Patents

Literature

1438 results about "Magnetic alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetic alloy is a combination of various metals from the periodic table such as ferrite that contains at least one of the three main magnetic elements: iron (Fe), nickel (Ni), or cobalt (Co) etc.. Such an alloy must contain but is not limited to one or more of these metals. Magnetic alloys have become common, especially in the form of steel (iron and carbon), alnico (iron, nickel, cobalt, and aluminum), and permalloy (iron and nickel). The strongest magnetic element is iron, which allows items made out of these alloys to attract to magnets.

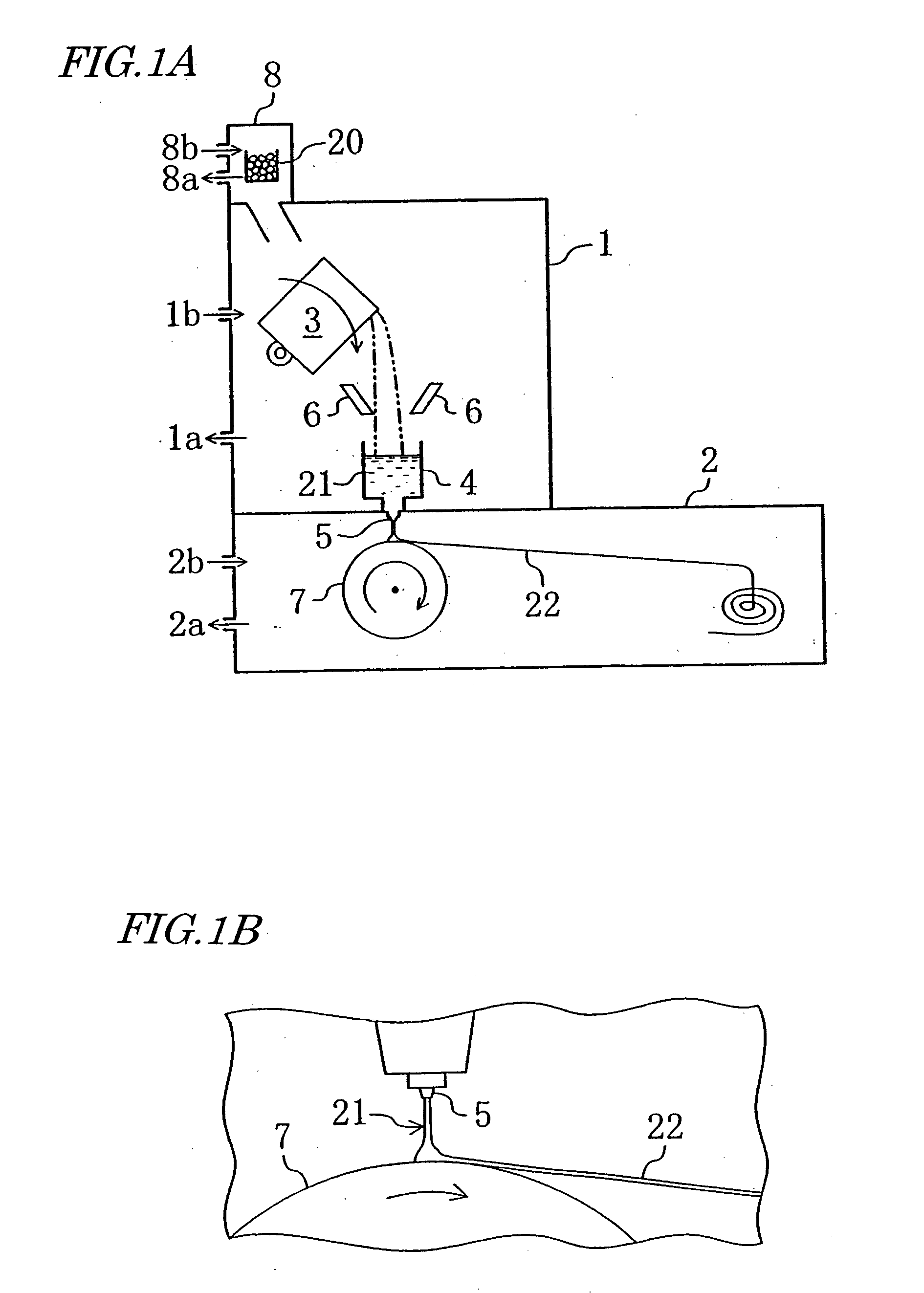

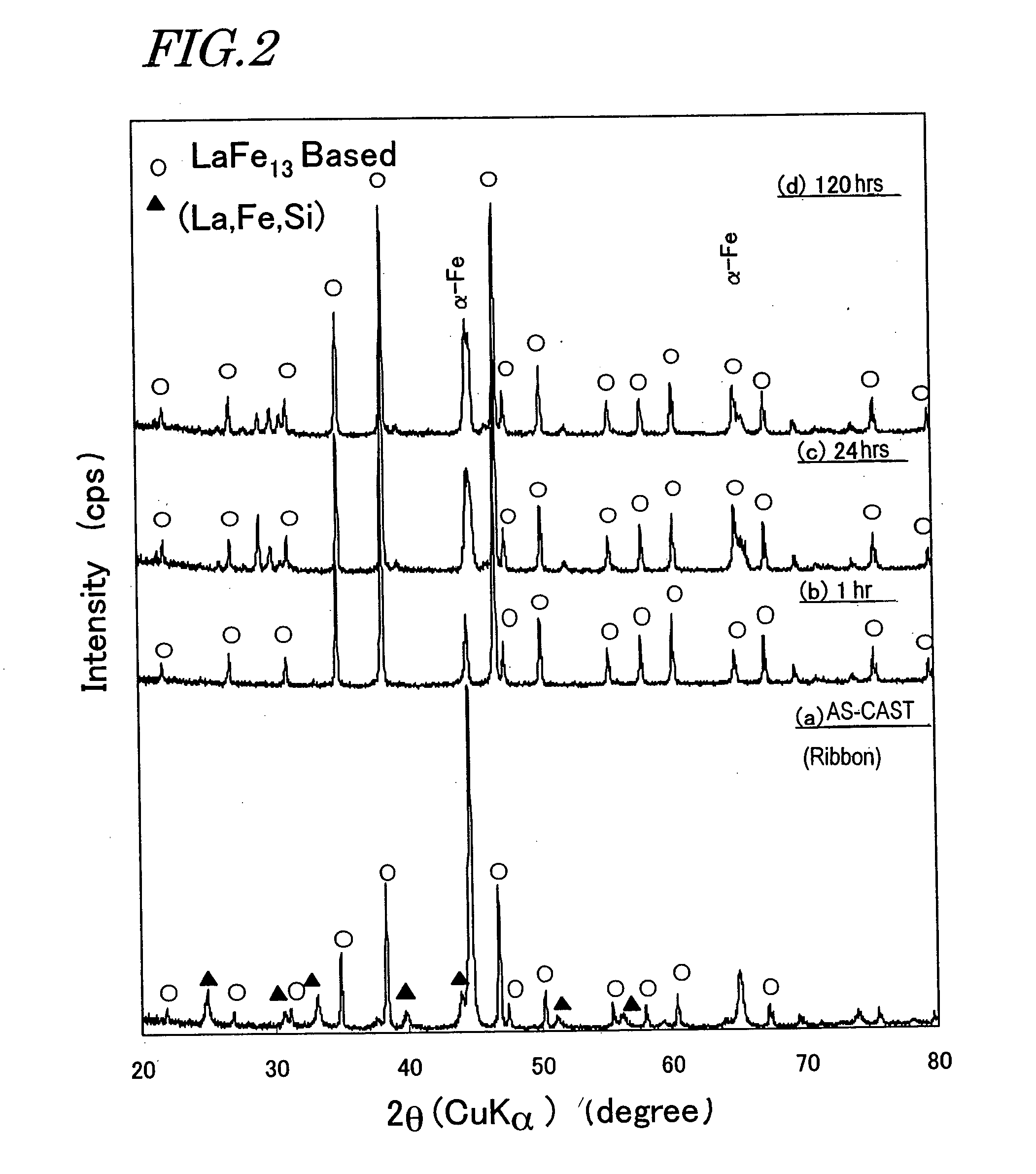

Magnetic alloy material and method of making the magnetic alloy material

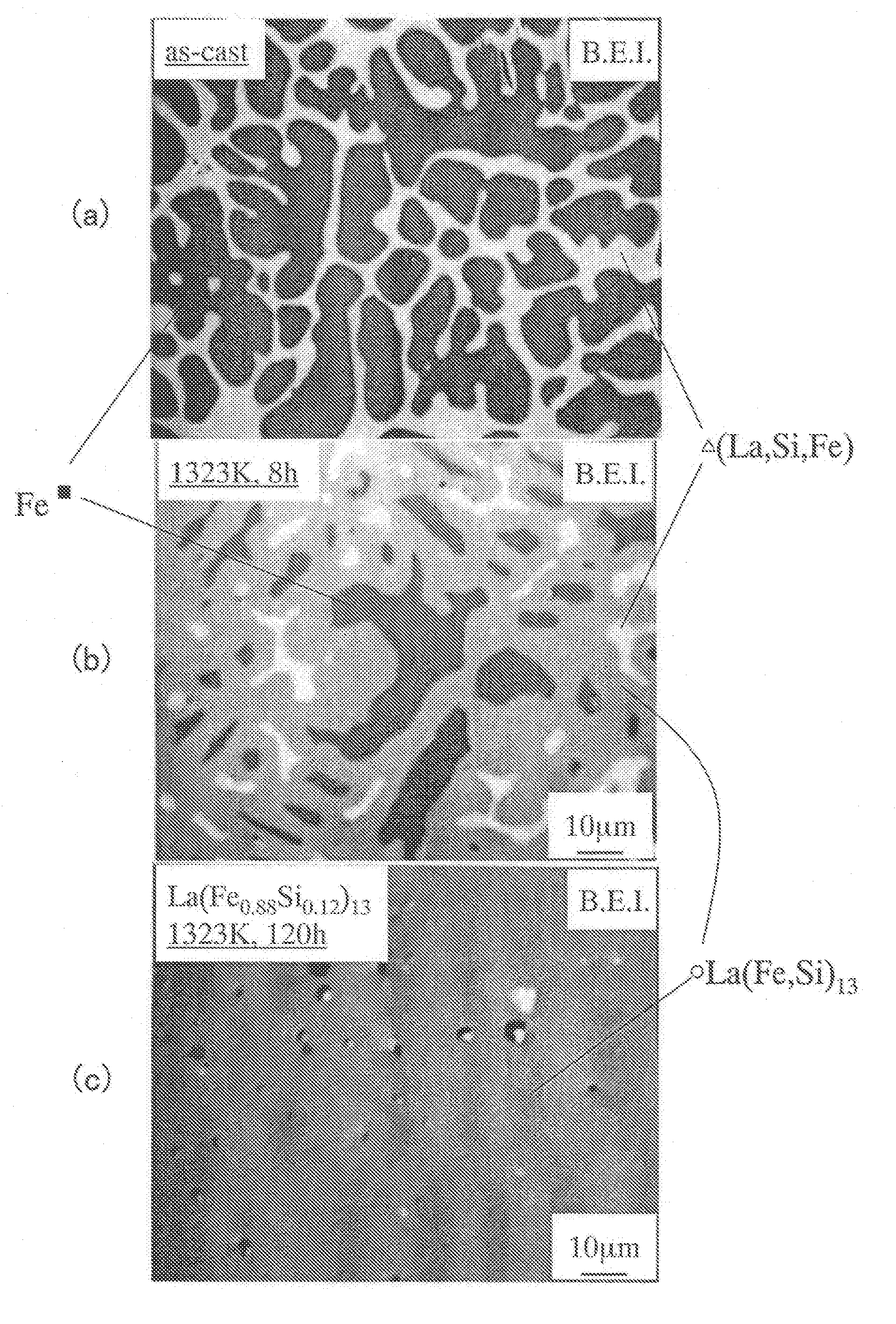

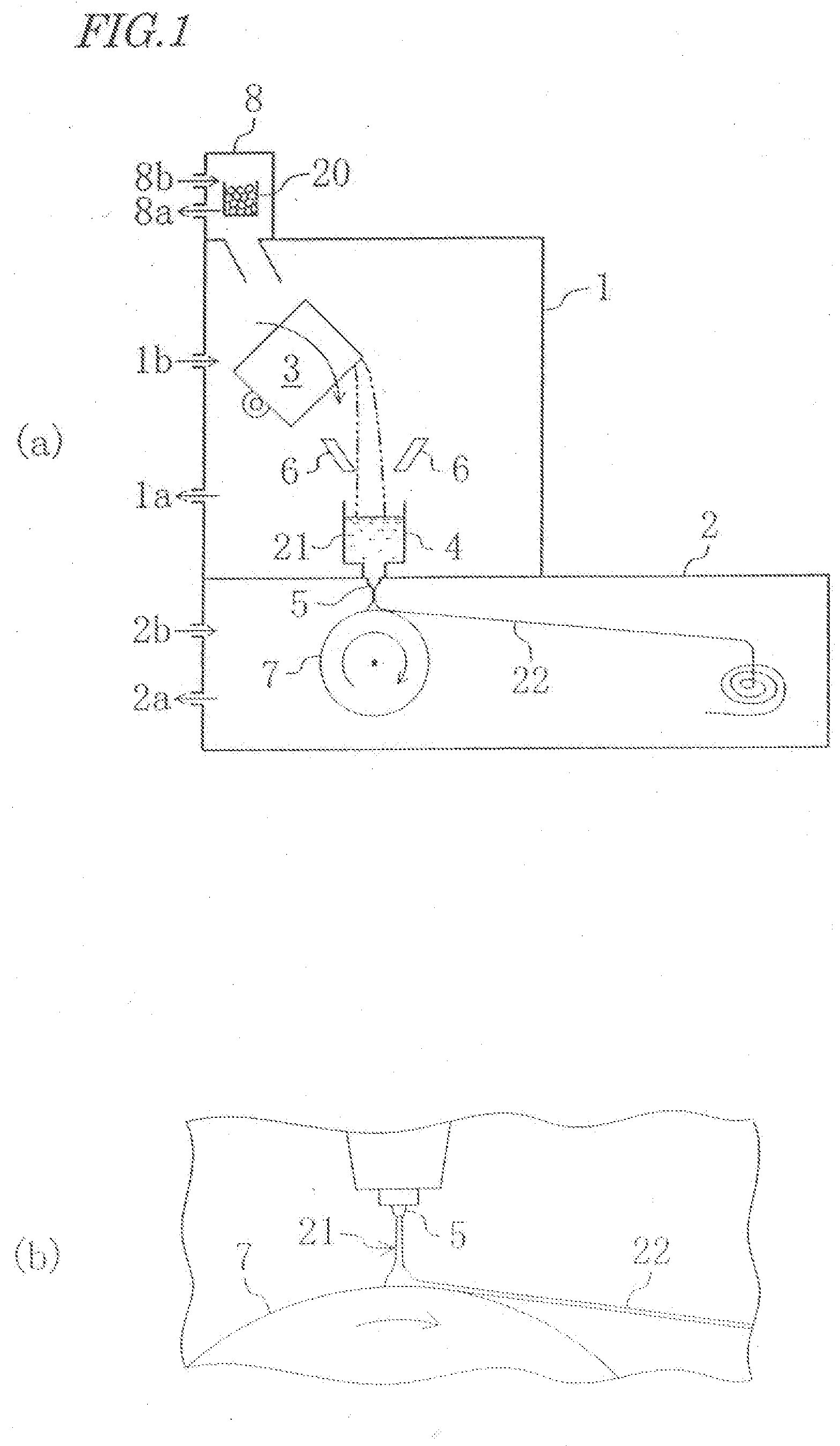

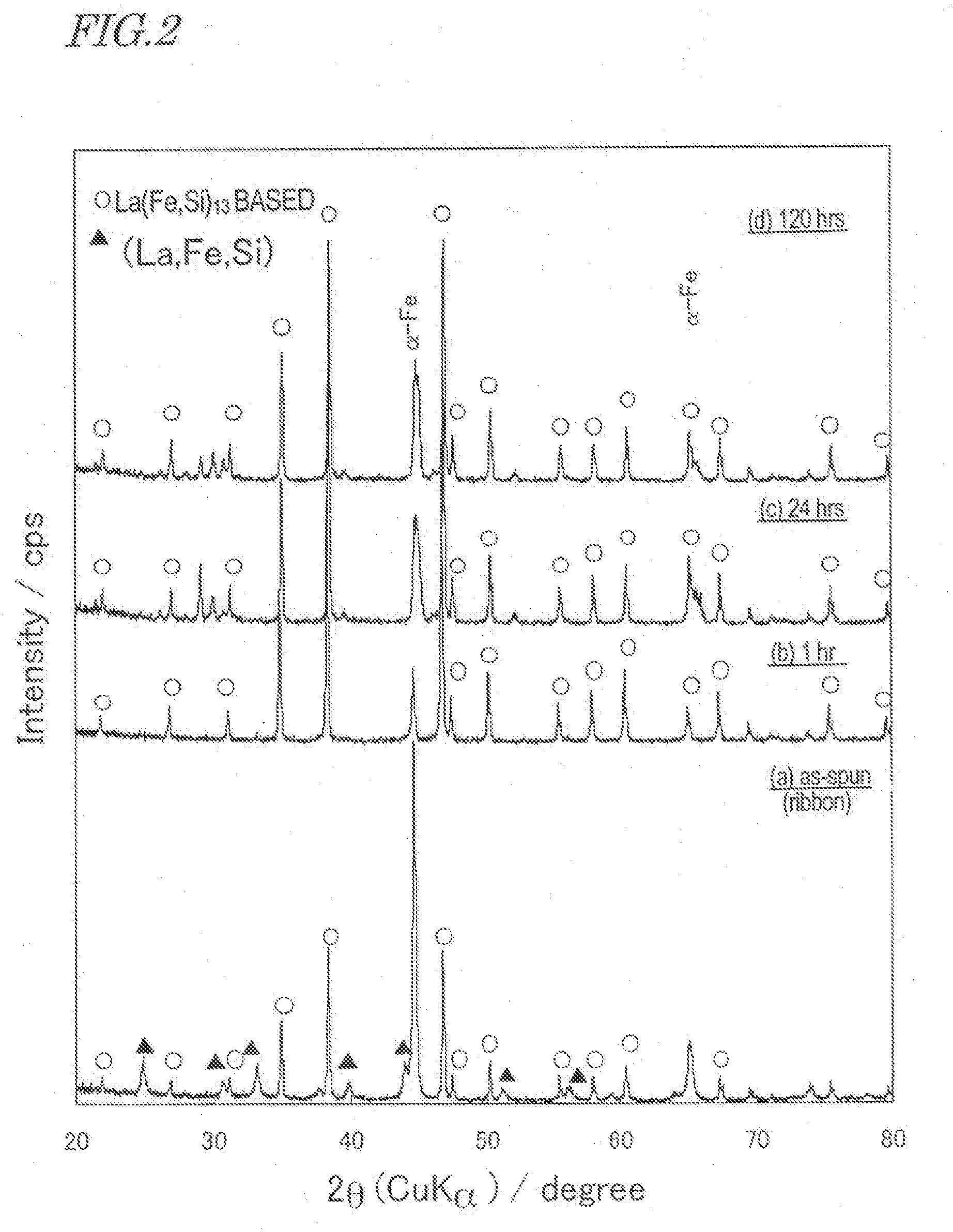

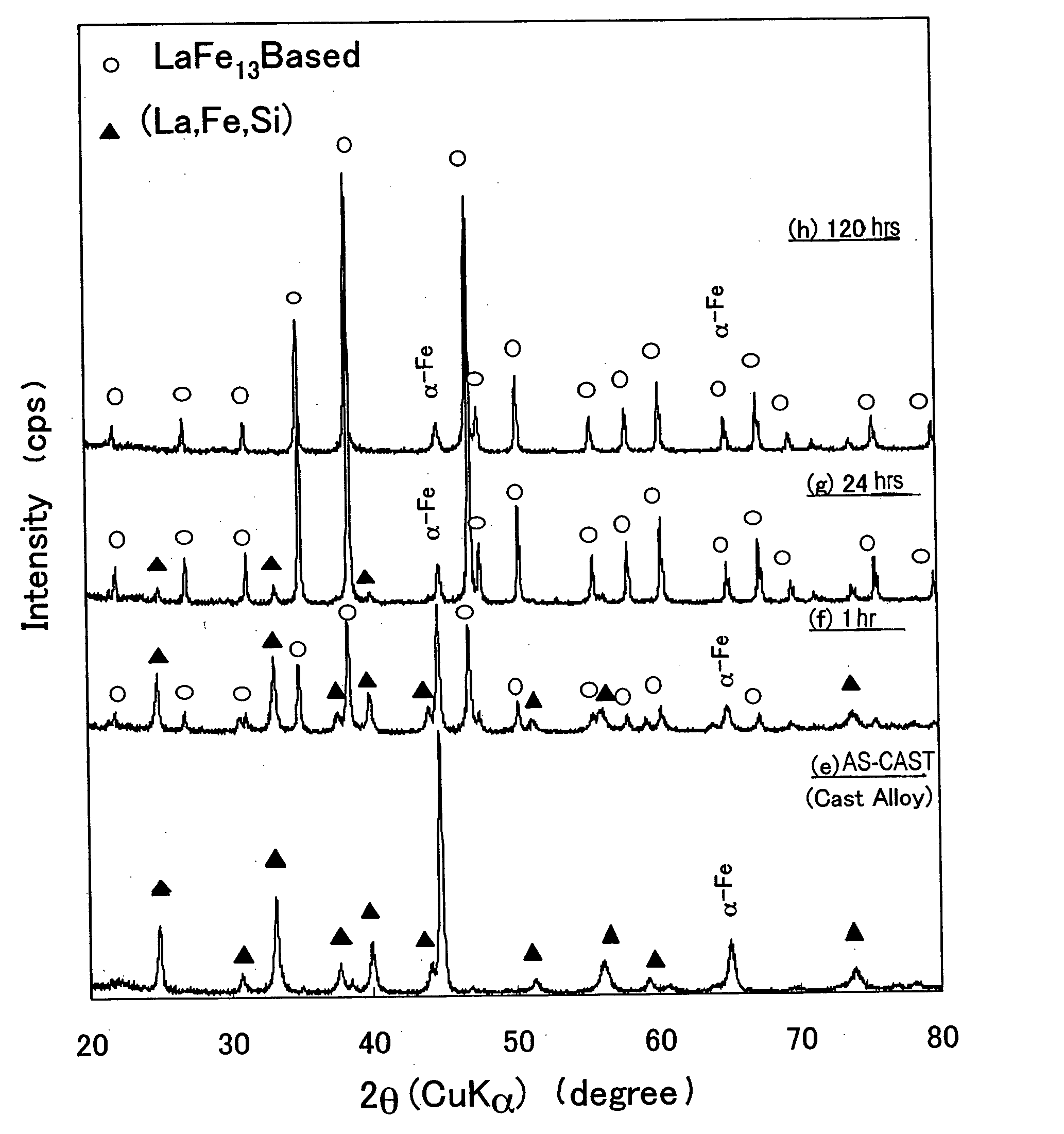

InactiveUS20060231163A1Short timeEasy to crushInorganic material magnetismRare-earth elementCrystal structure

A magnetic alloy material according to the present invention has a composition represented by Fe100-a-b-cREaAbCoc, where RE is a rare-earth element always including La, A is either Si or Al, 6 at %≦a≦11 at %, 8 at %≦b≦18 at %, and 0 at %≦c≦9 at %, and has either a two phase structure consisting essentially of an α-Fe phase and an (RE, Fe, A) phase including 30 at % to 90 at % of RE or a three phase structure consisting essentially of the α-Fe phase, the (RE, Fe, A) phase including 30 at % to 90 at % of RE and an RE(Fe, A)13 compound phase with an NaZn13-type crystal structure. The respective phases have an average minor-axis size of 40 nm to 2 μm.

Owner:HITACHI METALS LTD

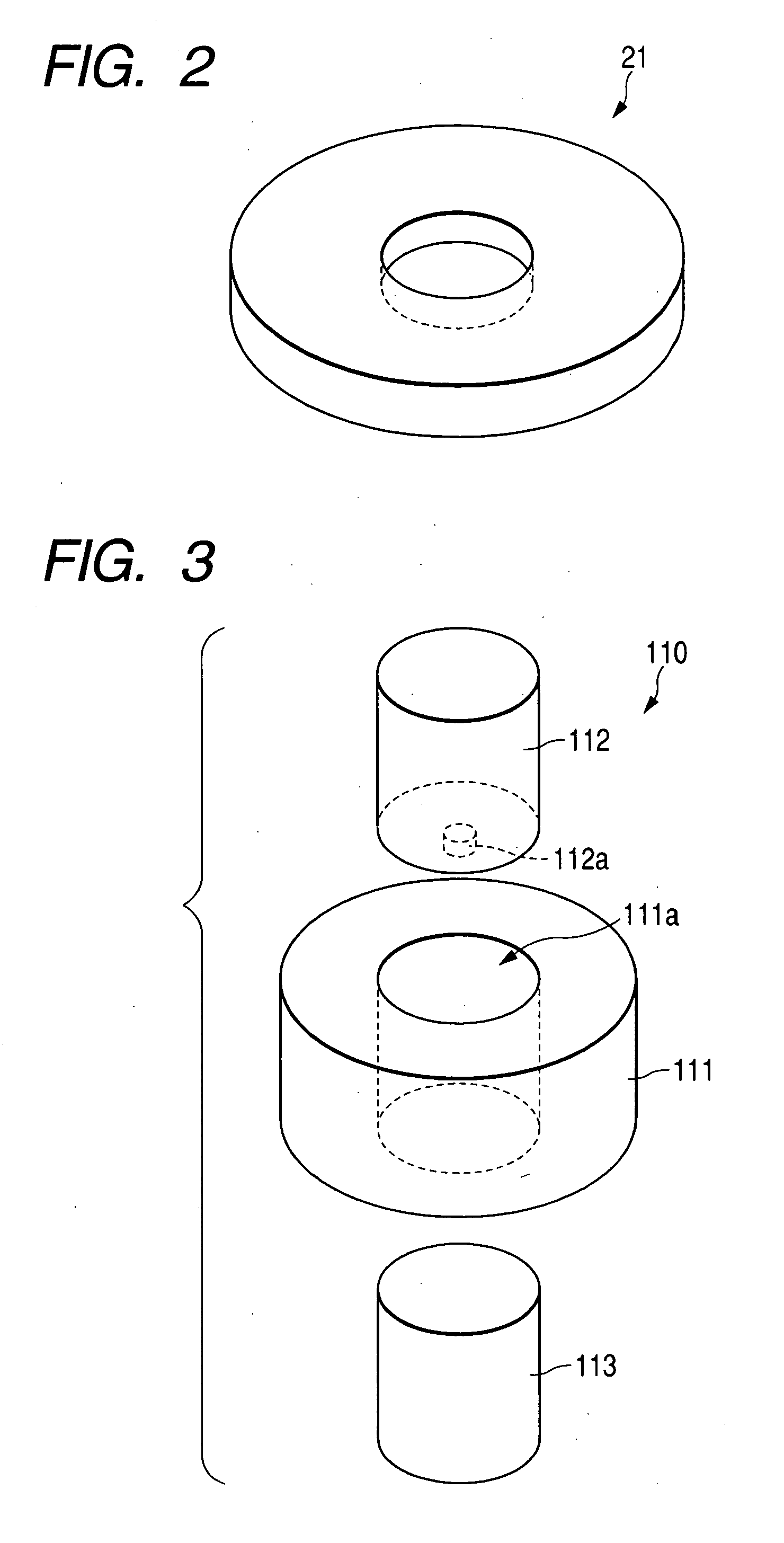

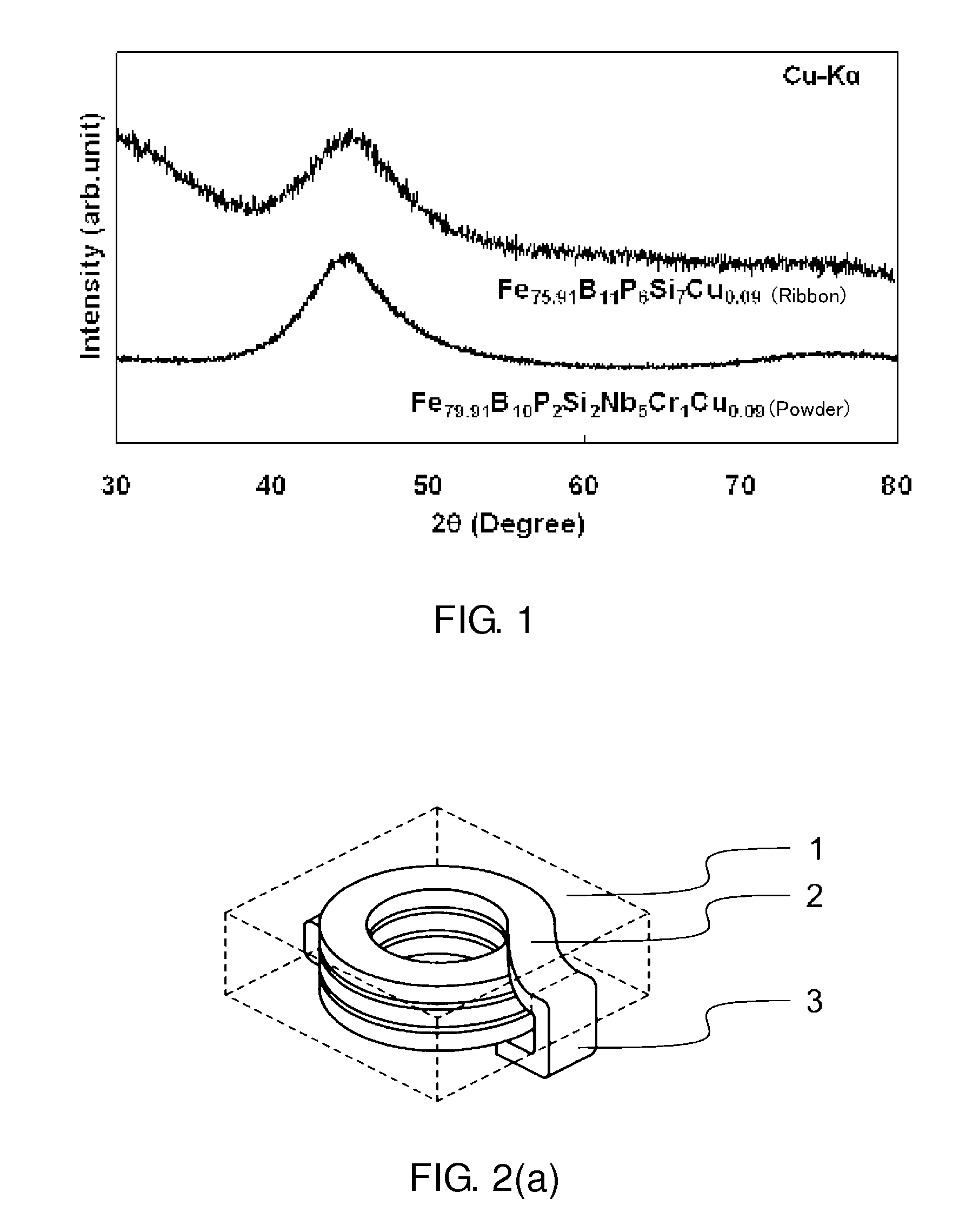

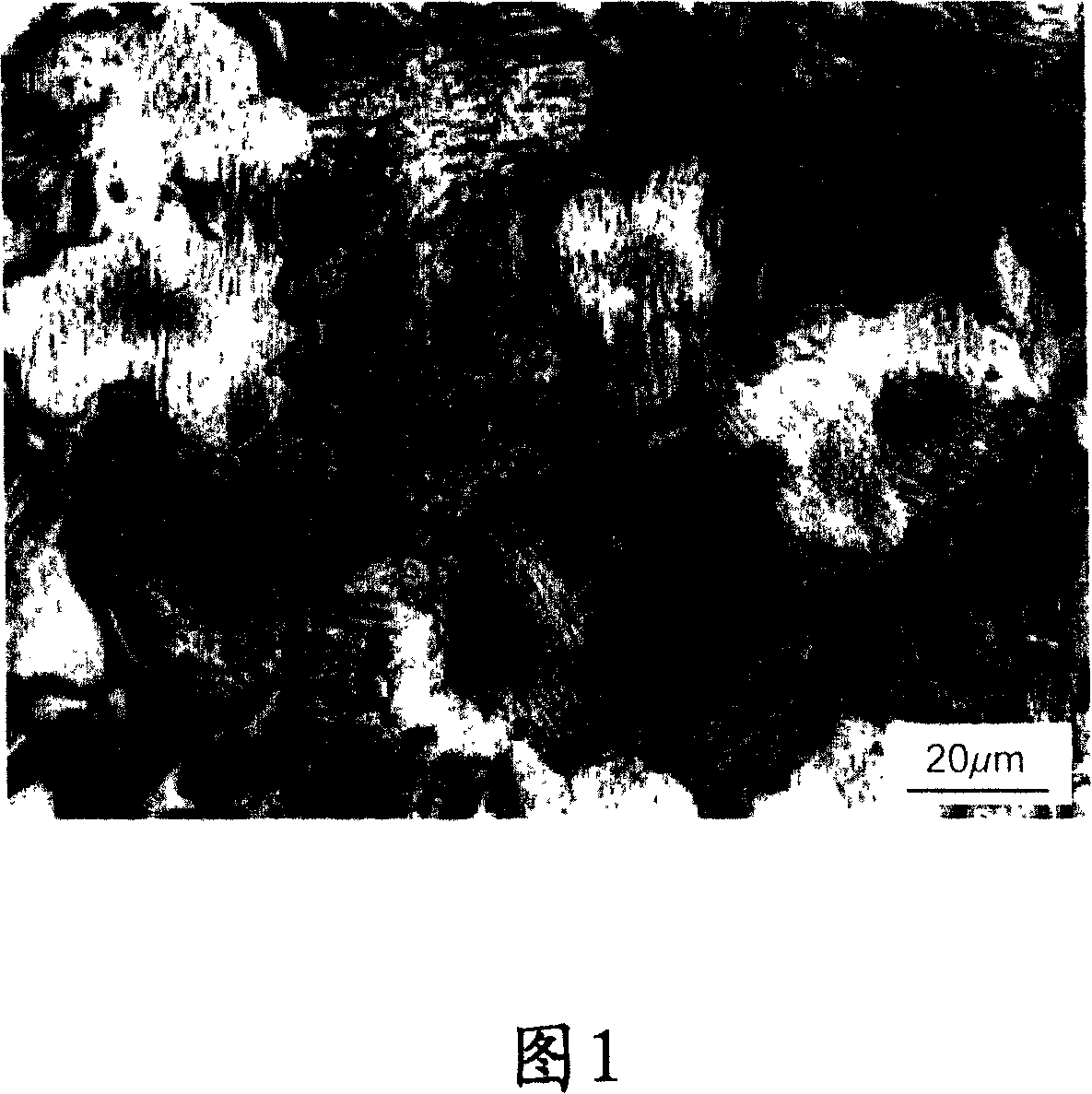

Amorphous soft magnetic alloy powder, and dust core and wave absorber using the same

