Patents

Literature

162 results about "Material physics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials physics is the use of physics to describe the physical properties of materials. It is a synthesis of physical sciences such as chemistry, solid mechanics, solid state physics, and materials science. Materials physics is considered a subset of condensed matter physics and applies fundamental condensed matter concepts to complex multiphase media, including materials of technological interest.

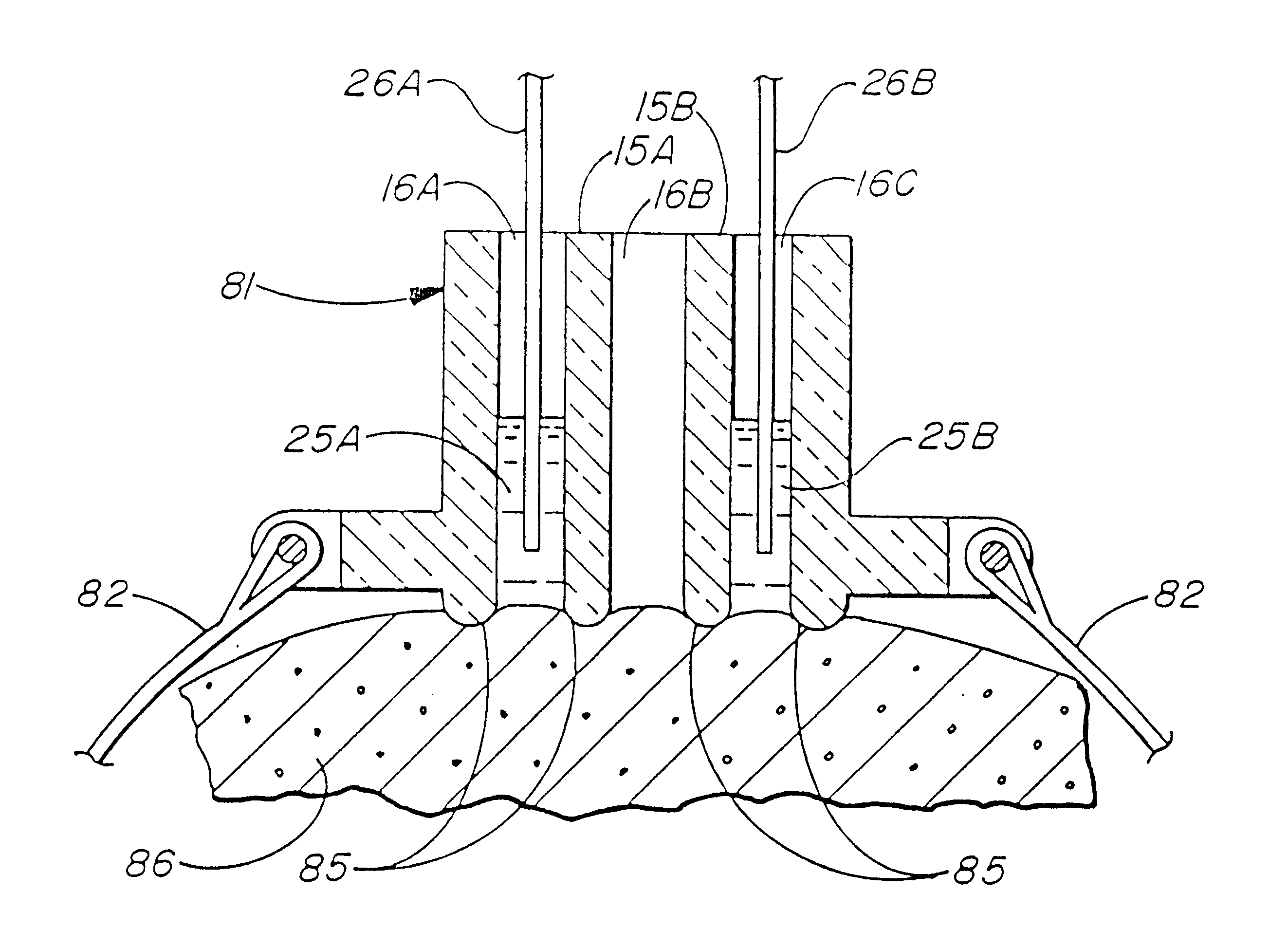

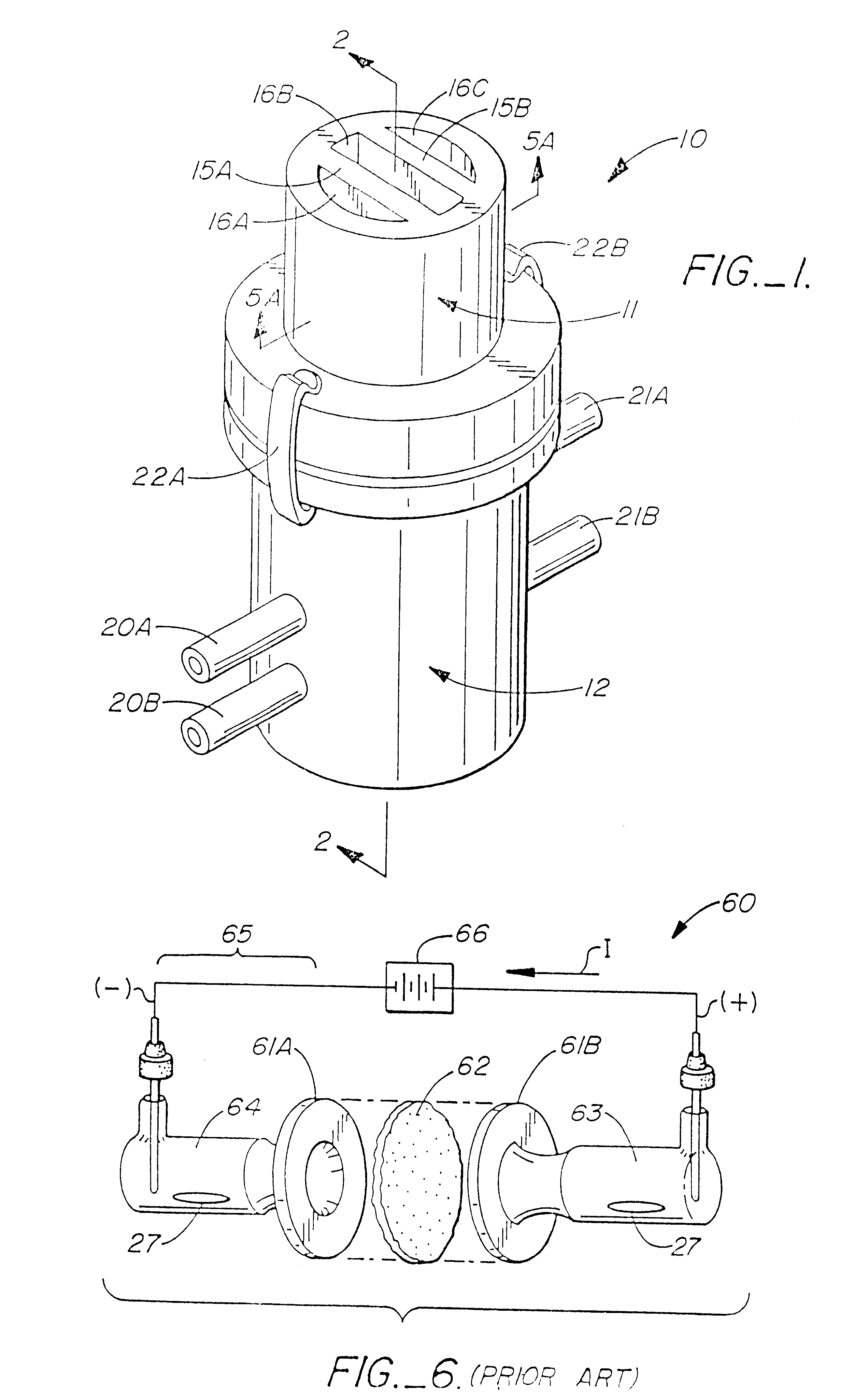

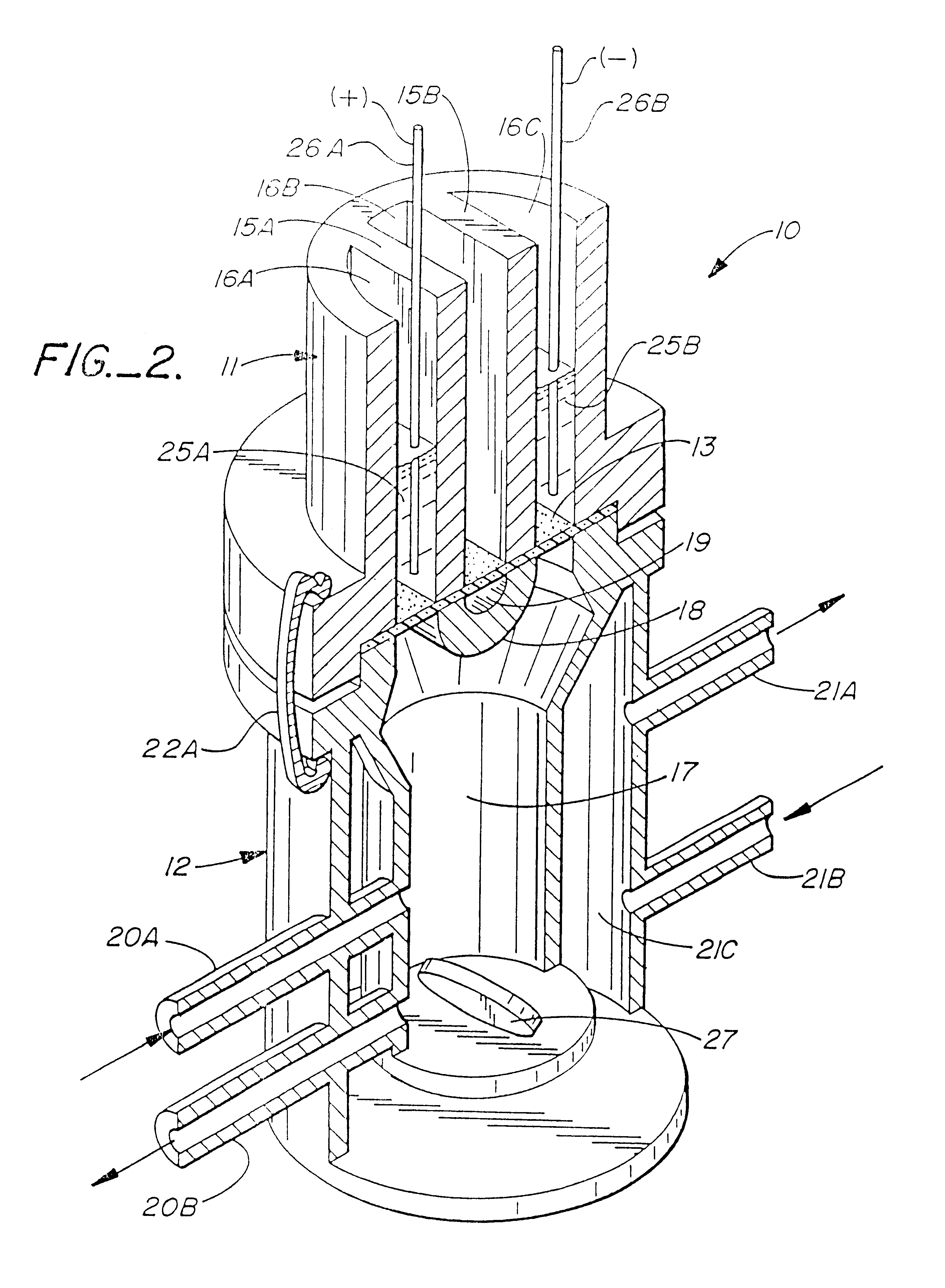

Method for the iontophoretic non-invasive determination of the in vivo concentration level of an inorganic or organic substance

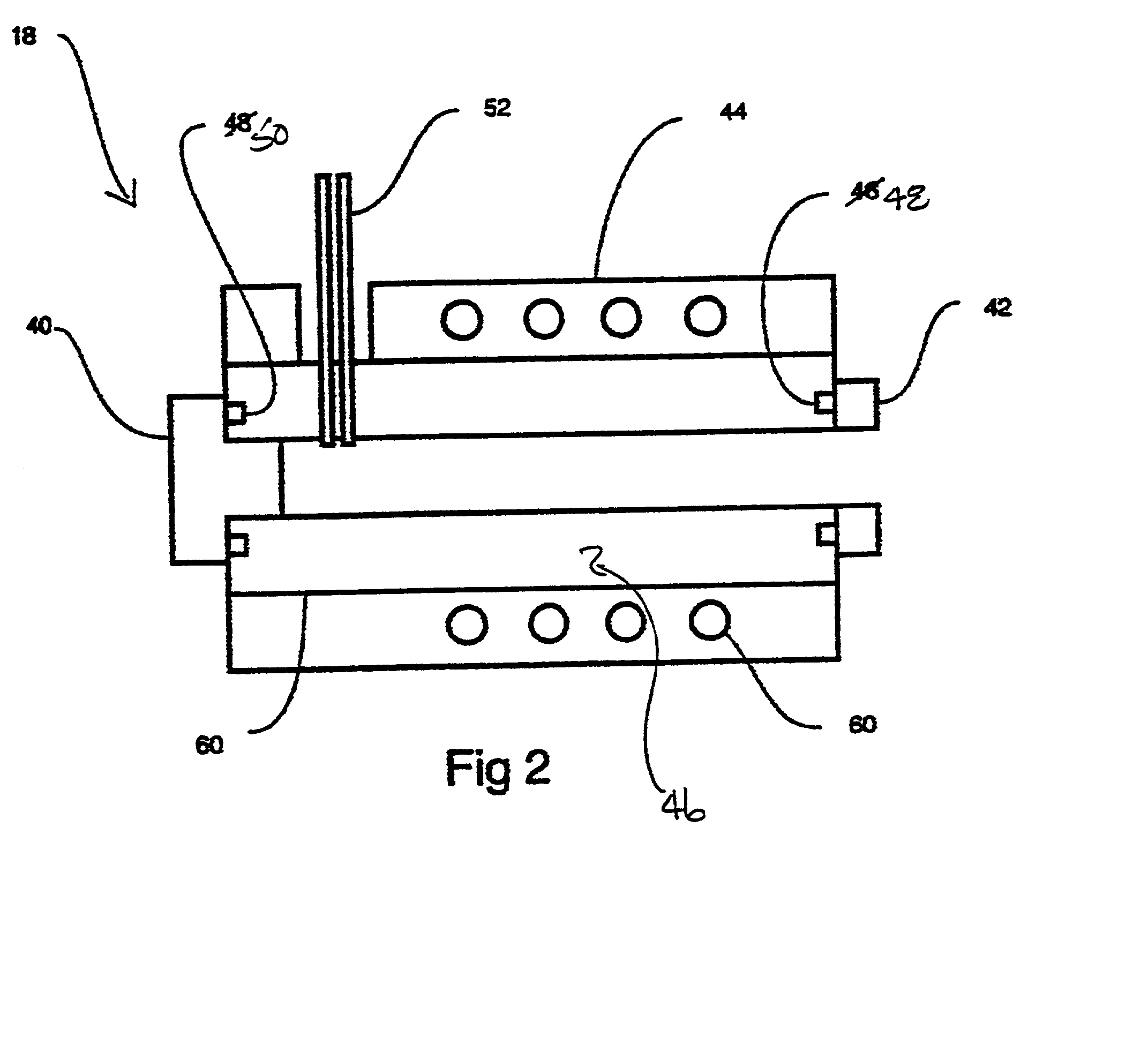

The present invention relates to an vitro device for the removal of ionized substances from a membrane sample without mechanical penetration, which device comprises:(a) a positive electrode;(b) a negative electrode, and(c) electrical insulation between subpart (a) and (b), wherein the positive electrode, and the negative electrode, and electrical insulation are positioned on the same side of the membrane sample.The present invention also relates to a device for the removal of or delivery of ionized substances to a mammal through intact skin or mucosal membrane without mechanical penetration, which device comprises: (a) a positive electrode, (b) a negative electrode, and (c) an electrically insulating material between subpart (a) and (b), wherein the positive electrode, negative electrode and insulating material are physically positioned so that each present a common surface of the device for contact with the same surface of the skin or mucosal membrane of the mammal.The present invention also relates to the use of iontophoresis to determine the level of a charged molecule in a living mammal, and with the use of a feedback mechanism, administer appropriate levels of therapeutic substances.

