Patents

Literature

624results about "Extrusion containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

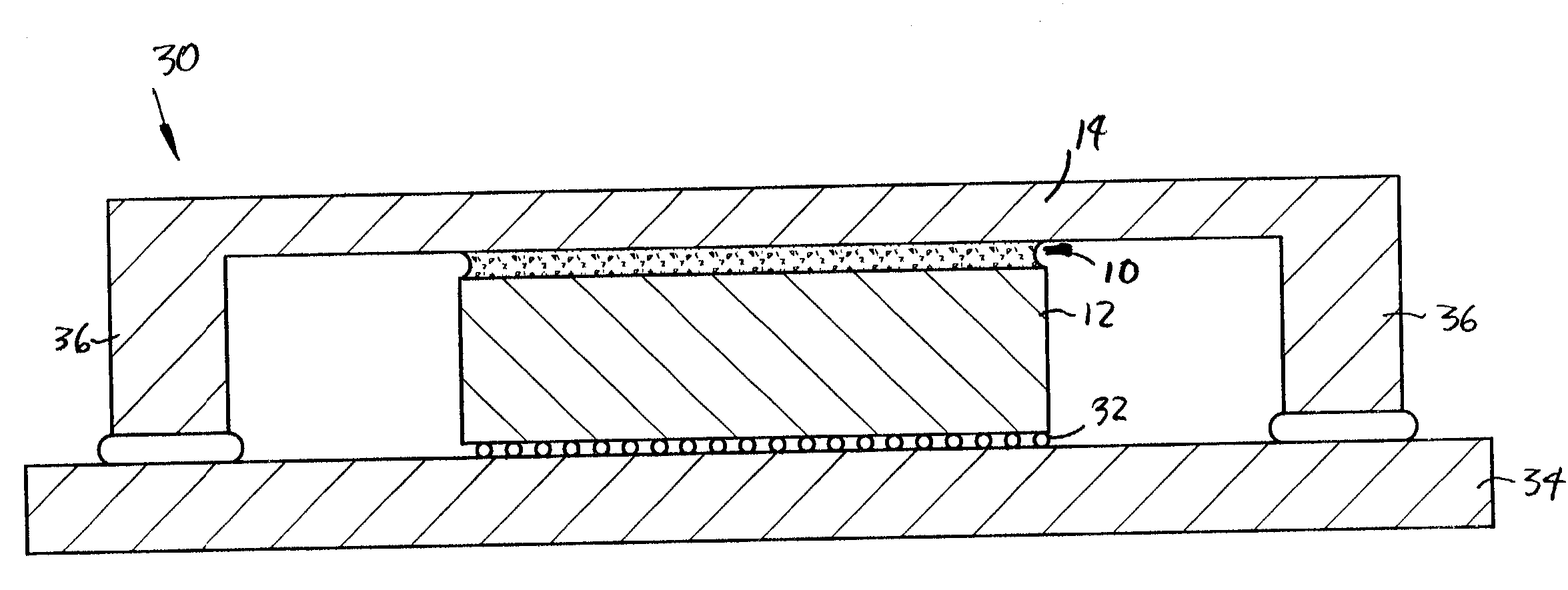

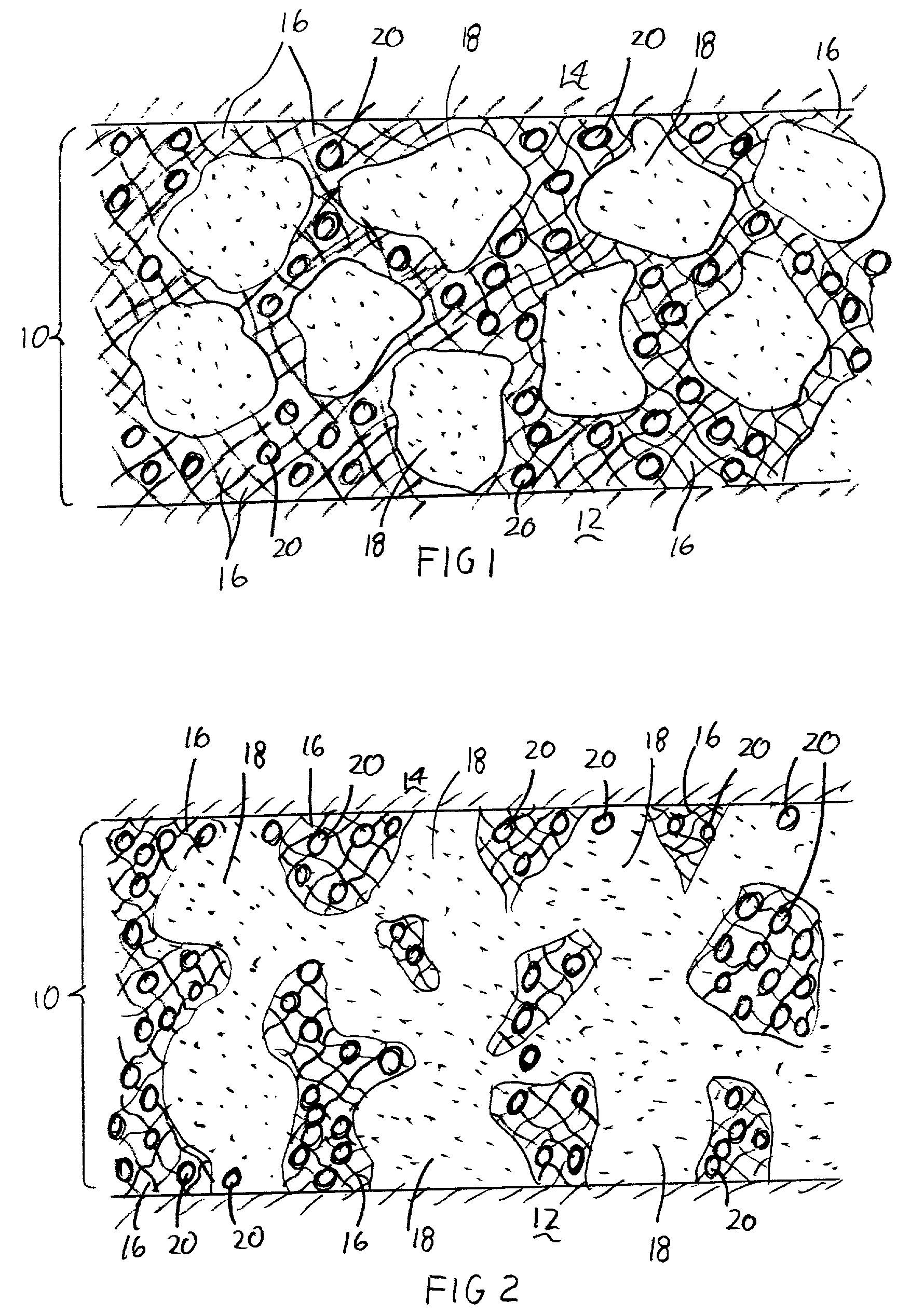

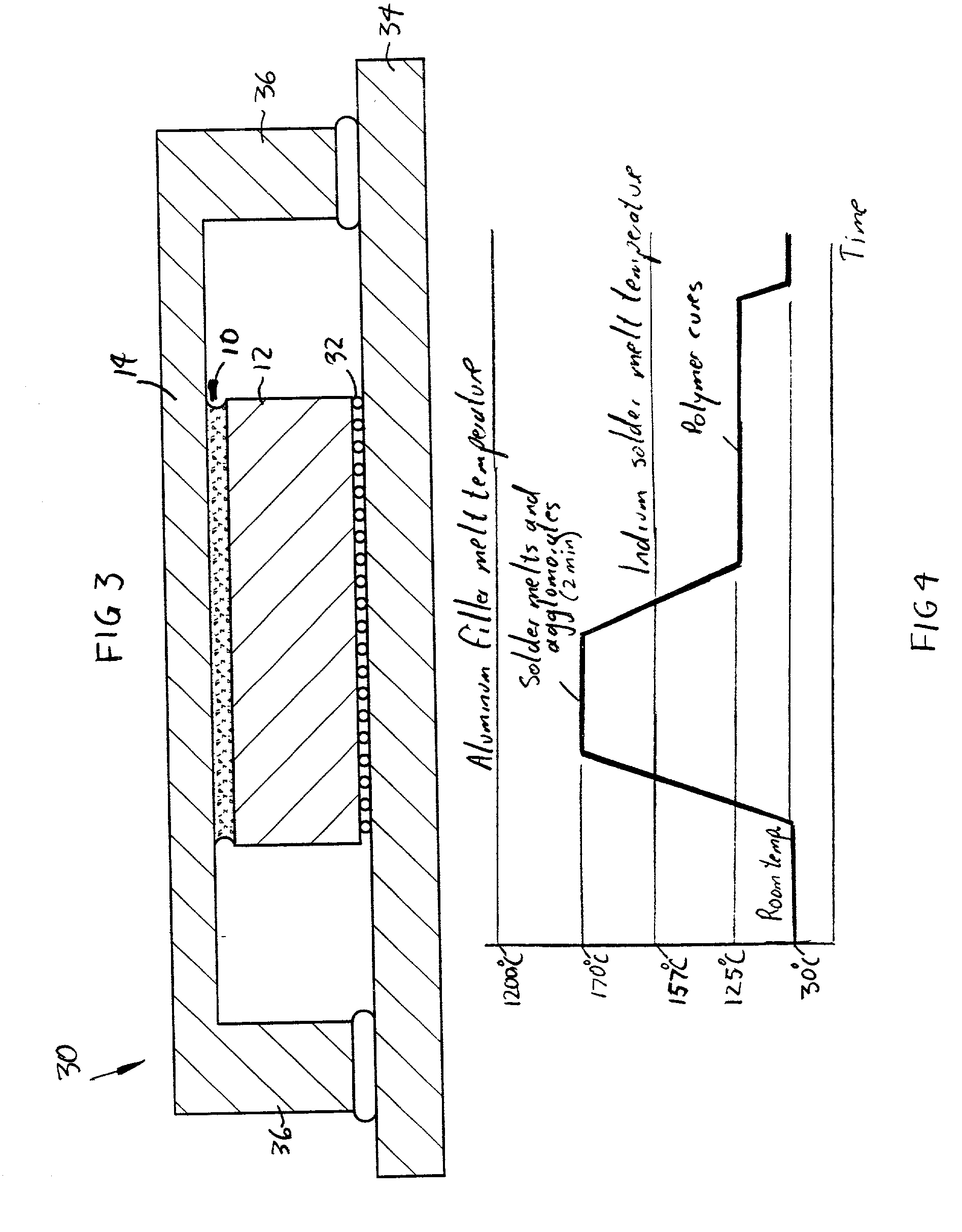

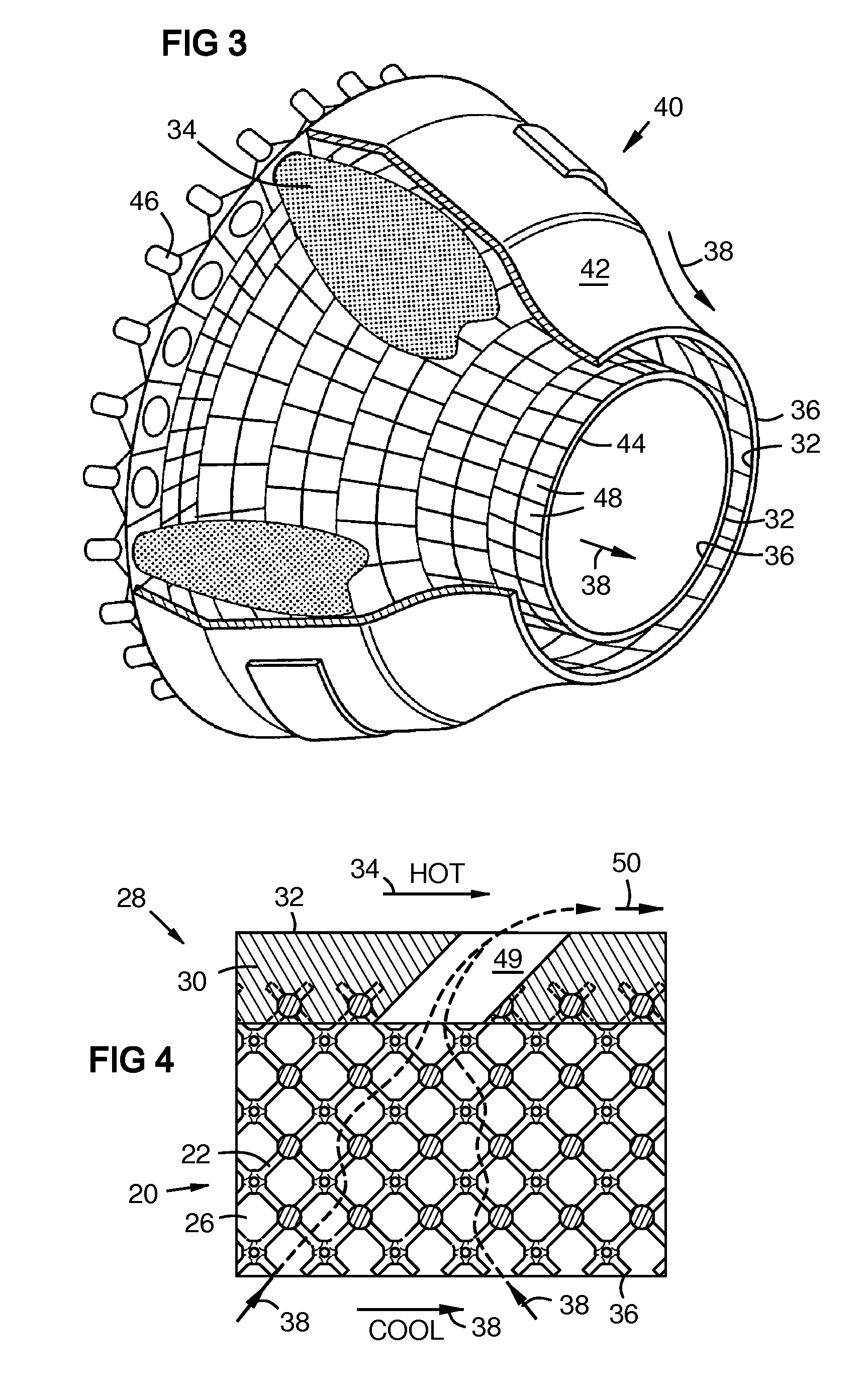

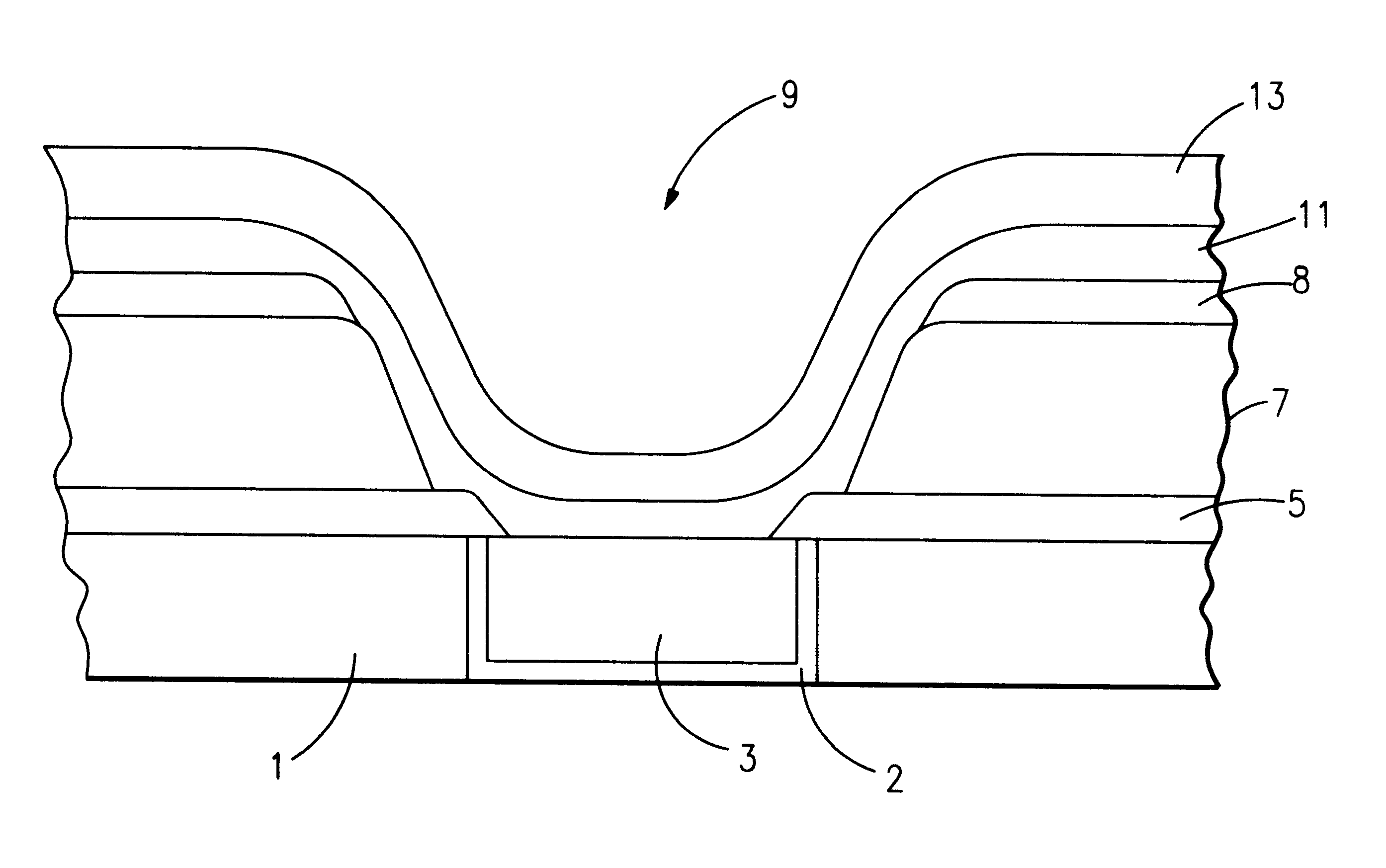

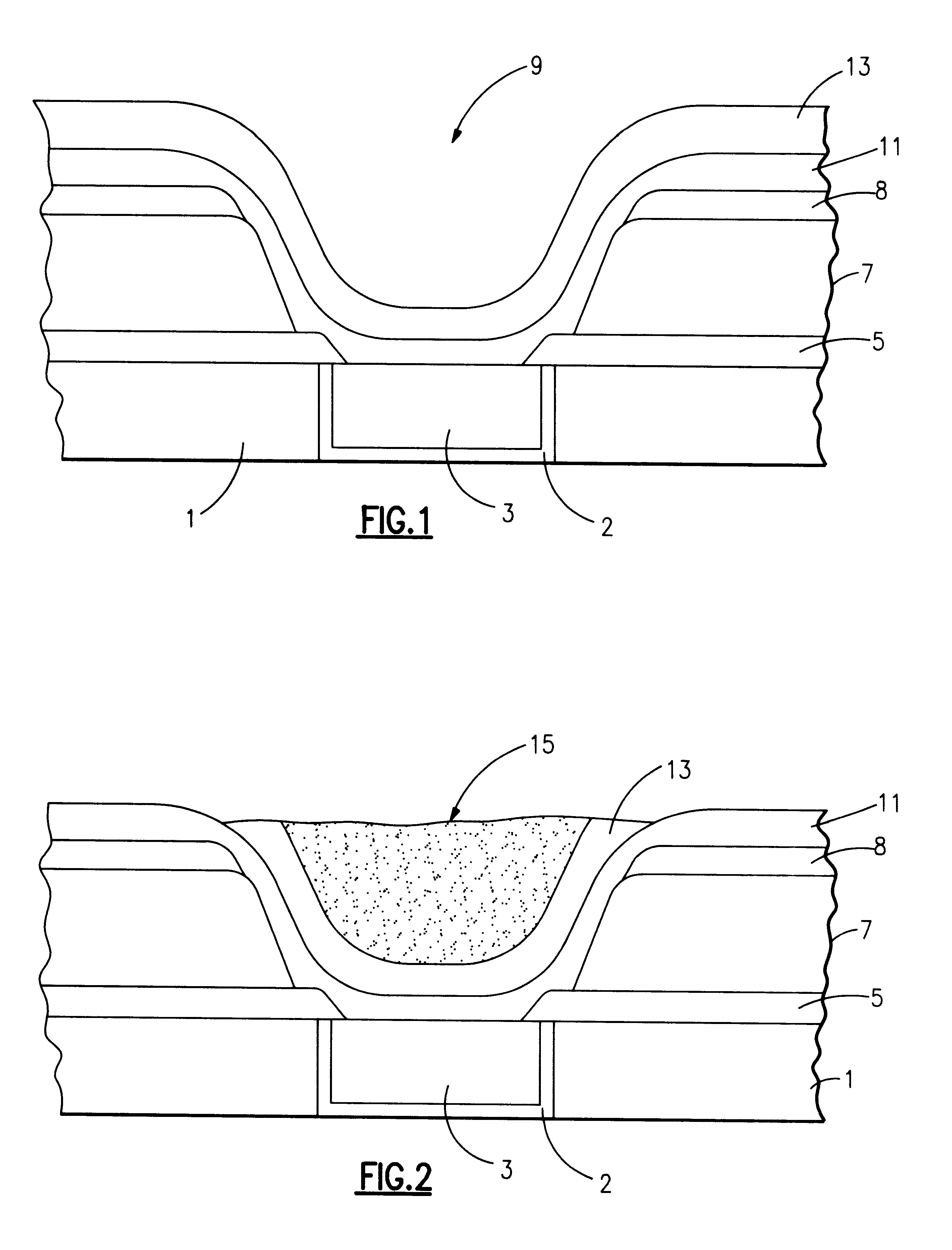

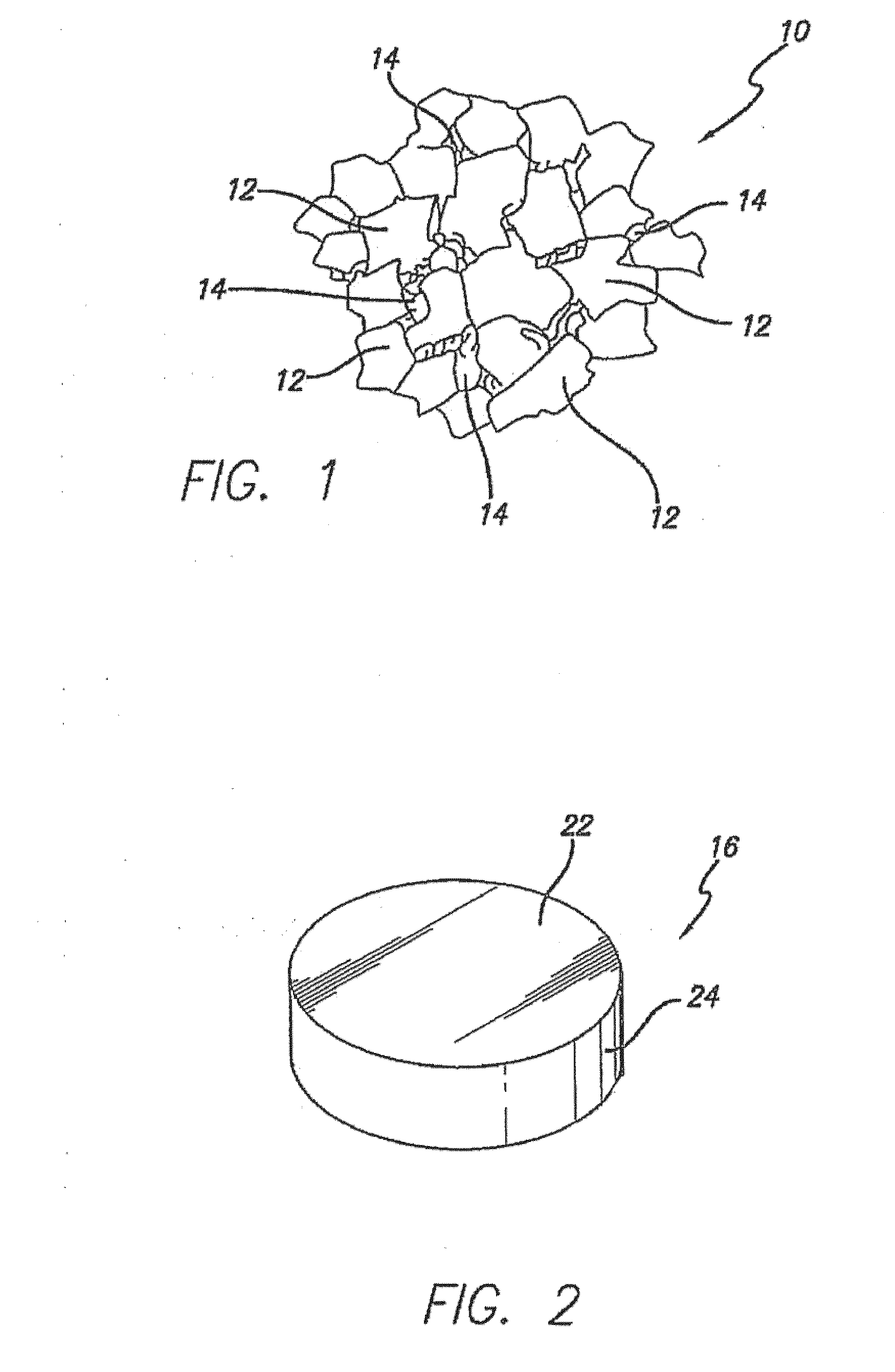

Thermal interface material and electronic assembly having such a thermal interface material

InactiveUS20030077478A1Artificial flowers and garlandsSemiconductor/solid-state device detailsStress conditionsIndium

A thermal interface material is described for thermal coupling of an electronic component to a thermally conductive member. The thermal interface material includes a viscoelastic polymer matrix material, fusible solder particles in the matrix material, and filler particles in the matrix material. The solder particles have a melting temperature below a selected temperature (e.g. 157° C. for indium) and the filler particles have a melting temperature substantially above the selected temperature (e.g. 961° C. for silver). The filler particles keep the thermal interface material intact under adverse thermal and stress conditions.

