Patents

Literature

2697results about How to "Reduce warpage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

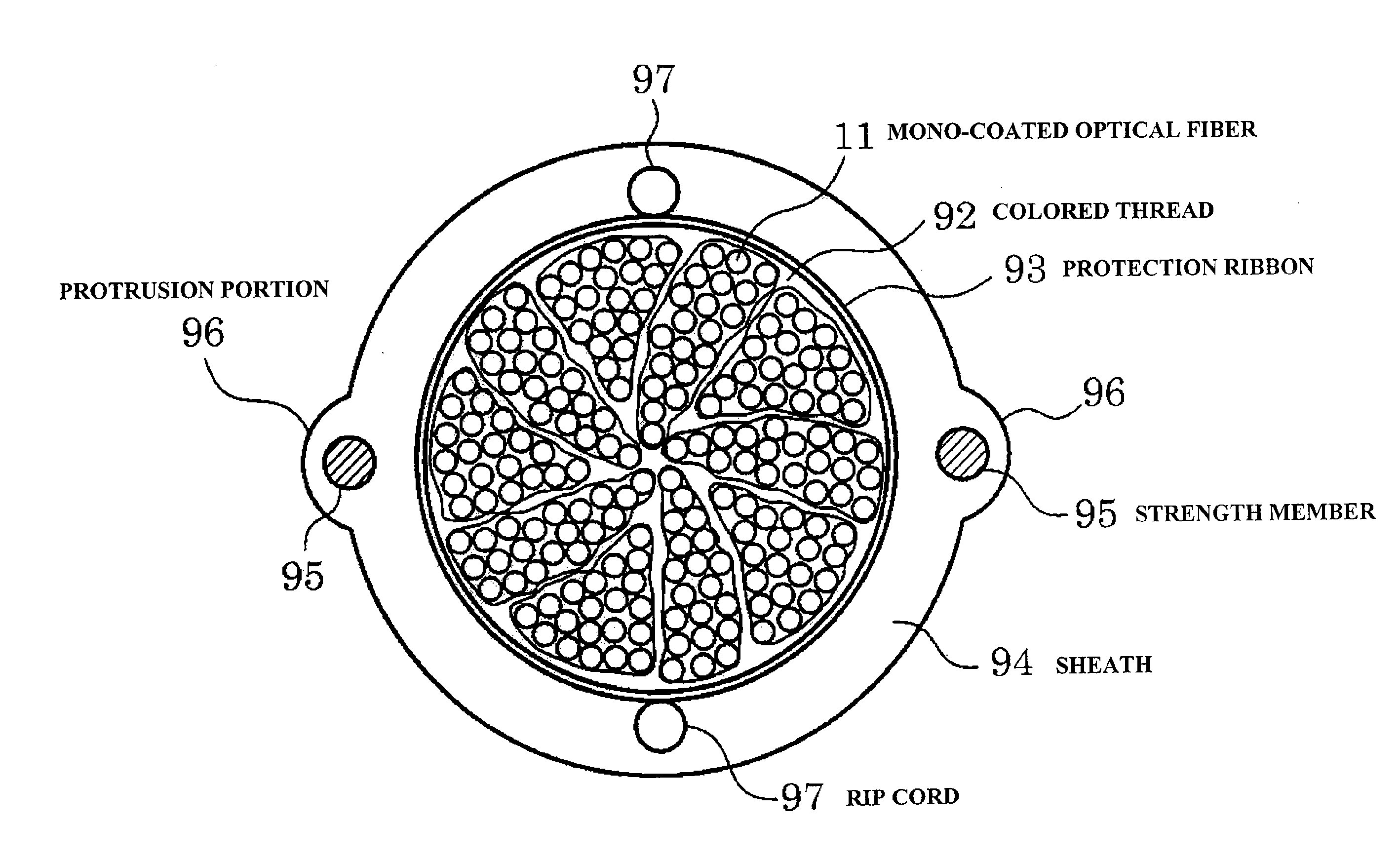

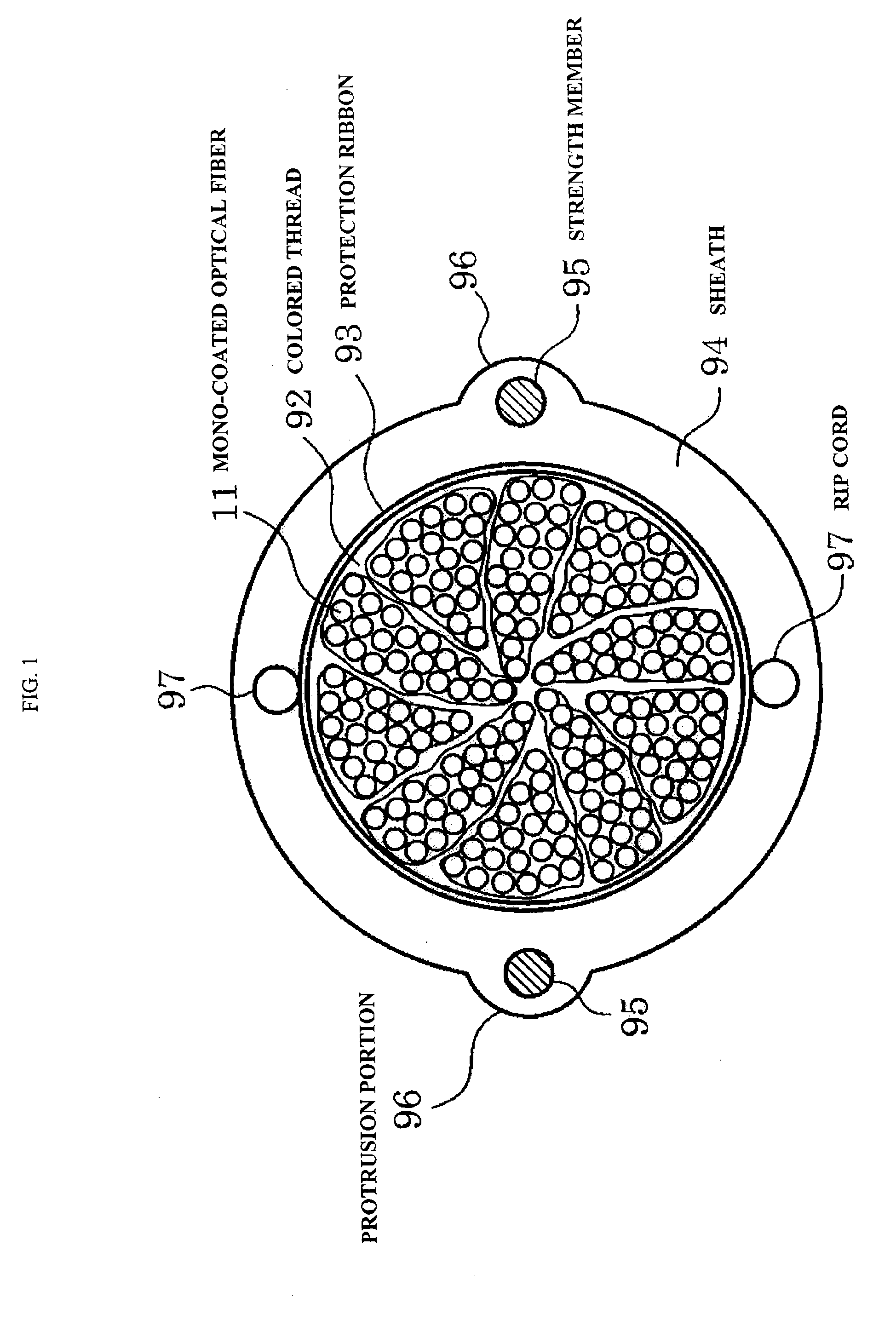

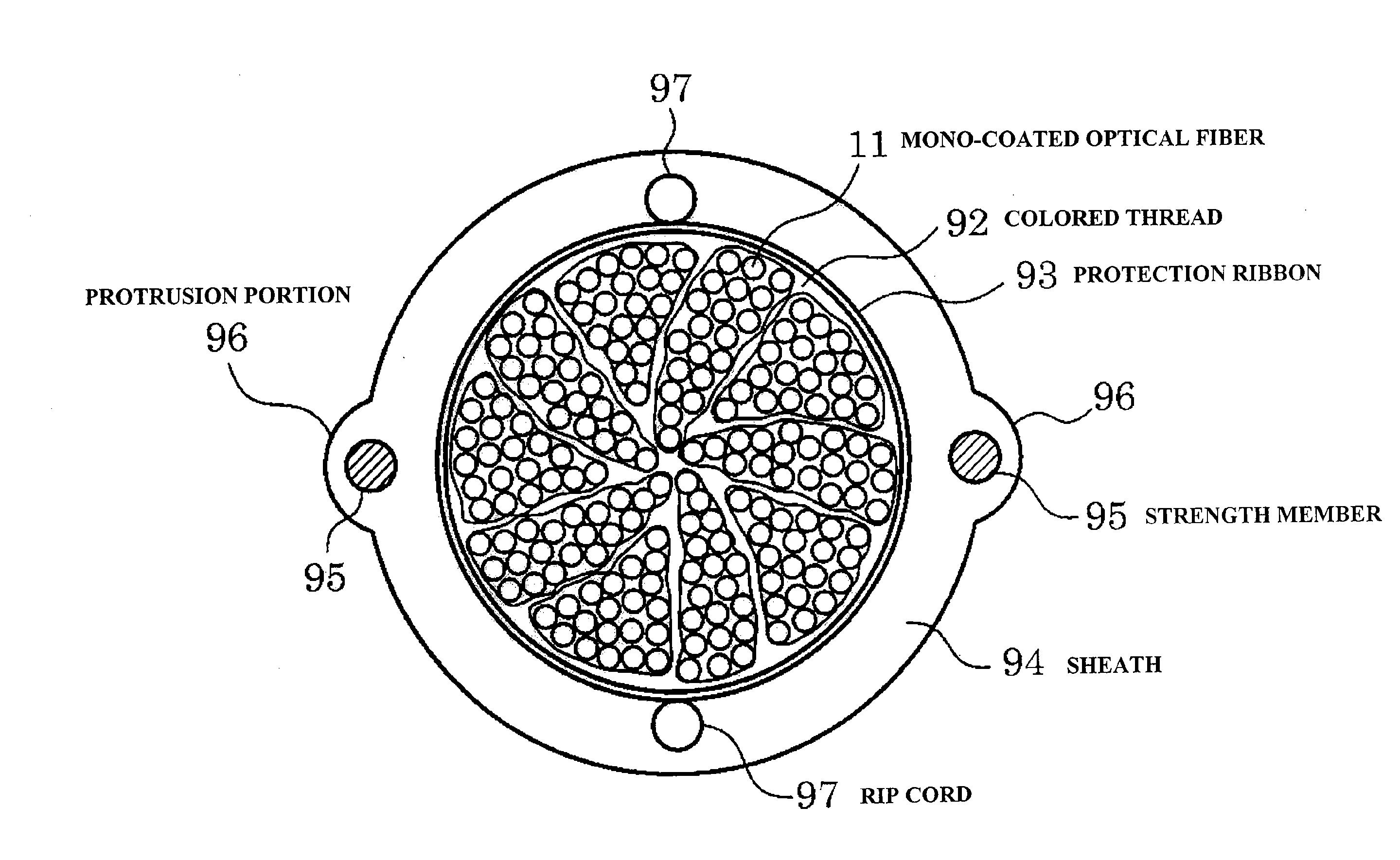

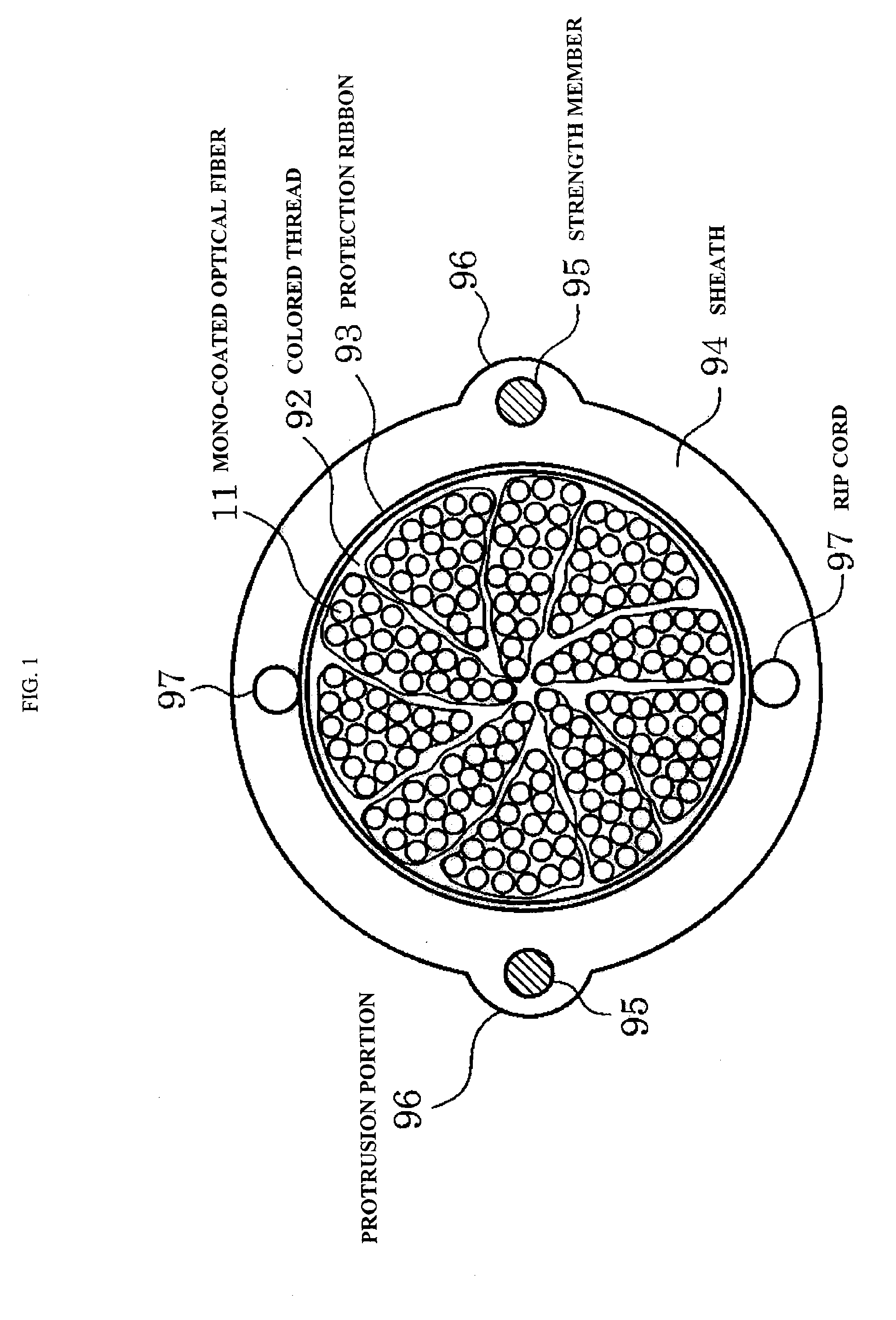

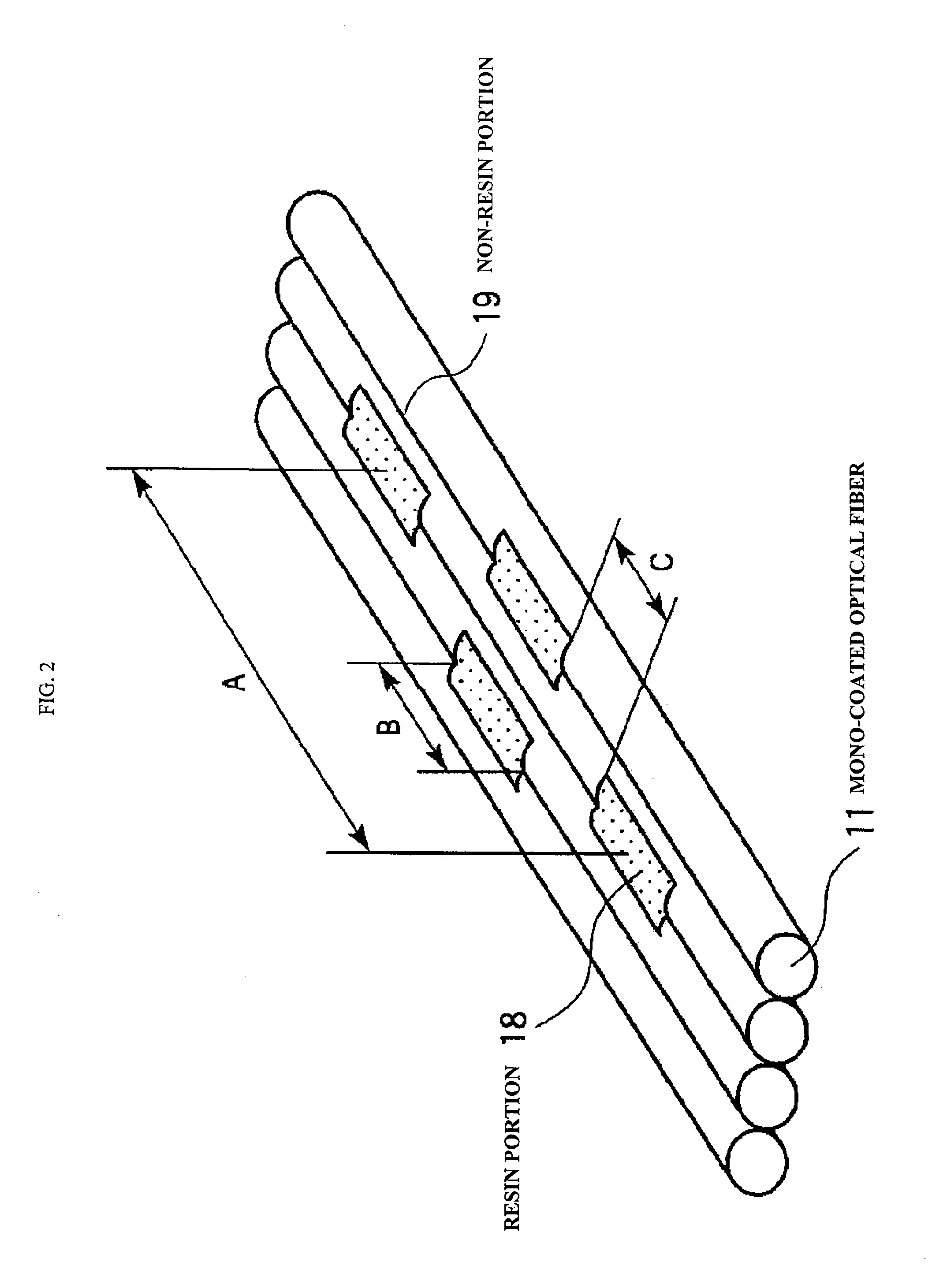

Optical fiber cable and optical fiber ribbon

ActiveUS8548294B2Stable optical loss characteristicReduce warpageFibre mechanical structuresEngineeringBend radius