Owner:RGT UNIV OF CALIFORNIA

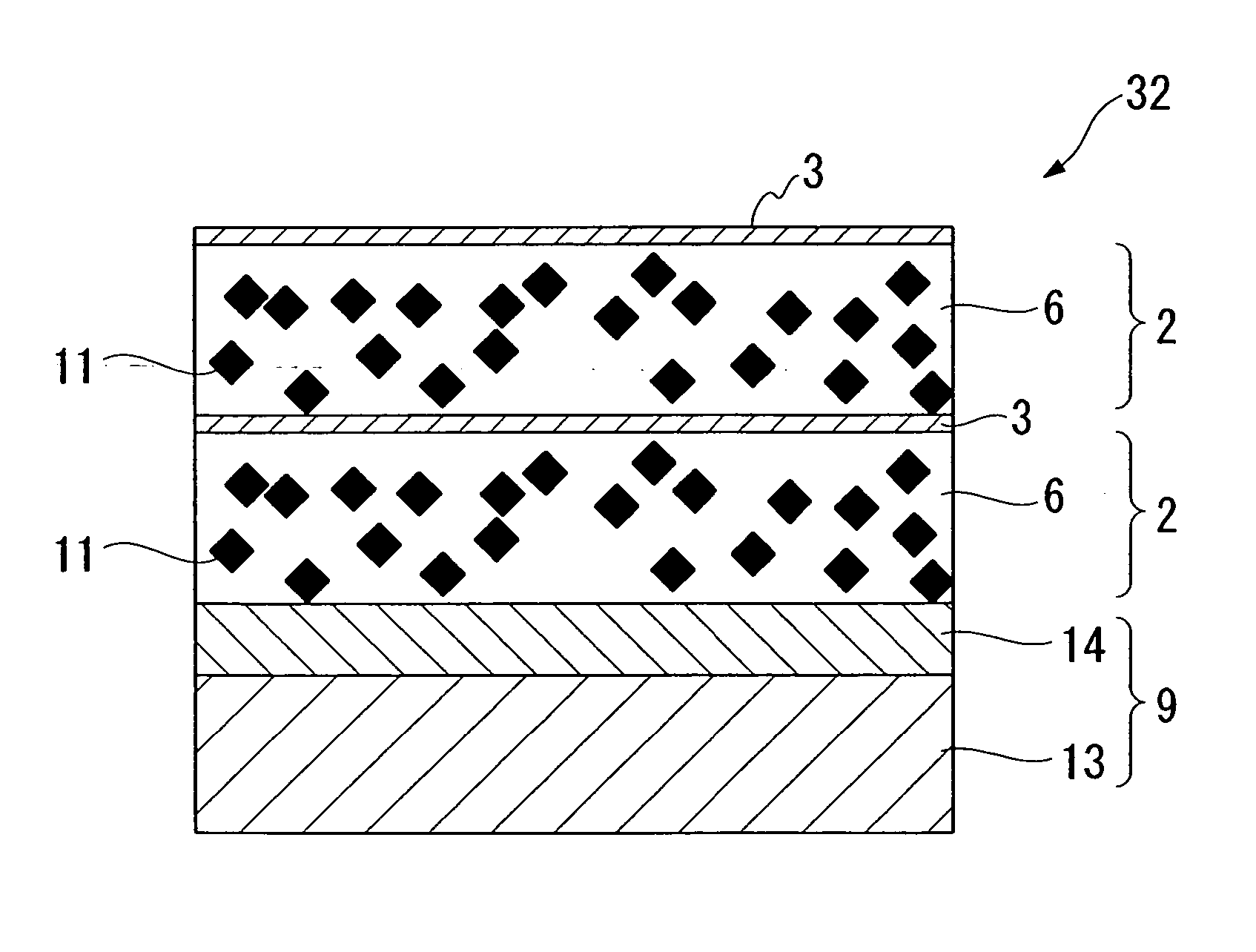

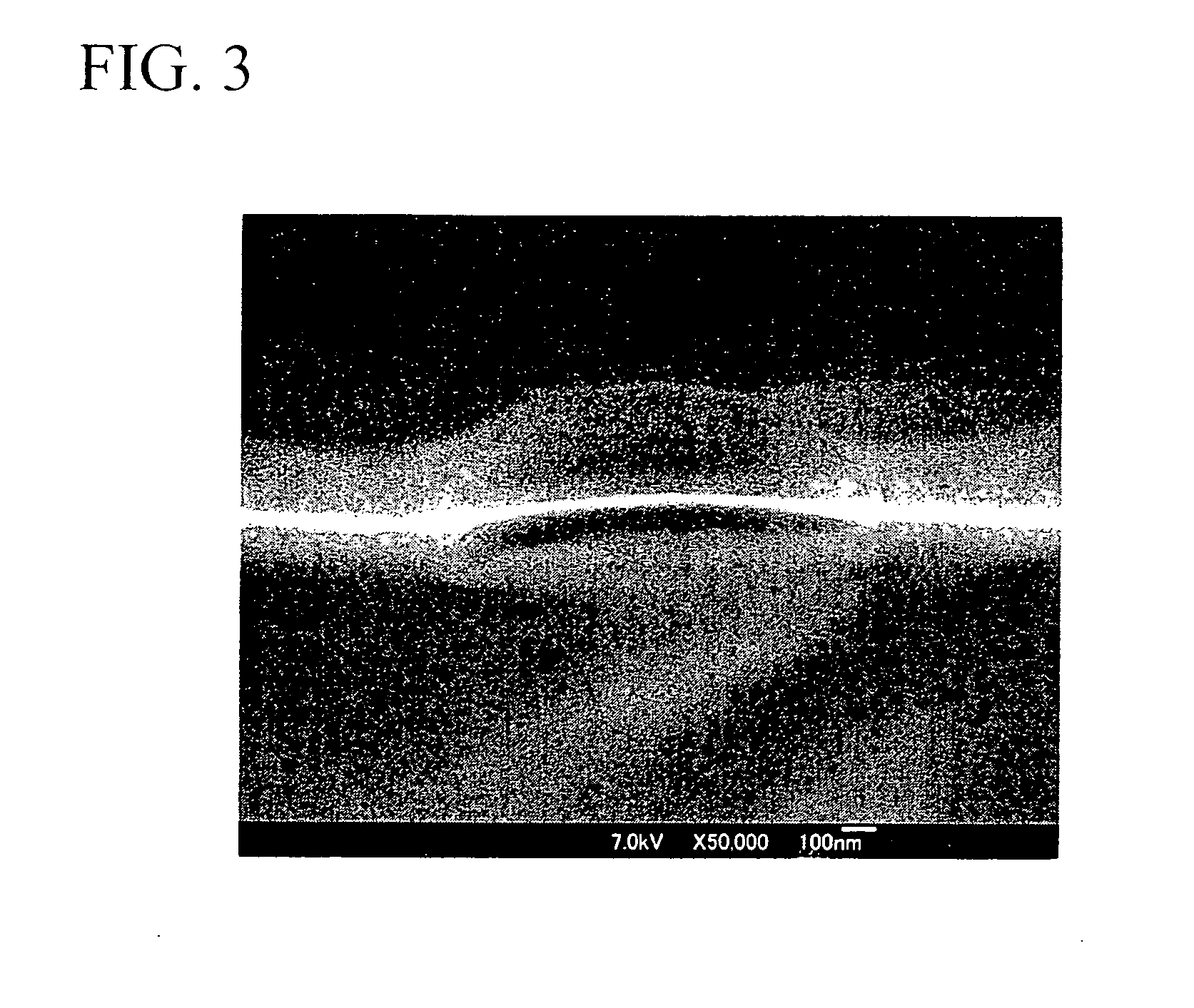

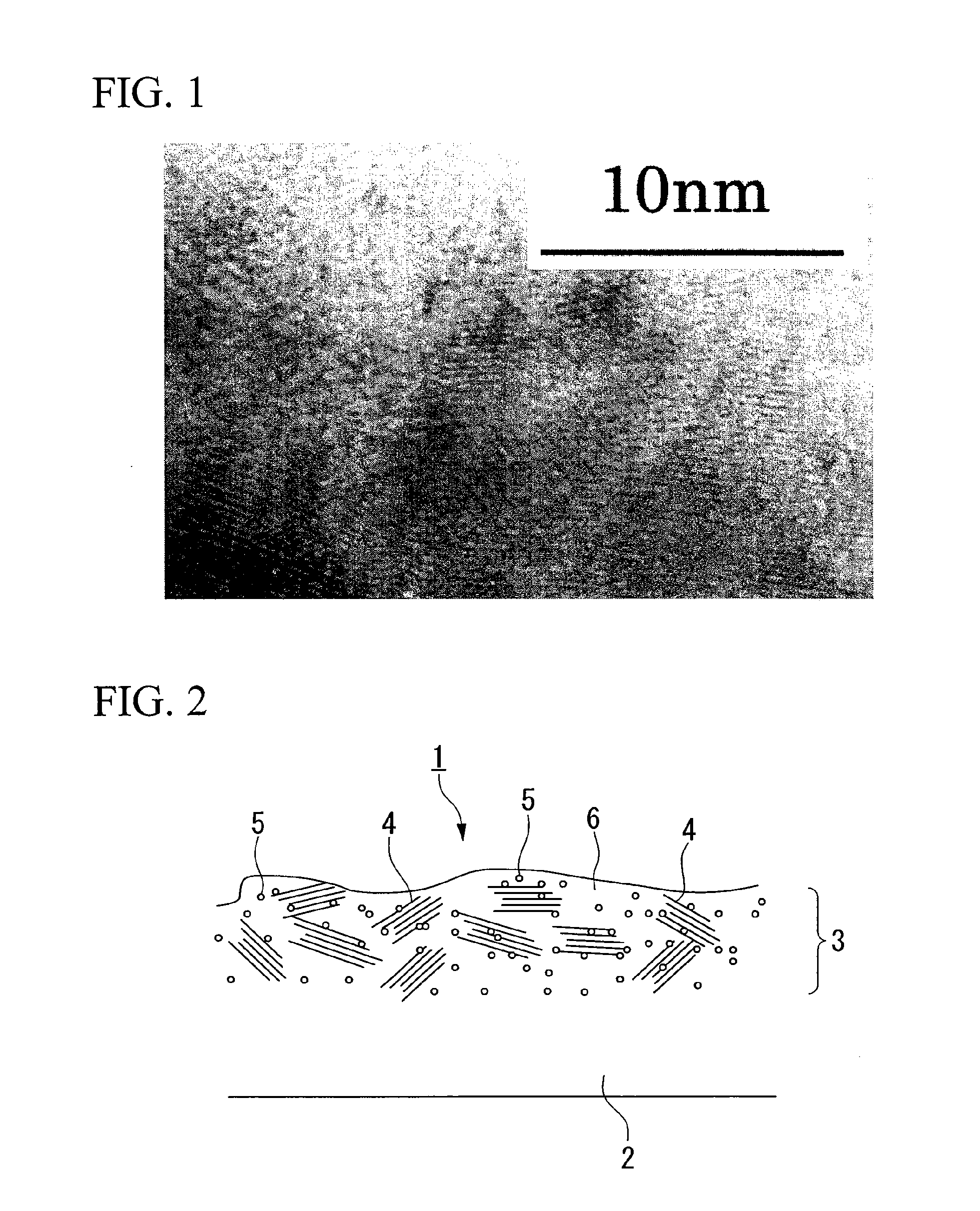

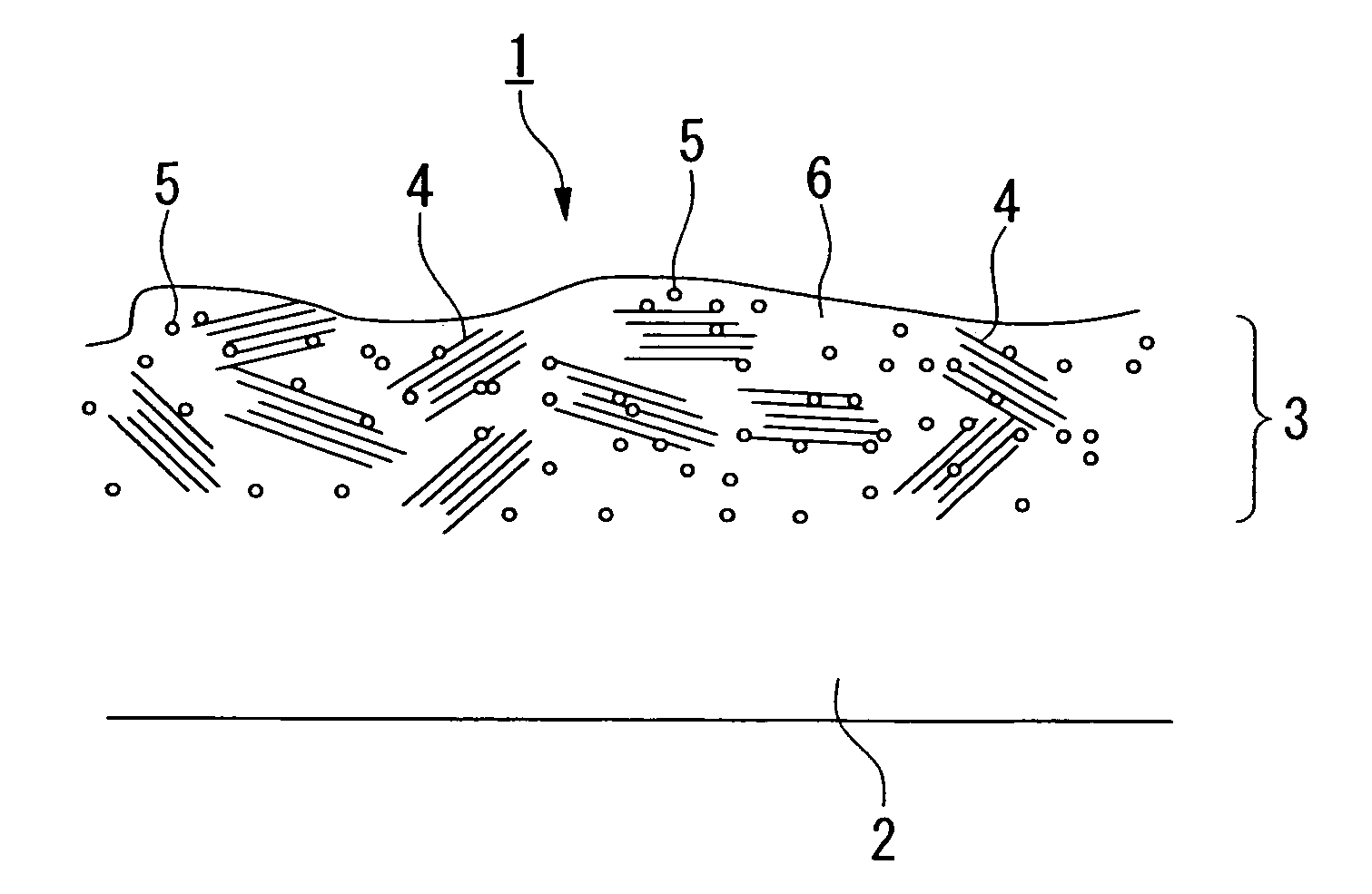

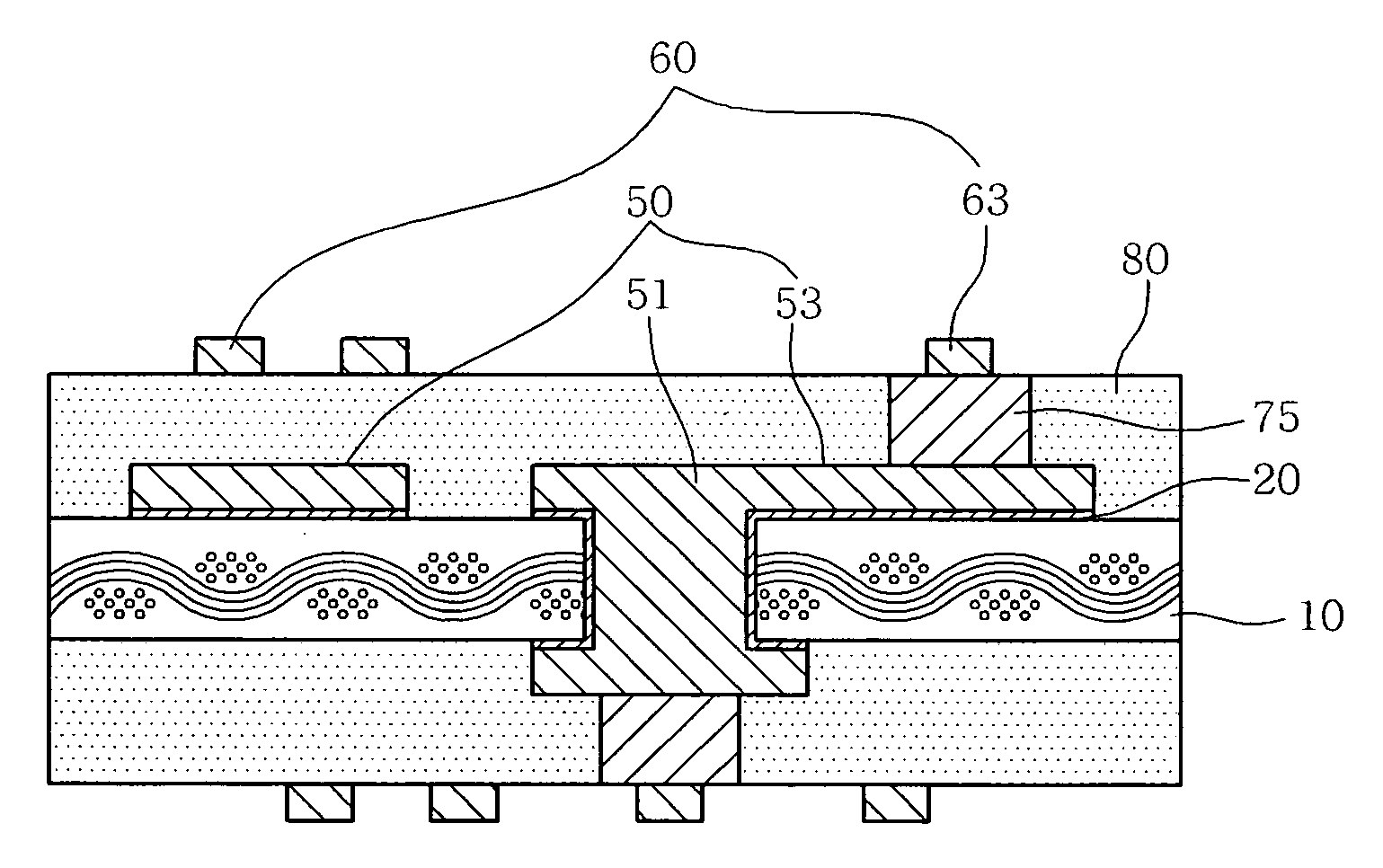

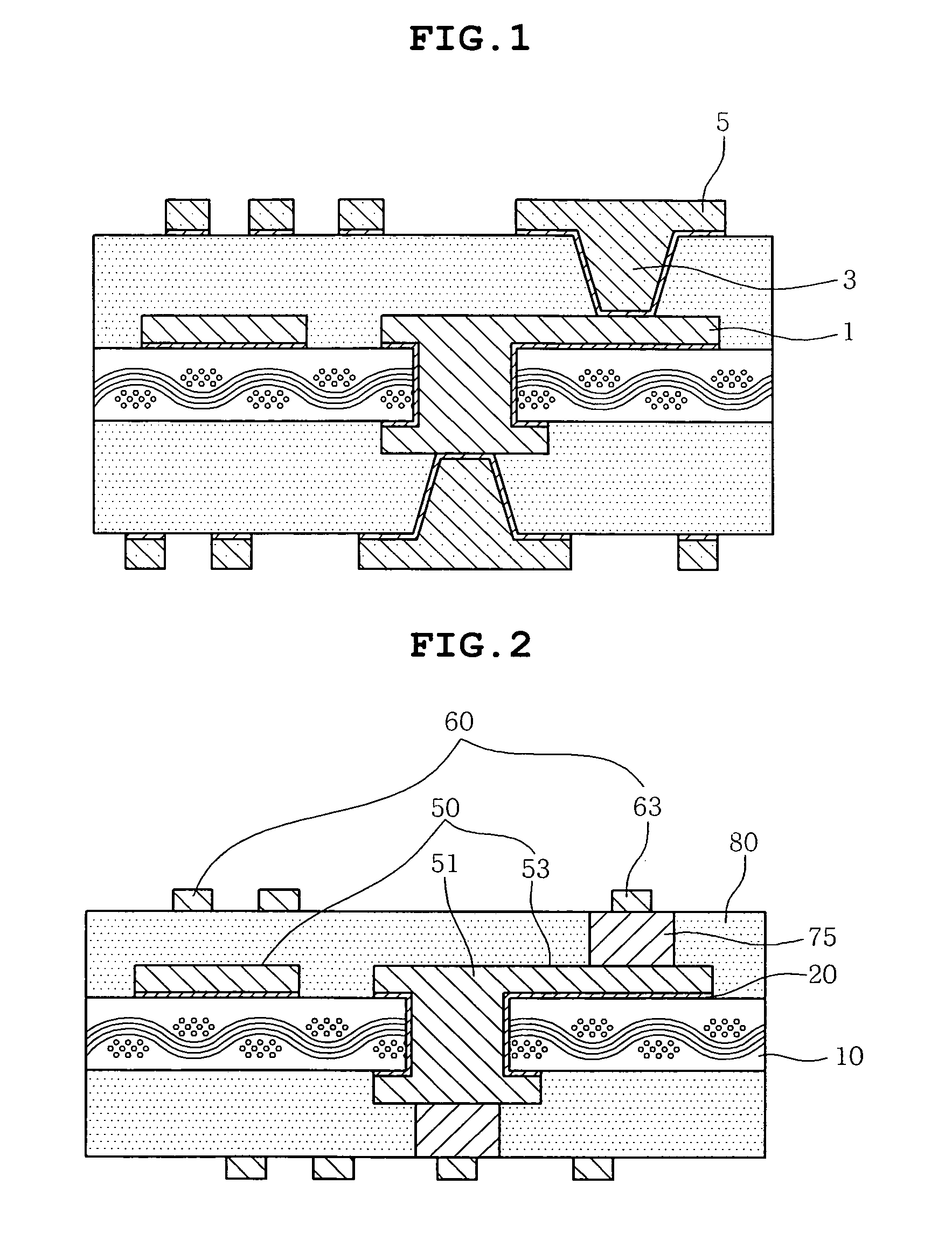

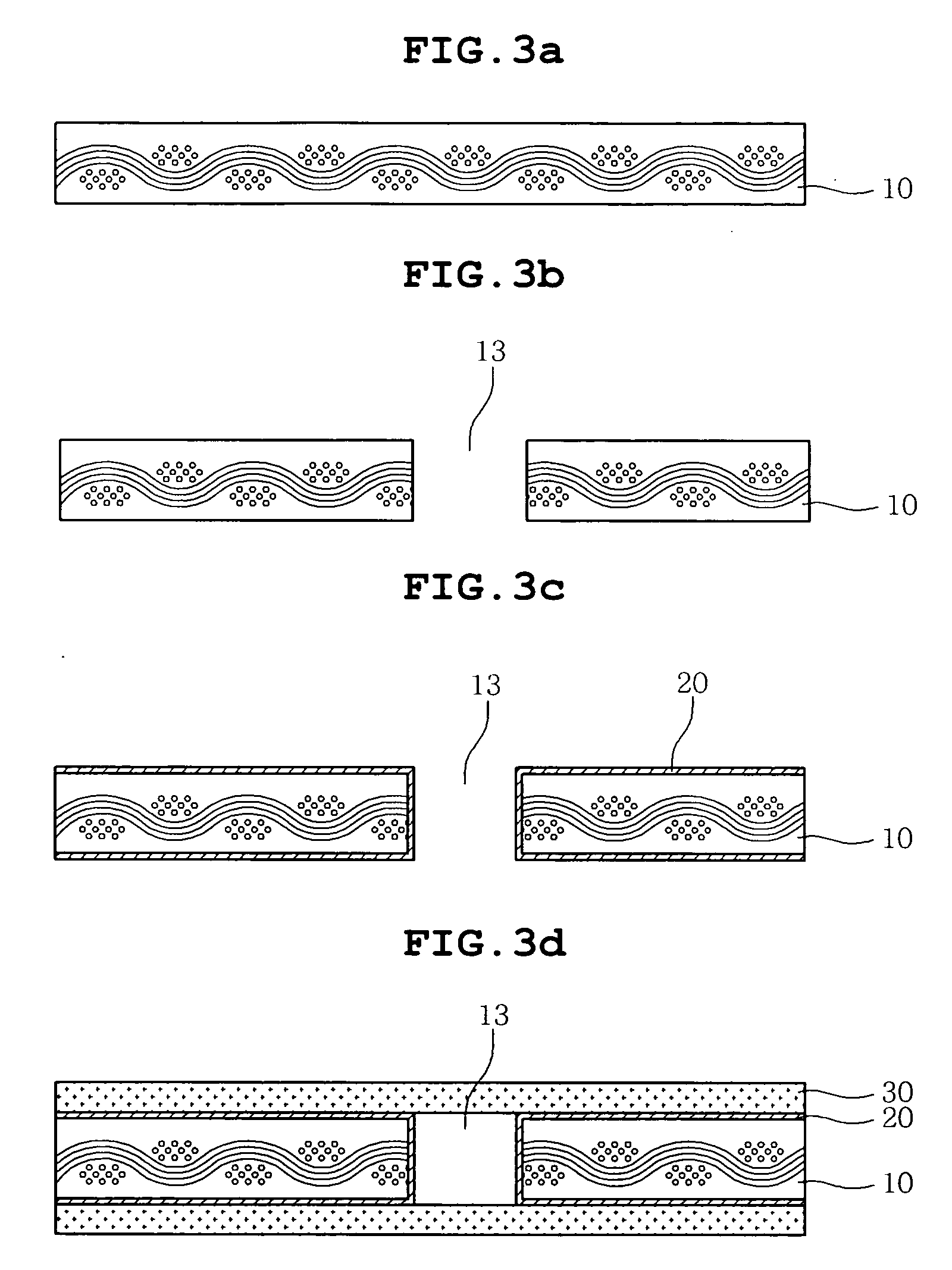

Electromagnetic noise suppressor, article with electromagnetic noise suppressing function, and their manufacturing methods

InactiveUS20060083948A1Eliminate the effects ofMeet cutting requirementsMagnetic/electric field screeningCross-talk/noise/interference reductionGas phaseSuppressor

An electromagnetic noise suppressor of the present invention includes a base material 2 containing a binding agent and a composite layer 3 formed by integrating the binding agent that is a part of the base material 2 and the magnetic material. This electromagnetic noise suppressor has high electromagnetic noise suppressing effect in the sub-microwave band, and enables it to reduce the space requirement and weight. The electromagnetic noise suppressor can be manufactured by forming the composite layer 3 on the surface of the base material 2 by physical vapor deposition of the magnetic material onto the surface of the base material 2. The article with an electromagnetic noise suppressing function of the present invention is an electronic component, a printed wiring board, a semiconductor integrated circuit or other article of which at least a part of the surface is covered by the electromagnetic noise suppressor of the present invention.

Owner:SHIN-ETSU POLYMER CO LTD

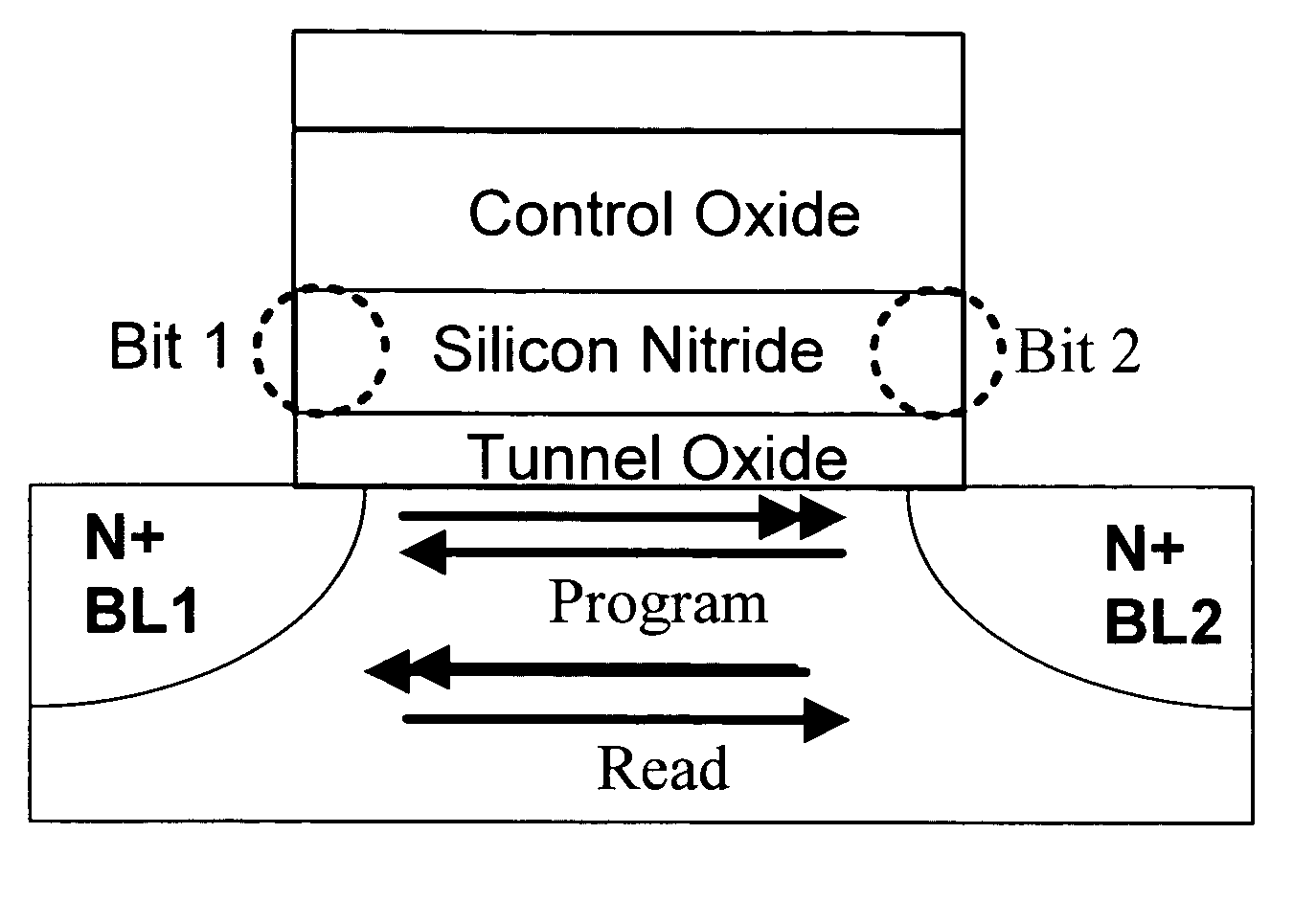

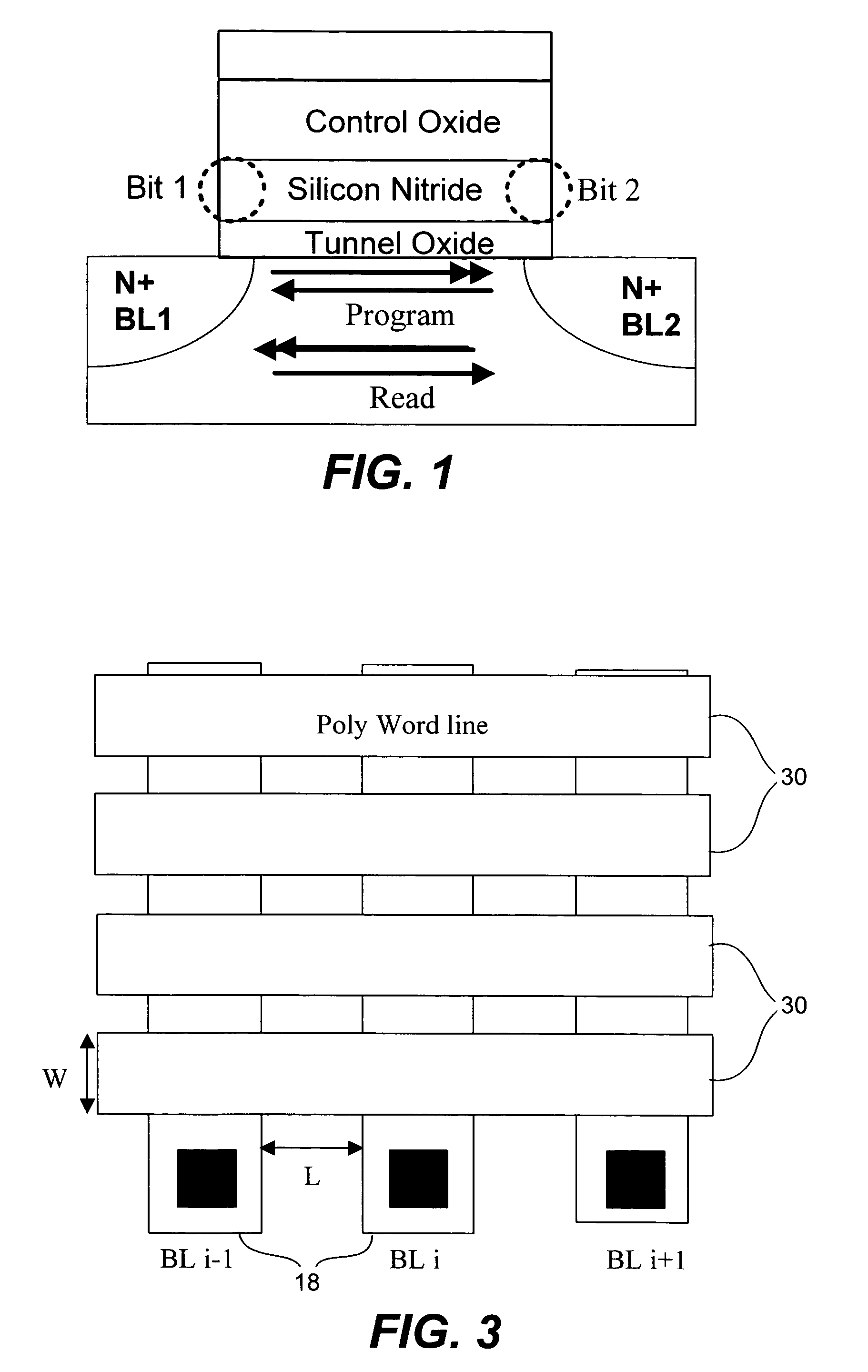

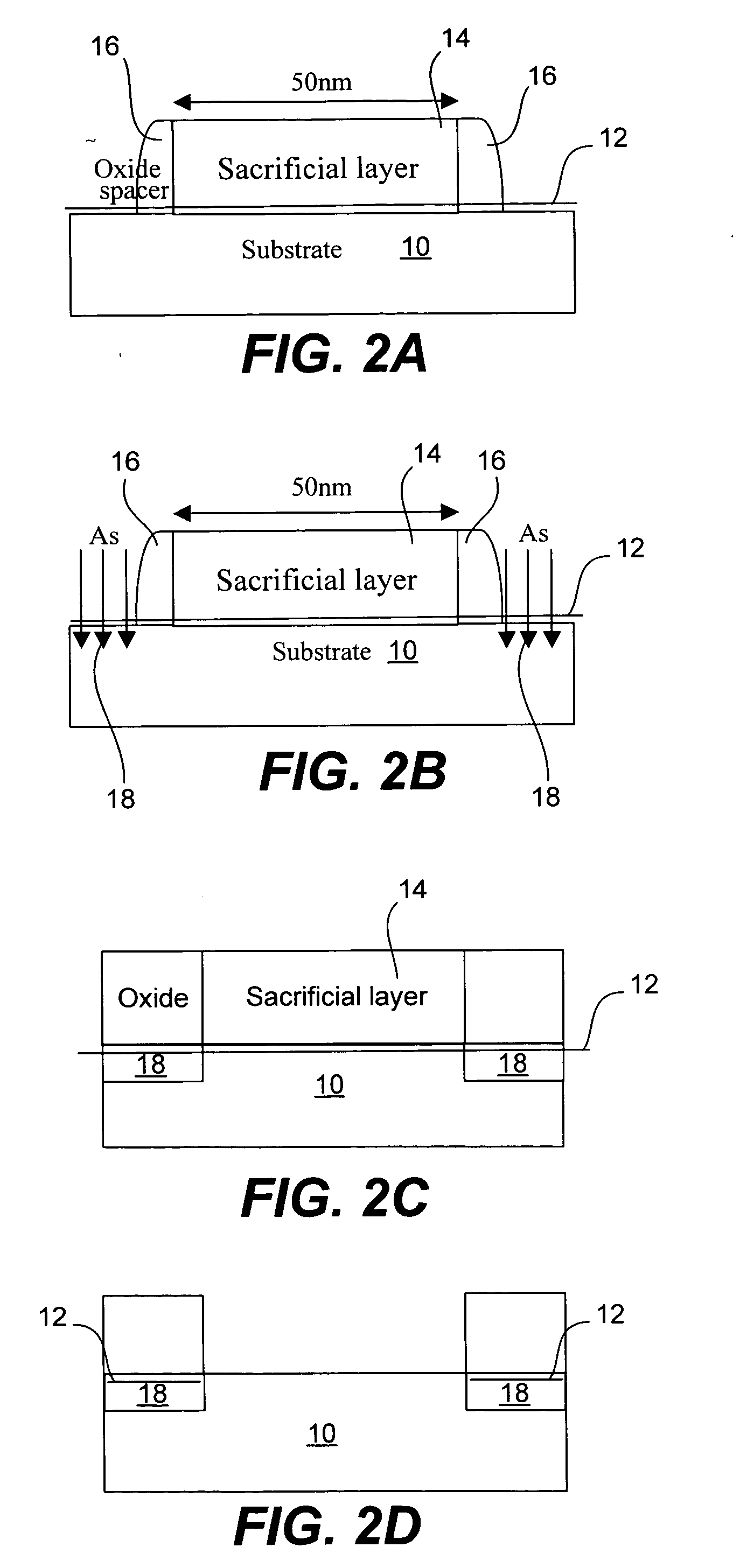

Two bit/four bit SONOS flash memory cell

InactiveUS20050242391A1Prevent lateral charge migrationMore charge injectionSolid-state devicesRead-only memoriesEngineeringMaterial physics

Charge migration in a SONOS memory cell is eliminated by physically separating nitride layer storage sites with dielectric material. Increased storage in a cell is realized with a double gate structure for controlling bit storage in line channels between a source and a drain, such as with a FinFET structure in which the gates are folded over the channels on sides of a fin.

Owner:RGT NIVERSITY OF CALIFORNIA THE

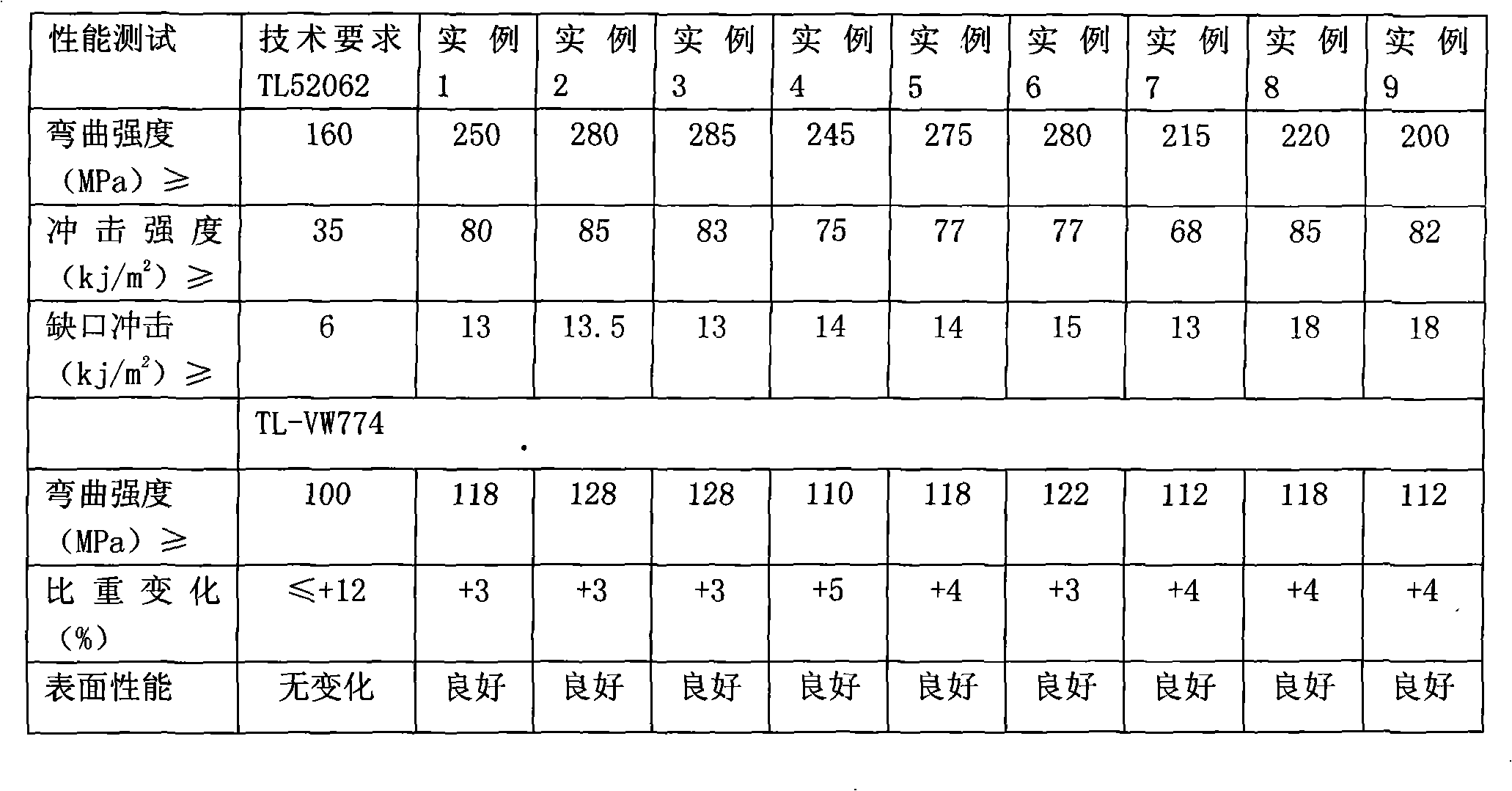

Alcoholysis resistance nylon composite material and preparation method thereof

The invention provides an alcoholysis resistance nylon composite material and a preparation method thereof; the composite material is applicable to the cooling water chamber of vehicles and comprises nylon, short glass fiber, glass fiber emergence resistance regulating additive, nucleating agent, colorant, heat stabilizer and alcoholysis resistance additive. The physical property of the nylon composite material provided by the invention can meet or exceed the TL52062 technical requirement and the alcoholysis resistance chemical property can meet the TL-VW774 technical requirement so that the surface of the product does not change and crack after being placing in 100% of glycol solution for 48h at 135 DEG C and the product has high shock resistance and dimension stability, thus ensuring that the stress cracking does not appear on joints.