Owner:INTEL CORP

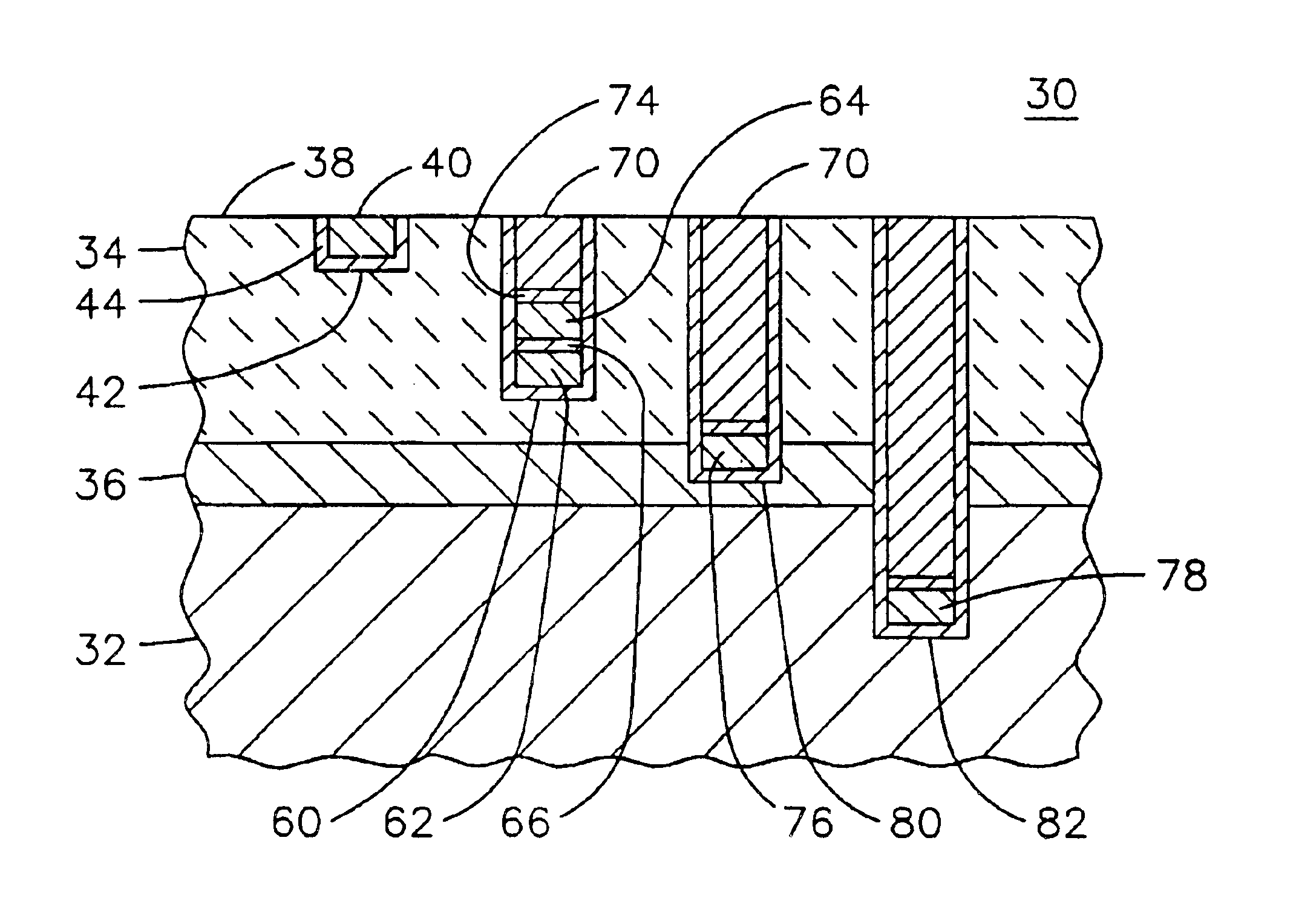

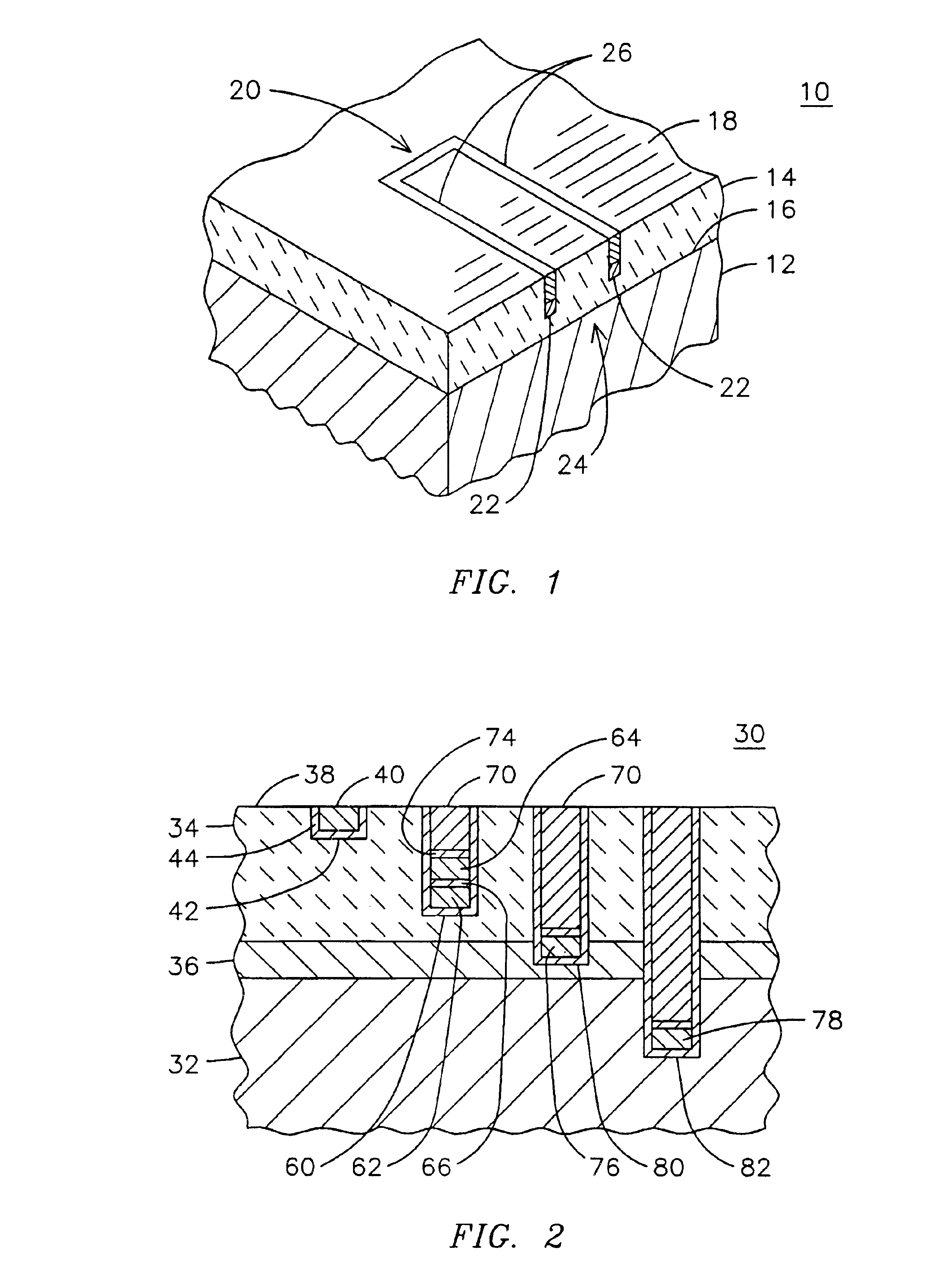

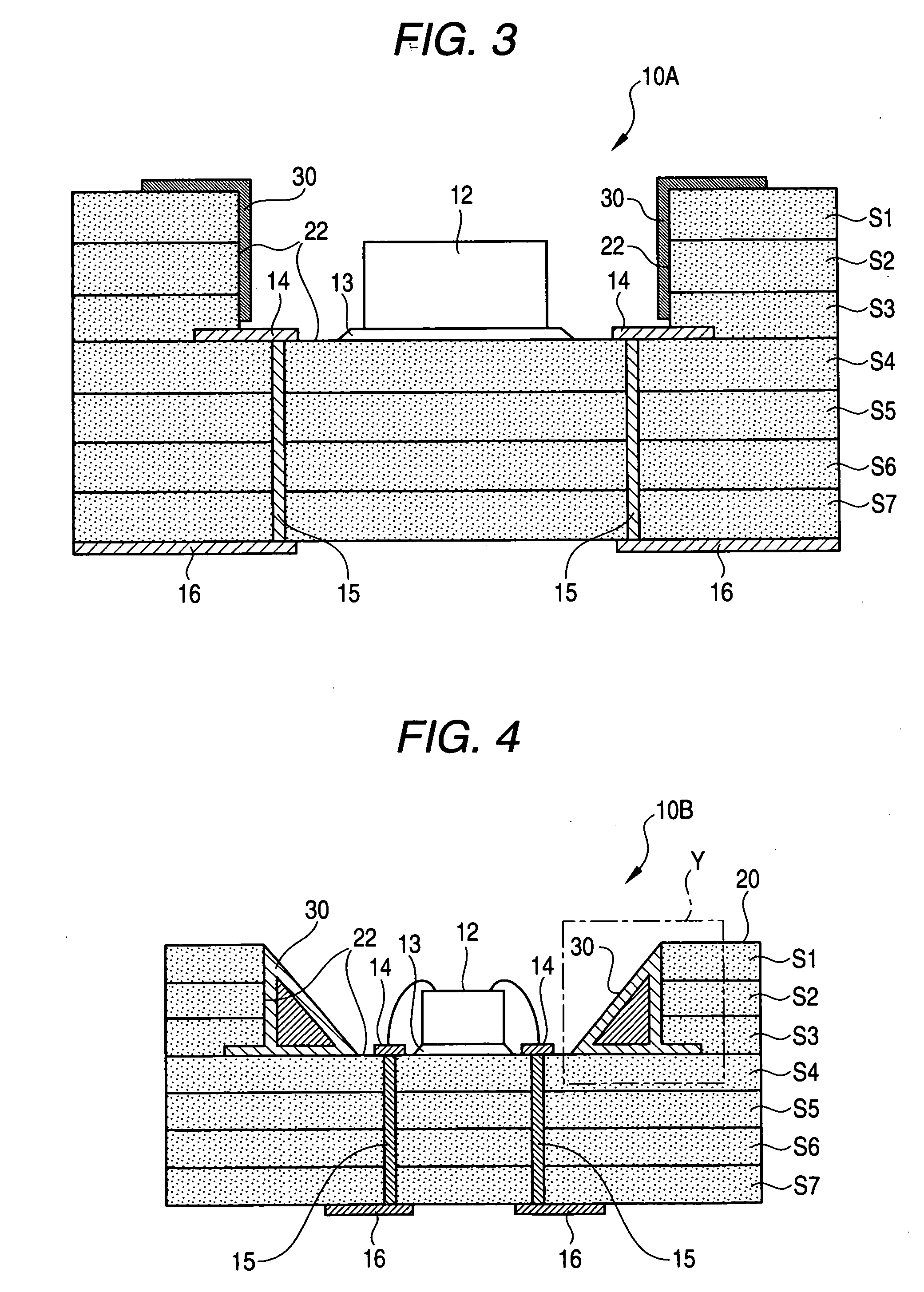

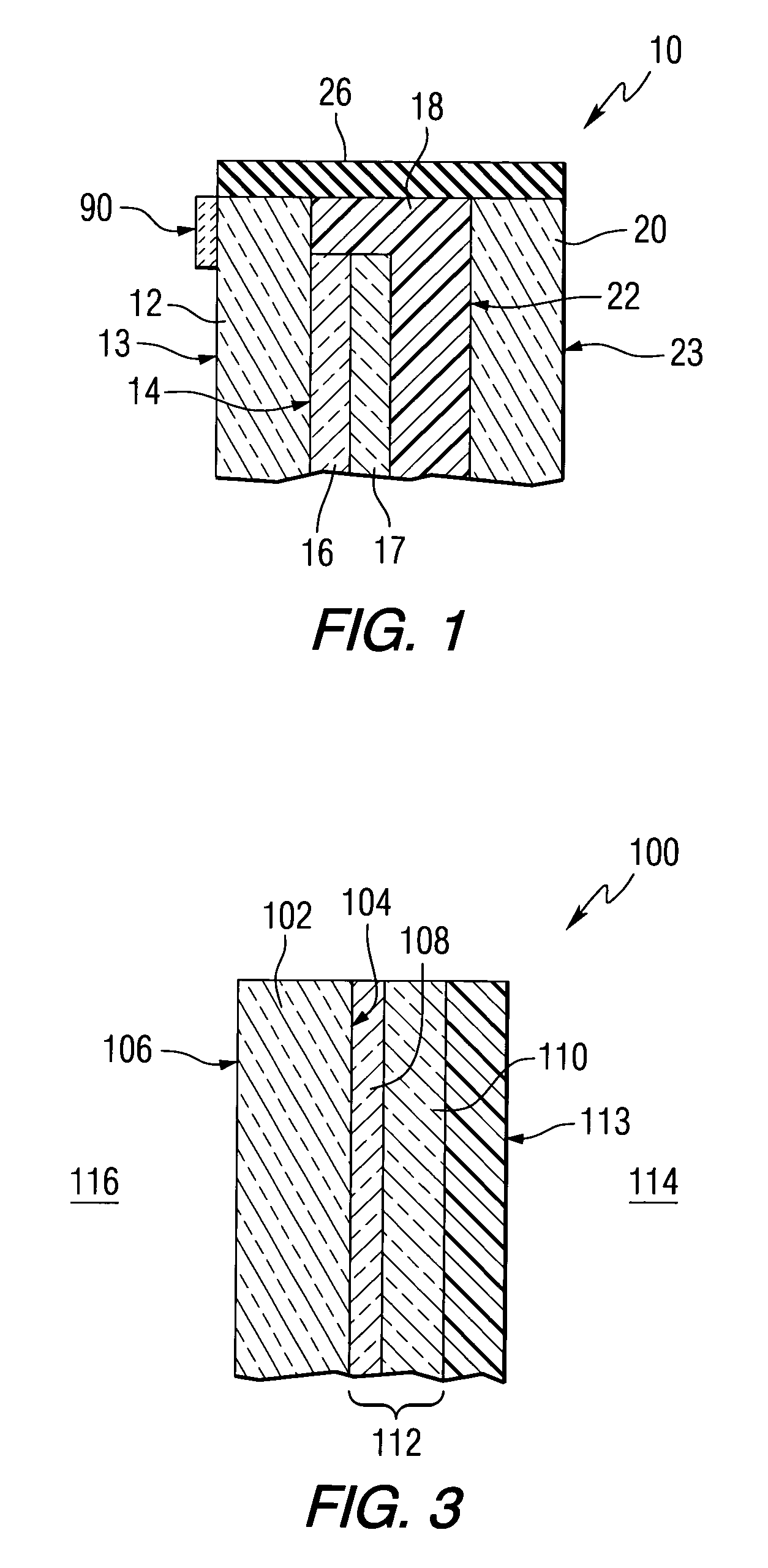

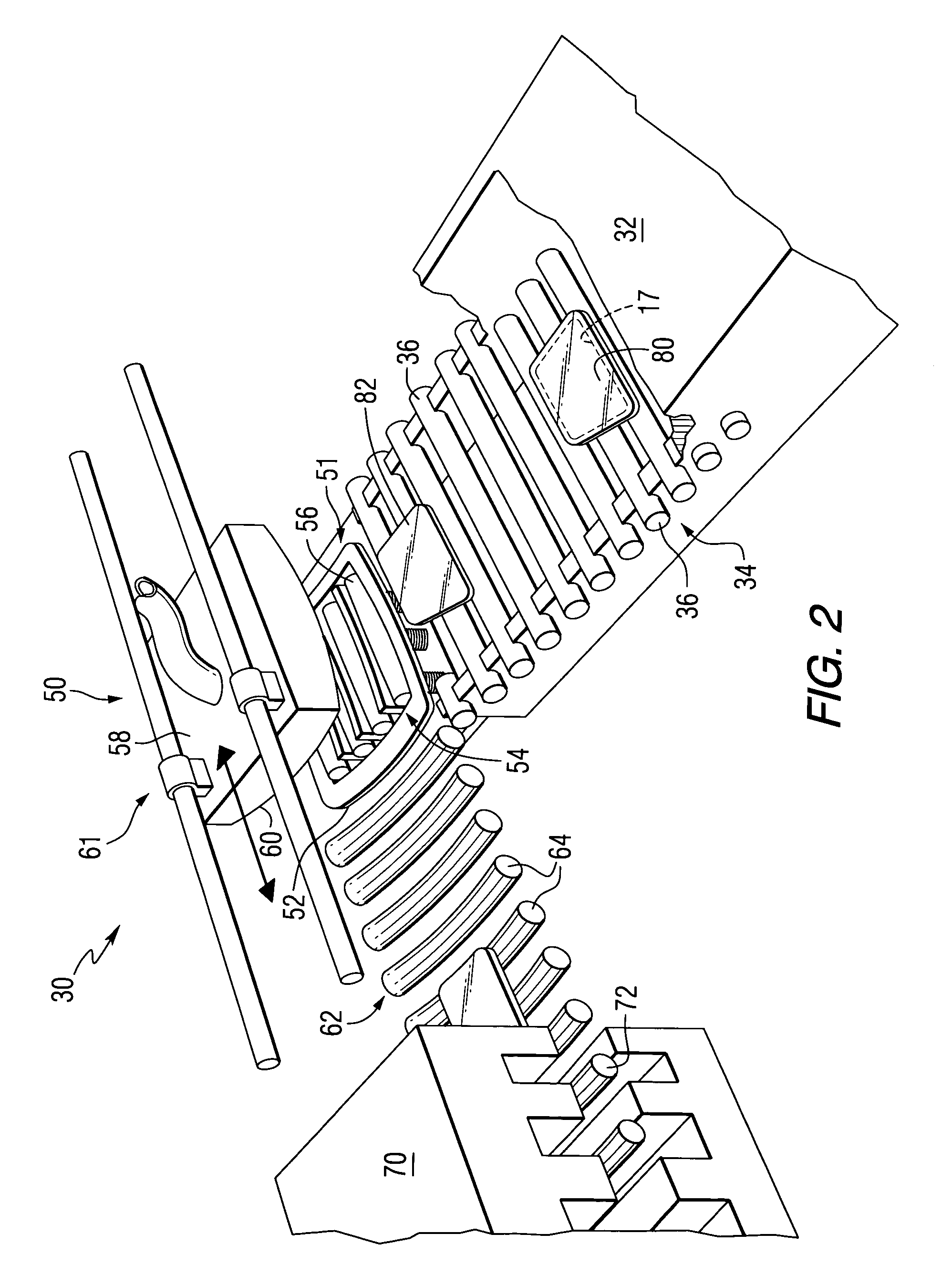

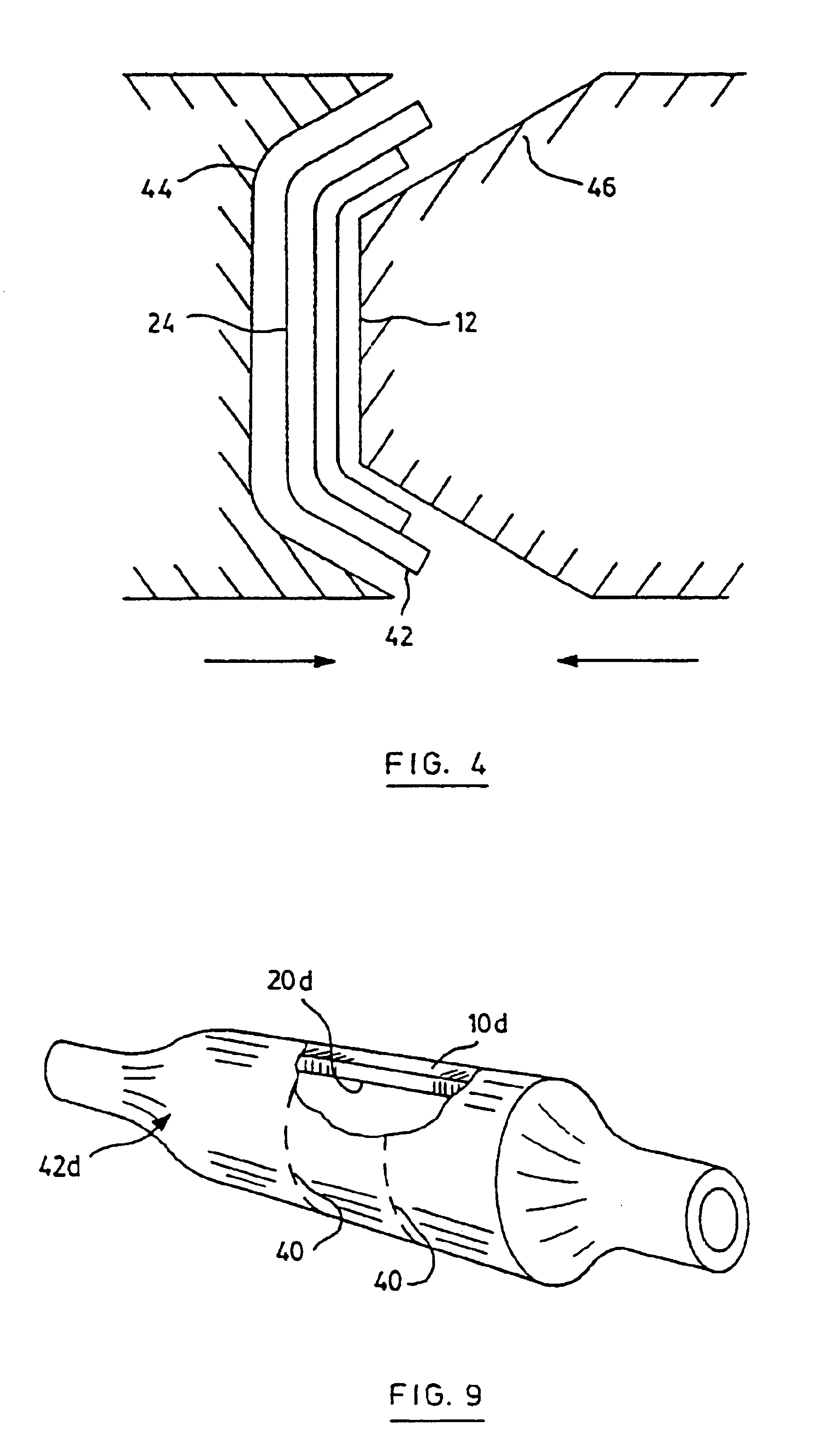

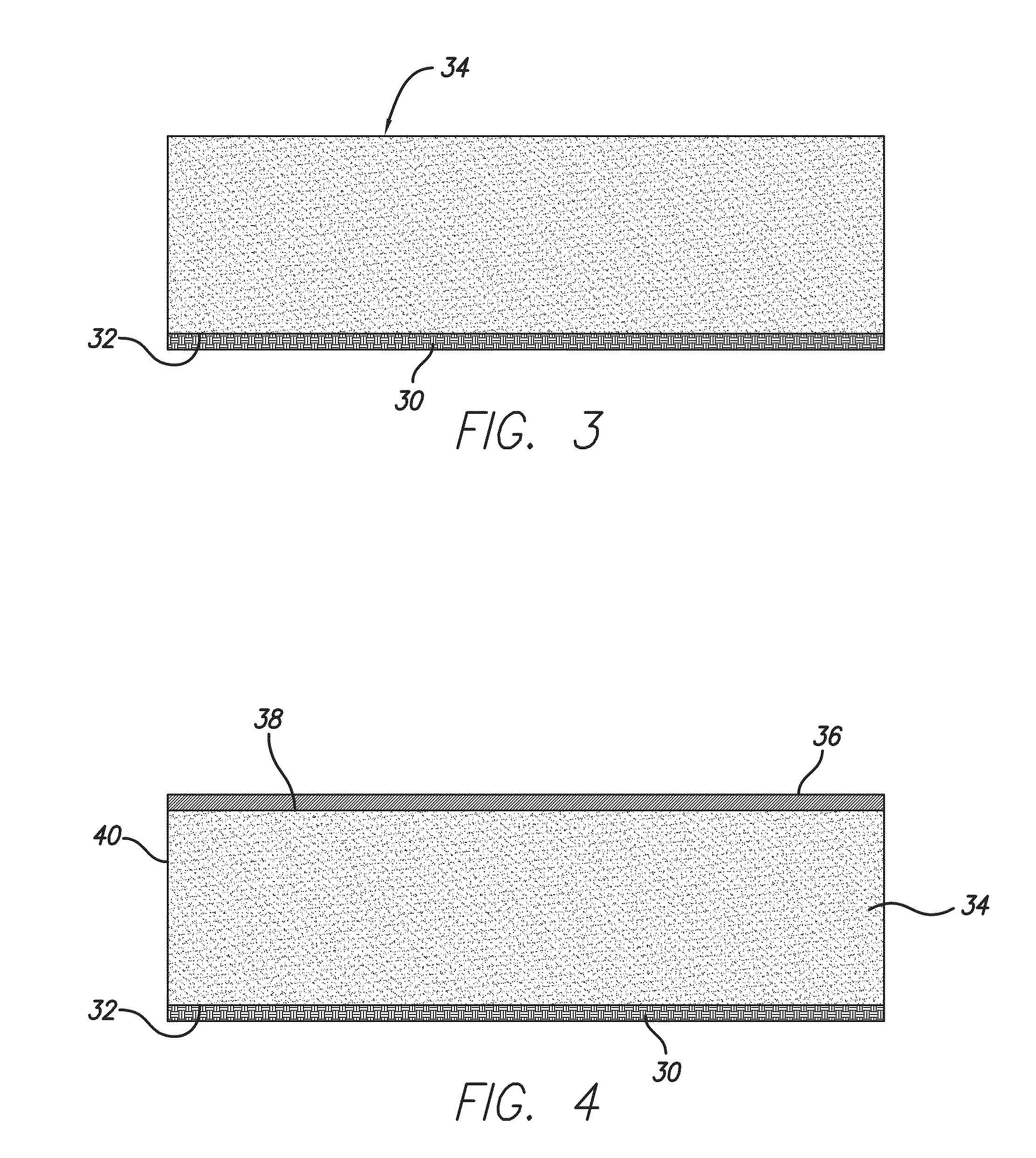

Method and apparatus for instrumenting a gas turbine component having a barrier coating

InactiveUS6838157B2Molten spray coatingVacuum evaporation coatingSelective laser meltingElectrical conductor

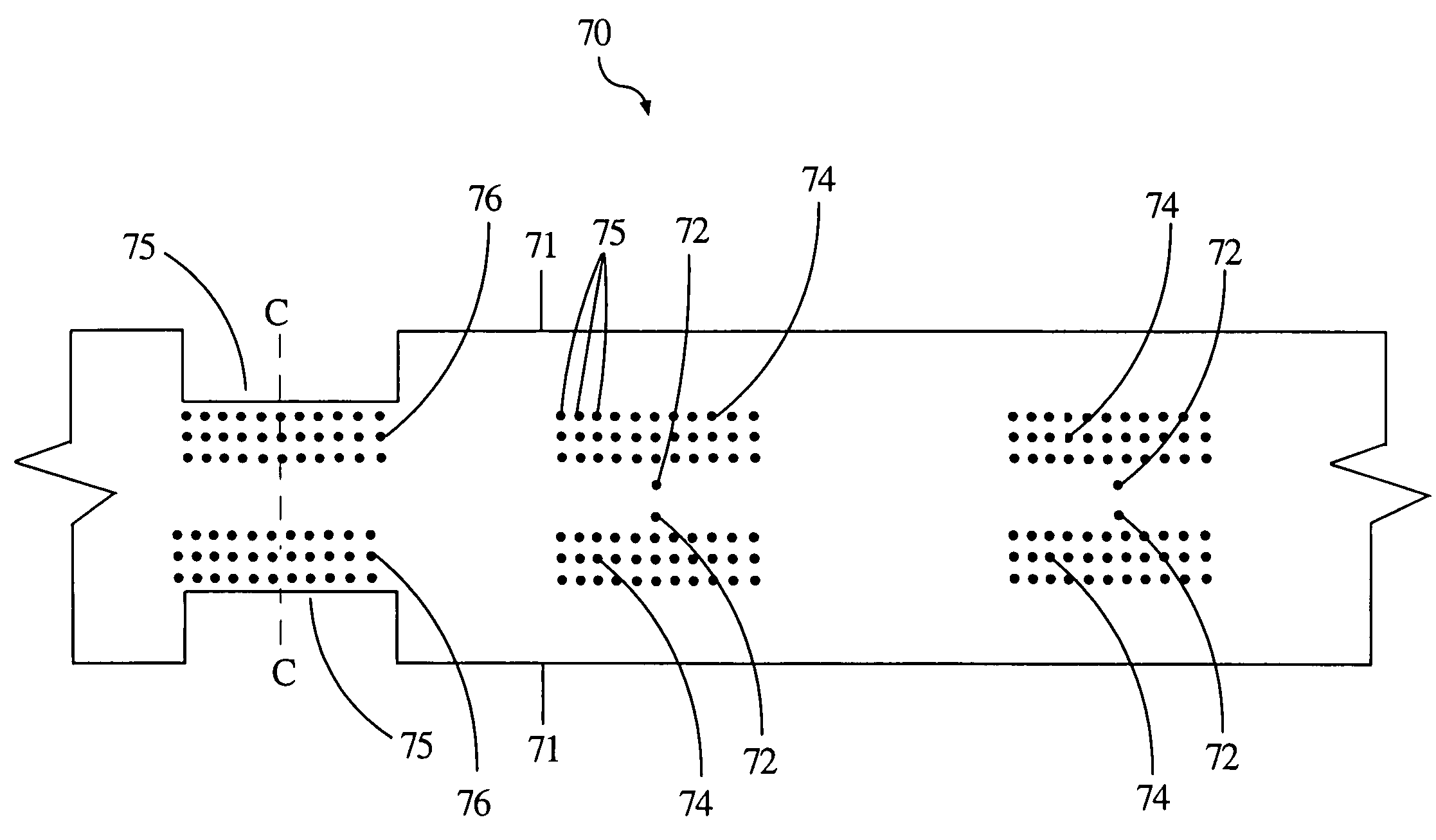

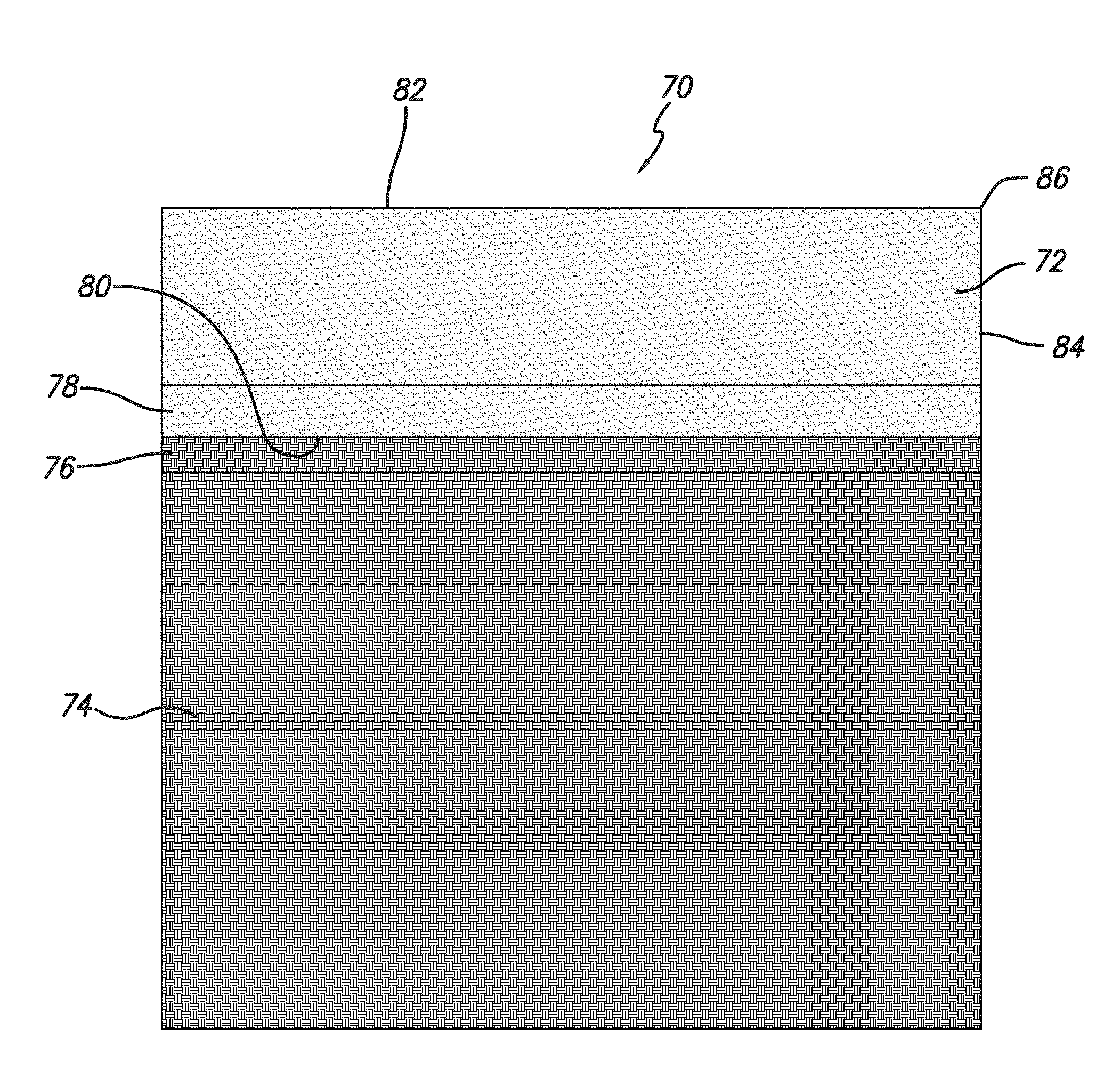

A method (50) of instrumenting a component (10) having a barrier coating (14). A sensor (76) is embedded within or below the coating. Material forming the sensor is deposited within a trench (80) formed into the barrier coating. The trench is then backfilled with material (70) to protect the sensor from the environment within which the component is operating. In this manner, the sensor may be embedded at any desired location and any desired depth within a barrier coating on a previously fabricated component. An array of sensors (98, 100, 102) may be embedded across the depth of the coating to provide signals indicative of operating conditions across the coating. The signals may be conducted to a connection location (24) by conductors (62, 64) that are deposited within the trench. The trench may be formed with a laser engraving process (54) and the material for the sensor and conductors may be deposited with a selective laser melting process (58).

Owner:SIEMENS ENERGY INC

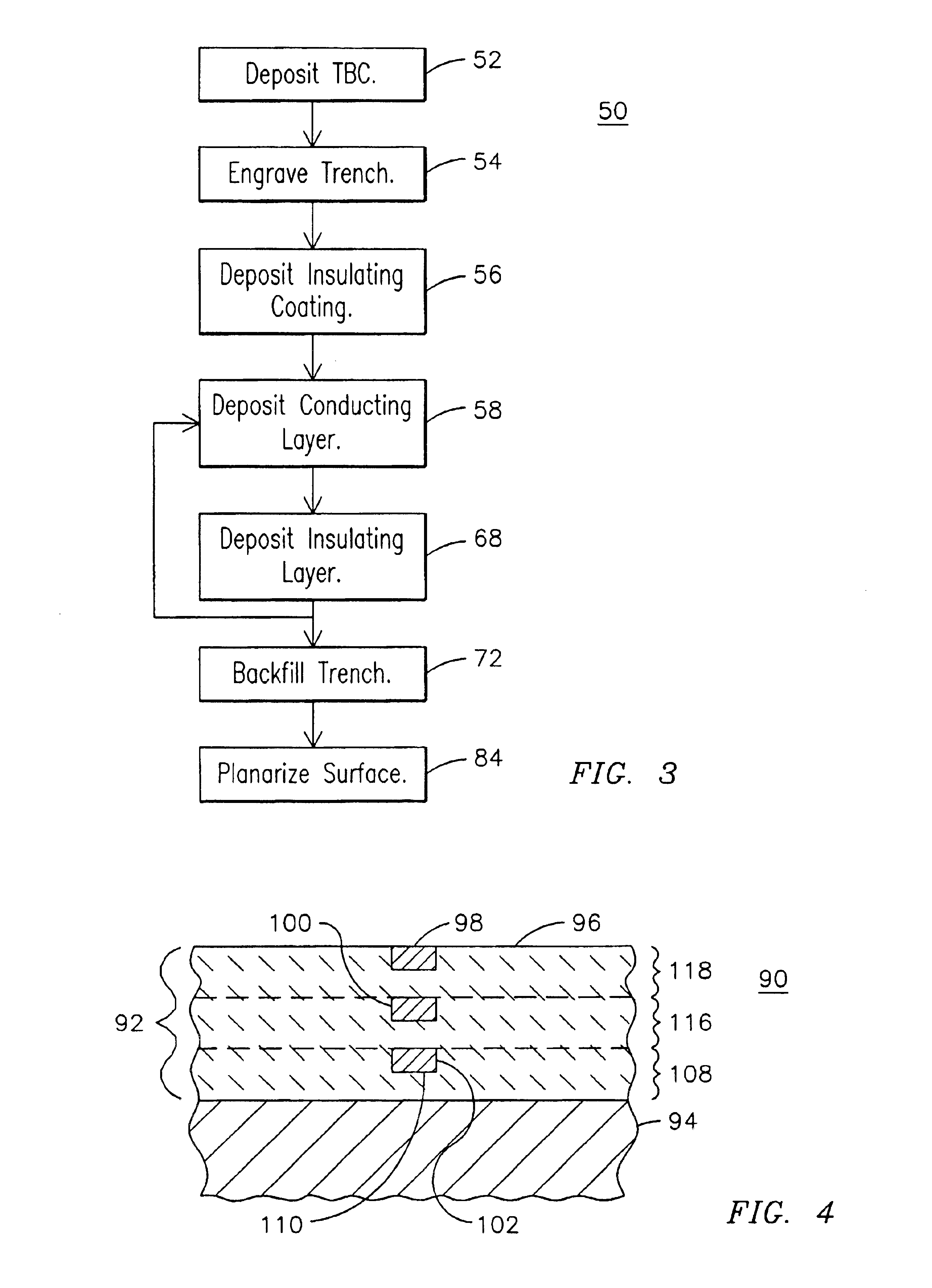

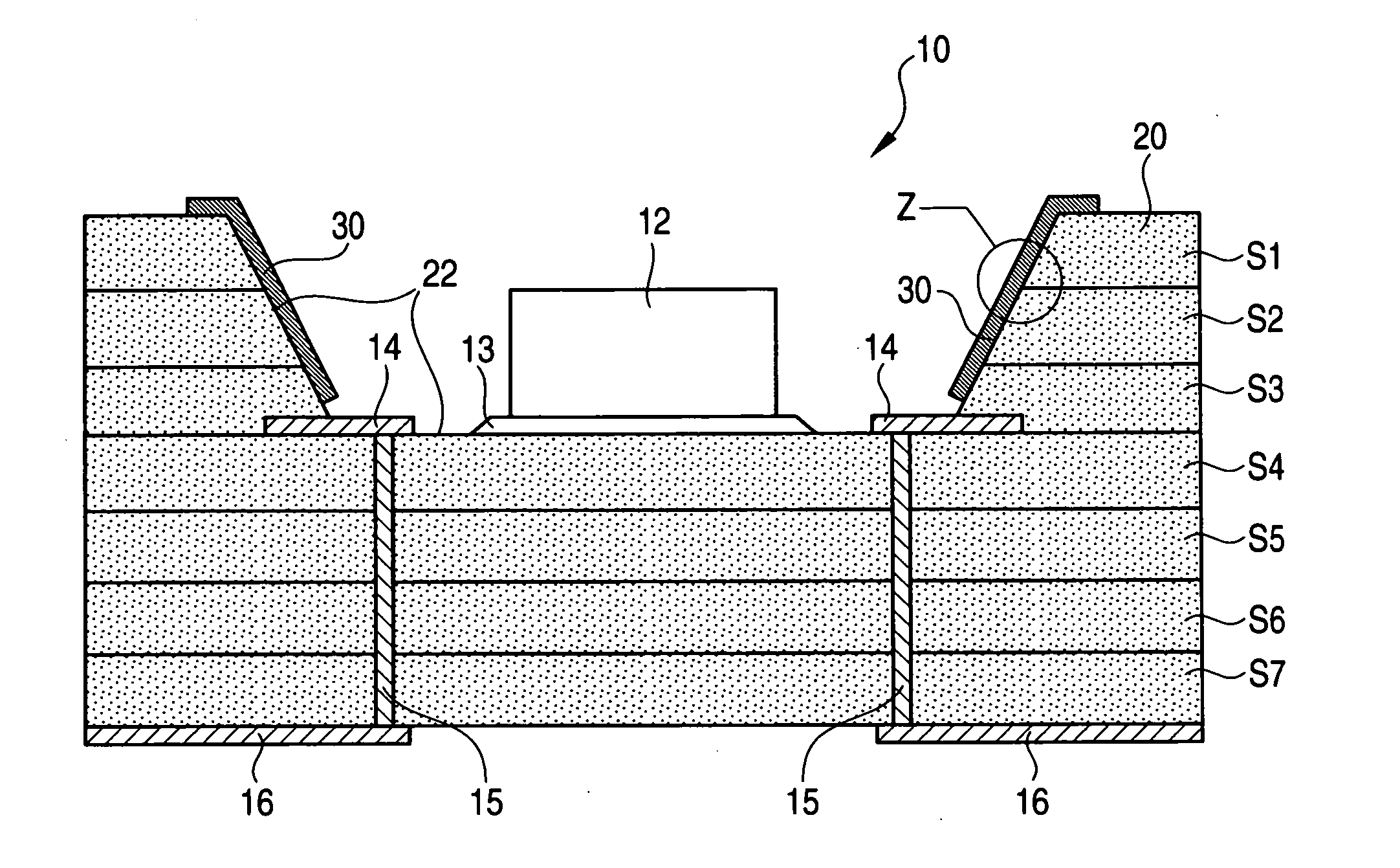

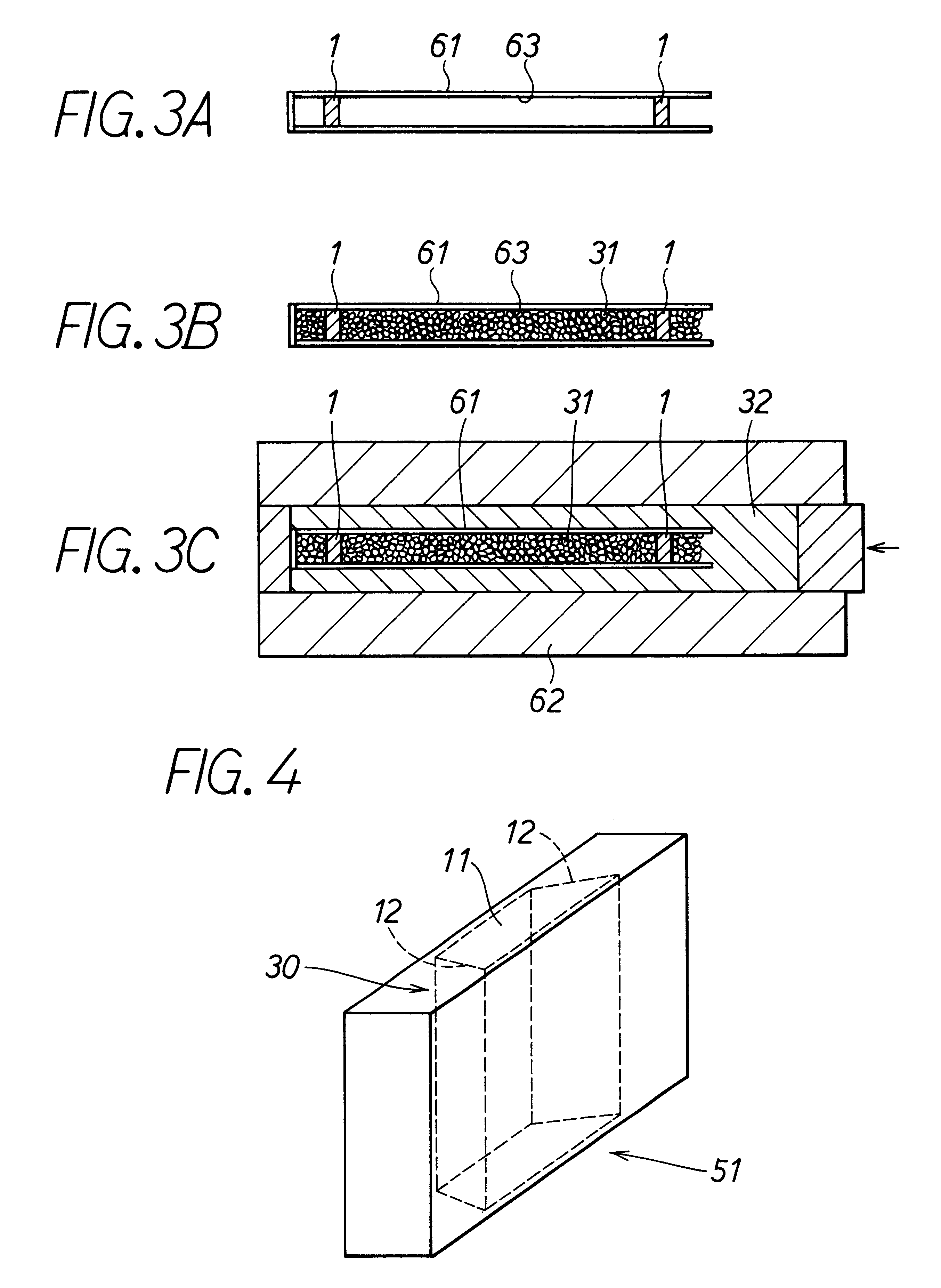

Ceramic substrate, ceramic package for housing light emitting element

InactiveUS20060147746A1Reduce smoothnessIncrease costExtrusion containersSolid-state devicesGold layerCeramic substrate

A ceramic substrate comprising a metallic layer on its surface, wherein said metallic layer includes: a silver layer containing silver; a gold layer containing gold; and a nickel layer containing nickel, in this order from an outermost layer of said metallic layer.

