Patents

Literature

194 results about "Crystal twinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

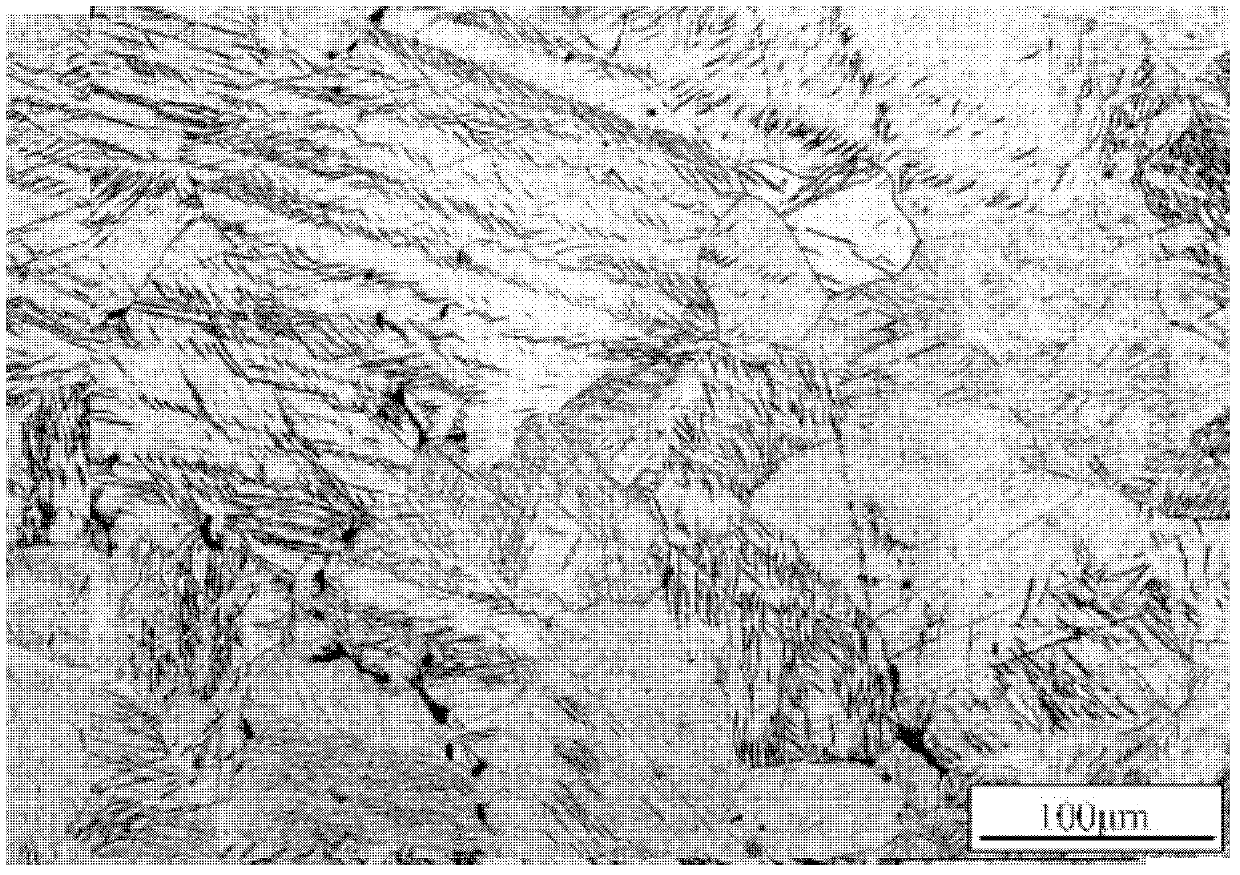

Crystal twinning occurs when two separate crystals share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals in a variety of specific configurations. The surface along which the lattice points are shared in twinned crystals is called a composition surface or twin plane.