Owner:辰东意普万新材料(广东)有限公司

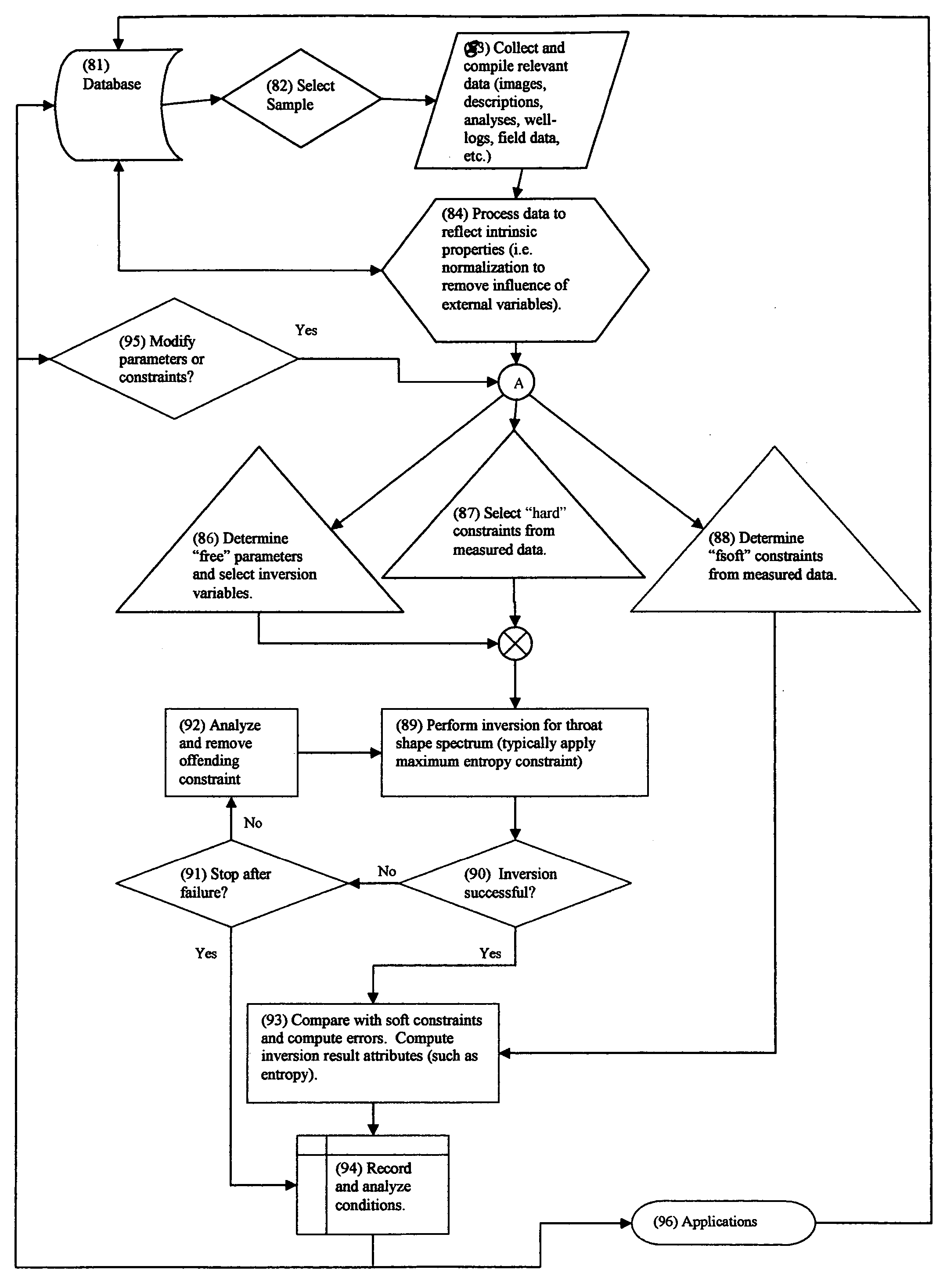

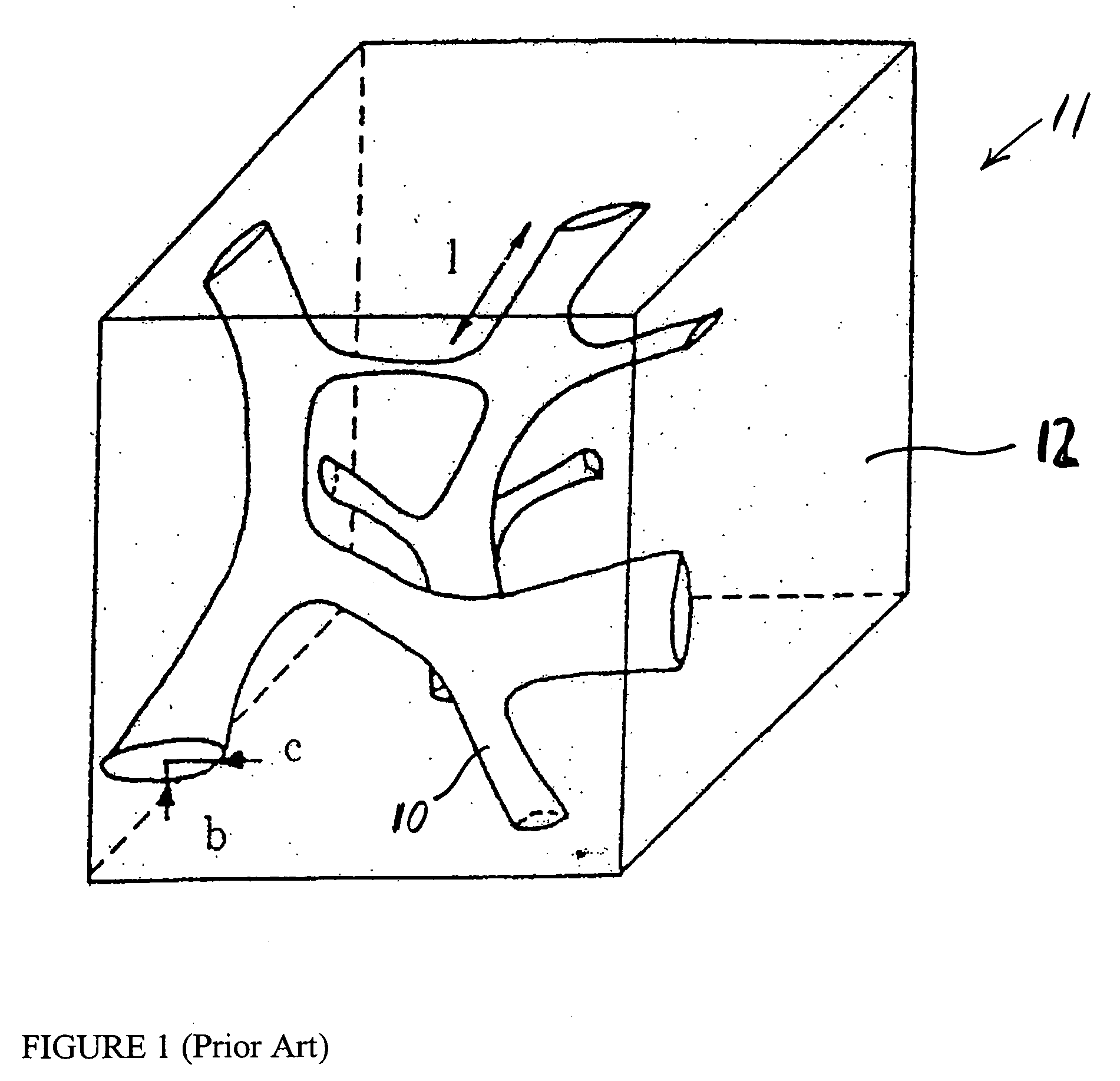

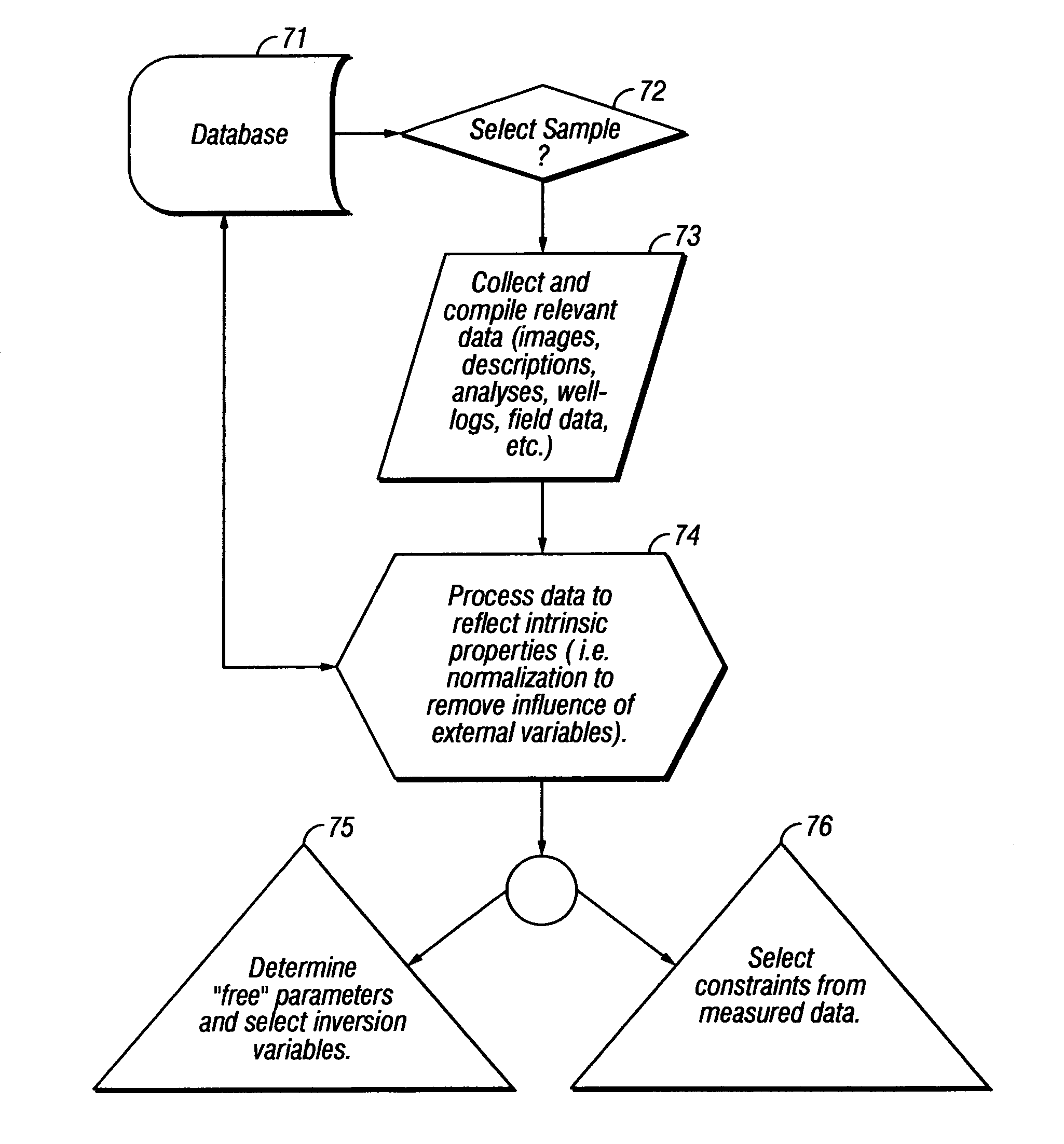

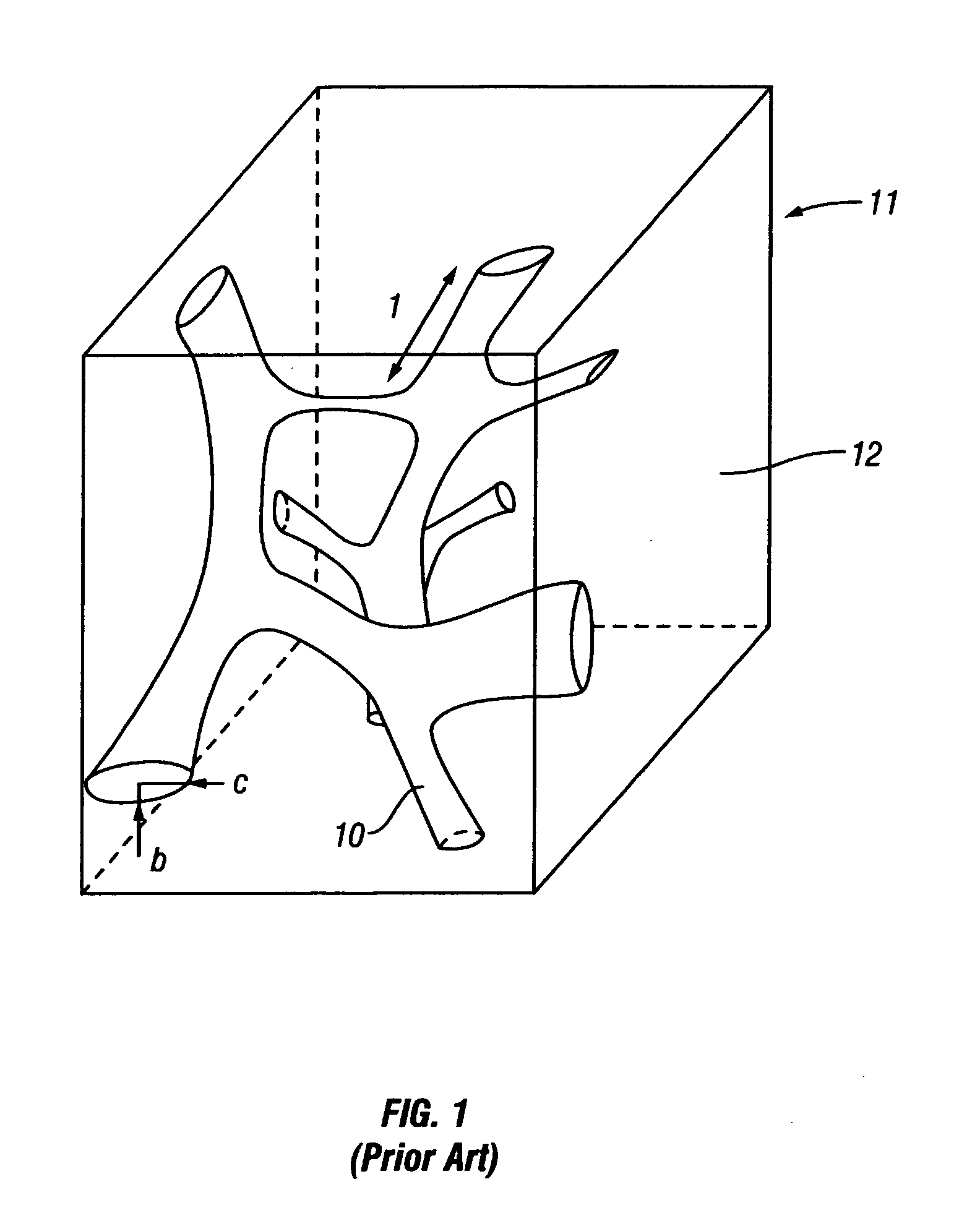

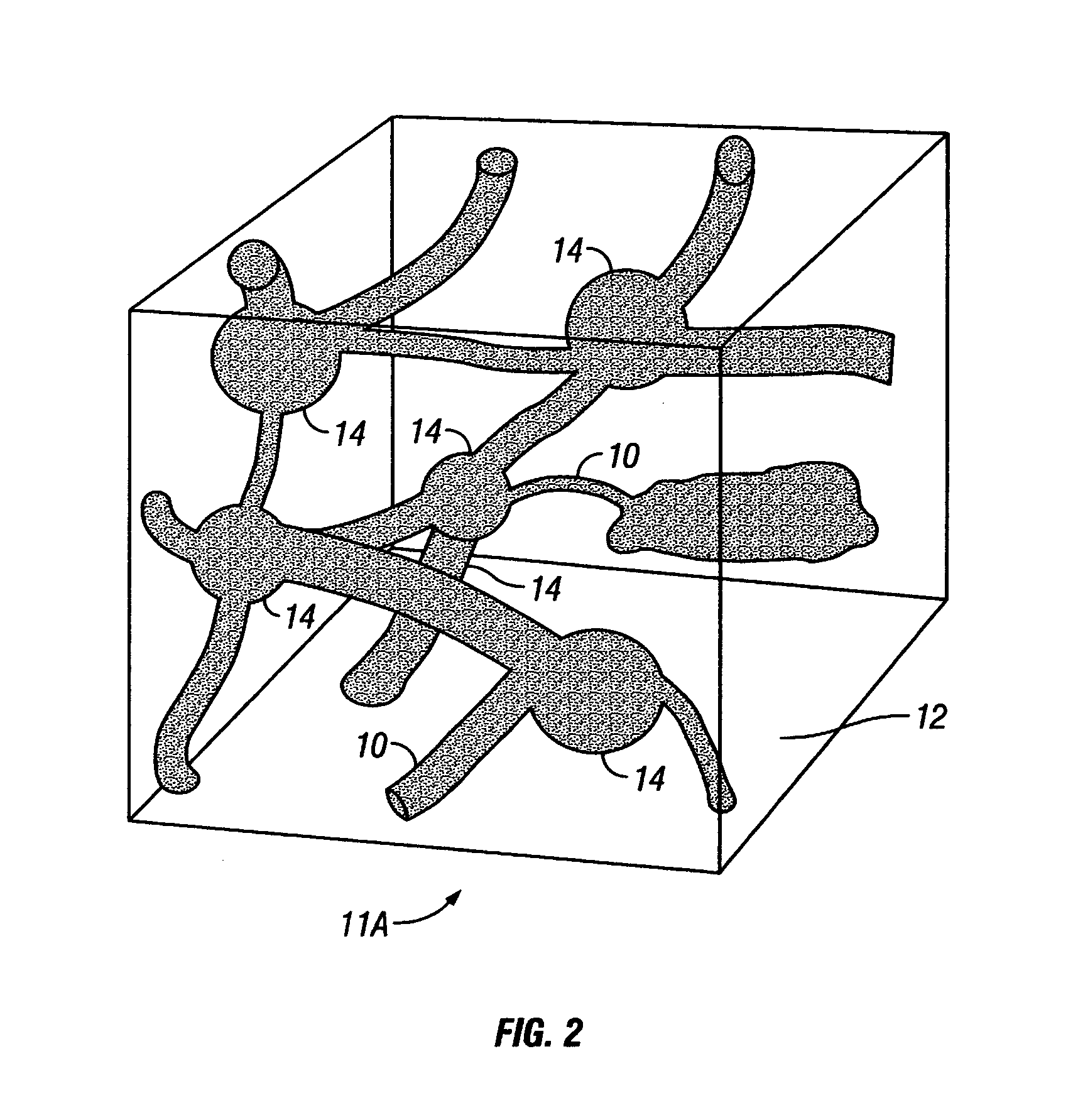

Method for estimating pore structure of porous materials and its application to determining physical properties of the materials

ActiveUS20050256643A1Electric/magnetic detection for well-loggingSeismology for water-loggingMaterial physicsComputer science