Owner:NGK SPARK PLUG CO LTD

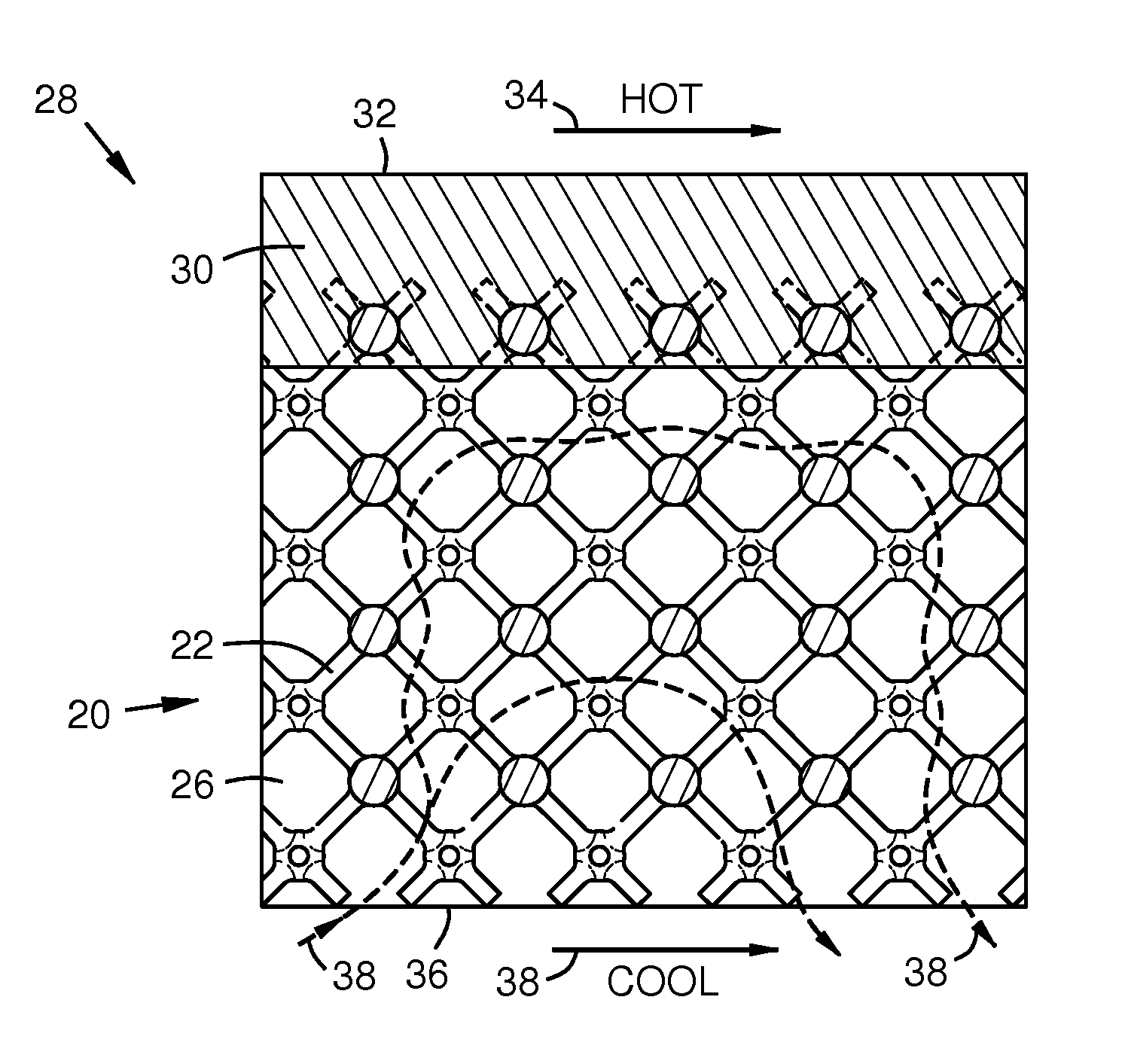

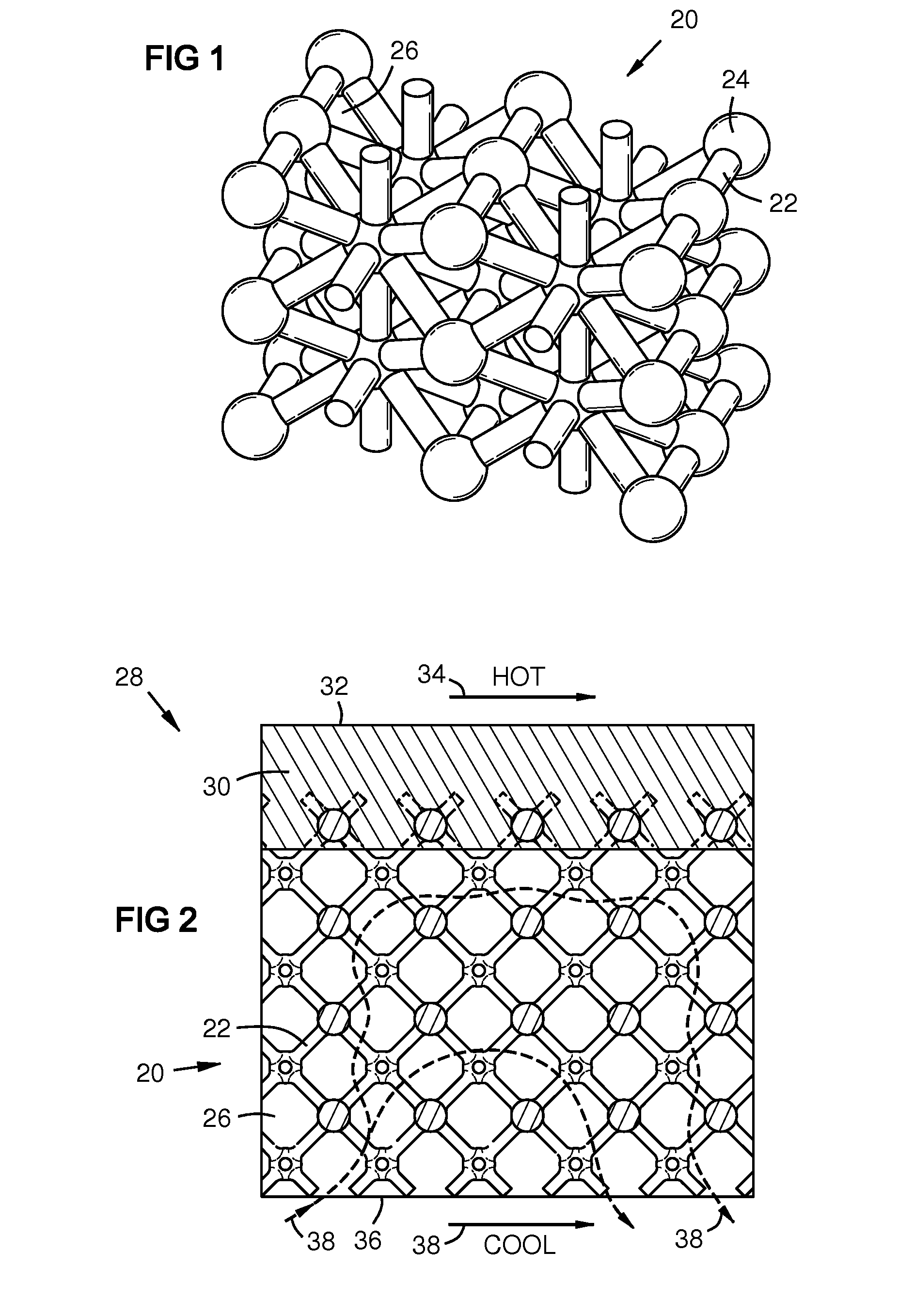

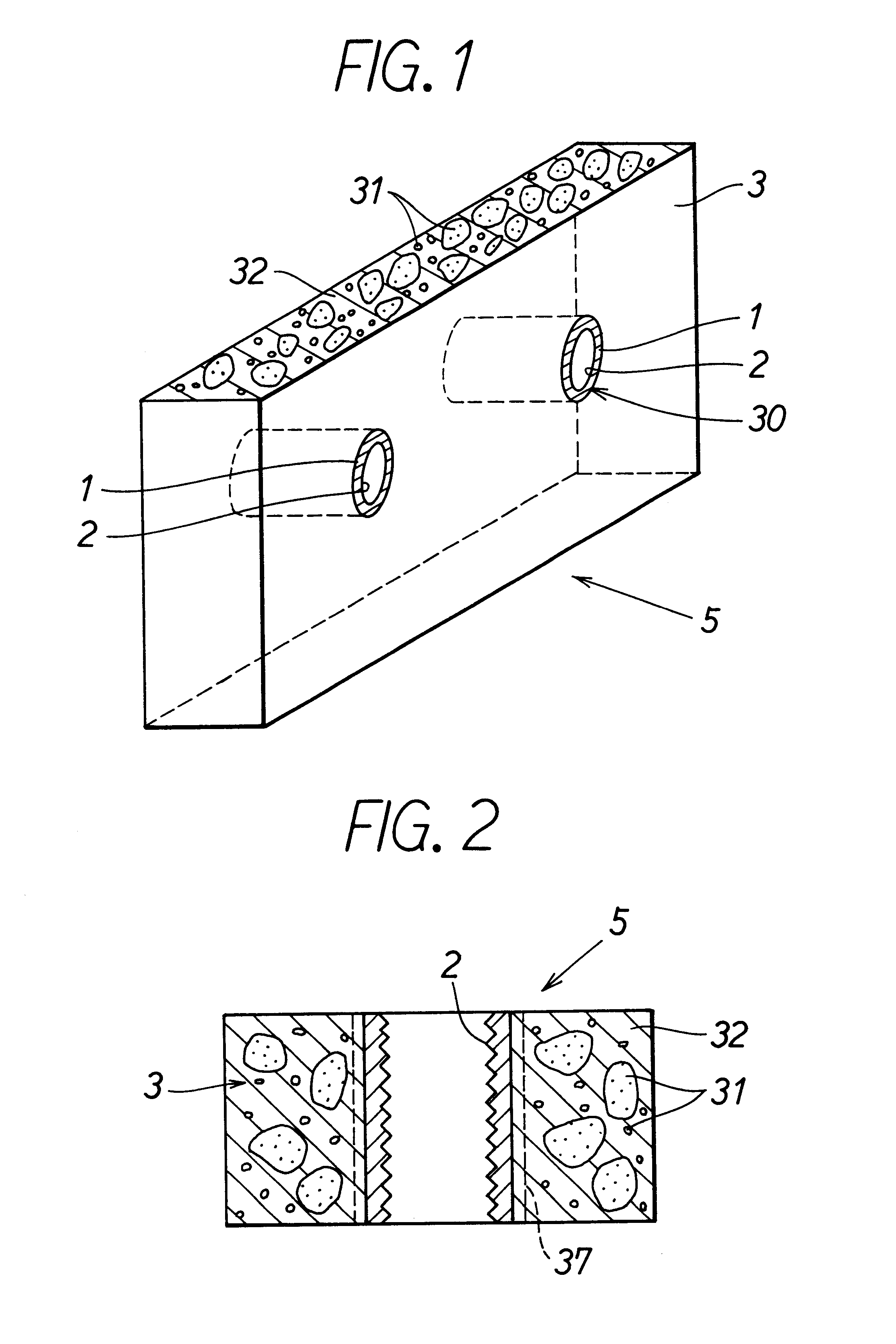

Process for making a wall with a porous element for component cooling

A structural layer (30) may be bi-cast onto ligaments (62) extending from a porous cooling construction (20). The material of the structural layer may be optimized for high-temperature strength, while the material of the porous construction may be optimized for high thermal conductivity. A fugitive material (56) such as wax may be formed on the ligaments of the porous construction. A second fugitive material (58) such as ceramic may fill the remaining part of the porous construction. An investment casting shell (60) may be disposed around the porous construction and the fugitive materials. The first fugitive material may then be replaced with the material of the structural layer (30), and the second fugitive material may be removed to provide coolant paths (26). A second structural layer (52) may be bi-cast onto further ligaments (62) on a second side of the porous construction.

Owner:SIEMENS ENERGY INC

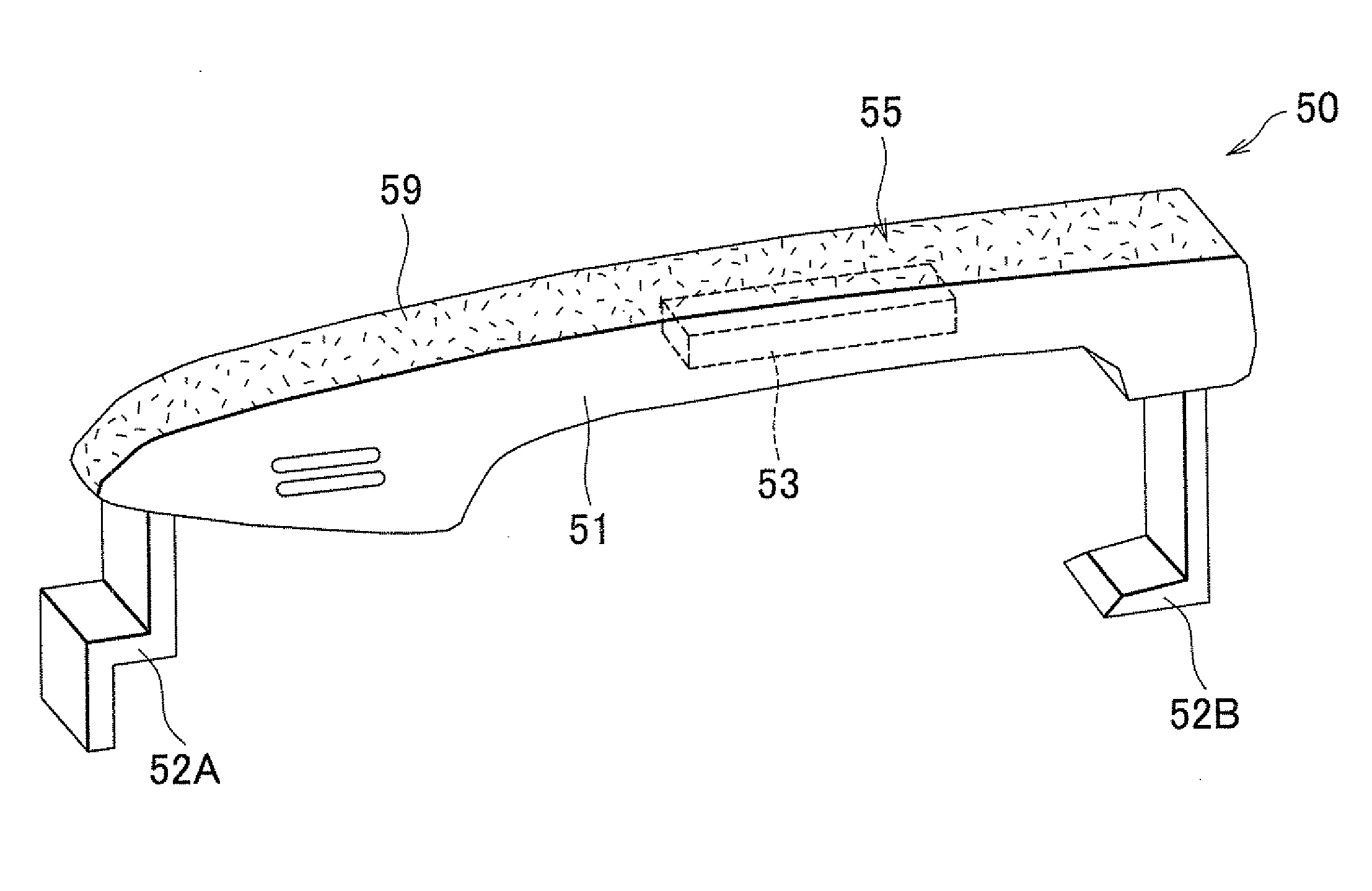

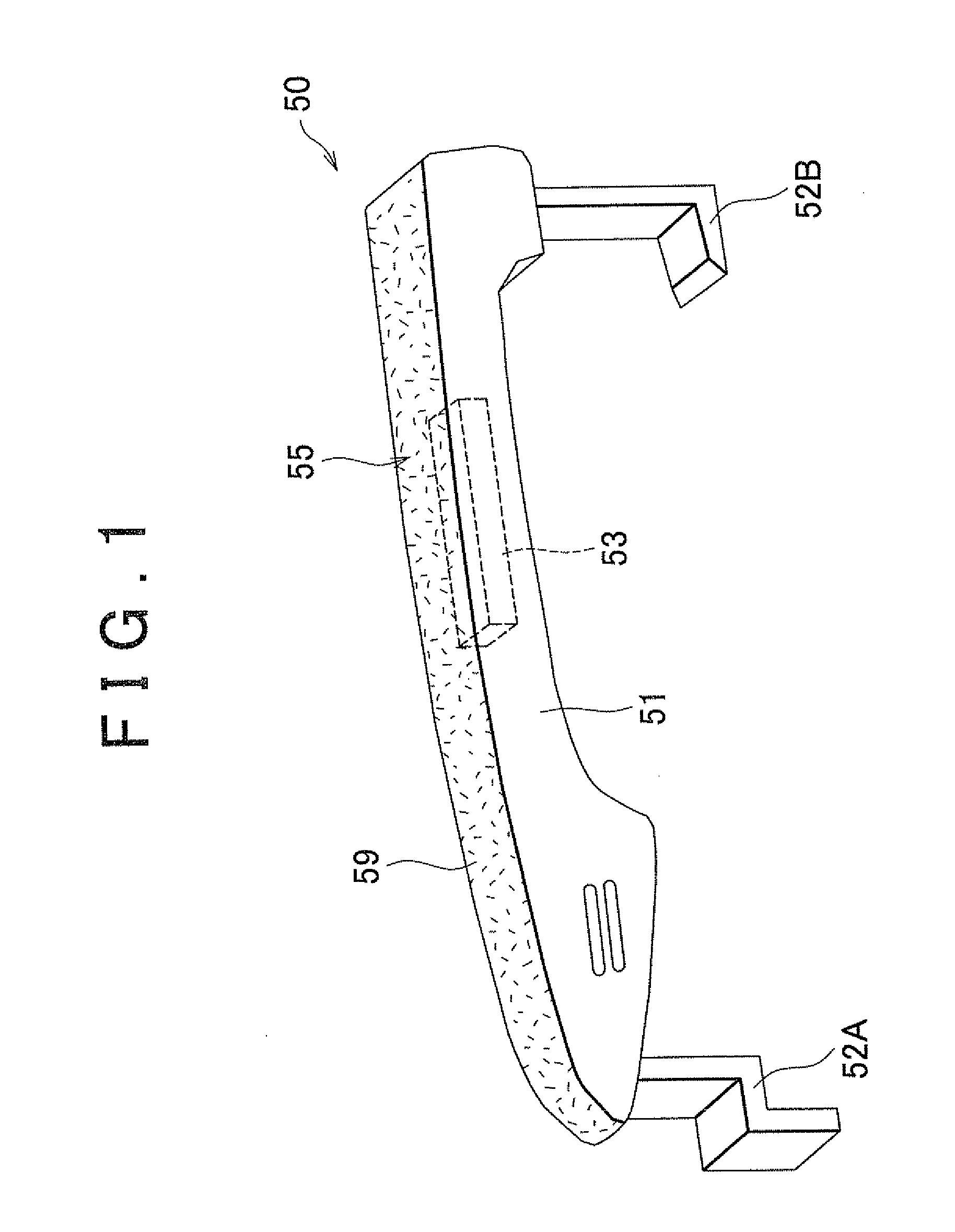

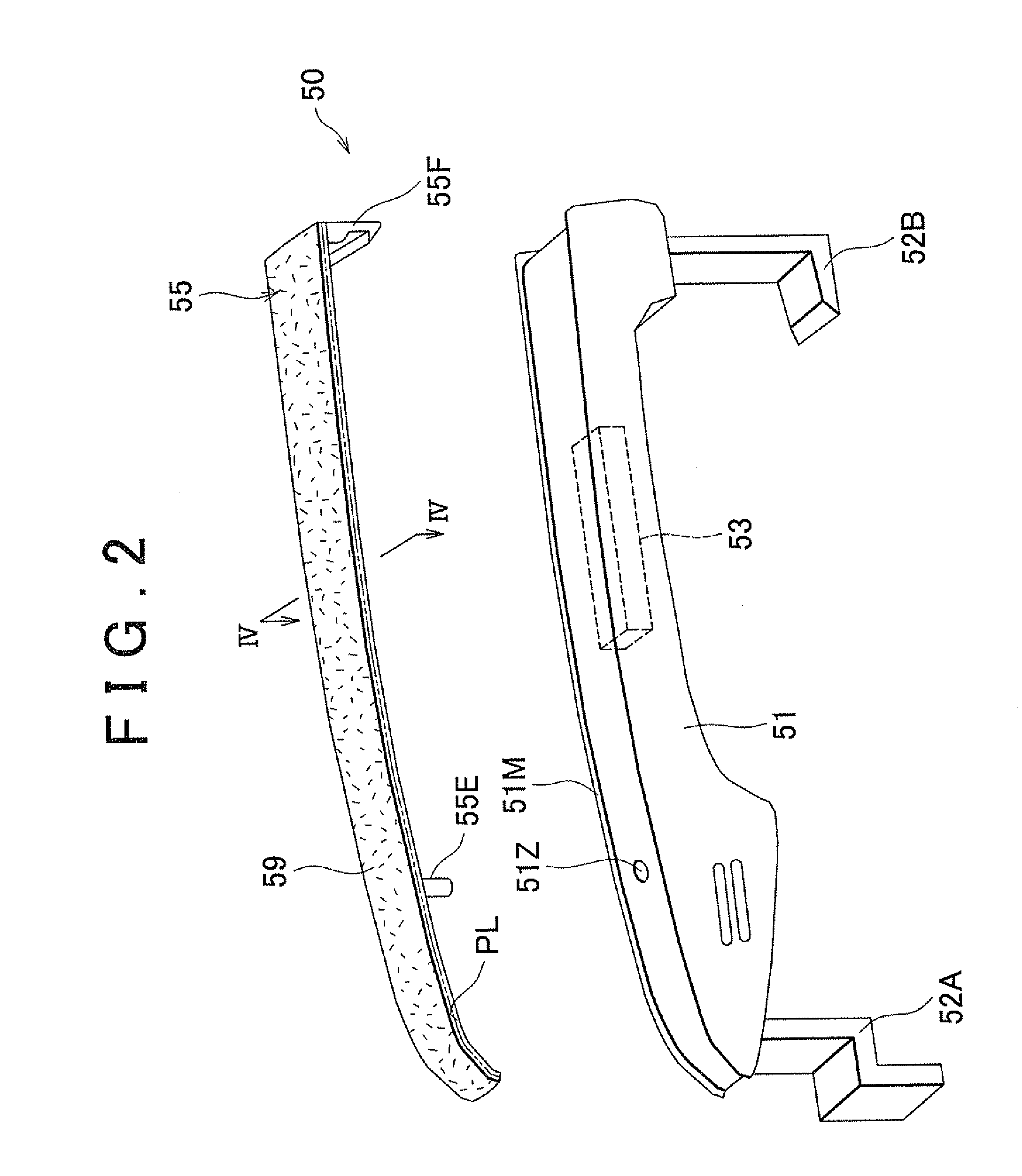

Metallic resin cover and method of producing the same, and door handle for vehicle

InactiveUS20110012378A1Improve the decorative effectReduce adverse effectsLock applicationsWing handlesCapacitance transducerBiomedical engineering

A metallic resin cover constitutes a portion of an outer wall of a human detection device in which a detection electrode of a capacitance sensor is provided, and which detects whether a human touches or approaches the human detection device. The metallic resin cover includes a covered body; and a metal layer that has a metal-object discretely arranged structure in which a plurality of metal objects are discretely arranged. The metal layer covers an outer surface of the covered body.

Owner:WAVELOCK ADVANCED TECH +1

Process for producing bioresorbable implants

A process for producing implants made of a bioresorbable metal, particularly magnesium alloys or zinc alloys, in which the material properties of the magnesium or the zinc are changed and the processing and utilization properties are improved by combining process steps for adjusting the properties of the material and subsequent machining. In this way it is possible to produce thin-walled tubular implants, particularly blood vessel support stents, from bioresorbable magnesium or zinc alloys, which are readily deformable without the risk of fracture during implantation.

Owner:UNIVERSITY OF HANOVER

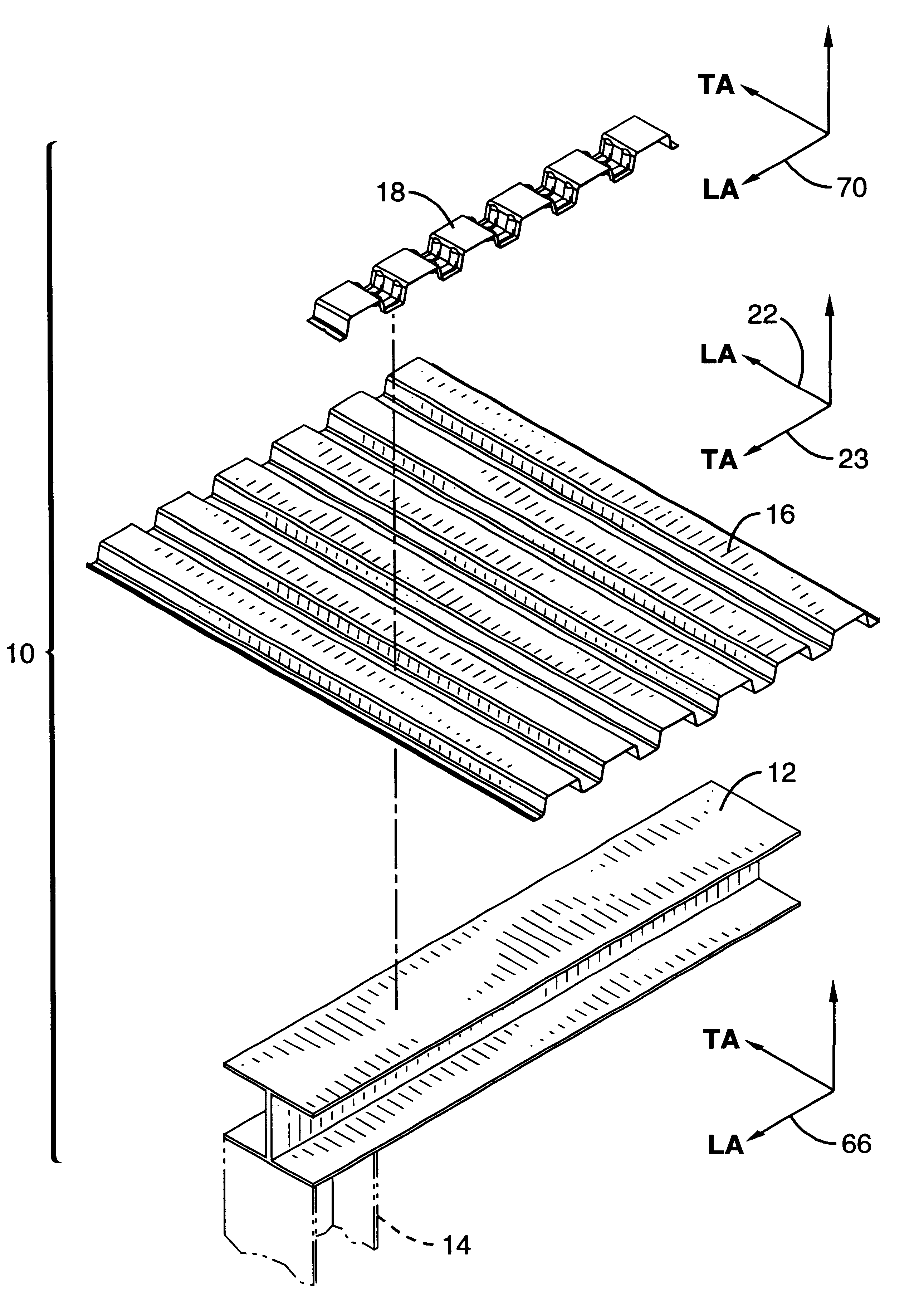

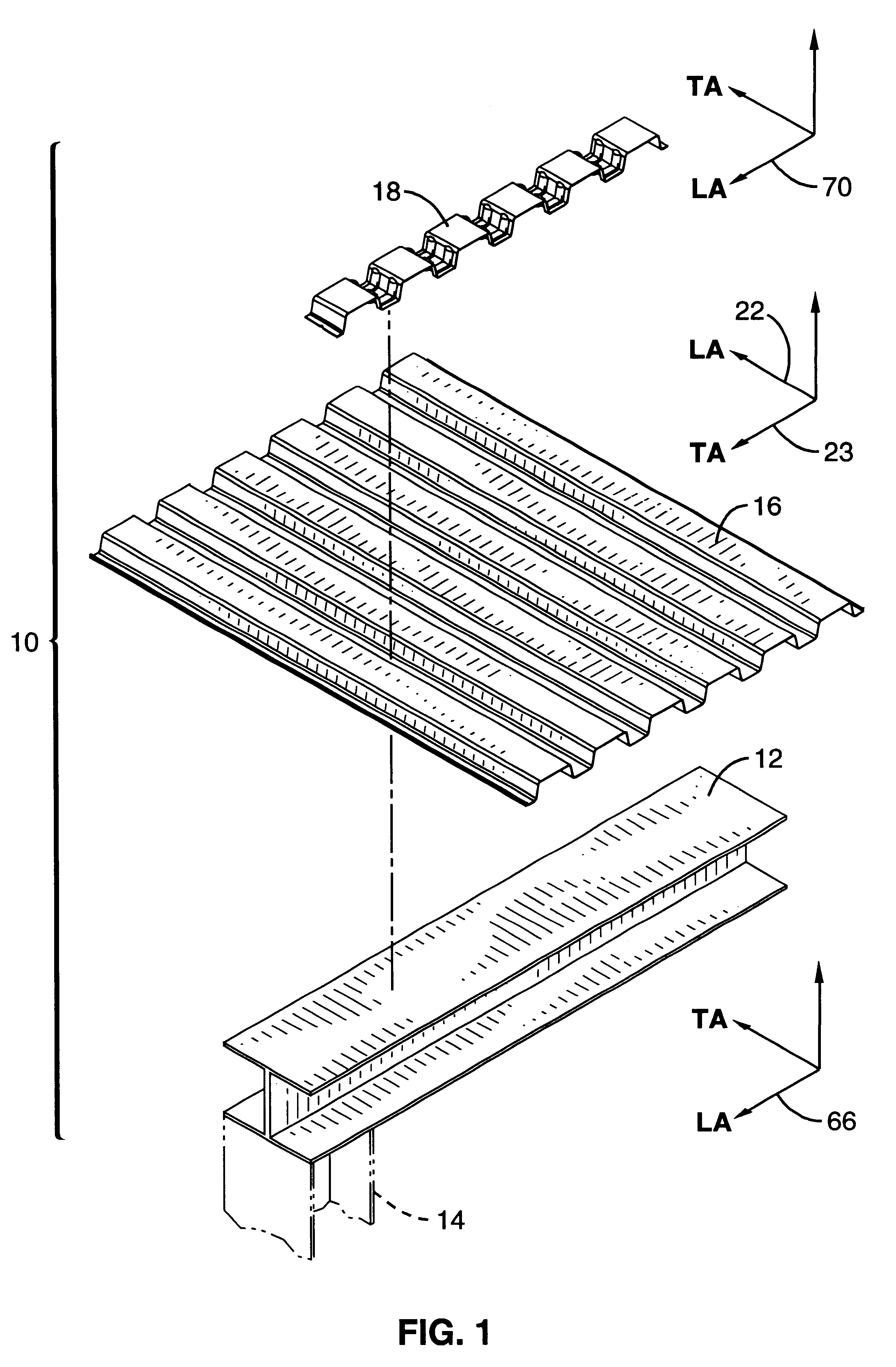

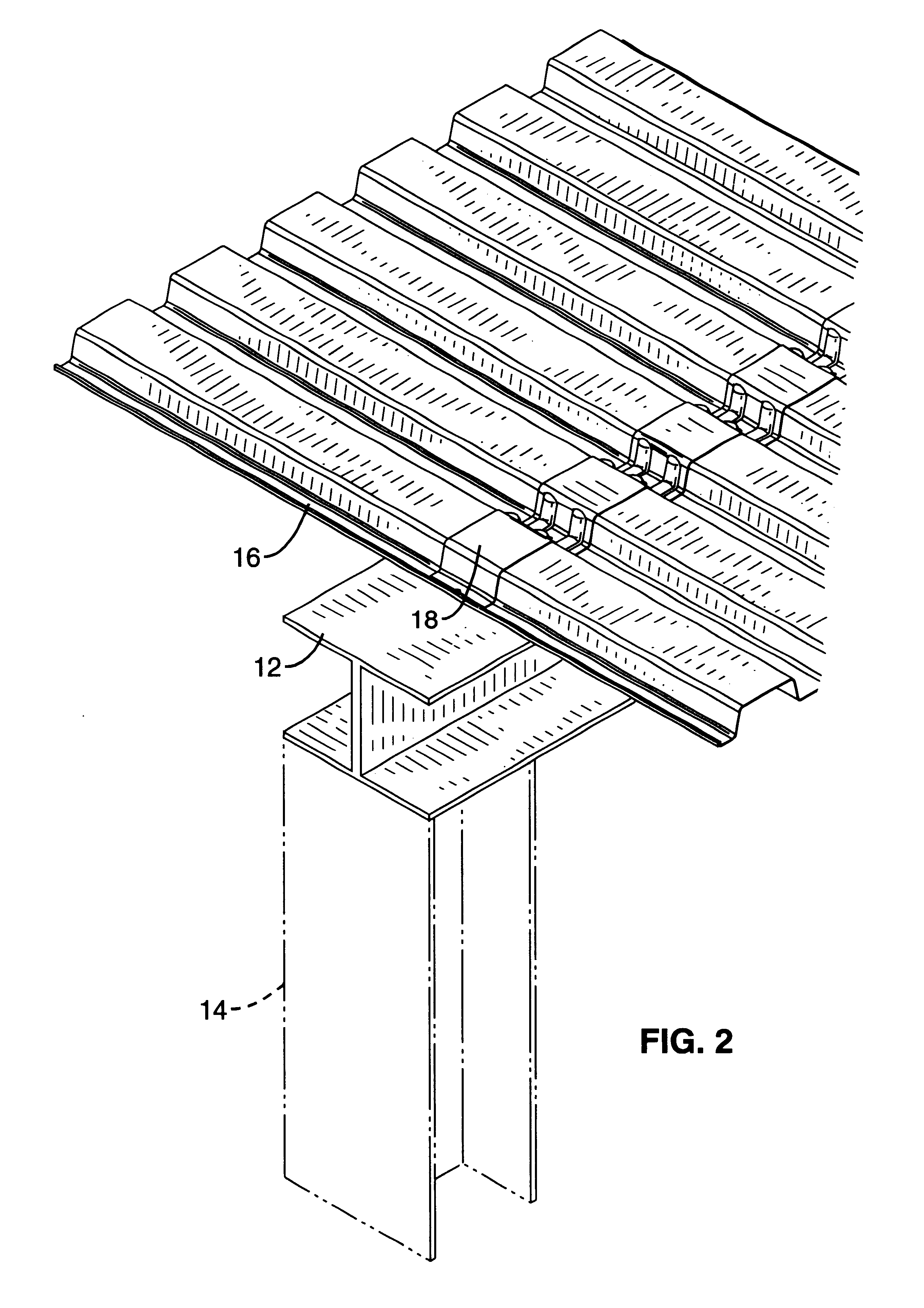

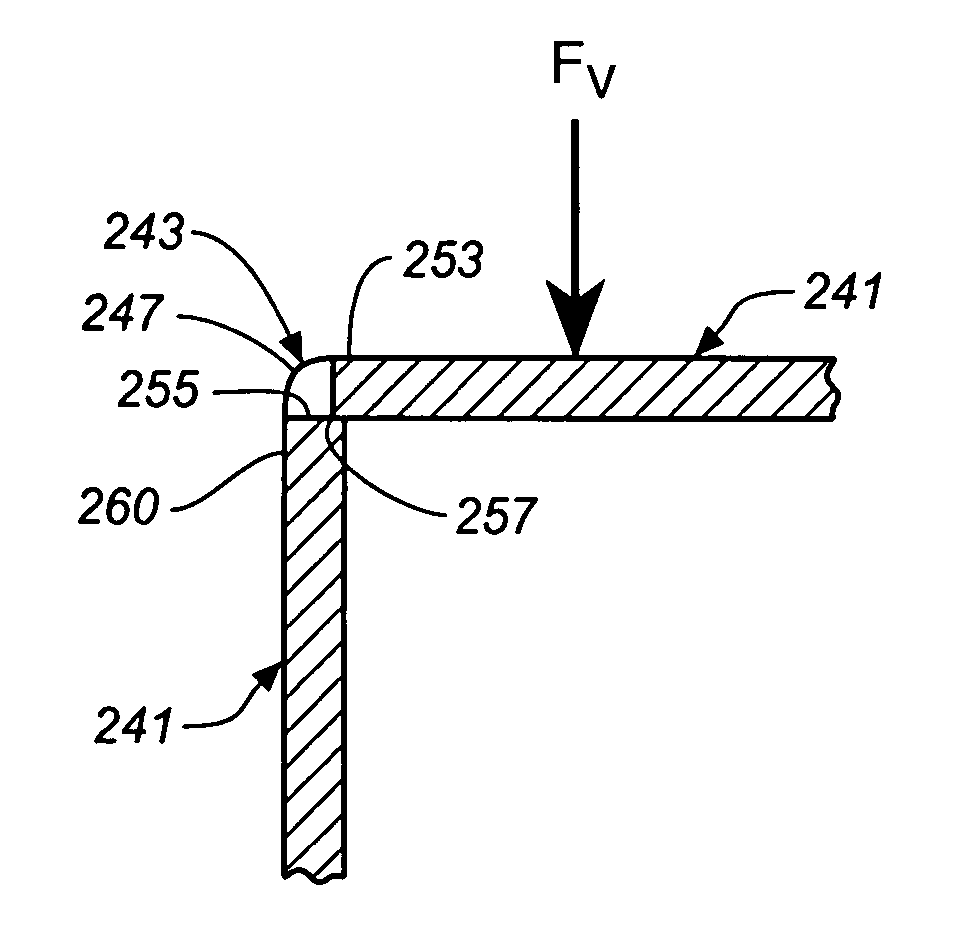

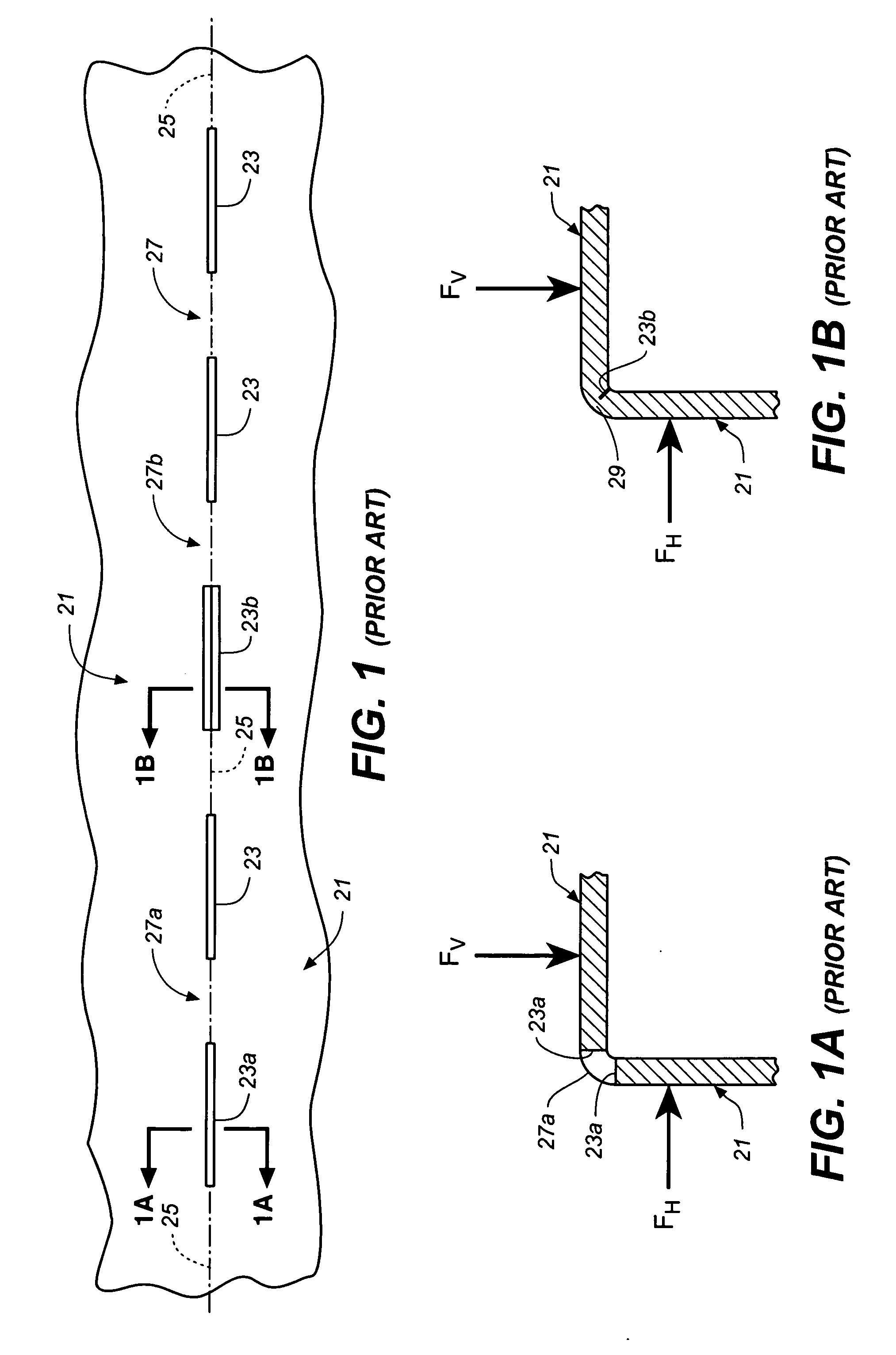

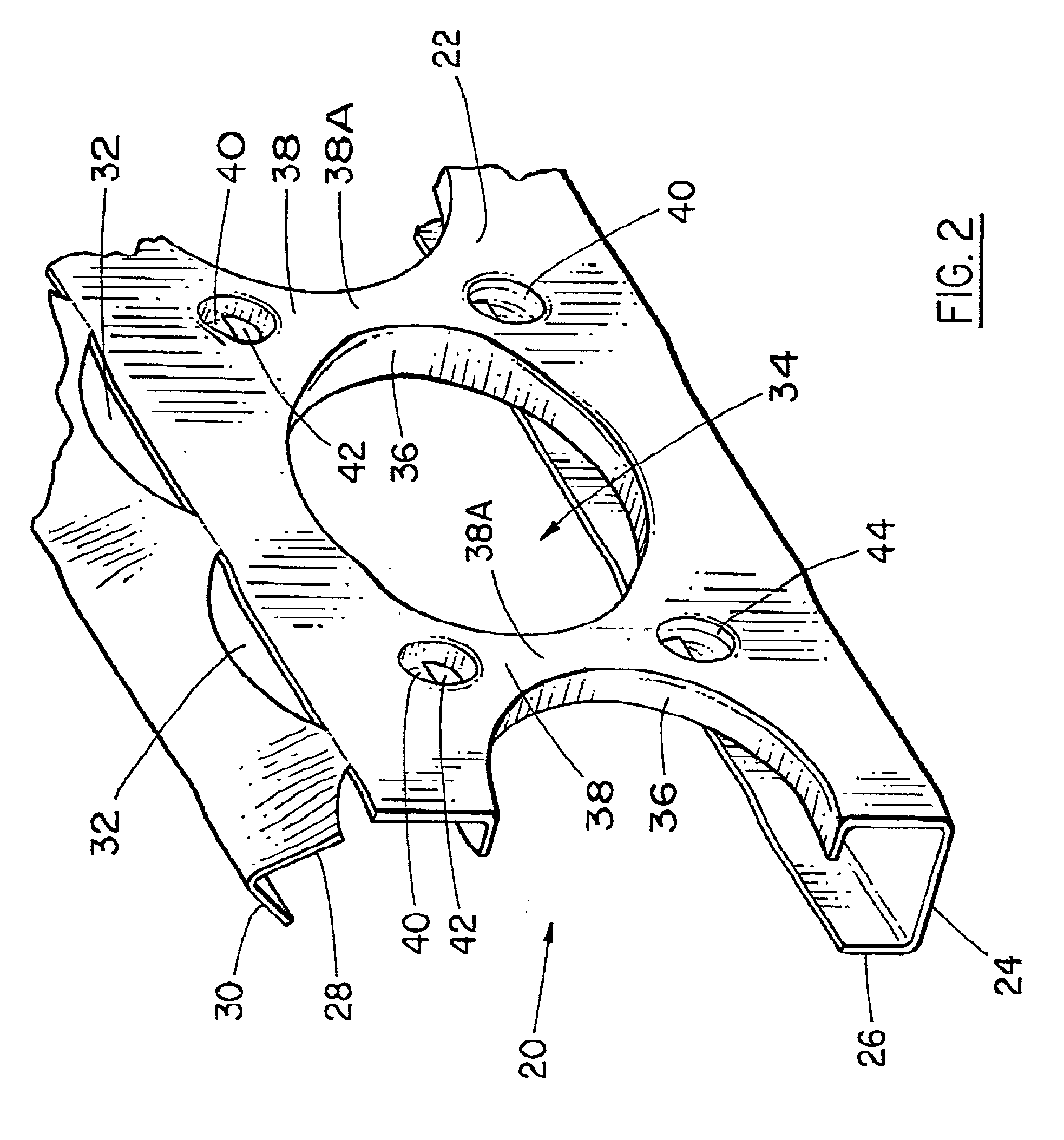

Corrugated stiffening member

InactiveUS6415581B1Easy and cost-effectiveLess-time-consuming fashionRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringFlange