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

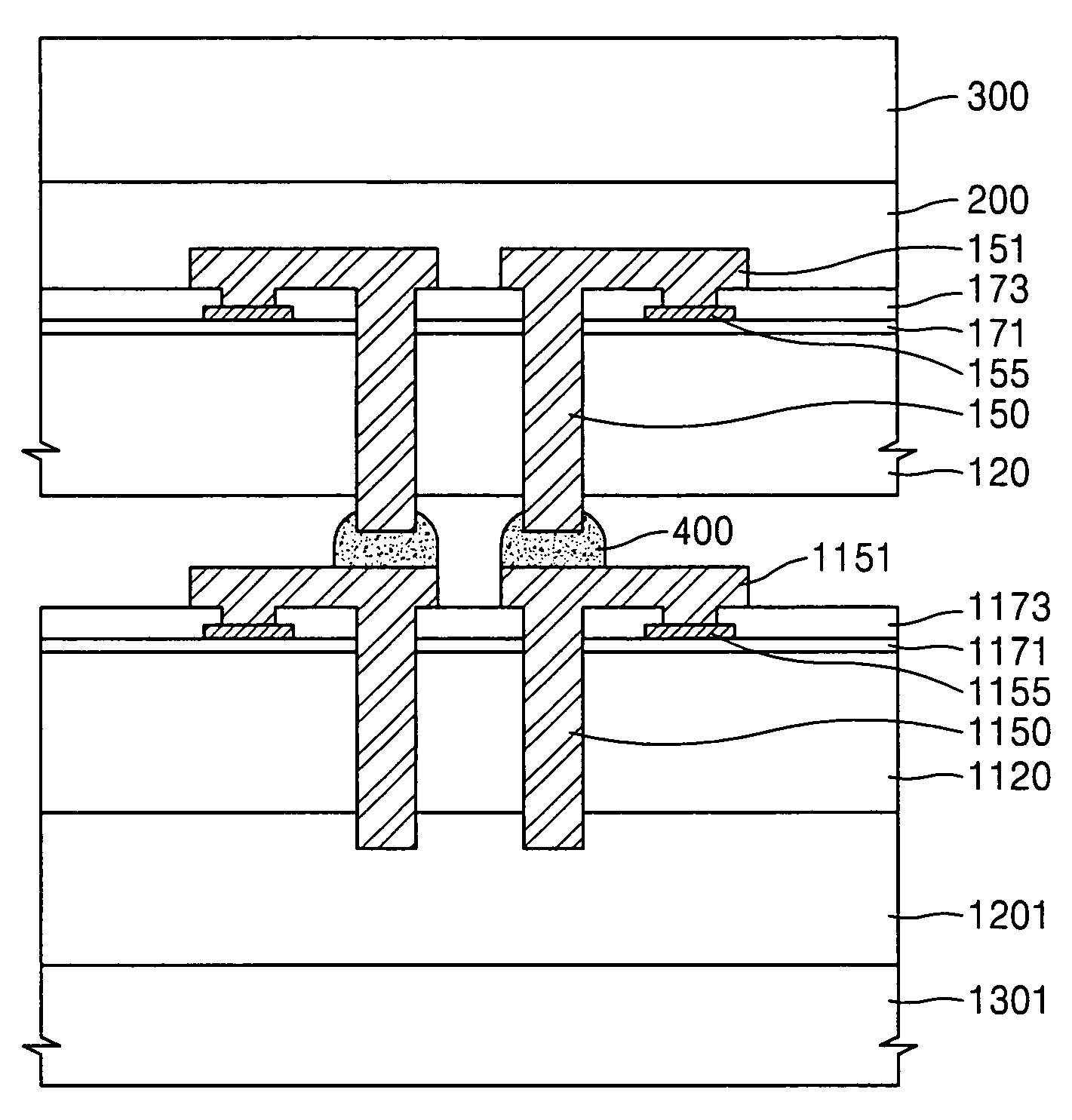

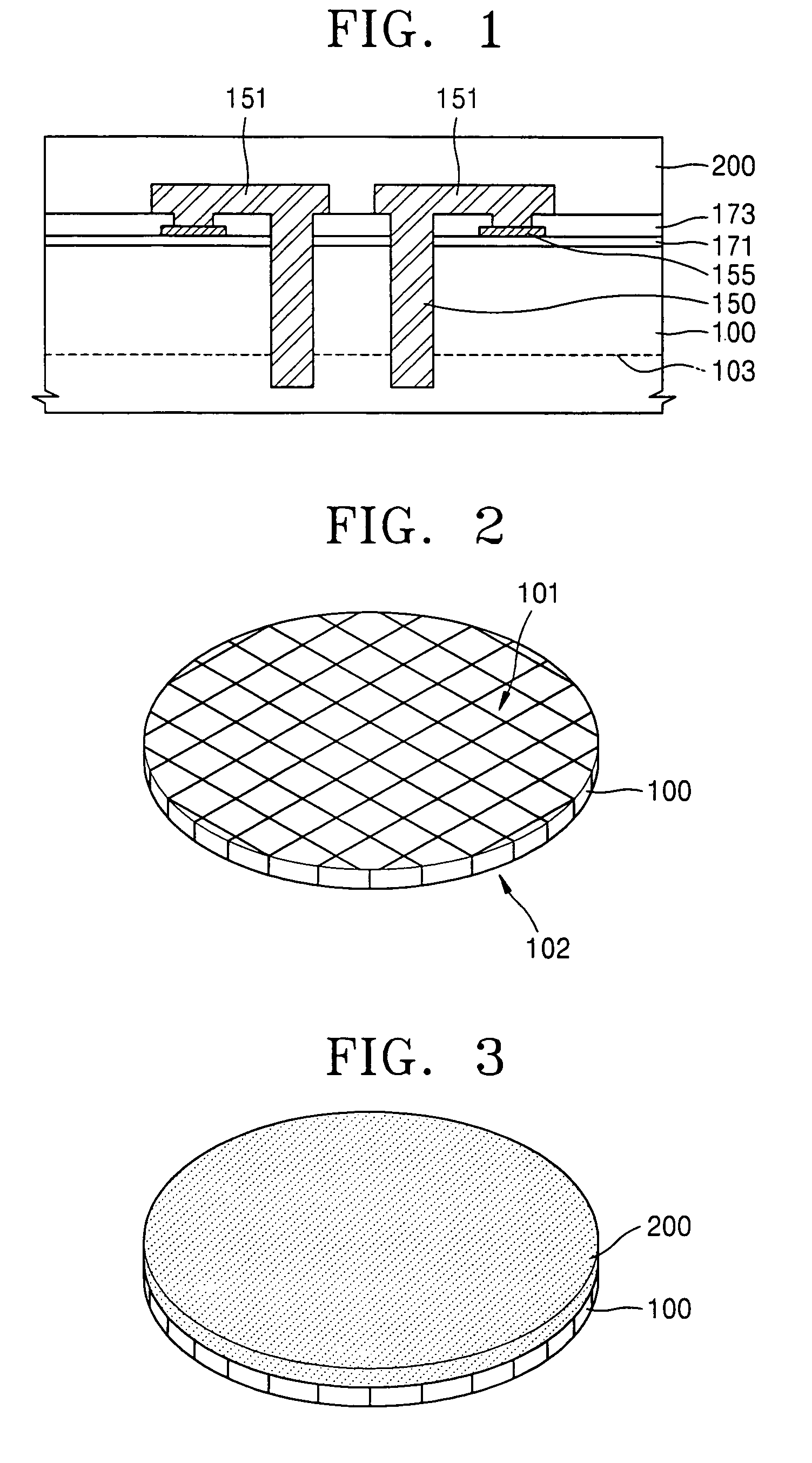

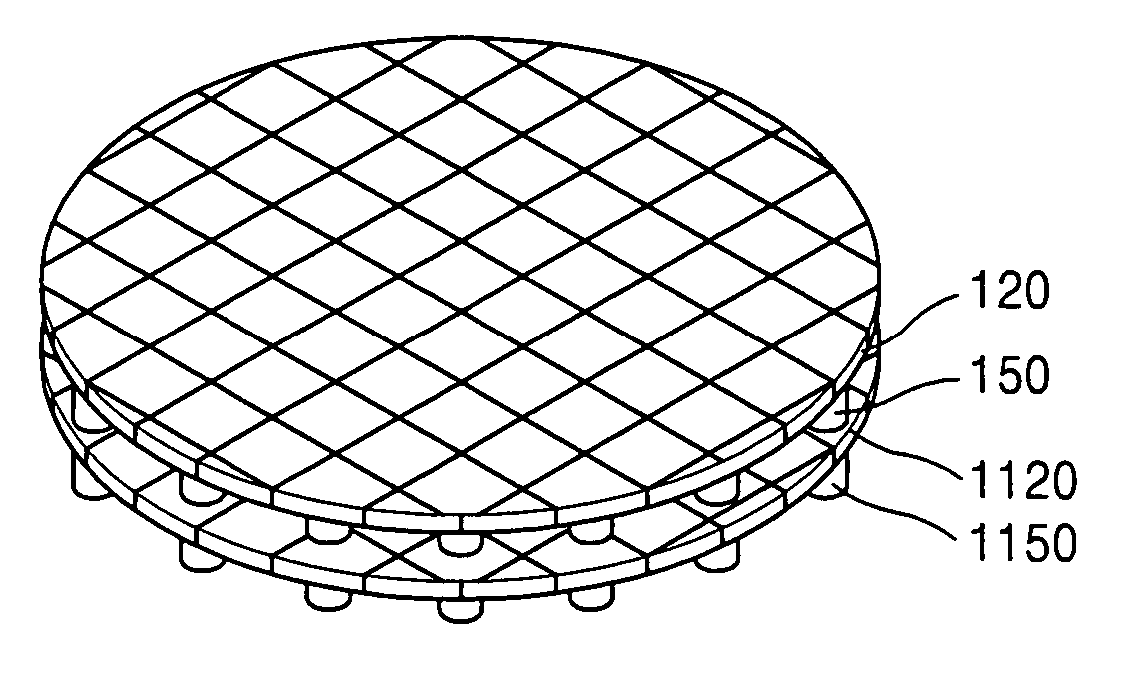

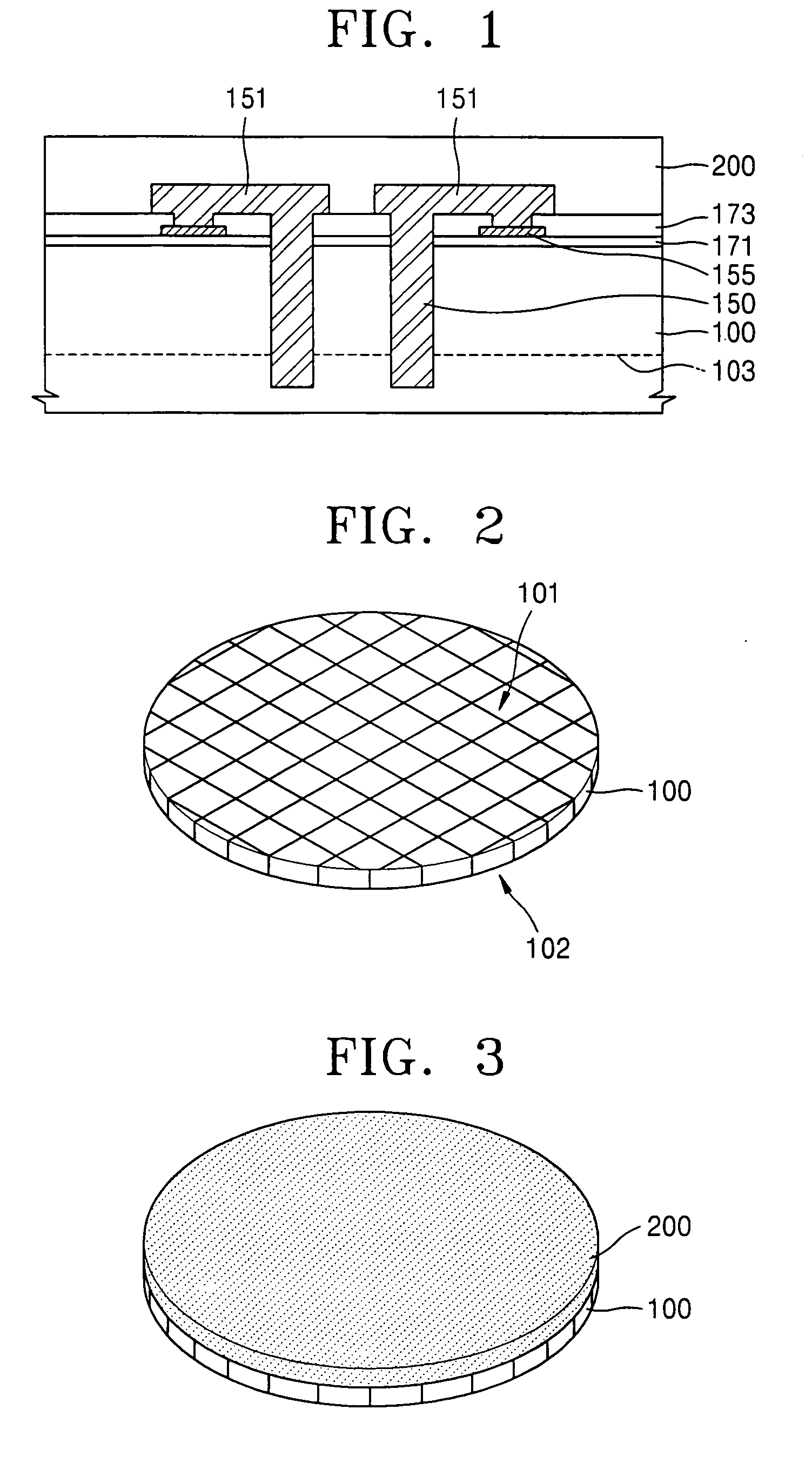

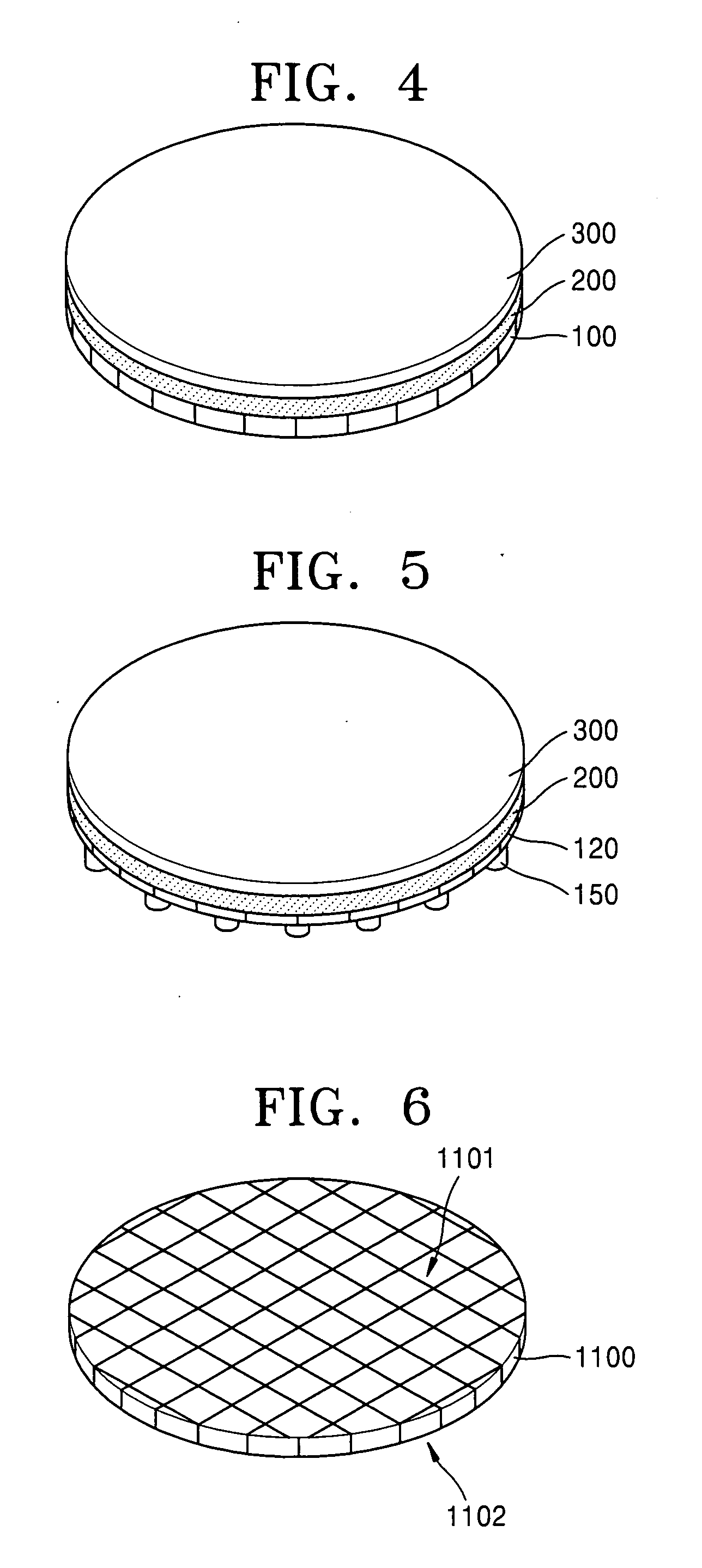

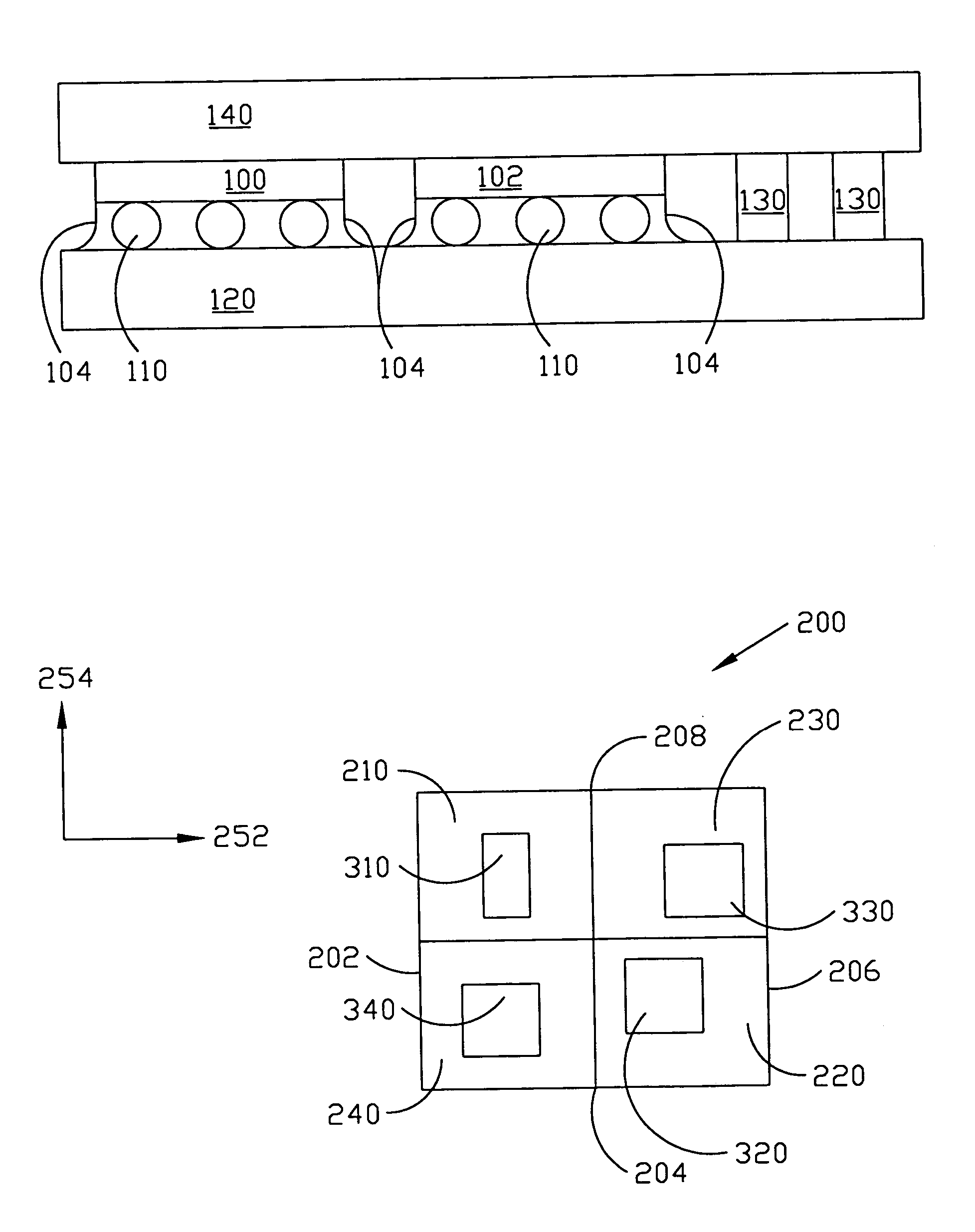

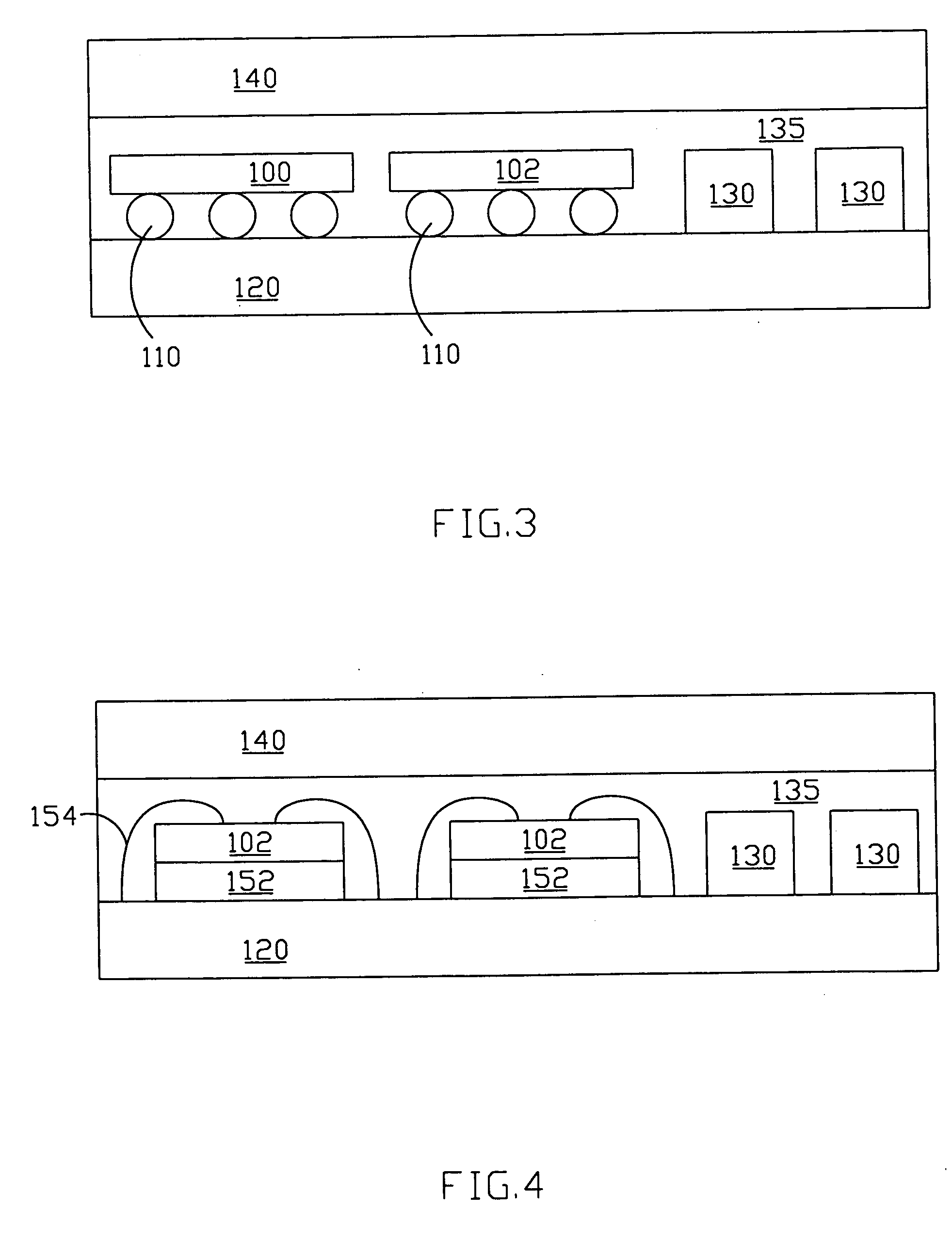

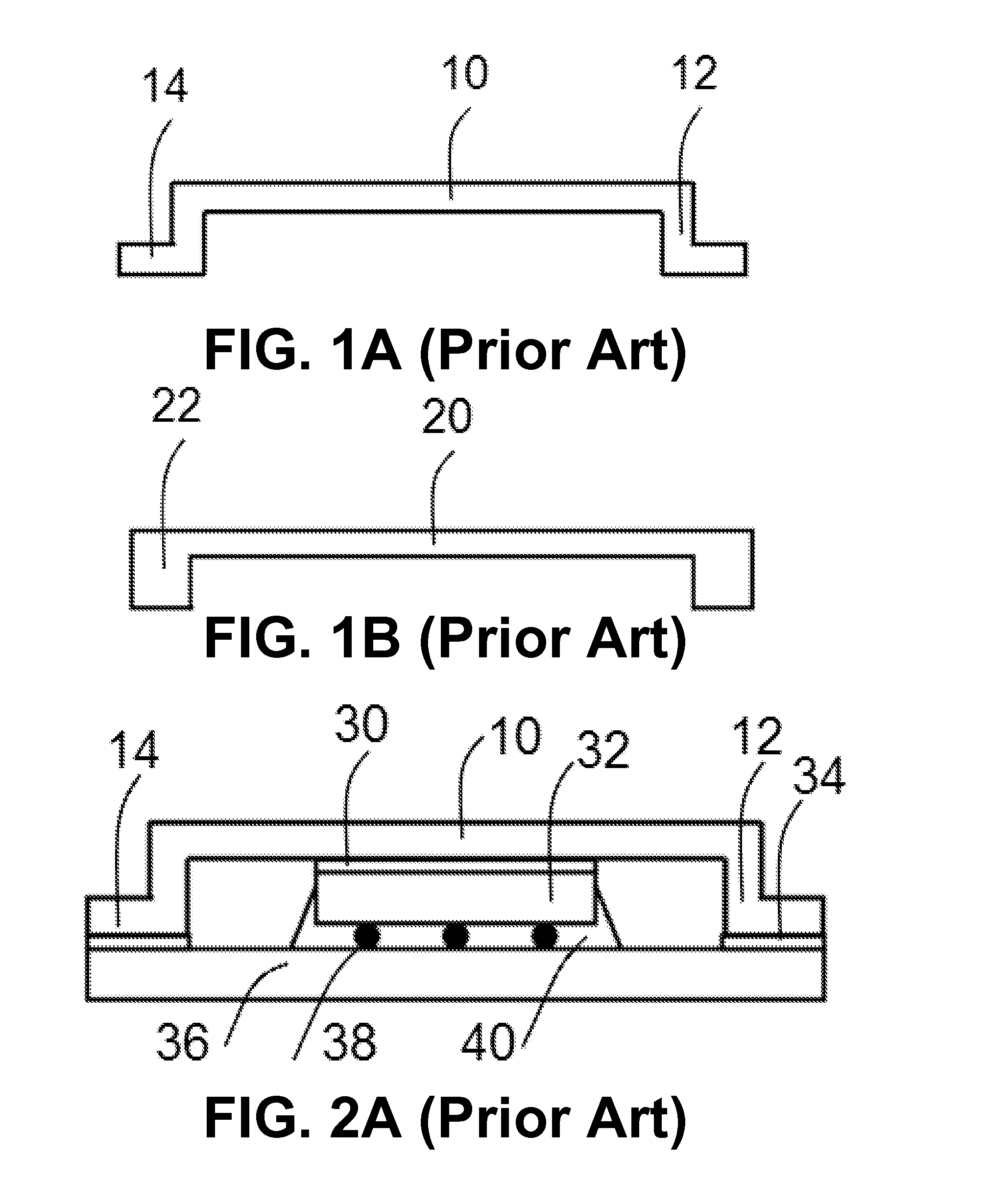

Method of forming a thin wafer stack for a wafer level package

InactiveUS7494845B2Reduce warpageTrend downSemiconductor/solid-state device detailsSolid-state devicesWaferingUltraviolet

A method of forming a stack of thin wafers provides a wafer level stack to greatly reduce process time compared to a method where individually separated chips are stacked after a wafer is sawed. A rigid planar wafer support member stabilizes and planarizes each wafer while it is thin or its thickness is reduced and during subsequent wafer processing. Thinned wafers are stacked and the external support members are removed by applying heat or ultraviolet (UV) light to an expandable adhesive layer between the support members and the thin wafers. The stacked wafers then can be further processed and packaged without thin-wafer warping, cracking or breaking. A wafer level package made in accordance with the invented method also is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

