Method and apparatus for coal coking

A technology for coking ovens and coal charging plates, which is applied to lighting and heating equipment, coking ovens, furnaces, etc. It can solve the problems of loading furnaces and coal that is not suitable for pre-compacting, so as to reduce sliding friction, reduce warping, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

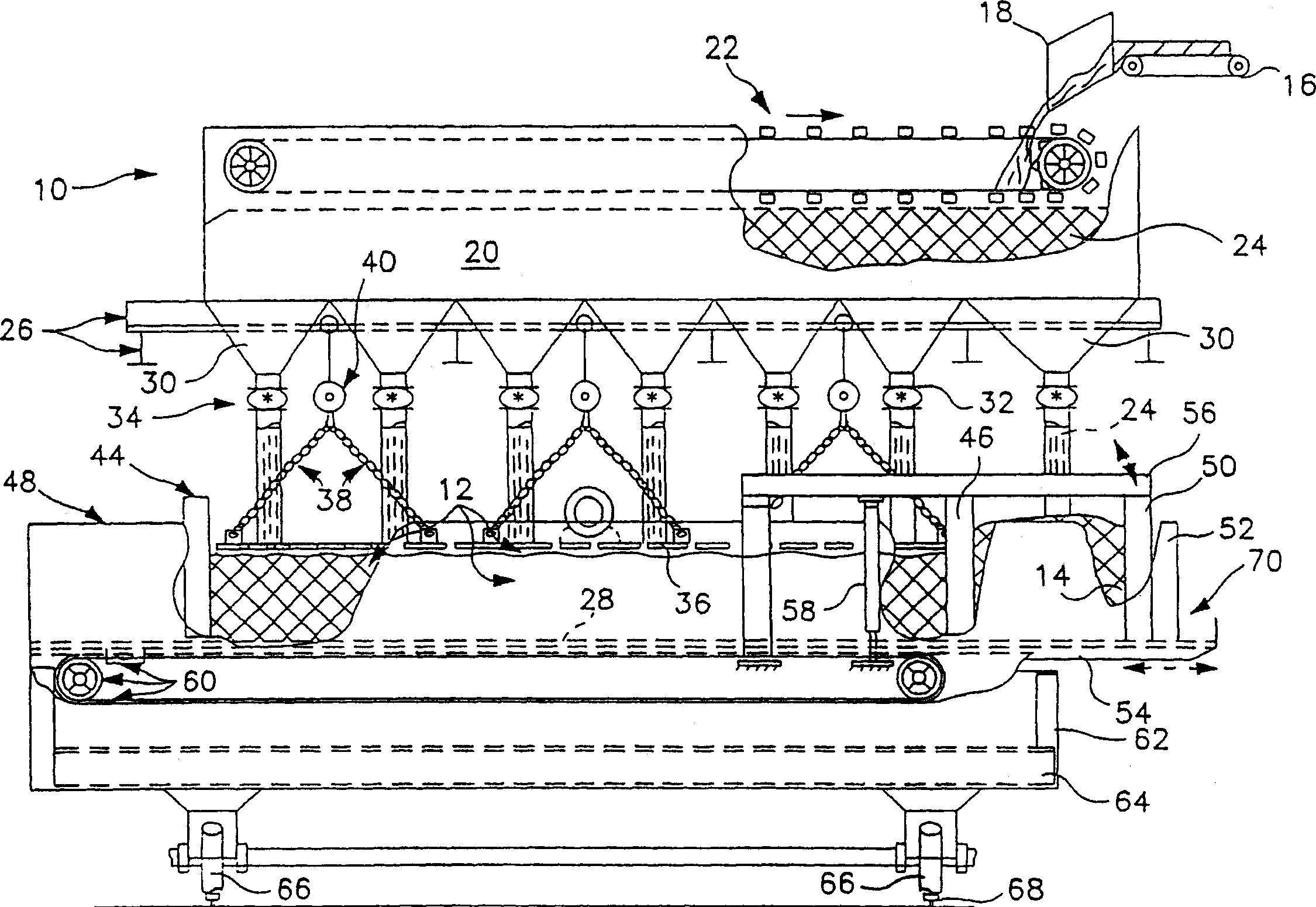

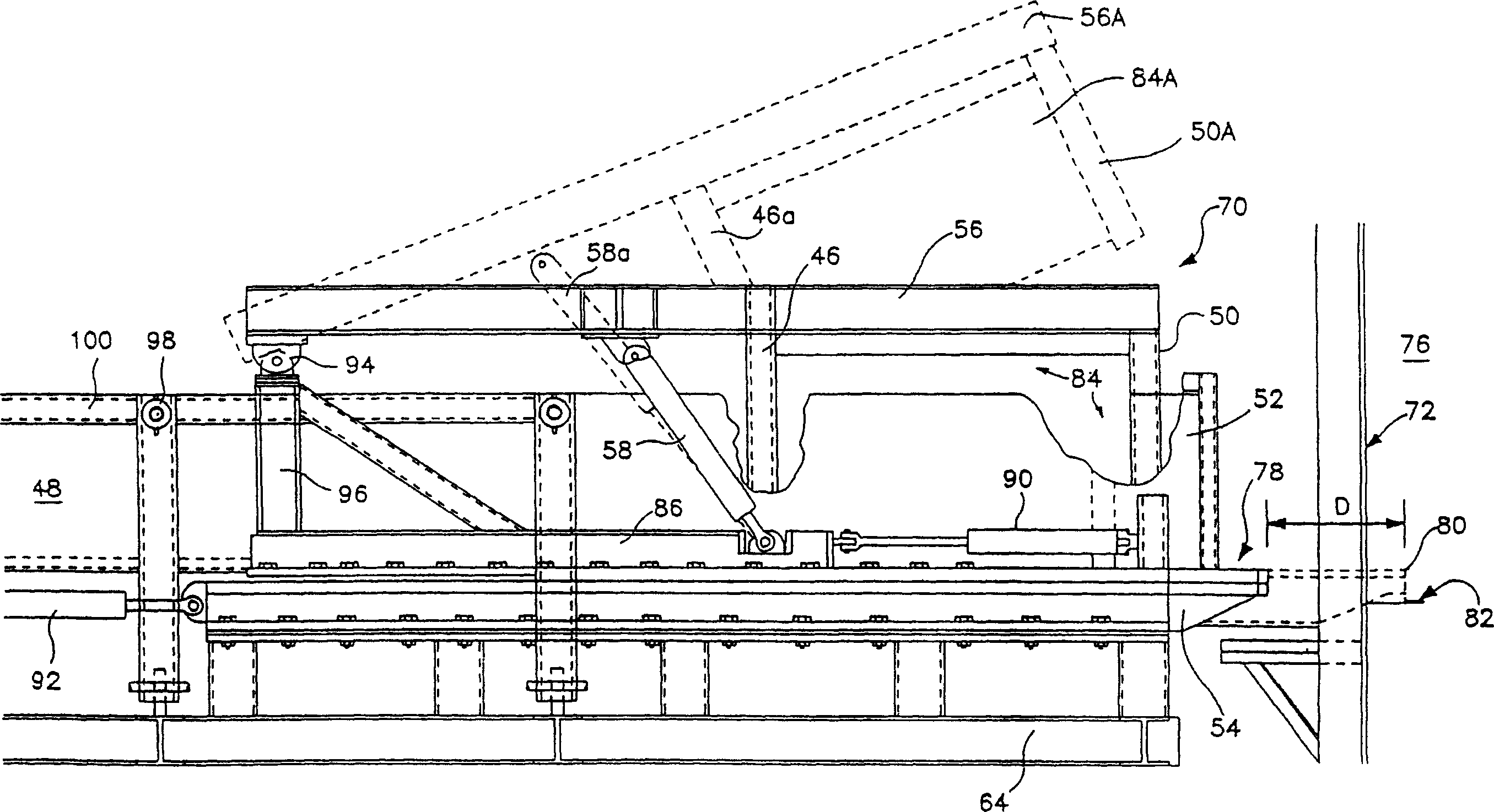

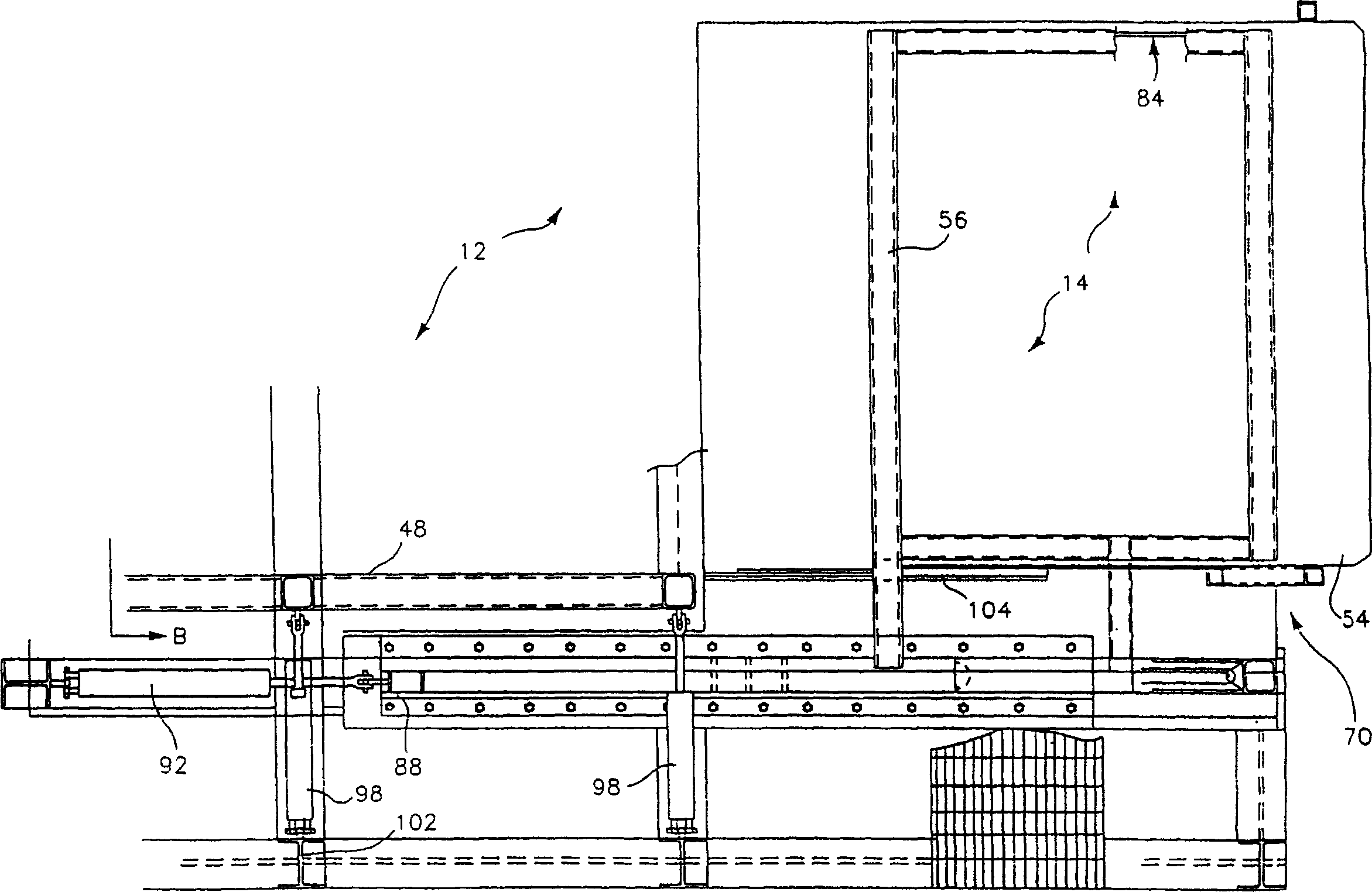

[0021] refer to figure 1 , a charging machine 10 for a coke oven is provided here. The loader includes a compacted coal bunker 12 and an uncompacted coal bunker 14 . Coal is supplied to both the compacted coal bunker and the uncompacted coal bunker by means of transverse conveyors 16 for conveying the coal from the coal source to the filling chute 18 and into the coal charging bunker 20 . The coal loading cabin 20 preferably includes leveling means, such as a chain leveling system 22, for spreading coal 24, preferably uncompacted coal, into the coal loading cabin 20. The coal loading bunker 20 is supported above the compacted coal bunker 12 and the uncompacted coal bunker 14 by respective support beams 26 .

[0022] The coal flows through two or more discharge chutes 30 to accumulate on the packing plate 28 and in the uncompacted coal bunker 14 . Each discharge chute 30 is preferably a pyramidal discharge chute with flanged outlets 32 provided therewith. Each discharge val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com