Copper pillar bump interconnection structure for directional growth and preparation method of copper pillar bump interconnection structure

An interconnection structure and directional growth technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., to achieve industrialization, improve interconnection performance and service reliability, and facilitate industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

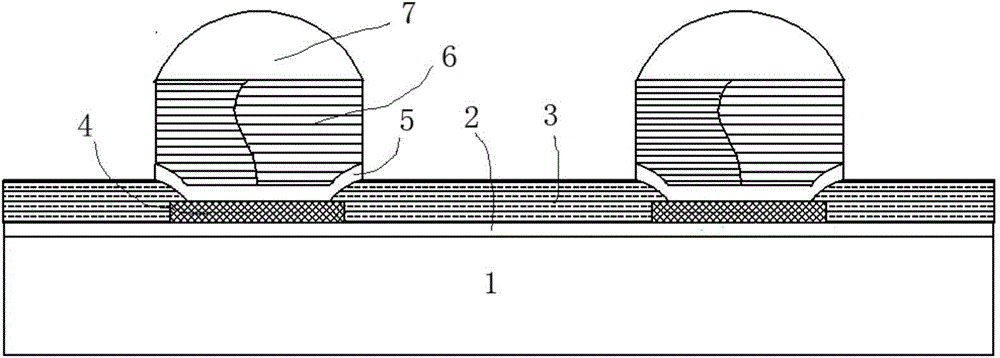

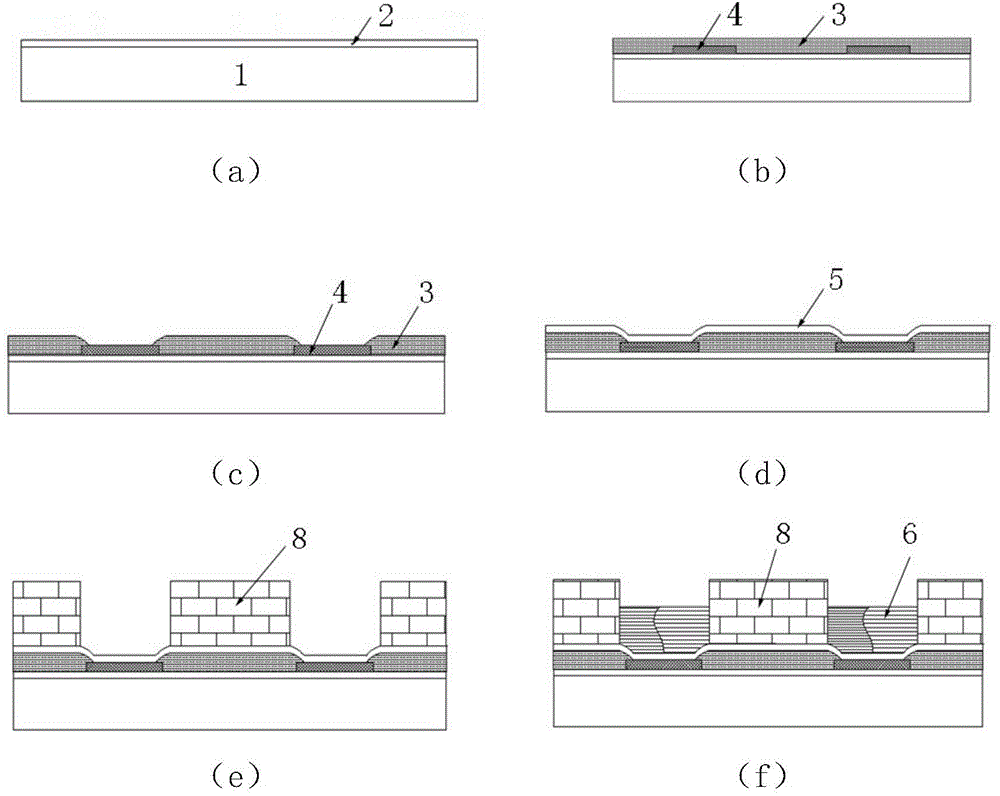

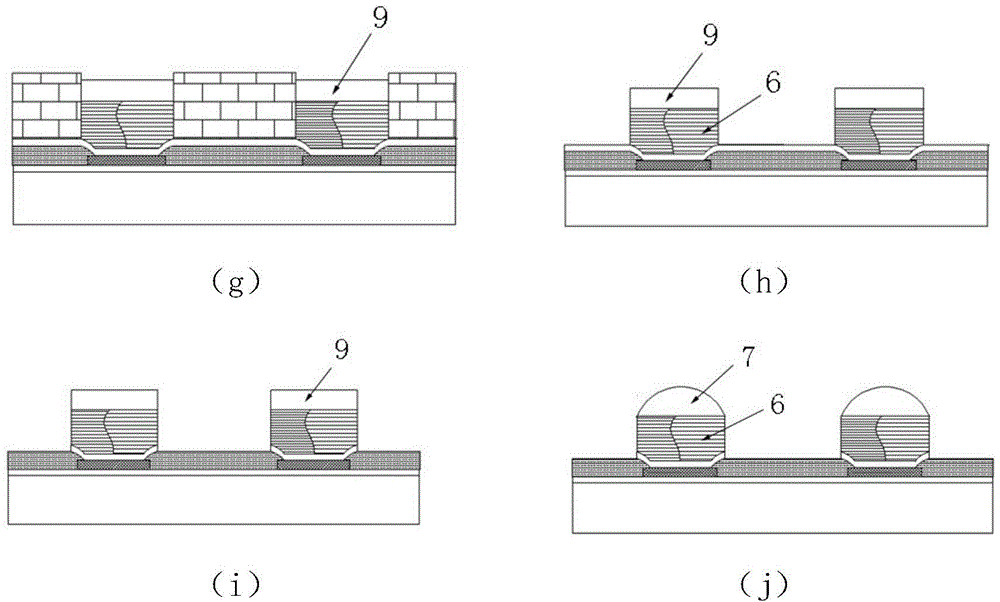

[0054] figure 2 It is a process flow chart for preparing a copper pillar bump interconnection structure of directional growth nano-twinned copper in the present invention, and the process steps are:

[0055] (1) Prepare the wafer base 1 with insulating layer 2, such as figure 2 (a), arranging a metal disc 4 on the insulating layer 2; or directly using a chip on which a metal disc and interconnection lines have been arranged as a substrate;

[0056] (2) deposit dielectric layer 3 on insulating layer 2 and metal plate 4, as figure 2 (b), selectively masking and etching the dielectric layer makes the surface of the metal disk 4 exposed in the window of the dielectric layer 3, such as figure 2 (c);

[0057] (3) Deposit seed layer 5 on dielectric layer 3 and exposed metal disk 4, as figure 2 (d); The method of depositing the seed layer is physical vapor deposition (PVD) or sputtering, etc., the thickness of the seed layer is about 200nm, and the materials are Ti and Cu;

...

Embodiment 2

[0068] This embodiment is a preparation process for a copper pillar bump interconnection structure of directional growth nano-twinned copper, which is different from Embodiment 1 in that: step (5) in the process of direct current electroplating copper pillars: the electroplating solution is composed of: copper sulfate 200g / L, methanesulfonic acid 40mL / L, sodium chloride 30ppm (calculated according to the chlorine content in sodium chloride), polyethyleneimine 5ppm, gelatin 20ppm, and the rest is water; the electroplating anode plate is phosphor copper plate, phosphor copper plate The P element content in the medium is 0.03‐0.075wt.%, and the current density is 40mA / cm 2 , Electromagnetic stirring is used in the electroplating process to ensure that the concentration in the plating solution is uniform.

[0069] The cross-sectional structure of the copper pillars in the copper pillar bump interconnection structure obtained in this embodiment is analyzed, and the result is the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com