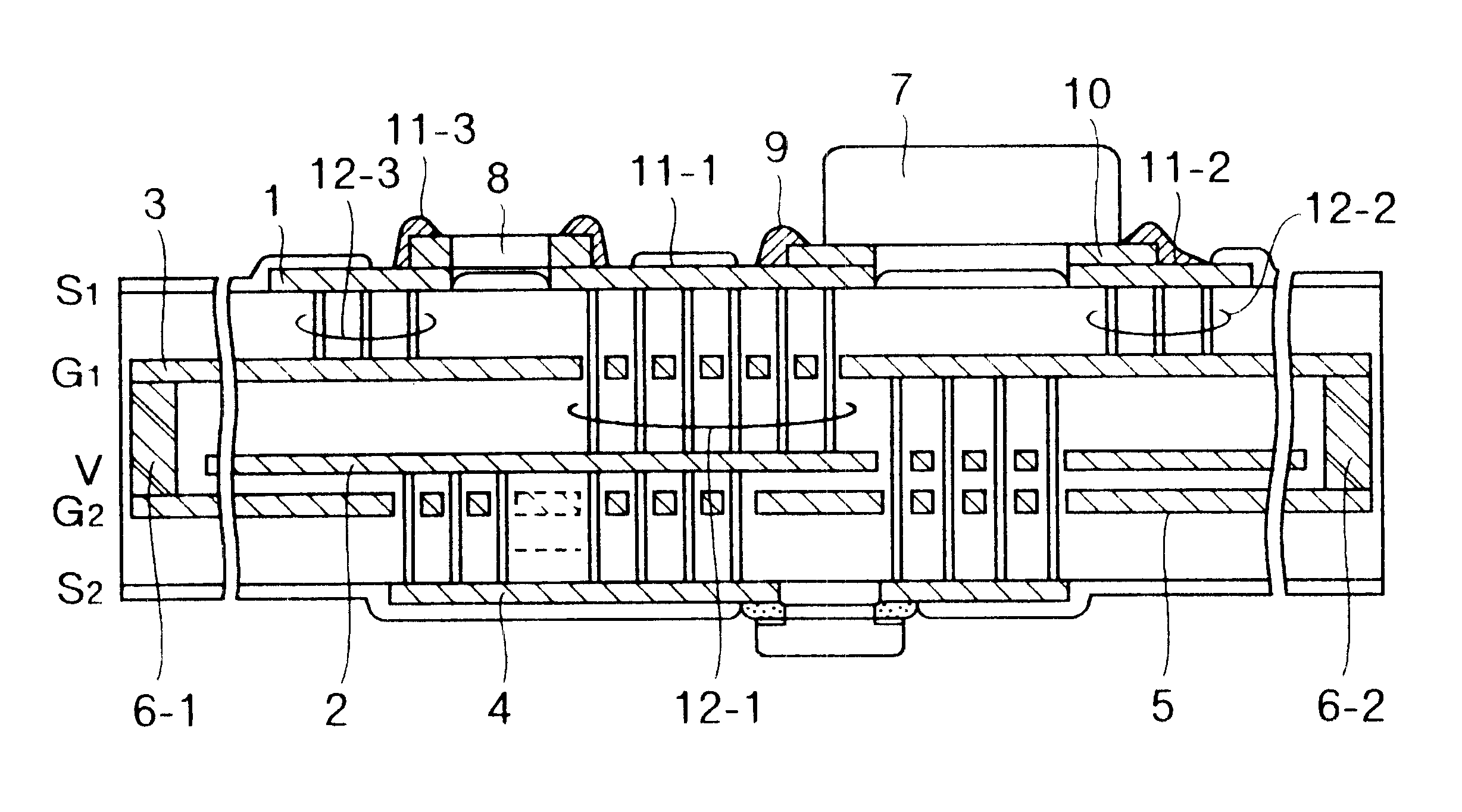

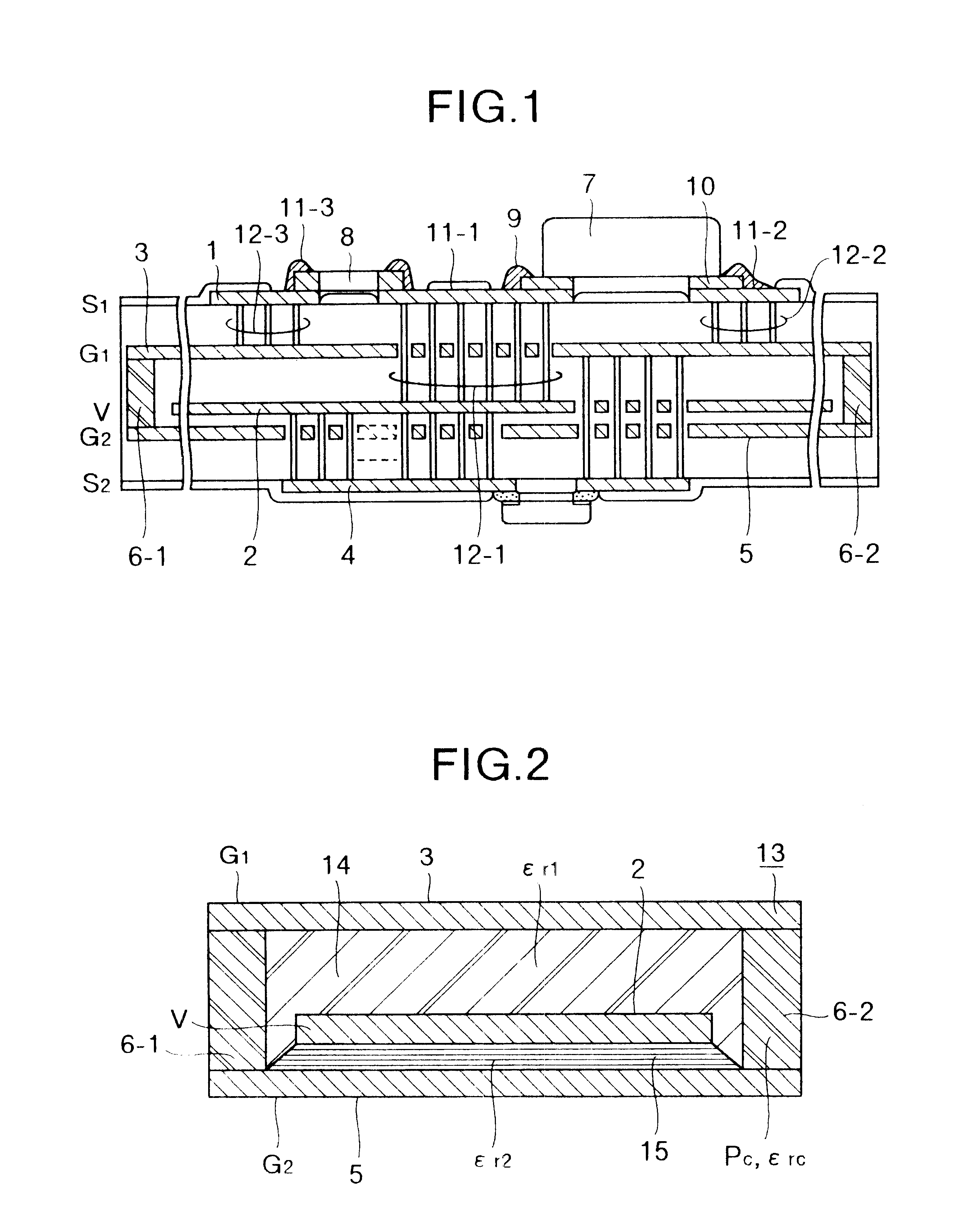

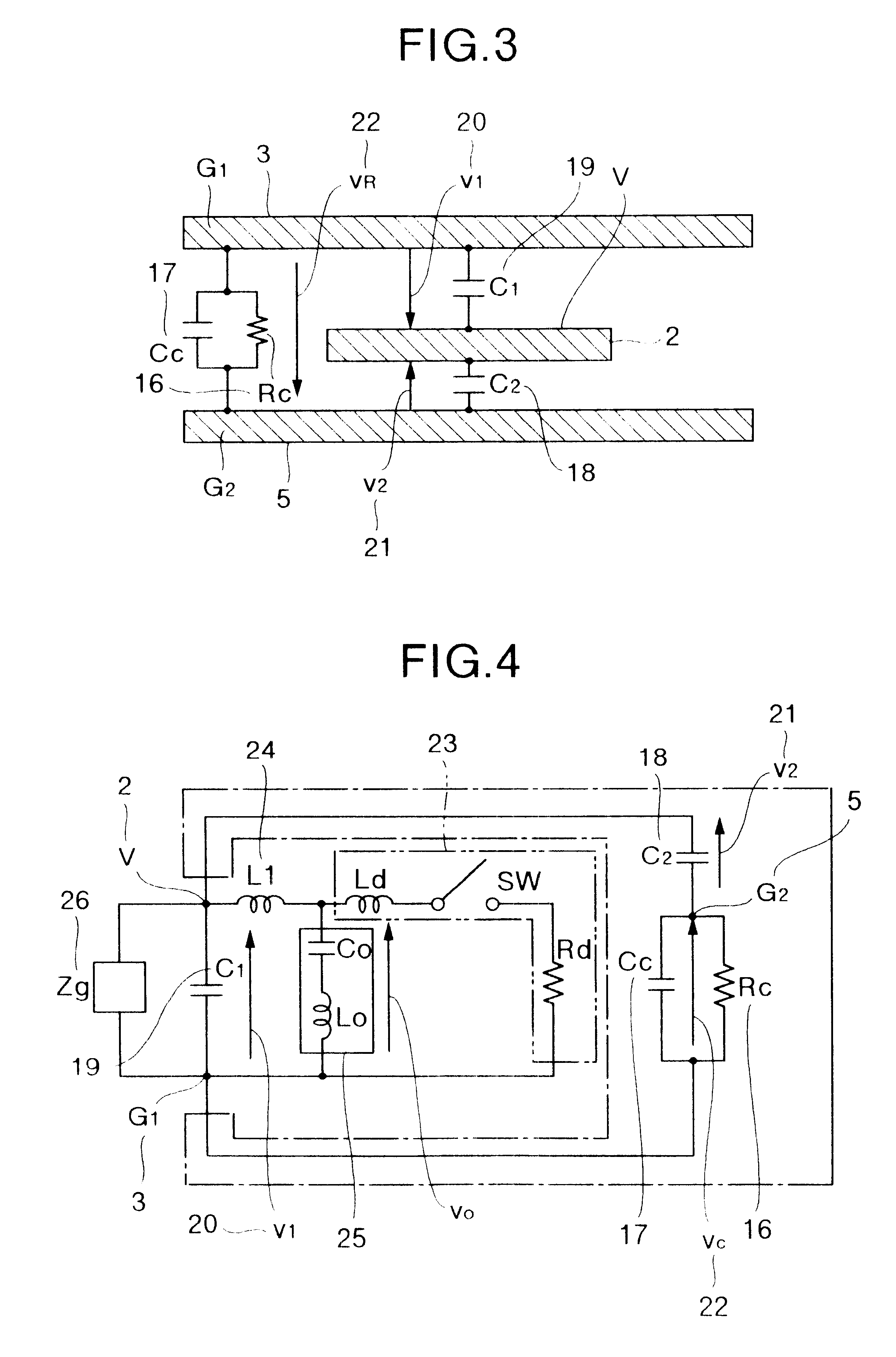

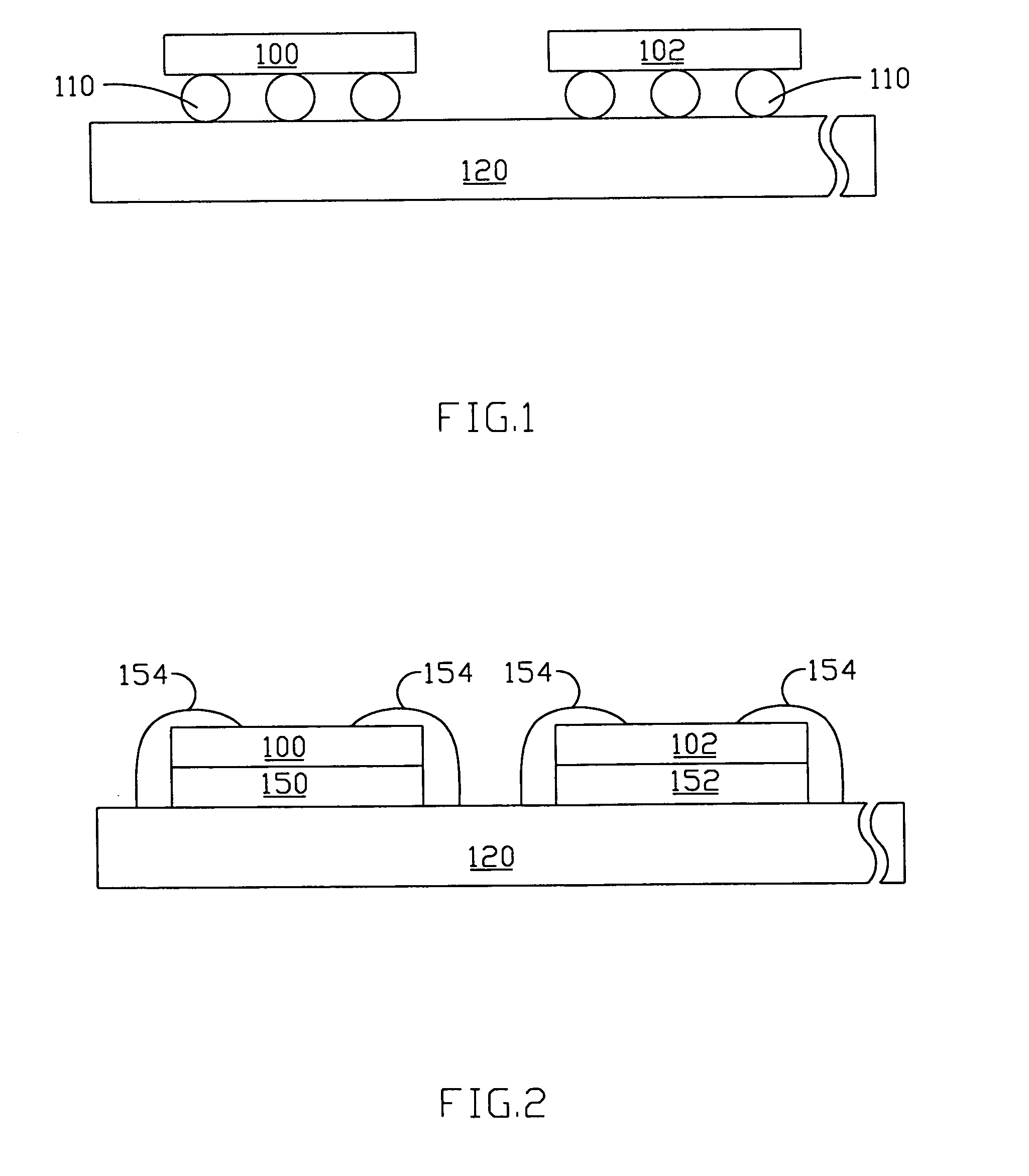

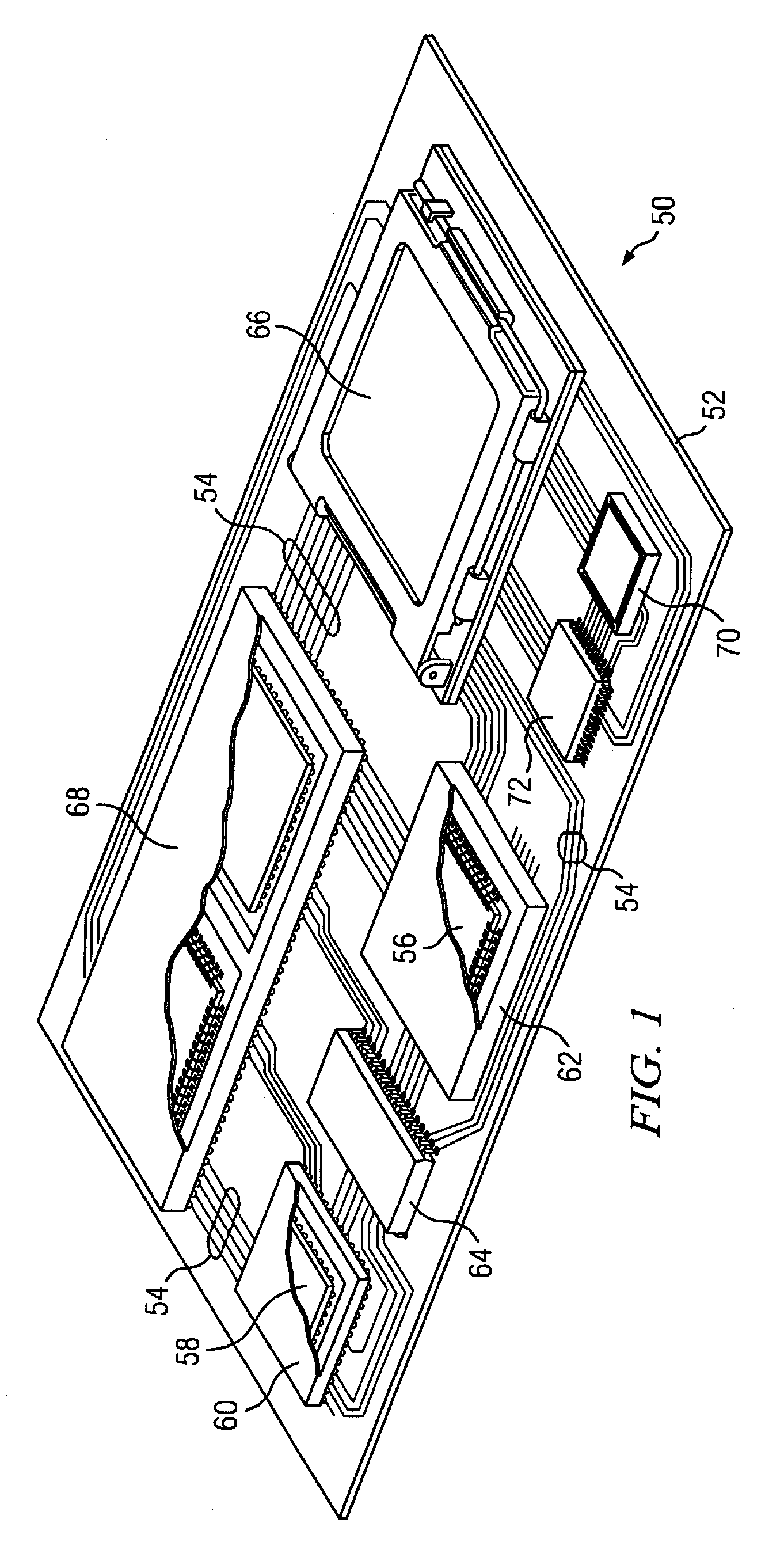

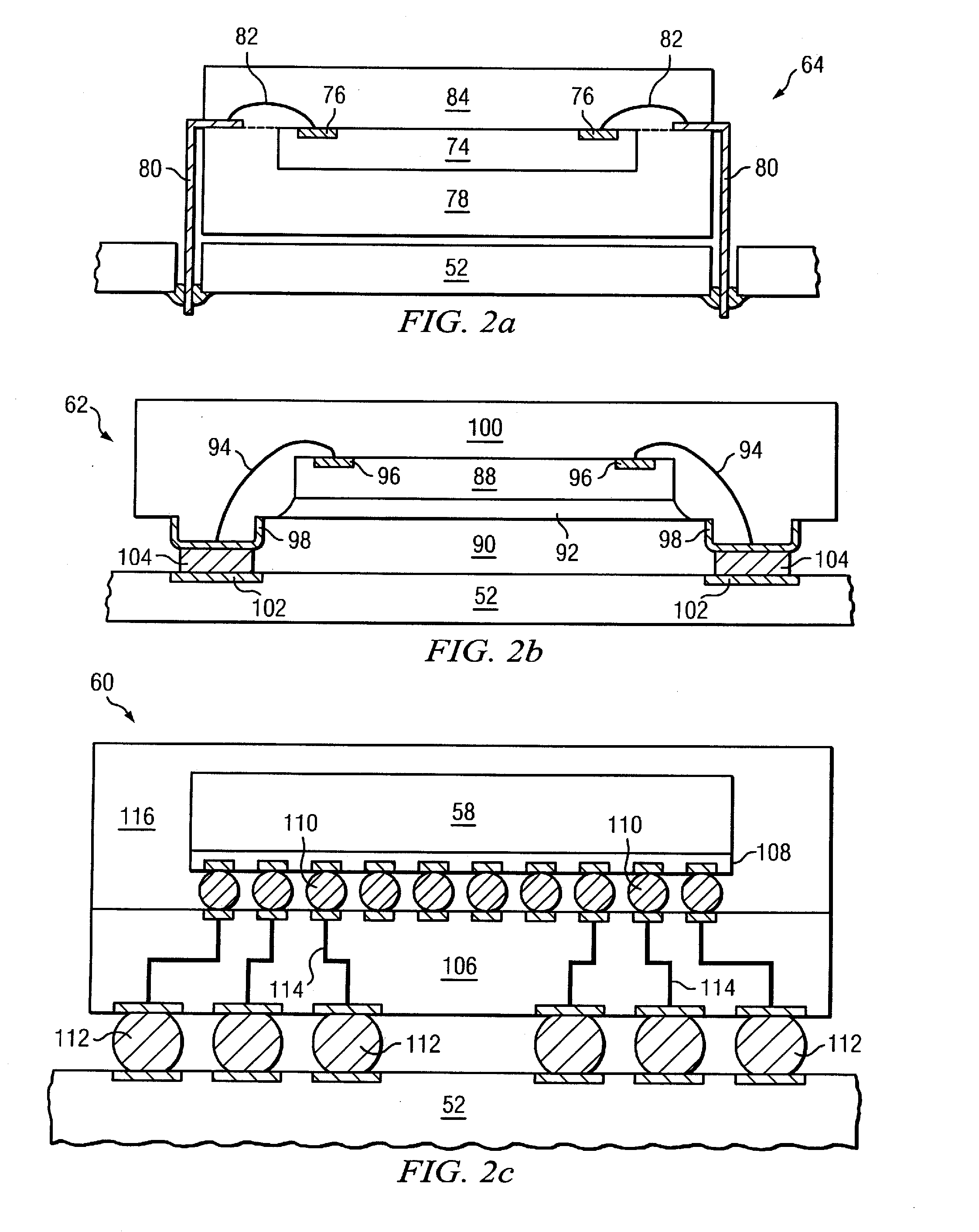

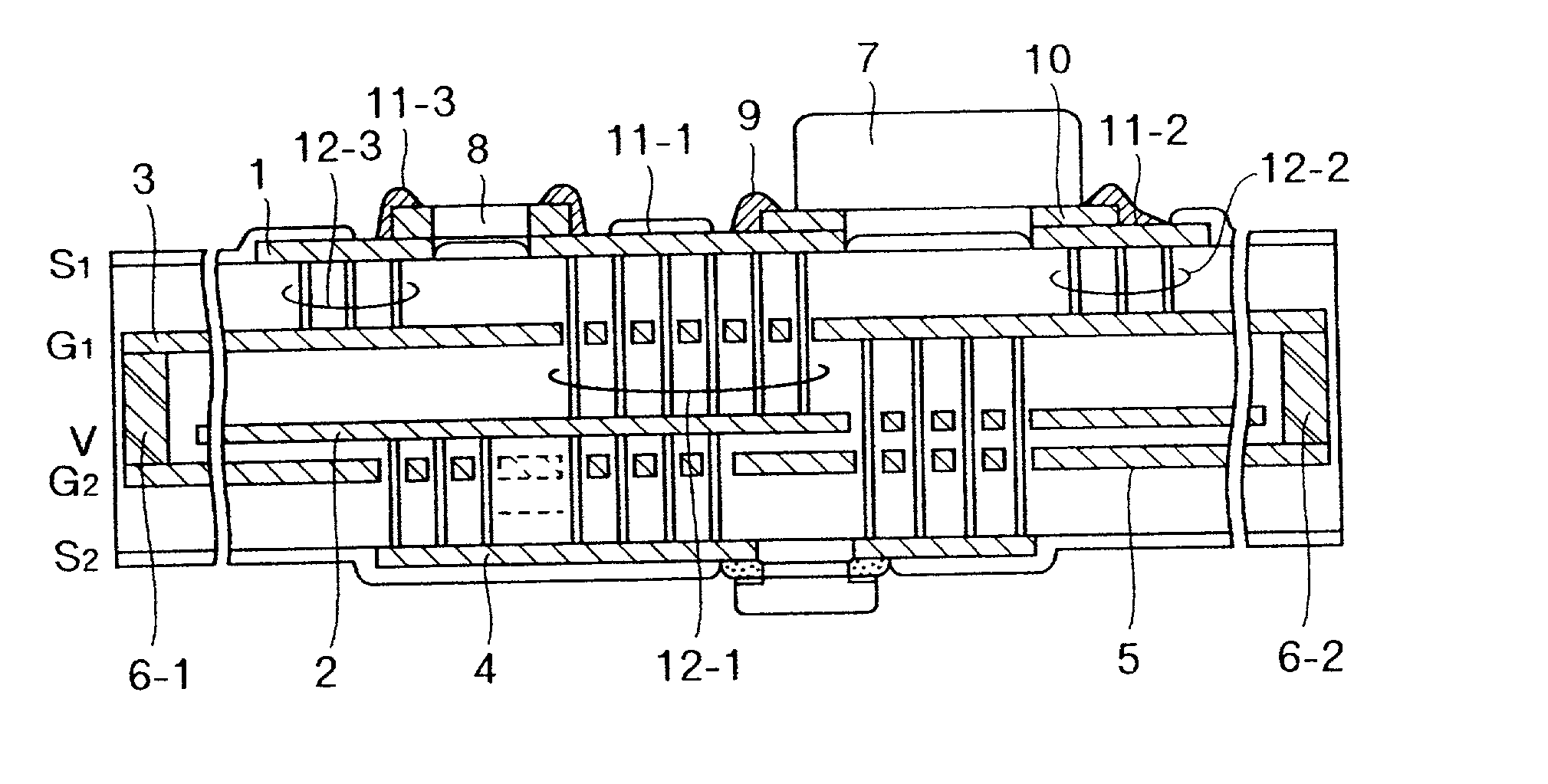

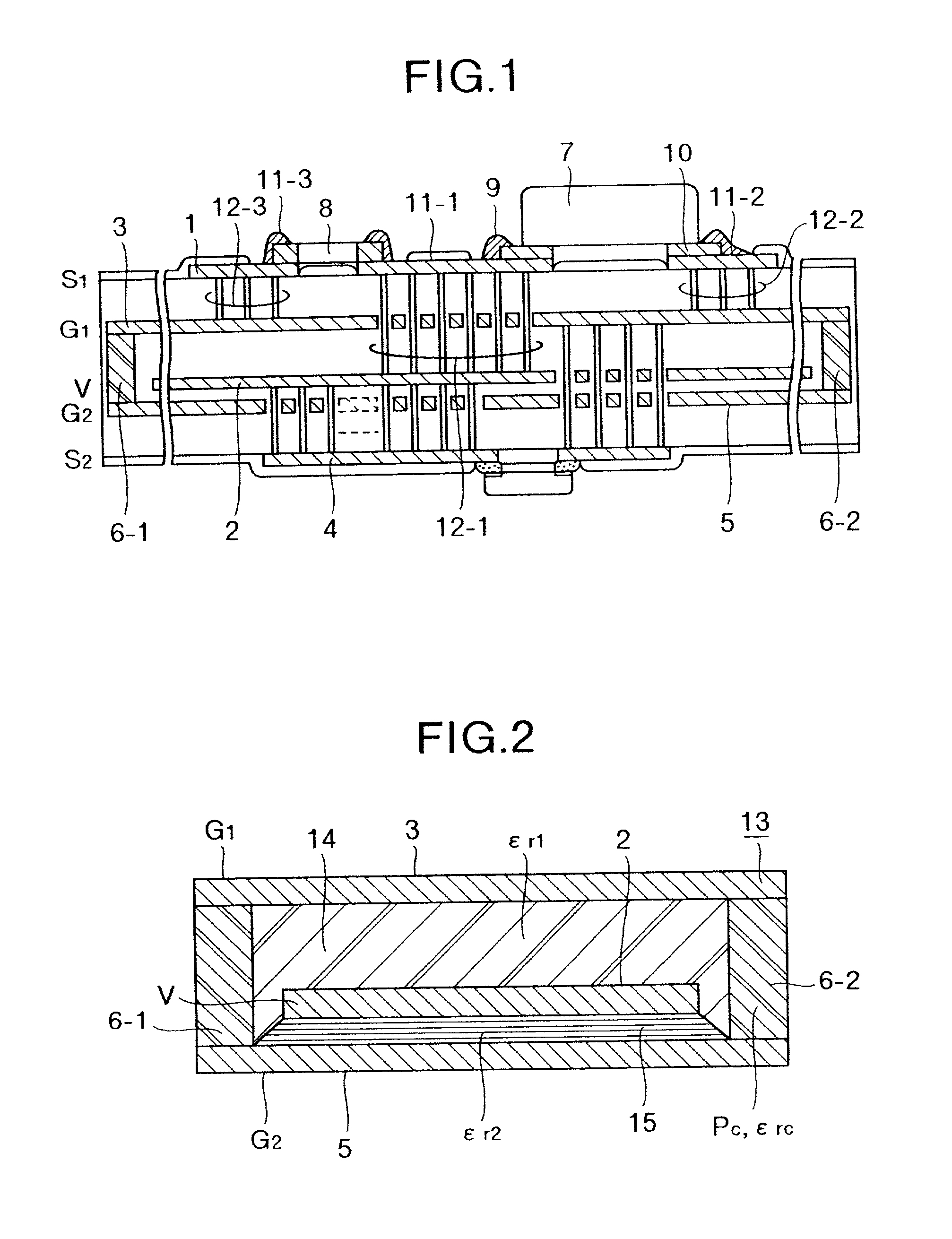

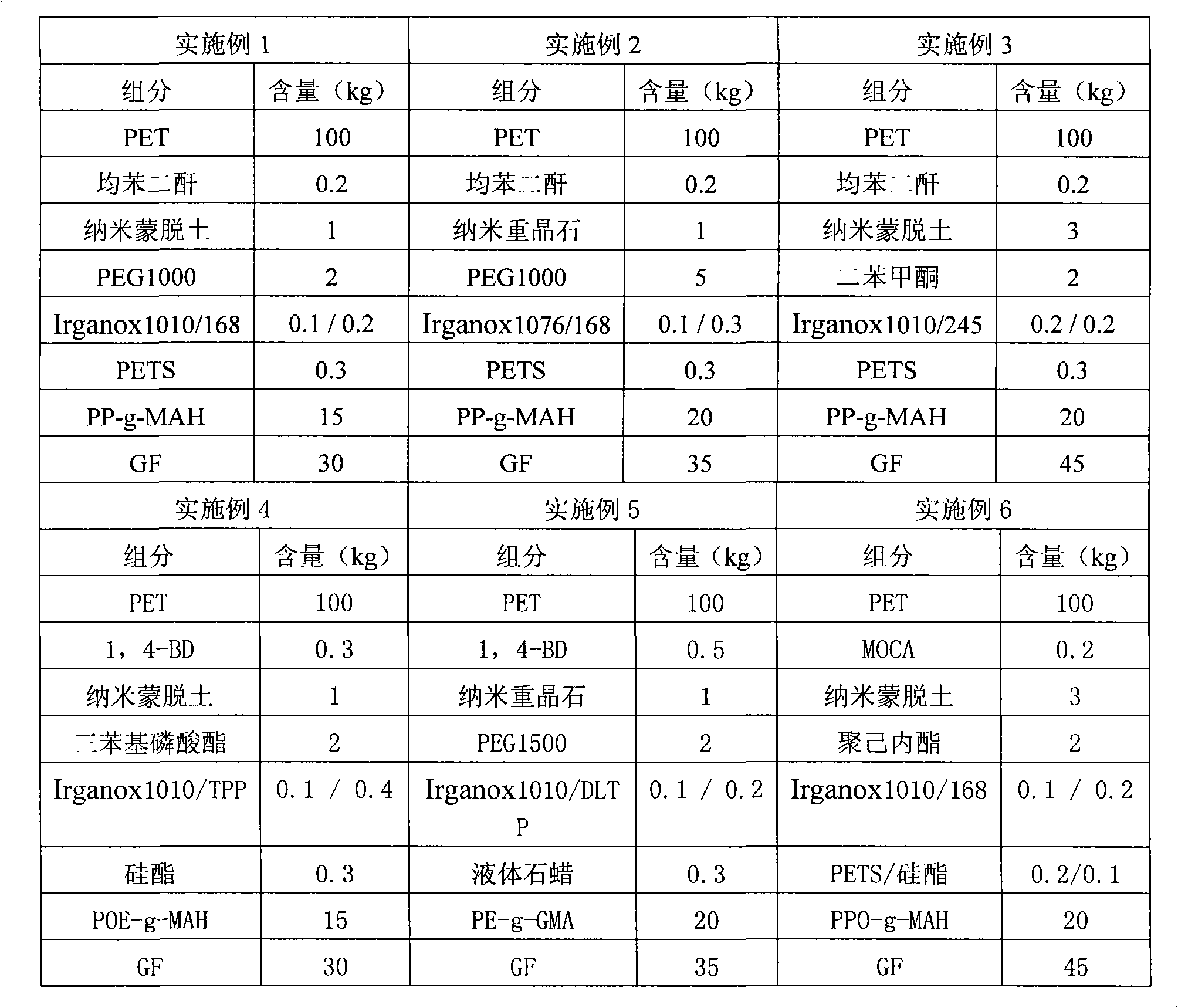

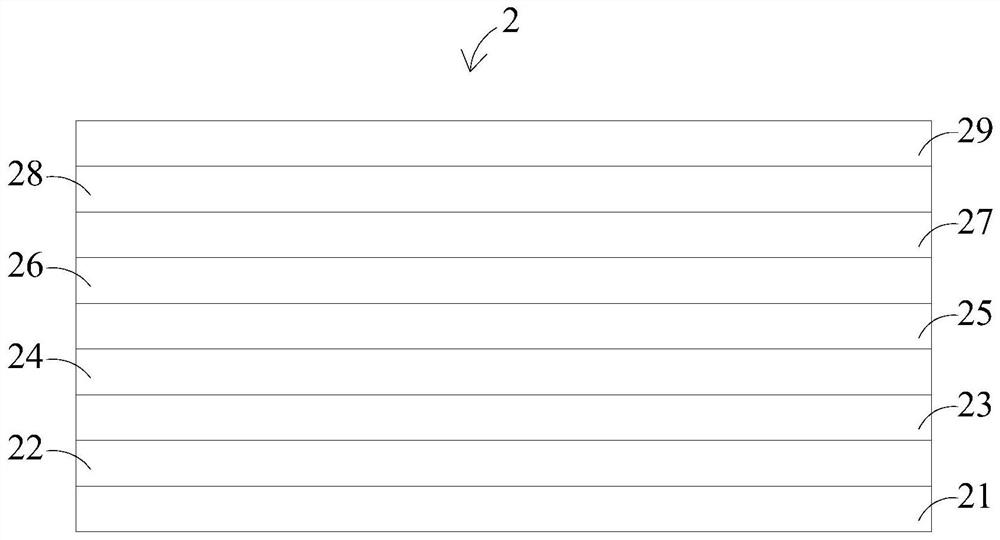

Low-EMI electronic apparatus, low-EMI circuit board, and method of manufacturing the low-EMI circuit board.

InactiveUS6353540B1Radiation suppressionHigh packageMagnetic/electric field screeningFinal product manufactureCapacitanceCountermeasure

Owner:HITACHI LTD

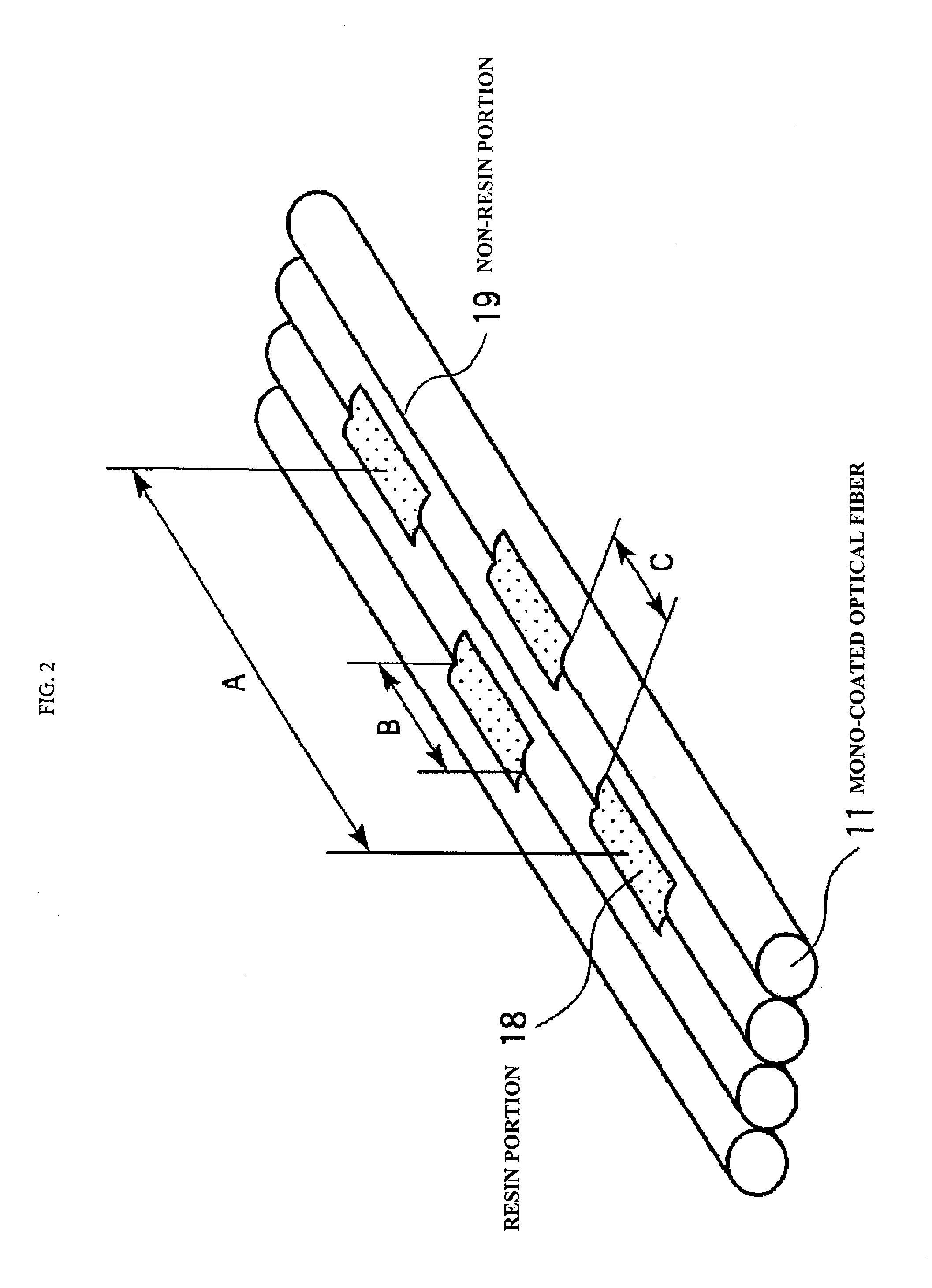

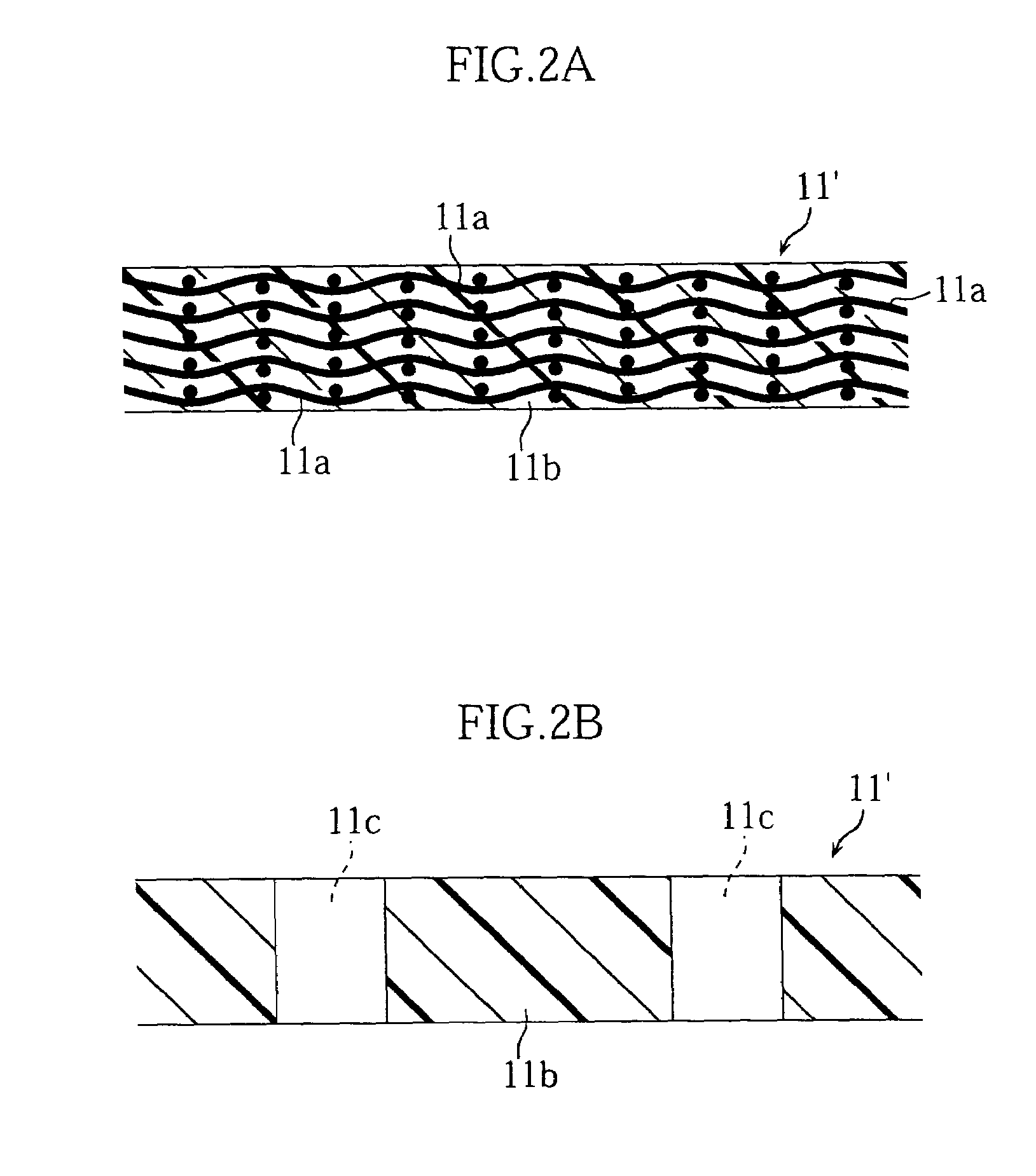

Optical fiber cable and optical fiber ribbon

ActiveUS20110110635A1Stable optical loss characteristicReduce warpageFibre mechanical structuresEngineeringBend radius

Amono-coated optical fiber that has a bending loss characteristic in which an optical loss increase at a bending radius 13 mm is 0.2 dB / 10 turn or less, an optical fiber ribbon that includes two-dimensionally disposed resin portions for bonding the adjacent 2-fiber mono-coated optical fibers in plural places, the resin portions being disposed apart from each other in the longitudinal direction of the optical fiber ribbon and an optical fiber cable that includes a cable core portion that stores twisting of plural units where the mono-coated optical fibers constituting the optical fiber ribbon are collected.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

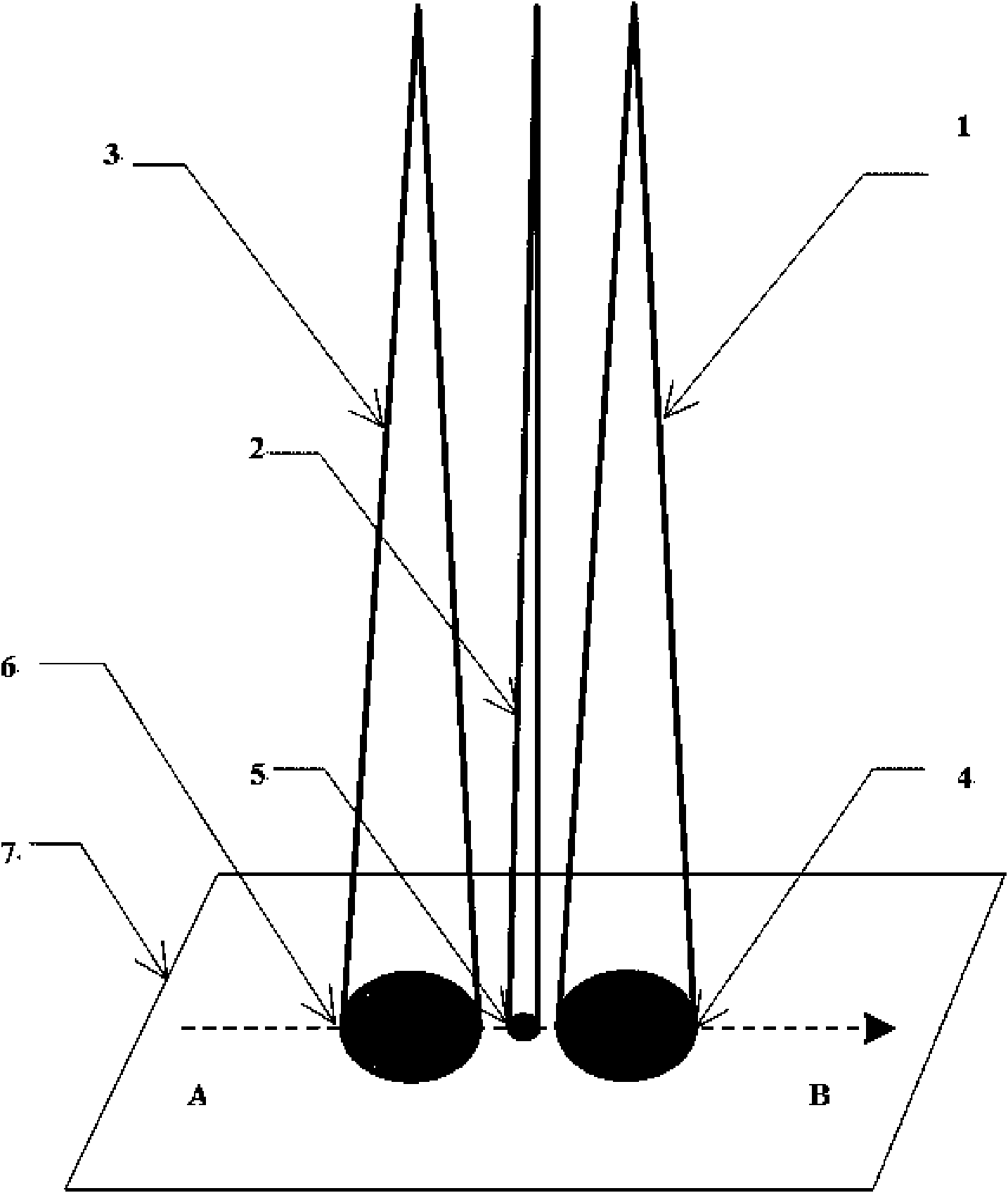

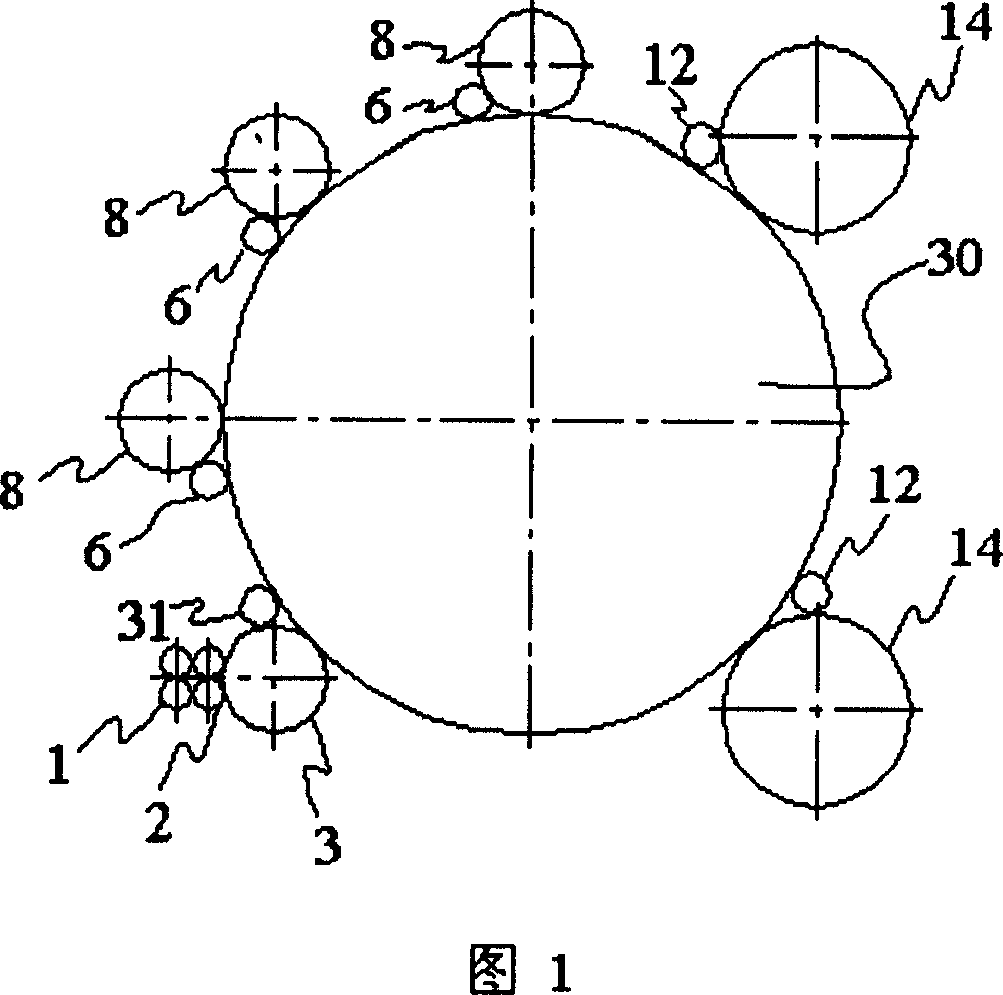

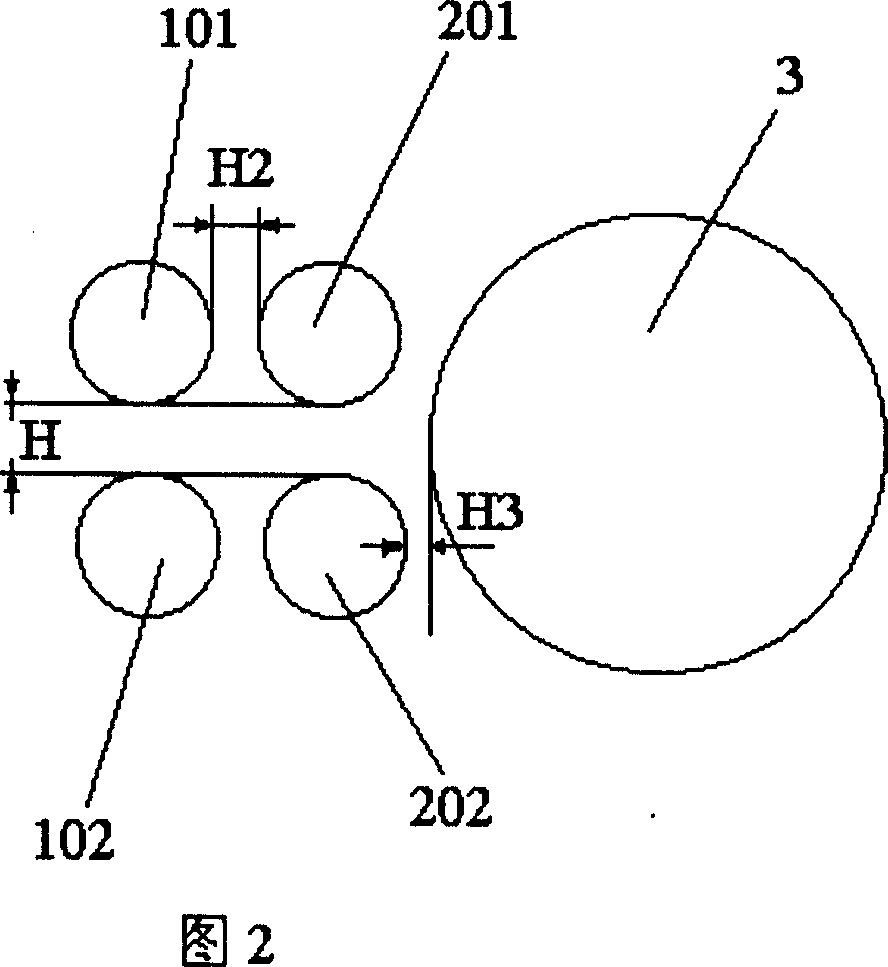

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of forming a thin wafer stack for a wafer level package

InactiveUS20050282374A1Wafer thickness reductionAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringWafer stacking

A method of forming a stack of thin wafers provides a wafer level stack to greatly reduce process time compared to a method where individually separated chips are stacked after a wafer is sawed. A rigid planar wafer support member stabilizes and planarizes each wafer while it is thin or its thickness is reduced and during subsequent wafer processing. Thinned wafers are stacked and the external support members are removed by applying heat or ultraviolet (UV) light to an expandable adhesive layer between the support members and the thin wafers. The stacked wafers then can be further processed and packaged without thin-wafer warping, cracking or breaking. A wafer level package made in accordance with the invented method also is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