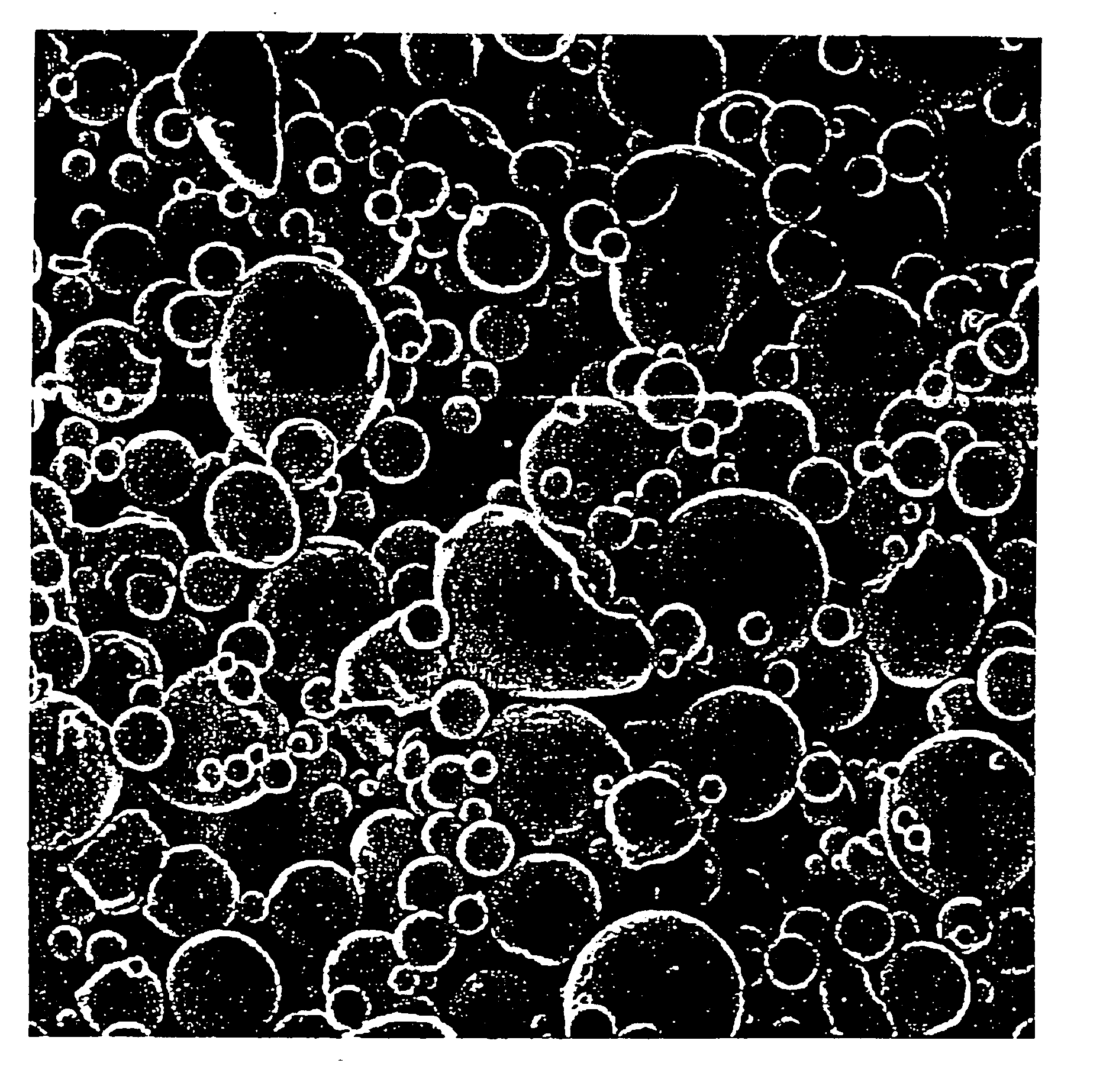

ActiveUS20050236071A1Inorganic material magnetismInductances/transformers/magnets manufactureHigh concentrationAmorphous phase

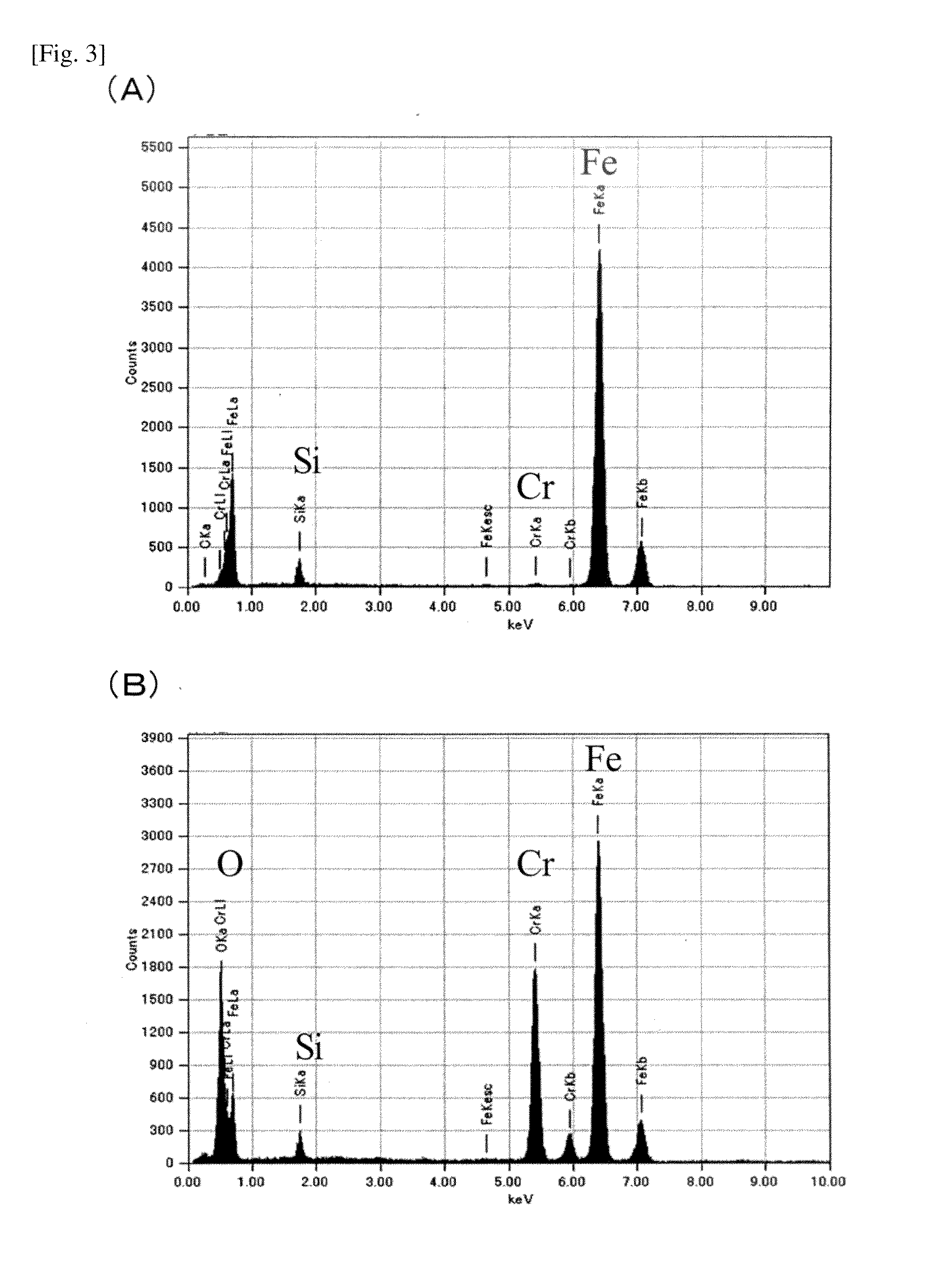

An amorphous soft magnetic alloy powder which is produced by a water atomization method is provided. The powder contains an amorphous phase having a temperature interval ΔTx of a supercooled liquid of 20K or more; having a hardness Hv of 1000 or less; is provided with a layer with a high concentration of Si at a surface portion thereof; and being represented by the following composition formula: Fe100-a-b-x-y-z-w-tCOaNibMxPyCzBwSit And M is one or two or more elements selected from Cr, Mo, W, V, Nb, Ta, Ti, Zr, Hf, Pt, Pd, and Au.

Owner:ALPS ALPINE CO LTD

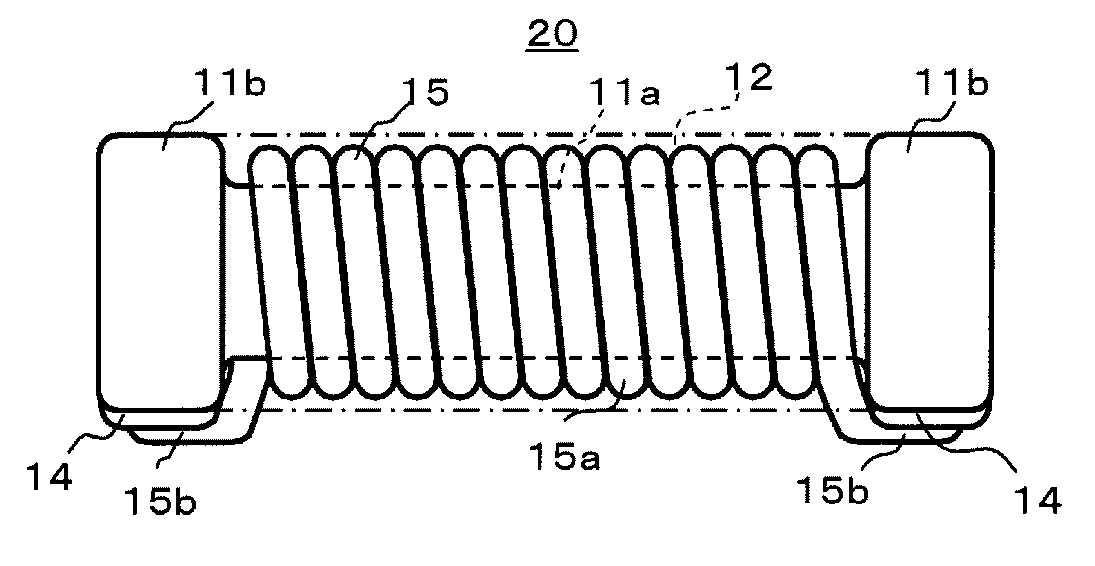

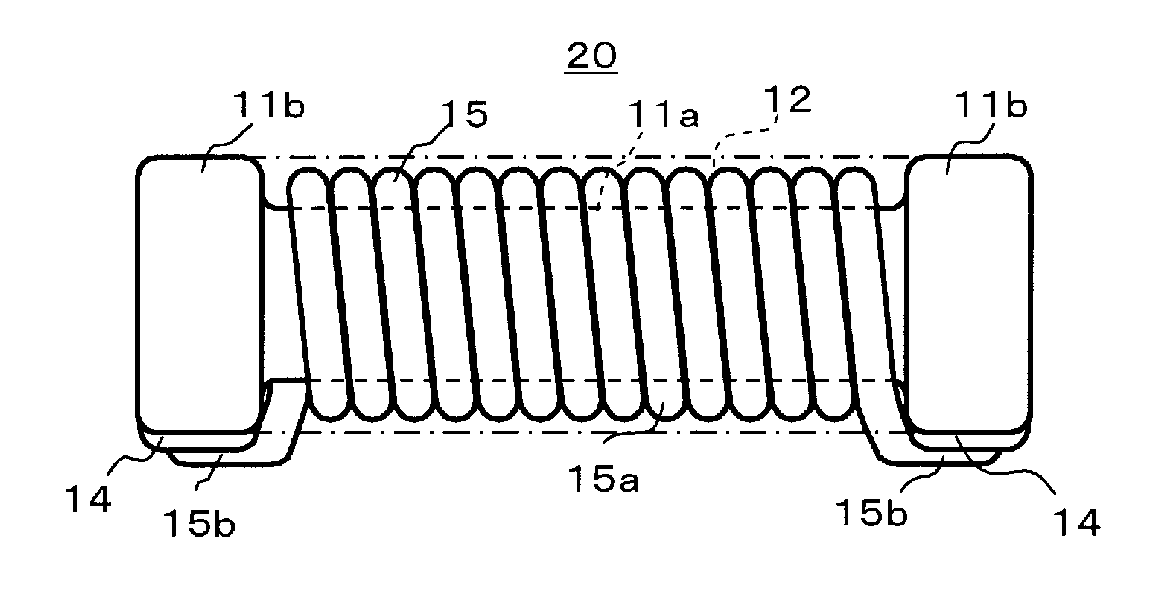

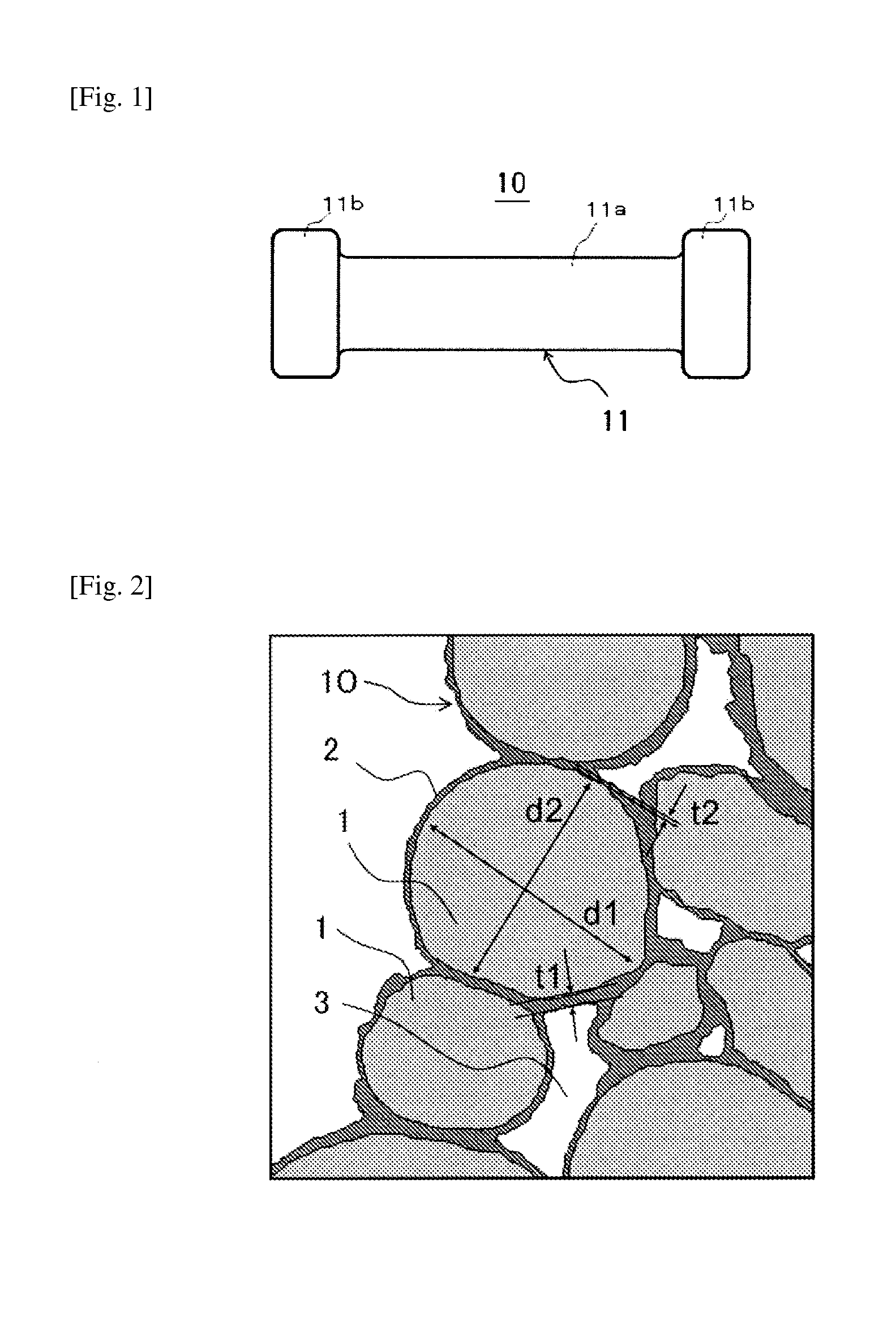

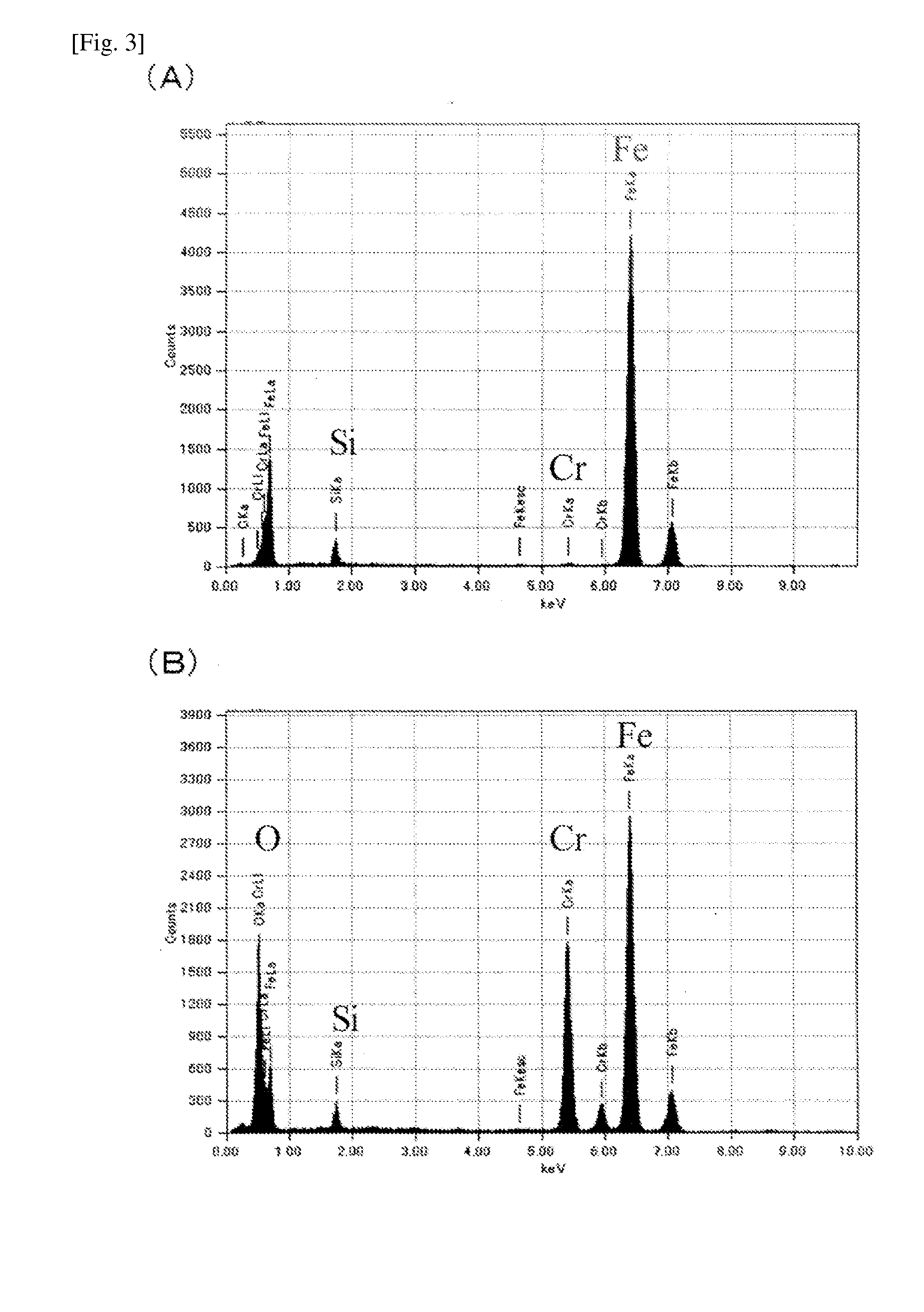

Coil-type electronic component and its manufacturing method

ActiveUS20110267167A1Low costHigh magnetic flux densityTransformers/inductances coils/windings/connectionsInorganic material magnetismElectronic componentElectron

A coil-type electronic component has a coil inside or on the surface of its base material and is characterized in that: the base material is constituted by a group of grains of a soft magnetic alloy containing iron, silicon and other element that oxidizes more easily than iron; the surface of each soft magnetic alloy grain has an oxide layer formed on its surface as a result of oxidization of the grain; this oxide layer contains the other element that oxidizes more easily than iron by a quantity larger than that in the soft magnetic alloy grain; and grains are bonded with one another via this oxide layer.