Owner:NEW ENGLAND RES

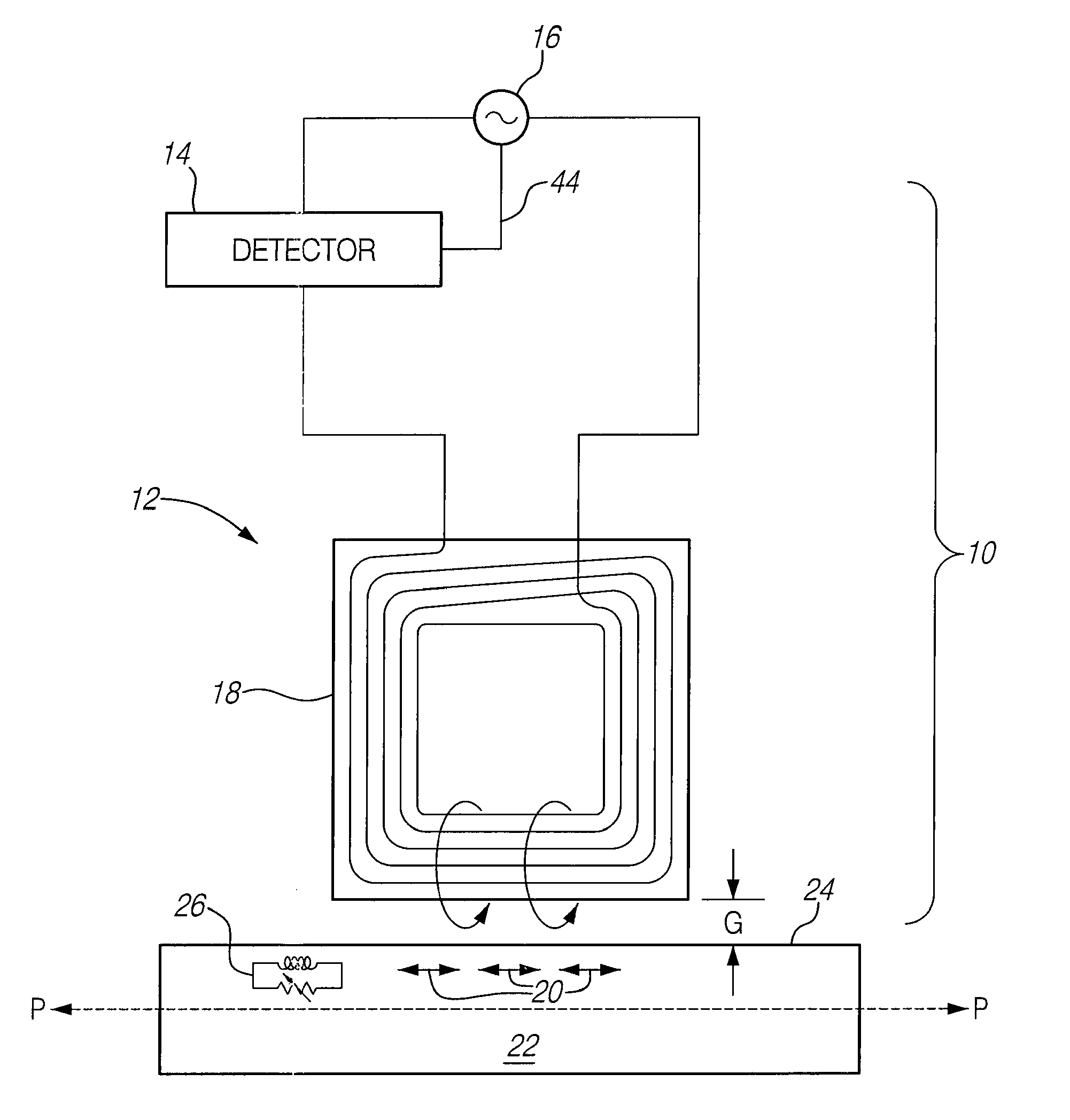

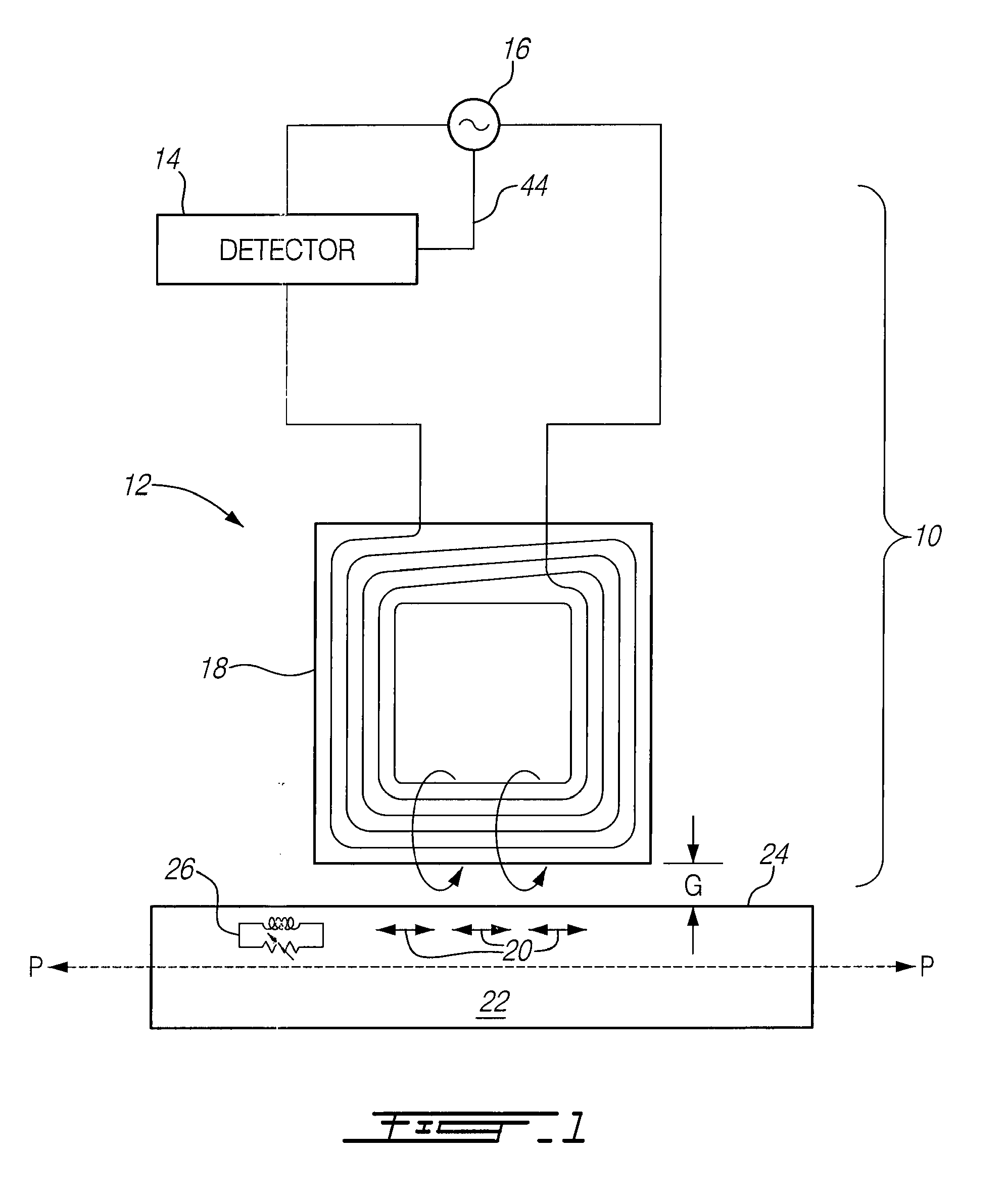

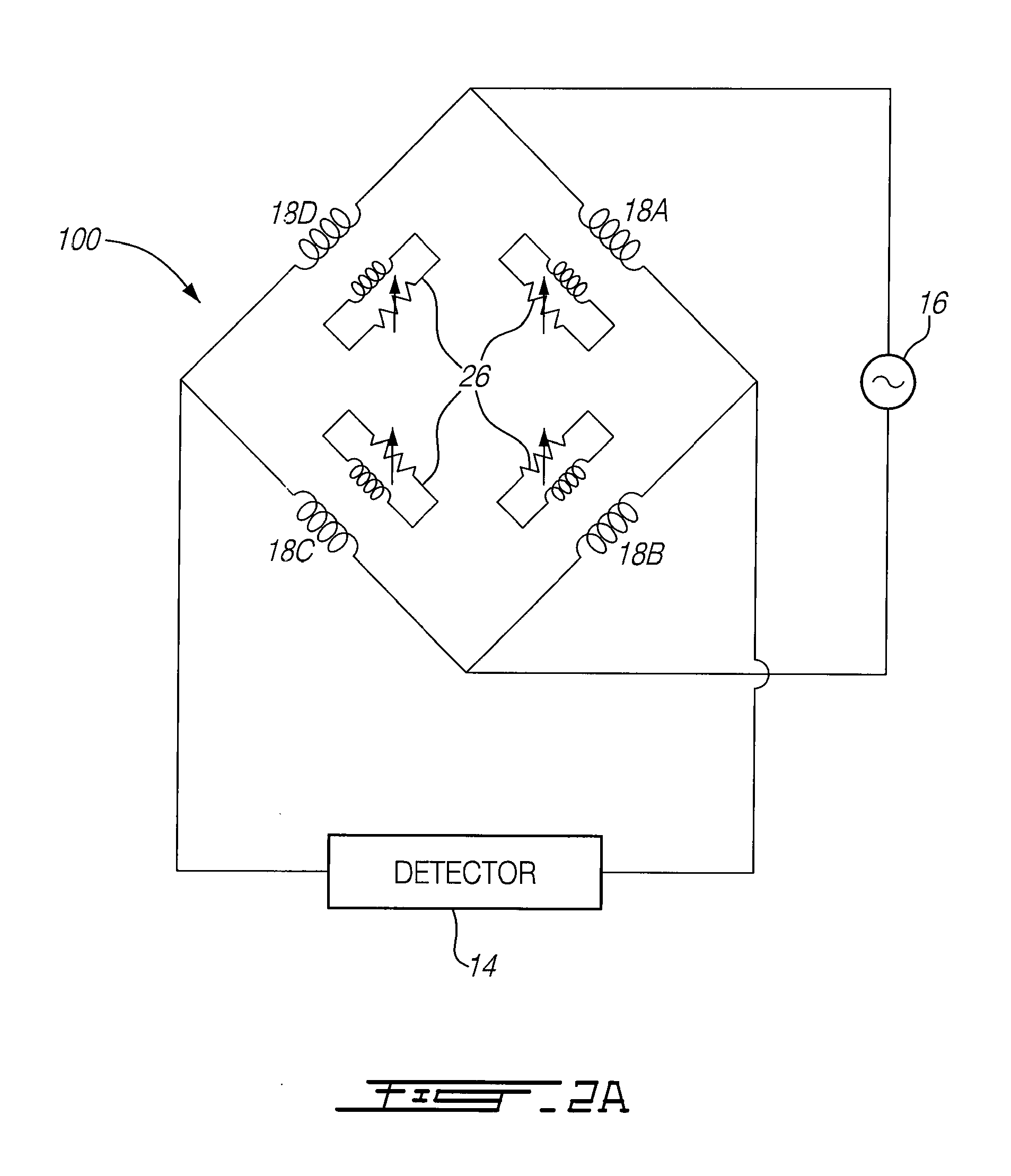

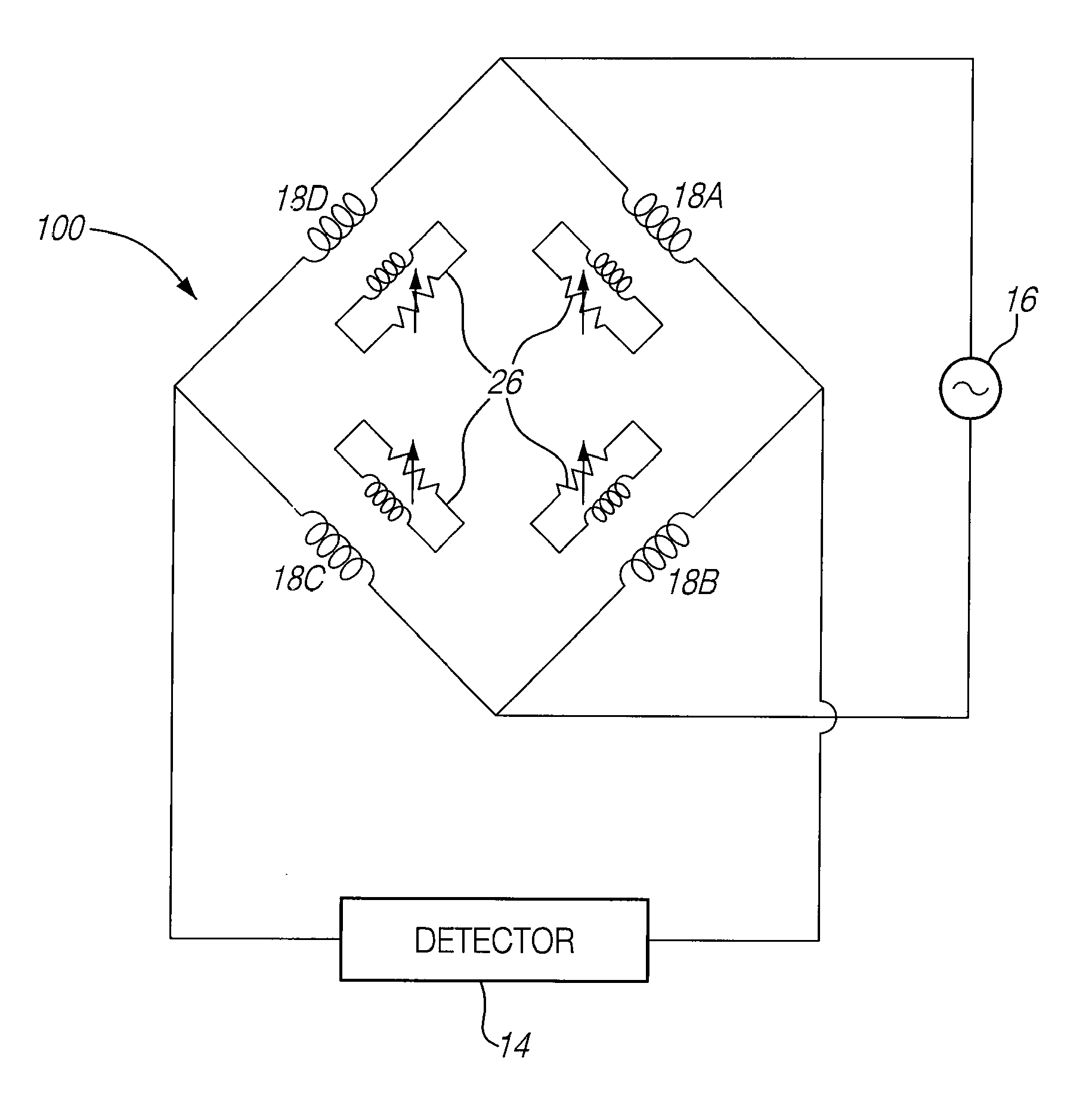

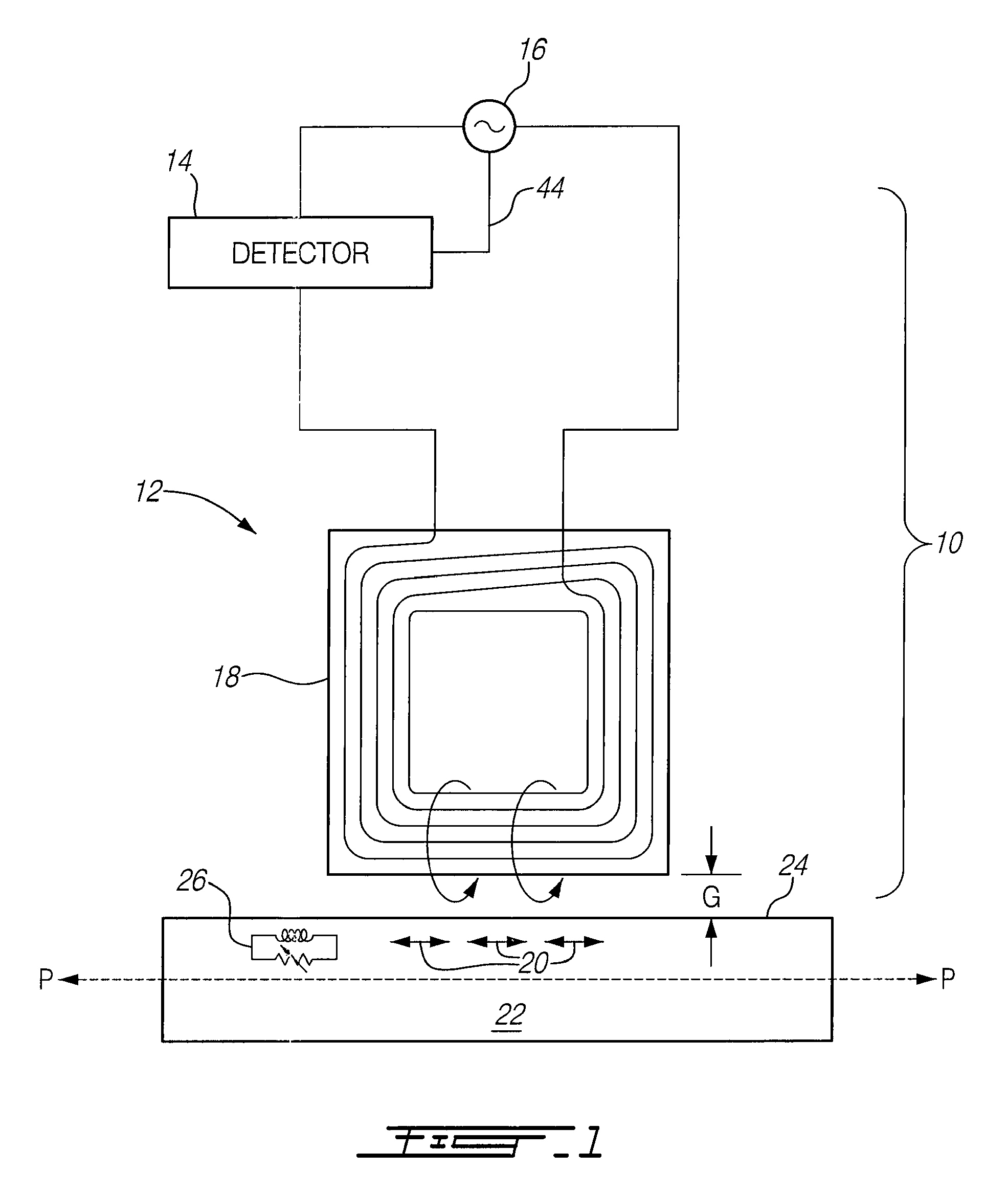

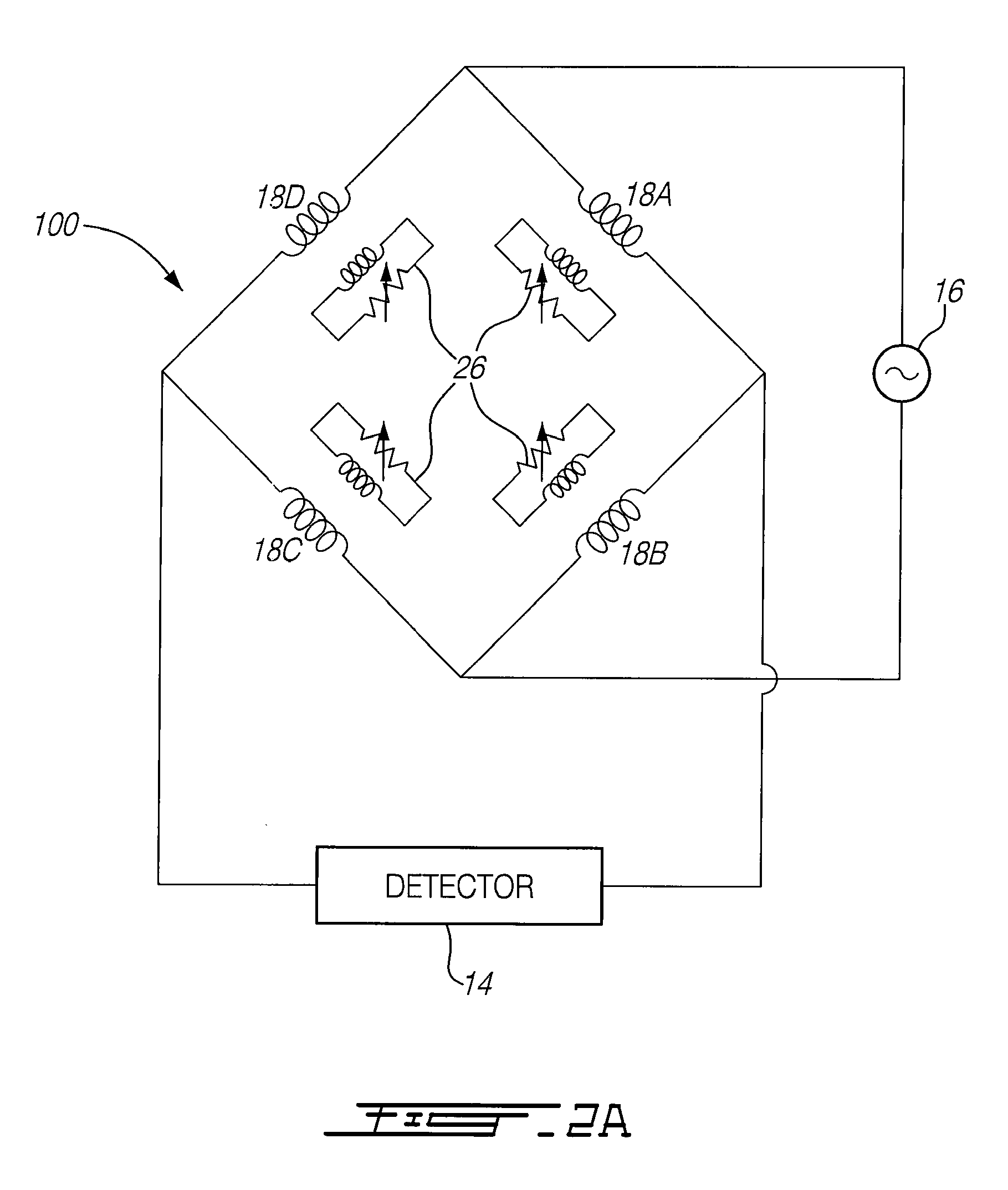

Non-contact stress measuring device

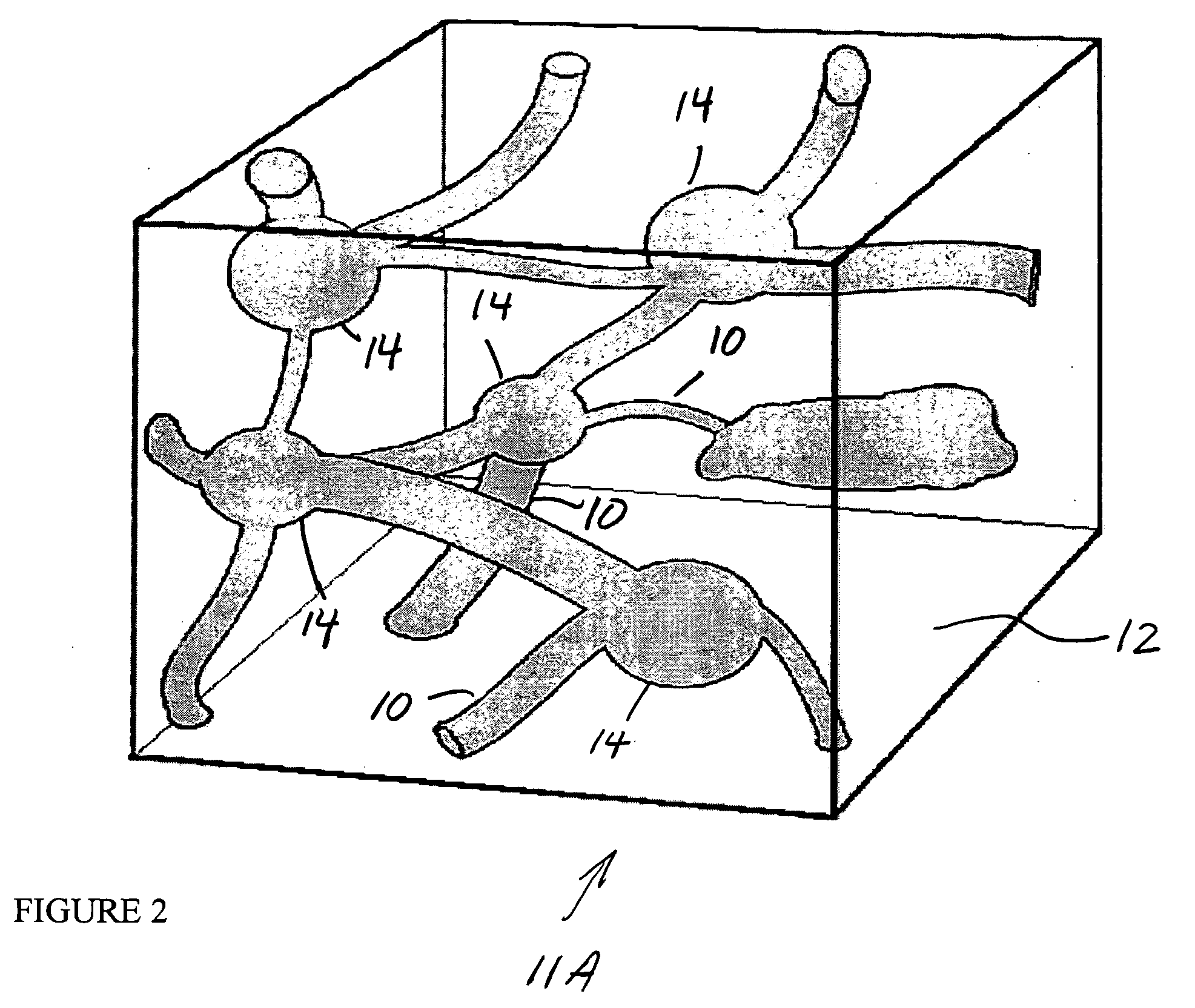

Apparatuses and methods for measuring stress or strain in a conductive material without physical contact with the material are provided. The device comprises an inductor circuit configured to induce an alternating current into the material along a first path; and a detector configured to detect a signal representative of the stress in the material along the first path when current is induced in the material.

Owner:PRATT & WHITNEY CANADA CORP

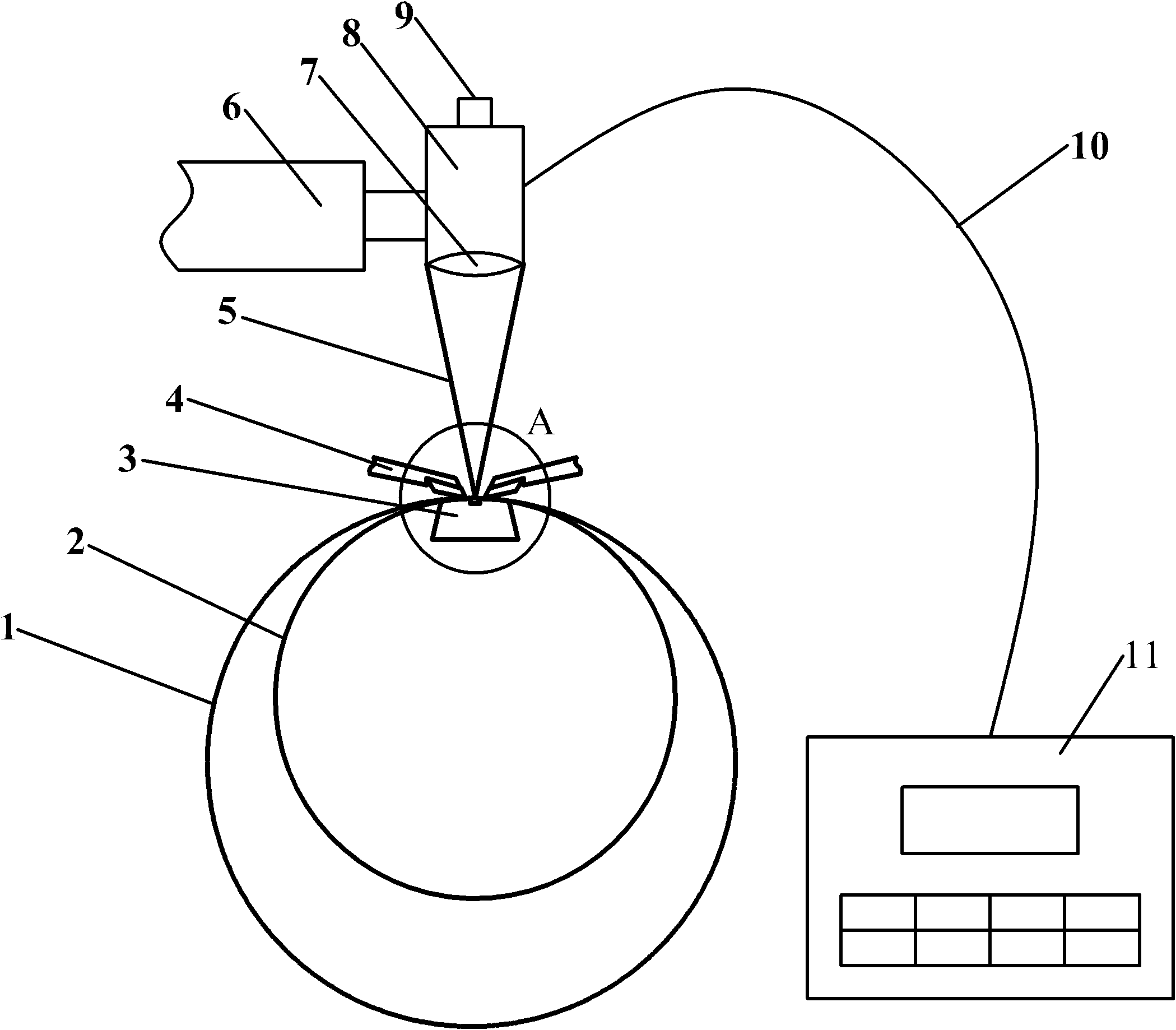

Quantitative analyzing method for non-metal residue in steel

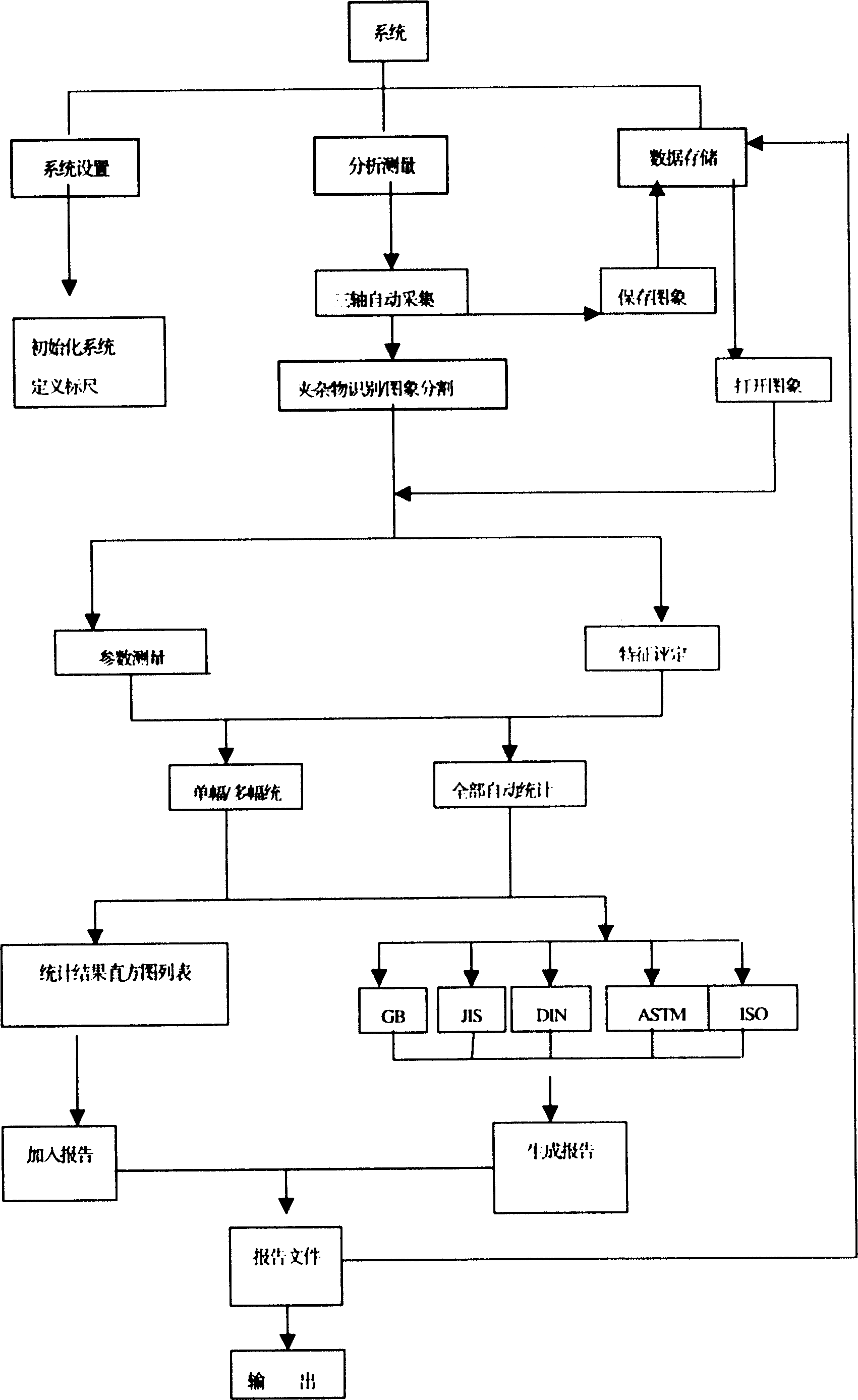

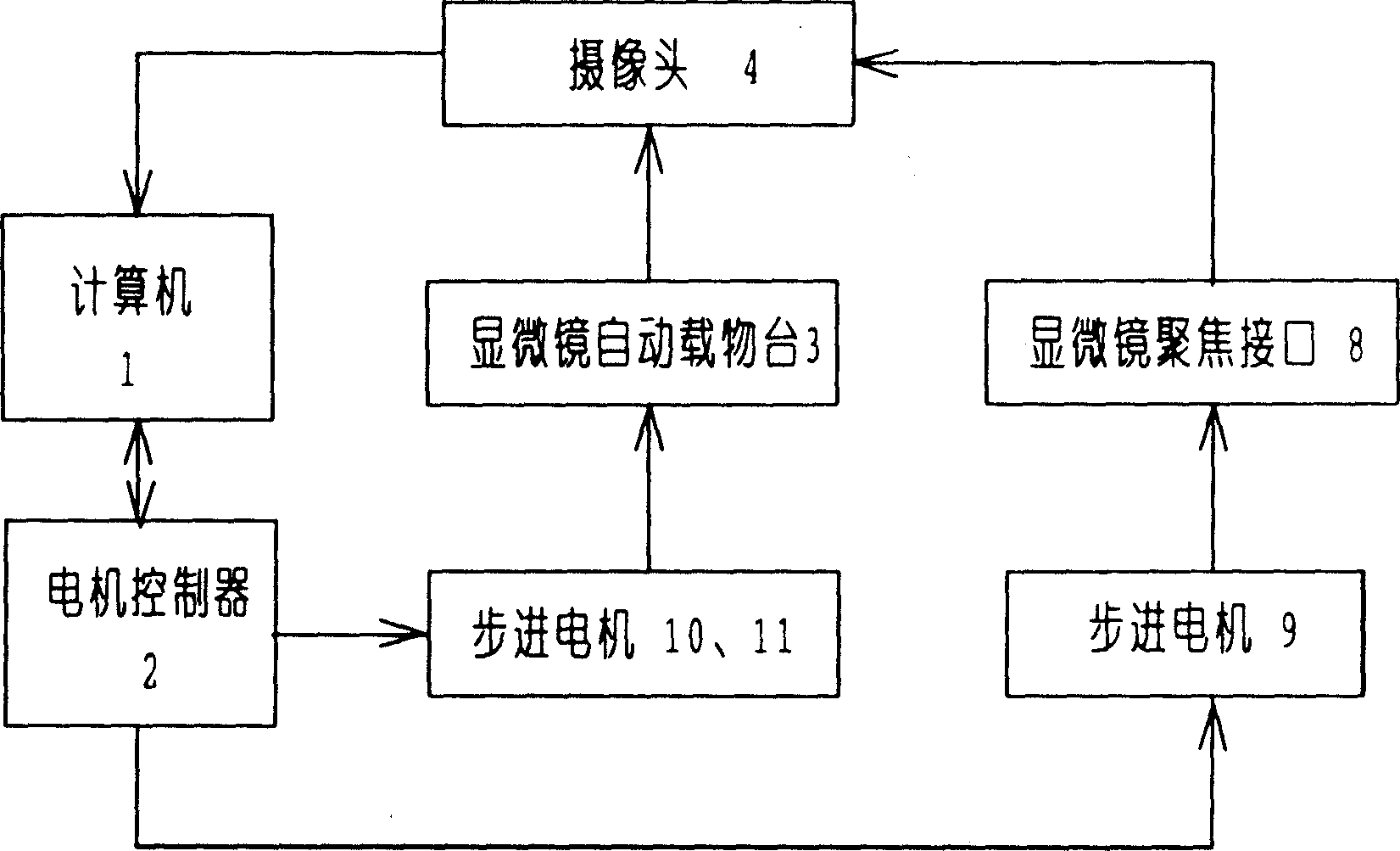

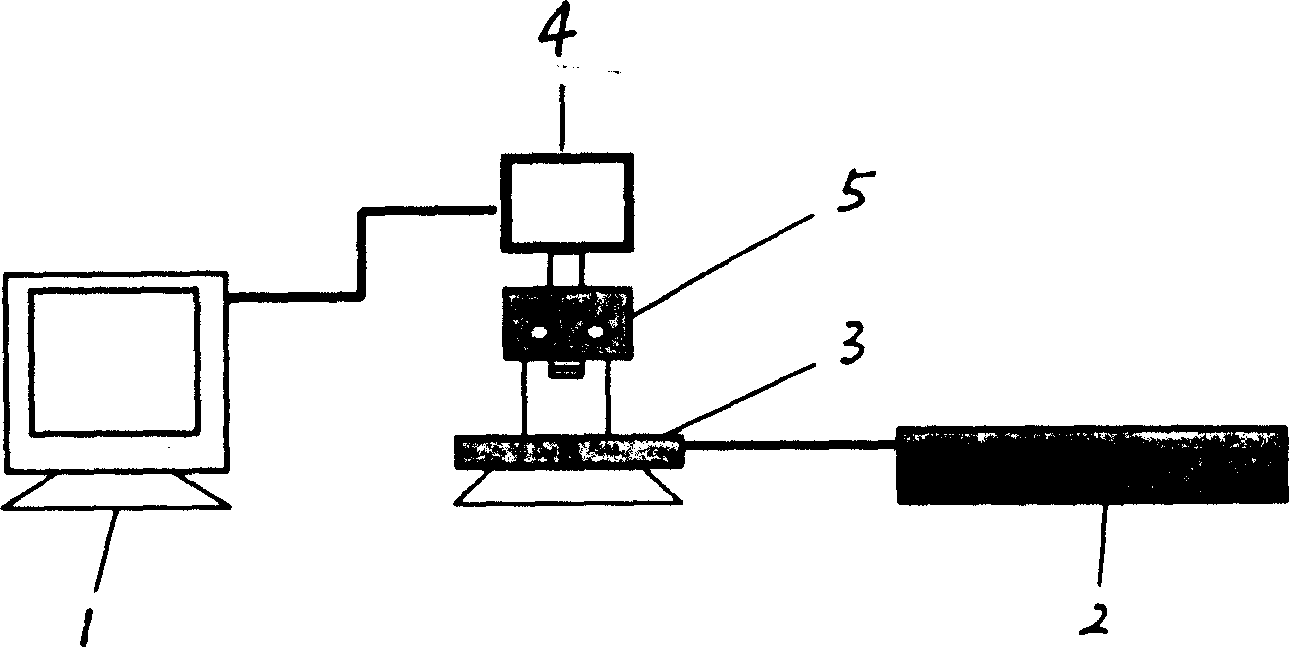

InactiveCN1651905ARealize fully automatic scanning focus set acquisitionHigh precisionImage analysisMaterial analysis by optical meansImaging processingNon-metallic inclusions

The present invention relates to a method for quantitatively analyzing non-metallic inclusion in steel. Said method is characterized by that it makes the metallurgical microscope and automatic objective table be connected with camera and computer, utilizes the camera to collect the inclusion image from metallurgical microscope and feed it into computer to make image processing so as to implement identification of inclusion and parameter measurement, then utilizing quantitative model to calculate the measurement result or make comparison analysis with standard map so as to obtain quantitative evaluated result. Said invention also provides the concrete steps of implementing said method.