A stiffening member, as well as a diaphragm of a building in which the stiffening member is used, is disclosed. The diaphragm includes a horizontal wide-flange beam, a corrugated deck, and a corrugated stiffening member. The stiffening member is an elongate, corrugated strip. The stiffening member's corrugations are formed by a series of U-shaped portions that alternate with, and are integrally connected to, a series of horizontal upper portions. Each U-shaped portion consists of three planar portions: two substantially vertical side portions and one horizontal floor portion. Each U-shaped portion is reinforced with two parallel raised ribs. In a second embodiment of the stiffening member, the U-shaped portion is reinforced with two parallel tab portions attached at the sides of the stiffening member. The stiffening member nestingly overlies the corrugated deck, and is attached to the deck and to the underlying horizontal beam with either welds or pins.

Owner:DECK WEST

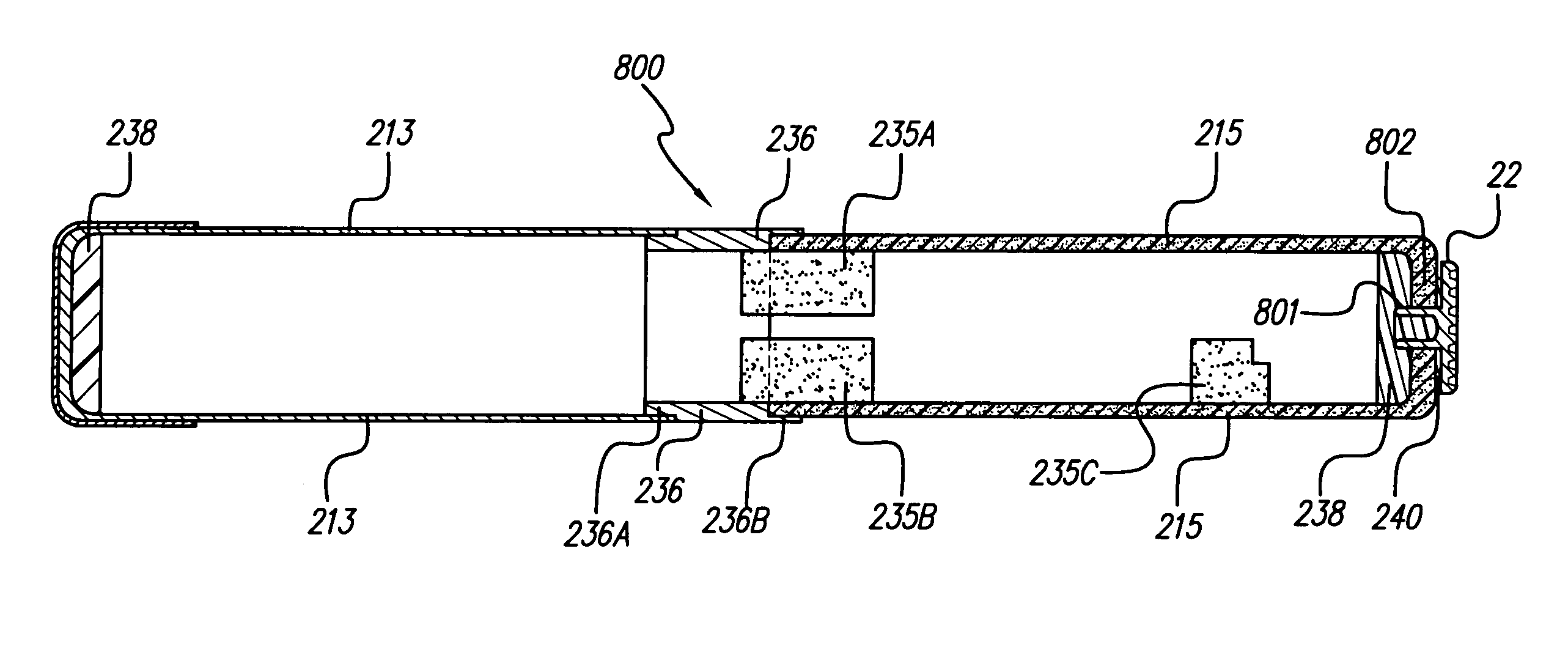

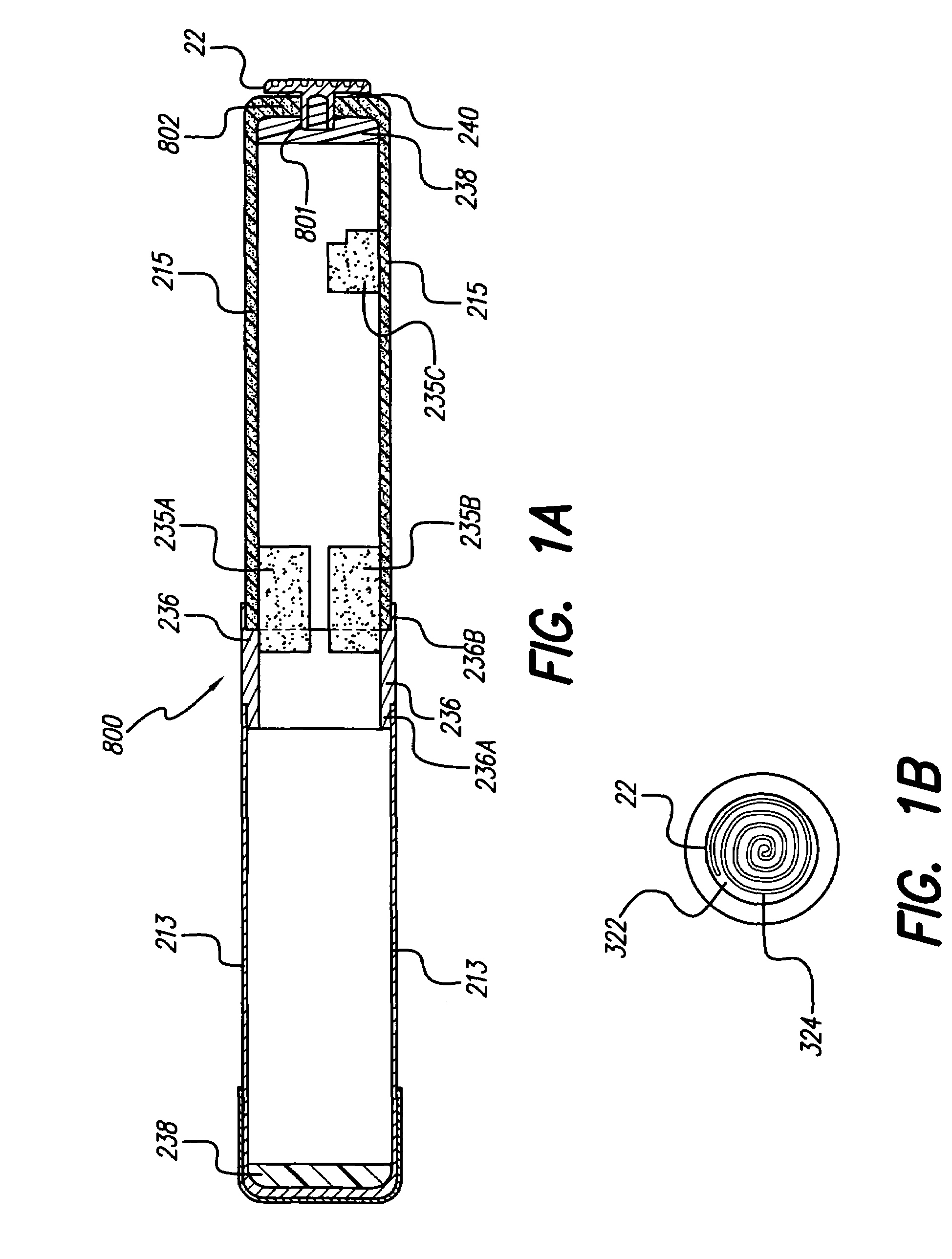

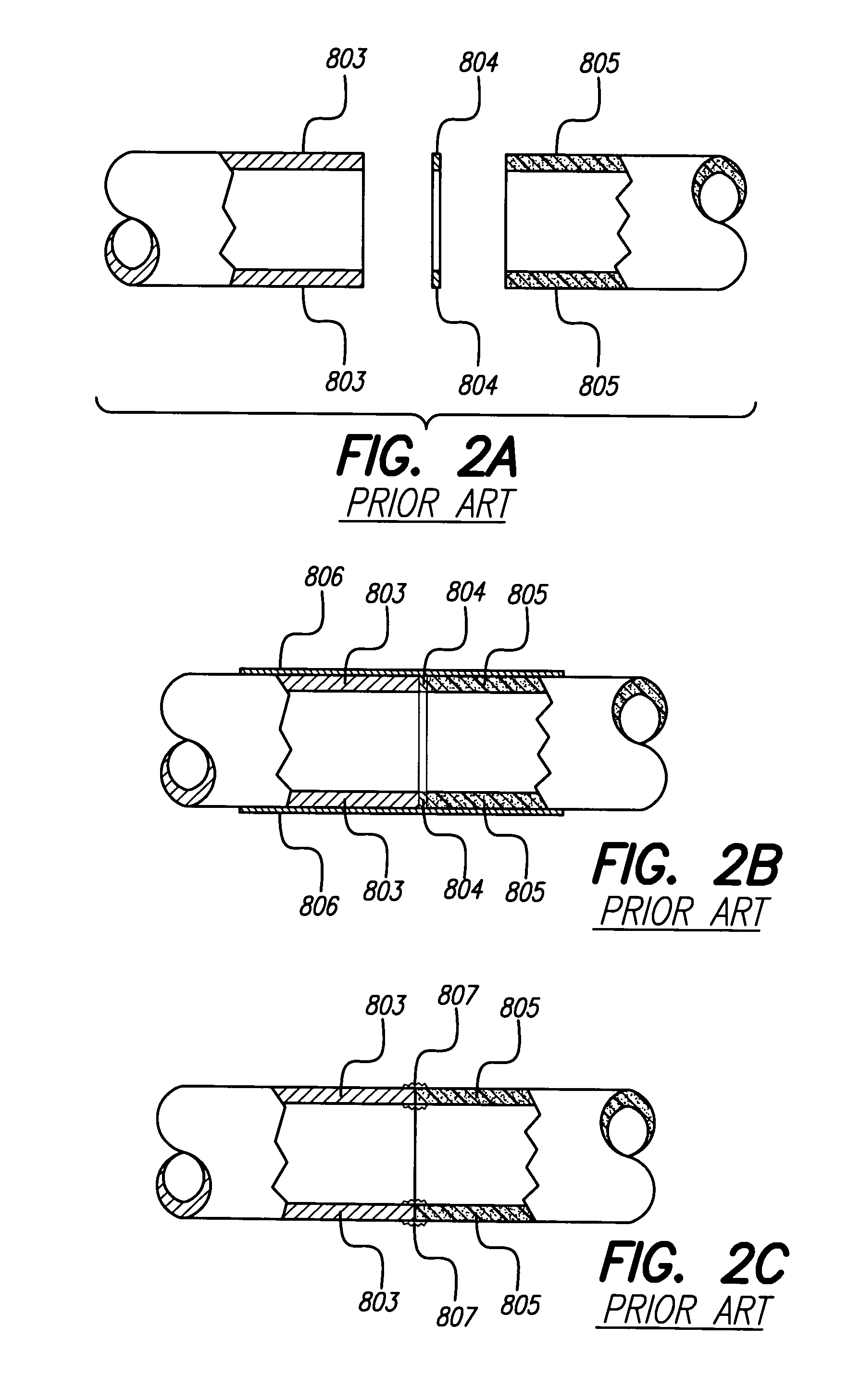

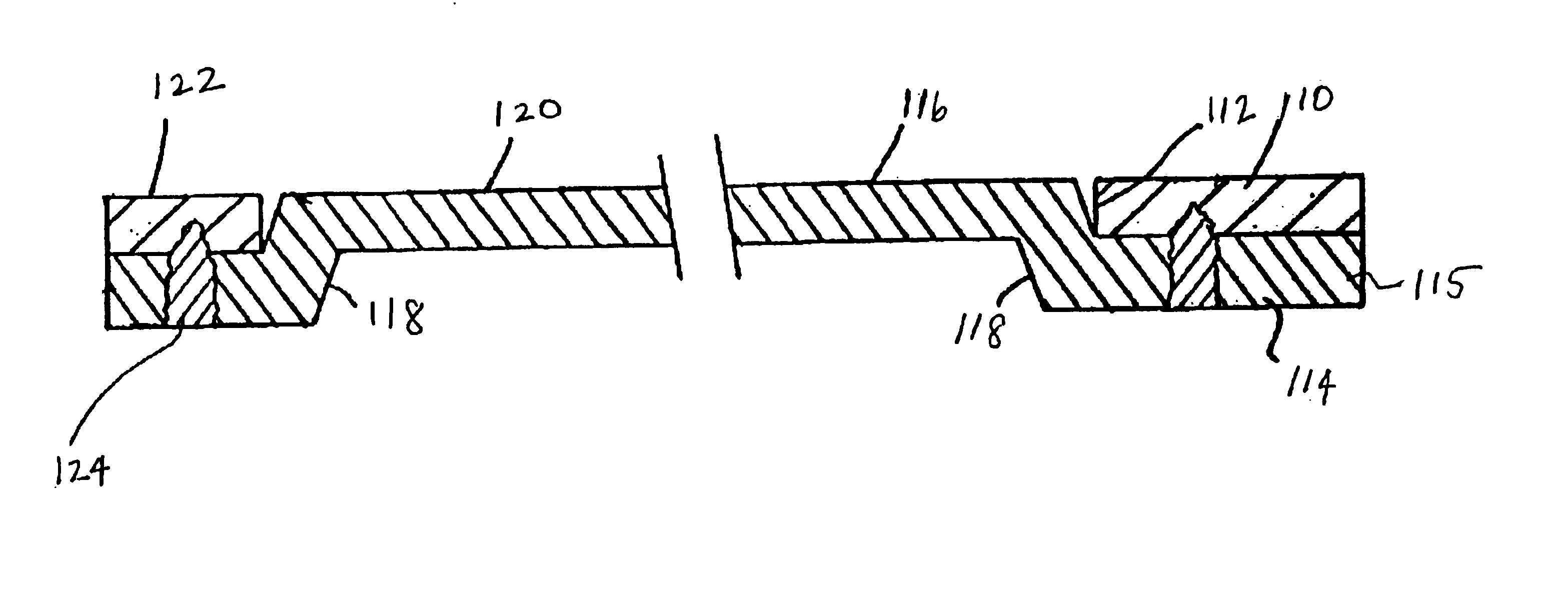

Self-centering braze assembly

ActiveUS7132173B2Increase surface areaPrevent materialNear-field transmissionBatteries circuit arrangementsConductive materialsMetal

Braze and electrode wire assemblies, e.g., used with an implantable microstimulator, include a wire welded in the through-hole of an electrode, which electrode is brazed to a ceramic case that is brazed to a metal ring that is welded to a metal can. The braze joints are step or similar joints that self-center the case, provide lateral support during braze assembly, and provide increased surface area that prevents braze material from exuding from the joints. The end of the ceramic case that is brazed to the metal ring need not be specially machined. The shell has a reference electrode on one end and an active electrode on the other, and is externally coated on selected areas with conductive and non-conductive materials.

Owner:BOSTON SCI NEUROMODULATION CORP

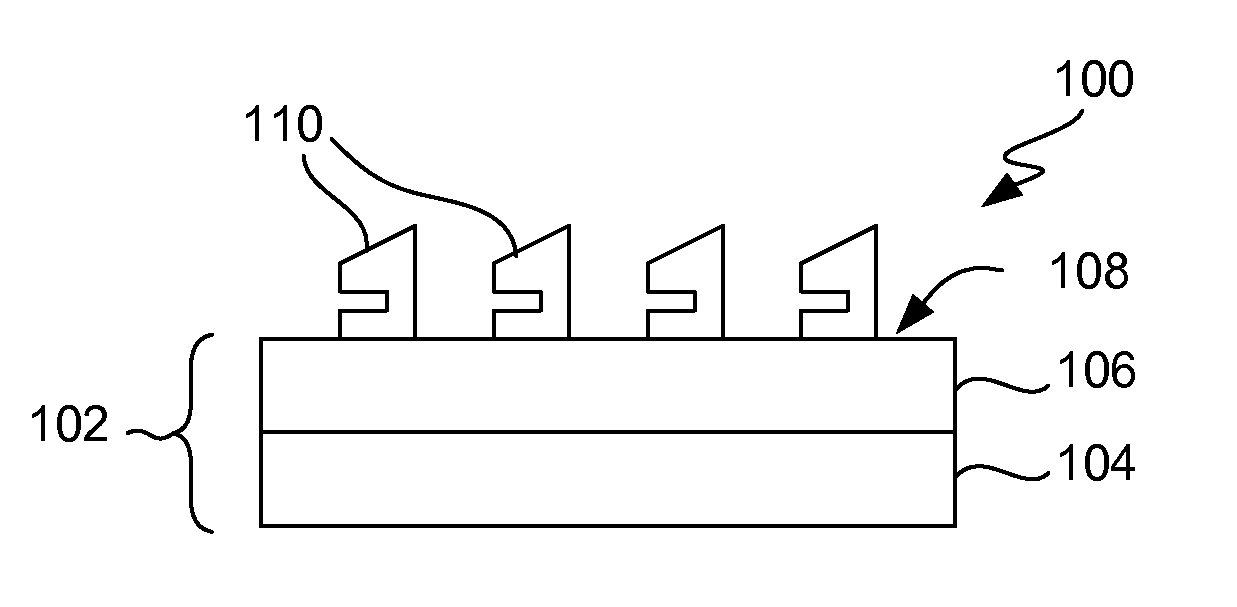

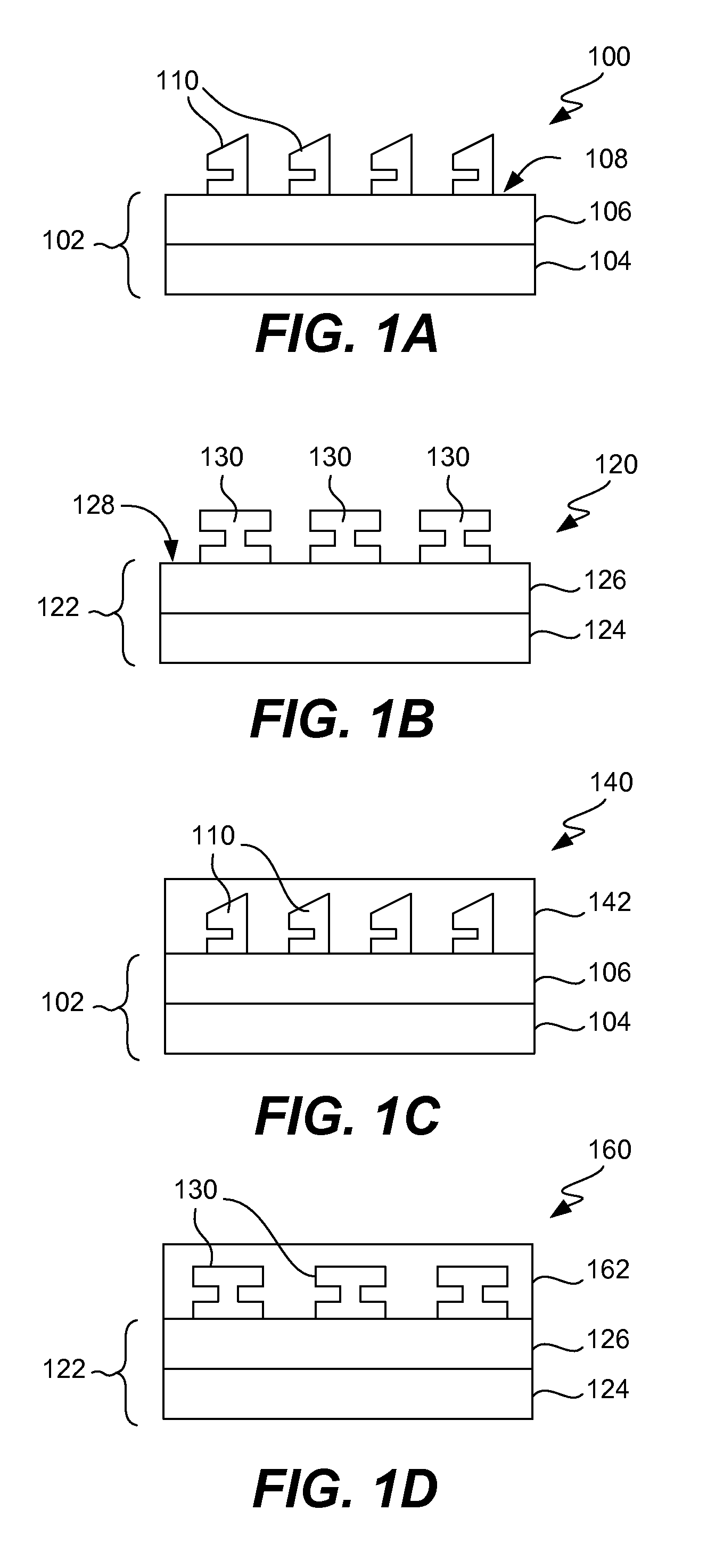

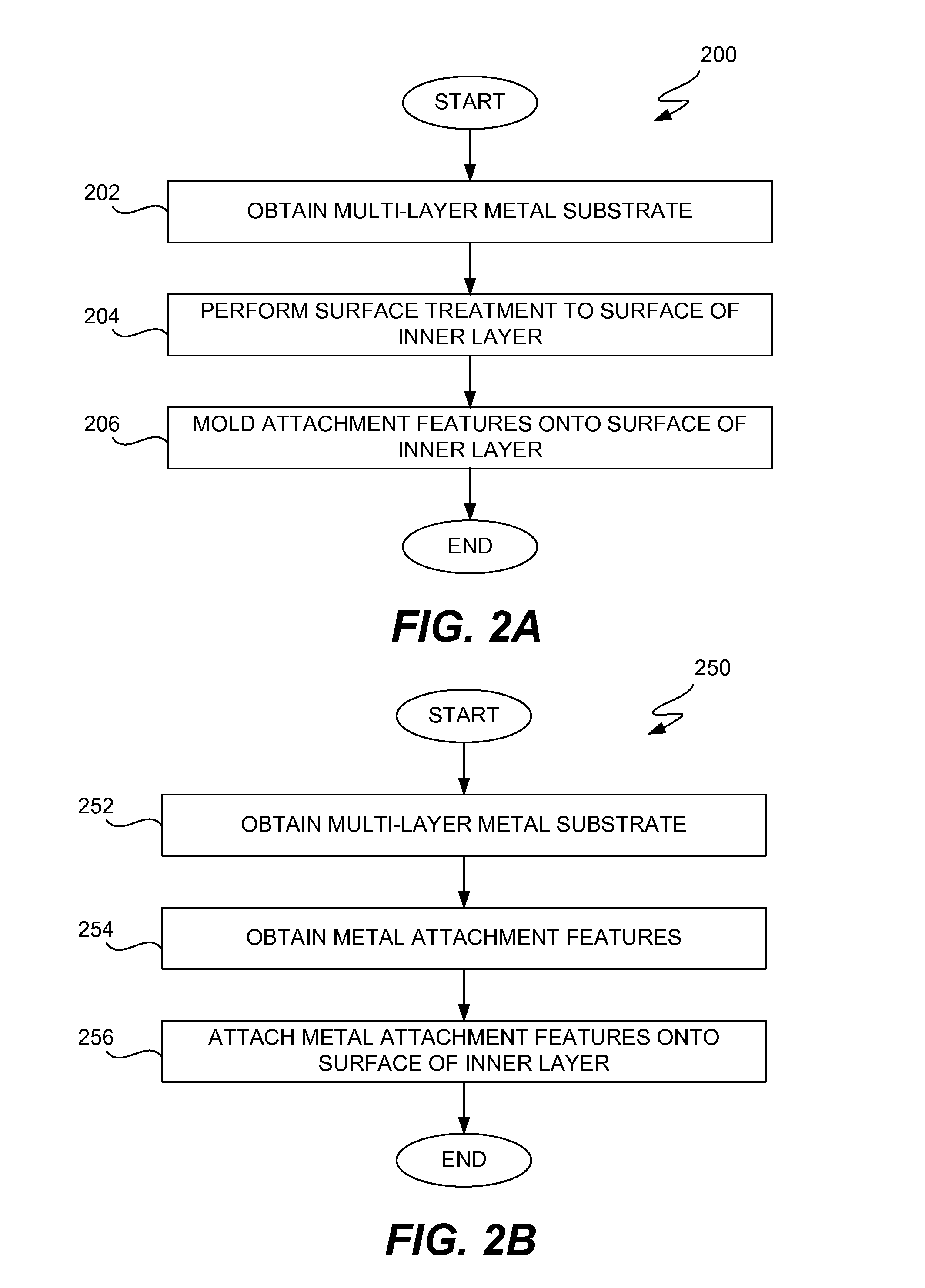

Methods and Systems for Forming Housings From Multi-Layer Materials

ActiveUS20090190290A1Easy to createFacilitate partDigital data processing detailsExtrusion containersElectronMetal

Methods and apparatus for forming a housing, such as for an electronic device, from multi-layer materials are disclosed. The multi-layer materials include at least two layers. Typically, one or more of the layers are metal. However, different layers of the multi-layer materials can be different metals. In one embodiment, an inner layer of the multi-layer materials can be provided with or form internal features that can be for attaching parts or components to the multi-layer materials. In another embodiment, processing of an inner layer of the multi-layer materials can facilitate part formation with increased curvature and / or internal part clearance. In another embodiment, the multi-layer materials can include an intermediate layer that facilitates creation of internal features that can be for attaching parts or components to the multi-layer materials. In still another embodiment, the multi-layer materials can provide a protective layer that serves to protect an outer surface of the housing during manufacturing and / or assembly.

Owner:APPLE INC

Metal matrix composite casting and manufacturing method thereof

InactiveUS6245442B1Well formedEasy to processHot-dipping/immersion processesSemiconductor/solid-state device detailsMetal matrix compositeCompound s

A metal matrix composite casting comprises a metal matrix composite and a processed member inserted in the metal matrix composite by enveloped casting. By the processed member which is easier to process than the metal matrix composite, a processed portion of a predetermined shape can be formed in the metal matrix composite. That is, by a simple processing such that the processed member is removed from the metal matrix composite or the processed portion is formed in the processed member itself, the processed portion having a desired shape can be easily formed in the metal matrix composite.

Owner:DENSO CORP +1

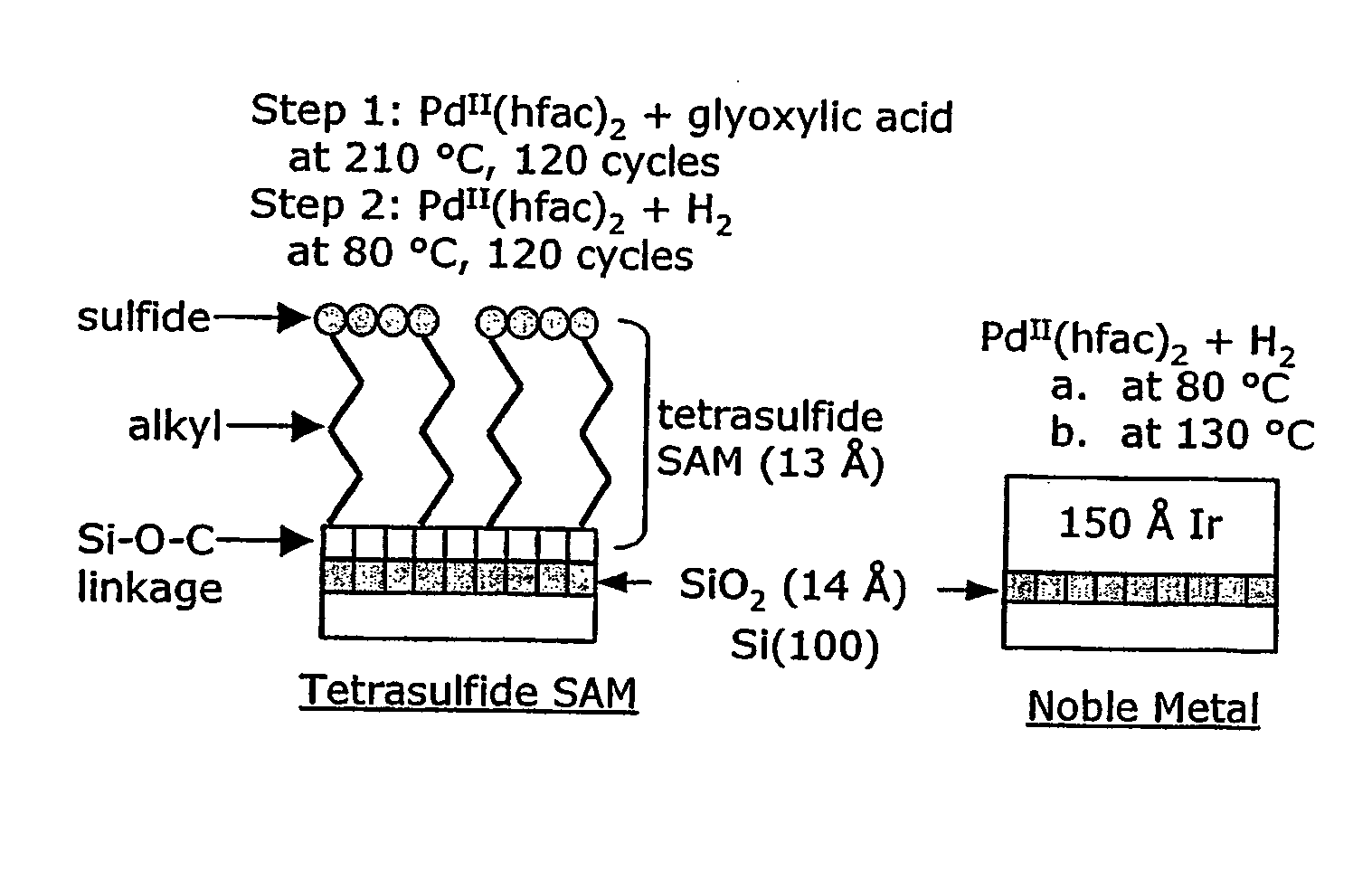

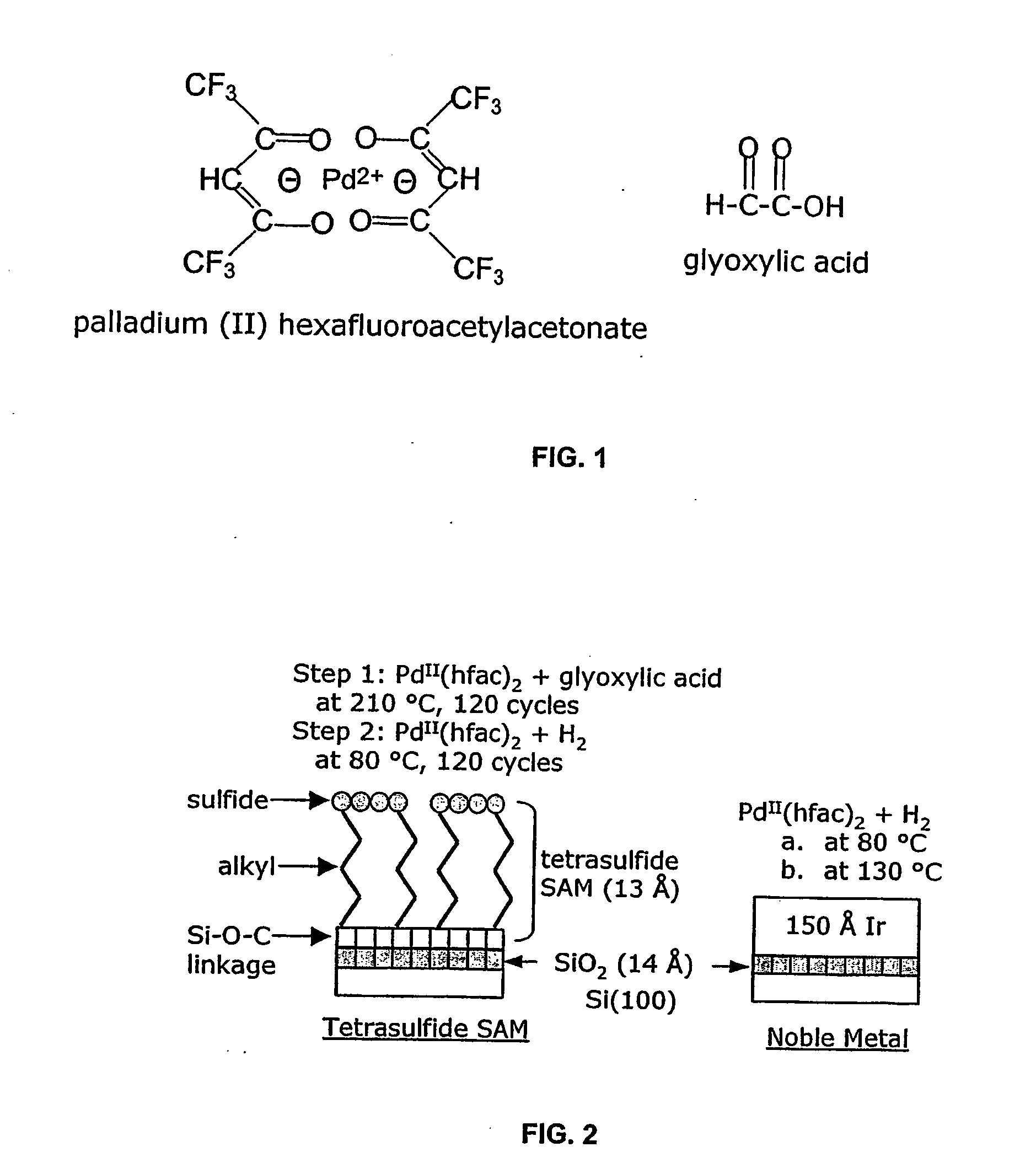

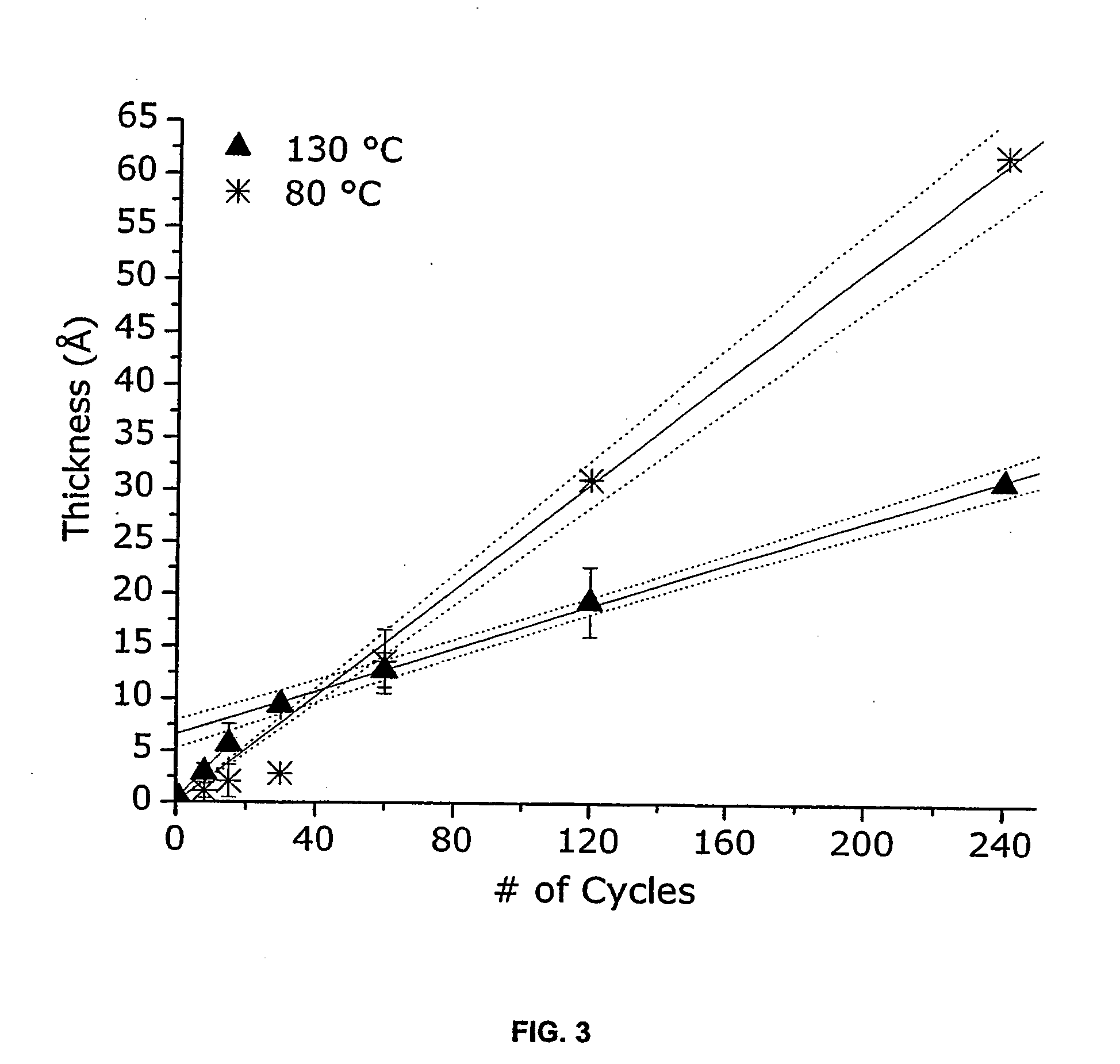

Atomic layer deposition of noble metals

The present invention relates to ALD processes for deposition of a metal selected from Pd, Rh, Ru, Pt and Ir wherein a layer including the metal is formed on a surface composed of a material selected from W, Ta, Cu, Ni, Co, Fe, Mn, Cr, V Nb, tungsten nitride, tantalum nitride, titanium nitride, dielectrics and activated dielectrics at a temperature ranging from >60° C. to <260° C. The layer is formed by sequentially pulsing into a chamber containing the surface a precursor for the metal and a reducing gas selected from hydrogen, glyoxylic acid, oxalic acid, formaldehyde, 2-propanol, imidazole and plasma-activated hydrogen.