Owner:TAIYO YUDEN KK

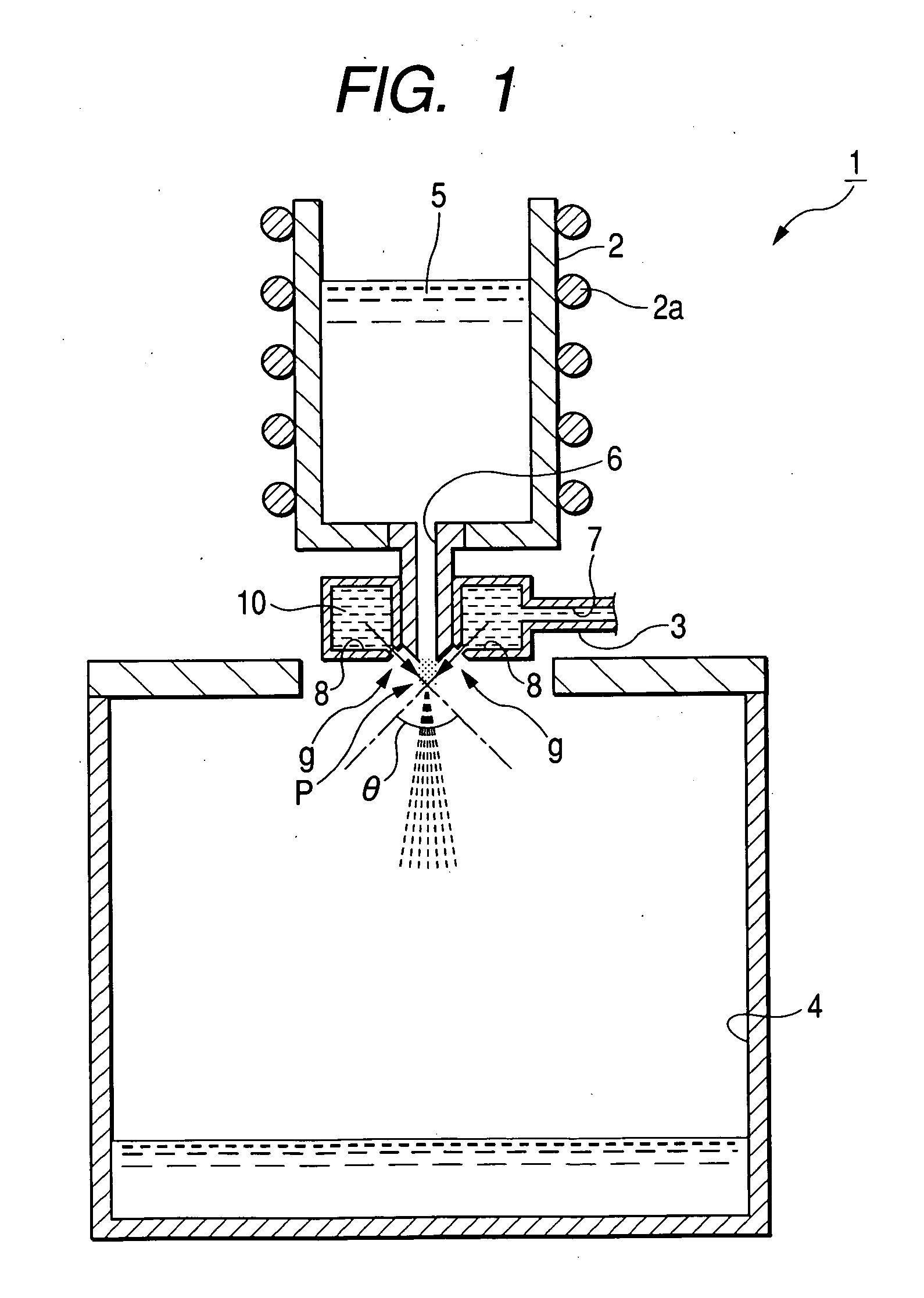

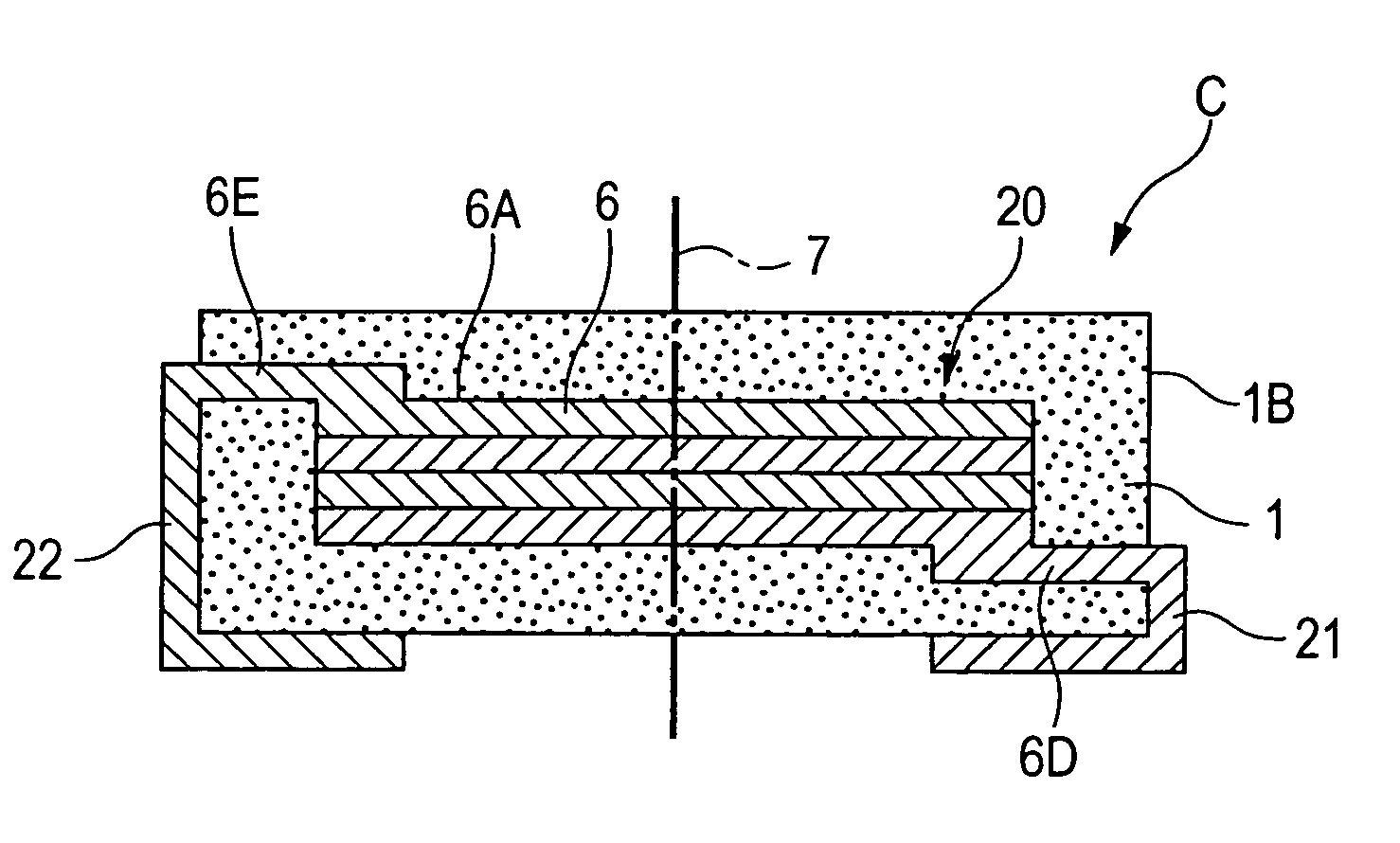

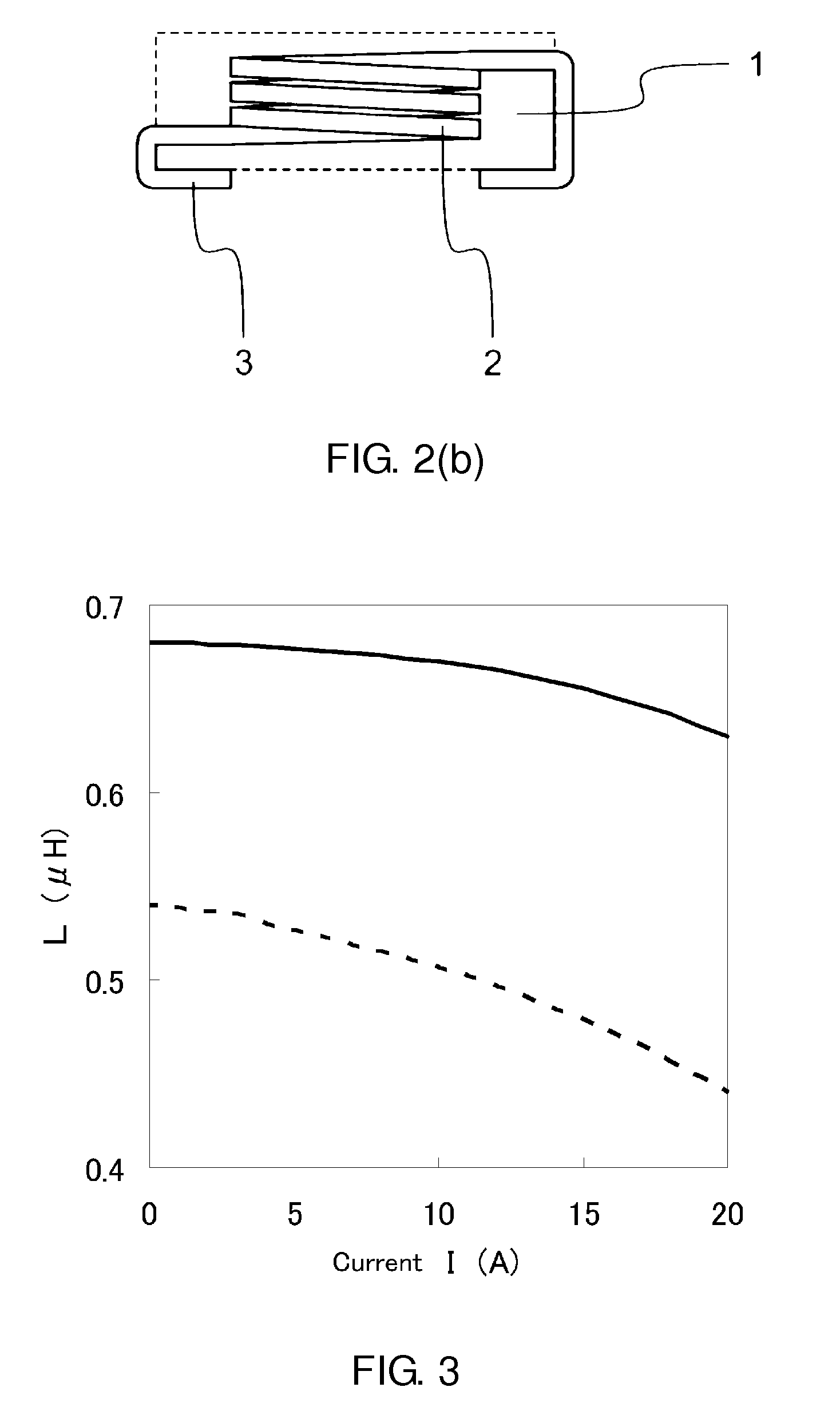

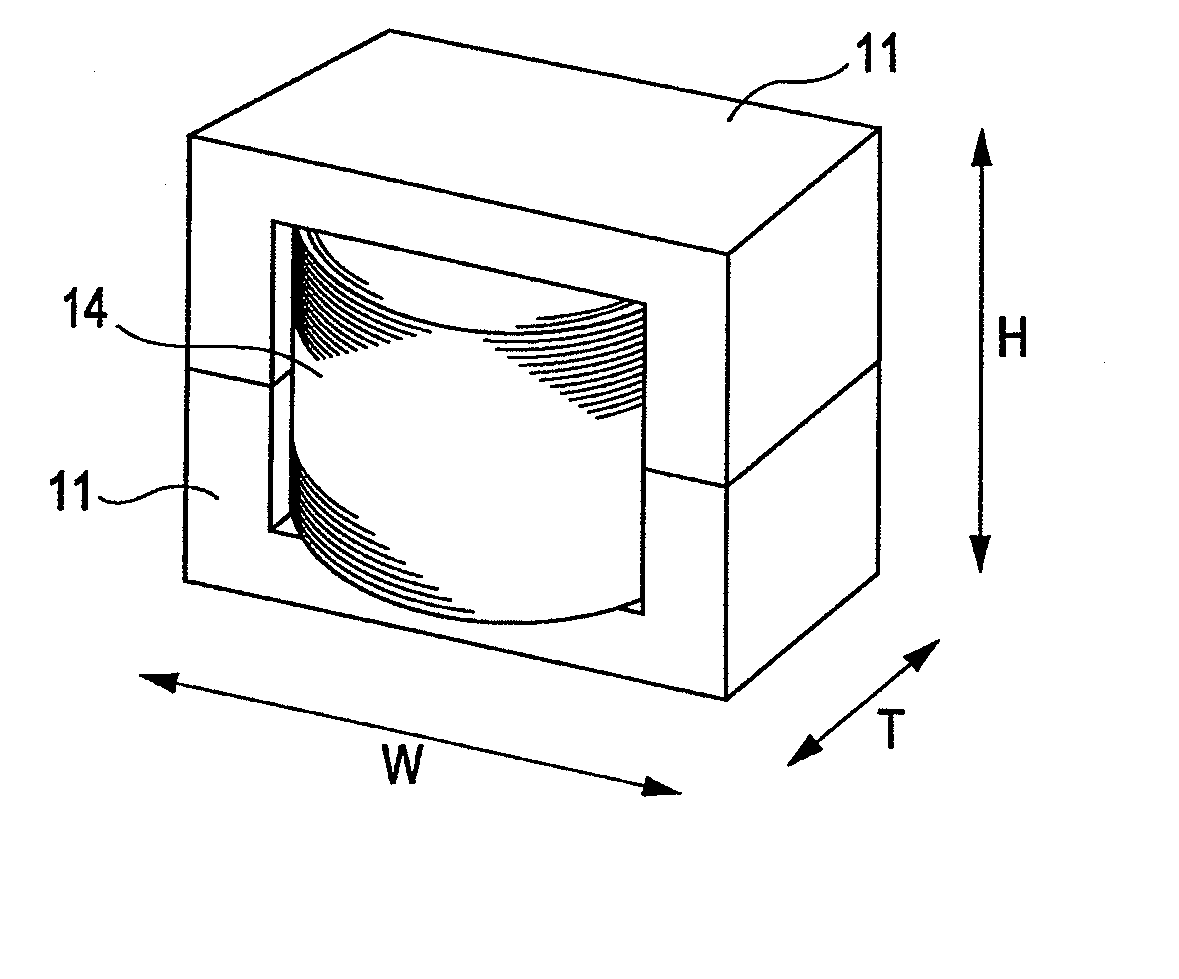

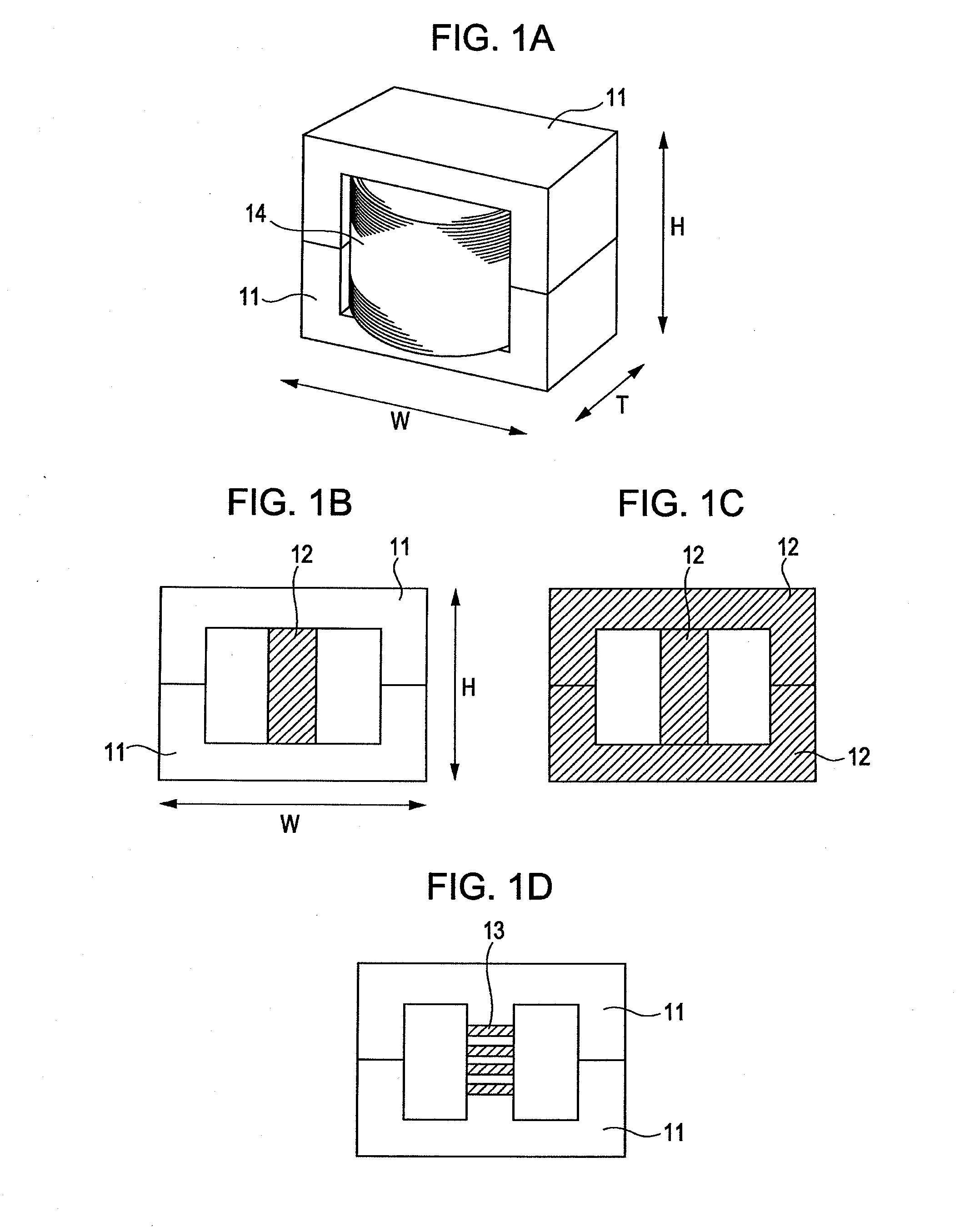

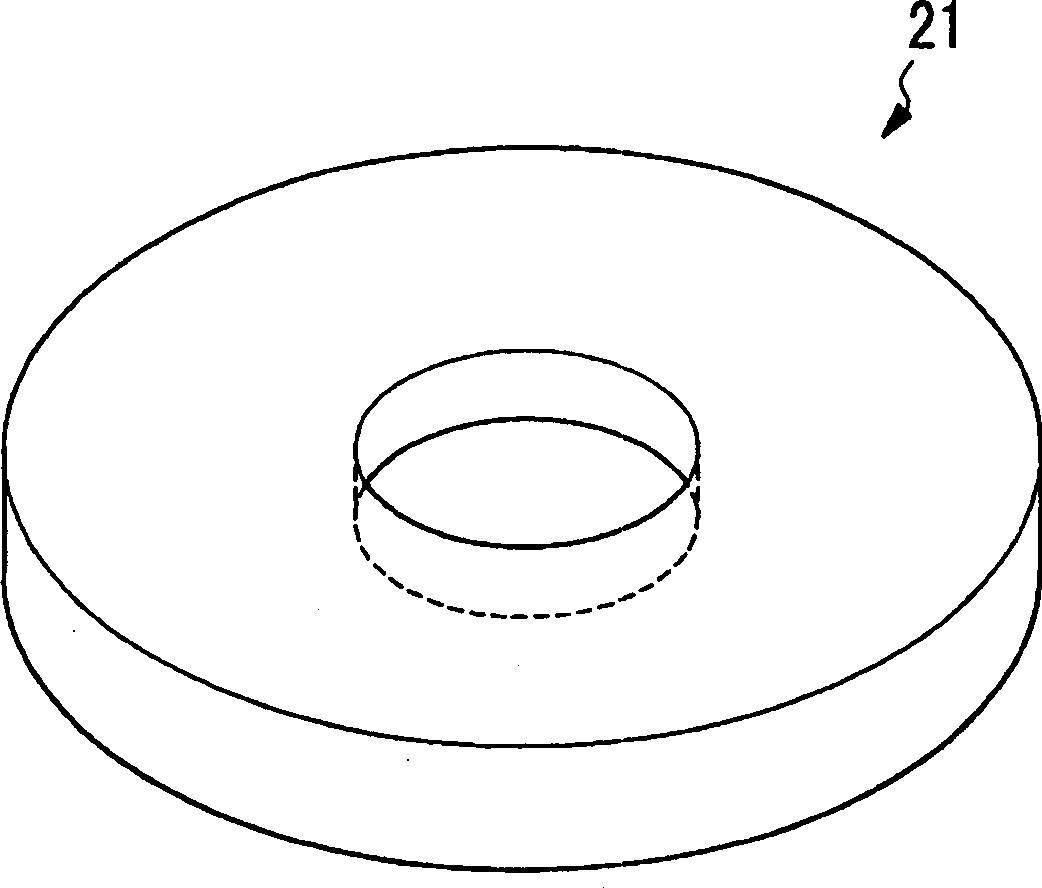

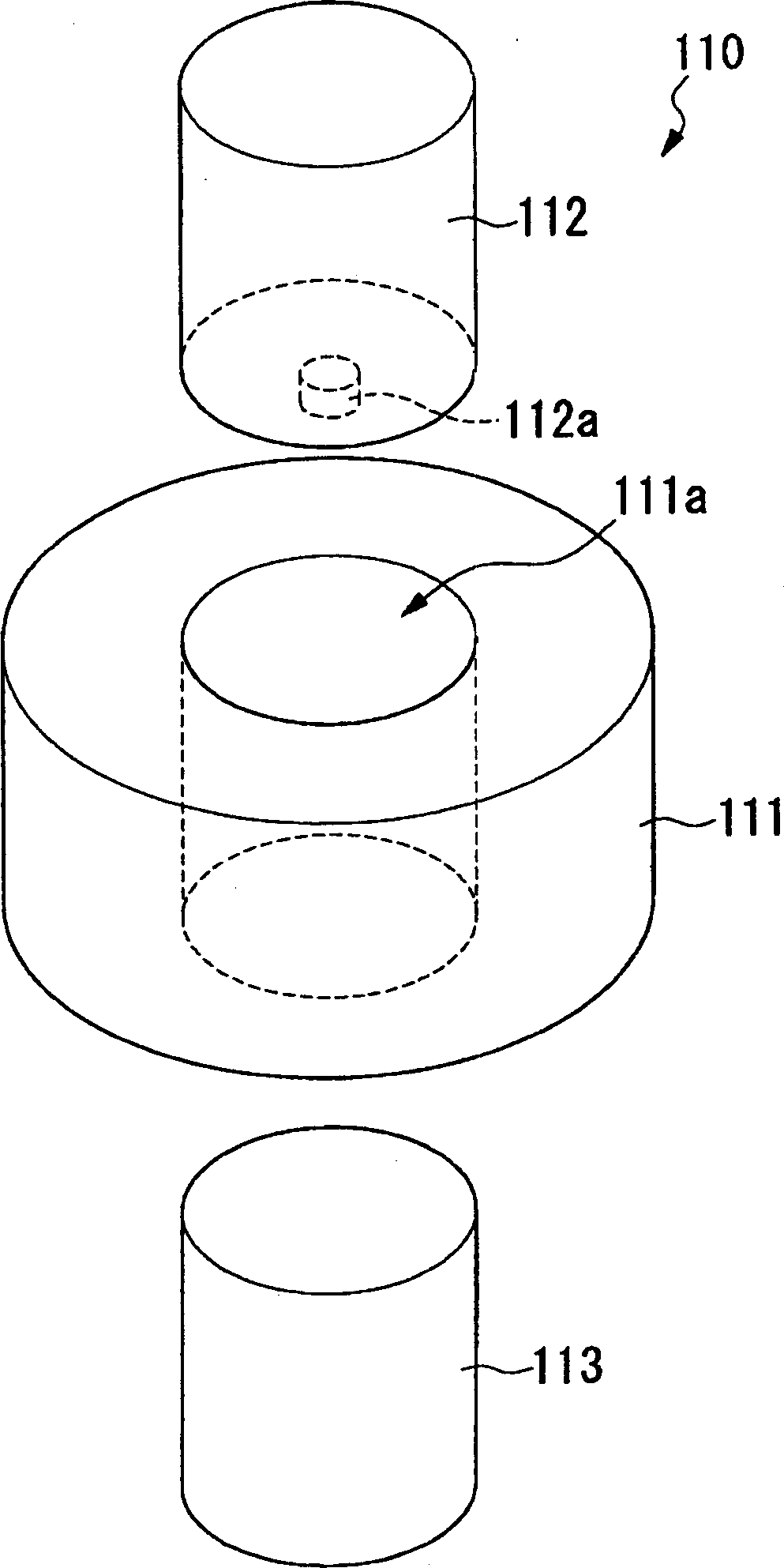

Coil-embedded dust core

InactiveUS20060038651A1No unevenness in compactionUniform compactionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

A coil-embedded dust core of the present invention is provided with a molded coil component including a coil main body having a structure in which a flat type conductor wire is wound edgewise, one end side terminal portion disposed by being lead in the thickness direction of the coil main body, the other end side terminal portion, one end side leading electrode portion disposed by extending the one end side terminal portion, and the other end side leading electrode portion disposed by extending the other end side terminal portion; and a dust core composed of a soft magnetic alloy powder disposed covering the coil main body, the one end side terminal portion, and the other end side terminal portion of the molded coil component.

Owner:ALPS ALPINE CO LTD

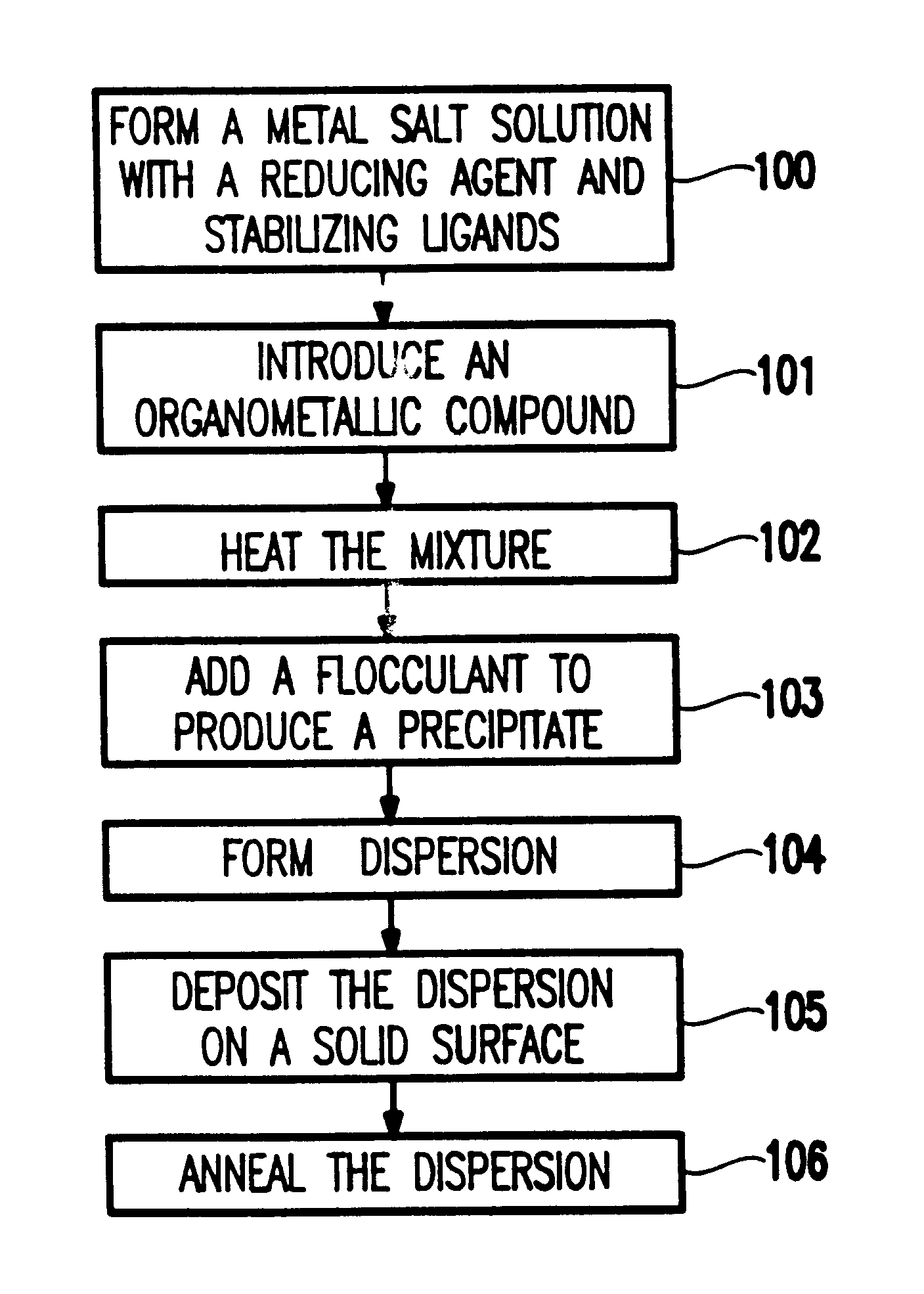

Amorphous soft magnetic alloy and inductance component using the same

InactiveUS20070175545A1Excellent in amorphous-forming abilityExcellent soft magnetic propertiesTransformers/inductances detailsInductances/transformers/magnets manufactureMetallurgyInductor

To provide an amorphous soft magnetic alloy having a supercooled liquid region and excellent in amorphous-forming ability and soft magnetic properties, by selecting and optimizing an alloy composition, and to further provide a ribbon, a powder, a high-frequency magnetic core, and a bulk member each using such an amorphous soft magnetic alloy. The amorphous soft magnetic alloy has a composition expressed by a formula of (Fe1-αTMα)100-w-x-y-zPwBxLySiz, wherein unavoidable impurities are contained, TM is at least one selected from Co and Ni, L is at least one selected from the group consisting of Al, V, Cr, Y, Zr, Mo, Nb, Ta, and W, 0≦α0.98, 2≦w≦16 at %, 2≦x≦16 at %, 0<y≦10 at %, and 0≦z≦8 at %).

Owner:TOKIN CORP +1

Soft magnetic alloy, magnetic component using the same, and thier production methods

ActiveUS20100097171A1Excellent soft magnetic propertiesGood formabilityTransportation and packagingMetal-working apparatusFe basedMagnetic alloy

A soft magnetic alloy contains P, B, and Cu as essential components. As a preferred example, an Fe-based alloy contains Fe of 70 atomic % or more, B of 5 atomic % to 25 atomic %, Cu of 1.5 atomic % or less (excluding zero), and P of 10 atomic or less (excluding zero).

Owner:TOKIN CORP +2

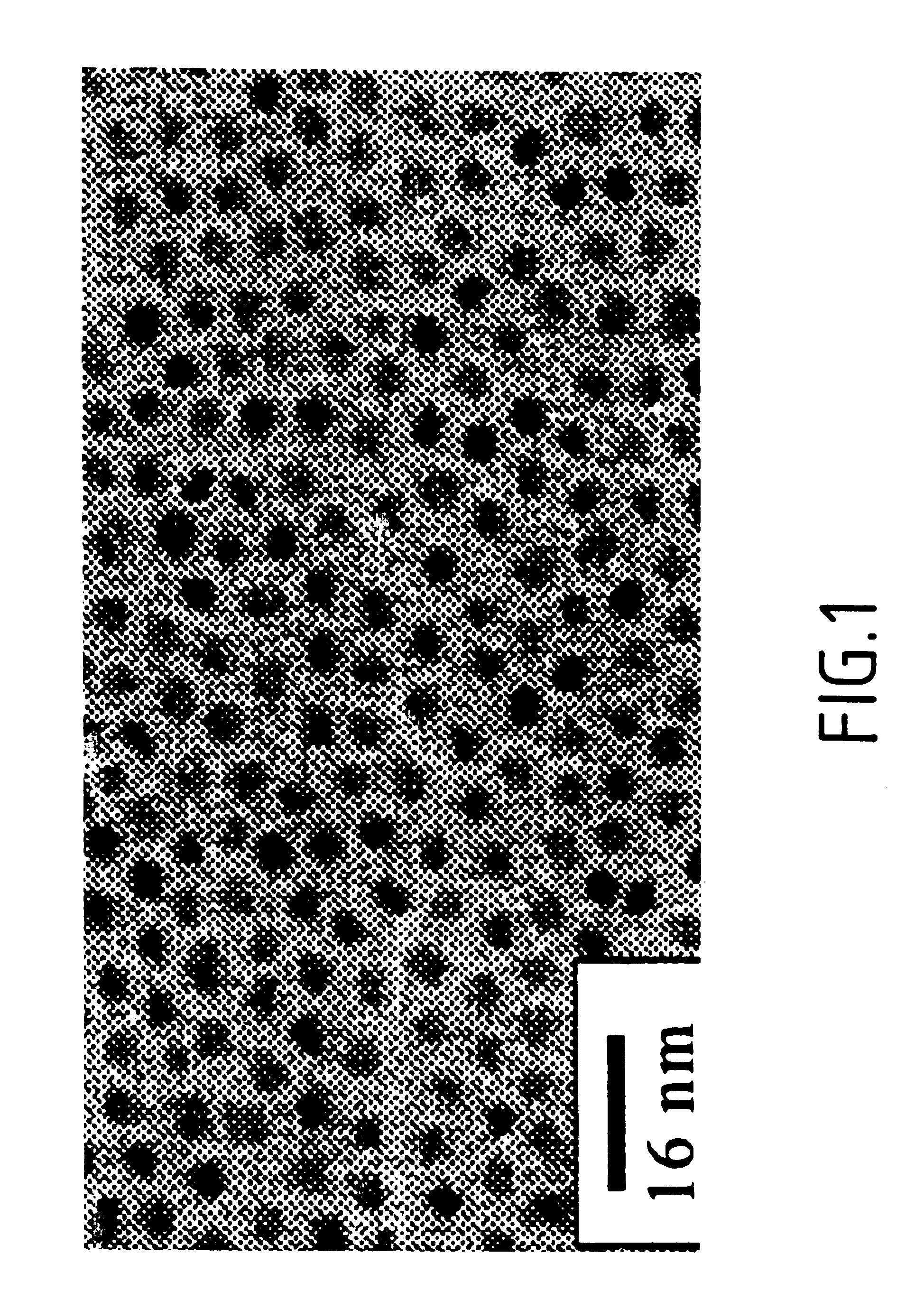

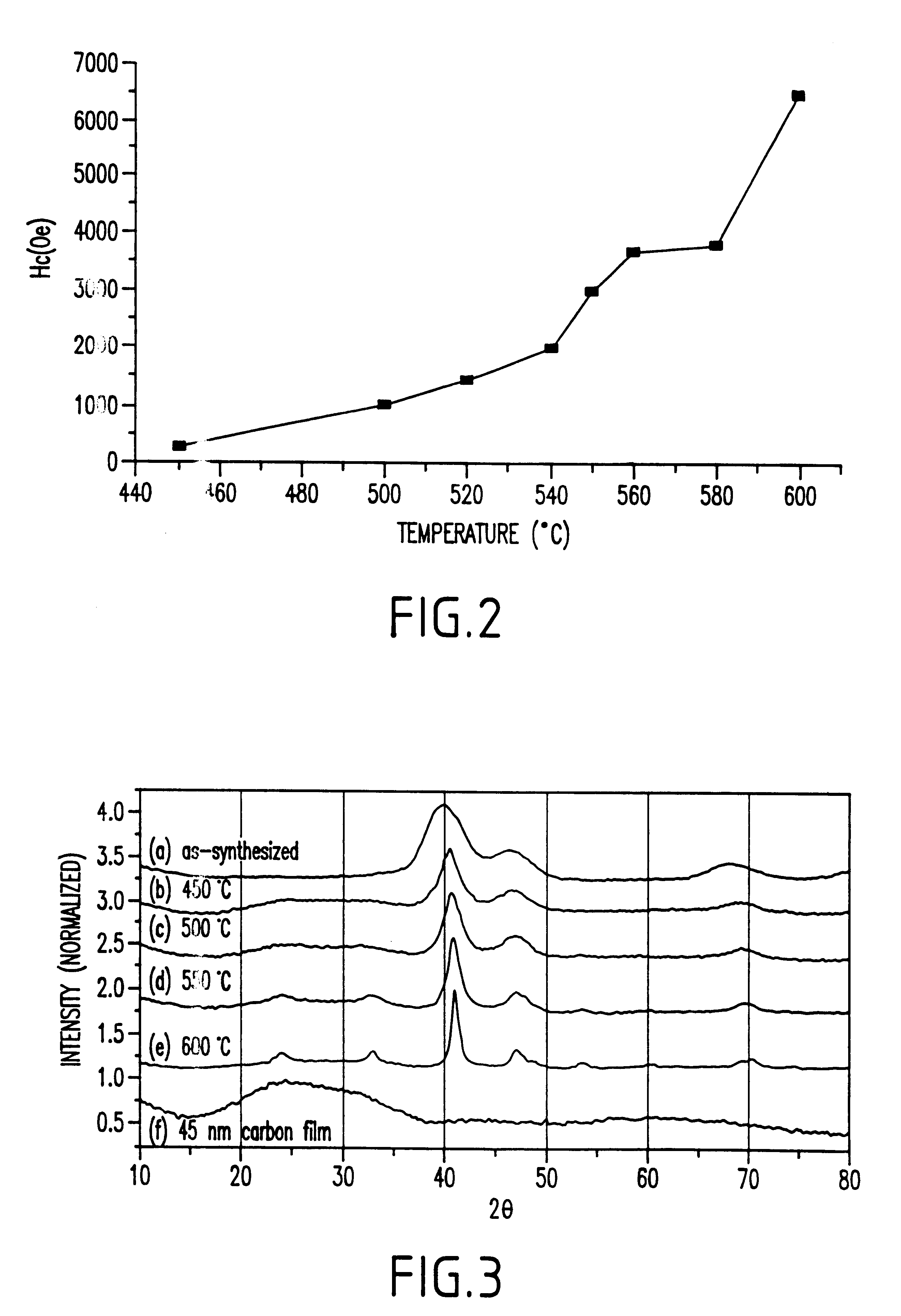

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

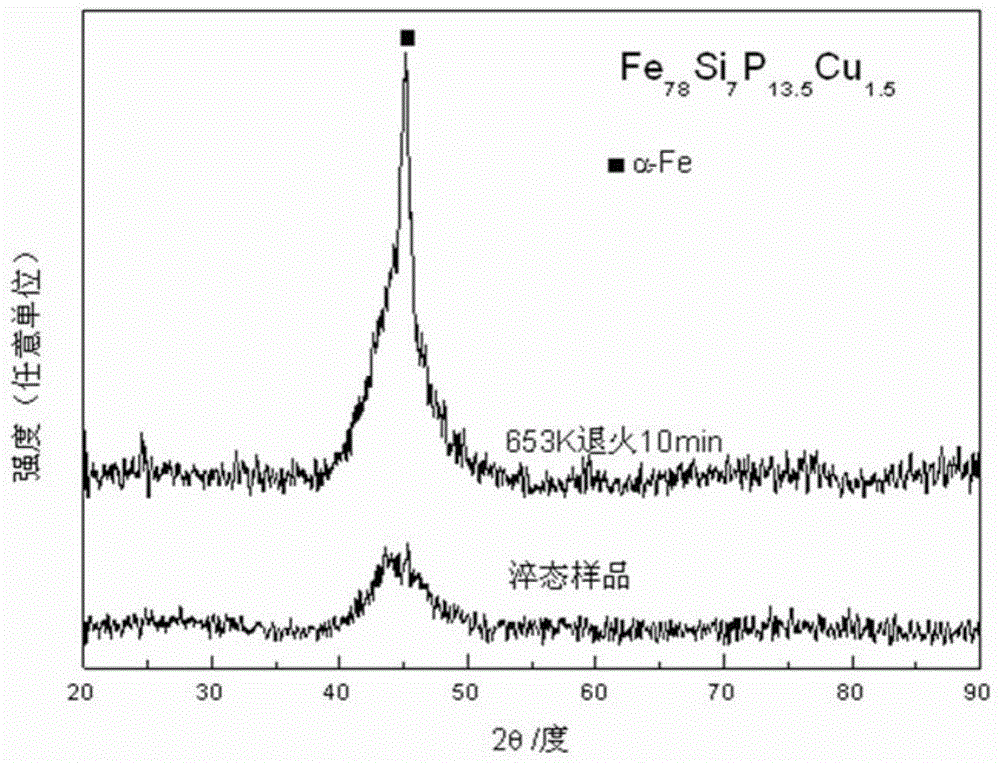

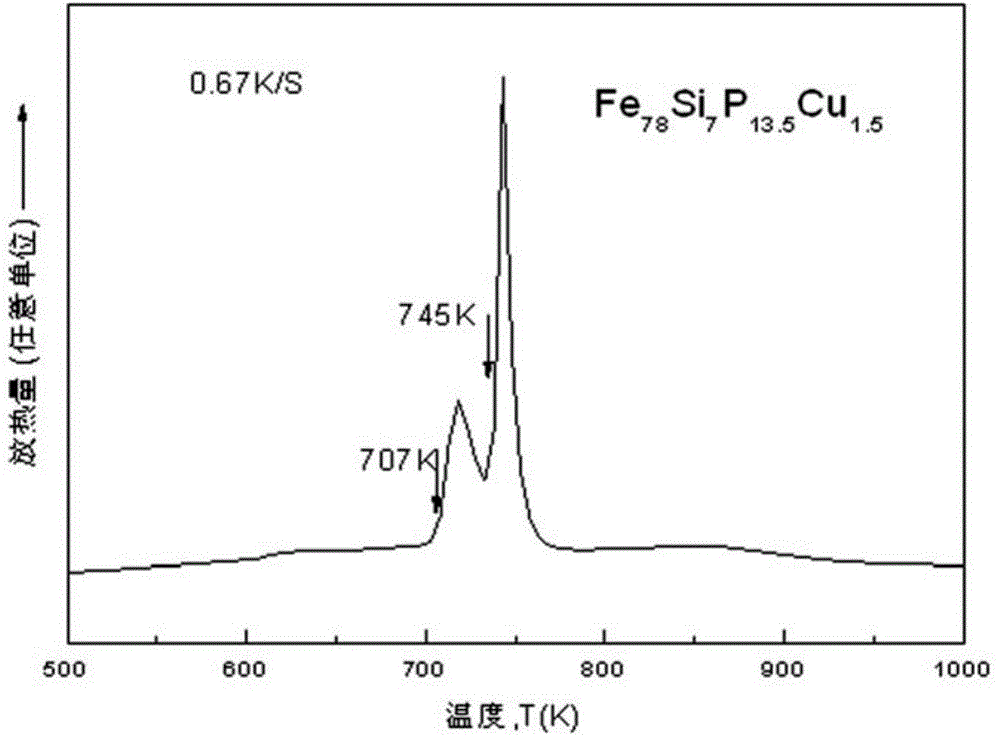

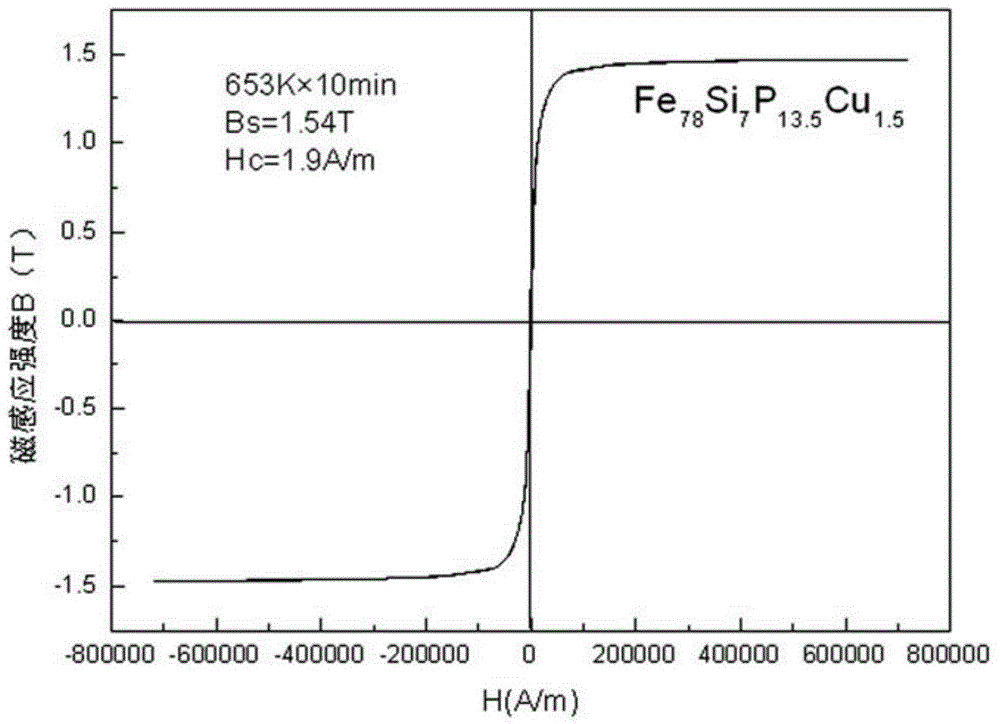

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Amorphous nano crystal soft magnet alloy strip with surface insulation coating and its preparation method

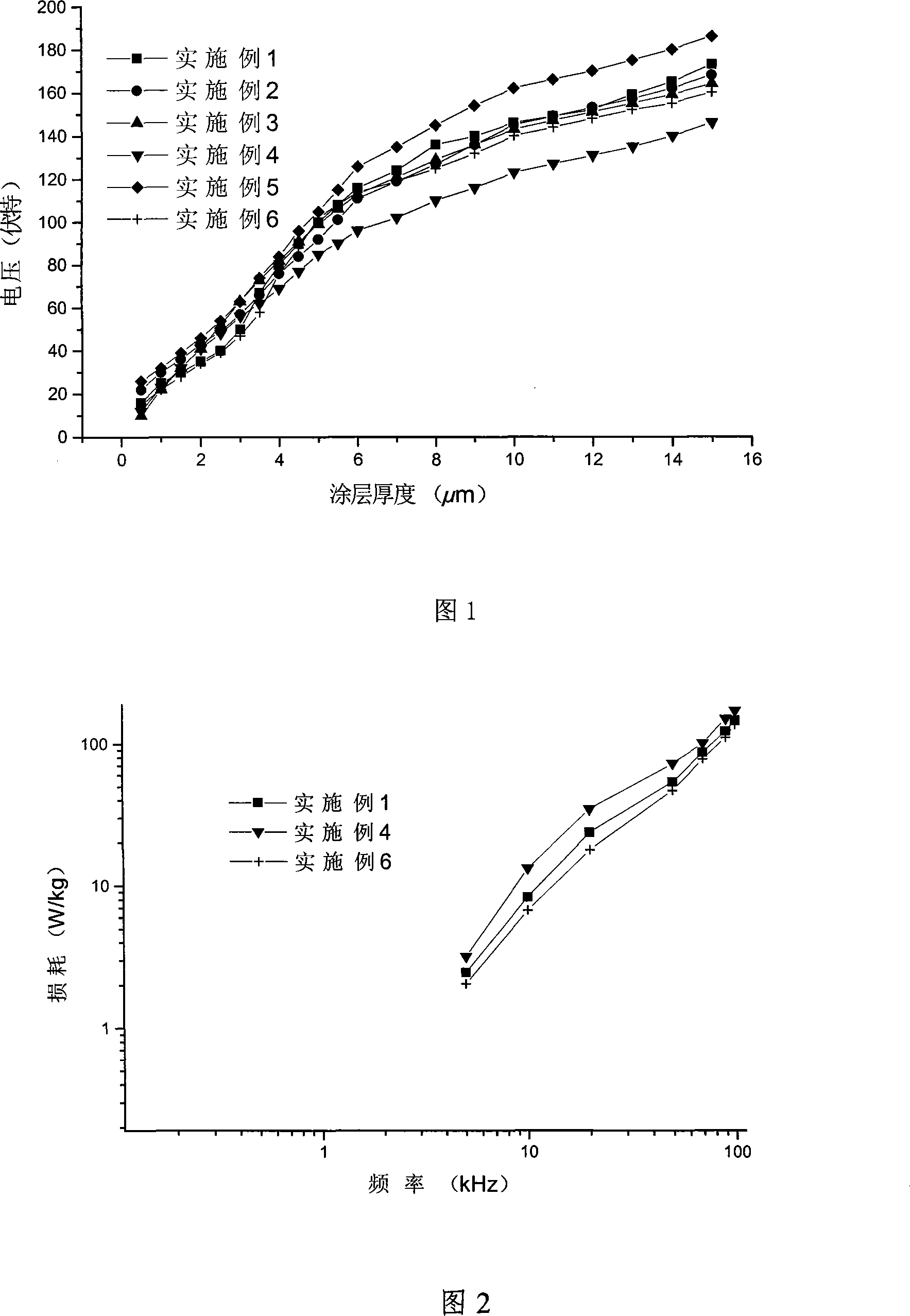

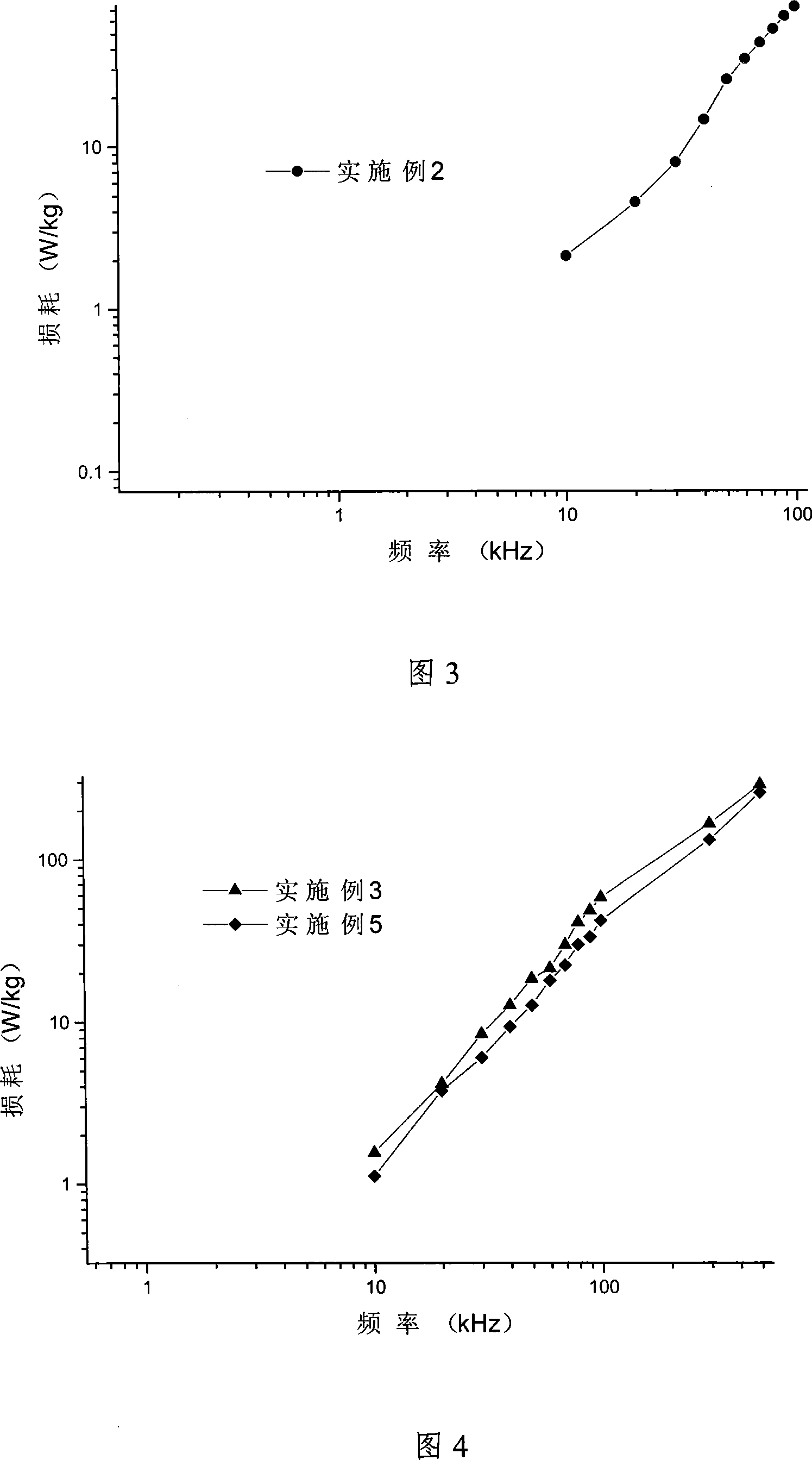

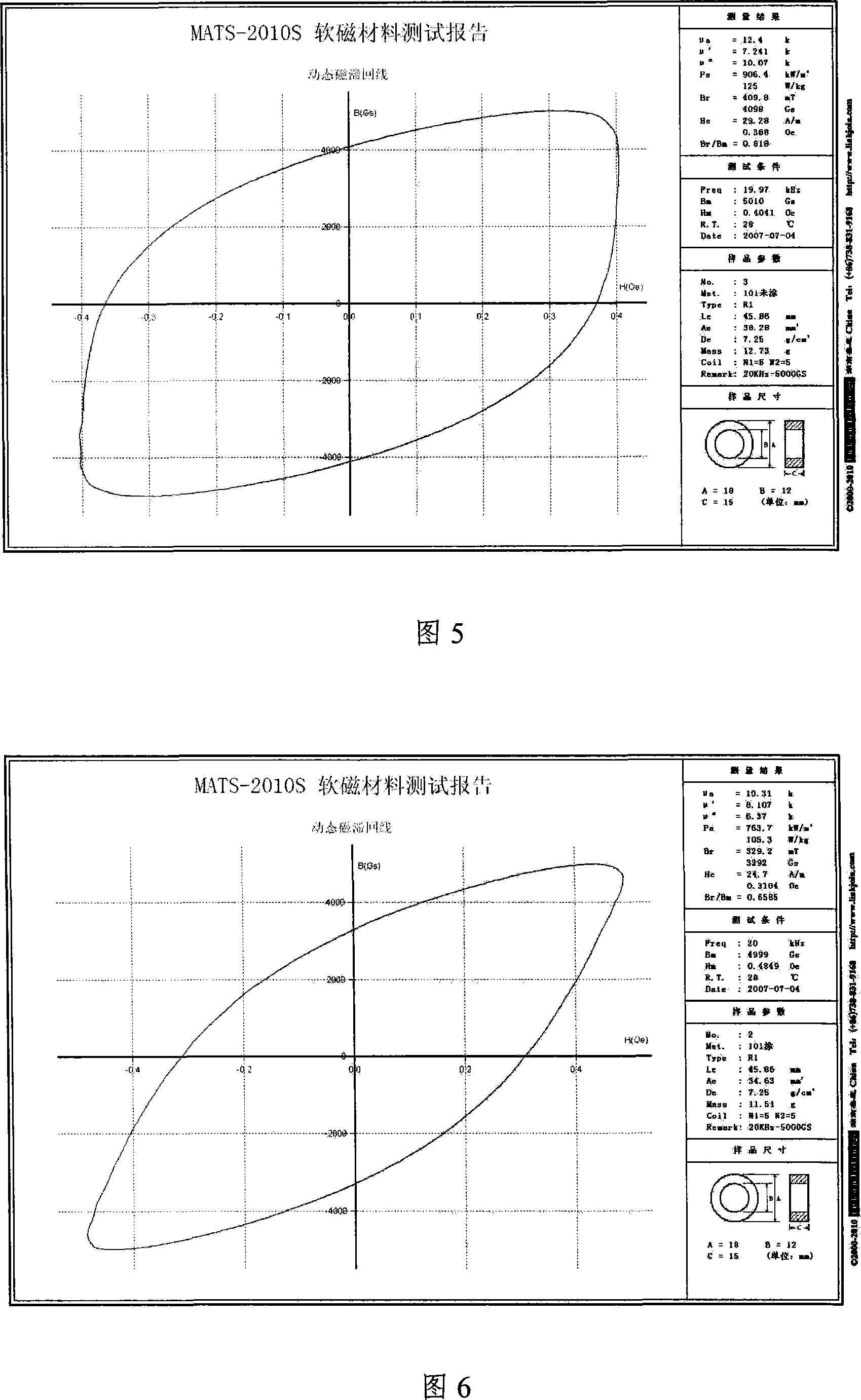

InactiveCN101127267AReduce lossPretreated surfacesInorganic material magnetismElectricityInsulation layer