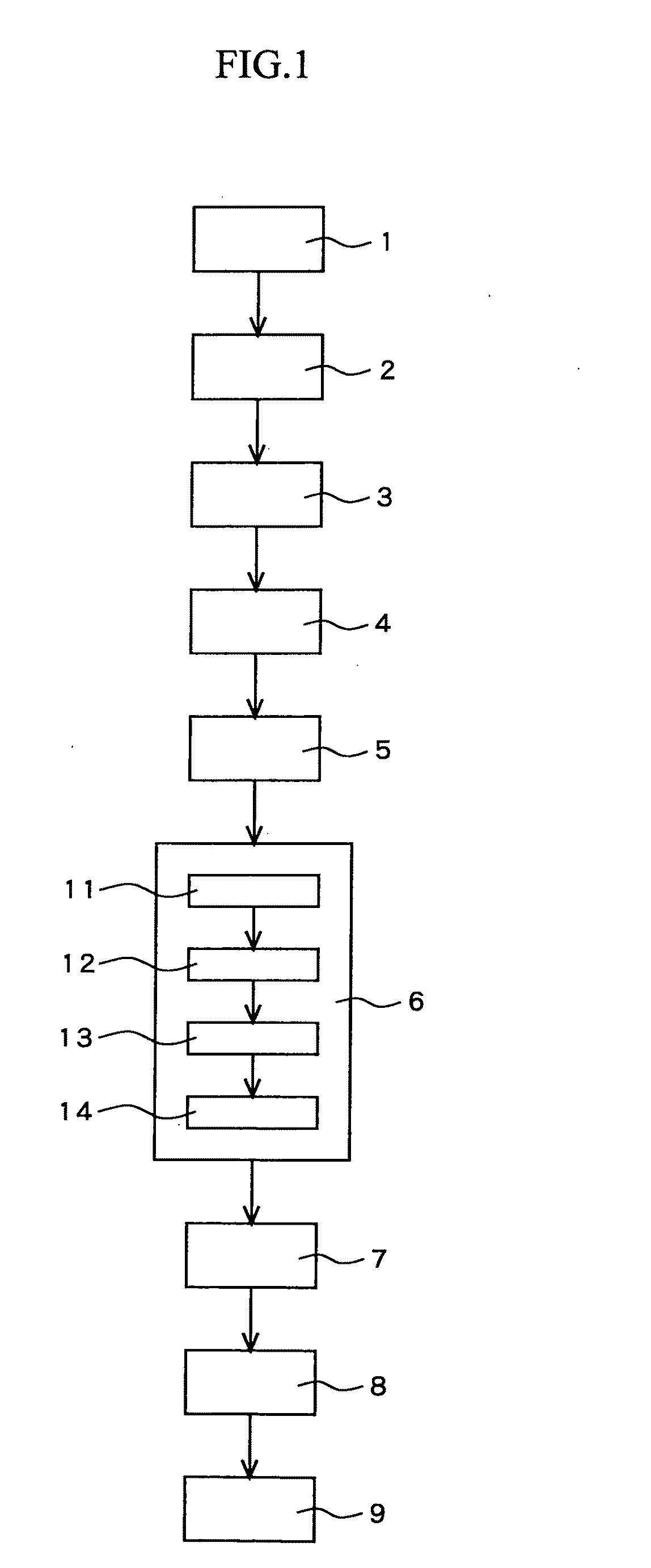

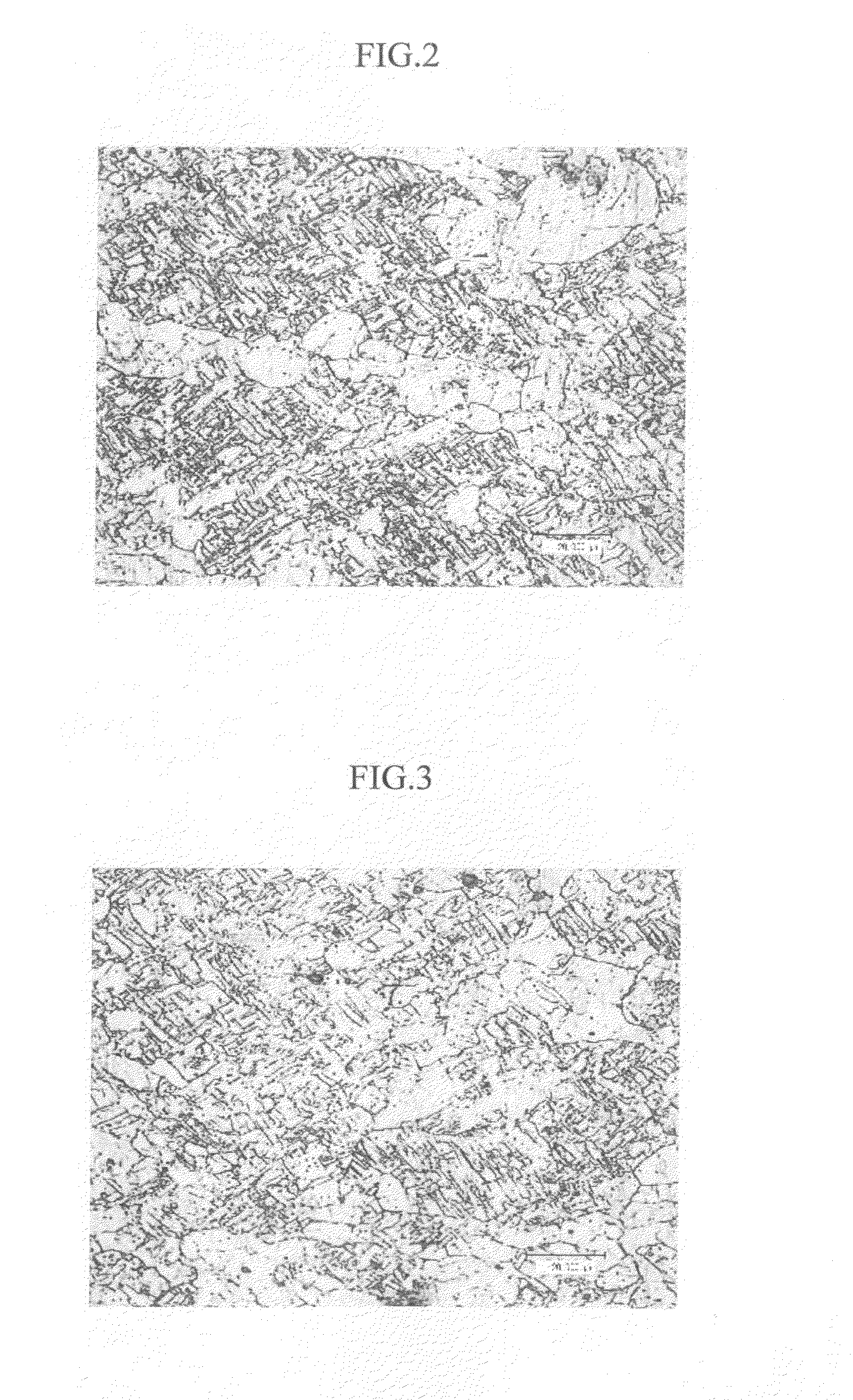

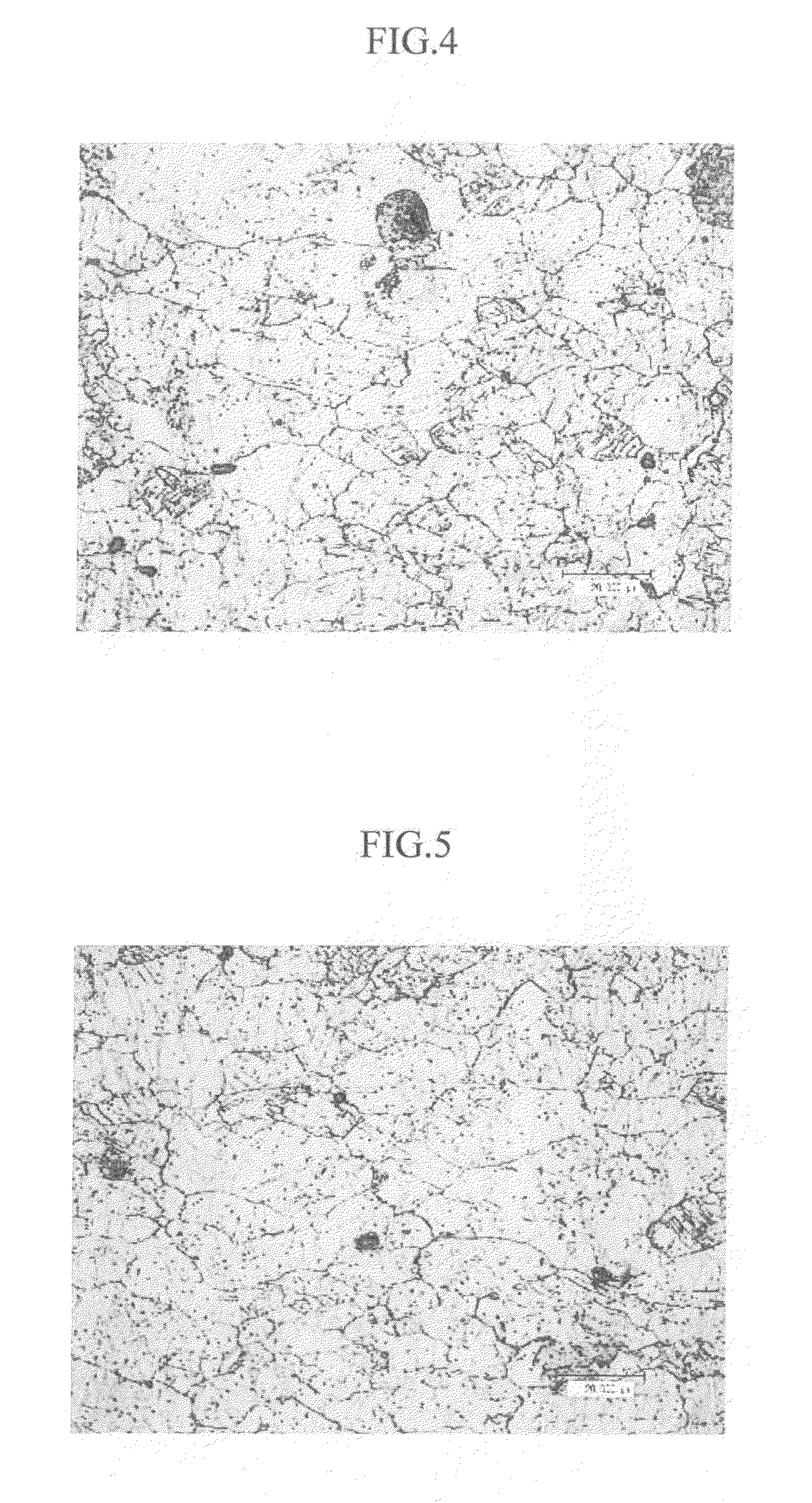

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

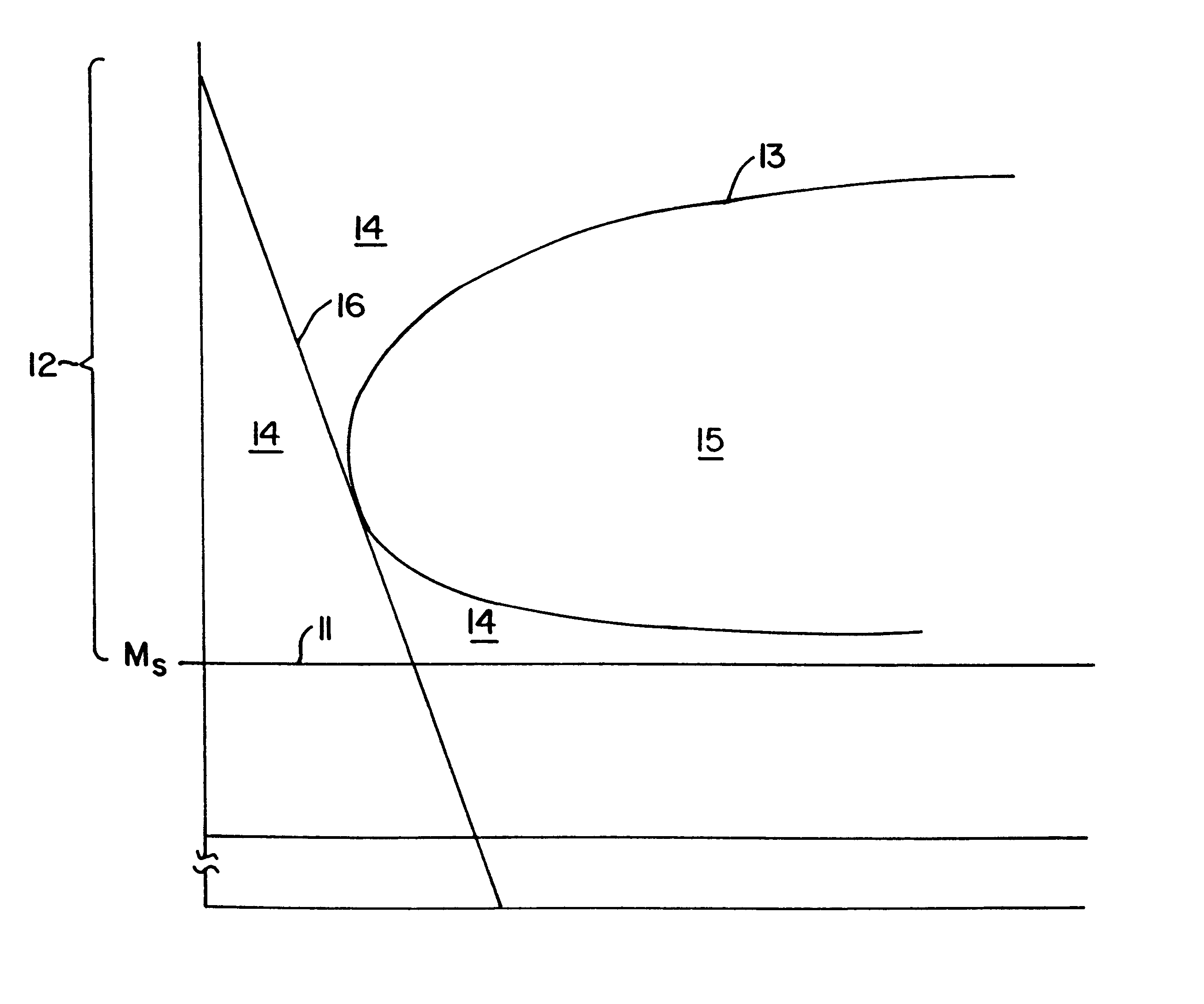

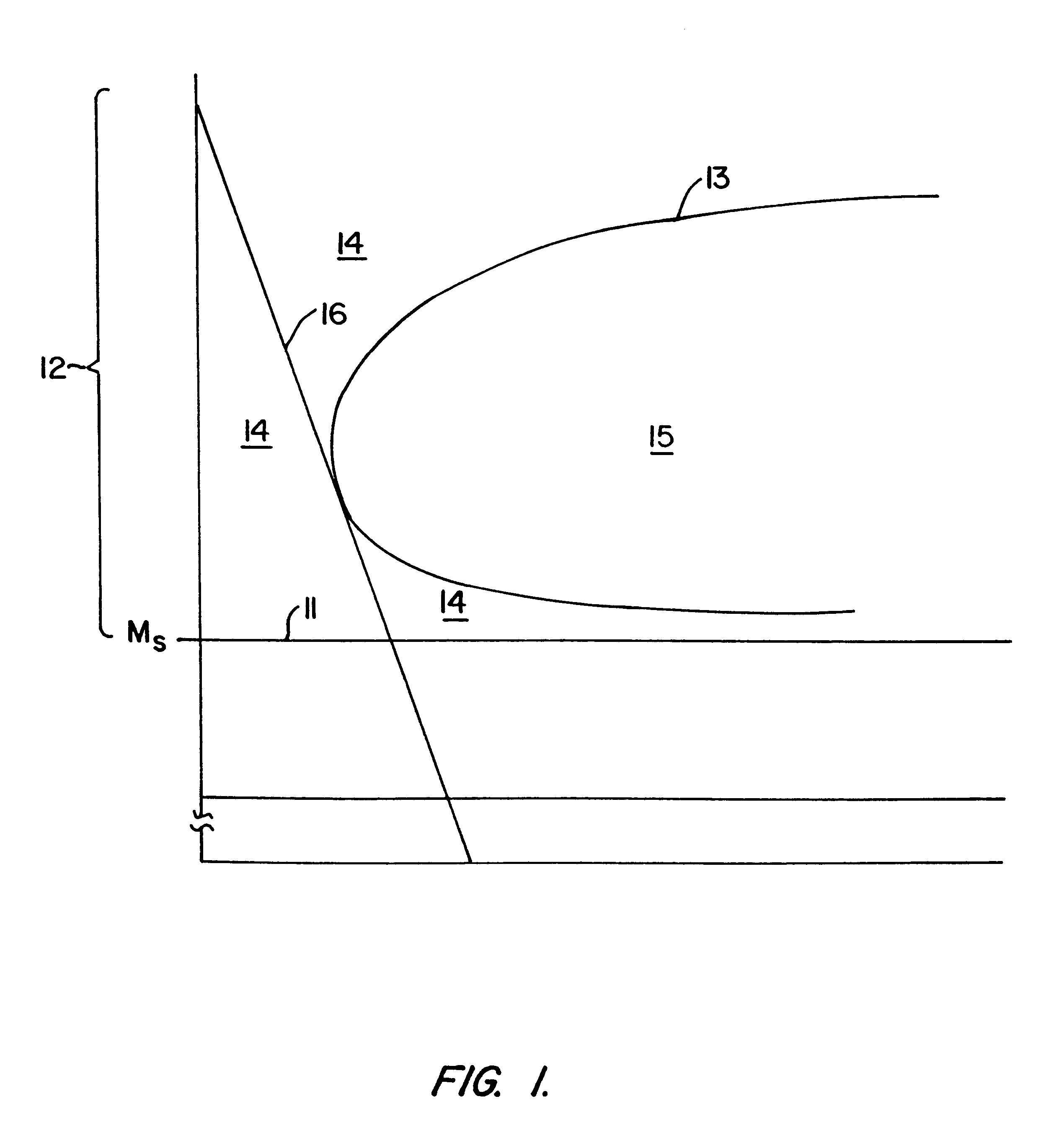

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

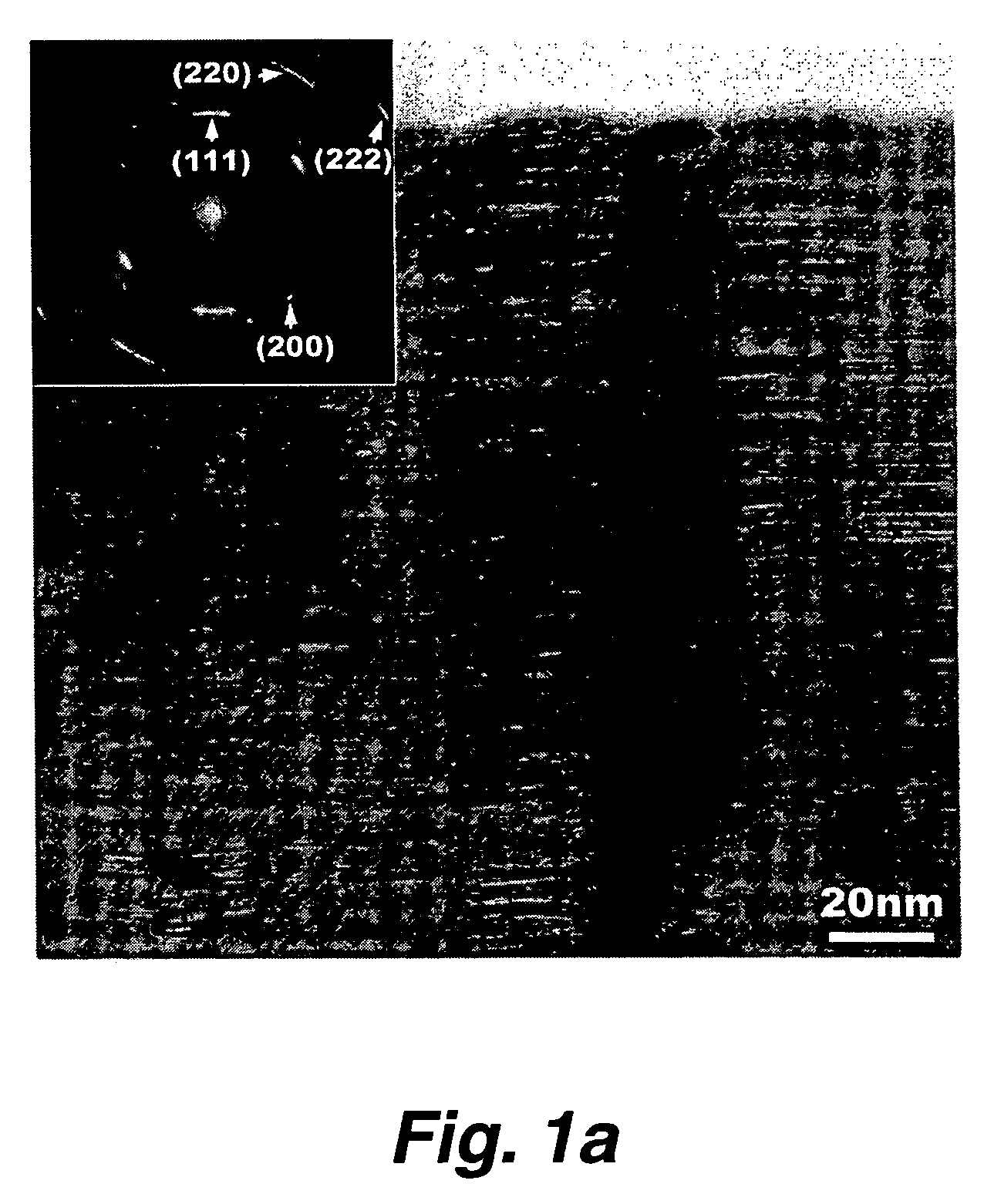

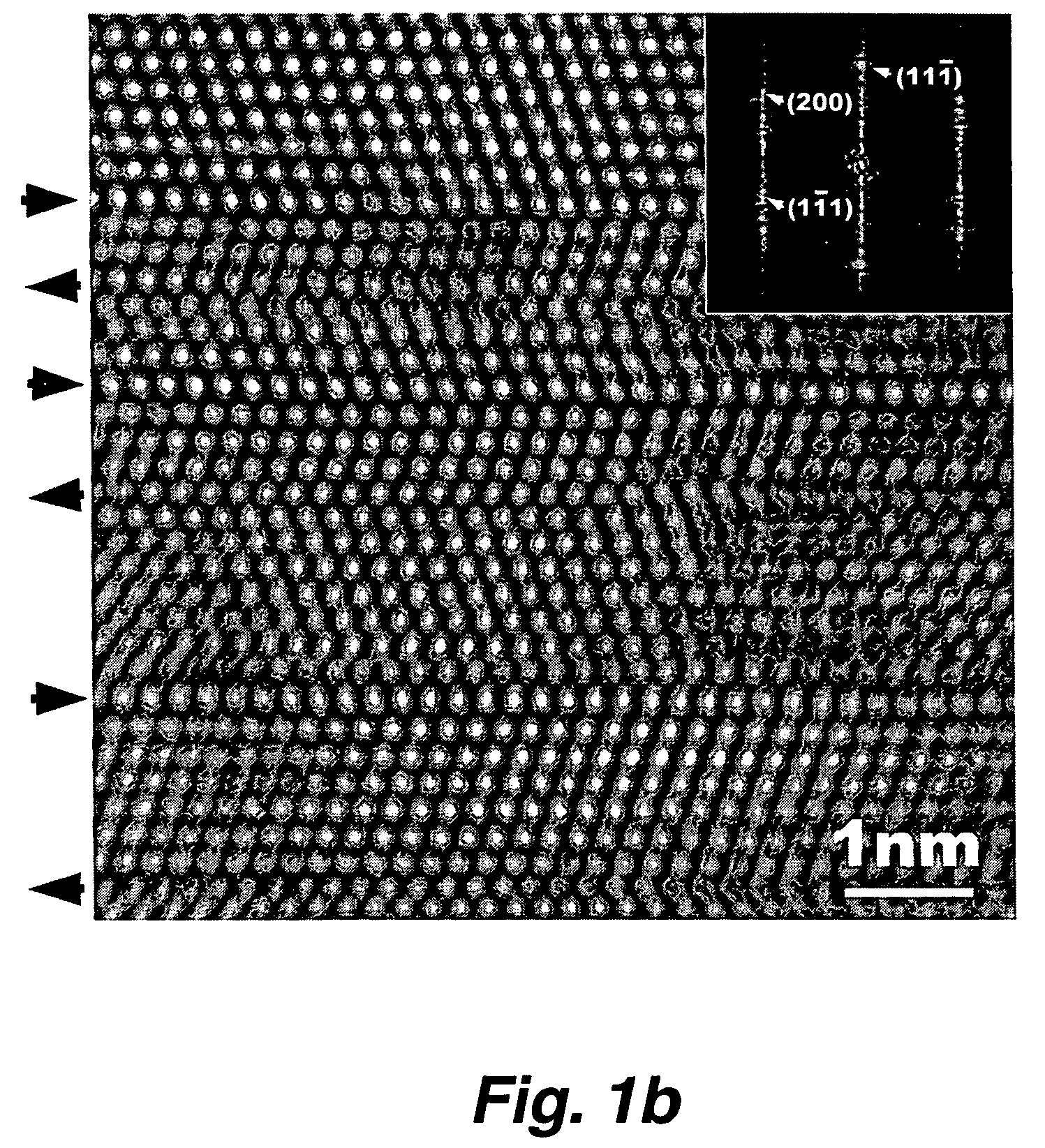

Preparation of high-strength nanometer scale twinned coating and foil

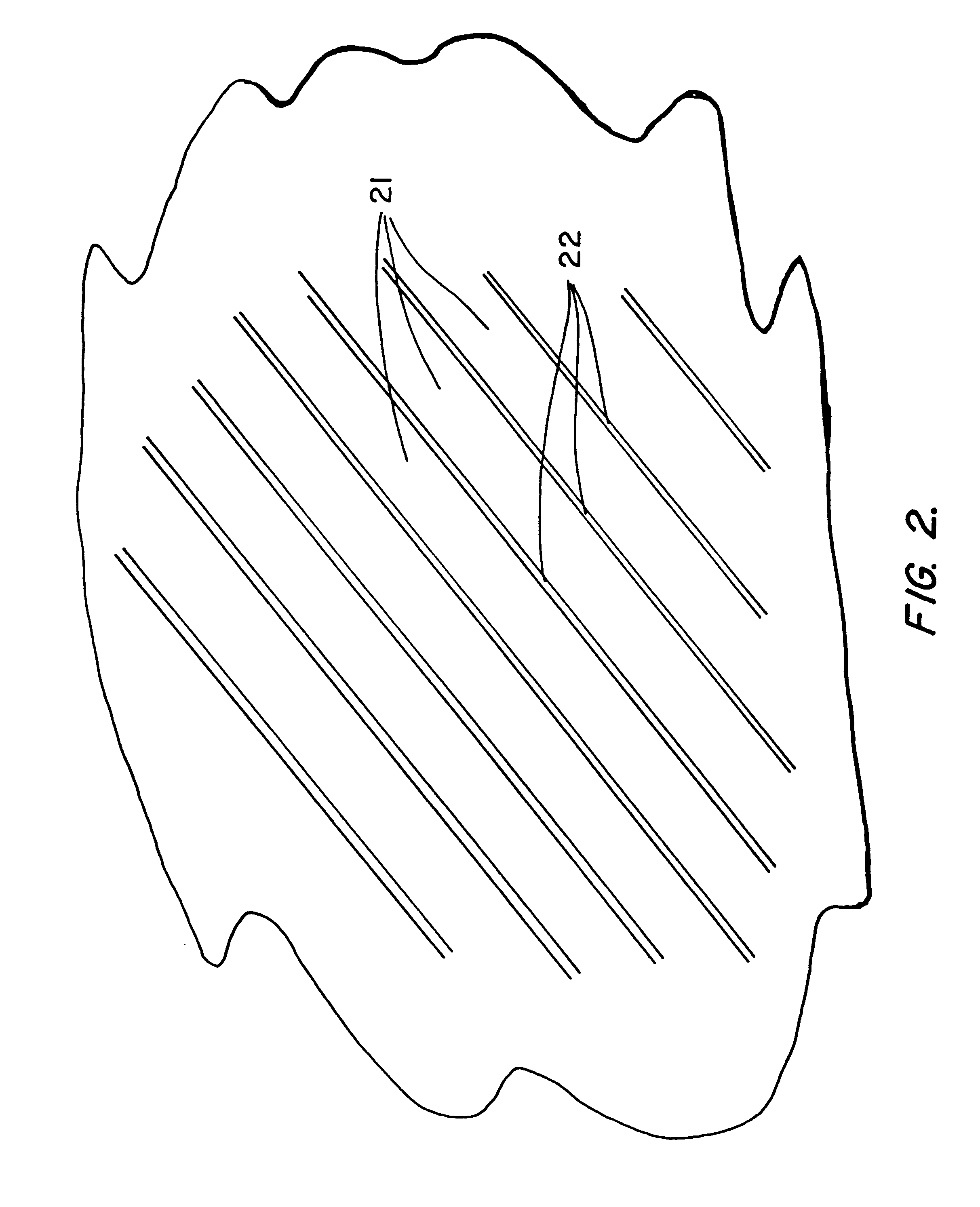

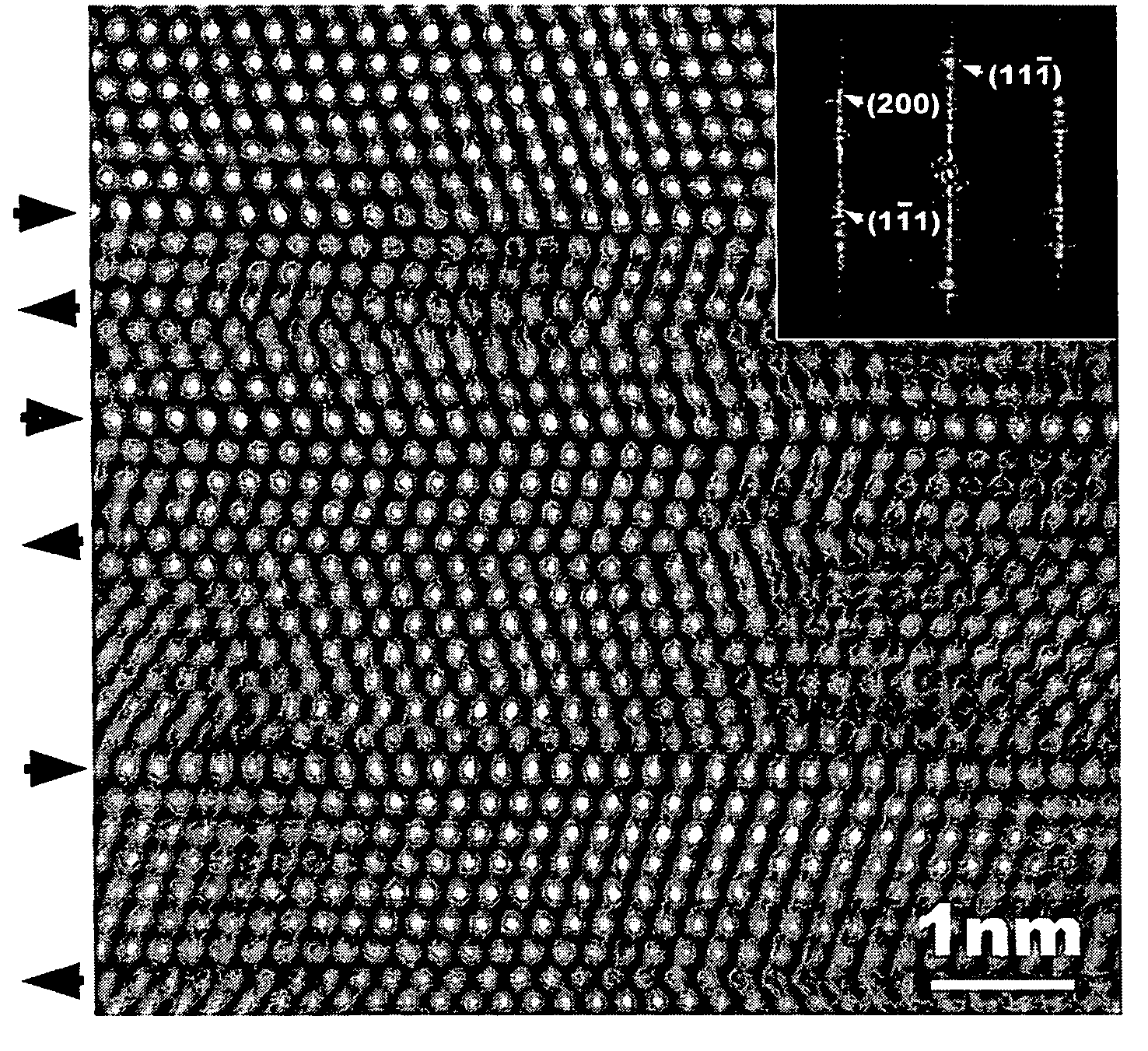

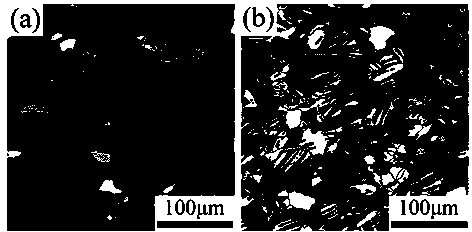

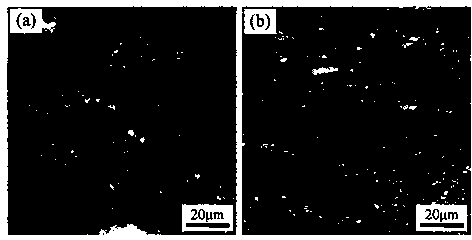

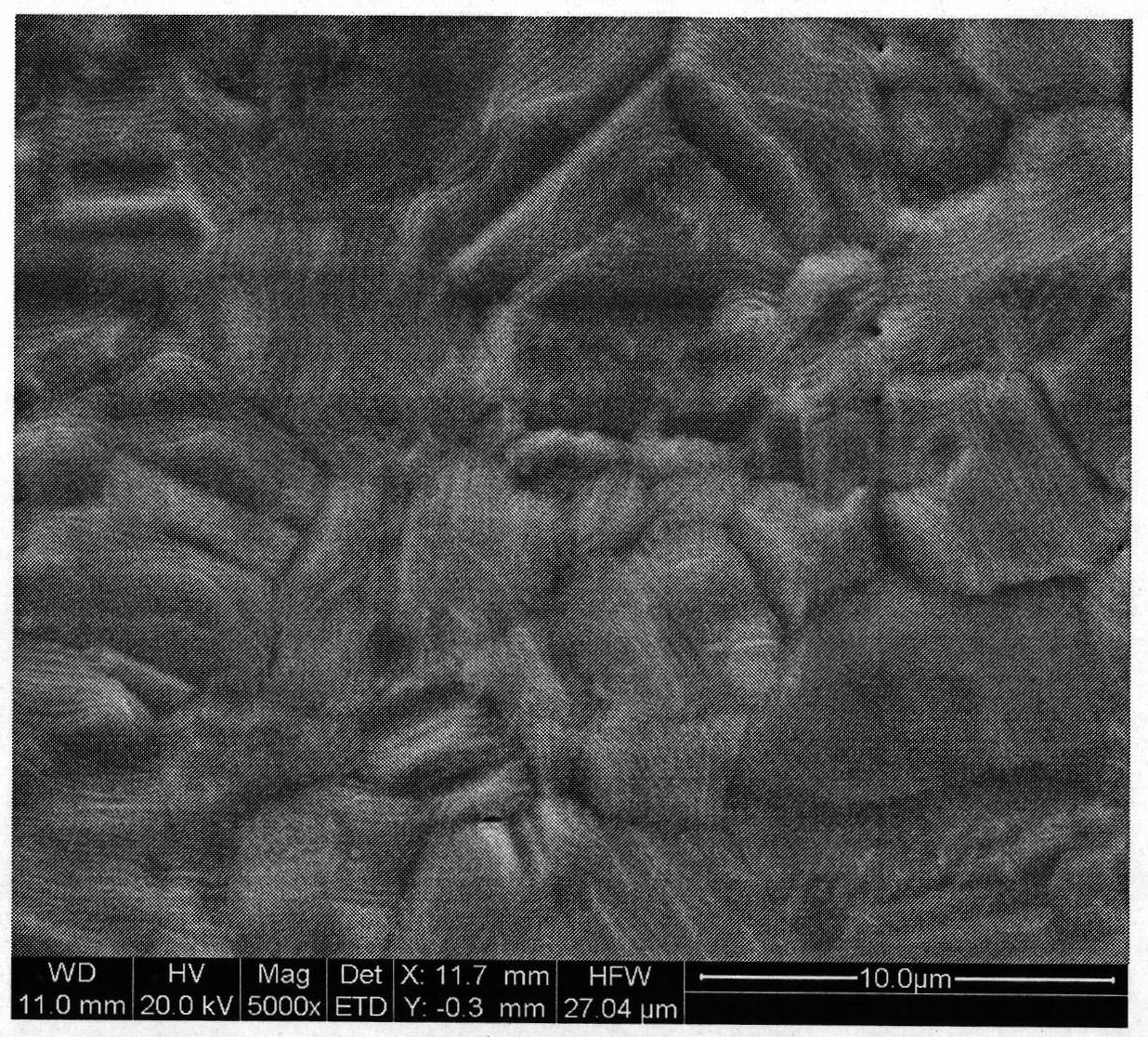

Very high strength single phase stainless steel coating has been prepared by magnetron sputtering onto a substrate. The coating has a unique microstructure of nanometer spaced twins that are parallel to each other and to the substrate surface. For cases where the coating and substrate do not bind strongly, the coating can be peeled off to provide foil.

Owner:LOS ALAMOS NATIONAL SECURITY

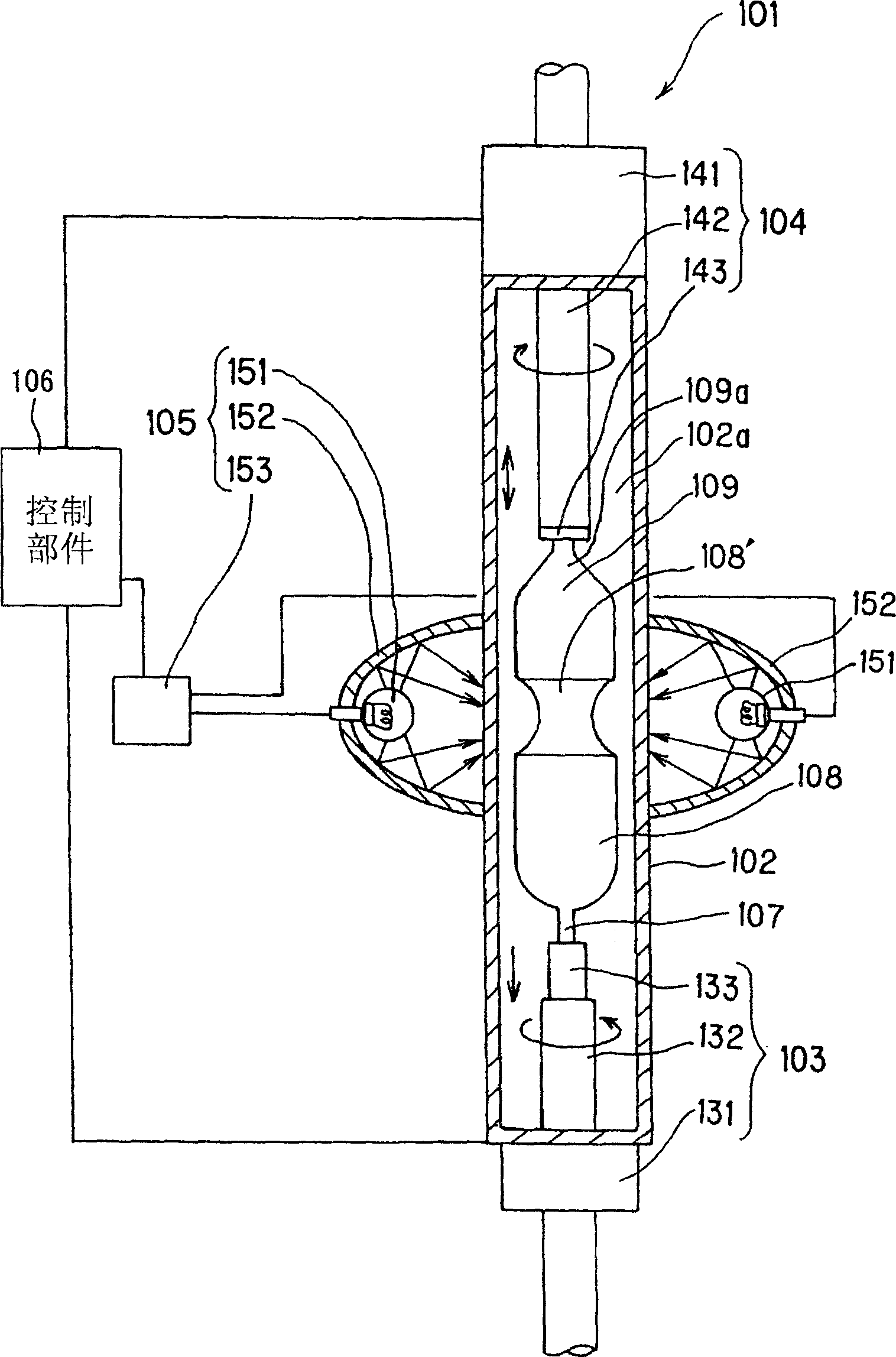

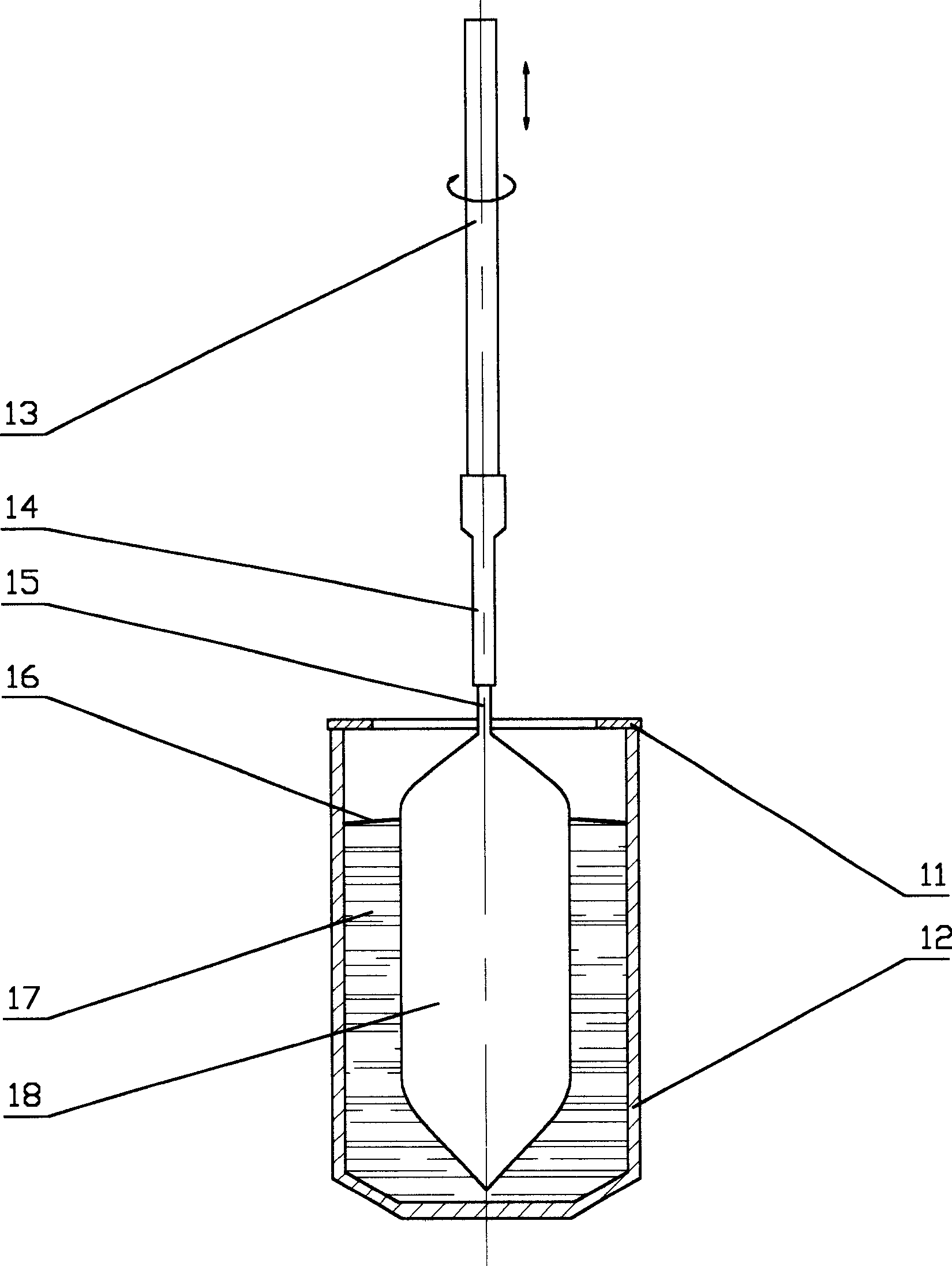

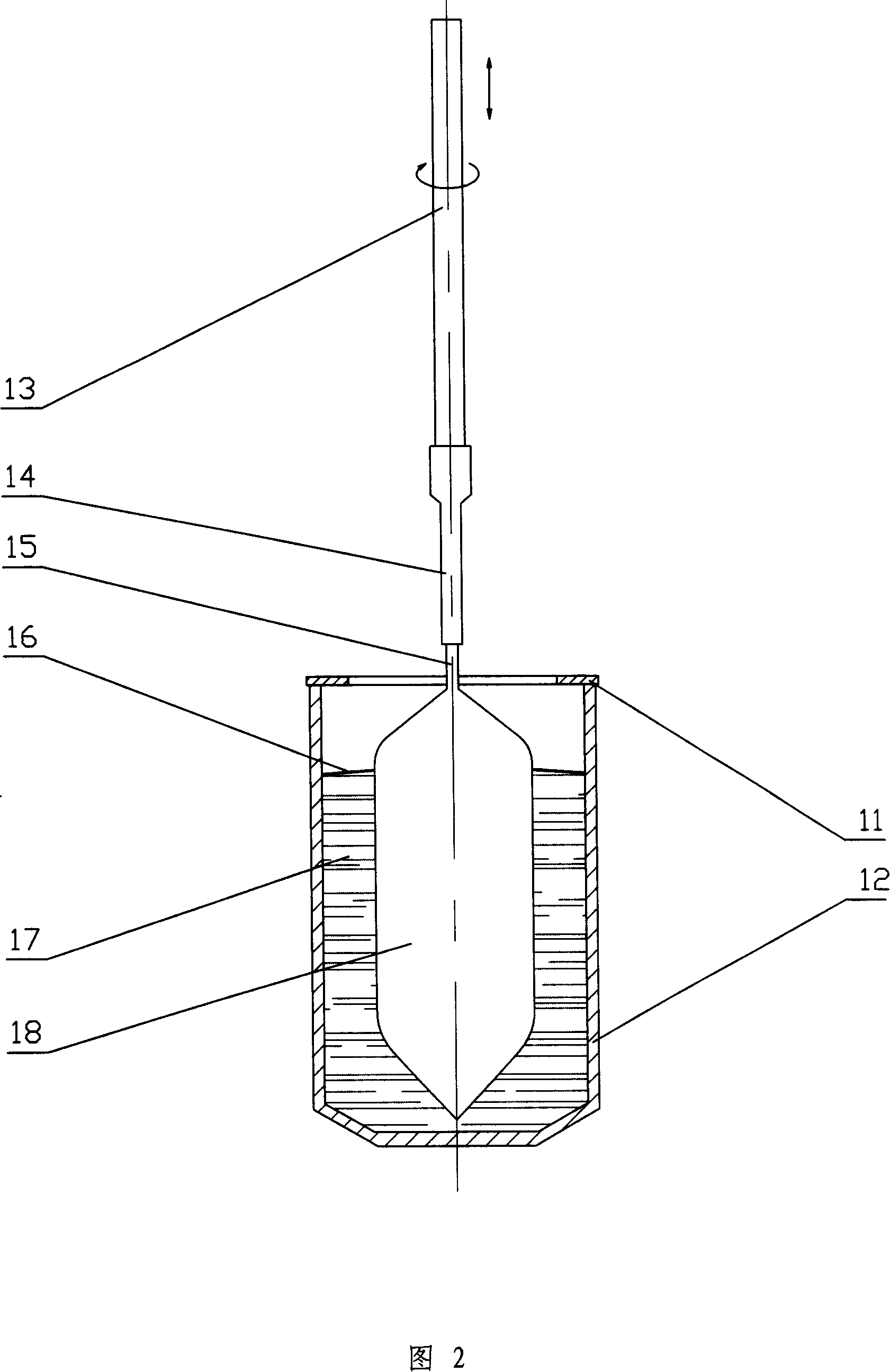

B-ga2o3 single crystal growing method, thin-film single crystal growing method, ga2o3 light-emitting device, and its manufacturing method

PROBLEM TO BE SOLVED: To provide a method for growing a β-f-based single crystal which is less prone to be cracked even when it is worked into a large size and high quality substrate or the like. ŽSOLUTION: The β-Ga<SB>2< / SB>O<SB>3< / SB>single crystal 8 is allowed to grow in one orientation selected from a-axis <100> orientation, b-axis <010> orientation, and the orientation inclined by 13.7°, determined crystallographically, from c-axis toward a-axis and having an angle of 90° with respect to a-axis by heating a seed crystal 7 and a polycrystalline base material 9 while rotating the crystal 7 and the base material 9 mutually in the opposite directions by using an infrared heating single crystal manufacturing device 1. Ž

Owner:WASEDA UNIV

Copper alloy sheet, manufacturing method of copper alloy sheet, and electric/electronic component

ActiveUS20110240180A1Excellent bending workabilityImprove conductivityConductive materialCrystal twinningCrystal orientation

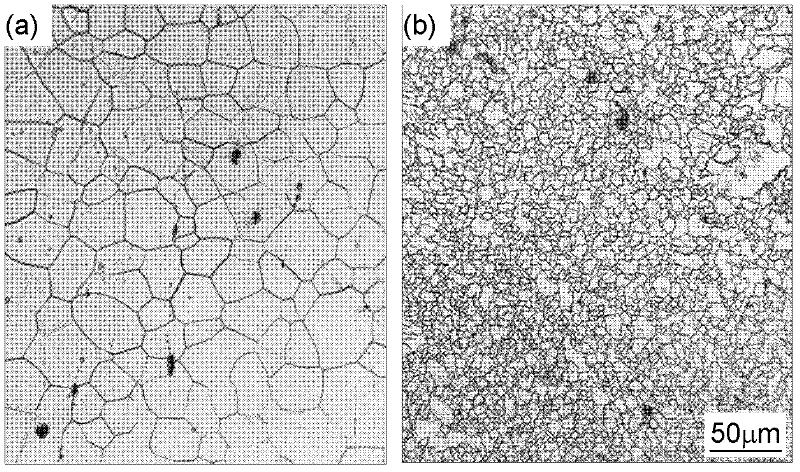

There is provided a copper alloy sheet including 1.0 to 3.5 mass % Ni, 0.5 to 2.0 mass % Co, and 0.3 to 1.5 mass % Si, a Co / Ni mass ratio being 0.15 to 1.5, an (Ni+Co) / Si mass ratio being 4 to 7, and a balance being composed of Cu and an unavoidable impurity, wherein in observation results of a crystal grain boundary property and crystal orientation by EBSP measurement, a density of twin boundaries among all crystal grain boundaries is 40% or more and an area ratio of crystal grains with Cube orientation is 20% or more, on a rolled surface.

Owner:DOWA METALTECH CO LTD

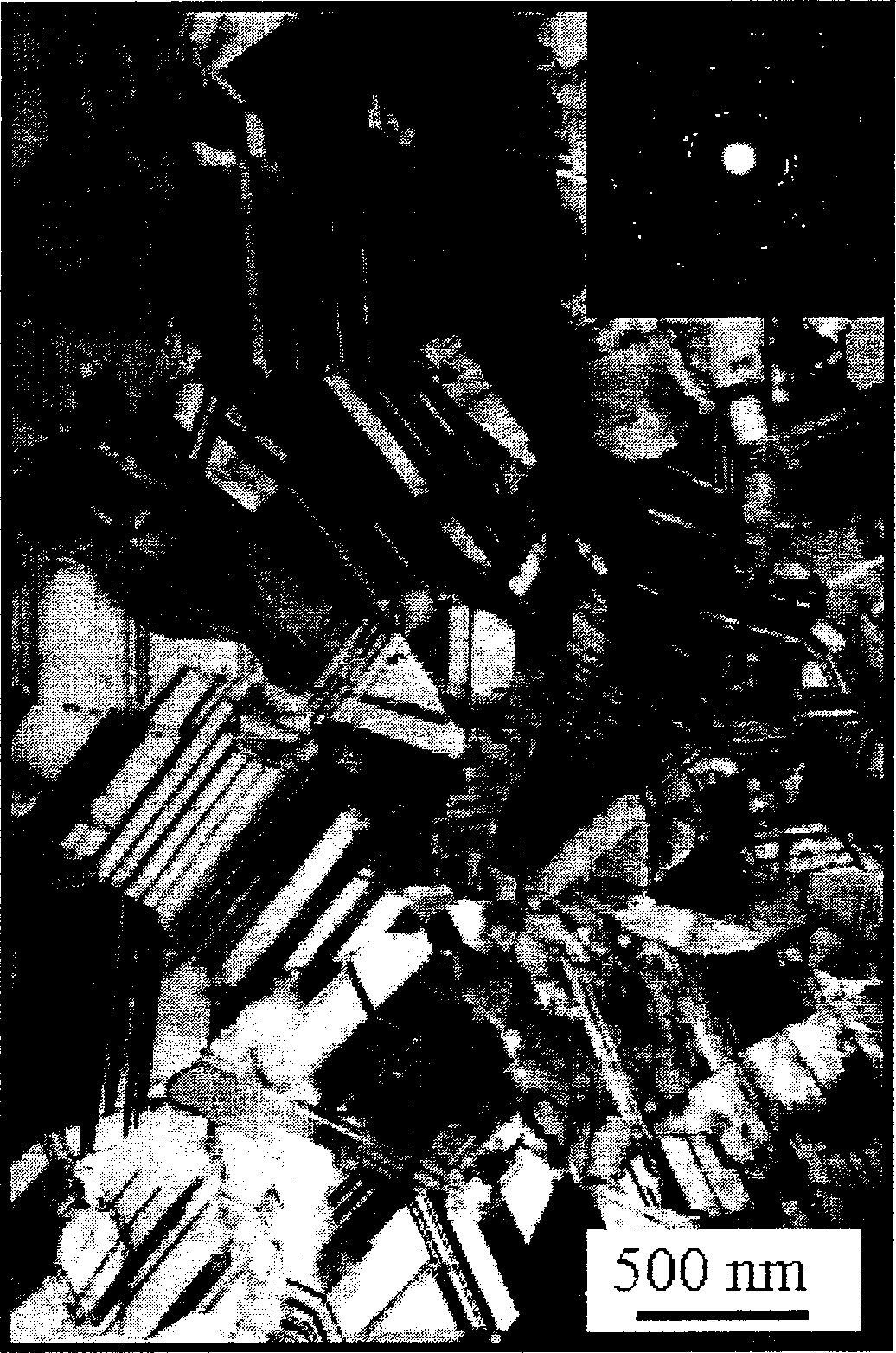

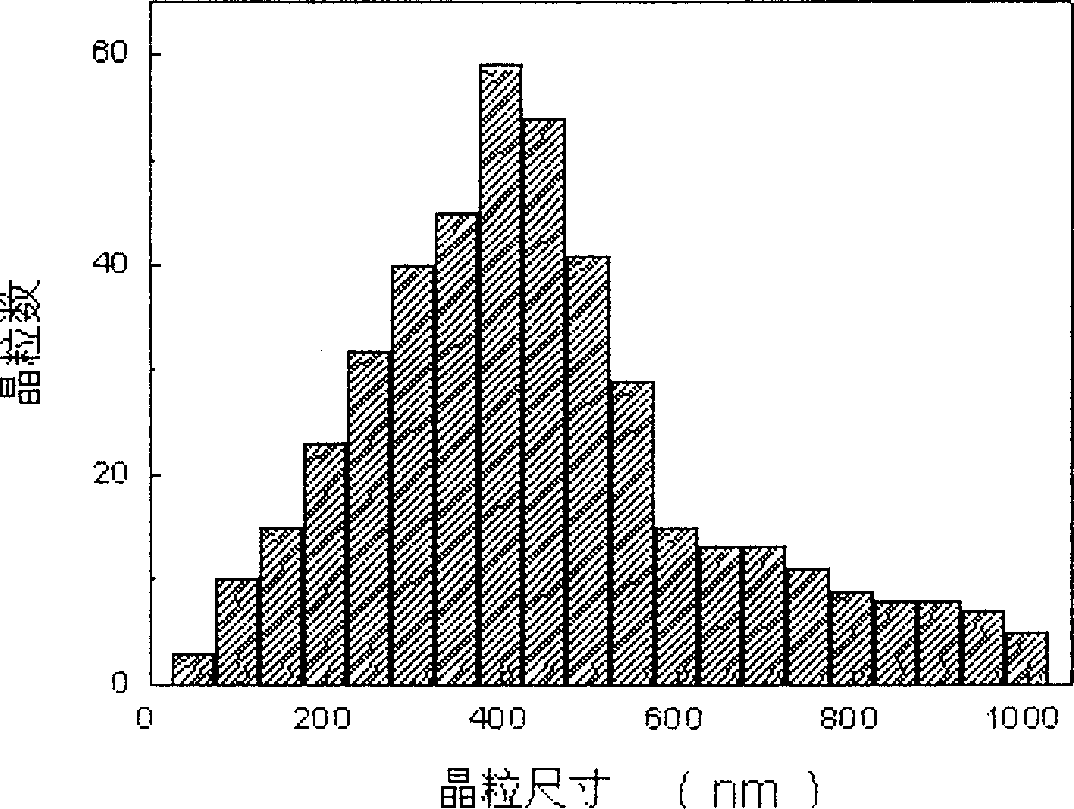

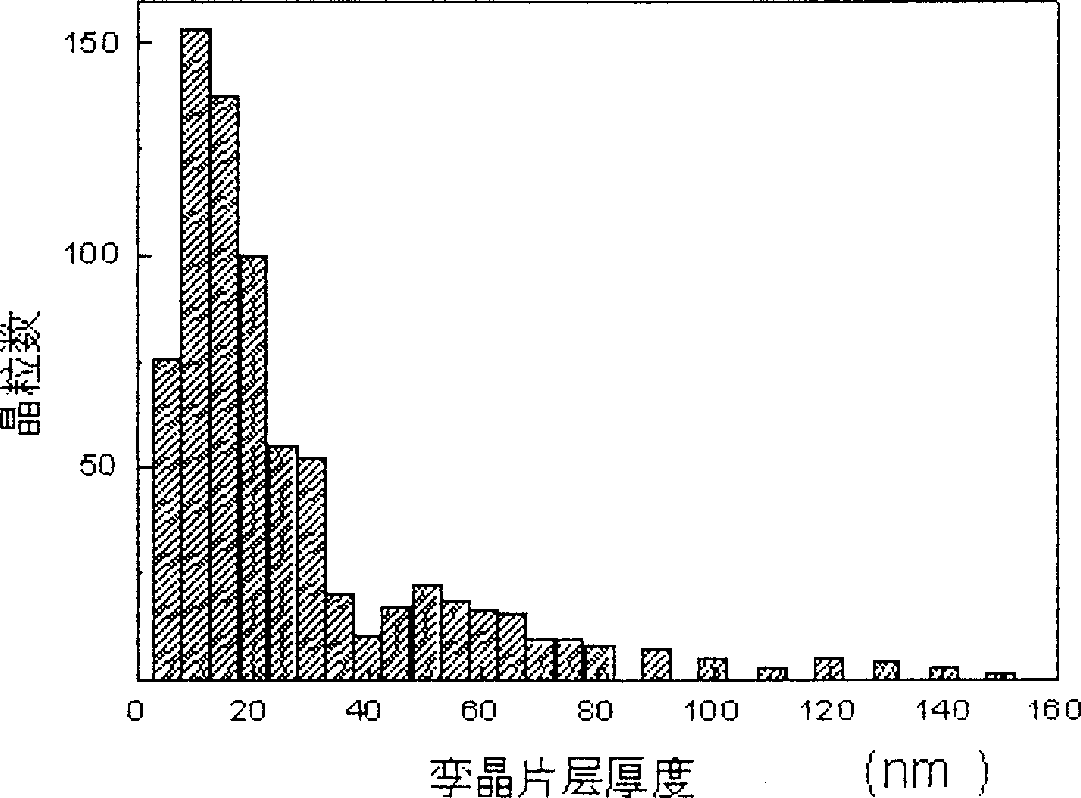

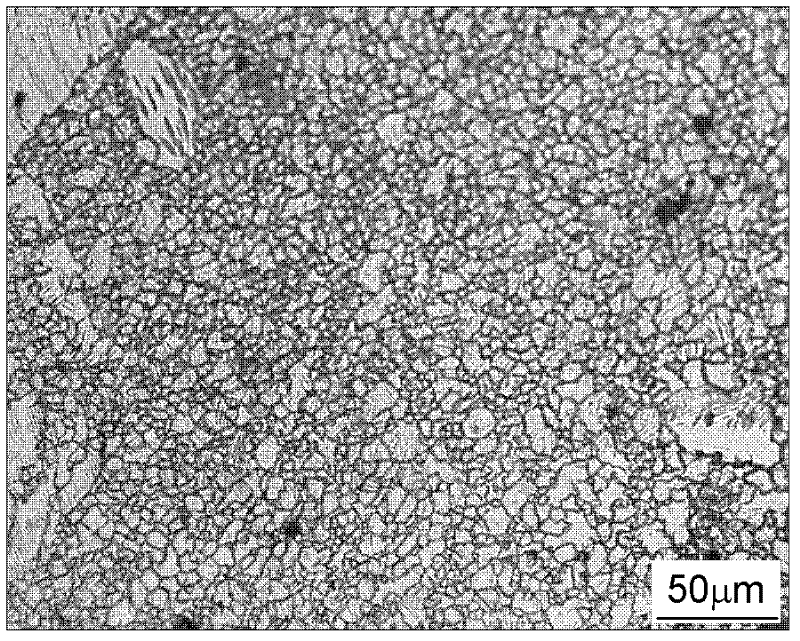

Nano twin crystal copper material with ultrahigh strength and superhigh conductivity as well as preparation method

