

Owner:QUALCOMM INC

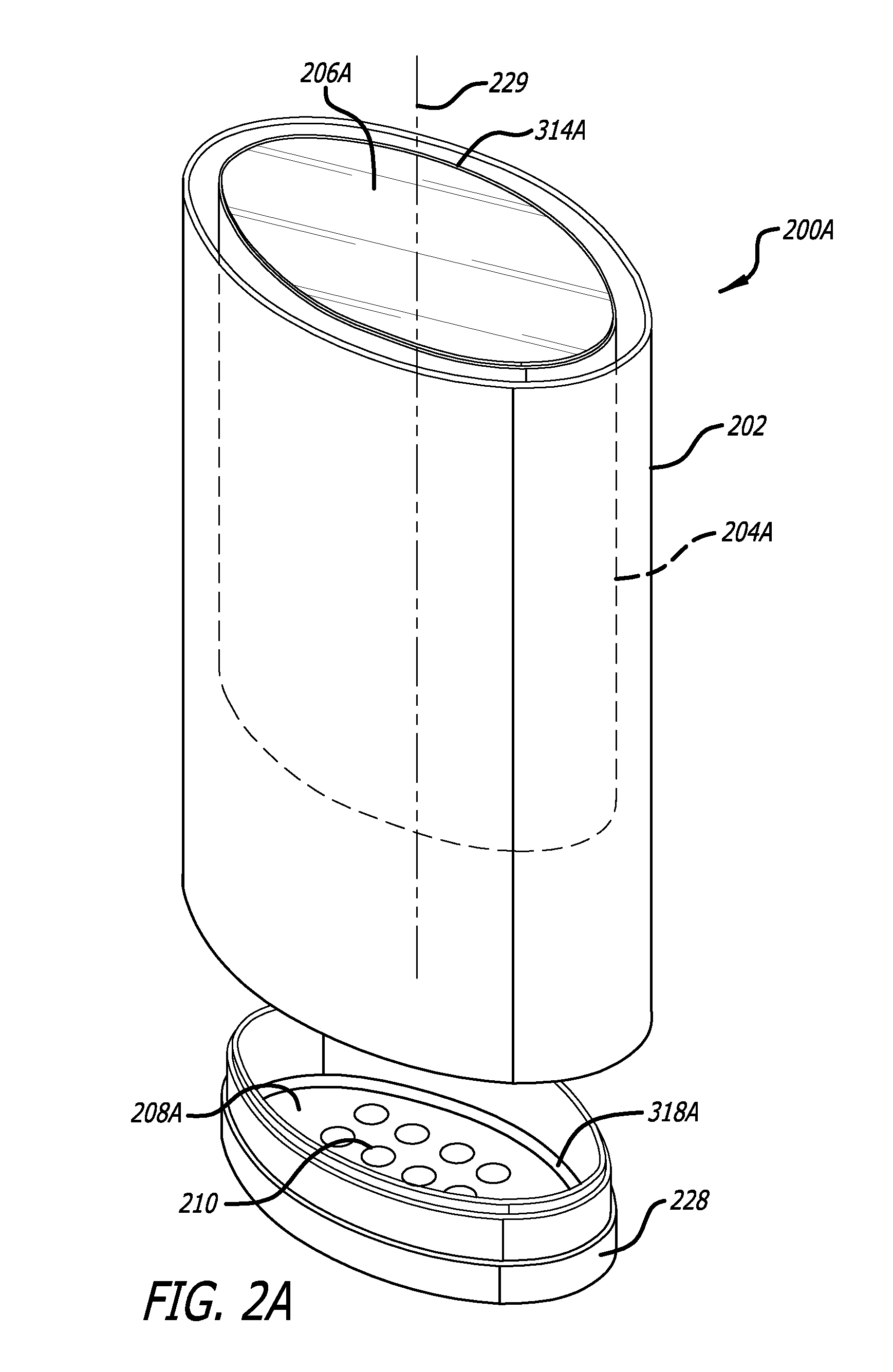

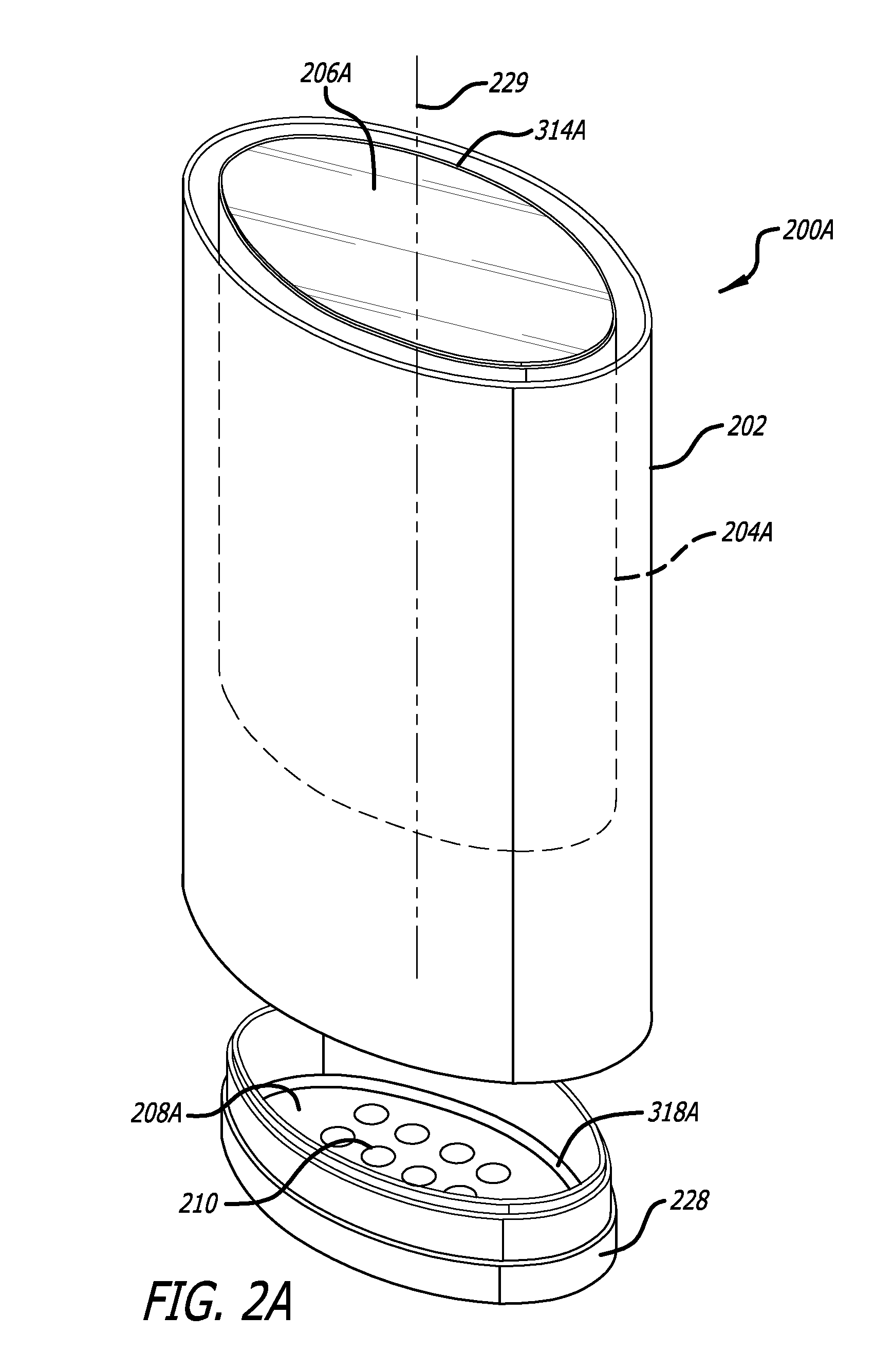

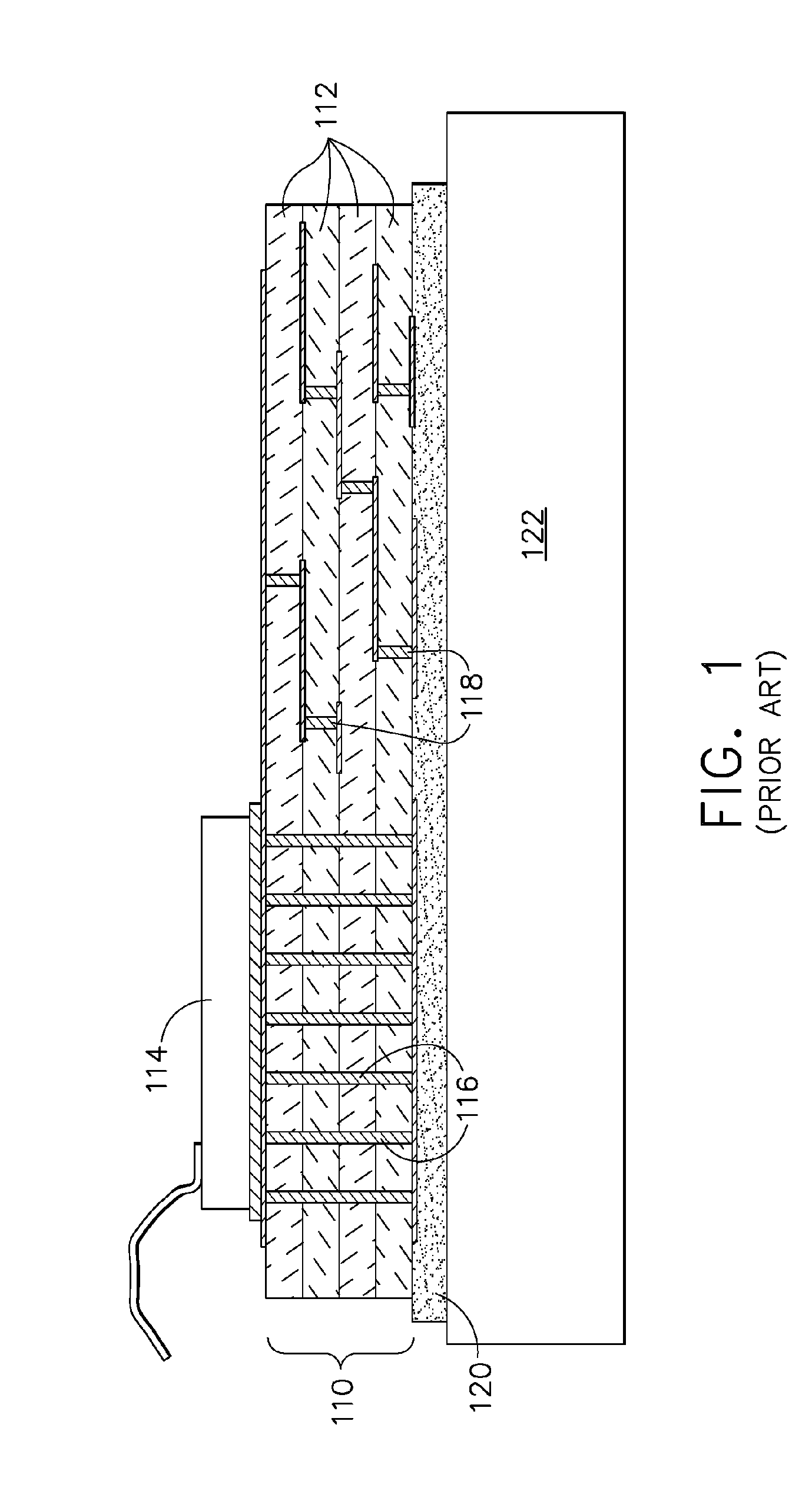

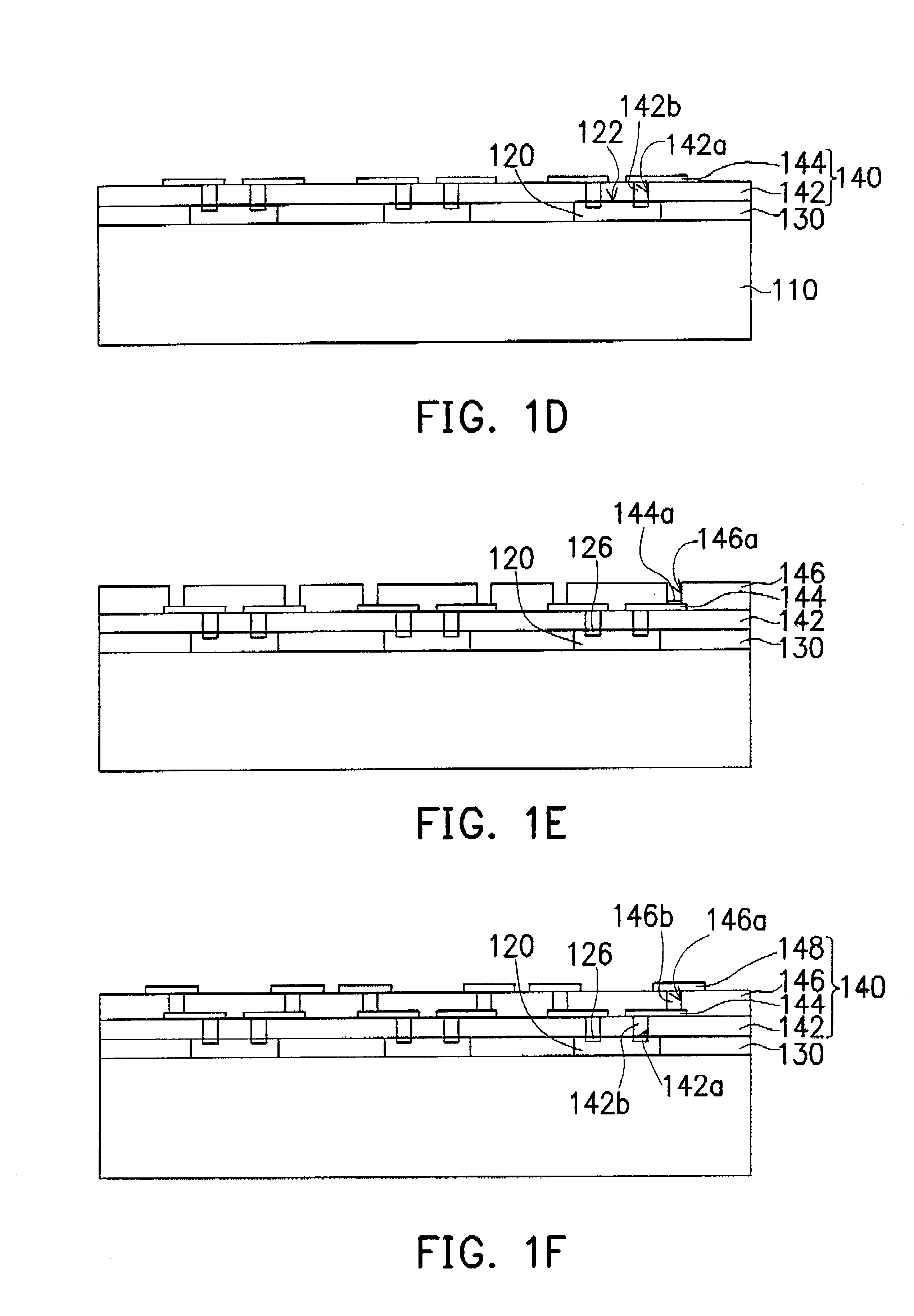

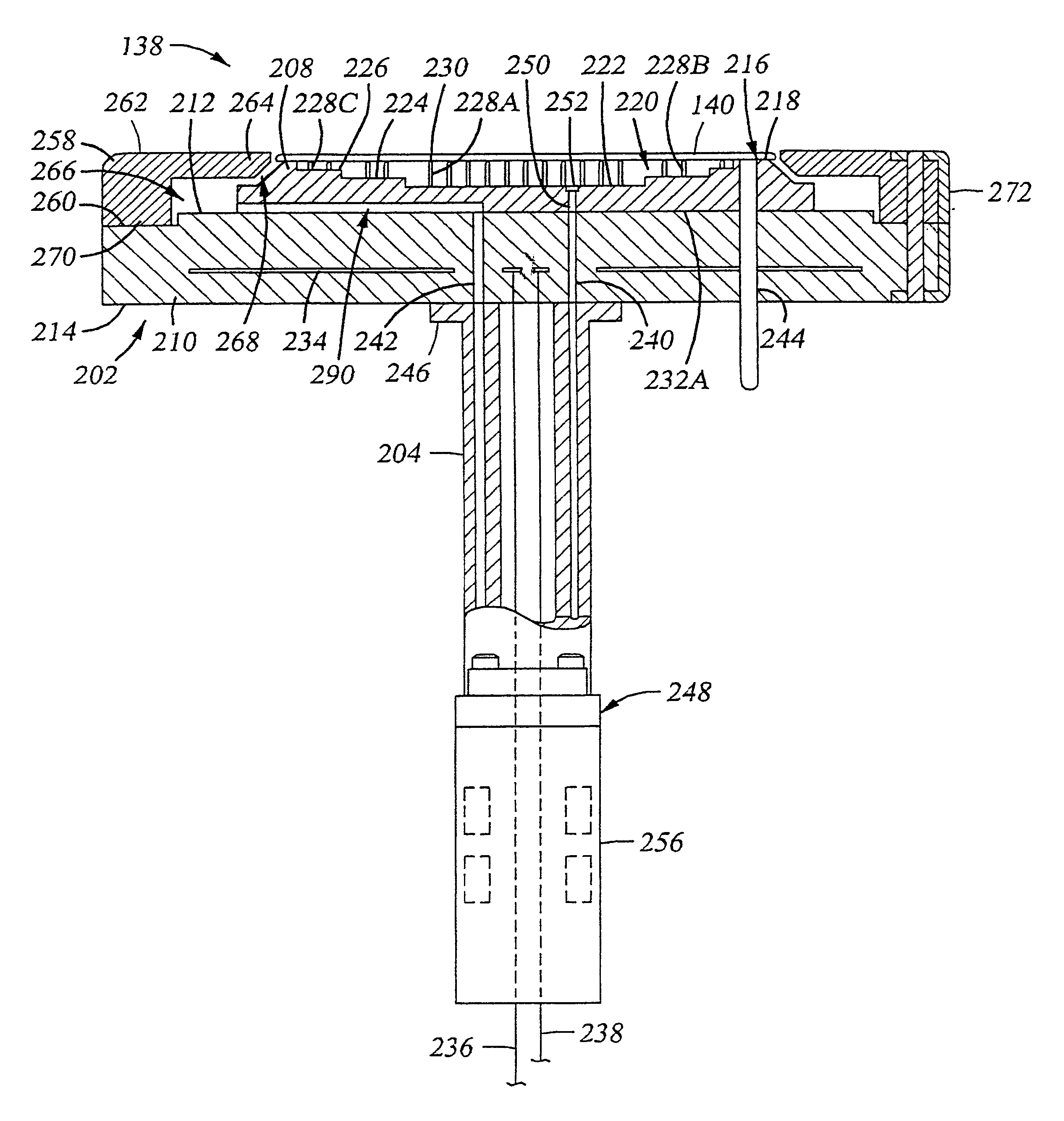