The utility model puts forward a soft magnetic alloy belt material and production method; wherein, the surface of the belt material has a coating layer with good electrical insulation properties. The soft magnetic alloy belt material is dip-coated in the treating liquid confected through the selection of at least one type of the inorganic matter suspension, the inorganic solution and organic solution with the soft magnetic alloy belt material being dip-coated for 60 to 600 seconds in the treating liquid; then the soft magnetic alloy belt material is baked under the temperature of 90 to 250 DEG C for 60 to 1200 seconds, which makes the thickness of the coating layer up to 0.5 to 15 Mum; the soft magnetic alloy belt material is wound to a magnetic core of corresponding size and then processed by annealing heat treatment to become a soft magnetic alloy belt material with an electrical insulation coated layer. The utility model has the outstanding advantages that the breakdown voltages of the electrical insulation layer per Mum of the soft magnetic alloy belt material are all above 20V and the loss is reduced about 25%; the electrical insulation layer can guarantee the outstanding insulation between the belt material layers; meanwhile, the belt material has the excellent medium high frequency soft magnetism, and the coating material can endure the high temperature above 500 DEG C; thus, the outstanding electric insulation properties and performance can be achieved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

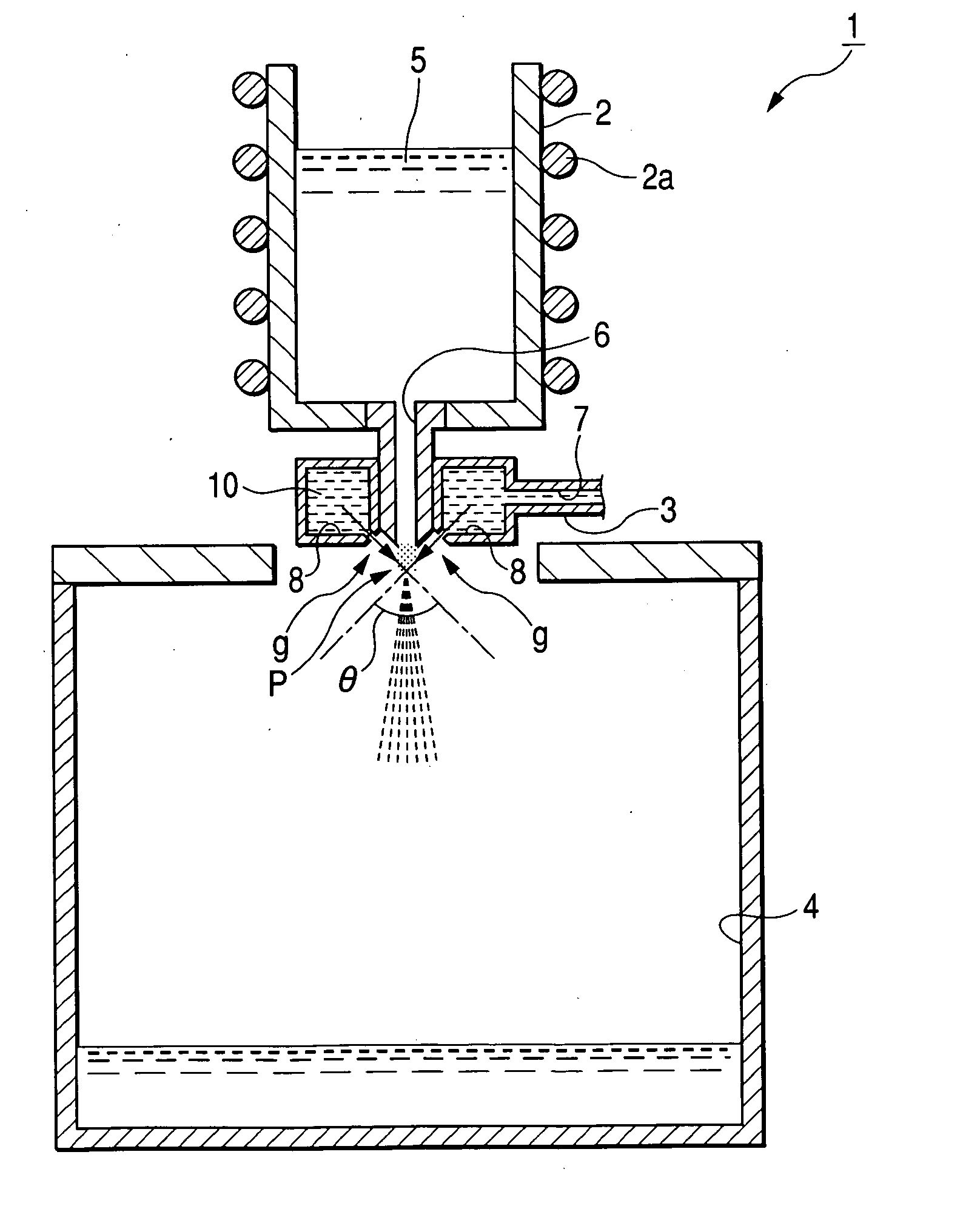

Magnetic alloy material and method of making the magnetic alloy material

A method of making a magnetic alloy material includes the steps of: preparing a melt of an alloy material having a predetermined composition; rapidly cooling and solidifying the melt to obtain a rapidly solidified alloy represented by: Fe100-a-b-cREaAbTMc where RE is at least one rare-earth element selected from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er and Tm and including at least about 90 at % of La; A is at least one element selected from Al, Si, Ga, Ge and Sn; TM is at least one transition metal element selected from Sc, Ti, V, Cr, Mn, Co, Ni, Cu and Zn; and 5 at %<=a<=10 at %, 4.7 at %<=b<=18 at % and 0 at %<=c<=9 at %; and producing a compound phase having an NaZn13-type crystal structure in at least about 70 vol % of the rapidly solidified alloy.

Owner:SUMITOMO SPECIAL METAL CO LTD

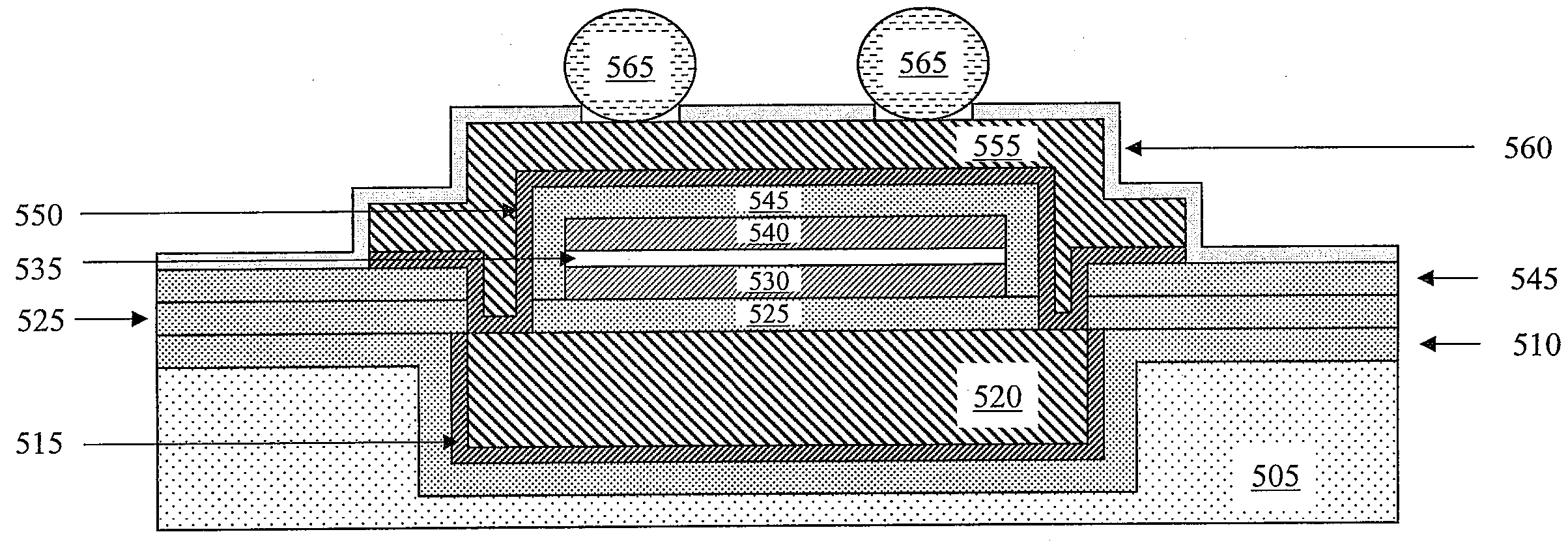

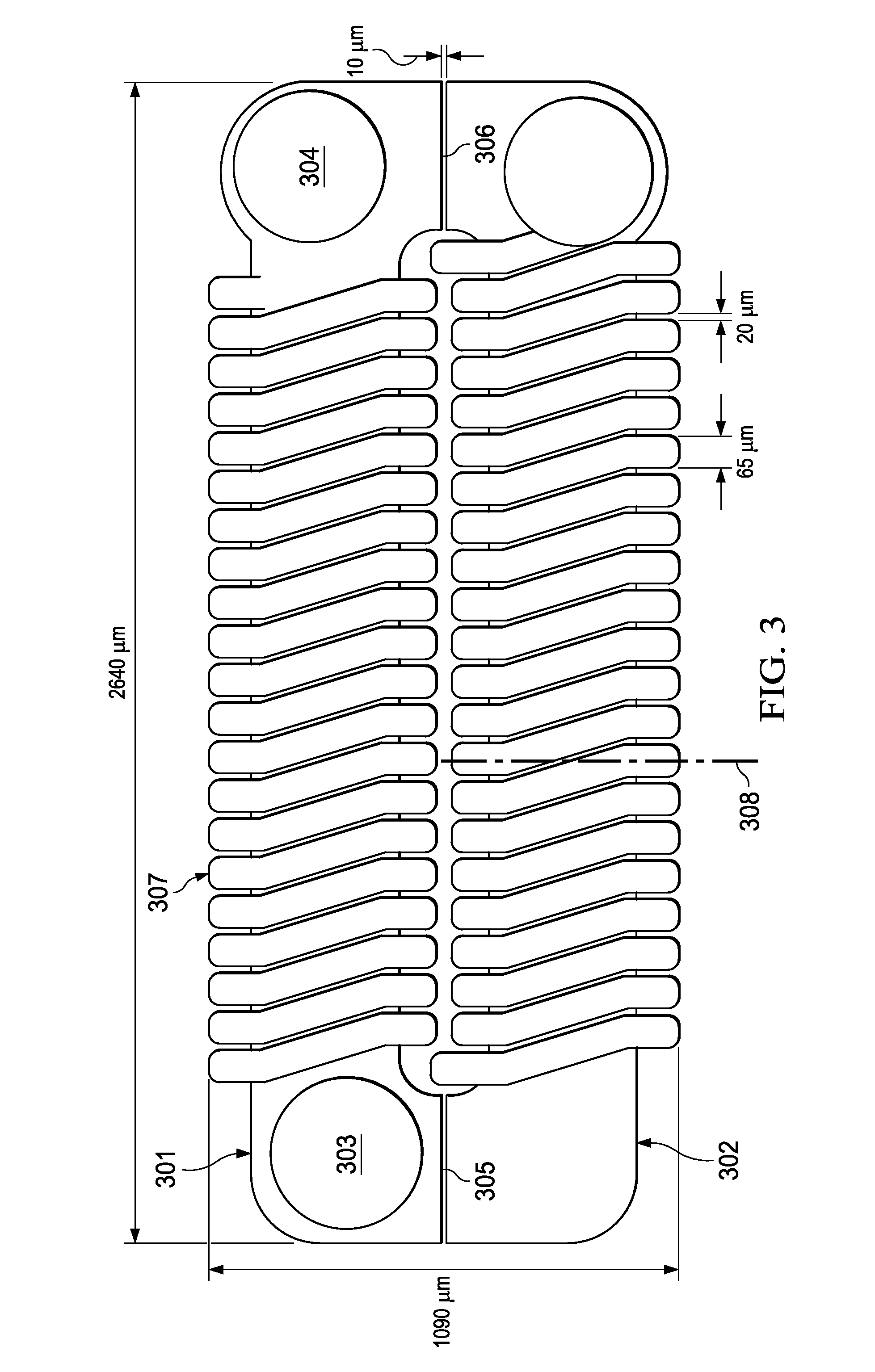

Method of Forming a Micromagnetic Device

A method of forming a micromagnetic device including providing a substrate and forming a magnetic core layer over the substrate from a magnetic alloy. The magnetic alloy includes iron, cobalt and phosphorous. A content of the cobalt is in a range of 1.8 to 4.5 atomic percent. A content of the phosphorus is in a range of 20.1 to 30 atomic percent. A content of the iron is substantially a remaining proportion of the magnetic alloy.

Owner:INTEL CORP

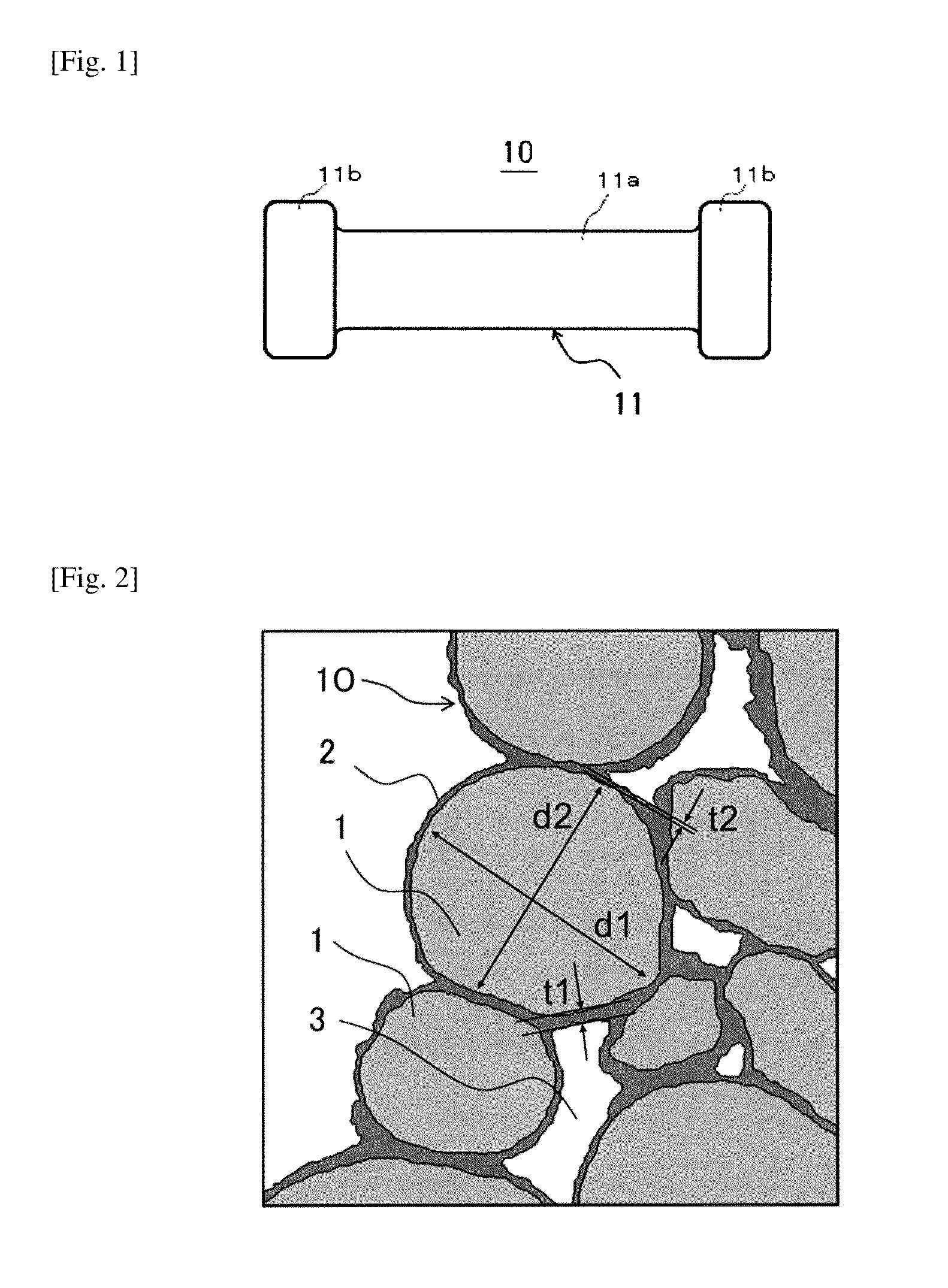

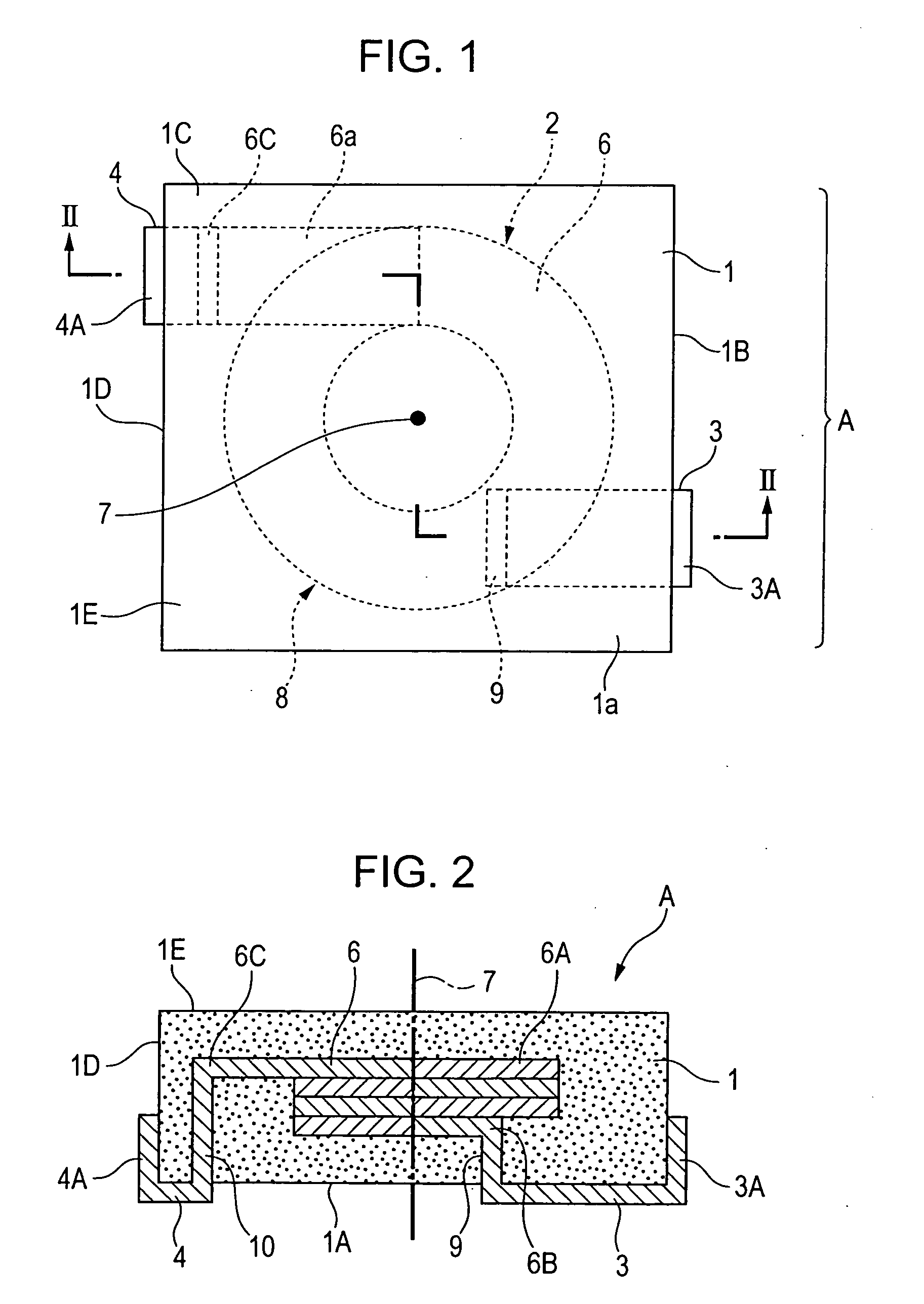

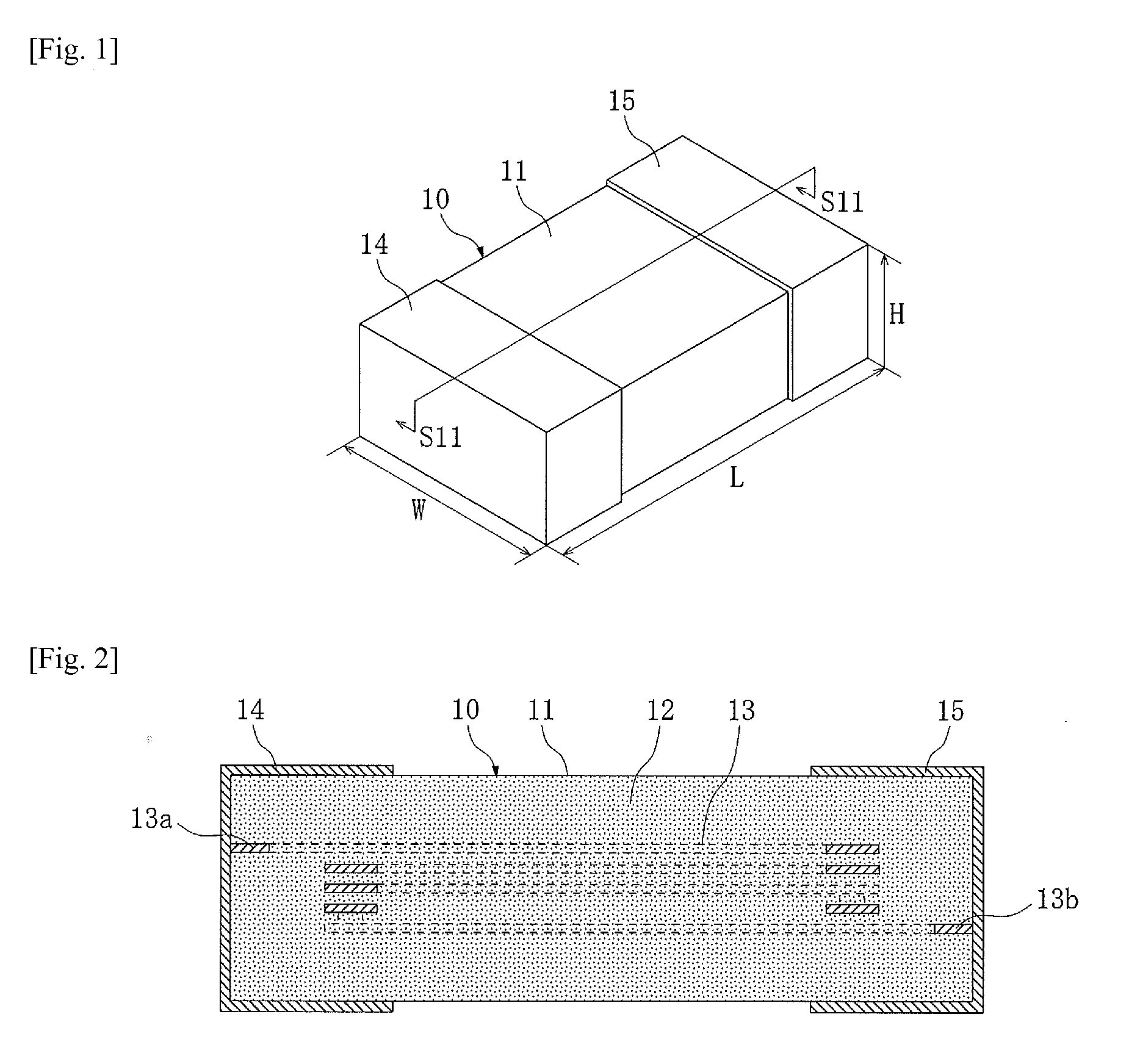

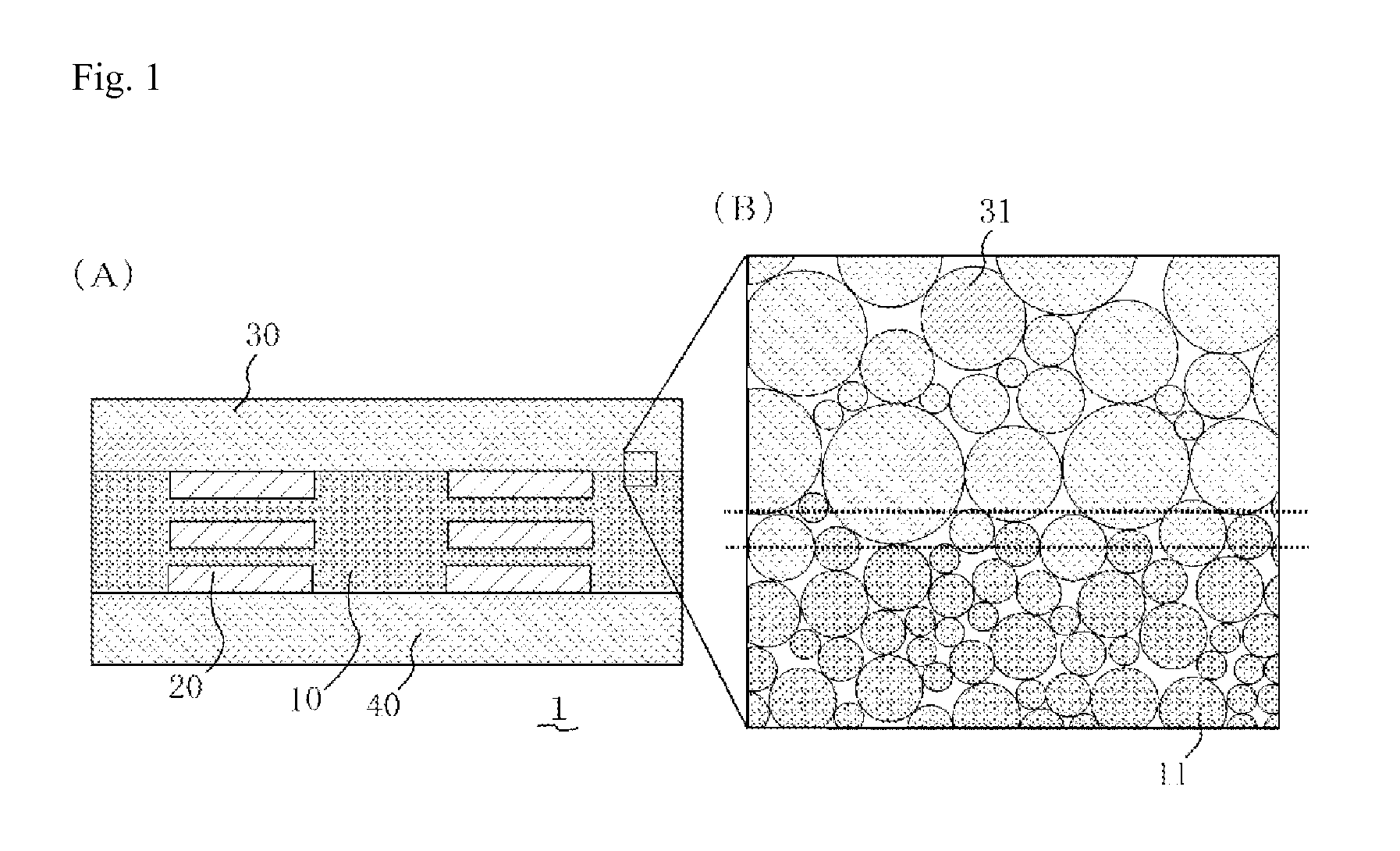

Coil component

ActiveUS20120188049A1High volume resistivityIncrease component densityTransportation and packagingMetal-working apparatusElectrical currentMaterials science

A coil component is of the type where a helical coil is directly contacting a magnetic body, which is still capable of meeting the demand for electrical current amplification. A coil component, comprising a magnetic body mainly constituted by magnetic alloy grains, and a coil formed on the magnetic body; wherein an oxide film of the magnetic alloy grains is present on the surface of each of the magnetic alloy grains, and based on grain size by volume standard, the magnetic alloy grains have a d50 in a range of 3.0 to 20.0 μm, d10 / d50 in a range of 0.1 to 0.7, and d90 / d50 in a range of 1.4 to 5.0.

Owner:TAIYO YUDEN KK

Electromagnetic wave absorbing materials

Electromagnetic wave absorbing materials comprising magnetic alloy particles and an insulating matrix are disclosed. The magnetic alloy particles comprise a transition metal such as Fe and / or Co, and further comprise at least one refractory metal such as Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and W. The magnet alloy particles may further include Ni and / or Al, or other alloying additions which provide the desired absorption characteristics. In a preferred embodiment, the magnetic alloy particles comprise an Fe-Cr-Ni-Al alloy. The insulating matrix of the electromagnetic wave absorbing material may comprise a water miscible polysilicate or a refractory cement. The materials may be provided in the form of coatings that are applied to a substrate, such as the hot engine exhaust area of an aircraft. The electromagnetic wave absorbing materials are capable of functioning at very high temperatures for extended periods of time while retaining satisfactory electromagnetic wave absorbing properties.

Owner:LOCKHEED MARTIN CORP

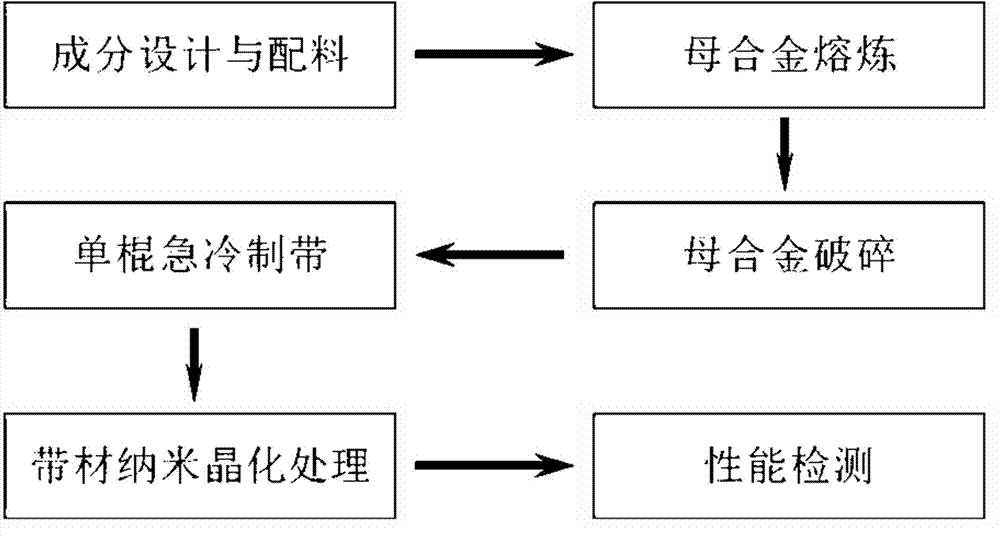

High-saturated magnetization intensity Fe-based amorphous nanocrystalline soft magnetic alloy and its preparation method

InactiveCN102732811AHigh saturation magnetizationSolve the problem of low saturation magnetic inductionMagnetic materialsMagnetizationCopper

The invention discloses a high-saturated magnetization intensity Fe-based amorphous nanocrystalline soft magnetic alloy and its preparation method. The alloy is prepared from the following components, by mole, 68-90% of Fe, 0-6% of X, 0-2% of Cu, 3-20% of Si, 4-20% of B and 0-10% of P, wherein the X comprises one or more of Al, Cr, Mn and Ti. The preparation method of the alloy comprises the technological steps of component designing and burdening, mother alloy melting, mother alloy fragmentation, band preparation through single-roller quenching, and band nanocrystallization processing. The preparation method of the invention can solve a problem of low saturated magnetic induction intensity of present Fe-based amorphous nanocrystalline soft magnetic alloys.

