Alcoholysis resistance nylon composite material and preparation method thereof

A nylon composite material and alcoholysis-resistant technology, which is applied in the field of nylon composite materials, can solve the problems of reducing the alcoholysis resistance performance, not using it, and difficult to improve the material's resistance to ethylene glycol, so as to achieve good surface finish and reduce molding shrinkage. , the effect of excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

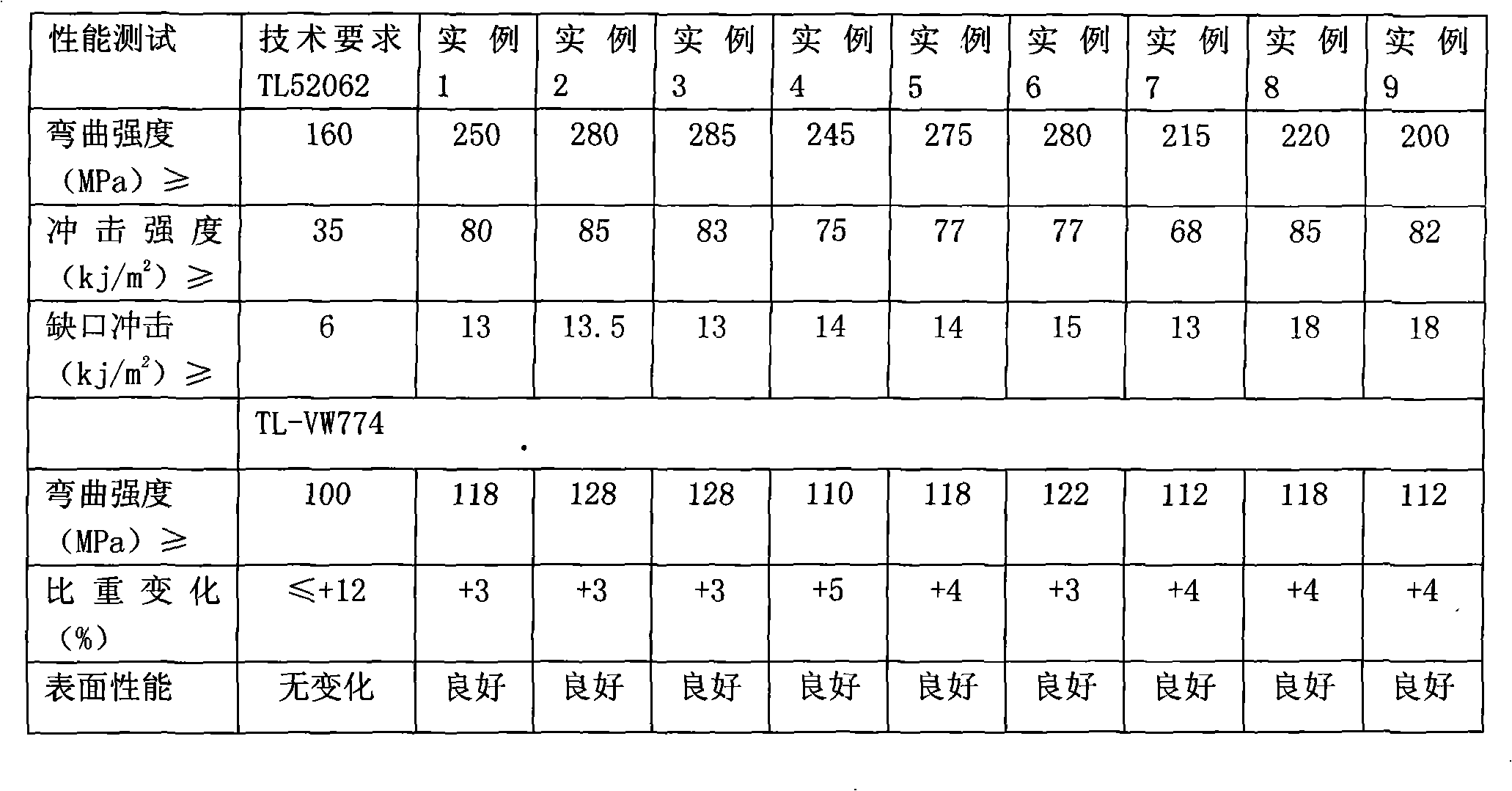

[0035] Table 1 is the content of each component of the alcoholysis-resistant nylon composite material of Examples 1 to 9, and the nylon is selected from the copolymer (PA66 / PA6) of nylon 66 (PA66), nylon 6 (PA6), nylon 66 and nylon 6 , one of nylon 11 (PA11) or nylon 12 (PA12); the short glass fiber is an alkali-free short glass fiber, which is treated with a silane coupling agent and coated with a silane-type wetting agent on the surface, which is resistant to ethylene glycol Characteristics, the present embodiment 1~9 selects the non-alkali short glass fiber that is produced by Chongqing International Composite Material Co., Ltd., model is ECS301G; The anti-glass fiber exposure adjustment auxiliary agent is selected from silicone powder and ethylene bisfatty acid amide 2~ 1: 1 mixture, the preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com