Owner:SENKEVICH JOHN JOSEPH +1

Method to plate C4 to copper stud

InactiveUS6251528B1Removing platingImprove productivitySolid-state devicesExtrusion containersCopper platingPhotoresist

A method for plating a second metal directly to a first metal without utilizing a mask. A semiconductor substrate is provided including at least one metal feature and at least one insulating layer covering the metal feature and the substrate. At least one recess is formed in the at least one insulating layer thereby exposing at least a portion of the metal feature. At least one conductive barrier layer is formed over the insulating layer and the exposed portion of the metal feature. A plating seed layer of a first metal is formed over the at least one barrier layer. A photoresist layer is deposited over the plating seed layer. Portions of the photoresist layer and of the plating seed layer outside of the at least one recess are removed. Photoresist remaining in the at least one recess is removed. A second metal is electroplated to the plating seed layer in the recess.

Owner:ULTRATECH INT INC

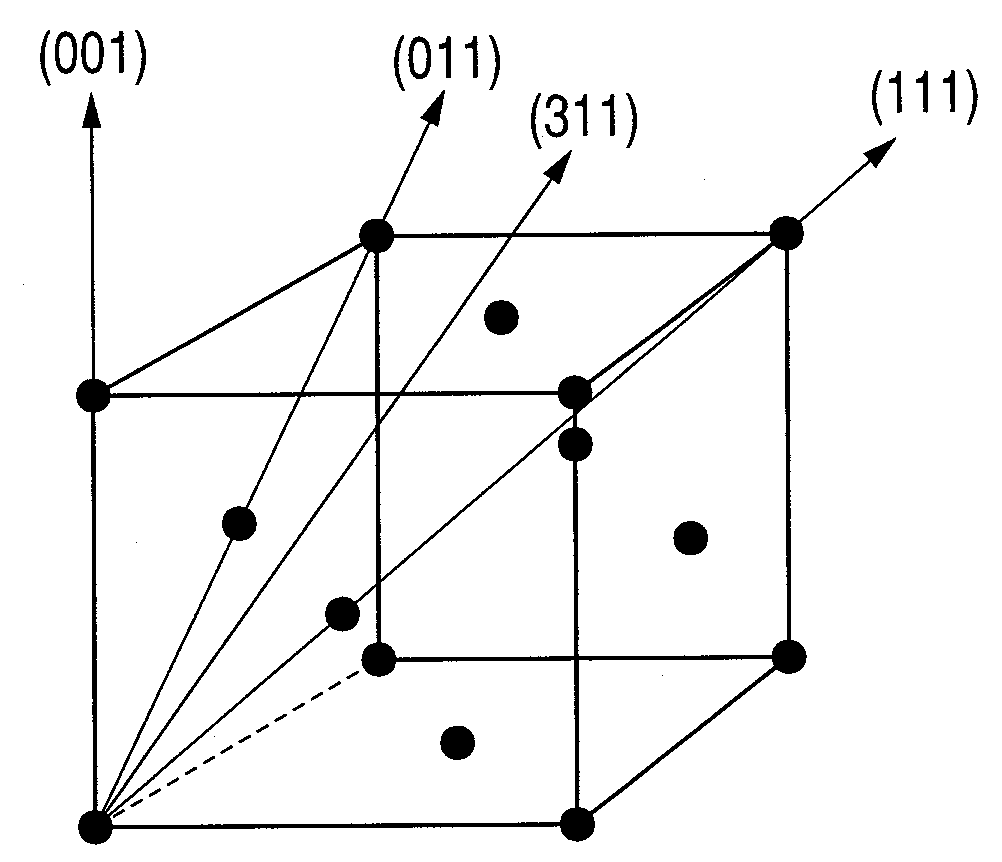

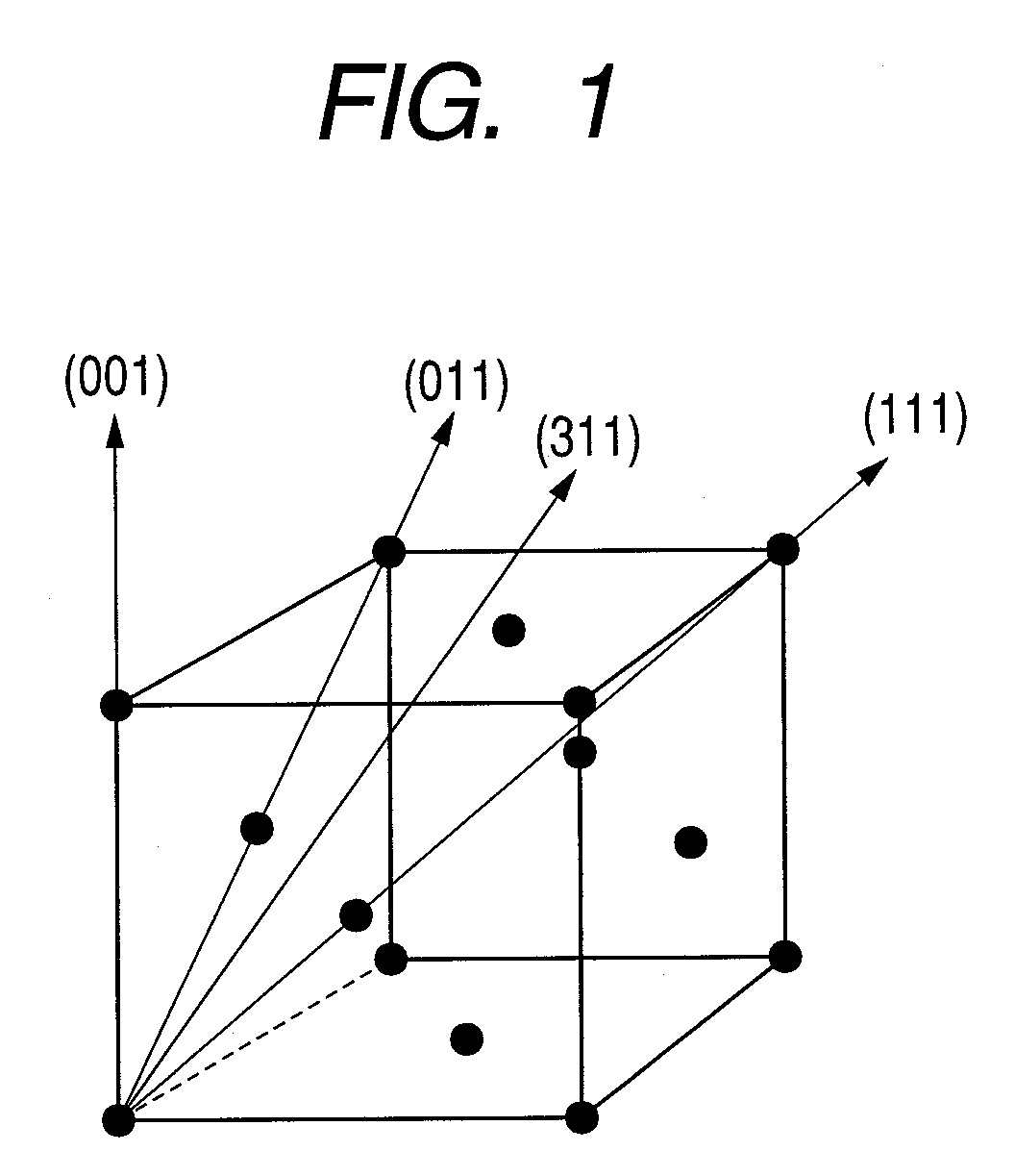

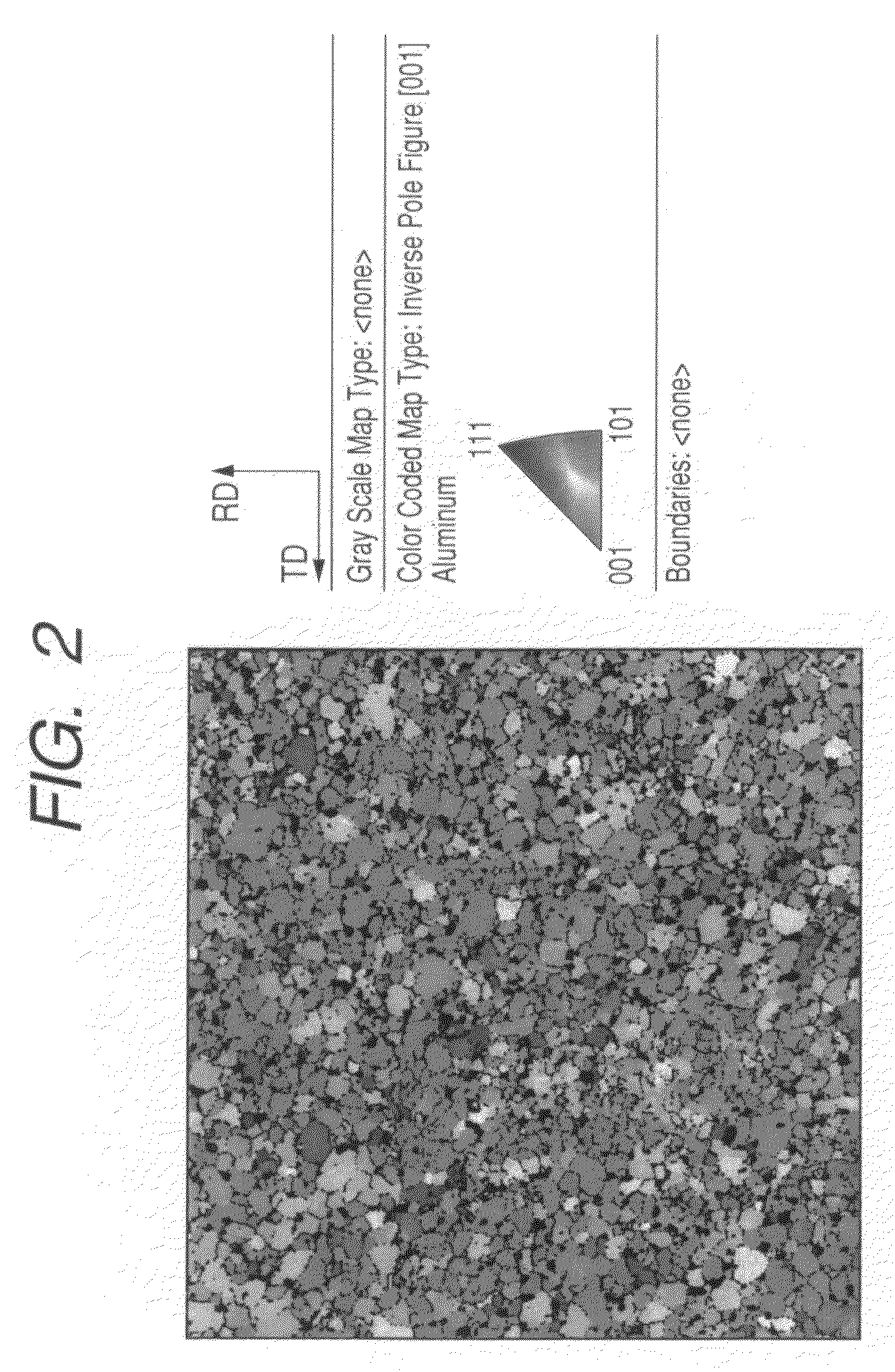

Ai-based alloy sputtering target and process for producing the same

InactiveUS20080223718A1Increase deposition rateSuppress the sputtering defectsCellsSemiconductor/solid-state device detailsSputteringAlloy

The present invention relates to an Al-based alloy sputtering target, comprising Ni in an amount of 0.05 to 10 atomic percent, wherein the Al-based alloy sputtering target satisfies: (1) that a ratio of a P value to a total area of a sputtering surface is 70% or more, wherein the P value indicates a total of area fractions of <001>±15°, <011>±15°, <111>±15° and <311>±15°; (2) that a ratio of the area fraction of <011>±15° to the P value is 30% or more; and (3) that a ratio of the area fraction of <111>±15° to the P value is 10% or less, when crystallographic orientations <001>, <011>, <111> and <311> in a normal line direction to a sputtering surface of the Al-based alloy sputtering target are observed in accordance with the electron backscatter diffraction pattern method.

Owner:KOBE STEEL LTD +1

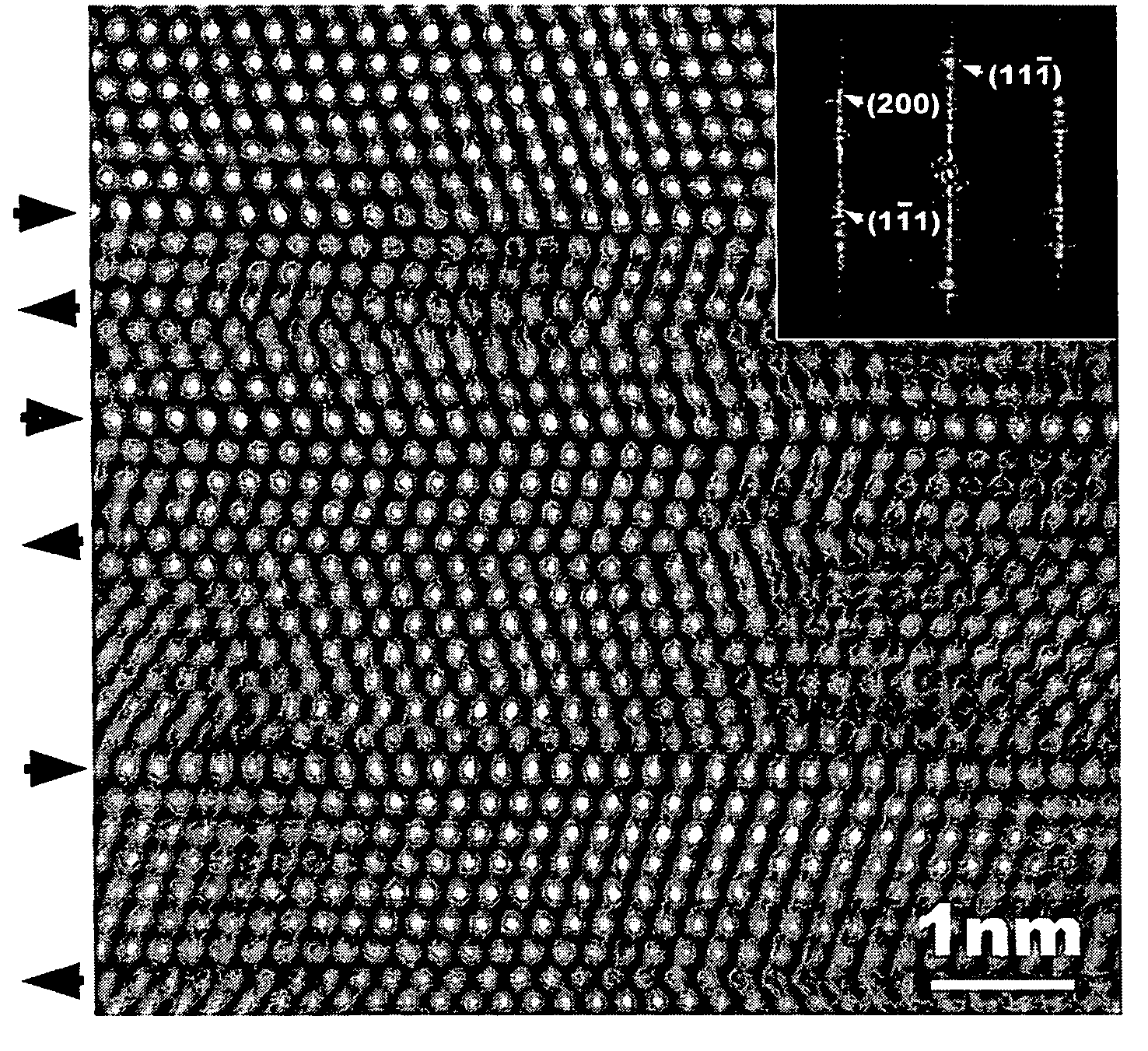

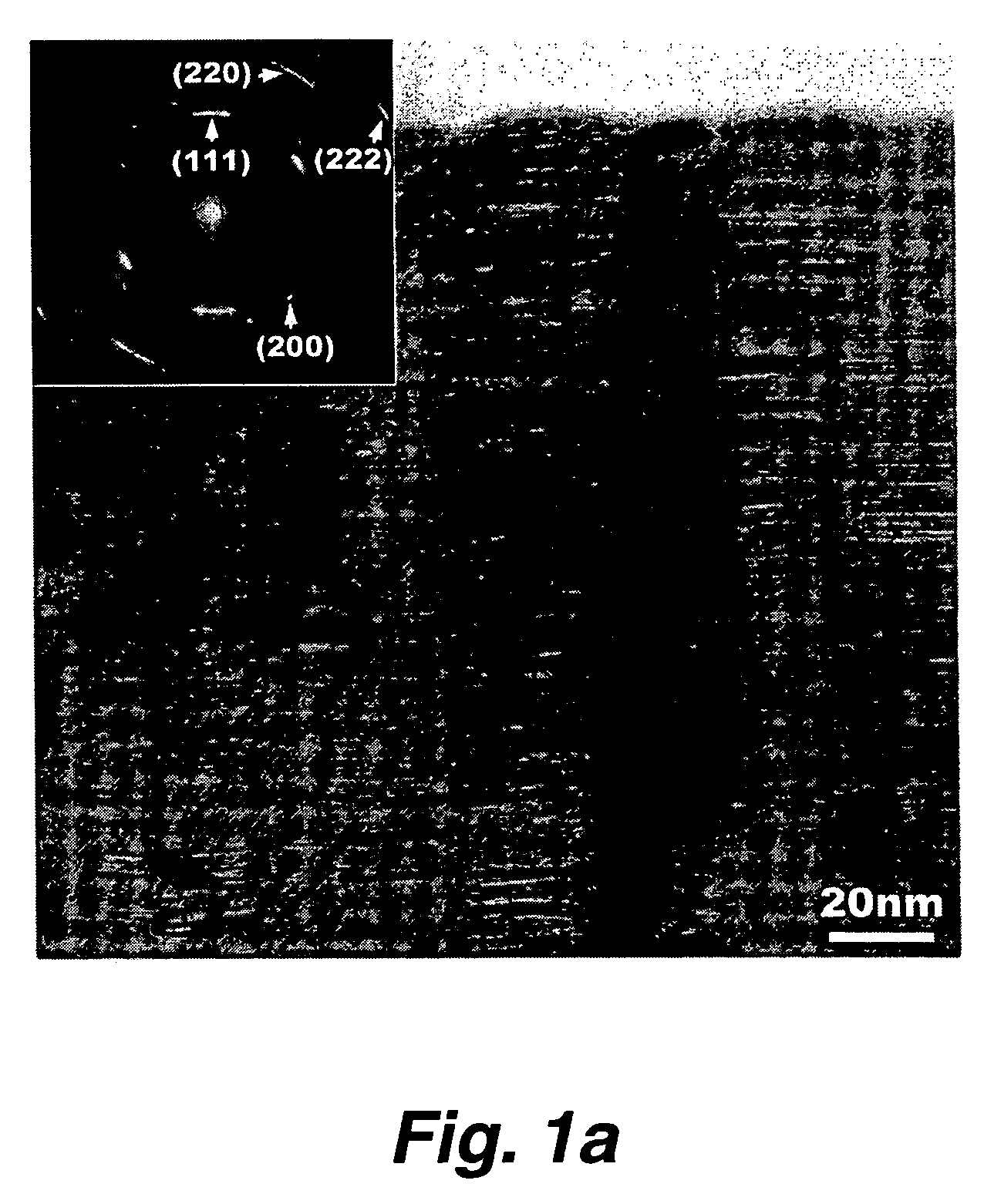

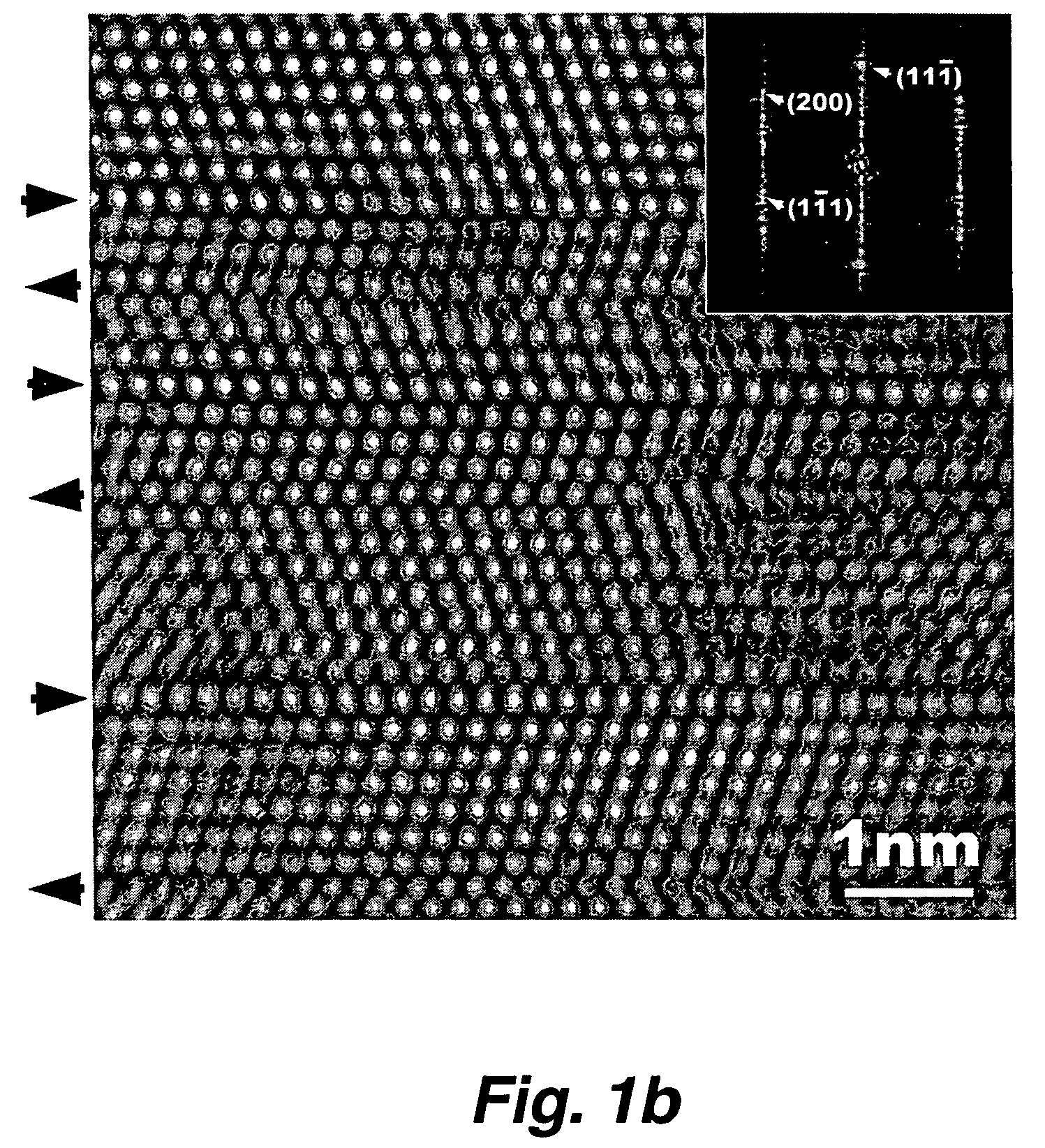

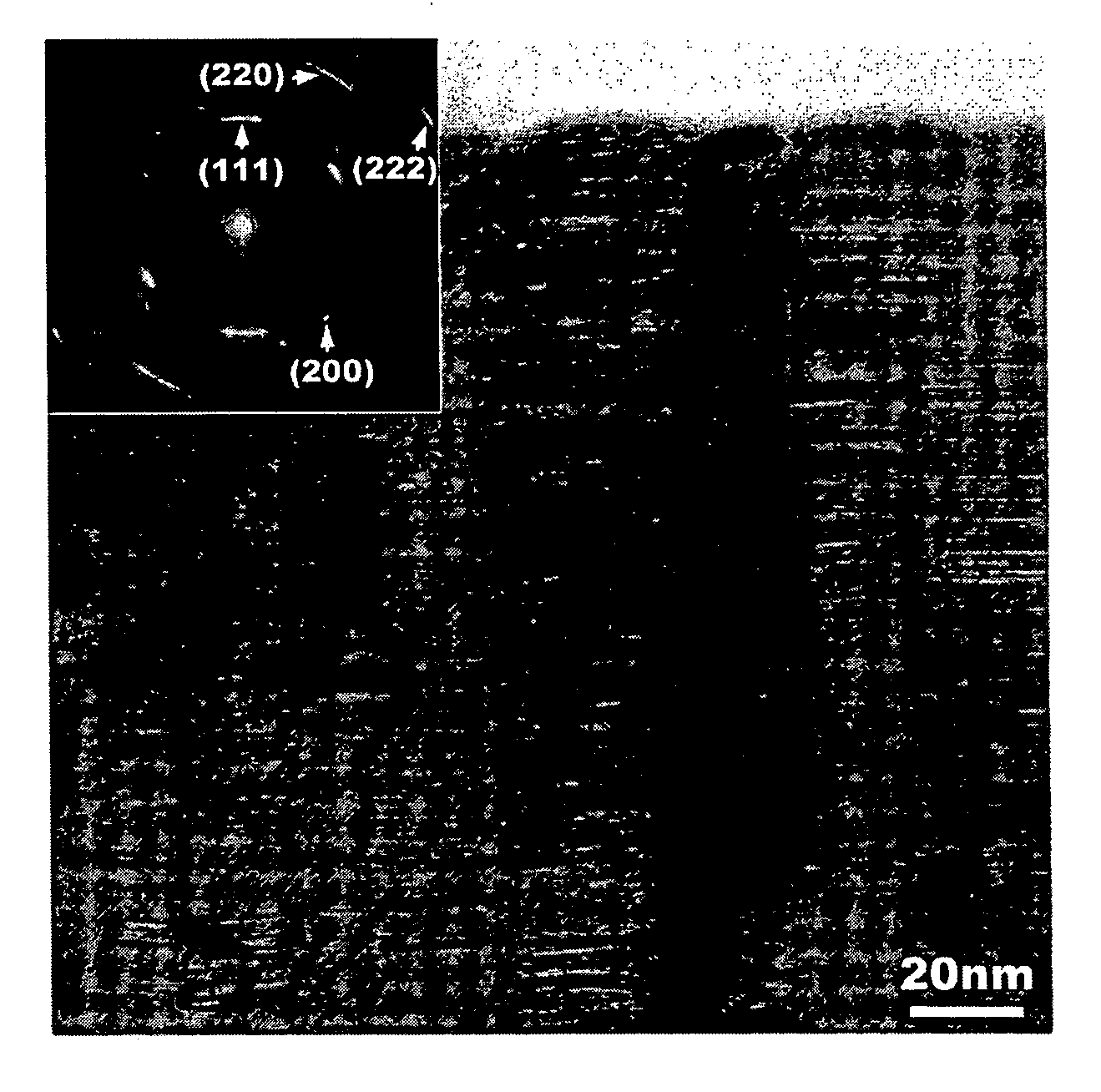

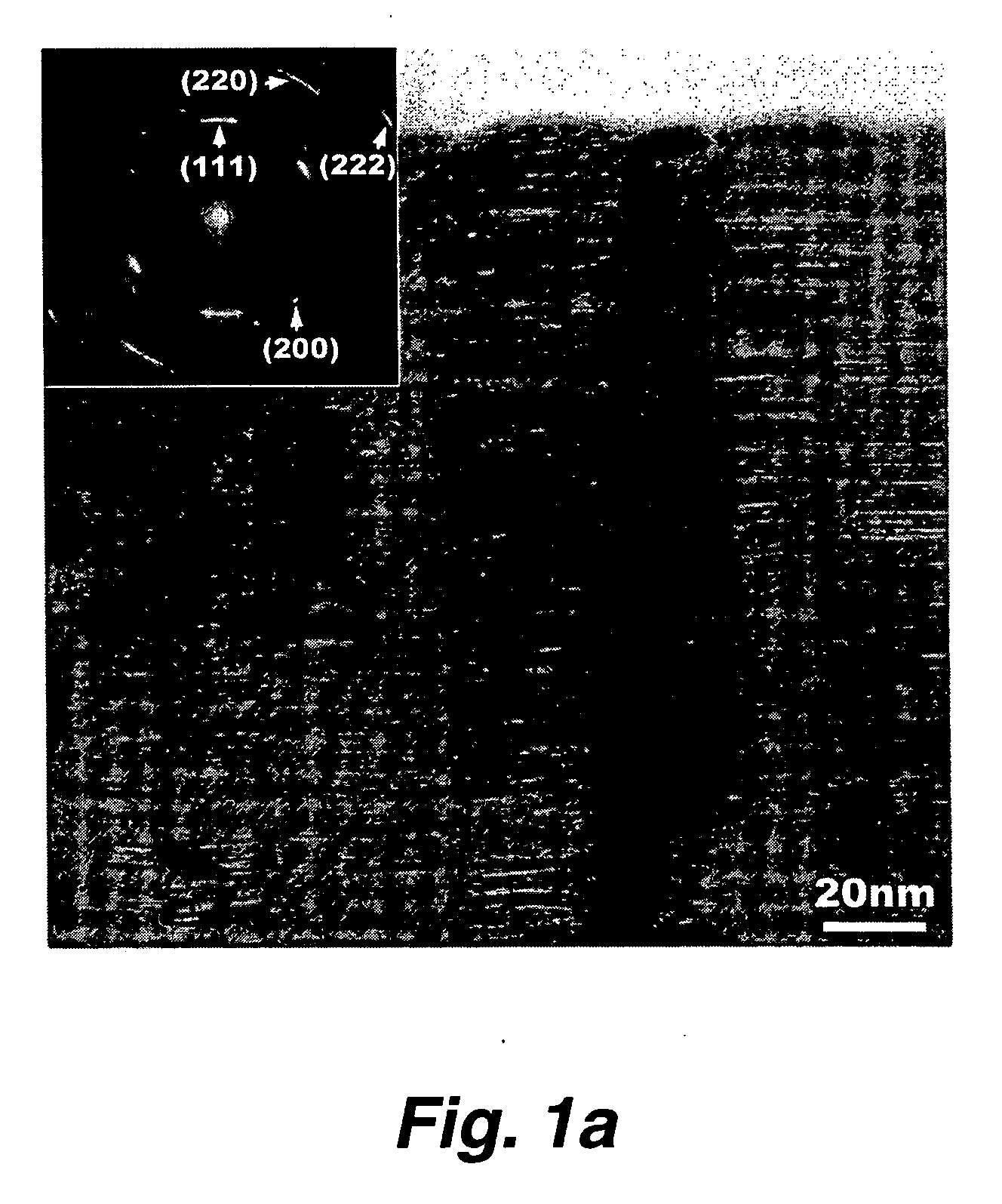

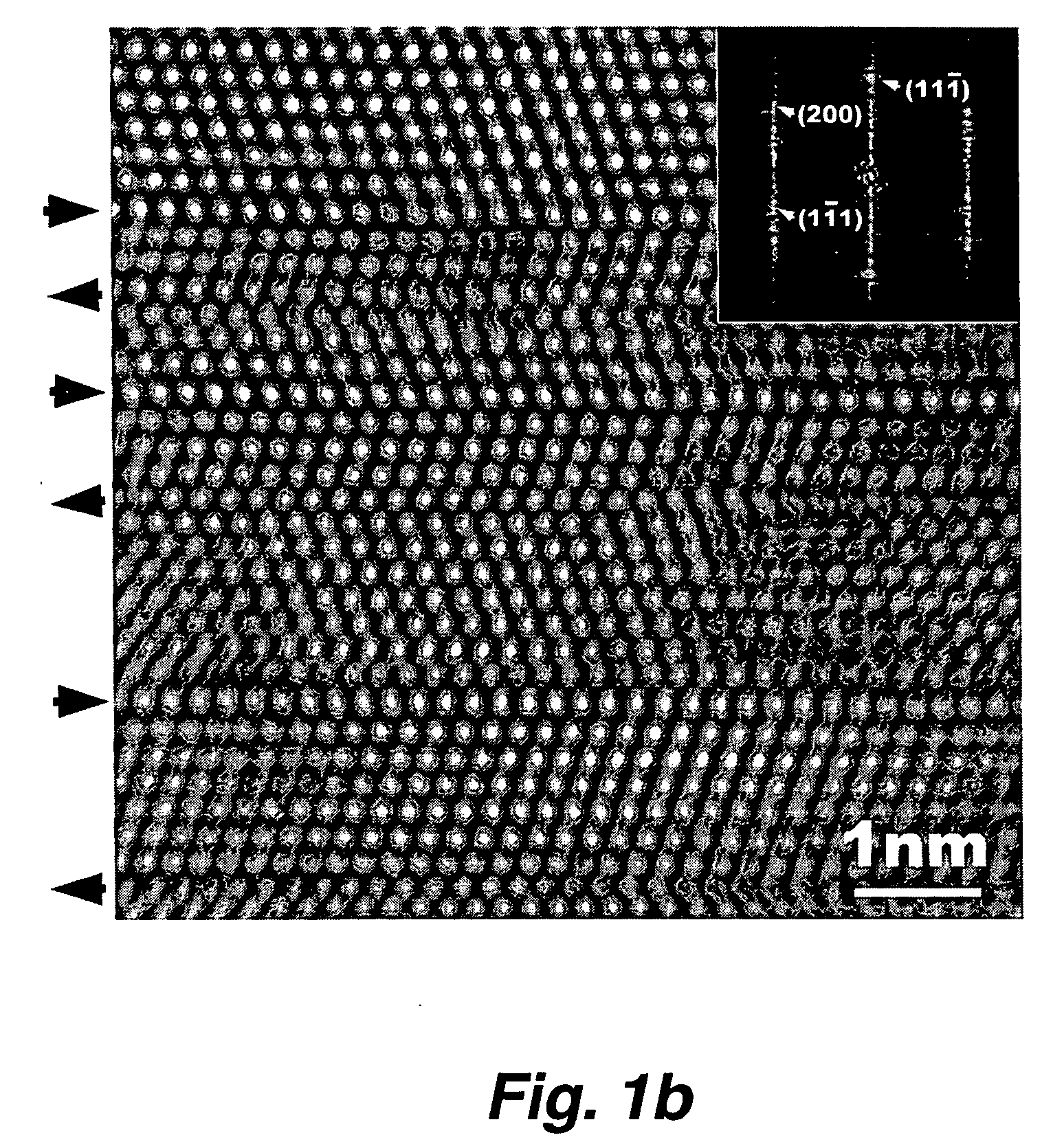

Preparation of high-strength nanometer scale twinned coating and foil

Very high strength single phase stainless steel coating has been prepared by magnetron sputtering onto a substrate. The coating has a unique microstructure of nanometer spaced twins that are parallel to each other and to the substrate surface. For cases where the coating and substrate do not bind strongly, the coating can be peeled off to provide foil.