Owner:四川大学苏州研究院

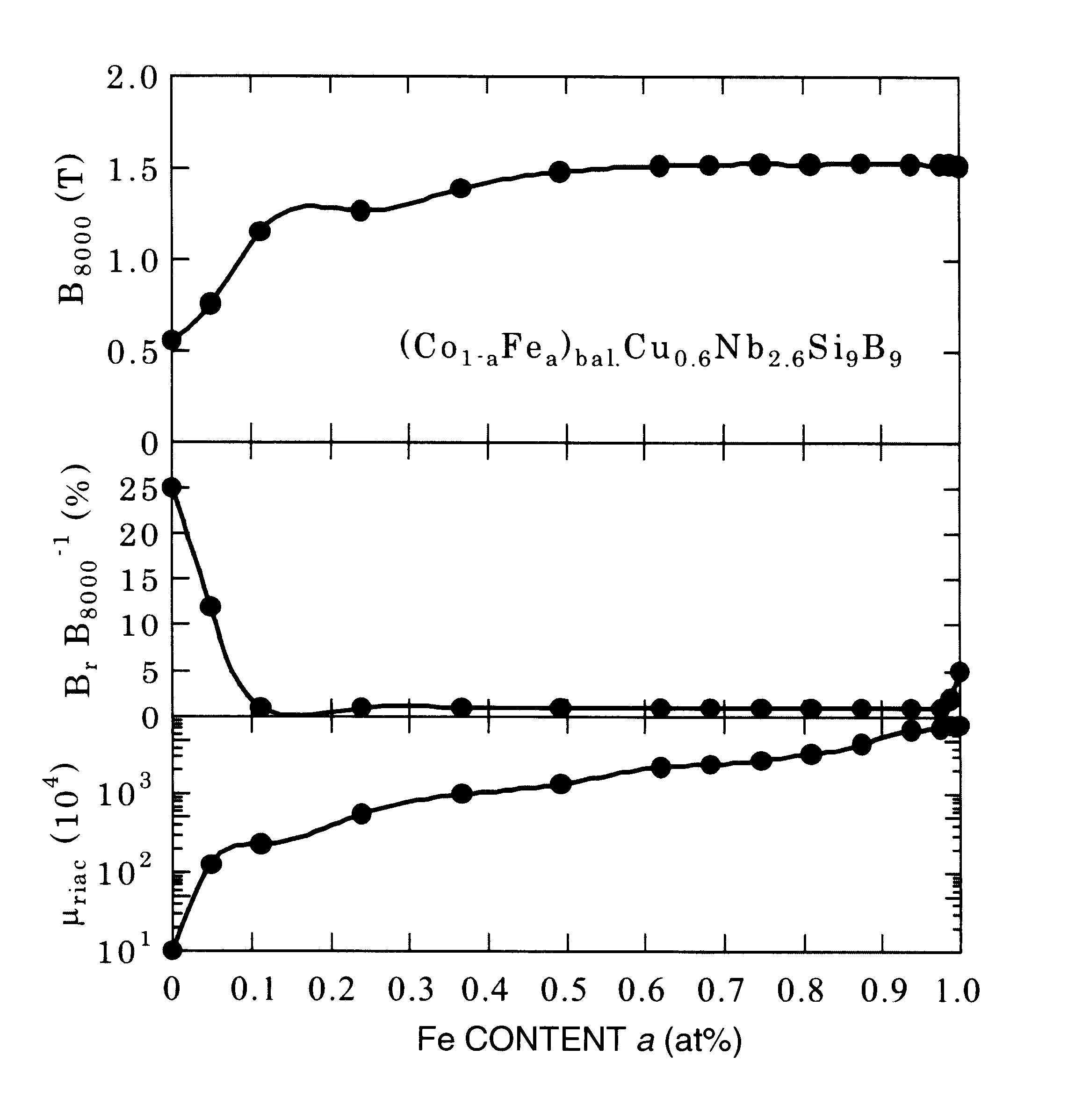

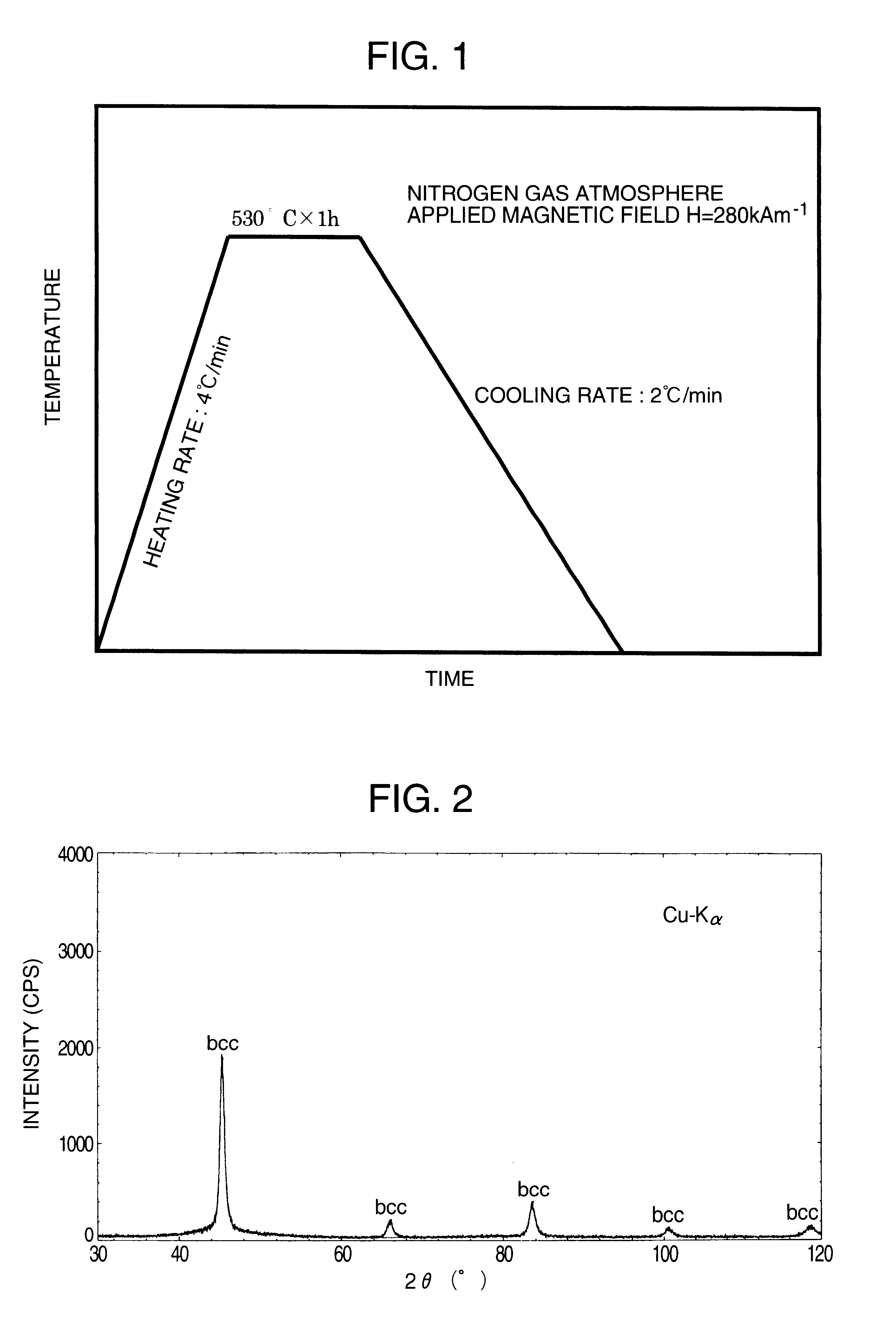

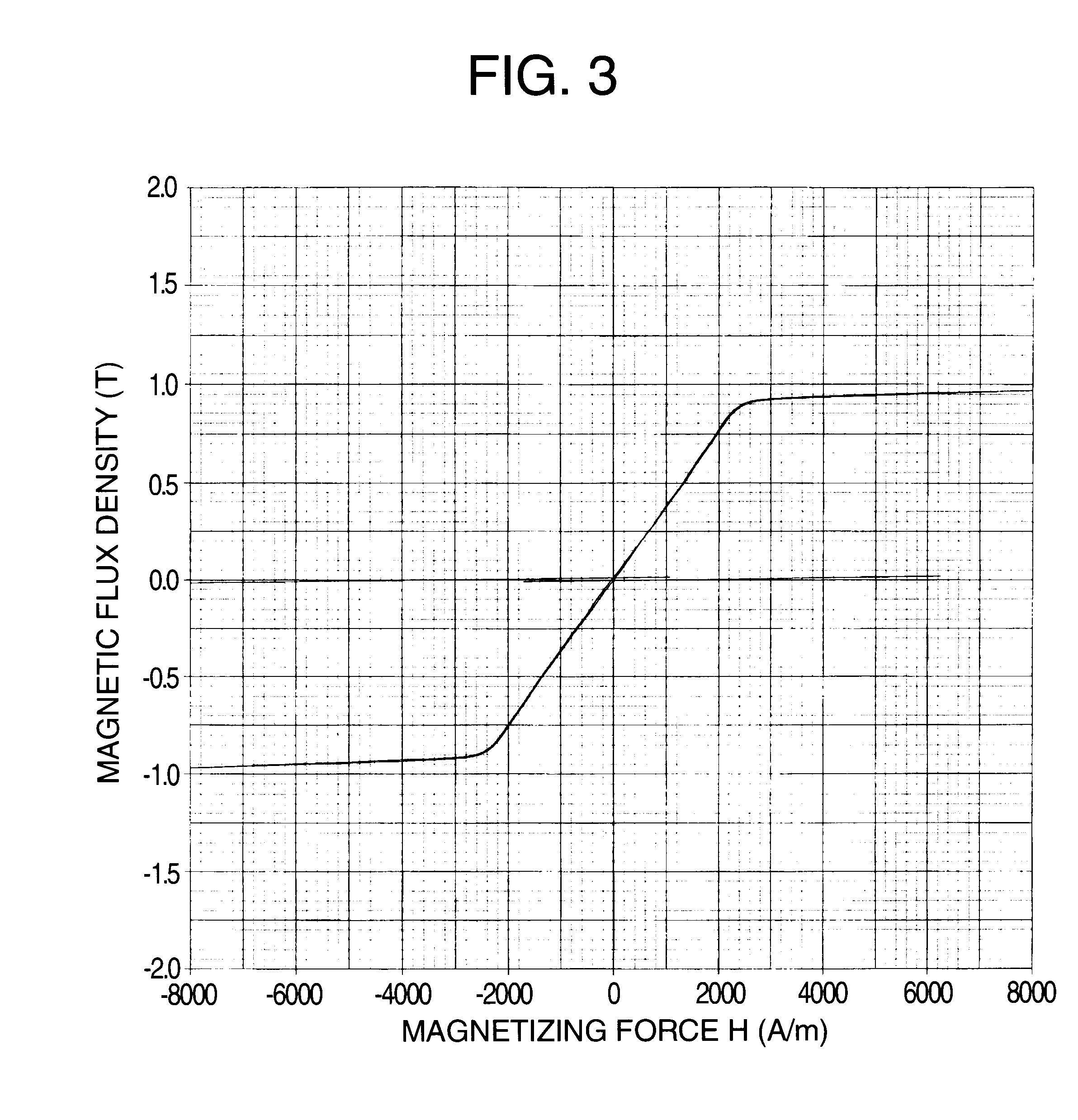

Co-based magnetic alloy and magnetic members made of the same

Disclosed is a Co-base magnetic alloy excellent in high-frequency magnetic properties, of which chemical composition is represented by the following general formula, by atomic %, (Co1-aFea)100-y-cM'yX'c, where M' is at least one element selected from the group consisting of V, Ti, Zr, Nb, Mo, Hf, Sc, Ta and W; X' is at least one element selected from the group consisting of Si and B; and a, y and c are defined by the formulas of a<0.35, 1.5<=y<=15, and 4<=c<=30, respectively. At least a part of the alloy structure of the alloy consists of crystal grains having an average grain size of not more than 50 nm. The alloy has a relative initial permeability of not more than 2000. It is suitably used for members of countermeasure against noise such as zero phase reactors for large current and electromagnetic shielding materials, inverter transformers, choke coils for active filters, antennas, smoothing choke coils, power supplies for lasers, pulse power magnetic members for accelerators.

Owner:HITACHI METALS LTD

Coil-type electronic component and its manufacturing method

ActiveUS20120038449A1Low costHigh magnetic flux densityInorganic material magnetismInductances/transformers/magnets manufactureElectronic componentElectron

A coil-type electronic component has a coil inside or on an outer surface of its base material and is characterized in that: the base material is constituted by a group of grains of a soft magnetic alloy containing iron, silicon and other element that oxidizes more easily than iron; the surface of each soft magnetic alloy grain has an oxide layer formed on its surface as a result of oxidization of the grain; the oxide layer contains the other element that oxidizes more easily than iron by a quantity larger than that in the soft magnetic alloy grain; and grains are bonded with one another via the oxide layer.

Owner:TAIYO YUDEN KK

Method for preparing complicated shape bonded magnet by utilizing 3D (three-dimensional) printing technology

ActiveCN103854844ASave raw materialsLow costInductances/transformers/magnets manufactureMagnetizationOperability

The invention relates to a method for a preparing complicated shape bonded magnet by utilizing a 3D (three-dimensional) printing technology, and belongs to the technical field of complicated shape bonded magnet preparation. According to the method, firstly, magnetic alloy powder, bonding agents and auxiliary agents are melted and mixed, then, a magnetic wire with a certain diameter is prepared through extrusion, next, a spray nozzle of 3D printing equipment is utilized for melting and accumulating the magnetic wire, in addition, orientation and curing are carried out, and finally, a required bonded magnet product with specific magnetism and complicated space shape is printed. The method has the advantages that the very thin bonded magnet (smaller than 0.4mm) with any complicated space shape can be prepared, the dimensional precision of the product is high, the product can be further subjected to magnetization and orientation control in the printing process, an isotropic or anisotropic permanent magnet product can be prepared, in addition, a blank and a mold are not needed in the printing process, raw materials can be greatly saved, the production efficiency can be improved, the process is stable and reliable, the operability is high, the repeatability is high, and the method is applicable to the batch production of the complicated shape bonded magnet.

Owner:UNIV OF SCI & TECH BEIJING

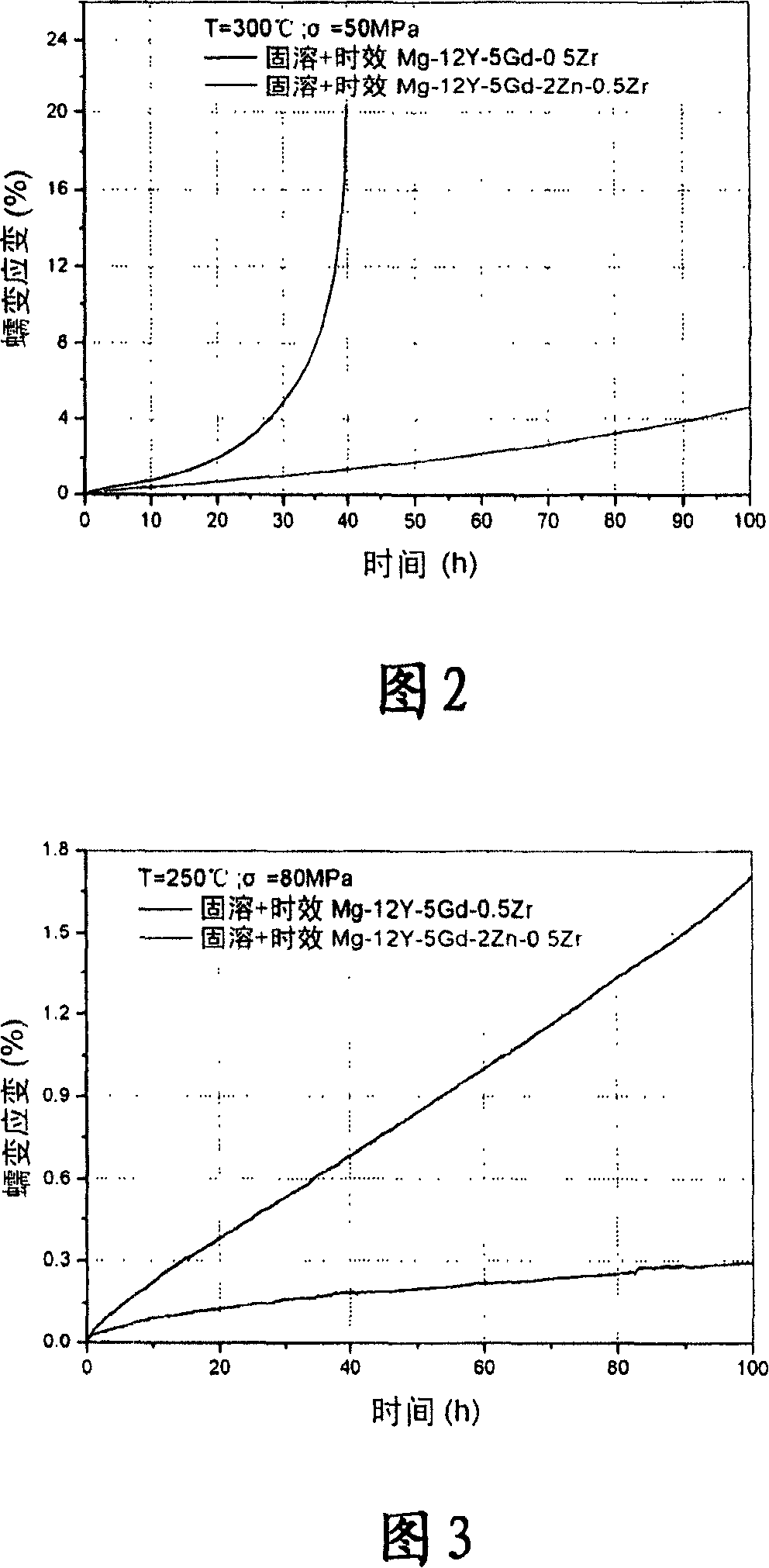

High-strength creep resistant magnesium alloy and method of producing the same

A high-intensity anti-creep magnesium alloy and the preparation method thereof, wherein, the compositions by weight percentage of magnesium alloy are as follows: Y is more than or equal to 6 percent and less than or equal to 12 percent, Gd is more than or equal to 1 percent and less than or equal to 6 percent, Zn is more than or equal to 0.5 percent and less than or equal to 3 percent, and Zr is more than or equal to 0.5 percent and less than or equal to 3 percent, the residue is Mg and the unavoidable impurities. When smelting, medium different alloys with Mg-Y, Mg-Gd, and Mg-Zr are used to add components of Y, Gd and Zr into the melted magnesium, the magnesium alloy after the melting undergoes melting for 6-24 hours at 500-550 DEG C, followed by seasoning for 12-48 hours at 225-300 DEG C, then the magnetic alloy is excellent in intensity and anti-creep function at 300 DEG C.

Owner:SHANGHAI JIAO TONG UNIV +1

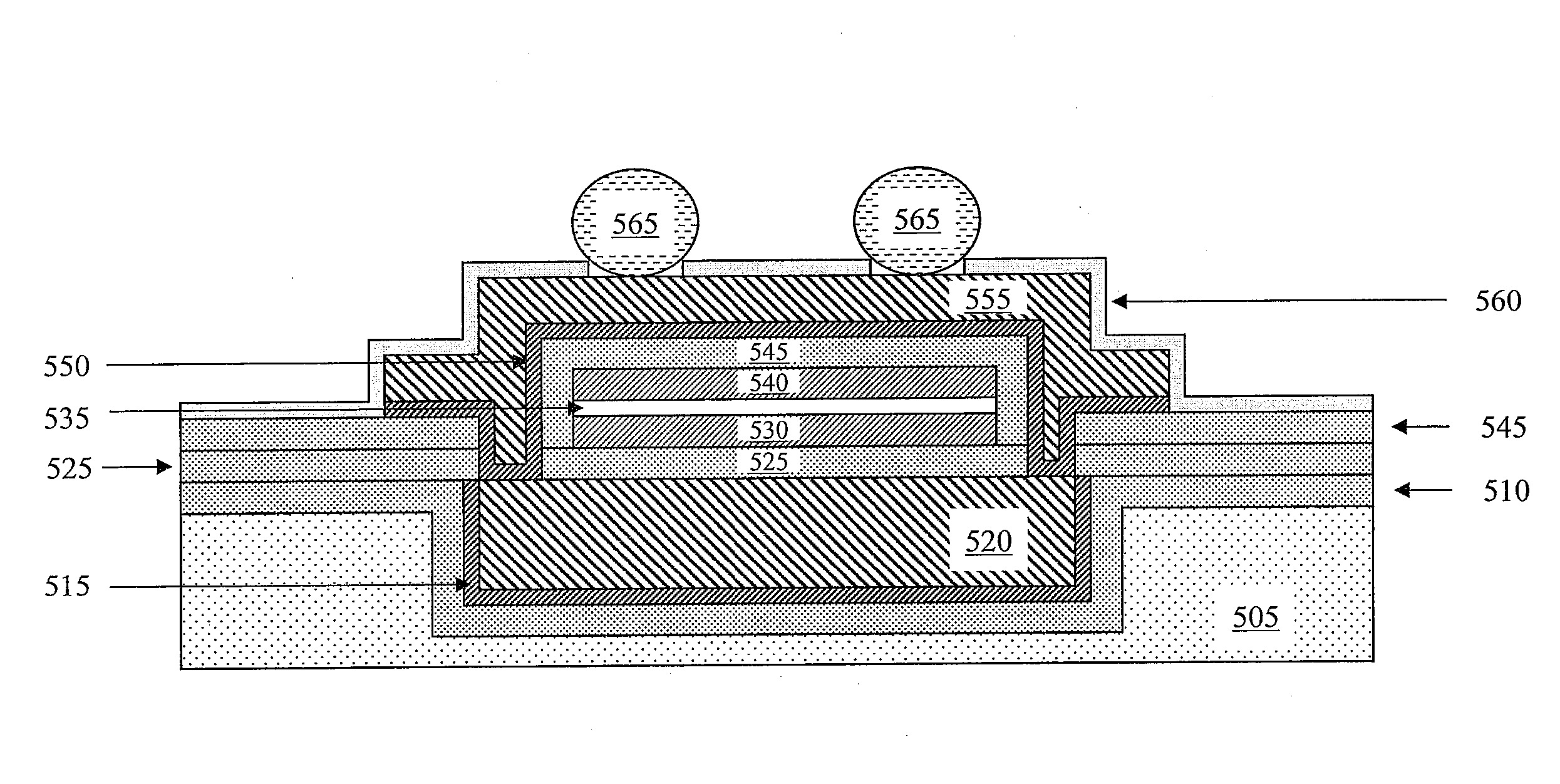

Micromagnetic device and method of forming the same

InactiveUS7952459B2Transformers/inductances magnetic coresThin magnetic filmsCobaltMaterials science

A micromagnetic device including a substrate, and a magnetic core layer formed over the substrate from a magnetic alloy. The magnetic alloy includes iron, cobalt and phosphorous. A content of the cobalt is in a range of 1.8 to 4.5 atomic percent. A content of the phosphorus is in a range of 20.1 to 30 atomic percent. A content of the iron is substantially a remaining proportion of the magnetic alloy.

Owner:INTEL CORP

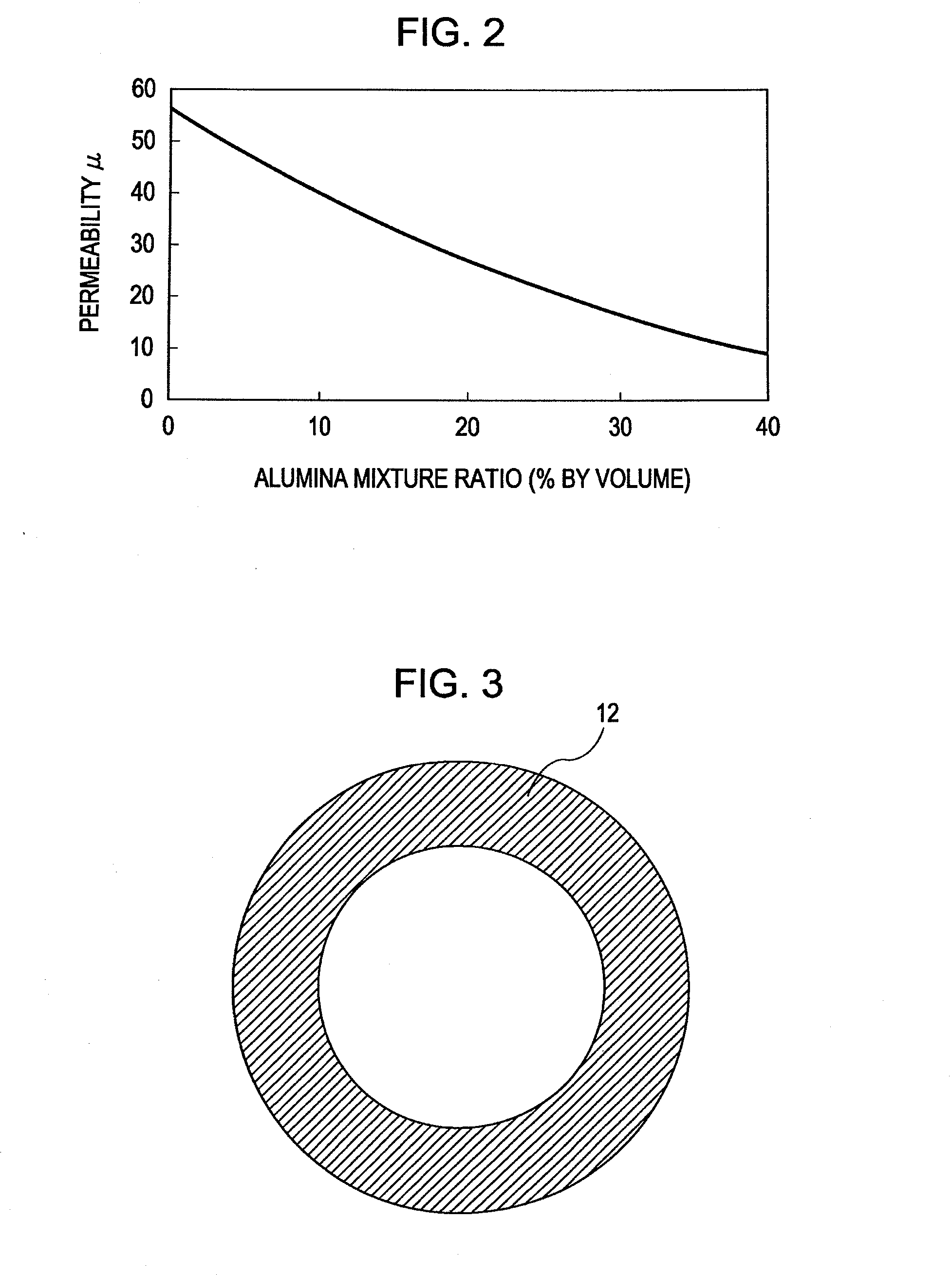

Magnetic core using amorphous soft magnetic alloy

ActiveUS20080078474A1Increase of core lossSuppress noiseTransformers/inductances magnetic coresMagnetic materialsIron alloysMaterials science

A magnetic core made of a mixed material including powder of an amorphous soft magnetic iron alloy and about 10% by volume or more of nonmagnetic inorganic powder, the amorphous soft magnetic iron alloy being expressed by the following composition: Fe100-a-b-x-y-z-w-tCOaNibMxPyCzBwSit wherein M is one or two or more elements selected from among Cr, Mo, W, V, Nb, Ta, Ti, Zr, Hf, Pt, Pd and Au, and a, b, x, y, z, w and t represent composition ratios satisfying 0 atom %≦x≦3 atom %, 2 atom %≦y≦15 atom %, 0 atom %≦z≦8 atom %, 1 atom %≦w≦12 atom %, 0.5 atom %≦t≦8 atom %, 0 atom %≦a≦20 atom %, 0 atom %≦b≦5 atom %, and 70 atom %≦(100-a-b-x-y-z-w-t)≦80 atom %.

Owner:ALPS ALPINE CO LTD

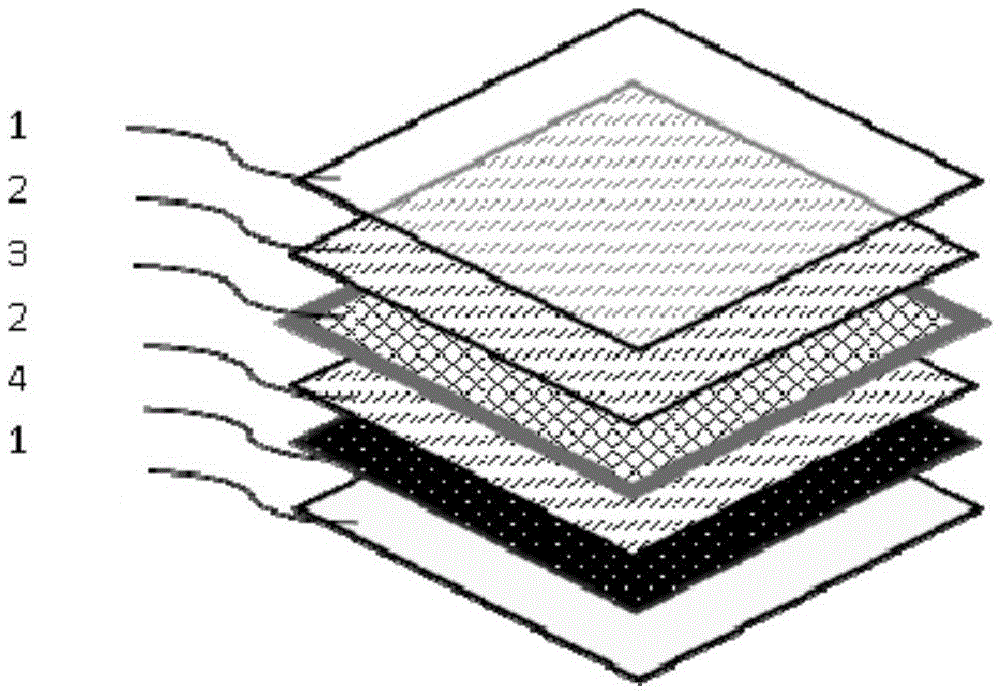

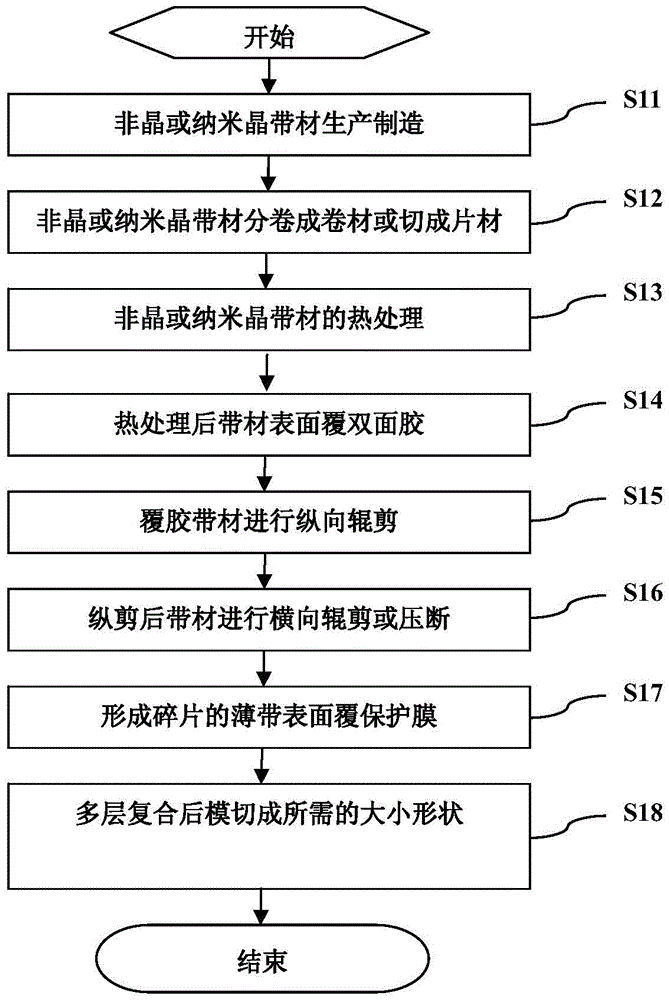

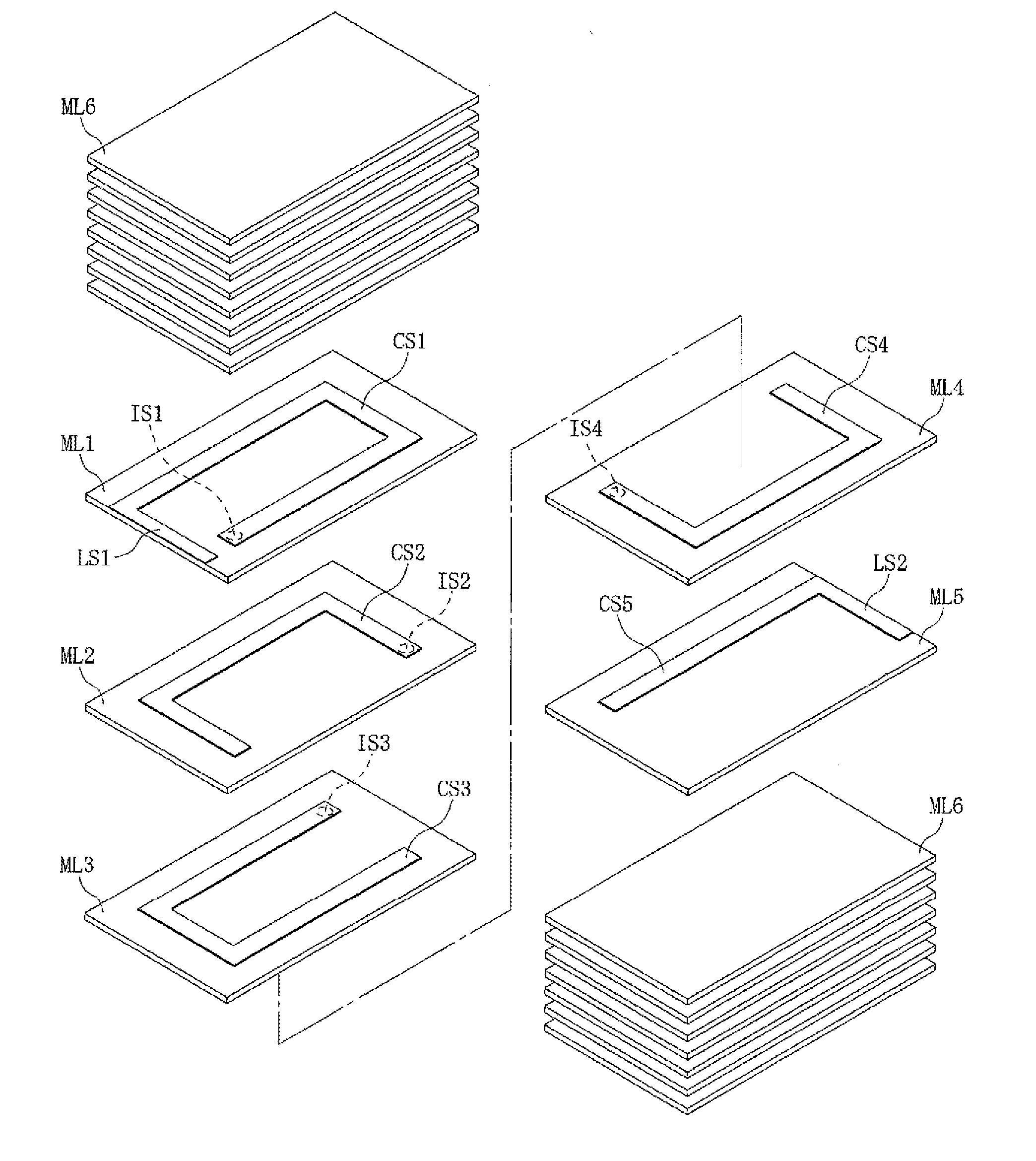

Non-contact type flexible magnetic conductive slice for charging and preparation method therefor

ActiveCN105632678APlay a magnetic functionGood flexibilityInductances/transformers/magnets manufactureCores/yokesEddy currentContact type

The invention discloses a non-contact type flexible magnetic conductive slice for charging and a preparation method therefor. The flexible magnetic conductive slice comprises at least one layer of non-crystal or nanocrystal soft magnetic alloy slices, double-sided adhesive tapes arranged between the soft magnetic alloy slice layers, and a protecting film arranged on the double-sided adhesive tape at the uppermost layer or the lowest layer, wherein each soft magnetic alloy slice layer is formed by fragments distributed with a latticed shape; the fragments are uniform in dimensions and are separated mutually; the preparation method comprises the main processes of performing thermal processing on strips, coating the protective film, performing longitudinal roll shearing, performing transverse roll shearing or transverse roll pressing, coating film and the like, and crushing the strips into the latticed fragment-structured magnetic conductive slice. Through the latticed fragments with controllable dimensions, the loss of the charging efficiency and the heating phenomenon caused by eddy current loss can be reduced; and therefore, the method is an efficient and continuous method for preparing the non-contact type flexible magnetic conductive slice for charging.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