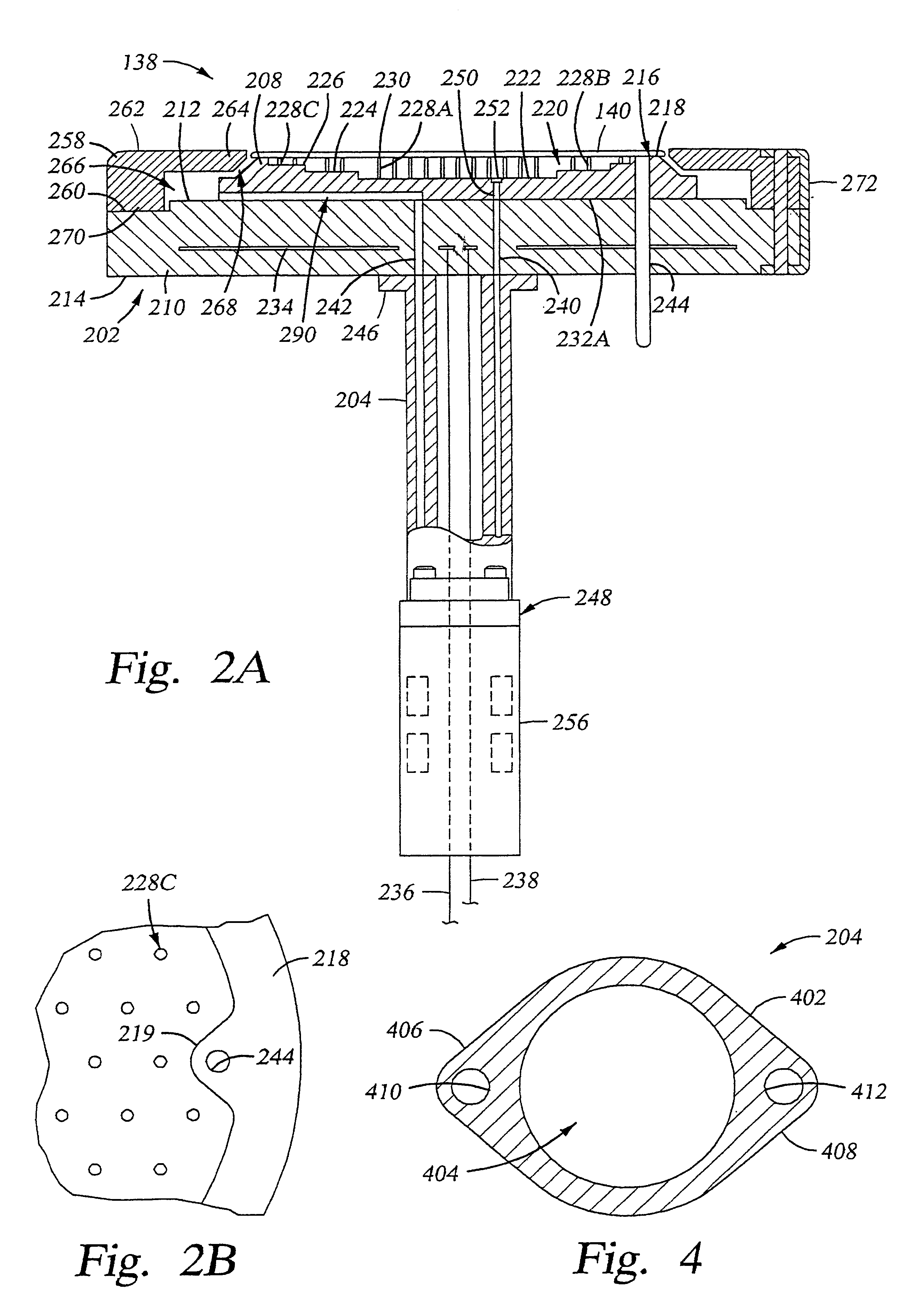

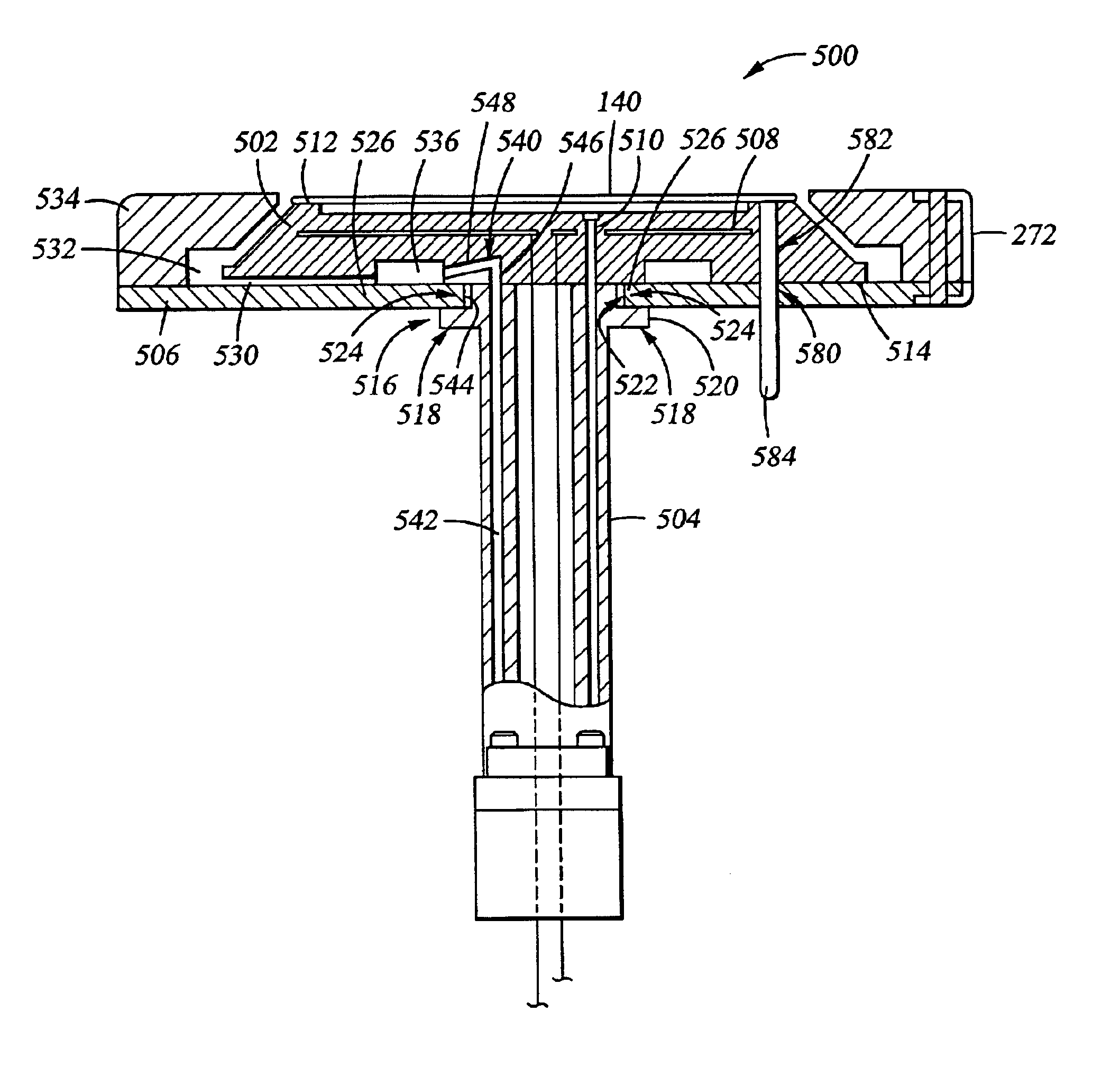

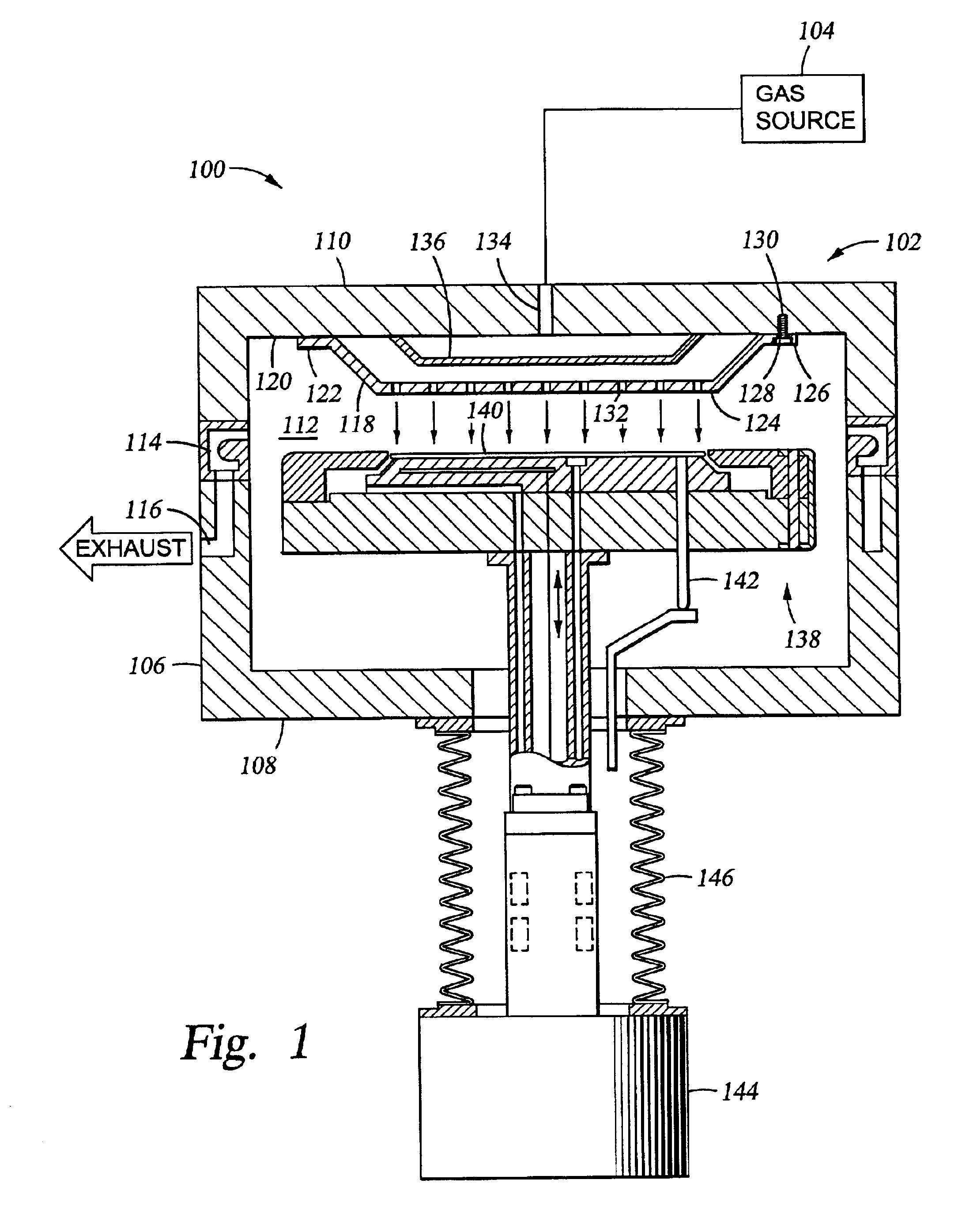

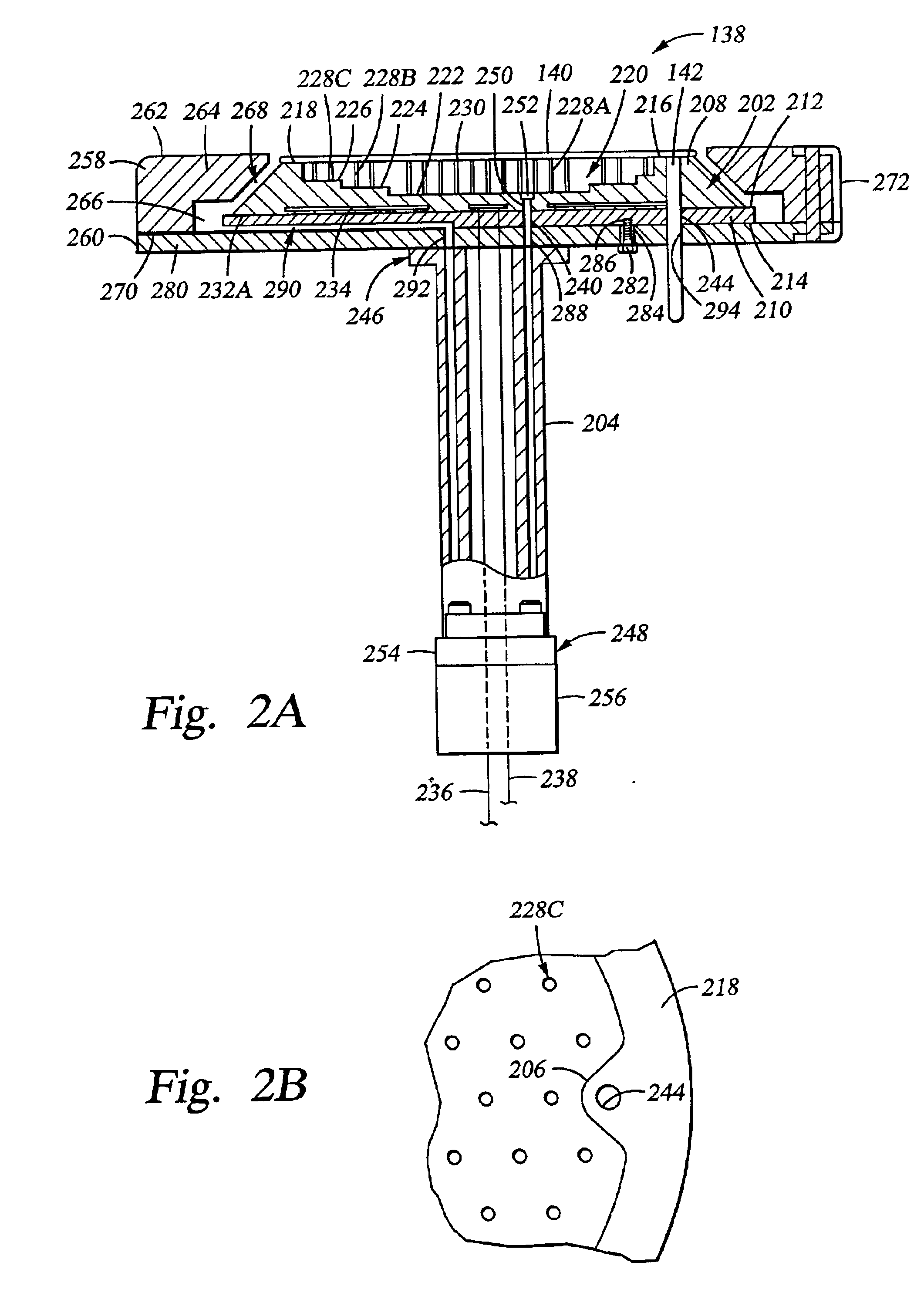

Ceramic substrate support

InactiveUS6494955B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A substrate support assembly for supporting a substrate during processing is provided. In one embodiment, a support assembly includes a top ceramic plate having a first side, a bottom ceramic plate having a first side and an embedded electrode, the first side of the bottom plate fused to the first side of the top plate defining a channel therebetween. In another embodiment, a support assembly includes a first plate having a first side and second side. A ring is disposed on the first side. A stepped surface is formed on the first side radially inward of the ring. A second plate is connected to the second side of the first plate.