Owner:LOS ALAMOS NATIONAL SECURITY

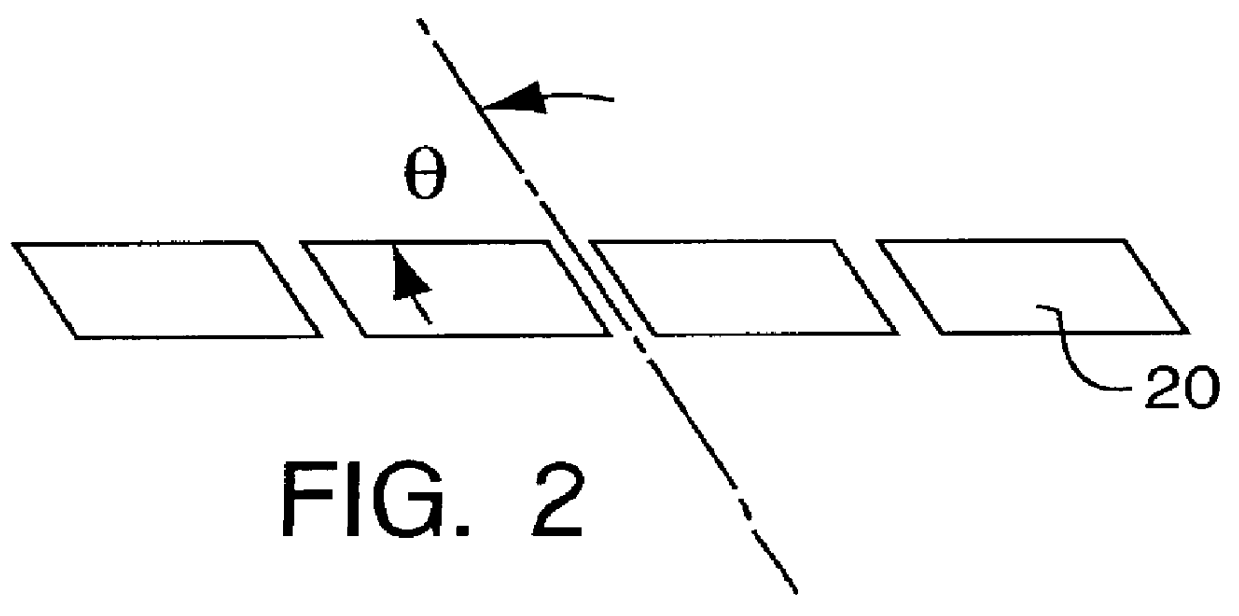

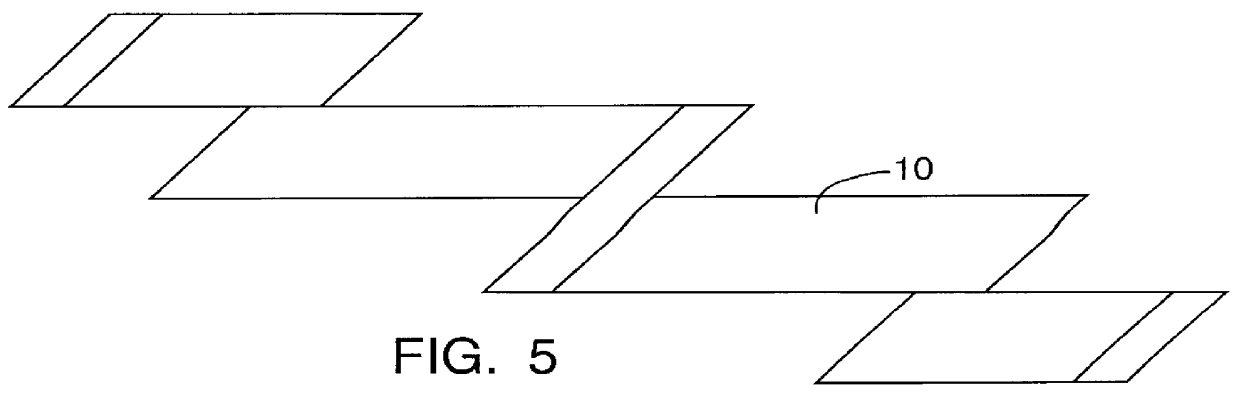

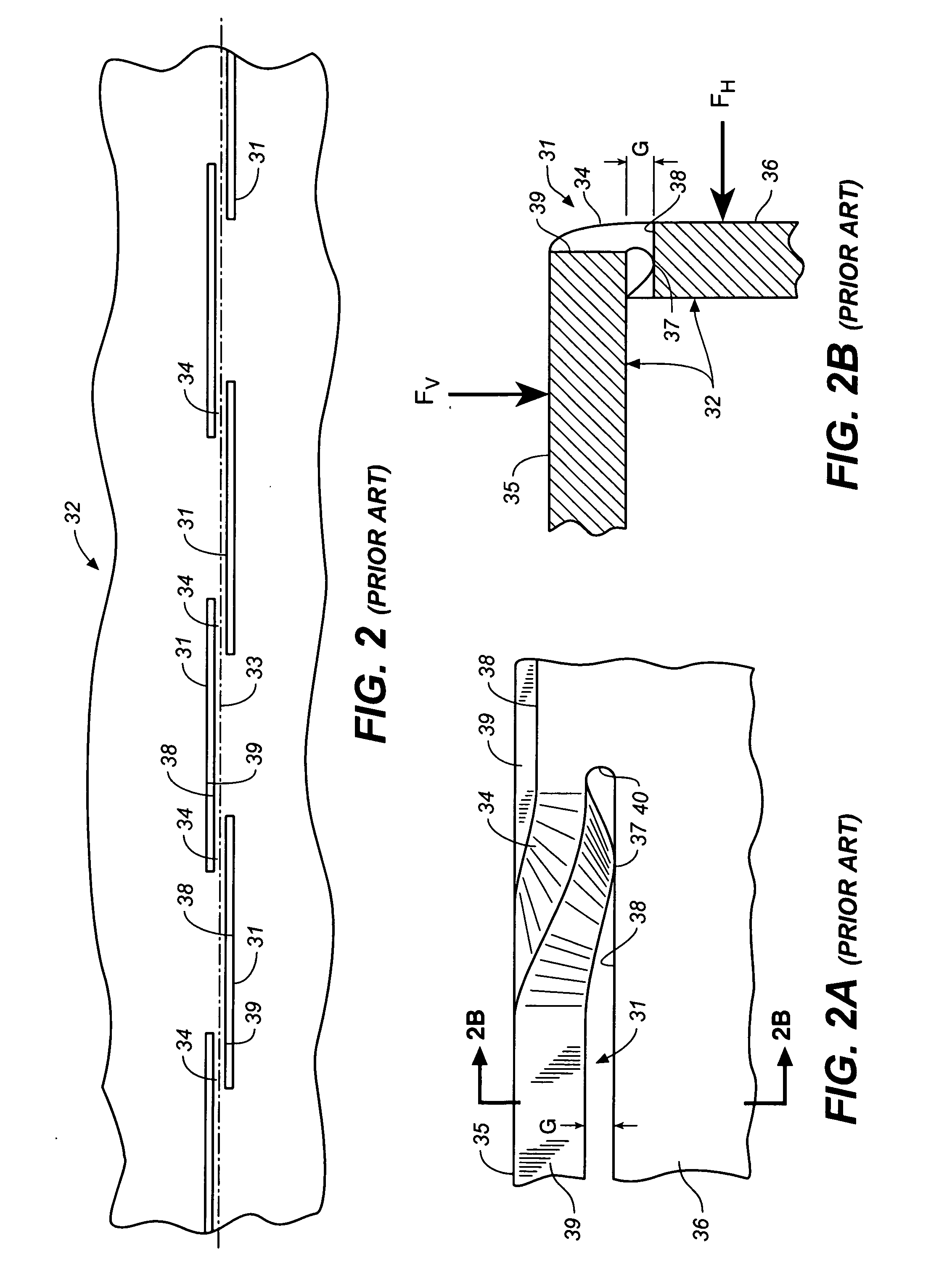

Structure for and method of manufacturing aerodynamic expanded metal

An expanded metal with an aerodynamic cross-section for use in high velocity fluid flows to decrease pressure drop. The expanded metal has a rhomboid cross-section with the acute angle of oriented into the flow. Also disclosed is a method of making the expanded metal.

Owner:PRECISION COMBUSTION

Precision-folded, high strength, fatigue-resistant structures and sheet therefor

Precision-folded, high strength, fatigue-resistant structures and a sheet therefore are disclosed. To form the structures, methods for precision bending of a sheet of material along a bend line and a sheet of material formed with bending strap-defining structures, such as slits or grooves, are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves through the sheet of material in axially spaced relation to produce precise bending of the sheet when bent along the bend line. The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges to be engaged and supported on faces of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line. Several slit embodiments suitable for producing edge-to-face engagement support and precise bending are disclosed. With these teachings, forming numerous three-dimensional load-bearing structures from a two dimensional sheet are enabled. Examples of straight and curved beams, chassis, and exoskeletons are disclosed.

Owner:IND ORIGAMI INC CA US

Method of making coated articles and coated articles made thereby

InactiveUS7311961B2Improve heat resistanceReducing and preventing oxidationLiquid surface applicatorsSemiconductor/solid-state device detailsRefractive indexPolymer

An article includes a first substrate, a functional coating deposited over at least a portion of the substrate, and a protective coating deposited over the functional coating. The functional coating and the protective coating define a coating stack. A polymeric material is deposited over at least a portion of the protective coating. The protective coating has a refractive index that is substantially the same as the refractive index of the polymeric material.

Owner:VITRO FLAT GLASS LLC

Preparation of high-strength nanometer scale twinned coating and foil

Very high strength single phase stainless steel coating has been prepared by magnetron sputtering onto a substrate. The coating has a unique microstructure of nanometer spaced twins that are parallel to each other and to the substrate surface. For cases where the coating and substrate do not bind strongly, the coating can be peeled off to provide foil.

Owner:LOS ALAMOS NATIONAL SECURITY

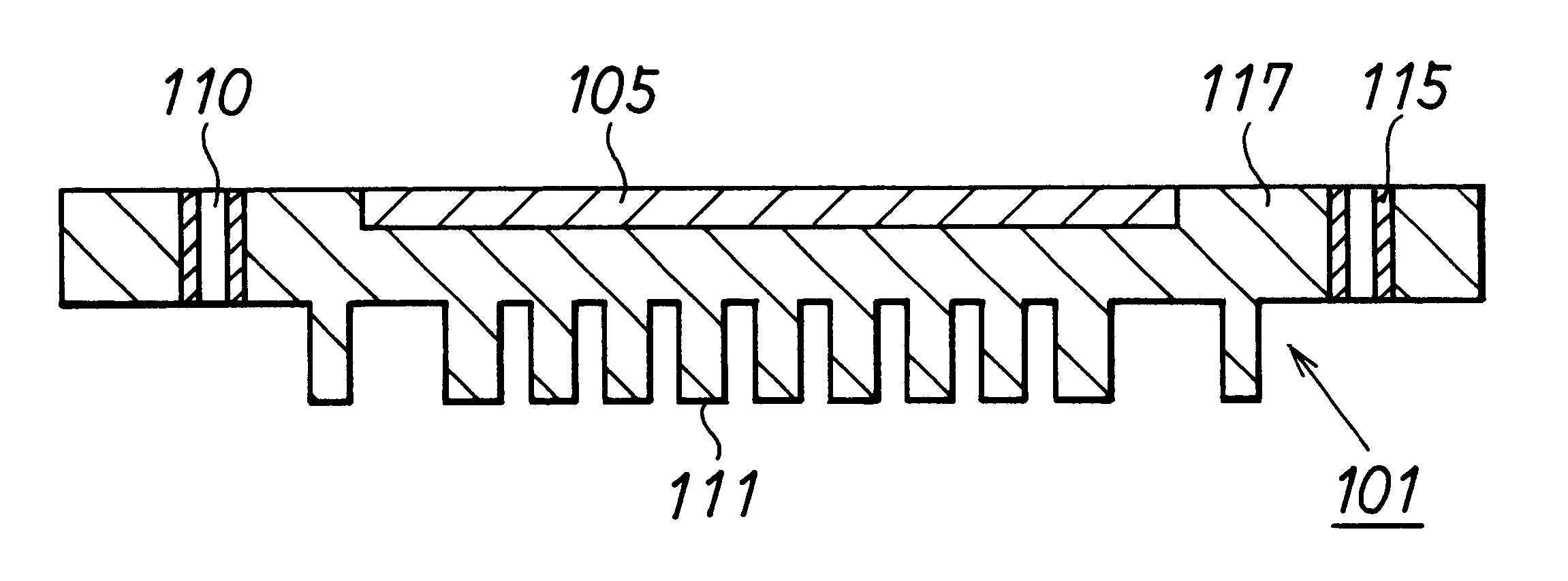

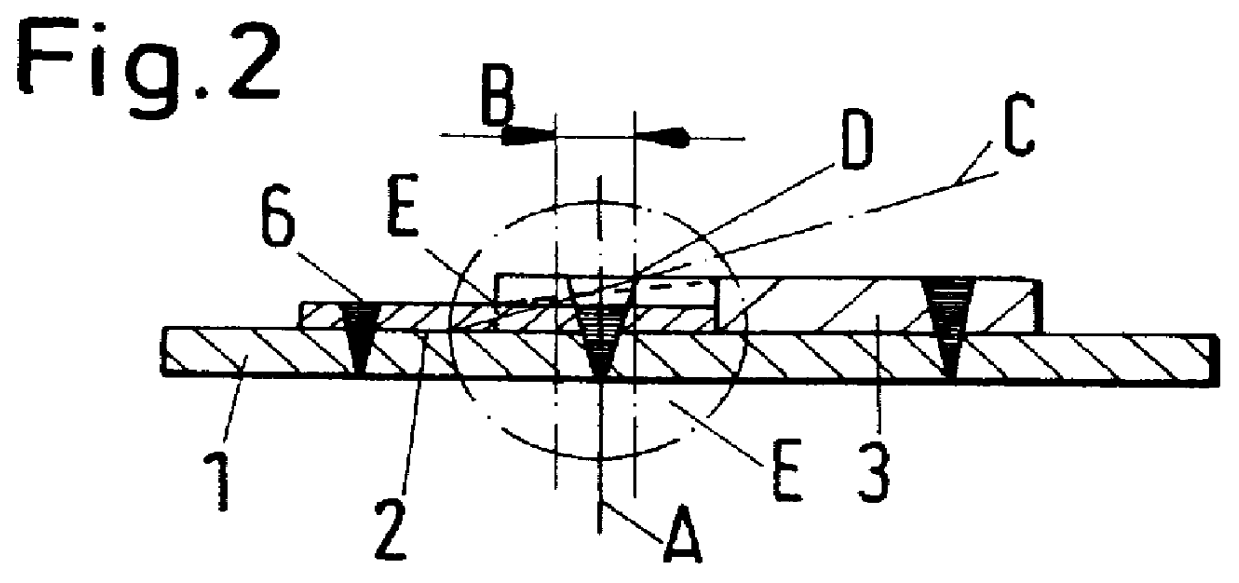

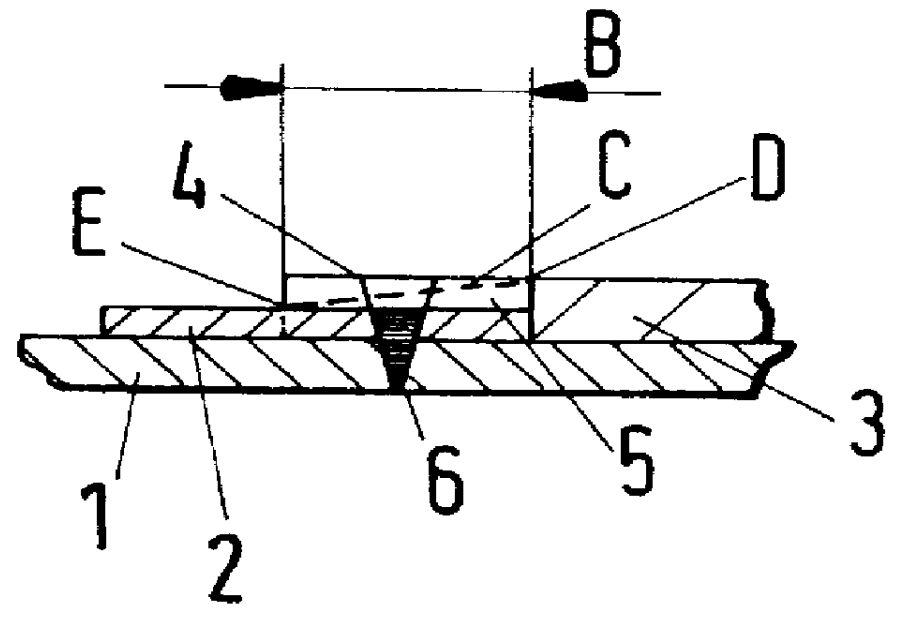

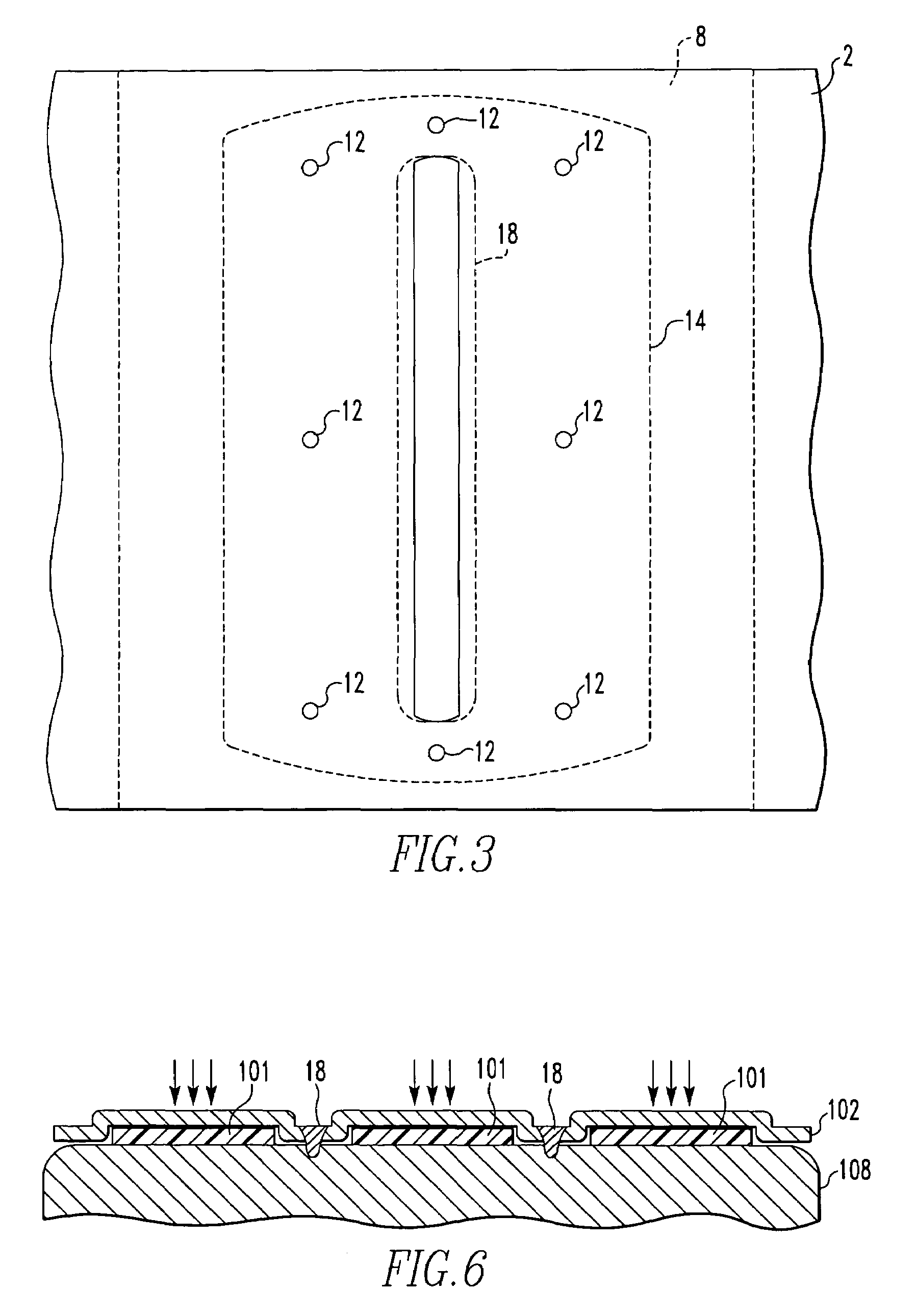

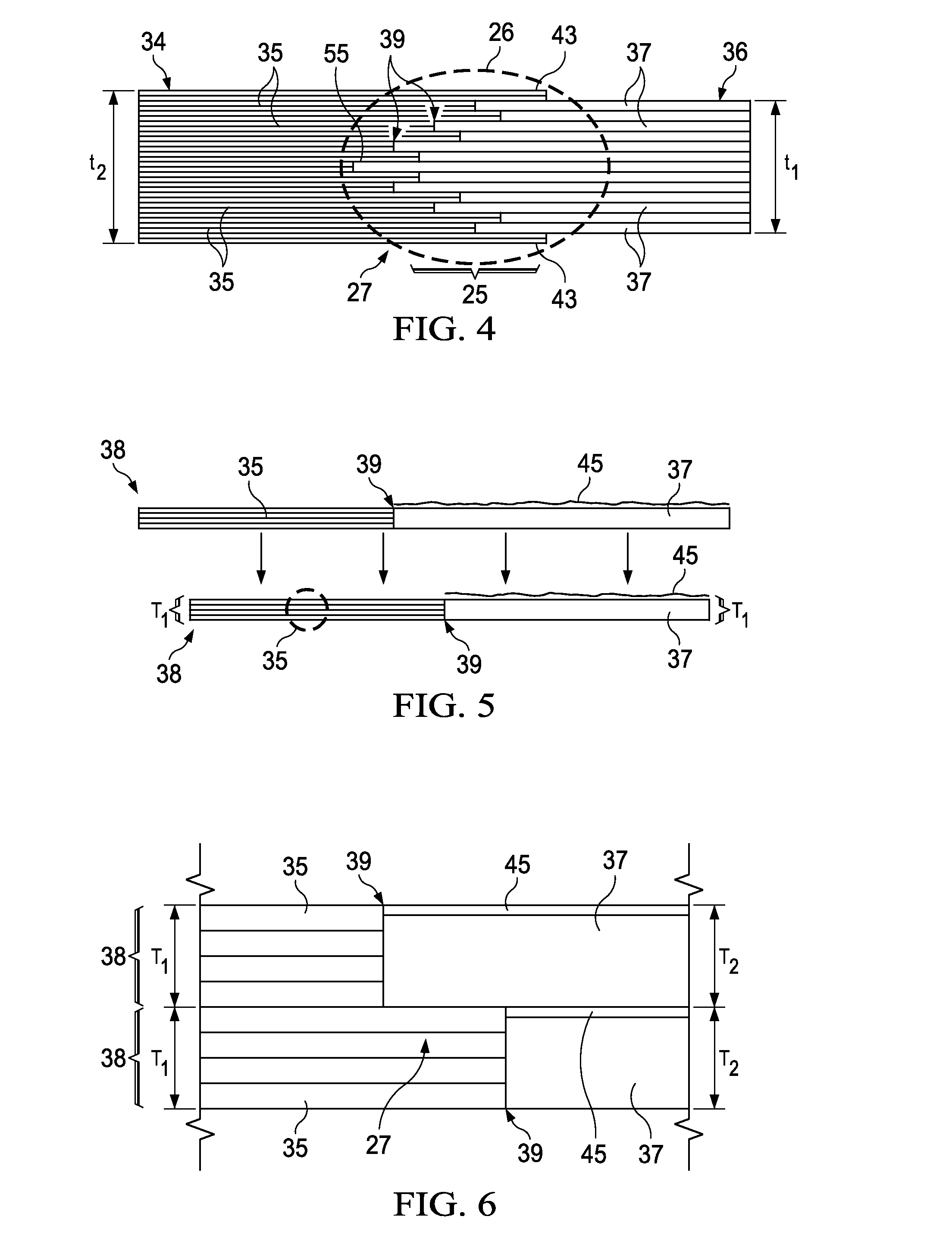

Multiple-plate structure of zonal design for a shaped part

InactiveUS6048628ALow production costLow costPig casting plantsExtrusion containersEngineeringLoad profile

A formed part having a multiple-plate structure of zonal design includes a base plate and a plurality of reinforcing plates fastened to the base plate. The multiple-plate structure is configured so that its strength is largely adapted to the load profile to be applied to the formed part and so that its cost of production is reduced. To this end, the thicknesses of the reinforcing plates vary as a function of the load structure to be applied to the formed part and the reinforcing plates engage each other in a positive locking manner so that the abutting edges are provided essentially with regularly arranged projections which are in mutual engagement.

Owner:VOLKSWAGEN AG

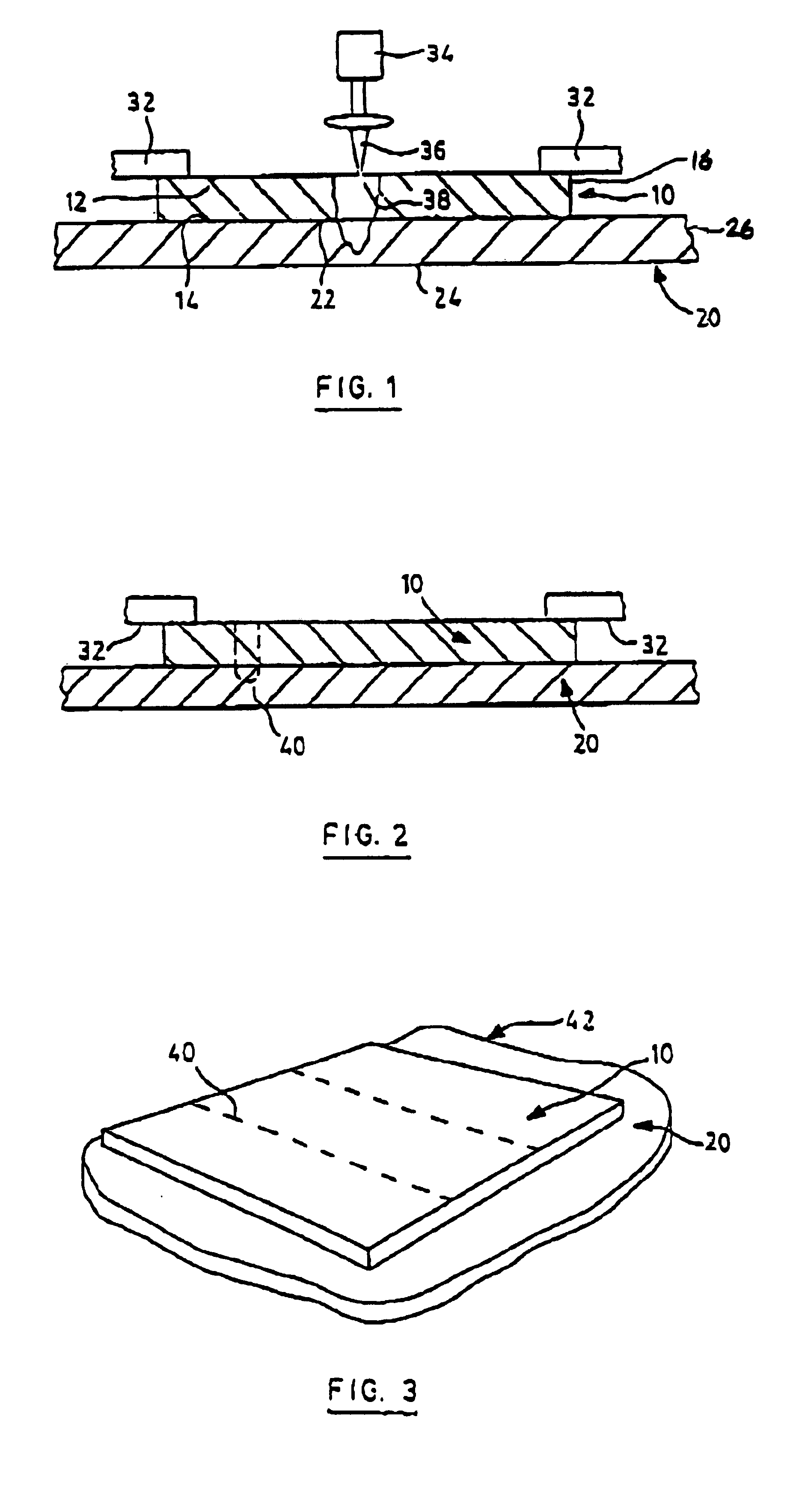

Method of combining welding and adhesive bonding for joining metal components

A method of joining metal components having the steps of depositing adhesive material between the components and welding the components together via solid-state or fusion welding. The welds are spaced apart from the adhesive material and are produced so as to prevent exposure of the adhesive material to the welding. The two types of bonds (adhesive and welding) are produced in the components separated by time and space.

Owner:ARCONIC INC

Sheet metal stud and composite construction panel and method

A composite construction panel having a thin panel of concrete material and a reinforcing grid of sheet metal studs with embedment portions which are actually embedded into the concrete panel, each of the studs having a web, right angular flange formed on a free edge of the web, an angled edge strip formed along the free edge of the right angular flange, an embedment angled flange portion formed along the opposite edge of the web, an edge strip formed on the angled flange at an angle thereto; and, spaced apart angled flange openings formed in the angled flange for flow of concrete therethrough. An alternate form of stud has a triangular tube structure along one edge of the web. Another form of stud has a discontinuous webs defining spaces between them. In one embodiment two concrete panels may be secured to the studs in spaced relation to create a hollow structure.