ActiveCN1498987AImprove propertiesUnique microstructurePhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceCrystal twinning

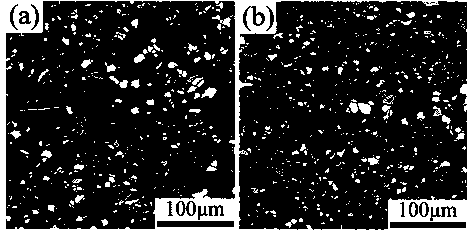

A nano-class twin-crystal copper material with ultrahigh strength and ultrahigh electric conductivity is prepared by electrolytic deposition technique. The resultant high-purity polycrystal copper material features that its microstructure is composed of nearly equiaxed submicron (300-1000 nm) crystals, and in the crystal there are high-density parallel twin crystal layers with different orientations. Its advantages are high yield strength up to 900 MPa and break strength up to 1086 MPa, and high electric conductivity (1.75+ / - 0.02 X to the power -8 ohm.m).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

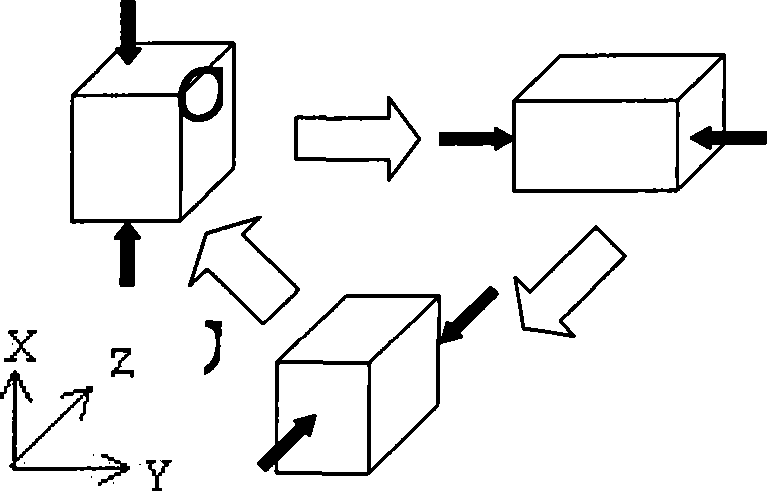

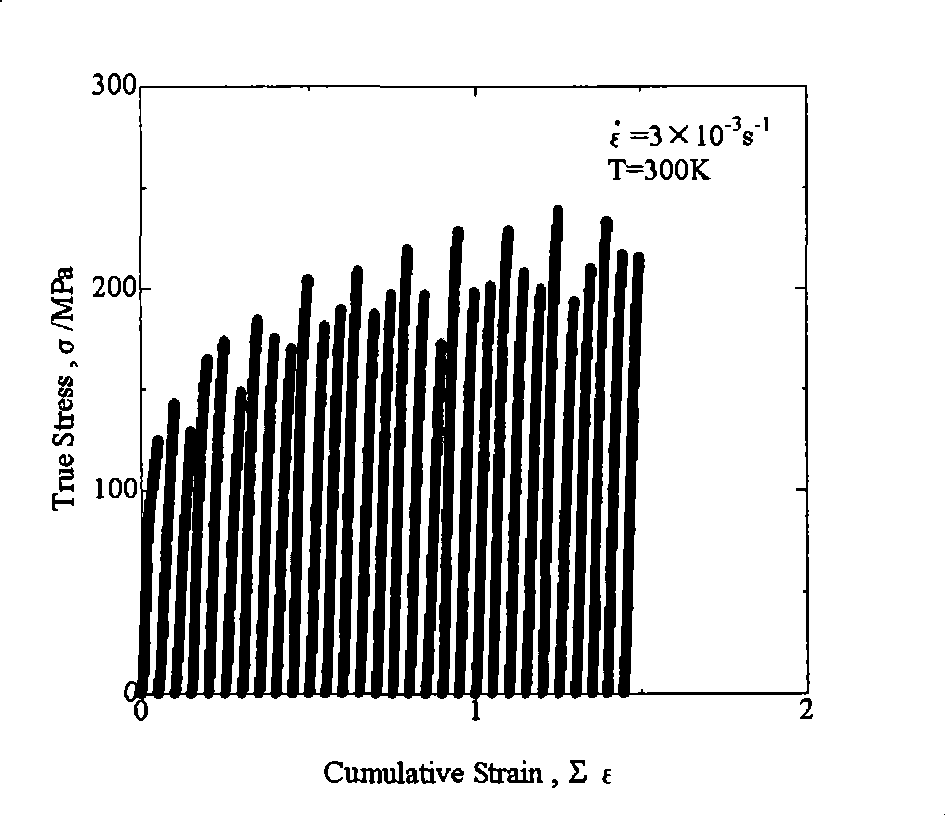

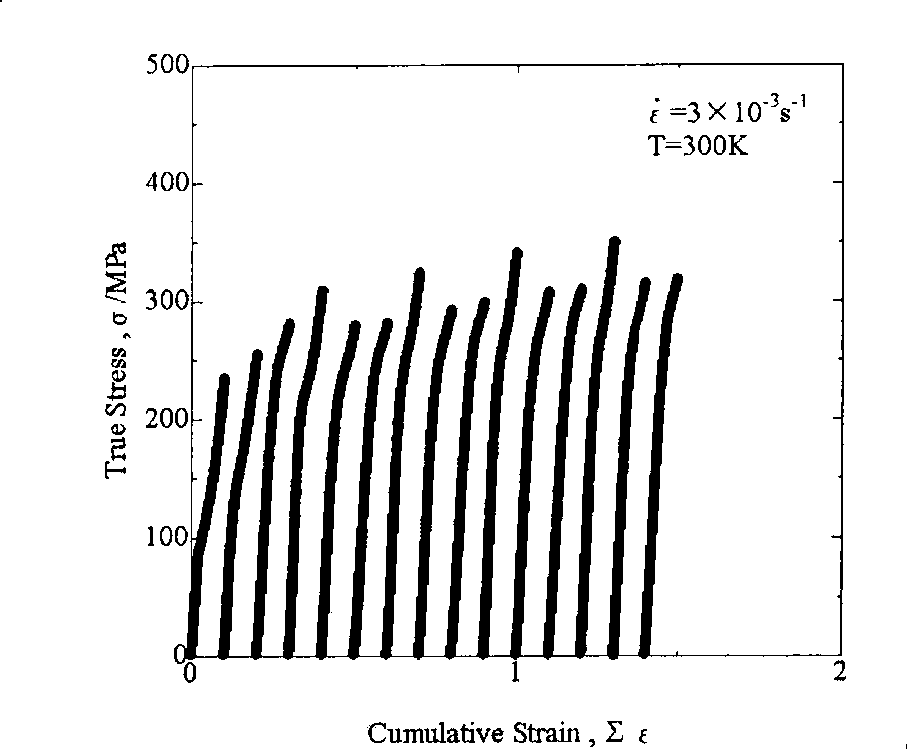

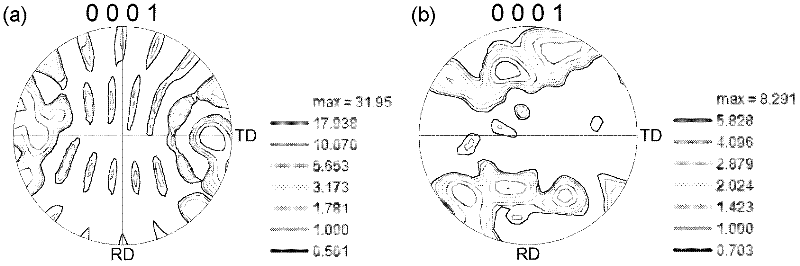

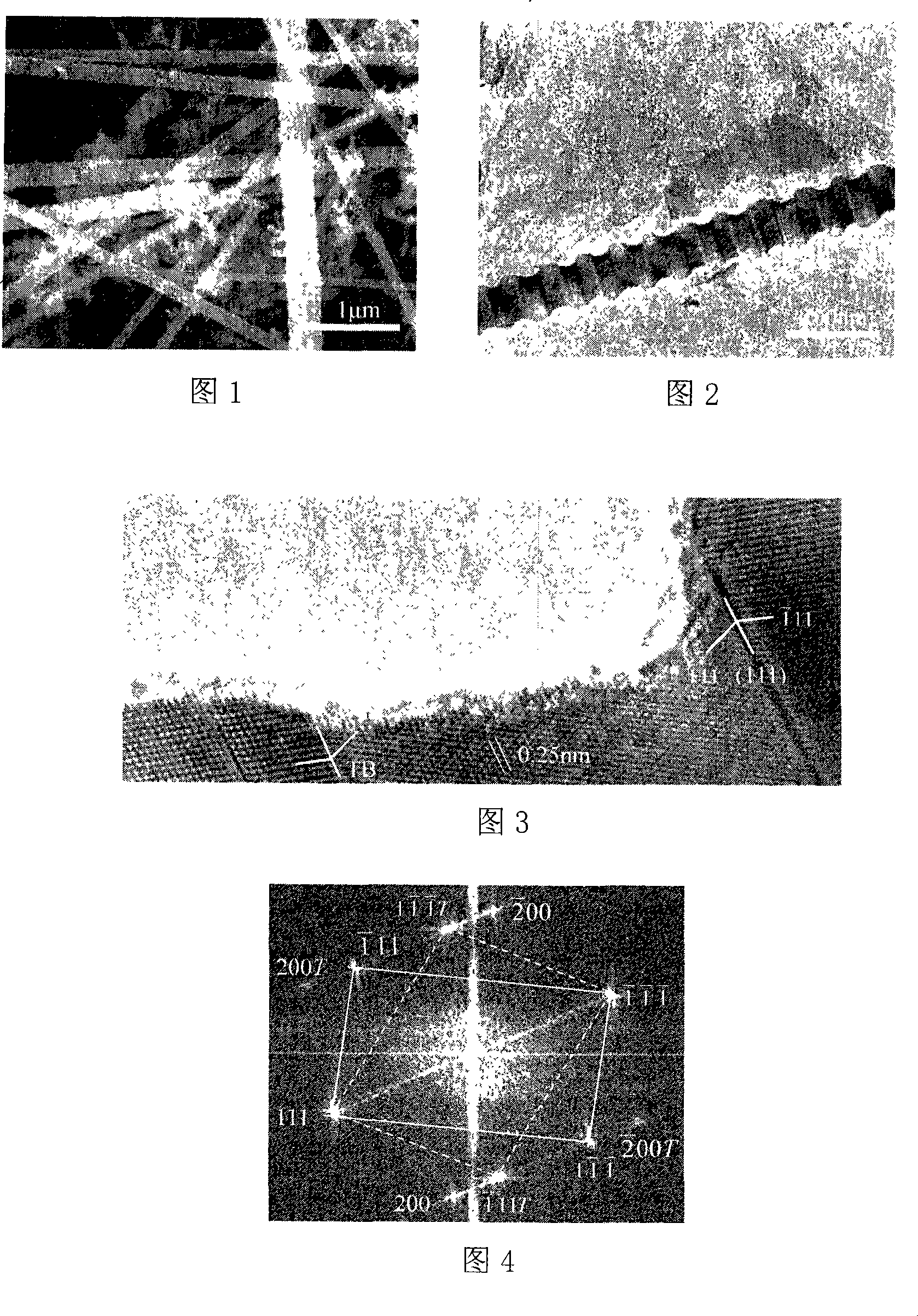

Method for preparing bulk nano/superfine crystal grain magnesium alloy by twinning deformation

A method for preparing block nano-magnesium alloy by utilizing twinning deformation comprises: magnesium alloy cast ingots or extruded bars are cut into rectangular blocks; compression twin crystal deformation with multiple channels and axes is respectively carried out along three direction of X axis, Y axis and Z axis of the rectangular block at the room temperature; the true strain capacity and the strain rate at every channel are controlled; when the true strain capacities along all the directions are accumulated to reach at least 1.5h, the twin crystal reinforced block nano-magnesium alloy having the average size being less than 0.5mum can be obtained. The method has simple processing technique and equipment requirements as well as convenient operation, and can overcome the problems of incontrollable recrystallization, poor effect of strain accumulation and difficult scale in severe plastic deformation of the prior art when in thinning magnesium alloy crystal grains; the method can be used for preparing large dense superfine grained magnesium alloy material and has good industrial application prospect.

Owner:CENT SOUTH UNIV

Biomedical Mg-Sn-Zn-Mn magnesium alloy and preparation method thereof

The invention provides a biomedical Mg-Sn-Zn-Mn magnesium alloy and a preparation method thereof. The preparation method comprises the following steps: (1) smelting and casting pure magnesium ingots, pure tin ingots, pure zinc ingots and an Mg-Mn intermediate alloy under the protection of a fusing agent to prepare Mg-Sn-Zn-Mn magnesium alloy ingots; (2) keeping the temperature of the Mg-Sn-Zn-Mn magnesium alloy ingots at 300-400 DEG C for 3-5 hours, and extruding or rolling for predeformation; and (3) performing solution heat treatment to the predeformed Mg-Sn-Zn-Mn magnesium alloy at 400-450 DEG C for 12-28 hours, and performing water quenching, furnace cooling or air cooling to the room temperature. The microstructural characteristic of the prepared alloy is that single phase-Mg grains contain a lot of tiny growth twins; and owning to the presences of the growth twins in the grains, the obdurability of the alloy is effectively increased, the tensile strength is up to 195-238MPa, the elongation rate is up to 23-30% and the hemolysis rate is up to 4.68-7.58%. Therefore, the alloy has the advantages of no toxicity, complete degradability and high obdurability, and can be used as orthopedic internal fixation and implantation materials such as intravascular stents, bone screws and bone plates.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

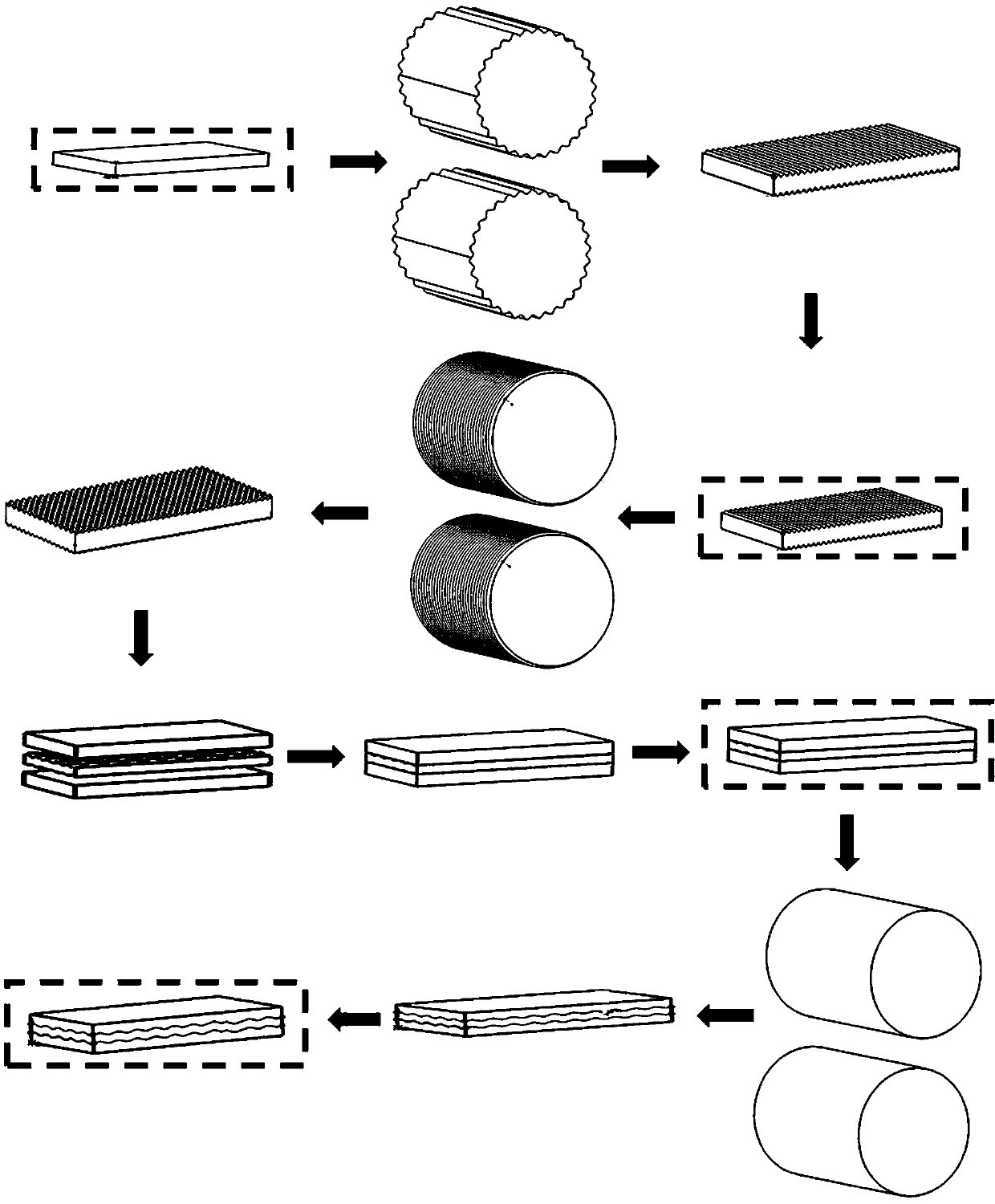

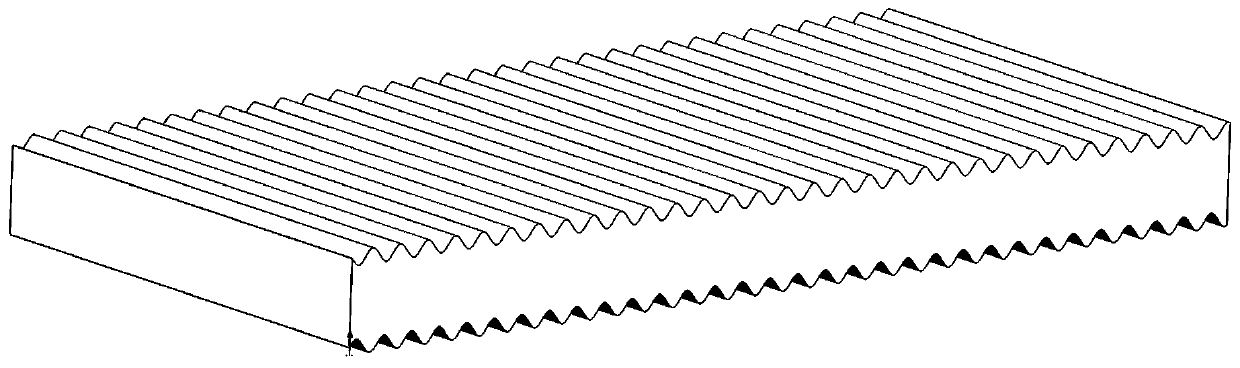

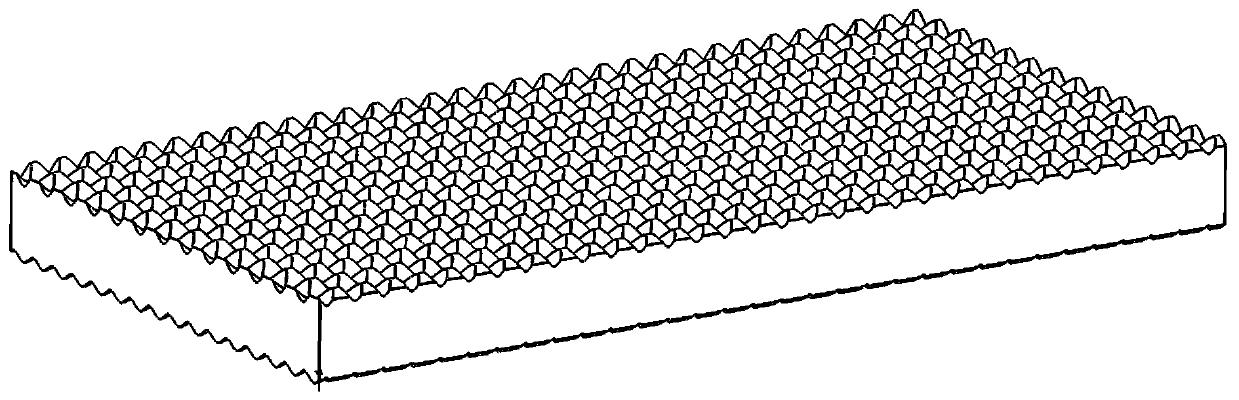

Method for preparing aluminum-magnesium-aluminum three-layer metal composite plate by prefabricating crossed corrugated interface

InactiveCN110548776AUniform mechanical propertiesEasy to slideMetal rolling arrangementsCrystal twinningComposite plate

The invention relates to the technical field of rolling of metal composite plates, specifically relates to a method for preparing an aluminum-magnesium-aluminum three-layer metal composite plate by prefabricating a crossed corrugated interface, and aims to solve the technical problems of low composite plate bonding strength and serious texture of a magnesium plate basal plane in a conventional method for preparing the aluminum-magnesium-aluminum three-layer metal plate. According to the technical scheme, the method comprises the following steps: rolling a magnesium plate into a double-faced crossed corrugated shape; then covering two layers of aluminum plates on the upper surface and the lower surface of the magnesium plate; flatly rolling the three layers of plates together; and processing to obtain the three-layer metal composite plate with the upper surface and the lower surface being planes and the middle bonding surface being crossed corrugated. With the adoption of the method, the basal plane texture of a magnesium plate can be effectively weakened, and the bonding strength can be improved. Magnesium with uniform mechanical property can be obtained when the texture strength is obviously reduced, and because a weak and dispersed basal plane texture is obtained, basal plane slippage and twin crystal formation are facilitated during stretching, so that the forming property of the plate is improved.