Owner:SHIJIAZHUANG IRON & STEEL

Method for estimating pore structure of porous materials and its application to determining physical properties of the materials

ActiveUS7277795B2Electric/magnetic detection for well-loggingSeismology for water-loggingMaterial physicsComputer science

Owner:NEW ENGLAND RES

Nano composite flame-retardant reinforced polyester engineering plastic and preparation method thereof

ActiveCN101928448AAvoid thermal decompositionAvoid burnsPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolyesterHalogen

The invention discloses a nano composite flame-retardant reinforced polyester engineering plastic and a preparation method thereof. The preparation method is characterized by comprising the following steps of: mixing 45 to 80 percent of polyester, 5 to 20 percent of metal hypophosphite, 3 to 15 percent of nitrogen-containing flame retardant and 0.5 to 5 percent of nano modified additive uniformlybased on the percentage of the total mass of the composite material, heating the mixture to be between 230 and 275 DEG C, and performing melting, blending, extrusion, bracing, cooling, granulation and drying on the mixture. The obtained nano composite flame-retardant reinforced polyester engineering plastic has good flame-retardant property and physical property, overcomes the defects of high environmental hazard of halogen-containing flame retardant, high addition of organic flame retardant, poor physical property of materials and the like in the conventional polyester reinforced material modification technology, and has strong application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

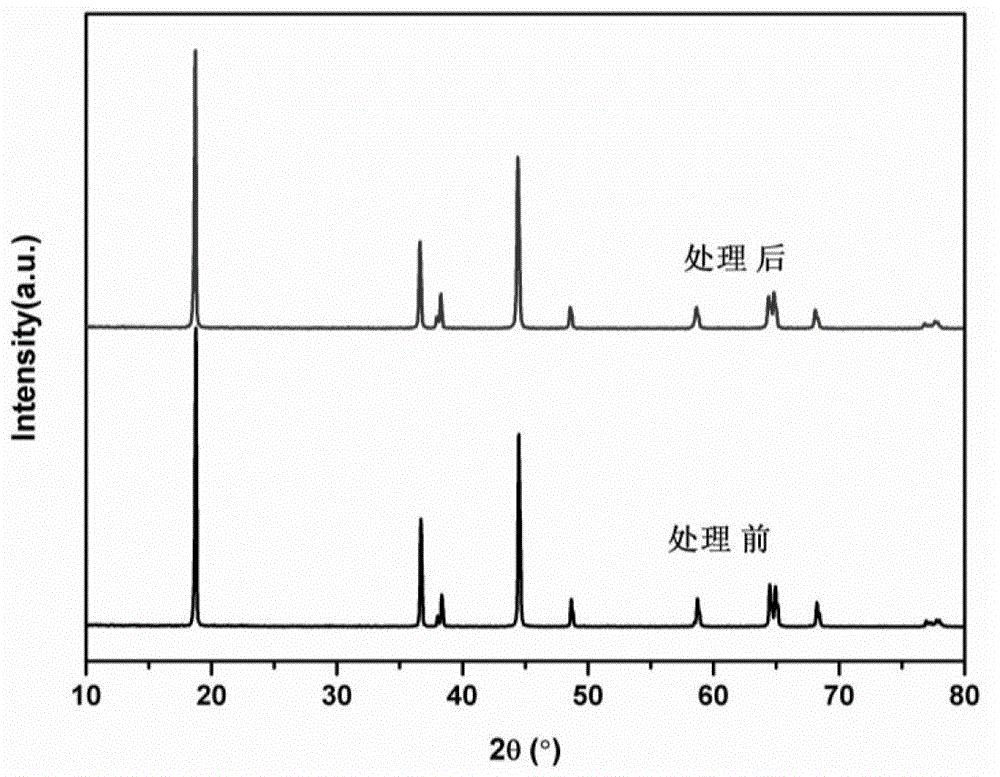

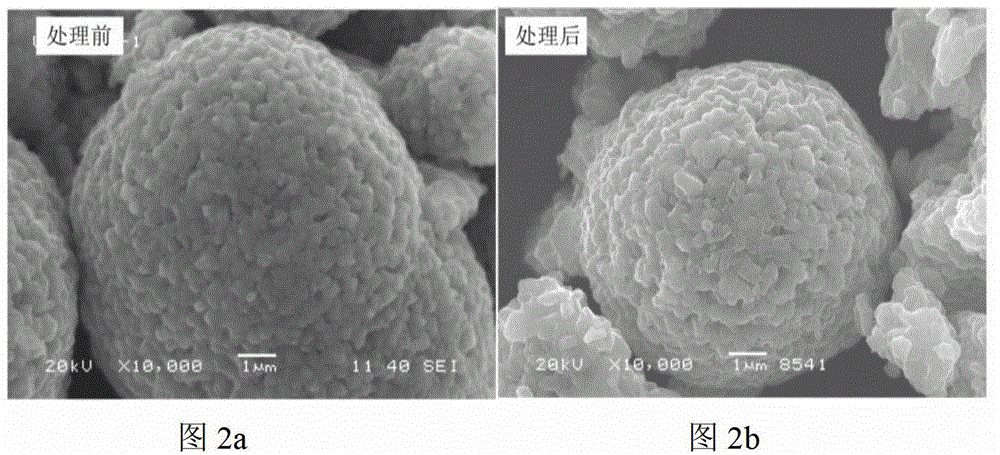

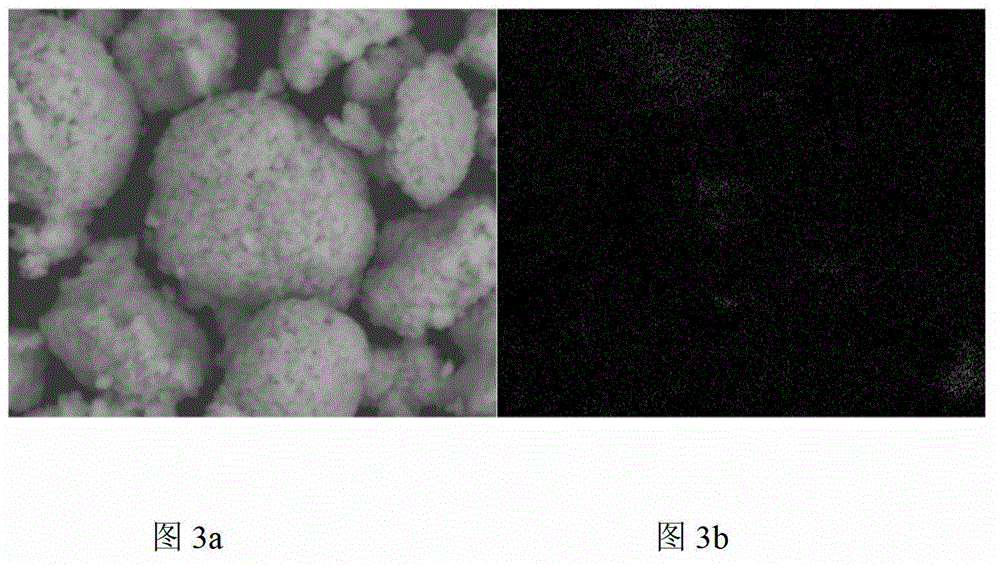

Method for removing lithium ion battery nickel-rich material surface lithium residues by liquid phase precipitation method

ActiveCN102881911ALow hygroscopicityGood hygroscopicityCell electrodesMoisture absorptionMaterial physics

The invention discloses a method for removing lithium ion battery nickel-rich material surface lithium residues by a liquid phase precipitation method. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method includes the steps: dispersing lithium ion battery nickel-rich materials into phosphate solution, combining the nickel-rich material surface lithium residues with phosphate radical ions so as to form precipitation, nucleating on the material surface, and calcining so that a material with the surface wrapped with a compact Li3PO4 layer is obtained. The wrapping layer prepared by the method is more uniform and compact than a traditional wrapping layer, and storage performance of the material in air is obviously improved; and the moisture absorption performance of the nickel-rich materials can be improved while water brought into electrolyte by electrode materials is reduced, and structural stability of the material is enhanced. Moreover, Li3PO4 is better in stability in the electrolyte than in the battery materials, so that the comprehensive electrochemical performance of a positive electrode material can be effectively improved. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method is simple in preparation process, short in flow path and low in production cost, and the prepared positive electrode material is excellent in physical performance and electrochemical performance.

Owner:CENT SOUTH UNIV

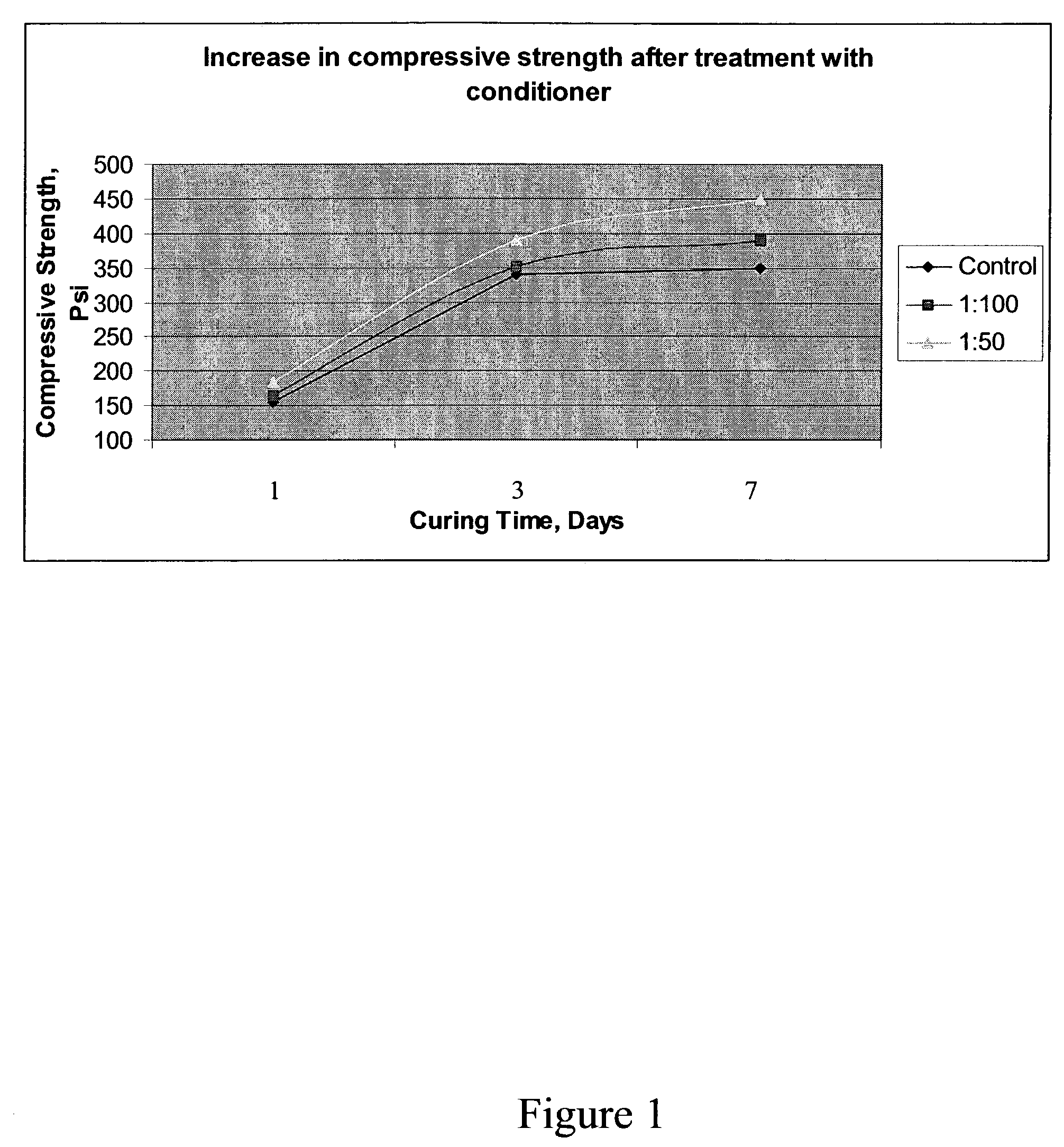

Material conditioner and stabilizer and method for making and using same

InactiveUS6982291B2Improve propertiesIn situ pavingsBuilding insulationsEmulsionChemical composition

A chemical composition and method for enhancing the physical properties of a materials. The composition may be used as a material conditioner and stabilizer is disclosed. The chemical composition may include a resin, a polymer, an emulsifier and an asphalt emulsion. The method of treating the material may include the steps of applying a chemical composition comprising a vinyl acrylic polymer, a styrene-butadiene copolymer, an anionic emulsifier and an asphalt emulsion. The materials treated may include soil.

Owner:DESIN LP

Solid oxide fuel battery anode and its production

InactiveCN1897337AOvercome carbon depositsOvercome stabilityCell electrodesCerium(IV) oxideMaterial physics

A solid oxide fuel battery anode and the preparation method, the characteristic is: adulterates the titanic mine cadmium acid lanthanum or the titanate compound oxide as the anode structure framework and the main electron conducting phase, uses the ion infusing method, the macromolecule modeling board method, the sol-gel method, or the suspending grain pulp spreading method, prepares the nanometer grain anode active substance multi-hole film with the thickness of 0.05-5 micron in the inner and outer hole surface of the multi-hole anode structure framework; the anode active substance includes the ceric oxide, or the adulterating ceric oxide, or the zirconia based oxygen ionic conductor electrolyte, or the cerate based proton conductor electrolyte, or the mixture of the above active substance, or the above active substance adding a small quantity of Ni or Ni-Cu and V2O5. The invention is structure stabilization, high conducting rate, high catalyzing activity of the fuel oxidation, matching with the closing material at physics and chemistry, structure size stabilization, anti-carbon deposition, is fit for the fuel operation of the hydrocarbon directly.

Owner:UNIV OF SCI & TECH OF CHINA

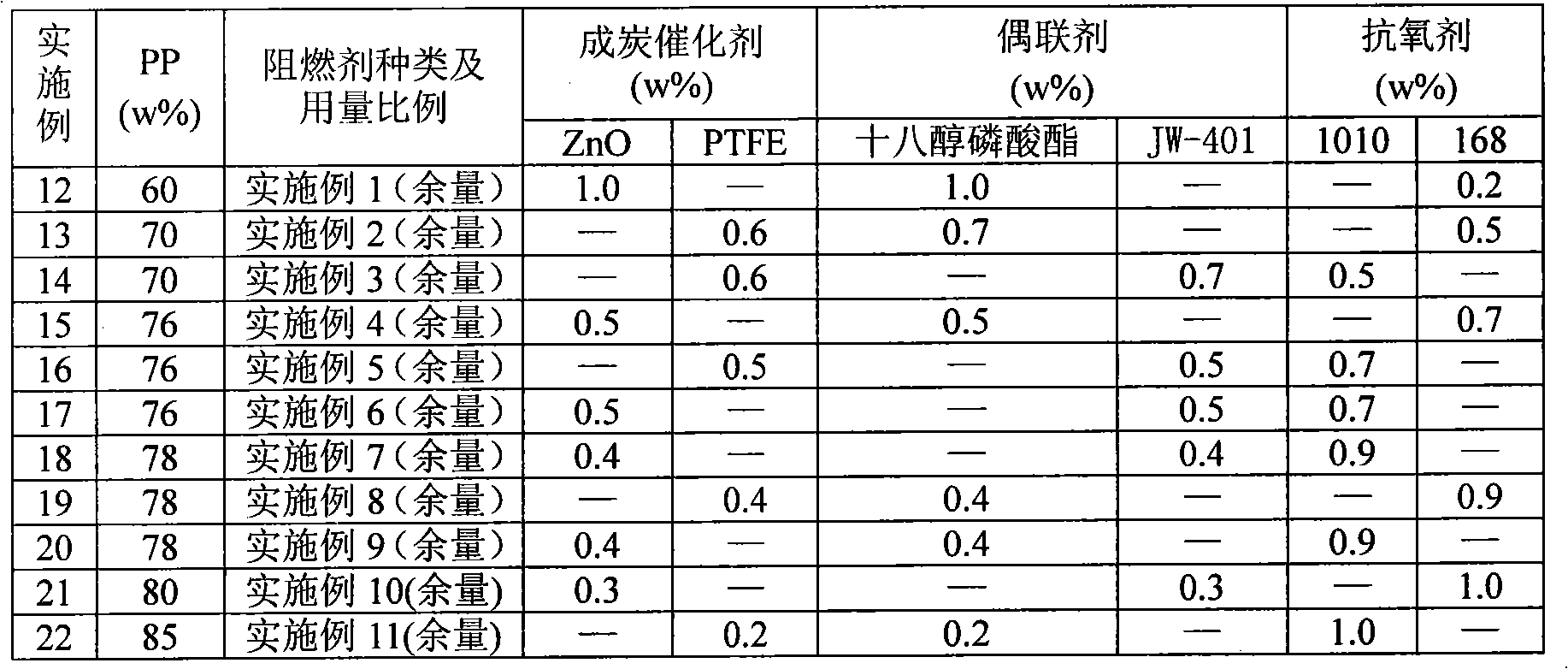

Halogen-free expansion type fire retardant and flame-proof polypropylene material

InactiveCN101260202AReduce the impact of physical and mechanical propertiesAdd lessPhosphatePolyphosphate

The invention relates to halogen-free expansion-type fire retardant and fire-retarding polypropylene material. The fire retardant is a composite expansion-type fire retardant consisting of melamine salt of bis (melabis) expansion-type fire retardant component, poly ammonium phosphate, triethylolisocyanurate, melamine cyanurate and melamine polyphosphate. Halogen-free expansion-type fire-retarding polypropylene material is made from polypropylene component, antioxidant, char-forming catalyst, phosphate ester coupling agent and the halogen-free expansion-type fire retardant through common milling. The halogen-free expansion-type fire retardant adopts MC or THEIC as one of the gas sources of the fire retardant, and is matched with melabis to substantially increase fire-retarding performance; moreover, the dosage of the halogen-free expansion-type fire retardant is less while ensuring fire-retarding performance, thereby furthest reducing the influence on the physical and mechanical properties of body materials such as polypropylene.

Owner:应急管理部四川消防研究所

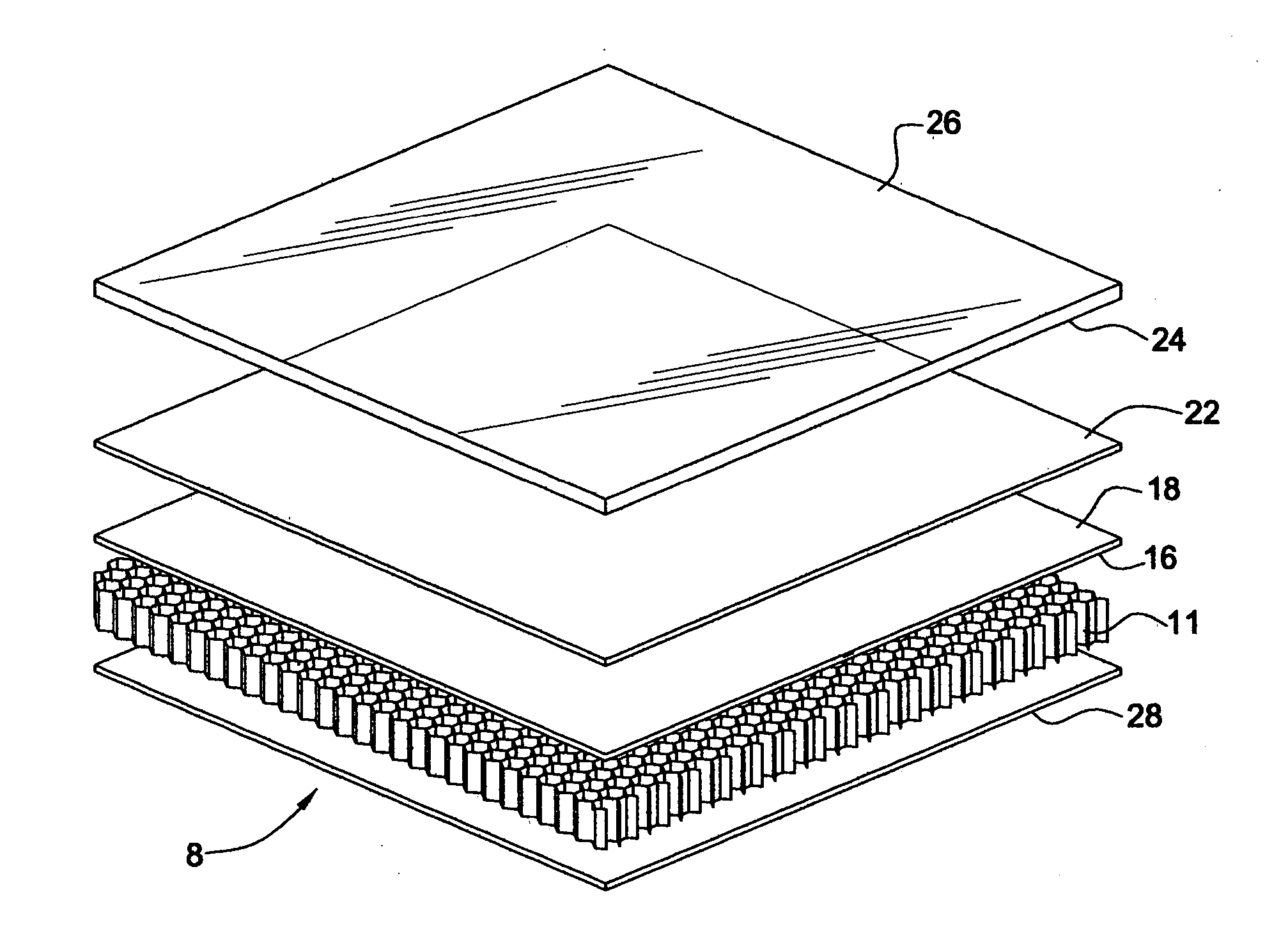

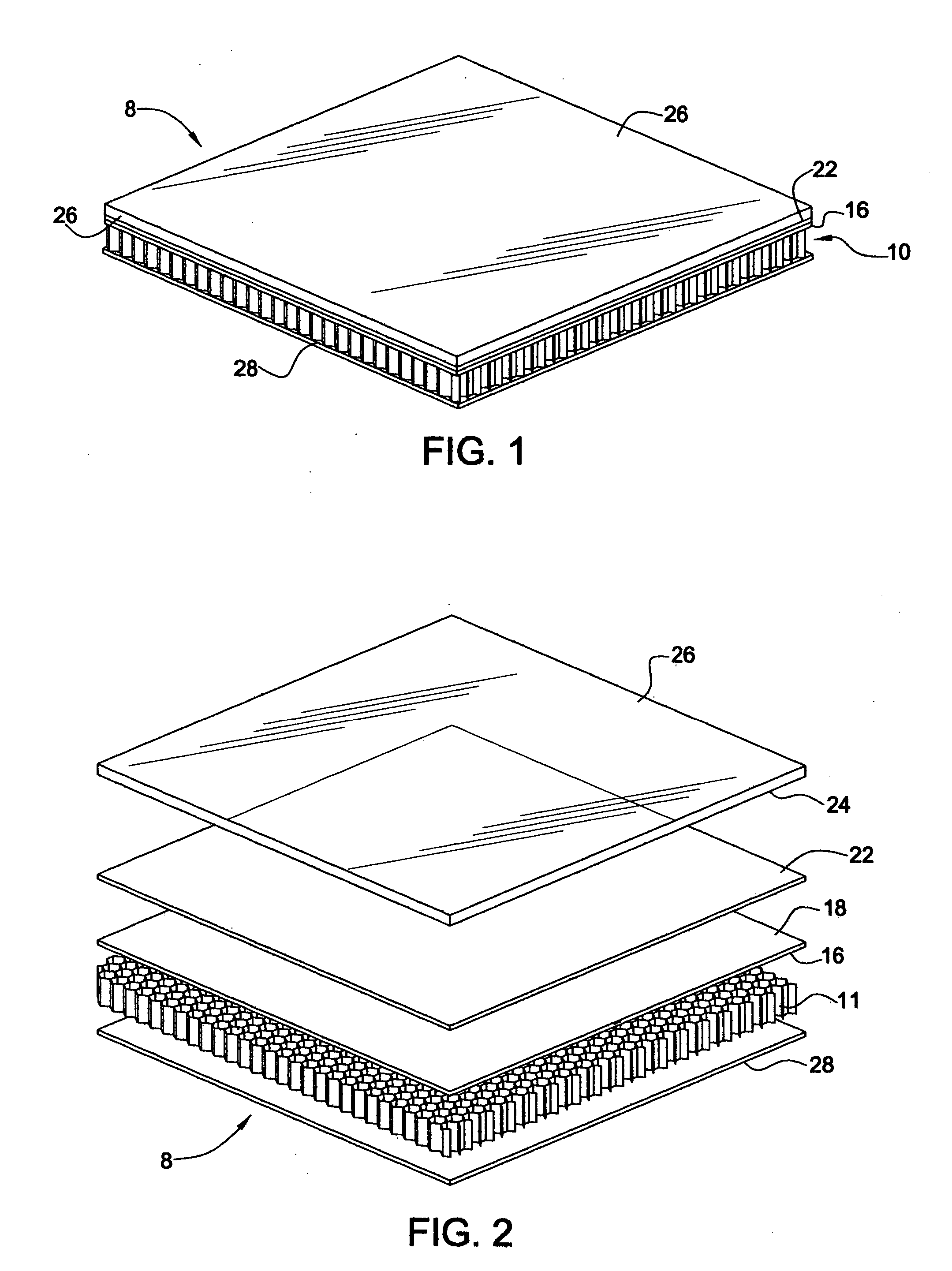

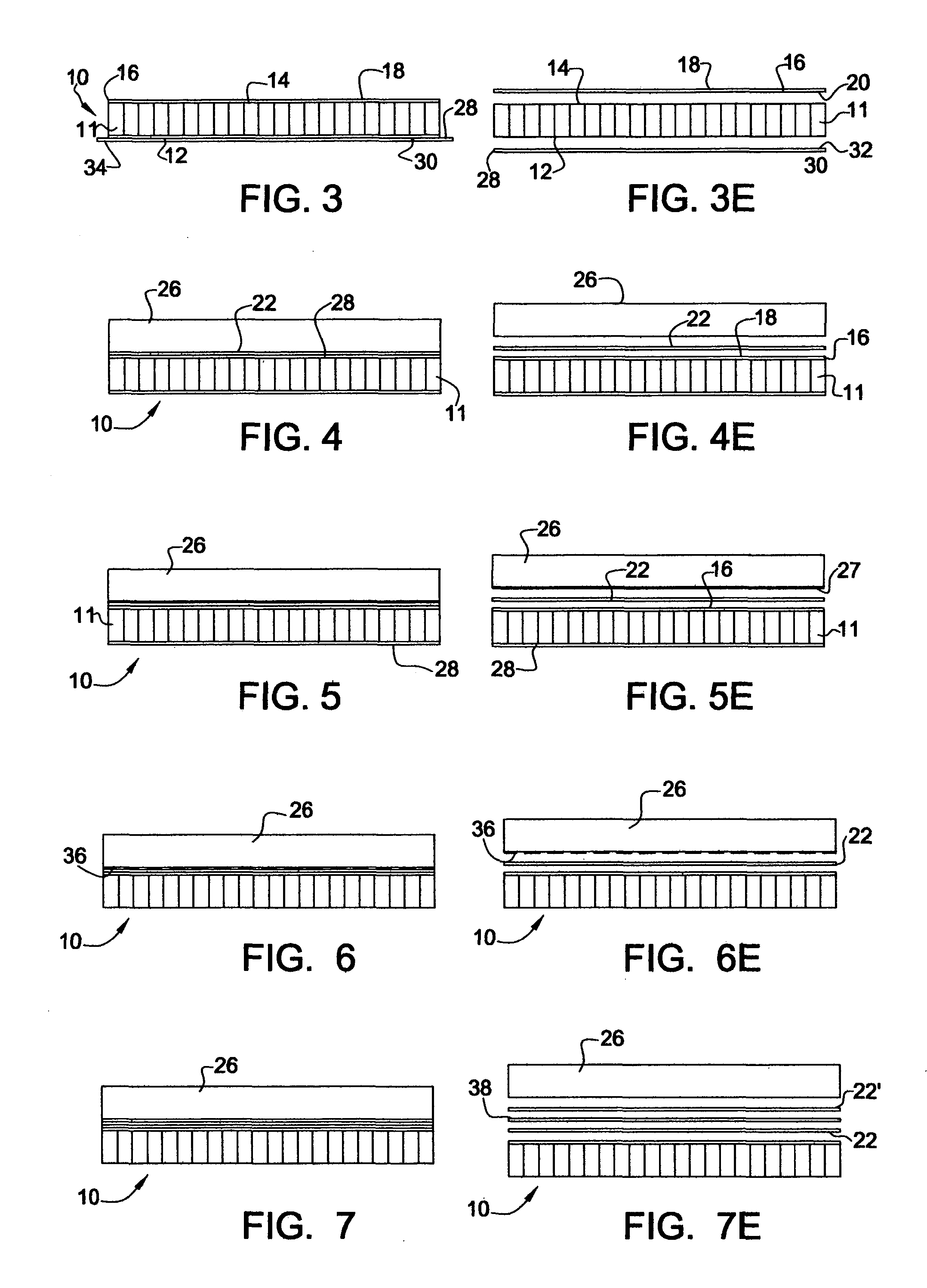

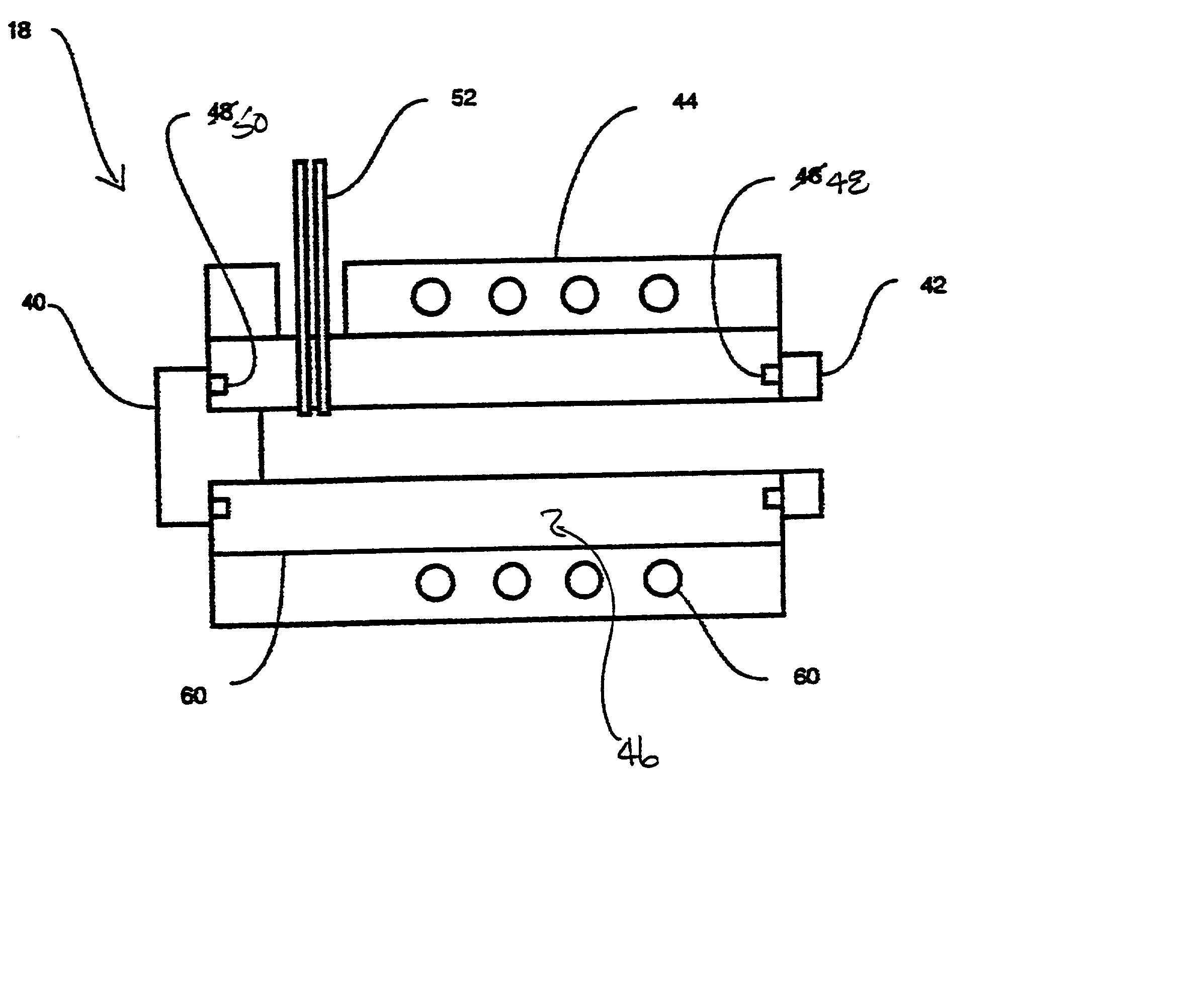

Single panel glass structural panel and method of making same

InactiveUS20050003148A1Improve rigidityHigh strengthGlass/slag layered productsThin material handlingColor effectGlass fiber