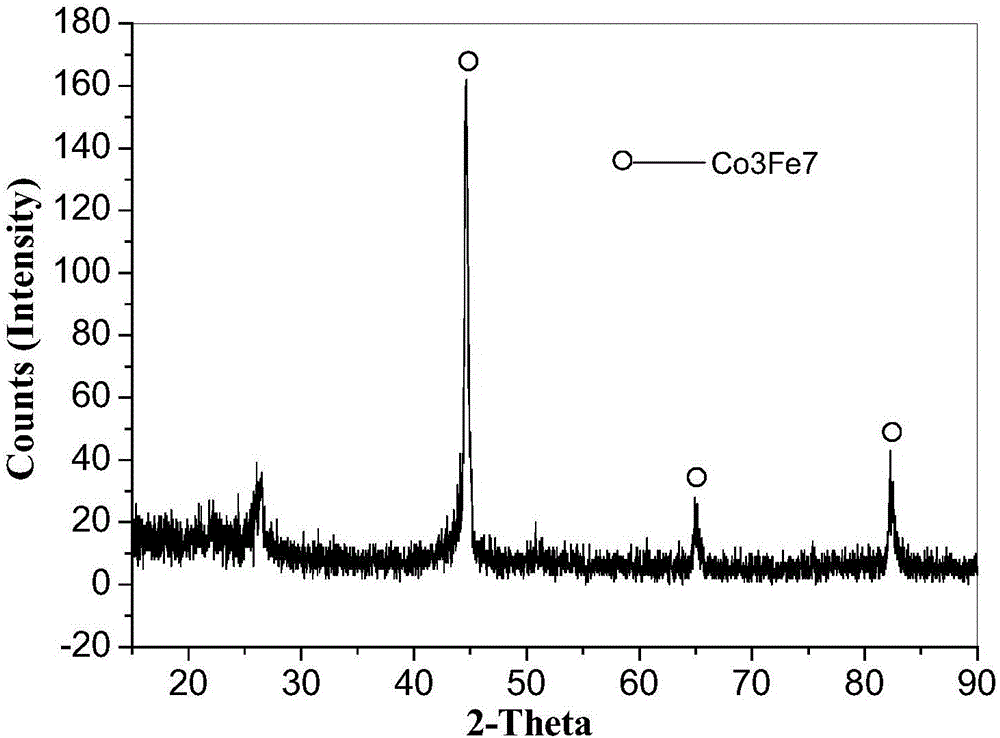

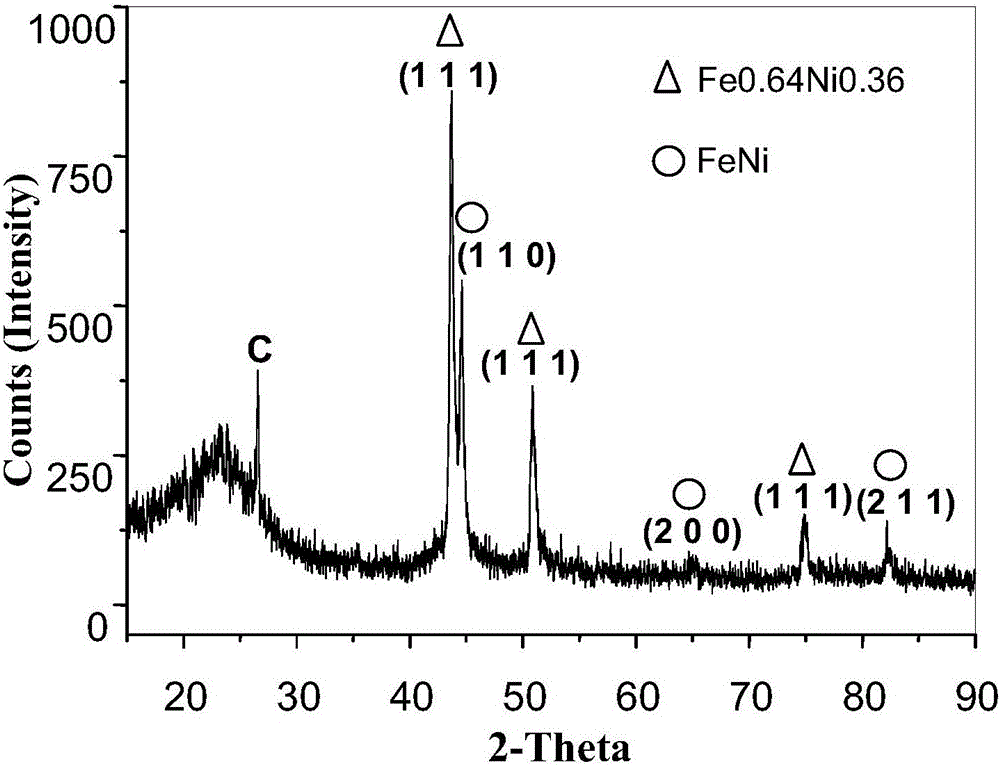

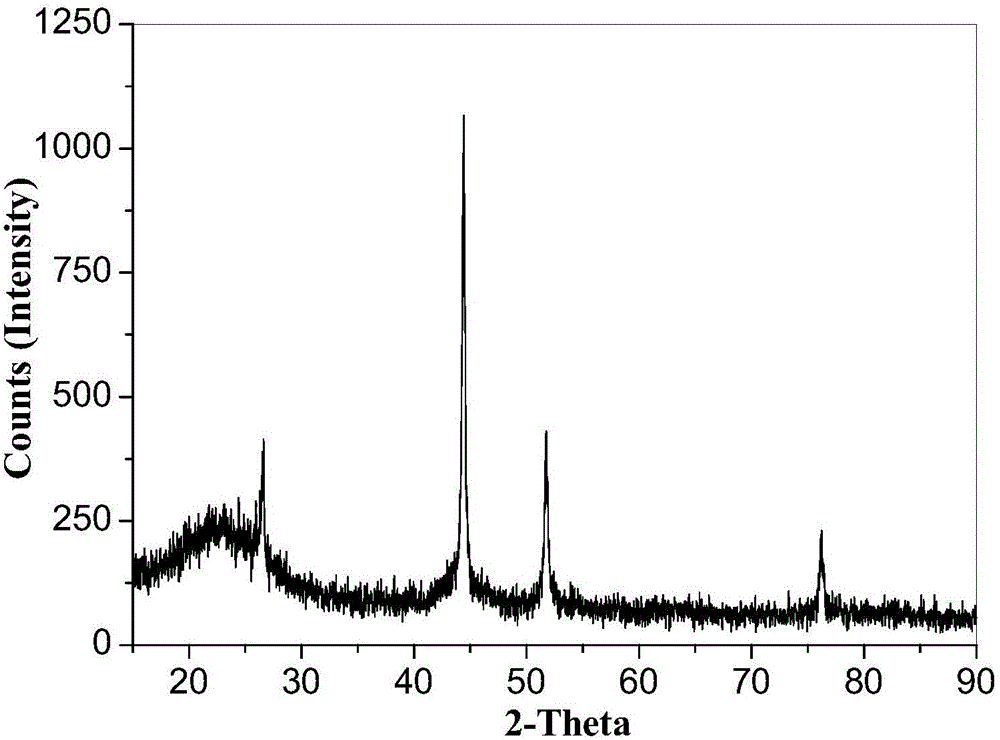

Preparation method of magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material

The invention relates to a preparation method of a magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material. The method comprises the following steps: 1) preparing a precursor solution containing two or more magnetic metal ion salts; 2) stirring the porous carbon spheres in the precursor solution for impregnation; 3) filtering out the porous carbon spheres, washing and drying; 4) calcining the dried porous carbon spheres in an inert atmosphere; and 5) cooling to room temperature in an inert atmosphere to obtain the magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material. The iron salt / cobalt salt, iron salt / nickel salt and cobalt salt / nickel salt mixed precursor solution are introduced to the inside of the ducts of the carbon spheres by using the high specific area and strong adsorptivity of the porous carbon spheres through the capillary actions and are combined with the hydrophilic oxygen-containing functional group; and finally, the drying and sintering treatment in the inert atmosphere are performed to obtain the iron-cobalt / iron-nickel / cobalt-nickel-alloy-loaded porous carbon sphere composite material. The whole preparation process is simple in technique and convenient to operate, and has low requirements for the production equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

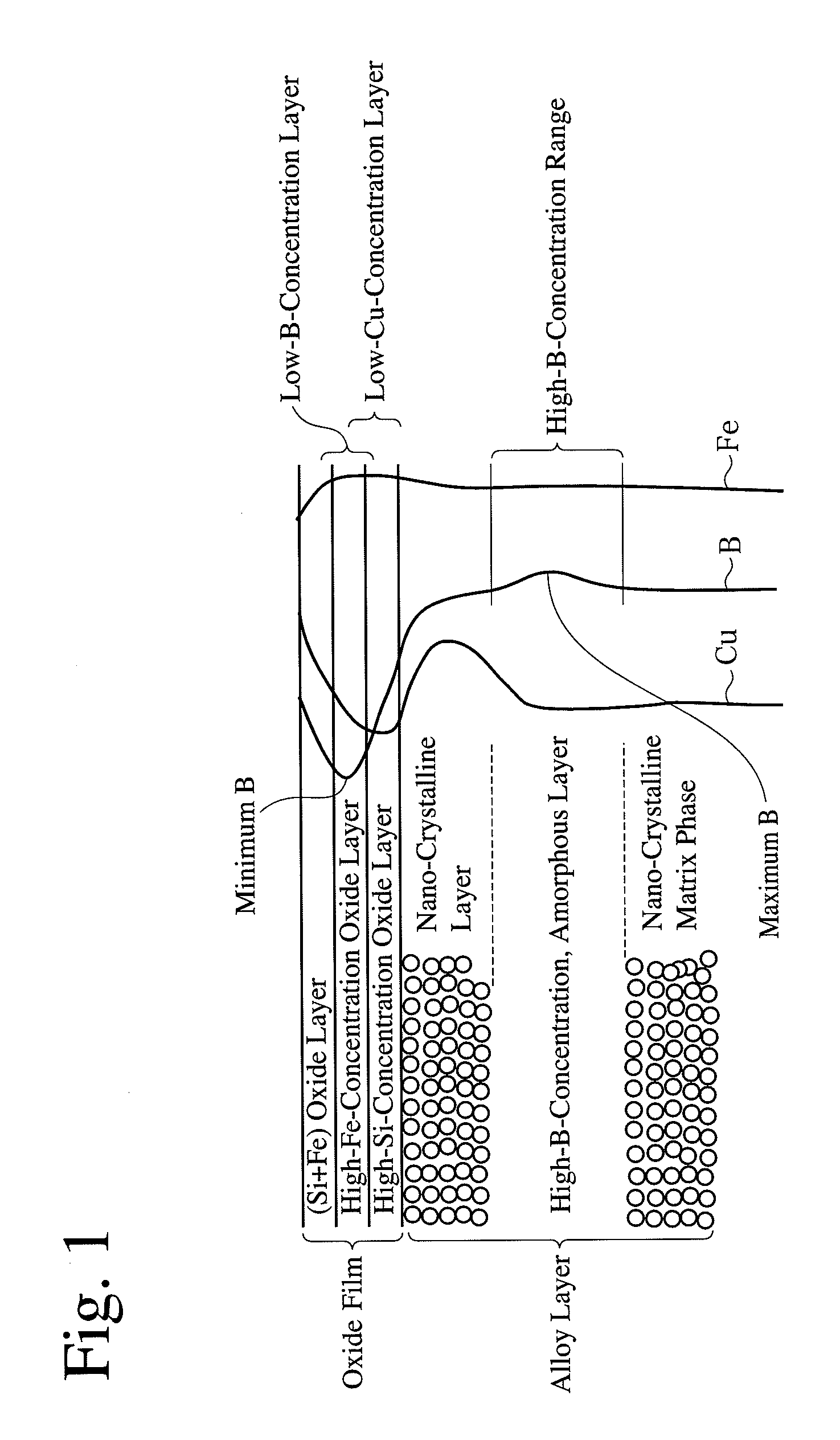

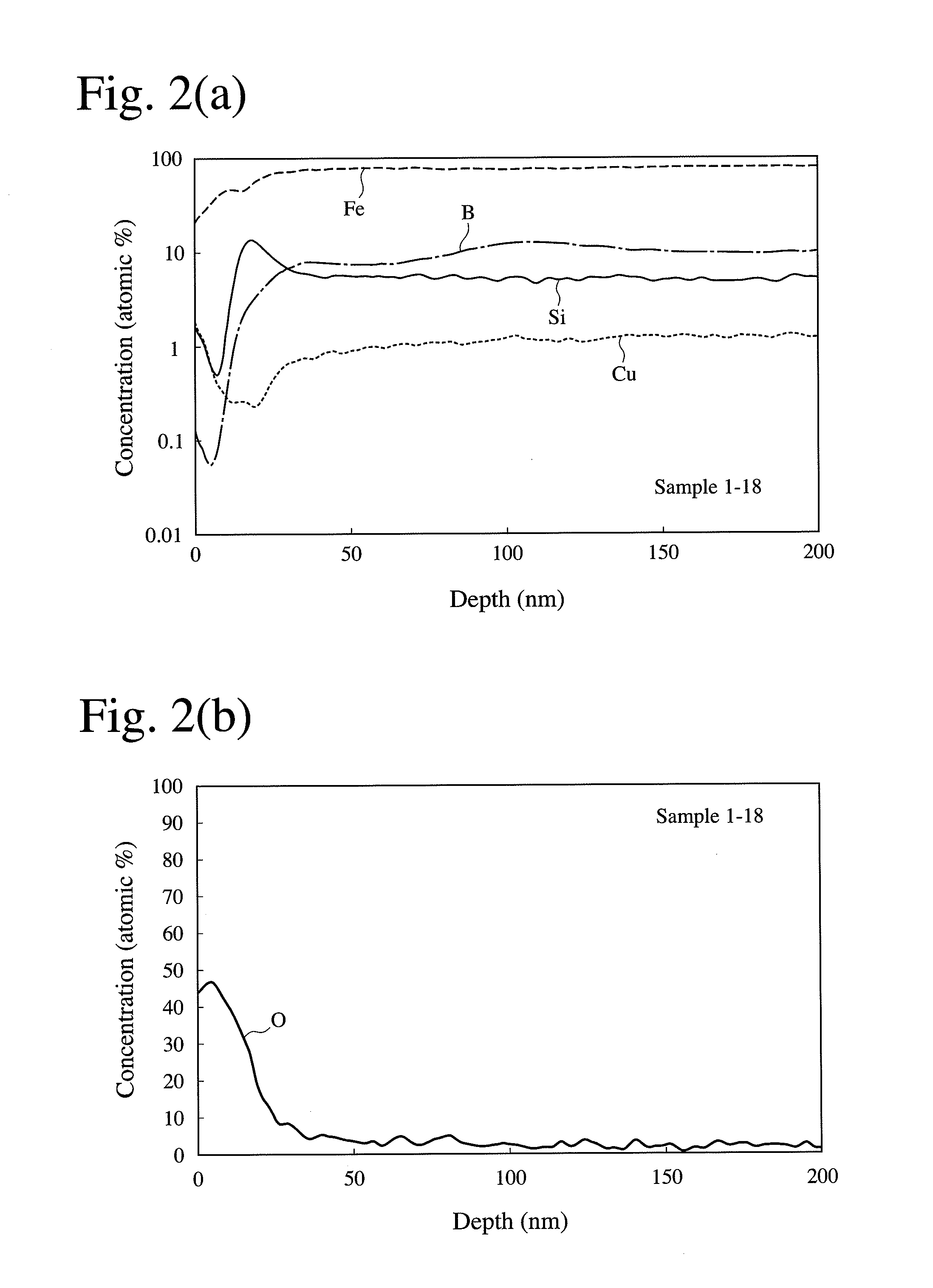

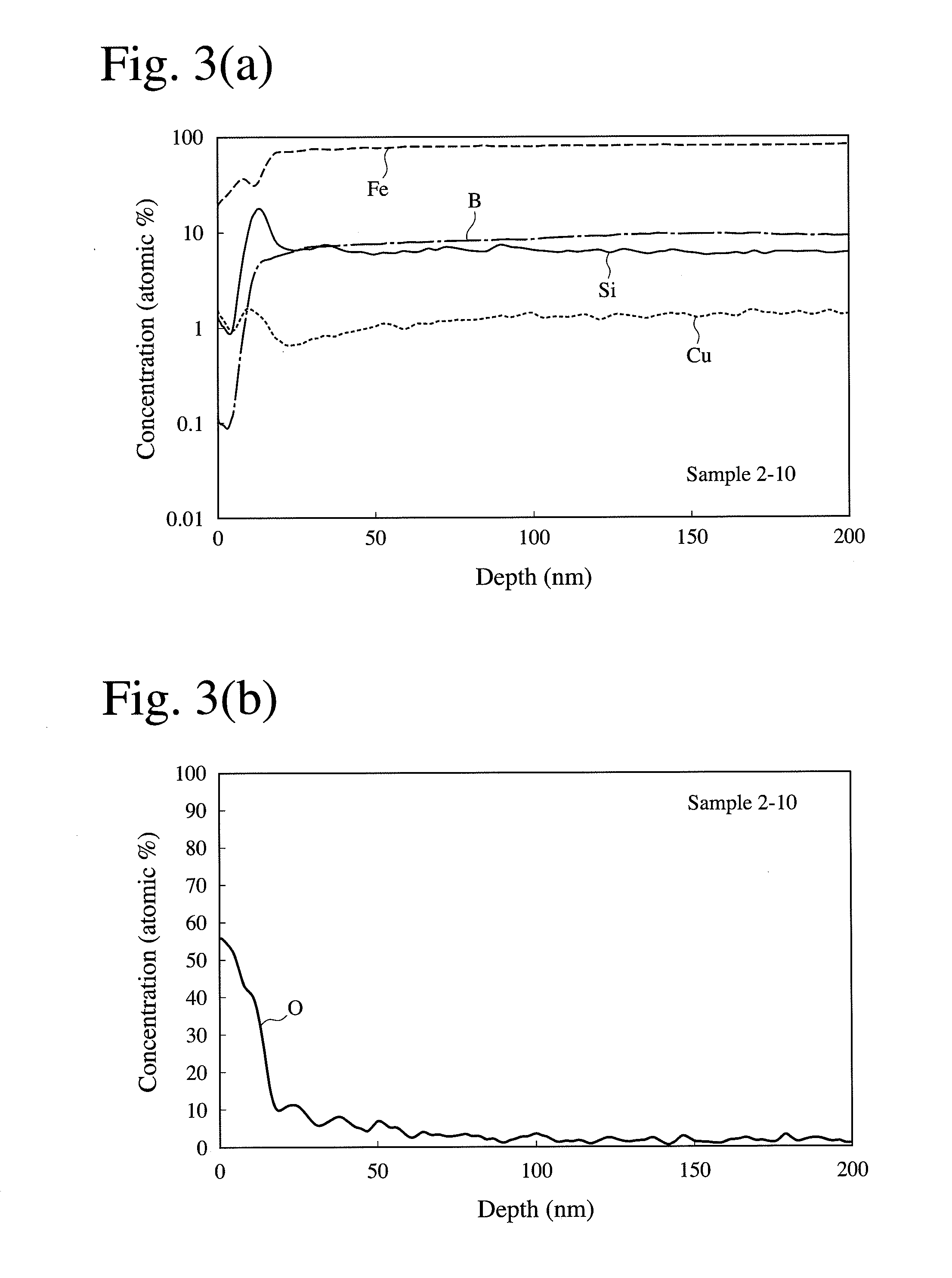

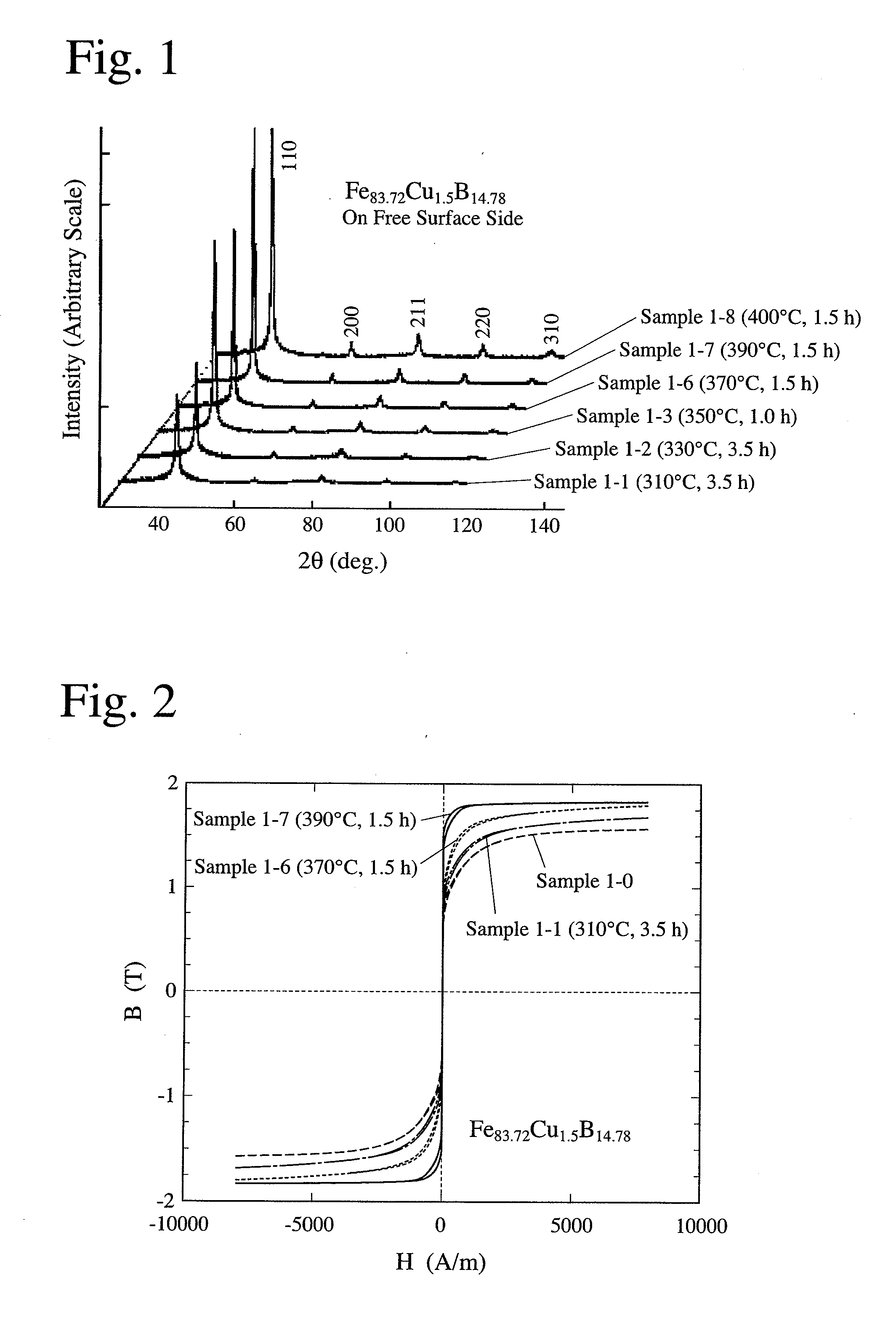

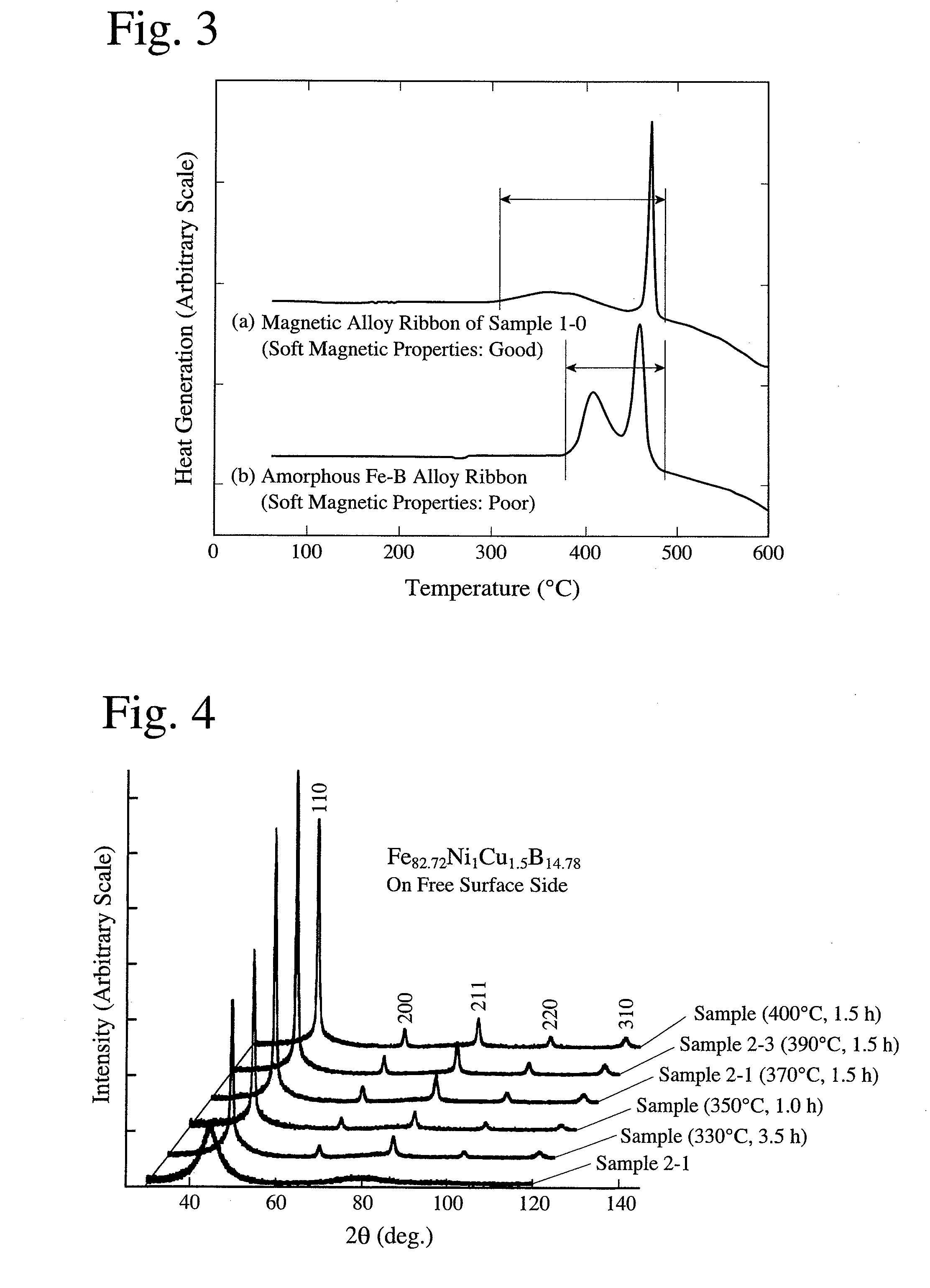

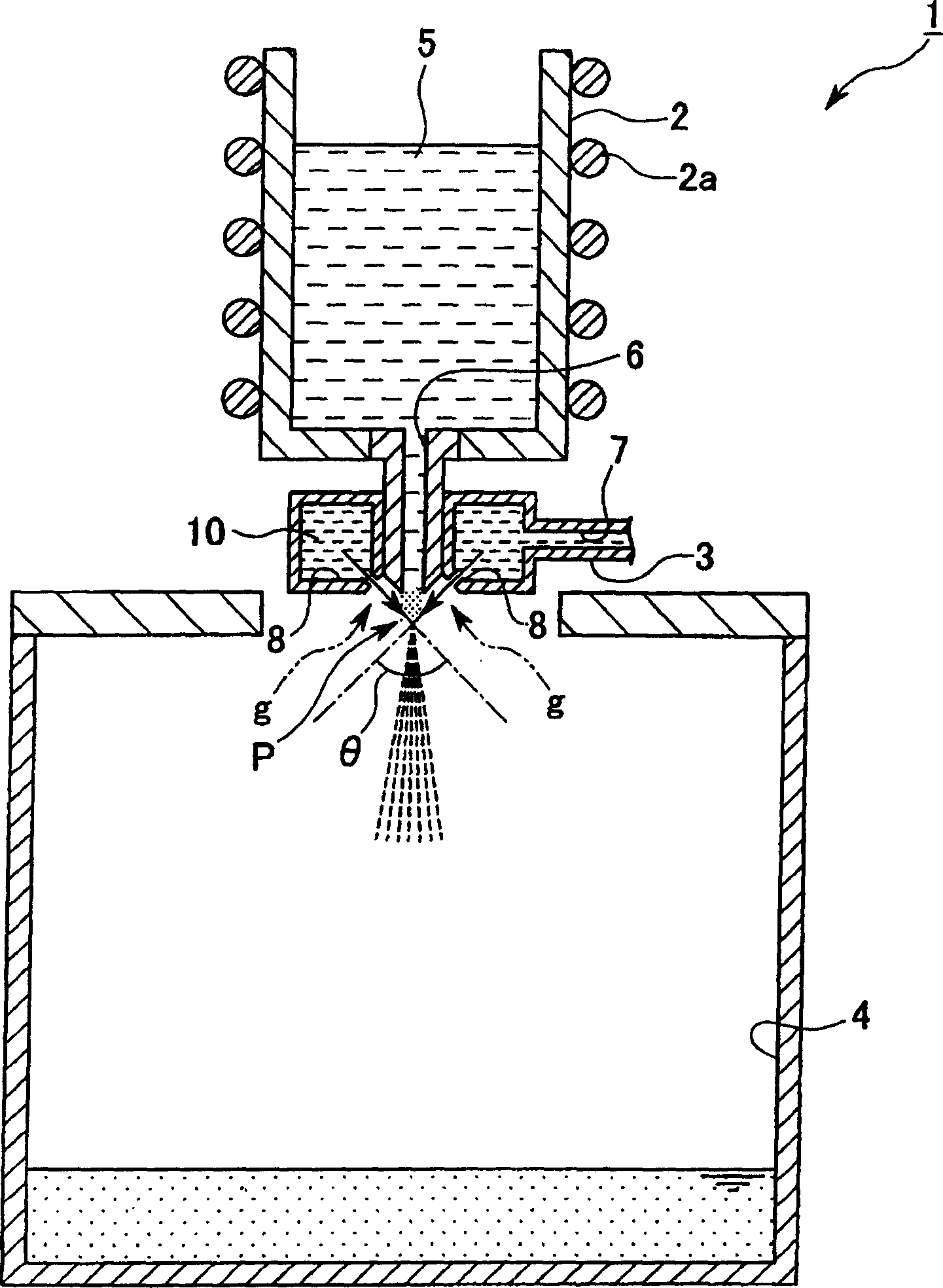

Soft magnetic alloy ribbon and its production method, and magnetic device having soft magnetic alloy ribbon

ActiveUS20110272065A1High saturated magnetic flux densityLow core lossMaterial nanotechnologyNanomagnetismAmorphous phaseQuenching

A method for producing a soft magnetic alloy ribbon having a composition represented by Fe100−x−y−zAxByXz, wherein A is Cu and / or Au, X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers (by atomic %) meeting the conditions of 0<x≦5, 10≦y≦22, 1≦z≦10, and x+y+z≦25, and comprising a matrix phase in which fine crystal grains having an average diameter of 60 nm or less are dispersed at a volume fraction of 50% or more, part of an oxide film formed on the surface being a layer having a lower B concentration than the average B concentration of the matrix phase; comprising the steps of (1) ejecting an alloy melt having the above composition onto a rotating cooling roll for quenching, to form a primary fine-crystalline alloy ribbon having a matrix phase, in which fine crystal nuclei having an average diameter of 30 nm or less are dispersed at a volume fraction of more than 0% and less than 30% in an amorphous phase; and then (2) annealing the primary fine-crystalline alloy ribbon in an atmosphere having an oxygen concentration of 6-18%.