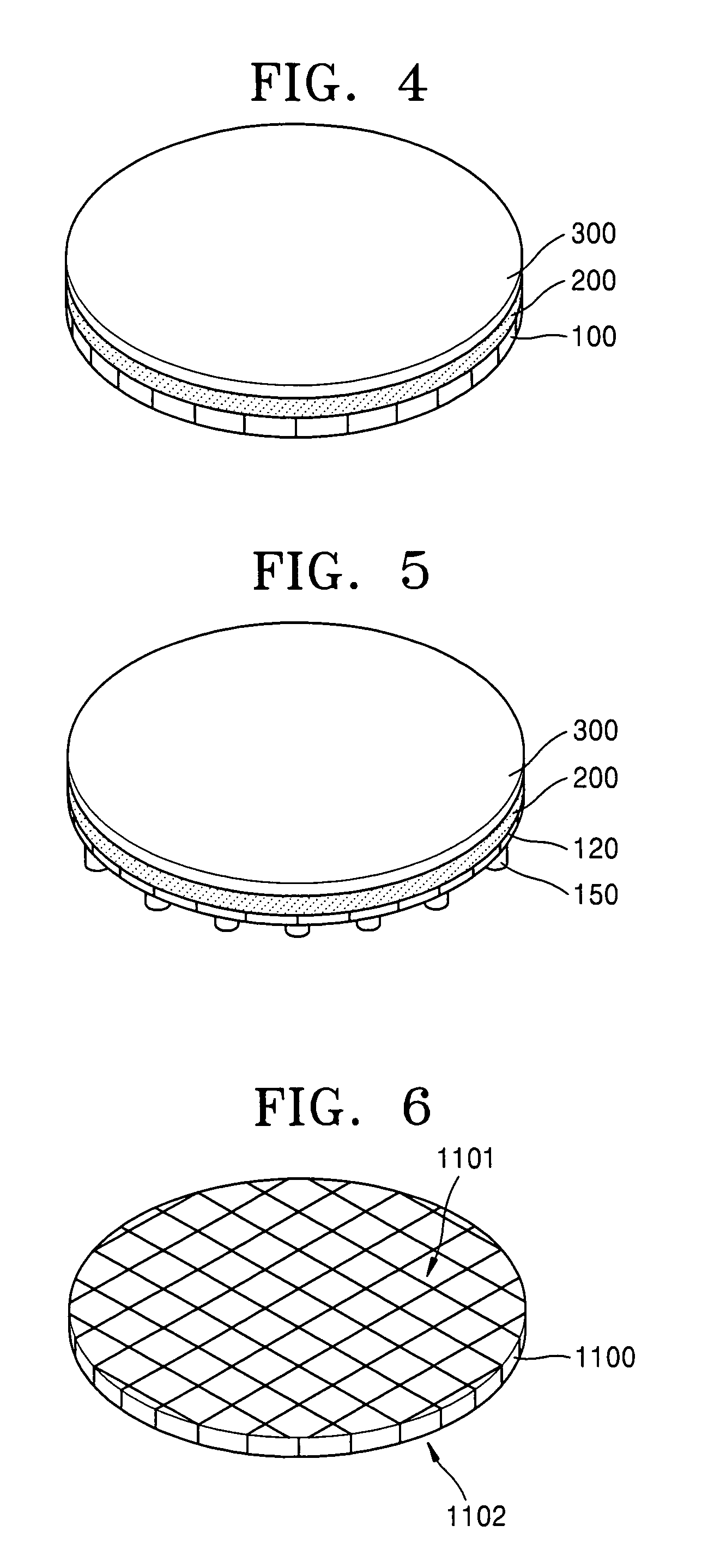

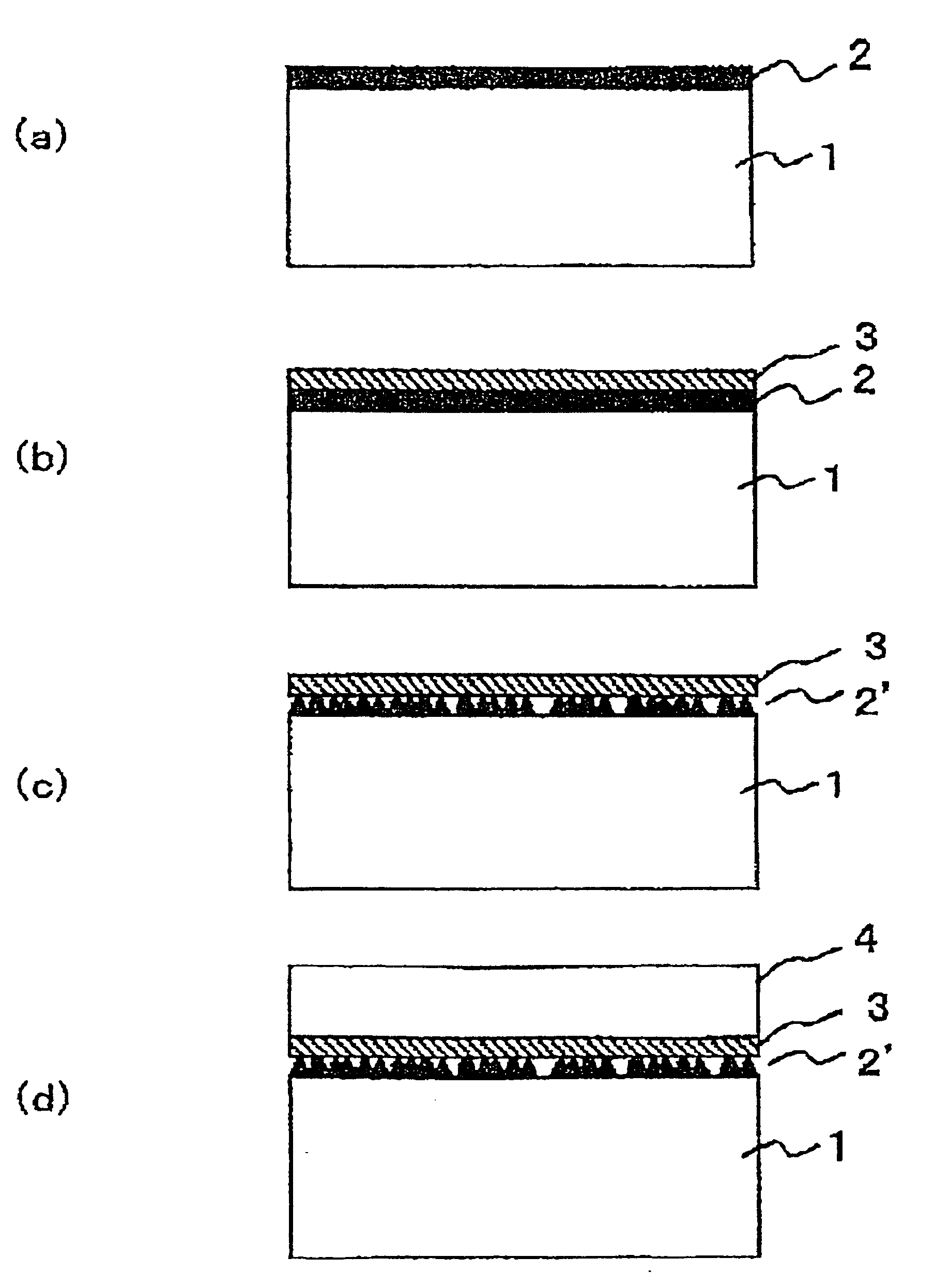

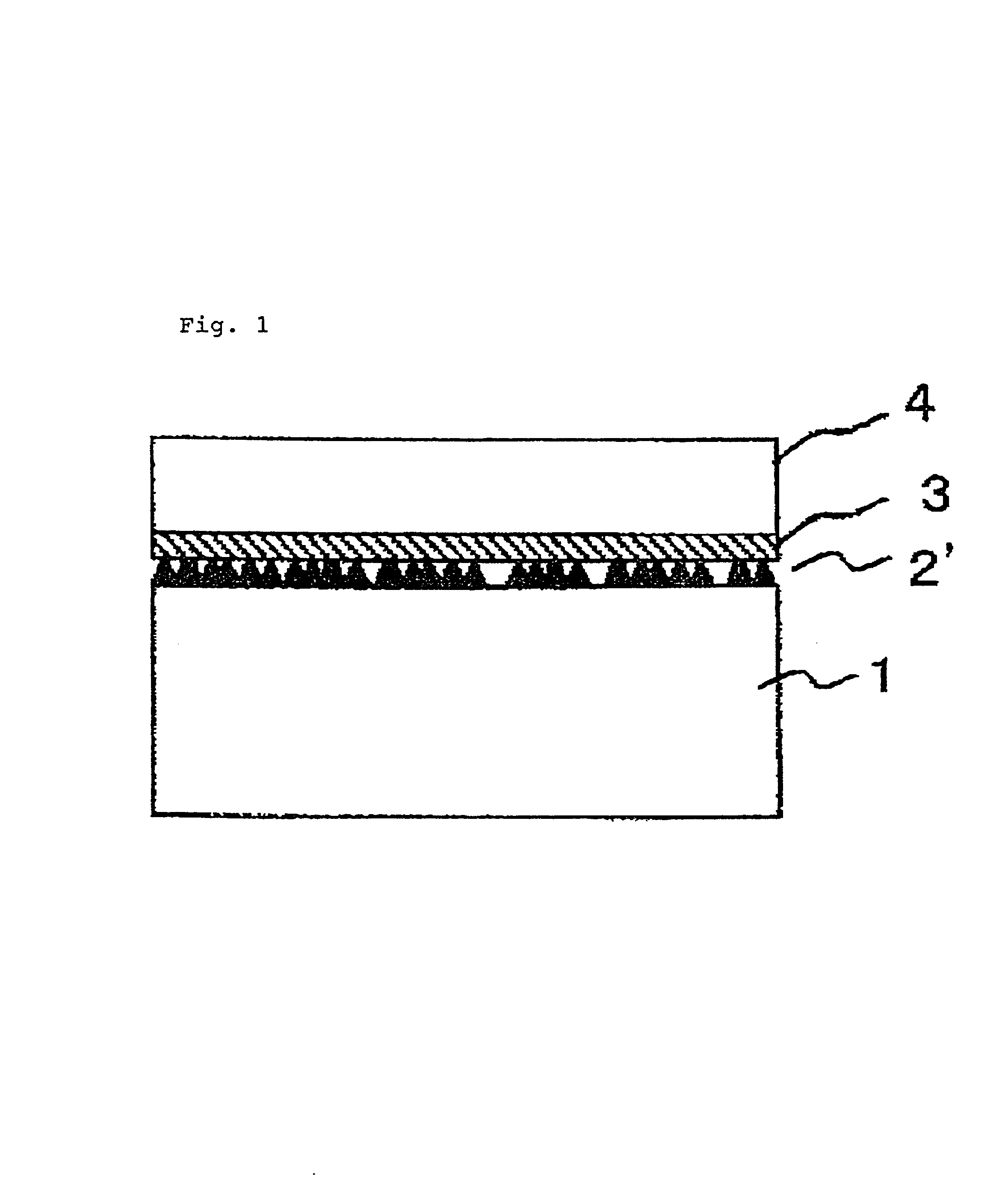

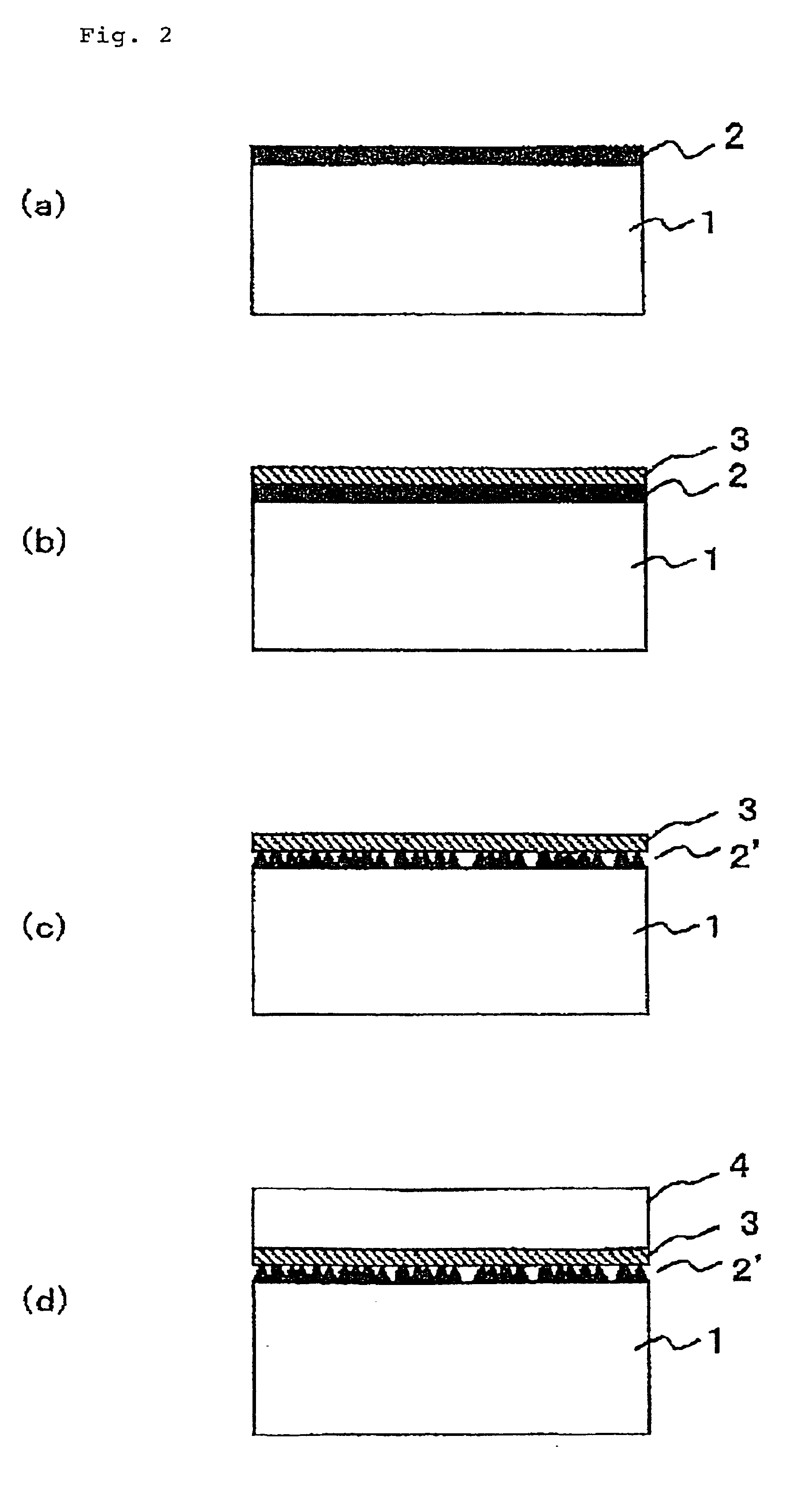

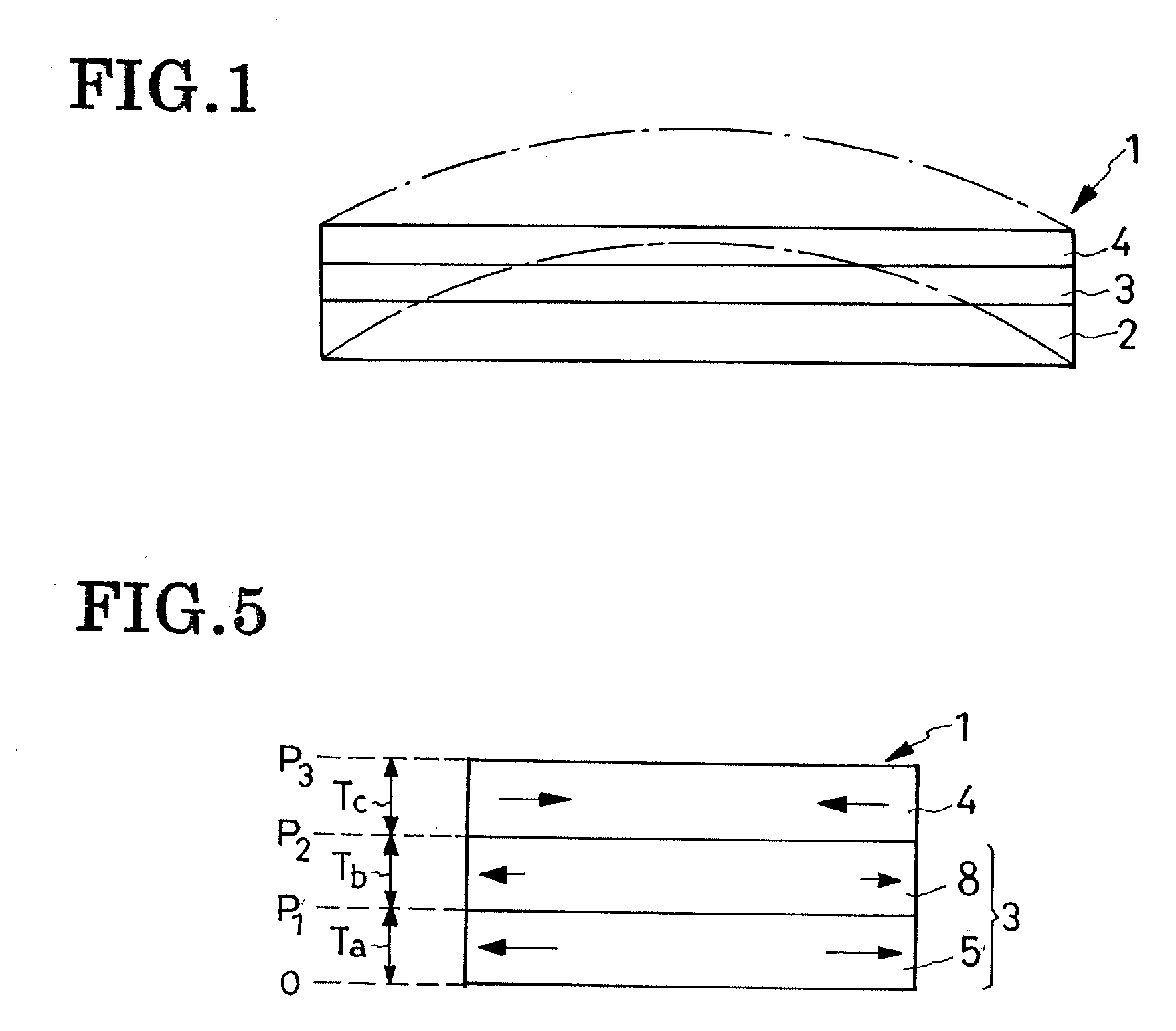

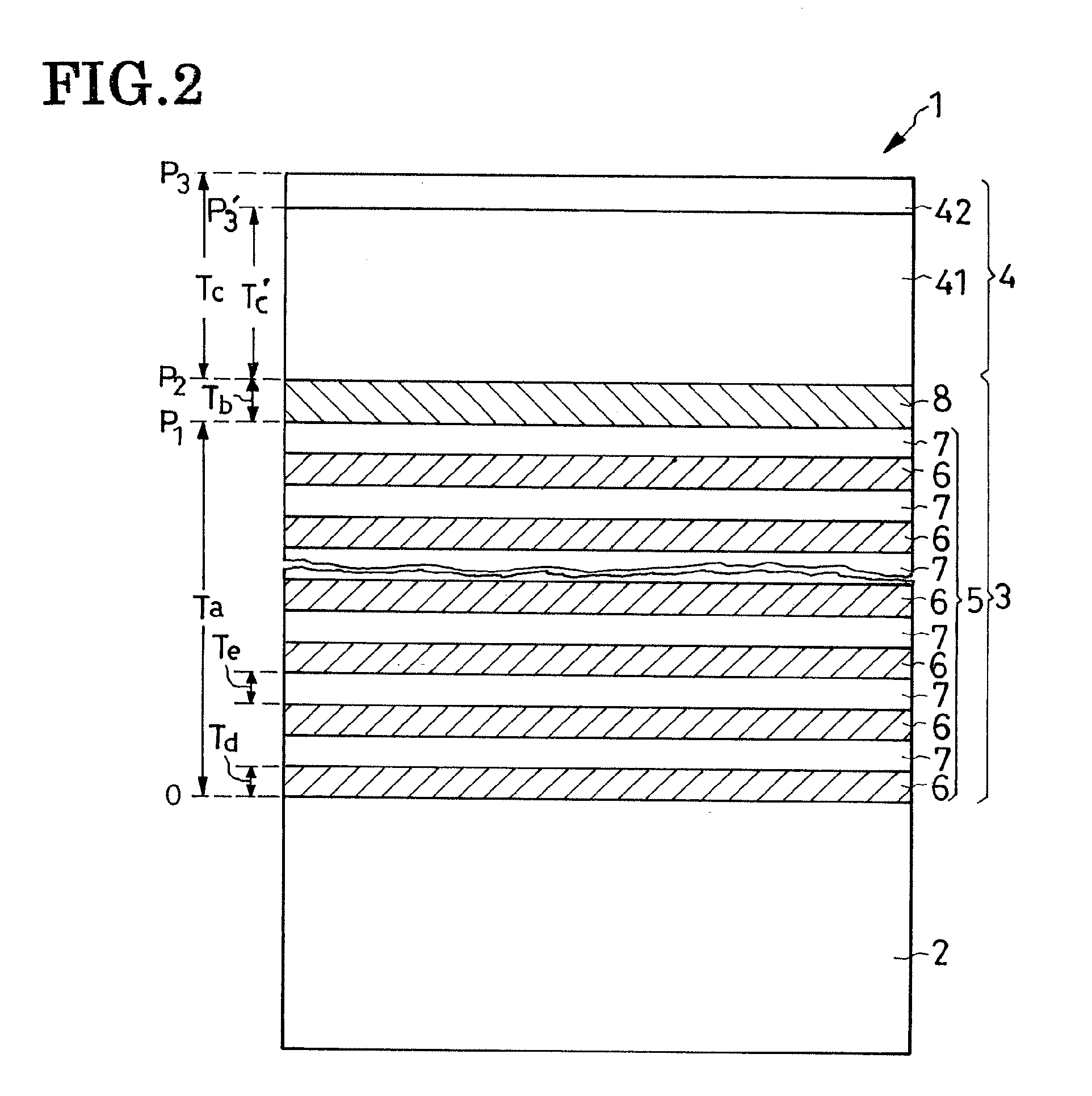

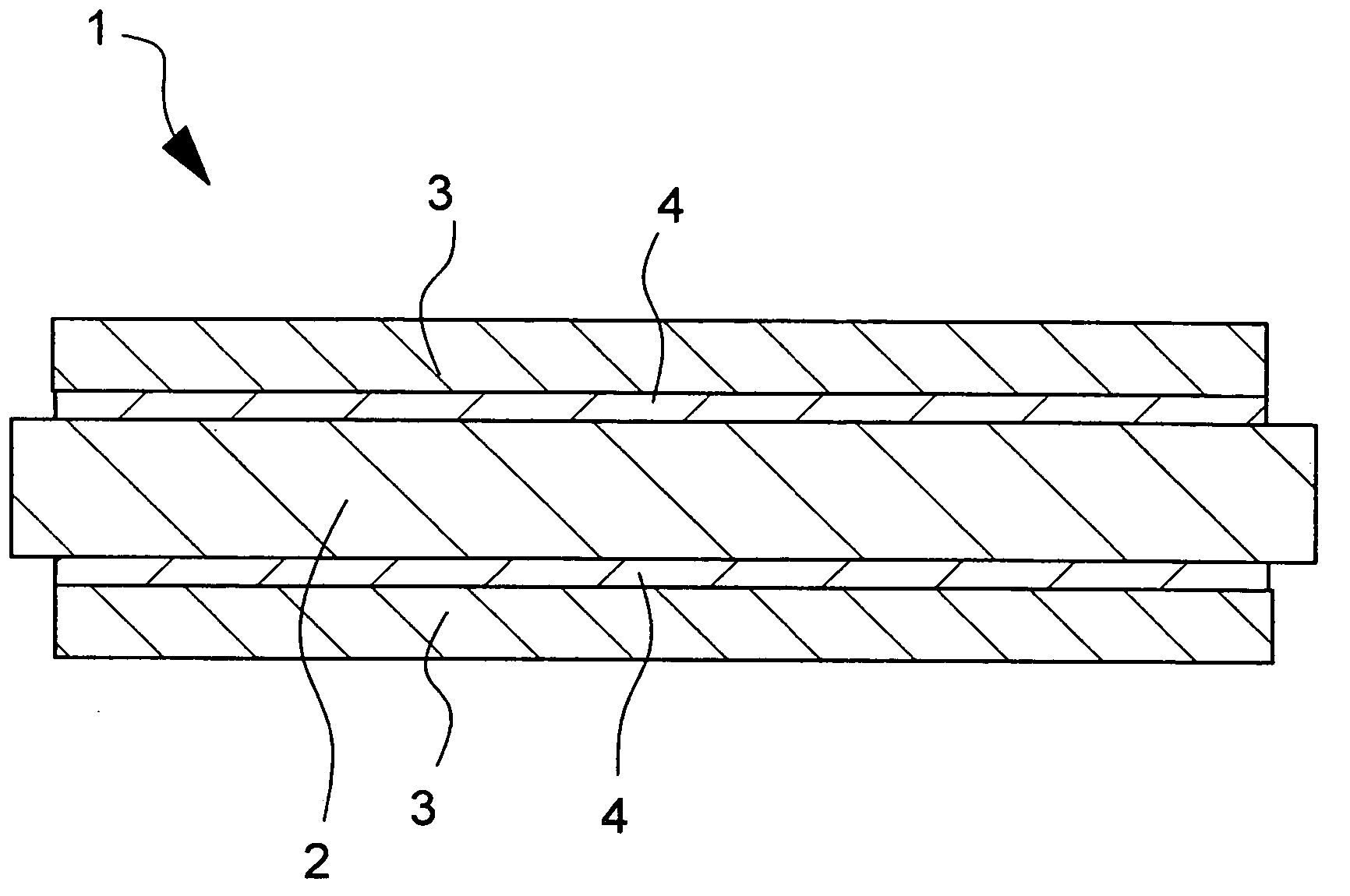

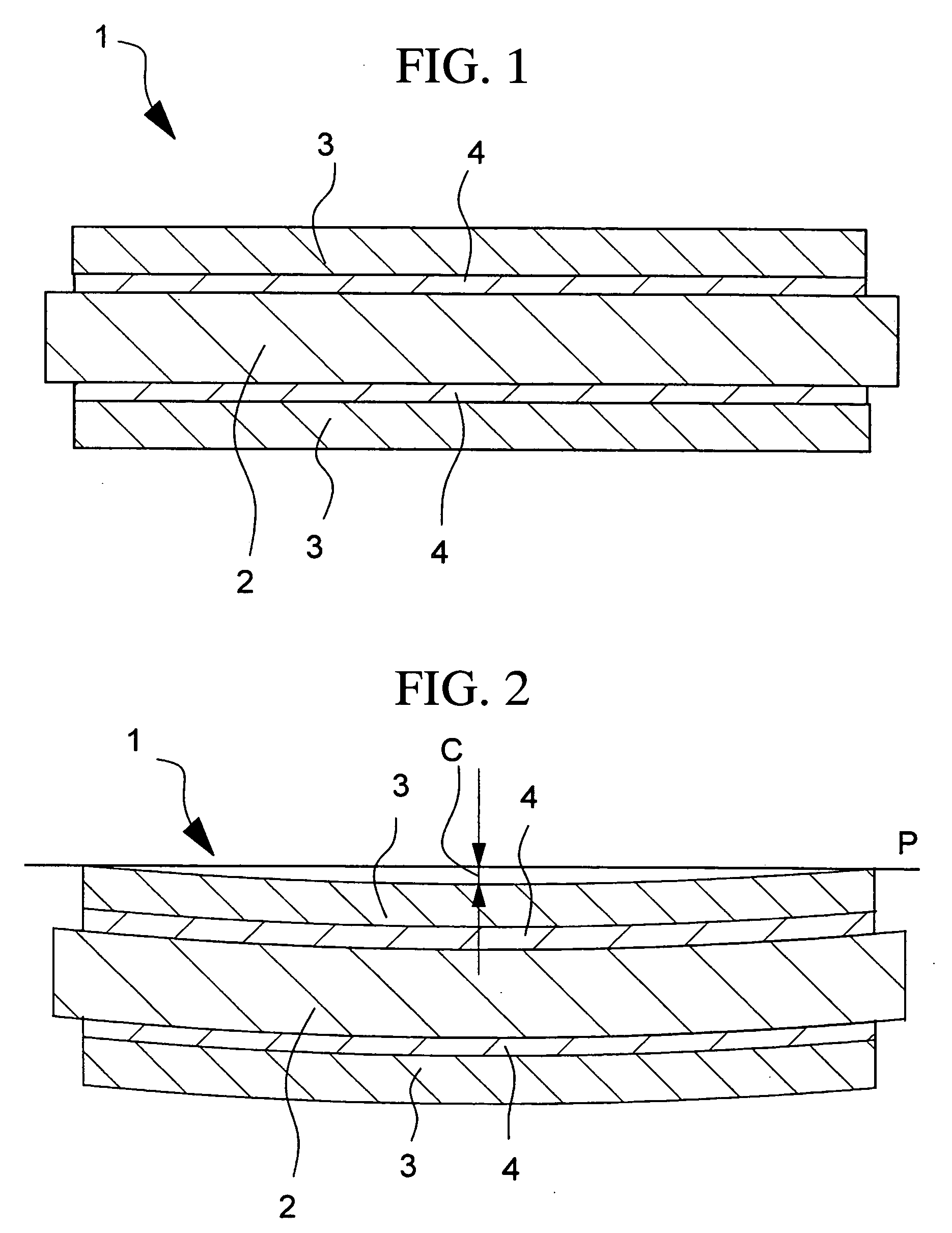

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS6924159B2Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingNitride semiconductorsSapphire substrate

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of:forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2′.