Owner:TAIYUAN UNIV OF TECH

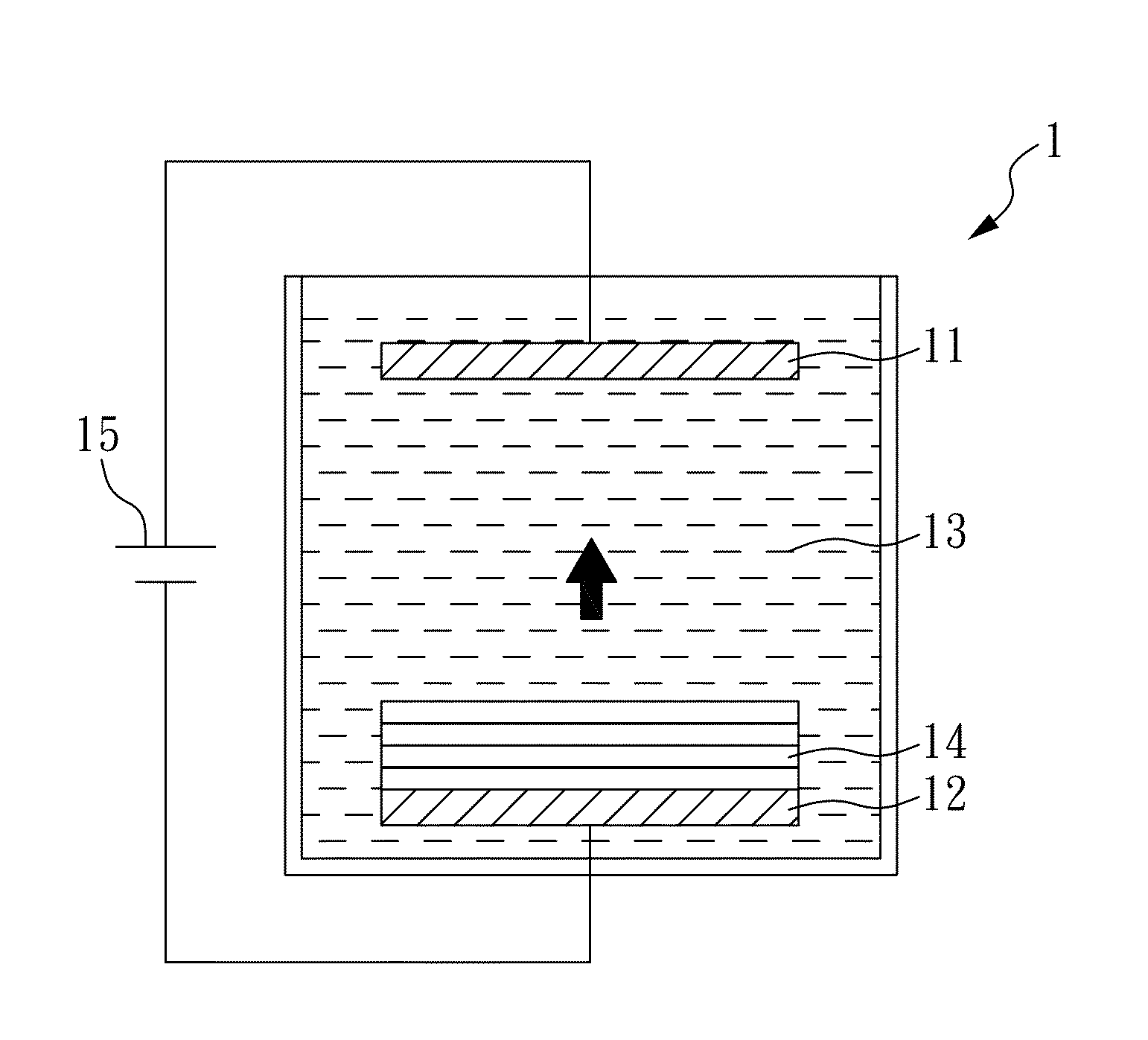

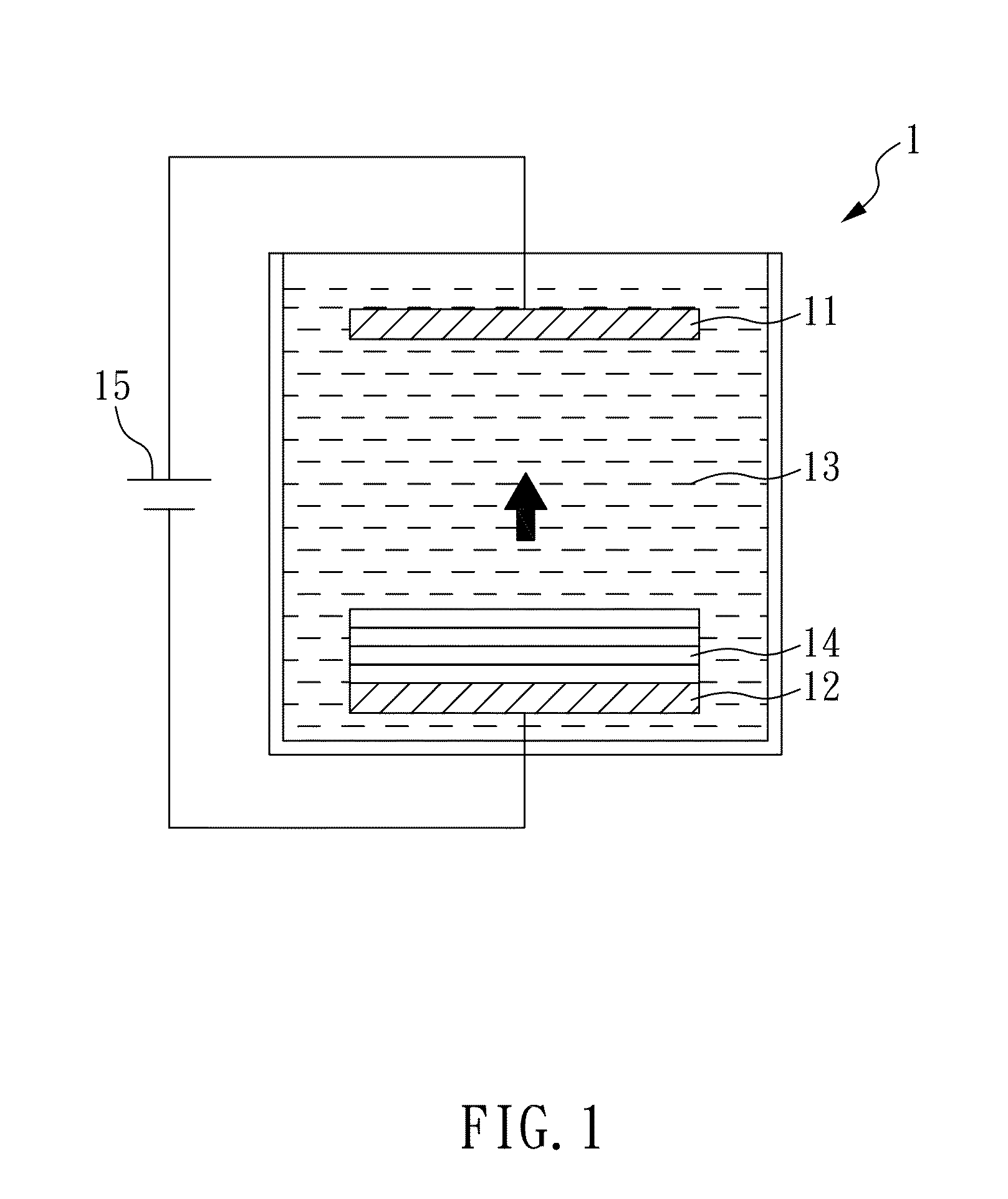

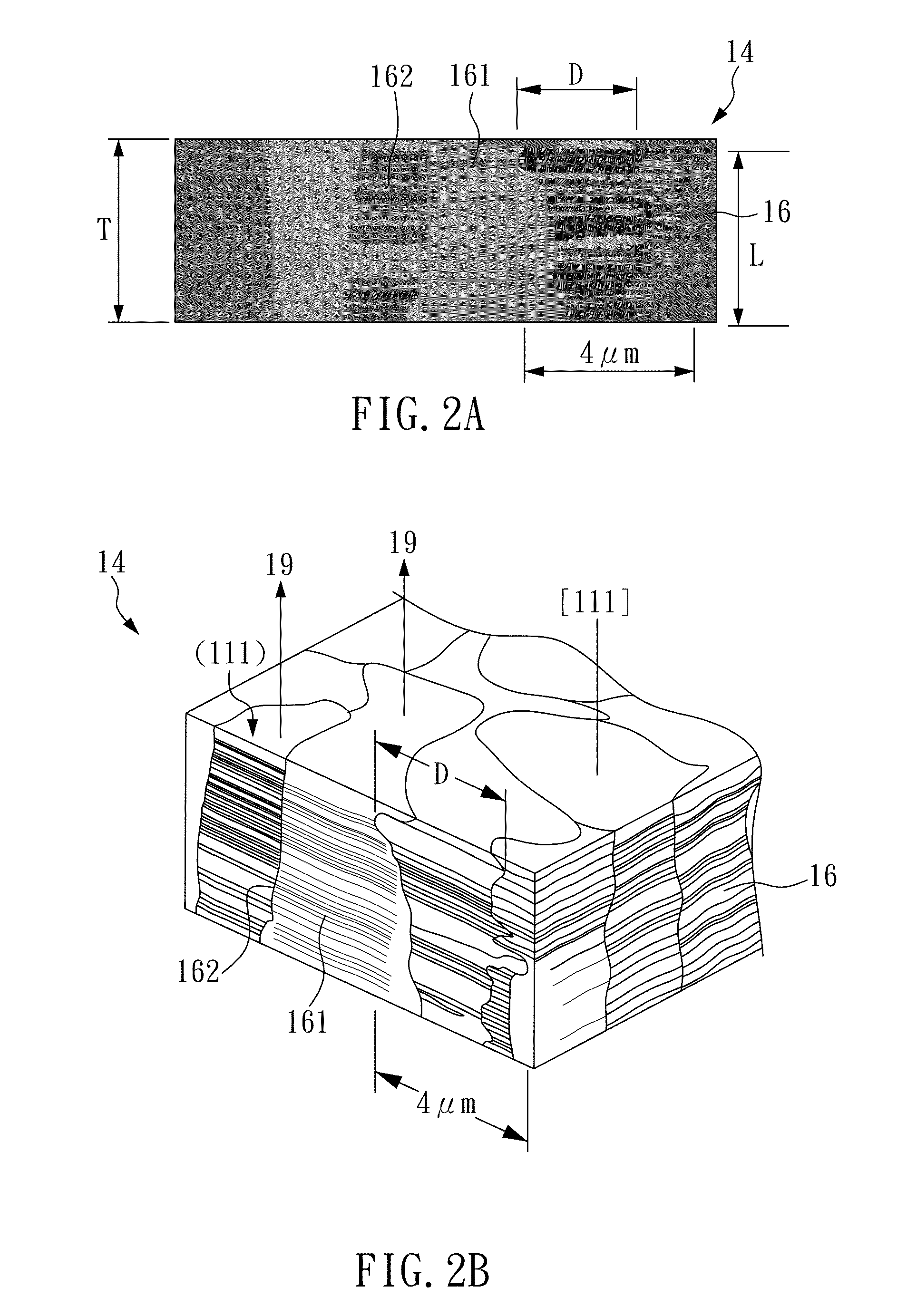

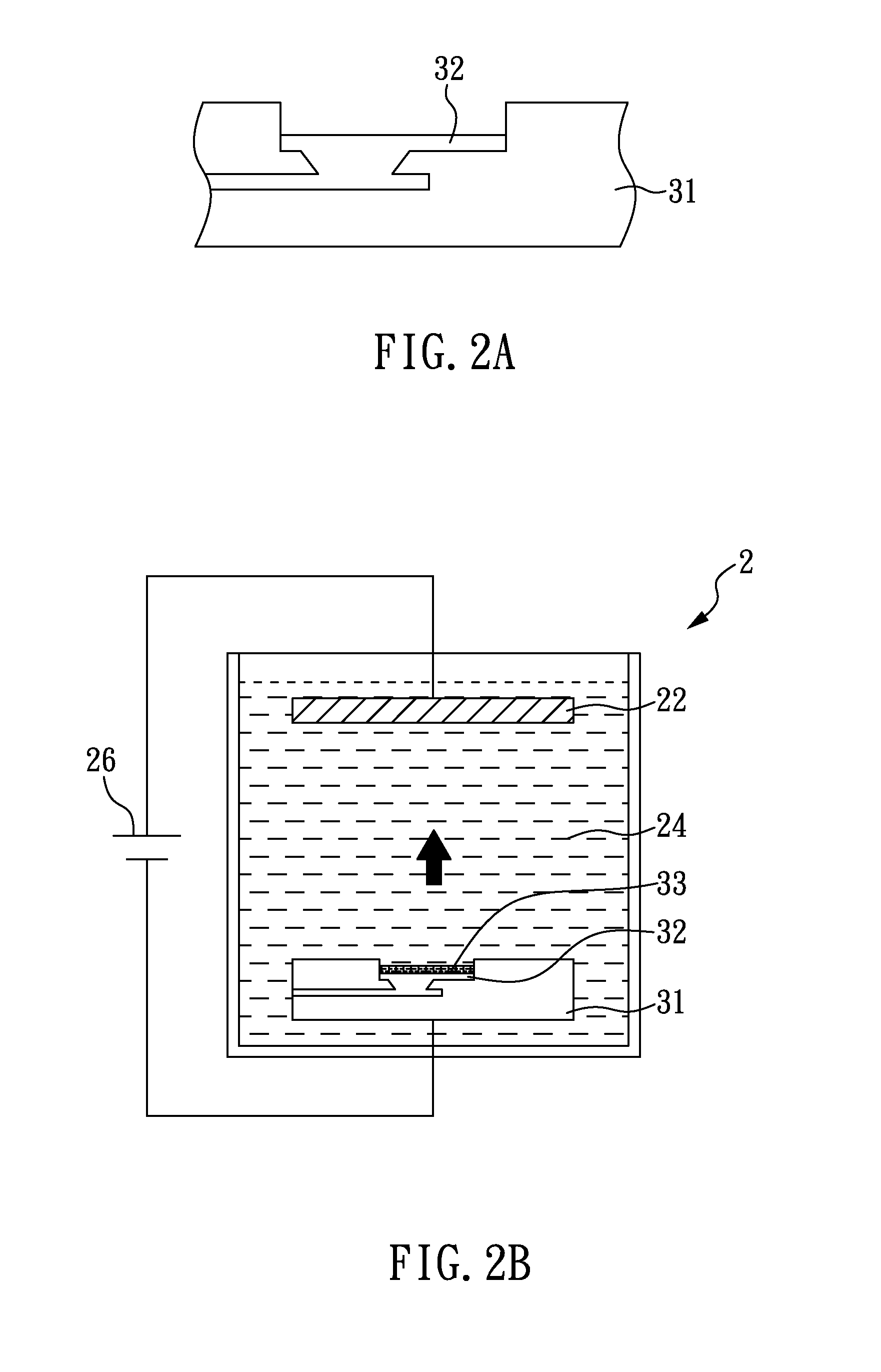

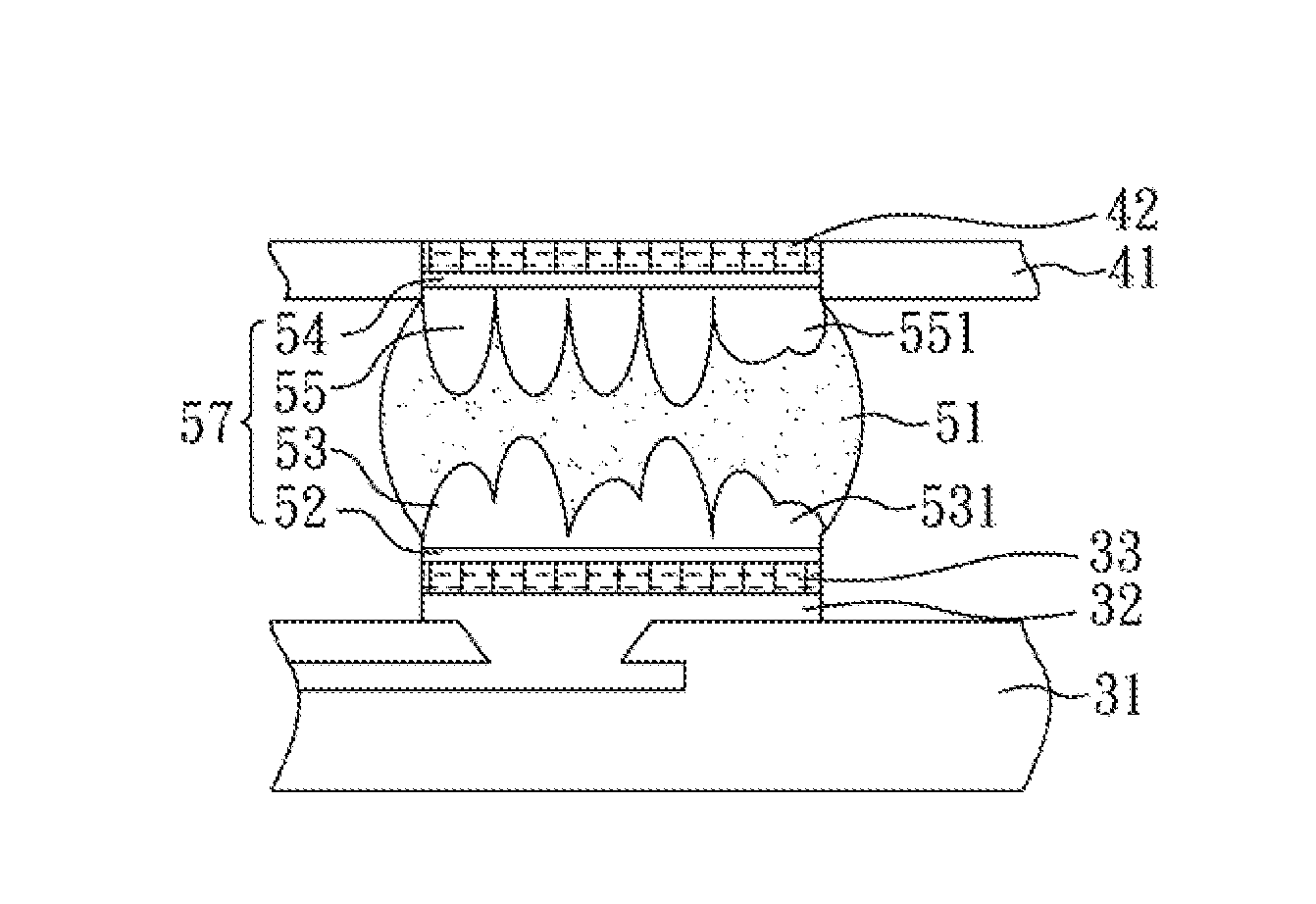

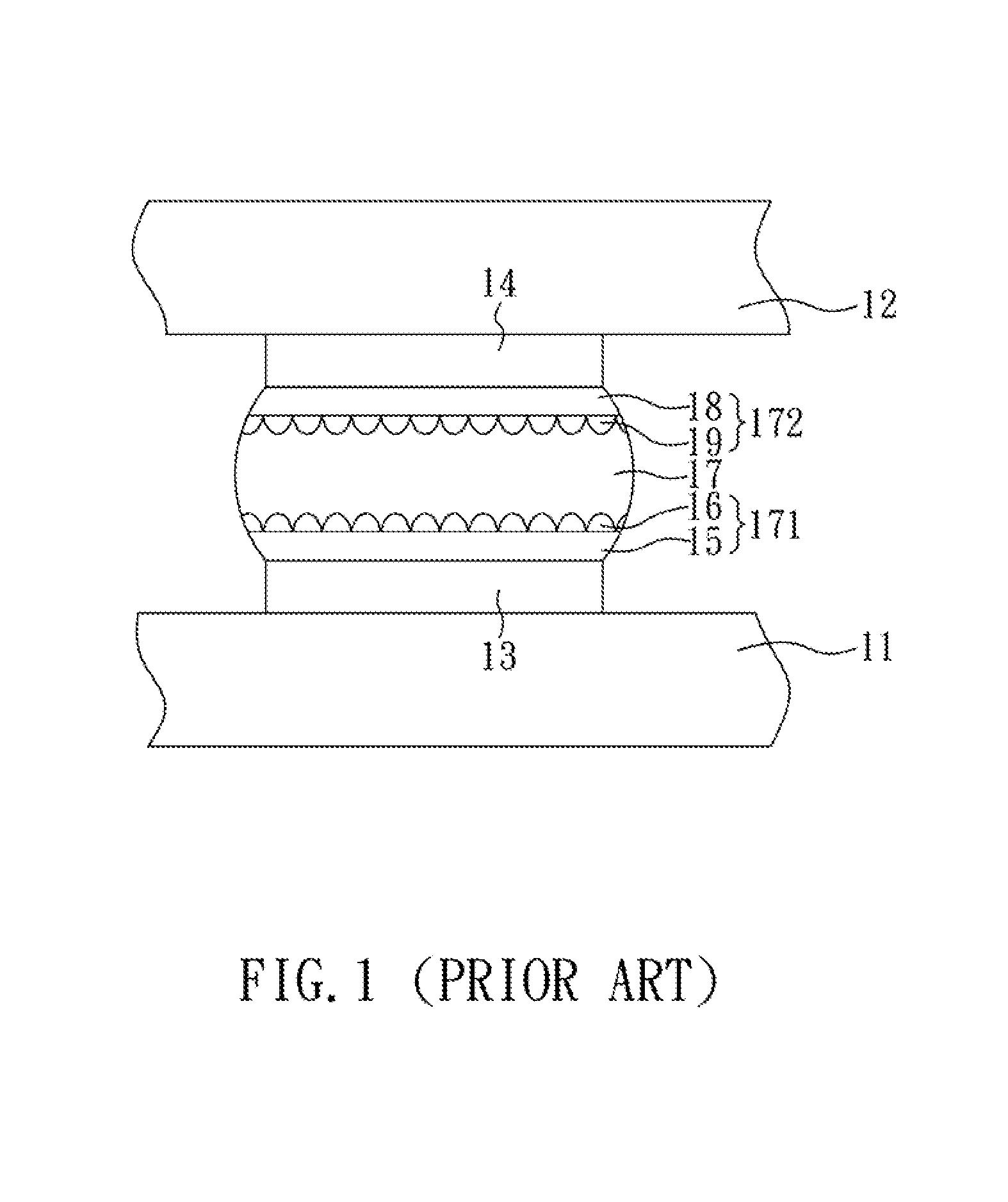

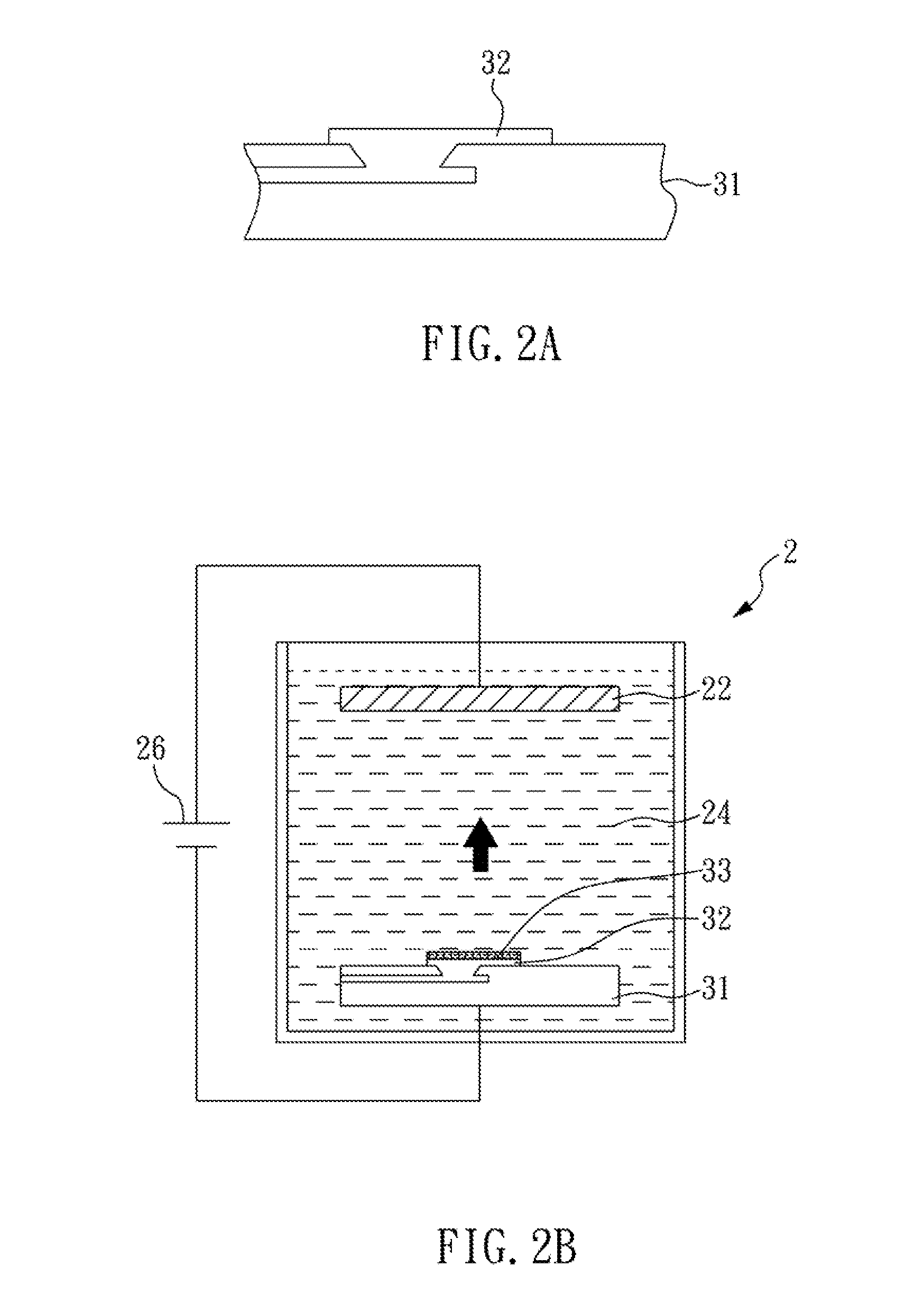

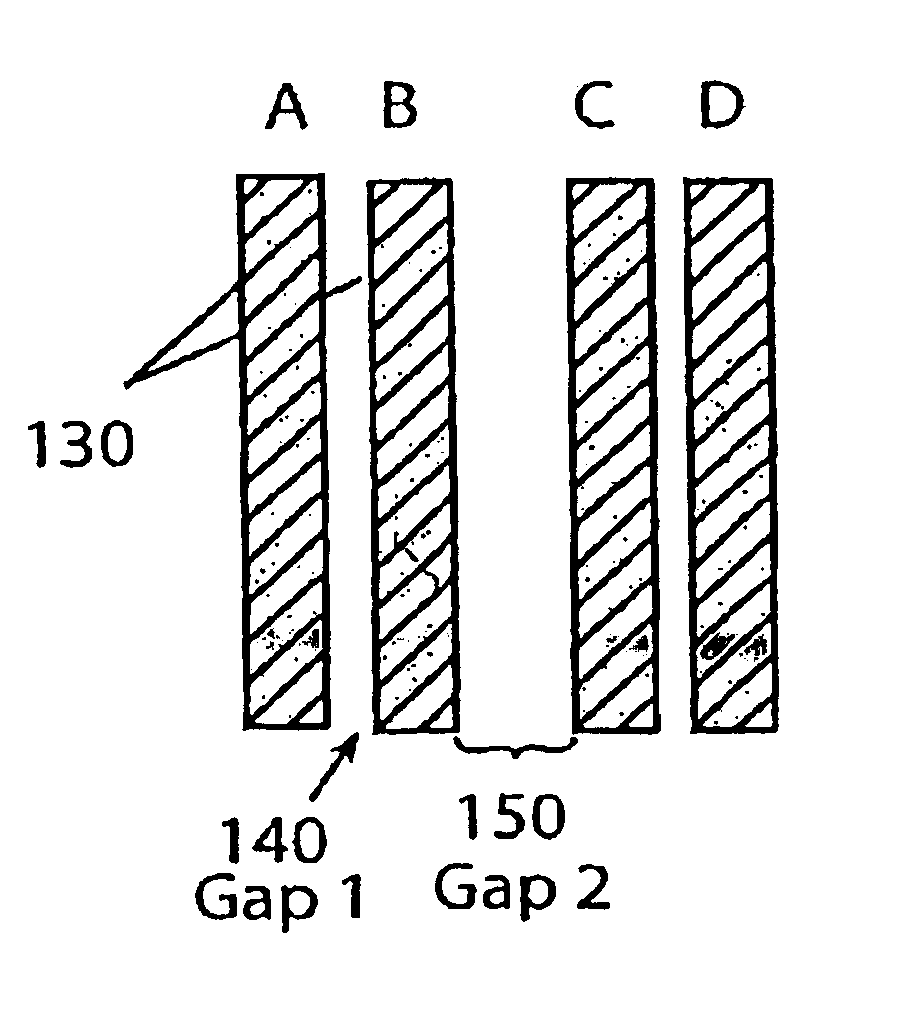

Electrodeposited Nano-Twins Copper Layer and Method of Fabricating the Same

ActiveUS20130122326A1Configuration and pattern may be more detailedImprove reliabilityAnodisationCellsCrystal twinningYoung's modulus

An electrodeposited nano-twins copper layer, a method of fabricating the same, and a substrate comprising the same are disclosed. According to the present invention, at least 50% in volume of the electrodeposited nano-twins copper layer comprises plural grains adjacent to each other, wherein the said grains are made of stacked twins, the angle of the stacking directions of the nano-twins between one grain and the neighboring grain is between 0 to 20 degrees. The electrodeposited nano-twins copper layer of the present invention is highly reliable with excellent electro-migration resistance, hardness, and Young's modulus. Its manufacturing method is also fully compatible to semiconductor process.

Owner:NAT CHIAO TUNG UNIV

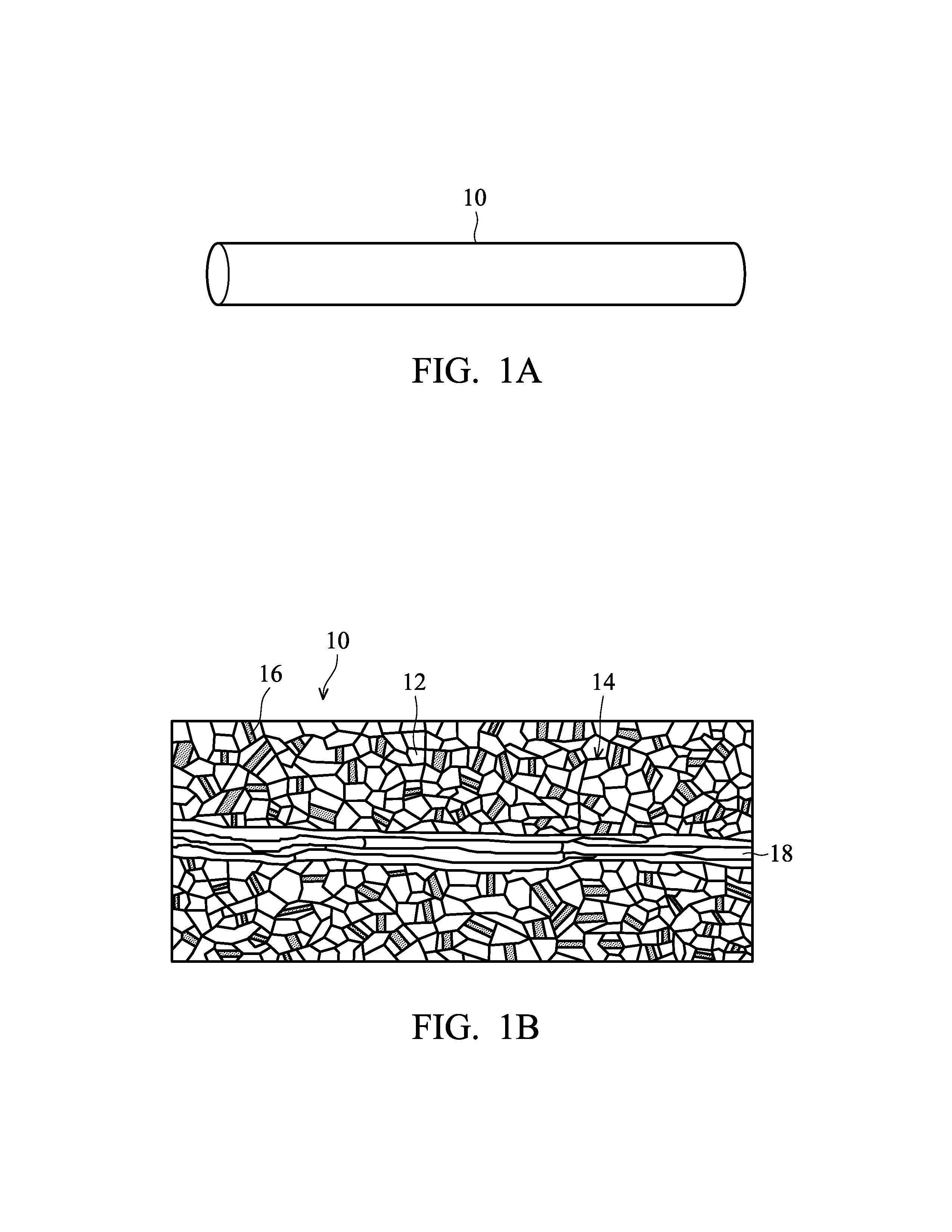

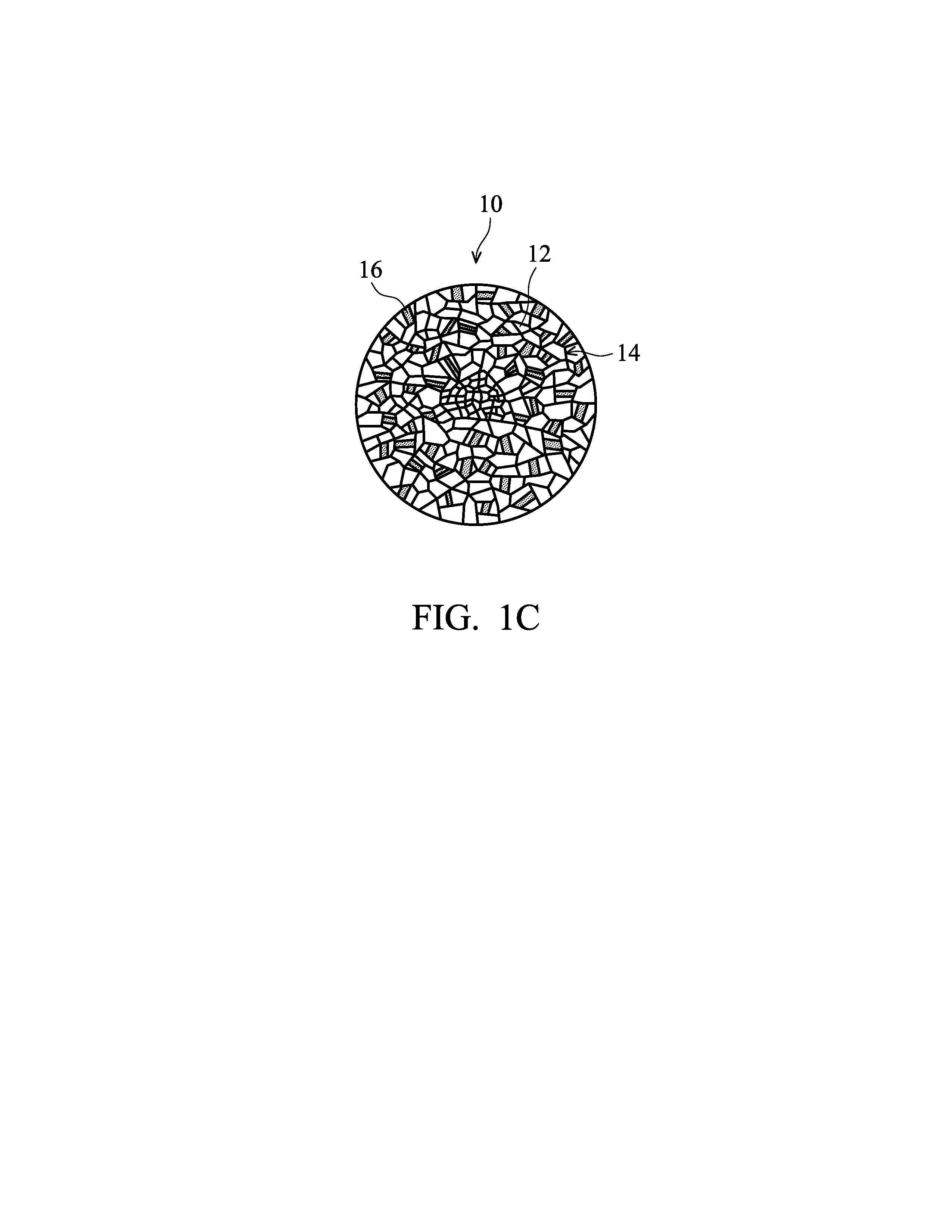

Alloy wire and methods for manufacturing the same

InactiveUS20130171470A1Semiconductor/solid-state device detailsSolid-state devicesCrystal twinningSilver-palladium alloy

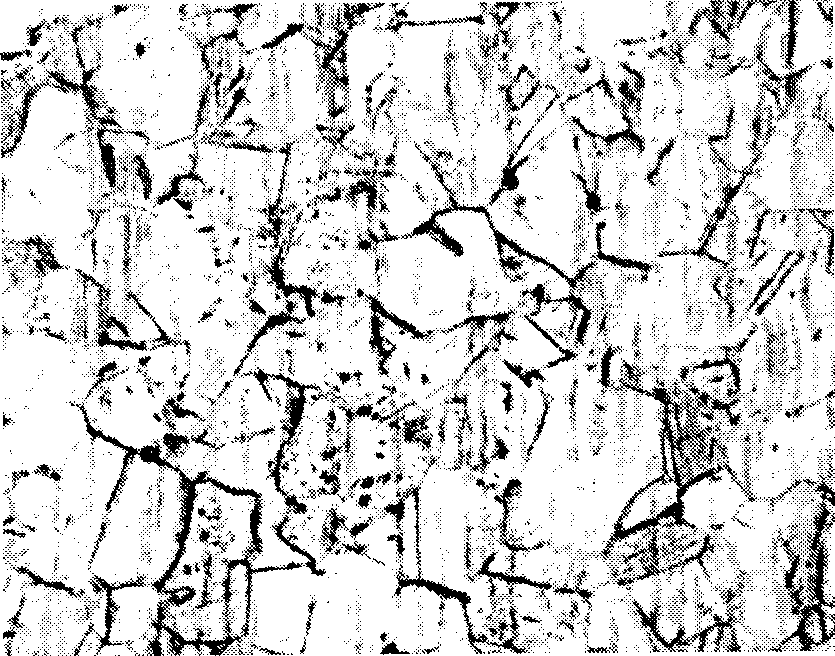

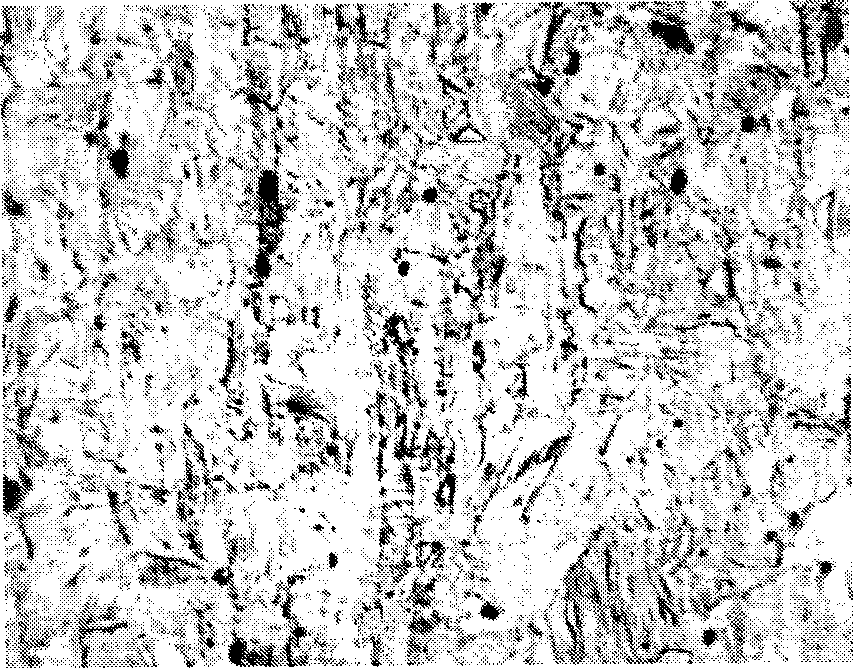

An alloy wire made of a material selected from one of a group consisting of a silver-gold alloy, a silver-palladium alloy and a silver-gold-palladium alloy is provided. The alloy wire is with a polycrystalline structure of a face-centered cubic lattice and includes a plurality of grains. A central part of the alloy wire includes slender grains or equi-axial grains, and the other parts of the alloy wire consist of equi-axial grains. A quantity of the grains having annealing twins was 20 percent or more of the total quantity of the grains of the alloy wire.