A window-type structural panel has a glass outer panel bonded to a core panel consisting of an aluminum honeycomb core having outer and inner skin surfaces of resin impregnated fiberglass having substantially the same coefficient of thermal expansion as the aluminum honeycomb core. Design and color effects are imparted to the glass panel by film sheets, printing on adhesive layers, physical insertion of wire, cloth or other solid materials bonded in position by heat and pressure to form a uniform rigid structure of great strength and a light weight.

Owner:CUNNINGHAM BETH KAY EKLAND +1

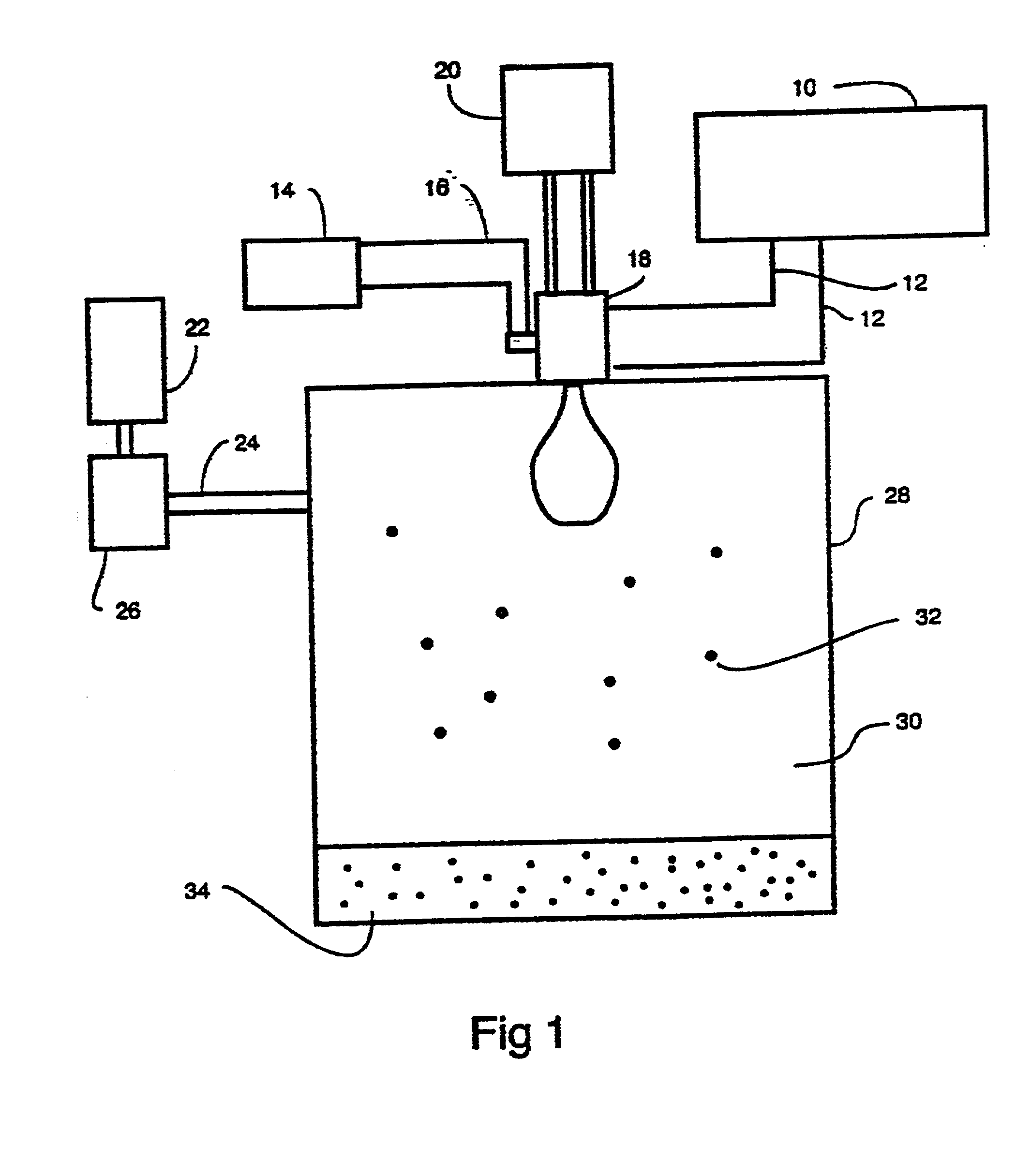

Electrothermal gun for direct electrothermal-physical conversion of precursor into nanopowder

InactiveUS20020046993A1More energyMaterialMaterial nanotechnologyArc welding apparatusParticulatesMaterial physics

A method of producing nanocrystalline ceramic powder by creating a plasma stream in a reactor vessel, and physically converting a ceramic precursor material into ceramic particles suspended in the vessel, using the plasma stream. A metallic reactant may additionally be introduced into the vessel using the plasma stream, wherein the metallic reactant forms ceramic particles having the same composition as the ceramic particles of the physical converting step. The plasma stream is created using an electrothermal gun. The gun may use a ceramic barrel which is eroded by the plasma stream. Alternatively (or additionally), the ceramic precursor material may be injected as particulates into the plasma stream, wherein the ceramic precursor particulates are micron-sized or larger. A novel electrothermal gun design may optionally use a replaceable insert constructed of the ceramic precursor material.

Owner:PETERSON DENNIS ROGER +1

Piezoelectric elastic-stress luminescent material and production method thereof

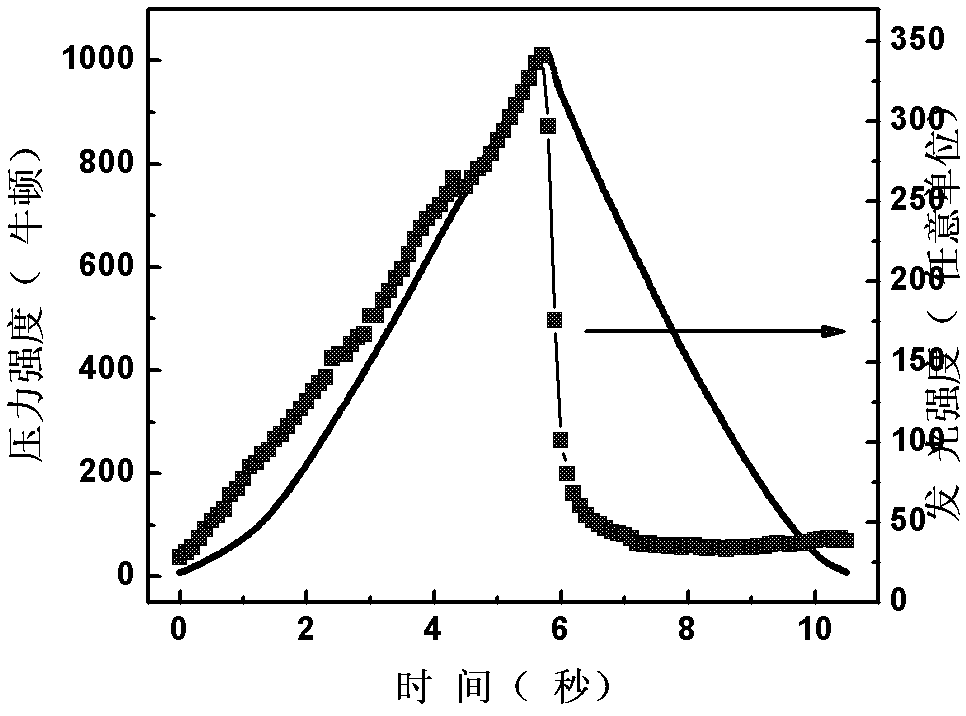

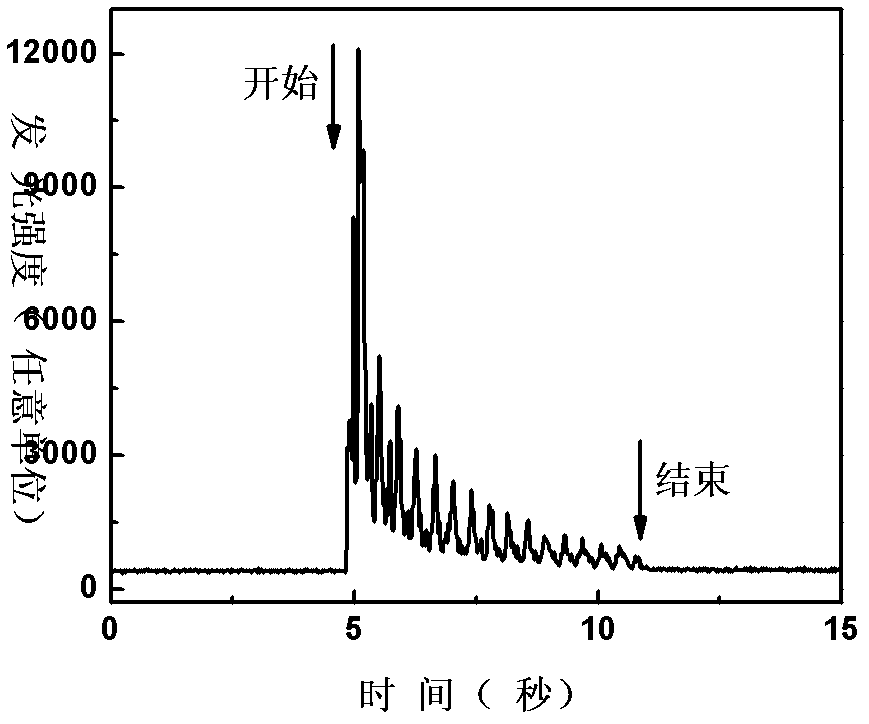

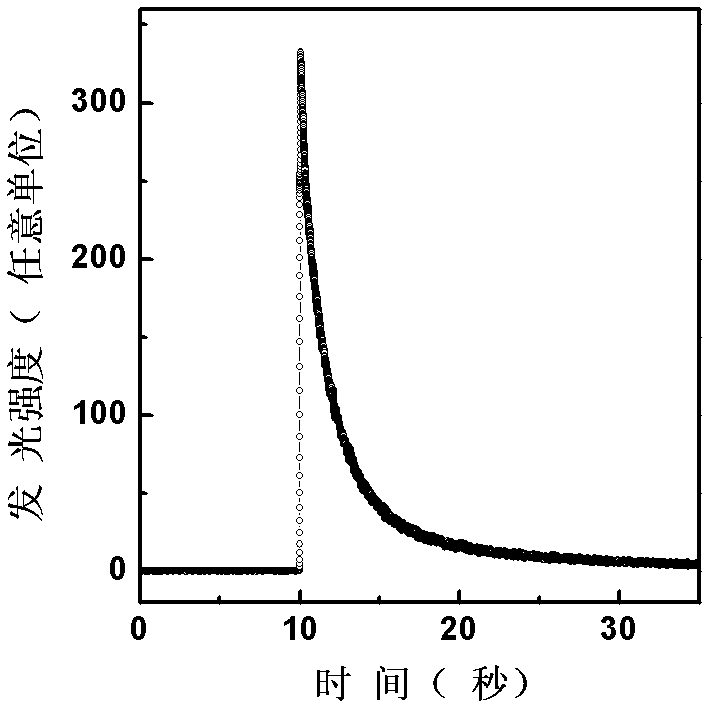

InactiveCN102634335AWide Adaptive Energy RangeLow mechanical energy widthForce measurement using piezo-electric devicesUsing mechanical meansTransitional UseInorganic compound

The invention belongs to the technical field of materials physics and relates to piezoelectric elastic-stress luminescent material and a production method thereof. The piezoelectric elastic-stress luminescent material is produced by using CaZnOS:Mn (thioxo-inorganic compound) activated by transitional metal manganous ions as substrate, subsitituting Ca-site and Zn-site metallic ions, and subjecting transitional metal and rear earth sensitizer ions to co-doping. A chemical formula of the luminescent material is (Ca1-xMx)(Zn1-yNy)1-aOS:(Mn1-zRz)a, wherein M stands for Ca-site substitute ions, Mg2+, Sr2+ and Ba2+ are selected, N stands for Zn-site substitute ions, Mg2+ and Al3+ selected, R stands for co-doped transitional metal or rear earth sensitive ions from Cu+, Cu2+, Cr3+, Ag+ and the like, and x, y, z and a stand for molar content and are not zero simultaneously. The production method of the material is simple in process, reliable in principle, low in cost, high in stress luminescence quality, fine in mechanical property, high in processibility, wide in application range and evident in economic value.

Owner:QINGDAO UNIV

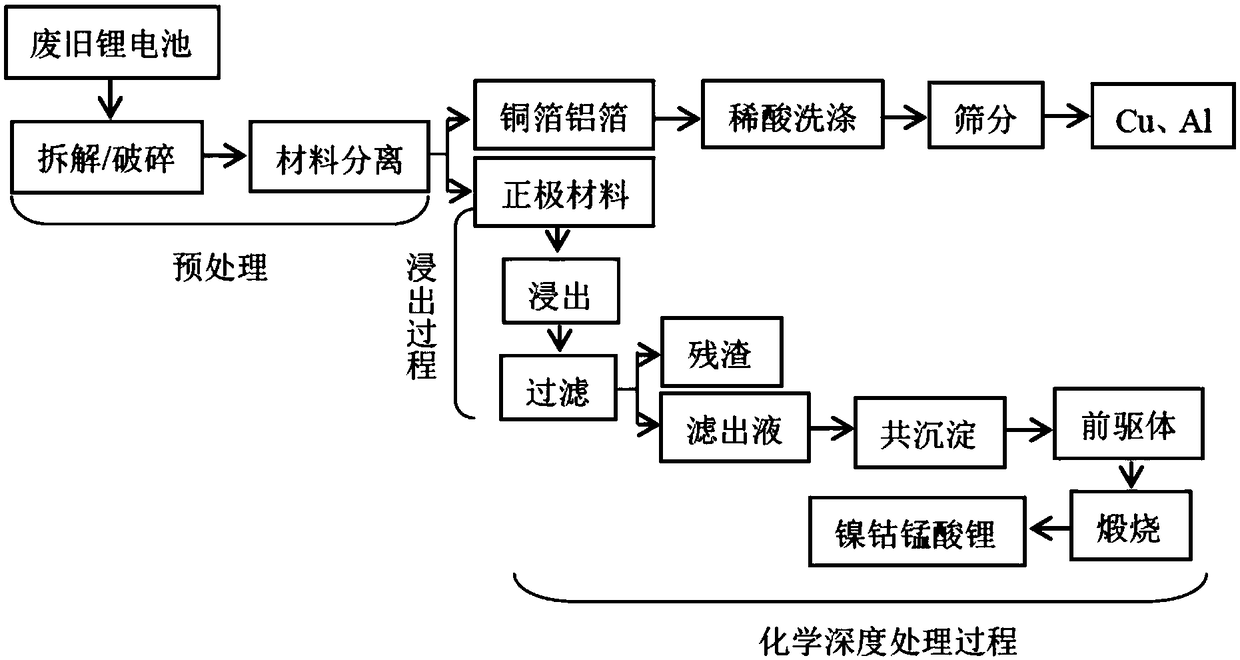

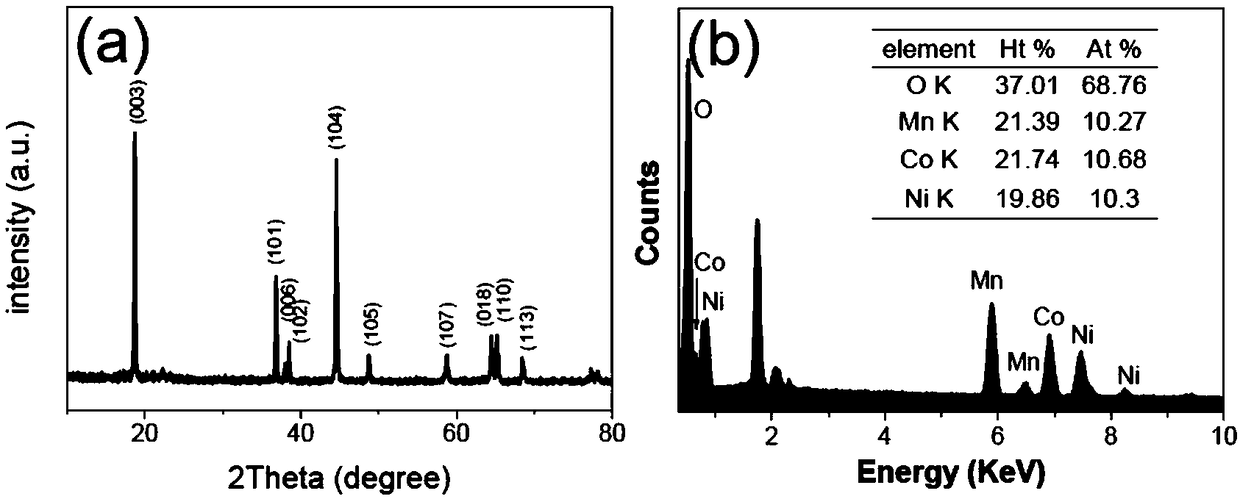

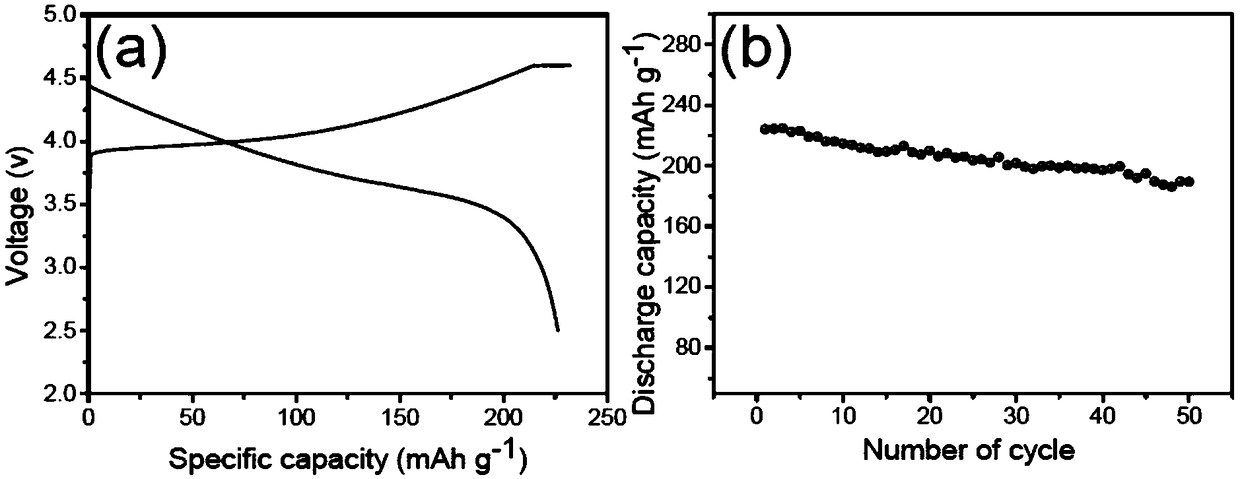

Process for recovering nickel cobalt lithium manganate positive electrode material by taking waste lithium ion battery as raw material

InactiveCN108649291AEfficient recyclingOmit strong base to adjust pH stepCell electrodesWaste accumulators reclaimingResource utilizationManganate

The invention provides a process for recovering a nickel cobalt lithium manganate positive electrode material by taking a waste lithium ion battery as a raw material, and belongs to the field of waster lithium battery recovery. The method comprises the following steps: crushing a positive plate of the waste lithium ion battery, performing pyrolysis at the temperature of 400 to 450 DEG C, and screening to physically separate positive electrode powder from other materials; calcining the positive electrode material and acidic sulfate, and dissolving a calcined product in deionized water, whereinspecific dissolution steps and the setting of various parameters in the dissolution process are specifically disclosed; and removing impurities in leachate, co-precipitating with sodium carbonate andsodium bicarbonate mixed solution as a precipitant to prepare a carbonate precursor, and then mixing with lithium carbonate and calcining to obtain a nickel cobalt lithium manganate ternary positive electrode material. According to the process for recovering the nickel cobalt lithium manganate positive electrode material by taking the waste lithium ion battery as the raw material provided by the invention, the positive electrode material of the waste lithium ion battery is recycled, and through a reverse recovery process, the nickel cobalt lithium manganate ternary positive electrode materialis re-manufactured to achieve resource utilization.

Owner:BEIJING UNIV OF CHEM TECH

Non-contact stress measuring device

ActiveUS9128063B2Force measurement by measuring magnetic property varationInductance measurementsPower flowStress measures

Apparatuses and methods for measuring stress or strain in a conductive material without physical contact with the material are provided. The device comprises an inductor circuit configured to induce an alternating current into the material along a first path; and a detector configured to detect a signal representative of the stress in the material along the first path when current is induced in the material.

Owner:PRATT & WHITNEY CANADA CORP

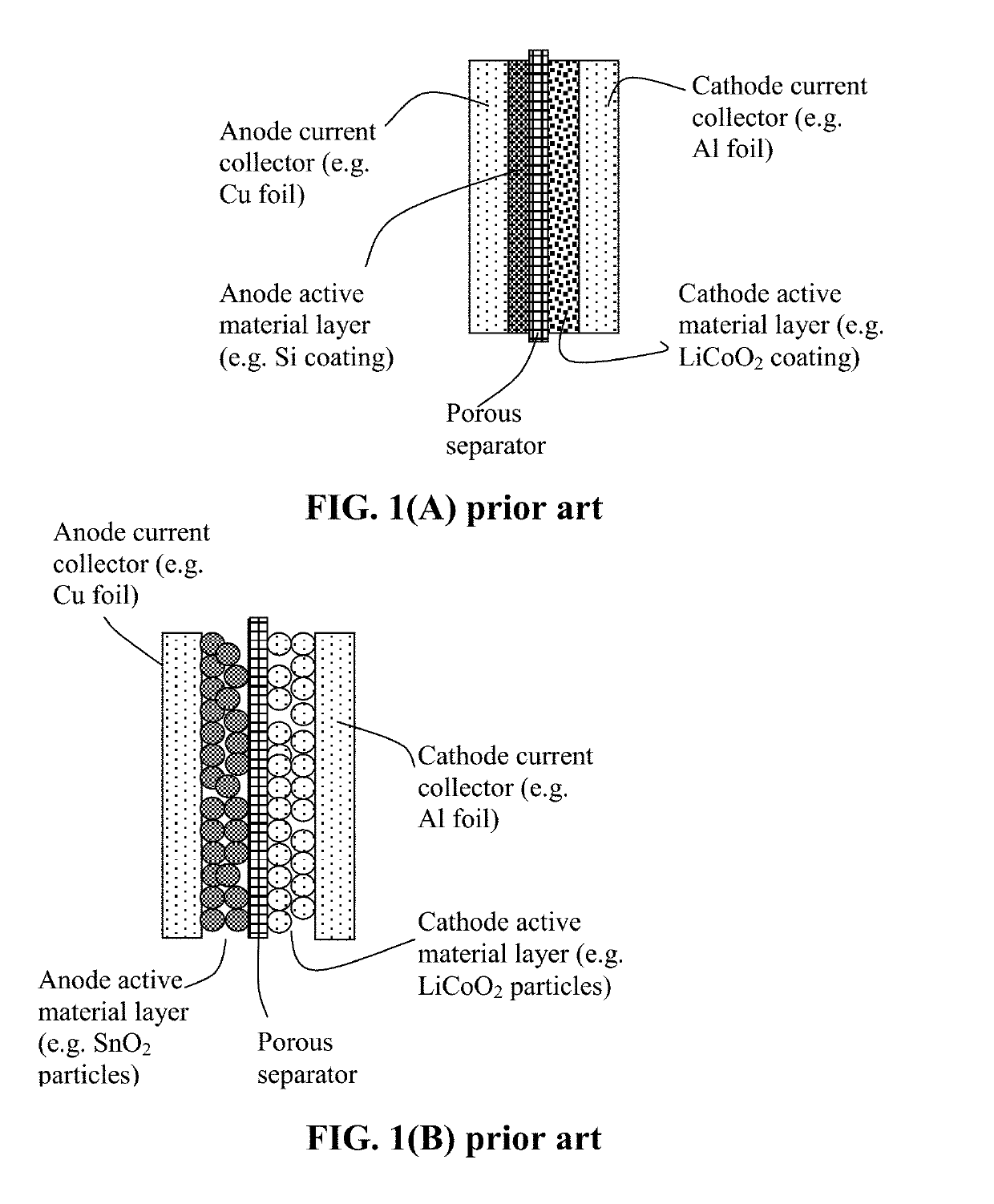

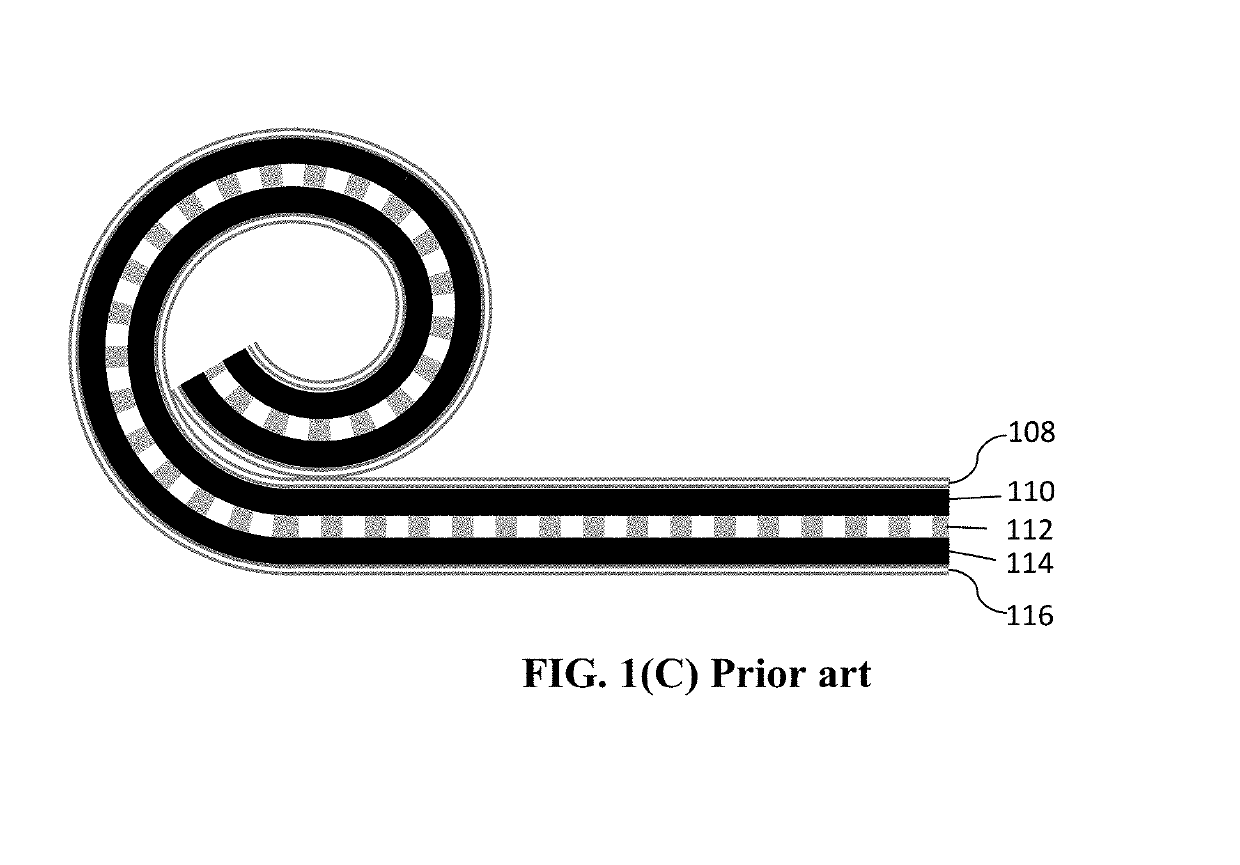

Anode Particulates or Cathode Particulates and Alkali Metal Batteries

Provided is an anode particulate, having a dimension from 10 nm to 300 μm, for use in an alkali metal battery, the particulate comprising (i) an anode active material capable of reversibly absorbing / desorbing lithium or sodium ions, (ii) an electron-conducting material, and (iii) a lithium or sodium salt with an optional polymer or its monomer, but without a liquid solvent, for an electrolyte, wherein the electron-conducting material forms a 3D network of electron-conducting pathways in electronic contact with the anode active material and the lithium or sodium salt is in physical contact with the anode active material (so that the salt, when later impregnated with a liquid solvent, becomes an electrolyte forming a 3D network of lithium or sodium ion-conducting channels in ionic contact with the anode active material). The particulate can be of any shape, but preferably spherical or ellipsoidal in shape. Also provided is a cathode particulate.