Owner:HITACHI METALS LTD

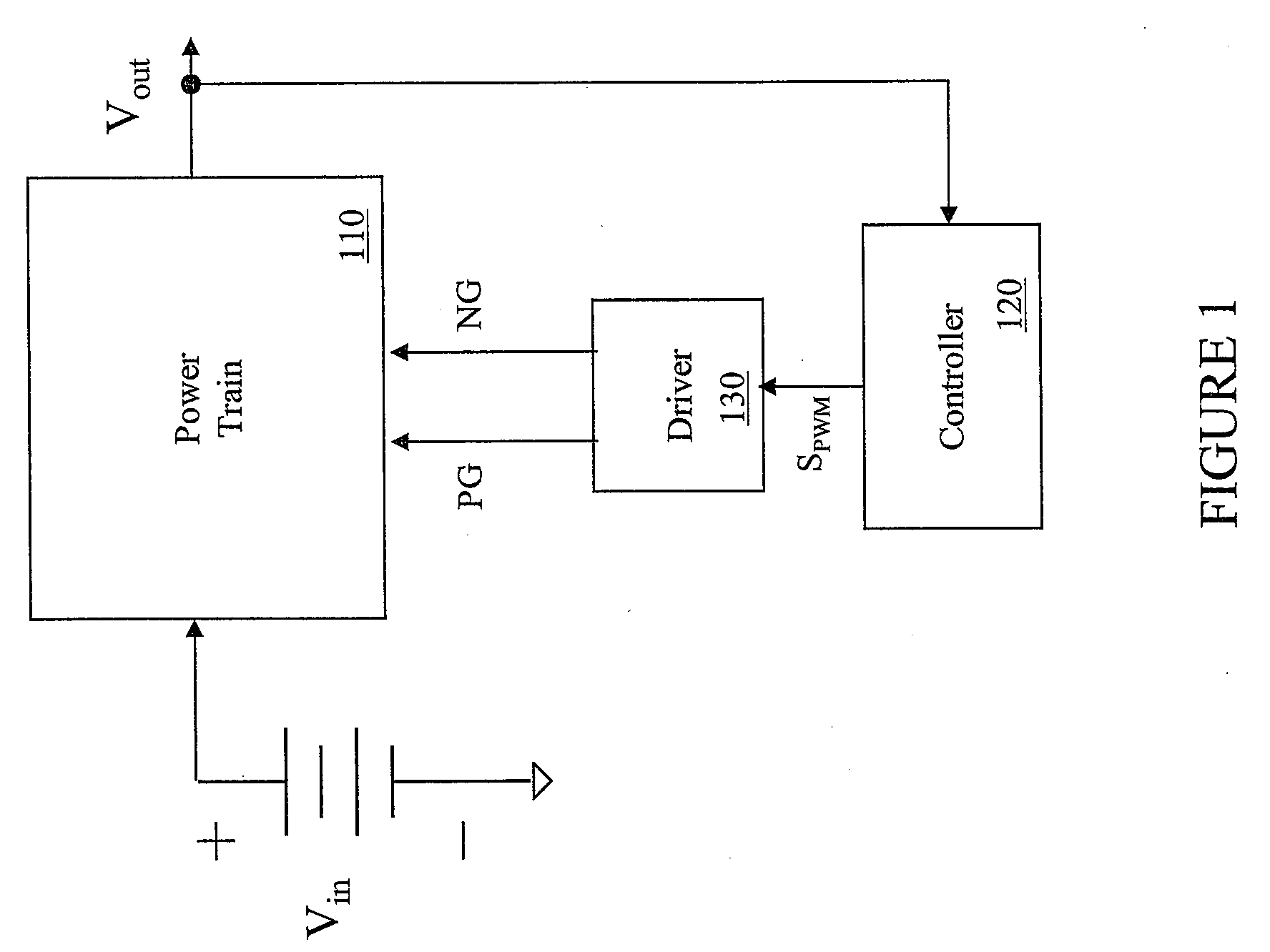

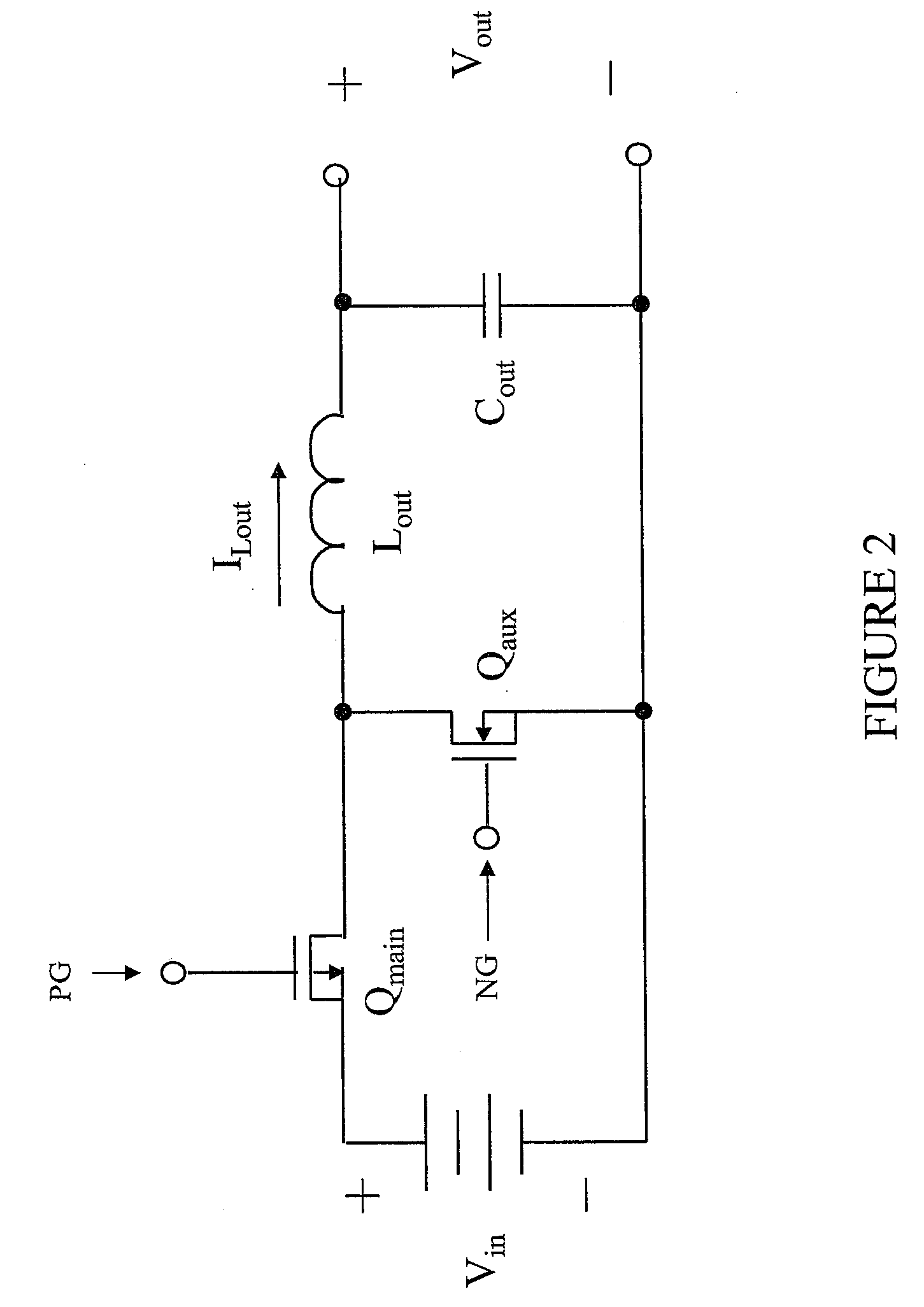

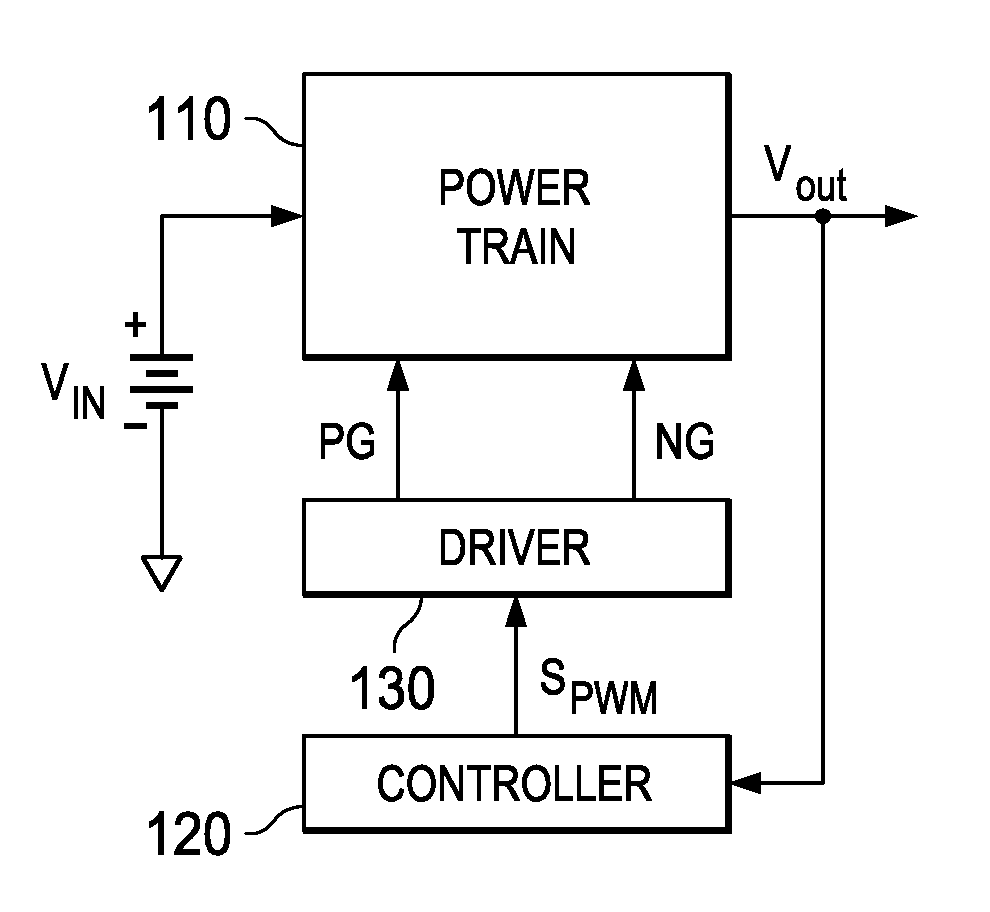

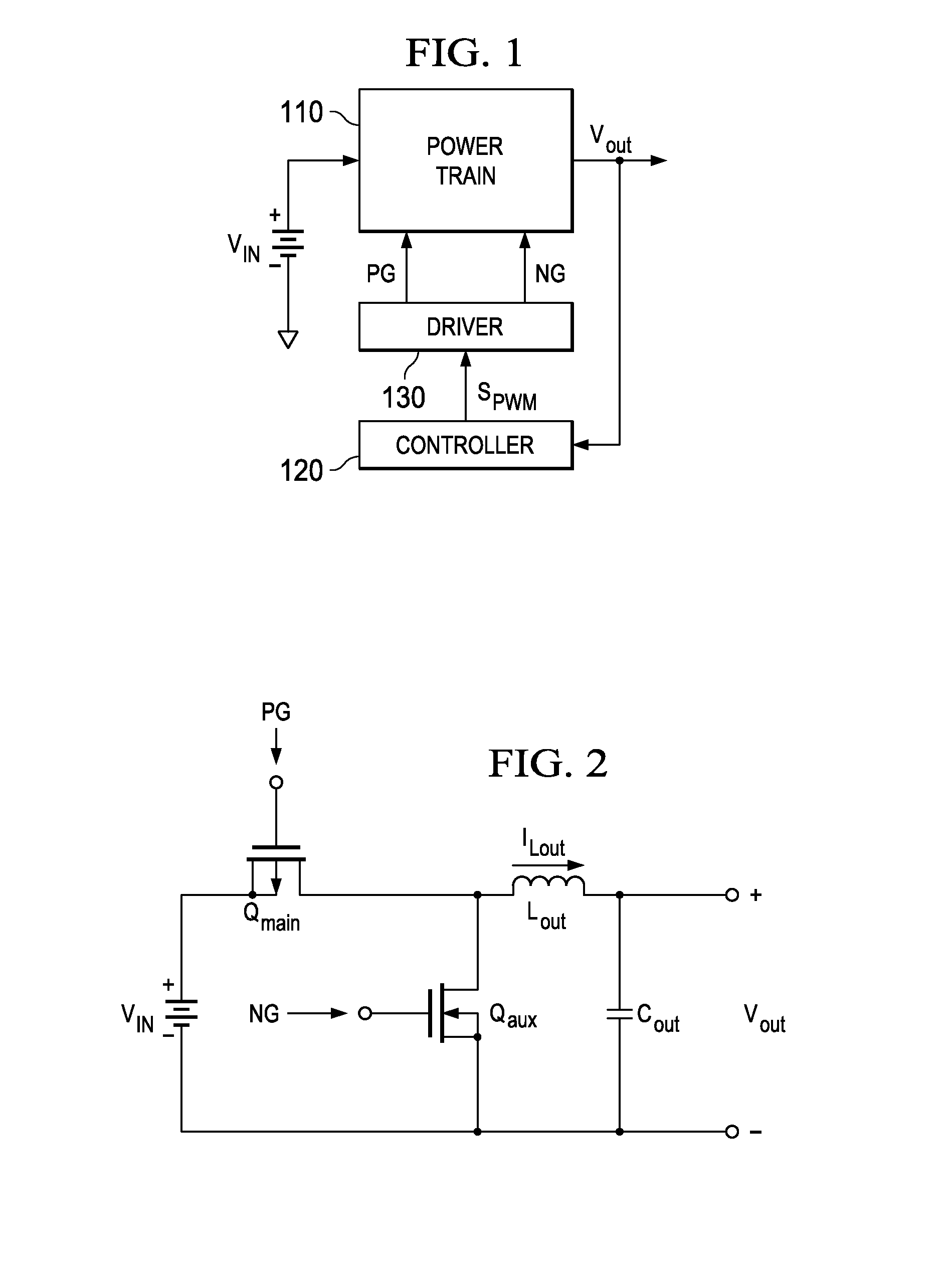

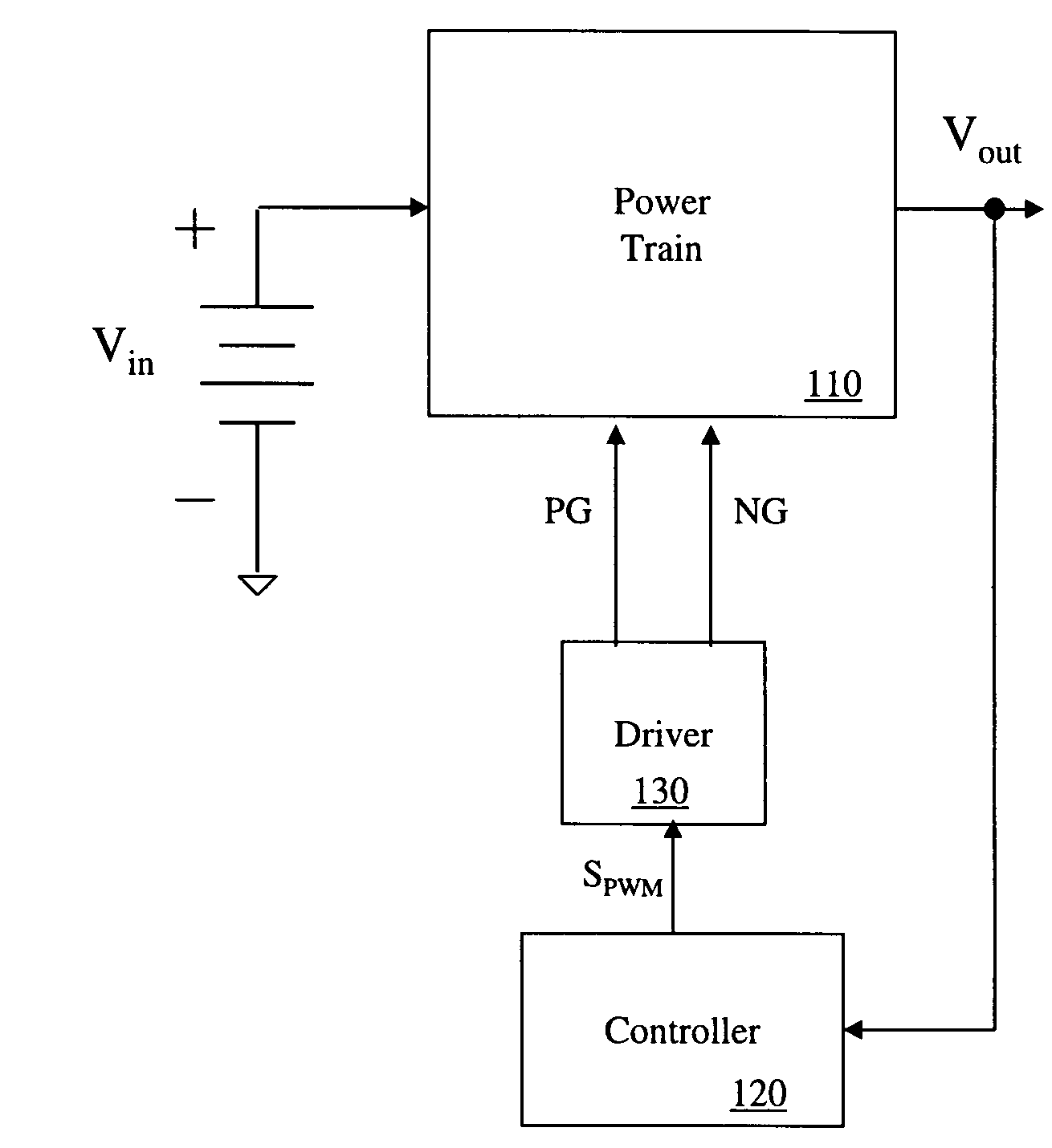

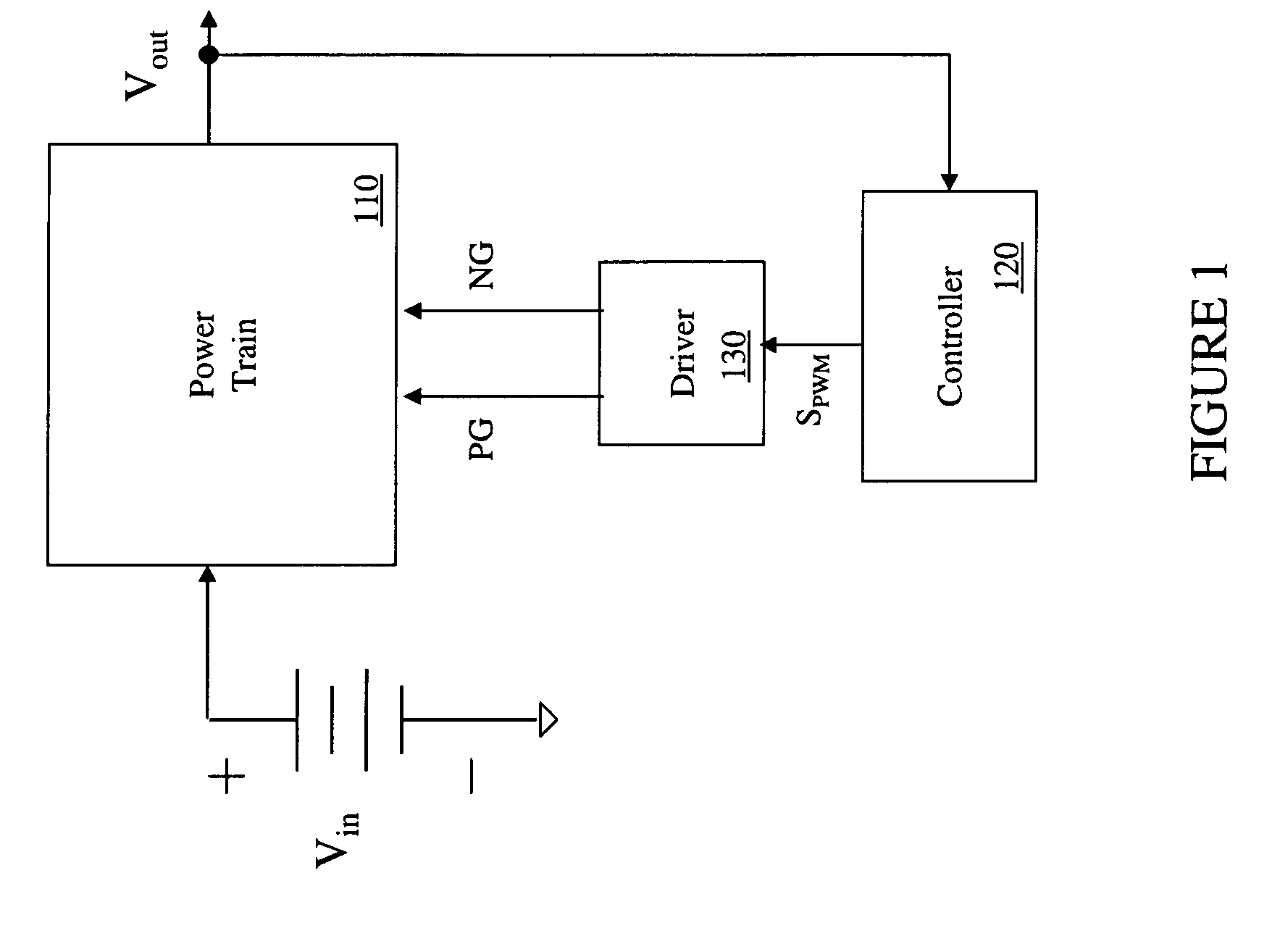

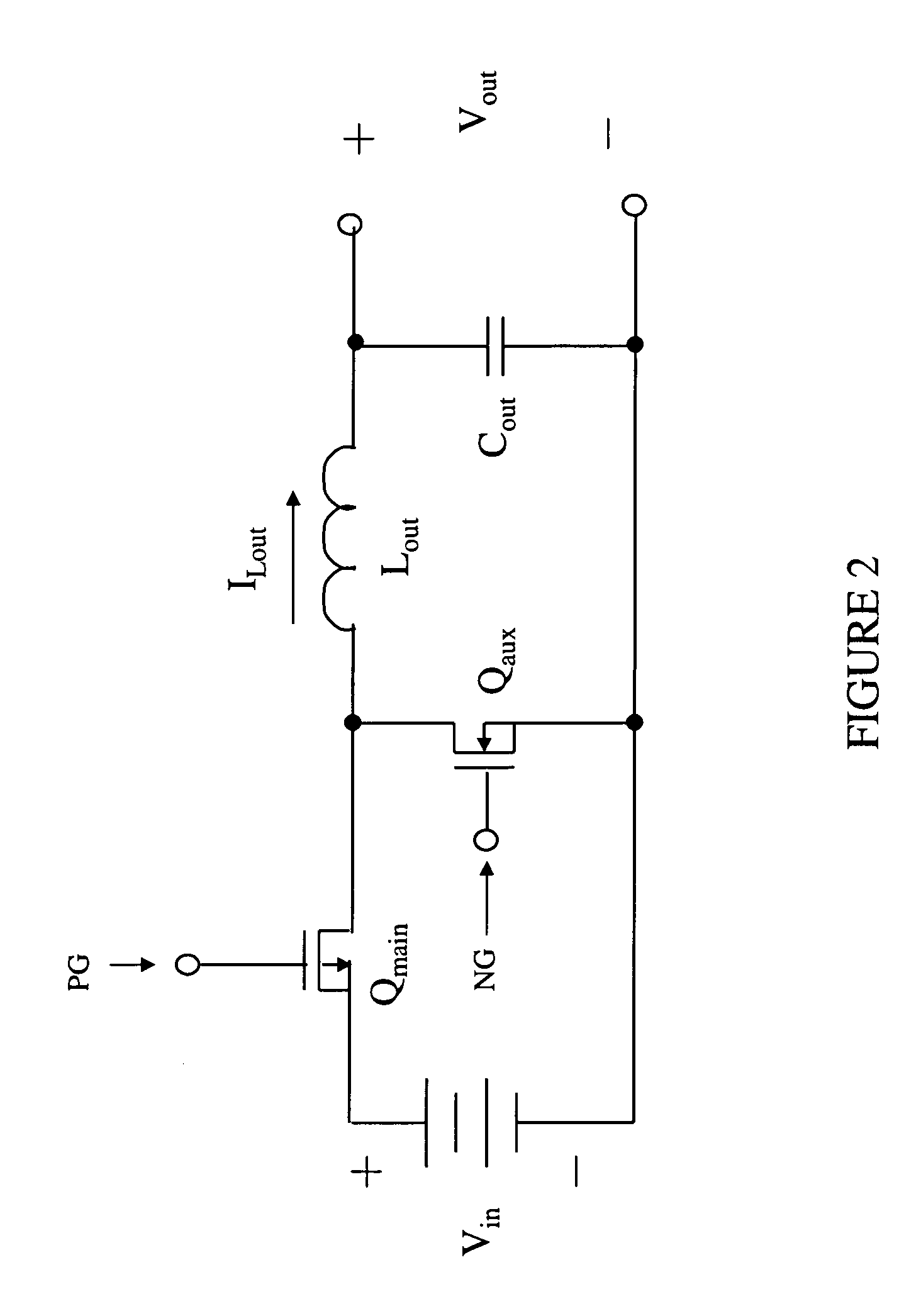

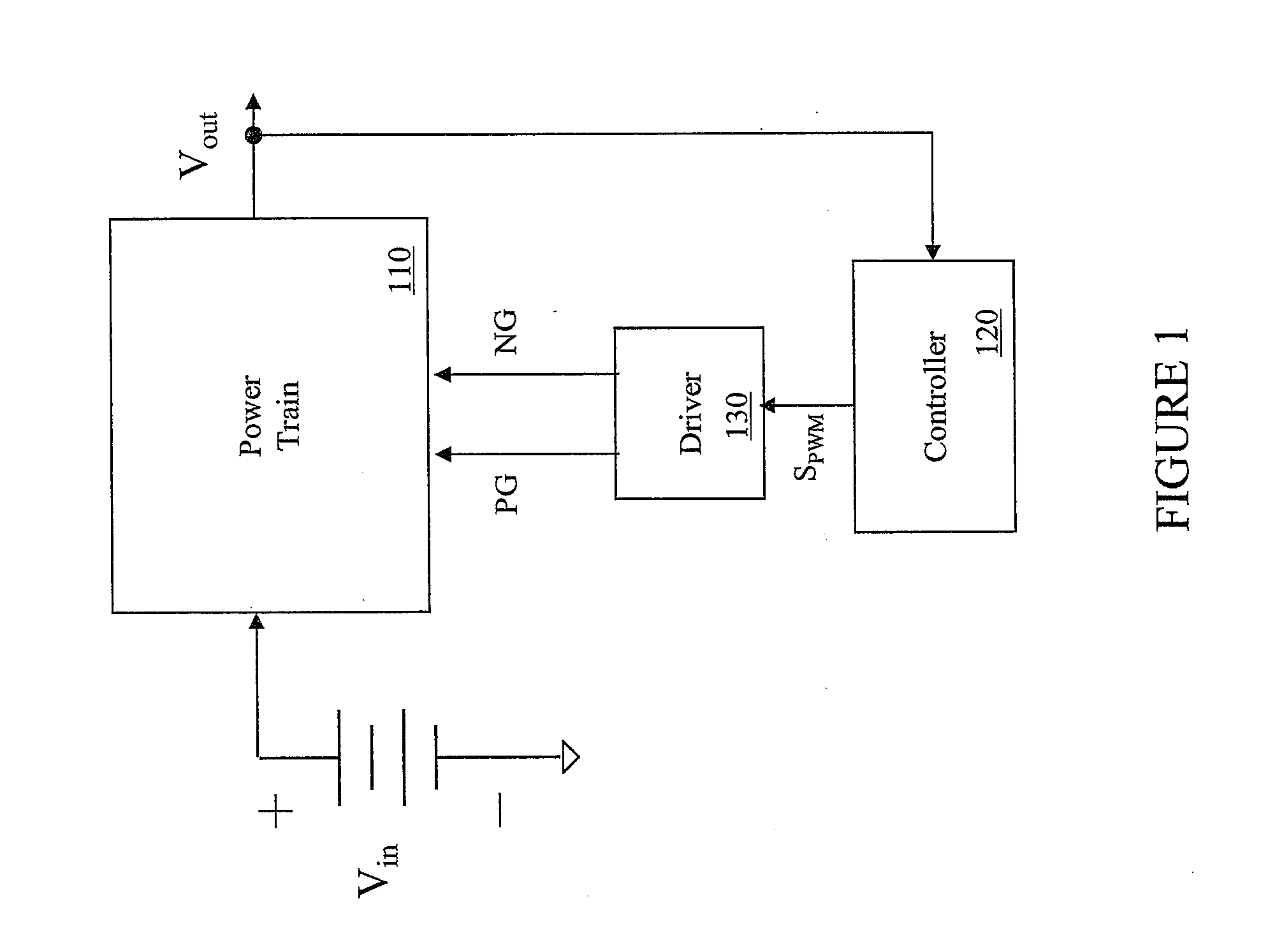

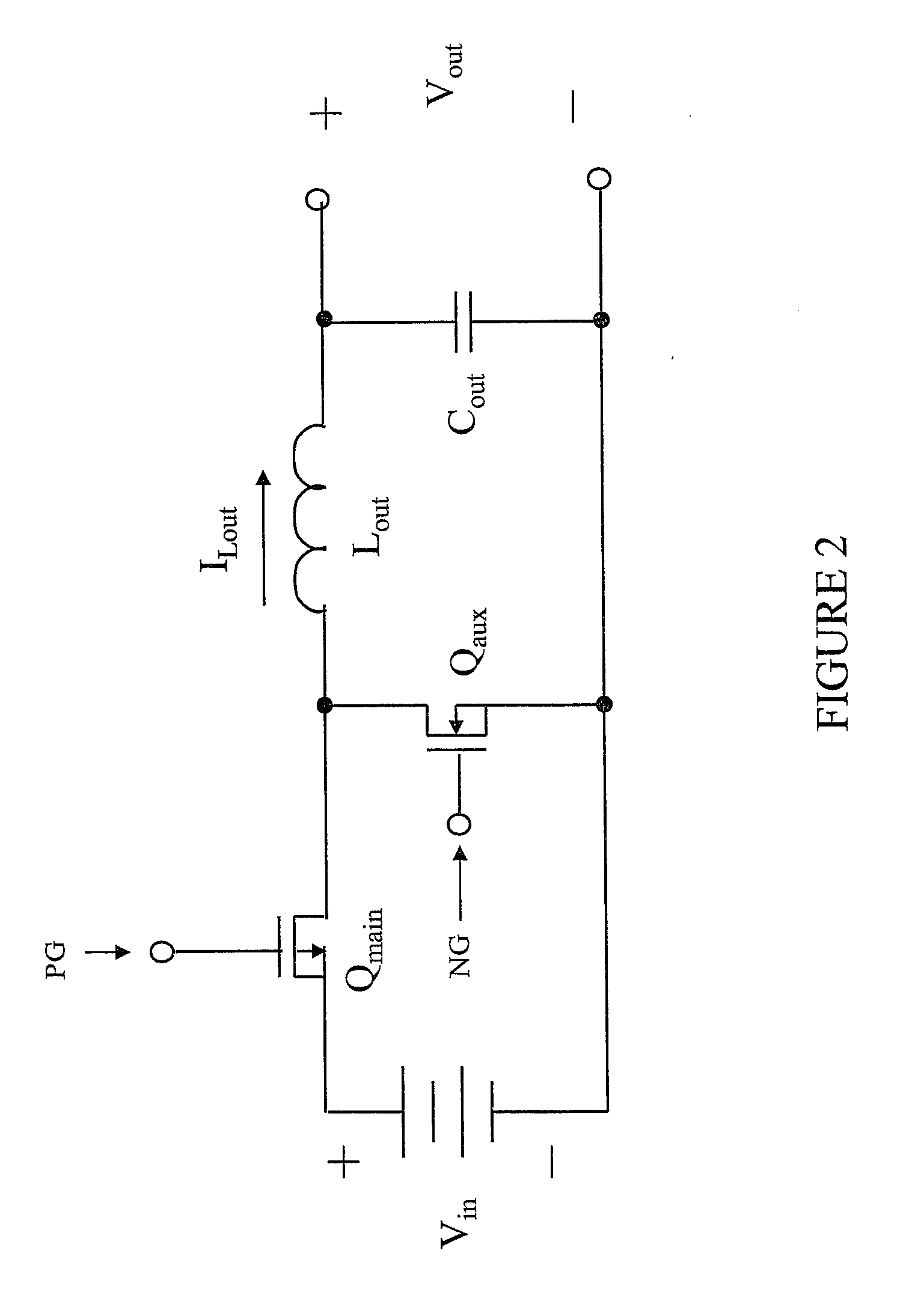

Power Converter Employing a Micromagnetic Device

ActiveUS20090066468A1Transformers/inductances coils/windings/connectionsSolid-state devicesEngineeringControl switch

A power converter including a power train, a controller and a driver. The power train includes a switch that conducts for a duty cycle and provides a regulated output characteristic for the power converter, and a micromagnetic device interposed between the switch and the output of the power converter. The micromagnetic device includes a substrate, and a magnetic core layer formed over the substrate from a magnetic alloy including iron, cobalt and phosphorous. A content of the cobalt is in a range of 1.8 to 4.5 atomic percent. A content of the phosphorus is in a range of 20.1 to 30 atomic percent. A content of the iron is substantially a remaining proportion of the magnetic alloy. The controller provides a signal to control the duty cycle of the switch. The driver provides a drive signal to the switch as a function of the signal from the controller.

Owner:INTEL CORP

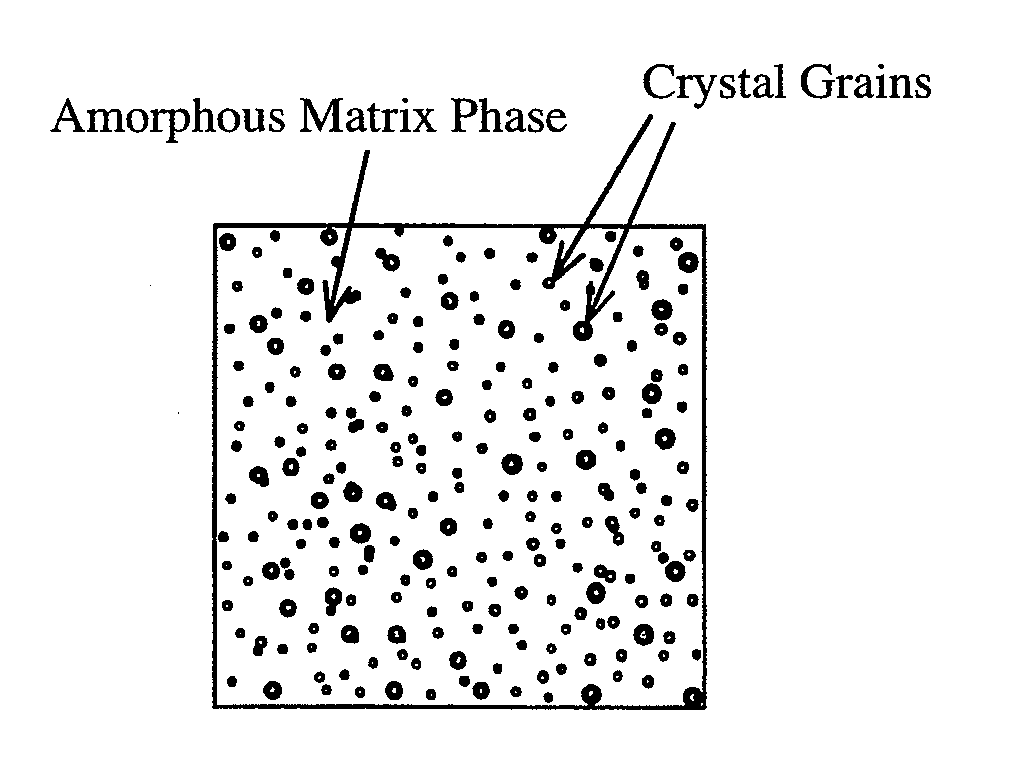

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

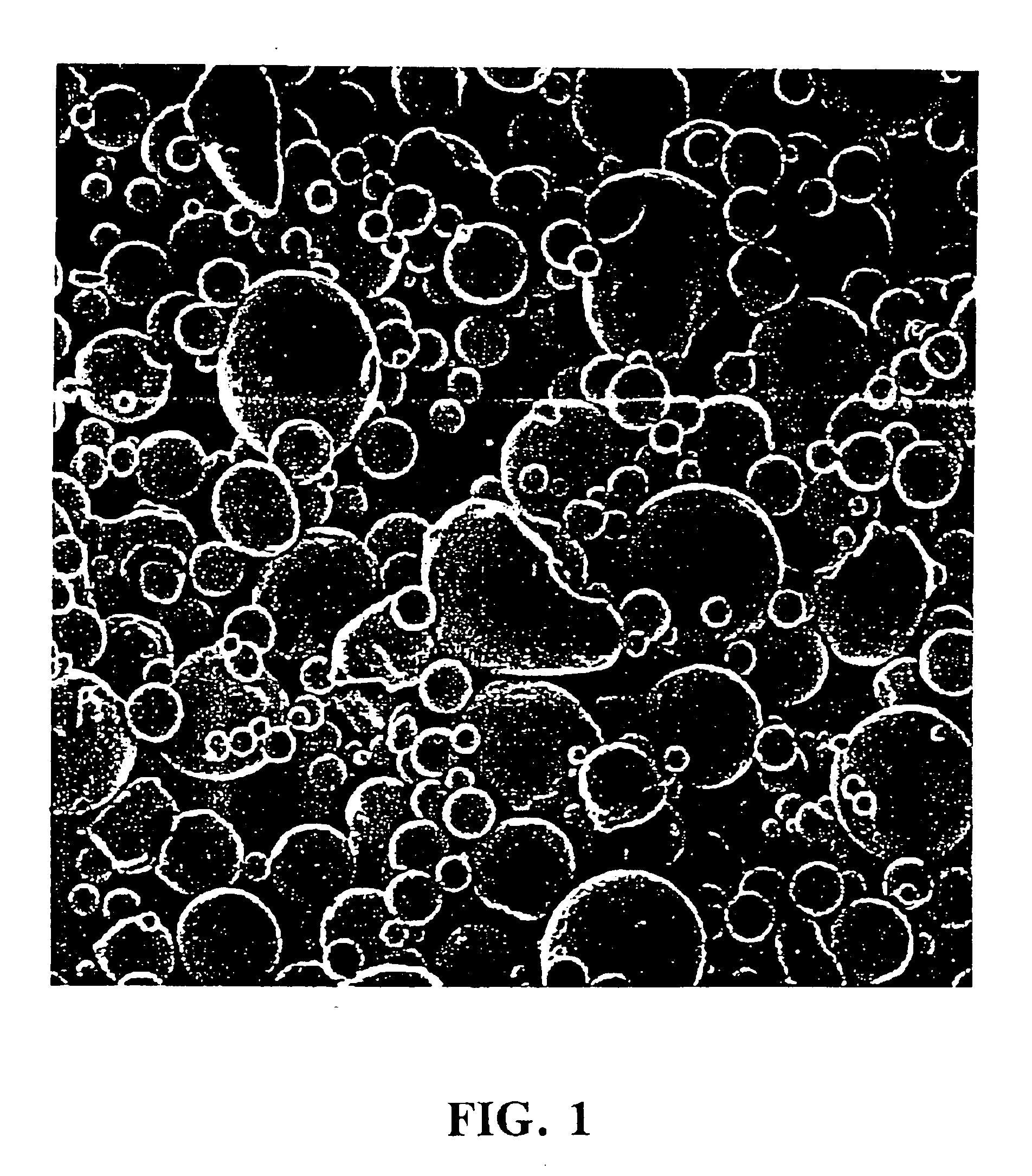

ActiveUS20090266448A1High magnetic flux densityLow coercivityMagnetic materialsVolumetric Mass DensityNano crystalline

A magnetic alloy having a composition represented by the general formula of Fe100-x-yCuxBy (atomic %), wherein x and y are numbers meeting the conditions of 0.1≦x≦3, and 10≦y≦20, or the general formula of Fe100-x-y-zCuxByXz (atomic %), wherein X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers meeting the conditions of 0.1≦x≦3, 10≦y≦20, 0≦z≦10, and 10<y+z≦24), the magnetic alloy having a structure containing crystal grains having an average diameter of 60 nm or less in an amorphous matrix, and a saturation magnetic flux density of 1.7 T or more.

Owner:HITACHI METALS LTD

Noncrystalline soft magnetic alloy powder and dust core, electricwale absorber using the same

ActiveCN1487536AExcellent soft magnetic propertiesSpeed up coolingInorganic material magnetismCores/yokesMetallurgyAmorphous phase

Provided is amorphous soft magnetic alloy powder which has high saturation magnetization and low core loss and which is almost spherical and manufactured by water atomization method, and to provide a green compact core and radio wave absorber using the same. This amorphous soft magnetic alloy powder is formed substantially spherical by the water atomization method. The powder mainly consists of Fe and contains at least P, C and B, and is formed of amorphous soft magnetic alloy powder consisting of an amorphous phase with a temperature interval DeltaTx of the supercooled liquid of >= 20K. A green compact core is formed by solidifying the granulated mixture of this amorphous soft magnetic alloy powder, insulator and lubricant. The radio wave absorber is formed by mixing the amorphous soft magnetic alloy powder the particles of which is flattened and insulator.