Owner:APPLIED MATERIALS INC

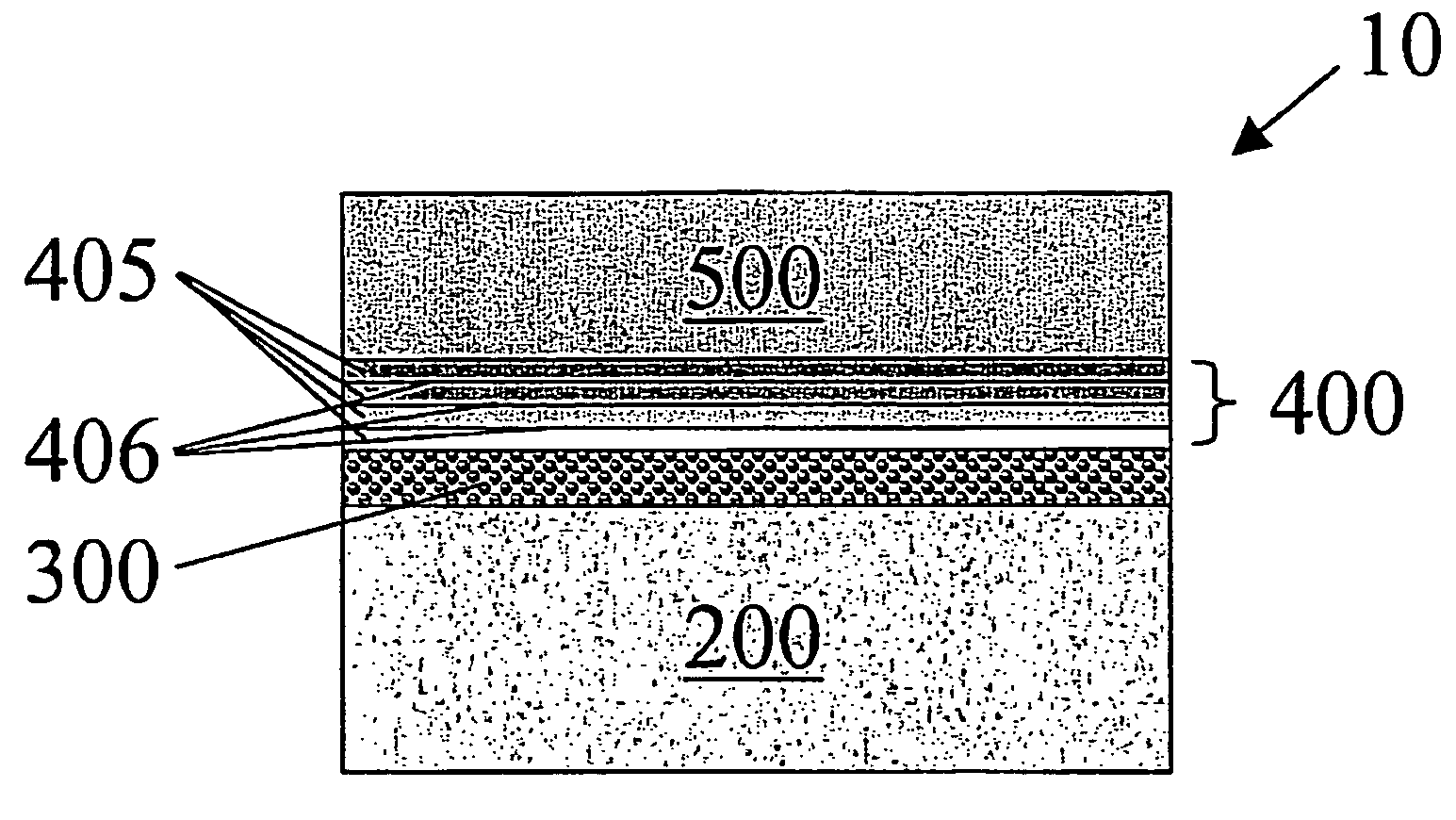

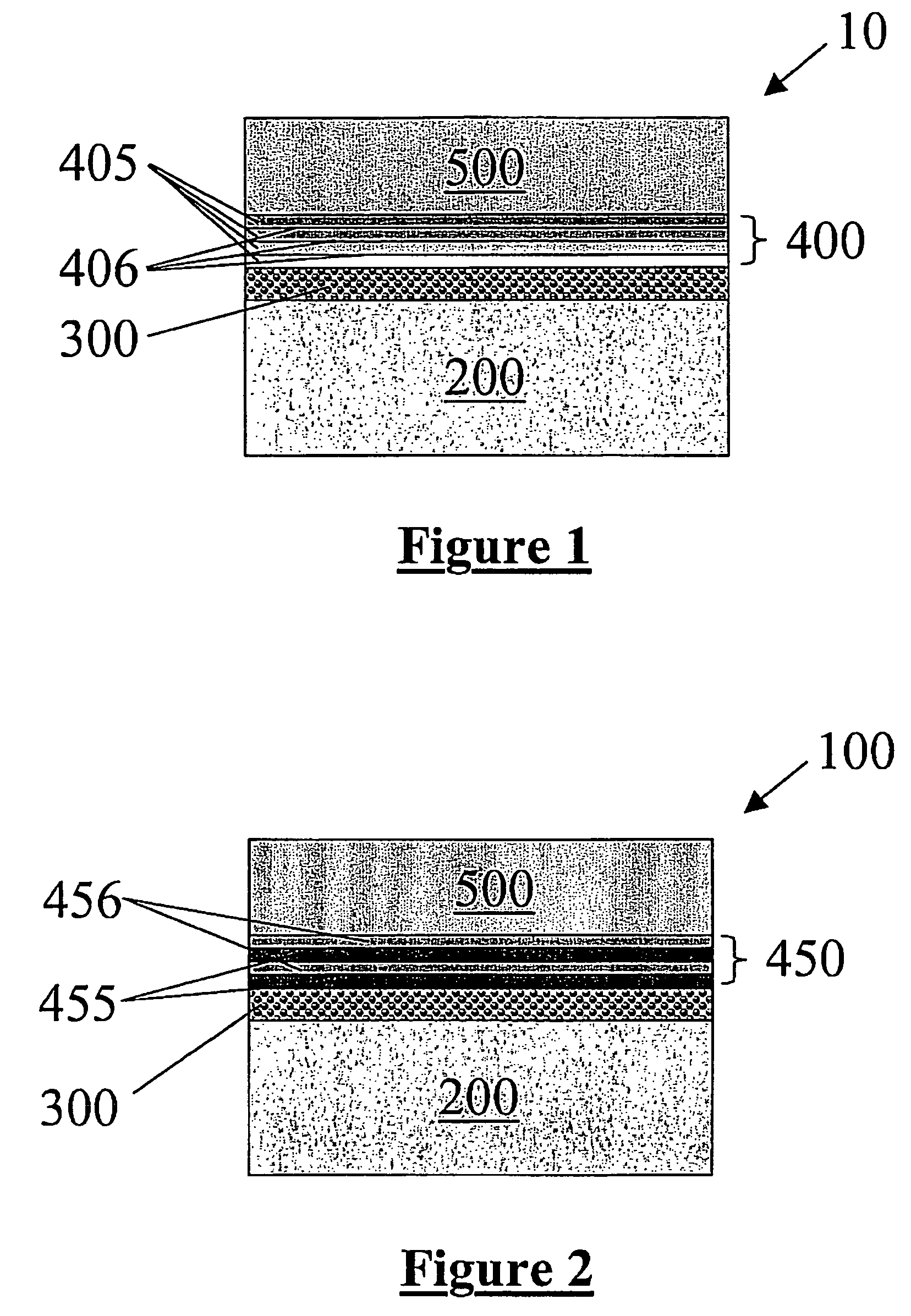