Owner:WIRE TECH CO LTD

Process for producing twin crystal inducement plastic steel material with high carbon content

InactiveCN101429590AHigh elongationImprove propertiesTemperature control deviceFurnace typesCrystal twinningHigh carbon

The invention belongs to the field of preparing a steel material and in particular relates to a method for preparing a twin crystal induced plastic steel material with high carbon content. The twin crystal induced plastic steel material comprises the following compositions in the range: 0.2 to 0.49weight percent or 0.55 to 1.5weight percent of C, 10 to 22weight percent or 23.1 to 35weight percent of Mn, less than 1weight percent of Al, less than 1weight percent of Si, less than 0.008 percent of S, less than 0.02 percent of P and the balance being Fe and inevitable impurities. The preparation method comprises the following steps: a plate blank prepared through smelting is subjected to a hot rolling process to obtain a hot rolled sheet in a use state; or the plate blank is subjected to hot rolling and cold rolling to obtain a cold rolled sheet; the sheet is subjected to heat treatment in order that the tensile strength is between 750 and 1,200 MPa, the yield strength is between 230 and 615 MPa, the extension rate is between 45 and 70 percent; and no tough brittle turning point exists at a temperature of more than 100 DEG C. The steel material with high strength and high plasticity has excellent comprehensive mechanical performance, machining performance and forming performance, can be used for a steel rail of a railroad, automobile manufacture, engineering machinery, an oil and gas transportation pipeline, a liquefied natural gas transportation ship, war industry and other industries and has important value and great application space for an automobile industry and a war industry with rapid development.

Owner:UNIV OF SCI & TECH BEIJING

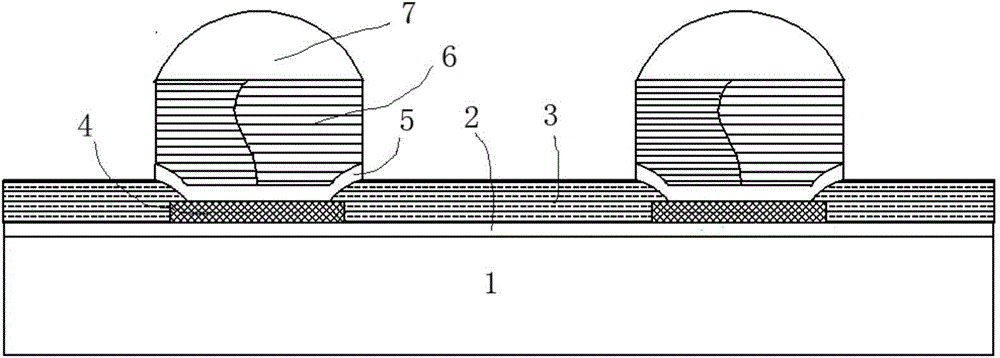

Electrical connecting element having nano-twinned copper, method of fabricating the same, and electrical connecting structure comprising the same

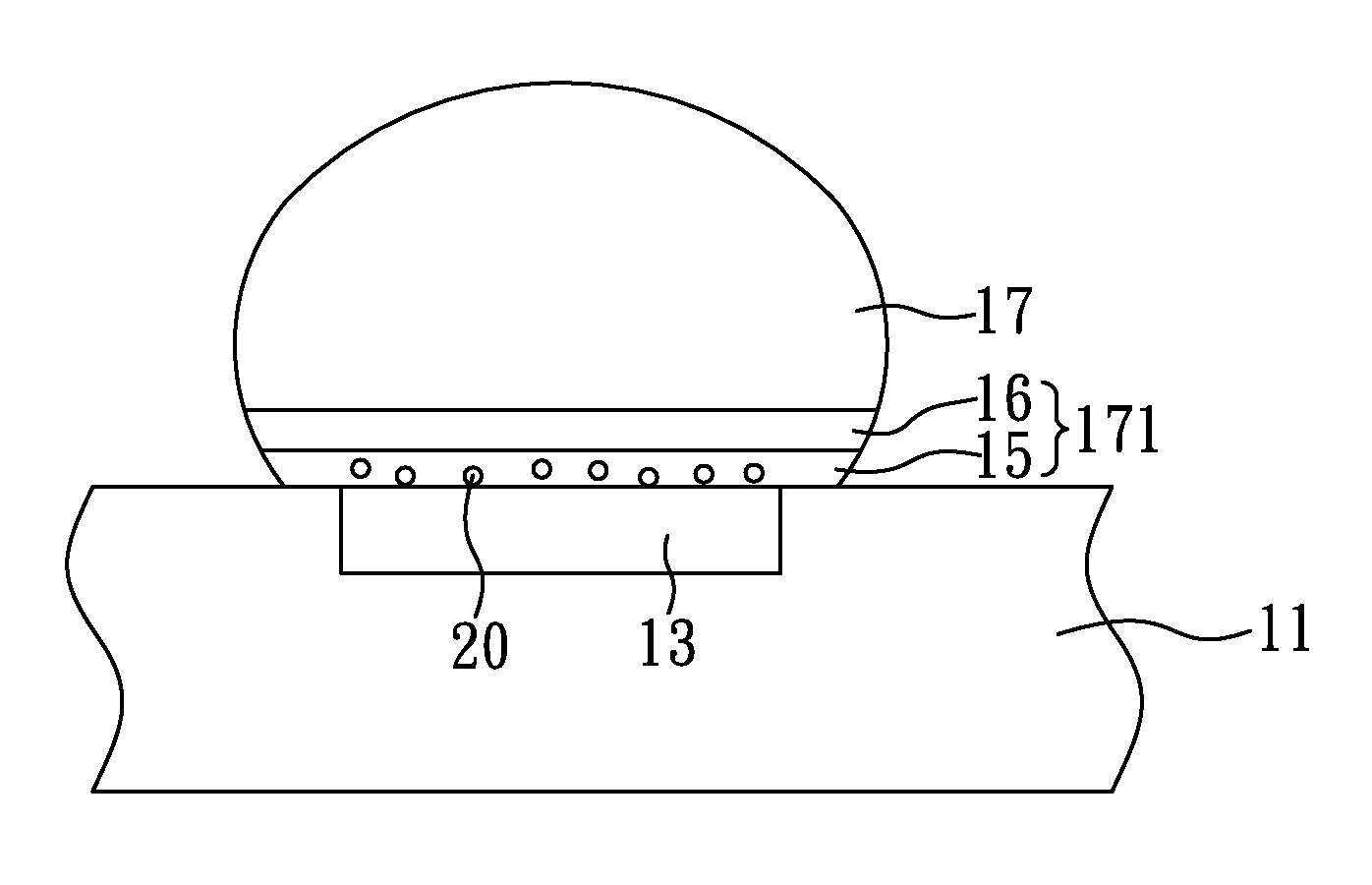

ActiveUS20140090880A1Reduce chanceImprove cooling effectElectrically conductive connectionsSemiconductor/solid-state device detailsCrystal twinningOptoelectronics

An electrical connecting element, a method of fabricating the same, and an electrical connecting structure comprising the same are disclosed. The method of fabricating the electrical connecting structure having twinned copper of the present invention comprises steps of: (A) providing a first substrate; (B) forming a nano-twinned copper layer on part of a surface of the first substrate; (C) forming a solder on the nano-twinned copper layer of the first substrate; and (D) reflowing the nano-twinned Cu layer and solder to produce a solder joint, wherein at least part of the solder reacts with the nano-twinned copper layer to produce an intermetallic compound (IMC) layer which comprises a Cu3Sn layer, This invention reduces the voids formation in the interface between the intermetallic compound and the solder, and then enhances the reliability of solder joints.

Owner:NAT CHIAO TUNG UNIV

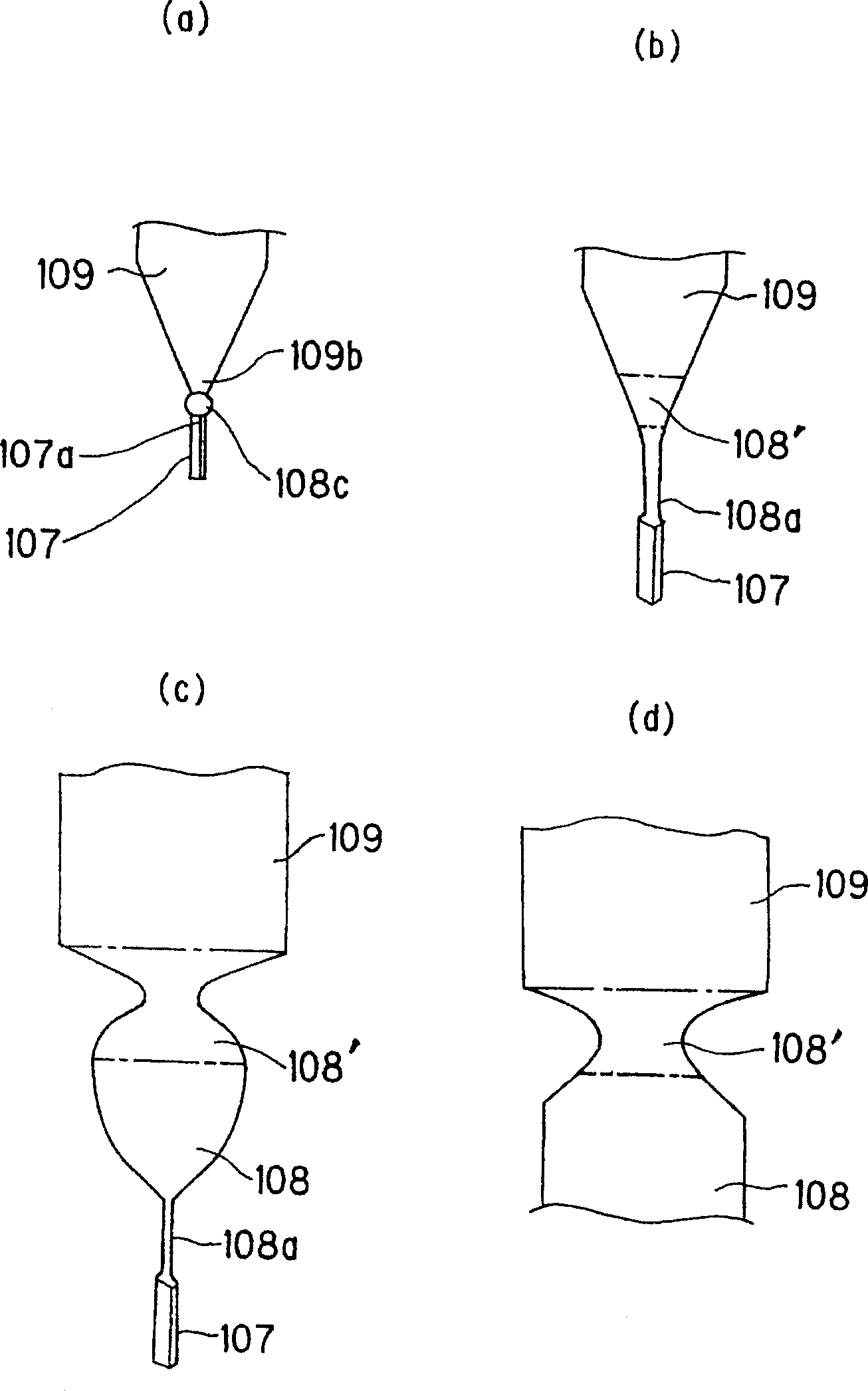

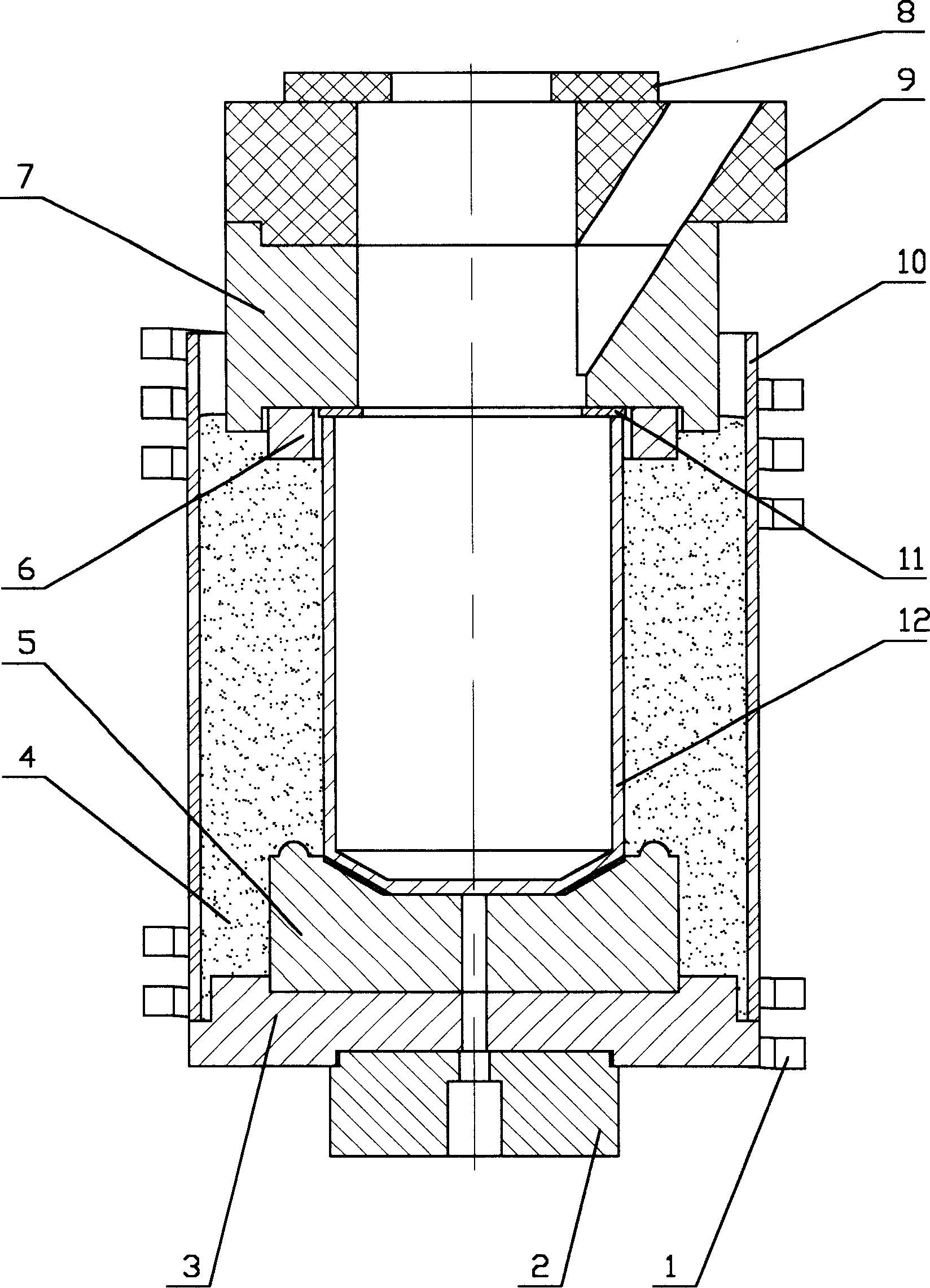

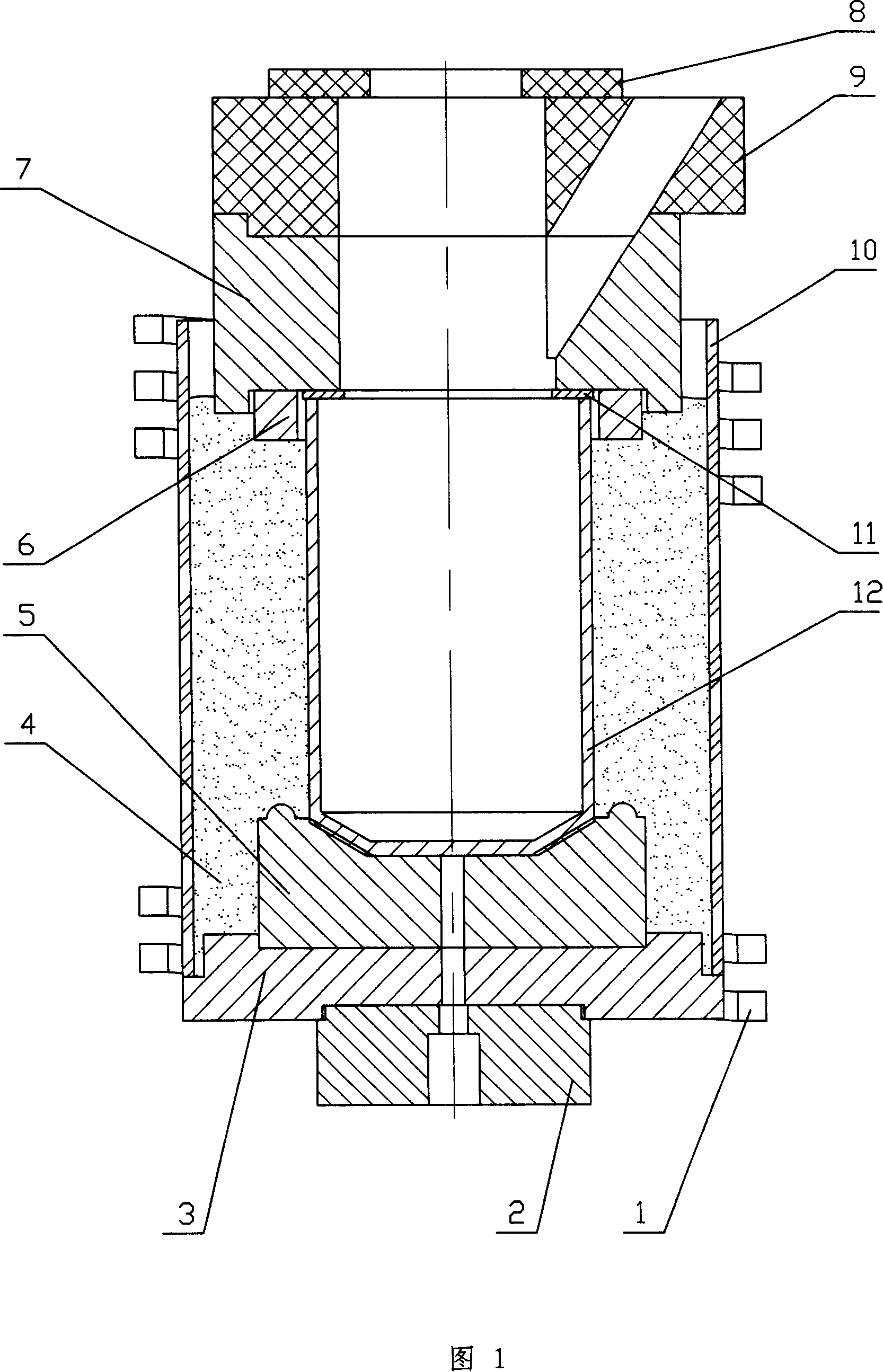

Integrated melt method for crystal growth

The invention provides a synthetic melting body method of growing crystal, using pulling method to seed, shrink neck, and extend shoulder, as the growth at equal diameter, adopting soaking method and / or temperature gradient method. It can grow large-sized high-quality crystals, especially oxide crystals like sapphire substrate crystal, doped or undoped aluminum oxide crystal, aluminate crystal, etc. It has the advantages of adopting pulling, soaking and temperature gradient methods: able to grow large-sized crystals, a little pollution, and able to observe the liquid surface and the growing situation of crystal; able to use the original pulling devices; the crystal quality is good, and has low dislocation density and good integrity and optical uniformity, easy to industrialize.

Owner:长治虹源科技晶体有限公司

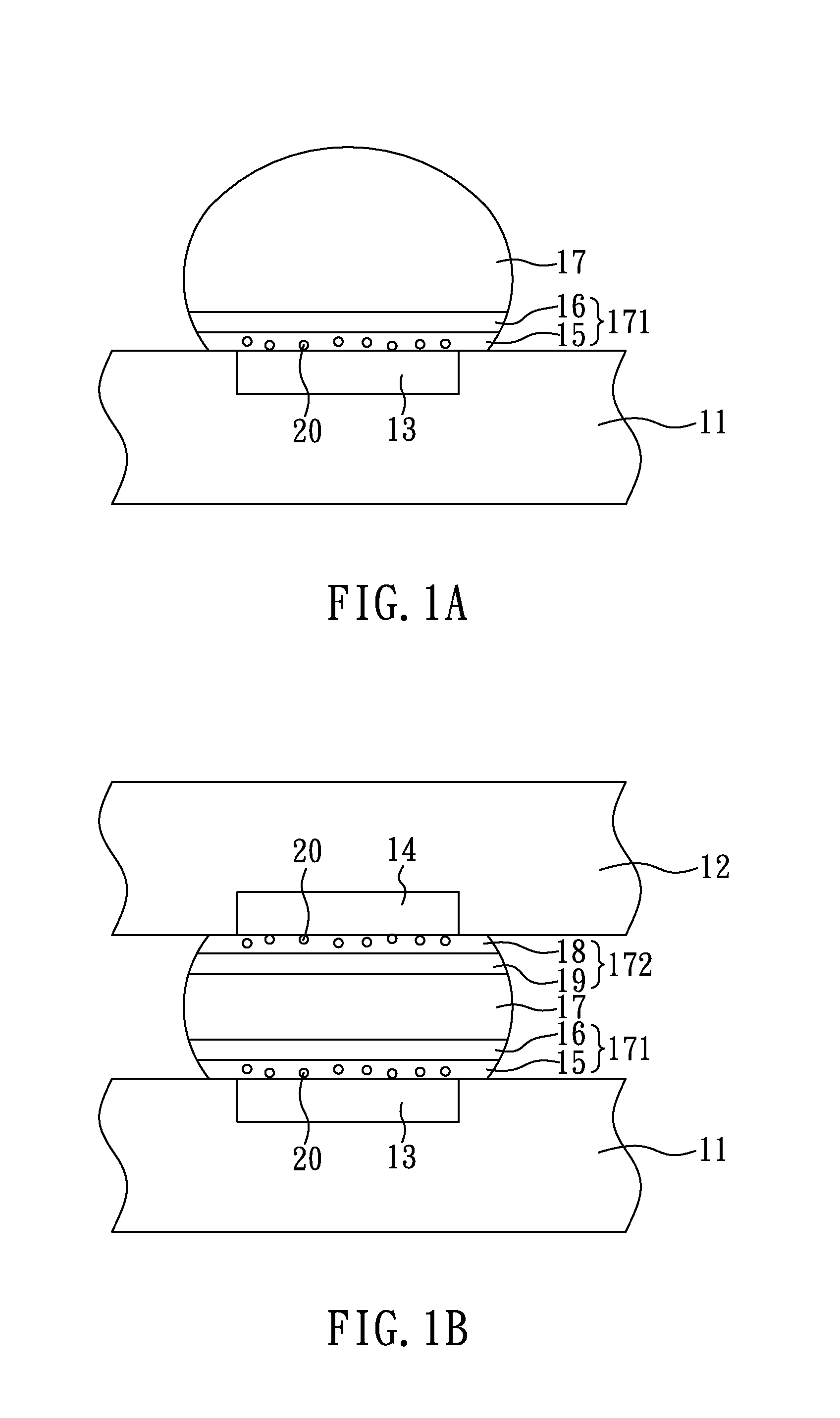

Electric connecting structure comprising preferred oriented Cu6Sn5 grains and method for fabricating the same

ActiveUS20130302646A1Improve electrical performanceControl mechanical property and electrical property and reliability and lifetimeLine/current collector detailsSolid-state devicesCrystal twinningCopper

An electric connecting structure comprising preferred oriented Cu6Sn5 grains and a method for fabricating the same are disclosed. The method of the present invention comprises steps: (A) providing a first substrate; (B) forming a first nano-twinned copper layer on part of a surface of the first substrate; (C) using a solder to connect the first substrate with a second substrate having a second electrical pad, in which the second electrical pad comprises a second nano-twinned copper layer, and the solder locates between the first nano-twinned copper layer and the second nano-twinned copper layer; and (D) reflowing at the temperature of 200° C. to 300° C. to transform at least part of the solder into an intermetallic compound (IMC) layer, in which the IMC layer comprises plural Cu6Sn5 grains with a preferred orientation; wherein at least 50% in volume of the first and second nano-twinned copper layer comprises plural grains.

Owner:NAT CHIAO TUNG UNIV

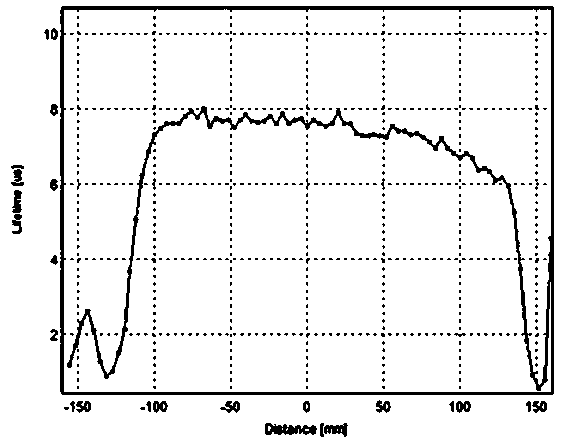

Preparation method of high-efficiency polycrystalline silicon ingots

ActiveCN104032368AImprove conversion efficiencyFine grainPolycrystalline material growthSingle crystal growth detailsBrickSlurry

The invention discloses a preparation method of high-efficiency polycrystalline silicon ingots. The method comprises the following steps: uniformly mixing a silicon sol with a highly pure quartz sand slurry to obtain a mixed slurry, and brushing the internal bottom of the crucible in a polycrystalline silicon ingot furnace with the mixed slurry to form an adhesive layer; brushing the adhesive layer with a nucleation source to form a nucleation source layer, and brushing the upper layer of the nucleation source layer and the inner sidewall of the crucible with a silicon nitride coating; adding a solid silicon material to the crucible, and melting to form a silicon fluid; and controlling the gradient of the temperature of the inside of the crucible to make a bottom-up vertical temperature gradient in the crucible, and opening a heat insulation cover to reduce the temperature of the bottom of the crucible. Polycrystalline silicon ingots prepared through the method have the advantages of high conversion efficiency, fine grains and uniform distribution, and corresponding minority carriers have the advantages of long life, few impurity points, regular crystal boundary distribution and no obvious dendrite and twin crystals.