Owner:SUMITOMO CHEM CO LTD

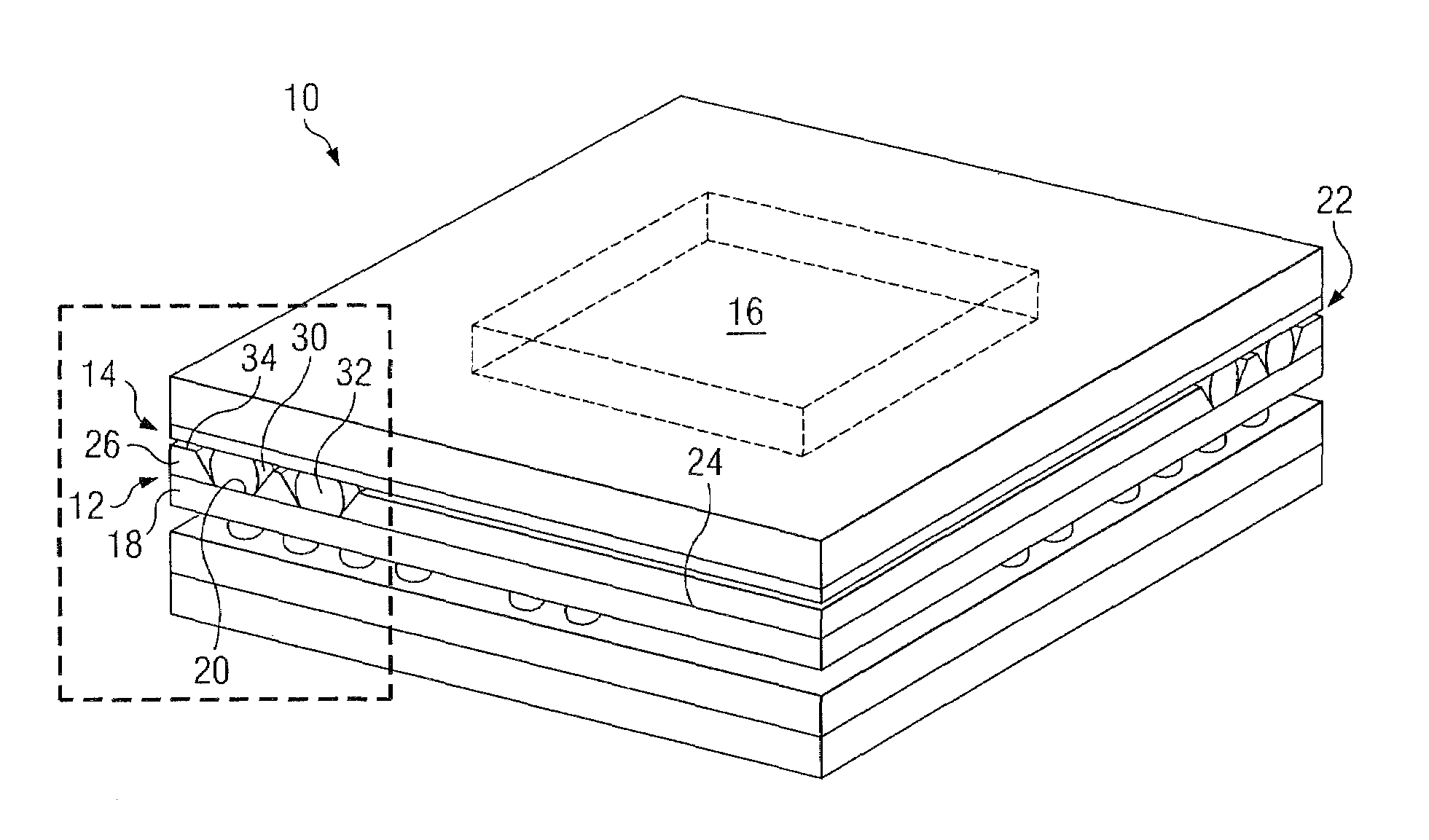

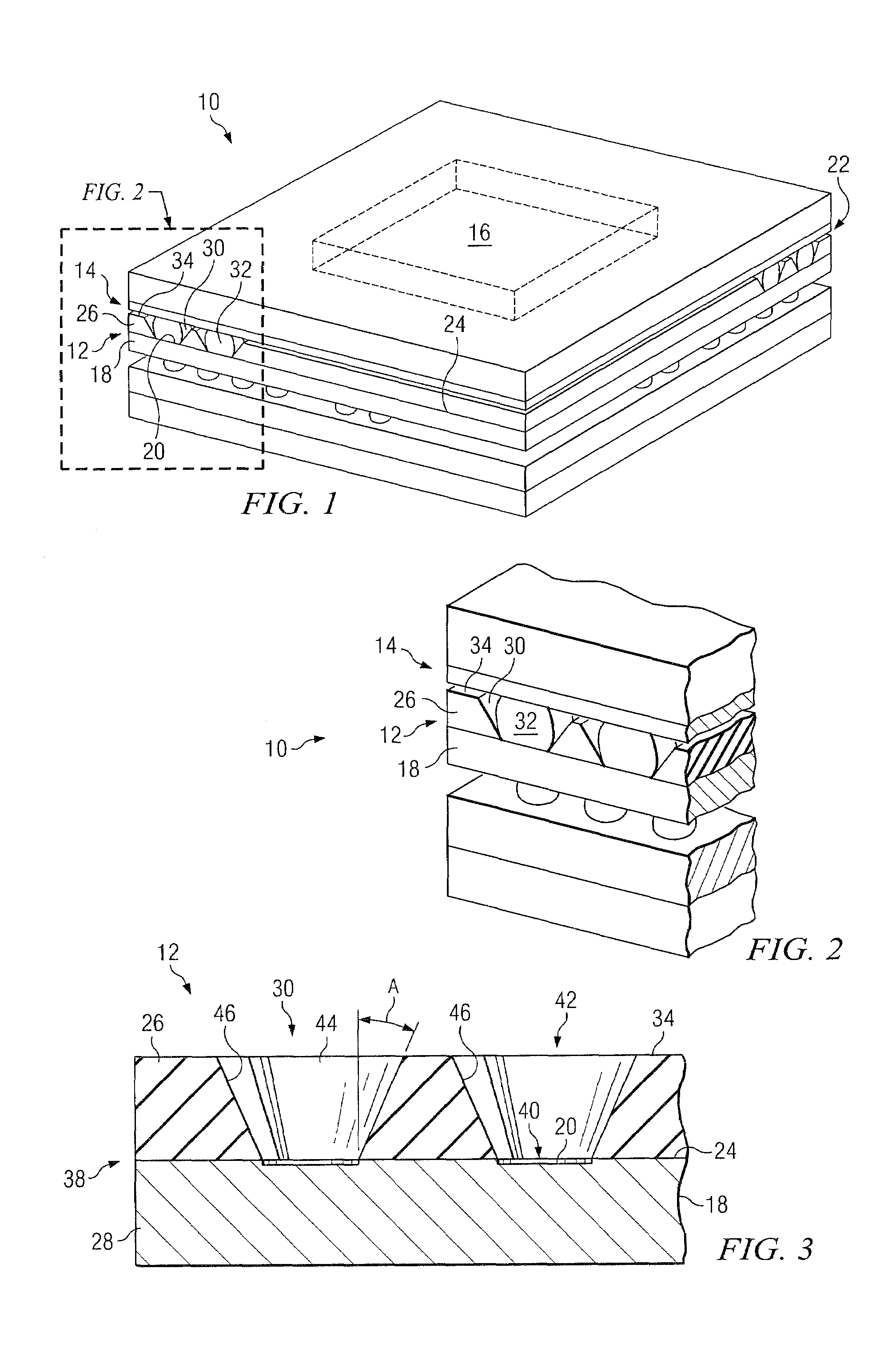

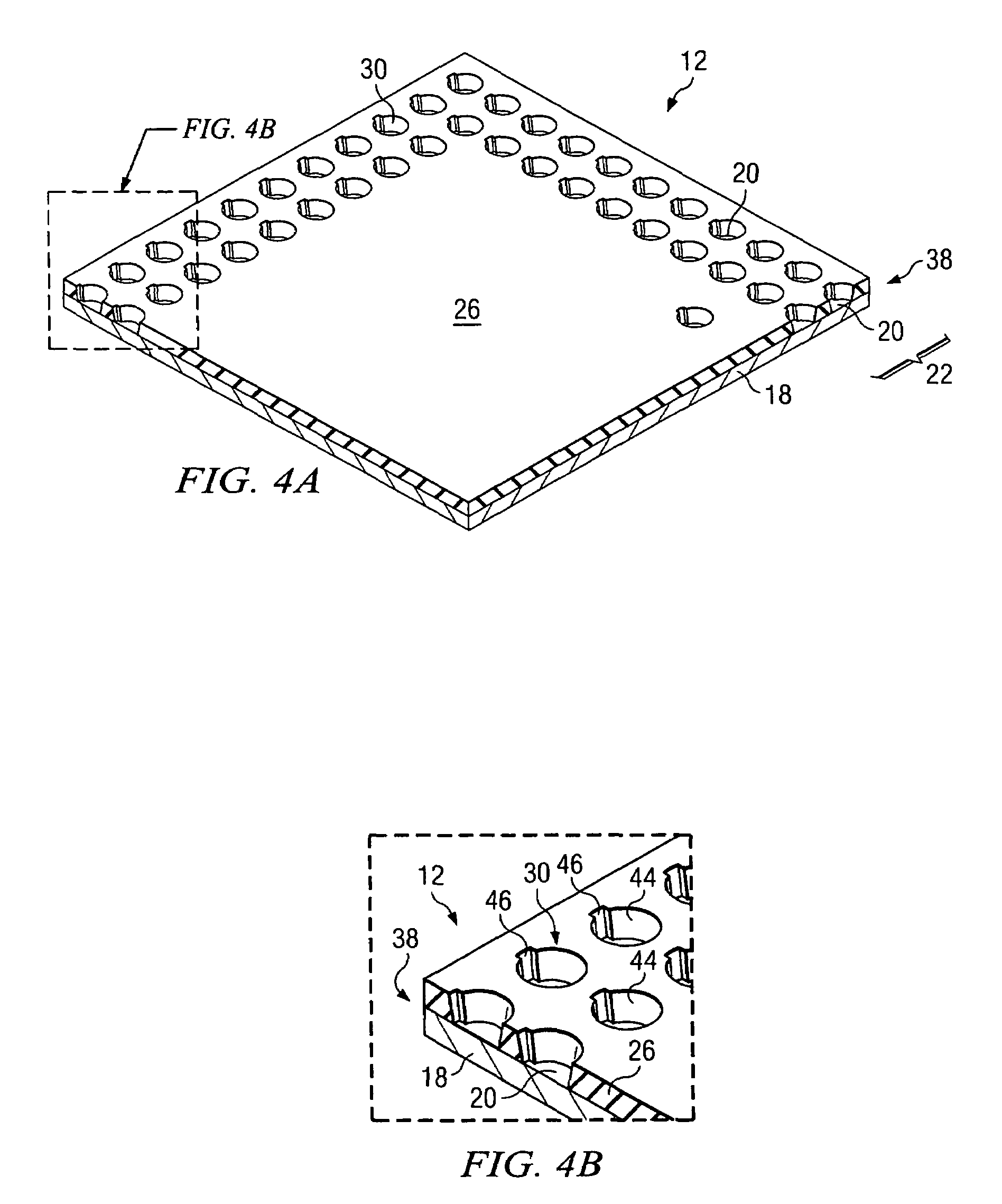

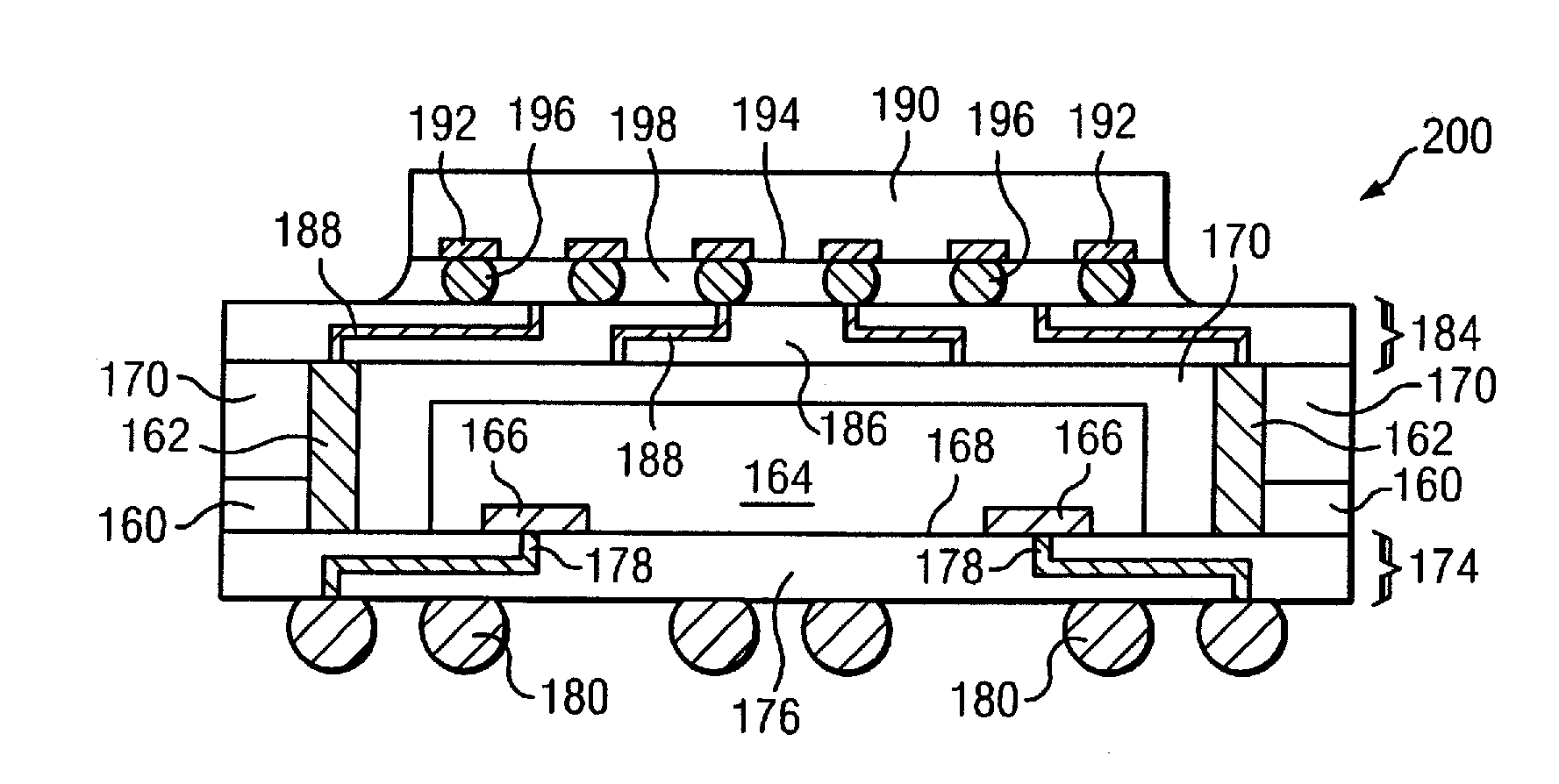

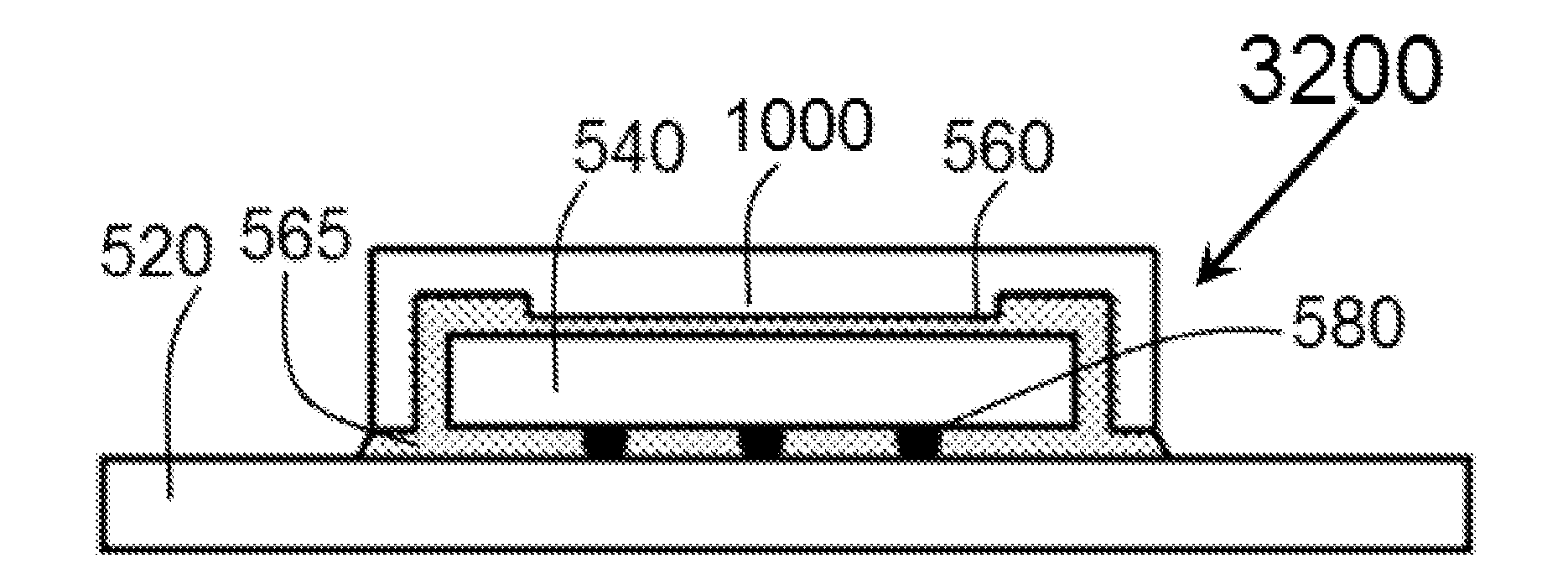

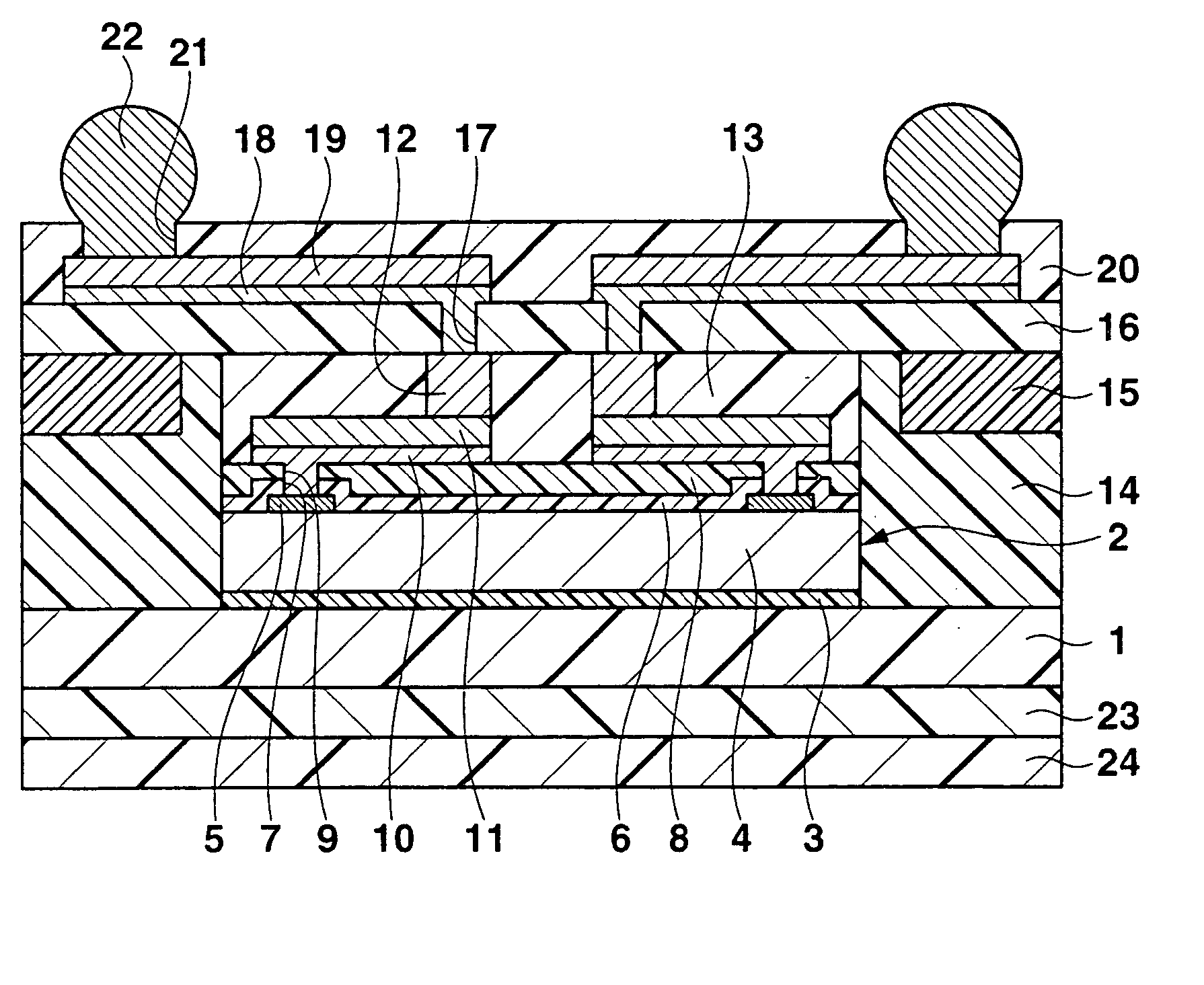

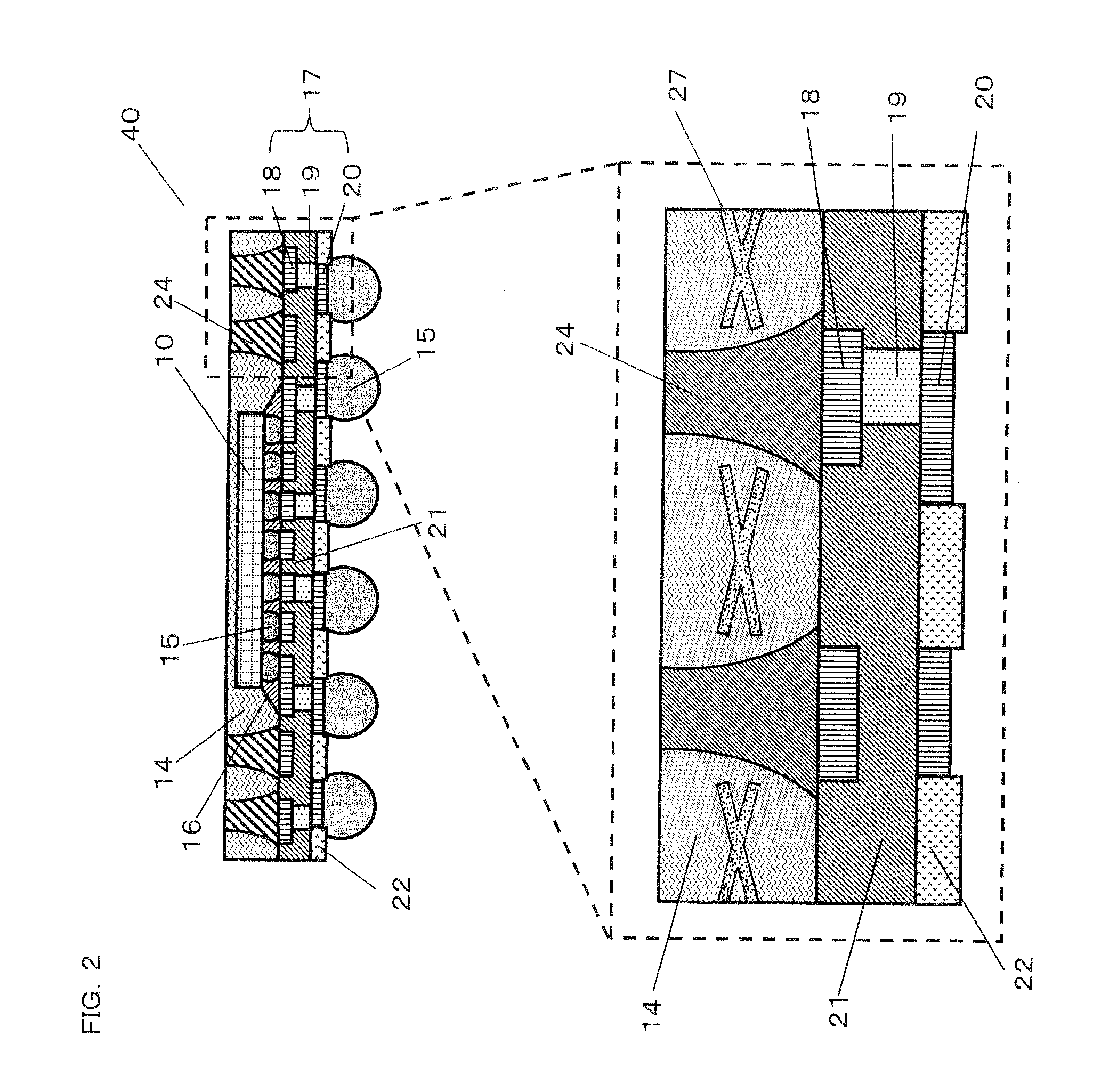

Package-on-package semiconductor assembly

ActiveUS7675152B2Improve robustnessReduce warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Disclosed are methods and devices for providing improved semiconductor packages and POP IC assemblies using the improved packages with reduced warping. According to disclosed embodiments of the inventions, a packaged semiconductor device for use in a POP assembly includes an encapsulated region generally defined by the substrate surface. The encapsulant is provided with contact apertures permitting external communication with contacts on the substrate and coupled to an encapsulated chip. Preferred embodiments of the invention are described in which the contact aperture sidewalls are angled within the range of approximately 10-30 degrees or more from vertical and in which the contact aperture is provided a gas release channel to permit gas to escape during reflow.

Owner:TEXAS INSTR INC

Integrated circuit package with a balanced-part structure

InactiveUS7176559B2Reduce warpageIncrease yield and stabilitySemiconductor/solid-state device detailsSolid-state devicesStress distributionEngineering

An integrated circuit package includes a balanced-part structure. The condition of thermal stress of chips connected on a substrate decides the amount, locations, weights, and the material of at least a balanced-part fastened on a substrate. The balanced-part is fastened on the substrate to balance stress distribution before an adhering heat sinks process and a packaging molding compound process. The balanced-part also decreases thermal stress affection and avoid warpage defects of the integrated circuit packages.

Owner:VIA TECH INC

Semiconductor Device and Method of Forming Dam Material Around Periphery of Die to Reduce Warpage

ActiveUS20110037155A1Reduce warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