Owner:BODNAR ERNEST R

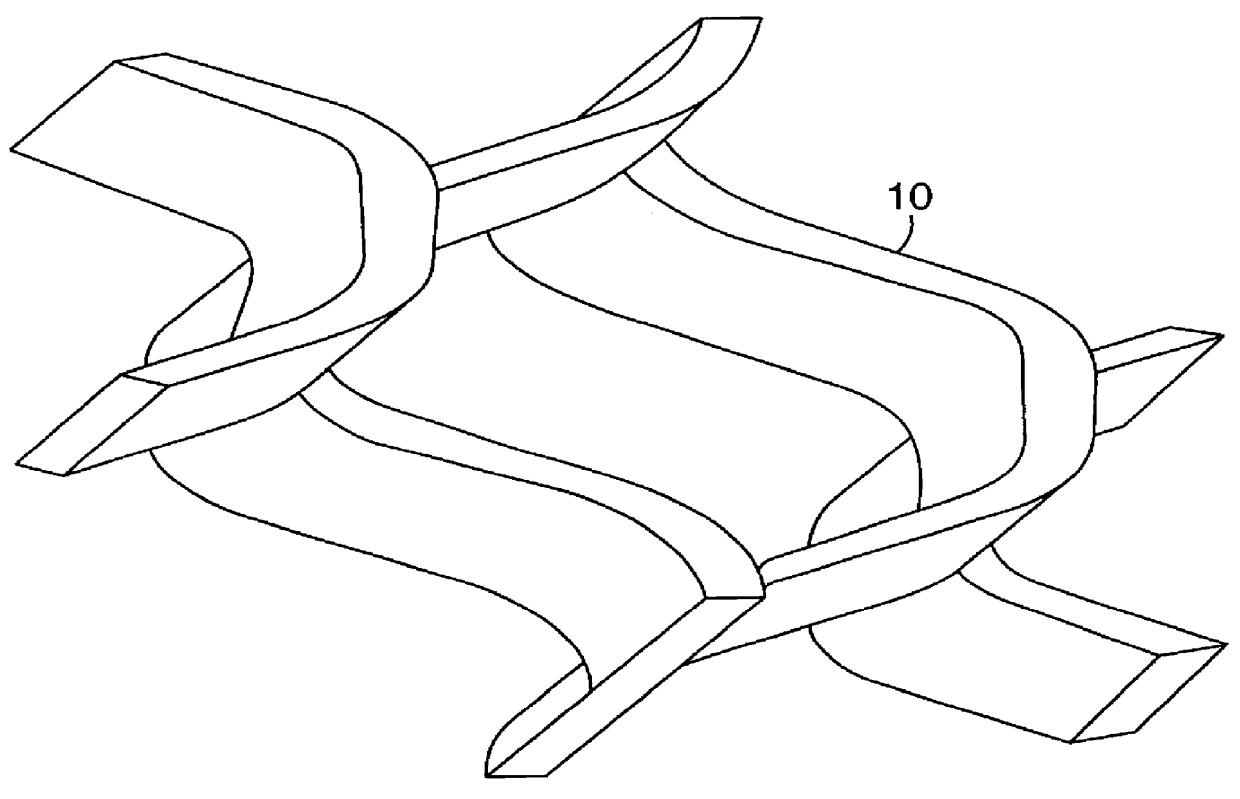

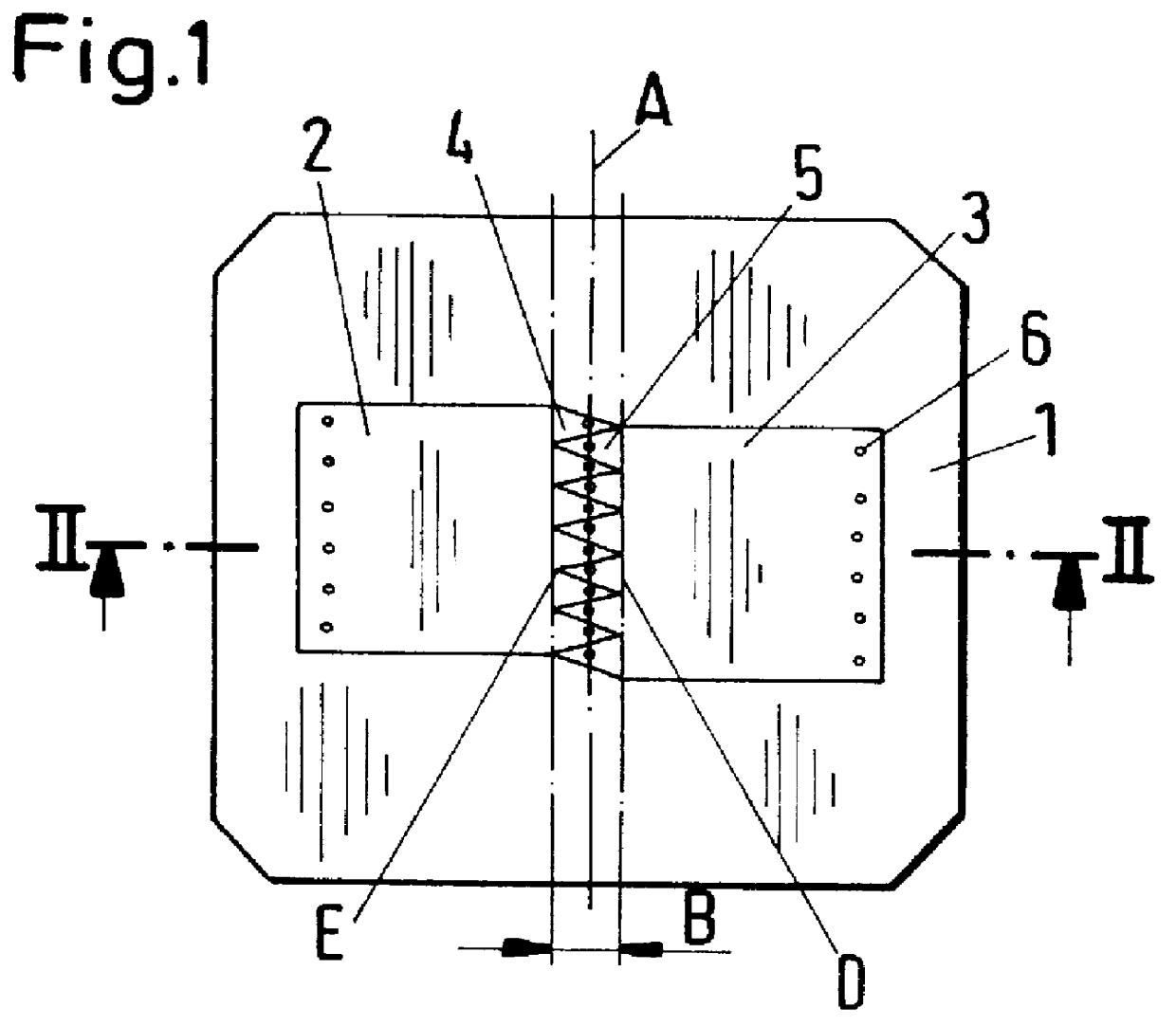

Equal channel angular extrusion method

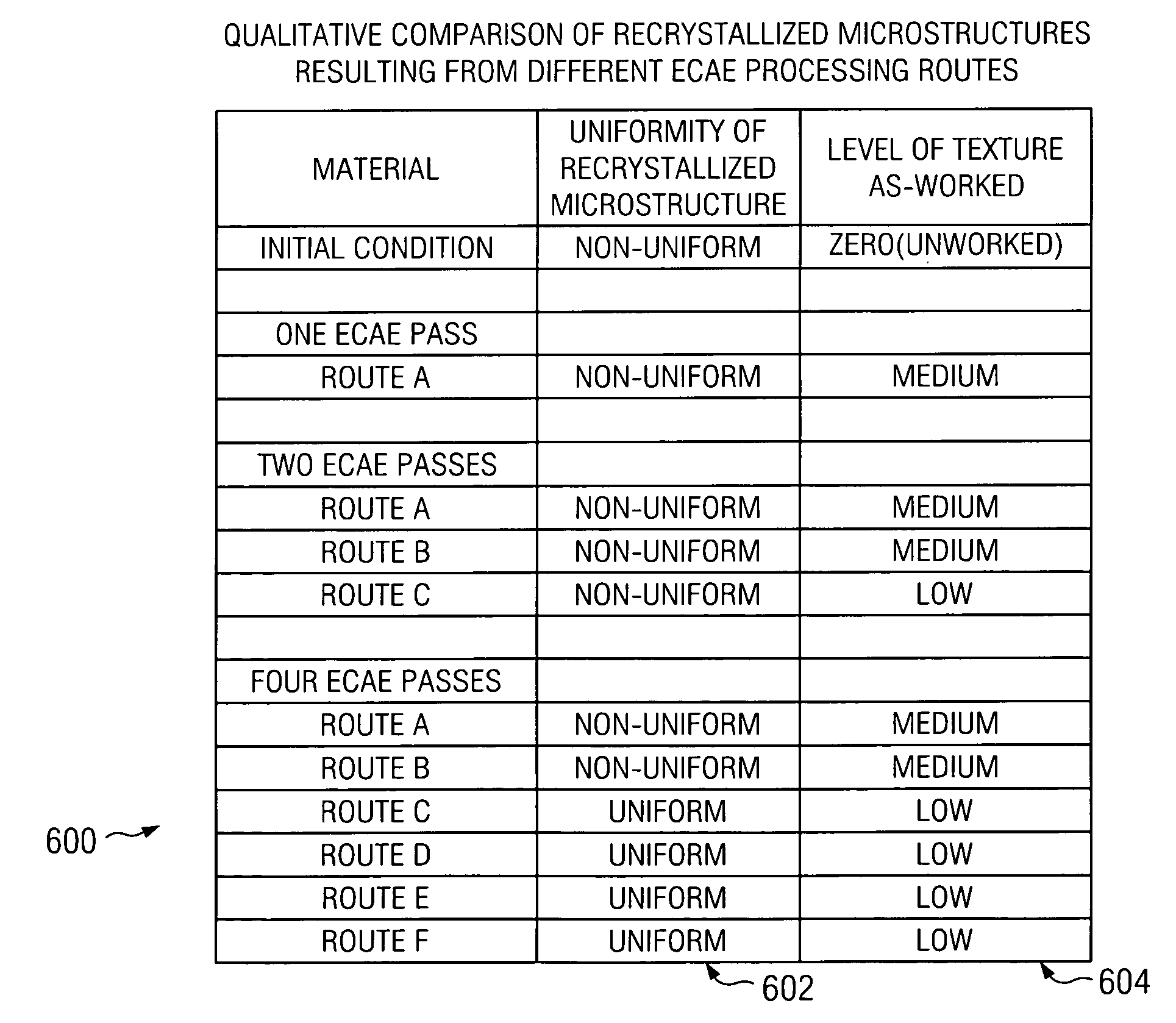

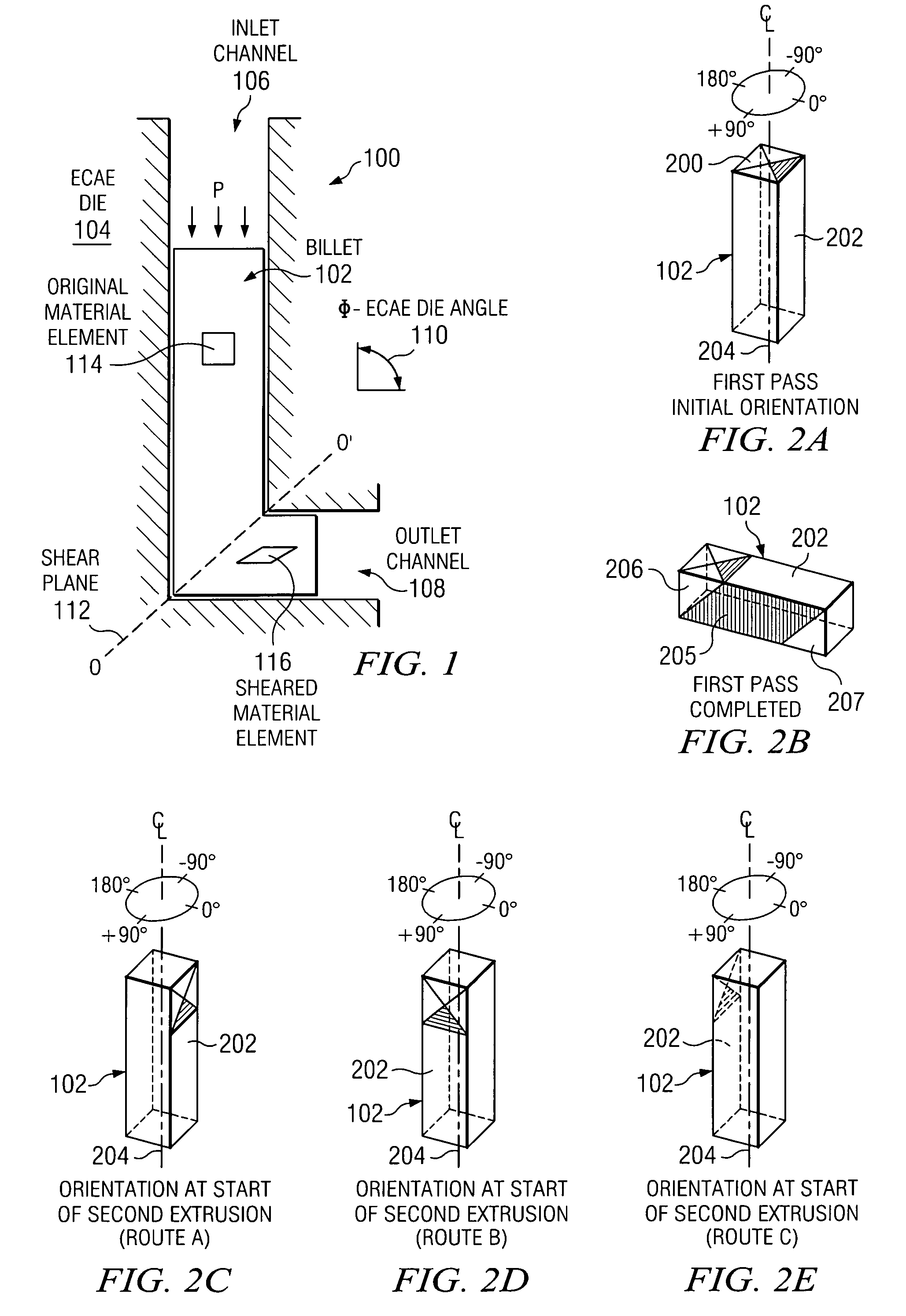

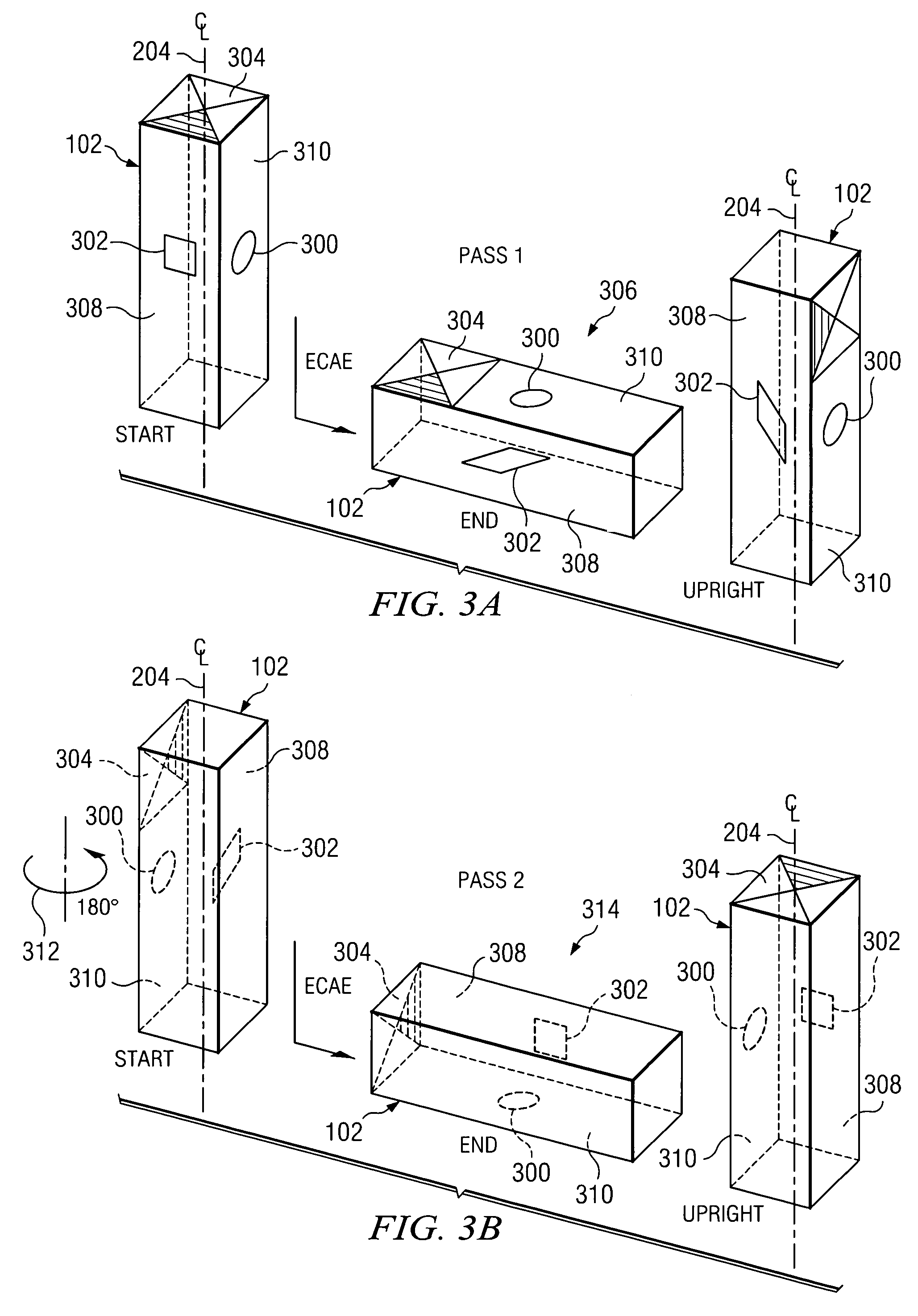

InactiveUS6883359B1Quantity minimizationMinimized volumeExtrusion containersClassical mechanicsEqual channel angular extrusion

According to one embodiment of the present invention, an equal channel angular extrusion (ECAE) method includes extruding a billet of material along a first axis in a first orientation through an ECAE die, extruding the billet along the first axis in a second orientation through the ECAE die, the second orientation oriented approximately 180° from the first direction, extruding the billet along the first axis in a third orientation through the ECAE die, the third orientation oriented approximately 90° from the second orientation, and extruding the billet along the first axis in a fourth orientation through the ECAE die, the fourth orientation oriented approximately 180° from the third orientation.

Owner:TEXAS A&M UNIVERSITY

Copper foil excellent in laser beam drilling performance and production method therefor

InactiveUS6638642B2Improve drilling effectFine surfaceRadiation applicationsExtrusion containersIndiumCopper foil

Owner:JX NIPPON MINING & METALS CORP

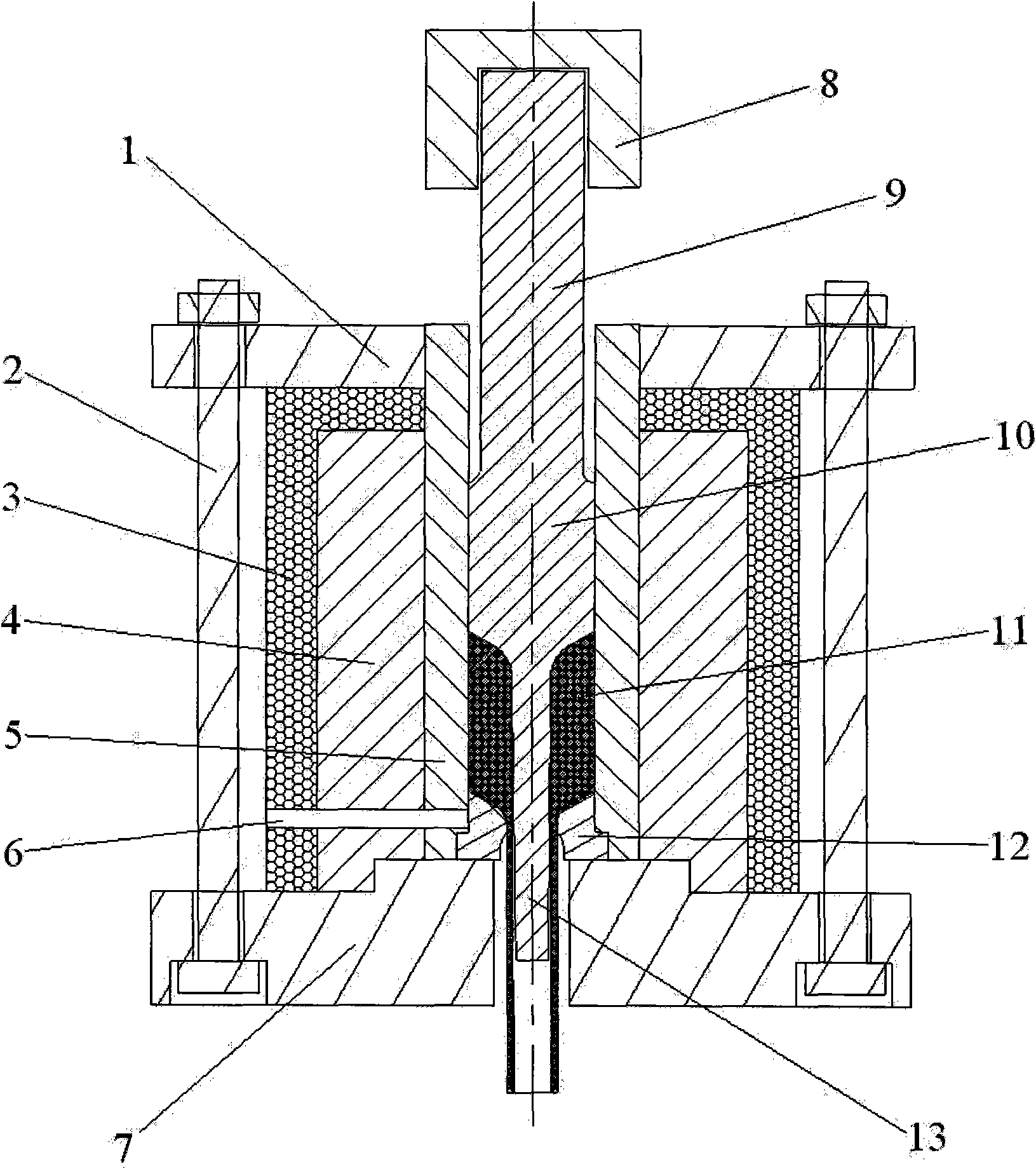

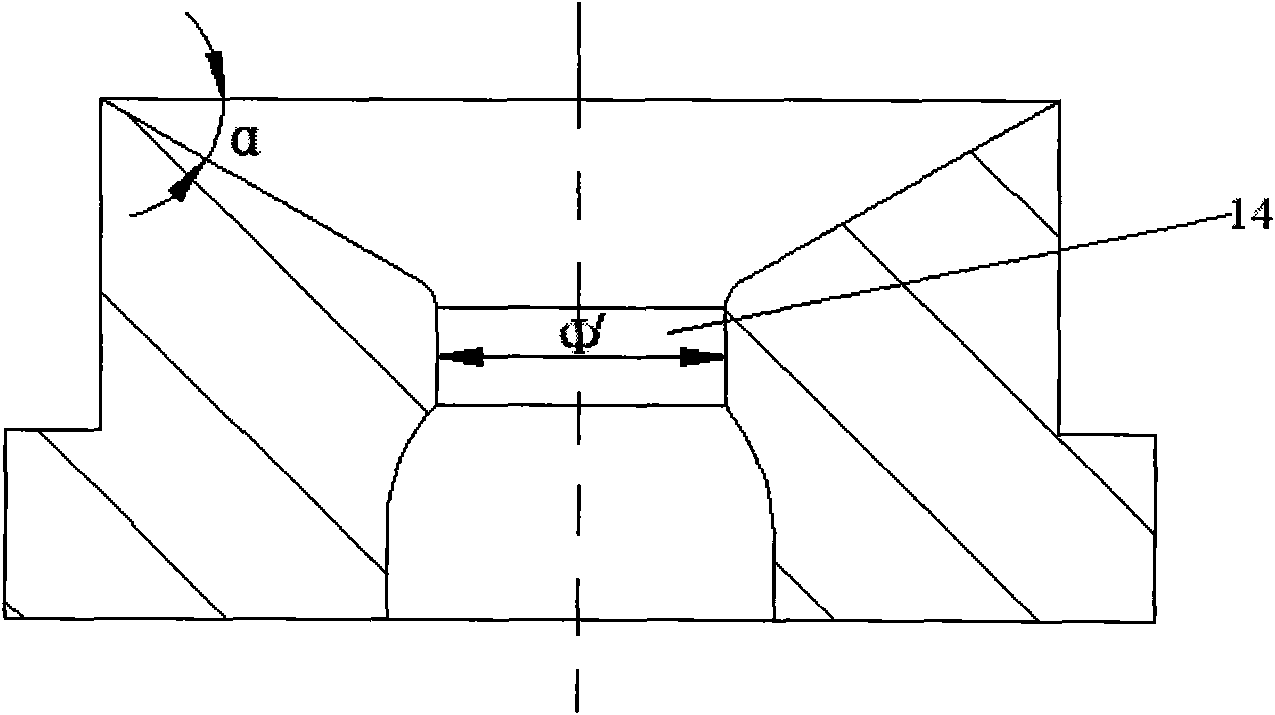

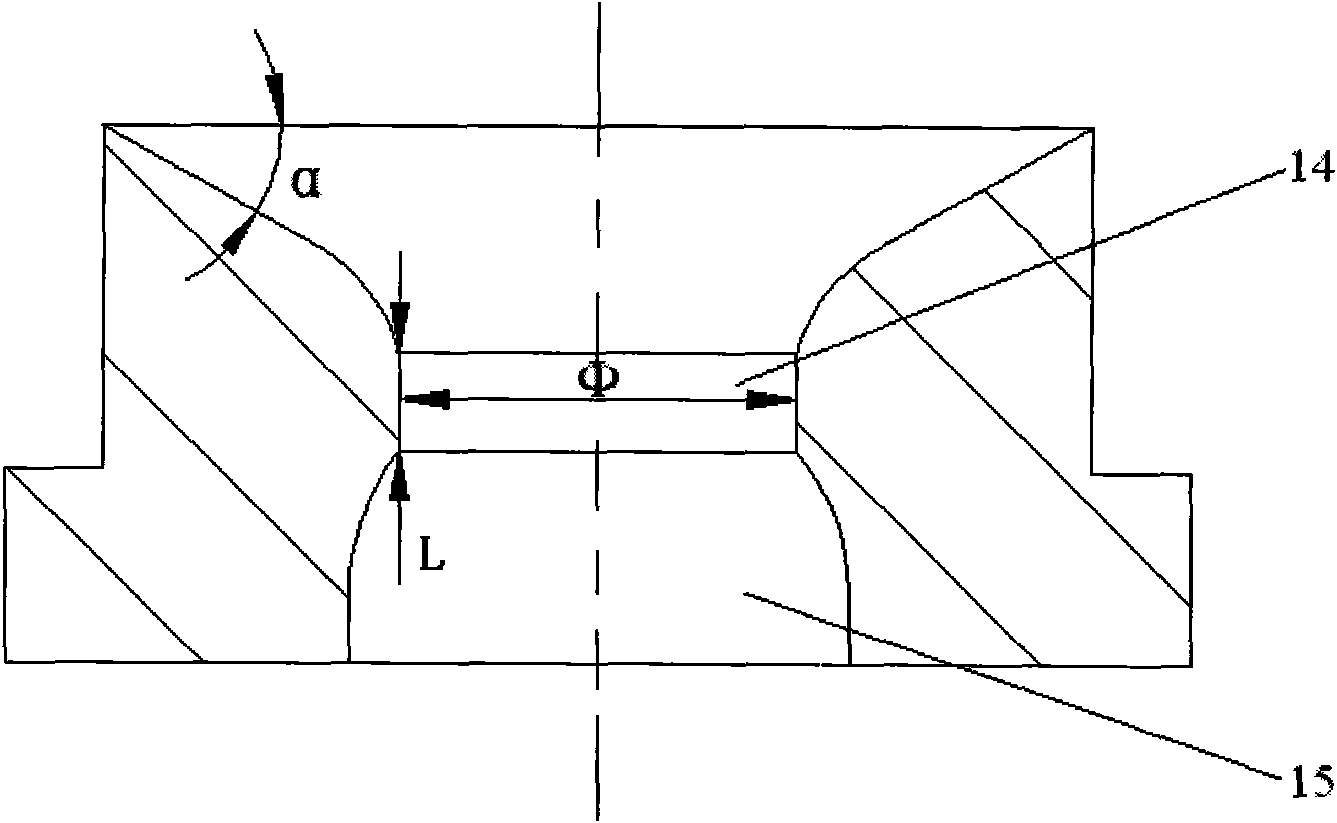

Rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold

InactiveCN101549361AIncrease profitReduce extrusion pressureExtrusion diesExtrusion containersThermal insulationRare earth

The invention relates to a rare-earth magnesium alloy seamless thin wall tubule hot-extrusion method and its specialized mold. The method includes: machine-tooling after casting ingot homogenization treatment into a hollow blank, performing pre-extrusion in the mold, extrusion molding after die change, and performing solid dissolving aging treatment for further improving the tube dynamics performance. The invention relates to a special mold, including an upper and a lower die holders, a thermal insulation sleeve, a squeezing barrel, a male die and a concave die, wherein, the concave die is composed of a pre-extrusion concave die and a shaping concave die, one of the pre-extrusion concave die and the shaping concave die is selected and interchangeable with the other, and is fixed on the lower die holder through a squeezing barrel. The invention can extrude a rare-earth magnesium alloy seamless thin wall tubule with the external diameter of 5-10mm and internal diameter of 4-8mm, which has features of high material utilization, small extruding force, high products dimensional precision, good surface accuracy, good dynamics performance and the like features. The inventive mold simultaneously has advantages of simple structure, easy operation, low cost, long life and so on.

Owner:CHONGQING UNIV

Aircraft structure element made of an Al-Cu-Mg alloy

InactiveUS6569542B2Pig casting plantsSemiconductor/solid-state device detailsAlloyStructuring element

The purpose of the invention is a structure element, particularly an lower wing element of an aircraft, manufactured from a rolled, extruded or forged product made of an alloy with composition (% by weight):Cu=4.6-5.3, Mg=0.10-0.50, Mn=0.15-0.45, Si <0.10, Fe<0.15, Zn<0.20, Cr<0.10, other elements <0.05 each and <0.15 total, the remainder being Al treated by solution heat treating, quenching, controlled tension to more than 1.5% permanent deformation and aging.

Owner:RHENALU PECHINEY

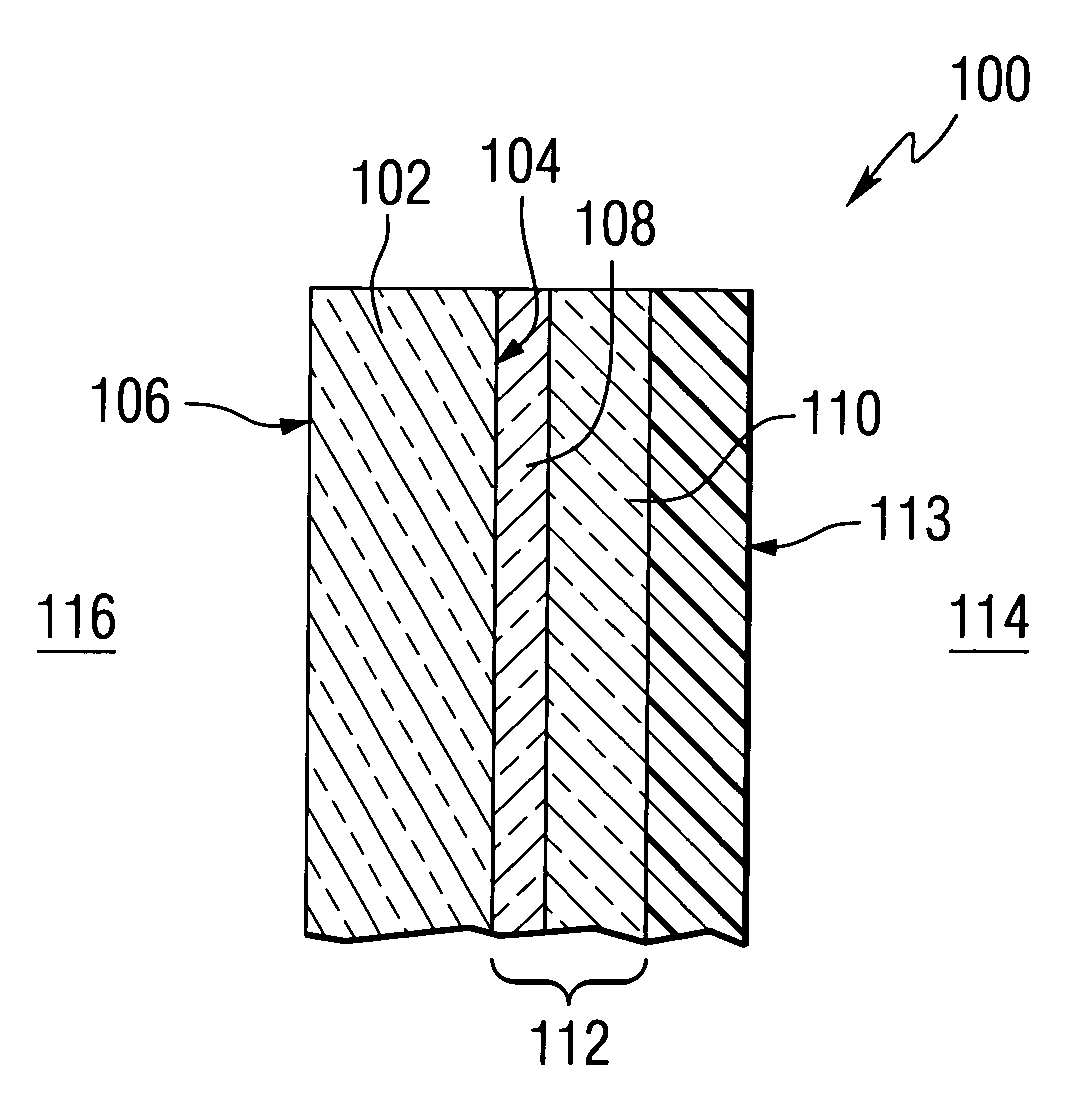

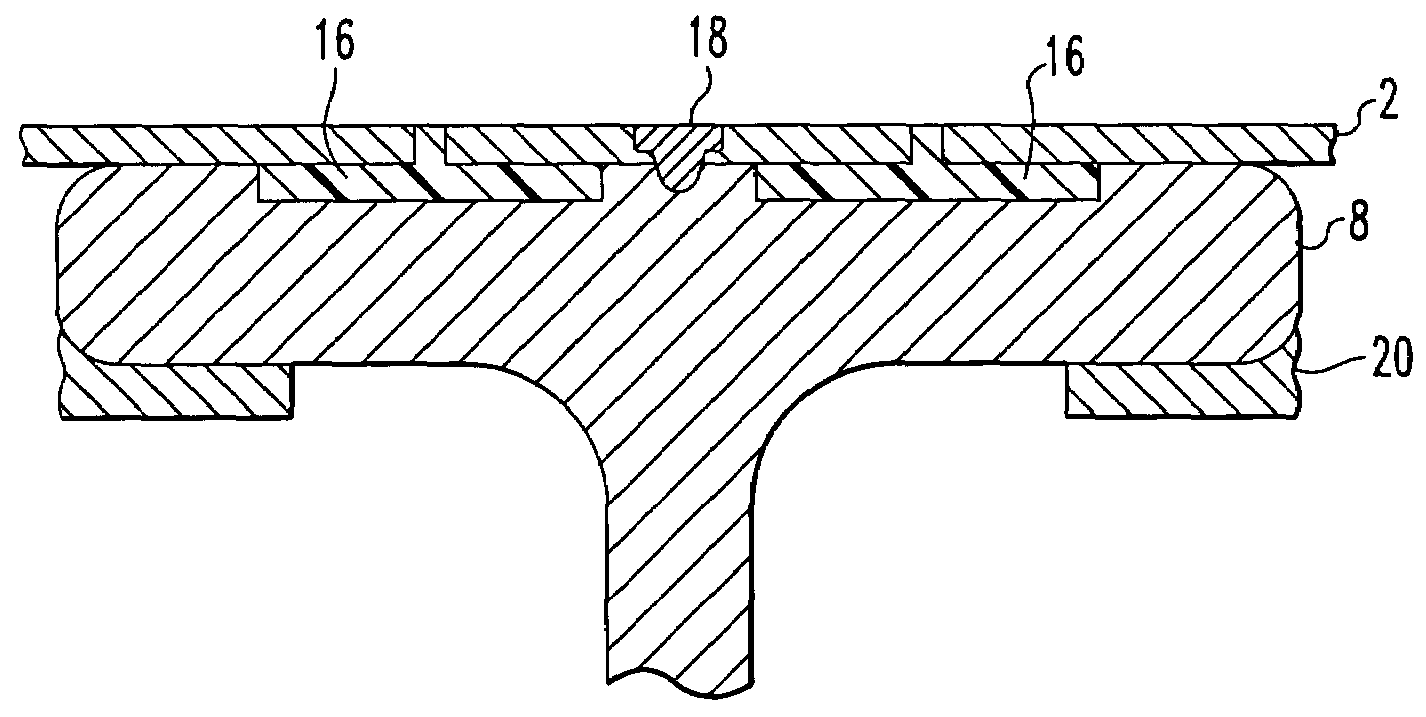

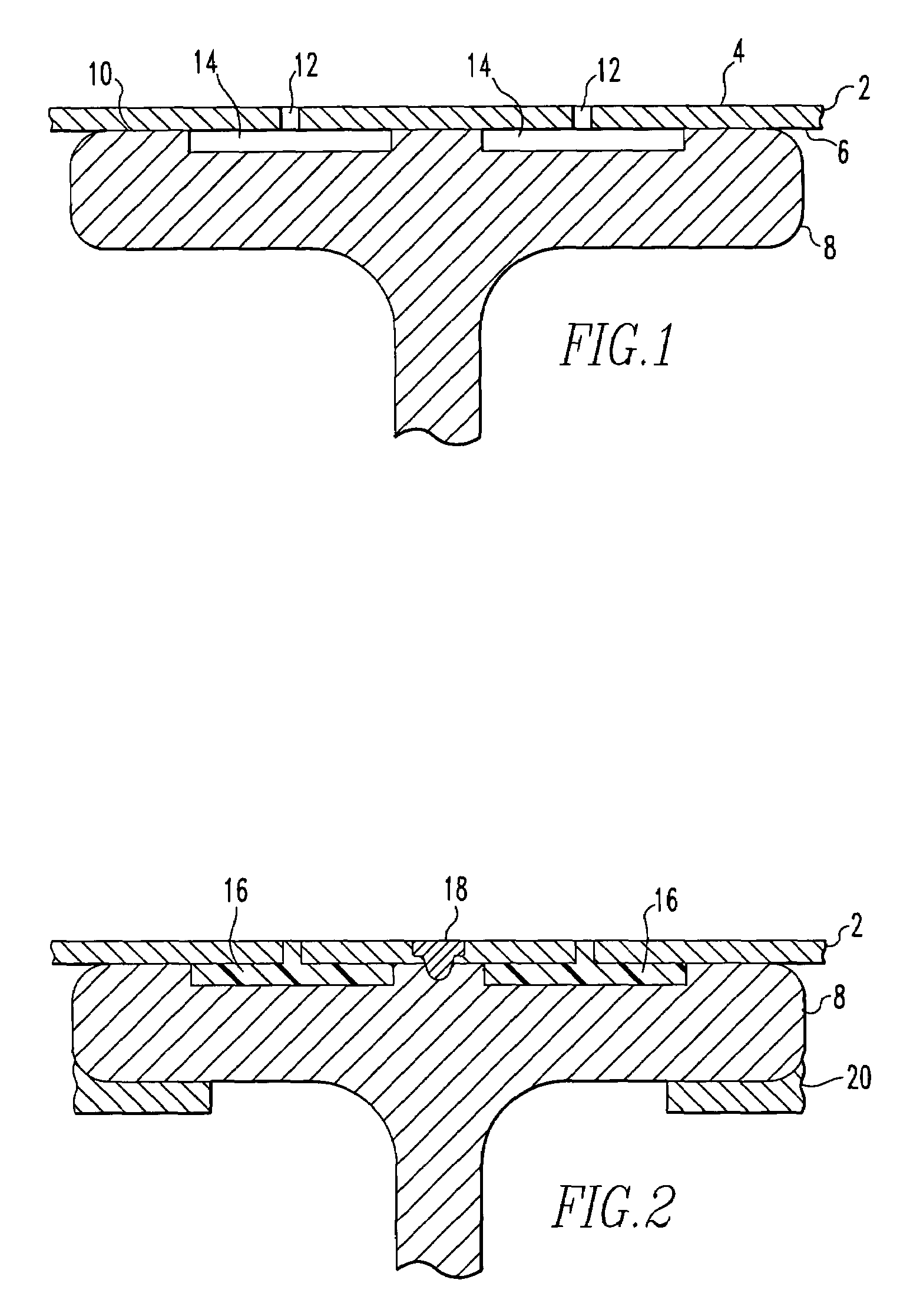

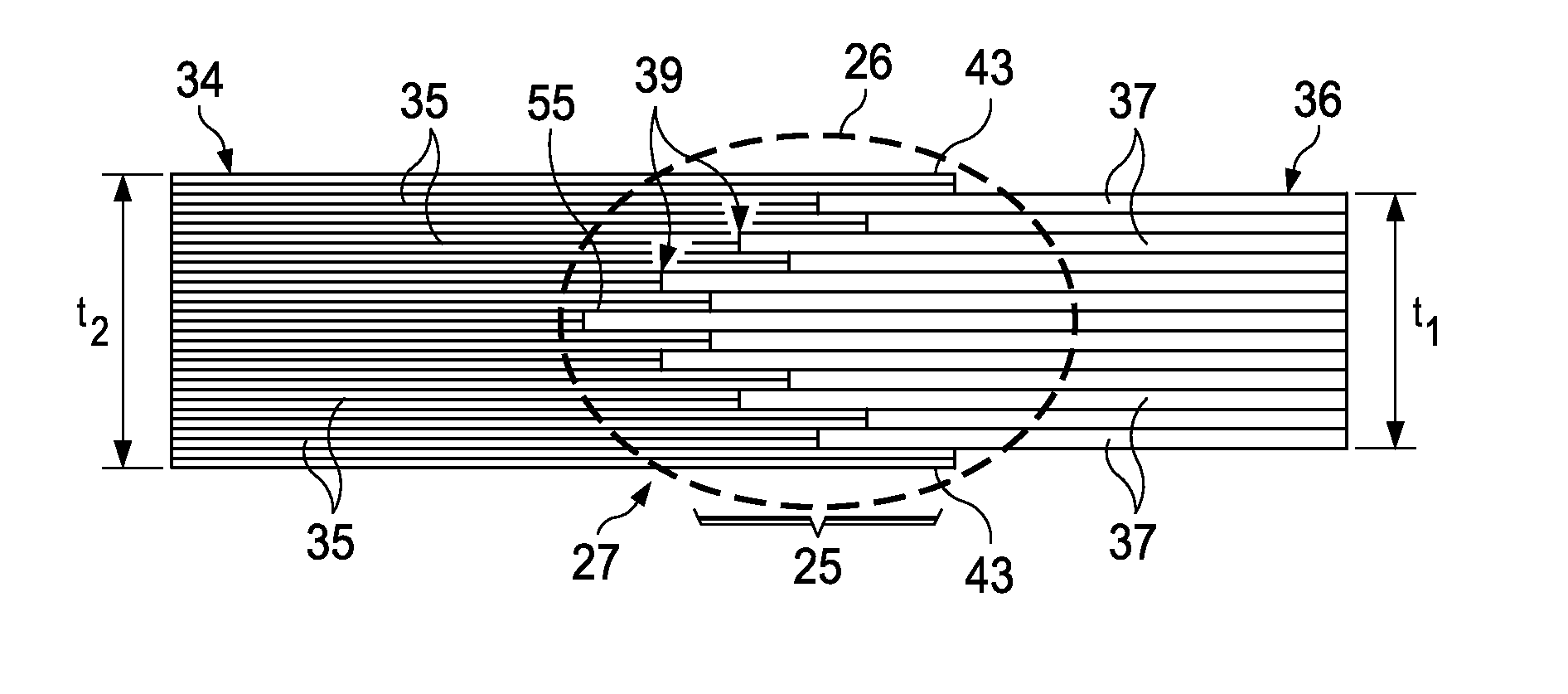

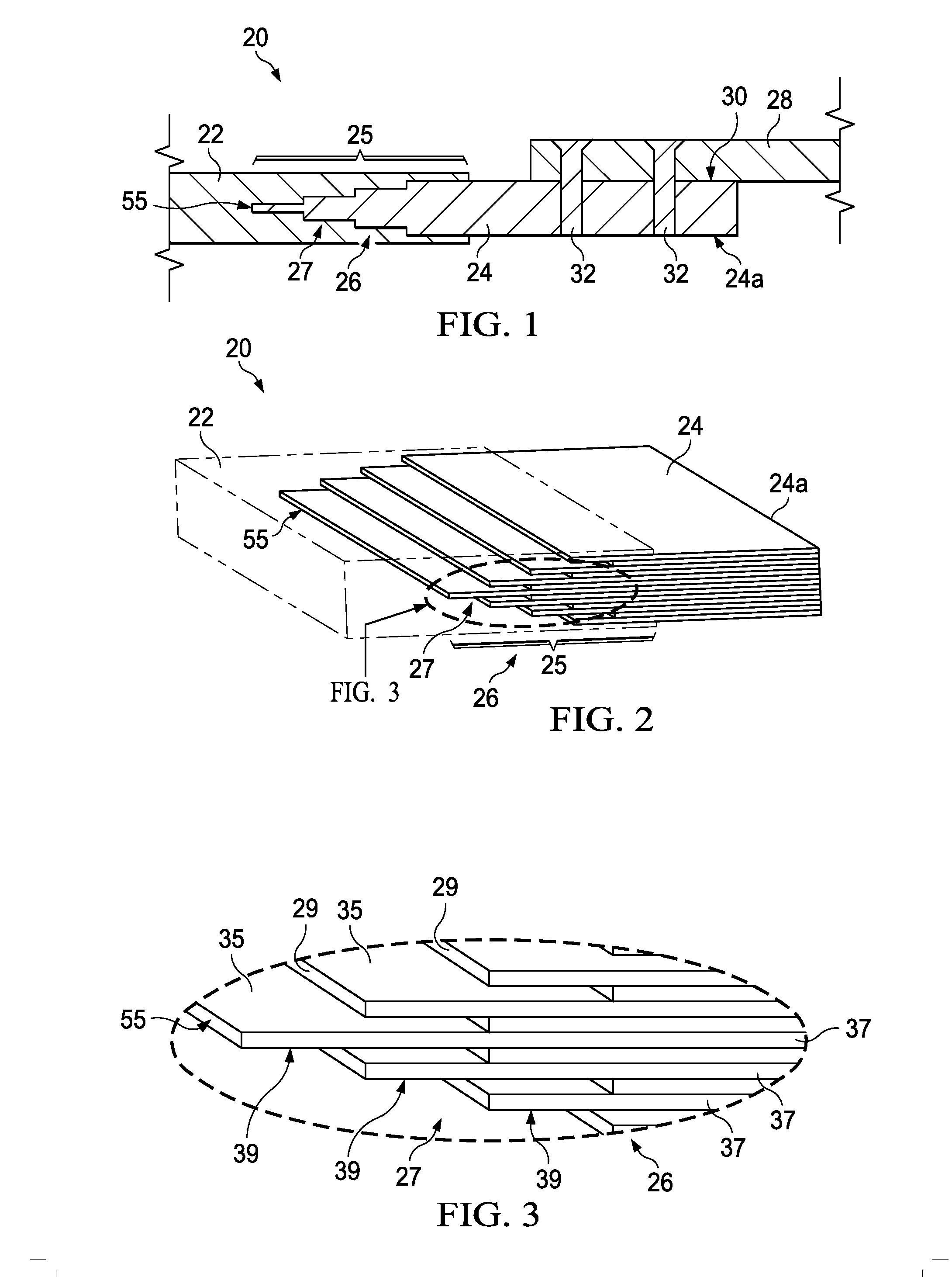

Multi-Layer Metallic Structure and Composite-to-Metal Joint Methods

ActiveUS20130075526A1Reduce eliminate possibilityReduce occurrence and propagationFuselage framesExtrusion containersFiberMetal sheet