Owner:GLOBAL GRAPHENE GRP INC

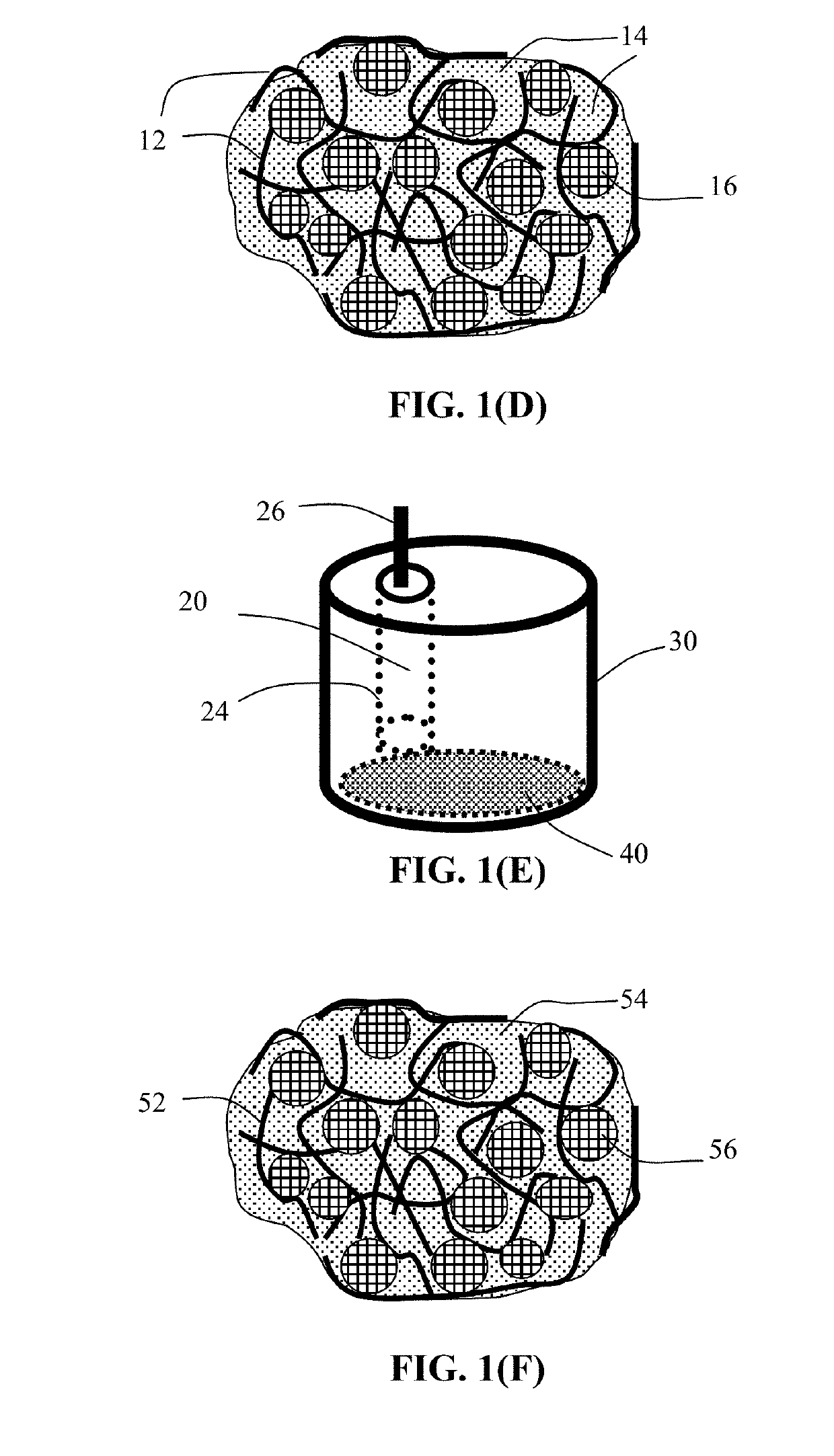

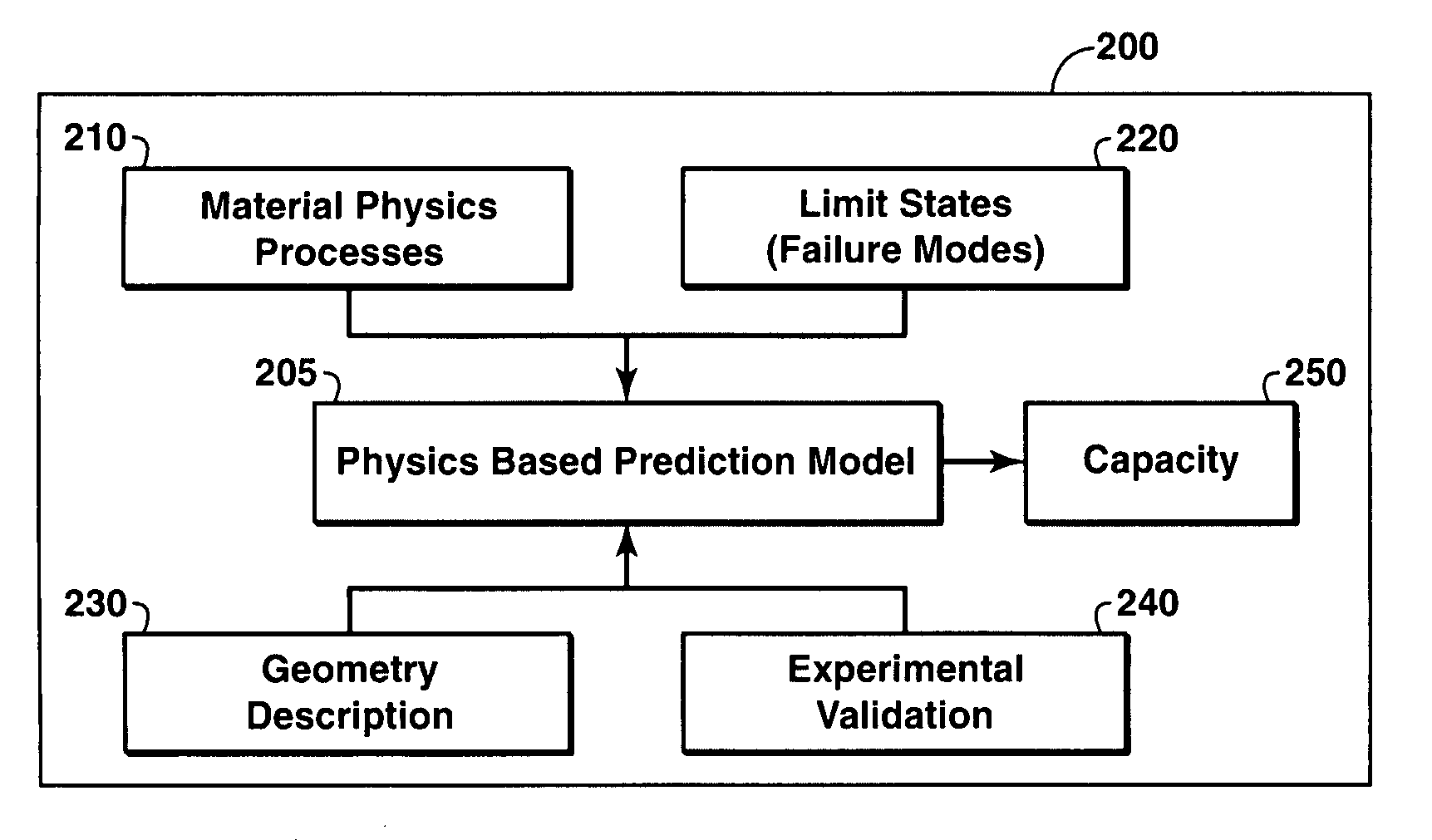

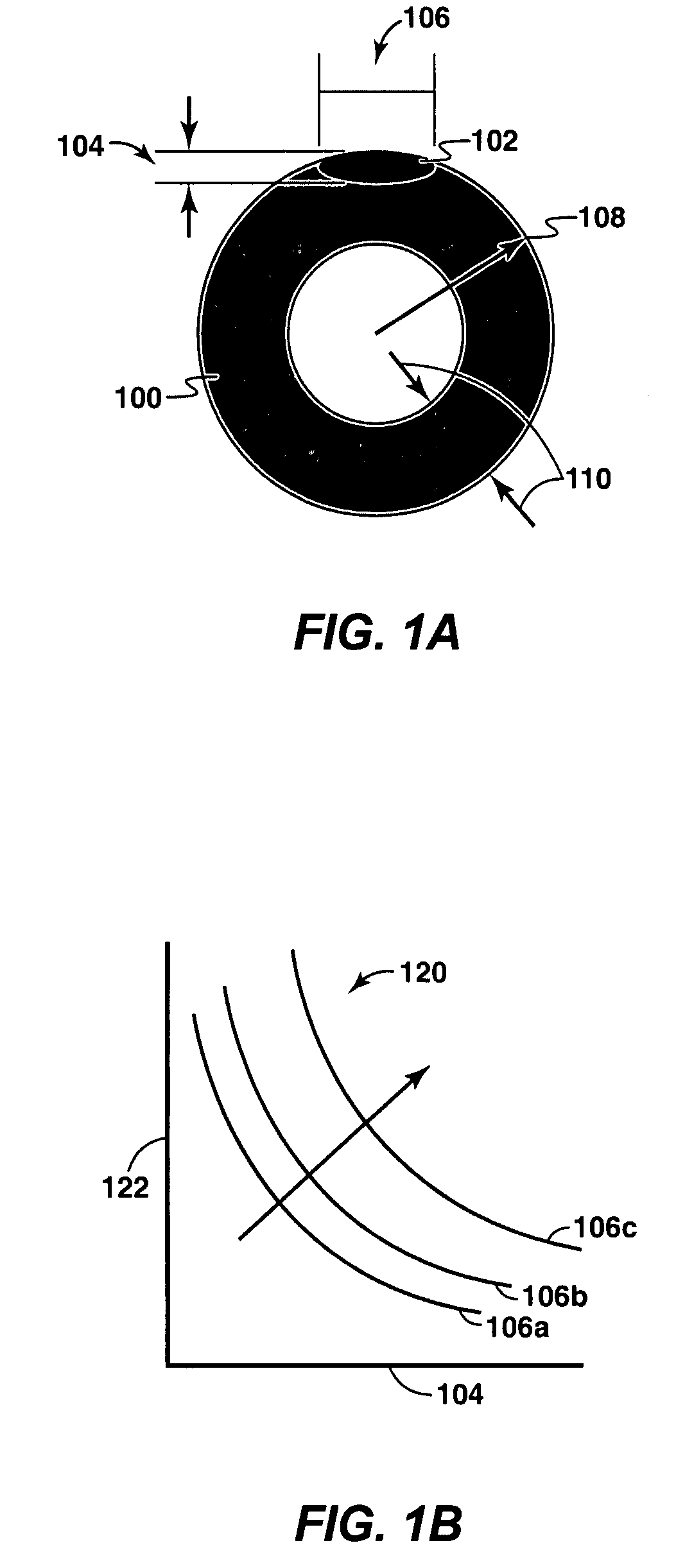

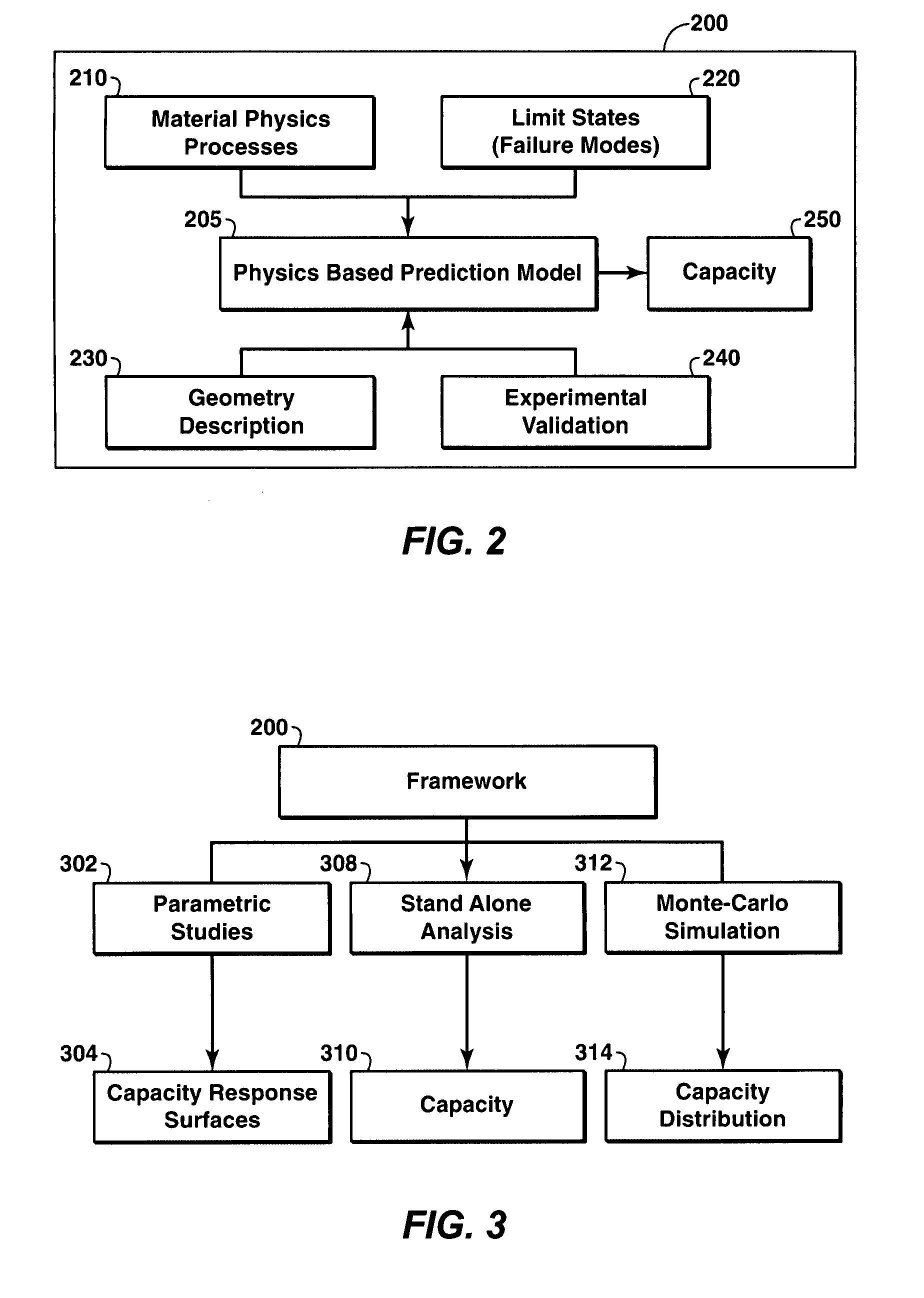

Framework to Determine the Capacity of A Structure

InactiveUS20100042379A1Computation using non-denominational number representationDesign optimisation/simulationPhysics basedType distribution

A framework for determining or predicting the capacity of a structure. The framework includes predicting the capacity of the structure utilizing a physics-based prediction model. The prediction model may be constructed from a variety of numerical analysis approaches. The prediction model further incorporates at least one material physics process, at least one geometry description, and at least one limit state. The limit states may include collapse, tensile fracture, and buckling. The framework calls for validation of the predicted capacity of the structure via experimental verification or other methods. In some embodiments, the structure is a pipeline for producing hydrocarbons and the modes of operation may include parametric studies, Monte-Carlo type distributions, or stand-alone values.

Owner:MINNAAR KAREL +4

Electromagnetic noise suppressor, article with electromagnetic noise suppressing function and their manufacturing methods

InactiveUS20090314539A1Eliminate the effects ofMeet cutting requirementsMagnetic/electric field screeningLayered productsGas phaseSuppressor

Owner:SHIN ETSU POLYMER CO LTD

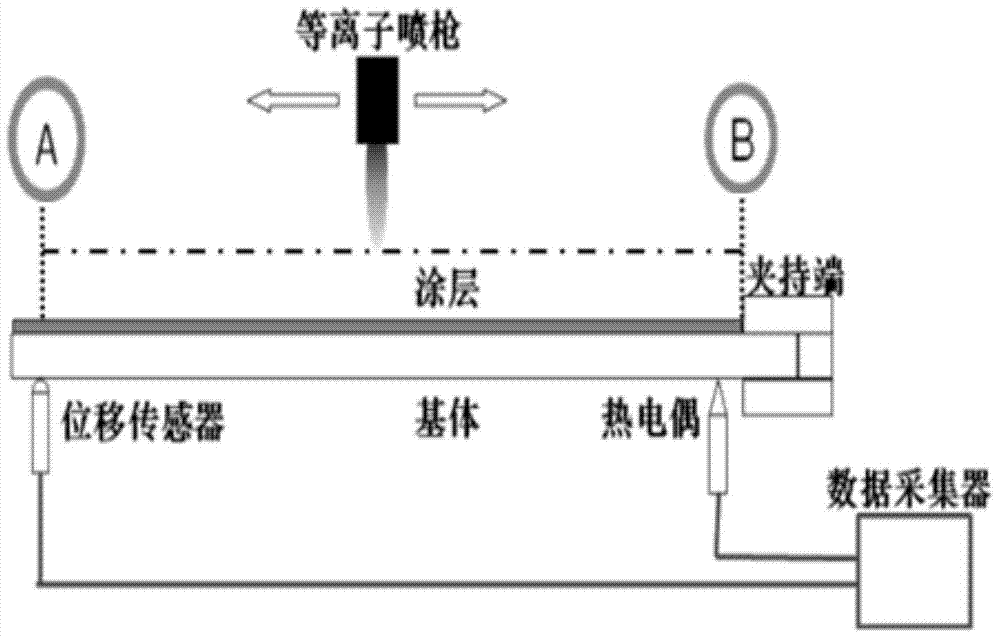

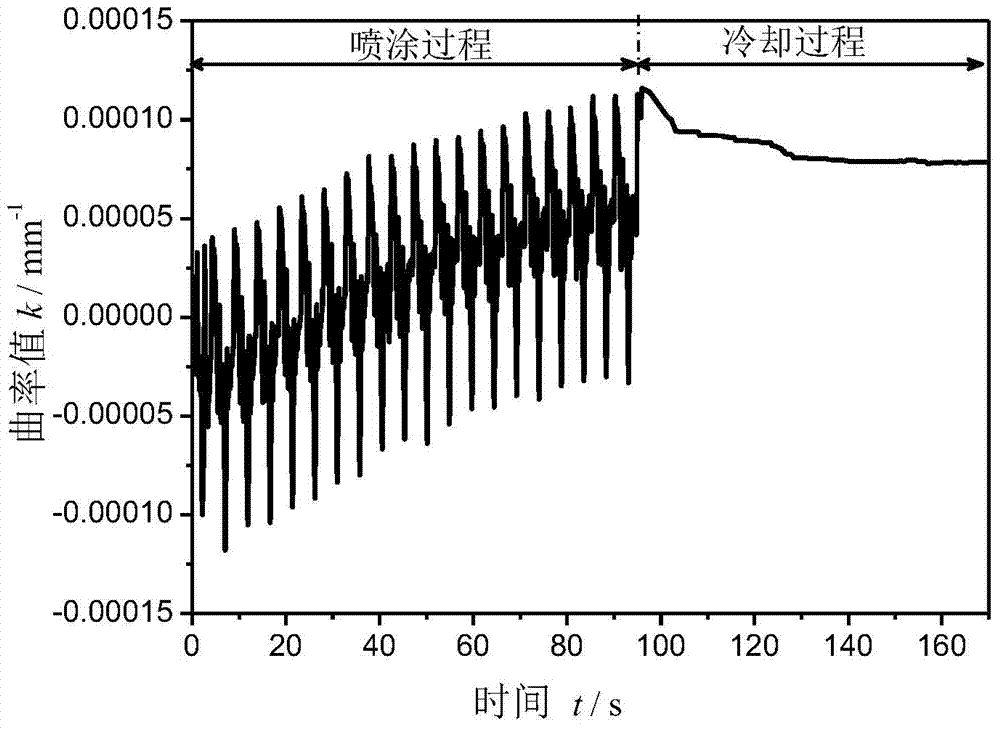

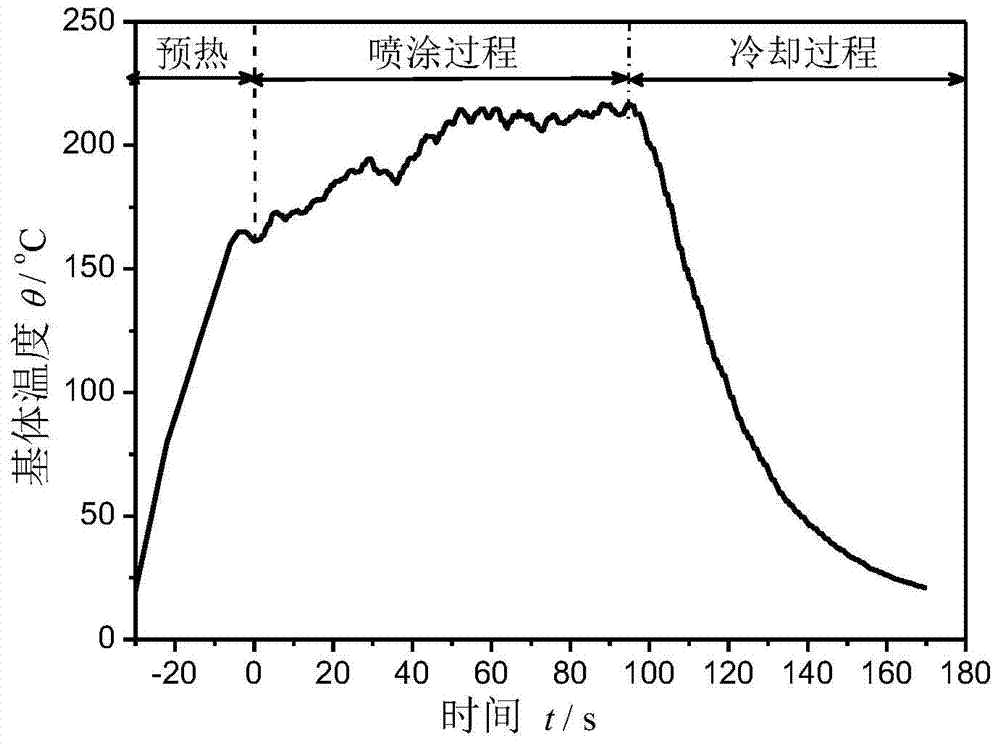

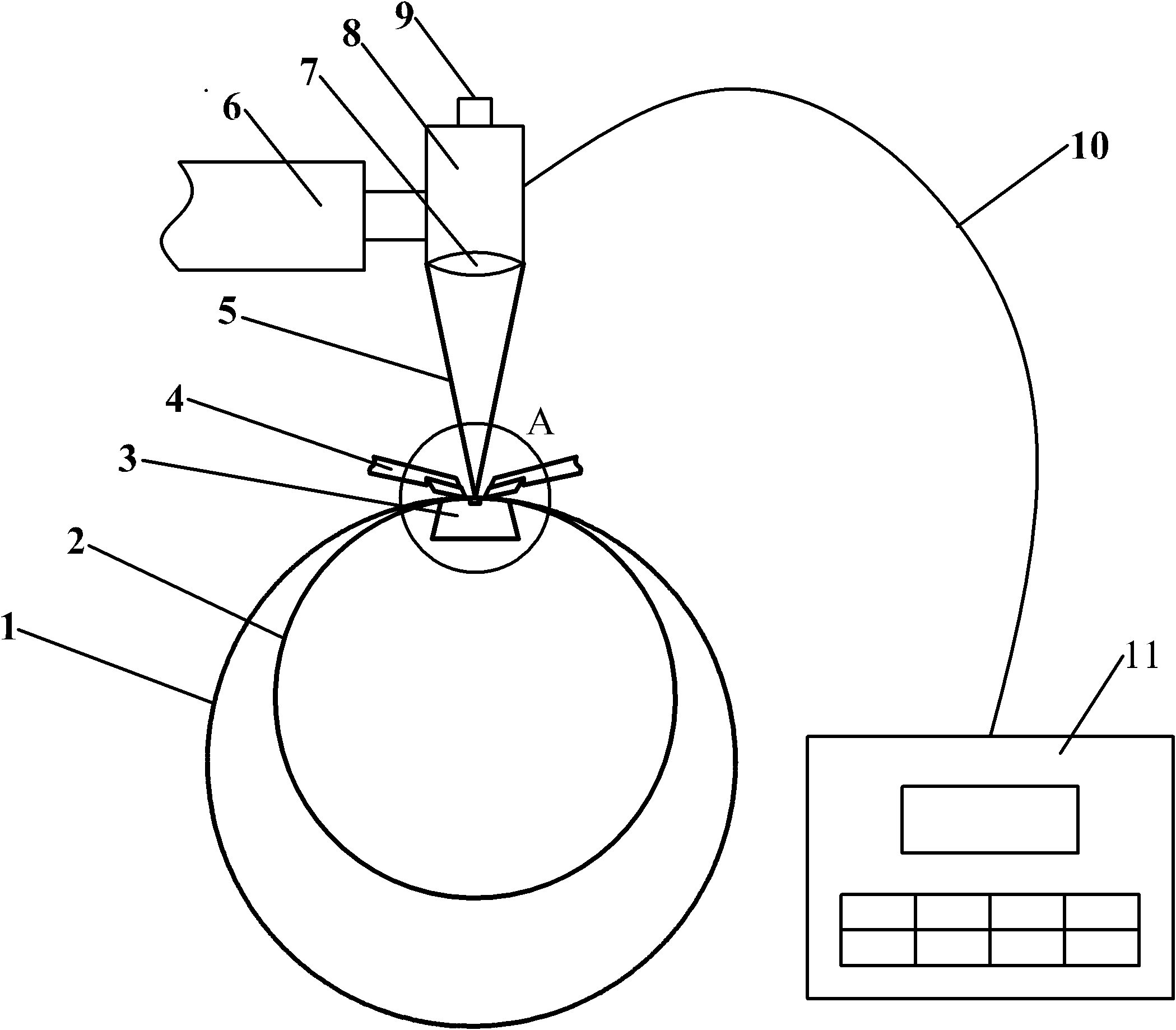

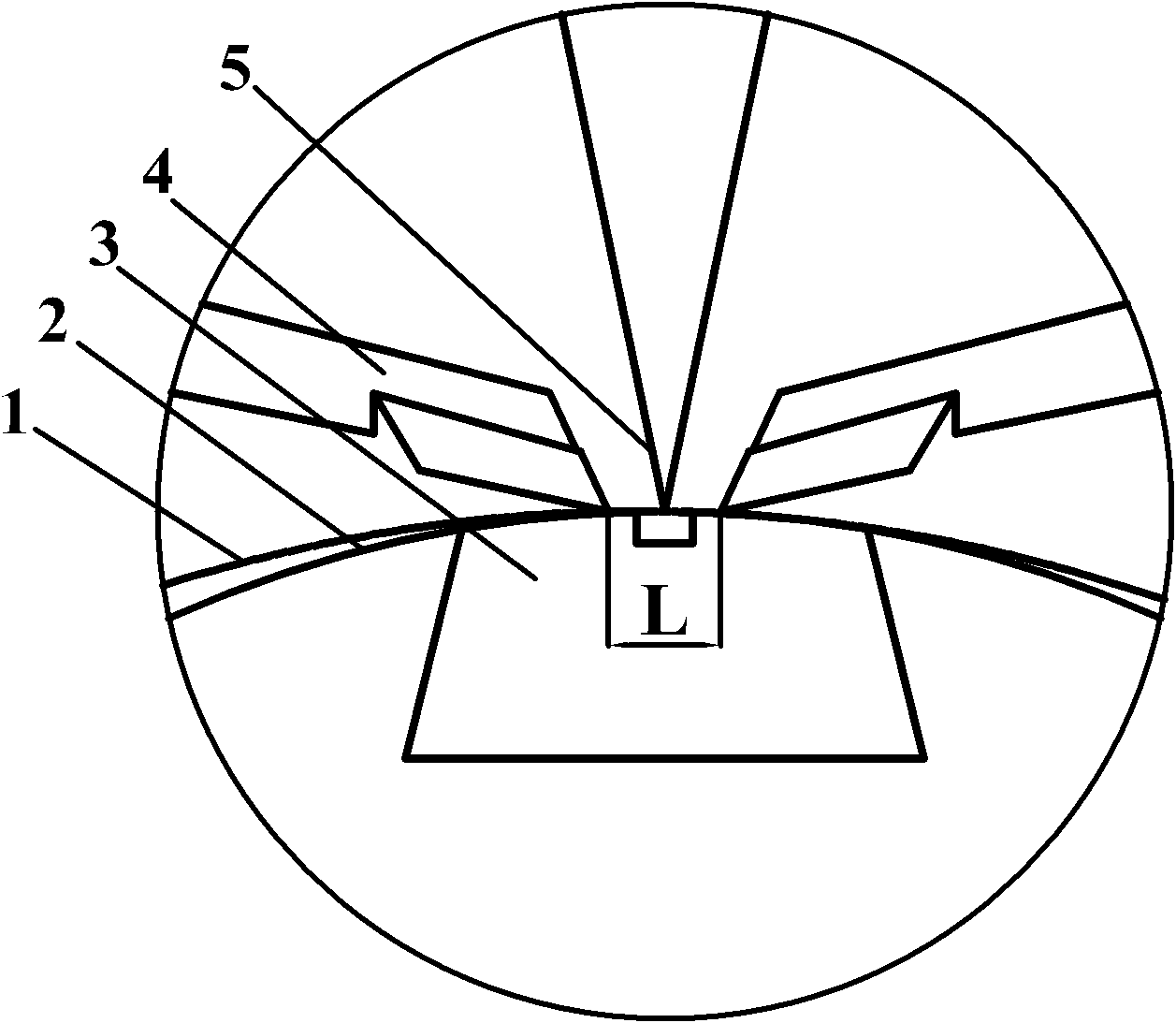

Test device and method for measuring residual stress of coating

The invention relates to a test device and method for measuring residual stress of a coating, and belongs to the field of thermal spraying. Curvature changes of the coating and a base body in the spraying process are measured on line, internal stress of the coating in the manufacturing process is calculated within an elastic scope, and the final residual stress of the coating is obtained. A sample to be sprayed is fixed at one end, wherein the clamping end is the B end, and the other end is the A end; then the surface of the sample is sprayed with a plasma spraying method, and the coating is formed. In the spraying process, due the temperature is uneven or the physical property of materials is coincident, the internal stress is generated between the coating and the base body of the sample. Displacement at an A point is measured through a displacement sensor fixed at the A end of the sample, and the curvature change of the sample is accordingly obtained. Temperature changes of the sample in the deposition stage and the cooling stage in the spraying process are measured. The elasticity modulus of the ceramic coating is reversely obtained according to the curvature changes of the coating and the base body, and the stress evolution in the coating manufacturing process and residual stress values of the manufactured coating are reversely obtained.