Owner:STATS CHIPPAC LTD

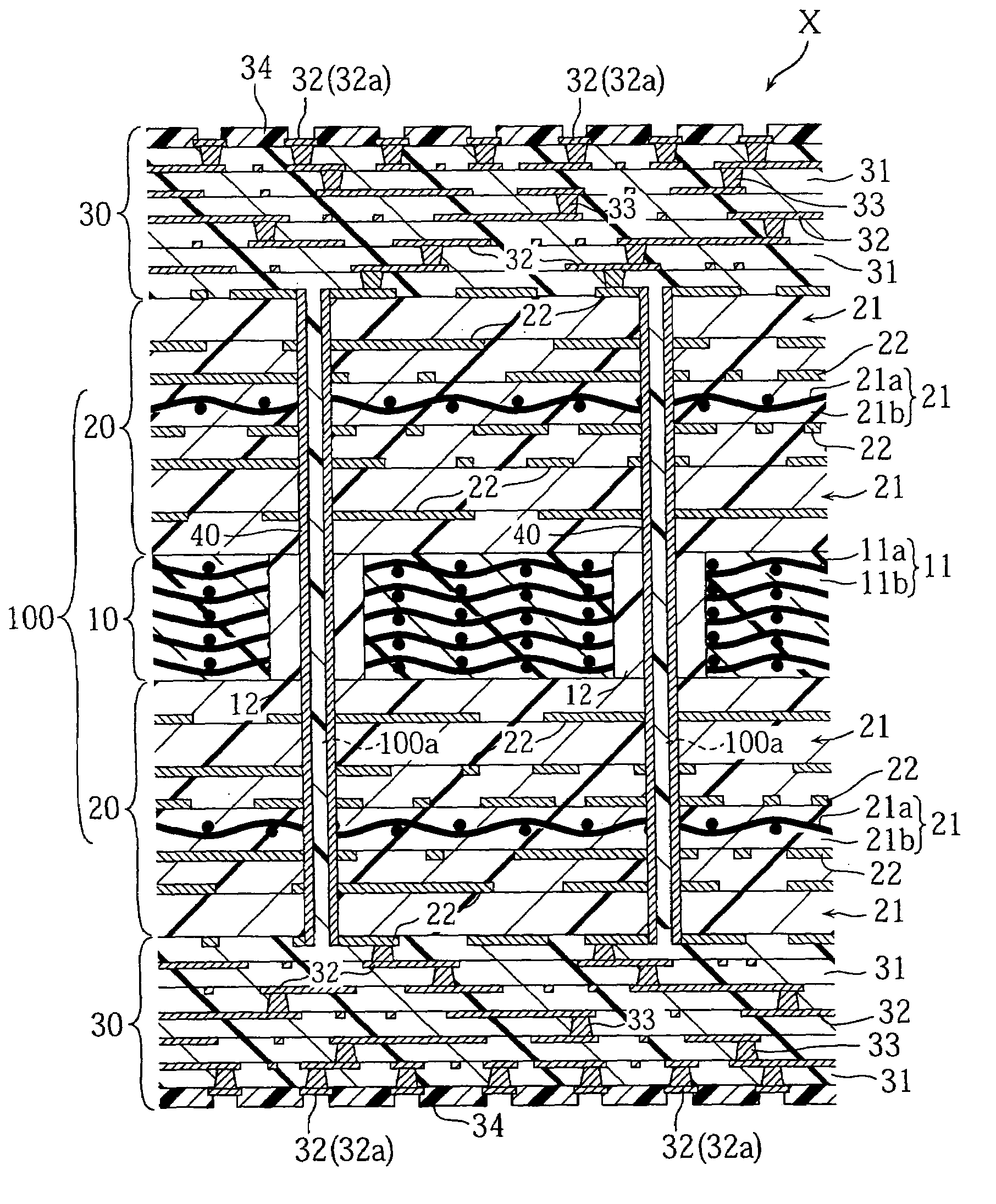

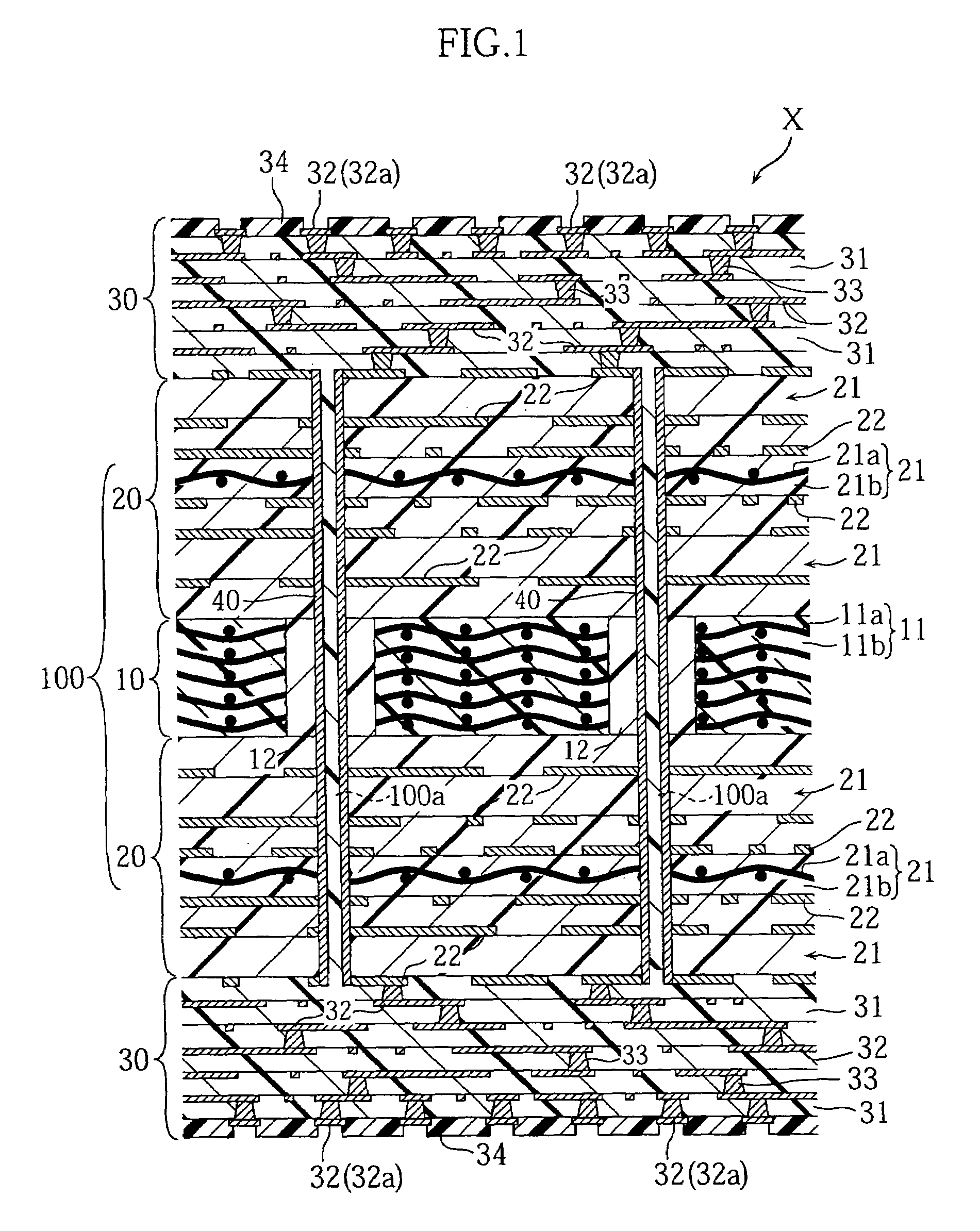

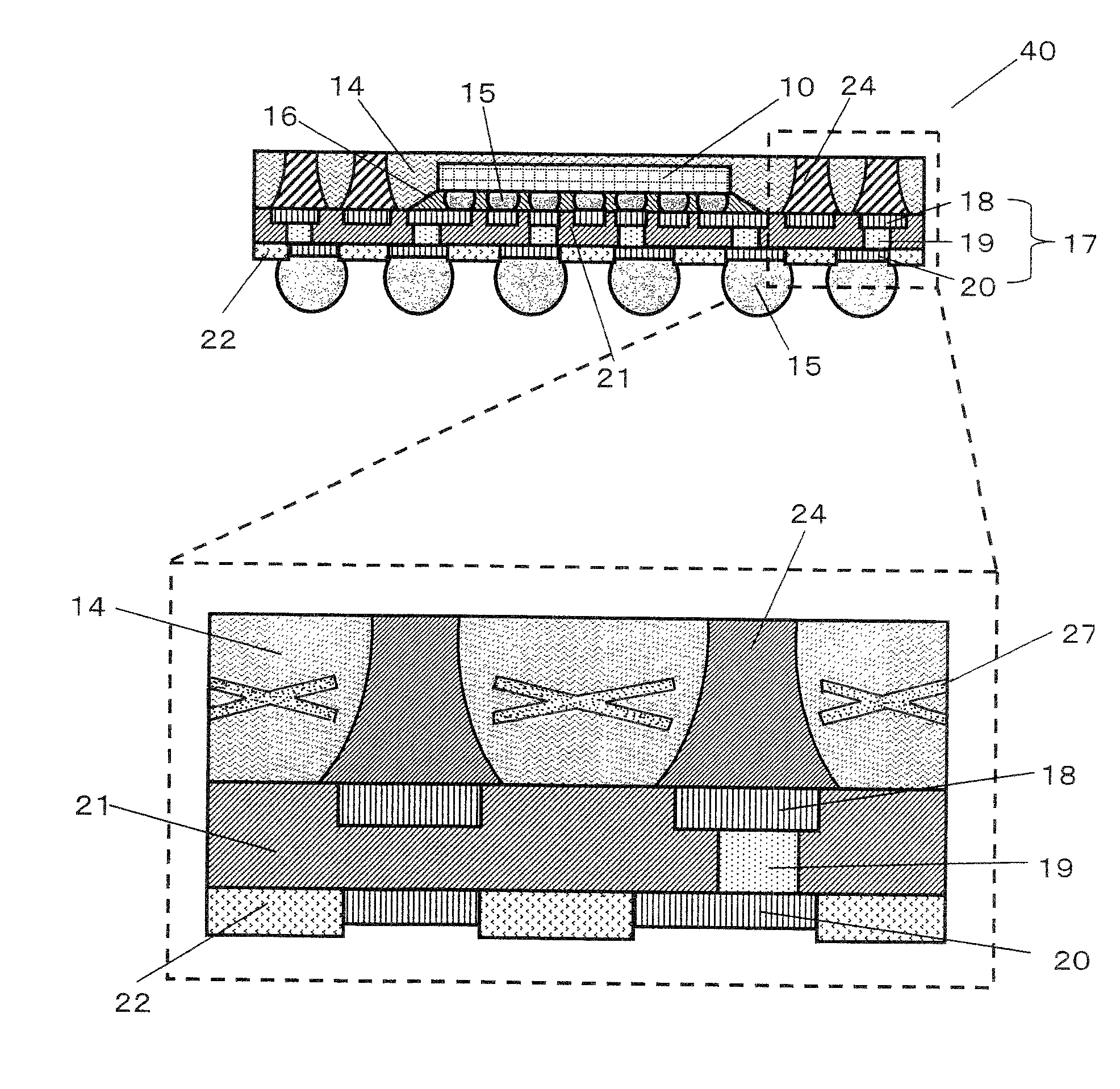

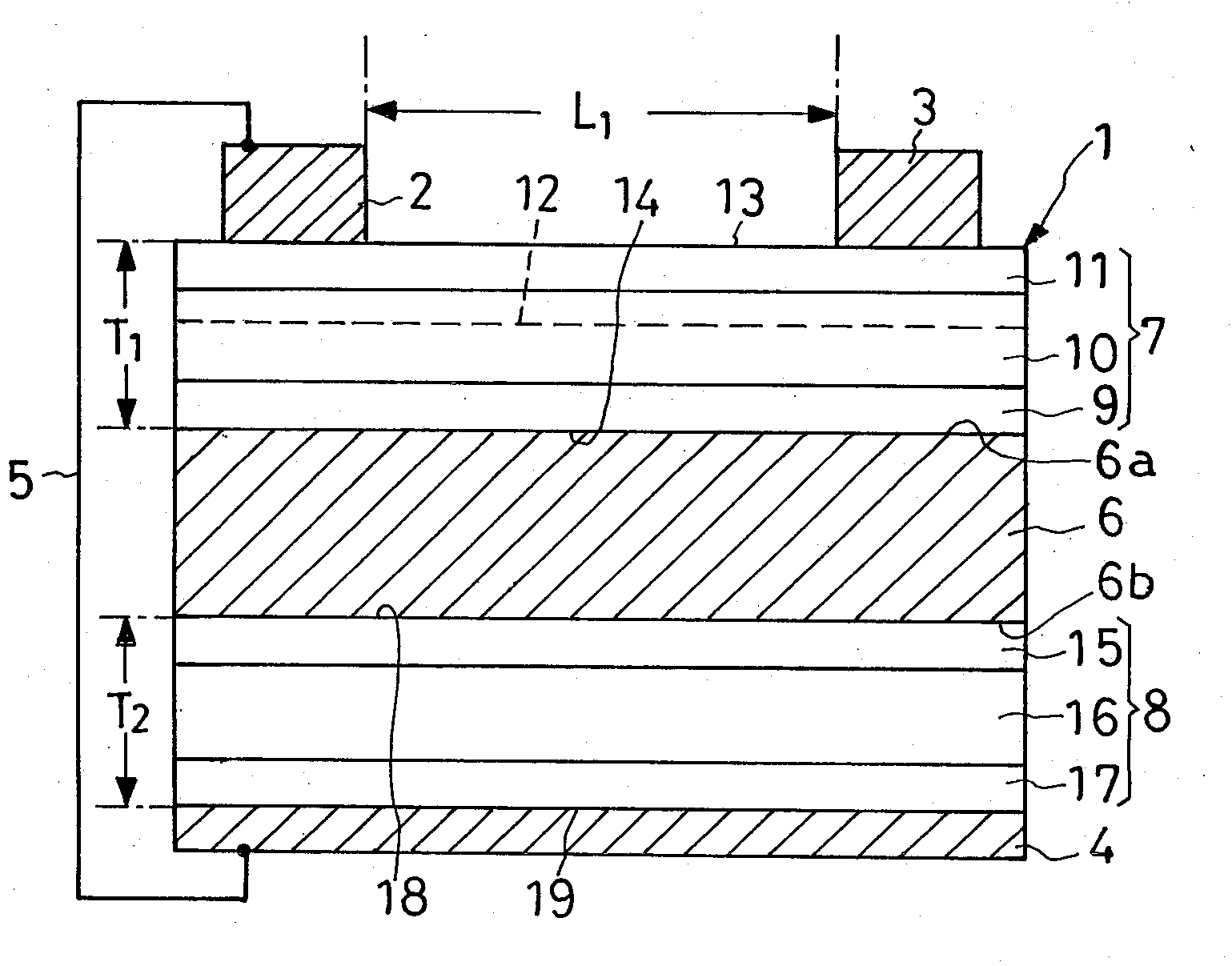

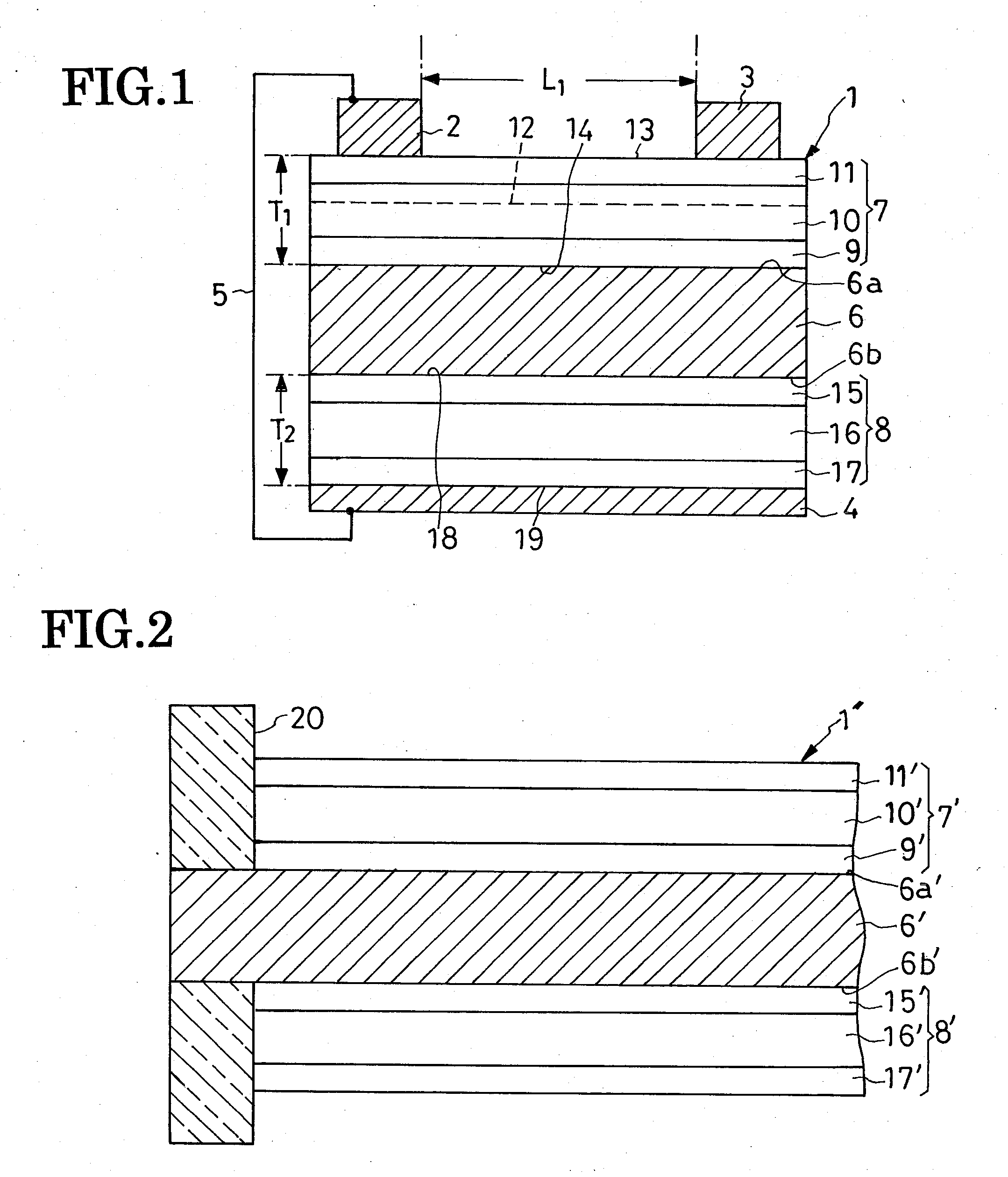

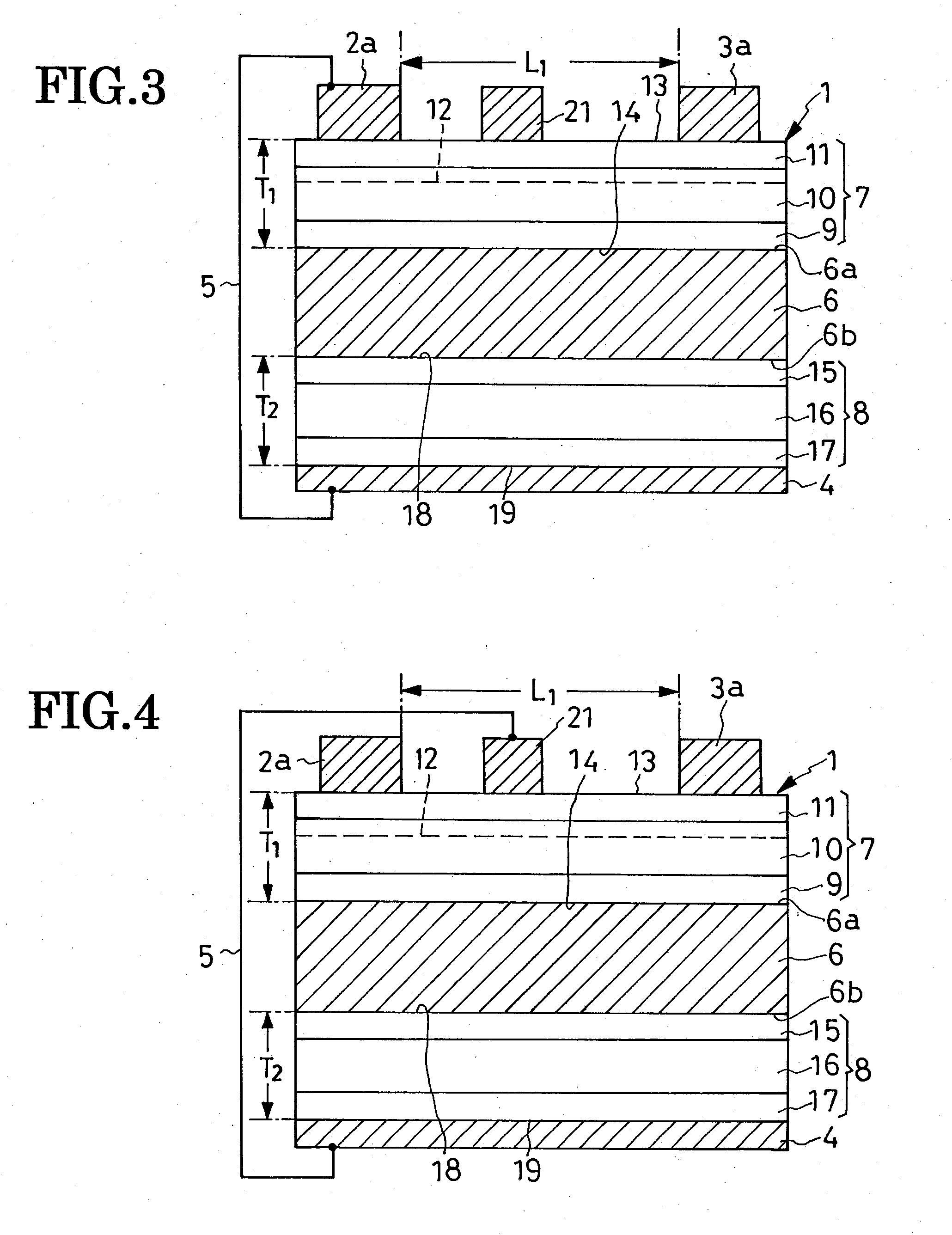

Multilayer wiring board

ActiveUS7002080B2High pin-count trendHigh densitySemiconductor/solid-state device detailsPrinted circuit aspectsFiberCarbon fibers

A multilayer wiring board is composed of a core portion, a first wiring portion and a second wiring portion. The core portion includes a core insulating layer containing a carbon fiber material. The first wiring portion is bonded to the core portion and has a laminated structure including at least a first insulating layer and a first wiring pattern, the first insulating layer containing glass cloth. The second wiring portion is bonded to the first wiring portion and has a laminated structure including at least a second insulating layer and a second wiring pattern. The core portion, the first wiring portion and the second wiring portion are arranged in a stack.

Owner:FUJITSU LTD

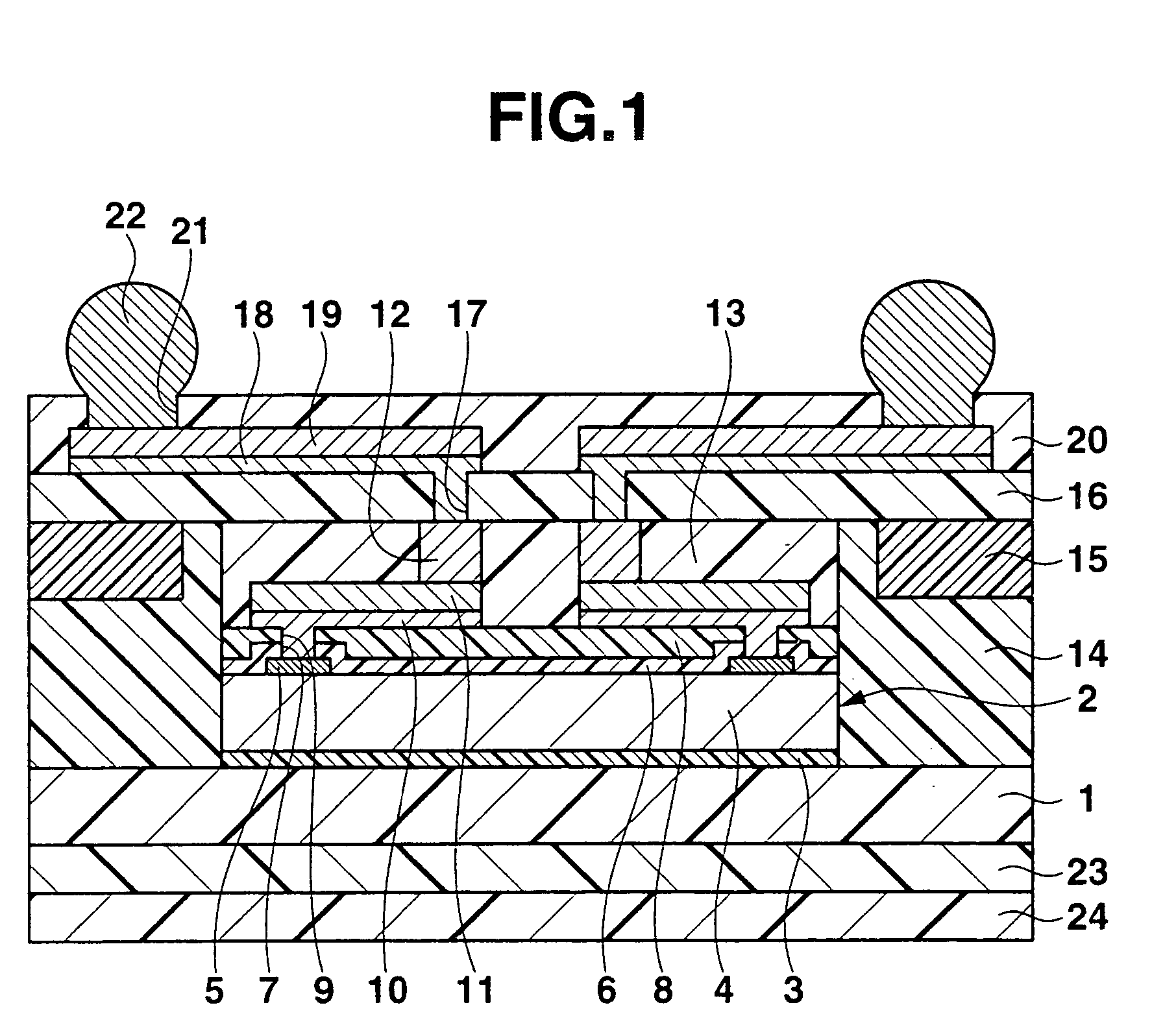

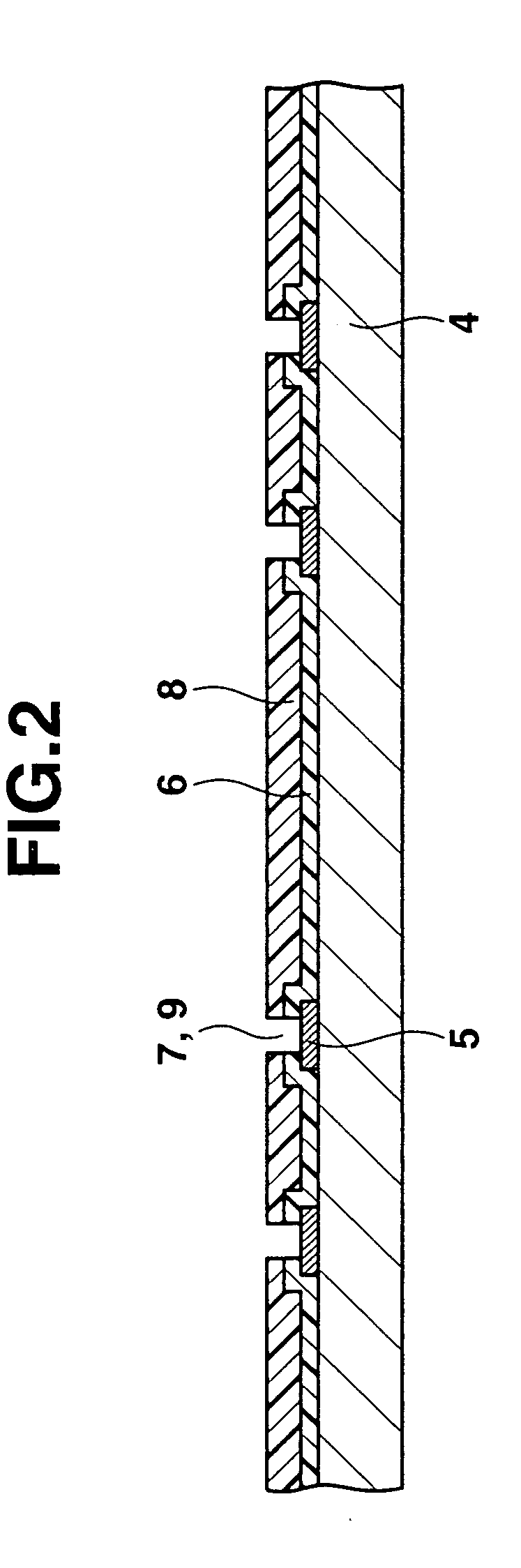

Low-EMI electronic apparatus, low-EMI circuit board, and method of manufacturing the low-EMI circuit board

InactiveUS20020015293A1Suppress spurious radiationIncrease costMagnetic/electric field screeningFinal product manufactureCapacitanceCountermeasure

A low-EMI circuit which realizes a high mounting density by converting the potential fluctuation of a power supply layer with respect to a ground layer which occurs on switching an IC device etc., into Joule's heat in the substrate without using any parts as a countermeasure against the EMI. Its structure, a circuit board using it, and a method of manufacturing the circuit board are also disclosed. Parallel plate lines in which the Q-value of the stray capacitance between solid layers viewed from the power supply layer and ground layer is equivalently reduced and which are matchedly terminated by forming a structure in which a resistor (resistor layer) and another ground layer are provided in addition to the power supply layer and the ground layer on a multilayered circuit board. A closed shield structure is also disclosed. This invention can remarkably suppress unwanted radiation by absorbing the potential fluctuation (resonance) which occurs in a power supply loop by equivalently reducing the Q-value of the stray capacitance, absorbing the standing wave by the parallel plate lines matchedly terminated and, closing and shielding the parallel plate lines.

Owner:SUMITOMO RUBBER IND LTD

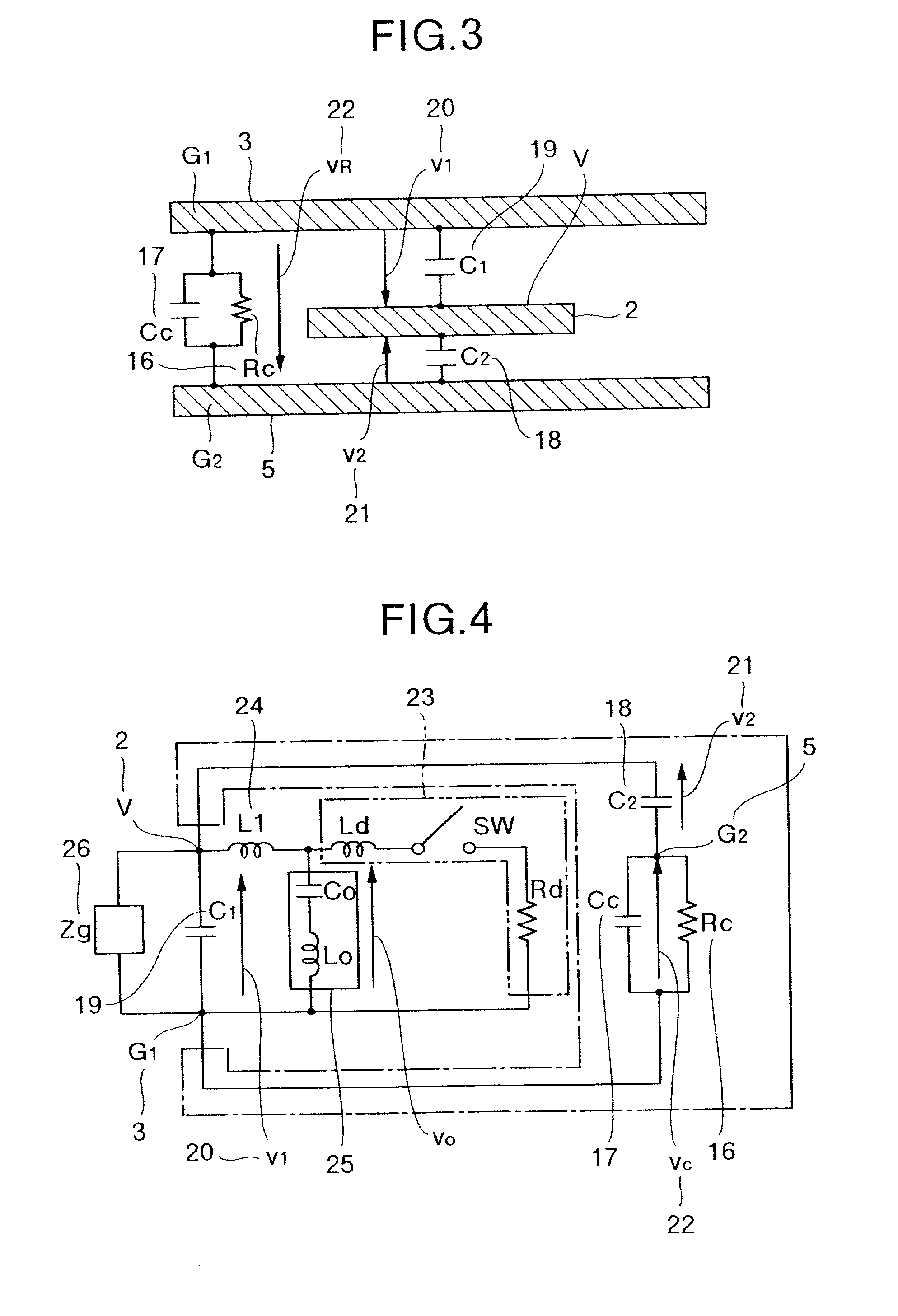

Glass fiber reinforced polyethylene glycol terephthalate composite material and preparation thereof

The invention relates to a PET glass fiber reinforced composite material, which has the following components based on weight proportion: 100 portions of PET, 10-45 portions of alkali-free glass fibers, 5.0-25 portions of toughener, 0.1-10 portions of crystallization promoter, 0.1-1.0 portion of chain extender, 0.5-5.0 portions of nucleating agent, 0.1-0.5 portion of antioxidant and 0.3-0.5 portion of lubricant. The preparation method is that the components are evenly mixed on a high-speed mixer and melted and blended by a twin-screw extruder to prepare the composite material. The composite material has the advantages of good mobility, high tensile strength and high impact strength, which aims to realize low-cost and high-quality PET engineering plastic scale production to effectively substitute for high-grade plastics and expensive imported special materials.

Owner:SHANGHAI UNIV +1

Die cap for use with flip chip package

InactiveUS20140091461A1Reduce riskImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal dilatationThermal deformation

A die cap for use with flip chip packages, flip chip packages using a die cap, and a method for manufacturing flip chip packages with a die cap are provided in the invention. A die cap encases the die of flip chip packages about its top and sides for constraining the thermal deformation of the die during temperature change. The CTE (coefficient of thermal expansion) mismatch between the die and substrate of flip chip packages is the root cause for warpage and reliability issues. The current inventive concept is to reduce the CTE mismatch by using a die cap to constrain the thermal deformation of the die. When a die cap with high CTE and high modulus is used, the die with the die cap has a relatively high overall CTE, reducing the CTE mismatch. As a result, the warpage and reliability of flip chip packages are improved.

Owner:SHEN YUCI

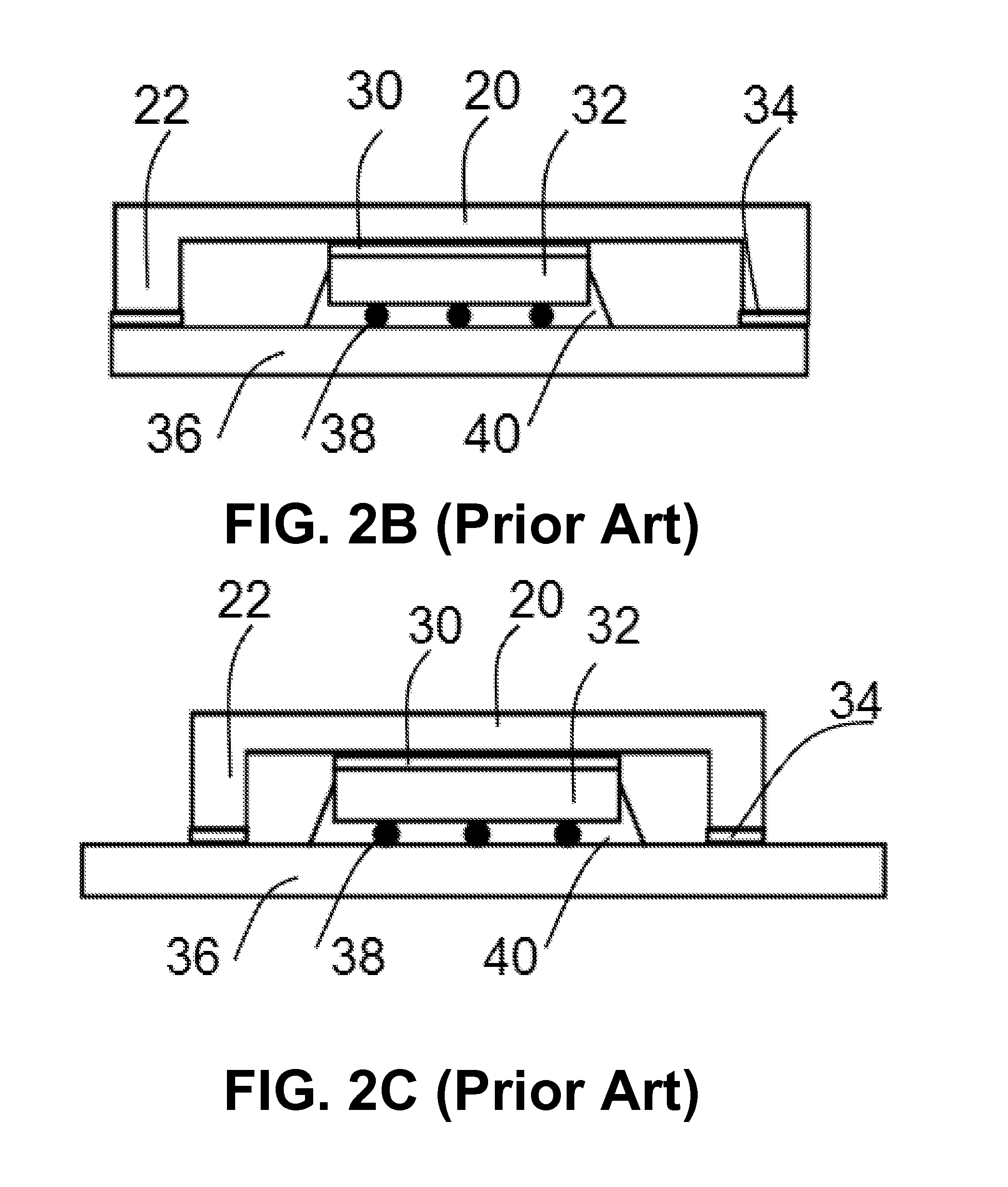

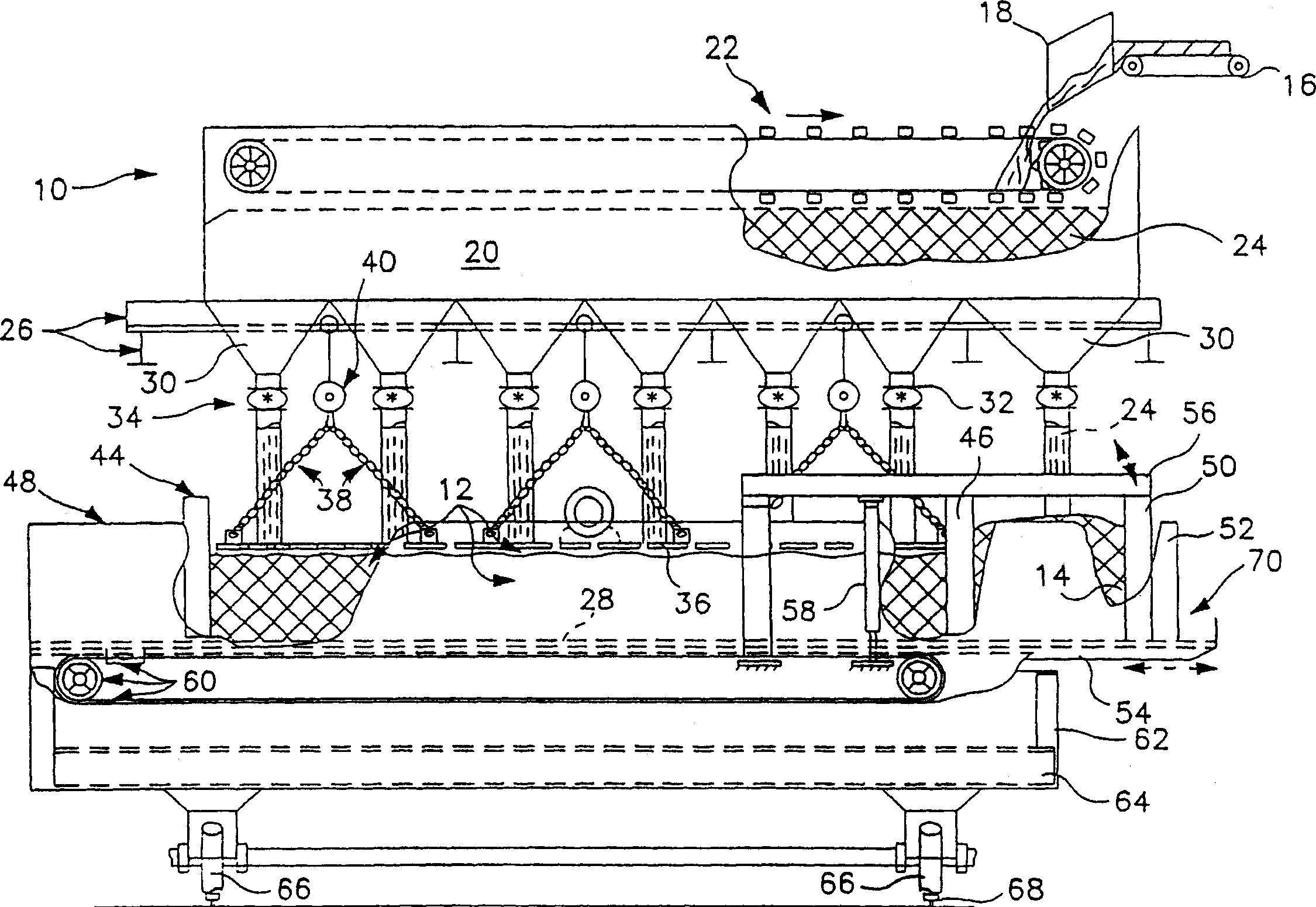

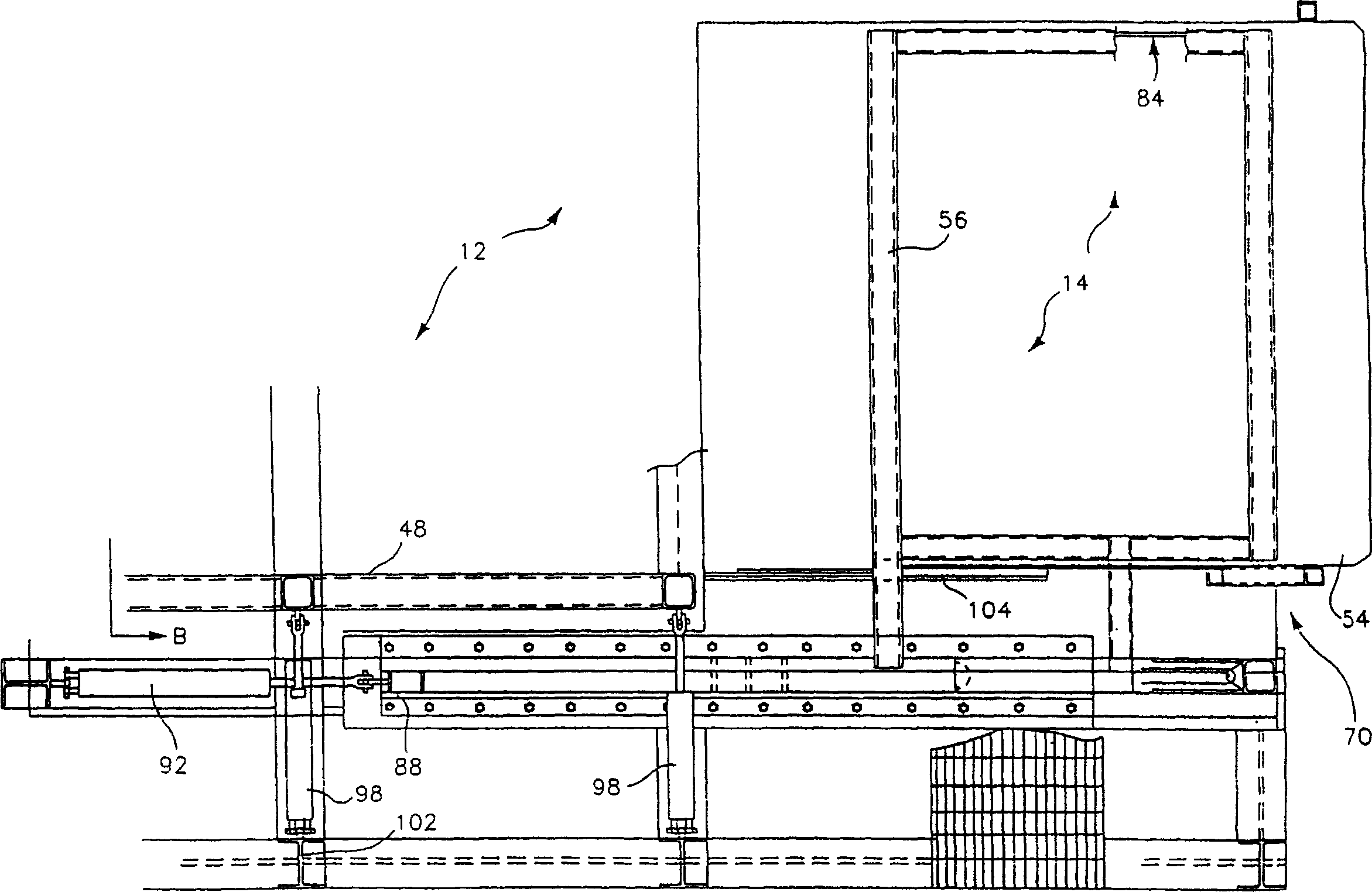

Method and apparatus for coal coking

InactiveCN1468364AReduce warpageReduce sliding frictionCharge manipulationCharging devicesEngineeringCoke oven

The invention provides a coke oven charging machine including a mobile frame and a coke oven feed device on the mobile frame. The coke oven feed device includes a movable, elongate charging plate having a first end and a second end, retractable side-walls adjacent the charging plate, first and second end walls adjacent the first and second ends of the charging plate and a shuttle section adjacent the first end of the charging plate for spanning an area between the first end of the charging plate and an entrance to the oven. The shuttle section has opposed shuttle side walls and a shuttle end wall. A charging plate moving device is provided for moving the charging plate into and out of the oven. The charging machine apparatus provides a means for quickly charging coking ovens with a compacted coal charge so that lower quality coals may be used to make metallurgical coke.