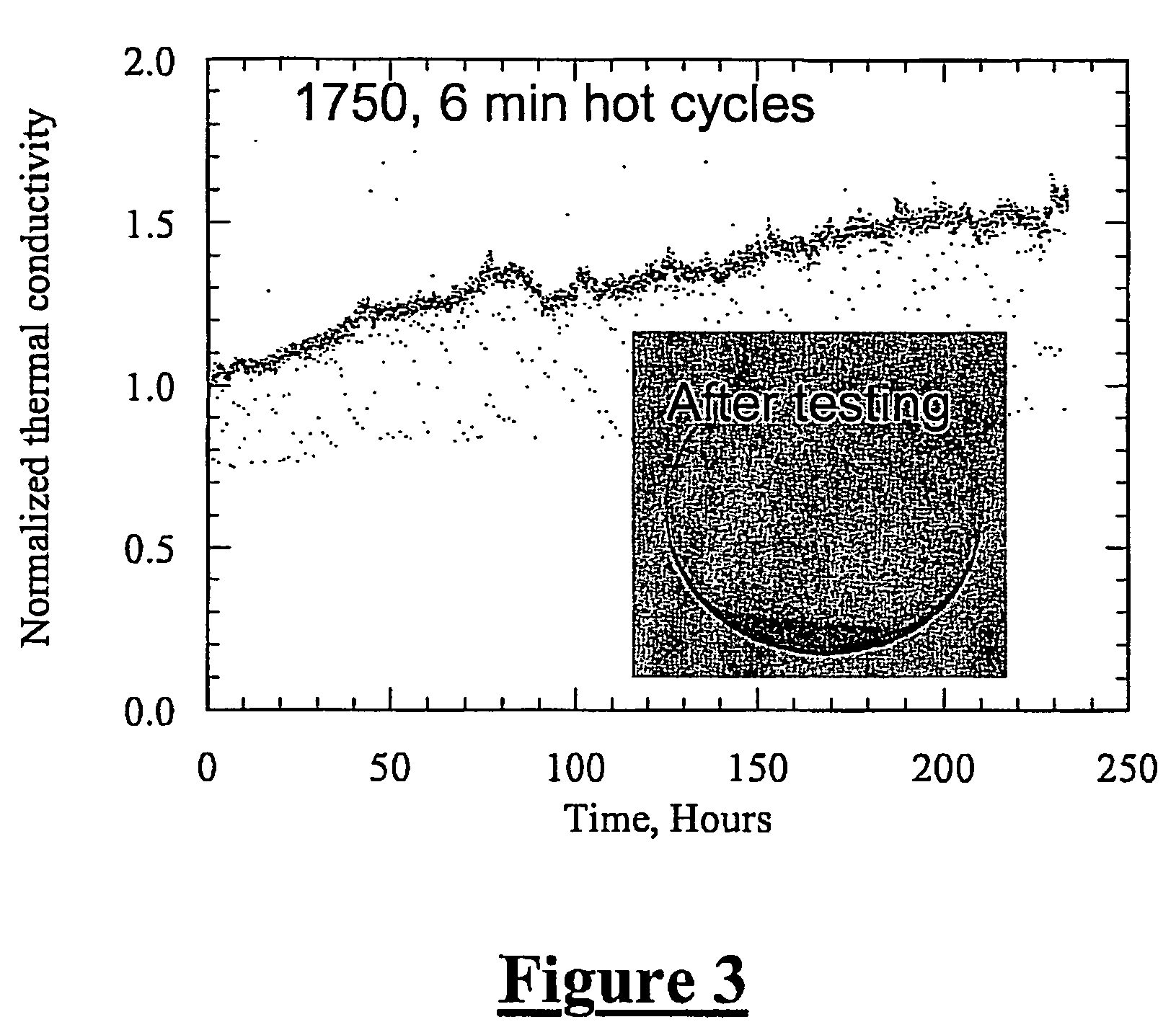

Multifunctionally graded environmental barrier coatings for silicon-base ceramic components