Owner:江苏美科太阳能科技股份有限公司

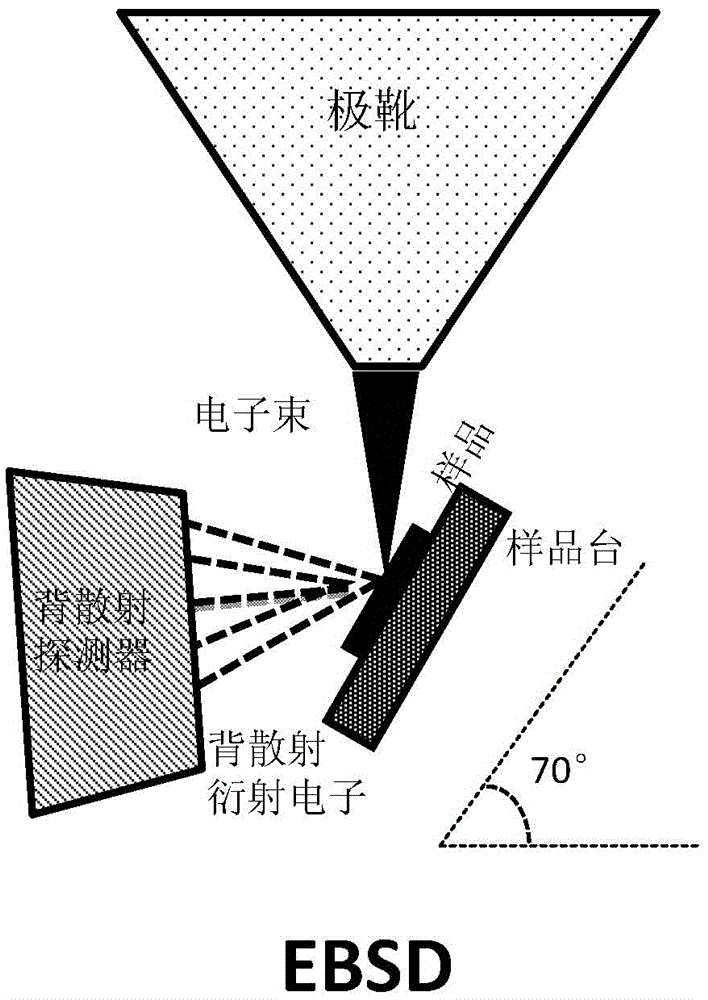

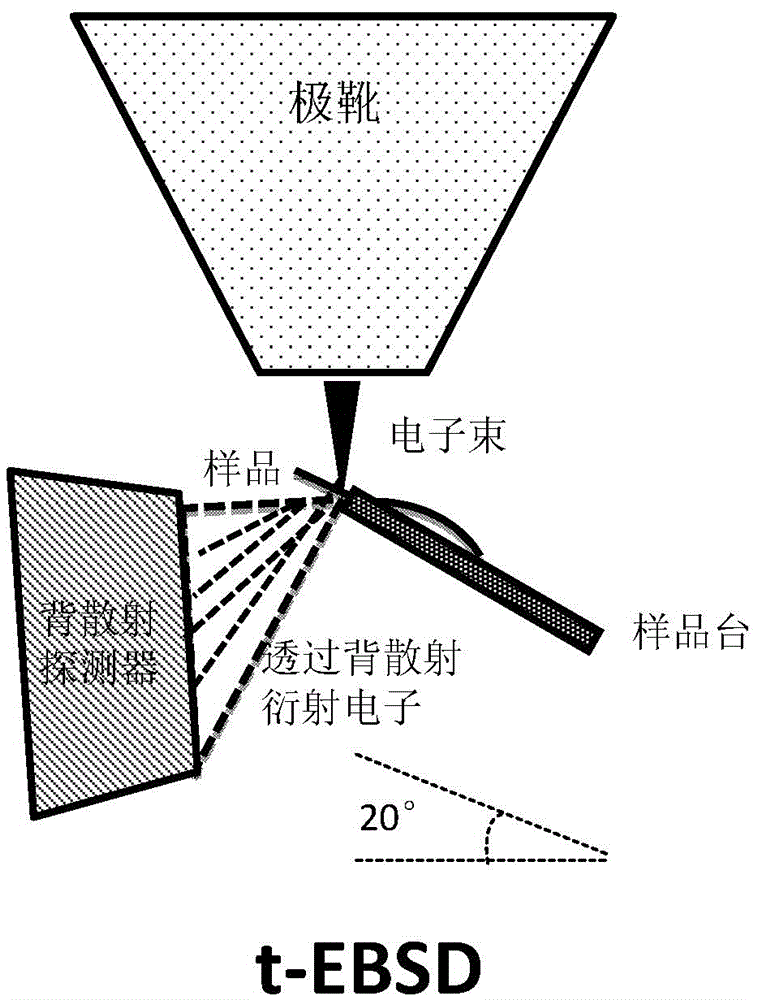

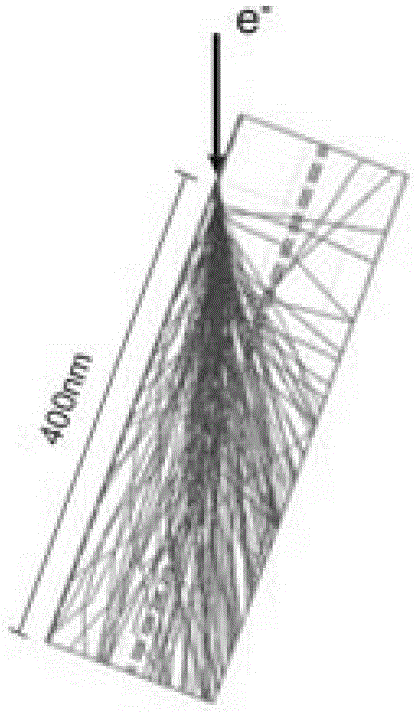

SEM transmission electron Kikuchi diffraction apparatus and analytical method

InactiveCN105651792AImprove spatial resolutionShorten working distanceNanoparticle analysisParticle size analysisCrystal twinningNanoscopic scale

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

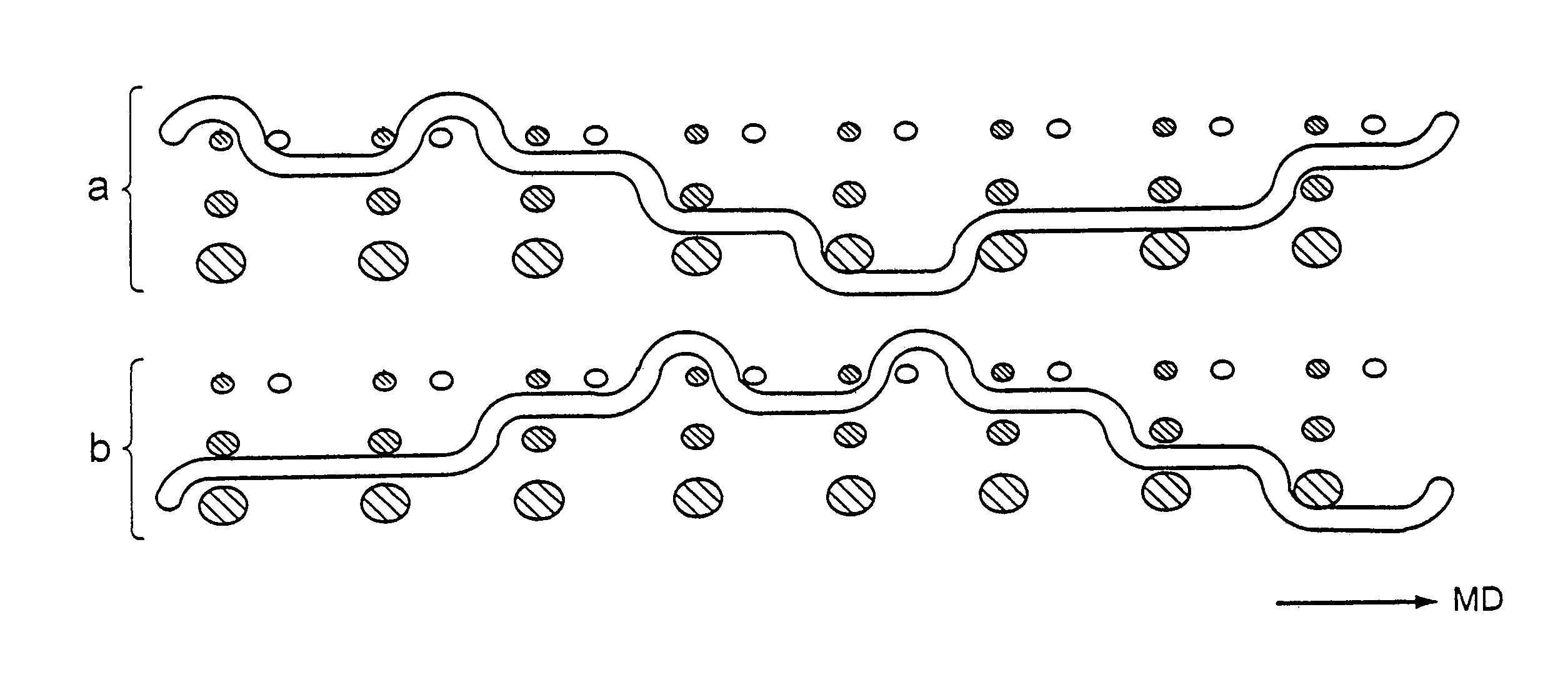

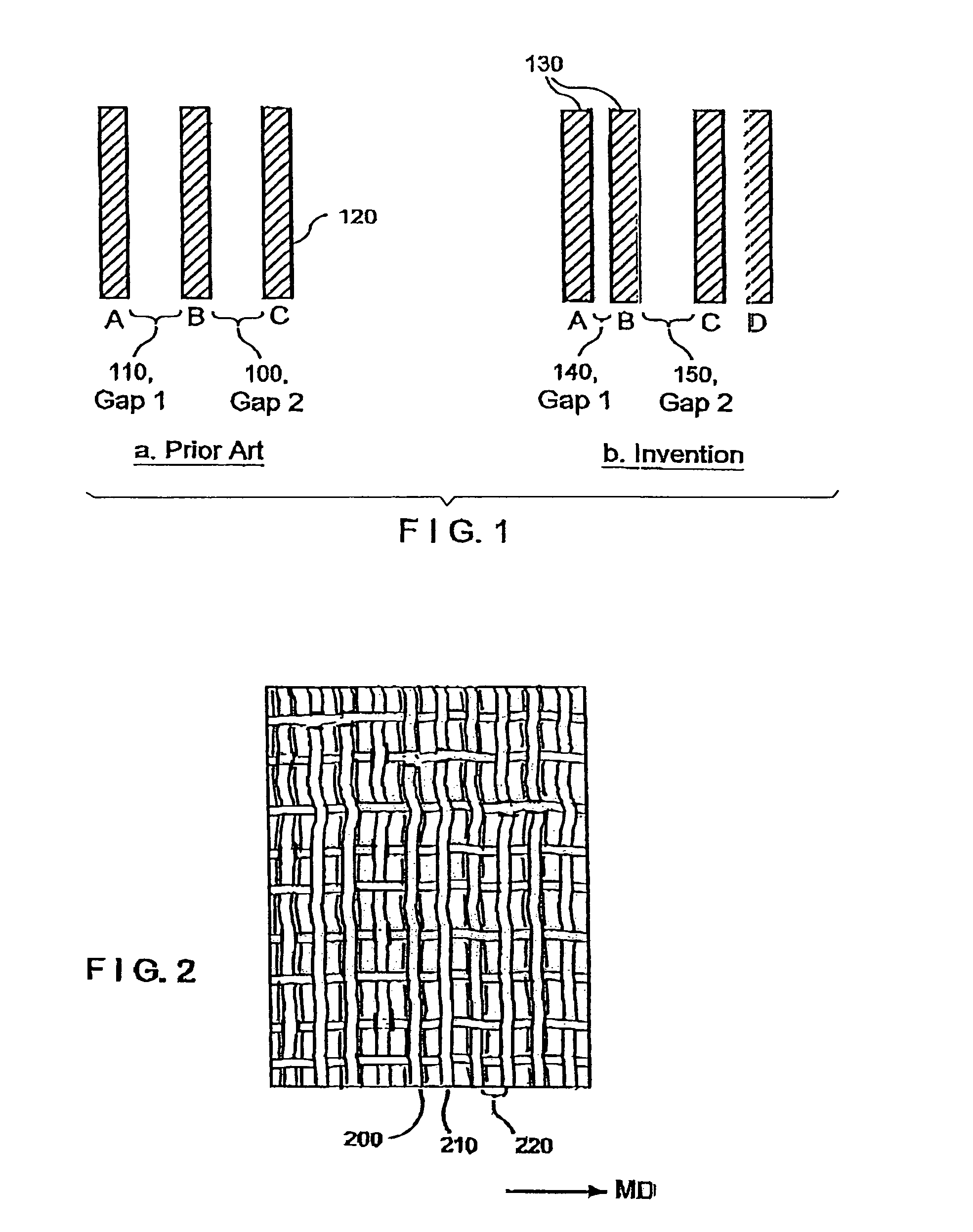

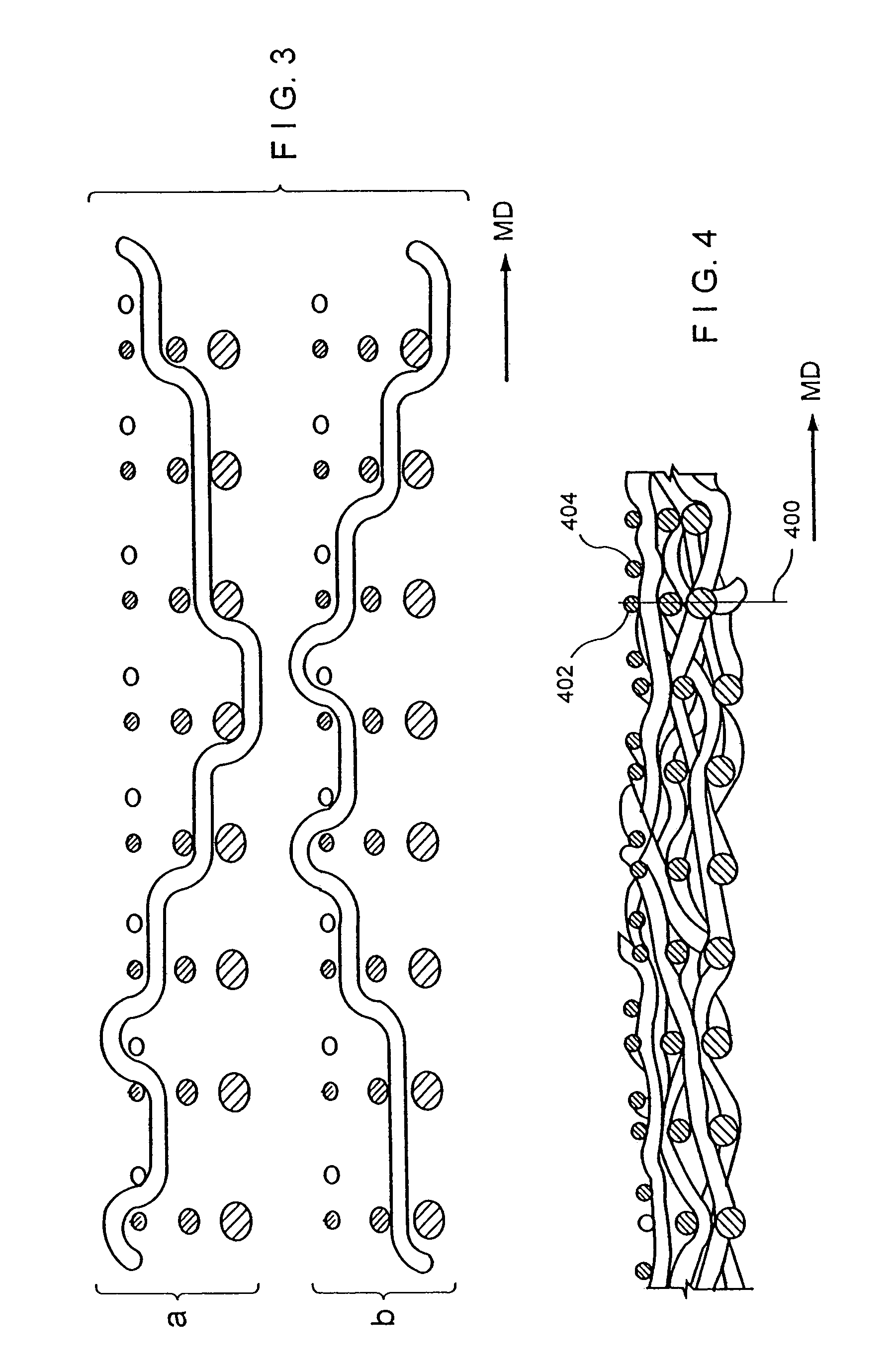

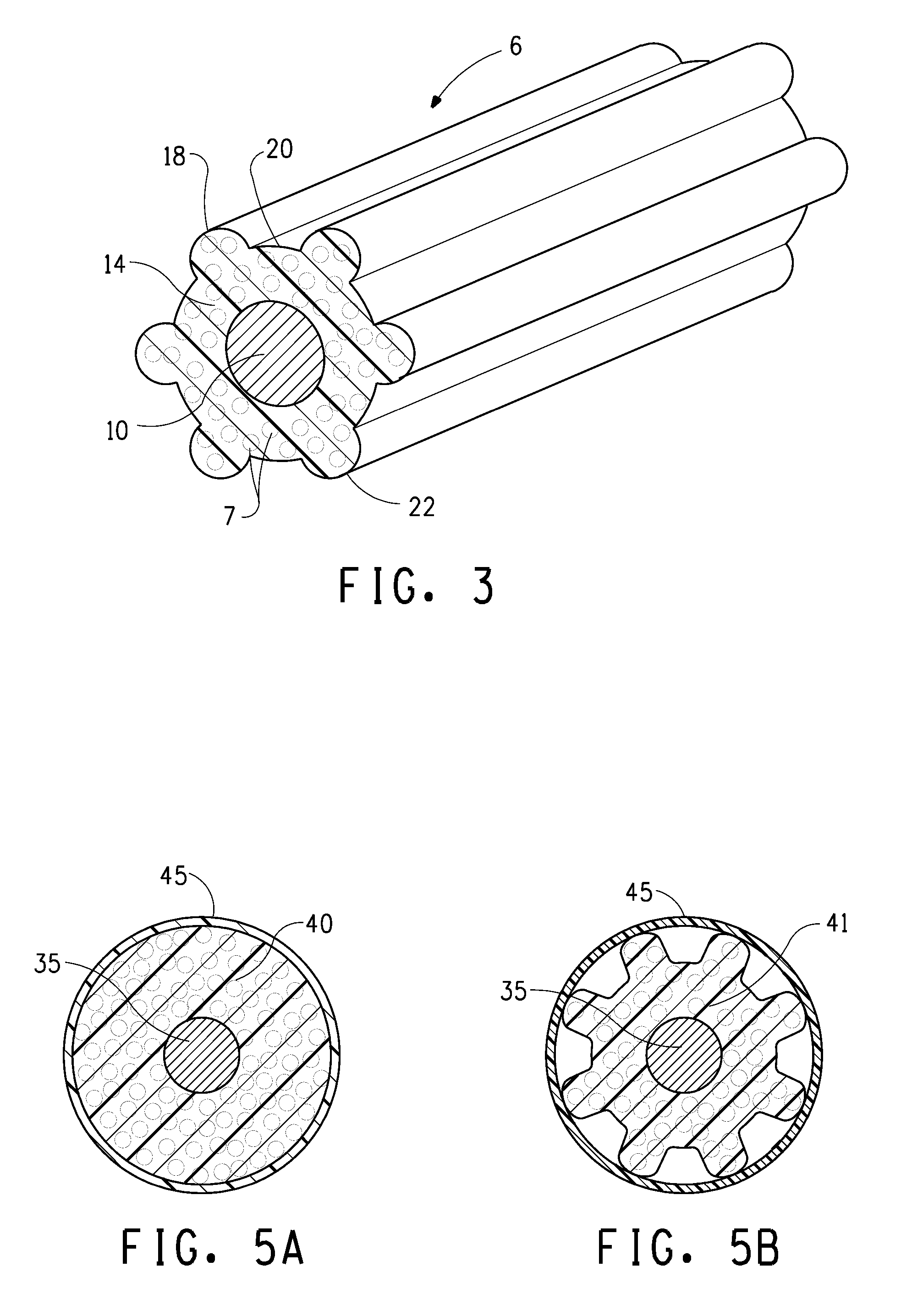

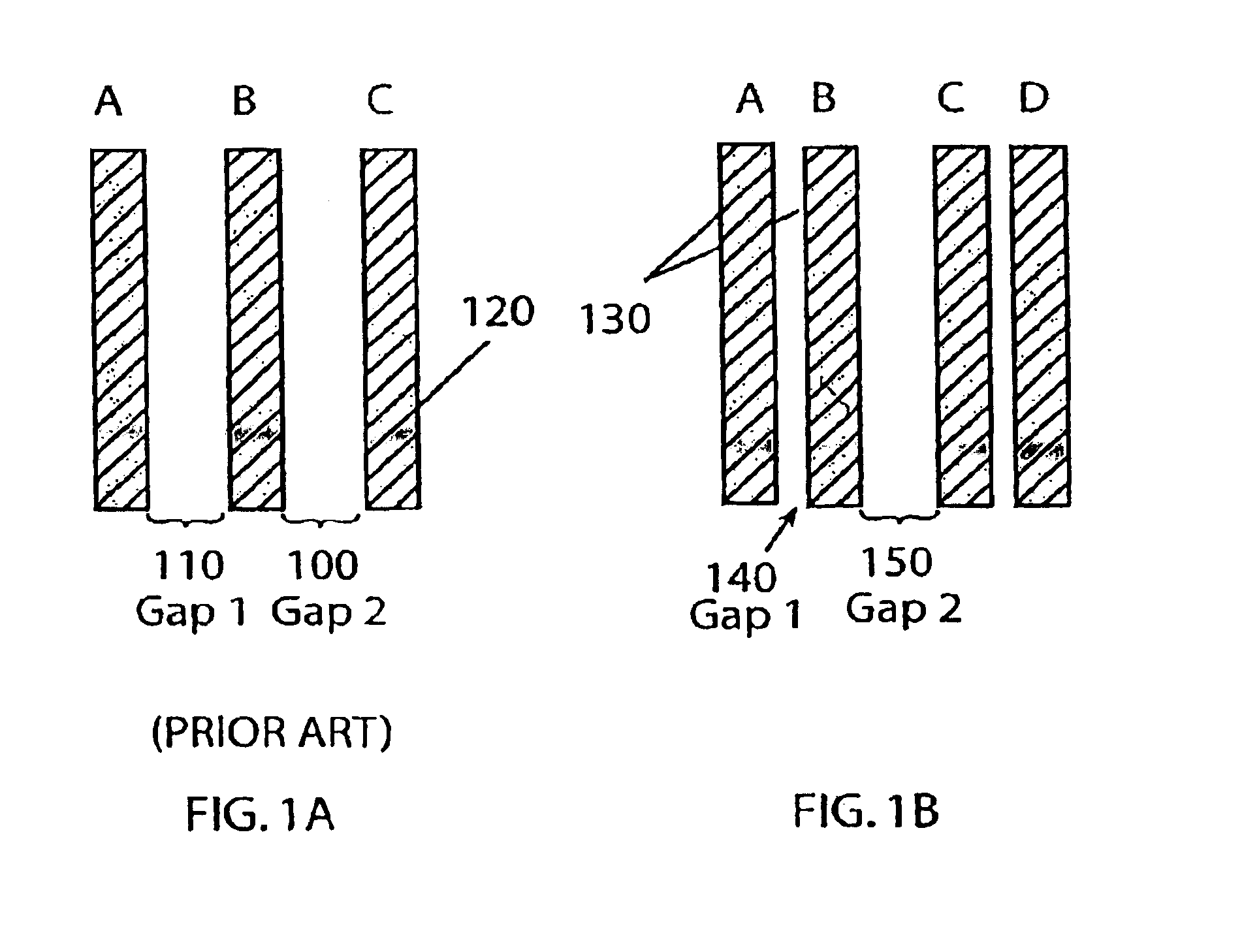

Fabric with three vertically stacked wefts with twinned forming wefts

InactiveUS7008512B2Improve stabilityMore stabilityPaper/cardboardMachine wet endCrystal twinningInter layer

A papermaker's fabric, usable in the forming section of a paper machine, has three layers of cross-machine-direction (CD) wefts. The forming layer wefts are grouped into pairs. This twinning of the top-layer wefts results in non-equal spacing in the forming layer. This spacing imparts a desired non-uniformity in the web-supporting surface, thereby reducing the fabric diagonal problem. One of the top-layer wefts in each pair is vertically stacked with the middle and wear side layer wefts. The other top-layer wefts in each pair are unstacked. This alignment increases the drainage properties of the fabric. The middle layer wefts provide extra stability in the CD.

Owner:ALBANY INT CORP

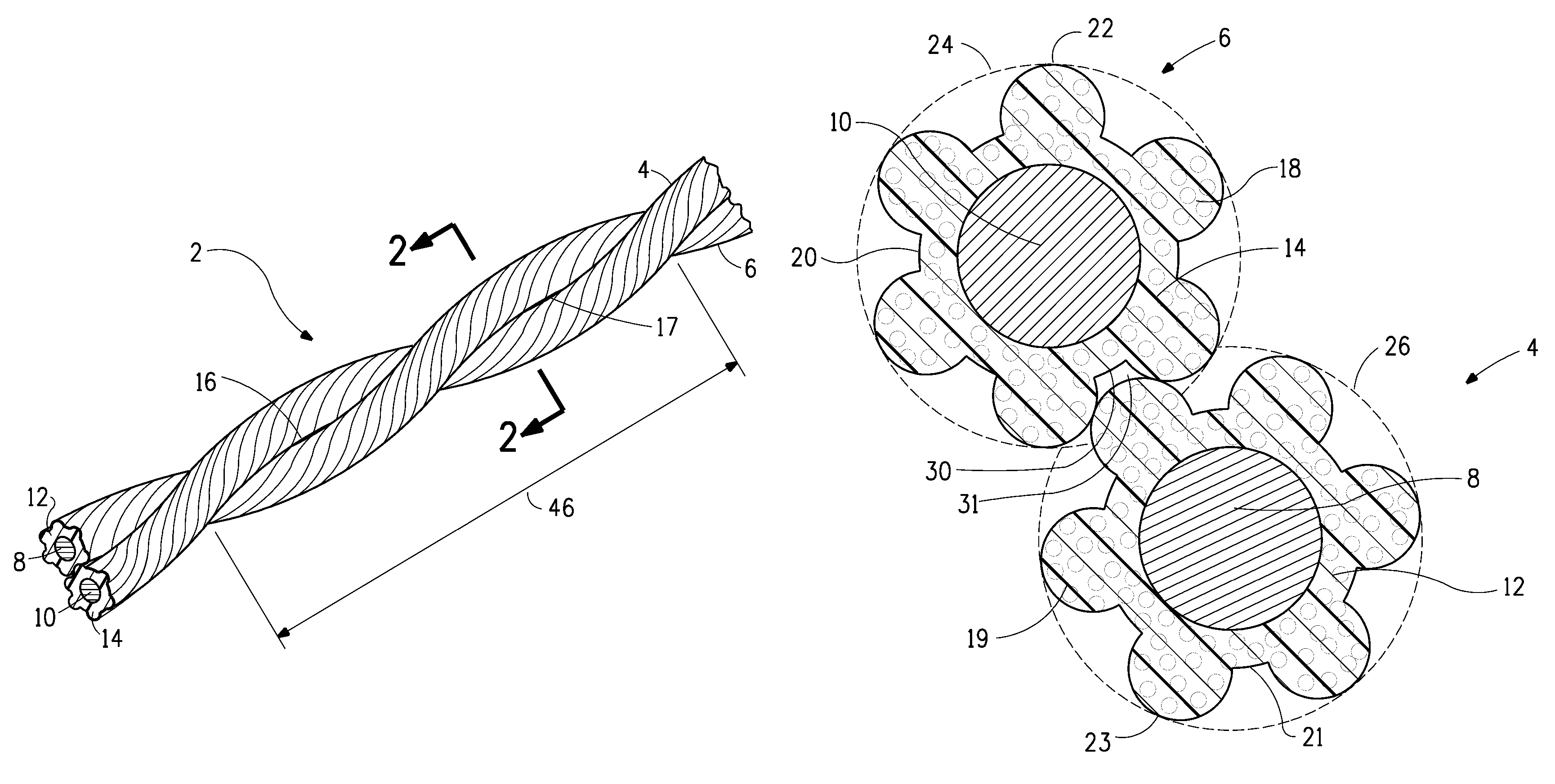

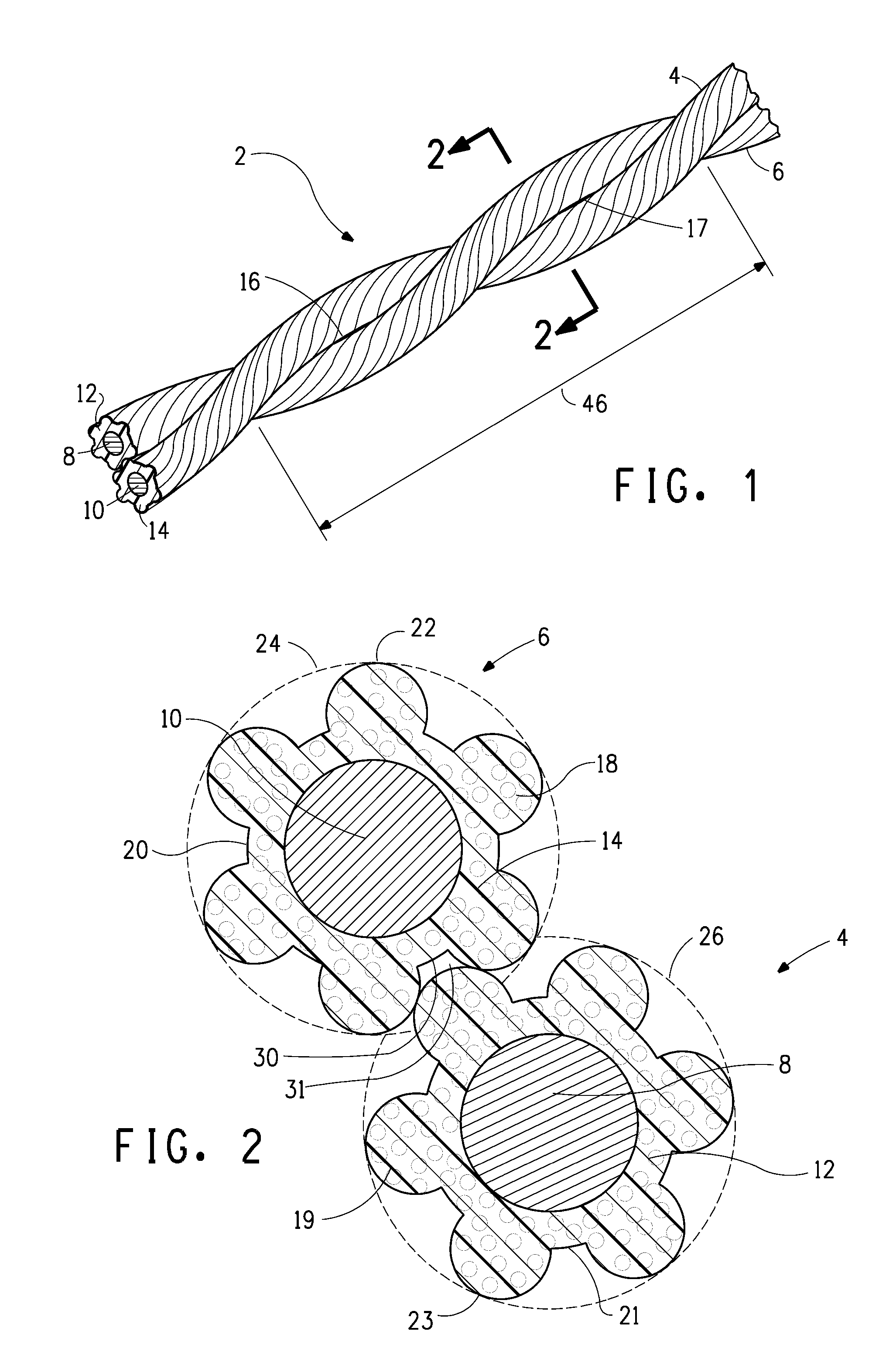

Crush resistant conductor insulation

InactiveUS7795539B2Improve instabilityClosely spacedPlastic/resin/waxes insulatorsInsulated cablesCrystal twinningElectrical conductor

A process of twinning a pair of polymer-insulated conductors to form a twisted pair, where the polymer-insulated conductors are formed by extruding a uniformly thick coating of polymer onto the conductors. More than one twisted pair is encased in a polymer jacket forming a cable. The twisted pair obtains a desirable average impedance performance using a reduced amount by weight of polymer forming said polymer-insulated conductors by: (i) extruding to form longitudinally running peaks and valleys in the exterior surface of each of the polymer-insulated conductors of the pair of polymer-insulated conductors and (ii) twinning resultant polymer-insulated conductors to nest at least one of the peaks in the exterior surface of one of the polymer-insulated conductors in at least one of said valleys in the exterior surface of the other of the polymer-insulated conductors of the pair of polymer-insulated conductors.