Owner:桑科克技术和发展有限责任公司

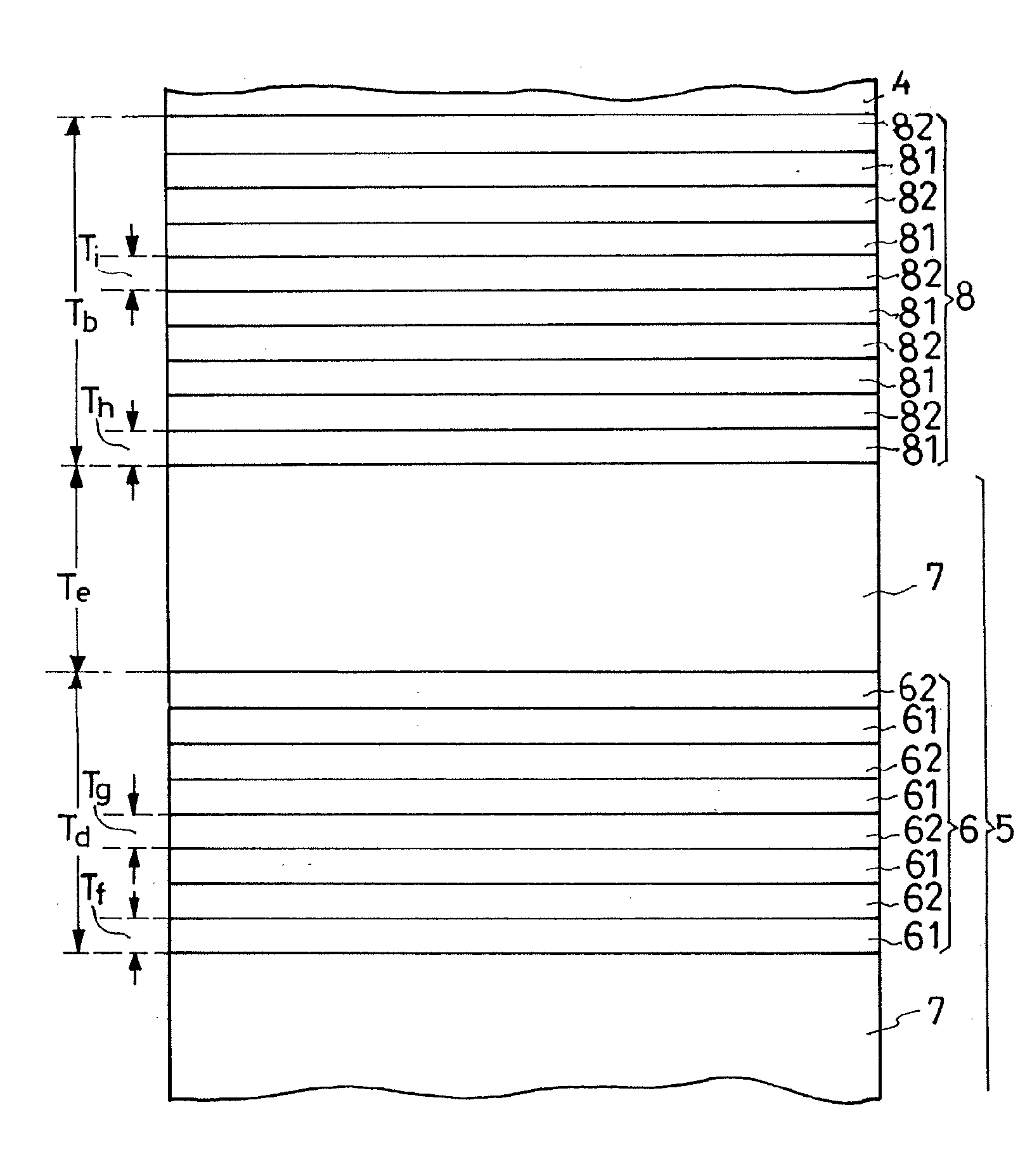

Semiconductor wafer, devices made therefrom, and method of fabrication

ActiveUS20080203382A1Reduce warpageReduce volatilitySemiconductor/solid-state device manufacturingSemiconductor devicesMESFETComputer science

A main semiconductor region of semiconducting nitrides is formed on a silicon substrate via a buffer region of semiconducting nitrides to provide devices such as HEMTs, MESFETs and LEDs. In order to render the wafer proof against warping, the buffer region is divided into a first and a second multilayered buffer subregion. The first buffer subregion comprises multiple alterations of a multi-sublayered first buffer layer and a non-sublayered second buffer layer. Each multi-sublayered first buffer layer of the first buffer subregion comprises multiple alternations of a first and a second buffer sublayer. The second buffer sublayers of each multi-sublayered first buffer layer either do not contain aluminum or do contain it in a higher proportion than do the first buffer sublayers. The second multilayered buffer subregion comprises multiple alternations of a first and a second buffer layer. The first buffer layers of the second multilayered buffer subregion are less in aluminum proportion than the fourth buffer layers of the second multilayered buffer subregion.

Owner:SANKEN ELECTRIC CO LTD

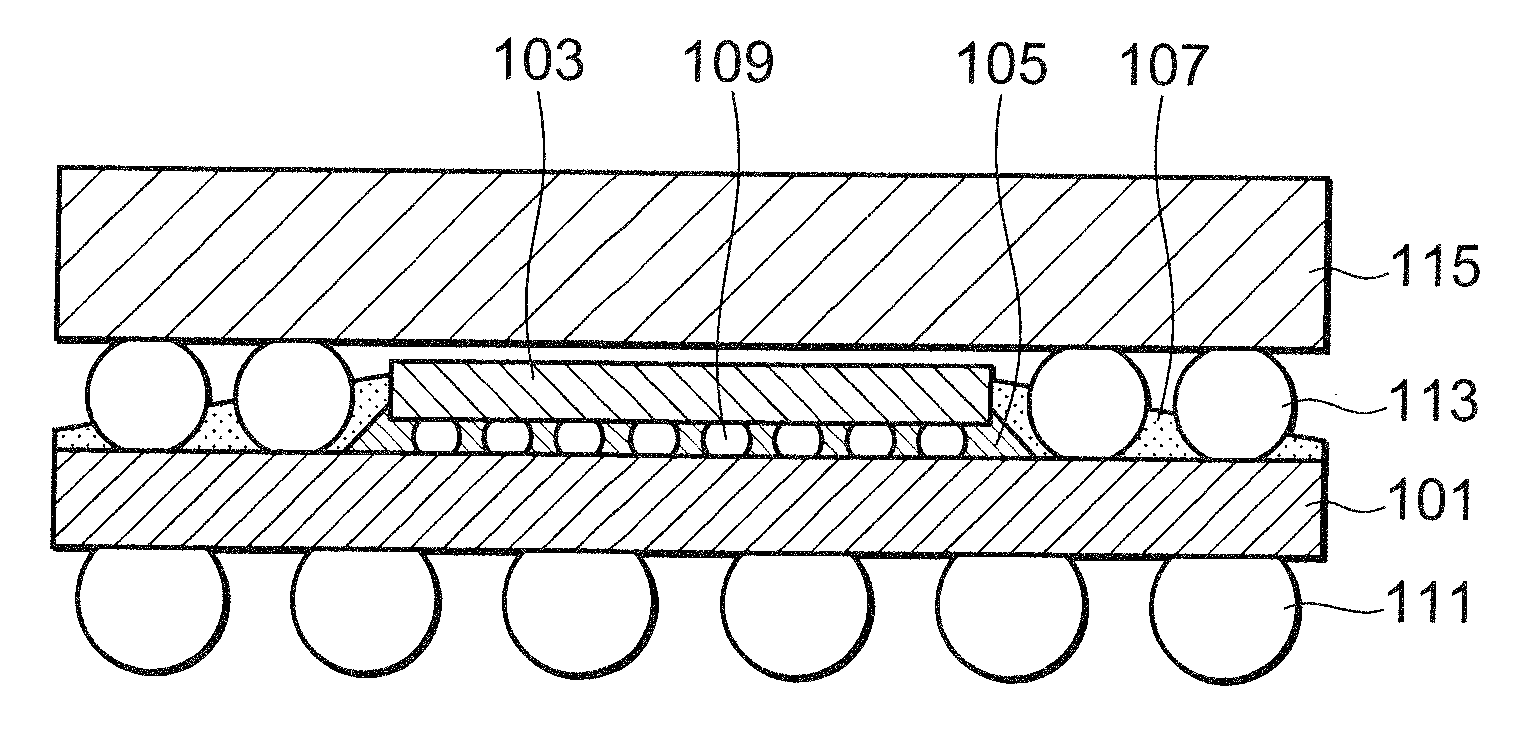

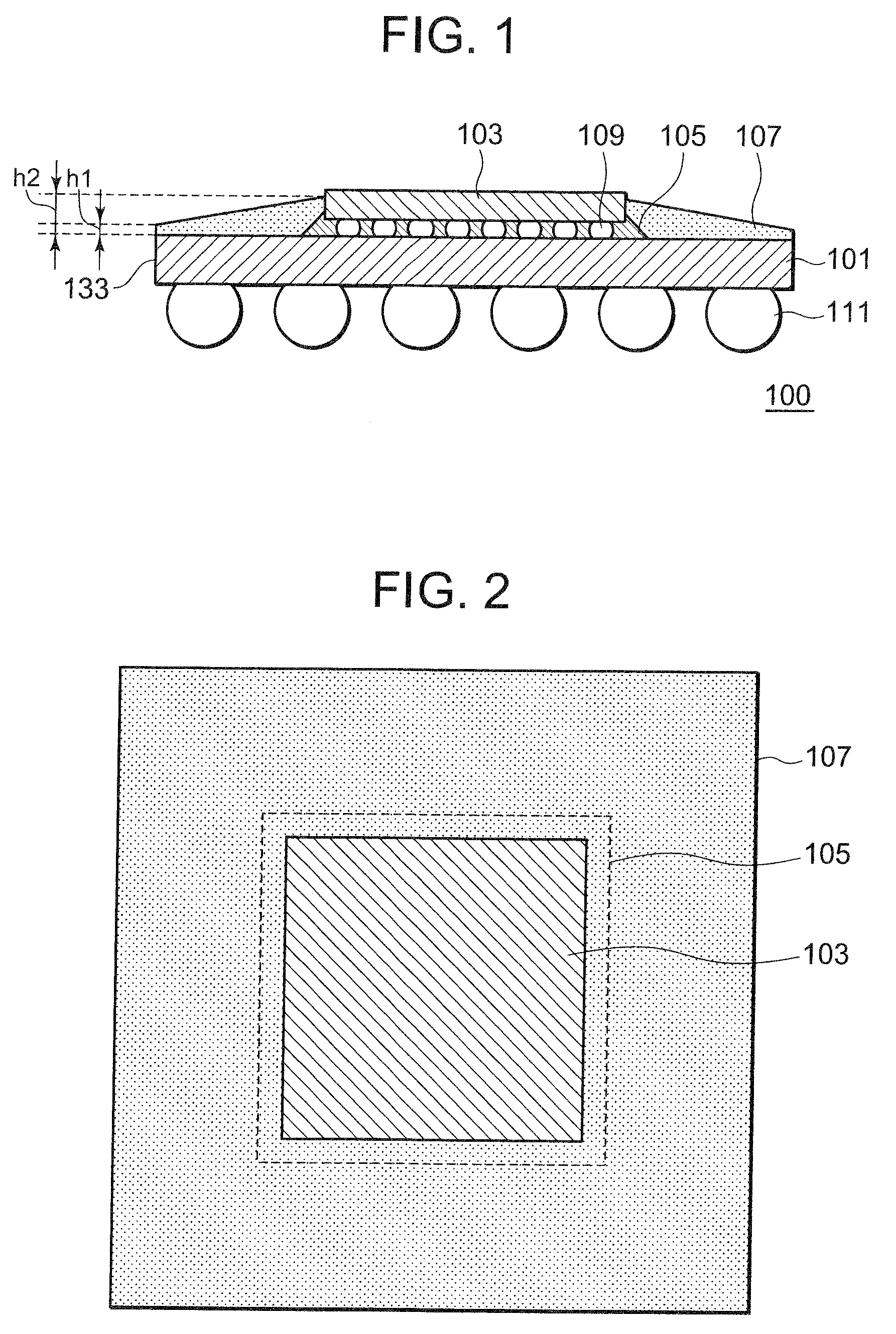

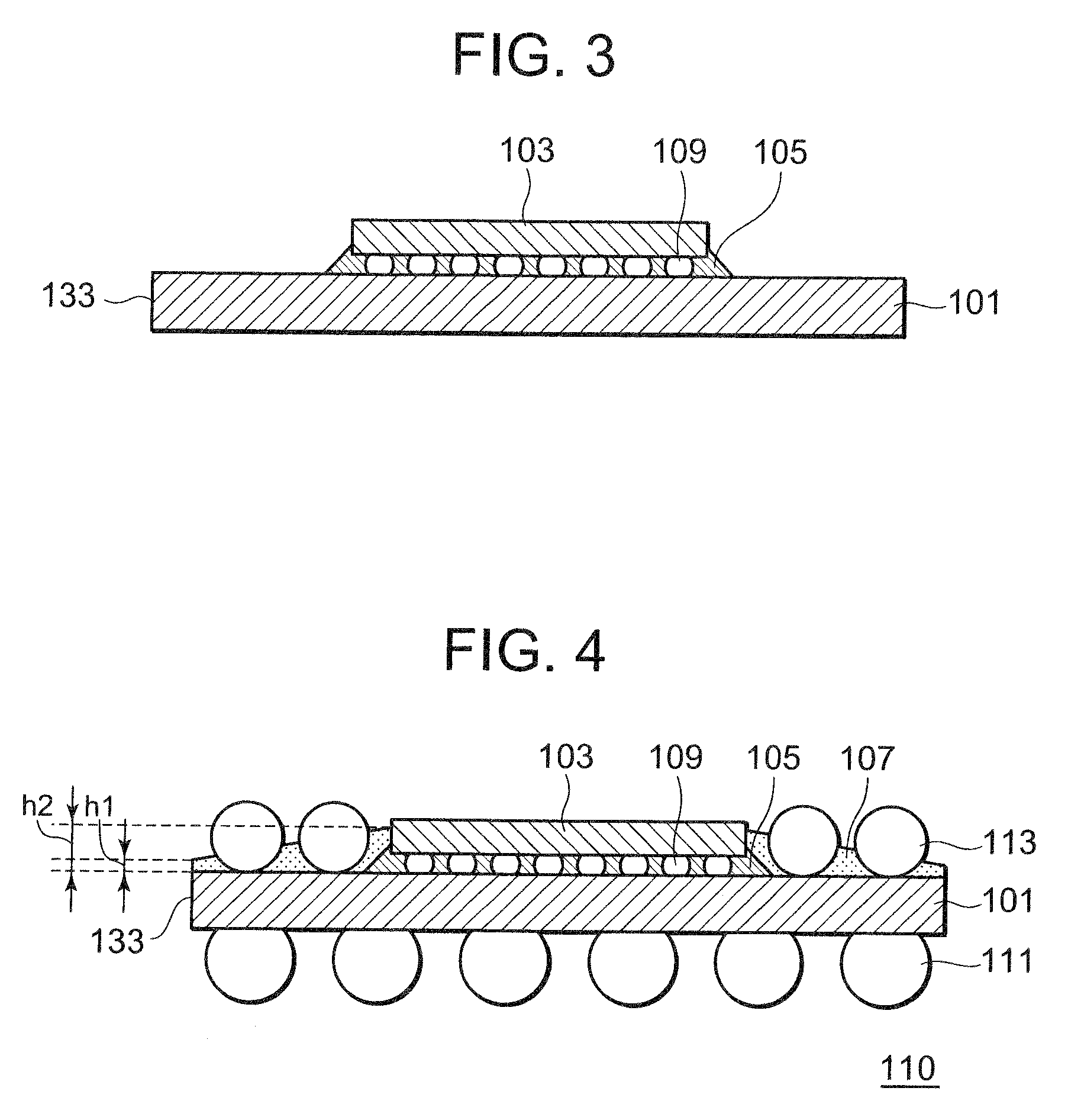

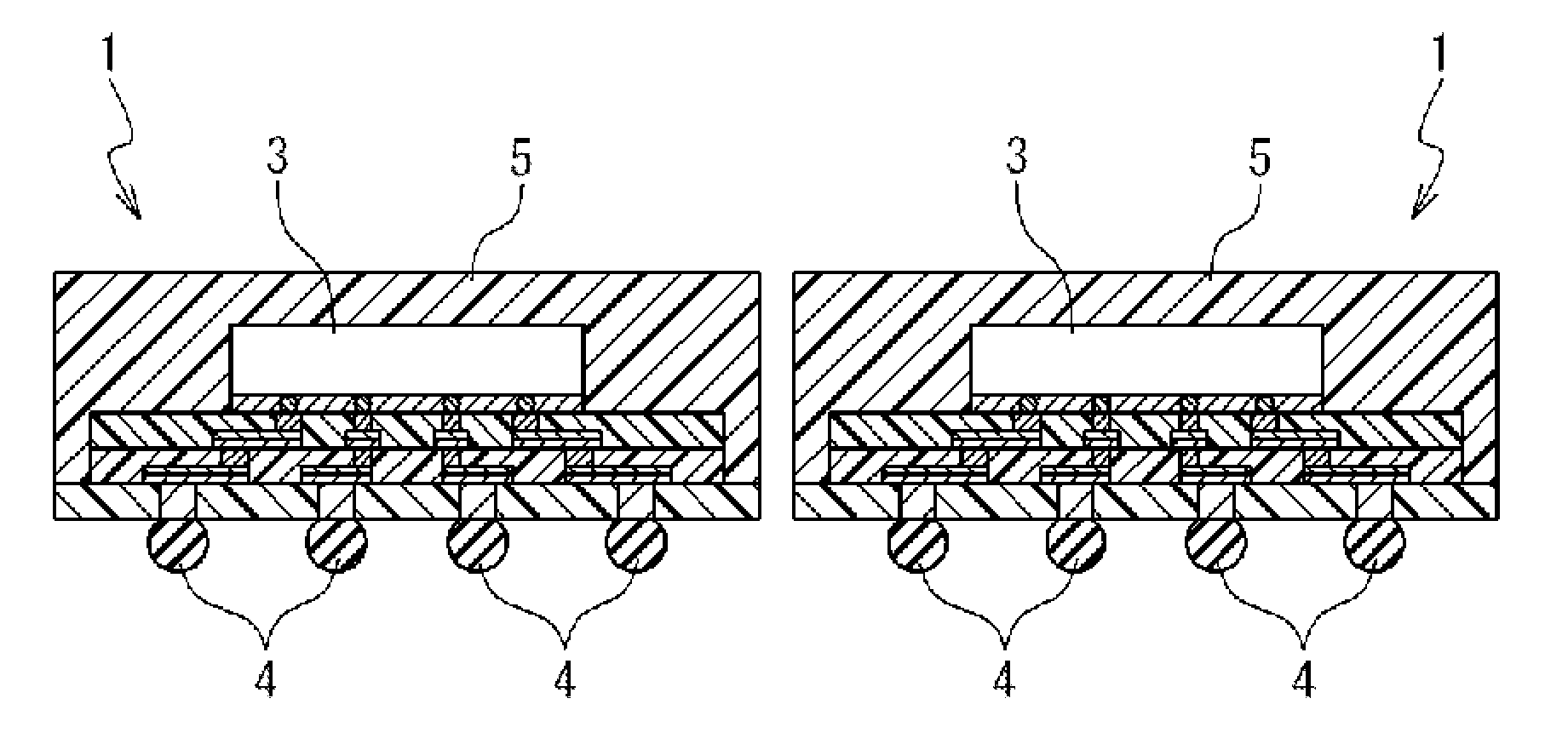

Semiconductor device including wiring substrate having element mounting surface coated by resin layer

InactiveUS20080251913A1Thin structureSuppression of decline in manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor device

In one embodiment of the present invention, there is provided a semiconductor device including a first semiconductor element mounted, through flip-chip bonding, on the element mounting surface of a first wiring substrate, and a resin layer that coats substantially the entire element mounting surface of the first wiring substrate. The first semiconductor element has two opposite surfaces. One surface faces the element mounting surface of the first wiring substrate, and the other surface is not coated by the resin layer.

Owner:NEC ELECTRONICS CORP

Semiconductor device and method of fabricating the same

InactiveUS20050140007A1Reduce warpageWarping of the base plate can be reducedSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a base plate, and a semiconductor constituent body formed on the base plate. The semiconductor constituent body has a semiconductor substrate and a plurality of external connecting electrodes formed on the semiconductor substrate. An insulating layer is formed on the base plate around the semiconductor constituent body. A hard sheet is formed on the insulating layer. An interconnection is connected to the external connecting electrodes of the semiconductor constituent body.

Owner:CMK

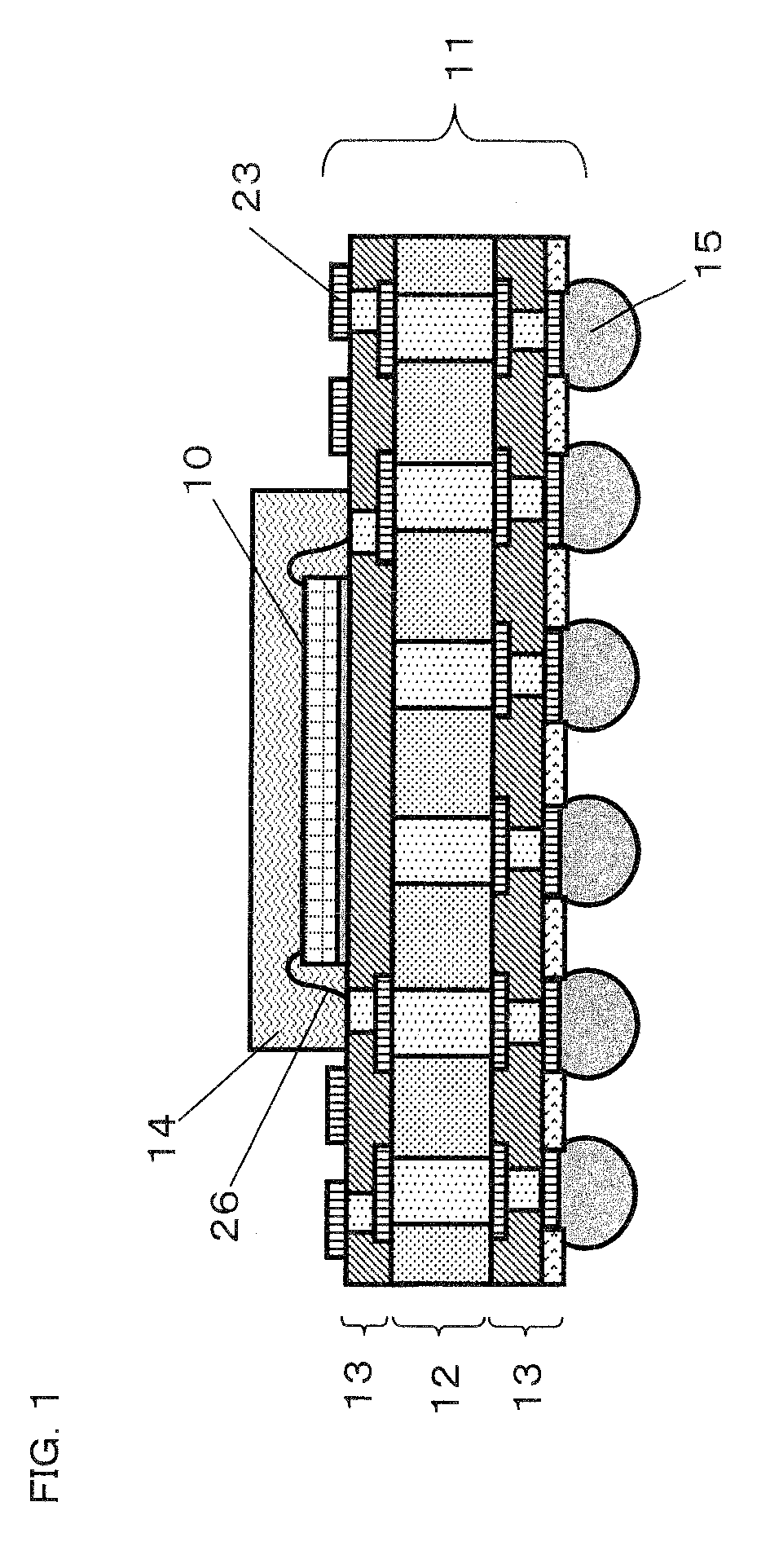

Electronic device and manufacturing method of electronic device

InactiveUS20110221071A1Reduce supportReduce warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

In an electronic device having multilayer resin interconnection layers, it is desired to reduce the warp of its support substrate. It is manufactured by: forming a lower layer including a via and a first insulating part on the support substrate; and forming an intermediate layer including a first interconnection and a second insulating part covering the first interconnection on the lower layer. The lower layer is formed by: forming the first insulating part on a first circuit region and a first region surrounding it; and forming the via on the first circuit region. The intermediate layer is formed by: forming the first interconnection on the first circuit region; forming a film of the second insulation part to cover the lower layer; and removing the second insulating part on the first region such that an outer circumferential part of an upper surface of the lower layer part is exposed.

Owner:RENESAS ELECTRONICS CORP

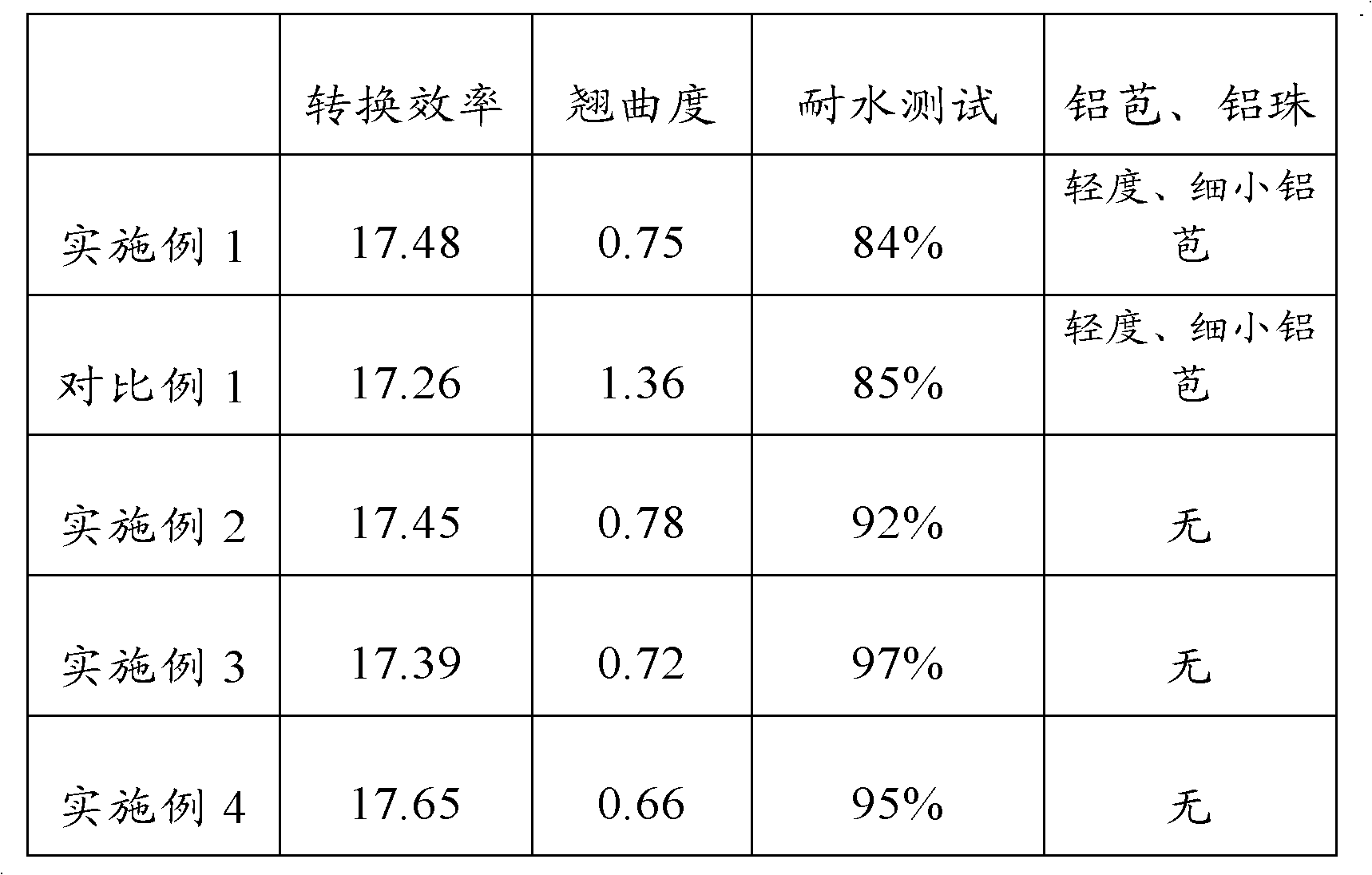

Back surface field aluminium paste for solar cells

ActiveCN102097154AReduce warpageNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

The invention relates to a back surface field aluminium paste for solar cells. The aluminium paste comprises the following components in parts by weight: 65-80 parts of aluminium powder, 1-5 parts of inorganic adhesive, 10-30 parts of organic carrier and 1-2 parts of modifier. Sintered films with lower warpage can be obtained through the back surface field aluminium paste.

Owner:长沙族兴新材料股份有限公司

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

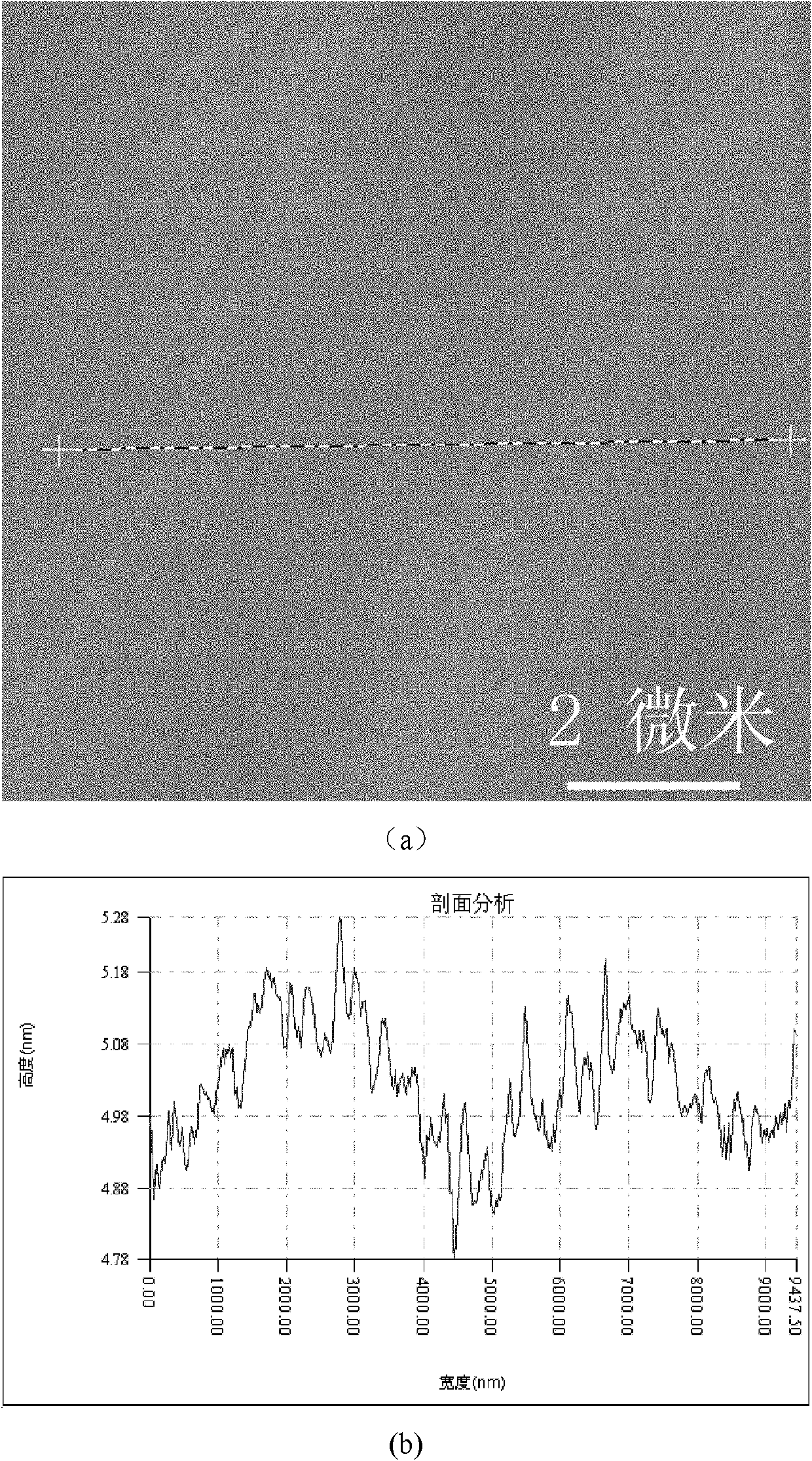

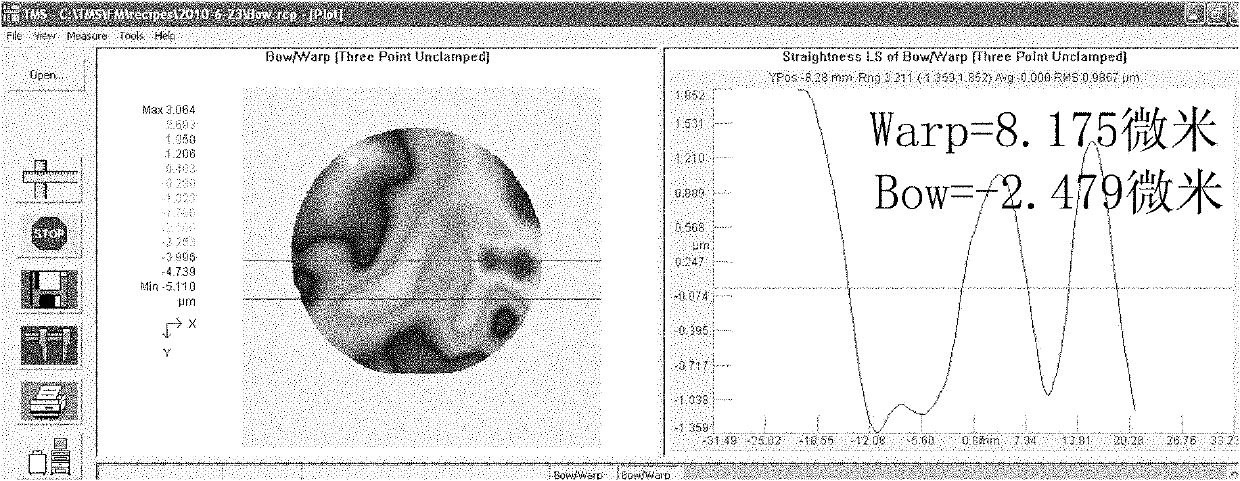

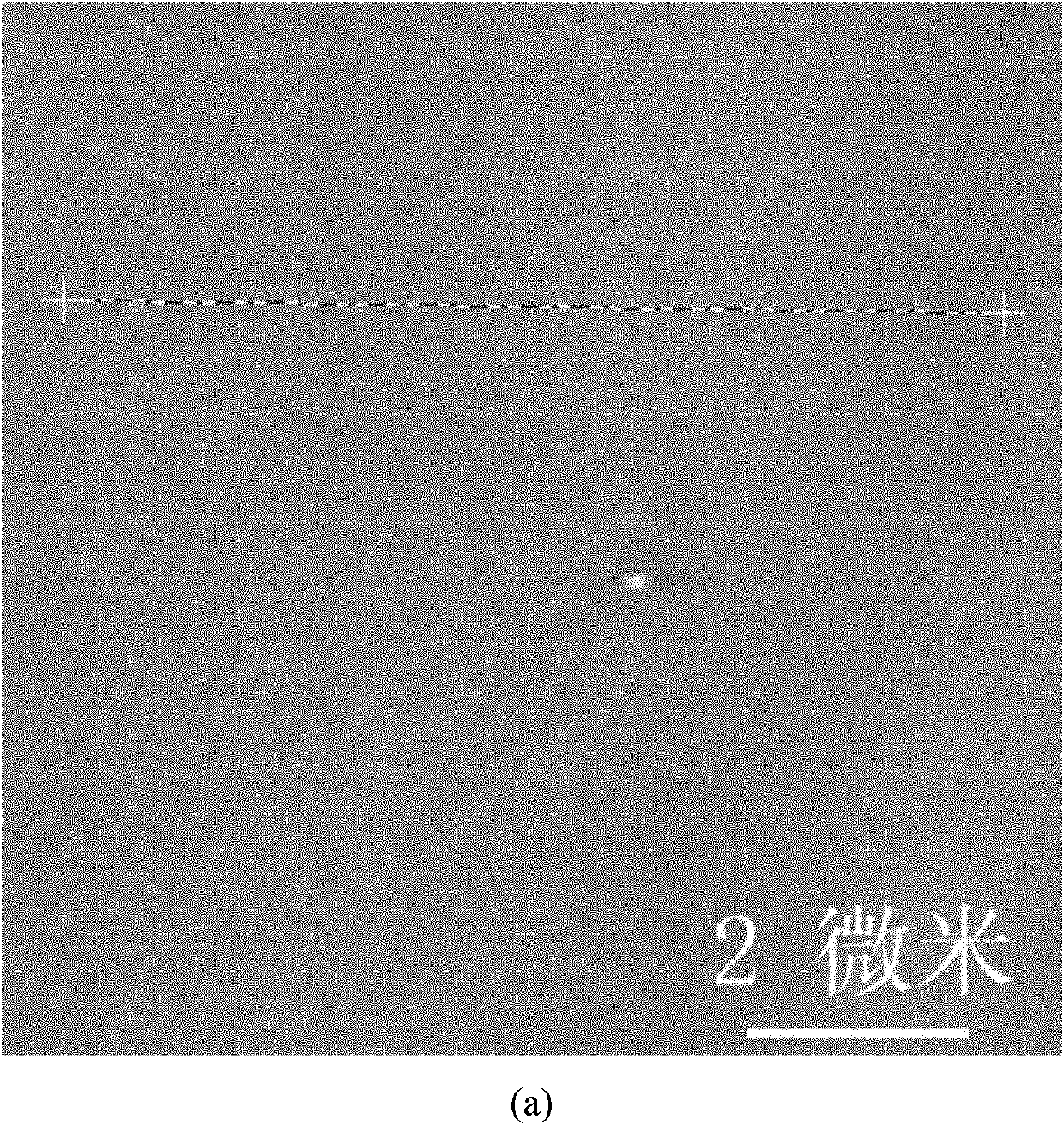

Adjustment method of SiC (silicon carbide) single crystal flatness by wet etching