Owner:ALPS ALPINE CO LTD

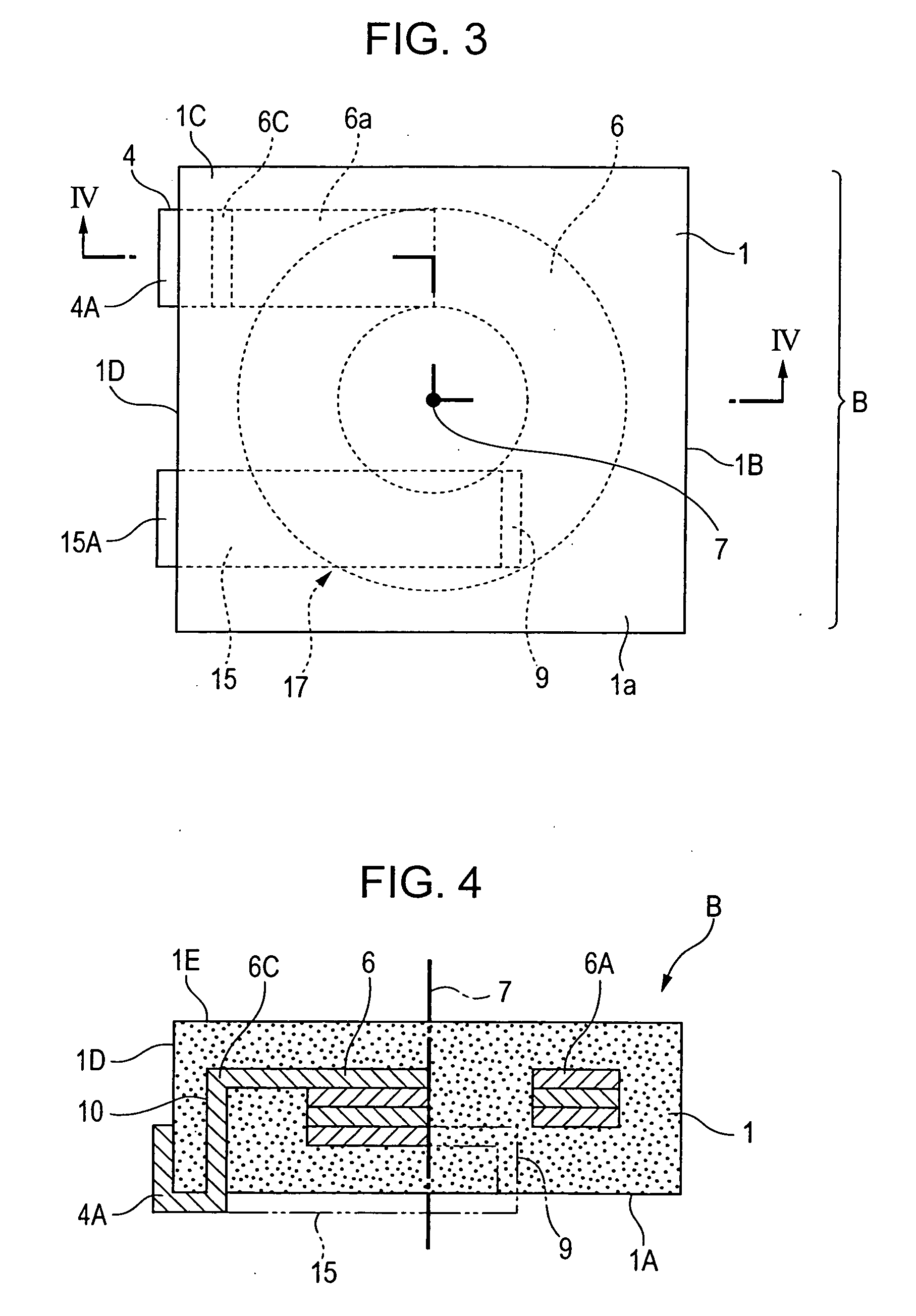

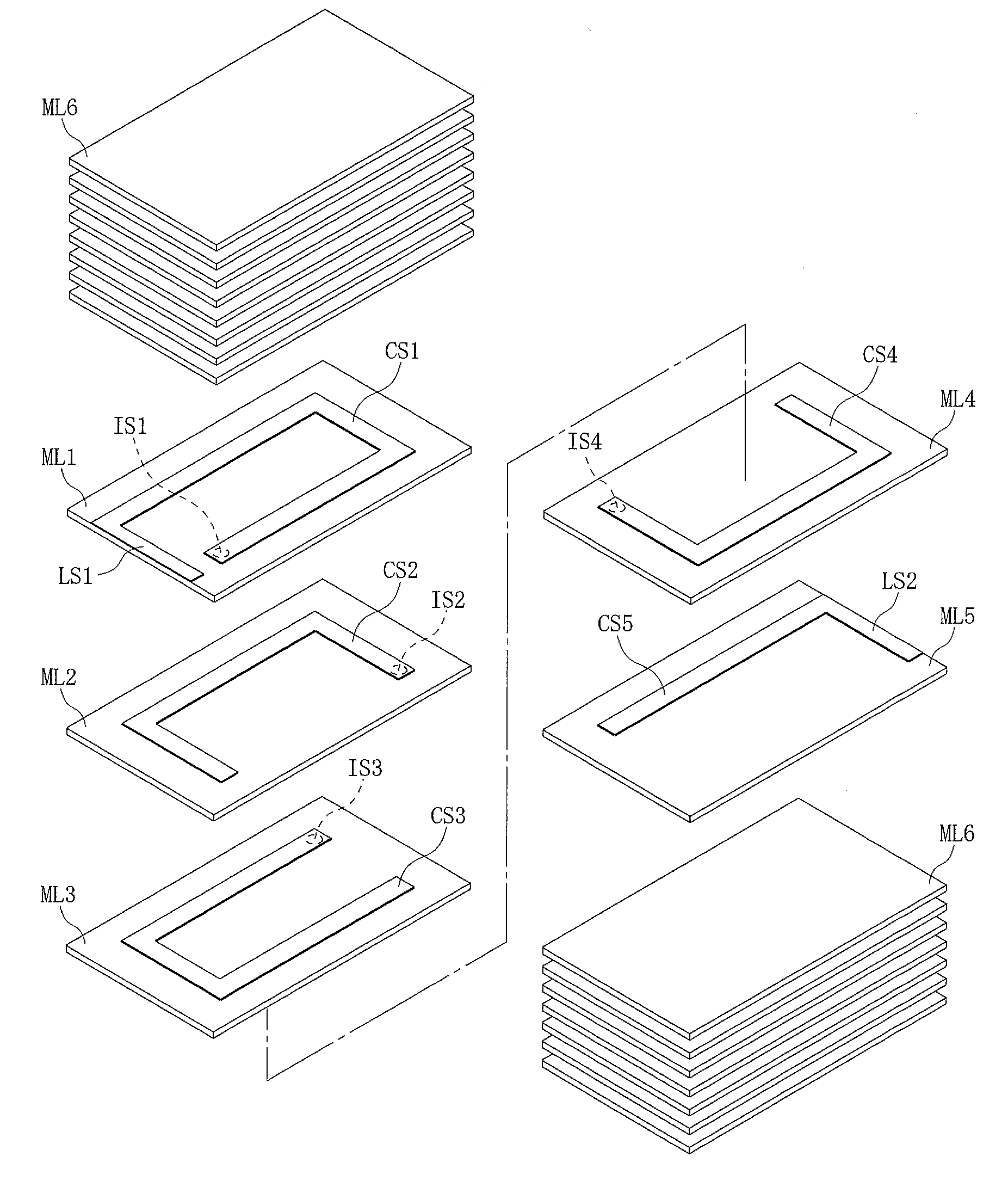

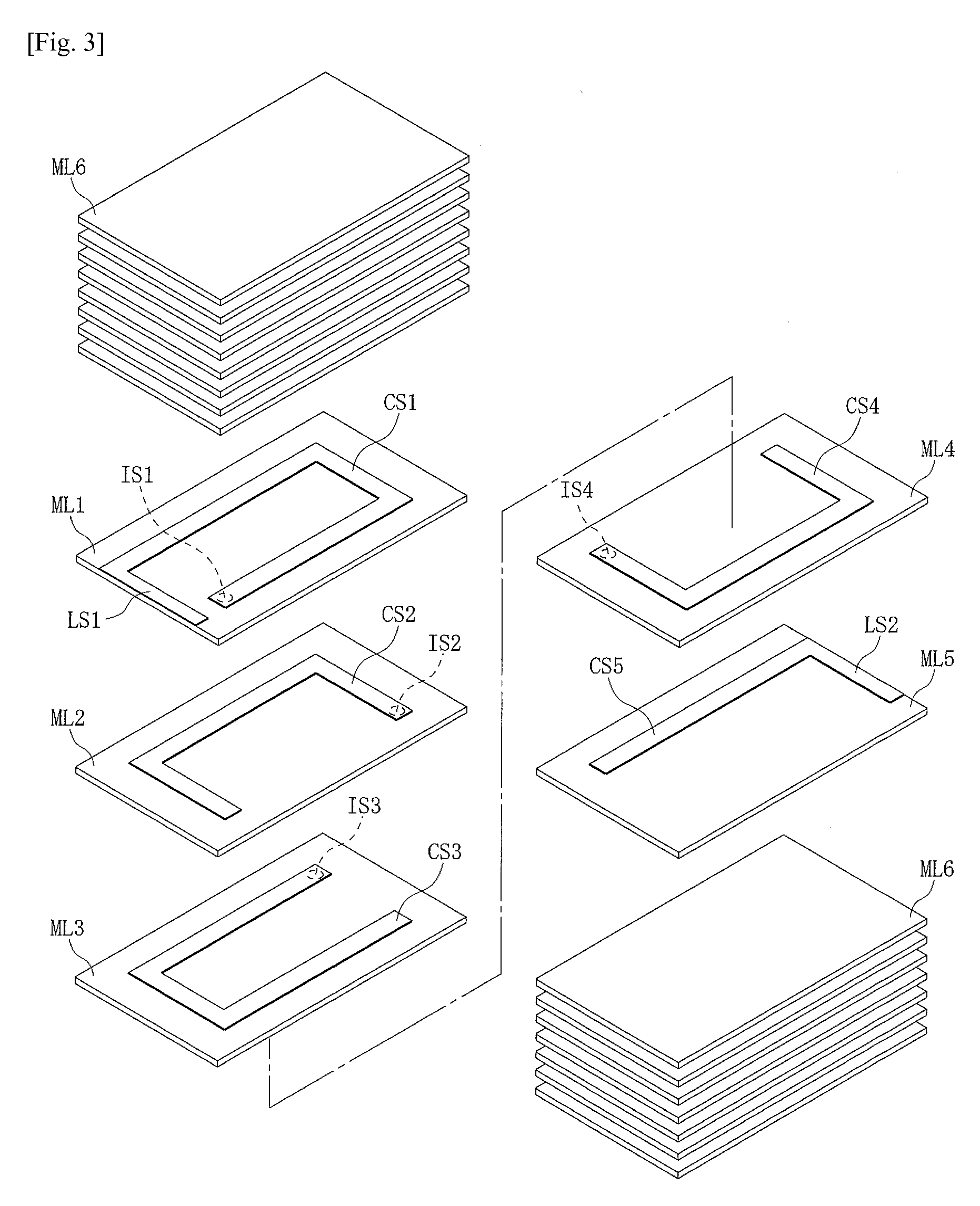

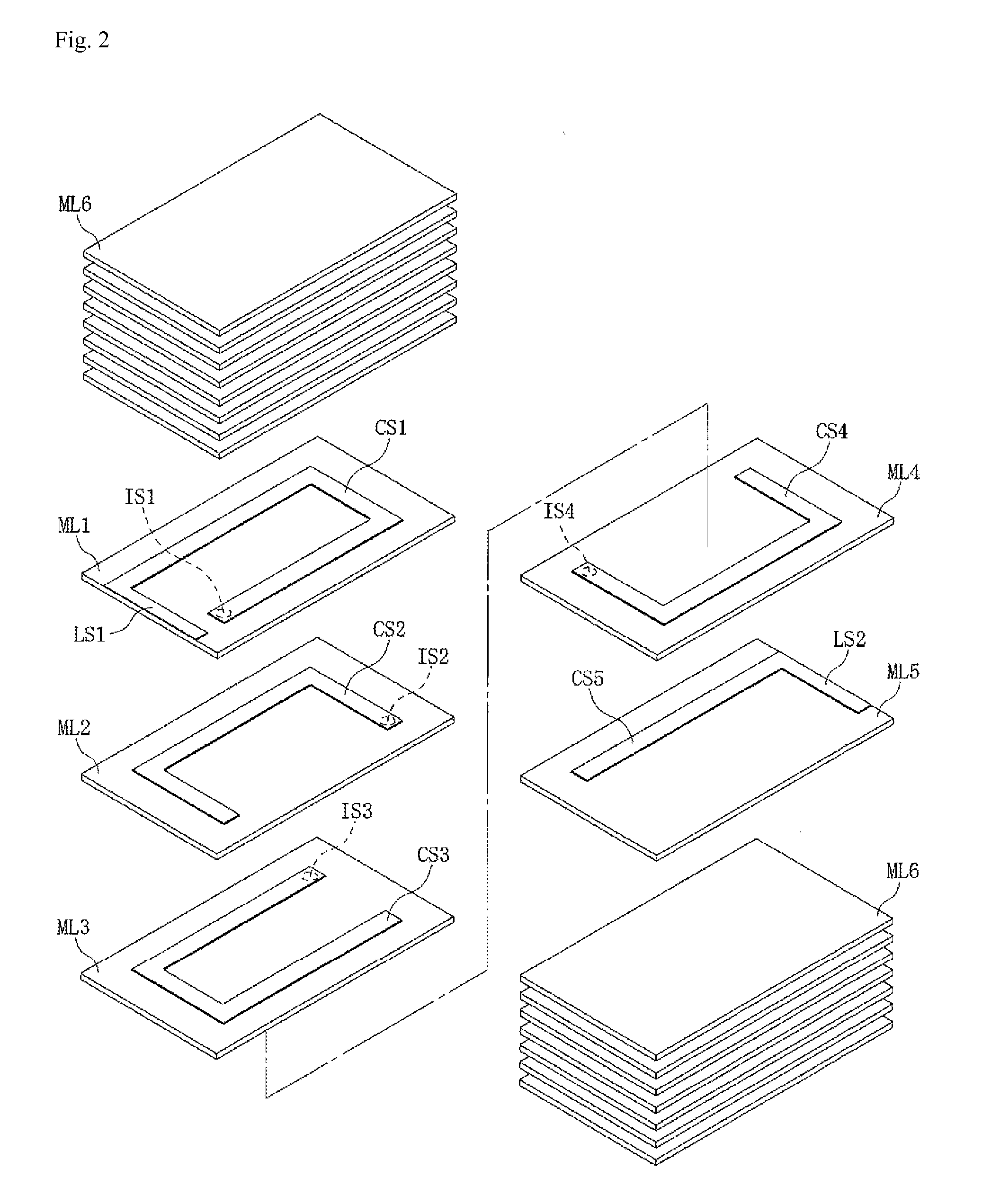

Laminated inductor

ActiveUS20130033347A1Improve permeabilityValue of inductor improvesTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorInductor

A laminated inductor having an internal conductive wire forming region, as well as a top cover region and bottom cover region formed in a manner sandwiching the internal conductive wire forming region between top and bottom; wherein the internal conductive wire forming region has a magnetic part formed with soft magnetic alloy grains, as well as helical internal conductive wires embedded in the magnetic part and constituted by a conductor; and at least one of the top cover region and bottom cover region (or preferably both) is / are formed with soft magnetic alloy grains whose constituent elements are of the same types as those of, and whose average grain size is greater than that of, the soft magnetic alloy grains constituting the magnetic part in the internal conductive wire forming region.

Owner:TAIYO YUDEN KK

Micromagnetic Device and Method of Forming the Same

ActiveUS20090066467A1Transformers/inductances magnetic coresThin magnetic filmsCobaltMaterials science

A micromagnetic device including a substrate, and a magnetic core layer formed over the substrate from a magnetic alloy. The magnetic alloy includes iron, cobalt and phosphorous. A content of the cobalt is in a range of 1.8 to 4.5 atomic percent. A content of the phosphorus is in a range of 20.1 to 30 atomic percent. A content of the iron is substantially a remaining proportion of the magnetic alloy.

Owner:INTEL CORP

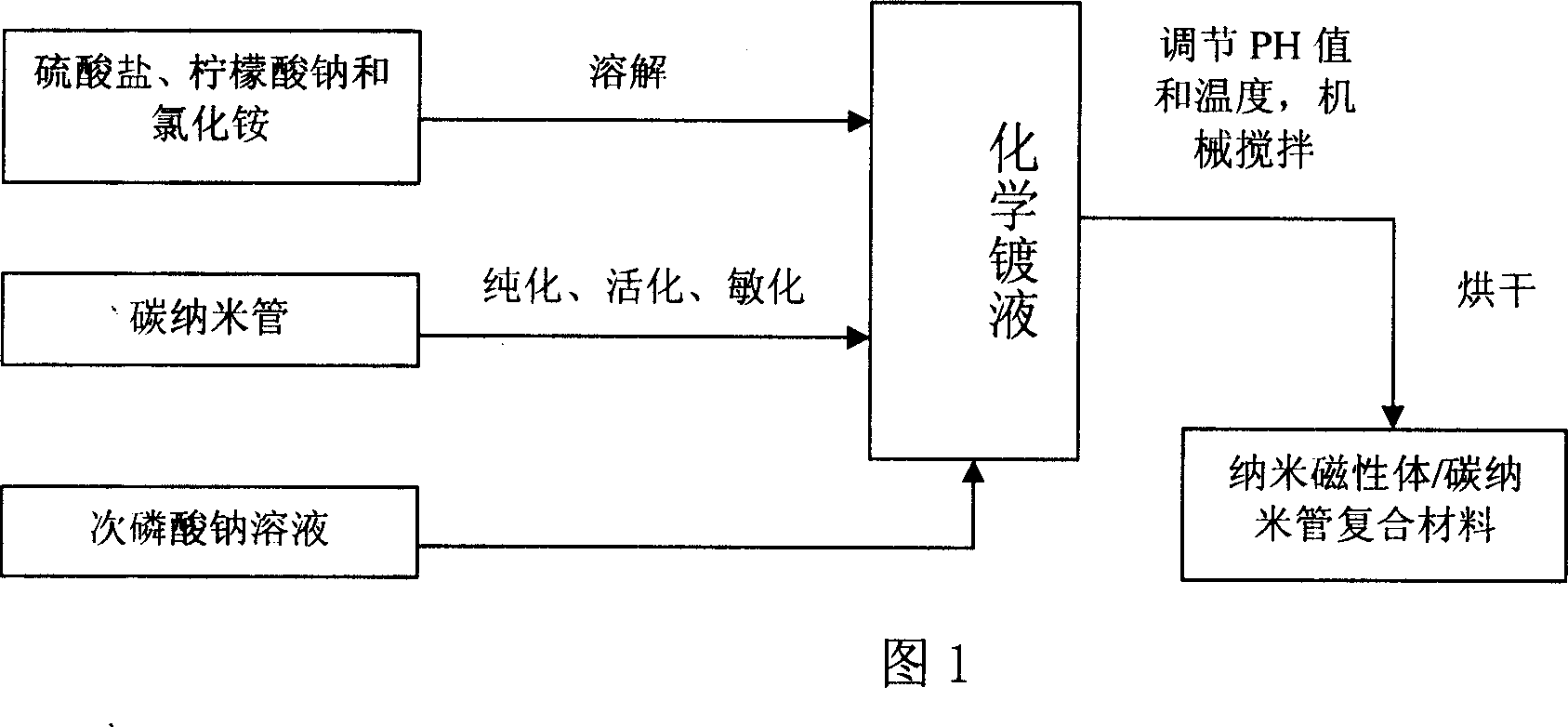

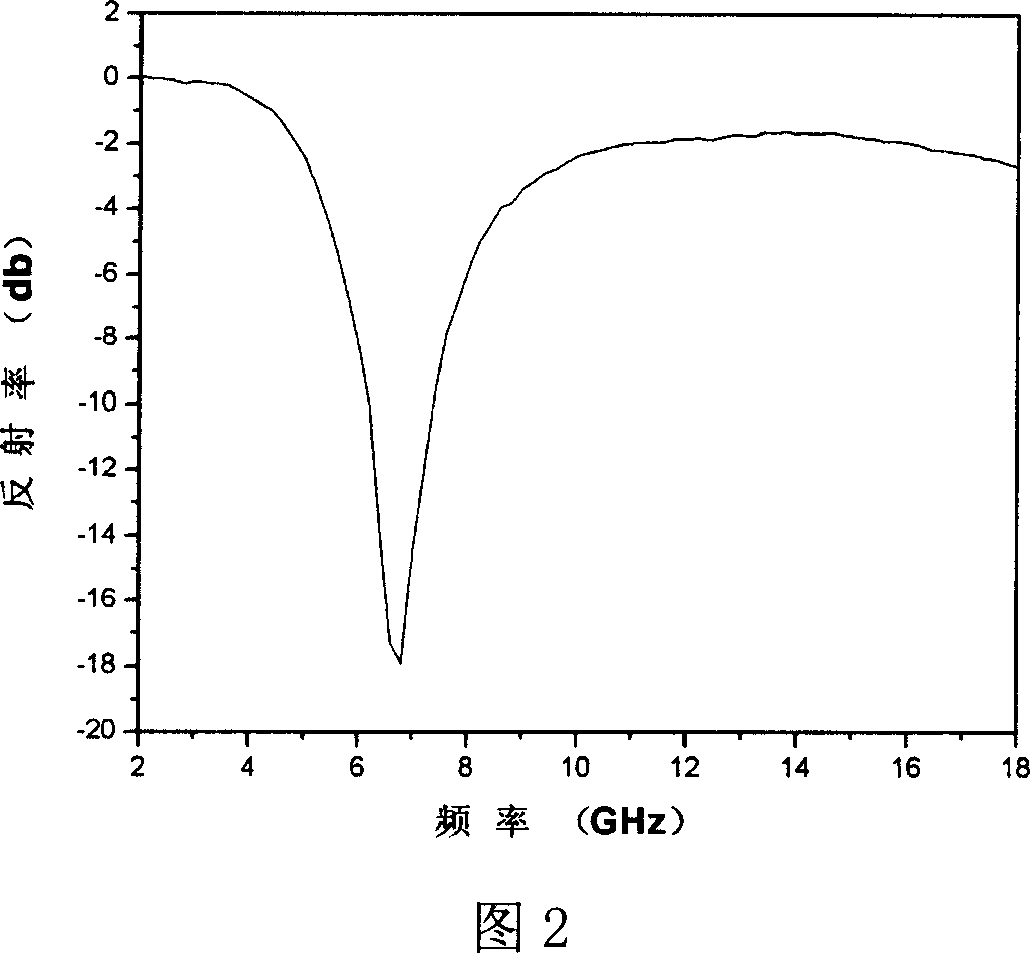

Carbon nano tube wave absorbtion mateirla of surface carried with magnetic alloy particle and preparation method thereof

InactiveCN101045533AGood electrical and magnetic propertiesSimple preparation processNanostructure manufactureScreening apparatusMicrowaveCarbon nanotube

A carbon nanotube carrying magnetic alloy particles on its surface and used as wave absorbing material is prepared through uniformly dispersing carbon nanotubes in the solution of the sulfate of Fe, Co and Ni, and oxidizing-reducing reaction for deposition the magnetic alloy particles on carbon nanotubes.

Owner:TSINGHUA UNIV

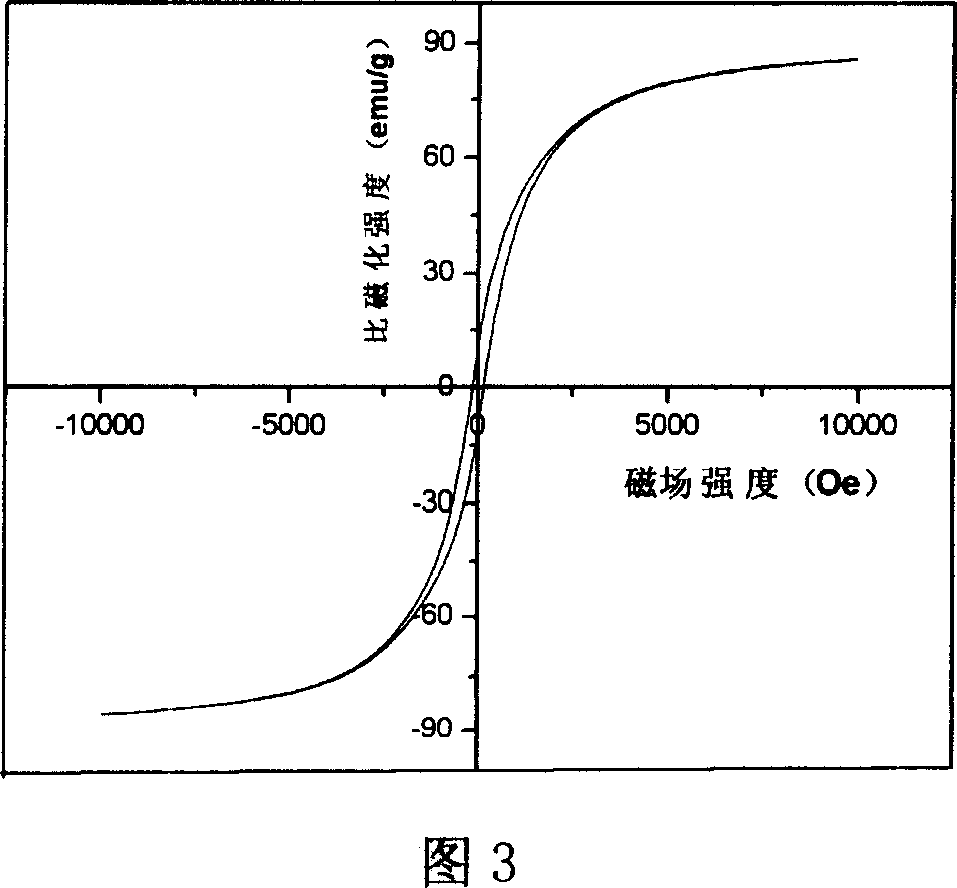

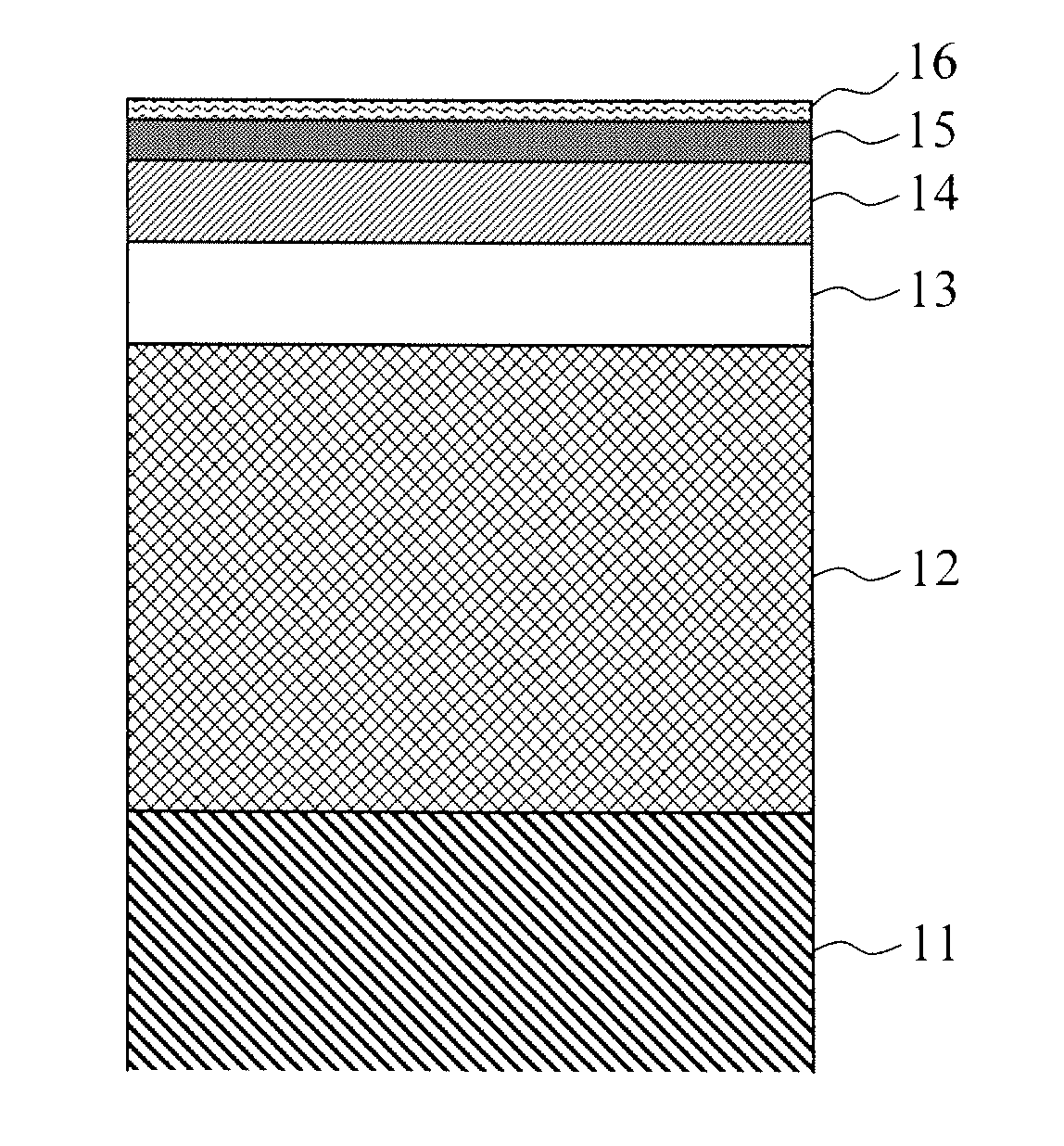

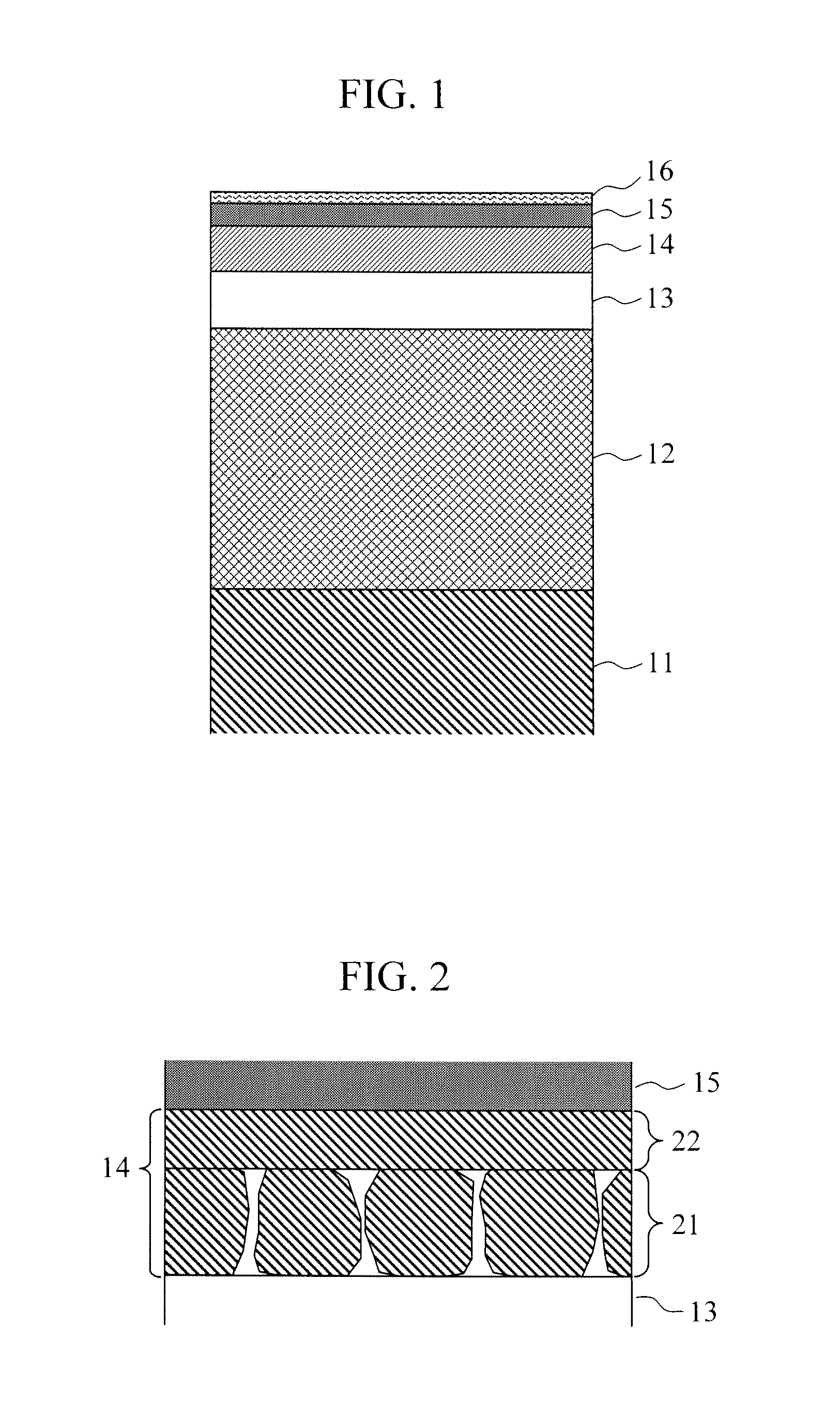

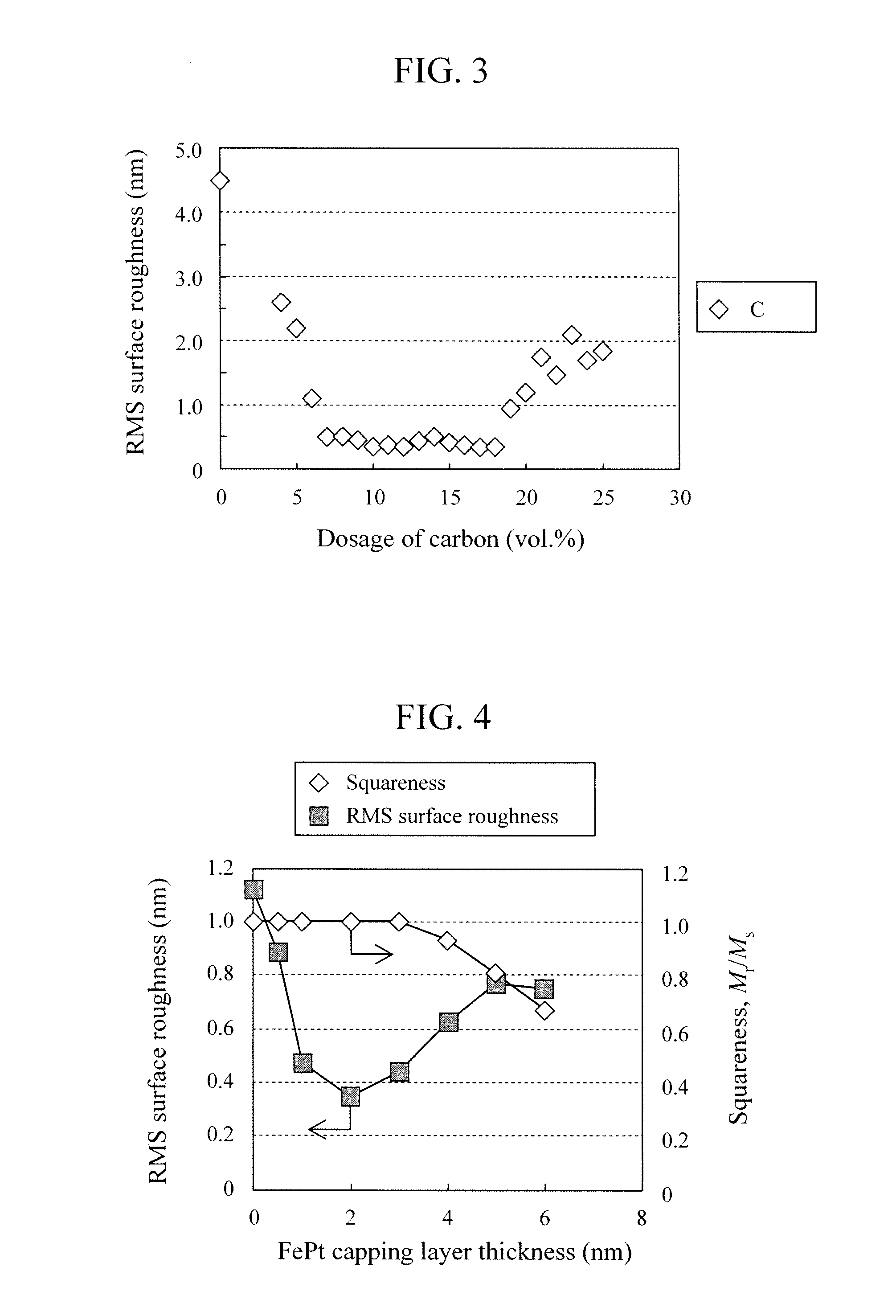

Magnetic recording medium

Surface flatness of magnetic recording medium to which a magnetic recording layer made of L10 FePt magnetic alloy thin film, with distance between a magnetic head and a magnetic recording medium sufficiently reduced. The magnetic recording layer includes: magnetic layers containing a magnetic alloy including Fe and Pt as principal materials; and one non-magnetic material selected from carbon, oxide and nitride. The first magnetic layer disposed closer to a substrate has a granular structure in which magnetic alloy grains including FePt alloy as the principal material are separated from grain boundaries including the non-magnetic material as the principal material. The second magnetic layer disposed closer to the surface than the first magnetic layer is fabricated so as to have a homogeneous structure in which an FePt alloy and the non-magnetic material are mixed in a state finer than diameters of the FePt magnetic alloy grains in the first magnetic layer.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com