Owner:THE CHEMOURS CO FC LLC

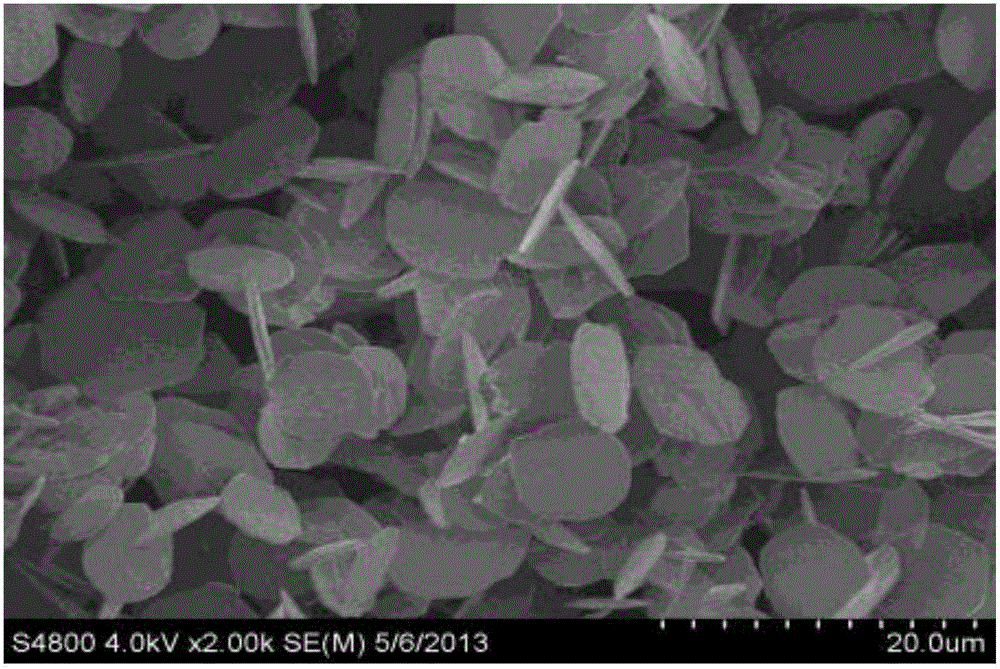

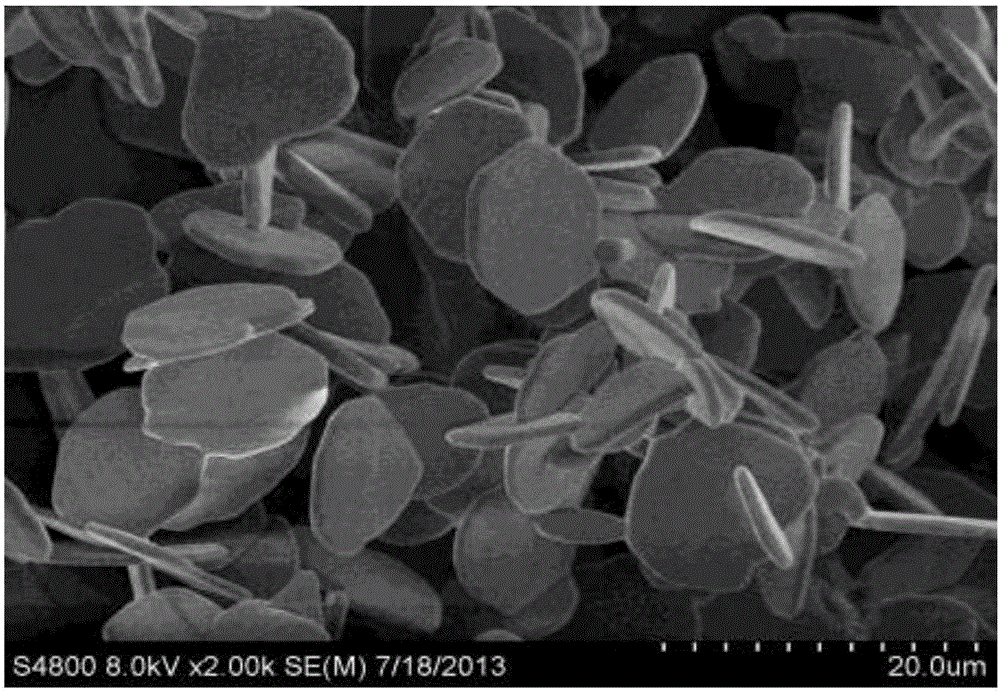

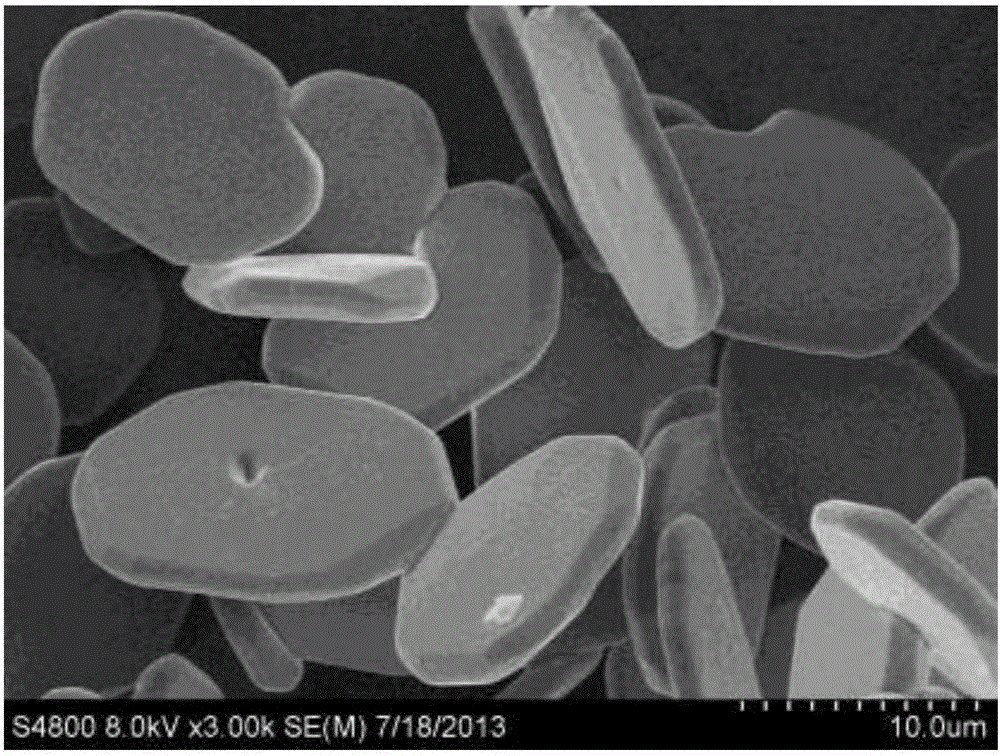

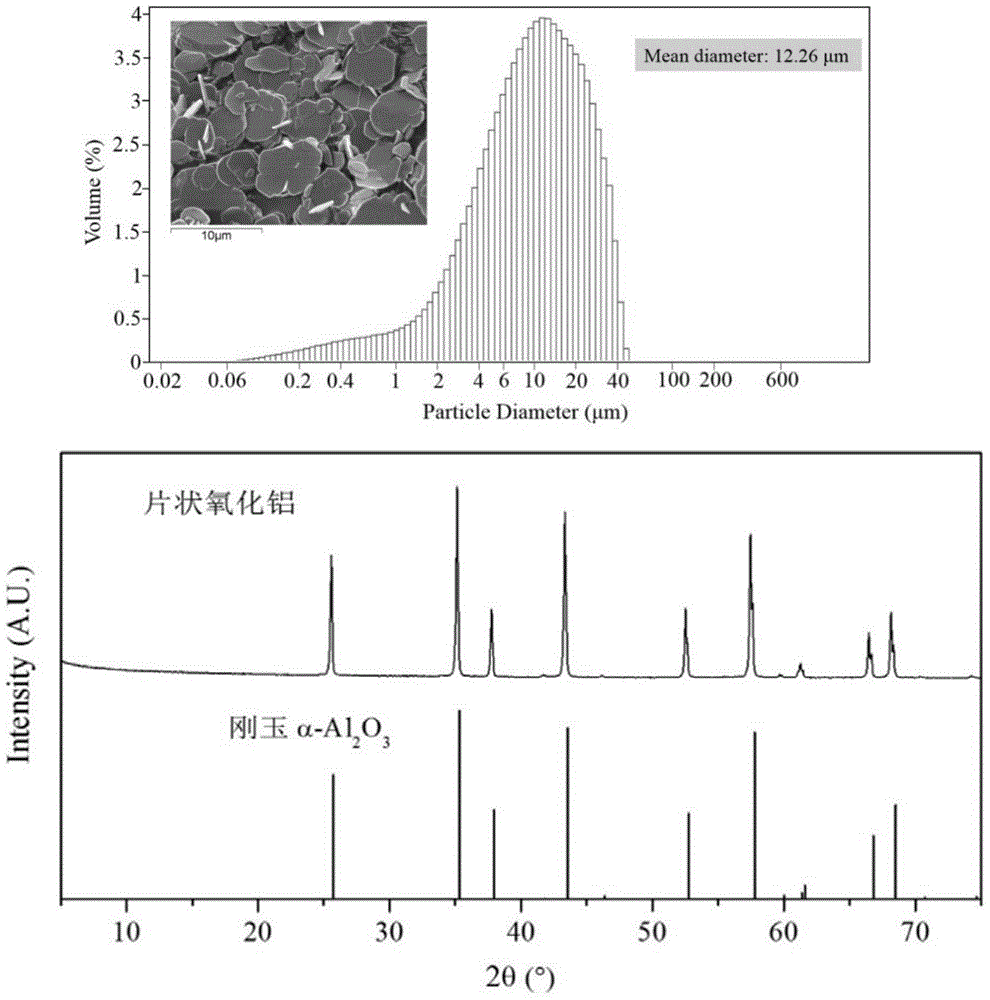

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

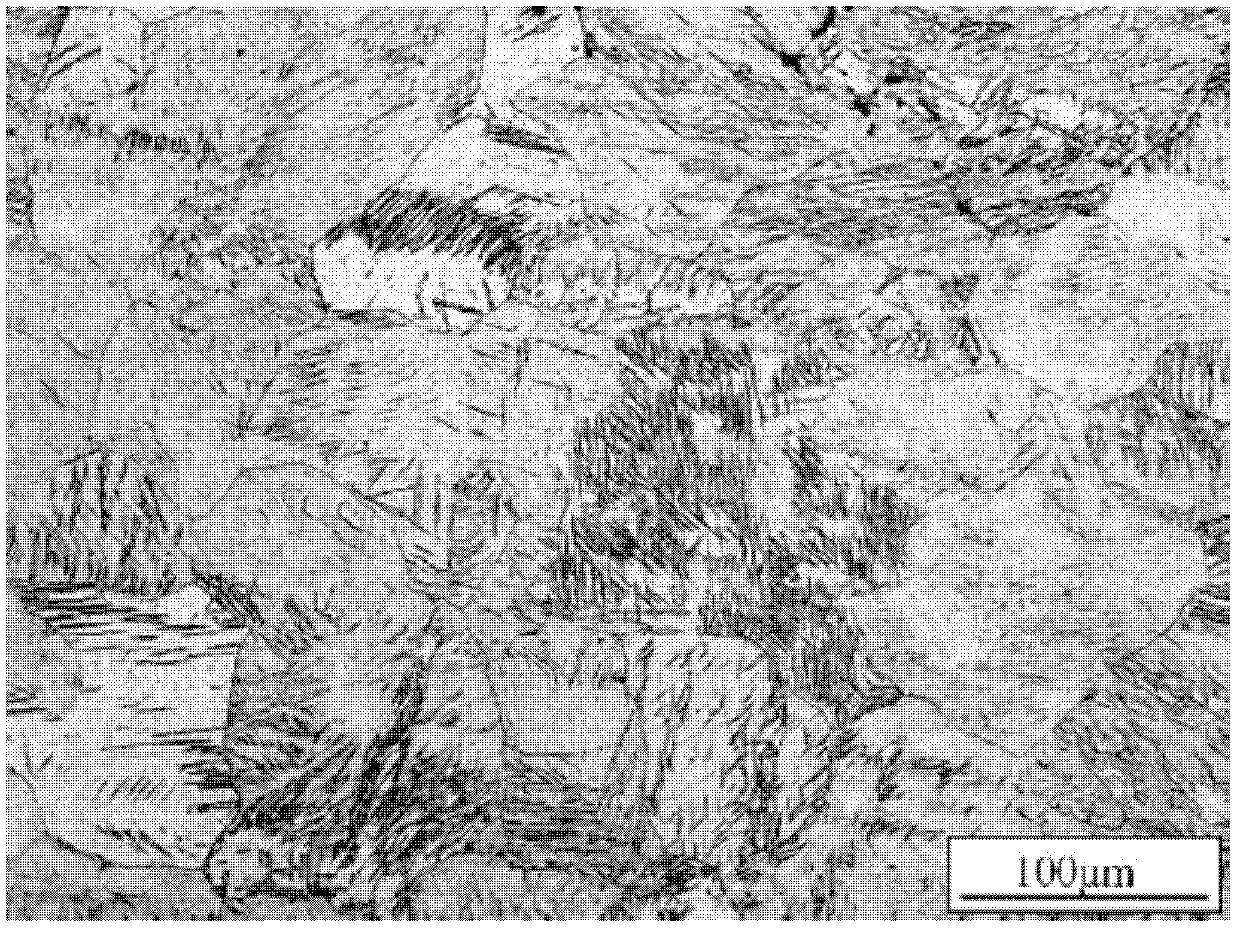

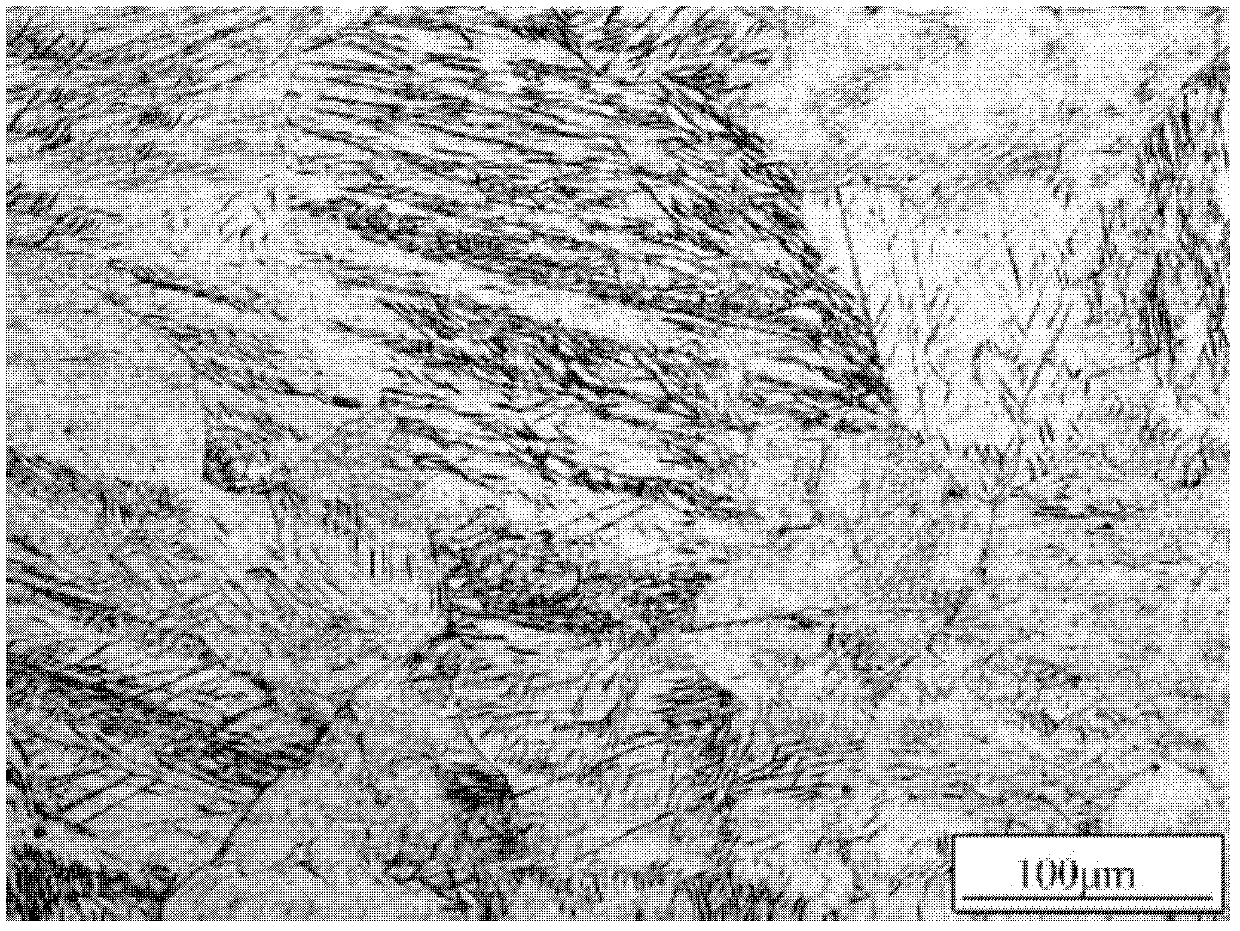

Method for refining magnesium alloy crystal grains

The invention discloses a method for refining magnesium alloy crystal grains, belonging to the technical field of plastic processing of nonferrous metals. According to the method, a magnesium alloy is easily subjected to twin dynamic recrystallization in a low-temperature thermal deformation process by virtue of the processes of twin crystal presetting, low-temperature annealing and low-temperature thermal deformation, and nucleation of new crystal grains is promoted by means of interaction of twin crystals as well as interreaction between the twin crystals and moving dislocation; twin crystal resetting can provide preferred nucleation points, including twin crystal boundaries, boundaries between twin crystals as well as boundaries between twin crystals and crystal boundaries, for dynamic recrystallization in order to accelerate a dynamic recrystallization process and realize refining of crystal grains. The method has the advantages of simple production equipment and low cost, is easy to implement and can be put into mass production.

Owner:TAIYUAN UNIV OF TECH

Method for weakening cardinal plane texture of magnesium alloy plate strip

InactiveCN102409273AImprove ductilityGood subsequent processing performanceCrystal twinningUltimate tensile strength

The invention relates to a method for weakening the cardinal plane texture of a magnesium alloy plate strip, which comprises the following steps of: placing the magnesium alloy plate strip between corrugated rollers, carrying out alternative rolling for many times under the temperature of 300-550 DEG C, straightening, and water quenching, or carrying out multi-channel one-way or alternative rolling for many times under the temperature of 150-300 DEG C, straightening, carrying out static recrystallization, and annealing; carrying out corrugated rolling at the temperature of over 300 DEG C, andincreasing along with the channel, wherein each flat surface which is vertical to normal direction of the plate strip is respectively applied with shearing force in different directions; inducing dynamic recrystallization, so that the orientation distribution of grains in the plate strip is randomized, and the strength of the cardinal plane texture is reduced; and carrying out corrugated rolling under the temperature of below 300 DEG C, wherein at the position in the plate strip, especially, the position where the repeated wave bending deformation is the most serious, a large amount of twin crystals are produced to enable the grain orientation to deflect, and further, the initial texture is weakened. The invention has the advantages that the process design is reasonable, the equipment is easy to manufacture, the operation process is easy to realize, the defects of the normal plastic deformation and difficulty in weakening of the texture in annealing of the magnesium alloy are overcome, and the efficiency is high. The method is suitable for the large scale of industrial production.

Owner:CENT SOUTH UNIV

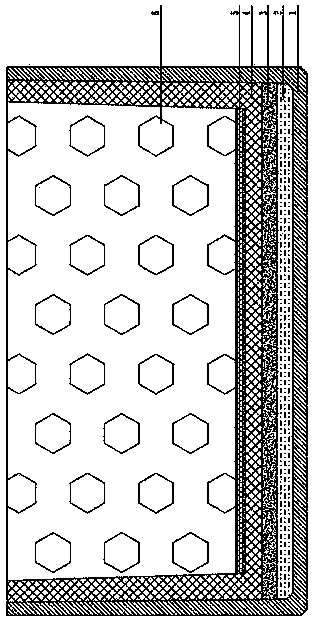

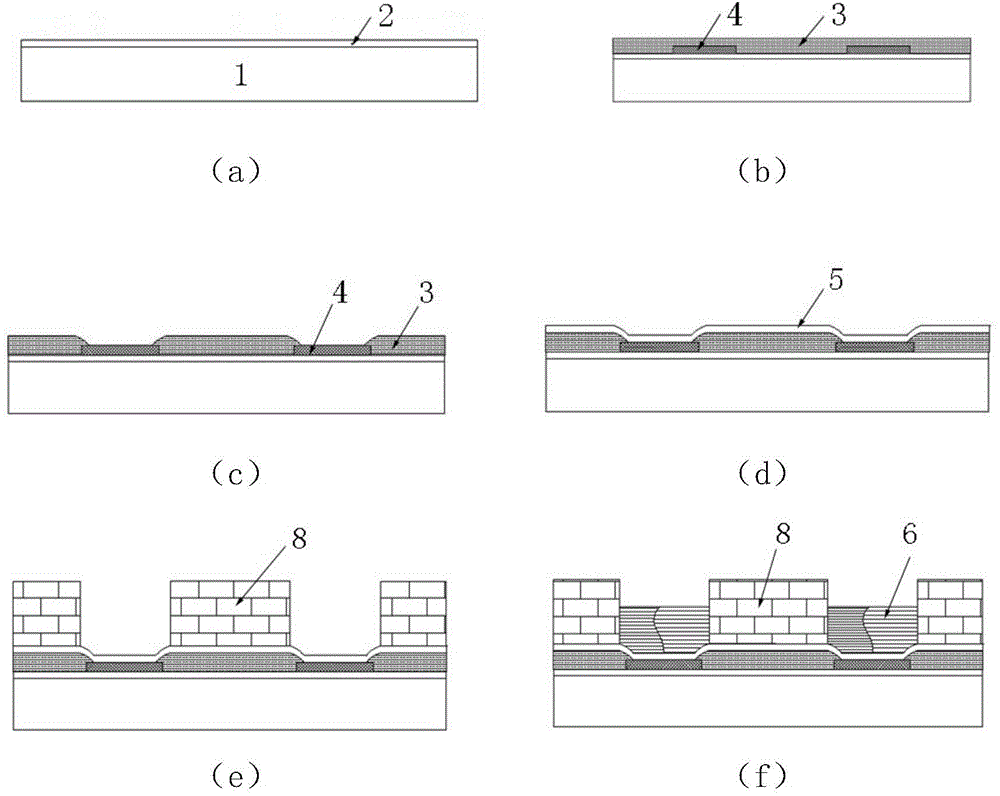

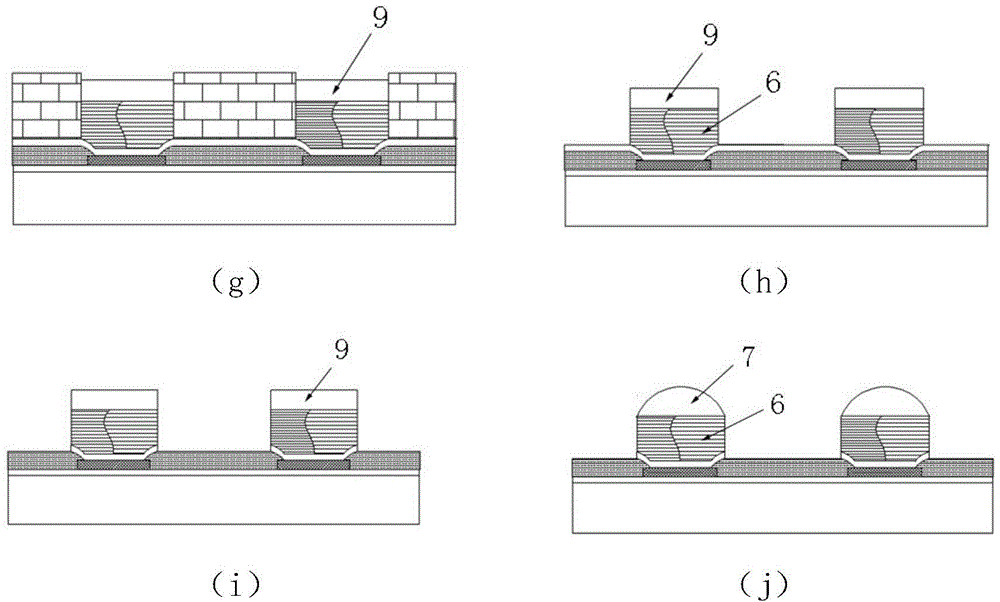

Copper pillar bump interconnection structure for directional growth and preparation method of copper pillar bump interconnection structure

ActiveCN105633038AImprove interconnect performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCrystal twinningInterconnection

The invention discloses a copper pillar bump interconnection structure for directional growth and a preparation method of the copper pillar bump interconnection structure, and belongs to the field of microelectronic and microelectromechnical system package. The copper pillar bump interconnection structure comprises a wafer substrate, an insulating layer, metal plates, a dielectric layer, seed layers, copper pillars and solder bumps, wherein each copper pillar contains a nano-twin copper structure for directional growth; and the solder bumps are arranged at the top ends of the copper pillars. The copper pillar bump interconnection structure containing nano-twin copper for directional growth is prepared on the wafer substrate by a traditional DC electroplating technology, so that, on one hand, the interconnection property and the operational reliability of the copper pillar bumps can be improved by excellent characteristics of high strength, high conductivity and the like of the nano-twin copper, and on the other hand, industrialization is relatively easy to achieve by the achievements of the invention due to the fact that the DC electroplating technology can be compatible to an existing wafer level packaging technique.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for growing R-surface sapphire crystal

InactiveCN101054723APolycrystalline material growthSingle crystal growth detailsCrystal twinningCzochralski method

The present invention provides a process for upgrowth of R surface sapphire to develop crystal with synthetic fused mass method, wherein a czochralski method is adopted for seminationsowing, neck receiving and shoulder putting, and a kyropoulos method and / or temperature gradient technique is adopted during the equal-diameter growth. The equipments and the modes of heating used in the process are not restricted strictly, and a czochralski equipment is adopted usually, which can be used regardless induction heating or resistance heating. Said process possess the advantages of czochralski method, kyropoulos method and temperature gradient technique: it can develop crystal with large size without much pollution, wherein the liquid level and the instances of crystal growth can be observed; it can also adopt the existent czochralski method equipment. At the same time, the process overcomes the shortcomings (such as high color centre and location erroneous rate) of the czochralski method and the temperature gradient technique, can produce crystal with excellent quality, small stress, without slip band and twins defects, with low dislocation density, with excellent crystal perfection and optical homogeneity, easy to its industrialization.

Owner:深圳市淼浩高新科技开发有限公司

Forming fabric with twinned top wefts and an extra layer of middle wefts

InactiveUS6899143B2More stabilityMore stiffnessMachine wet endPaper/cardboardCrystal twinningEngineering

A papermaker's fabric, usable in the forming section of a paper machine, has three layers of cross-machine-direction (CD) wefts. The forming layer wefts are grouped into pairs. This twinning of the top-layer wefts results in non-equal spacing in the forming (top) layer. This spacing imparts a desired non-uniformity in the web-supporting surface, thereby reducing diagonal fabric pattern. The forming layer wefts are vertically offset from the middle and wear side layer wefts, which are vertically stacked. This unstacked alignment reduces the caliper of the fabric and lowers the void volume. The middle layer wefts provide extra stability in the CD.

Owner:ALBANY INT CORP

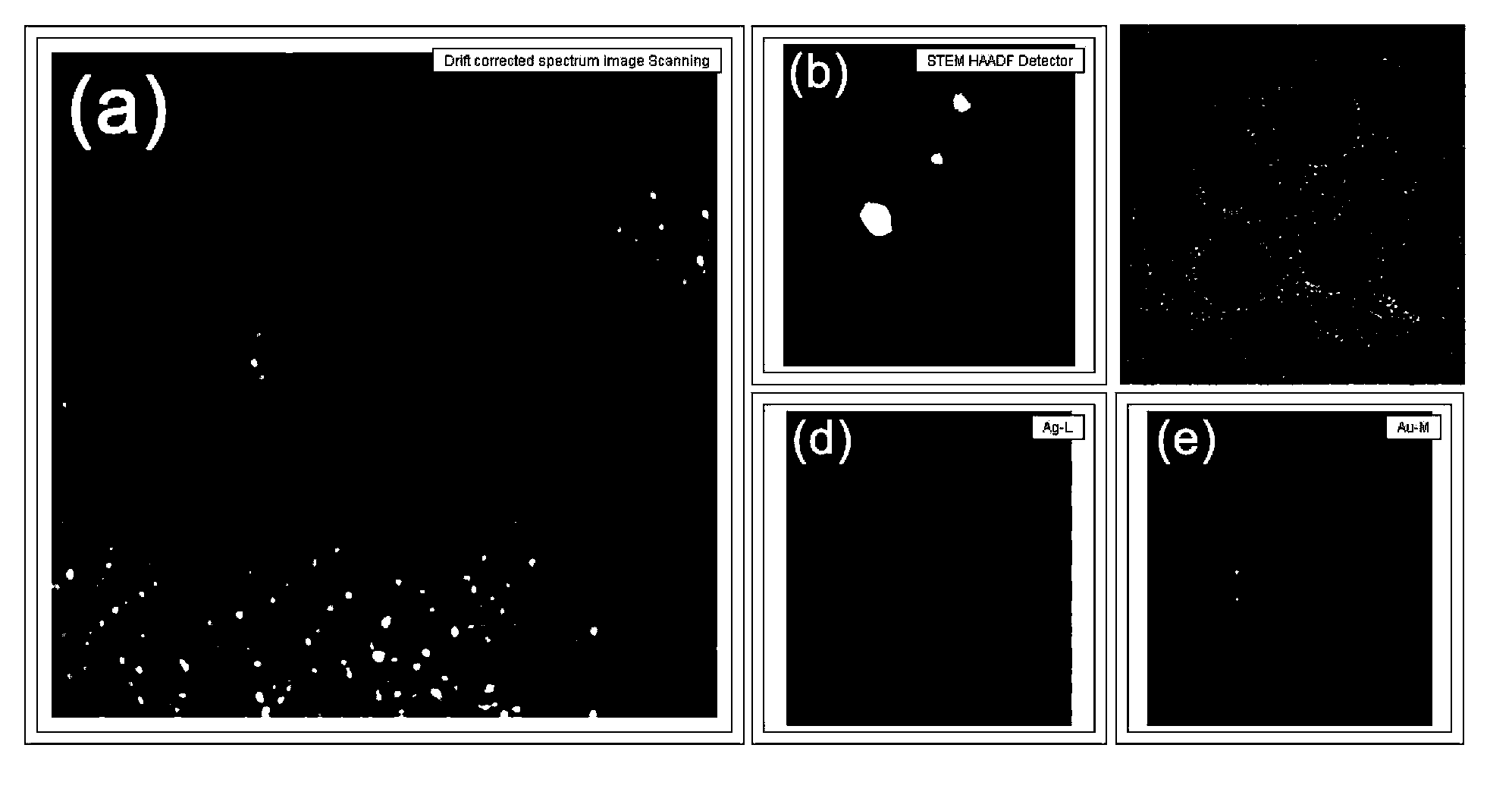

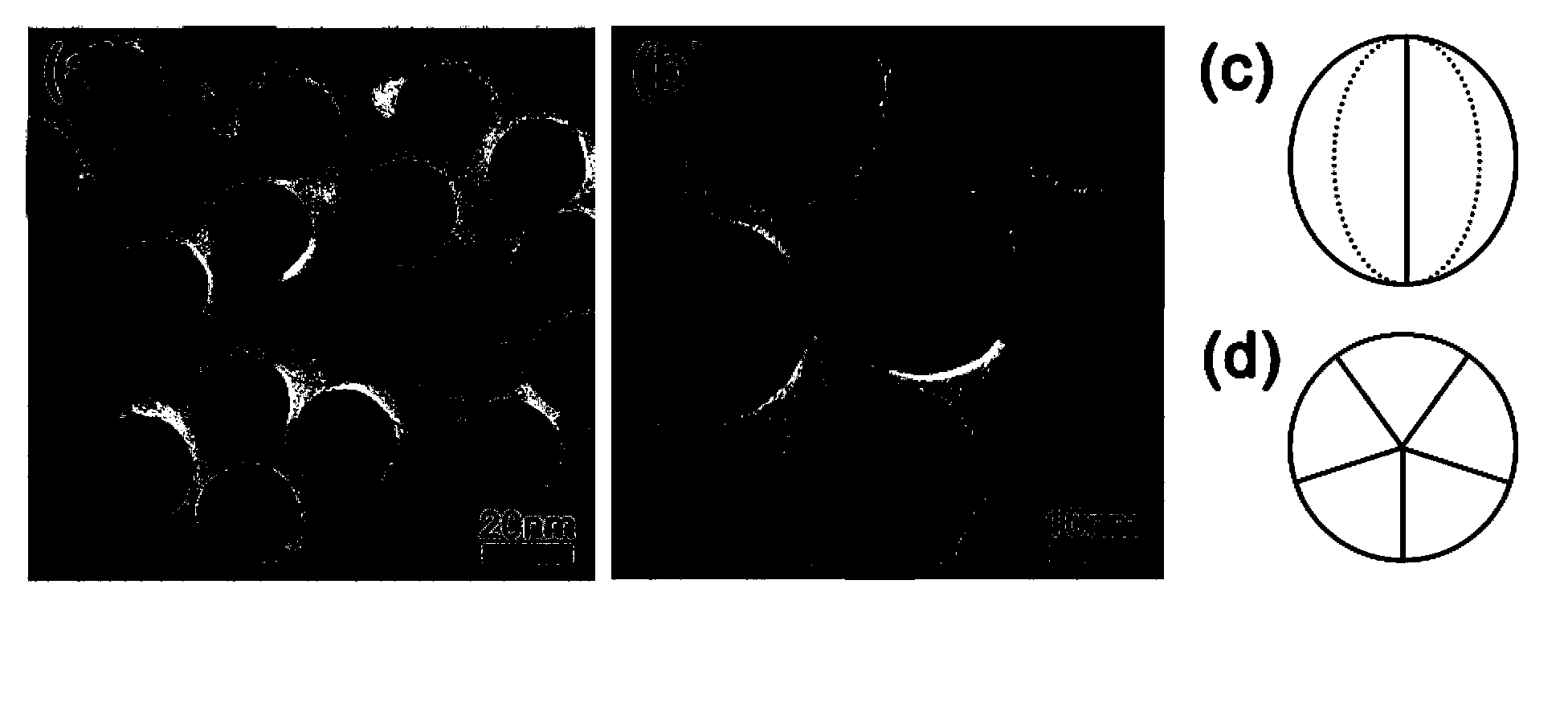

Five-twin-crystal gold-silver alloy particles, preparation method of five-twin-crystal gold-silver alloy particles, five-twin-crystal gold particles and preparation method of five-twin-crystal gold particles