ActiveCN102569055AWafer Quality ImprovementWafer flatness improvementPolycrystalline material growthAfter-treatment detailsEtchingSingle crystal

The invention provides a method for improving silicon carbide single chip flatness and crystal surfaces by using wet etching. By cleaning, preheating and oxygen-blowing etching silicon carbide single crystal and the like, the method removes dot, line and surface defects on the surfaces of the silicon carbide single crystal and furthest eliminates defects, stress and damaged layers on the surfaces of wafers to a maximum extent, so that the flatness of the silicon carbide wafers can be adjusted to the following parameters: Warp is less than 15mum, absolute Bow is less than 15mum and, and finally the single crystal silicon carbide wafers with high qualities are obtained.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

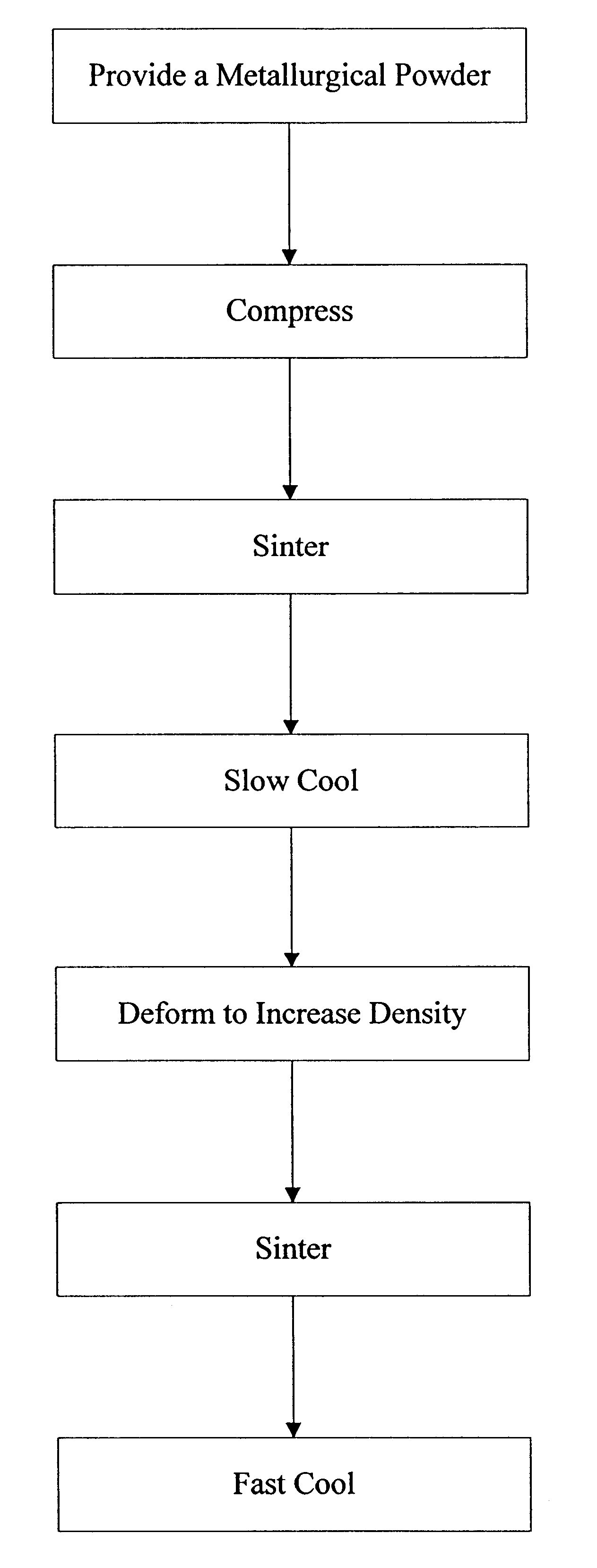

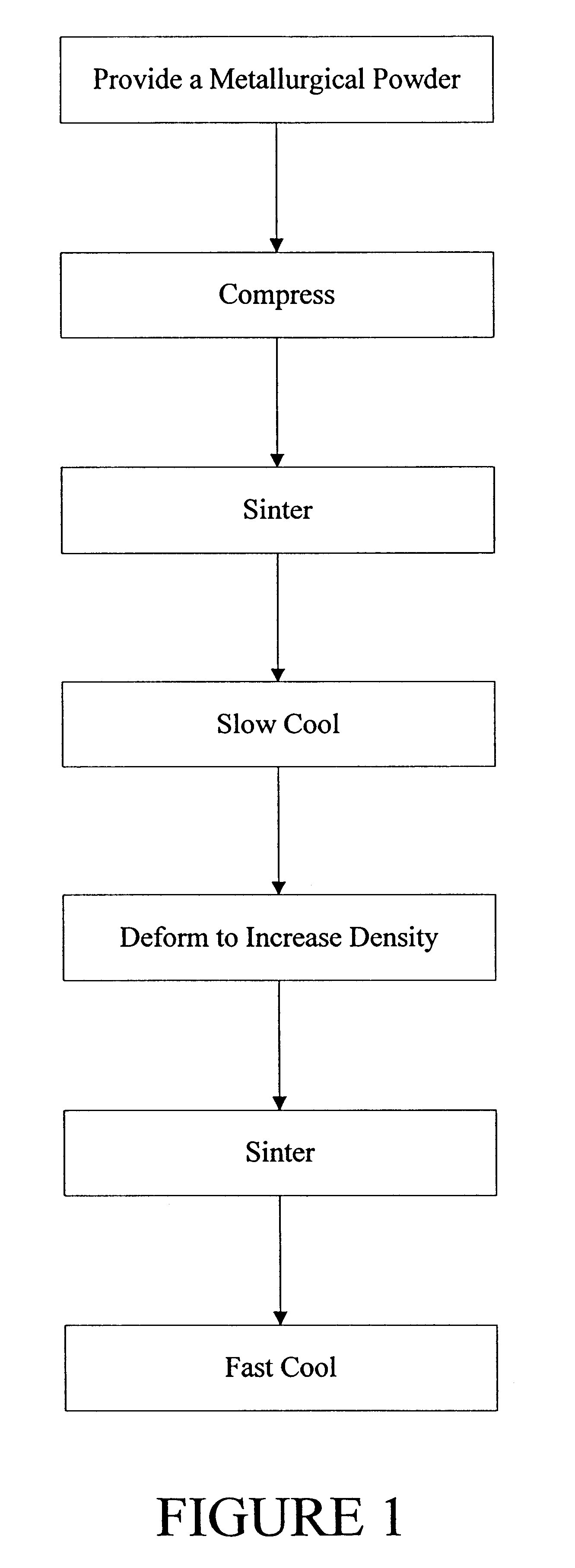

Method for producing powder metal materials

A method for producing a material includes providing a metallurgical powder including iron, 1.0 to 3.5 weight percent copper, and 0.3 to 0.8 weight percent carbon. At least a portion of the powder is compressed at 20 tsi to 70 tsi to provide a compact, and subsequently the compact is heated at high temperature and then cooled at a cooling rate no greater than 60° F. per minute to increase the surface hardness of the compact to no greater than RC 25. The density of at least a region of the sintered compact is increased, by a mechanical working step or otherwise, to at least 7.6 grams / cc. The sintered compact is then re-heated to high temperature and cooled at a cooling rate of at least 120° F. / min. so as to increase the surface hardness of the compact to greater than RC 25, and preferably at least RC 30. Material made by the method of the invention also is disclosed.

Owner:KEYSTONE INVESTMENT CORP

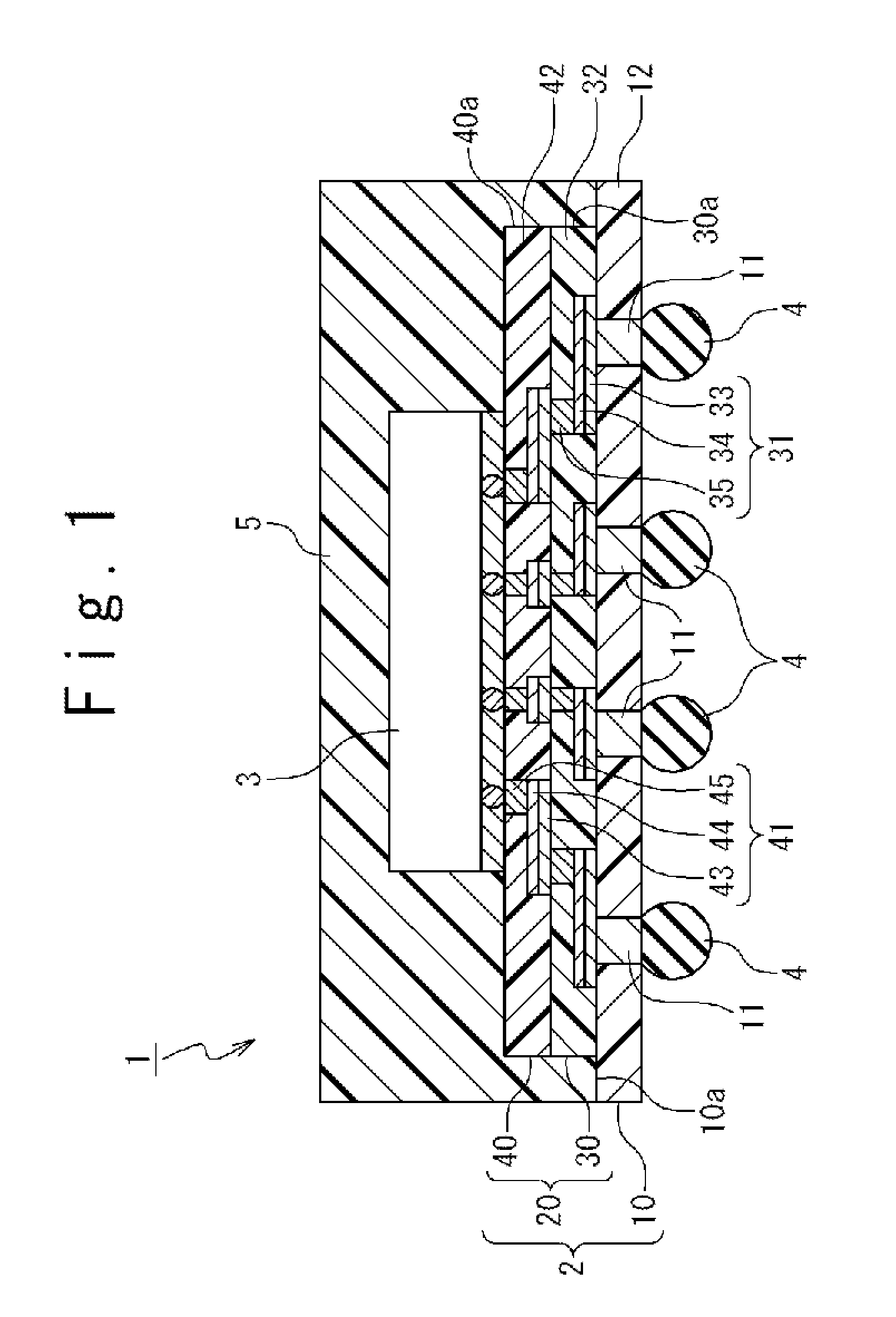

Semiconductor device and fabrication method

ActiveUS8004074B2Low profileReduce warpageSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor device

A semiconductor device, in which a semiconductor element is mounted on one side of a circuit board that is made up from an insulating layer and a wiring layer, includes metal posts provided on the side of the circuit board on which the semiconductor element is mounted; and a sealing layer provided on the side of the circuit board on which the semiconductor element is mounted such that the semiconductor element is covered and such that only portions of the metal posts are exposed.

Owner:GK BRIDGE 1

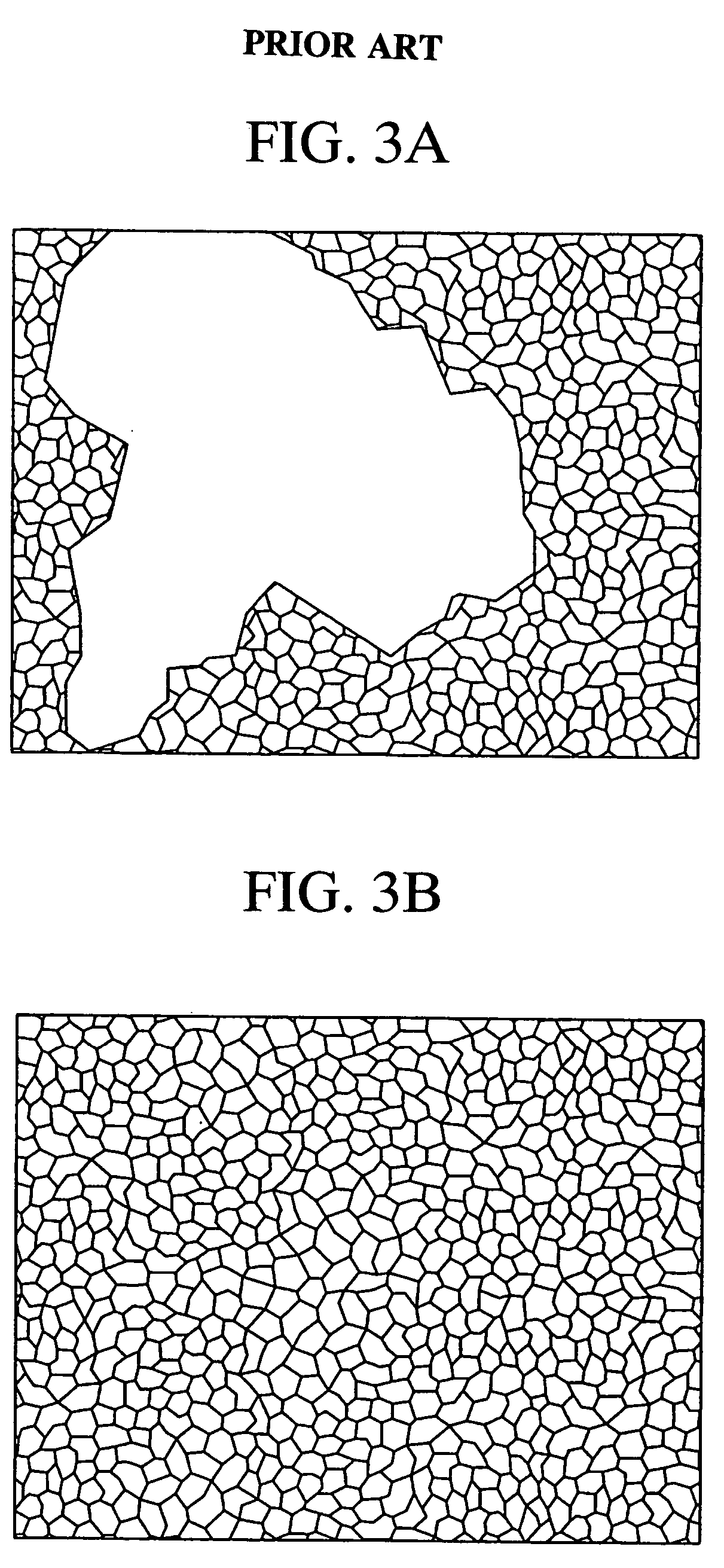

Warp-free semiconductor wafer, and devices using the same

A semiconductor wafer to be diced into individual SBDs, HEMTs or MESFETs has a substrate with a main semiconductor region and counter semiconductor region formed on its opposite surfaces. The main semiconductor region is configured to provide the desired semiconductor devices. In order to counterbalance the warping effect of the main semiconductor region on the substrate, as well as to enhance the voltage strength of the devices made from the wafer, the counter semiconductor region is made similar in configuration to the main semiconductor region. The main semiconductor region and counter semiconductor region are arranged in bilateral symmetry as viewed in a cross-sectional plane at right angles with the substrate surfaces.

Owner:SANKEN ELECTRIC CO LTD

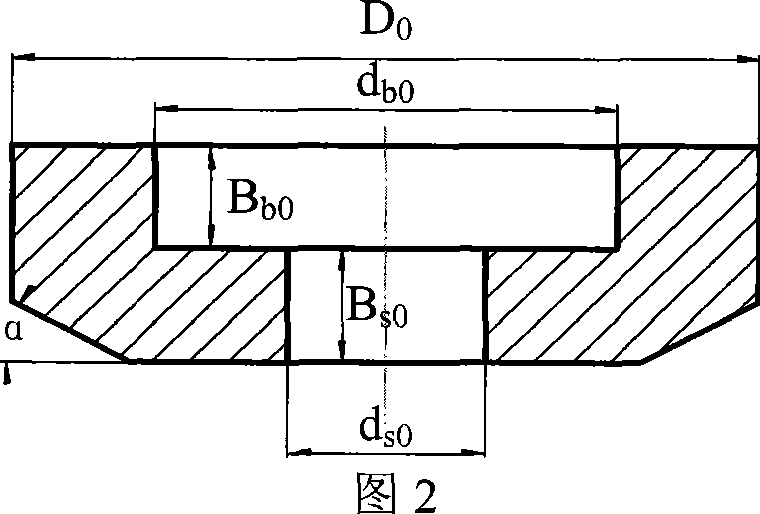

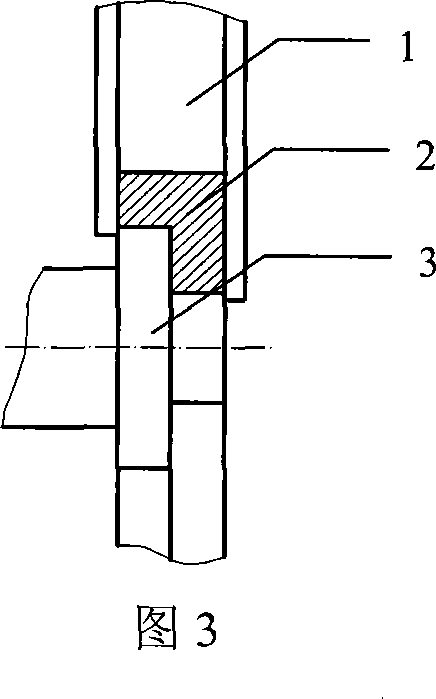

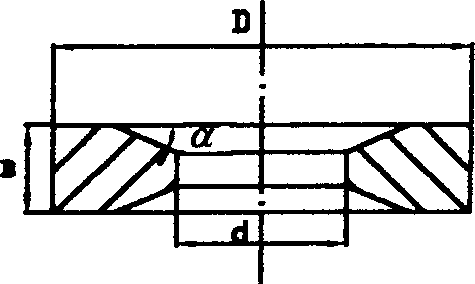

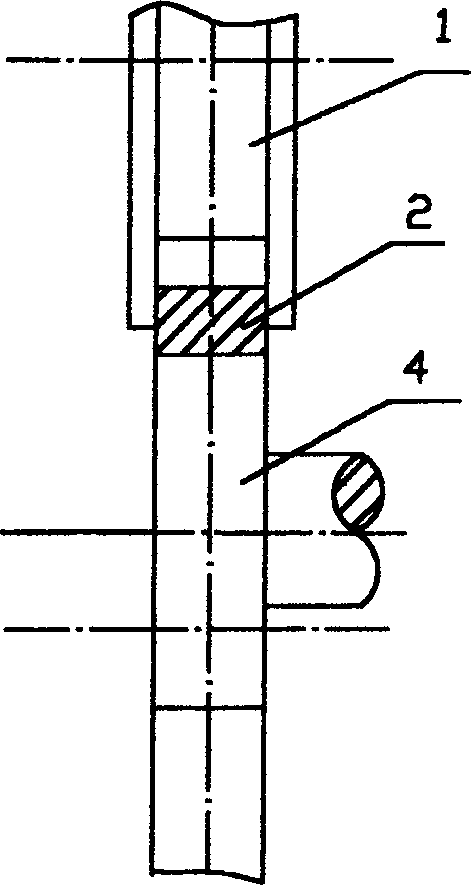

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

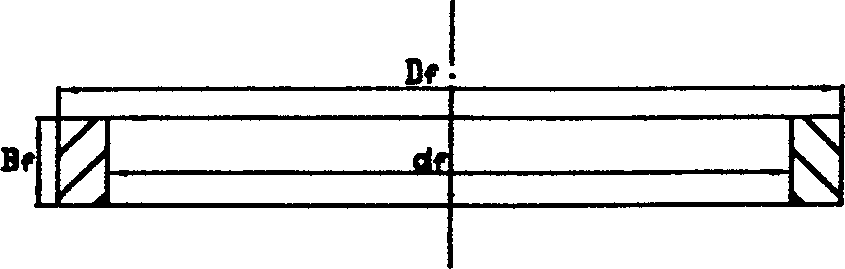

Method for rolling and forming rectangular section aluminium alloy ring piece

InactiveCN1586753AImprove metal structureImprove performanceMetal rolling arrangementsPunchingRoom temperature

The process of rolling to form aluminum alloy ring with rectangular cross section includes the following steps: sawing aluminum alloy rod into section; making ring blank via homogeneous heating from room temperature to the heat deforming temperature of 350-550 deg.c, upsetting, punching hole and punching coating; rolling the blank heated in a heating furnace to 350-550 deg.c via radial or radial-axial rolling inside groove; and cutting mechanically into the product. The present invention has the features of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

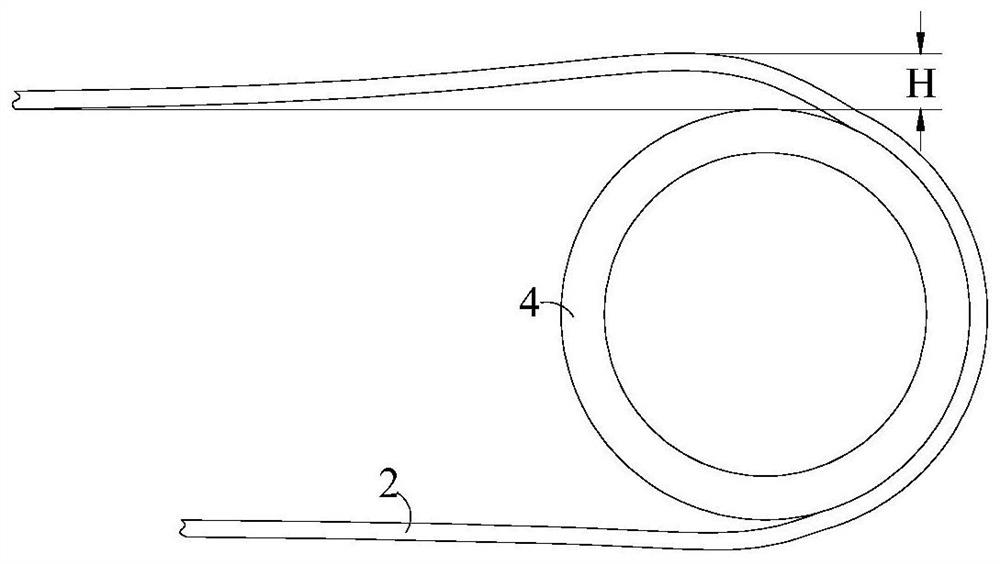

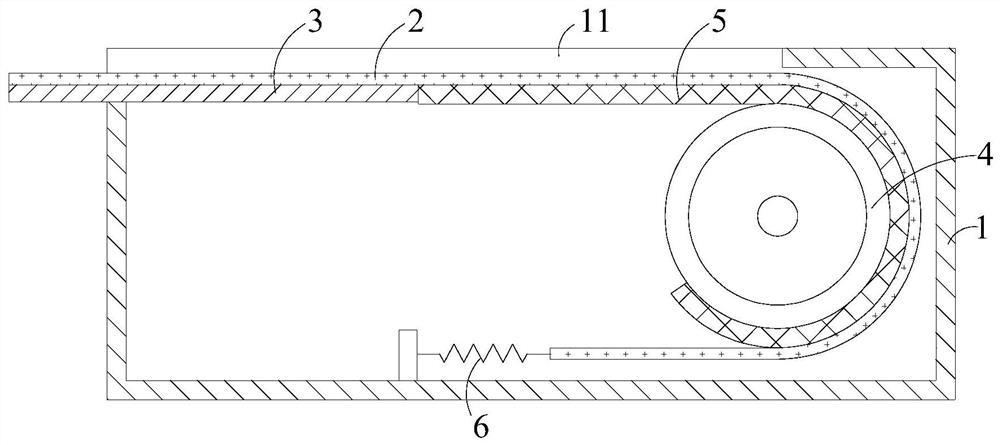

Flexible display device and sliding and rolling method thereof

PendingCN111862822ALess prone to damageReduce warpageDigital data processing detailsIdentification meansComputer hardwareEngineering

The invention relates to the technical field of the display and provides a flexible display device and a sliding and rolling method thereof. The flexible display device comprises a shell, a flexible display panel, a fixed supporting piece, a sliding scroll and a support piece, wherein the flexible display panel is provided with a first end and a second end which are oppositely arranged; the fixedsupporting piece is fixedly connected with the first end of the flexible display panel, is used for supporting the first end of the flexible display panel and is movably connected to the shell; the flexible display panel is arranged on the sliding scroll in a rolling manner and is rotatably arranged in the shell; the supporting piece is arranged on the sliding scroll in a rolling mode and locatedbetween the sliding scroll and the flexible display panel, one end of the supporting piece is fixedly connected with the sliding scroll, the other opposite end of the supporting piece is fixedly connected with the fixed supporting piece, and the supporting piece is used for supporting the flexible display panel when the flexible display panel is unfolded. When the flexible display panel is used bya user, the flexible display panel is not prone to damage, poor display is avoided, the poor touch of the area in the using process is avoided, and the warping amount of the flexible display panel can be reduced.

Owner:BOE TECH GRP CO LTD

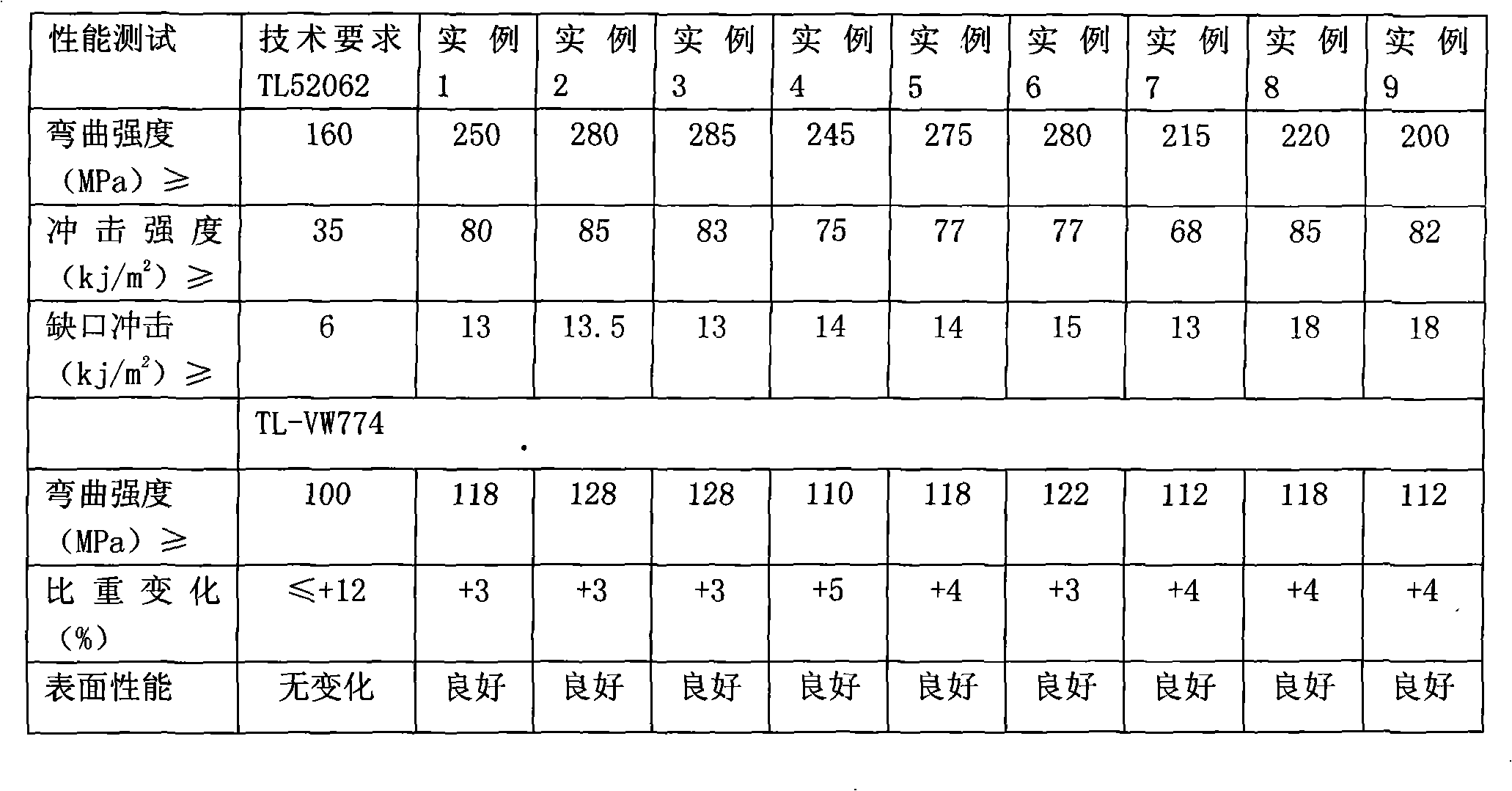

Alcoholysis resistance nylon composite material and preparation method thereof

The invention provides an alcoholysis resistance nylon composite material and a preparation method thereof; the composite material is applicable to the cooling water chamber of vehicles and comprises nylon, short glass fiber, glass fiber emergence resistance regulating additive, nucleating agent, colorant, heat stabilizer and alcoholysis resistance additive. The physical property of the nylon composite material provided by the invention can meet or exceed the TL52062 technical requirement and the alcoholysis resistance chemical property can meet the TL-VW774 technical requirement so that the surface of the product does not change and crack after being placing in 100% of glycol solution for 48h at 135 DEG C and the product has high shock resistance and dimension stability, thus ensuring that the stress cracking does not appear on joints.

Owner:辰东意普万新材料(广东)有限公司

Circuit board, process for producing the same, and power module

InactiveUS20050214518A1Reduce variationAbnormal growthSemiconductor/solid-state device detailsSolid-state devicesCrystalliteAluminium

A circuit board including conductive layers bonded to both surfaces of an insulating ceramic substrate, with a brazing material disposed therebetween. The conductive layers comprise at least 99.98% by mass of aluminum, and display an average crystal grain diameter within a range from 0.5 mm to 5 mm and a standard deviation σ for that crystal grain diameter of no more than 2 mm. Each conductive layer comprises at least 20 ppm of Cu, Fe and Si. The surface area of the crystal with the maximum crystal grain diameter within the conductive layers accounts for no more than 15% of the surface area of the insulating ceramic substrate.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com