InactiveUS7740960B1Low thermal conductivityIncrease flow ratePropellersReaction enginesCombustionWater vapor

A multilayered coating system consisting of a multicomponent zirconia-base or hafnia-base oxide top layer, an interlayer comprised of a plurality of sublayers and a bond coat layer is provided. The multilayered coating system of the present invention, with an interlayer comprised of a plurality of sublayers, provides a protective coating solution for silicon-base ceramic components exposed to very high temperatures and / or high gas flow velocity water vapor combustion environments. The plurality of sublayers affords for a multitude of interfaces that aid in phonon scattering within the coating system and thereby reduces its thermal conductivity. Furthermore, the plurality of interlayer sublayers afford a strain tolerant buffer between the top layer and substrate and thereby accommodate the thermal expansion mismatch between the oxide top layer (coefficient of thermal expansion (CTE) up to ˜8-10×10−6 m / m-C) and the silicon-base ceramic substrate (CTE≈4-5×10−6 m / m-C).

Owner:ARMY US SEC THE

Ceramic substrate support

A substrate support assembly for supporting a substrate during processing is provided. In one embodiment, a support assembly includes a ceramic body having an embedded heating element and a base plate. The base plate and the ceramic body define a channel therebetween adapted to supply purge gas to a perimeter of a substrate disposed on the support assembly. The base plate is fastened to the body by brazing, adhering, fastening, press fitting or by mating engaging portions of a retention device such as a bayonet fitting.

Owner:APPLIED MATERIALS INC

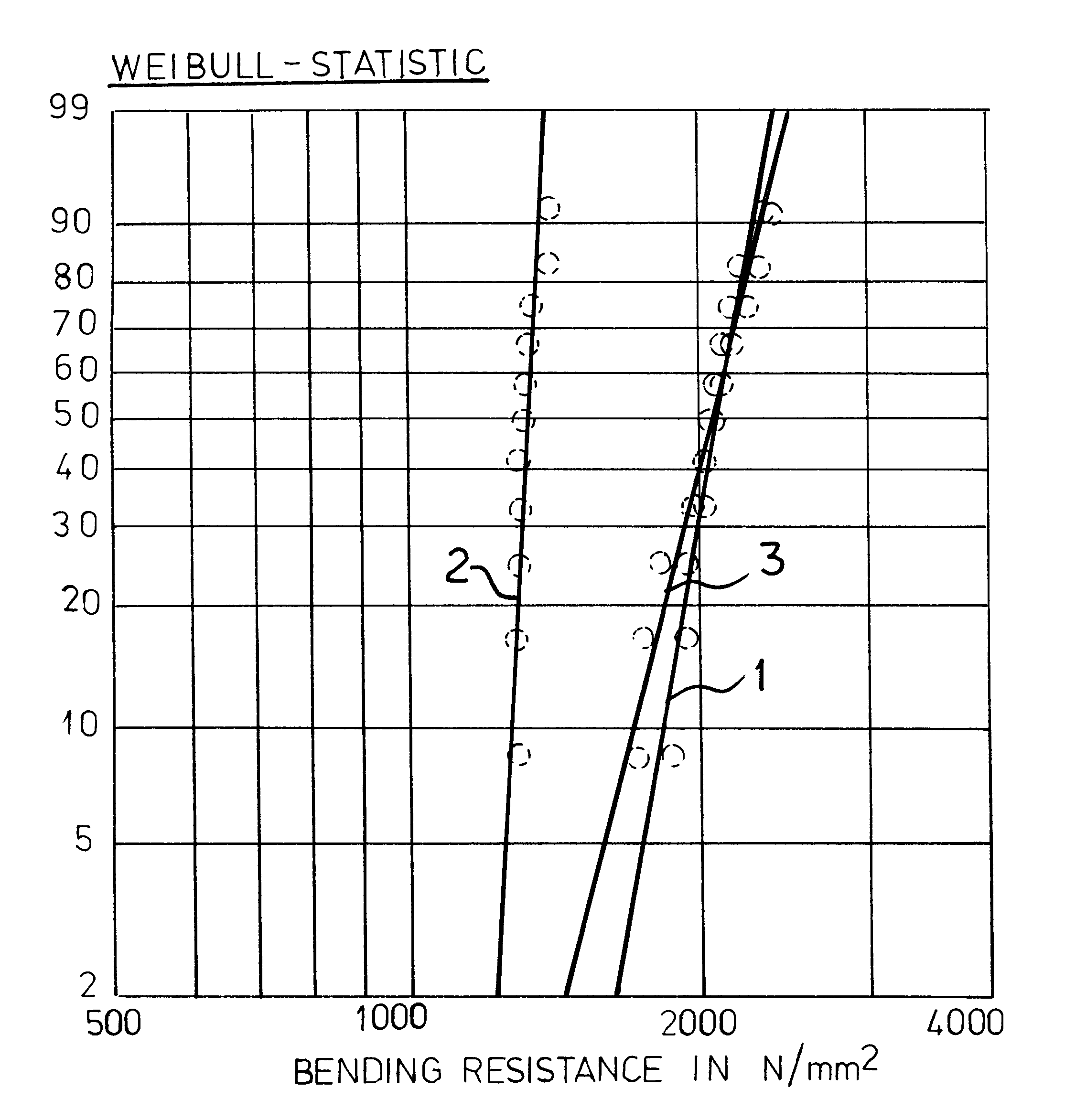

Processing insert, and production of same

InactiveUS6350510B1Improve fracture resistanceAvoid disadvantagesVacuum evaporation coatingSputtering coatingHard metalCarbide

The invention pertains to a processing insert comprised of a body with a hard metal or ceramic substrate and with a multilayer coating and the manufacture of same. In order to have a highly fracture-tough insert with a relatively thick coating, it is suggested that an external layer (protective layer) be applied according to the CVD process, said layer being either a monophase or multiphase layer of Zr-based or Hf-based carbide nitride or carbonitride, and presenting internal compressive stresses. The layer(s) underlying the external layer, also applied according to the CVD process, also present(s), without any exception, internal compressive stresses, while at least one of them, maybe the only one laying under the protective layer is made of TiN, TiC and / or TiCN. The coating is applied according to a continuous CVD process at temperatures of 900° C. to 1100° C. and involves a specific modification of the gas compounds.

Owner:WIDIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com