InactiveCN103537707AUniform gold and silver distributionSleek shapeCrystal twinningN dimethylformamide

The invention discloses a preparation method of five-twin-crystal decanedron gold-silver alloy particles comprising chloroauric acid, silver nitrate, polyvinylpyrrolidone, water and N, N-dimethylformamide, and the five-twin-crystal decanedron gold-silver alloy particles prepared through the preparation method. The invention further discloses a preparation method of five-twin-crystal gold particles comprising chloroauric acid, the five-twin-crystal decanedron gold particles, polyvinylpyrrolidone, water and N, N-dimethylformamide, and also discloses the five-twin-crystal gold particles with the shape similar to spheroids, the pentagon dodecahedral five-twin-crystal gold particles with all crystal faces being {110} crystal faces, the pentagon-star five-twin-crystal gold particles with a part of crystal faces being {110} crystal faces, and the chamfered-decanedron five-twin-crystal gold particles with a part of crystal faces being {110} crystal faces, wherein all the five-twin-crystal gold particles are prepared through the preparation method. According to the five-twin-crystal gold-silver alloy particles, the preparation method of the five-twin-crystal gold-silver alloy particles, the five-twin-crystal gold particles and the preparation method of five-twin-crystal gold particles, the five-twin-crystal structure and the high-energy {110} crystal faces are combined for the first time, so that the five-twin-crystal gold particles have more physicochemical properties determined by shapes and forms.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

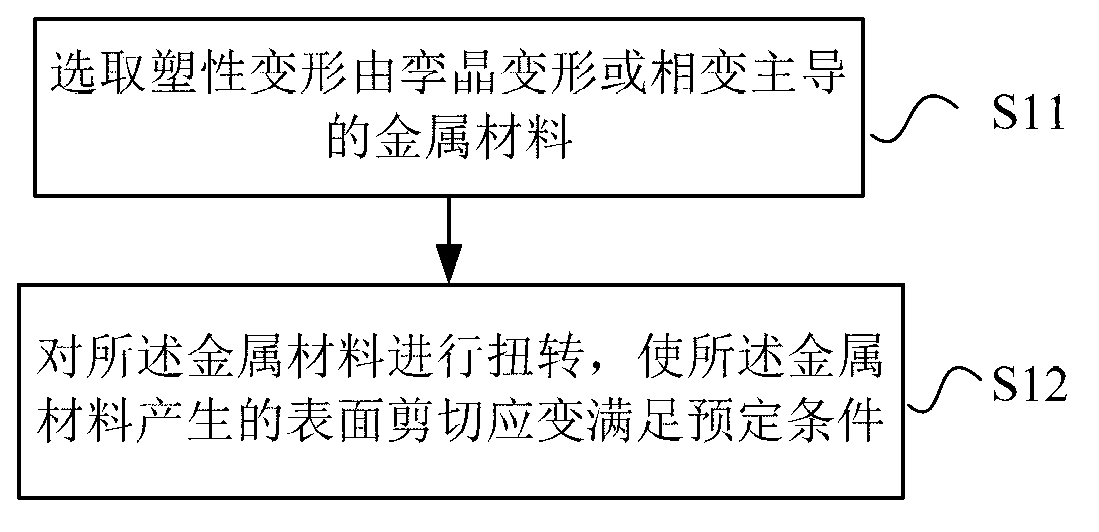

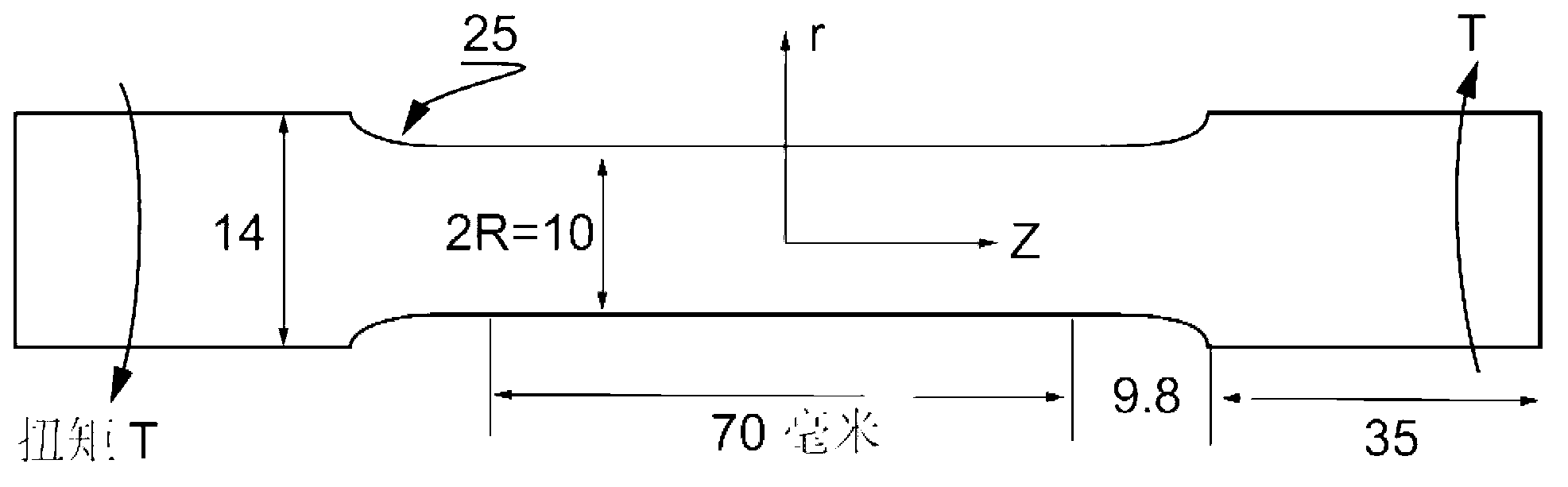

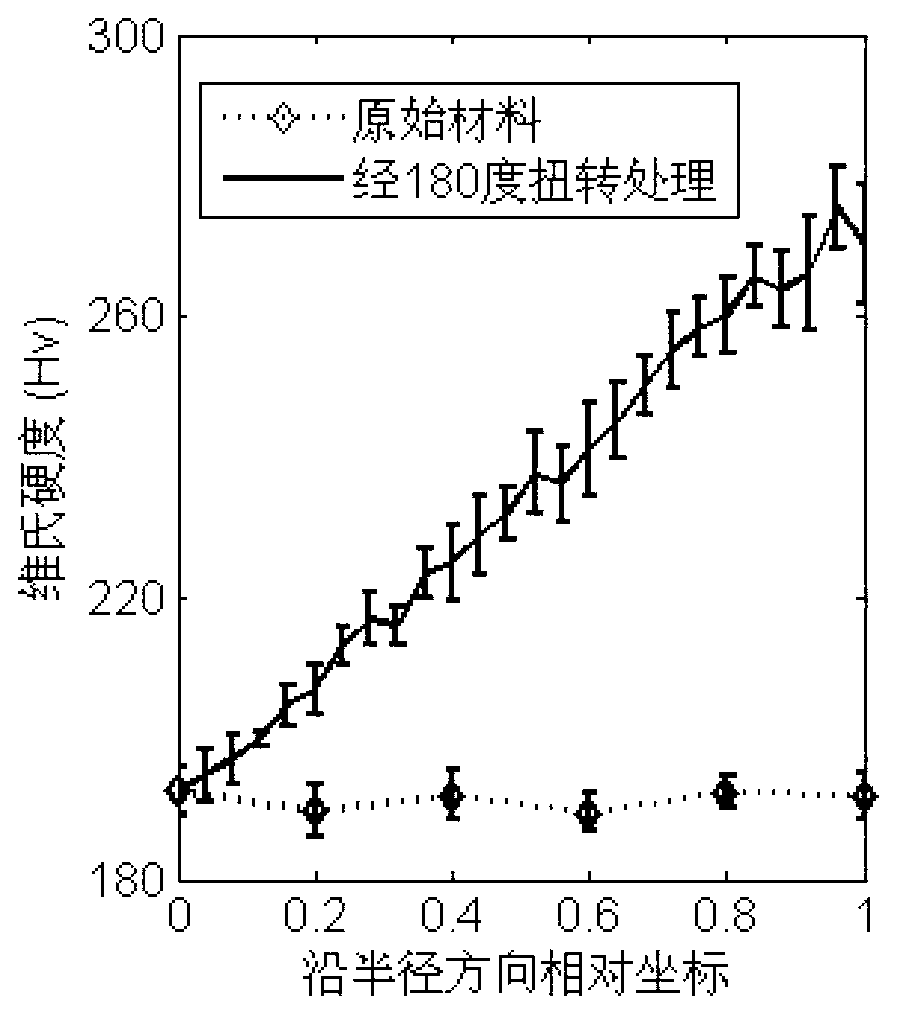

Method for improving intensity of metal material

The invention provides a method for improving the intensity of a metal material. The method comprises the following steps of: selecting the metal material, of which the plastic deformation is guided by twin crystal deformation or phase change; twisting the metal material, so that surface strain generated by the metal material meets predetermined conditions. According to the method provided by the invention, the intensity of the metal material can be improved observably without influences on the tension toughness of the metal material.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method for preparing silicon carbide nano-wire with periodical twin crystal structure

InactiveCN101186297AReduce manufacturing costLow reaction temperatureNanostructure manufactureReaction temperatureHydrolysis

The invention relates to a preparation method of silicon carbide nano-wire having periodic twin structure. Biphenyl is dissolved in acetone; nitrate is added and dissolved, tetraethyl orthosilicate is added into the solution and well mixed to be hydrolyzed to form sol; hexamethylene tetramine is added in the sol to form gel and the obtained gel is dried for 5-30h at the temperature of 80-110 DEG C to obtain dry gel; the dry gel is heated to 1200-1400 DEG C to be constantly reacted for 3-20h under the condition of argon, naturally cooled to room temperature, oxidized for 1-6h at the temperature of 600-800 DEG C, pickled by hydrochloride and hydrofluoric acid, then is cleaned by water and dried, and at last the silicon carbide nano-wire having periodic twin structure is obtained. The invention has the advantages of low production cost, low reaction temperature and simple and straightforward technique.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

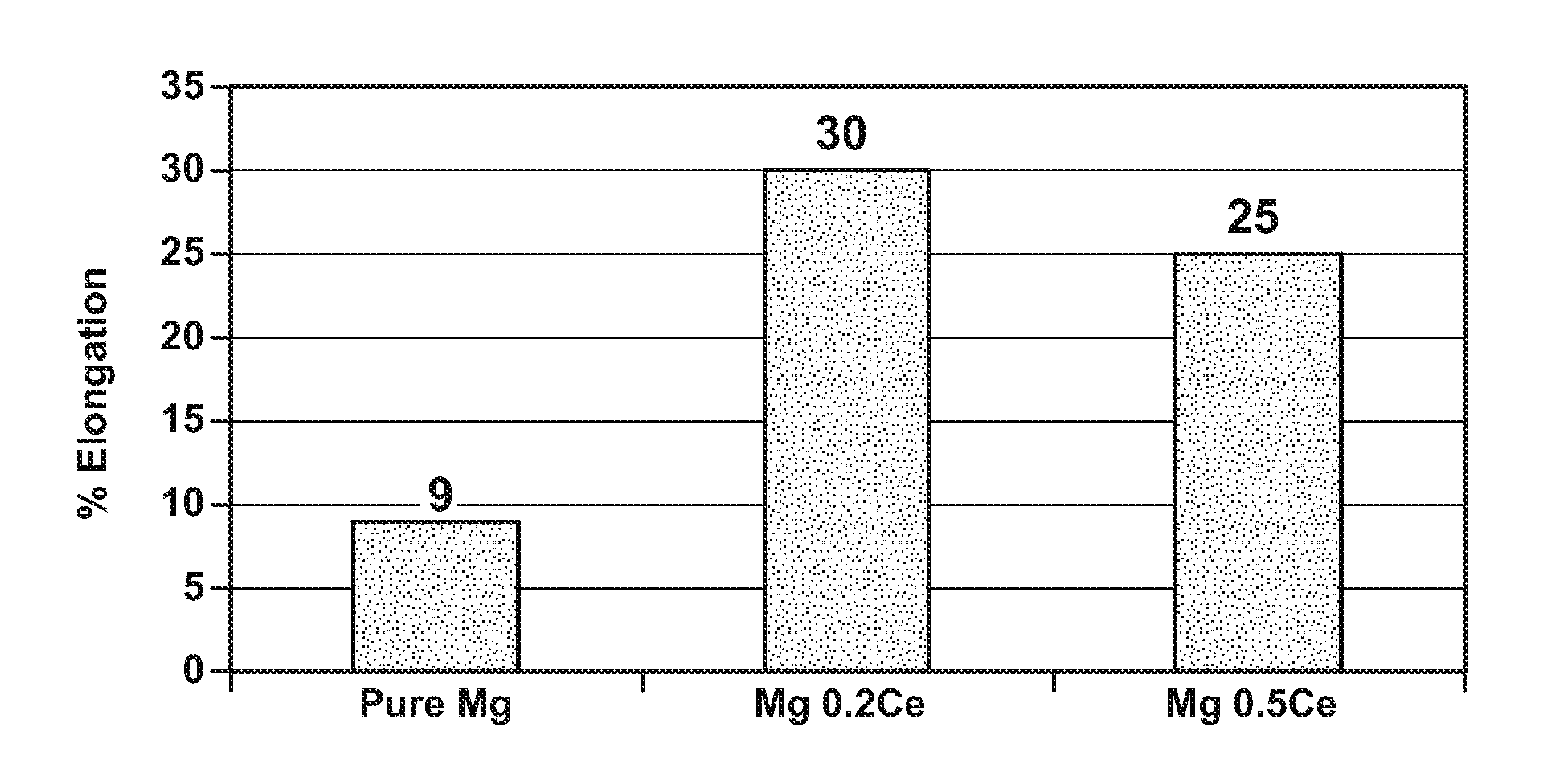

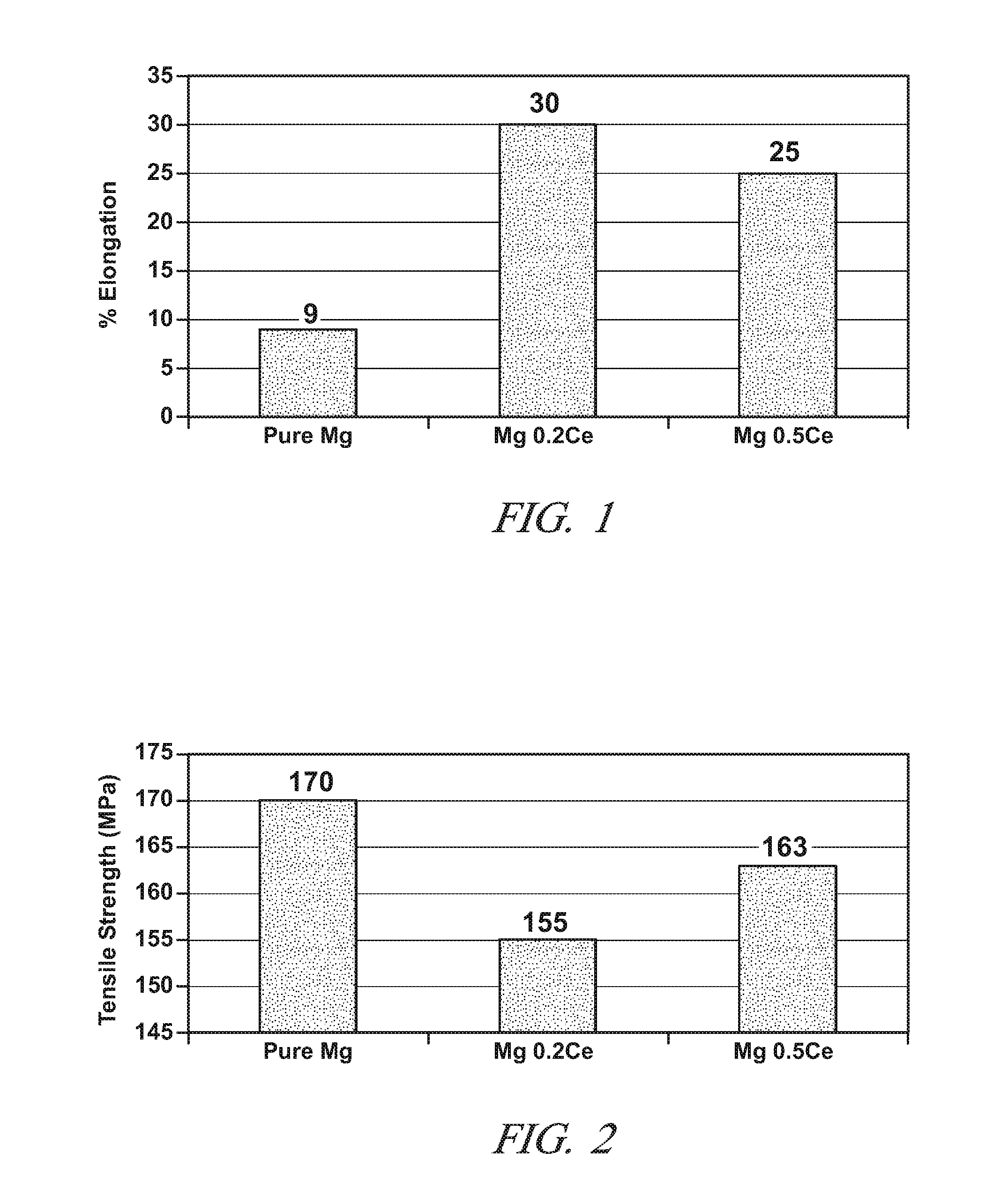

Forming magnesium alloys with improved ductility

A magnesium alloy comprising up to about one weight percent of cerium may be hot worked to produce an intermediate or final alloy workpiece that exhibits enhanced ductility at room temperature. The addition of a small amount of cerium may affect the magnesium alloy by reducing yield strength, refining grain size, and improving the work hardening behavior. Recrystallization during hot deformation of the rare earth containing magnesium material alters the texture of the alloy and orients the grains in a manner that favors basal slip activity. The alloy thus deforms at room temperature by a combination of twinning and slip mechanisms.

Owner:GM GLOBAL TECH OPERATIONS LLC

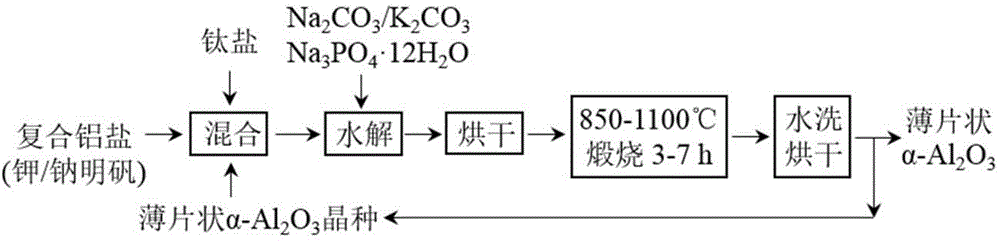

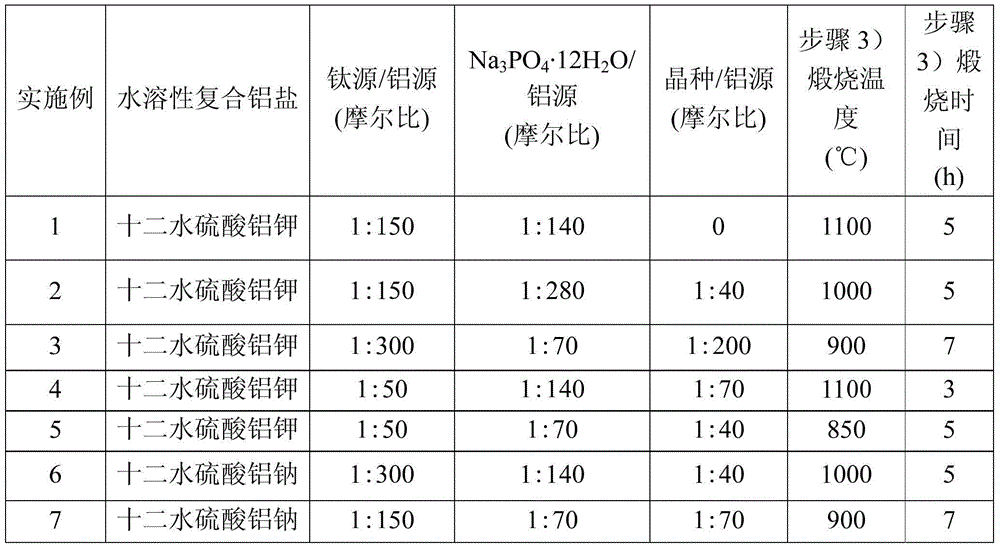

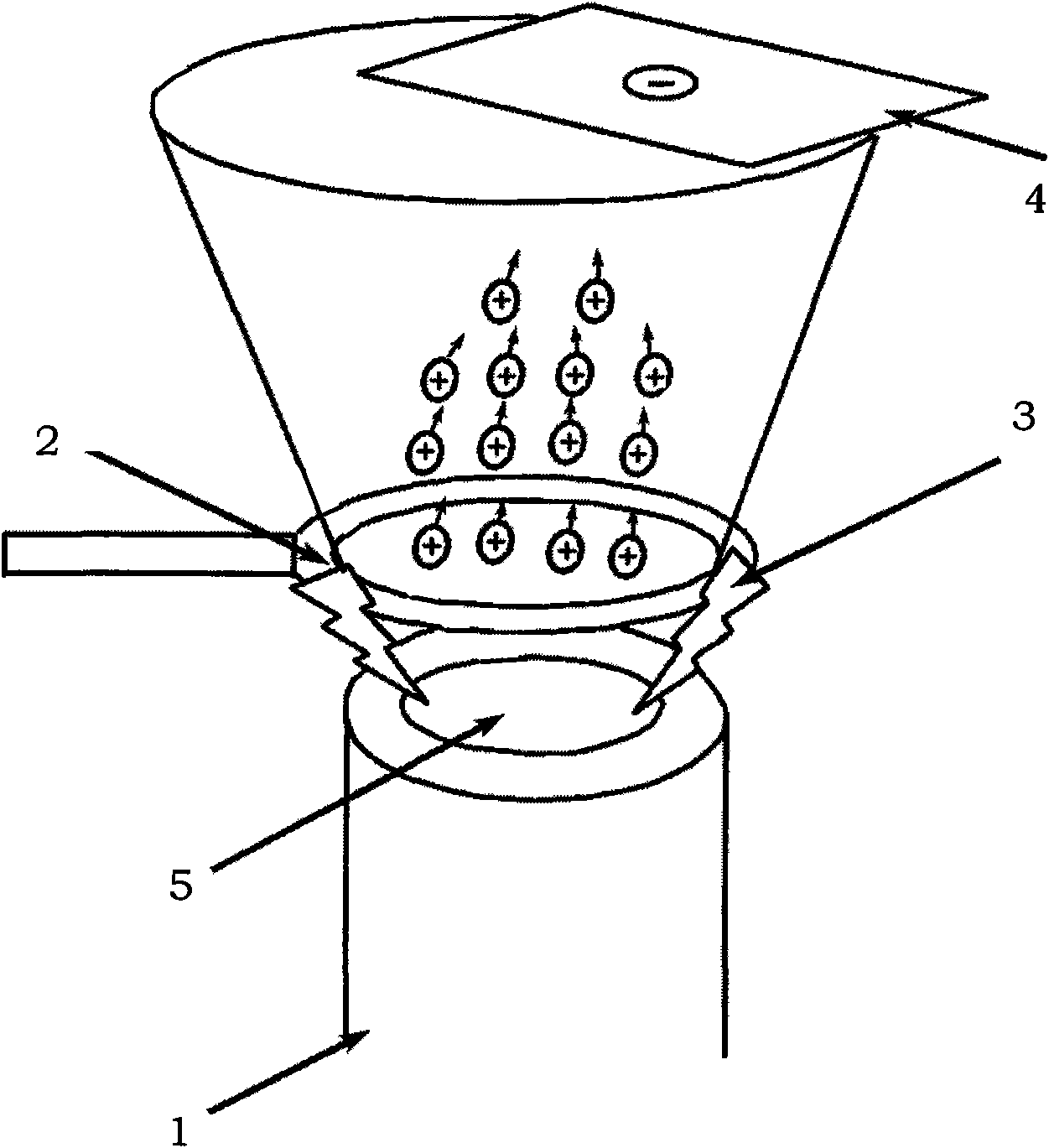

Method for preparing laminar alpha-Al2O3 pearlescent pigment base material by use of compound aluminum salt

The invention discloses a method for preparing a laminar alpha-Al2O3 pearlescent pigment base material by use of compound aluminum salt. The compound aluminum salt (aluminium potassium sulfate or aluminum sodium sulfate) is selected as the aluminium source, and is hydrolyzed to produce a required fused salt in situ; under the condition of adding laminar alpha-Al2O3 seed crystals and crystal growth regulators (a titanium salt and a phosphate), a gel produced by reaction is dried and calcined at 850-1100 DEG C to prepare laminar alpha-Al2O3 with favorable properties, so that the method is simple in process. The obtained laminar alumina (0.2-0.5 [mu]m in average thickness, 11-15 [mu]m in average particle diameter, larger than 20 in diameter-to-thickness ratio and no clustering or crystal twinning) can serve as the pearlescent pigment base material.

Owner:TSINGHUA UNIV

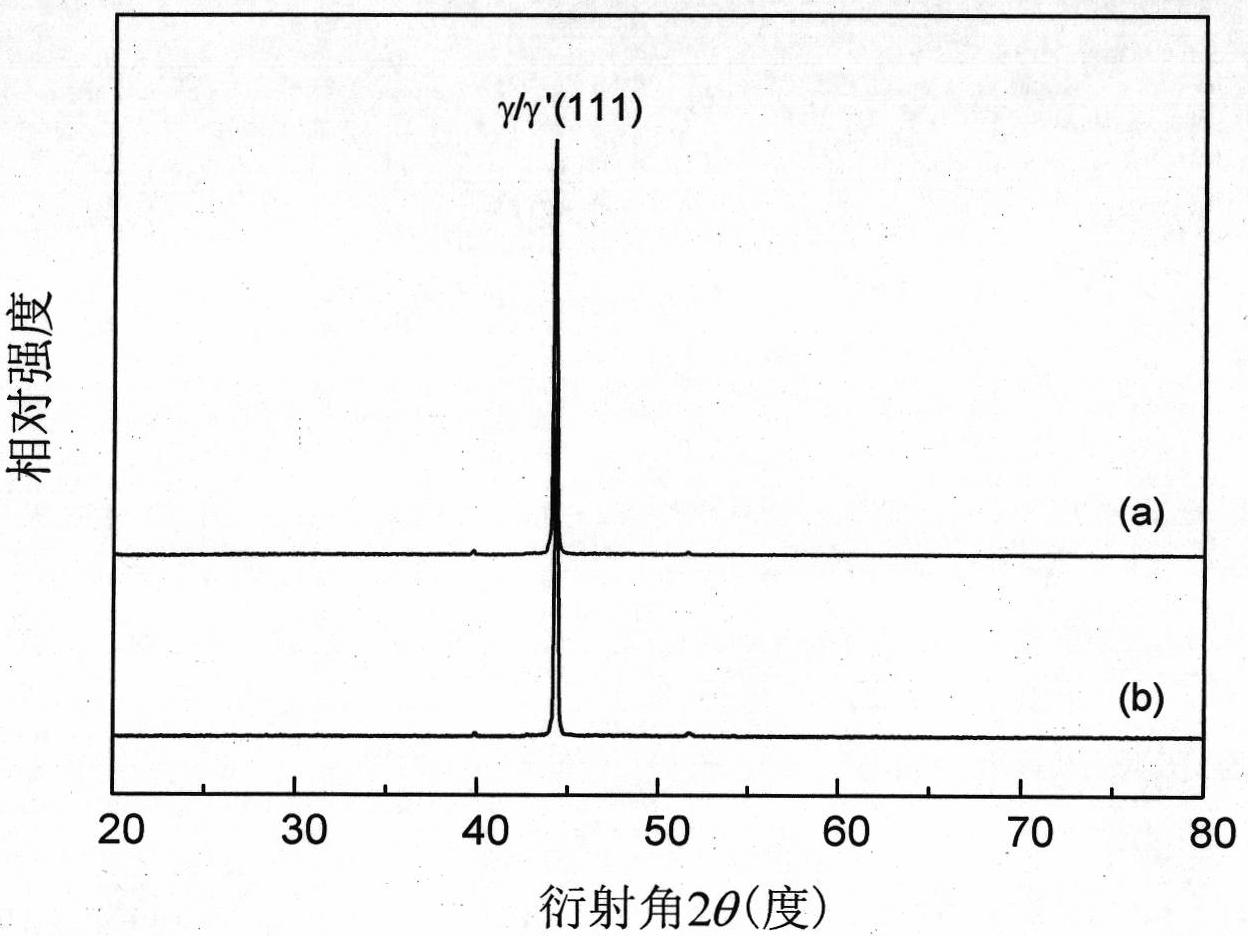

MCrAlY coating with excellent oxidation resistance and preparation method thereof

InactiveCN101787516AAvoid damageLow oxidation rate constantVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionBeta phase

The invention discloses an MCrAlY coating with excellent oxidation resistance and a preparation method thereof. By adopting a plasma-assisted electron beam physical vapor deposition technique and controlling the substrate temperature, the anodal discharge voltage, the evaporation voltage and the bias voltage applied on a matrix, the MCrAlY coating is prepared, and the crystallite dimension of the coating is 10 Mu m to 50 Mu m of isometric crystal structure; the orientation of the coating along a (111) close-packed direction is strong; the twin crystal dimension in the coating is 200nm to 500nm; the Beta phase in the coating is uniformly distributed in the form of strips along the growing direction, moreover, the dimension of the Beta phase is less than 1 Mu m, and a large quantity of phase interfaces are formed. When the coating is used under the temperature of 1150 DEG C, the high-density twin crystals and the phase interfaces provide passages for Al element to quickly diffuse outwards, so that a dense Alpha-Al2O3 protective film can be more easily formed, meanwhile, the destructive effect of the outward diffusion of the matrix element on the oxide film is weakened, and thereby the oxidation resistance of the coating is excellent, and is increased by one order of magnitude compared with the oxidation resistance of the conventional EB-PVD coating.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com