A composite structure comprises stacked sets of laminated fiber reinforced resin plies and metal sheets. Edges of the resin plies and metal sheets are interleaved to form a composite-to-metal joint connecting the resin plies with the metal sheets.

Owner:THE BOEING CO

Tailored blank

The present invention provides a tailored blank having a pair of sheet metal constituent parts each having a pair of oppositely directed major surfaces. The first constituent part has an aperture while the second constituent part has an embossment to fit the aperture. The first and second constituent parts are then secured to one another to form the tailored blank. The blank may then be subsequently formed into a component of varying material characteristics.

Owner:DULEY WALTER +5

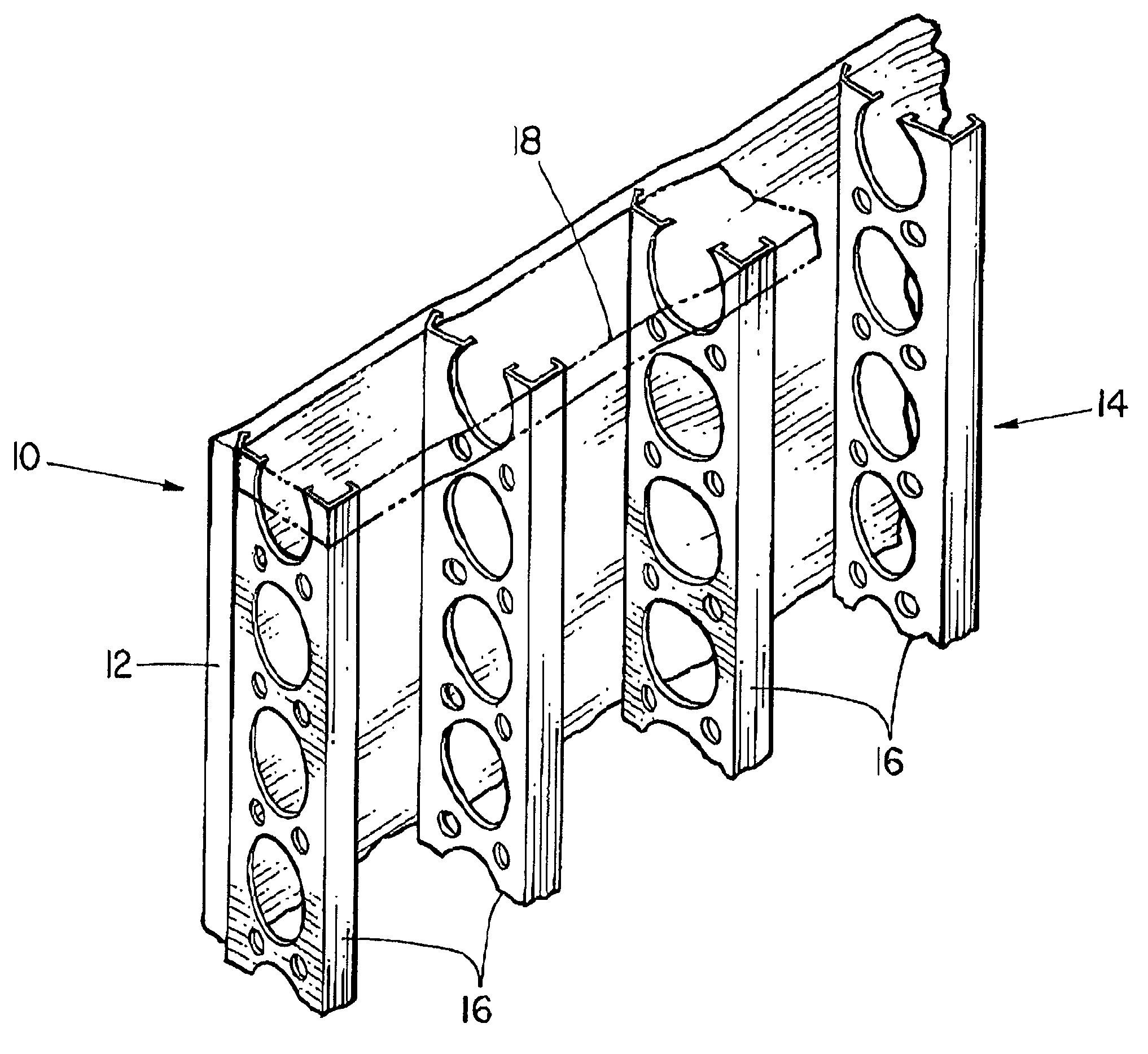

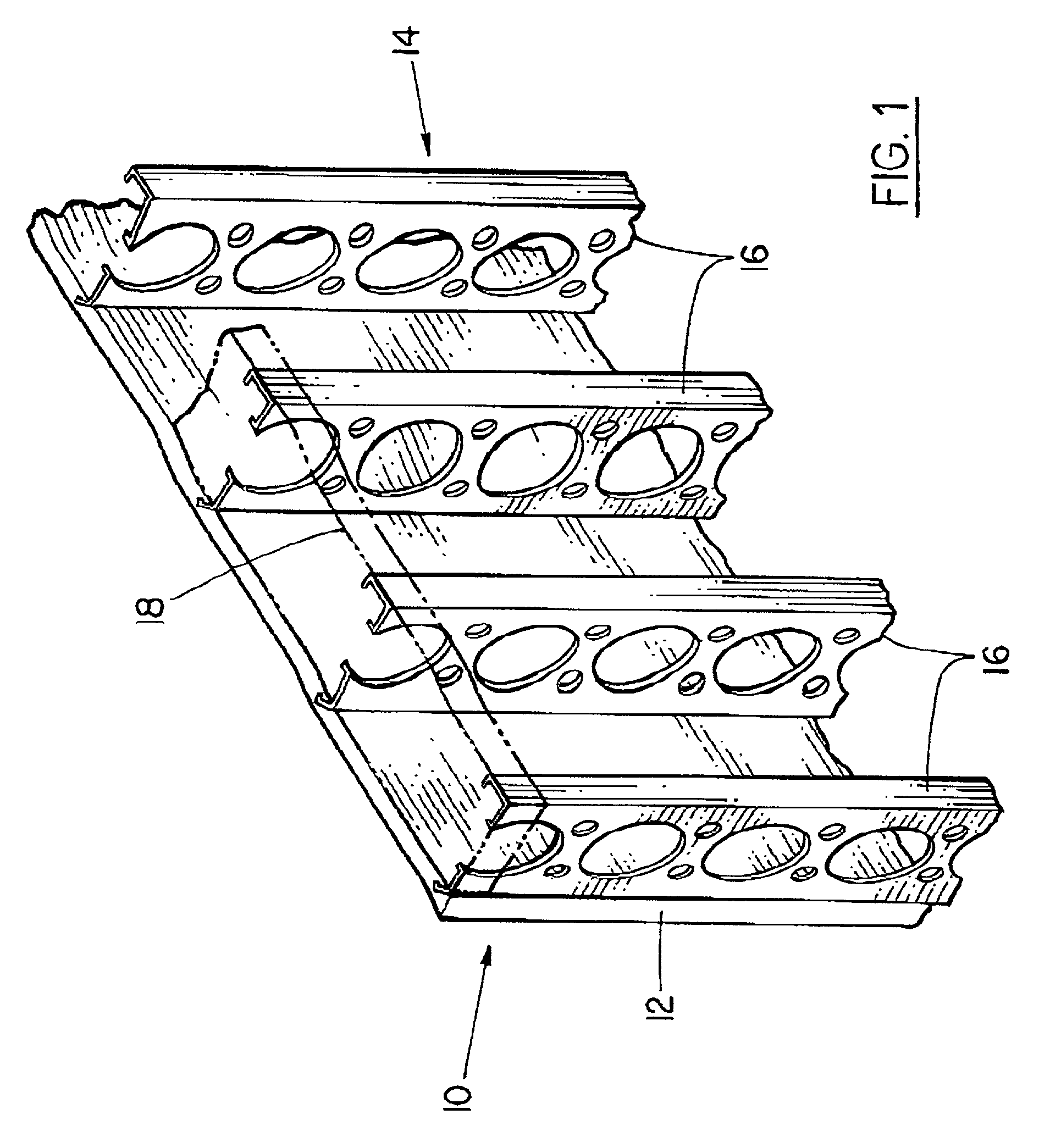

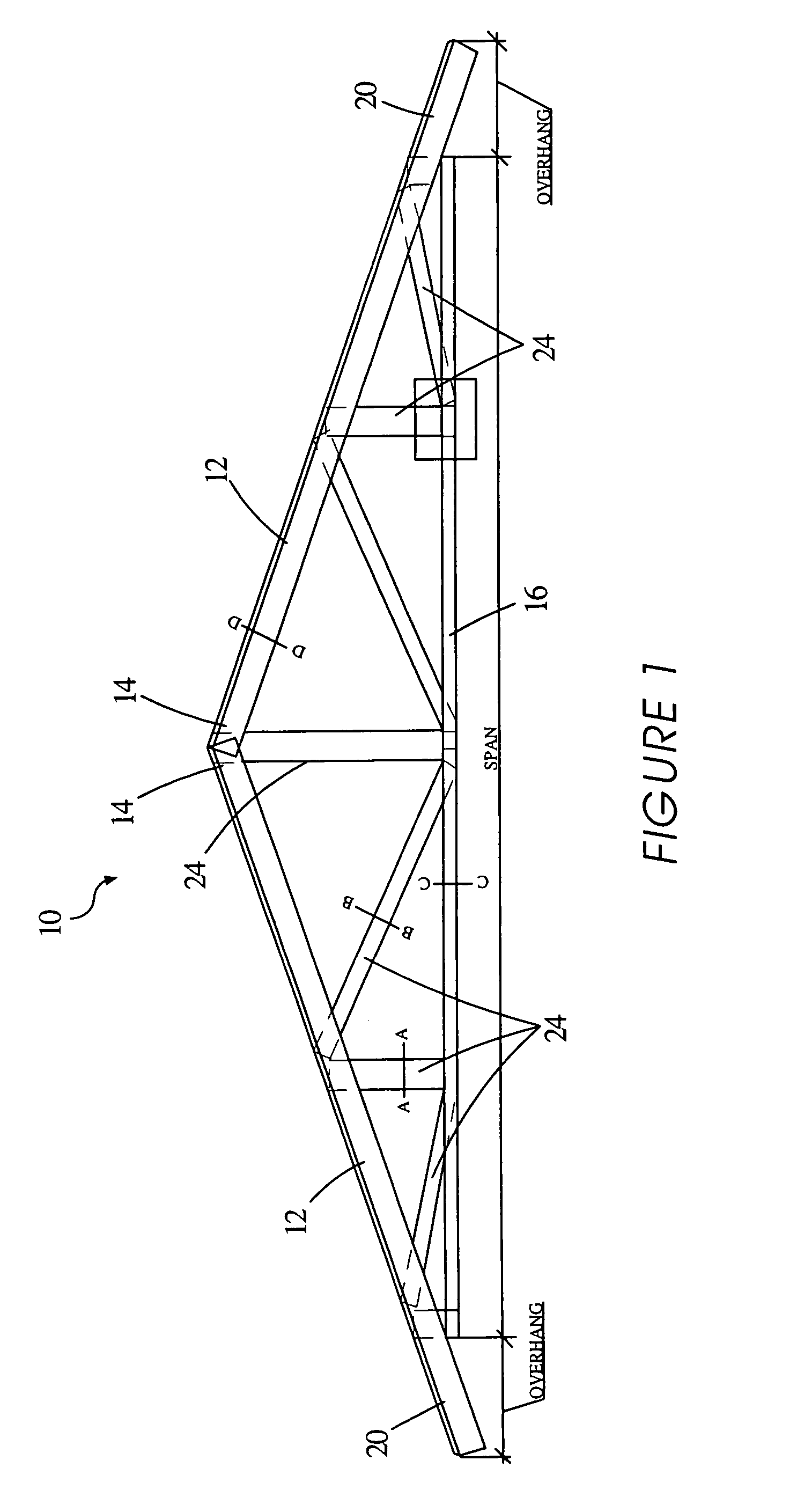

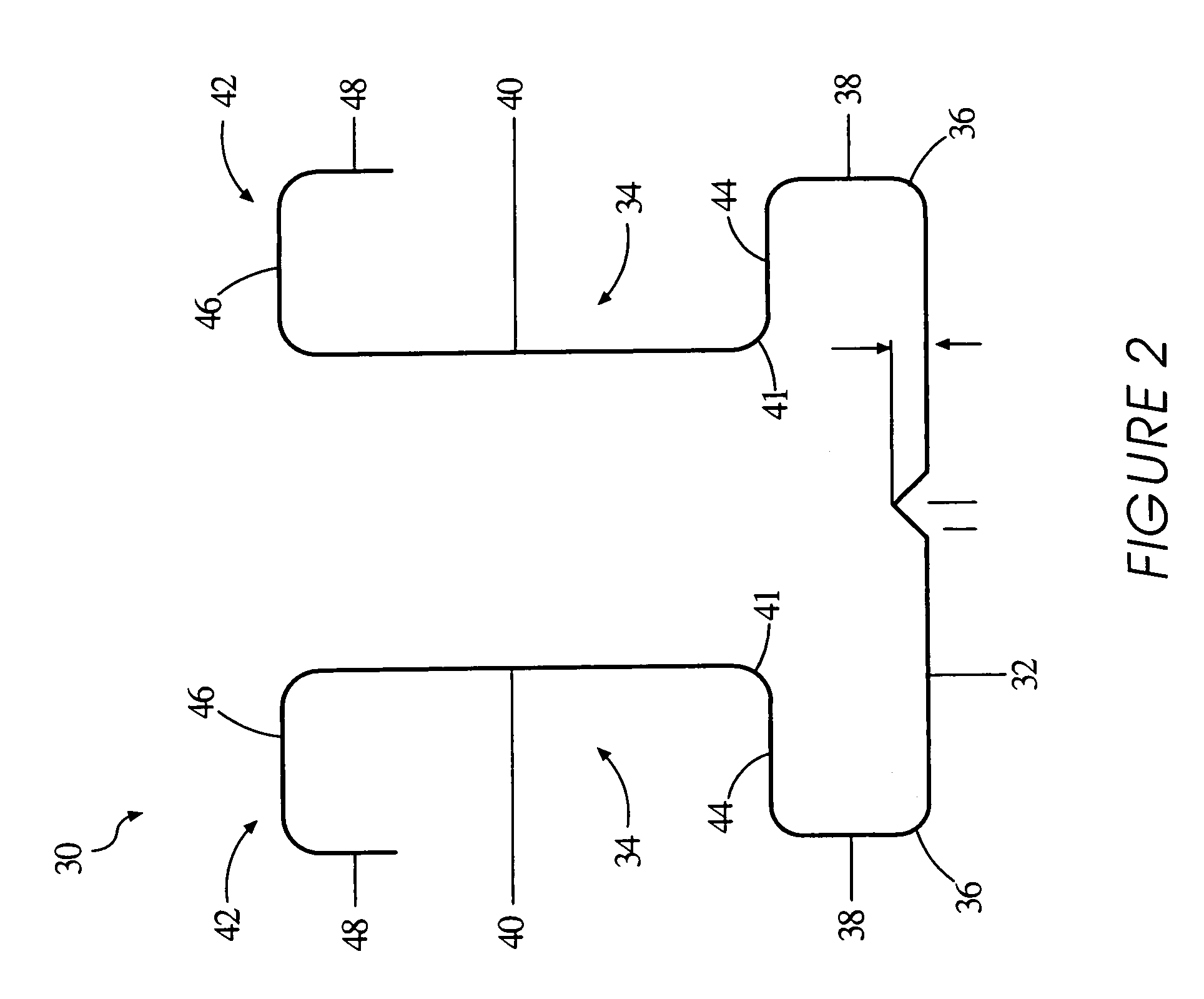

Light gauge metal truss system and method

InactiveUS7093401B2Easy to engageConvenient nestingBuilding roofsLayered productsEngineeringUltimate tensile strength

A truss system wherein the structural components and fixtures are formed from light gauge metal. The trusses are fabricated from roll formed truss chord members and truss web members. The truss chord members are roll formed to have a generally U-shaped cross-section with a base and two substantially parallel legs with recessed web attachment faces and outwardly extending stiffening flanges to improve structural capacity thus improving the strength-to-weight ratio of the chord member and minimizing costs. The truss web members are formed by nesting two roll formed C-shaped members to form a web member which is box-shaped in cross section. The web members provide the structural advantages of a box-shaped member and the ease and flexibility of a roll formed member. The truss system and method provides improved means and methods for positioning and attaching the web members to the chord members as well as improved truss clips for resistance to uplifting forces and improved truss jack clips for forming hip connections.

Owner:INNOVATIVE STEEL TECH

Diamond Bonded Construction with Improved Braze Joint

ActiveUS20100300767A1Improve thermal stabilityImproved degree of attachmentDrill bitsConstructionsMetallic materialsMetallizing

Diamond bonded constructions comprise a body comprising a plurality of bonded together diamond grains with interstitial regions disposed between the grains that are substantially free of the catalyst material used to initially sinter the body. A metallic substrate is attached to the body, and a braze joint is interposed between the body and the substrate. The body is metallized to include a metallic material disposed along a substrate attachment surface in contact with the braze joint, wherein the metallic material is different from the braze joint material. The metallic material may exist within a region of the body extending fully or partially into the body, and / or may exist as a layer extending away from the substrate attachment surface. The body includes a working surface characterized by empty interstitial regions or by interstitial regions filled with an infiltrant material, wherein the infiltrant material is different from the metallizing material.

Owner:SMITH INT INC

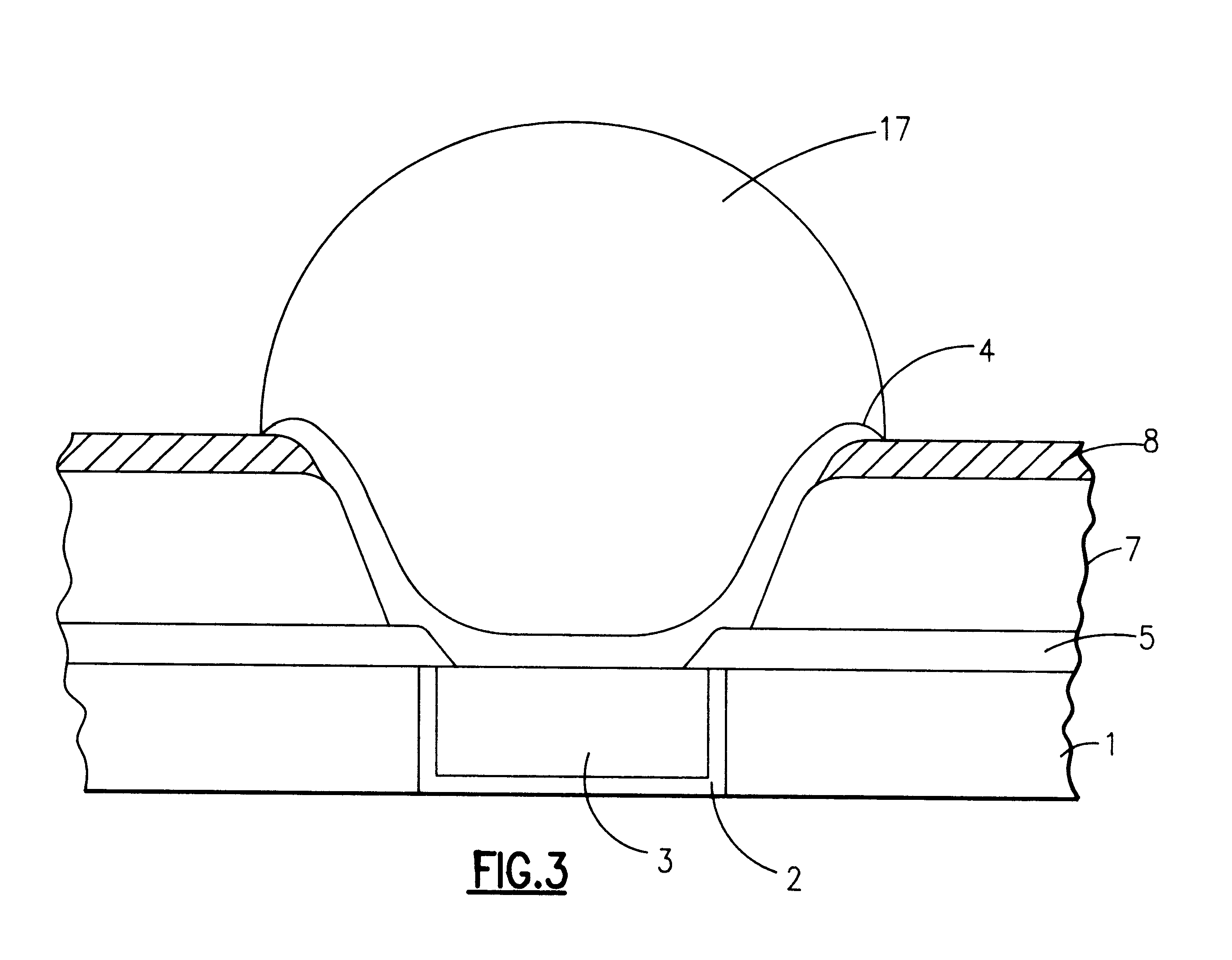

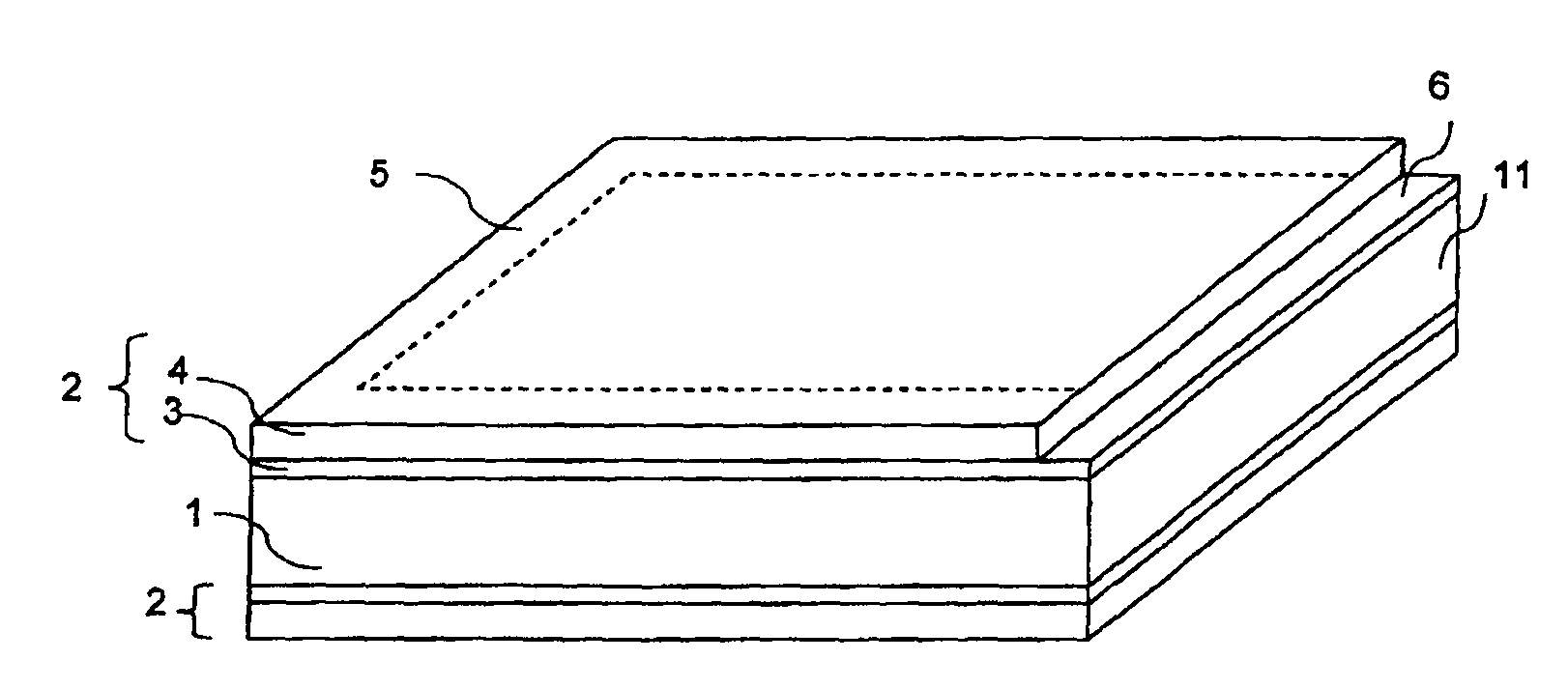

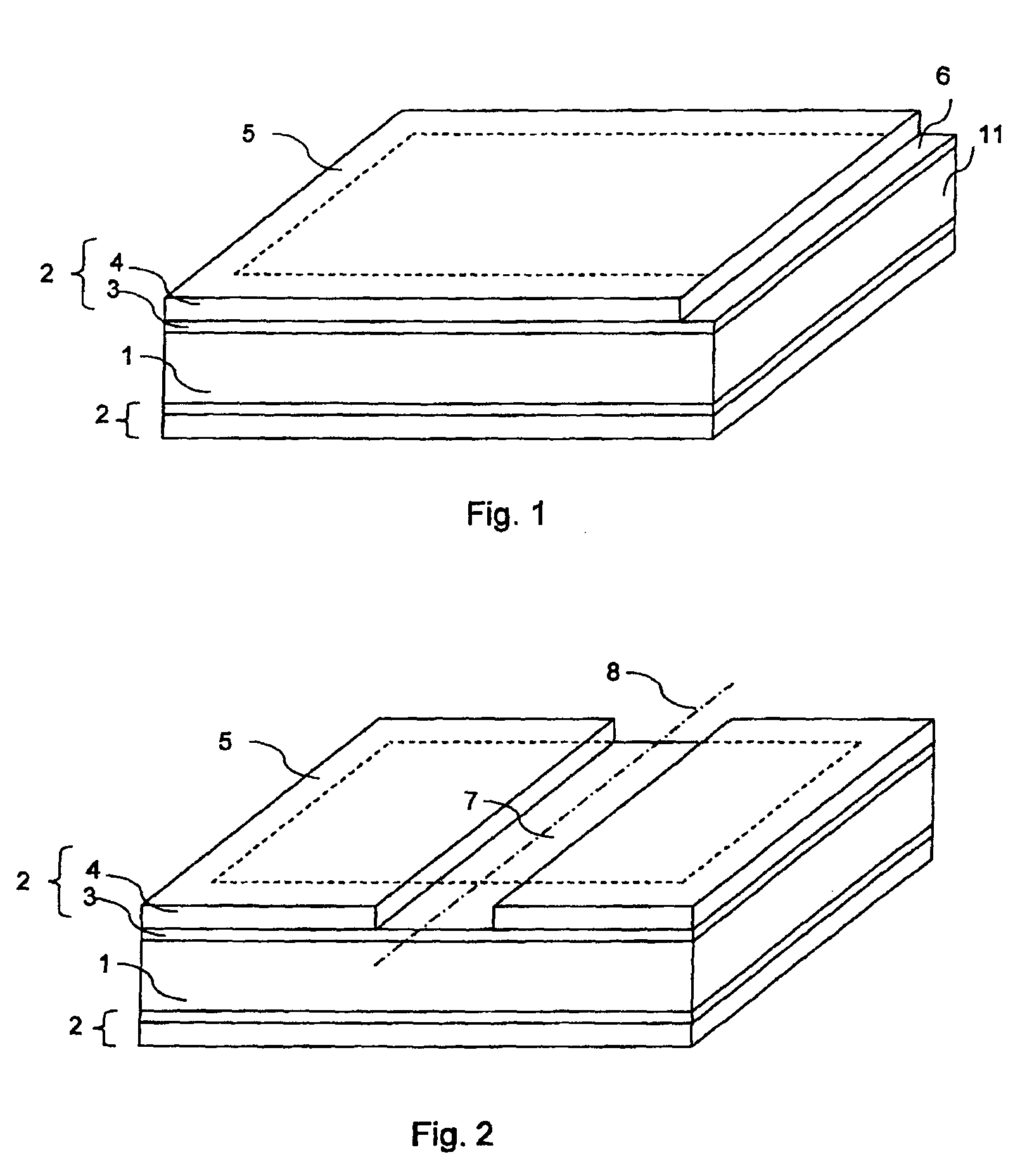

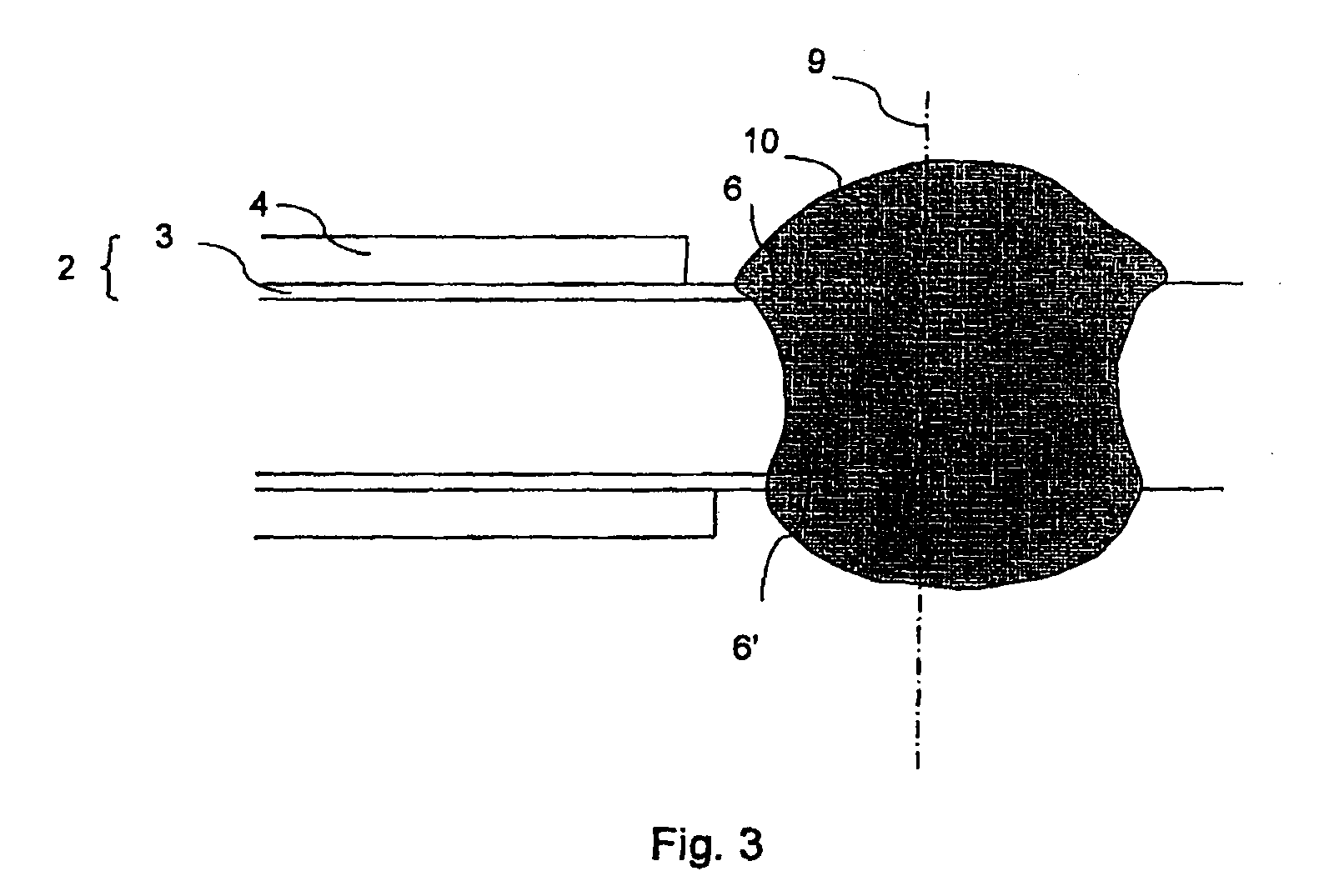

Plate

ActiveUS8614008B2Hot-dipping/immersion processesSemiconductor/solid-state device detailsMetal alloyIntermetallic

Plate consisting of a steel substrate (1) and a precoat (2) consisting of a layer of intermetallic alloy (3) in contact with said substrate, topped by a layer of metal alloy (4), characterized in that, on at least one precoated face of said plate, an area (6) situated at the periphery of said plate has said metal alloy layer removed.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com