Owner:BEIJING UNIV OF TECH

Small fiber balls for solid buoyancy material and preparation method of small fiber balls

The invention discloses small fiber balls for a solid buoyancy material and a preparation method of the small fiber balls. The small fiber balls have nuclear shell structures, nucleating carriers are foam balls, and shell layers are powdery fiber reinforced resin matrix composite layers; the small fiber balls with the nuclear shell structures are prepared by adopting the expandable polystyrene foam balls as the nucleating carriers, uniformly coating the surfaces of the expandable polystyrene foam balls with powdery fiber reinforced resin systems, solidifying and washing. The physical performance of the small fiber balls can be conveniently and effectively controlled and improved by changing the foam diameter, the fiber and resin type and the coating thickness according to different environmental usage requirements.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Electromagnetic noise suppressor, article with electromagnetic noise suppressing function, and their manufacturing methods

InactiveUS7625633B2Eliminate the effects ofMeet cutting requirementsMagnetic/electric field screeningCross-talk/noise/interference reductionGas phaseSuppressor

Owner:SHIN-ETSU POLYMER CO LTD

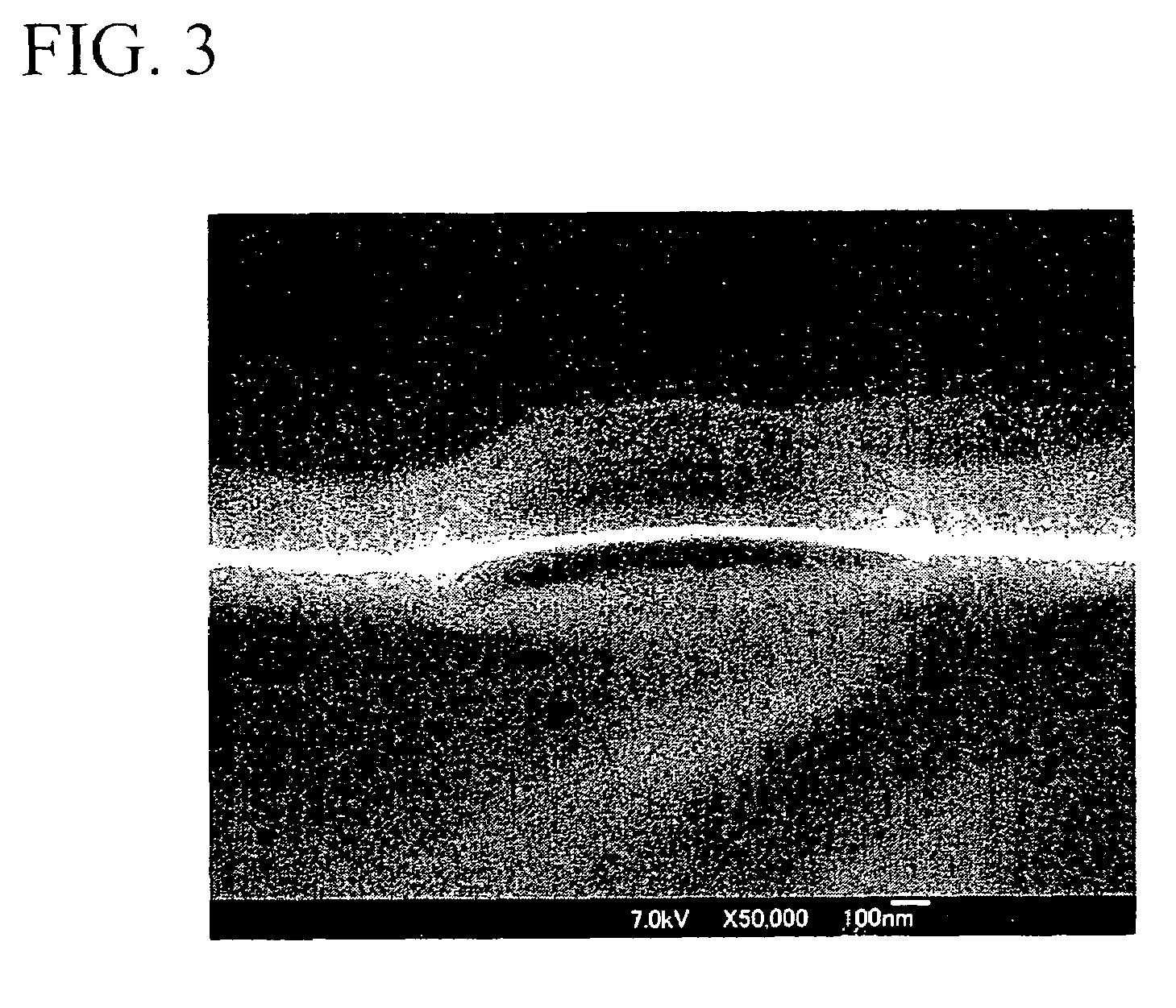

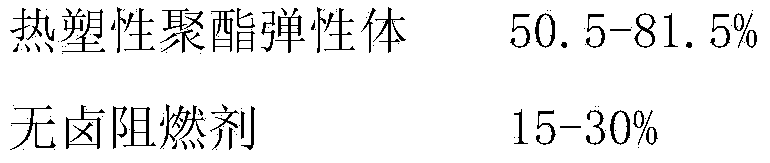

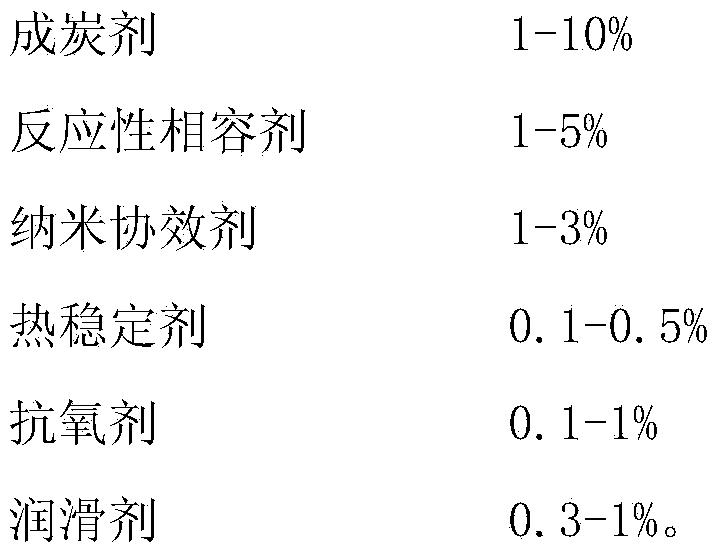

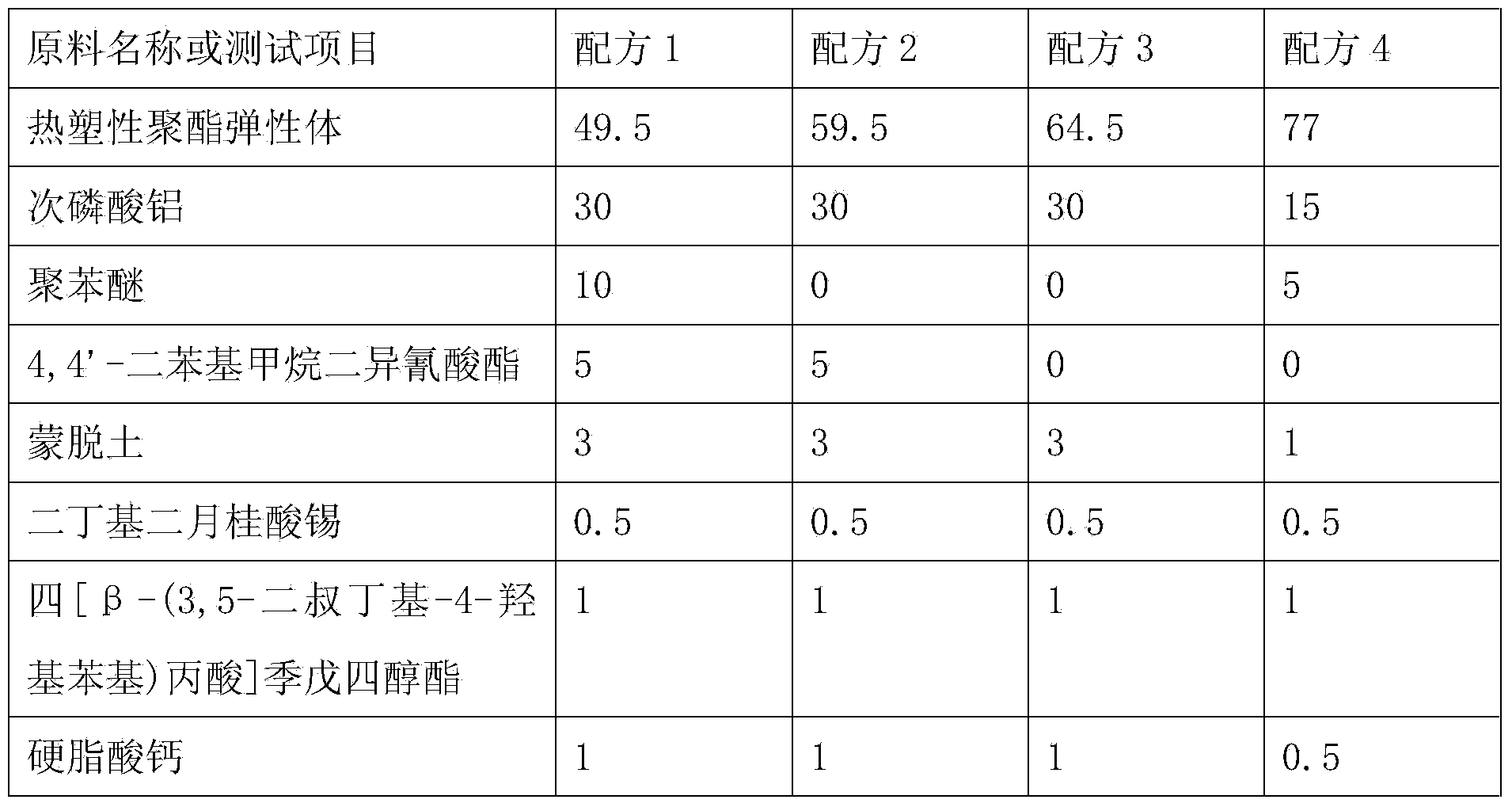

Halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and preparation method thereof

ActiveCN103642178AImprove flame retardant performanceImprove mechanical propertiesElastomerPolyester

The invention discloses a halogen-free flame-retardant thermoplastic polyester elastomer nano composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 50.5-81.5 percent of thermoplastic polyester elastomer, 15-30 percent of halogen-free flame retardant, 1-10 percent of charring agent, 1-5 percent of reactive compatibilizer, 1-3 percent of nucleating agent, 0.1-0.5 percent of heat stabilizer, 0.1-1 percent of antioxidant and 0.3-1 percent of lubricating agent according to the total mass percentage of the composite material, heating to the temperature of 210-225 DEG C, performing melt blending, extruding, bracing, cooling, sized dicing and drying to obtain the halogen-free flame-retardant thermoplastic polyester elastomer nano composite material. The nano composite material has excellent flame-retardant property and physical performance, the defects that a halogen-containing flame retardant is high in environmental hazard, the addition amount of an inorganic flame retardant is high, the physical performance of the material is poor and the like in the conventional composite material modification technology are overcome, and the composite material has high application prospects.

Owner:合肥安聚达新材料科技有限公司

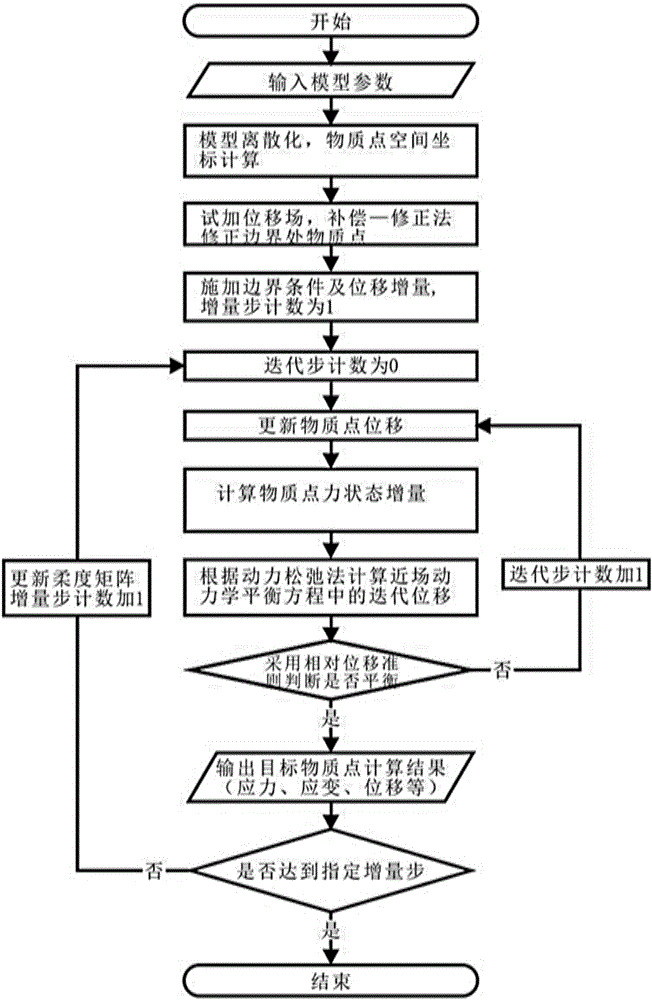

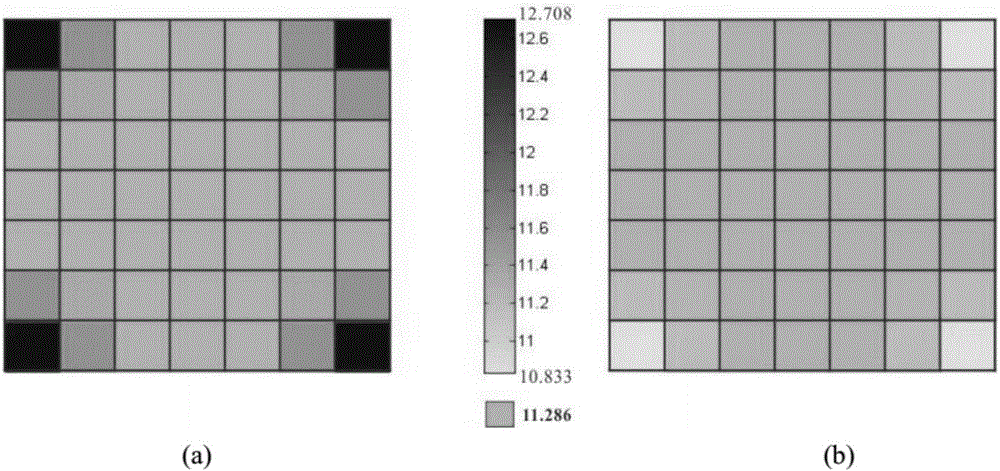

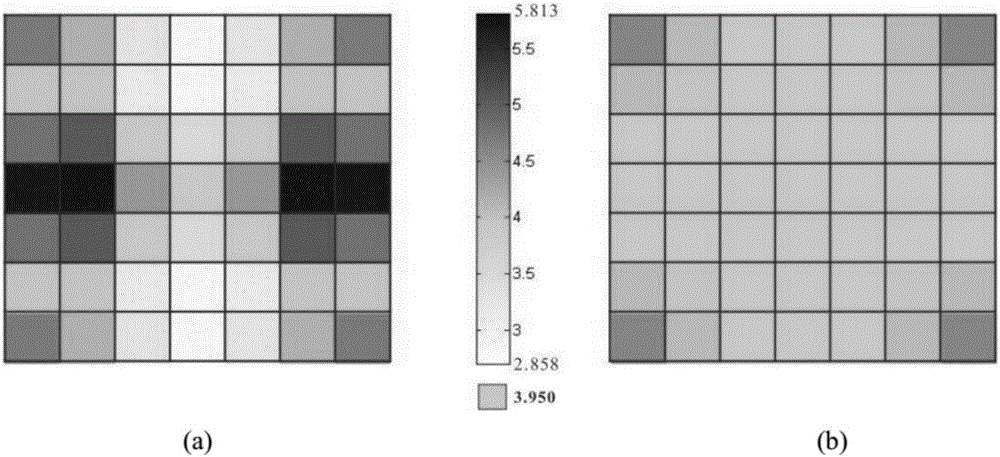

State-based peridynamics method of physical nonlinear simulation of fiber reinforced composite material

ActiveCN105930619AReduce mistakesEnhanced Physical Nonlinear ResponseSpecial data processing applicationsDynamic methodResin matrix

The invention discloses a state-based peridynamics method of physical nonlinear simulation of a fiber reinforced composite material. The state-based peridynamics method of physical nonlinear simulation of the fiber reinforced composite material comprises the steps of firstly dispersing a to-be-simulated composite material structure into a series of space material points, generating space coordinates of the material points, correcting non-local strain of the material points at the border by adopting a compensation-correction method, dividing the total displacement of the structure into multiple increment steps for applying, and judging whether the structure reaches to a balanced state within each increment step by adopting a relative displacement criterion so as to obtain displacement in the balanced state; after applying all the increment steps, realizing simulation of a physical nonlinear behavior of the composite material. The state-based peridynamics method of physical nonlinear simulation of the fiber reinforced composite material can efficiently simulate physical nonlinear response of an orthogonal layer fiber reinforced resin matrix composite material, an unidirectional fiber reinforced resin matrix composite material and the like under the action of a partial axial tensile load; and the compensation-correction method provided and adopted in the simulation method can reduce an error between a density calculation value and a theoretical value of elastic strain energy at the border of the state-based peridynamics model under the action of a stretching and shearing displacement field remarkably.

Owner:SHANGHAI JIAO TONG UNIV

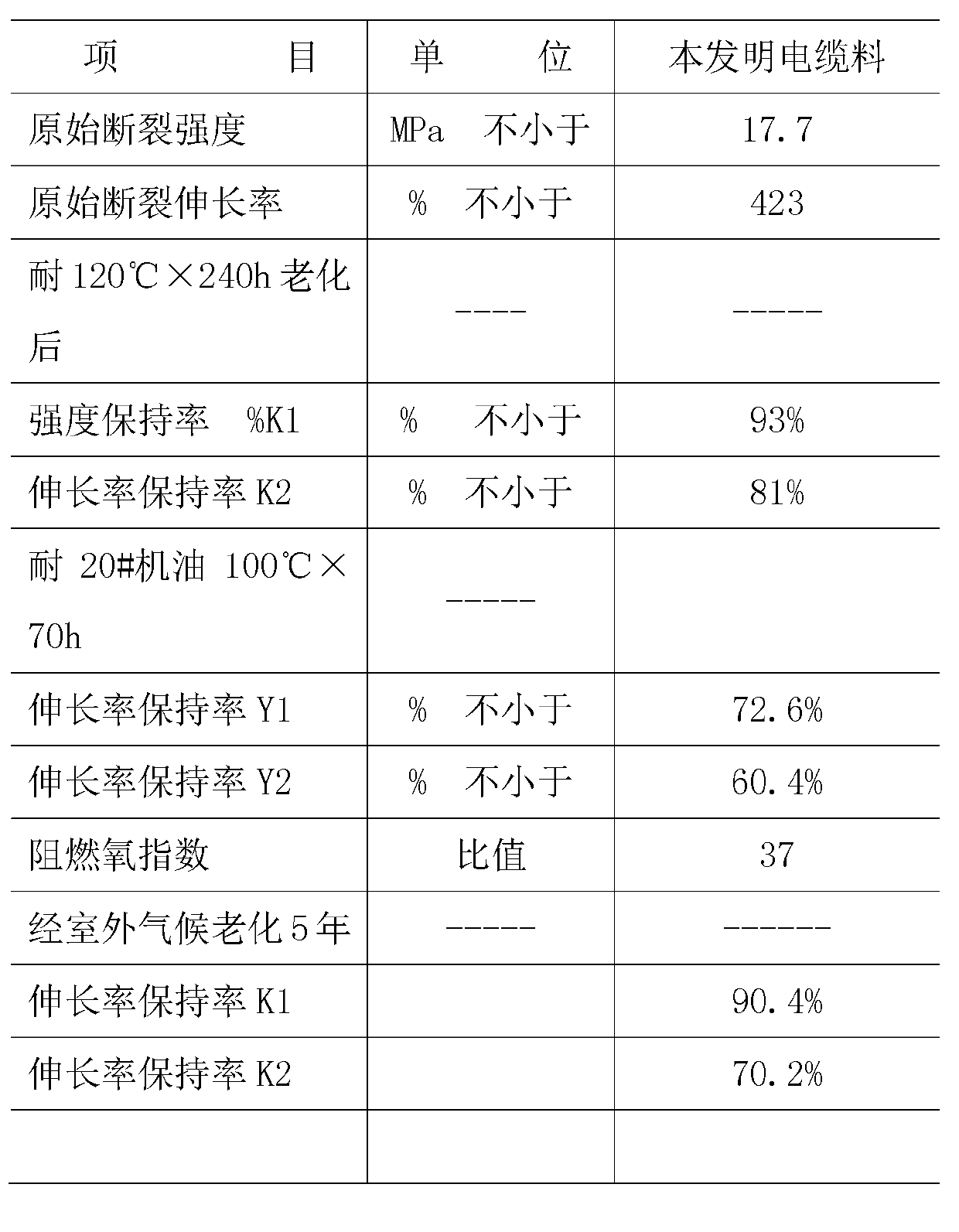

High-temperature resistant cable sheath insulation material and preparation method thereof

InactiveCN102993522AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsPolyesterSodium Bentonite

The invention discloses a stretch-proof cable sheath insulation material and a preparation method thereof. The stretch-proof cable sheath insulation material comprises the following raw materials in parts by weight: 97-103 parts of neoprene CR121, 13-17 parts of SG-4 type PVC (Polyvinyl chloride) resin, 14-22 parts of semi-reinforcing carbon black N774, 2-3 parts of magnesium oxide, 1-2 parts of aluminic acid ester coupling agent, 30-33 parts of blanc fixe, 1-2 parts of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-7 parts of polyamine wax micro powder, 1-2 parts of promoter DM1, 0.8-1 part of promoter TMTD, 14-18 parts of high wear resistance carbon black N330, 1.-1.2 parts of adipic acid propylene glycol polyester, 2-4 parts of zinc borate, 4-6 parts of glass powder, 0-8-1 part of zinc oxide, 2-3 parts of modified bentonite, 4-6 parts of ethylene thiourea, 2-3 parts of ammonium dihydrogen phosphate and 0.8-1 part of N-2-(amino ethyl group)-3-aminopropyl trimethoxy silane. The stretch-proof cable sheath insulation material prepared by the method has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increases tensile strength, tearing strength and resilience force performance and has the performances of common silicon rubber at the normal temperature and forms a hard shell after ablated in high-temperature fire to protect a burned objected from being damaged.

Owner:安徽文峰电子科技集团有限公司

Printed circuit board and method of manufacturing the same

InactiveUS20090260868A1High-density circuit patternSmall line widthStacked resist layersPrinted circuit aspectsElectrical connectionEngineering

The printed circuit board includes the via formed with the electroplating layer unlike a conventional via formed with an electroless plating layer and an electroplating layer and having a cylindrical shape, and thus exhibits good interlayer electrical connection and high reliability of physical contact upon thermal stress caused by the variance in physical properties of material depending on changes in temperature. The via has no upper land, and thus a fine circuit pattern of the circuit layer can be formed on the via.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Coated magnetic alloy material and method for the manufacture thereof

InactiveCN102246248AExcellent mechanical propertiesImprove application feasibilityInorganic material magnetismLiquid/solution decomposition chemical coatingCrystal structureMaterial physics

The invention refers to the area of materials science and material physics and relates to a coated magnetic alloy material that can be used, for example, as a magnetic cooling material for cooling purposes. The object of the present invention is to provide a coated magnetic alloy material that exhibits improved mechanical and / or chemical properties. The object is accomplished by a magnetic alloy material having an Na Zn13-type crystalline structure and having a composition according to the formula Ra Fe100-a-x-y-z Tx My Lz, the surface of said alloy material being coated with a material comprising at least one element from the group of Al, Si, C, Sn, Ti, V, Cd, Cr, Mn, W, Co, Ni, Cu, Zn, Pd, Ag, Pt, Au or combinations thereof. The object is further achieved by a method in which the magnetic alloy material is coated by way of fluid phase processes.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

Method for welding nuclear main pump shielding can

ActiveCN102091867AReduce the impactGuaranteed dimensional accuracyLaser beam welding apparatusHeat-affected zoneEngineering

The invention discloses a method for welding a nuclear main pump shielding can. A laser welding machine is utilized to perform pulse laser welding on the nuclear main pump shielding can. The method comprises the following steps of: bending and rolling a Hastelloy C-276 alloy sheet into a drum, arranging into a special welding fixture, protecting the front and back of a welding line by using inertgas, connecting a laser welding head with a Nd:YAG solid pulse laser through a transmission fiber, and welding a longitudinal seam of the nuclear main pump shielding can by controlling the accurate positioning and continuous movement of a laser welding head. By the method, on the one hand, a weld heat-affected zone of the nuclear main pump shielding can is small, a workpiece is not deformed, the diameter is high in precision, the correction treatment is not needed after welding, and the influence on the physical and mechanical properties of materials can be reduced to the minimum; on the other hand, a welding wire is not needed to be filled in the welding process, the size of the welding line is narrow, the complexity of controlling welding equipment and adjusting process parameters is simplified, and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com